Patents

Literature

1149 results about "Mems sensors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sensors that are now captured in MEMS include sensors for measuring pressure, motion, acceleration, temperature, magnetic field, and light, as well as gyroscopes, inclinometers, switches, capacitive touch sensors, and even microphones. As a relatively new technology, new MEMS devices can continually be found at Mouser.

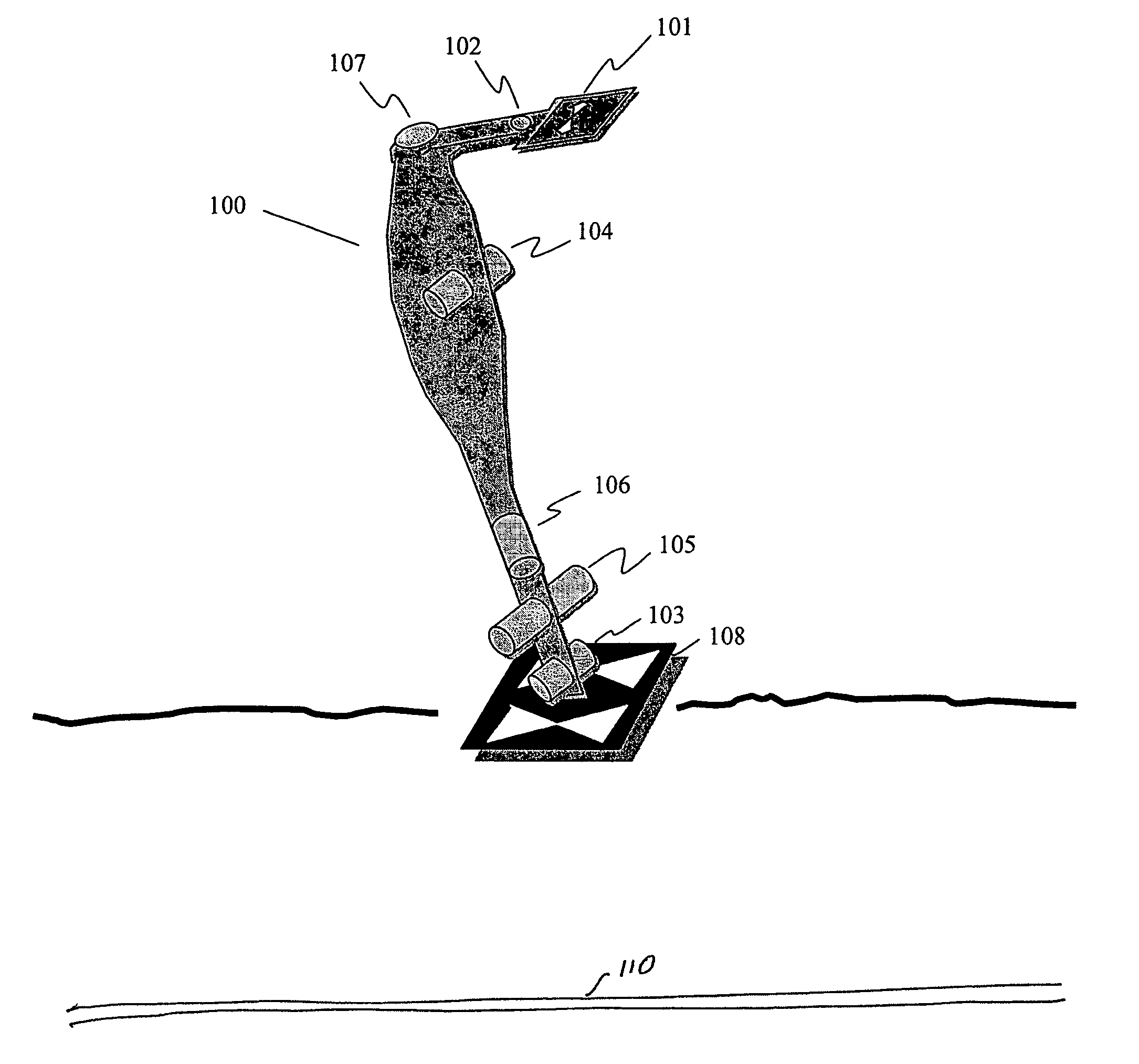

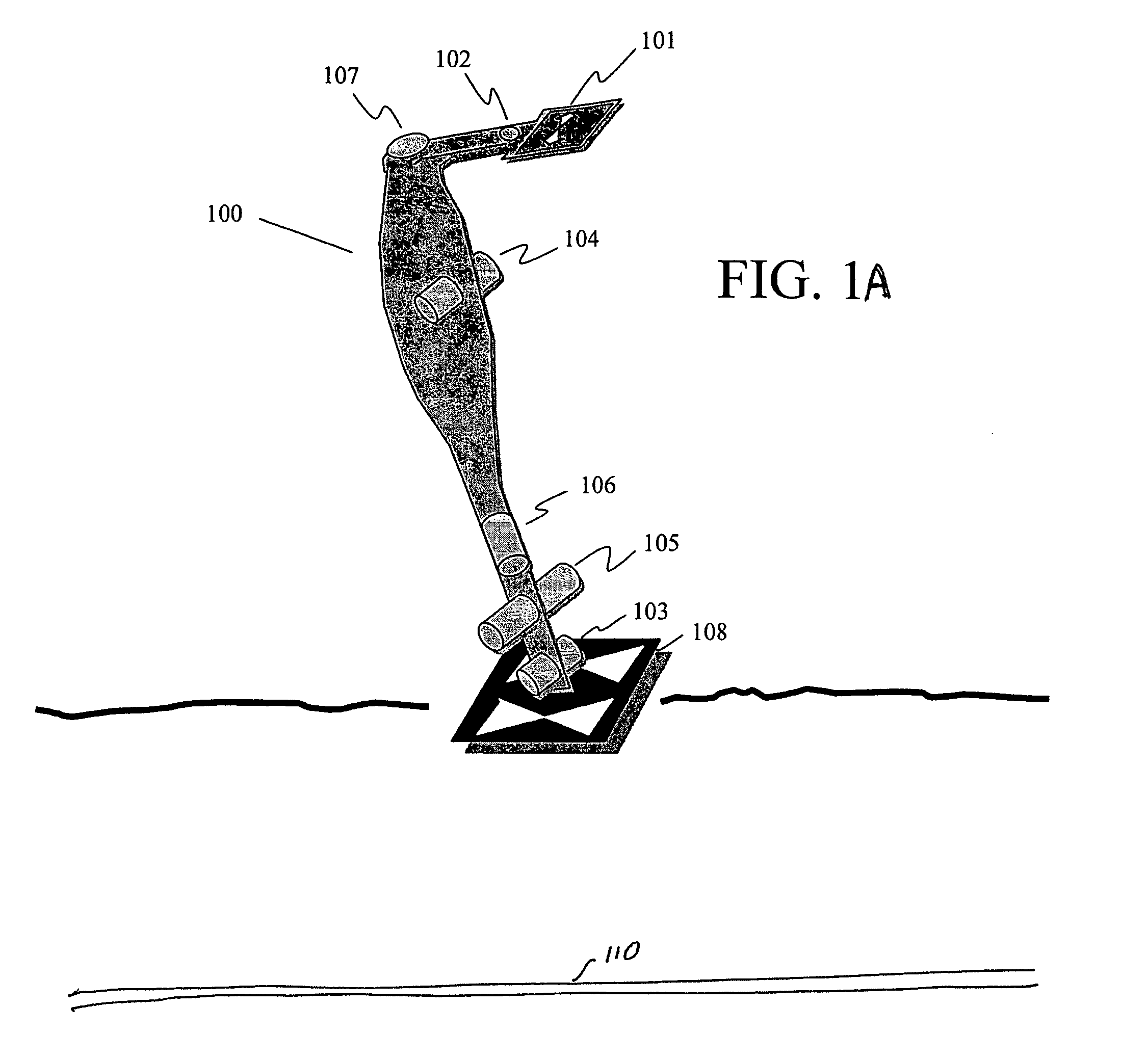

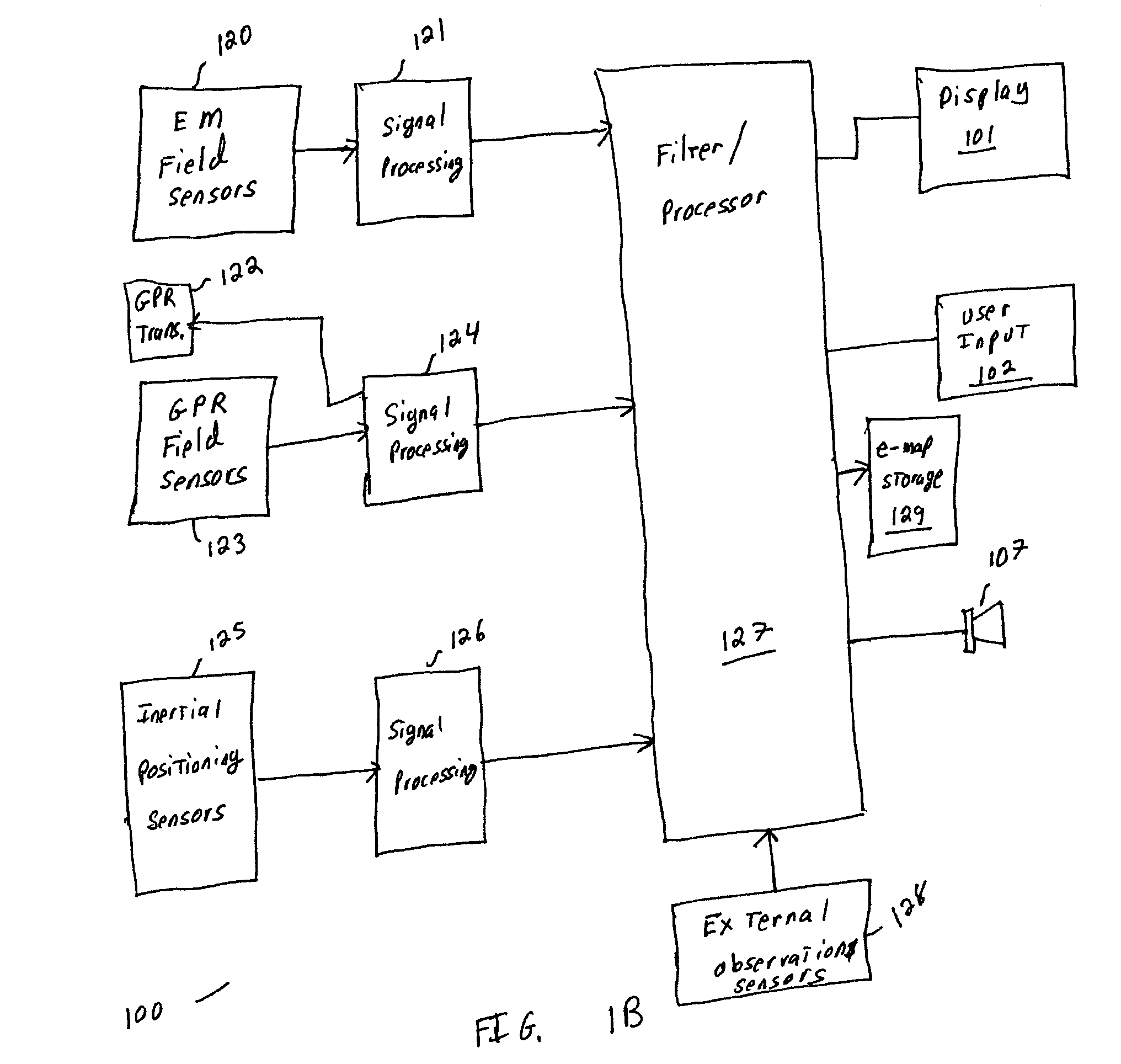

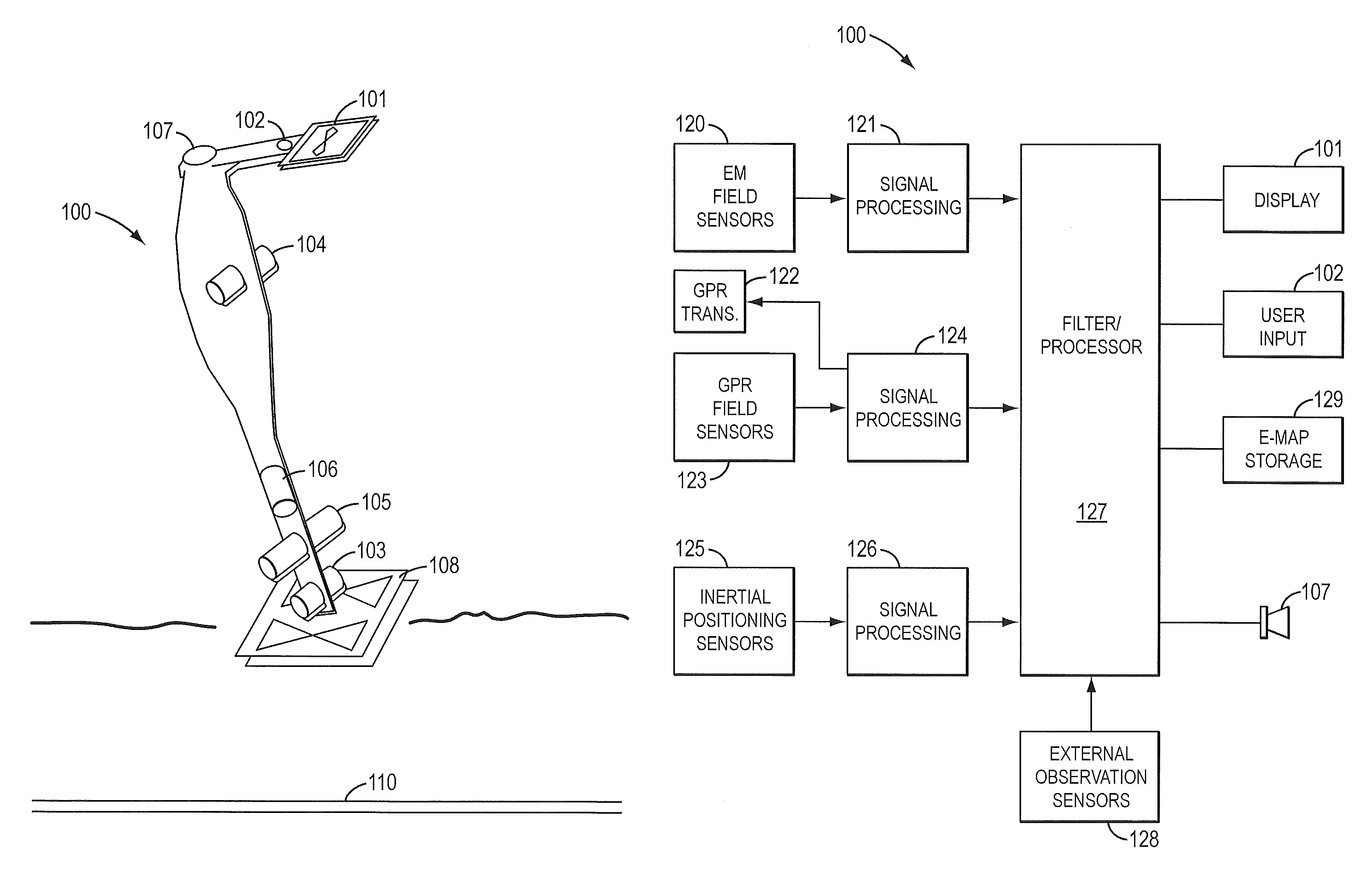

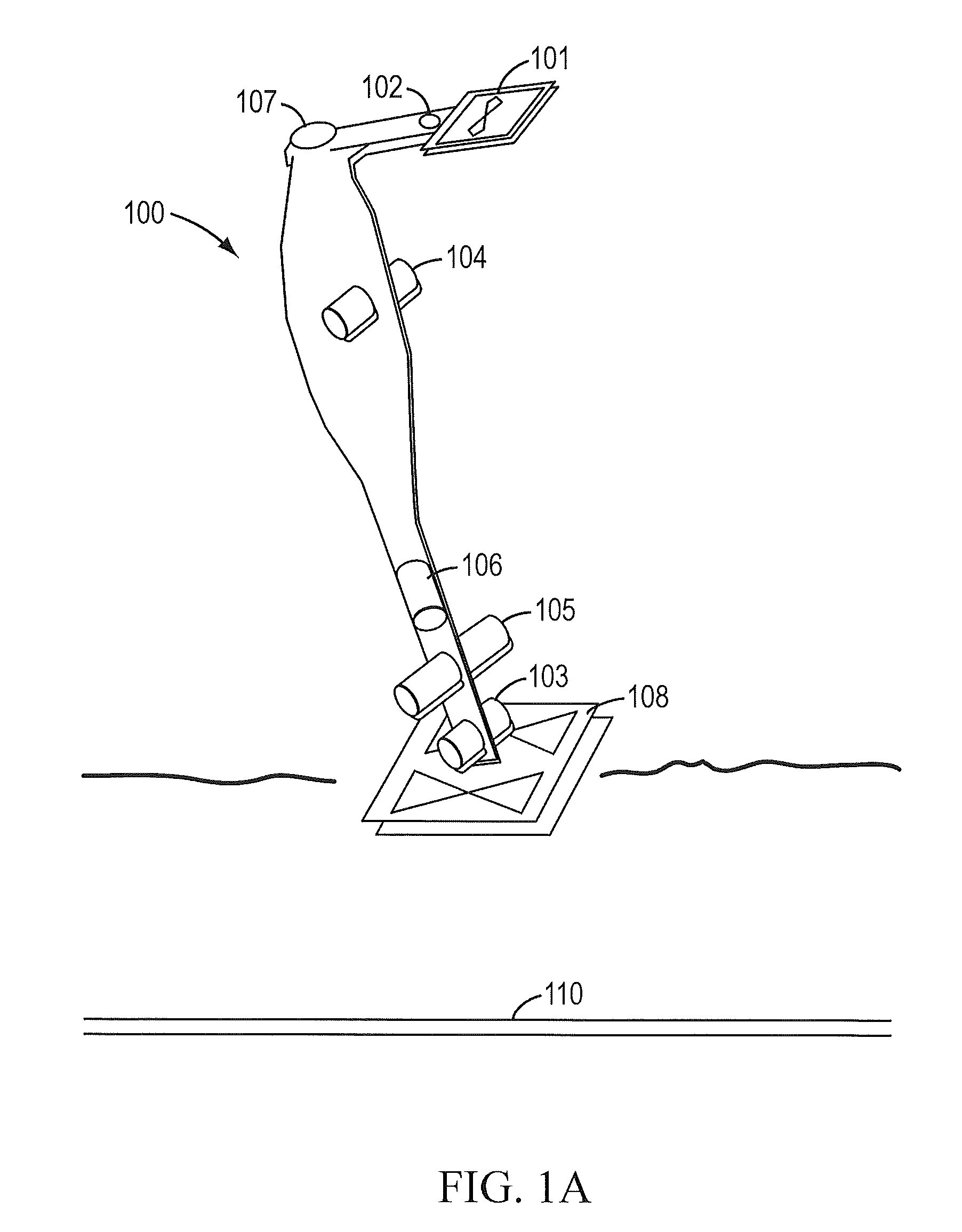

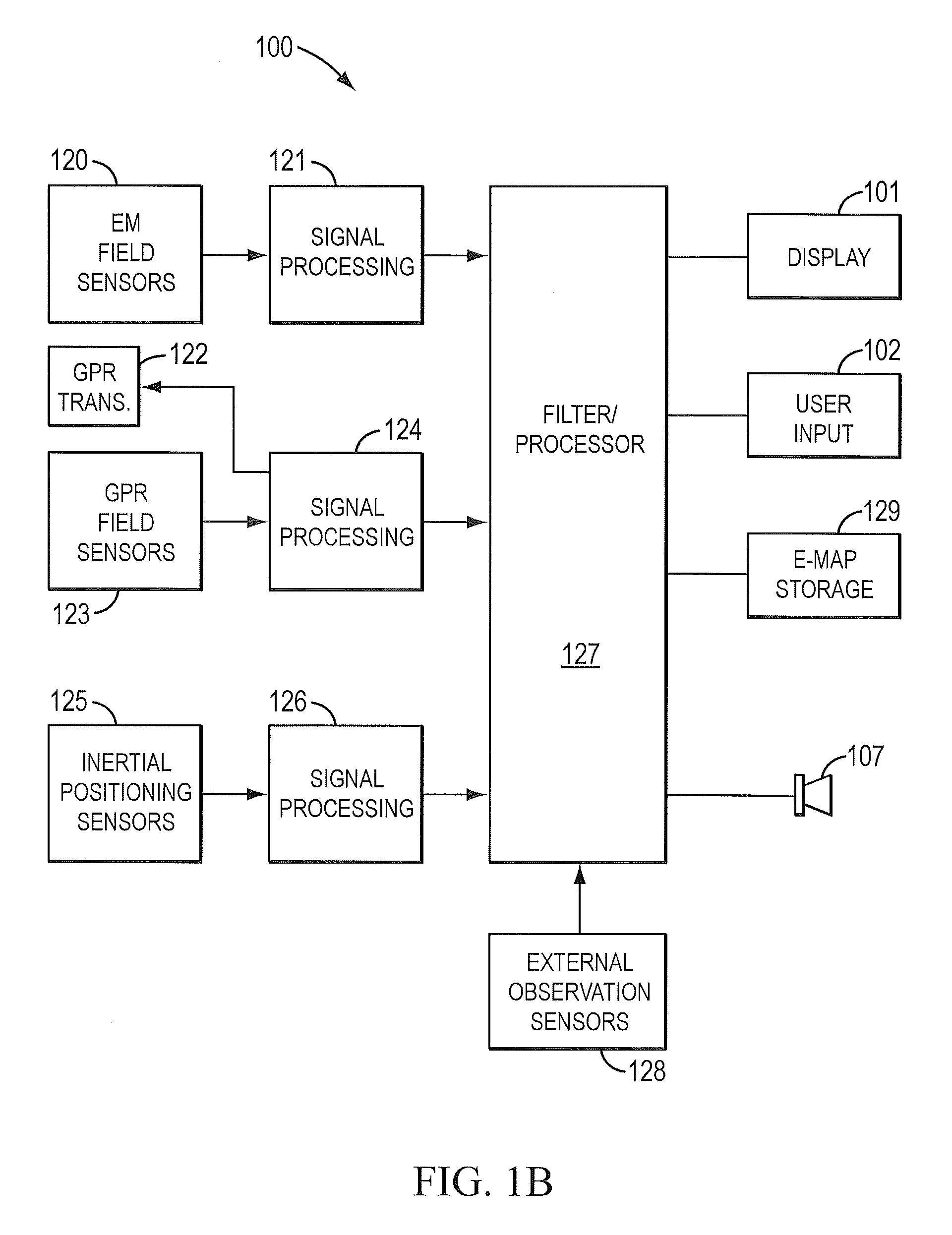

Sensor fusion for model-based detection in pipe and cable locator systems

ActiveUS20060055584A1Improve positionSatellite radio beaconingDetection using electromagnetic wavesAccelerometerGyroscope

Line locator systems that fuse traditional sensors used in a combined pipe and cable locator (electromagnetic coils, magnetometers, and ground penetrating radar antennas) with low cost inertial sensors (accelerometers, gyroscopes) in a model-based approach are presented. Such systems can utilize inexpensive MEMS sensors for inertial navigation. A pseudo-inertial frame is defined that uses the centerline of the tracked utility, or an aboveground fixed object as the navigational reference. An inertial sensor correction mechanism that limits the tracking errors over time when the model is implemented in state-space form using, for example, the Extended Kalman Filter (EKF) is disclosed.

