Patents

Literature

2902results about "Sealing arrangements for engines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

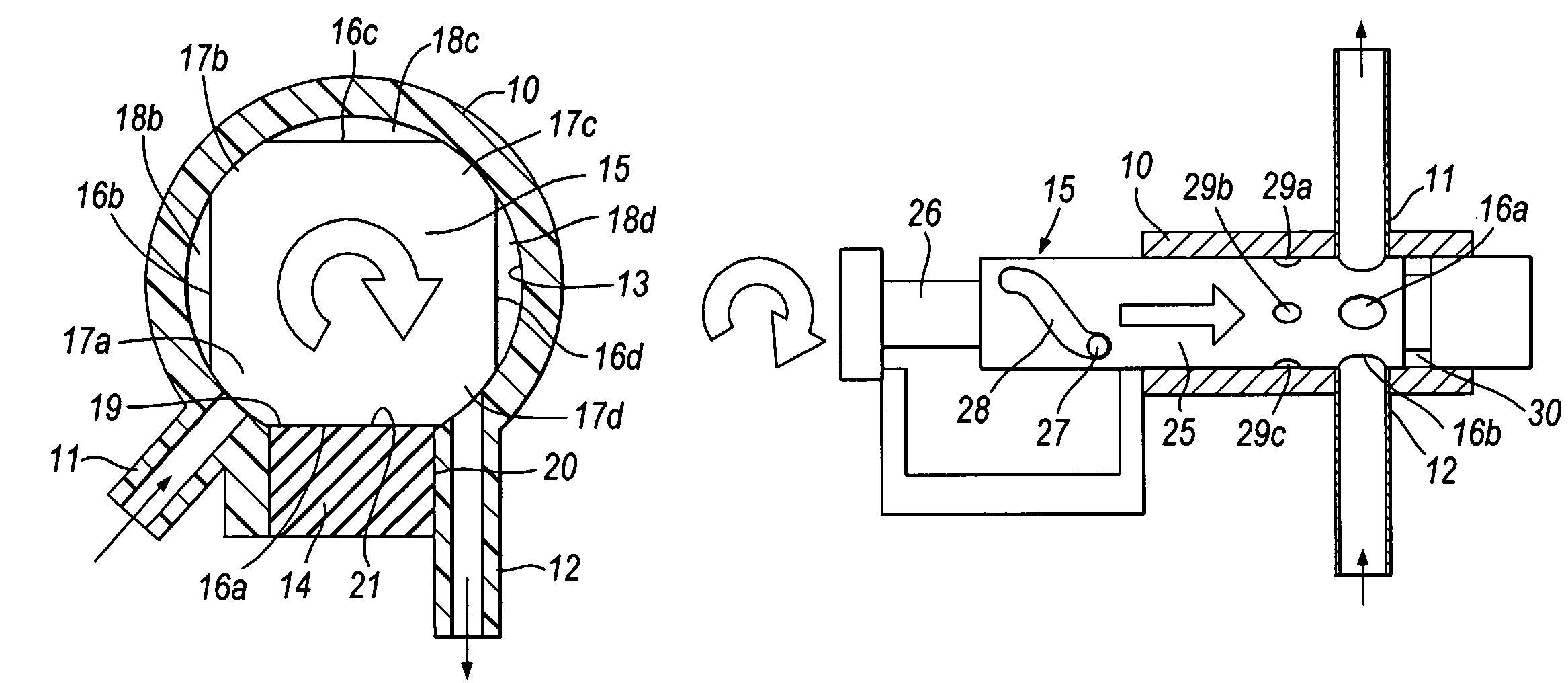

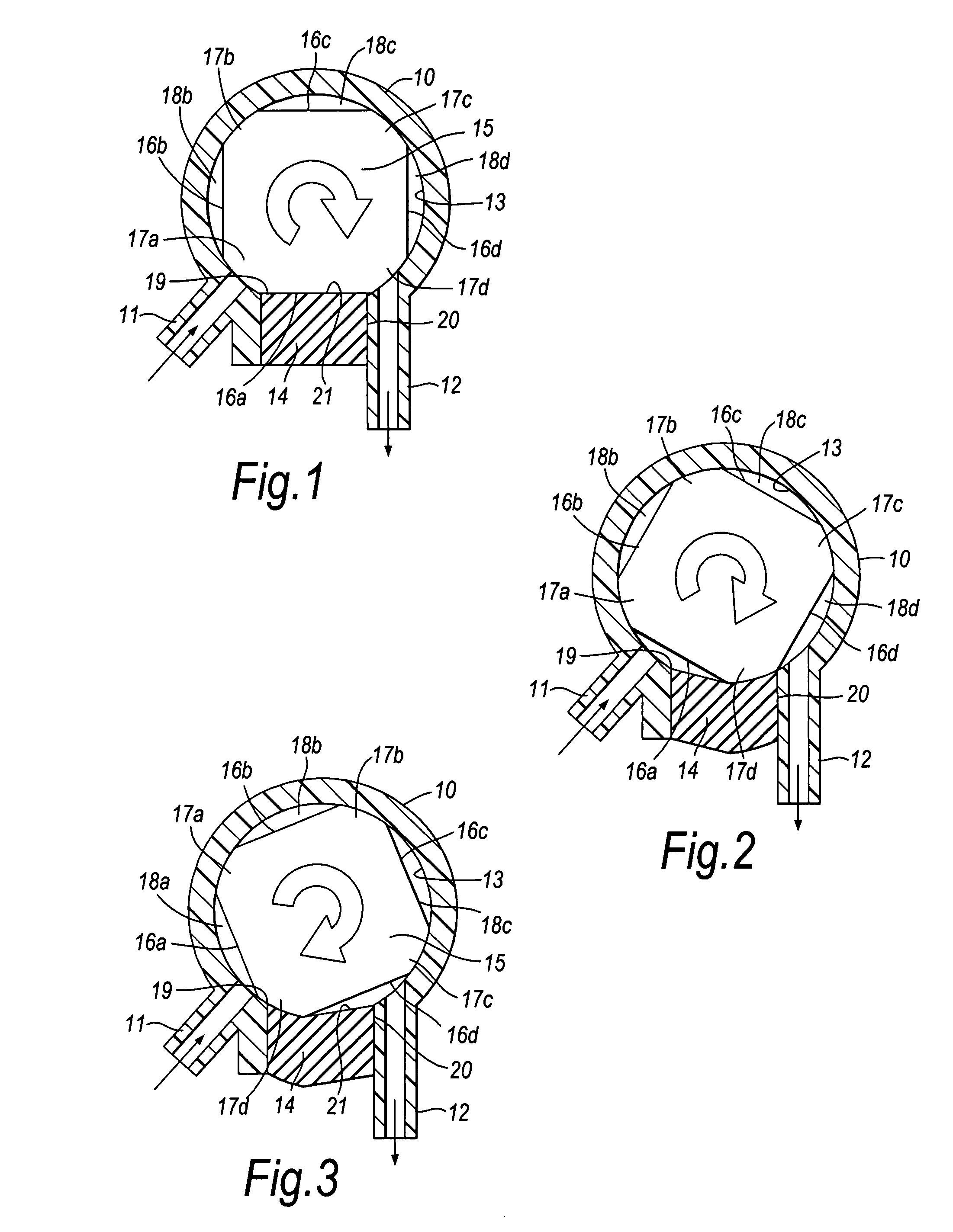

Fluid machine

InactiveUS20050214148A1Improve sealingSmall sizeCompressorEngine of arcuate-engagement typeEngineeringSliding contact

An outer end of a seal element for a fixed scroll is extended to a position close to an end of an inside spiral wall of the fixed scroll, and an outwardly extended portion is formed at an outer periphery of a disc-shaped base plate of a movable scroll, so that a bottom surface of the movable scroll is always kept in a sliding contact entirely with the seal element during the orbital movement of the movable scroll. A thickness of the outwardly extended portion formed at the outer periphery of the disc-shaped base plate is made smaller than that of the disc-shaped base plate, so that the weight of the fluid machine can be smaller.

Owner:NIPPON SOKEN +1

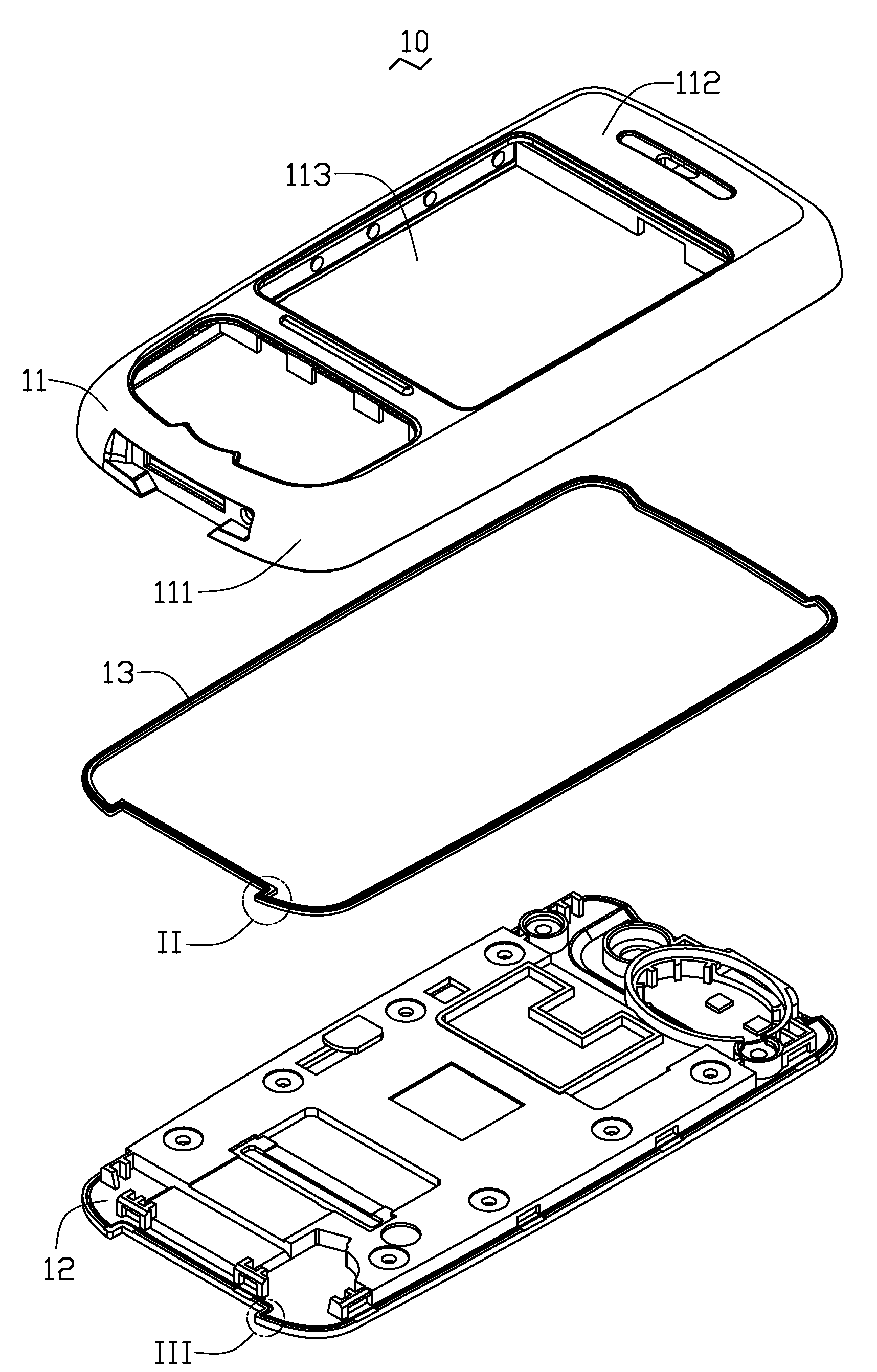

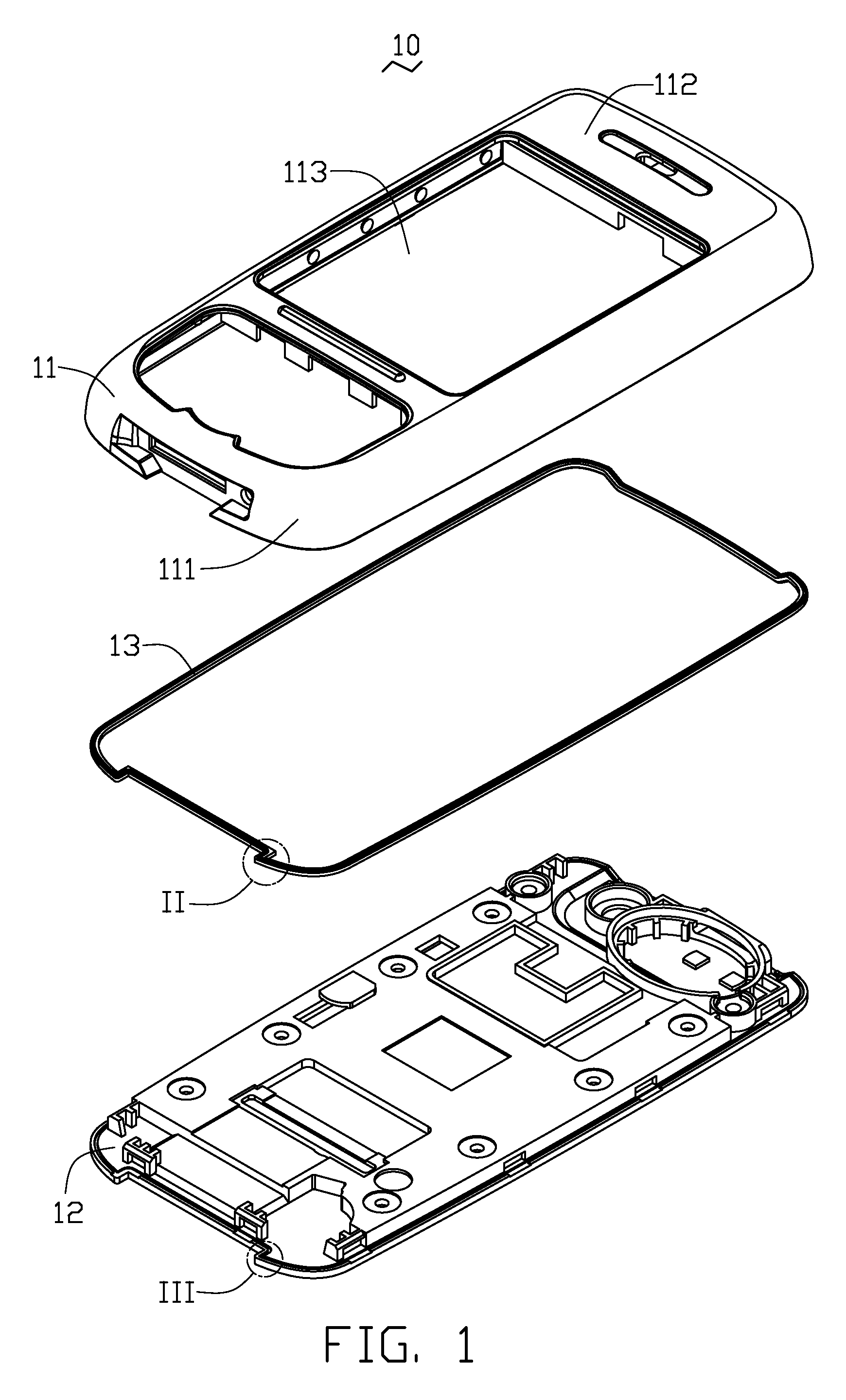

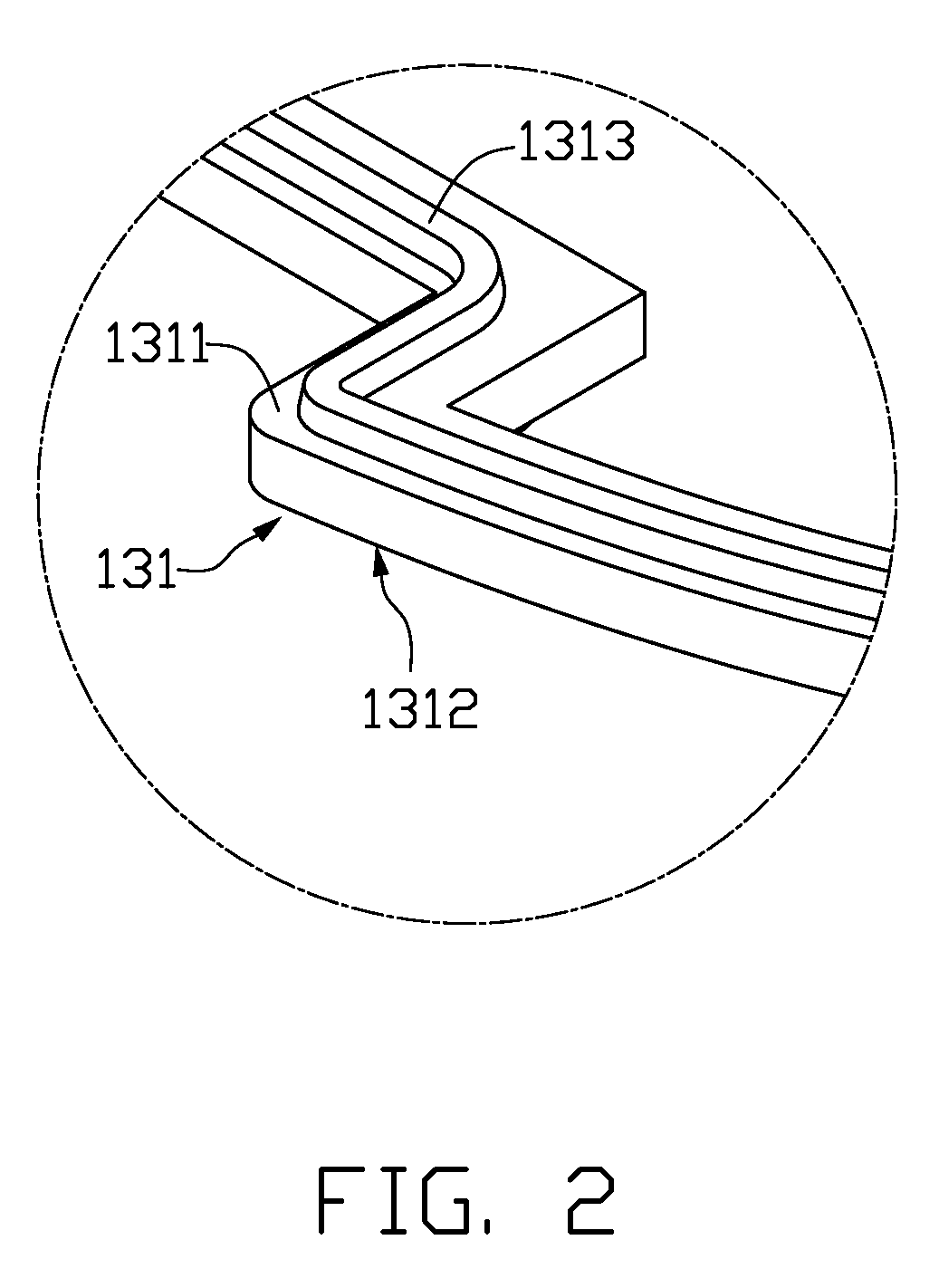

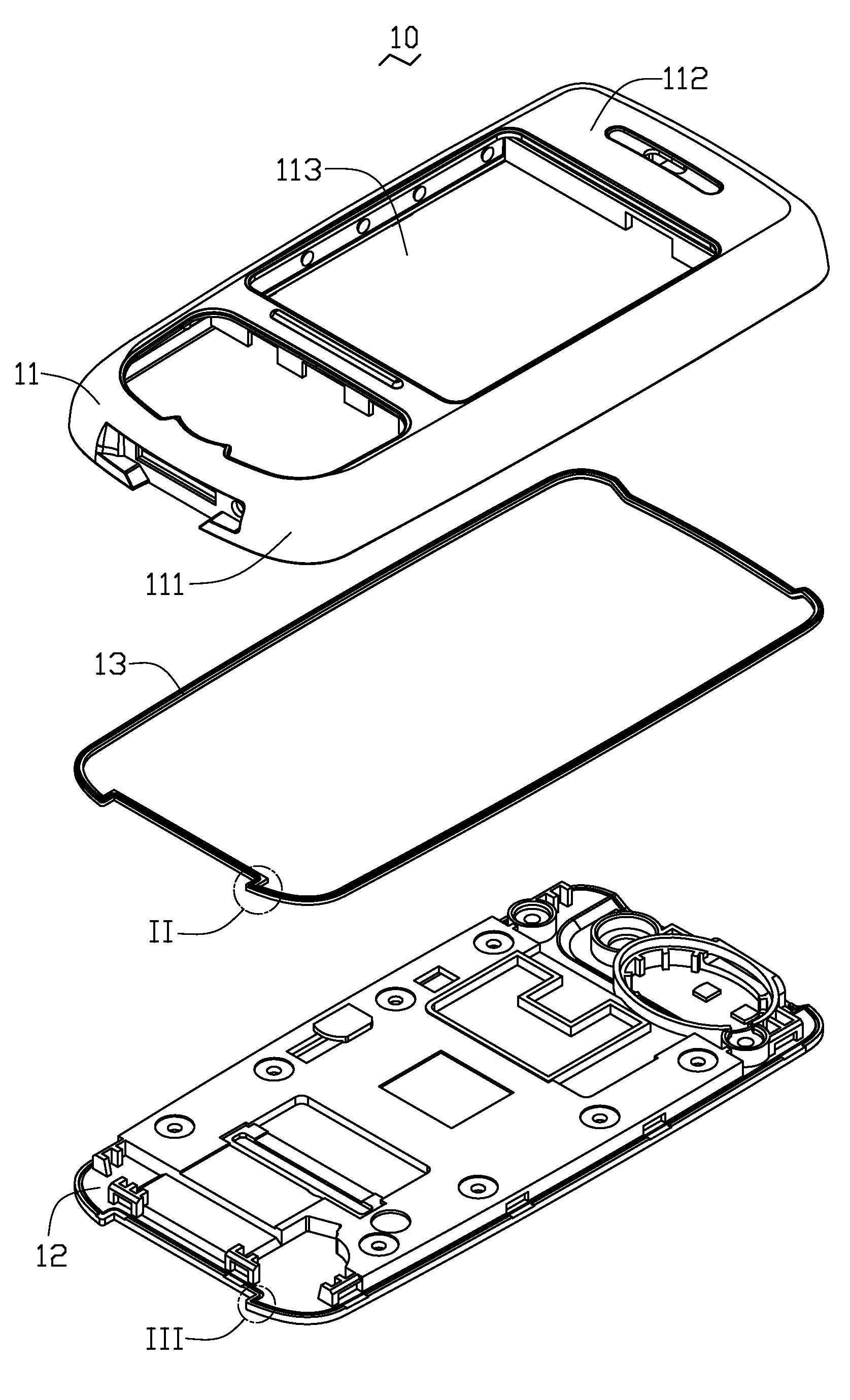

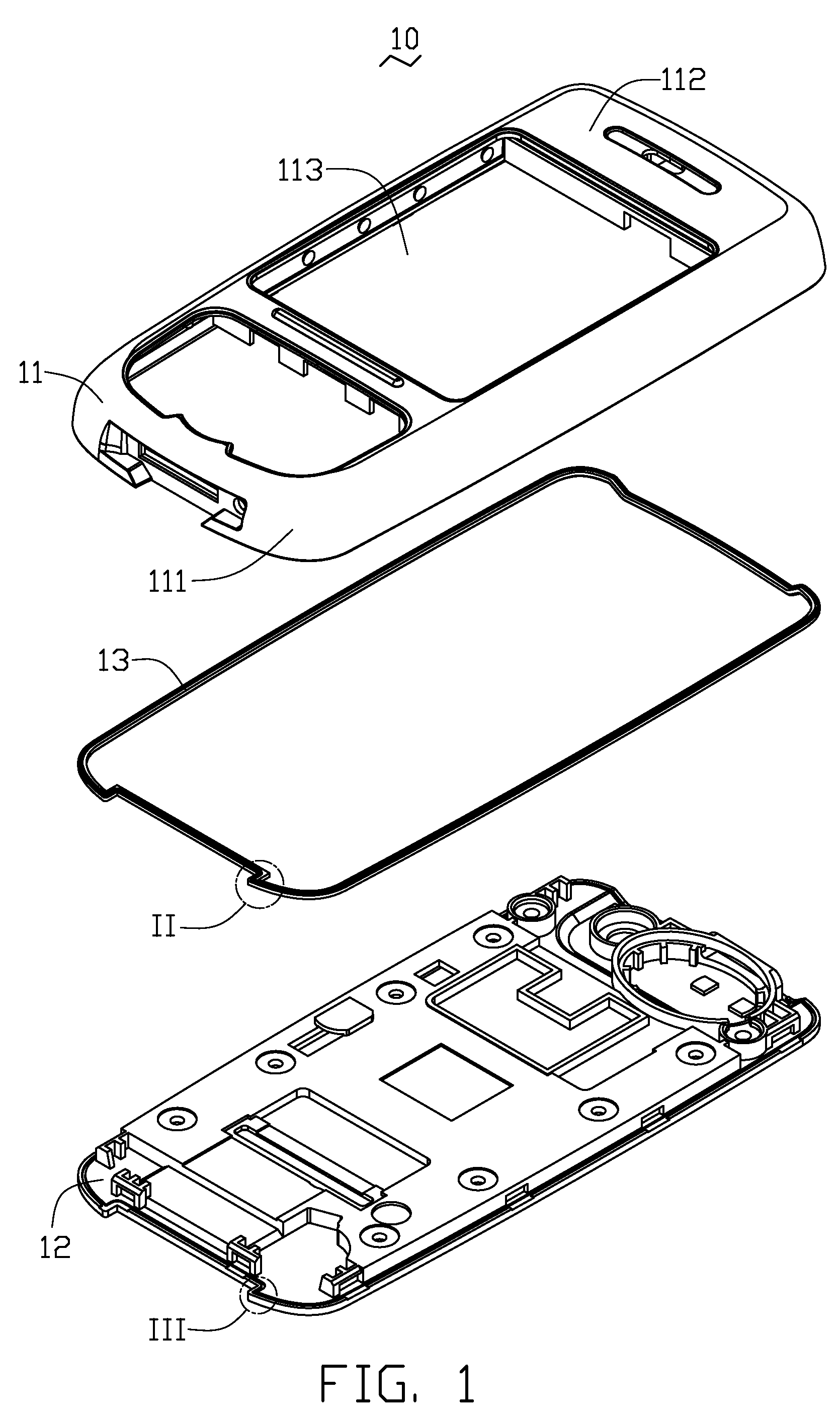

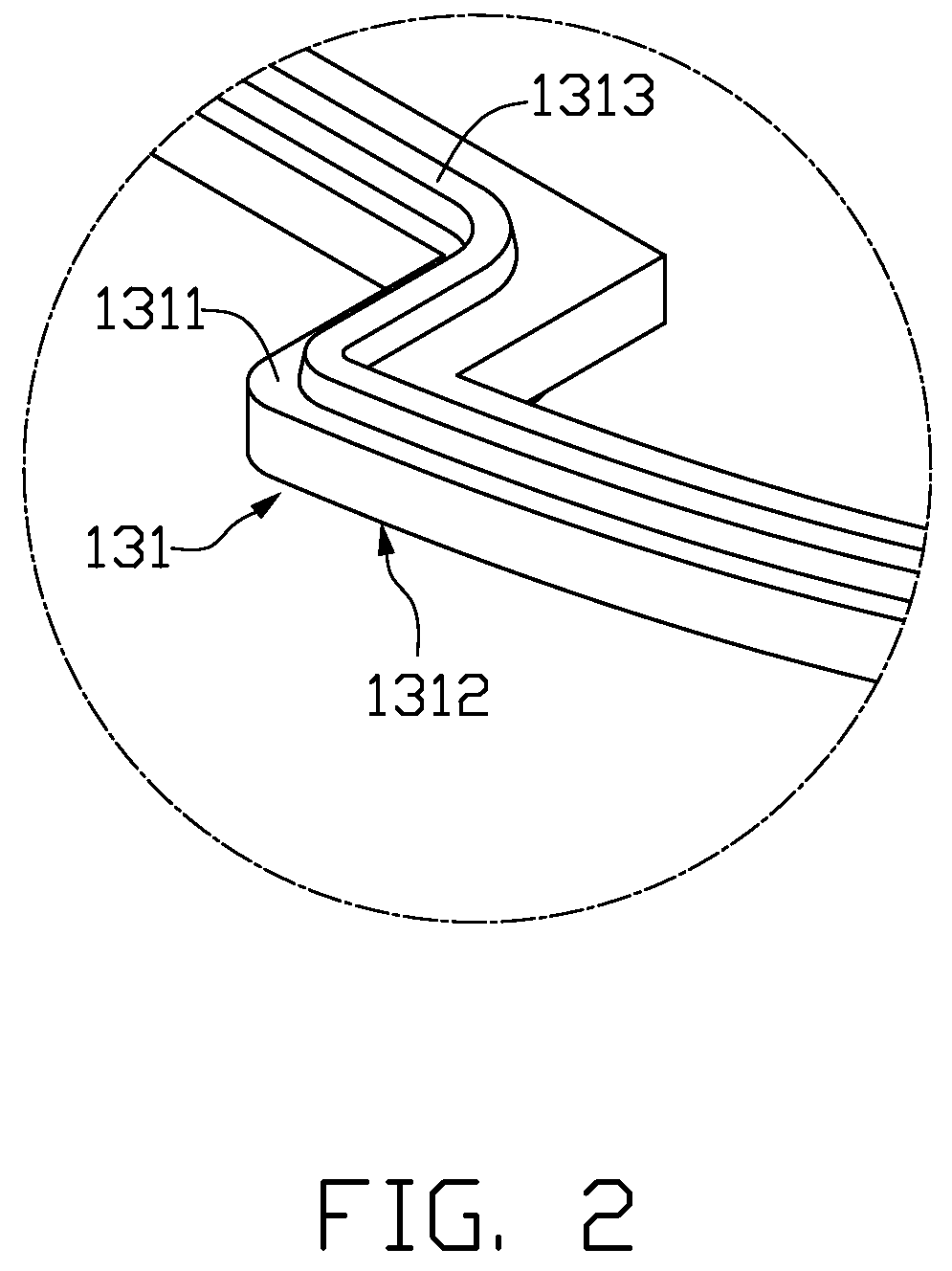

Housing of portable electronic devices

ActiveUS20090215412A1Interconnection arrangementsSealing arrangements for enginesMechanical engineering

