Patents

Literature

4495 results about "Oil temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A quality conventional motor oil will tolerate oil sump temperatures of up to 250 degrees, but starts breaking down over 275 degrees. The traditional approach is to try to hold oil temperatures between 230 and 260 degrees.

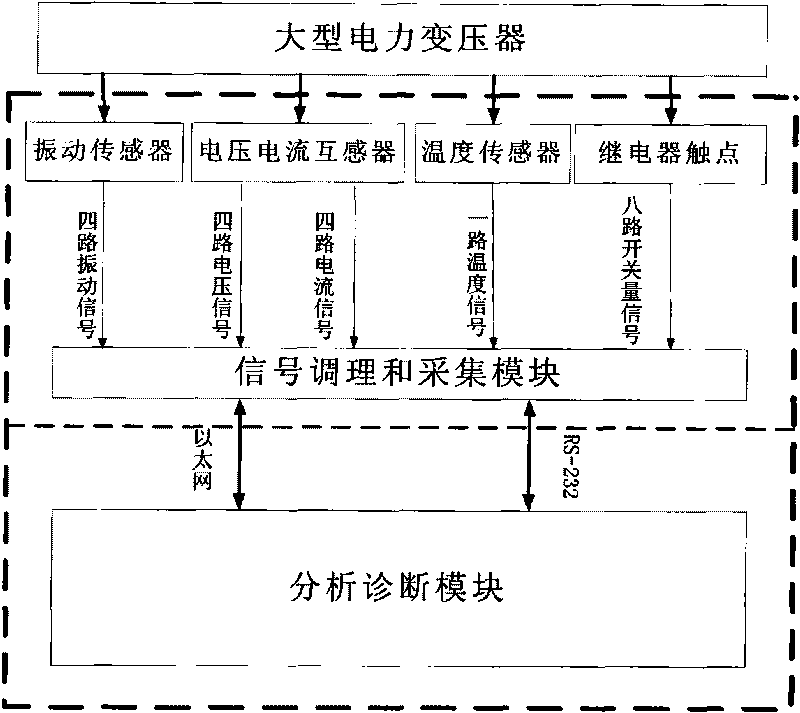

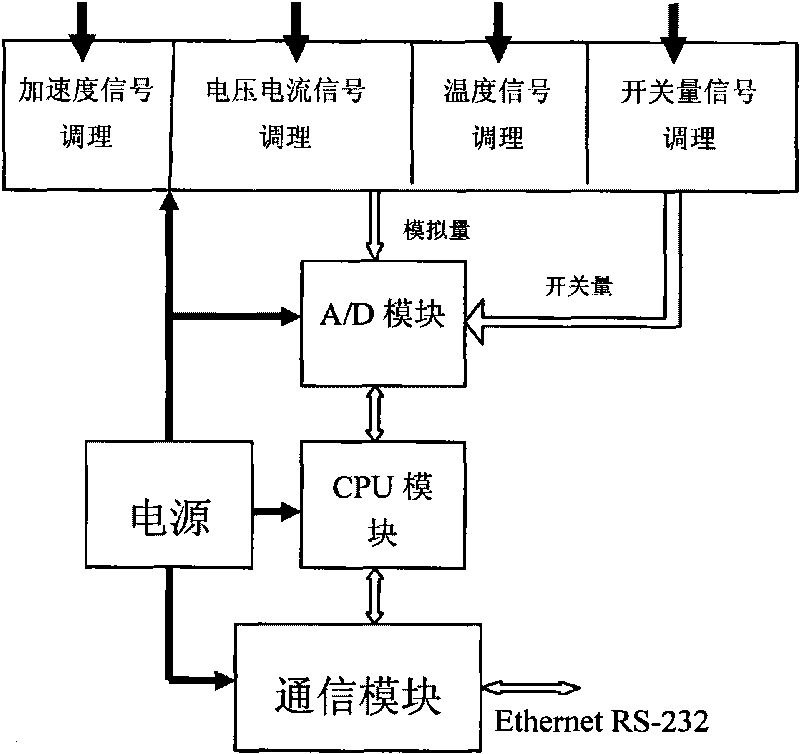

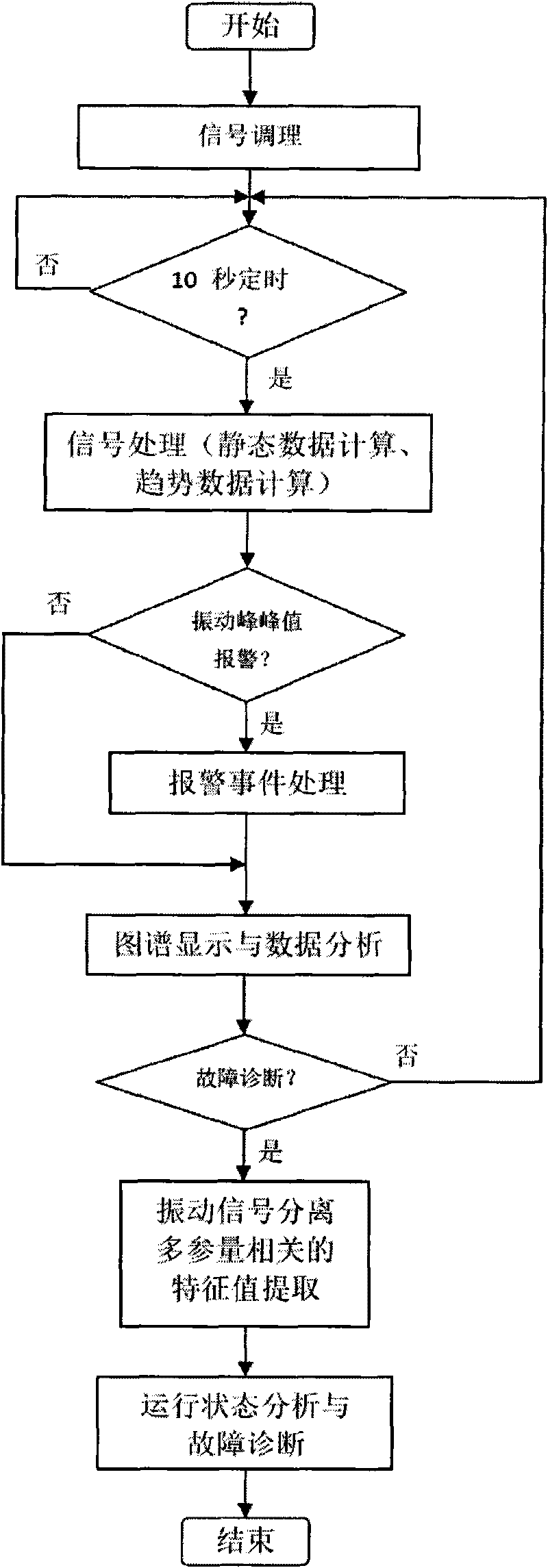

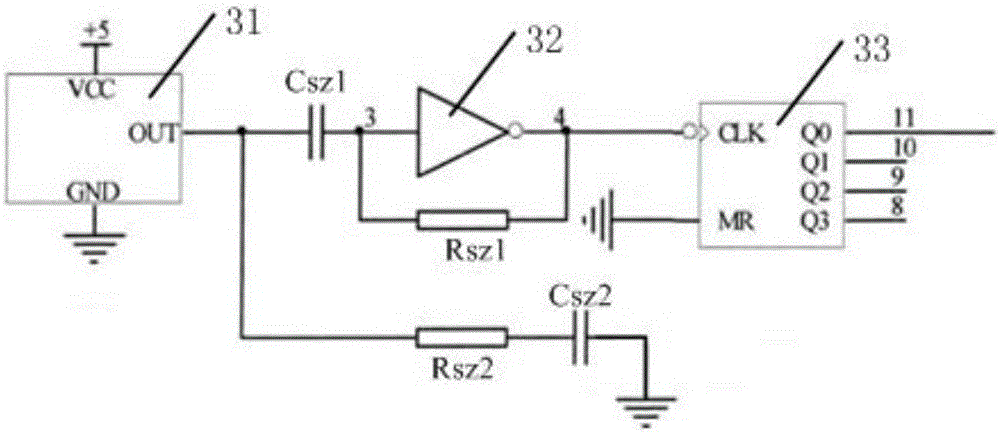

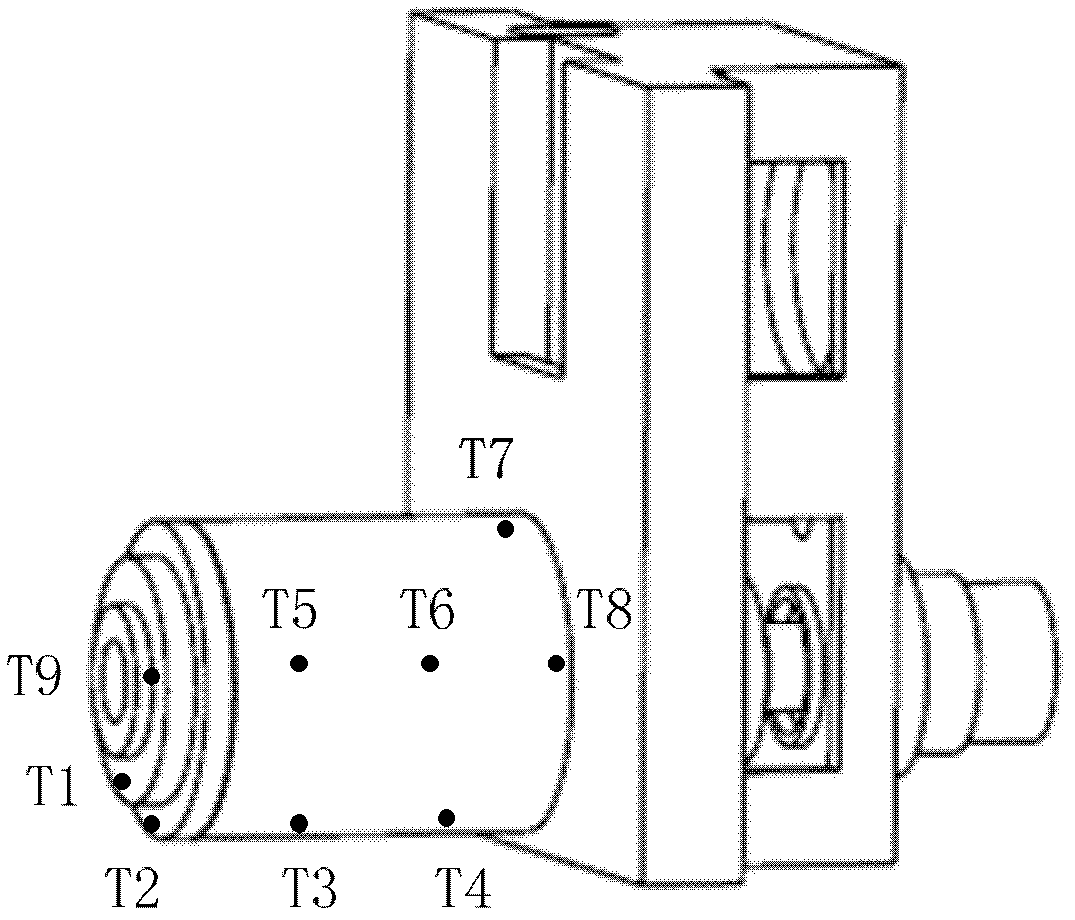

Methods for vibration online monitoring and fault diagnosis of power transformer

InactiveCN101709995ASafe and stable operationImprove accuracyThermometer detailsSubsonic/sonic/ultrasonic wave measurementSignal conditioningEngineering

The invention discloses a method for vibration online monitoring and fault diagnosis of a power transformer. The surface vibration of an oil tank of a transformer, the voltage, the current and the oil temperature of the transformer, and the switching values reflecting the on-states of a vibration source fan and the oil tank of the transformer are taken as basic monitoring parameters to be monitored; after signal conditioning is performed on the monitoring parameters, continuous synchronous waveform data sampling, processing and saving are performed; then the processed waveform data are continuously displayed in real time; signal decomposition, multi-parameter correlation analysis and characteristic vector magnitude extraction are performed on the waveform data; and then various characteristic vector thresholds of a specific transformer are compared to analyze and diagnose the operating state and the fault of the transformer. With the method, the operating state of the power transformer can be monitored in real time, and early warning as well as the analysis and the diagnosis of the fault condition of the transformer are provided, thus guaranteeing the secure and stable operation of the transformer.

Owner:ZHEJIANG UNIV

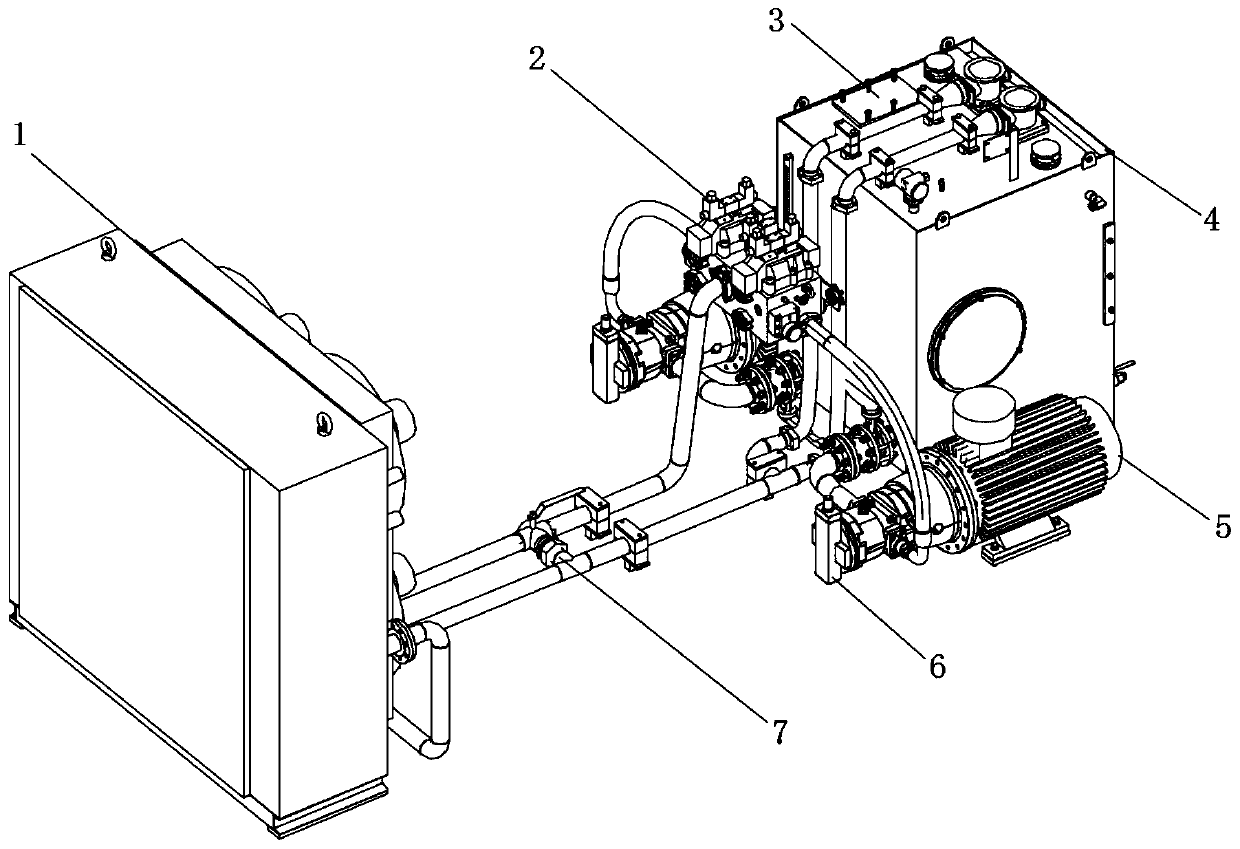

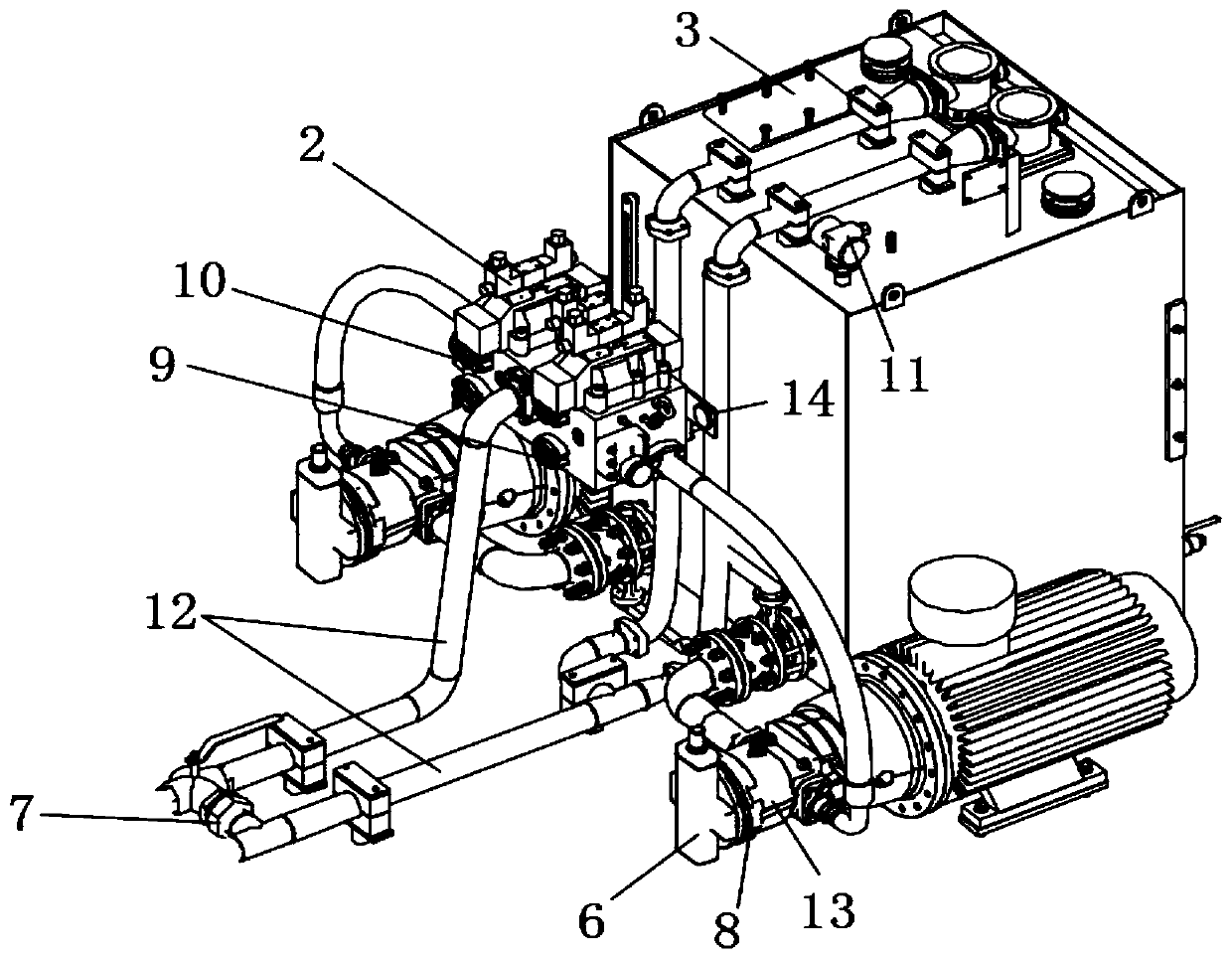

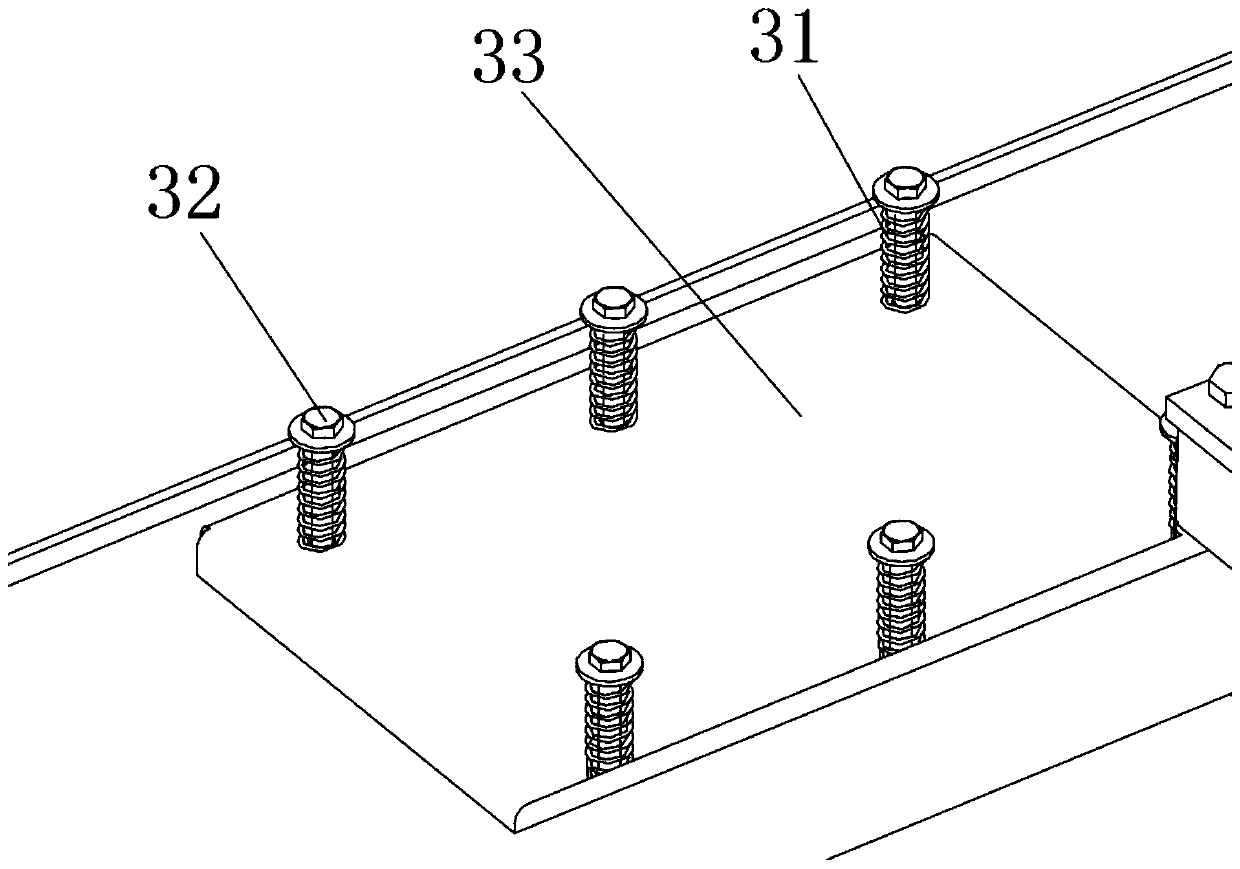

Integrated hydraulic station

InactiveCN110873093AAchieve high integrationRealize automatic control functionFluid-pressure actuator safetyFluid-pressure actuator componentsCompressed natural gasPressure difference

The invention belongs to the technical field of compressed natural gas filling, and particularly relates to an integrated hydraulic station which realizes high integration of an oil tank, plunger pumps, motors, a valve block, a cooler, an instrument and a sensor. The reversing function of hydraulic oil is provided through cooperation of an electro-hydraulic reversing valve and a proximity switch on a hydraulic cylinder, the functions of circulating heating of the low-temperature hydraulic oil, discharging of the high-pressure hydraulic oil and avoiding the hydraulic oil channeling back betweenthe double pumps are realized through cooperation of an unloading valve, a one-way valve and the electro-hydraulic reversing valve in the valve block, the high-pressure difference automatic stop function and the high-pressure gas discharging function are provided, combustible gas leakage and expansion deformation of the oil tank which cannot be recovered caused by high-pressure gas channeling back are avoided, the functions of low oil level monitoring alarm, temperature monitoring alarm and low oil temperature automatic circulating heating before starting of the hydraulic oil tank are provided, a three-way ball valve is adopted to replace an oil return valve block in the aspect of cooling oil return of the hydraulic oil, thus the oil return control function is realize, and the cost and space of the hydraulic station are also reduced.