Owner:BUSAN TRANSPORTATION CORPORATION

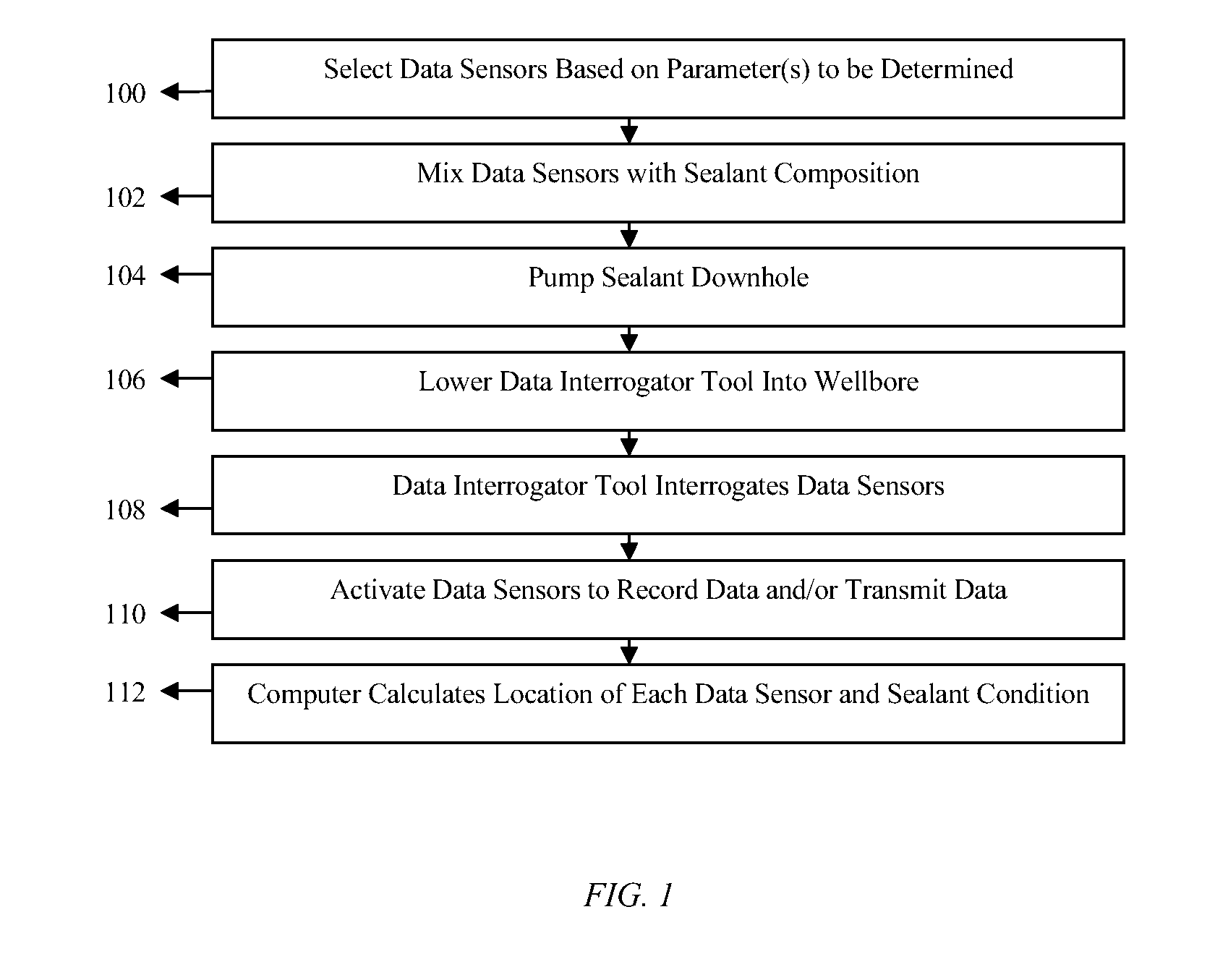

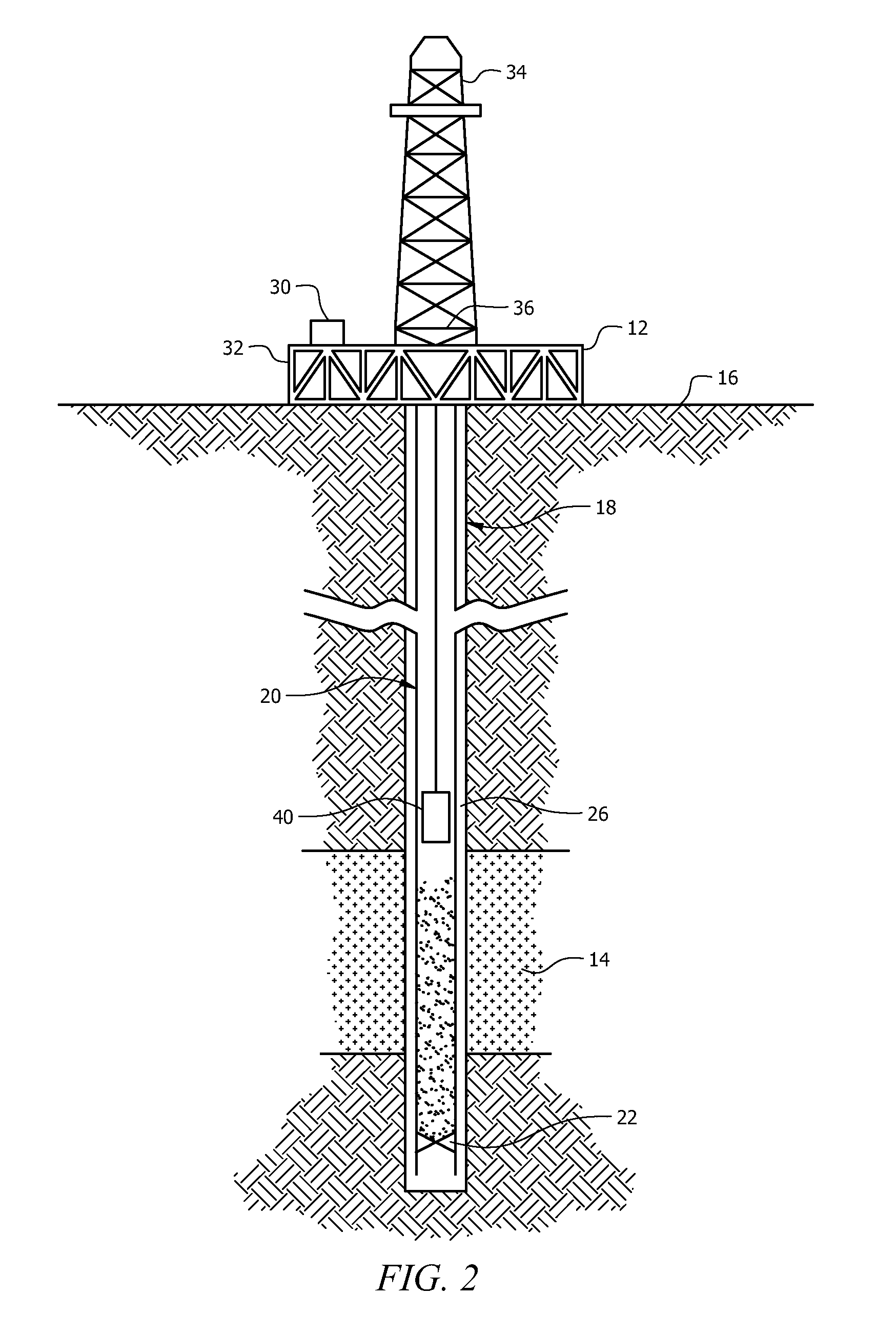

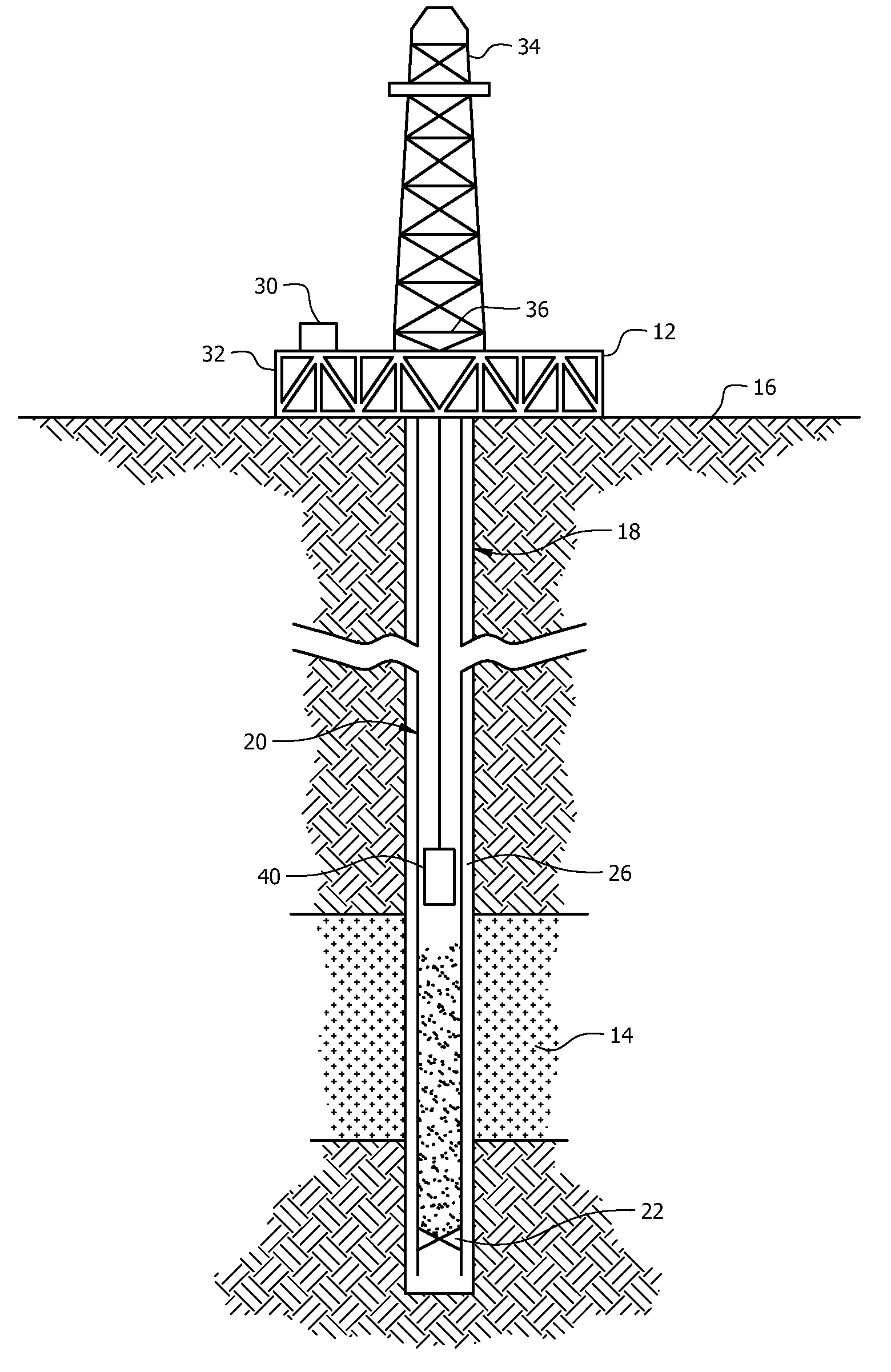

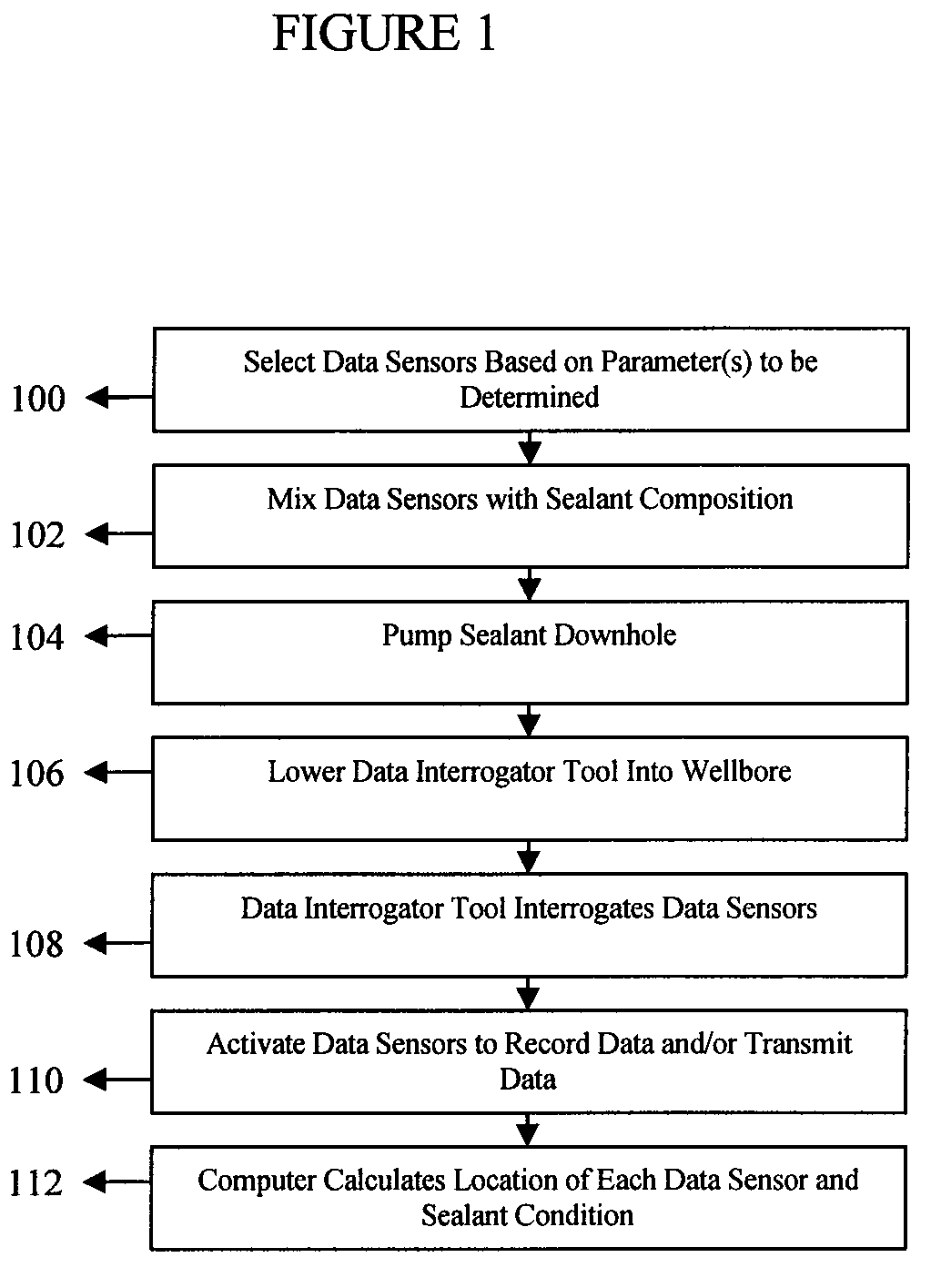

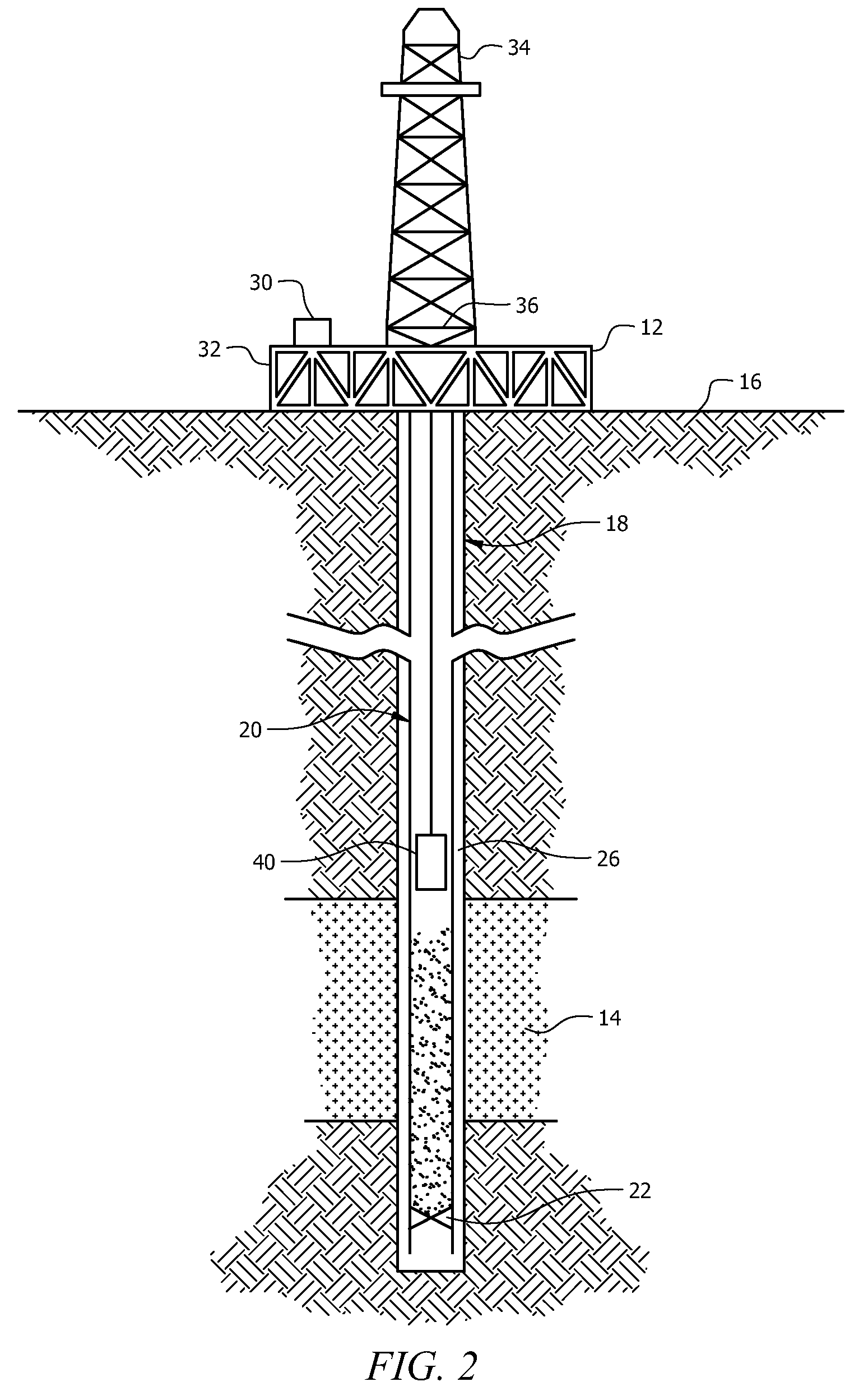

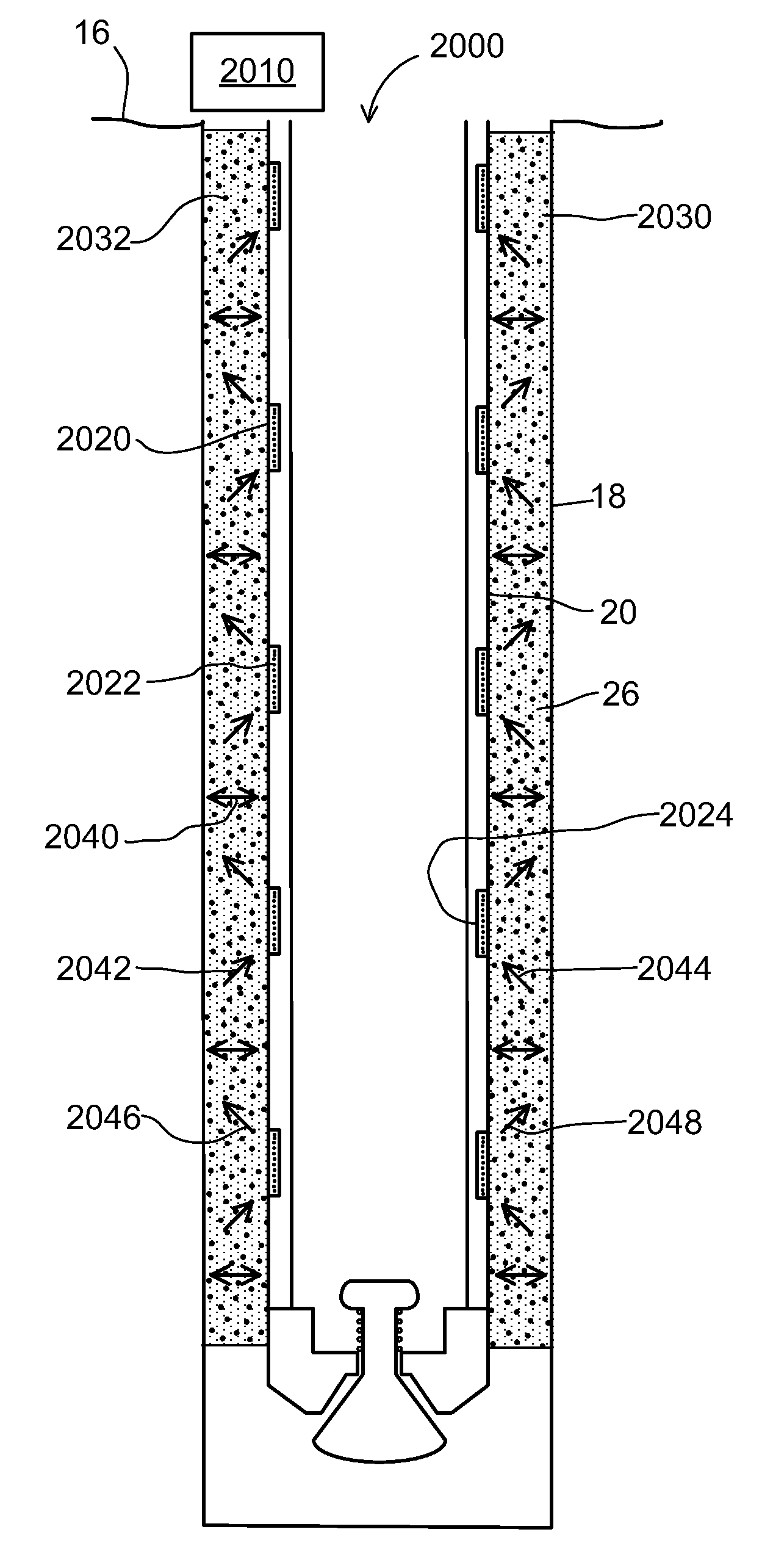

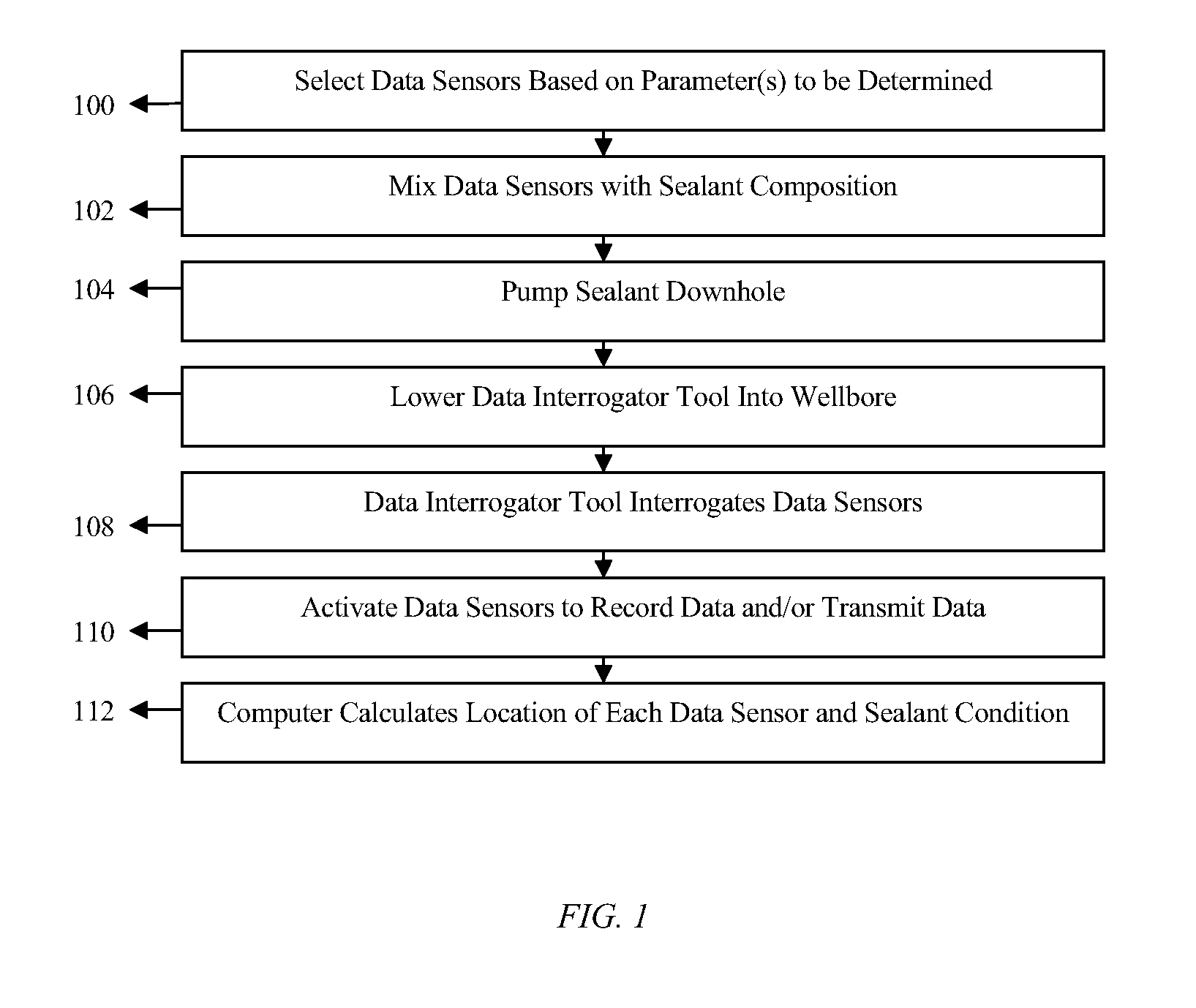

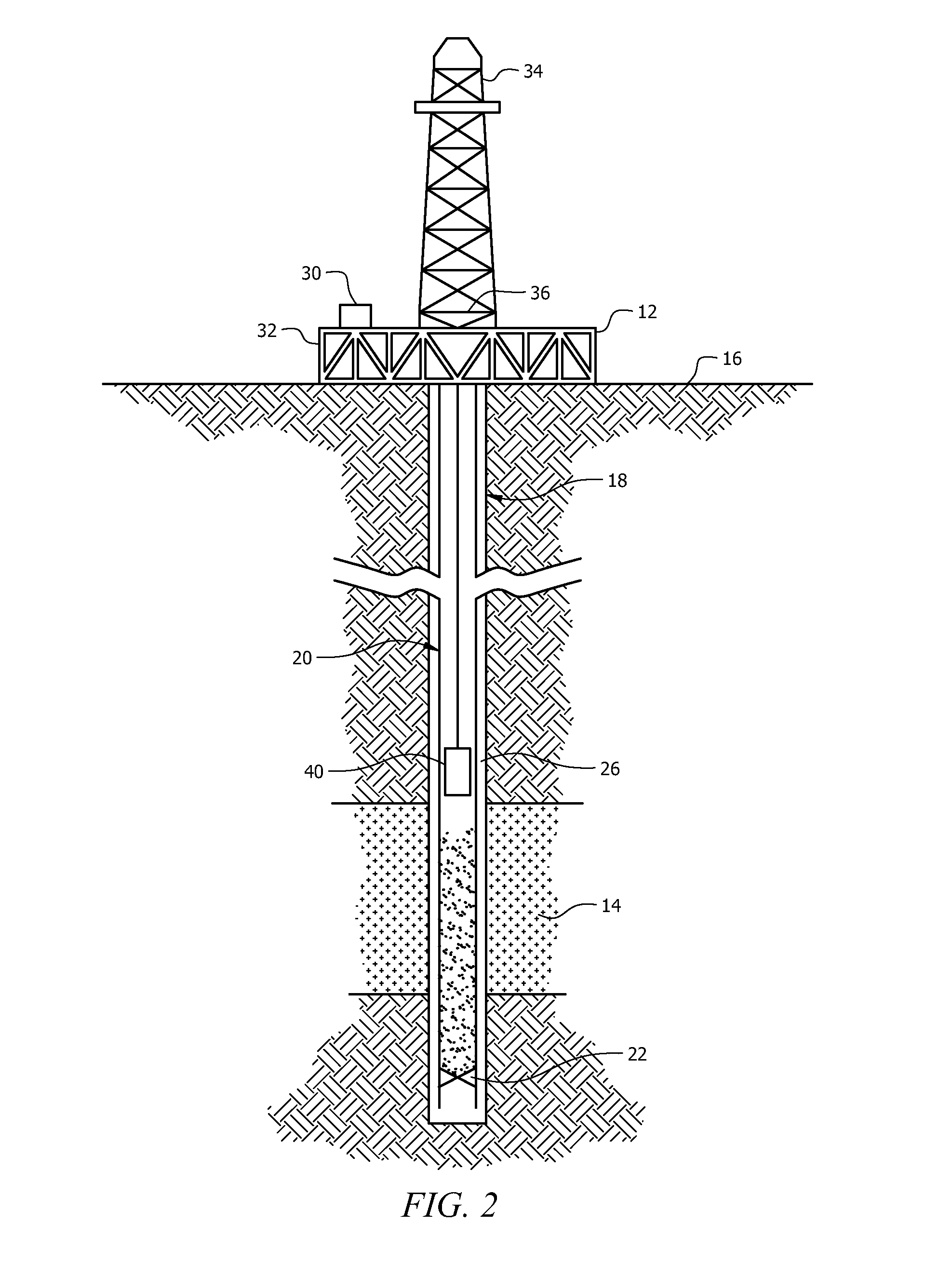

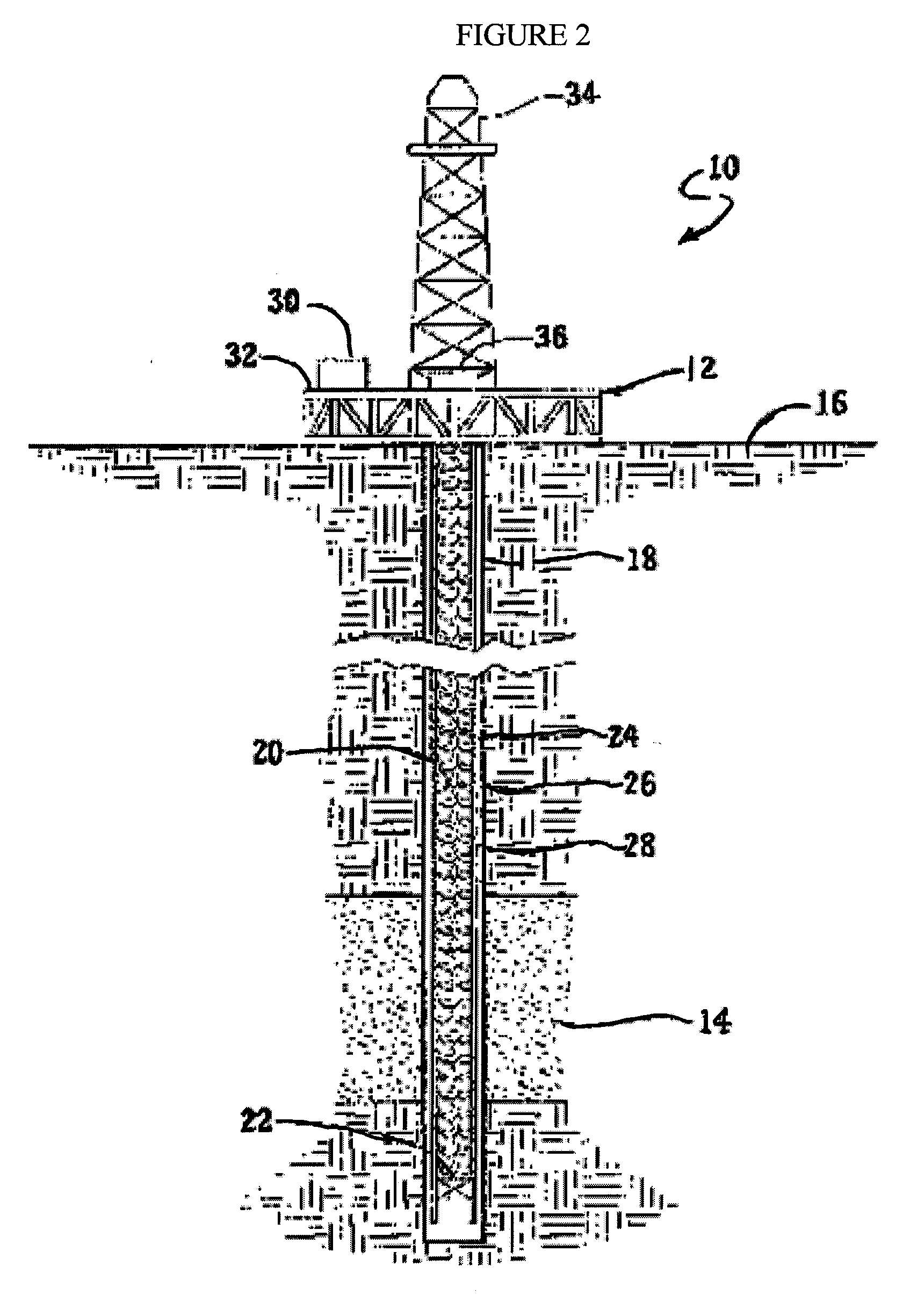

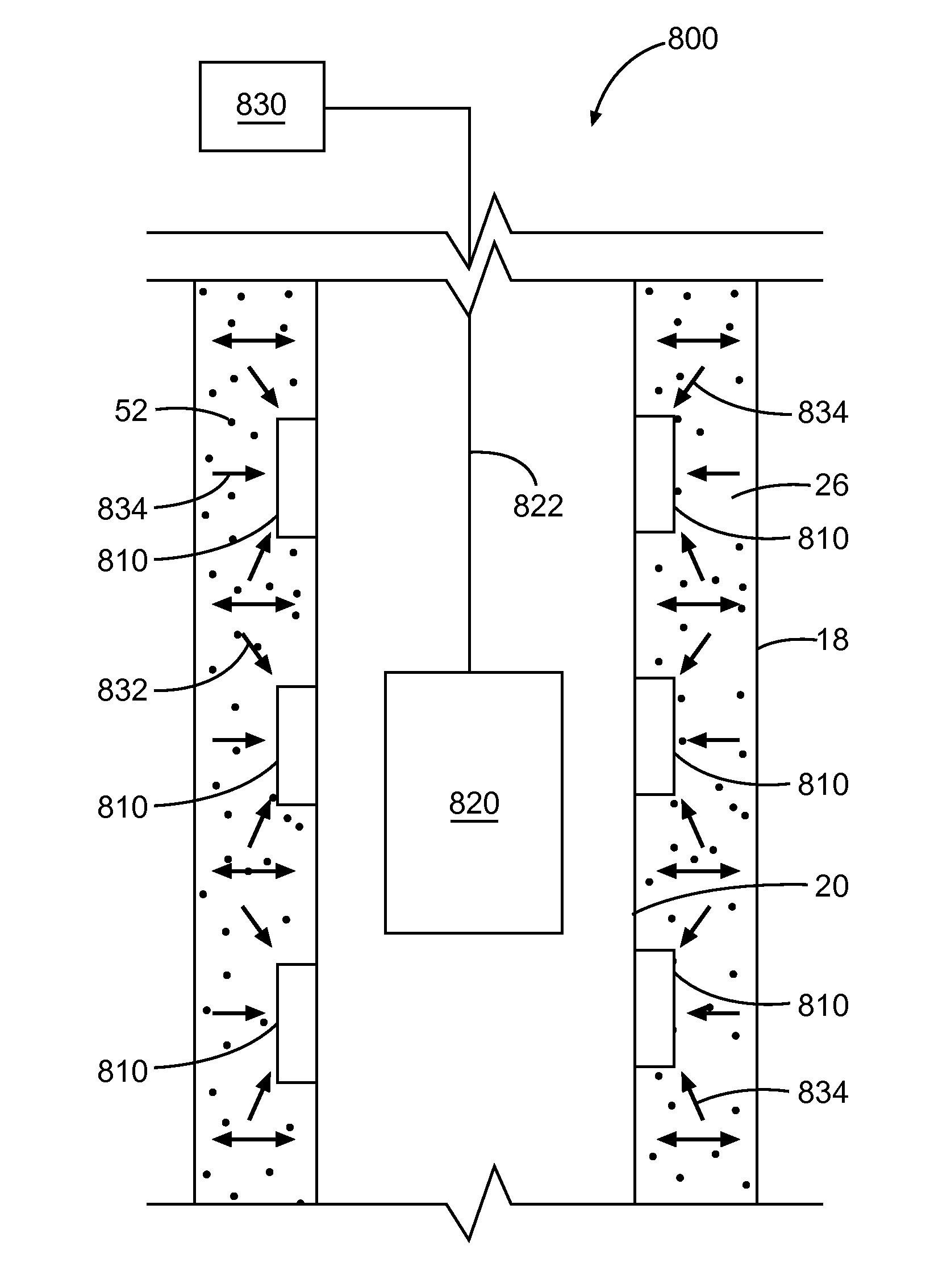

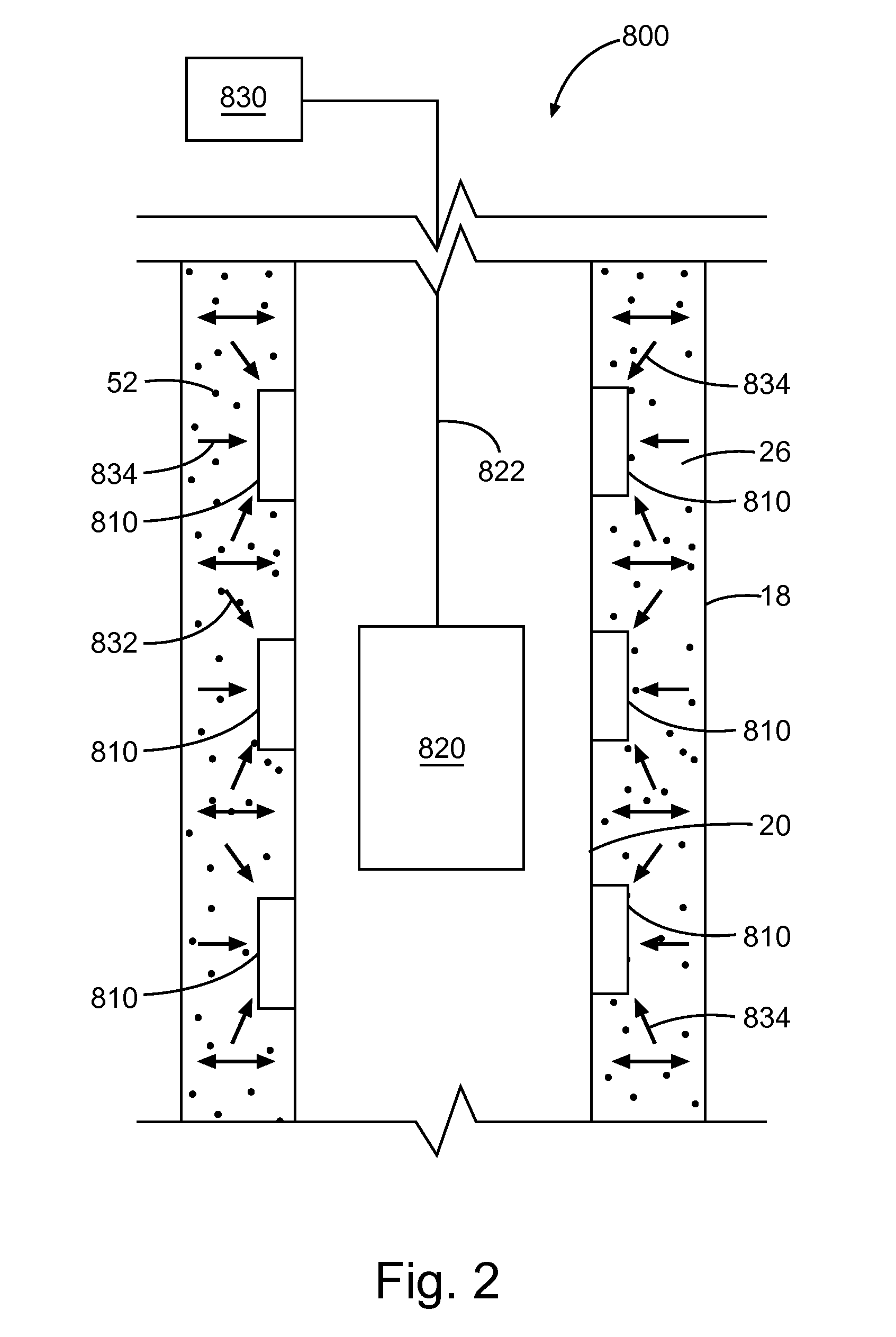

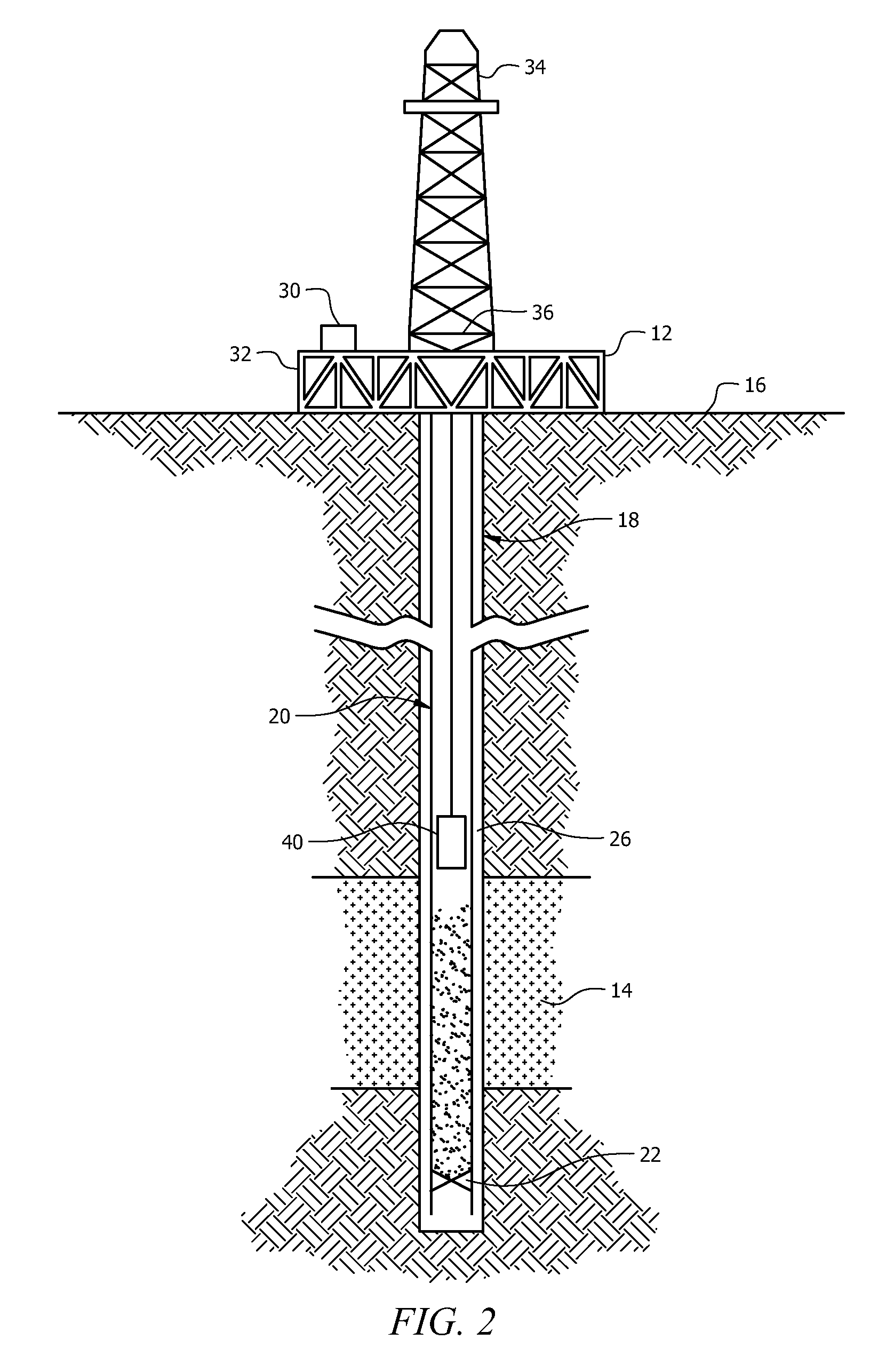

Use of micro-electro-mechanical systems (MEMS) in well treatments

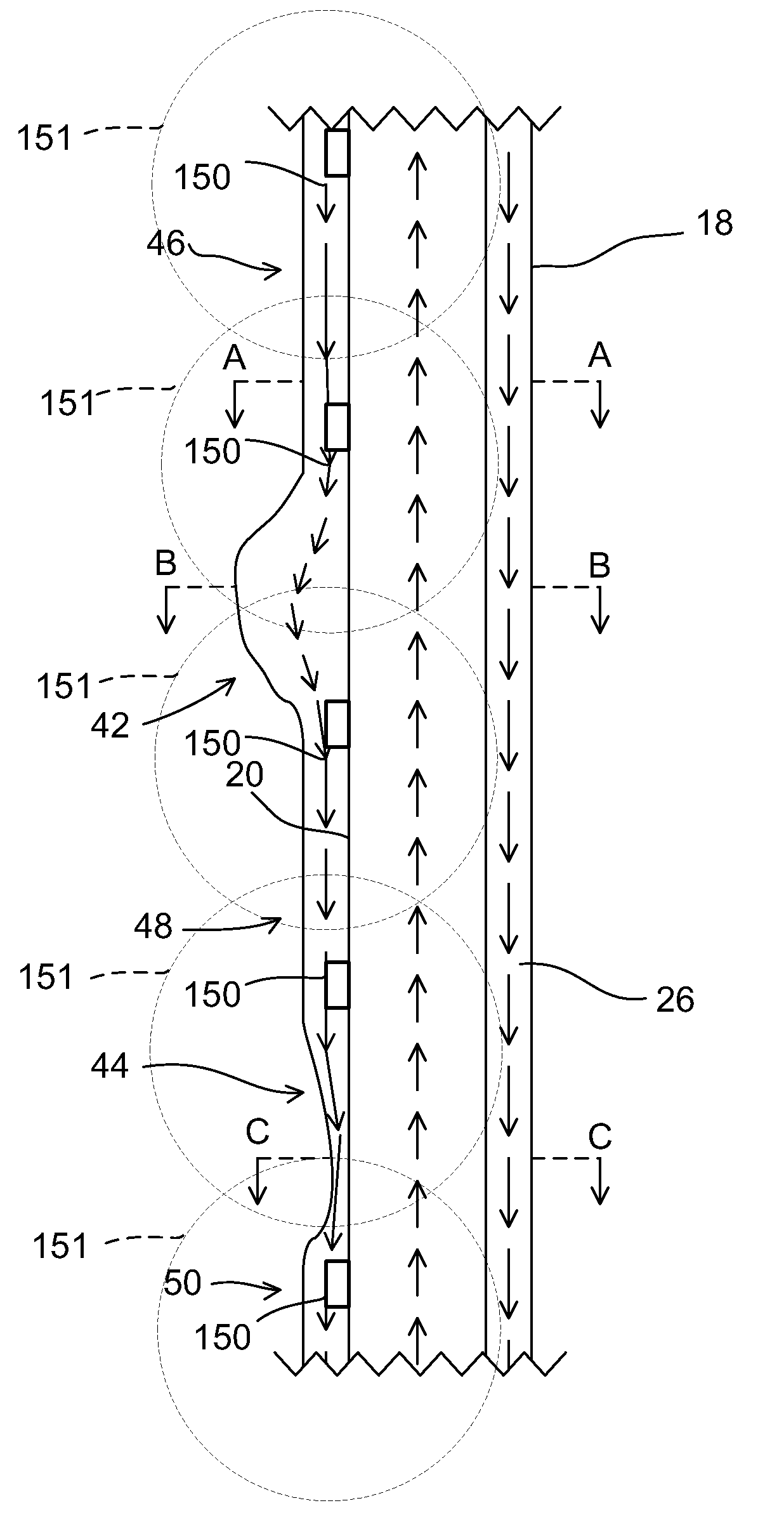

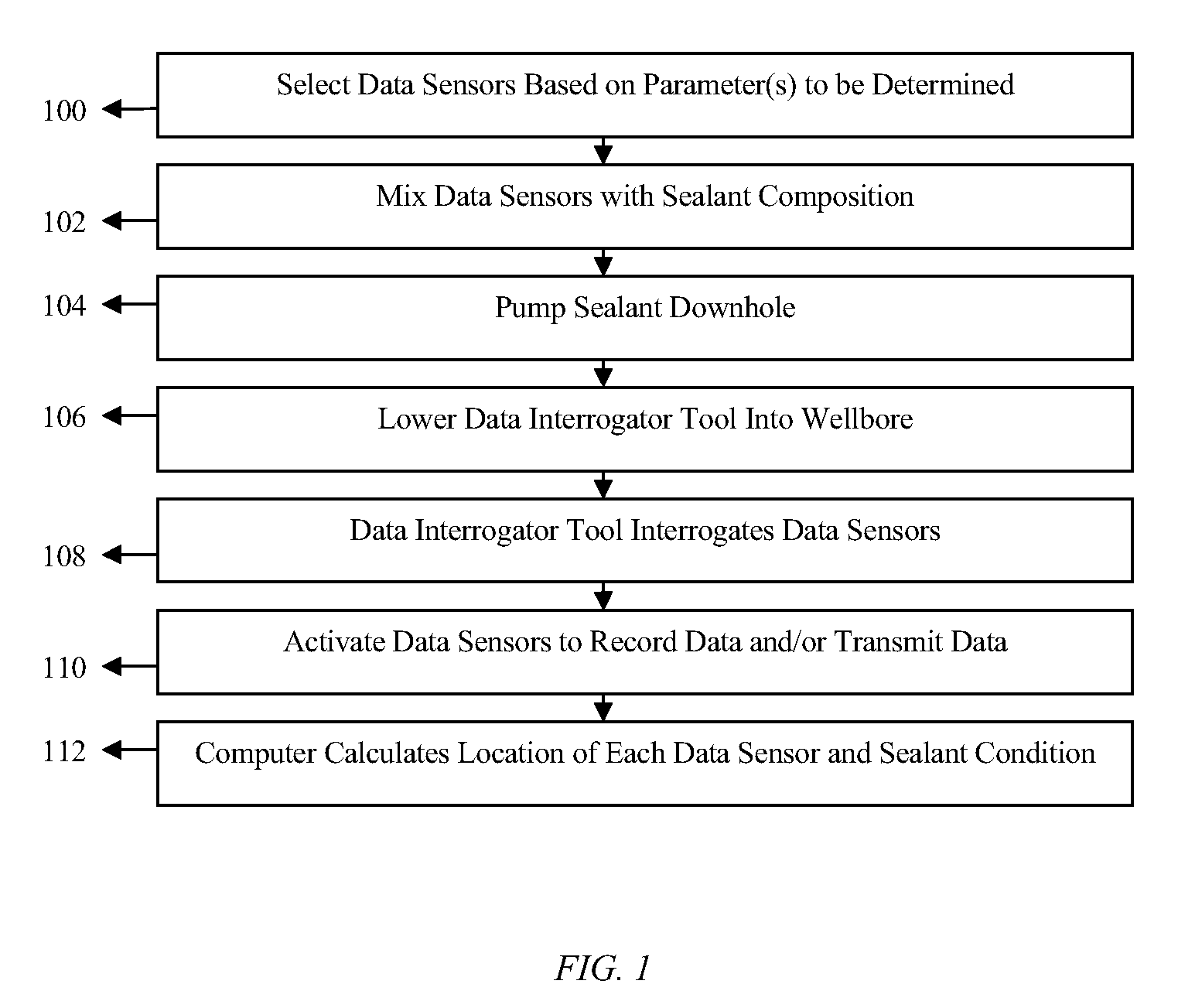

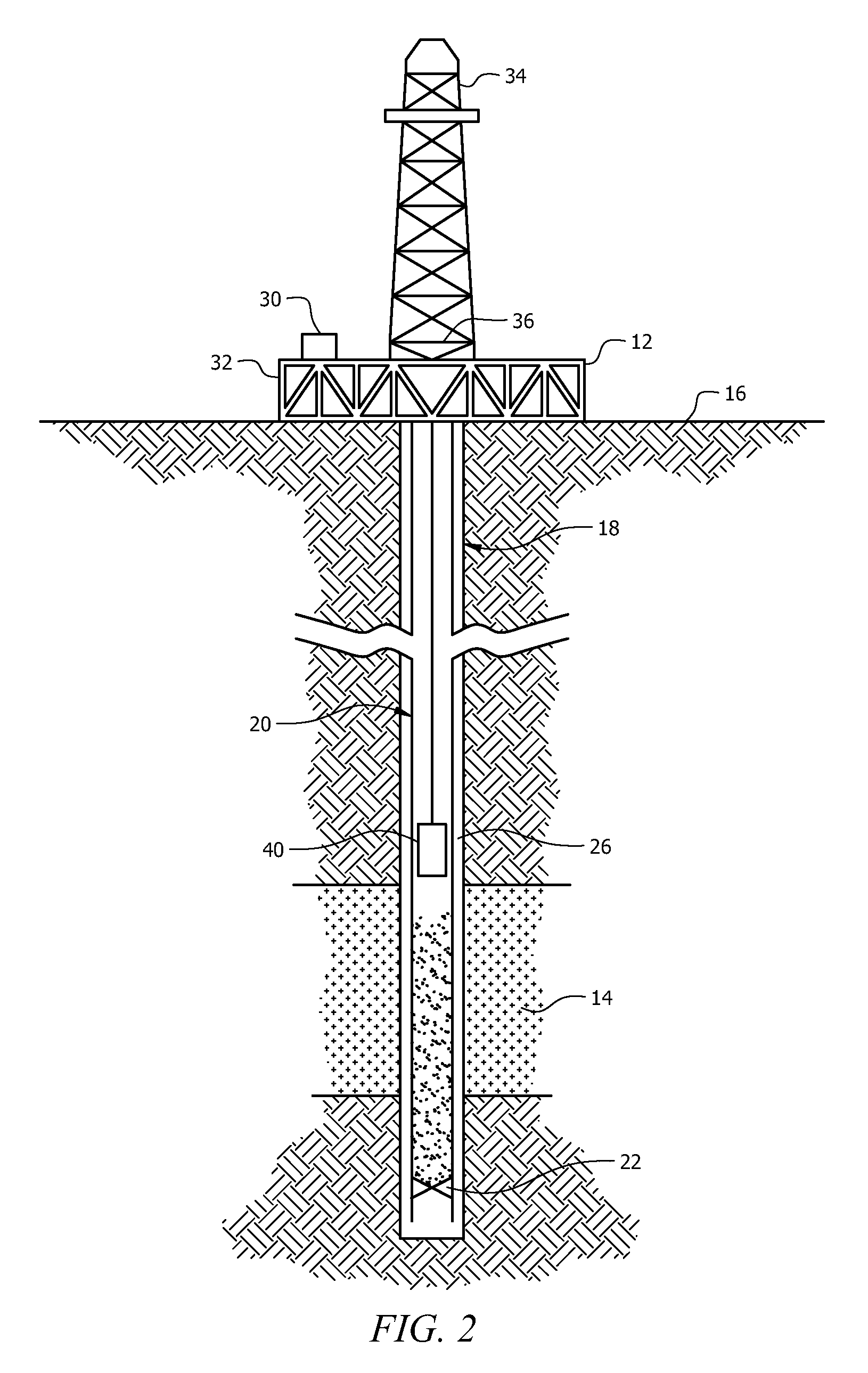

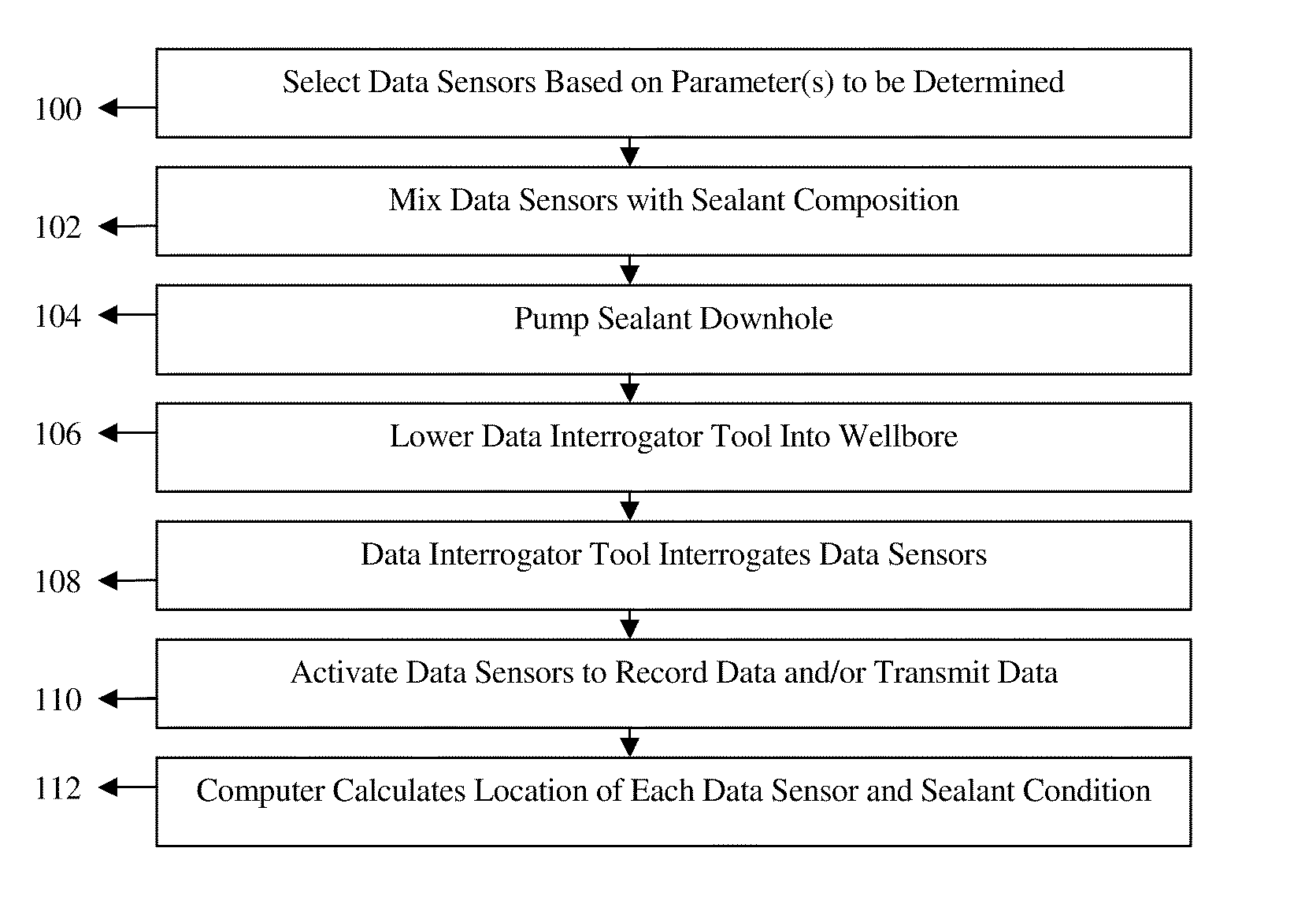

A method of servicing a wellbore, comprising placing a wellbore composition comprising a plurality of Micro-Electro-Mechanical System (MEMS) sensors in the wellbore, placing a plurality of acoustic sensors in the wellbore, obtaining data from the MEMS sensors and data from the acoustic sensors using a plurality of data interrogation units spaced along a length of the wellbore, and transmitting the data obtained from the MEMS sensors and the acoustic sensors from an interior of the wellbore to an exterior of the wellbore. A method of servicing a wellbore, comprising placing a wellbore composition comprising a plurality of Micro-Electro-Mechanical System (MEMS) sensors in the wellbore, and obtaining data from the MEMS sensors using a plurality of data interrogation units spaced along a length of the wellbore, wherein one or more of the data interrogation units is powered by a turbo generator or a thermoelectric generator located in the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