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

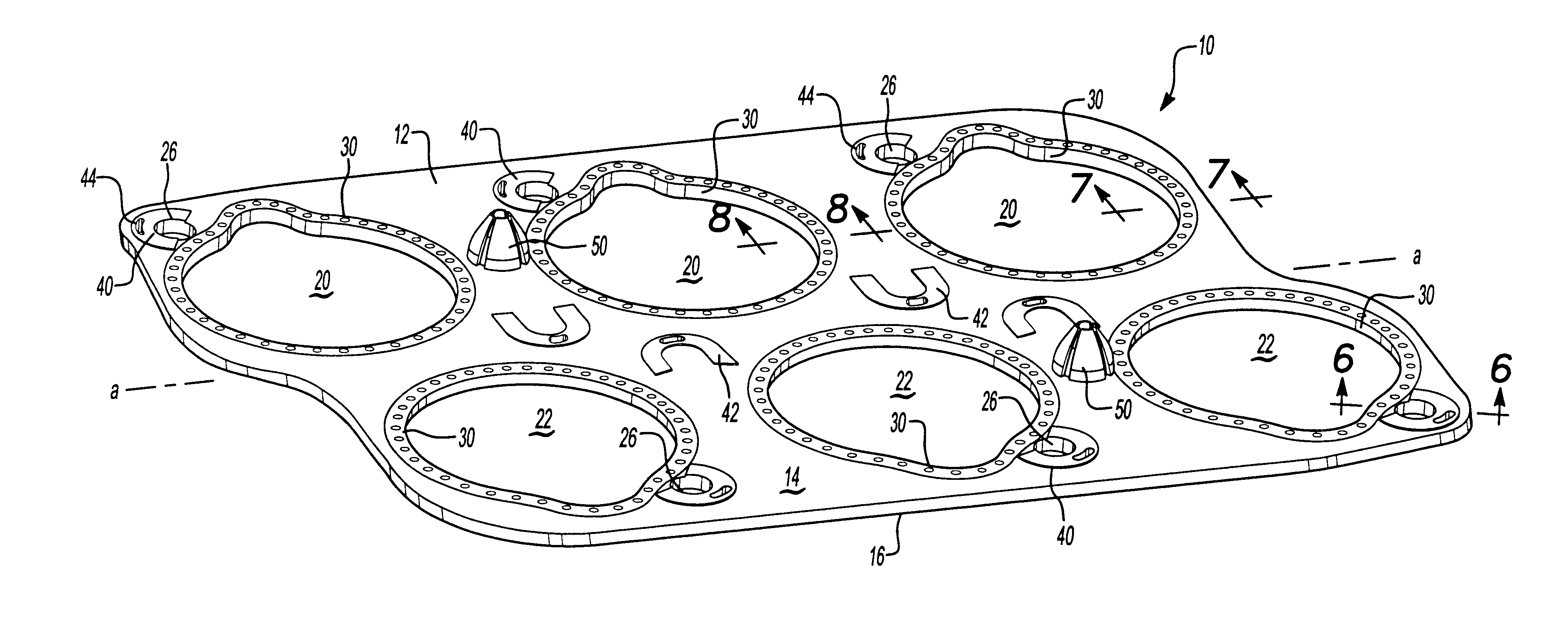

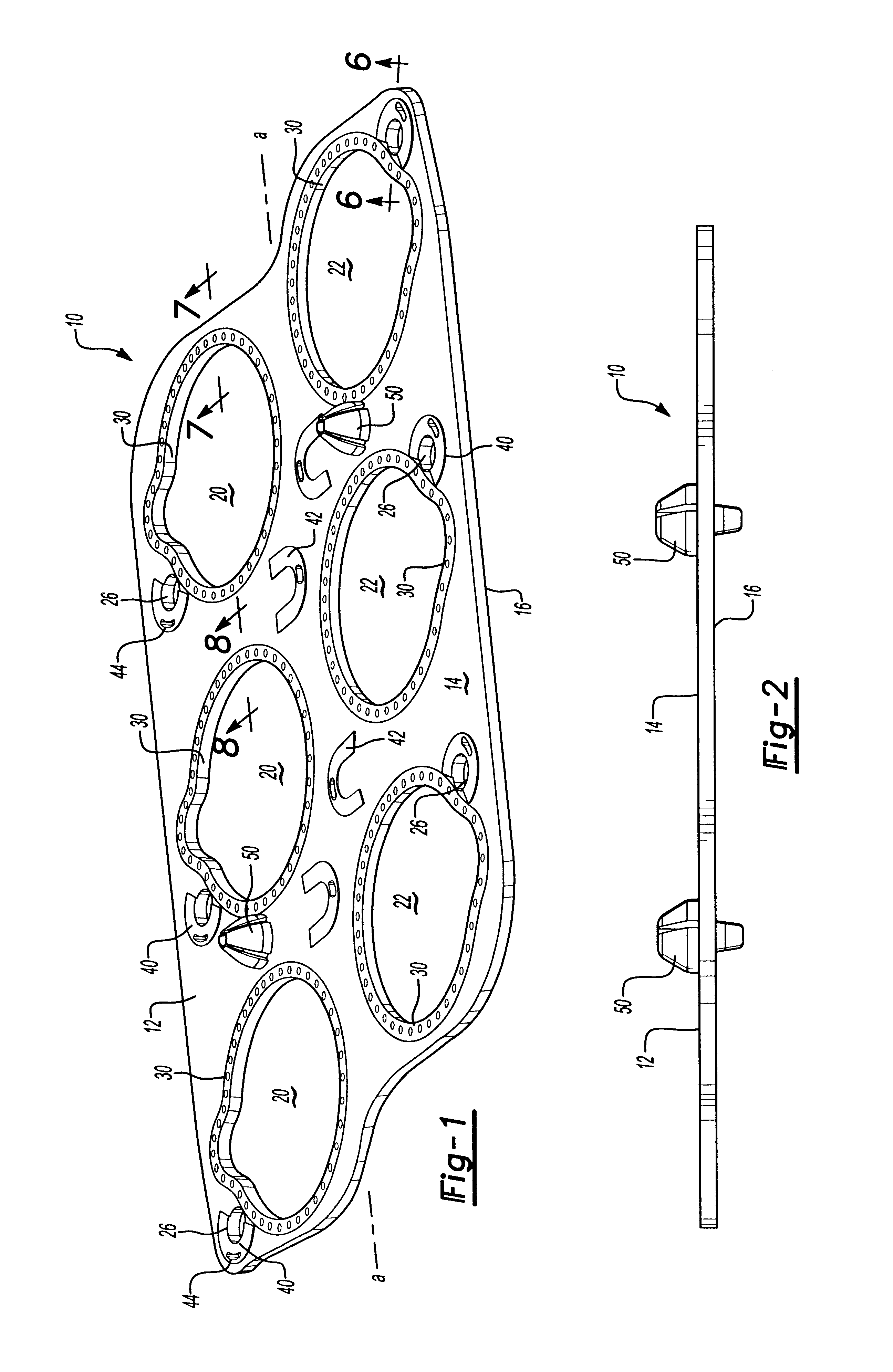

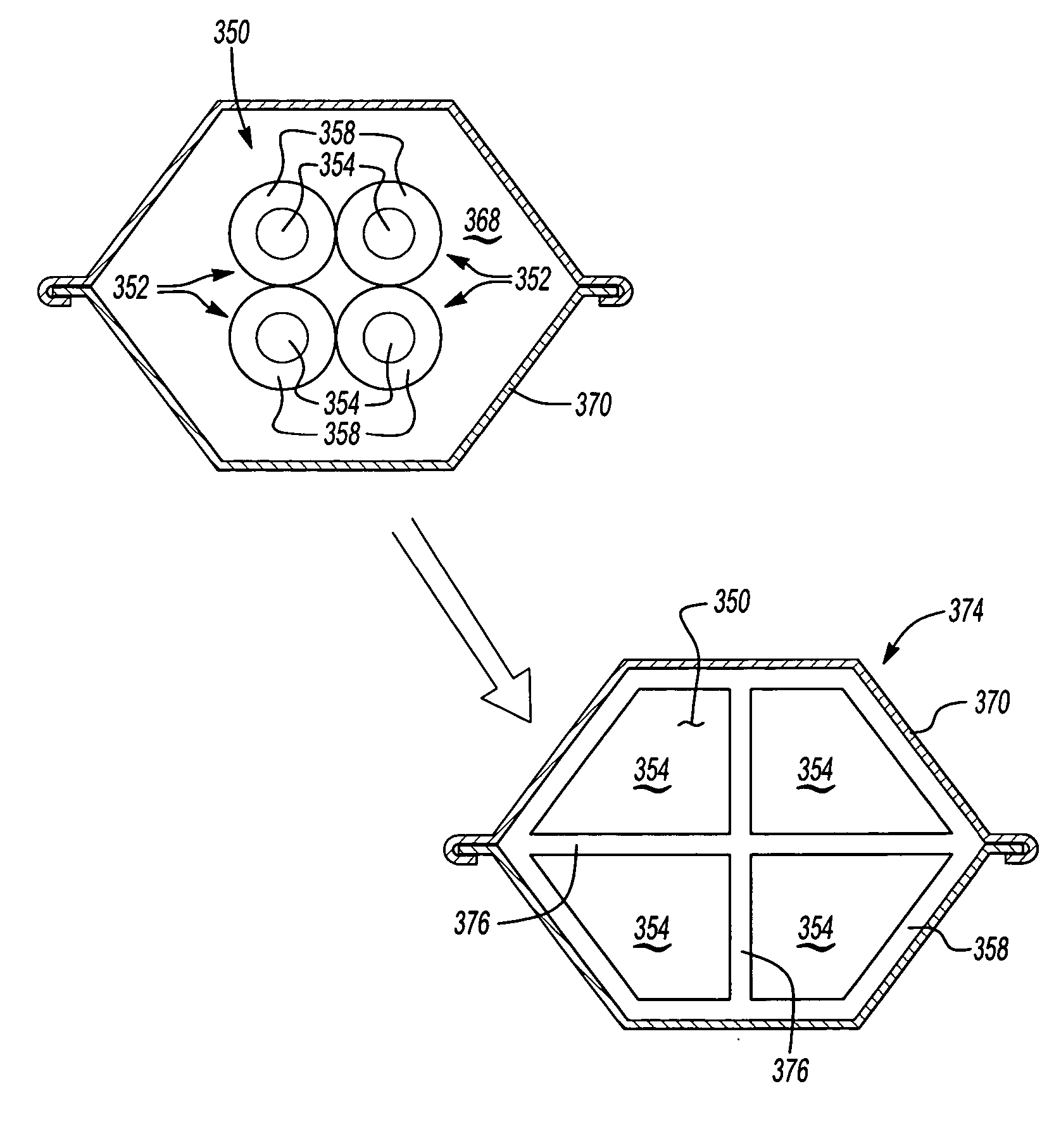

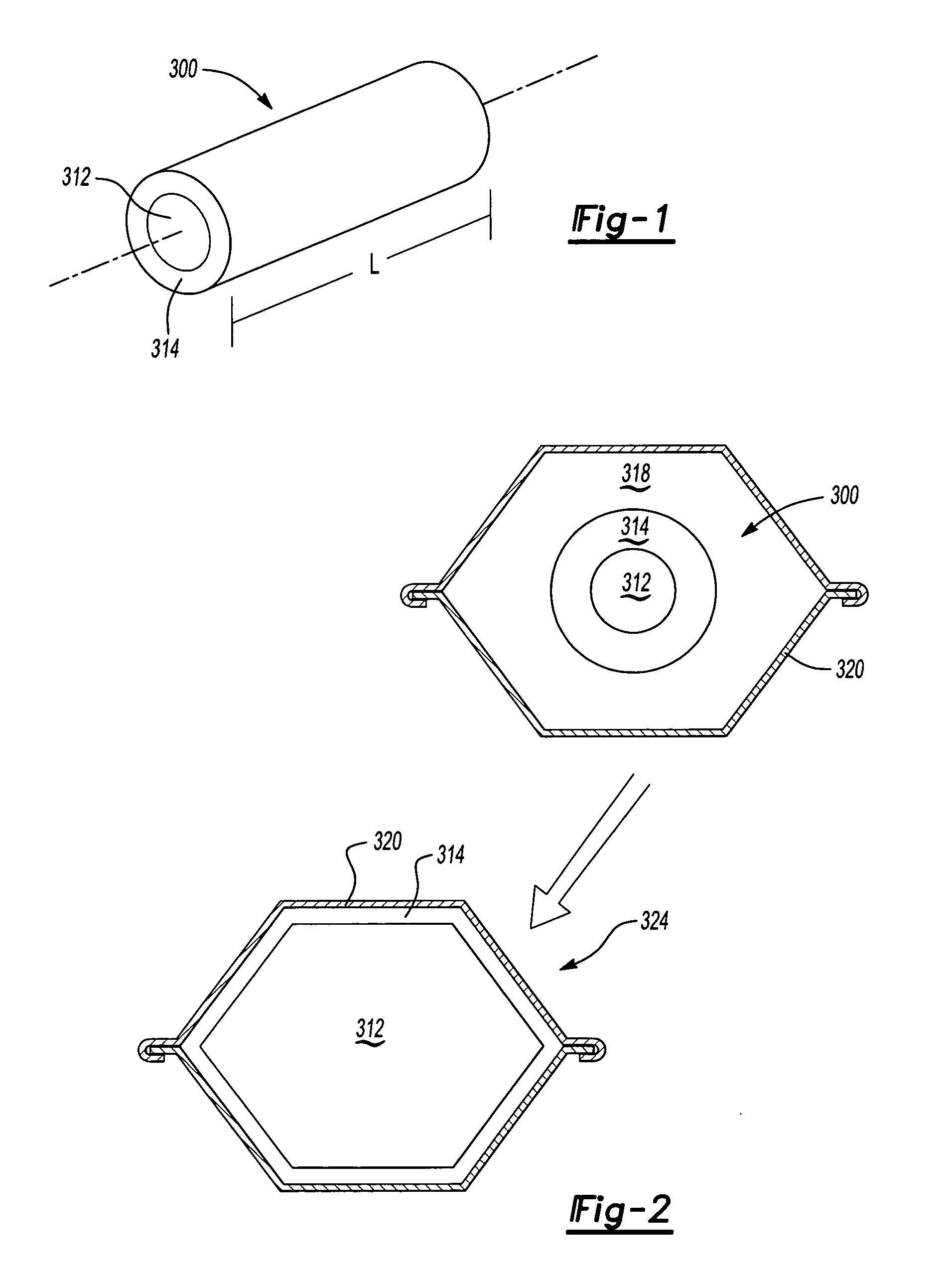

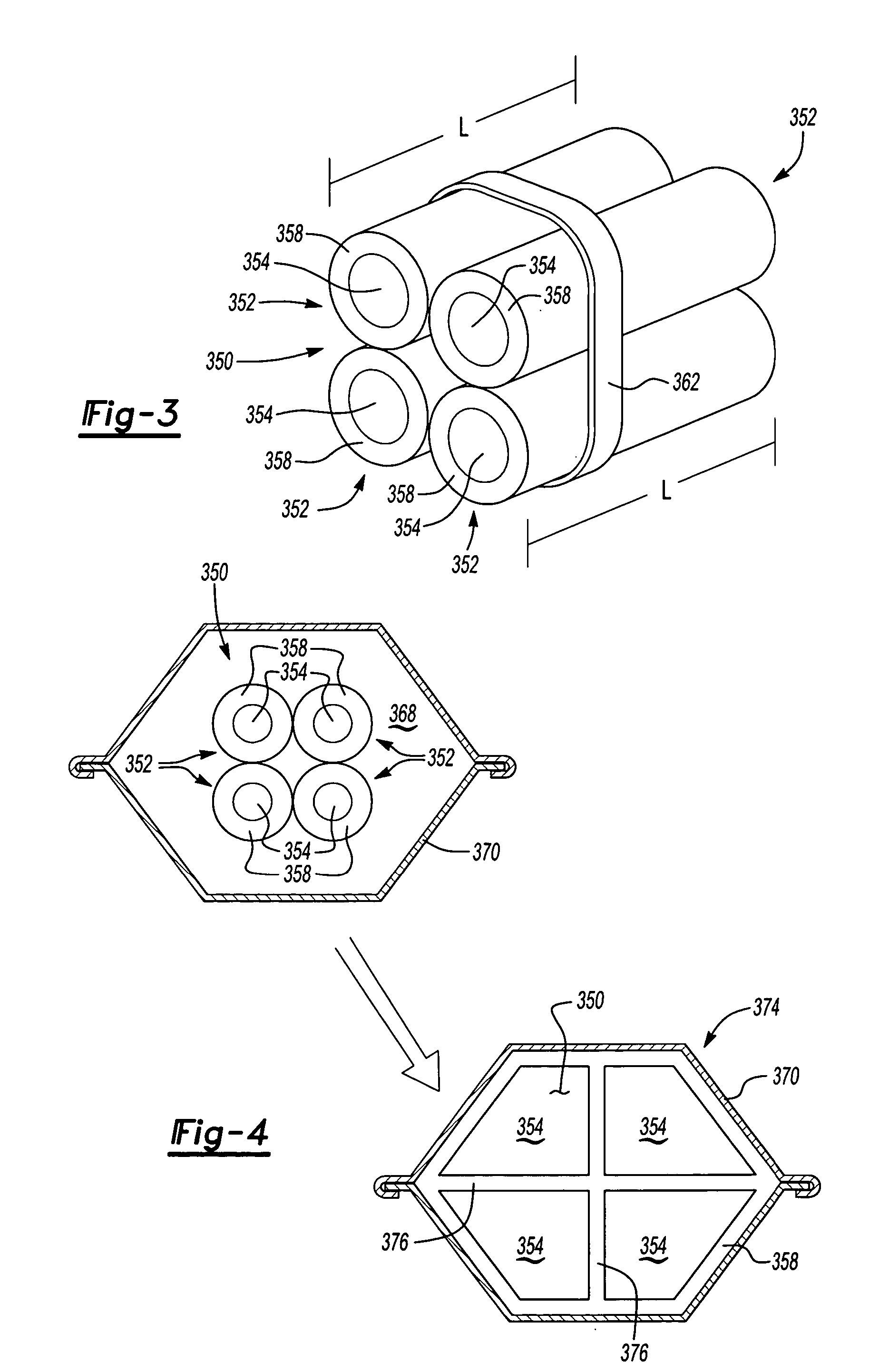

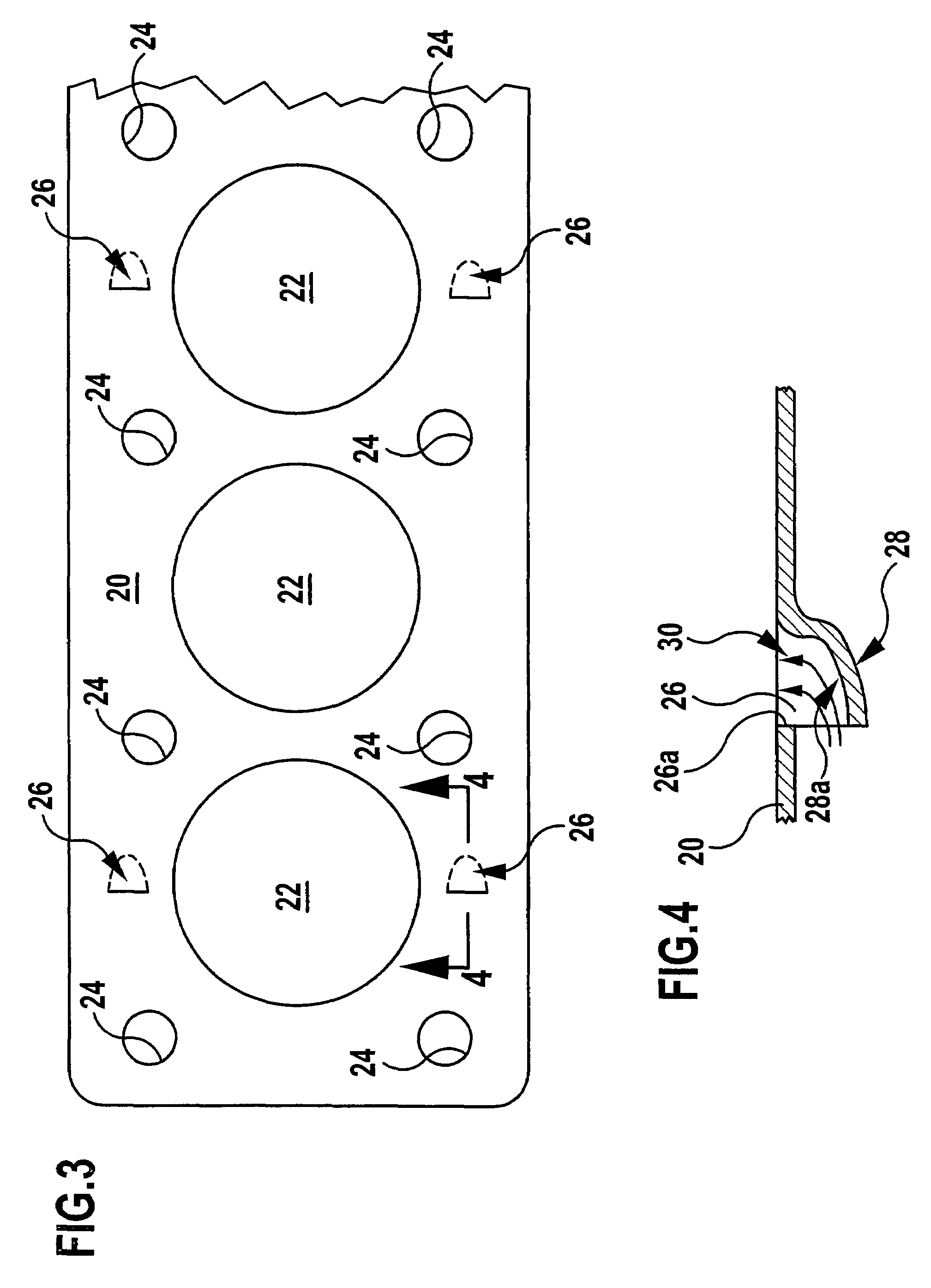

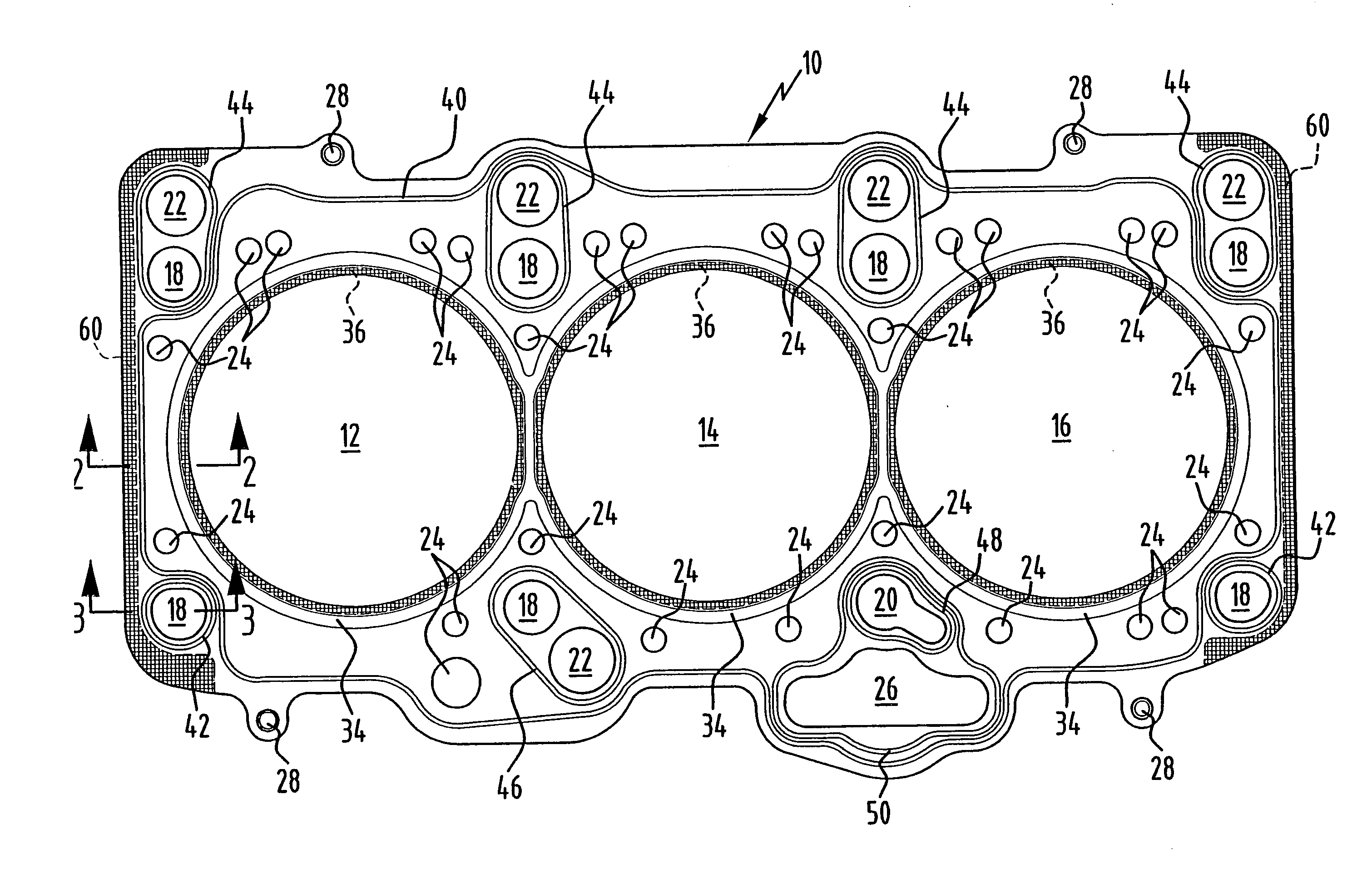

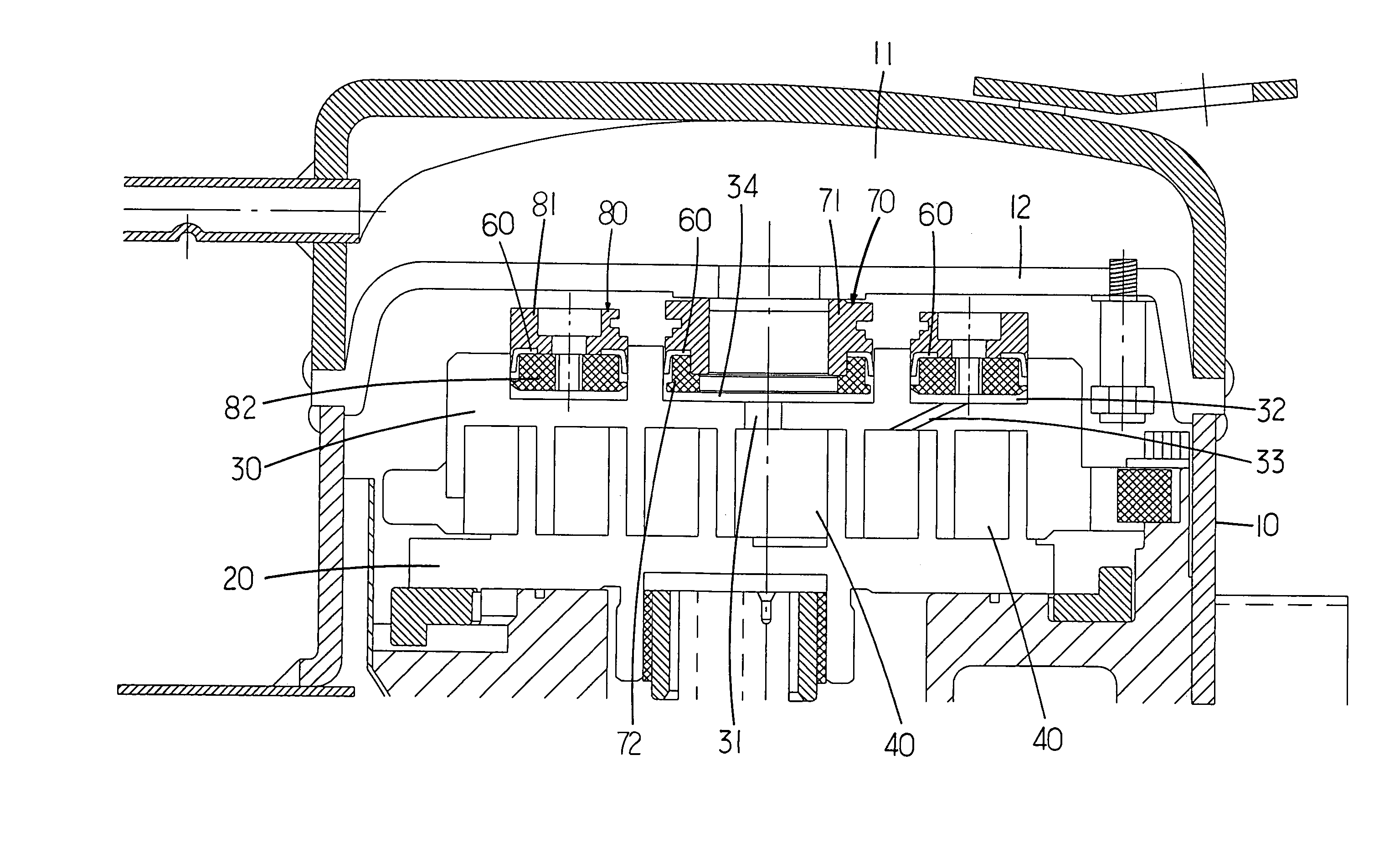

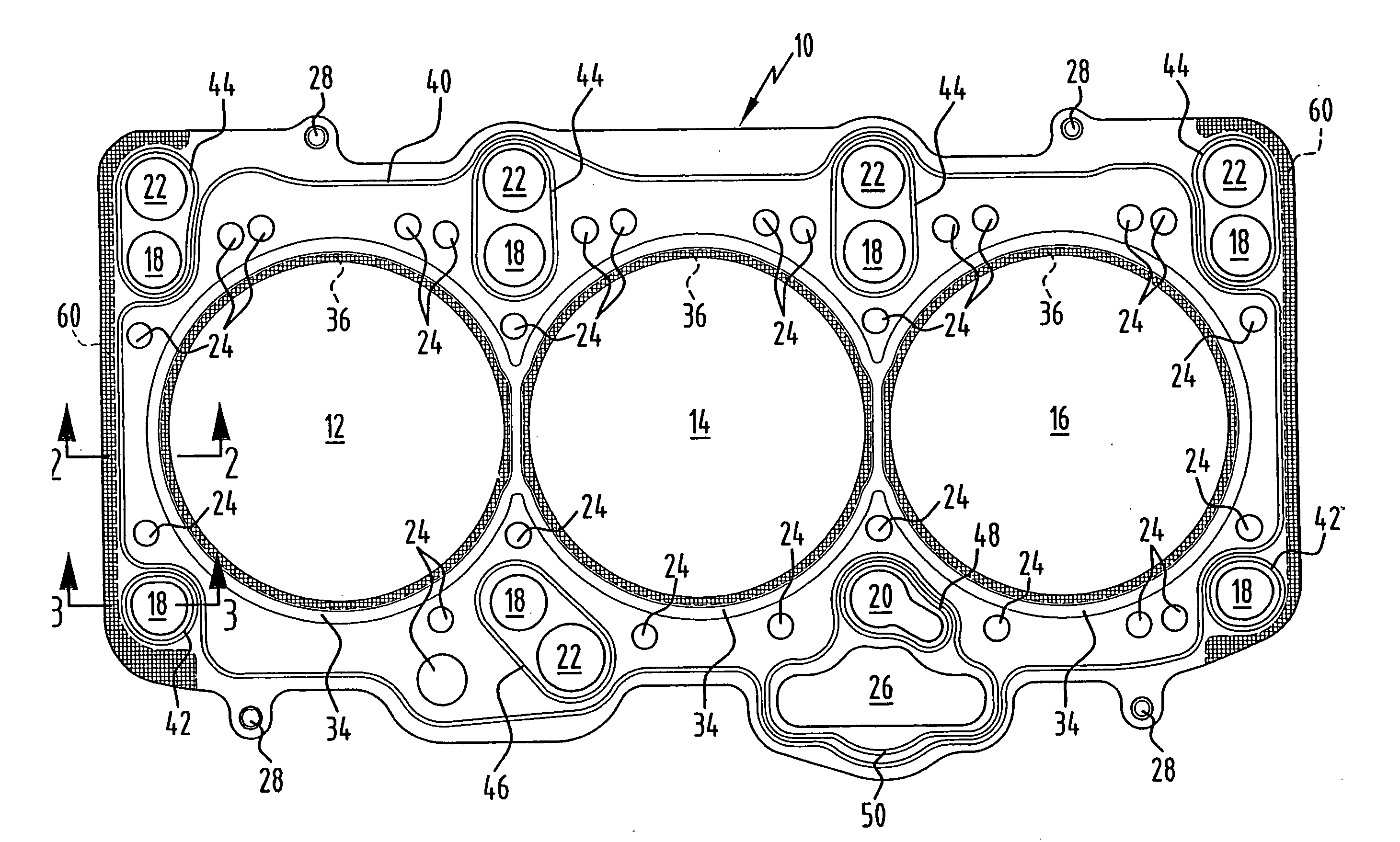

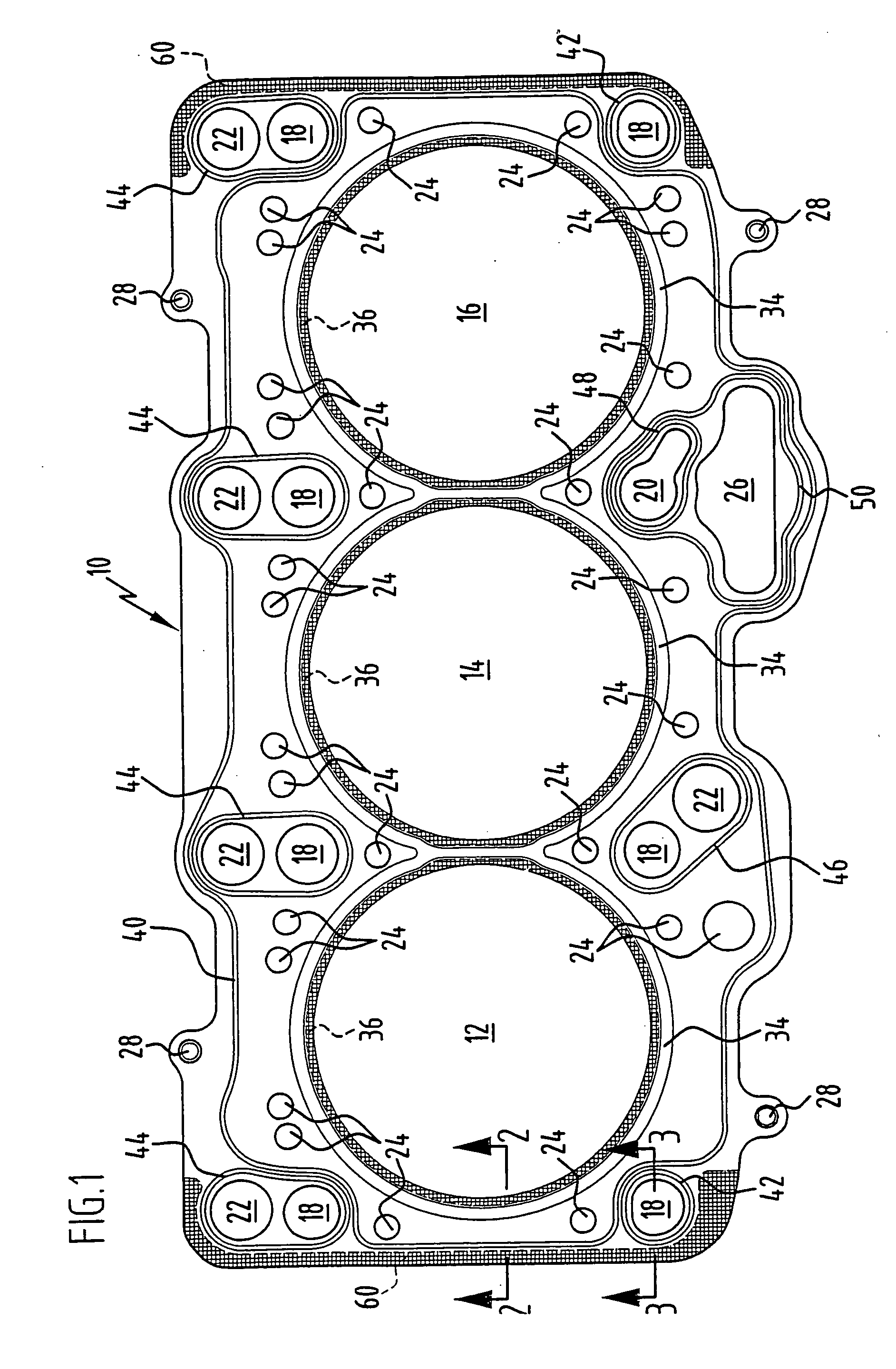

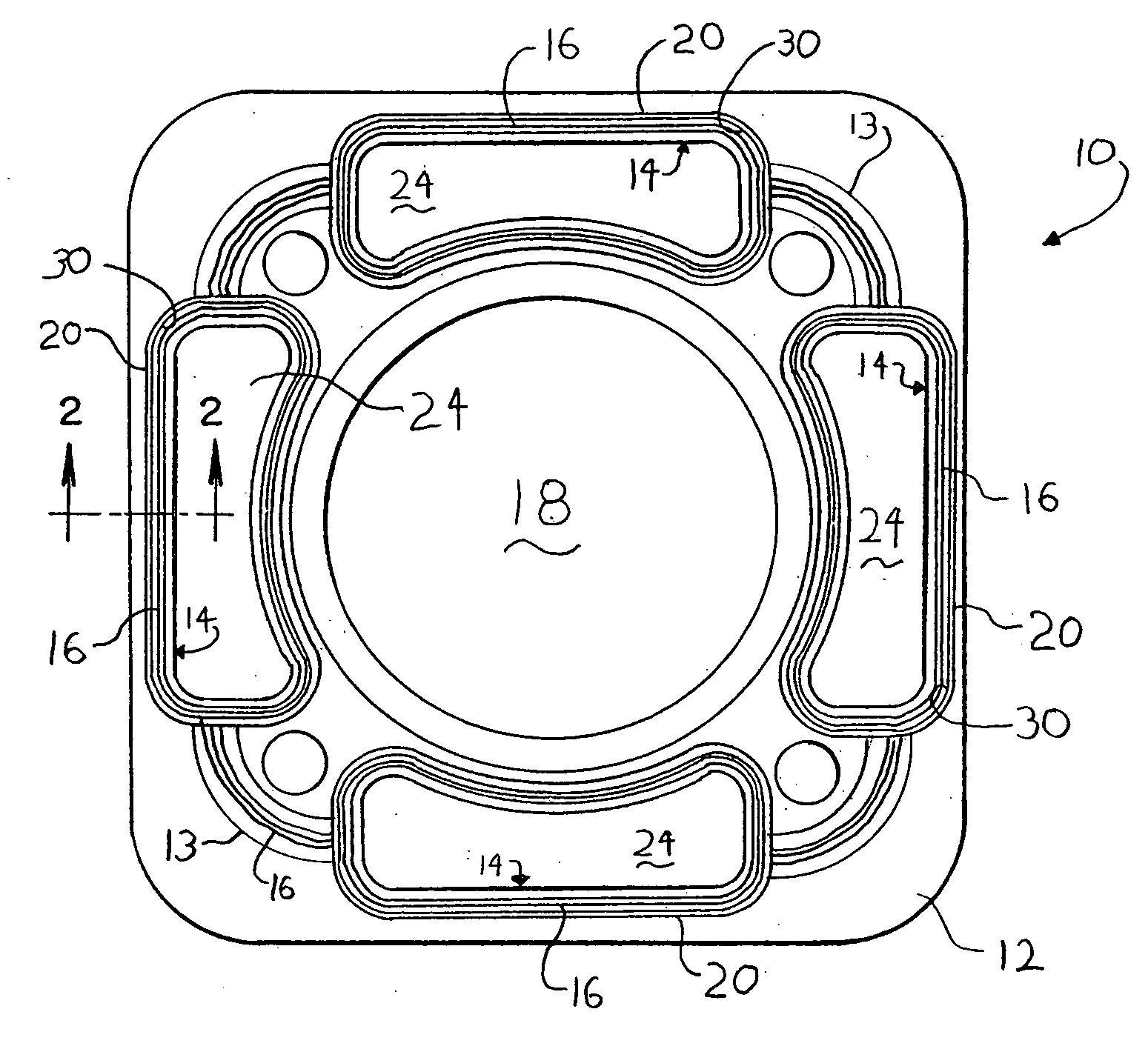

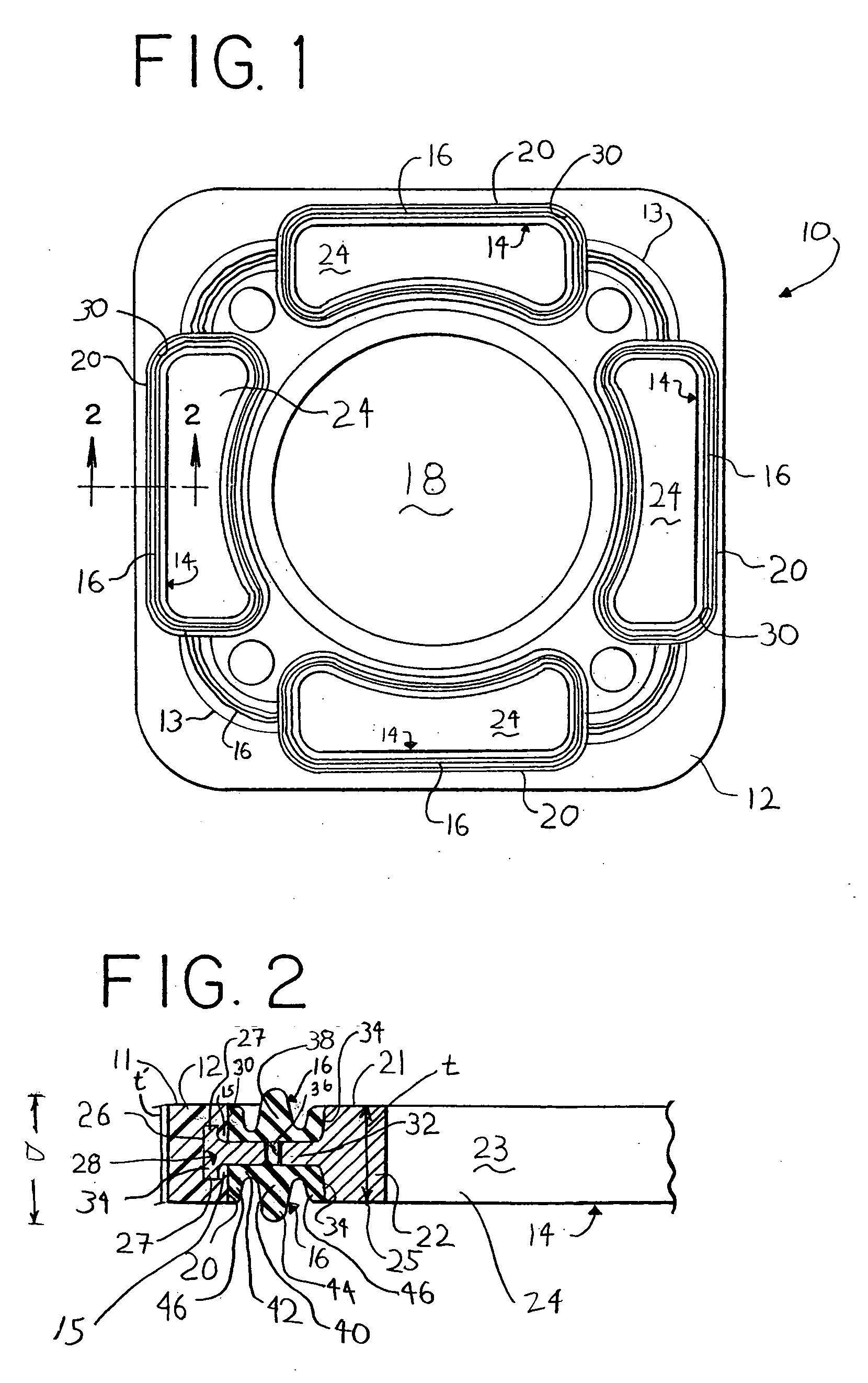

Thermoplastic gasket with edge bonded rubber apertures and integral alignment grommets

A gasket for sealing an intake manifold of an internal combustion engine, includes a plastic body defining substantially co-planar surfaces that define top and bottom surfaces of the gasket. Each of a plurality of air intake apertures includes an interiorly molded circumferential elastomeric edge bead. Each aperture edge includes a circumferential array of small openings for mechanical securement of the elastomeric bead to the plastic carrier, and each opening fills with elastomer upon the overmolding of the bead to the edge during manufacture. The gasket also includes primary and secondary compression limiters, formed of powdered metal in described embodiment, located immediately adjacent bolt holes and symmetrically between air intake apertures, respectively. Finally, the gasket includes flexible locator grommets for assuring positive alignment between the cylinder head and intake manifold. Each locator includes a frustum-like body and a cylindrical post extending oppositely outwardly of top and the bottom of the gasket, respectively.

Owner:DANA AUTOMOTIVE SYST GRP LLC

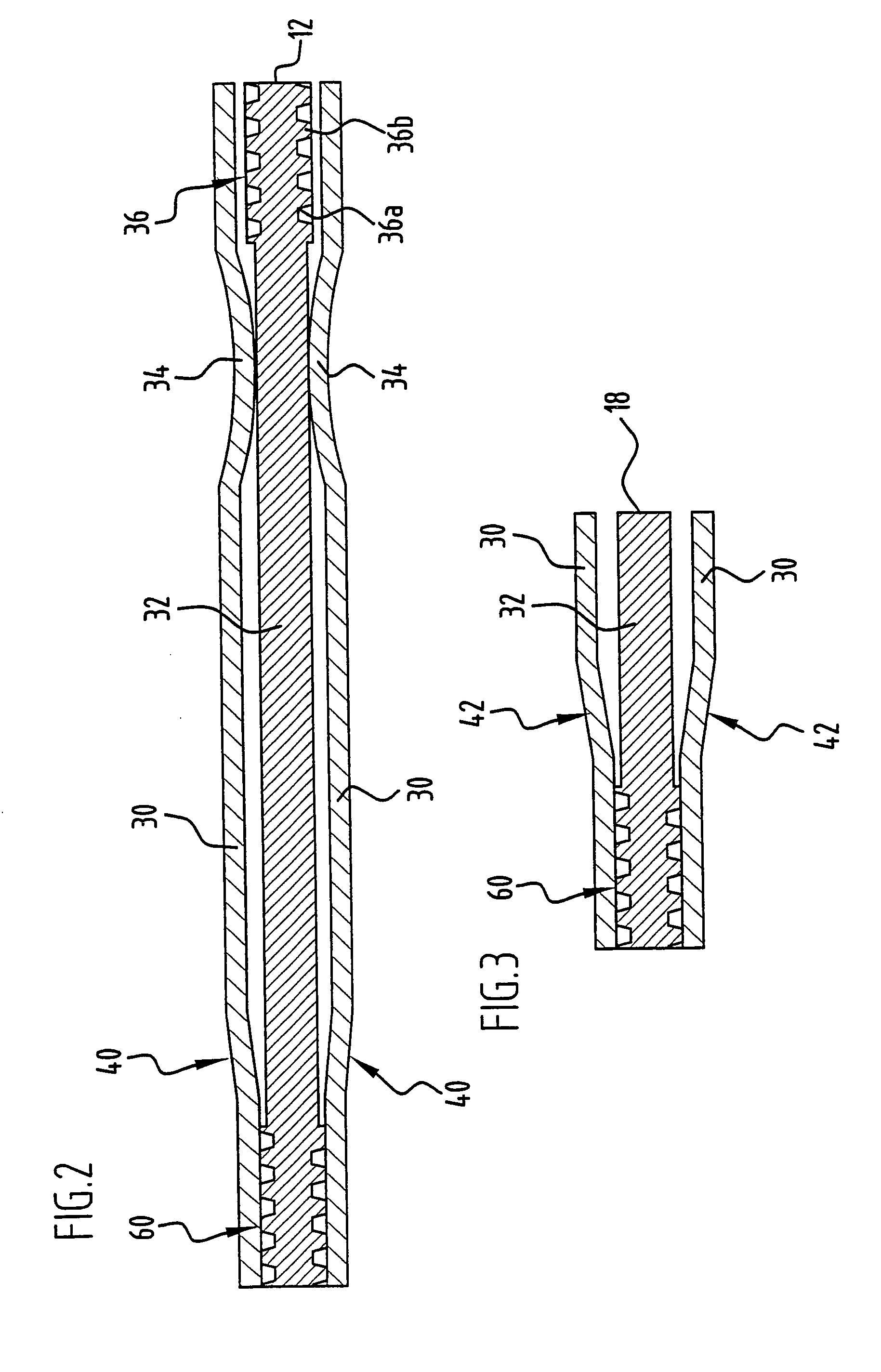

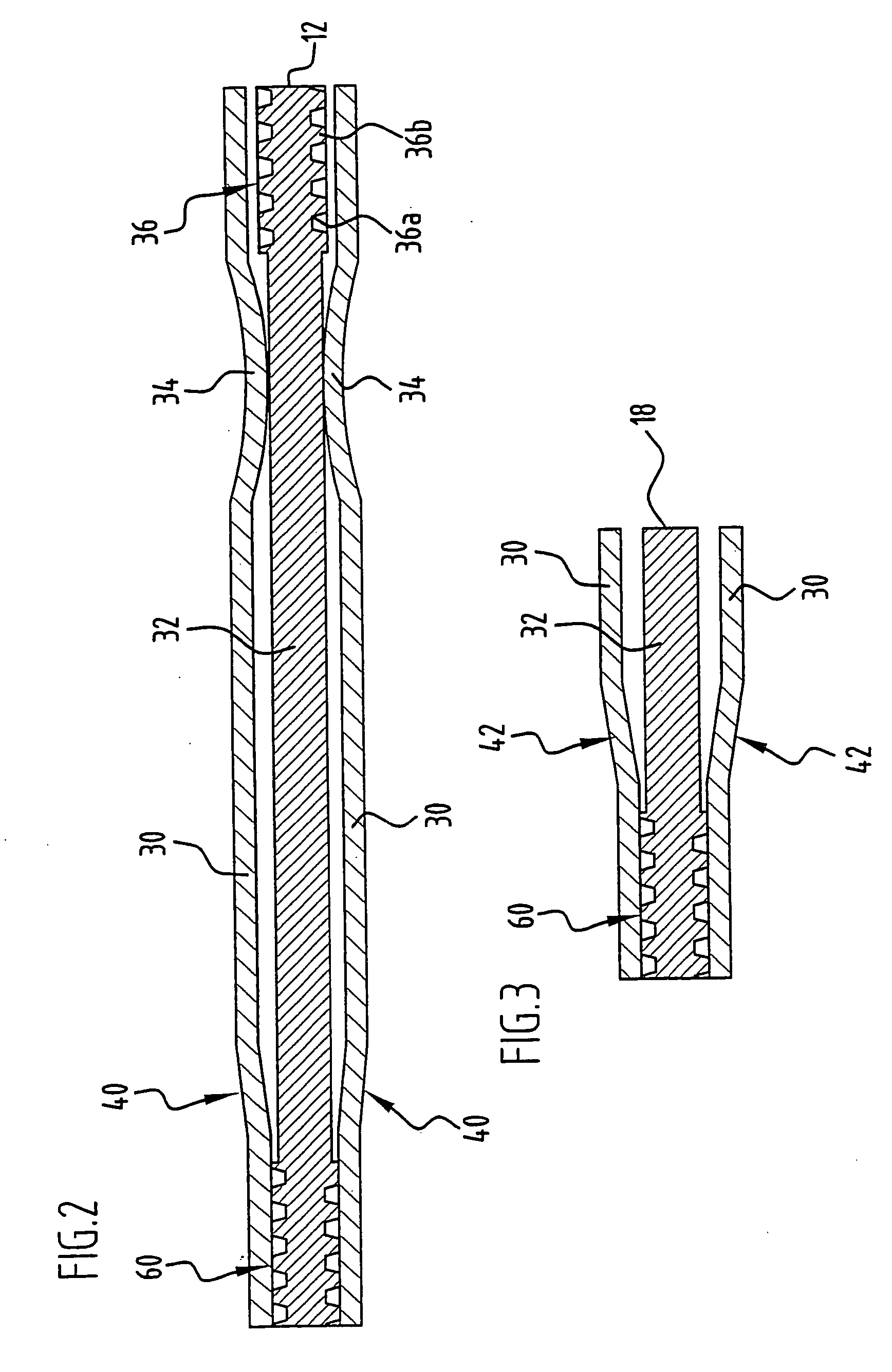

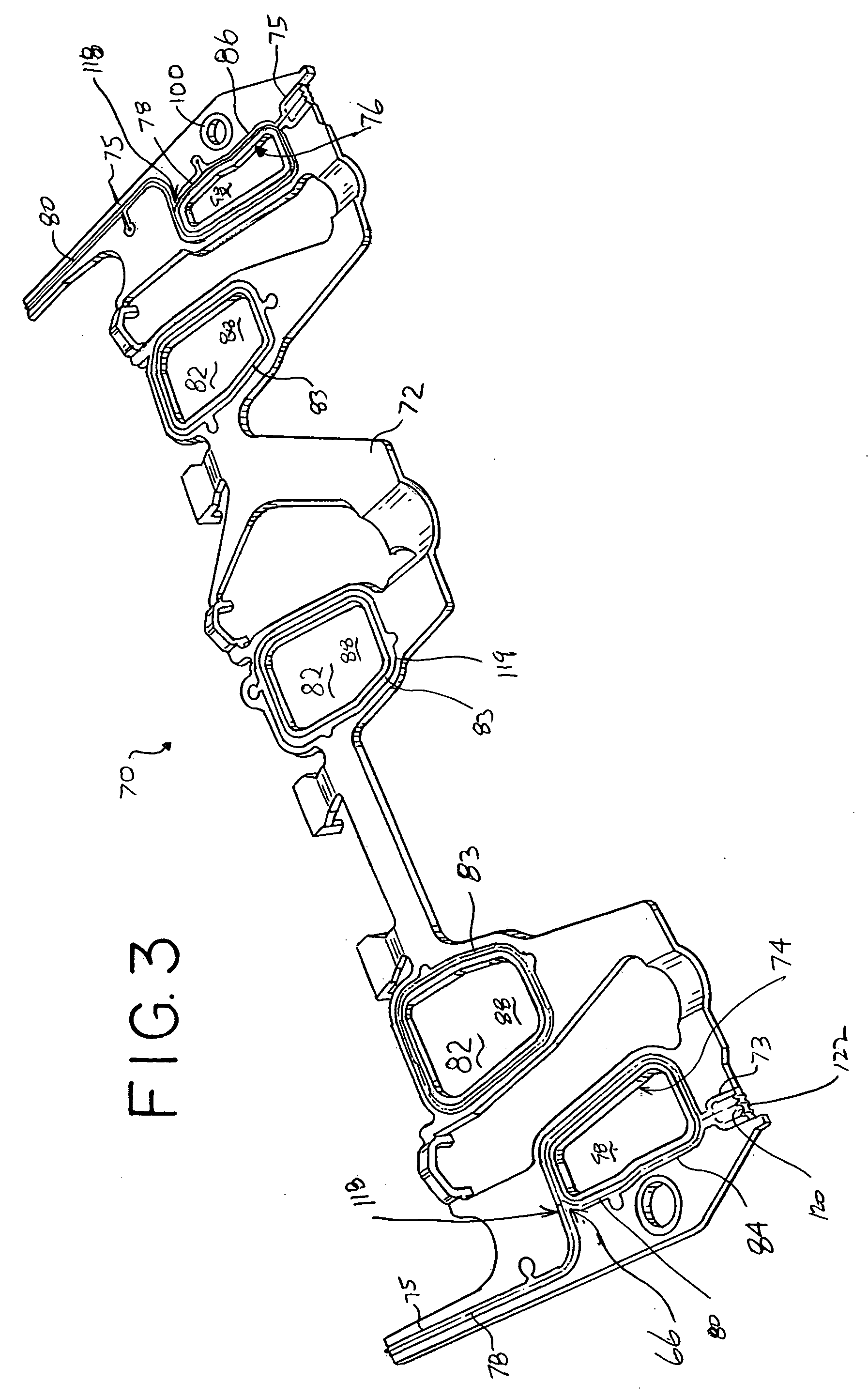

Member for sealing, baffling or reinforcing and method of forming same

InactiveUS20050172486A1Metal-working apparatusSealing arrangements for enginesEngineeringMechanical engineering

There is disclosed a member for sealing, baffling and / or reinforcing components of an automotive vehicle. The assembly generally includes a carrier and an expandable material.