Owner:JEREH OIL & GAS ENG

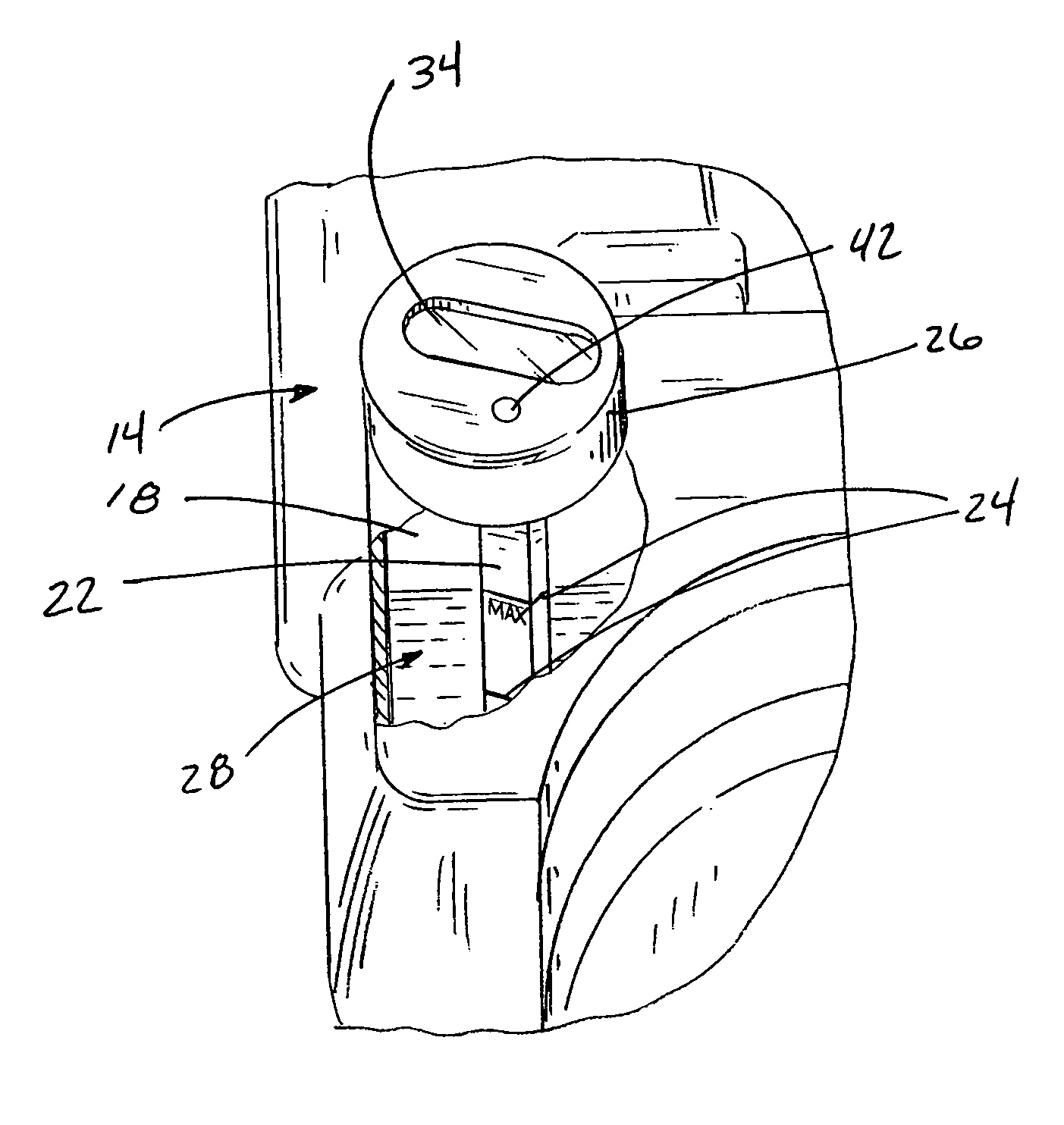

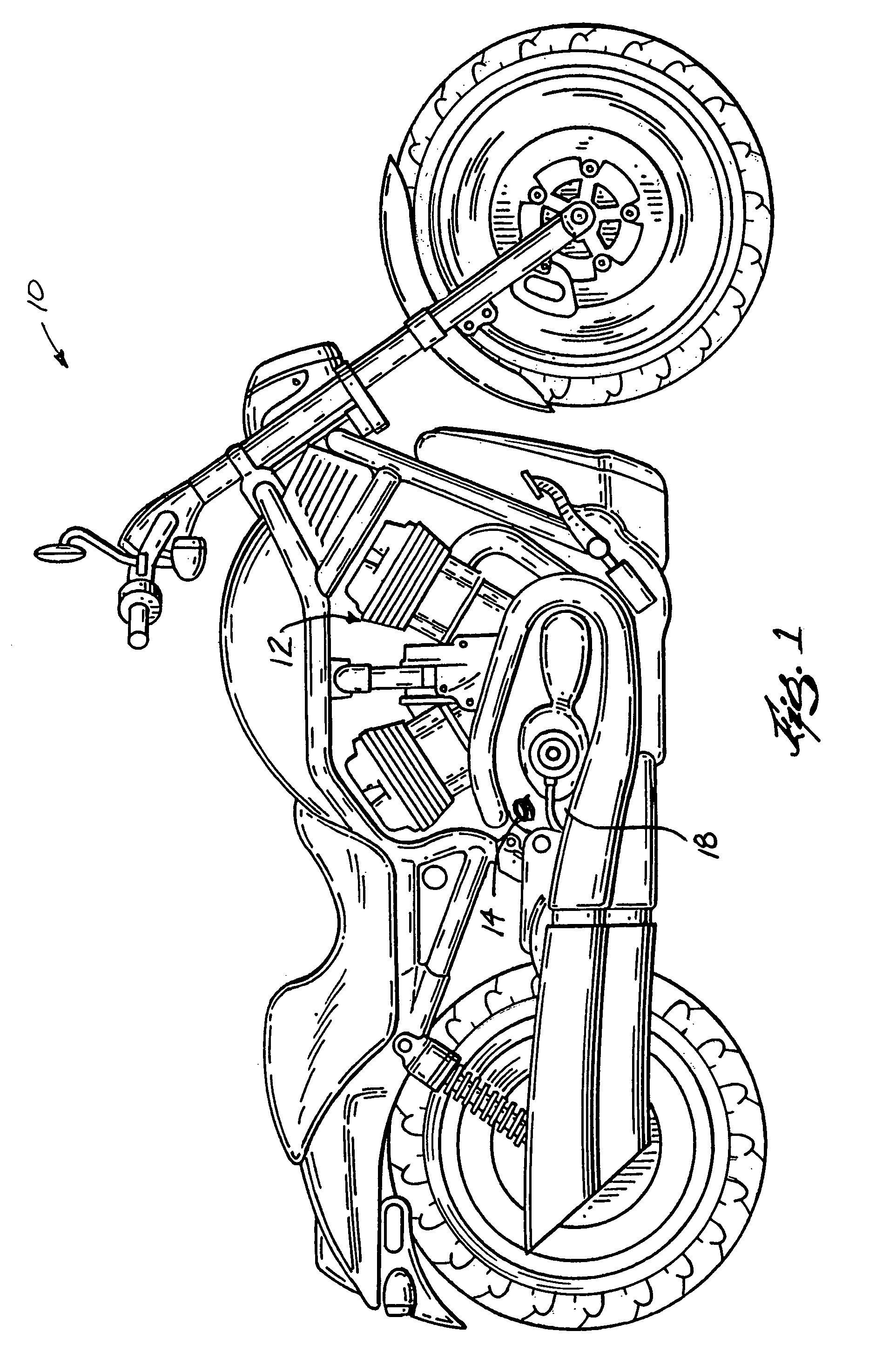

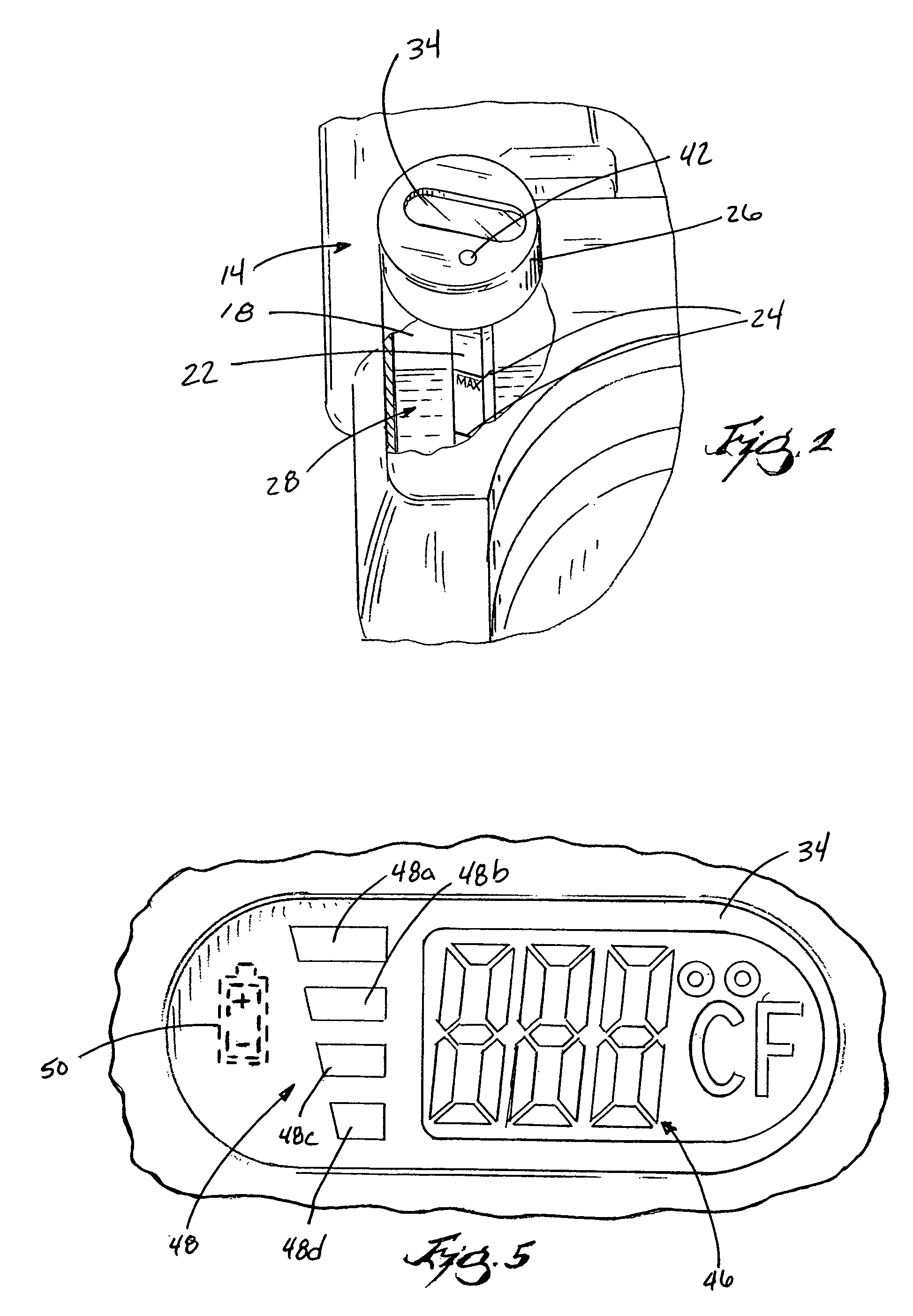

Apparatus for indicating oil temperature and oil level within an oil reservoir

Owner:HARLEY DAVIDSON MOTOR COMPANY GROUP INC

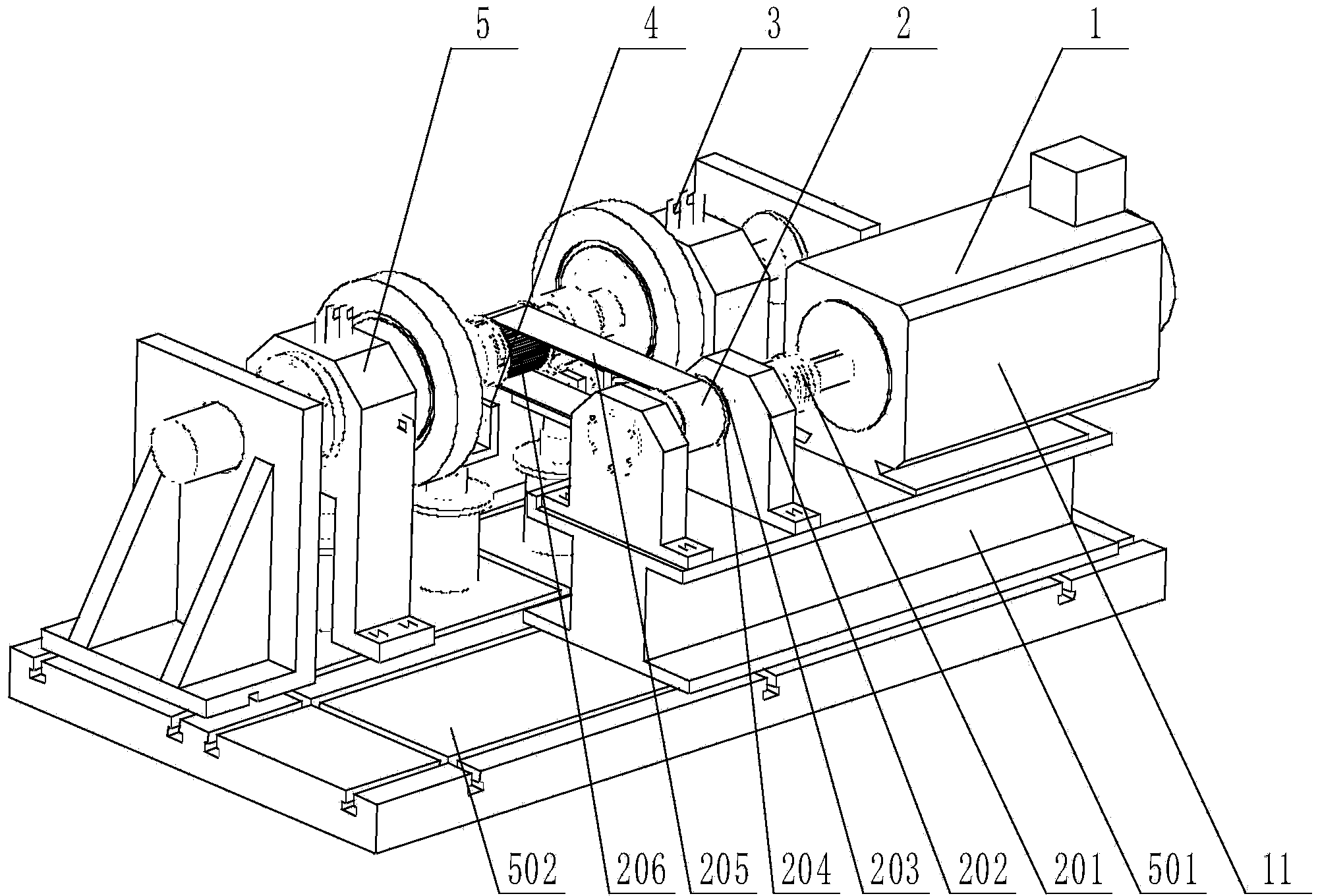

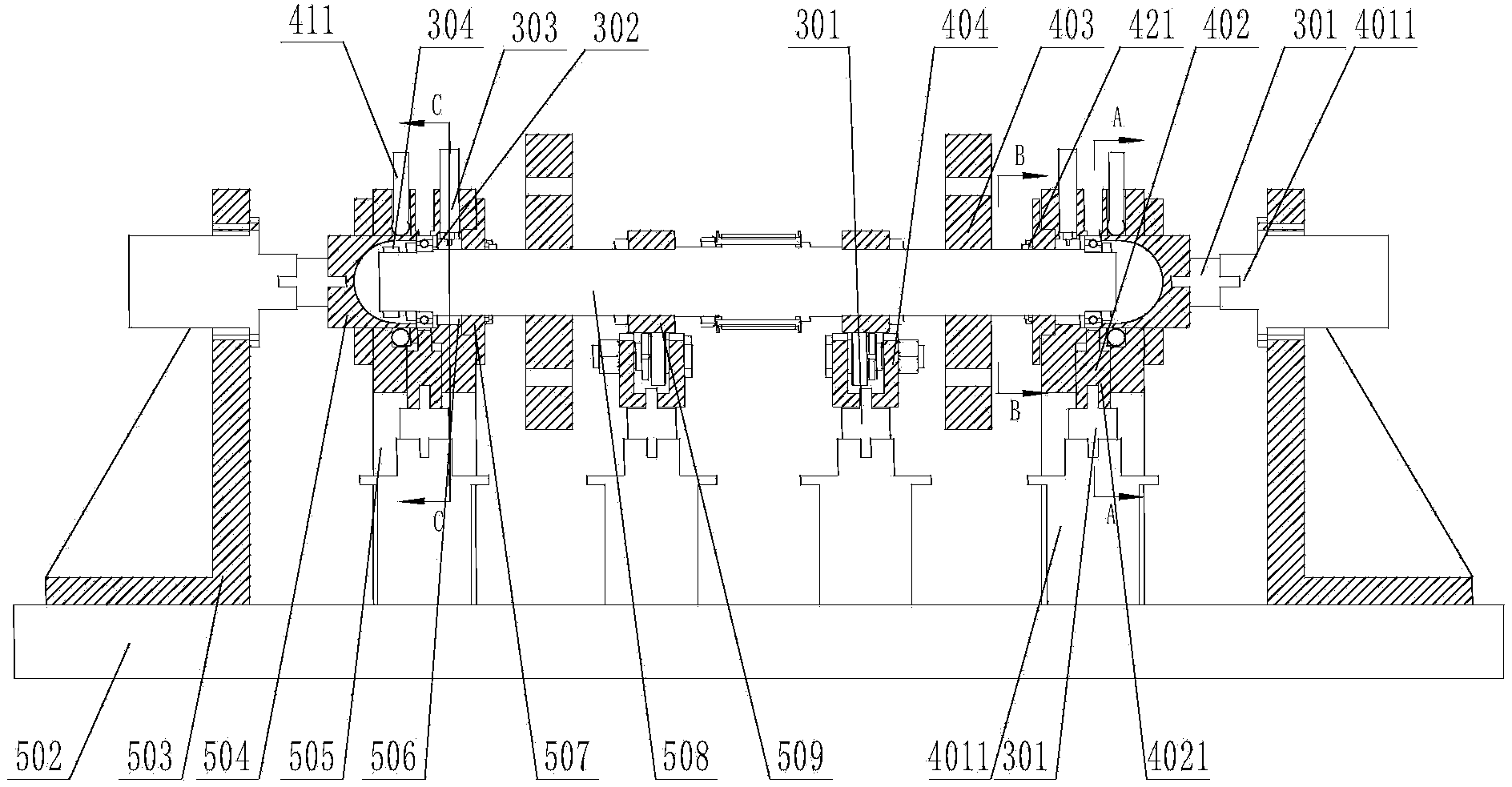

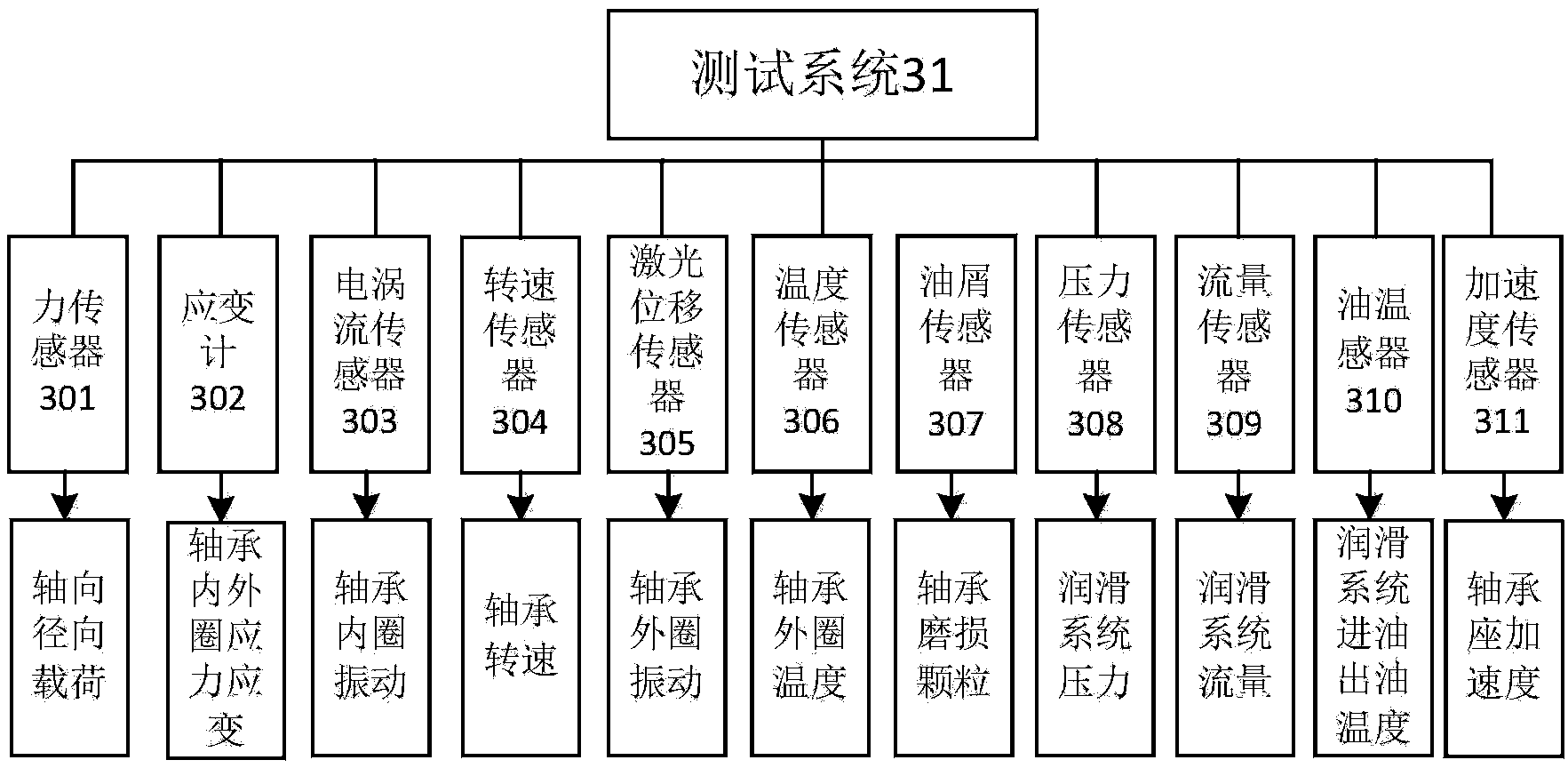

Bearing integrated dynamic performance test device and method

The invention relates to the technical field of bearing testing, in particular to a bearing integrated dynamic performance test device and method. The bearing integrated dynamic performance test device comprises a drive system, a transmission system, a measurement and control system, an environmental simulation system and a mechanical body structure. A motor is adopted by the drive system for driving. The measurement and control system controls the rotation speed of the motor. The transmission system is in a belt transmission mode or a coupler transmission mode. The measurement and control system is provided with a force sensor, a strainmeter, an eddy current transducer, a rotation speed sensor, a laser displacement sensor, a temperature sensor, a magnetic oil residue sensor, a pressure sensor, a flow sensor, an oil temperature sensor, an acceleration sensor and other related sensors used for bearing testing. The control system is driven in a servo mode, and is composed of a frequency converter, a hydraulic solenoid valve, a heating controller, a flow control device and a pressure control device. The environmental simulation system is adopted for simulating a real bearing testing working condition, and the performance and service life testing of the real bearing testing working condition is achieved.

Owner:DALIAN UNIV OF TECH

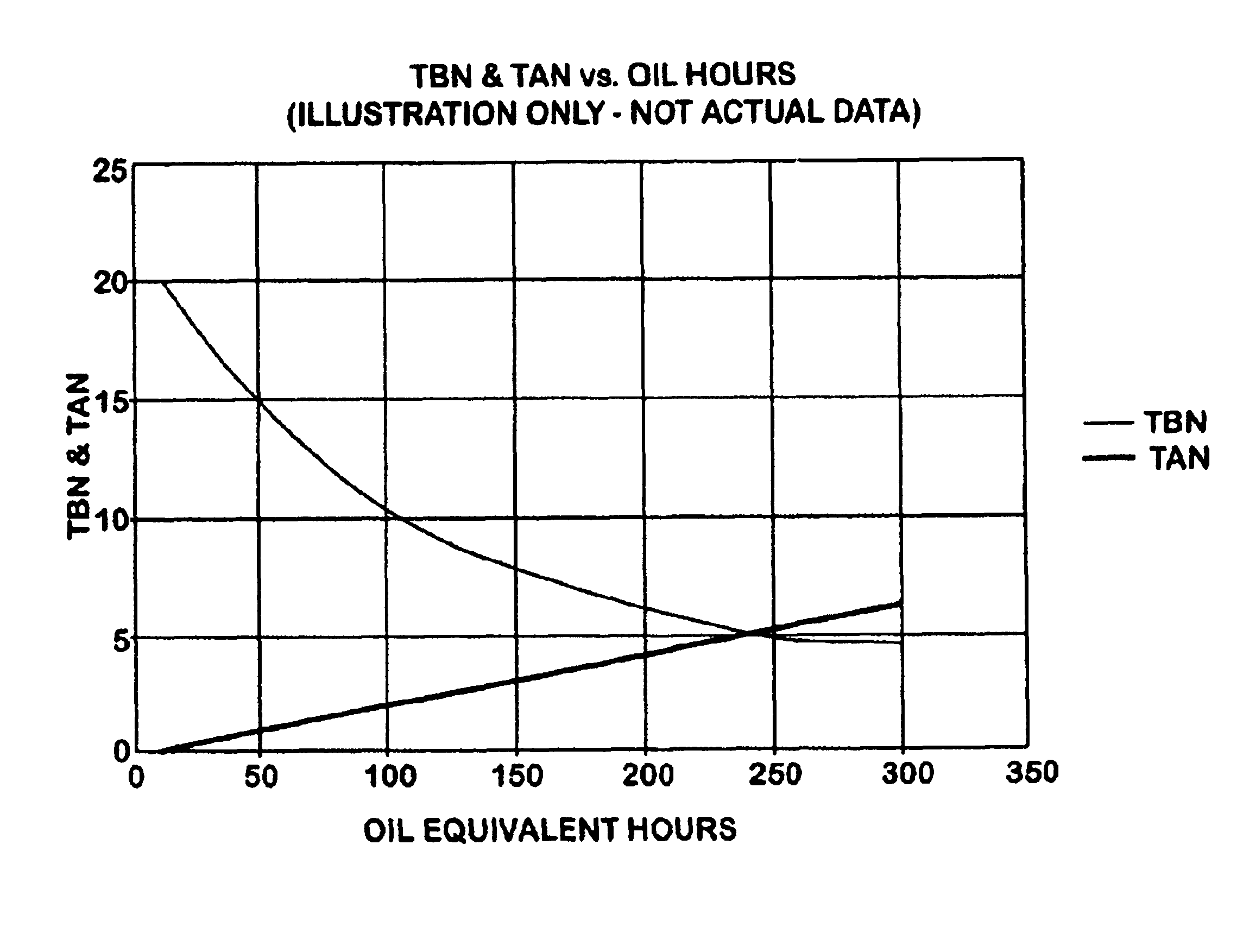

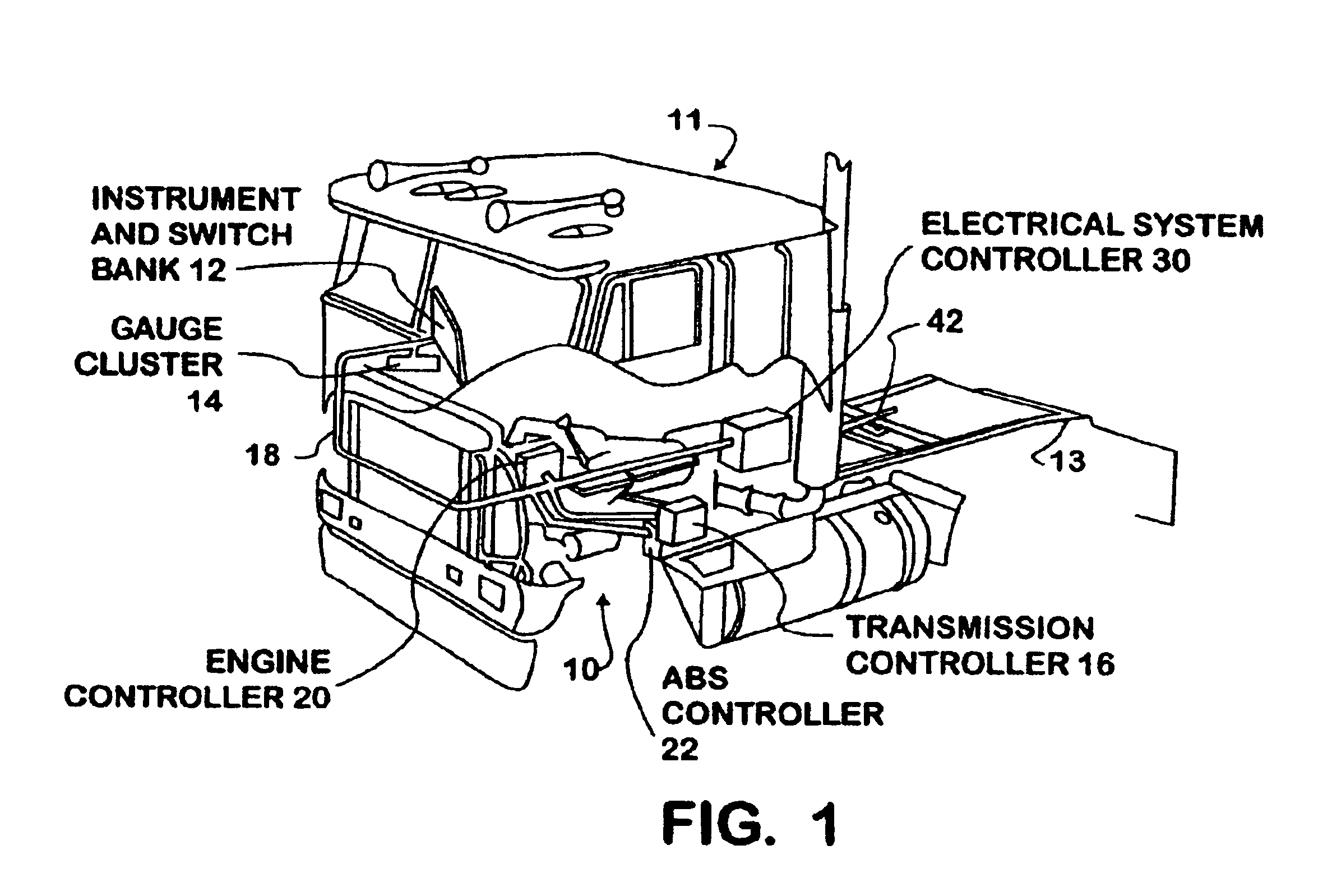

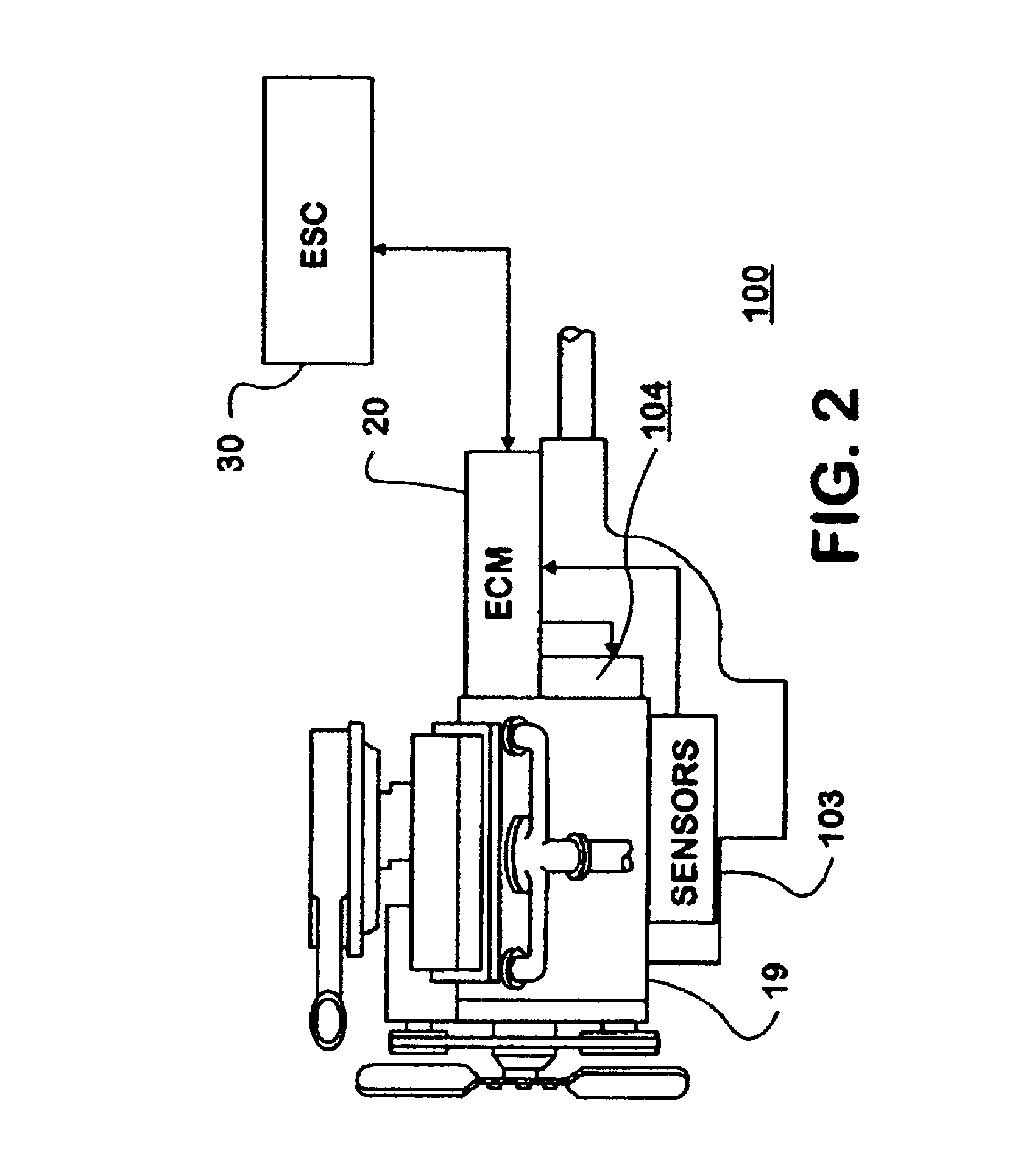

Method of estimating engine lubricant condition

A motor vehicle having an internal combustion engine and a lubricating oil circulation system provides estimates of the distance remaining before an oil change becomes imperative. An indirect estimate of the depletion of various additives and the deterioration of oil operating characteristics is based on engine operating variables including oil temperature, ignition timing and engine load. The limit of depletion of total base number is dynamic, since it is set against total acid number and the two figures are independently calculated.

Owner:INT TRUCK INTPROP LLC

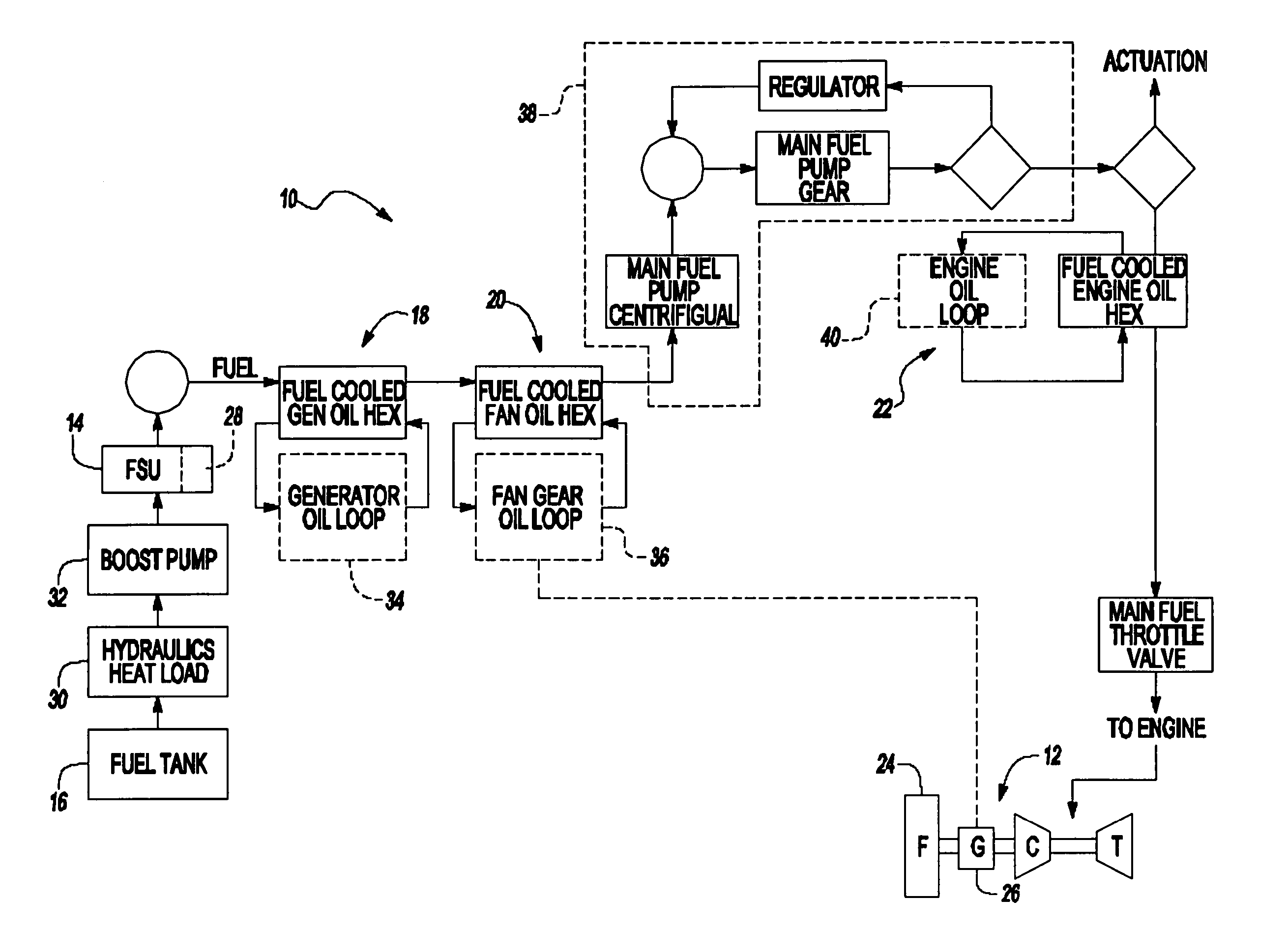

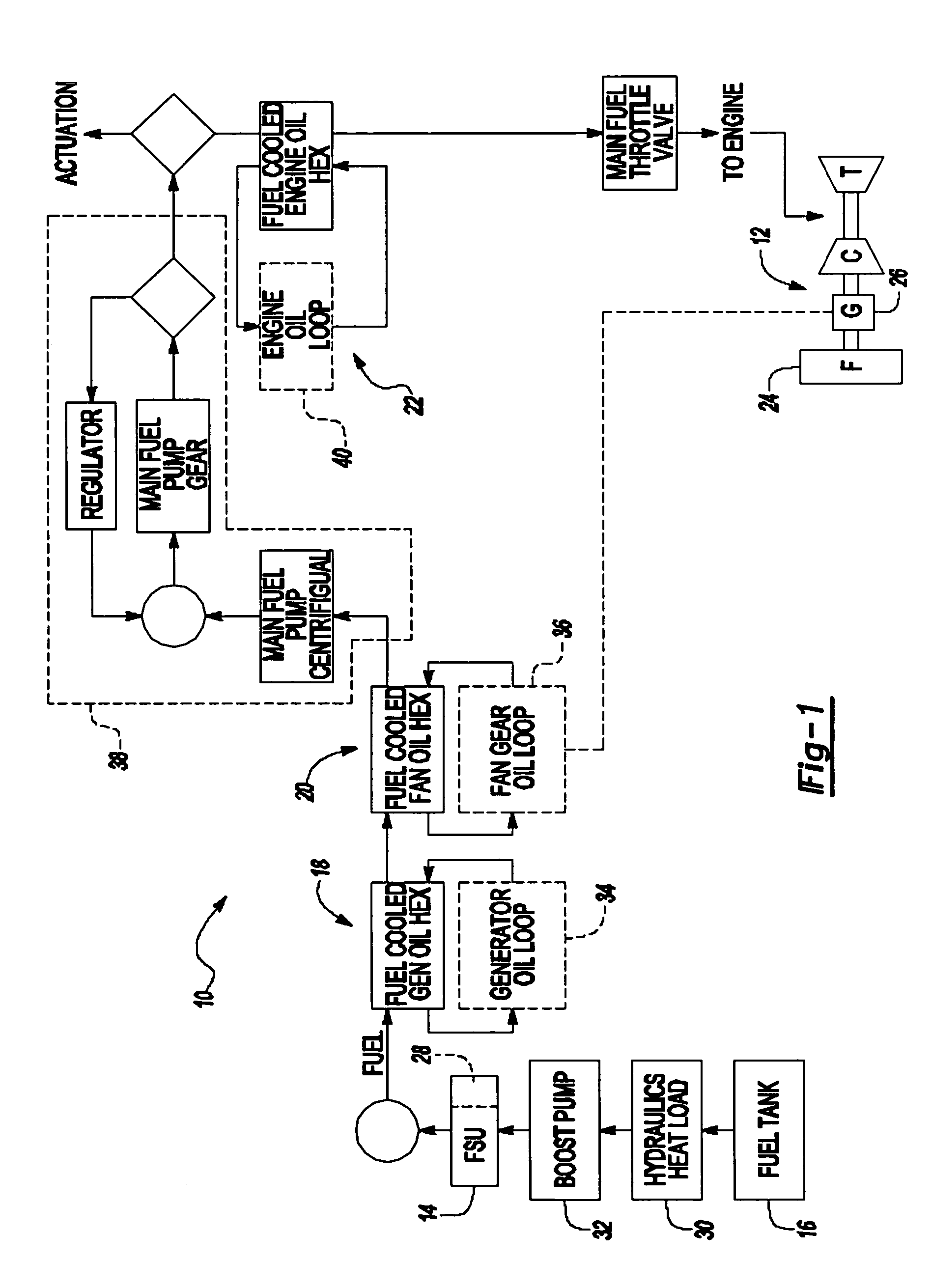

Thermal management system for an aircraft

ActiveUS7260926B2Minimizes air-to-liquid heat exchangersEngine fuctionsTurbine/propulsion fuel deliveryThermal management systemProcess engineering

A fuel based thermal management system includes a fuel stabilization system which permits the fuel to exceed the traditional coking temperatures. High temperature components are arranged along the fuel flow path such that even at the higher operating temperatures the fuel operates as a heat sink to transfer heat from high temperature components to the fuel. An optimal high temperature ester-based oil permits an oil-loop to exceed current oil temperature limits and achieve a high temperature to permit efficient rejection of heat to the fuel late in the fuel flow path.

Owner:RTX CORP

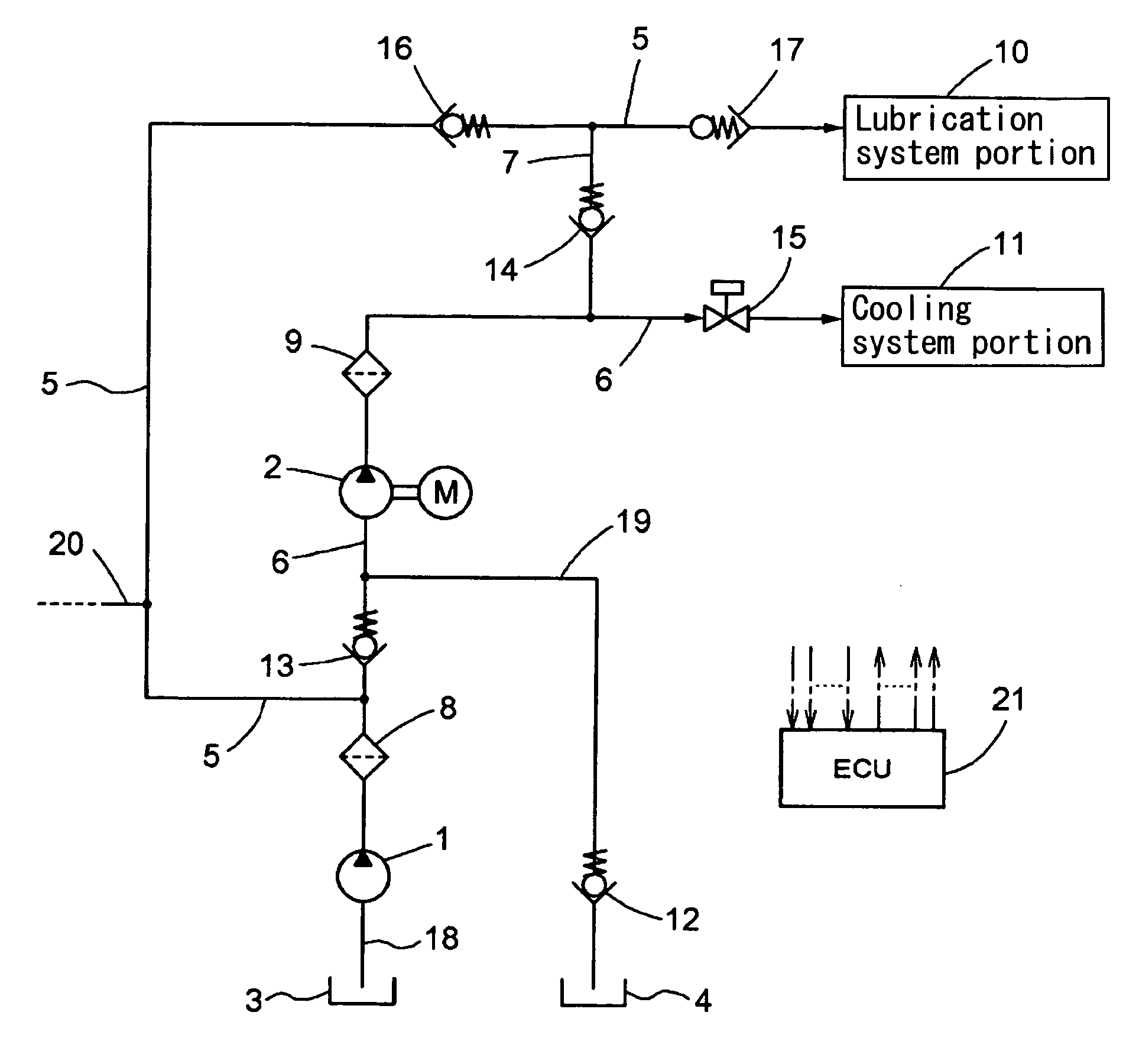

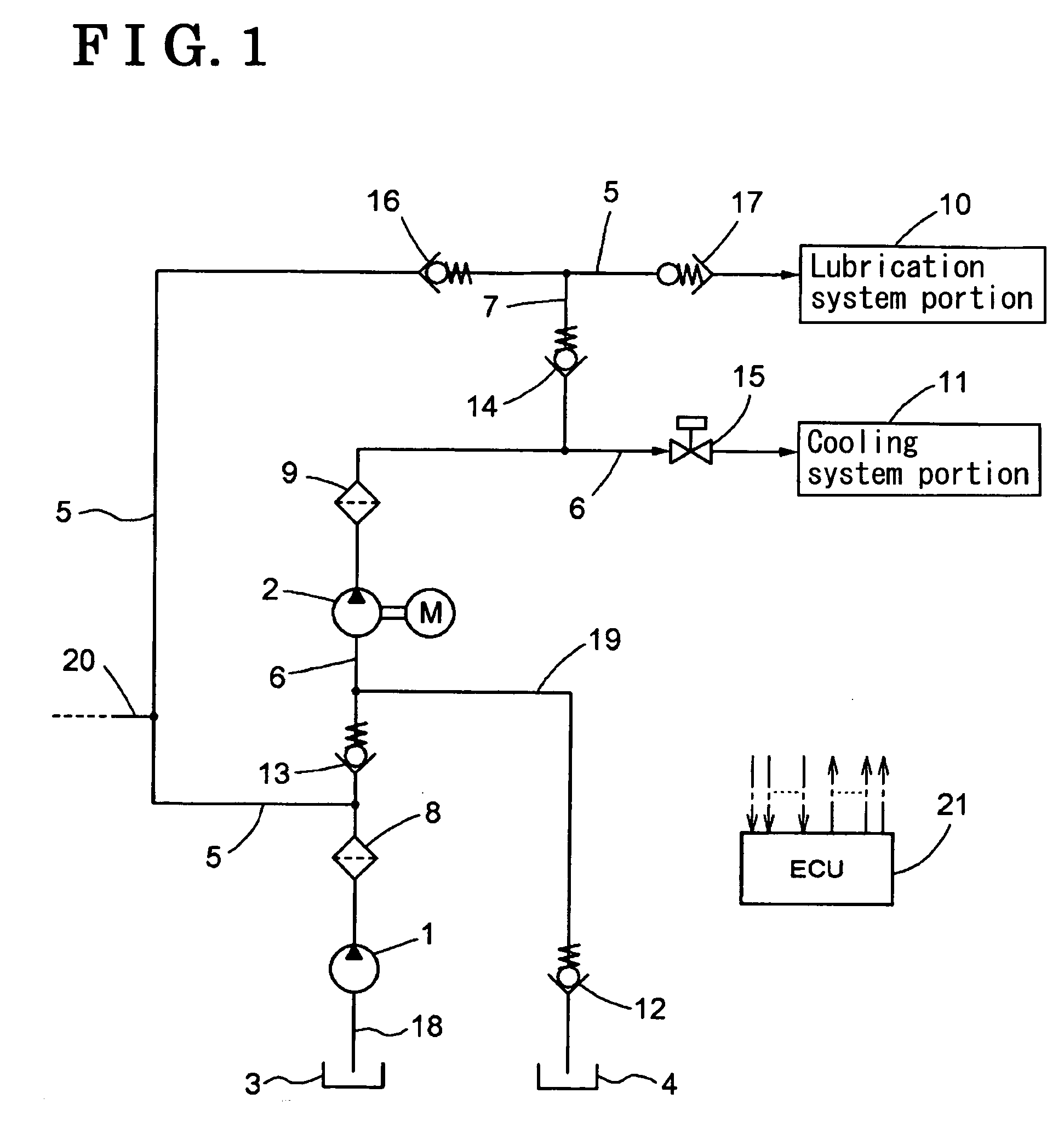

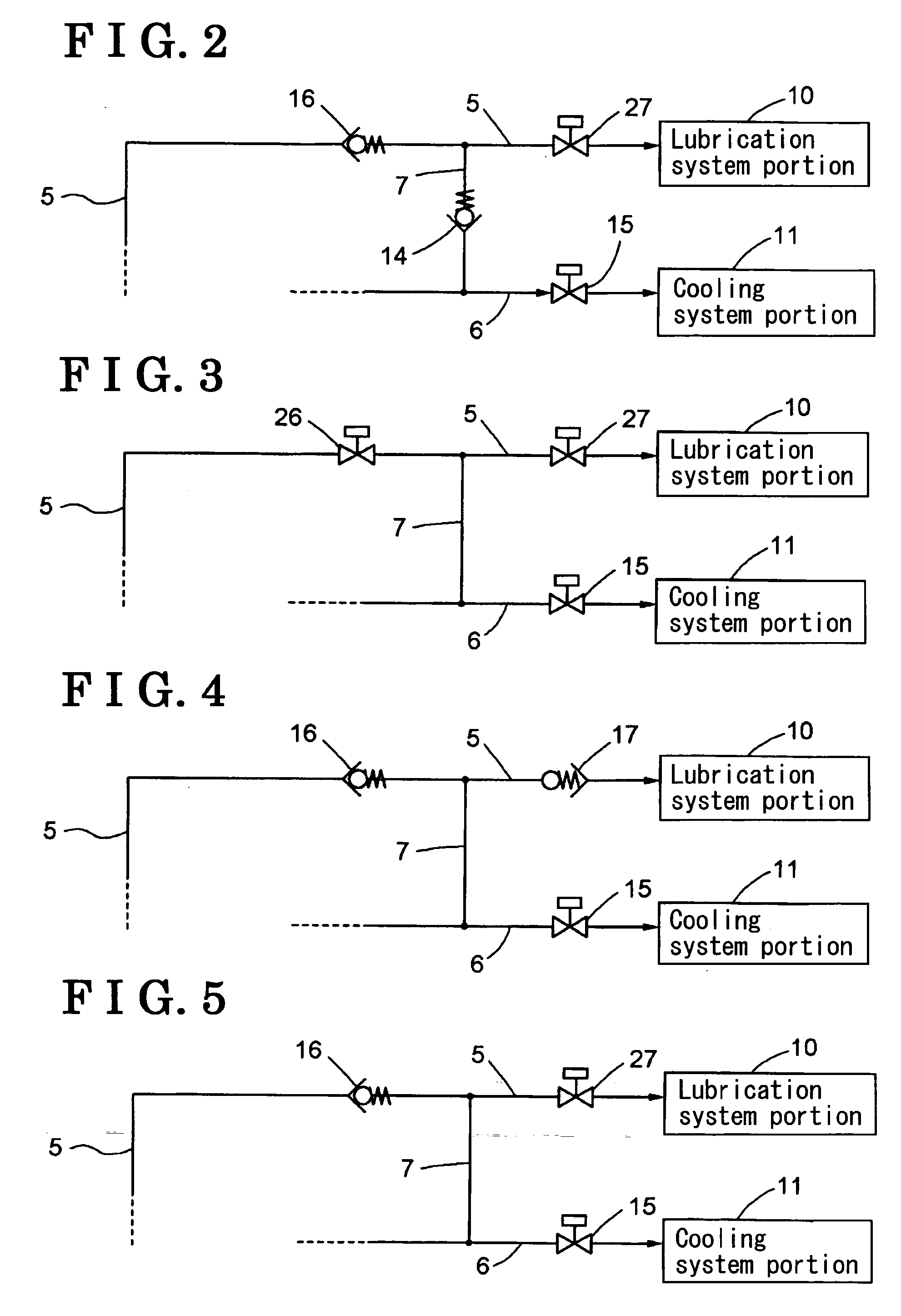

Oil supply device for engine

An oil supply device for an engine includes a first oil suction passage, a second oil suction passage, a first pump for sucking and discharging oil from the first oil suction passage, a second pump arranged in series with the first pump, the second pump for sucking and discharging oil from at least one of the first pump and the second oil suction passage, a check valve for blocking oil circulation, a first oil passage, a second oil passage, a third oil passage for establishing communication between the first oil passage and the second oil passage, and a supply volume control device for varying oil supply volume to a lubrication system portion, to a cooling system portion, or to the lubrication system portion and the cooling system portion in accordance with a change in at least one of an engine oil temperature, an engine rotation speed, and an engine load.