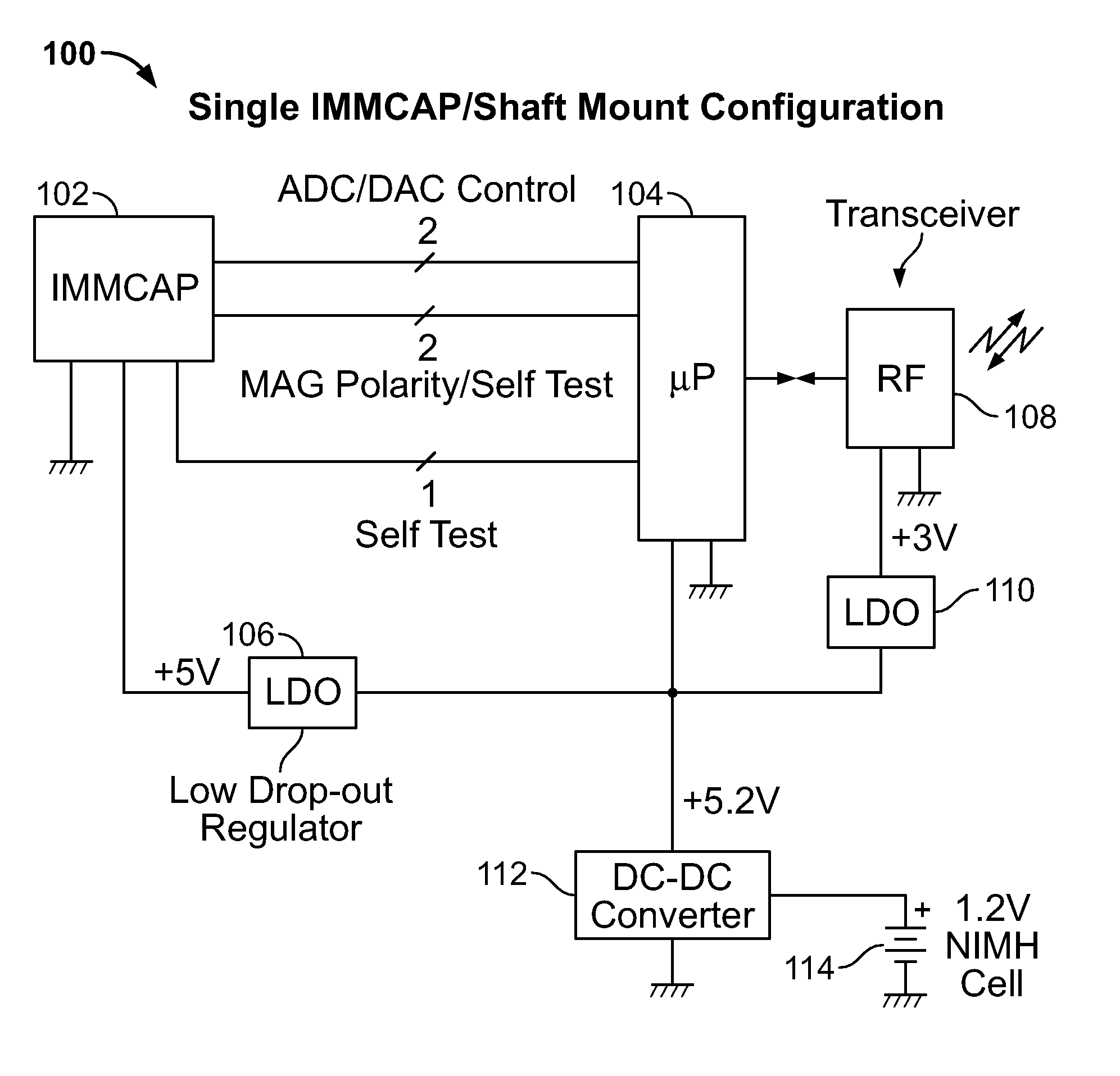

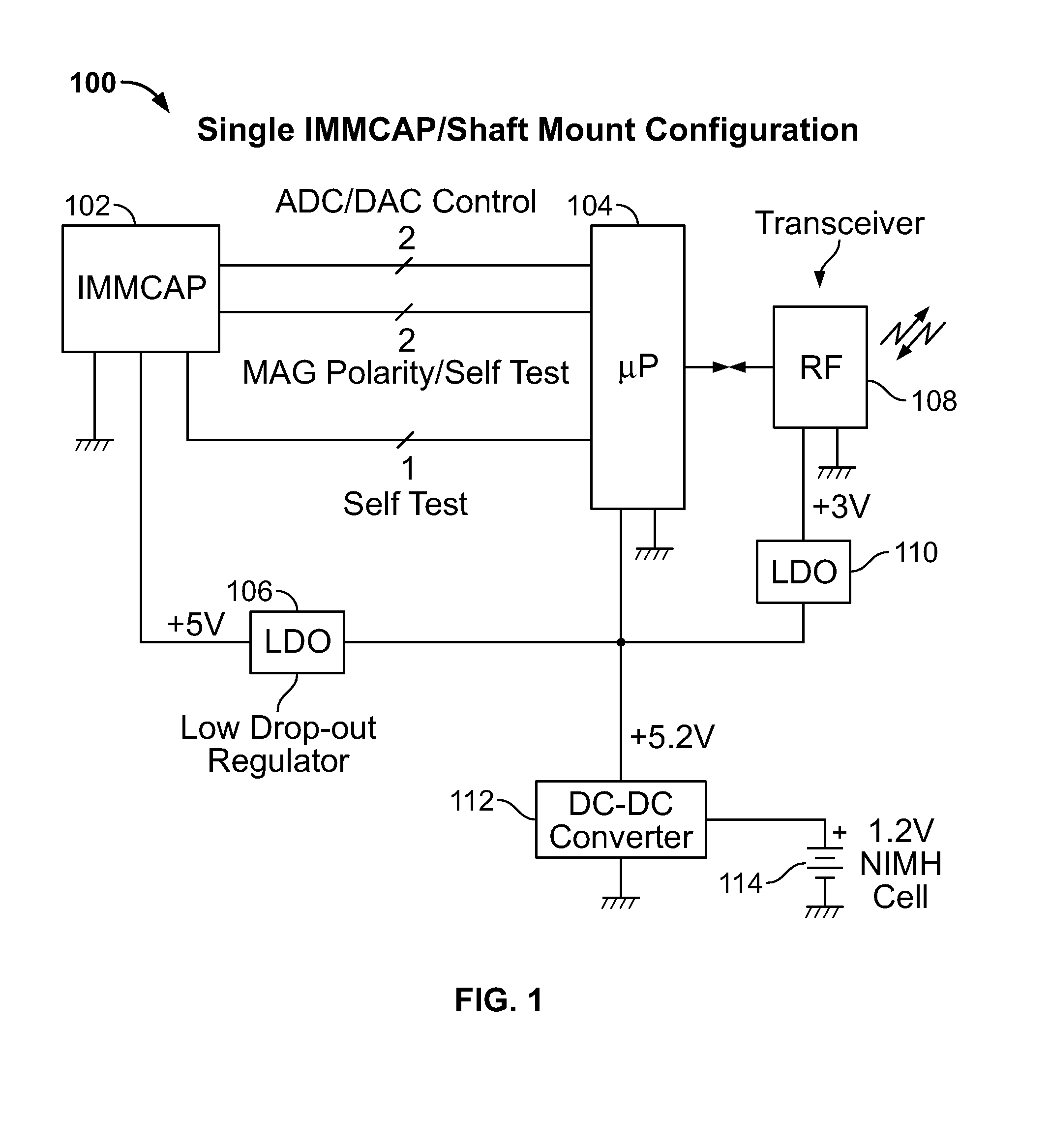

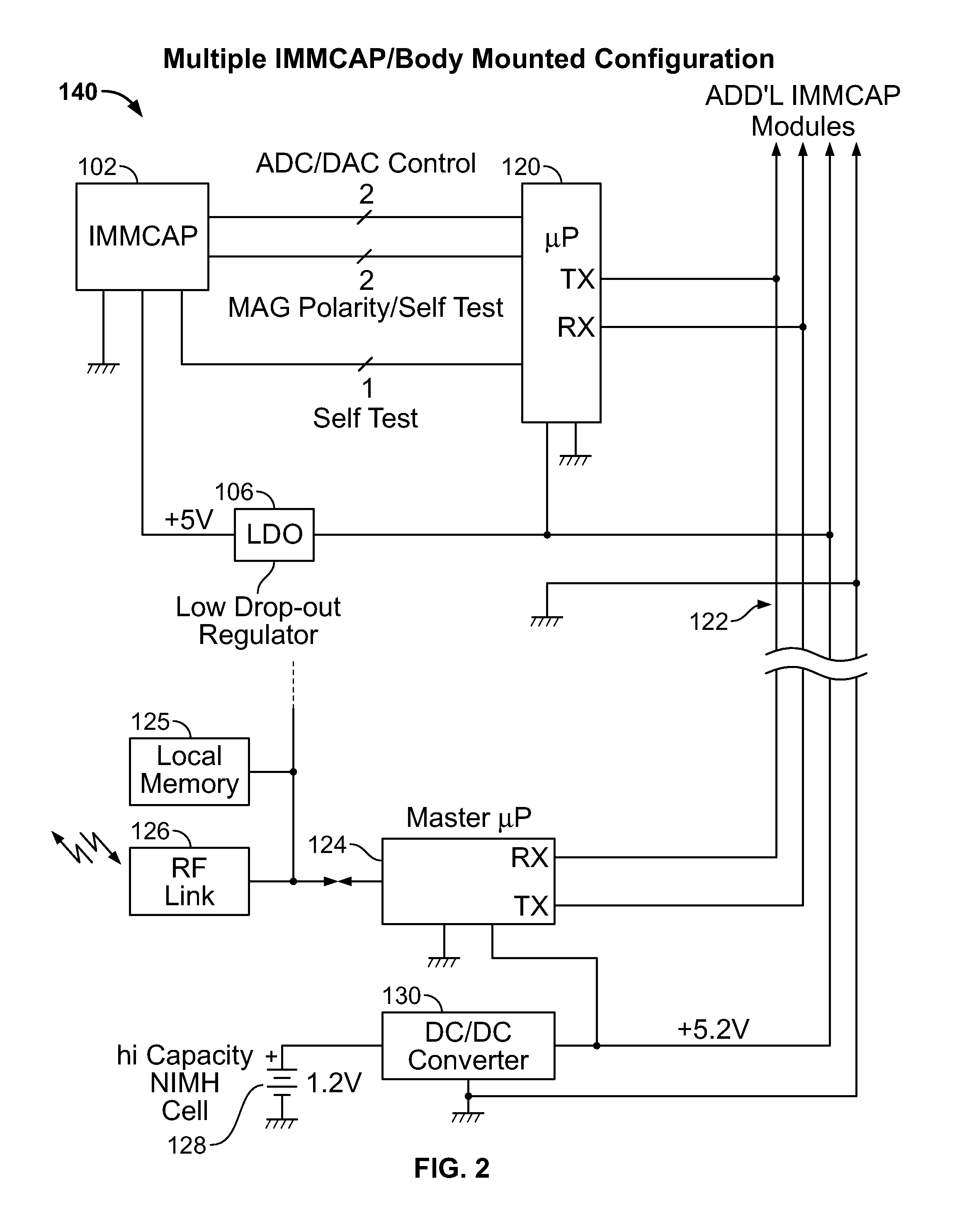

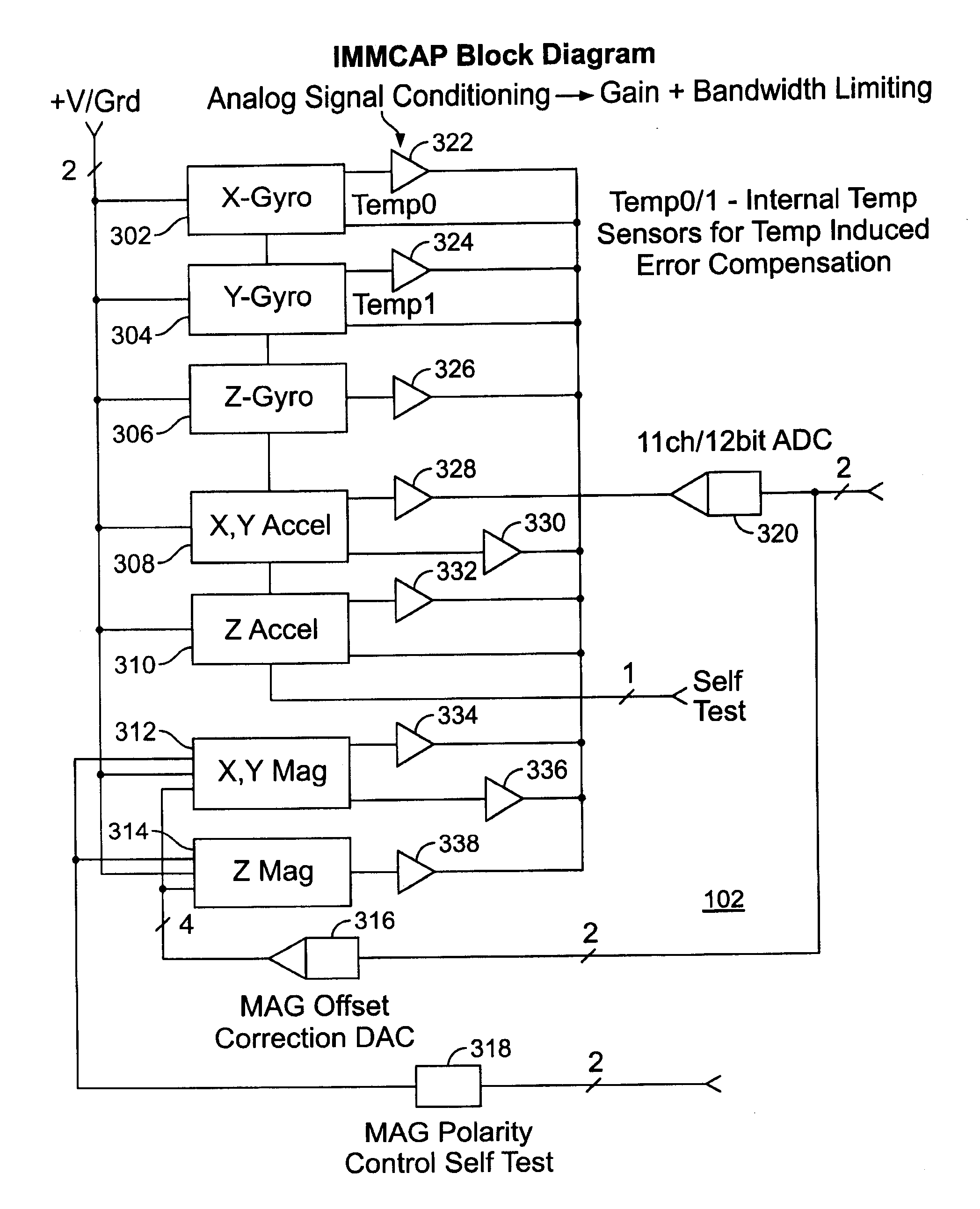

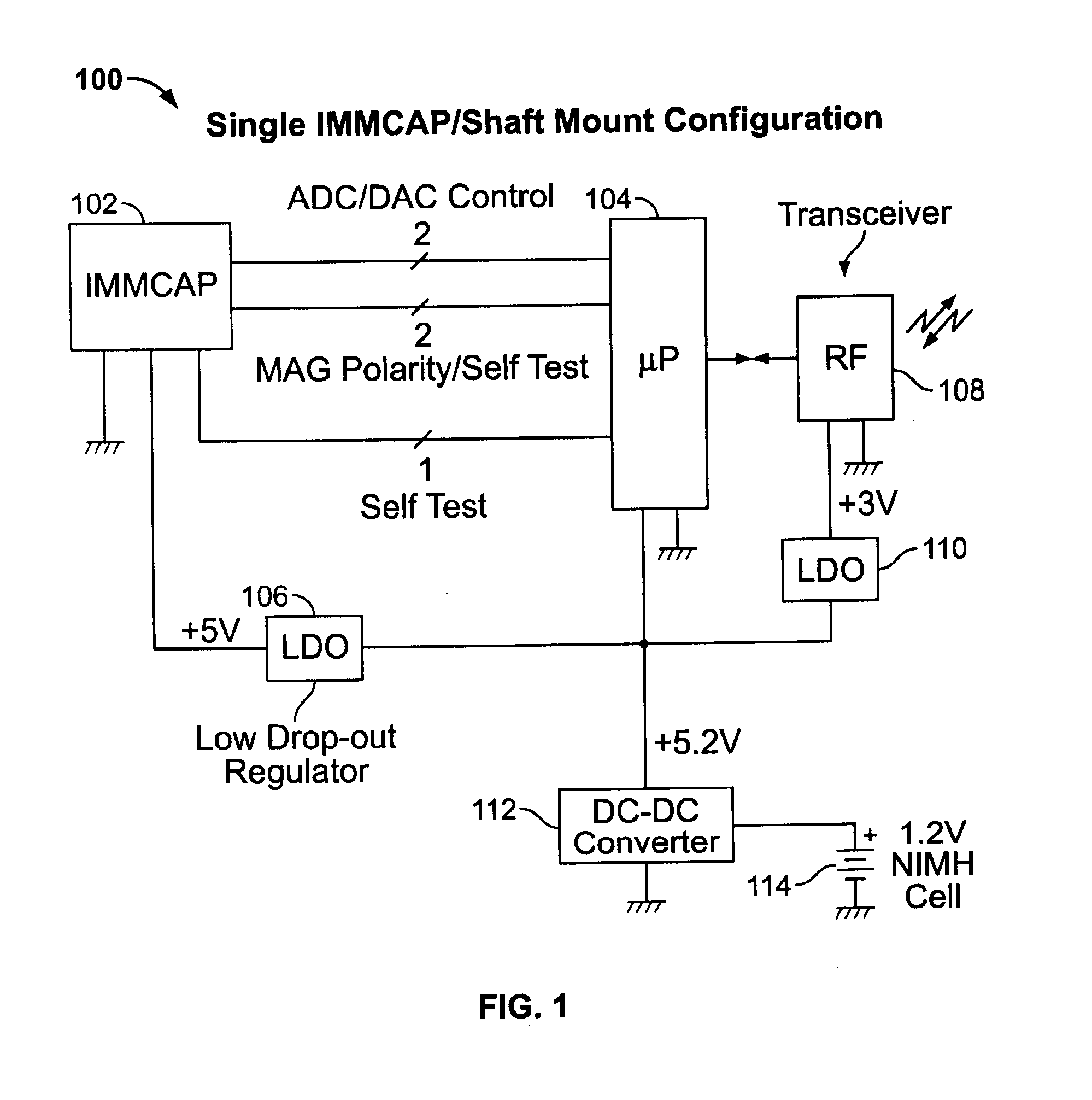

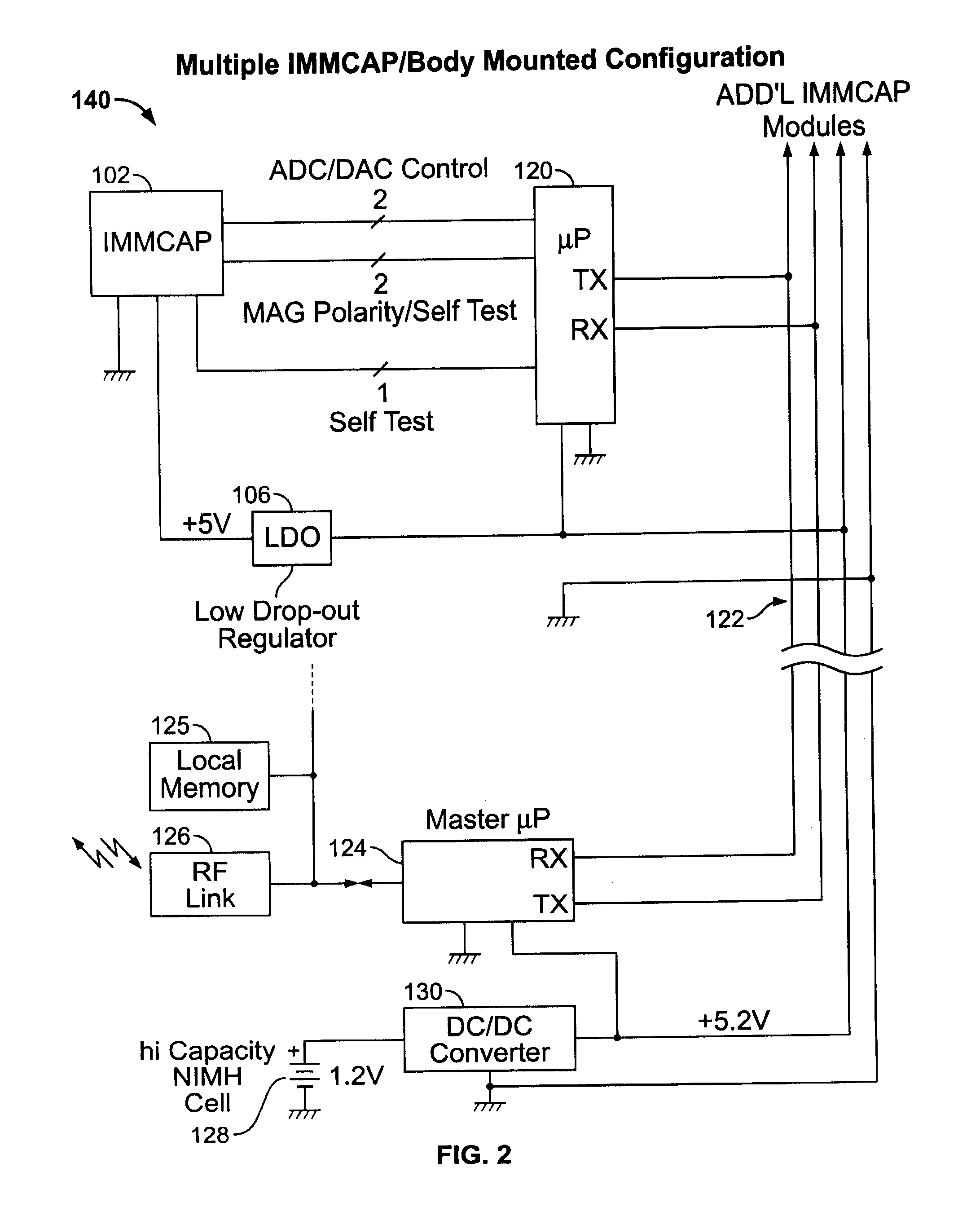

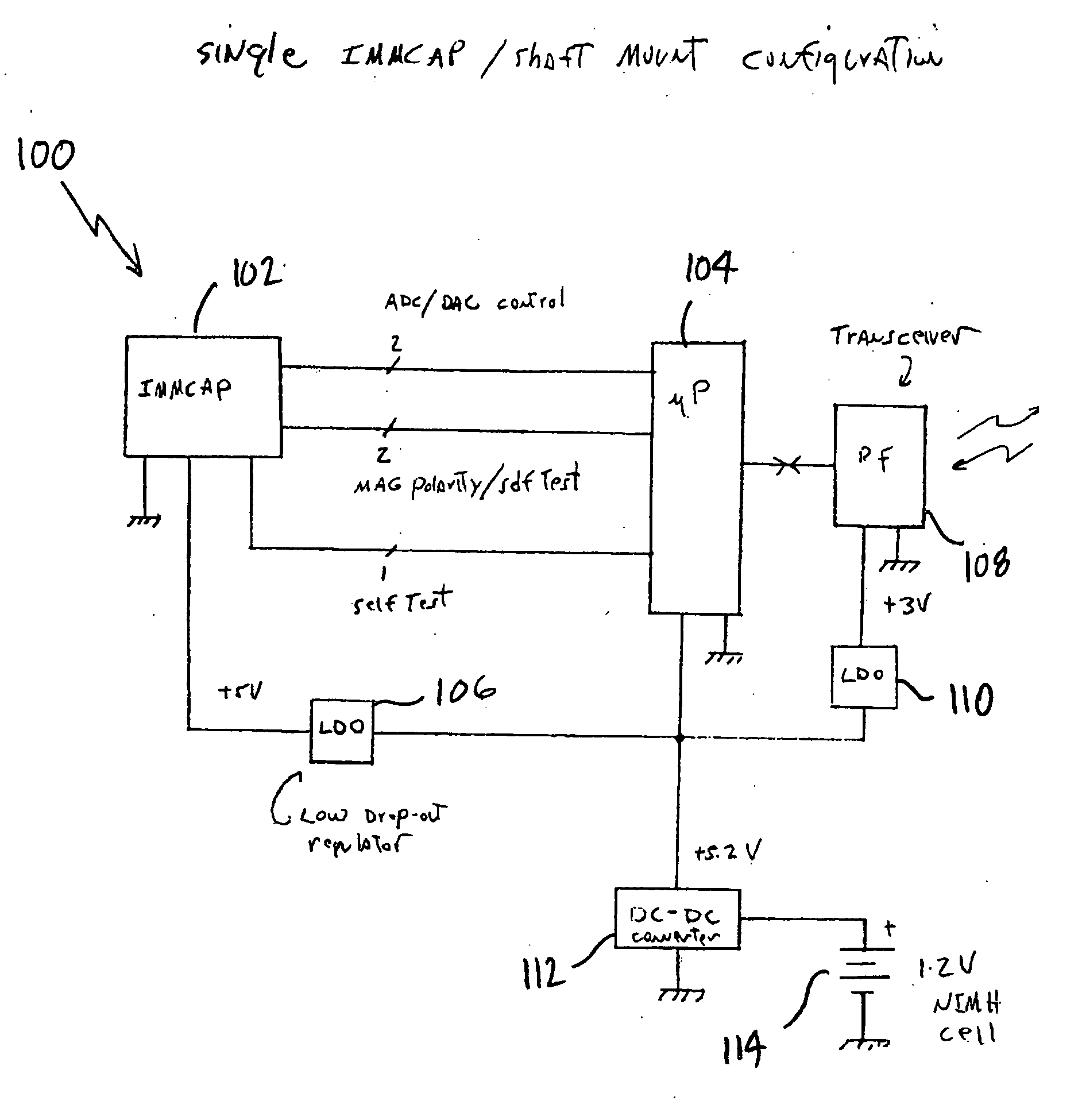

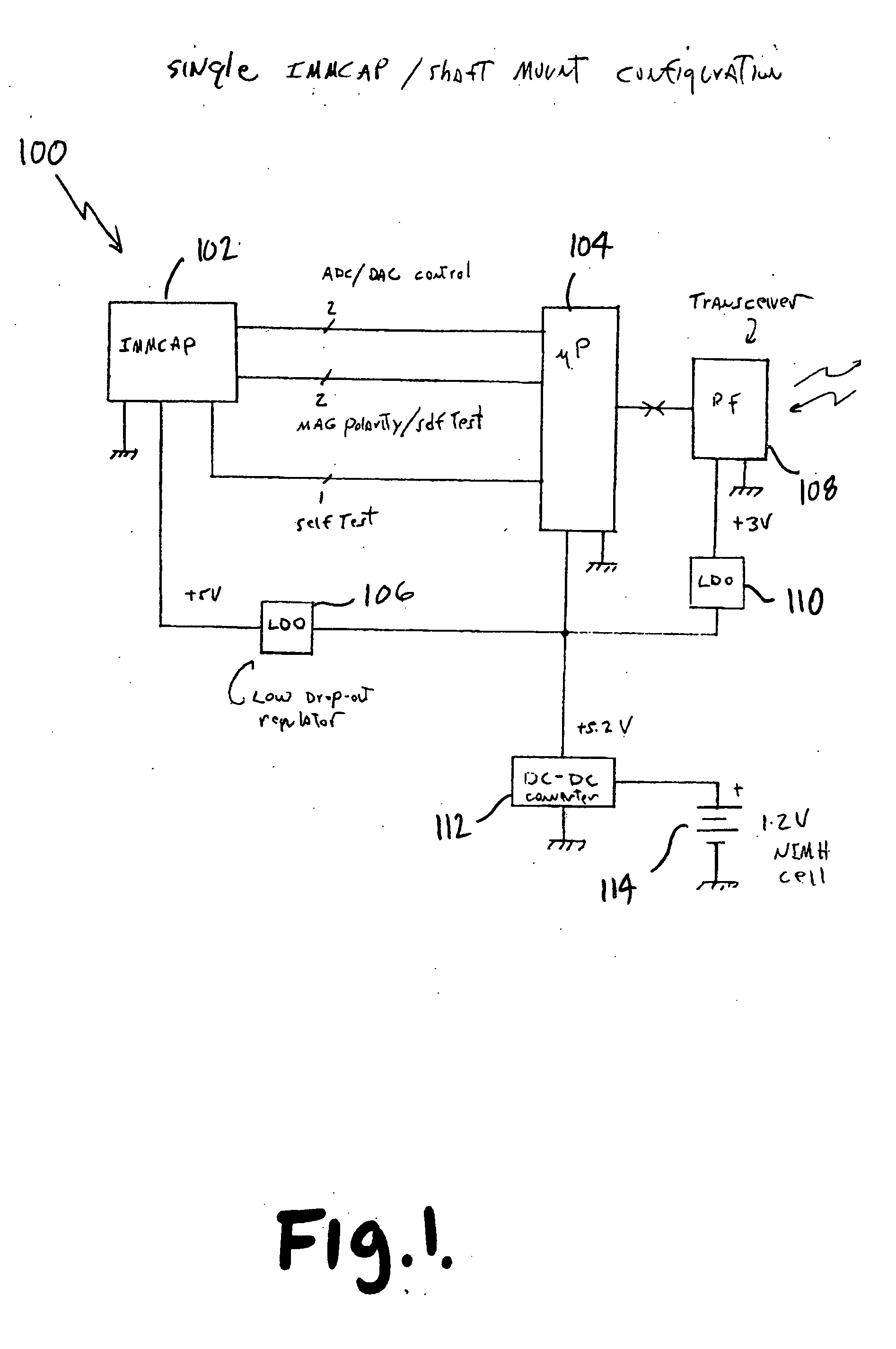

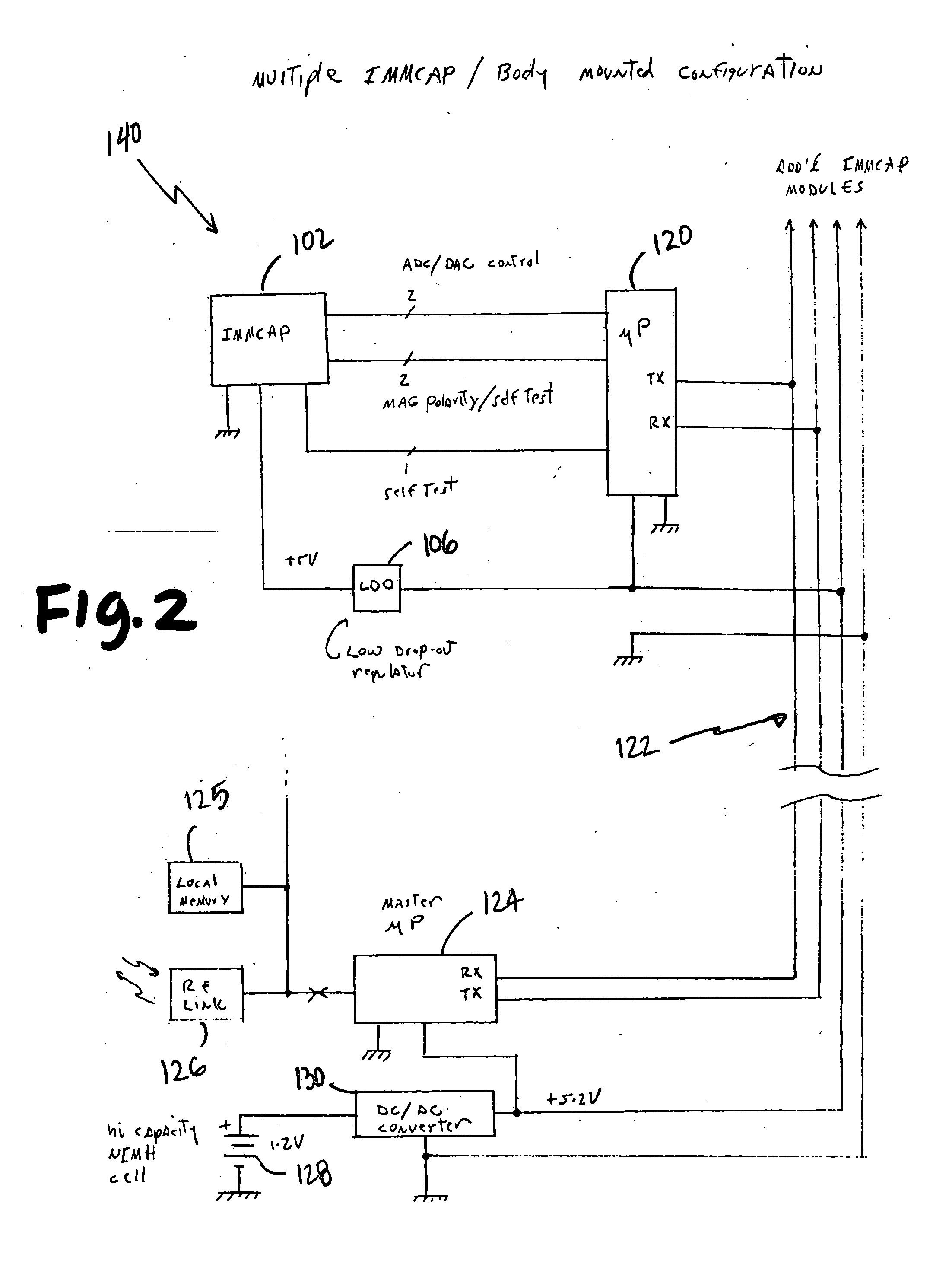

Single/multiple axes six degrees of freedom (6 DOF) inertial motion capture system with initial orientation determination capability

A highly miniaturized electronic data acquisition system includes MEMS sensors that can be embedded onto moving device without affecting the static / dynamic motion characteristics of the device. The basic inertial magnetic motion capture (IMMCAP) module consists of a 3D printed circuit board having MEMS sensors configured to provide a tri-axial accelerometer; a tri-axial gyroscope, and a tri-axial magnetometer all in communication with analog to digital converters to convert the analog motion data to digital data for determining classic inertial measurement and change in spatial orientation (rho, theta, phi) and linear translation (x, y, z) relative to a fixed external coordinate system as well as the initial spatial orientation relative to the know relationship of the earth magnetic and gravitational fields. The data stream from the IMMCAP modules will allow the reconstruction of the time series of the 6 degrees of freedom for each rigid axis associated with each independent IMMCAP module.

Owner:MAGNETO INERTIAL SENSING TECH

Motion sensing apparatus, systems and techniques

InactiveUS20070219744A1Gymnastic exercisingNavigation by speed/acceleration measurementsDigital data3d print

A highly miniaturized electronic data acquisition system includes MEMS sensors that can be embedded onto moving device without affecting the static / dynamic motion characteristics of the device. The basic inertial magnetic motion capture (IMMCAP) module consists of a 3D printed circuit board having MEMS sensors configured to provide a tri-axial accelerometer; a tri-axial gyroscope, and a tri-axial magnetometer all in communication with analog to digital converters to convert the analog motion data to digital data for determining classic inertial measurement and change in spatial orientation (rho, theta, phi) and linear translation (x, y, z) relative to a fixed external coordinate system as well as the initial spatial orientation relative to the know relationship of the earth magnetic and gravitational fields. The data stream from the IMMCAP modules will allow the reconstruction of the time series of the 6 degrees of freedom for each rigid axis associated with each independent IMMCAP module.

Owner:C LAN WIRELESS

Single/multiple axes six degrees of freedom (6 DOF) inertial motion capture system with initial orientation determination capability

A highly miniaturized electronic data acquisition system includes MEMS sensors that can be embedded onto moving device without affecting the static / dynamic motion characteristics of the device. The basic inertial magnetic motion capture (IMMCAP) module consists of a 3D printed circuit board having MEMS sensors configured to provide a tri-axial accelerometer; a tri-axial gyroscope, and a tri-axial magnetometer all in communication with analog to digital converters to convert the analog motion data to digital data for determining classic inertial measurement and change in spatial orientation (rho, theta, phi) and linear translation (x, y, z) relative to a fixed external coordinate system as well as the initial spatial orientation relative to the know relationship of the earth magnetic and gravitational fields. The data stream from the IMMCAP modules will allow the reconstruction of the time series of the 6 degrees of freedom for each rigid axis associated with each independent IMMCAP module.