Owner:ZEPHYROS INC

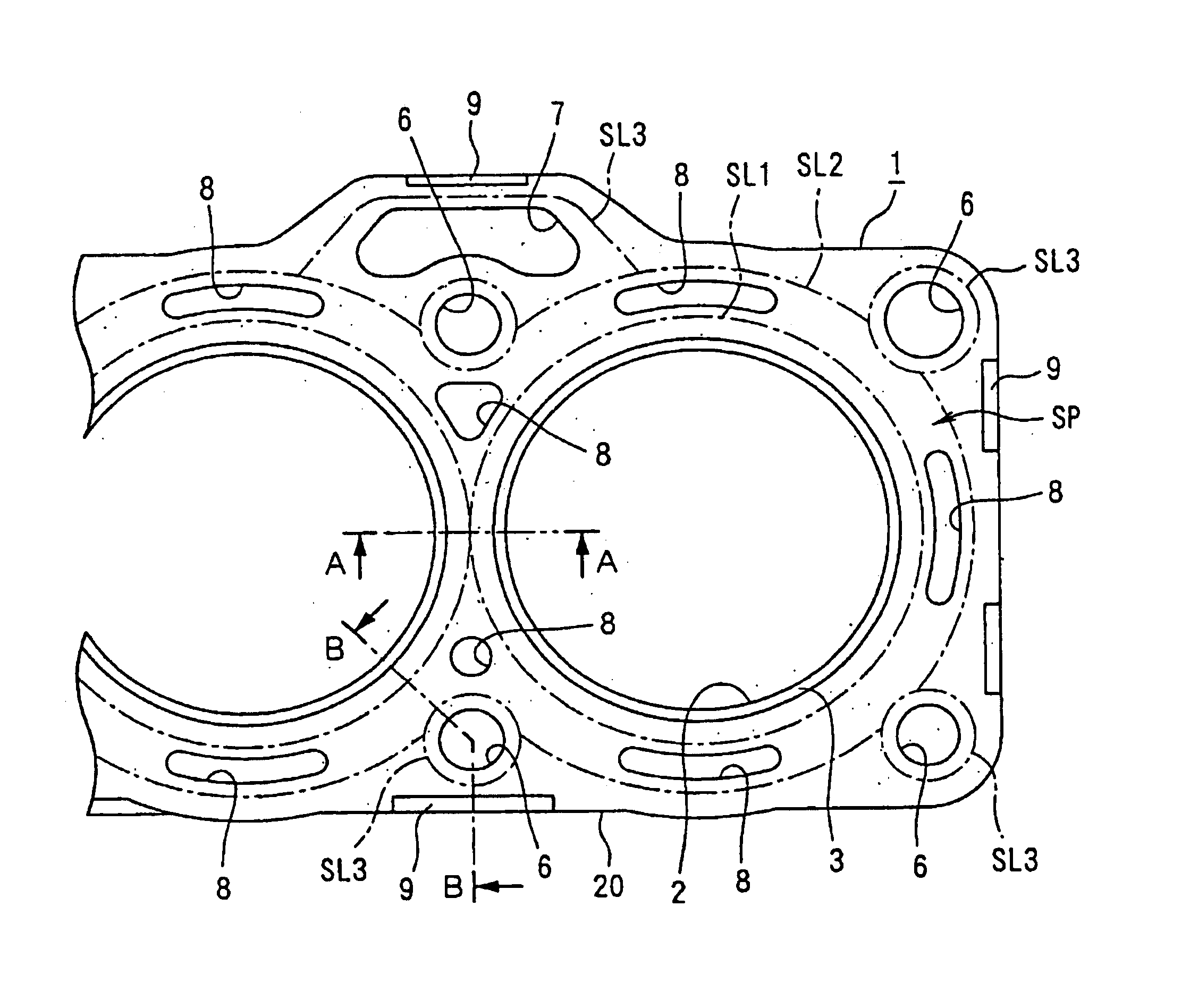

Pump with conveying chamber formed in outer rotor surface

ActiveUS7674100B2Avoid flowEngine of arcuate-engagement typeRotary piston pumpsMechanical engineeringMedical treatment

Owner:QUANTEX ARC LTD

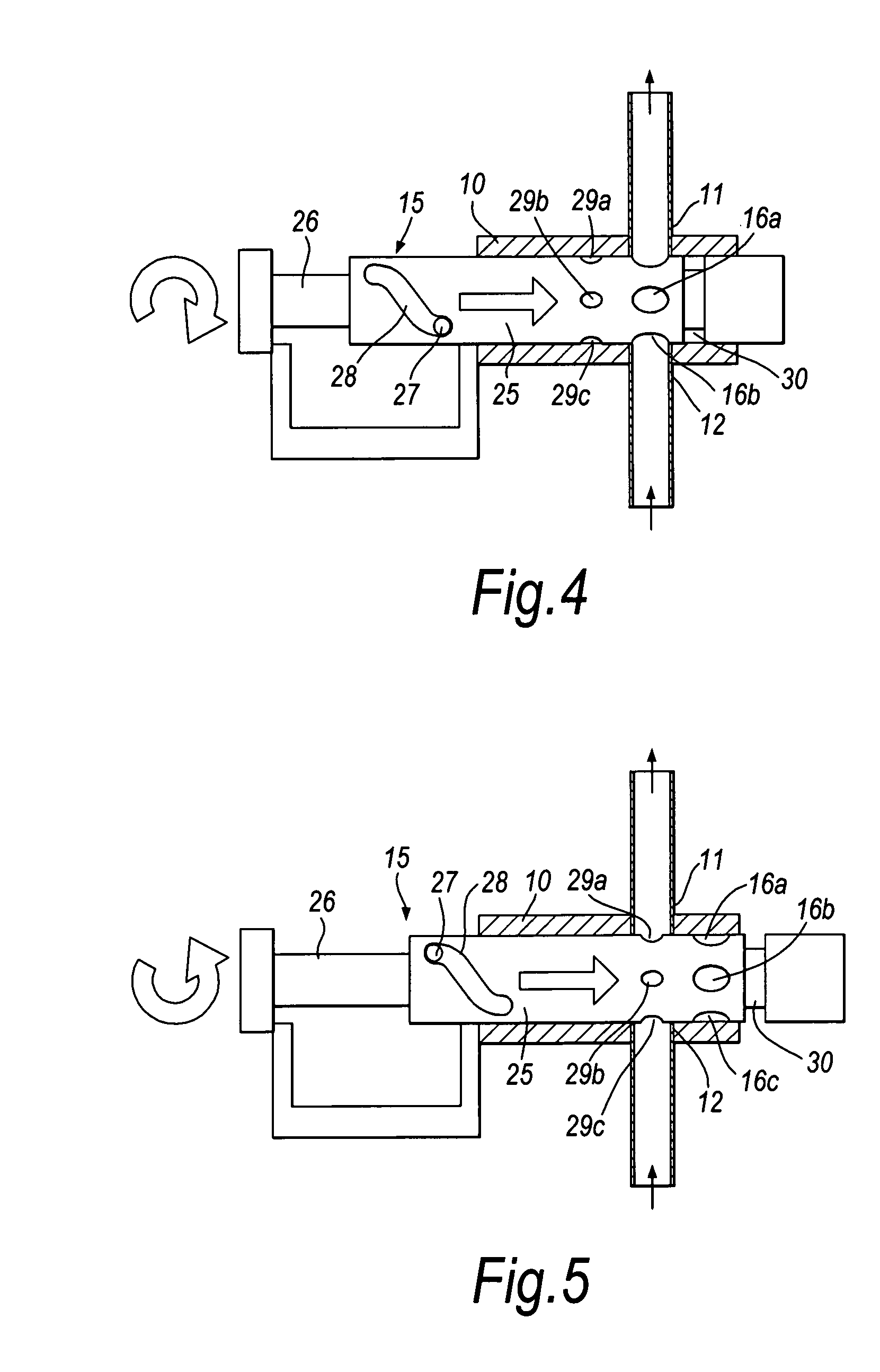

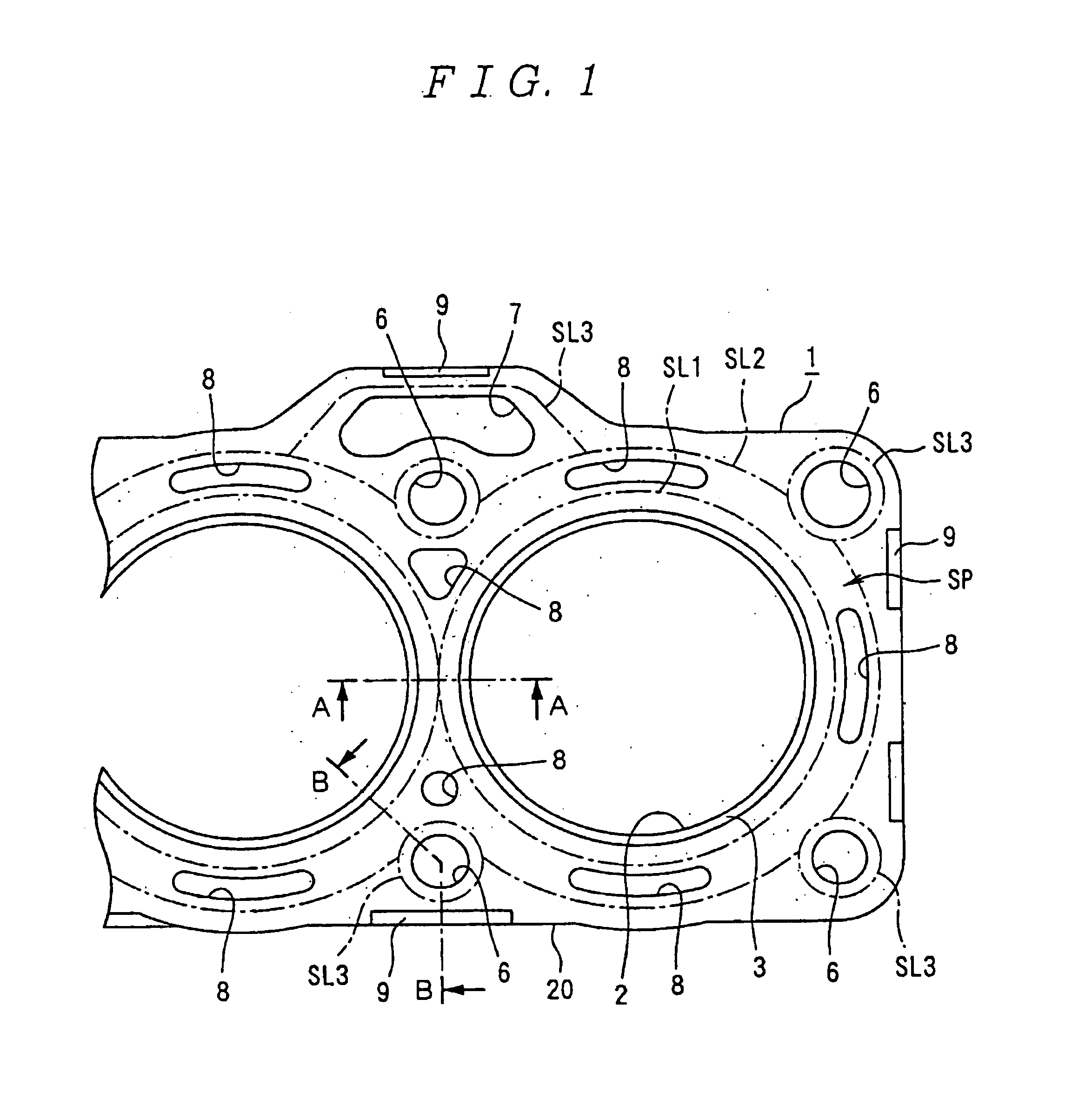

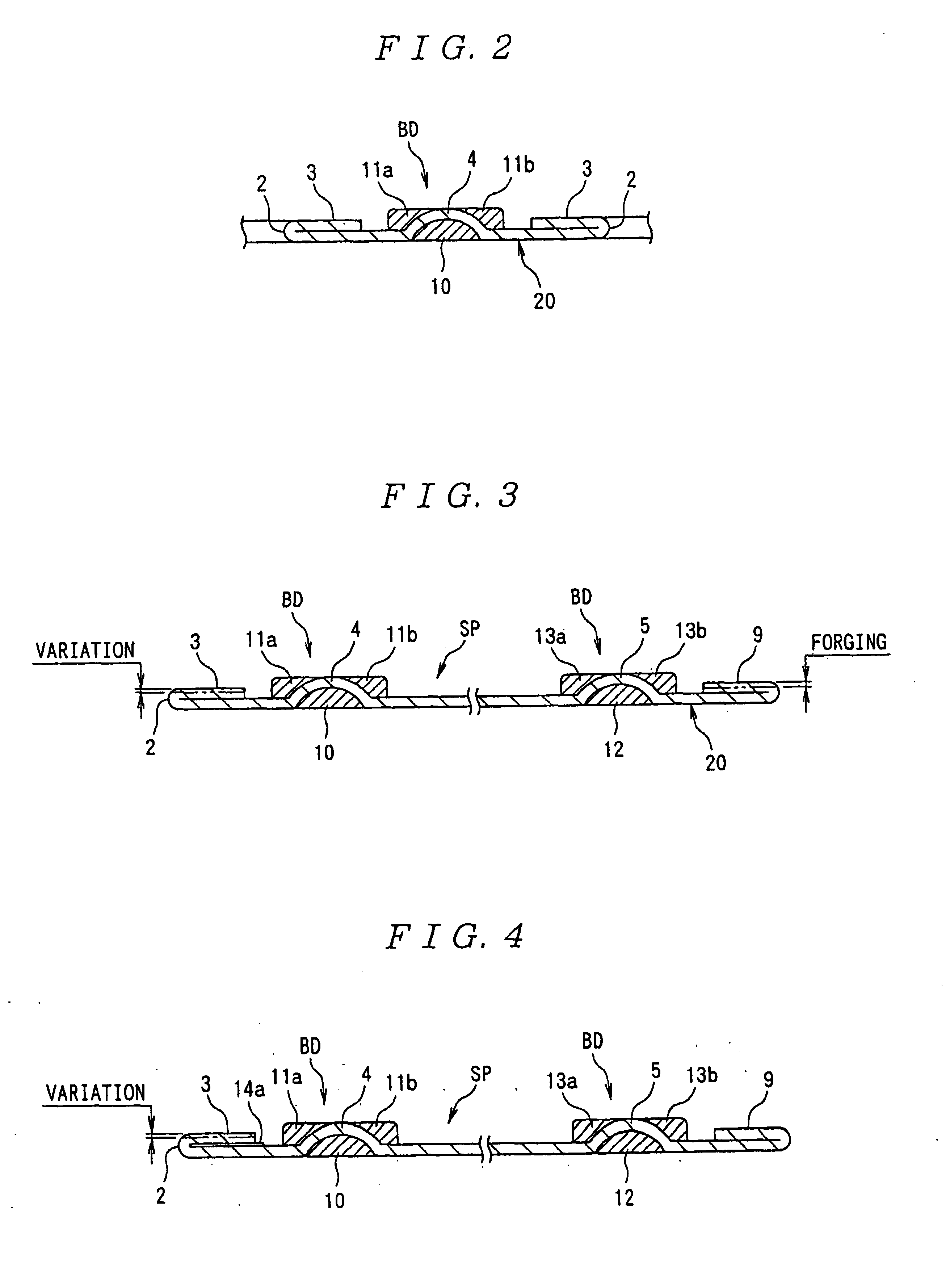

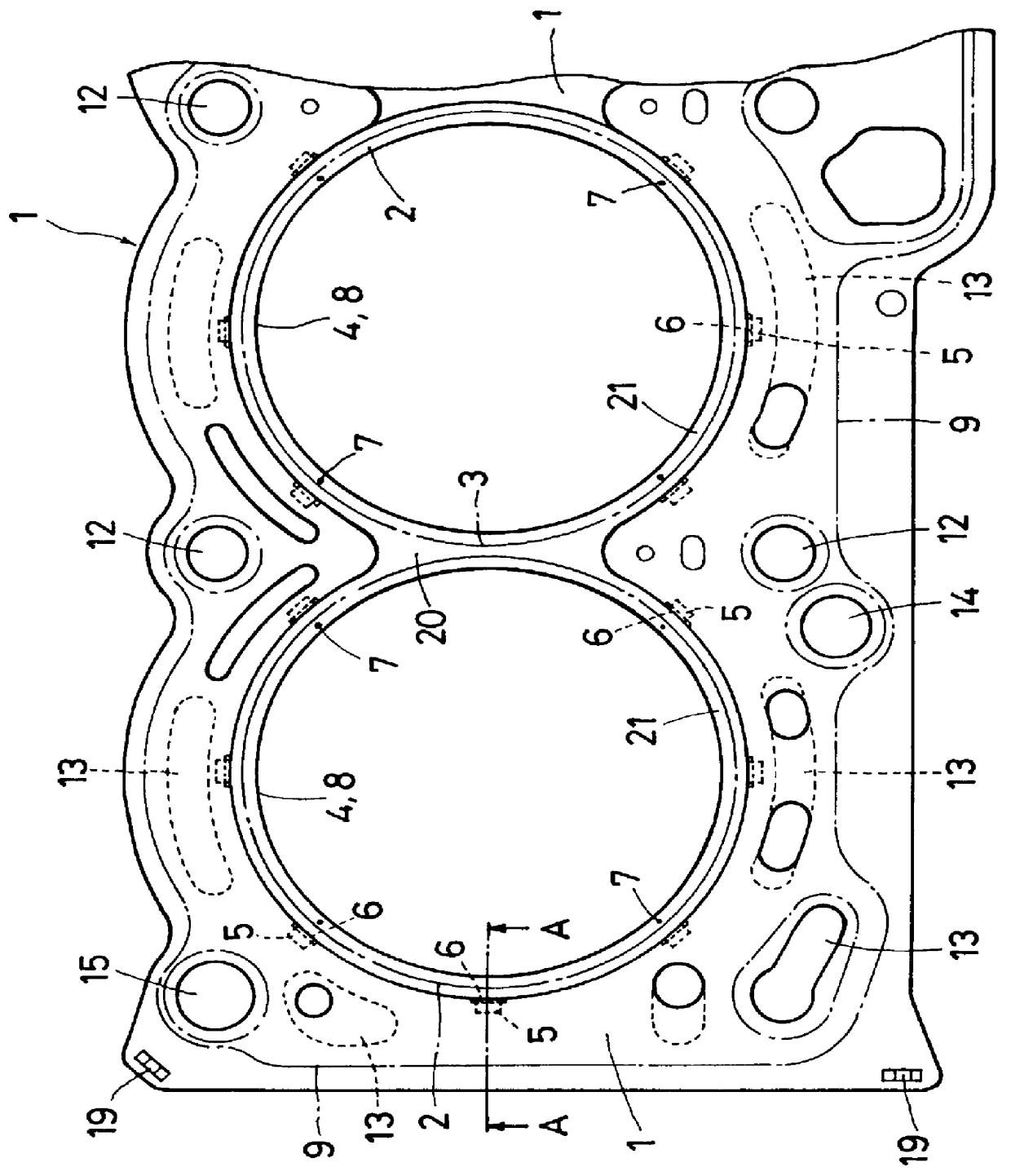

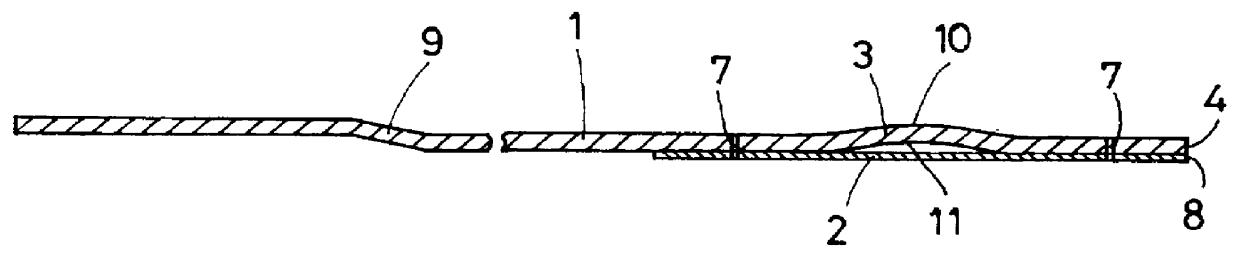

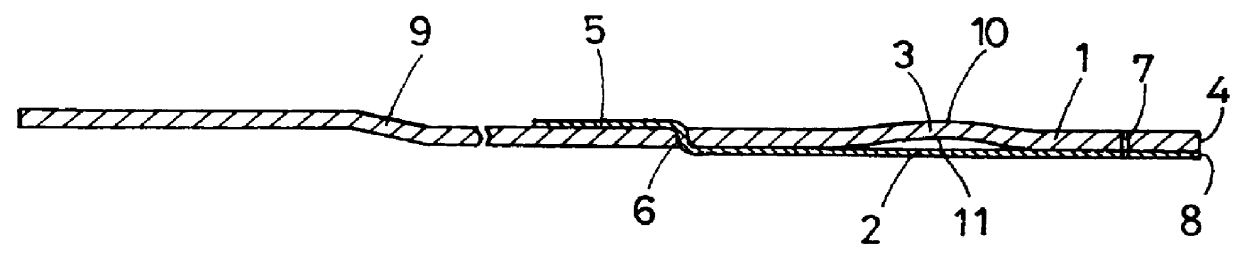

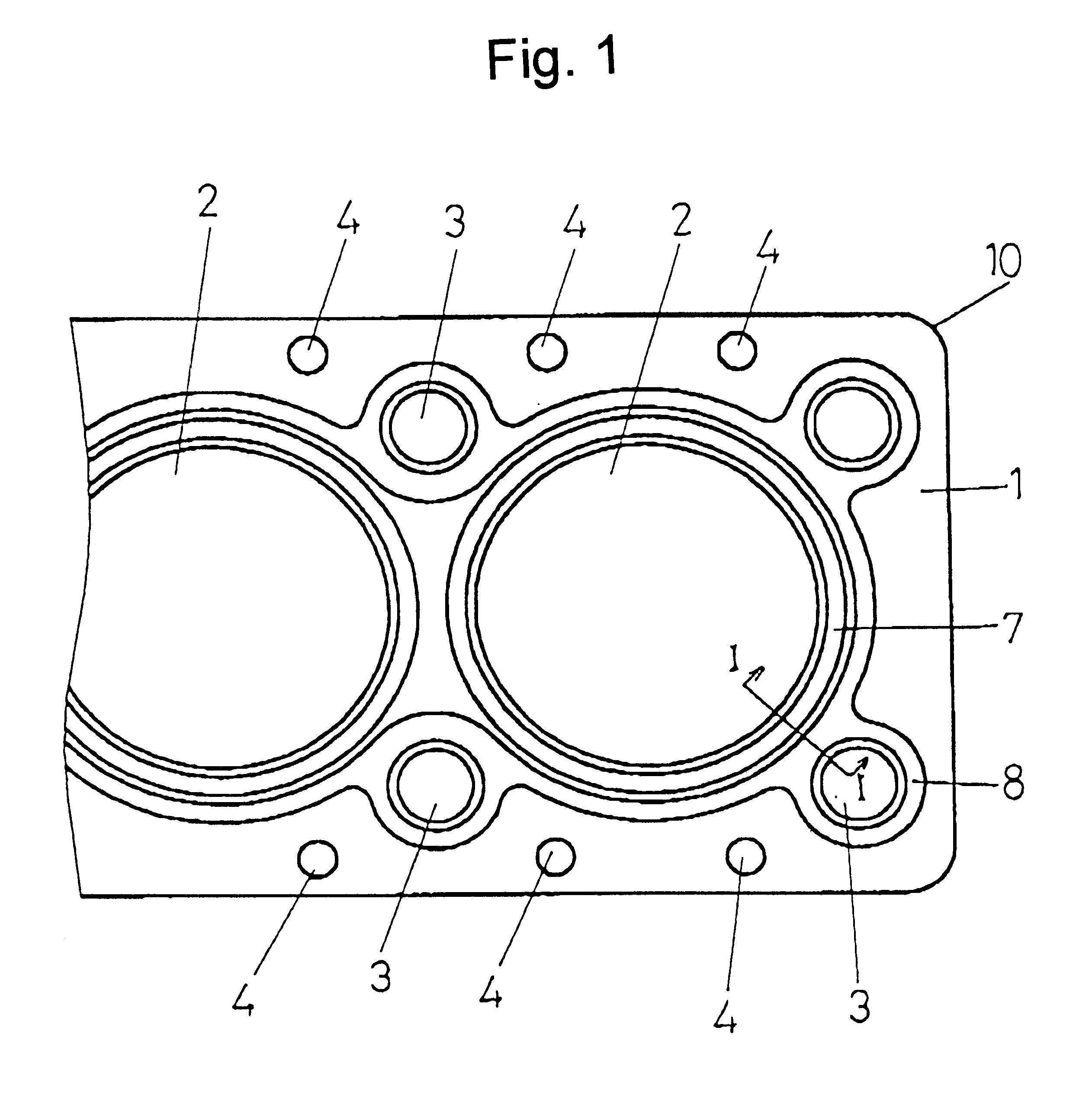

Metallic gasket

InactiveUS7025358B2Improve machining accuracyImprove cooling effectEngine sealsSealing arrangements for enginesCombustion chamberCooling effect

A metallic gasket comprising a base plate having a first thickness-increased portion 3 formed at a peripheral edge on a combustion chamber opening 3 side of a base plate, and a first seal line SL1 and a second seal line SL2 arranged on the outer side of said first thickness-increased portion 3. No openings other than a cooling water hole 8 exist between said two seal lines. Beads formed along said seal lines SL1 and SL2 each consist of a convex metal bead raised only upward from an upper surface of said base plate and a rubber bead made of an elastic sealing material fixed to a convex portion and a concave portion of said metal bead. This structure of said metallic gasket can improve a processing accuracy of said metal bead and also enhance cooling effects on said metallic gasket itself and said joint surfaces of an engine, between which said metallic gasket is disposed.

Owner:JAPAN METAL GASKET CO LTD

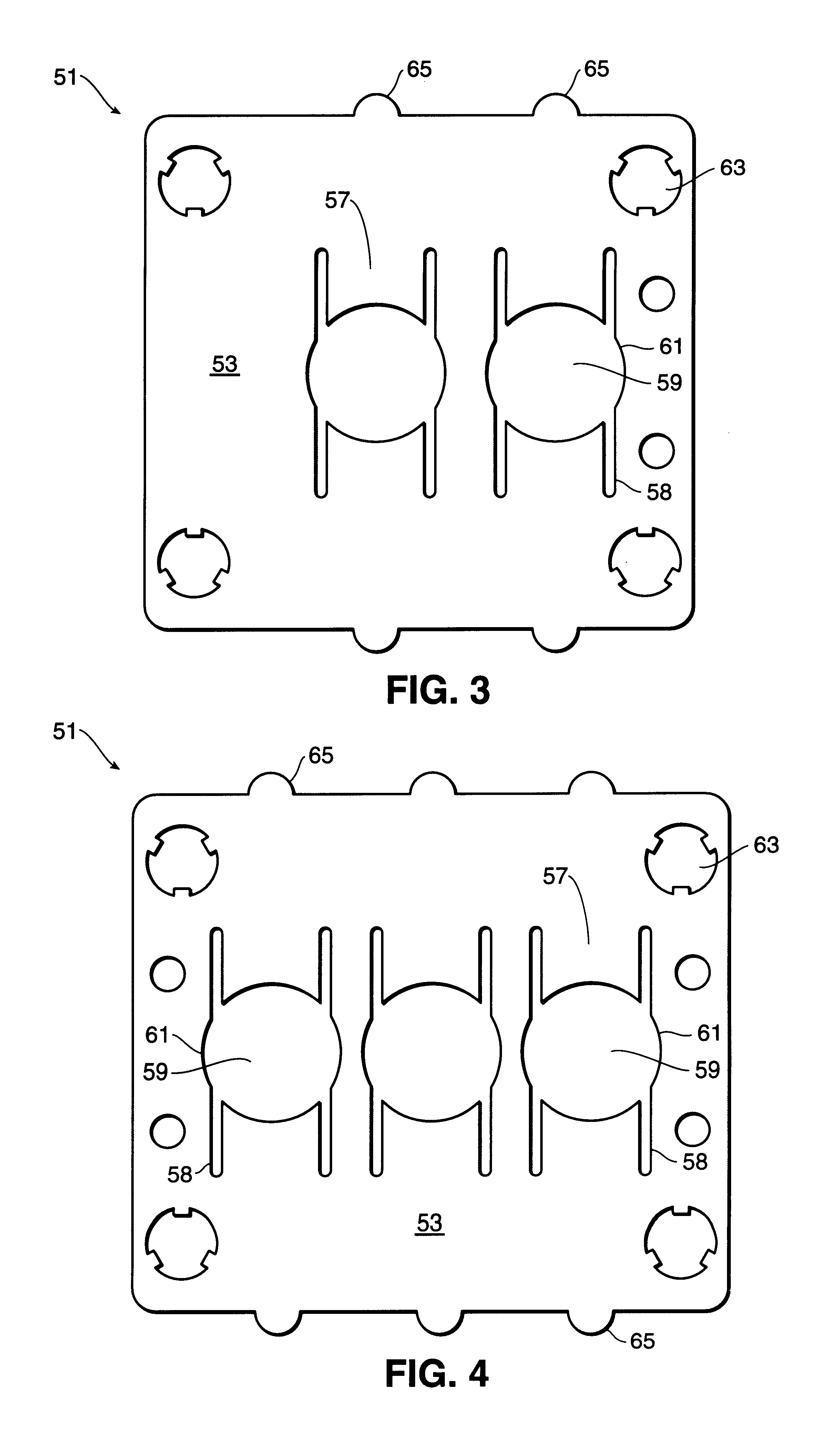

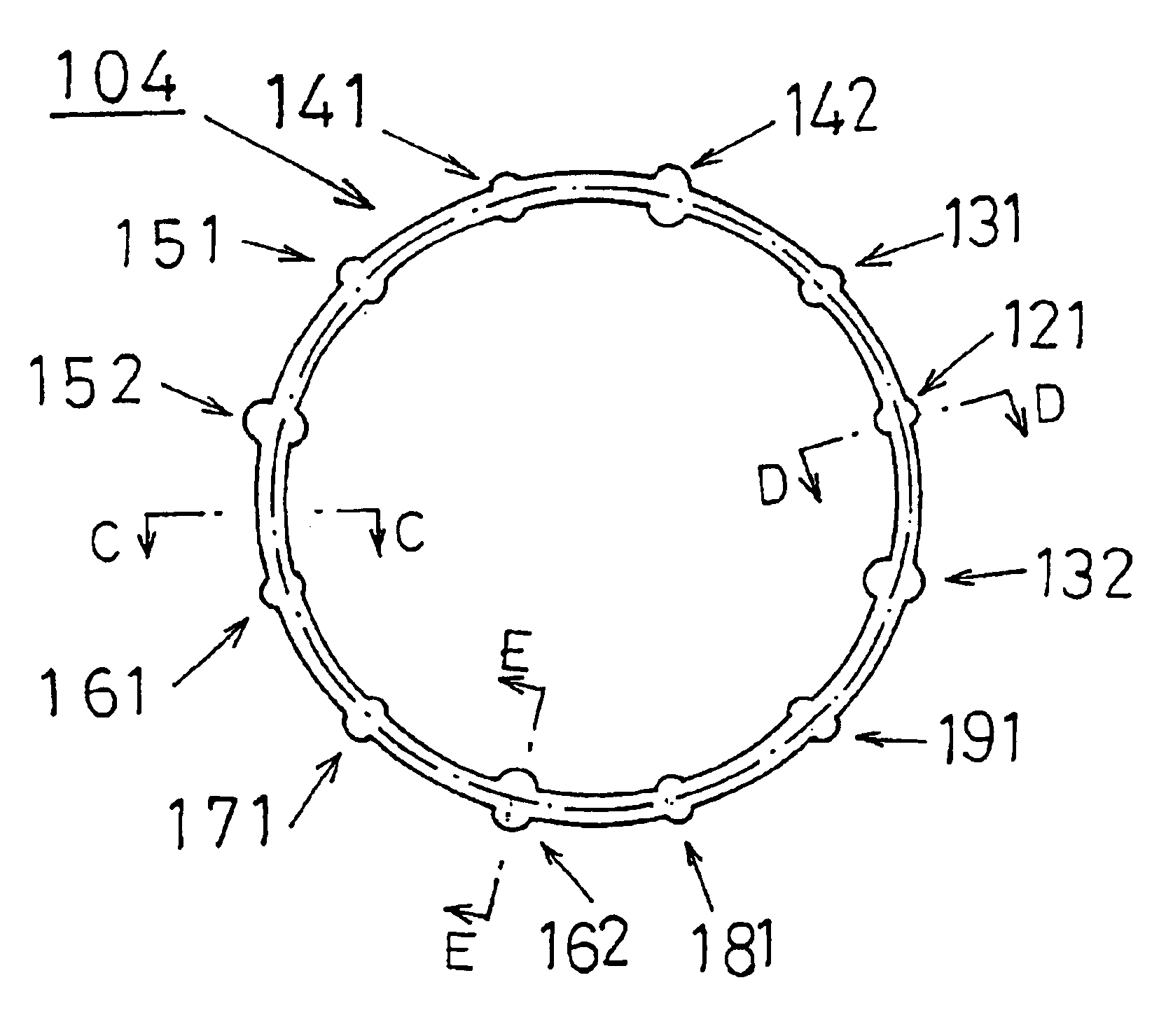

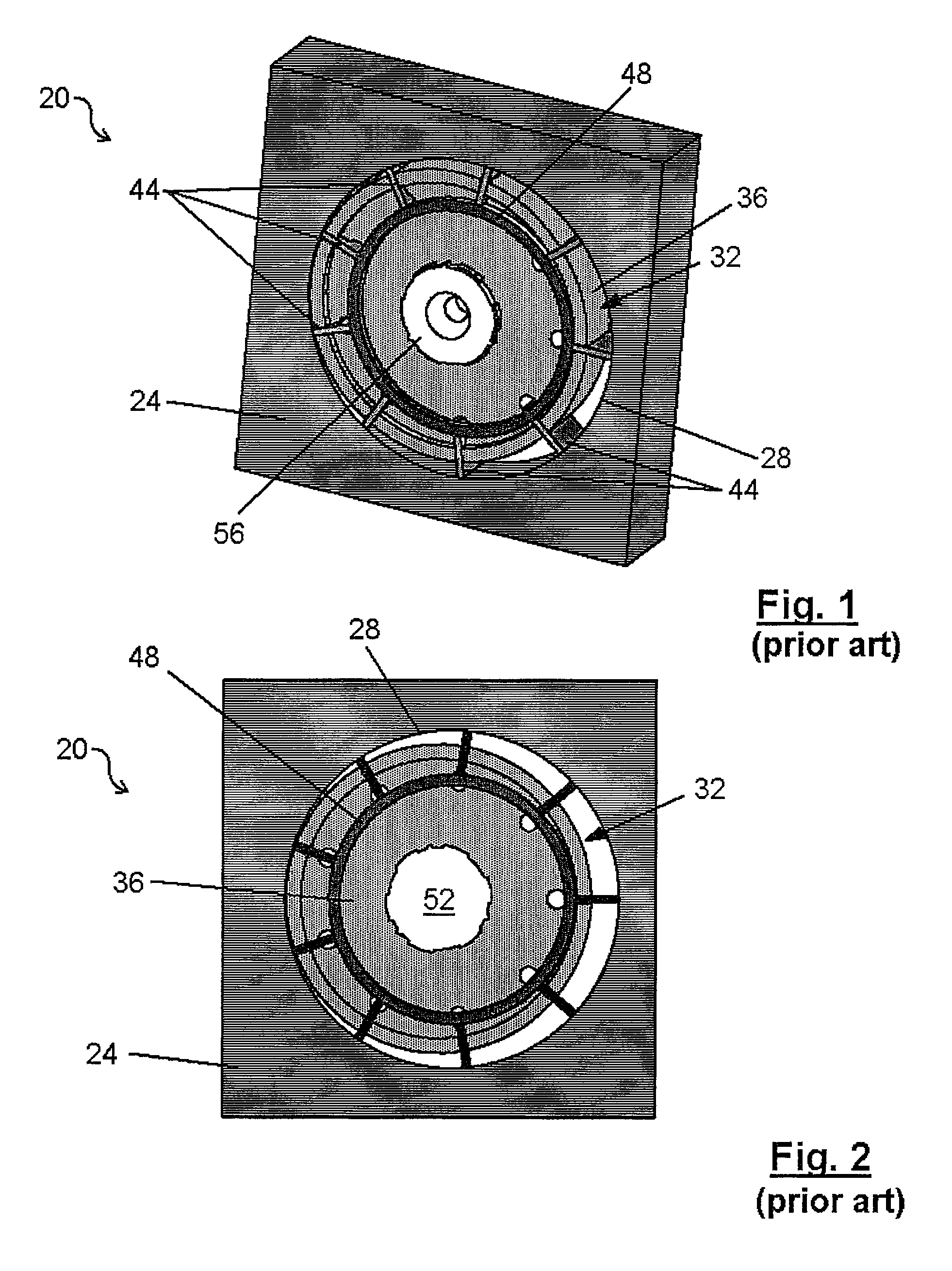

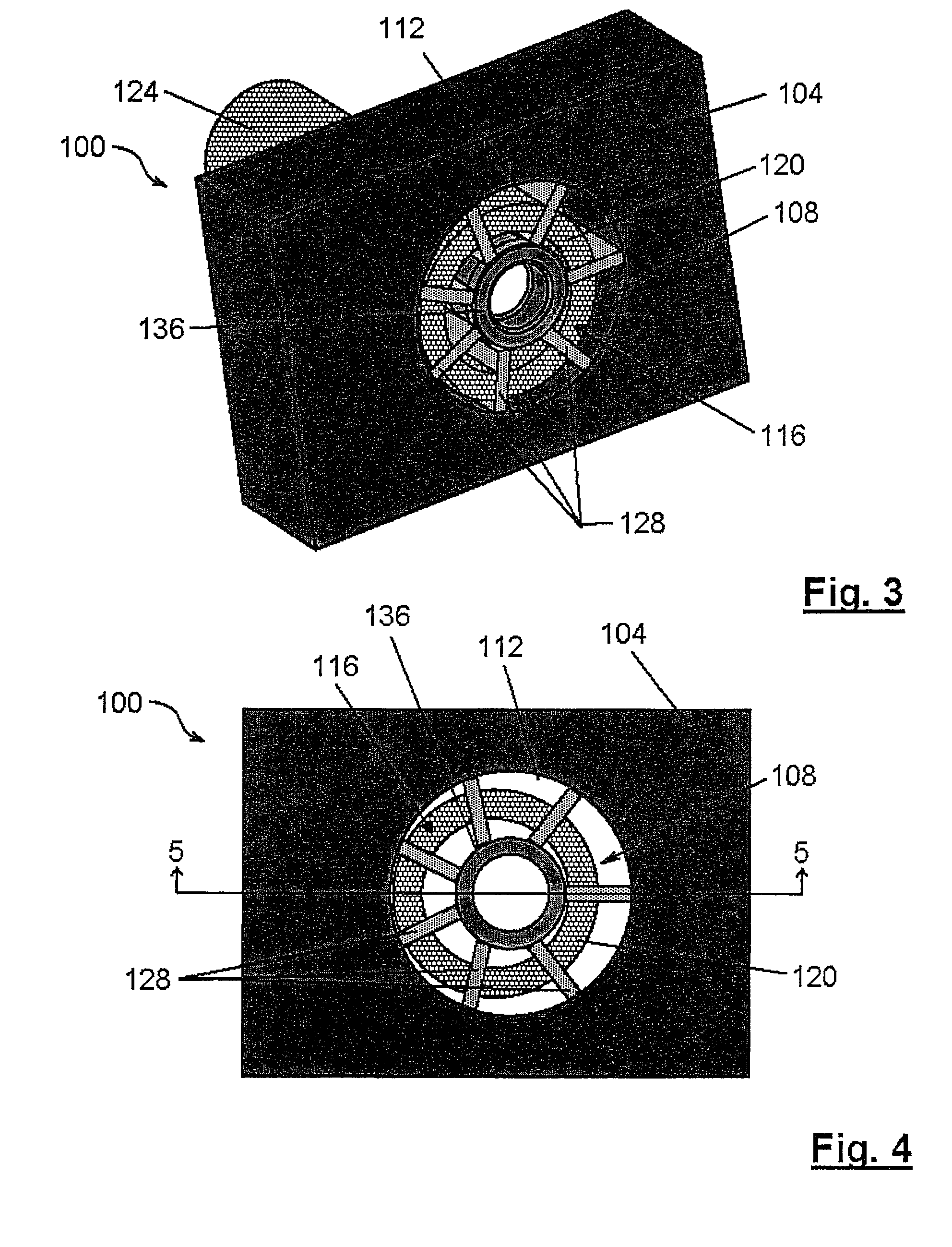

Keeper for positioning ring seals

An improved keeper for positioning ring seals is provided. The keeper includes a substantially planar sheet defining upper and lower surfaces. Projecting through the planar sheet are one or more holes configured for affixing corresponding one or more ring seals. The keeper further includes one or more nodes which extend outwardly from the planar sheet beyond the dimensions of the mating surfaces between which a sealed joint is obtained. The one or more nodes identify the position and number of holes constructed for receiving corresponding ring seals.