Owner:AISIN SEIKI KK

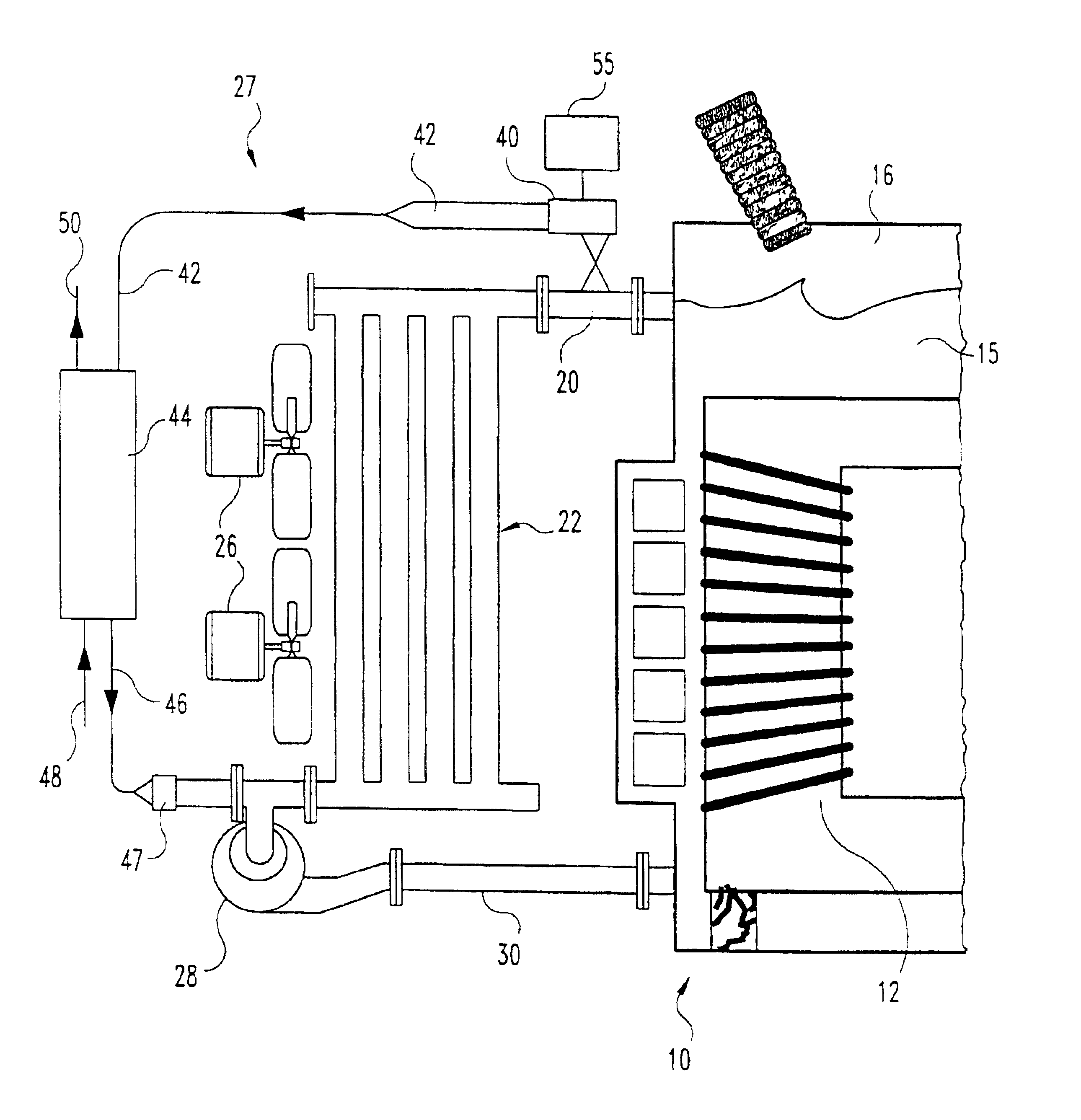

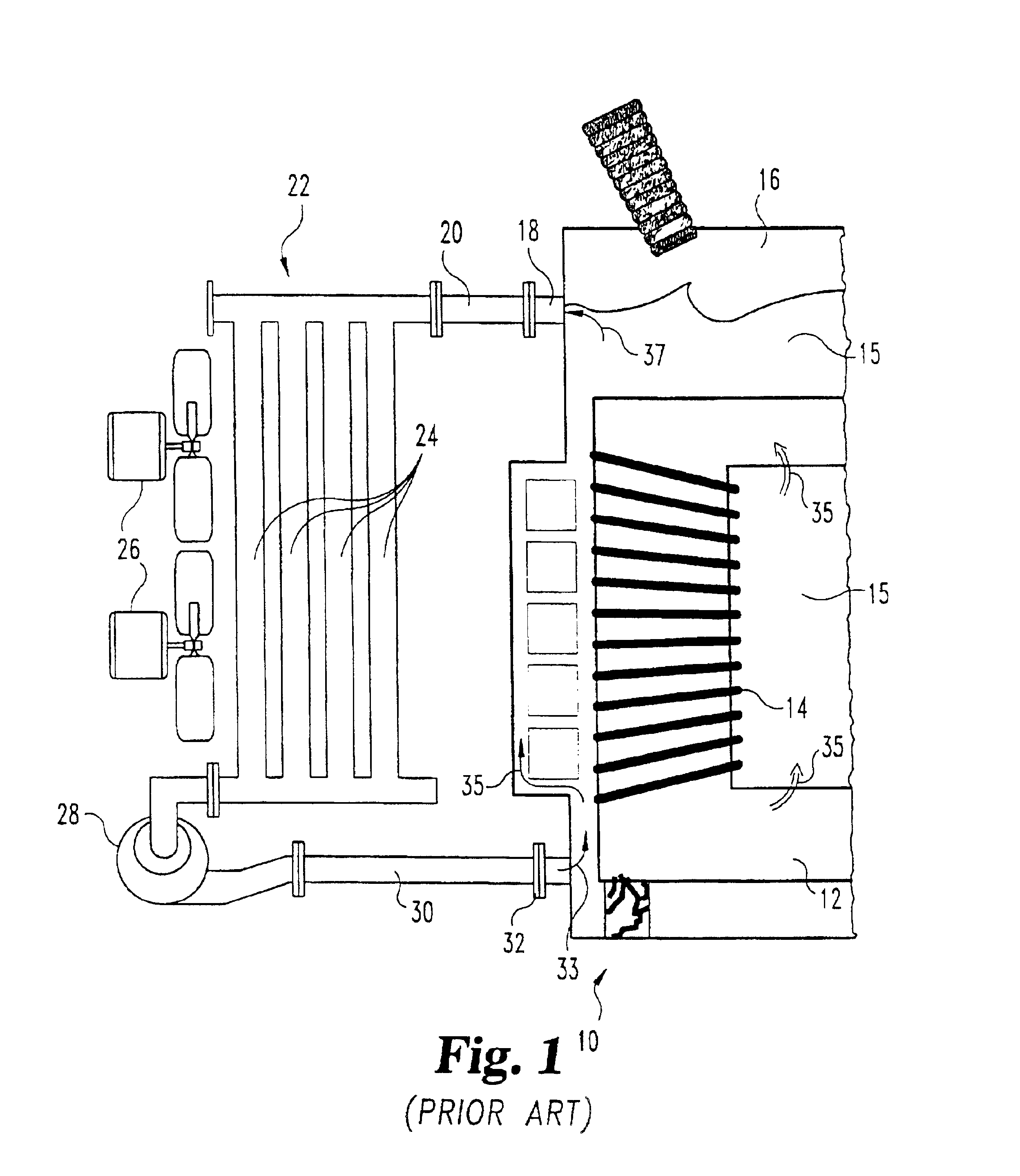

Apparatus and method for cooling power transformers

InactiveUS6909349B1Improve cooling effectReduce operating costsTransformers/inductances coolingHeat storage plantsTransformerCoolant flow

A system (27) for reducing the temperature of cooling oil for a power transformer (12) includes a heat exchanger (44) interposed in the cooling oil system. The heat exchanger (44) relies upon a liquid-to-liquid exchange of heat from the heated oil to a coolant flowing through the heat exchanger. In one embodiment, the coolant provided to the heat exchanger is obtained from an absorption chiller (65). Heat energy is provided to the chiller (65) from a heat storage device (80). In a specific embodiment, the heat storage source (80) can be a phase change material device. In a preferred cooling system, a programmable controller (55) determines the activation and operation of the system. The controller (55) can sense transformer or cooling oil temperature to trigger activation. In a preferred embodiment, the controller (55) compares a current temperature history against a temperature profile to anticipate increased cooling requirements. In certain embodiment, excess, off-peak or waste heat from the transformer (12) itself is provided to the heat storage device (80) or to the phase change heat exchanger.

Owner:TRW INC +1

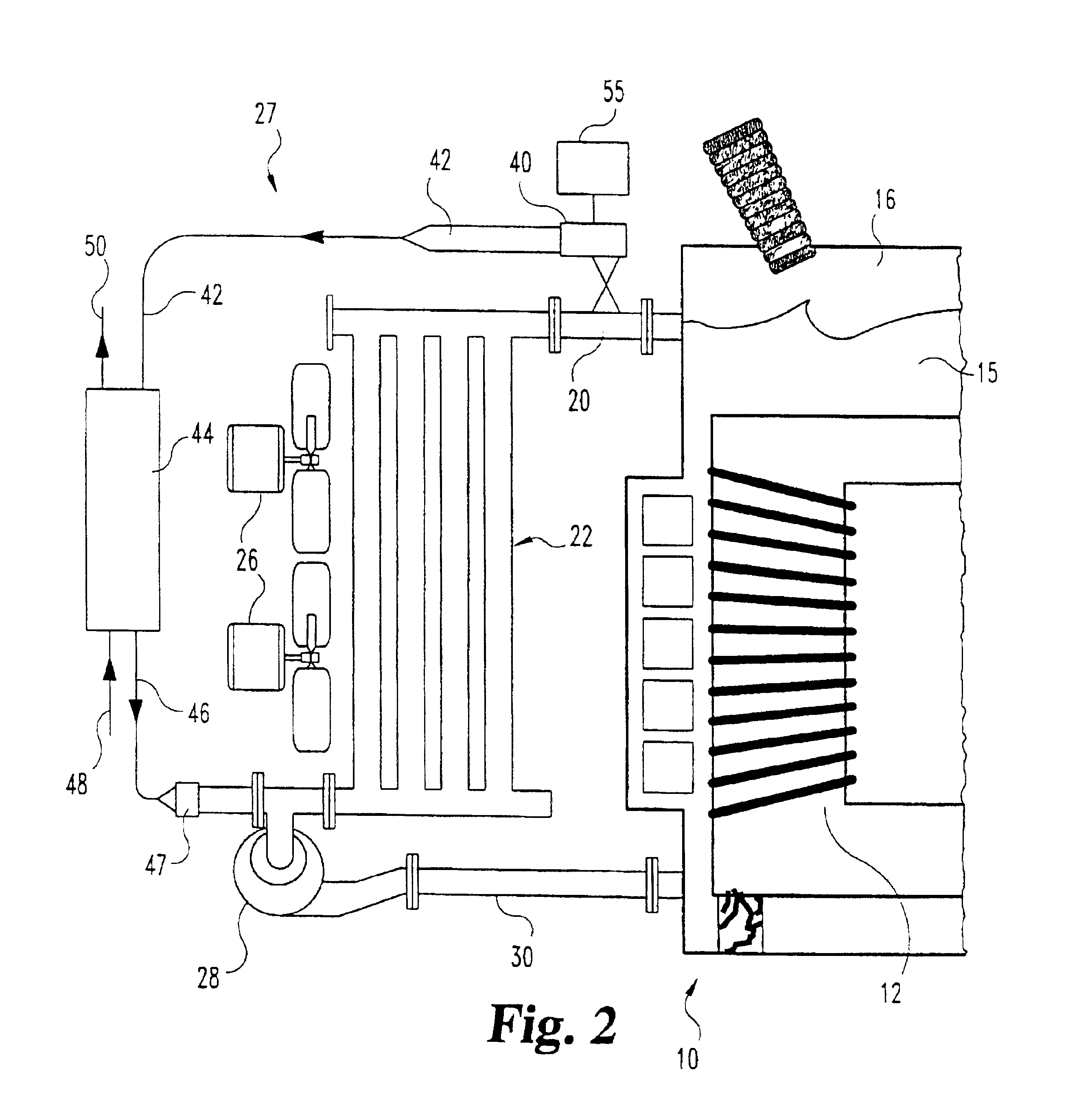

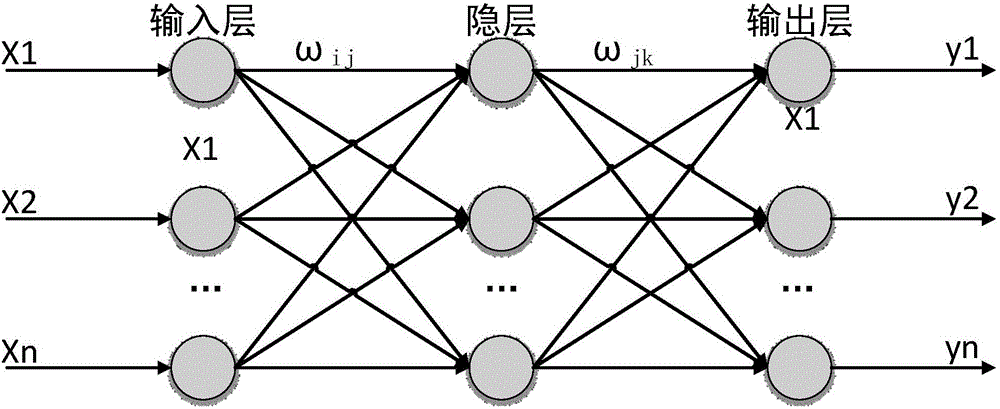

Automatic expert integrated fault diagnosis system and diagnosis method for wind turbine generator system

InactiveCN106124982ASafe and stable operationImprove accuracyDynamo-electric machine testingNacelleData acquisition

The invention discloses an automatic expert comprehensive fault diagnosis system and a diagnosis method for wind turbines, which include: a data acquisition module that collects relevant data of a main control unit and a vibration signal acquisition unit and transmits it to a fault diagnosis module; a fault diagnosis module that comprehensively uses The neural network knowledge and expert system module use forward reasoning and compare the parameter fluctuation values obtained in real time with the data in the fault sample knowledge base to generate fault information in real time; the fault diagnosis module passes the diagnosed fault information through the human-machine interface module for output. This invention uses the main control unit to read parameters such as instantaneous power, rotation speed, propeller angle, cabin temperature, wind speed, oil temperature, yaw status and other parameters of the wind turbine to improve the accuracy of fault diagnosis, and uses a neural network expert system based on wavelet packet analysis Carry out automatic analysis and give operation and maintenance suggestions through the expert diagnosis system.

Owner:STATE GRID CORP OF CHINA +4

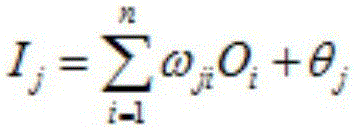

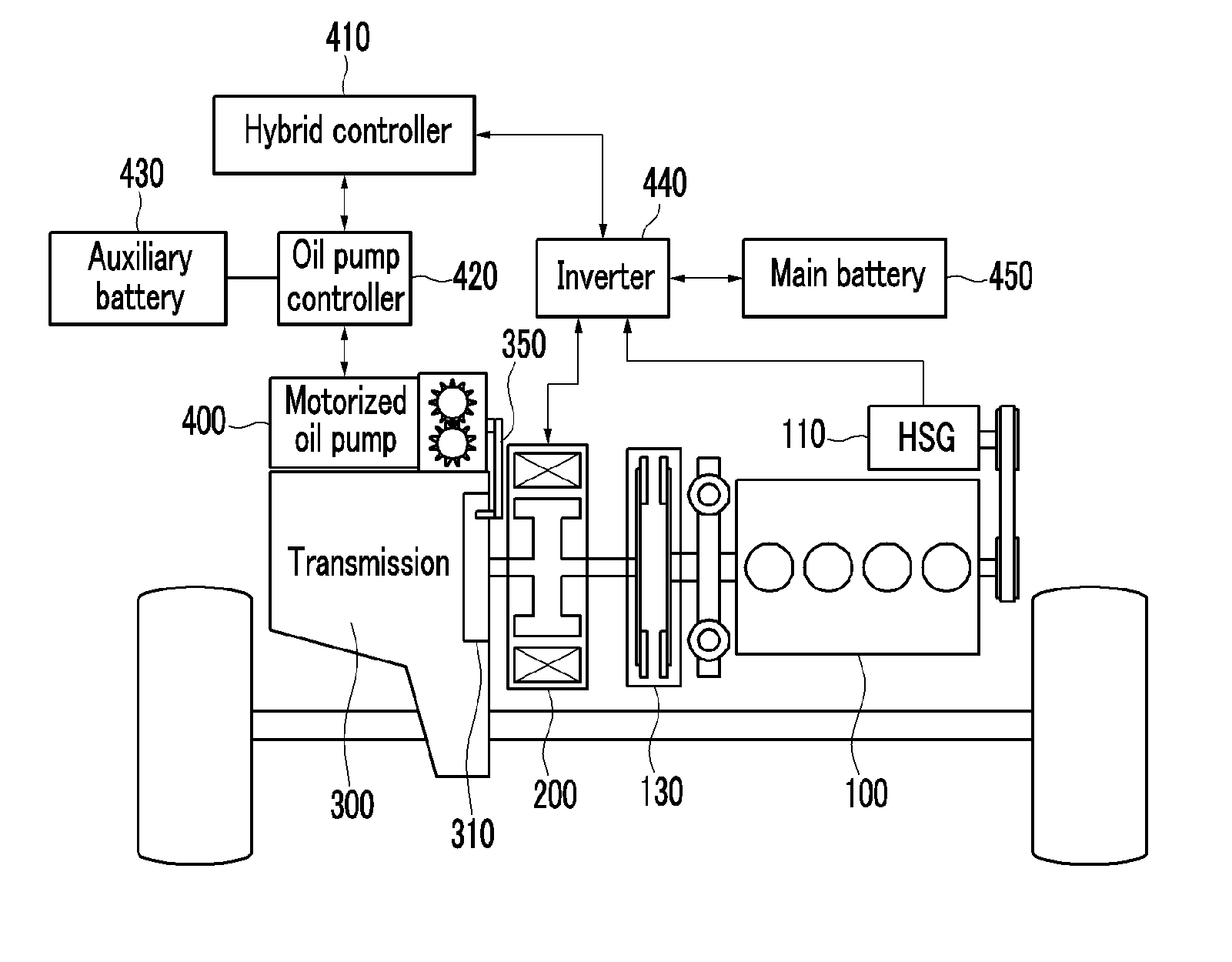

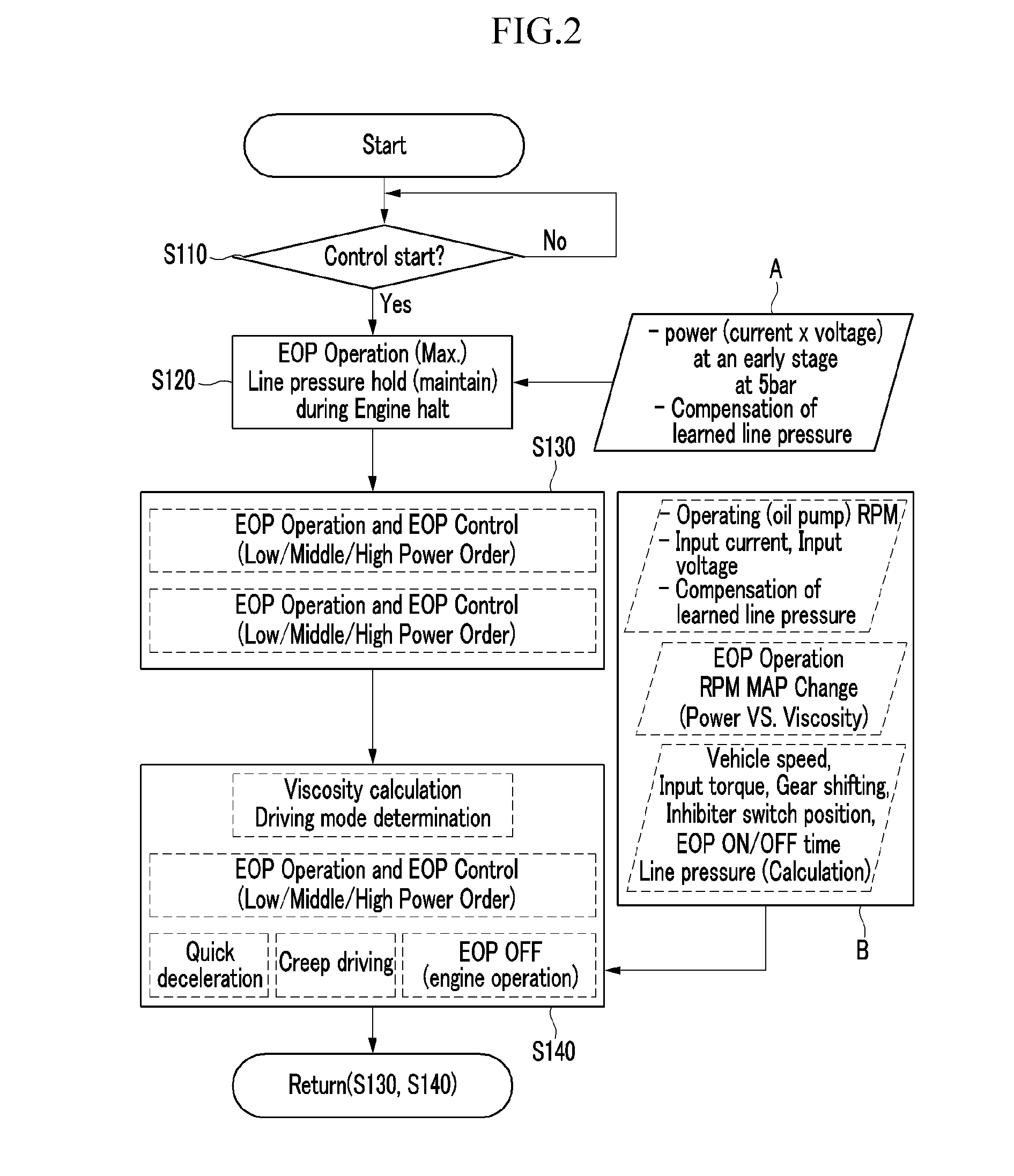

Oil pump controlling system of hybrid vehicle and method thereof

ActiveUS20120141297A1Reduce power consumptionImprove fuel consumption efficiencyPropulsion using engine-driven generatorsGearing controlControl systemHybrid vehicle

The present invention relates to an oil pump control apparatus of a hybrid vehicle that controls an oil pump according to a demand of an output torque and oil temperature, and a method thereof. A oil pump control method includes controlling hydraulic line pressure by operating a oil pump at a maximum power if a starting demand for a hybrid vehicle is detected, calculating a viscosity to correspond to an oil temperature in an engine stop mode and controlling a rotation speed of the oil pump at a low power, and calculating a viscosity according to a variation of a line pressure in a driving mode and controlling the rotation speed of the electric oil pump in either a low power, a middle power, and a high power state.

Owner:HYUNDAI MOTOR CO LTD +1

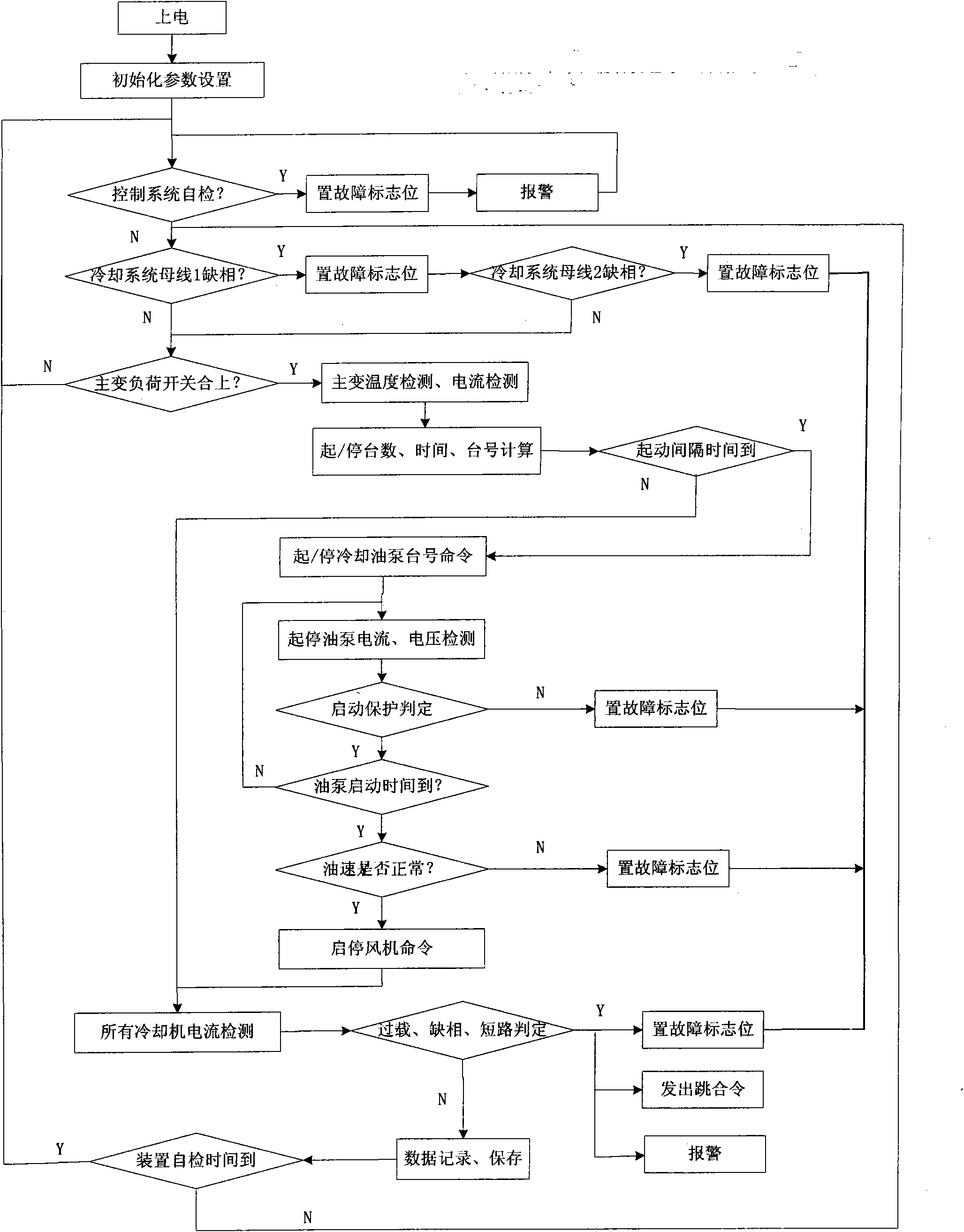

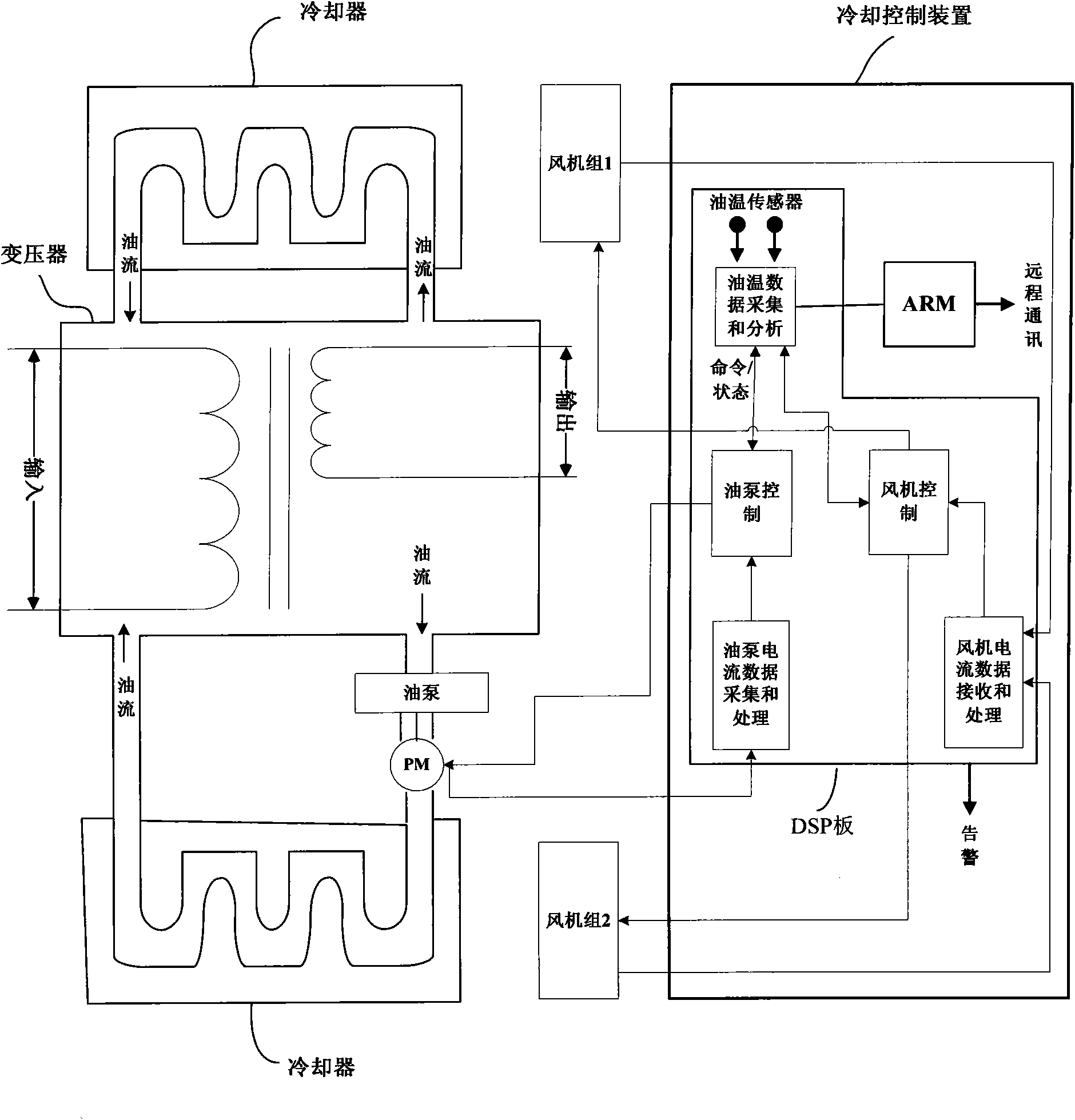

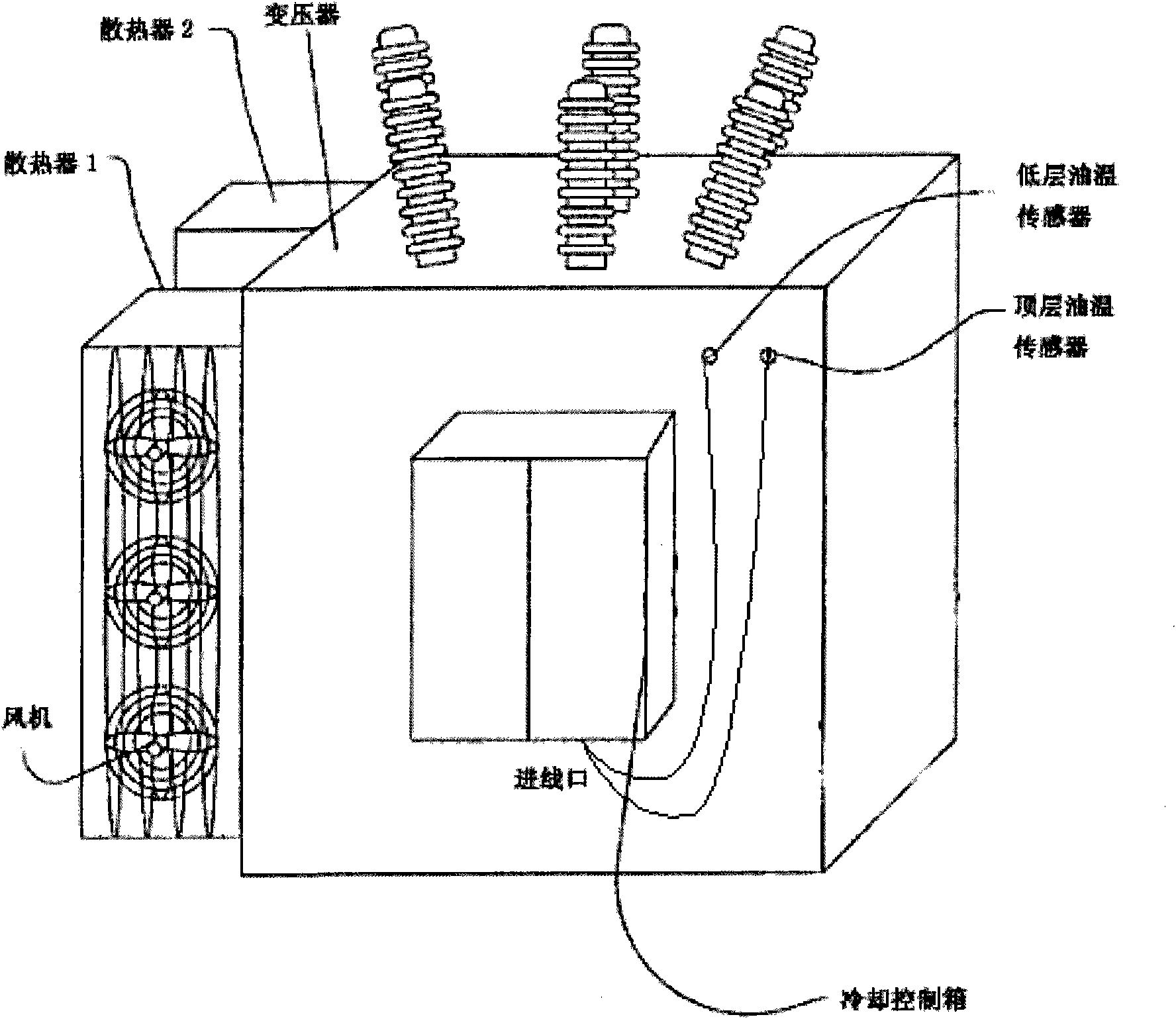

Intelligent control method and intelligent control device of transformer cooling system

ActiveCN101943921AIncrease the level of automationIntelligent online real-time controlTransformers/inductances coolingPower network operation systems integrationTransformerDual core

The invention discloses an intelligent control method and an intelligent control device of a transformer cooling system. The method comprises the following steps: detecting the cooling oil temperature and the load current value of the upper layer and the lower layer of a transformer; determining the group number, the table number and the time of a start / stop cooler; starting / stopping at least one oil pump; starting / stopping at least one fan in a delay mode; detecting the current of the oil pump and the fan; entering a device debug mode; and recording events. The device comprises a DSP and ARM double-core hardware platform, wherein a DSP plate comprises a cooling oil temperature data acquisition and analysis module, an oil pump motor current data acquisition and processing module, an oil pump motor control module, a fan motor current data acquisition and processing module and a fan motor control module; and the ARM plate comprises a user interface, a communication module and a data storage module. The invention combines control, relay protection, real-time monitoring and diagnosis as a whole, has more intelligent on-line real-time control, can define and configure the parameter of the transformer cooling system, improves the production efficiency and saves the operation and maintenance cost of the transformer.

