Patents

Literature

168results about How to "Raise the transition temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

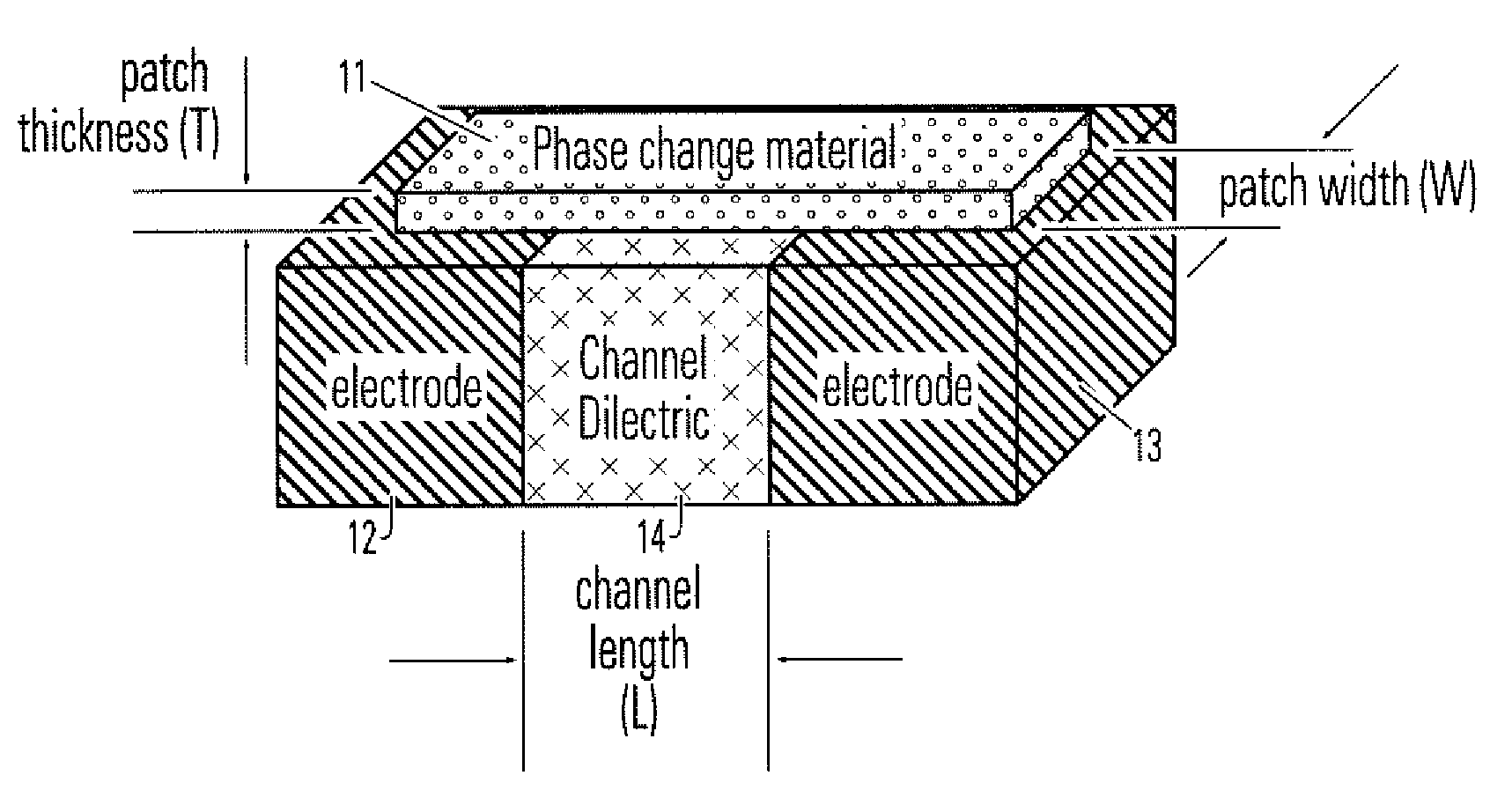

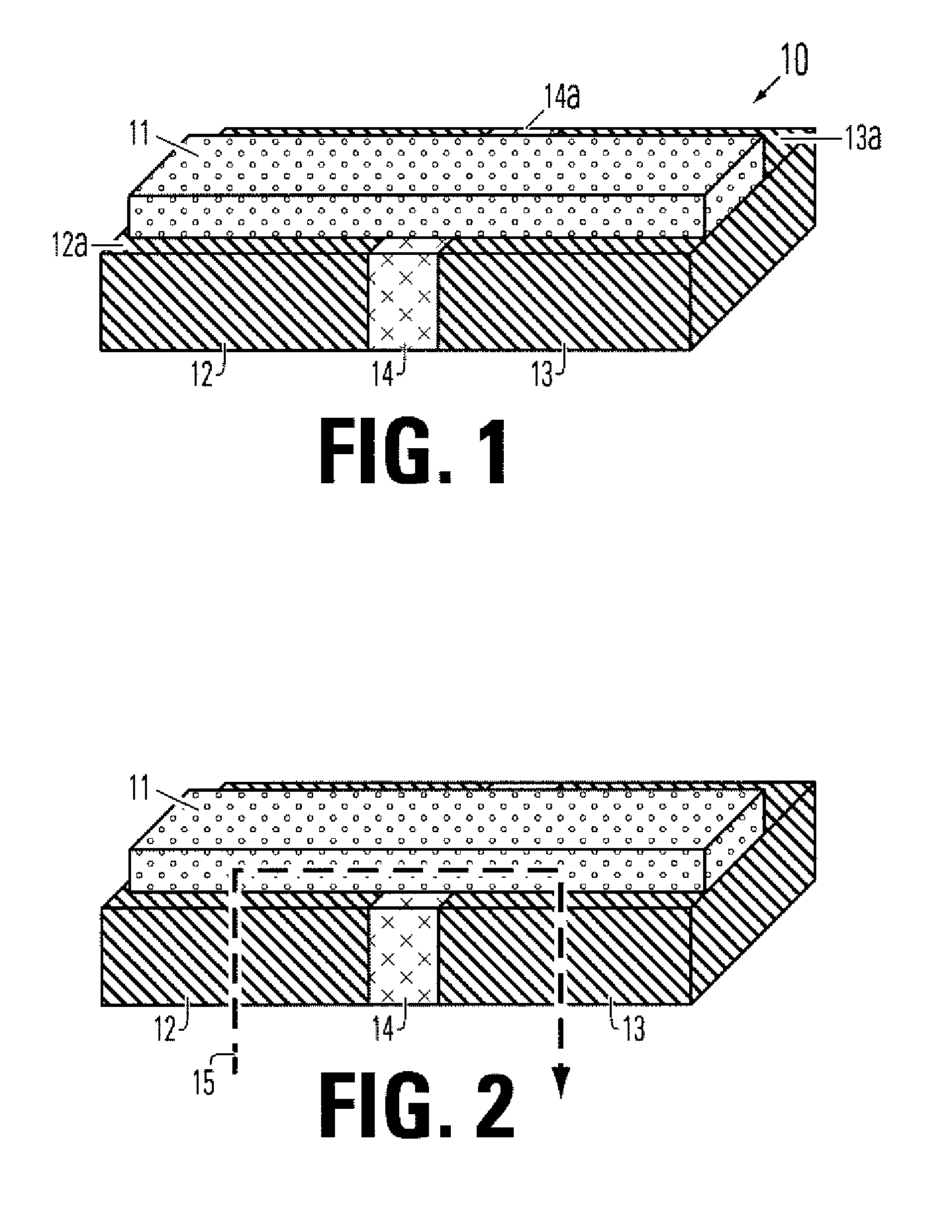

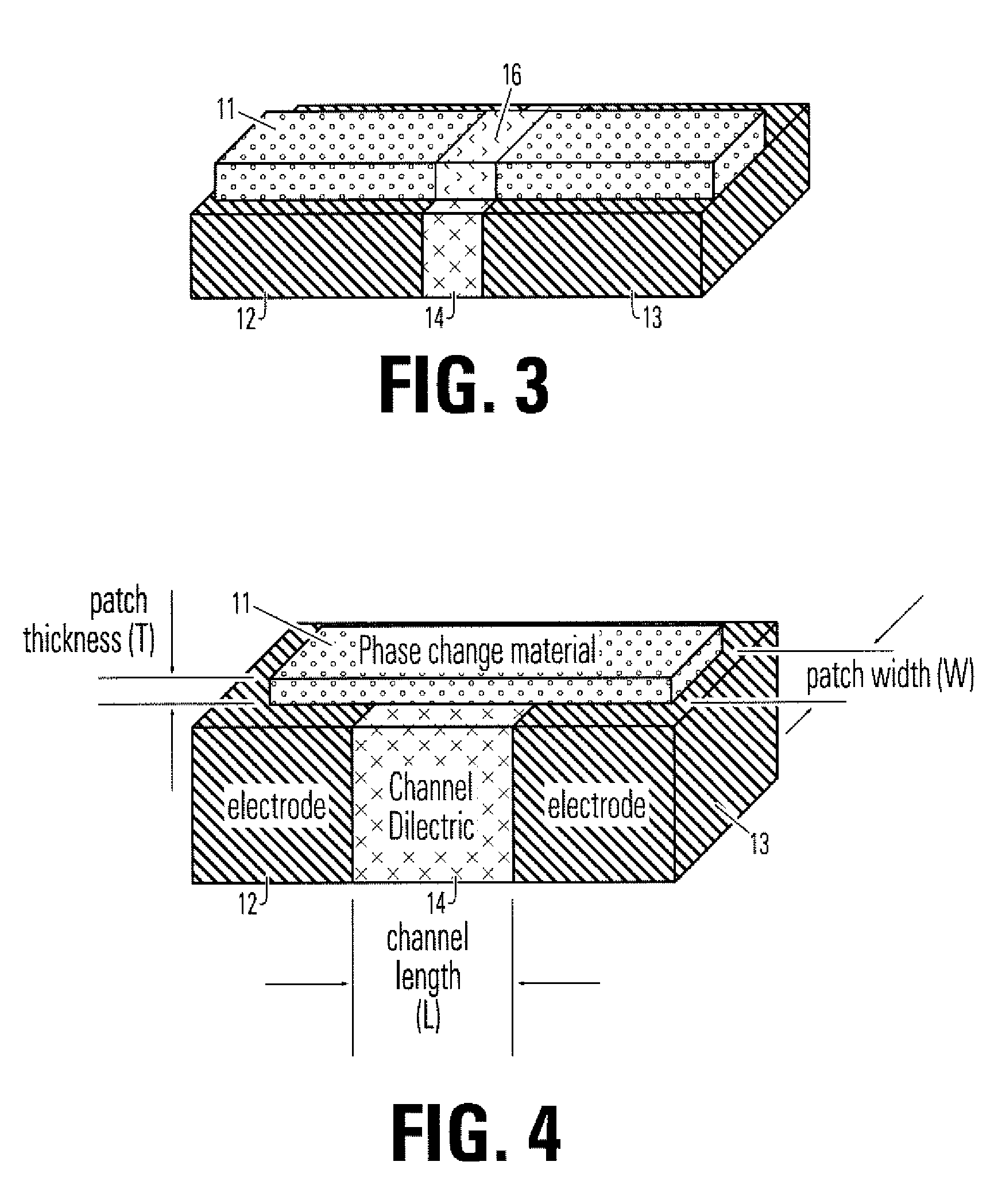

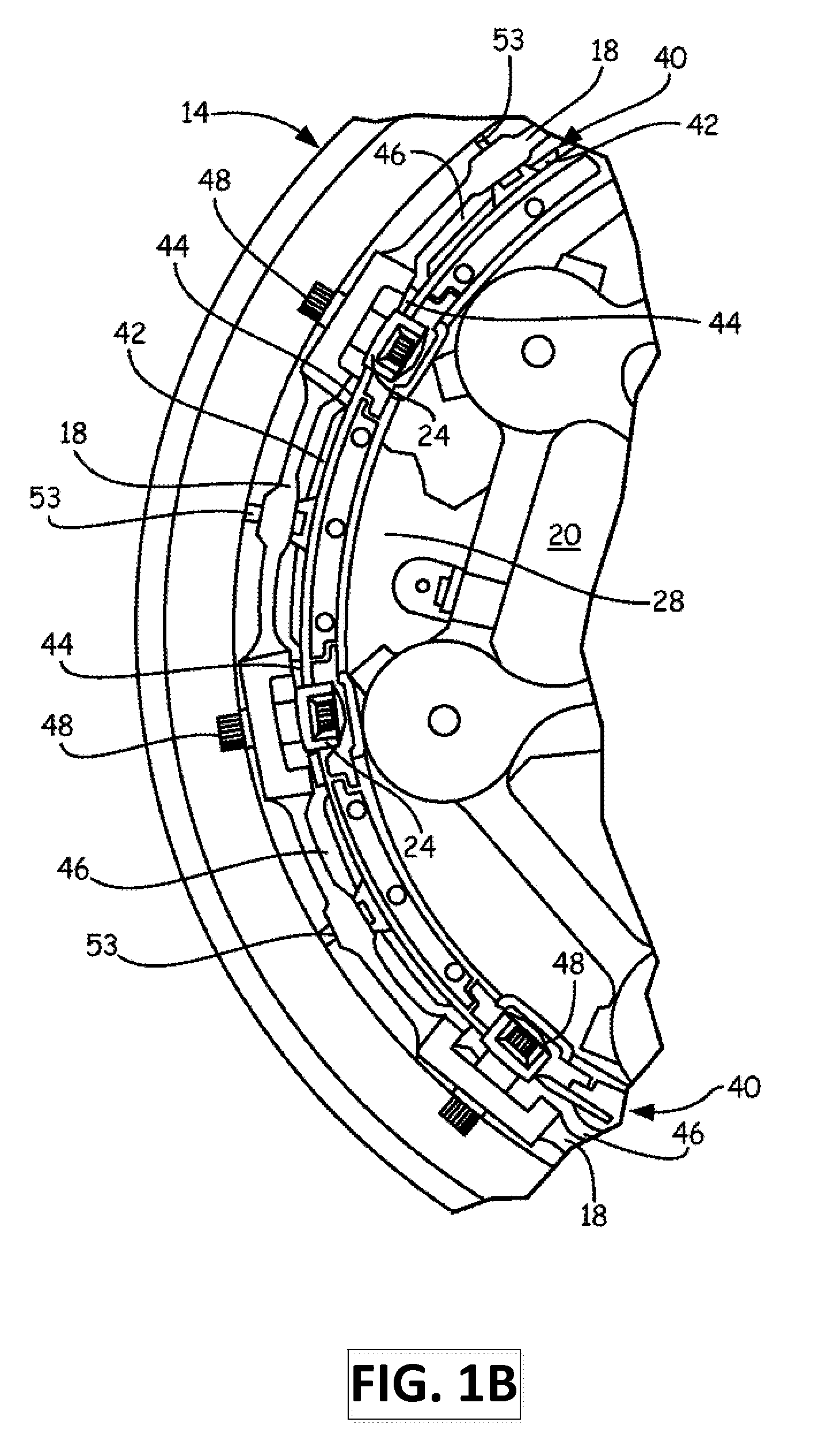

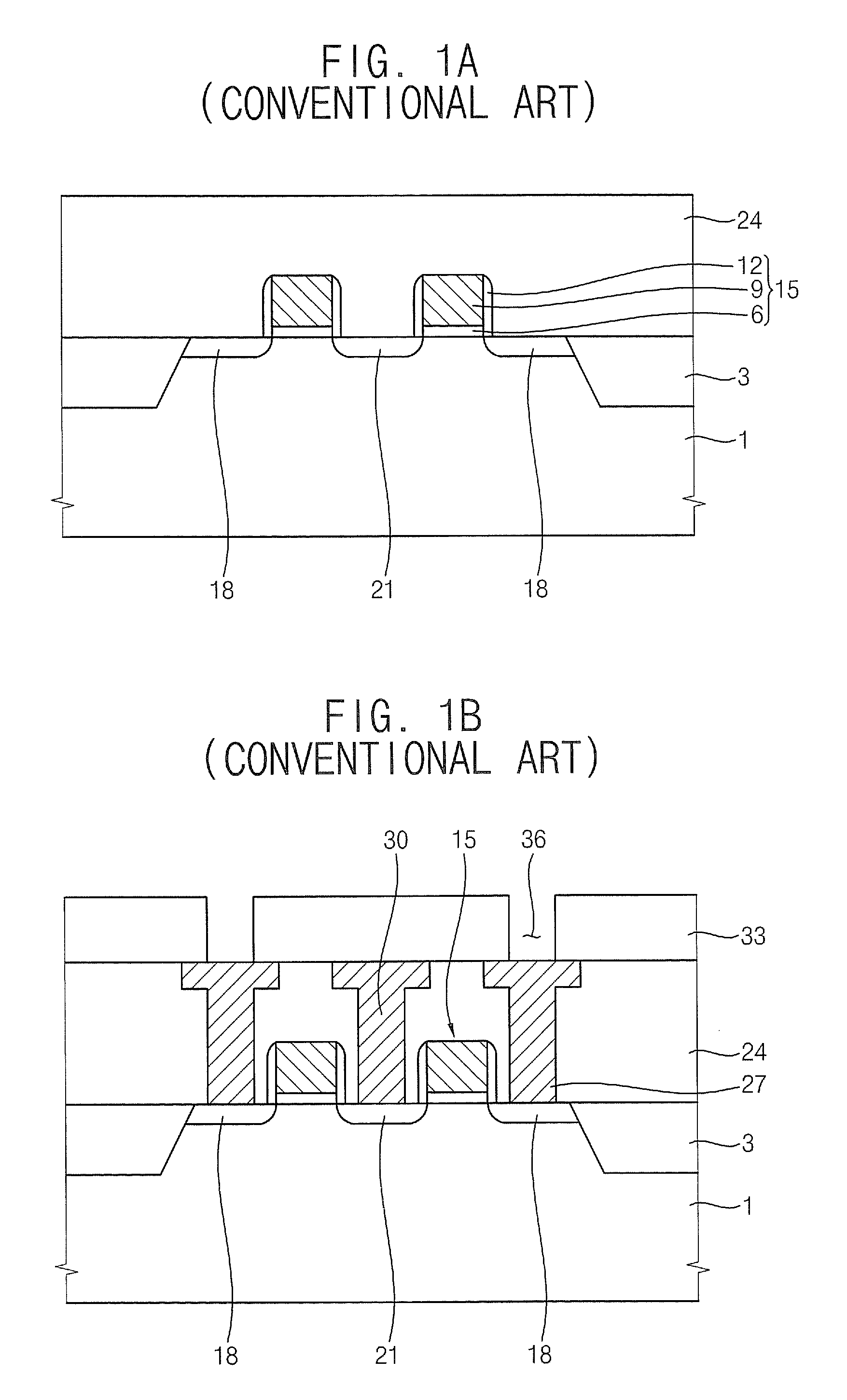

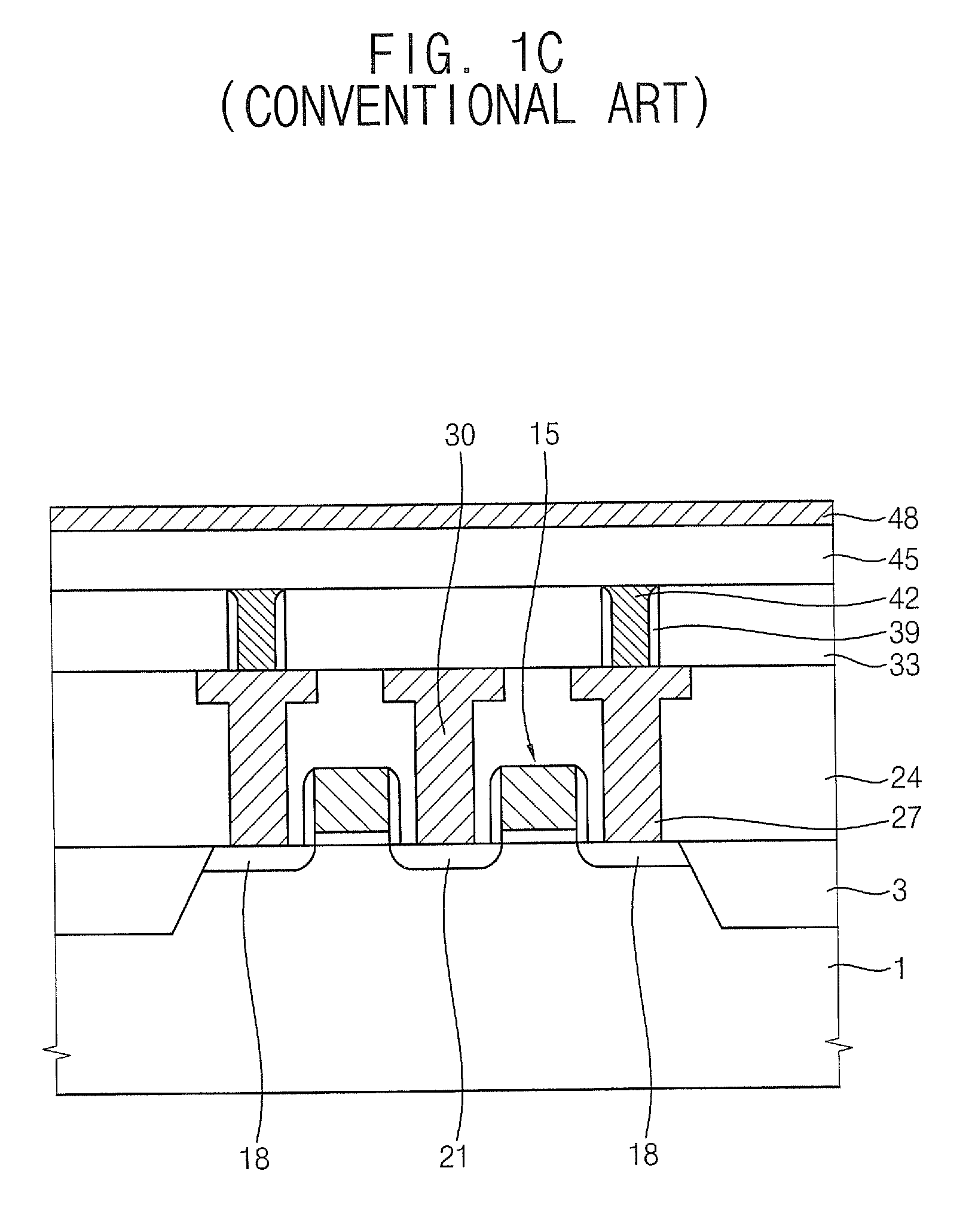

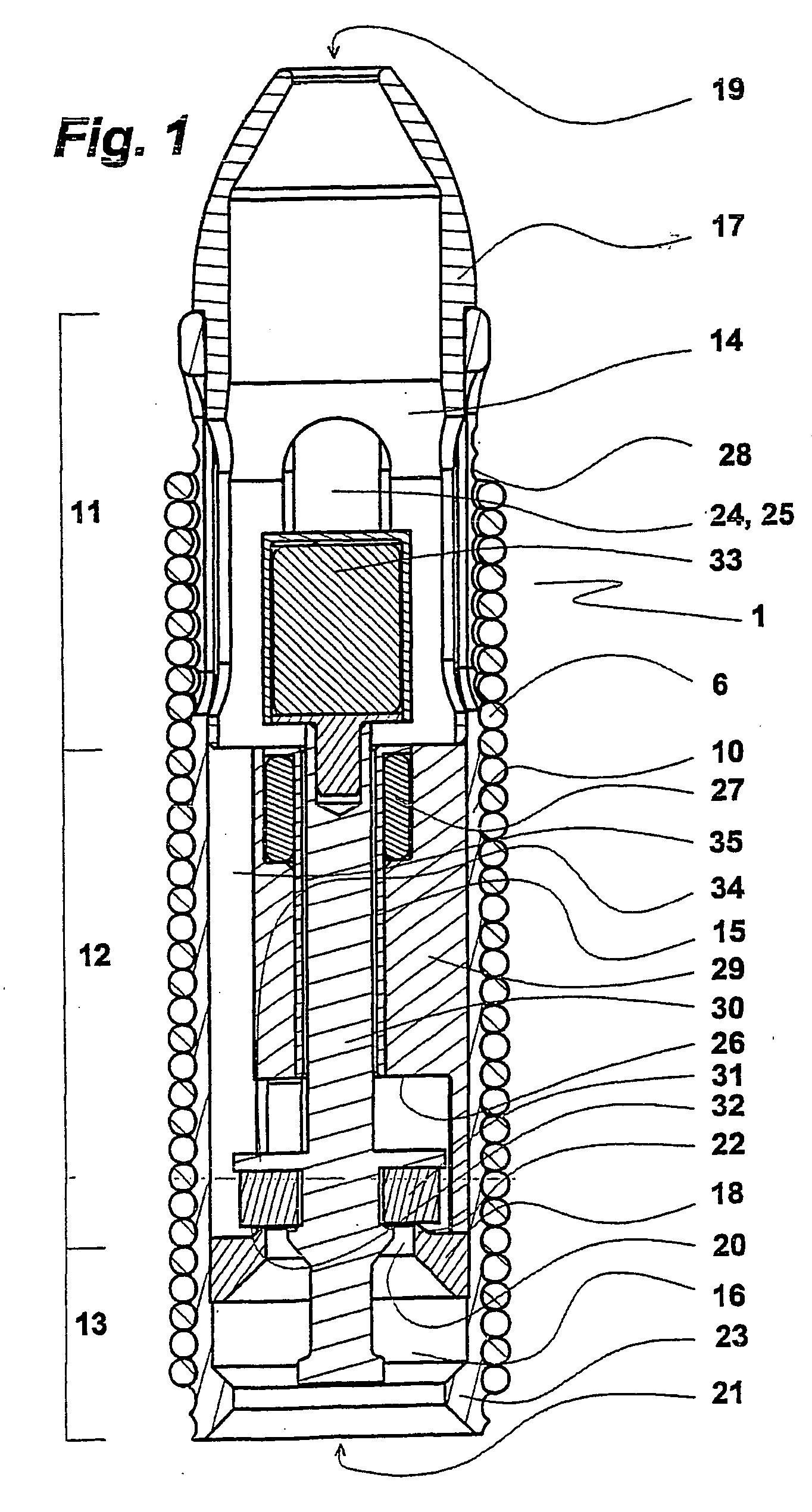

Phase Change Memory Cell and Manufacturing Method

ActiveUS20070121363A1Raise the transition temperatureLower transition temperatureSolid-state devicesDigital storageElectricityPhase-change memory

A phase change memory cell includes first and second electrodes having generally coplanar surfaces spaced apart by a gap and a phase change bridge electrically coupling the first and second electrodes. The phase change bridge may extend over the generally coplanar surfaces and across the gap. The phase change bridge has a higher transition temperature bridge portion and a lower transition temperature portion. The lower transition temperature portion comprises a phase change region which can be transitioned from generally crystalline to generally amorphous states at a lower temperature than the higher transition temperature portion. A method for making a phase change memory cell is also disclosed.