Owner:MAGNETO INERTIAL SENSING TECH

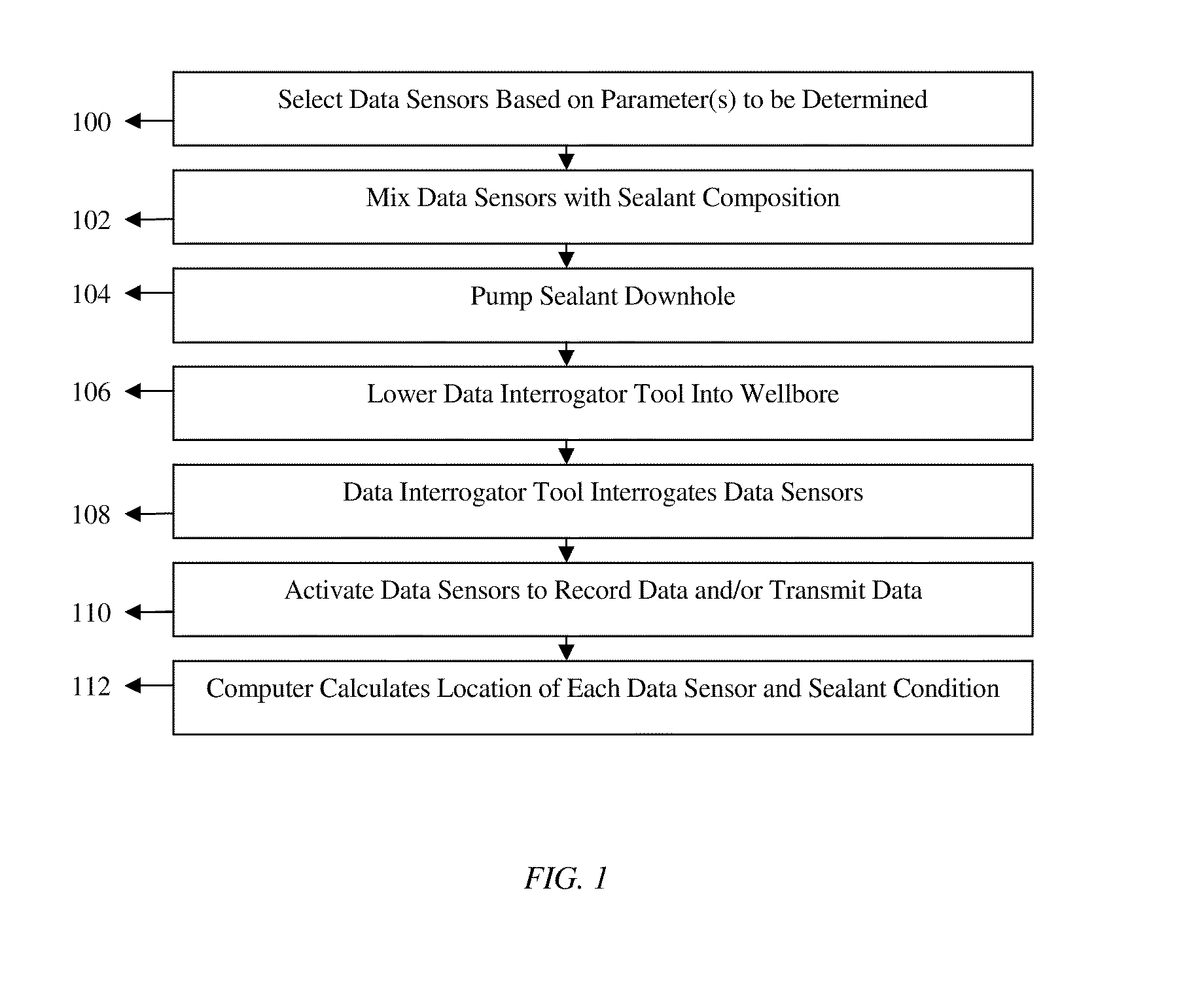

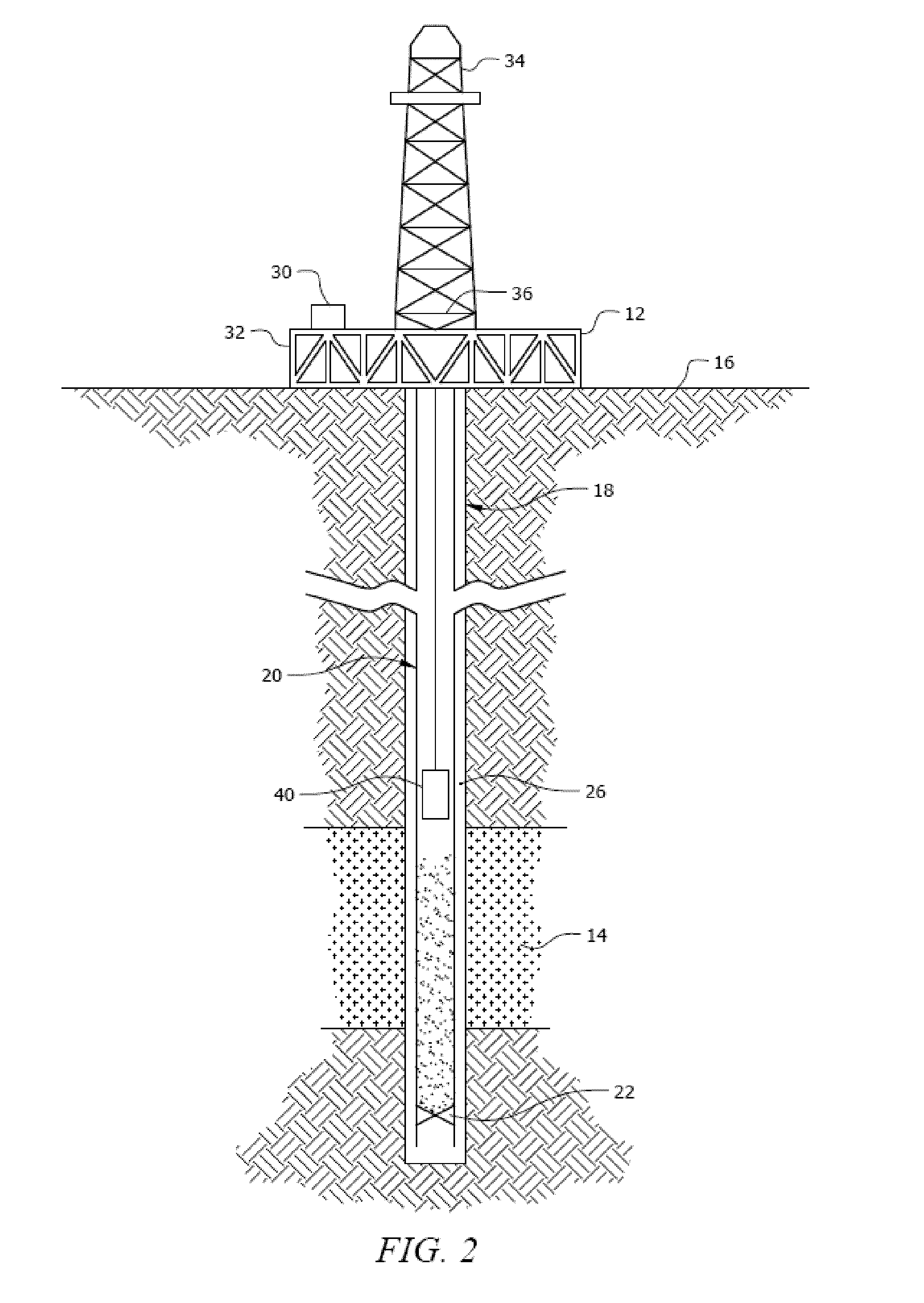

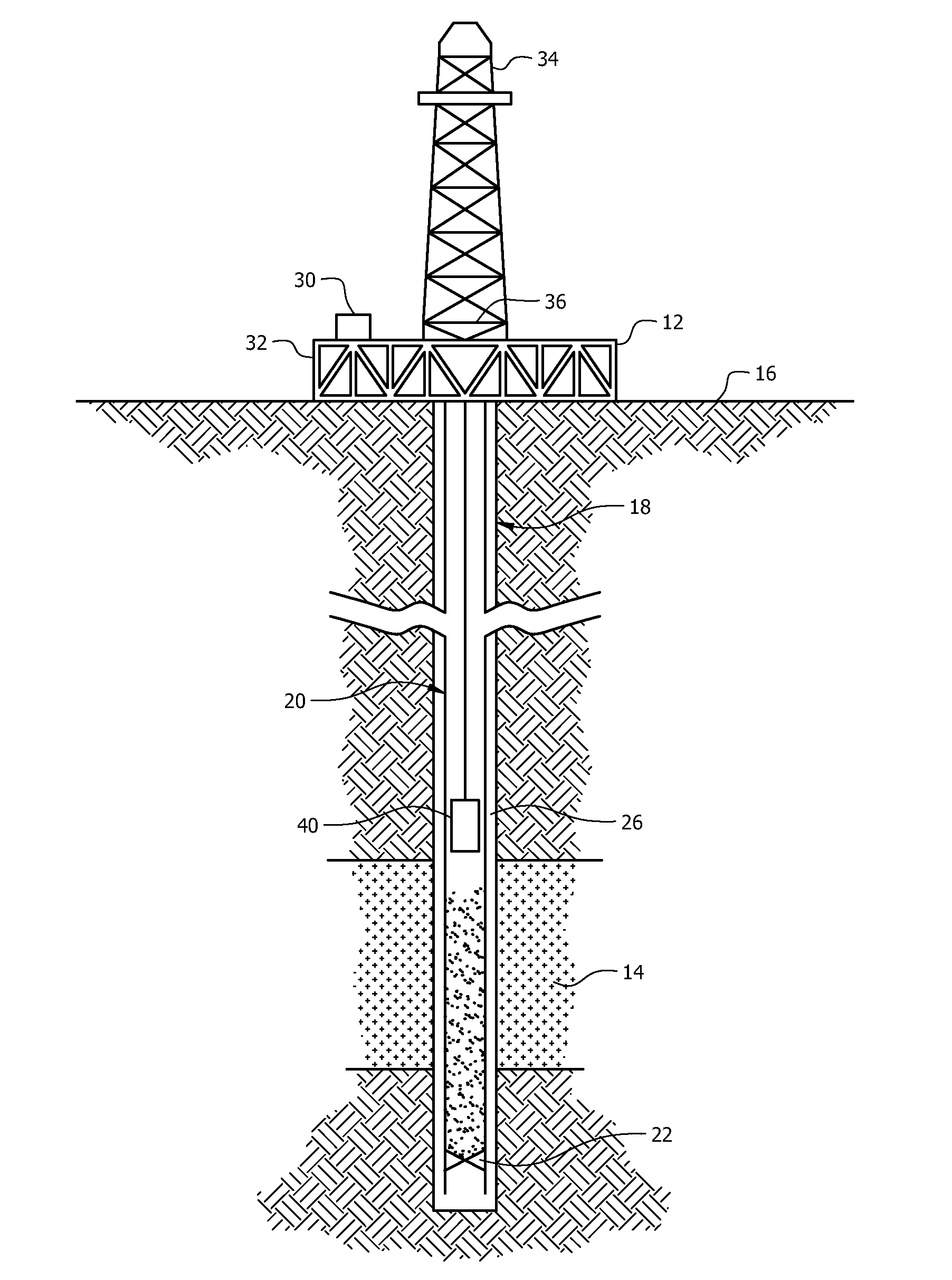

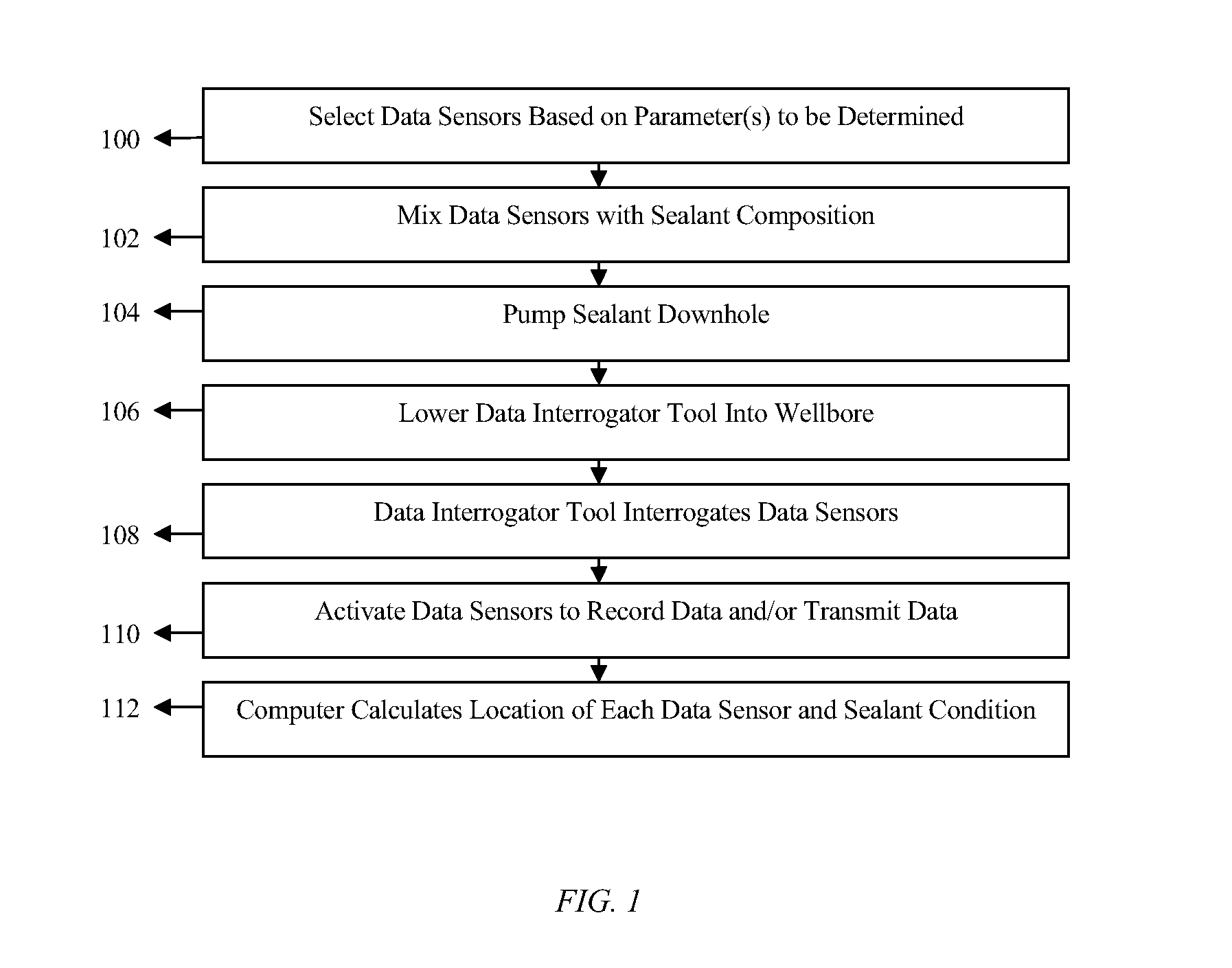

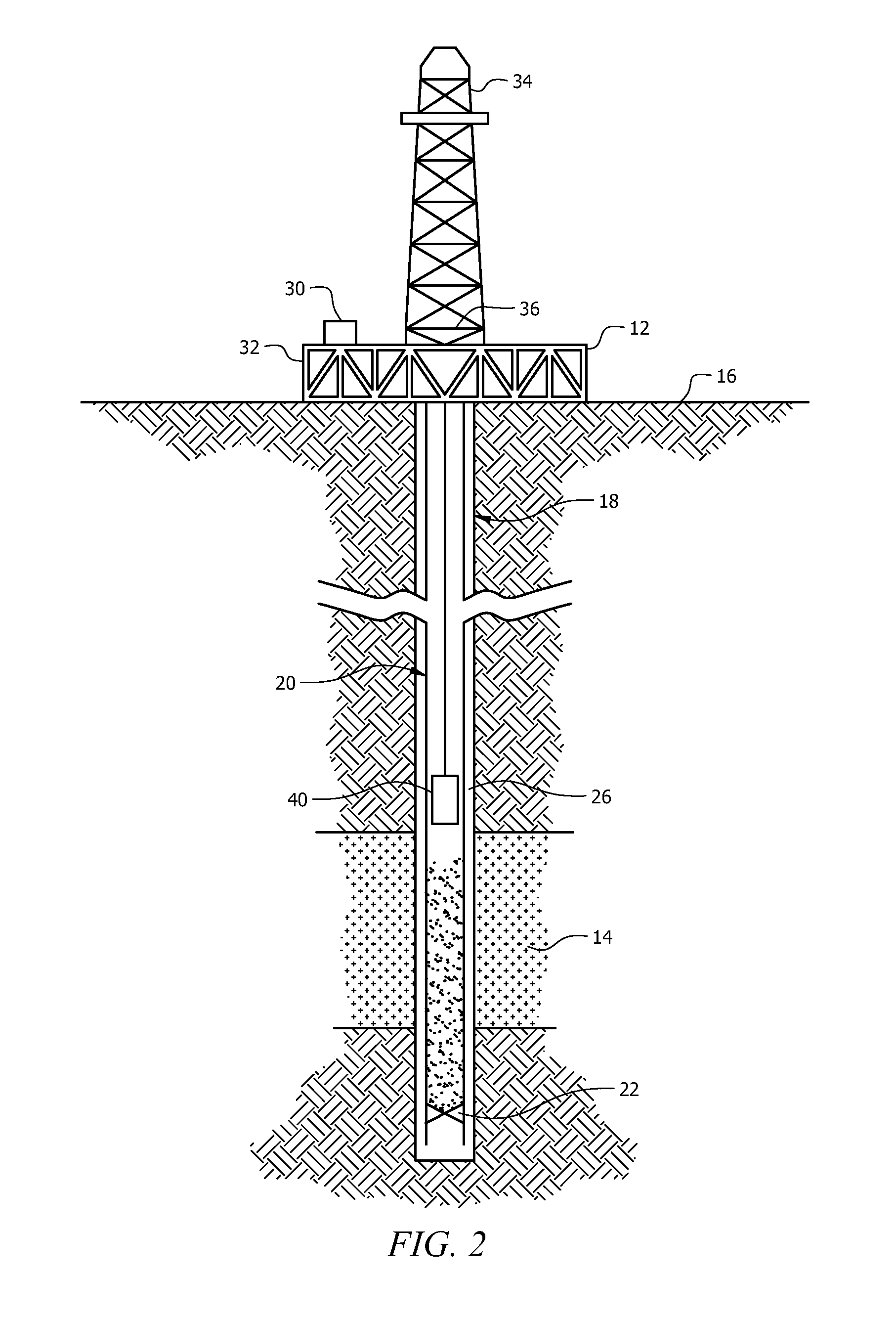

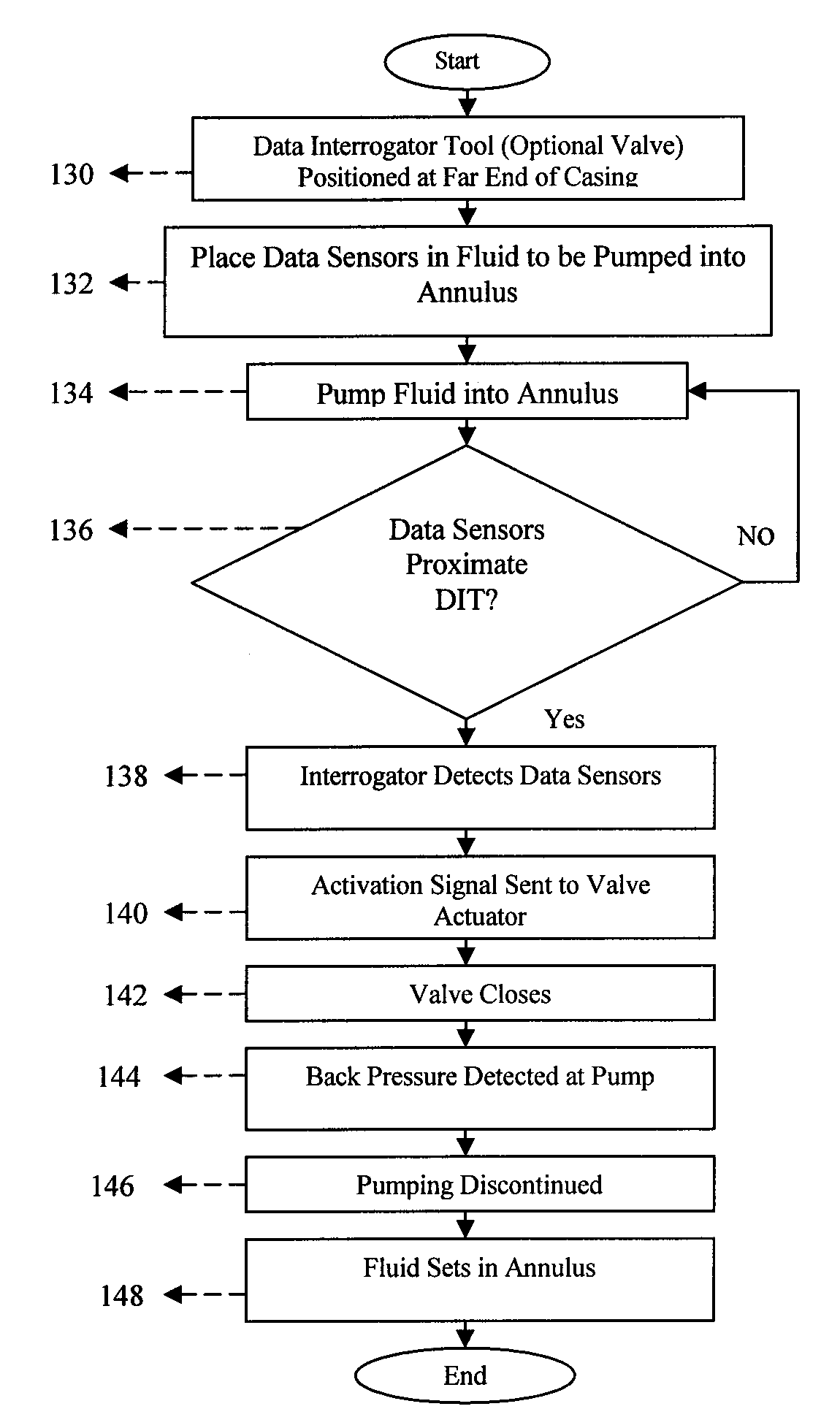

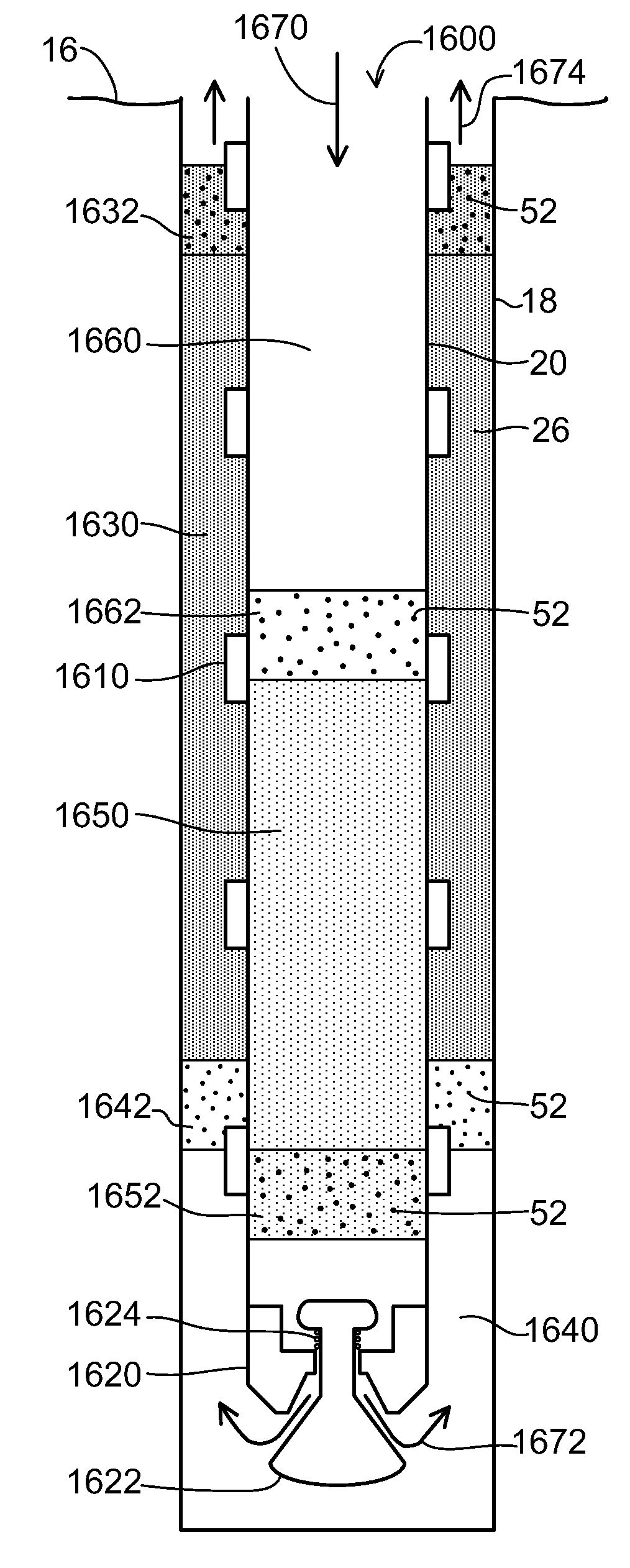

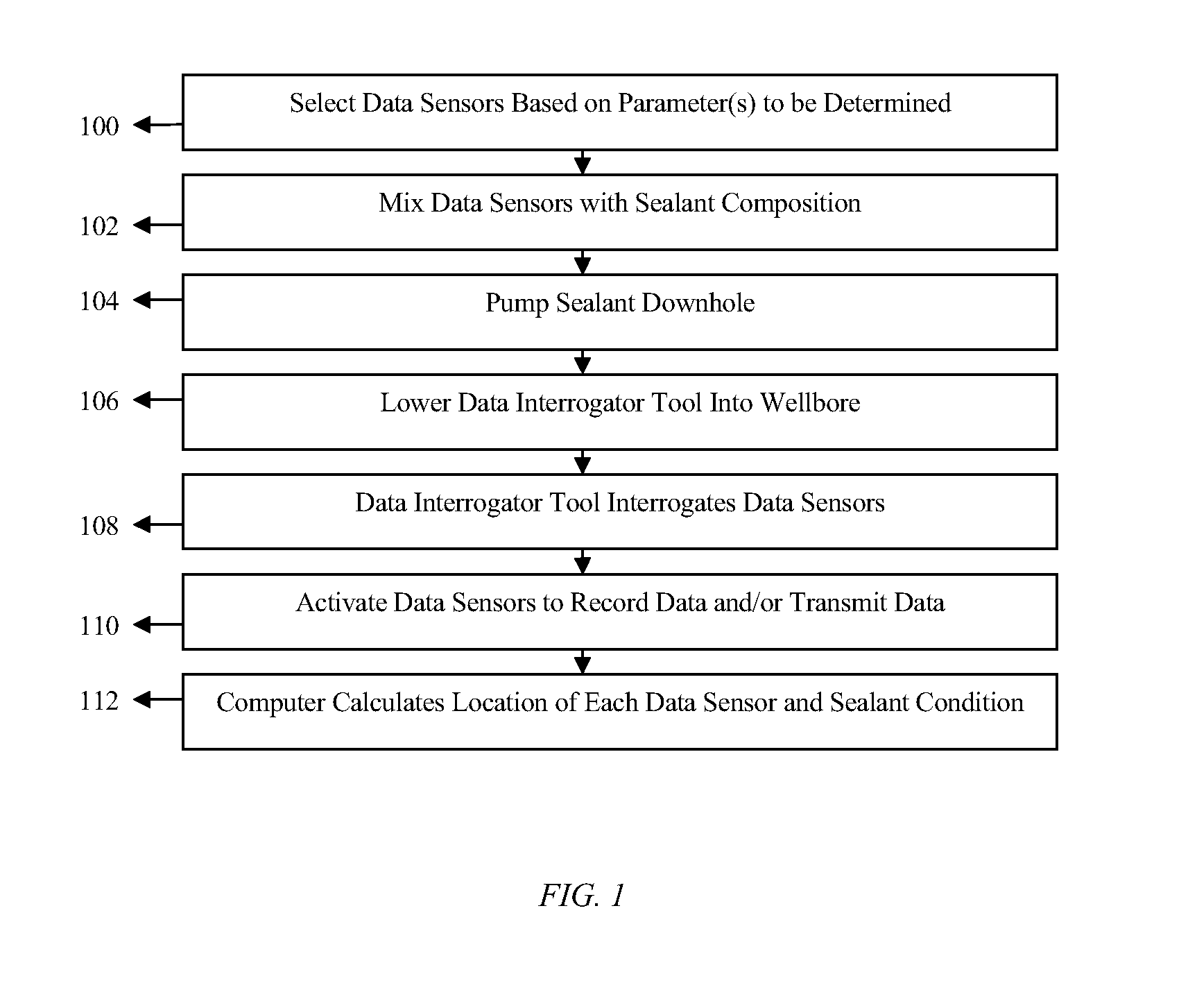

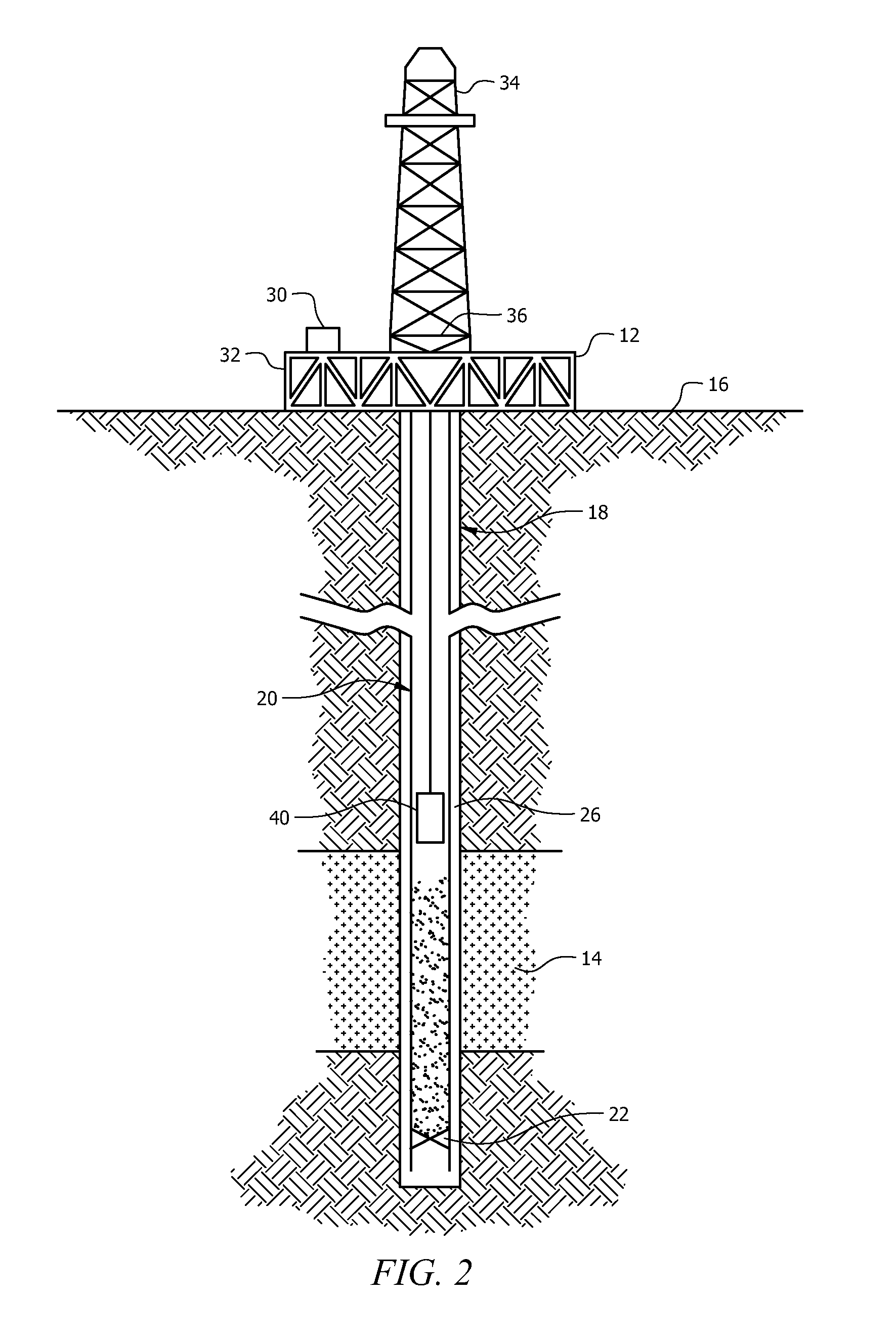

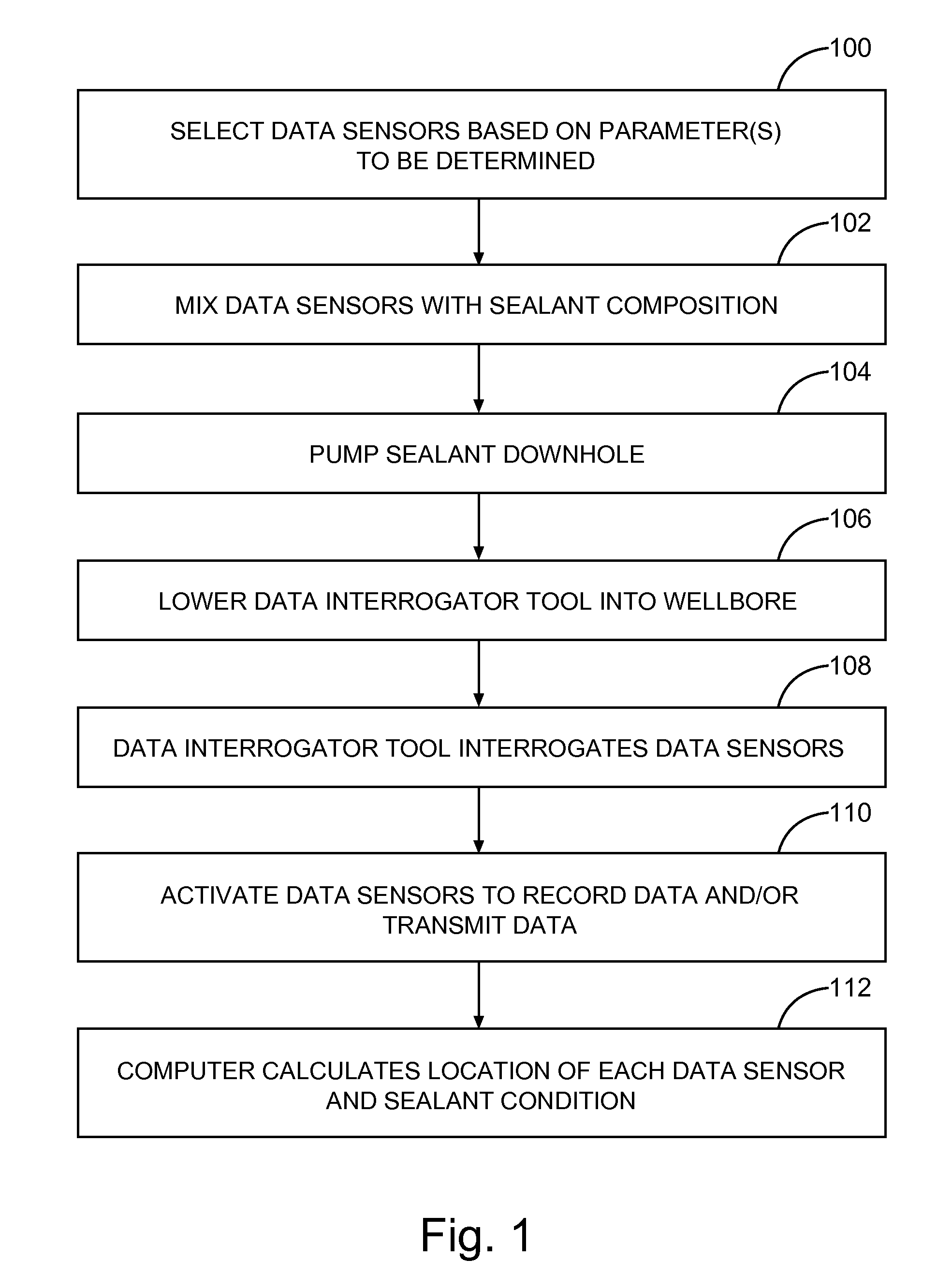

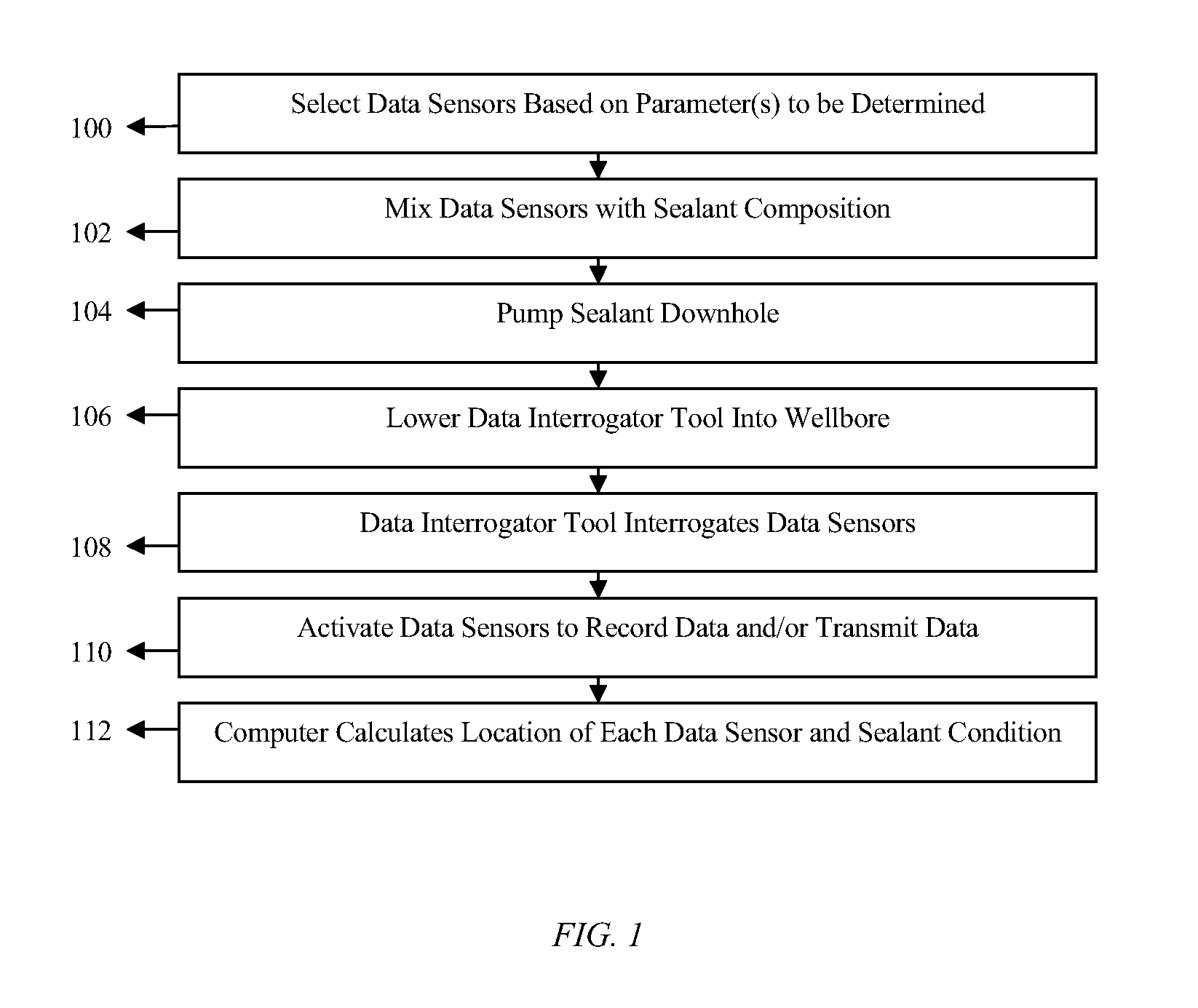

Use of micro-electro-mechanical systems (MEMS) in well treatments

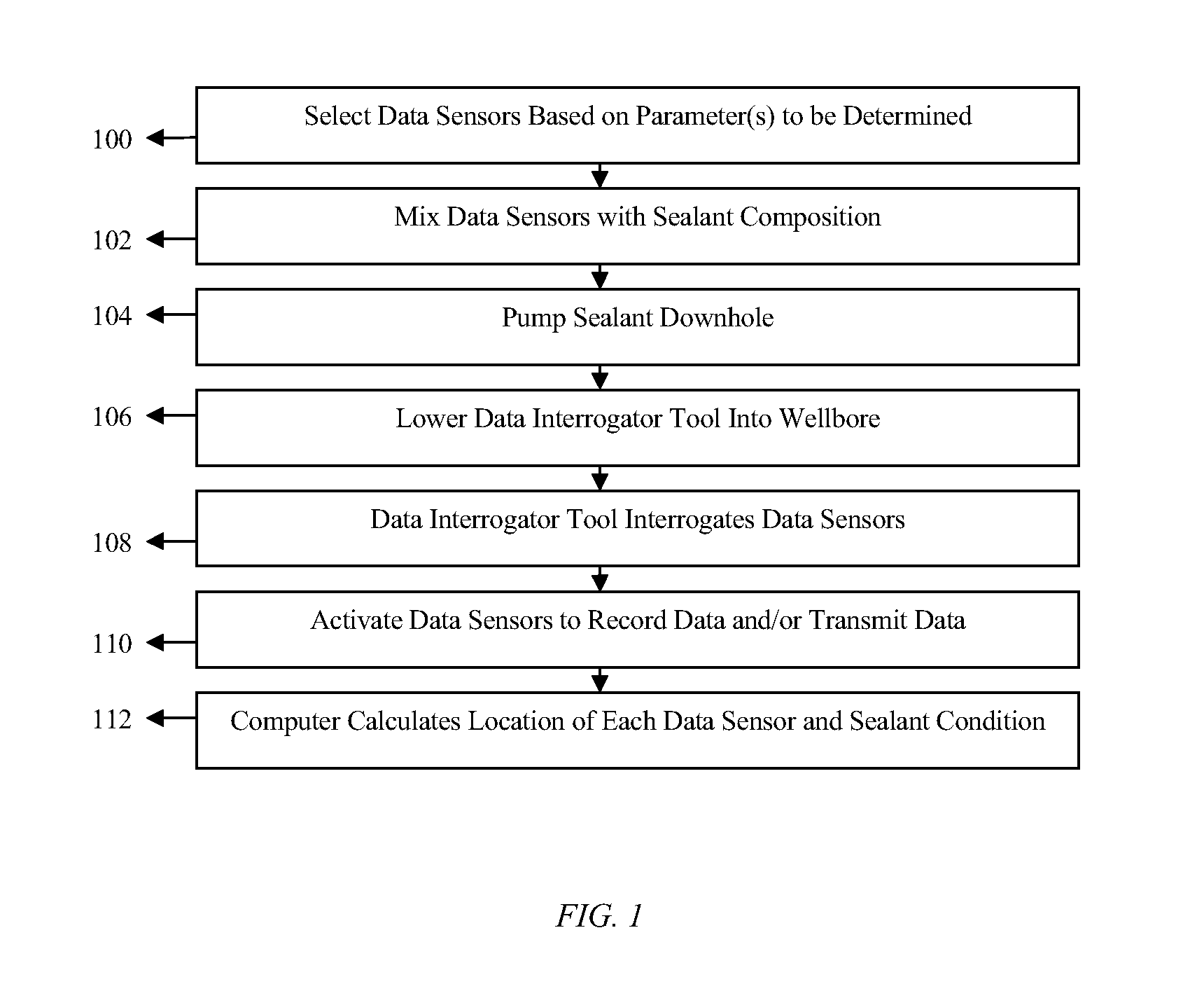

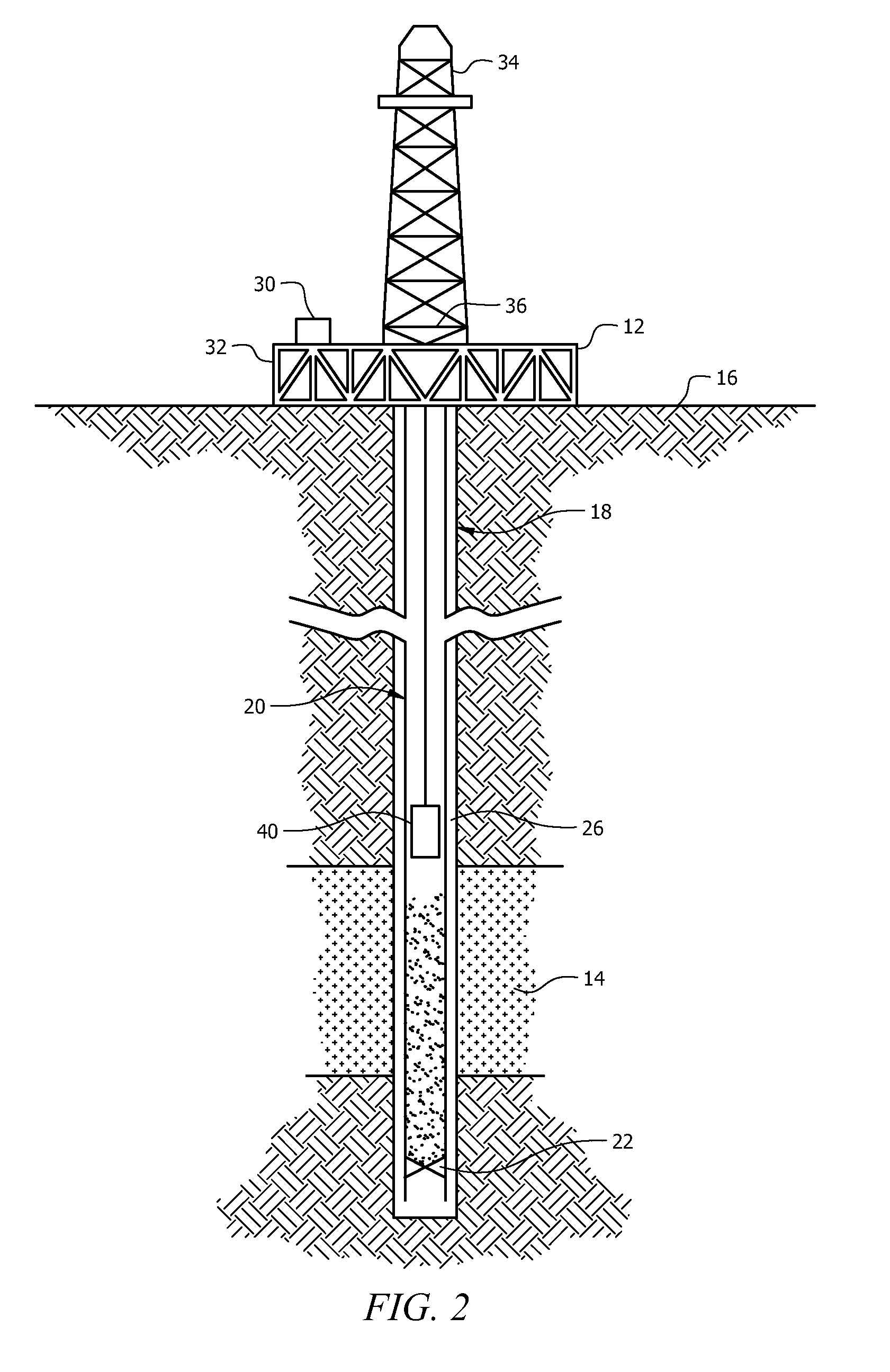

A method comprising placing a sealant composition comprising one or more MEMS sensors in a wellbore and allowing the sealant composition to set. A method of servicing a wellbore comprising placing a MEMS interrogator tool in the wellbore, beginning placement of a sealant composition comprising one or more MEMS sensors into the wellbore, and terminating placement of the sealant composition into the wellbore upon the interrogator tool coming into close proximity with the one or more MEMS sensors. A method comprising placing a plurality of MEMS sensors in a wellbore servicing fluid. A wellbore composition comprising one or more MEMS sensors, wherein the wellbore composition is a drilling fluid, a spacer fluid, a sealant, or combinations thereof.

Owner:HALLIBURTON ENERGY SERVICES INC

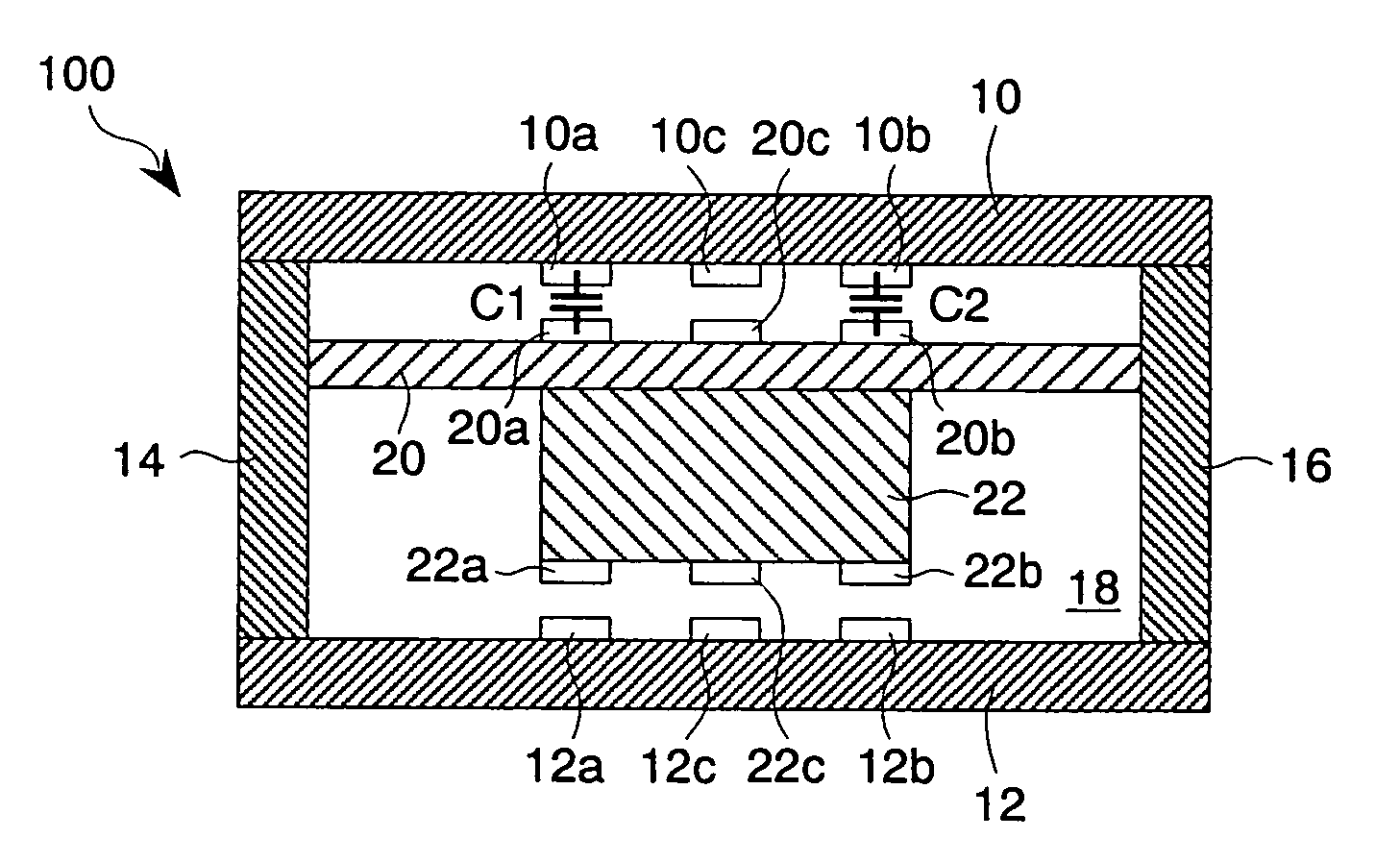

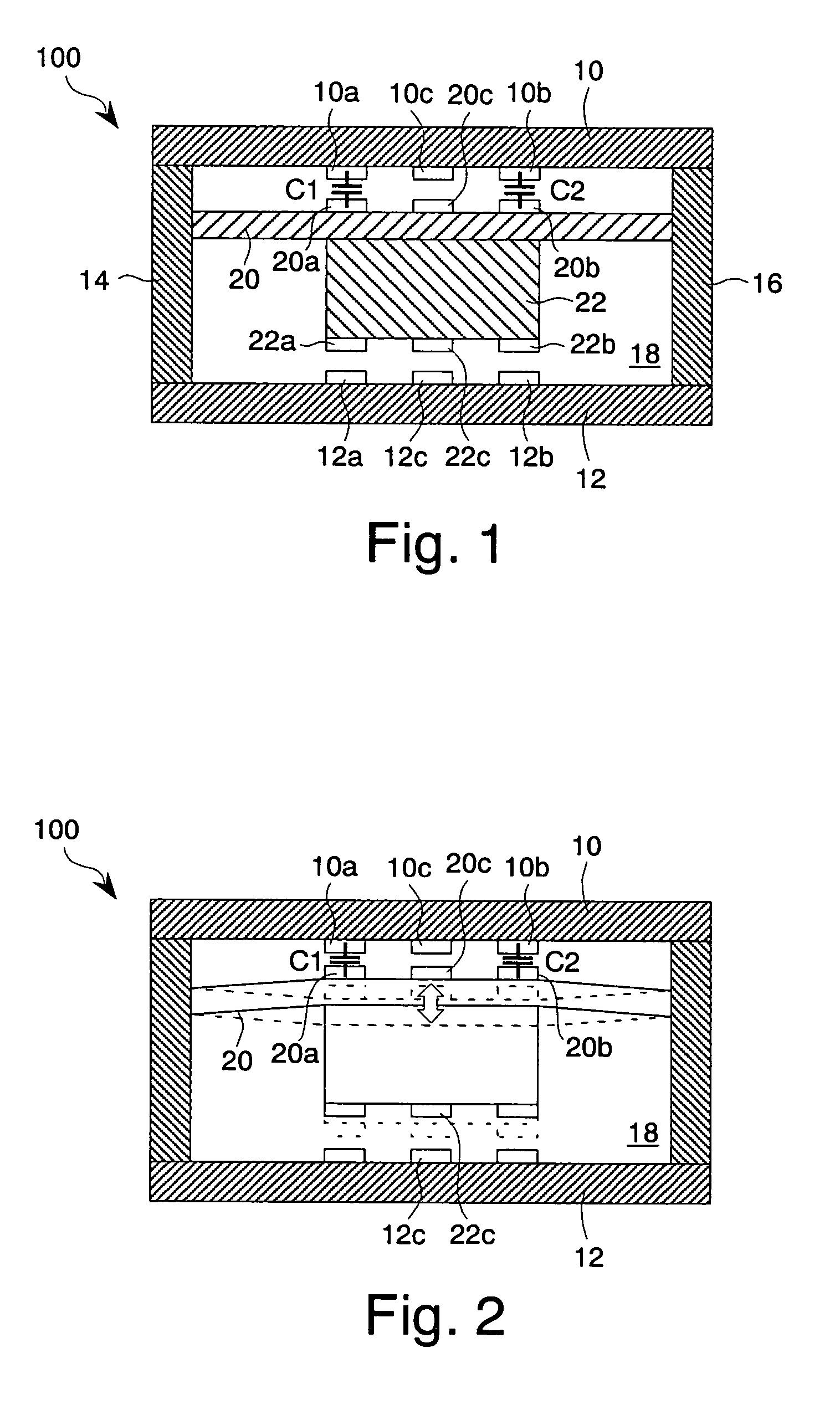

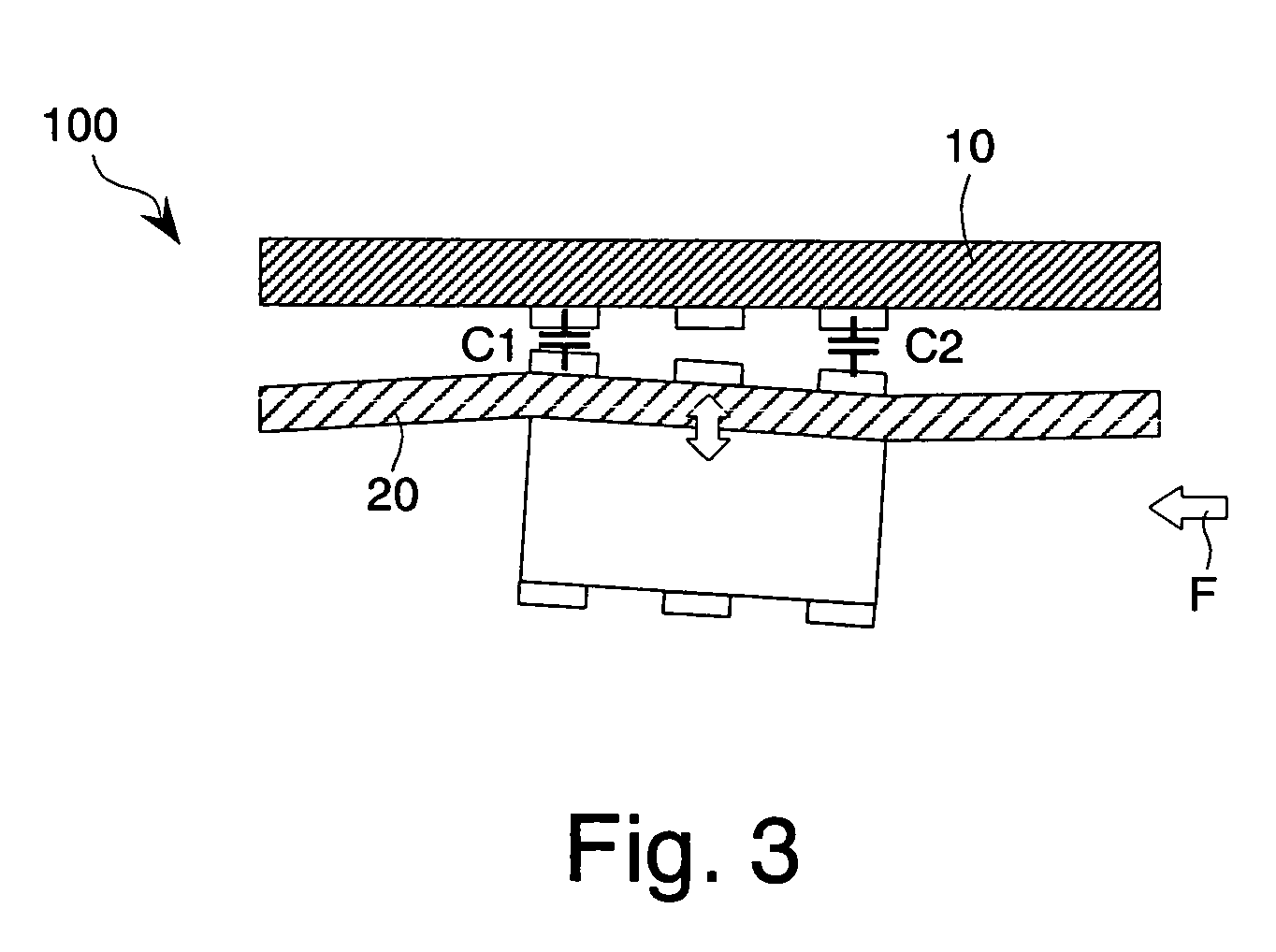

Capacitance difference detecting circuit and MEMS sensor

ActiveUS7119550B2Improve accuracyAcceleration measurement using interia forcesResistance/reactance/impedenceCapacitanceMems sensors

Oscillators have capacitors, respectively, whose capacitances change according to an external force and generate first oscillating signals according to the capacitances. Each of the capacitors is disposed, for example, between a substrate and a mass body that is movably disposed to face the substrate and oscillates in a direction perpendicular to the substrate. A detecting unit detects a relative difference between the capacitances of the capacitors as a difference between frequencies of the first oscillating signals. An angular speed or acceleration applied in a horizontal direction of the substrate is calculated according to the frequency change detected by the detecting unit. Therefore, a capacitance difference detecting circuit and a MEMS sensor that detect a minute change in the capacitances of the two capacitors caused by the external force are formed.

