Patents

Literature

1245 results about "Thermoelectric generator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

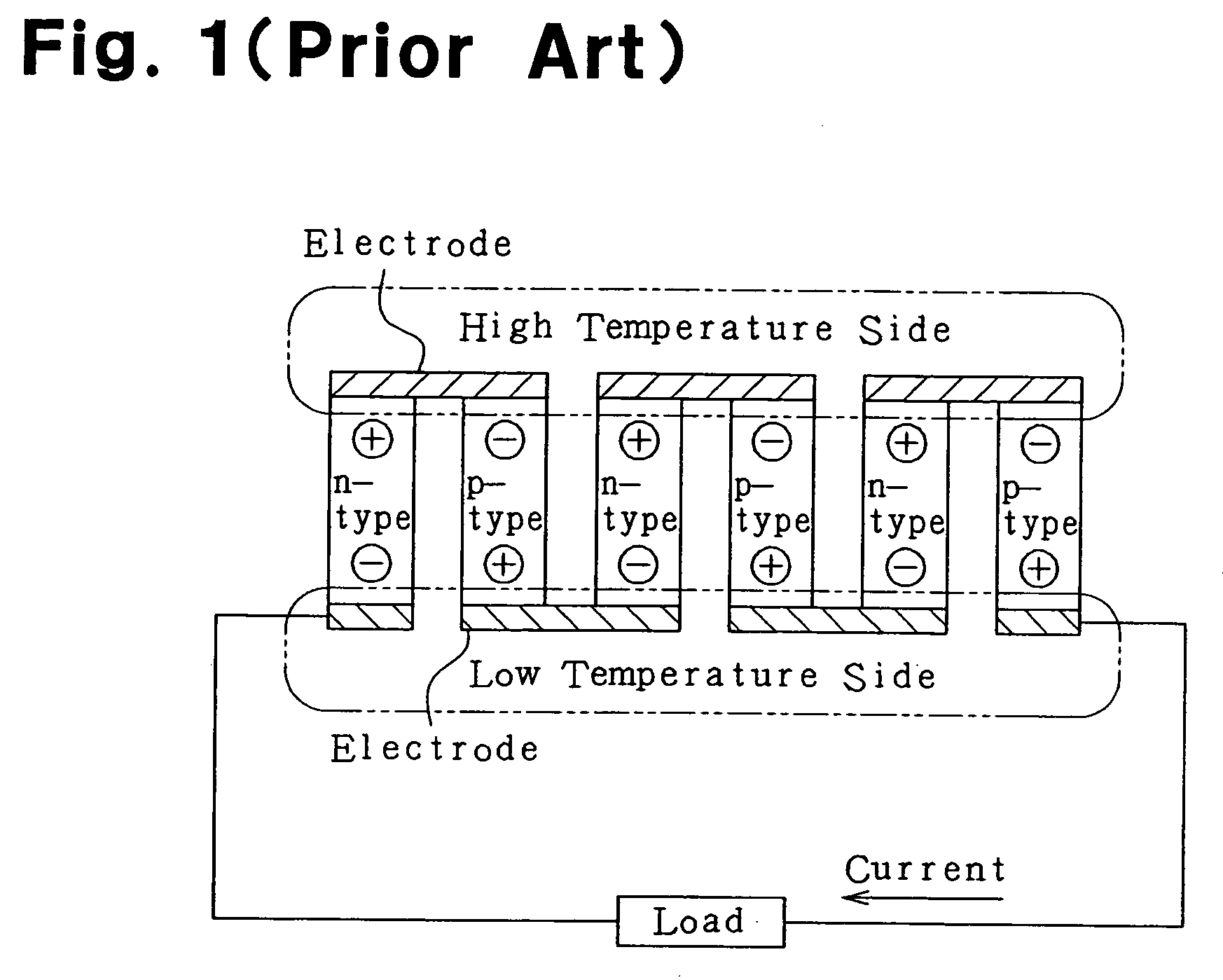

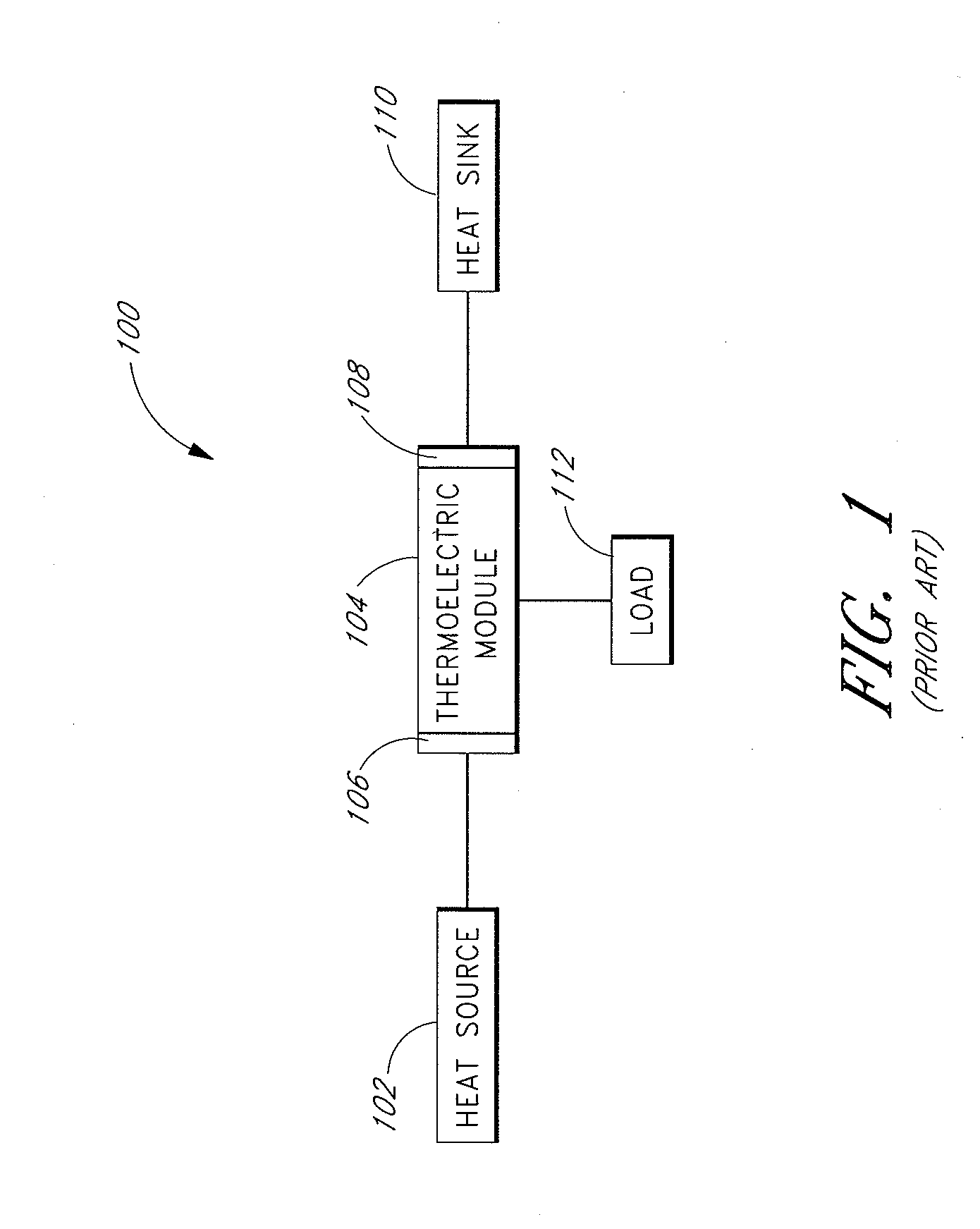

A thermoelectric generator (TEG), also called a Seebeck generator, is a solid state device that converts heat flux (temperature differences) directly into electrical energy through a phenomenon called the Seebeck effect (a form of thermoelectric effect). Thermoelectric generators function like heat engines, but are less bulky and have no moving parts. However, TEGs are typically more expensive and less efficient.

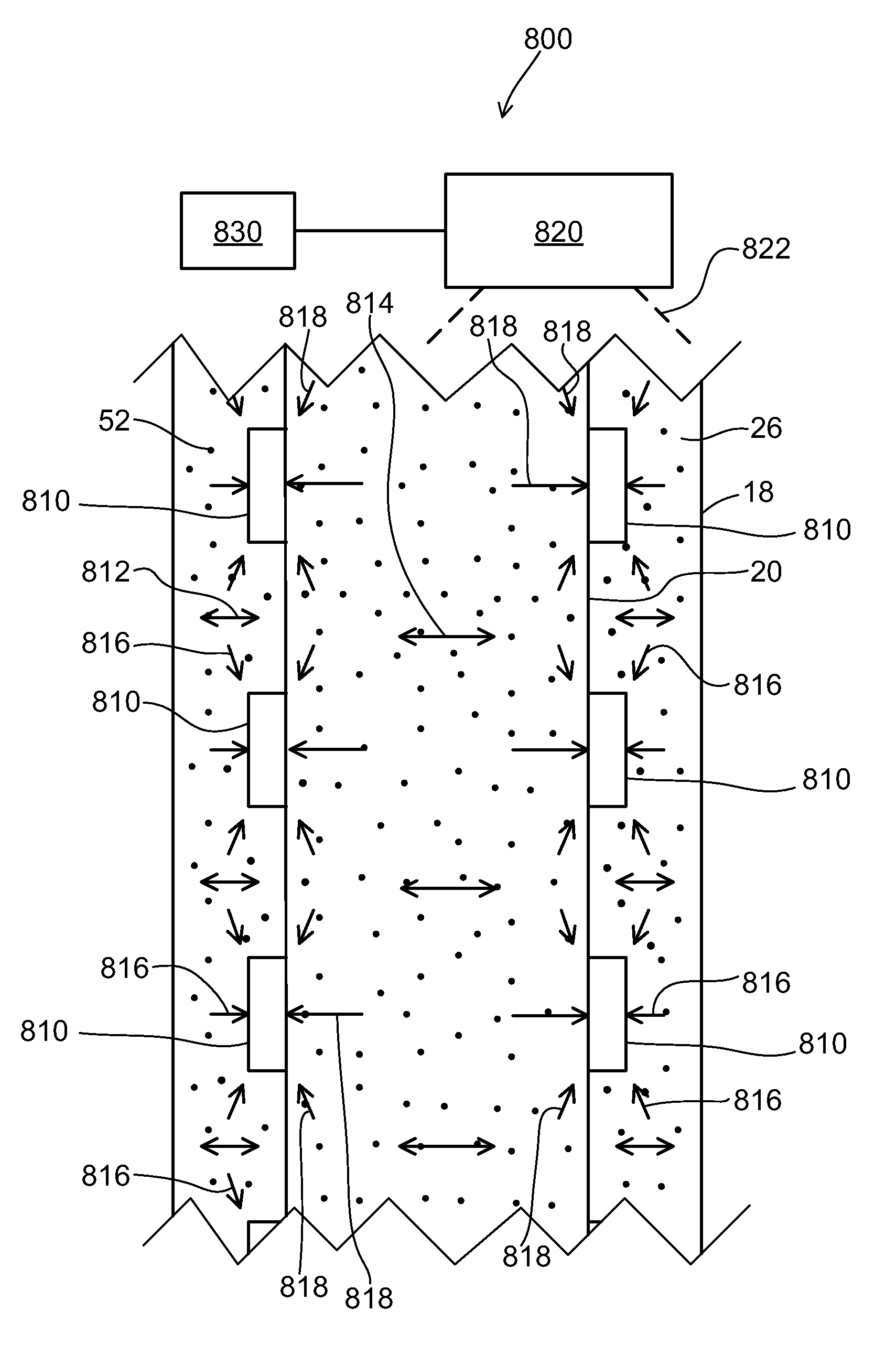

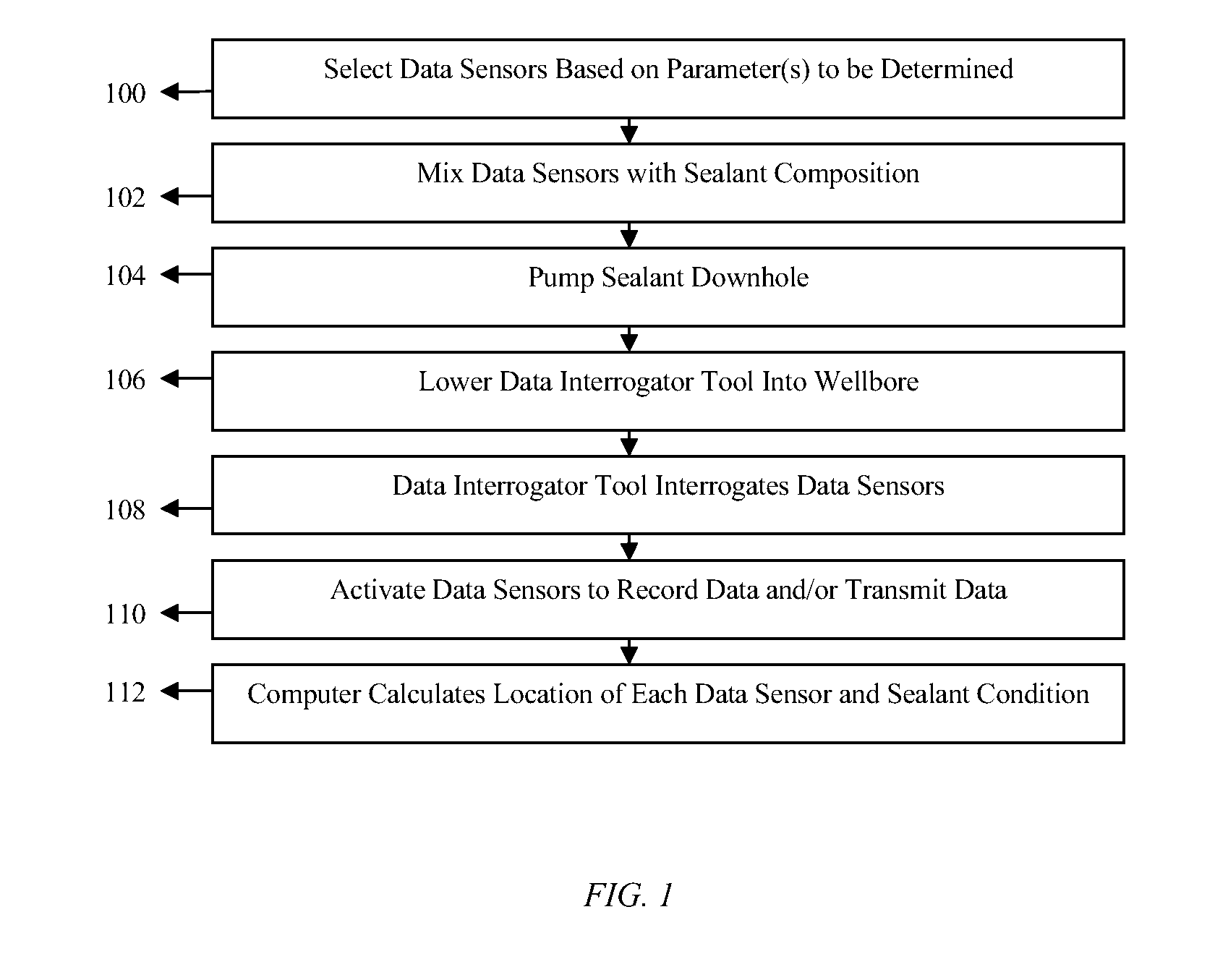

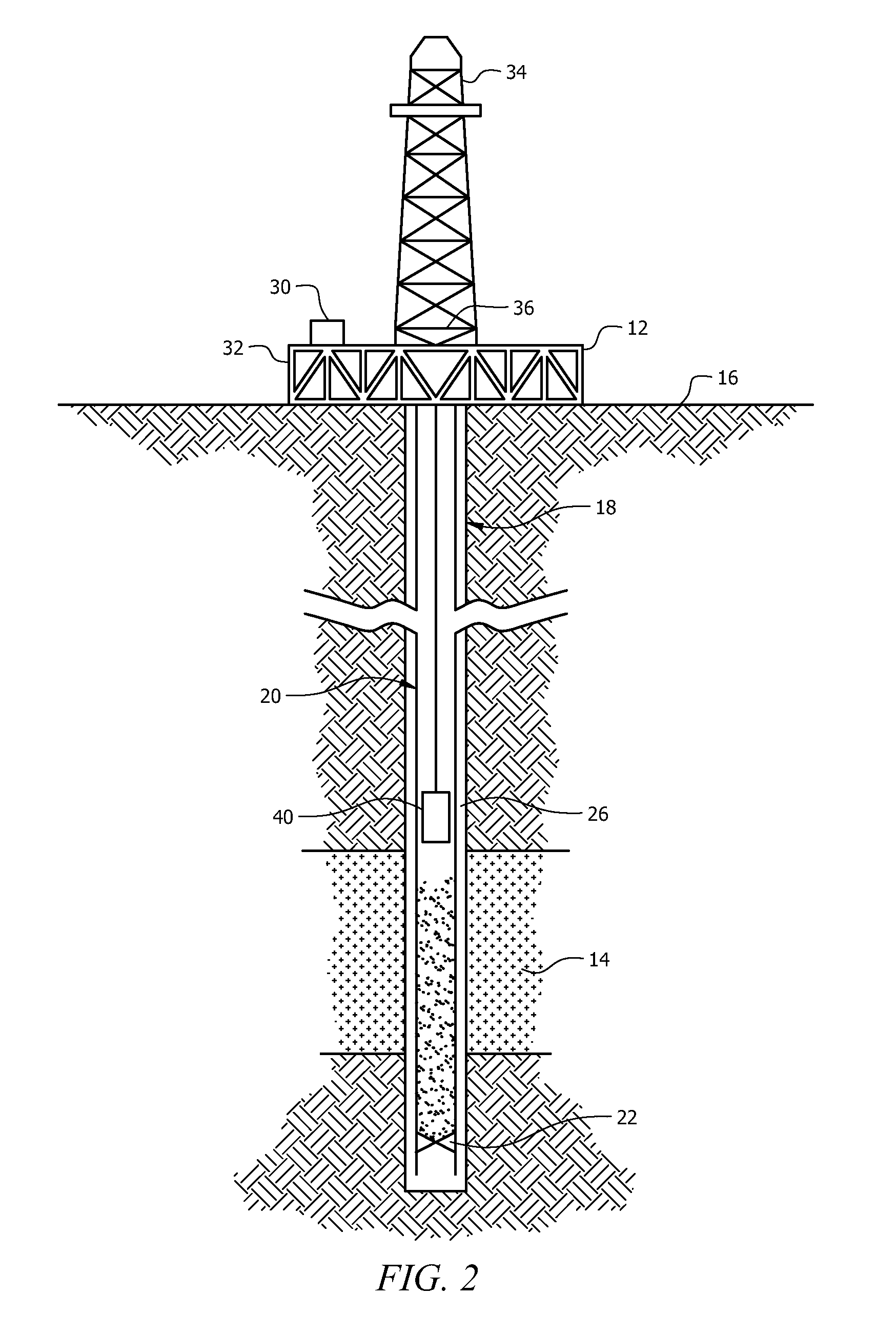

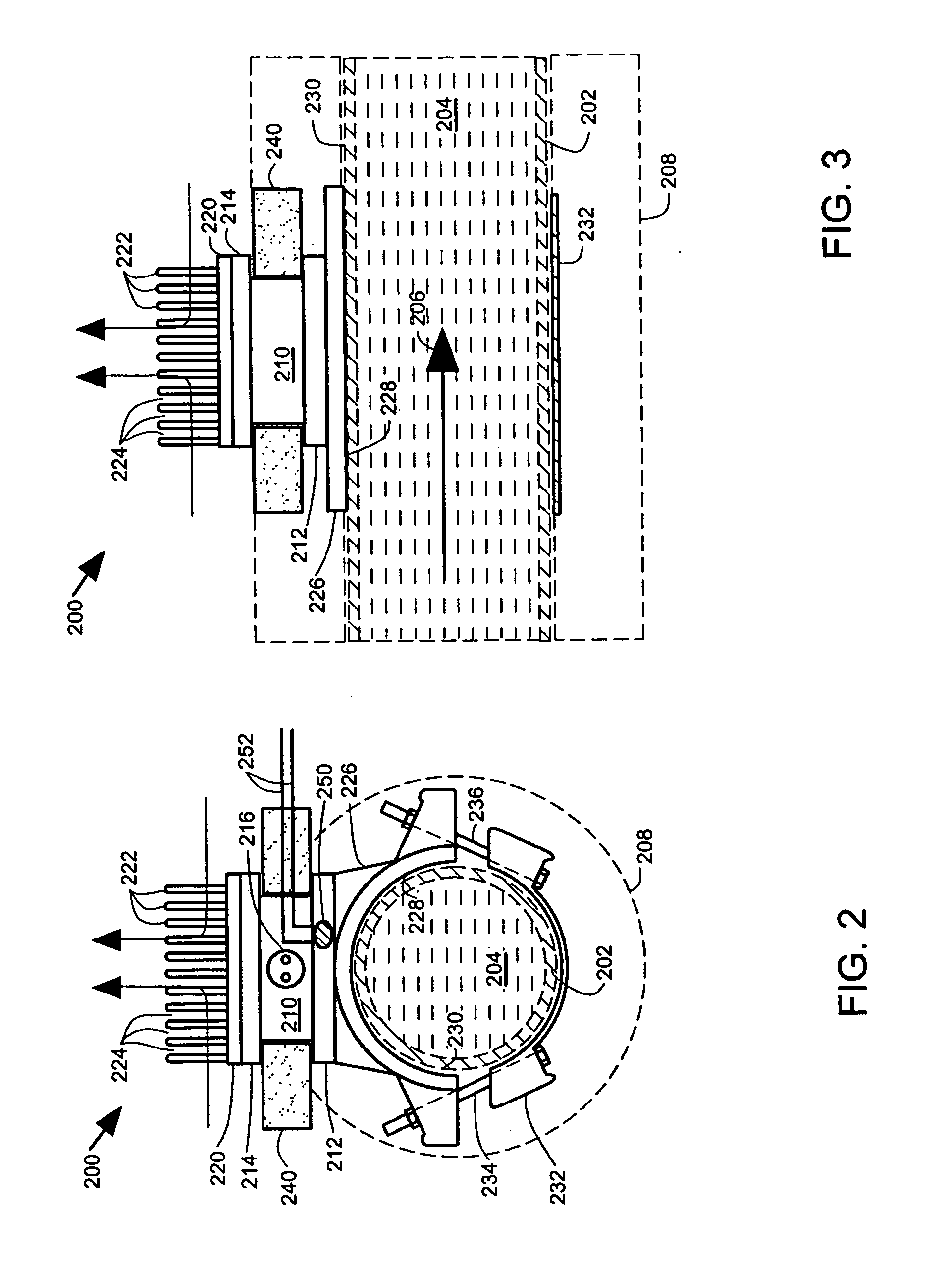

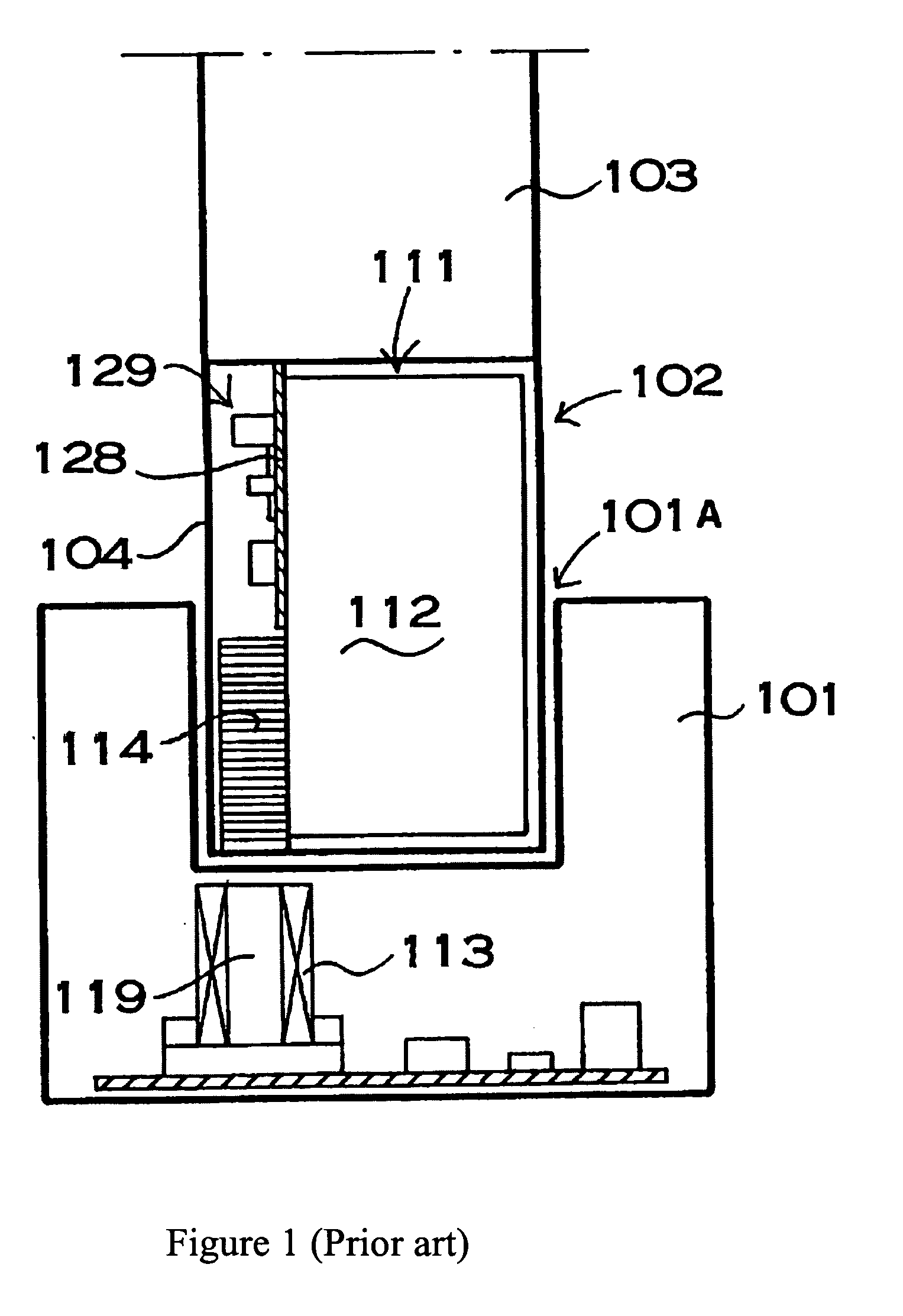

Use of micro-electro-mechanical systems (MEMS) in well treatments

A method of servicing a wellbore, comprising placing a wellbore composition comprising a plurality of Micro-Electro-Mechanical System (MEMS) sensors in the wellbore, placing a plurality of acoustic sensors in the wellbore, obtaining data from the MEMS sensors and data from the acoustic sensors using a plurality of data interrogation units spaced along a length of the wellbore, and transmitting the data obtained from the MEMS sensors and the acoustic sensors from an interior of the wellbore to an exterior of the wellbore. A method of servicing a wellbore, comprising placing a wellbore composition comprising a plurality of Micro-Electro-Mechanical System (MEMS) sensors in the wellbore, and obtaining data from the MEMS sensors using a plurality of data interrogation units spaced along a length of the wellbore, wherein one or more of the data interrogation units is powered by a turbo generator or a thermoelectric generator located in the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

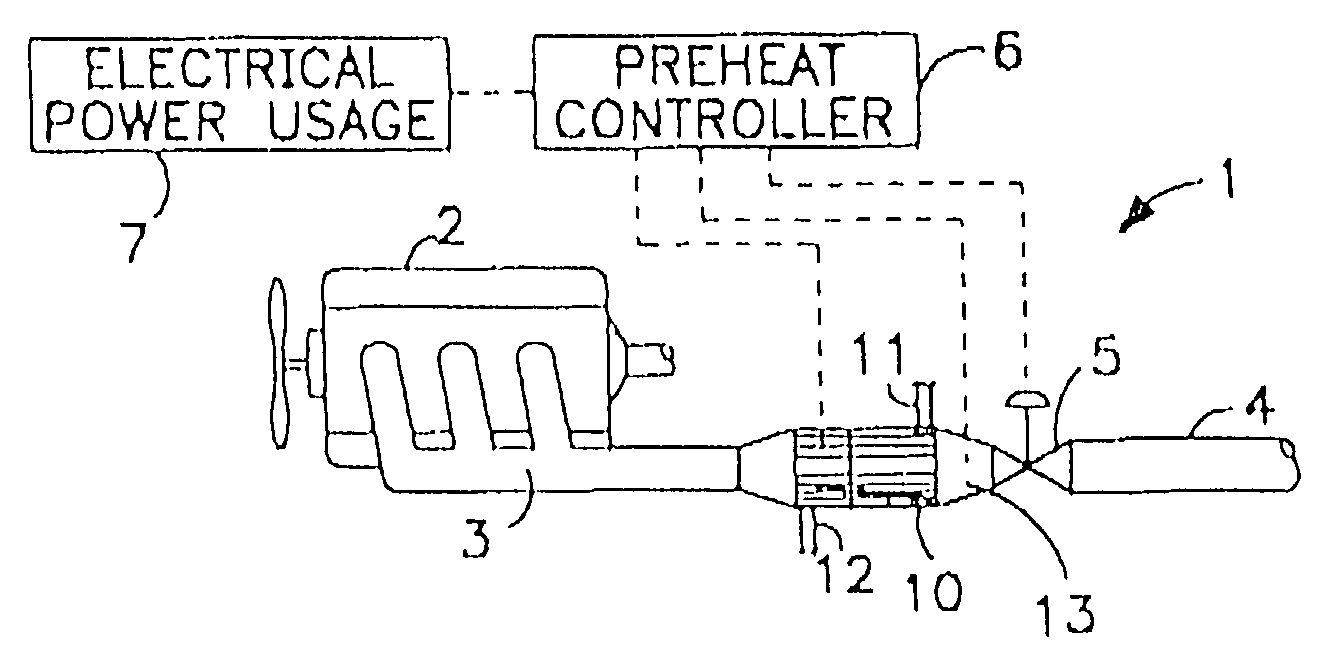

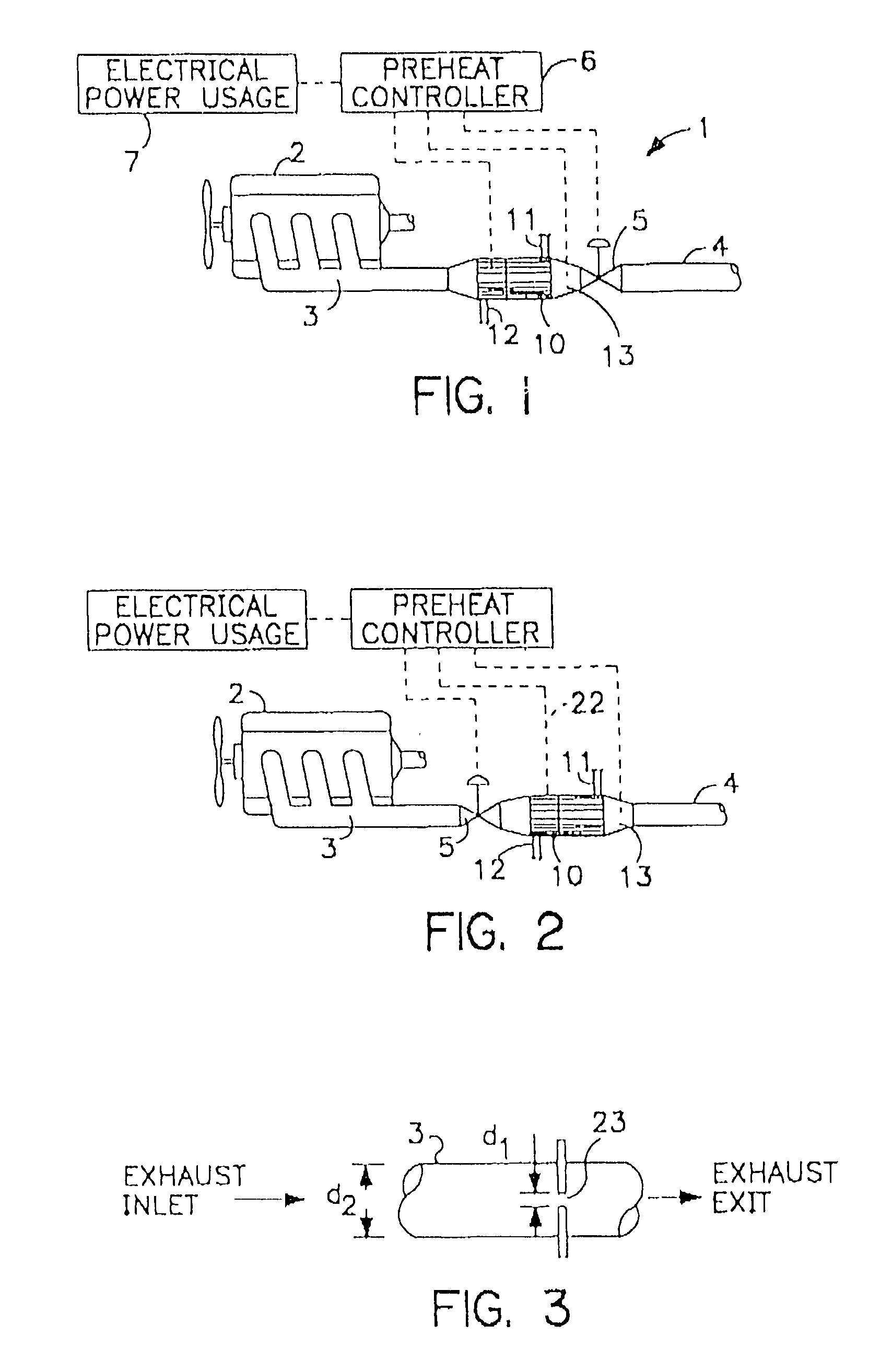

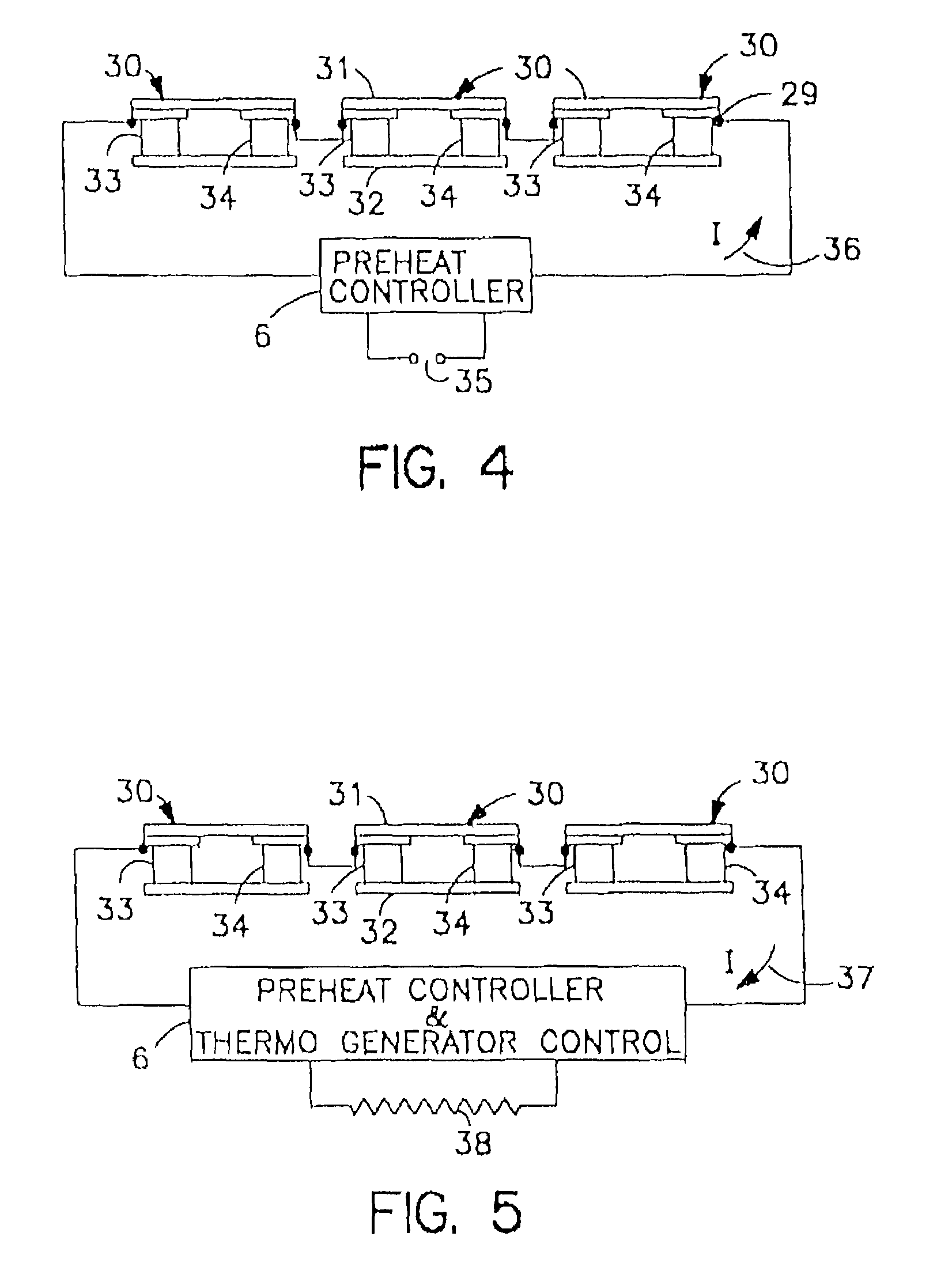

Thermoelectric catalytic power generator with preheat

InactiveUS6986247B1New pollutionMeet the test requirementsBatteries circuit arrangementsFuel cell heat exchangePollutant emissionsEngineering

An automobile catalytic converter that utilizes the energy of the exothermic reactions that take place in the catalysis substrate to produce electrical energy with a thermoelectric generator. On vehicle cold start, the thermoelectric generator is used as a heat pump to heat the catalyst substrate to reduce the time to catalyst light-off. In this way, the catalytic converter comes up to operating temperature more rapidly, reducing the amount of pollutant emissions at vehicle start-up.

Owner:PARISE RONALD J

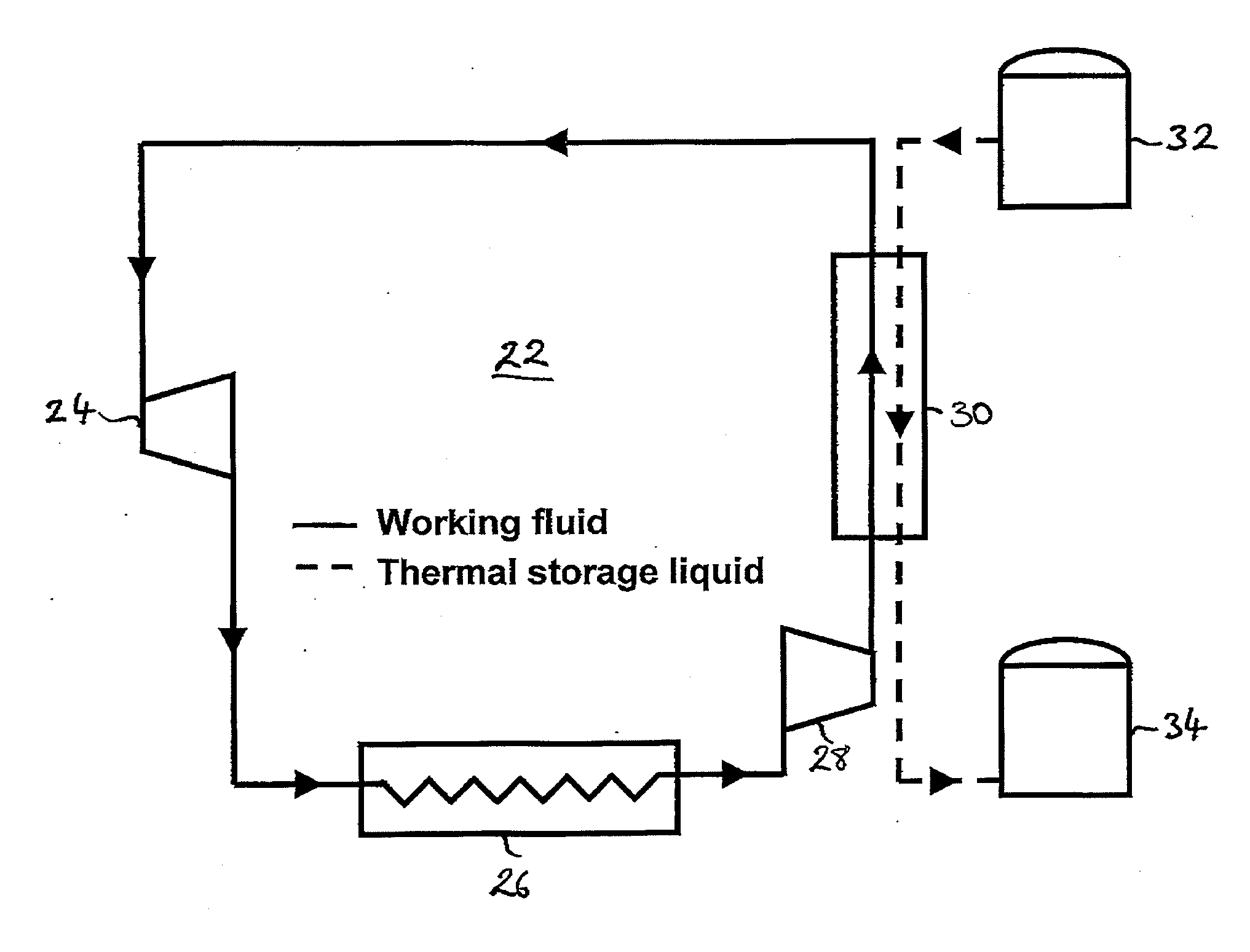

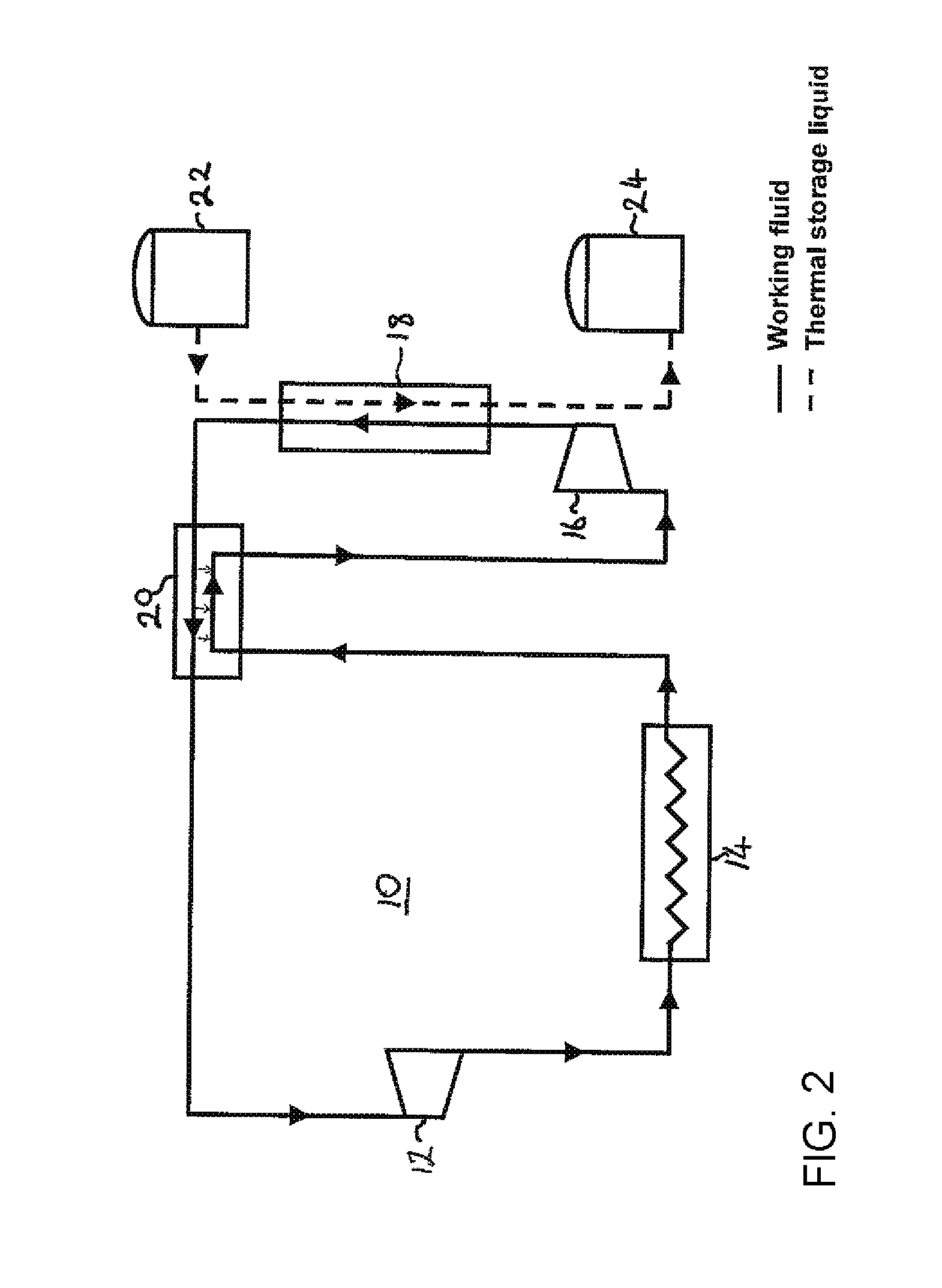

Thermoelectric energy storage system and method for storing thermoelectric energy

InactiveUS20110100611A1Minimize temperature differenceMinimize the differenceStorage heatersIndirect heat exchangersWorking fluidThermal energy storage

A system and method are provided for thermoelectric energy storage. A thermoelectric energy storage system having at least one hot storage unit is provided. In an exemplary embodiment, each hot storage unit includes a hot tank and a cold tank connected via a heat exchanger and containing a thermal storage medium. The thermoelectric energy storage system also includes a working fluid circuit for circulating working fluid through each heat exchanger for heat transfer with the thermal storage medium. Improved roundtrip efficiency is achieved by minimizing the temperature difference between the working fluid and the thermal storage medium in each heat exchanger during heat transfer. Exemplary embodiments realize this improved roundtrip efficiency through modification of thermal storage media parameters.