Owner:MICROFLEX TECH INC

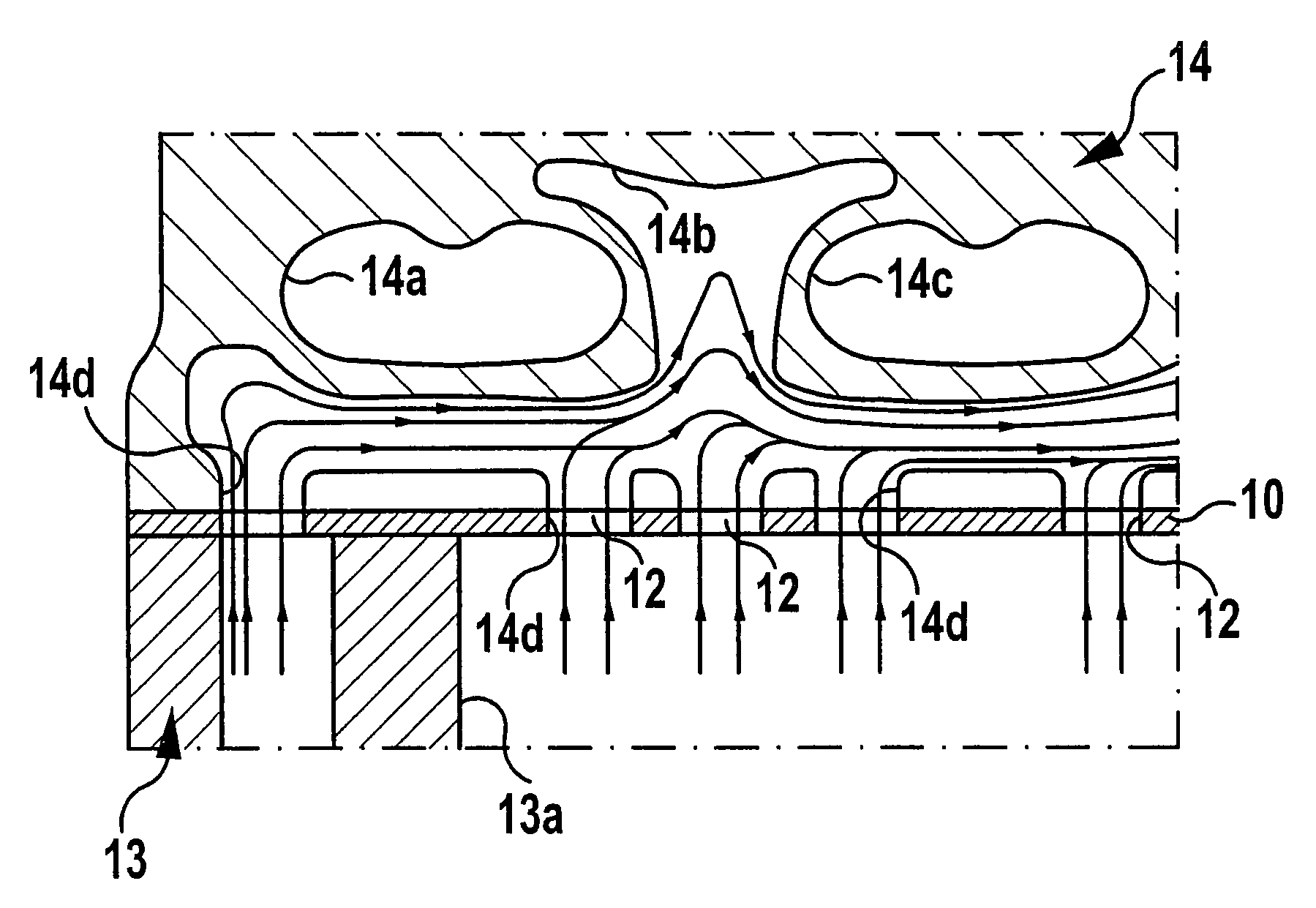

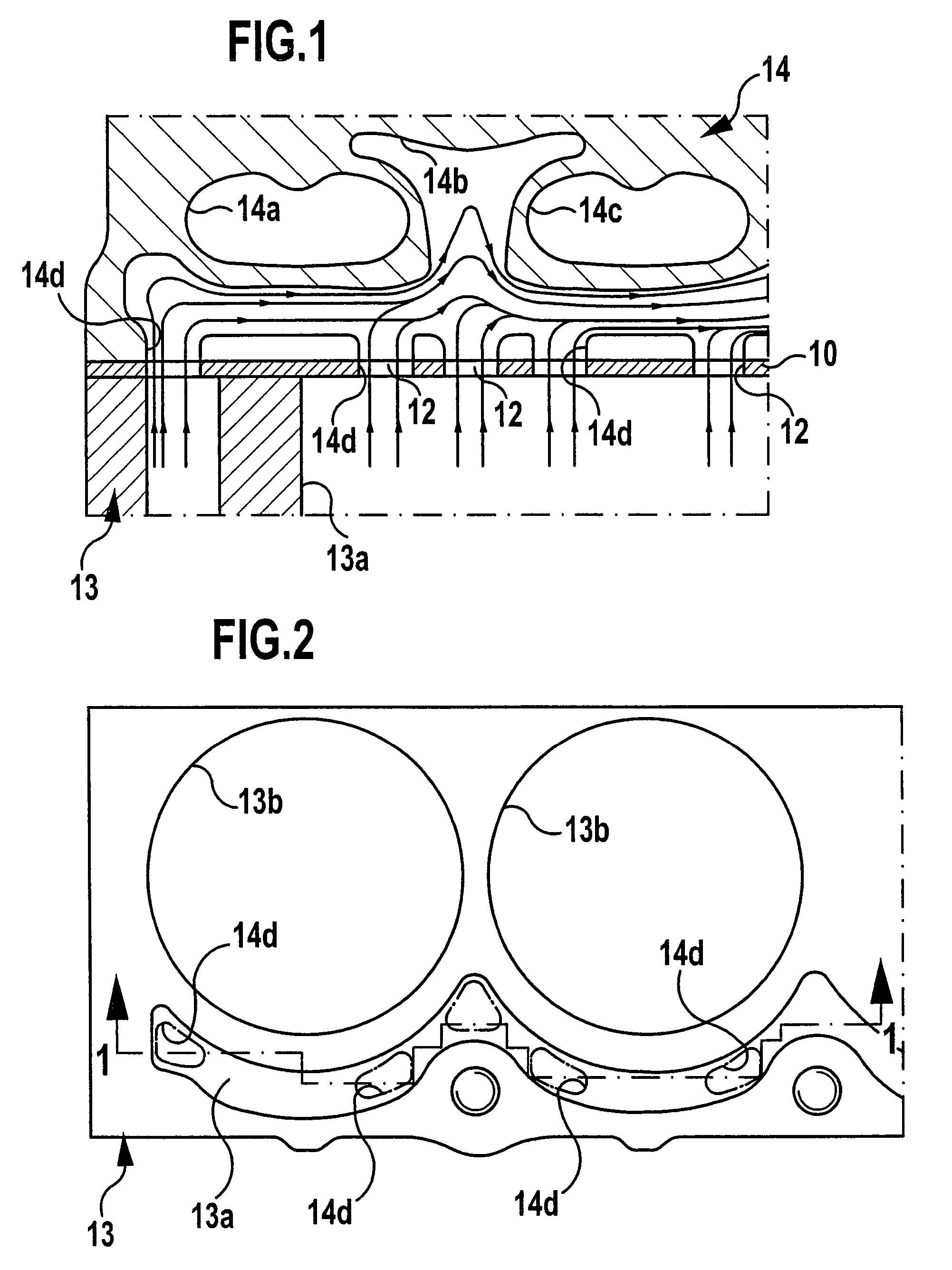

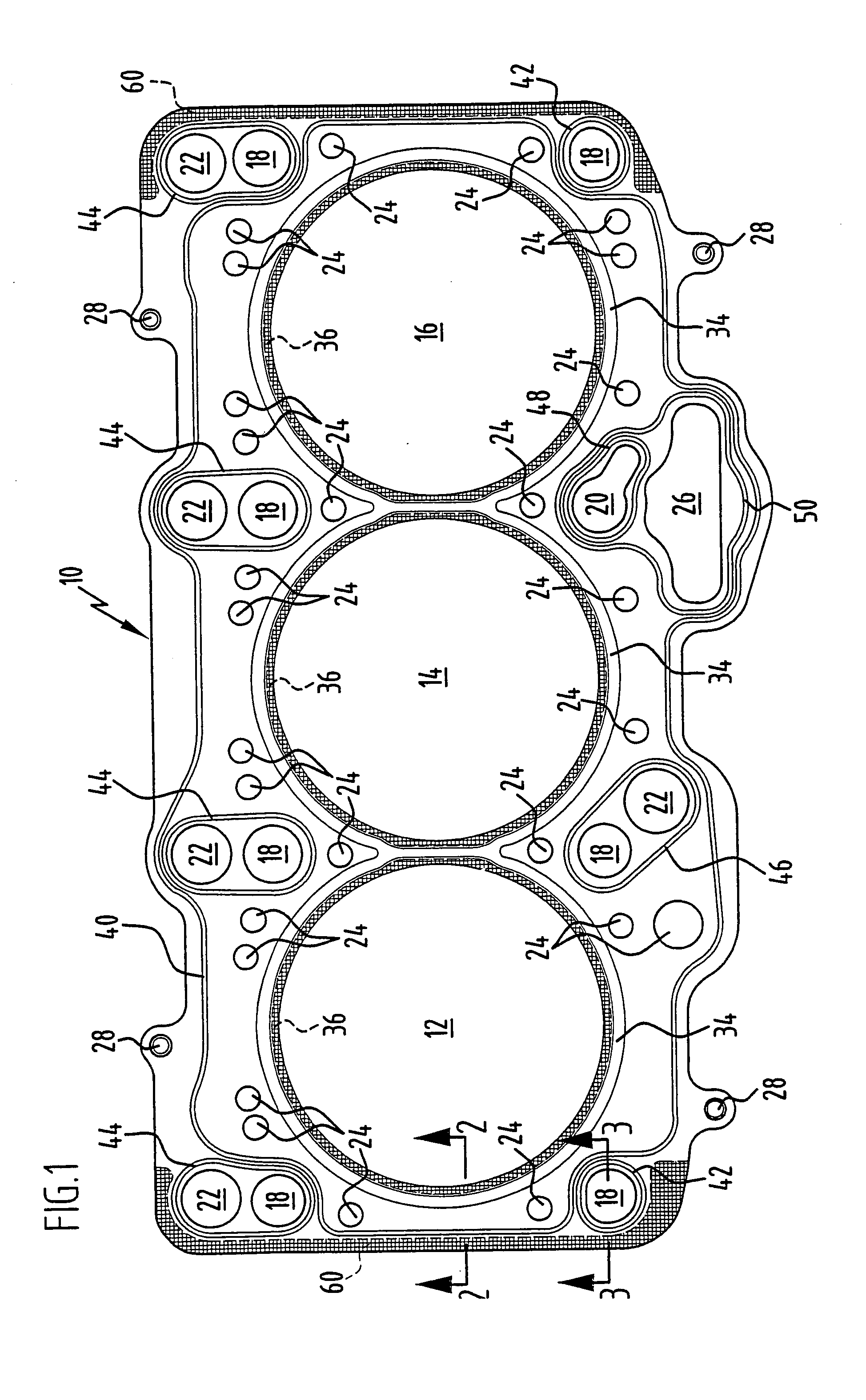

Cylinder head gasket

A cylinder head gasket comprising a gasket plate for an engine in which at least one first coolant cavity is formed in the engine block adjacent to the cylinder head gasket, with the gasket plate comprising coolant passage openings via which the first coolant cavity is connectable to at least one second coolant cavity formed in the cylinder head of the engine; for improved cooling of the engine the cylinder head gasket comprises at least one flow conducting element for the coolant protruding from the gasket plate, the at least one flow conducting element being of such configuration and being joined to a coolant passage opening of the gasket plate in such a way that the flow conducting element forms a flow path with the coolant passage opening and is designed so as to engage in at least one of the first and second coolant cavities and to generate a directed flow of coolant at the outlet end of the flow path.

Owner:ELRINGKLINGER AG

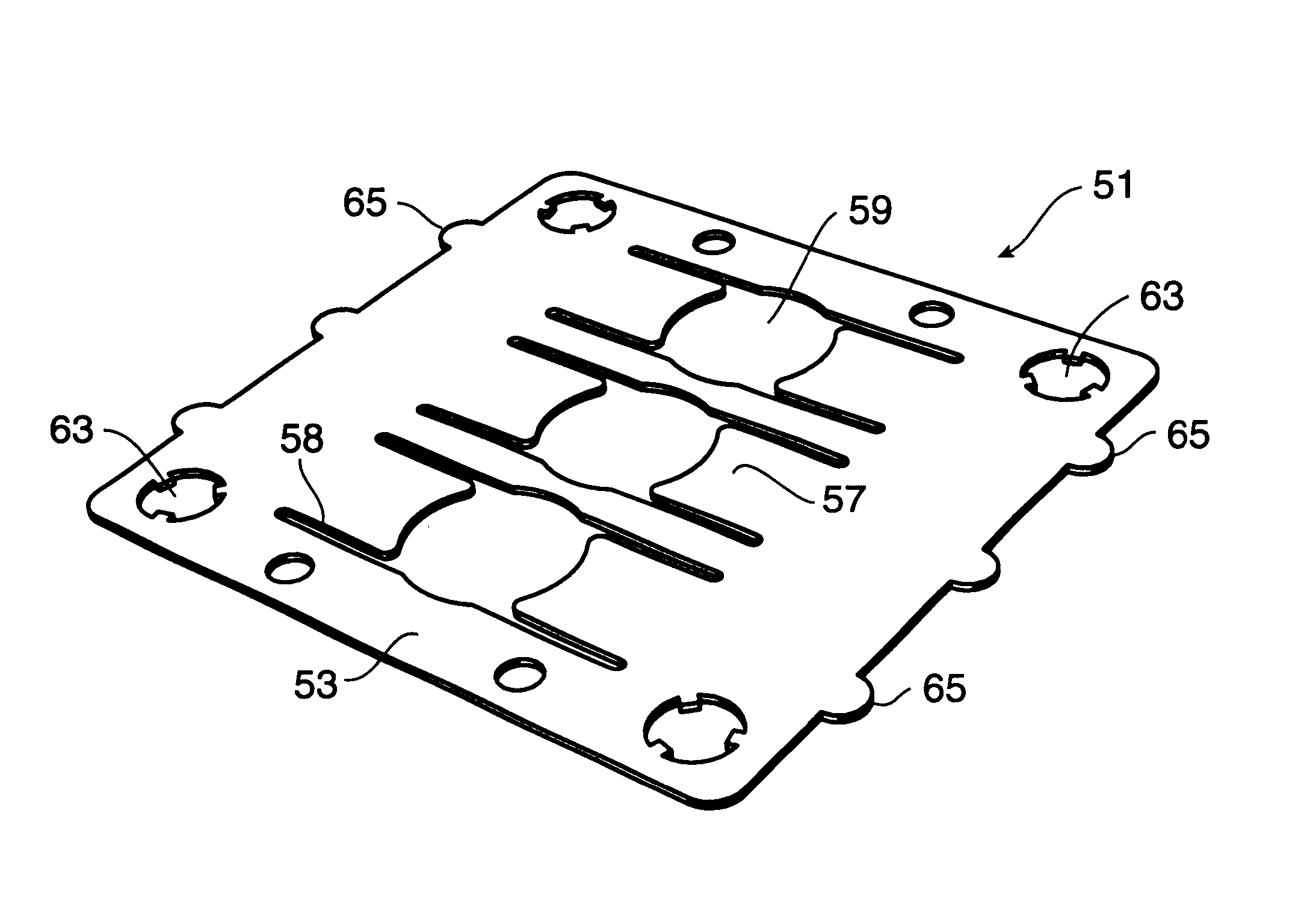

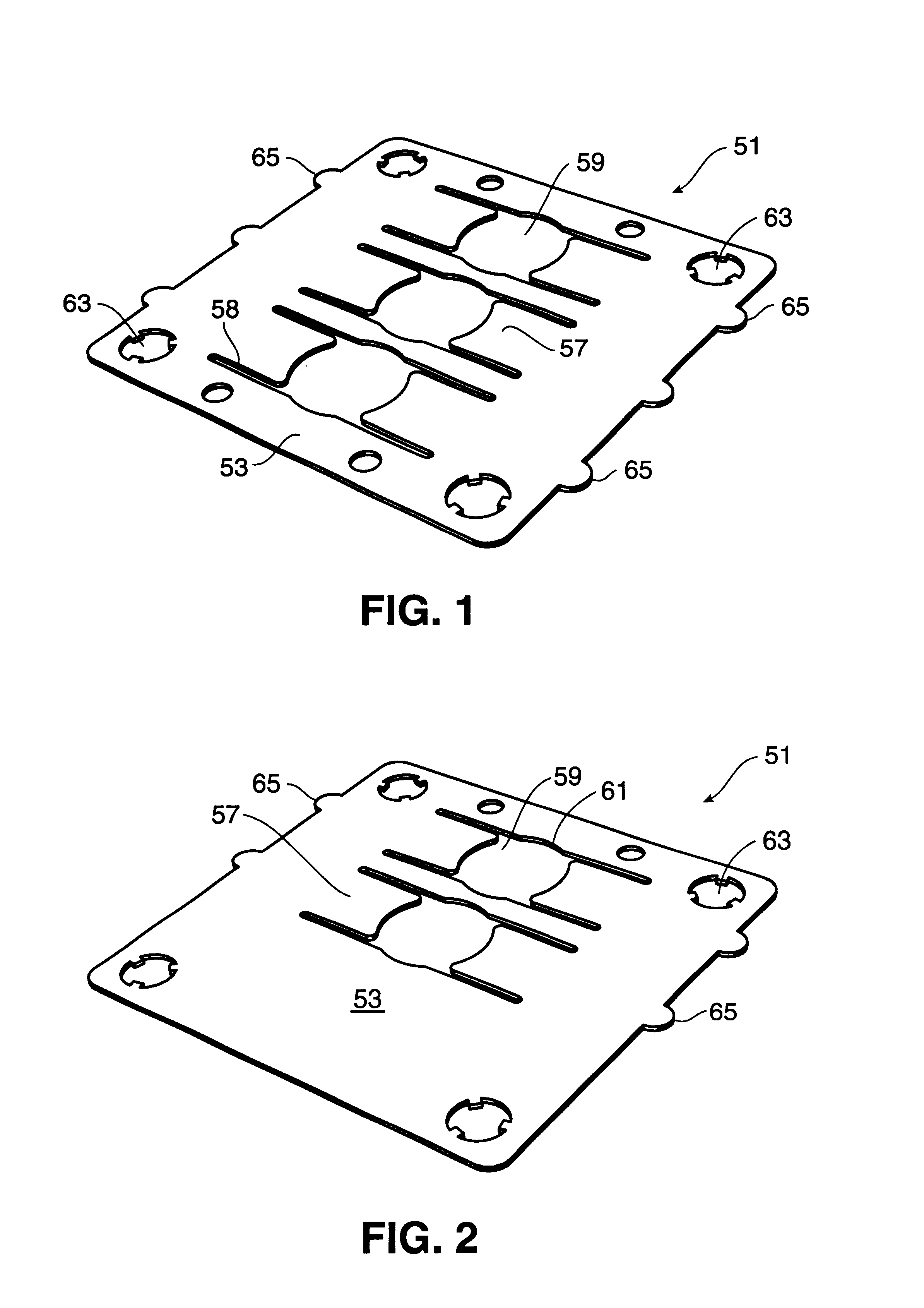

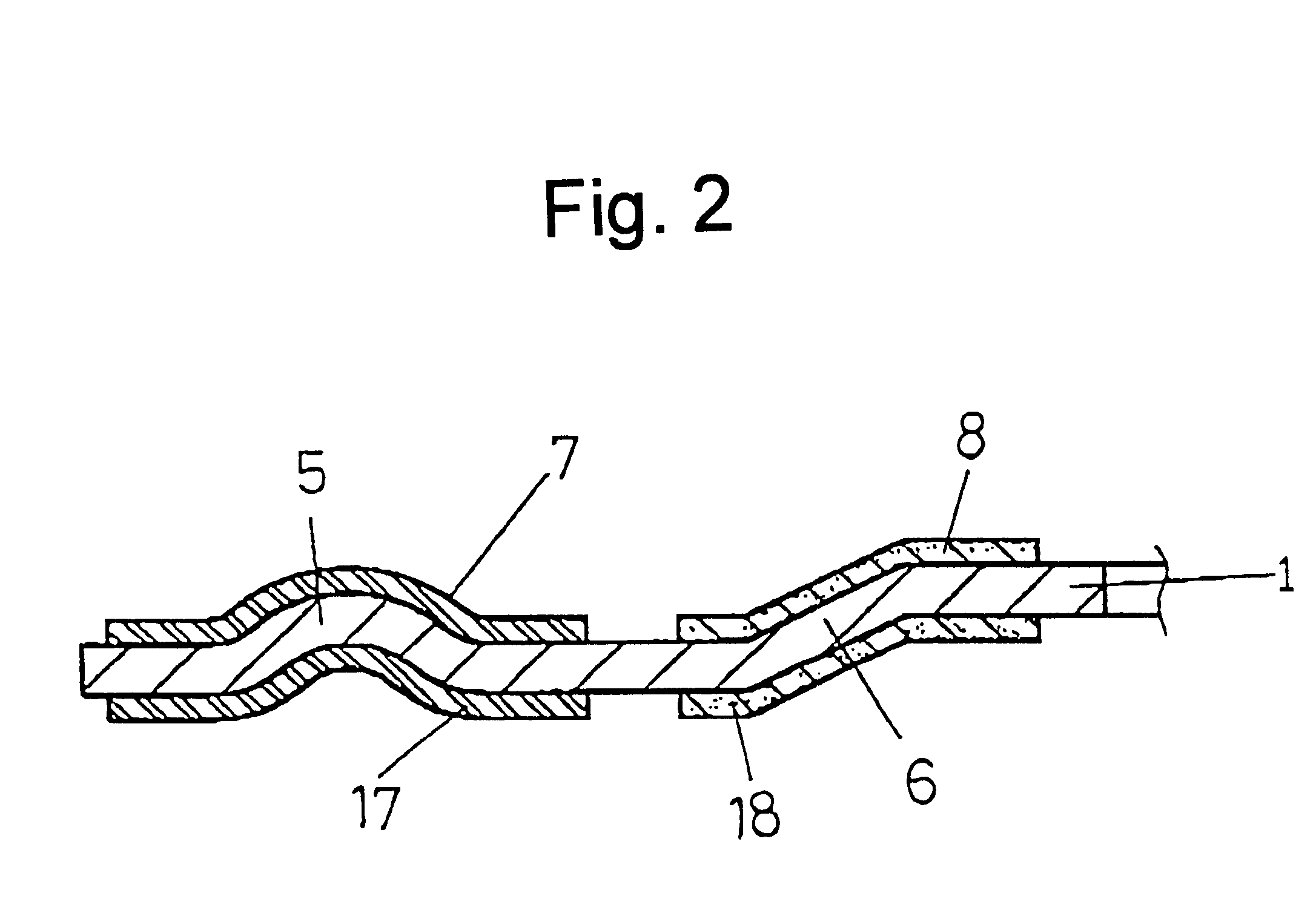

Metal gasket

InactiveUS6027124AImprove sealingImprove balanceEngine sealsSealing arrangements for enginesThin metalCombustion chamber

A metal gasket in which a thin metal plate for reinforcing the beads of an elastic metal plate is laminated on bead regions only of the elastic metal plate, whereby a stable sealing performance is secured for a long period of time. This metal gasket comprises a thin metal plate provided with beads extending around the circumferences of parallel arranged combustion chamber holes, and an elastic metal plate having combustion chamber holes and extending with a predetermined width and laminated on the portions of the thin metal plate which are around the combustion chamber holes so as to be opposed to valley portions of the beads. The thickness of the thin metal plate is set smaller than that of the elastic metal plate. The thin metal plate is fixed to the elastic metal plate with locking portions formed at the outer circumference of the former engaged with slits formed in the regions of the latter which are on the outer sides of the beads, the thin metal plate being combined with the elastic metal plate at joint portions thereof by spot welding or laser welding.

Owner:NIPPON GASKET CO LTD

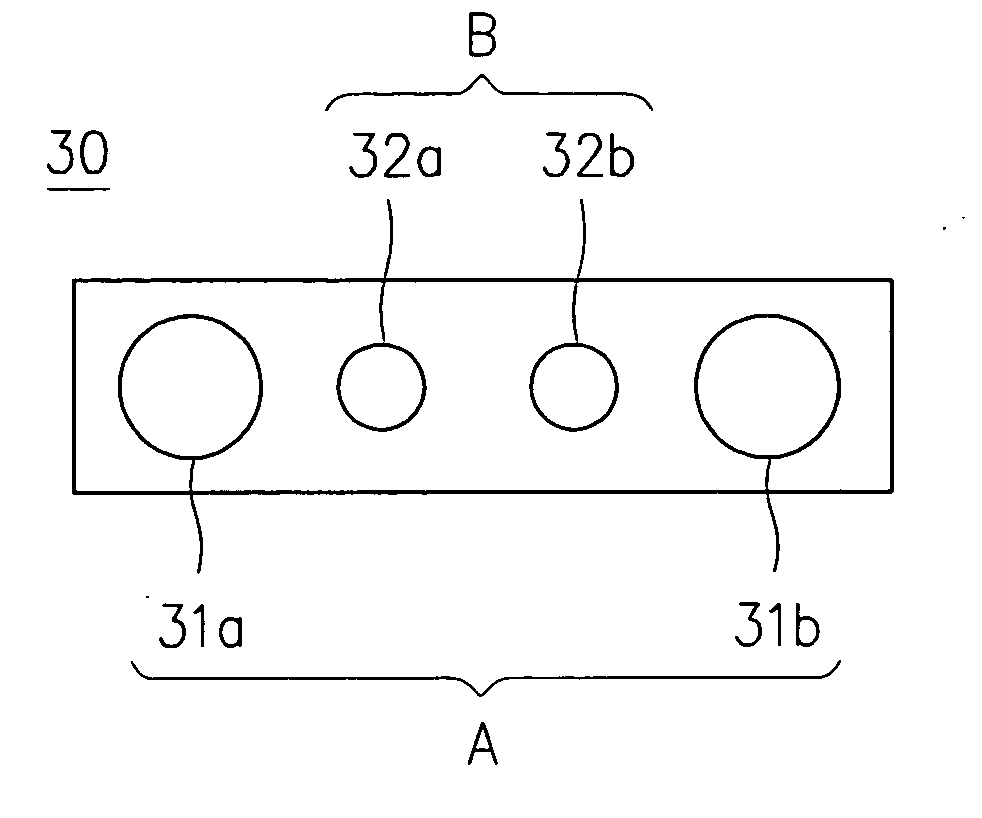

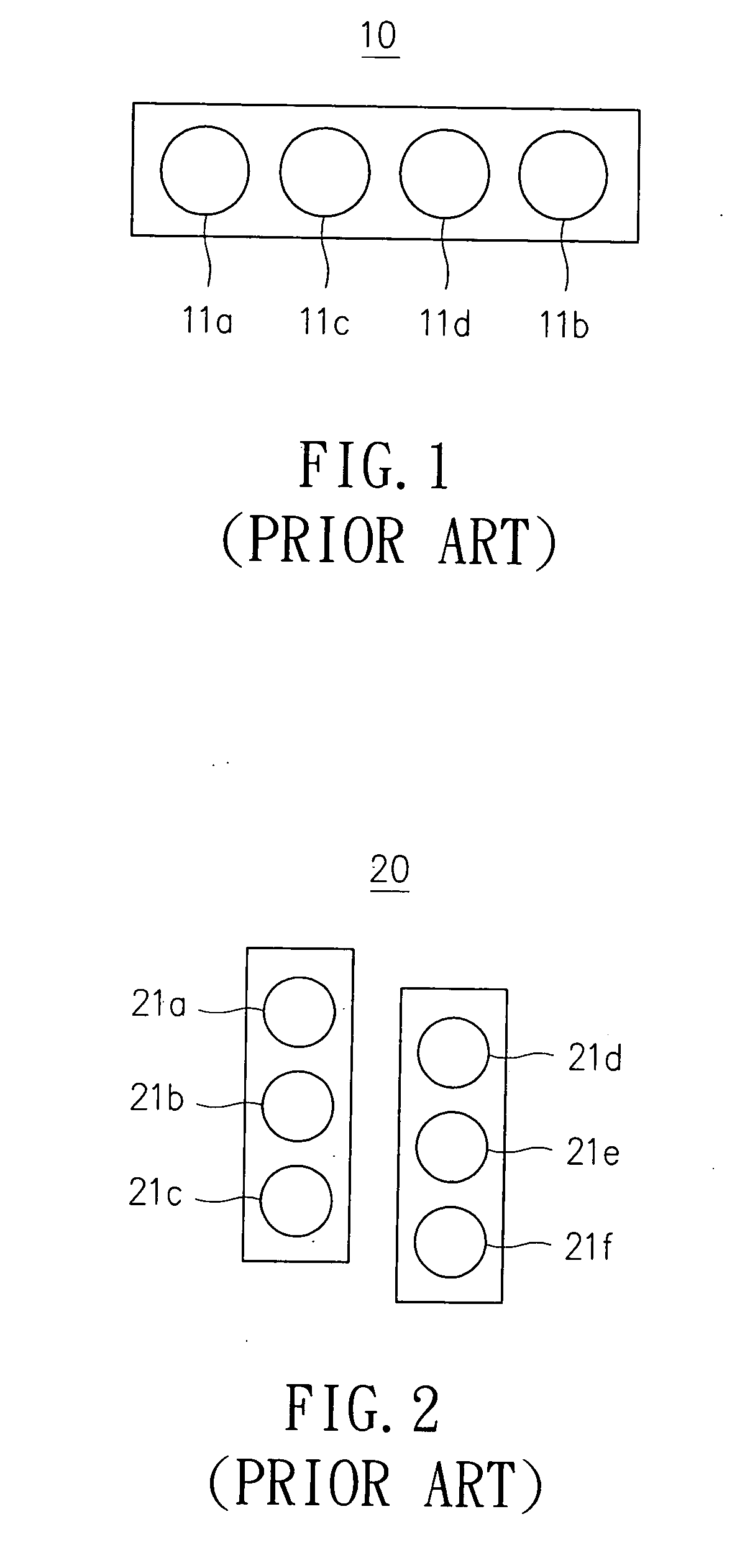

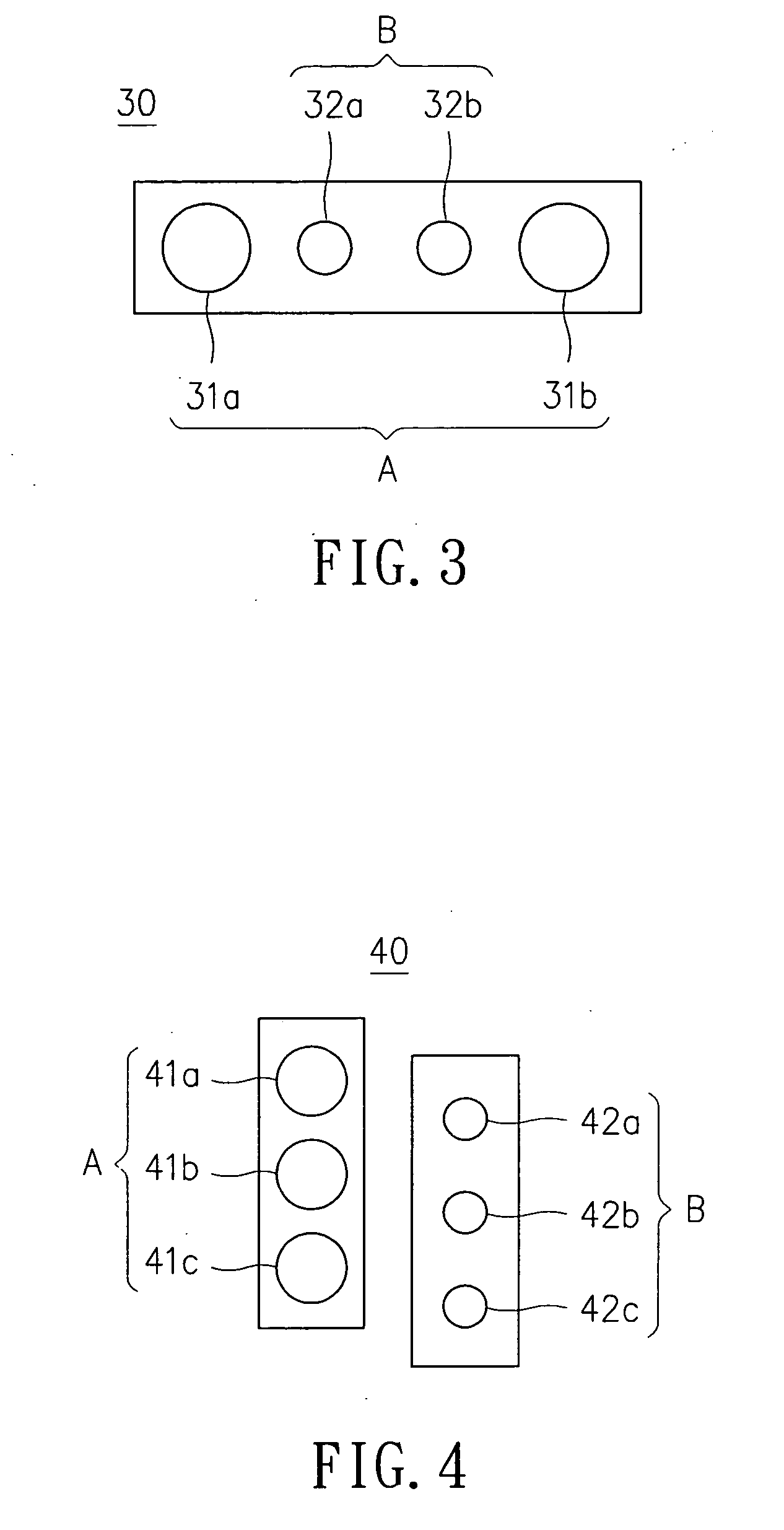

Multi-stage variable displacement engine

InactiveUS20070131183A1Improve efficiencyReduce fuel consumptionInternal combustion piston enginesCylinder headsCurrent loadFiring order

The present invention relates to an uneven cylinder displacement arrangement of a multi-stage variable displacement engine. By arranging a plurality of cylinders of at least two different cylinder bores or at least two different strokes in an engine while grouping the plural cylinders into at least two cylinder groups, e.g. grouping odd-numbered cylinders in an ignition sequence of the engine into a first group while grouping even-numbered cylinders in an ignition sequence of the engine into a second group, the engine is enabled to have multi-stage displacement capability adapted to various operation speeds for reducing fuel consumption since the displacement of the engine can be varied by using the ignition sequence to control and select which groups are to be ignited for matching the current load of the engine. In a preferred embodiment of the invention, there are two kinds of cylinders of different cylinder bores arranged in an engine which are grouped into two cylinder groups by the control of the ignition sequence of the engine, whereas the cylinder bore of a cylinder grouped in one of the two cylinder group is the same as another cylinder of the same cylinder group, but is different to those grouped in another cylinder group.

Owner:IND TECH RES INST

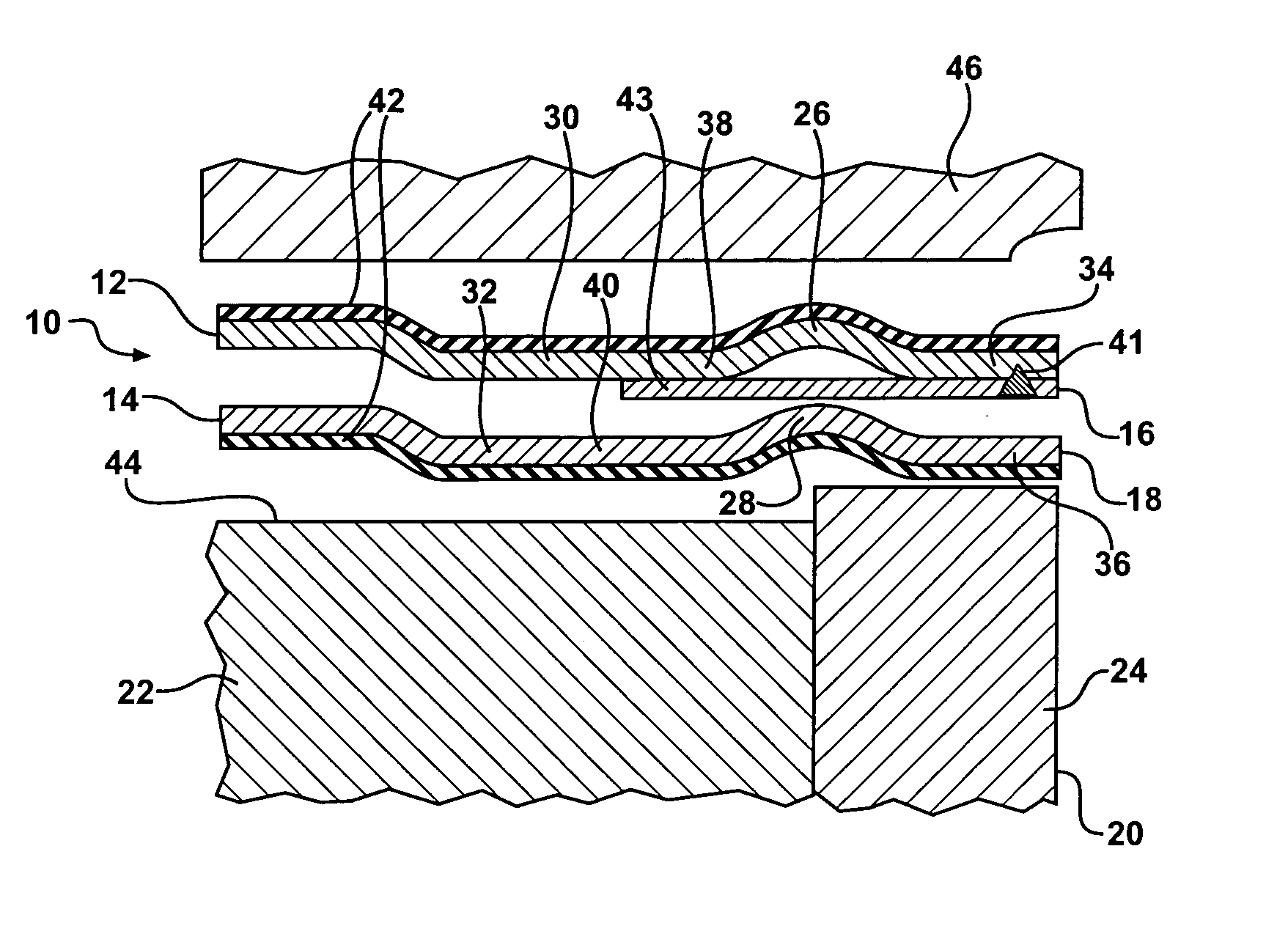

Metal gasket

InactiveUS20050189724A1Minimal thicknessSoft compressibilityEngine sealsSealing arrangements for enginesEngineeringMetal

A multilayer metal gasket includes at least two metal gasket layers formed with an aligned opening and aligned opposing sealing beads surrounding the opening. A partial stopper layer is interposed between the gasket layers and is of lesser area than either of the gasket layers. The partial stopper layer extends from the opening outwardly beyond the sealing beads and is fixed to one of the layers on only one side of the sealing beads and is free on the opposite side.

Owner:FEDERAL MOGUL WORLD WIDE +1

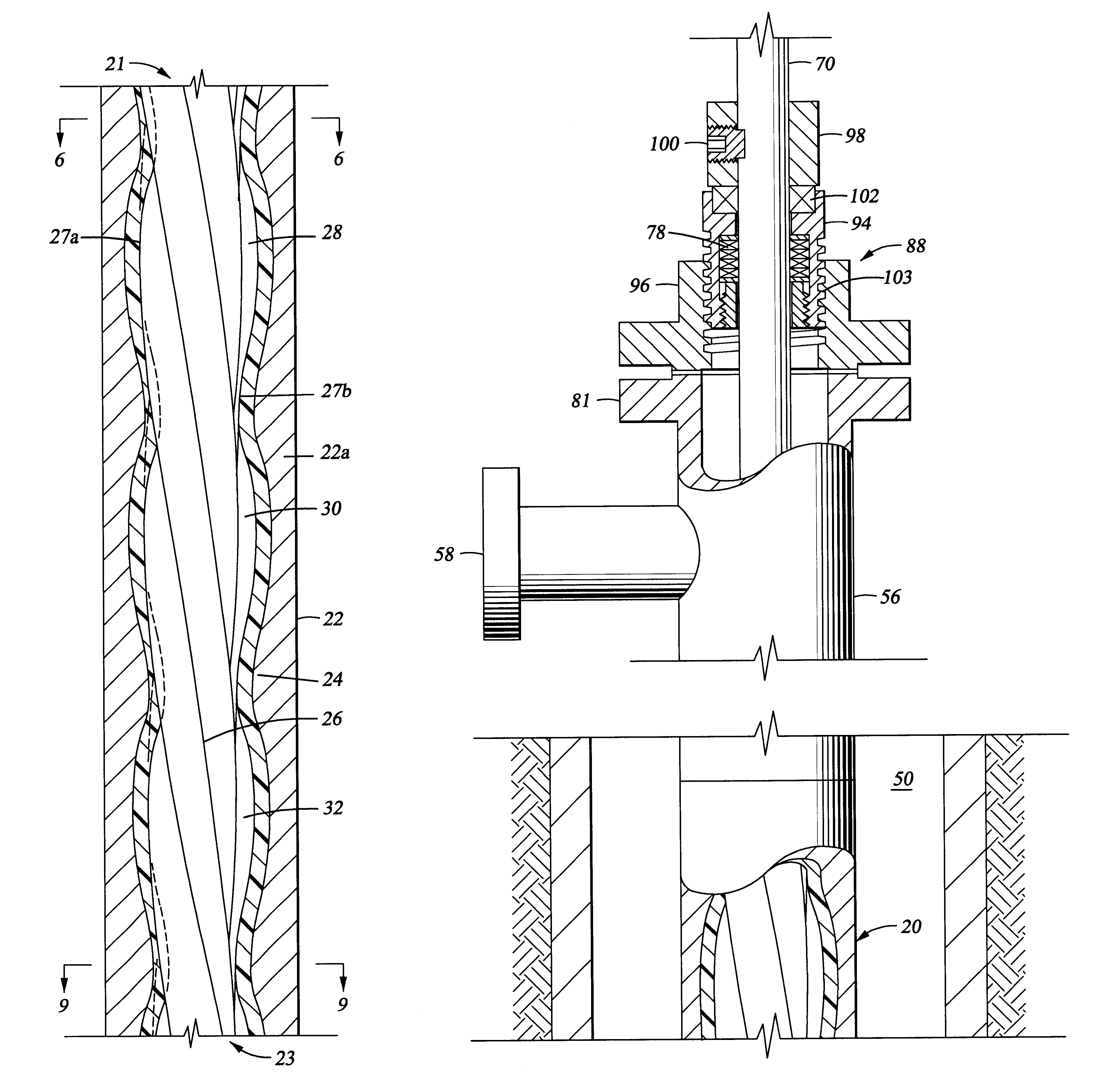

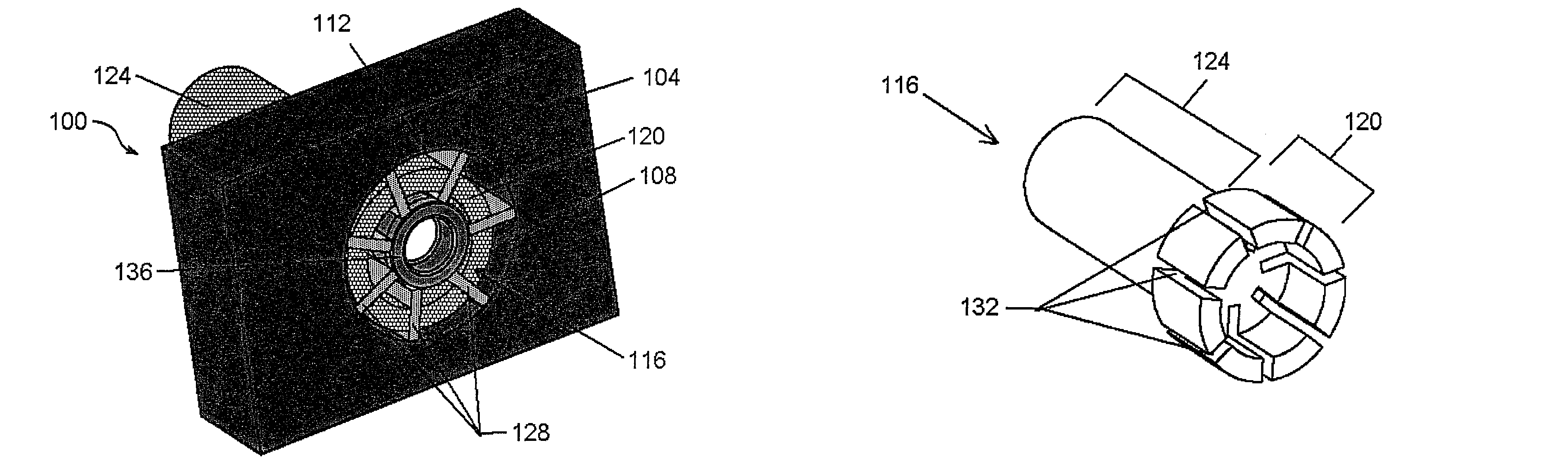

Adjustable fit progressive cavity pump/motor apparatus and method

InactiveUS6358027B1Oscillating piston enginesSealing arrangement for pumpsInterference fitEngineering

The present invention provides an adjustable rotor and / or stator, so that the interference fit and / or clearance can be adjusted. The rotor and / or stator are tapered to provide a difference in fit between the rotor and stator by longitudinal adjustment of their relative position. In one embodiment, the adjustment may occur while the PCP in mounted downhole in a wellbore. In another embodiment, the adjustment may occur automatically depending on sensor input of operating conditions of the PCP.