Owner:MONTEREY RES LLC

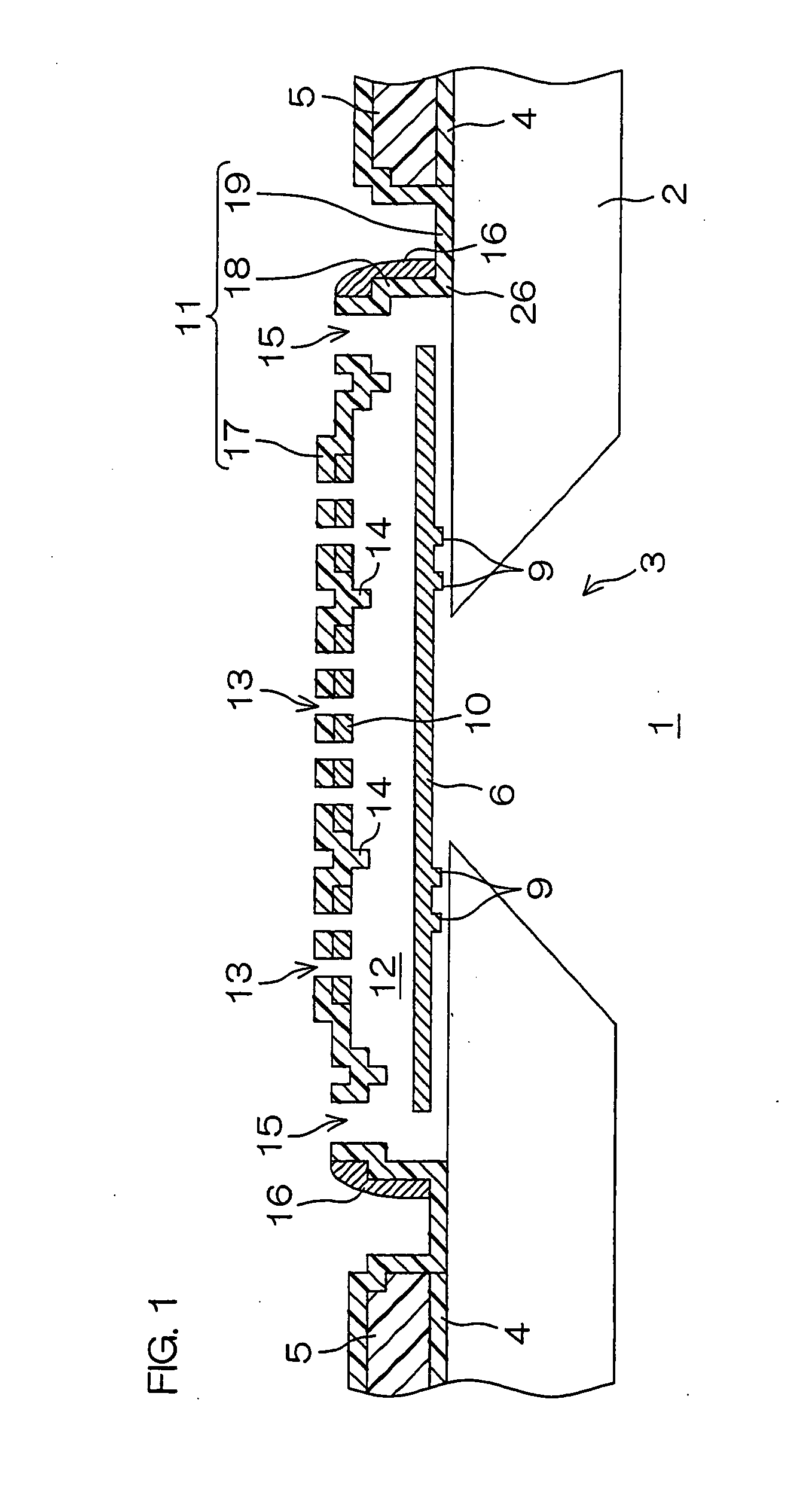

Method of etching sacrificial layer, method of manufacturing MEMS device, MEMS device and MEMS sensor

InactiveUS20100065930A1Damage suppressionSimple structureSemiconductor electrostatic transducersSemiconductor/solid-state device detailsEngineeringMems sensors

The method of etching a sacrificial layer according to the present invention includes the steps of forming a sacrificial layer having a protrusive shape on a base layer, forming a covering film covering the sacrificial layer, forming a protective film made of a material whose etching selection ratio to the sacrificial layer is greater than the etching selection ratio of the covering film to the sacrificial layer on a portion of the covering film opposed to the side surface of the sacrificial layer, and etching the sacrificial layer after the formation of the protective film.

Owner:ROHM CO LTD

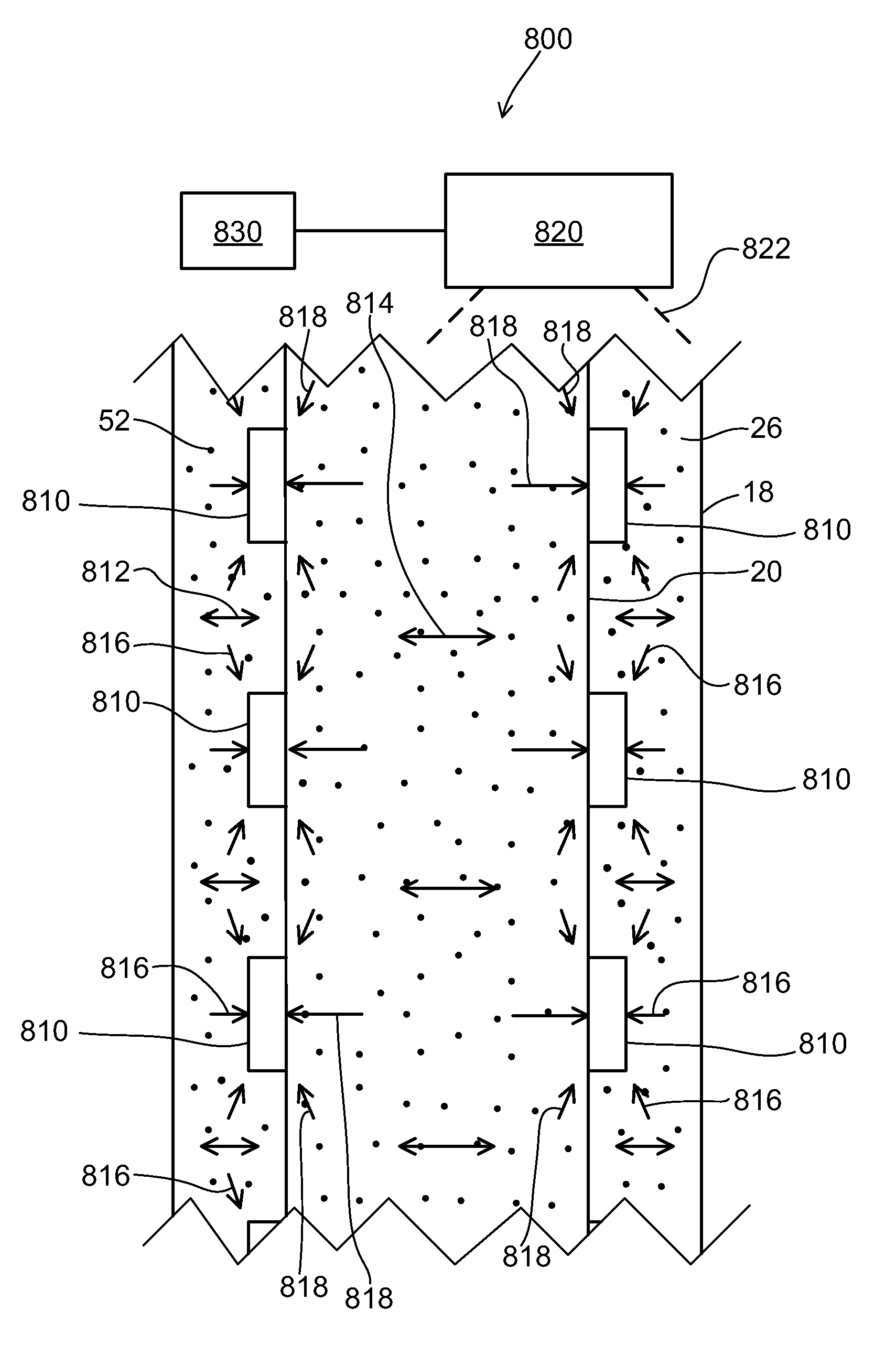

Use of micro-electro-mechanical systems (MEMS) in well treatments

A method of servicing a wellbore, comprising placing a plurality of Micro-Electro-Mechanical System (MEMS) sensors in a wellbore composition, pumping the wellbore composition into the wellbore at a flow rate, determining velocities of the MEMS sensors along a length of the wellbore, and determining an approximate cross-sectional area profile of the wellbore along the length of the wellbore from at least the velocities of the MEMS sensors and the fluid flow rate. A method of servicing a wellbore, comprising placing a plurality of Micro-Electro-Mechanical System (MEMS) sensors in a wellbore composition, pumping the wellbore composition into the wellbore, determining positions of the MEMS sensors relative to one or more known positions along a length of the wellbore, and determining an approximate cross-sectional area profile of the wellbore along the length of the wellbore from at least the determined positions of the MEMS sensors.

Owner:HALLIBURTON ENERGY SERVICES INC

Use of Micro-Electro-Mechanical Systems (MEMS) in Well Treatments

A method comprising placing a Micro-Electro-Mechanical System (MEMS) sensor in a subterranean formation, placing a wellbore composition in the subterranean formation, and using the MEMS sensor to detect a location of the wellbore composition. A method comprising placing a Micro-Electro-Mechanical System (MEMS) sensor in a subterranean formation, placing a wellbore composition in the subterranean formation, and using the MEMS sensor to monitor a condition of the wellbore composition. A method comprising placing one or more Micro-Electro-Mechanical System (MEMS) sensors in a subterranean formation, placing a wellbore composition in the subterranean formation, using the one or more MEMS sensors to detect a location of at least a portion of the wellbore composition, and using the one or more MEMS sensors to monitor at least a portion of the wellbore composition. A method comprising placing one or more Micro-Electro-Mechanical System (MEMS) sensors in a subterranean formation using a wellbore composition, and monitoring a condition using the one or more MEMS sensors.

Owner:HALLIBURTON ENERGY SERVICES INC

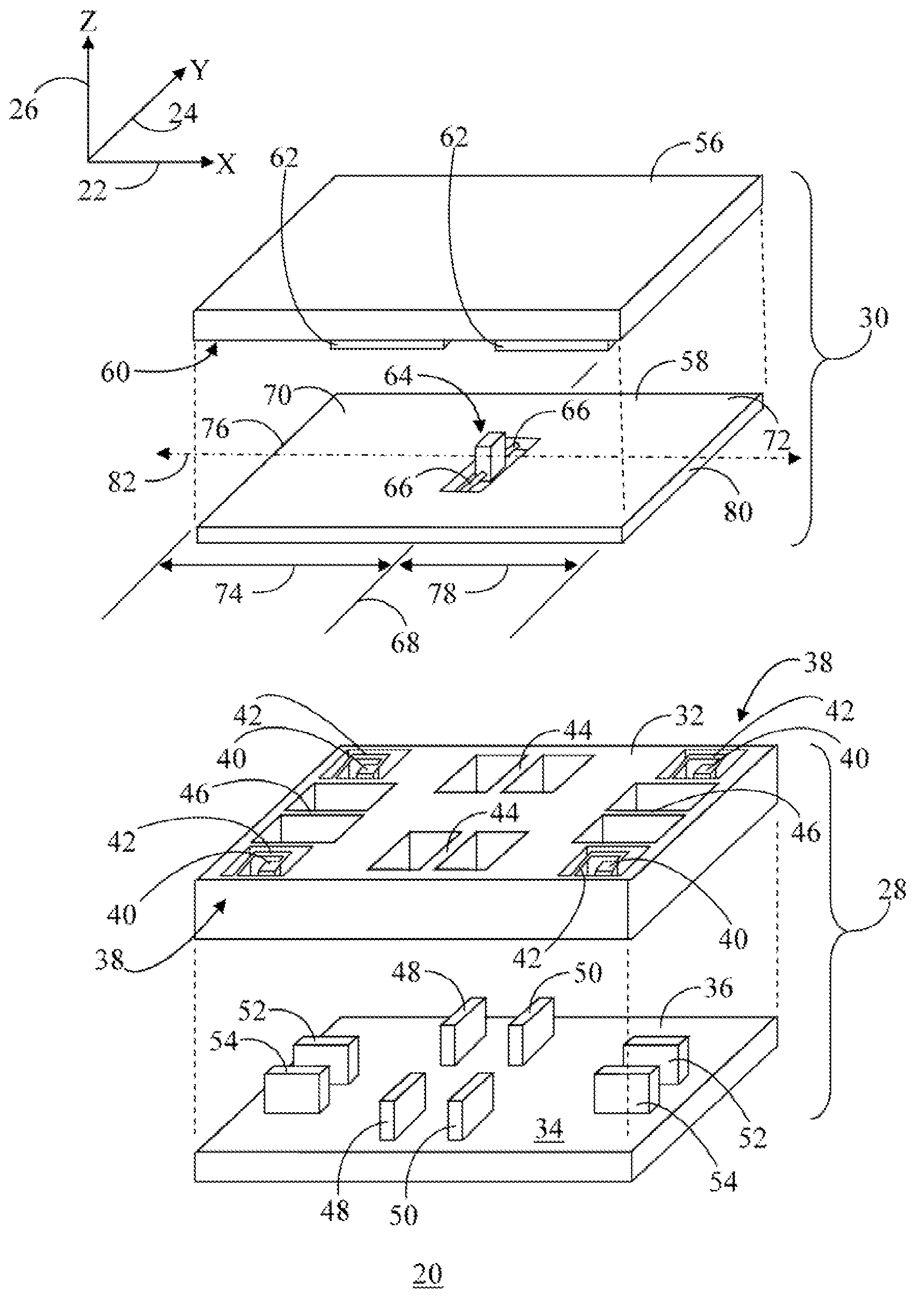

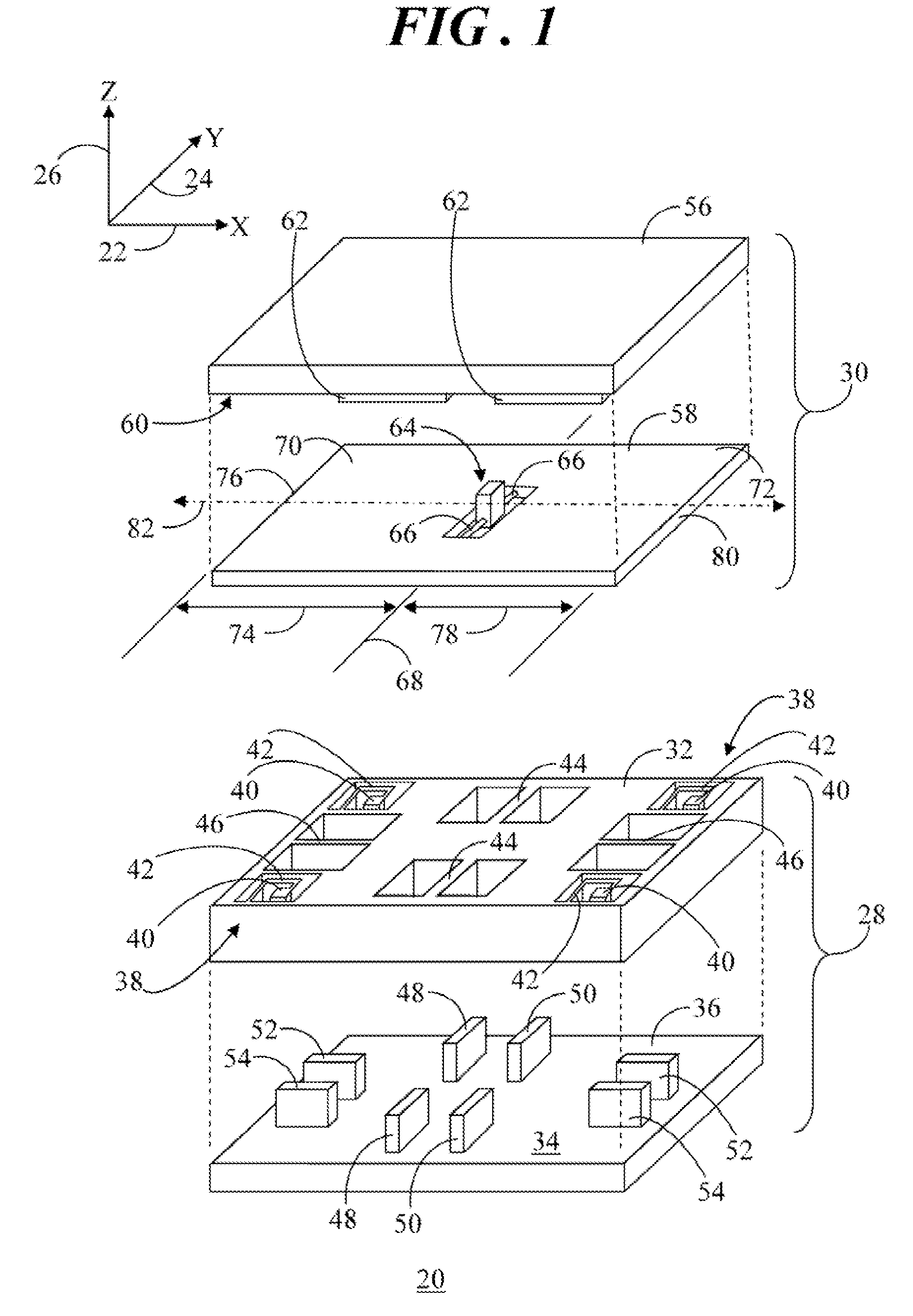

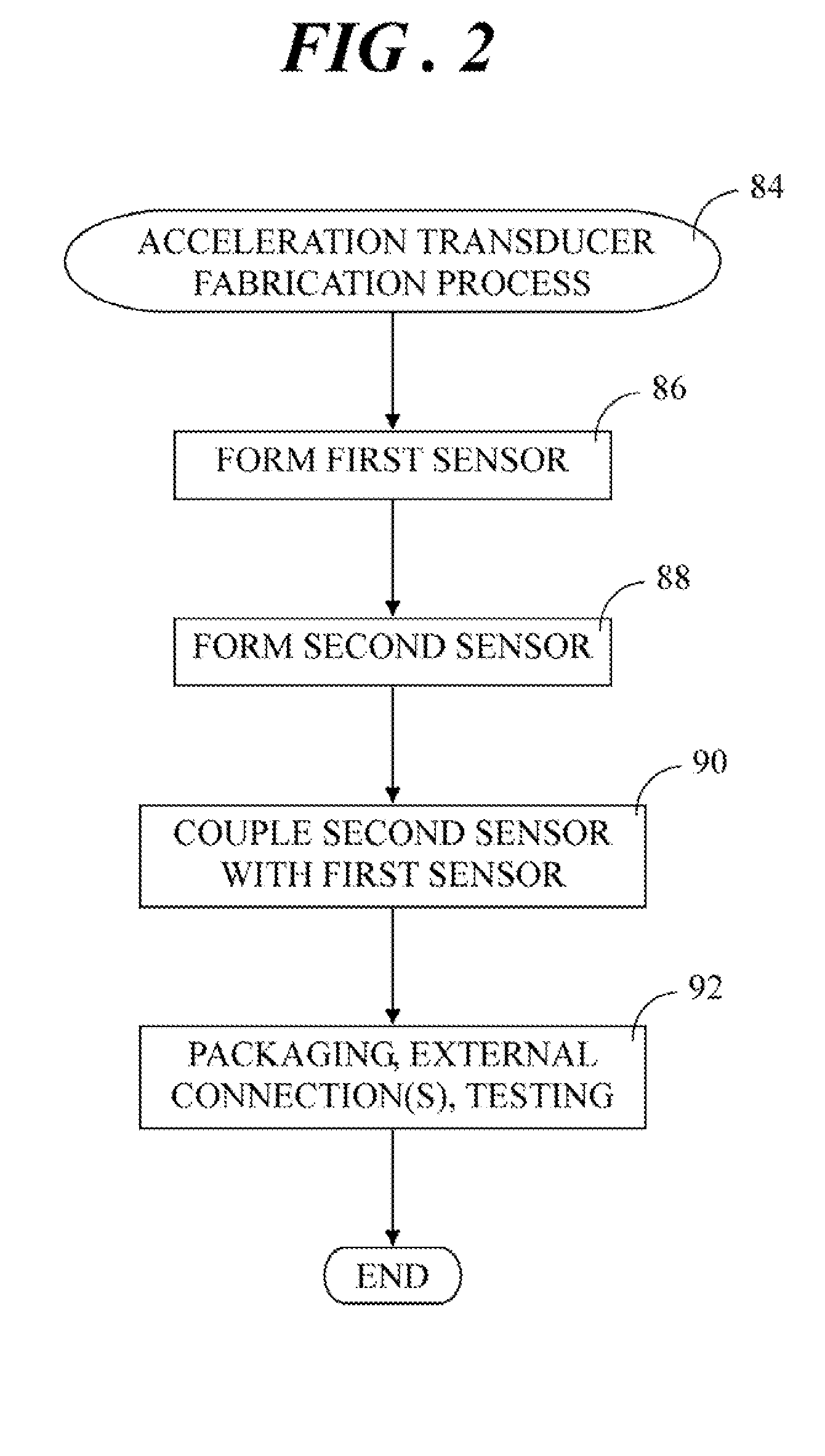

Vertically integrated MEMS sensor device with multi-stimulus sensing

InactiveUS20100242603A1Printed circuit assemblingSpeed/acceleration/shock instrument detailsEngineeringMems sensors

A microelectromechanical systems (MEMS) sensor device (184) includes a sensor portion (180) and a sensor portion (182) that are coupled together to form a vertically integrated configuration having a hermetically sealed chamber (270). The sensor portions (180, 182) can be formed utilizing different micromachining techniques, and are subsequently coupled utilizing a wafer bonding technique to form the sensor device (184). The sensor portion (180) includes one or more sensors (186, 188), and the sensor portion (182) includes one or more sensors (236, 238). The sensors (186, 188) are located inside the chamber (270) facing the sensors (236, 238) also located inside the chamber (270). The sensors (186, 188, 236, 238) are configured to sense different physical stimuli, such as motion, pressure, and magnetic field.

Owner:NORTH STAR INNOVATIONS

Use of Micro-Electro-Mechanical Systems (MEMS) in Well Treatments

A method of servicing a wellbore, comprising placing a plurality of Micro-Electro-Mechanical System (MEMS) sensors in a wellbore composition, placing the wellbore composition in the wellbore, obtaining data from the MEMS sensors using a plurality of data interrogation units spaced along a length of the wellbore, and telemetrically transmitting the data from an interior of the wellbore to an exterior of the wellbore using a conduit positioned in the wellbore. A system, comprising a wellbore extending the earth's surface, a conduit positioned in the wellbore, a wellbore composition positioned in the wellbore, the wellbore composition comprising a plurality of Micro-Electro-Mechanical System (MEMS) sensors, and a plurality of data interrogation units spaced along a length of the wellbore and adapted to obtain data from the MEMS sensors and telemetrically transmit the data from an interior of the wellbore to an entrance of the wellbore via the conduit.

Owner:HALLIBURTON ENERGY SERVICES INC

Use of Micro-Electro-Mechanical Systems (MEMS) in Well Treatments

A method of servicing a wellbore, comprising placing into a wellbore a first wellbore composition comprising a plurality of Micro-Electro-Mechanical System (MEMS) sensors having a first identifier, and determining positions in the wellbore of the MEMS sensors having the first identifiers. A method of servicing a wellbore, comprising placing into a wellbore a first wellbore composition comprising a plurality of Micro-Electro-Mechanical System (MEMS) sensors having a first identifier, placing into the wellbore a second wellbore composition comprising a plurality of MEMS sensors having first identifier, and determining positions in the wellbore of the MEMS sensors having the first identifier, wherein the MEMS sensors of the first wellbore composition are added to a portion of the first wellbore composition added to the wellbore prior to a remainder of the first wellbore composition, and the MEMS sensors of the second wellbore composition are added to a portion of the second wellbore composition added to the wellbore prior to a remainder of the second wellbore composition.

Owner:HALLIBURTON ENERGY SERVICES INC

Sensor fusion for model-based detection in pipe and cable locator systems

ActiveUS7834801B2Improve positionSatellite radio beaconingElectric/magnetic detectionGyroscopeAccelerometer

Line locator systems that fuse traditional sensors used in a combined pipe and cable locator (electromagnetic coils, magnetometers, and ground penetrating radar antennas) with low cost inertial sensors (accelerometers, gyroscopes) in a model-based approach are presented. Such systems can utilize inexpensive MEMS sensors for inertial navigation. A pseudo-inertial frame is defined that uses the centerline of the tracked utility, or an aboveground fixed object as the navigational reference. An inertial sensor correction mechanism that limits the tracking errors over time when the model is implemented in state-space form using, for example, the Extended Kalman Filter (EKF) is disclosed.

Owner:BUSAN TRANSPORTATION CORPORATION

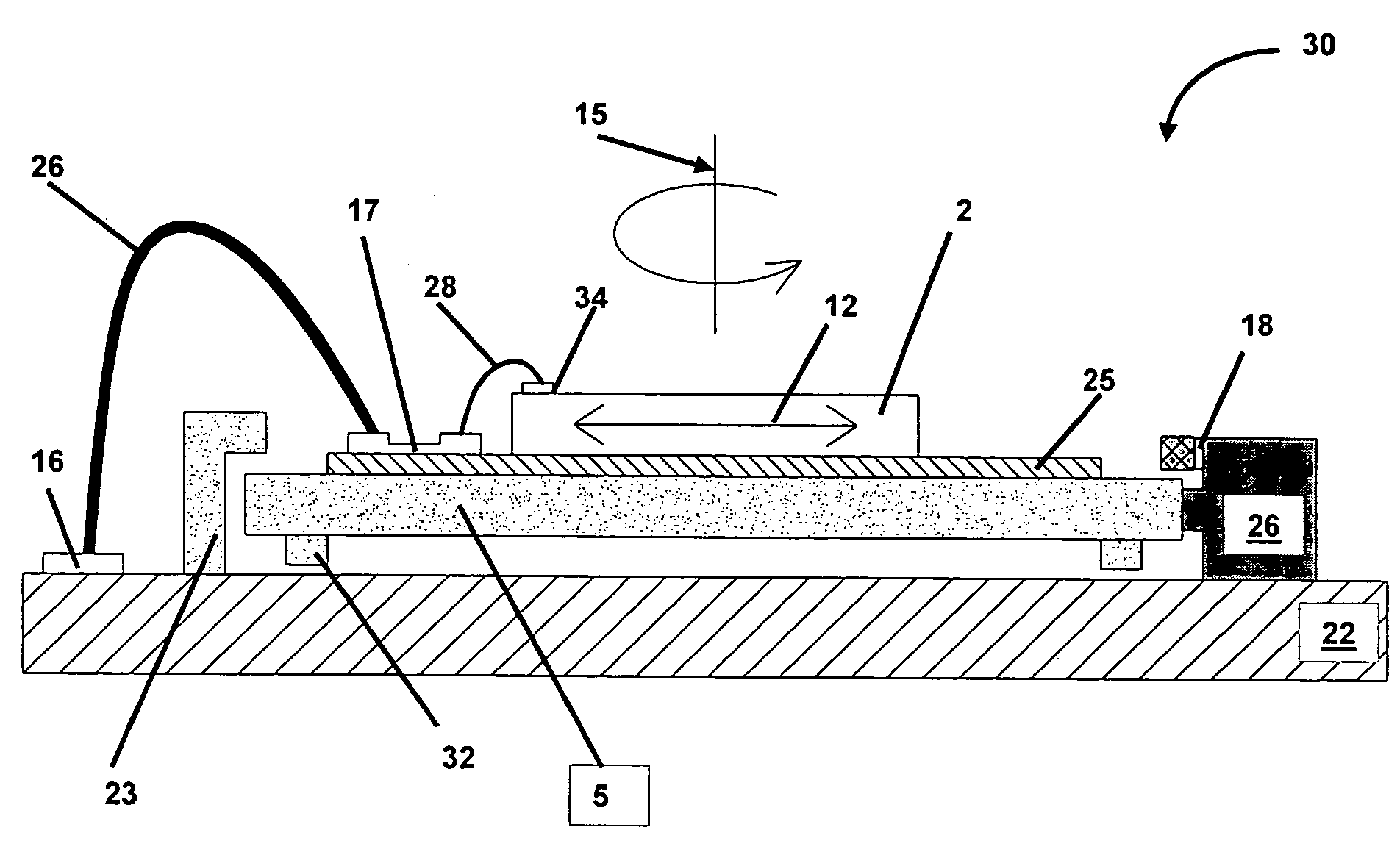

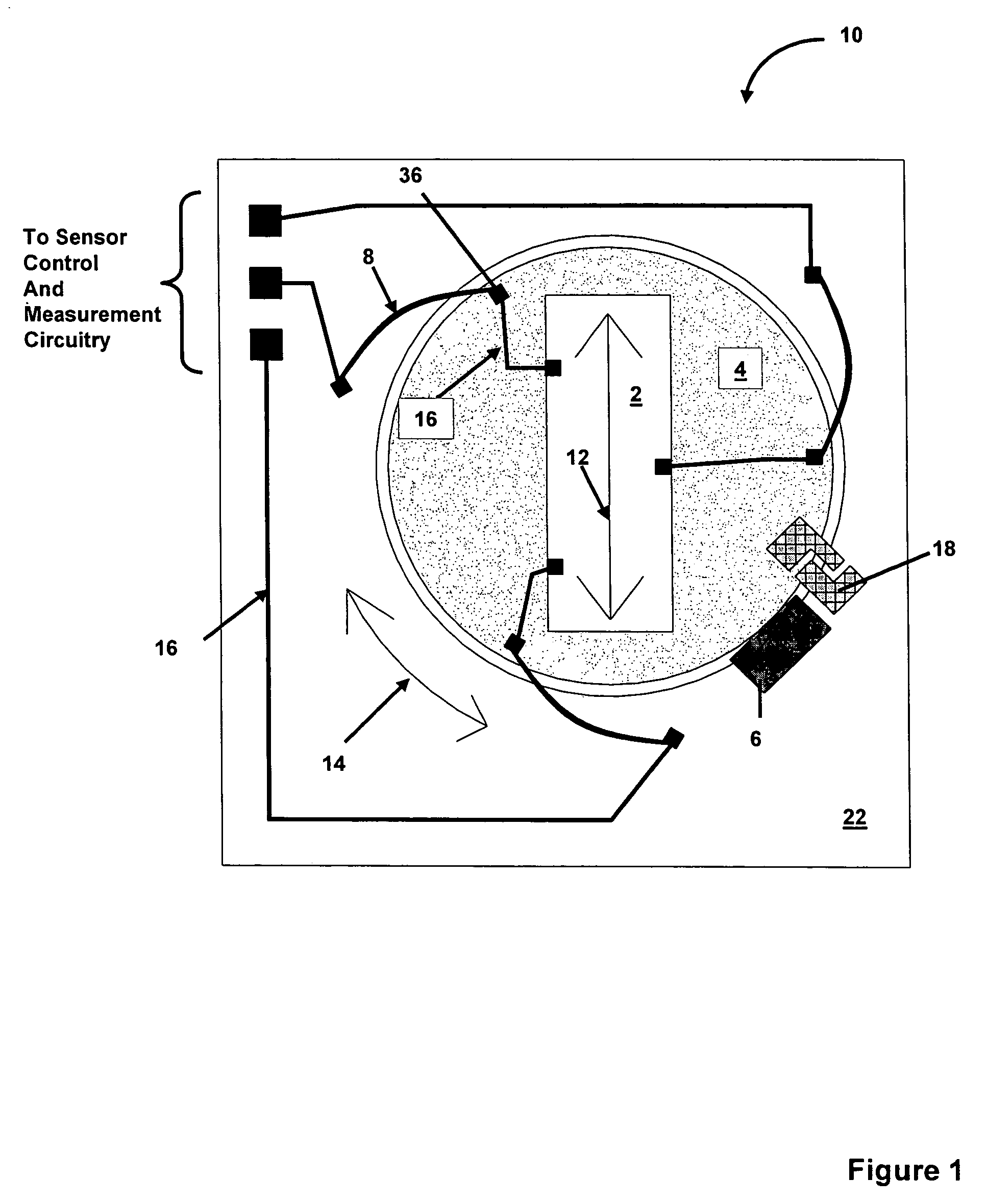

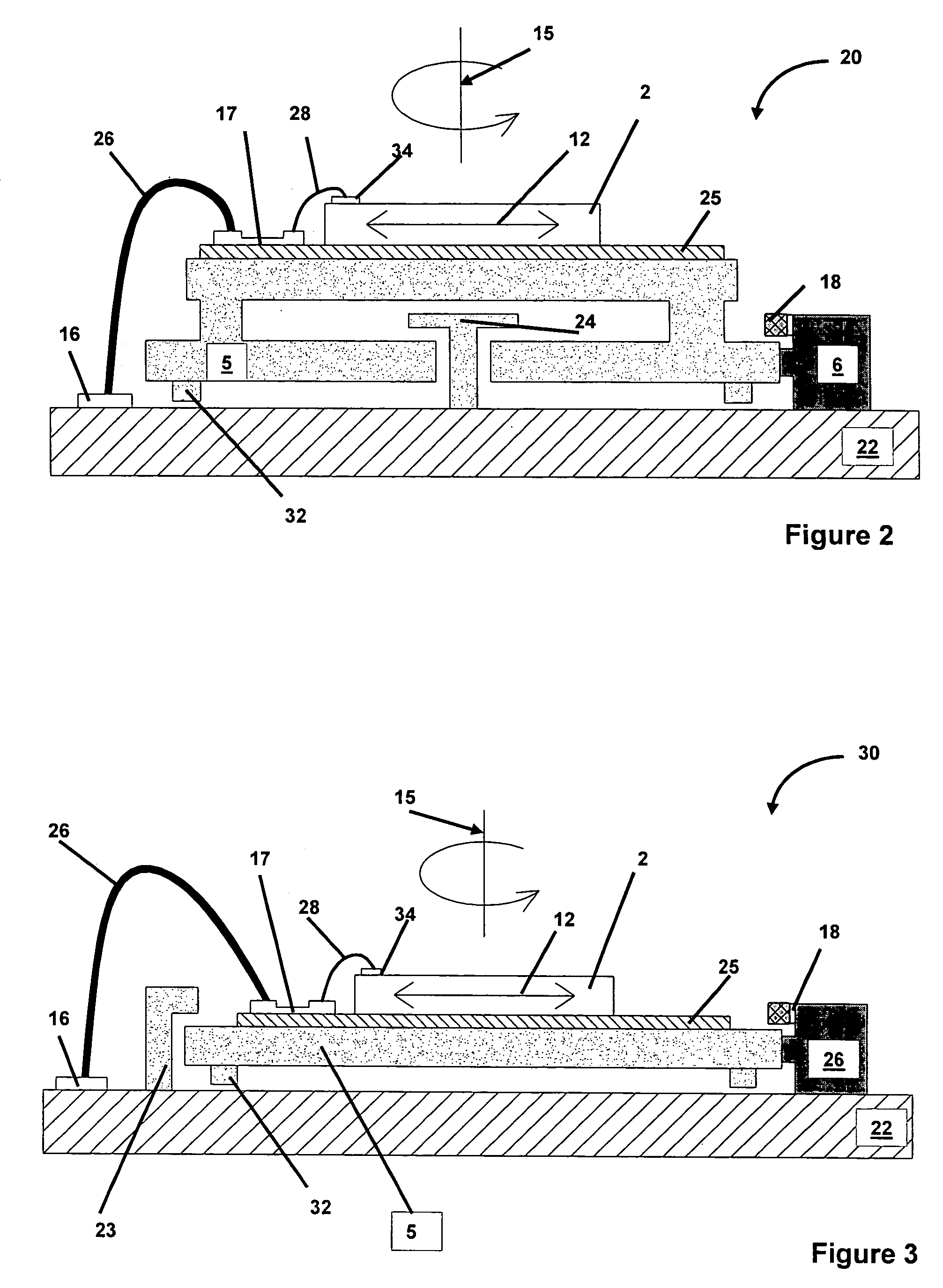

Inertial measurement unit using rotatable MEMS sensors

ActiveUS7066004B1Improve sensing accuracyReduce the impactSpeed/acceleration/shock instrument detailsElectrical measurementsGyroscopeAccelerometer

A MEM inertial sensor (e.g. accelerometer, gyroscope) having integral rotational means for providing static and dynamic bias compensation is disclosed. A bias compensated MEM inertial sensor is described comprising a MEM inertial sense element disposed on a rotatable MEM stage. A MEM actuator for drives the rotation of the stage between at least two predetermined rotational positions. Measuring and comparing the output of the MEM inertial sensor in the at least two rotational positions allows, for both static and dynamic bias compensation in inertial calculations based on the sensor's output. An inertial measurement unit (IMU) comprising a plurality of independently rotatable MEM inertial sensors and methods for making bias compensated inertial measurements are disclosed.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Use of micro-electro-mechanical systems (MEMS) in well treatments

A method comprising placing a sealant composition comprising one or more MEMS sensors in a wellbore and allowing the sealant composition to set. A method of servicing a wellbore comprising placing a MEMS interrogator tool in the wellbore, beginning placement of a sealant composition comprising one or more MEMS sensors into the wellbore, and terminating placement of the sealant composition into the wellbore upon the interrogator tool coming into close proximity with the one or more MEMS sensors. A method comprising placing a plurality of MEMS sensors in a wellbore servicing fluid. A wellbore composition comprising one or more MEMS sensors, wherein the wellbore composition is a drilling fluid, a spacer fluid, a sealant, or combinations thereof.

