Patents

Literature

690 results about "Temperature limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Temperature is the average kinetic energy of a material's atoms or molecules, plus any other energy that can be transferred. The lower limit of temperature is absolute zero. Heating material gives the particles kinetic energy. The upper temperature limit is when all of the object's particles are traveling at the speed of light.

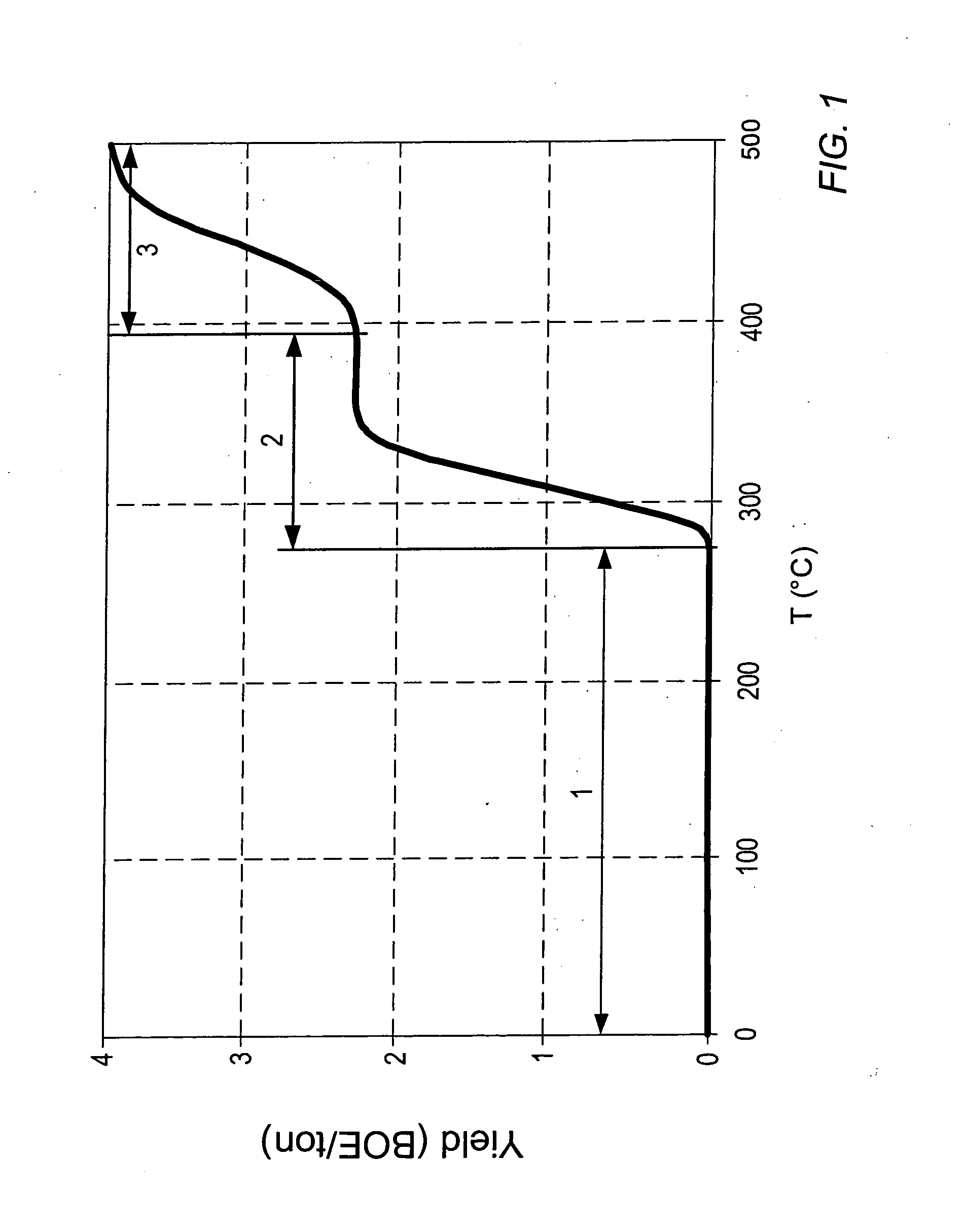

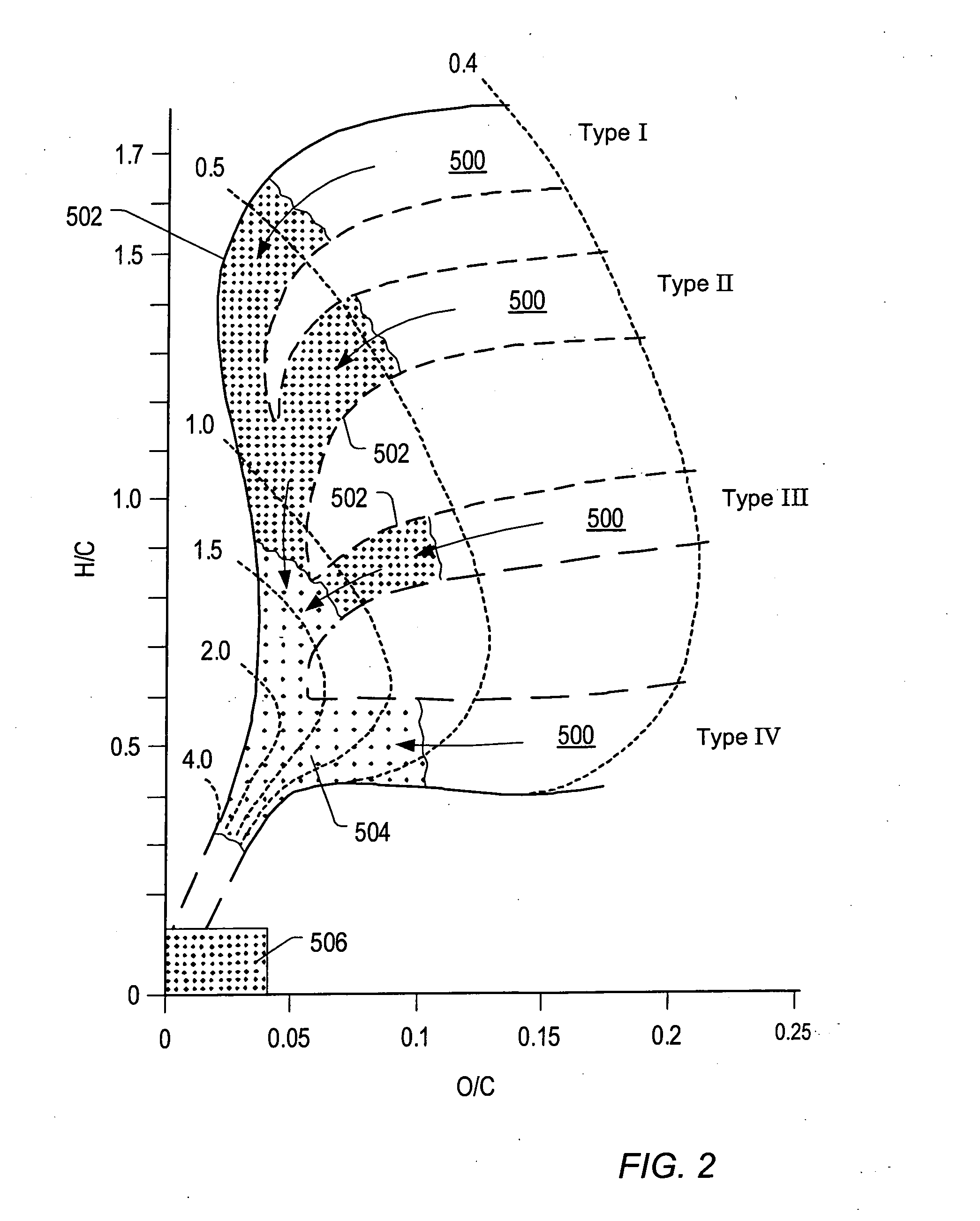

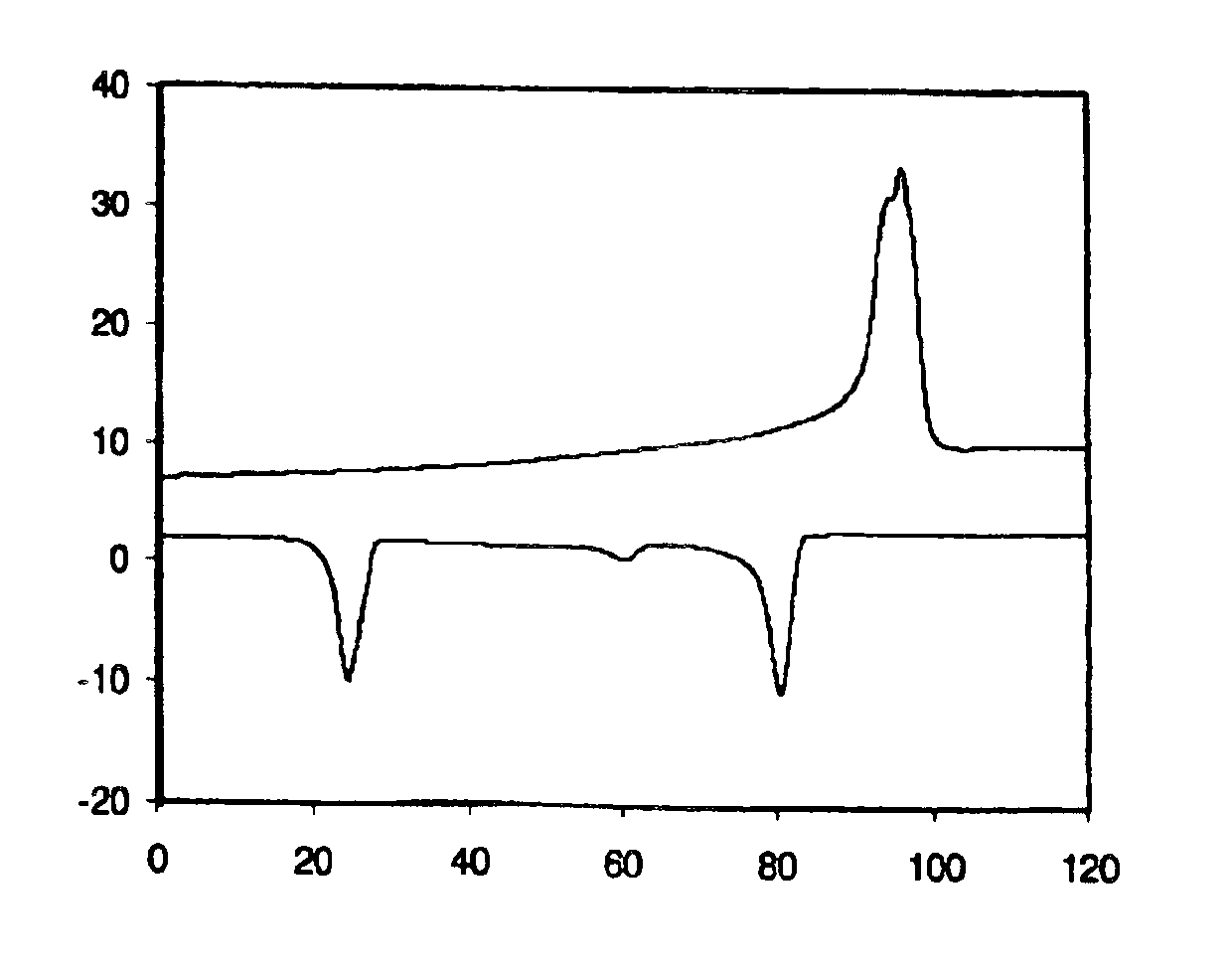

Variable frequency temperature limited heaters

InactiveUS20050006097A1Avoid deformationReduce heatThermal drillingInsulationElectrical resistance and conductancePower flow

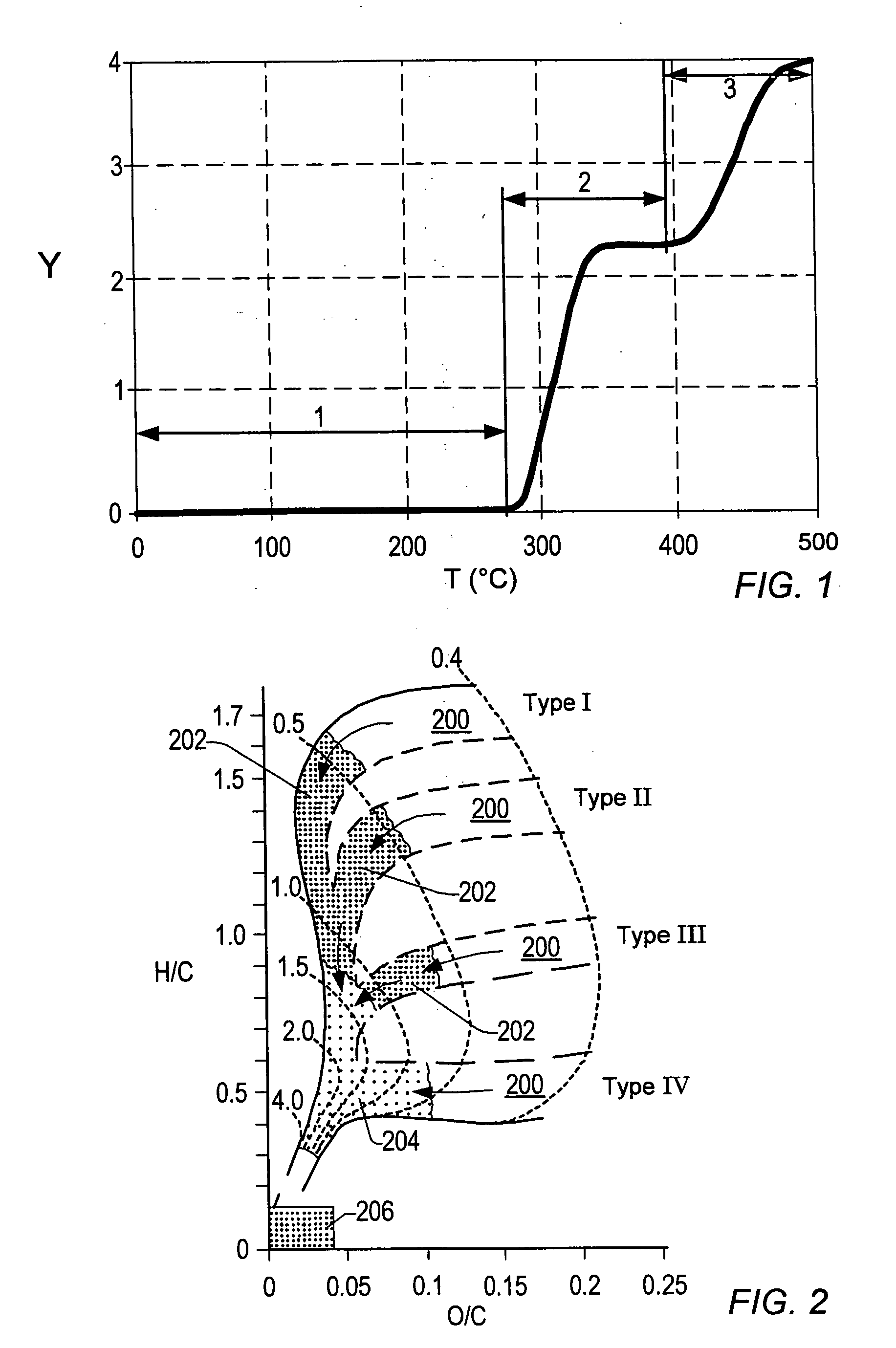

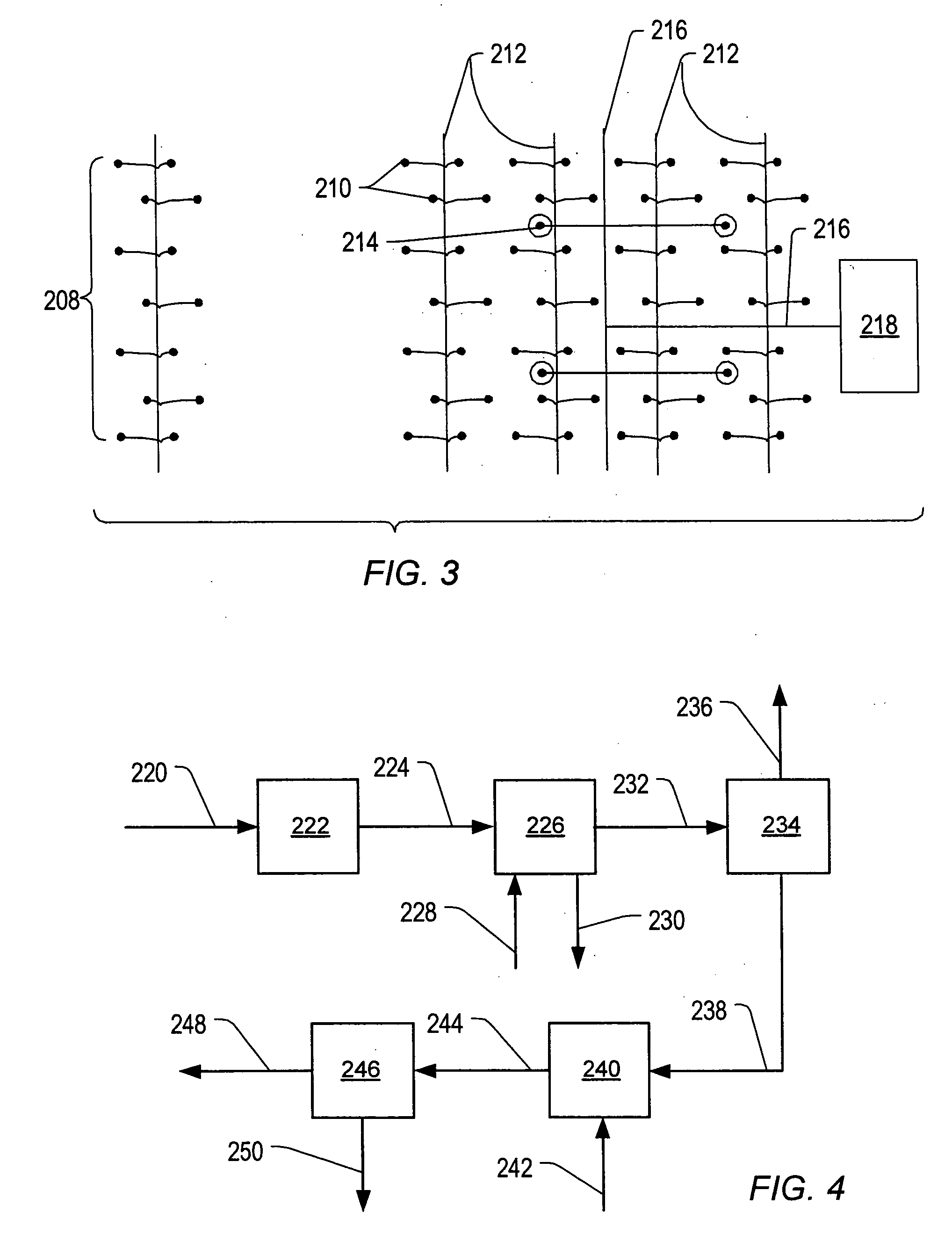

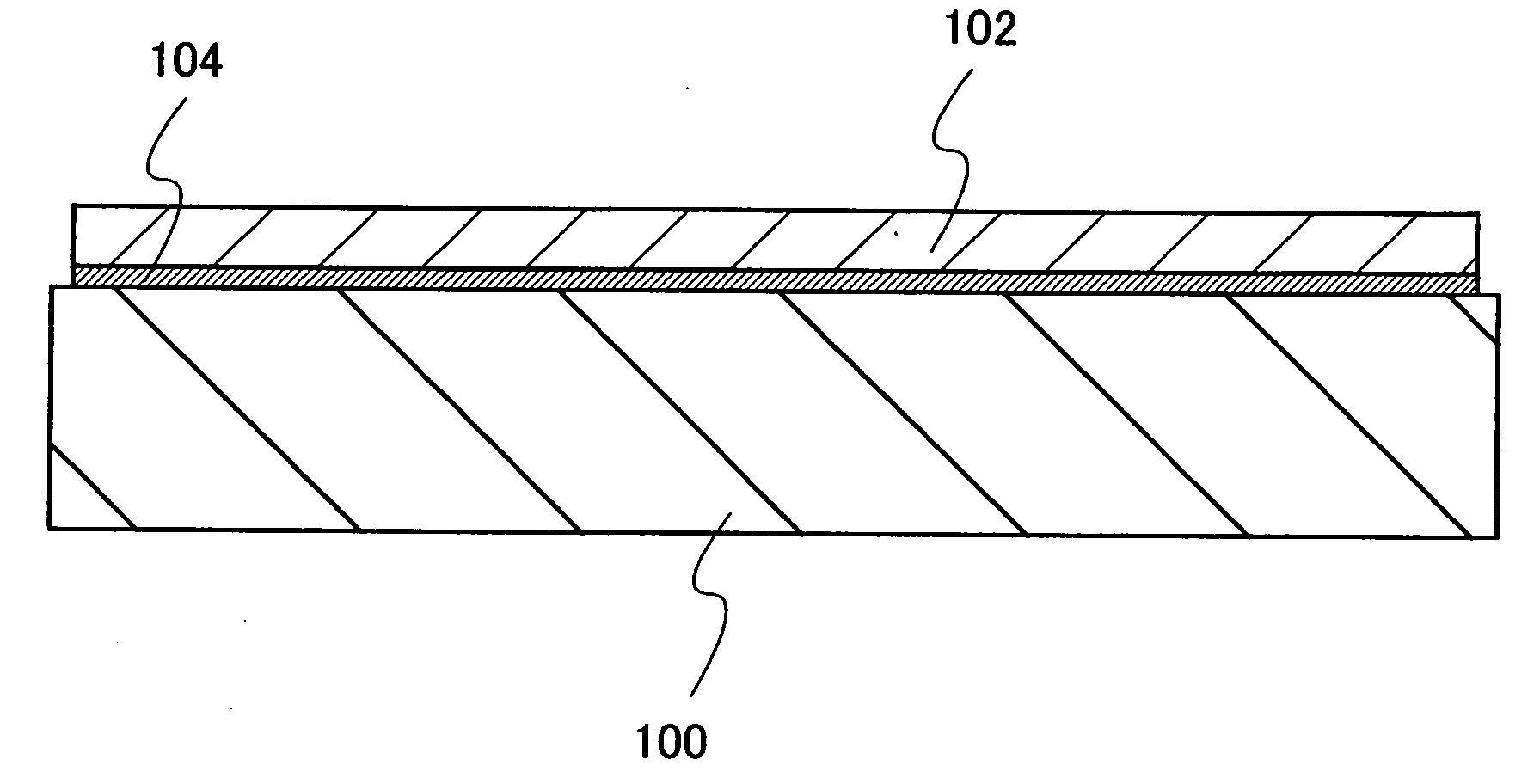

A heater system may include an alternating current supply and an electrical conductor. Alternating current may be applied to one or more electrical conductors at a frequency between about 100 Hz and about 1000 Hz. The electrical conductors may be located in a formation. The electrical conductors may resistively heat upon application of the alternating electrical current. At least one of the electrical conductors may include an electrically resistive ferromagnetic material. The electrical conductor may provide a reduced amount of heat above or near a selected temperature. Heat may transfer from the electrical conductor to a part of formation.