Owner:WEATHERFORDLAMB

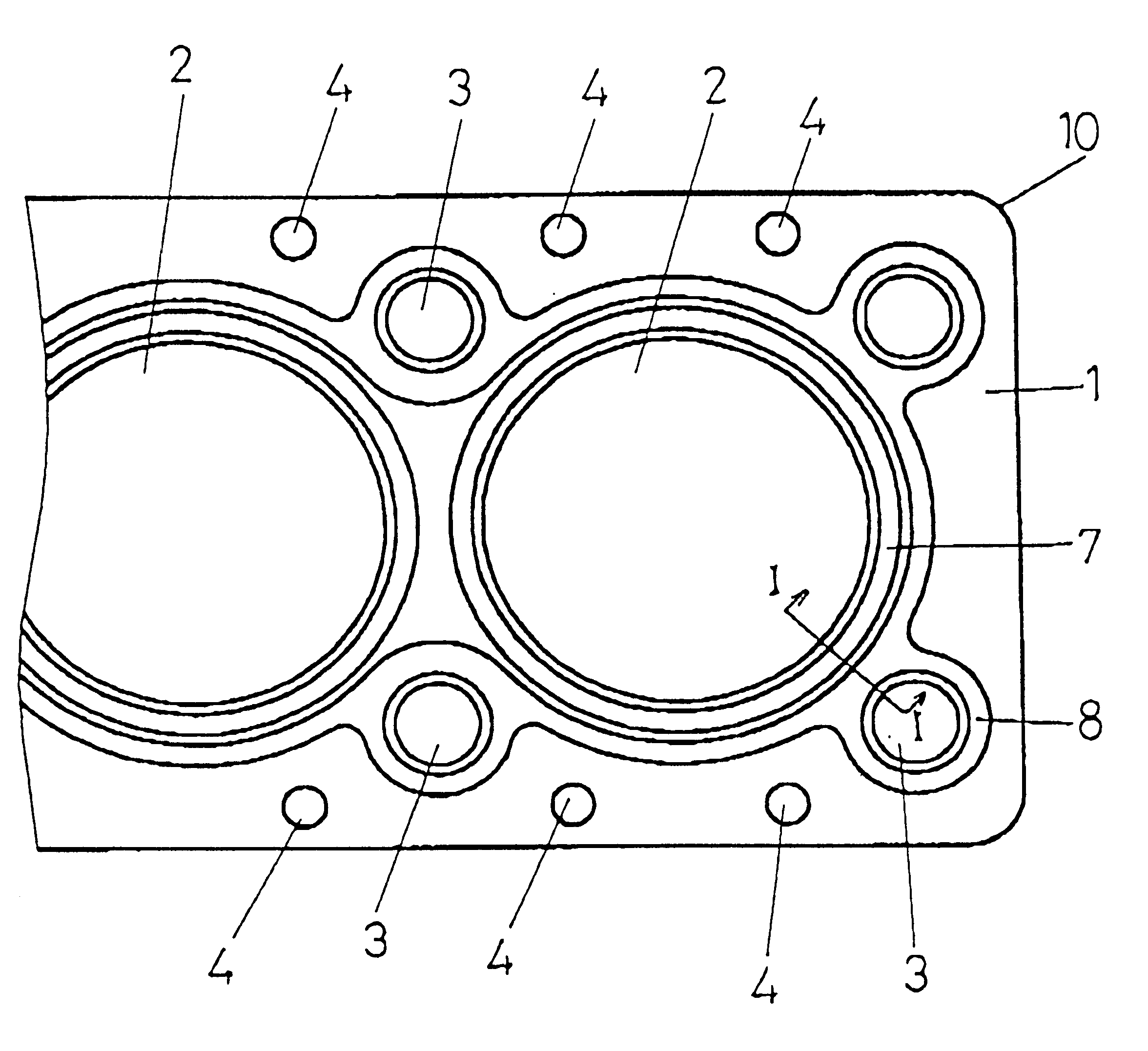

Cylinder head gasket

InactiveUS6550782B2Improve heat resistanceIncrease production costEngine sealsSealing arrangements for enginesExternal combustion engineMetal sheet

Owner:UCHIYAMA MFG

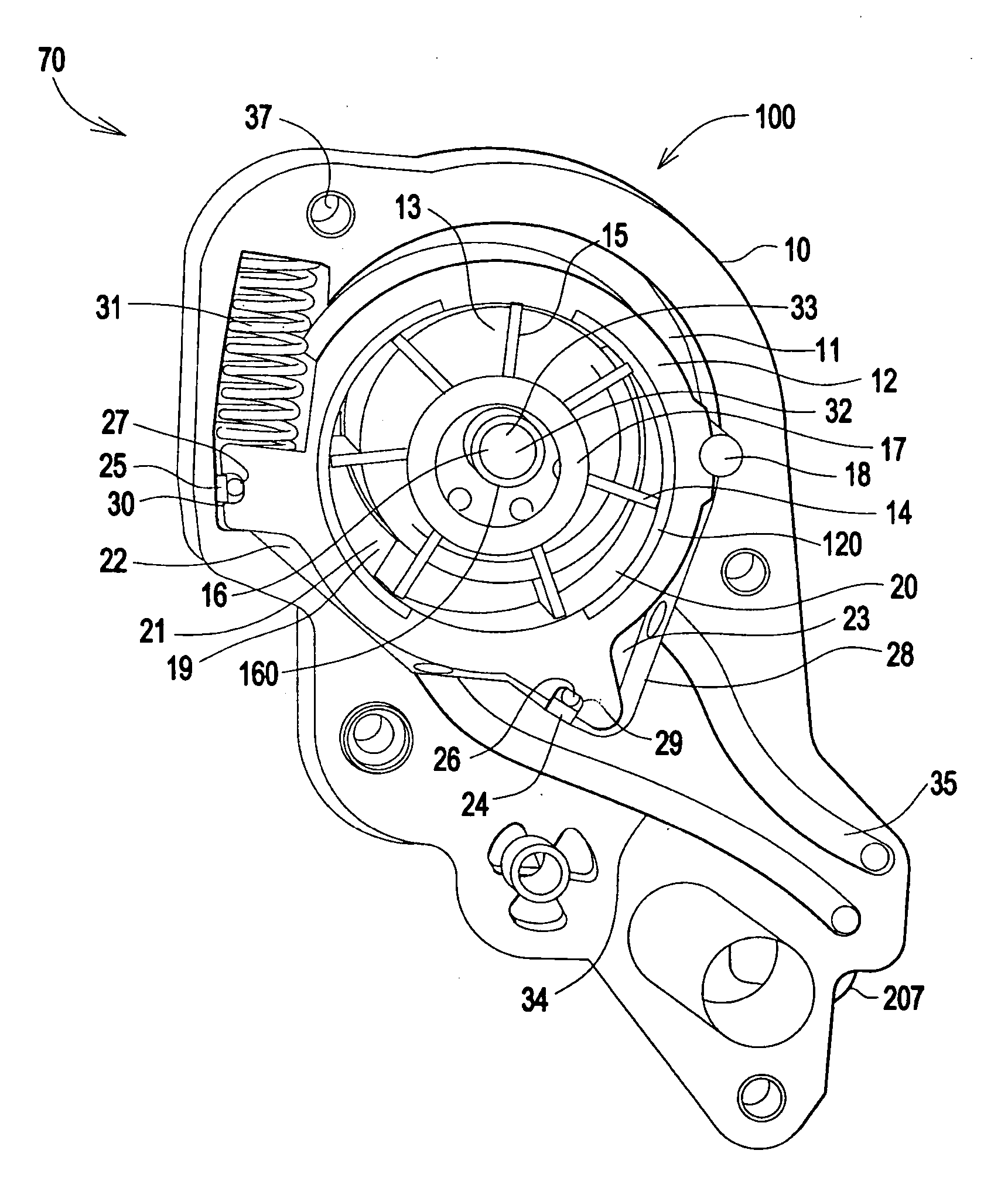

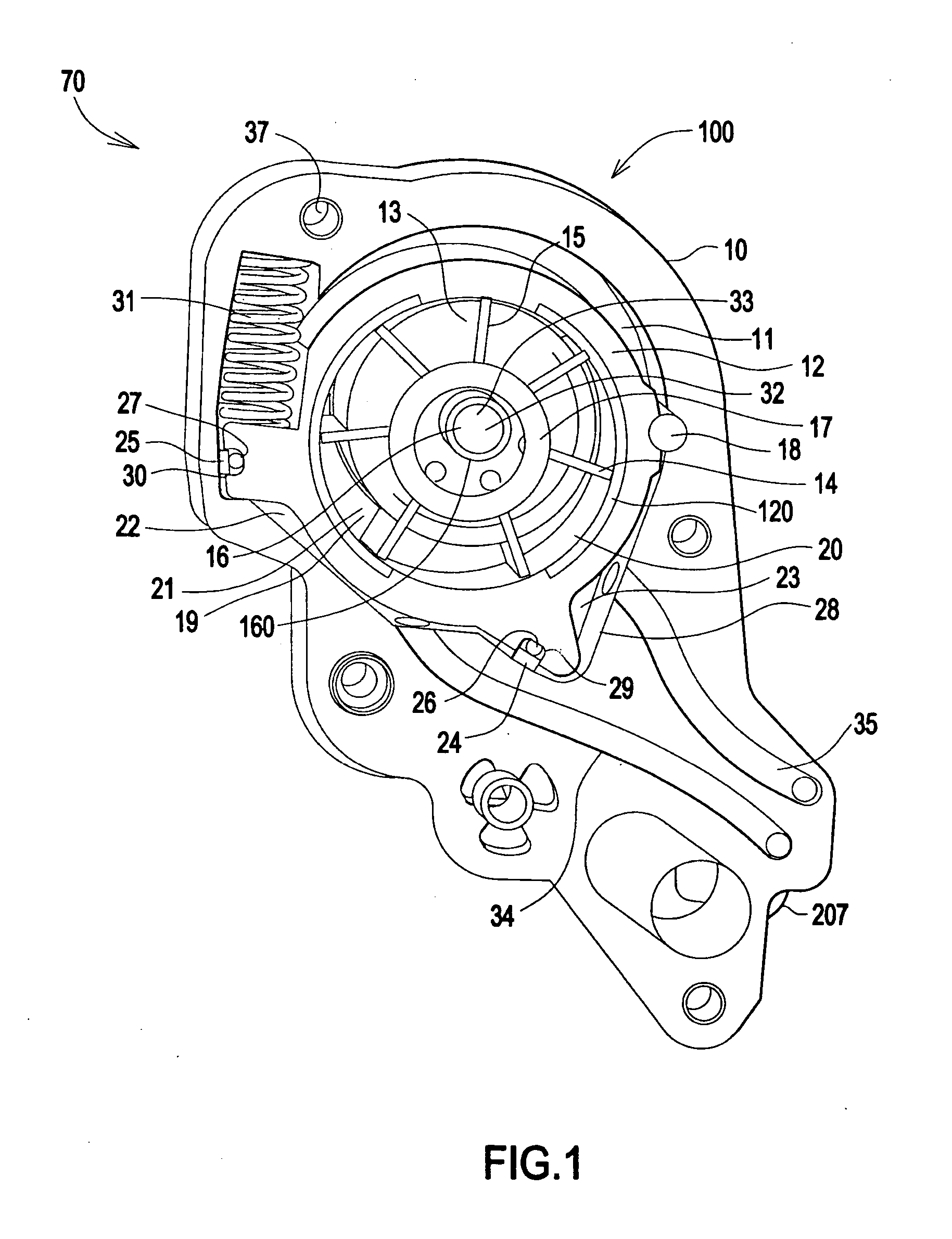

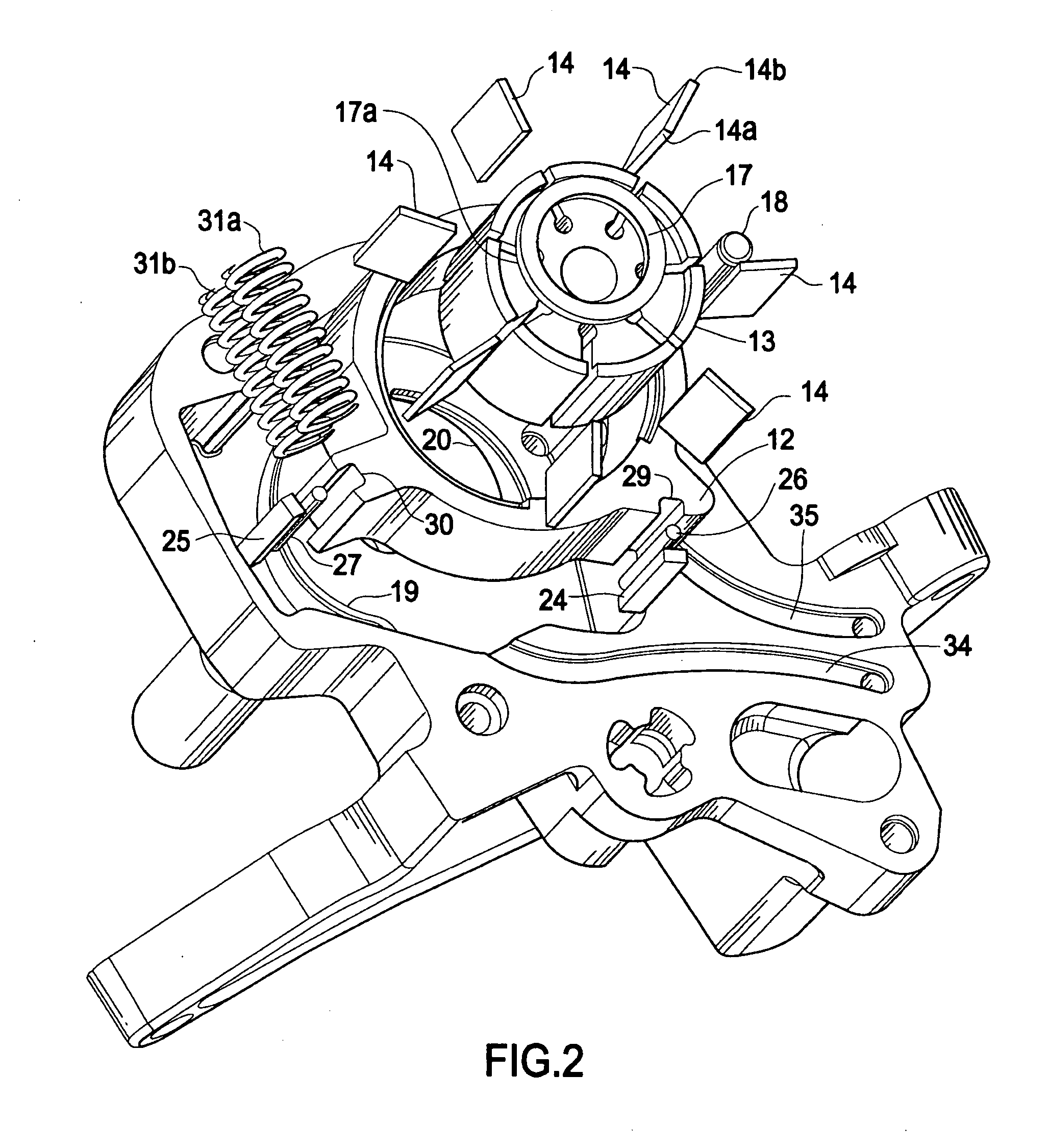

Variable displacement sliding vane pump

InactiveUS20070224067A1Oscillating piston enginesSealing arrangement for pumpsDrive shaftEngineering

A variable displacement sliding vane pump comprising a pump body, inlet and outlet ports formed in said pump body, a drive shaft rotatably mounted in said pump body, a rotor driven by said drive shaft and co-axially aligned therewith, a plurality of radially extending vanes slidably disposed in said rotor, a pivot disposed in said pump body, a slide pivotally disposed on said pivot in said pump body and having a central axis eccentric to the axis of said rotor, a plurality of fluid chambers defined by said rotor, said vanes, and said slide that are successively connected to said inlet and outlet ports, a spring acting on said slide to urge said slide in one direction, a first chamber and a second chamber, each suitable for receiving a fluid pressure and each disposed between said pump body and an outer surface of said slide, the first chamber in fluid communication with a pump outlet discharge pressure, and a valve operable to selectively pressurize and depressurize the second chamber.

Owner:STACKPOLE POWERTRAIN INT ULC

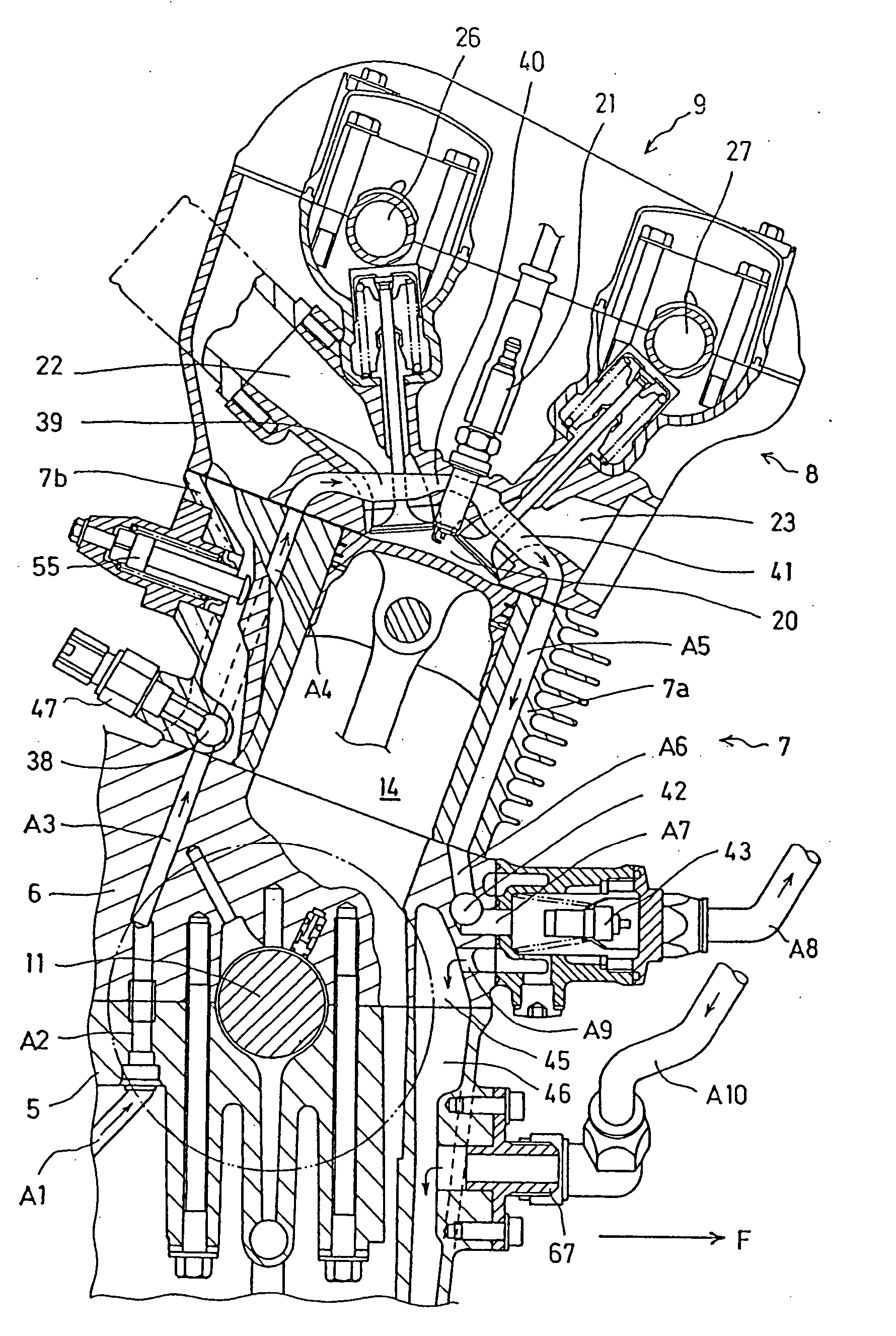

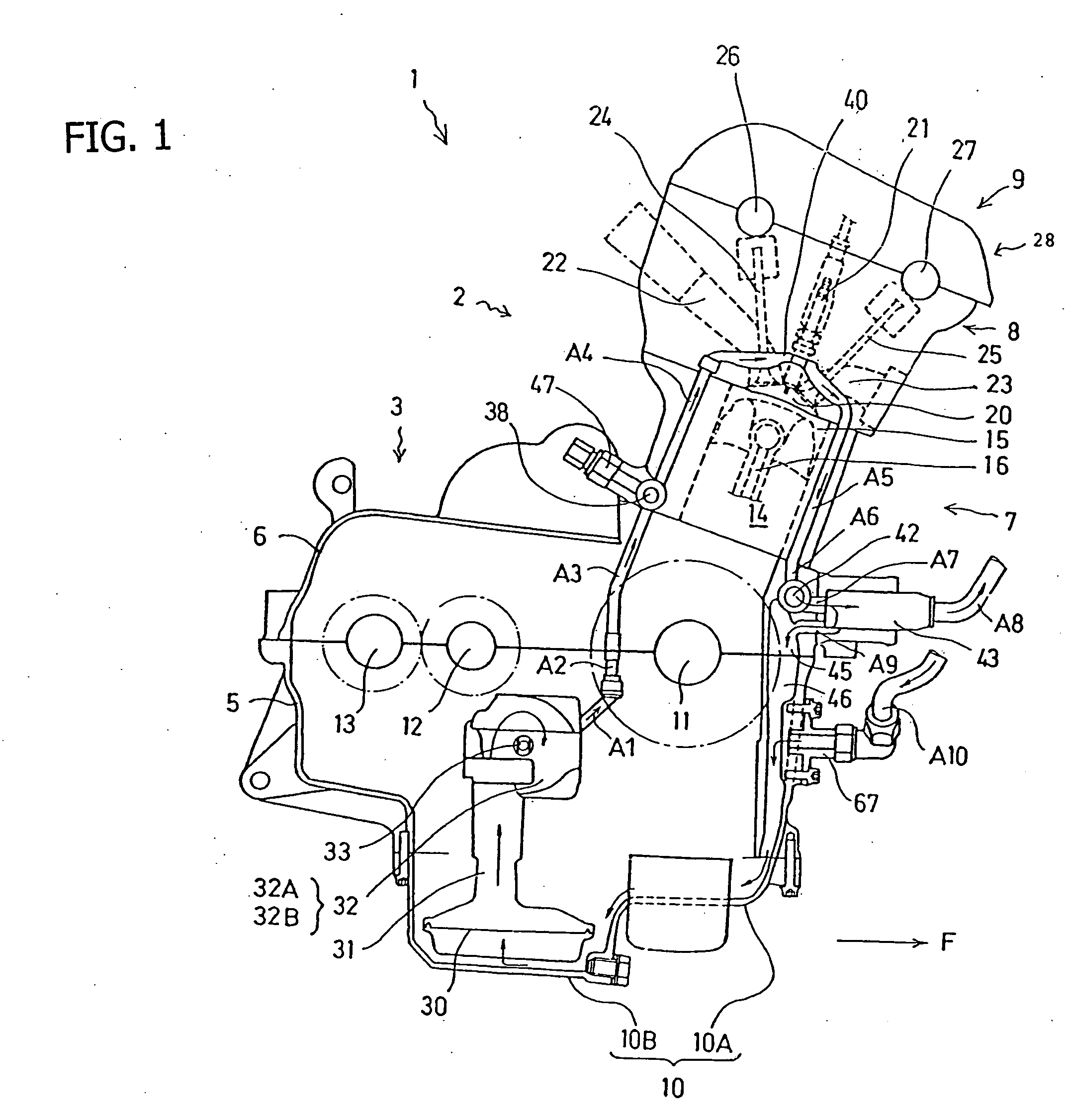

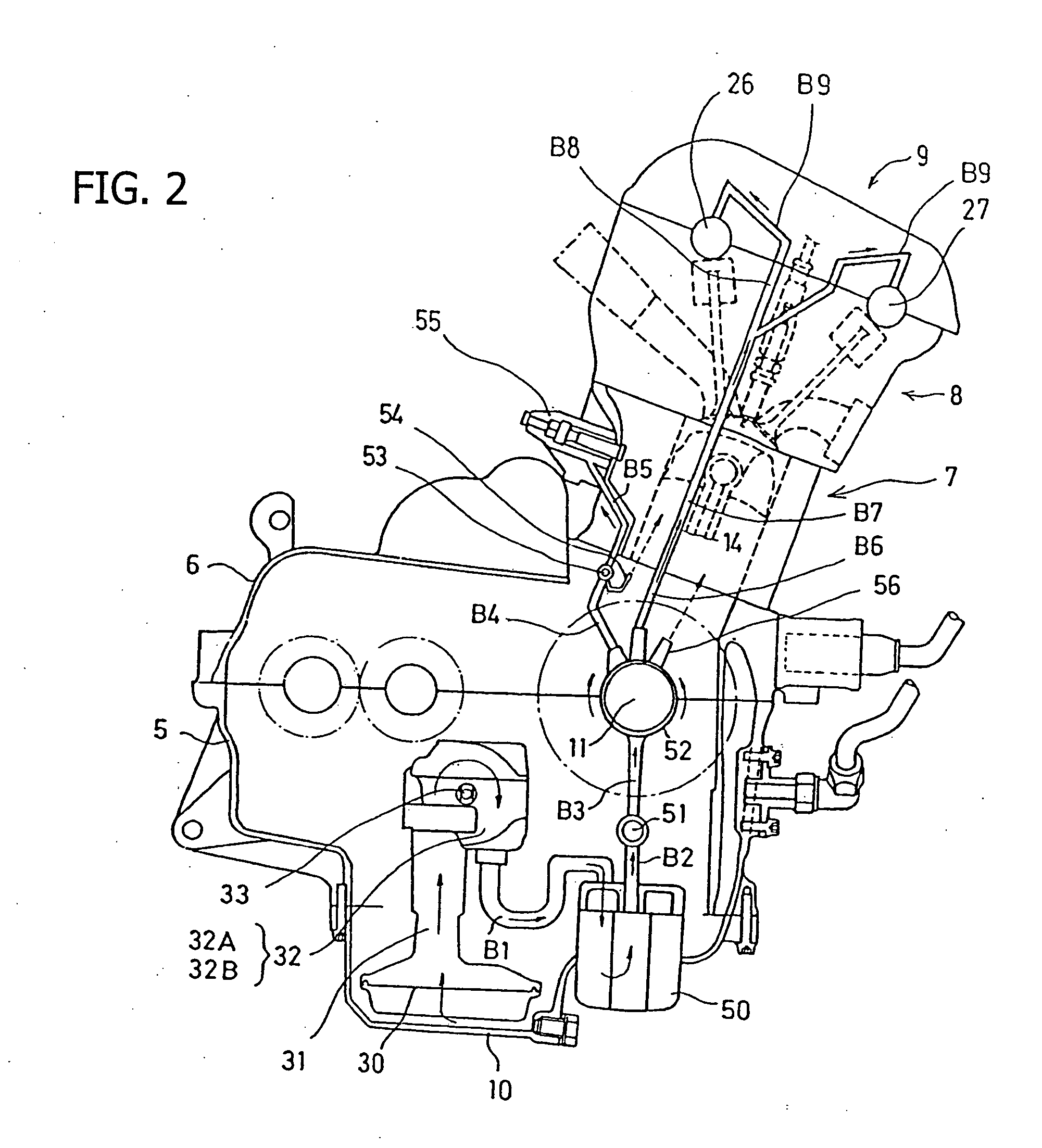

Cylinder head cooling structure for an internal combustion engine, including an oil temperature sensor and an oil temperature control system

ActiveUS20060065218A1Efficient use ofAvoid contactLiquid coolingCoolant flow controlTemperature controlCylinder head

A cylinder head cooling structure and an oil temperature control system are provided for an internal combustion engine having a plurality of cylinders, each having a plurality of intake ports and a plurality of exhaust ports. The engine includes cooling oil jackets surrounding the spark plugs in the cylinder head, a thermostat attached to the front surface of the crankcase independently of an oil filter, and an oil temperature sensor disposed on a rear face of the cylinder block above the crankcase in an oil supply path formed on the cylinder rear face for supplying oil to the oil jackets. Oil passages conducting oil into the oil jacket are provided between two separate parts of a bifucated intake port and between two separate parts of a bifurcated exhaust port, and only cooling system oil reaching high temperatures is allowed to flow through the thermostat, thereby improving temperature control response.

Owner:HONDA MOTOR CO LTD

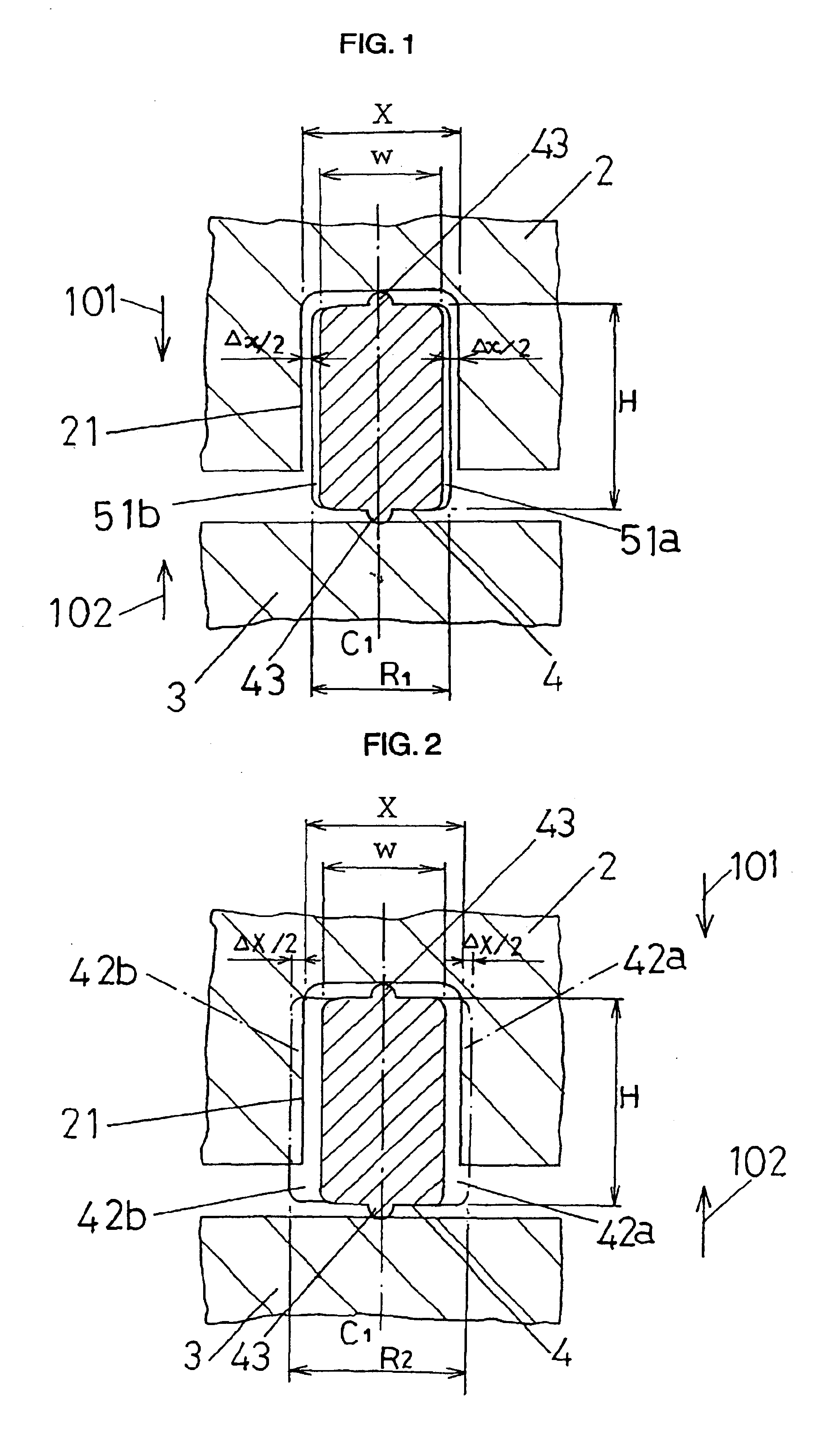

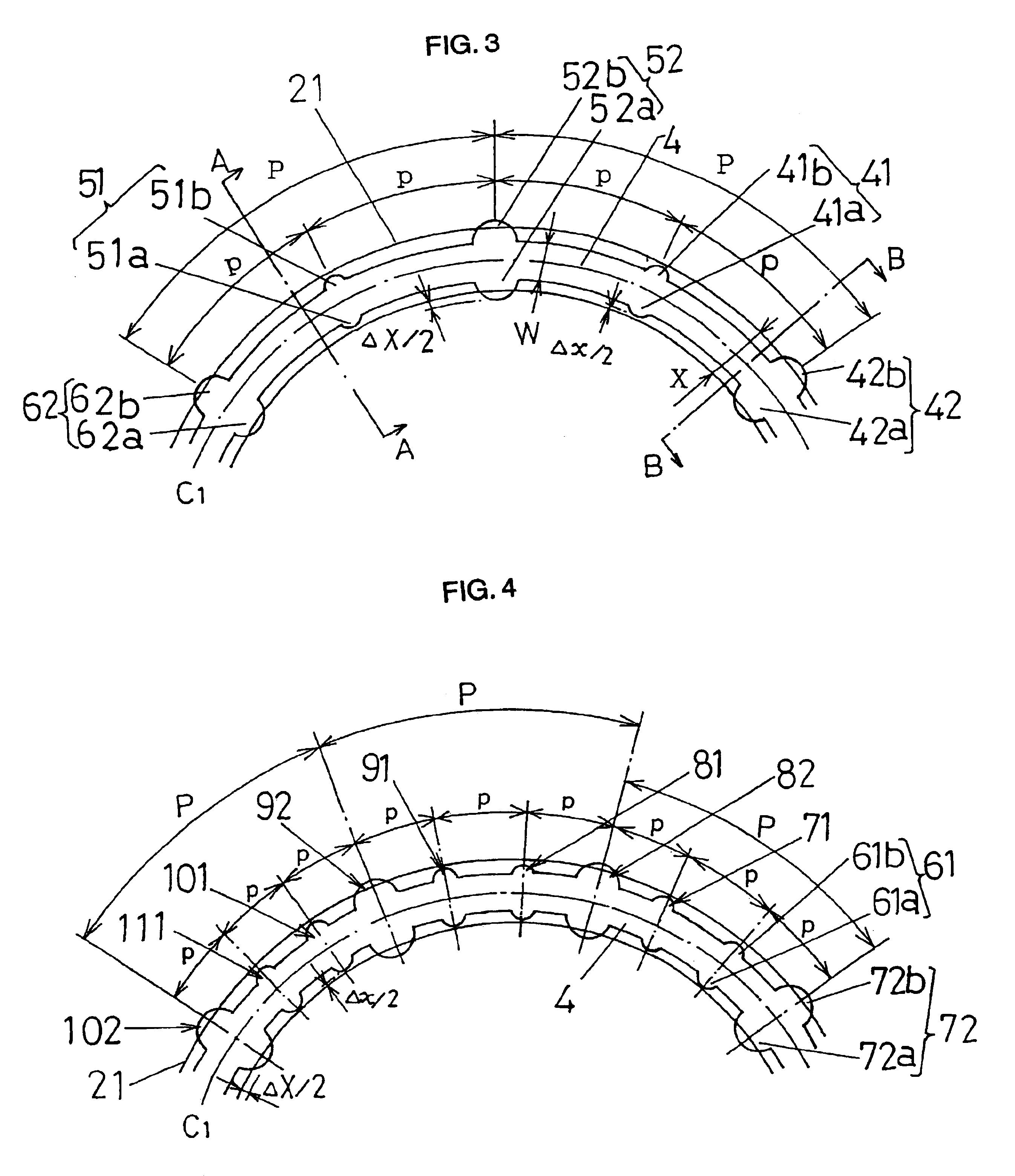

Gasket

A longitudinally-endless gasket mounted into a groove portion formed in one of members to provide sealing between this one member and another of the members when they are fastened to each other. The gasket has a sectional shape corresponding to a sectional shape of the groove portion with a ratio (H / W) between a height (H) and a width (W) of the sectional shape being 0.8 to 5.0. The gasket is provided with a plurality of large projecting portions at intervals of 30 to 100 mm and a plurality of small projecting portions at intervals of 5 to 15 mm in a longitudinal direction of the gasket. A width (R2) of each large projecting portion is larger than a width (X) of the groove portion by 0.01 to 0.9 mm. A width (R1) of each small projecting portion is smaller than the width (X) of the groove portion by 0.01 to 0.6 mm. A filling rate of the groove portion by the gasket when the members are fastened to each other is 80 to 100%.