Owner:XIAN SHUANGHE SOFTWARE ENG +1

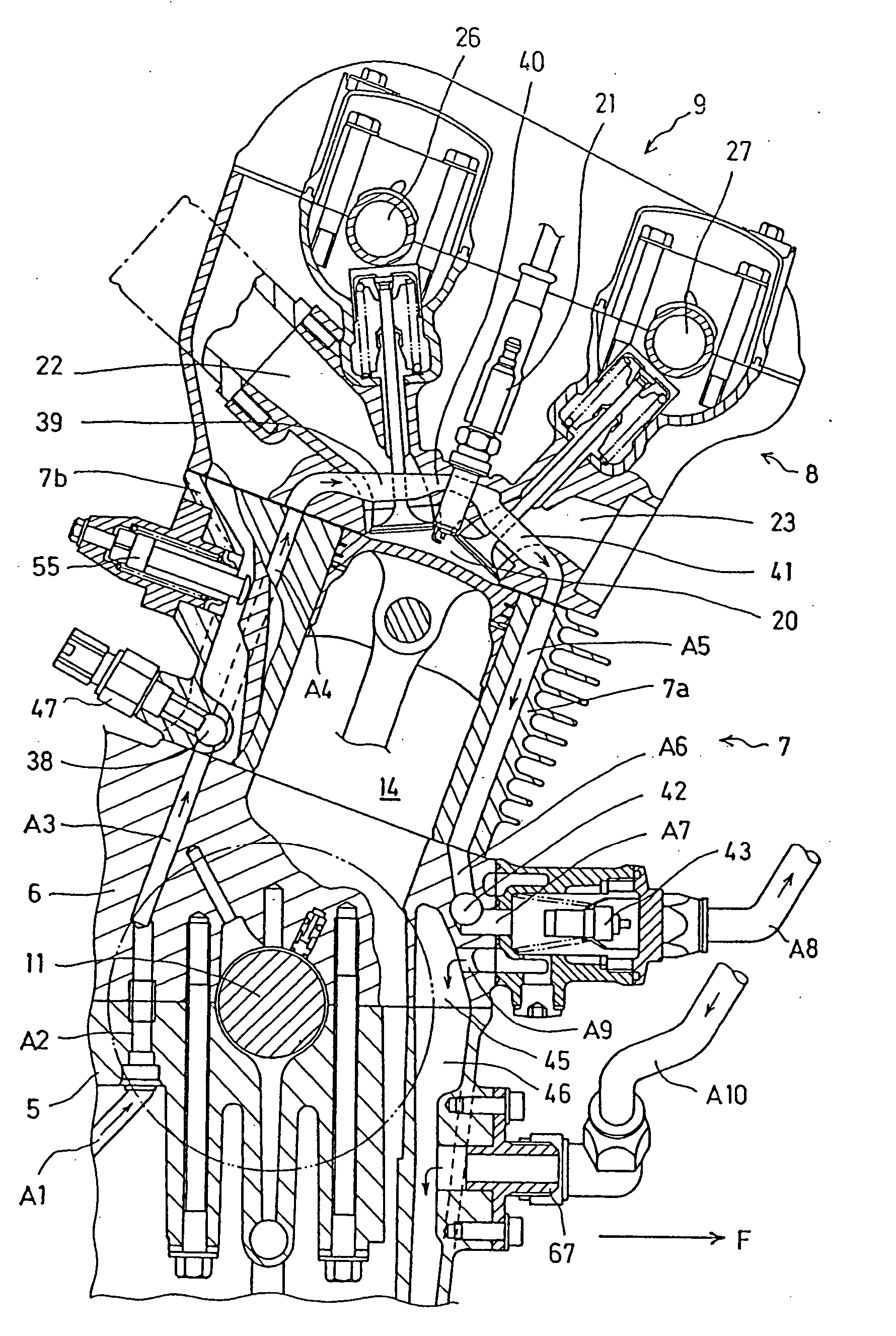

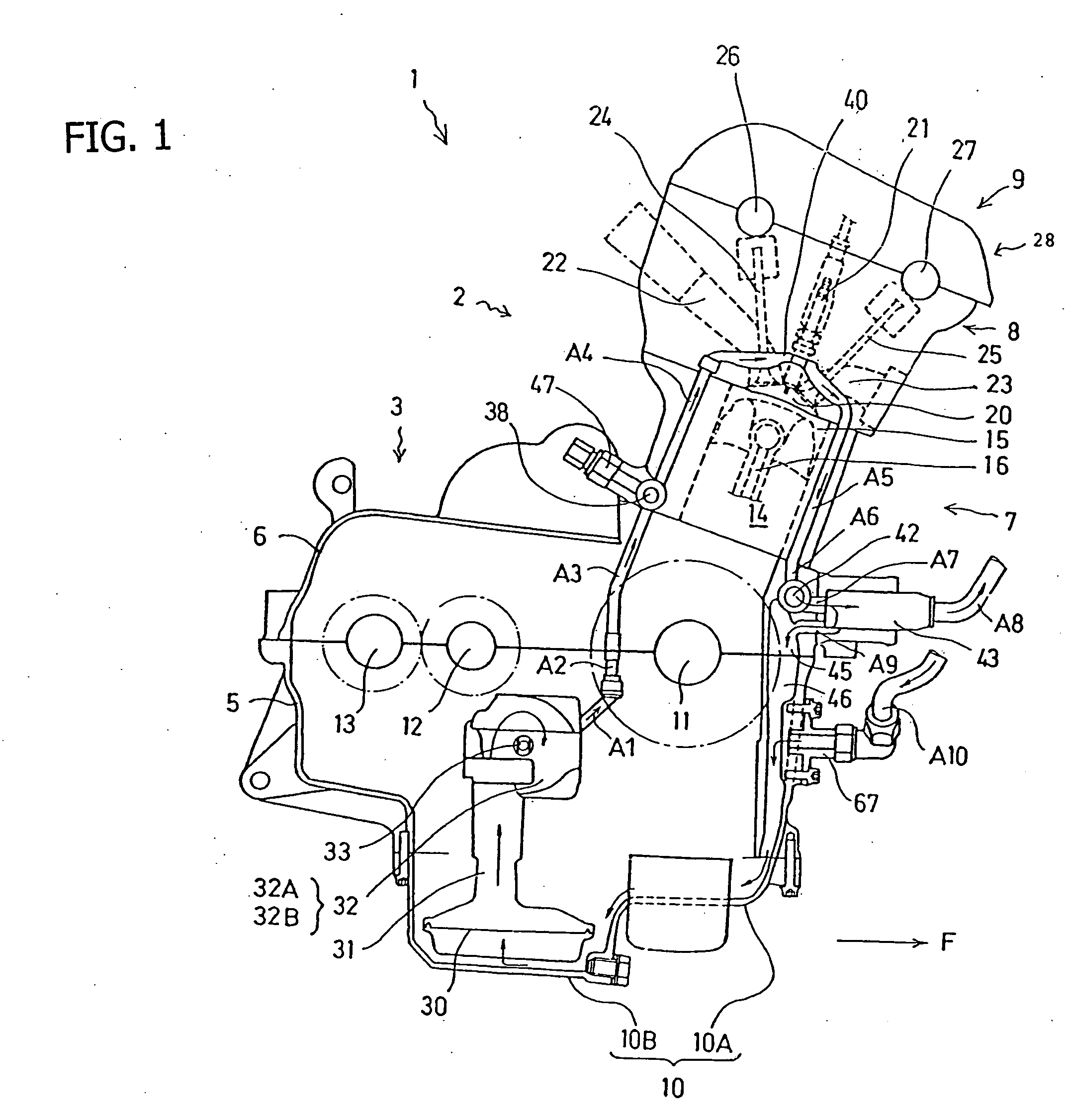

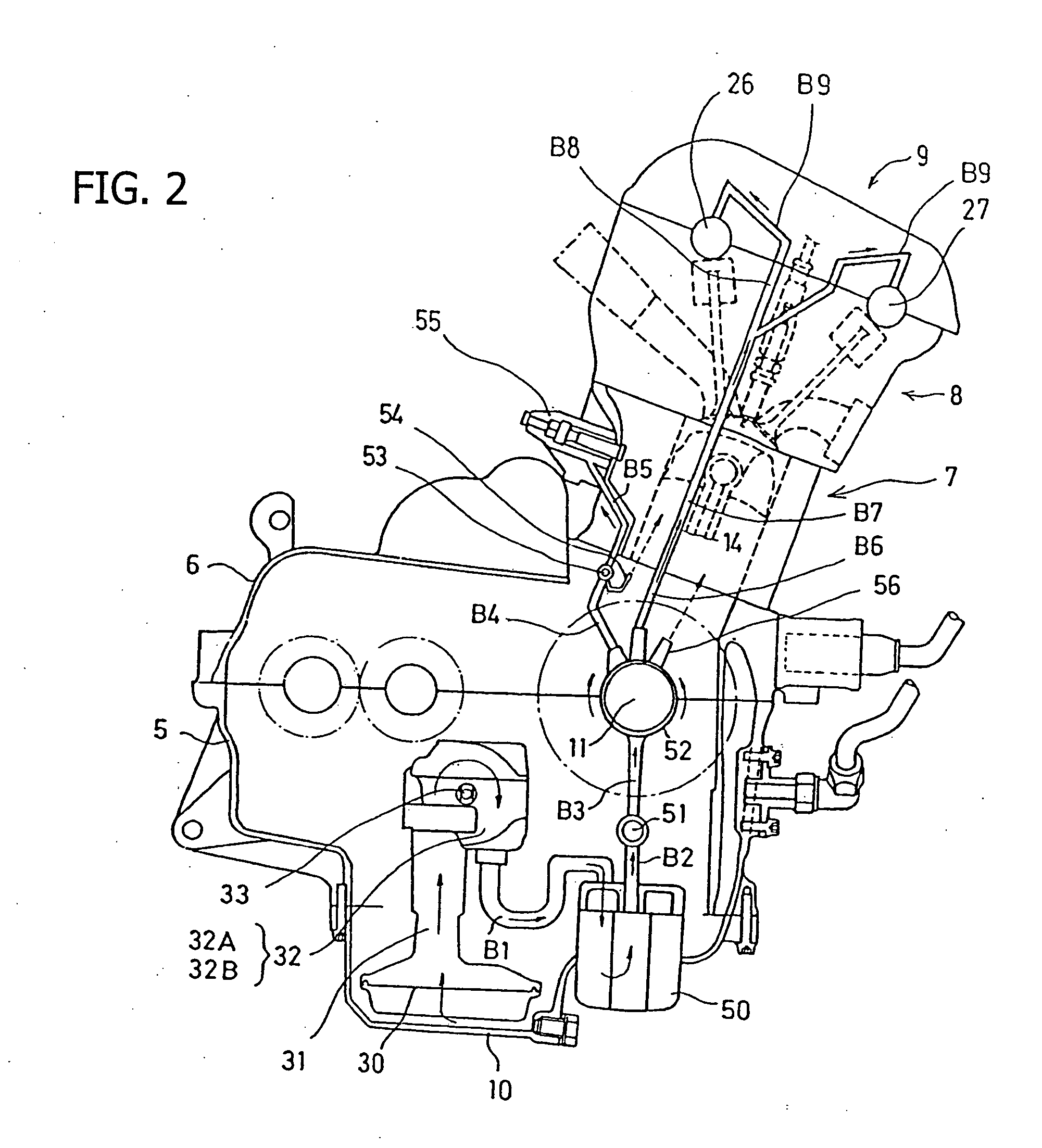

Cylinder head cooling structure for an internal combustion engine, including an oil temperature sensor and an oil temperature control system

ActiveUS20060065218A1Efficient use ofAvoid contactLiquid coolingCoolant flow controlTemperature controlCylinder head

A cylinder head cooling structure and an oil temperature control system are provided for an internal combustion engine having a plurality of cylinders, each having a plurality of intake ports and a plurality of exhaust ports. The engine includes cooling oil jackets surrounding the spark plugs in the cylinder head, a thermostat attached to the front surface of the crankcase independently of an oil filter, and an oil temperature sensor disposed on a rear face of the cylinder block above the crankcase in an oil supply path formed on the cylinder rear face for supplying oil to the oil jackets. Oil passages conducting oil into the oil jacket are provided between two separate parts of a bifucated intake port and between two separate parts of a bifurcated exhaust port, and only cooling system oil reaching high temperatures is allowed to flow through the thermostat, thereby improving temperature control response.

Owner:HONDA MOTOR CO LTD

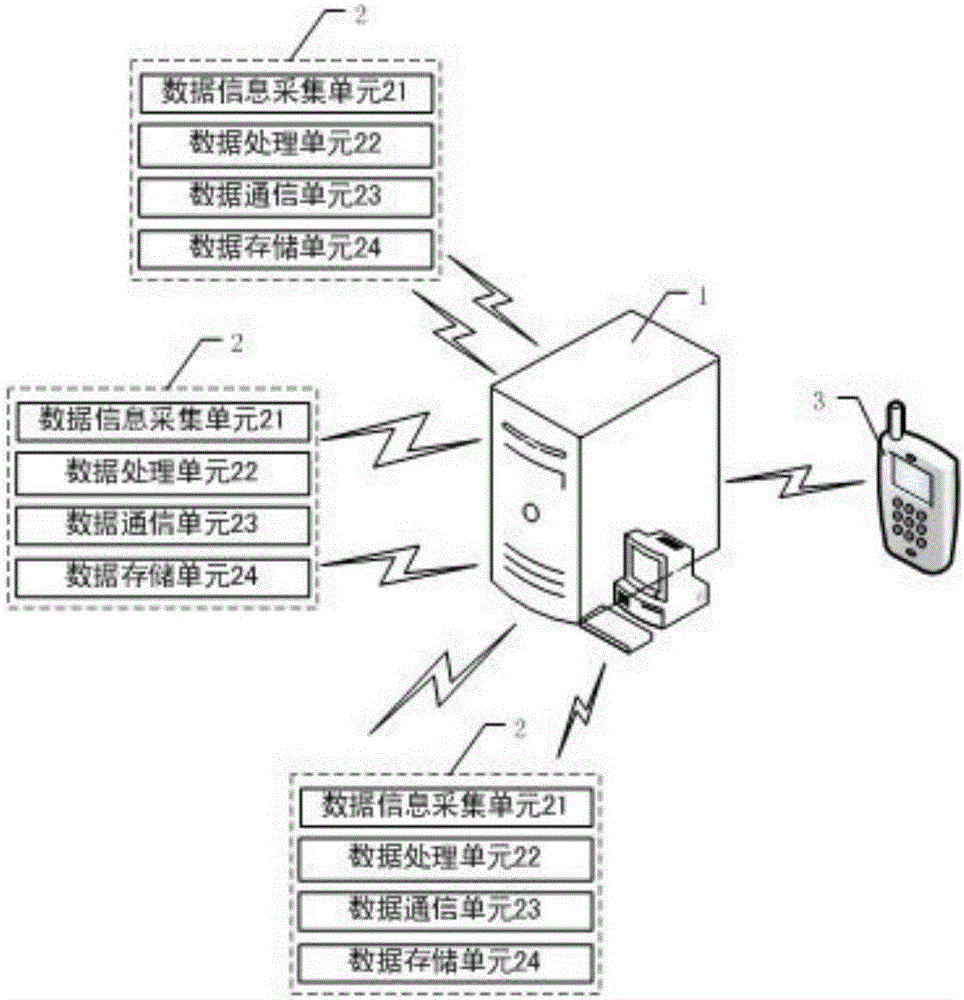

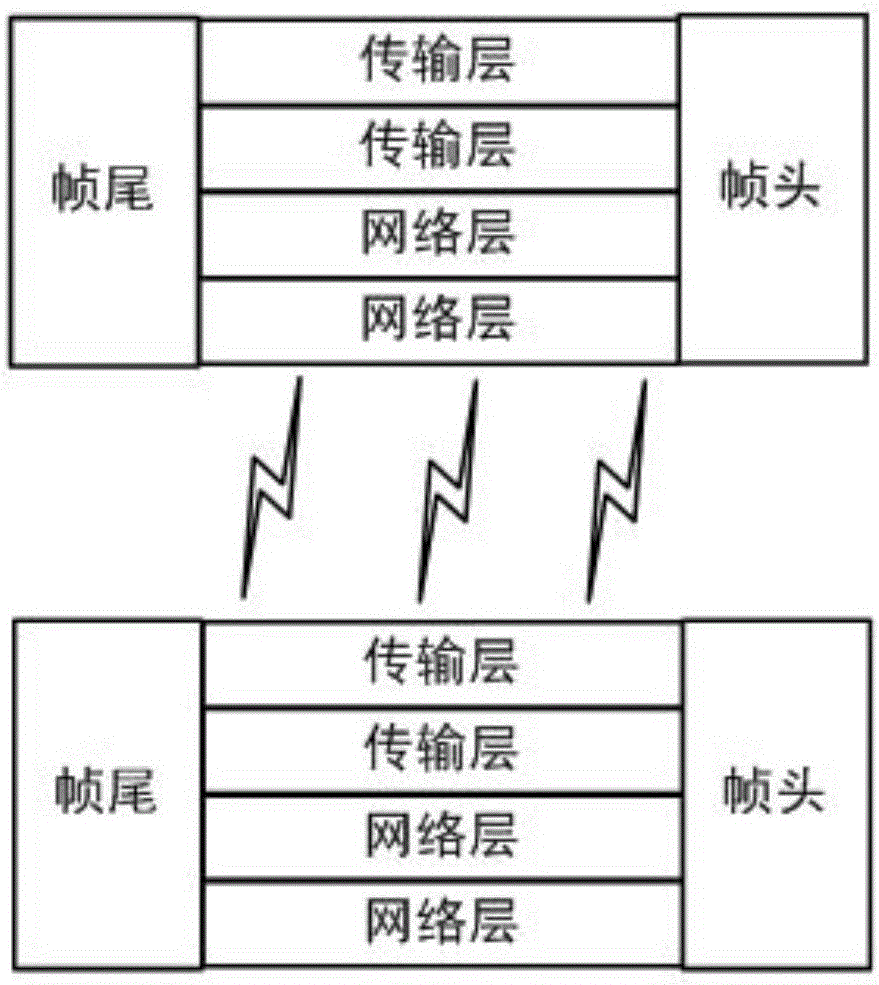

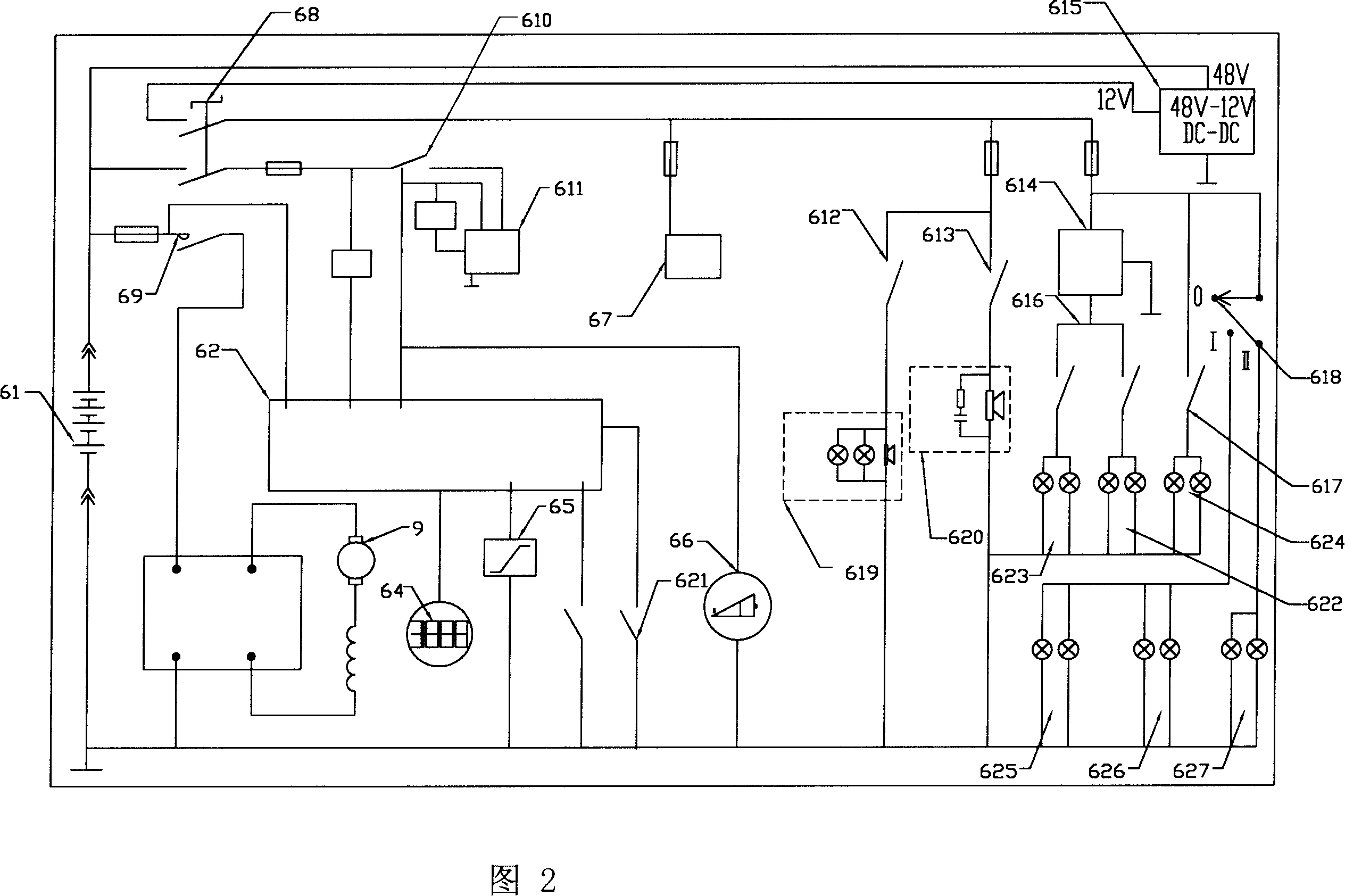

Power supply system remote monitoring system

ActiveCN106059067ARealize remote monitoringReal-time monitoring of operationPower network operation systems integrationCircuit arrangementsSpecification documentData information

The invention provides a power supply system remote monitoring system. A transformer equipment data acquisition module acquires the analog quantity of field transformer equipment and the current, voltage, active power, reactive power, coil temperature and oil temperature at each side of the transformer. A power supply circuit data acquisition module acquires the current, active power and reactive power of a power supply line, the voltage and frequency of a bus, and the three-phase voltage, three-phase current, zero-sequence voltage and zero-sequence current of the power supply line. A circuit breaker data acquisition module, an isolating switch data acquisition module and a grounding switch data acquisition module are respectively used for acquiring the switching quantity of the field equipment. Through a monitoring platform, systematic data storage is performed, monitoring clients can be connected to share data information, and grid maintenance personnel can exchange knowledge and accumulate data. Typical cases are formed based on stored maintenance process logs, maintenance process cases and related standard or specification files. Related standards, specification documents and operation procedures are provided. Knowledge and experience sharing and management are realized.

Owner:国网山东省电力公司泗水县供电公司 +1

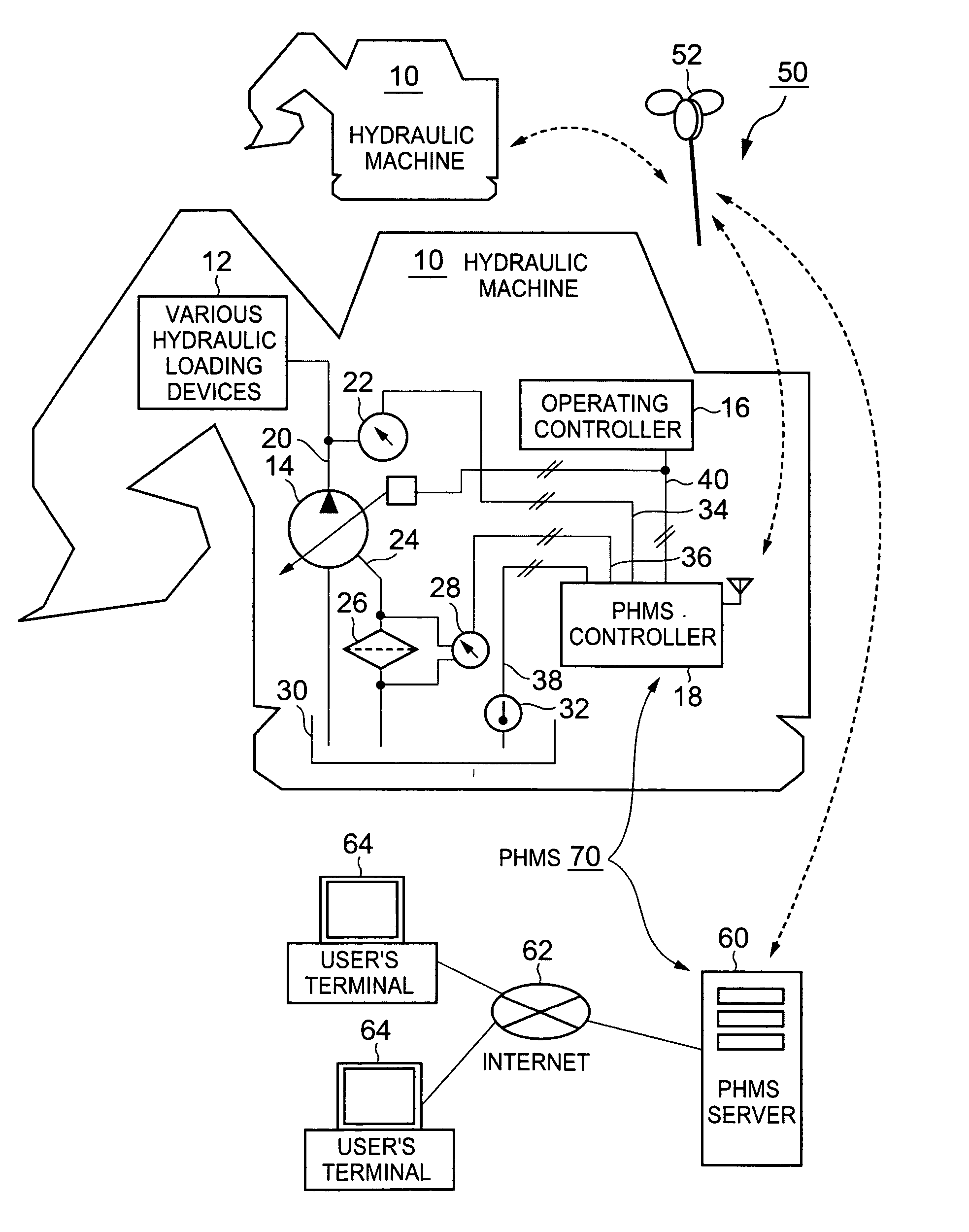

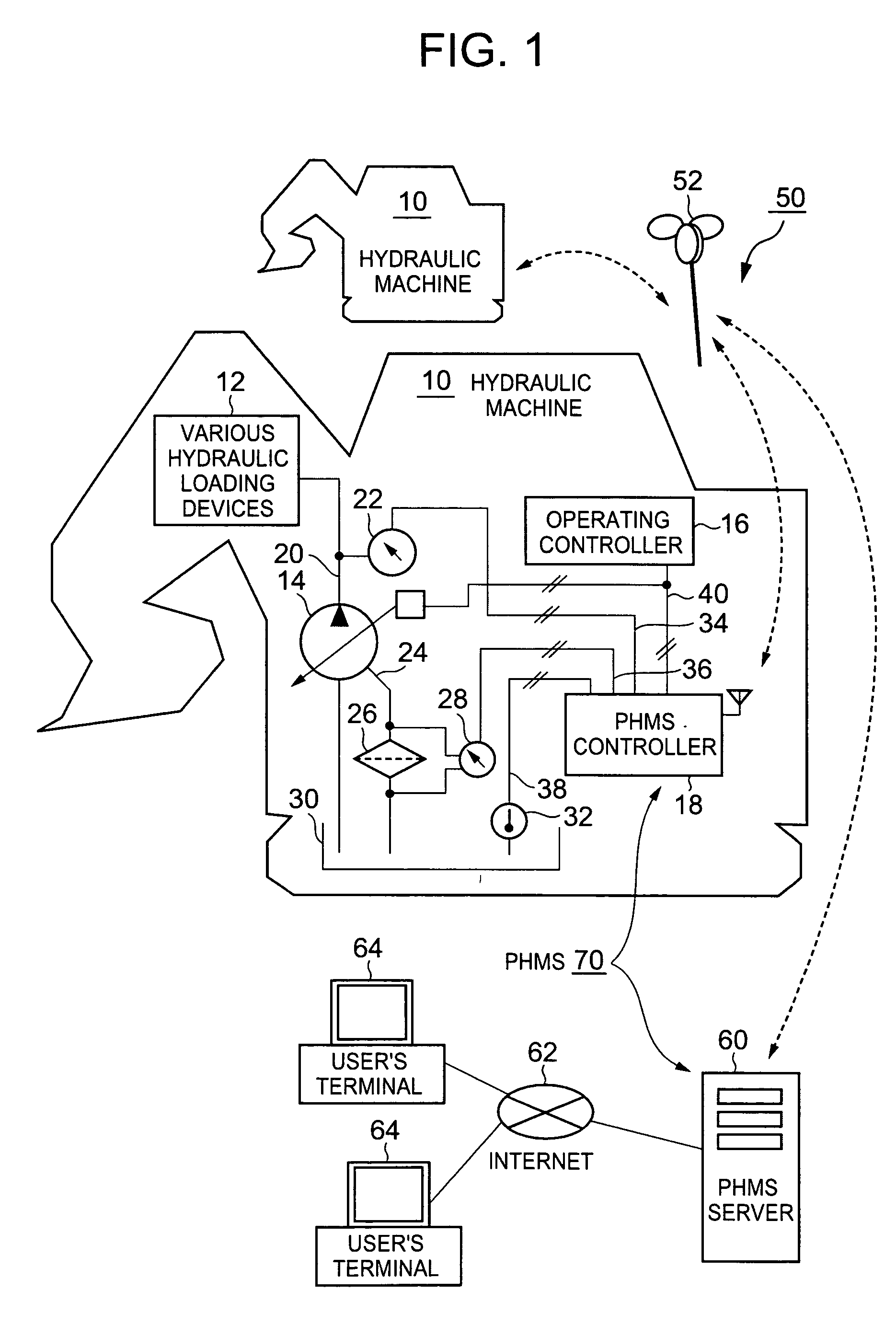

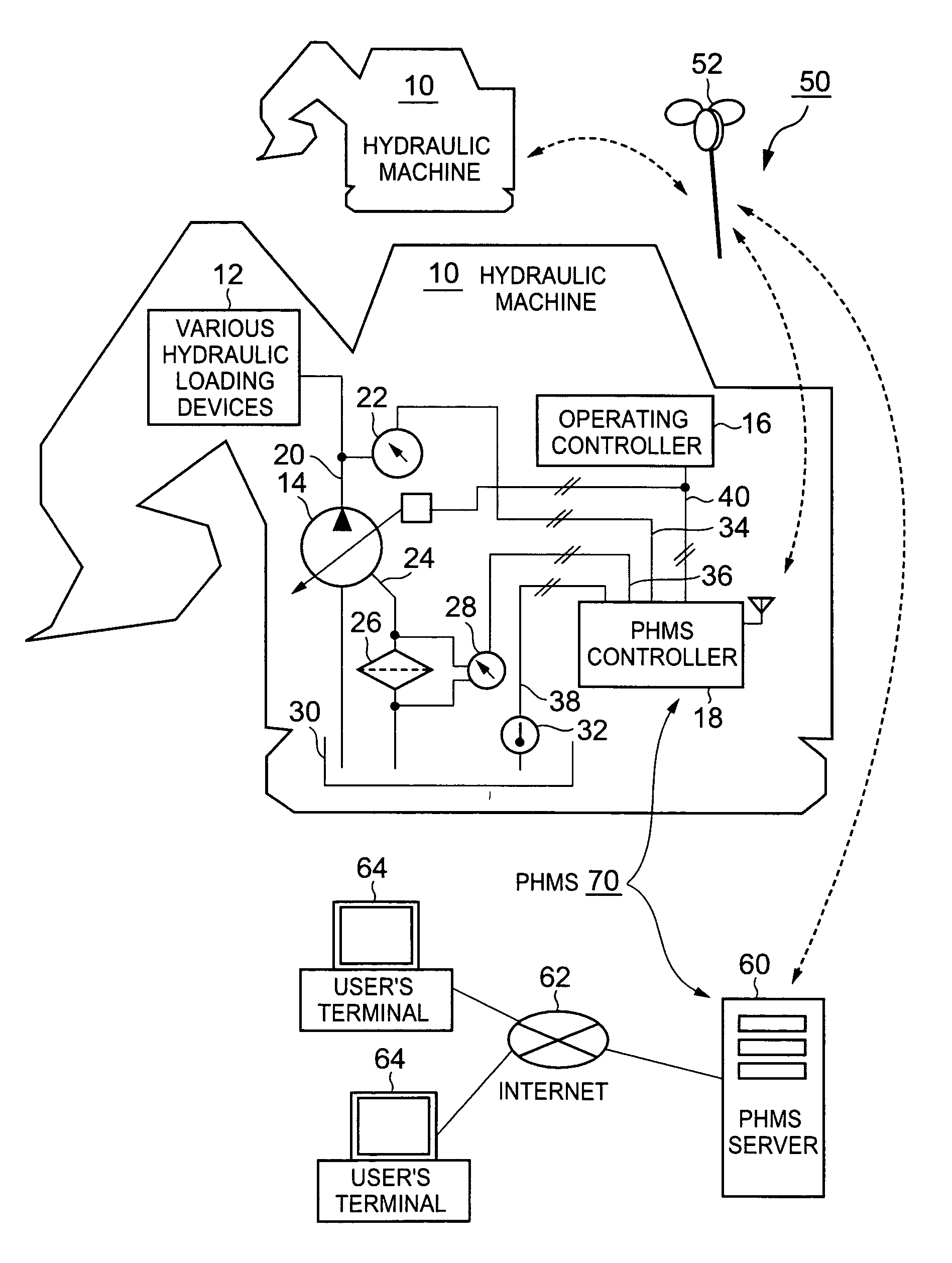

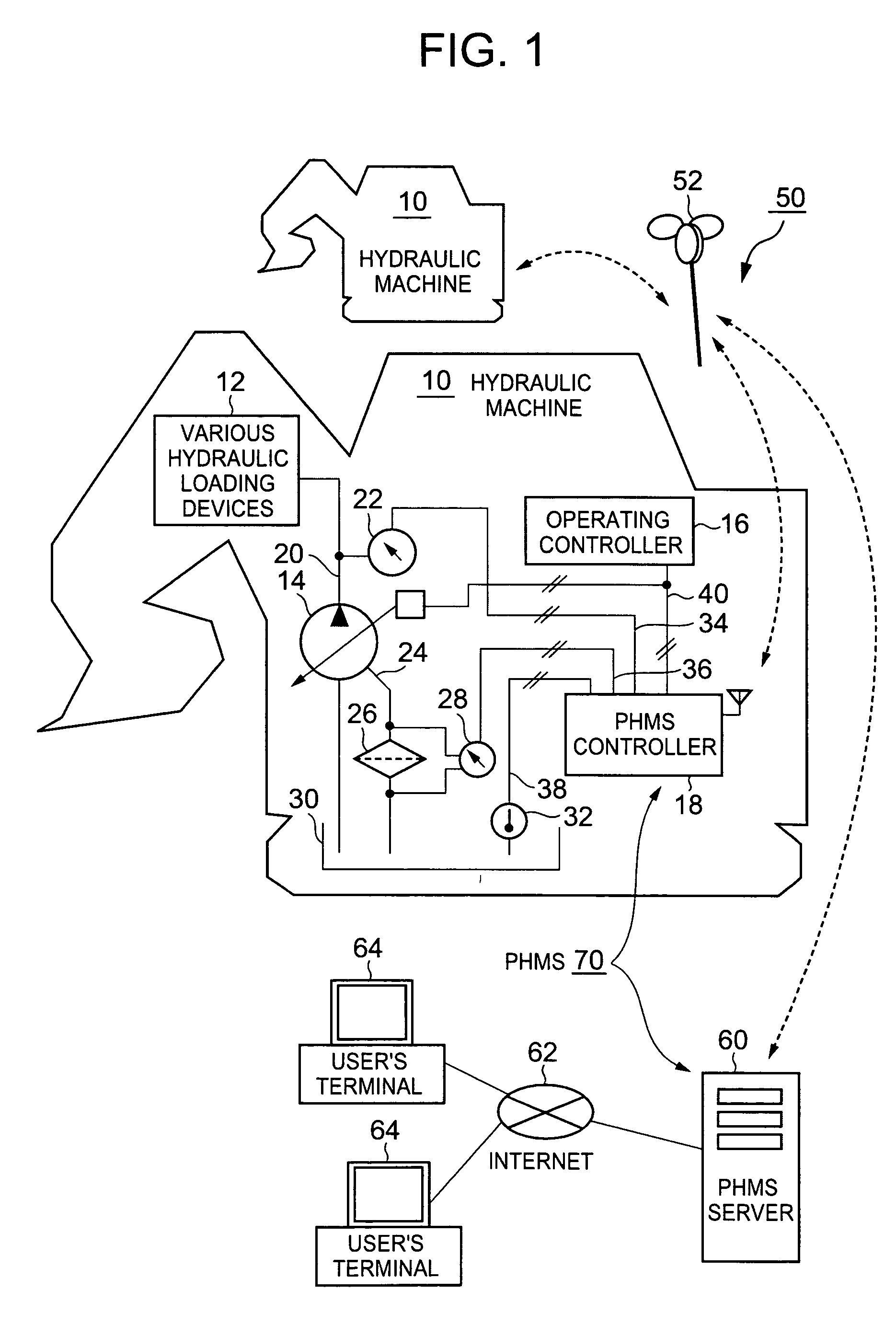

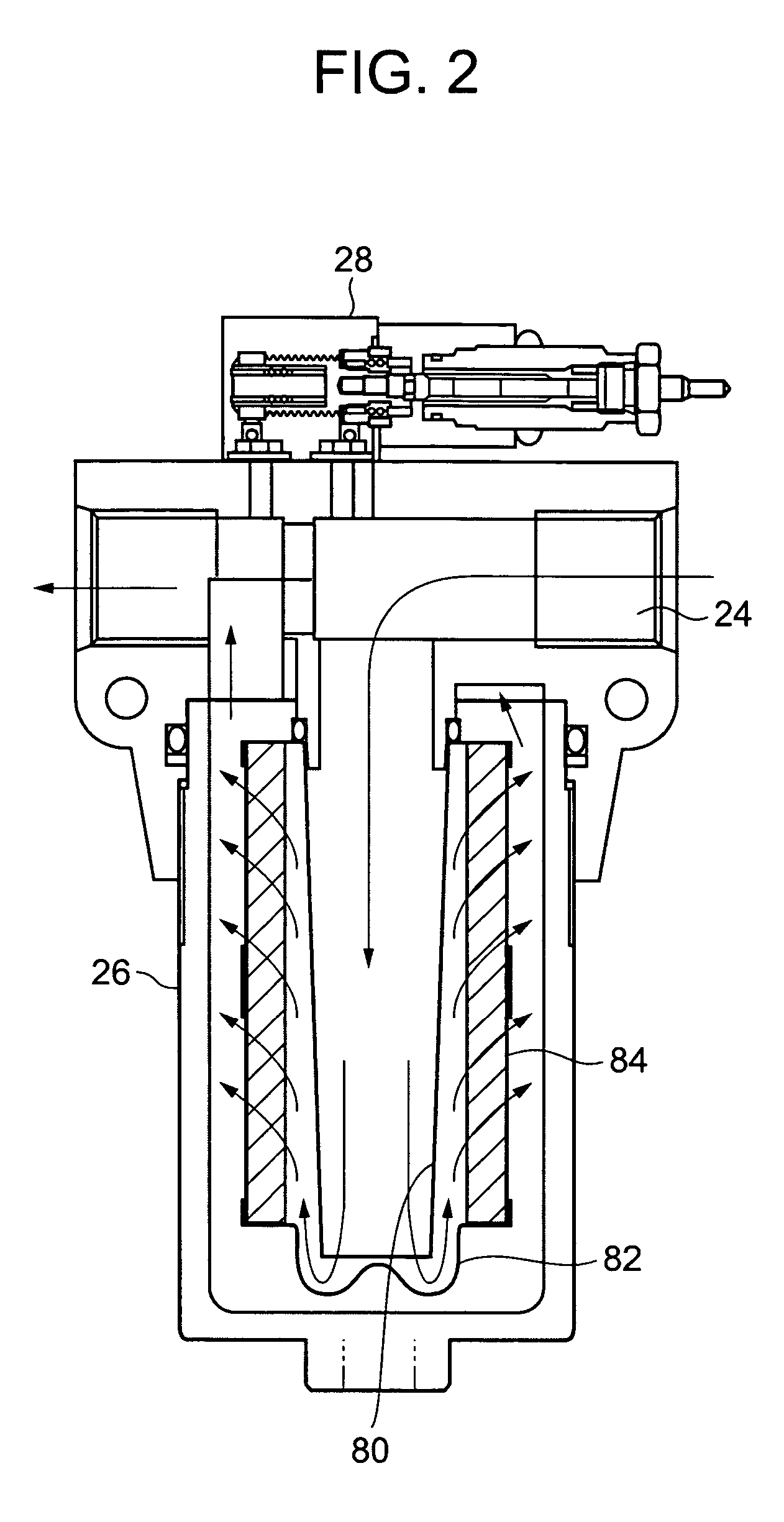

Hydraulic machine, system for monitoring health of hydraulic machine, and method thereof

InactiveUS20050262838A1Improve reliabilityAvoid failureFluid-pressure actuator safetyMachine part testingDifferential pressureCorrelation function

In a hydraulic machine, hydraulic pump failure is detected and the pump lifespan is estimated before the pump failure occurs. The discharge pressure 122, oil temperature 126, and drain filter differential pressure 120 are measured, a correlative relationship 128 between the filter differential pressure and the discharge pressure is determined, and a representative filter differential pressure 130 is calculated from this correlative relationship. Using an oil temperature-differential pressure correlation function, the representative differential pressure value 130 is corrected so that the variable component 132 caused by the oil temperature 126 is eliminated therefrom. The long-term trend and the short-term trend of the increase over time of the corrected differential pressure is calculated. A pump failure is predicted or the pump lifespan is estimated based on the degree of deviation between the long-term trend and the short-term trend.

