Patents

Literature

3000 results about "Frustum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geometry, a frustum (plural: frusta or frustums) is the portion of a solid (normally a cone or pyramid) that lies between one or two parallel planes cutting it. A right frustum is a parallel truncation of a right pyramid or right cone.

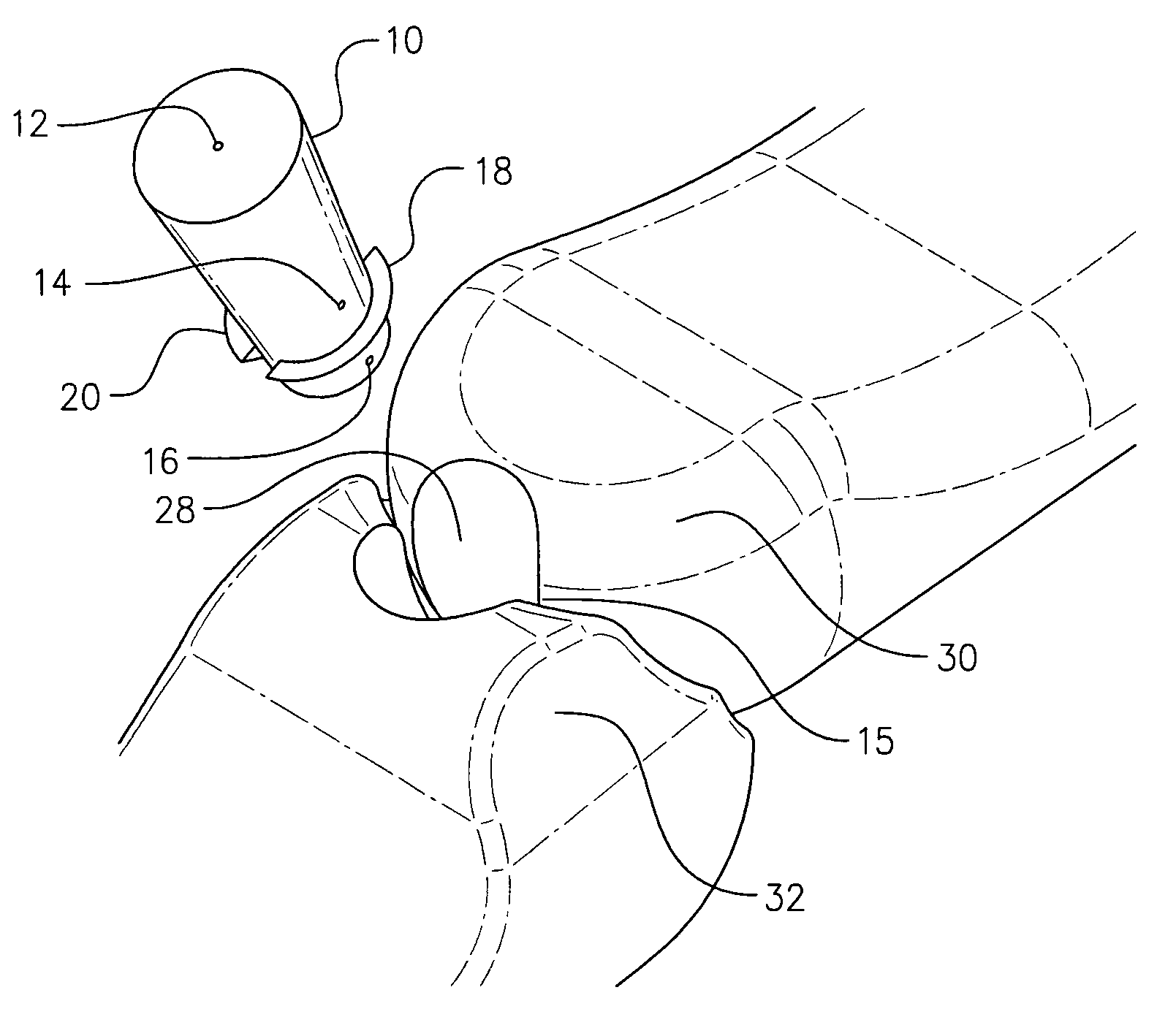

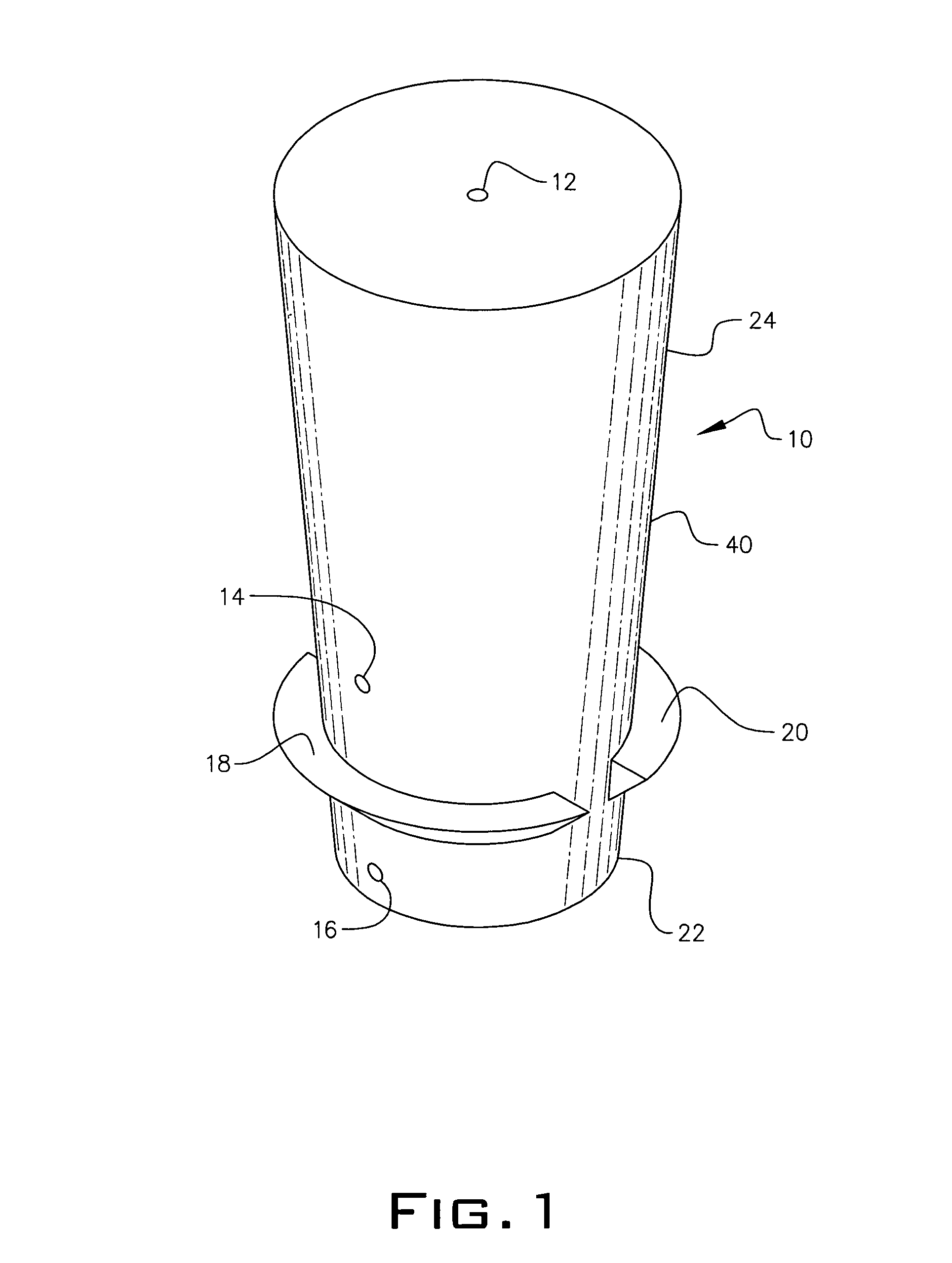

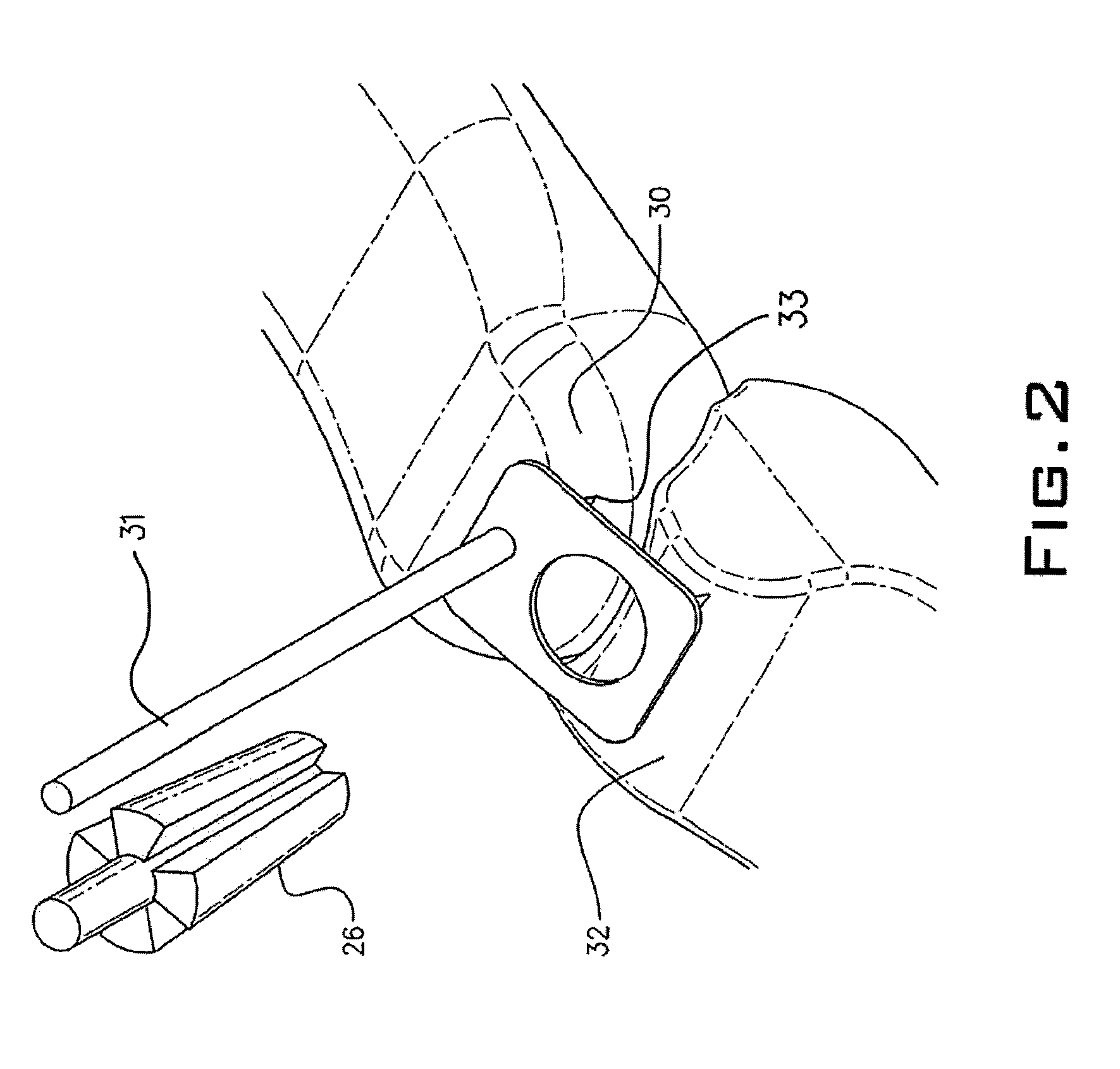

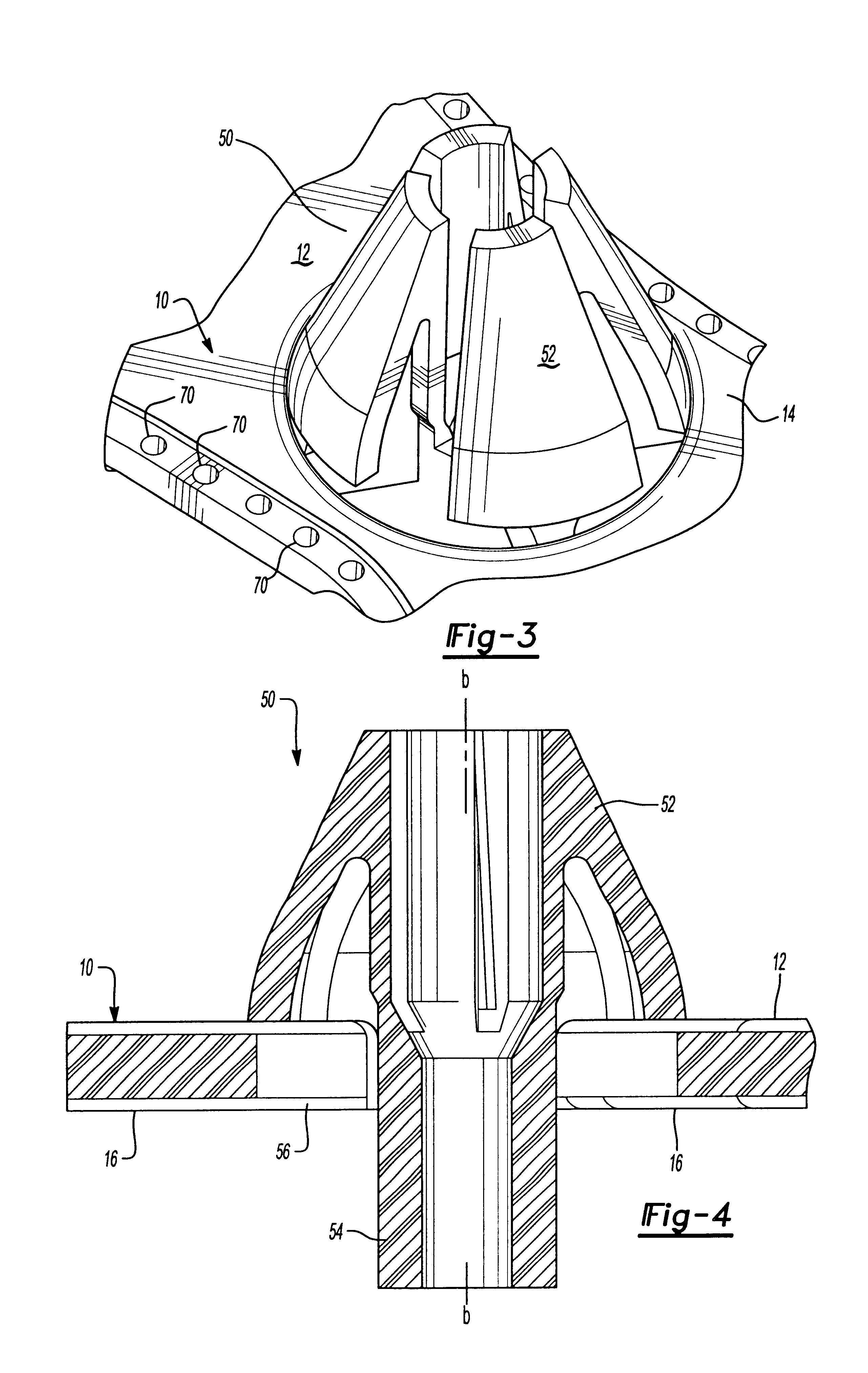

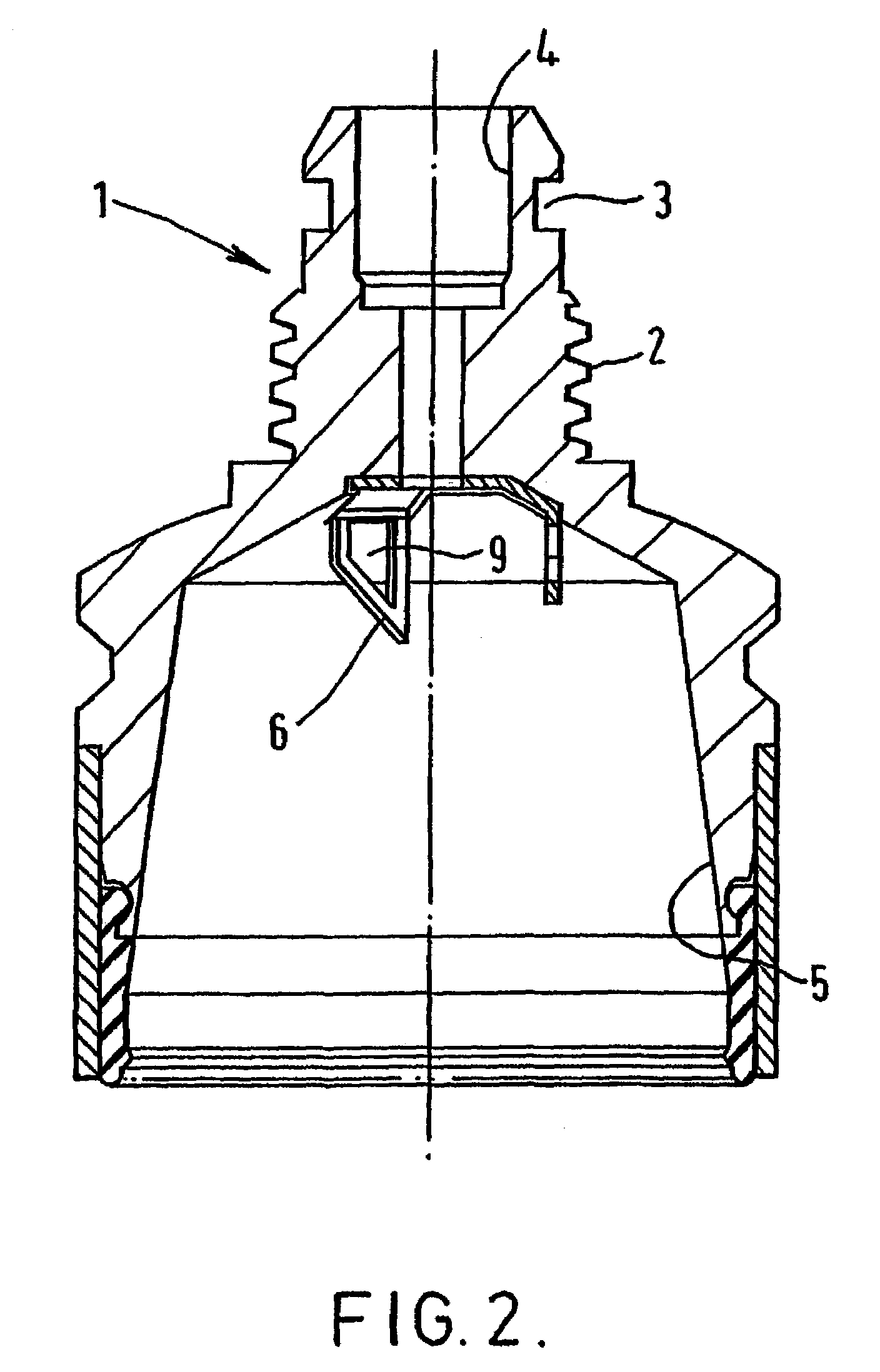

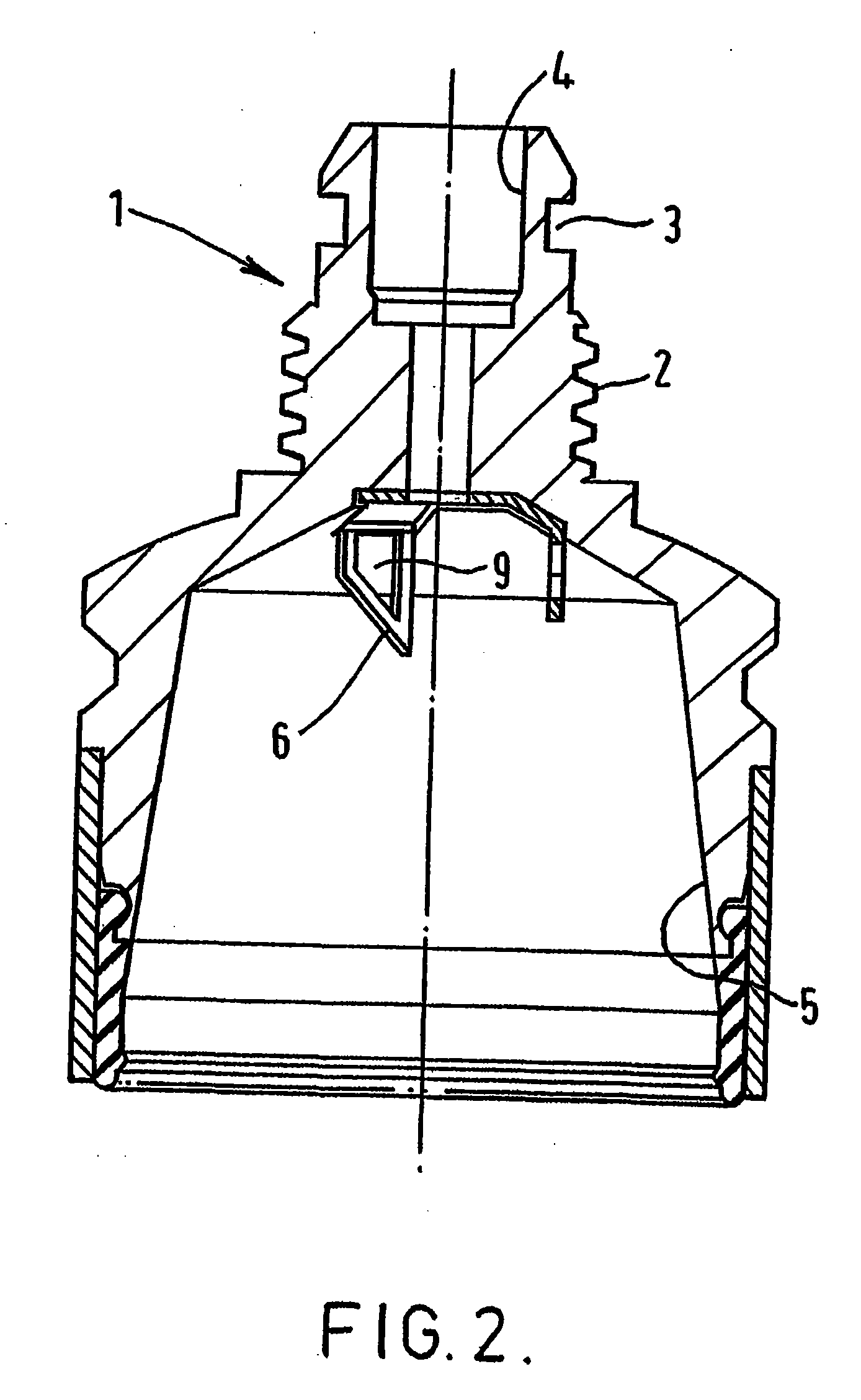

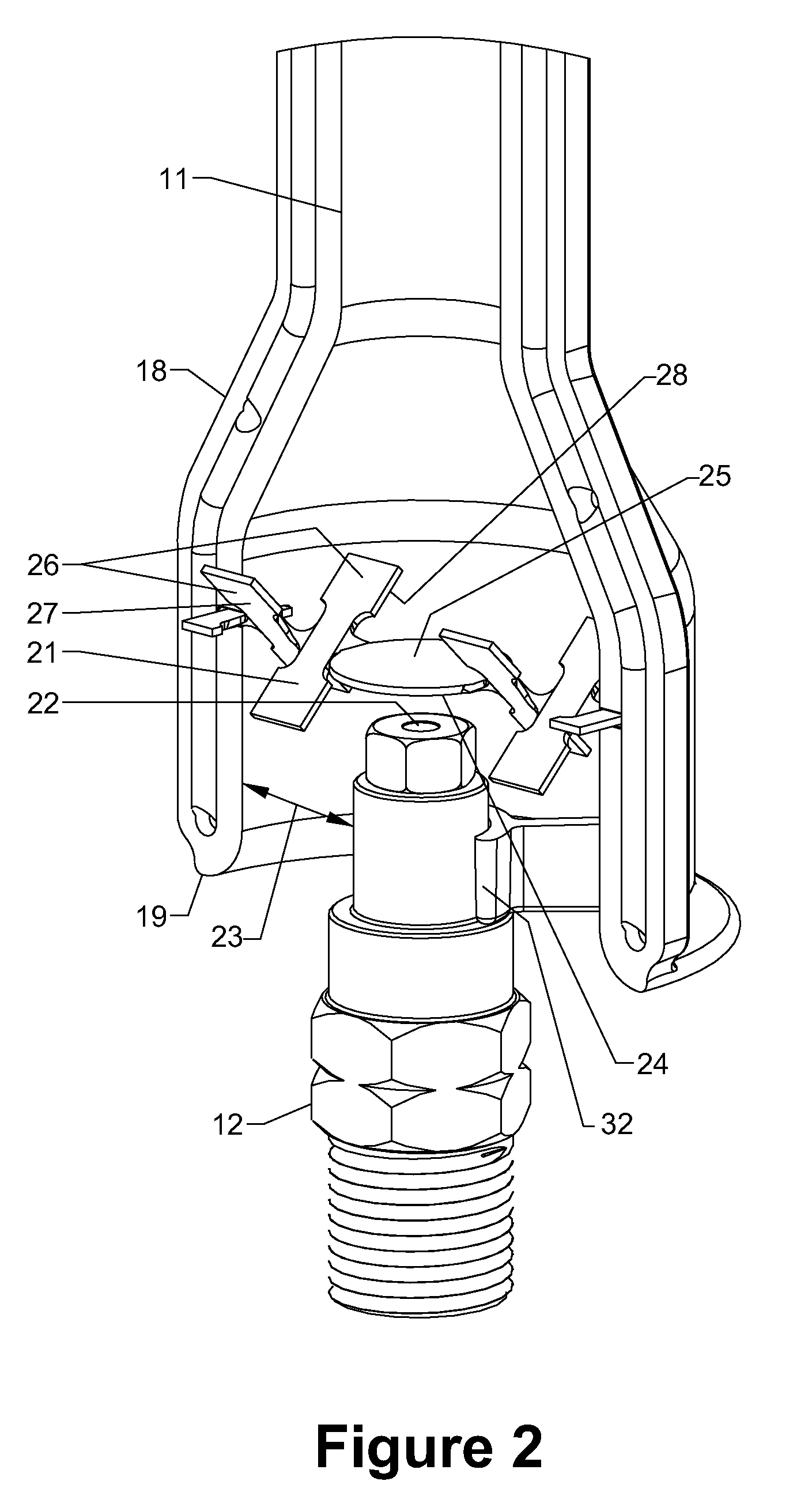

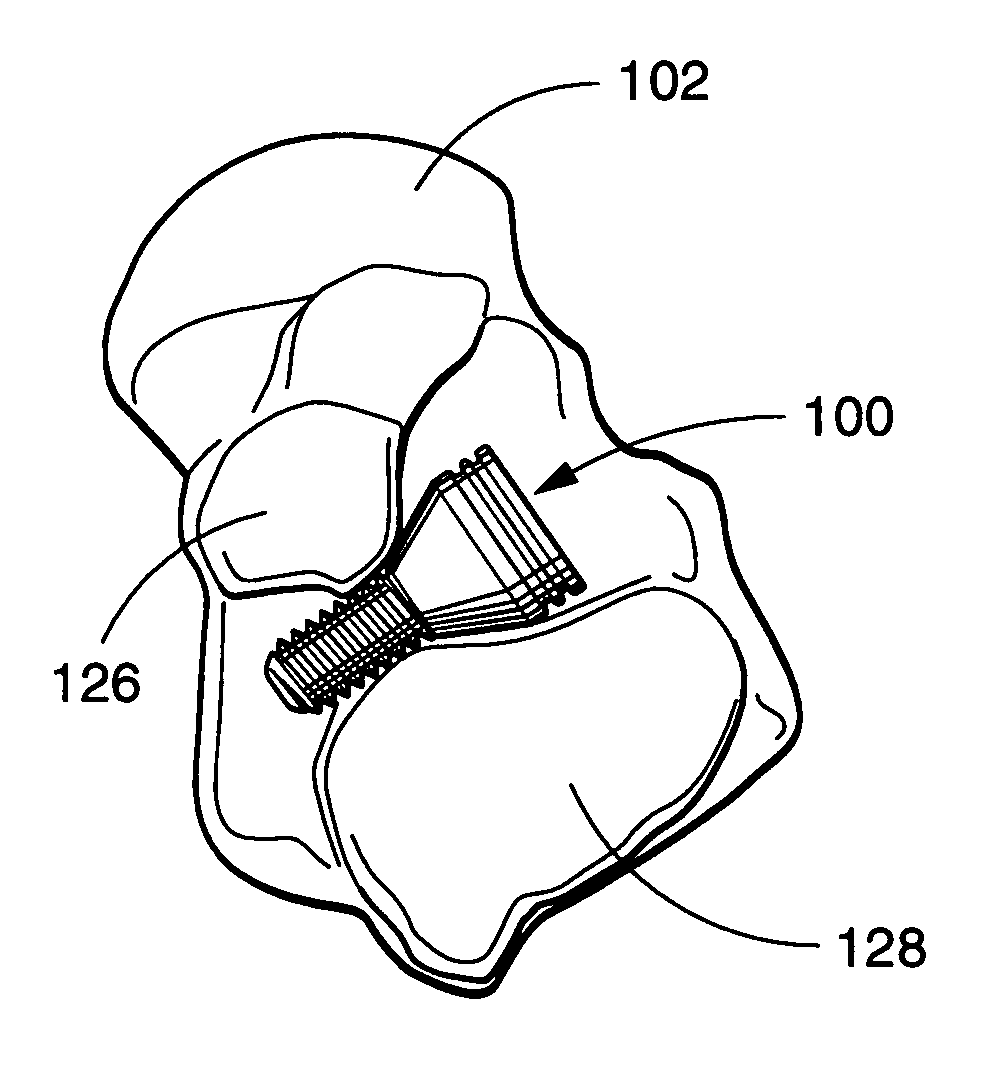

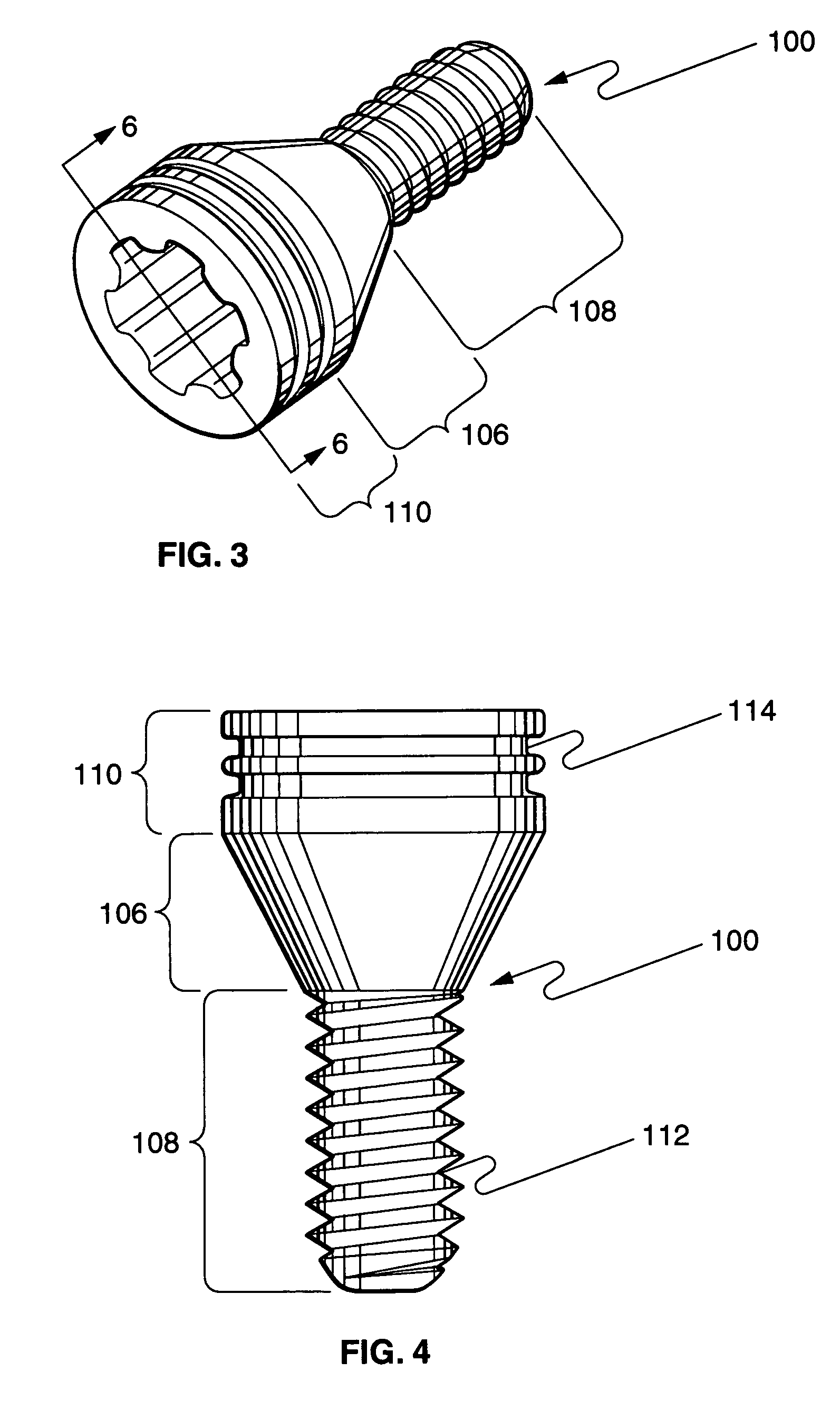

Spinal plug for a minimally invasive facet joint fusion system

InactiveUS7708761B2Strong and unique and superior fusionReduce riskInternal osteosythesisBone implantSpinal columnDetent

A frustum shaped body has an aperture in a top surface and a pair of first and second opposed apertures in a side surface, first and second horizontal internal channels connect both the first and second opposed apertures. A vertical channel from the top aperture connects with the first and second channels. After the body is inserted into a hole in a facet joint, compatible synthetic or biologic material is inserted into the vertical channel until the material exits from the first and second apertures in the side surface. At least one pair of flanges on a portion of an exterior side surface of the body acts as a detent to hold the body in place within the facet joint hole.

Owner:MINSURG INT INC

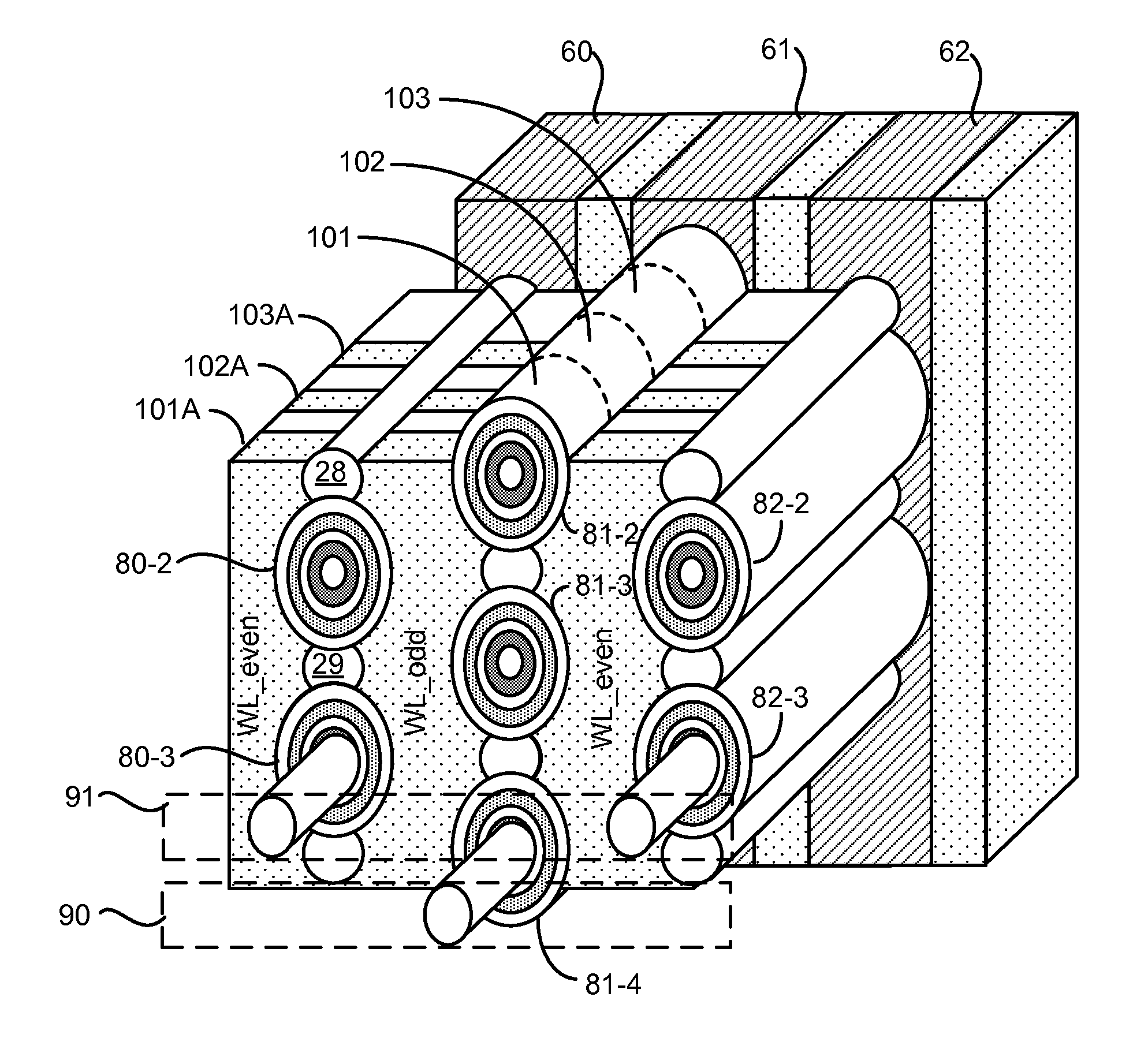

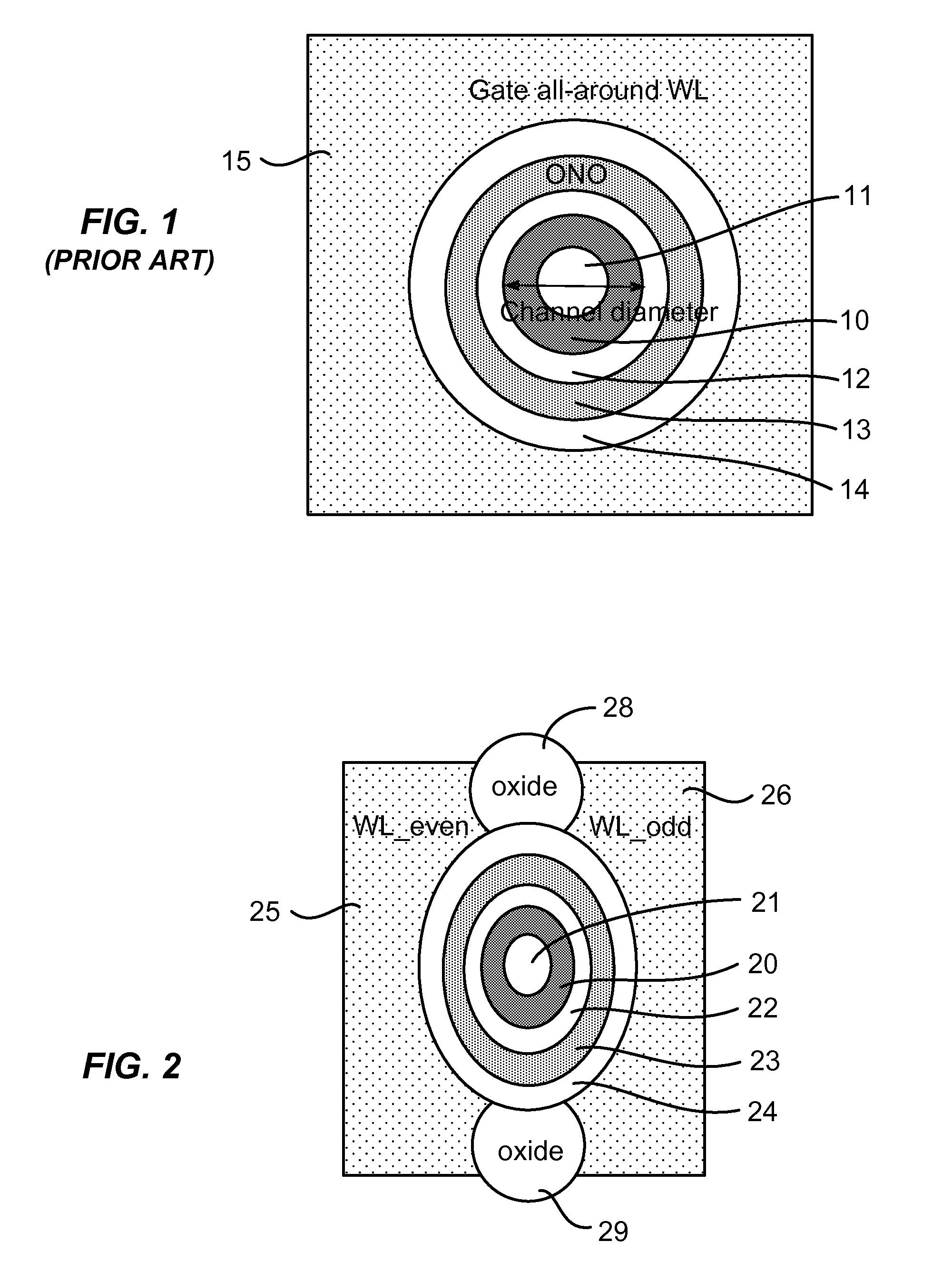

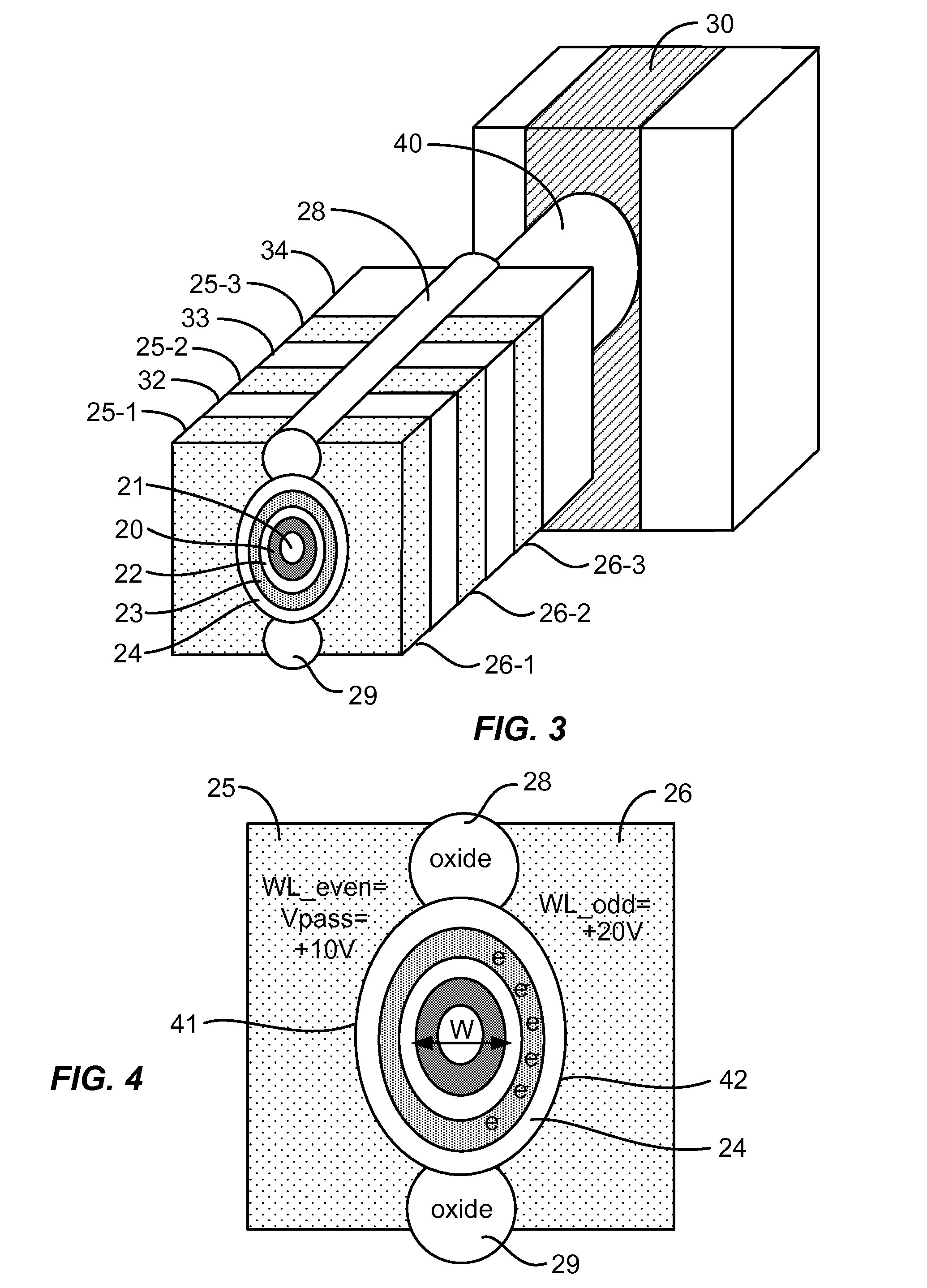

3D independent double gate flash memory on bounded conductor layer

ActiveUS20150340371A1High density data storageIncrease data storageSolid-state devicesRead-only memoriesElectrical conductorVertical channel

A memory device configurable for independent double gate cells, storing multiple bits per cell, includes multilayer stacks of conductive strips configured as word lines. Active pillars are disposed between pairs of first and second stacks, each active pillar comprising a vertical channel structure extending from an underlying bounded conductive layer, a charge storage layer and an insulating layer. The insulating layer in a frustum of an active pillar contacts a first arcuate edge of a first conductive strip in a layer of the first stack and a second arcuate edge of a second conductive strip in a same layer of the second stack. The conductive strips can comprise a metal. The active pillar can be generally elliptical with a major axis parallel with the first and second conductive strips.