Owner:ABB RES LTD

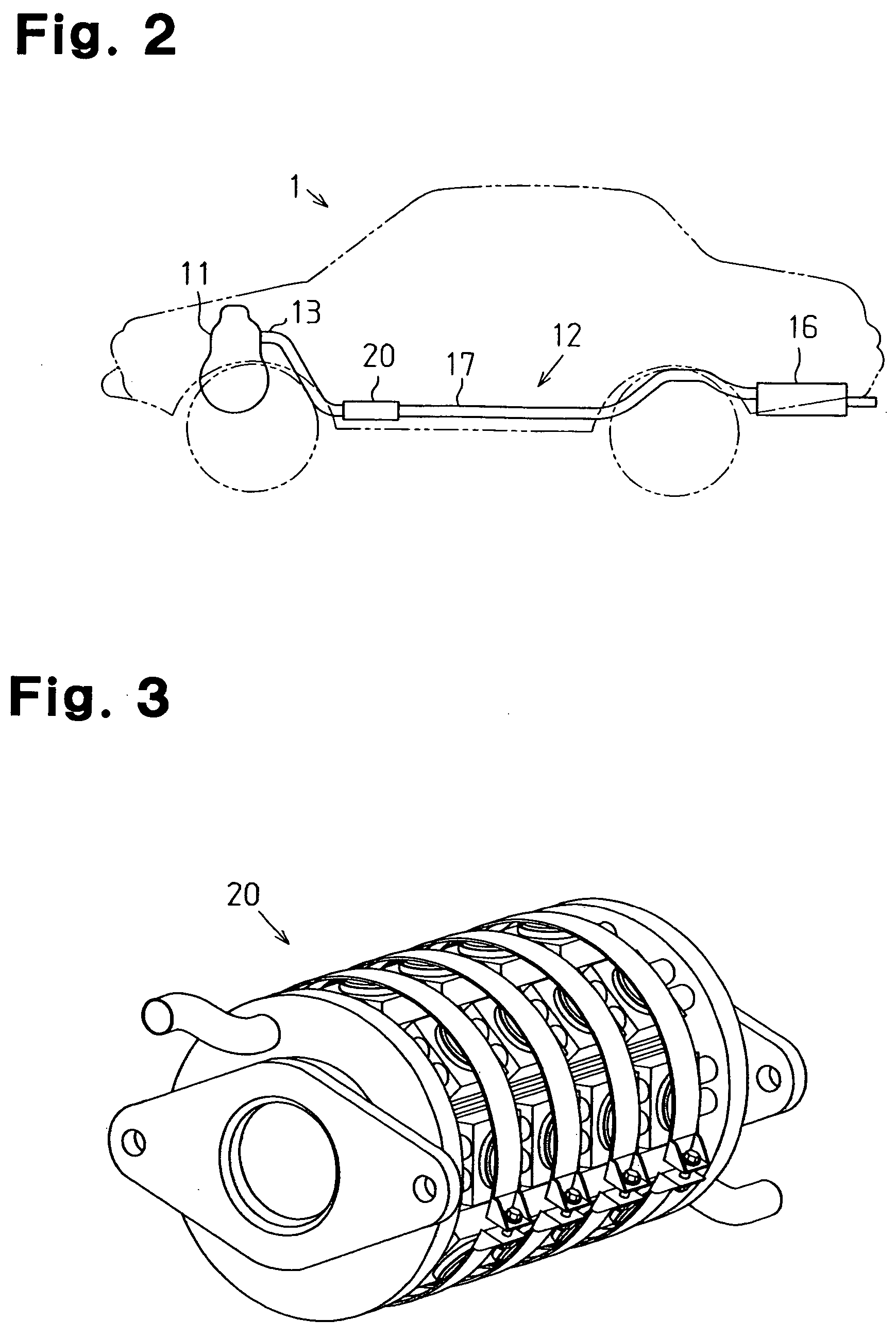

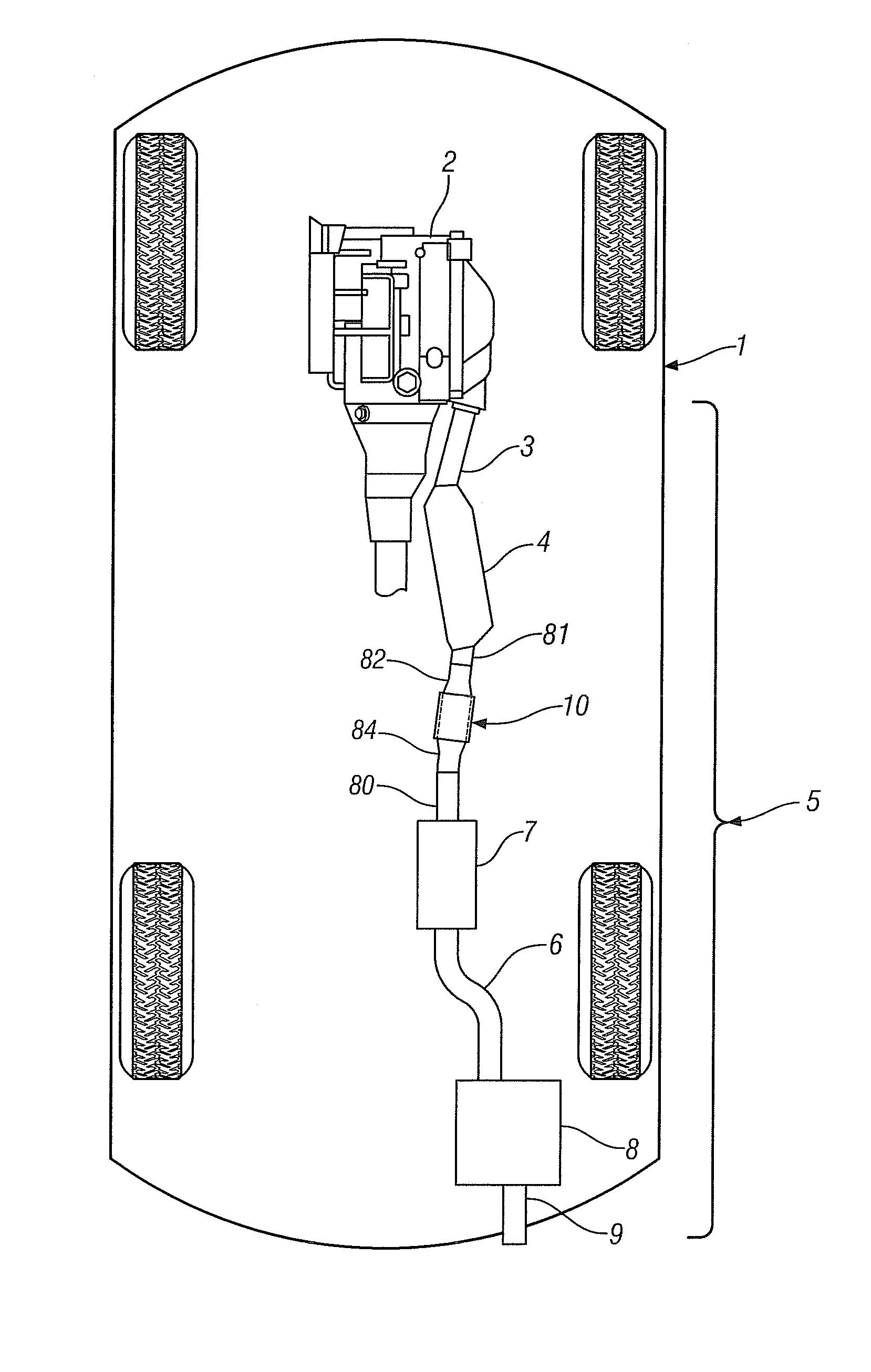

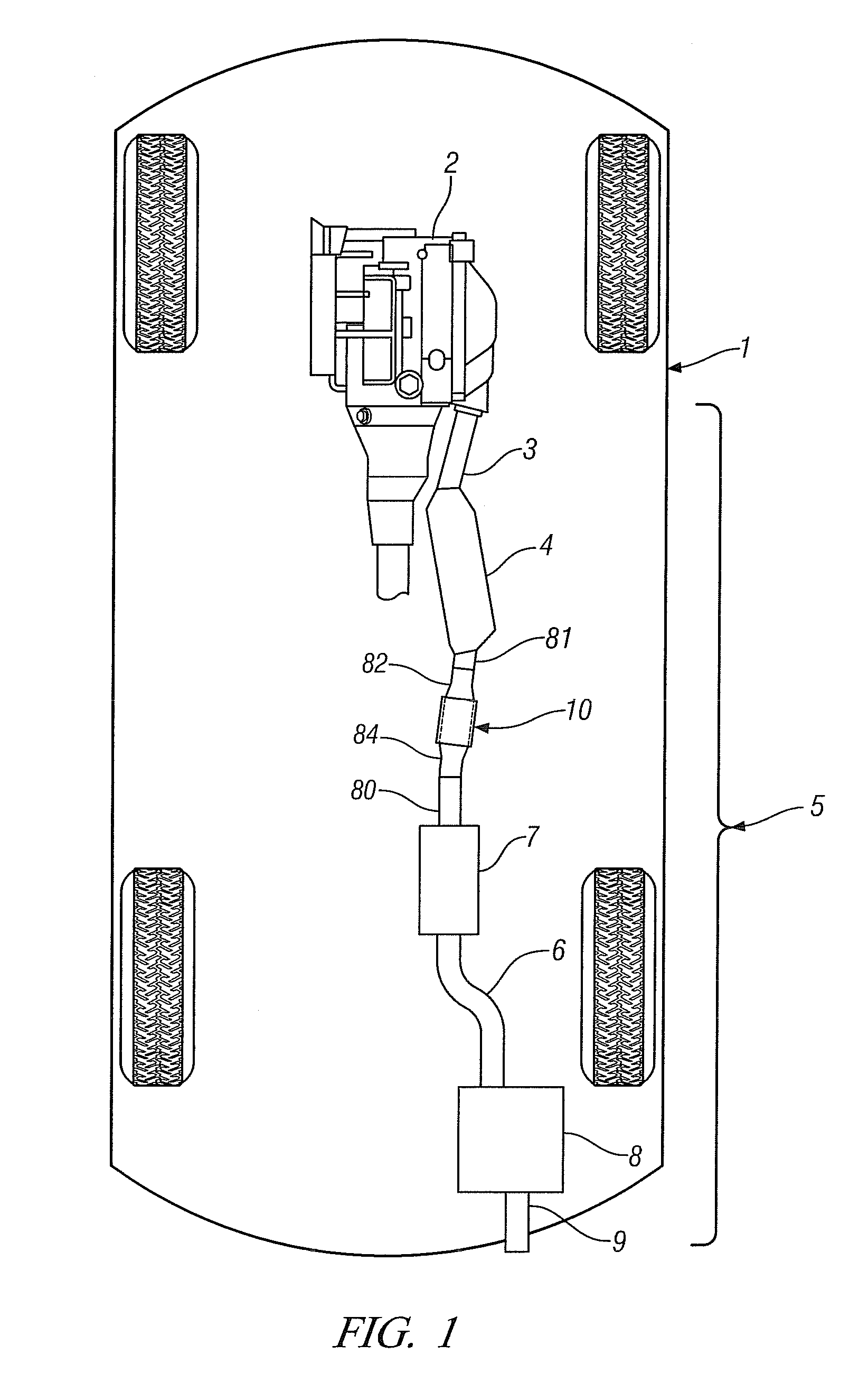

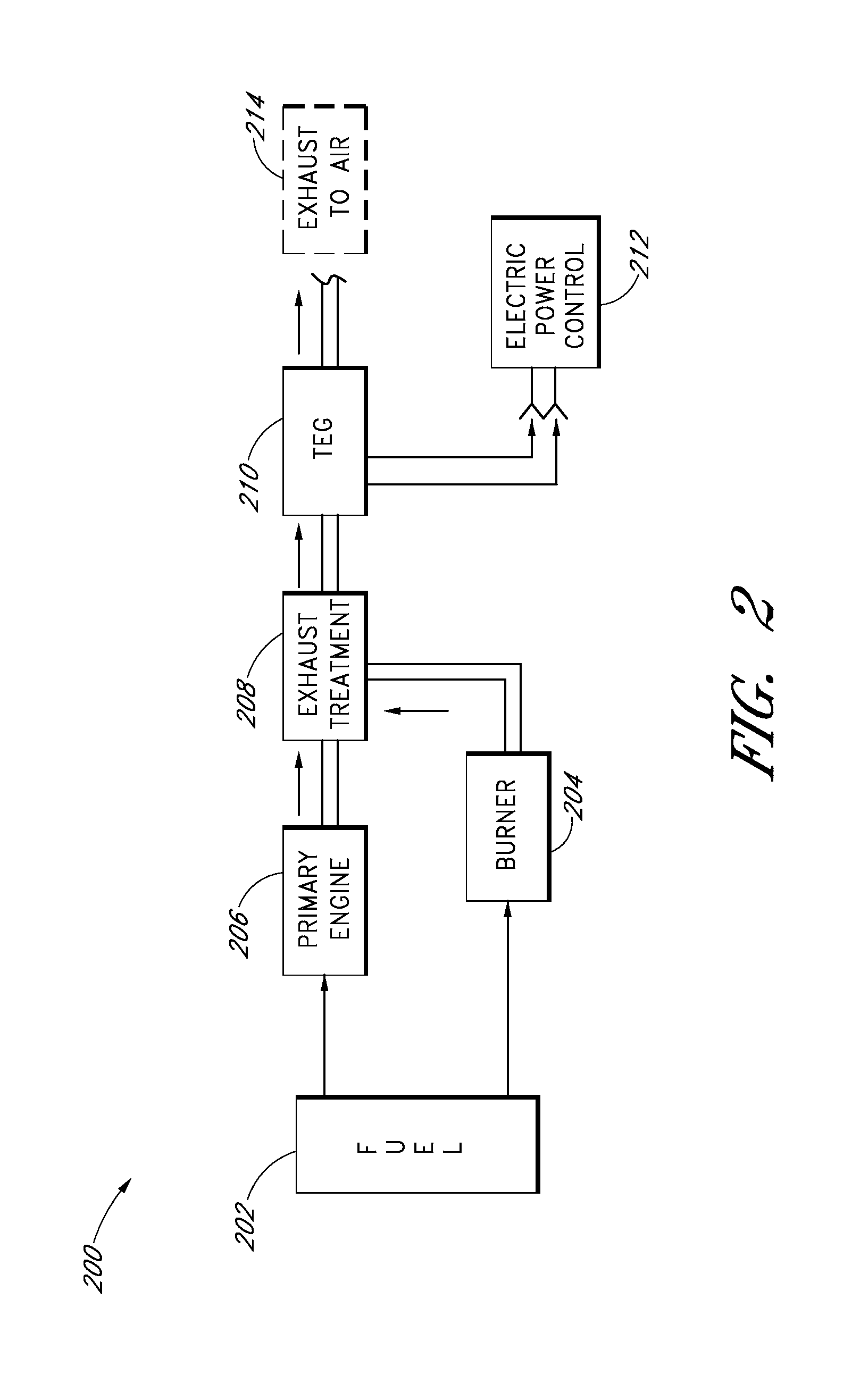

Thermoelectric generator for internal combustion engine

InactiveUS20050172993A1Reduce the possibilityThermoelectric device with peltier/seeback effectElectric/fluid circuitEngineeringInternal combustion engine

A thermoelectric generator for an internal combustion engine that prevents a thermoelectric generation element from being damaged. The thermoelectric generator includes a casing, which is arranged in an exhaust passage, and a sleeve. A cooling mechanism is arranged outside the sleeve. Thermoelectric generation elements are arranged between the sleeve and the cooling mechanism in a manner movable relative to both the sleeve and the,cooling mechanism. The thermoelectric generation elements convert heat energy from exhaust in the exhaust passage to electric energy.

Owner:TOYOTA JIDOSHA KK

Flow-through mufflers with optional thermo-electric, sound cancellation, and tuning capabilities

InactiveUS20070045044A1Reduce engine fuel consumptionInternal combustion piston enginesThermoelectric device with peltier/seeback effectHeat conductingAcoustic wave

Owner:SULLIVAN JOHN TIMOTHY

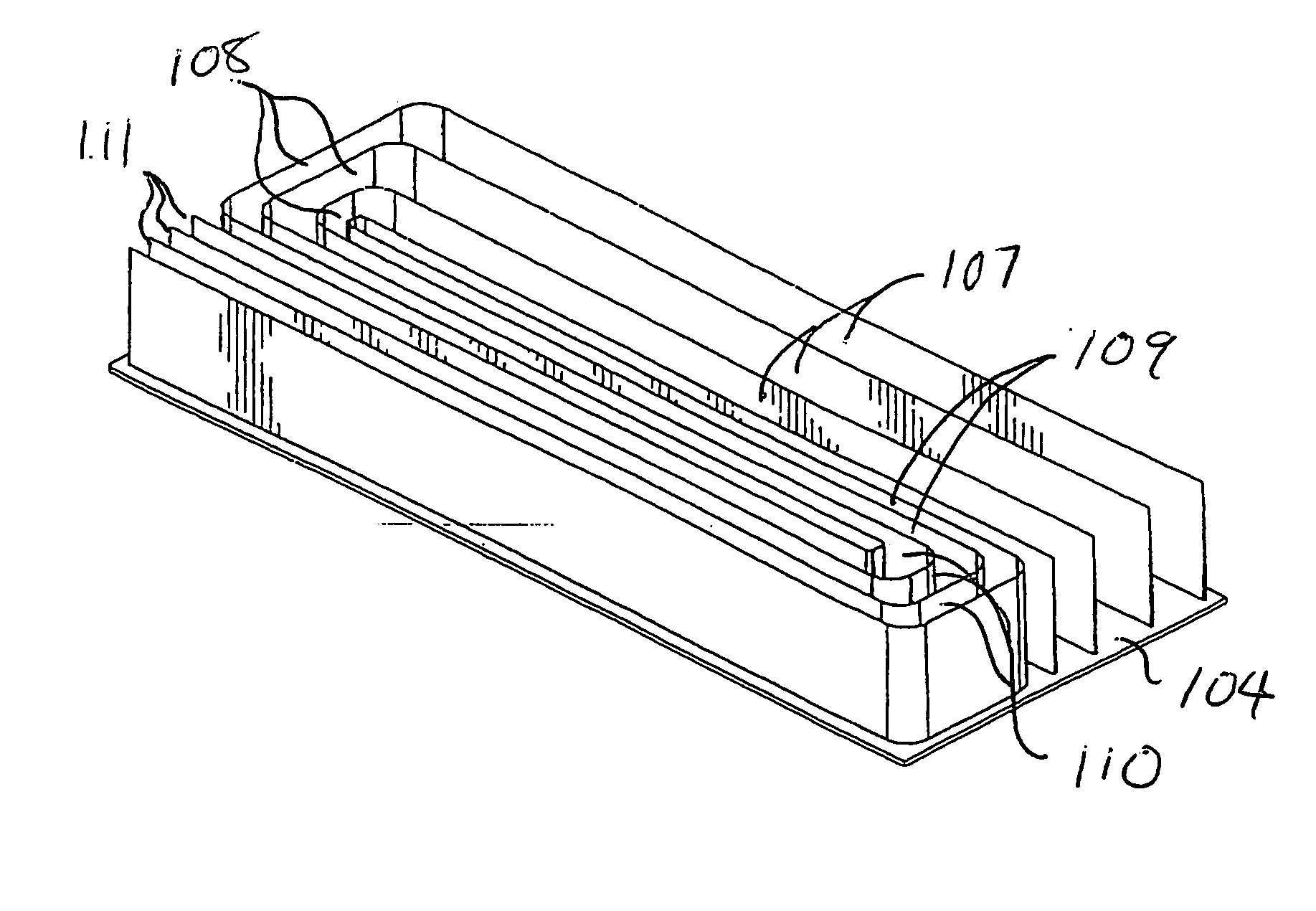

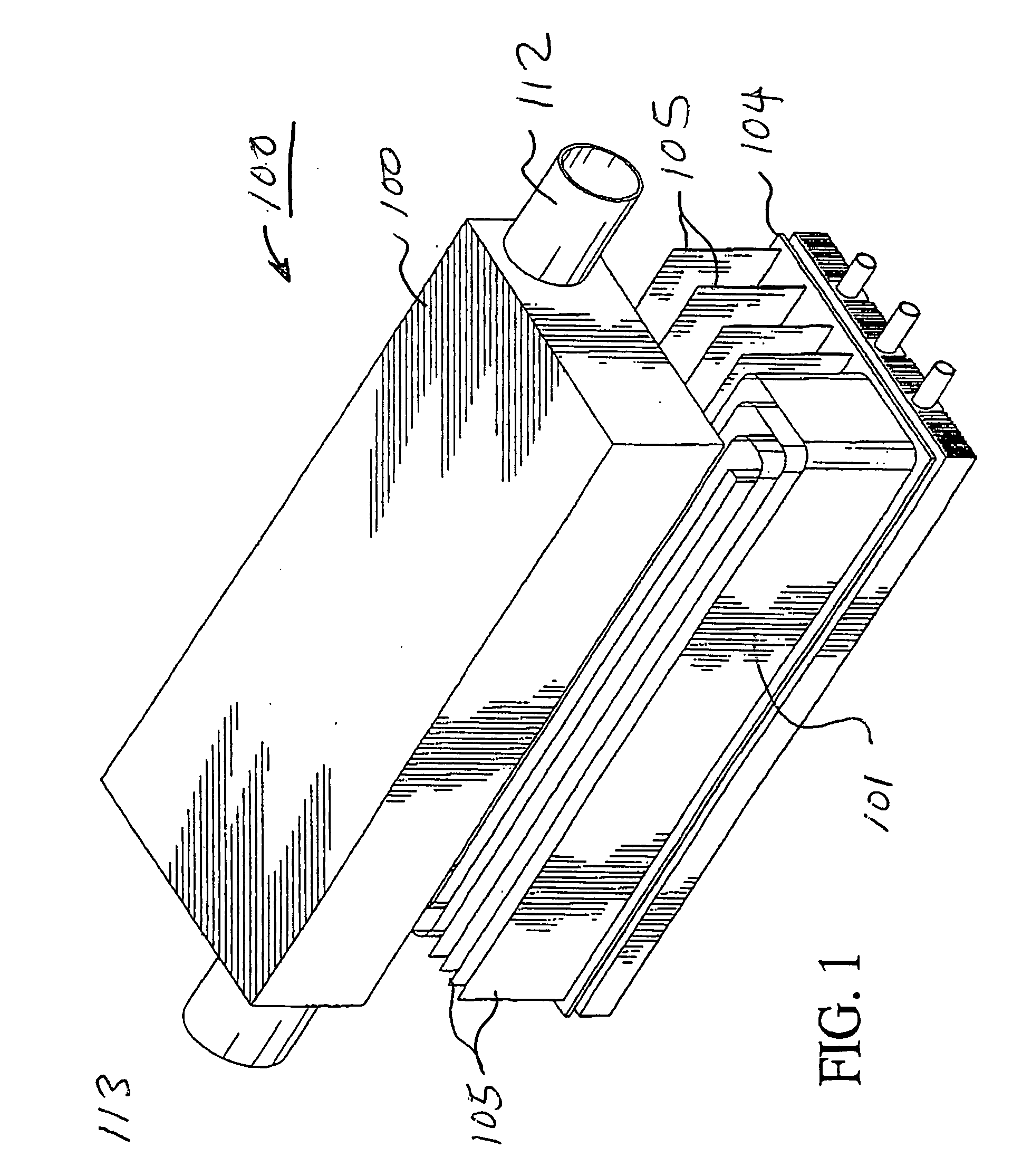

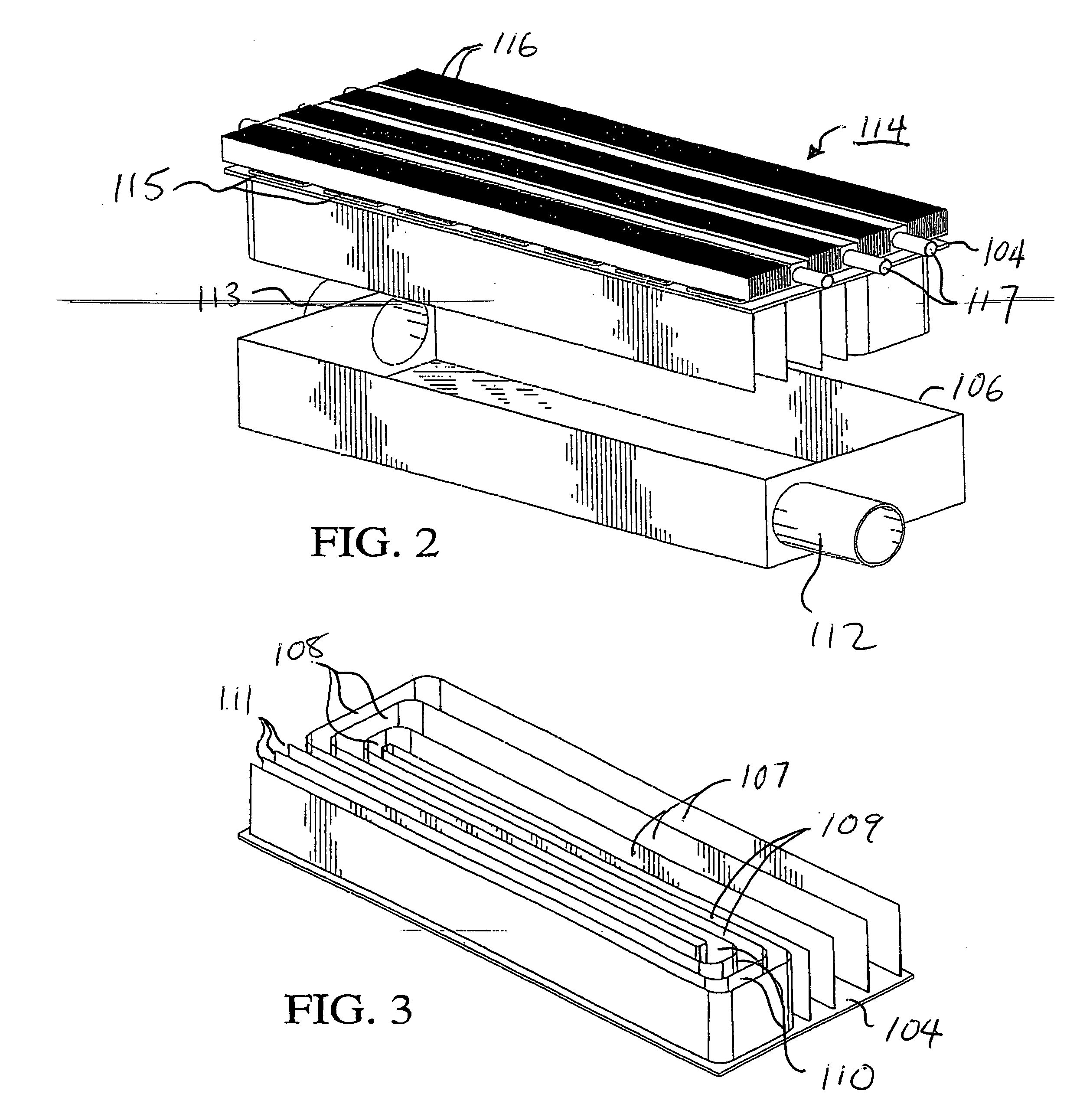

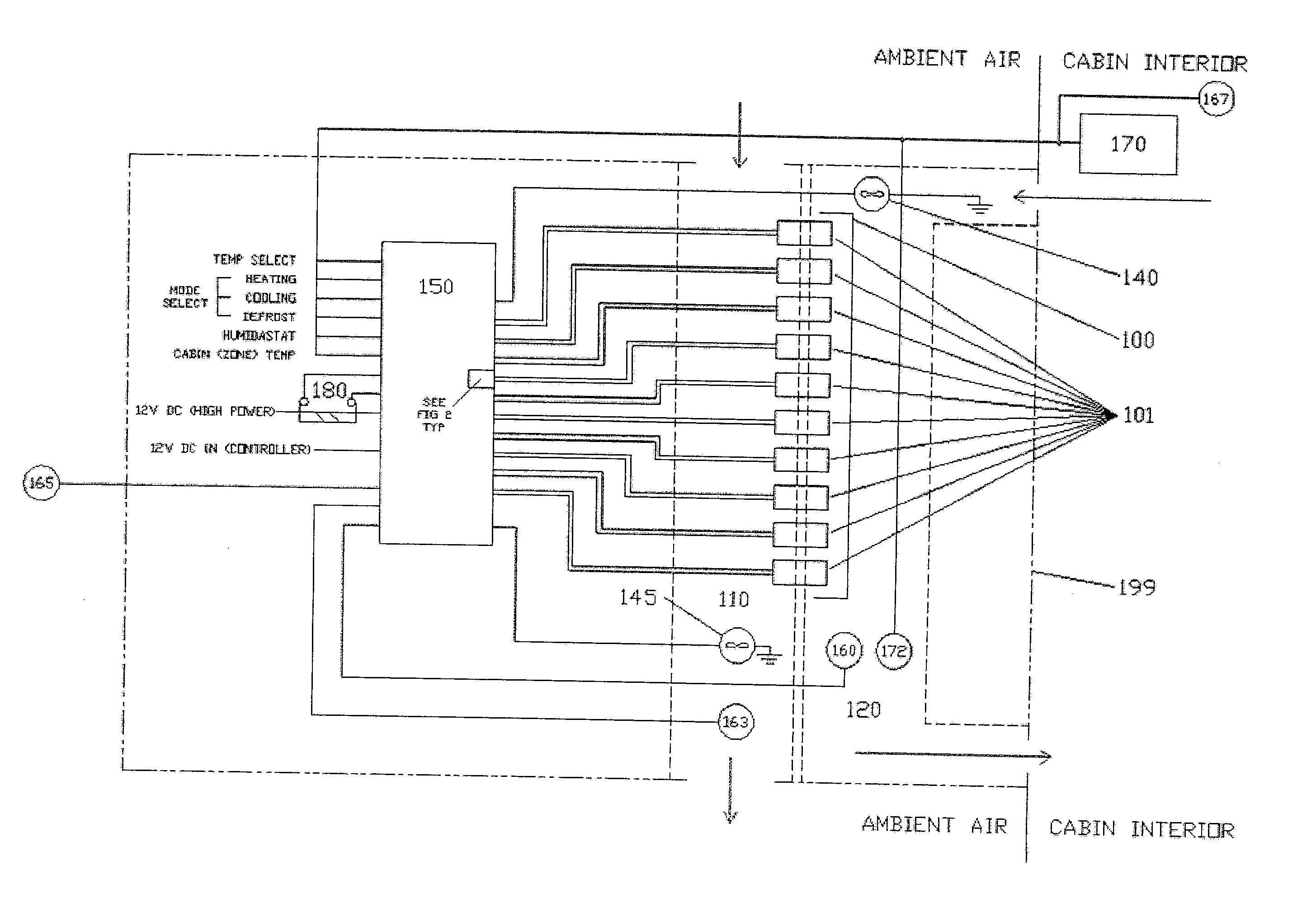

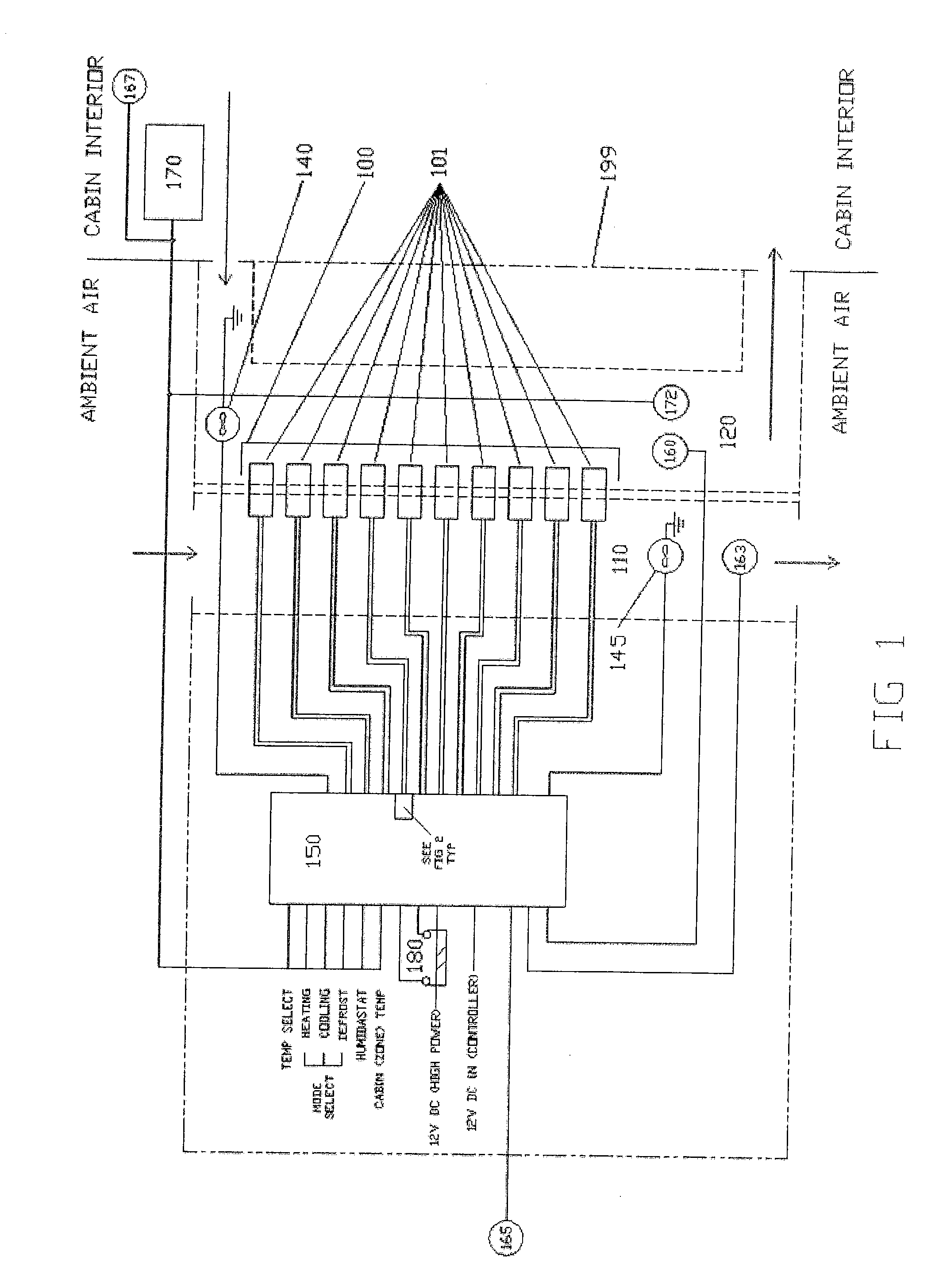

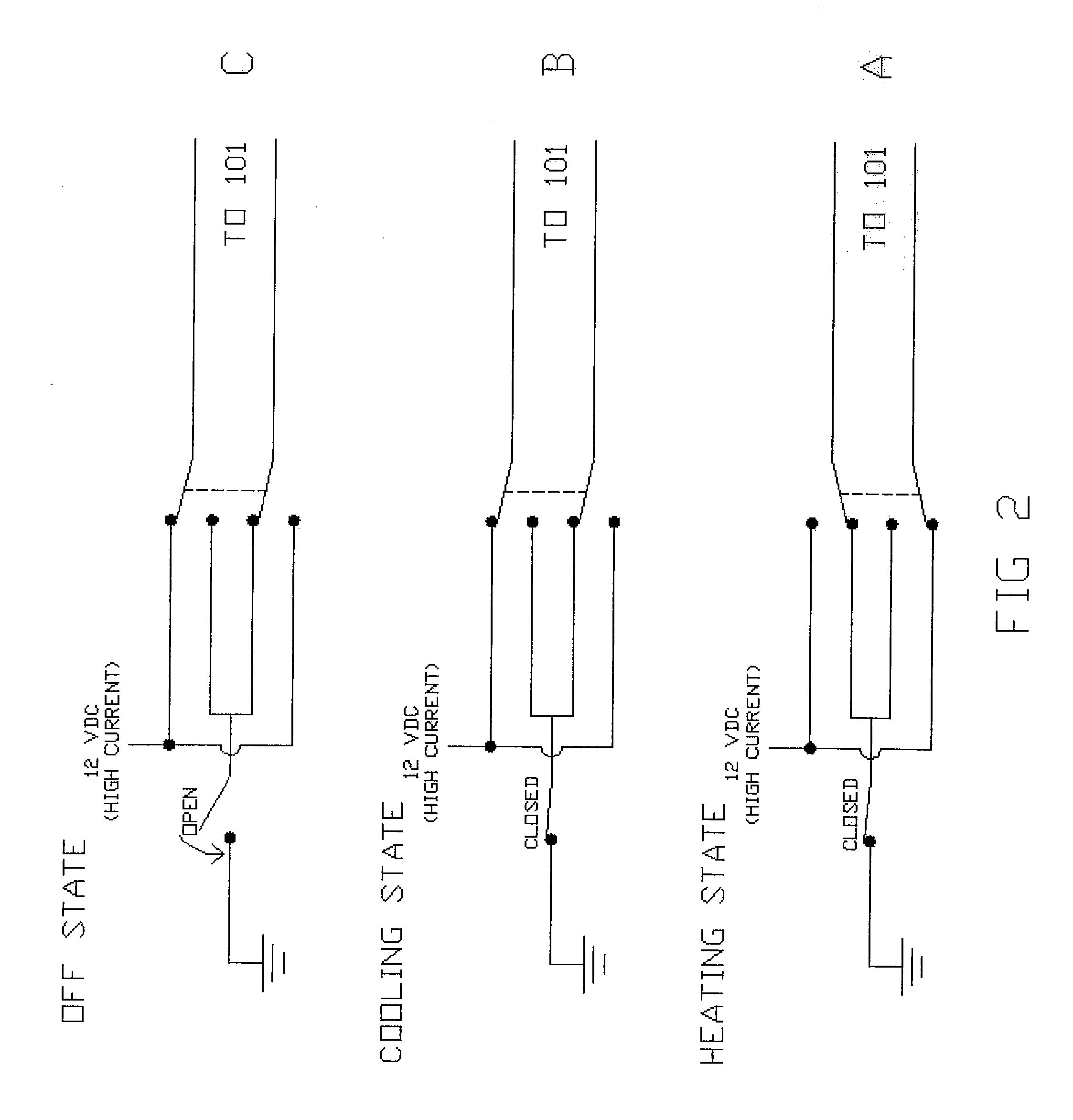

Regulating vehicle cabin environment and generating supplemental electrical current from waste heat

InactiveUS20070272290A1Reduce utilizationReduce weightInternal combustion piston enginesThermoelectric device with peltier/seeback effectNacelleElectrical devices

A method and system for environmental control and supplementary power generation in conventional and hybrid vehicle applications is presented. A thermoelectric heat pump function regulates vehicular interior temperature environments and uses the waste heat from a vehicles engine to power thermocouples and generate supplemental electrical current to power electrical devices. Thermocouples are used to gauge changes in temperature. The Peltier Effect is used to provide both primary cabin environmental control and supplementary power generation for motorized vehicle applications. Thermoelectric generators can be used for both primary internal climate control and supplementary power generation in the vehicular environment. Thermoelectric heat pumps' special characteristics are used to provide (a) primary cabin environment control including cooling, heating, dehumidifying, defrosting, pre-heating / pre-cooling and (b) supplemental DC power generation functions for conventional fossil fueled and / or biomass-fueled vehicles as well as emerging hybrid or all electric vehicle applications.