Owner:KOMATSU LTD

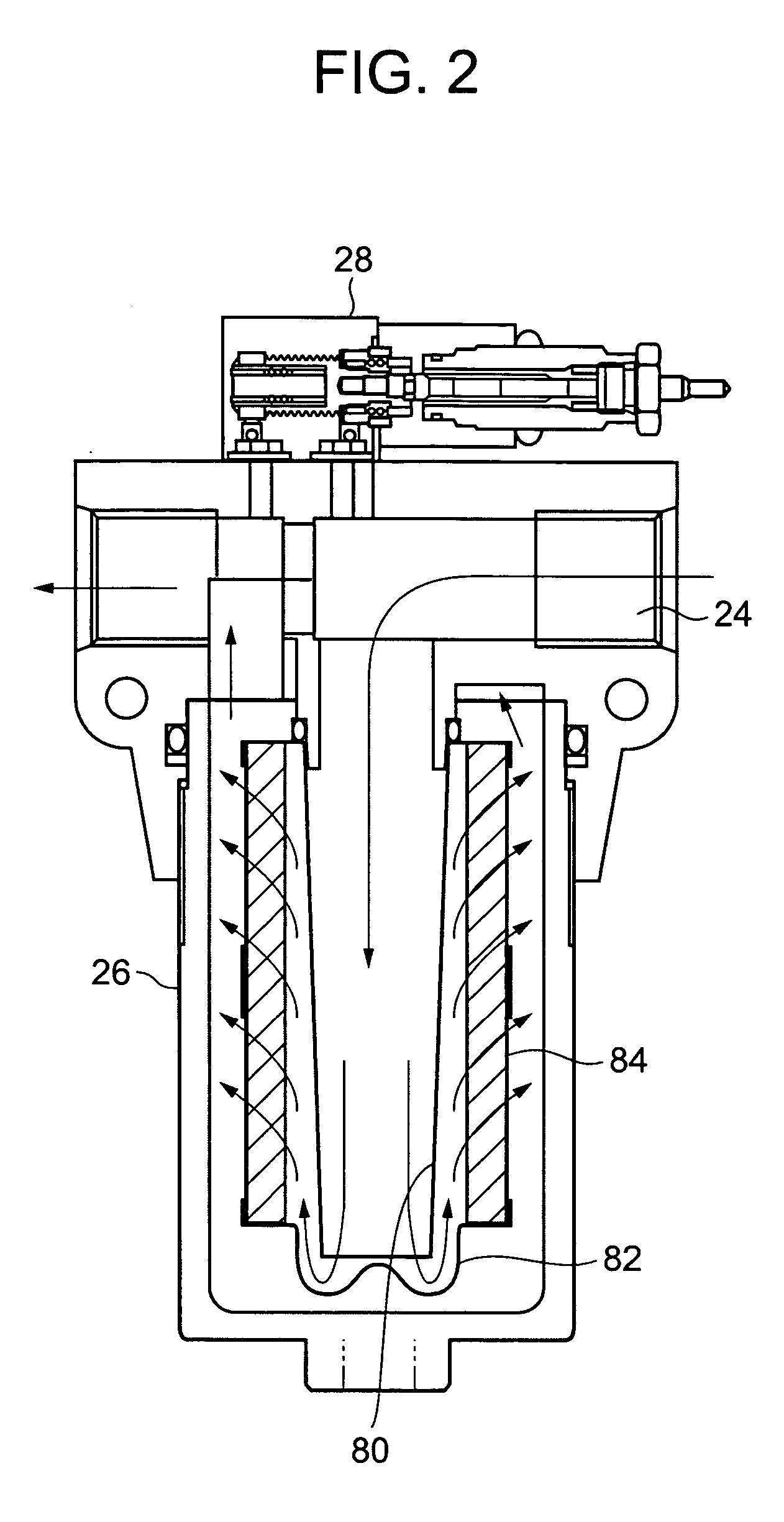

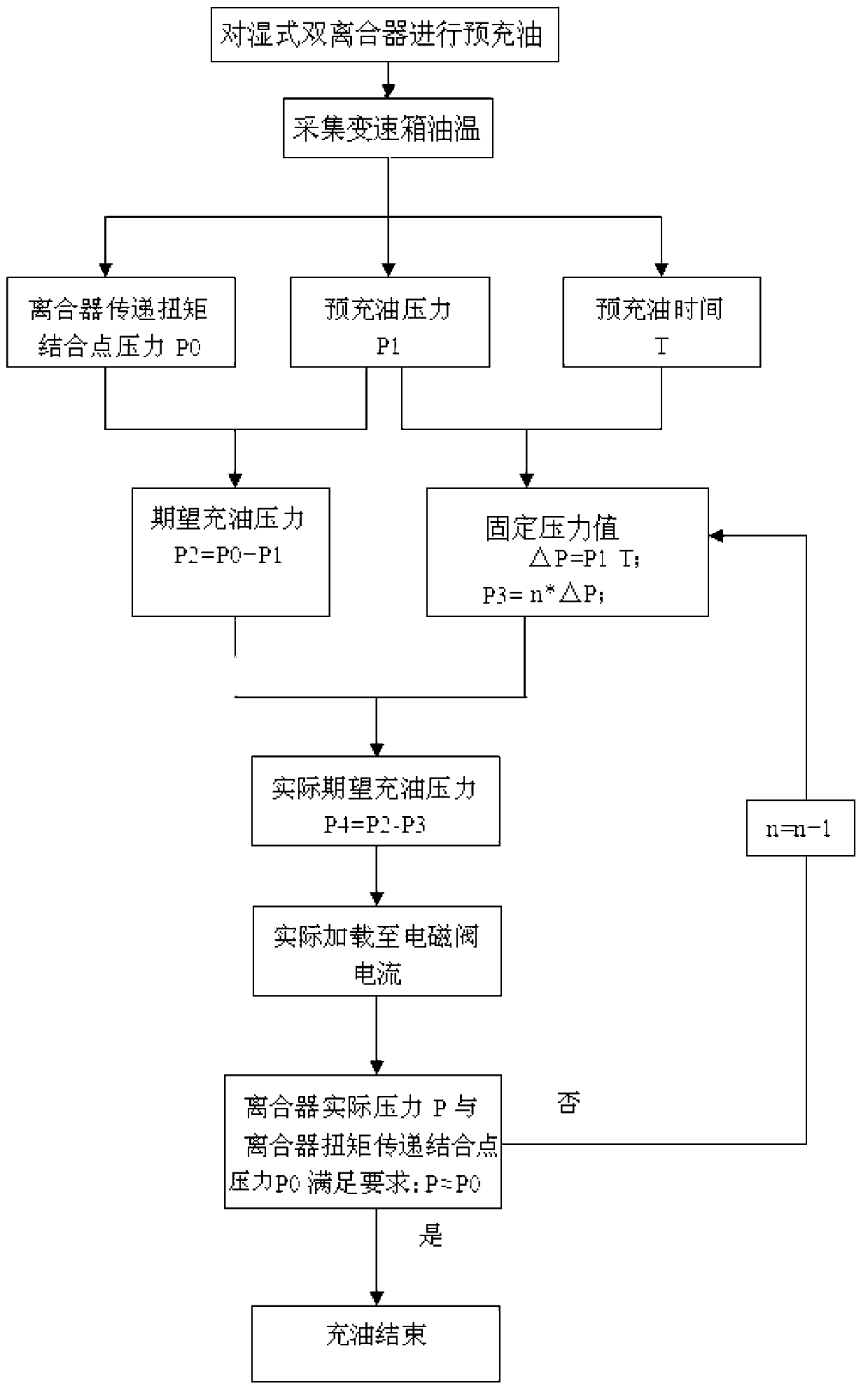

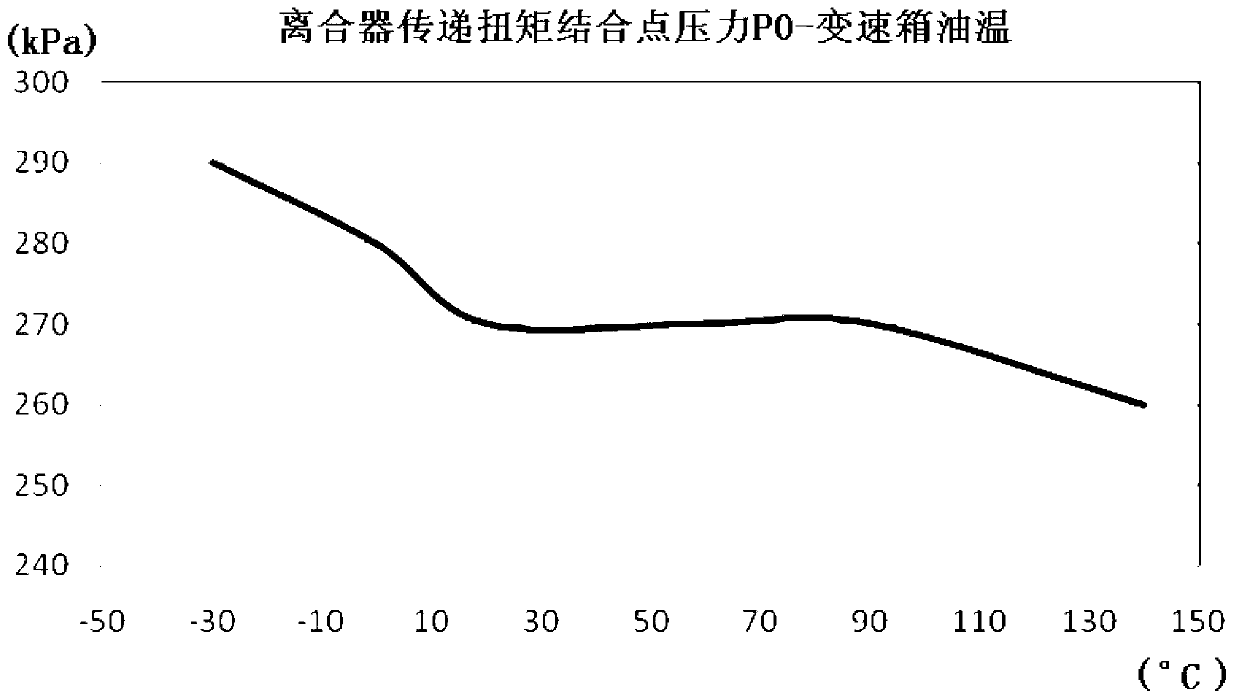

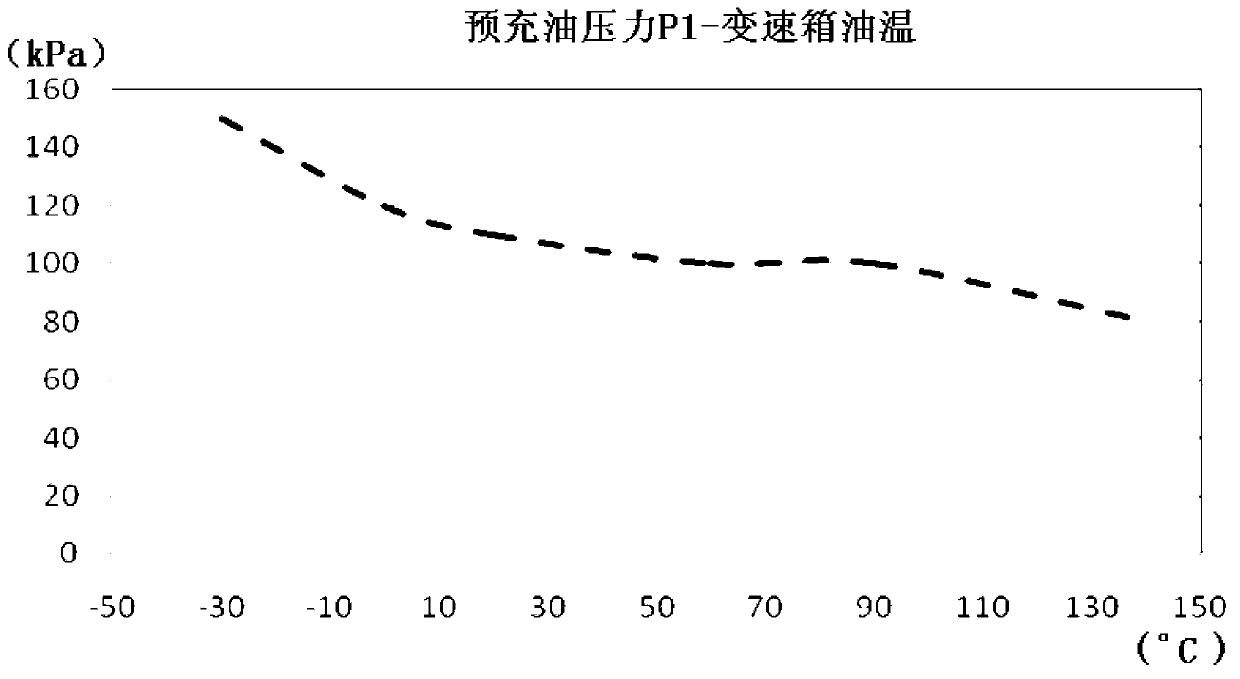

Wet dual-clutch automatic transmission and precharging pressure control method thereof

The invention discloses a wet dual-clutch automatic transmission and a precharging pressure control method thereof. The control method includes the steps: 1, performing oil precharging on duel wet clutches; 2, acquiring clutch torque transmission combination point pressure P0 and oil precharging pressure P1 according to acquired transmission oil temperature; 3, acquiring actual expected oil charging pressure P4 according to the formula that P4=P0+P1; 4, loading electromagnetic valve current corresponding to the P4 to an electromagnetic valve of the clutches according to the actual expected oil charging pressure P4; 5, measuring actual pressure P of the clutches, judging difference between the actual pressure P of the clutches and the clutch torque transmission combination point pressure P0 is within a preset error range or not, if so, executing a step 6, and otherwise, subtracting a fixed pressure value delta P from the actual expected oil charging pressure P4, and then executing the step 4; and 6, finishing oil charging. During oil precharging of the clutches, oil can be charged into a hydraulic oil chamber of each clutch quickly, oil pressure is established, conditions for torque transmission are satisfied, and response is rapid.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

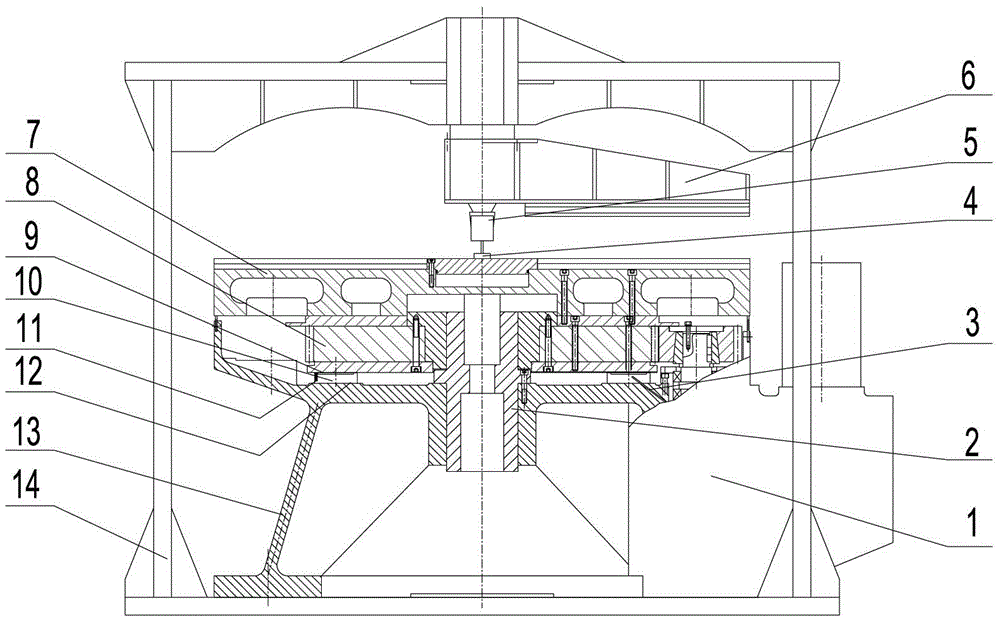

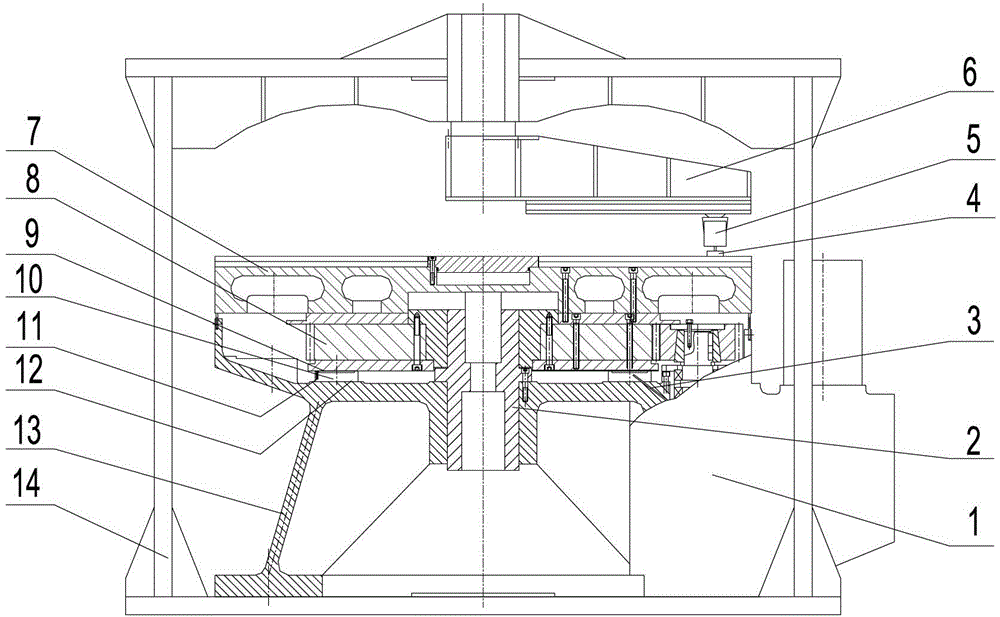

Quantitive type experimental device for dynamic and static performances of static-pressure rotary table

ActiveCN102980755AStructural parameter optimizationImprove machining accuracyMachine part testingElectricityEddy current

The invention provides a quantitive type experimental device for dynamic and static performances of a static-pressure rotary table, and belongs to the field of machinery design and manufacture. According to the experimental device, a loading device (5) and a loading arm (6) are used for changing magnitude of loads or changing oil supply pressure to control the distance between a static-pressure oil cushion (10) and a rotary table disc chuck (7), a pressure sensor (12) is used for measuring pressure in an oil cavity, an eddy current displacement sensor (11) is used for measuring the thickness of an oil film, a thermocouple temperature sensor (3) is used for measuring oil temperature, a force sensor (4) is used for obtaining magnitude of loading force, a pressure gauge a (15) on a multi-head pump at an oil inlet in the oil cavity is used for measuring pressure of the oil inlet of the oil cavity, and a pressure gauge b (16) arranged between an oil pump and the multi-head pump is used for measuring the oil supply pressure of the static-pressure rotary table. By means of the experimental device, a test of the dynamic and static performances of the static-pressure rotary table is carried out under the condition that temperature is between minus 10 DEG C and 60 DEG C and pressure is not more than 100 MPa, and the experimental device provides guarantee for solving problems in engineering, optimizing structural parameters of the rotary table, and improving machining precision of the rotary table.

Owner:BEIJING UNIV OF TECH

Hydraulic machine, system for monitoring health of hydraulic machine, and method thereof

InactiveUS7082758B2Improve reliabilityFluid-pressure actuator safetyMachine part testingDifferential pressureCorrelation function

In a hydraulic machine, hydraulic pump failure is detected and the pump lifespan is estimated before the pump failure occurs. The discharge pressure 122, oil temperature 126, and drain filter differential pressure 120 are measured, a correlative relationship 128 between the filter differential pressure and the discharge pressure is determined, and a representative filter differential pressure 130 is calculated from this correlative relationship. Using an oil temperature-differential pressure correlation function, the representative differential pressure value 130 is corrected so that the variable component 132 caused by the oil temperature 126 is eliminated therefrom. The long-term trend and the short-term trend of the increase over time of the corrected differential pressure is calculated. A pump failure is predicted or the pump lifespan is estimated based on the degree of deviation between the long-term trend and the short-term trend.

Owner:KOMATSU LTD

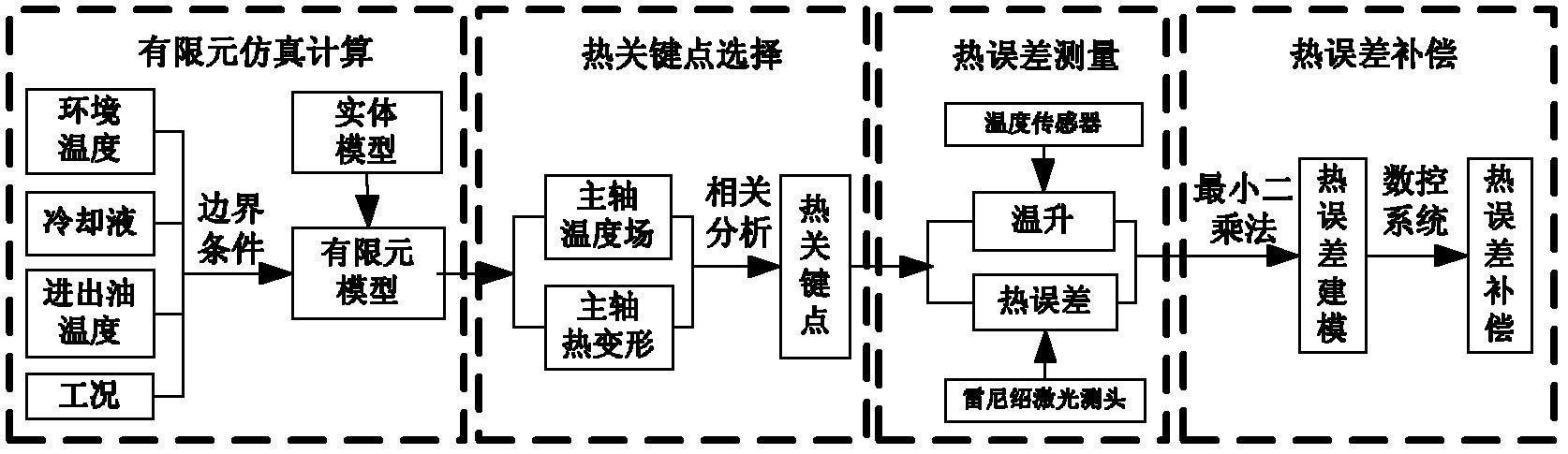

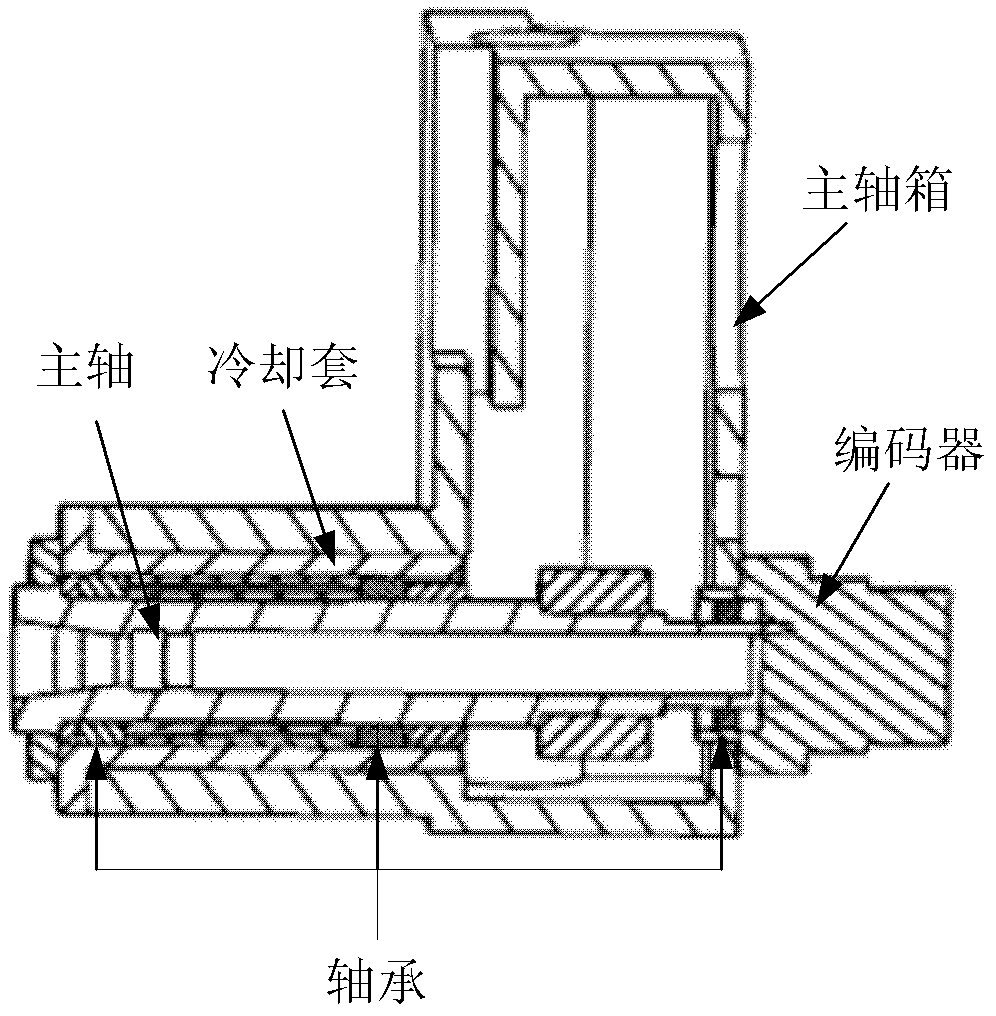

Spindle thermal distortion compensation method for precision horizontal machining center

InactiveCN102658499AReduce thermal errorsMeasurement/indication equipmentsMaintainance and safety accessoriesElement modelEngineering

A spindle thermal distortion compensation method for a precision horizontal machining center comprises the steps as follows: a spindle model of a machine tool is simplified structurally; an ANSYS (finite element analysis software)-Workbench is utilized to perform mesh generation on a spindle entity model that is simplified, so as to obtain a spindle finite element model; and boundary conditions are calculated by combining with the practical spindle rotational speed, the environmental temperature, the coolant velocity, the flow rate, the inlet and outlet oil temperature and the like, and configuration is performed. Thermodynamics analysis and statics analysis are carried out in the ANSYS-Workbench to obtain more accurate spindle temperature field distribution and thermal deformation. Based on a finite element emulation result, the spindle temperatures in different positions and the spindle thermal deformations are analyzed at different rotational speeds by utilizing the Spearman rank correlation analysis, and spindle thermal key points are found out, so that references are provided to spindle thermal error tests and thermal error compensation. Finally, a thermal error compensation model is built up by utilizing a least squares method according to the key point temperature of the spindle and the thermal errors in the practical tests. Based on the thermal error compensation model, the spindle thermal error compensation is carried out by combining with thermal error compensation strategies of a numerical control system of the machine tool.

Owner:XI AN JIAOTONG UNIV +1

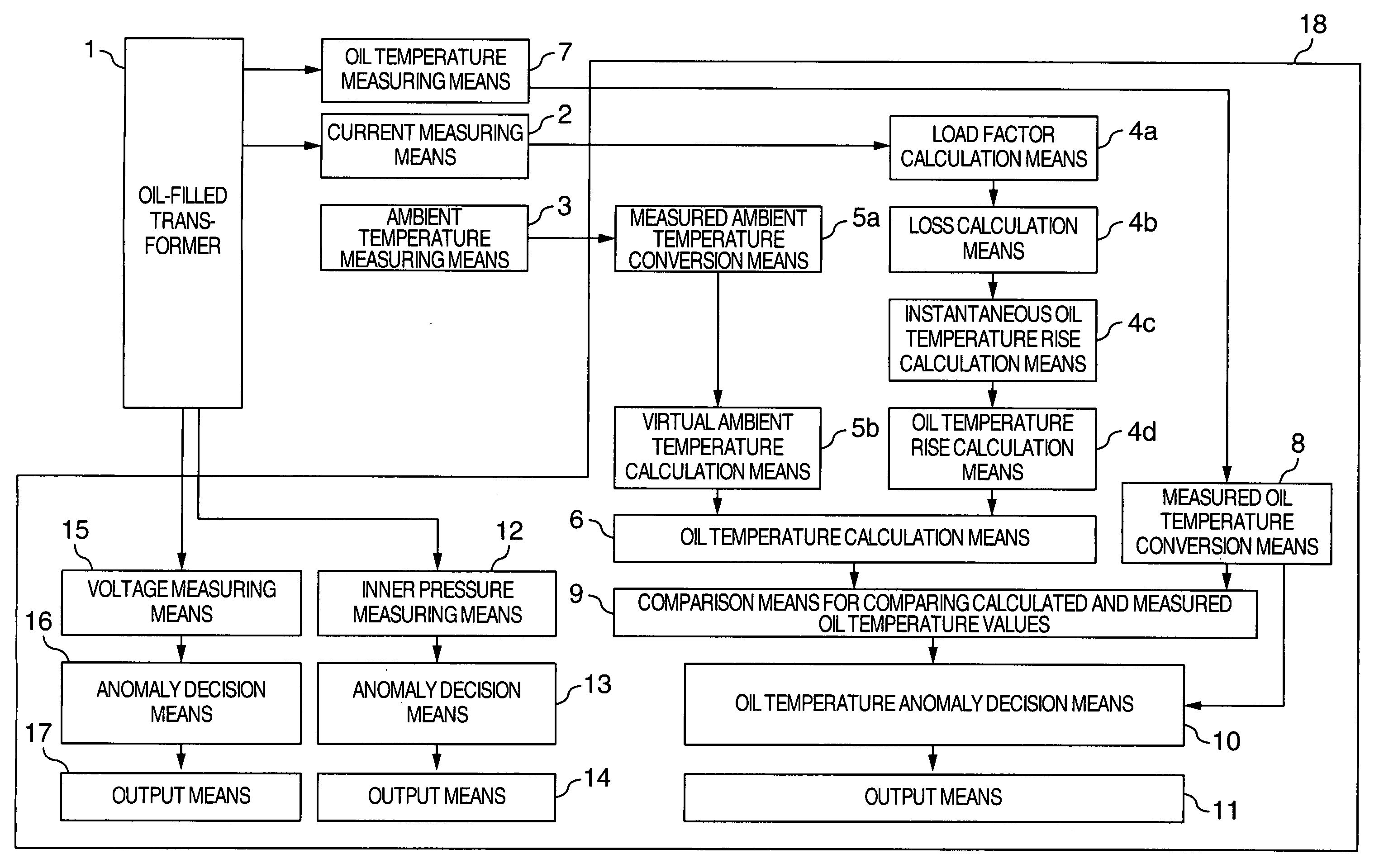

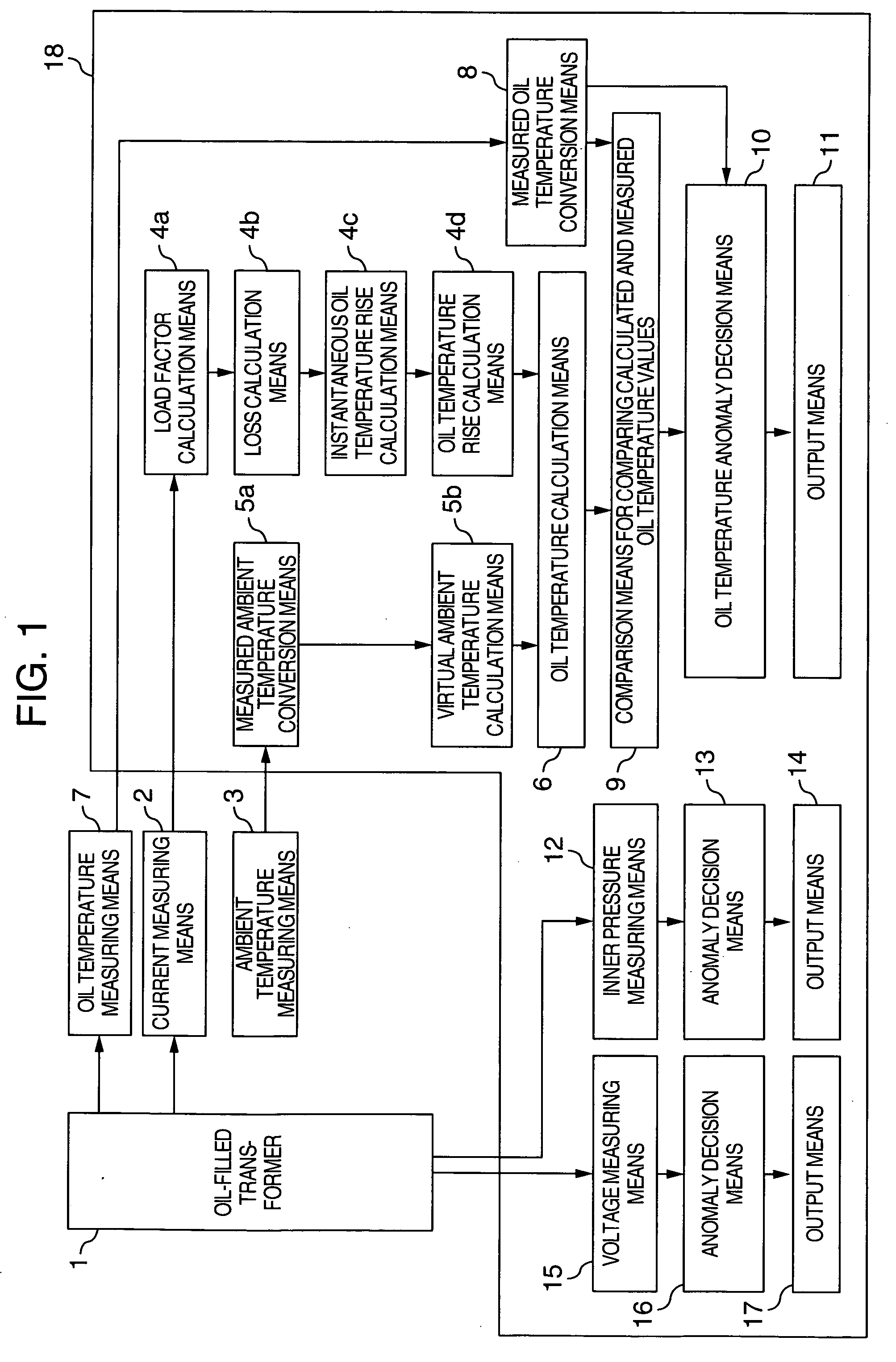

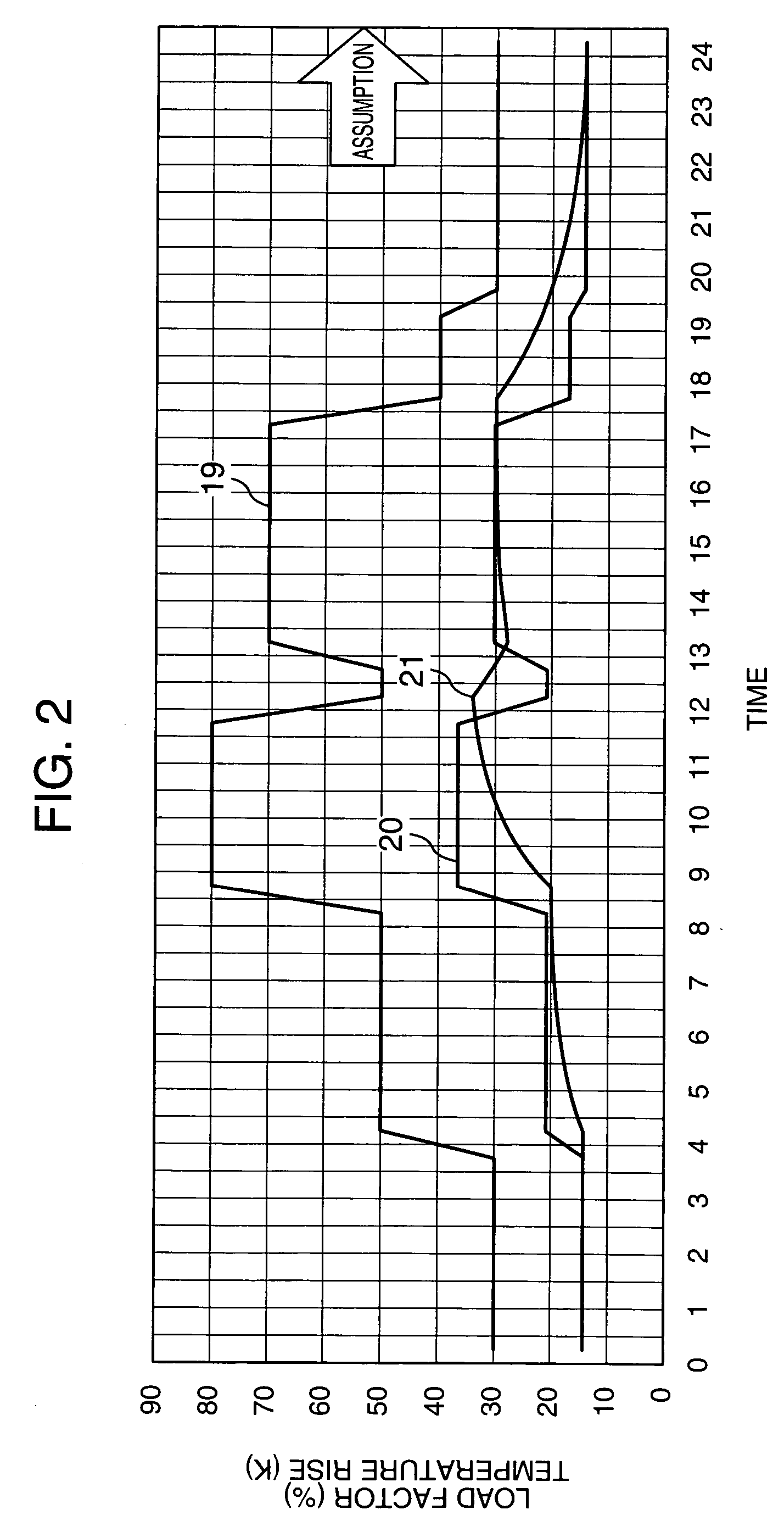

Transformer monitoring system

InactiveUS20050223782A1Improve accuracySolve the real problemFlow propertiesEmergency protective circuit arrangementsMeasurement deviceMonitoring system

An oil-filled transformer monitoring system is provided which calculates an oil temperature of an oil-filled transformer with high precision from a current of the transformer and an ambient temperature. The oil-filled transformer monitoring system of this invention has an oil temperature calculation device to calculate a transformer oil temperature using measurements from a transformer current measuring device and an ambient temperature measuring device. The transformer monitoring system also has an oil temperature measuring device and compares an output value from the oil temperature calculation device with an output value from the oil temperature measuring device to detect any anomaly.