Owner:MACRONIX INT CO LTD

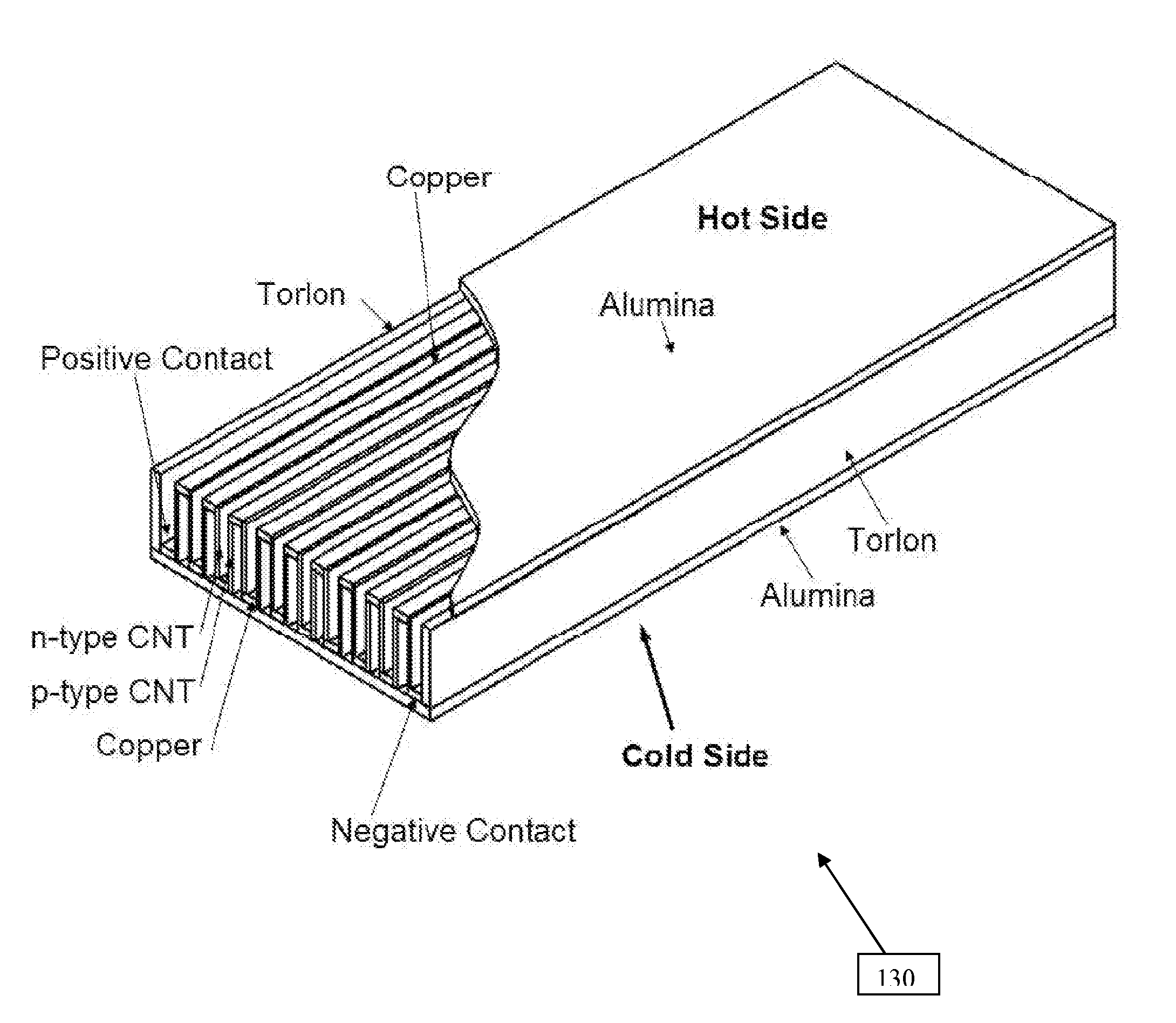

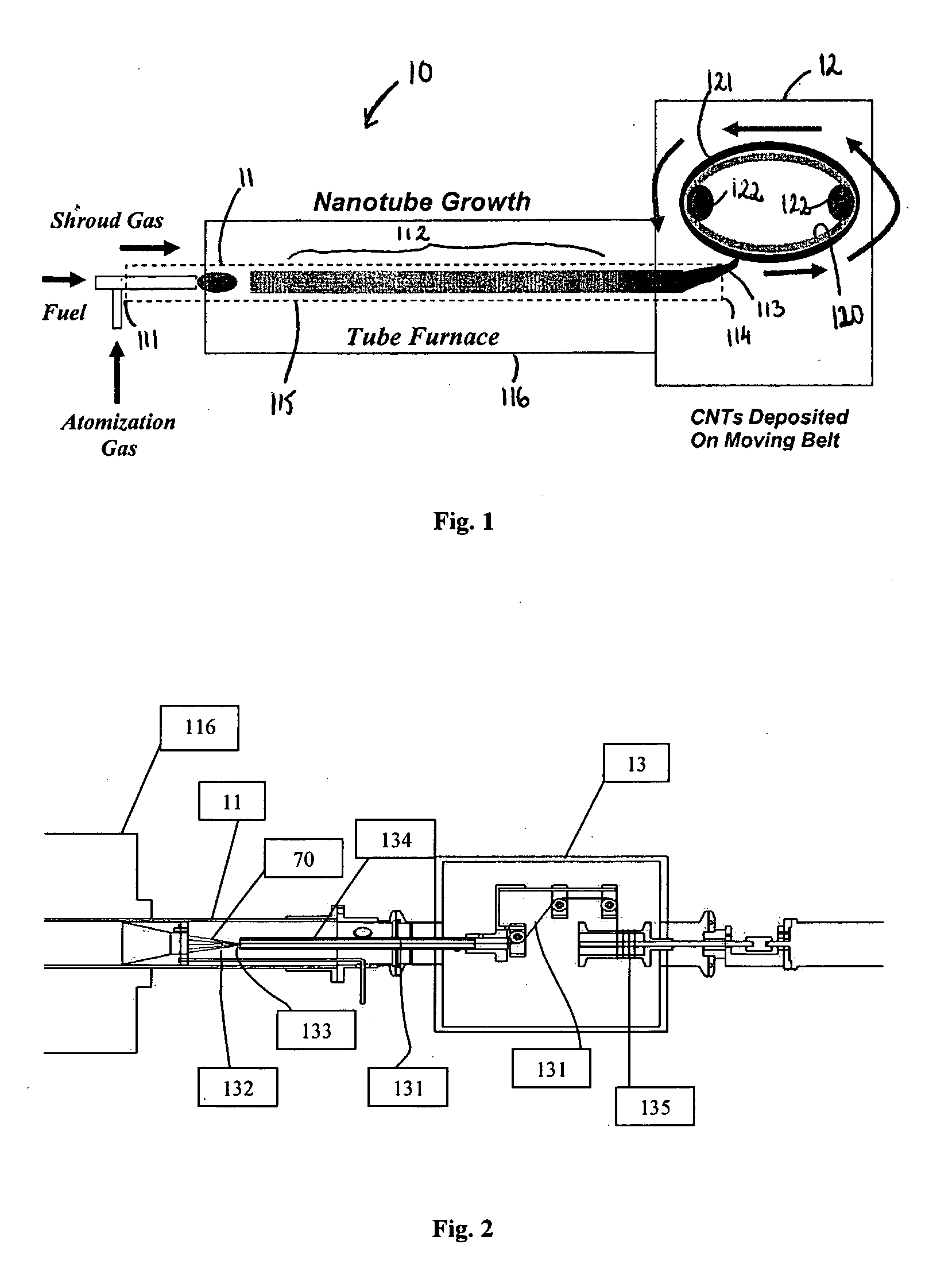

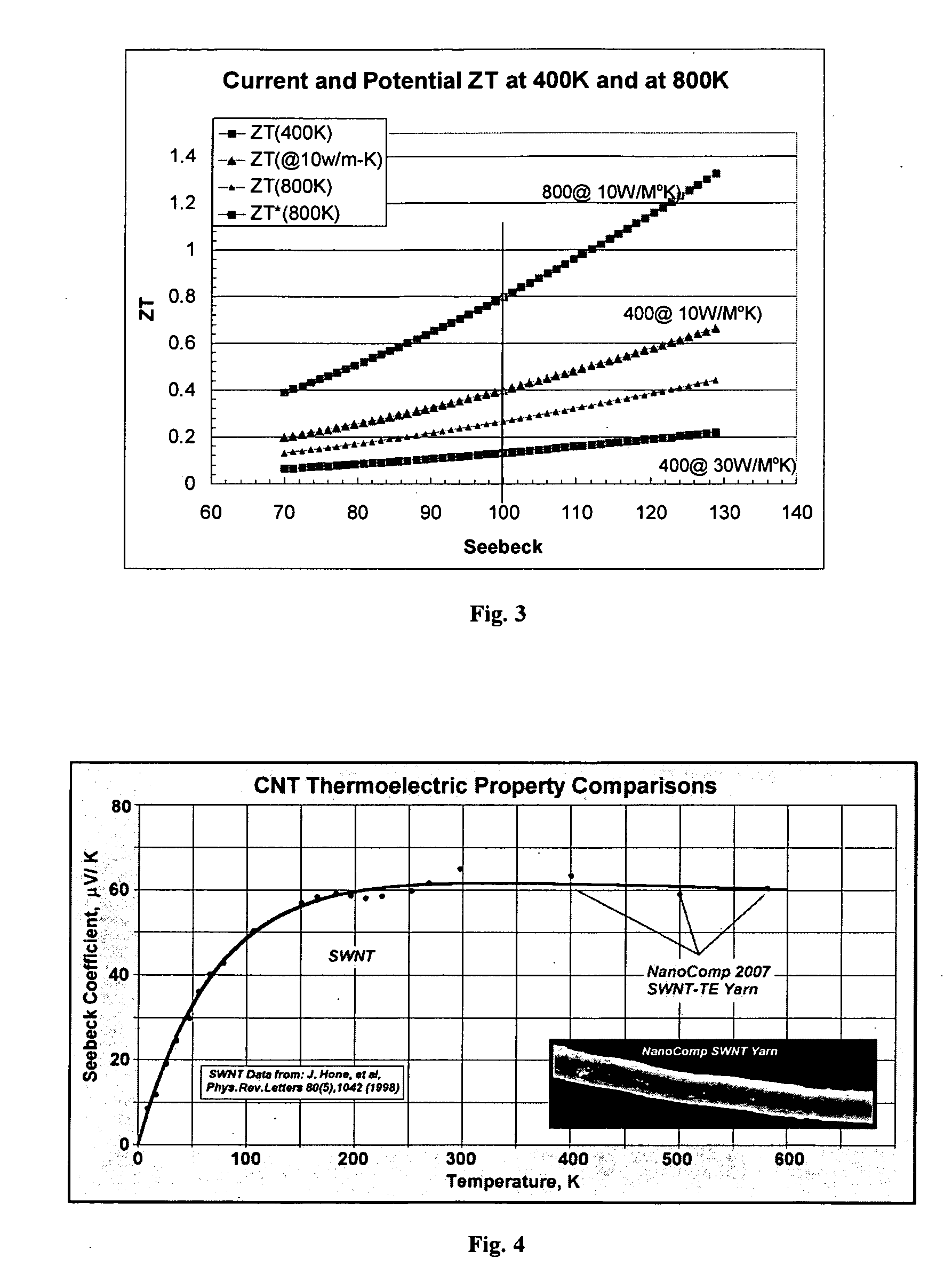

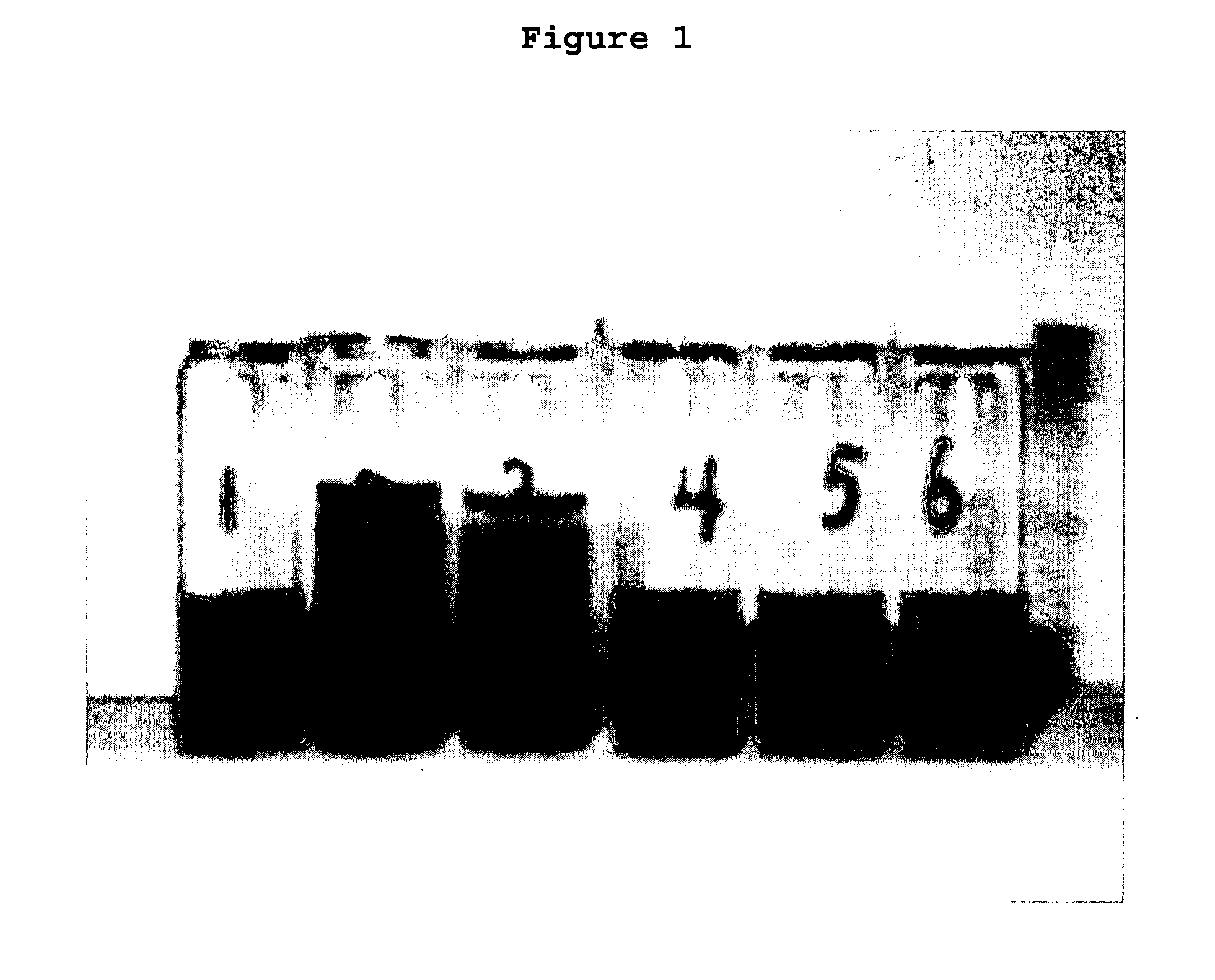

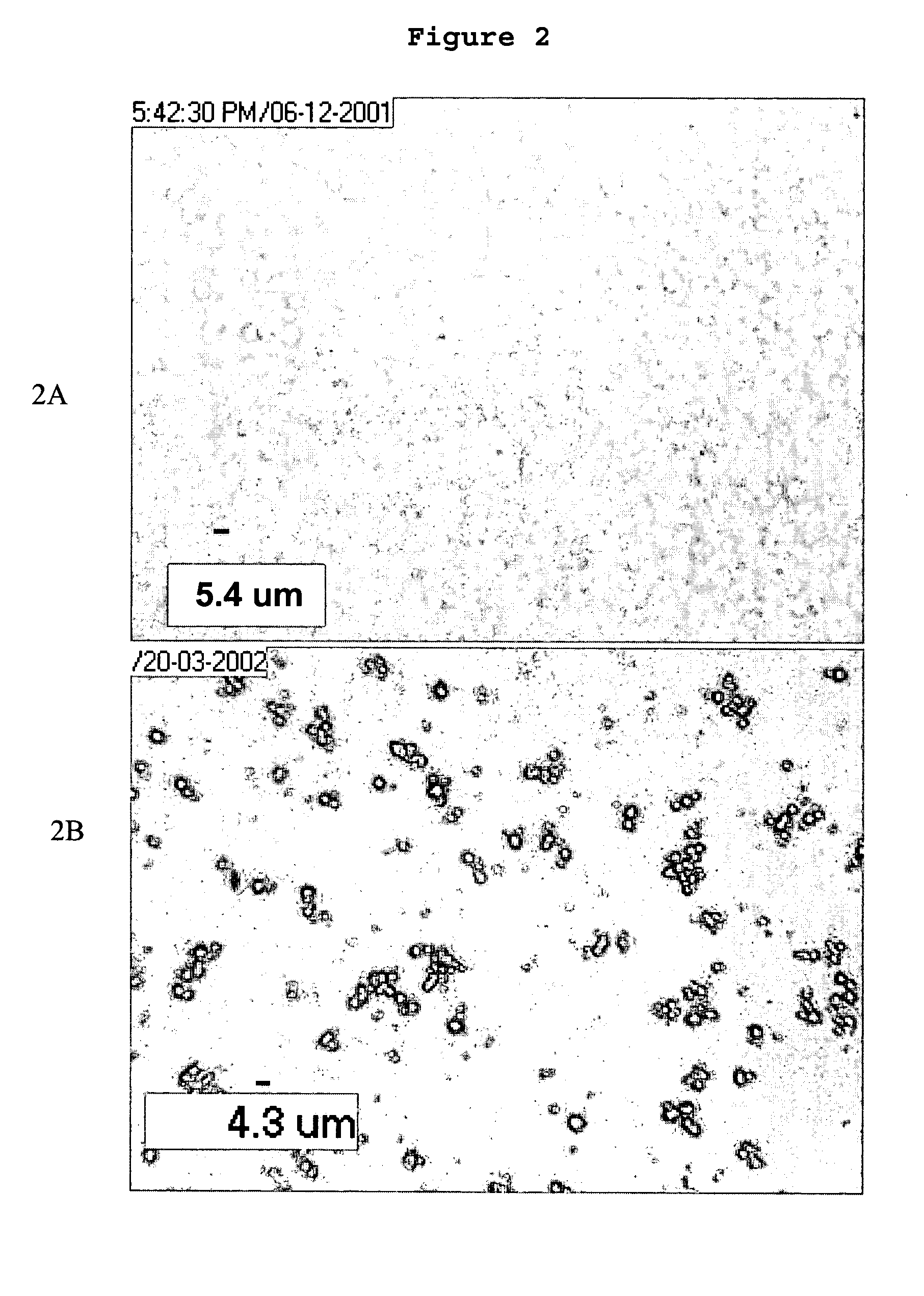

Nanostructured Material-Based Thermoelectric Generators

InactiveUS20090044848A1Improvement factorRaise the transition temperatureAuxillary drivesFrom solar energyCarbon nanotubeEngineering

A thermoelectric device that can exhibit substantially high specific power density is provided. The device includes core having a p-type element made from carbon nanotube and an n-type element. The device also includes a heat plate in and a cool plate, between which the core can be positioned. The design of the thermoelectric device allows the device to operate at substantially high temperature and to generate substantially high power output, despite being light weight. A method for making the thermoelectric device is also provided.

Owner:NANCOMP TECHNOLOGIES INC

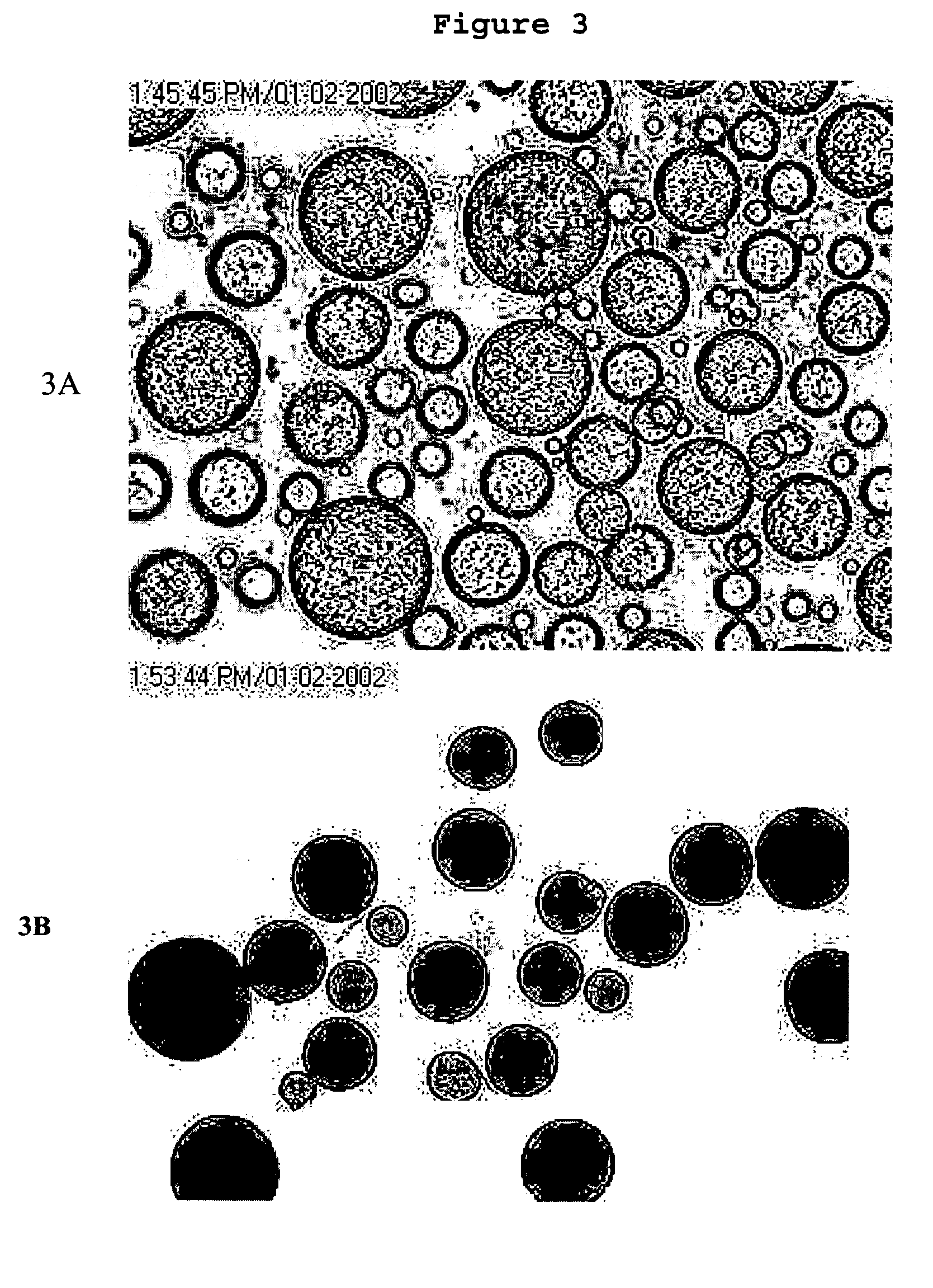

Aquespheres, their preparation and uses thereof

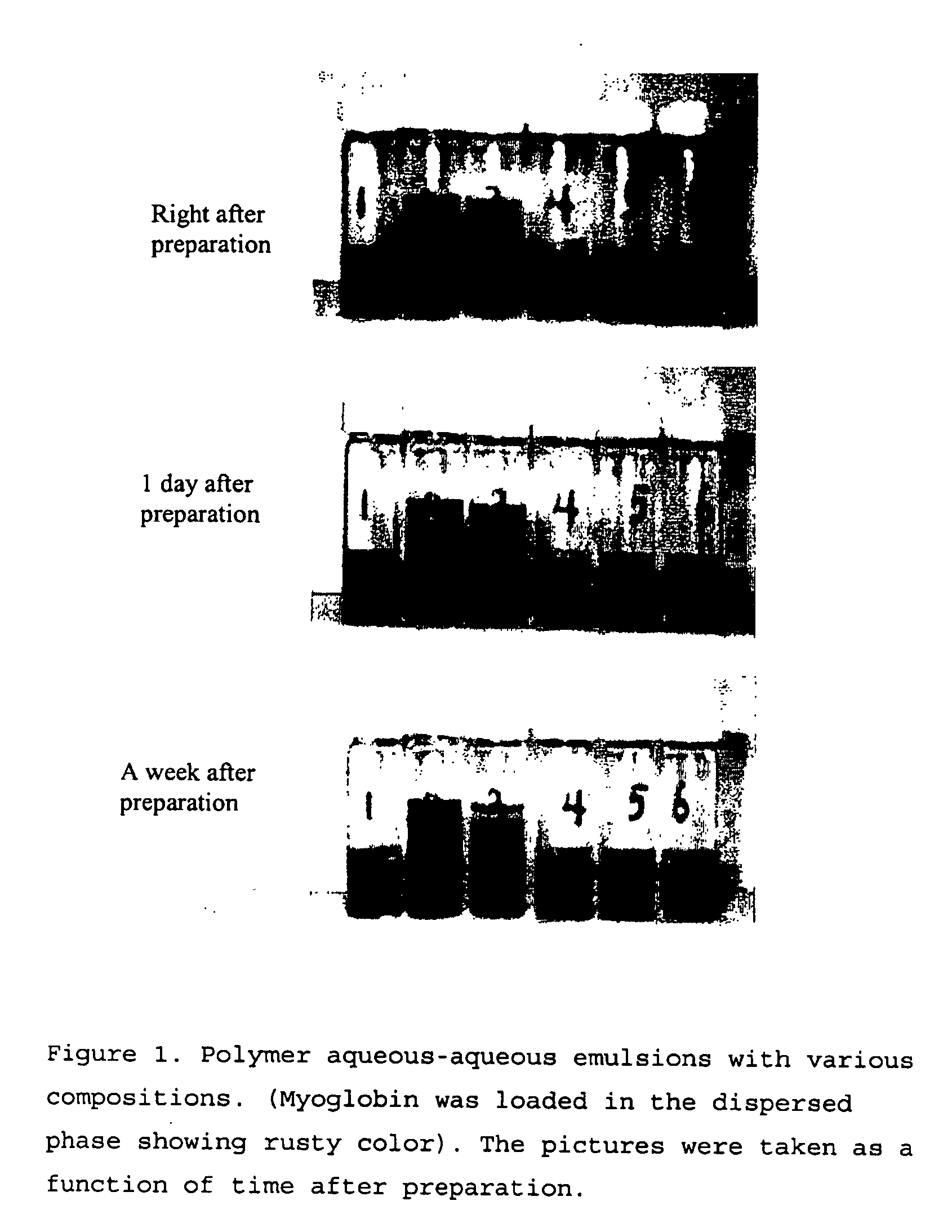

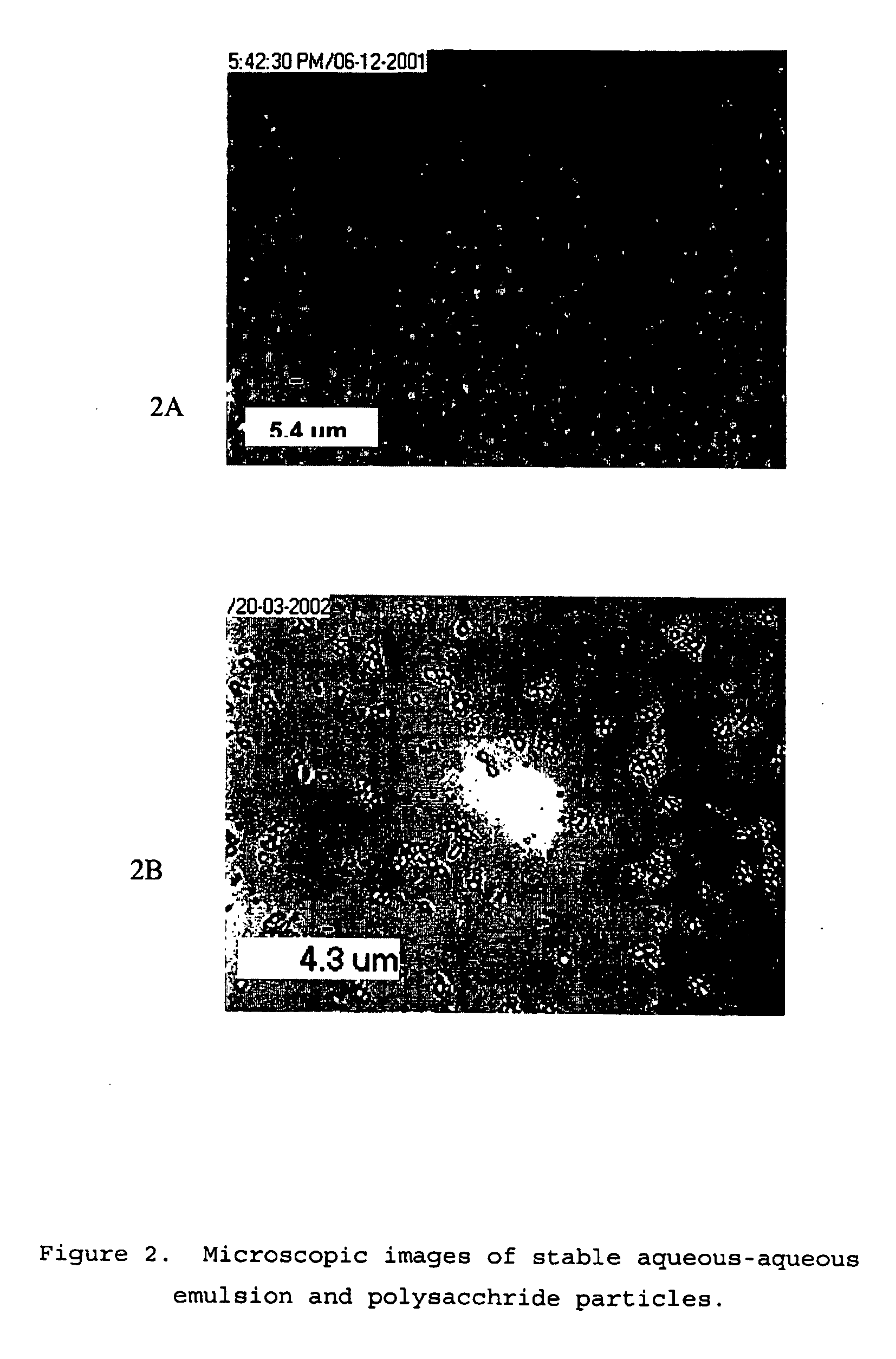

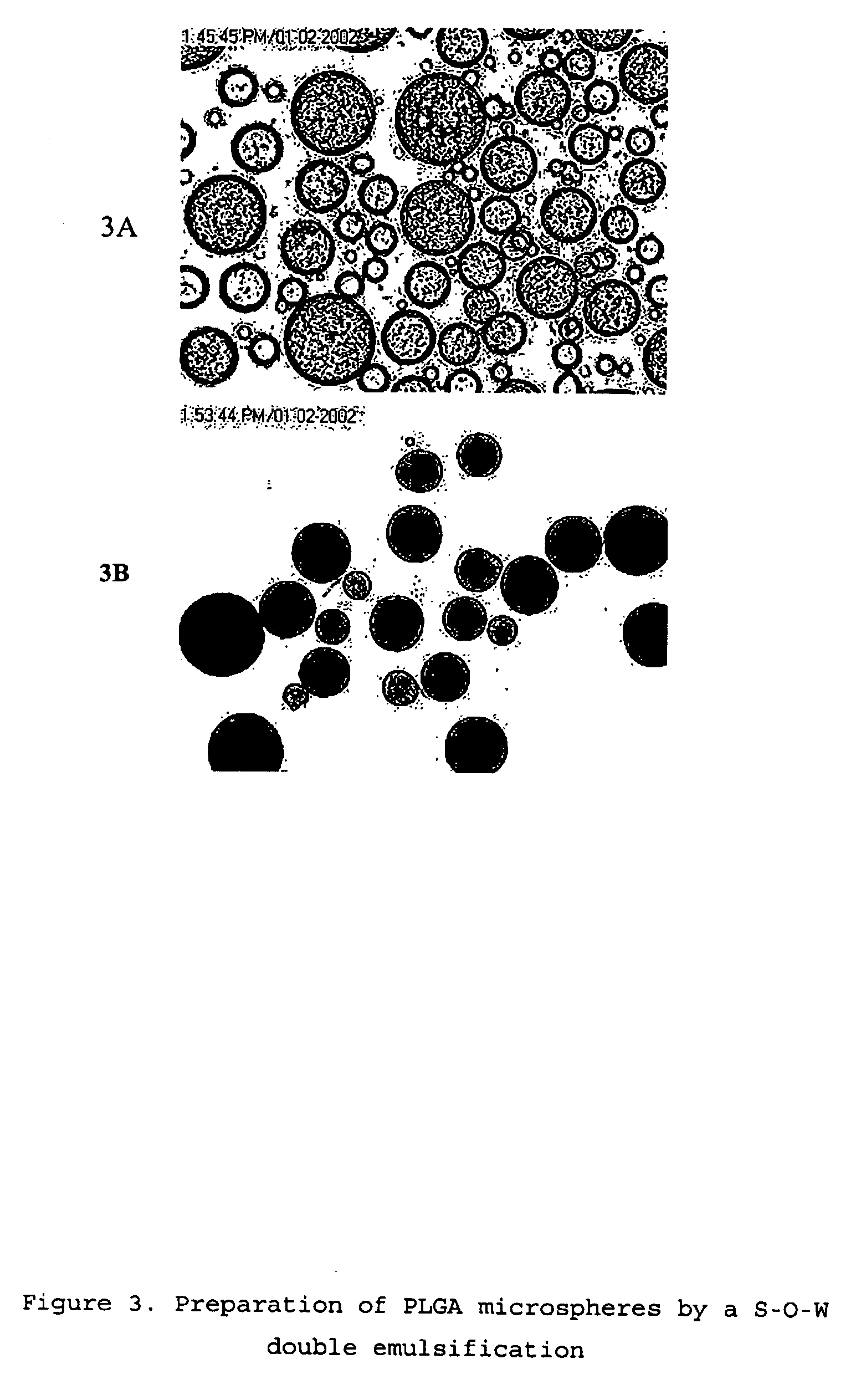

InactiveUS6998393B2Avoid the burst effectCutting portionBiocideOrganic active ingredientsCross-linkEmulsion

This invention provides method for sustained release delivery of structurally delicate agents such as proteins and peptides. Using a unique emulsion system (Stable polymer aqueous-aqueous emulsion), proteins and peptides can be microencapsulated in polysacchride glassy particles under a condition free of any chemical or physical hazard such as organic solvents, strong interfacial tension, strong shears, elevated temperature, large amount of surfactants, and cross-linking agents. Proteins loaded in these glassy particles showed strong resistance to organic solvents, prolonged activity in hydrated state, and an excellent sustained release profile with minimal burst and incomplete release when being further loaded in degradable polymer microspheres. This invention provides a simple yet effective approach to address all the technical challenges raised in sustained release delivery of proteins.