Owner:SHELL OIL CO

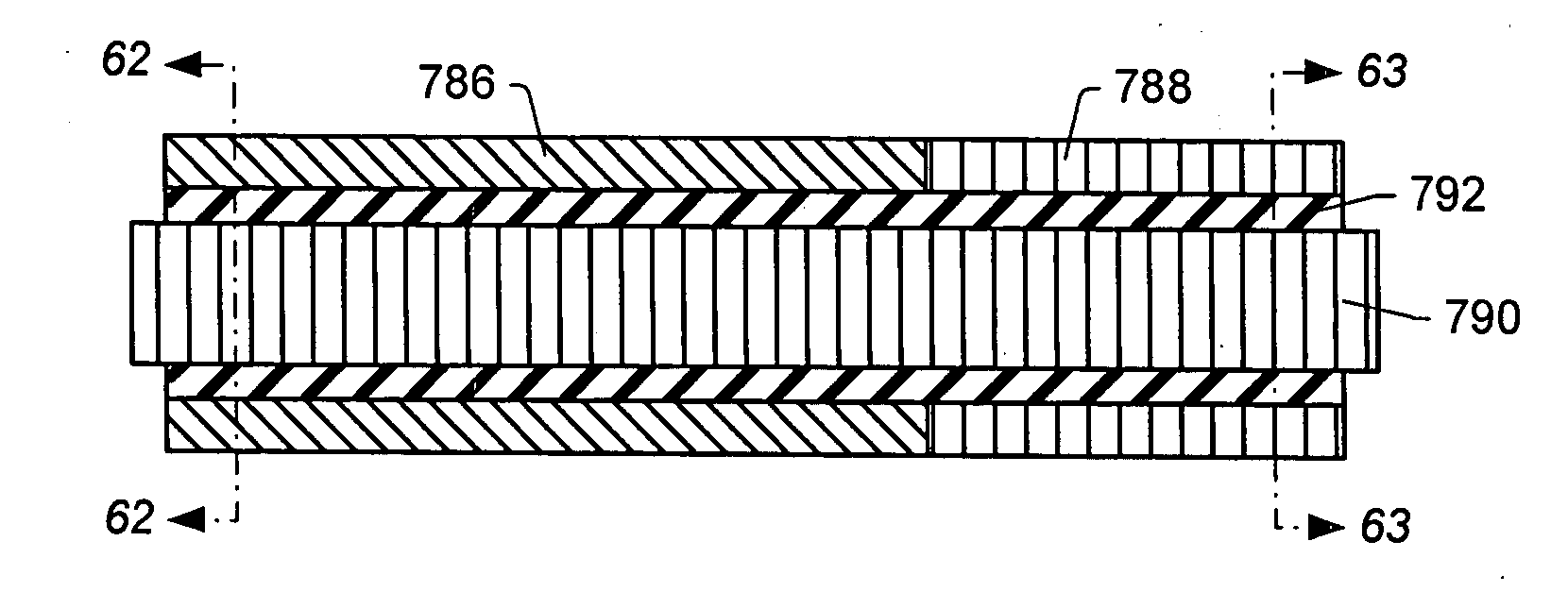

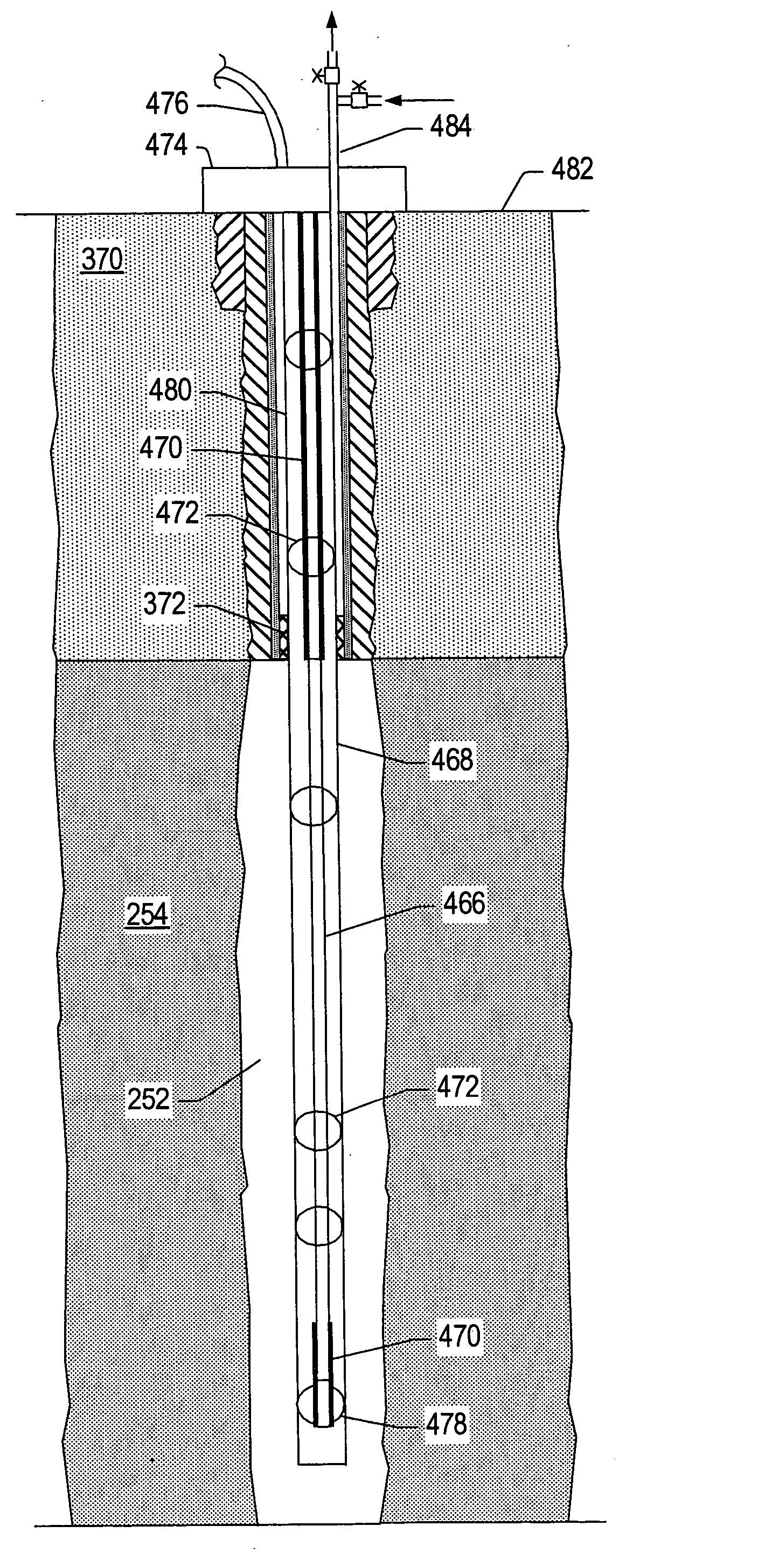

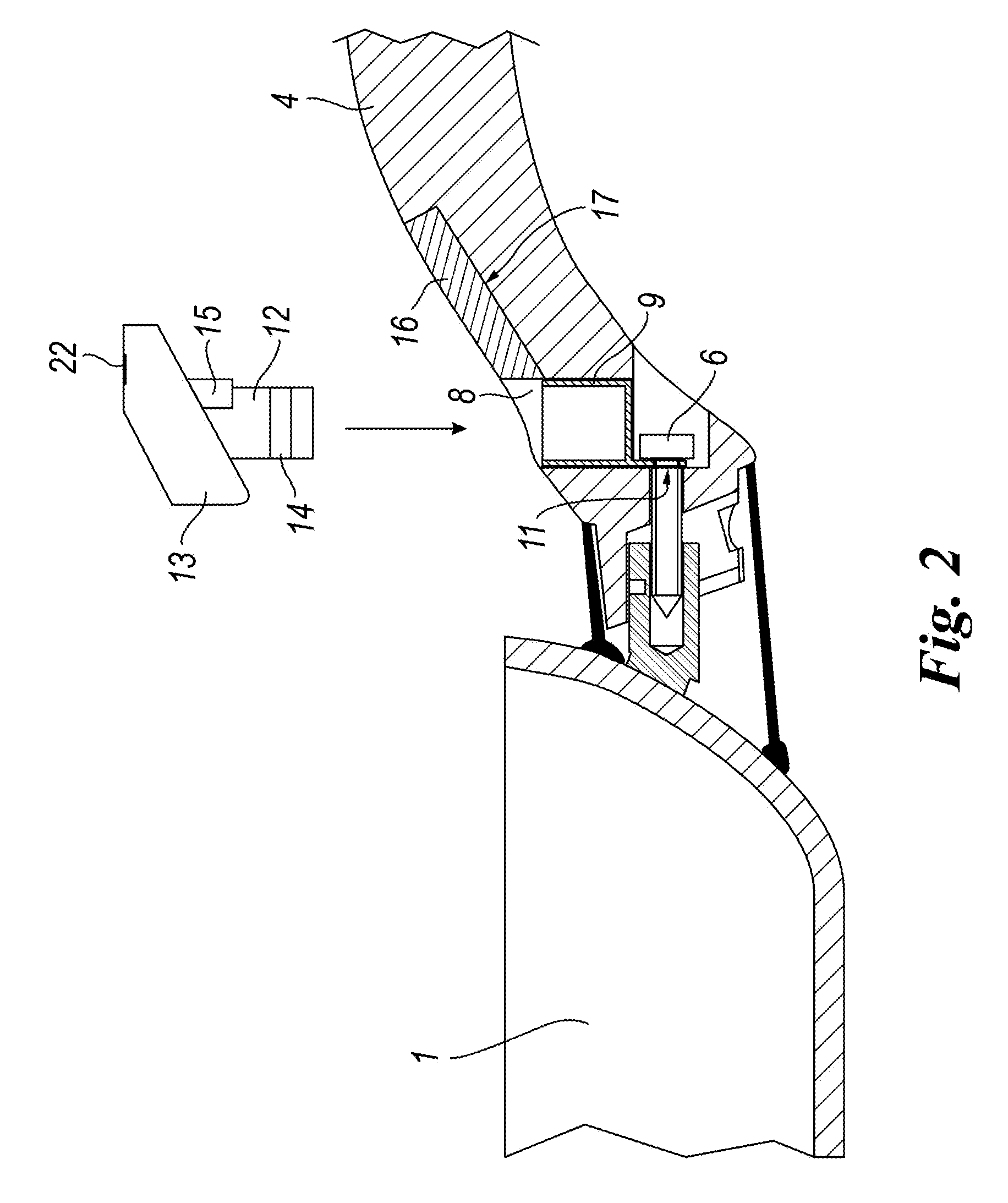

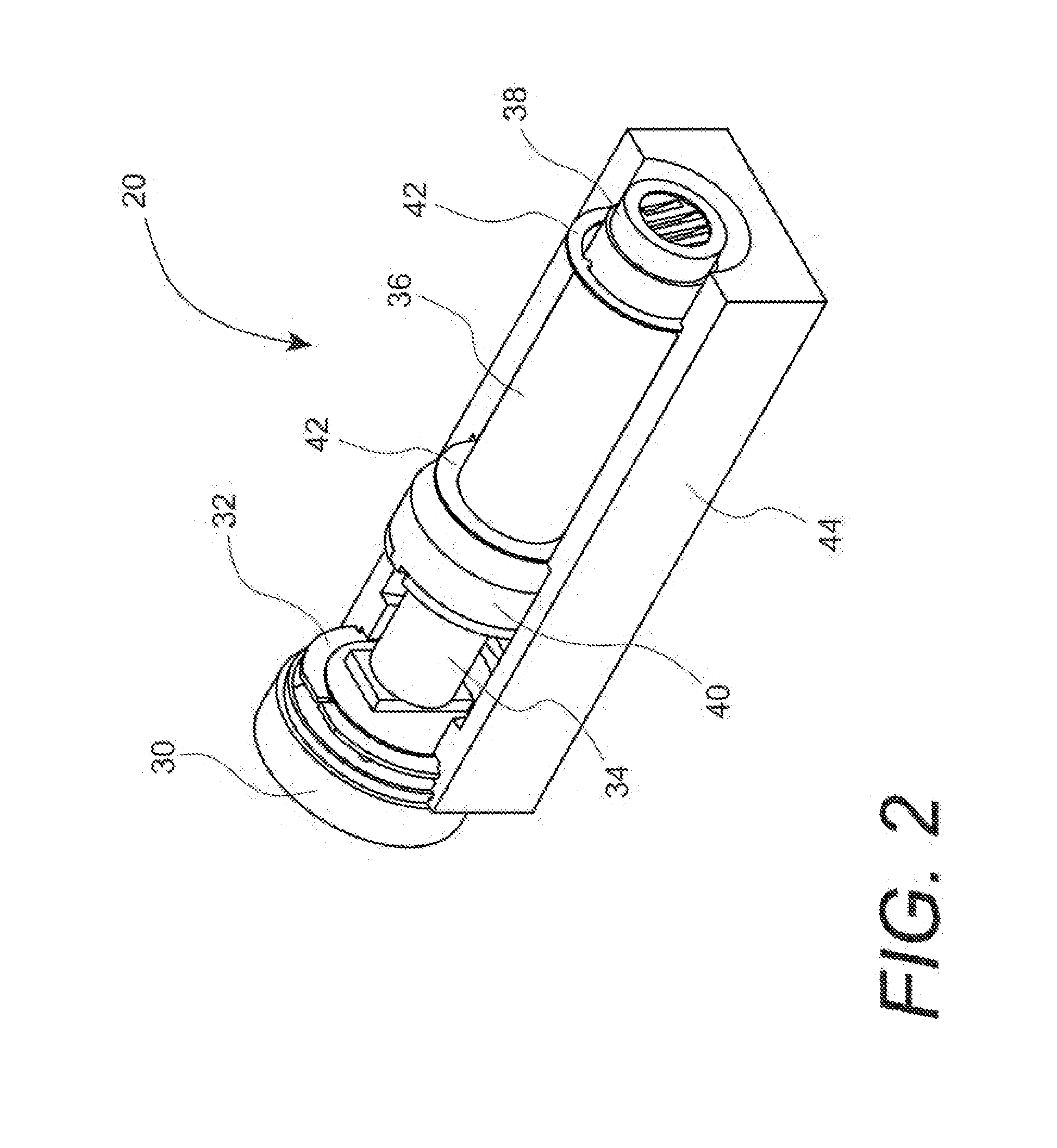

Triaxial temperature limited heater

InactiveUS20050269094A1InsulationFluid removalElectrical resistance and conductanceElectrical conductor

Certain embodiments provide a heater. The heater includes an inner electrical conductor. A heater section at least partially surrounds the inner electrical conductor. The heater section is configured to generate an electrically resistive heat output during application of time-varying electrical current to the heater section. The heater section includes ferromagnetic material. An outer electrical conductor at least partially surrounds the heater section. An applied time-varying electrical current is configured to propagate through the inner electrical conductor and the outer electrical conductor in substantially the same direction. The applied time-varying electrical current is configured to propagate through the heater section in a substantially opposite direction. The heater provides a first heat output when time-varying electrical current is applied to the heater below a selected temperature, and a second heat output approximately at and above the selected temperature during use. The second heat output is reduced compared to the first heat output.