Owner:HITACHI IND EQUIP SYST CO LTD

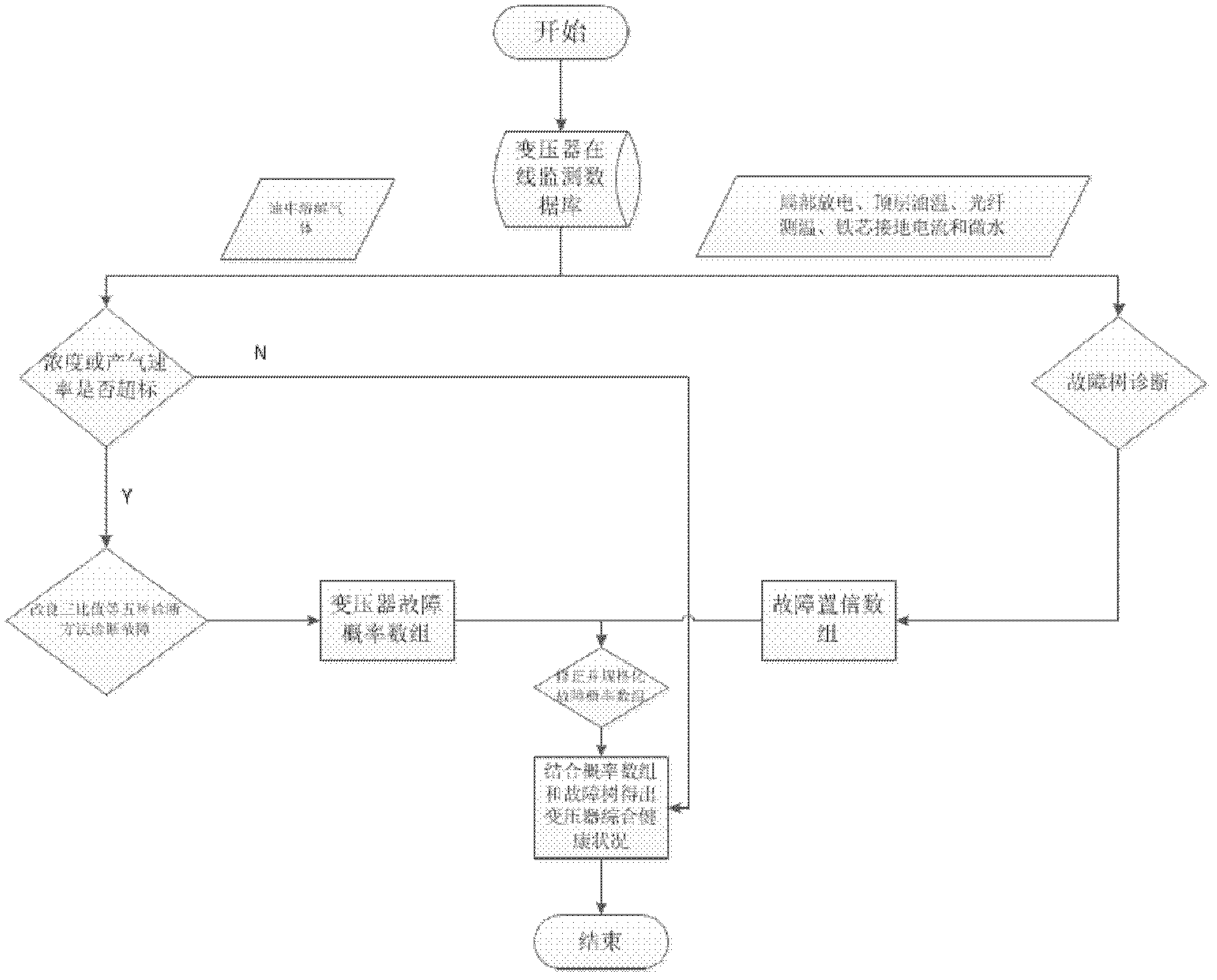

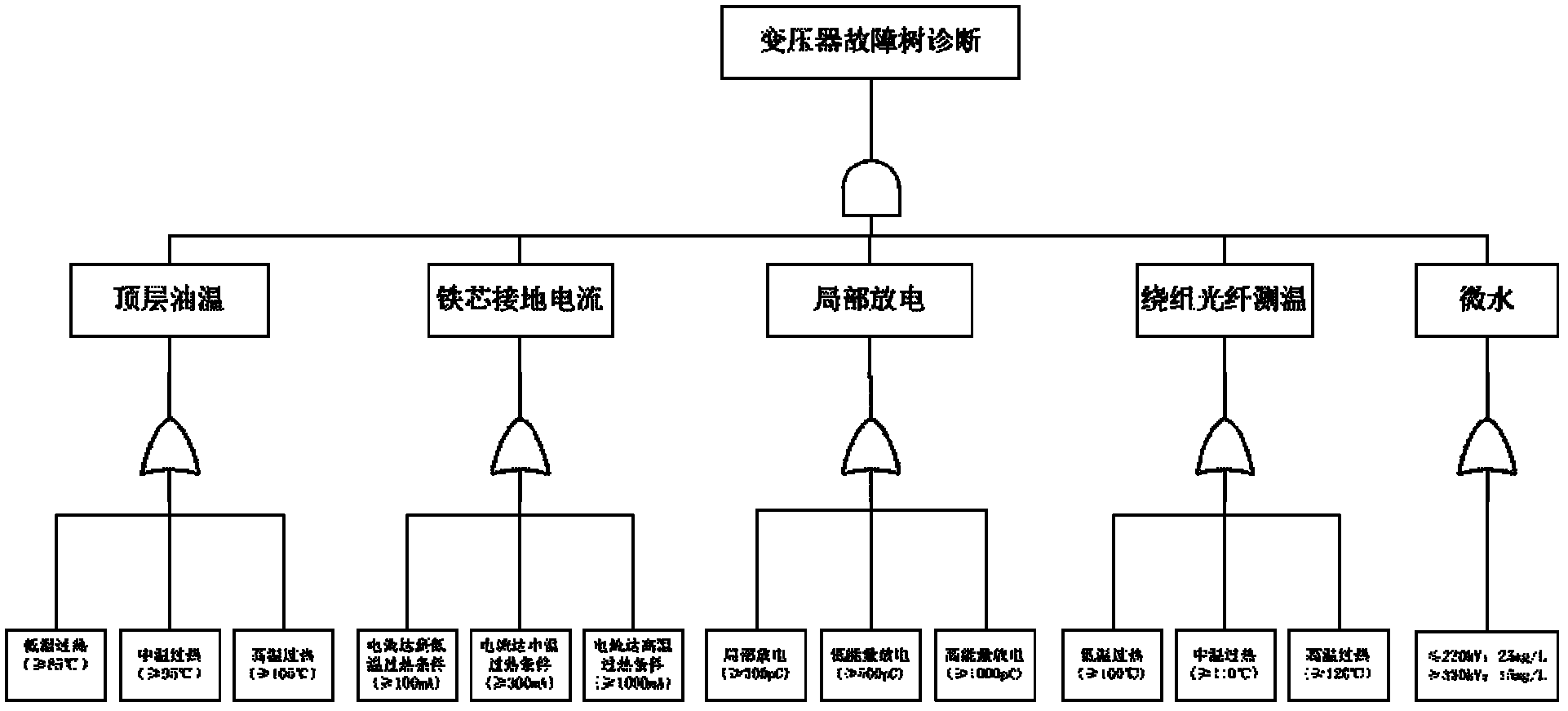

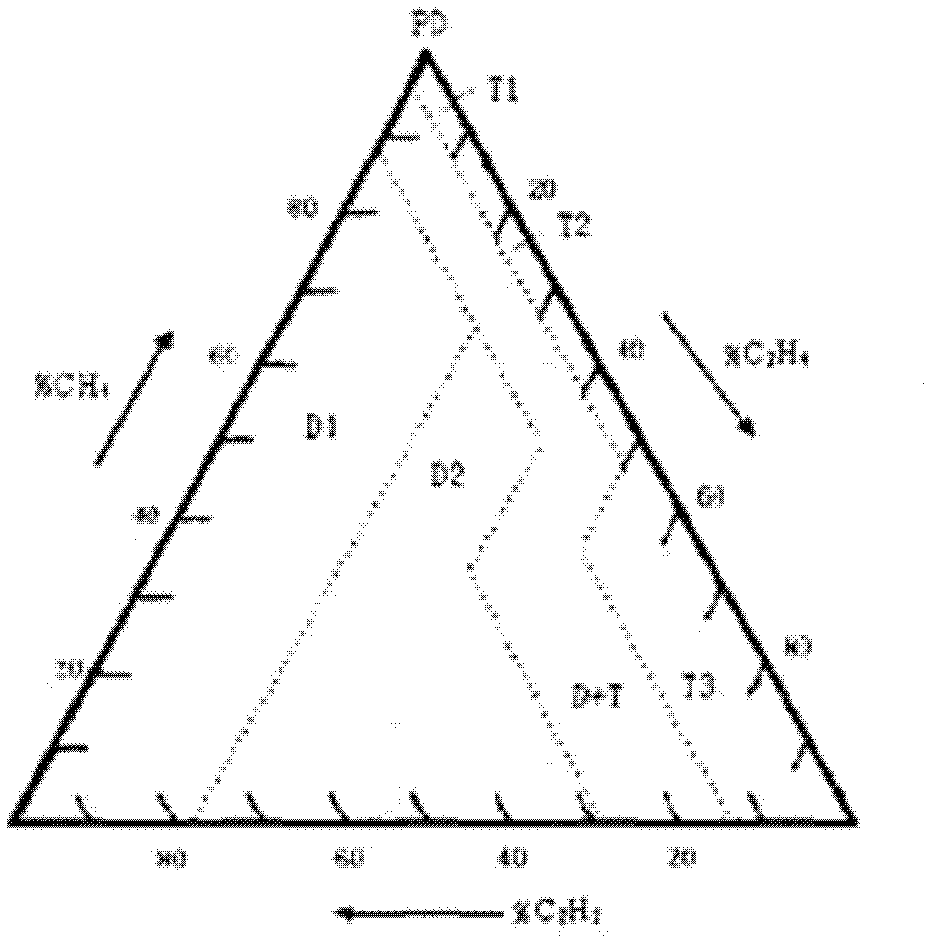

Comprehensive diagnosis method of oil-immersed transformer based on fault tree

ActiveCN102662113AMacroscopically control the health of the operationSafe and stable operationElectrical testingTransformerDiagnosis methods

The invention discloses a comprehensive diagnosis method of an oil-immersed transformer based on a fault tree, which includes steps: (1) collecting correlated condition characteristic parameter values of gas dissolved in oil, moisture in oil, local discharge, iron core grounding current, top oil temperature and winding optical fiber temperature measurement of the transformer in real time, (2) normalizing by aid of diagnosed fault types of gas dissolved in oil, (3) counting fault diagnose accuracy of all diagnose methods, (4) obtaining state quantity of measured gas dissolved in oil for respective diagnose, (5) obtaining a fault confidence digit group, and (6) integrating to obtain a fault diagnose result of the transformer. The comprehensive diagnosis method combines advantages of various oil chromatographic diagnose methods, overcomes defects of a single diagnose method, adopts gas dissolved in oil as a diagnose core, is supplemented by fault tree diagnose, masters operation health conditions of the transformer macroscopically, can achieve fault positioning of devices, and has important practical meaning for finding potential hidden fault danger of devices and ensuring safe and stable operation of an electrical power system.

Owner:STATE GRID ELECTRIC POWER RES INST +2

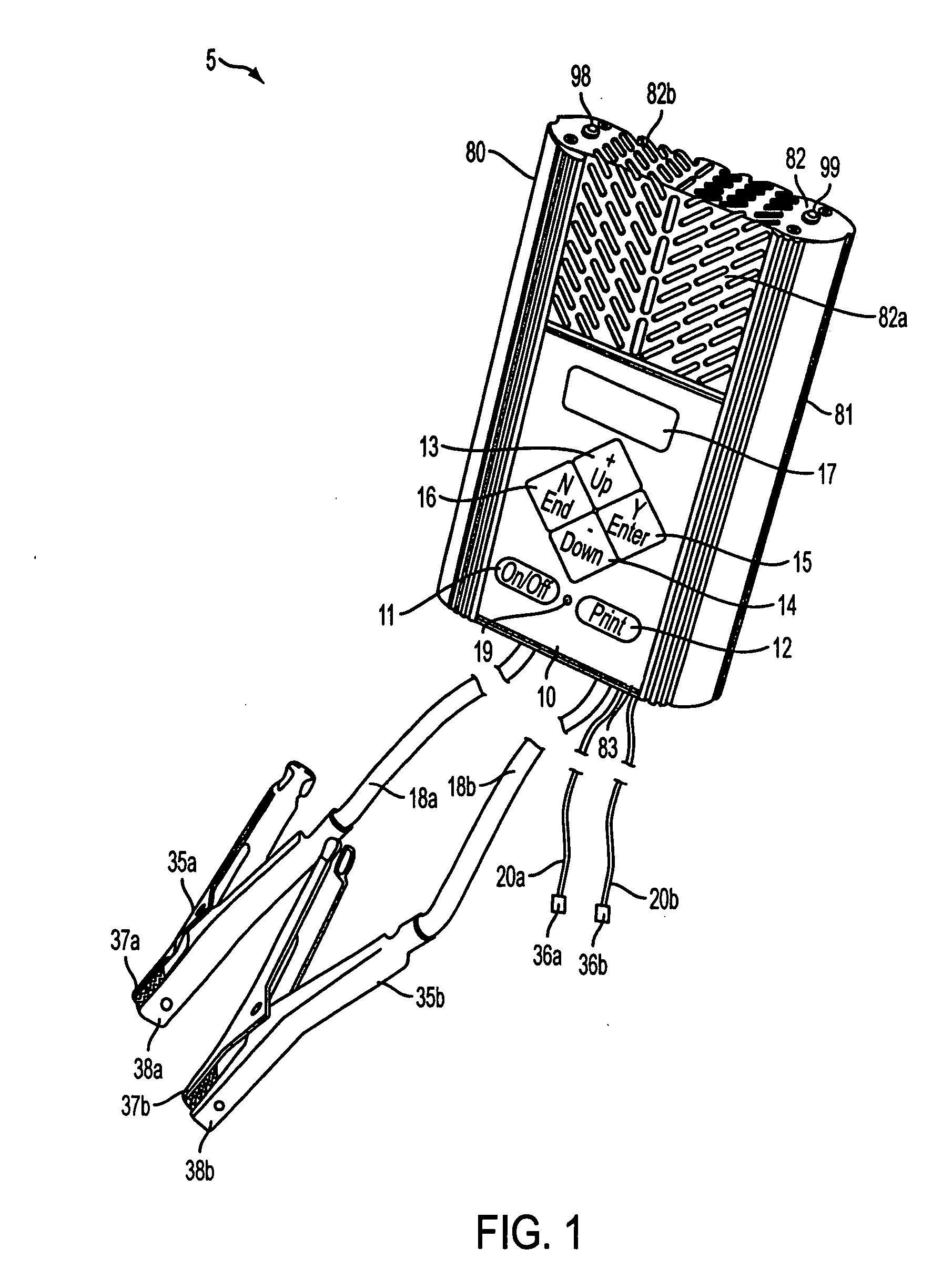

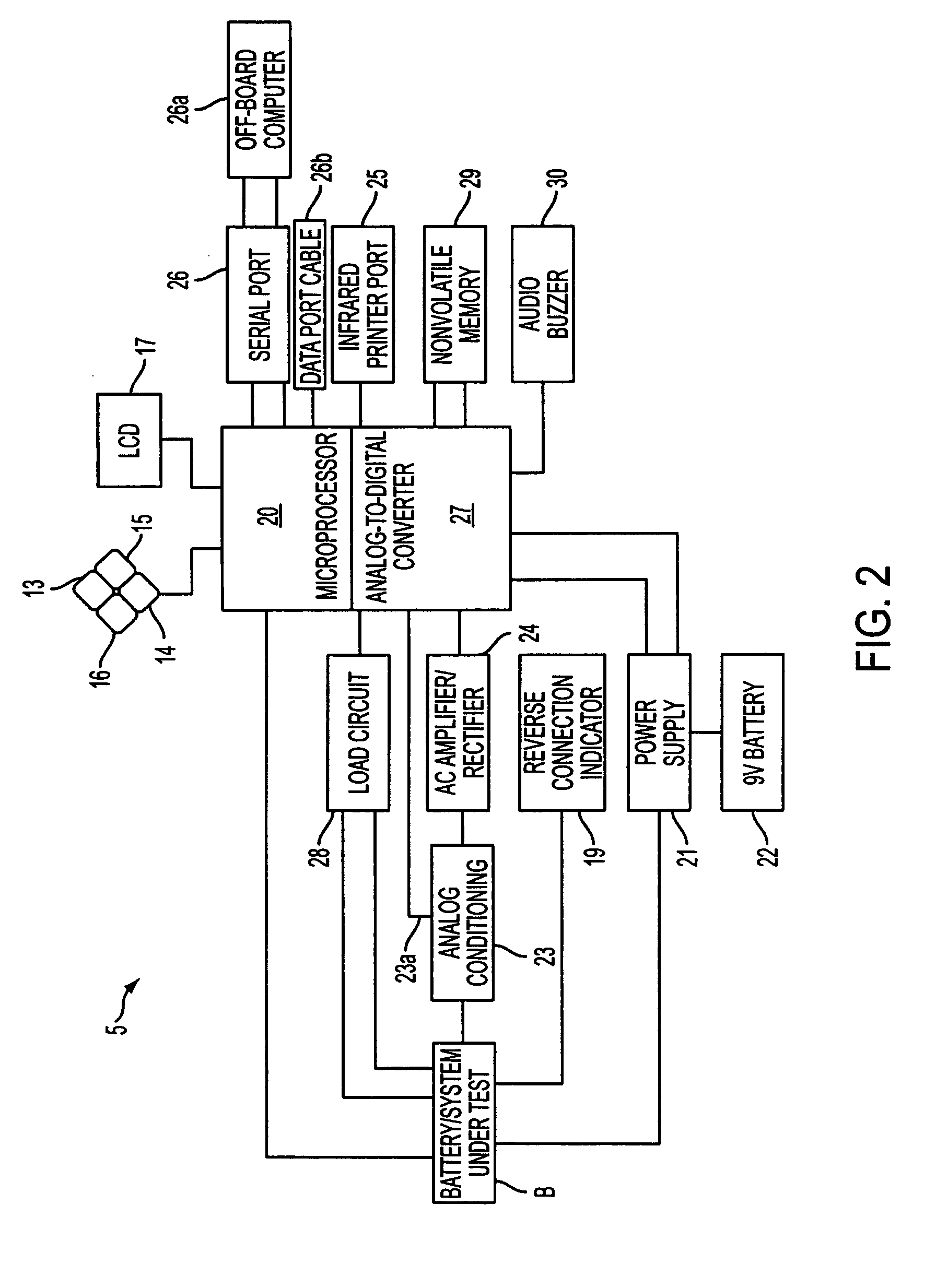

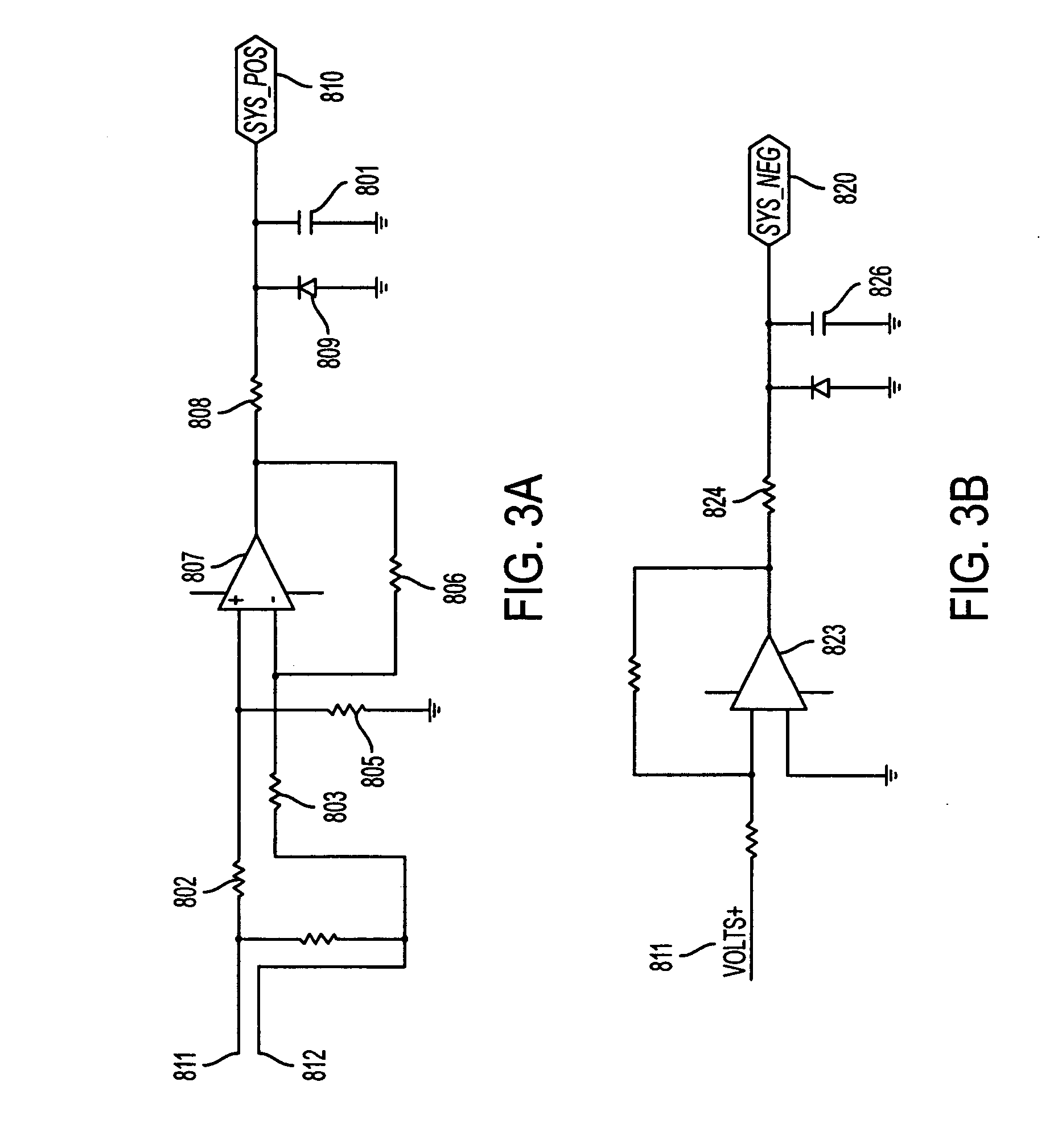

Heavy duty charging and starting system testor and method

InactiveUS20060244457A1Material analysis by electric/magnetic meansTesting electric installations on transportAlternatorElectrical battery

A systematic method and system for testing the charging and starting systems of a vehicle, which requires each individual test to pass before proceeding is provided. In addition, the system and method incorporates an improved alternator test that determines whether the alternator belt is slipping using data read using a vehicle data port. Further, the system and method provides a battery bank test that correlates the voltage before and after a load is applied to the battery bank to the batteries' conditions. When testing the starter, the oil temperature is read via the vehicle data port, allowing for a determination of whether the current draw is abnormally high.

Owner:AUTO METER PROD INC

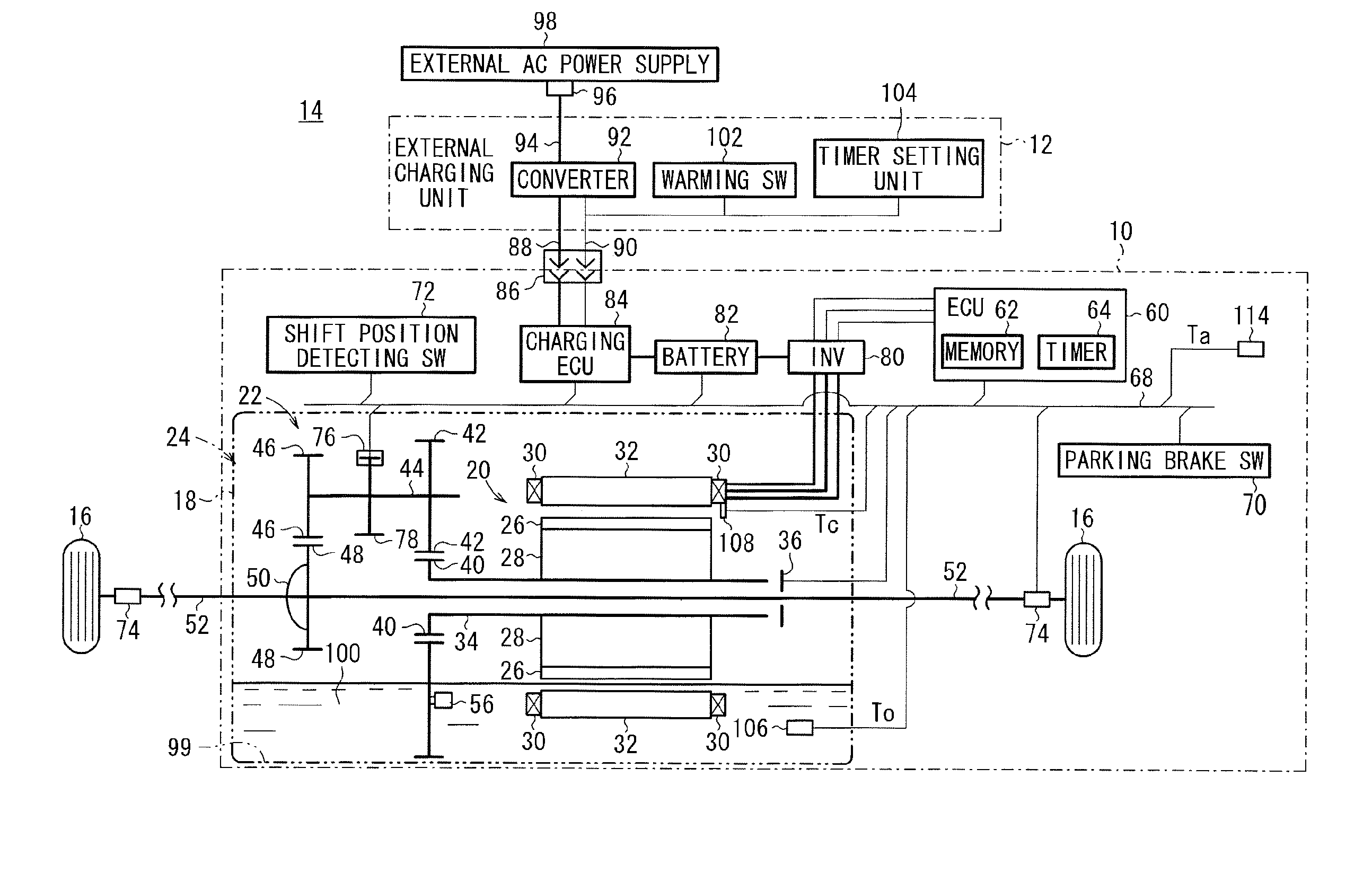

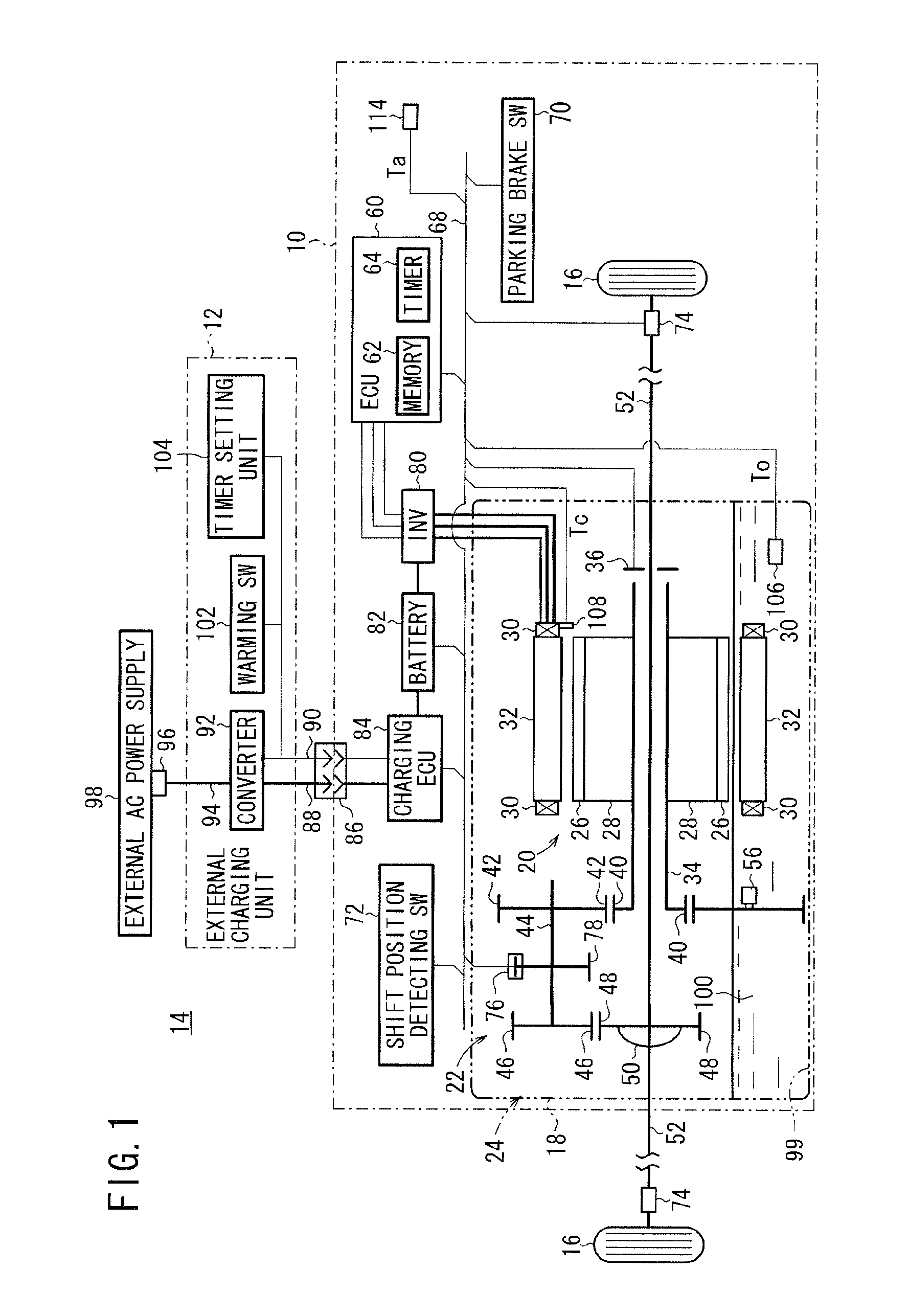

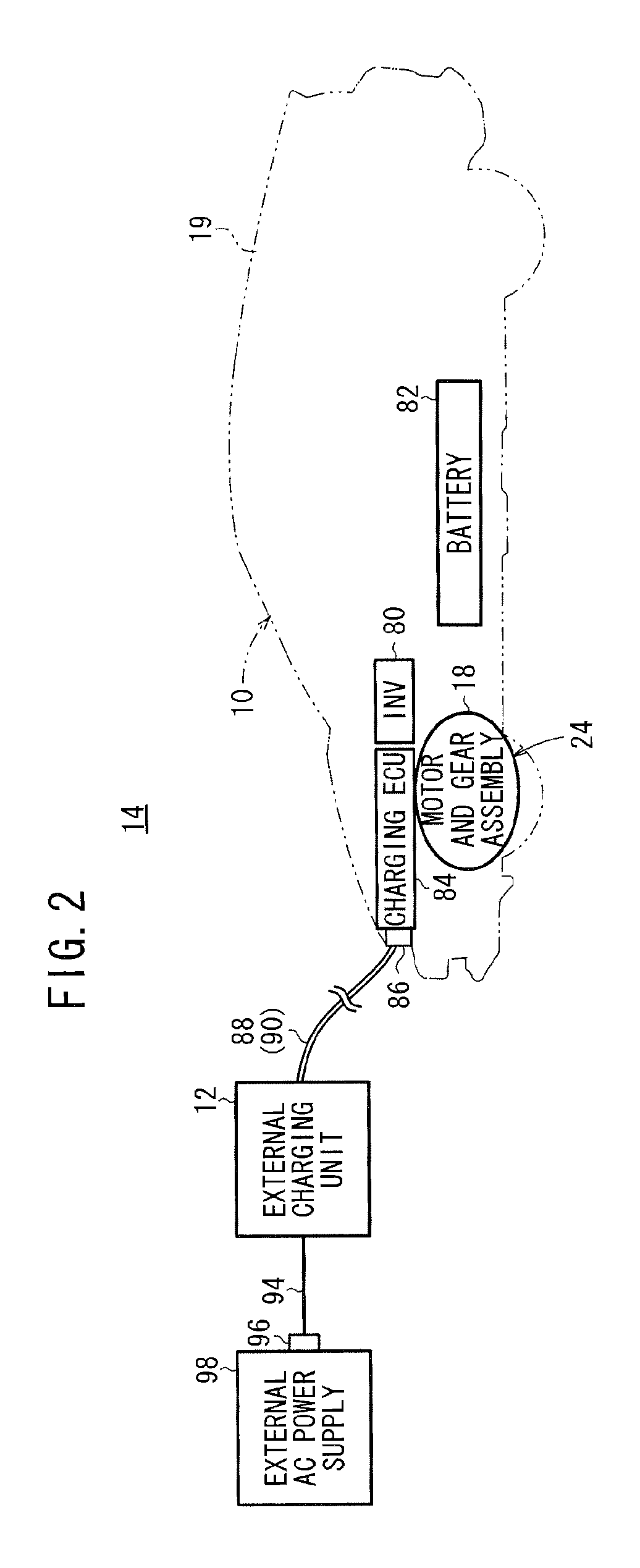

Method of and apparatus for controlling oil temperature increase for electric vehicle and electric vehicle

InactiveUS20110095717A1Heating up fastHeating fastTemperatue controlEmergency protective arrangements for automatic disconnectionElectric vehicleOil temperature

An electric vehicle employs an oil commonly used as a lubricating oil for gears and a coolant for a motor and is propelled by transmitting the rotational torque of the motor to wheels through the gears, the motor being partly immersed in the oil. It is determined whether the motor is in a state prior to being started or not. If it is judged that the motor is in the state prior to being started, coils of the motor are energized alternately with a first current supplied to the motor at an advanced angle for no torque to generate a magnetic flux, and a second current supplied to the motor at another advanced angle for no torque to generate a magnetic flux in a direction opposite to the magnetic flux generated by the first current, thereby heating the oil.