Owner:HALLIBURTON ENERGY SERVICES INC

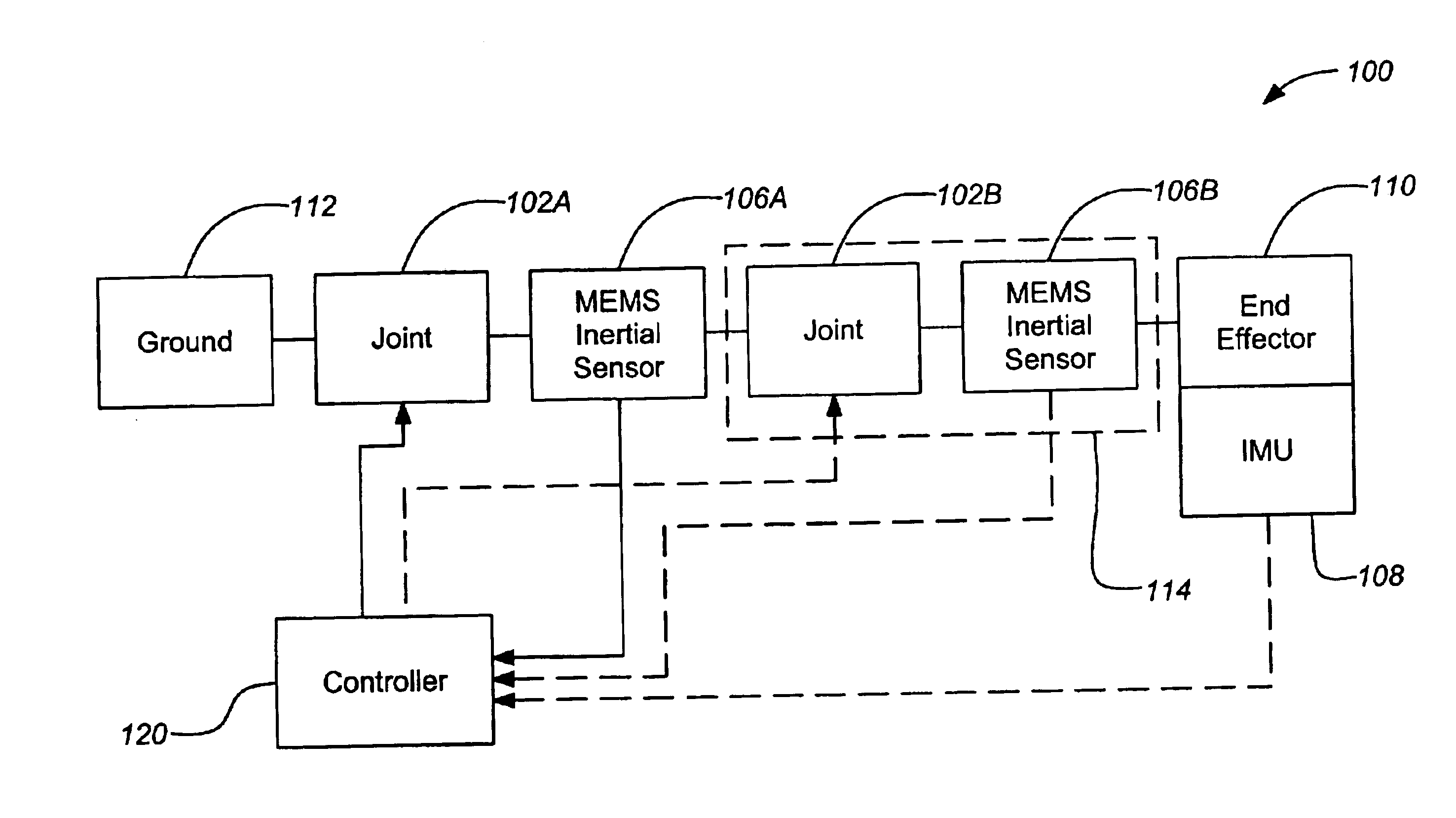

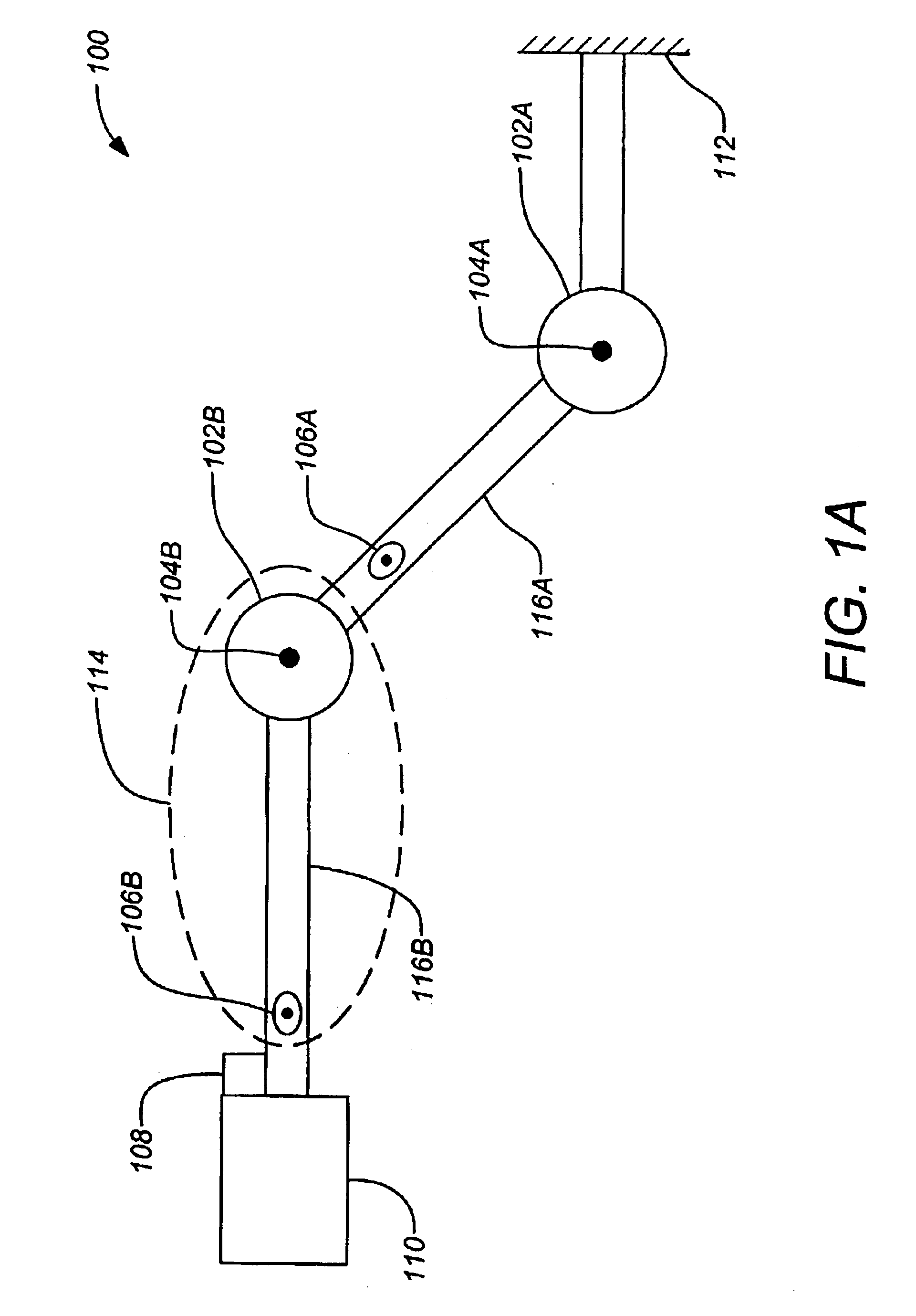

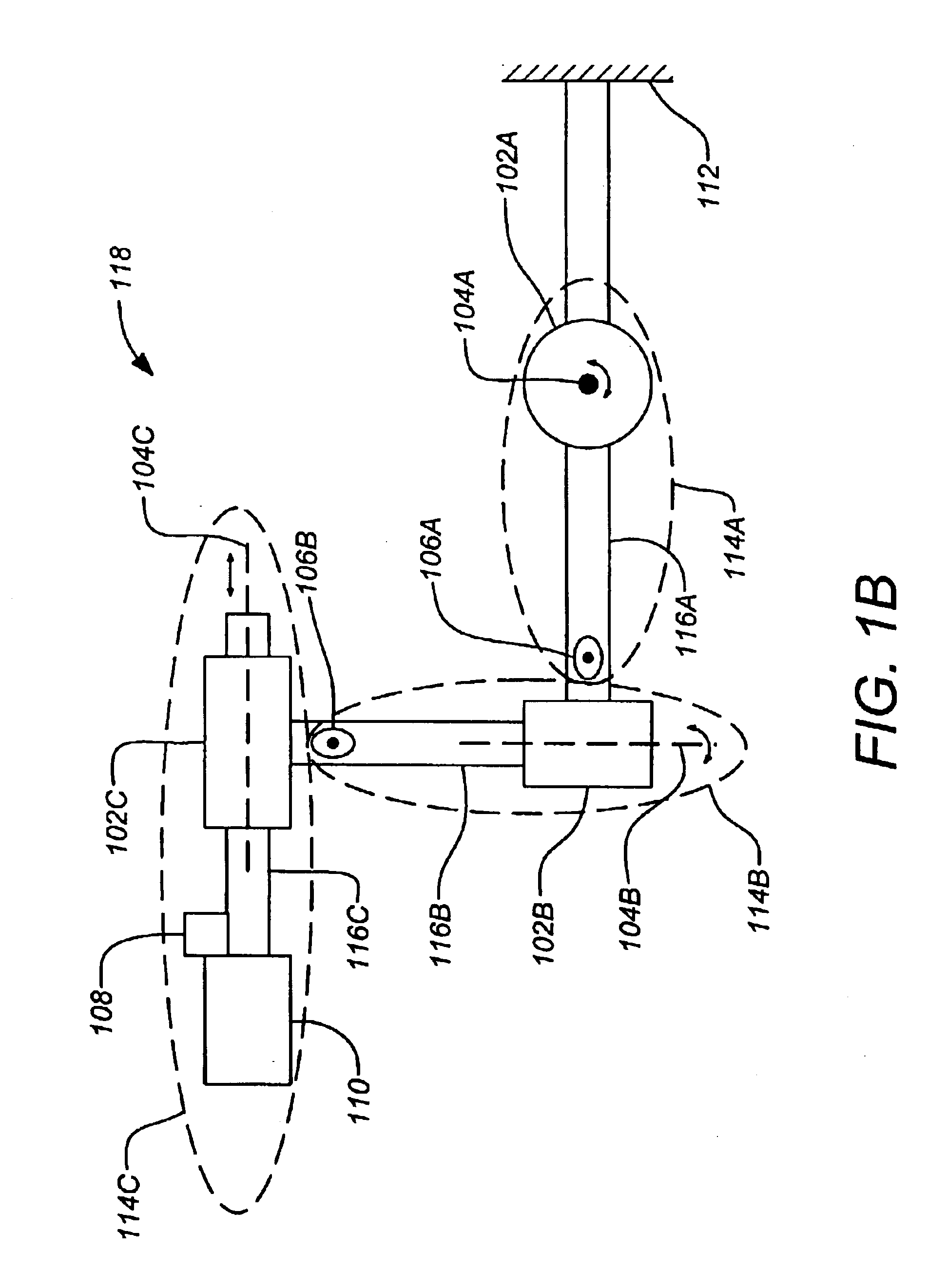

Low cost robot manipulator

InactiveUS6995536B2Reduce business operating costsRobust servo controlProgramme-controlled manipulatorSafety arrangmentsEngineeringMems sensors

The present invention discloses a robotic manipulator, comprising at least one joint, each joint having a drive axis and at least one microelectromechanical system (MEMS) inertial sensor aligned with at least one drive axis providing sensing of a relative position of the drive axis. The robotic manipulator can include an inertial measurement unit (IMU) coupled to the robotic manipulator for determining the end effector position and orientation. A controller can be used, receiving a signal from at least one MEMS inertial sensor and controlling at least one joint drive axis in response to the signal to change the relative position of the joint drive axis. Rate information from MEMS sensors can be integrated to determine the position of their respective drive axes.

Owner:THE BOEING CO

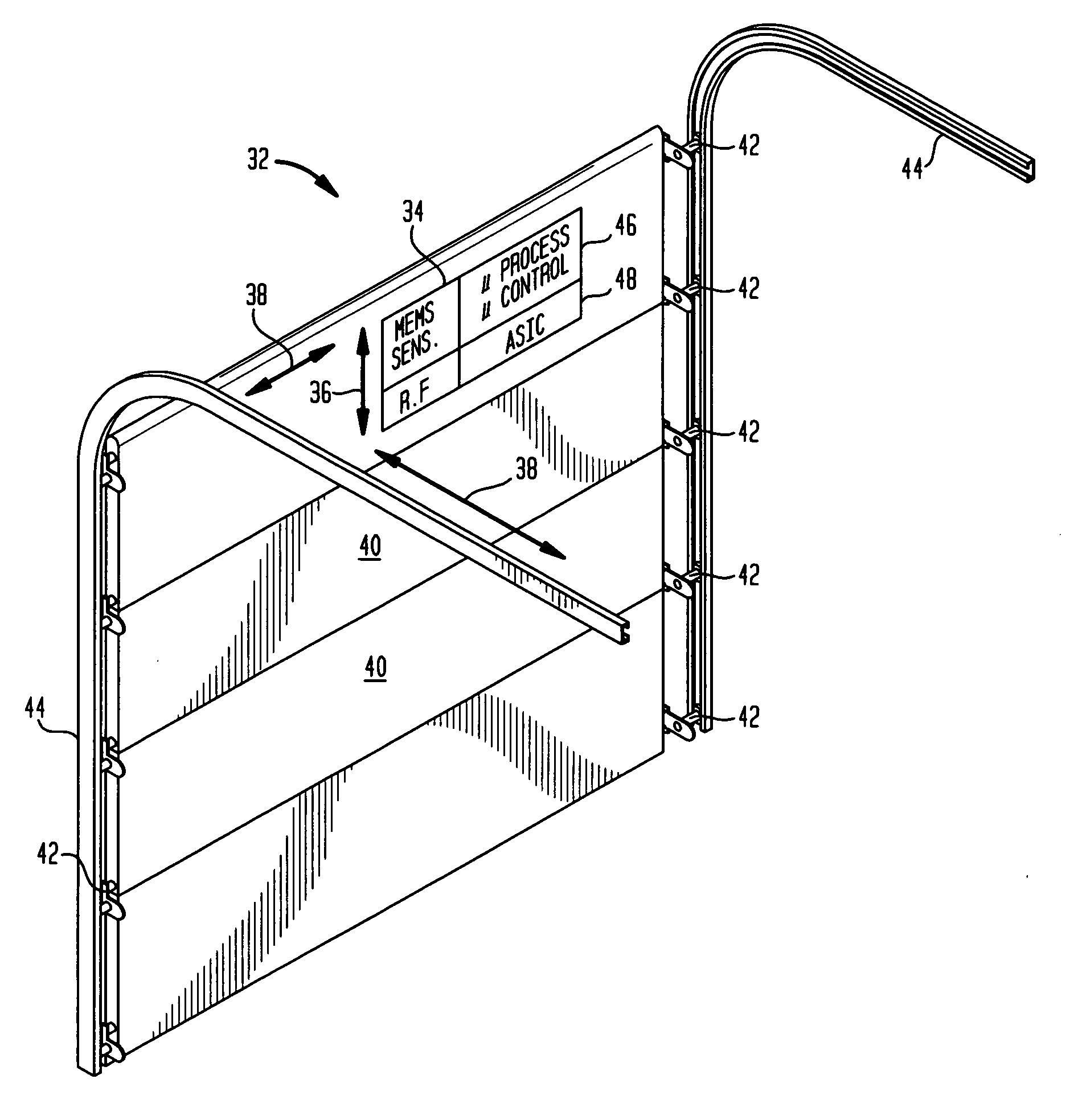

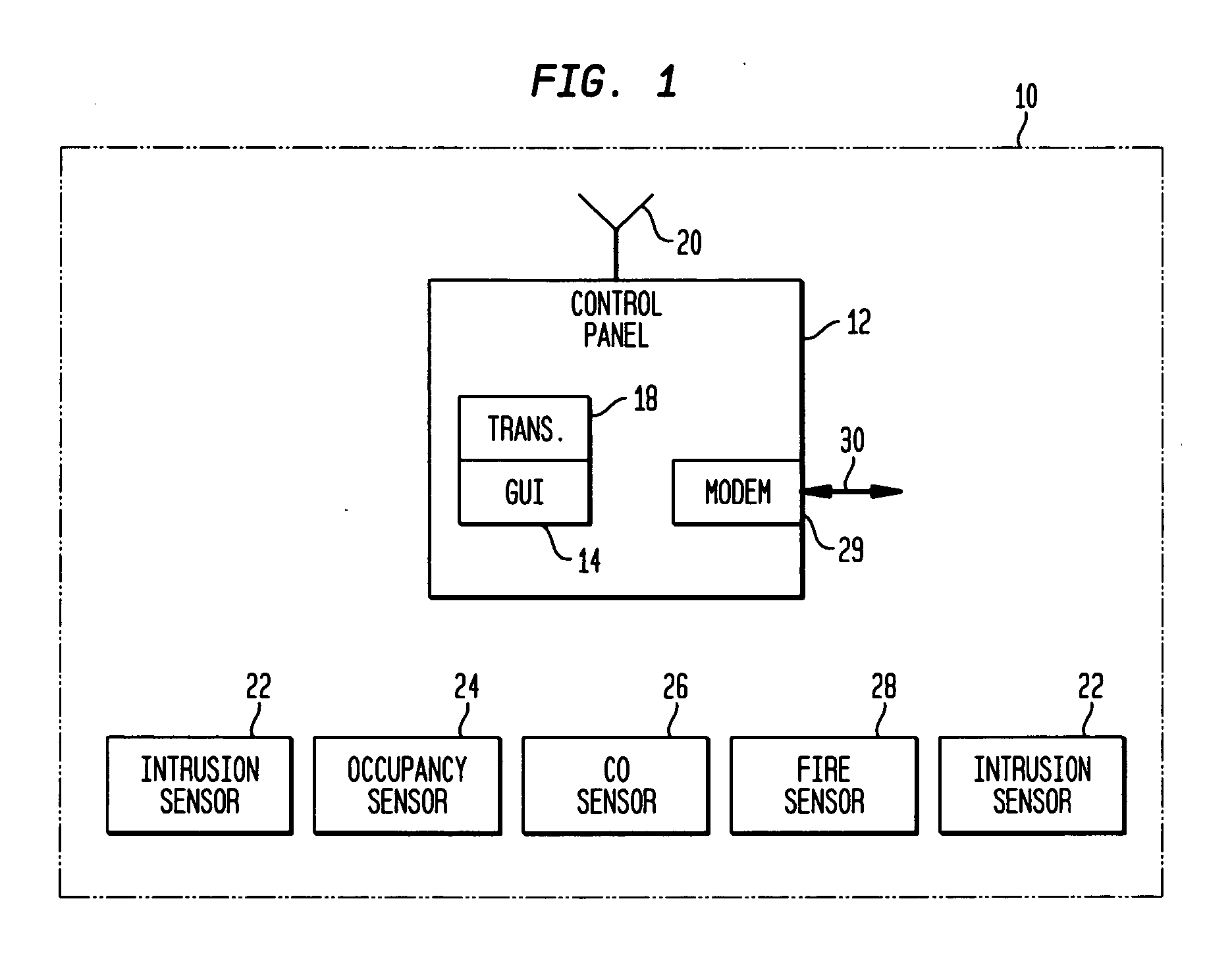

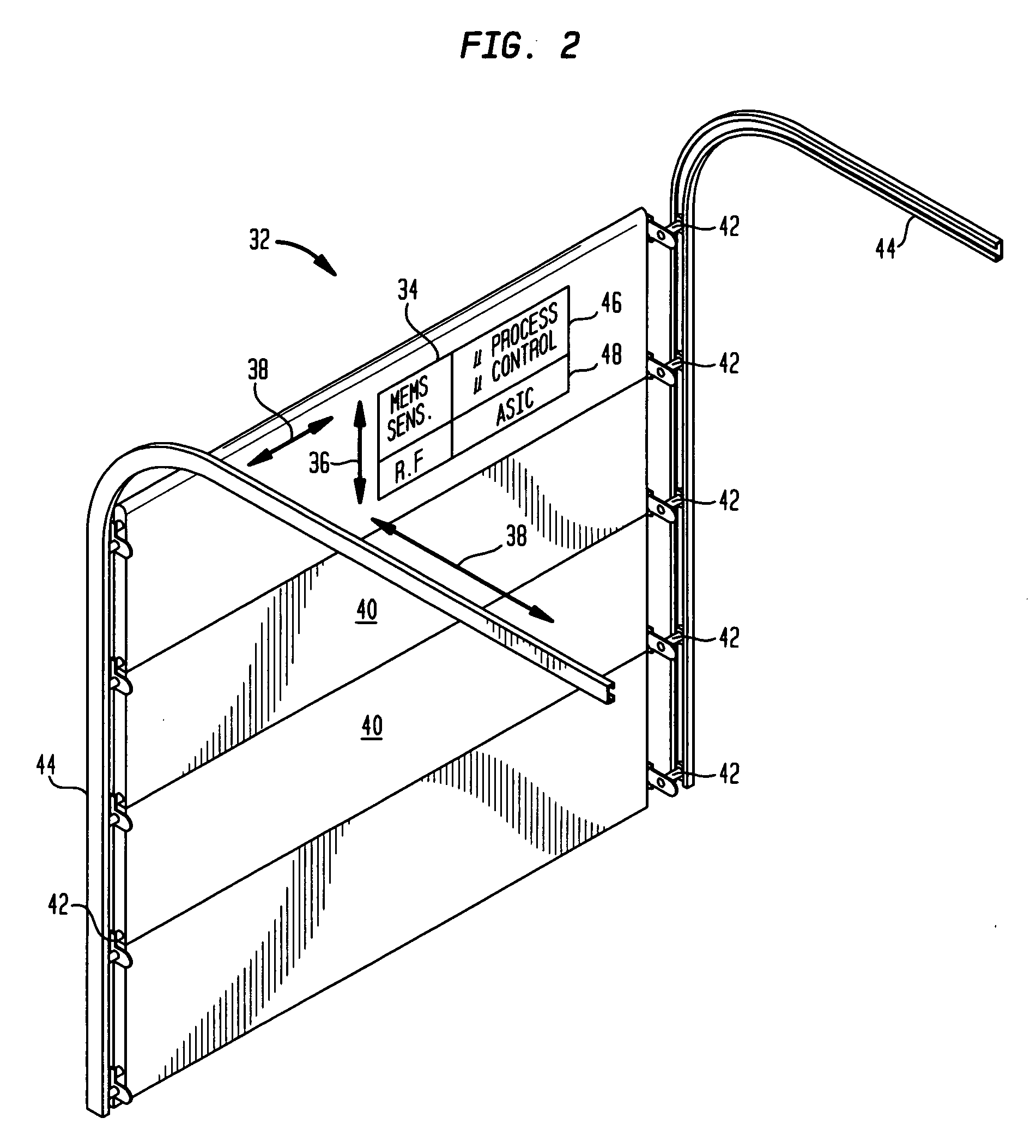

MEMS based garage door sensor

ActiveUS20050253710A1OperationOperability of the MEMS sensor to be checkedBurglar alarm by openingPower-operated mechanismMicrocontrollerAccelerometer

A MEMS based overhead garage door intrusion sensor for a security system, such as a residential / home security system, for detecting an intrusion through an overhead garage door. In one embodiment, a MEMS sensor accelerometer is mounted with a sensitive axis of the MEMS device, along which the MEMS device measures acceleration / gravity, pointing vertically downward towards the earth when the overhead garage door is closed, such that the MEMS sensor measures a 1 g acceleration / gravity force, and when the overhead garage door is open, the sensitive axis of the MEMS device points horizontally with respect to the earth, such that the MEMS sensor measures a 0 g acceleration / gravity force, such that the output of the MEMS sensor, indicating either a 1 g or a 0 g measured acceleration / gravity force, indicates whether the overhead garage door is respectively closed or open. Alternatively, the MEMS sensor can be a MEMS switch. An ASIC or microcontroller can monitor the output of the MEMS sensor, and one embodiment employs wireless RF technology.

Owner:ADEMCO INC

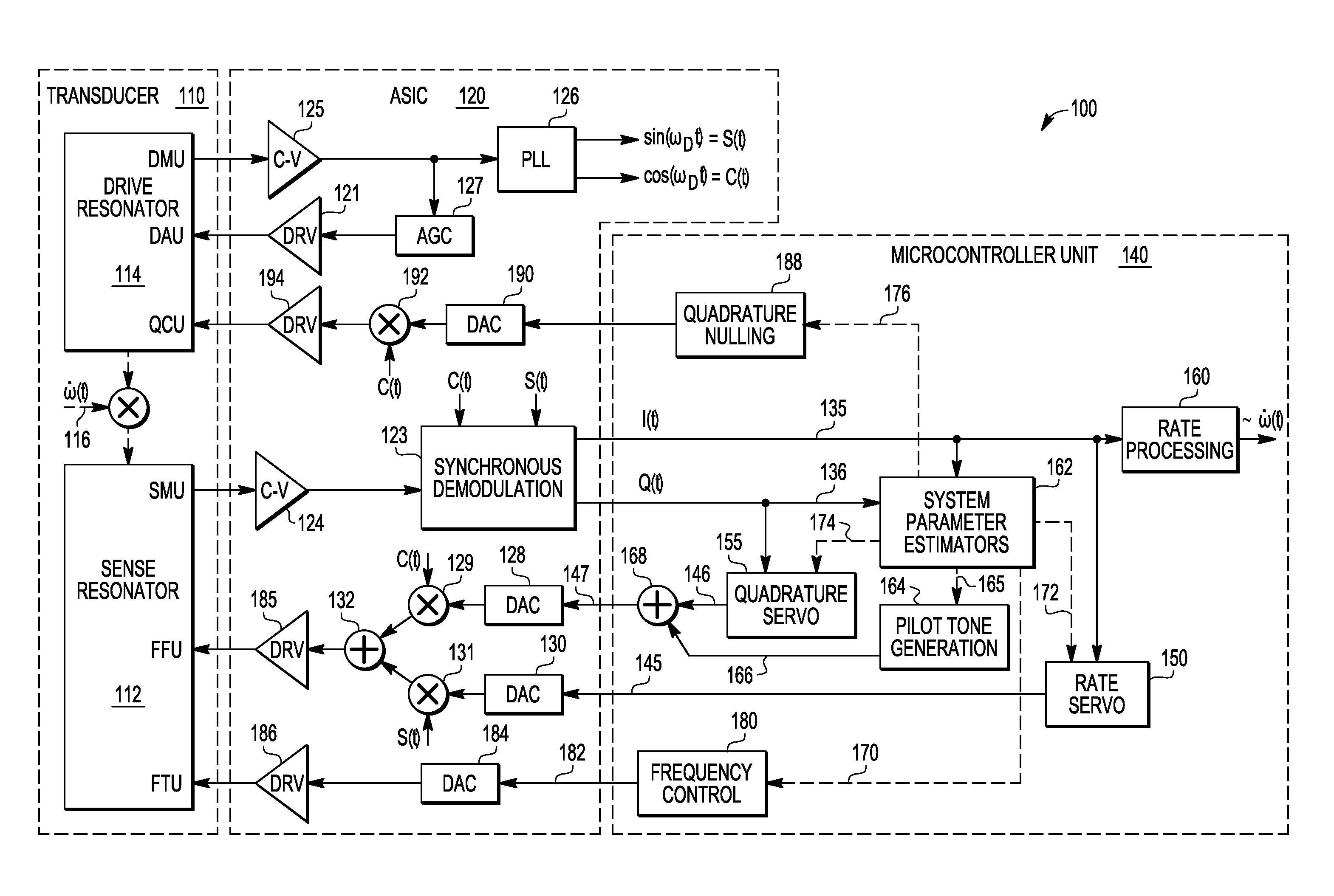

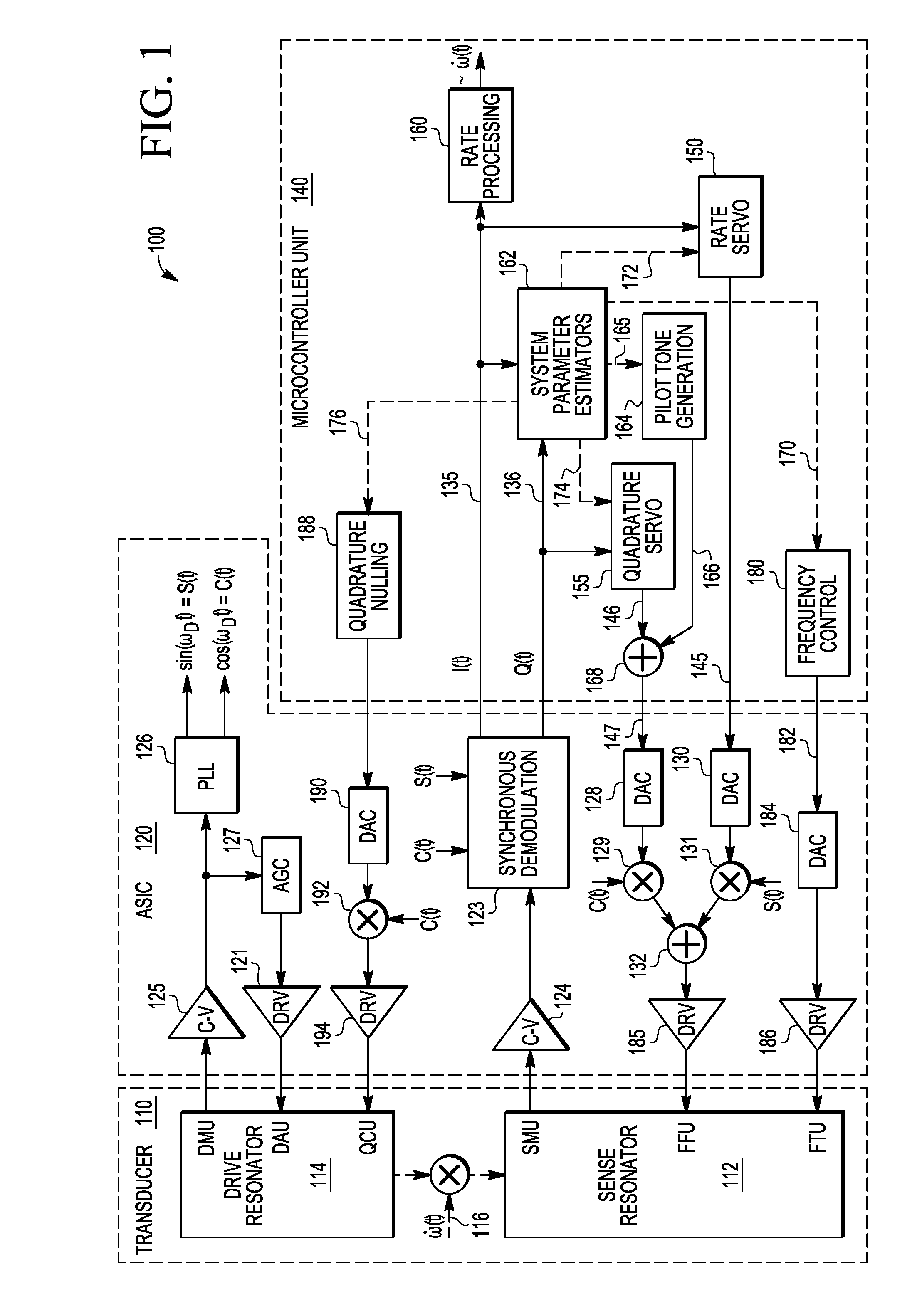

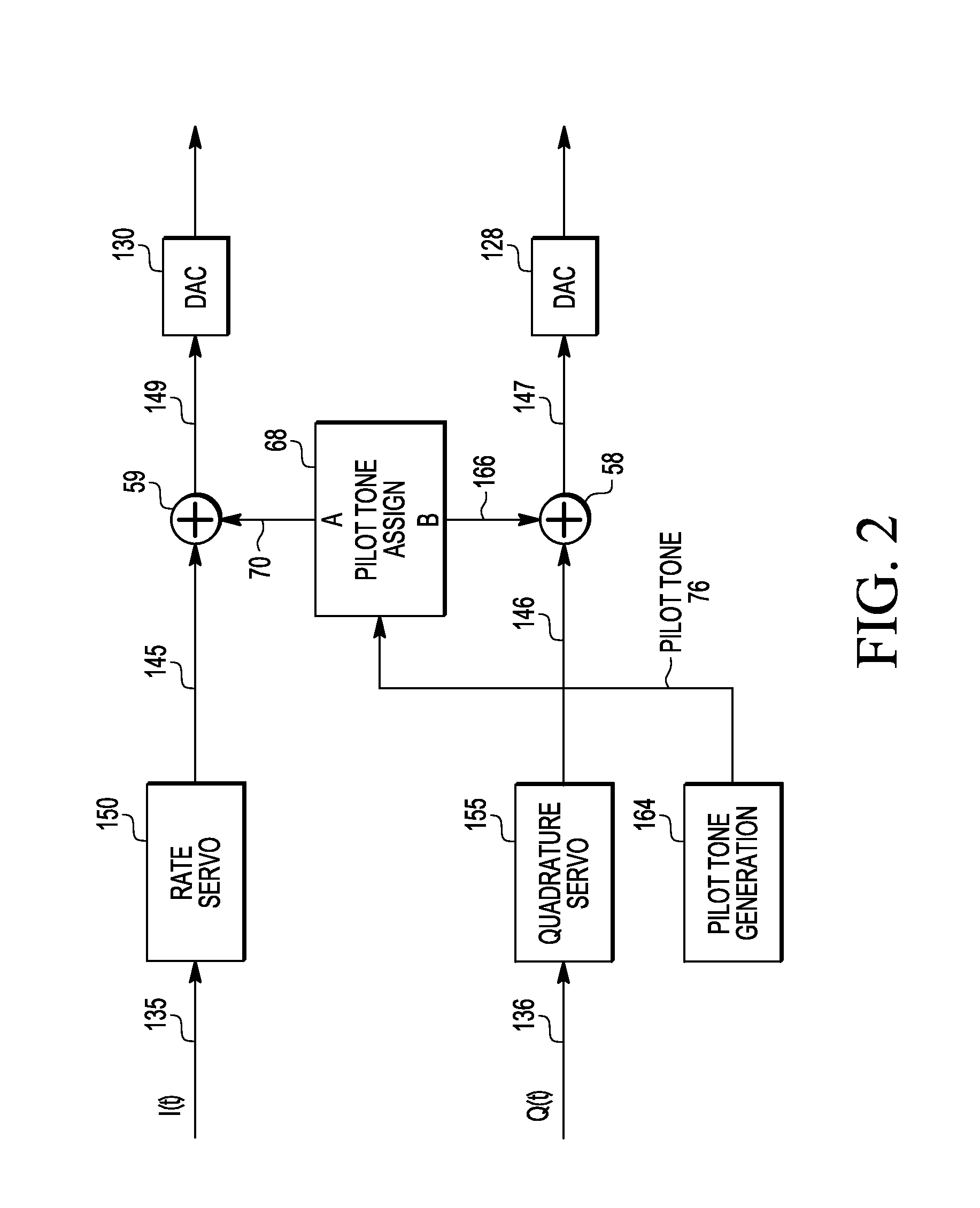

Generation, Injection and Use of Pilot Tones for Gyro System Characterization

ActiveUS20110192226A1Acceleration measurement using interia forcesTesting/calibration apparatusMicrocontrollerGyroscope

A microcontroller-based method and apparatus are described for generating one or more amplitude and frequency selectable low frequency pilot tone signals (PT) that are injected into an embedded MEMS sensor (110) and mixed signal ASIC (120) and then recovered at the microcontroller (140) to compute or measure various gyro parameters during operational use of the device with no down time or interference with normal operations.

Owner:NXP USA INC

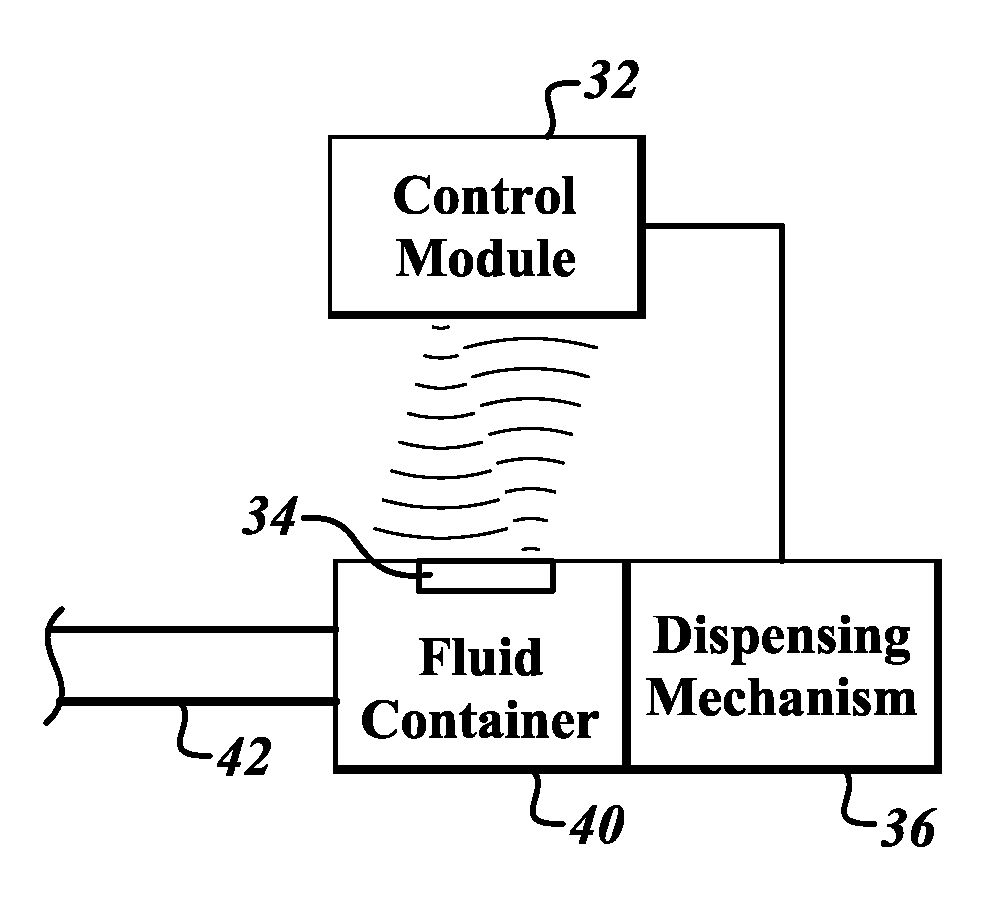

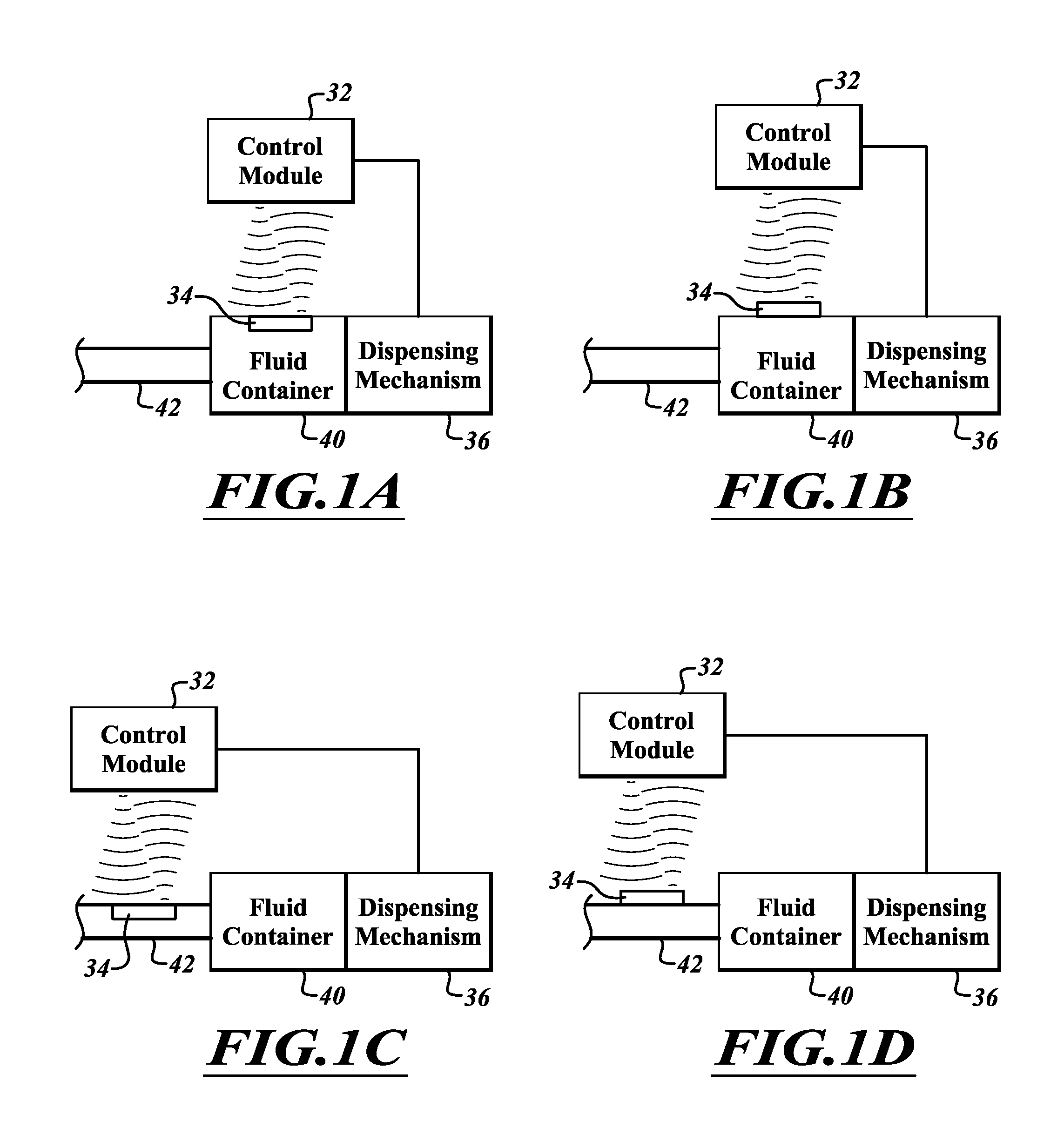

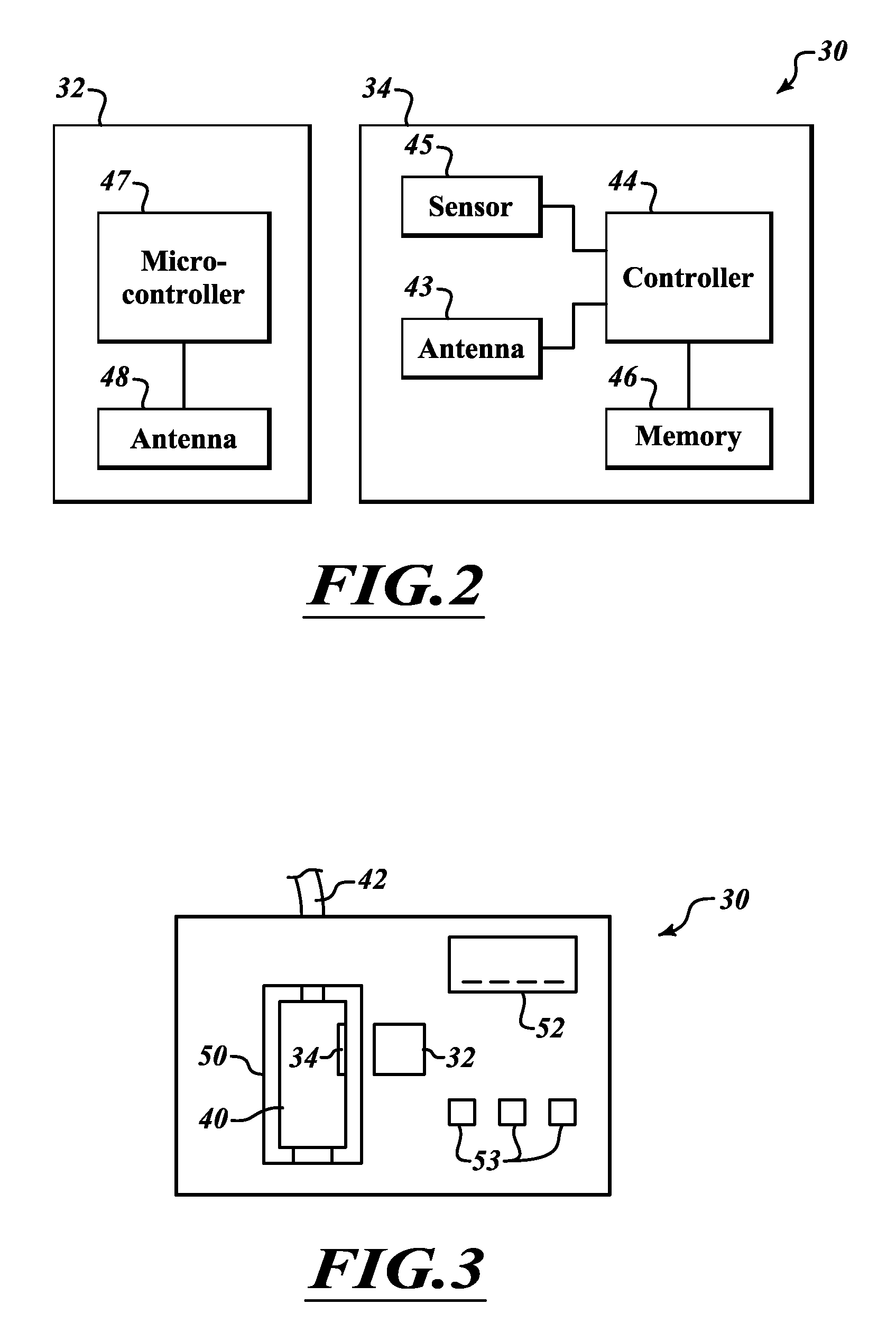

Wireless strain gauge/flow sensor

ActiveUS20130204202A1Inexpensively attachedCheap manufacturingMedical devicesFlow monitorsMems sensorsEngineering

A flow rate sensor is provided in a wireless, leadless package. The flow rate sensor includes a MEMs sensor coupled to an ASIC and an antenna. The flow rate sensor is powered by radiation received from a control module adjacent the flow rate sensor. The flow rate sensor is placed within a fluid and monitors the flow rate of the fluid. The control module is not in the fluid and receives flow rate data from the flow rate sensor.