Owner:BIODVERY PHARMATECH LTD

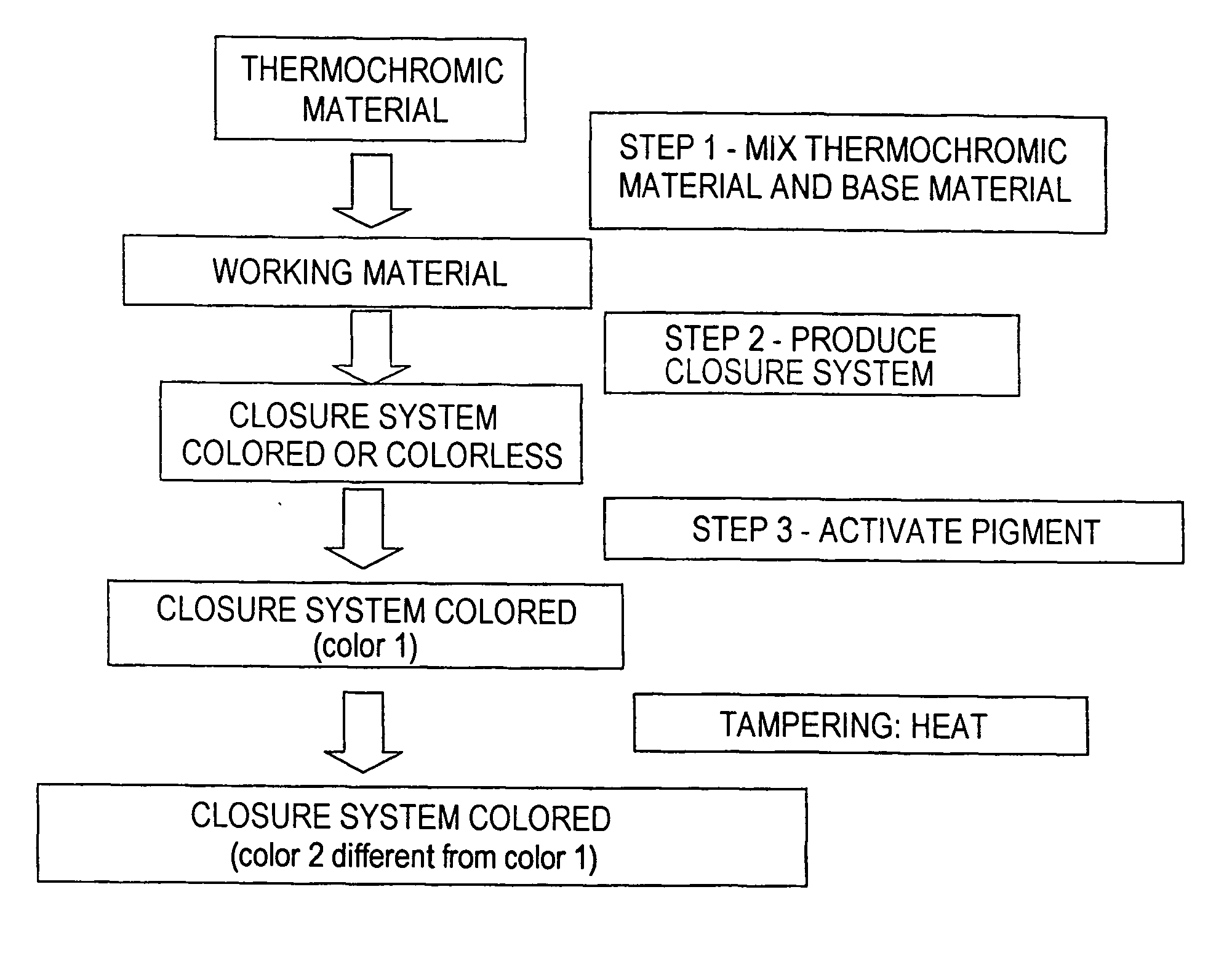

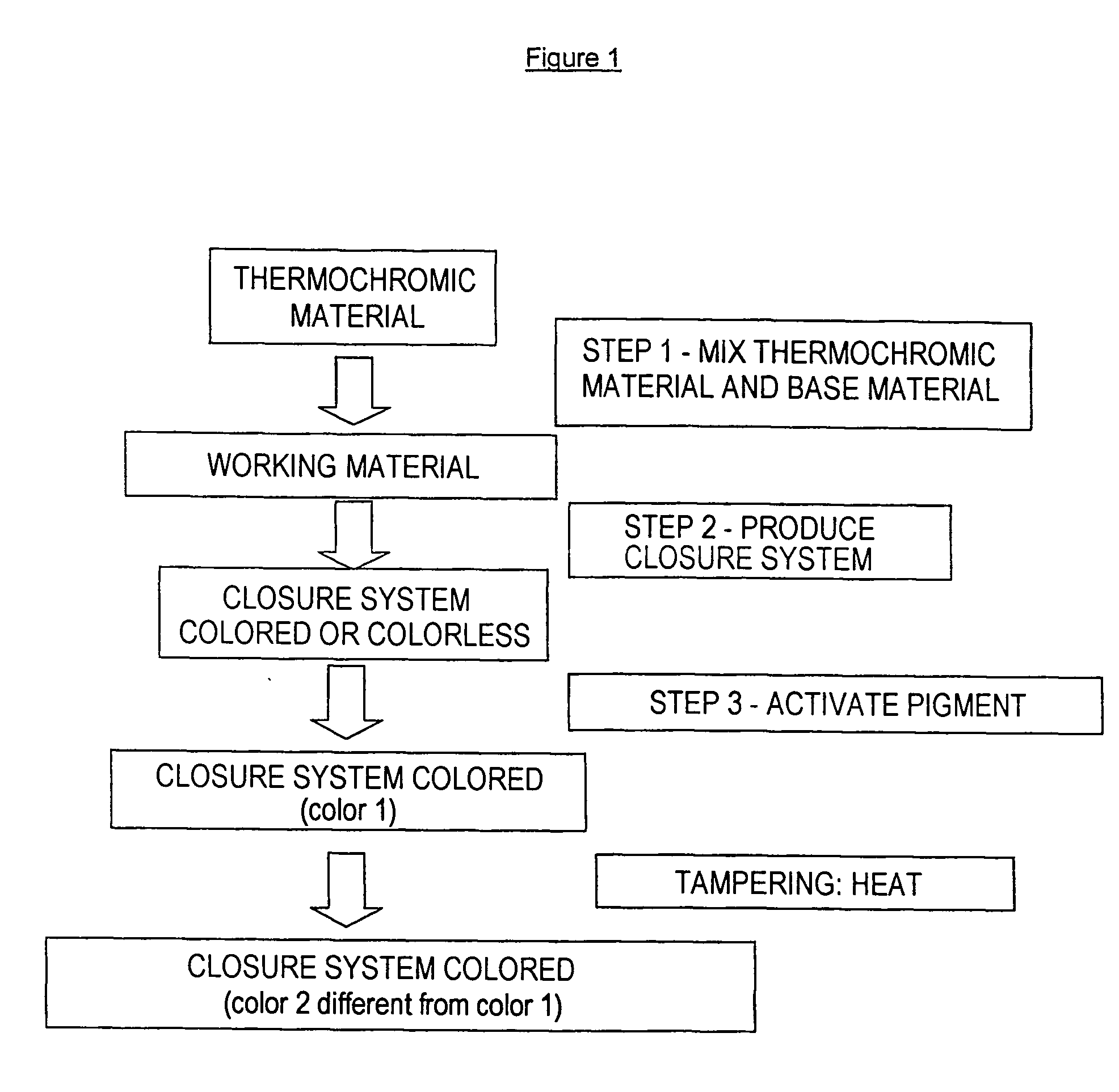

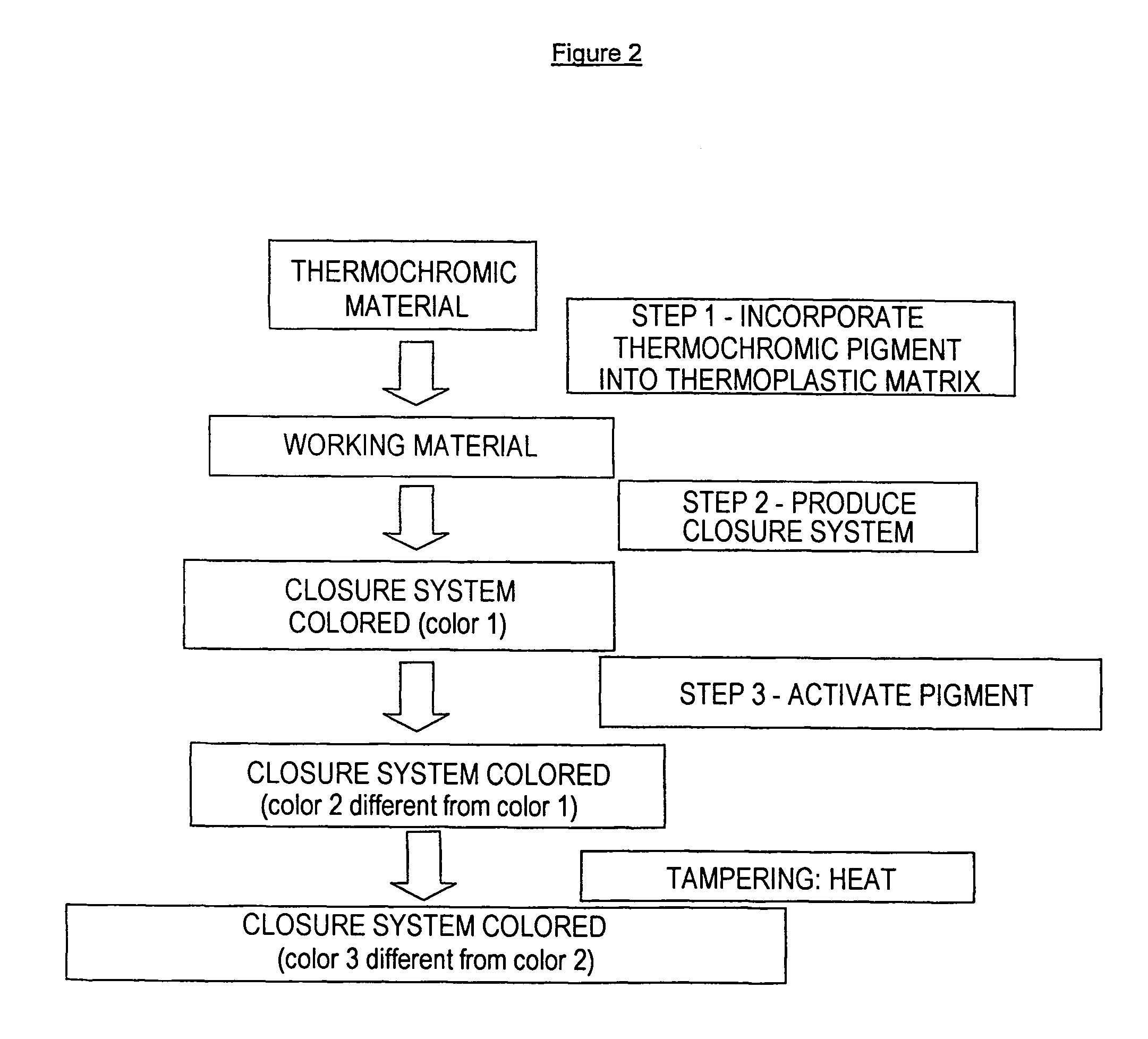

Closure System With Thermochromic Tamper-Control Means

InactiveUS20070251912A1Decrease in conjugation lengthModifies the absorption spectrumClosure using stoppersWood working apparatusEngineeringThreshold temperature

The present invention relates to a closure system including a thermochromic tamper-control means of color that is irreversibly modified in the event of the temperature of the closure system being raised above a threshold temperature, said closure system comprising a polymer matrix having incorporated therein at least one thermochromic pigment of color that is irreversibly modified after said closure system has been exposed to a temperature close to or above a threshold temperature. The invention also relates to a method of preparing a thermochromic closure system, and to receptacles provided with said system.