Owner:SHELL OIL CO

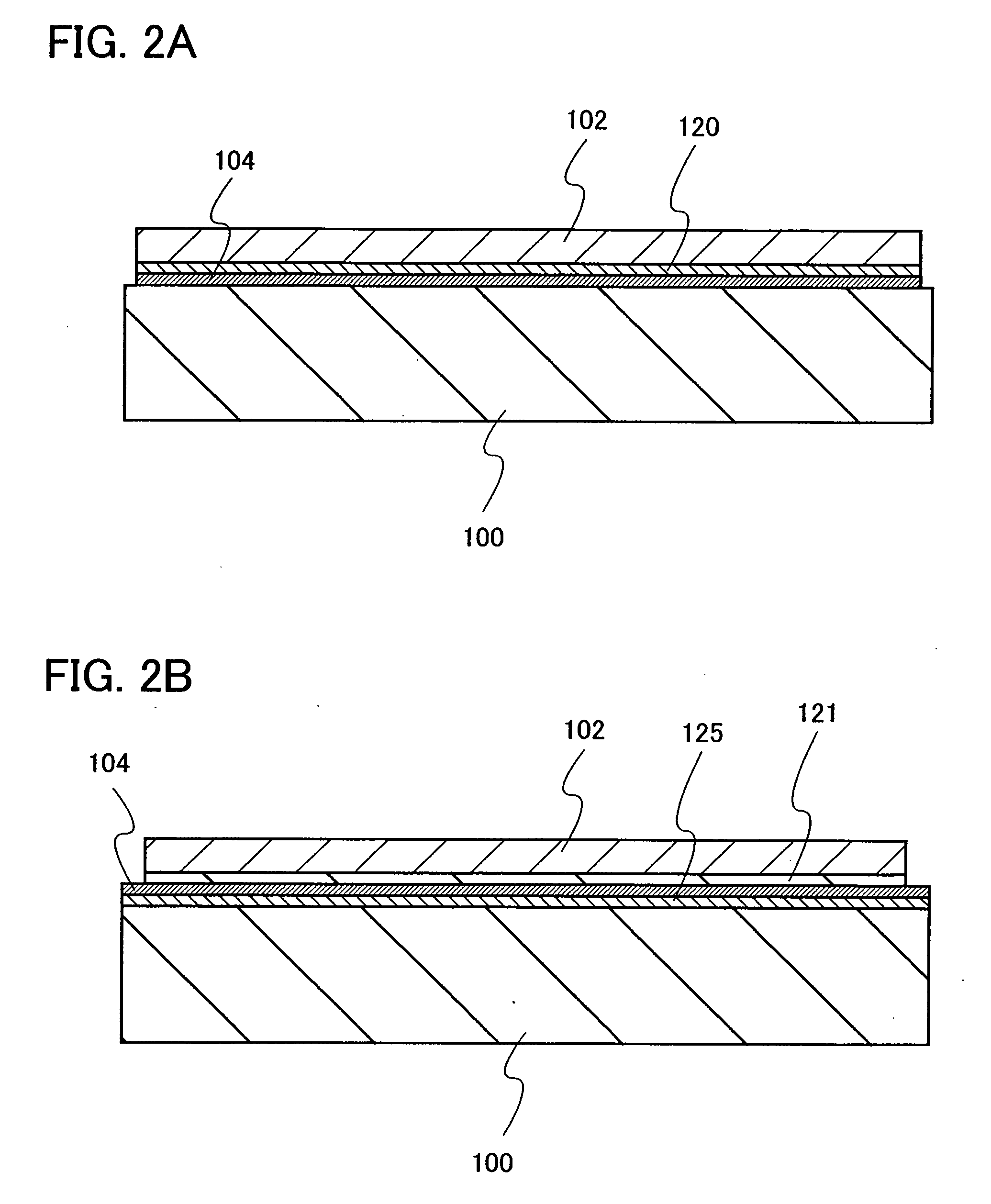

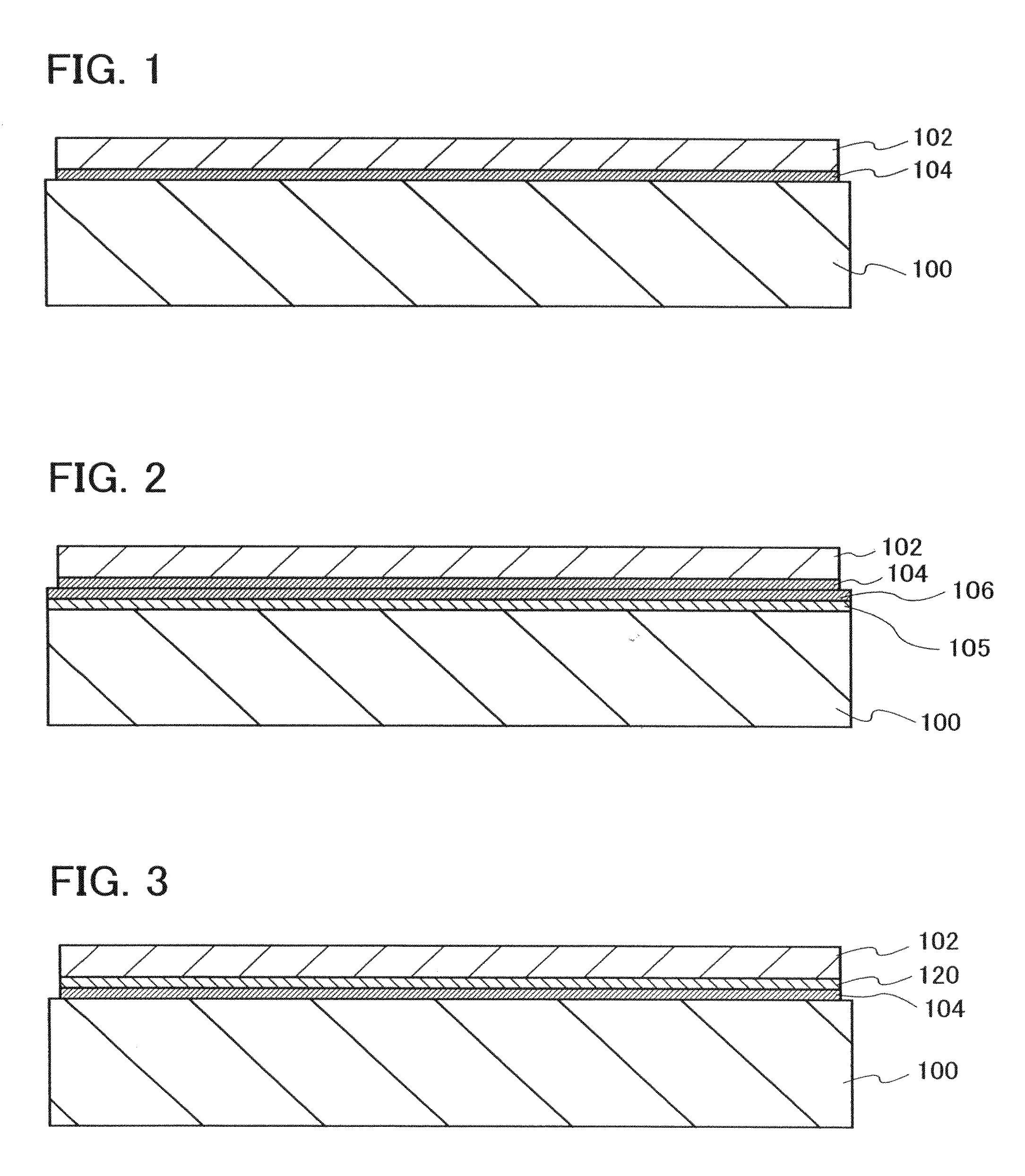

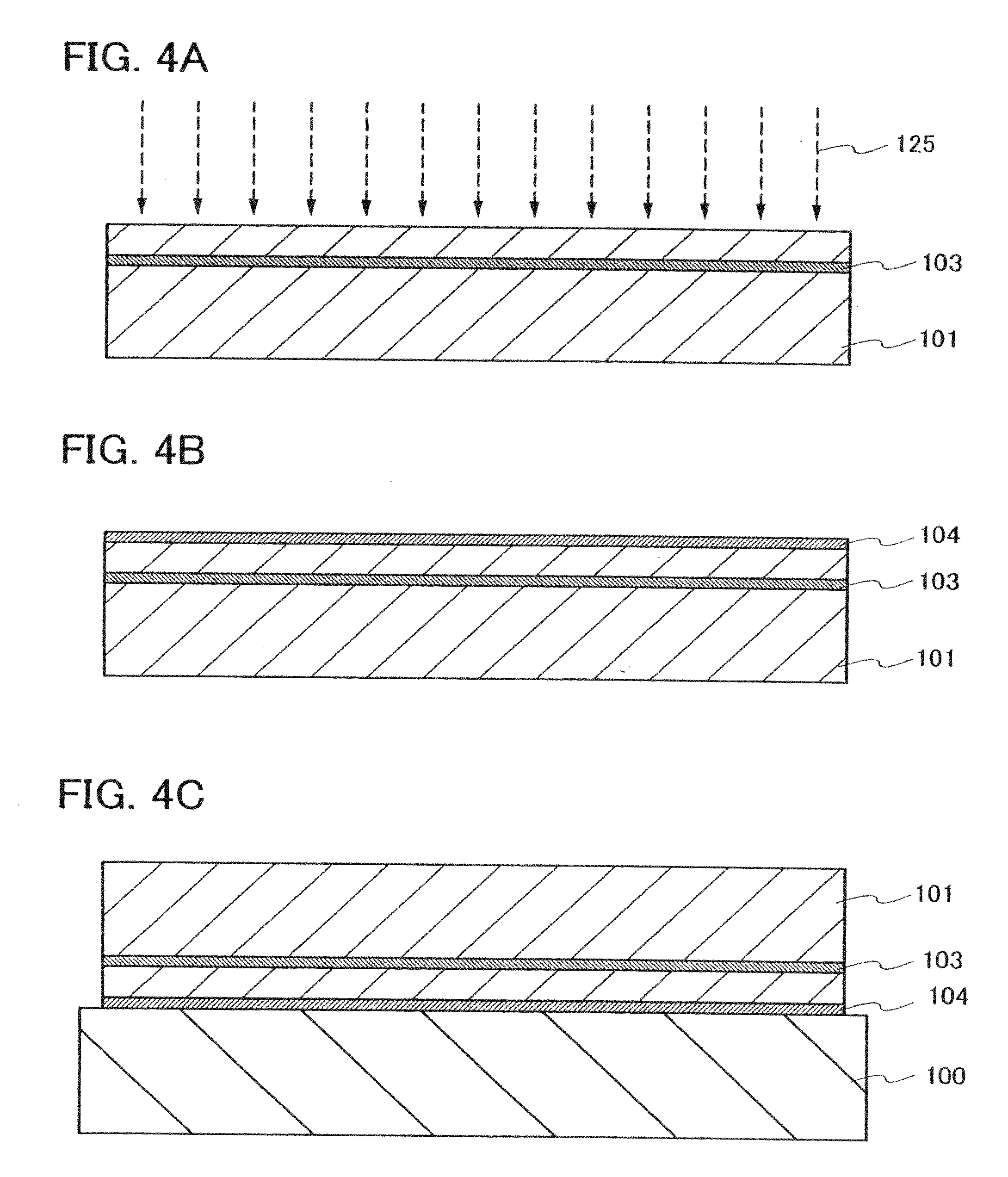

SOI substrate, method for manufacturing the same, and semiconductor device

InactiveUS20080246109A1Solid-state devicesSemiconductor/solid-state device manufacturingSilanesSilicon oxide

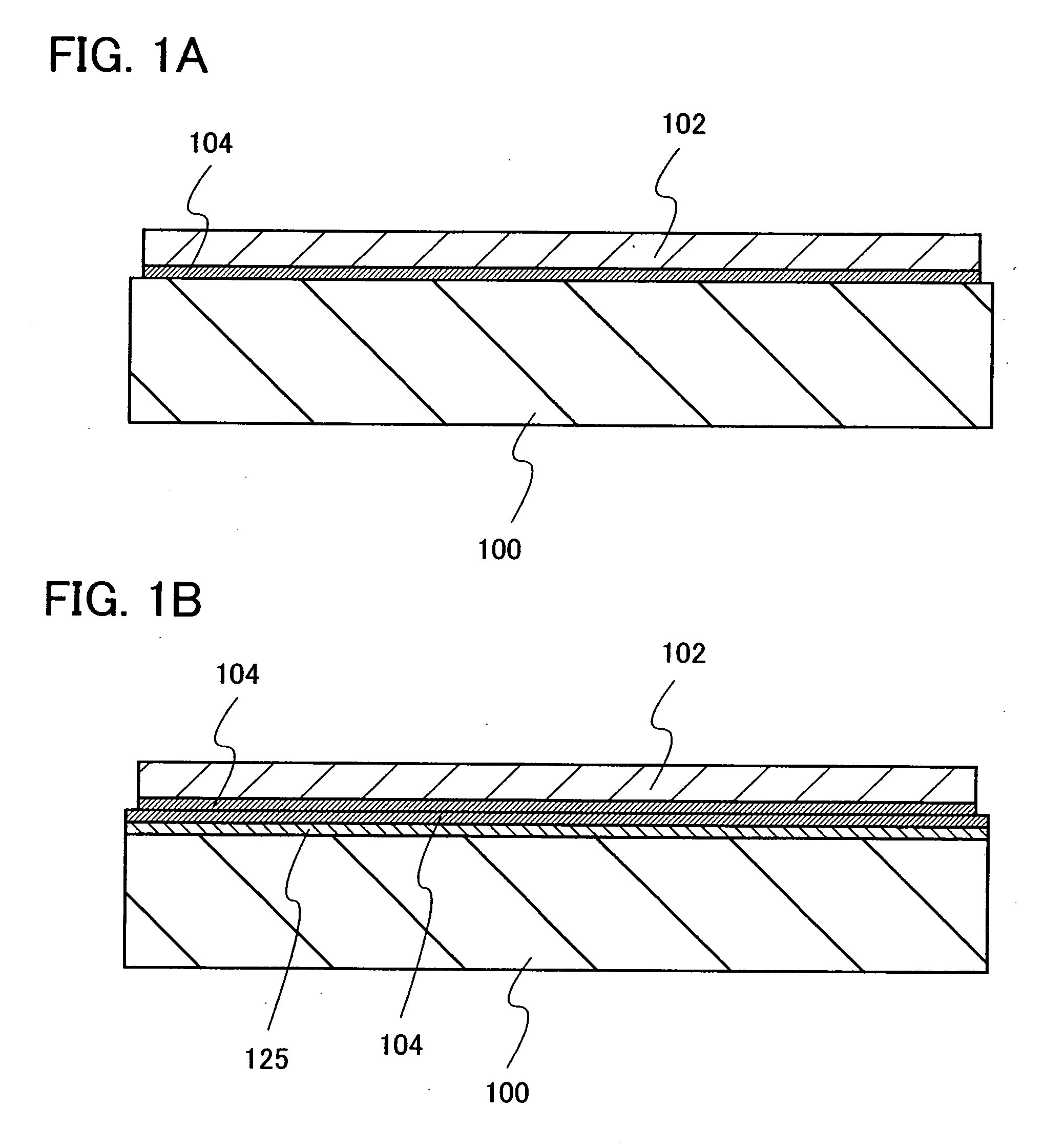

An SOI substrate having an SOI layer that can be used in practical applications even when a substrate with low upper temperature limit, such as a glass substrate, is used, is provided. A semiconductor device using such an SOI substrate, is provided. In bonding a single-crystal semiconductor layer to a substrate having an insulating surface or an insulating substrate, a silicon oxide film formed using organic silane as a material on one or both surfaces that are to form a bond is used. According to the present invention, a substrate with an upper temperature limit of 700° C. or lower, such as a glass substrate, can be used, and an SOI layer that is strongly bonded to the substrate can be obtained. In other words, a single-crystal semiconductor layer can be formed over a large-area substrate that is longer than one meter on each side.