Owner:STATE OF FRANKLIN INNOVATIONS

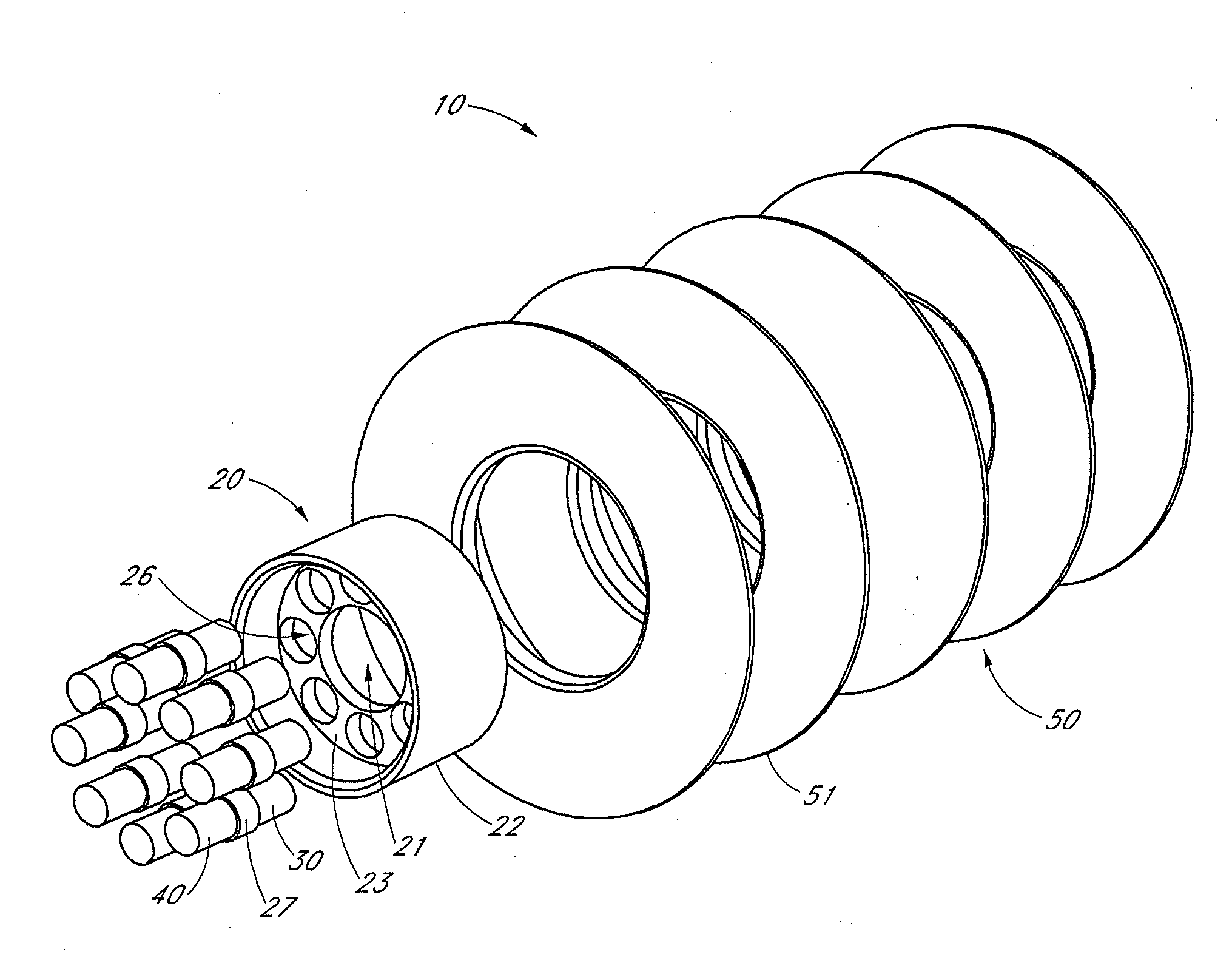

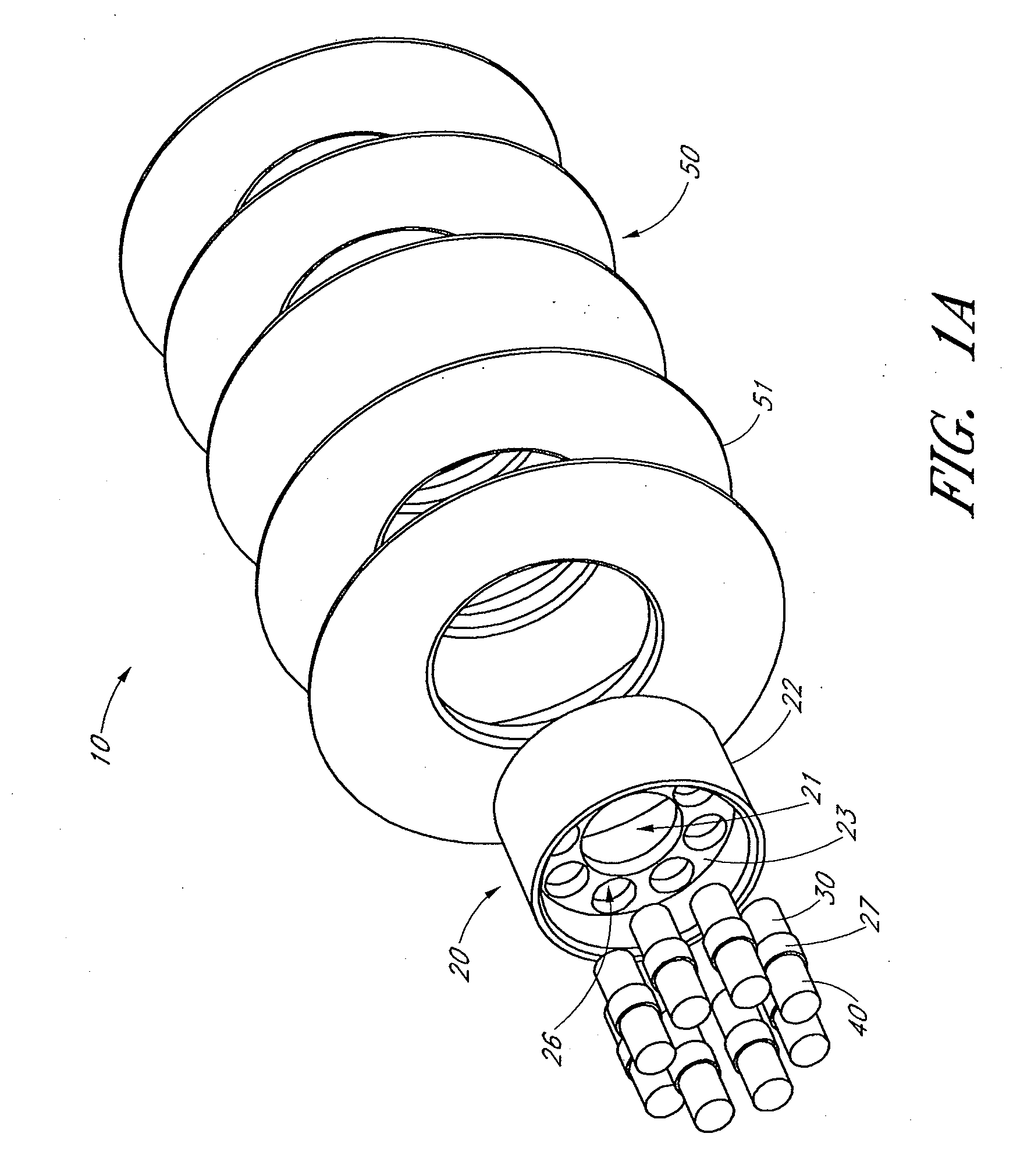

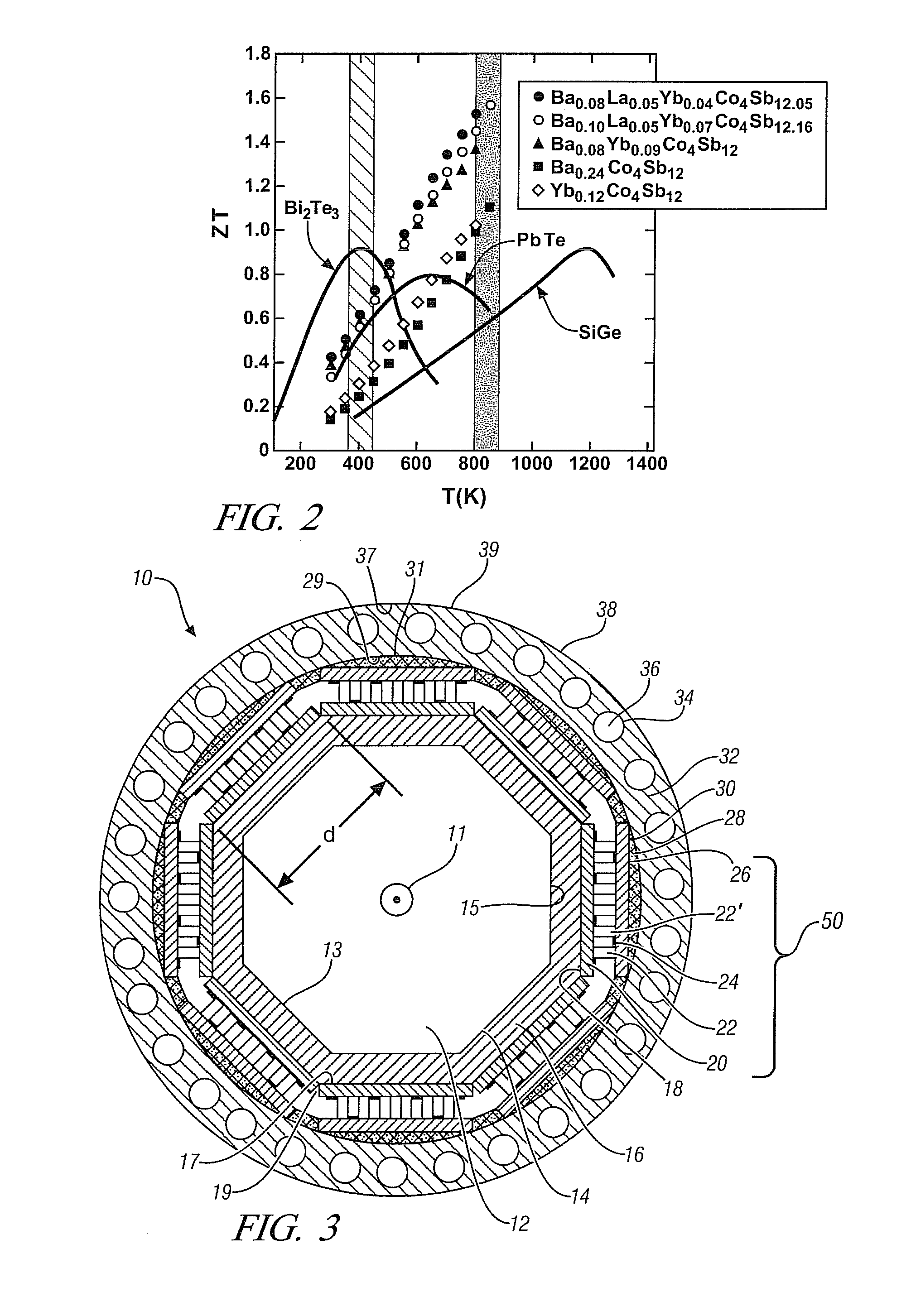

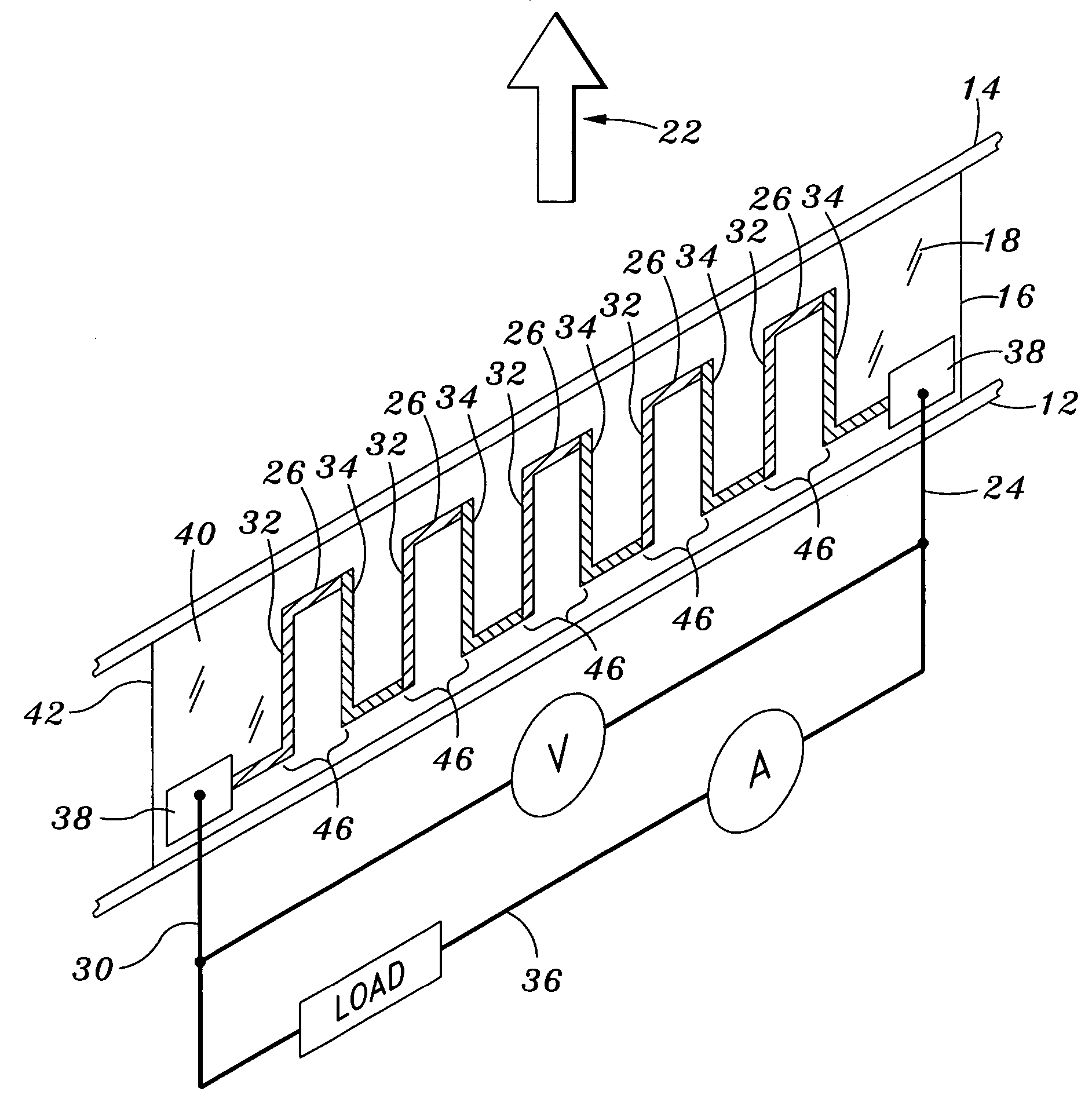

Catalyst-thermoelectric generator integration

InactiveUS20130186448A1Internal combustion piston enginesThermoelectric device with peltier/seeback effectEngineeringThermoelectric element

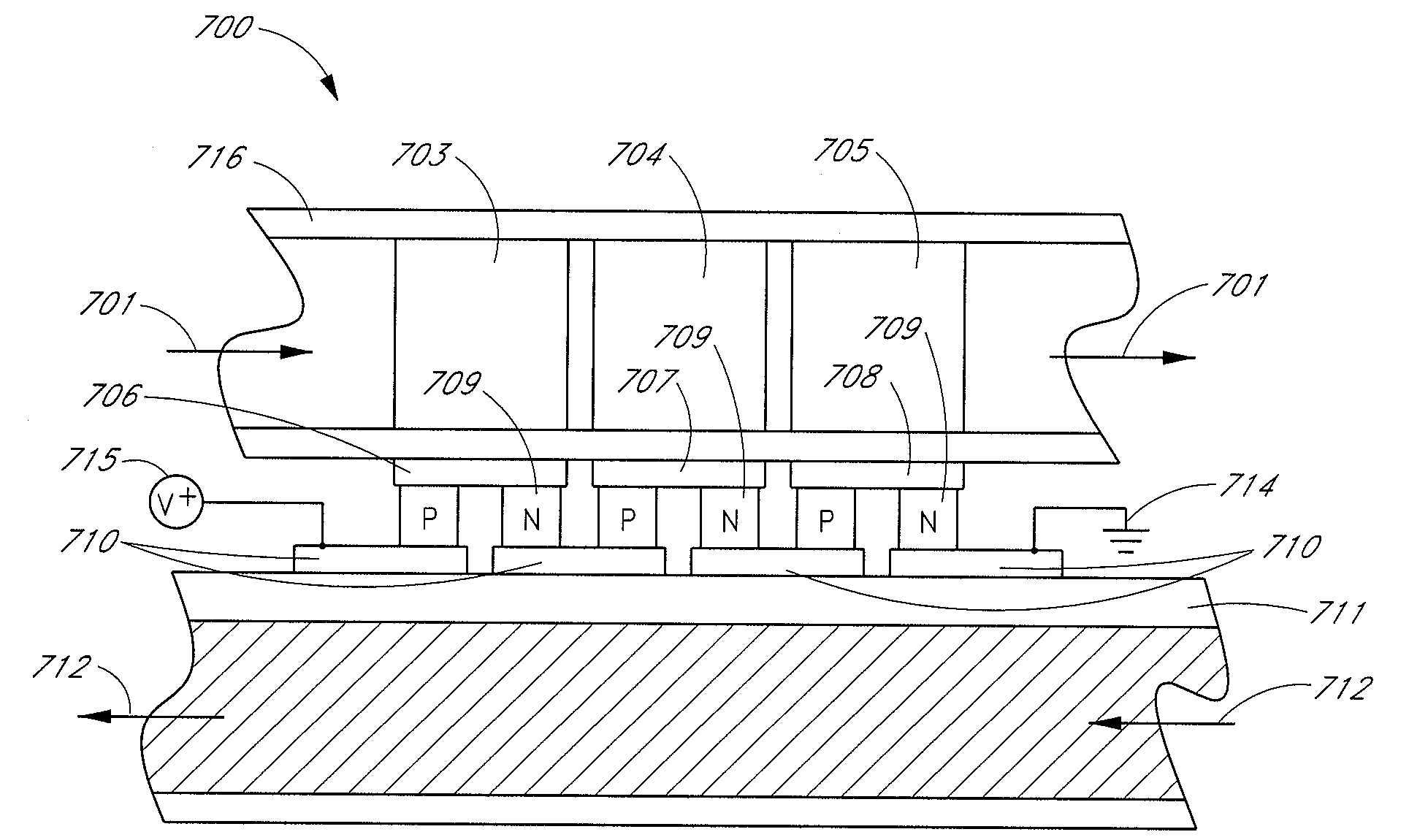

A thermoelectric system is provided which includes at least one tubular conduit configured to be in thermal communication with at least one first fluid flowing through the at least one tubular coolant conduit in a first direction. A plurality of thermoelectric elements can be in thermal communication with the at least one tubular conduit. A heat exchanger in thermal communication with the plurality of thermoelectric elements is configured to be in thermal communication with at least one second fluid and to surround at least a portion of the tubular conduit and plurality of thermoelectric elements. The heat exchanger can include at least one coating configured to catalyze reactions of at least one portion of the second fluid.

Owner:GENTHERM INC

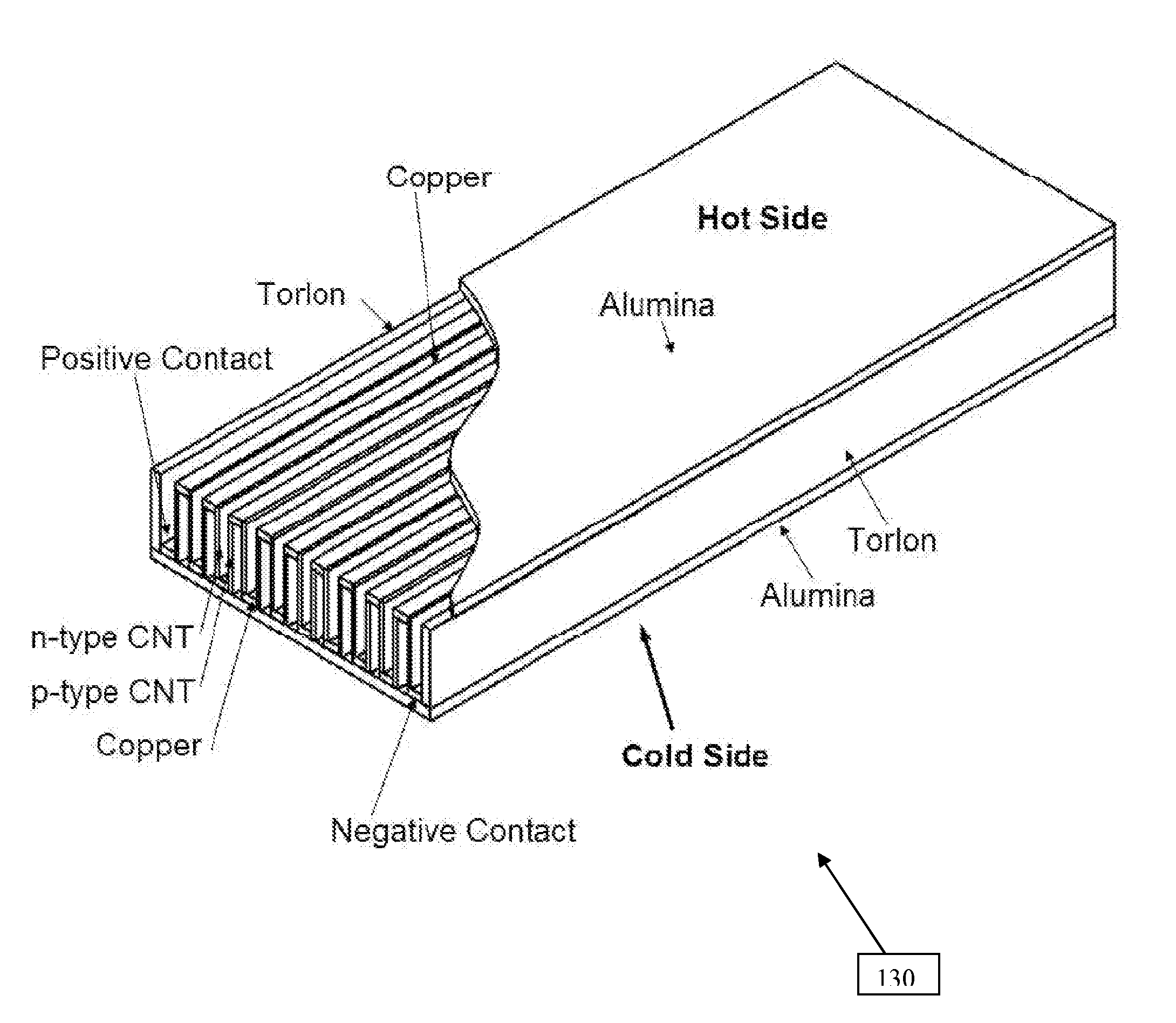

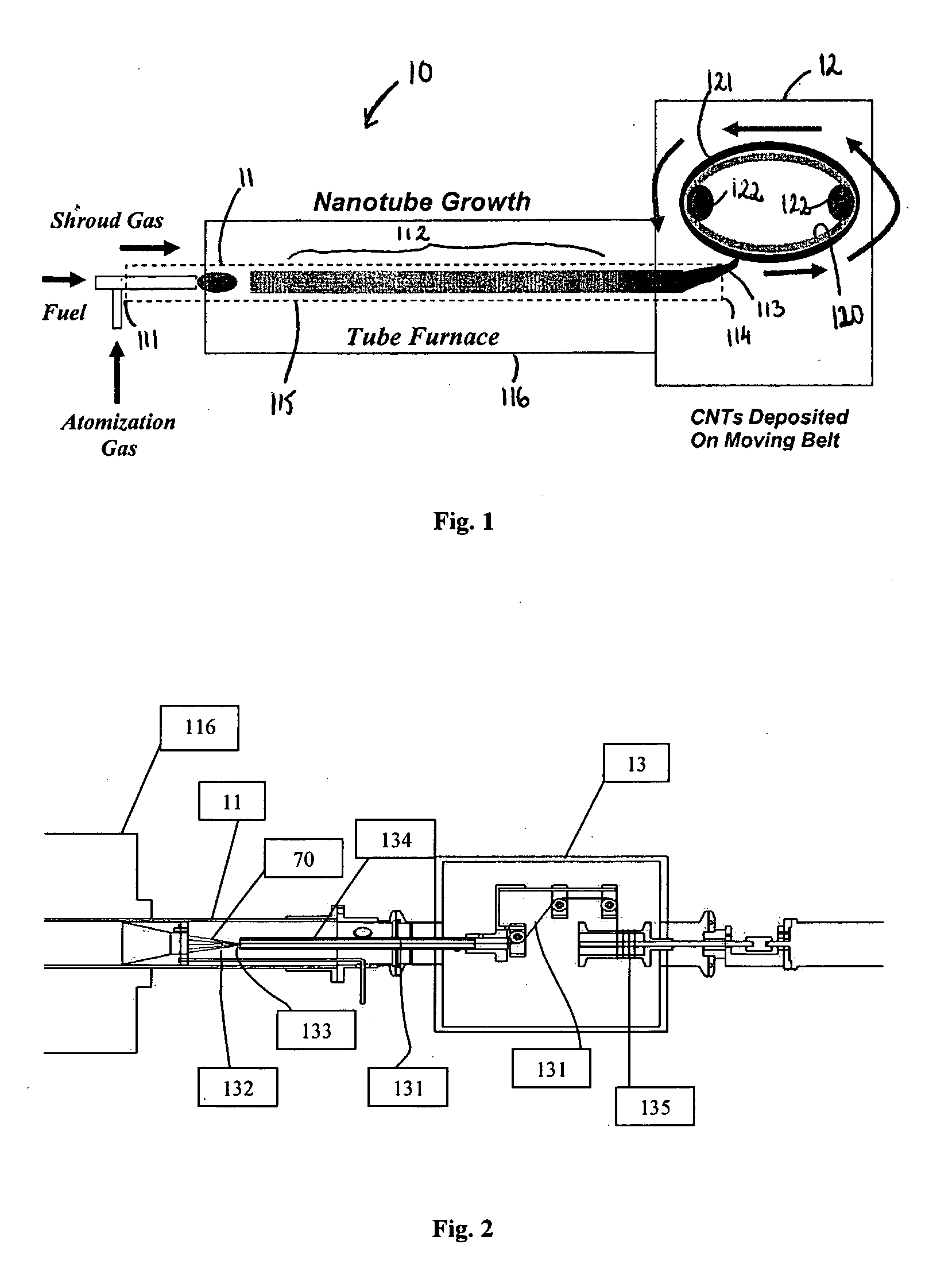

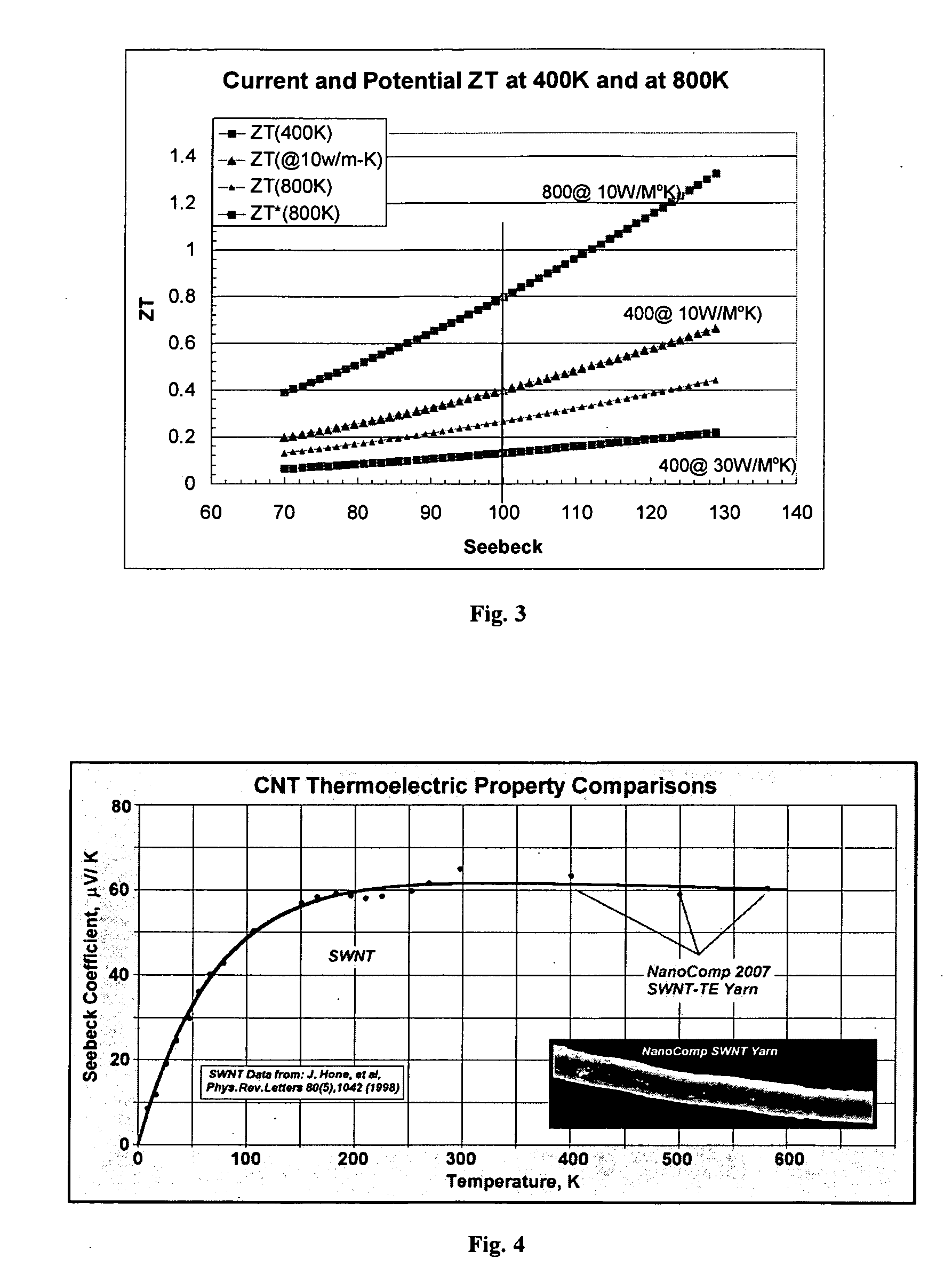

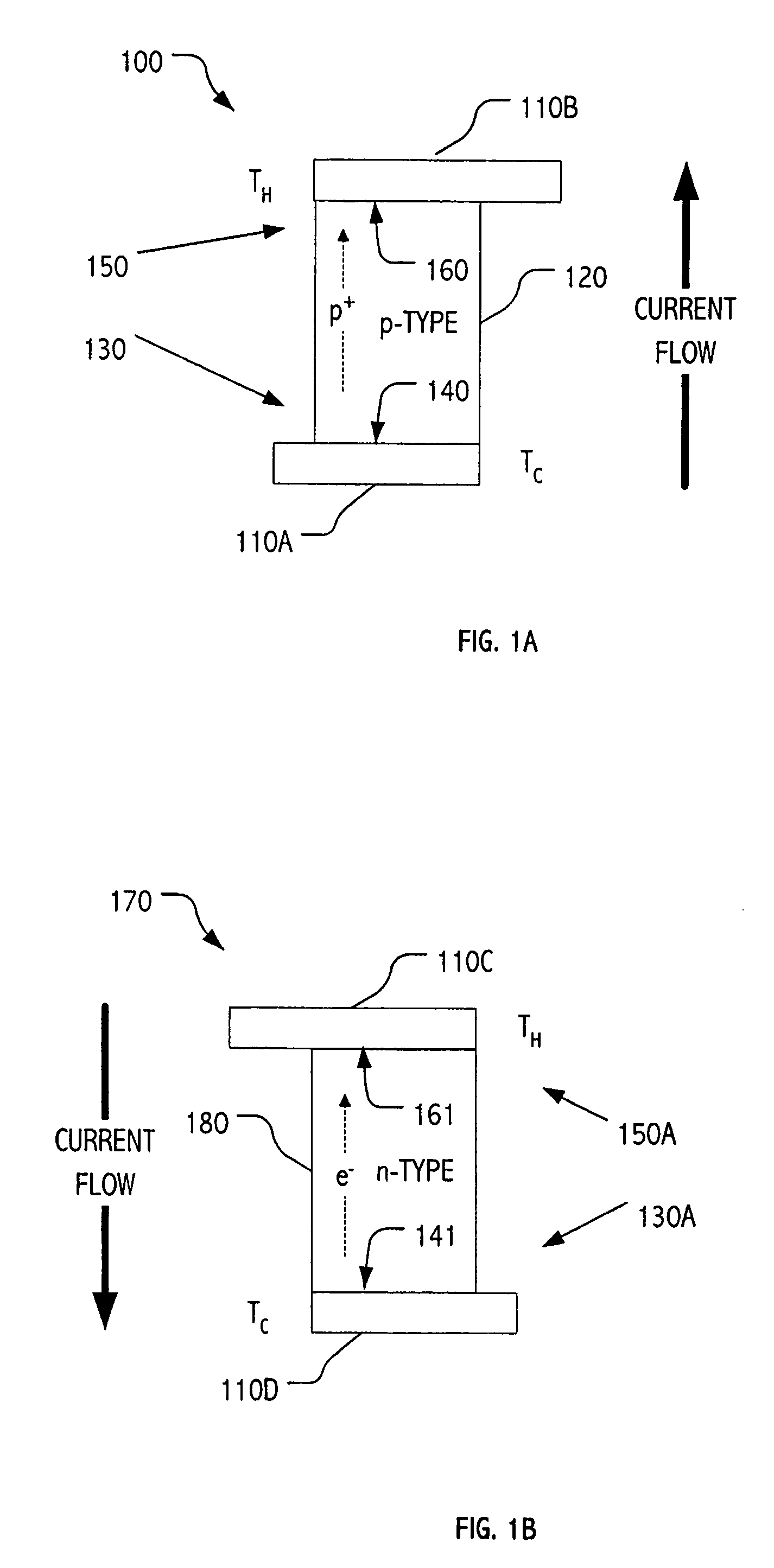

Nanostructured Material-Based Thermoelectric Generators

InactiveUS20090044848A1Improvement factorRaise the transition temperatureAuxillary drivesFrom solar energyCarbon nanotubeEngineering

A thermoelectric device that can exhibit substantially high specific power density is provided. The device includes core having a p-type element made from carbon nanotube and an n-type element. The device also includes a heat plate in and a cool plate, between which the core can be positioned. The design of the thermoelectric device allows the device to operate at substantially high temperature and to generate substantially high power output, despite being light weight. A method for making the thermoelectric device is also provided.

Owner:NANCOMP TECHNOLOGIES INC

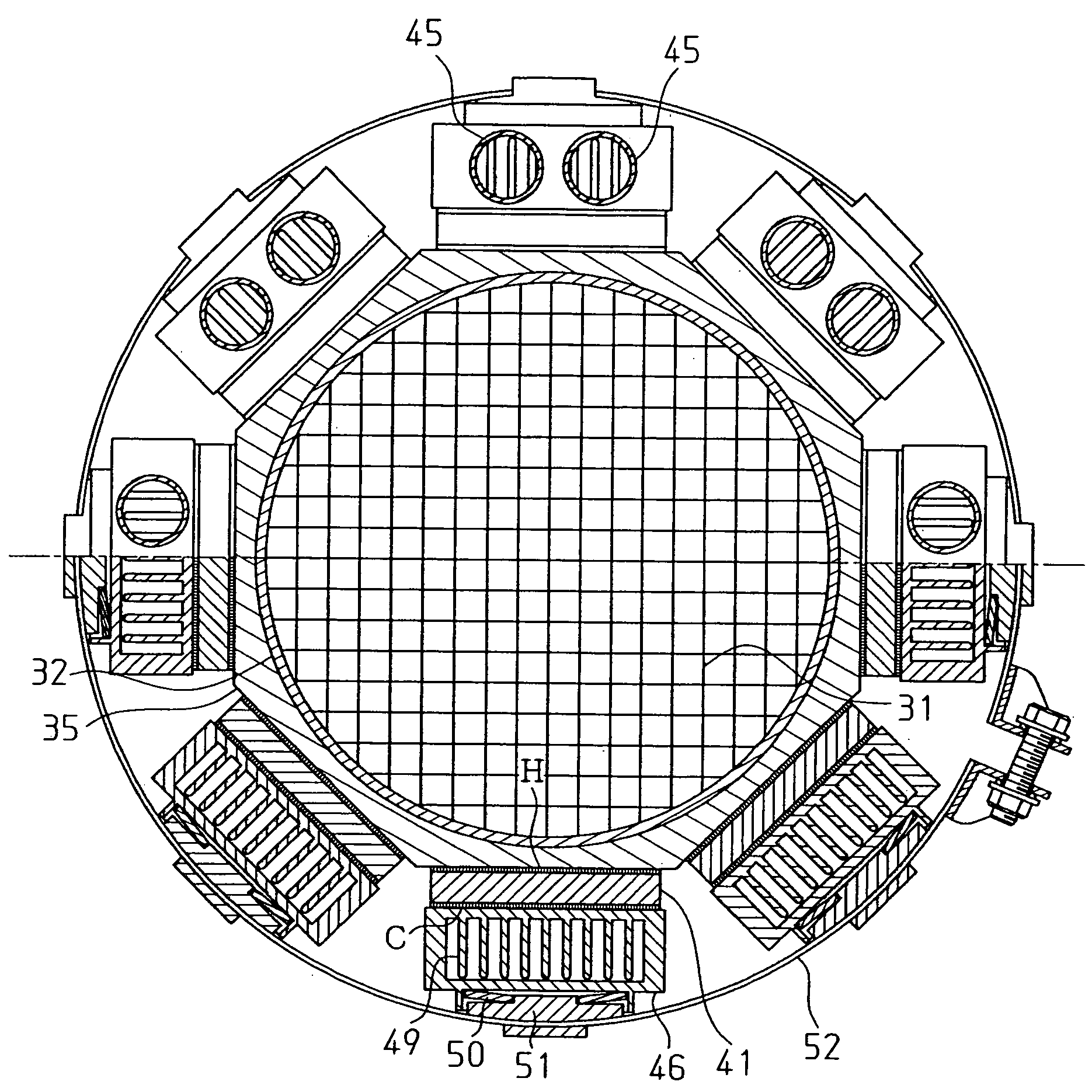

Thermoelectric generators incorporating phase-change materials for waste heat recovery from engine exhaust

ActiveUS20120073276A1Efficient extractionThermoelectric device with peltier/seeback effectExhaust apparatusEngineeringInternal combustion engine

Thermoelectric devices, intended for placement in the exhaust of a hydrocarbon fuelled combustion device and particularly suited for use in the exhaust gas stream of an internal combustion engine propelling a vehicle, are described. Exhaust gas passing through the device is in thermal communication with one side of a thermoelectric module while the other side of the thermoelectric module is in thermal communication with a lower temperature environment. The heat extracted from the exhaust gasses is converted to electrical energy by the thermoelectric module. The performance of the generator is enhanced by thermally coupling the hot and cold junctions of the thermoelectric modules to phase-change materials which transform at a temperature compatible with the preferred operating temperatures of the thermoelectric modules. In a second embodiment, a plurality of thermoelectric modules, each with a preferred operating temperature and each with a uniquely-matched phase-change material may be used to compensate for the progressive lowering of the exhaust gas temperature as it traverses the length of the exhaust pipe.