Owner:TETRA LAVAL HLDG & FINANCE SA

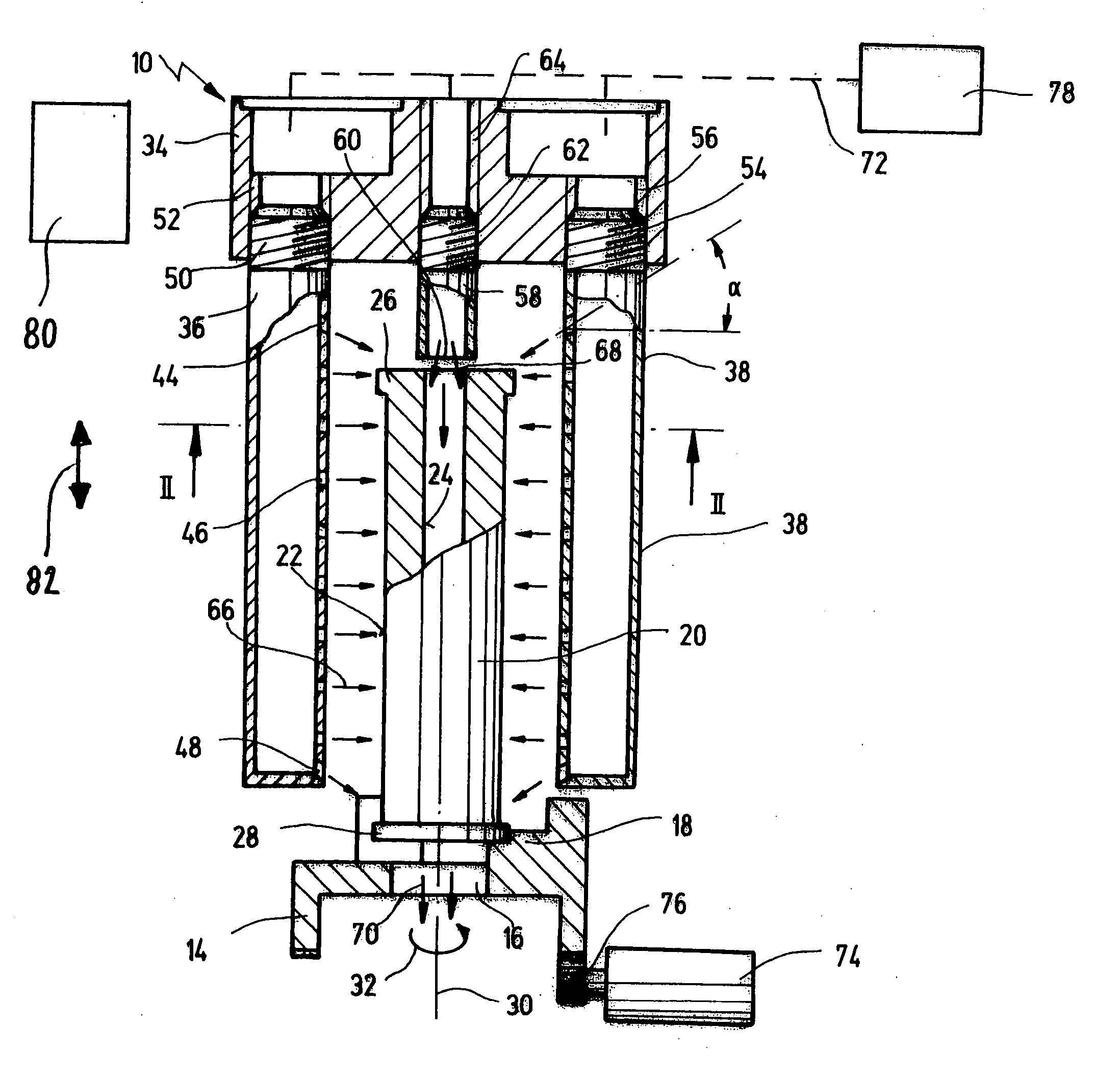

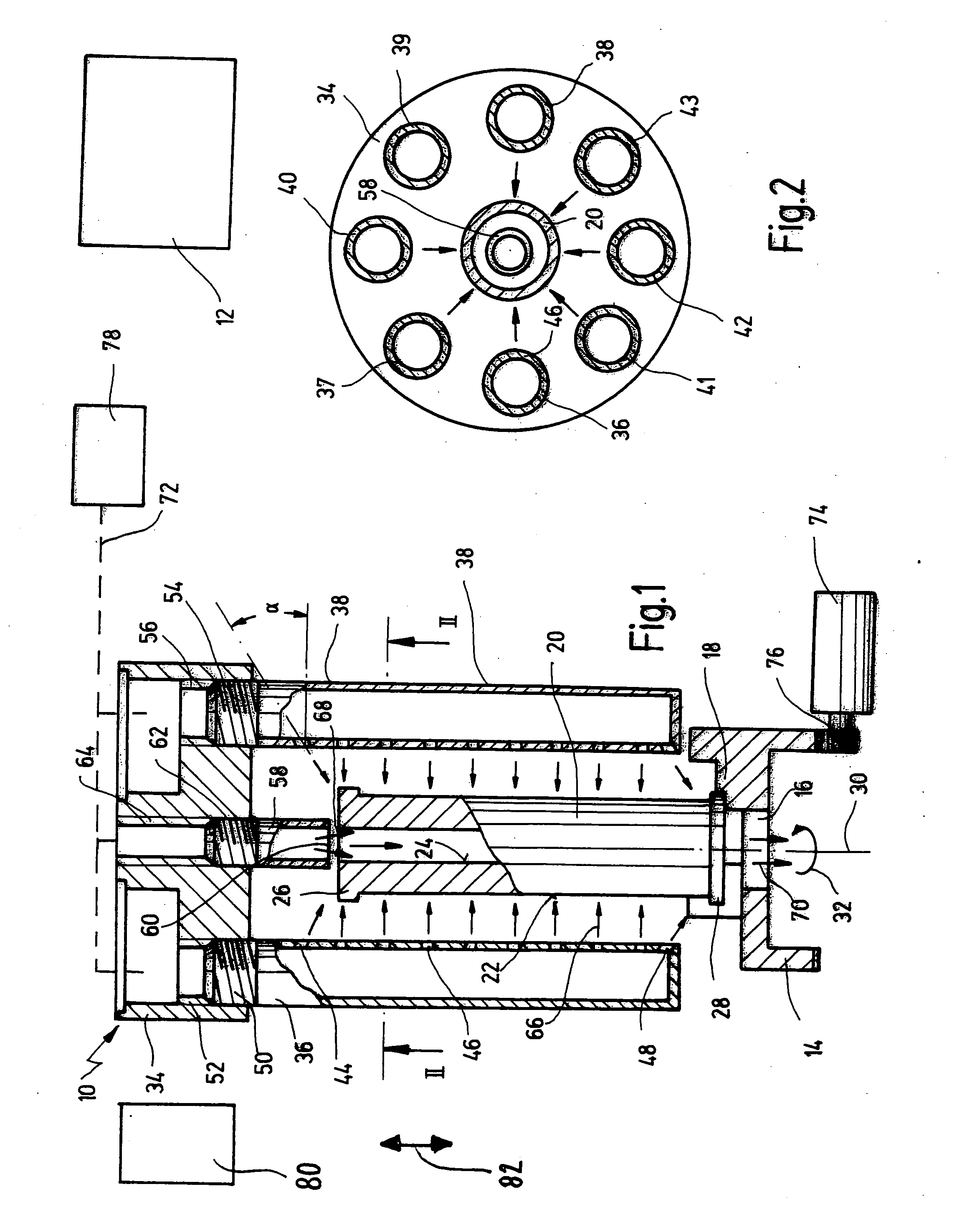

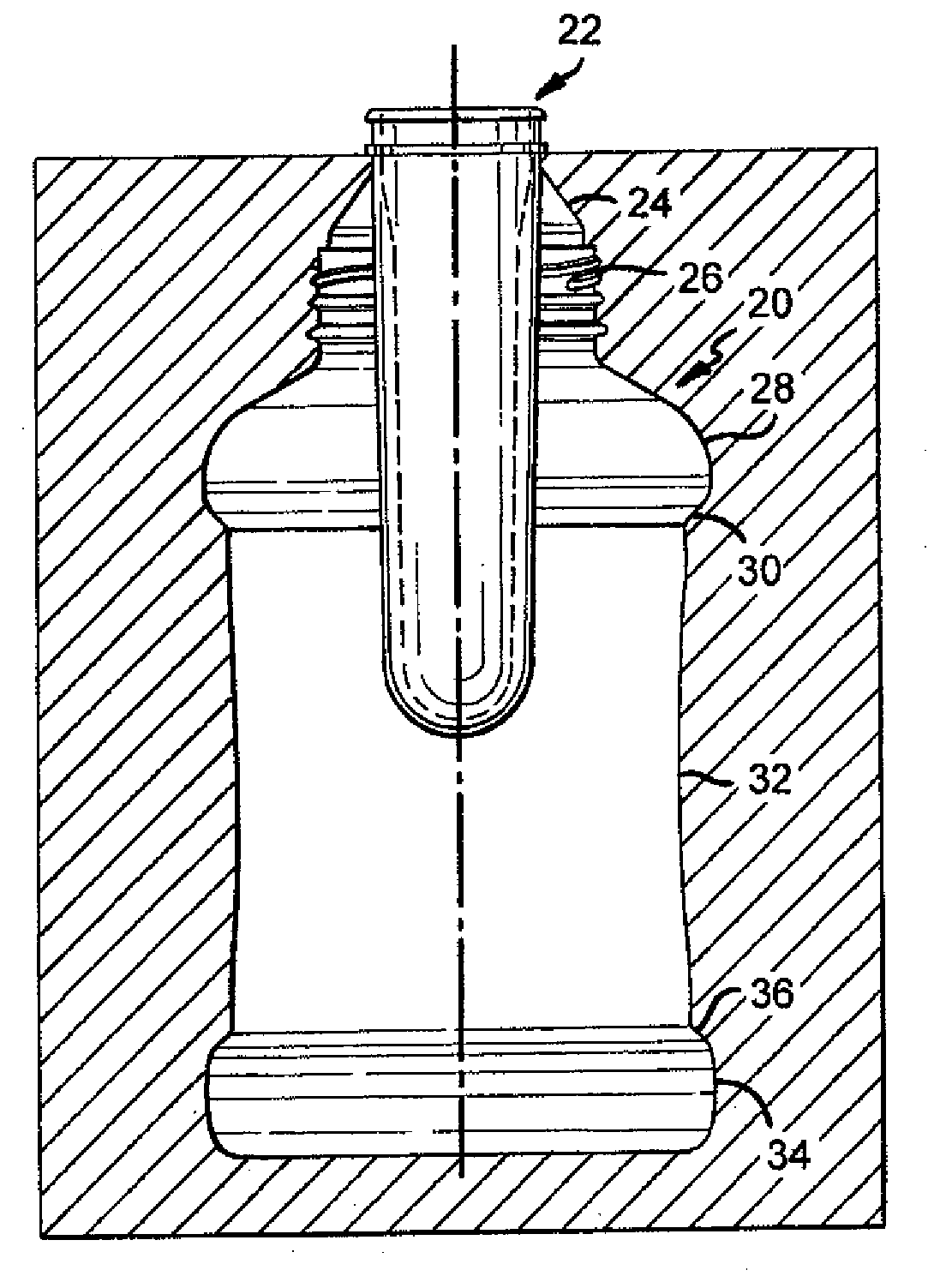

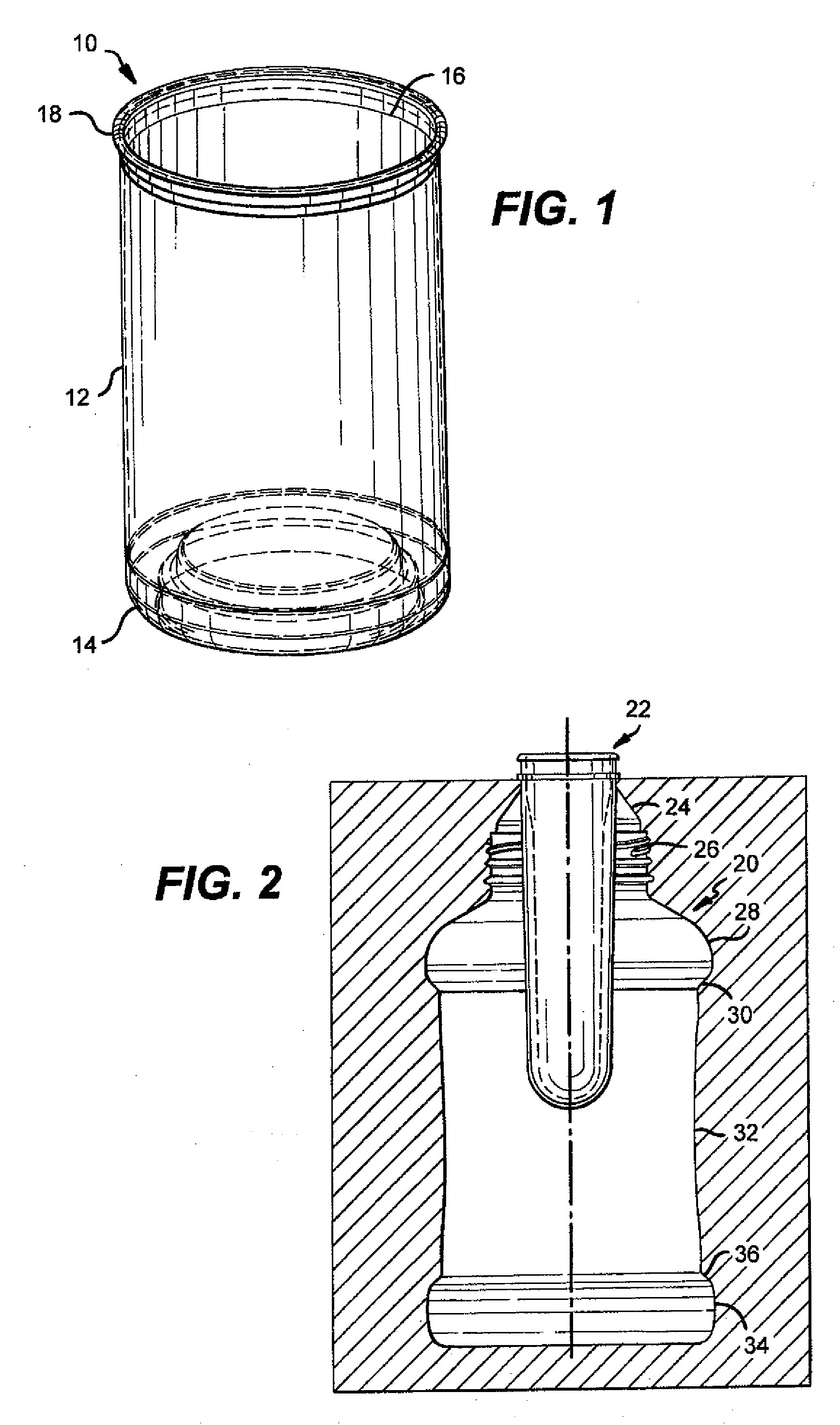

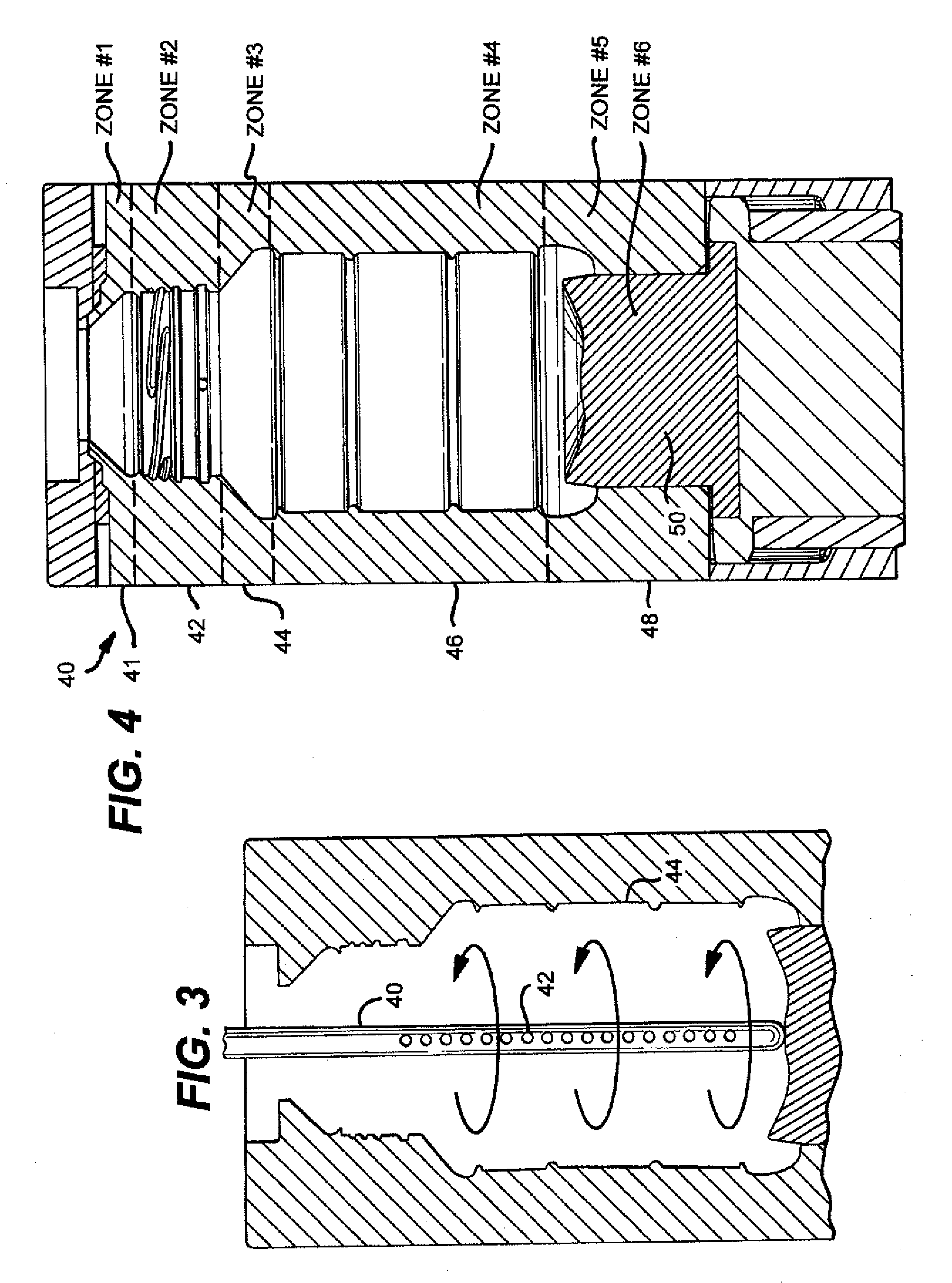

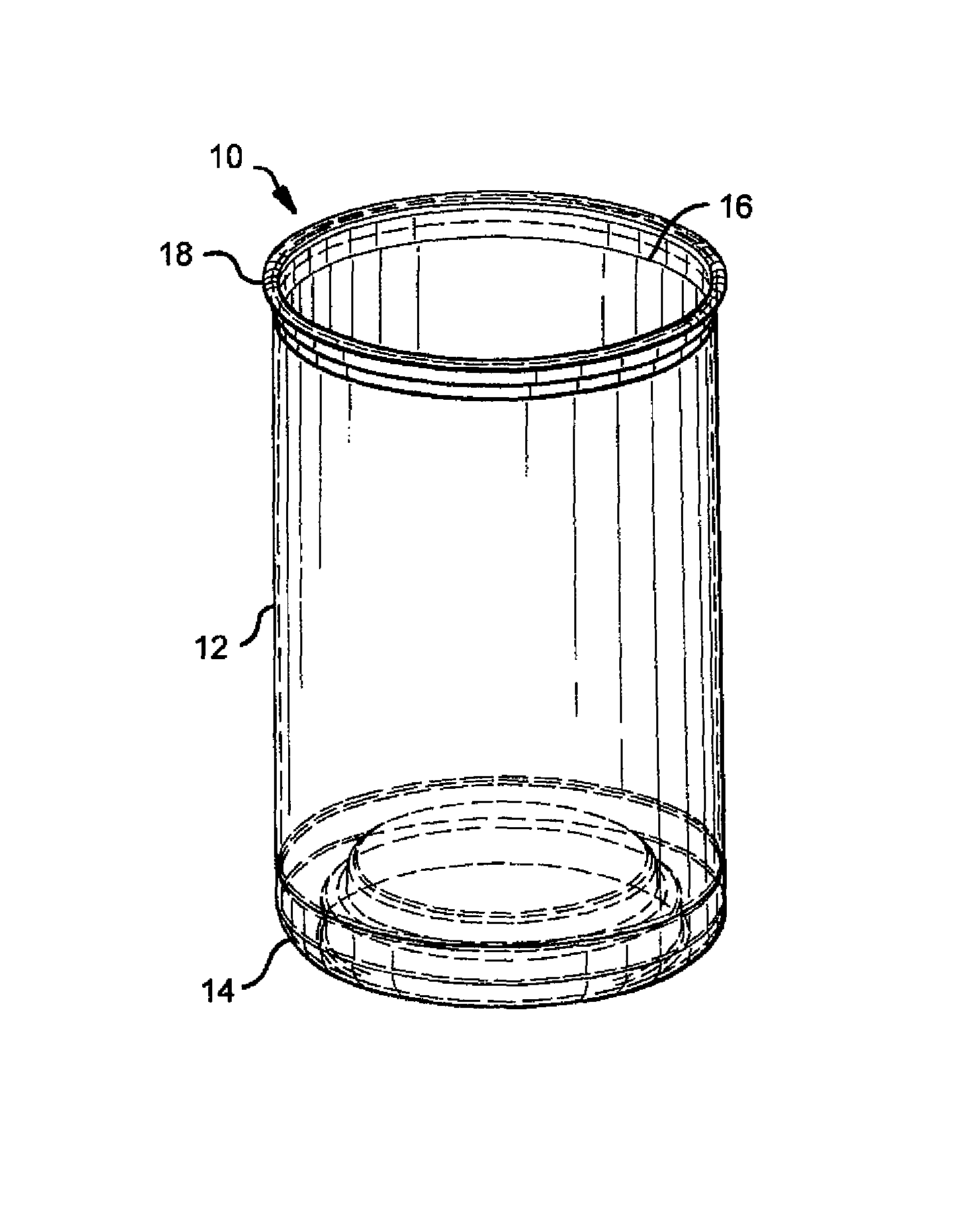

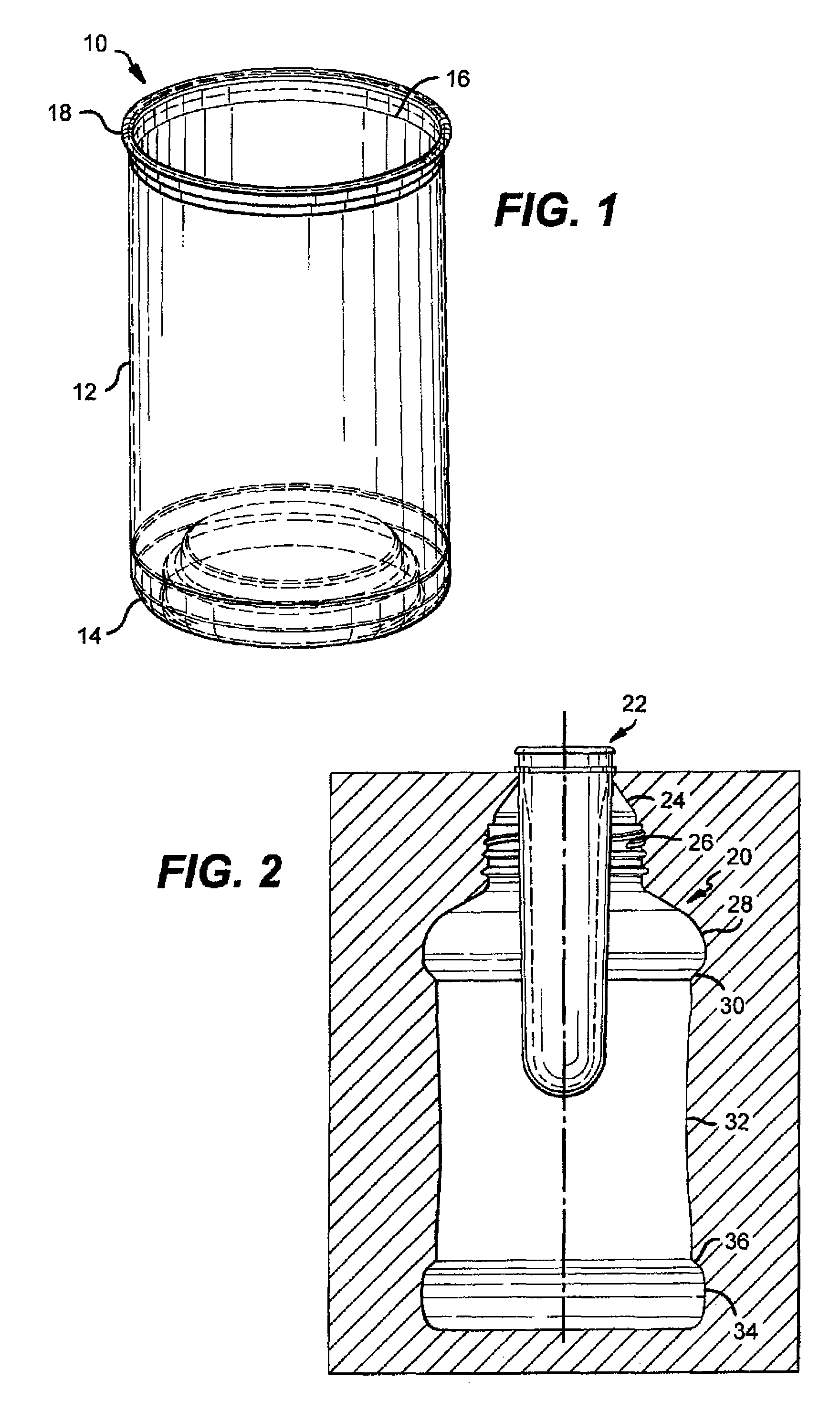

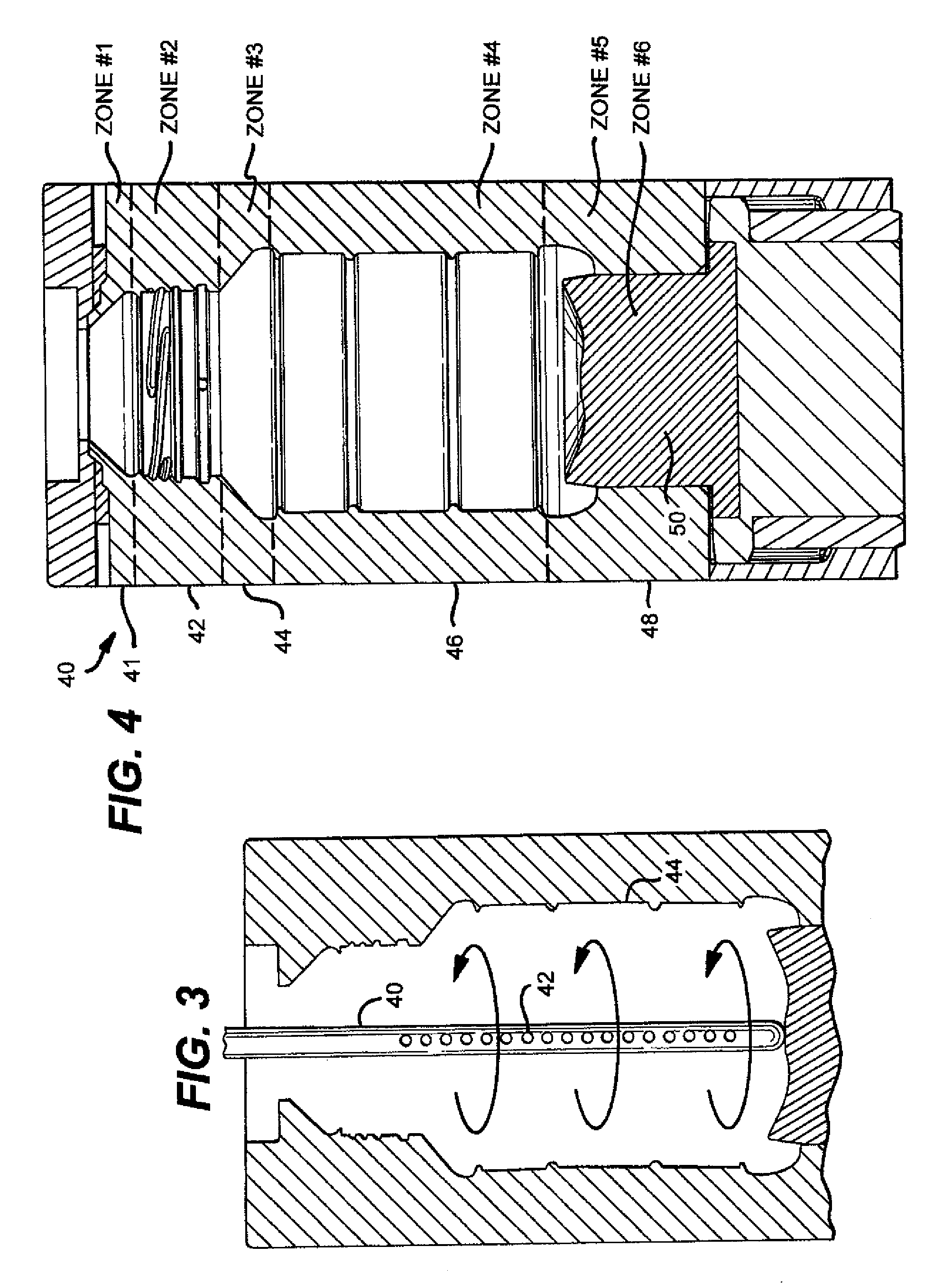

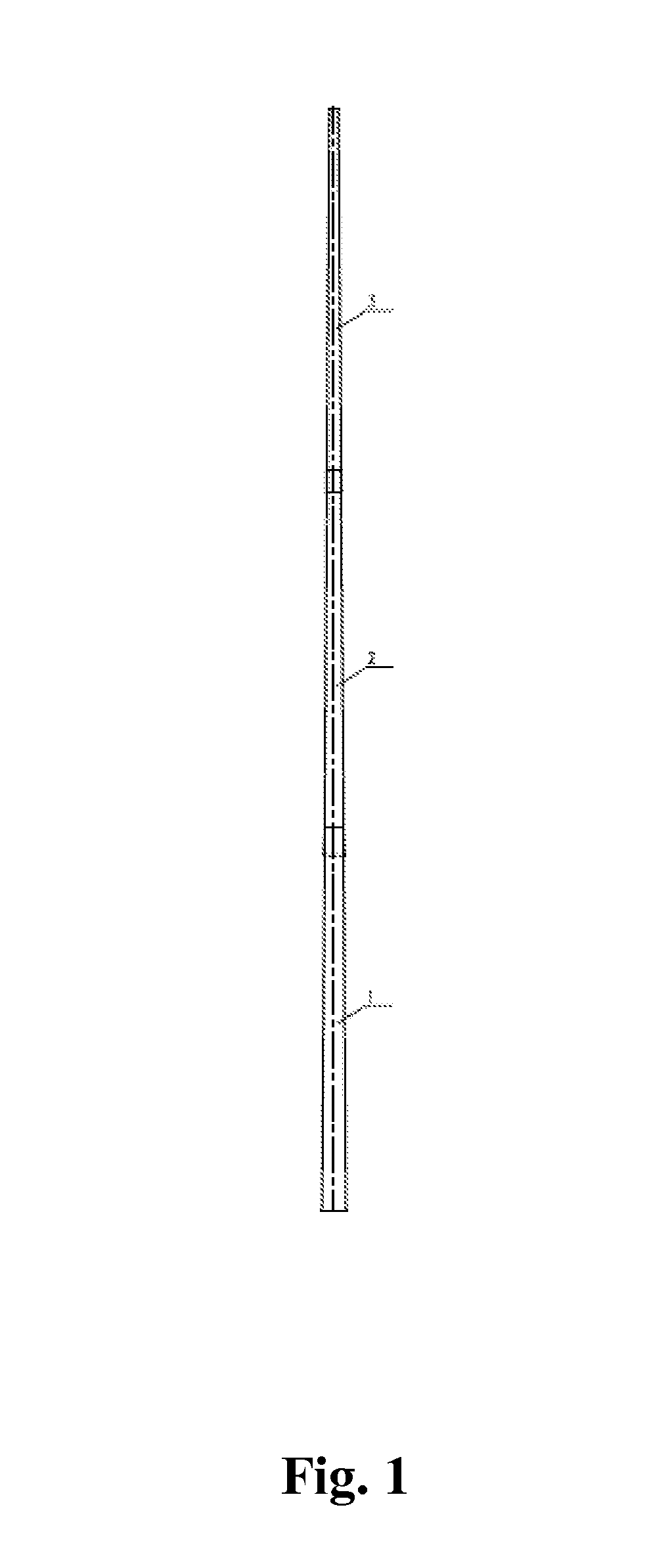

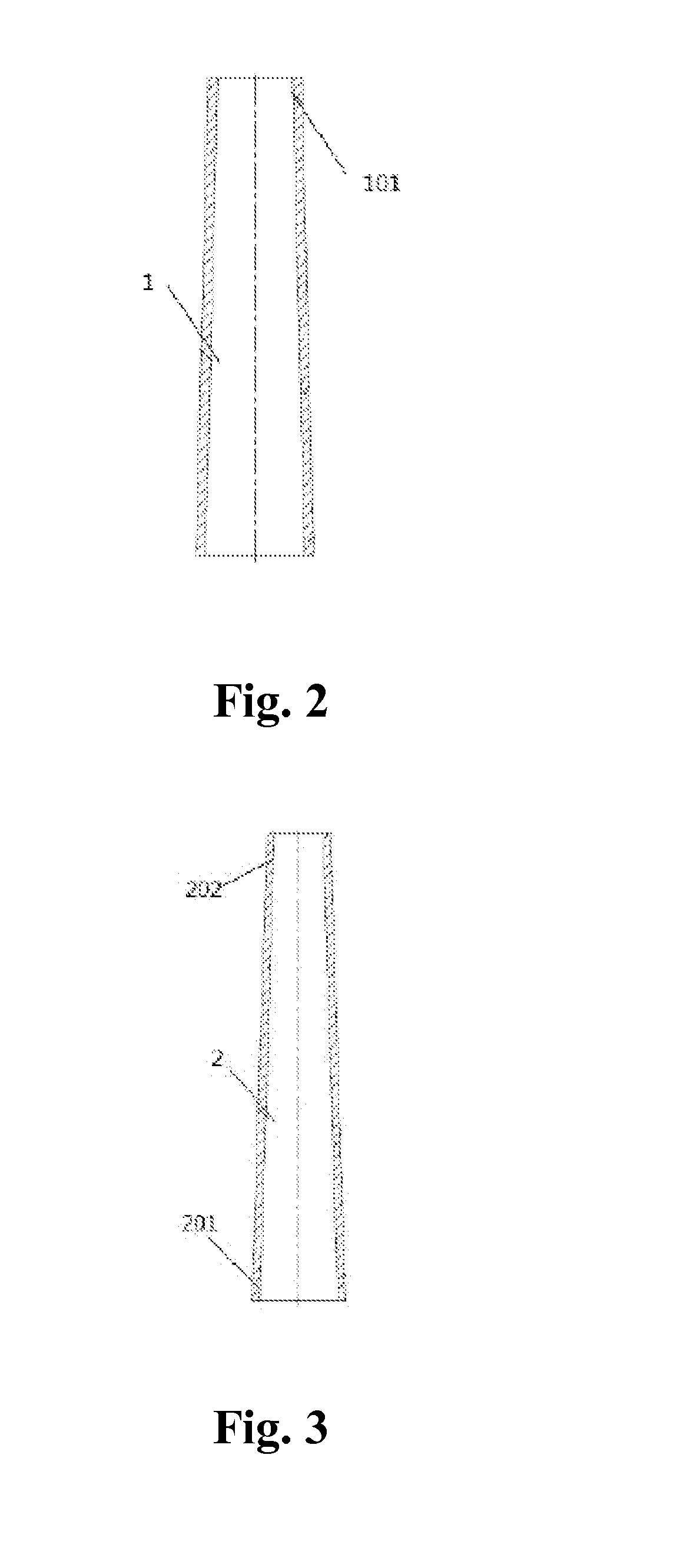

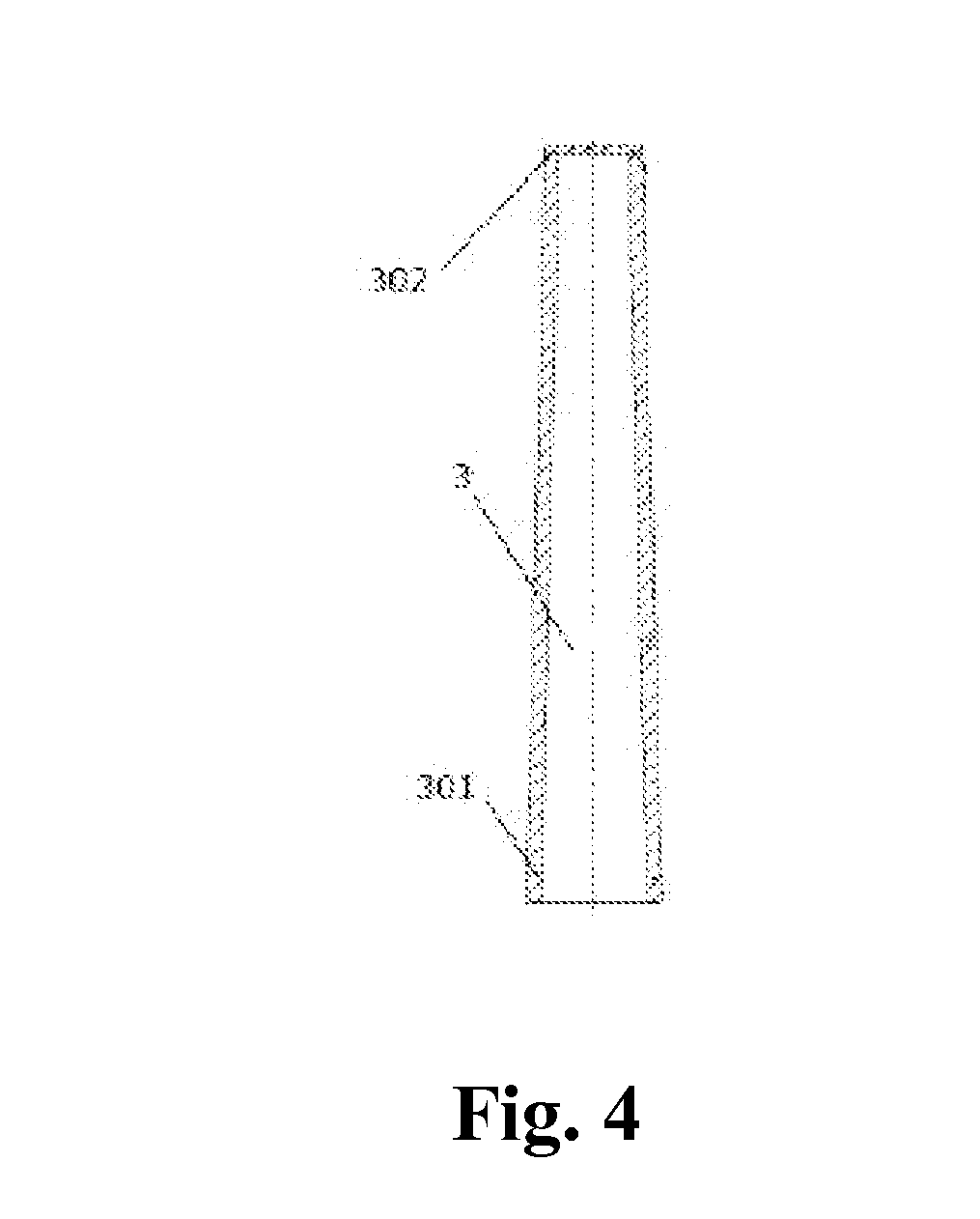

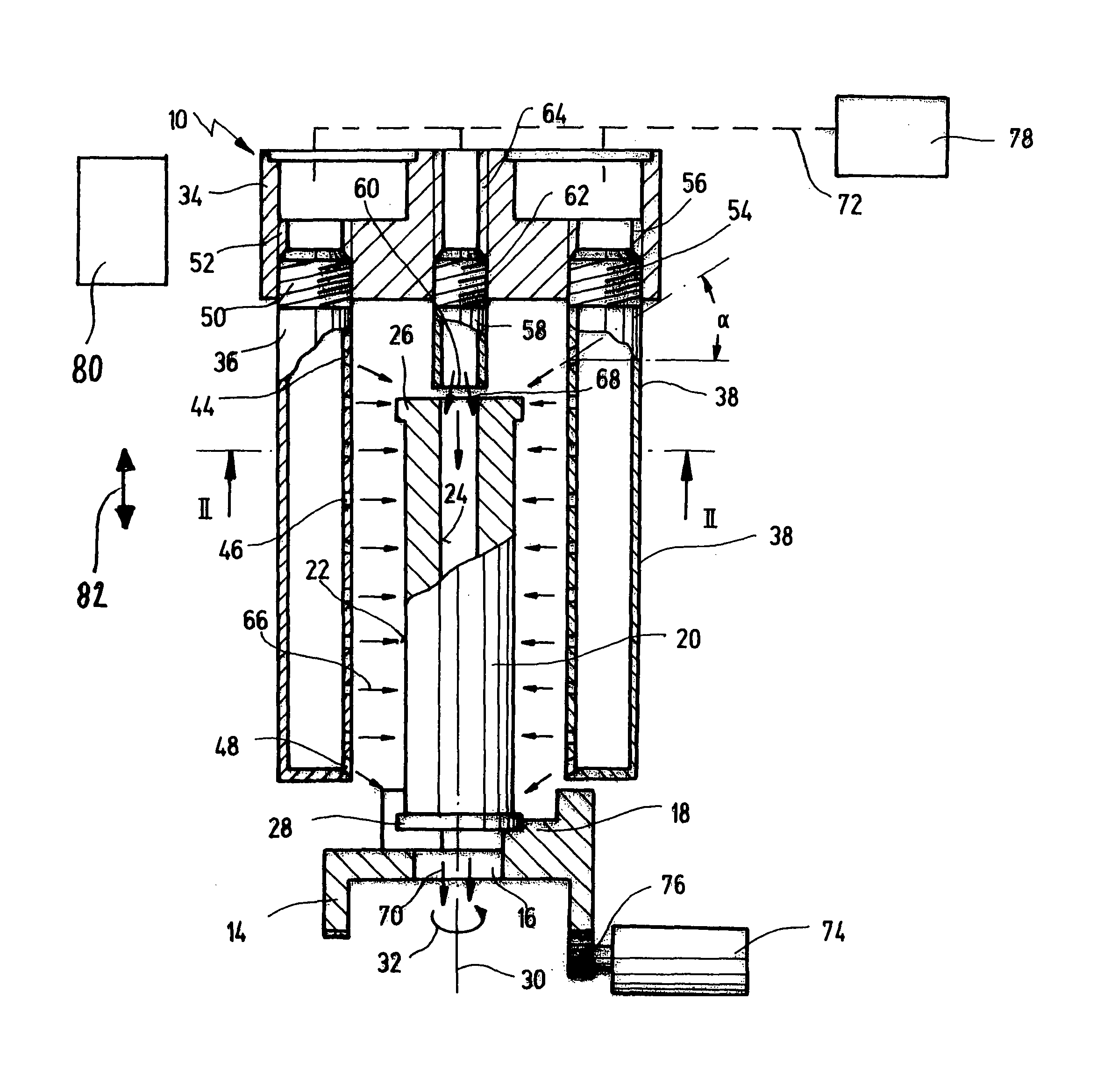

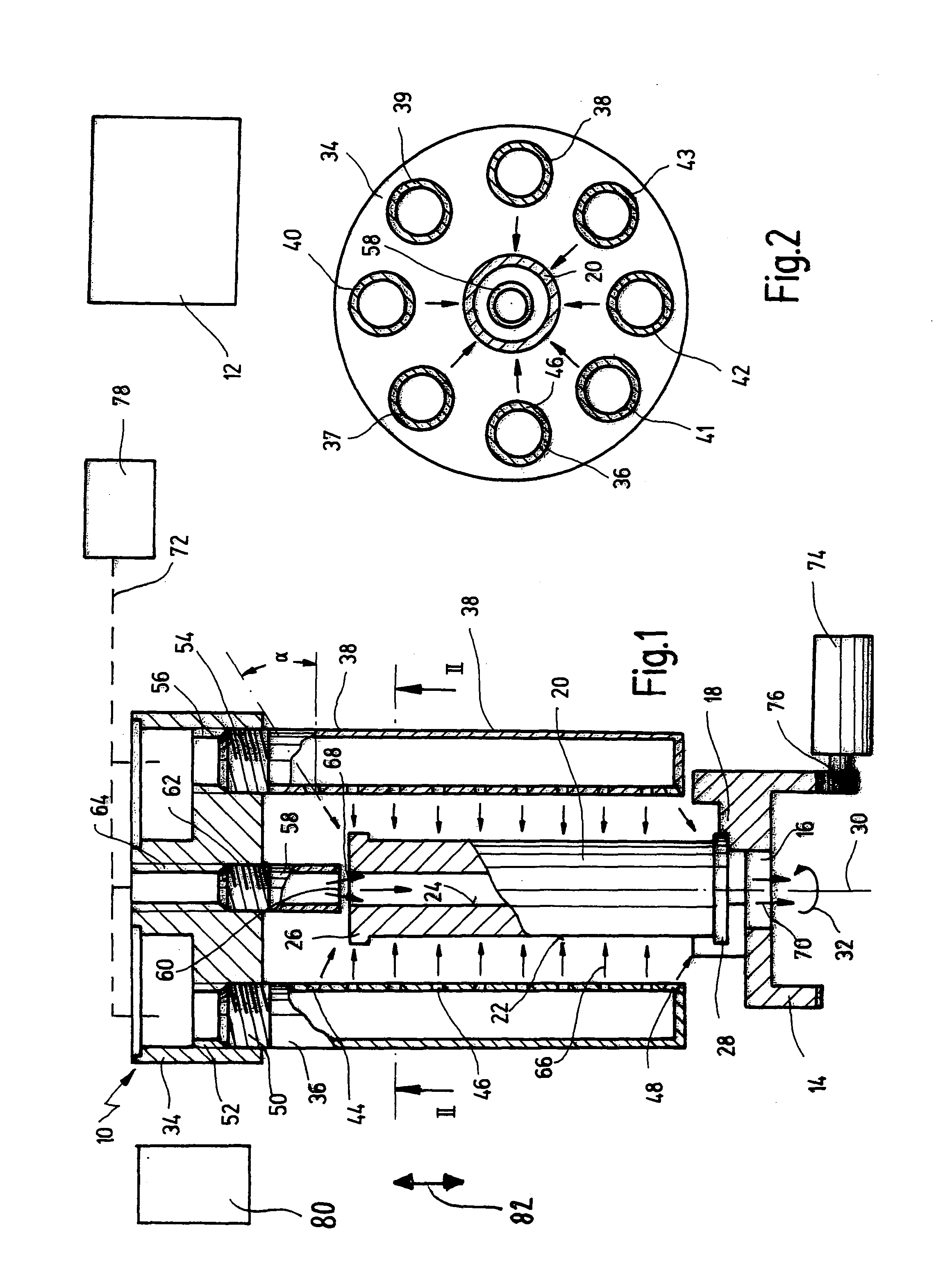

Device and method for thermally pre-stressing elongated hollow objects

ActiveUS20060016220A1Improve heat transfer performanceHigh pre-stress valueGlass tempering apparatusPre stressPre stressing

A device and a method for thermal pre-stressing lengthy hollow objects, in particular glass tubes, are disclosed. The device comprises a heating device, a fixture for receiving an object, and a coolant feed device comprising an outer coolant feed unit with a plurality of nozzles for feeding coolant against an outer surface of the object, and further comprising an inner coolant feed device for feeding coolant against an inner surface of the object.

Owner:SCHOTT PHARMA AG & CO KGAA

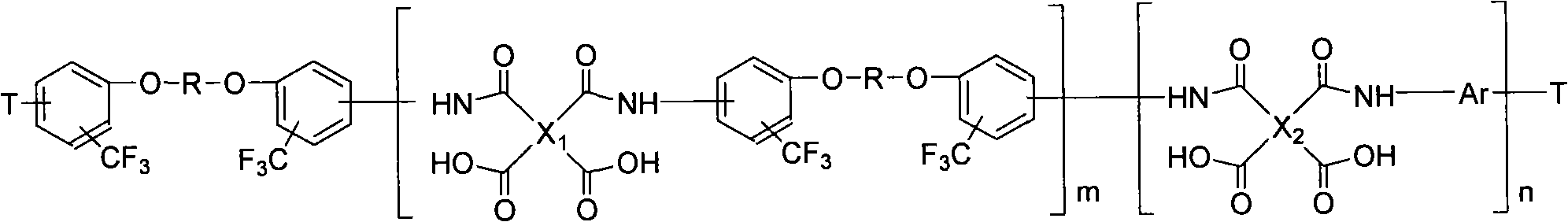

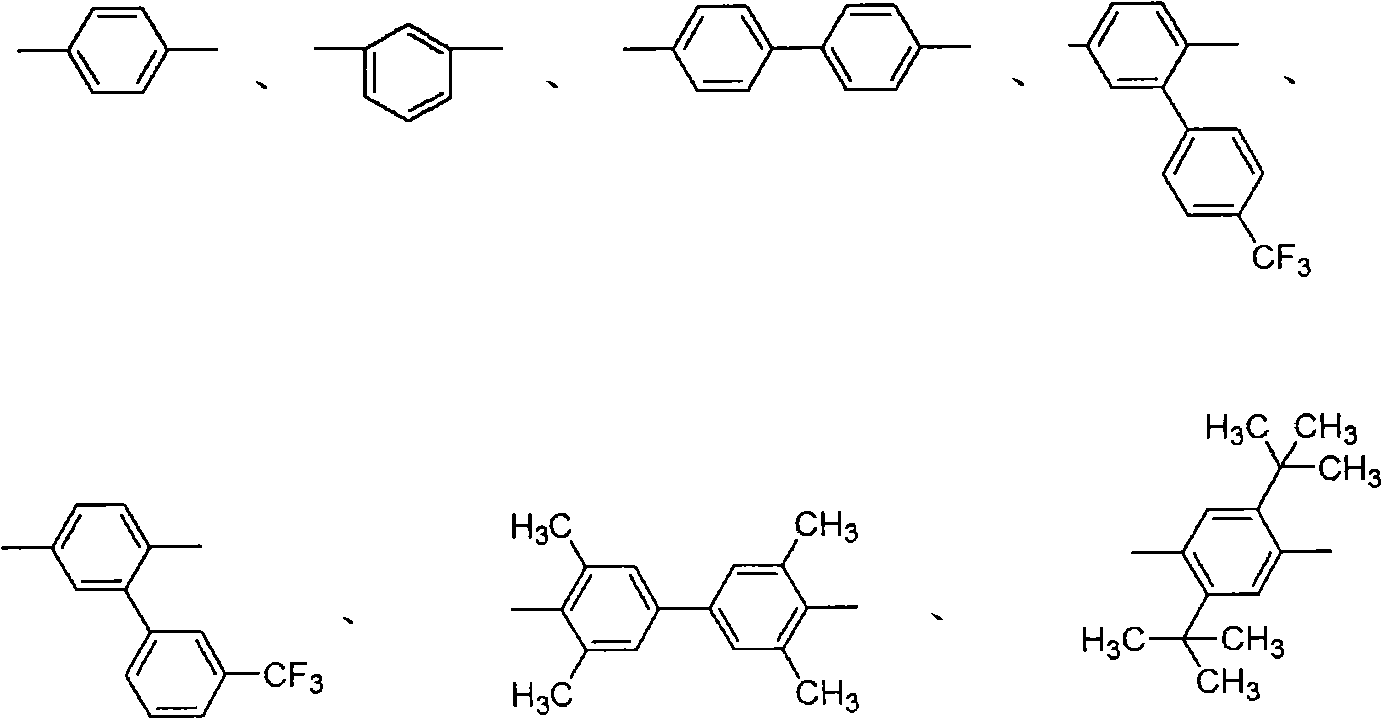

Polyimide resin, its midbody, preparation method and application thereof

ActiveCN101343362AImprove heat resistanceImprove mechanical propertiesLamination ancillary operationsSynthetic resin layered productsChemical structureMetal foil

The invention discloses polyamide resin and intermediate compound thereof as well as the preparation method and the application. The polyamide resin is provided with the chemical structure shown in formula II, wherein, X1 and X2 can be identical or different, representing quadrivalent aryl; Ar represents bivalent aryl, and T represents end capping reagent. The polyamide resin is obtained by polyamic acid shown in formula I structure general formula through chemical imidization or thermal imidization. The polyamide resin is dipped through prosomatic polyamic acid solution or polyamic acid solution being obtained after being dissolved with solvent with a low-boiling point, the basal body is strengthened, and the prepreg is obtained. After the heat-press forming operation is performed, a metal foil layer is covered, and a metal foil layer pressing plate is obtained. The polyamide resin provided by the invention has the advantages of excellent heat resisting property, high mechanical property, low dielectric constant and dissipation, high electrical insulation property and low water absorbing capacity, thereby being especially suitable for manufacturing core plates of packaging subsctrates for packaging super large-scale integrated circuits.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Noble metal-rare-earth catalyst for purifying waste gas and its preparation

InactiveCN1473651AIncreased durabilityIncreased chance of collisionDispersed particle separationCatalyst activation/preparationMischmetalMixed oxide

The catalyst includes alumina, RE metal oxide, composite Al-La oxide, and active metal Pt, Pd and Rh. It features that the mixed oxide grain with aluina, cerium oxide and Al-La oxide carries at least one of Pt and Pd as well as Rh. The mixed oxide grain is prepared through dissolving salt of Al, Ce and La in water, adding NH3OH to produce precipitate, and heating to decompose the precipitate. The catalyst preparing process includes carrying mixed oxide grains onto the carrier, carrying least one of Pt and Pd onto the mixed oxide grains, and carrying Rh finally. The catalyst is especially suitable for purifying automobile tail gas of gasoline engine near the theoretical air / fuel ratio, and has the features of lasting use, less noble metal consumption, high purifying efficiency and powerful sulfur poison resistance.