Owner:SEMICON ENERGY LAB CO LTD

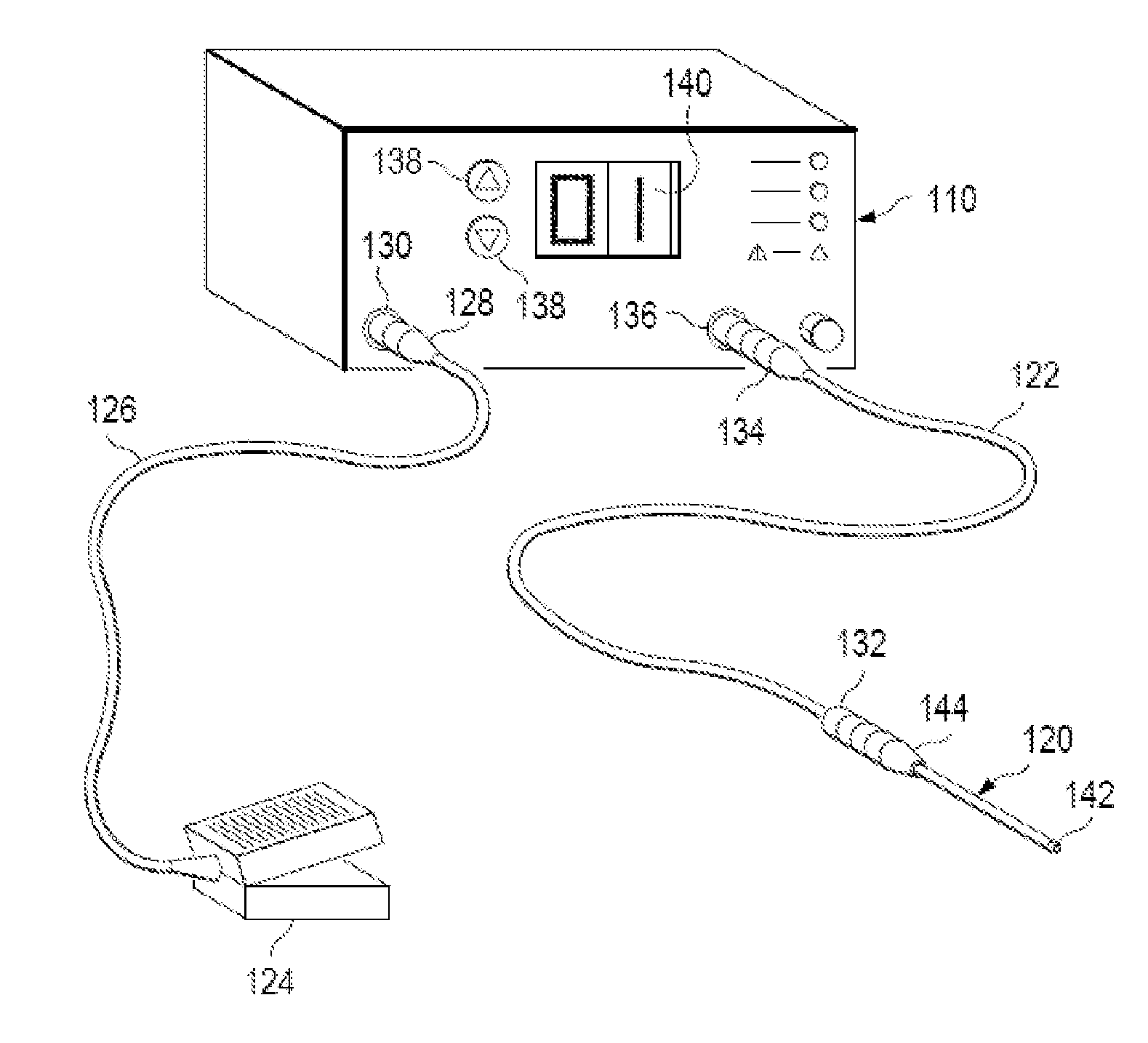

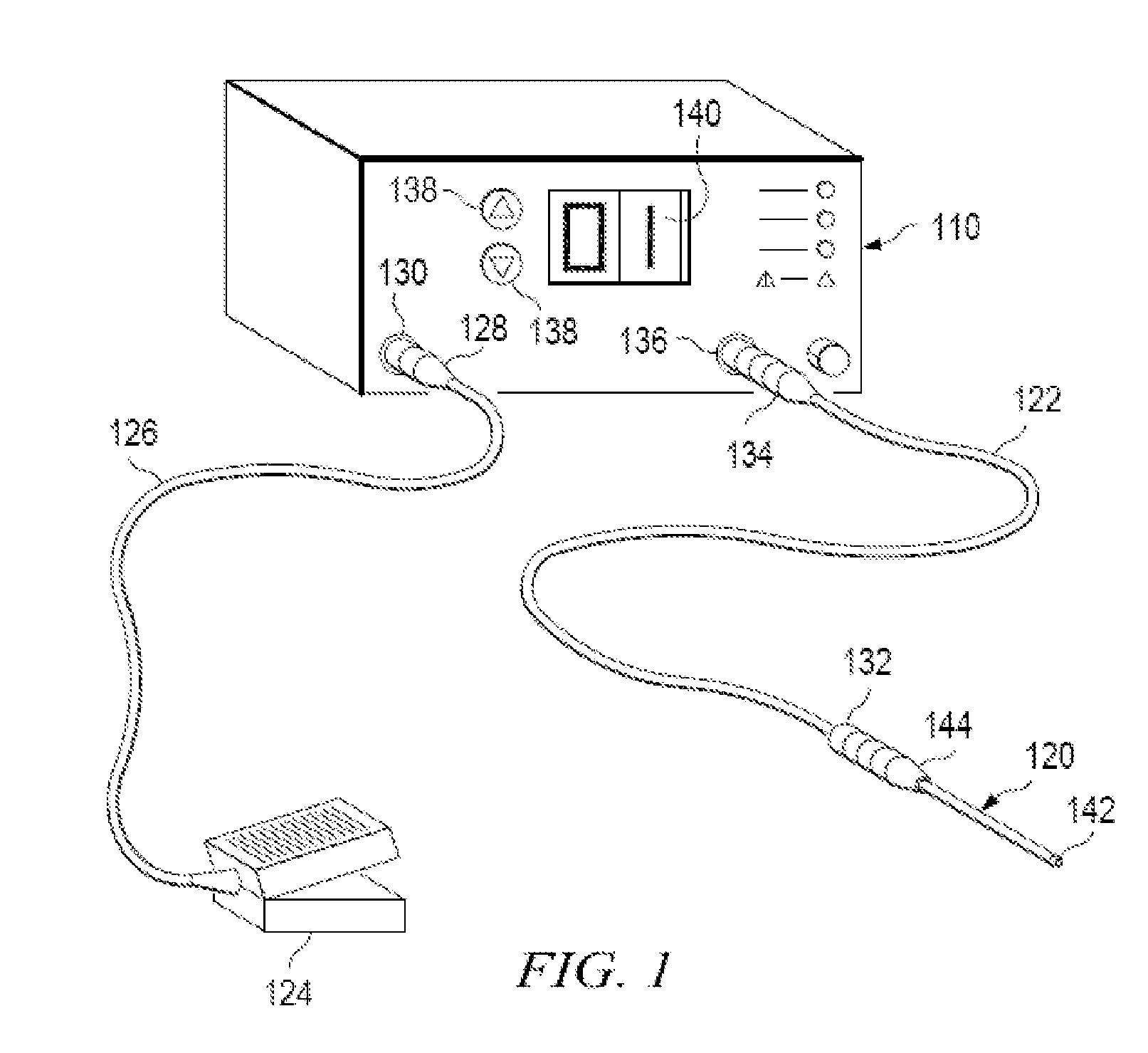

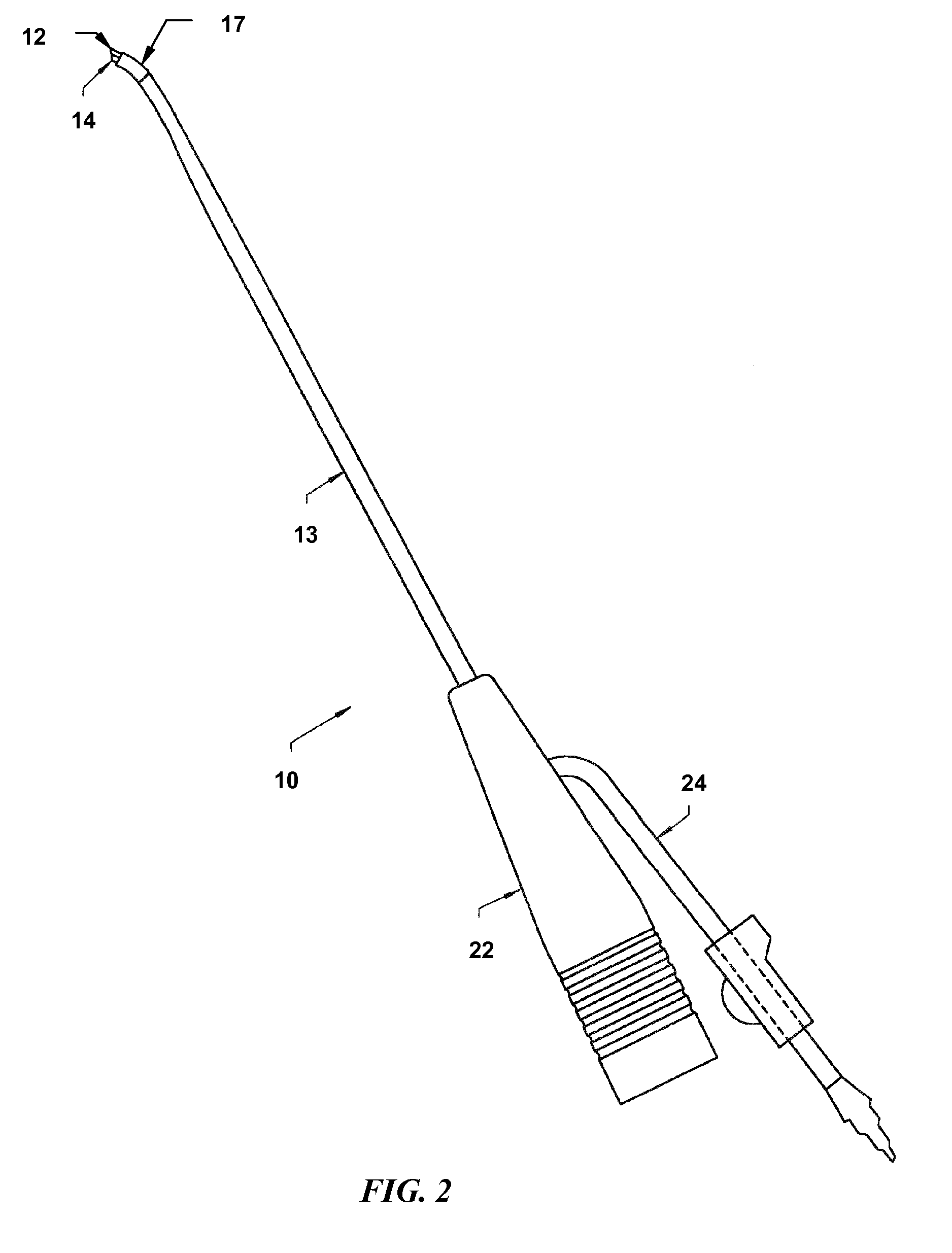

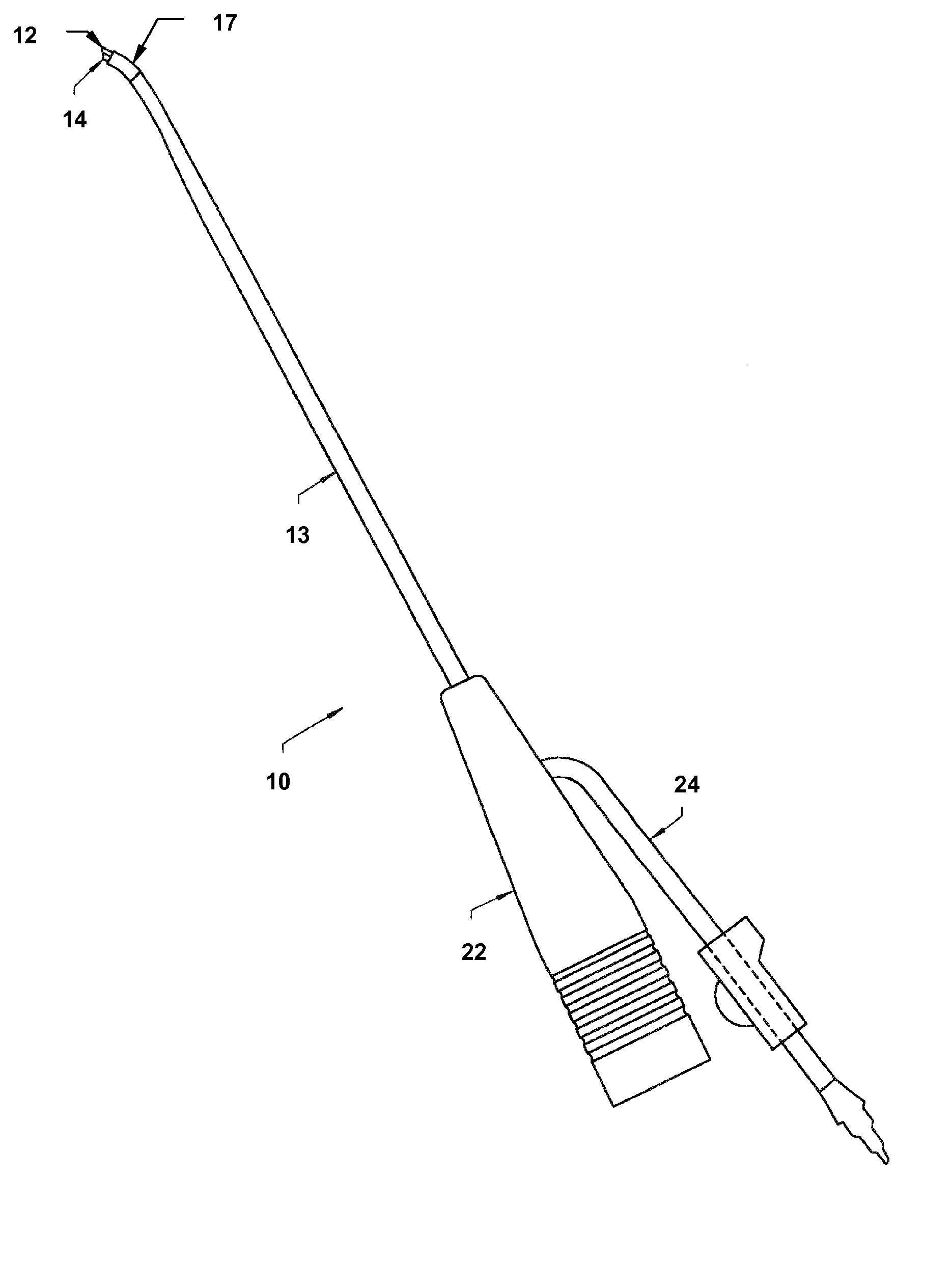

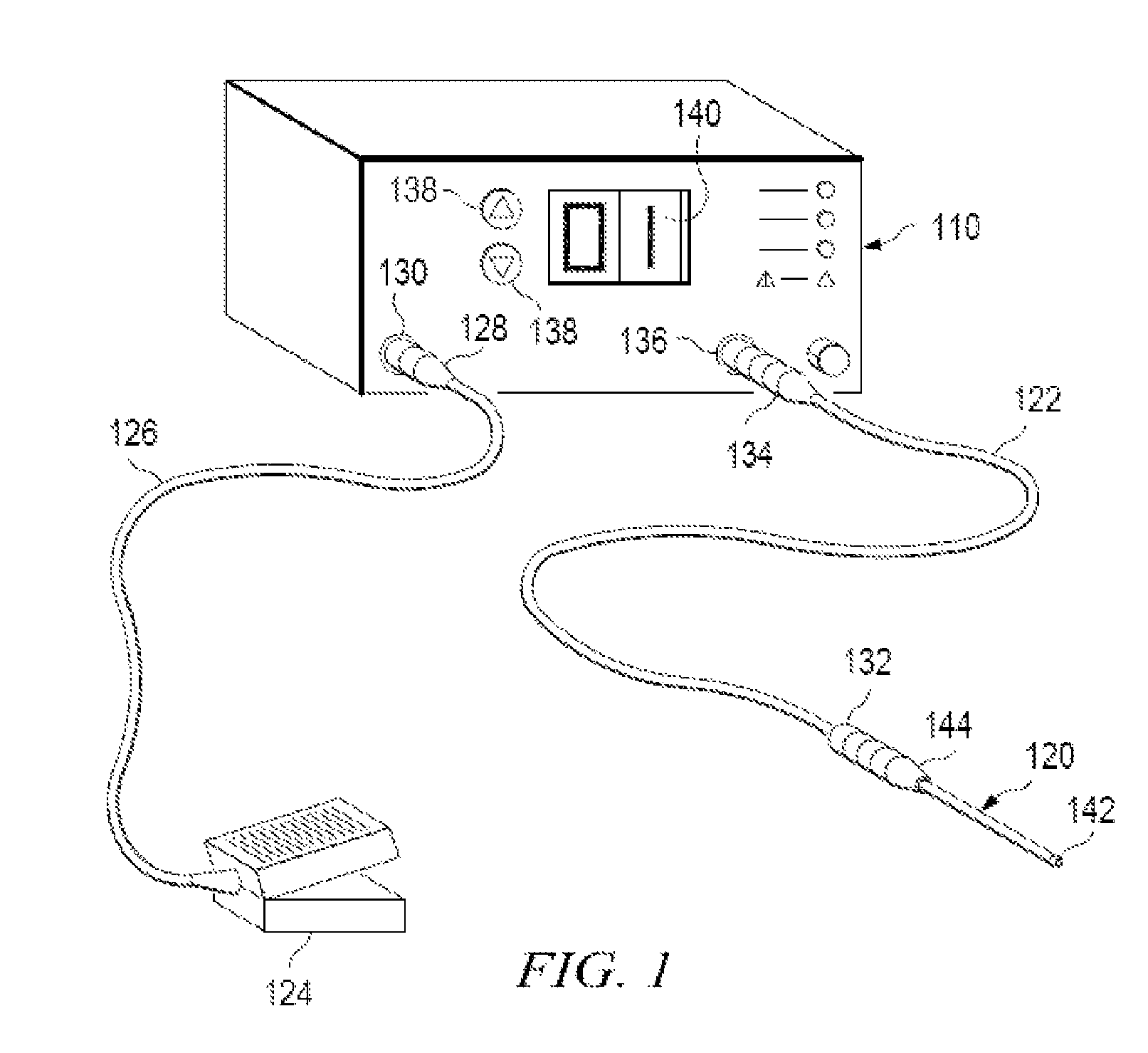

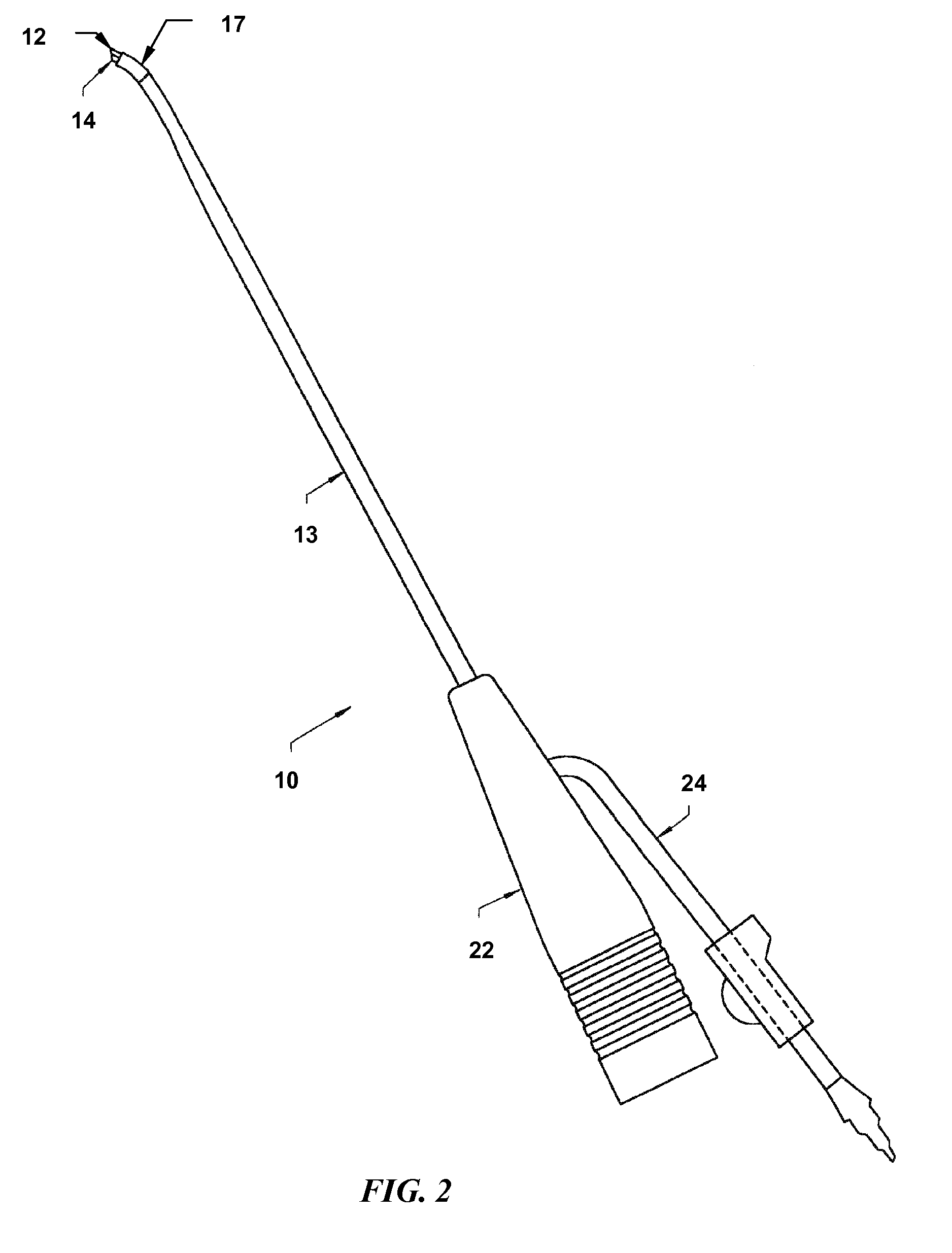

Systems and methods for limiting joint temperature

ActiveUS20100152724A1Reduce the risk of injuryReduce and eliminate temperature influenceDiagnostic recording/measuringSensorsTarsal JointFluid temperature

Joint temperature monitoring and control systems and methods are described herein in which the temperature of a fluid within a body or joint space is determined and / or monitored despite the energy generated during treatment by an ablation probe. One or more temperature sensors are positioned along the probe proximally of the electrode assembly and measure the temperature of an electrically conductive fluid without being overly influenced by the surgical effect occurring proximate the electrode assembly. The controller coupled to the probe can also be configured to set temperature limits and treatment times as well as moderating joint temperature by altering the electrically conductive fluid flow.