Owner:HONDA MOTOR CO LTD

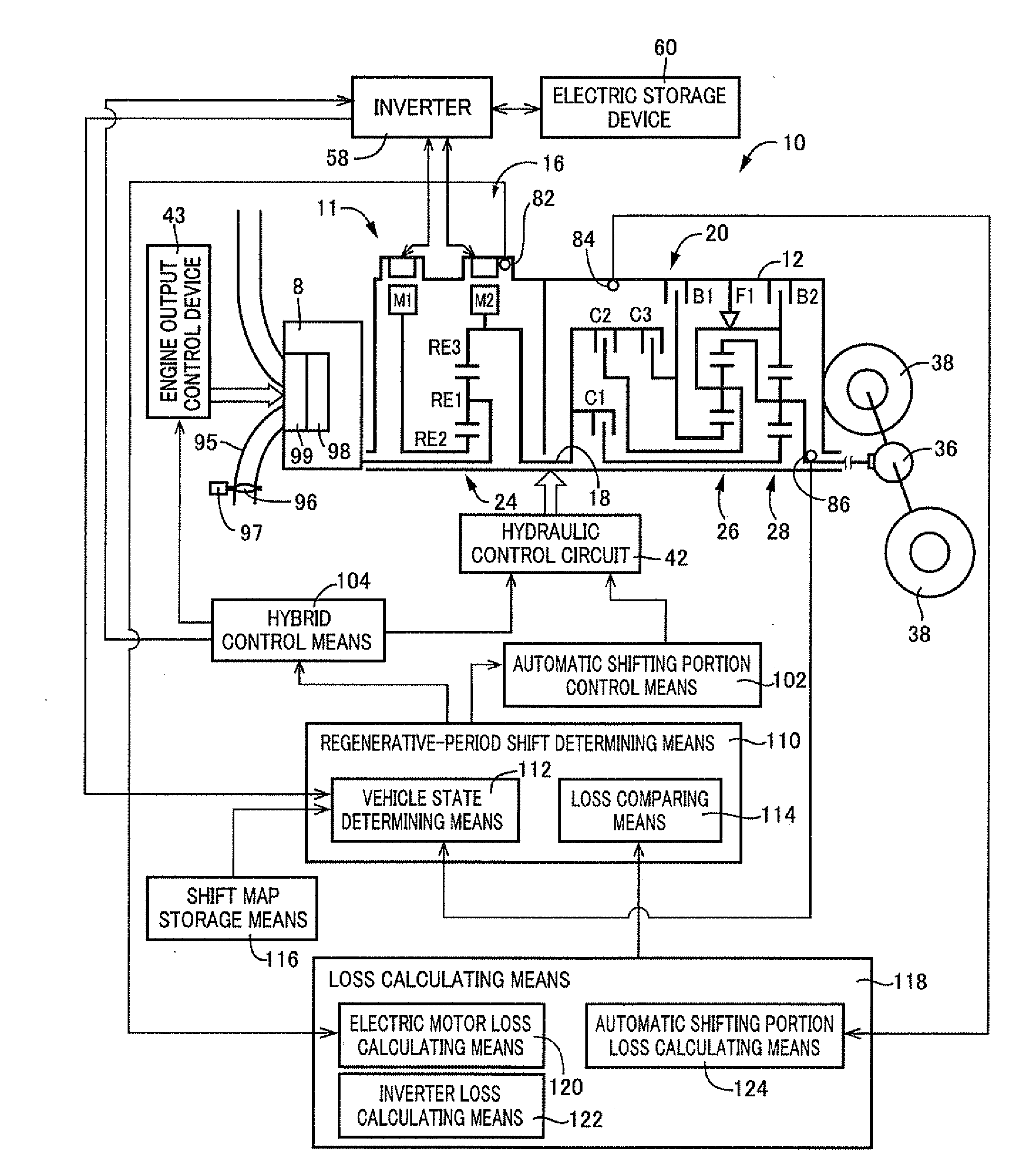

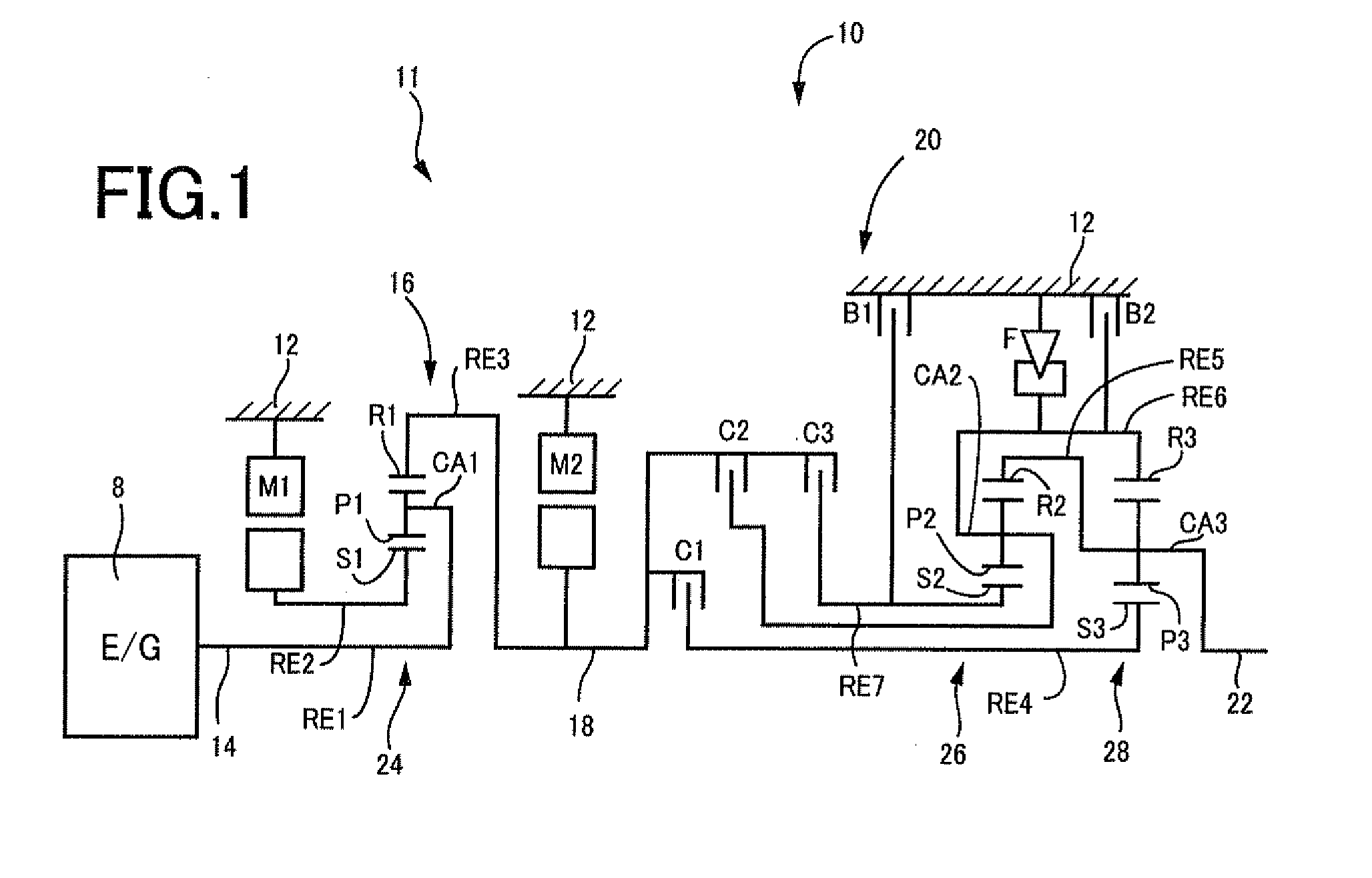

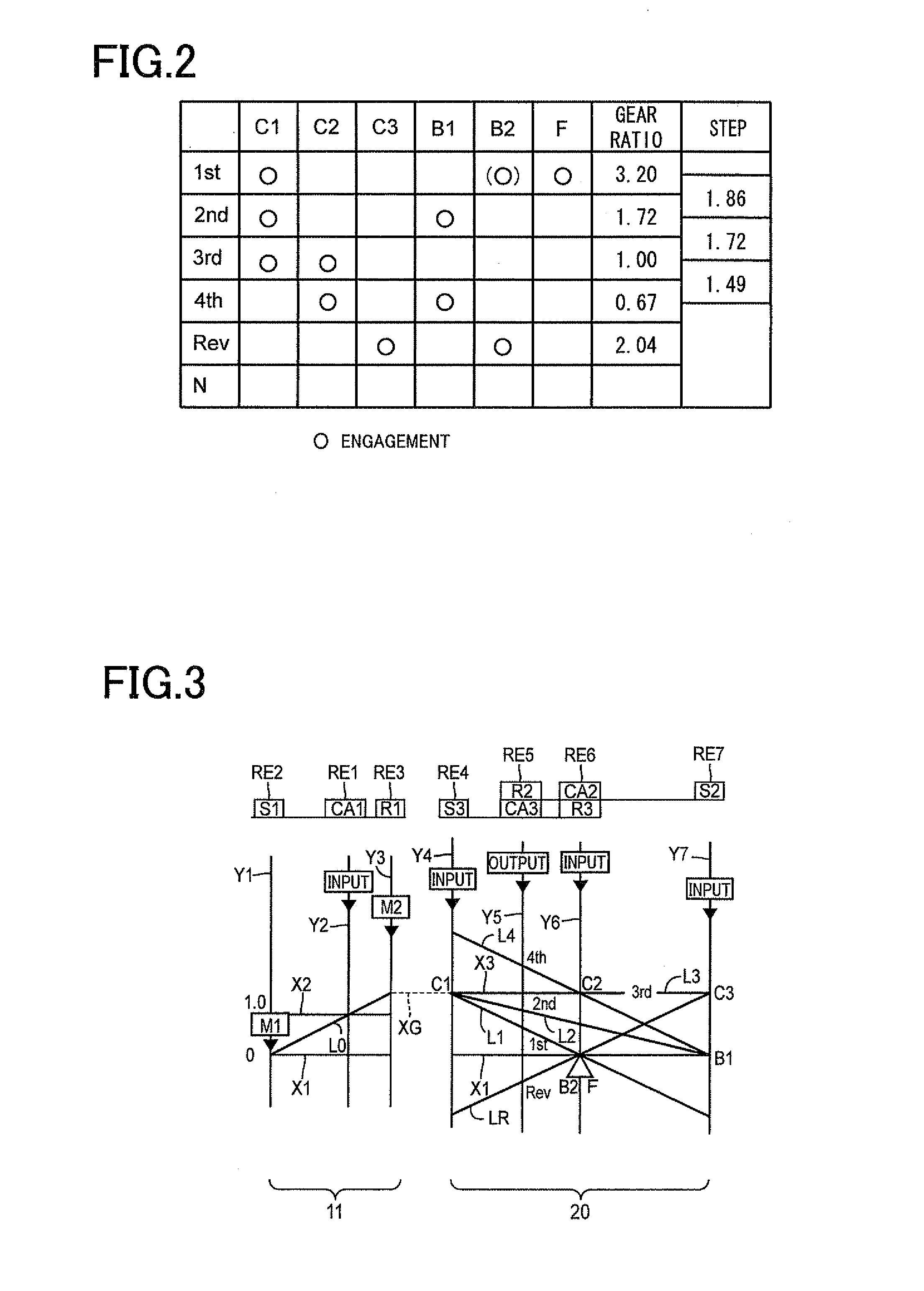

Control device for vehicle power transmission device

InactiveUS20120022737A1Improve fuel economyIncrease in sizeInternal combustion piston enginesDigital data processing detailsEngineeringOil temperature

It is provided a control device for a vehicle power transmission device including a shifting portion and an electric motor that provides regeneration via the shifting portion, the control device executing a downshift of the shifting portion if a traveling loss in the vehicle power transmission device after the shift is smaller than a traveling loss in the vehicle power transmission device at a current gear ratio during regenerative traveling, and the traveling loss in the vehicle power transmission device including at least one of a loss in the shifting portion and a loss in the electric motor, the loss in the shifting portion being calculated based on the operating oil temperature of the shifting portion and the loss in the electric motor being calculated based on the temperature of the electric motor.

Owner:TOYOTA JIDOSHA KK

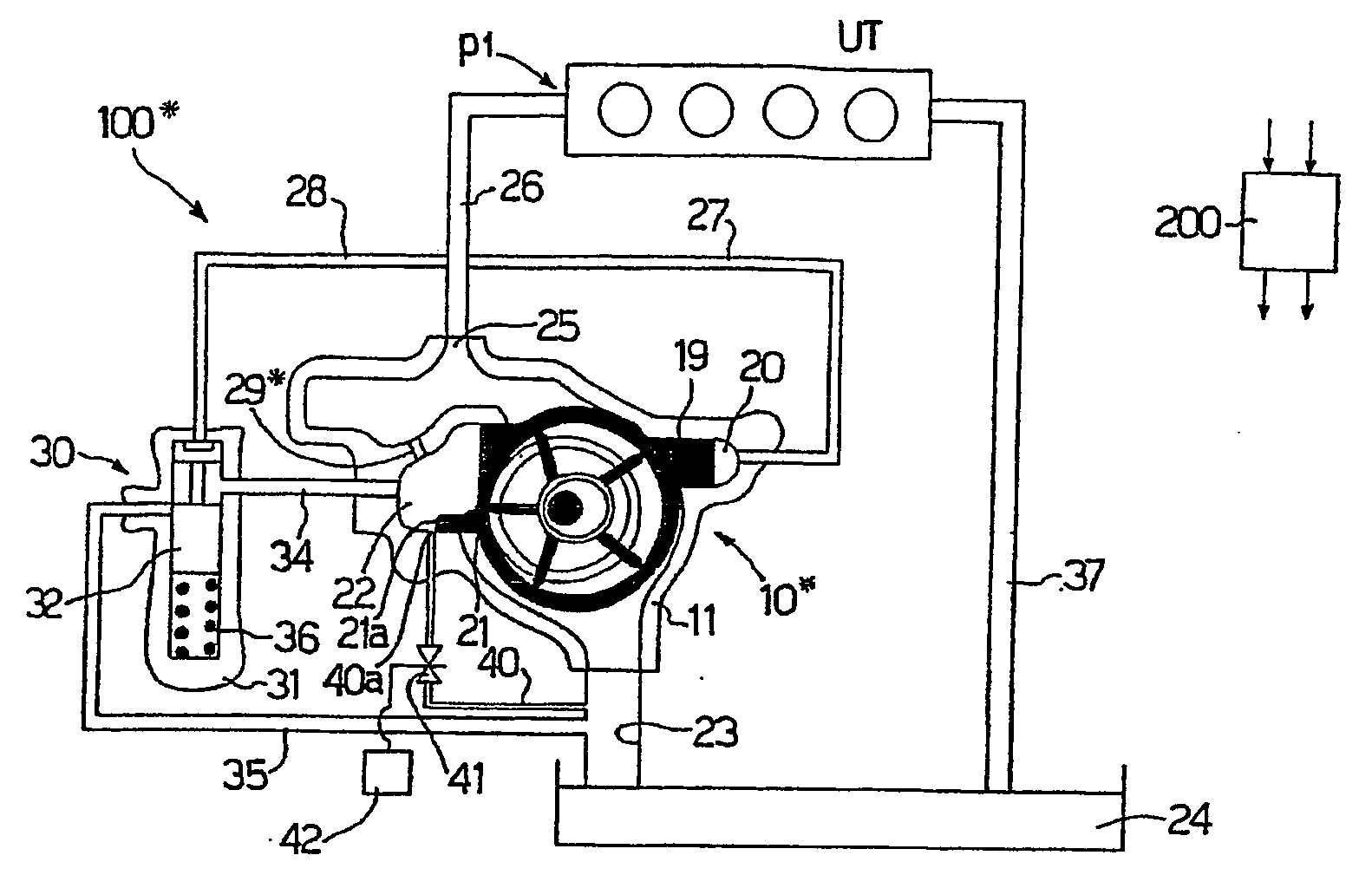

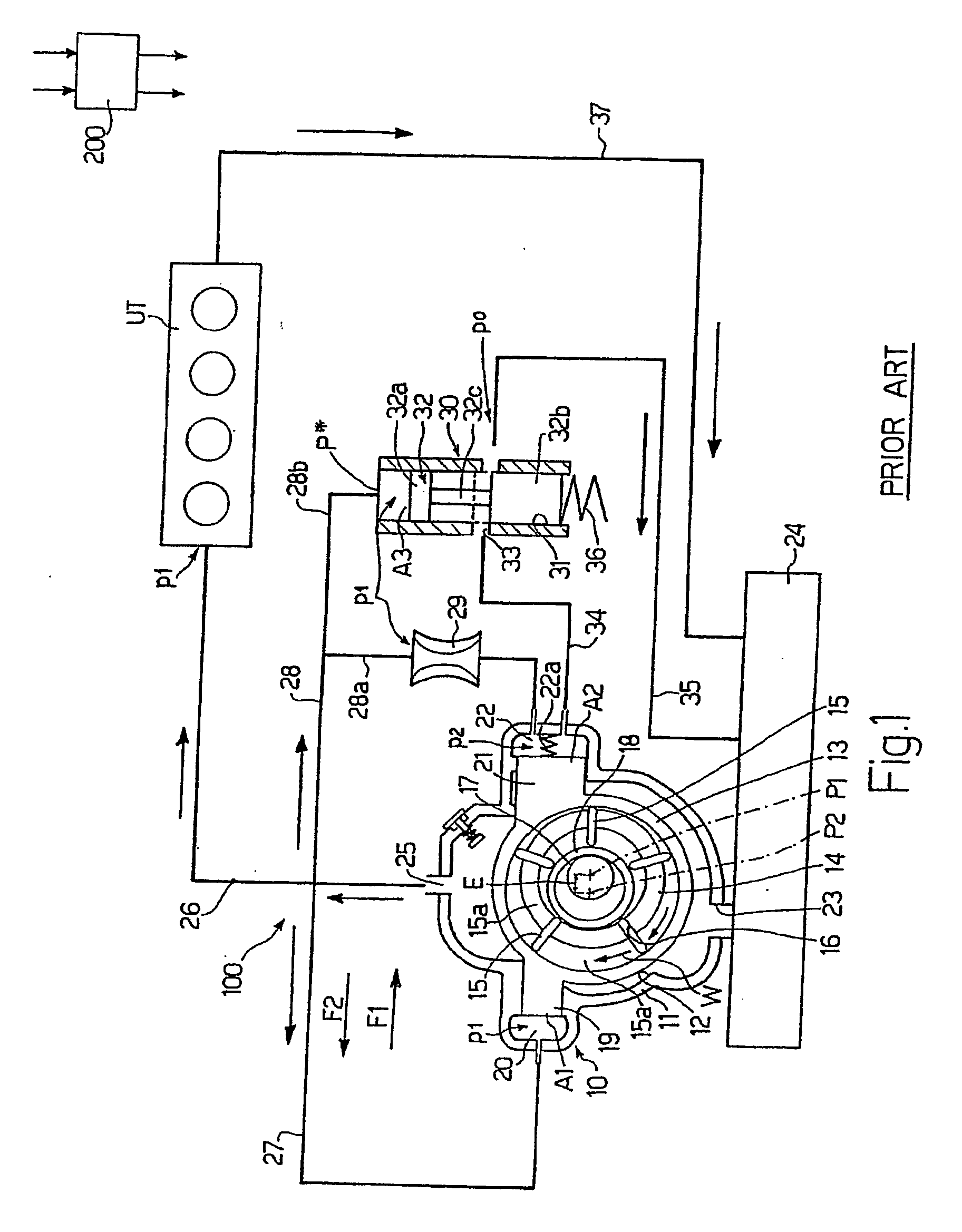

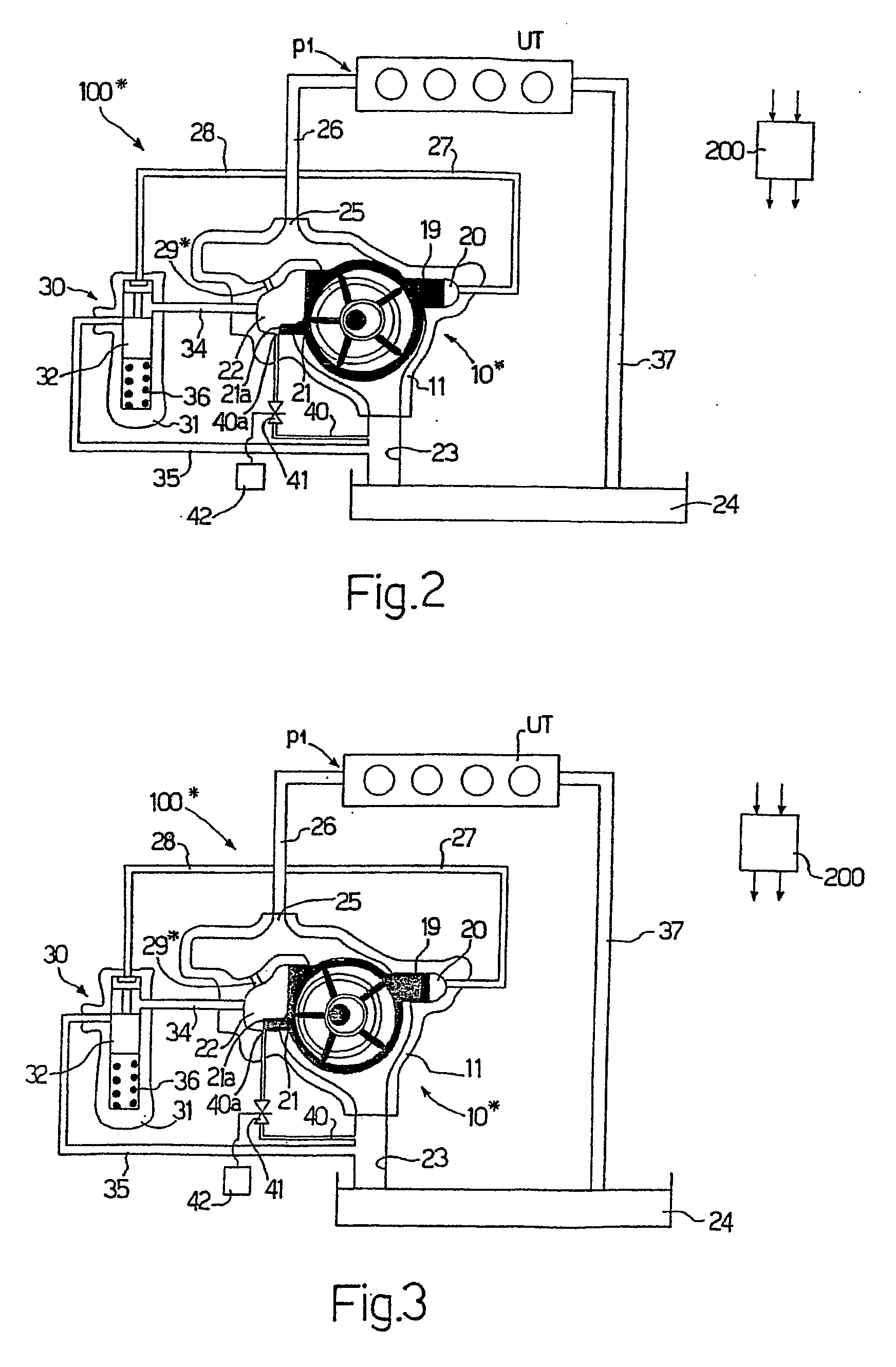

Pumping System

A pumping system (100*) having a pump (10*), such as a variable-displacement vane pump (10*) or a gear pump. The pump (10*) in turn has hydraulic pressure-control dissipating devices (29, 30) for imparting to the oil in a first control chamber (22) a pressure (p2) lower than the pressure of a second chamber (20). The system (100*) is characterized in that the first control chamber (22) of the pump (10*) has a channel (40) connecting the first control chamber to an oil inlet (23). And the channel (40) has an opening / closing device (41) controlled selectively by an engine operating parameter, such as oil temperature.

Owner:PIERBURG PUMP TECH ITAL

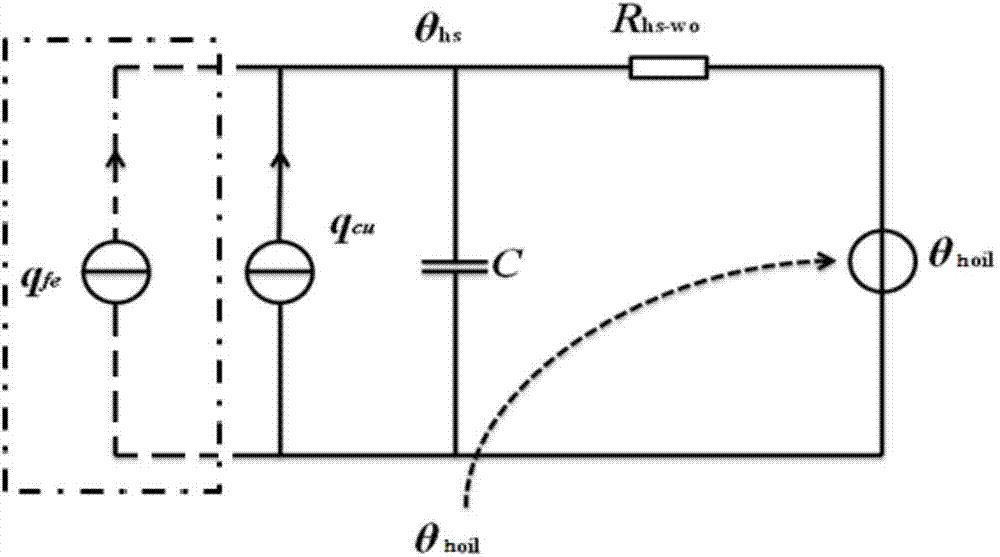

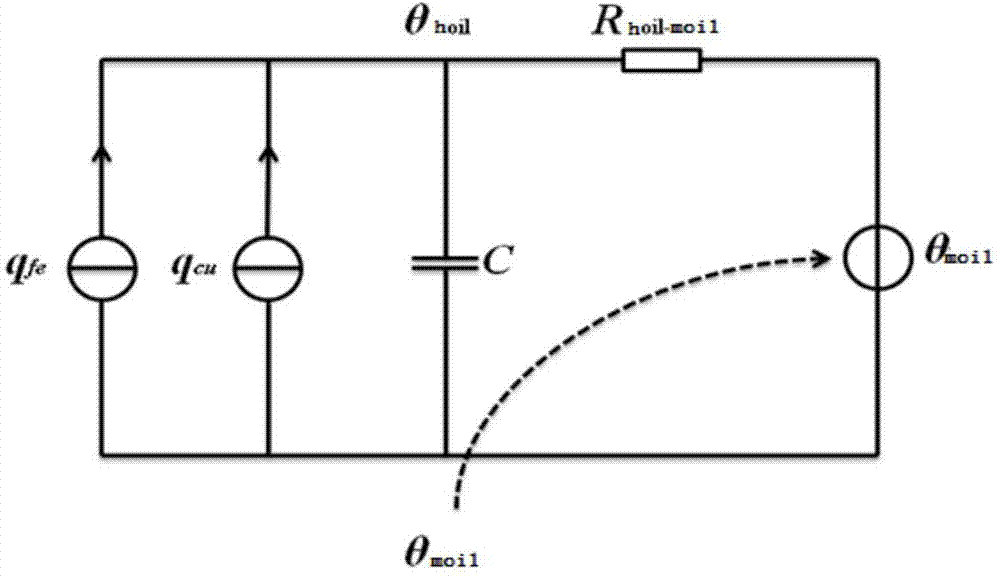

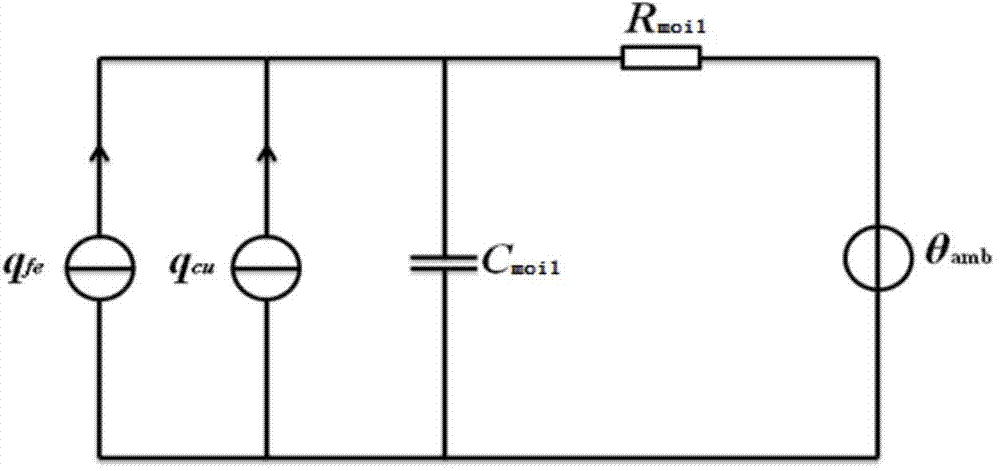

Dynamic capacity increasing method for oil-immersed transformer

ActiveCN103779059ADynamic capacity increase real-time monitoringAvoid overall overheatingInductances/transformers/magnets manufactureThermometer applicationsSteady state temperatureTime delays

The invention relates to a dynamic capacity increasing method for an oil-immersed transformer, and belongs to the field of transformers. The method includes the steps that heat conduction process in the transformer is simplified into a circuit model; winding hot-spot temperature, top oil temperature, average oil temperature, average winding temperature of the transformer under the current load condition are calculated; according to the limit that the winding hot-spot temperature does not exceed 140 DEG C, whether temperature in the transformer will exceed the limit temperature or not under the current load and environment conditions is calculated, whether a temperature limit value is reached or not if long-term emergency loads or short-term emergency loads occur at the moment is calculated, and if the temperature in the transformer possibly exceeds the limit value of the short-term emergency loads, the time for reaching the limit value and the finally reached steady state temperature are calculated to serve as alarm signals; if it is monitored that the temperature will exceed the standard within t minutes, an early-warning signal is sent out, certain time delay is set, and if the loads are not reduced within the set time delay, a cooling fan of the transformer is turned on. Long-term continuous operation of cooling equipment can be avoided, and operation life of the cooling equipment is prolonged.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

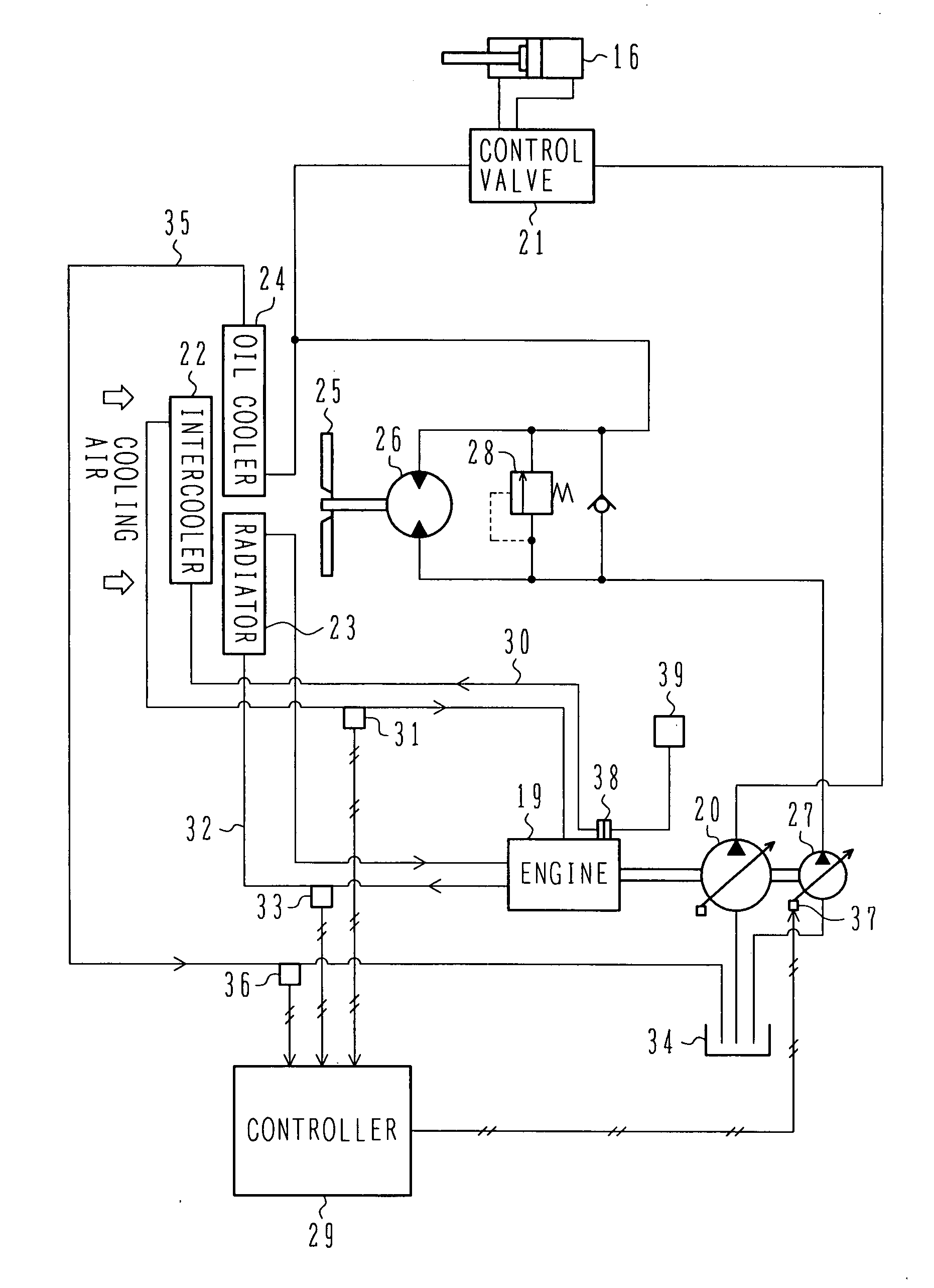

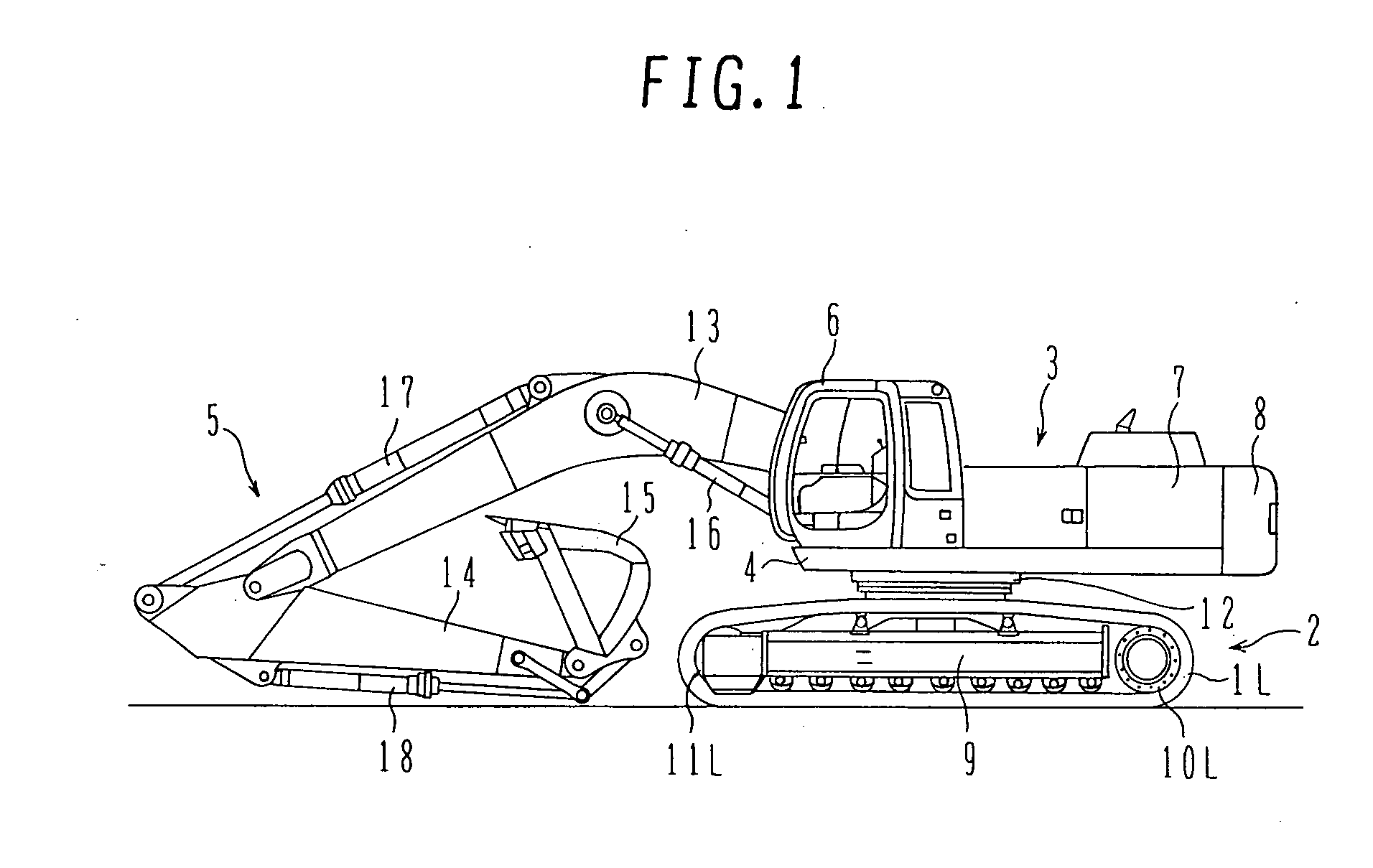

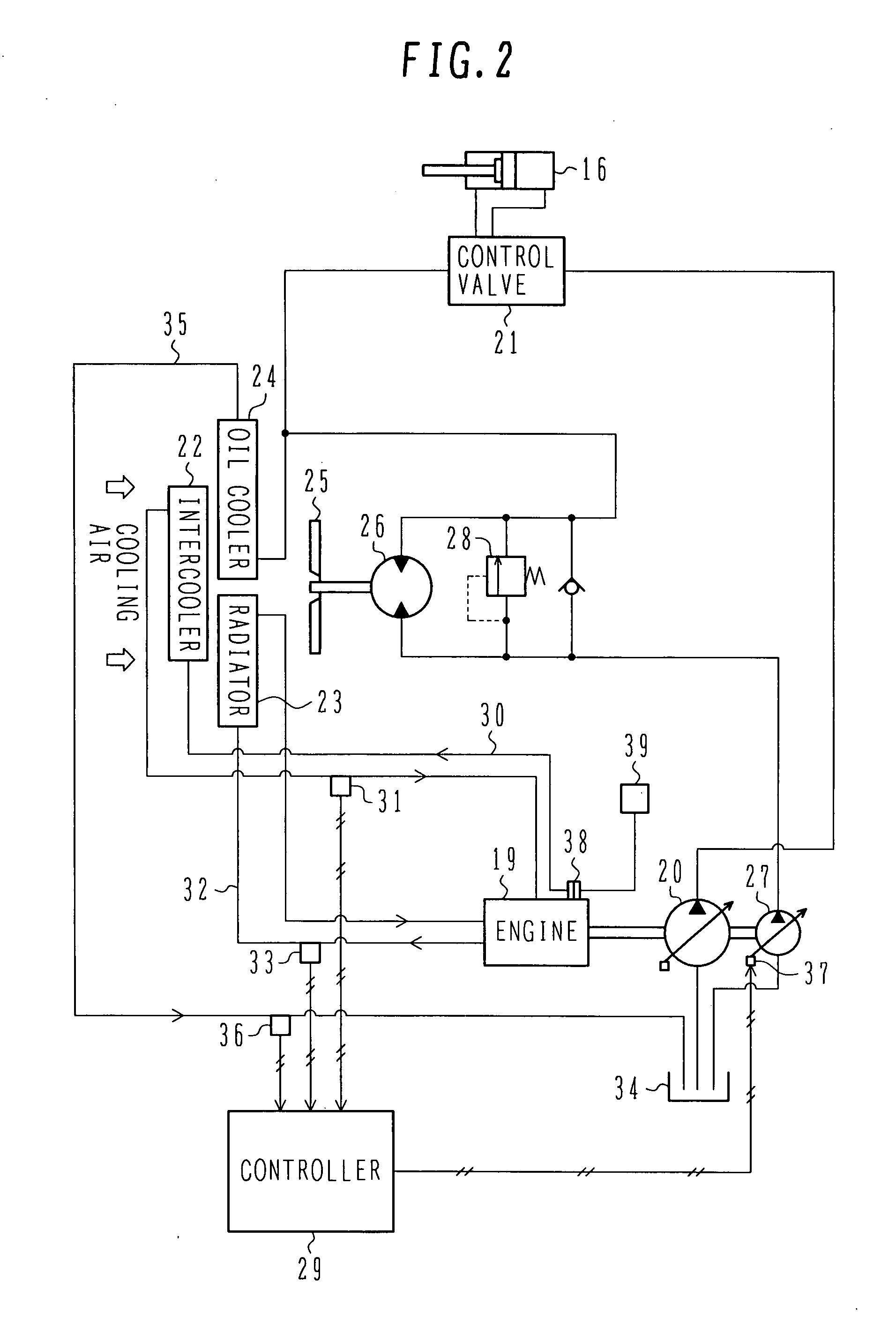

Cooling System for Construction Machine

ActiveUS20090217655A1Reduce noiseReliably producedFluid couplingsCoolant flow controlHydraulic motorControl signal

A cooling system for a construction machine, which can reduce noise of a cooling fan and can reliably produce cooling air at a required flow rate.The cooling system comprises a cooling fan 25 for producing cooling air introduced to an intercooler 22, a radiator 23 and an oil cooler 24, a fan hydraulic motor 26 for driving the cooling fan 25, a fan hydraulic pump 27 for delivering a hydraulic fluid to the fan hydraulic motor 26, an air temperature sensor 31 for detecting an air temperature T1 at an outlet of the intercooler 22, a cooling water temperature sensor 33 for detecting a temperature T2 of cooling water for the radiator 23, a working oil temperature sensor 36 for detecting a temperature T3 of working oil for the oil cooler 24, and a controller 29 for outputting a control signal corresponding to a maximum value among calculation values N1, N2 and N3 of cooling fan rotation speed, which correspond respectively to detected values T1, T2 and T3 from the air temperature sensor 31, the cooling water temperature sensor 33 and the working oil temperature sensor 36.