Owner:昆明贵研催化剂有限责任公司

Hazard-free microencapsulation for structurally delicate agents, an application of stable aqueous-aqueous emulsion

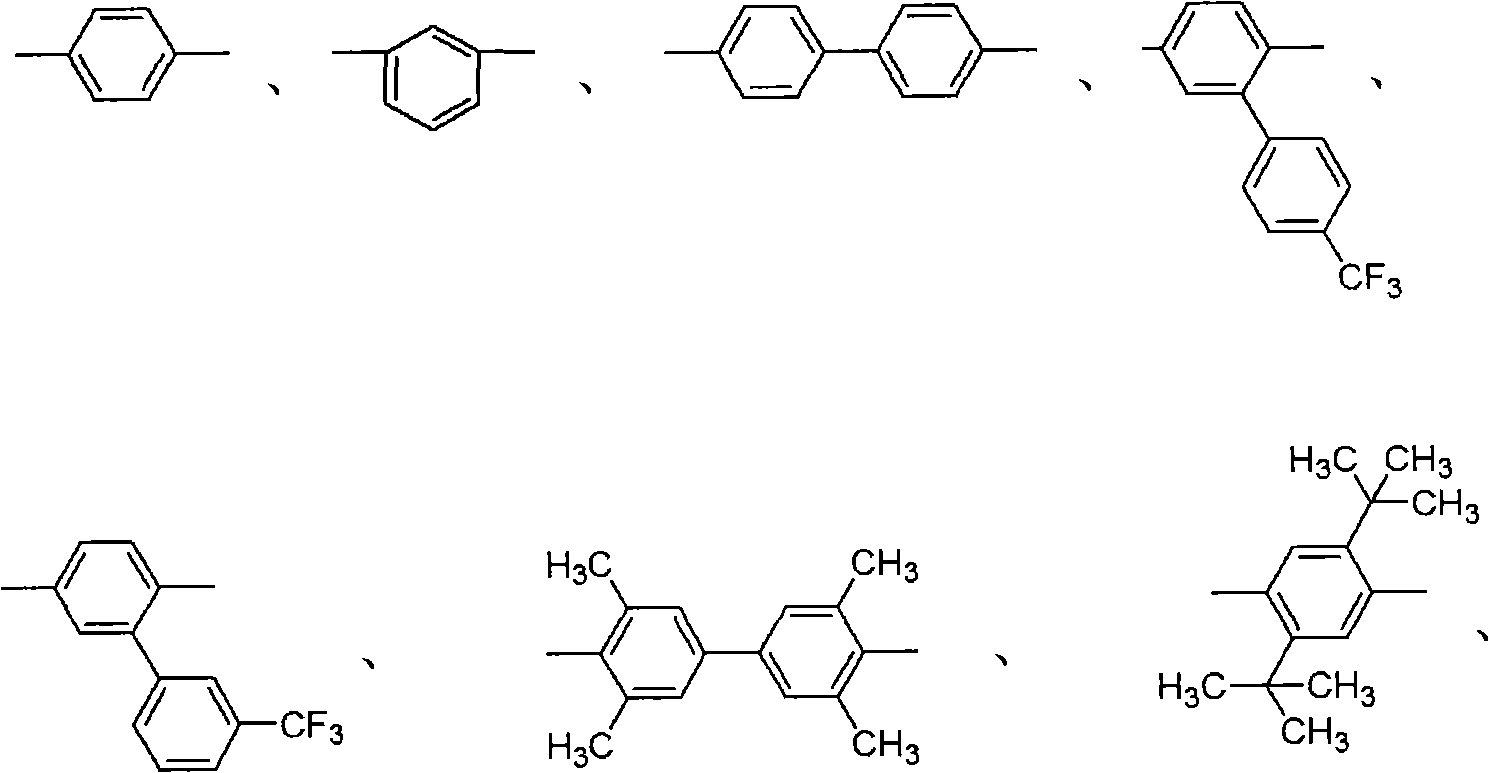

InactiveUS20060121121A1Strong resistanceRaise the transition temperaturePowder deliveryPeptide/protein ingredientsCross-linkOrganic solvent

This invention provides method for sustained release delivery of structurally delicate agents such as proteins and peptides. Using unique emulsion system (Stable polymer aqueous-aqueous emulsion), proteins and peptides can be microencapsulated in polysacchride glassy particles under a condition free of any chemical or physical hazard such as organic solvents, strong interfacial tension, strong shears, elevated temperature, large amount of surfactants, and cross-linking agents. Proteins loaded in these glassy particles showed strong resistance to organic solvents, prolonged activity in hydrated state, and an excellent sustained release profile with minimal burst and incomplete release when being further loaded in degradable polymer microspheres. This invention provides a simple yet effective approach to address all the technical challenges raised in sustained release delivery of proteins.

Owner:BIOPHARM SOLUTIONS

Pet containers with enhanced thermal properties

ActiveUS20110070388A1Improve thermal performanceImprove thermal stabilityLayered productsBottlesVitrificationGlass transition

The present invention provides a blow molded heat set PET container having enhanced thermal properties and a first glass transition temperature and a second endothermic transition temperature substantially higher than the glass transition temperature.

Owner:GRAHAM PACKAGING PET TECH

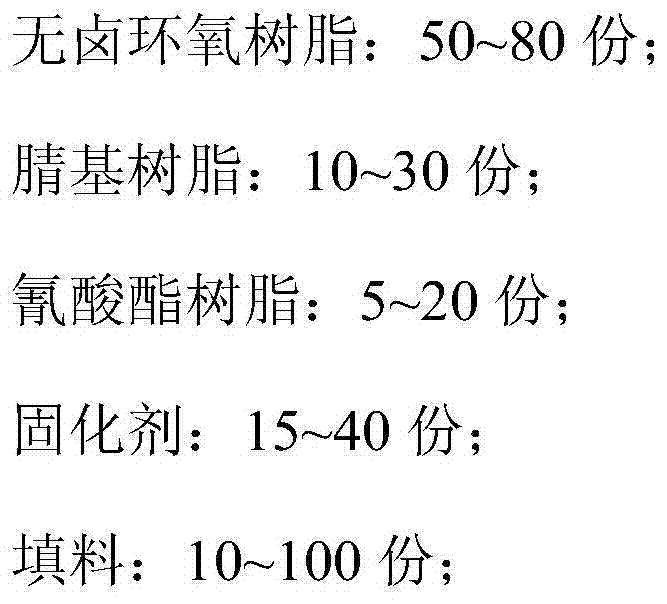

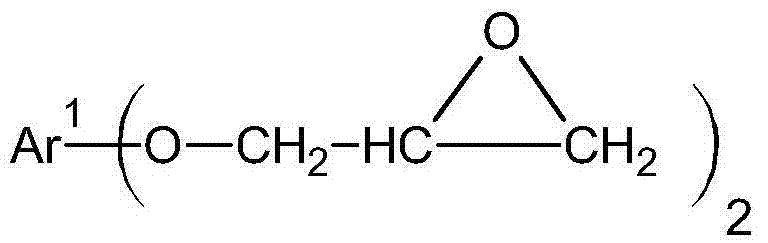

Halogen-free non-phosphorus flame-retarded resin composition

ActiveCN103881309AGood heat resistance and toughnessImprove thermal stabilityFilm/foil adhesivesSynthetic resin layered productsTemperature resistanceSolvent

The invention relates to a halogen-free non-phosphorus flame-retarded resin composition which is composed of a constituent and a solvent; the constituent comprises the following components in parts by weight: 50-80 parts of halogen-free epoxy resin, 10-30 parts of nitrile-group resin, 5-20 parts of cyanate ester resin, 15-40 parts of curing agent and 10-100 parts of filler, wherein the constituent is dissolved in the solvent and accounts for 65wt%-75wt% of the total weight. According to the invention, the nitrile-group resin is added in the halogen-free non-phosphorus flame-retarded resin composition, so that a purpose of improving resin flame resistance, high temperature resistance and dielectric properties is realized; the halogen-free epoxy resin and the cyanate ester resin are supplemented to overcome the defects that nitrile-group resin is sufficient in toughness and machinability is poor, and water absorption of the resin is improved; and moreover, the UL-V0-grade green and environment-friendly halogen-free non-phosphorus flame-retarded resin composition with excellent toughness, machinability and water absorption is obtained.

Owner:GUANGDONG SHENGYI SCI TECH

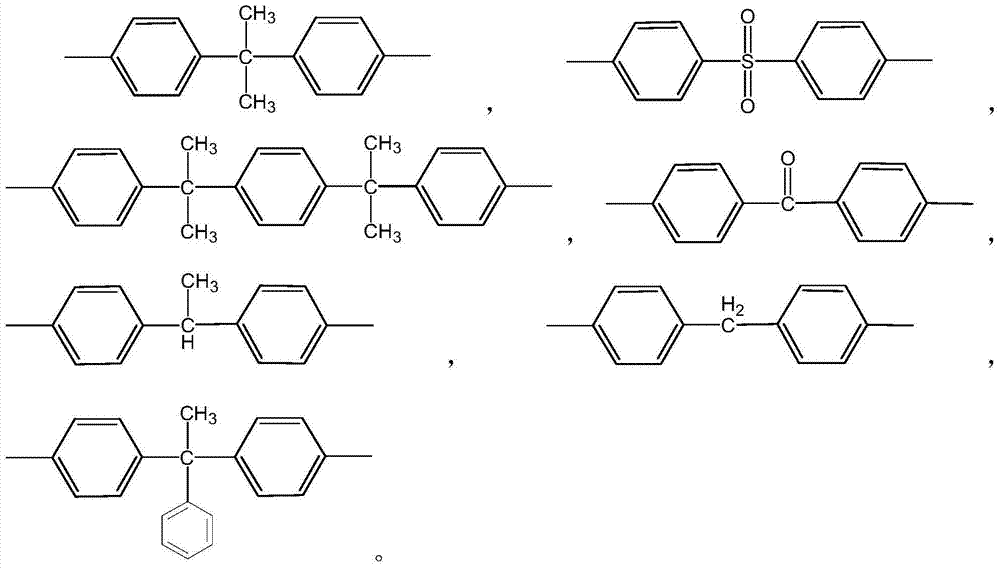

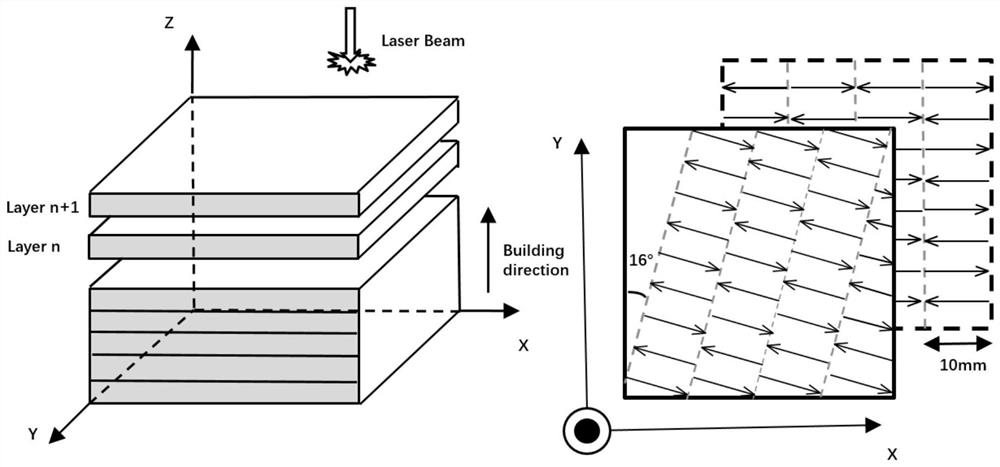

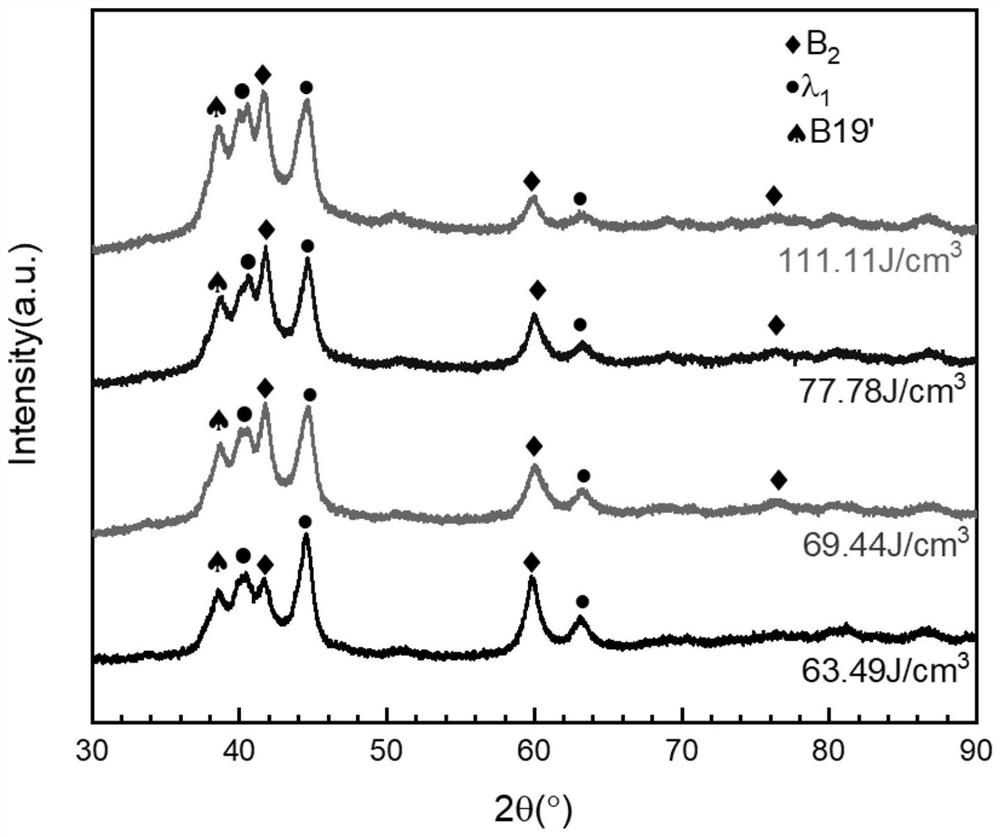

4D printing method of nickel-titanium-based ternary shape memory alloy

InactiveCN111842888AHas shape memory effectRaise the transition temperatureAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingBinary alloy

The invention belongs to the technical field of 4D printing additive manufacturing, and discloses a 4D printing method of a nickel-titanium-based ternary shape memory alloy. The 4D printing method ischaracterized in that a selective laser melting technology is adopted for printing gas atomized prefabricated NiTiZr ternary alloy powder, and a component obtained through printing has the shape memory function; and the laser energy density is changed by changing the technological parameters adopted in the selective laser melting technology, and therefore the changes of the structure and performance of the printed piece are regulated and controlled. According to the 4D printing method, the ternary component Zr is introduced into an existing nickel-titanium binary alloy, the martensite phase transformation temperature is obviously increased, the selective laser melting technology is adopted for forming, and complex parts uniform in structure and high in density can be obtained while the excellent shape memory performance and mechanical performance are guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

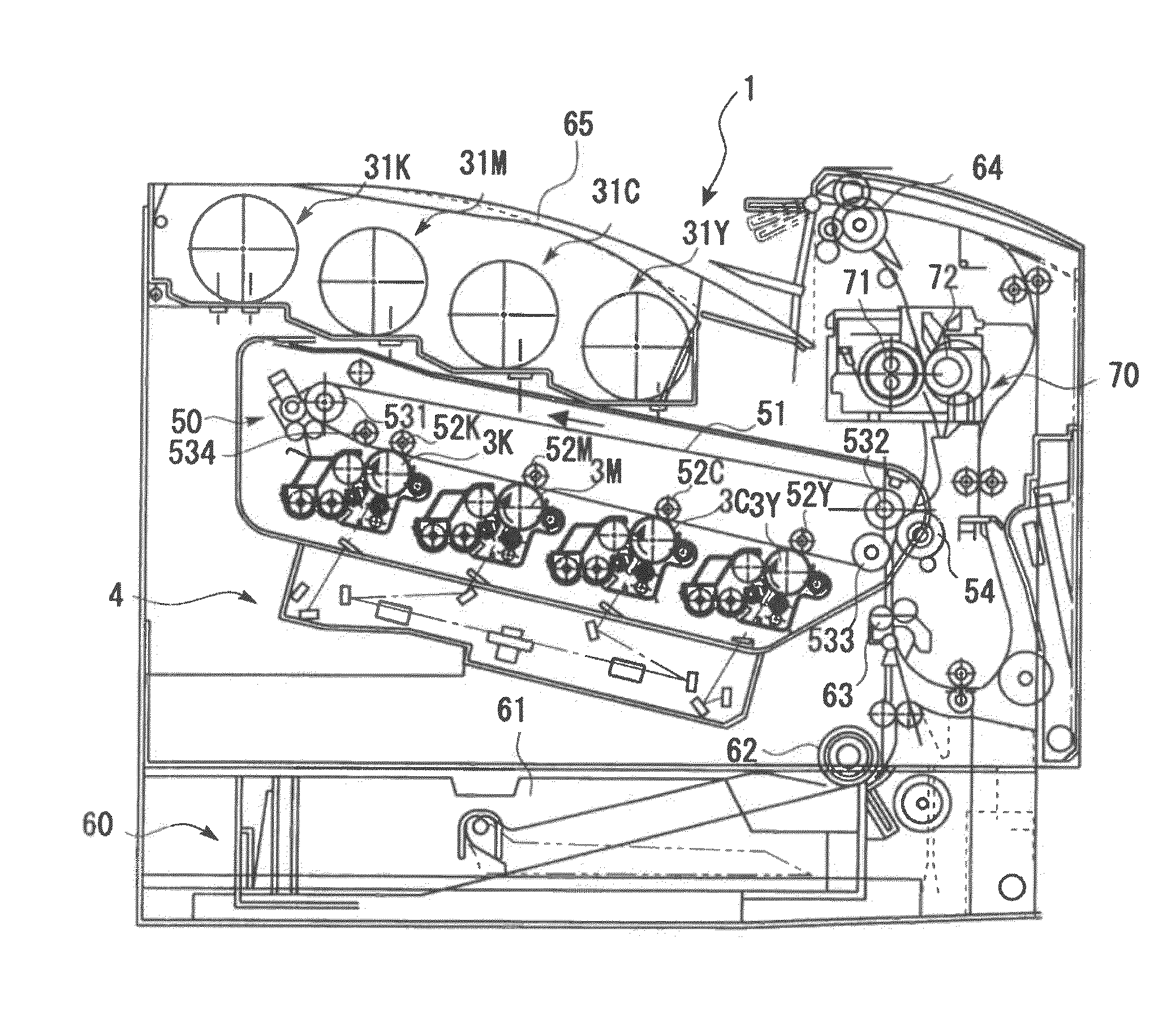

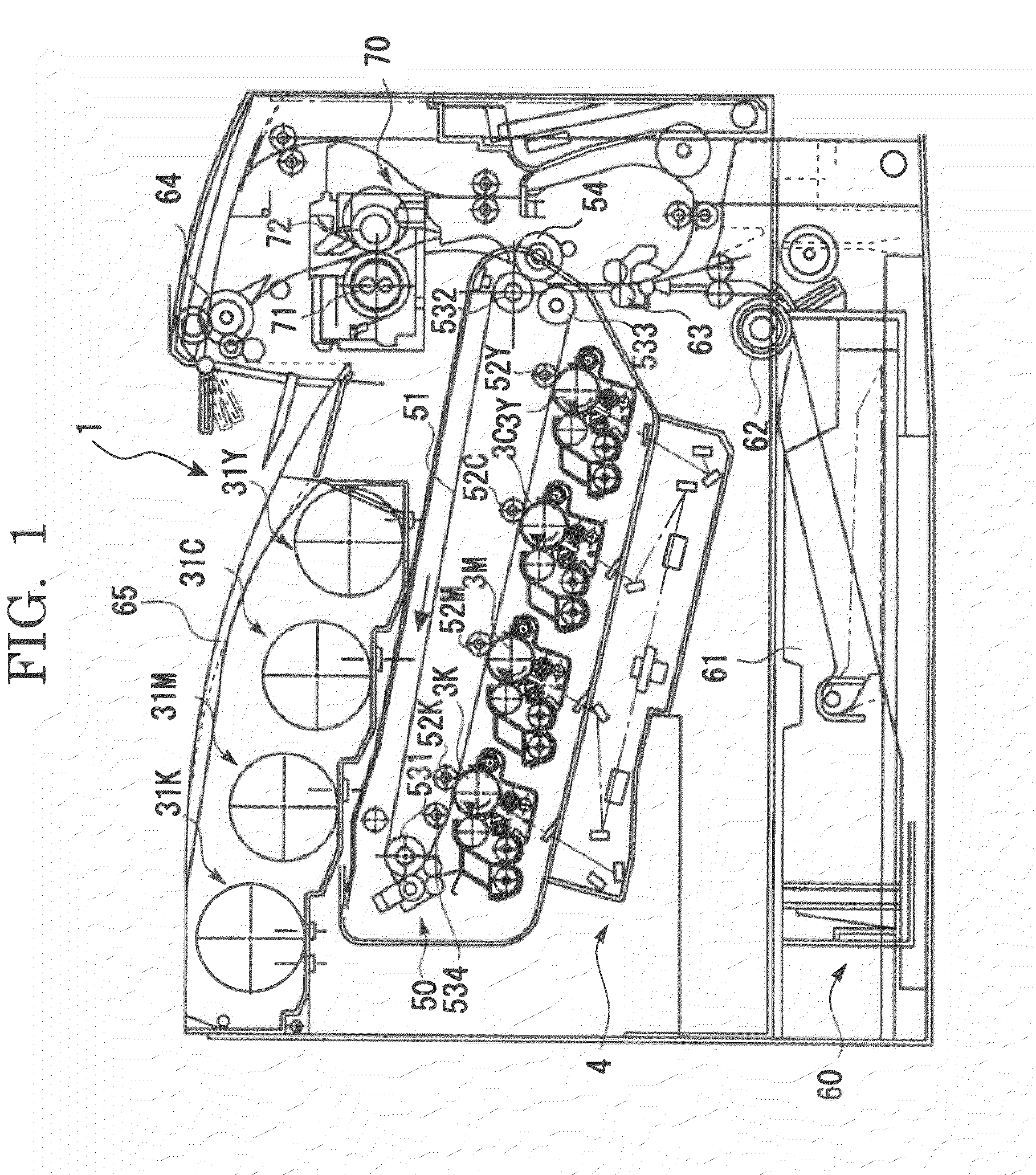

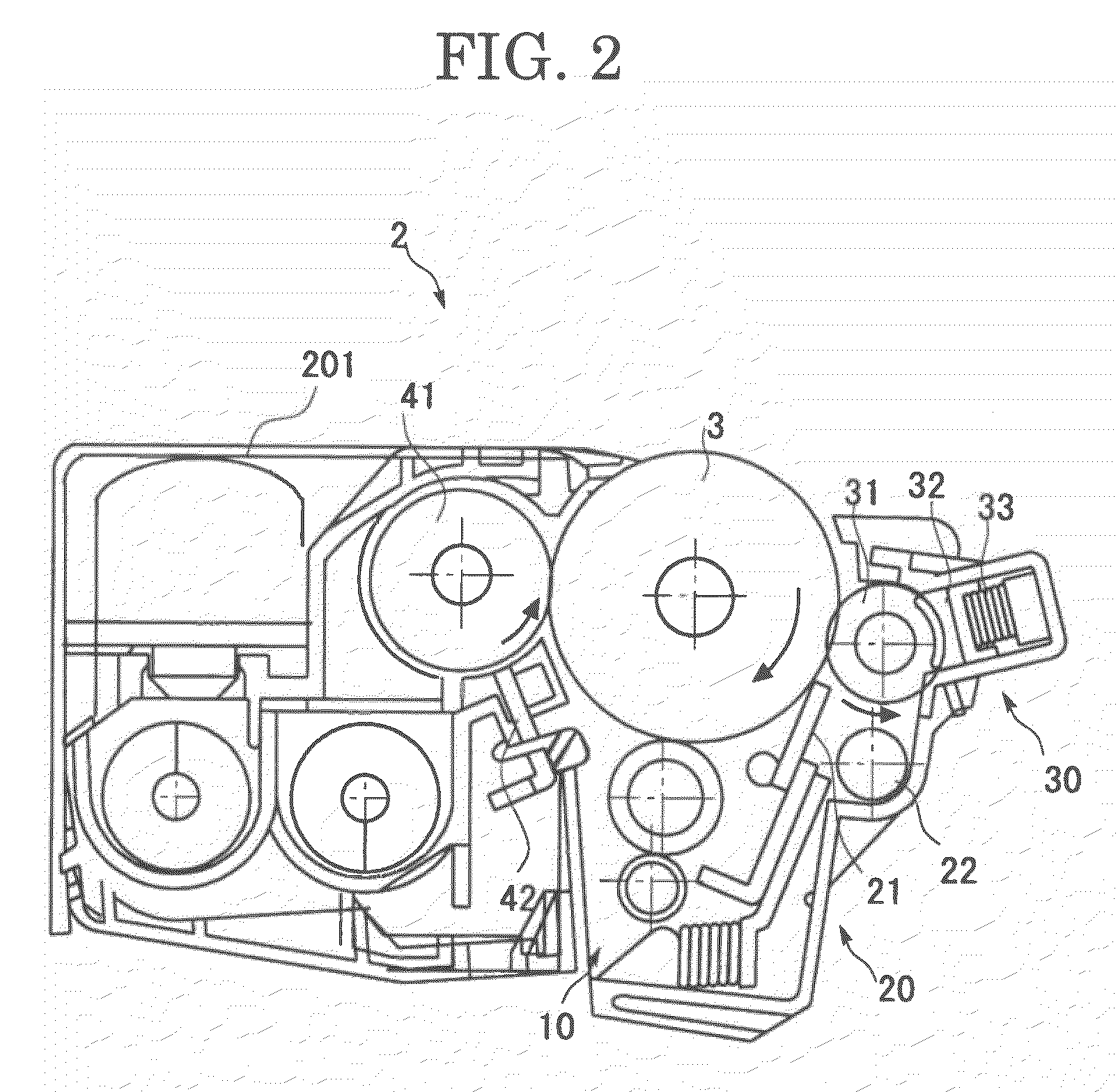

Toner and method for producing the same

ActiveUS20110164901A1Achieving fixabilityGood fixabilityElectrographic process apparatusDevelopersPolyesterChemistry

A toner containing core particles each containing at least a resin A having a polyester skeleton and a colorant; and vinyl resin fine particles each of which encapsulates a resin B having at least a polyester skeleton and an endothermic peak measured by differential scanning calorimeter (DSC) at 40° C. to 110° C., wherein the vinyl resin fine particles are attached onto each of the core particles.