Owner:ARTHROCARE

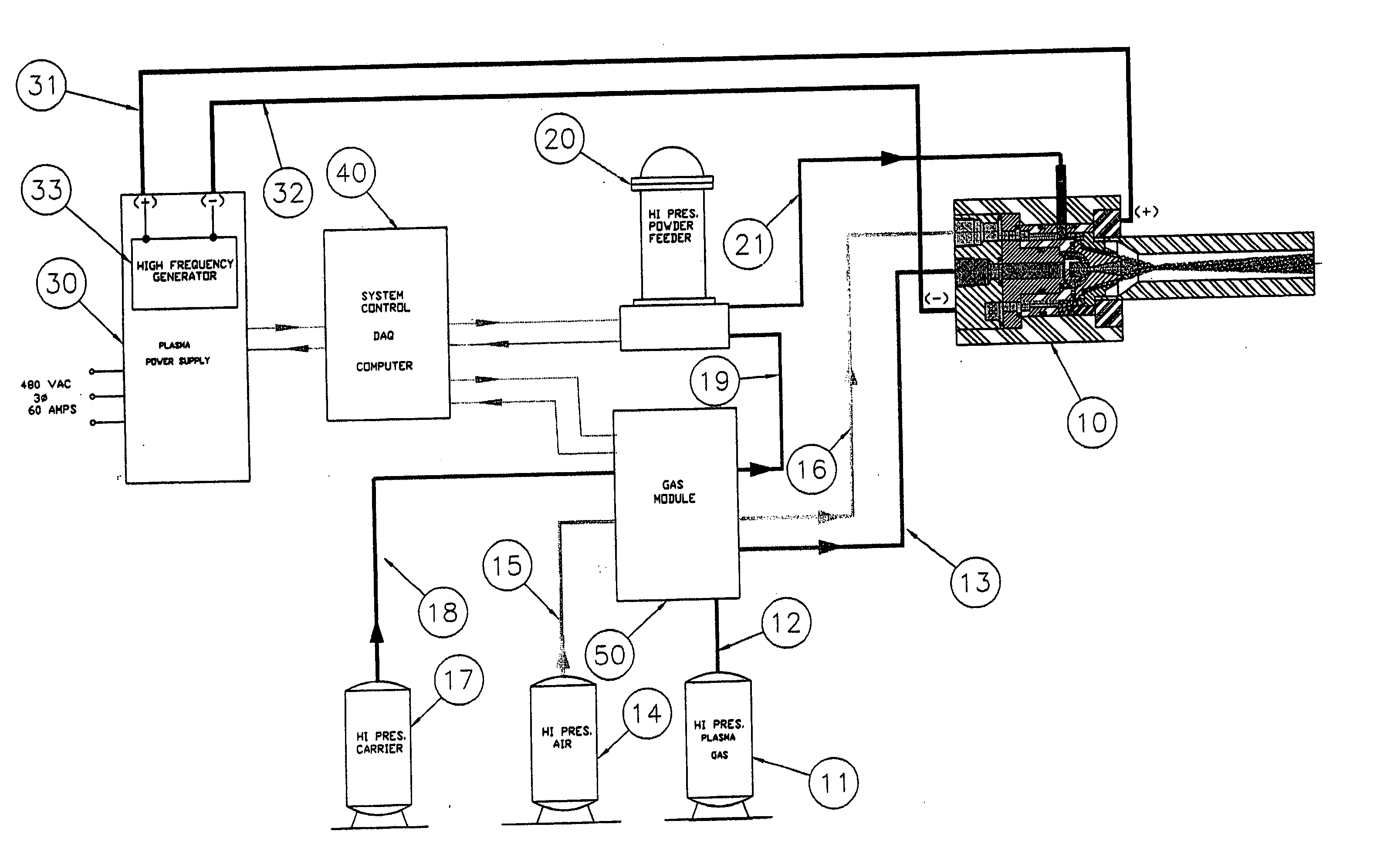

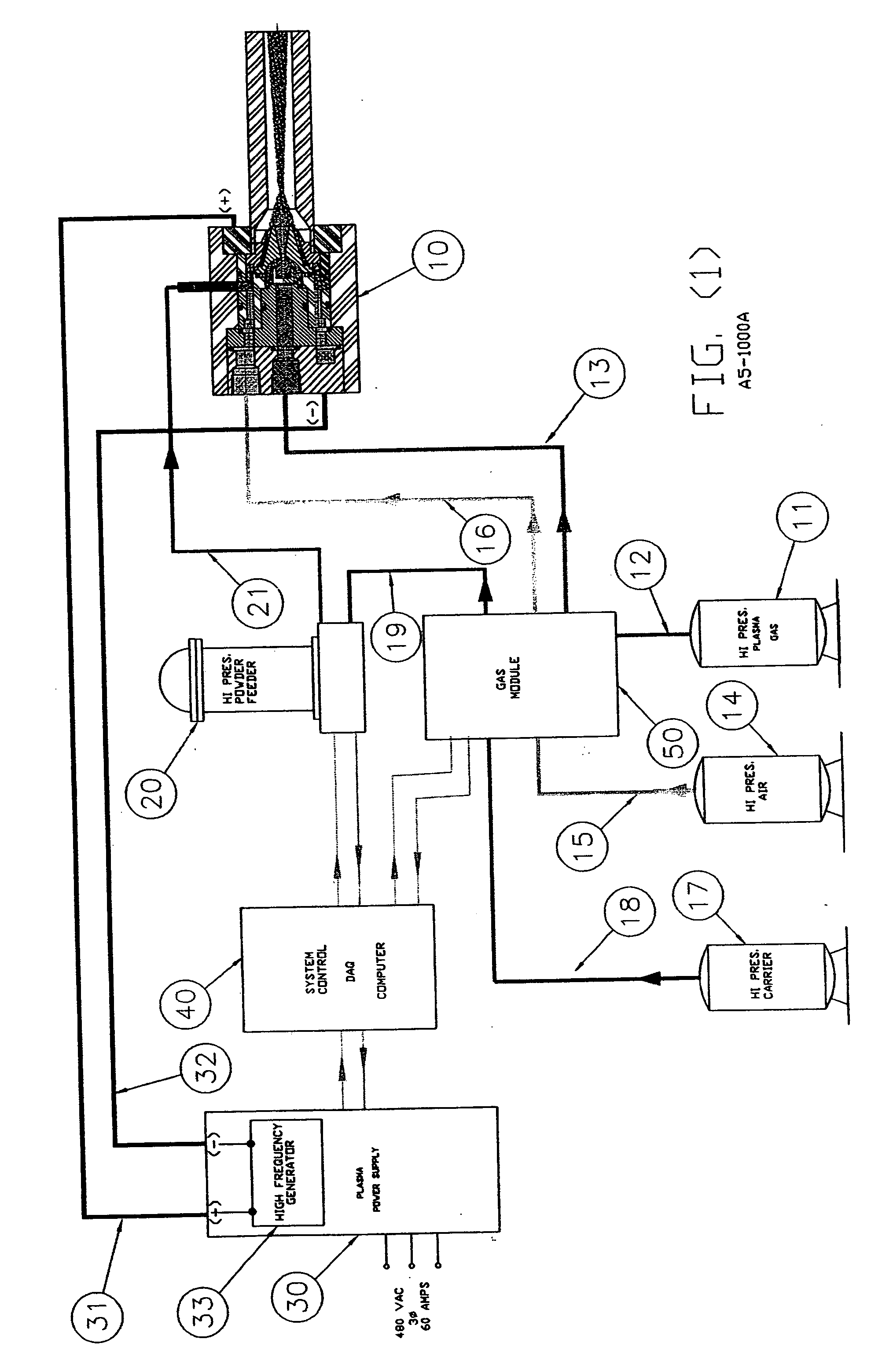

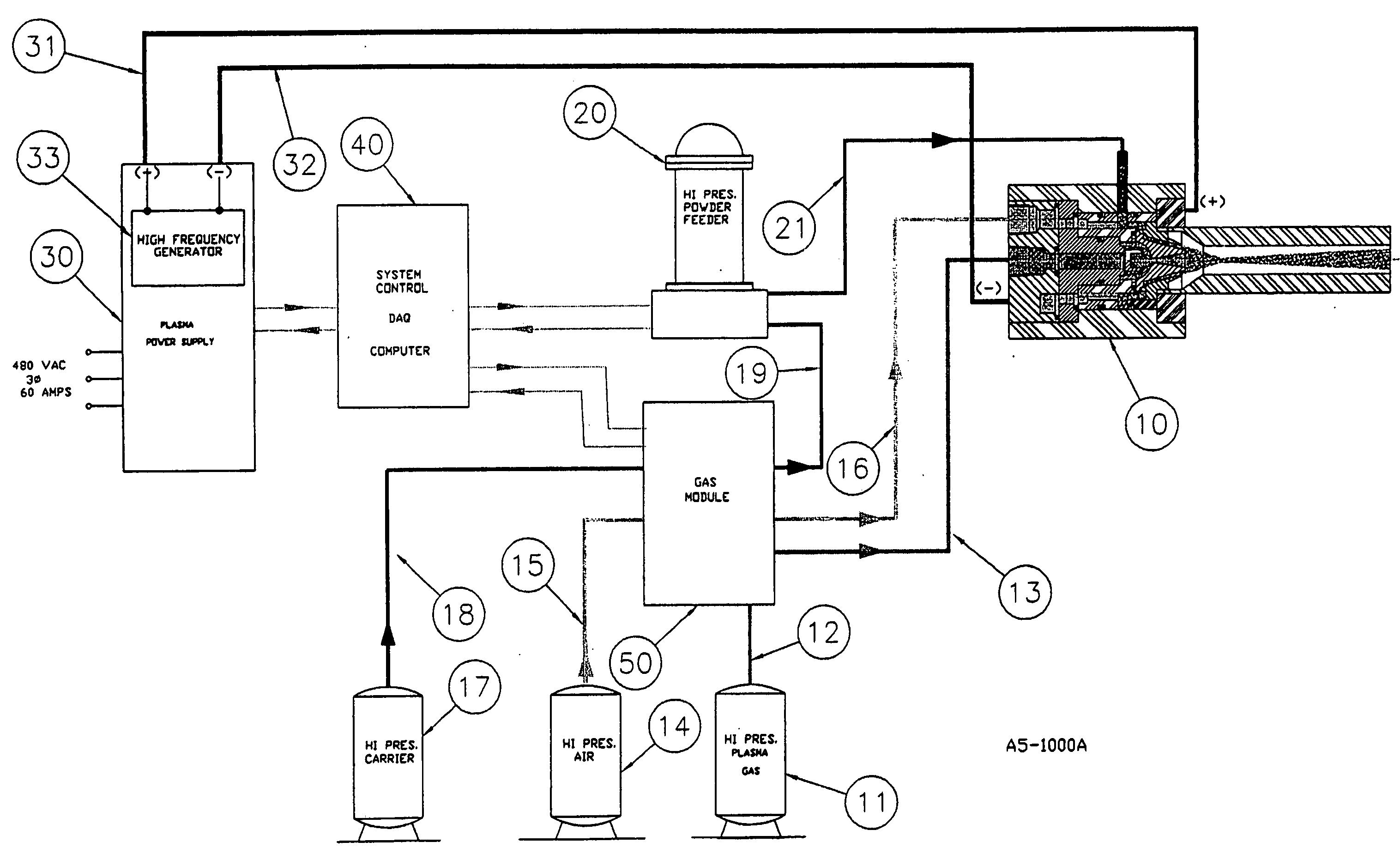

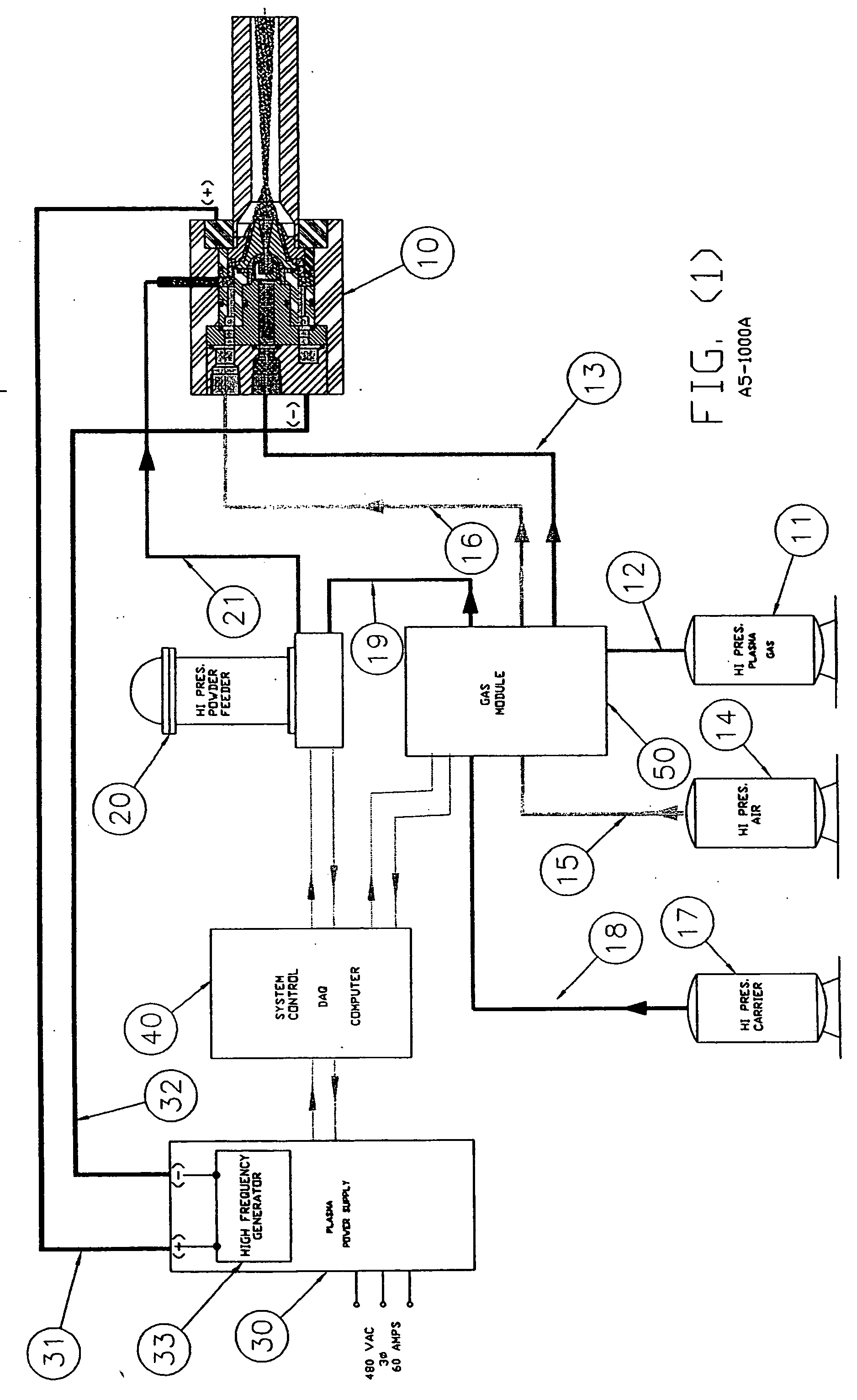

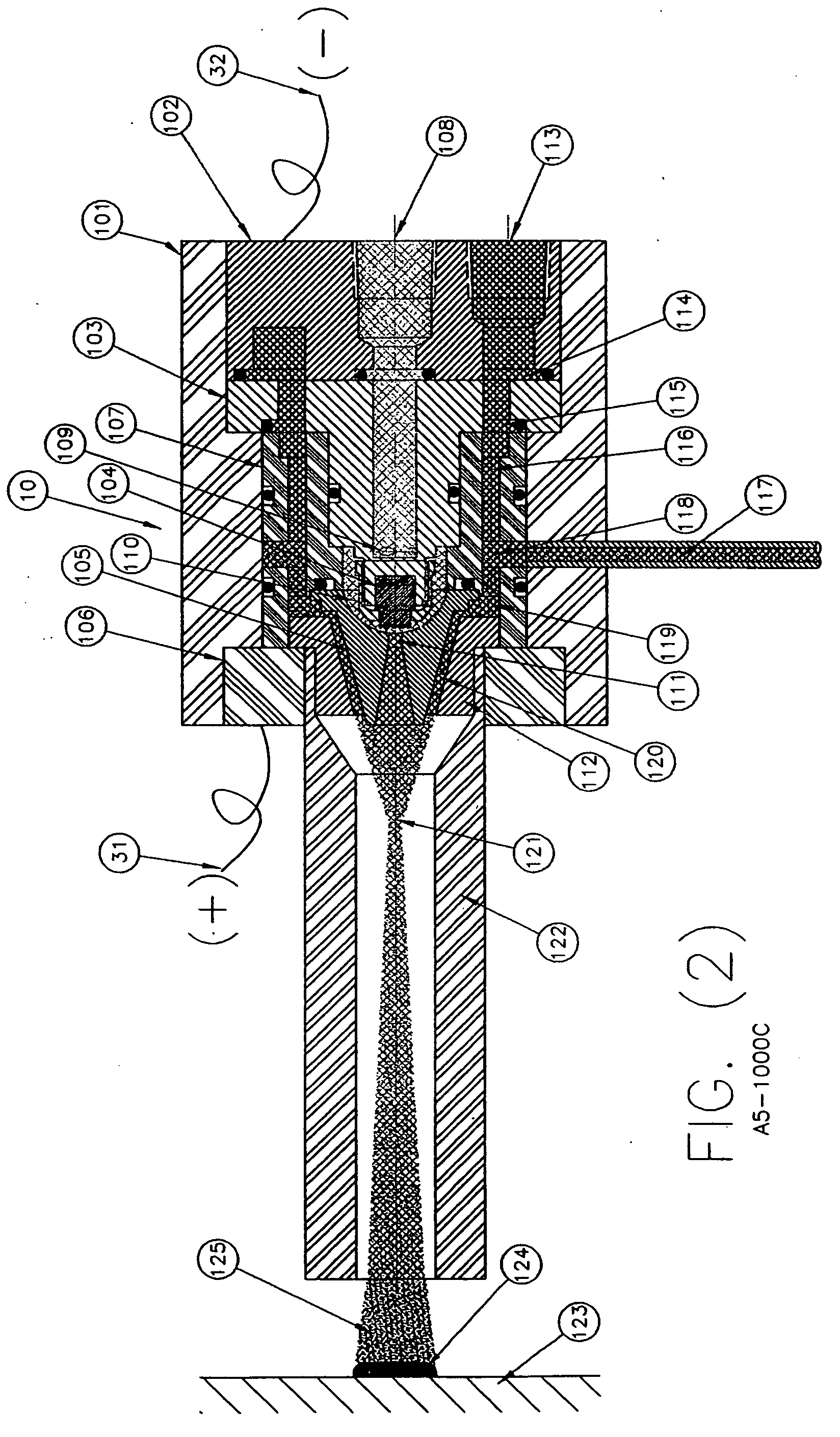

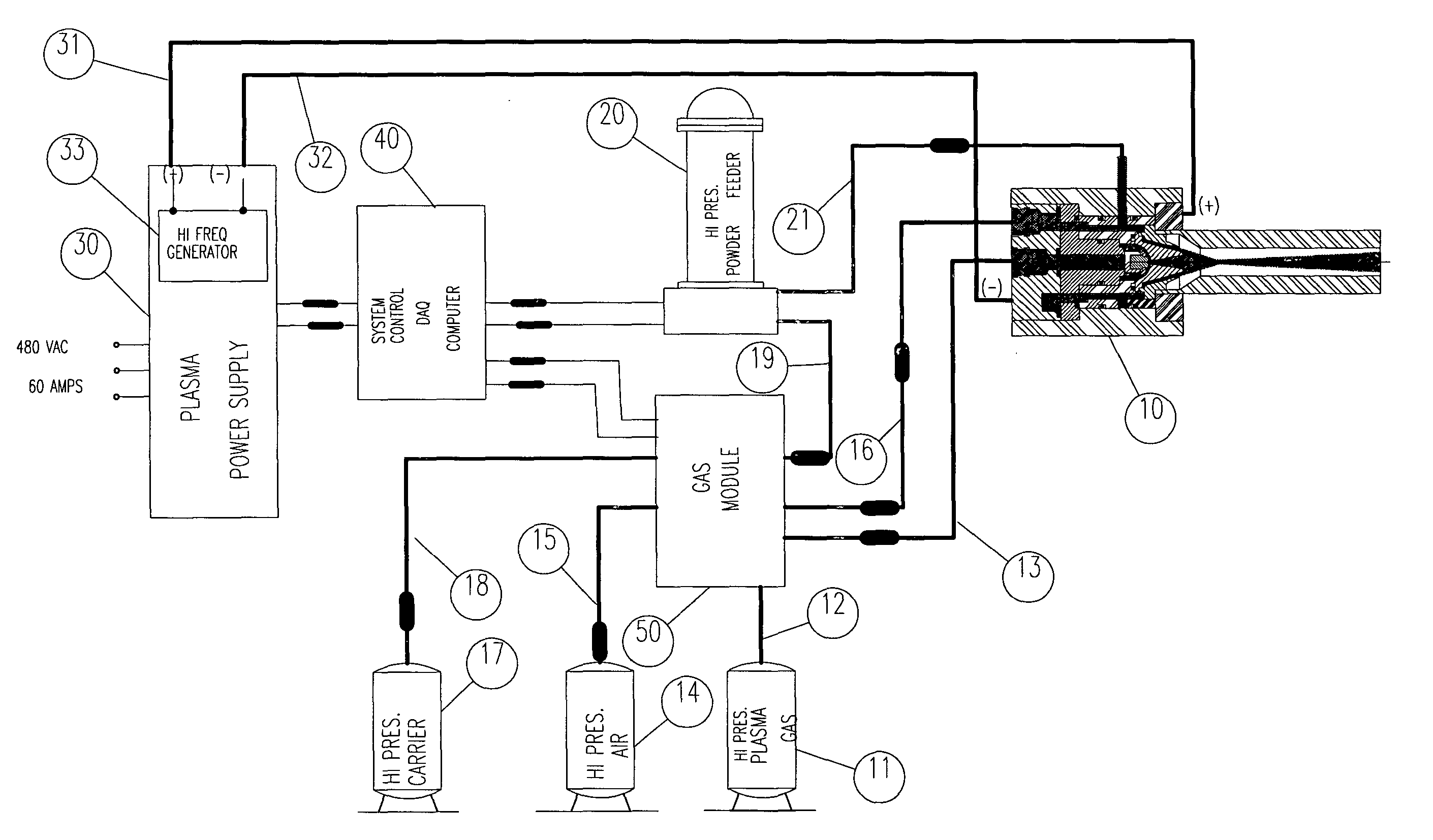

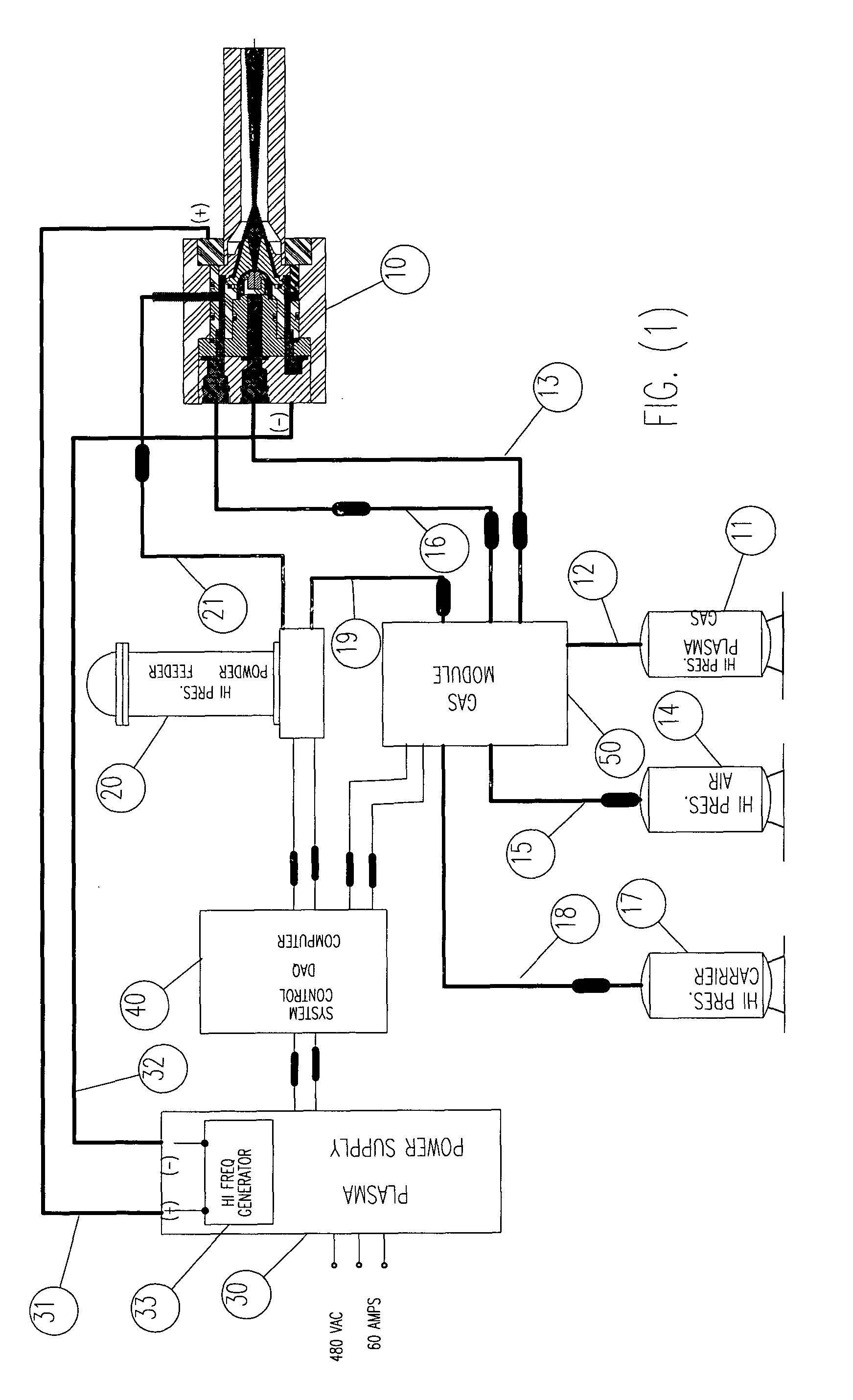

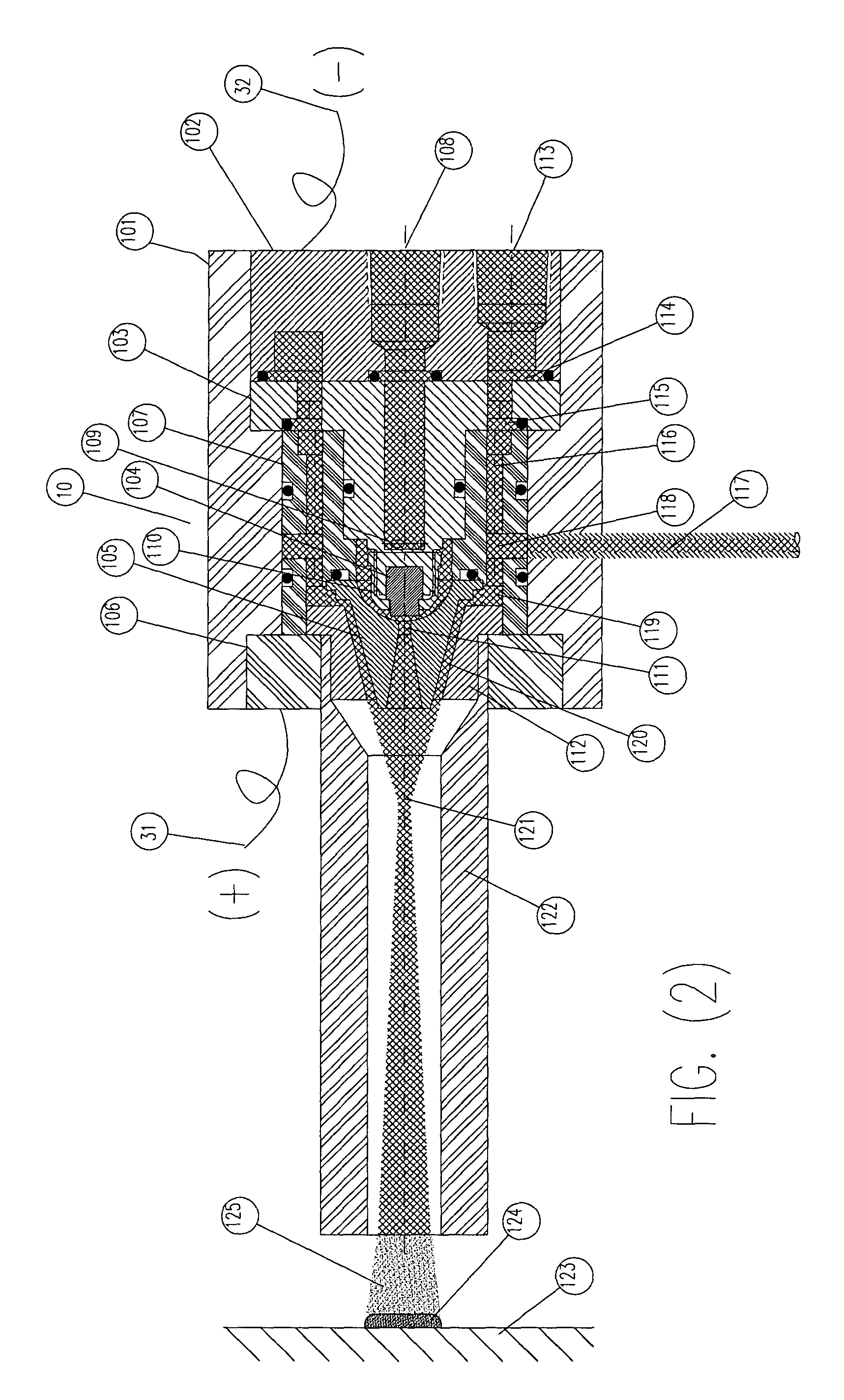

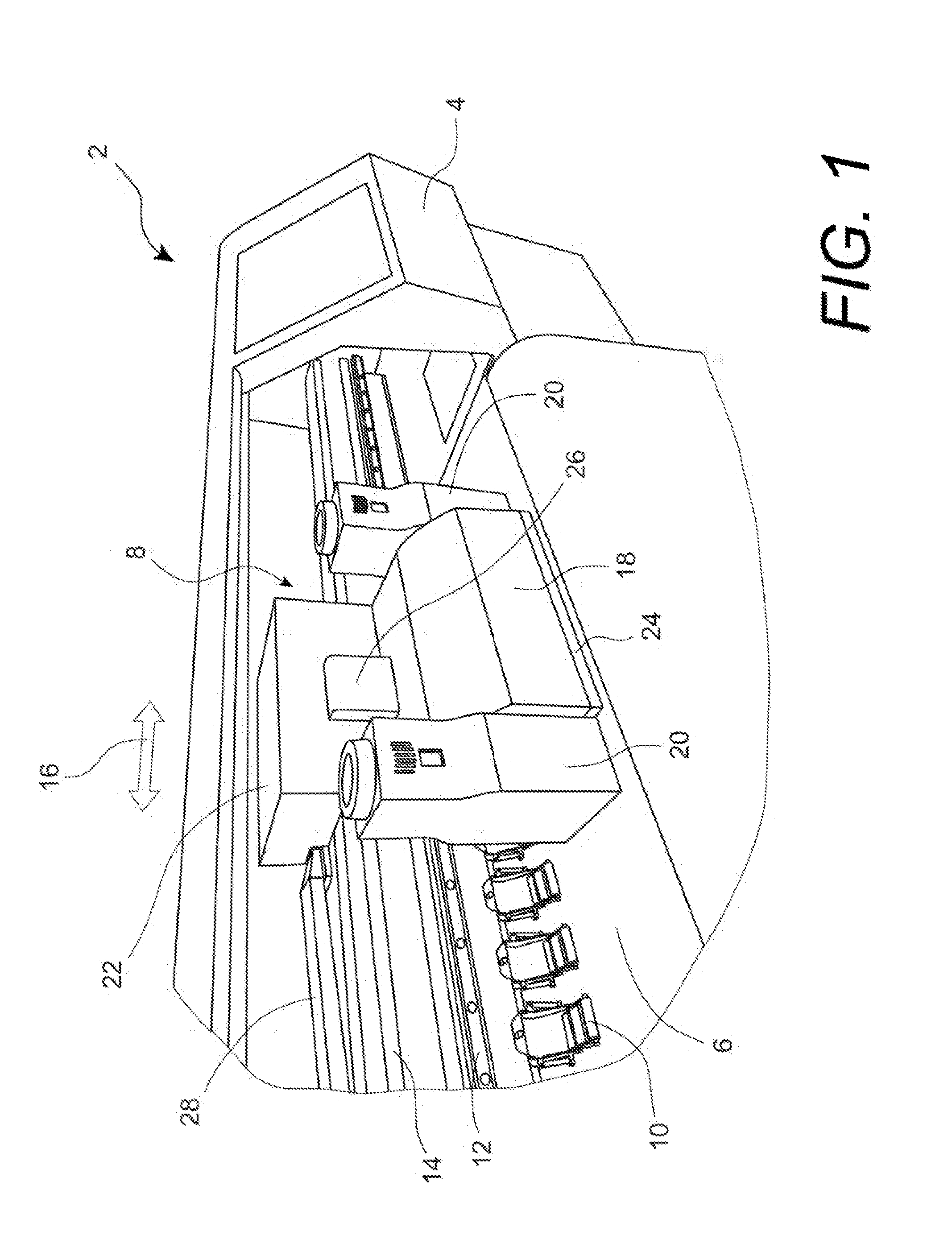

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050120957A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns.

Owner:FLAME SPRAY IND

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050252450A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns. The system also includes a rotating member for coating concave surfaces and internal bores or other such devices which can be better coated using rotation.

Owner:FLAME SPRAY IND

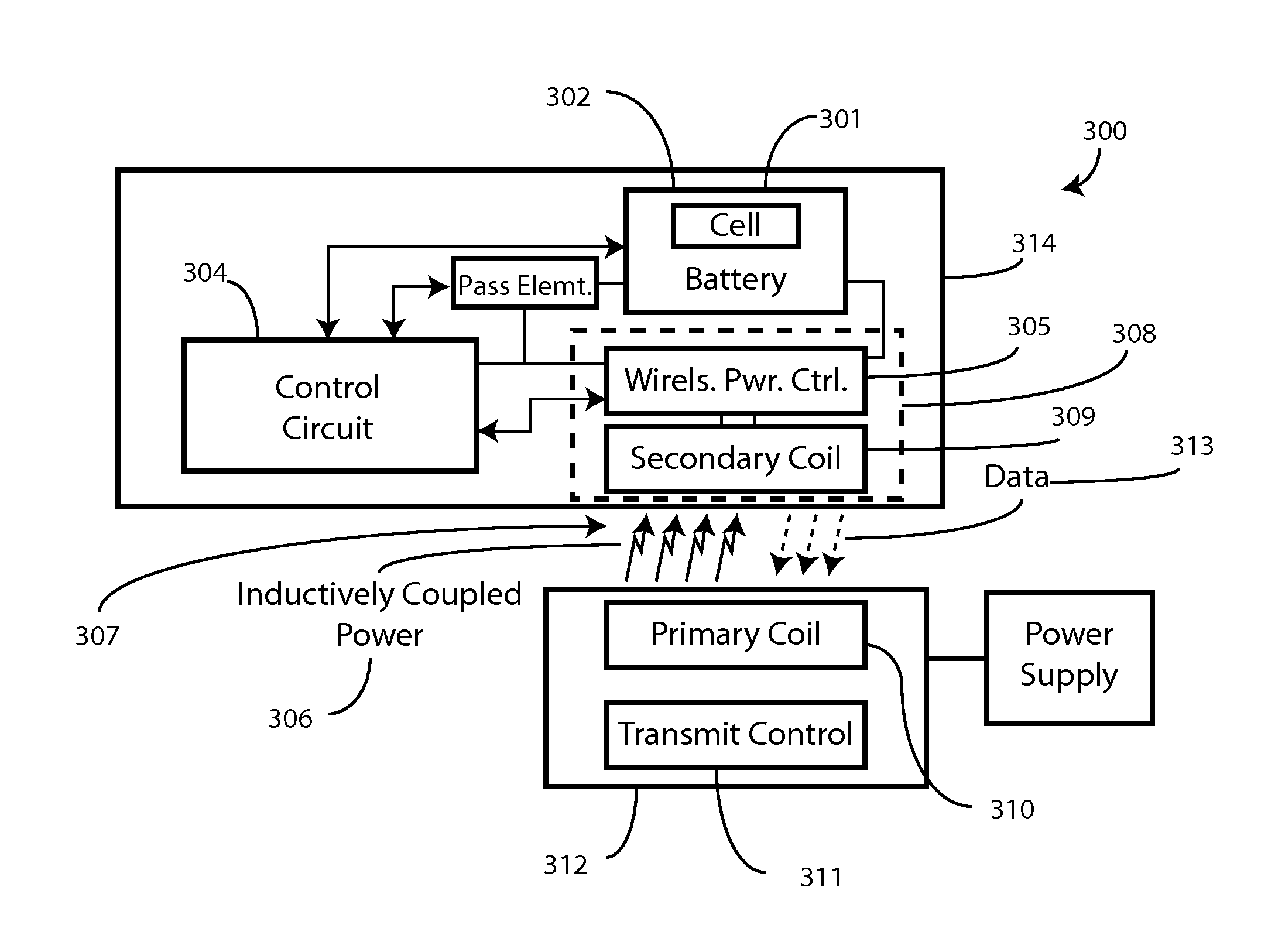

Methods and systems for rapid wireless charging

A system (300) and method (400) for wireless charging are provided. A control circuit (304) charges one or more cells (301) in a secondary wireless charging circuit (308) that receives power wirelessly from a primary (312). The control circuit determines the state of charge and temperature of the cells. The control circuit then calculates a current limit as a function of a combination of the state of charge, input voltage to the control circuit for the wireless controller, FET power dissipation and the temperature and adjusts a wireless power control device (305) in the secondary such that its current limit is set to the state of charge current limit. Different temperature limits can be used for different states of charge such that the cells can be charged at higher temperatures at low states of charge than at higher states of charge.