Owner:MACRONIX INT CO LTD

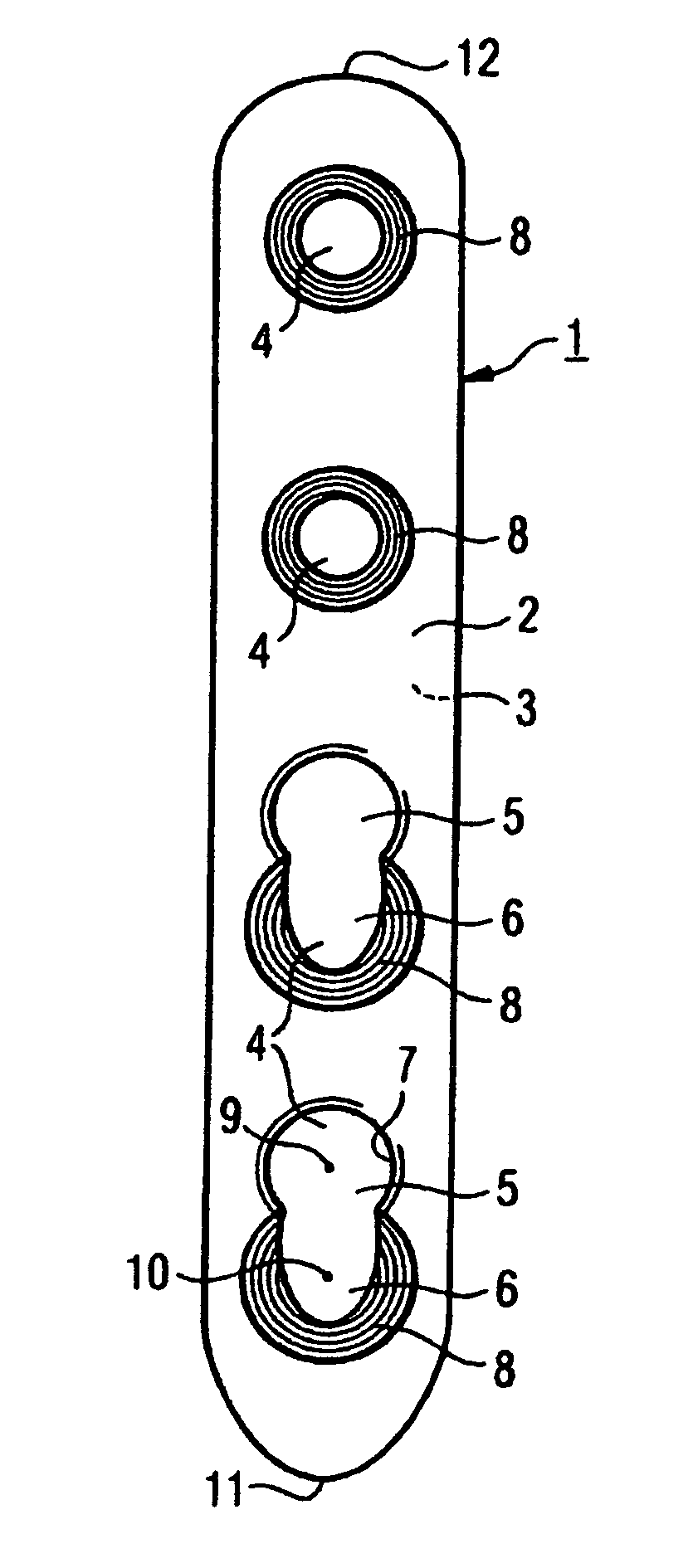

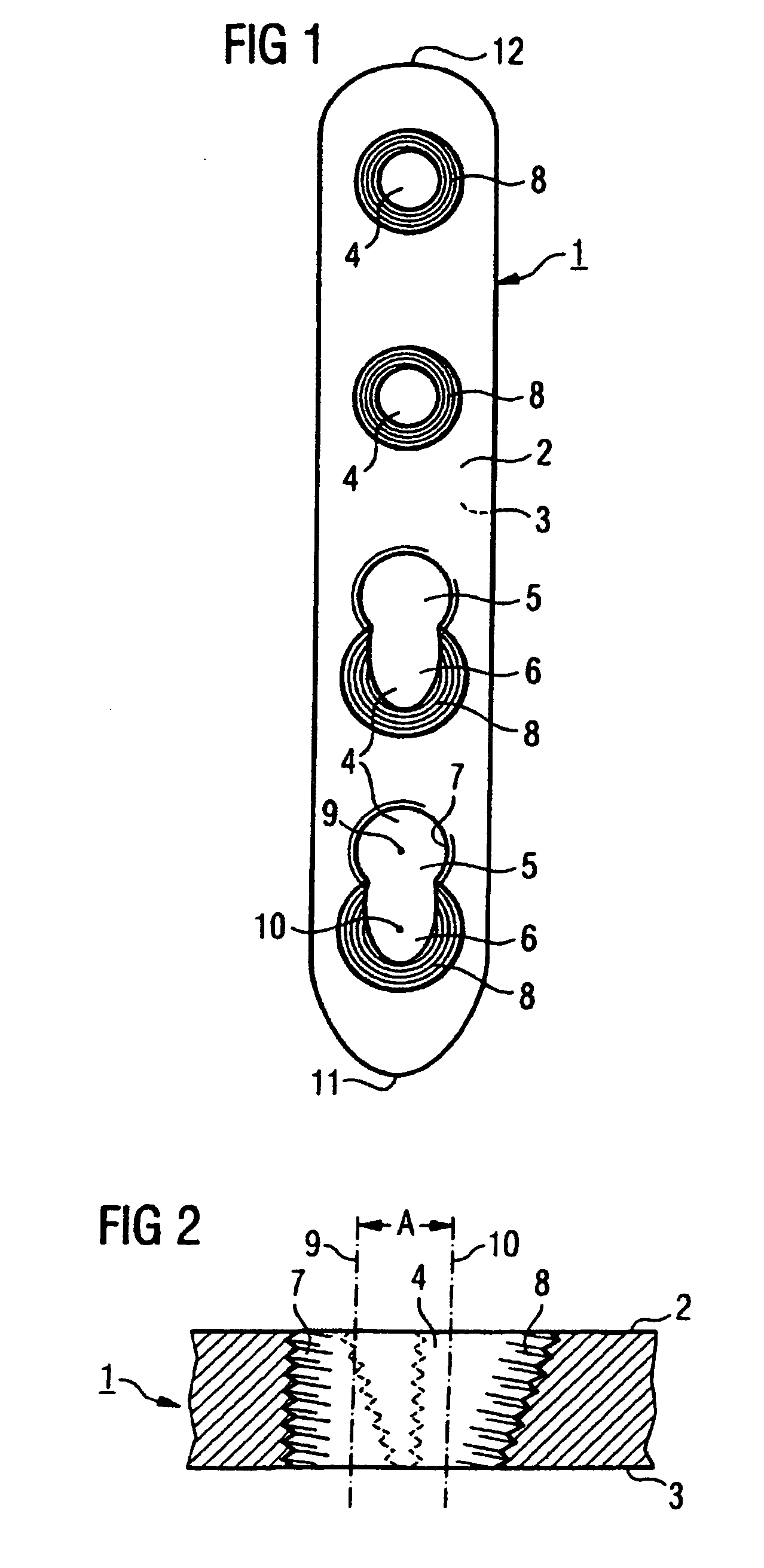

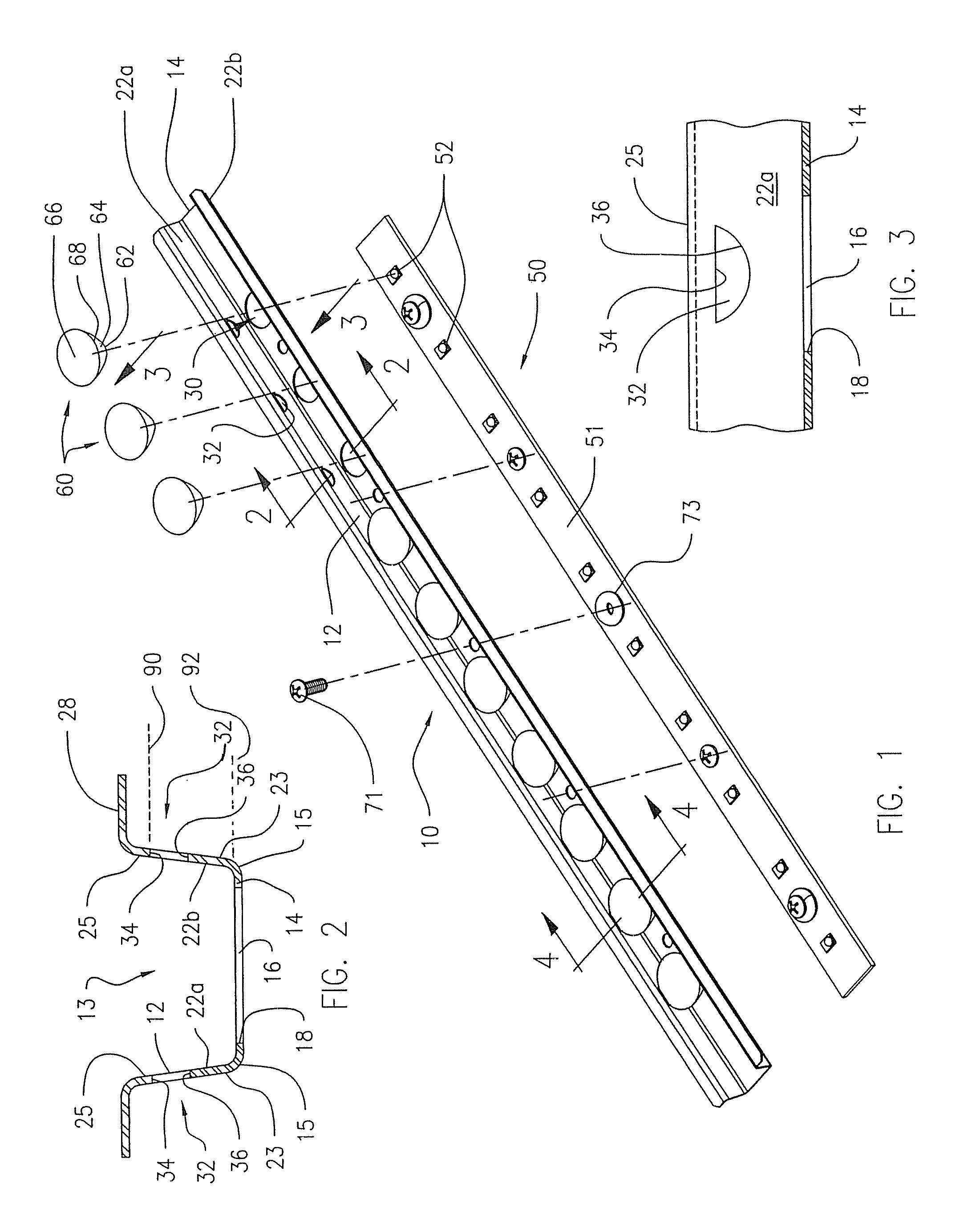

Bone plate

ActiveUS20070016205A1Little material wasteShort processInternal osteosythesisJoint implantsFrustumBone screws

A bone plate (1) having an upper side (2), a bone-sided lower side (3), a first end (11), a second end (12) and several plate holes (4) arranged between the two ends (11, 12) and connecting the upper side (2) to the lower side (3), the plate holes being provided for receiving bone screws. Two of the plate holes (4) are formed by a combination of two partially overlapping boreholes (5, 6) of different type. The first (5) of the two boreholes is a circular cylindrical bore, having an internal thread (7) and a cylinder axis (9). The second borehole (6) has a cone axis (10) and tapers from the upper side (2) to the lower side (3) in the form of a frustum of a cone. The second borehole (6) is provided with an internal thread (8). The cylinder axis (9) is situated at a distance A from the cone axis (10), where A is different than zero.

Owner:SYNTHES USA

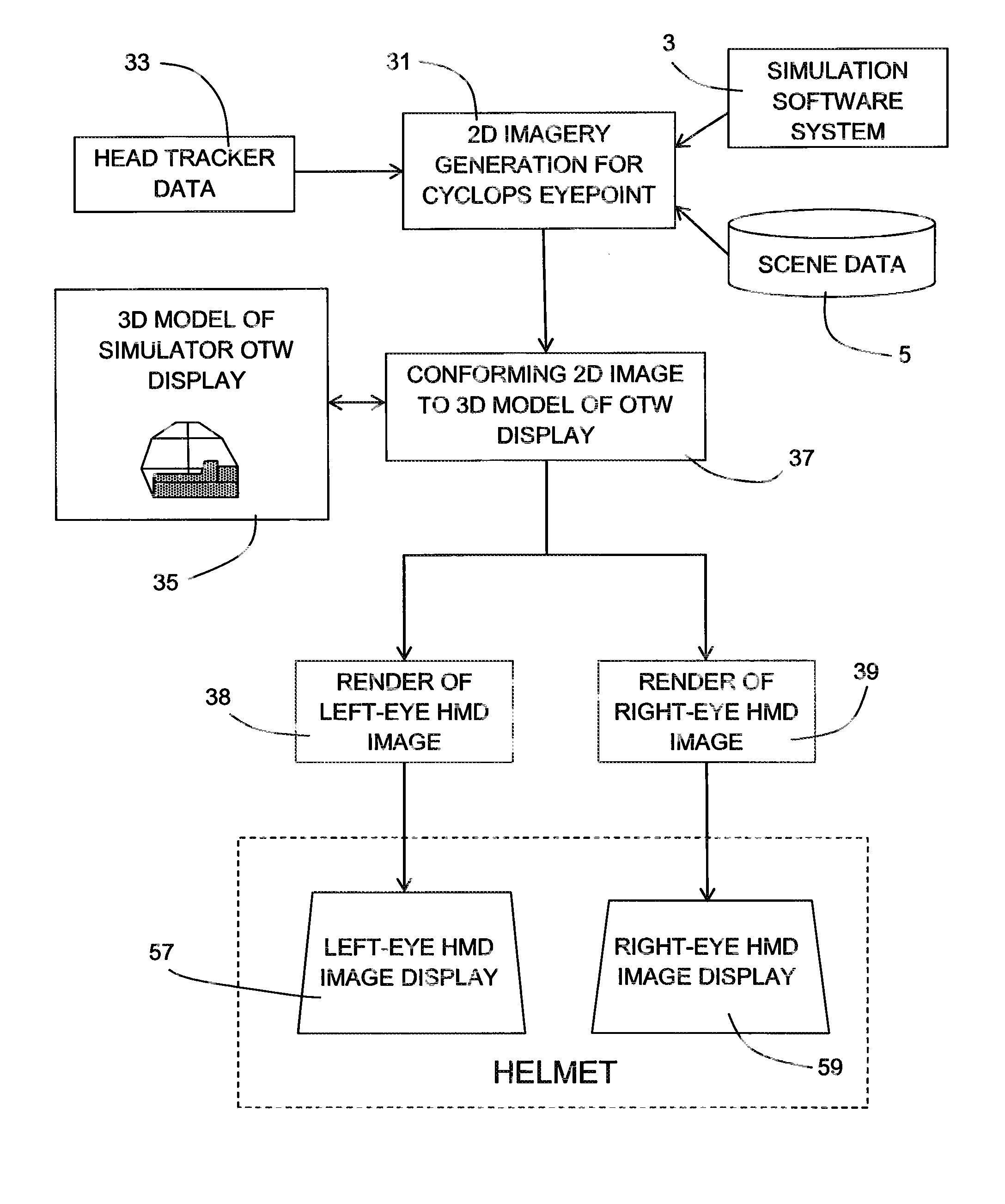

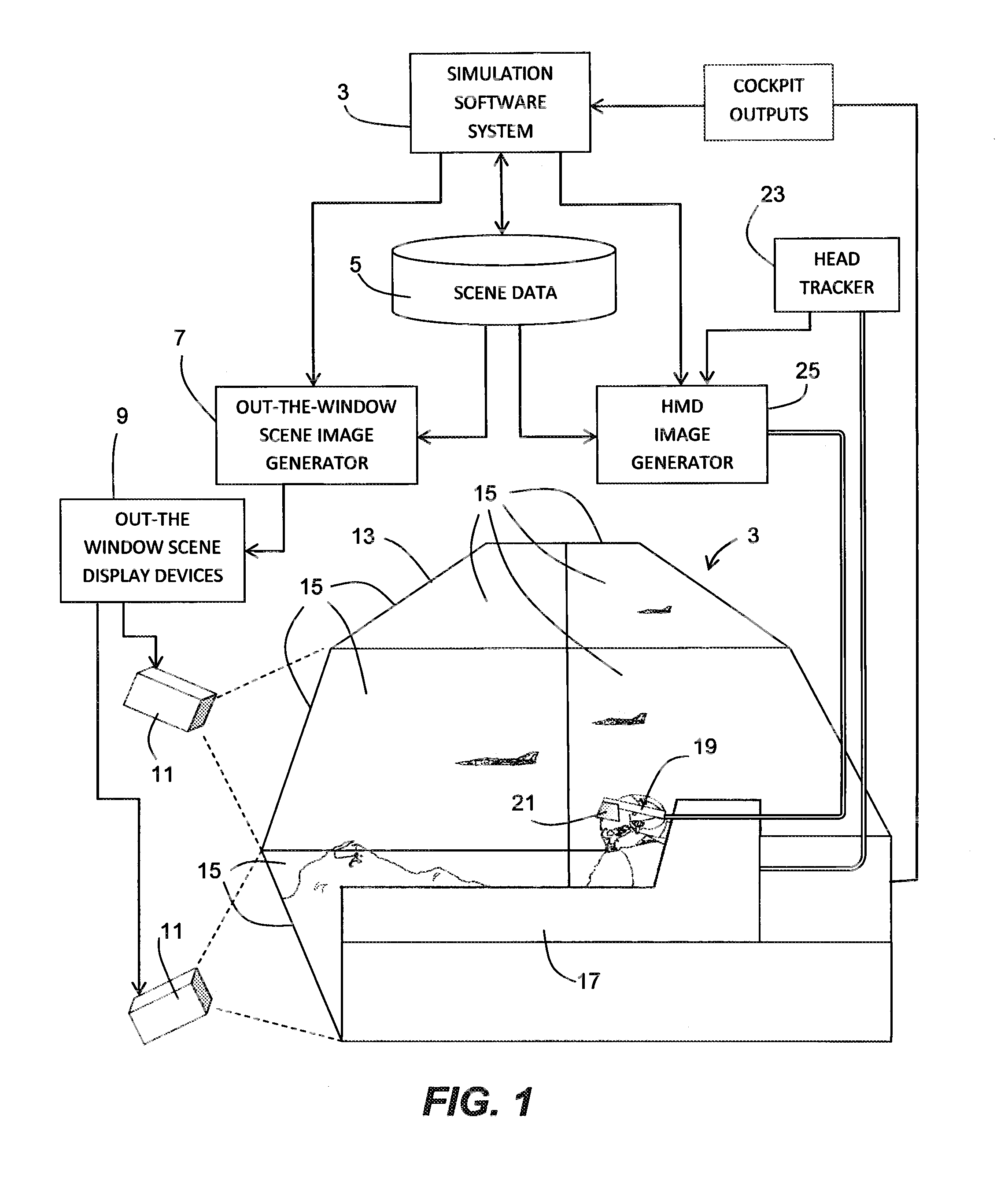

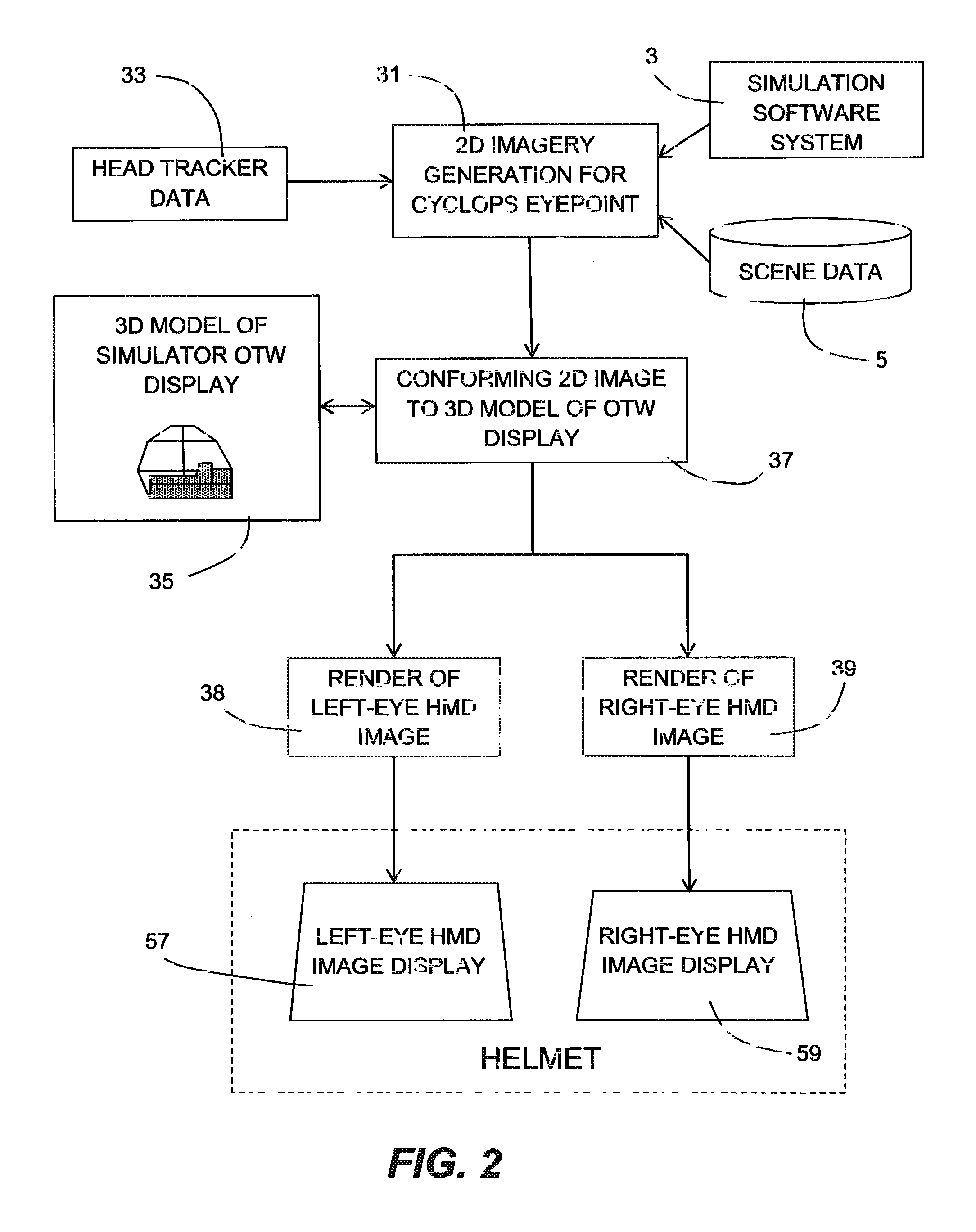

Simulated head mounted display system and method

InactiveUS8704882B2Cosmonautic condition simulationsColor television detailsVergence movementViewpoints

To overcome problems with vergence, a binocular head mounted display (HMD) is used in a simulator in which an out-the-window scene is displayed in real time on a screen arrangement. Imagery for the left and right eyes of the HMD is derived by generating a starting HMD image for a Cyclops viewpoint between the user's eves, and then rendering respective views for each eve from the position of the eye in a virtual 3D model of the screen arrangement, wherein the starting HMD image is frustum projected against the screen arrangement of the 3D model.

Owner:L 3 COMM CORP

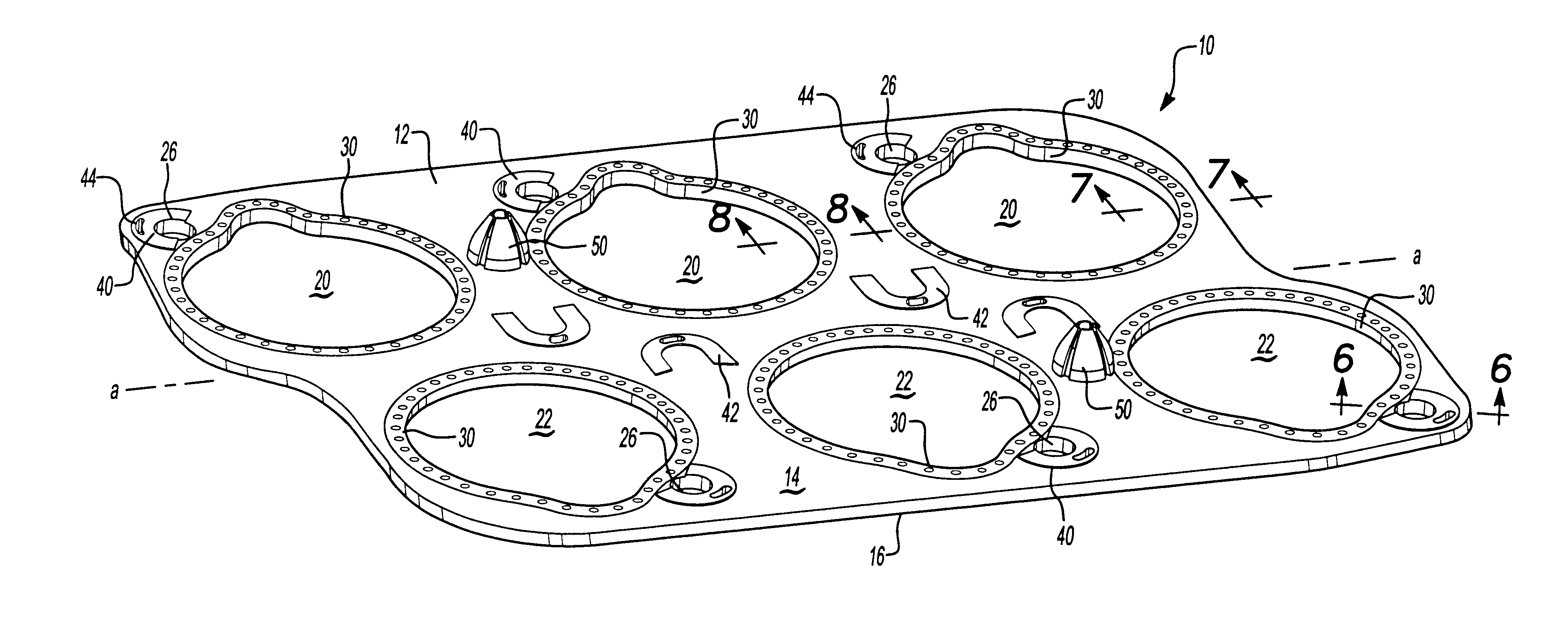

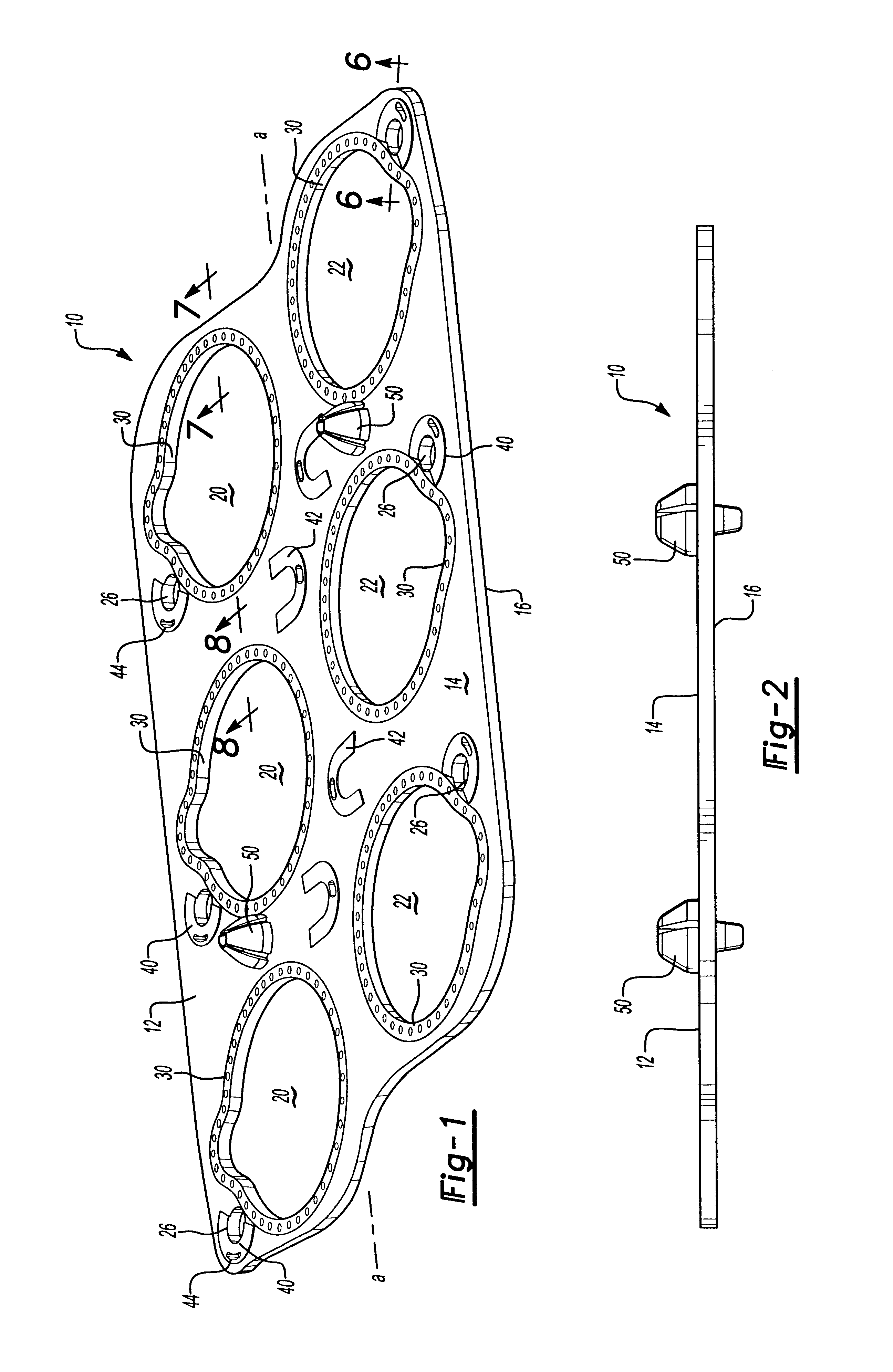

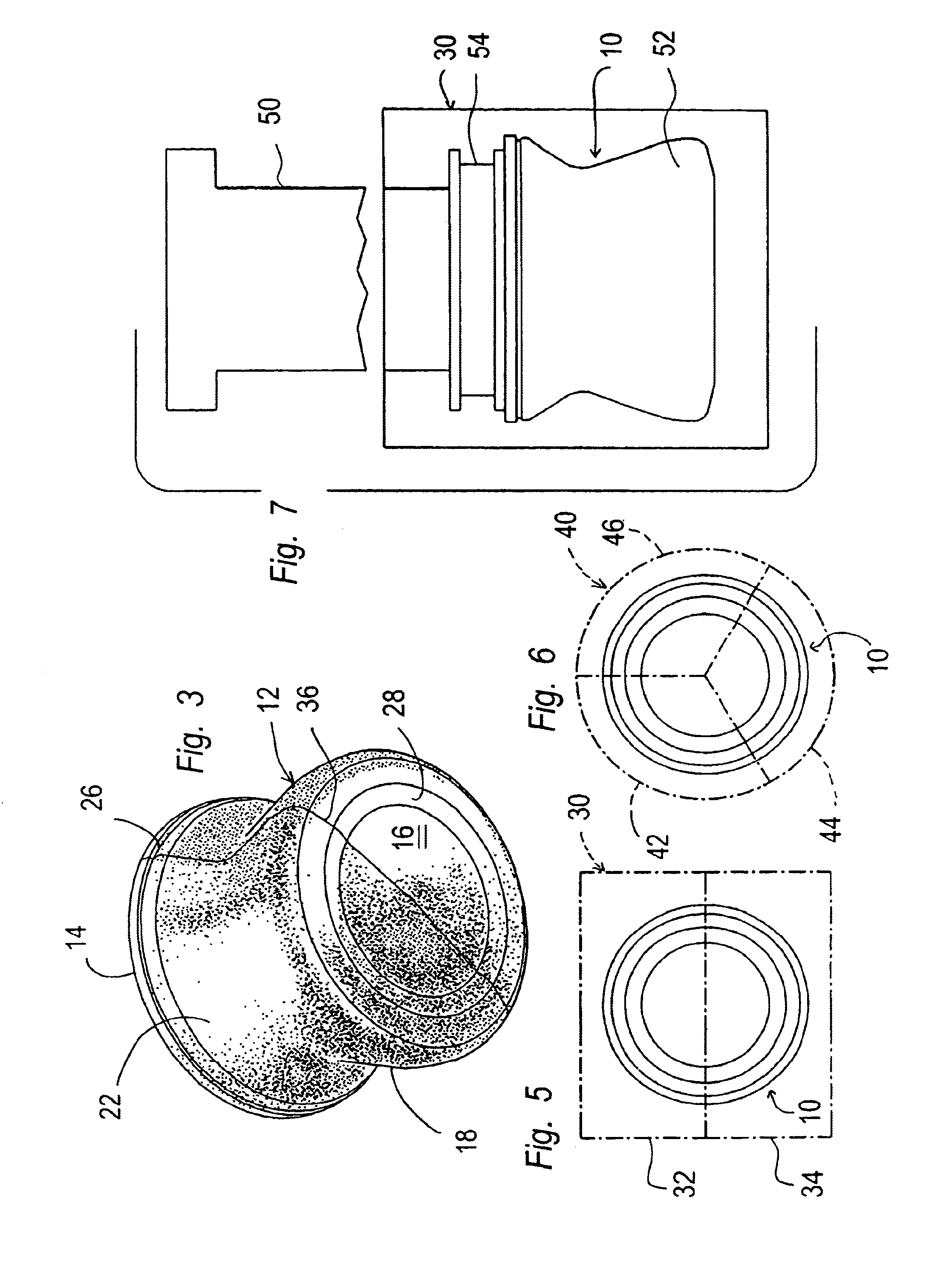

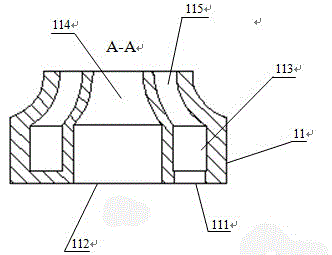

Thermoplastic gasket with edge bonded rubber apertures and integral alignment grommets

A gasket for sealing an intake manifold of an internal combustion engine, includes a plastic body defining substantially co-planar surfaces that define top and bottom surfaces of the gasket. Each of a plurality of air intake apertures includes an interiorly molded circumferential elastomeric edge bead. Each aperture edge includes a circumferential array of small openings for mechanical securement of the elastomeric bead to the plastic carrier, and each opening fills with elastomer upon the overmolding of the bead to the edge during manufacture. The gasket also includes primary and secondary compression limiters, formed of powdered metal in described embodiment, located immediately adjacent bolt holes and symmetrically between air intake apertures, respectively. Finally, the gasket includes flexible locator grommets for assuring positive alignment between the cylinder head and intake manifold. Each locator includes a frustum-like body and a cylindrical post extending oppositely outwardly of top and the bottom of the gasket, respectively.