Owner:RICOH KK

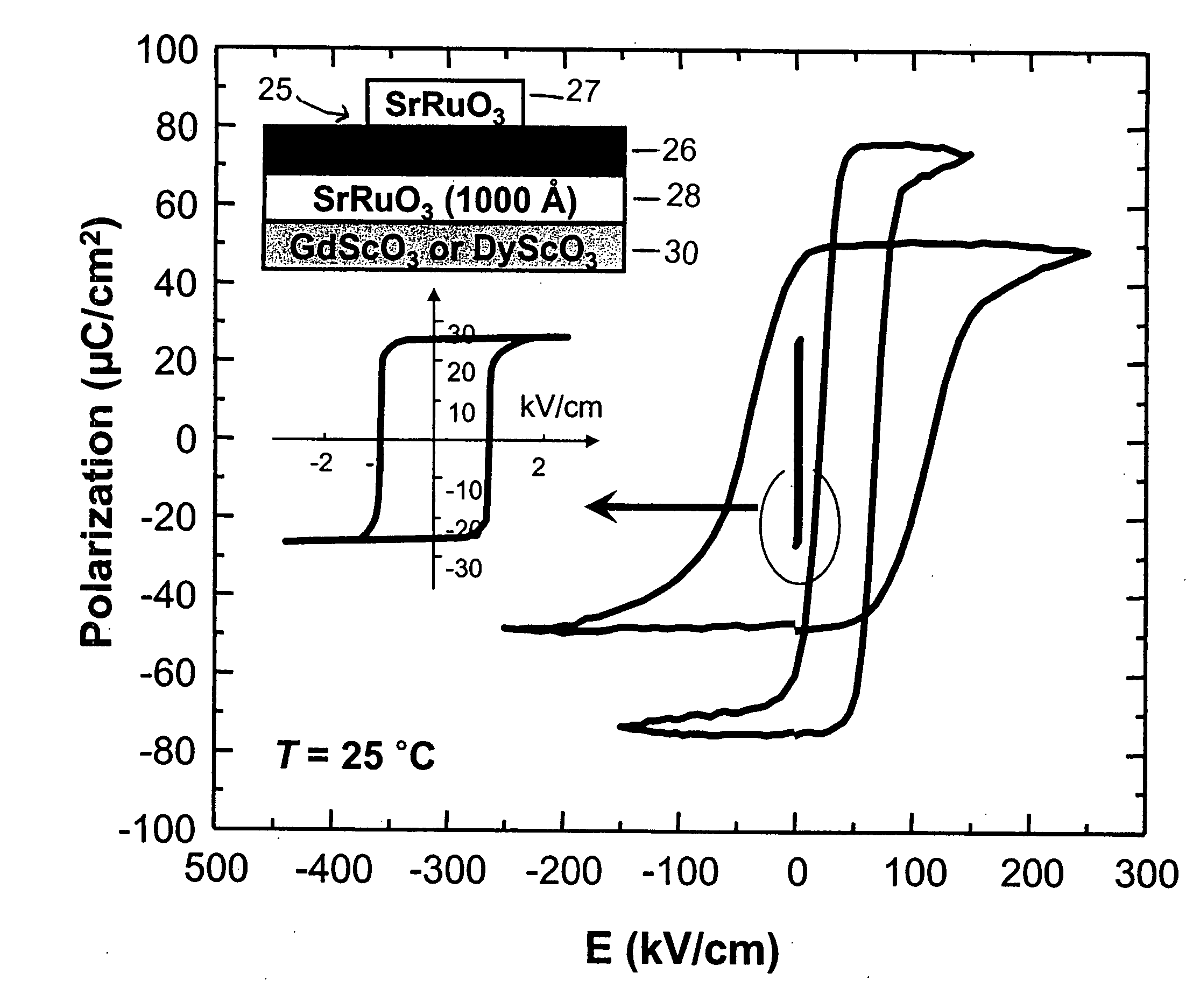

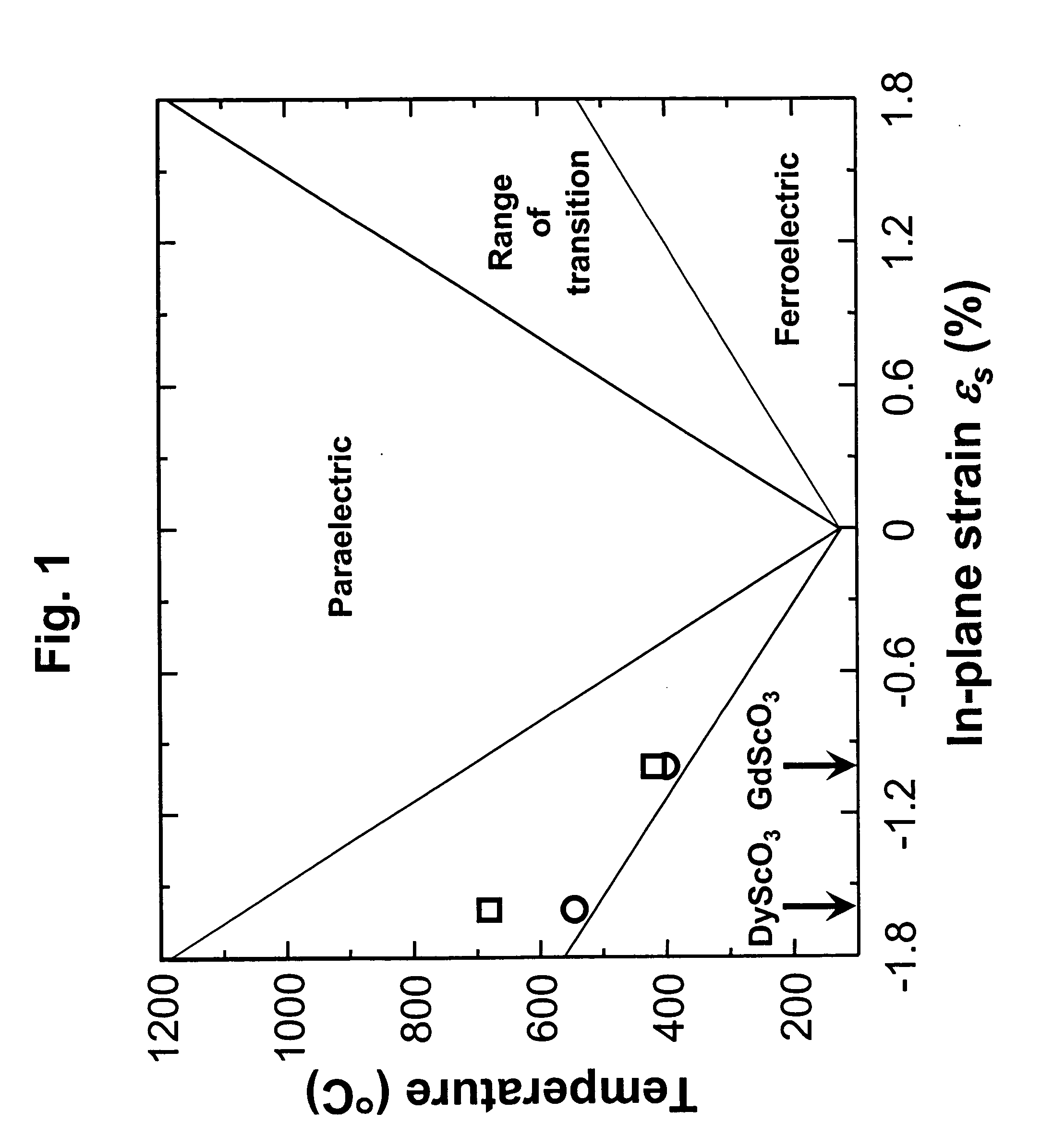

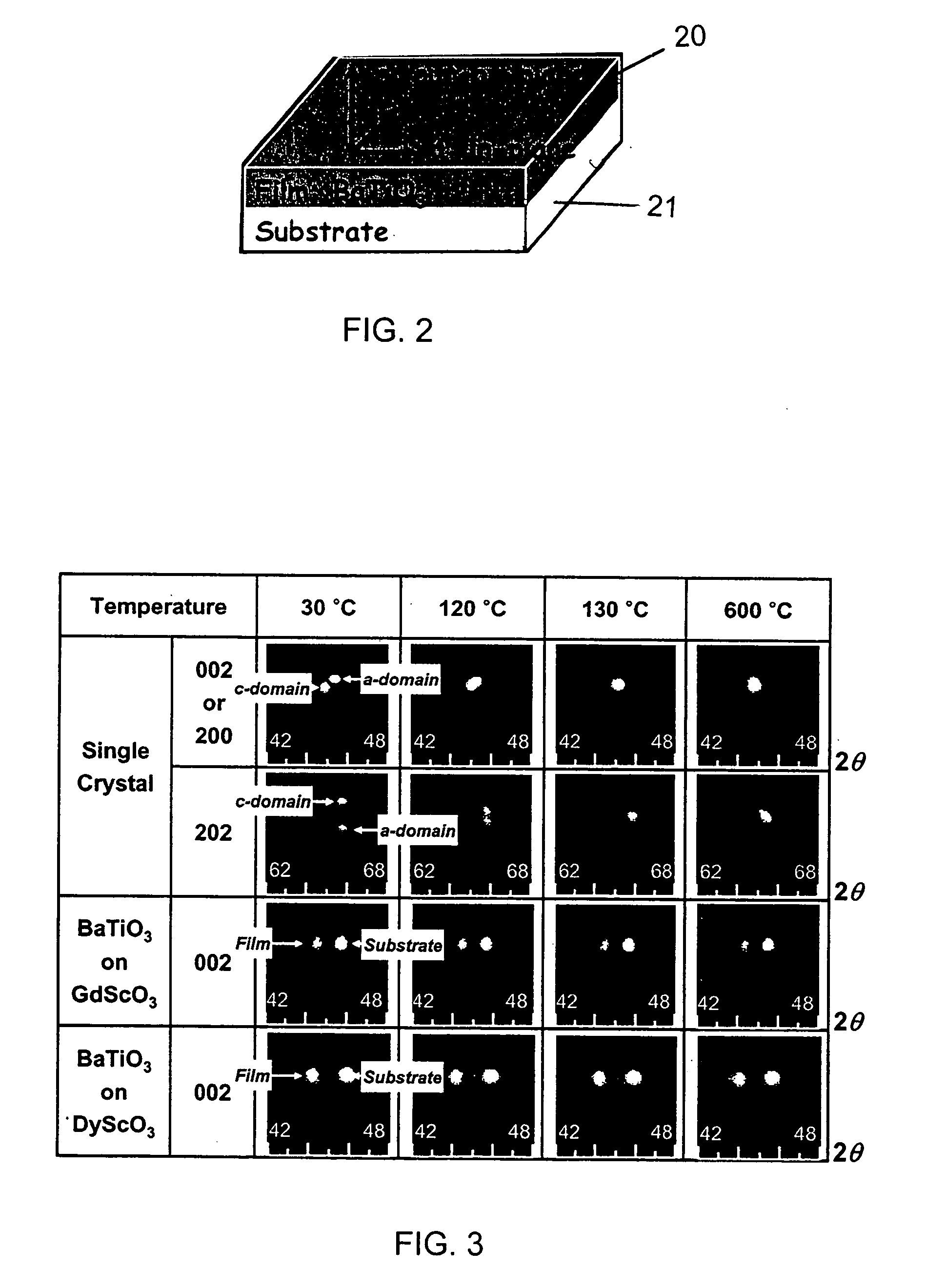

Strain-engineered ferroelectric thin films

ActiveUS20060091434A1Improve ferroelectric propertiesRaise the transition temperatureSemiconductor/solid-state device manufacturingSemiconductor devicesInter layerFerroelectric thin films

A strained thin film structure includes a substrate layer formed of a crystalline scandate material having a top surface, and a strained layer of crystalline ferroelectric epitaxially grown with respect to the crystalline substrate layer so as to be in a strained state and at a thickness below which dislocations begin to occur in the crystalline ferroelectric layer. An intermediate layer may be grown between the top surface of the substrate layer and the ferroelectric layer wherein the intermediate layer carries the lattice structure of the underlying substrate layer. The properties of the ferroelectric film are greatly enhanced as compared to the bulk ferroelectric material, and such films are suitable for use in applications including ferroelectric memories.

Owner:PENN STATE RES FOUND +1

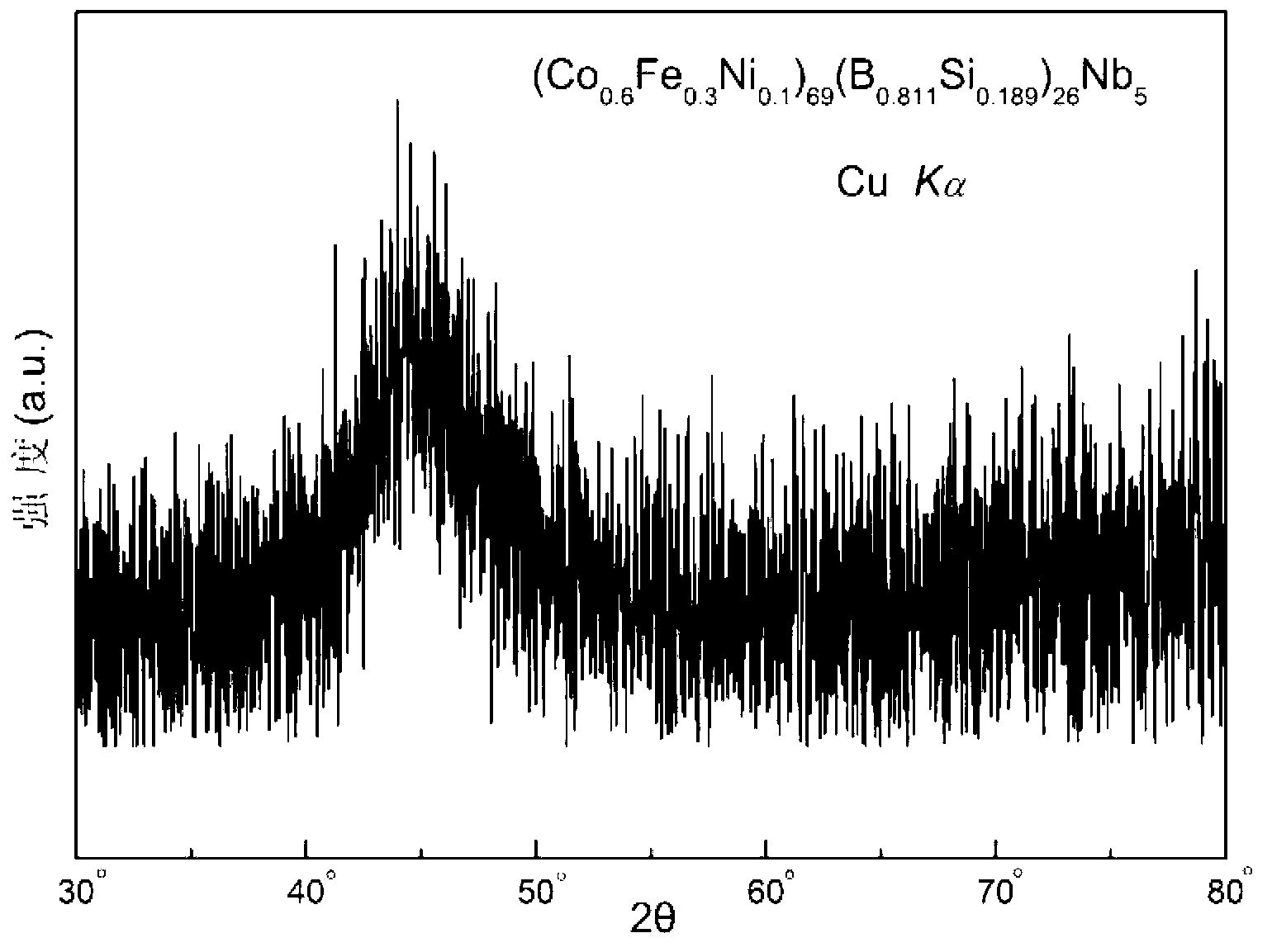

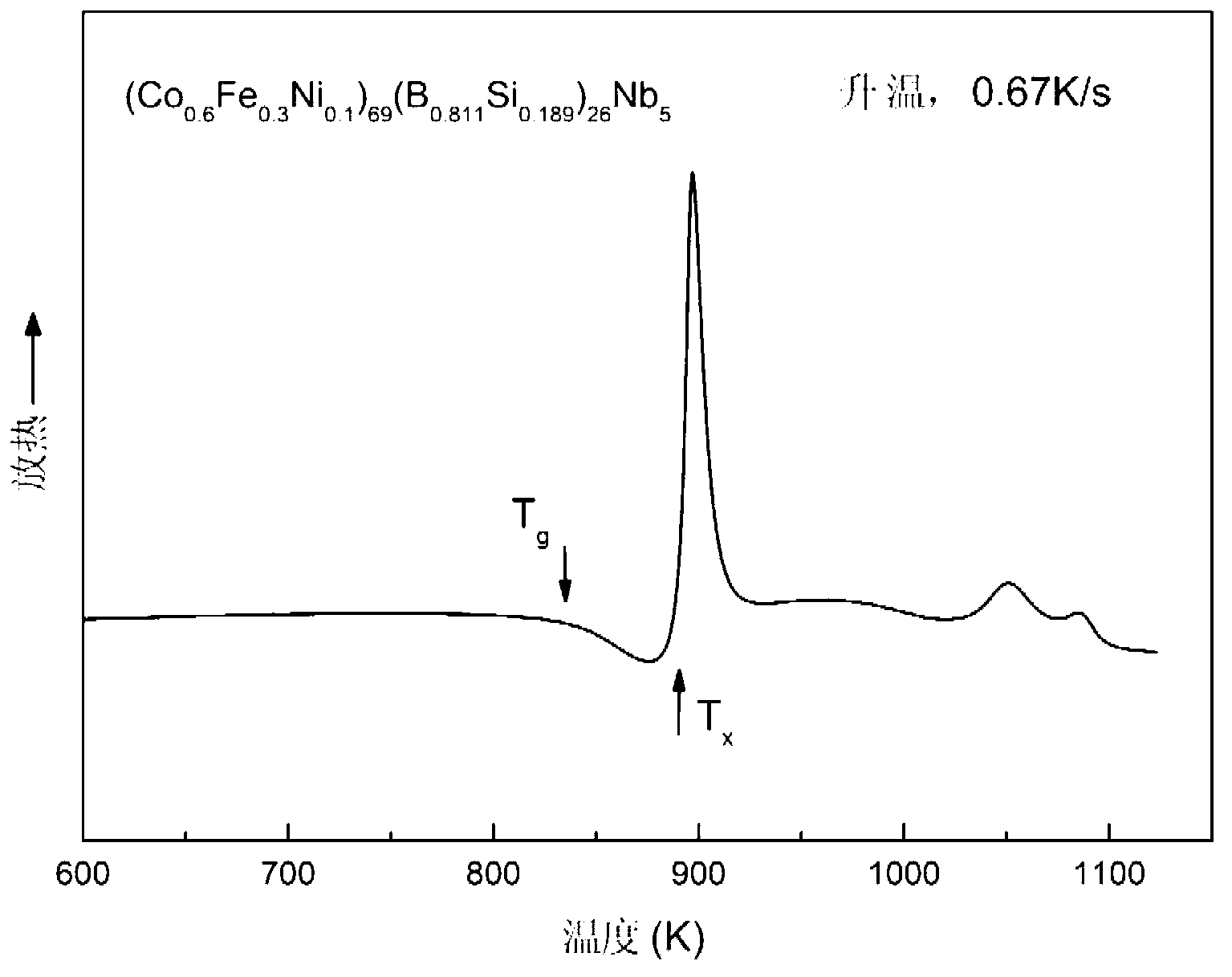

Cobalt-base block amorphous soft magnetic alloy with high amorphous forming ability and preparation method thereof

InactiveCN102915820ARaise the transition temperatureEnhanced Amorphous Formation AbilityMagnetic materialsMechanical properties of carbon nanotubesLiquid phase

The invention provides a cobalt-base block amorphous soft magnetic alloy with high amorphous forming ability and a preparation method thereof. The molecular formula of the amorphous soft magnetic alloy is CoaFebNicBdSieNb5, in which a, b, c, d and e are atomic percents, wherein a is larger than or equal to 25 and smaller than or equal to 60, b is larger than or equal to 10 and smaller than or equal to 28, c is larger than or equal to 2 and smaller than or equal to 10, d is larger than 0, e is larger than 0, d+e is larger than or equal to 14 and smaller than or equal to 39, and a+b+c+d+e+5 is equal to 100. Compared with the prior art, the alloy material has the advantages of high amorphous forming ability, excellent soft magnetic property and mechanical property, the reduced glass transition temperature of the alloy material reaches 0.5-0.7, the coercive force of the alloy material reaches below 1.5A / m, the rupture strength of the alloy material is larger than 4200MPa, and the alloy material can be prepared into amorphous bars with the diameters of 1mm-7mm due to the high amorphous forming ability; therefore, the alloy material can be widely applied in the fields of transformers, magnetic sensors and the like, and has good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Multiphase compositions for oxidation protection of composite articles

ActiveUS20160280612A1Raise the transition temperaturePretreated surfacesCoatingsCarbon compositesMetallurgy

The present disclosure includes carbon-carbon composite articles having multiphase glass oxidation protection coatings for limiting thermal and / or catalytic oxidation reactions and methods for applying multiphase glass oxidation protection coatings to carbon-carbon composite articles.

Owner:THE BF GOODRICH CO

Compound nitrogen alloy core spun yarn and preparation method thereof

ActiveCN103966396AEnhance precipitation strengtheningComprehensive effect of refinementYarnVanadium nitride

The invention provides compound nitrogen alloy core spun yarn and a preparation method thereof, and belongs to the technical field of molten steel refinement. The core spun yarn comprises inner core materials and a coating layer, wherein the inner core materials are formed by mixing more than three of ferrovanadium, nitrided ferrovanadium, vanadium nitride, ferro-silicon nitride, silicomanganese nitride, ferrotitanium nitride, ferroboron, ferroboron nitride, ferrocolumbium and ferrocolumbium nitride, the inner core materials at least comprise more than two nitrides or nitralloy, and the coating layer adopts a bright steel belt. The preparation method of the core spun yarn comprises the steps as follows: the inner core materials are prepared firstly; materials are prepared according to required nitrogen content, alloy elements and types of targeted steel; the inner core materials are prepared through powder grinding, uniform mixing and granulating; and the inner core materials are coated with the bright steel belt to form the round core spun yarn. The core spun yarn provided by the invention can improve the strengthening effect of the alloy elements and optimize the microalloying technology, and purposes of stabilizing the target steel performance and reducing the cost are achieved.

Owner:安徽中元新材料技术有限公司

Pet containers with enhanced thermal properties

ActiveUS8507063B2Improve thermal performanceRaise the transition temperatureEnvelopes/bags making machineryBottlesVitrificationGlass transition

The present invention provides a blow molded heat set PET container having enhanced thermal properties and a first glass transition temperature and a second endothermic transition temperature substantially higher than the glass transition temperature.

Owner:GRAHAM PACKAGING PET TECH

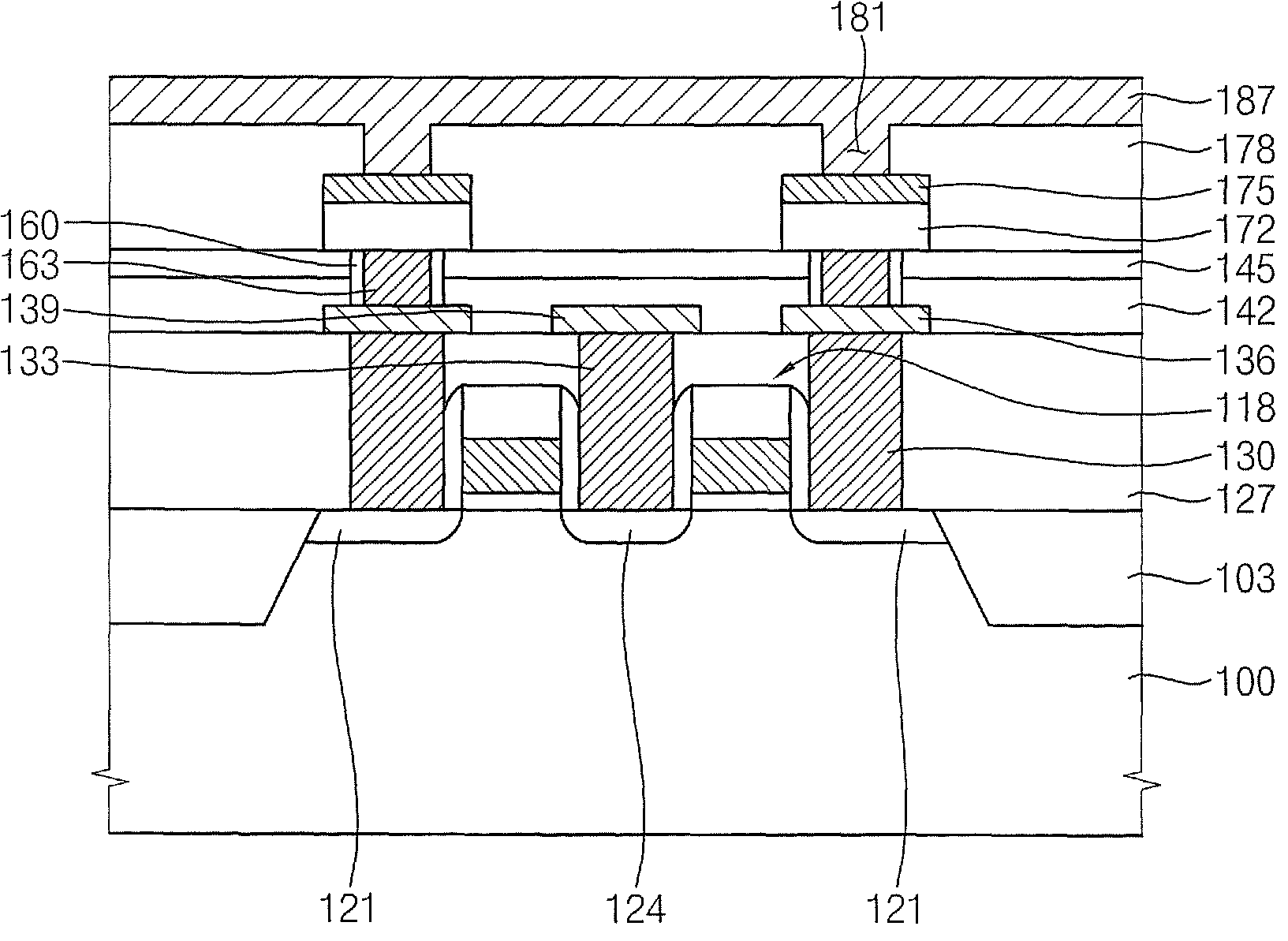

Phase-change material layer and phase-change memory device including the phase-change material layer

ActiveUS7791932B2Reduced driving currentIncrease resistanceSolid-state devicesDigital storageDriving currentElectricity

A phase-change memory device includes a substrate having a contact region, an insulating interlayer on the substrate, a lower electrode electrically connected to the contact region, a phase-change material layer pattern formed on the lower electrode, and an upper electrode formed on the phase-change material layer pattern. The phase-change material layer pattern includes a chalcogenide compound doped with carbon and at least one of nitrogen and metal. The phase-change memory device may have a considerably reduced driving current without increasing a set resistance thereof. Further, the phase-change material layer pattern may have an increased crystallization temperature so as to ensure improved data retention characteristics of the phase-change memory device.

Owner:SAMSUNG ELECTRONICS CO LTD

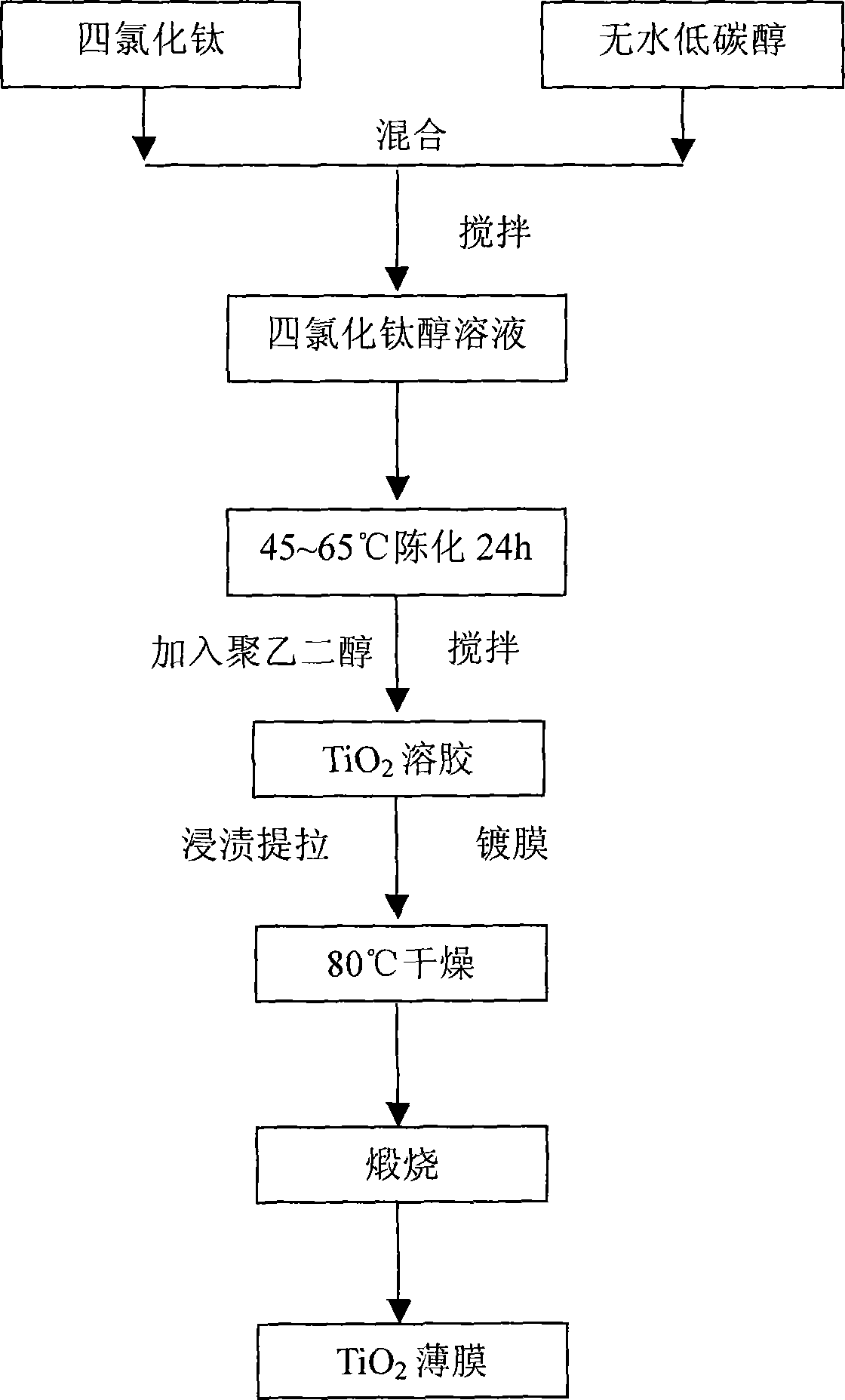

Method for preparing porous titanium dioxide photocatalysis film with non-hydrolyzed sol-gel method

InactiveCN101053829ARaise the transition temperatureSimple preparation processPhysical/chemical process catalystsAlcoholPolyethylene glycol

The invention discloses a method for preparing a porous titania photocatalysis film by a non-hydrolyzed sol-gel process, including the following steps of: mixing titanium tetrachloride and anhydrous lower alcohol as main materials into TiCl4 alcoholic solution, adding polyethylene glycol after aging the solution for 24 hours at the temperature of 45-65 DEG C. to form a transparent precursory sol; filming the preprocessed substrate material in a drying environment by a dip-coating method, then drying and calcining to form the porous titania photocatalysis film of the invention. Compared with a traditional sol-gel process, the porous titania photocatalysis film prepared by the method of the invention has advantages of simple process, operation convenience and low cost.

Owner:JINGDEZHEN CERAMIC INSTITUTE

High strength nodular cast iron pole and preparation technology thereof

ActiveUS20160024623A1Large thicknessHeavy weightFurnace typesHeat treatment process controlHigh intensityTower

The invention discloses a high strength nodular cast iron pole and a preparation technology thereof. The preparation technology is characterized by comprising the following steps: (1) preparation before pole casting, to be specific, preparation of raw materials, smelting of iron, adding of alloying elements and nodulizing; (2) a pole casting procedure, to be specific, casting and inoculation treatment; and (3) heat treatment. The invention also provides the high strength nodular cast iron pole prepared by adopting the preparation technology, comprising multiple tower poles which are sequentially connected in an inserted manner, wherein each tower pole is a cone-frustum hollow column which has the conicity of 1000: 11-26; the top end of the high strength nodular cast iron pole is equipped with a tower cap. The high strength nodular cast iron pole has the advantages of high bearing capacity, thin wall thickness, light weight, low manufacturing cost and the like.

Owner:RAHIM RICE DALIAN TECH

Glass that withstands high-temperatures for lamp bulbs, and its use

InactiveUS20060068982A1Improve thermal stabilityRaise the transition temperatureSolid cathode detailsGas discharge lamp detailsSilicate glassAlkaline earth oxides

The alumino-silicate glass for lamp bulbs with molybdenum components contains alkaline earth metals and has the following composition (in % by weight based on oxide): SiO2>58 to 62, Al2O3 15 to 17.5, MgO 0.1 to <1, CaO 5.5 to 14, SrO 0 to 8, BaO 6 to 17, ZrO2 0 to 1, CeO2 0 to 0.3, TiO2 0 to 5, MoO30 to 2, Bi2O3 0 to 4, with a sum total amount of alkaline earth oxides from 11.6 to 29. Lamp bulbs made with this glass can withstand a bulb temperature of greater than 650° C.

Owner:SCHOTT AG

Device and method for thermally pre-stressing elongated hollow objects

ActiveUS7805962B2Good effectRaise the transition temperatureGlass tempering apparatusPre stressPre stressing

A device and a method for thermal pre-stressing lengthy hollow objects, in particular glass tubes, are disclosed. The device comprises a heating device, a fixture for receiving an object, and a coolant feed device comprising an outer coolant feed unit with a plurality of nozzles for feeding coolant against an outer surface of the object, and further comprising an inner coolant feed device for feeding coolant against an inner surface of the object.