Owner:GOOGLE TECH HLDG LLC

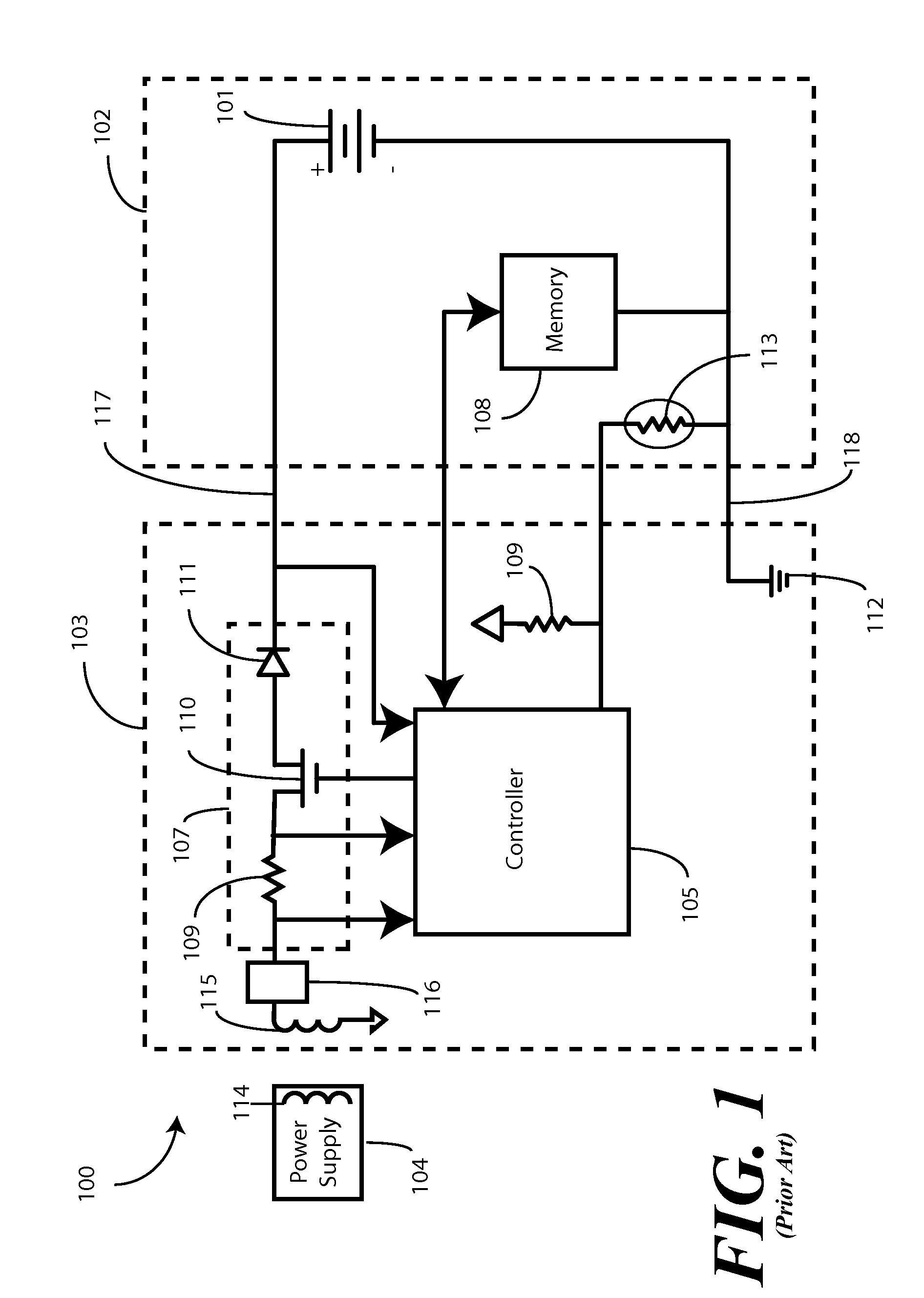

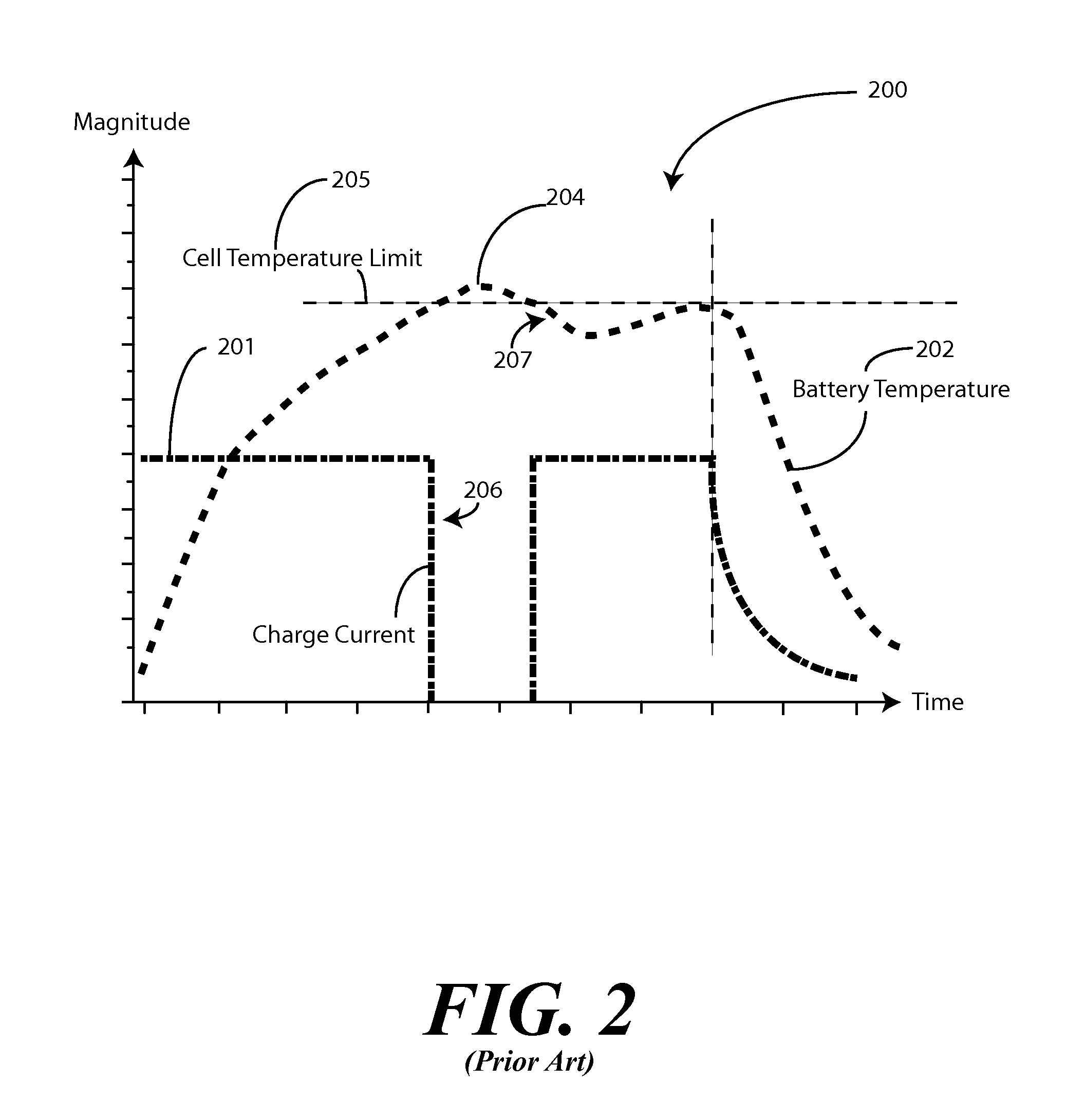

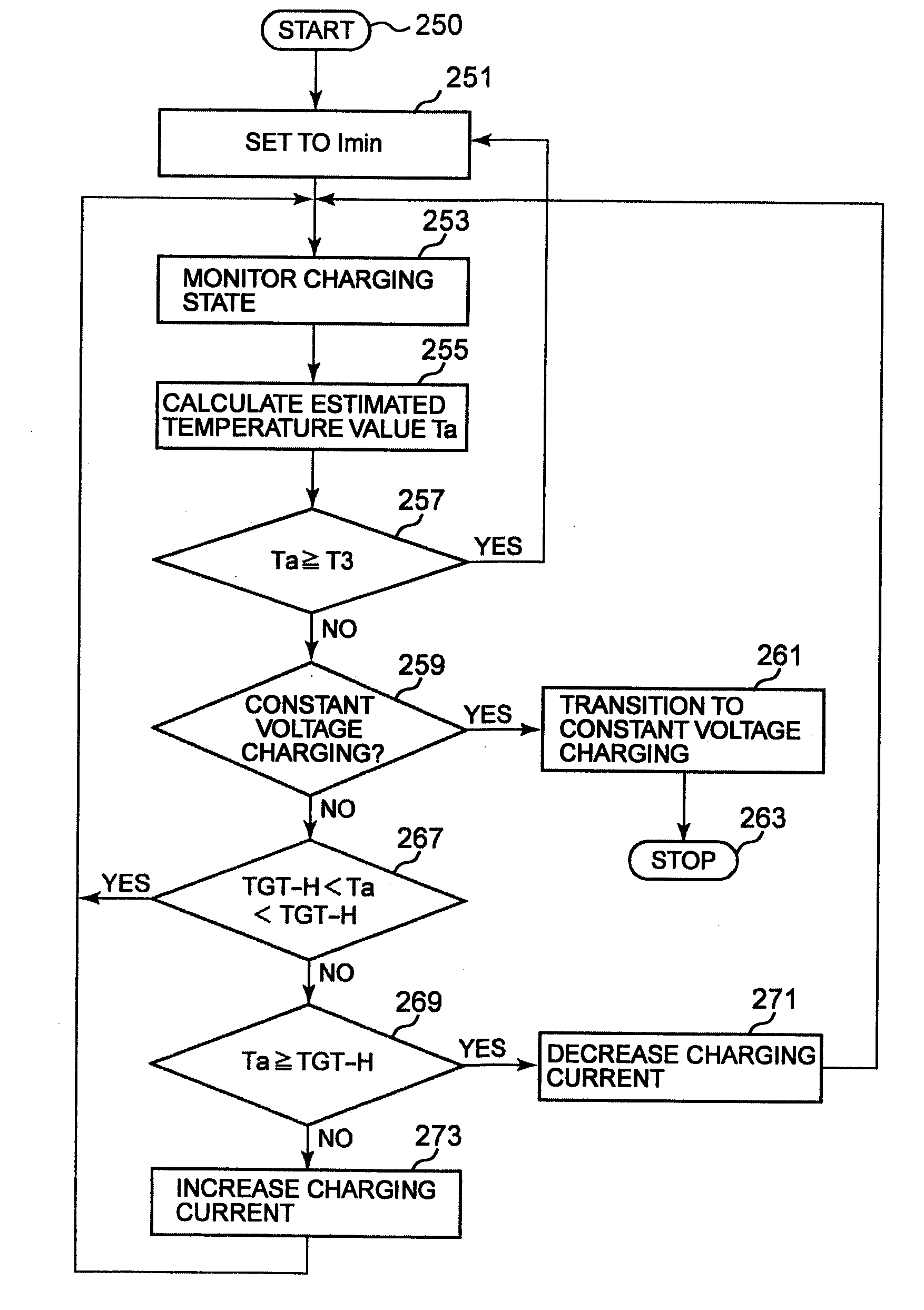

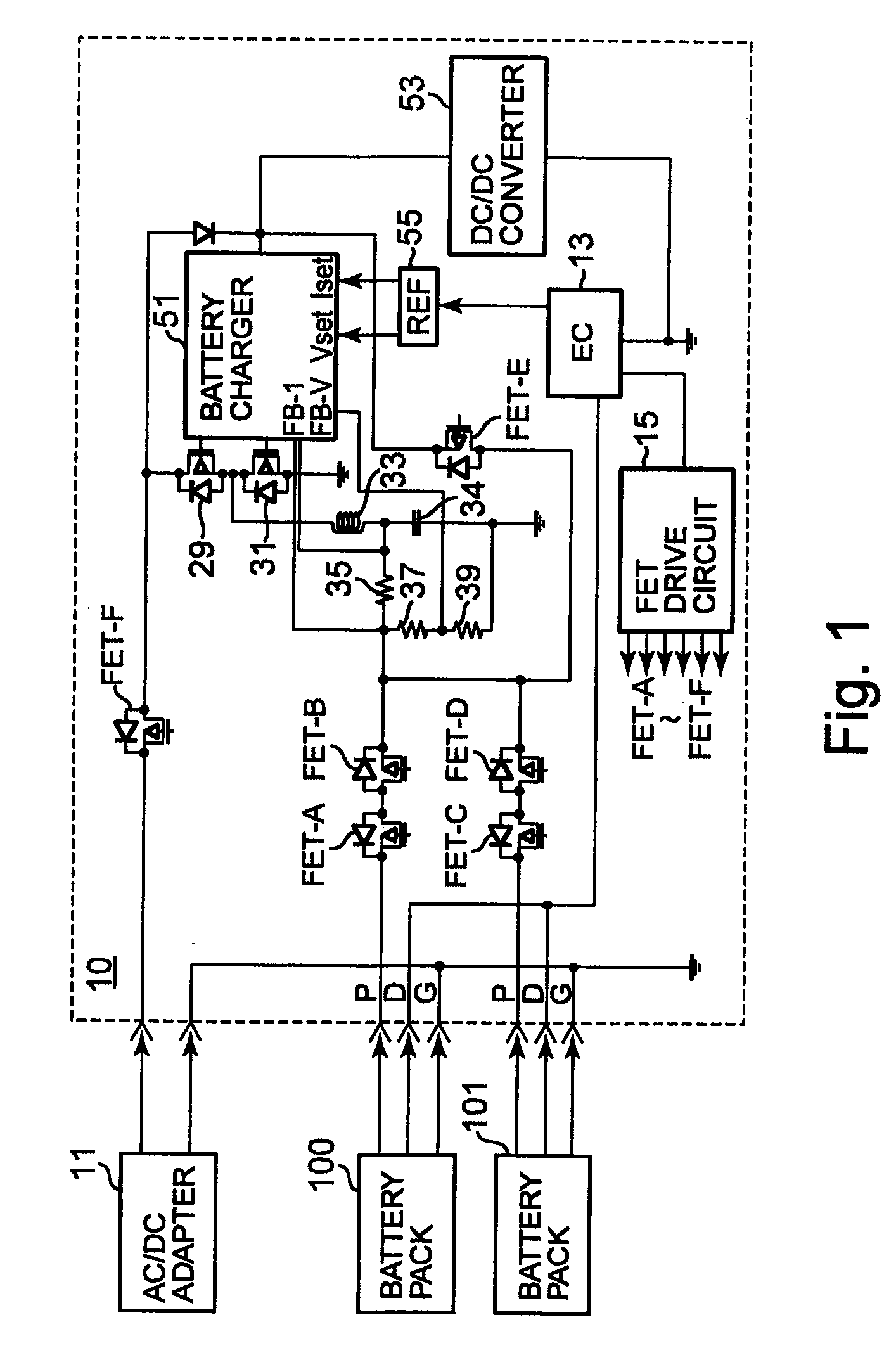

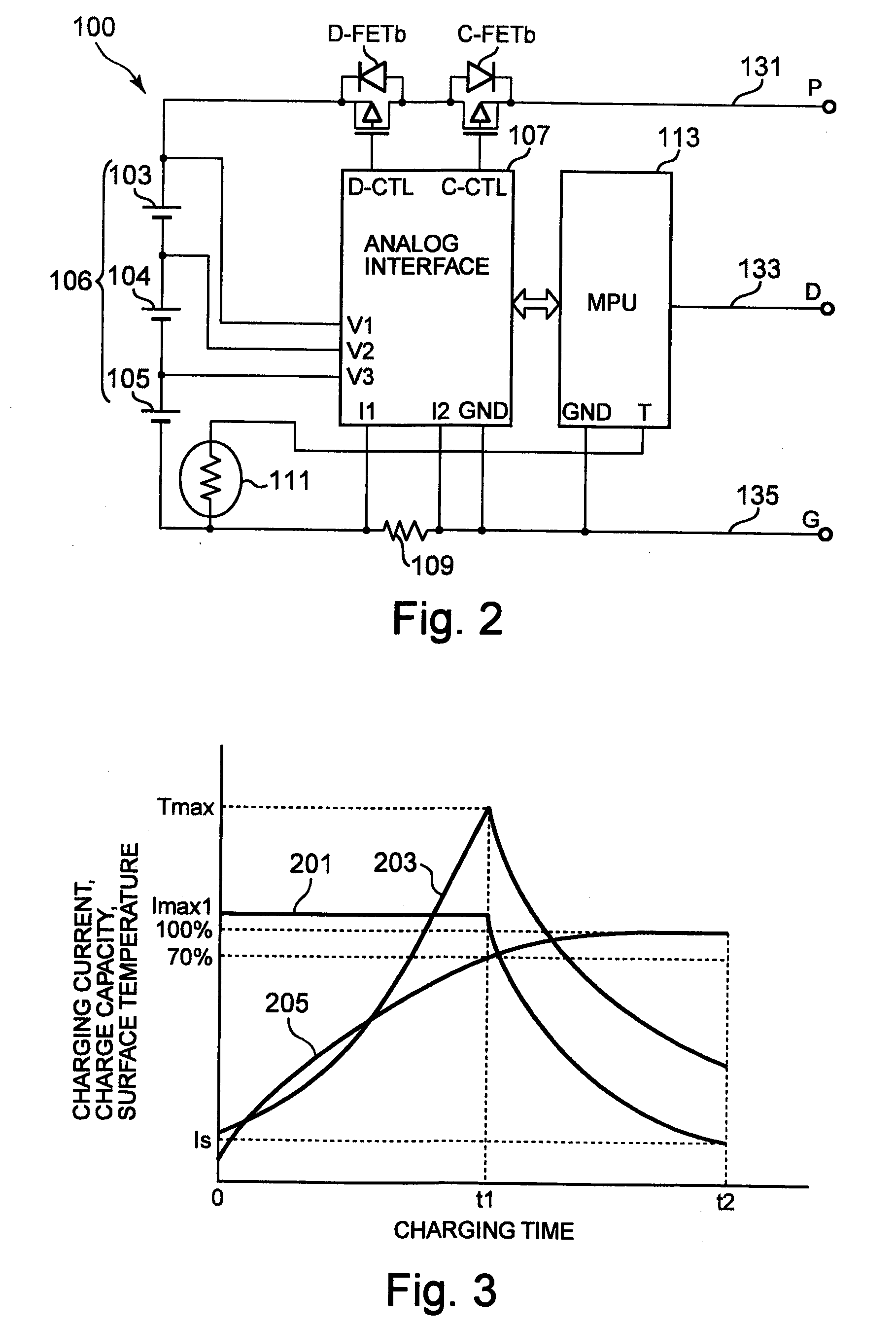

Surface temperature dependent battery cell charging system

ActiveUS20090085527A1Prevent surface temperatureBatteries circuit arrangementsElectric powerCharge currentBattery cell

A charging system capable of charging a battery cell so that the surface temperature of the battery cell does not exceed an upper temperature limit, is provided. A battery charger is configured in a manner such that a setting current is variable during charging. The battery charger starts charging of a secondary battery with a setting voltage set to a minimum charging current value. The surface temperature of the secondary battery is measured during charging. An estimated temperature value is calculated which is a surface temperature of the secondary battery, at which the secondary battery is charged up until a charging amount corresponding to the maximum surface temperature under assumption that the charging is performed with a present charging current value. The setting current is increased when the estimated temperature value is lower than the target temperature range and is reduced when the estimated temperature value is higher than the target temperature range. When the estimated temperature value belongs to the target temperature range, a present setting current is maintained.