Owner:DANA AUTOMOTIVE SYST GRP LLC

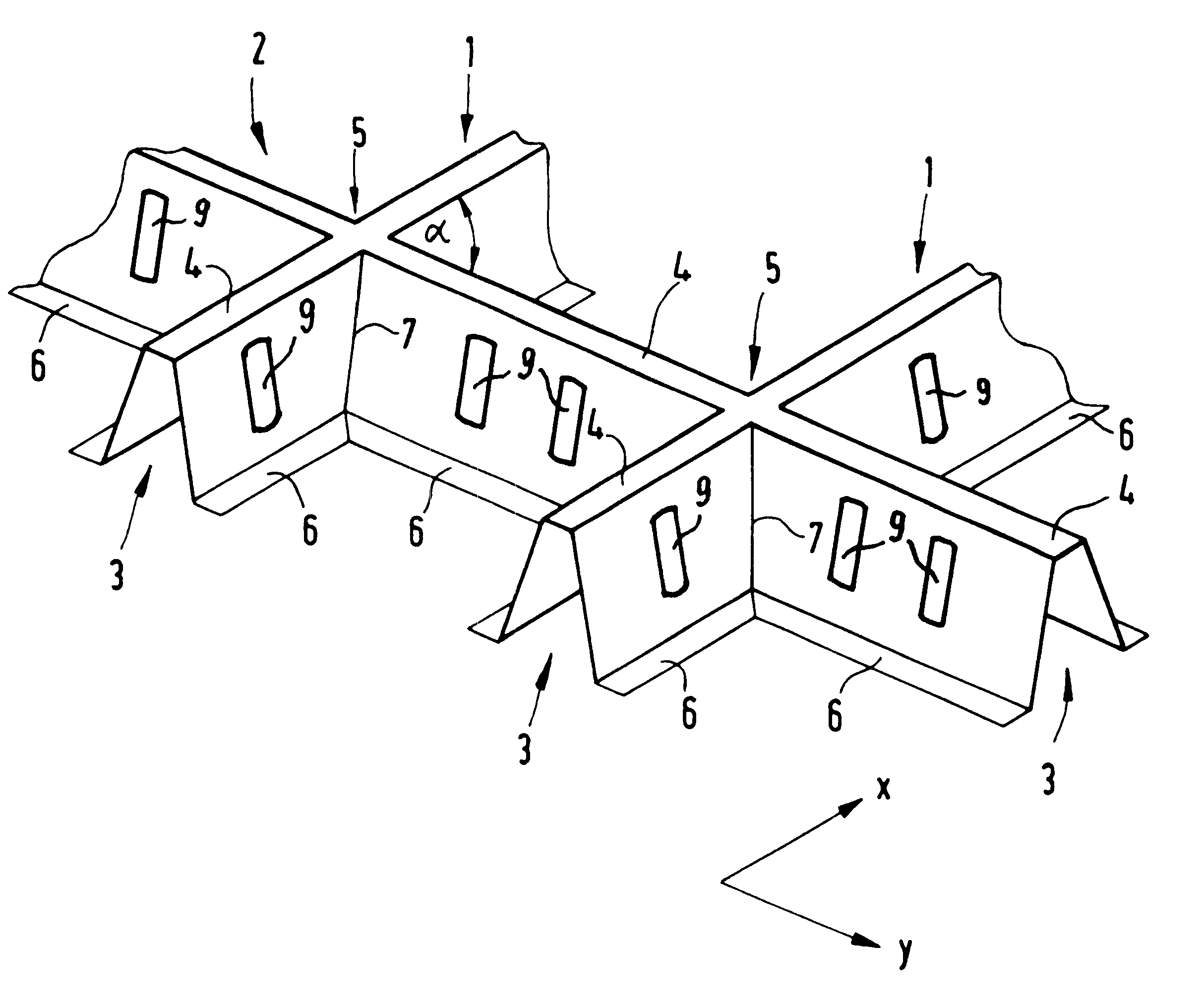

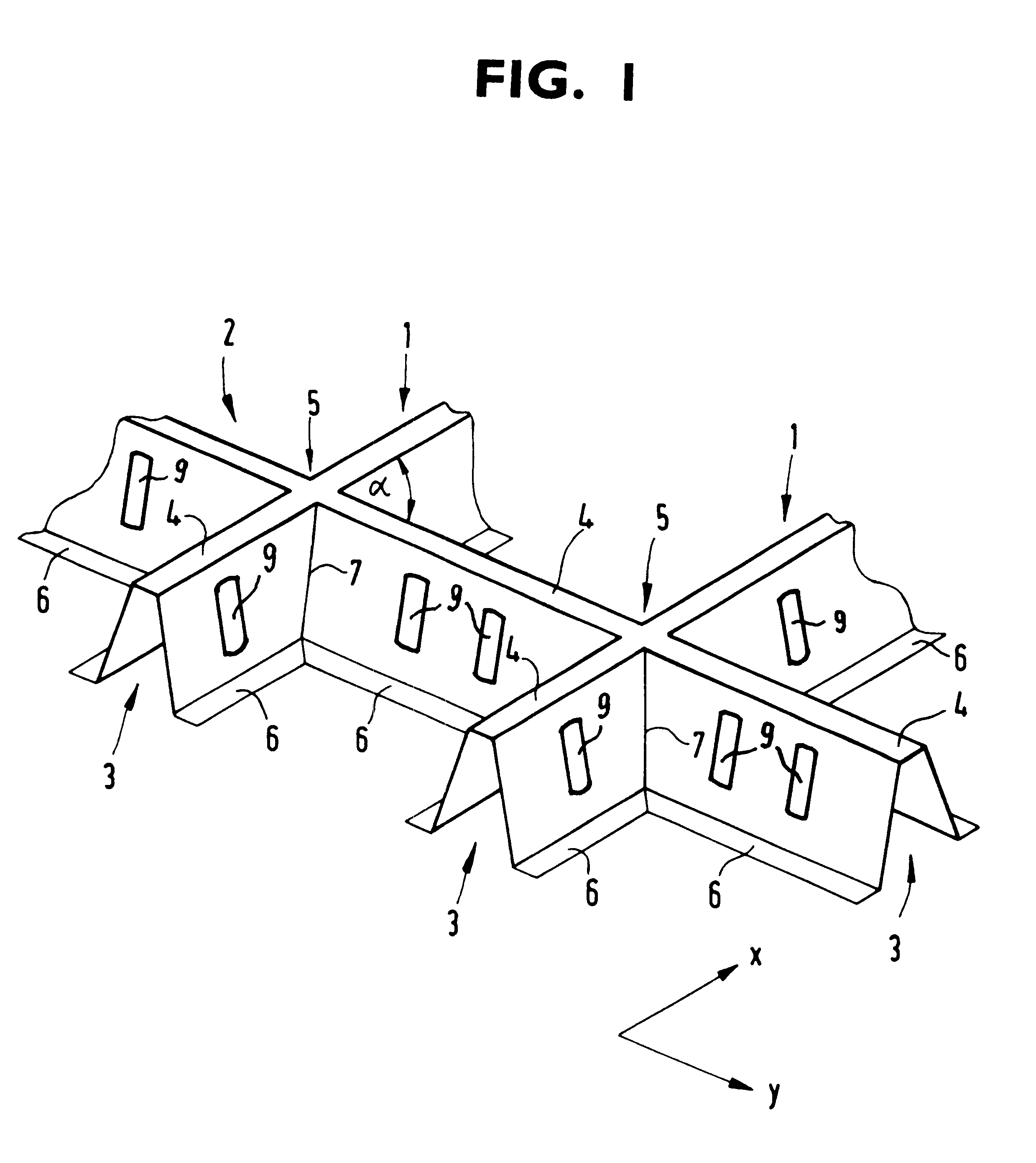

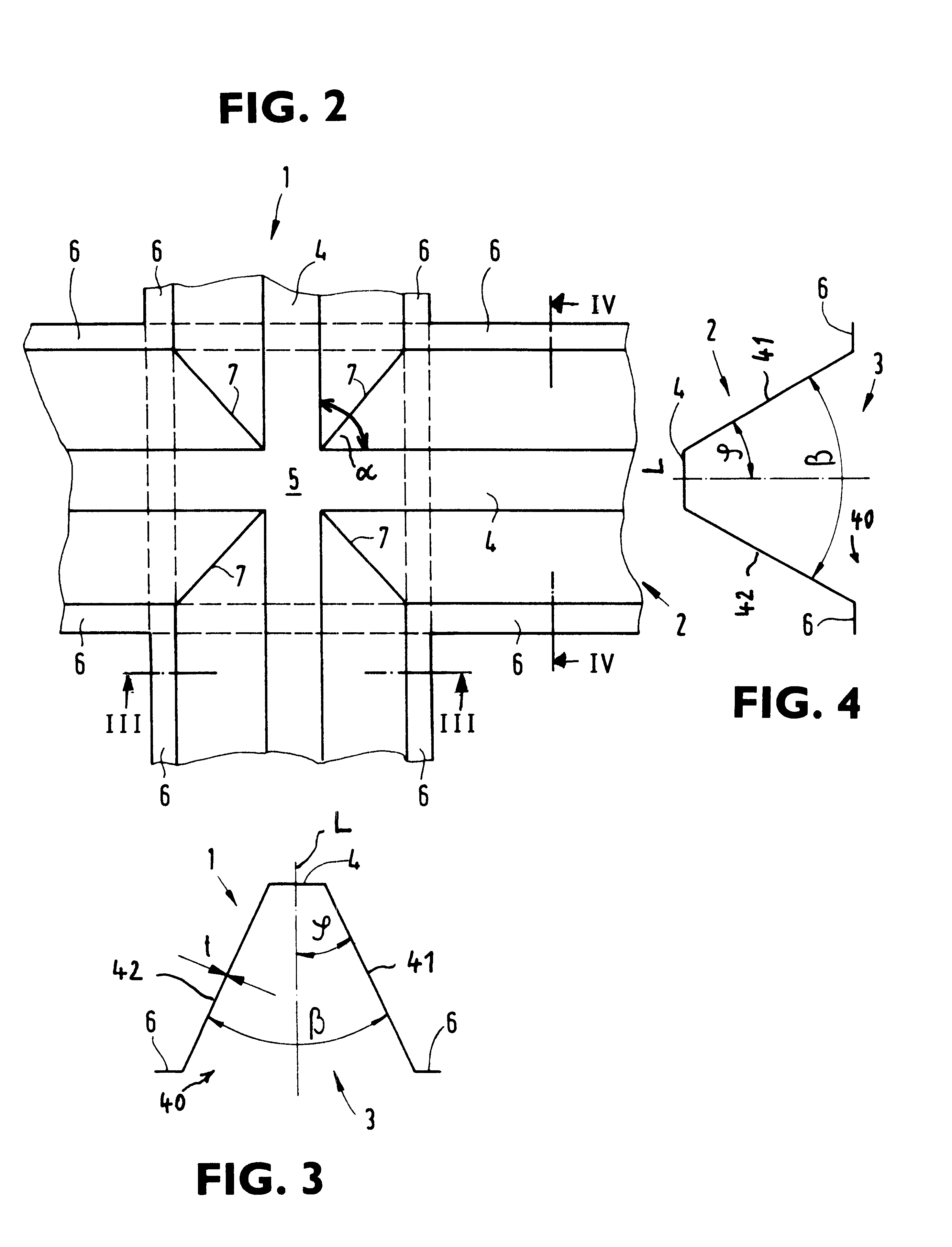

Subfloor structure of an aircraft airframe

A subfloor structure of an aircraft airframe, particularly of a helicopter, includes longitudinal beams and crossbeams that intersect each other and are interconnected to form a grid that is fixedly attached to the floor and the bottom skin of the aircraft fuselage. Structural elements such as pyramid frustums and reinforcements are arranged on the beams. The longitudinal beam and the crossbeam have a trapezoidal cross-section that is preferably open on the wider base side, closed by a spine web along the narrow side, and bounded laterally by inclined leg webs that extend downwardly from the spine web at an angle outwardly relative to each other. The subfloor structure grid effectively absorbs the energy of a crash impact having both axial or vertical as well as non-axial or lateral impact force components.

Owner:AIRBUS HELICOPTERS DEUT GMBH

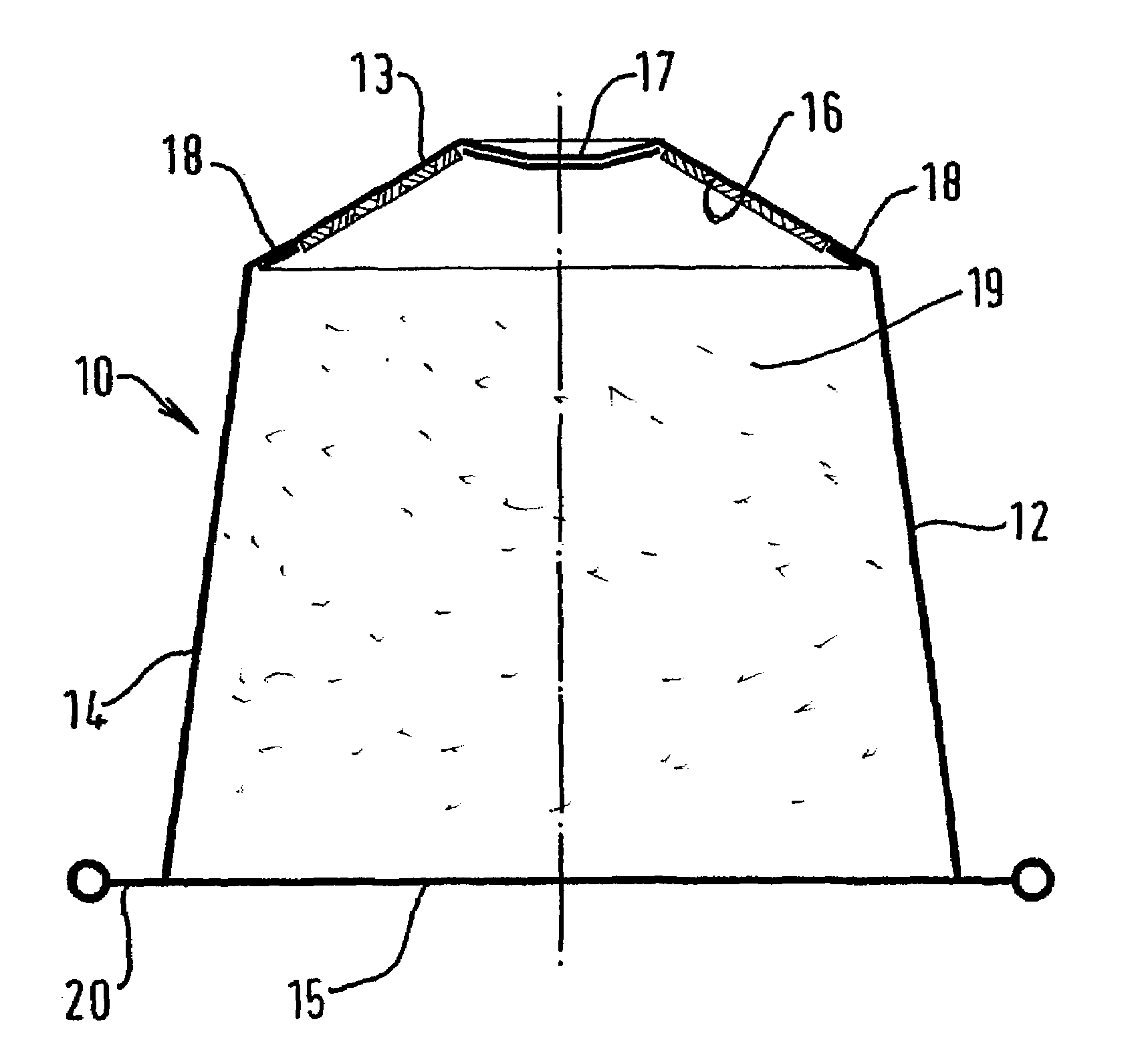

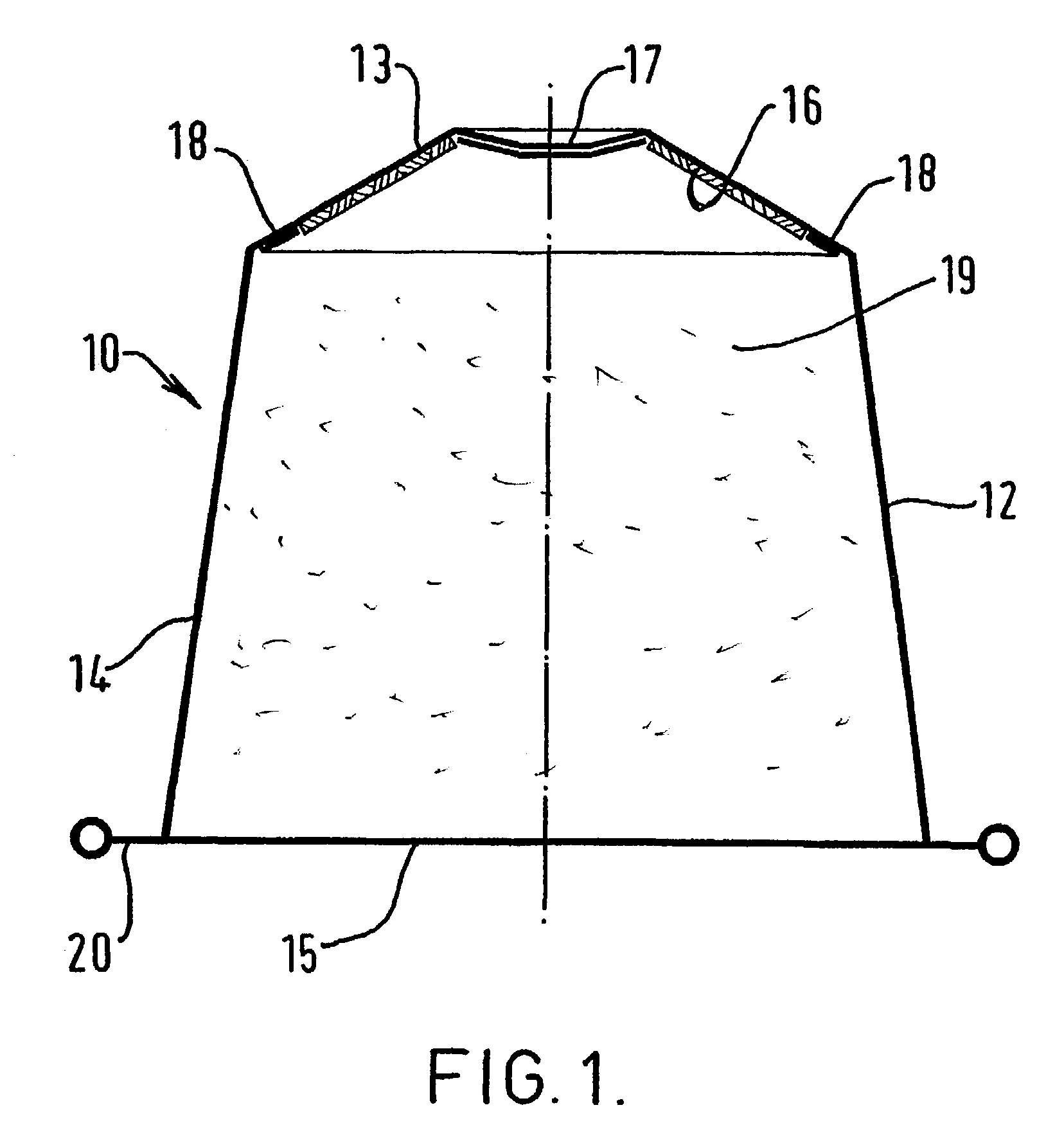

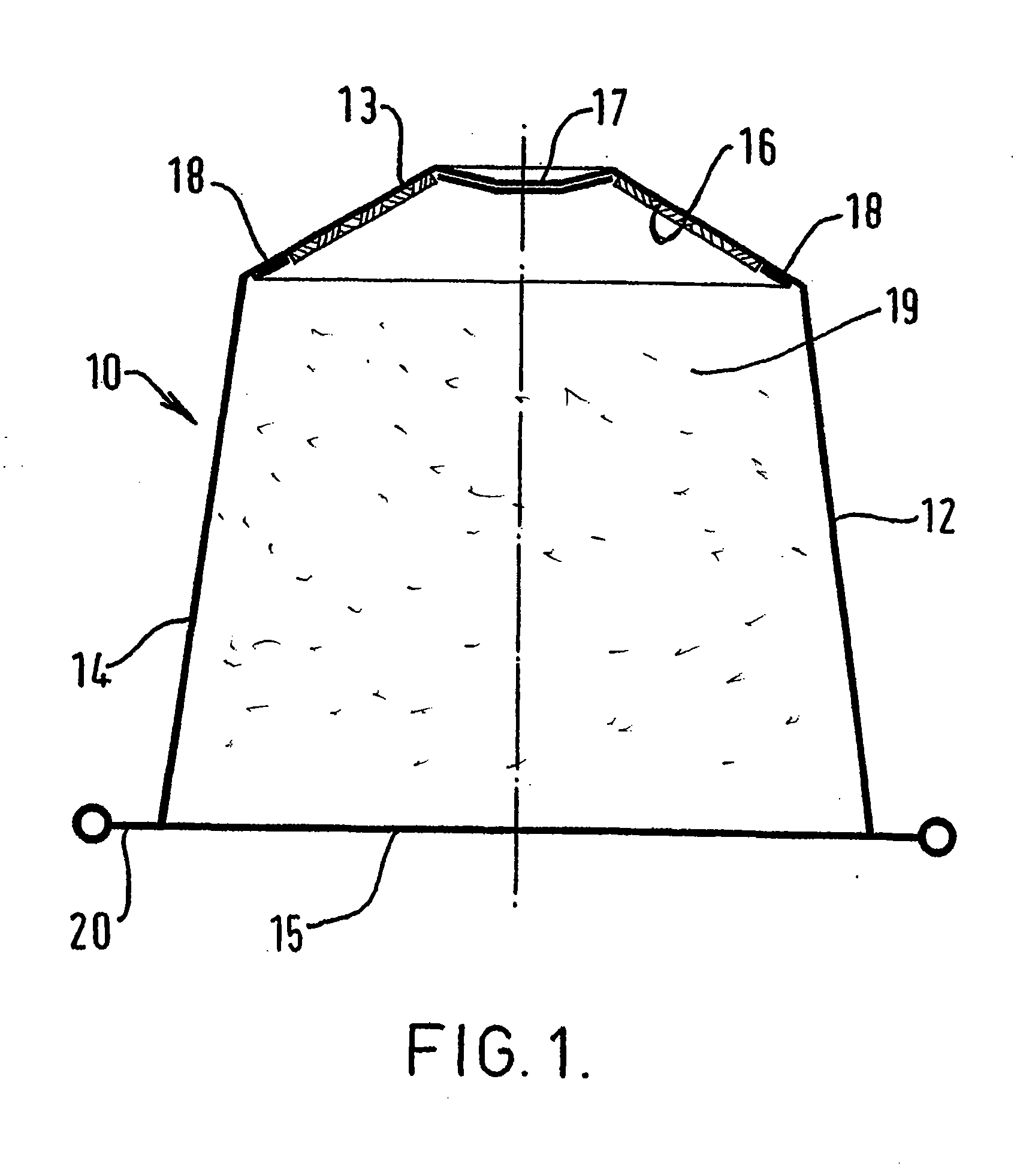

Closed cartridge for preparing a beverage for extraction under pressure

InactiveUS7153530B2Guaranteed retentionEasy to produceReady-for-oven doughsDispensing apparatusEngineeringFrustum

The present invention relates to a closed cartridge (10), for extraction under pressure, comprising a dish (12) with a bottom (13 ) with a central part and a peripheral part and a side wall having substantially the shape of a frustum of a cone and a circular edge with a diameter greater at the bottom and a cover (15) welded to the periphery of the edge of the dish and the cover is intended to be torn only through the effect of the force of the extraction fluid when extraction starts, the cartridge comprising, in the dish at the level of the bottom, a fabric (16) guaranteeing retention of the solid substance when it is opened,in which the fabric guaranteeing retention of solid substance is a sheet of fabric sealed in the bottom of the dish in two zones, on the one hand in the central part (17) and on the other hand in the peripheral part (18) of the bottom (13).