Owner:UCHIYAMA MFG

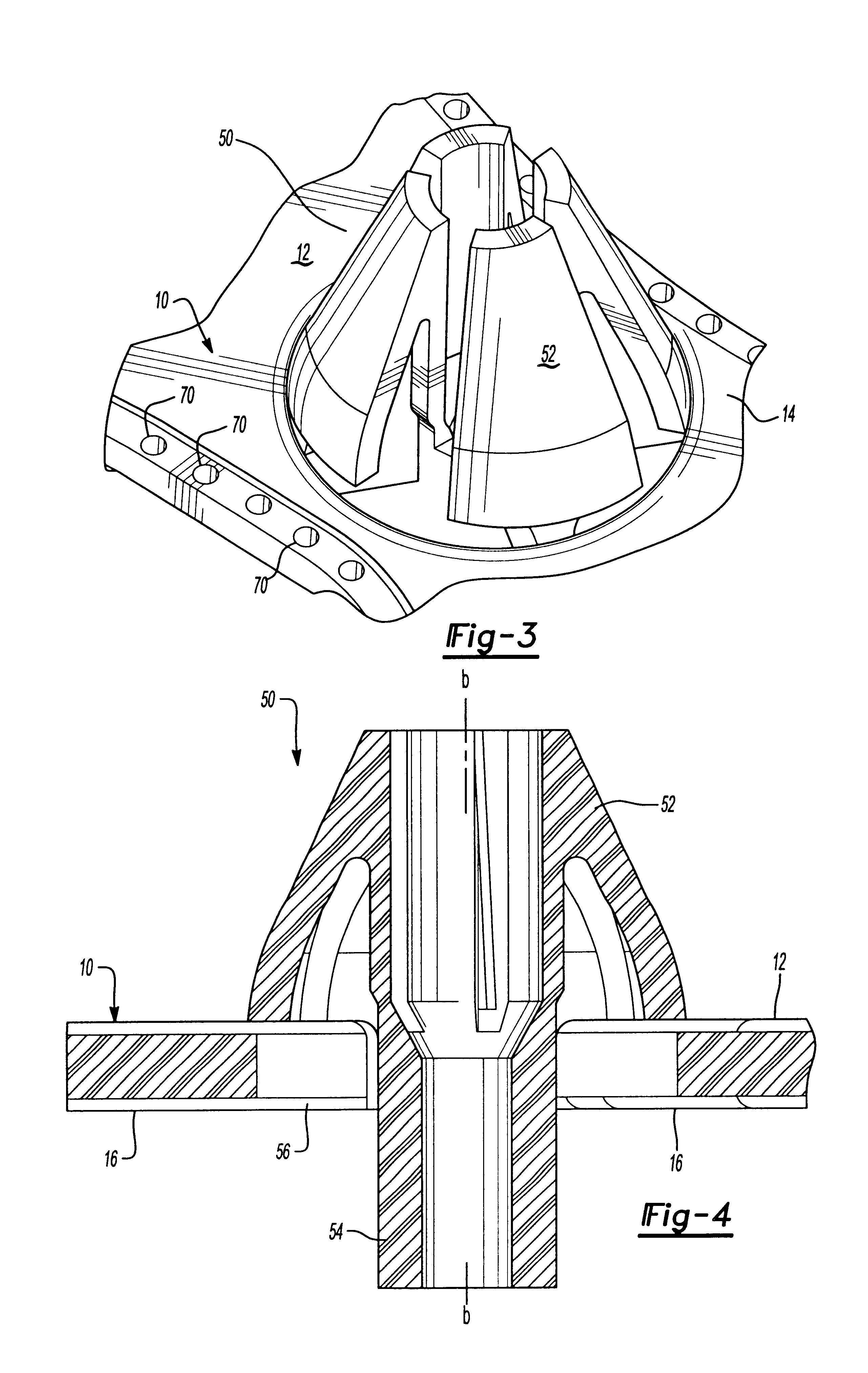

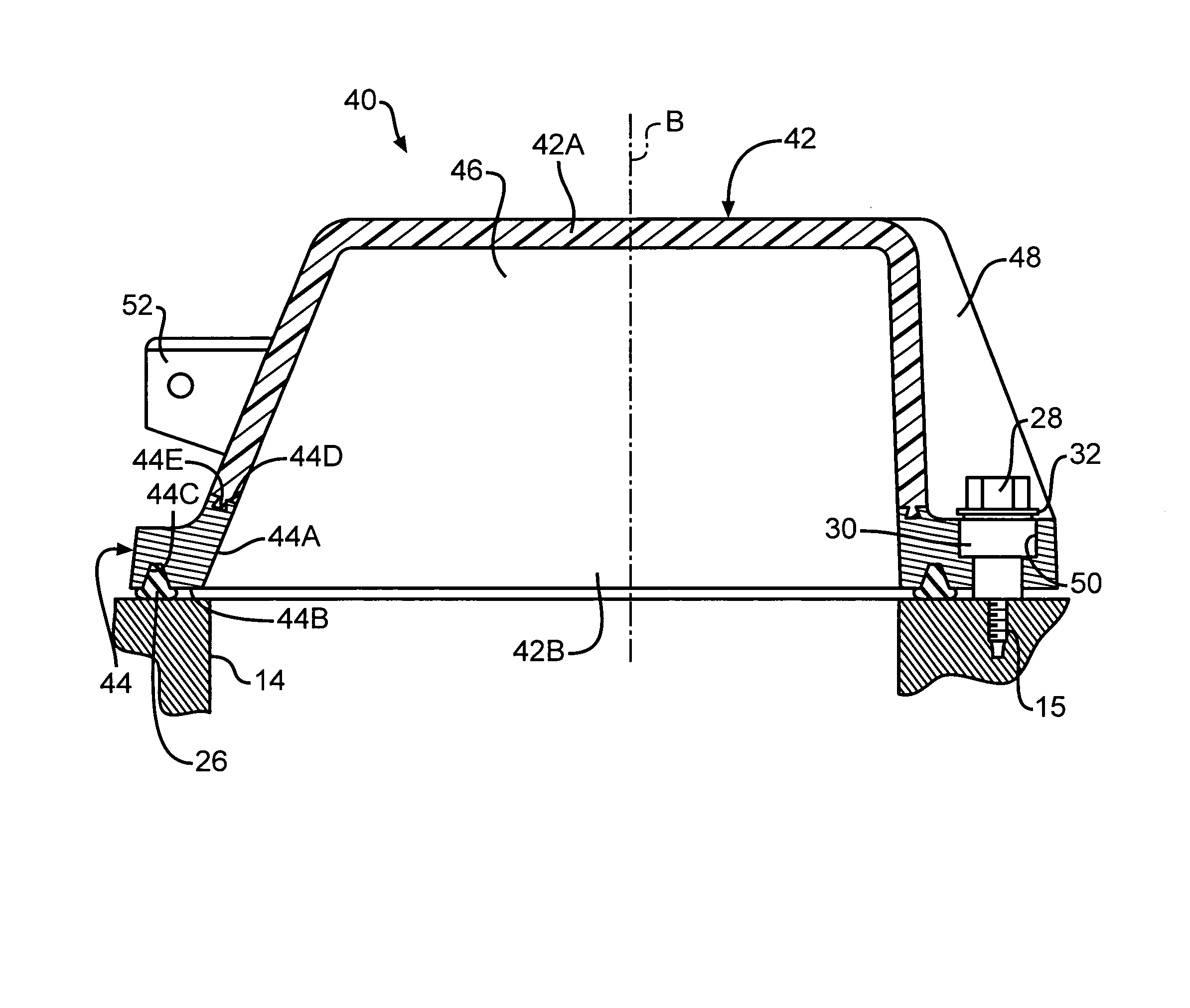

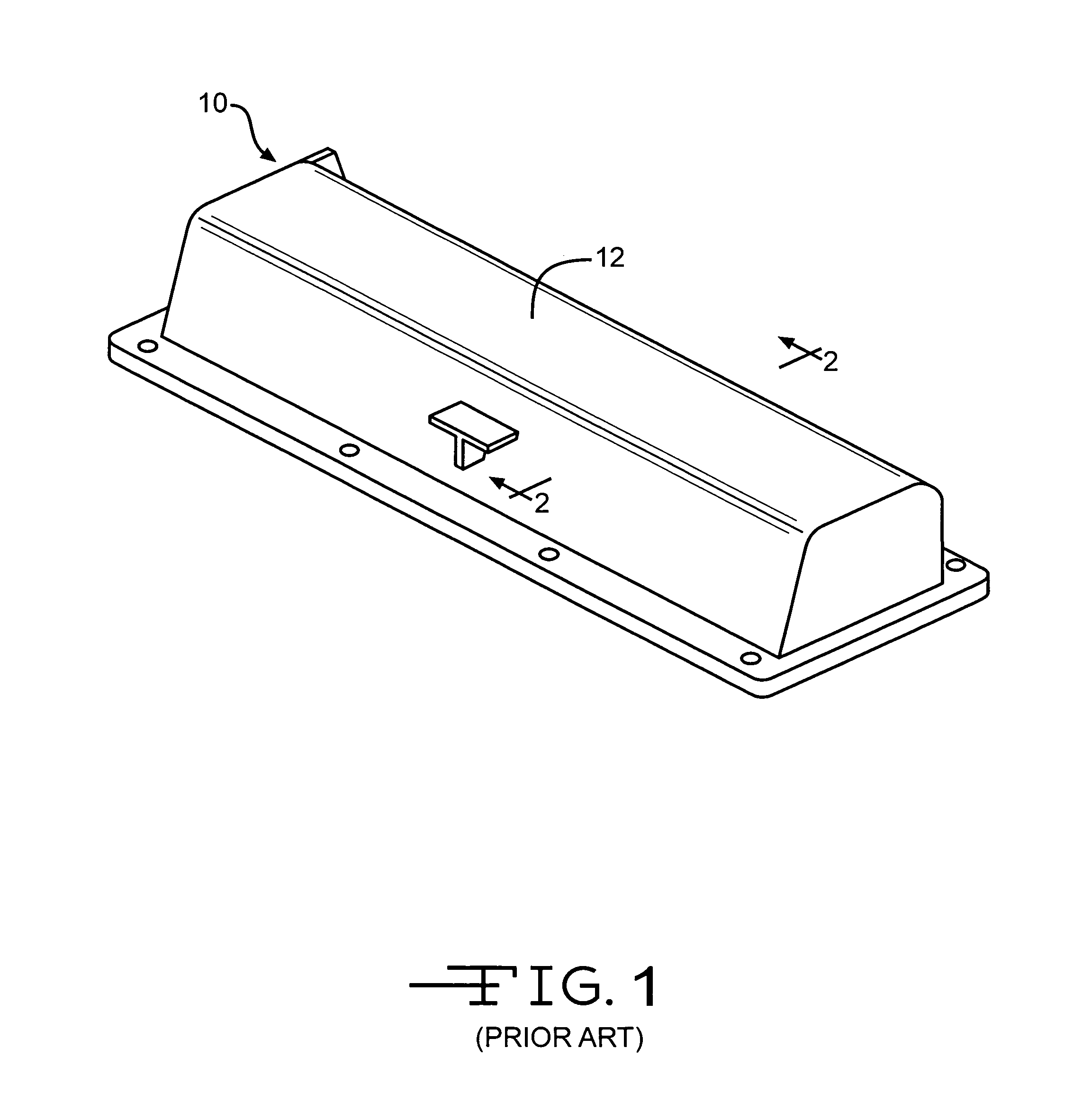

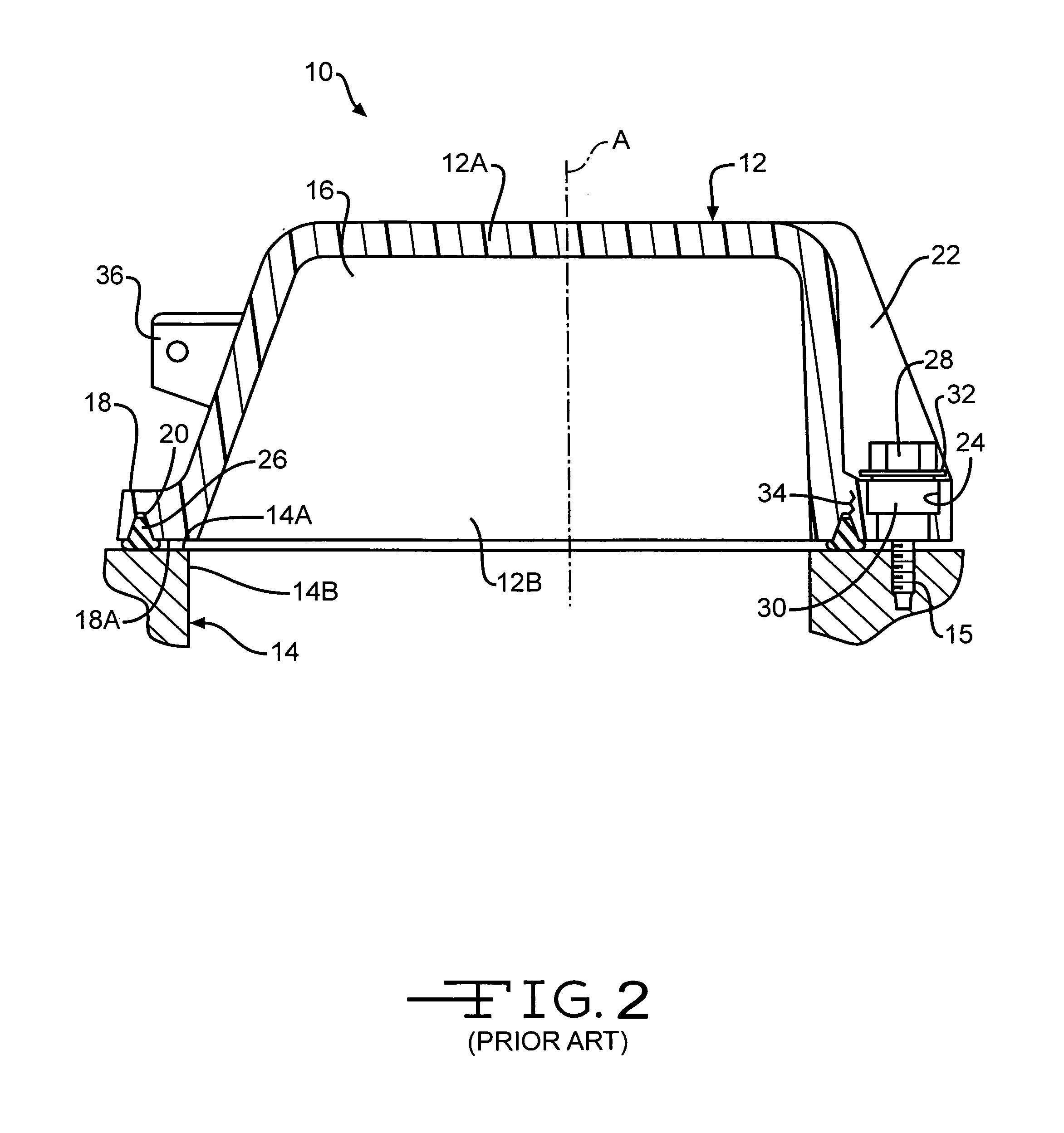

Valve cover assembly for a vehicle engine and method for producing same

The present invention relates to a valve cover assembly adapted to be secured to a cylinder head of a vehicle engine. The valve cover assembly includes a valve cover body formed from a first material and an attachment member formed from a second material and attached to the valve cover body.

Owner:HARVEY HLDG

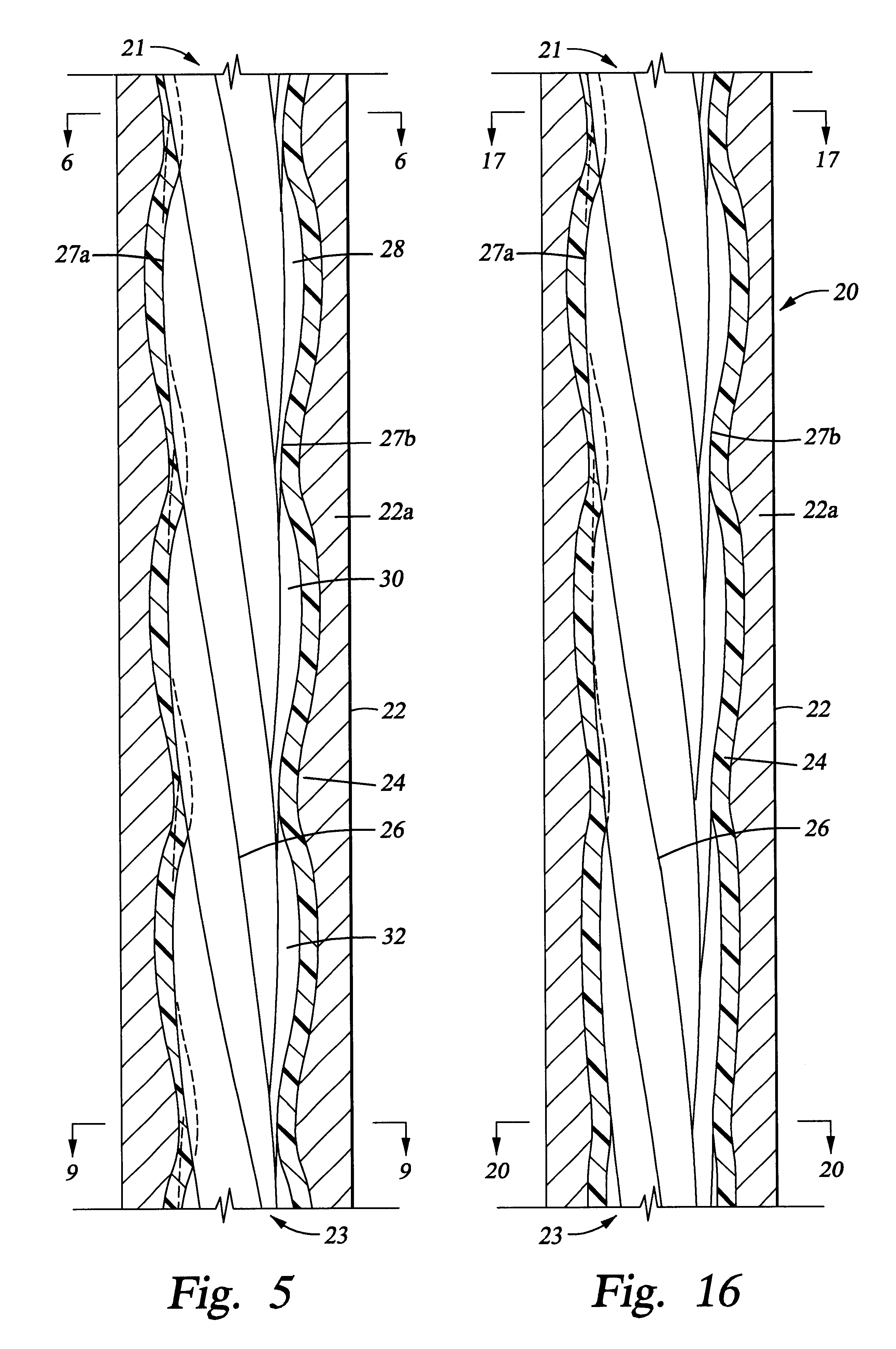

Reduced rotor assembly diameter vane pump

InactiveUS7997882B2Reduce the overall diameterReduce radial sizeOscillating piston enginesSealing arrangement for pumpsWorking fluidDrive shaft

A vane pump with a reduced rotor diameter is provided. The reduced rotor diameter allows a reduction in the overall size of the pump which allows the pump to be used in circumstances wherein sufficient packaging volume does not exist for conventional vane pumps. Further, the reduced rotor diameter permits operation of the pump at a higher speed, in comparison to conventional vane pumps, for a given working fluid and pump rate. The rotor includes an integrally formed drive shaft and a cylindrical rotor head. Both fixed displacement and variable displacement embodiments are shown.

Owner:MAGNA POWERTRIAN INC (US)

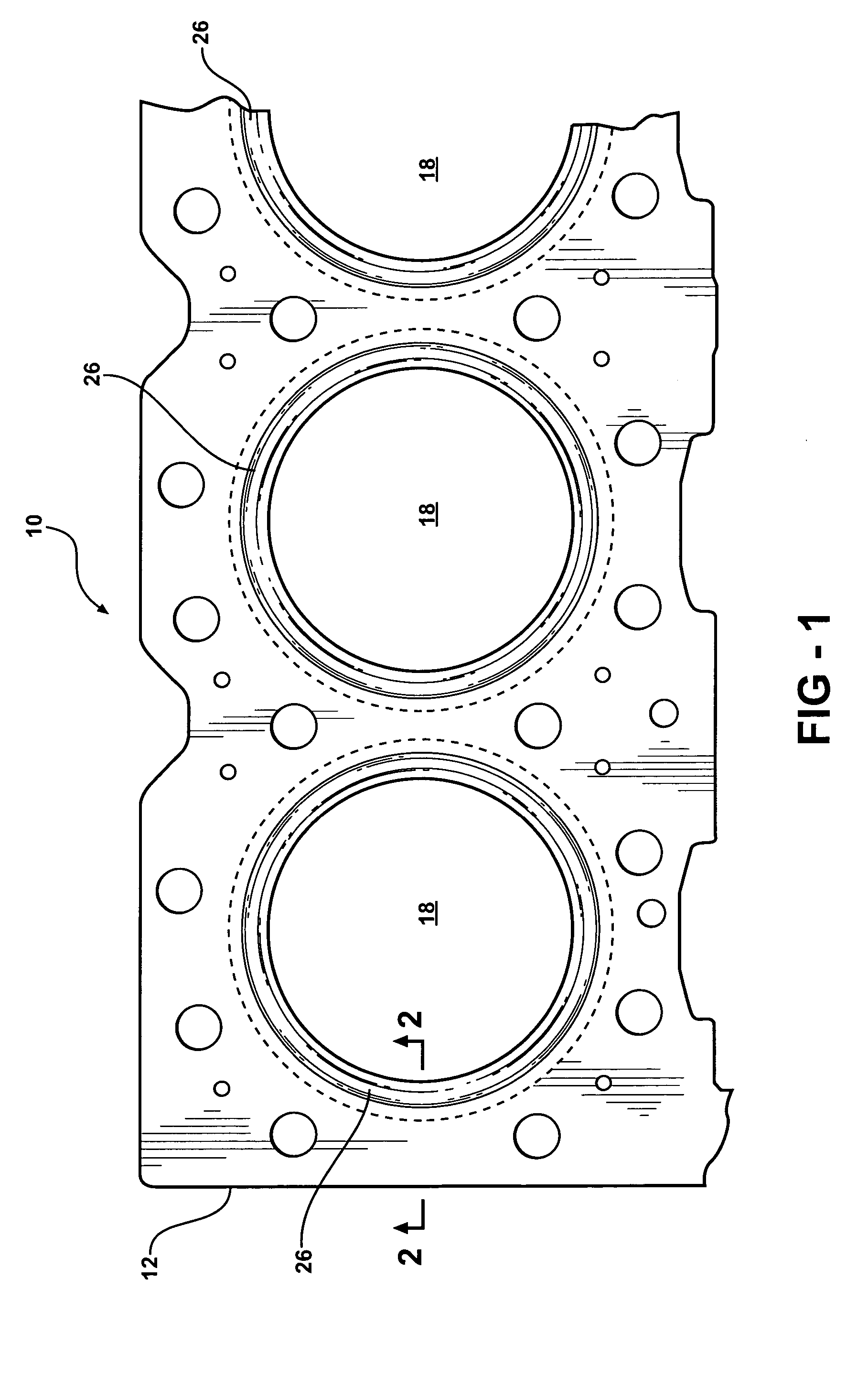

Cylinder head gasket

InactiveUS20050206091A1Average thicknessIncreasing the thicknessEngine sealsSealing arrangements for enginesCombustion chamberCylinder head

Cylinder head gasket with a gasket plate formed by at least one layer of sheet metal and at least one combustion chamber aperture which is enclosed by a sealing device serving the purpose of sealing the combustion chamber, wherein in order to reduce any warpages of an engine block and / or of a cylinder head a supporting device is provided radially outside the sealing device on the gasket plate; so that the supporting device can be produced in a material-saving and procedurally reliable manner, the supporting device has an area of the sheet-metal layer which is thickened by way of embossing and does not enclose any of the apertures of the gasket to be sealed completely or almost completely and has at least one embossed supporting bead with a meandering shape or a two-dimensional pattern of cup-like recesses and associated elevations.

Owner:ELRINGKLINGER AG

Housing of portable electronic devices

InactiveUS8032194B2Interconnection arrangementsSealing arrangements for enginesEngineeringElectron device

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

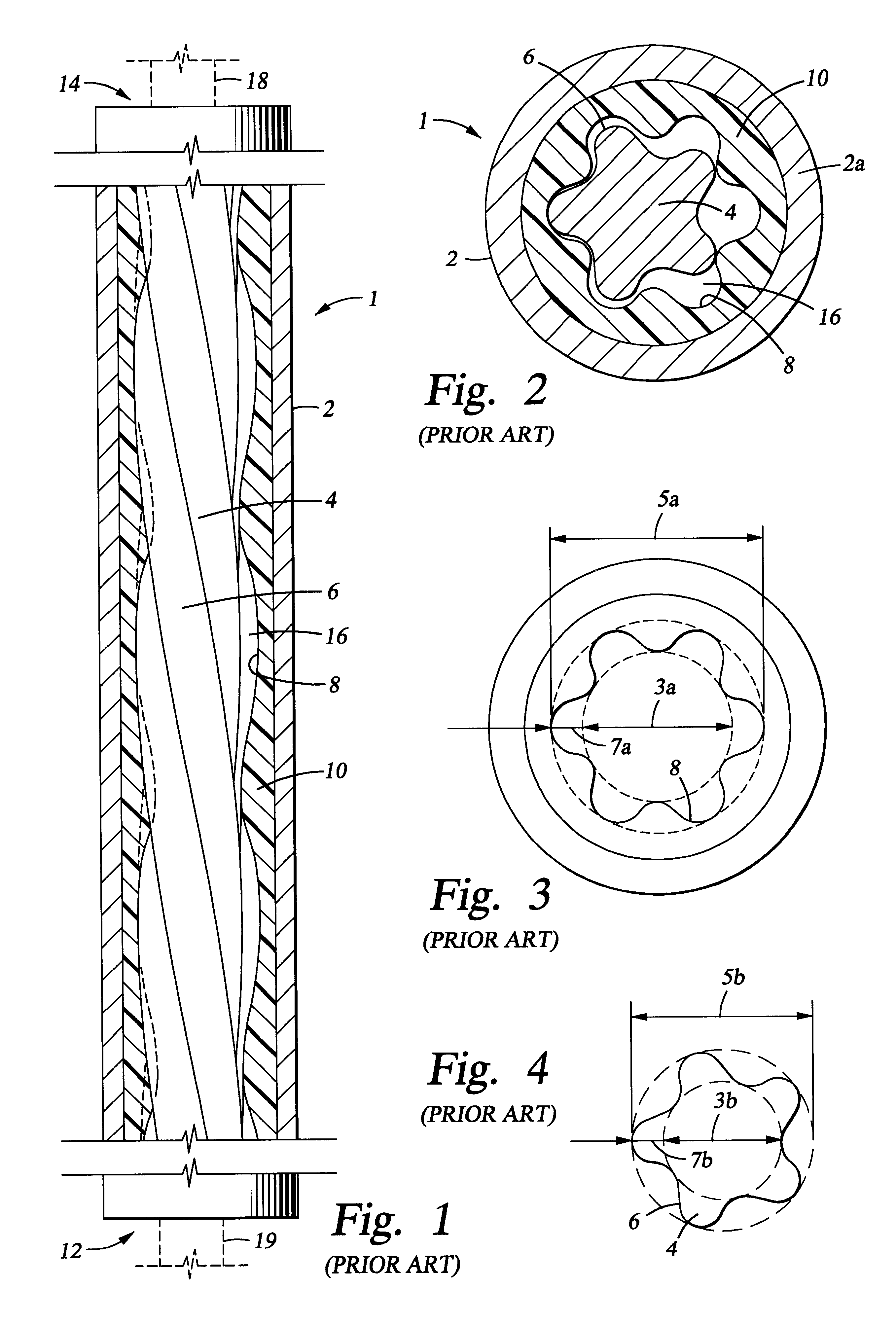

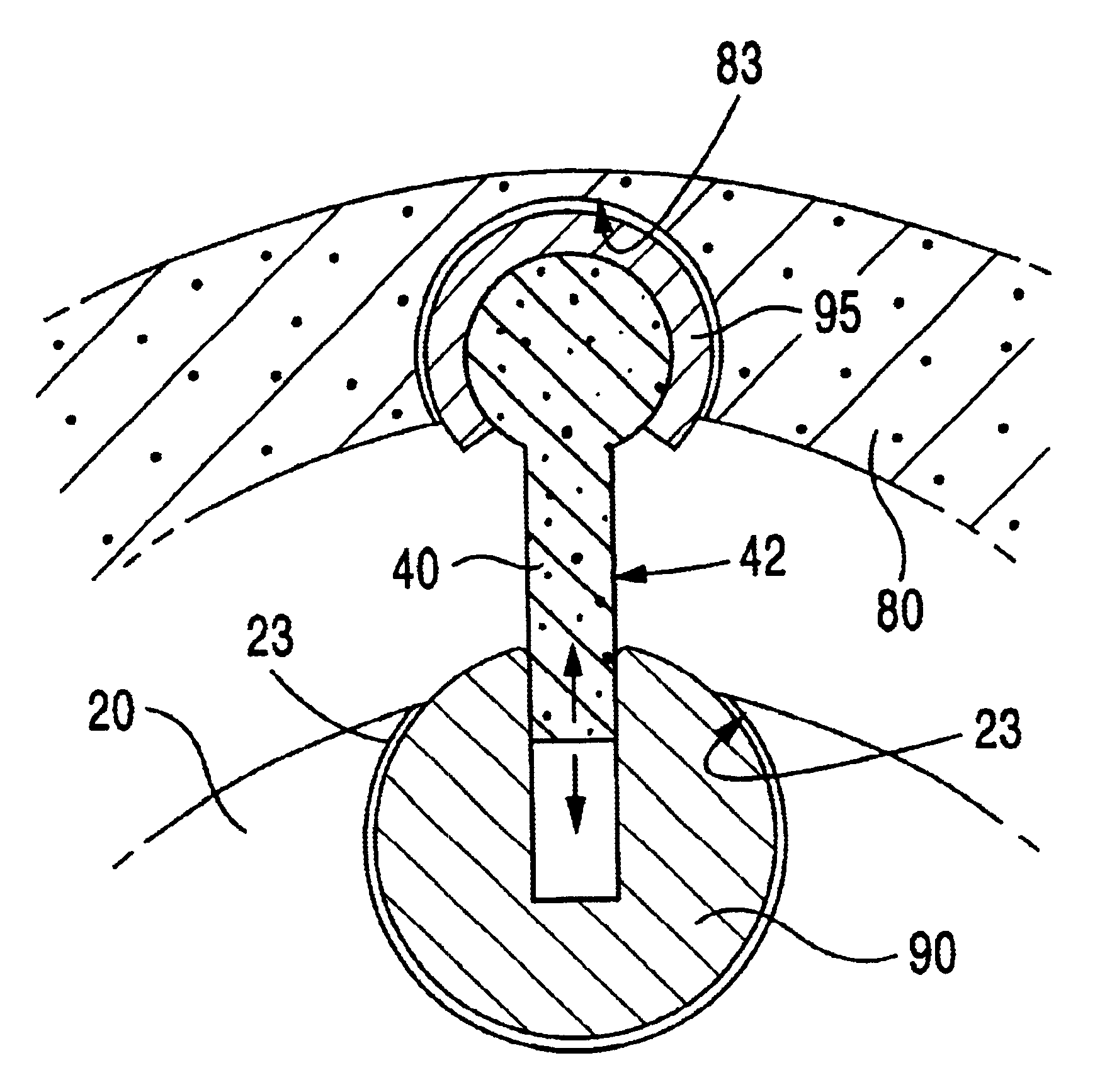

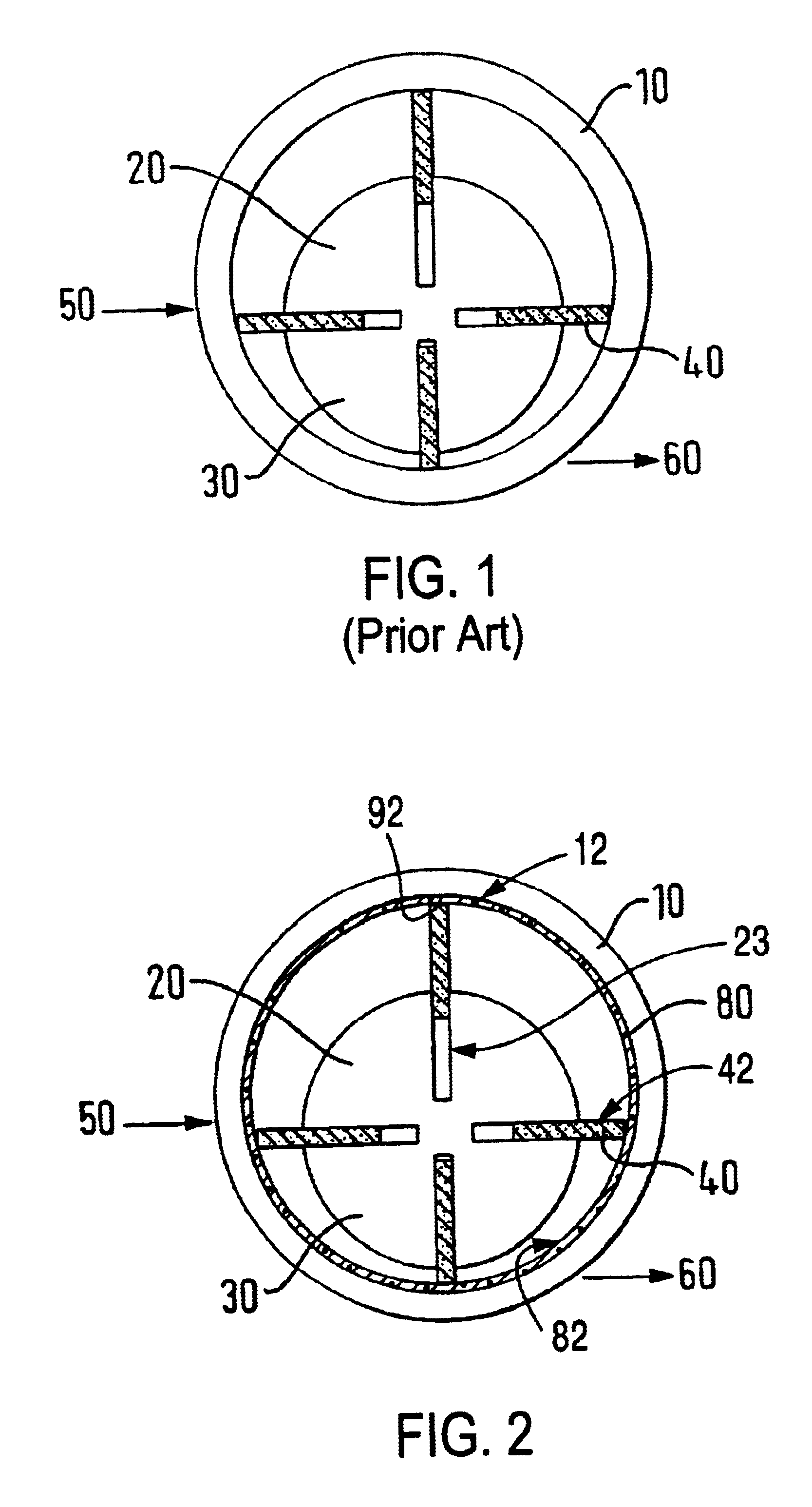

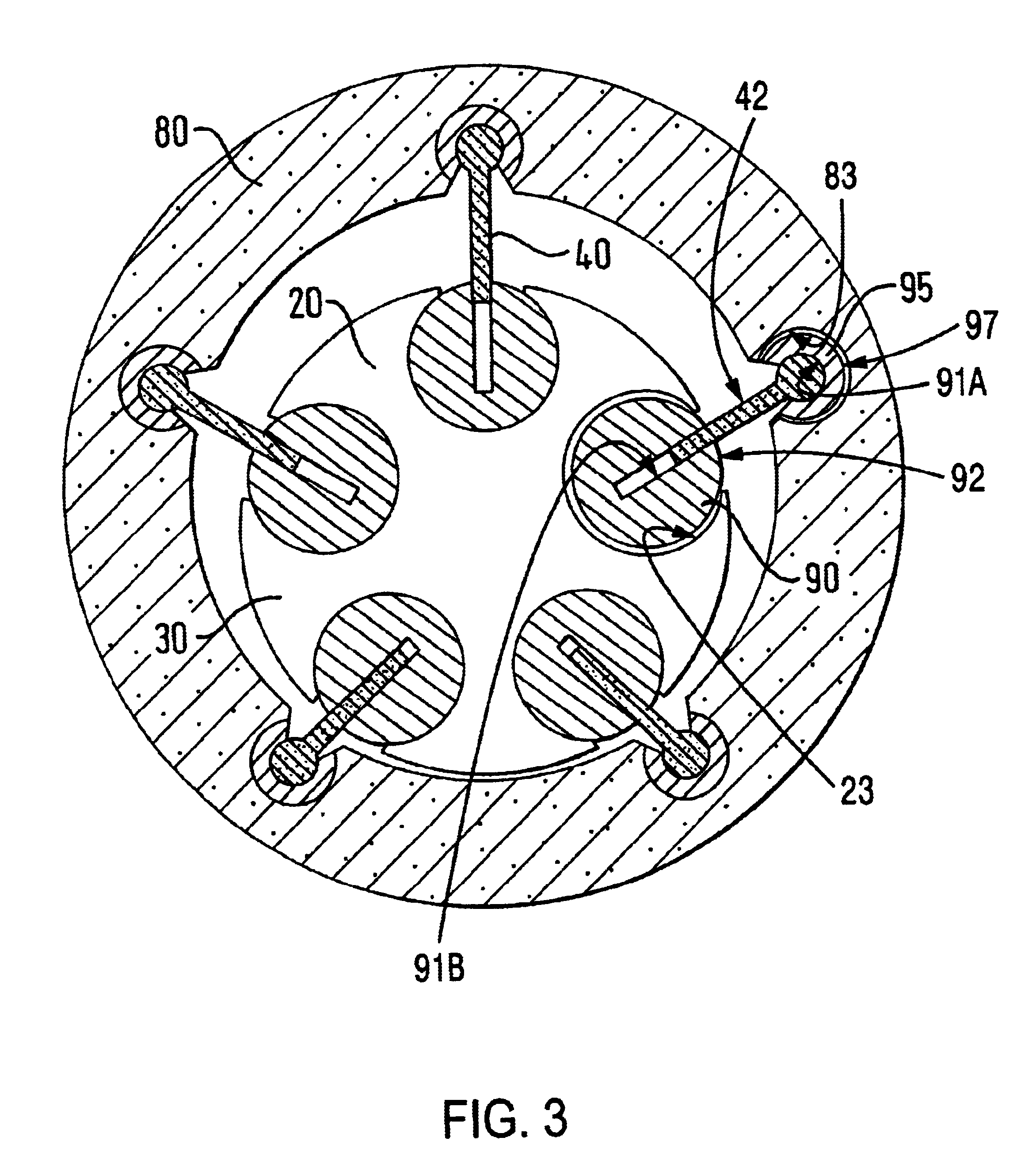

Rotary pump

InactiveUS6666671B1Shorten speedReduce wear rateOscillating piston enginesSealing arrangement for pumpsRotary pumpFree rotation

A rotary pump for pumping compressible fluid comprising an eccentrically mounted rotor 20 and a stator 10. The stator 10 comprises a stator inner liner 80 that is free to rotate, driven directly or in response to rotation of the rotor 20 such that the relative velocity between the outer surface of the rotor 20 and the inner surface of the stator 10 is reduced. The vanes 40 are held at each end by sockets 90, 95 in the rotor 20 and stator 10. The vane 40 and socket 90, 95 coupling provides fluid sealing without liquid lubricant. Opposing solid lubricant and hard surfaces are used on contact surfaces between the elements.

Owner:IC INNOVATIONS

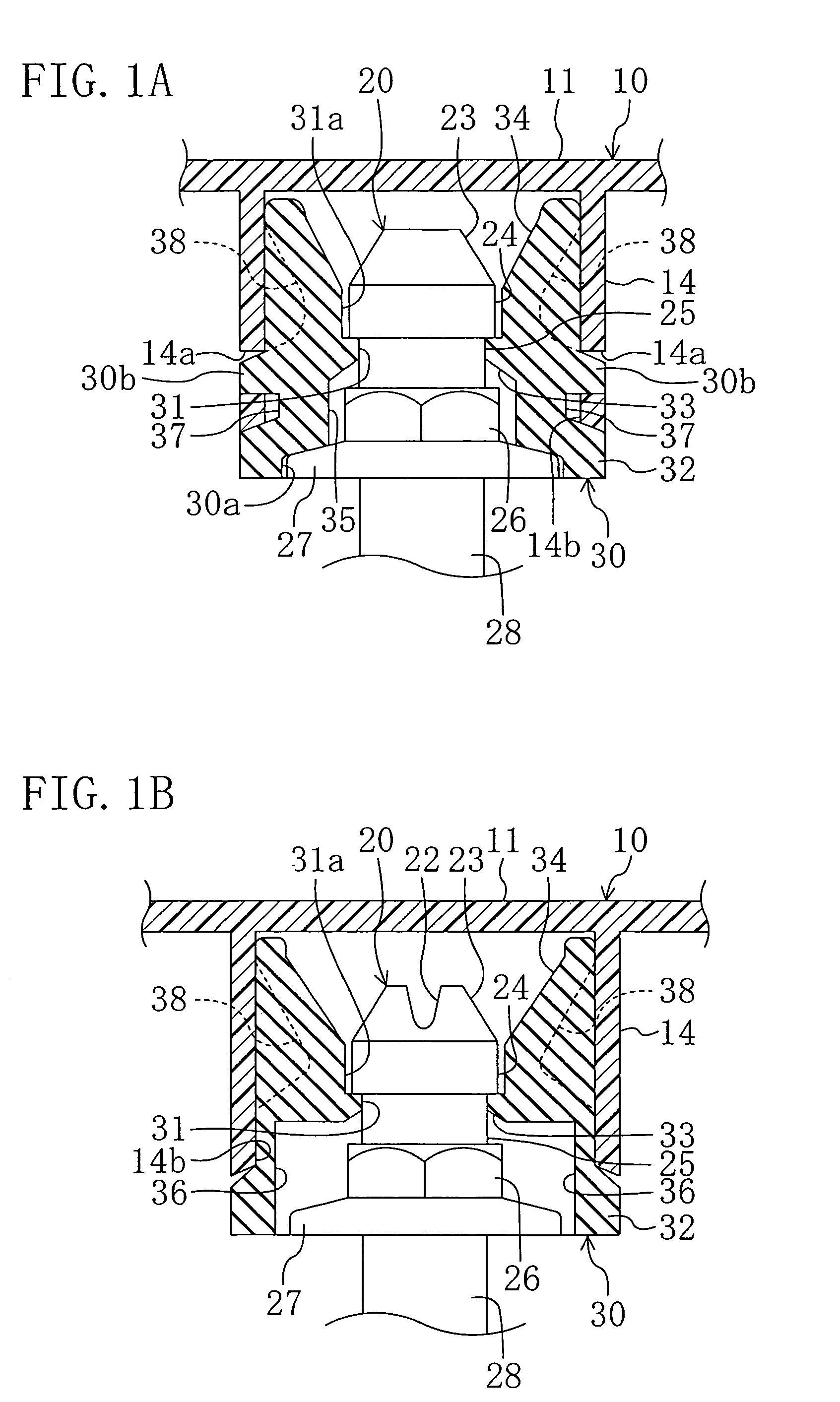

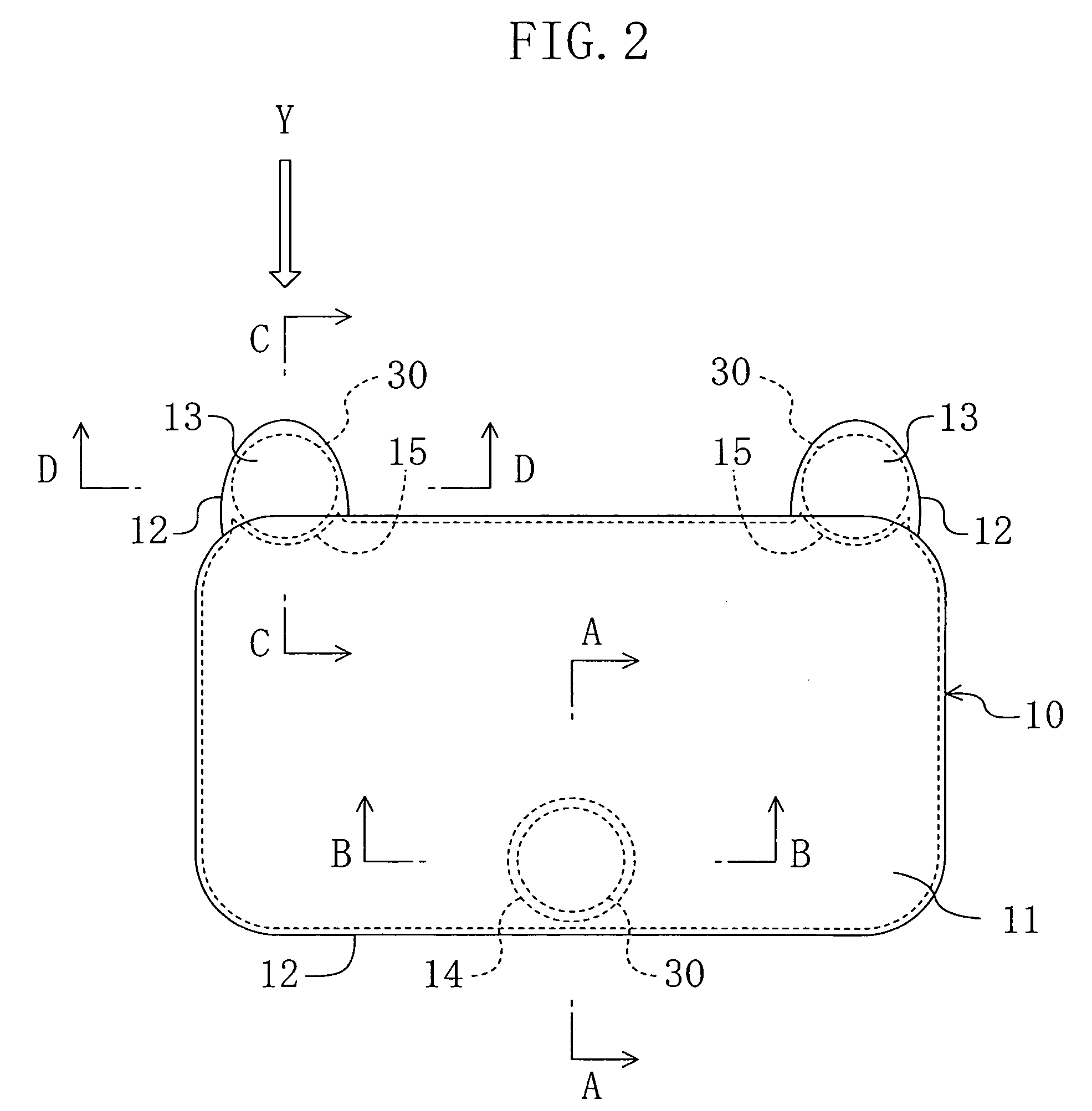

Joint structure between members

A first annular frame is formed on the bottom surface of an engine cover. A mount rubber of columnar shape is inserted into the first annular frame. Projections of the mount rubber are fitted into holes of the first annular frame. A through hole is formed in the mount rubber. An engagement projection is formed on the inner surface of the through hole. An adapter has a small-diameter part formed in the vicinity of the top end and a predetermined distance away from the top end toward the root thereof. The adapter has a flange formed below the smaller-diameter part. The top end part of the adapter is inserted into the through hole of the mount rubber to fit the engagement projection into the small-diameter part and bring the flange into abutment on the bottom surface of the mount rubber.