Owner:GM GLOBAL TECH OPERATIONS LLC

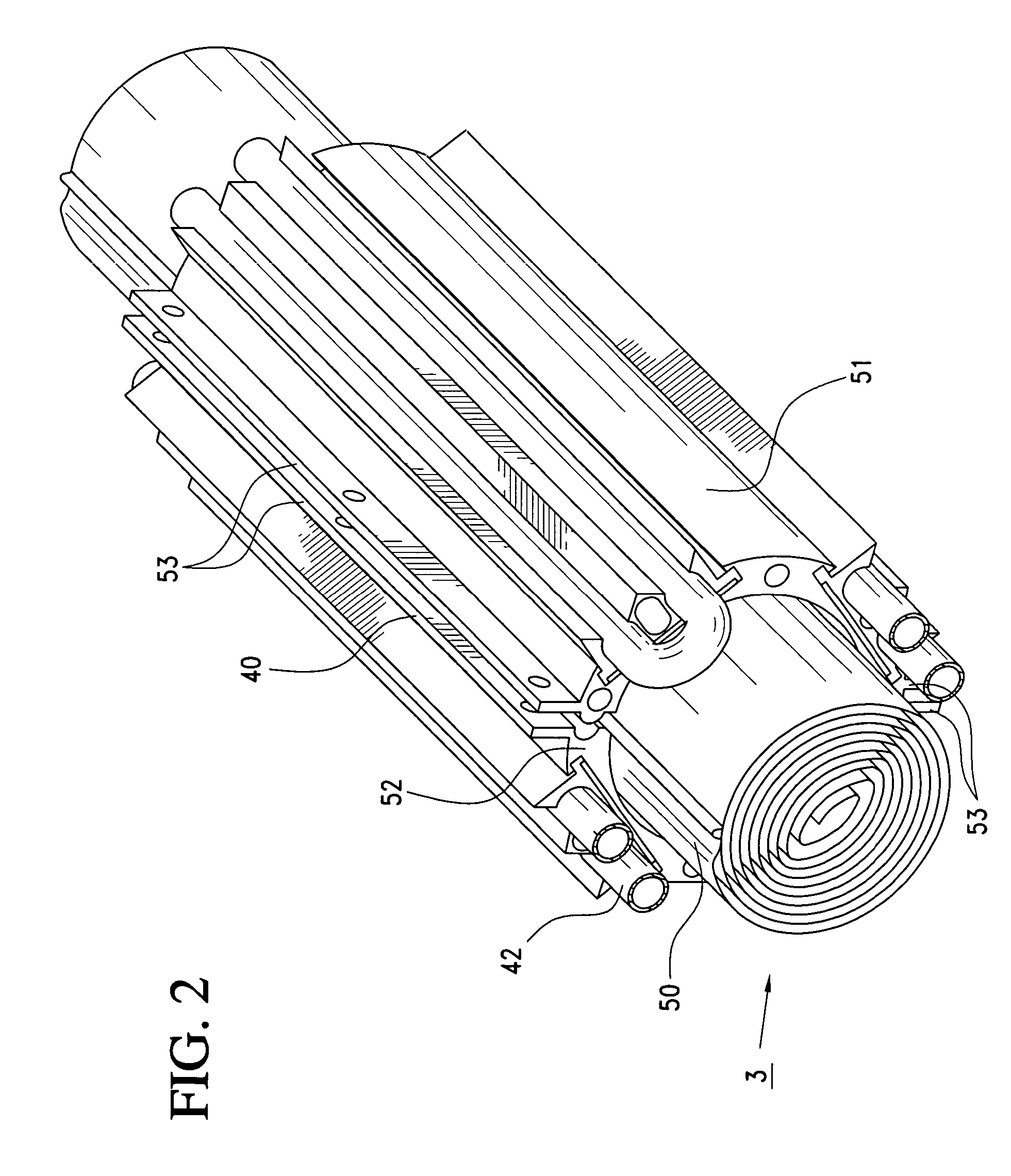

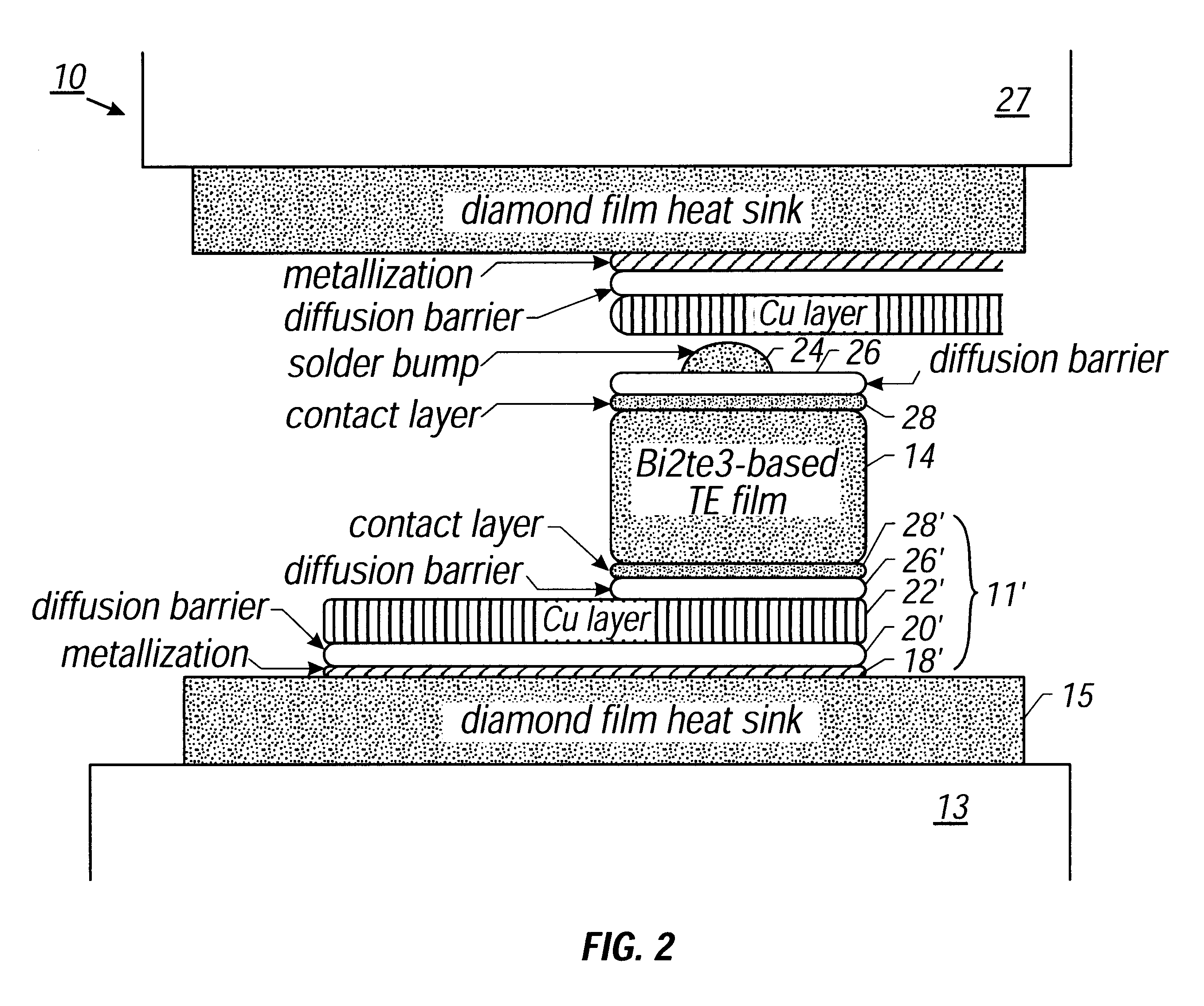

Low power thermoelectric generator

InactiveUS20060151021A1Improve thermoelectric performanceEnhance fabricationThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentBismuth tellurideEngineering

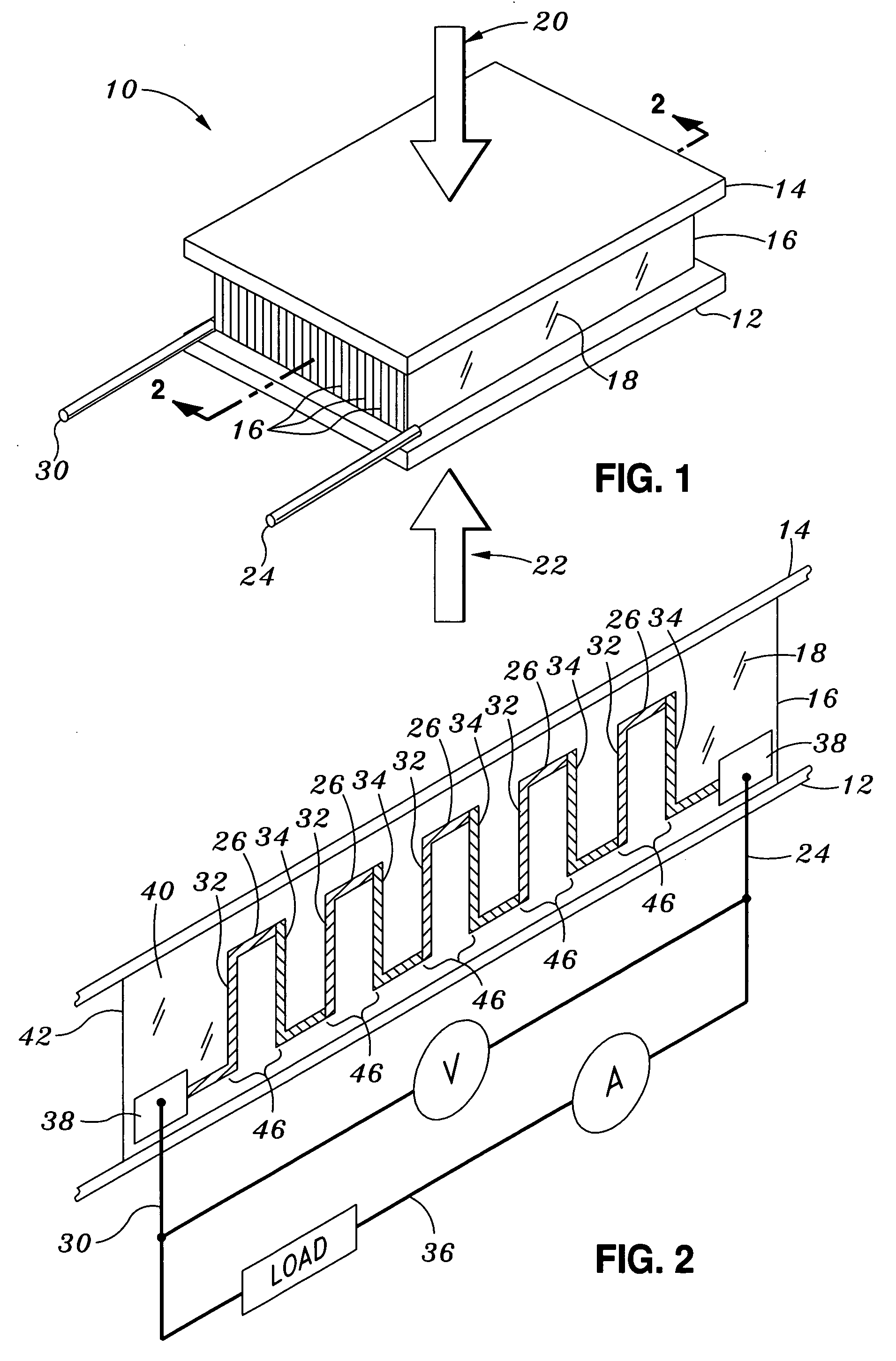

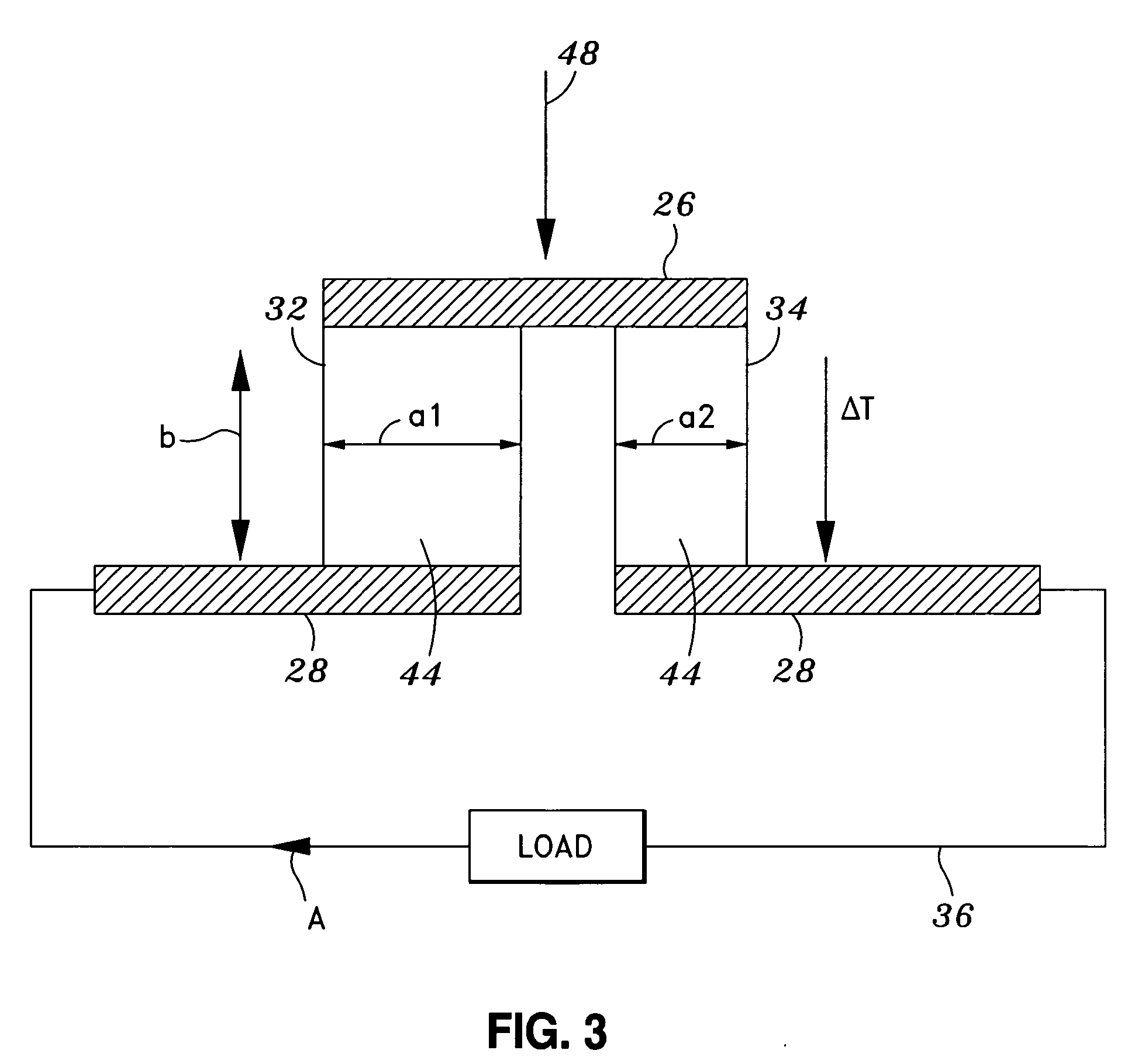

A thermoelectric generator has a top plate disposed in spaced relation above a bottom plate. A series of foil segments are electrically and mechanically connected end-to-end to generate a foil assembly that is spirally wound and in thermal contact with the bottom and top plates. Each foil segment comprises a substrate having a series of spaced alternating n-type and p-type thermoelectric legs disposed in parallel arrangement on the front substrate surface. Each of the n-type and p-type legs is formed of a bismuth telluride-based thermoelectric material having a thickness of about 10-100 microns, a width of about 10-100 microns and a length of about 100-500 microns. The alternating n-type and p-type thermoelectric legs are electrically connected in series and thermally connected in parallel such that a temperature differential between the bottom and top plates results in the generation of power.

Owner:DIGITAL ANGEL CORP

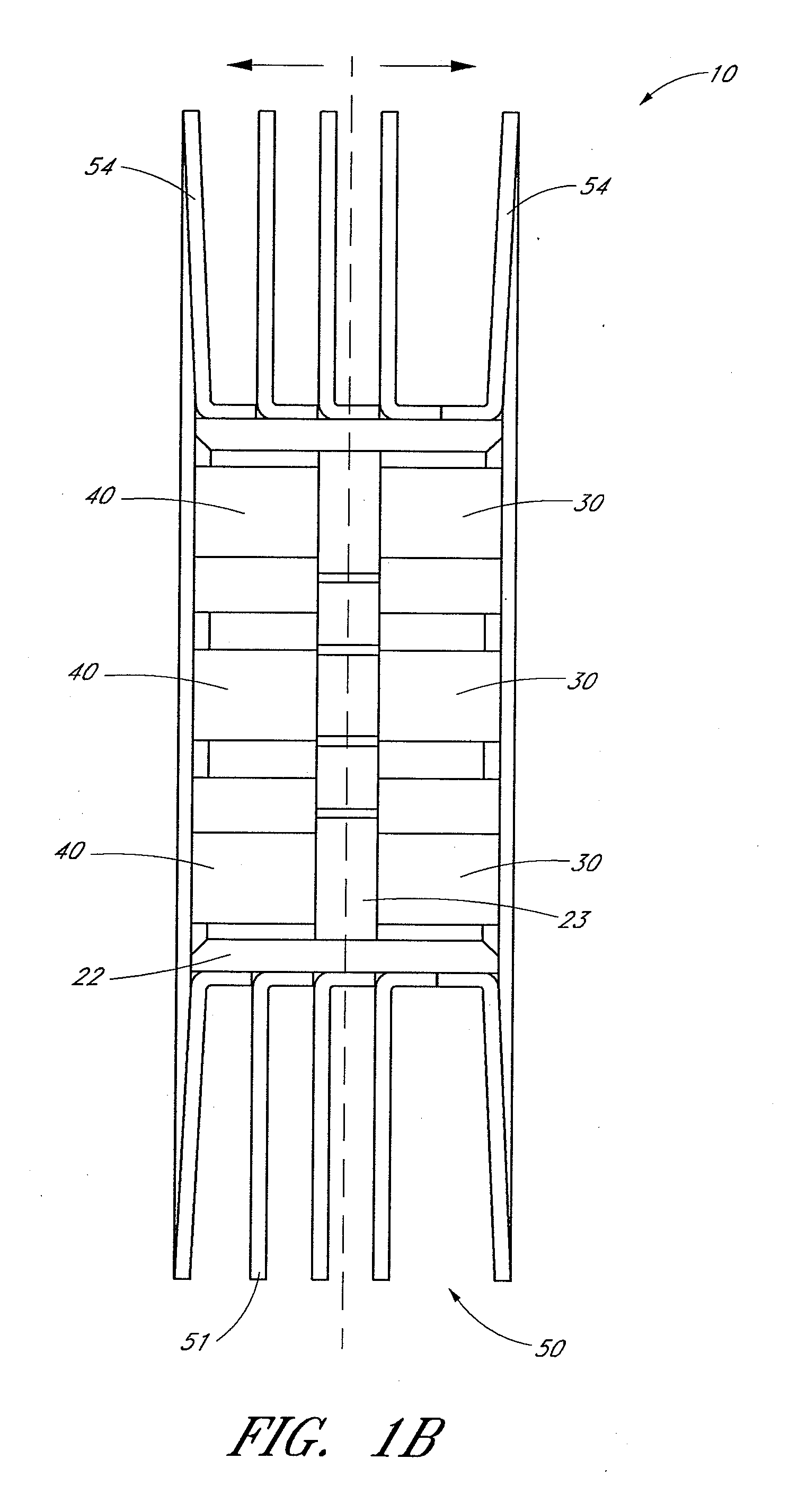

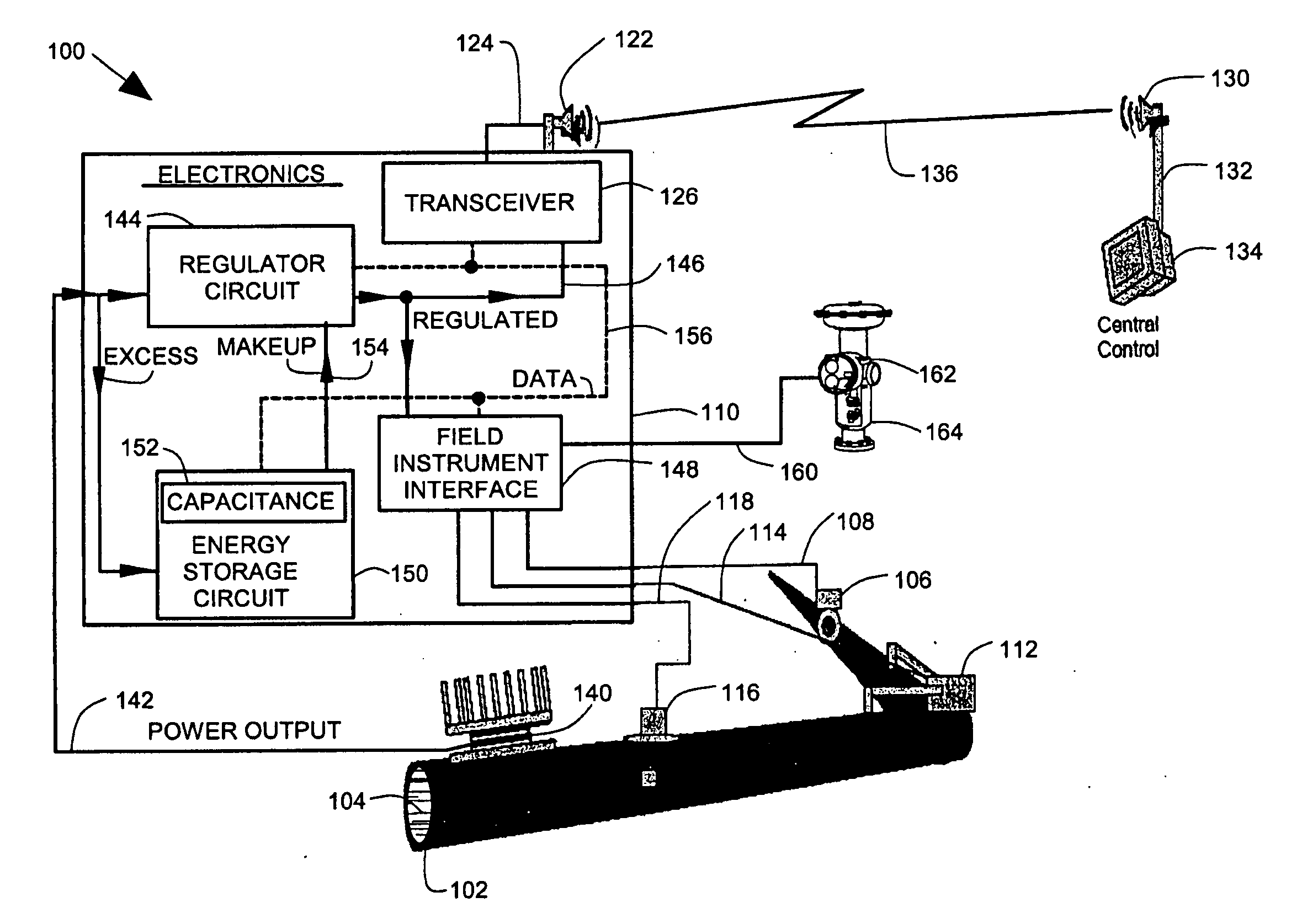

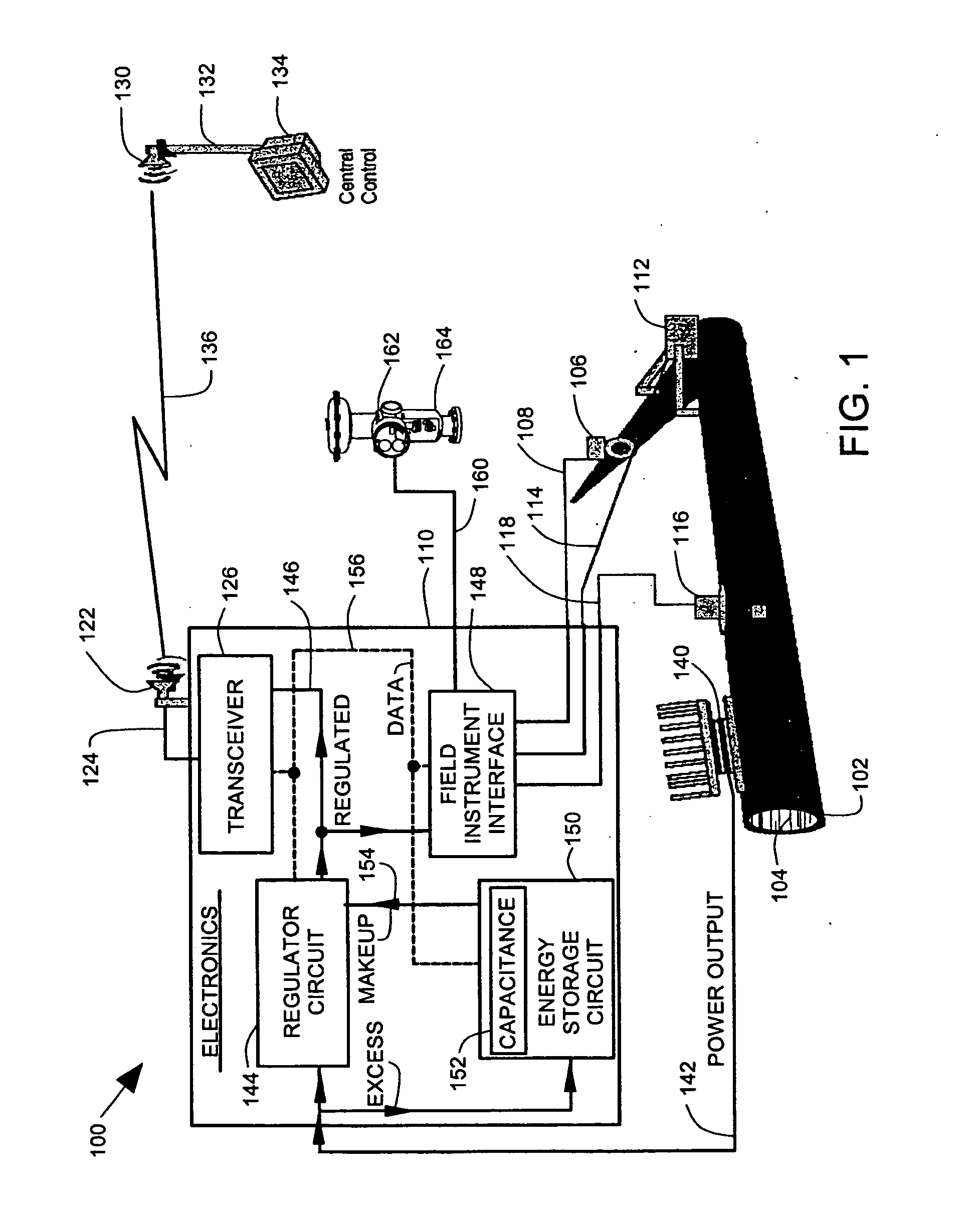

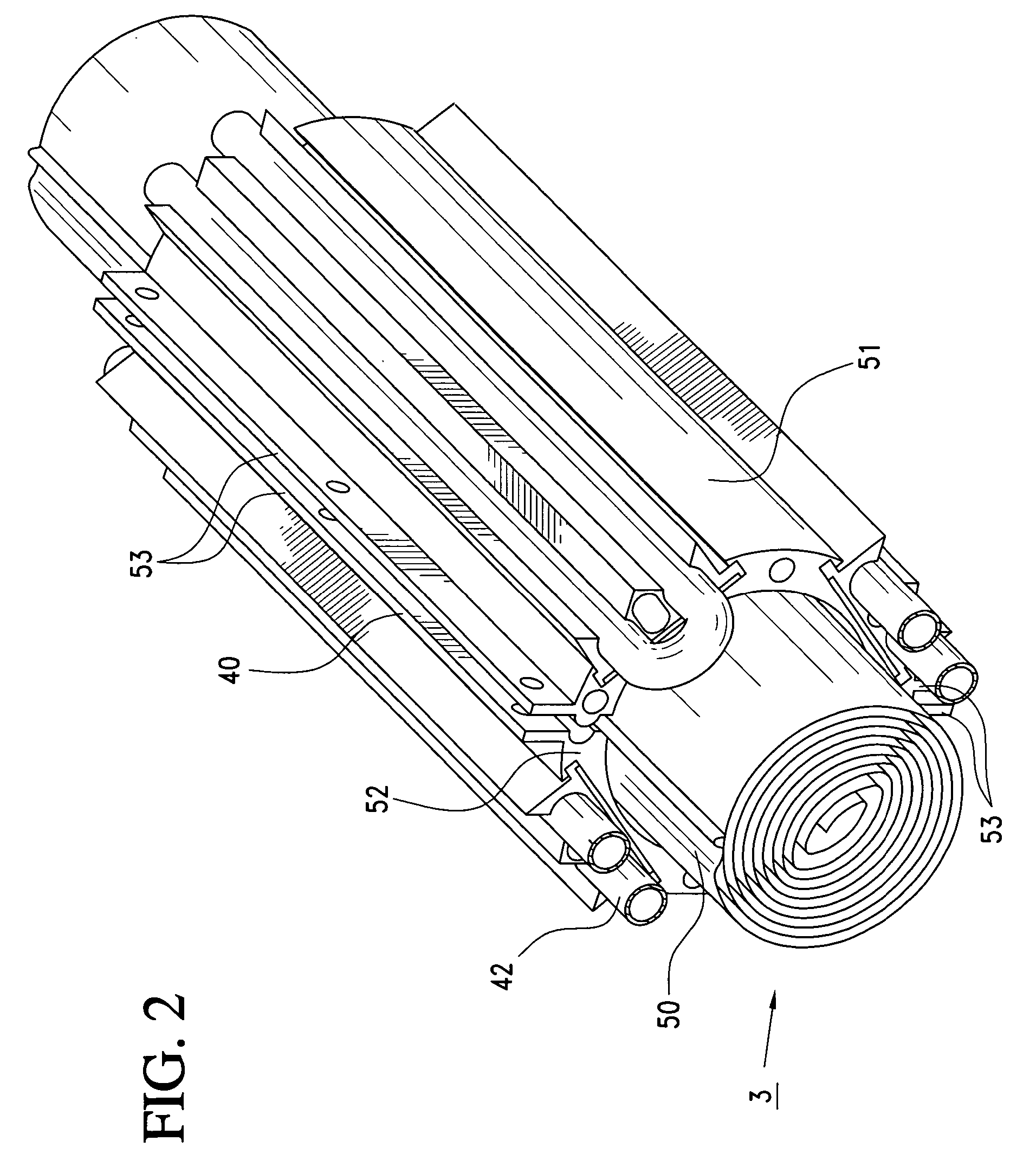

Pipeline thermoelectric generator assembly

A thermoelectric generator assembly. The thermoelectric generator assembly comprises a thermoelectric generator. The thermoelectric generator has a hot junction flange, a cold junction flange and a thermoelectric power output. The thermoelectric generator assembly generates electrical power from heat differentials for use in powering field devices in industrial process monitoring and control systems.