Owner:SOC DES PROD NESTLE SA

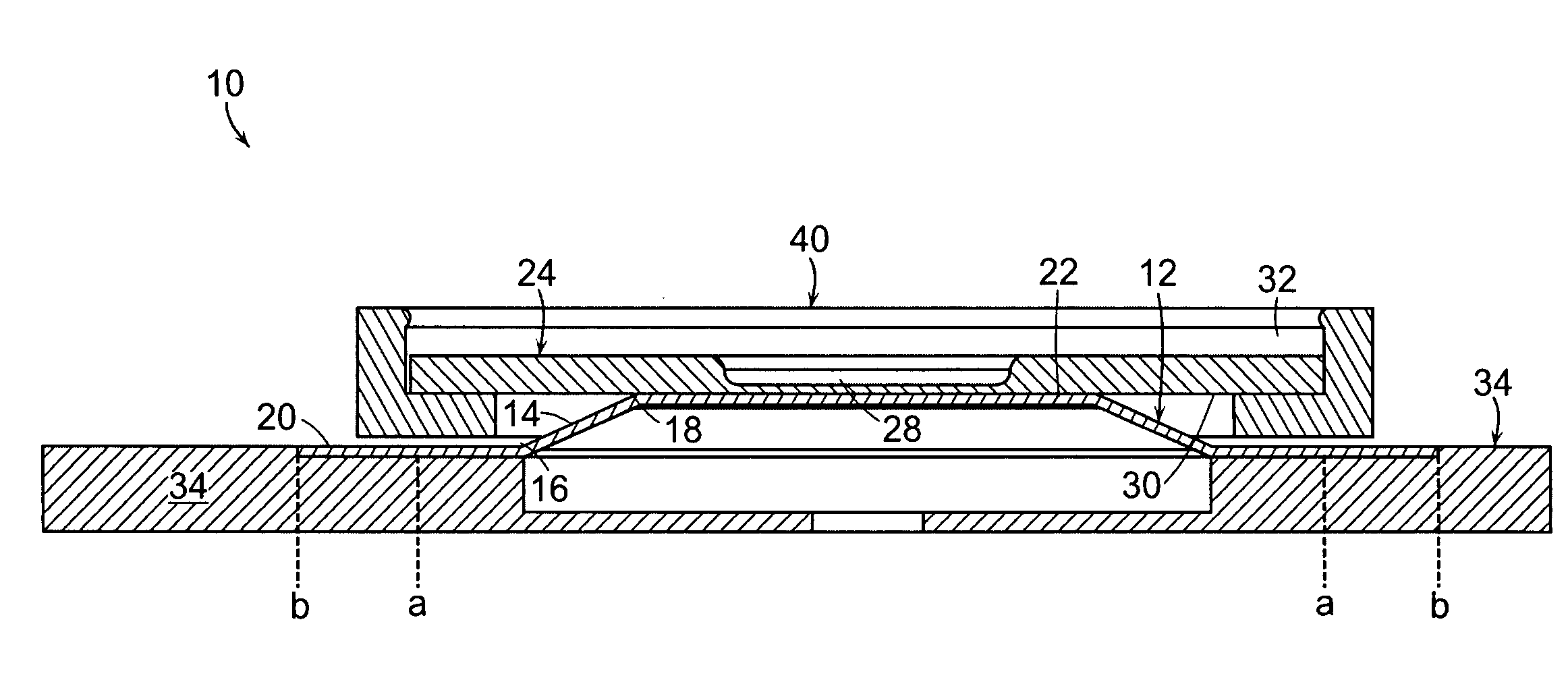

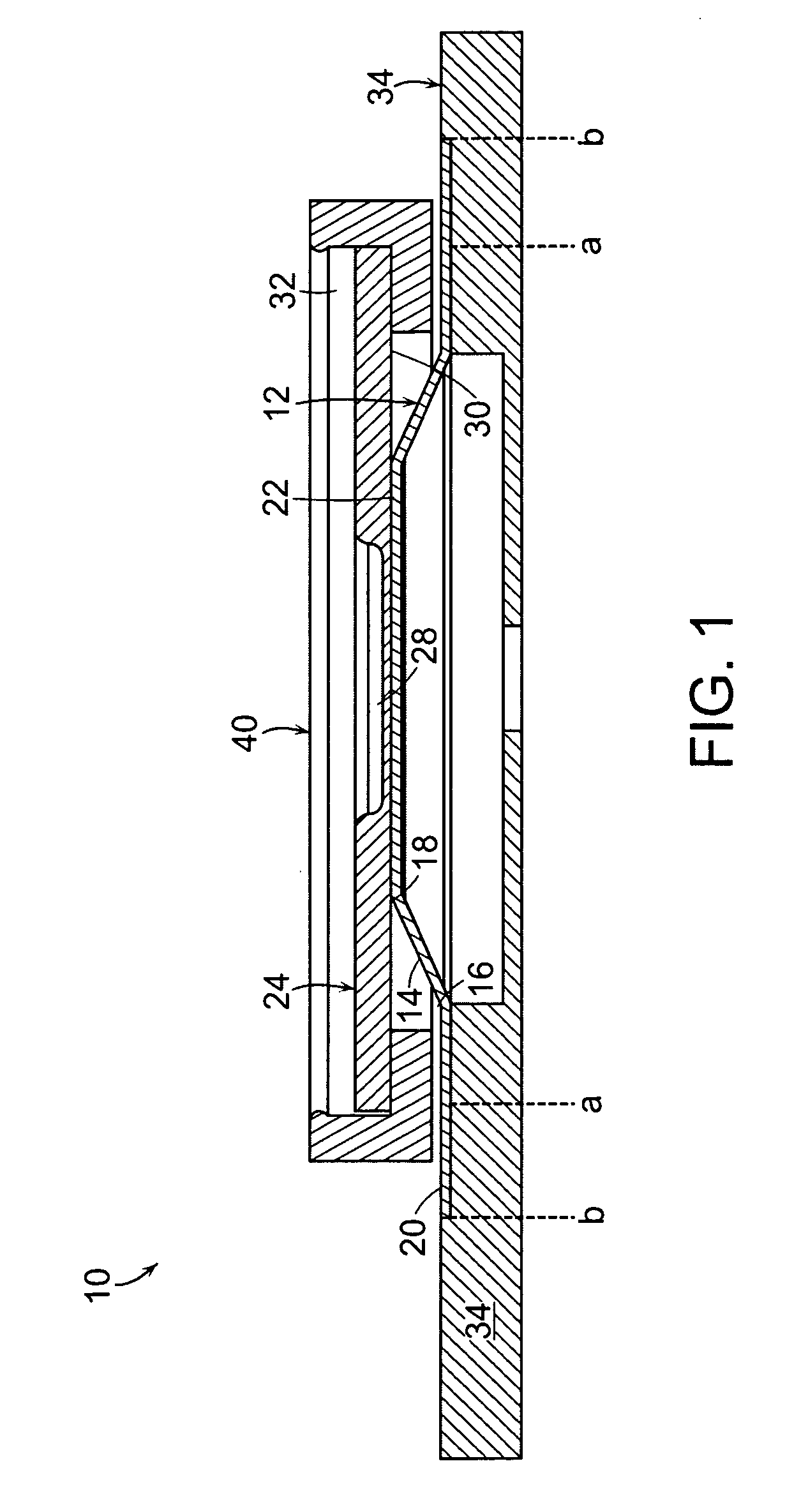

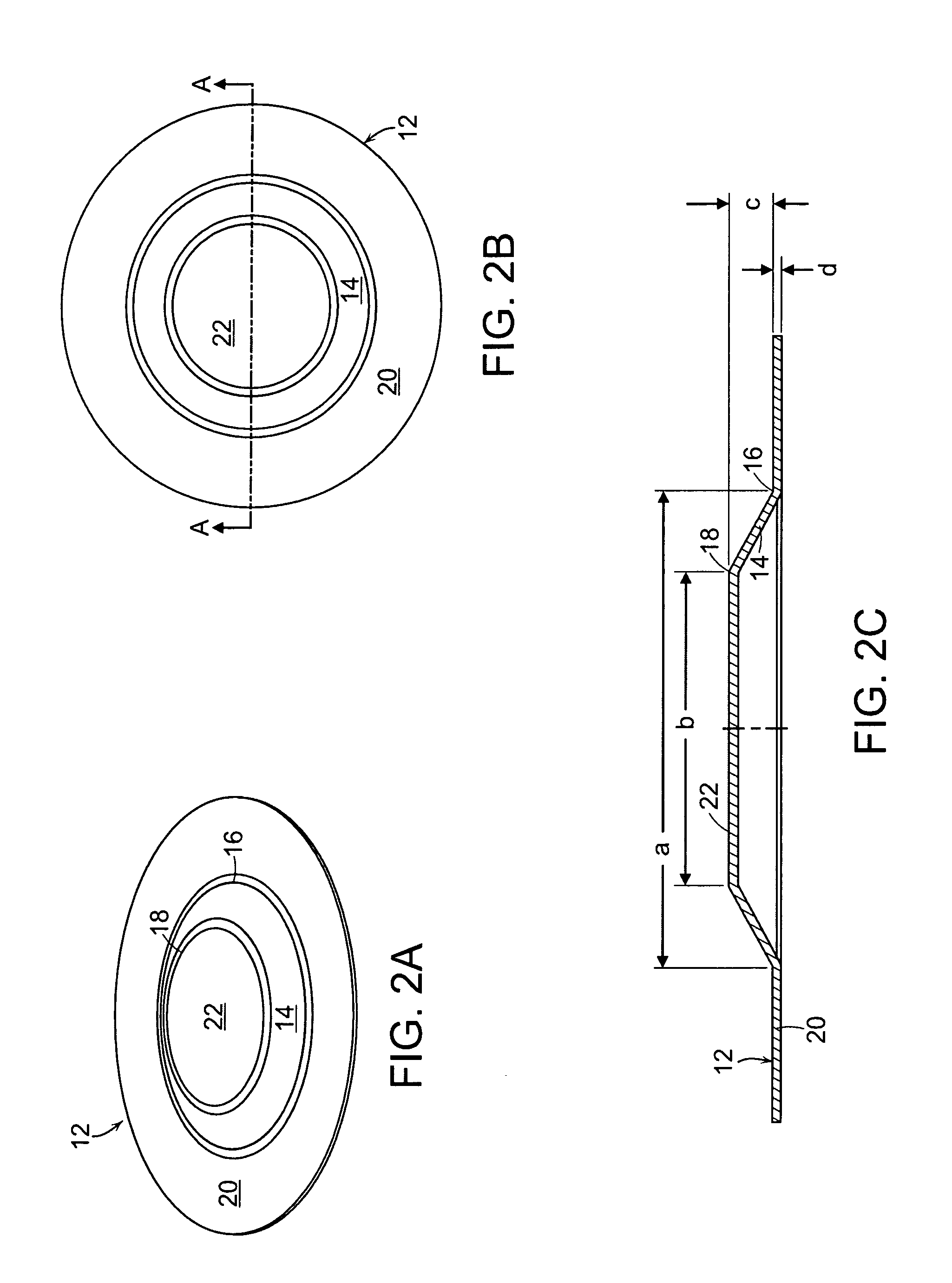

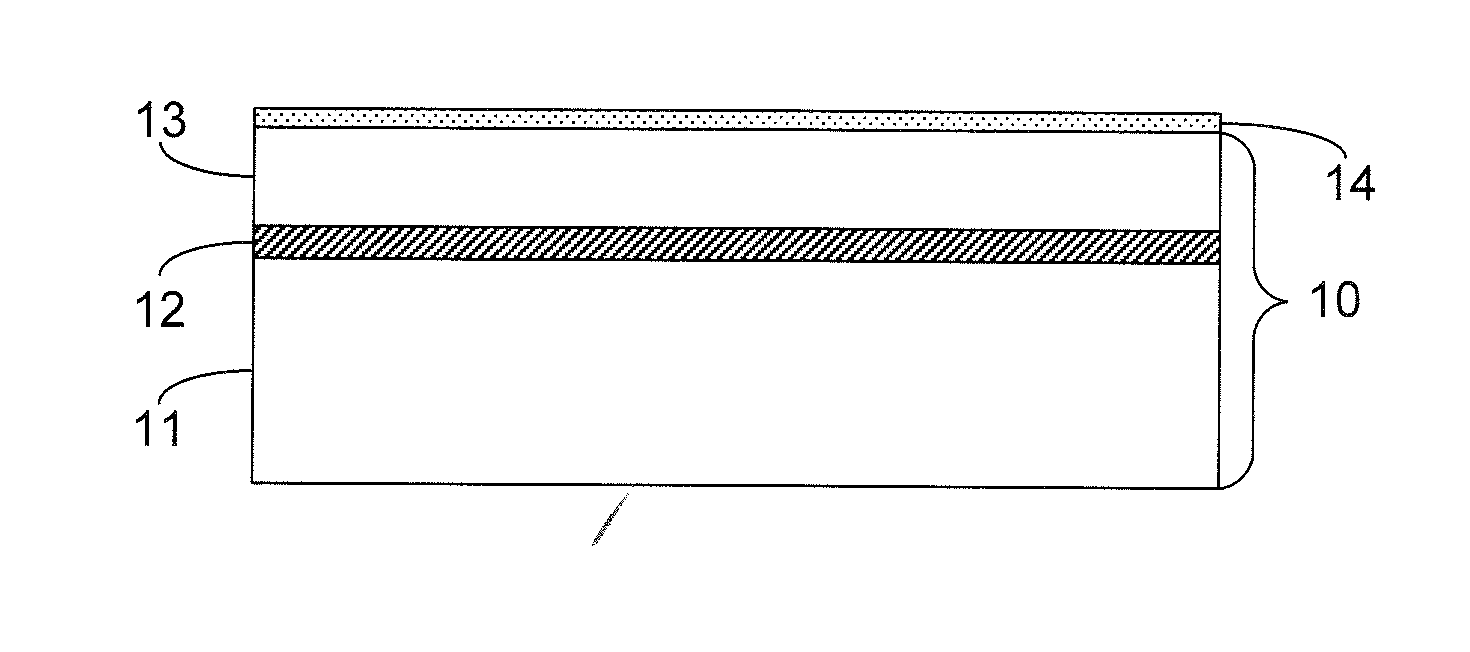

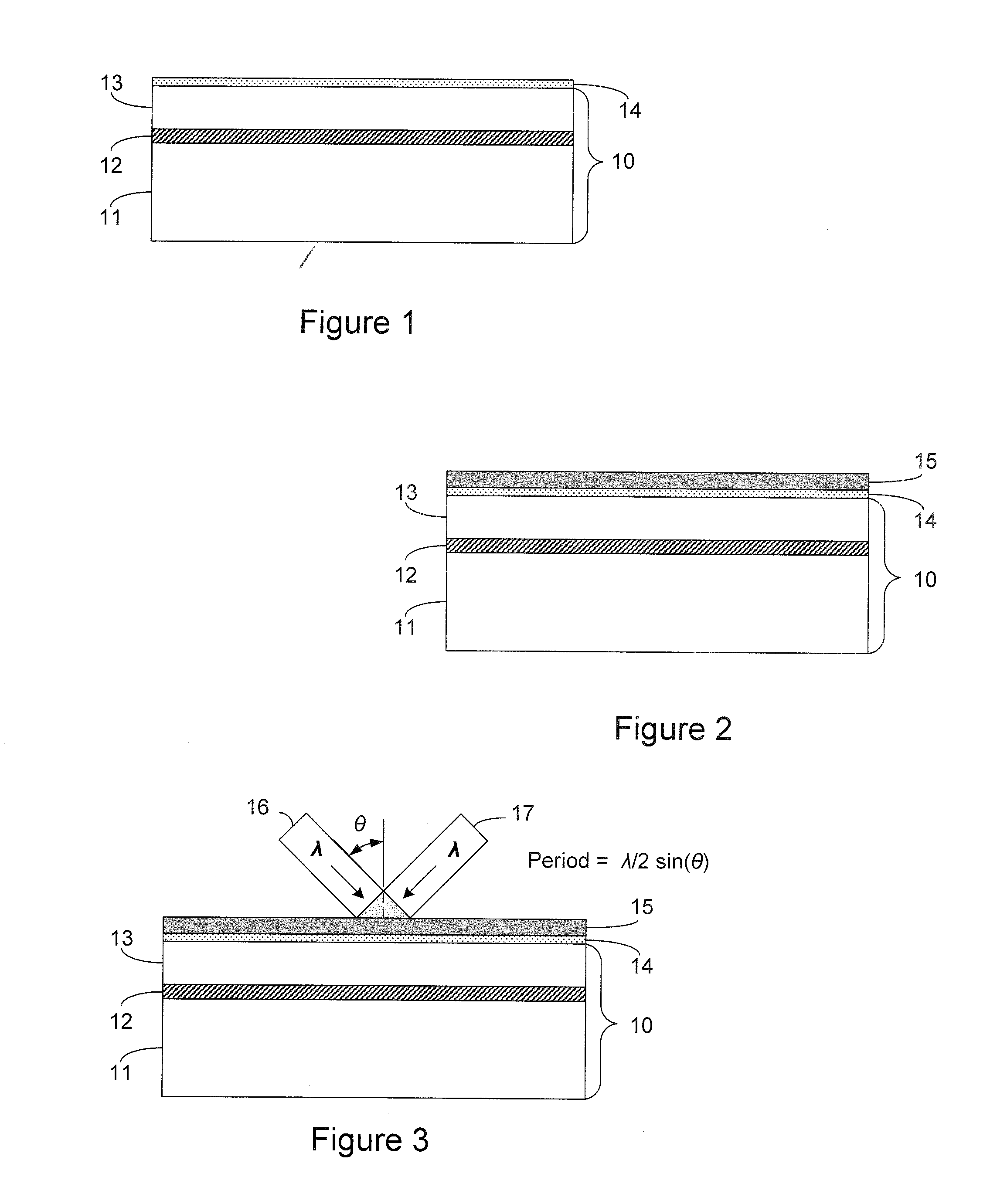

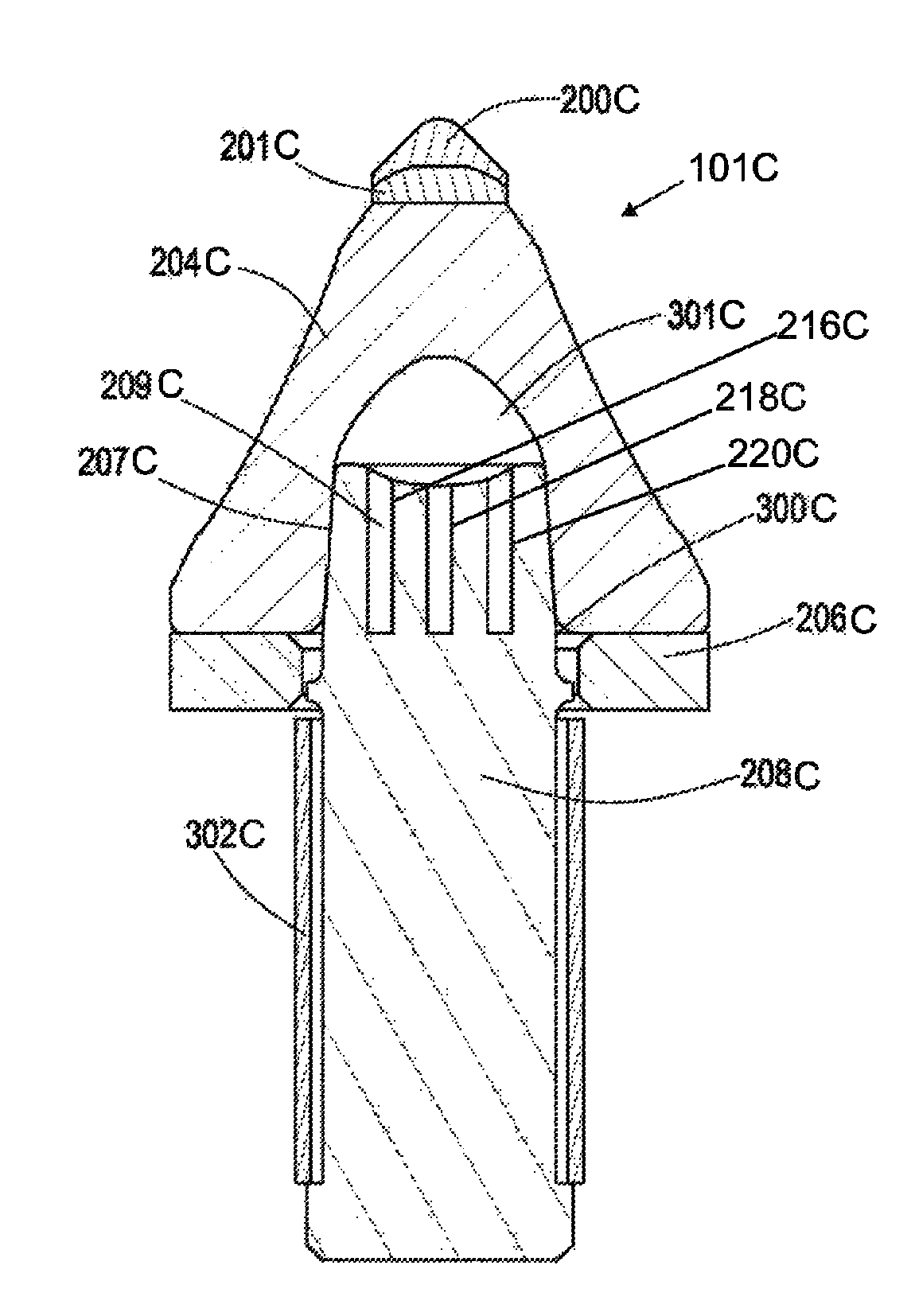

CID retention device for Li-ion cell

InactiveUS20090029193A1Reduce riskIncrease capacityFinal product manufactureSmall-sized cells cases/jacketsLithium-ion batteryFrustum

A low pressure current interrupt device (CID) activates at a minimal threshold internal gauge pressure in a range of, for example, between about 4 kg / cm2 and about 9 kg / cm2. Preferably, the CID includes a first conductive plate and a second conductive plate in electrical communication with the first conductive plate, the electrical communication between the first and the second conductive plates being interrupted at the minimal threshold internal gauge pressure. More preferably, the first conductive plate includes a frustum having a first end and a second end, a base extending radially from a perimeter of the first end of the frustum, and an essentially planar cap sealing the second end of the frustum. The first end has a broader diameter than the second end. More preferably, the second conductive plate is in electrical contact with the essentially planar cap through a weld. A battery, preferably a lithium-ion battery, comprises a CID as described above. A method of manufacturing such a CID comprises forming first and second conductive plates as described above, and welding the second conductive plate onto the first conductive plate while a temperature of the first conductive plate is controlled so as not to exceed the melting point of a surface of the first conductive plate opposite the weld.

Owner:BOSTON POWER INC

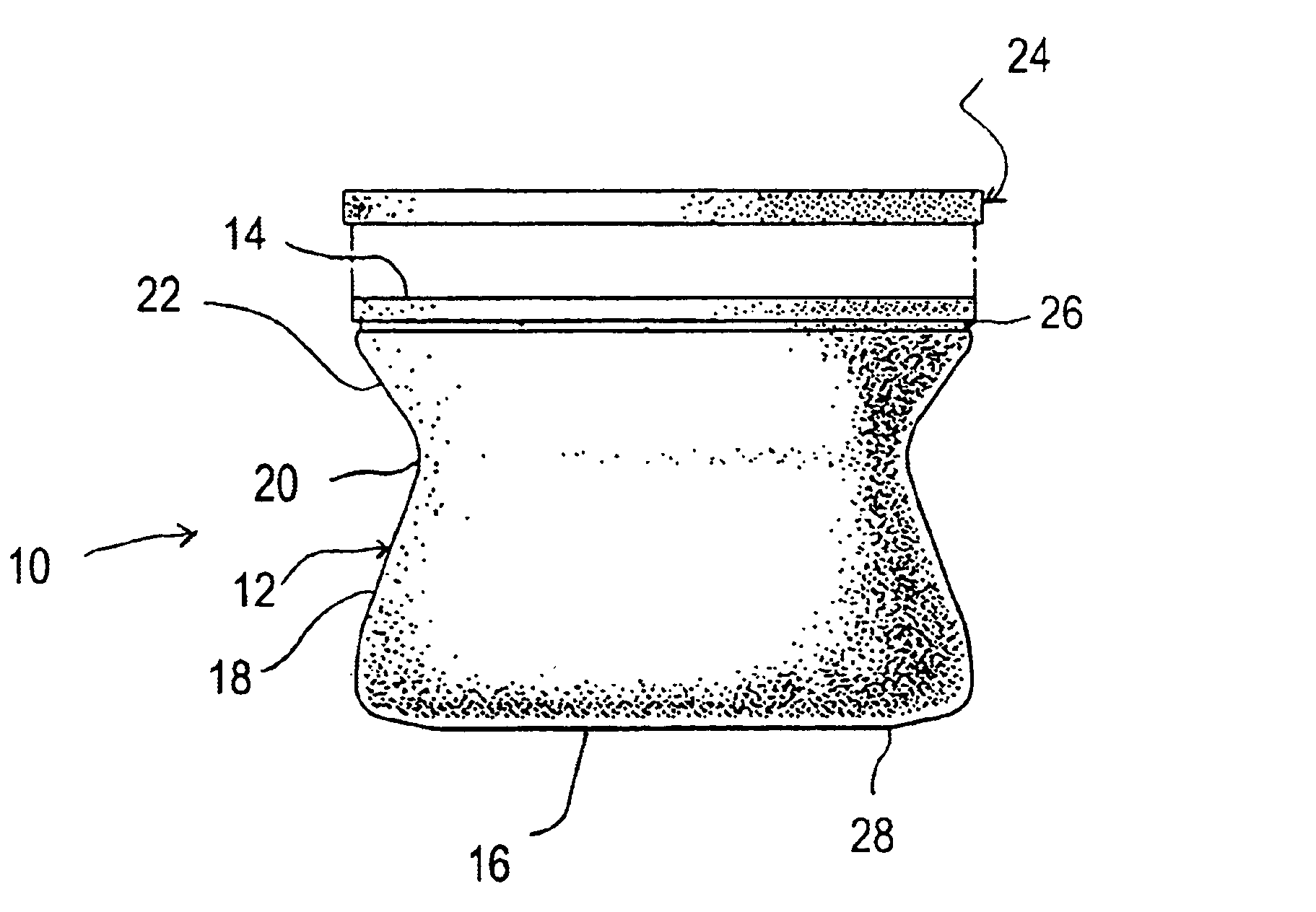

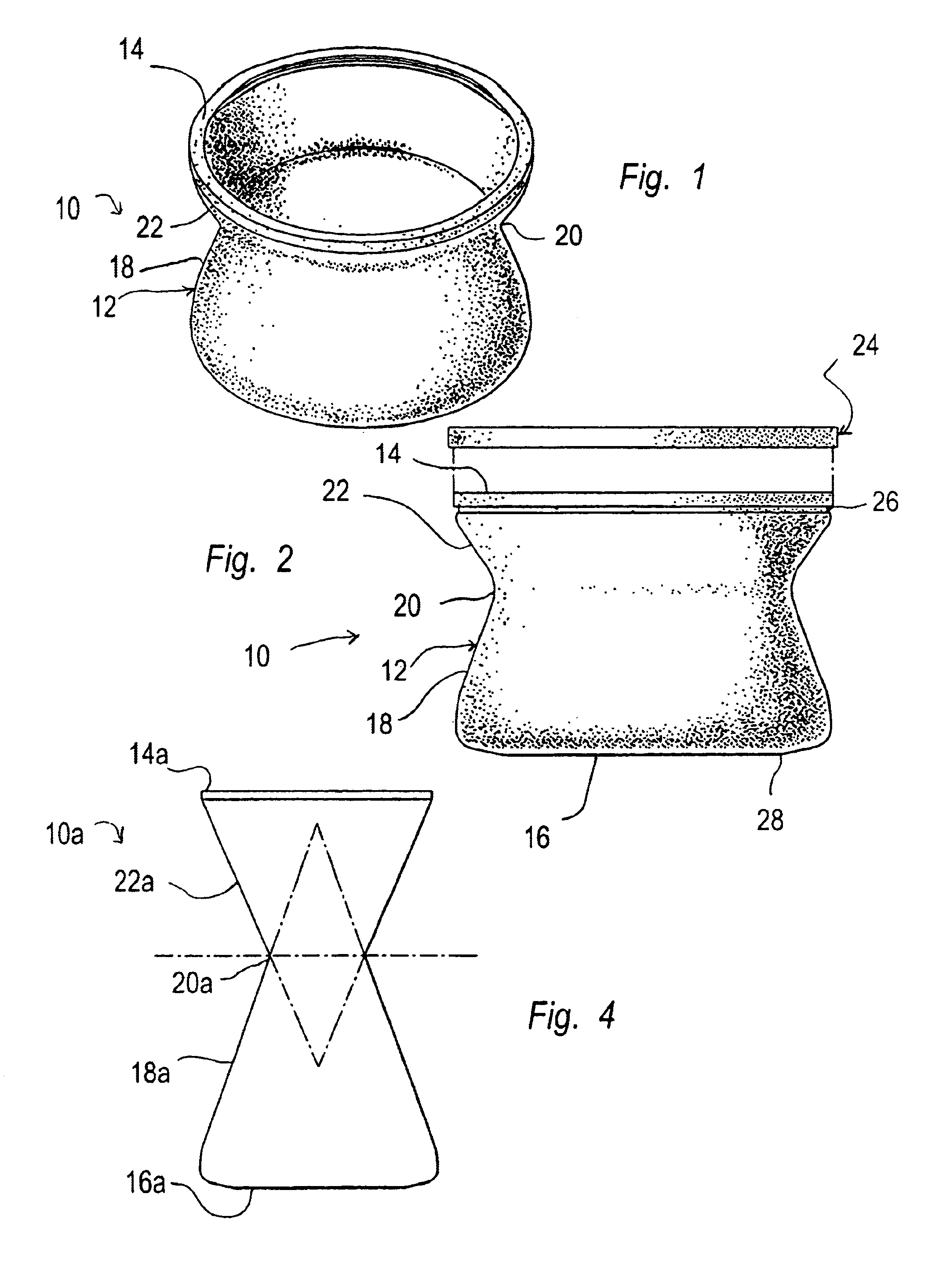

Moldable plastic container with hourglass profile

A molded plastic container with a sidewall having a general hourglass configuration. The container structure includes an upper rim, a bottom and a sidewall that extends between the upper rim and the bottom. The sidewall includes a lower frustum section, a narrow mid-section and an upper frustum section. The lower frustum section connects the bottom to the narrow mid-section and decreases in width as it extends from the bottom to the narrow mid-section. The upper frustum section extends from the upper rim to the narrow mid-section and decreases in width as it extends from the upper rim to the mid-section. A method of making such a container, a method of hot-filling such a container and a method of retorting material enclosed in such a container are also disclosed.

Owner:ALTIUM PACKAGING LP

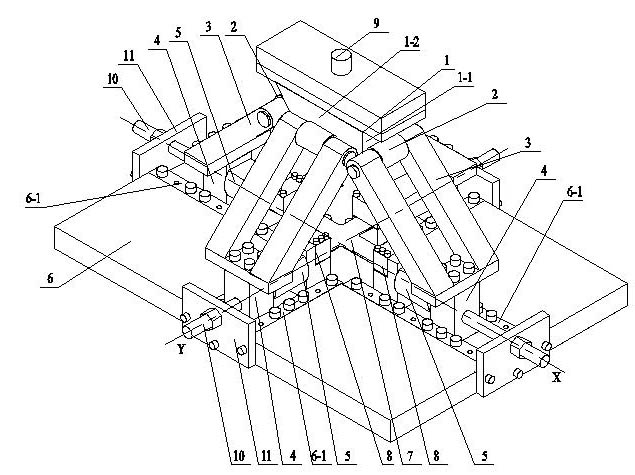

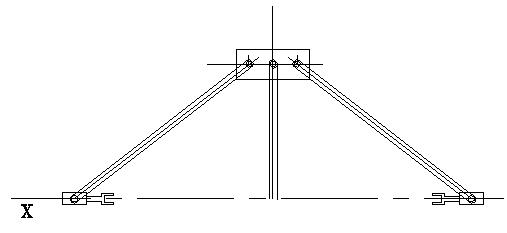

Mechanical biaxial tension tester with variable proportion loading

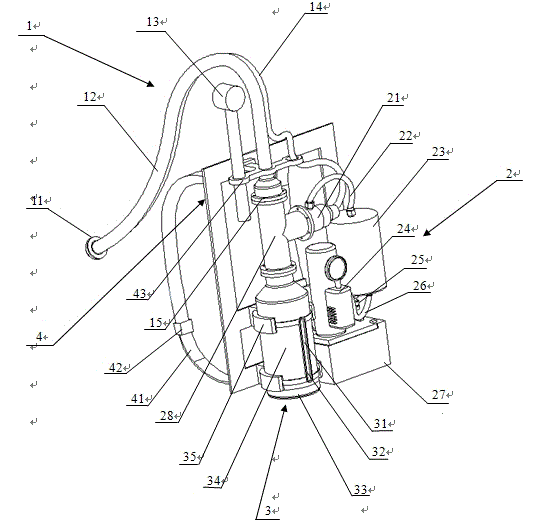

InactiveCN101907538AReduce frictionRatio unchangedMaterial strength using tensile/compressive forcesCruciformTension compression

The invention discloses a mechanical biaxial tension tester with variable proportion loading, relating to a biaxial tension tester. The invention solves the problem that the traditional biaxial tension testing device can not realize variable proportion loading under a complex loading path. In the invention, a slanting slide block is an inverted trapezoidal quadrangular frustum pyramid, a workbench is provided with a cruciform chute, a cruciform test piece is arranged above the cruciform chute, four ends of the cruciform test piece are respectively and fixedly connected with a clamping head, a tension-compression sensor is fixedly connected to the outer end surface of each clamping head, the outer end of each tension-compression sensor is fixedly connected with a horizontal slide block, each horizontal slide block is installed on the workbench, the lower end of each slant beam is fixedly connected with a horizontal slide block, a rolling bearing is installed at the upper end of each slant beam, and each rolling bearing is contacted with a corresponding trapezoidal inclined plane of each slant beam and rolls on the corresponding trapezoidal inclined plane of each slant beam. The invention is suitable for a tension test of the cruciform test piece.

Owner:HARBIN INST OF TECH

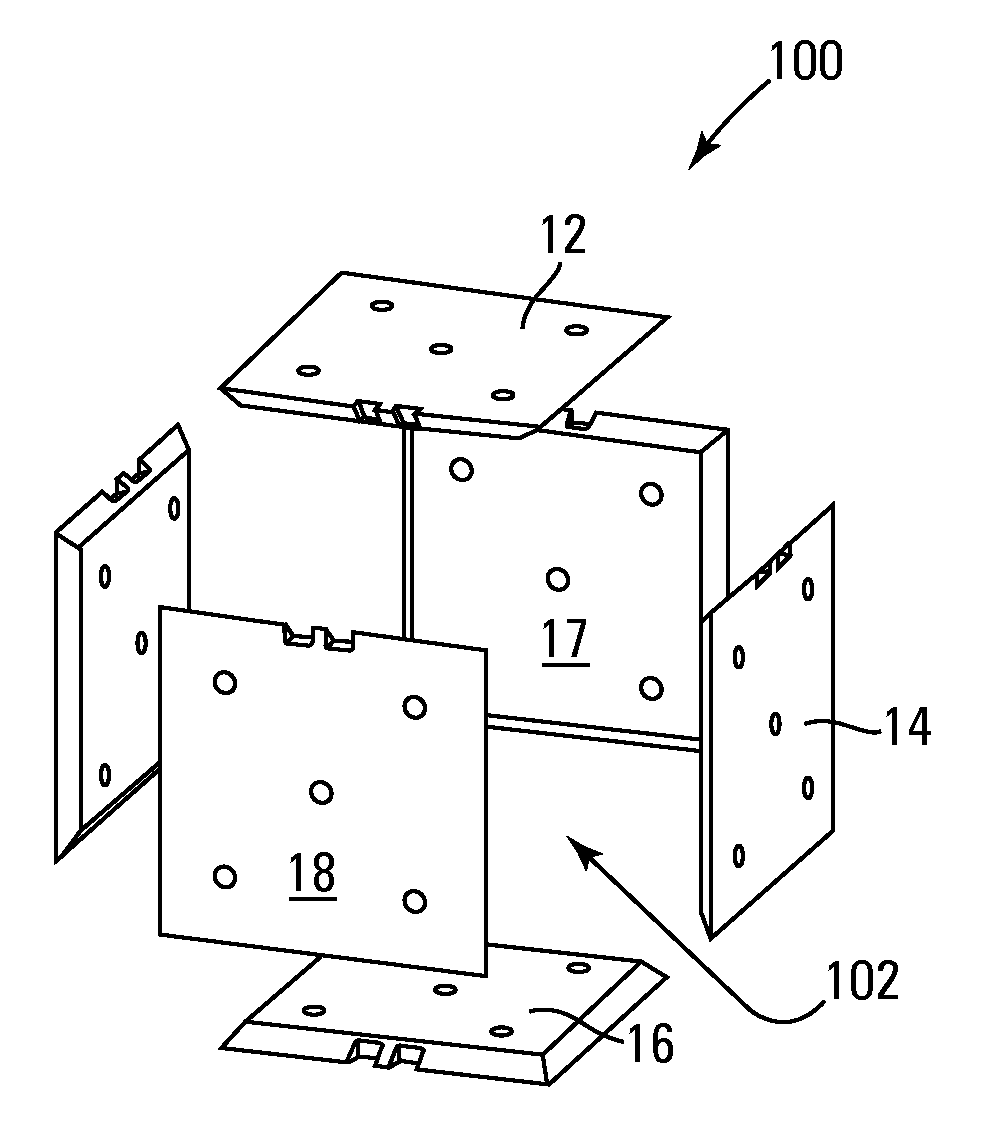

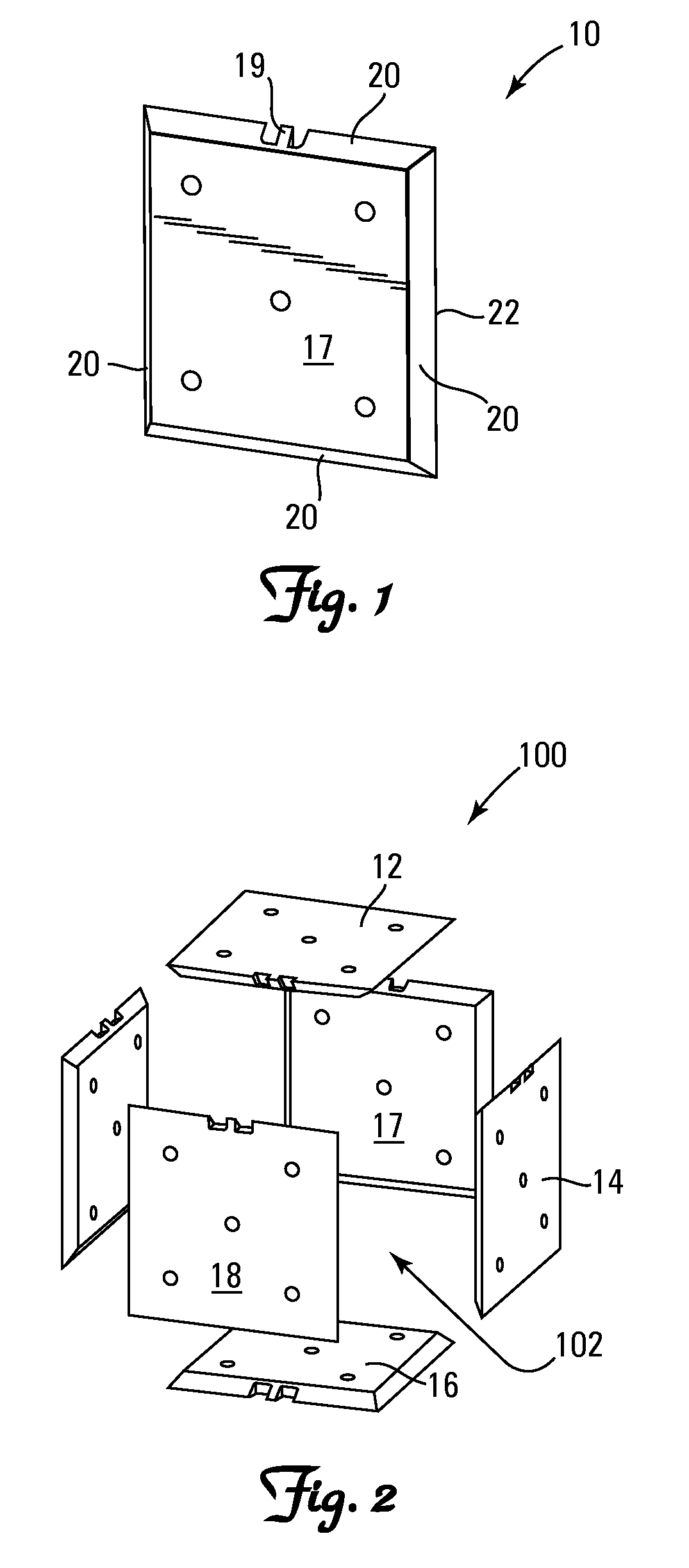

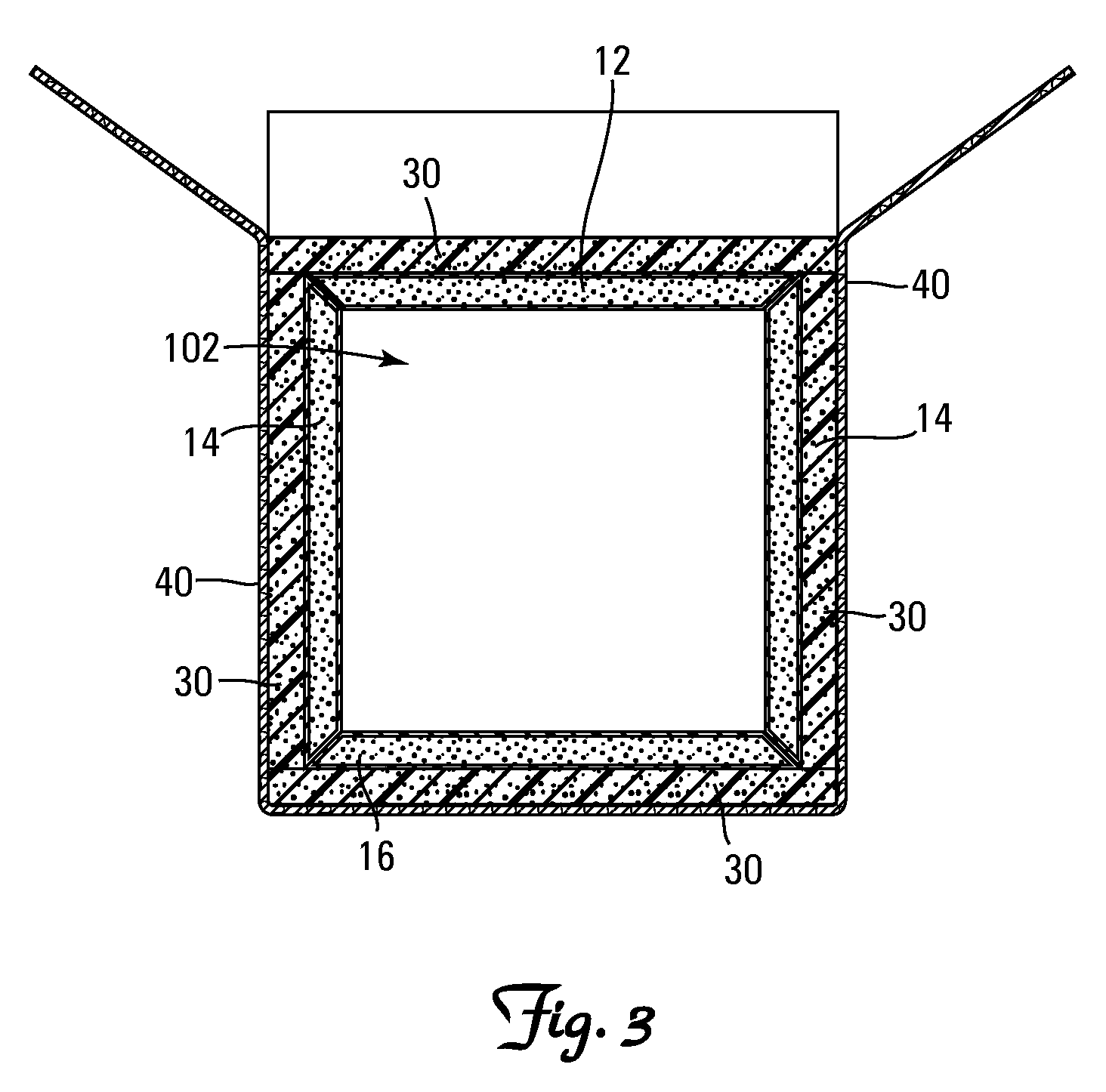

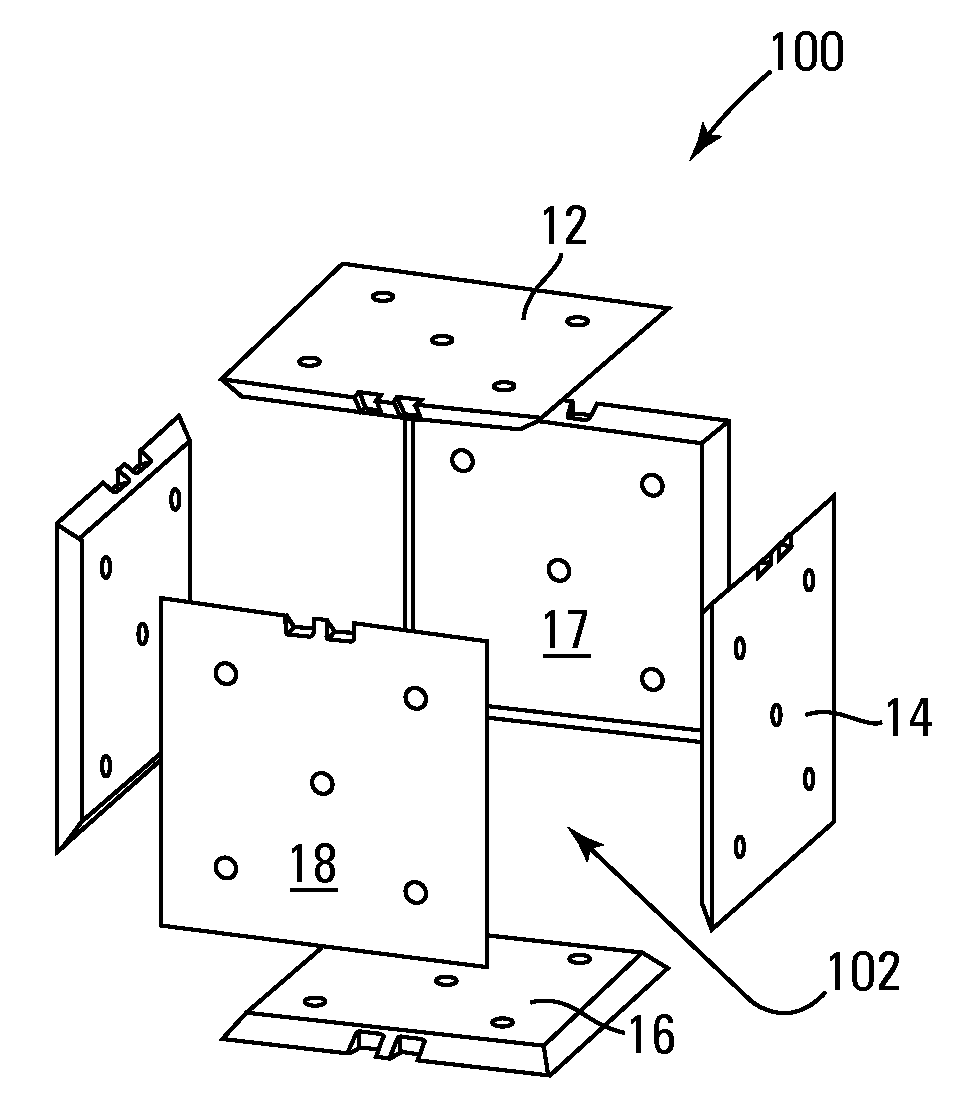

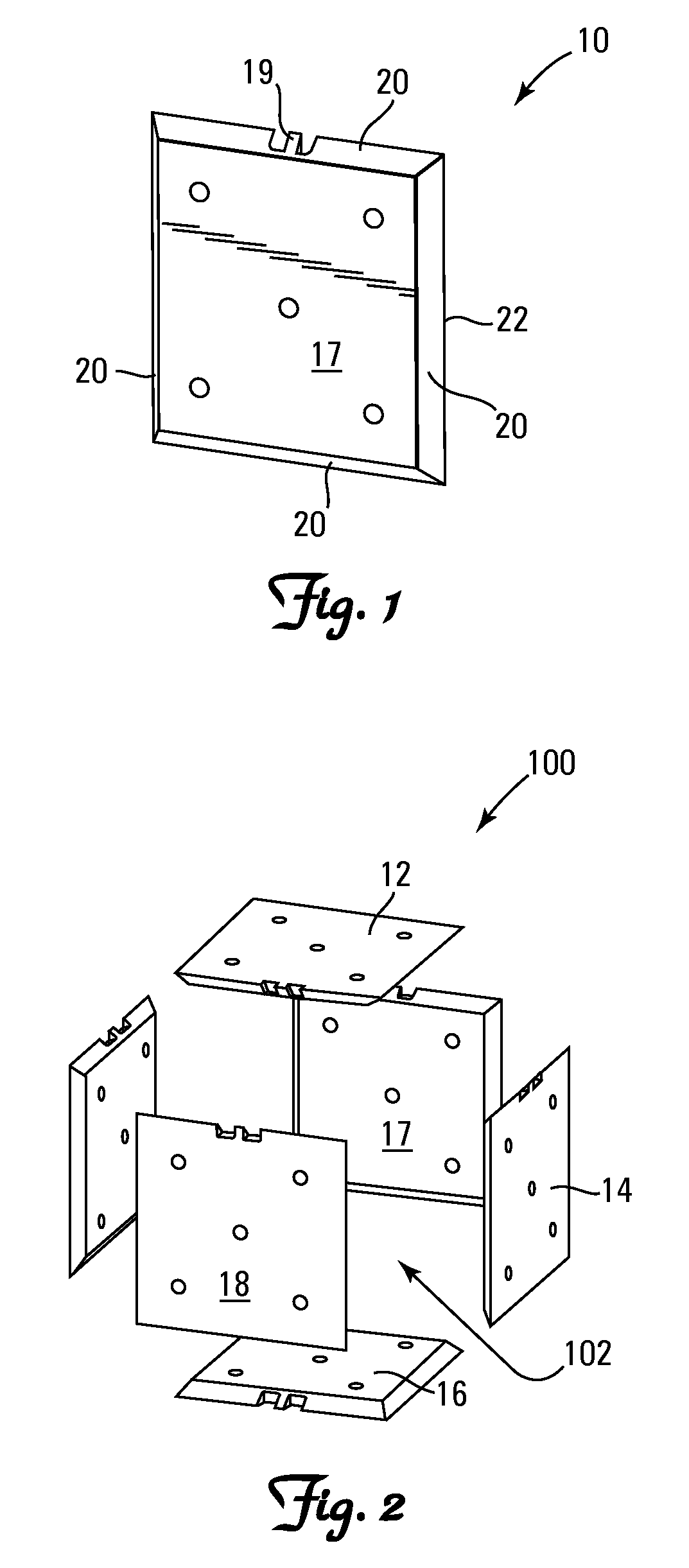

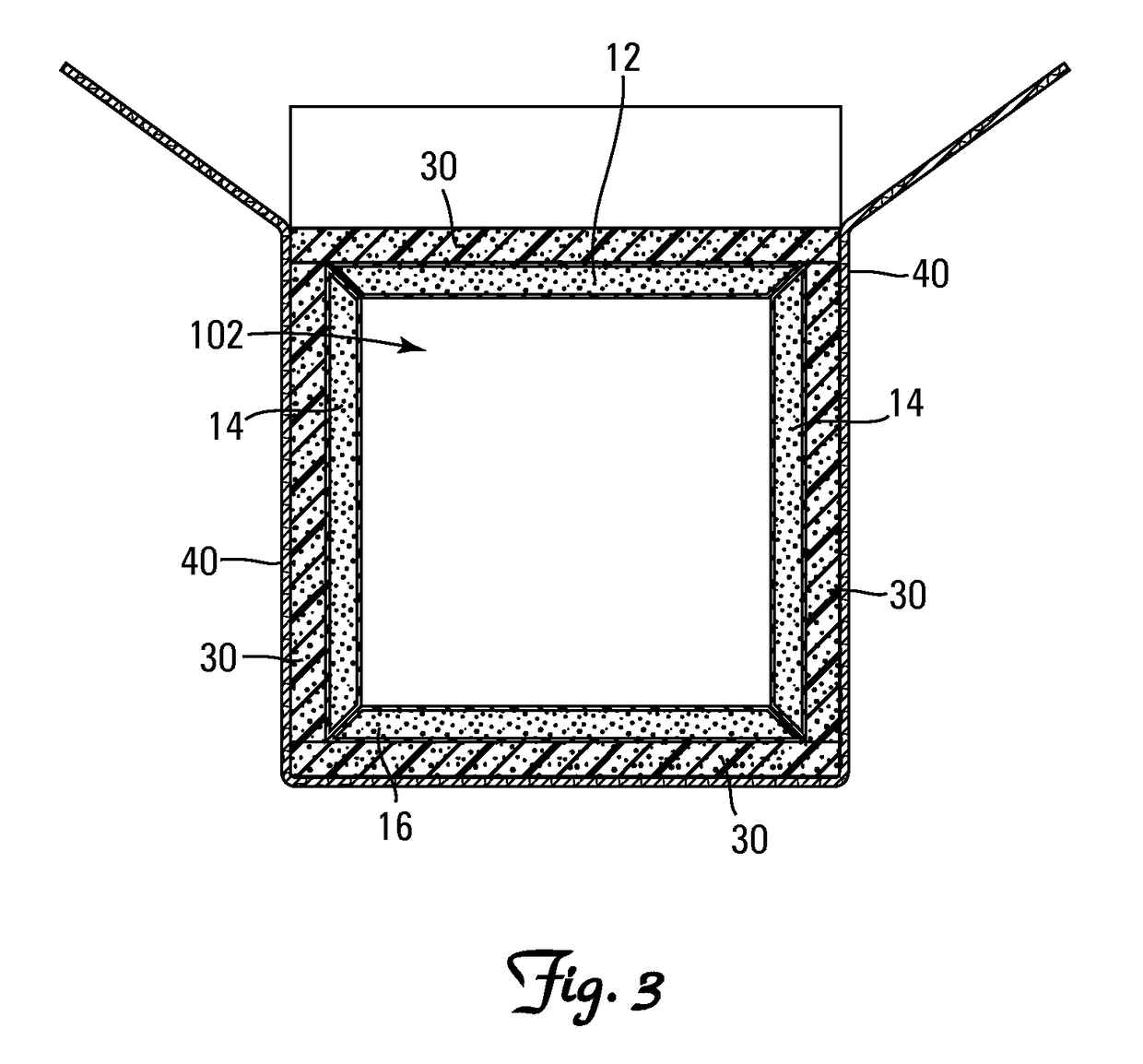

Modular cuboidal passive temperature controlled shipping container

Owner:PELI BIOTHERMAL LLC (N D GES D STAATES DELAWARE)