Owner:SCHOTT PHARMA AG & CO KGAA

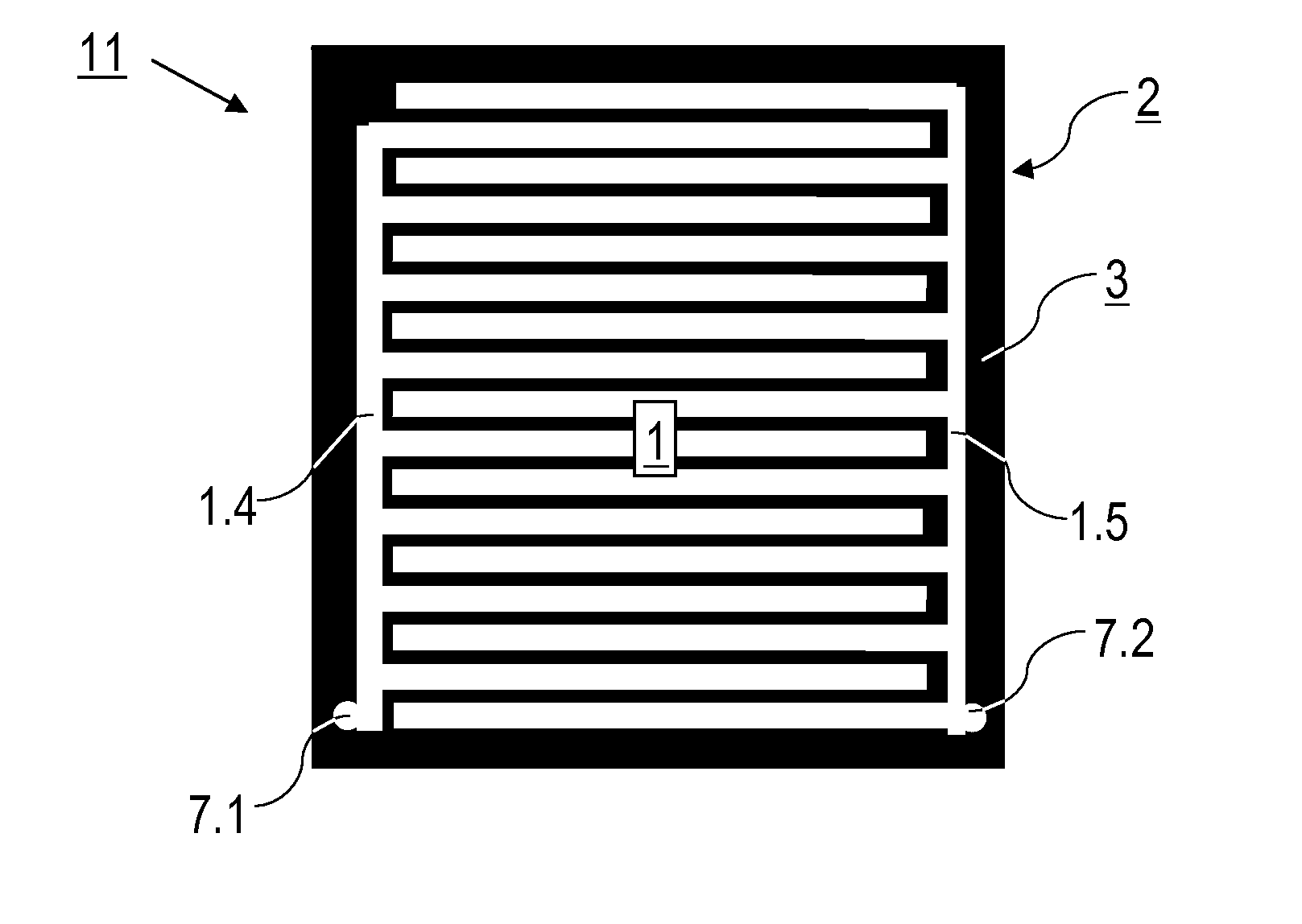

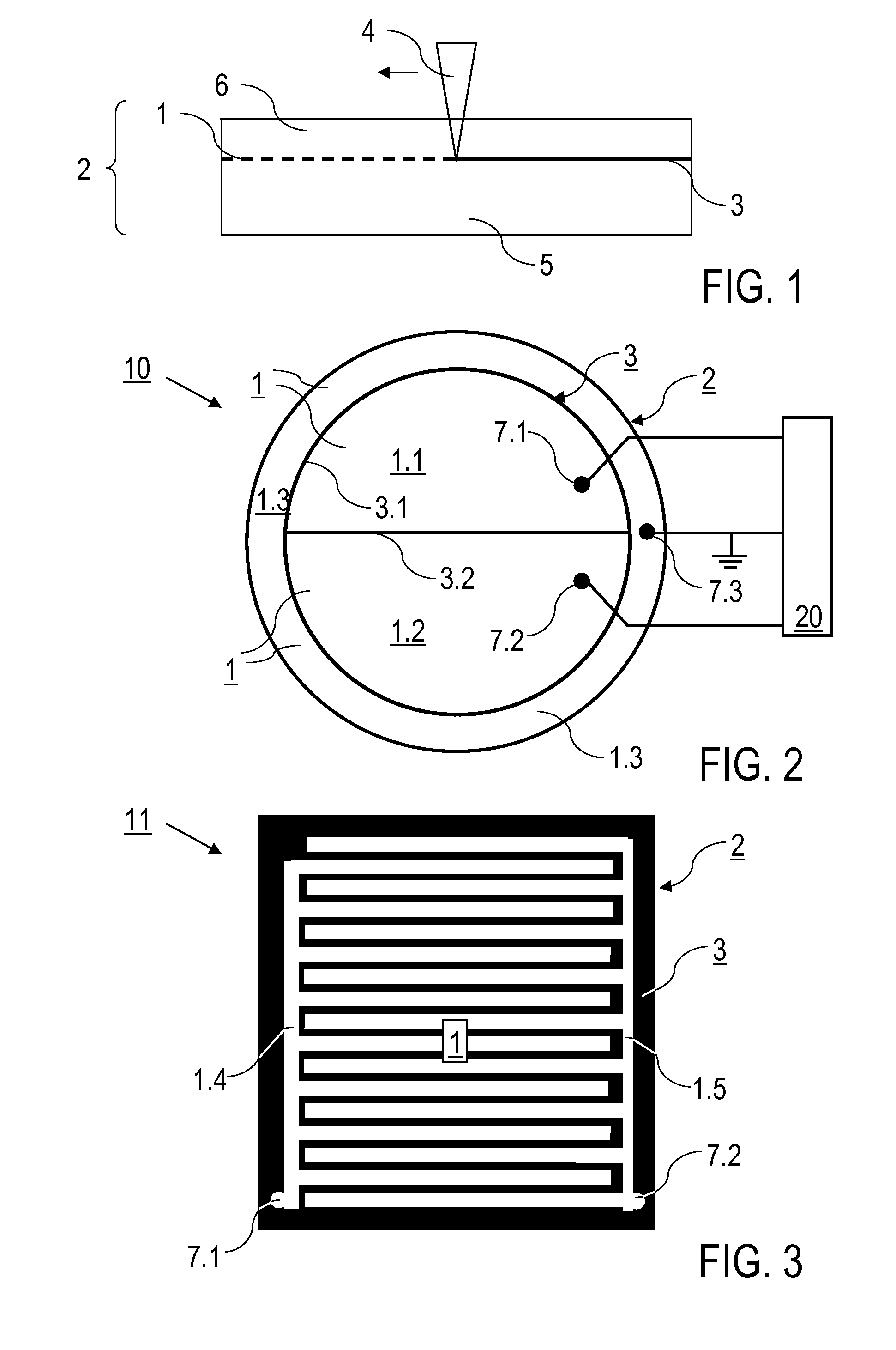

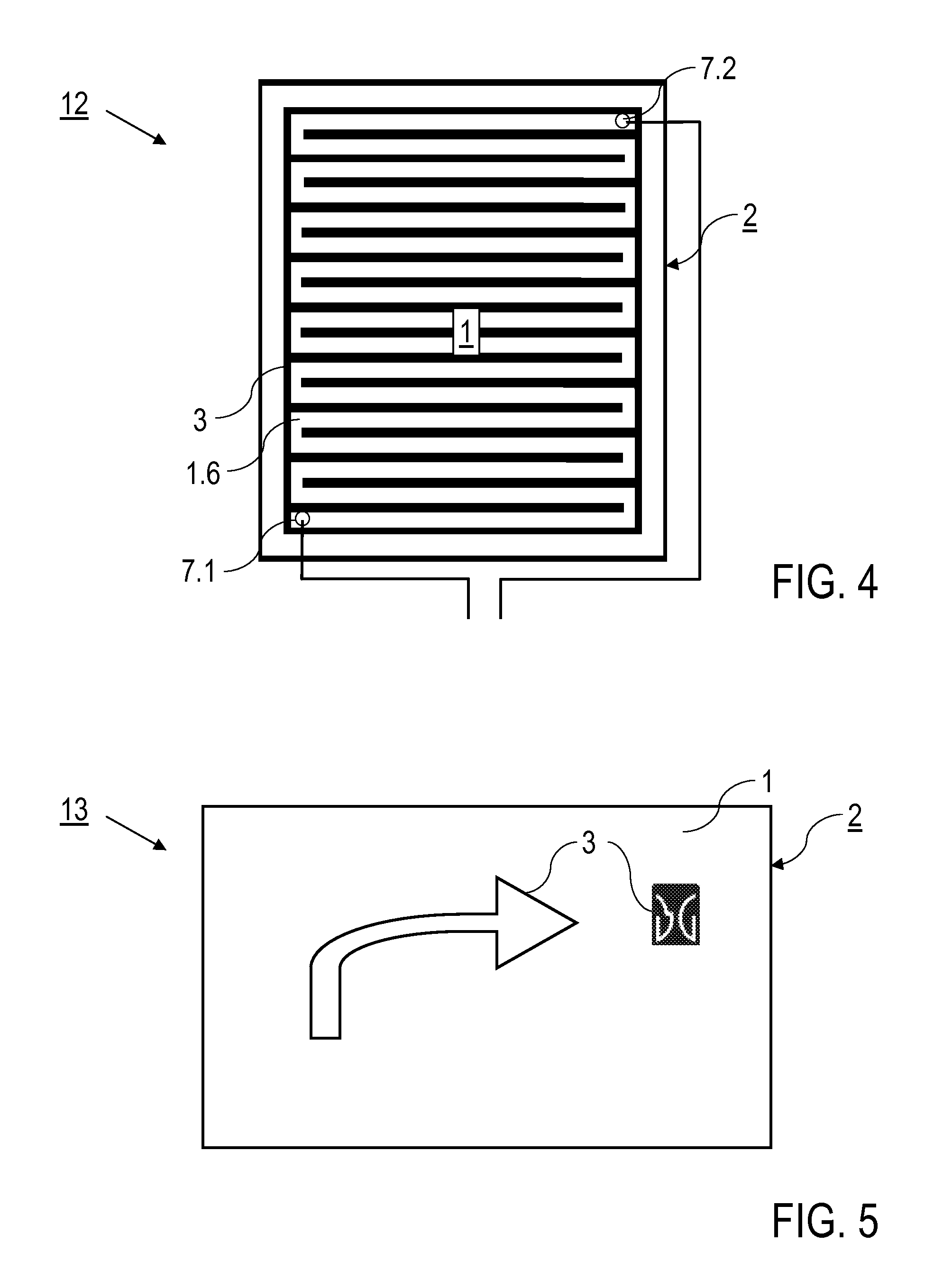

Processing an embedded metal film, and component with an embedded metal film

ActiveUS20120236458A1Improve spatial resolutionLocal heating is possibleElectric heatingSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

A method for processing a metal film (1) embedded in a carrier (2) includes the step of heating the metal film (1) in such a way that the metal film (1) is transformed in a subregion into at least one insulator section (3). The metal film (1) is preferably locally heated by laser radiation (4). Also described is a component (10, 11, 12, 13) which is produced by the method and includes an electrostatic clamp, a drive mechanism which is adapted for moving a workpiece under the action of electrical fields, a resistor element or a display device, for example.

Owner:ASML NETHERLANDS BV

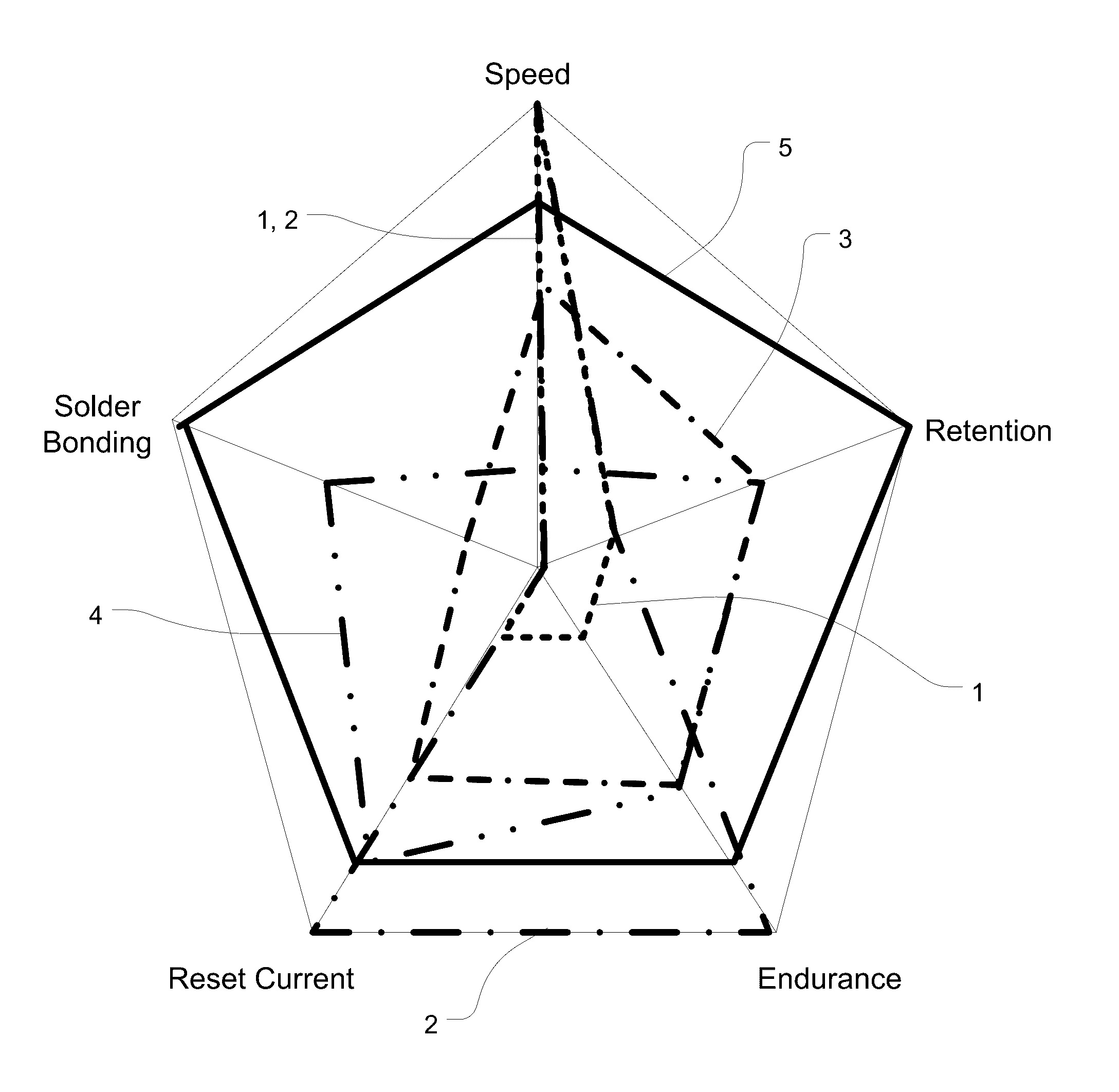

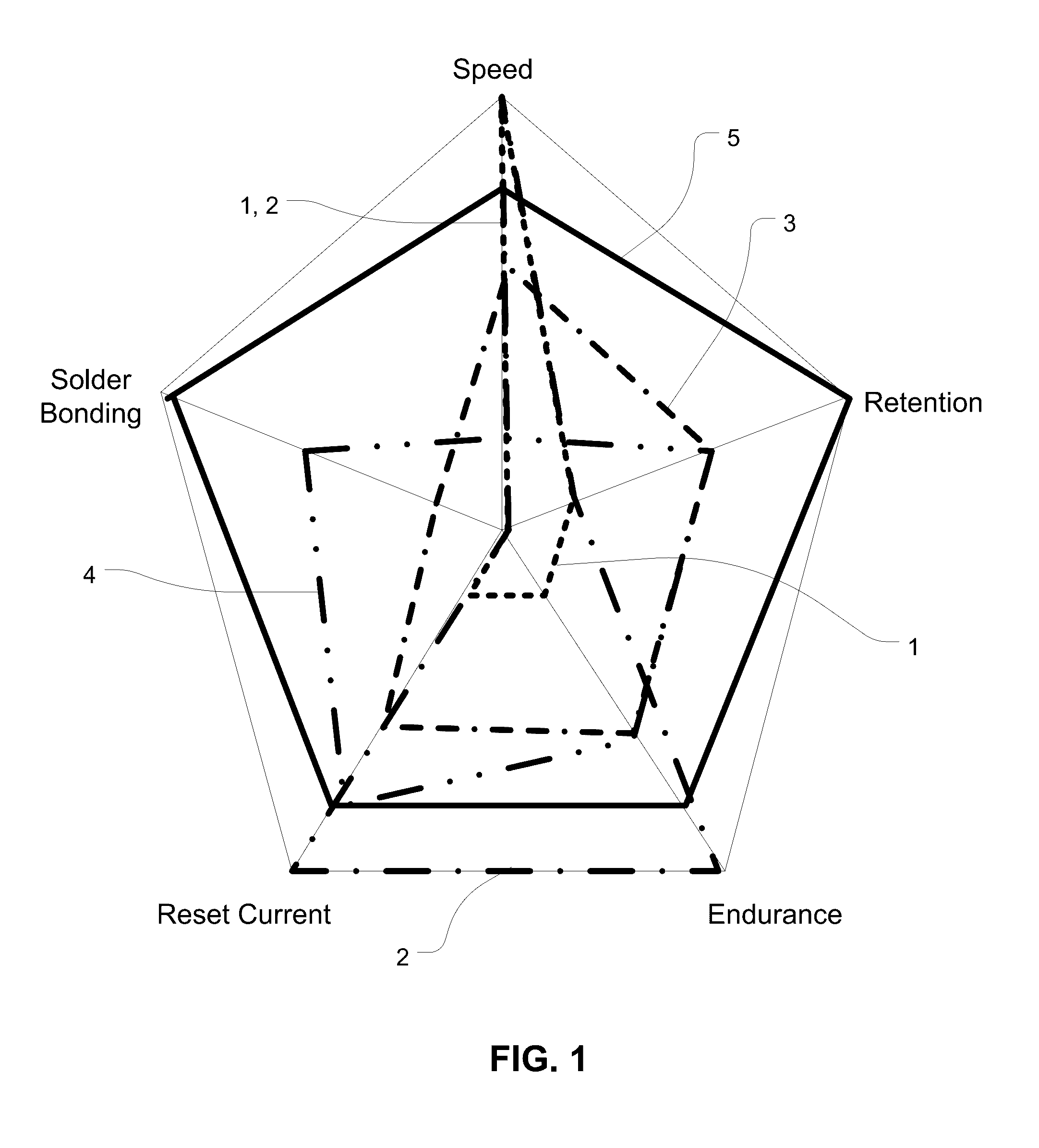

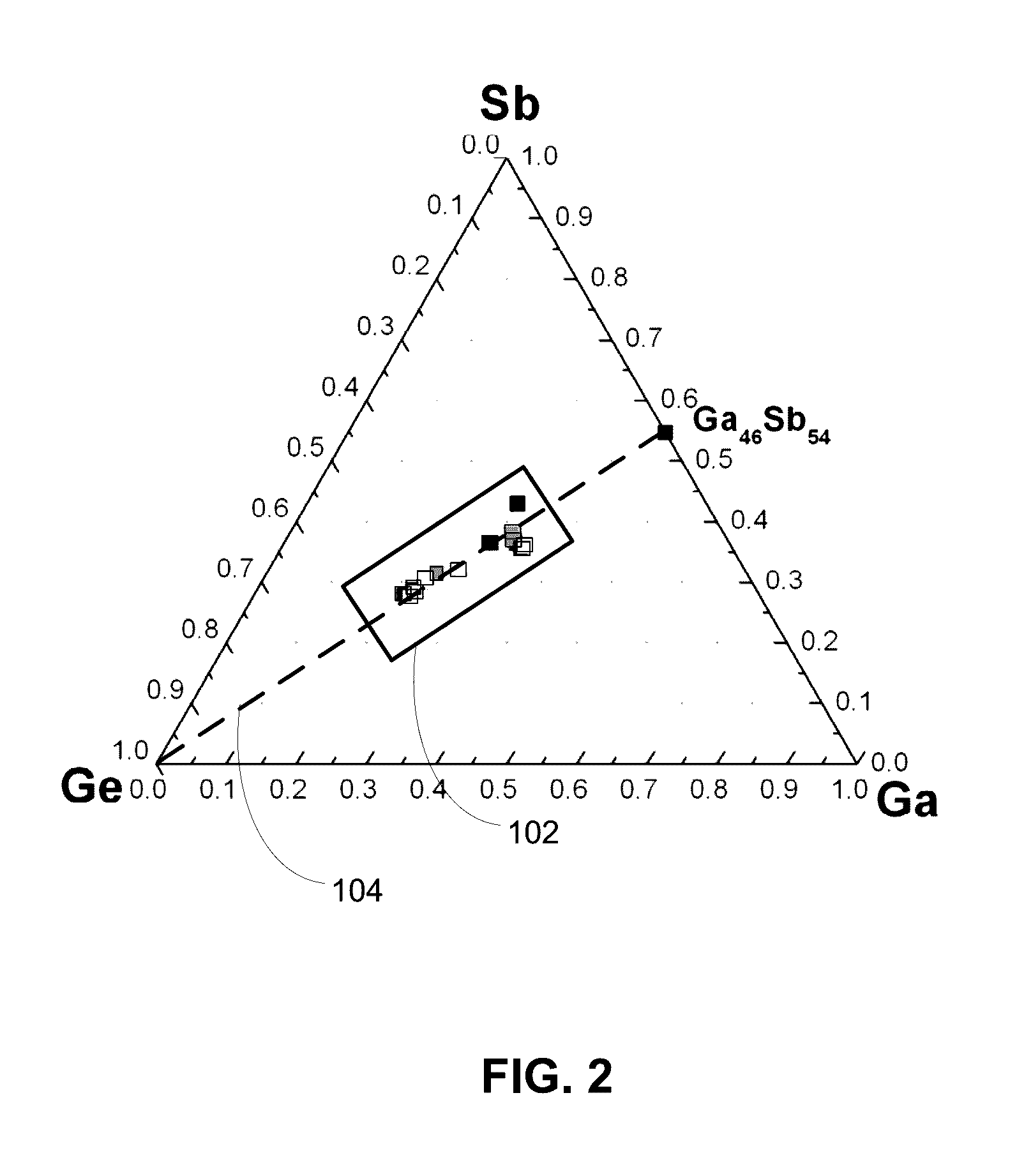

GaSbGe PHASE CHANGE MEMORY MATERIALS

ActiveUS20160372661A1High crystallization transition temperatureReduce reset currentSolid-state devicesMetal/alloy conductorsPhase-change memoryNitrogen

A Ga—Sb—Ge family of phase change memory materials is described, including GaxSbyGez, wherein a Ga atomic concentration x is within a range from 20% to 45%, a Sb atomic concentration y is within a range from 25% to 40% and a Ge atomic concentration z is within a range from 25% to 55%, is described wherein the material has a crystallization transition temperature Tx greater than 360° C. Adding impurities including one or more element selected from silicon Si, carbon C, oxygen O and nitrogen N, can also increase the crystallization transition temperature Tx to temperatures greater than 400° C., and also reduce reset current.

Owner:MACRONIX INT CO LTD

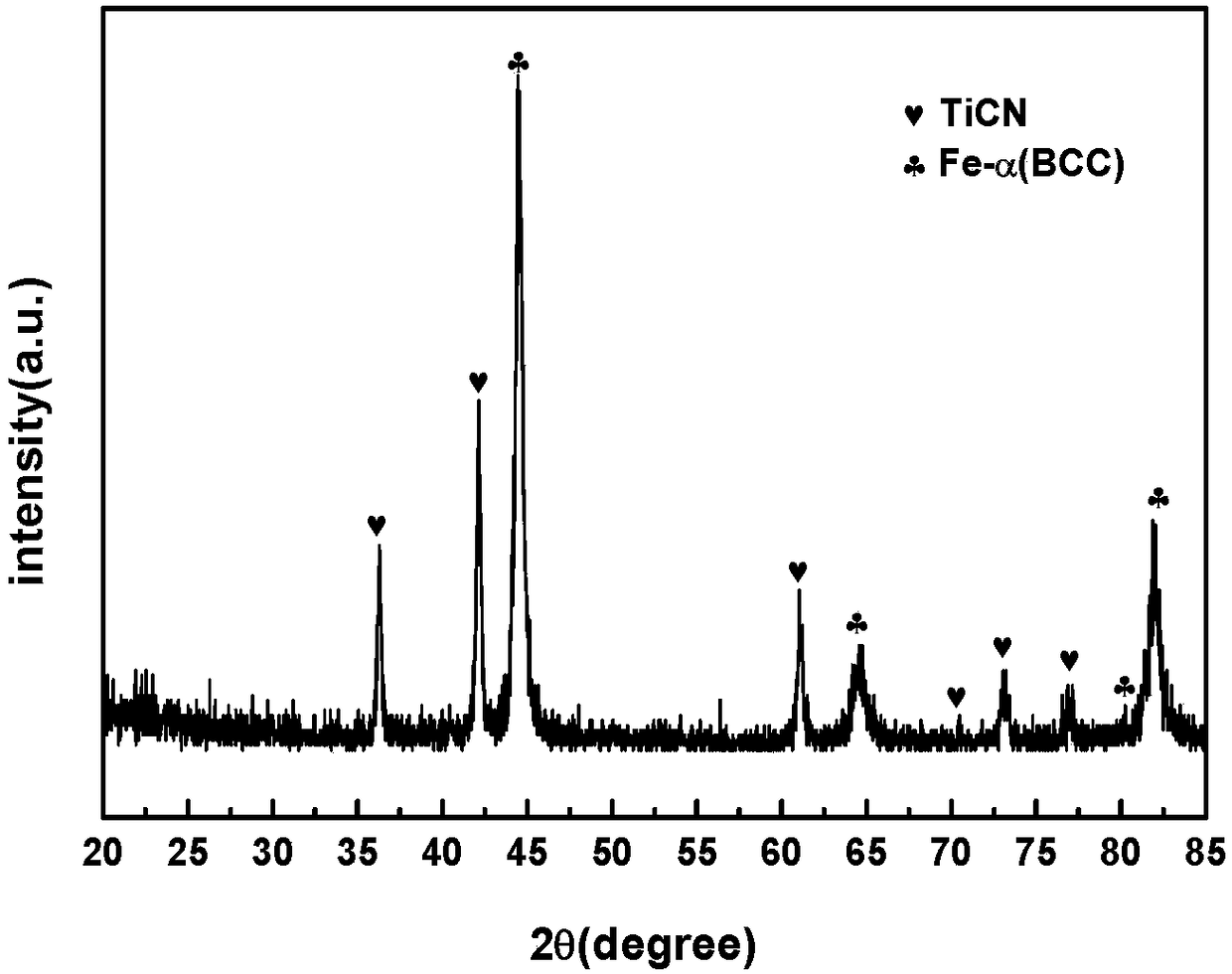

Ultrahigh-strength TiCN-base Co-containing steel-bonded hard alloy threading tool capable of coating and preparation method

The invention relates to an ultrahigh-strength TiCN-base Co-containing steel-bonded hard alloy threading tool capable of coating and a preparation method. The preparation method is characterized by comprising the following steps that the ultrahigh-strength TiCN-base Co-containing steel-bonded hard alloy threading tool takes Co-containing Fe-Mo-Cr alloy steel as a matrix, and TiCN with the mass fraction of 20-35% is added as a hard phase; the surface of powder is activated by adopting the method that quantitative preoxidation oxygen aeration is carried out after high-energy ball milling, the sintering activity of the matrix is improved, then the oxygen content (less than 800 ppm) is reduced substantially by a carbon and oxygen reduction reaction in the sintering process, and the sintering temperature is reduced; and the tempering resistance, the PVD coating property, the strength and the toughness of the ultrahigh-strength TiCN-base Co-containing steel-bonded hard alloy threading tool are improved by leading in a strengthening element of Co. The ultrahigh-strength TiCN-base Co-containing steel-bonded hard alloy threading tool has high strength (2800-4000 MPa) and high toughness (alpha k is equal to 7-15 J / cm2, KIC is equal to 20-28 MPa.m1 / 2), the limitation that a traditional steel-bonded hard alloy is only used for mid-and-low-end wear-resistant pieces can be broken through, and threading tools such as a PVD coating and squeezing screw tap and a cutting screw tap which are more wear-resistant than high-speed steel and are more edge-breaking-resistant than hard alloy are prepared.

Owner:XIANGTAN UNIV

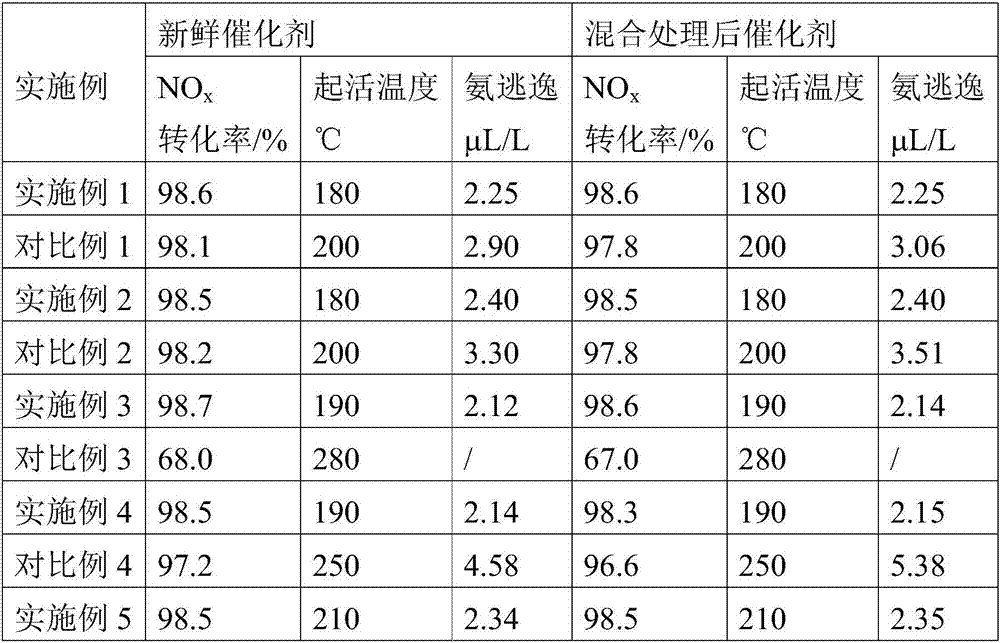

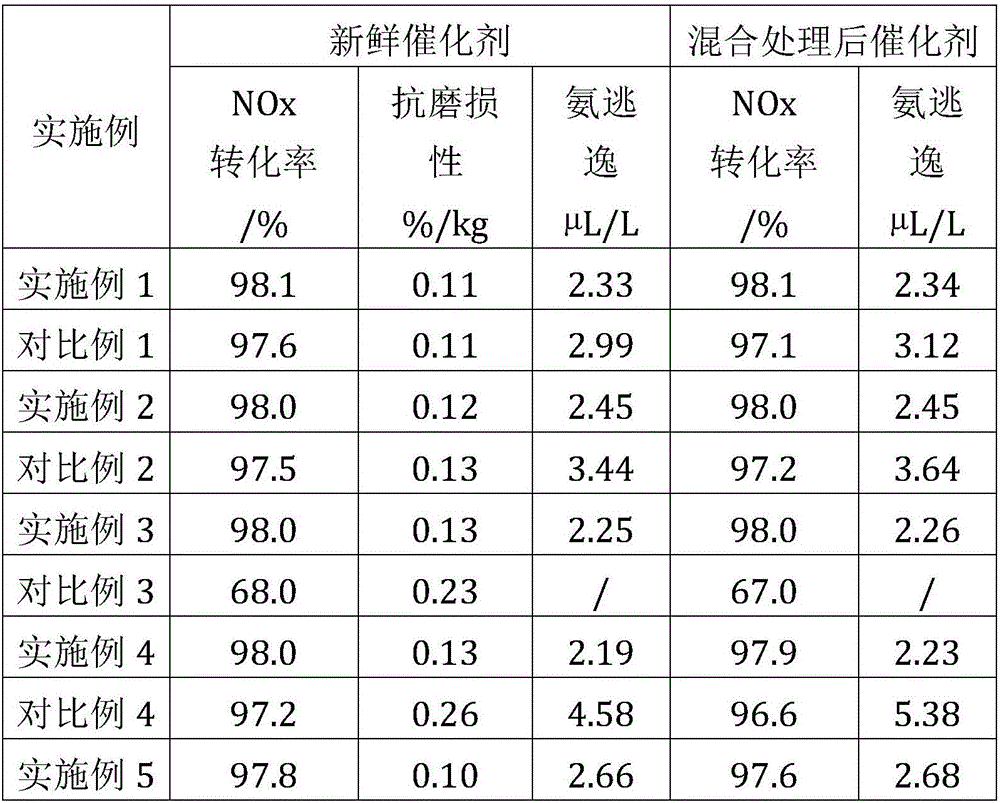

Cellular denitrification catalyst and preparation method thereof

InactiveCN107126950AHigh activityPenetration deepGas treatmentHeterogenous catalyst chemical elementsGlass fiberFiltration

The invention discloses a cellular denitrification catalyst and a preparation method thereof. The catalyst preparation method comprises the following steps: dissolving a titanium source precursor in an acid to form a solution; respectively dissolving a molybdenum source precursor and a rare earth precursor to form solutions; uniformly mixing the above solutions, regulating the pH value to 7-12, and performing precipitation and filtration; then adding deionized water to form a pulp through blending; adding a vanadium source precursor solution, performing uniform mixing, and then directly performing drying, roasting and powder grinding; then adding an extrusion aid, the molybdenum source precursor solution and a pore forming agent into the powder, adding water with stirring to form a paste through blending, and regulating the pH value to alkaline; then adding nano silicon dioxide, glass fibers and an adhesive, and performing uniform mixing; and conducting extruding through an extruder to obtain a cellular blank, and performing drying and roasting to obtain the finished product. The cellular denitrification catalyst prepared by the preparation method disclosed by the invention can overcome the defects of the denitrification catalyst in the prior art, such as active center imbalance and unstable activity in flue gas.