Owner:ROSEMOUNT INC

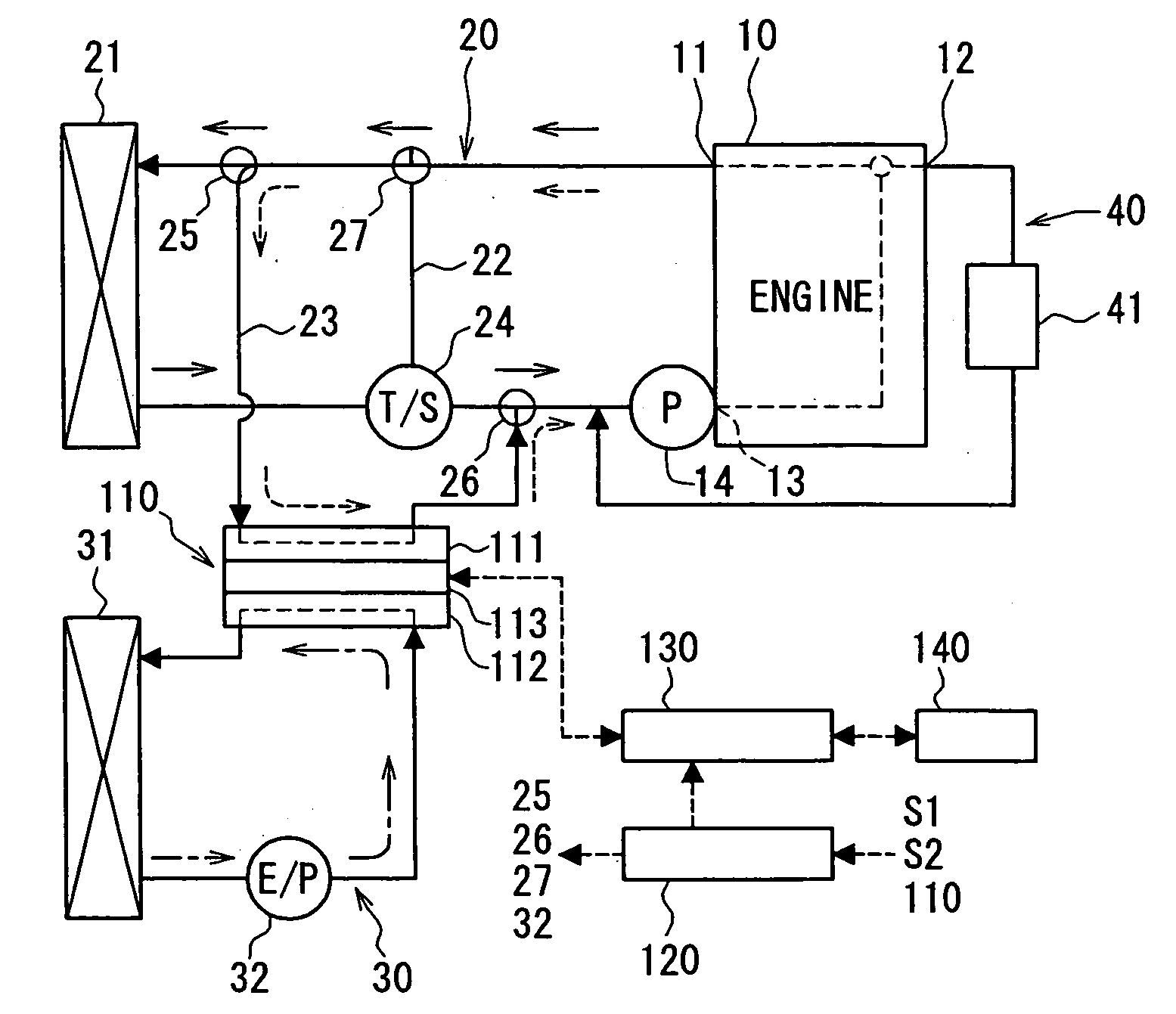

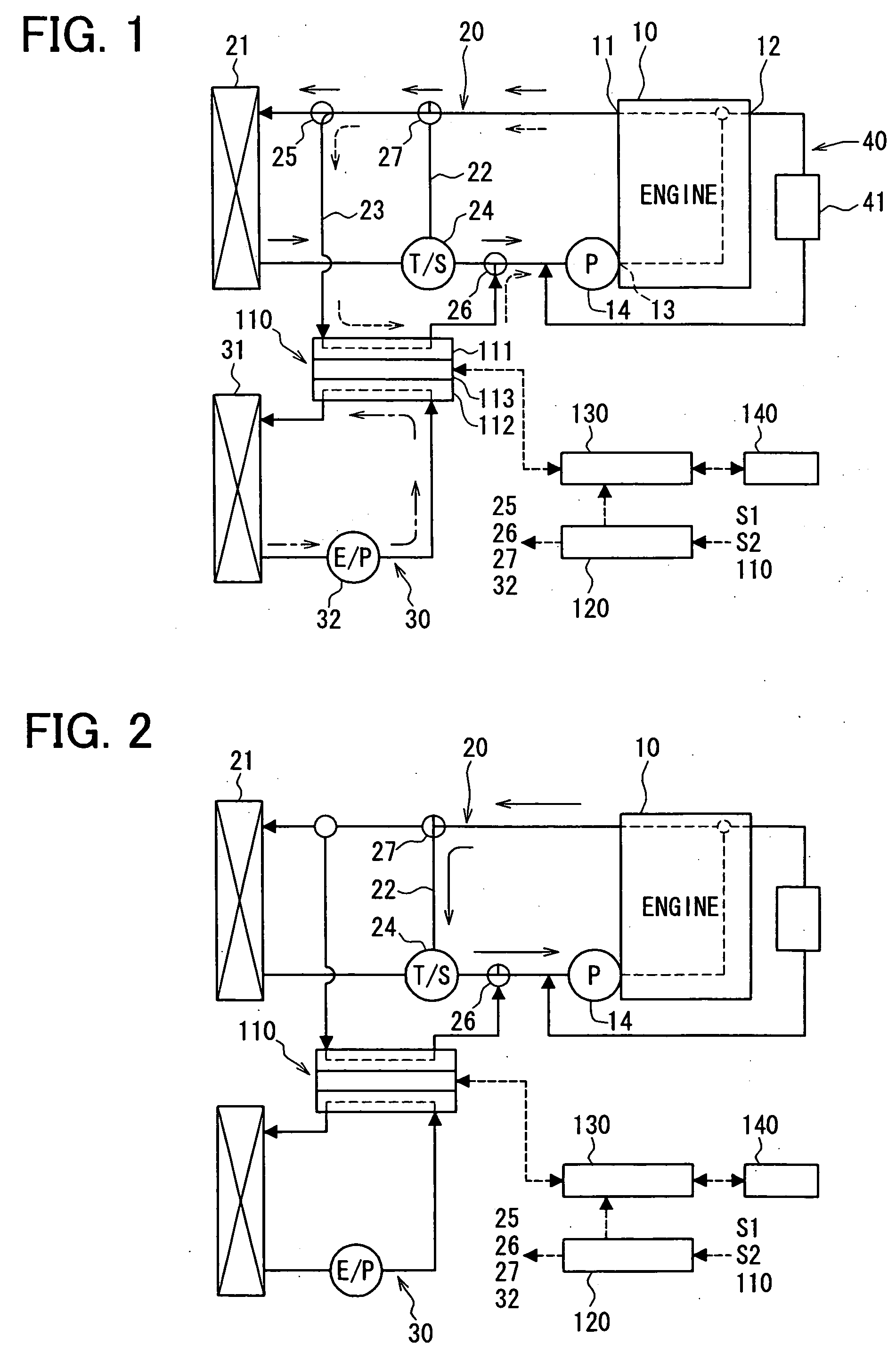

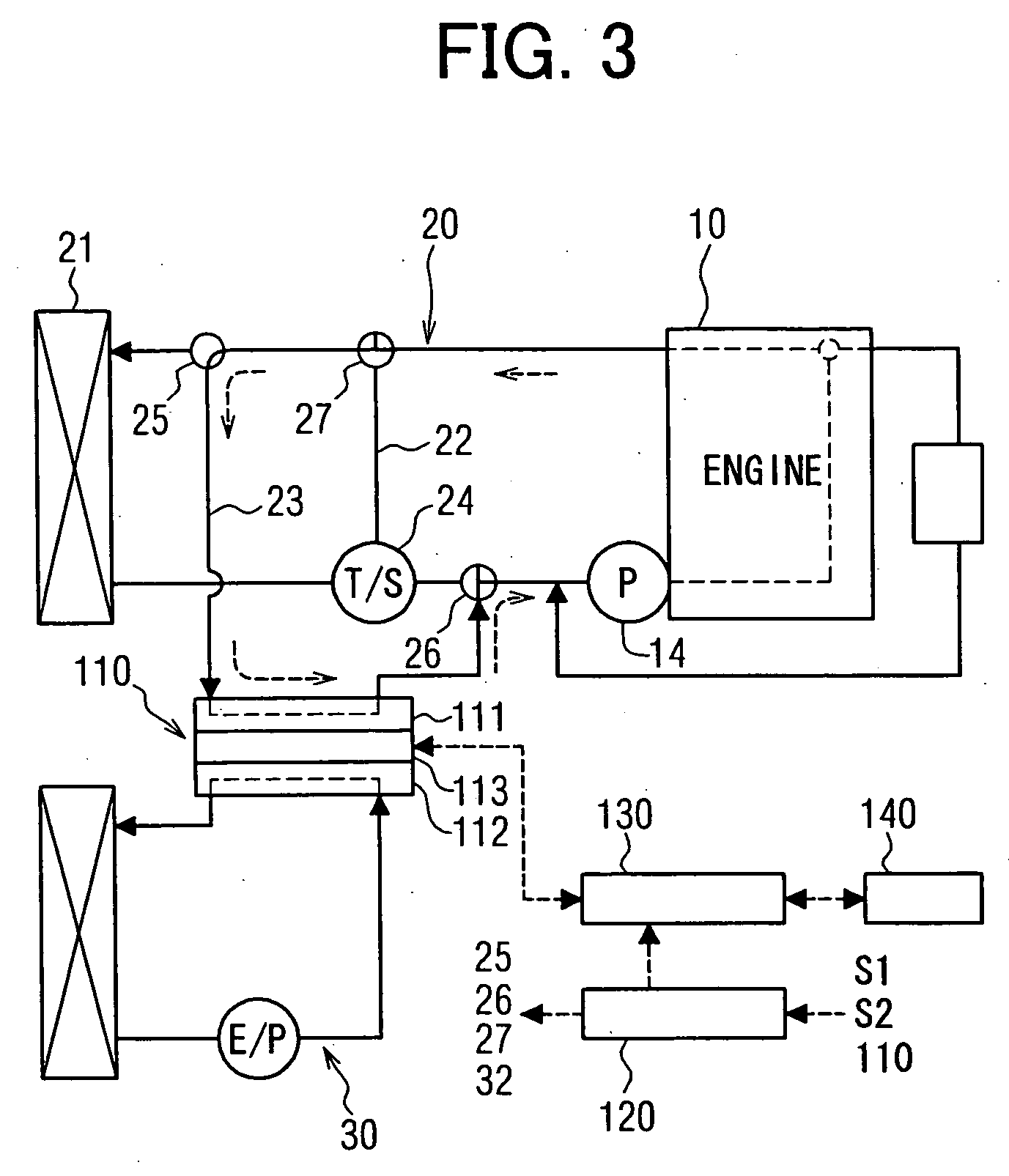

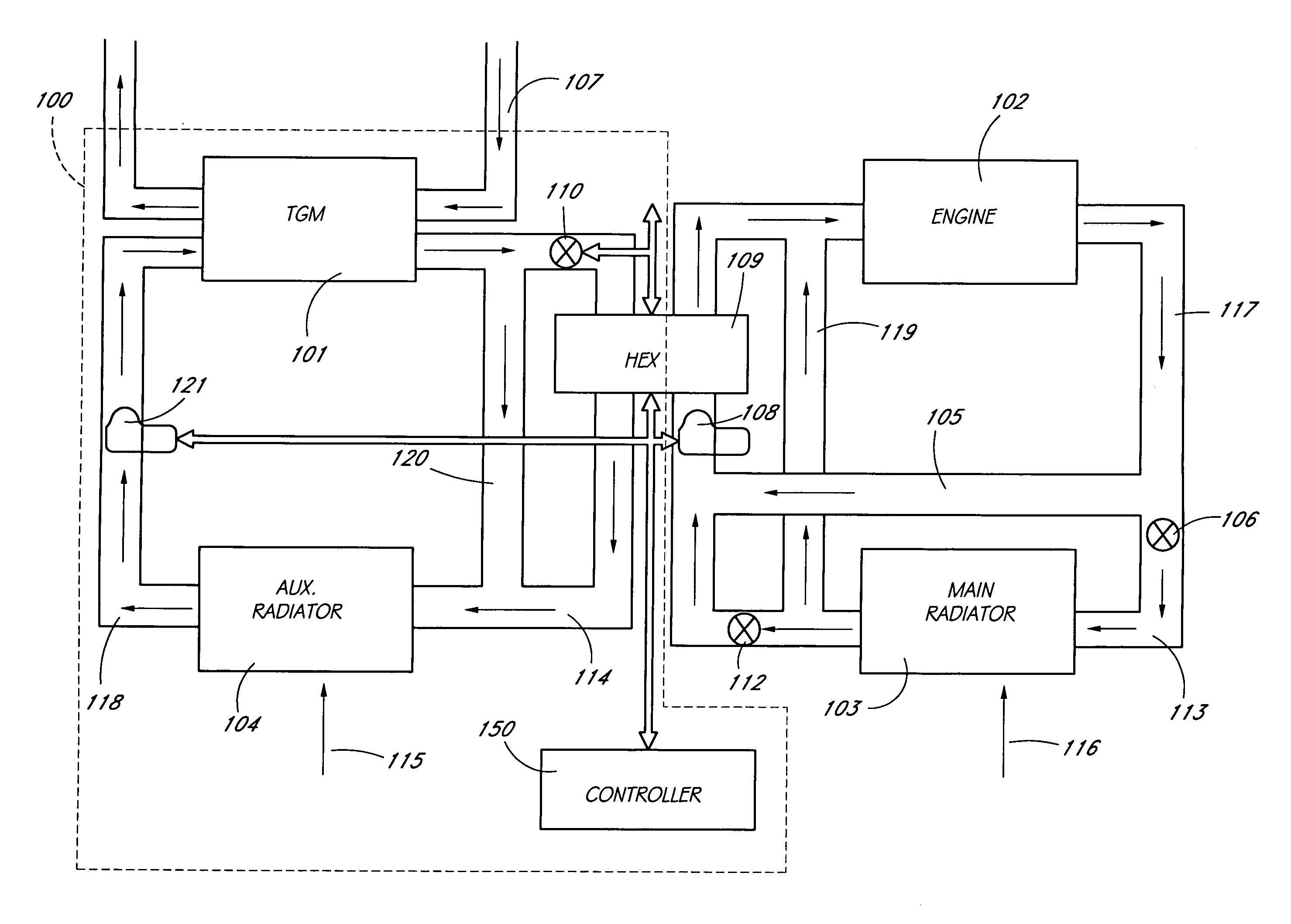

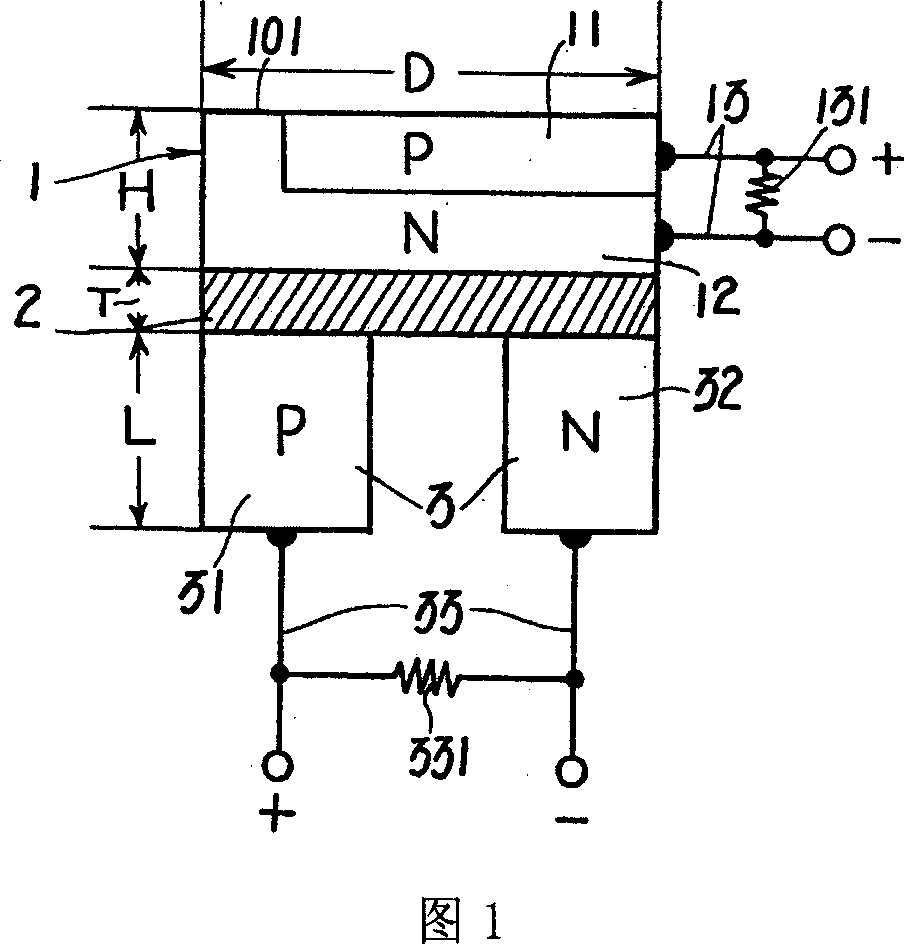

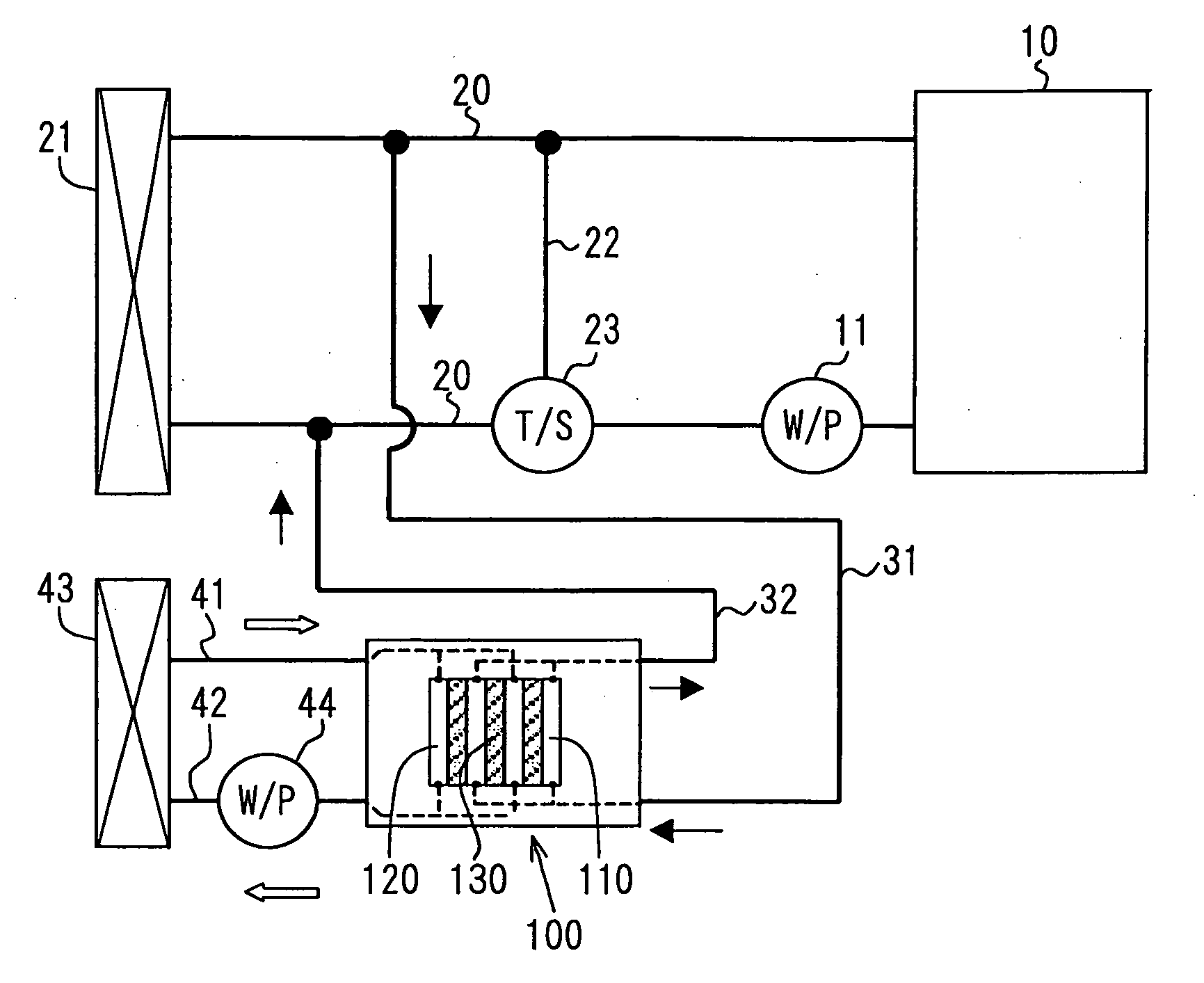

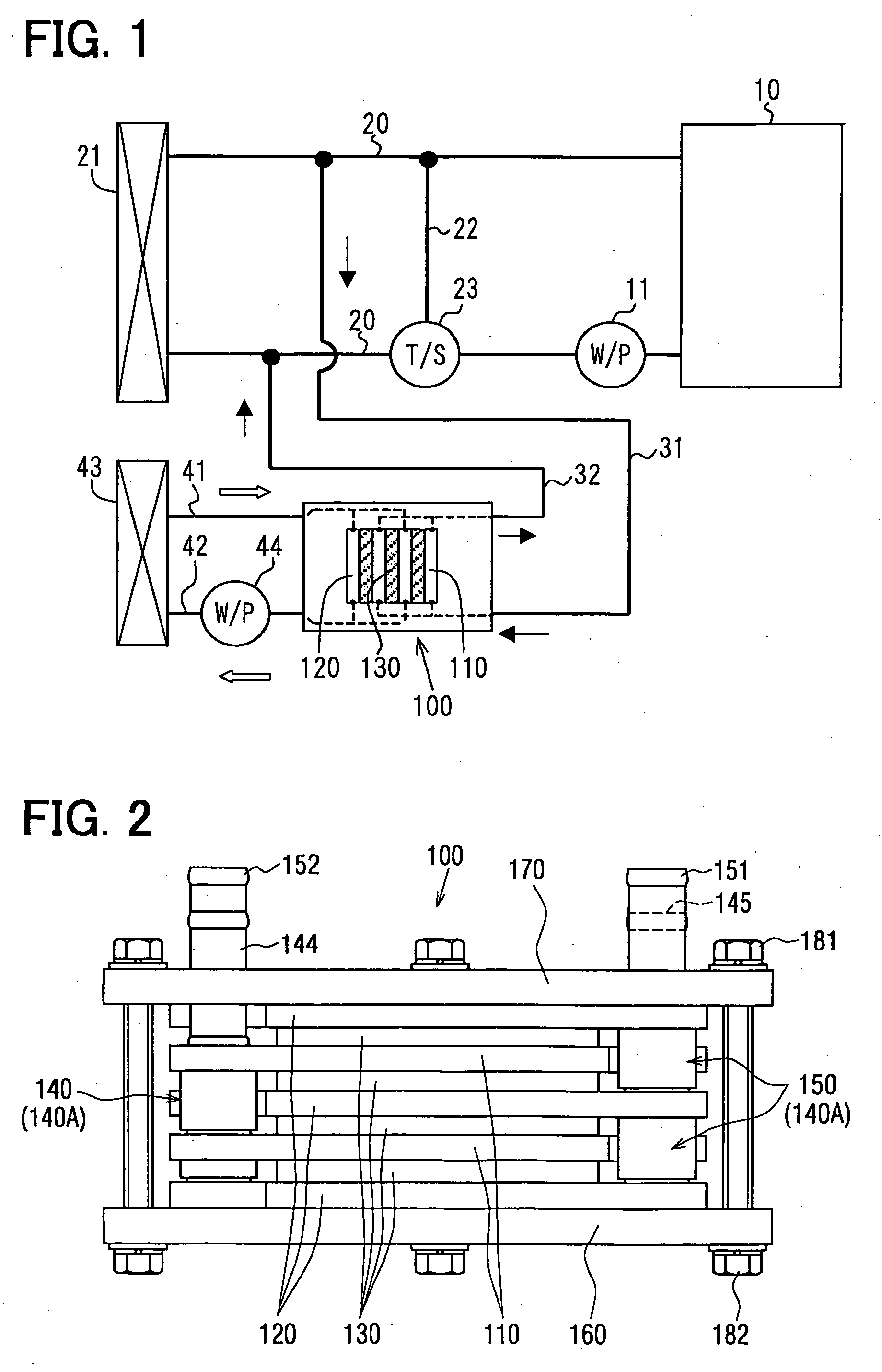

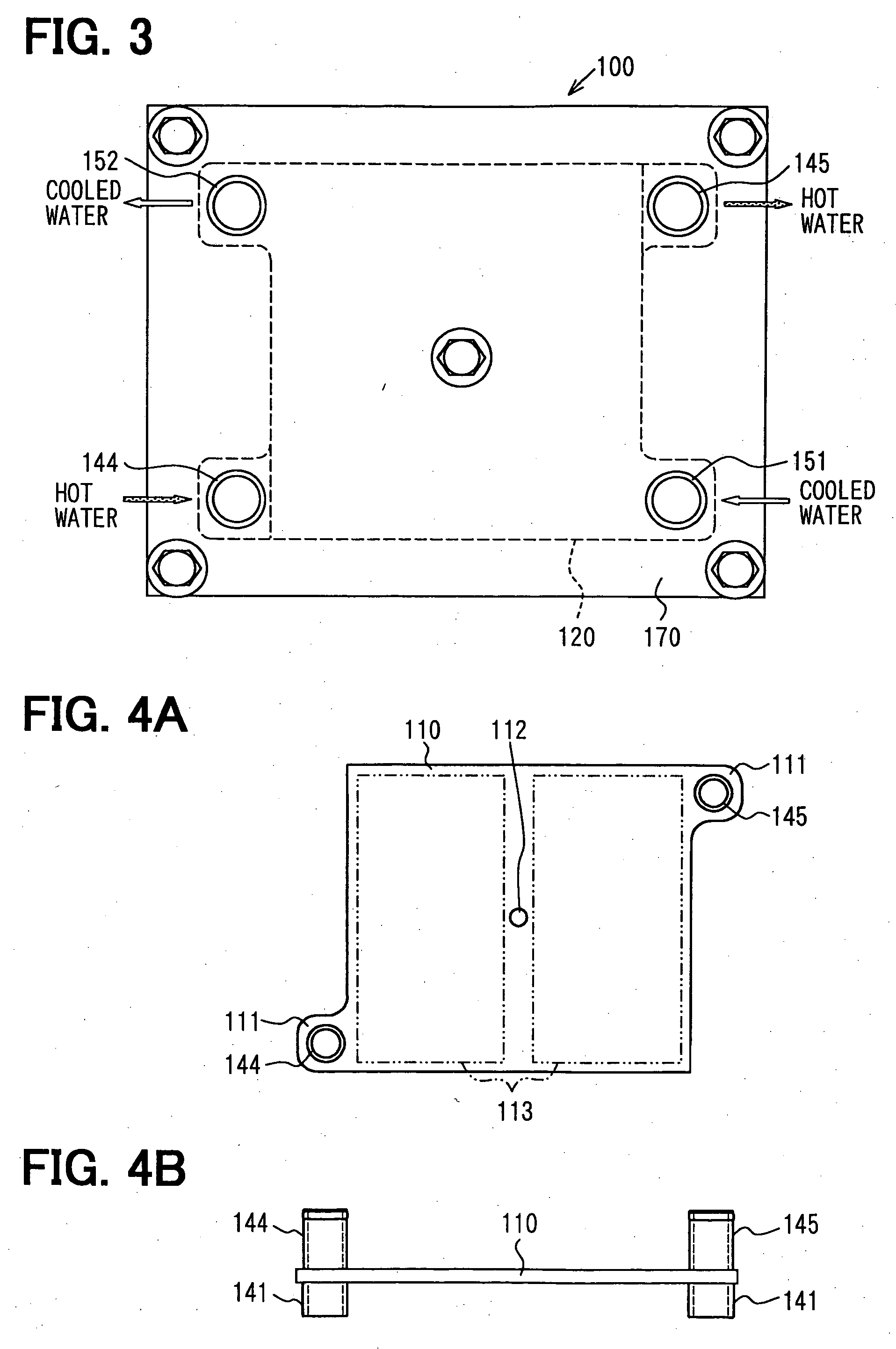

Thermoelectric generator

InactiveUS20060130888A1Suppressing decreaseSolve insufficient capacityLiquid coolingCoolant flow controlEngineeringTemperature difference

A thermoelectric generator has a high temperature heat source part provided on a first passage through which a first fluid for cooling an engine flows, a low temperature heat source part provided on a second passage through which a second fluid having a temperature lower than that of the first fluid flows, and a thermoelectric element for producing electric power by a temperature difference produced between the high temperature heat source part and the low temperature heat source part. The first passage is included in a first circuit in which the engine and a first radiator for cooling the first fluid are connected in loop through a main passage. Further, the first passage is in parallel to the first radiator in the first circuit. The second passage is included in a second circuit that is separate from the first circuit and includes a second radiator for cooling the second fluid.

Owner:DENSO CORP +1

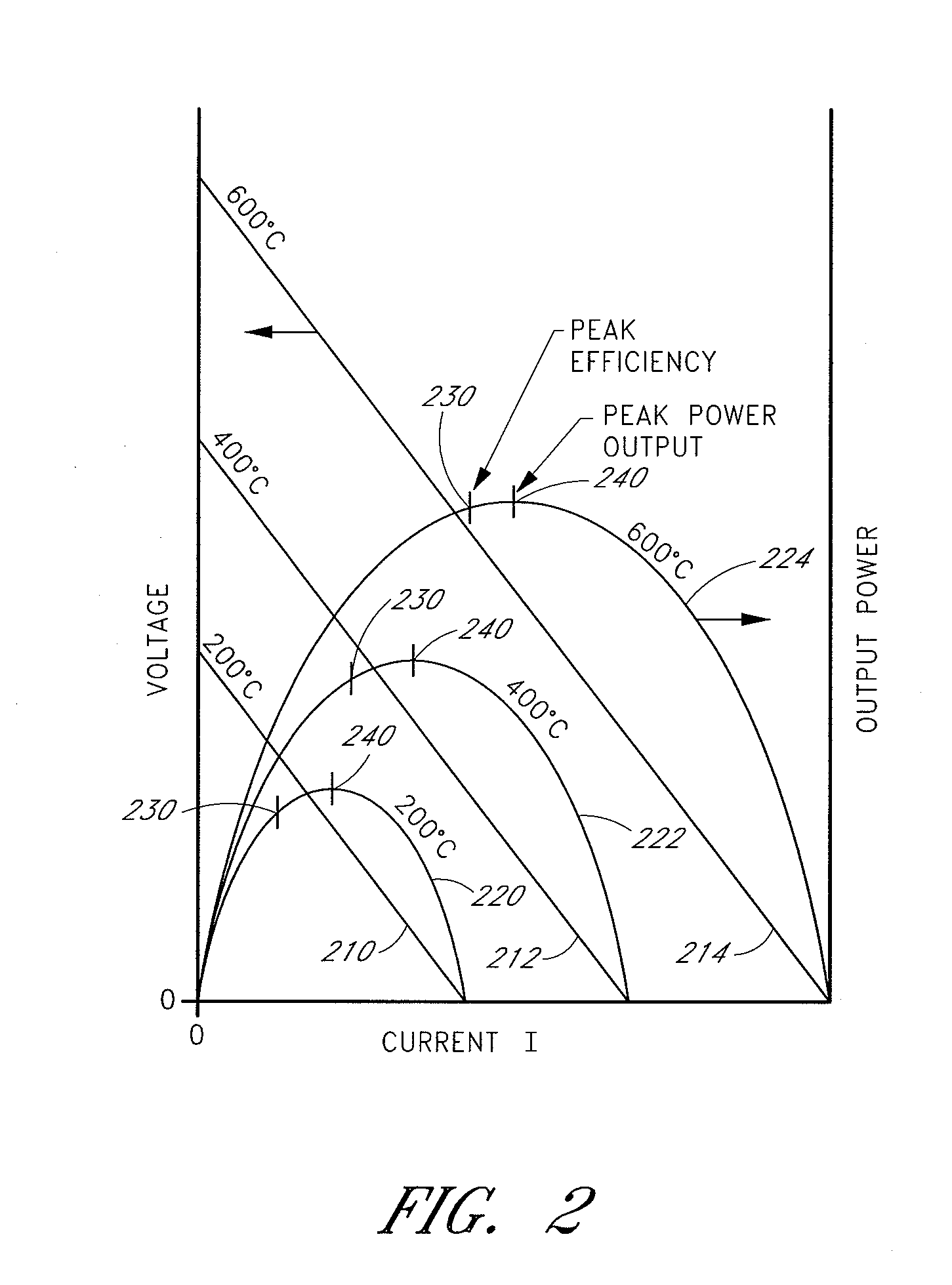

Thermoelectric power generator for variable thermal power source

InactiveUS20100024859A1Avoid flowInternal combustion piston enginesThermoelectric device with peltier/seeback effectWorking fluidEngineering

A thermoelectric generator includes a first thermoelectric segment including at least one thermoelectric module. The first thermoelectric segment has a working fluid flowing therethrough with a fluid pressure. The thermoelectric generator further includes a second thermoelectric segment including at least one thermoelectric module. The second thermoelectric segment is configurable to allow the working fluid to flow therethrough. The thermoelectric generator further includes at least a first variable flow element movable upon application of the fluid pressure to the first variable flow element. The first variable flow element modifies a flow resistance of the second thermoelectric segment to flow of the working fluid therethrough.

Owner:GENTHERM INC

Thermoelectric power generator with intermediate loop

InactiveUS7608777B2Performance maximizationIncrease temperature differenceThermoelectric device with peltier/seeback effectMachines/enginesHeat fluxNuclear engineering

A thermoelectric power generator is disclosed for use to generate electrical power from heat, typically waste heat. An intermediate heat transfer loop forms a part of the system to permit added control and adjustability in the system. This allows the thermoelectric power generator to more effectively and efficiently generate power in the face of dynamically varying temperatures and heat flux conditions, such as where the heat source is the exhaust of an automobile, or any other heat source with dynamic temperature and heat flux conditions.

Owner:GENTHERM INC

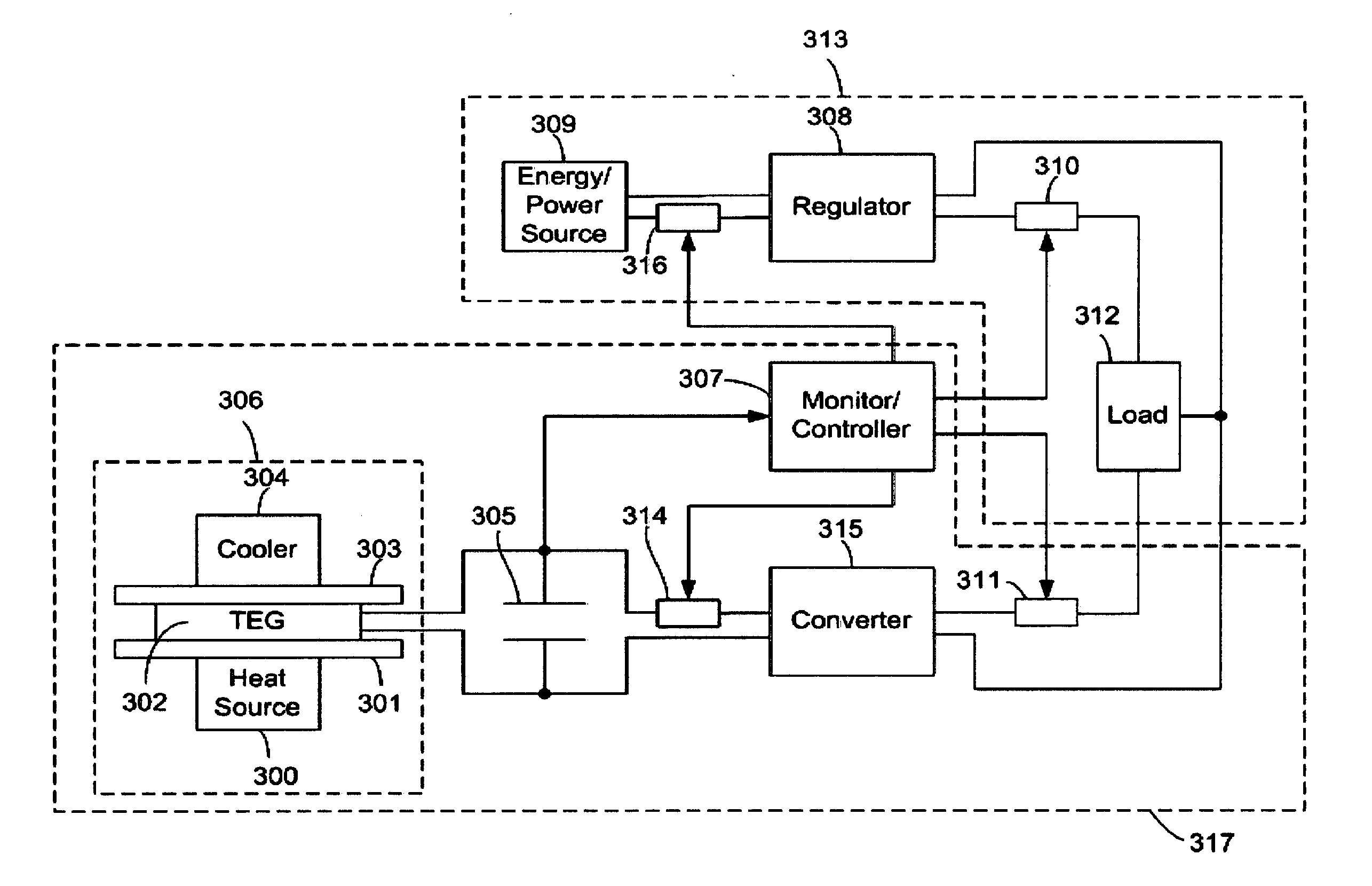

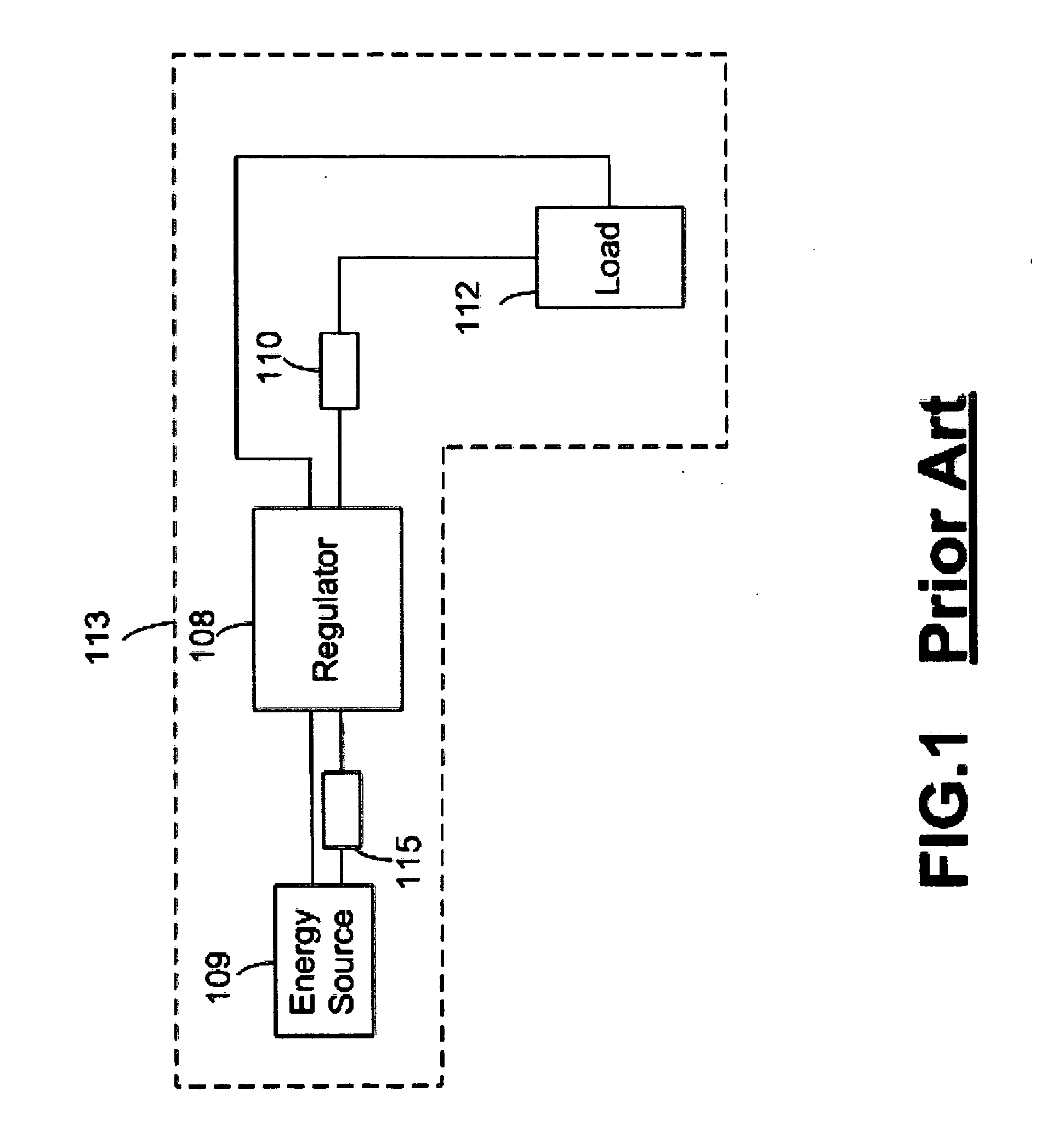

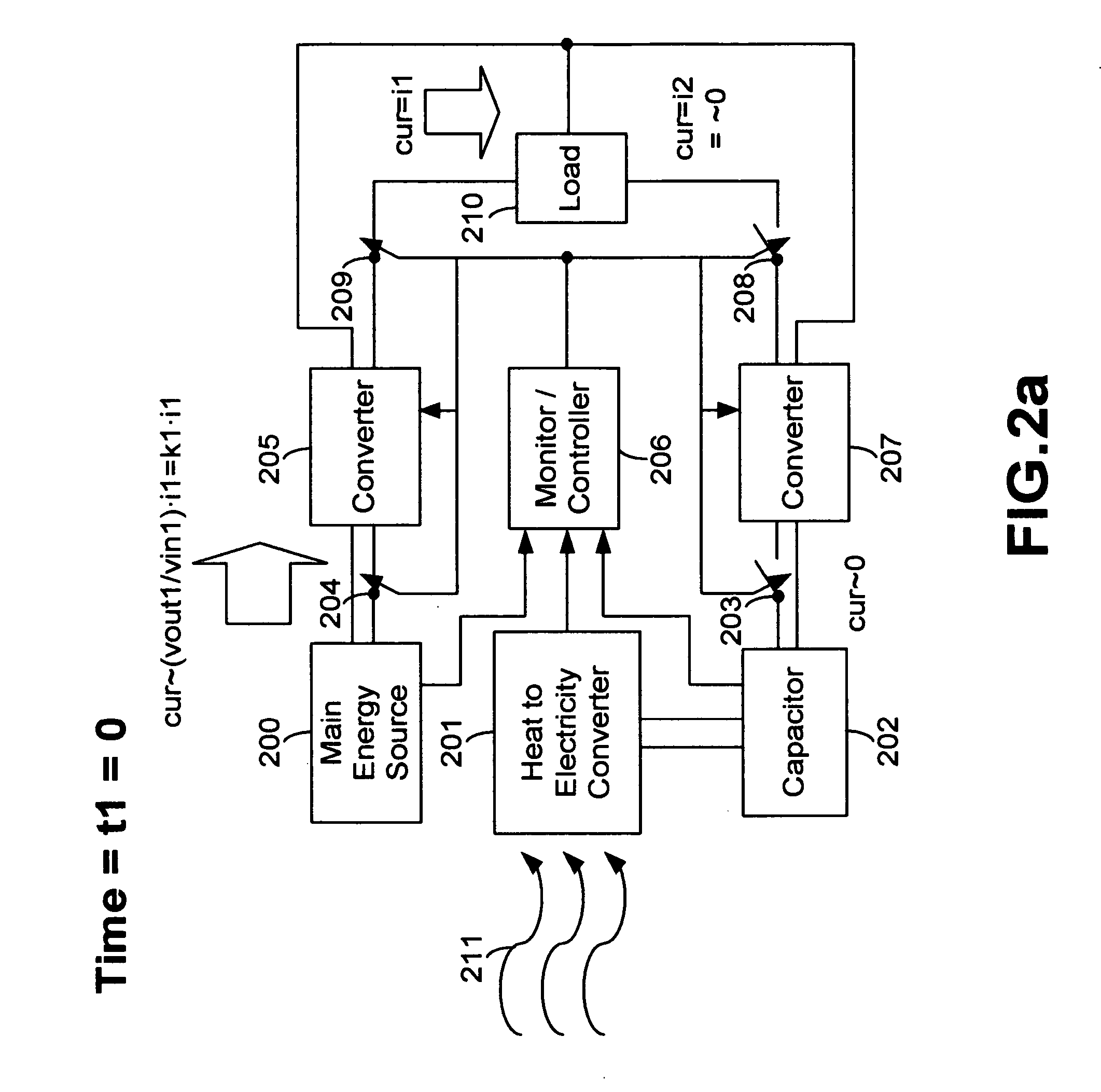

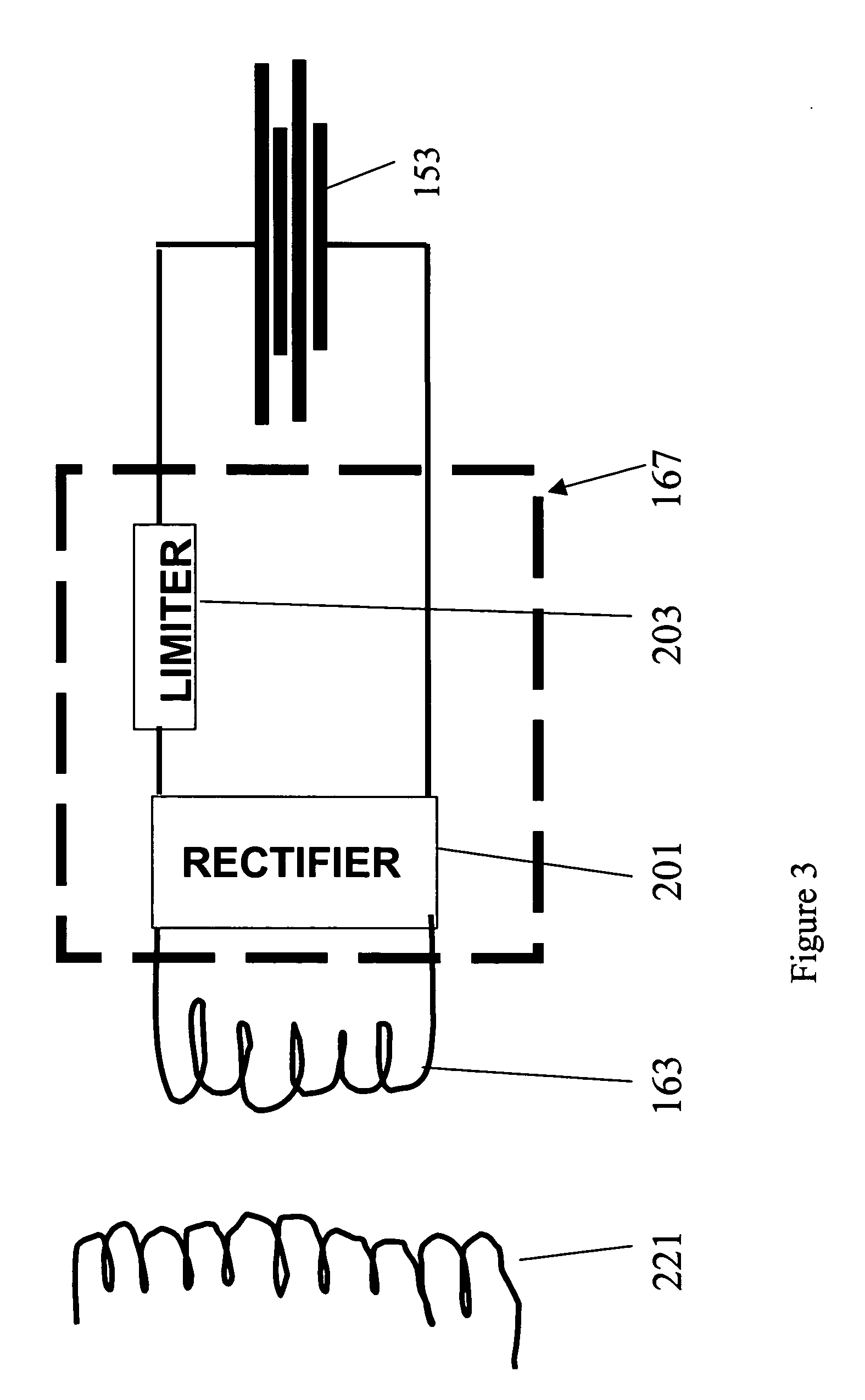

System and method for efficient power utilization and extension of battery life

ActiveUS20070096564A1Reduce the amount of powerProlong lifeBatteries circuit arrangementsElectric power transfer ac networkThermal energyCapacitor

A circuit which extends the operational life of a main energy source coupled to a load, said circuit comprising a power generator having a heat source and a cooler thermally coupled to a thermoelectric generator (TEG) for converting thermal energy into electrical energy; and a first capacitor coupled to the TEG for receiving and storing the electrical energy from the TEG. The circuit further comprising at least one switching element coupled between the first capacitor and the load, a converter coupled between the capacitor and the at least one switching element for generating a regulated output, and a controller for activating the at least one switching element when the charge stored on the first capacitor reaches a predetermined level, thereby delivering power from the first capacitor to the load, via the converter, and reducing the amount of power drawn from the main energy source, thereby extending the operational life of the main energy source.