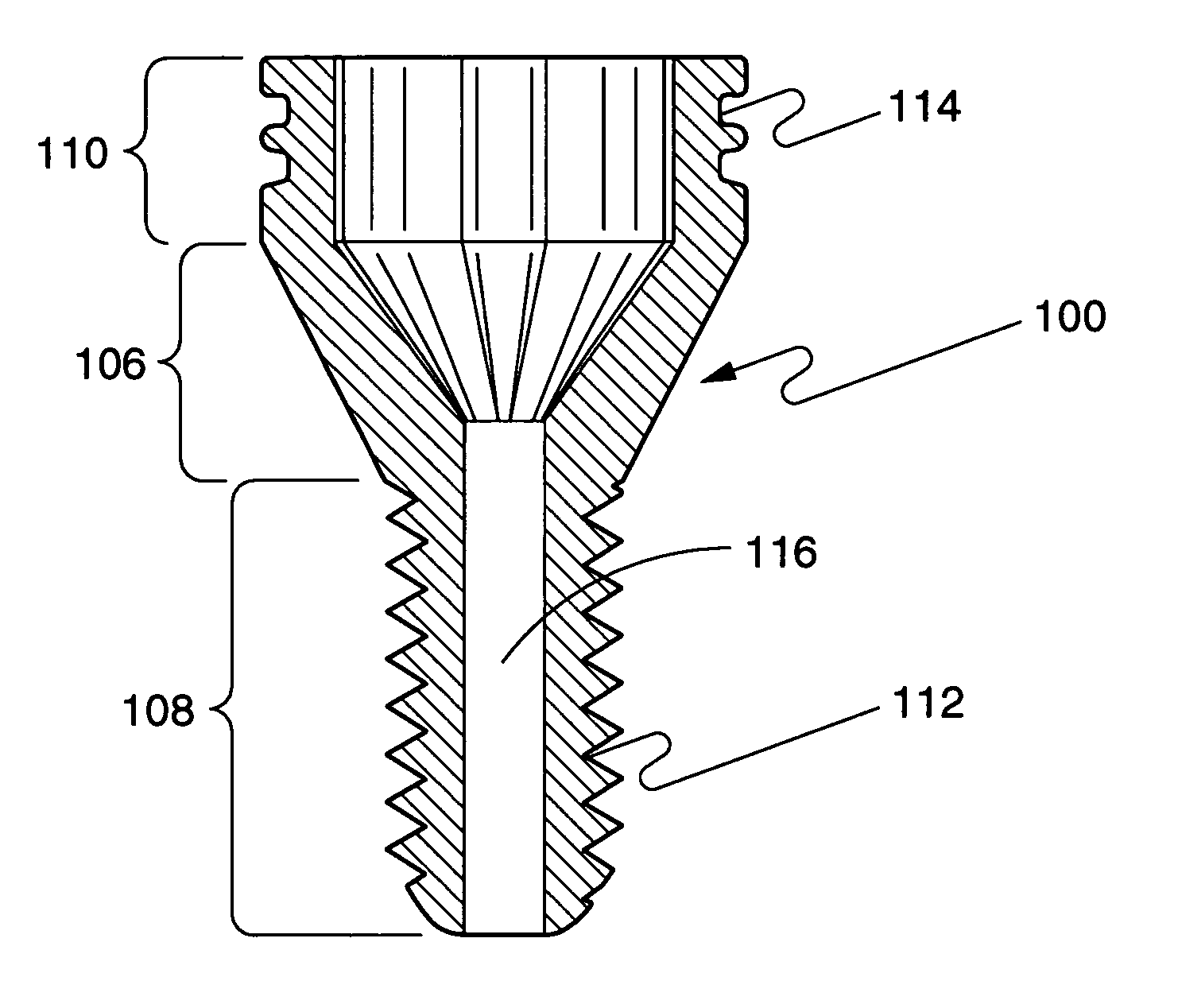

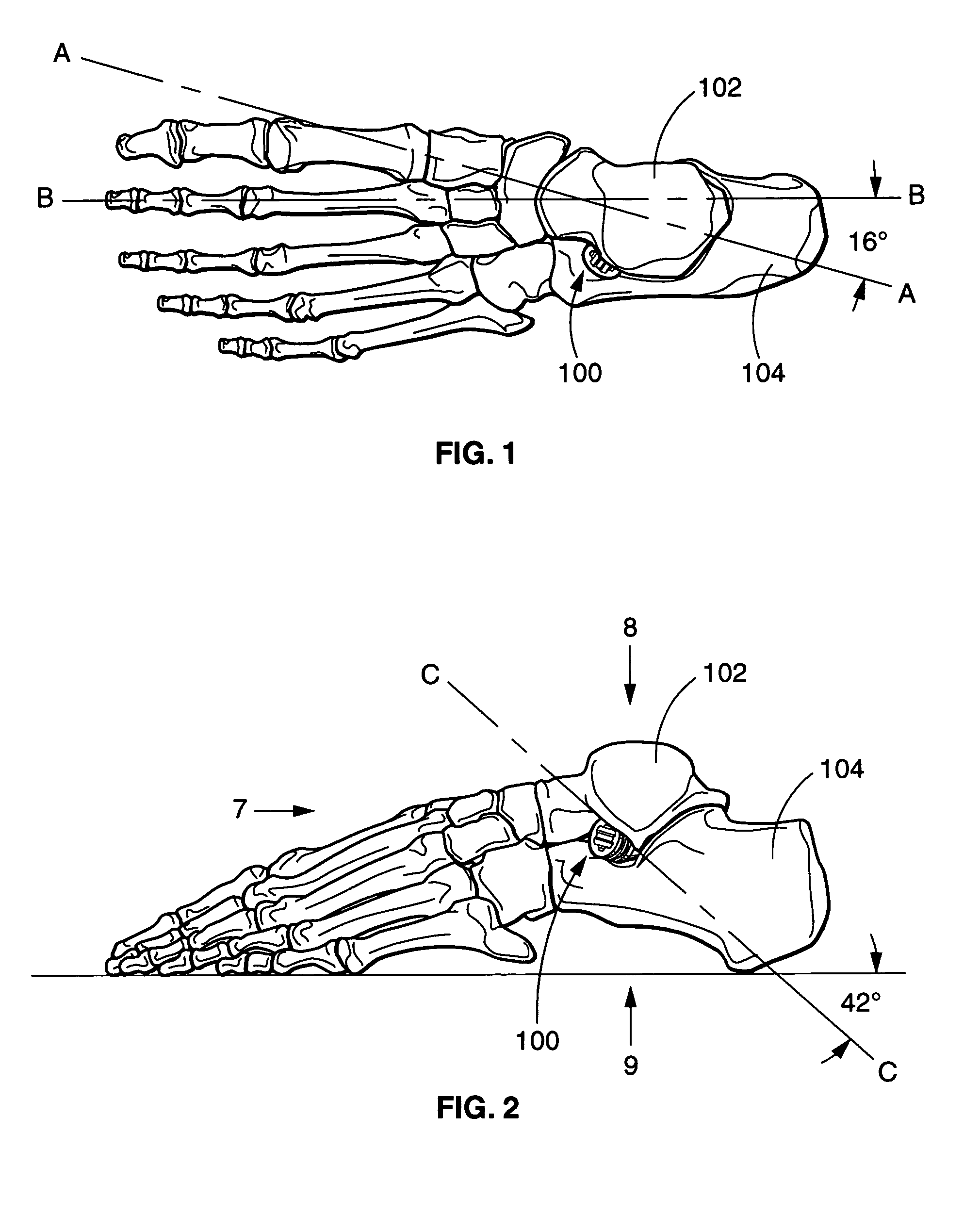

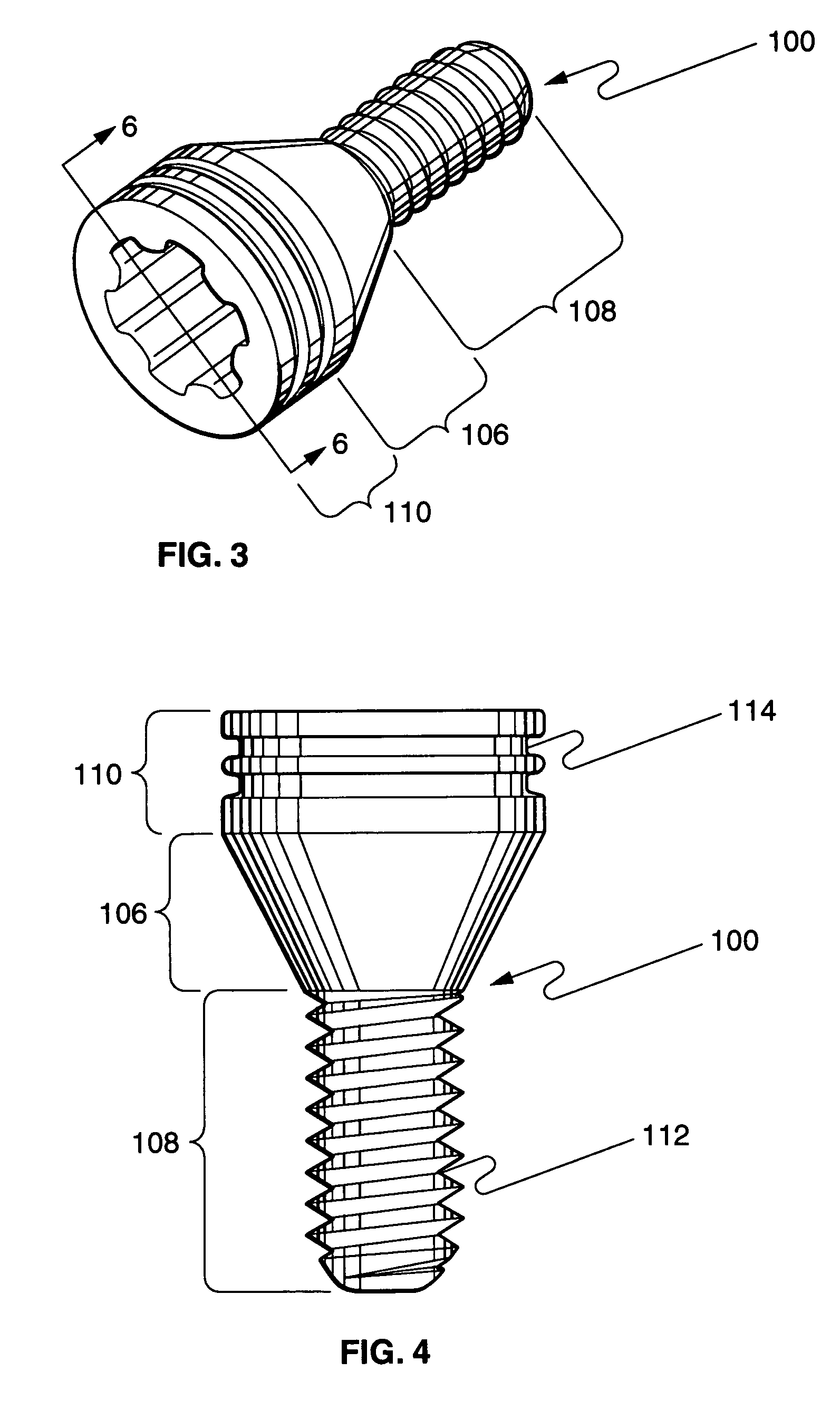

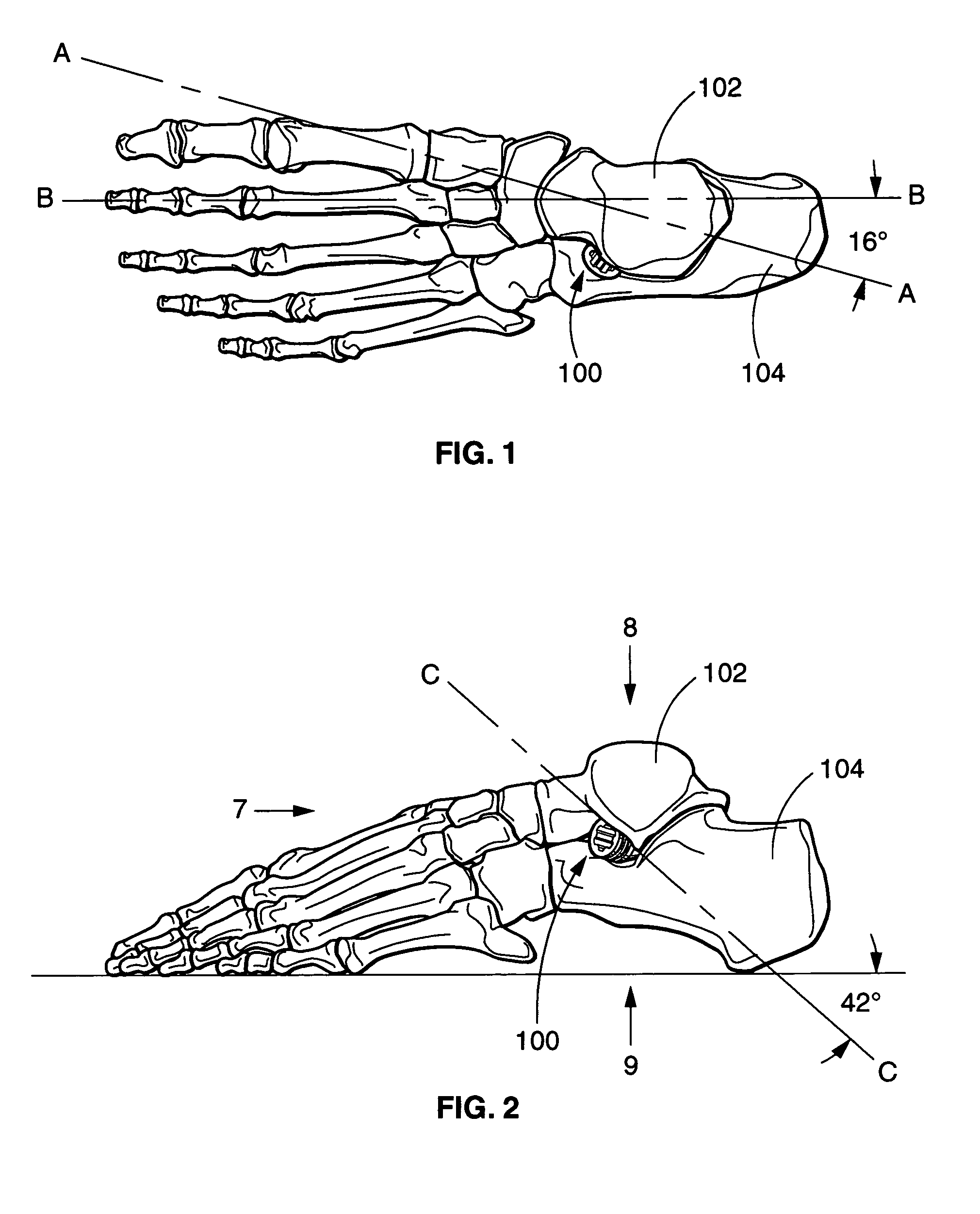

Sinus tarsi implant

An arthroeresis-prosthesis (endorthosis) system comprising a sinus tarsi implant for the purpose of blocking abnormal motion between the talus and calcaneus while allowing normal motion and alignment. In a preferred embodiment, the prosthetic device is composed of a non-metallic, specialized medical grade polymer (polyetheretherketone-PEEK) that is a combination of a frustum of a right cine and an axially extending cylinder that is cannulated and partially structured on the exterior surface.

Owner:GRAHAM MEDICAL TECH LLC

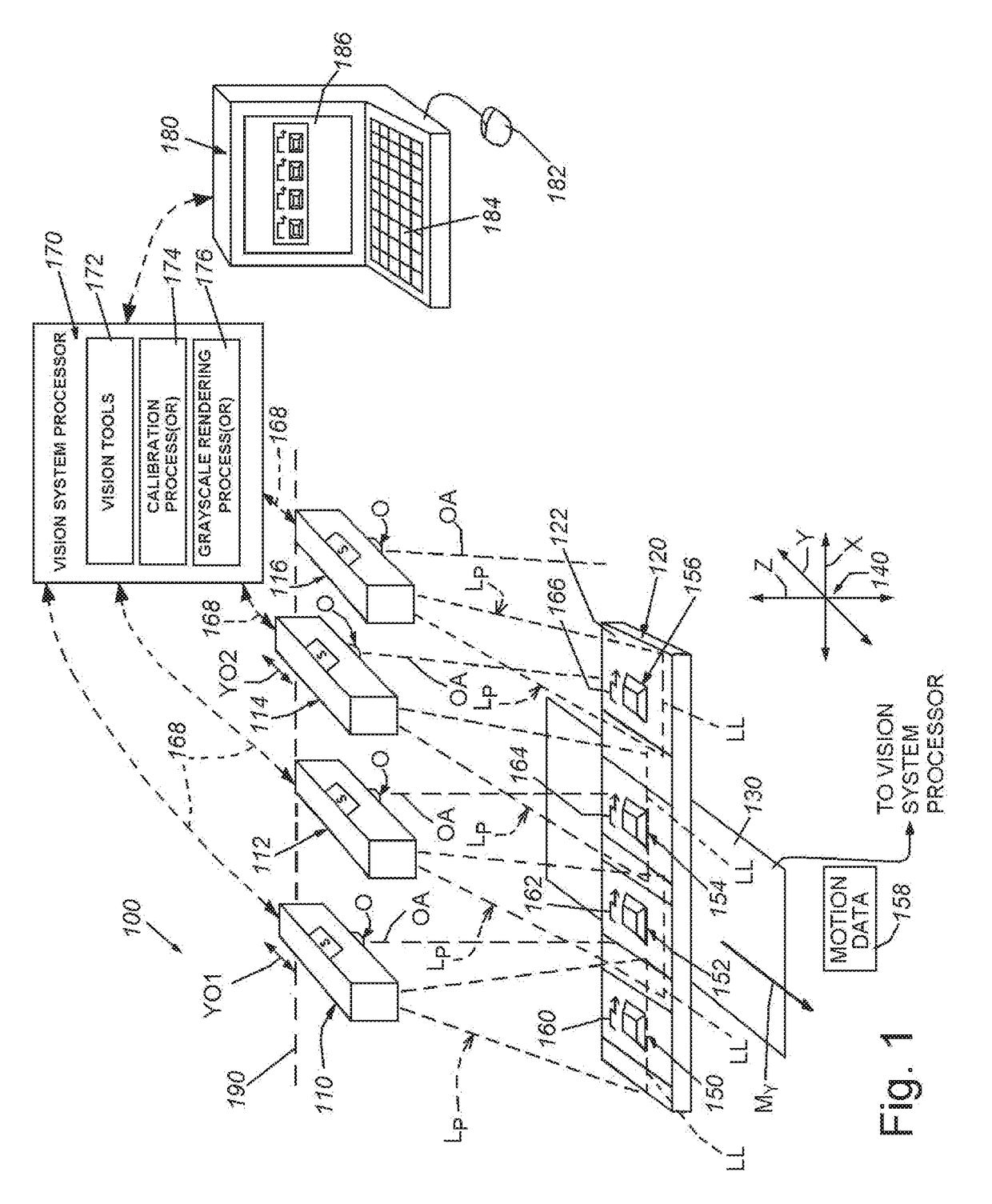

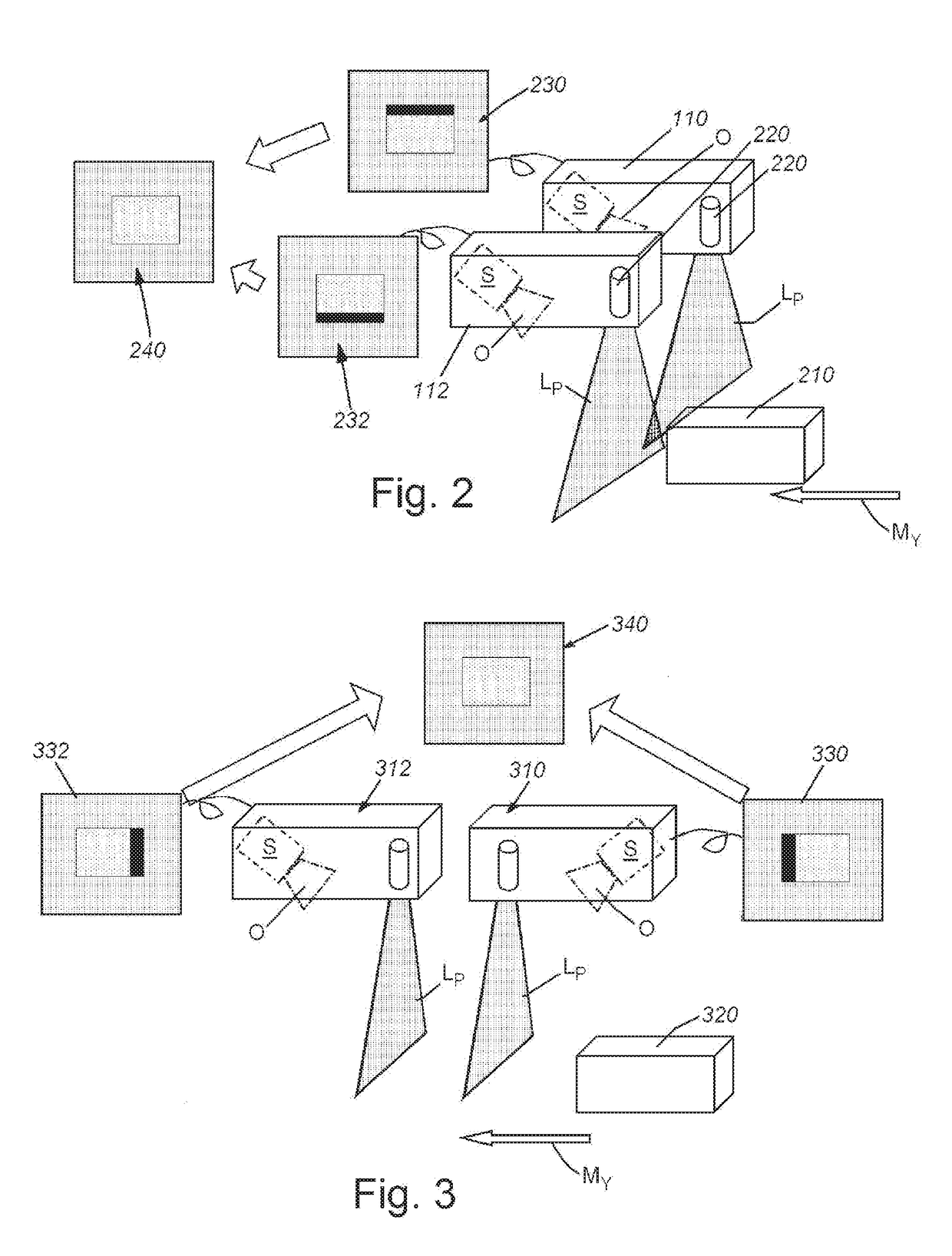

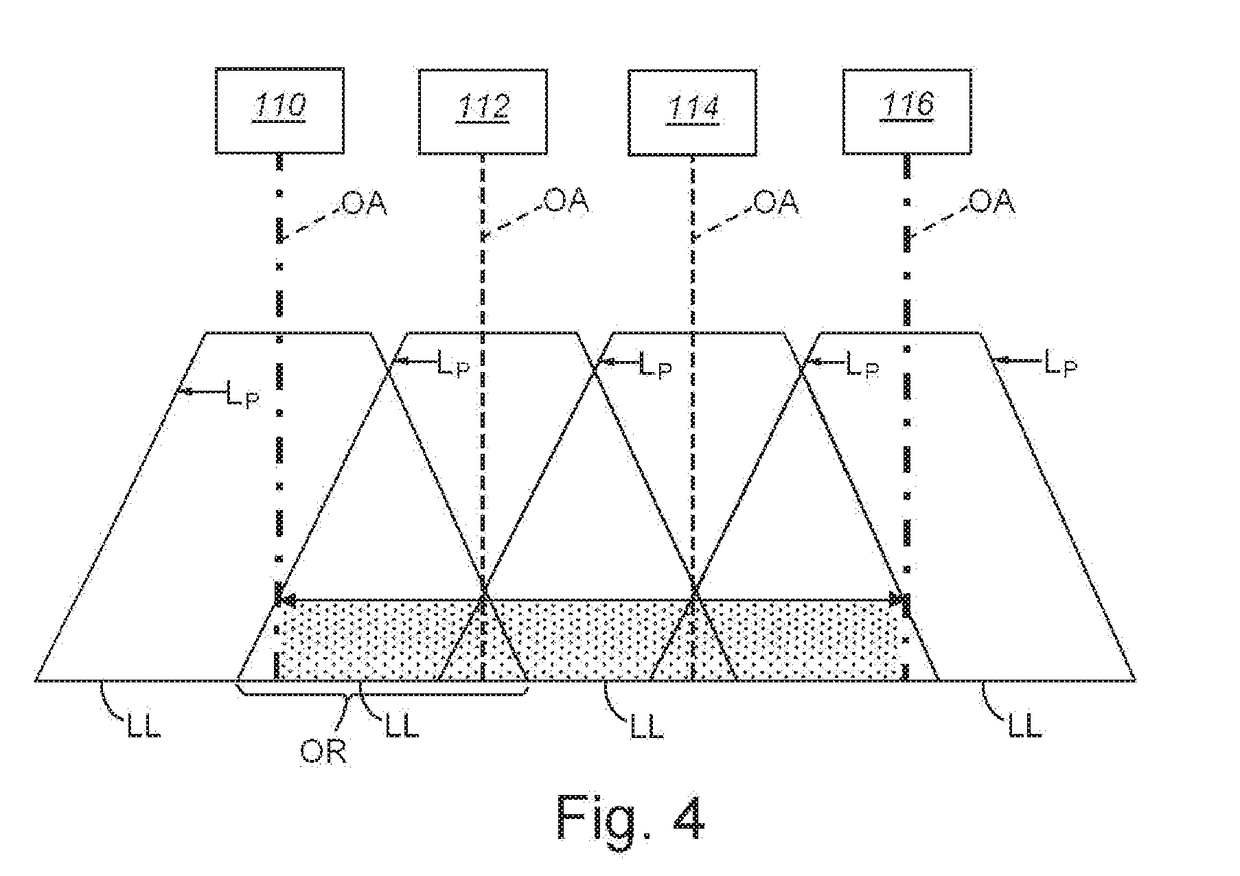

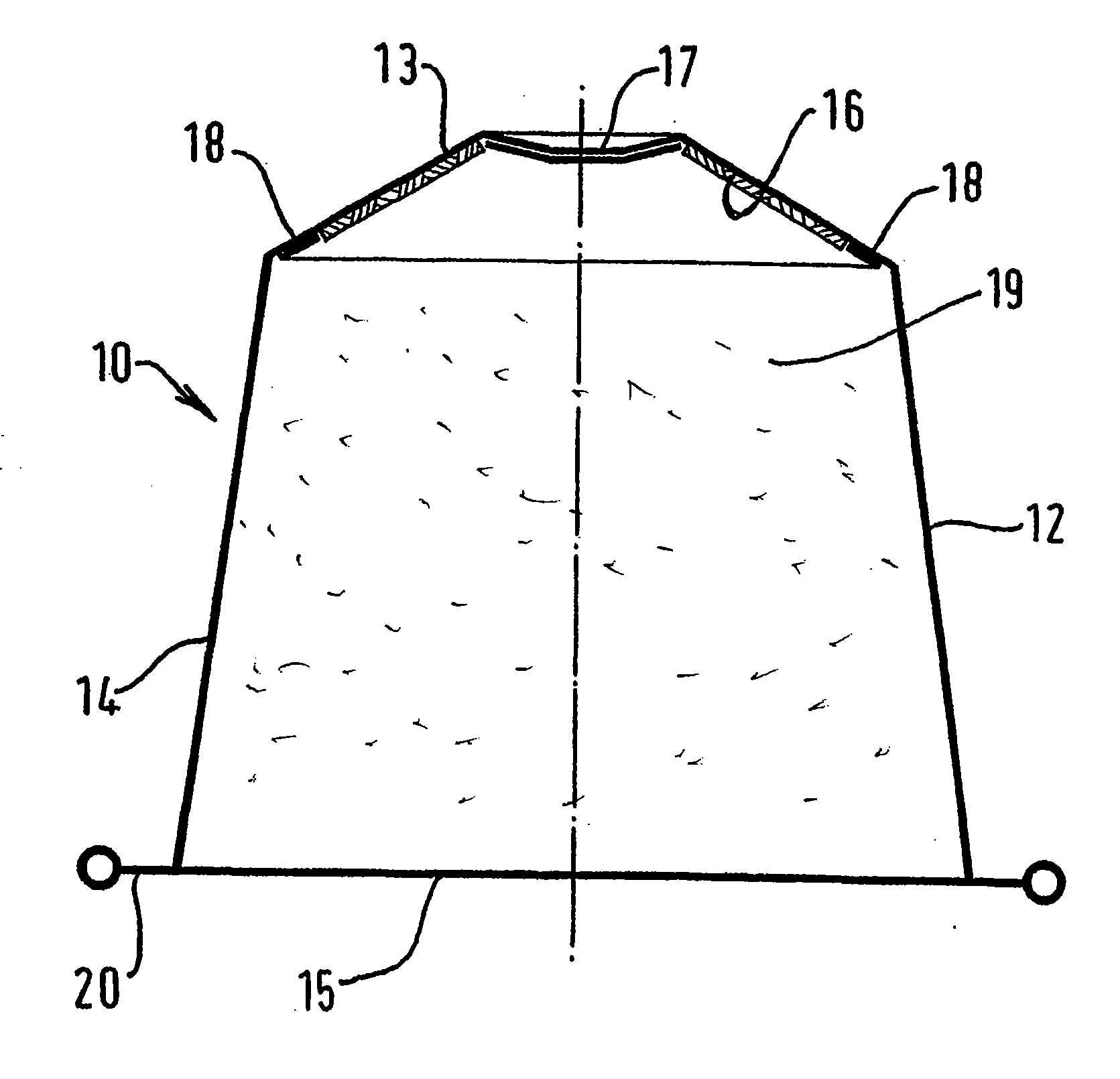

System and method for field calibration of a vision system imaging two opposite sides of a calibration object

InactiveUS20180374239A1Simple field calibrationOvercome disadvantagesImage analysisUsing optical meansComputer visionVisual perception

This invention provides an easy-to-manufacture, easy-to-analyze calibration object which combines measurable and repeatable, but not necessarily accurate, 3D features—such as a two-sided calibration object / target in (e.g.) the form of a frustum, with a pair of accurate and measurable features, more particularly parallel faces separated by a precise specified thickness, so as to provide for simple field calibration of opposite-facing DS sensors. Illustratively, a composite calibration object can be constructed, which includes the two-sided frustum that has been sandblasted and anodized (to provide measurable, repeatable features), with a flange whose above / below parallel surfaces have been ground to a precise specified thickness. The 3D corner positions of the two-sided frustum are used to calibrate the two sensors in X and Y, but cannot establish absolute Z without accurate information about the thickness of the two-sided frustum; the flange provides the absolute Z information.

Owner:COGNEX CORP

Closed cartridge for preparing a beverage for extraction under pressure

InactiveUS20070068395A1Easy to produceSatisfactory closureDispensing apparatusBeverage vesselsEngineeringStructural engineering

The present invention relates to a closed cartridge (10), for extraction under pressure, comprising a dish (12) with a bottom (13) with a central part and a peripheral part and a side wall having substantially the shape of a frustum of a cone and a circular edge with a diameter greater at the bottom and a cover (15) welded to the periphery of the edge of the dish and the cover is intended to be torn only through the effect of the force of the extraction fluid when extraction starts, the said cartridge comprising, in the dish at the level of the bottom, a means (16) guaranteeing retention of the solid substance when it is opened, in which the means guaranteeing retention of solid substance is a sheet of fabric sealed in the bottom of the dish in two zones, on the one hand in the central part (17) and on the other hand in the peripheral part (18) of the said bottom (13).

Owner:SOC DES PROD NESTLE SA

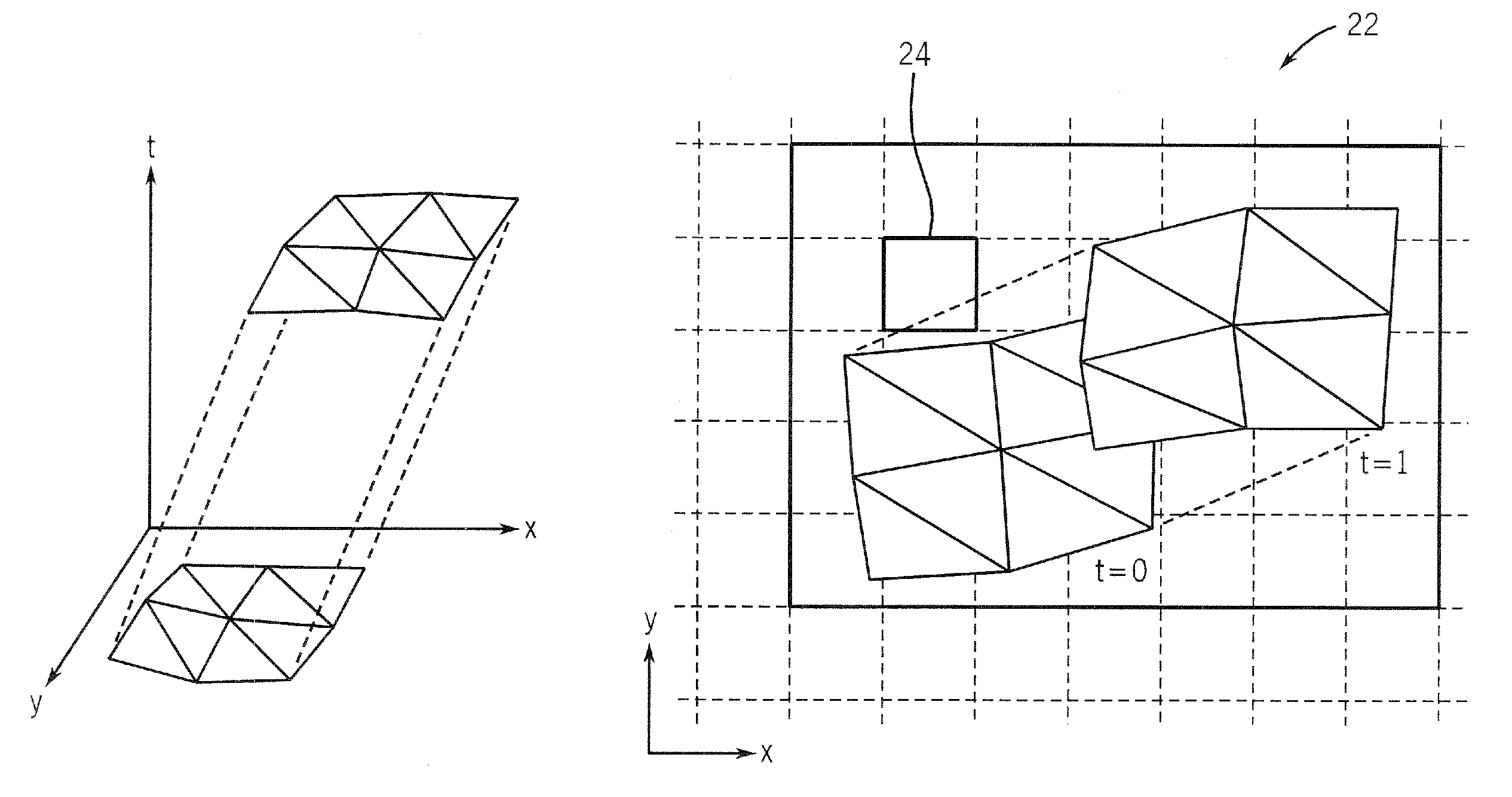

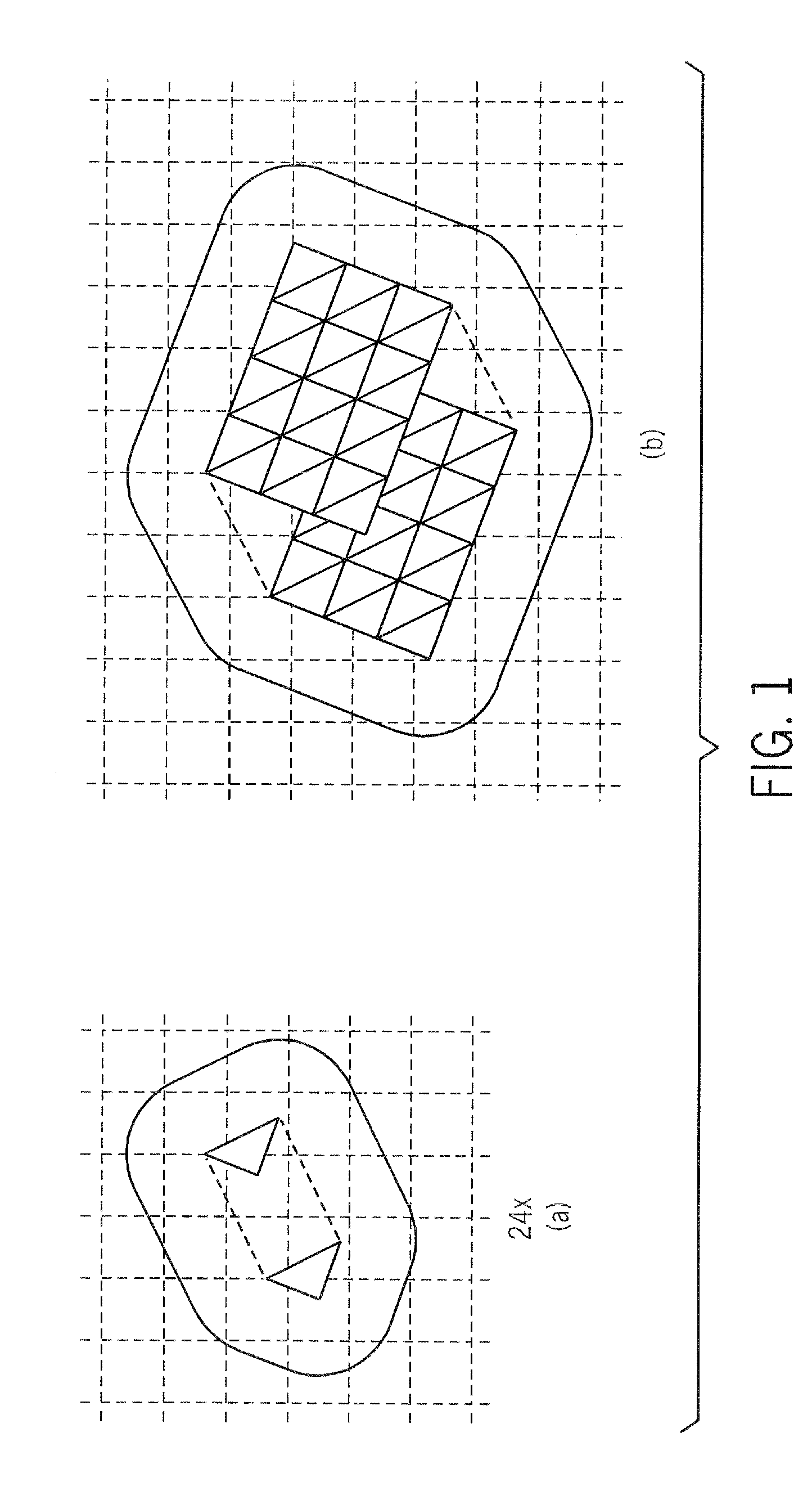

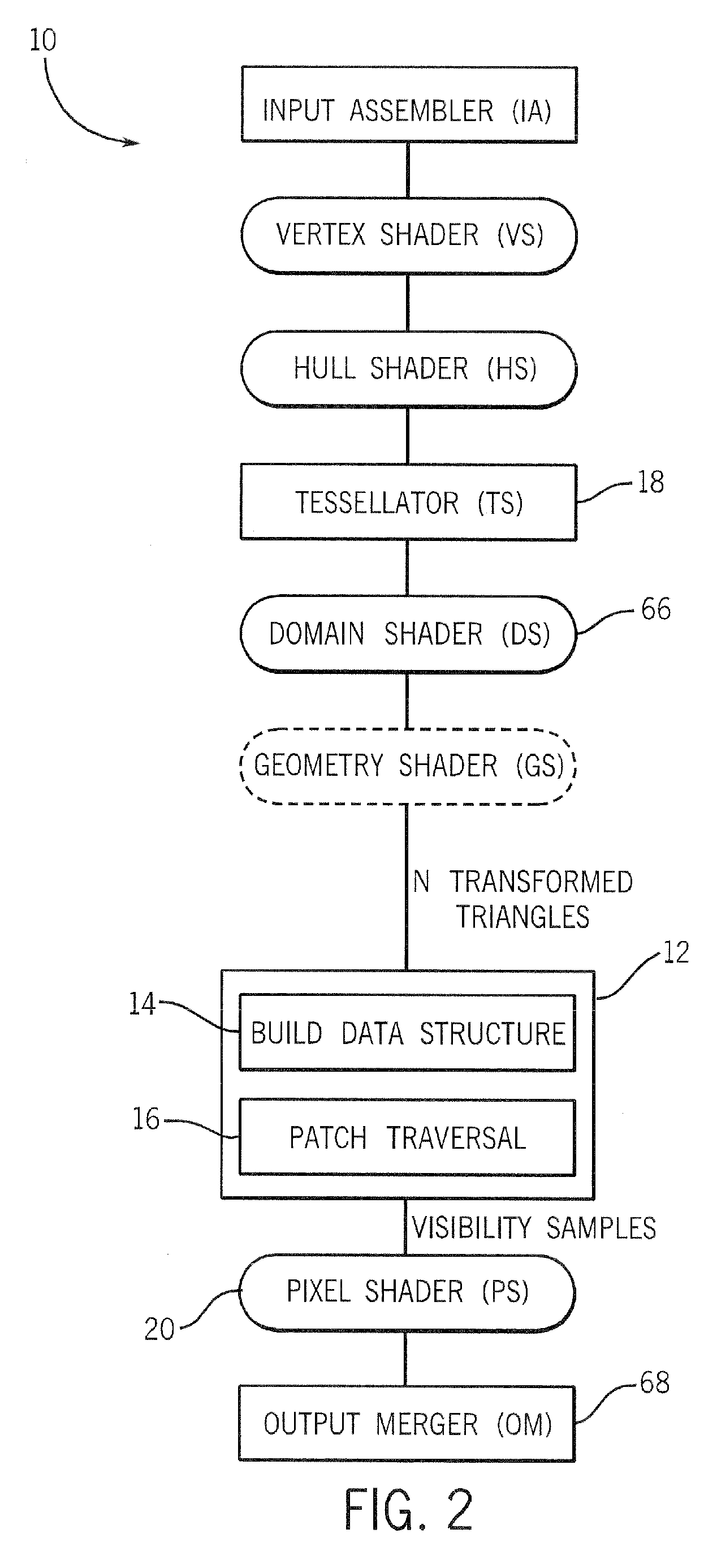

Rendering Tessellated Geometry With Motion and Defocus Blur

InactiveUS20120293515A1Drawing from basic elements3D-image renderingComputer graphics (images)Frustum

A moving or defocused geometry may be stochastically rendered by grouping a plurality of primitives of that geometry in a hierarchical data structure. Visible fragments may be located in that data structure by hierarchically traversing a ray frustum through the structure. A time-dependent ray tracing data structure may be used in some embodiments.