Owner:PIOLAX CO LTD +1

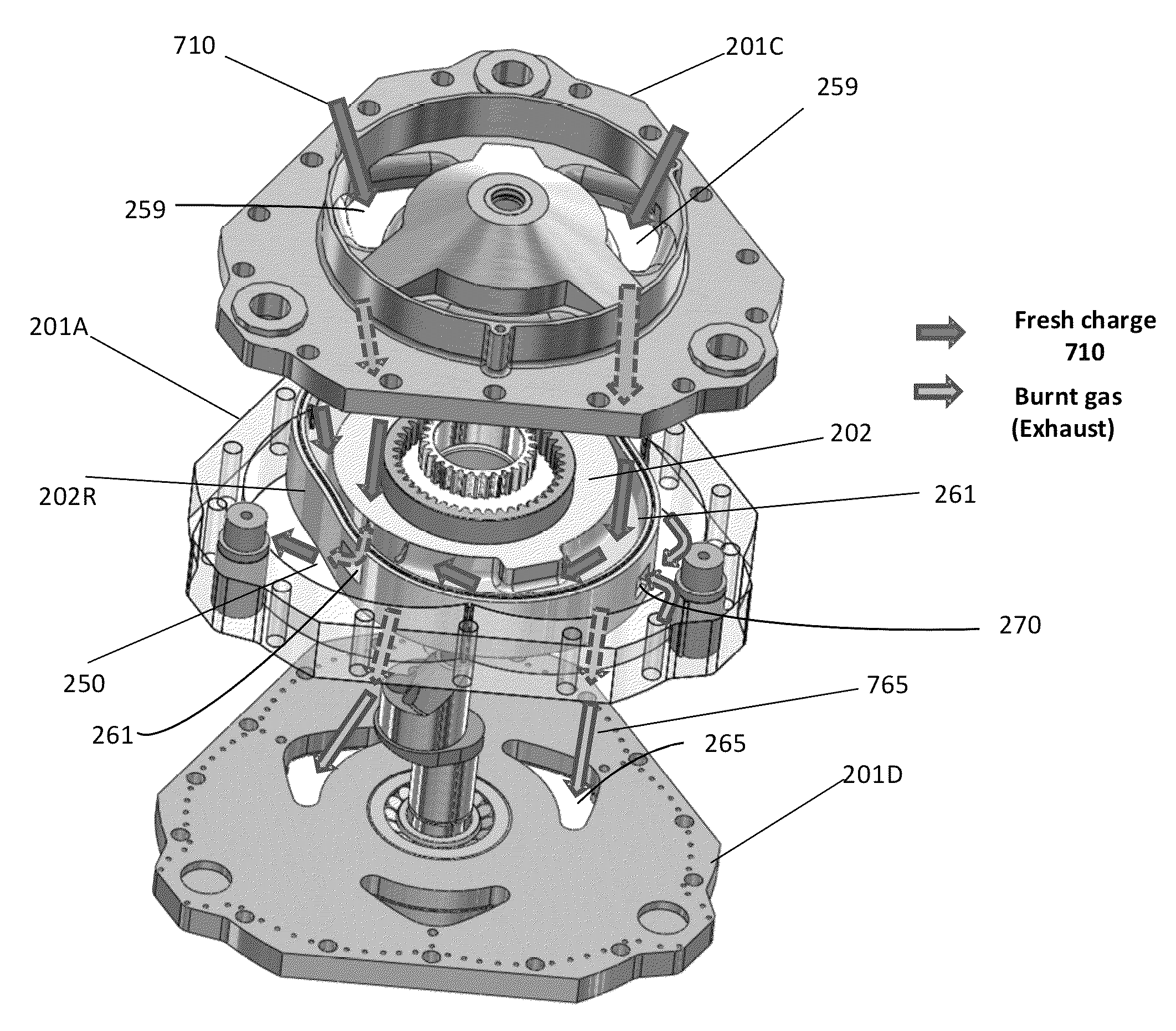

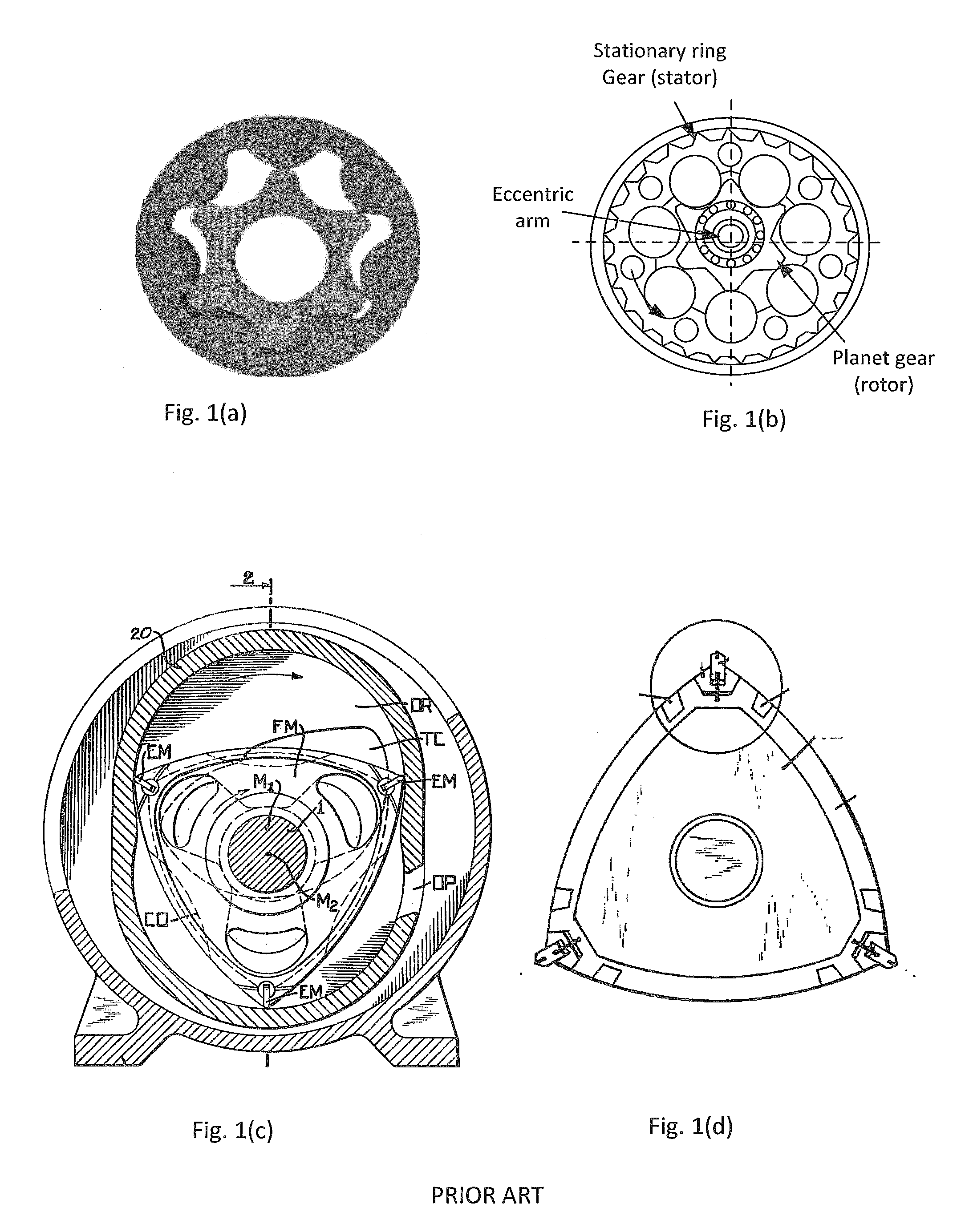

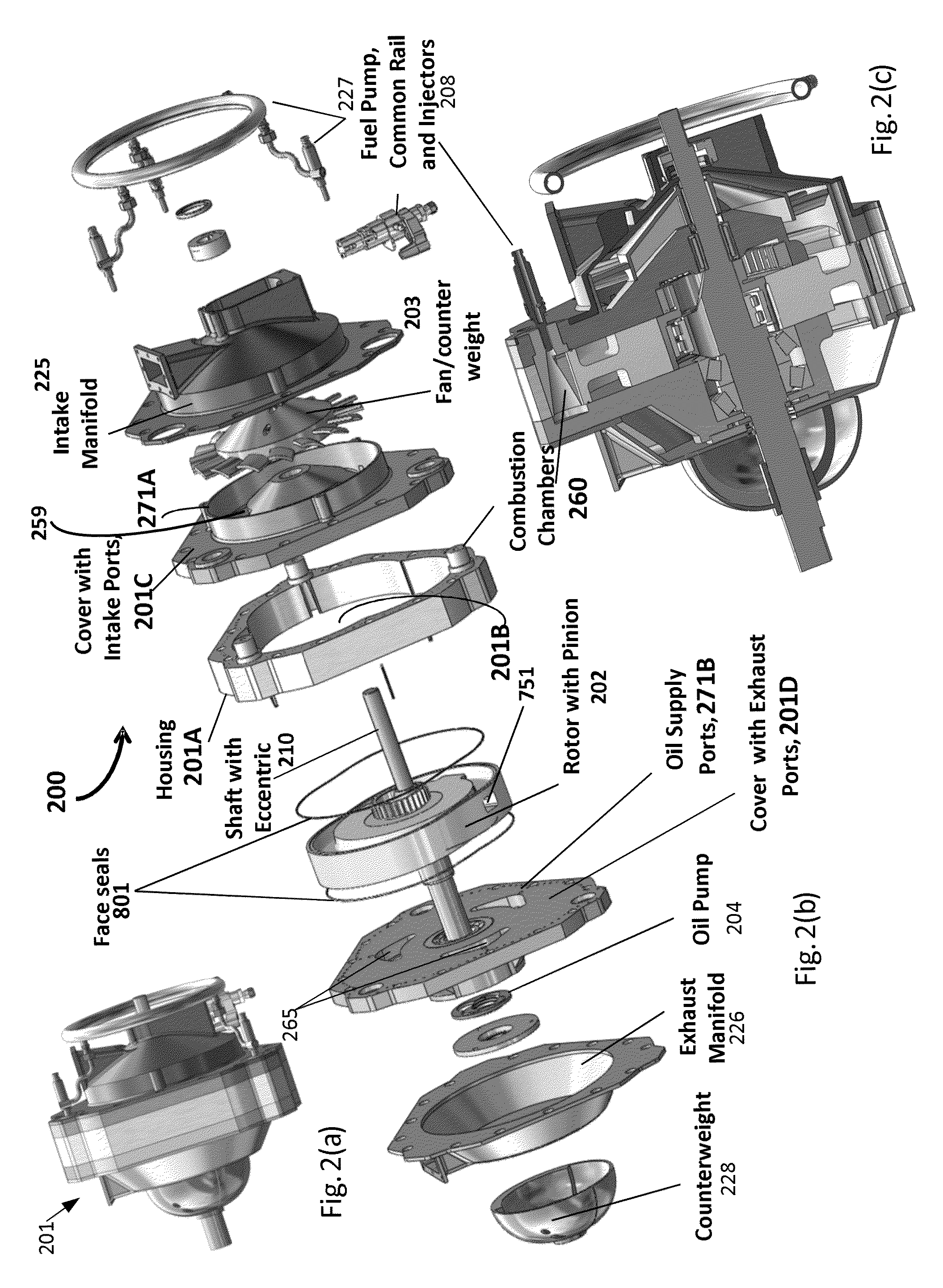

Cycloid rotor engine

ActiveUS8523546B2Internal combustion piston enginesEngine of arcuate-engagement typeRotary engineEngineering

Owner:LIQUIDPISTON INC

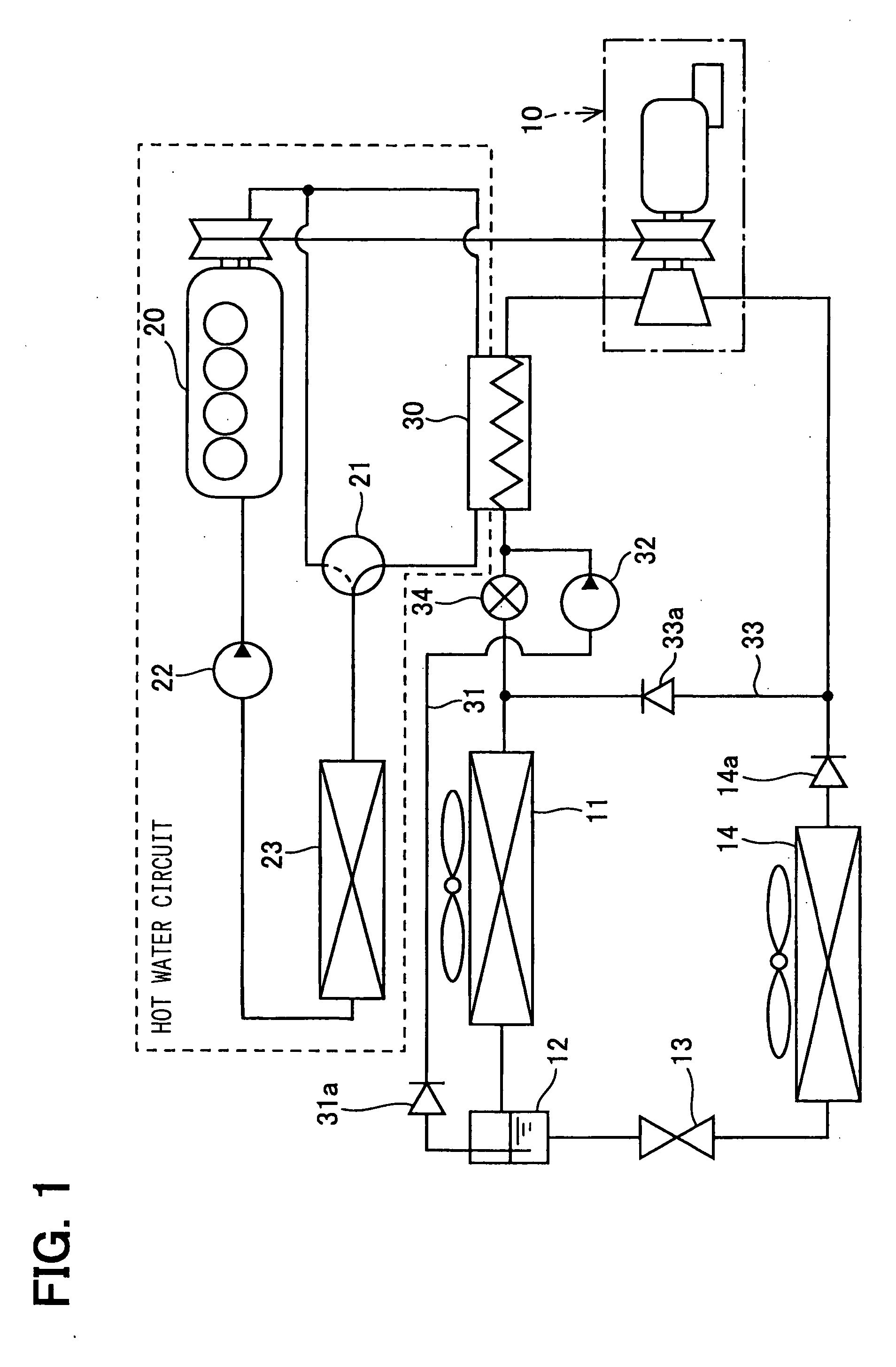

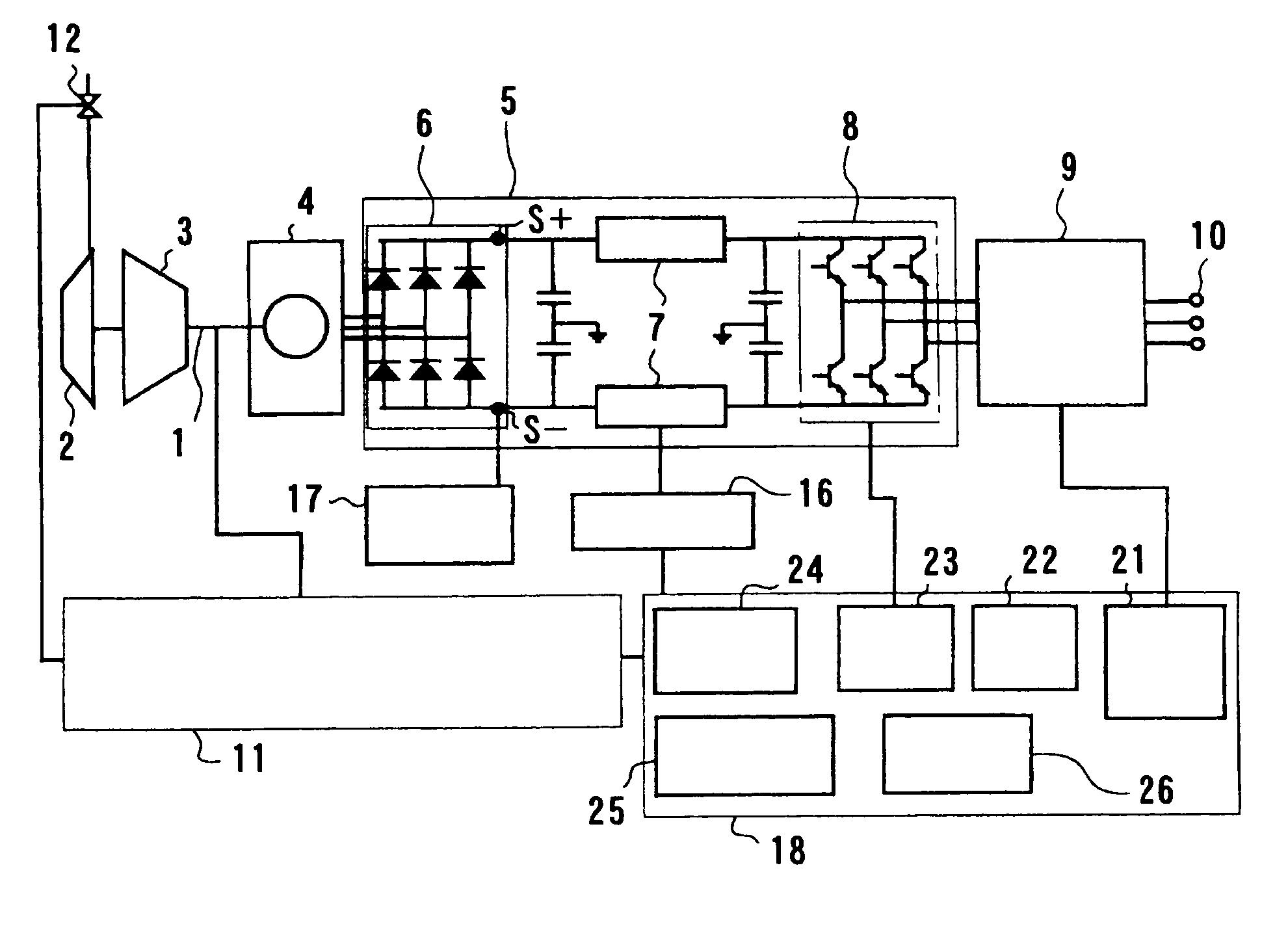

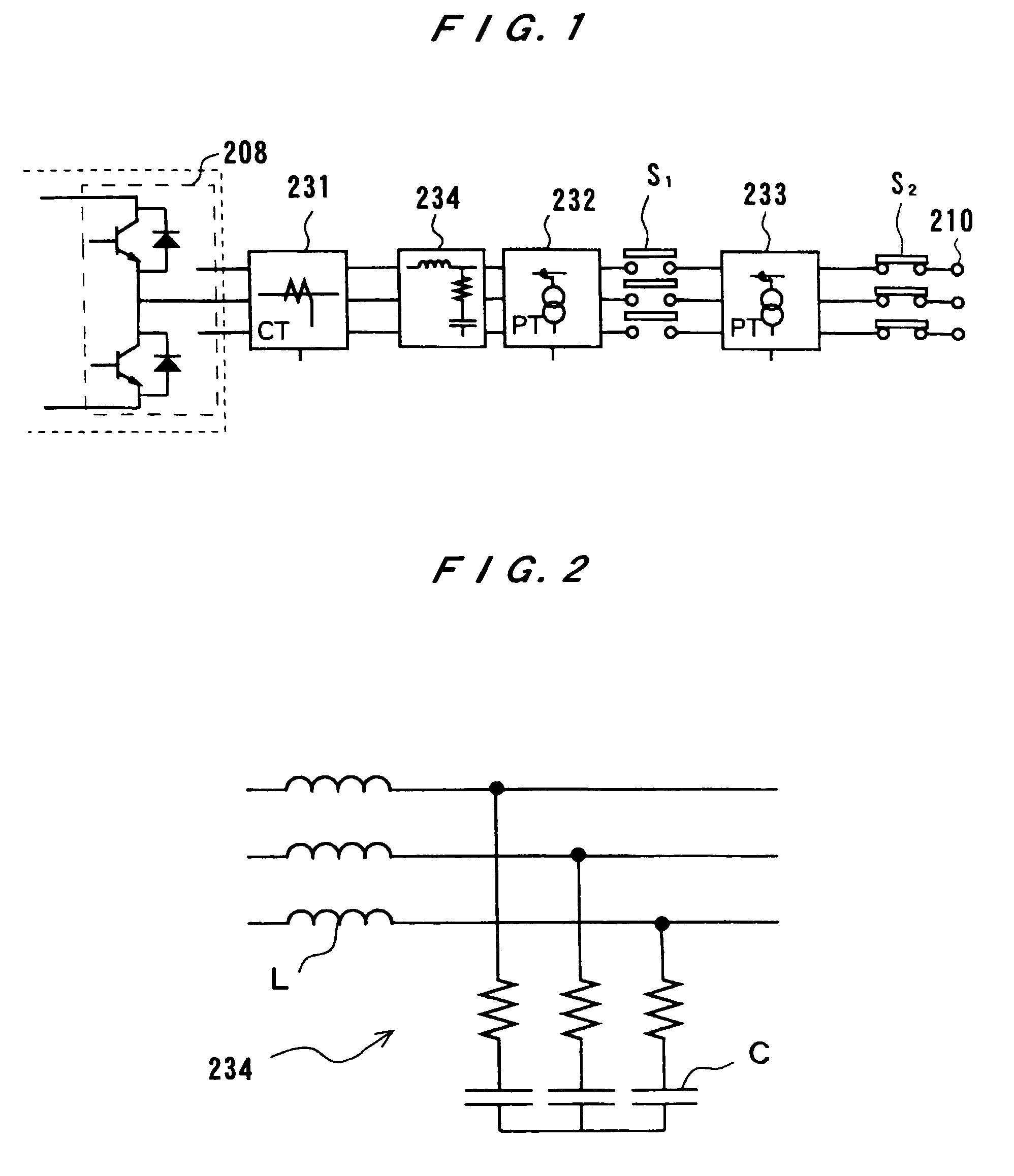

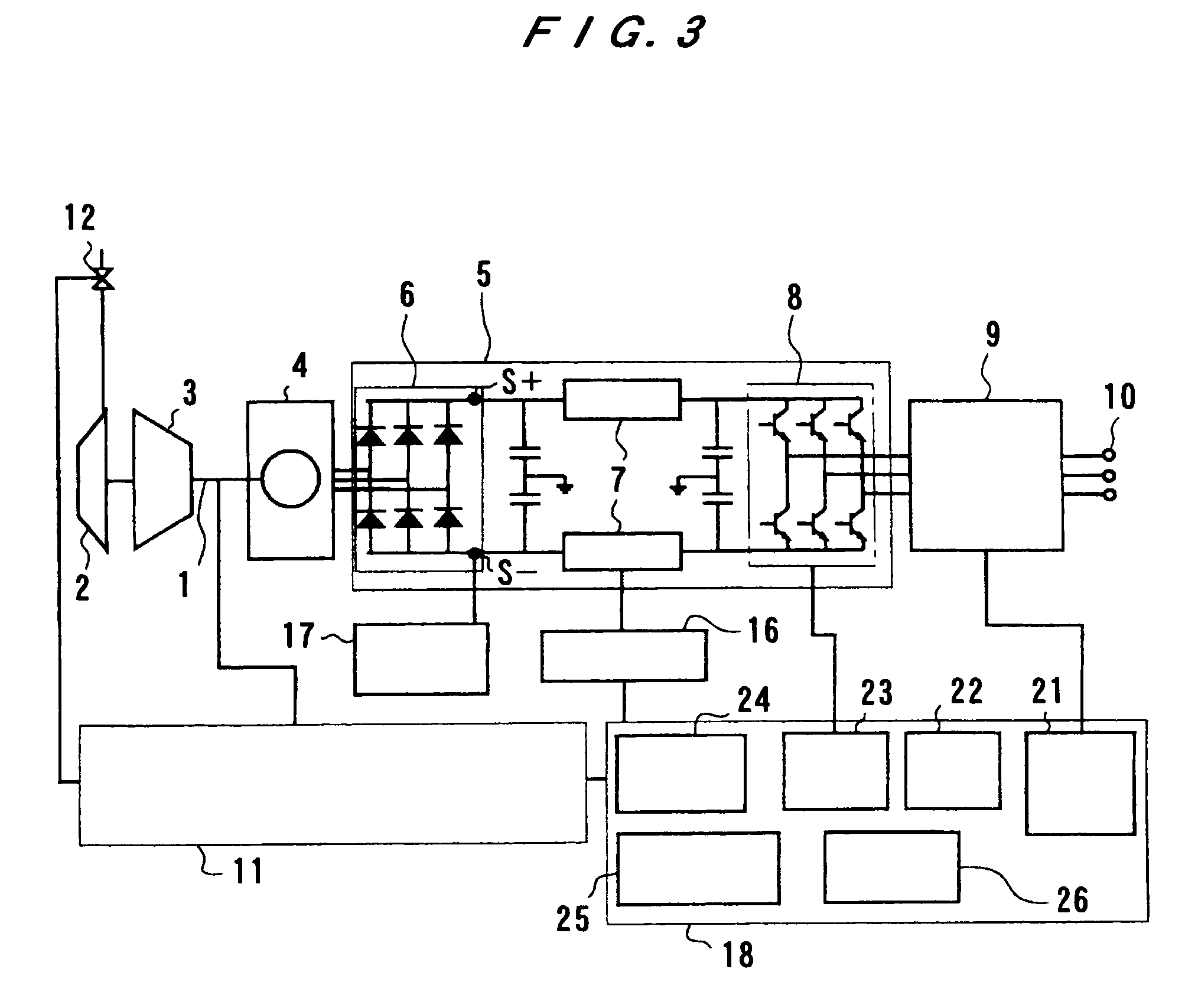

Power generating apparatus

InactiveUS6979914B2Firmly connectedGuaranteed uptimeSealing arrangements for enginesGas turbine plantsGas turbinesFull wave

A power generating apparatus has a power generator 4 for generating AC power, a gas turbine engine 2 for driving the power generator 4, and an inverter device 5 for converting the AC power into commercial AC power. The power generating apparatus includes an interconnection switch S1 for connecting an output of the inverter device 5 with a commercial AC power supply system, a first voltage detector 46 for detecting a DC power supply voltage Vdc-in of the inverter device 5, and a second voltage detector 33, 45 for detecting a full-wave rectification voltage of the commercial AC power supply system. The power generating apparatus also includes an interconnection control part 18 for closing the interconnection switch S1 when the DC power supply voltage of the inverter device 5 exceeds the full-wave rectification voltage of the commercial AC power supply system.

Owner:EBARA CORP

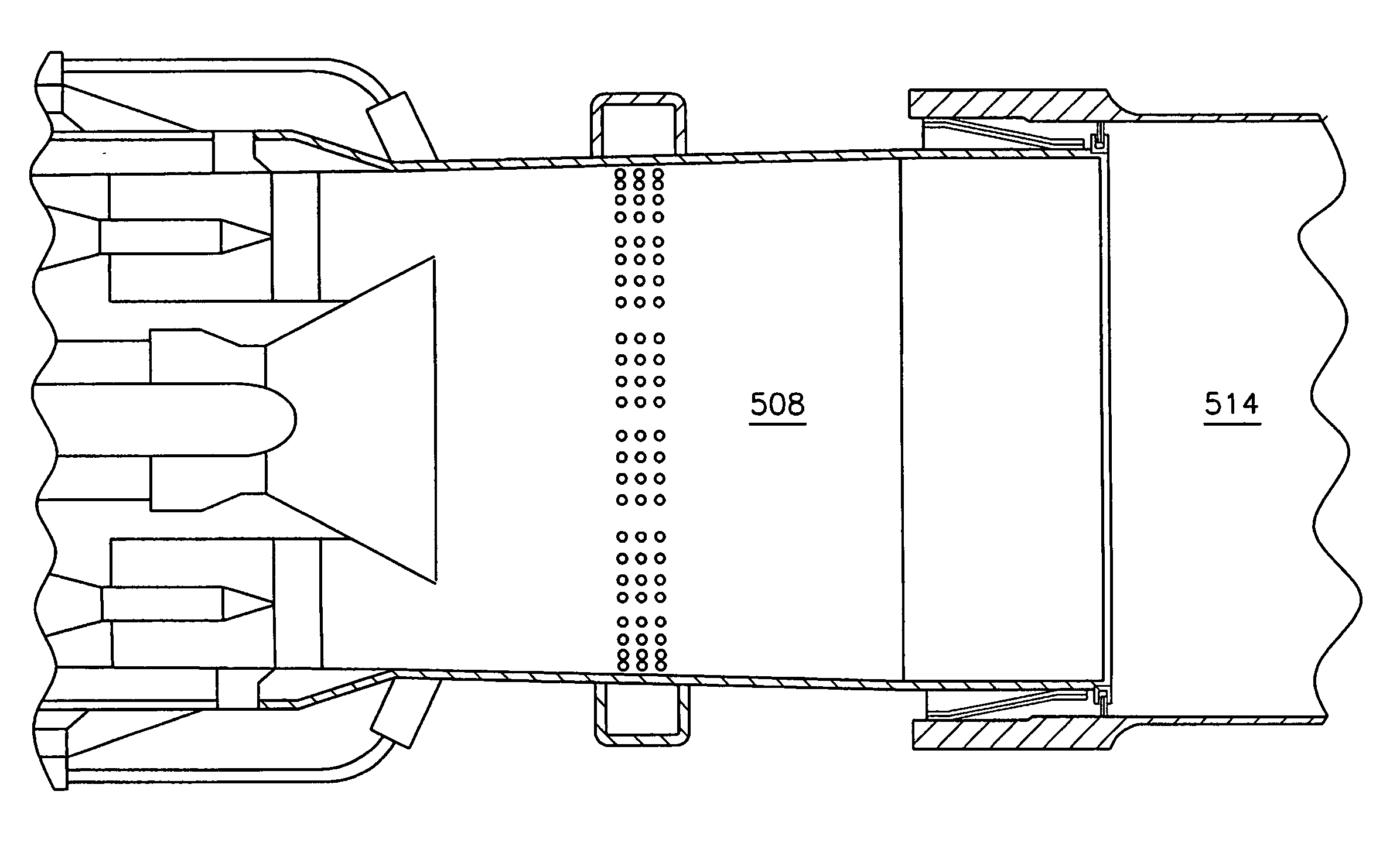

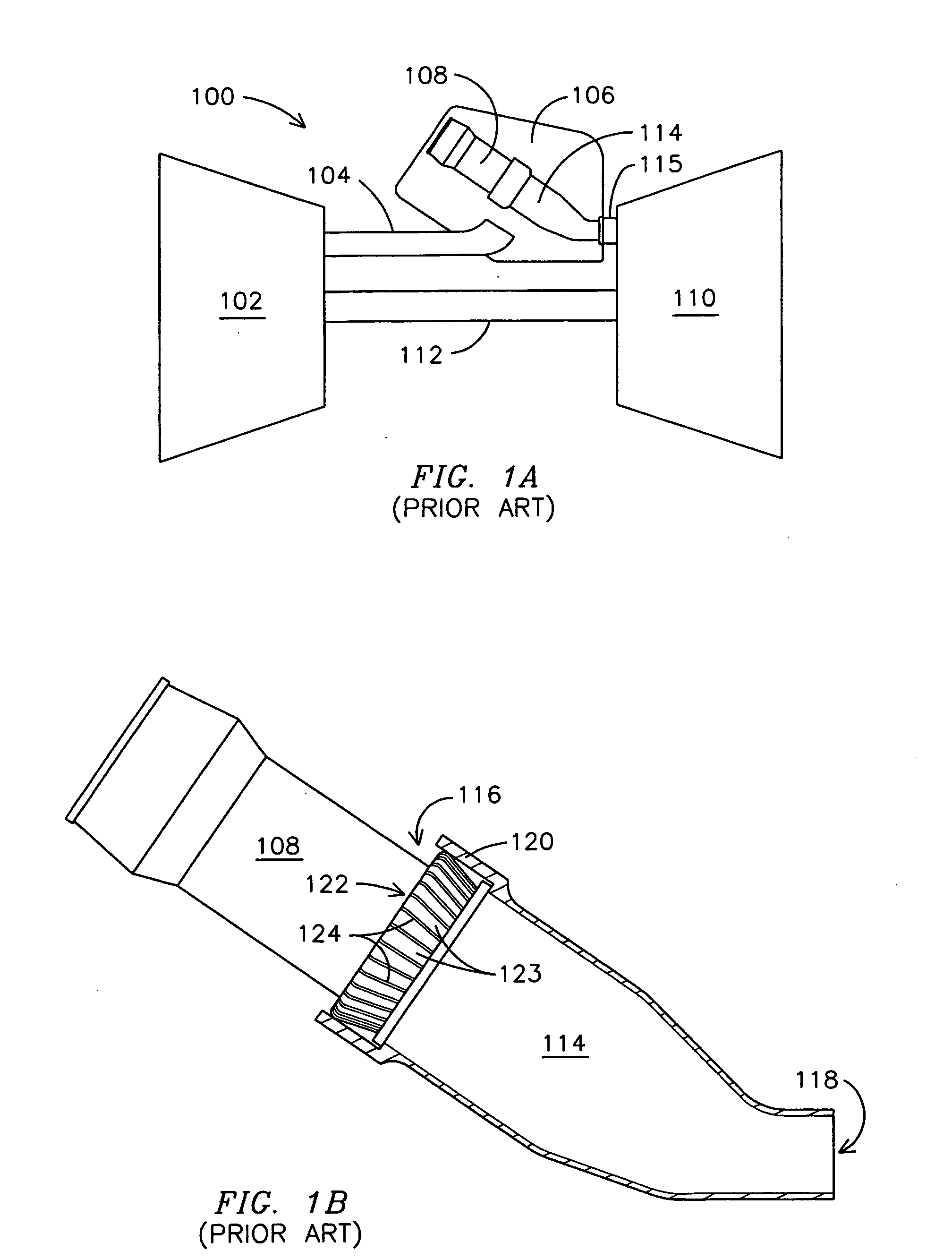

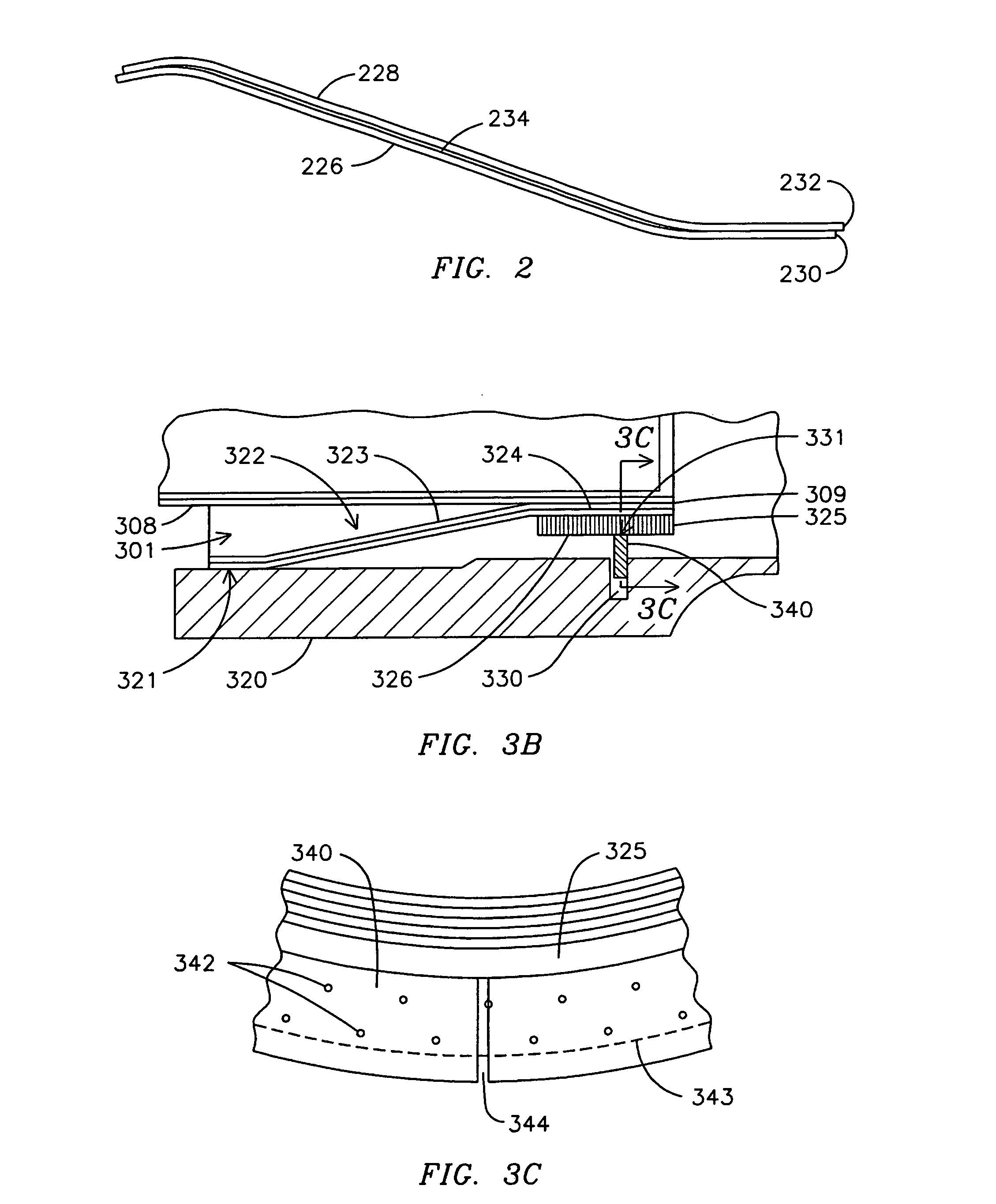

Low leakage spring clip/ring combinations for gas turbine engine

A combustor-to-transition seal (301) includes a spring clip assembly (322, 422, 522) and a first spring metal ring (340, 441) or a ring assembly (440,540) that includes the first spring metal ring (441) and a second spring metal ring (442). Such combustor-to-transition seal (301) provides a first seal (321) and a second seal (331, 531) when at a junction of a combustor (108, 308, 508) and a transition (114, 314, 514). In an embodiment, the first spring metal ring (340) has a plurality of apertures (342) through the ring (340) that provide effusion cooling of the ring (340). The plurality of apertures (342) regulates a flow of cooling fluid to maintain an acceptable temperature of the ring (340). In an alternative embodiment, the second spring metal ring (442) has grooves (446) that regulate a flow of cooling fluid to maintain an acceptable temperature of the ring assembly (440).