Owner:MAEDA RYUJI

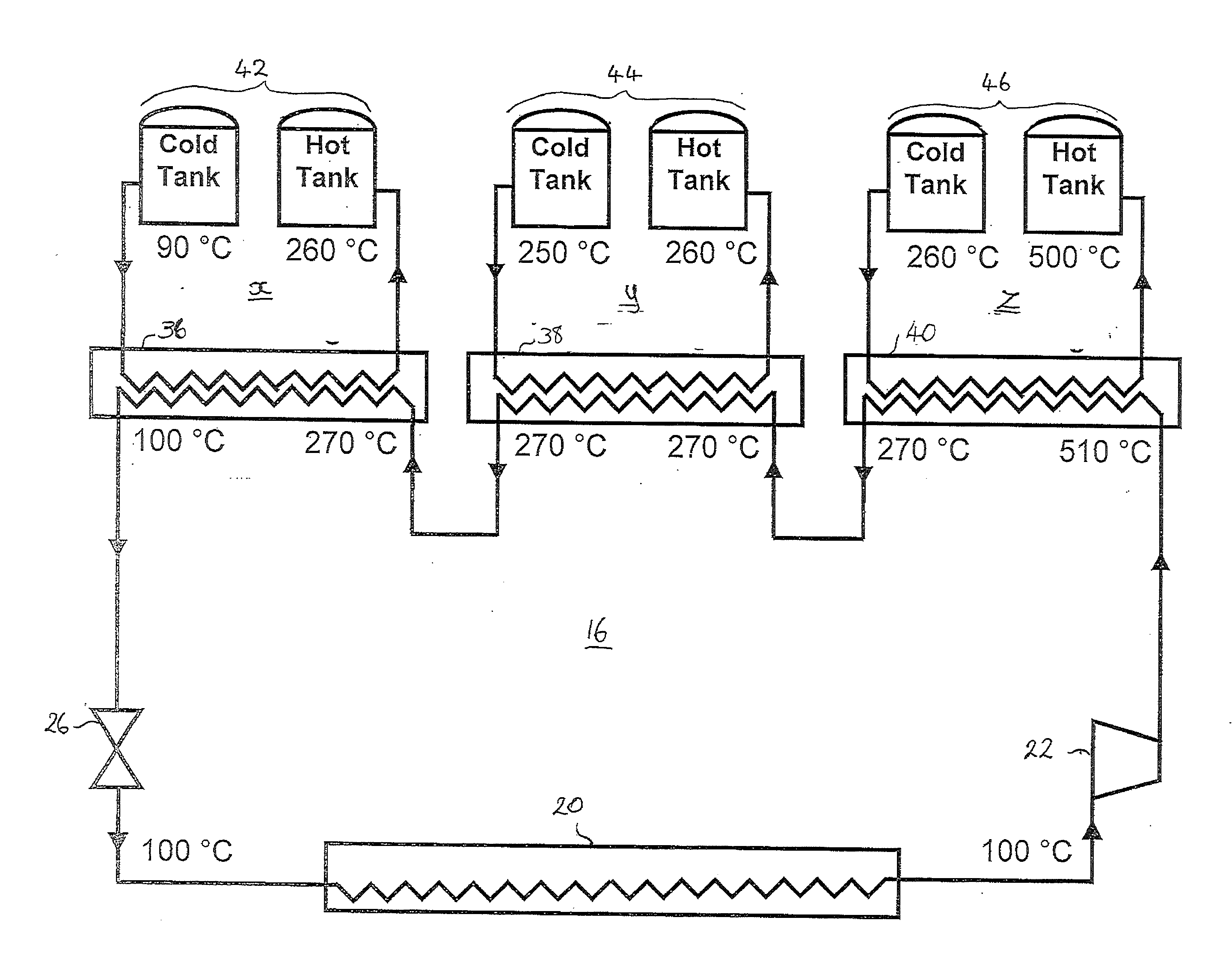

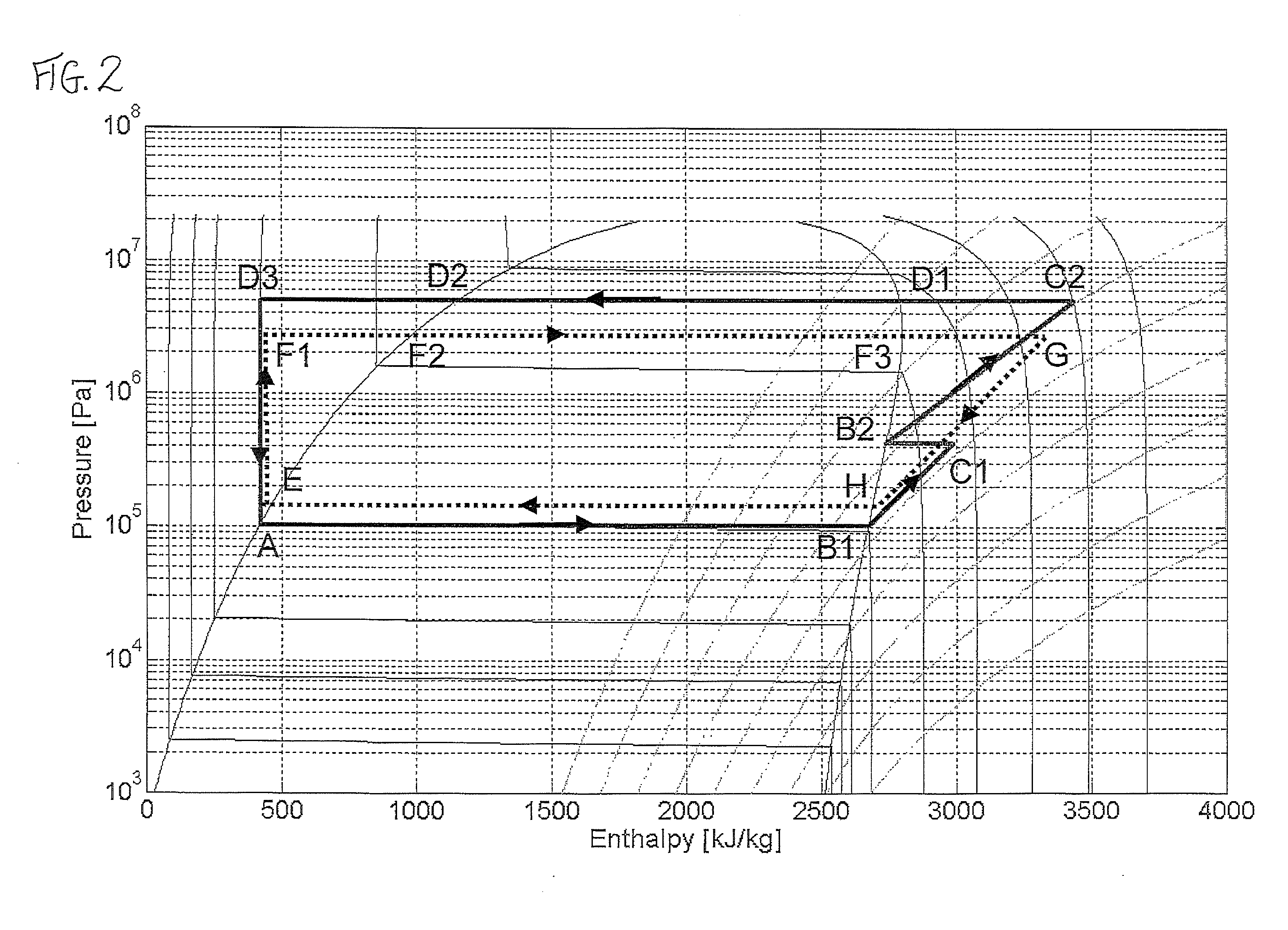

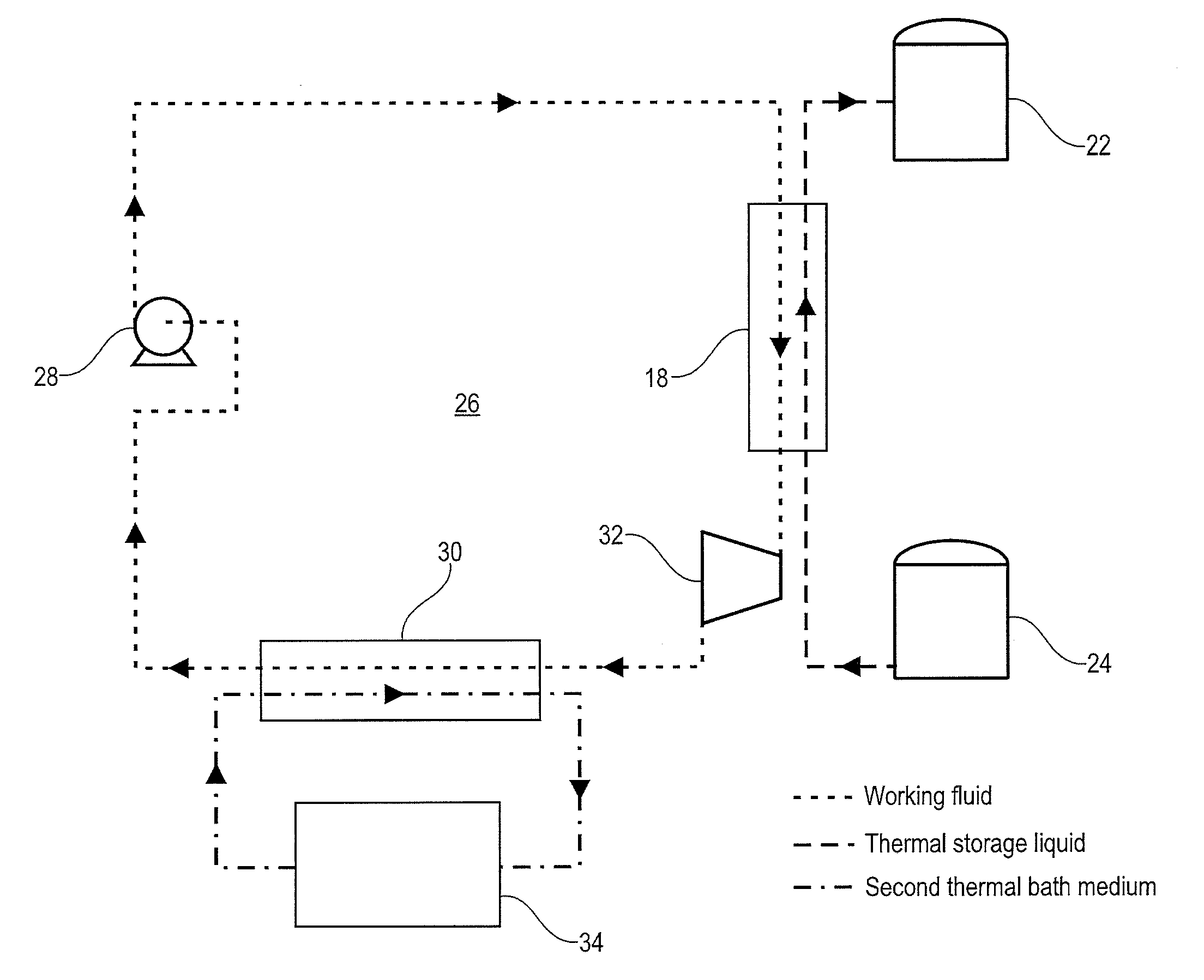

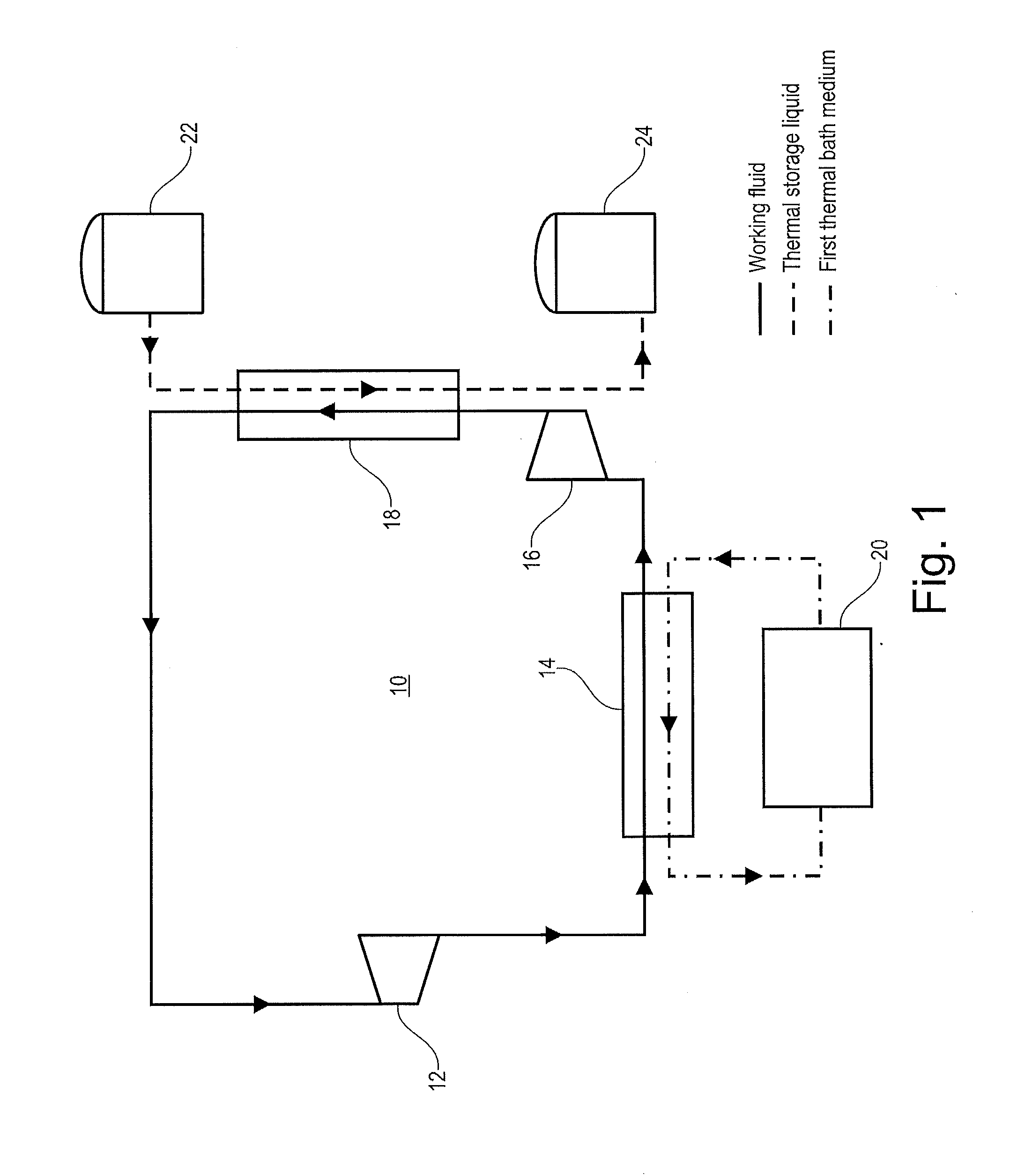

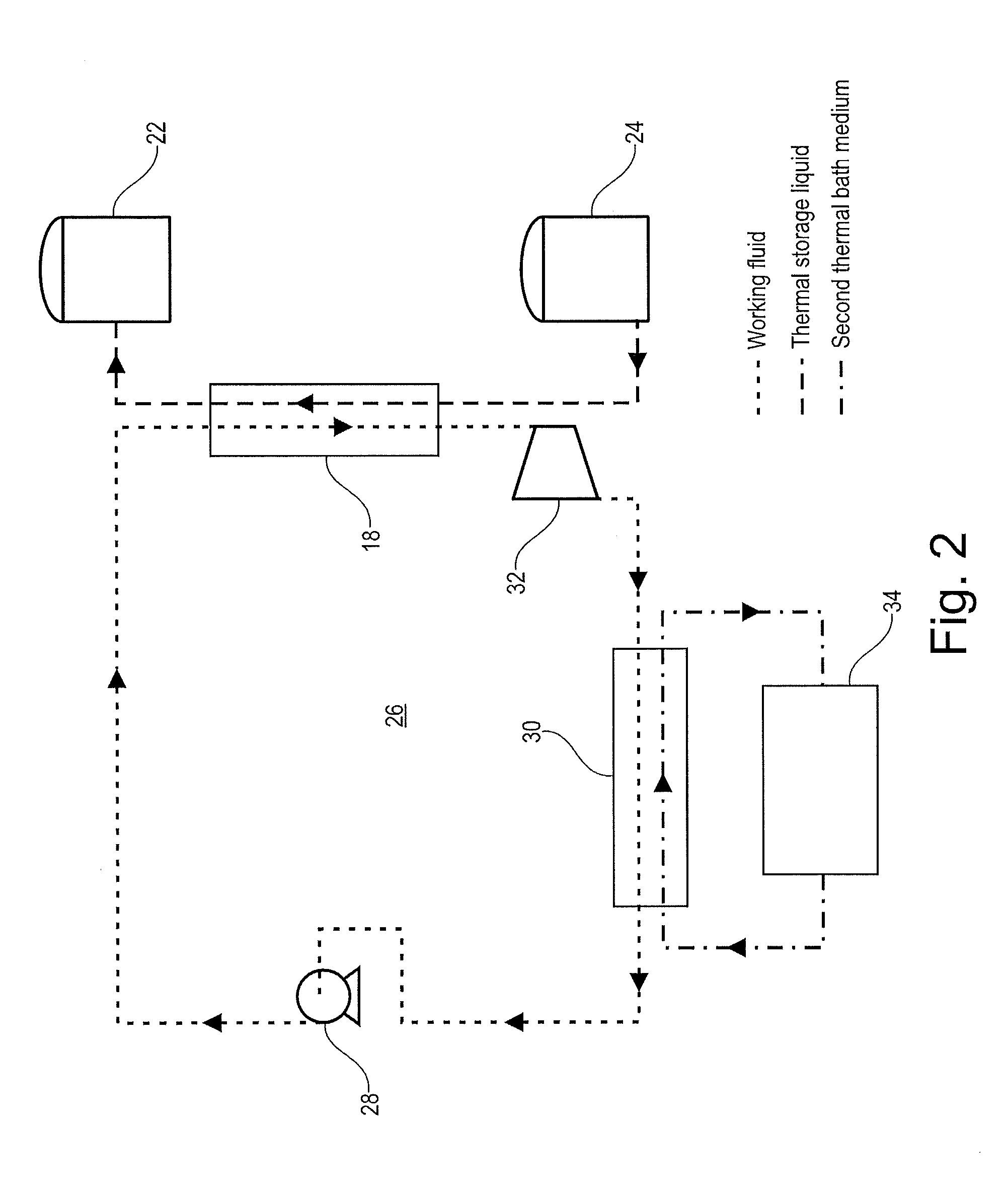

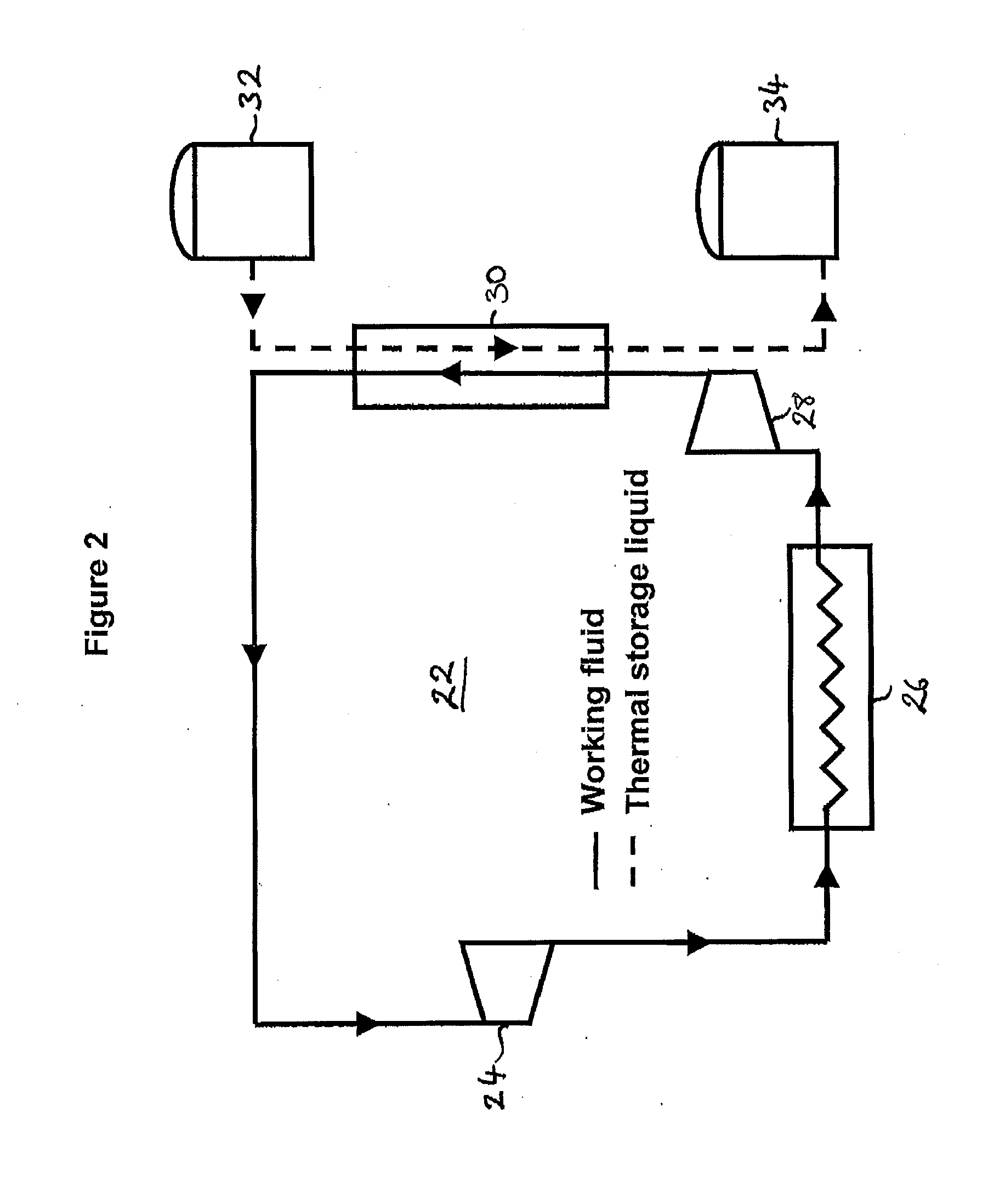

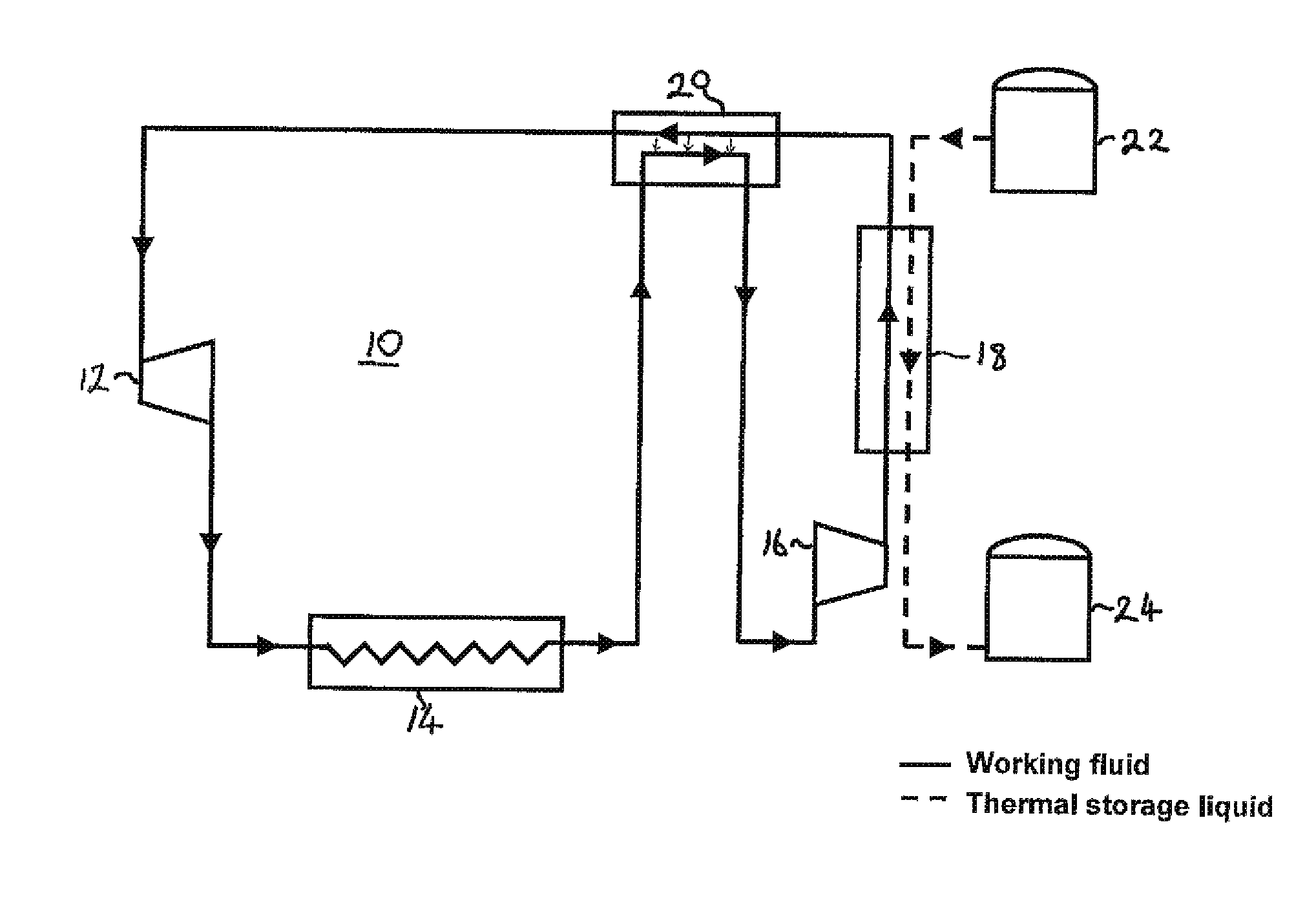

Thermoelectric energy storage system having two thermal baths and method for storing thermoelectric energy

ActiveUS20120060501A1High round-trip efficiencySystem costs involvedThermoelectric device with peltier/seeback effectHeat storage plantsWorking fluidThermal energy storage

An exemplary system and method for storing and retrieving energy in a thermoelectric energy storage system is disclosed. The thermoelectric energy storage system includes a working fluid that is circulated through a first and second heat exchanger, and a thermal storage medium that is circulated through the first heat exchanger. The second heat exchanger is in connection with a first thermal bath during a charging cycle and with a second thermal bath during a discharging cycle. In this way roundtrip efficiency is improved through minimizing the temperature difference between the first thermal bath and the hot storage tank during charging, and maximizing the temperature difference between the second thermal bath and the hot storage tank during discharging.

Owner:ABB (SCHWEIZ) AG

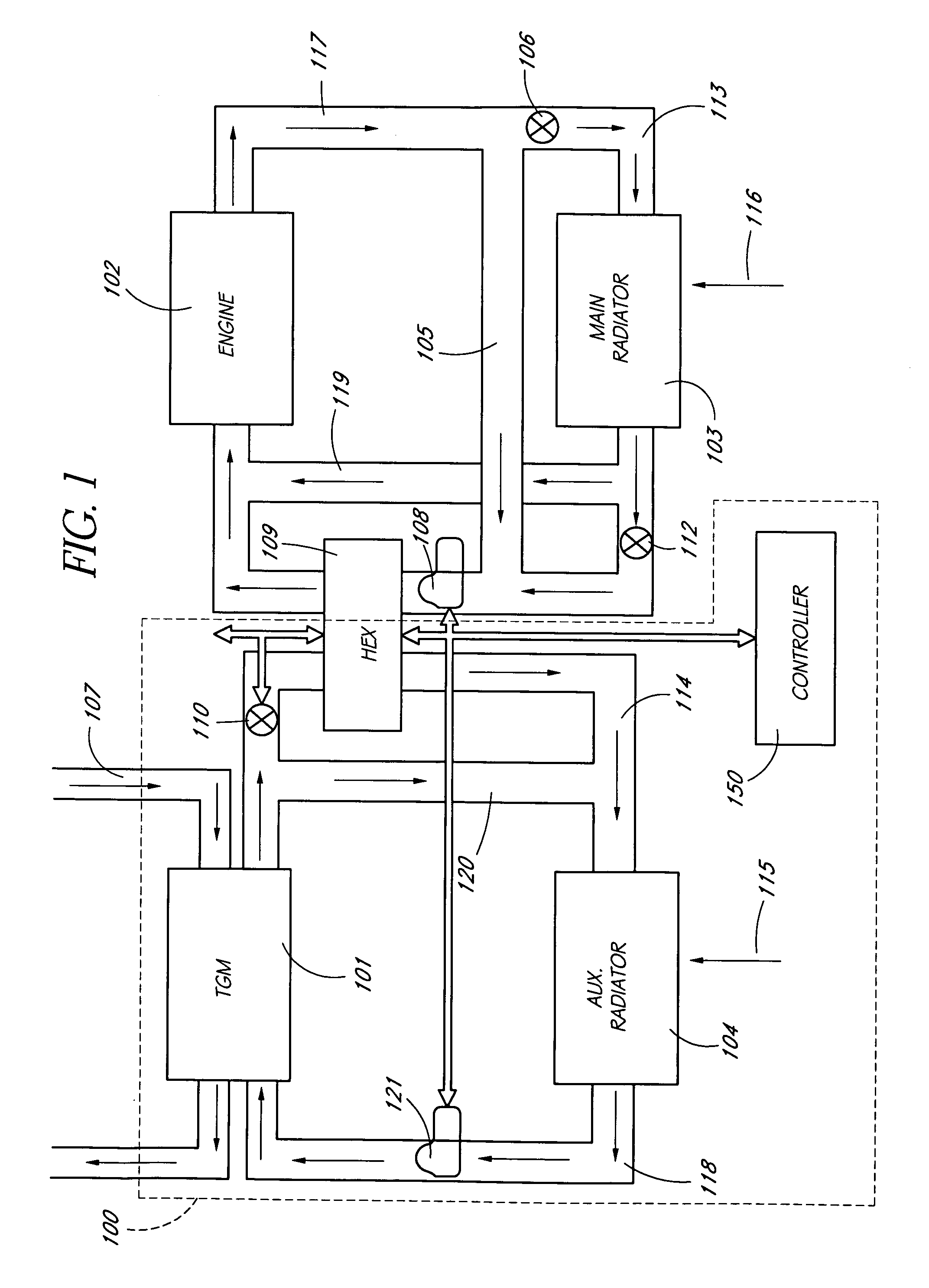

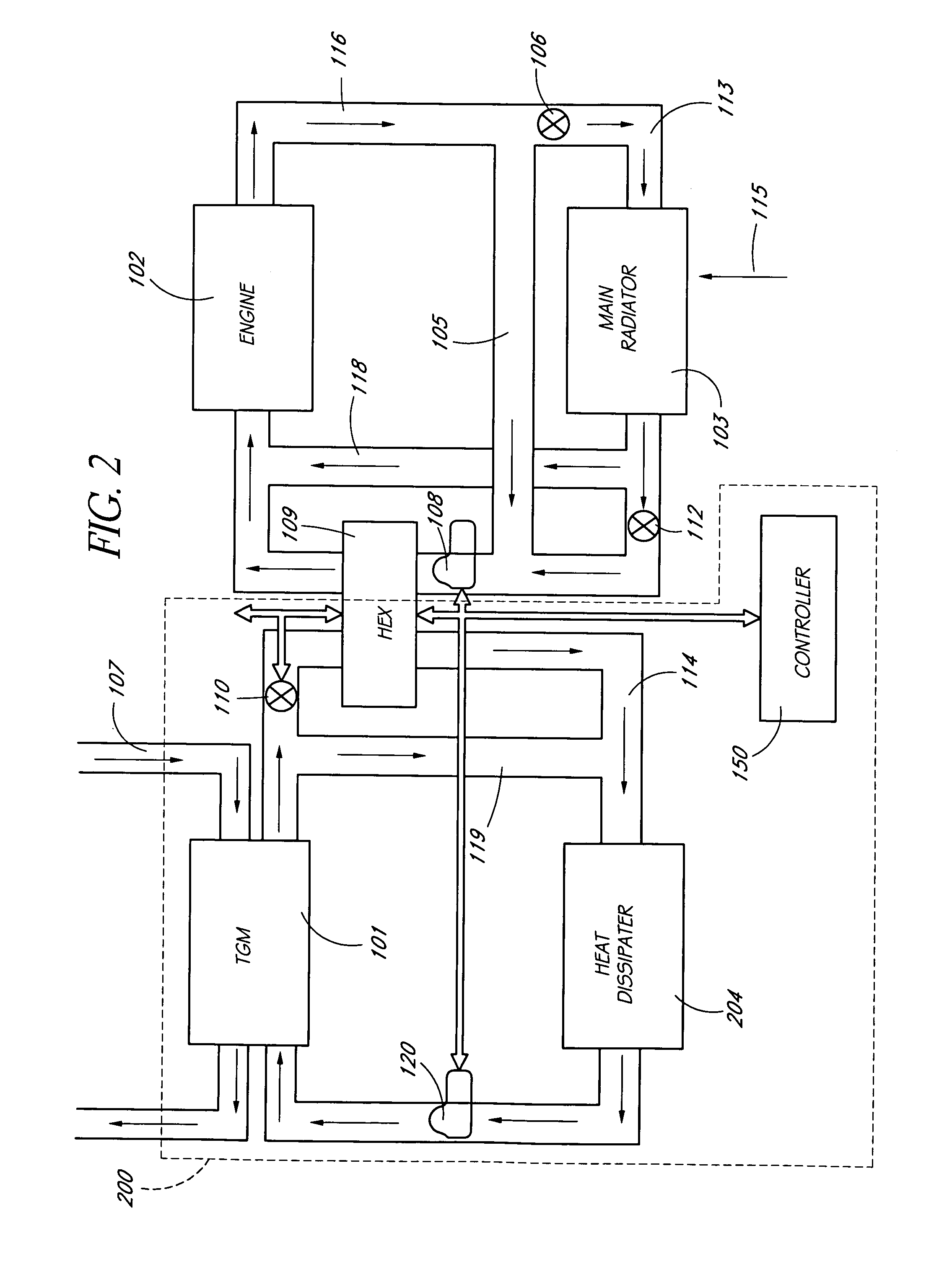

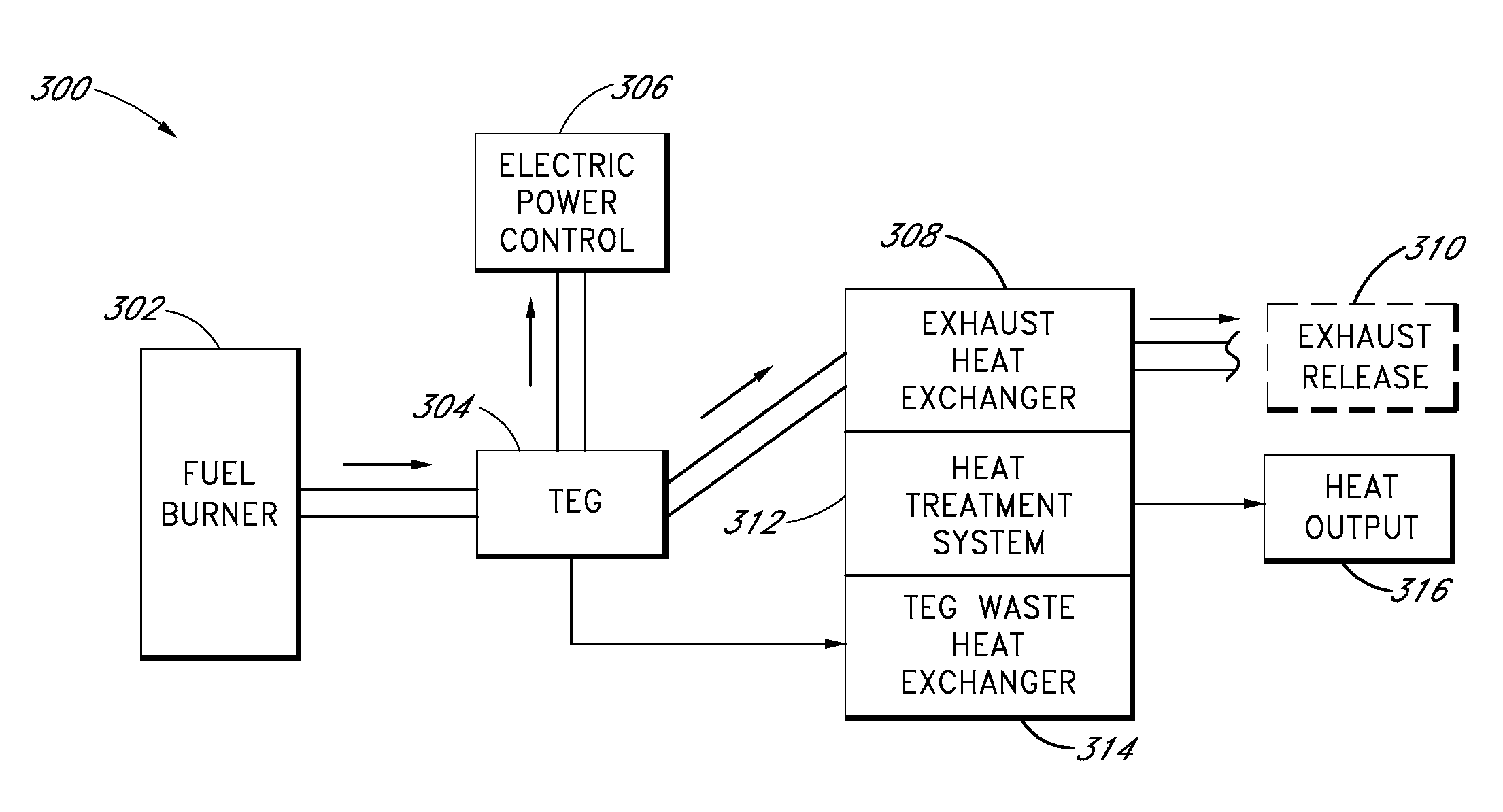

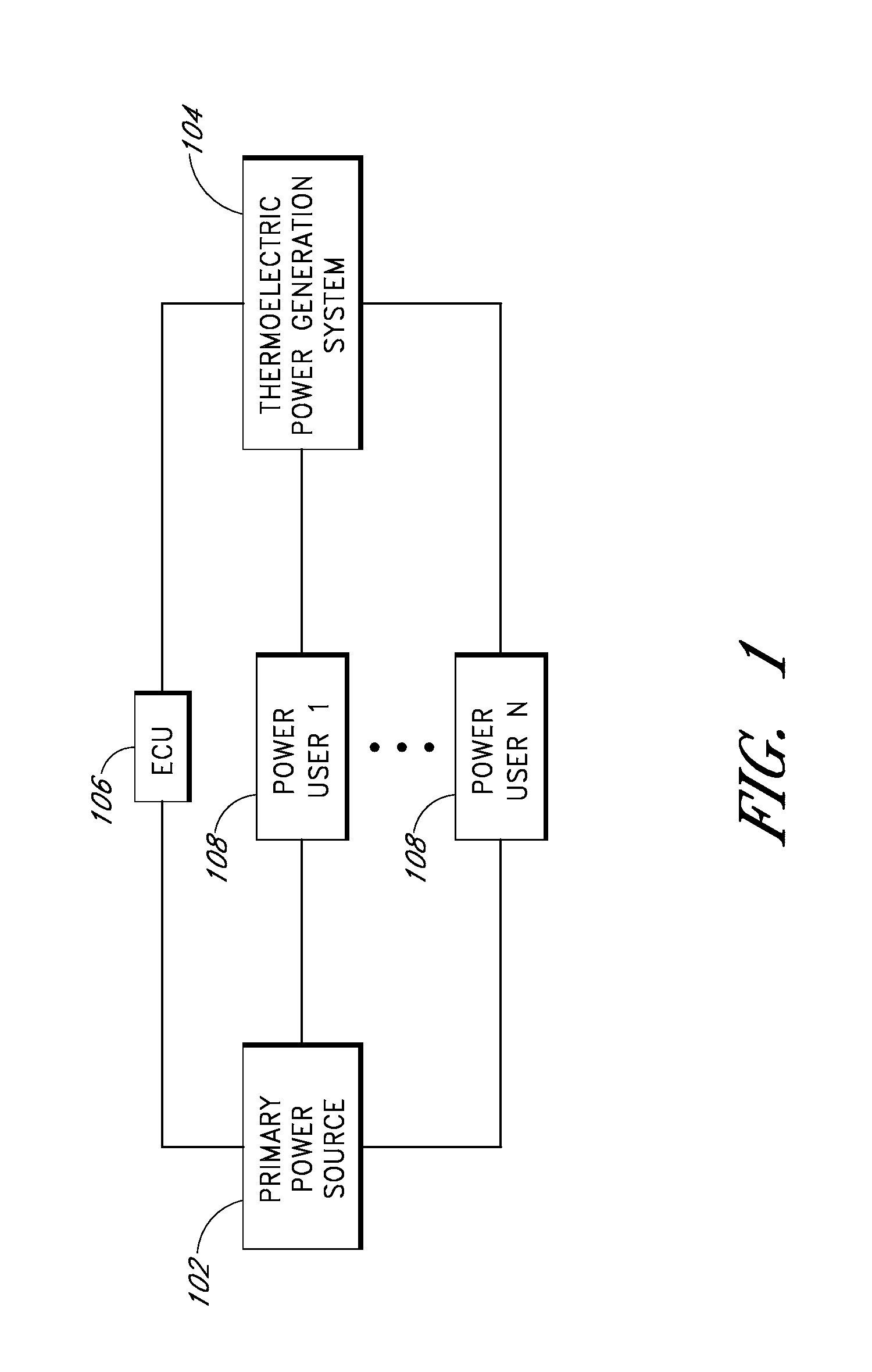

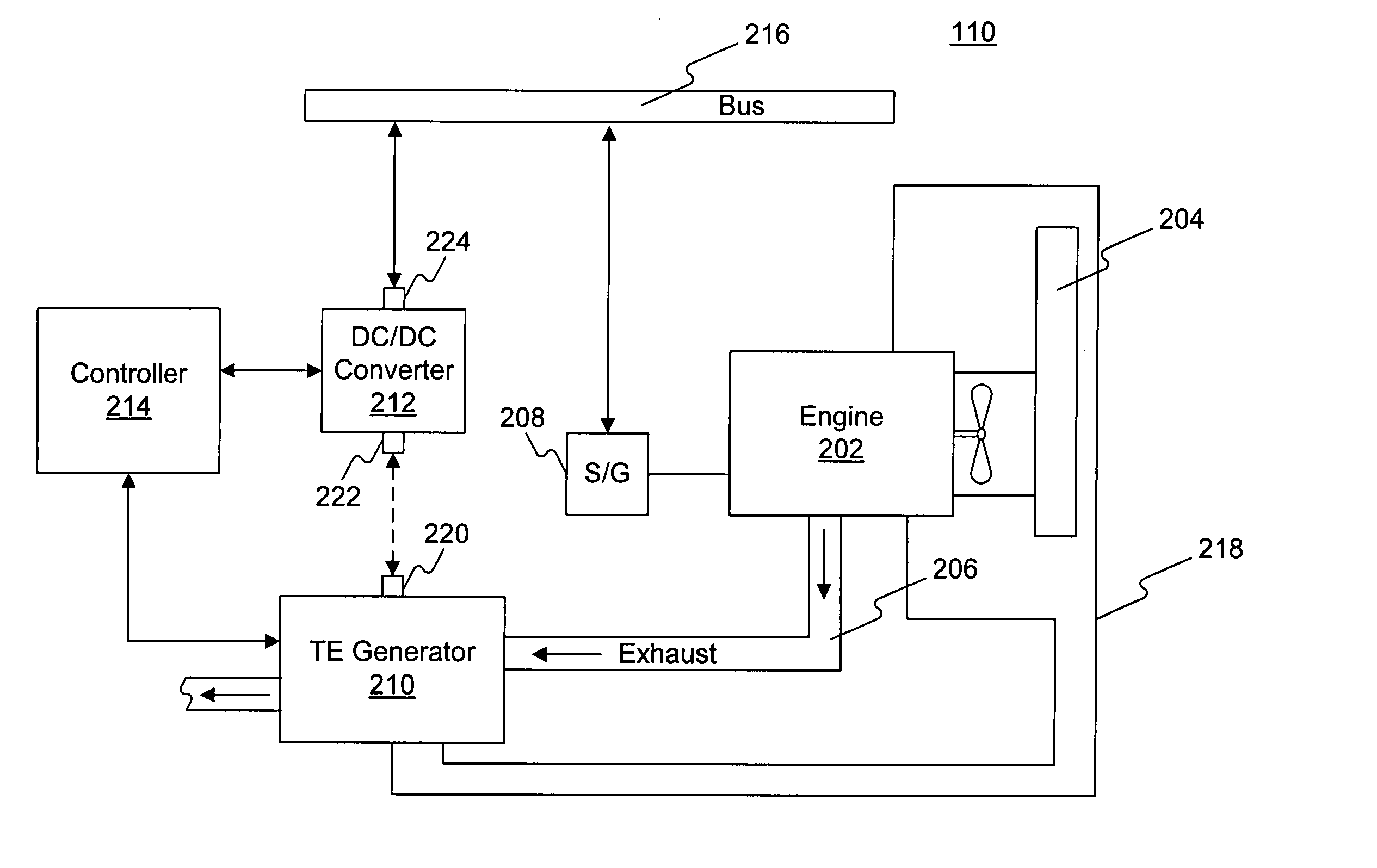

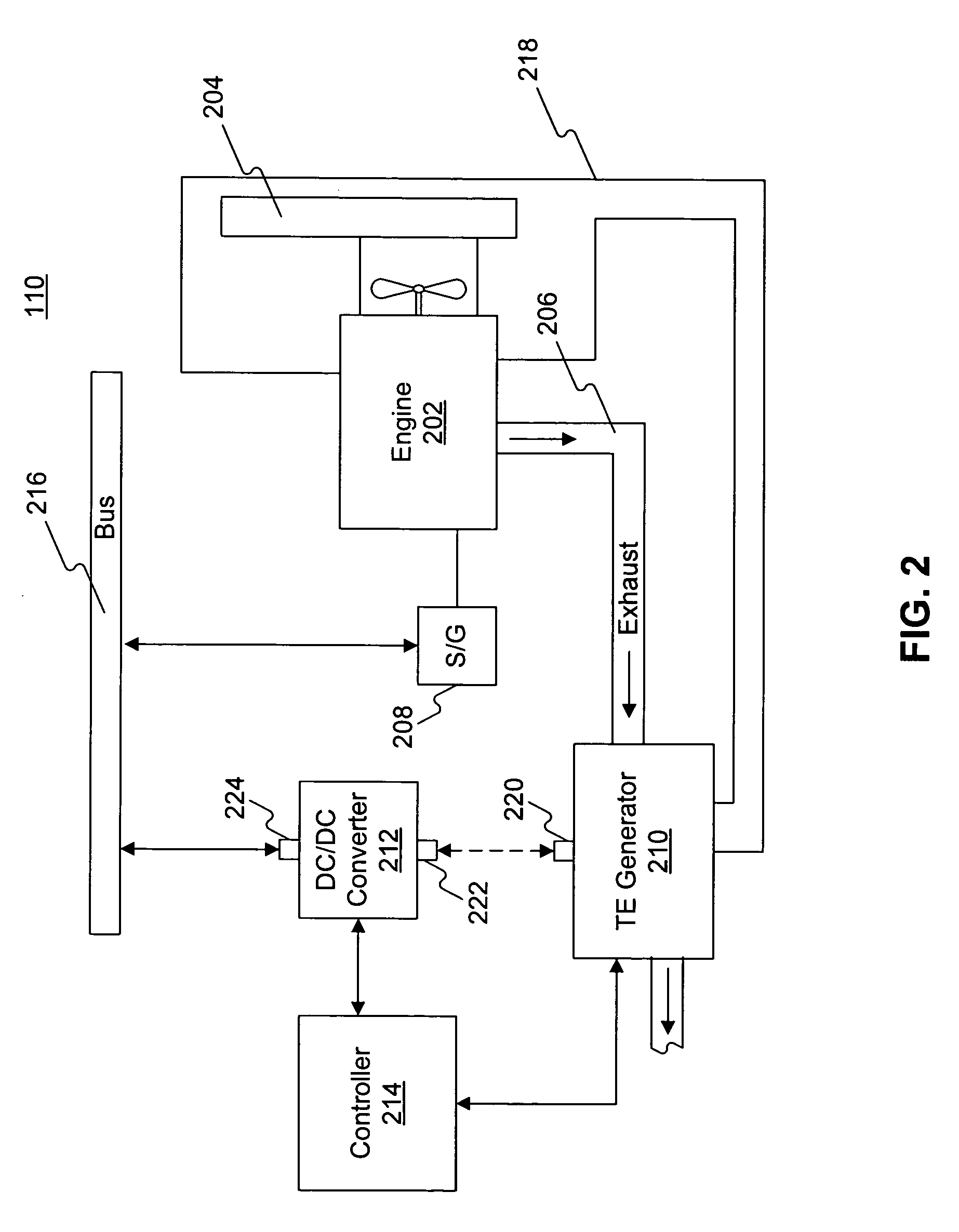

Energy management systems and methods with thermoelectric generators

InactiveUS20120111386A1Improve efficiencyImprove operationMechanical power/torque controlLevel controlElectronic controllerPower user

In some embodiments, an integrated power generation system includes a primary power source supplying power to a primary power user, a thermoelectric power generator system thermally coupled to a heat source, and an electronic controller unit. In certain embodiments, an electronic controller unit monitors the power output of the primary power source and operatively connects the thermoelectric power generating system to the primary power user when one or more power usage factors occurs. One power usage factor that can occur is the power output of the primary power source falling below a threshold power level.