Owner:INTEL CORP

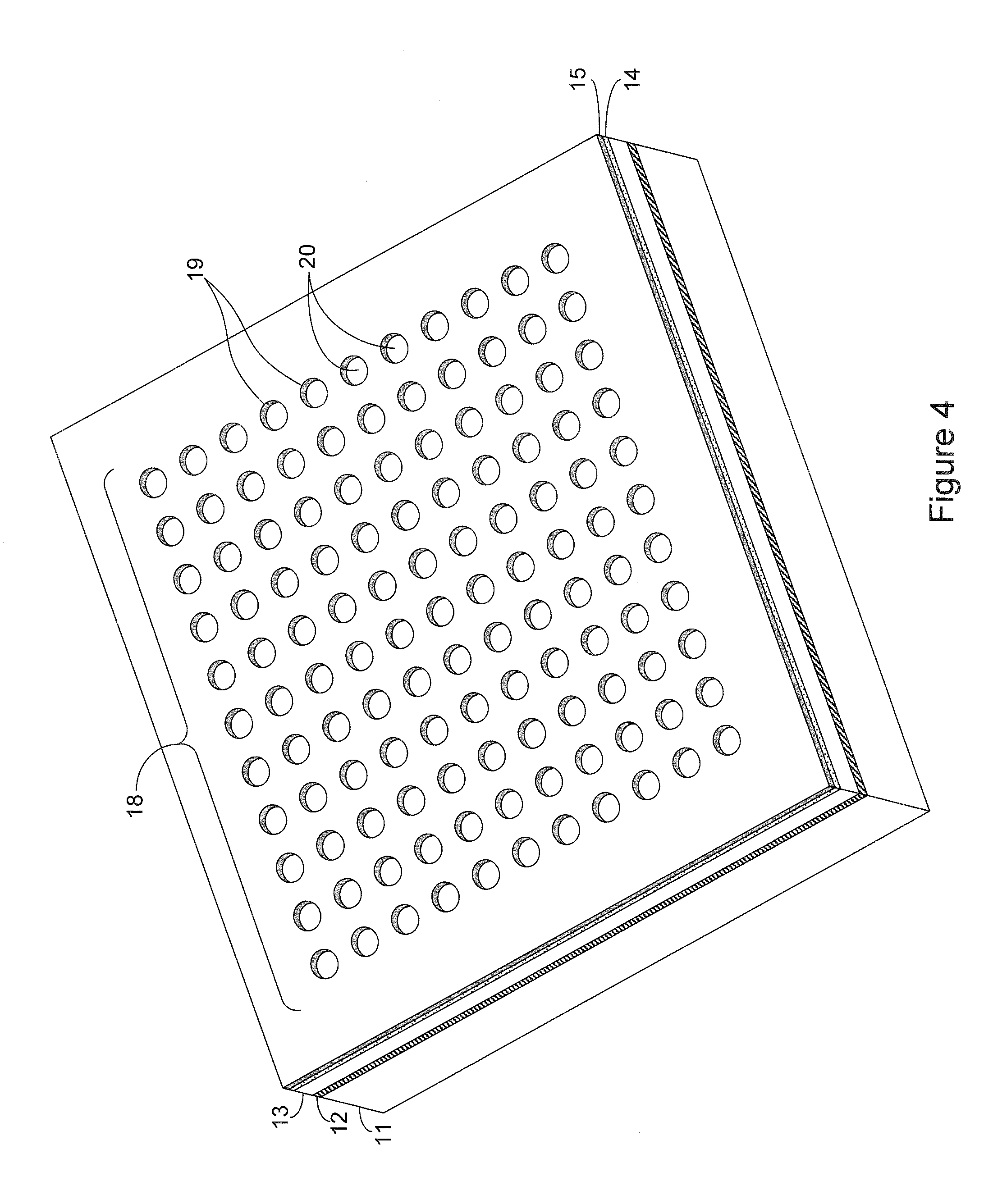

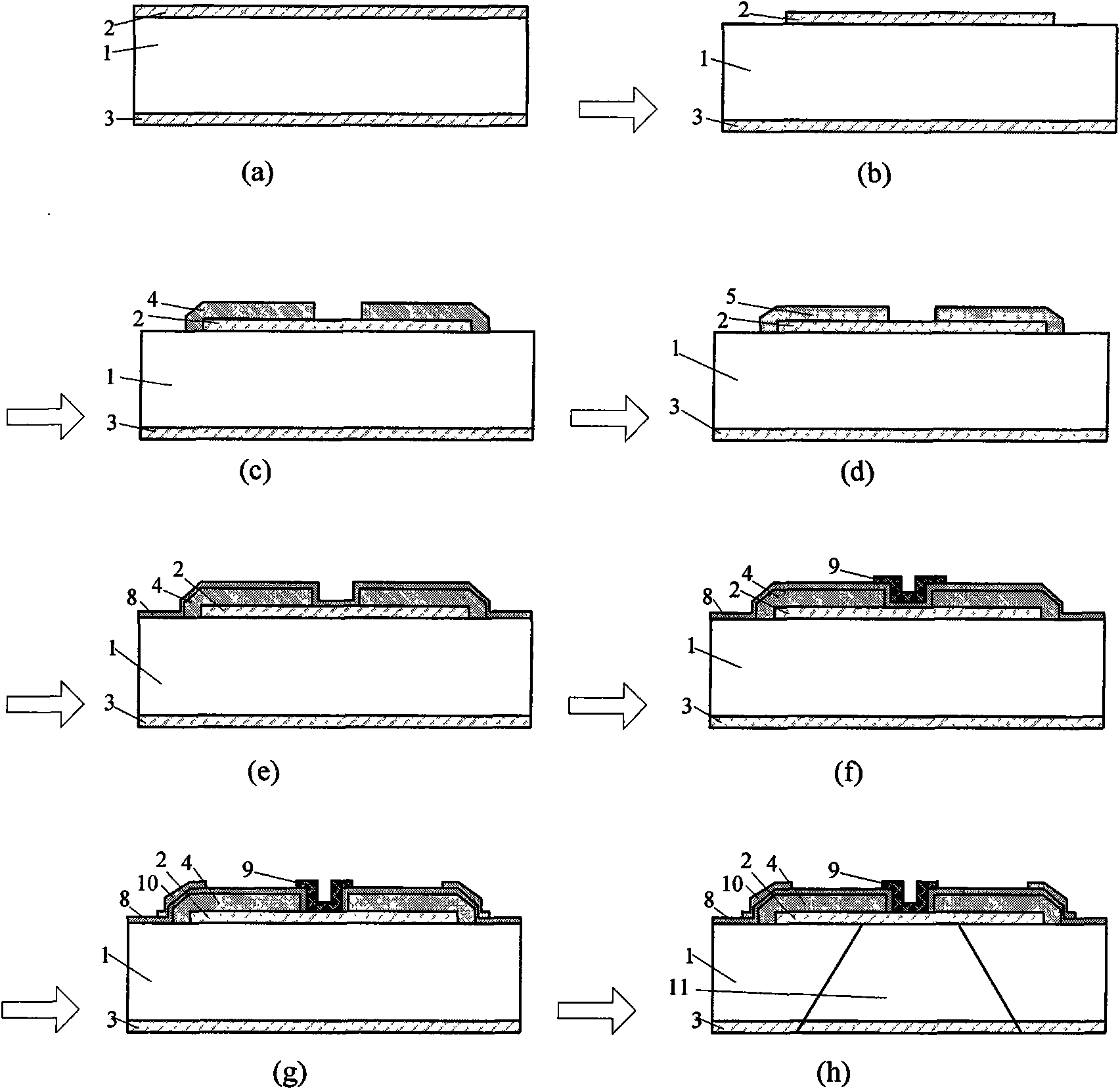

Method of fabricating a scalable nanoporous membrane filter

ActiveUS20120037591A1Reduce manufacturing costSpeed and efficiency of transportMaterial nanotechnologySemi-permeable membranesNanoporous membraneEngineering

A method of fabricating a nanoporous membrane filter having a uniform array of nanopores etch-formed in a thin film structure (e.g. (100)-oriented single crystal silicon) having a predetermined thickness, by (a) using interferometric lithography to create an etch pattern comprising a plurality array of unit patterns having a predetermined width / diameter, (b) using the etch pattern to etch frustum-shaped cavities or pits in the thin film structure such that the dimension of the frustum floors of the cavities are substantially equal to a desired pore size based on the predetermined thickness of the thin film structure and the predetermined width / diameter of the unit patterns, and (c) removing the frustum floors at a boundary plane of the thin film structure to expose, open, and thereby create the nanopores substantially having the desired pore size.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

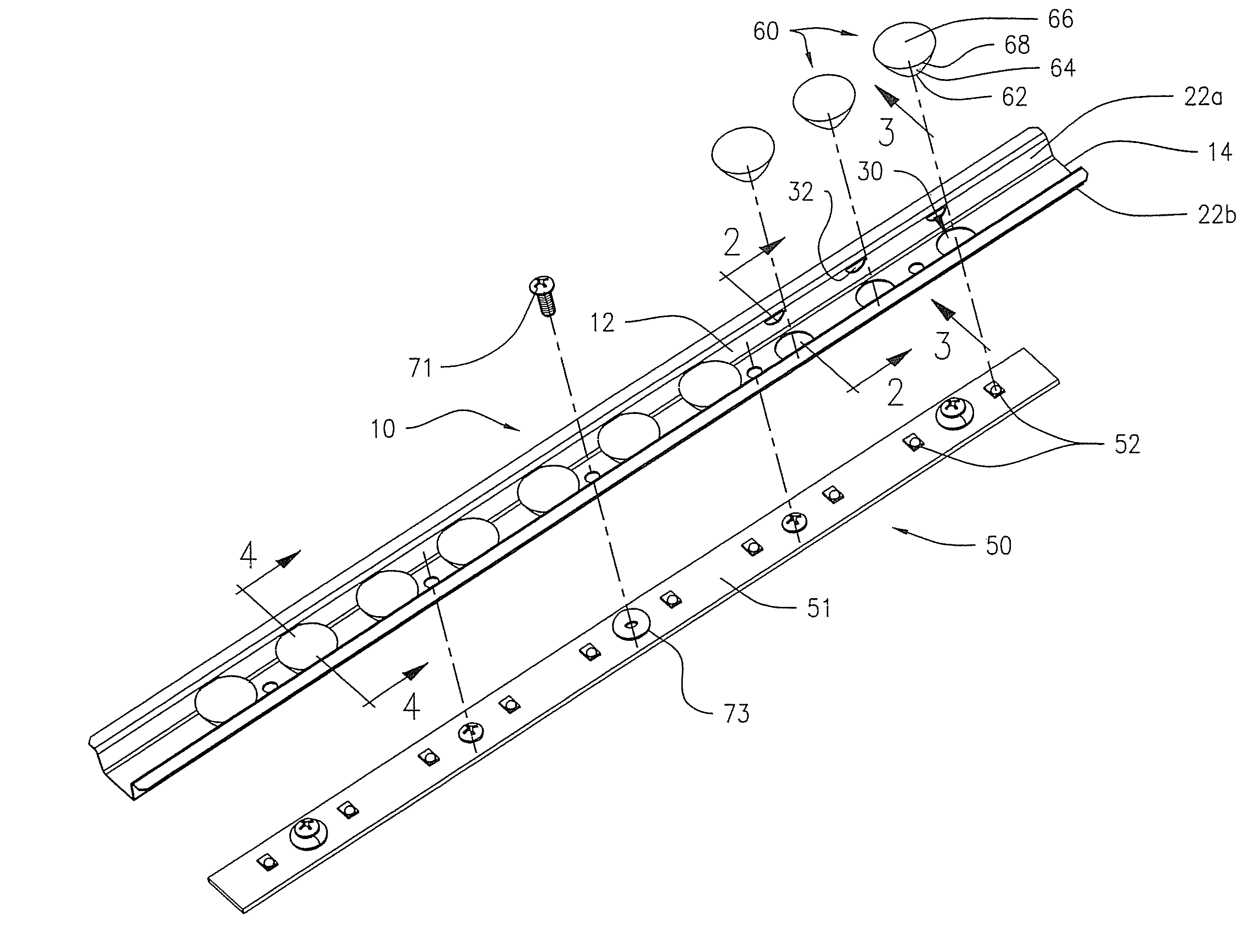

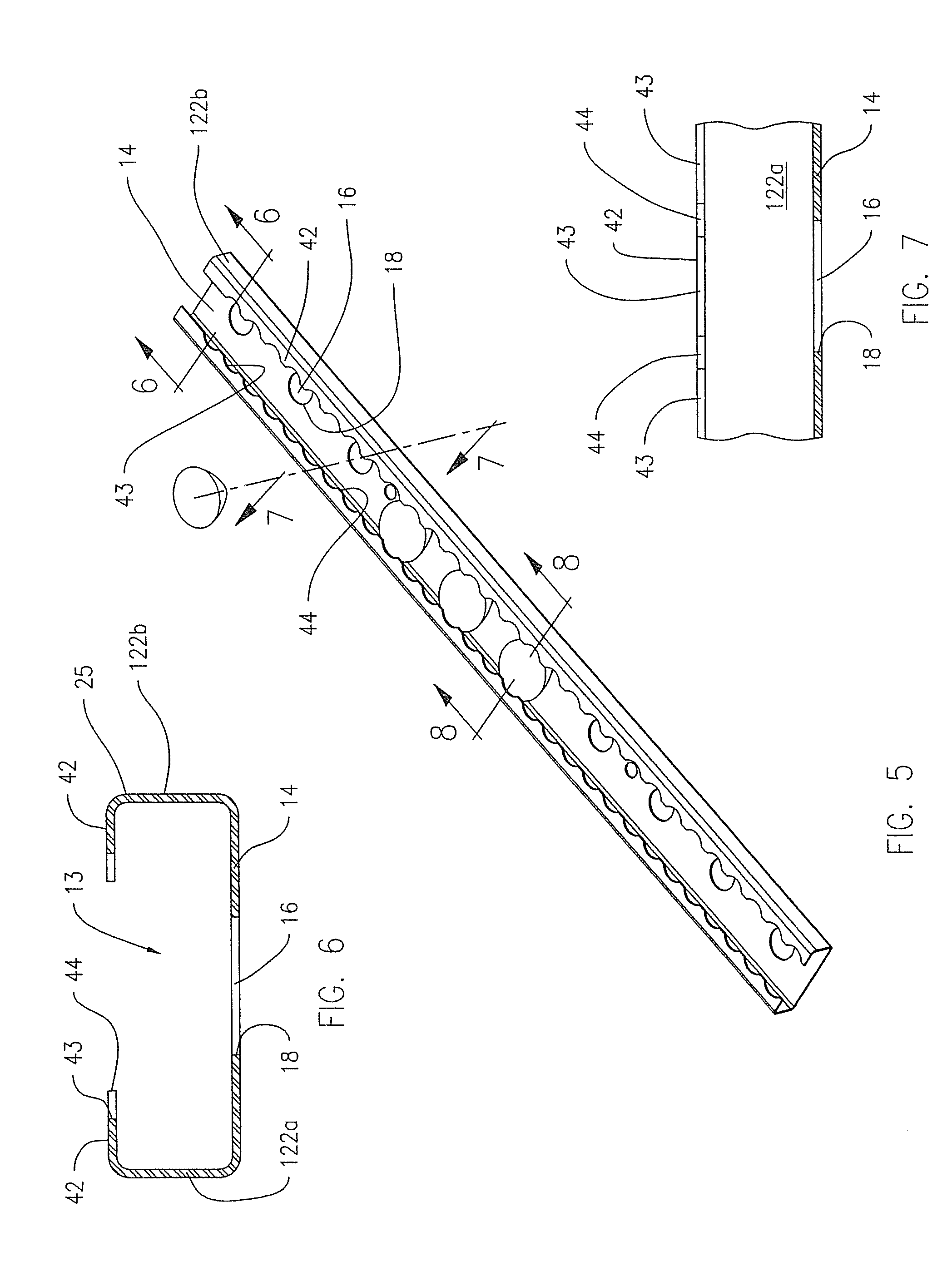

Optic positioning device

ActiveUS20090103299A1Insertion and removal of the opticEasy to insertNon-electric lightingPoint-like light sourceRefractive lensEngineering

A device for holding and positioning an optic, such as a refractive lens, over a light source such as a light emitting diode. The refractive lens is frustum-shaped with an upper light-exiting end having an upper rim, a lower light-entering end, and a conical sidewall that tapers from the upper rim to the lower end. The device has a channel including a base and first and second sidewalls extending from the opposed side edges of the base, and further having one or more optic holding positions. The optic holding position includes an aperture formed in the base that is configured to receive the conical sidewall of the optic, and an aperture formed in a portion of each sidewall, adjacent the aperture in the base, for retaining a portion of the upper rim of the optic lens. The aperture can include a slot opening through which a portion of the upper rim of the optic lens at least partially extends.

Owner:LSI INDS

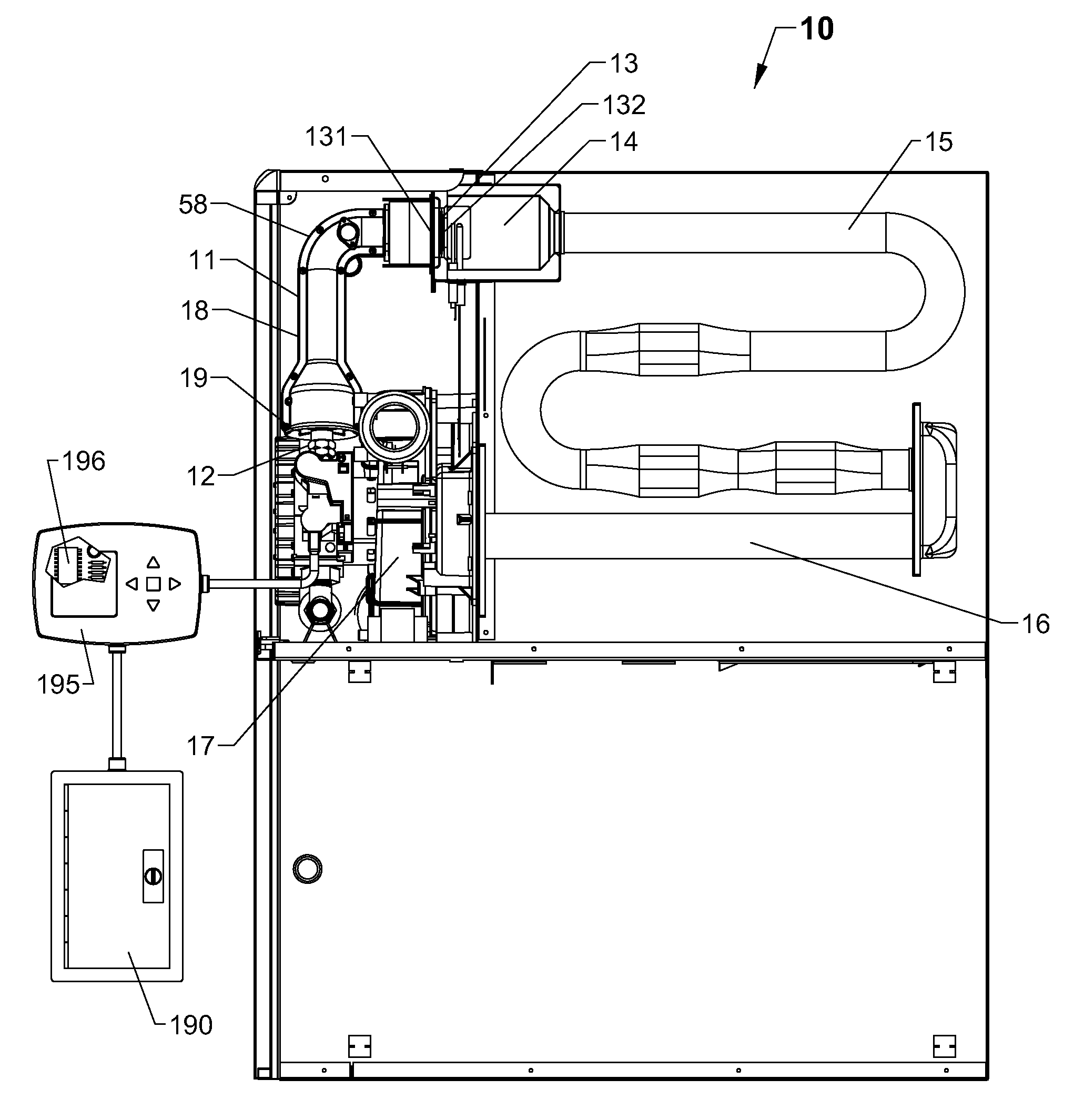

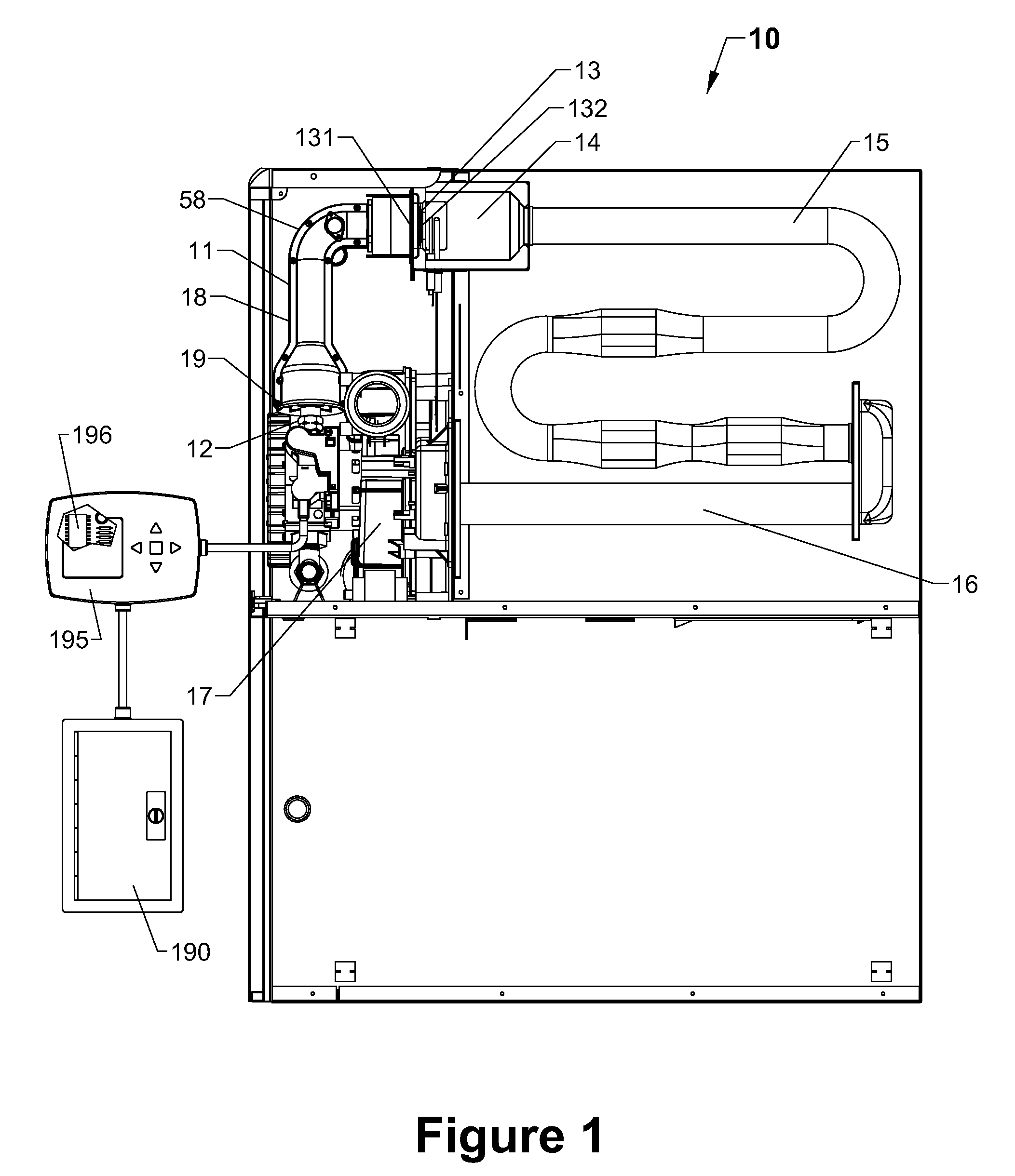

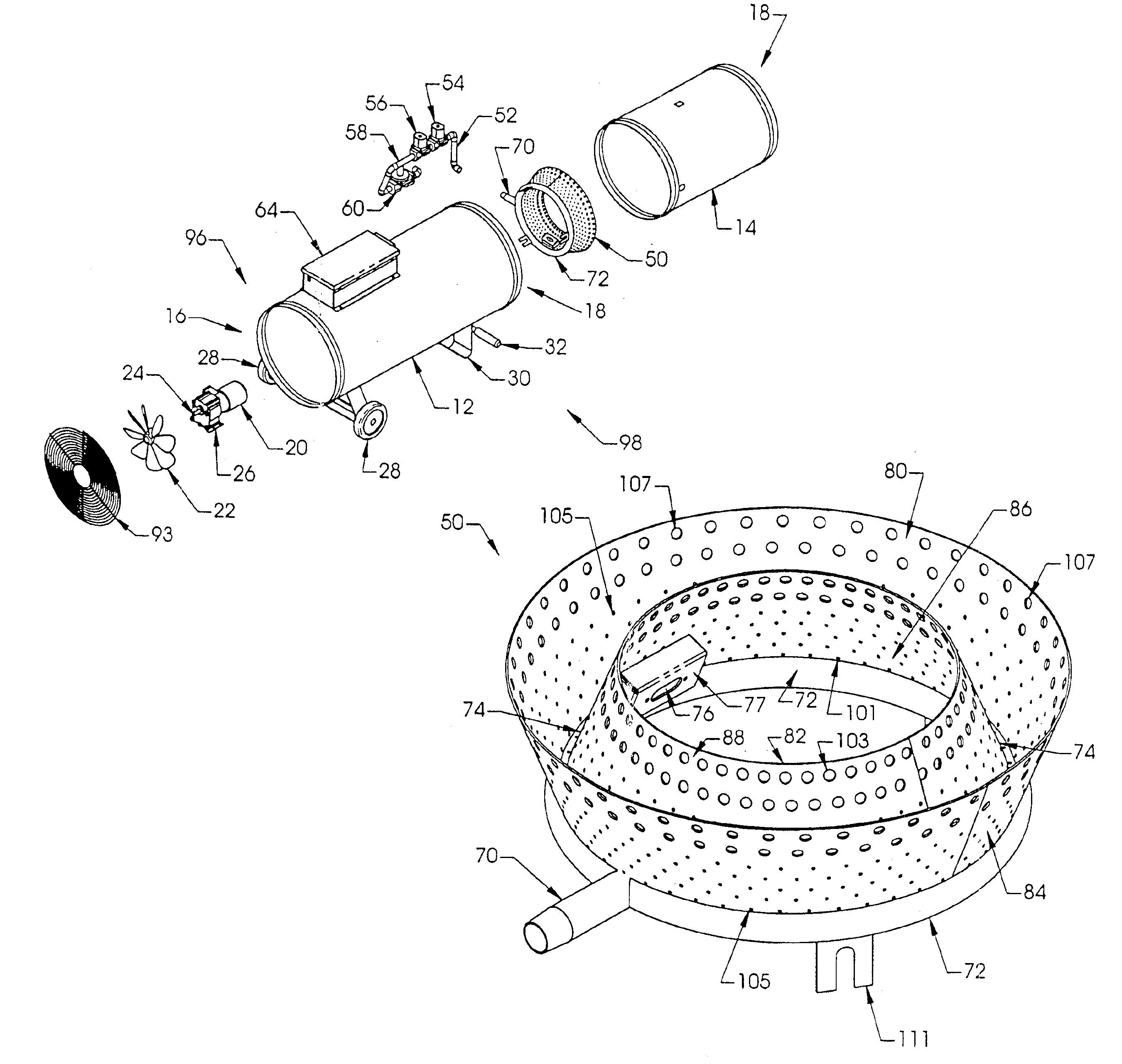

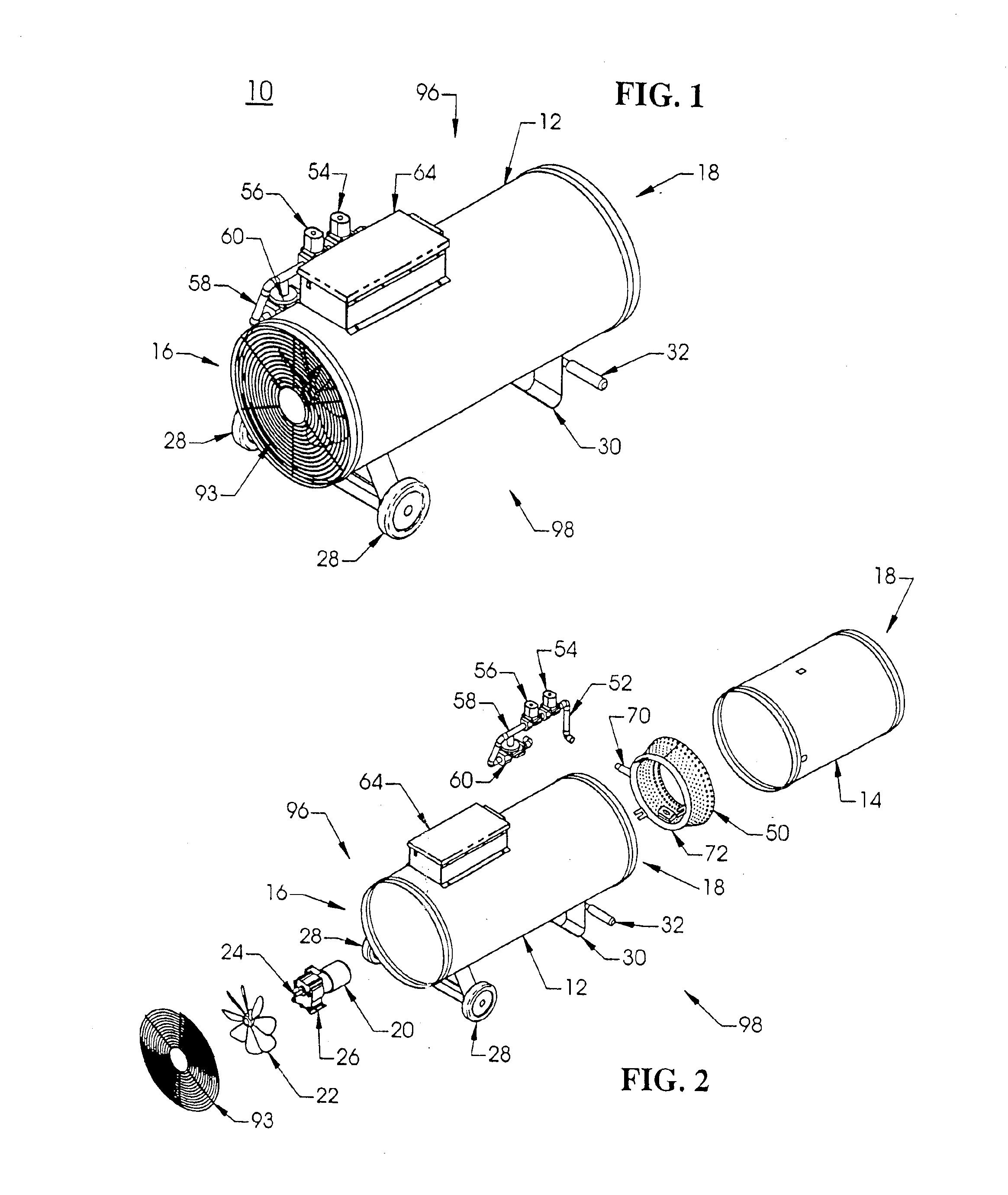

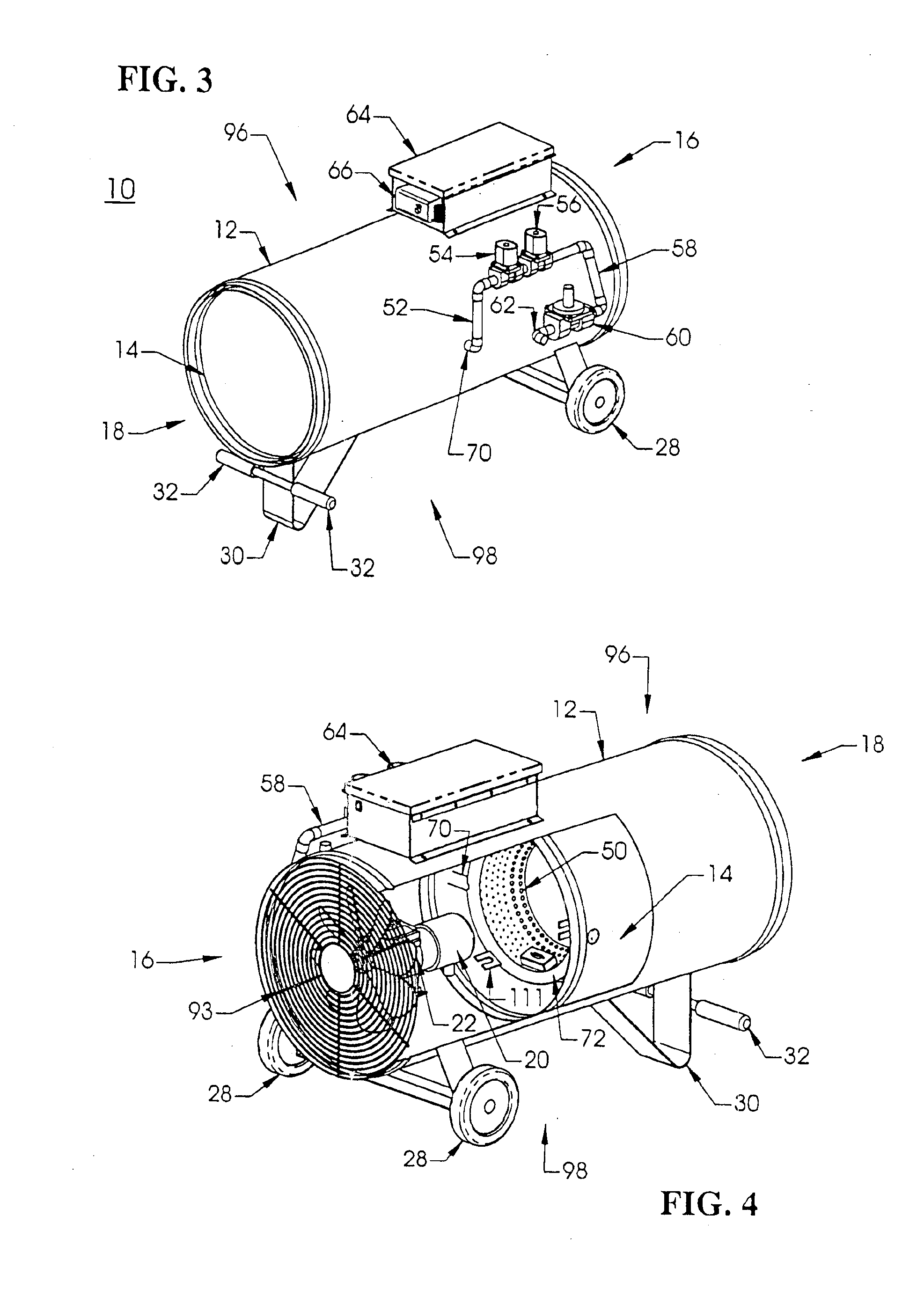

Premix furnace and methods of mixing air and fuel and improving combustion stability

ActiveUS20100310998A1Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberCombustor

Premix furnace for heating an occupied space while producing lower NOx emissions and methods of mixing air and fuel delivered to a premix burner and of improving combustion stability. A mixing device may be located within an inlet tube, may have a flat surface that is perpendicular to the direction of fuel flow, or may have two surfaces held at substantially opposite angles to induce swirl. A mixing device may be attached to the fuel injector, may be made from a piece of sheet metal, and may have bends and a hole for attachment to the fuel injector. A fluidic diode in the inlet tube may improve combustion stability and may include a hollow frustum or a frustoconical portion, a cylinder concentric with the inlet tube, or a combination thereof. Some embodiments include refractory insulation lining the combustion chamber or may adjust for elevation or fuel characteristics.