Owner:NIHON KENKI CO LTD

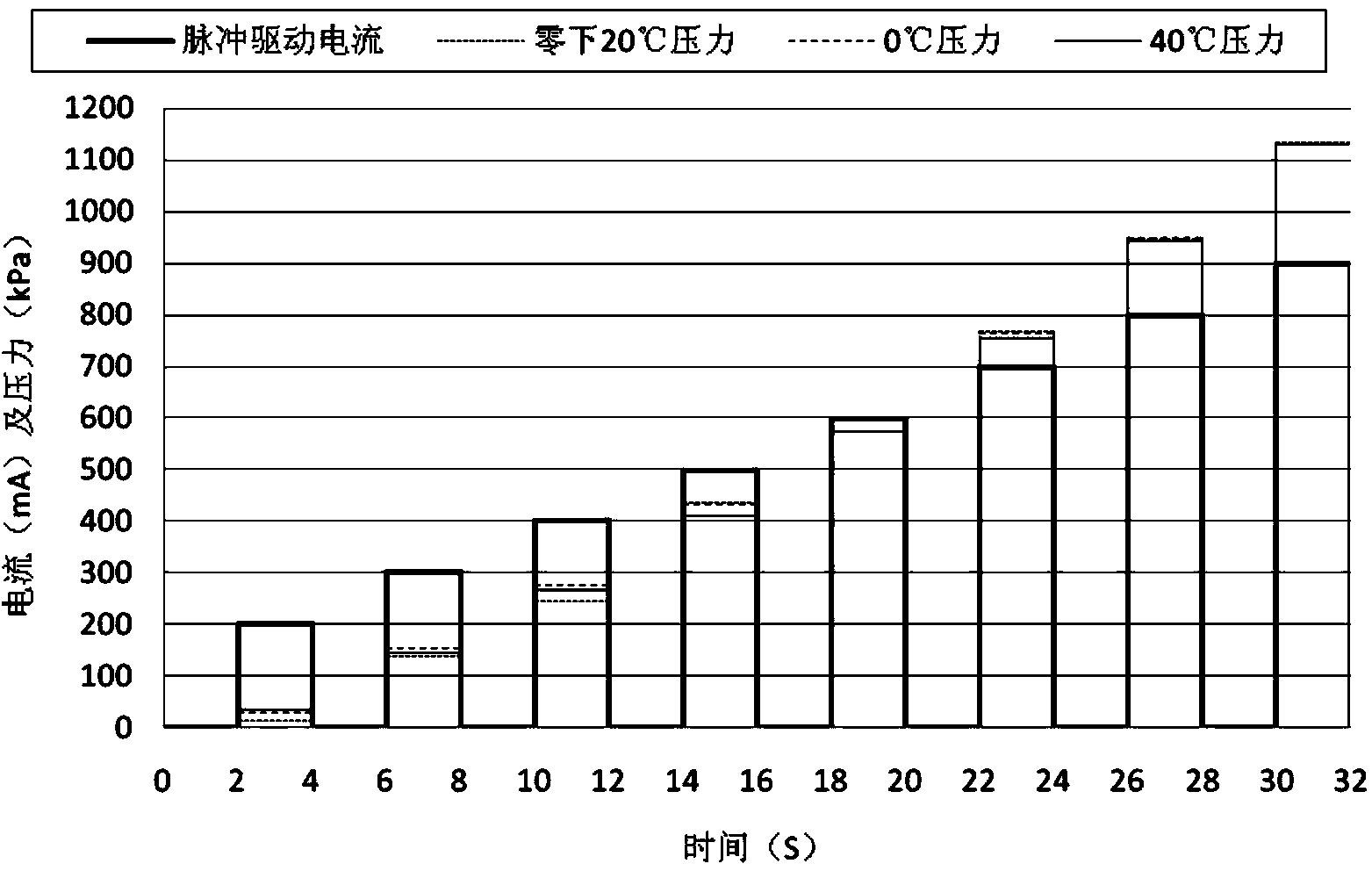

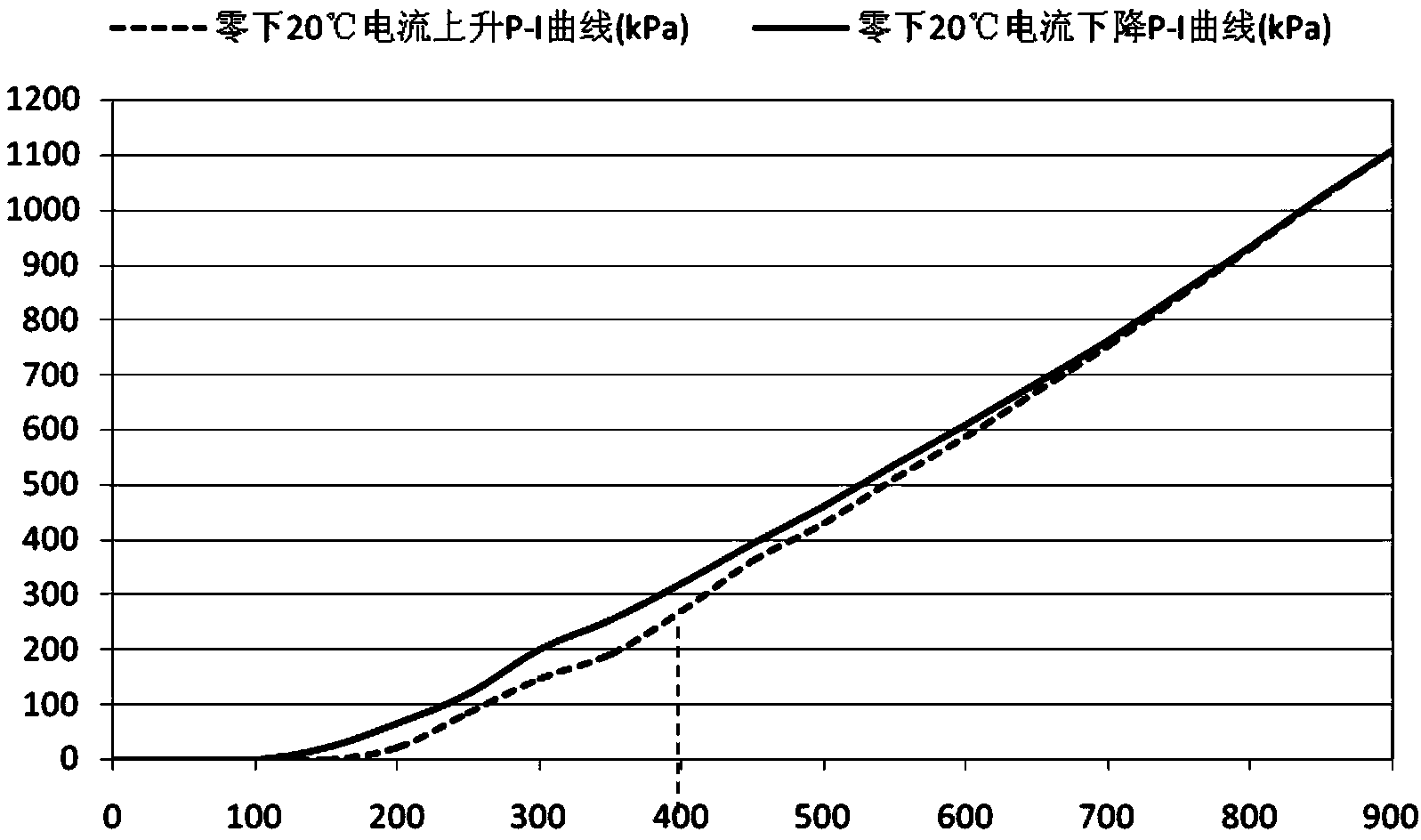

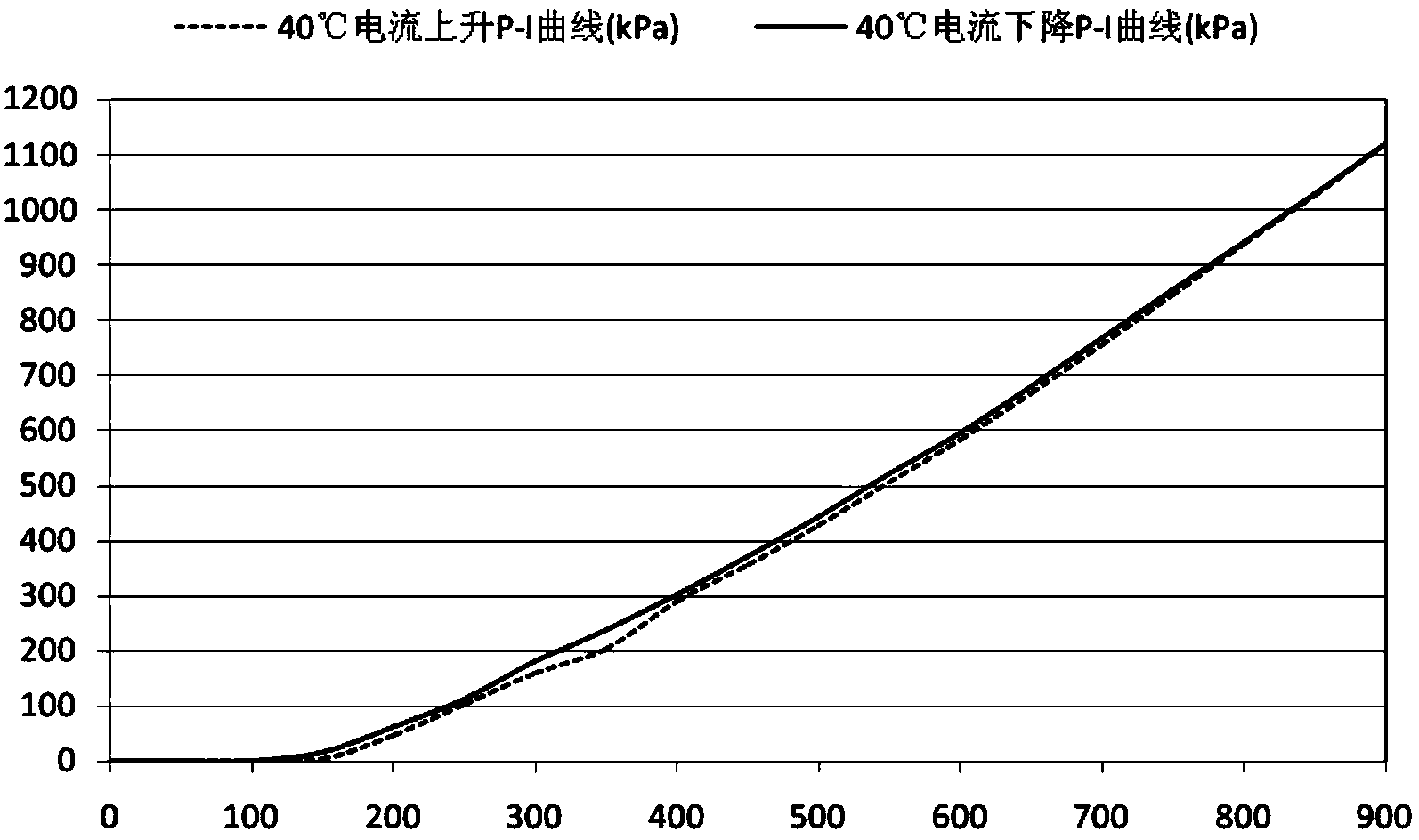

Wet-type double-clutch automatic transmission electromagnetic valve characteristic curve compensation method

ActiveCN103629341AReduced impact on drivabilityHigh control precisionGearing controlHysteresisAutomatic transmission

The invention provides a wet-type double-clutch automatic transmission electromagnetic valve characteristic curve compensation method. The method comprises the following steps: computing the current expectation pressure of the clutch under actual working condition, judging whether to perform compensation treatment, wherein the compensation treatment comprises oil temperature compensation and / or hysteresis compensation, if so, obtaining a compensation value, and computing a final expectation pressure according to the compensation value and the current expectation pressure; searching a corresponding current value in the electromagnetic valve characteristic curve under basic oil temperature according to the final expectation pressure, and exerting the searched current value on the electromagnetic valve; if not, searching the corresponding current value in the electromagnetic valve characteristic curve under base oil temperature according to the current expectation pressure, and exerting the searched current value on the electromagnetic valve. The control precision of a transmission control unit to the transmission is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

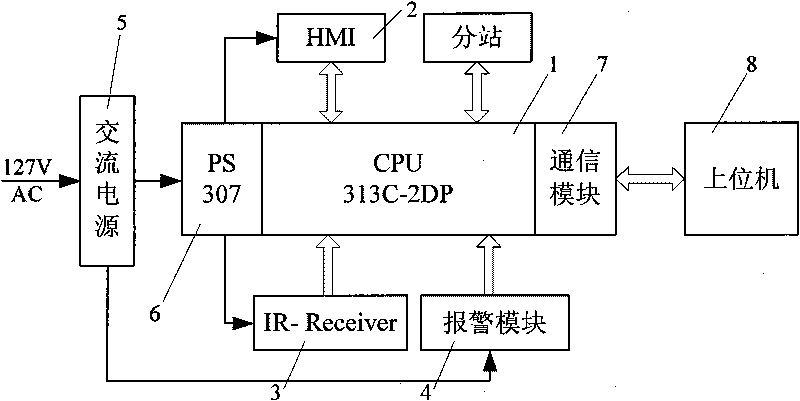

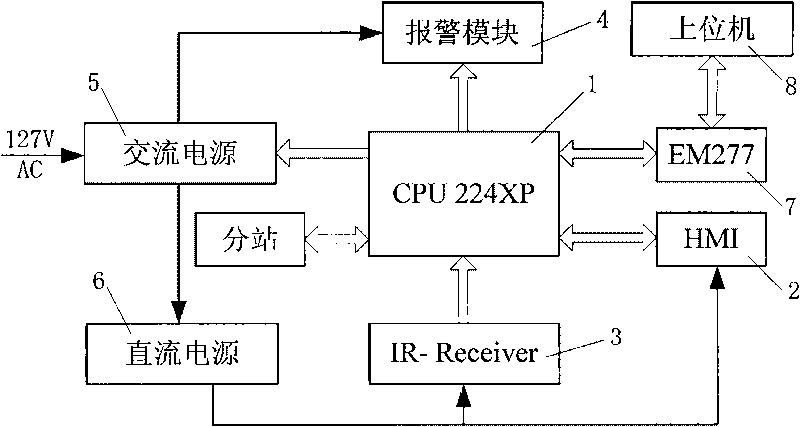

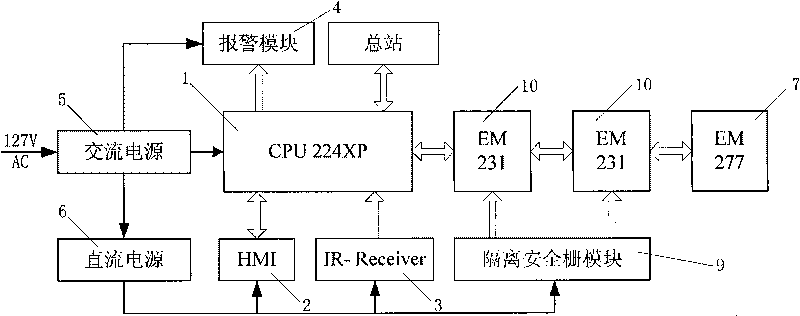

Device for monitoring states and diagnosing faults of coal mine underground working surface conveyer

InactiveCN101727085AEasy to expand monitoring volumeSimple structureComputer controlSimulator controlEngineeringCrusher

The invention discloses a device for monitoring conditions and diagnosing faults of a coal mine underground working surface conveyer, which consists of a state monitoring and fault diagnosis central station and a substation, uses PLC for control, adopts a modularization design, and supports multi-bus data transmission. The device realizes the real-time monitoring and display of the following parameters: the bearing temperature, the oil temperature and the oil level of a speed reducer matched with the devices of a working surface conveyer namely a slat conveyer, a reversed loader, a crusher and the like; the stator temperature and the rotor bearing temperature of a motor; and the flow and the pressure of cooling water, and the distance between a coal mining machine and the slat conveyer, and the like. The device diagnoses the running states of the conveyer and makes an early warning or an alarm. The device can meet different requirements underground a coal mine, has the advantages of simple structure, convenient maintenance and expansion, convenient and fast network deployment and the like, reaches the aims of performing long-distance and on-site real-time monitoring and fault diagnosis on the working surface conveyer, and realizes the production target of safe, stable and reliable operations in a coal mine.

Owner:TAIYUAN UNIV OF TECH

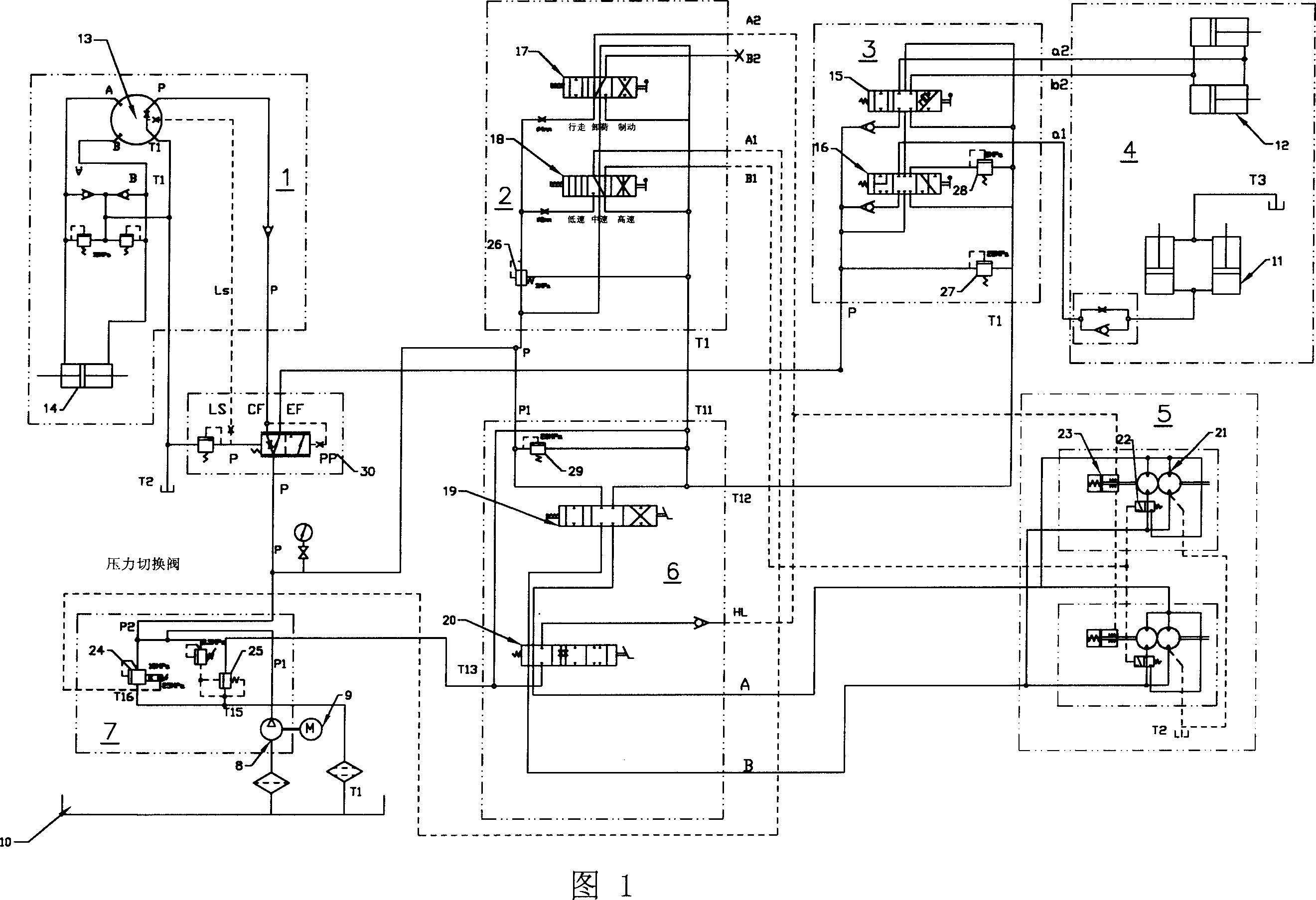

Full hydraulic electric forklift hydraulic system

InactiveCN101058395AEasy to controlImprove operational efficiencyLifting devicesHydraulic motorElectricity

The overall hydraulic electric forklift hydraulic system comprises the hoist oil cylinder, slanting oil cylinder formed slanting lifting device, steering device mainly made of the deflector and the steering oil cylinder, hydraulic motor, hydraulic motor brake and its speed regulating valve. The above mentioned three devices can get hydraulic energy form a generator driven gear pump, the said gear pump generated hydraulic energy divided into two ways, one passing through the optimal valve supplying to the said steering device and several valve controlled lifting device, the other way going to the control valve and converting brake valve drive device through change-over valve. It can replace variable pump for the control of the generator gear pump through electricity, getting rid of the low efficiency, big energy consumption, high oil temperature, long time damage to the hydraulic motor, traveling, and poor brake stability.

Owner:ZHEJIANG JIALI TECH

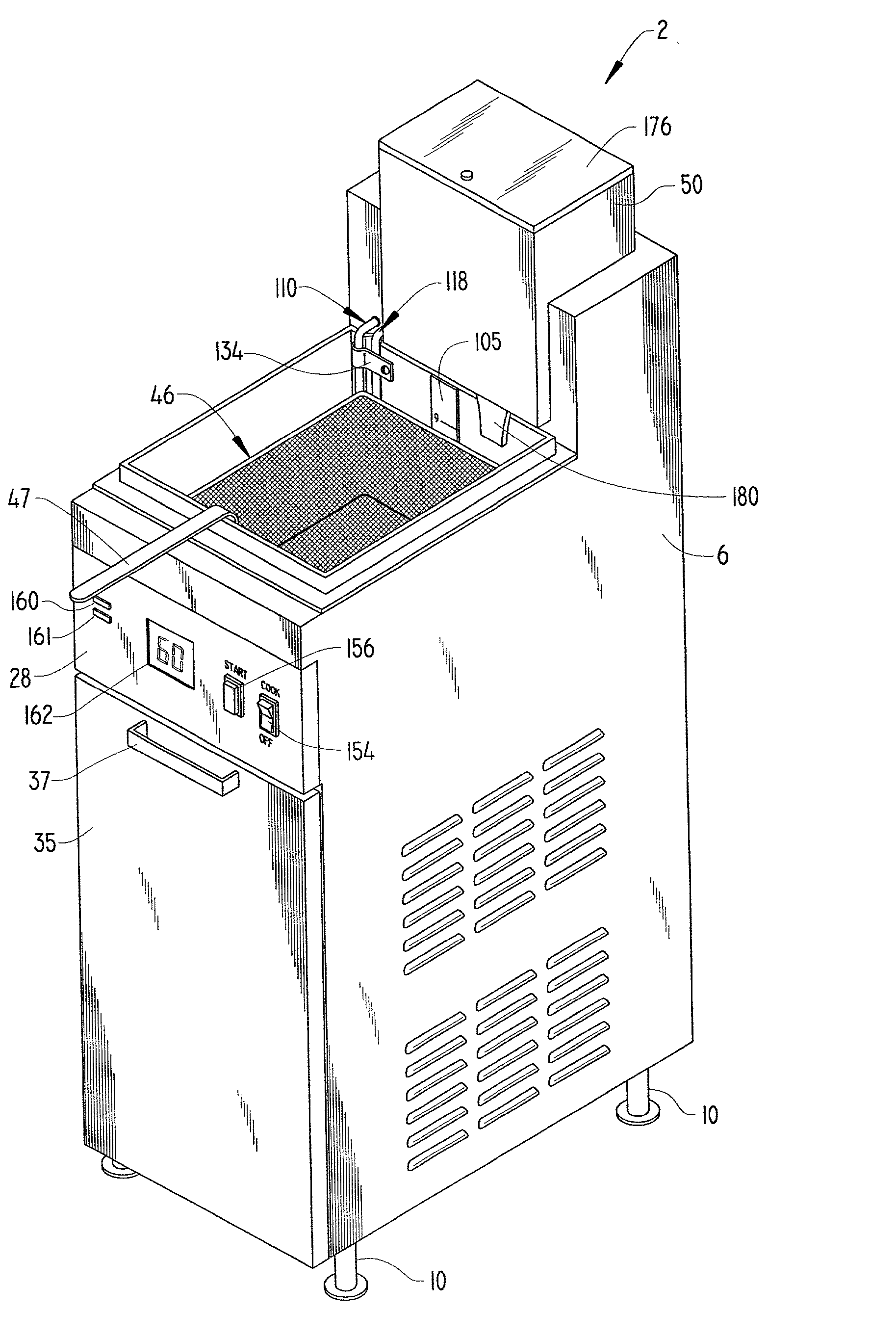

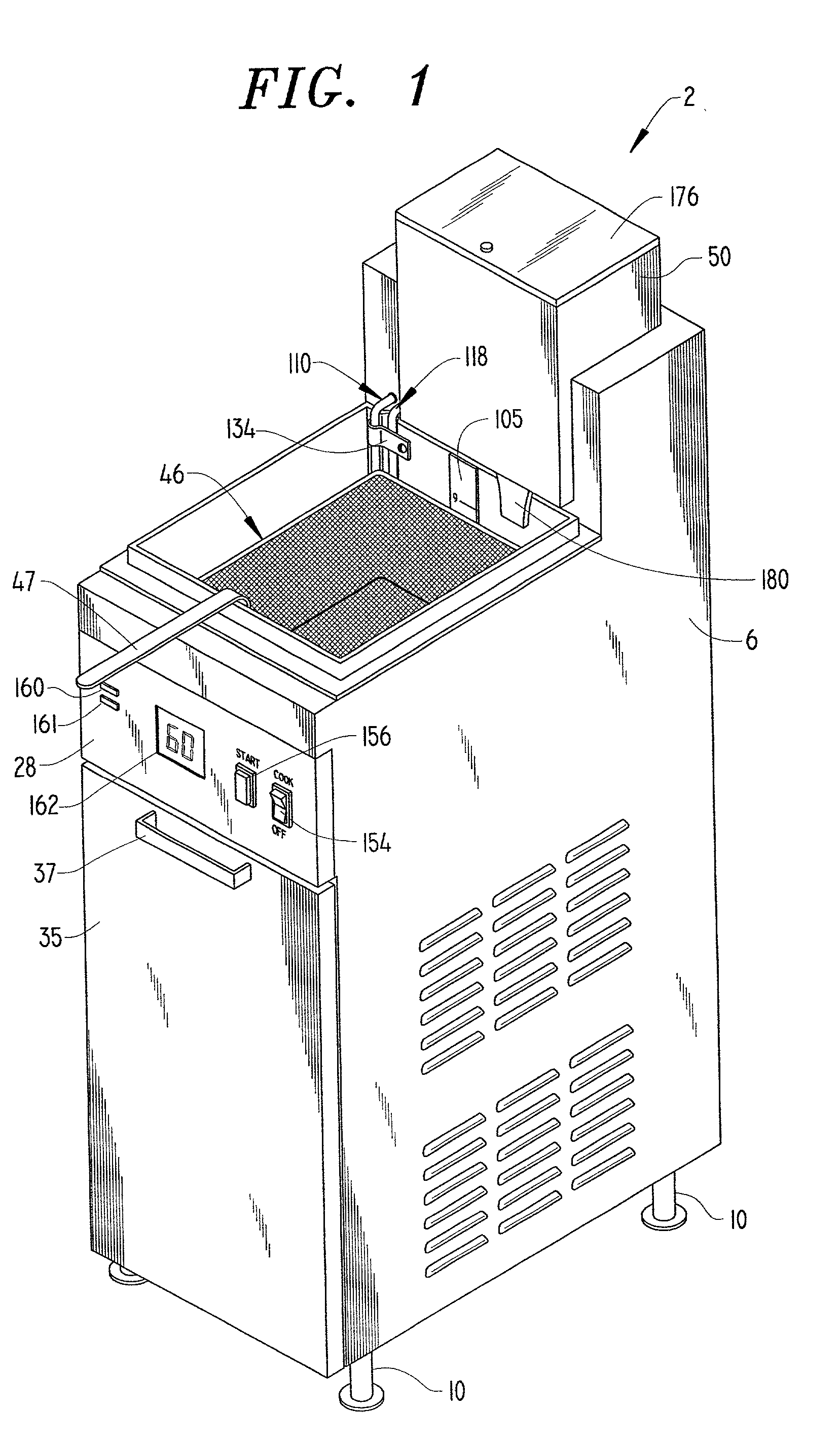

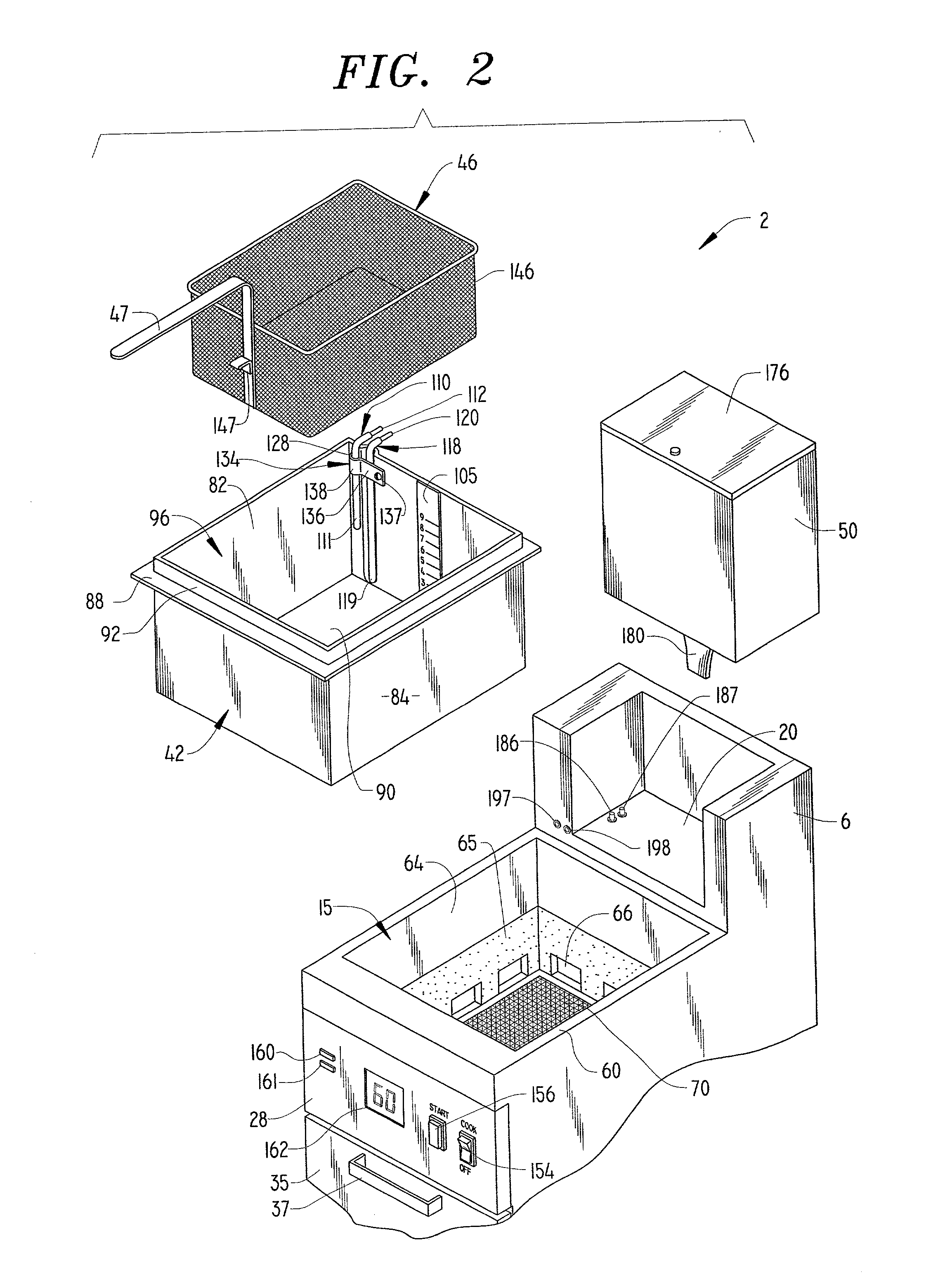

High temperature, oil saving, rapid cook fryer system

A deep fat fryer able to quickly cook food items, in about one-third to one-half of a typical cook time in the art for corresponding food items, includes a high powered, preferably high efficiency heating unit utilized to establish a cooking oil temperature in the order of about forty or more degrees Fahrenheit above a typical cook time, while preferably remaining lower than or equal to 410° F. A controller regulates the heat input from the heating unit so as to keep the temperature of the oil from dropping drastically after a product to be fried is placed in the oil for cooking. The amount of cooking oil employed is minimized. A sensing arrangement is utilized to input sensed operating conditions to the controller in order to maintain a desired operating temperature and oil level.

Owner:PITCO FRIALATOR LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com