Owner:GENTHERM INC

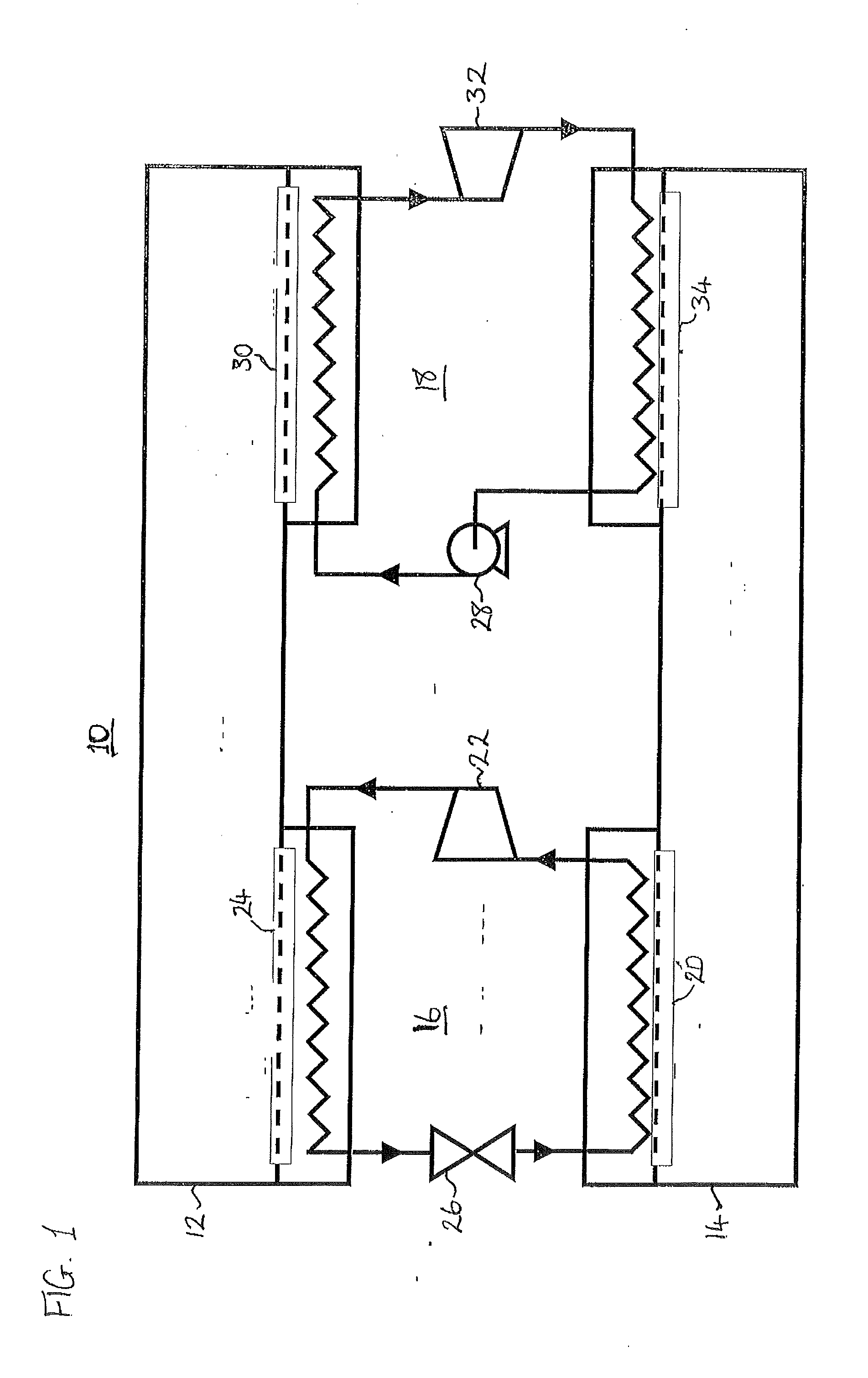

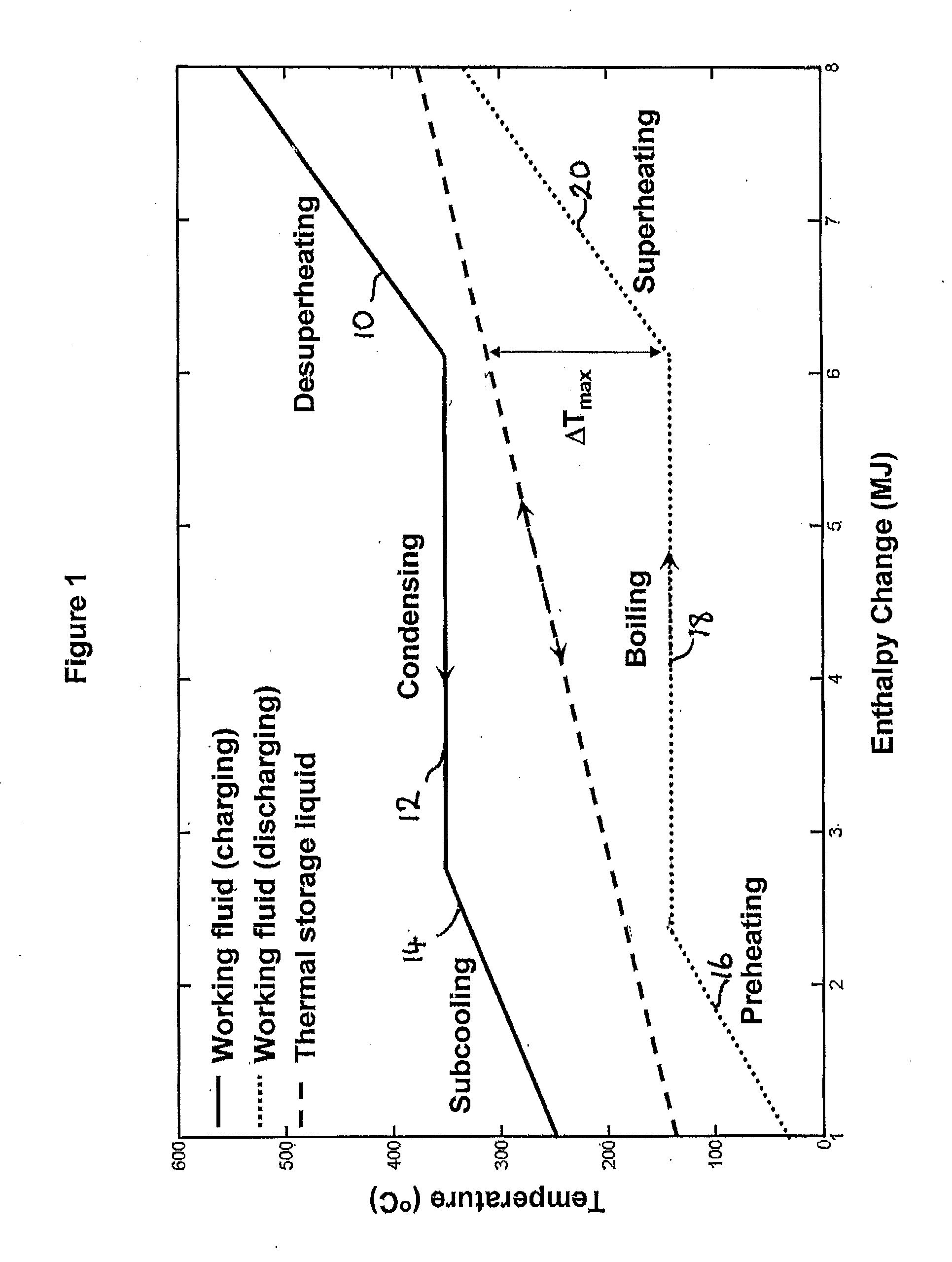

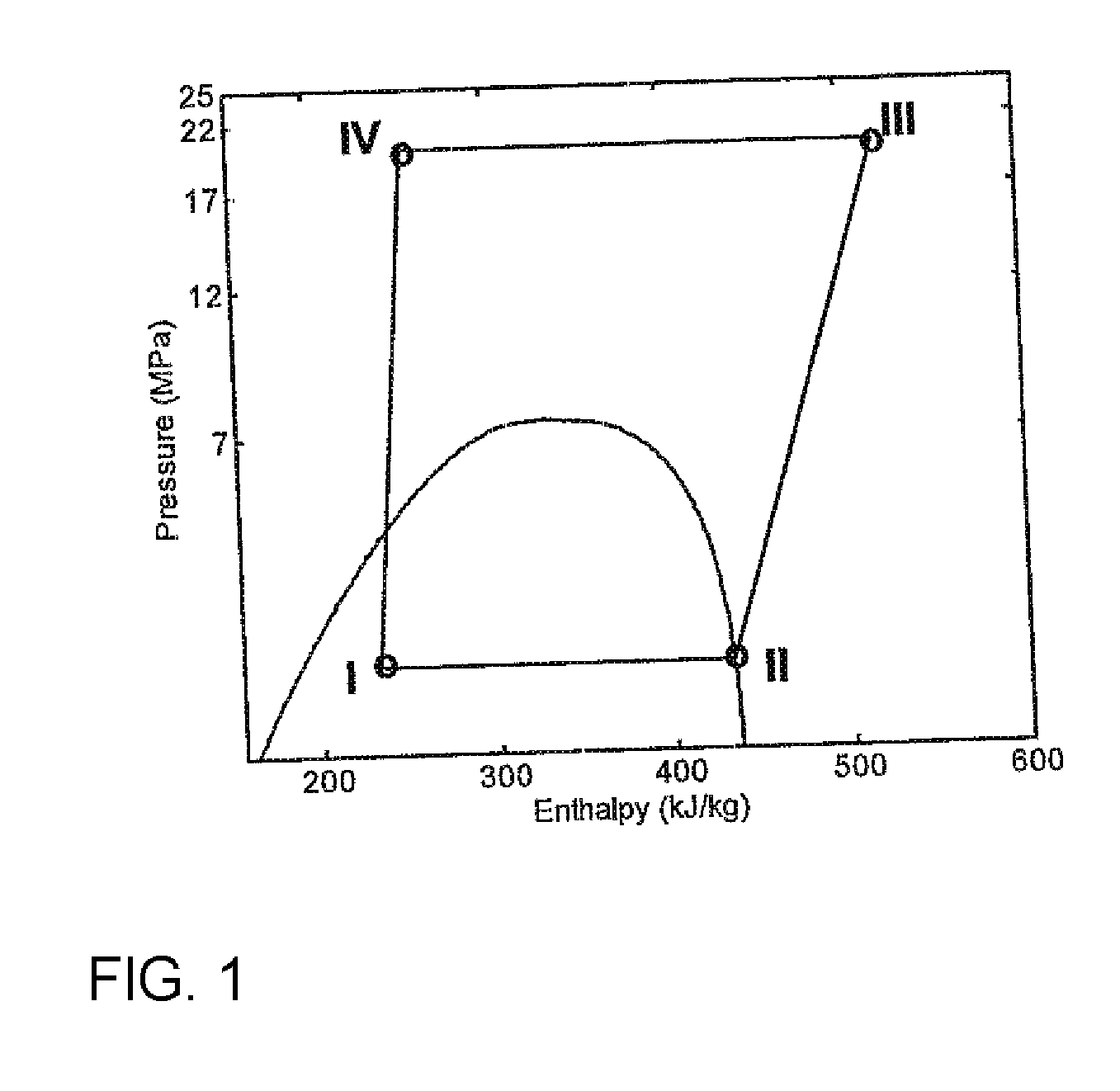

Thermoelectric energy storage system and method for storing thermoelectric energy

InactiveUS20110139407A1Suitable for storageIndirect heat exchangersHeat-exchange elementsWorking fluidThermal energy storage

A system and method for thermoelectric energy storage are disclosed. A thermoelectric energy storage system can include a heat exchanger which contains a thermal storage medium, and a working fluid circuit for circulating a working fluid through the heat exchanger for heat transfer with the thermal storage medium. The working fluid undergoes transcritical cooling during the charging and transcritical heating during the discharging cycle as it exchanges heat with the thermal storage medium. Improved roundtrip efficiency can be achieved through minimizing the maximum temperature difference (ΔTmax) between the working fluid and the thermal storage medium during operating cycles.

Owner:ABB RES LTD

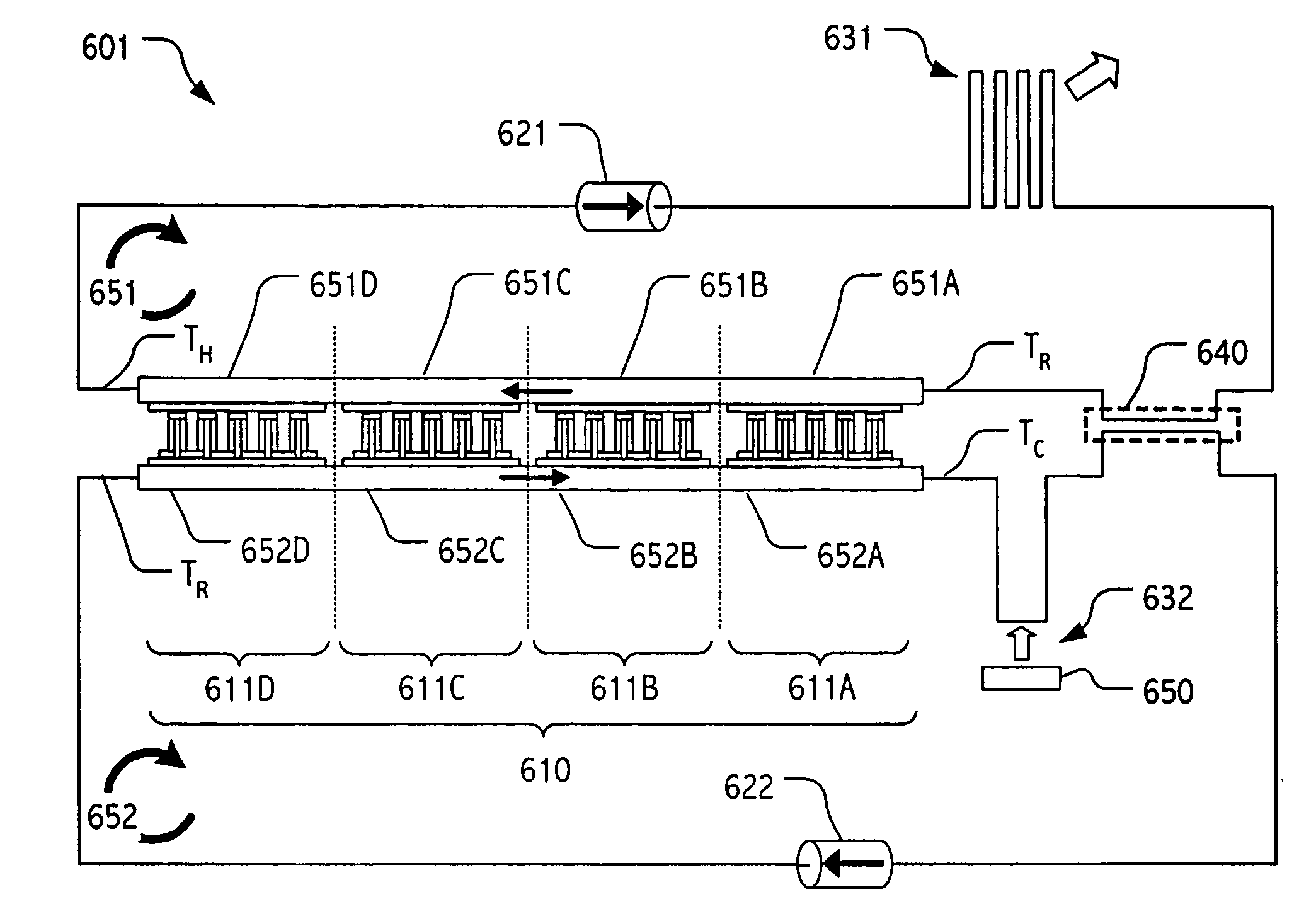

System employing temporal integration of thermoelectric action

InactiveUS7475551B2Thermoelectric device with peltier/seeback effectMachines using electric/magnetic effectsThermoelectric materialsCold side

Active cooling technologies such as thermoelectrics can be used to introduce thermal “gain” into a cooling system and, when employed in combination with forced flow cooling loops, can provide an attractive solution for cooling high heat flux density devices and / or components. In such configurations, it can be advantageous to discontinuously flow thermal transfer fluid into thermal contact with the hot or cold side of a thermoelectric module (TEM), allow it to dwell while heat is transferred from or to the TEM, and resume the flow. In configurations in which the TEM operation is itself discontinuous, various relationships between thermal transfer fluid flow and TEM operation can be advantageously employed to temporally integrate thermoelectric action.

Owner:ZAGORIN OBRIEN GRAHAM

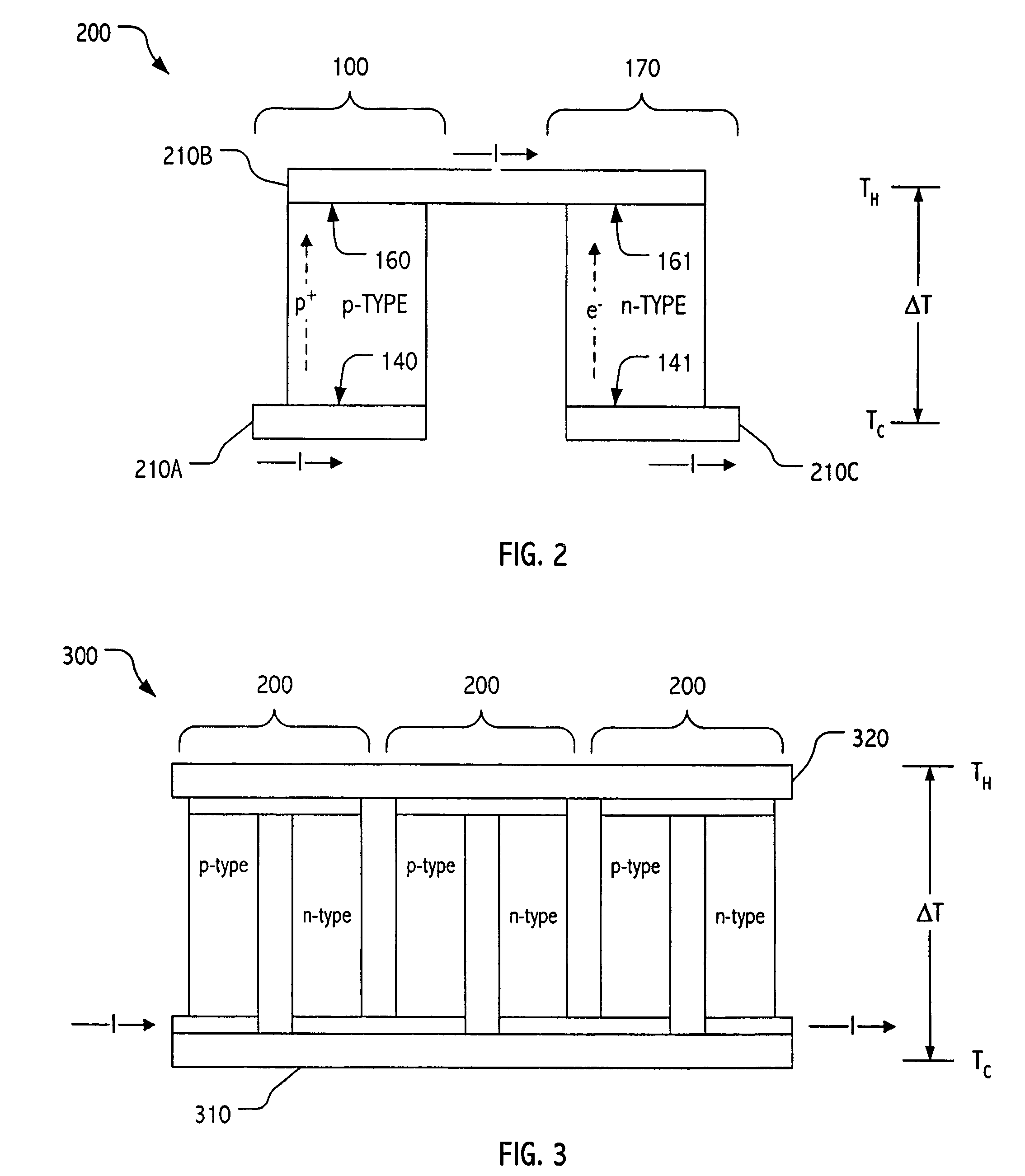

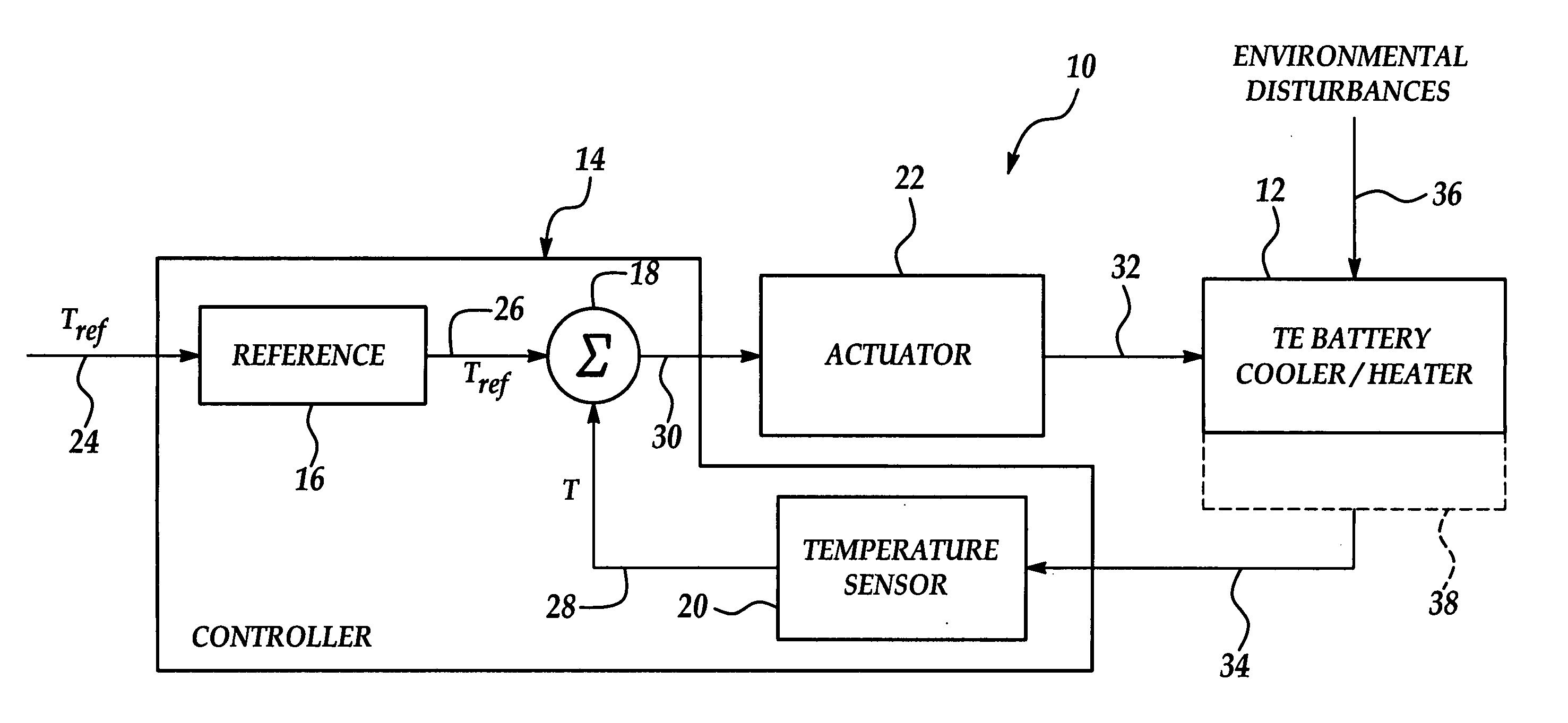

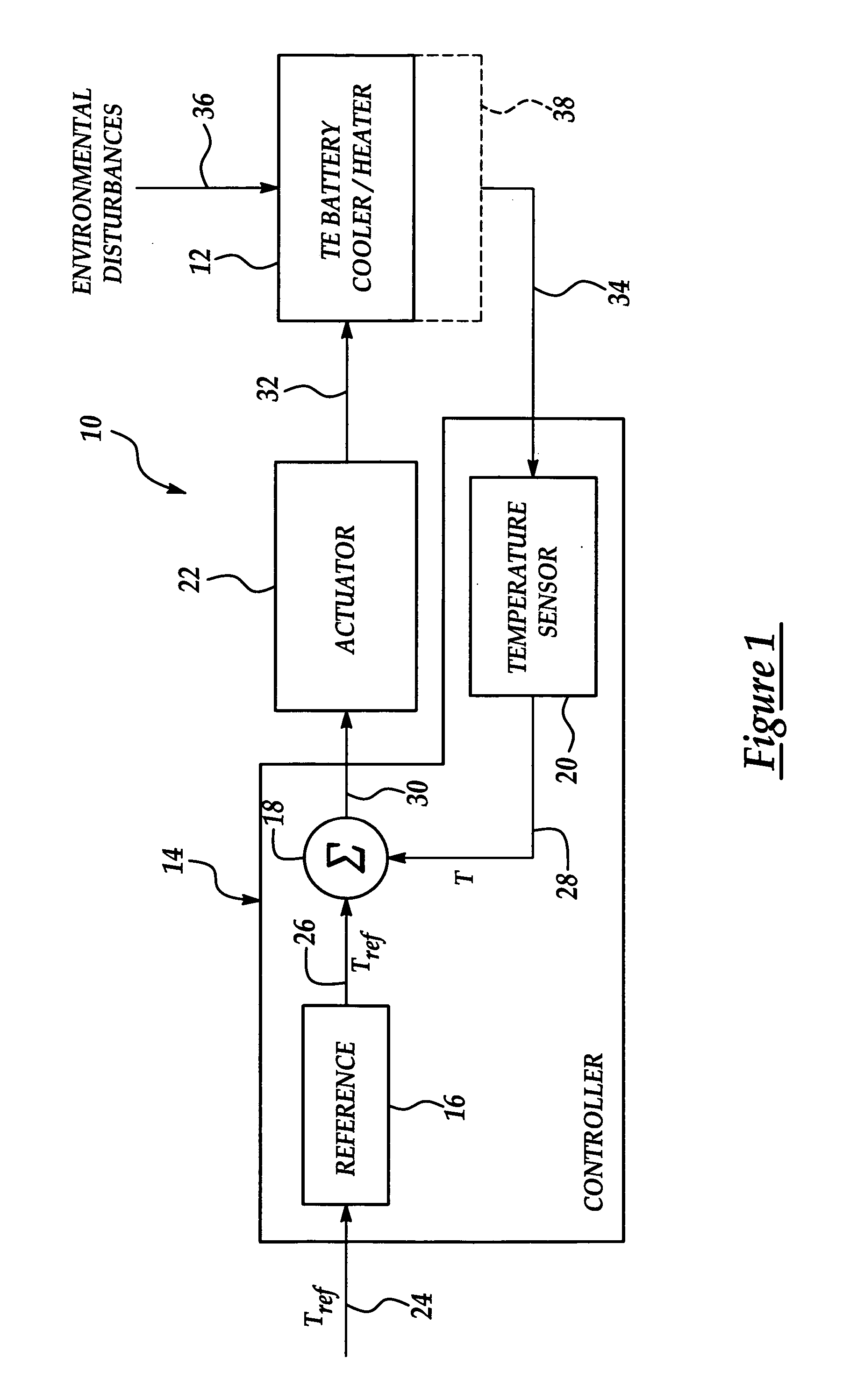

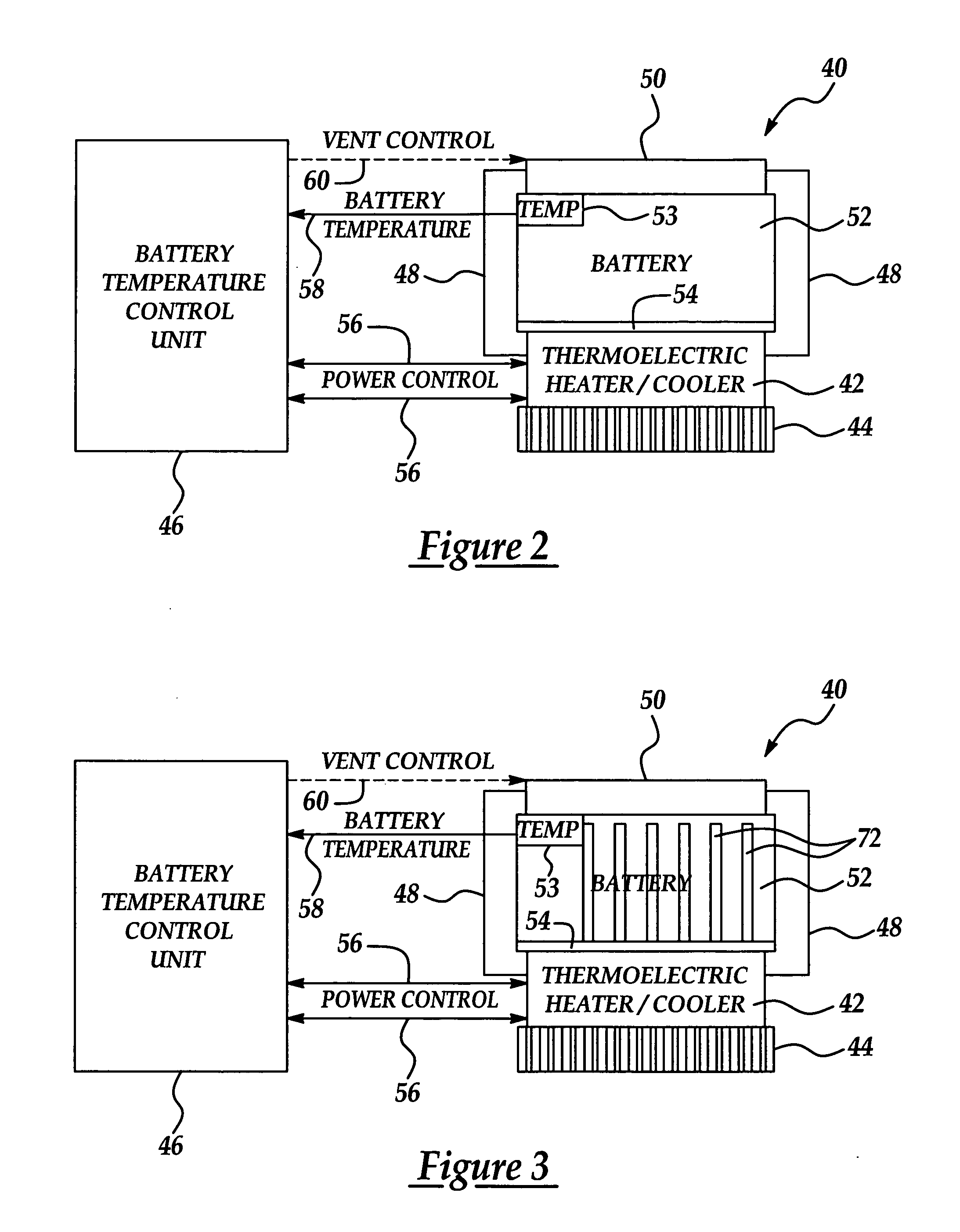

Thermoelectric methods to control temperature of batteries

InactiveUS20060028182A1Batteries circuit arrangementsSecondary cellsThermoelectric generatorElectrical and Electronics engineering

Owner:GENERAL MOTORS COMPANY

Thermoelectric material and thermoelectric converting element using the same

Compounds are expressed by general formula of AxBC2-y where 0<=x<=2 and 0<=y<1, and have CdI2 analogous layer structures; A-site is occupied by at least one element selected from the group consisting of Li, Na, K, Rb, Cs, Mg, Ca, Sr, Ba, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Zr, Nb, Mo, Ru, Rh, Pd, Ag, Cd, Hf, Ta, W, Re, Ir, Pt, Au, Sc, rare earth elements containing Y, B, Al, Ga, In, Tl, Sn, Pb and Bi; B-site is occupied by at least one element selected from the group consisting of Ti, V, Cr, Zr, Nb, Mo, Hf, Ta, W, Ir, and Sn; C-site is occupied by at least one element selected from the group consisting of S, Se and Te; the compounds exhibit large figure of merit so as to be preferable for thermoelectric generator / refrigerator.

Owner:NEC CORP

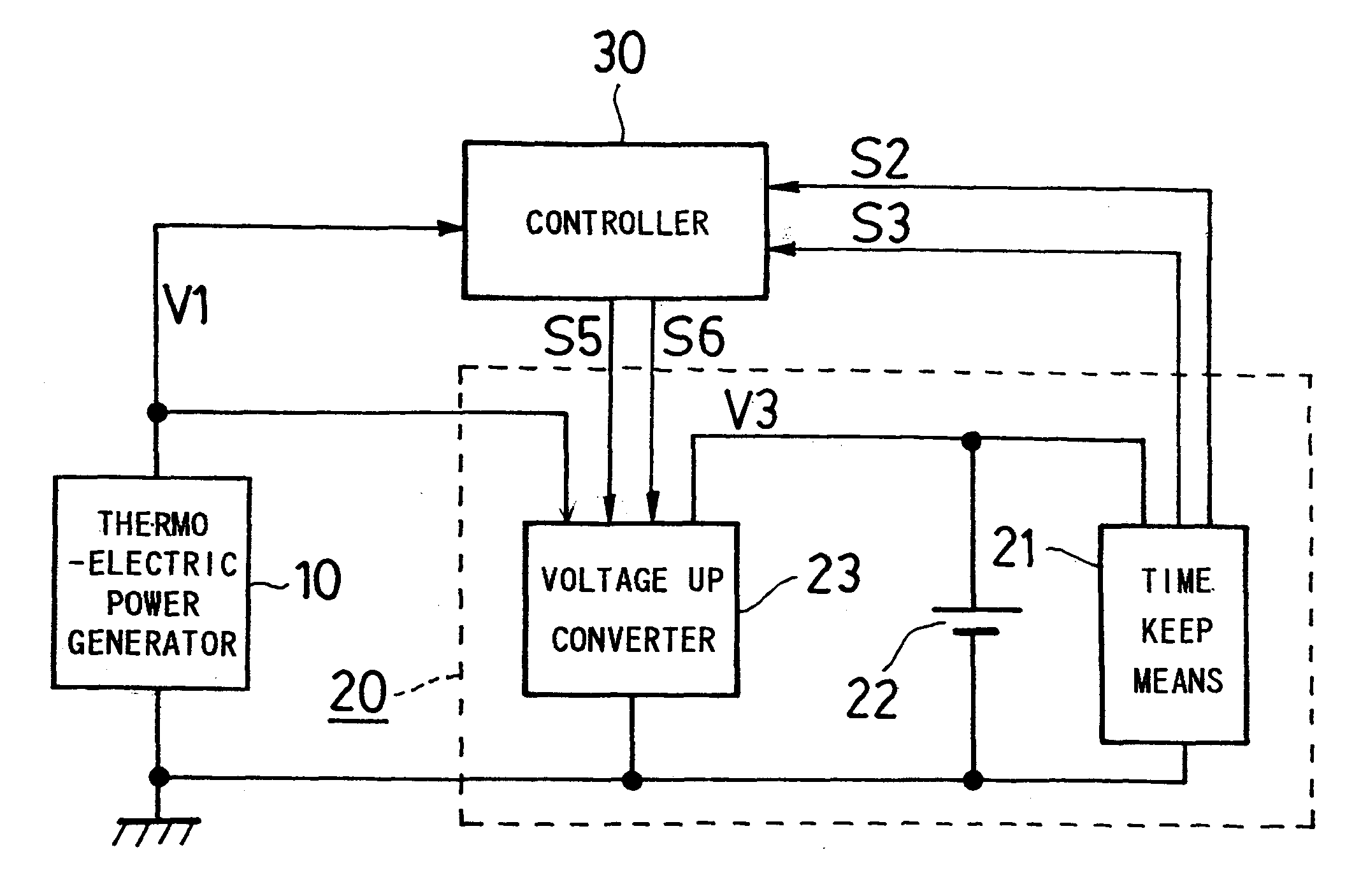

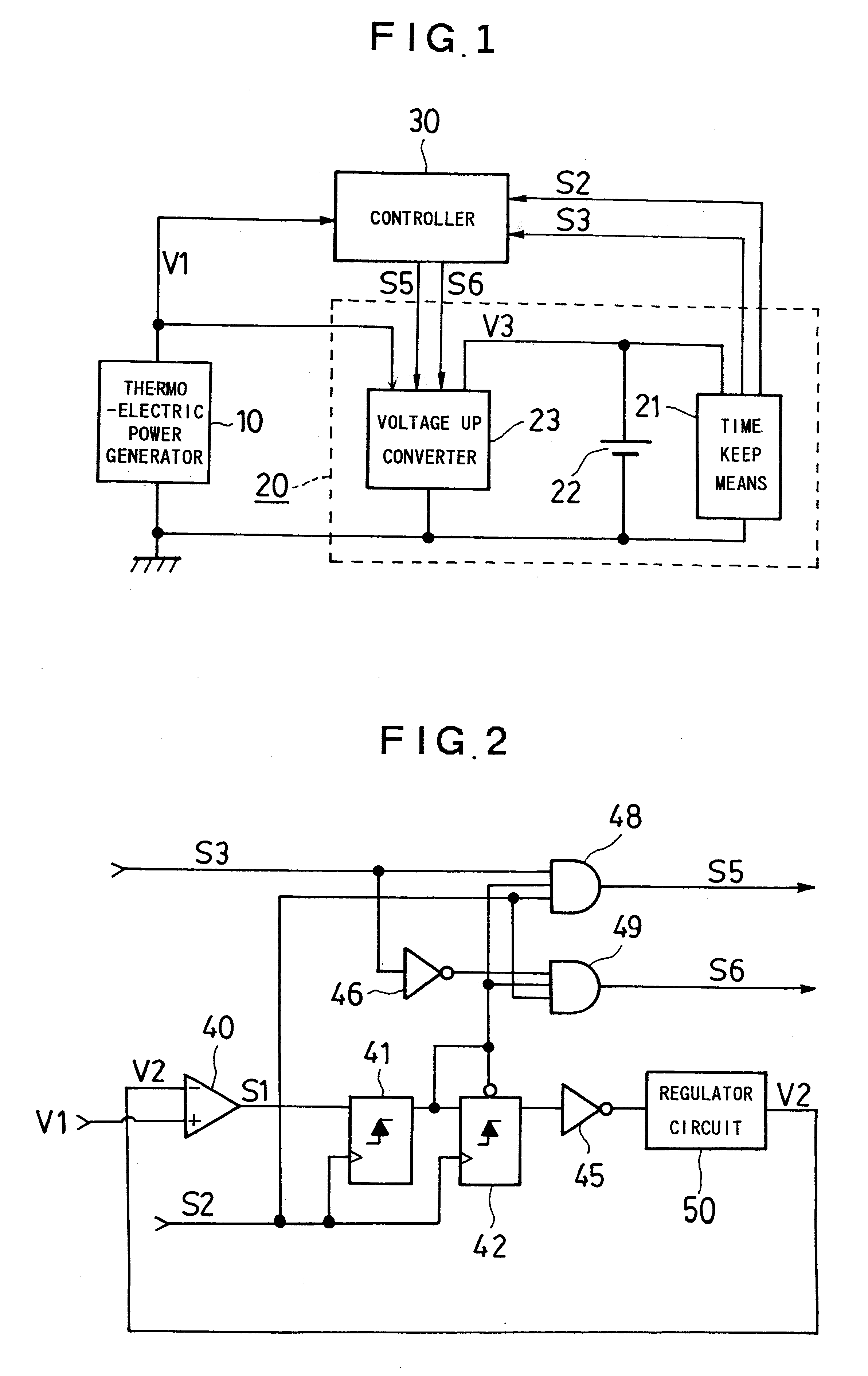

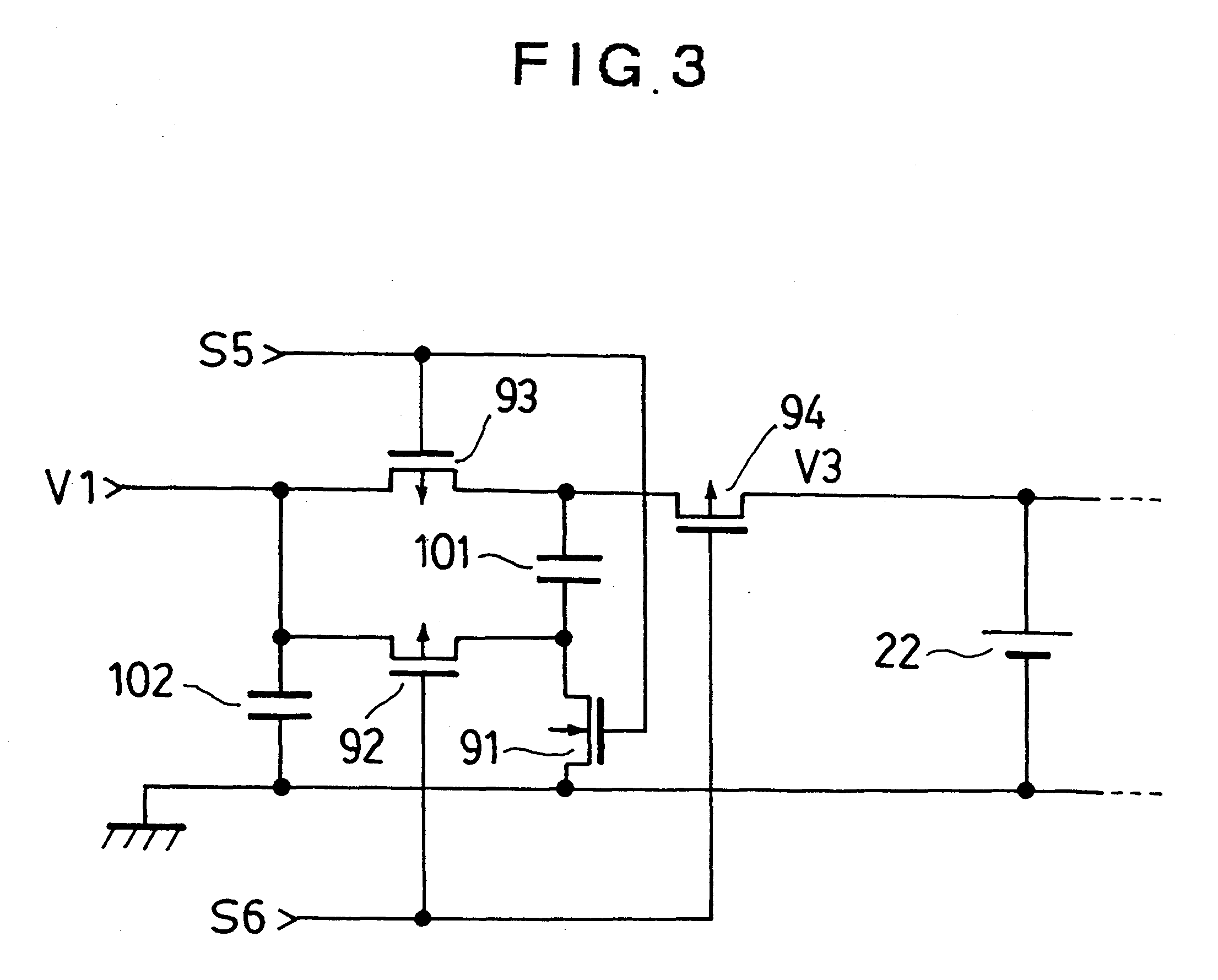

Thermoelectric generator and control system

InactiveUS20060118157A1Batteries circuit arrangementsThermoelectric device with peltier/seeback effectDc dc converterControl system

A method is provided for use in a thermoelectric generator control system including a thermoelectric generator, a DC-DC converter, and a controller. The method may include monitoring a voltage output of the thermoelectric generator and determining a voltage change on the voltage output. The method may also include calculating an adjustment for the DC-DC converter in response to the voltage change on the voltage output such that an output voltage from the DC-DC converter remains at a predetermined voltage level. Further, the method may include applying the adjustment to the DC-DC converter.