Owner:NORTEK GLOBAL HVAC

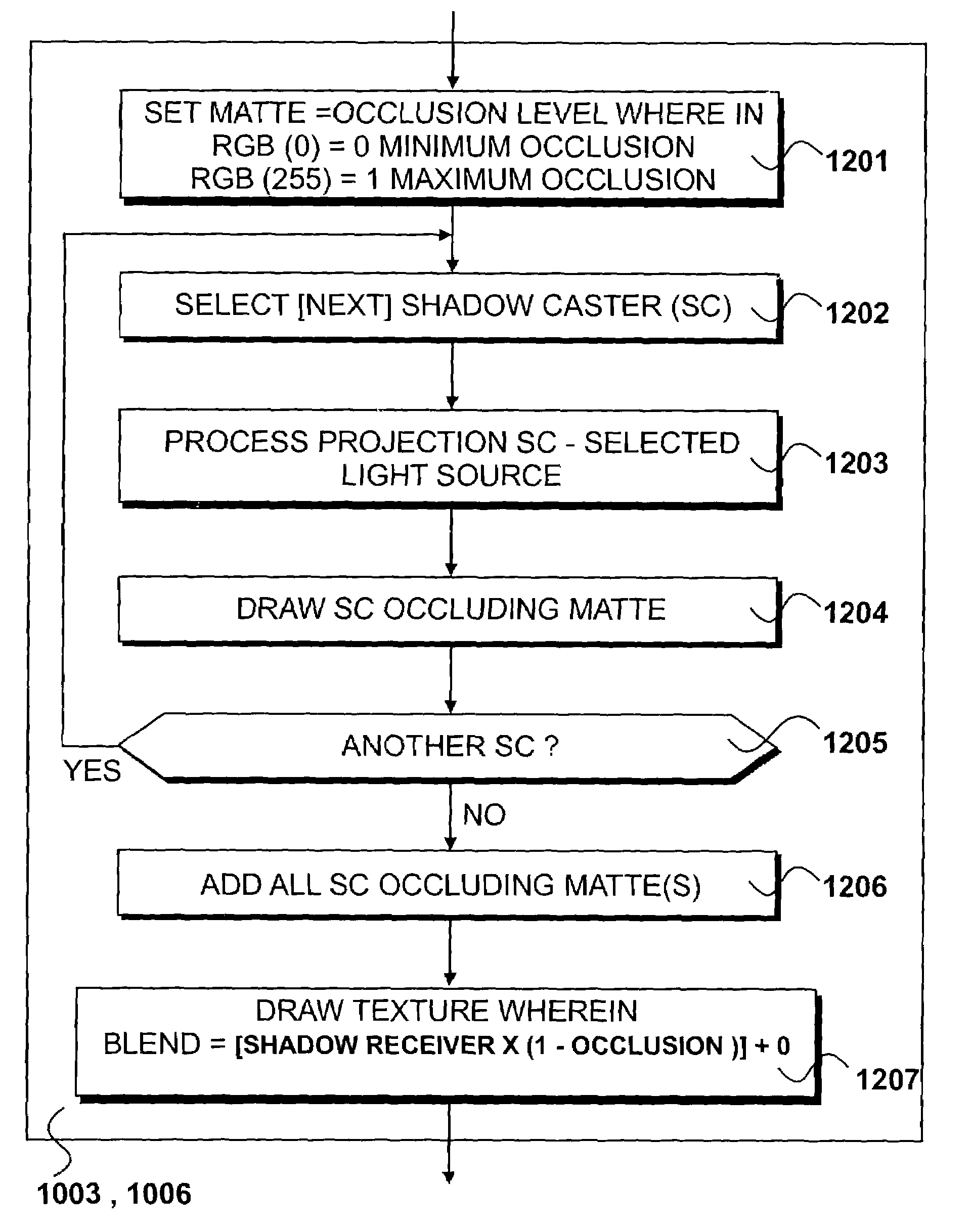

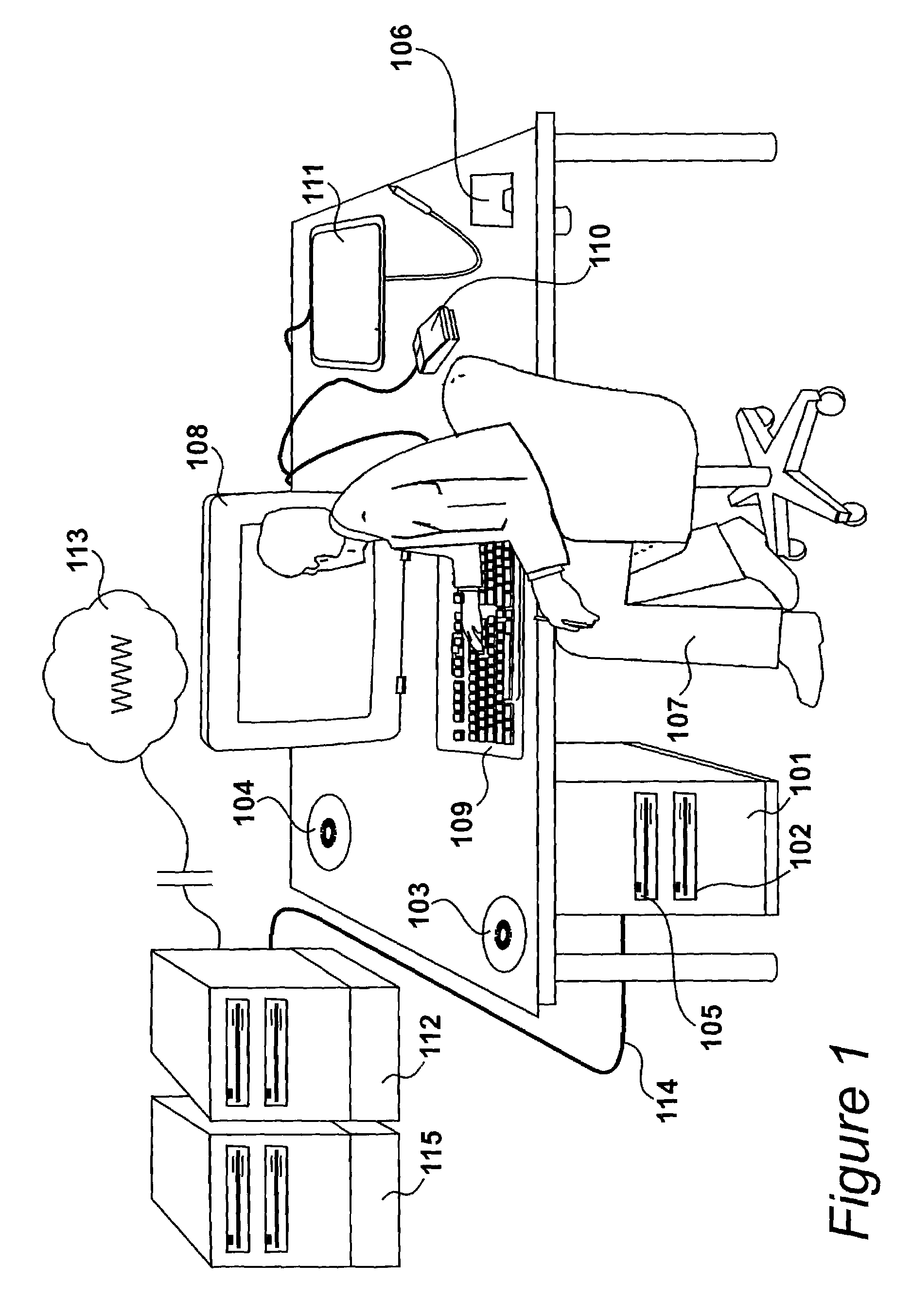

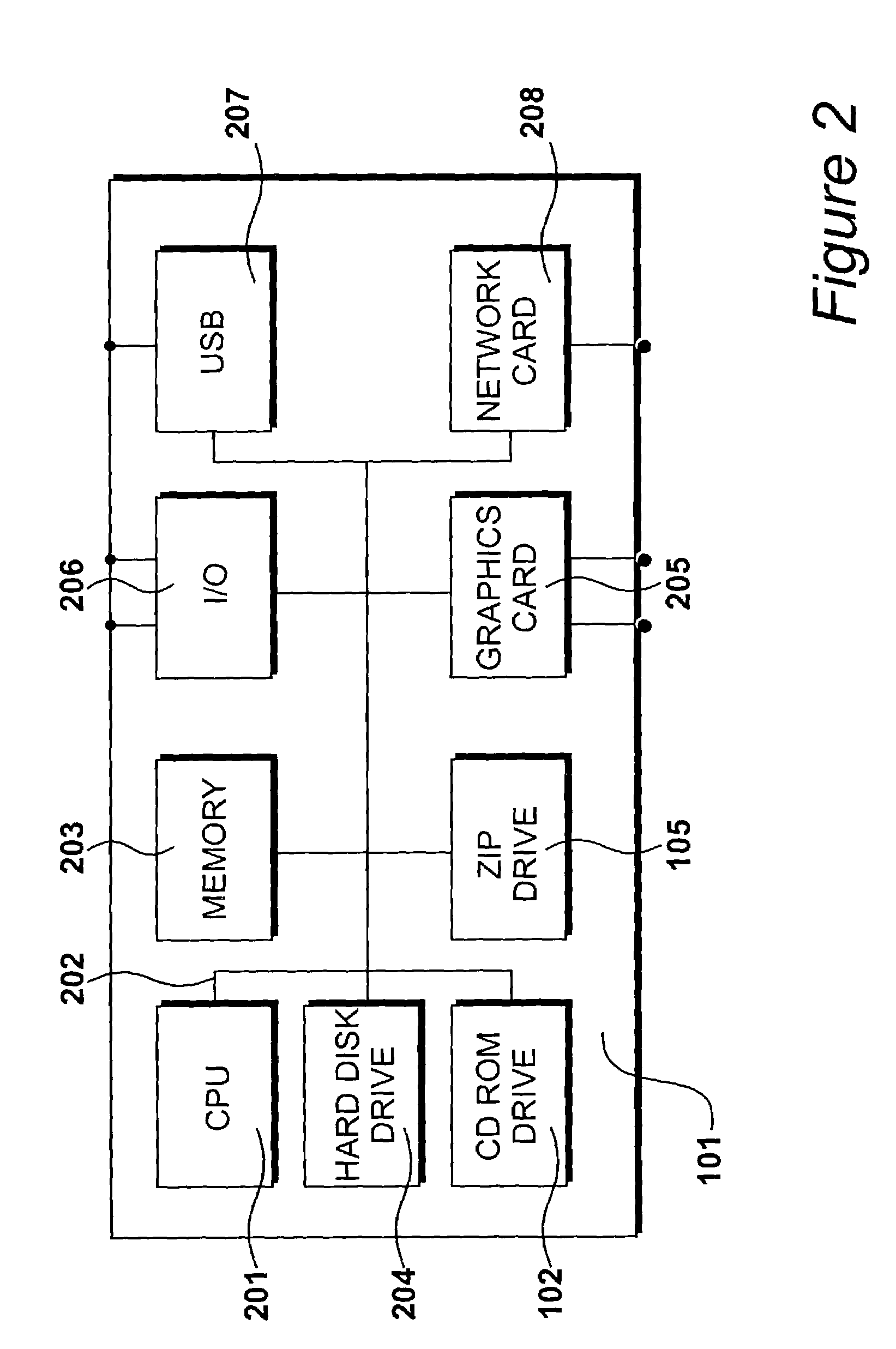

Generating image data

ActiveUS7142709B2Character and pattern recognitionCathode-ray tube indicatorsComputer scienceFrustum

A method, apparatus, and article of manufacture provide the ability to process image data. A data structure includes a plurality of nodes that represent processing to be performed upon image data. At least one node is generated as a three-dimensional object within a compositing space having a; least one light source. A viewport is defined in a space configured with a frustum enclosing the 3D object. A matte of the object is generated in relation to the light source within the space. The matte is accumulated in an accumulating shadow texture and the object is rendered including the accumulating shadow texture in an image frame defined by the frustum.

Owner:AUTODESK INC

Combustion system for a heater

InactiveUS6880549B2Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion systemGas heater

A combustion system for a portable forced air heater having two frusta-conical sections attached to a circular burner tube, wherein each frusta-conical section has pre-determined vent hole patterns that allow the gas heater to have a variable burn rate.

Owner:SUNBELT RENTALS INC

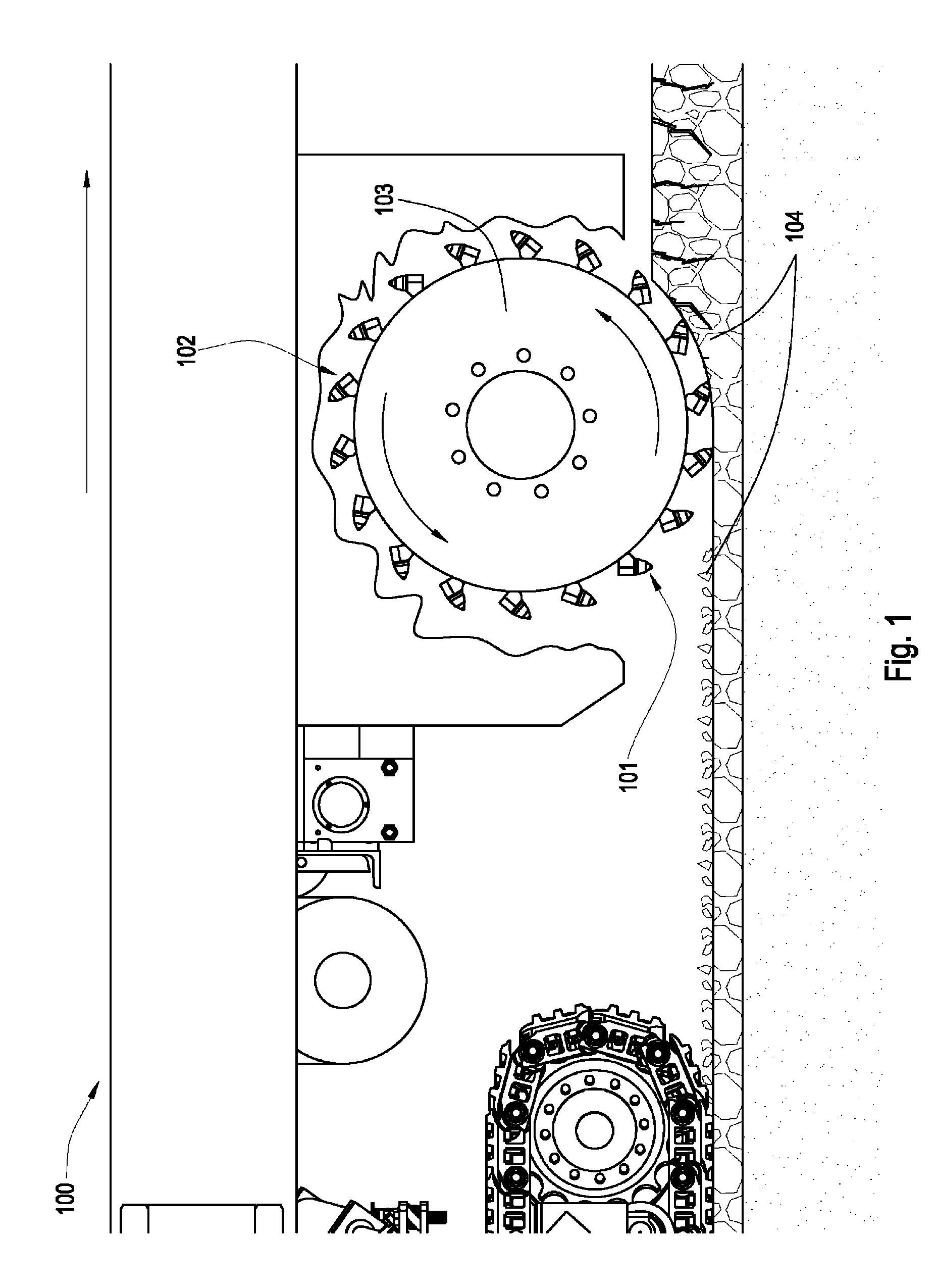

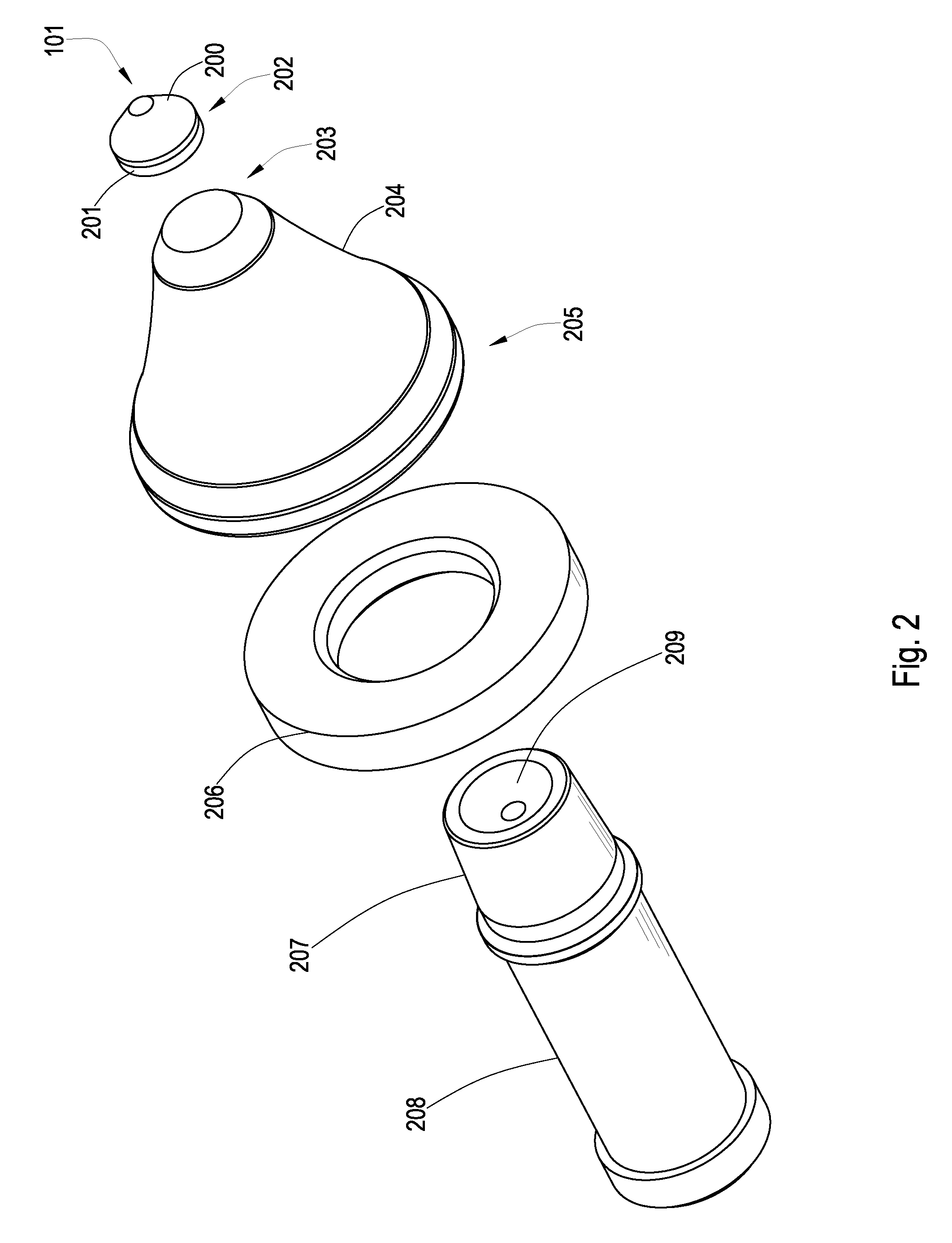

Tapered bore in a pick

In one aspect of the present invention, a high impact resistant excavation pick having a super hard material is bonded to a cemented metal carbide substrate at a non-planar interface. The cemented metal carbide substrate is bonded to a front end of a cemented metal carbide frustum. A tapered bore is formed in the base end of the carbide frustum opposite the front end and a steel shank with a tapered interface is fitted into the tapered bore.

Owner:SCHLUMBERGER TECH CORP

Sinus tarsi implant

An arthroeresis-prosthesis (endorthosis) system comprising a sinus tarsi implant for the purpose of blocking abnormal motion between the talus and calcaneus while allowing normal motion and alignment. In a preferred embodiment, the prosthetic device is composed of a non-metallic, specialized medical grade polymer (polyetheretherketone-PEEK) that is a combination of a frustum of a right cine and an axially extending cylinder that is cannulated and partially structured on the exterior surface.

Owner:GRAHAM MEDICAL TECH LLC

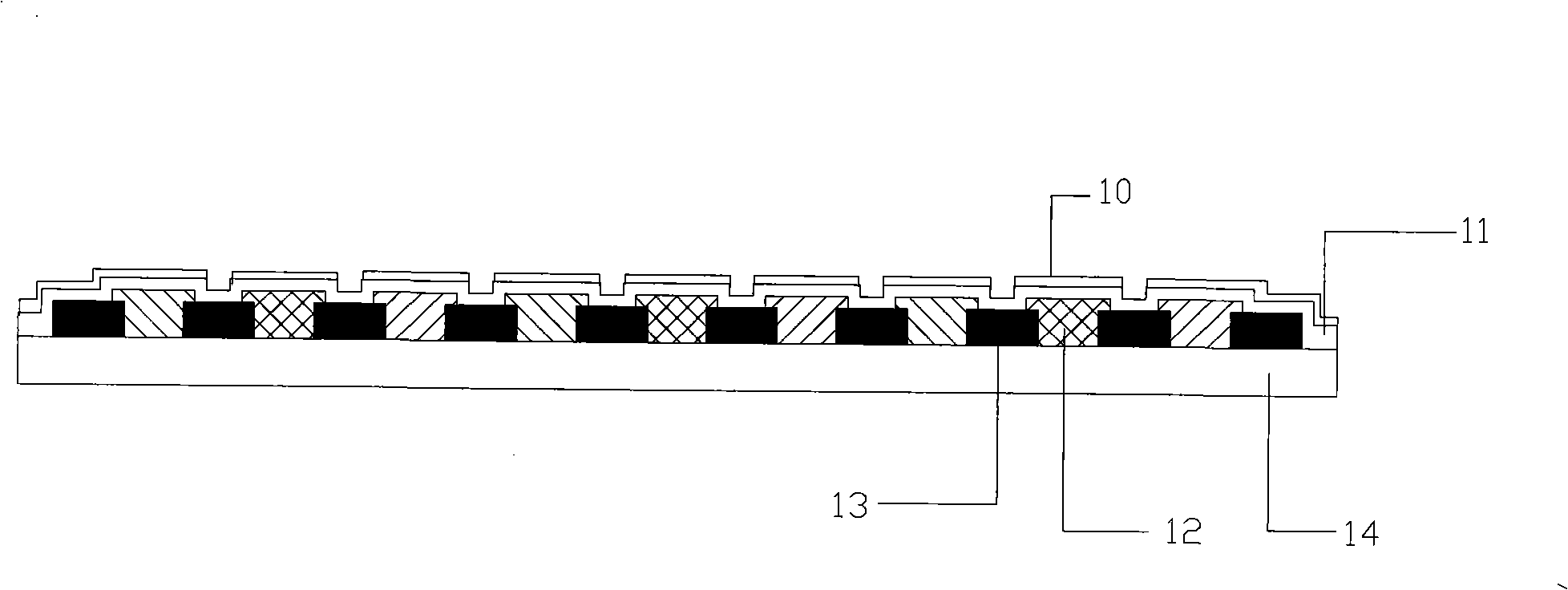

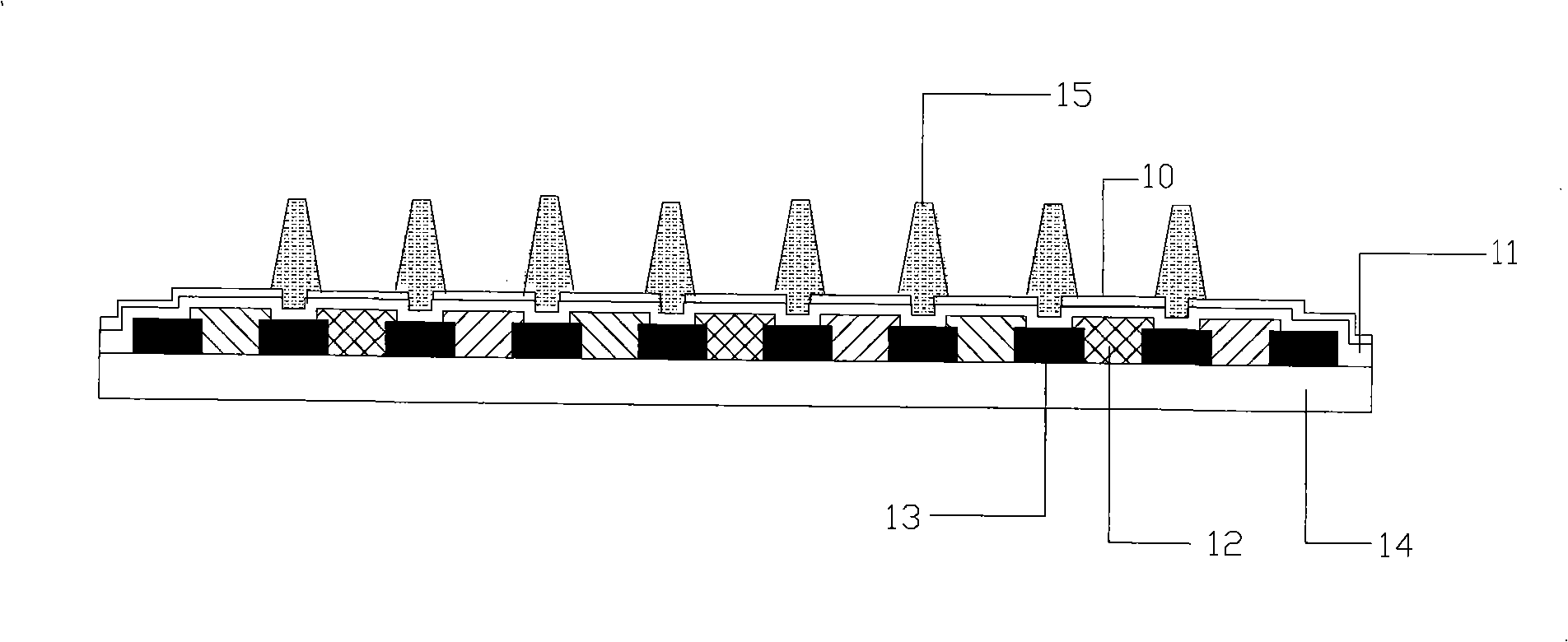

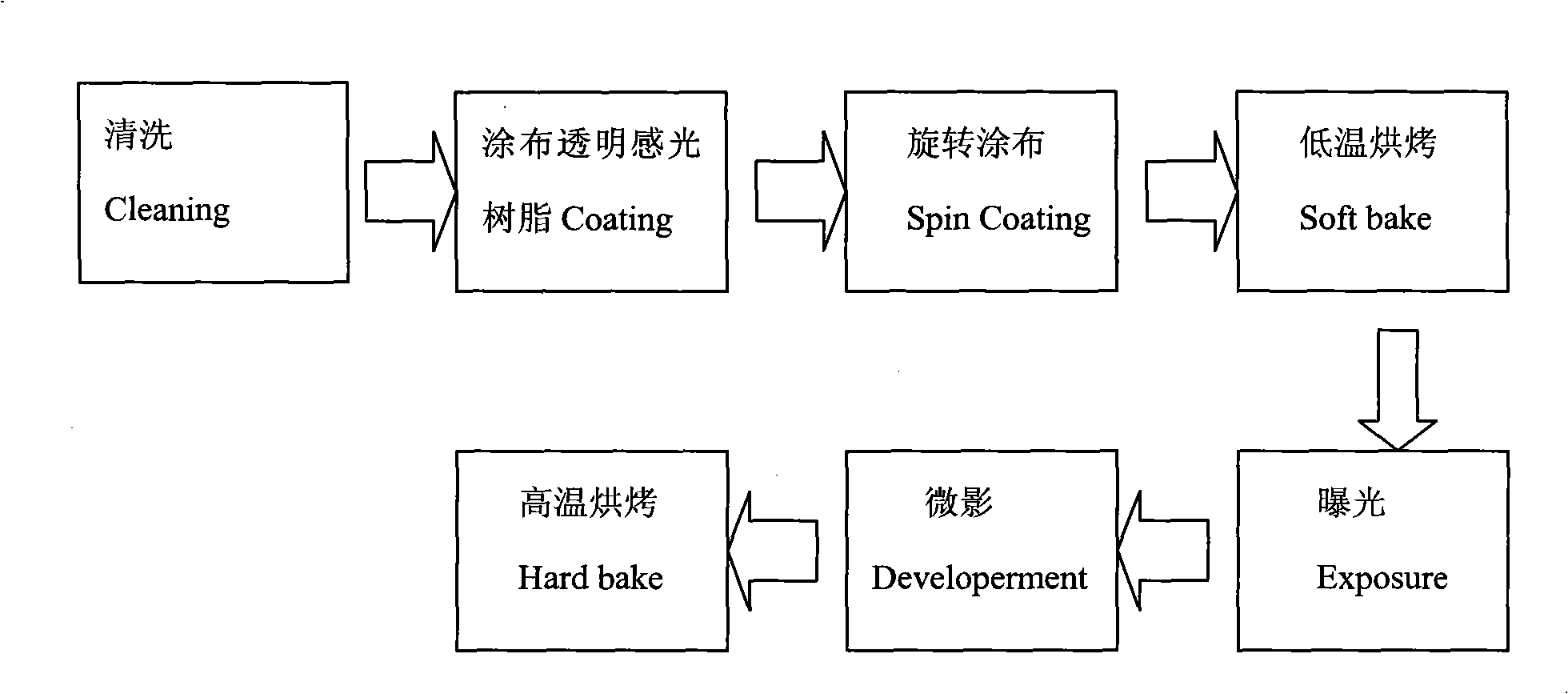

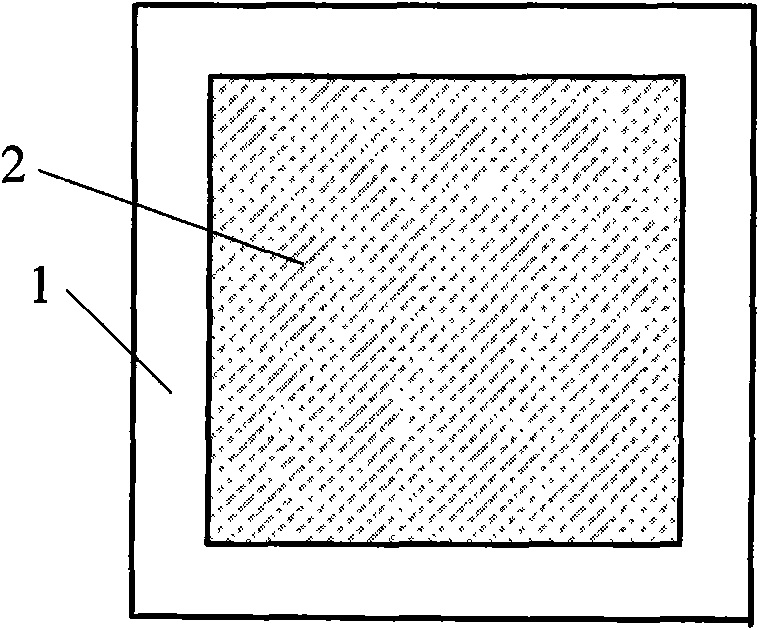

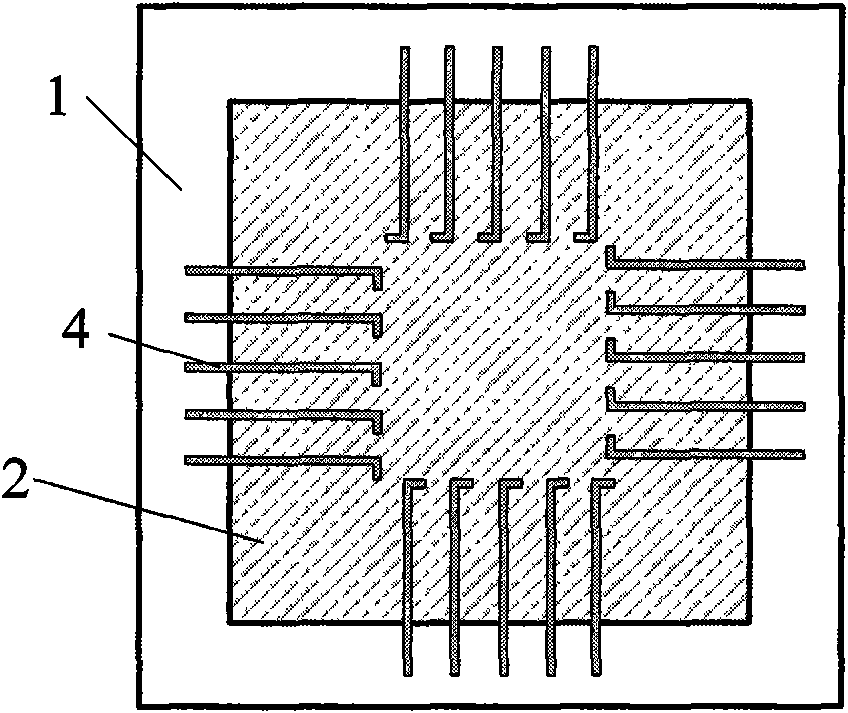

Colored filter with spacer, liquid crystal display device and method for making the same

InactiveCN101303522AEvenly distributedUniform thicknessPhotomechanical apparatusNon-linear opticsPorosityLithographic artist

The invention discloses a colorful optical filter base plate with fixed spacers and a manufacturing method thereof. The colorful optical filter comprises a transparent substrate, a colorful film layer, a latticed black matrix, a flat layer, a transparent electrode layer and a columnar spacer. Firstly, the well-known colorful optical filter base plate is coated with transparent photosensitive material and then exposed by a mask with preset patterns, after being treated by adopting micro-lithography, the transparent columnar or frustum-shaped spacers are directly formed on the colorful optical filter base plate; the central shafts of the spacers are perpendicular to the surface of the flat layer and corresponding to the intersection of gridlines of the black matrix. Since the spacers are directly formed on the colorful optical filter base plate and the height, distribution and density thereof are all preset and controllable, the liquid crystal thickness (CELL GAP) between LCD base plates can be kept uniform, thus avoiding arranging the spacers within a pixel to affect the porosity of LCD.

Owner:BYD CO LTD

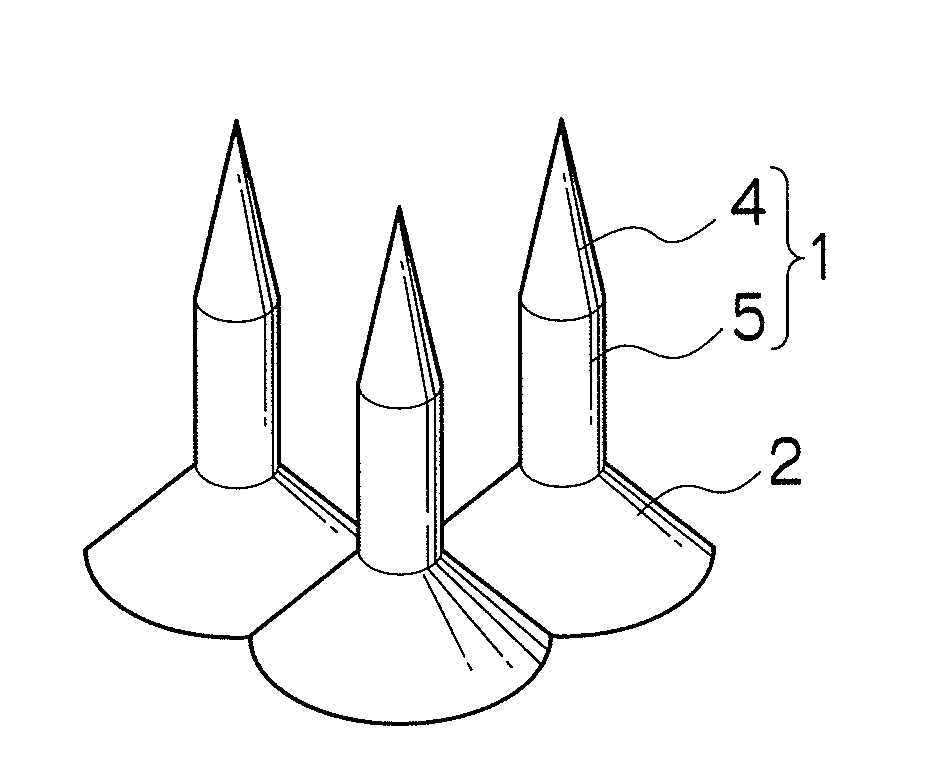

Air suction type medlar picking machine

InactiveCN103141220AExtend working hoursNo or little harmPicking devicesAudio power amplifierEngineering

The invention discloses an air suction type medlar picking machine, which comprises a rack, and a collection device, a power device and a storage device which are mounted on the rack, and is characterized in that the collection device comprises a suction head, a suction hose, an air outlet hose and a suction hose connector, wherein the suction head is provided with a compound body formed by connecting a cylinder body and a frustum body; two holes are arranged in the axial direction of the cylinder body part of the suction head, one hole is a center hole, and the other hole is a side hole; a cylinder-shaped groove is arranged in the periphery of the center hole and is communicated with the side hole; a frustum-shaped through-hole is arranged in the axial direction of the frustum body part and is communicated with the center hole; a frustum-shaped groove is arranged in the periphery of the frustum-shaped through-hole and is matched and communicated with the cylinder-shaped groove; the center hole is matched and connected with the suction hose; the side hole is externally matched and connected with the air outlet hose; and the power device comprises an air amplifier, an air outlet connection hose, an air cylinder, an air pump, a safety valve, an air inlet connection hose, a storage battery and an amplifier connector.