Owner:PETROCHINA CO LTD

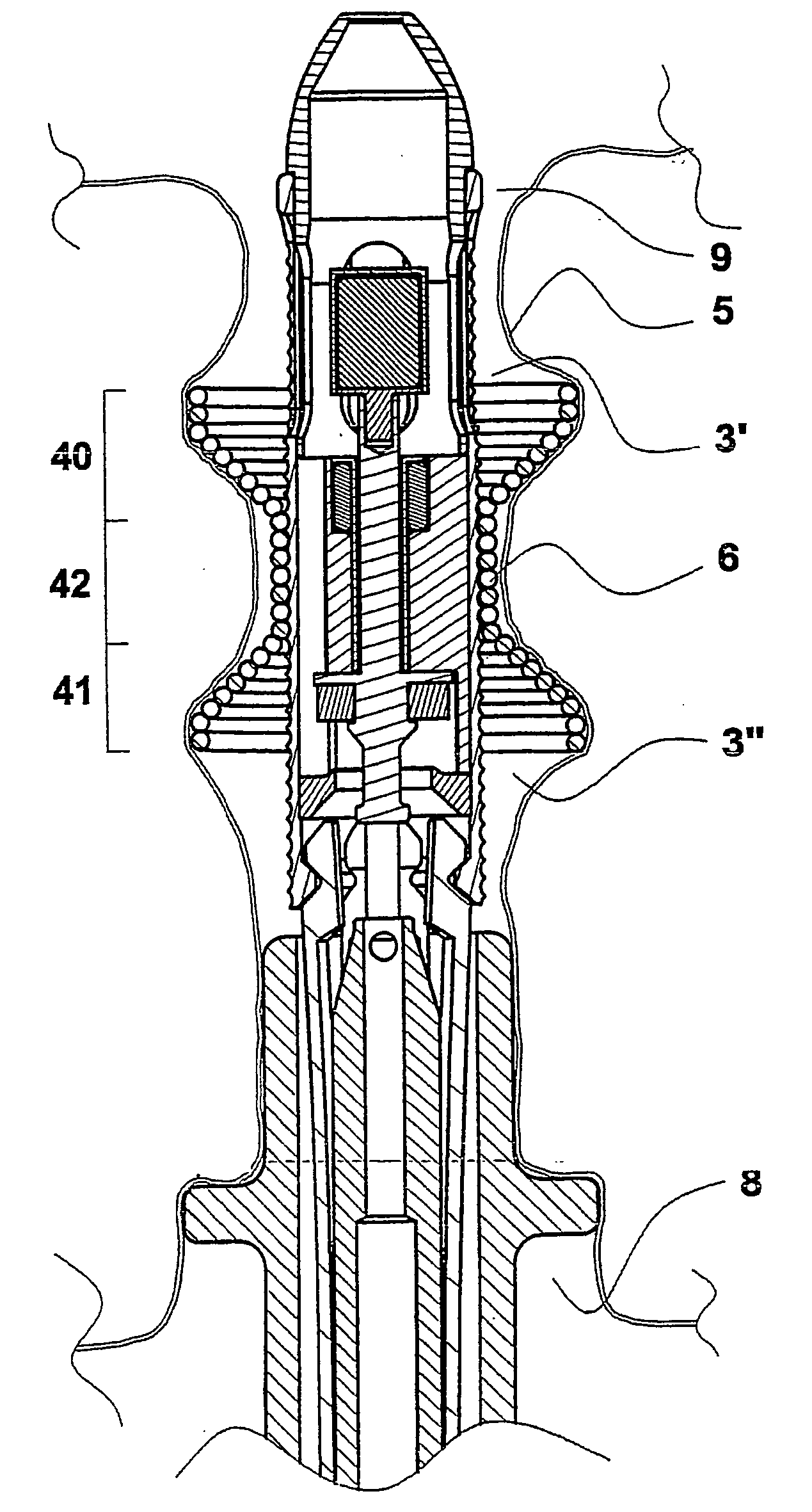

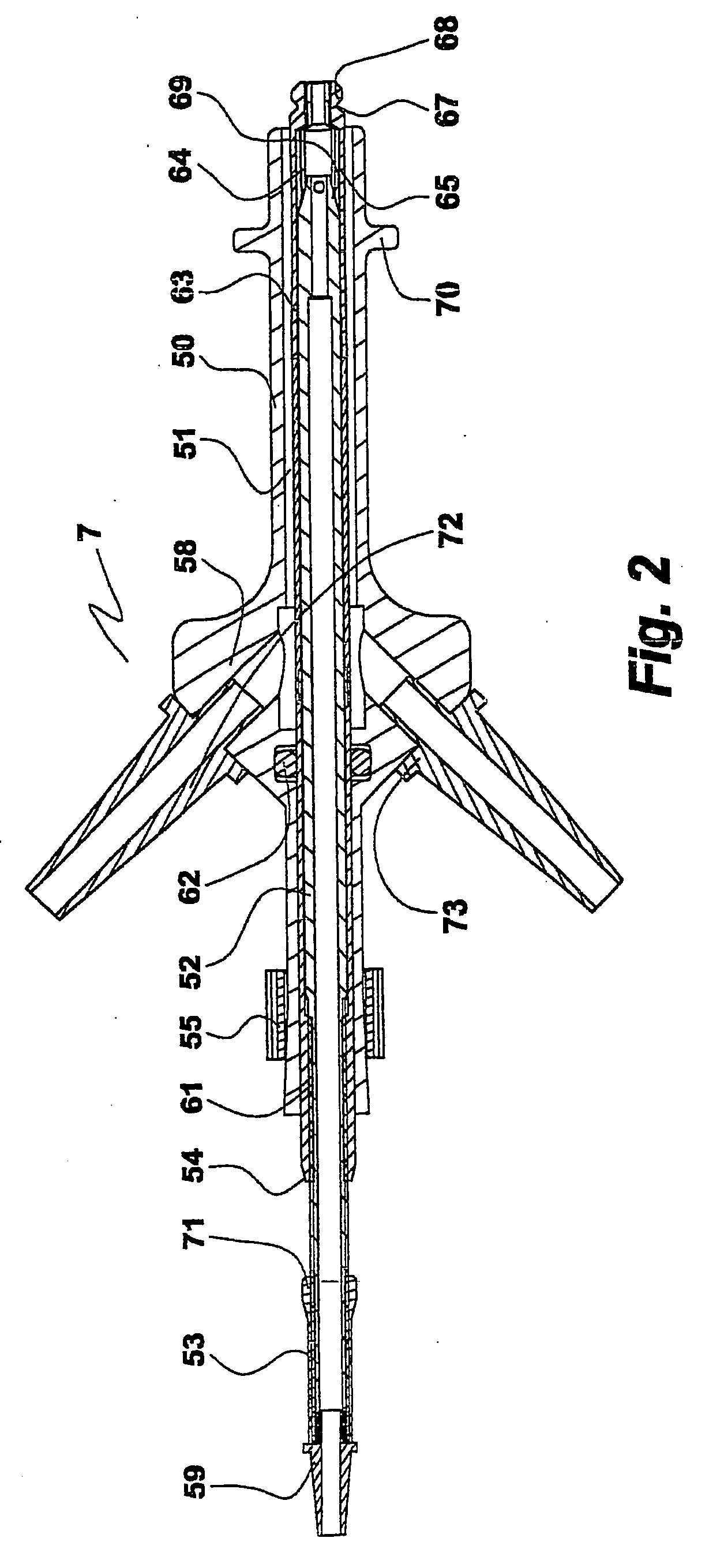

Intra-urethral sphincter and method and means for anchoring it in a urethra

InactiveUS20050187428A1High transition temperatureAvoid irreversible damageAnti-incontinence devicesHuman body temperatureUrethral sphincter function

An artificial sphincter comprises an anchoring element in form of a shape memory coil, which has a transition temperature, which is significantly higher than the human body temperature of about 37° C. At lease a portion of the cylindrical sphincter body is enclosed by the coil. The coil to be threaded onto threads provided at the exterior mantle face of the body. Also disclosed is a method for inserting and anchoring the sphincter in an urethra and a device for inserting and anchoring the sphincter which comprises a proximal end portion of about cylindrical shape, means for coupling with the sphincter disposed at the proximal end of said proximal end portion and being operable from a distal end portion thereof, a channel disposed within the proximal end portion which has an opening at the proximal end thereof for adducing an aqueous fluid of a temperature above 37° C. to the shape memory metal coil.

Owner:EUTECH MEDICAL

Anti-abrasion denitration catalyst and preparation method thereof

InactiveCN107175122ASmall and uniform particle sizeRaise the transition temperatureCatalyst activation/preparationSlurrySilicon dioxide

The invention discloses an anti-abrasion denitration catalyst and a preparation method thereof. The preparation method comprises the following steps of dissolving titanium source precursors into acid to form a solution; respectively dissolving molybdenum source precursors, phosphorus source precursors and magnesium source precursors to form solutions; uniformly mixing the solutions; regulating the pH value; performing precipitation, filtering and washing; then adding deionized water; preparing the materials into slurry; adding a vanadium source precursor solution; after uniform mixing, directly performing drying and roasting; grinding the materials into powder; next, adding extrusion auxiliary agents, a solution formed by the molybdenum source precursors and pore forming agents; adding water during the stirring to obtain paste; regulating the pH value; adding nanometer silicon dioxide, wollastonite, glass fiber and bonding agents; performing uniform mixing; extruding honeycomb-shaped blanks by an extruding machine; performing drying and roasting; then, obtaining a finished product. The prepared anti-abrasion denitration catalyst can overcome the defects of unstable activity, poor anti-abrasion performance and activity center unbalance of a denitration catalyst in flue gas in the prior art.

Owner:PETROCHINA CO LTD

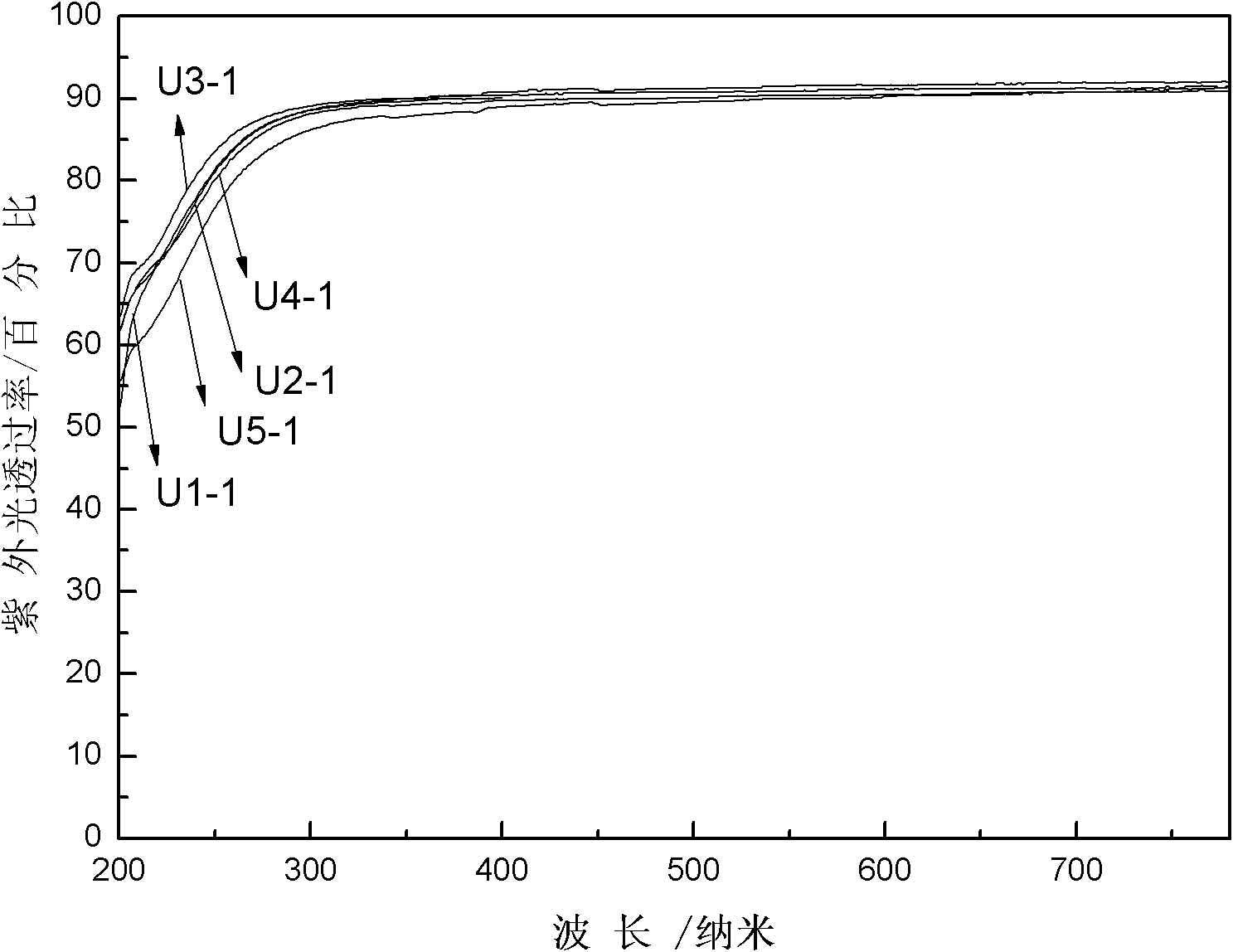

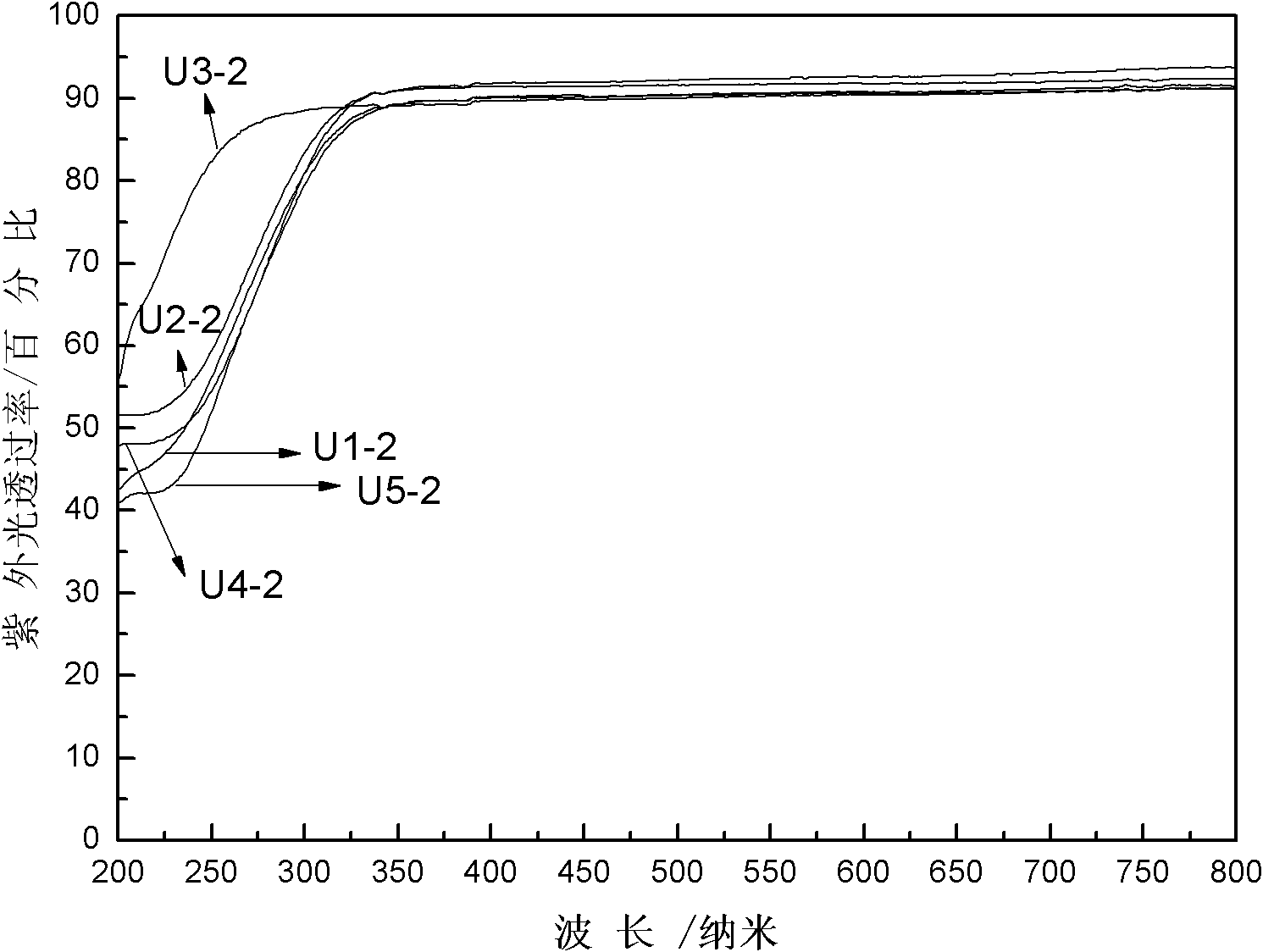

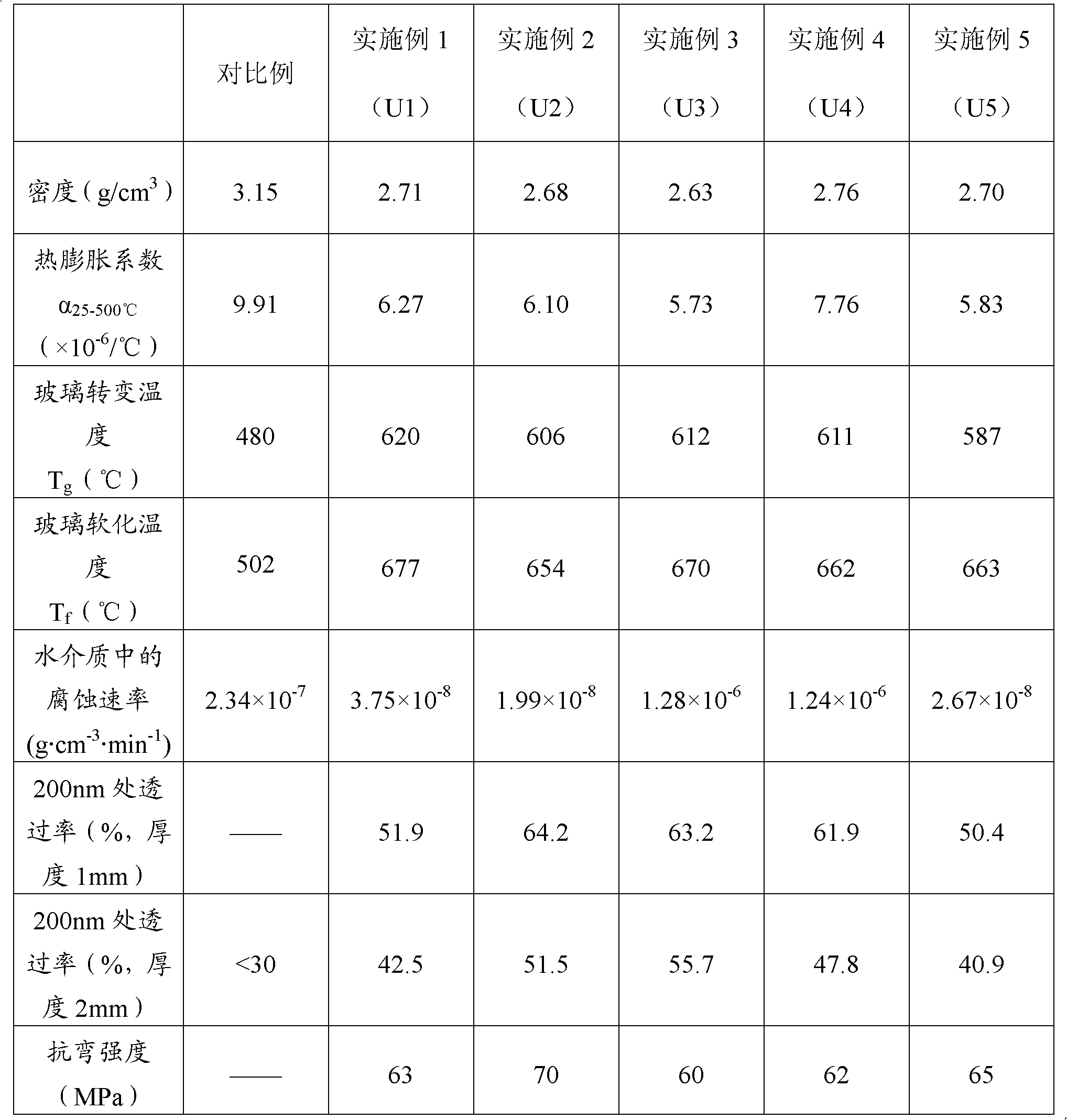

Borosiliphosphate glass with high ultraviolet light transmissivity and preparation method thereof

ActiveCN102211868ALow purity requirementSmall coefficient of thermal expansionUltraviolet lightsThermal expansion

The invention relates to borosiliphosphate glass with high ultraviolet light transmissivity and a preparation method thereof. The glass comprises the following components: SiO2, B2O3, P2O5, ZnO and SrO. The preparation method comprises the following steps: carrying out ball-milling on raw materials corresponding to the oxide components, screening with a 80-mesh sieve, and evenly mixing so as to prepare a mixture; and placing the mixture in a crucible for melting, pouring the melting glass liquid into a stainless steel mould for molding, and annealing so as to obtain the colorless, transparent, uniform and bubble-free blocky glass. The glass prepared by the method is superior to the existing ultraviolet-transmitting glass material in the aspects of comprehensive properties such as thermal expansion coefficient, density, ultraviolet light transmissivity, corrosion rate in water medium, bending strength and the like. According to the invention, the method is simple and environmentally-friendly, heavy metal ions are not introduced, the purity requirement of raw materials is low, melting temperature is low, and production cost is low; and the prepared ultraviolet-transmitting glass material is good in property and has a wide market application prospect.

Owner:CENT SOUTH UNIV

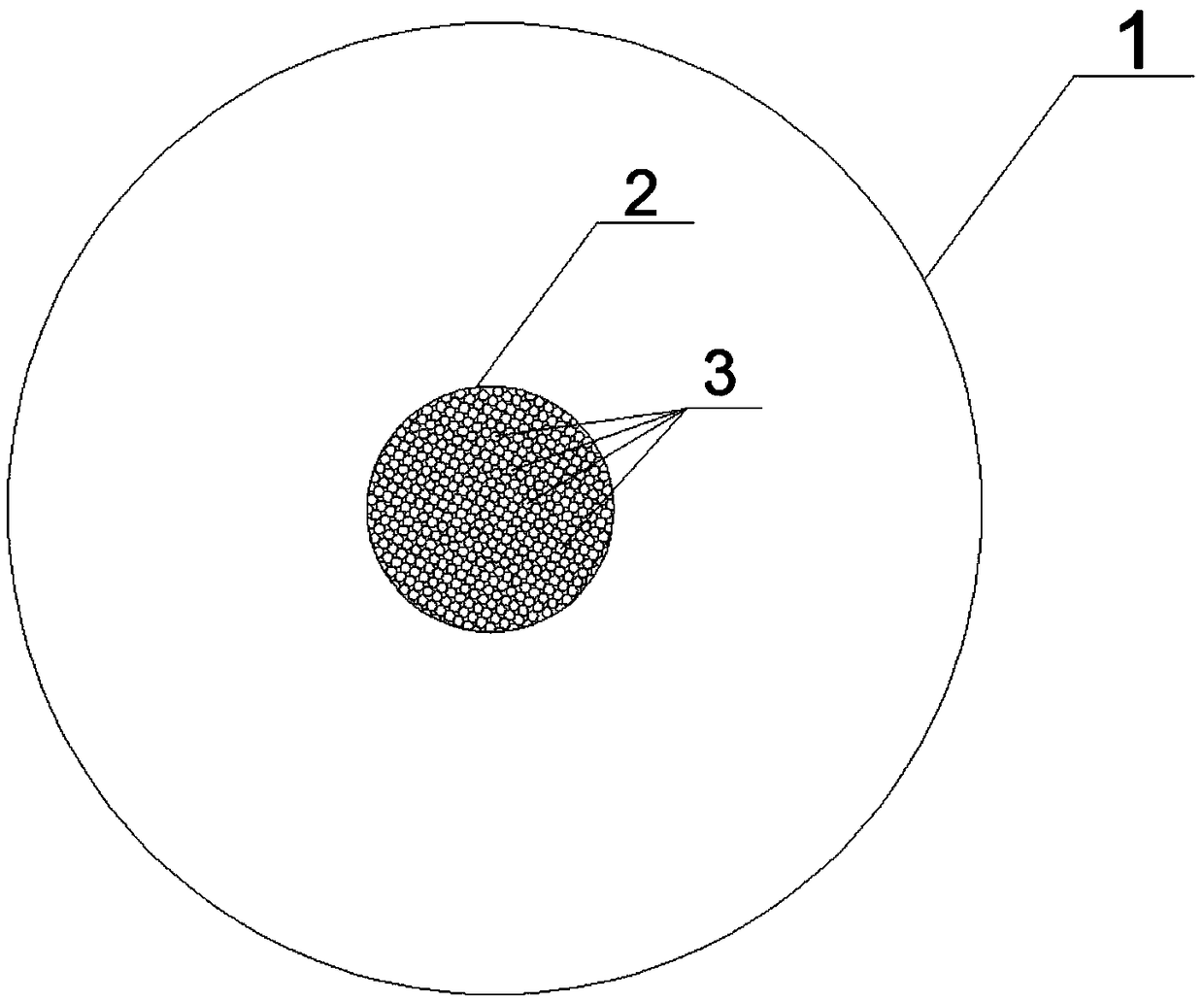

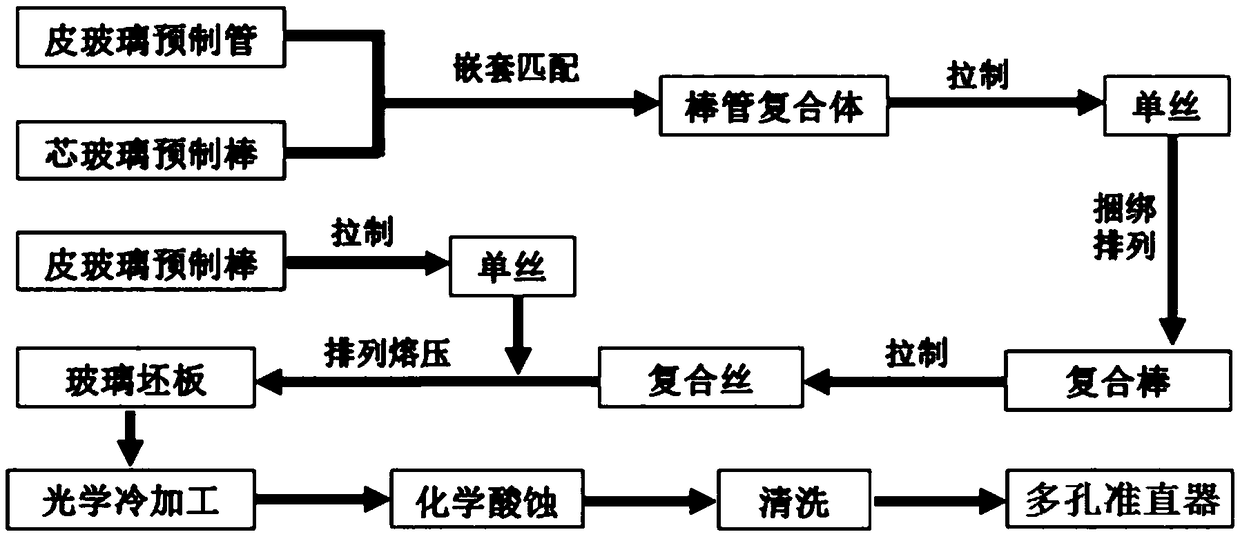

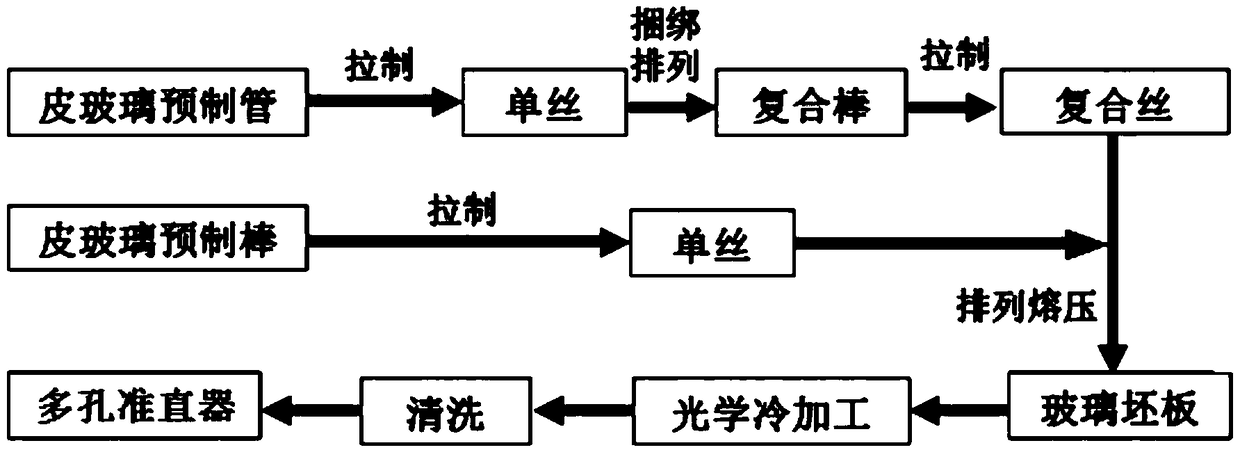

Collimator and manufacturing method

ActiveCN108922646ASolve Dimensional Accuracy IssuesUniform sizeGlass making apparatusHandling using diaphragms/collimetersAcid etchingFilling materials

The invention relates to a collimator and a manufacturing method. The collimator includes a base body of a flat plate shape, wherein the upper surface and lower surface of the base body are parallel to each other, at least a through hole which penetrates through the upper surface and the lower surface and has a pore diameter of 1-100 [mu]m is formed in the base body, and the base body is made of glass. A glass blank plate is prepared by using a glass rod tube nested drawing method, optical cold processing is conducted, and then chemical etching is performed so as to obtain the collimator. After the glass of the collimator is determined, core glass matched with the determined glass is designed, and the core glass is removed through acid etching, wherein the core glass is mainly used as a filling material of micropores during manufacture so as to ensure the roundness of the micropores. Through the collimator, the collimation efficiency of particles and stability of particle movement canbe improved effectively, the scattering angle of the particles is reduced, and conditions for high stability, high reliability and miniaturization of atomic clocks, ray cameras and other precision equipment are created.

Owner:CHINA BUILDING MATERIALS ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com