Owner:CATERPILLAR INC

Thermoelectric system

InactiveUS6232543B1Guaranteed effective useEfficient use ofThermoelectric device with peltier/seeback effectElectric windingElectricityControl power

In order to optimally control supply of electric power to a load means and efficiently utilize generated energy of a thermoelectric power generator in consideration of influence of the Peltier effect against generated voltage of the thermoelectric power generator, a thermoelectric system is structured by connecting a load means (20) utilizing the generated power of the thermoelectric power generator (10), and a controller (30) for measuring the generated voltage (V1) of the thermoelectric power generator (10) and controlling power supply and suspension of the power supply to the load means (20) in accordance with the measured result to the thermoelectric power generator (10) provided with a plurality of thermocouples electrically in series, and a compensating means to perform measurement with compensating for the generated voltage when power is supplied from the thermoelectric power generator (10) to the load means (20) continuously for more than a predetermined period of time, is provided to the controller.

Owner:CITIZEN WATCH CO LTD

Thermoelectric energy storage system having an internal heat exchanger and method for storing thermoelectric energy

InactiveUS20120222423A1Minimized in sizeMaximizes workFeed water supplySteam accumulatorsThermal energyWorking fluid

Exemplary embodiments are directed to a thermoelectric energy storage system (TEES) and method for converting electrical energy into thermal energy to be stored and converted back to electrical energy with an improved round-trip efficiency are disclosed. The TEES includes a working fluid circuit for circulating a working fluid through a first heat exchanger and a second heat exchanger, a thermal storage medium circuit for circulating a thermal storage medium, the thermal storage medium circuit having at least one hot storage tank coupled to a cold storage tank via the first heat exchanger. The arrangement maximizes the work performed by the cycle during charging and discharging for a given maximum pressure and maximum temperature of the working fluid.

Owner:ABB RES LTD

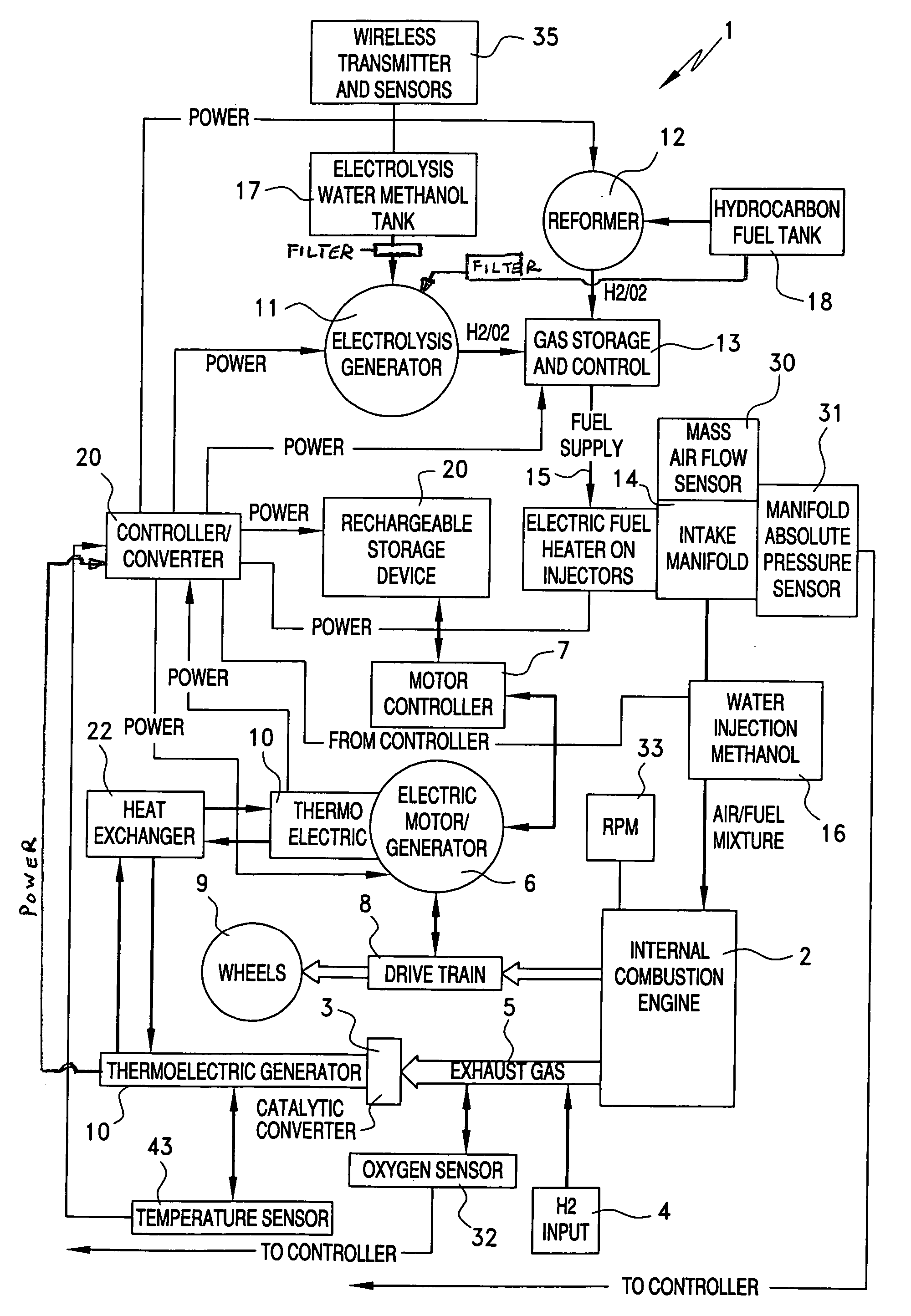

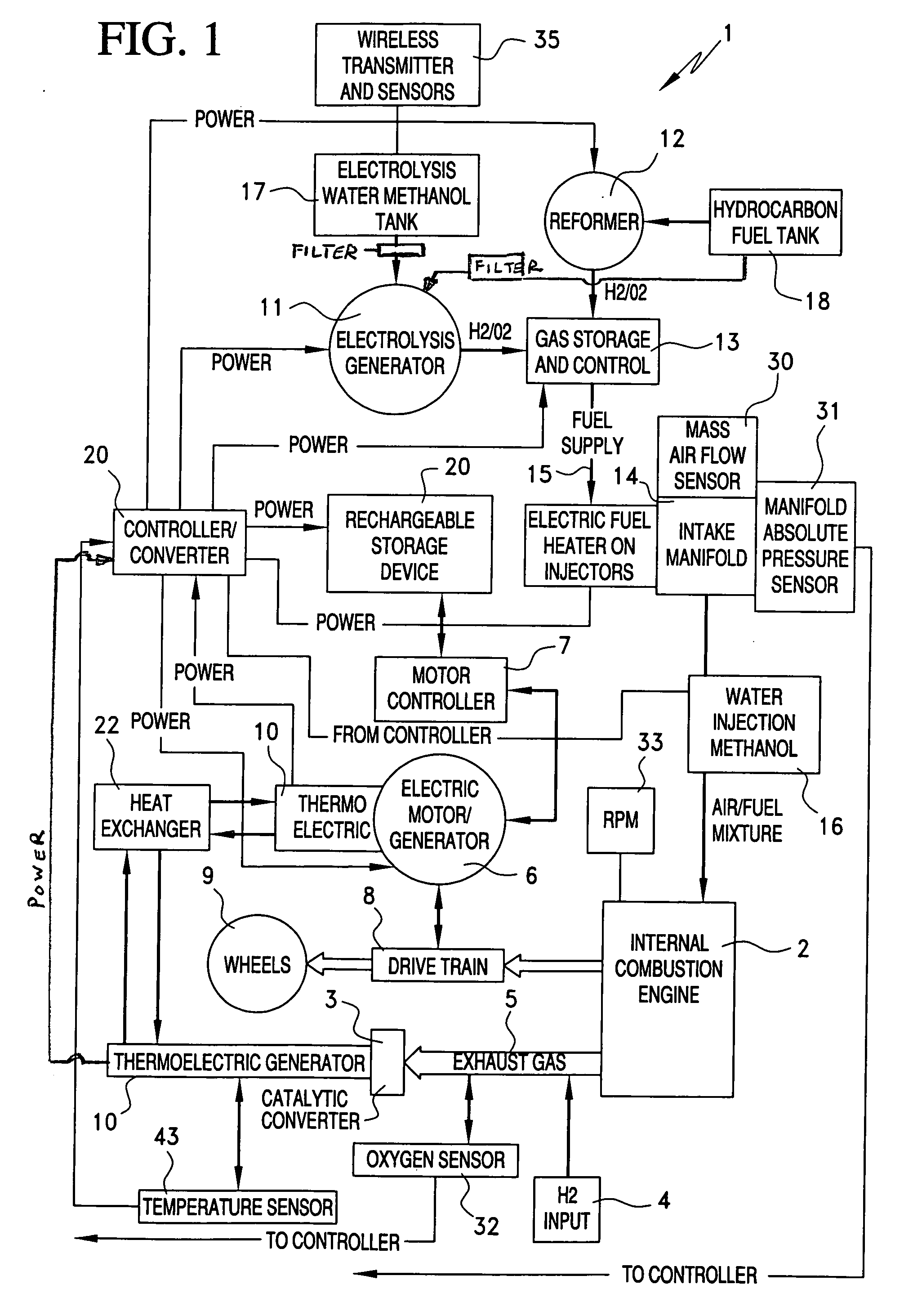

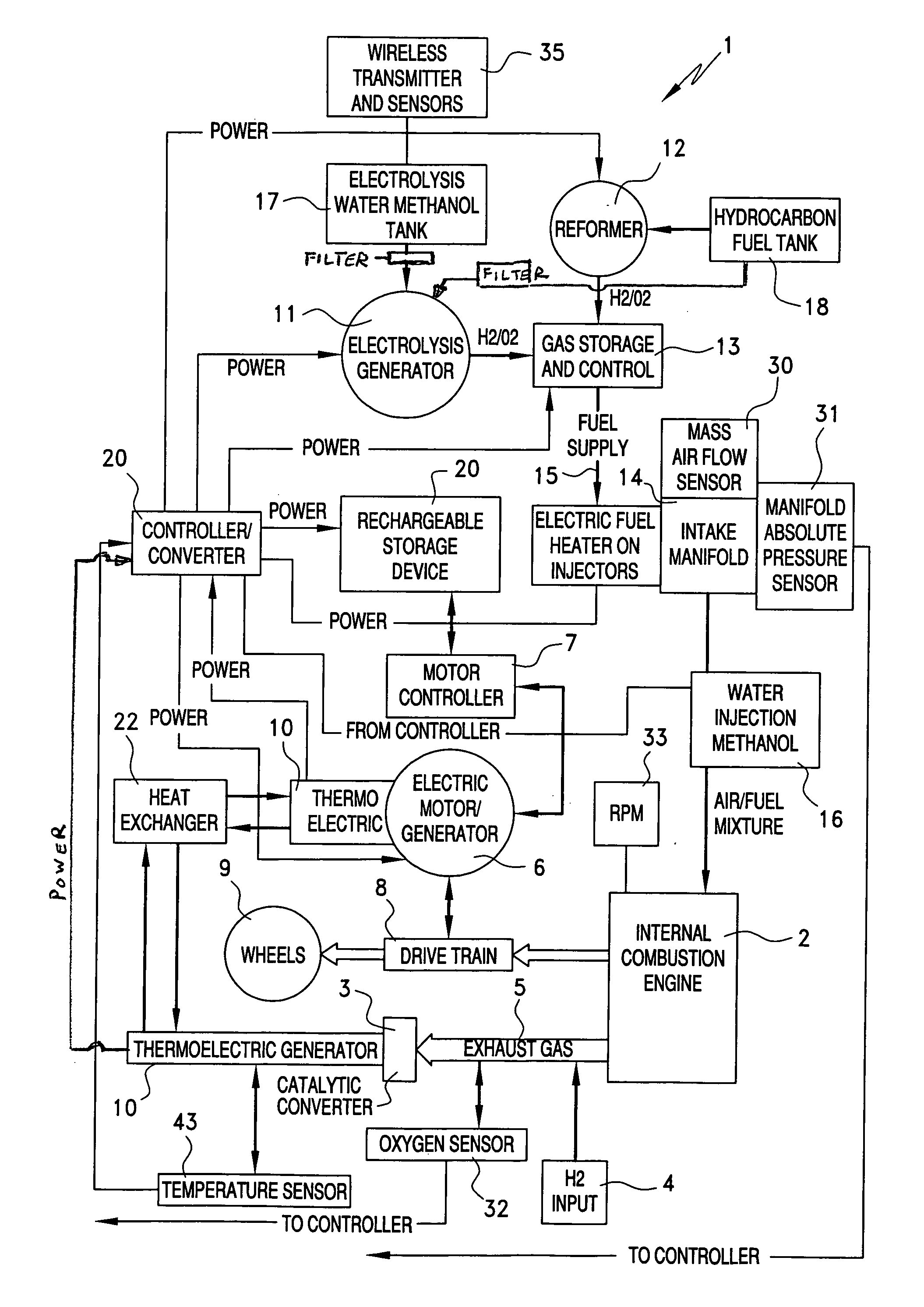

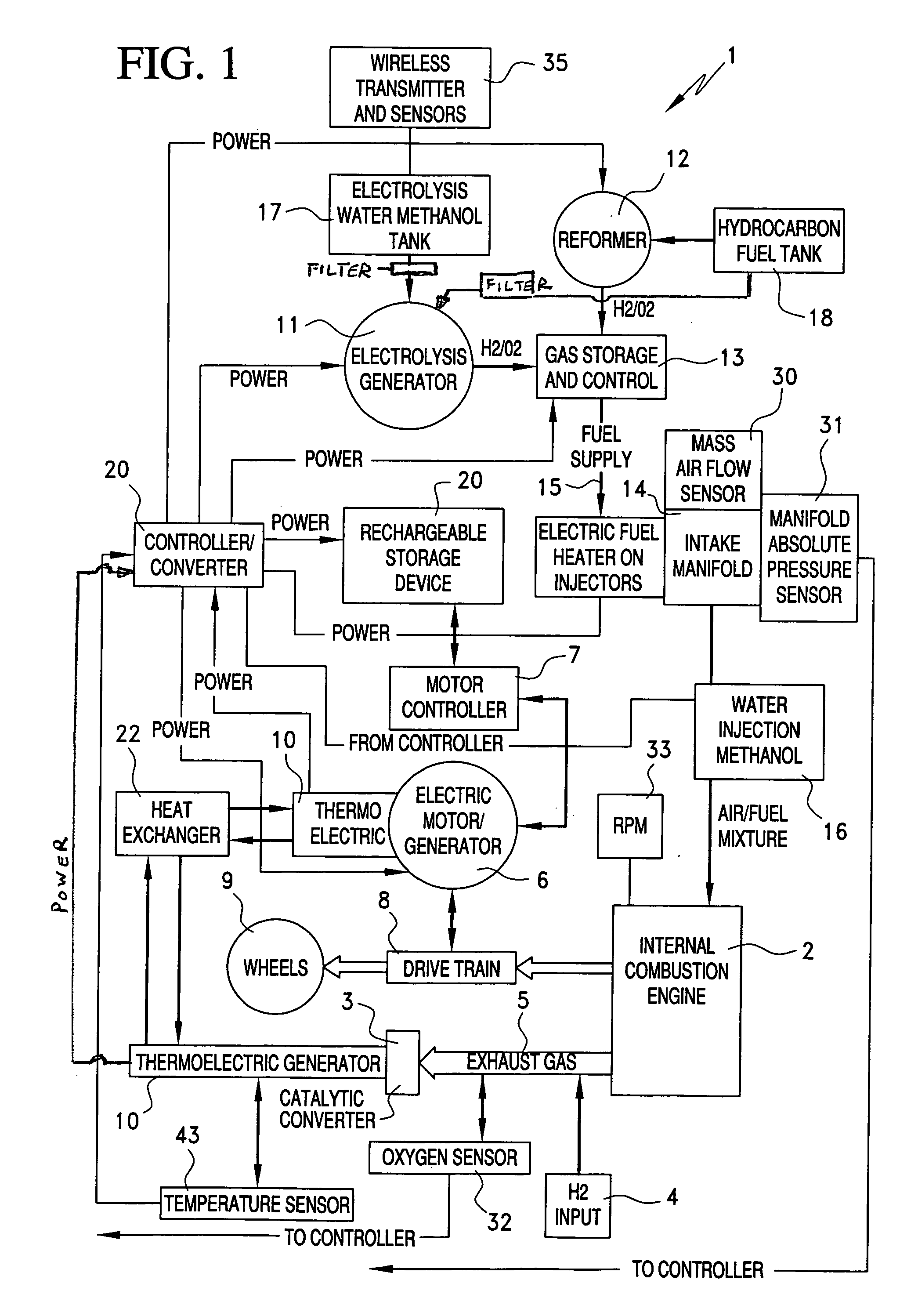

System and method for reducing vehicle emissions and/or generating hydrogen

InactiveUS20060179820A1Emission reductionIncrease consumptionInternal combustion piston enginesExhaust apparatusElectricityHydrogen

Emissions from systems that use a catalytic converter are substantially reduced by introducing hydrogen, or a hydrogen containing fluid or fuel component, into the exhaust stream being scrubbed by the catalytic converter, resulting in instant lightoff and a significant reduction in emissions. Hydrogen for injection into the exhaust stream may, optionally, be generated within the vehicle using heat recovered from the catalytic converter, and / or the engine or elsewhere in the exhaust system, by a thermoelectric generator, the electrical output of which may be used to perform electrolysis and / or to power a reformer in order to generate the hydrogen. The thermoelectric generator may be retrofit onto the catalytic converter, or integrated in a way that enhances thermoelectric generation, including providing a catalyst coated heat sink and integrated cooling pipes to enhance the thermal differential required for thermoelectric generation. Sensors such as an oxygen sensor and temperature sensor may be provided to assess converter performance and adjust the temperature differential to ensure that the temperature of the converter remains optimum.

Owner:SULLIVAN JOHN TIMOTHY

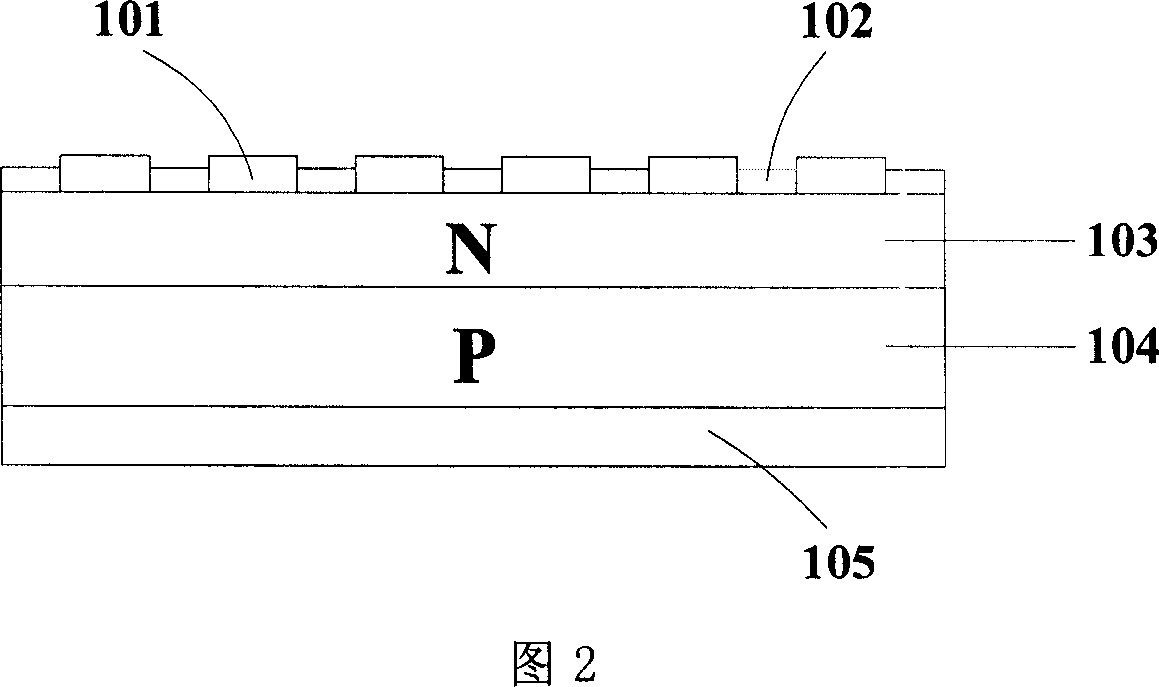

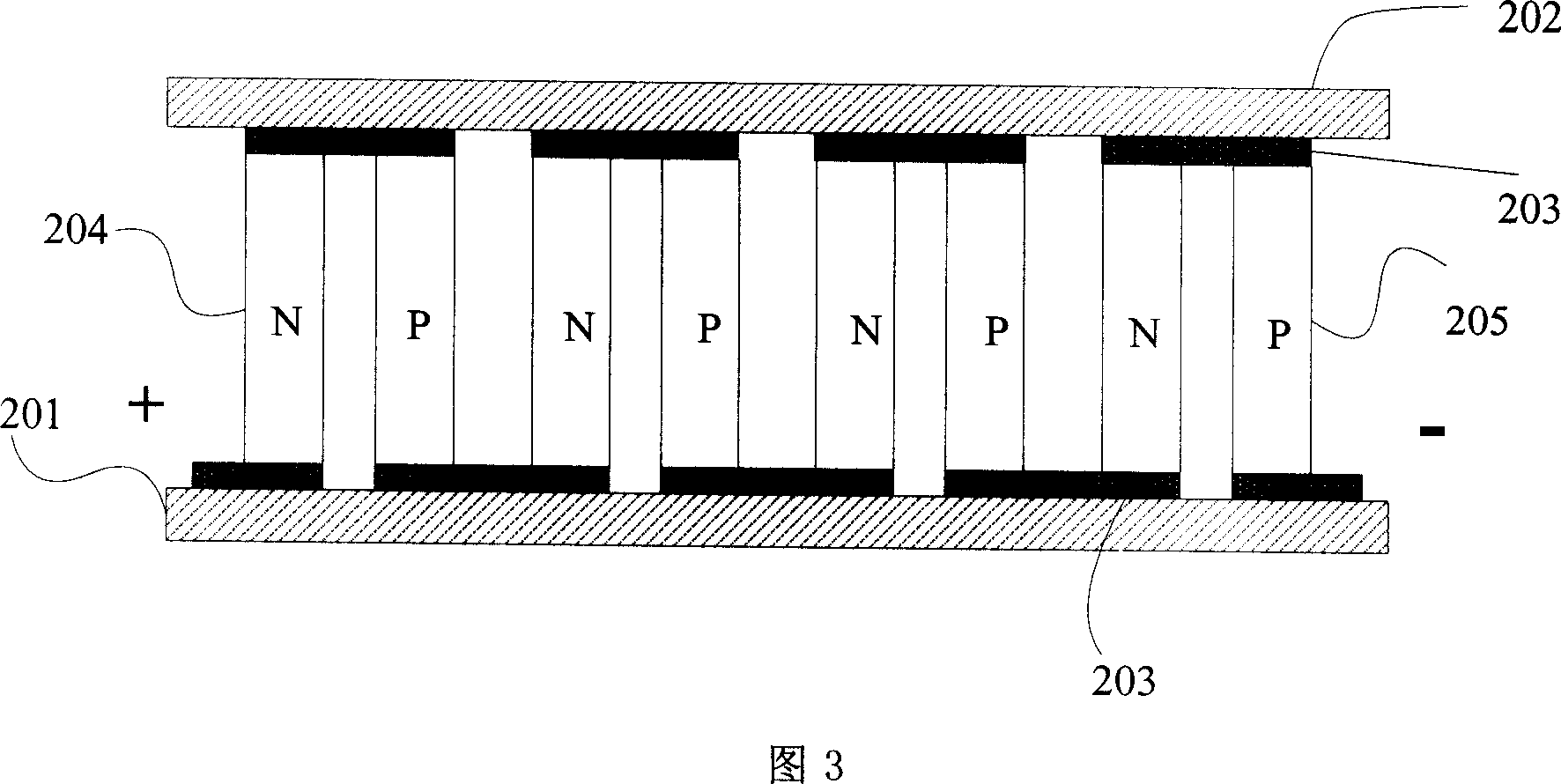

Power generation system of hybrid energy sources based on photovoltaic effect, and thermoelectric effect of solar energy

InactiveCN1960118ASolve insulation problemsSolve heat transferBatteries circuit arrangementsPV power plantsEngineeringSilica gel

The system mainly consists of the solar energy photo-volt battery (PV) and the semi-conductor thermo electric generator module (SG). The hot end insulated heat-lead board of SG contacts with the bottom electrode of PV via the heat-lead silica gel. PV and SG connect to the power supply circuit via a lead. The hot end insulated heat-lead board of SG contacts with the radiator via the heat-lead silica gel. The energy produced by PV and the energy output by SG and boosted by a DC / DC circuit are stored respectively into the different lithium ion batteries. Via control and distribution by the consequent power circuit, these energies are converted into the DC working voltage. The invention utilizes fully the low-level heat energy and solves the problem of PV performance under hi temperature. The invention raises the generating efficiency and extends PV life.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Thermoelectric generator

InactiveUS20050194034A1Liquid coolingThermoelectric device with peltier/seeback effectCold sideEngineering

A thermoelectric generator has a plurality of hot-side heat source portions, a plurality of cold-side heat source portions, a thermoelectric element, a hot-side communicator and a cold-side communicator. Hot fluid flows in the plurality of hot-side heat source portions, and cold fluid colder than the hot fluid flows in the plurality of cold-side heat source portions. The heat source portions are alternately stacked in such a manner of interposing the thermoelectric element between the hot-side heat source portion and the cold-side heat source portion. The hot-side communicator communicates the hot-side heat source portions, and the cold-side communicator communicates the plurality of cold-side heat source portions. Each of the hot-side communicator and the cold-side communicator has a distance adjuster for adjusting distances between the hot-side heat source portions and the cold-side heat source portions so as to bring them in contact with the thermoelectric elements in the stacking direction thereof.

Owner:DENSO CORP +1

System and method for reducing vehicle emissions and/or generating hydrogen

InactiveUS20060179819A1Emission reductionIncrease consumptionInternal combustion piston enginesExhaust apparatusElectricityHydrogen

Emissions from systems that use a catalytic converter are substantially reduced by introducing hydrogen, or a hydrogen containing fluid or fuel component, into the exhaust stream being scrubbed by the catalytic converter, resulting in instant lightoff and a significant reduction in emissions. Hydrogen for injection into the exhaust stream may, optionally, be generated within the vehicle using heat recovered from the catalytic converter, and / or the engine or elsewhere in the exhaust system, by a thermoelectric generator, the electrical output of which may be used to perform electrolysis and / or to power a reformer in order to generate the hydrogen. The thermoelectric generator may be retrofit onto the catalytic converter, or integrated in a way that enhances thermoelectric generation, including providing a catalyst coated heat sink and integrated cooling pipes to enhance the thermal differential required for thermoelectric generation. Sensors such as an oxygen sensor and temperature sensor may be provided to assess converter performance and adjust the temperature differential to ensure that the temperature of the converter remains optimum.

Owner:SULLIVAN JOHN TIMOTHY

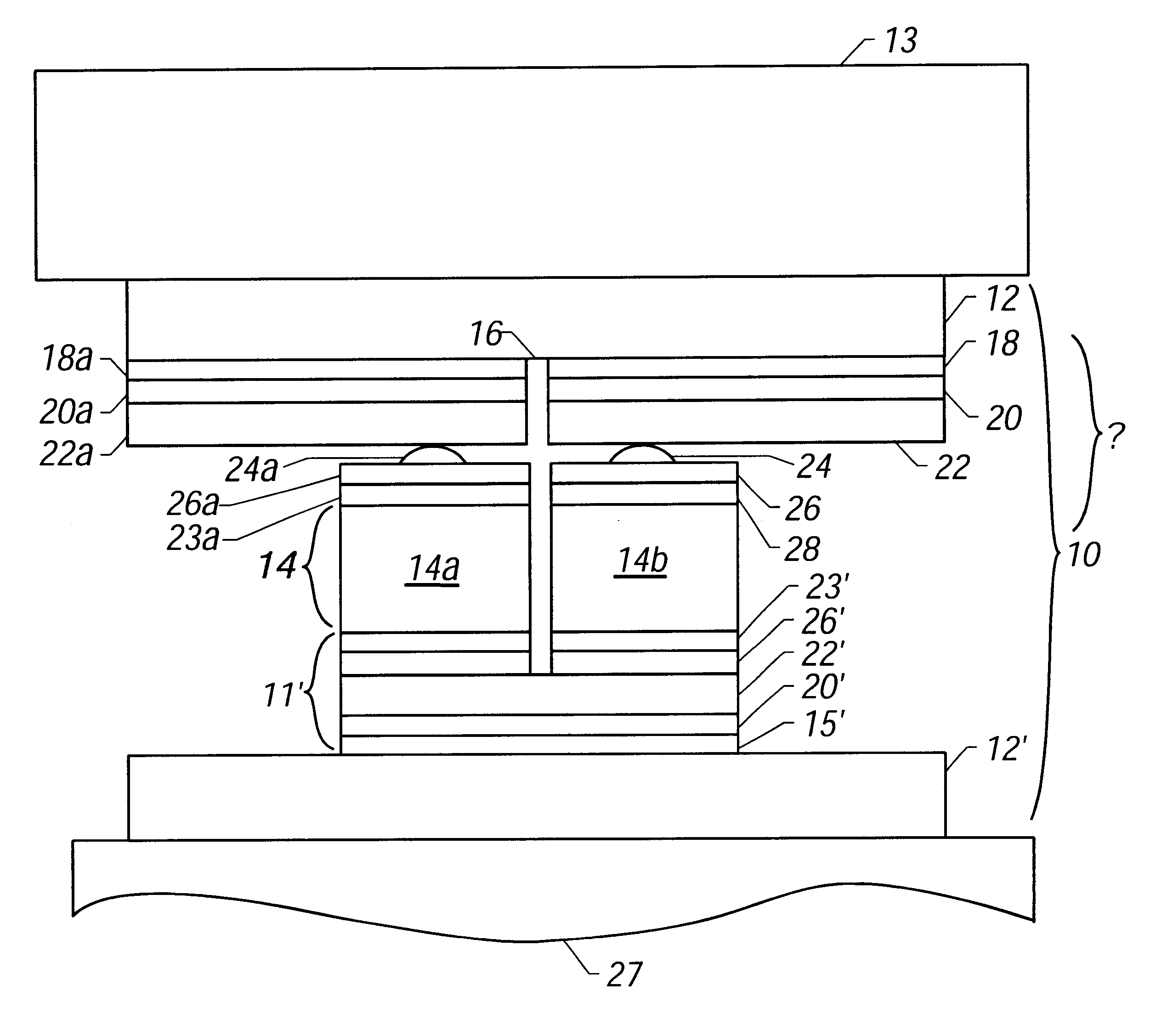

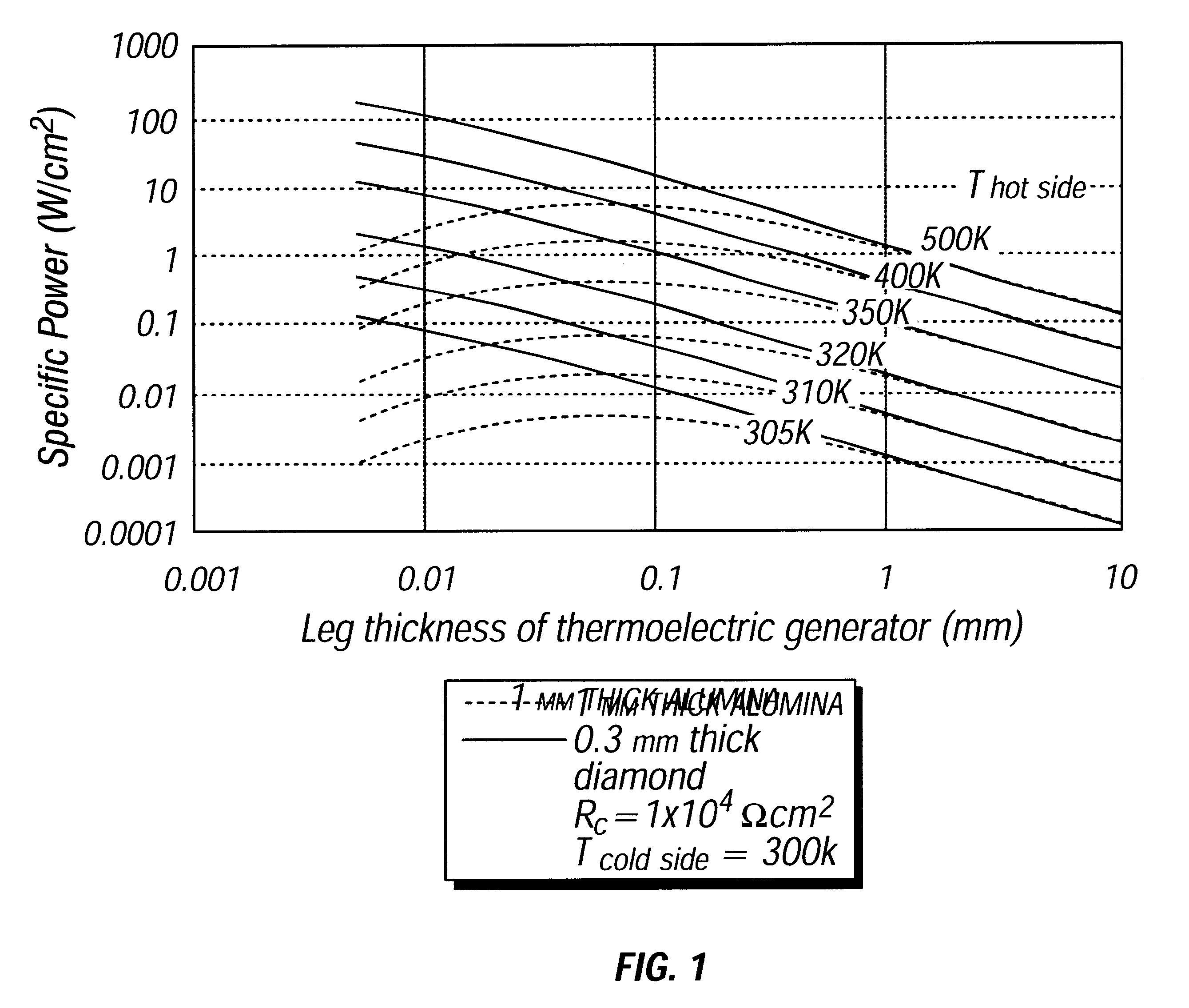

Electronic device featuring thermoelectric power generation

InactiveUS6288321B1Small sizeThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsHeat conducting

A device for generating power to run an electronic component. The device includes a heat-conducting substrate (composed, e.g., of diamond or another high thermal conductivity material) disposed in thermal contact with a high temperature region. During operation, heat flows from the high temperature region into the heat-conducting substrate, from which the heat flows into the electrical power generator. A thermoelectric material (e.g., a Bi2Te3-based film or other thermoelectric material) is placed in thermal contact with the heat-conducting substrate. A low temperature region is located on the side of the thermoelectric material opposite that of the high temperature region. The thermal gradient generates electrical power and drives an electrical component.

Owner:CALIFORNIA INST OF TECH

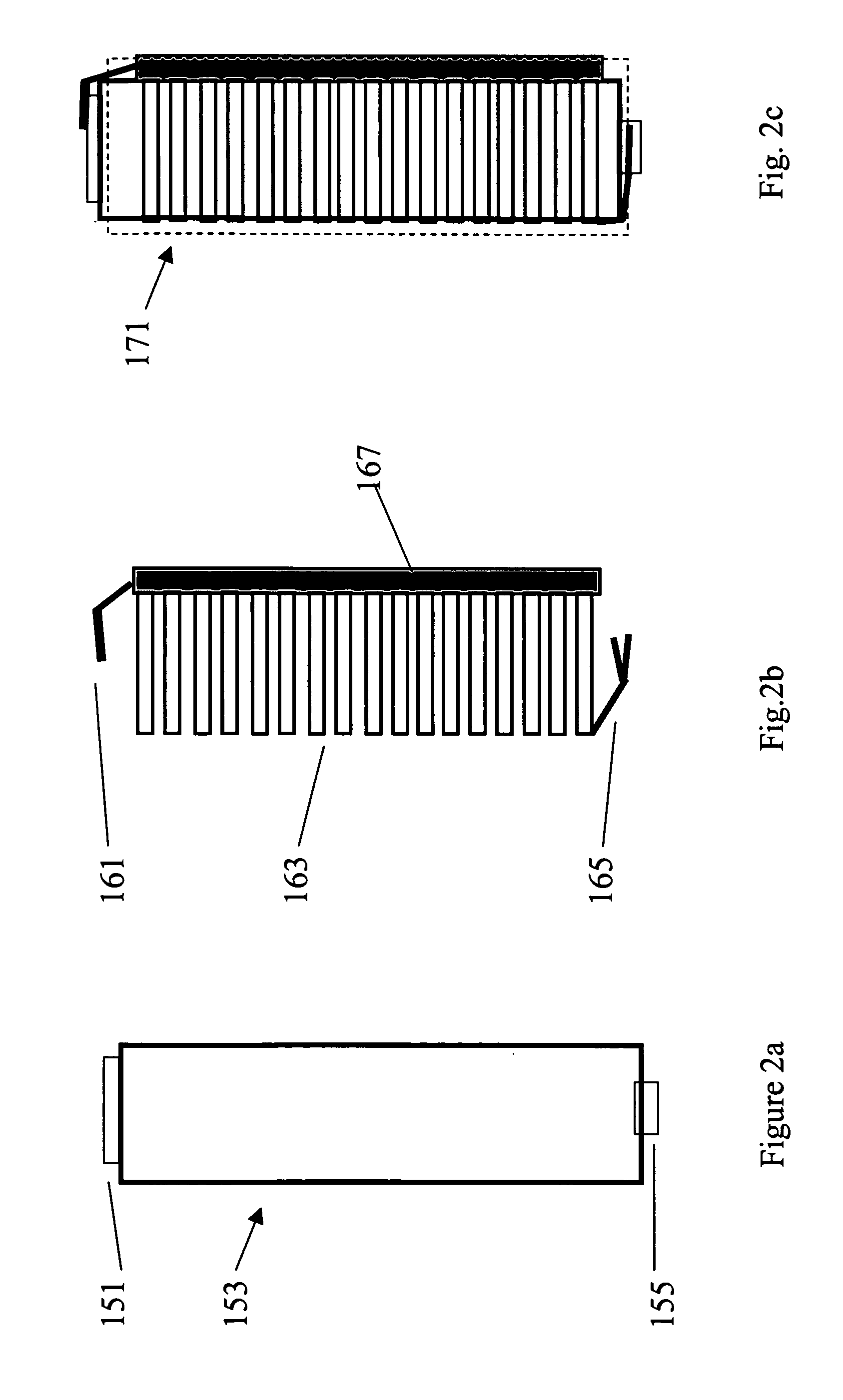

Generic rechargeable battery and charging system

A rechargeable battery includes a rechargeable element, a transfer device and control circuitry. The transfer device may be a secondary coil with a corresponding primary coil that is supplied electrical power. The transfer device may be a photovoltaic cell supplied with light energy or a thermoelectric generator supplied with heat.

Owner:CASTILLO HOMERO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com