Owner:LENOVO PC INT

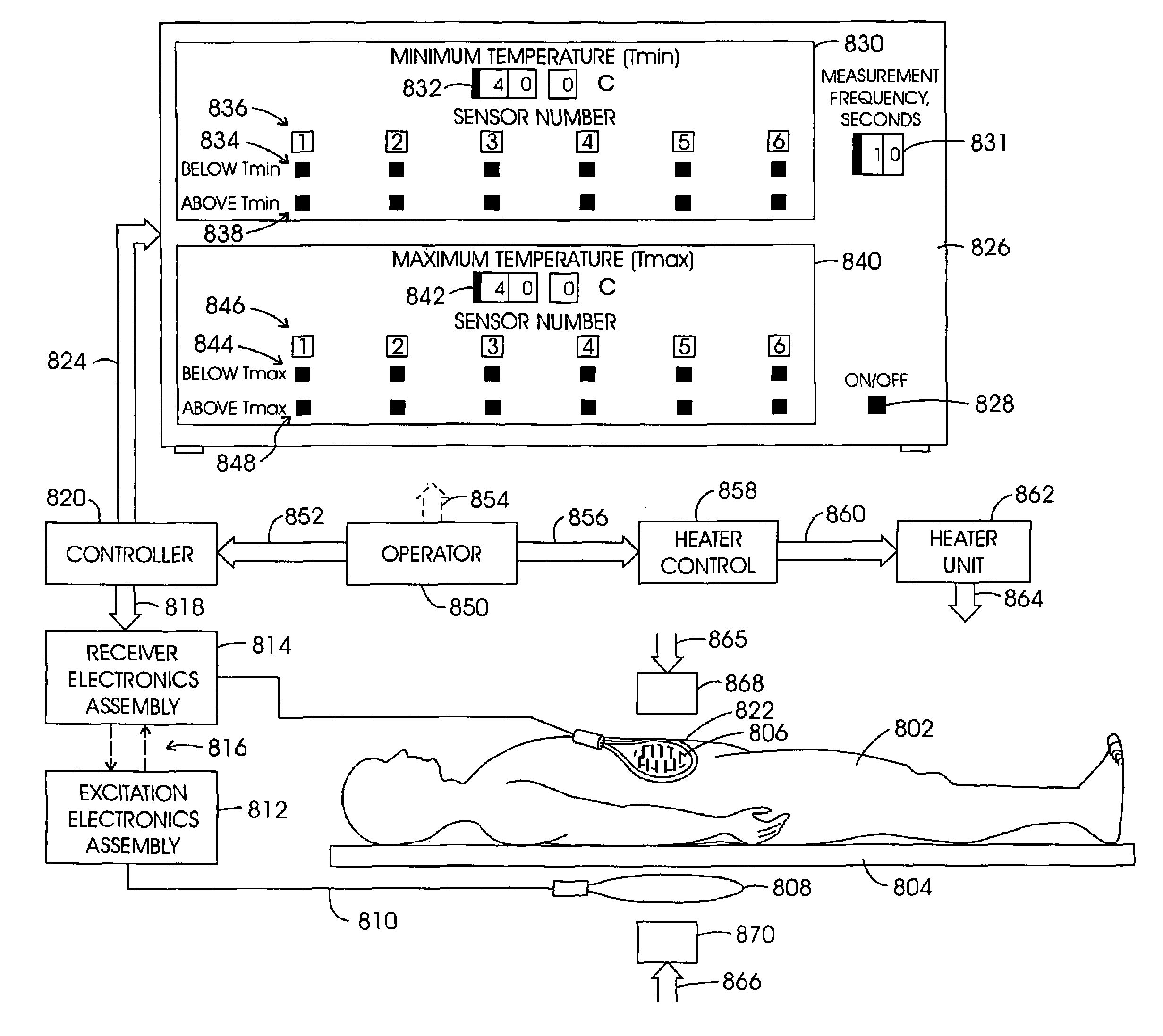

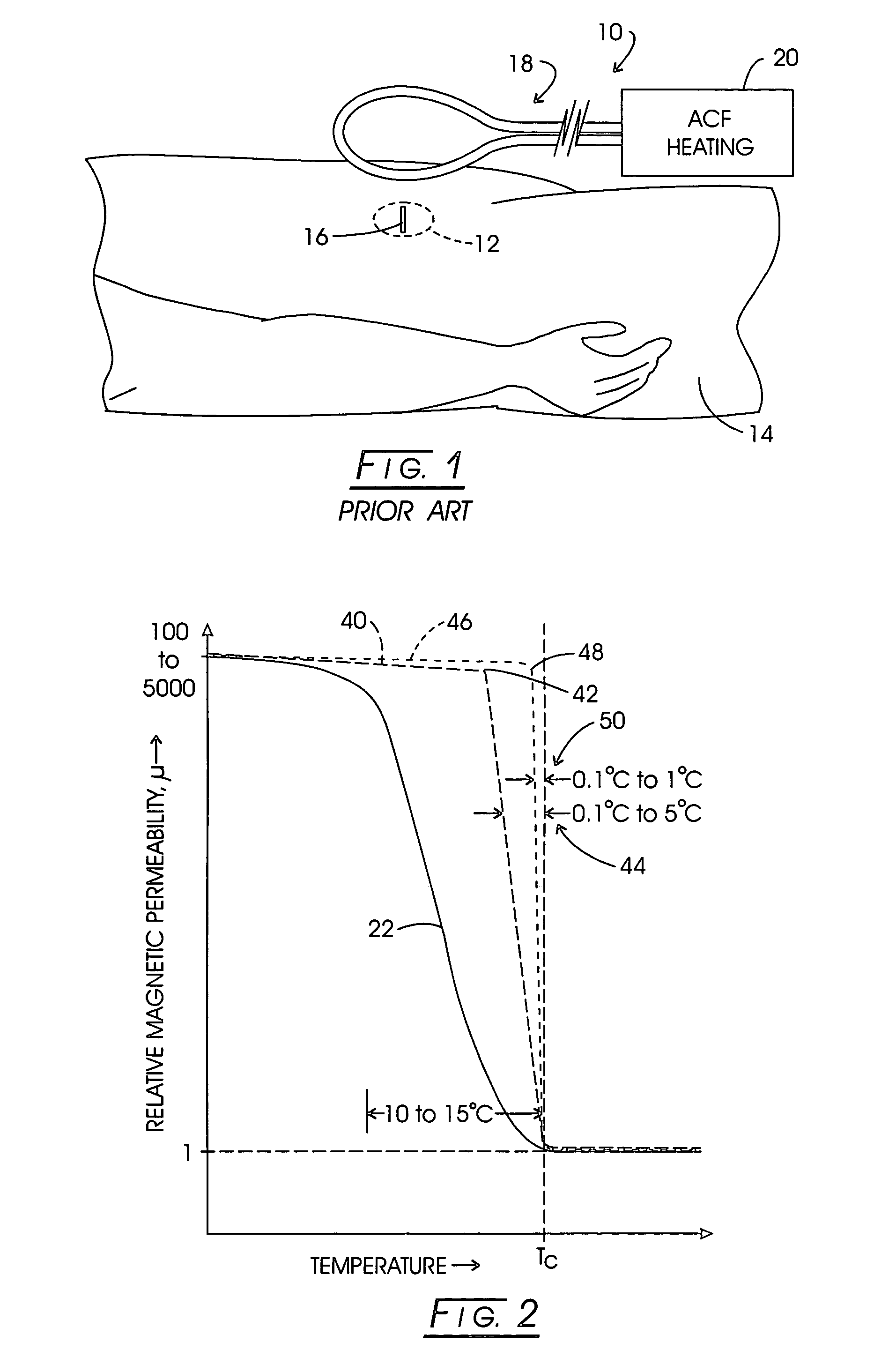

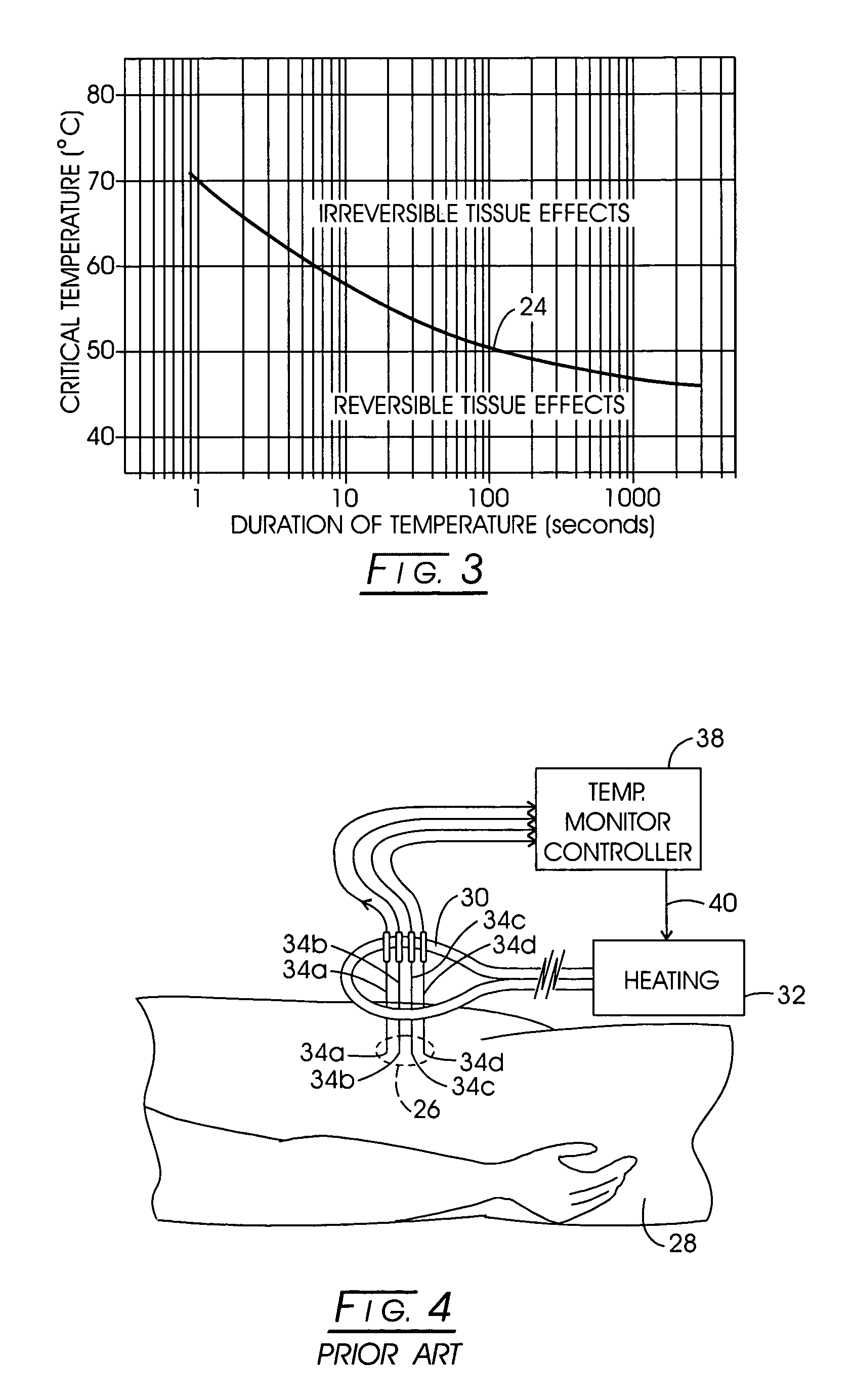

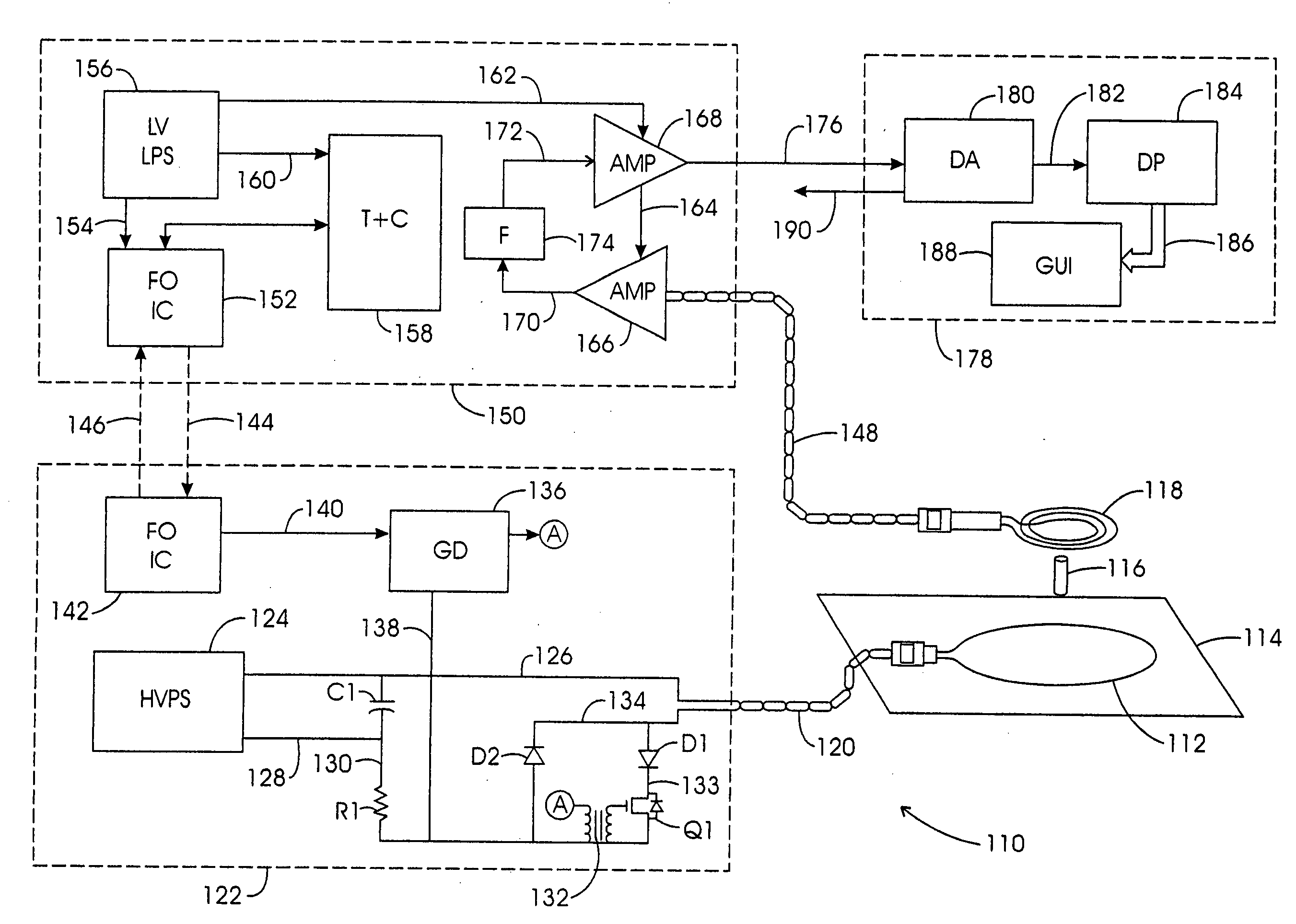

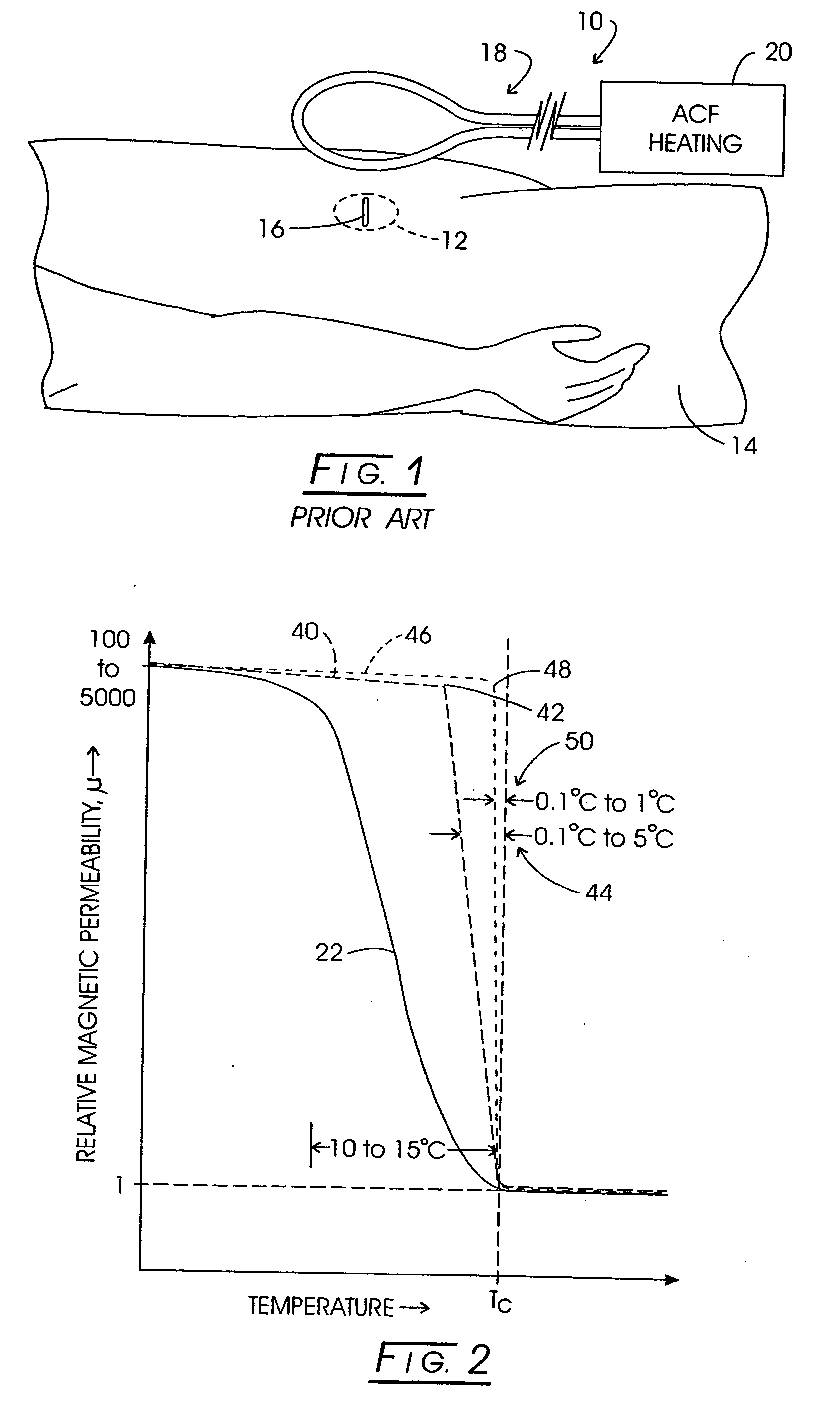

System, method and apparatus for evaluating tissue temperature

InactiveUS7048756B2Accurate assessmentReduce intensityStentsElectrotherapyCapacitanceTemperature response

Method, system and apparatus for monitoring target tissue temperatures wherein temperature sensors are configured as passive resonant circuits each, with a unique resonating signature at monitoring temperatures extending below a select temperature setpoint. The resonant circuits are configured with an inductor component formed of windings about a ferrite core having a Curie temperature characteristic corresponding with a desired temperature setpoint. By selecting inductor winding turns and capacitance values, unique resonant center frequencies are detectable. Temperature monitoring can be carried out with implants at lower threshold and upper limit temperature responses. Additionally, the lower threshold sensors may be combined with auto-regulated heater implants having Curie transitions at upper temperature limits.