Owner:SIEMENS ENERGY INC

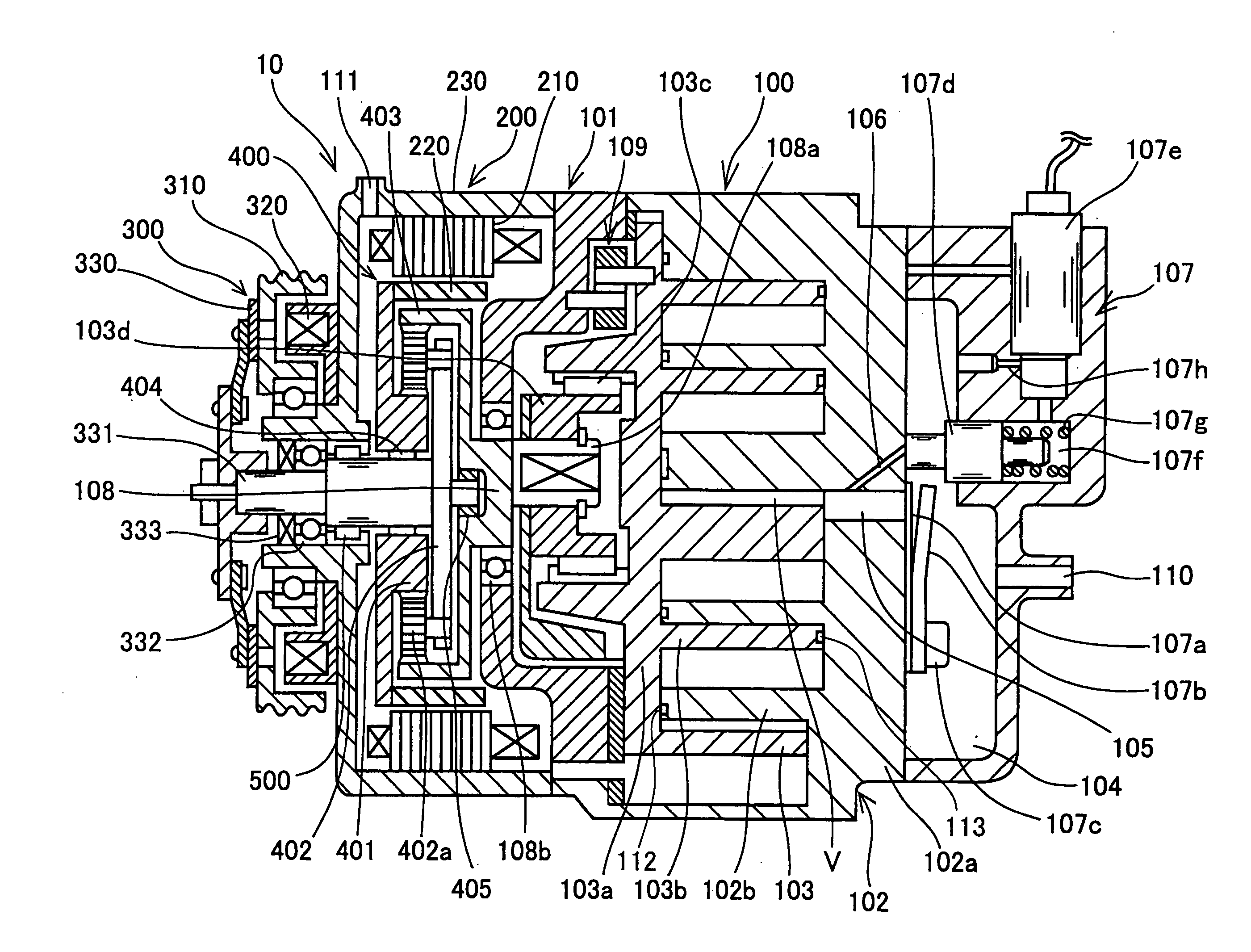

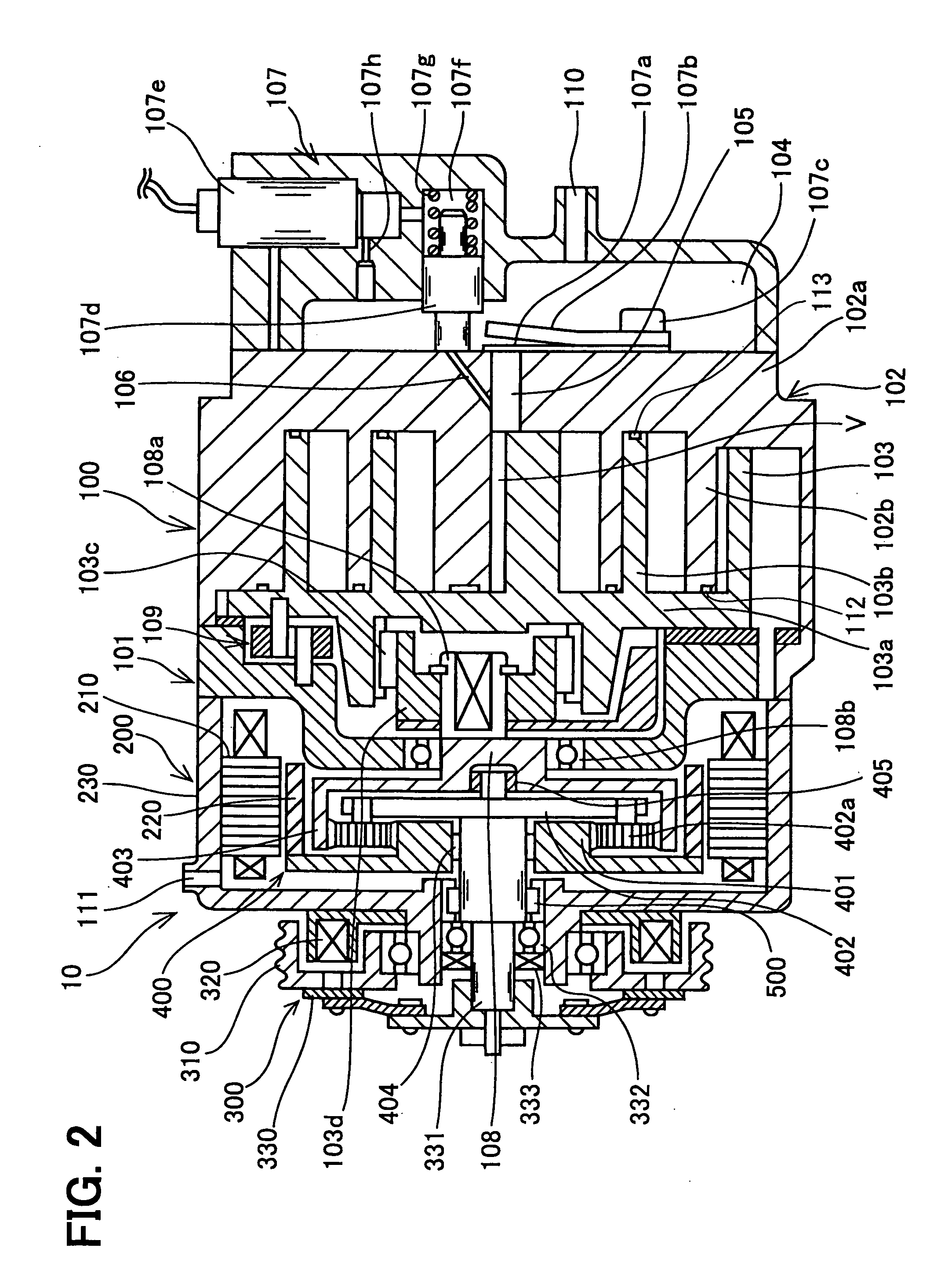

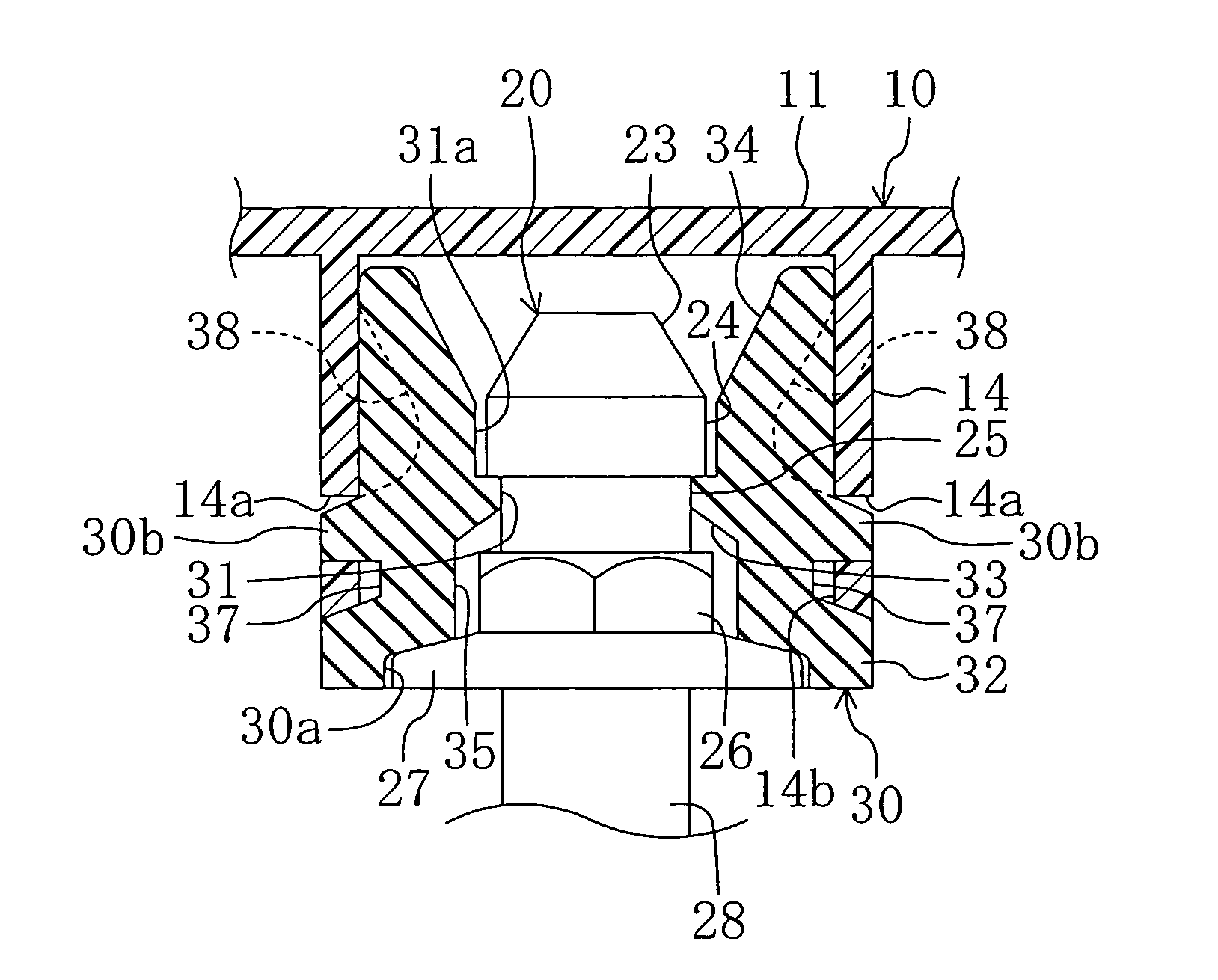

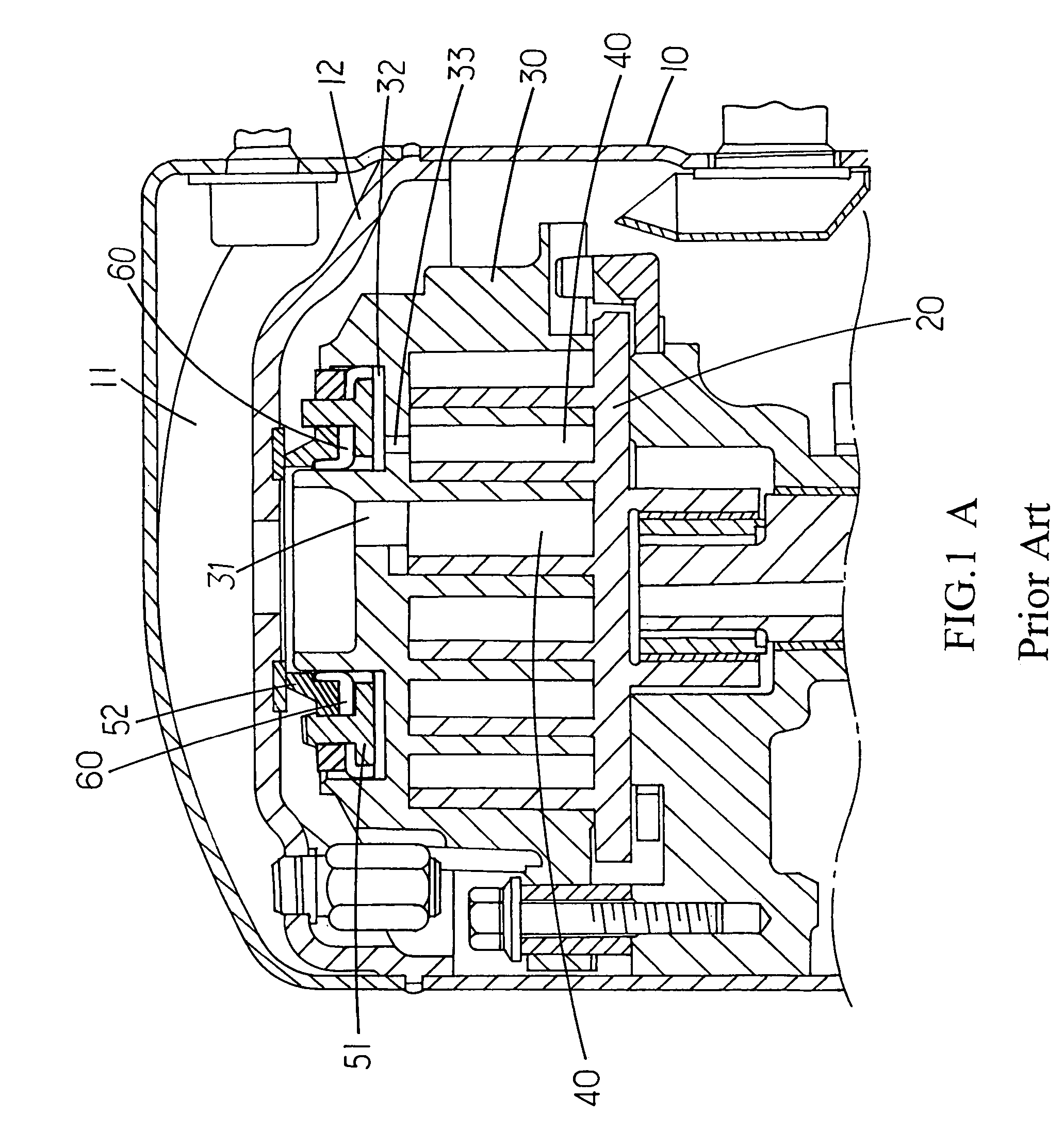

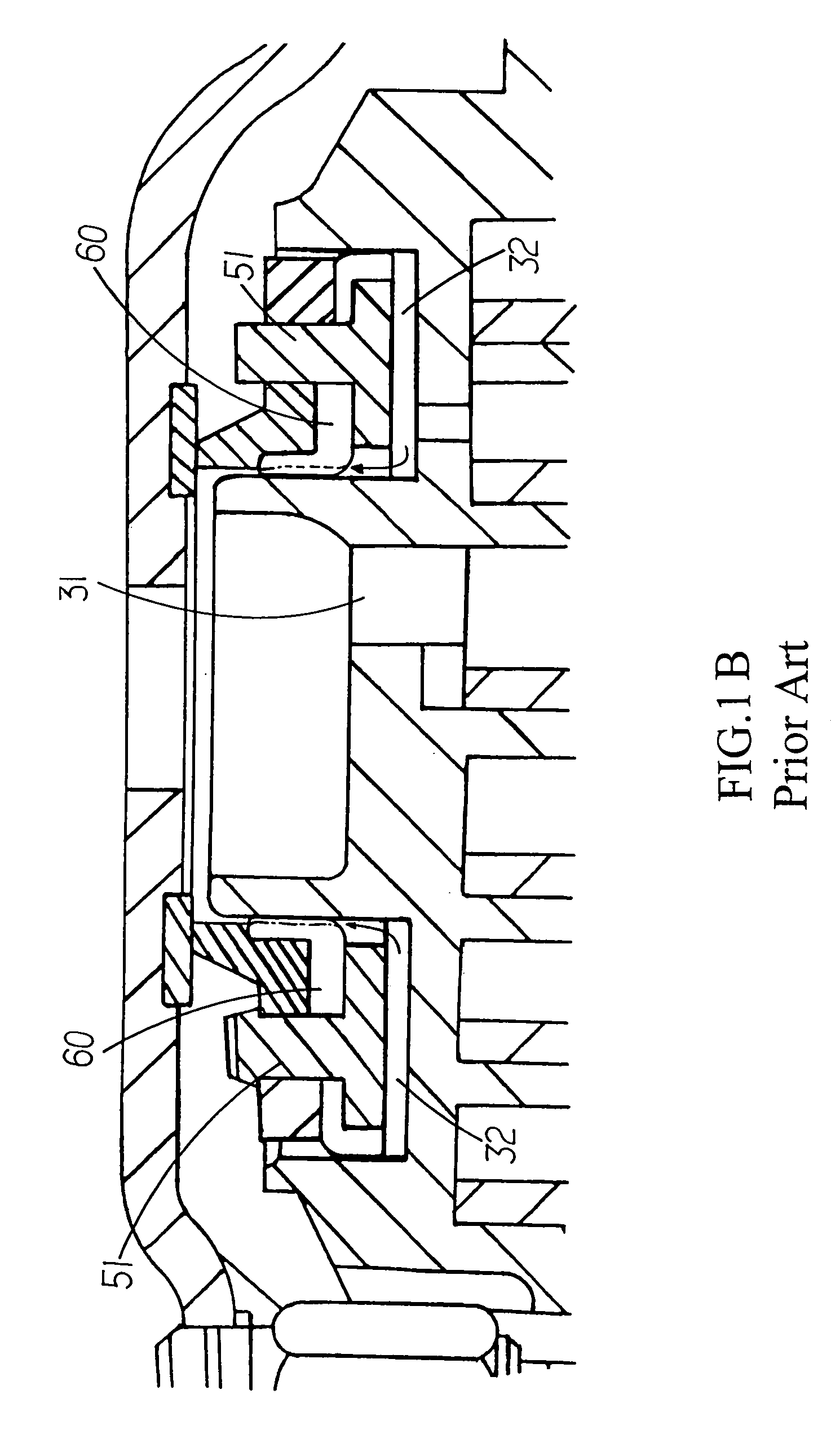

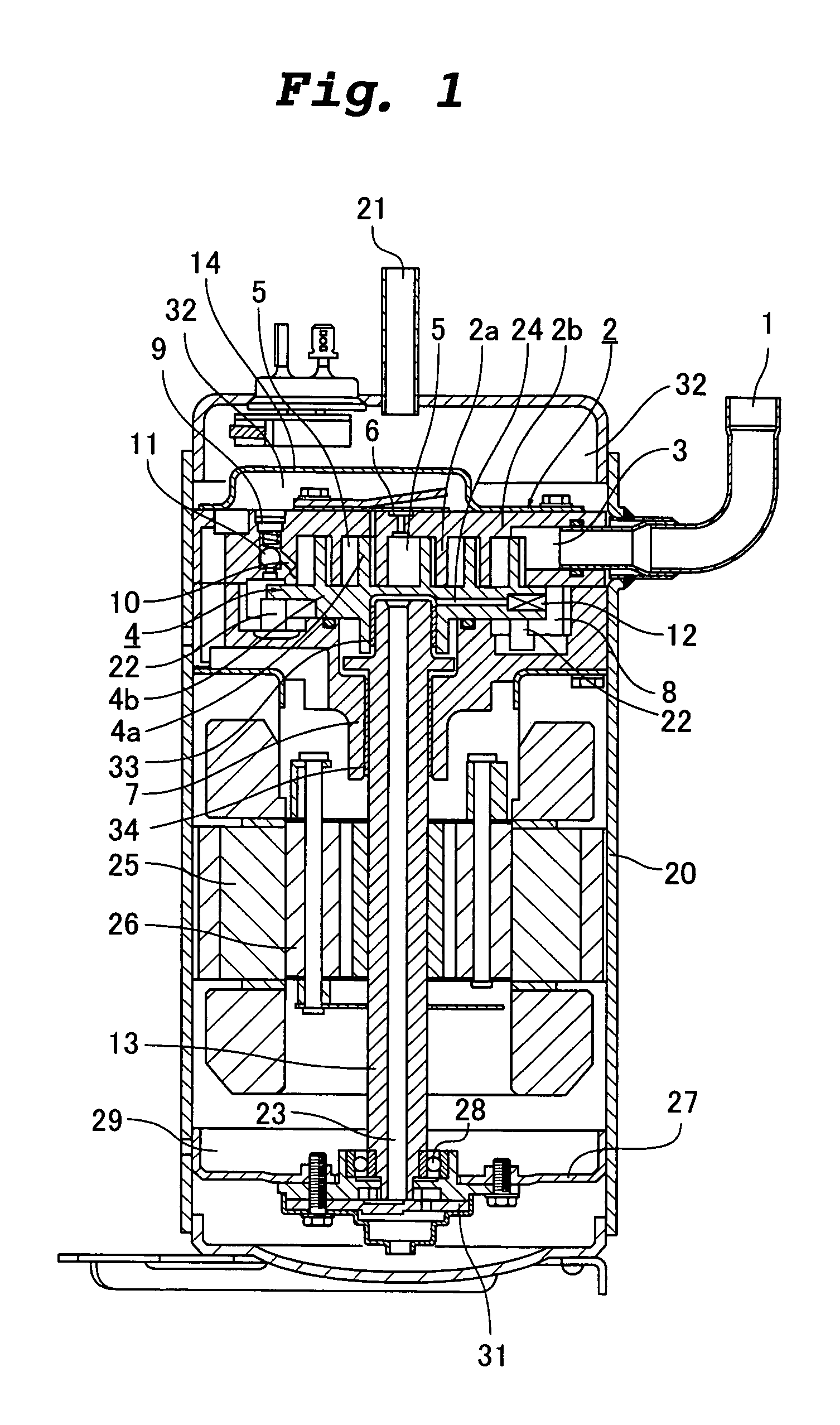

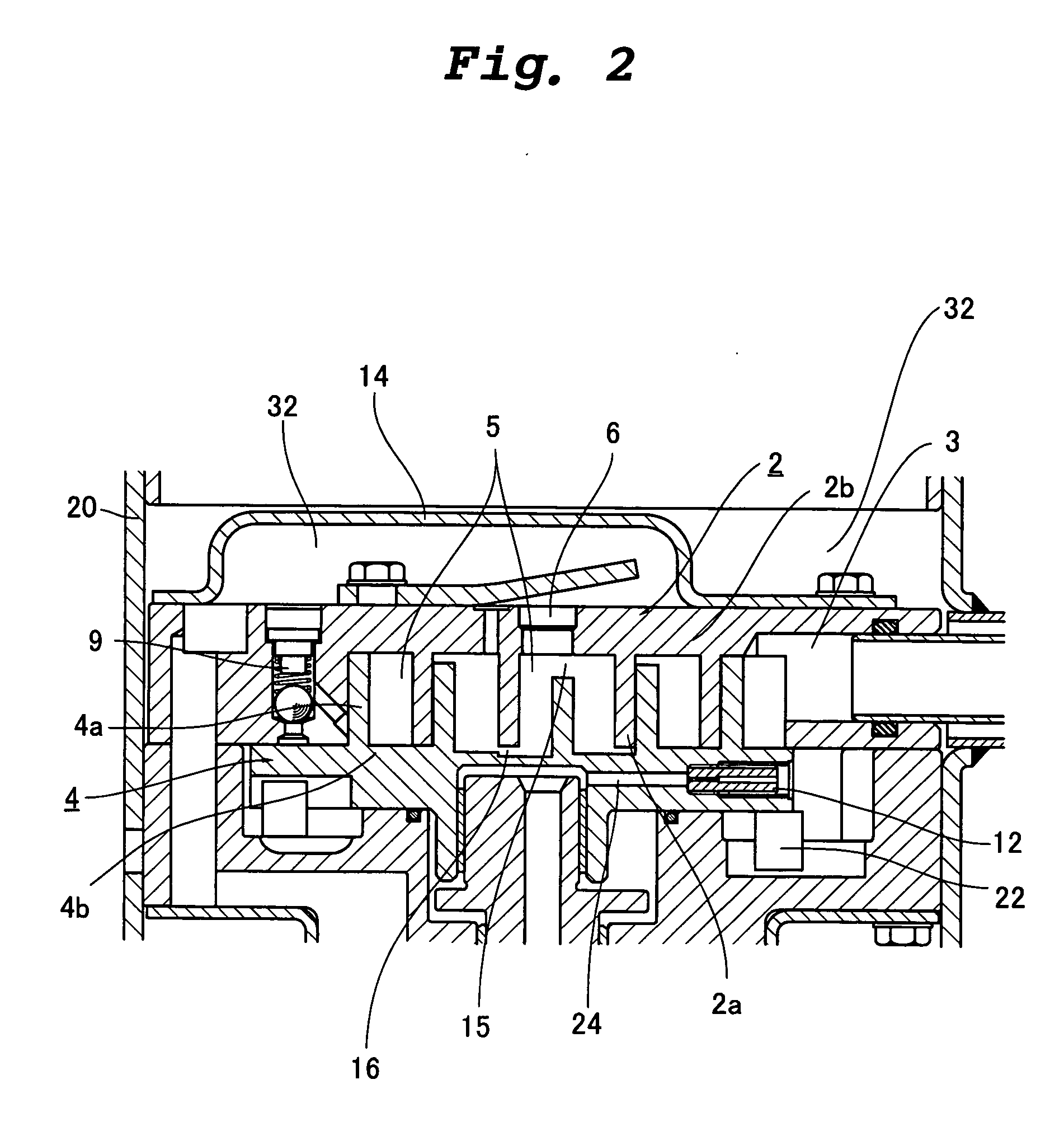

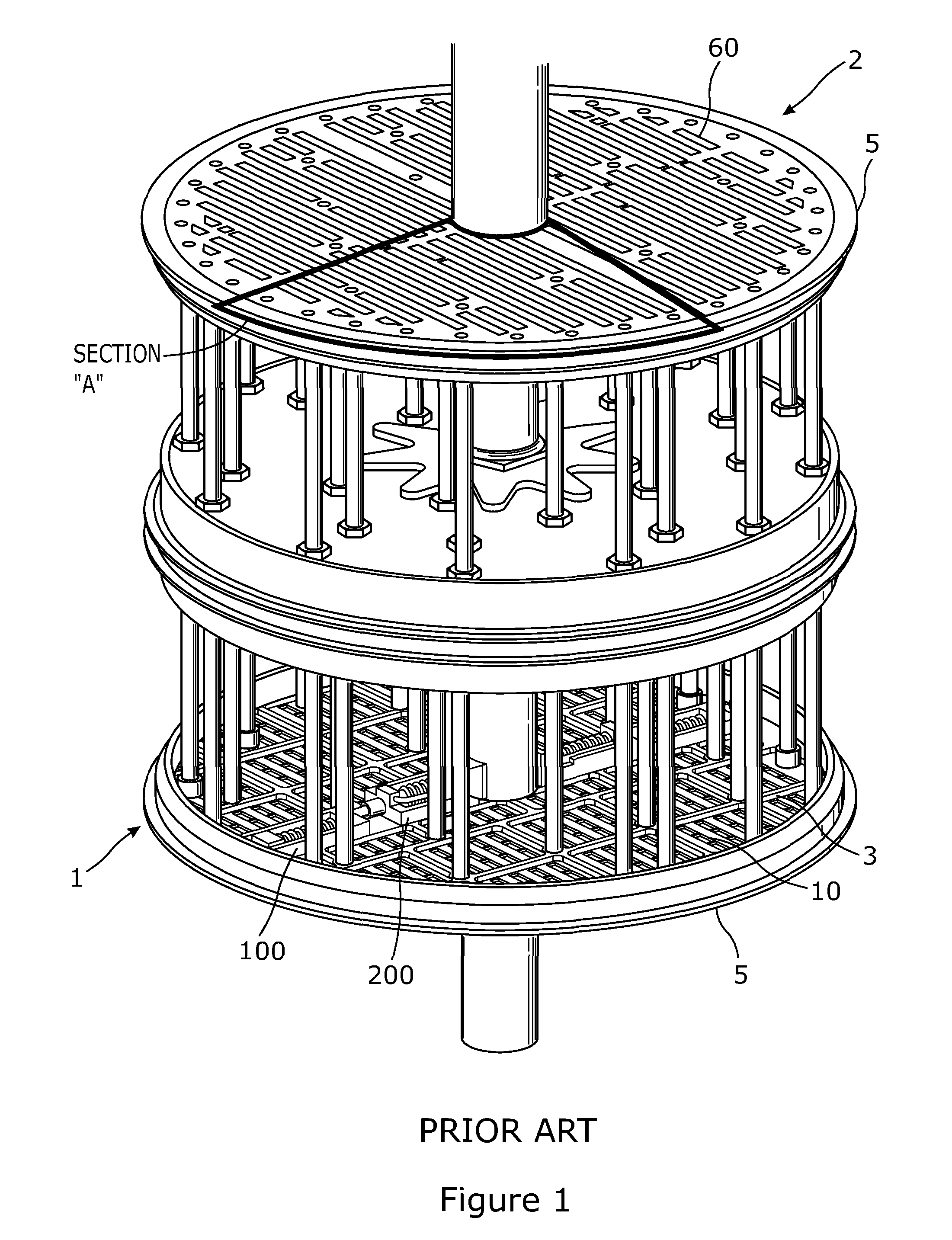

Backpressure mechanism of scroll type compressor

InactiveUS7029251B2Improve operational efficiencySimple structureEngine of arcuate-engagement typeOscillating piston enginesHigh pressureMedium pressure

A backpressure mechanism for a scroll type compressor to effectively prevent leakage of coolant; a recessed seat being provided at the top of a coolant passage at the center of a fixed scroll; a ring groove being disposed on the outer circumference of the recessed seat; a high-pressure sealing assembly comprised of a high-pressure ring, a sealing device and a high pressure ring seat and a medium-pressure sealing assembly comprised of a medium-pressure ring, a sealing device and a medium-pressure ring seat being respectively provided to the recessed seat and the ring groove; pressure from the compressed coolant causing an axially compromising vacuum unloading function to float the both sealing assemblies.

Owner:RECHI PRECISION

Cylinder head gasket

Cylinder head gasket with a gasket plate formed by at least one layer of sheet metal and at least one combustion chamber aperture which is enclosed by a sealing device serving the purpose of sealing the combustion chamber, wherein in order to reduce any warpages of an engine block and / or of a cylinder head a supporting device is provided radially outside the sealing device on the gasket plate; so that the supporting device can be produced in a material-saving and procedurally reliable manner, the supporting device has an area of the sheet-metal layer which is thickened by way of embossing and does not enclose any of the apertures of the gasket to be sealed completely or almost completely and has at least one embossed supporting bead with a meandering shape or a two-dimensional pattern of cup-like recesses and associated elevations.

Owner:ELRINGKLINGER AG

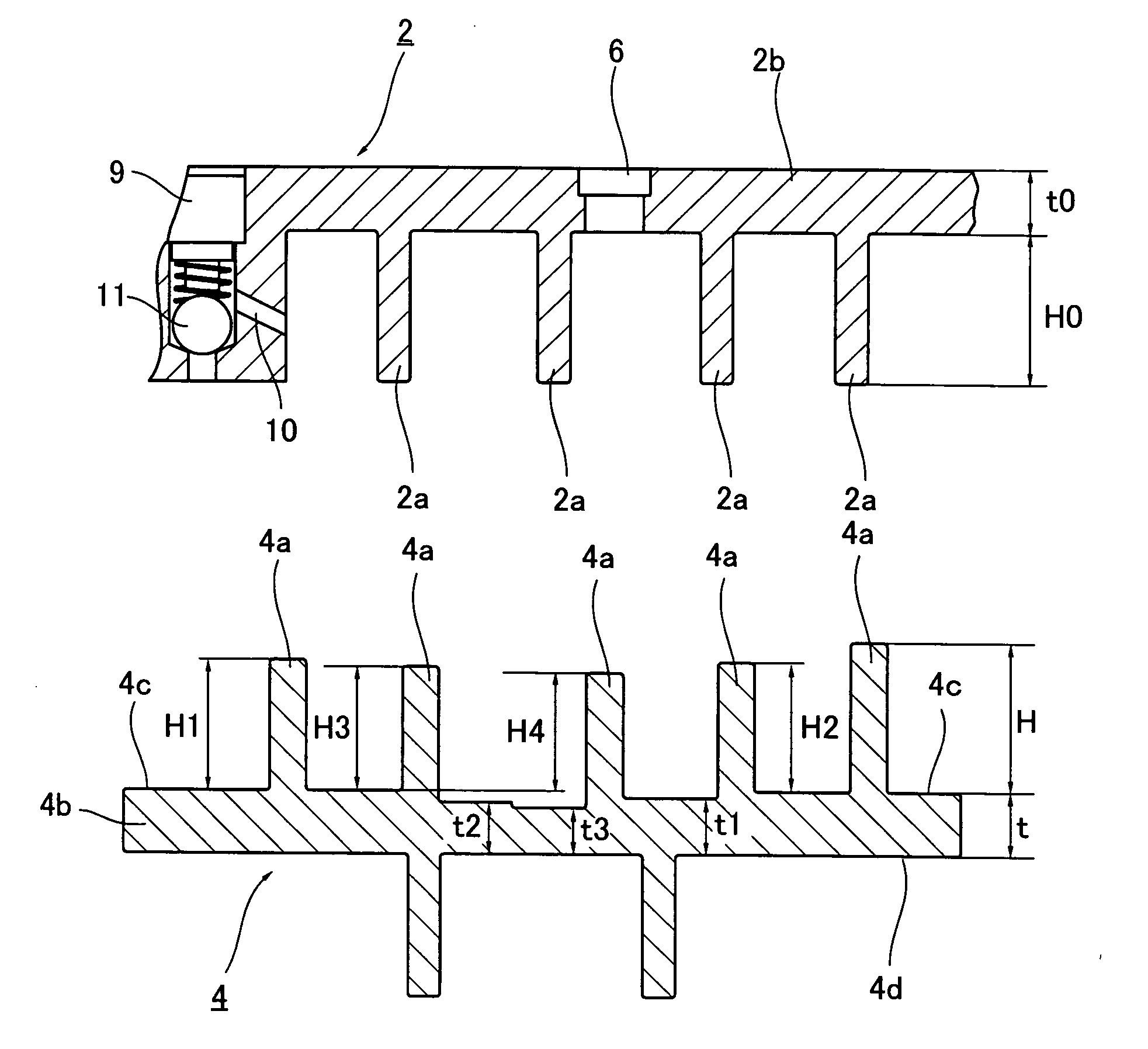

Scroll compressor

InactiveUS20070178002A1Avoid abnormal wearReliable scroll compressorEngine of arcuate-engagement typeOscillating piston enginesContact pressureScroll compressor

a First gap 15 in a thrust direction between teeth bottoms of a fixed mirror plate 2b and teeth tips of an orbiting lap 4a, and a second gap 16 in the thrust direction between teeth bottoms of an orbiting mirror plate 4b and teeth tips of a fixed lap 2a are formed such as to gradually increase from an outer peripheral side to an inner peripheral side of a scroll compressor, the first gap 15 is made greater than the second gap 16. Contact surface pressures of the laps 2a and 4a are kept low with respect to pressure deformation, contact pressure of the teeth tips of the fixed scroll part 2 and the teeth bottoms of the orbiting scroll part 4 are equally maintained. With this loads applied to the scroll parts 2 and 4 are equally received by a thrust surface.

Owner:PANASONIC CORP

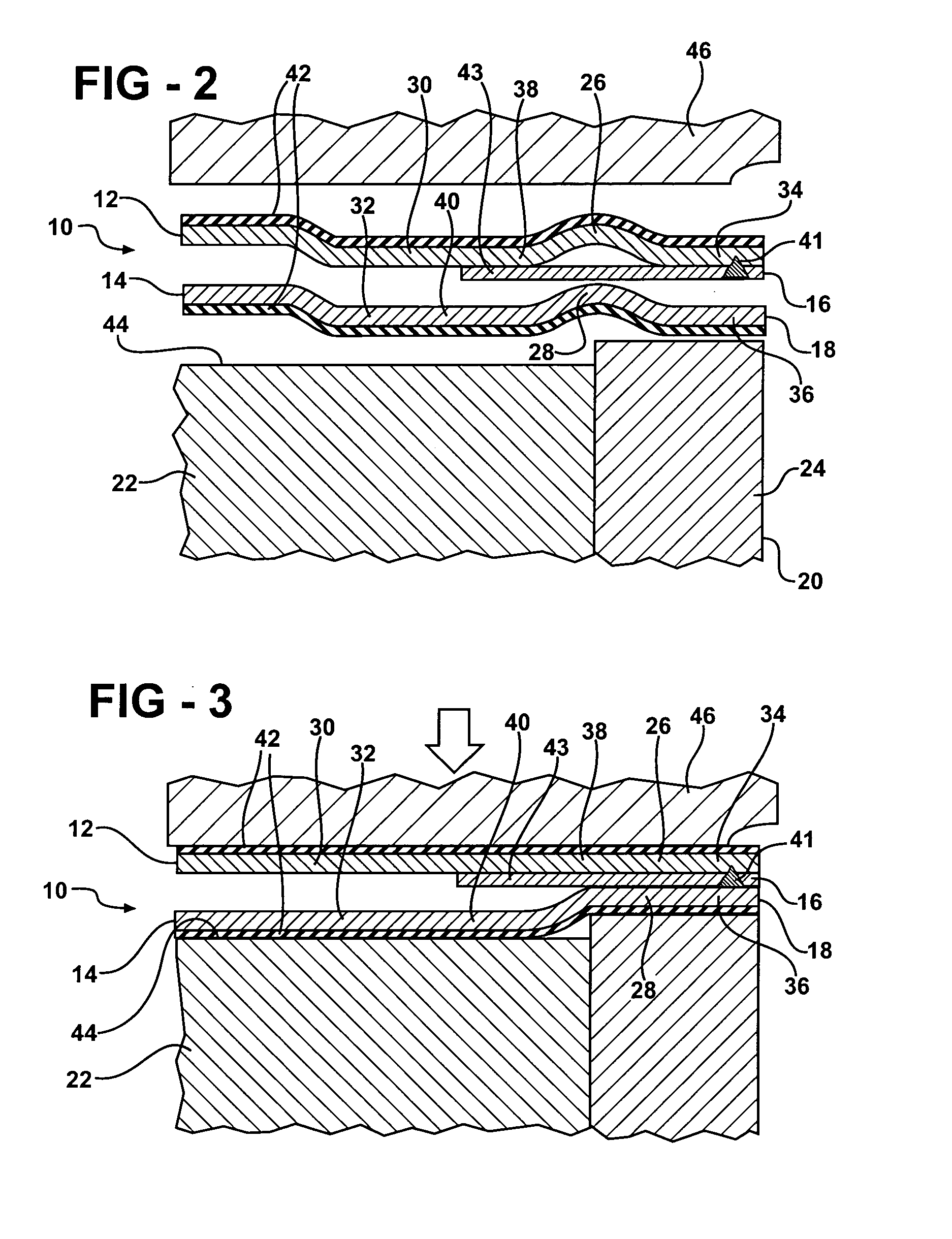

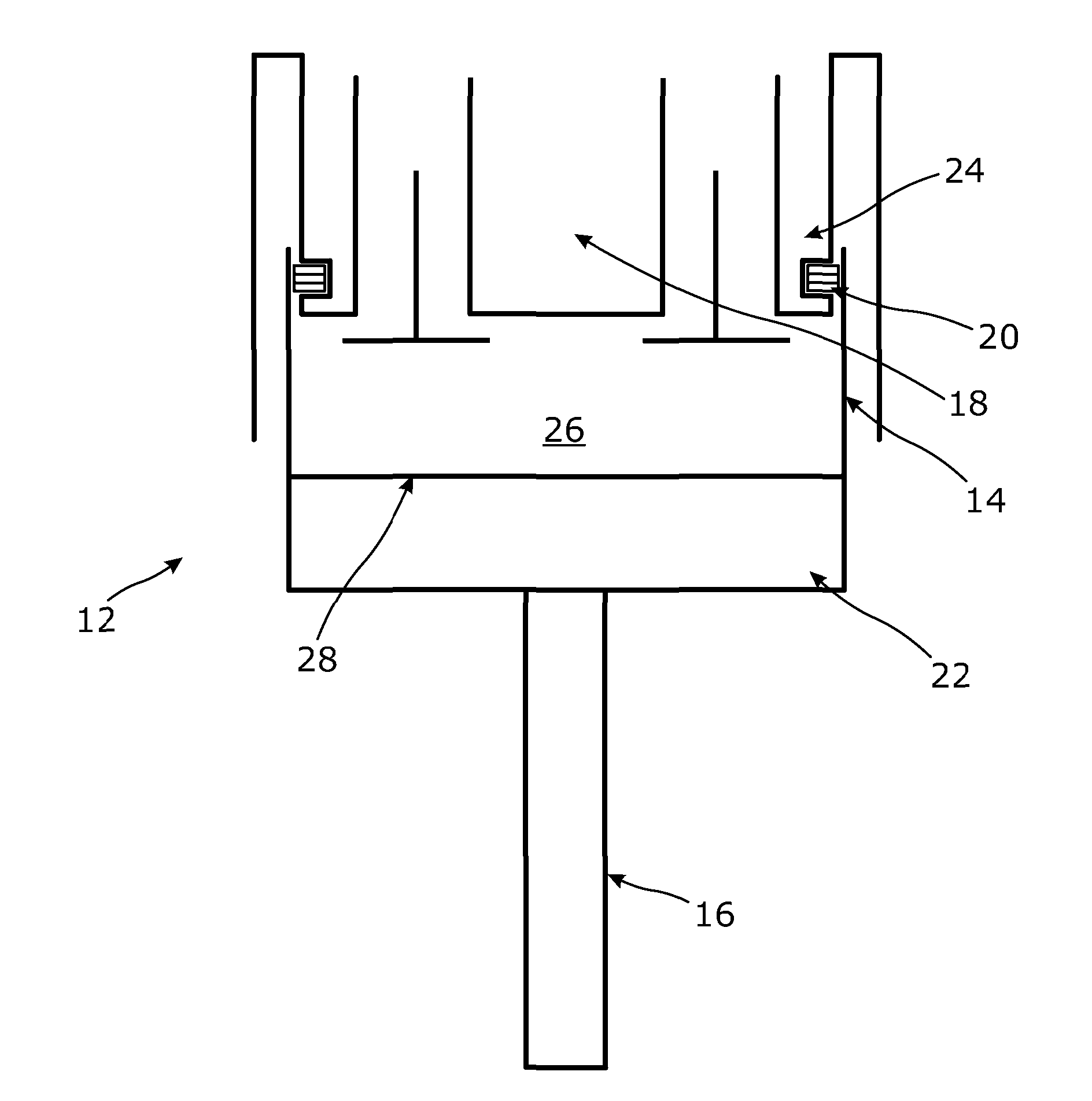

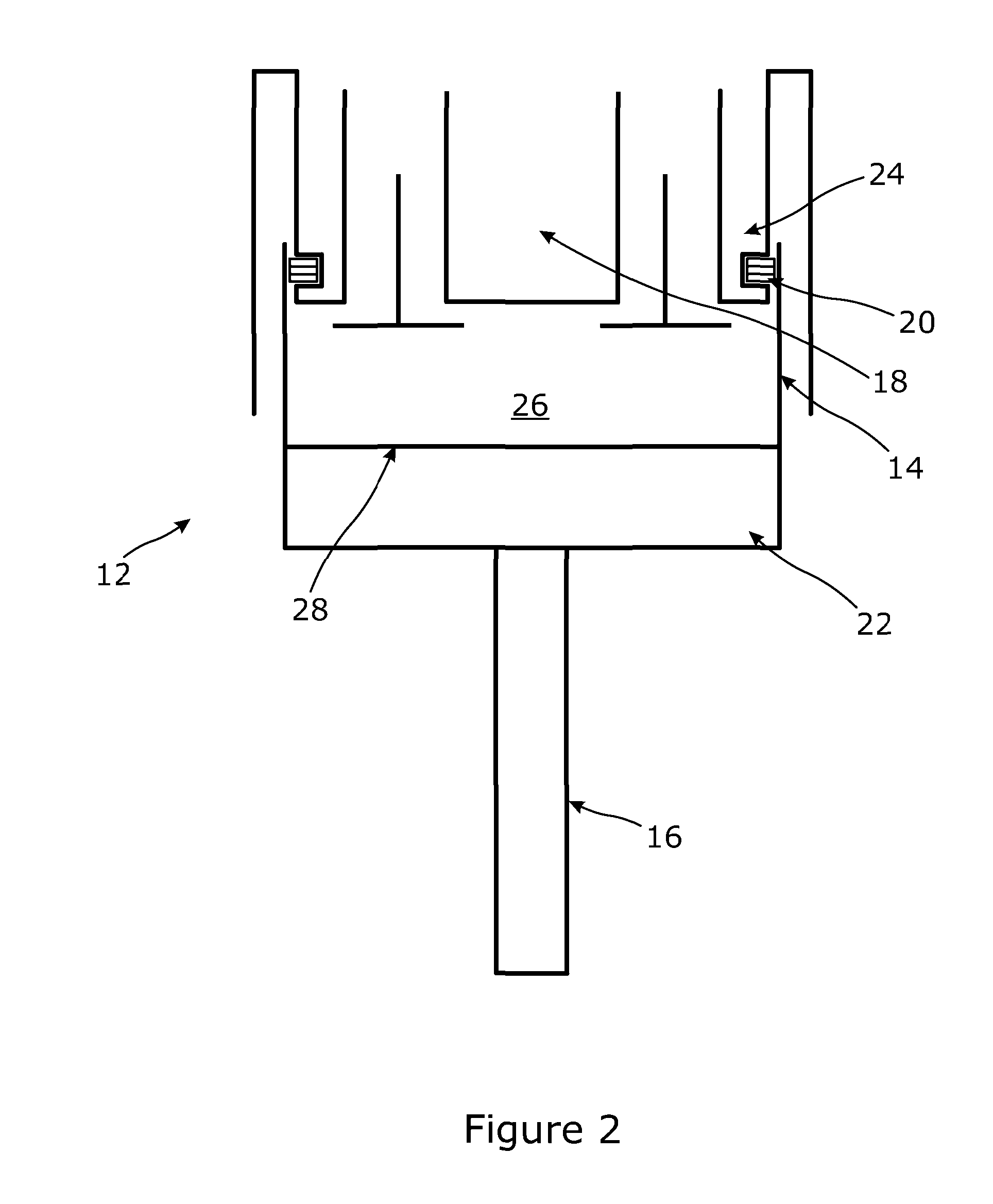

Gasket assembly and method

A gasket assembly (10) for use with a first engine component having a first coolant passageway and a second engine component having a second coolant passageway is provided. The gasket assembly (10) comprises a plastic base (12) adapted to be disposed between the first engine component and the second engine component The plastic base (12) defines an opening (20) adapted to align with the first coolant passageway and the second coolant passageway when the base (12) is disposed between the first engine component and the second engine component. The gasket assembly (10) also includes a protector (14) associated with the coolant opening (20) of the base (12) and adapted to protect the base (12) from a coolant flowing through the first coolant passageway and the second passageway wherein the coolant is adapted to contact the protector (14) and not the base (12).

Owner:GRUNFELD ARON A

Piston Assembly

InactiveUS20150114217A1Reduce inertia forceReduce quality problemsEngine sealsPositive displacement pump componentsCylinder headGraphite

A piston assembly (12) comprising a reciprocating sleeve (14) incorporating an integral internal piston surface (28), which sleeve is slidably mounted upon a cylinder head (18) so as to define a piston chamber (26) therewith, the piston chamber being sealed in the vicinity of the cylinder head (18) by a circumferential static seal (20) that acts to seal against the reciprocating sleeve (14). The static seal (20) may occupy a horizontal plane and may include sacrificial wear zones and be formed from a graphite-based material. The piston assembly may be an oversquare assembly for use in an oil-free environment for processing high temperature gases, for example, a hot gas engine or heat pump or heat engine such as may be used in an energy storage system.

Owner:ENERGY TECH INST

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com