Owner:STMICROELECTRONICS SRL

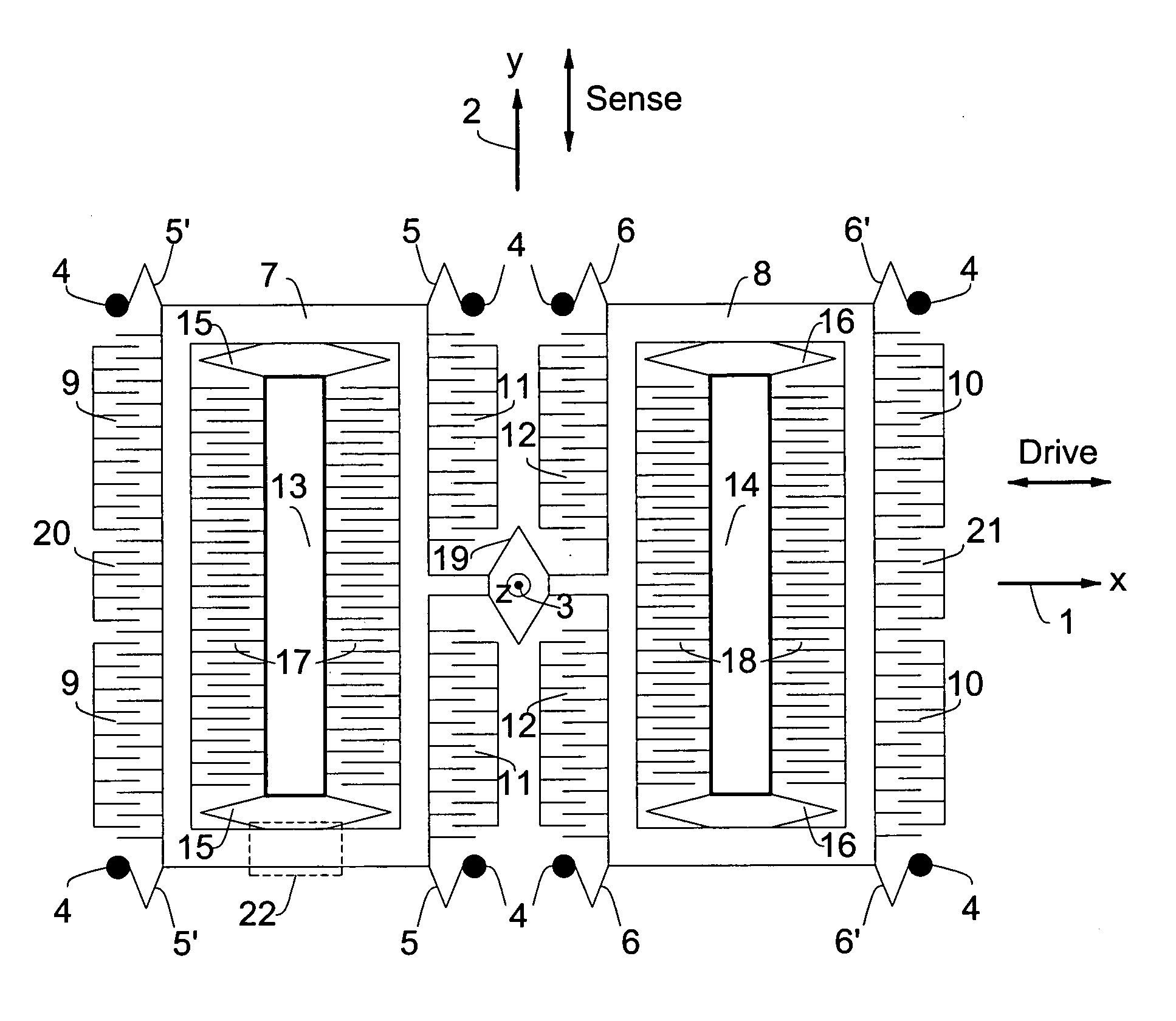

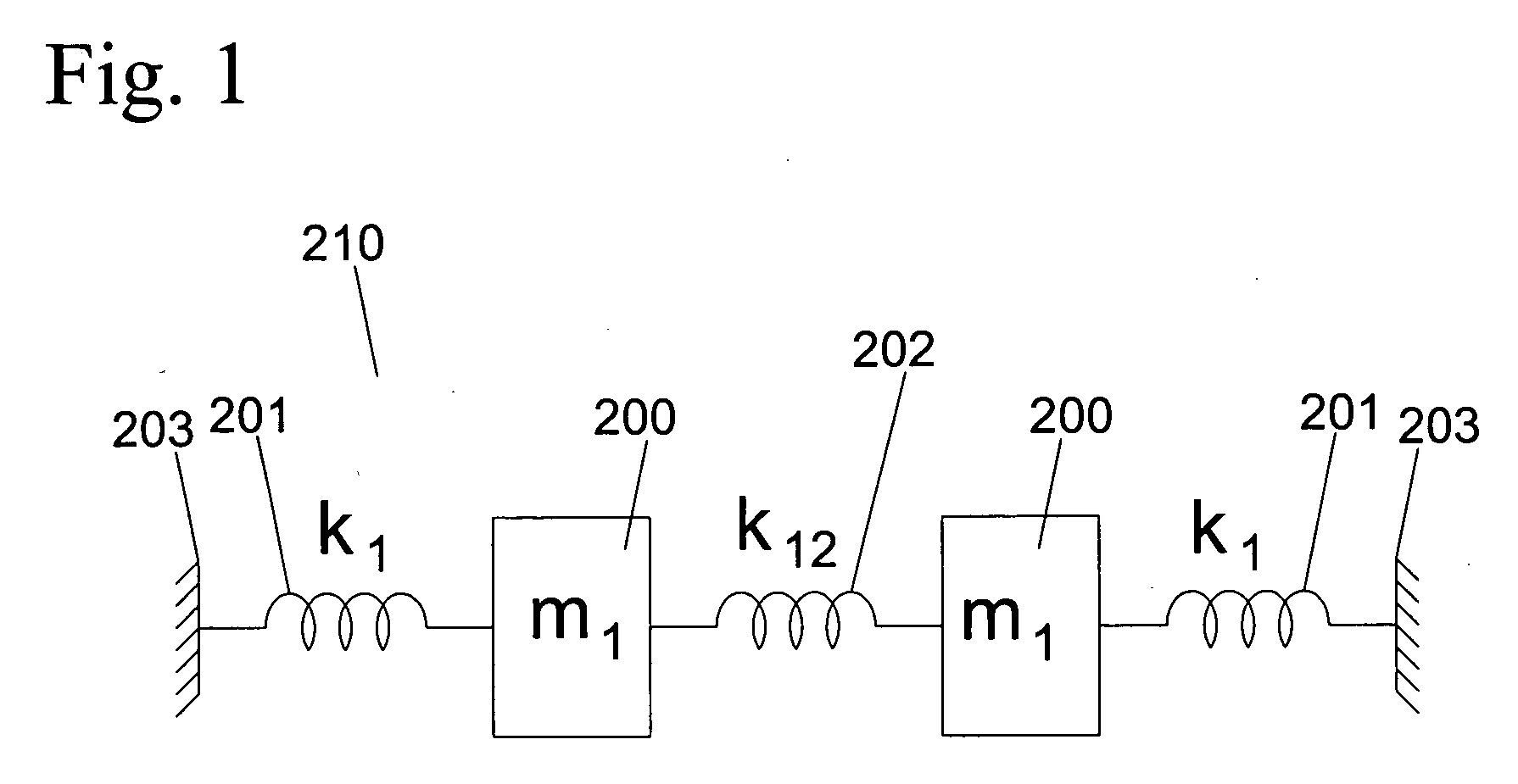

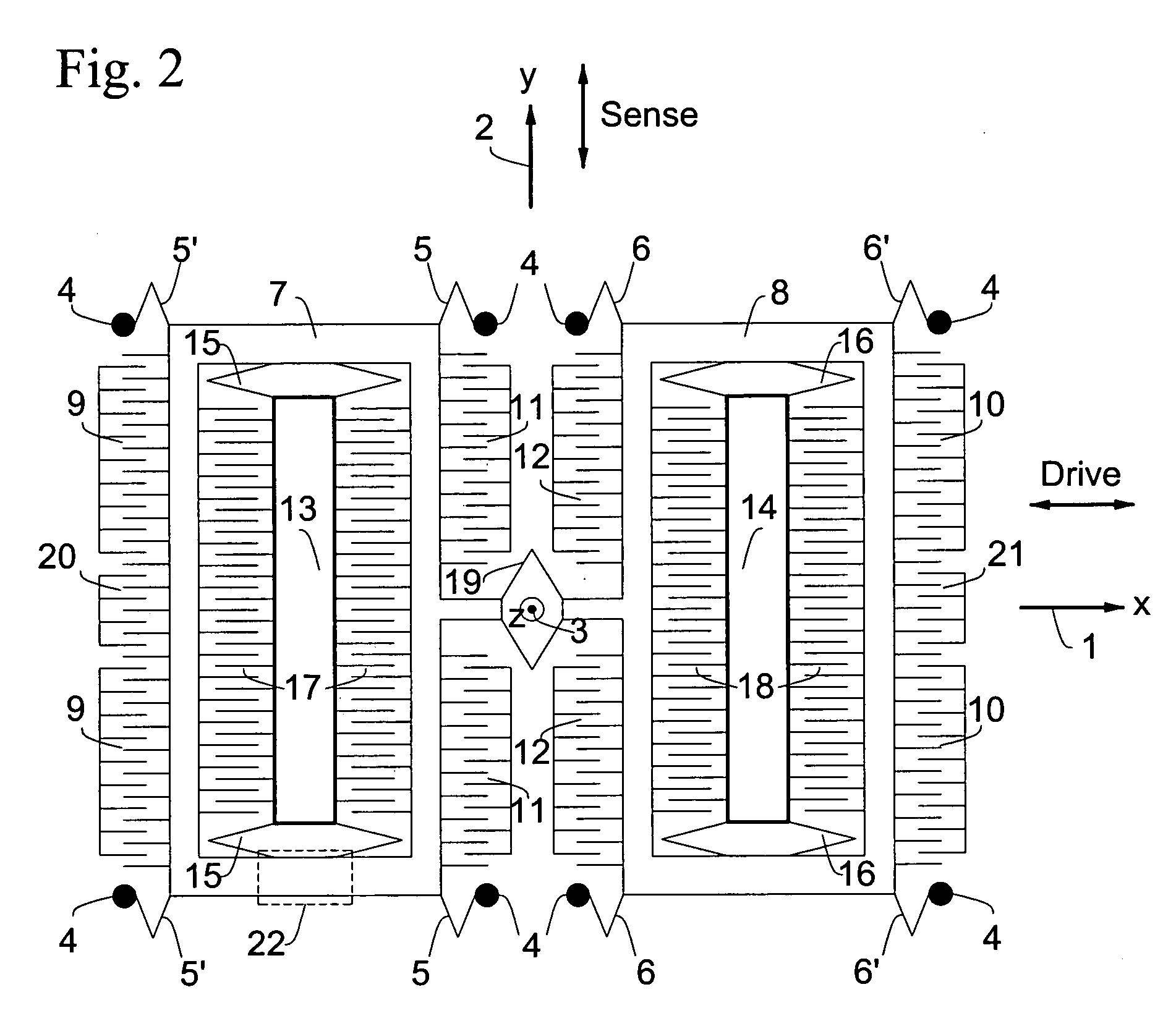

Z-axis angular rate micro electro-mechanical systems (MEMS) sensor

InactiveUS20050066728A1Avoid using forceAcceleration measurement using interia forcesTurn-sensitive devicesTuning forkMems sensors

An oscillatory angular rate MEMS sensor is described for sensing rotation about the “Z-axis”. Embodiments are either coupled-mass tuning-fork or single oscillating-mass in nature. The sensor includes mechanical and electrical function integration, and is preferably manufactured by a unique MEMS fabrication process.

Owner:KIONIX CORP

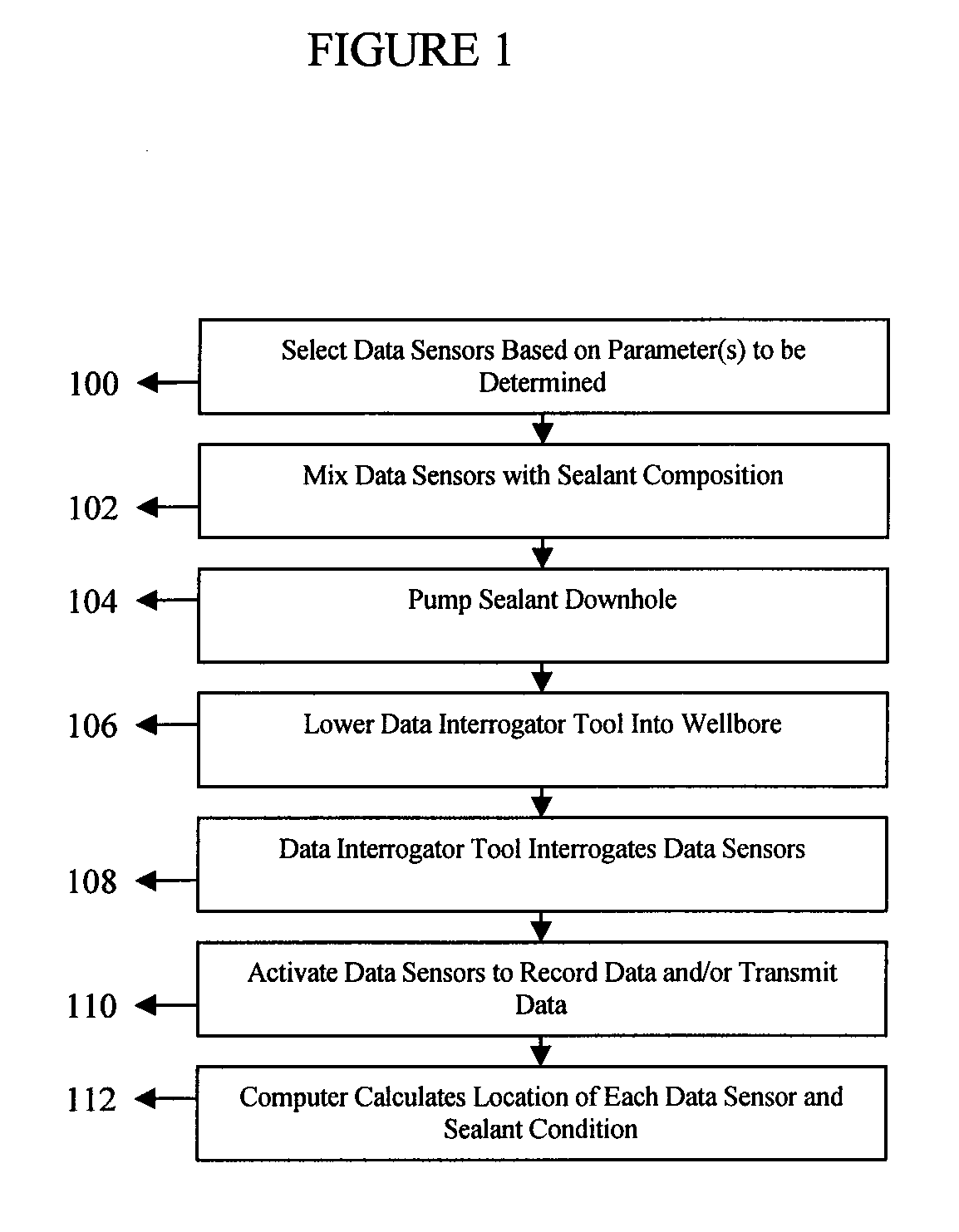

Use of Micro-Electro-Mechanical Systems (MEMS) in Well Treatments

A method of servicing a wellbore, comprising placing a plurality of Micro-Electro-Mechanical System (MEMS) sensors in at least a portion of a sealant composition, placing the sealant composition in an annular space formed between a casing and the wellbore wall, and monitoring, via the MEMS sensors, the sealant composition and / or the annular space for a presence of gas, water, or both. A method of servicing a wellbore, comprising placing a plurality of Micro-Electro-Mechanical System (MEMS) sensors in a wellbore composition, placing the wellbore composition in the wellbore, and monitoring, via the MEMS sensors, the wellbore and / or the surrounding formation for movement.

Owner:HALLIBURTON ENERGY SERVICES INC

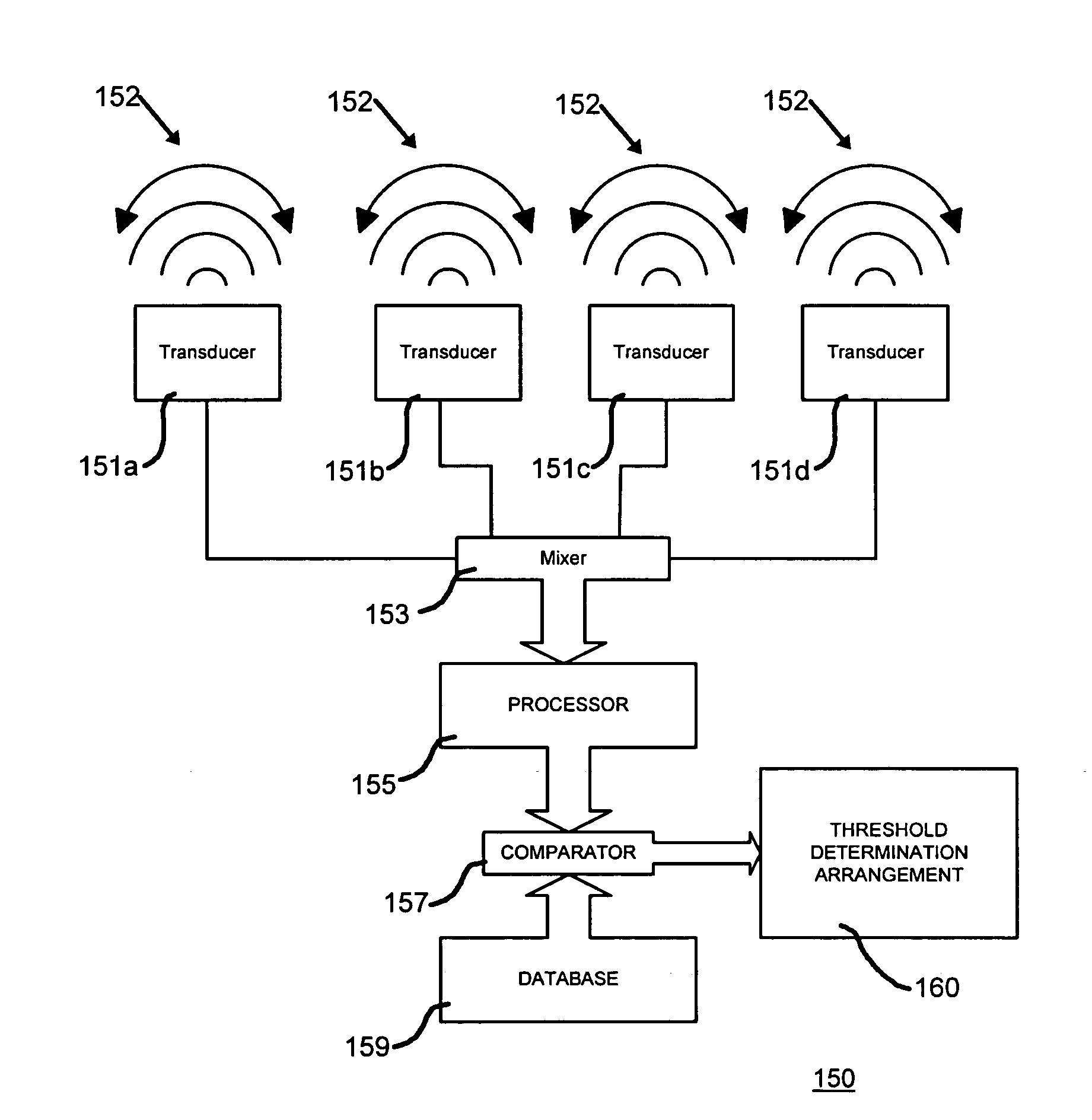

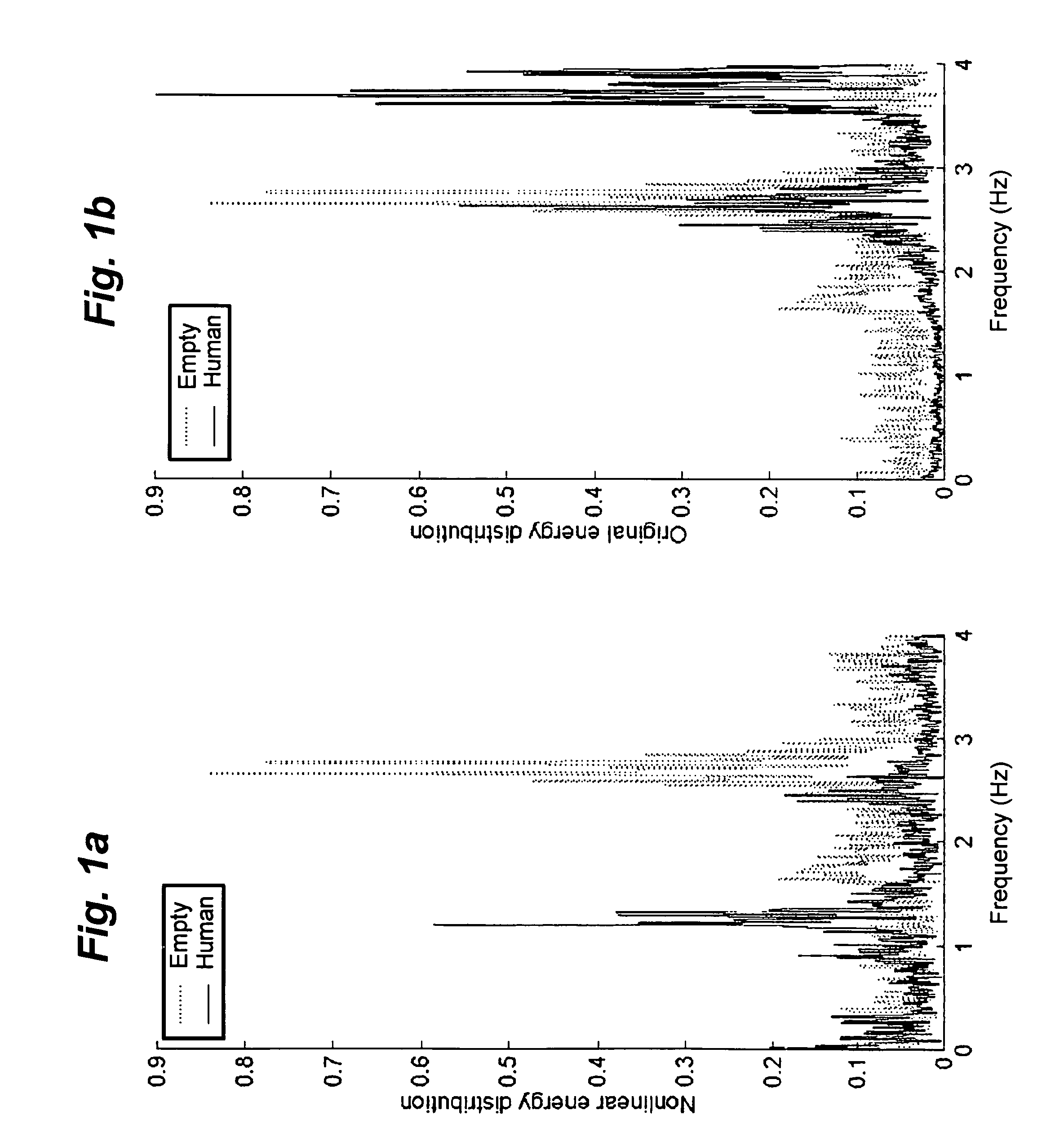

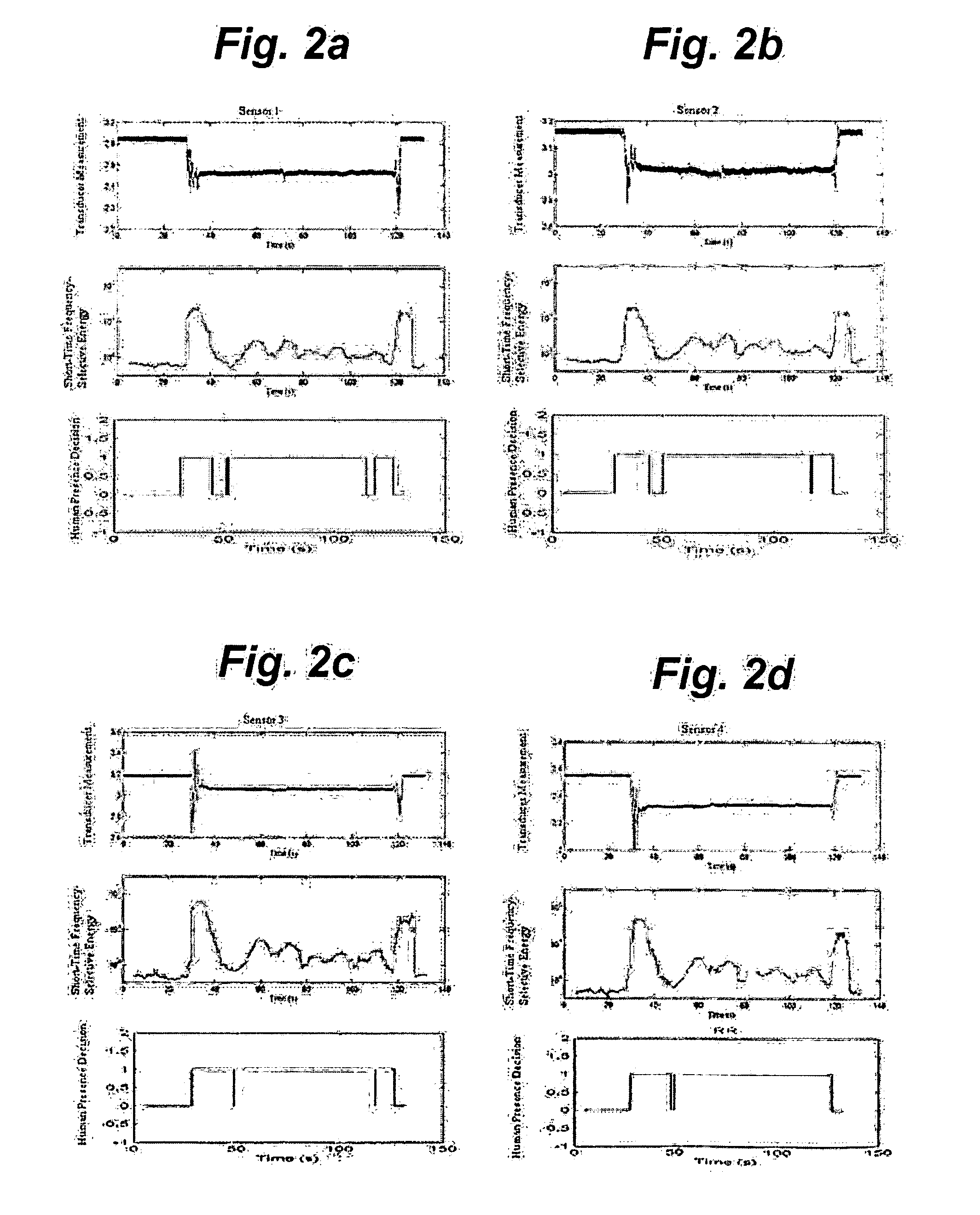

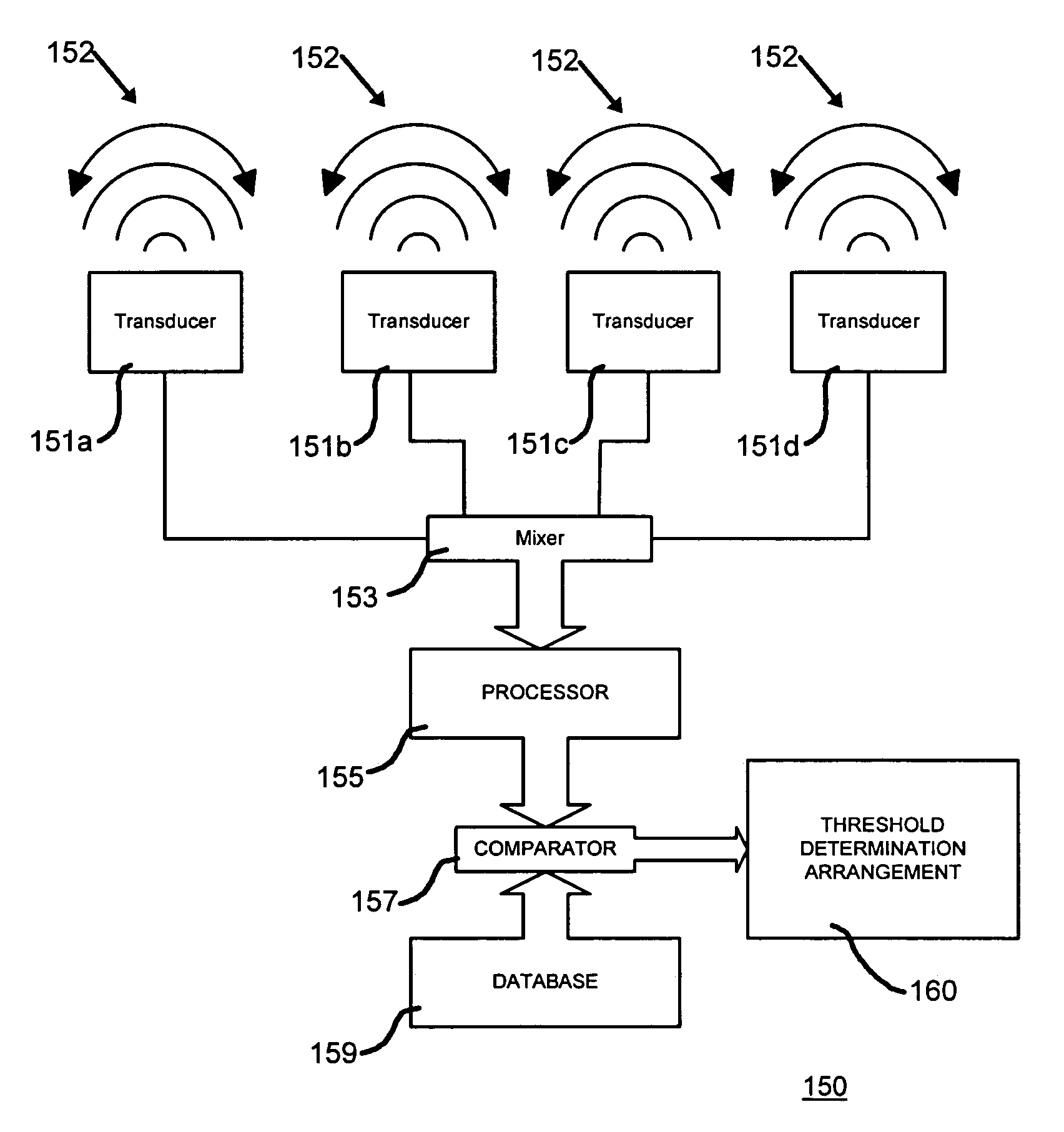

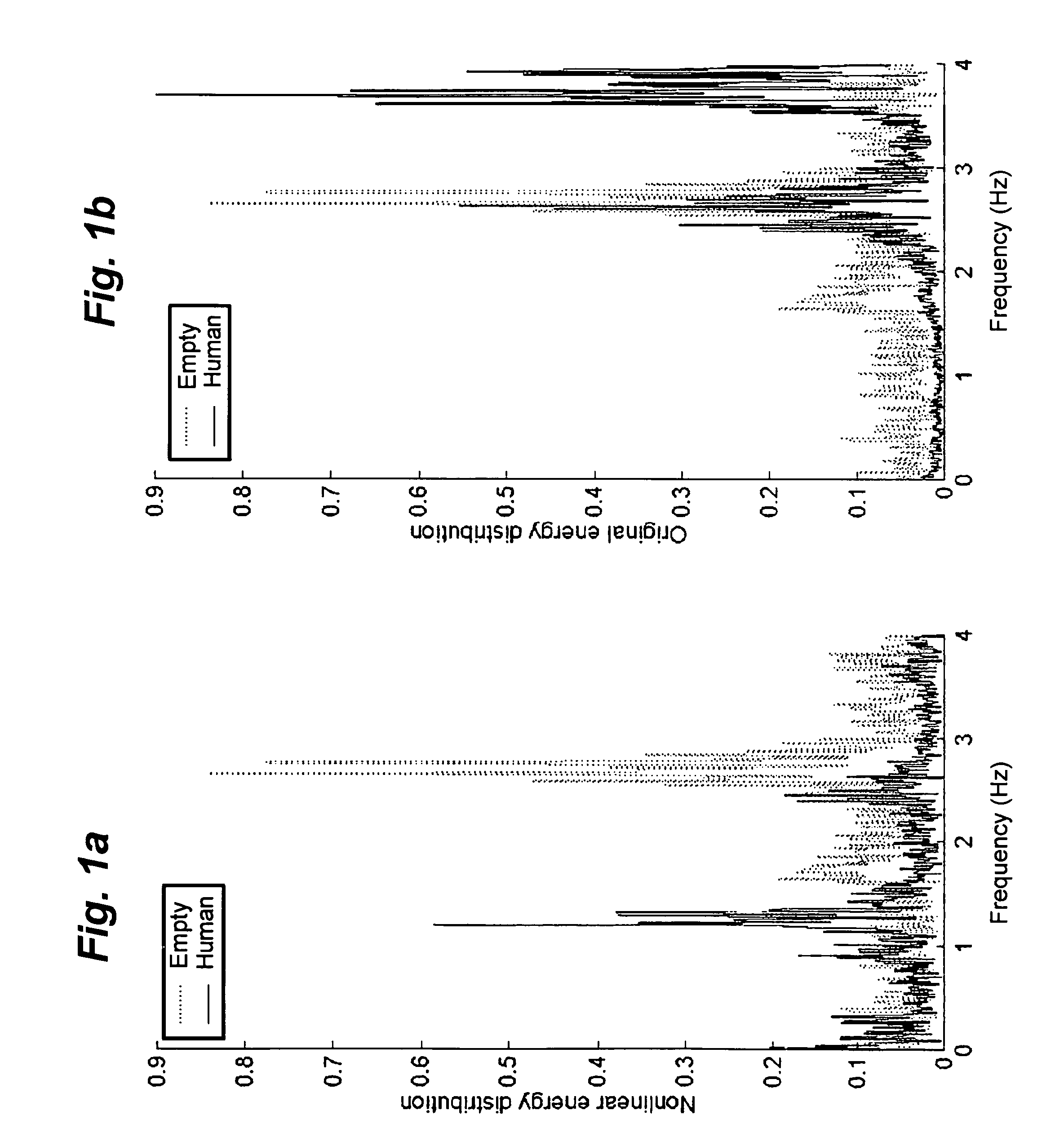

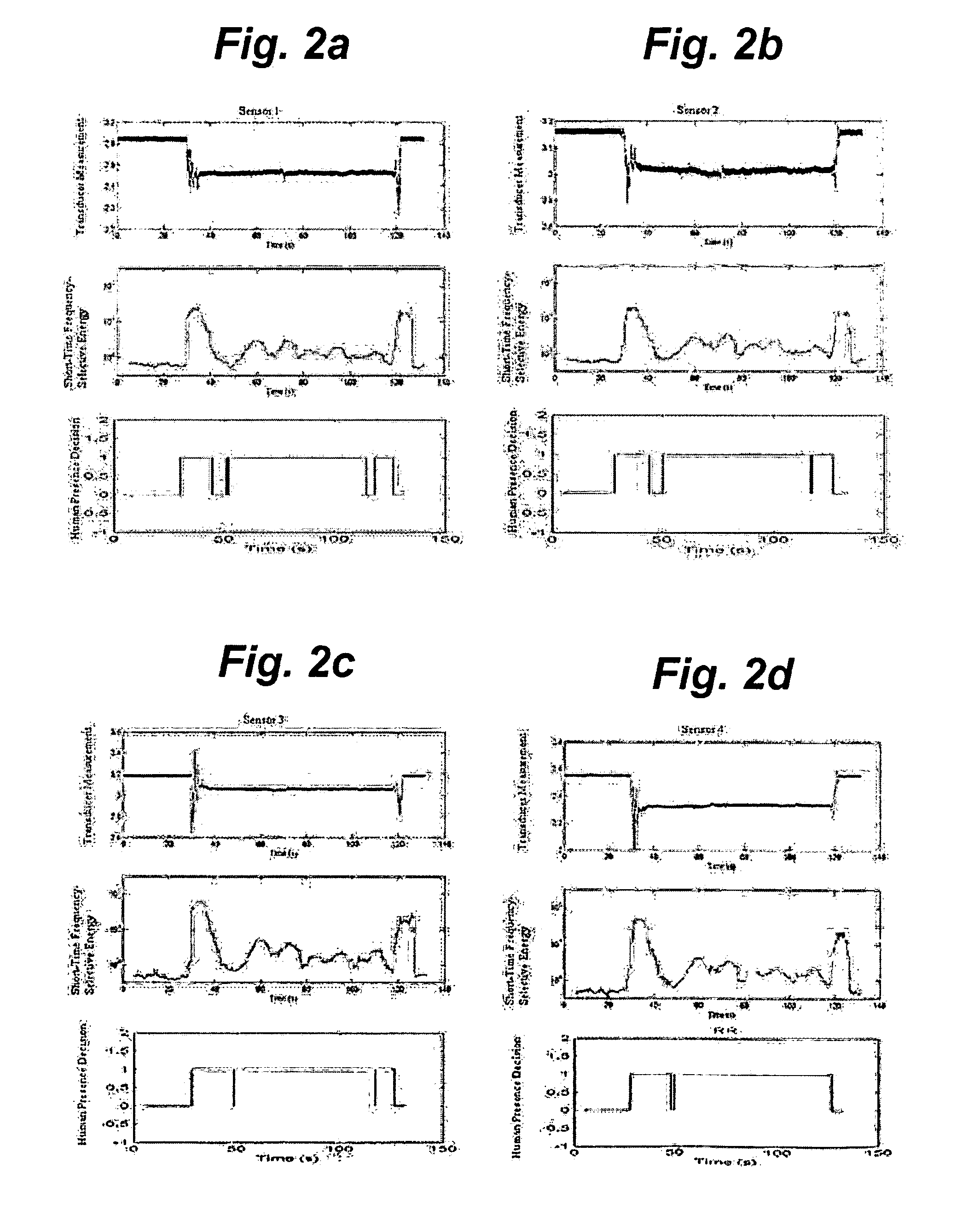

Living being presence detection system

InactiveUS20070103328A1Detect presenceAvoid accidentsFrequency-division multiplex detailsDigital data processing detailsBiological bodyTransducer

A system for distinguishing between a first condition corresponding to a living subject being directly in contact with an object of interest, and a second condition corresponding to the absence of contact between the living subject and the object of interest. A transducer, which may be a MEMs sensor, is disposed in predetermined relationship to the object of interest and produces a transducer signal responsive to a pressure wave resulting from the living subject being directly in contact the object of interest. A database stores data corresponding to the first condition and may contain additional data corresponding to the second condition. A processor calculates an algorithm of a non-linear short-term frequency-selective energy distribution of the transducer signal over time to produce transducer signal data. An arrangement, which may be a human listener or a processor system, determines a threshold between the first and second conditions in response to the transducer signal data and the first and second data. The direct contact may be a tap or stroking contact by a living subject. The transducer can be disposed within, or on the exterior of, the object of interest.

Owner:LAKSHMANAN SRIDHAR +3

Use of Micro-Electro-Mechanical Systems (MEMS) in Well Treatments

A method of servicing a wellbore, comprising placing a plurality of Micro-Electro-Mechanical System (MEMS) sensors in a wellbore composition, flowing the wellbore composition in the wellbore, and determining one or more fluid flow properties or characteristics of the wellbore composition from data provided by the MEMS sensors during the flowing of the wellbore composition. A method of servicing a wellbore, comprising placing a plurality of Micro-Electro-Mechanical System (MEMS) sensors in at least a portion of a spacer fluid, a sealant composition, or both, pumping the spacer fluid followed by the sealant composition into the wellbore, and determining one or more fluid flow properties or characteristics of the spacer fluid and / or the cement composition from data provided by the MEMS sensors during the pumping of the spacer fluid and sealant composition into the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

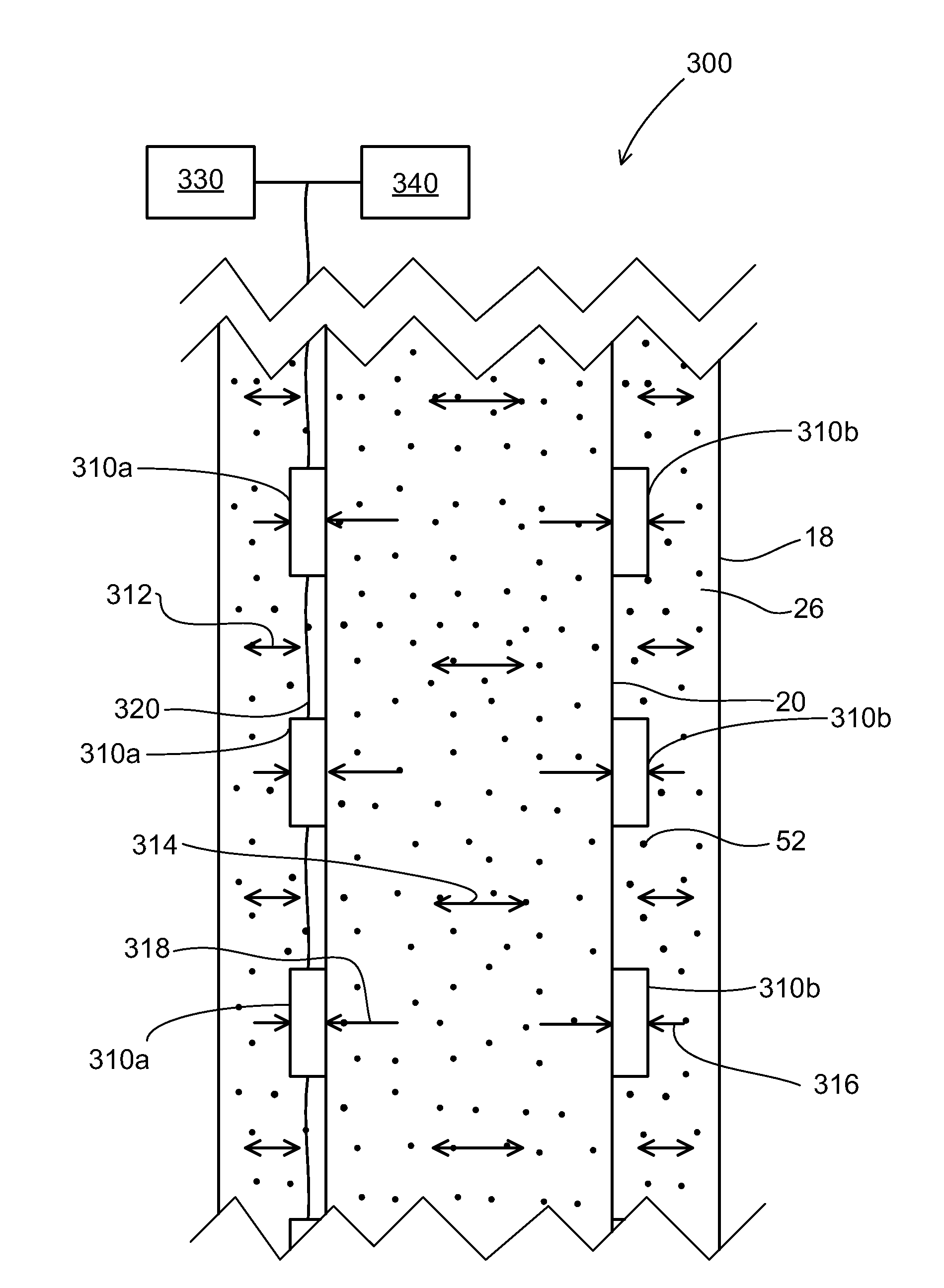

Methods and apparatus for evaluating downhole conditions with RFID MEMS sensors

A radio frequency identification (RFID) tag can include a die attached to an inductive-capacitive (LC) circuit including a capacitive element coupled to an inductive element. The LC circuit can have a resonant frequency that varies according to properties of fluid proximate the RFID tag. The RFID tag can further include a coating material disposed around the die to form an outer surface of the RFID tag. The coating material may have a thickness over a portion of the LC circuit, to permit a conductivity property of a fluid proximate the outer surface to affect the resonant frequency of the LC circuit such that the resonant frequency shifts to a second resonant frequency. Additional apparatus, systems, and methods are disclosed.