Owner:HEBEI UNIV OF TECH

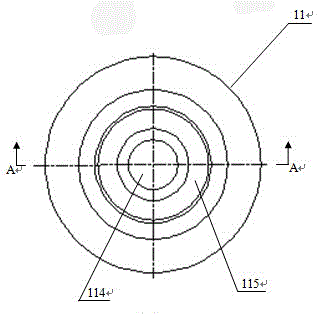

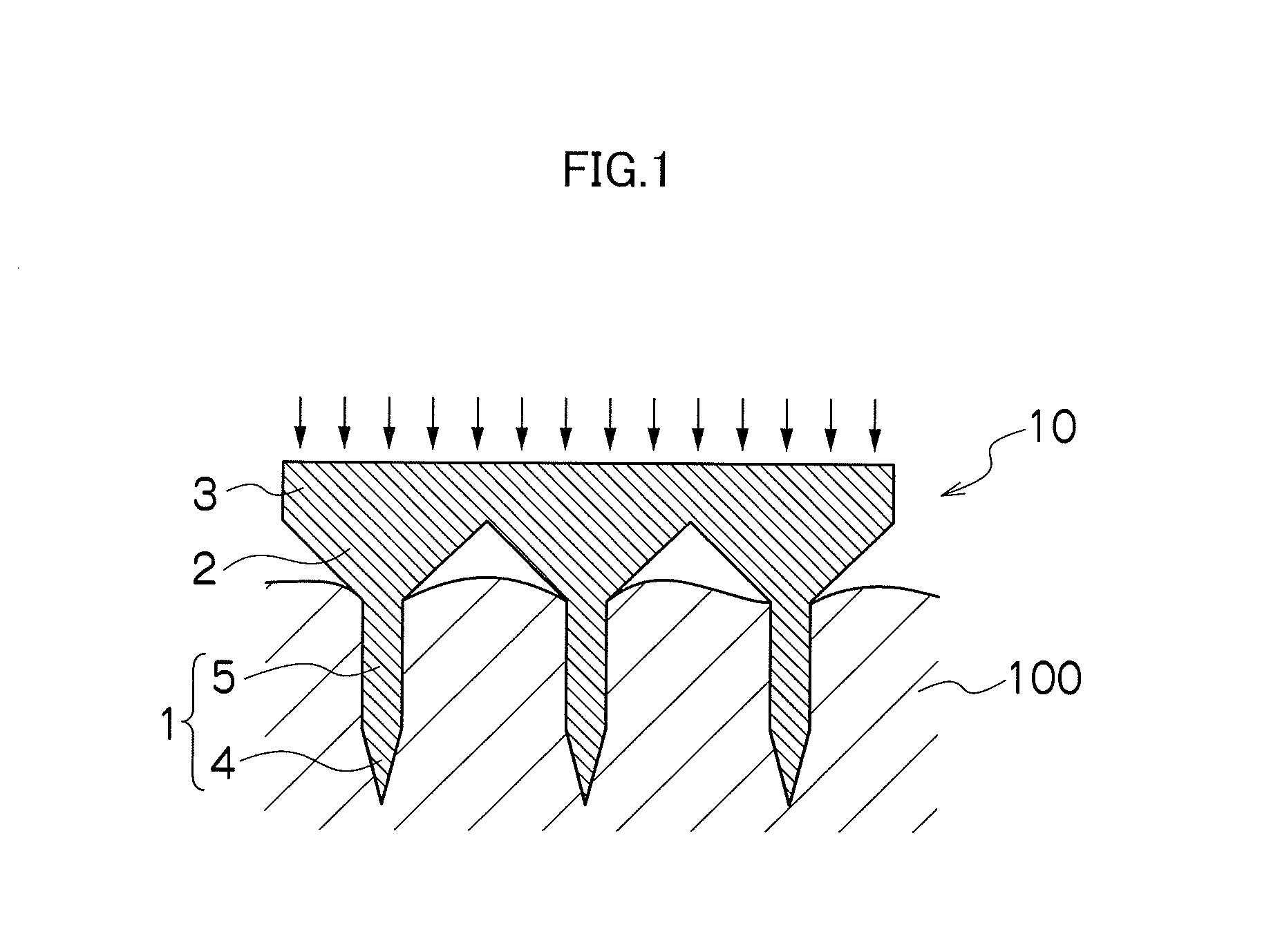

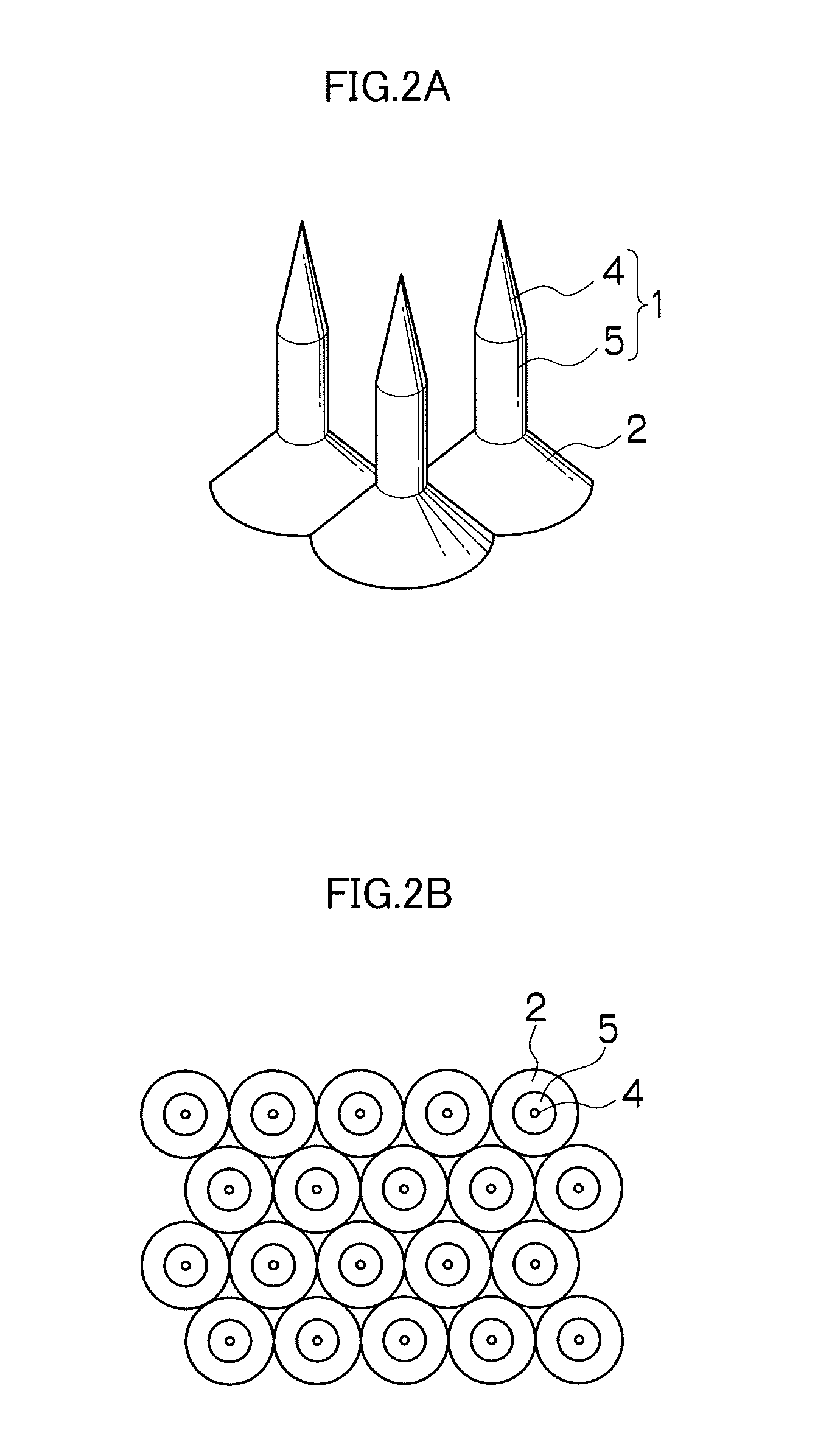

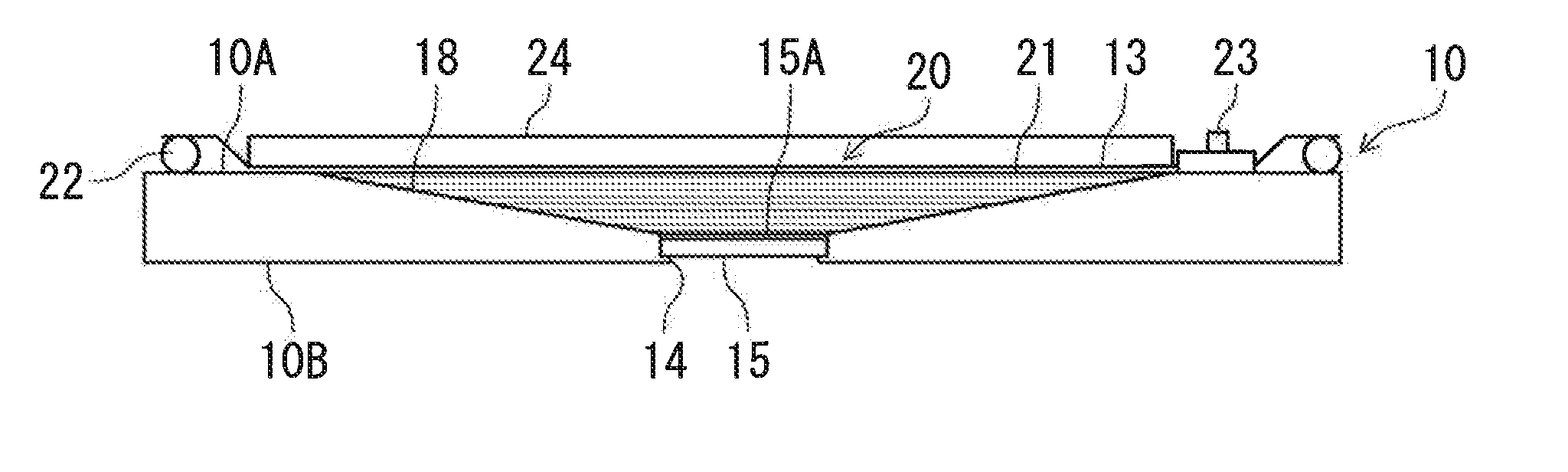

Needle array transdermal absorption sheet and method for manufacturing needle array transdermal absorption sheet

A needle array transdermal absorption sheet to be attached onto a skin for supplying a drug into the skin, includes: a plurality of needle portions each having a tapered shape, each of the needle portions including a needle having a conical or pyramidal shape and a body part which has a columnar shape and whose end surface is connected to a base of the needle; a sheet portion having a flat-plate shape; and a plurality of frustum portions each having a frustum shape, the frustum portions which are arranged on a surface of the sheet portion in a manner that perimeters of larger bases of adjacent frustum portions are in contact with each other on the surface of the sheet portion, and smaller bases of which are respectively connected to the body parts of the needle portions.

Owner:FUJIFILM CORP

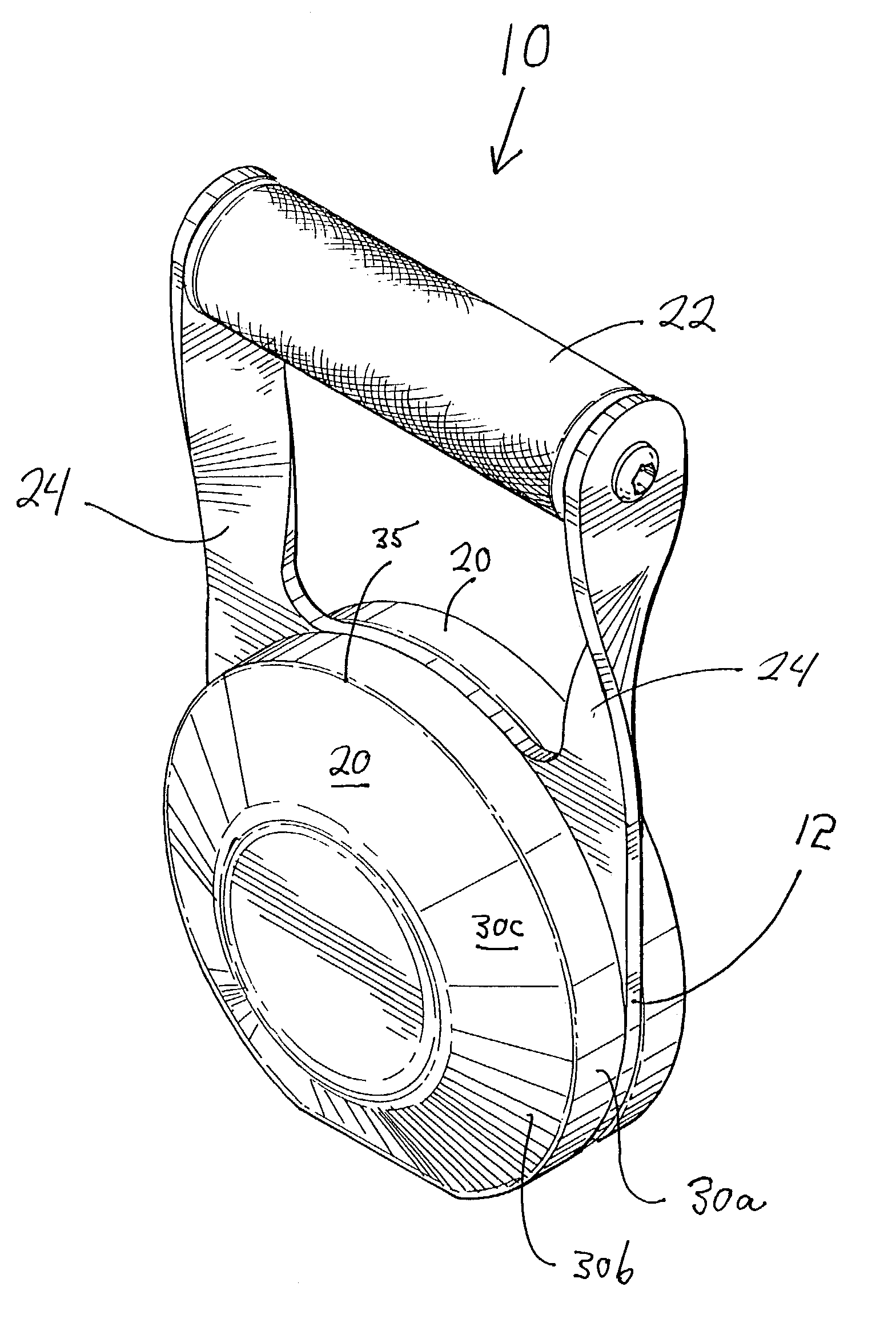

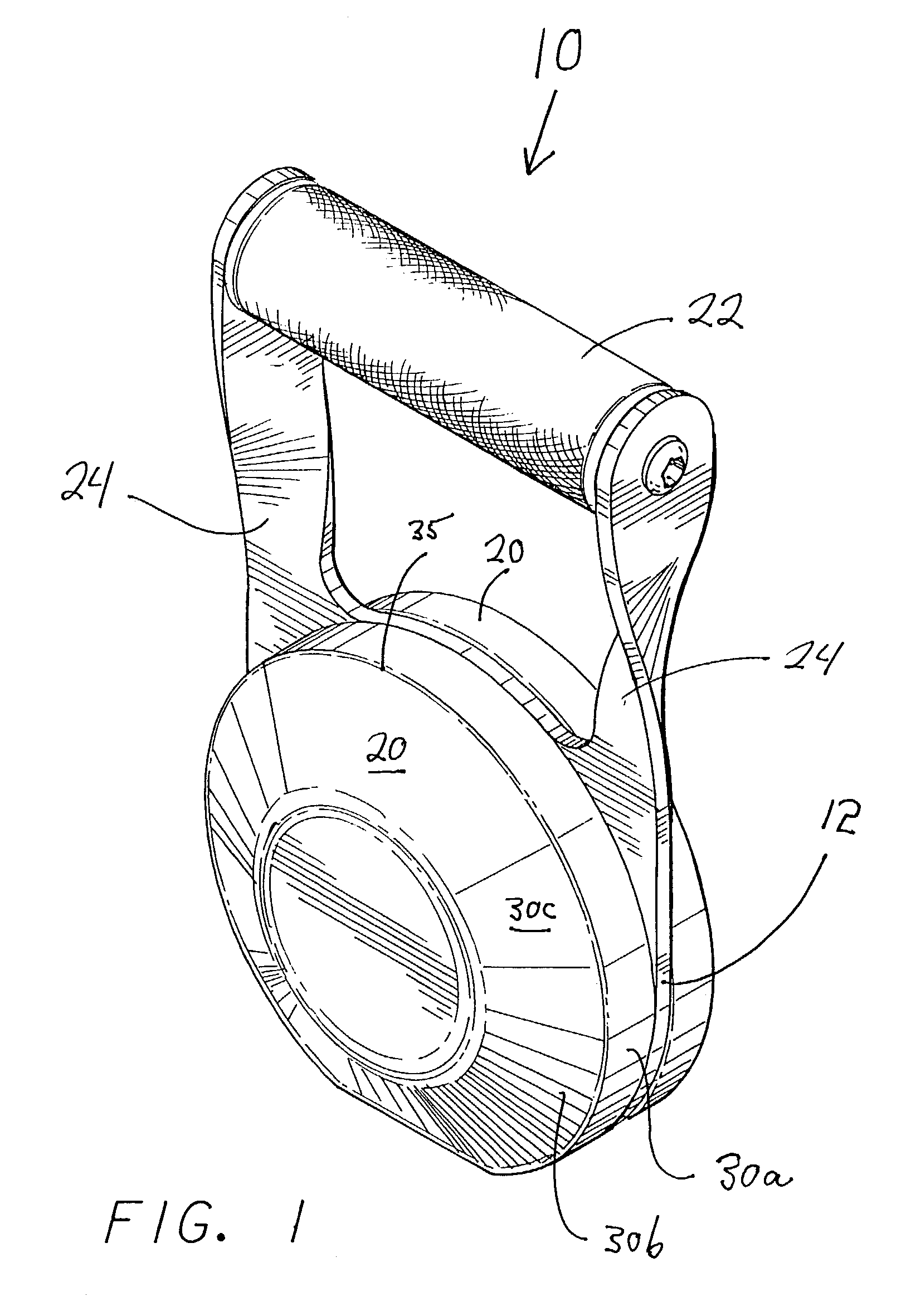

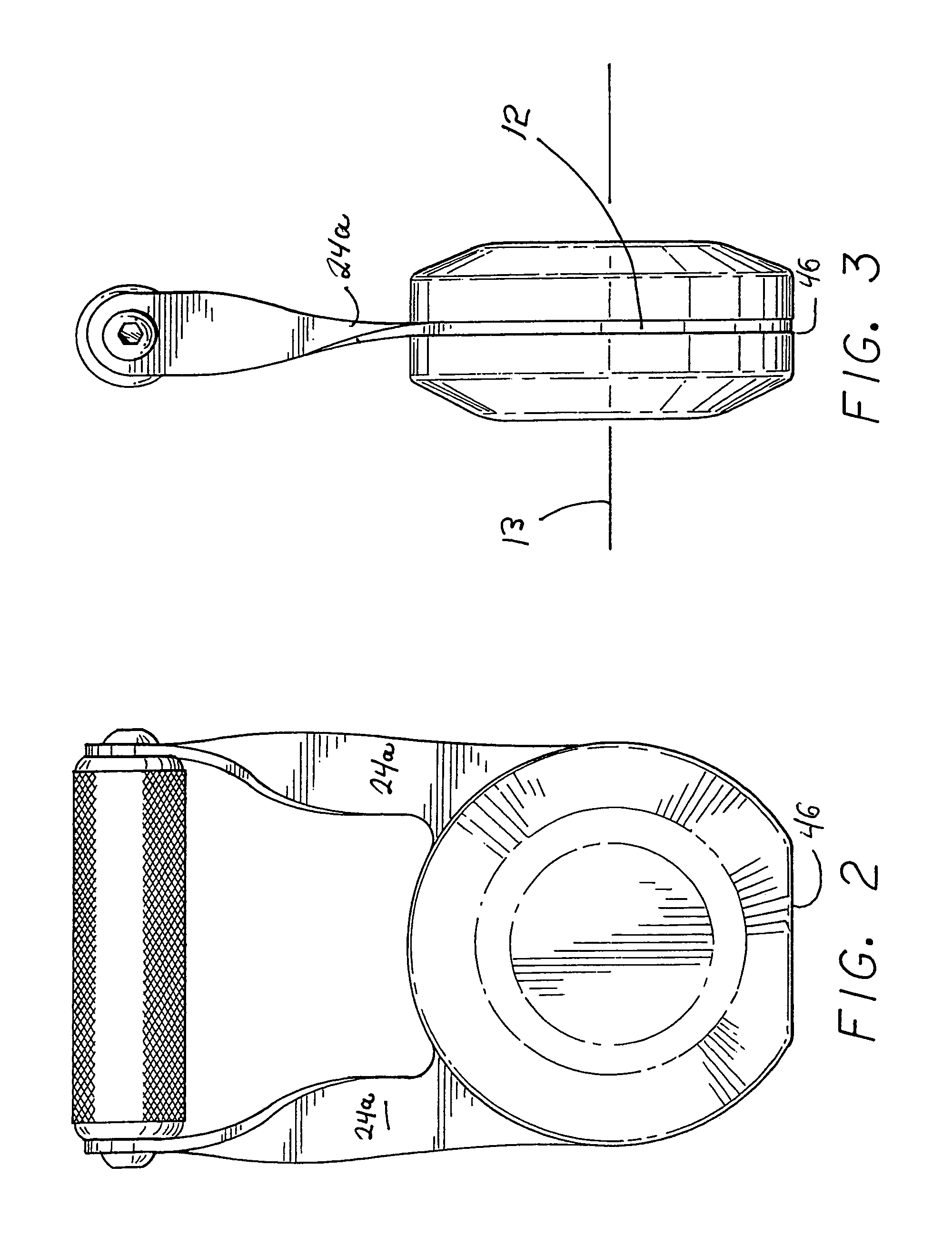

Kettlebell

A kettlebell is disclosed herein having, in its preferred embodiment, a pair of oppositely-facing, generally frustum-shaped weightplates disposed about a first axis that is perpendicular to the axis of its handle. The frustum shape reduces the force of impact against the user's forearm during certain exercise movements. The preferred handle includes places which can be held between the user's thumb and remaining fingers for improved control during other exercise movements.

Owner:ACE SPECIALTY +1

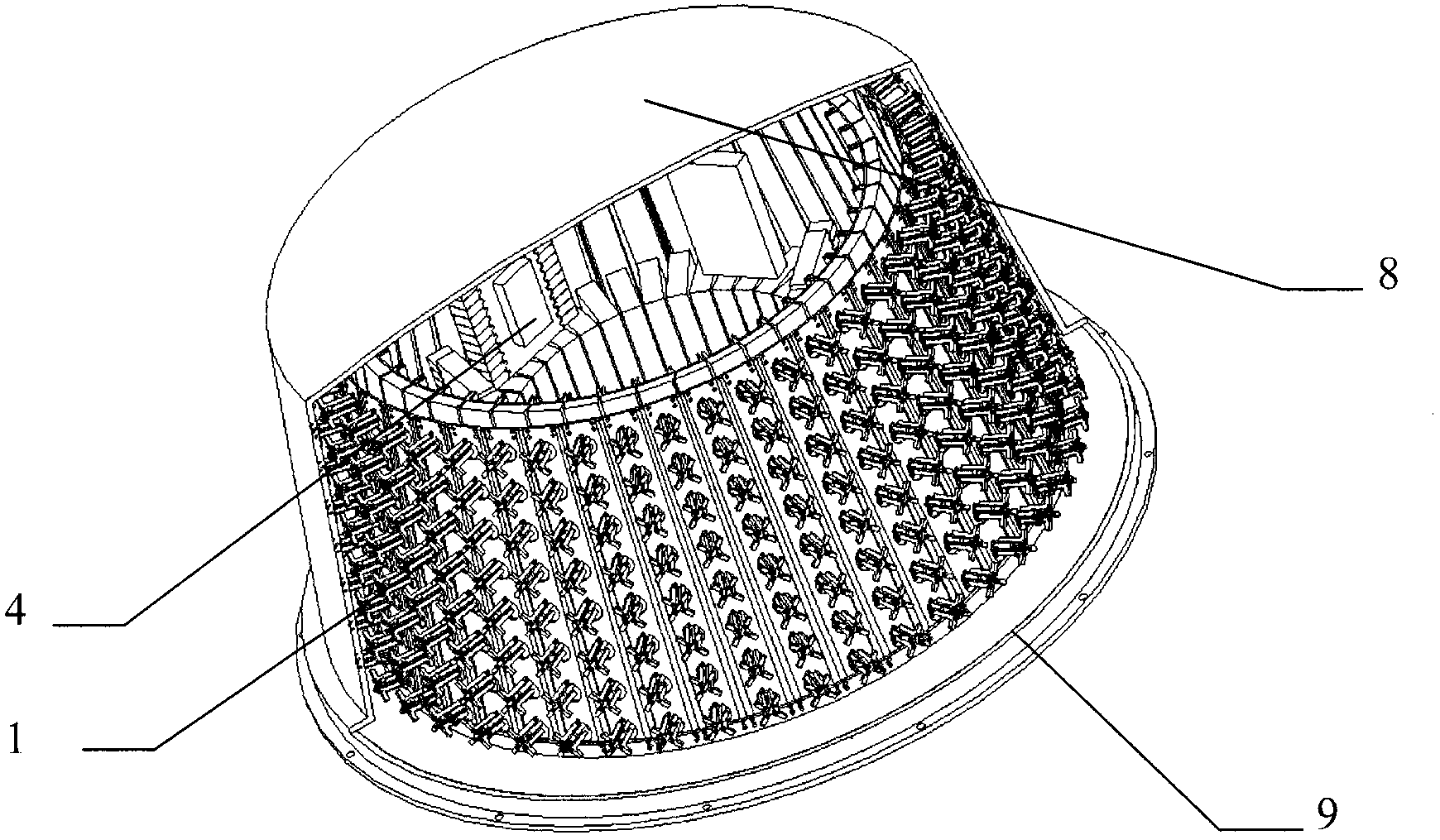

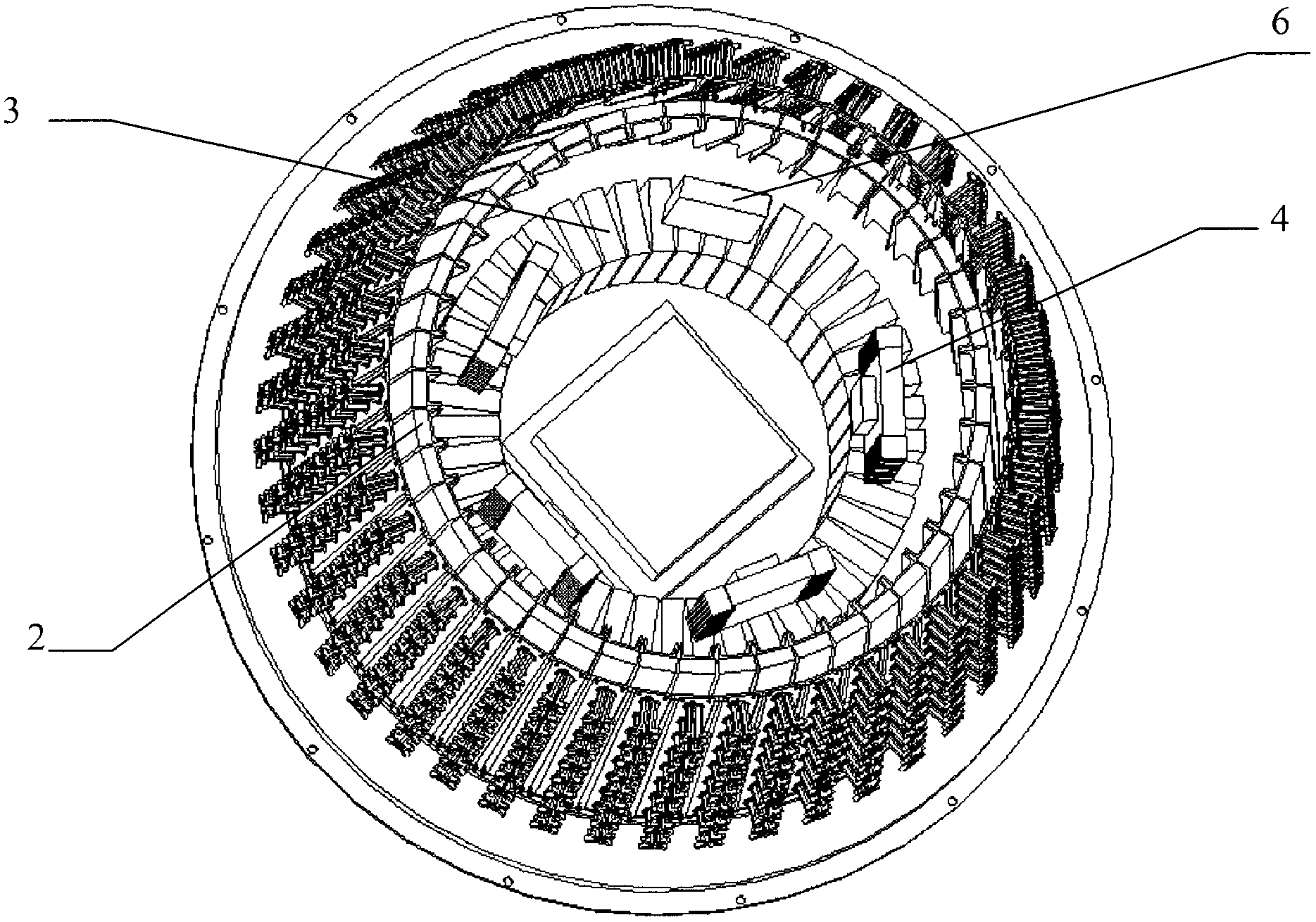

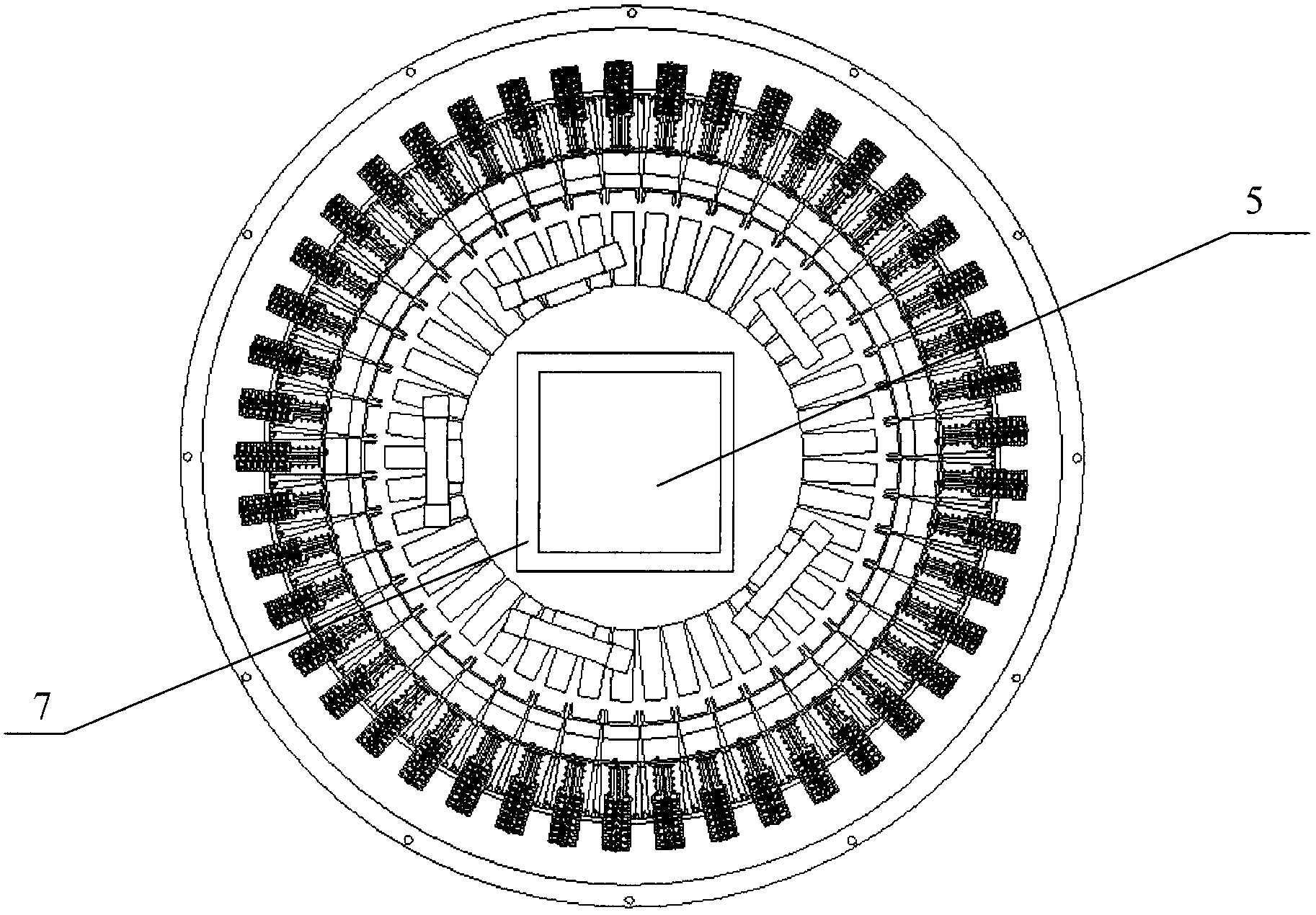

Full-airspace-covering beamforming phased array antenna (PAA)

InactiveCN103022726ASolve the multi-target tracking problemReduce usageAntenna arraysPhase shiftedMulti target tracking

The invention discloses a full-airspace-covering beamforming PAA for aircraft target tracking and measurement and control. The PAA comprises a passive array surface (1), a beam forming network, a beam controller (5), a calibration network (6), a secondary power supply (7) and a support structure (9), wherein the passive array surface (1) is composed of a plurality of antenna array elements; the beam forming network is formed by a beamforming network (2), an R assembly (3) and a beam synthetic network (4); the beam controller (5) is used for generating beam-controlled codes, the calibration network (6) is used for calibrating each access amplitude, the secondary power supply (7) is used for supplying power for an active circuit, and the support structure (9) is used for installation and fixation. According to the PAA, a one-dimensional forming and one-dimensional cone frustum PAA scanning mode is adopted, cosecant square beams with the highest gains horizontally are formed in the array direction through the beamforming network, coverage ranging from 0 degree to 90 degrees in the pitching direction is achieved, coverage at 360 degrees is achieved circumferentially through phased array beam scanning, and independent multiple beams are formed through multi-channel phase shift and beam synthesis to solve the multi-target tracking problem.

Owner:BEIJING RES INST OF TELEMETRY +1

Micromachined thermopile infrared detector

ActiveCN101575083AReduce stressNo high temperature annealing requiredTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesThermopileReflective layer

The invention relates to the field of an infrared detector, in particular to a micromachined thermopile infrared detector. The manufacturing technique is simplified and the performance and finished product rate are improved. The manufacture of the micromachined thermopile infrared detector comprises the following steps of: (1) depositing silicon nitride film on the both sides of a silicon substrate by an LPCVD method; (2) etching to remove peripheral silicon nitride film on the frontal side of the silicon substrate by lithography; (3) manufacturing a plurality of Poly-Si strips both ends of which are respectively arranged on the silicon nitride film and the silicon substrate by LPCVD method and photolithographic process; (4) manufacturing a plurality of aluminum strips which form a thermocouple with the plurality of Poly-Si strips by sputtering and photolithographic processes; (5) depositing the silicon nitride film on the frontal side of the silicon substrate by PECVD method; (6) manufacturing an infrared absorption layer (a carbonized photoresist layer) covering the hot junction area of the thermopile with photolithographic process; (7) manufacturing a metal reflective layer (a metal layer) covering the cold junction area of the thermopile with lift-off process; and (8) eroding the back side of the silicon substrate to form a square frustum pyramid shaped groove. The micromachined thermopile infrared detector has reasonable structure design, simple manufacturing process, high detector performance, high finished product rate, good development prospect and is easy to realize.

Owner:ZHONGBEI UNIV

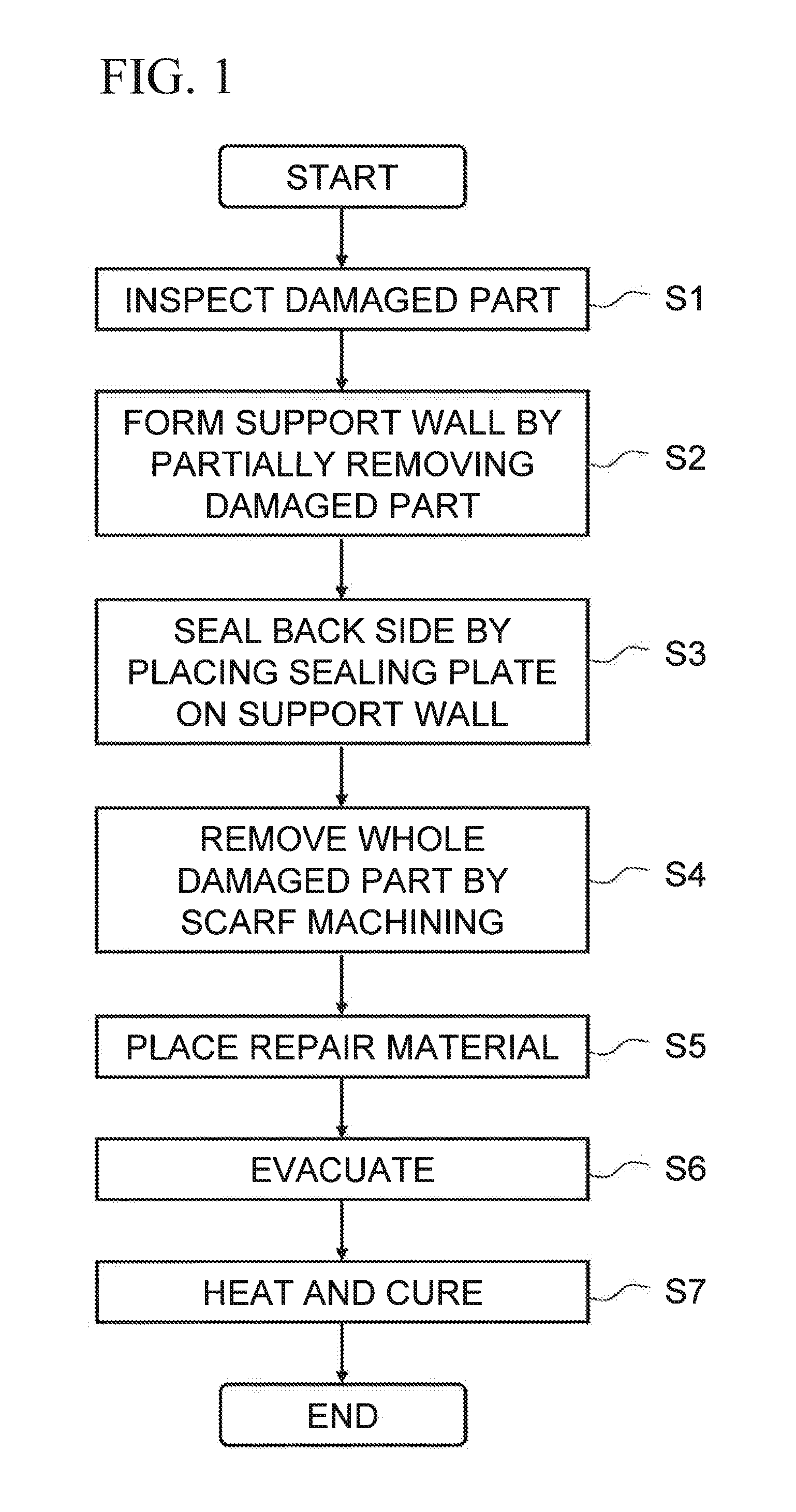

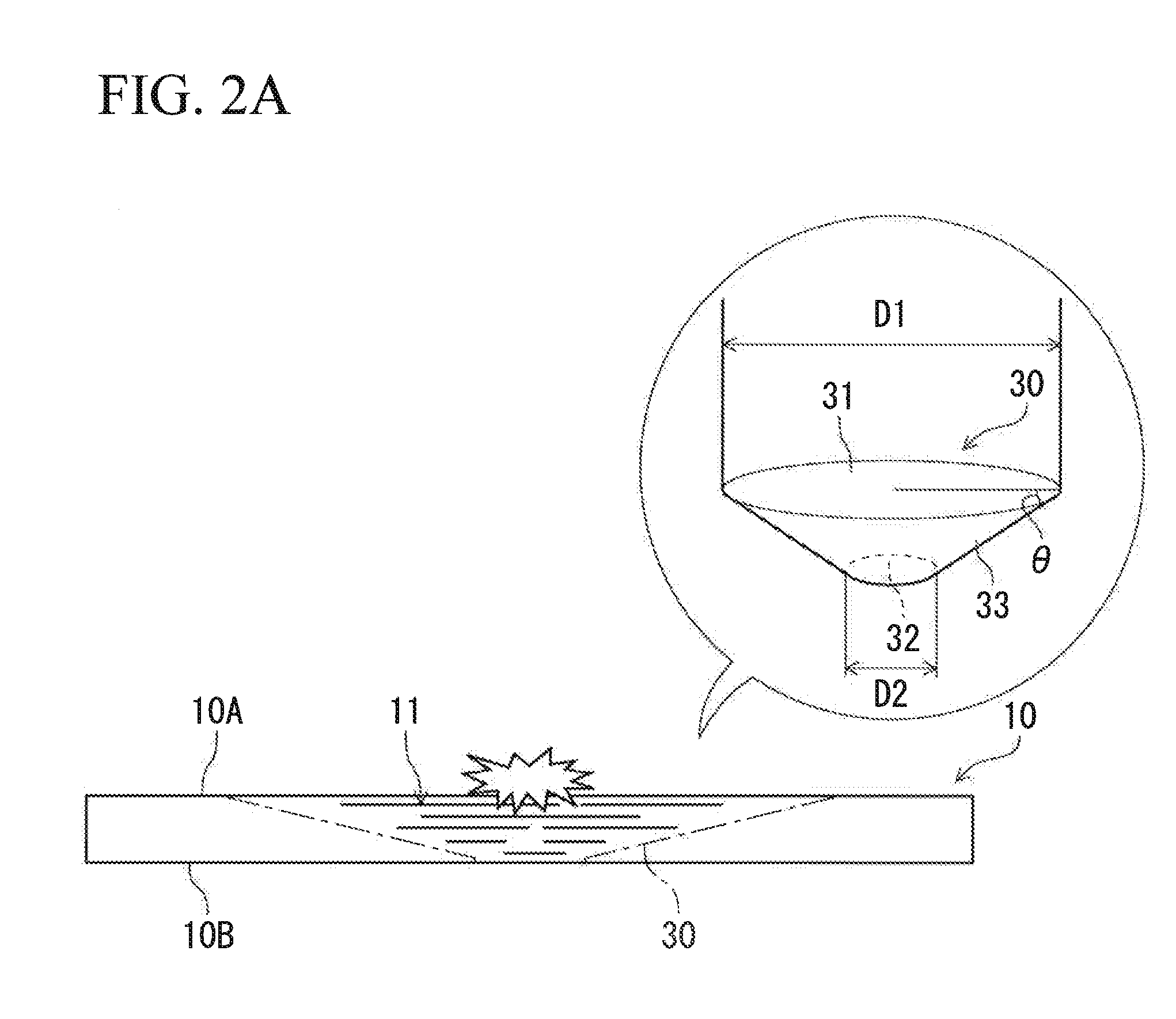

Method of repairing composite material and composite material

A method of repairing a composite material is provided in which a frustum-shaped portion of a composite material is removed, and the composite material and a repair material are bonded with each other while evacuating. The repair method includes step S2 of removing a damaged part 11 from the front side so as to pass through in the thickness direction while leaving a support wall protruding inward in the radial direction from the periphery of the top face of the frustum-shaped portion; step S3 of sealing the back side by placing a sealing plate, which is inserted from the front side into a through hole formed by the removing step, on the support wall; step S5 of placing the repair material through an adhesive on the composite material where the frustum-shaped portion has been removed; and step S6 of evacuating in a state in which the front side is sealed.

Owner:MITSUBISHI AIRCRAFT

Modular cuboidal passive temperature controlled shipping container

Owner:PELI BIOTHERMAL LLC (N D GES D STAATES DELAWARE)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com