Owner:HALLIBURTON ENERGY SERVICES INC

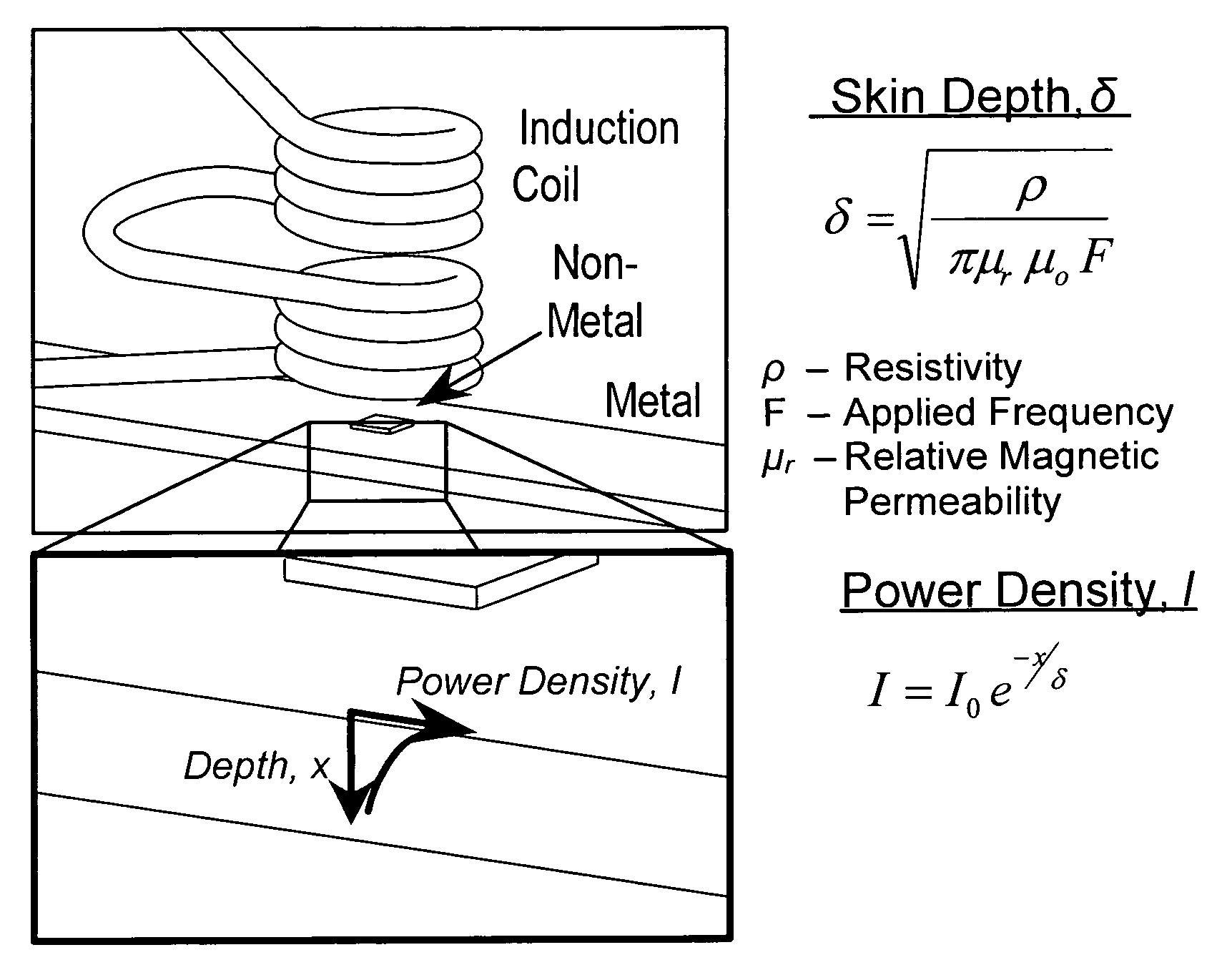

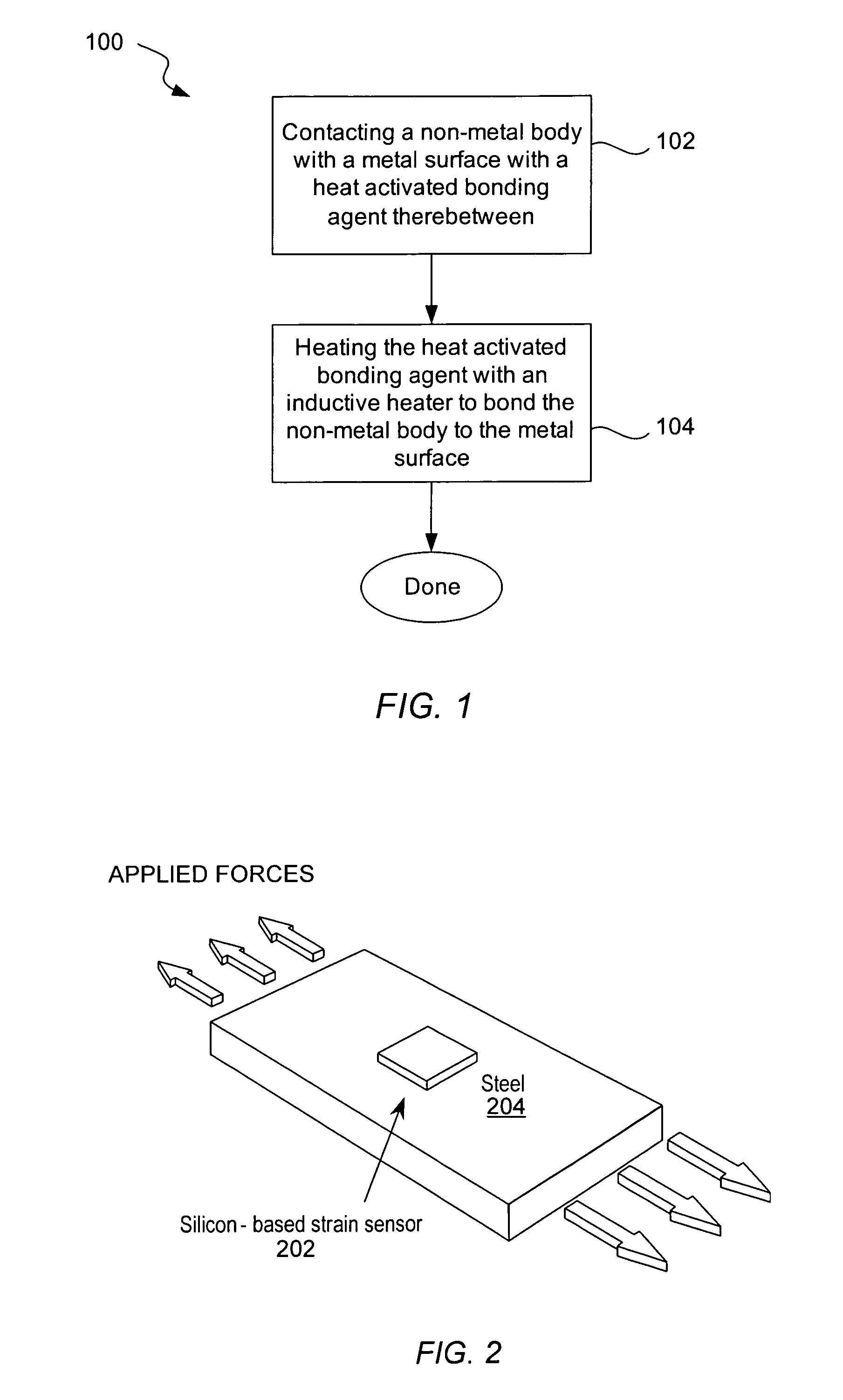

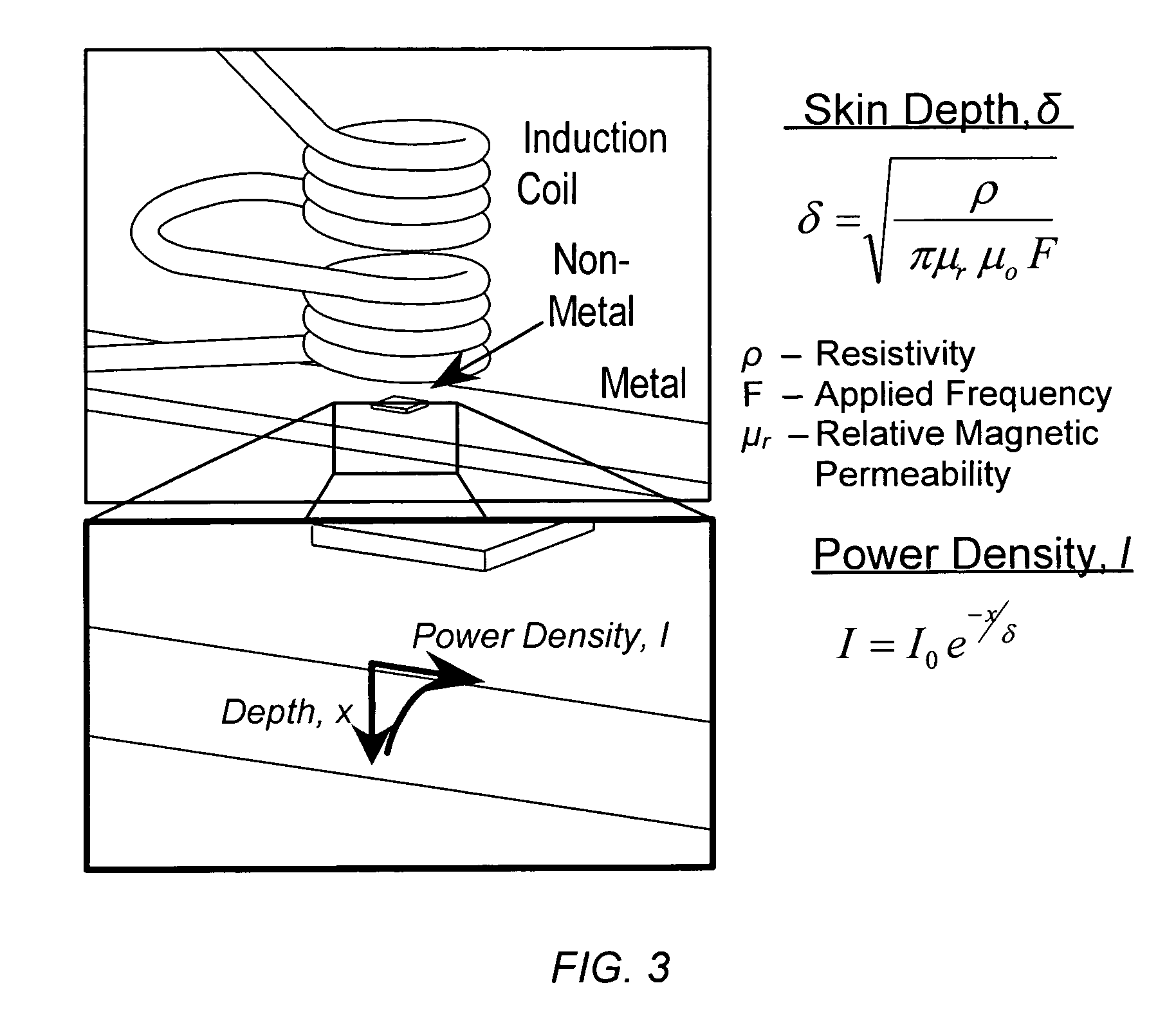

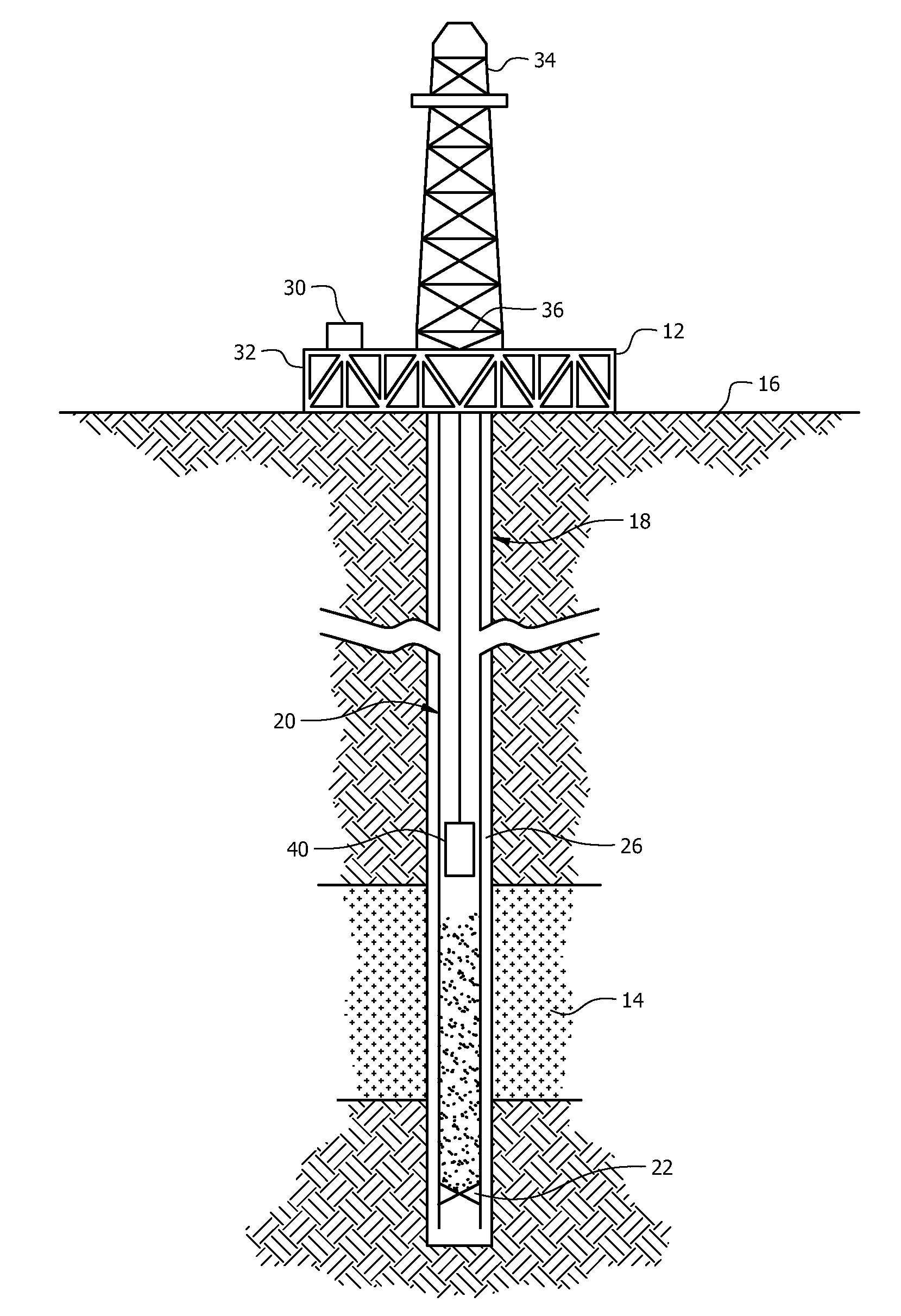

Bonding a non-metal body to a metal surface using inductive heating

InactiveUS7452800B2Change propertiesQuickly and effectively bondSolid-state devicesForce measurementMechanical componentsMems sensors

A bonding technique suitable for bonding a non-metal body, such as a silicon MEMS sensor, to a metal surface, such a steel mechanical component is rapid enough to be compatible with typical manufacturing processes, and avoids any detrimental change in material properties of the metal surface arising from the bonding process. The bonding technique has many possible applications, including bonding of MEMS strain sensors to metal mechanical components. The inventive bonding technique uses inductive heating of a heat-activated bonding agent disposed between metal and non-metal objects to quickly and effectively bond the two without changing their material properties. Representative tests of silicon to steel bonding using this technique have demonstrated excellent bond strength without changing the steel's material properties. Thus, with this induction bonding approach, silicon MEMS devices can be manufacturably bonded to mechanical steel components for real time monitoring of the conditions / environment of a steel component.

Owner:RGT UNIV OF CALIFORNIA

Use of Micro-Electro-Mechanical Systems (MEMS) in Well Treatments

A method of servicing a wellbore, comprising placing a plurality of Micro-Electro-Mechanical System (MEMS) sensors in a wellbore composition, placing the wellbore composition in the wellbore, and obtaining data from the MEMS sensors using a plurality of data interrogation units spaced along a length of the wellbore. A method of servicing a wellbore, comprising placing a plurality of Micro-Electro-Mechanical System (MEMS) sensors in a wellbore composition, placing the wellbore composition in the wellbore, forming a network comprising the MEMS sensors, and transferring data obtained by the MEMS sensors from an interior of the wellbore to an exterior of the wellbore via the network.

Owner:HALLIBURTON ENERGY SERVICES INC

Living being presence detection system

InactiveUS7417536B2Facilitates the rescue of living beingsDetect presenceFrequency-division multiplex detailsDigital data processing detailsTransducerMems sensors

A system for distinguishing between a first condition corresponding to a living subject being directly in contact with an object of interest, and a second condition corresponding to the absence of contact between the living subject and the object of interest. A transducer, which may be a MEMs sensor, is disposed in predetermined relationship to the object of interest and produces a transducer signal responsive to a pressure wave resulting from the living subject being directly in contact the object of interest. A database stores data corresponding to the first condition and may contain additional data corresponding to the second condition. A processor calculates an algorithm of a non-linear short-term frequency-selective energy distribution of the transducer signal over time to produce transducer signal data. An arrangement, which may be a human listener or a processor system, determines a threshold between the first and second conditions in response to the transducer signal data and the first and second data. The direct contact may be a tap or stroking contact by a living subject. The transducer can be disposed within, or on the exterior of, the object of interest.

Owner:LAKSHMANAN SRIDHAR +3

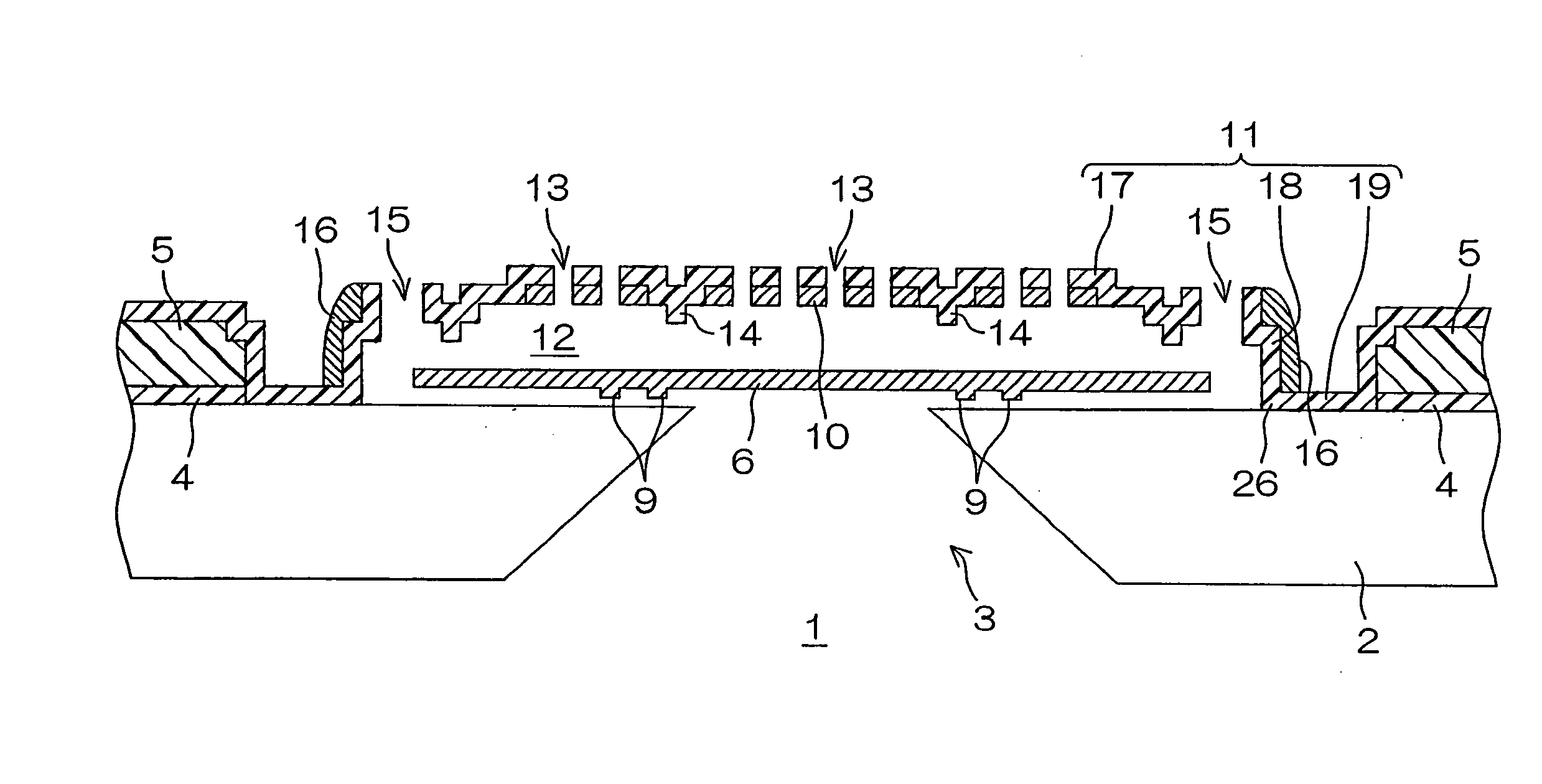

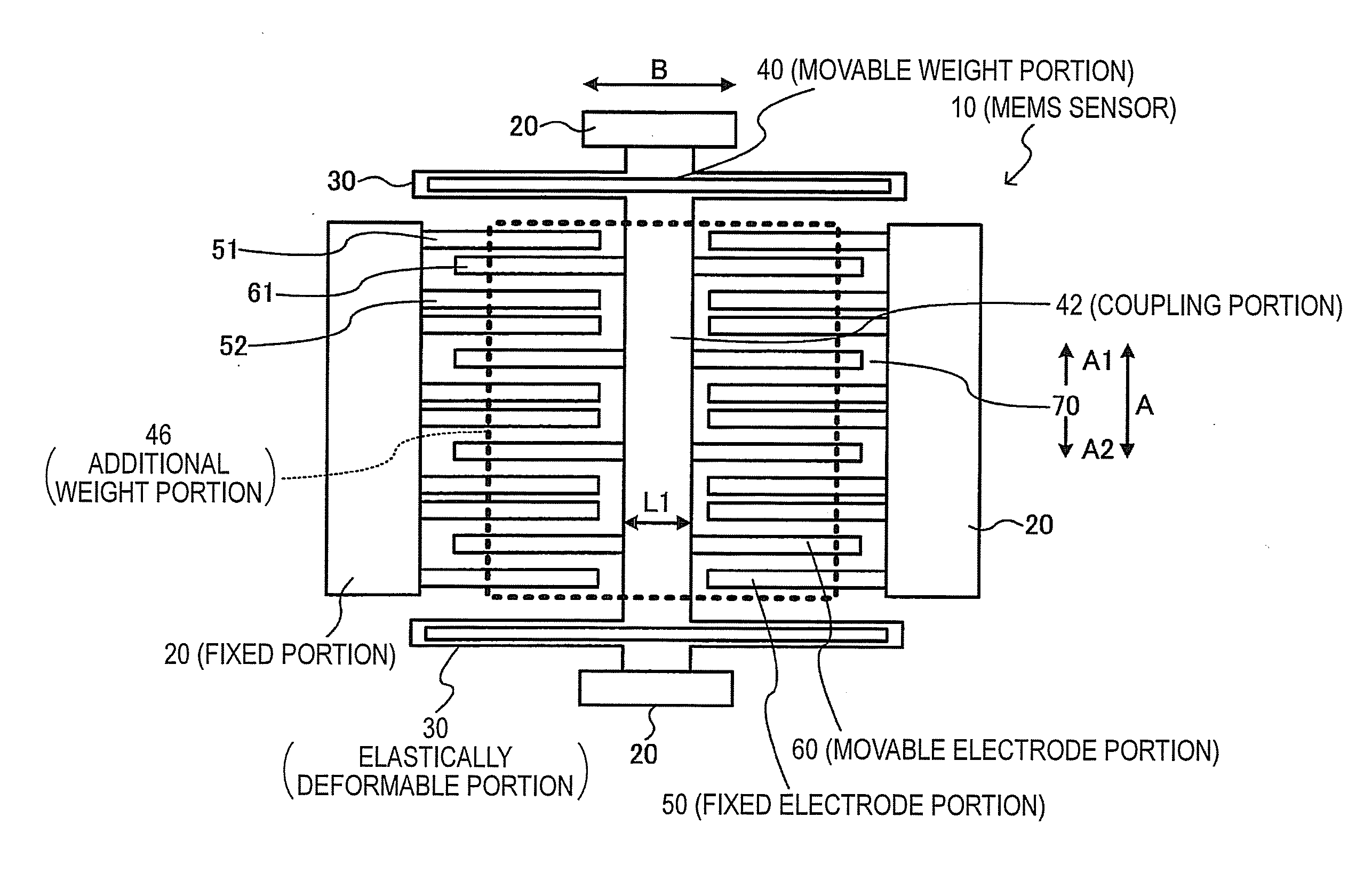

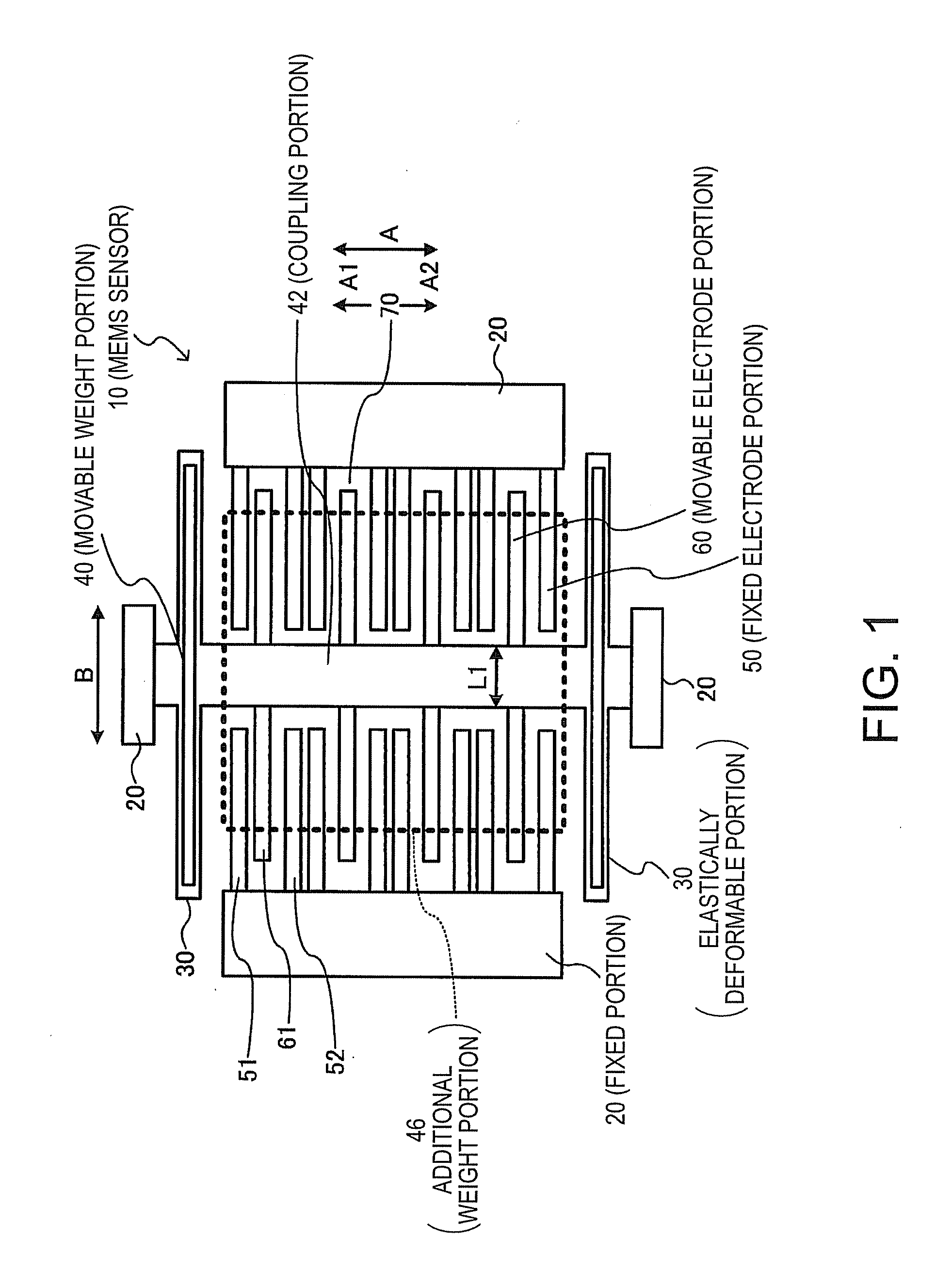

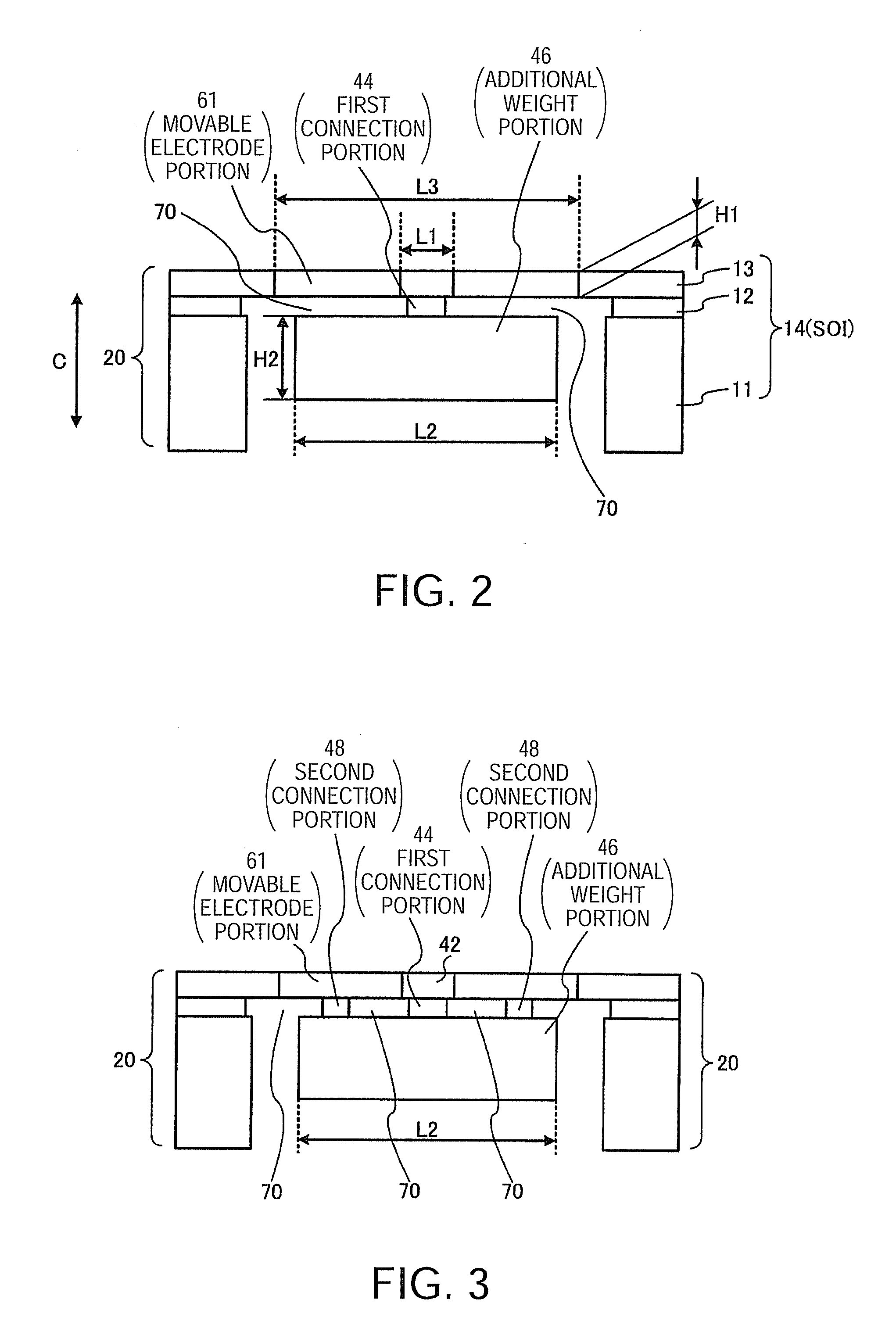

MEMS sensor, method of manufacturing thereof, and electronic apparatus

InactiveUS20110120221A1Improve detection accuracyDecorative surface effectsFluid pressure measurement by electric/magnetic elementsCouplingMems sensors

A MEMS sensor includes: a fixed portion; an elastically deformable portion; a movable weight portion coupled to the fixed portion via the elastically deformable portion, the movable weight portion including a coupling portion; a plurality of fixed electrode portions arranged in a first direction and protruding in a second direction perpendicular to the first direction; and a plurality of movable electrode portions protruding from the coupling portion in the second direction, provided to respectively face the plurality of fixed electrode portions, and arranged in the first direction, wherein the movable weight portion has an additional weight portion connected to the coupling portion.

Owner:SEIKO EPSON CORP

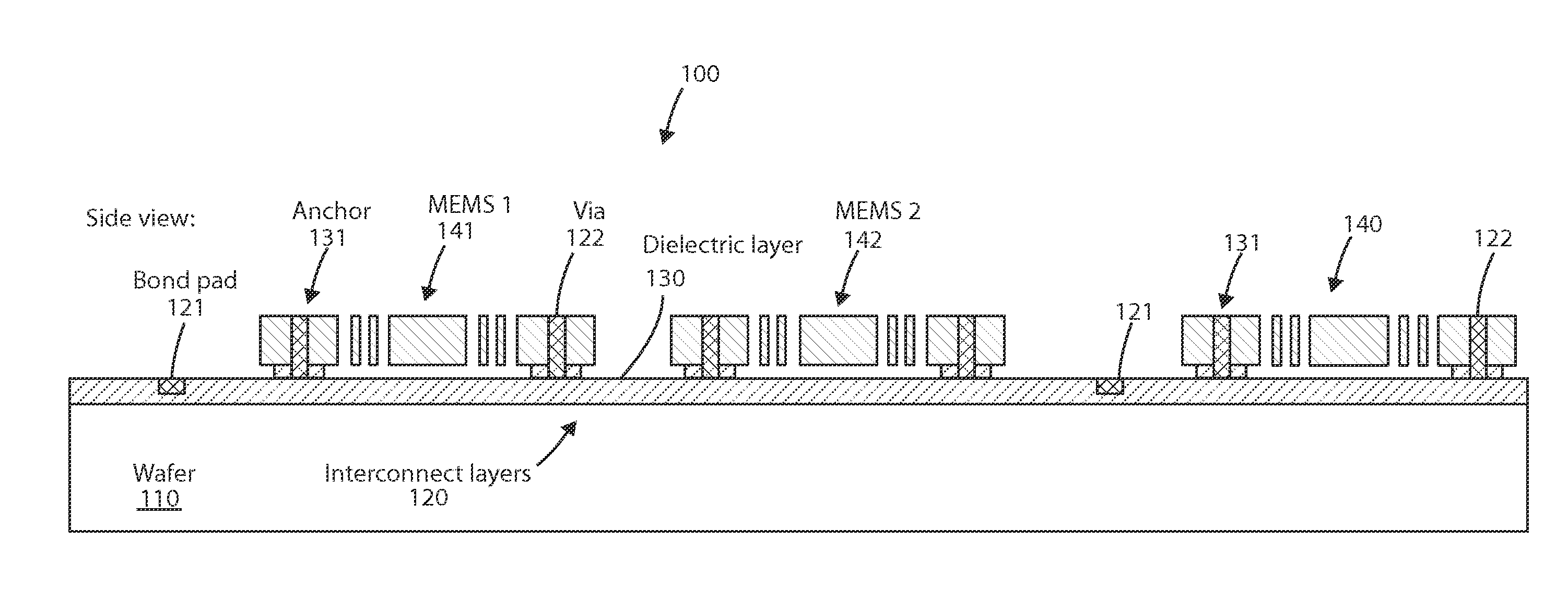

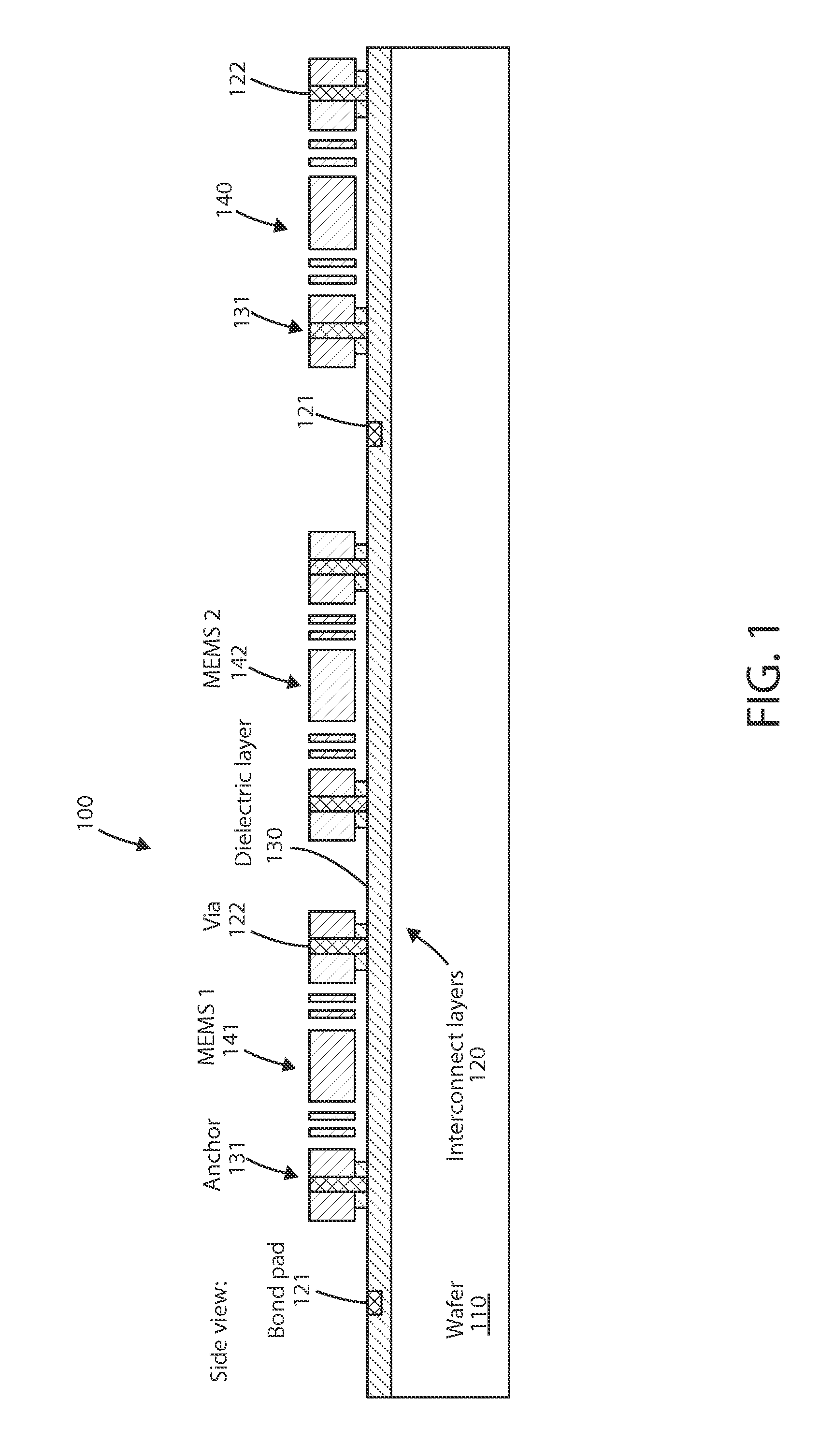

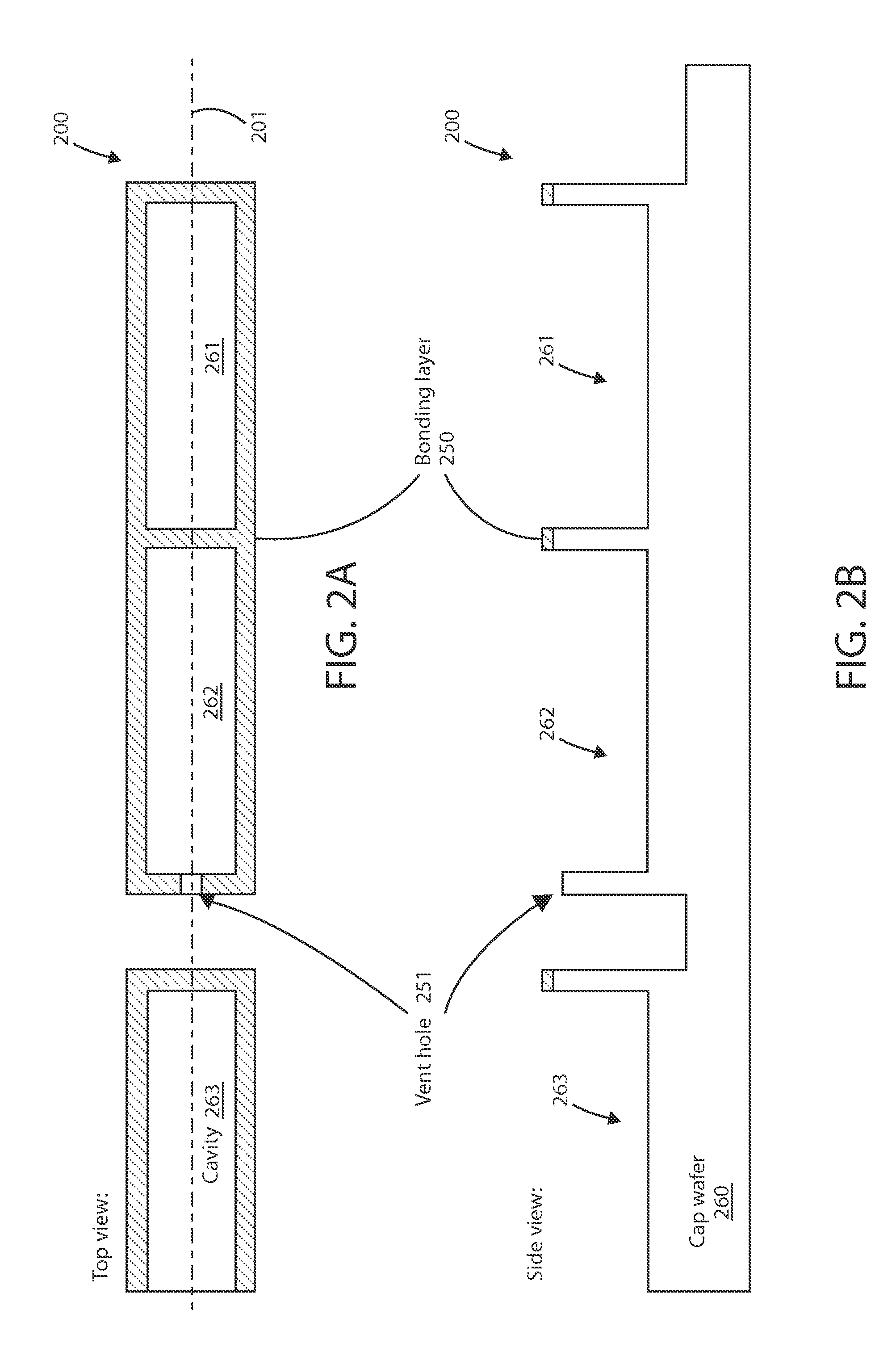

Method to package multiple MEMS sensors and actuators at different gases and cavity pressures

ActiveUS20140227816A1Increase dampingPerformanceDecorative surface effectsSemiconductor/solid-state device manufacturingCavity pressureMems sensors

A method for fabricating a multiple MEMS device. A semiconductor substrate having a first and second MEMS device, and an encapsulation wafer with a first cavity and a second cavity, which includes at least one channel, can be provided. The first MEMS can be encapsulated within the first cavity and the second MEMS device can be encapsulated within the second cavity. These devices can be encapsulated within a provided first encapsulation environment at a first air pressure, encapsulating the first MEMS device within the first cavity at the first air pressure. The second MEMS device within the second cavity can then be subjected to a provided second encapsulating environment at a second air pressure via the channel of the second cavity.

Owner:MOVELLA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com