Owner:APSARA MEDICAL

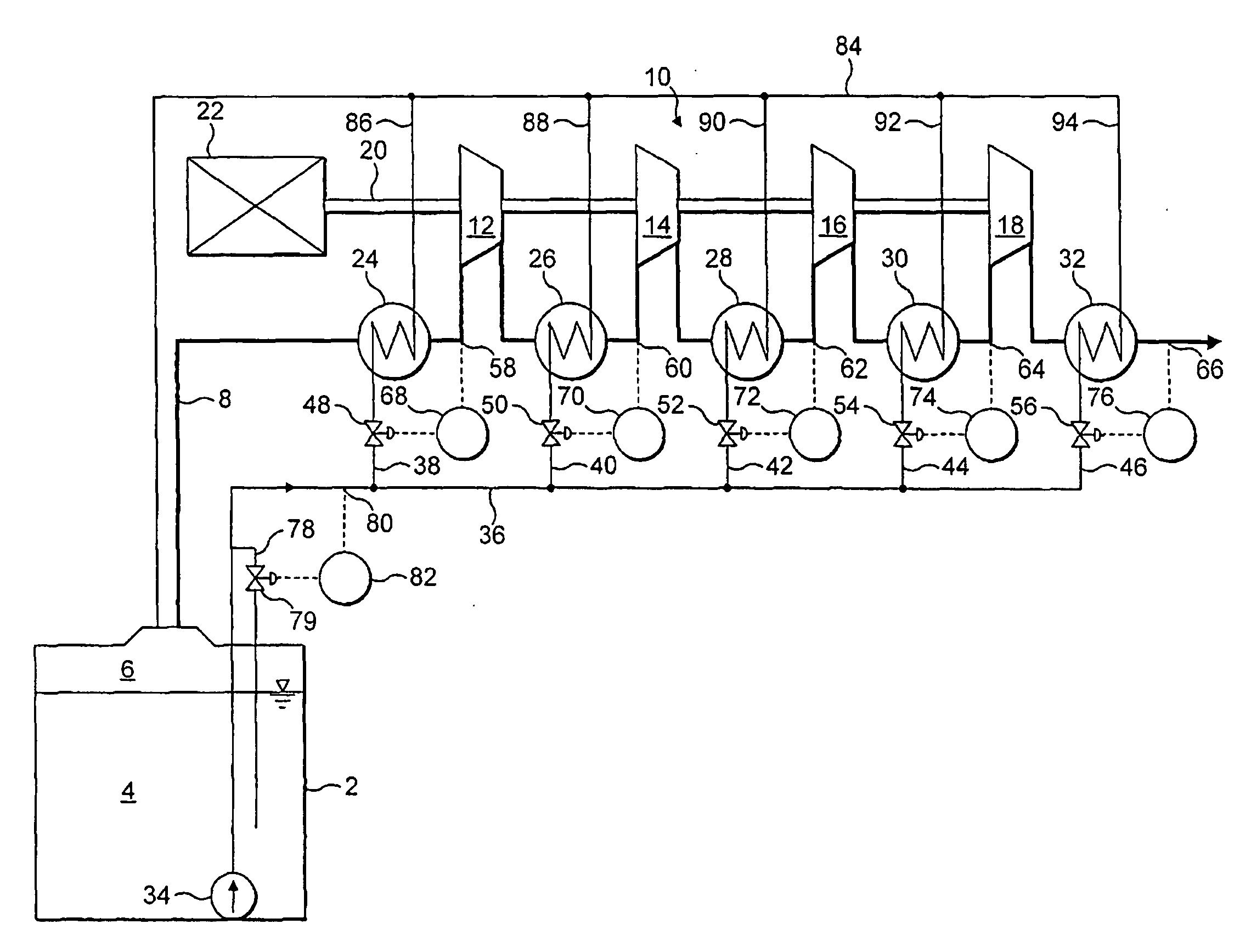

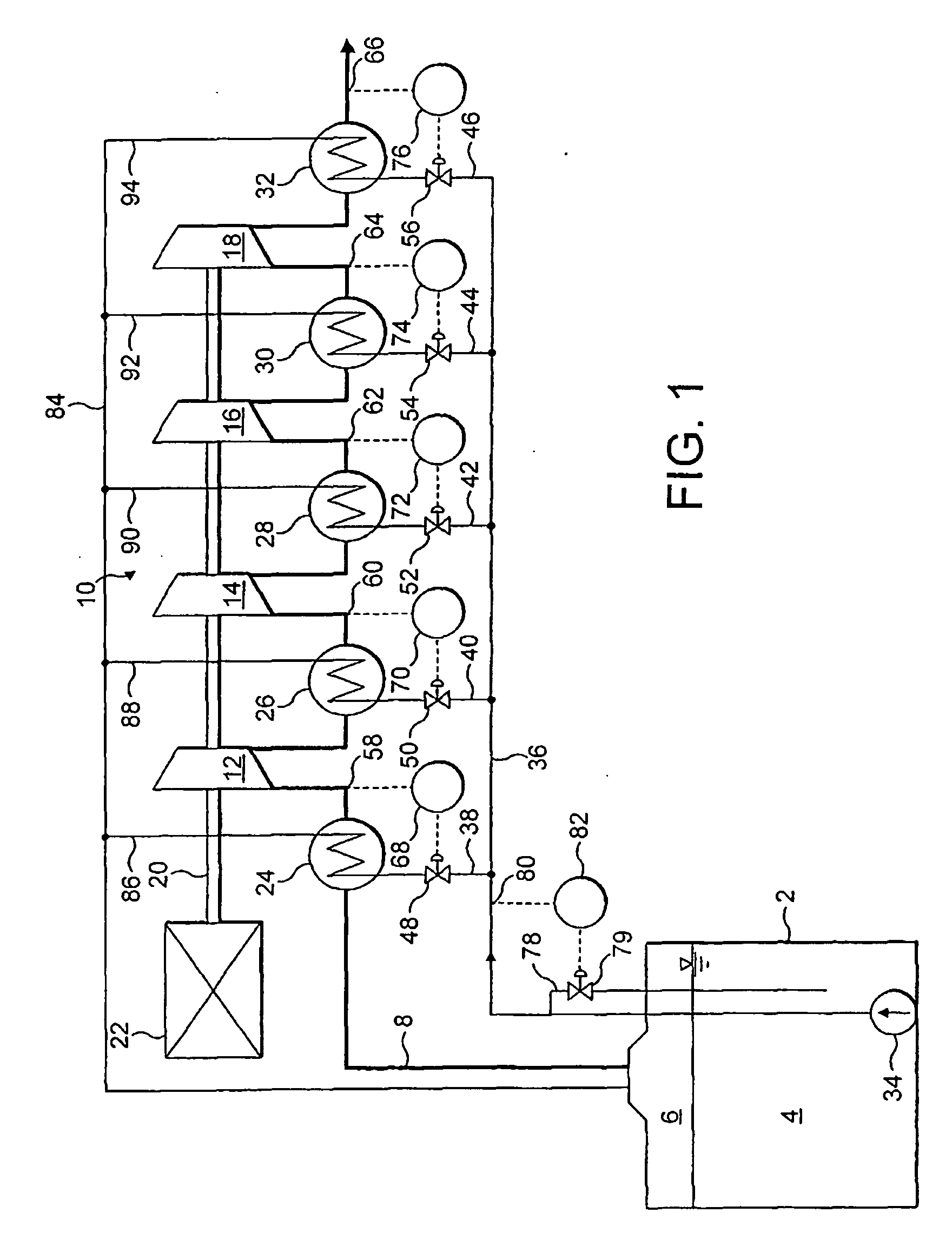

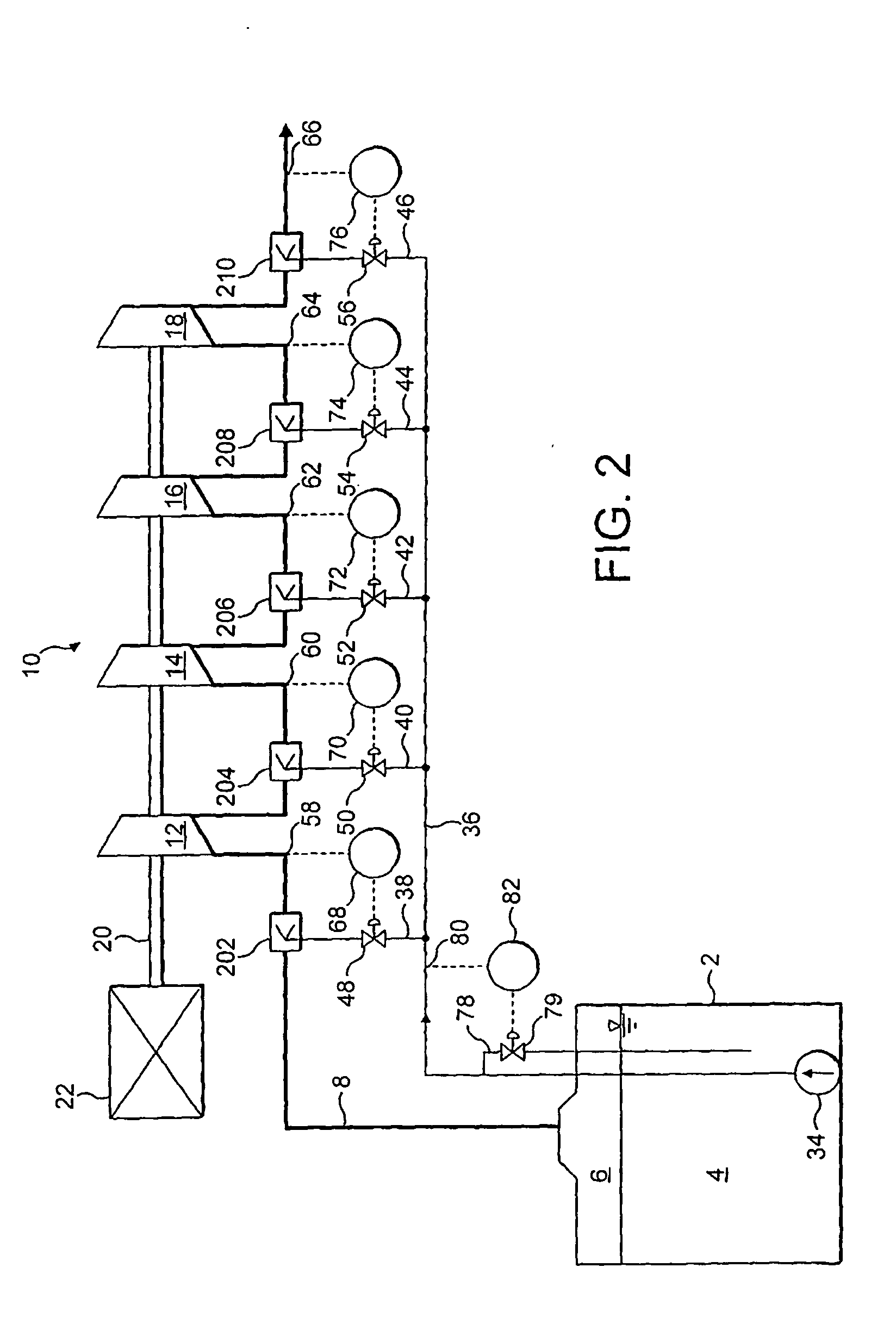

Compressor

InactiveUS20080008602A1Reduce consumptionSmall sizeAuxillariesContainer filling methodsEngineeringControl valves

A rotary liquefied natural gas boil-off compressor has a series of compression stages. A gas passage passes through the series of compression stages. The gas passage extends through and is in heat exchange relationship with cooling means in the form of indirect heat exchangers. Each of the heat exchangers is cooled by LNG supplied from a pipeline. Flow control valves are provided for controlling the flow of LNG to the heat exchangers respectively. The valves are controlled in response to temperature sensors respectively, so as to maintain the inlet temperature of each of the compression stages at a chosen sub-ambient temperature or between chosen sub-ambient temperature limits.

Owner:THE BOC GRP PLC

Food cooking container provided with a thermal indicator

ActiveUS8783947B2Well formedConveniently formedThermometer detailsSealingThermal energyElectronic temperature

A food cooking container provided with an electronic temperature monitoring device, the electronic temperature monitoring device being powered by converting thermal energy into electrical energy by the parasitic exploitation of temperature differences generated between the hot container and a heat dissipating metal mass, and activates a device in the form of a piezoelectric buzzer or LEDs, to indicate pre-set safety temperature limits. The electronic temperature monitoring device includes an electronic thermoelectric harvesting sensor for converting thermal energy into electrical energy via its electronic thermoelectric harvesting system.

Owner:BALLARINI PAOLO E FILI SPA

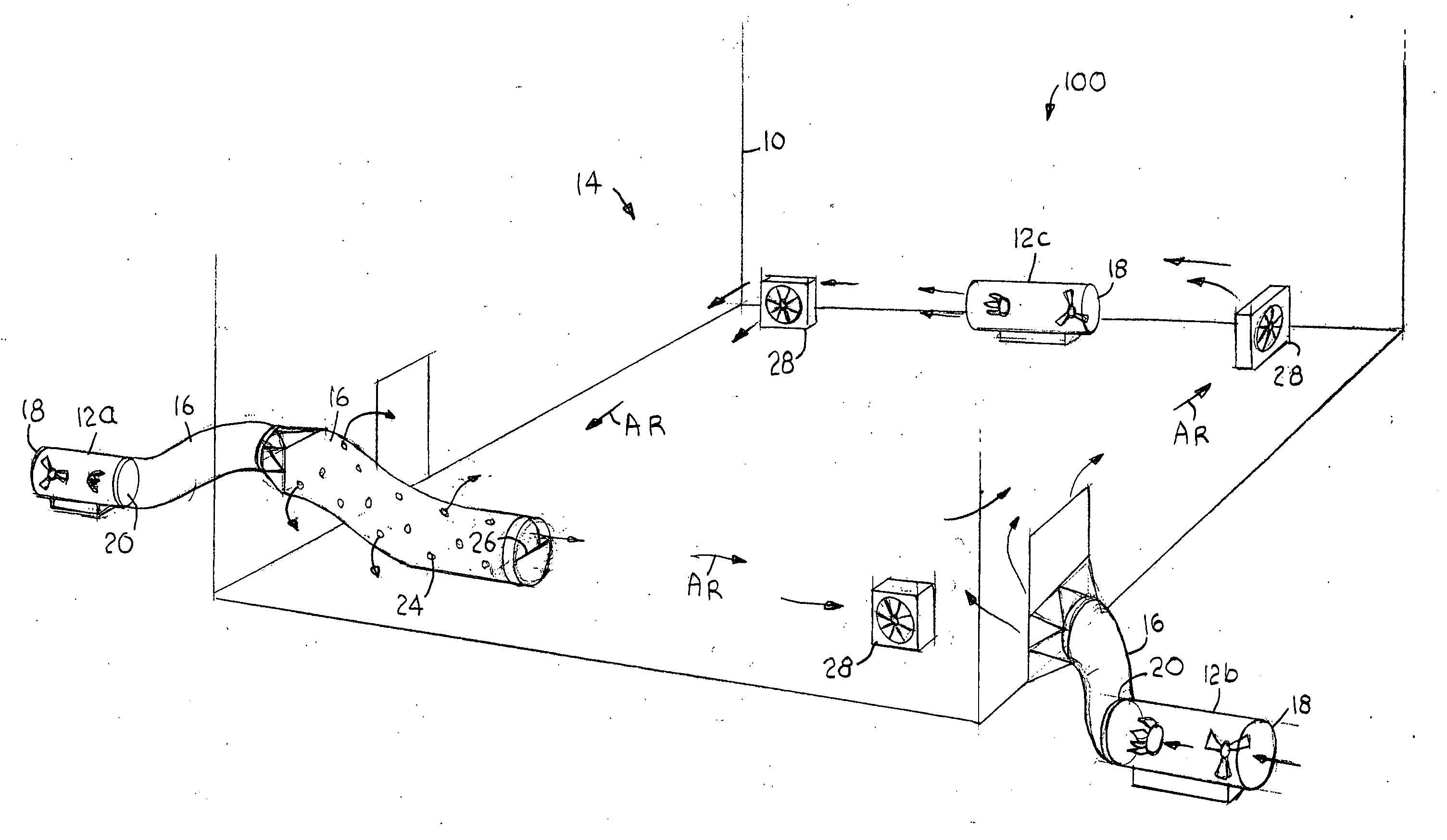

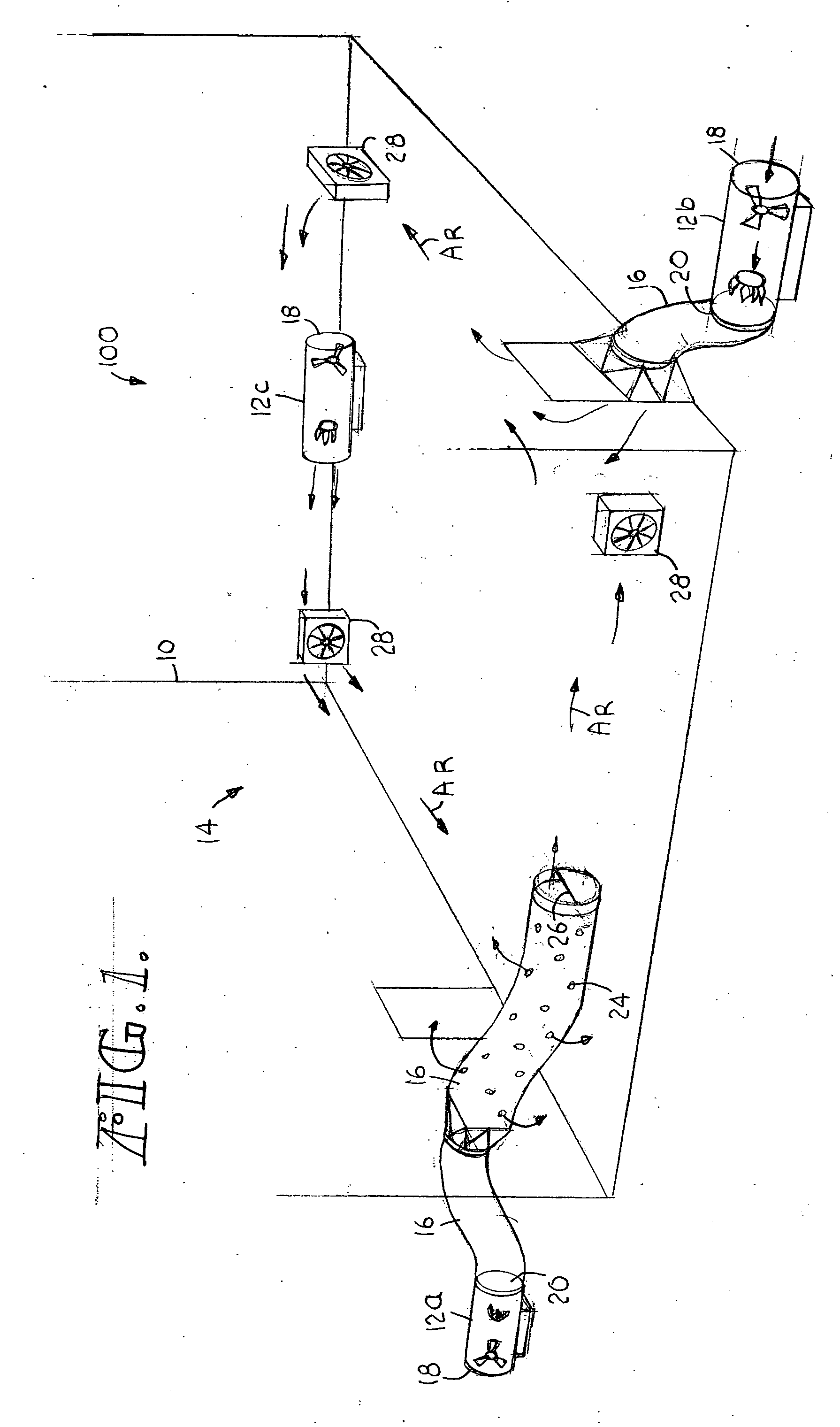

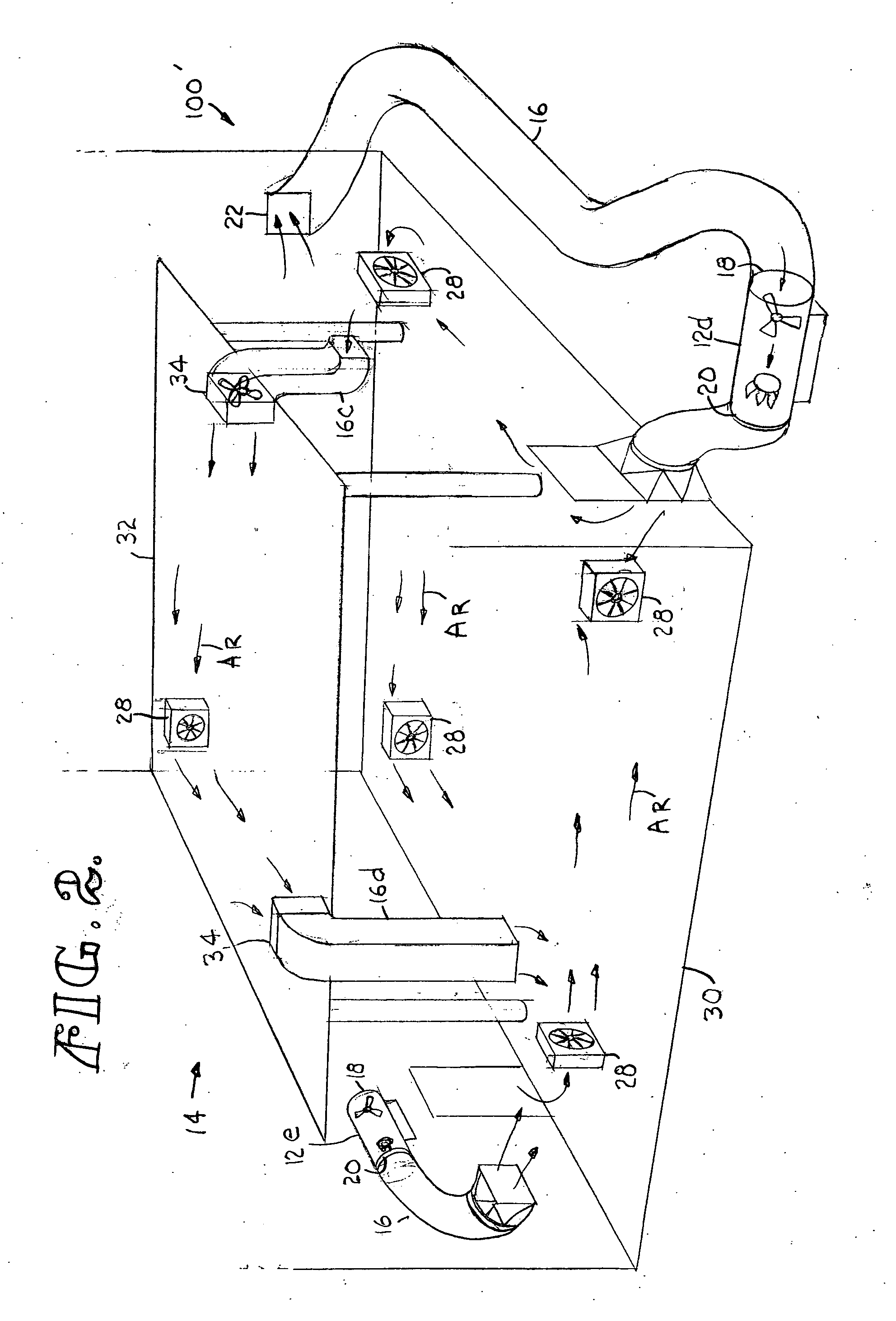

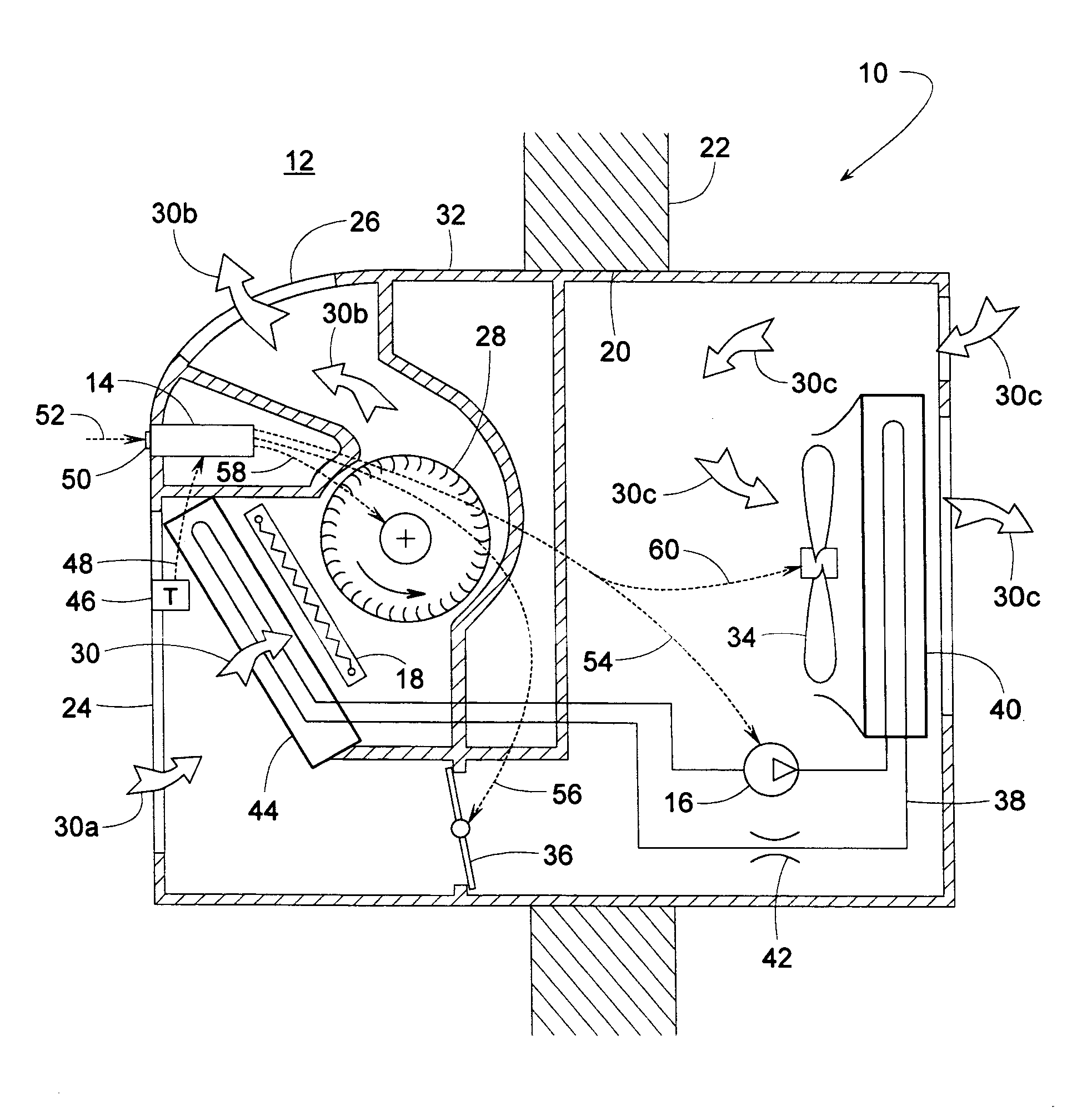

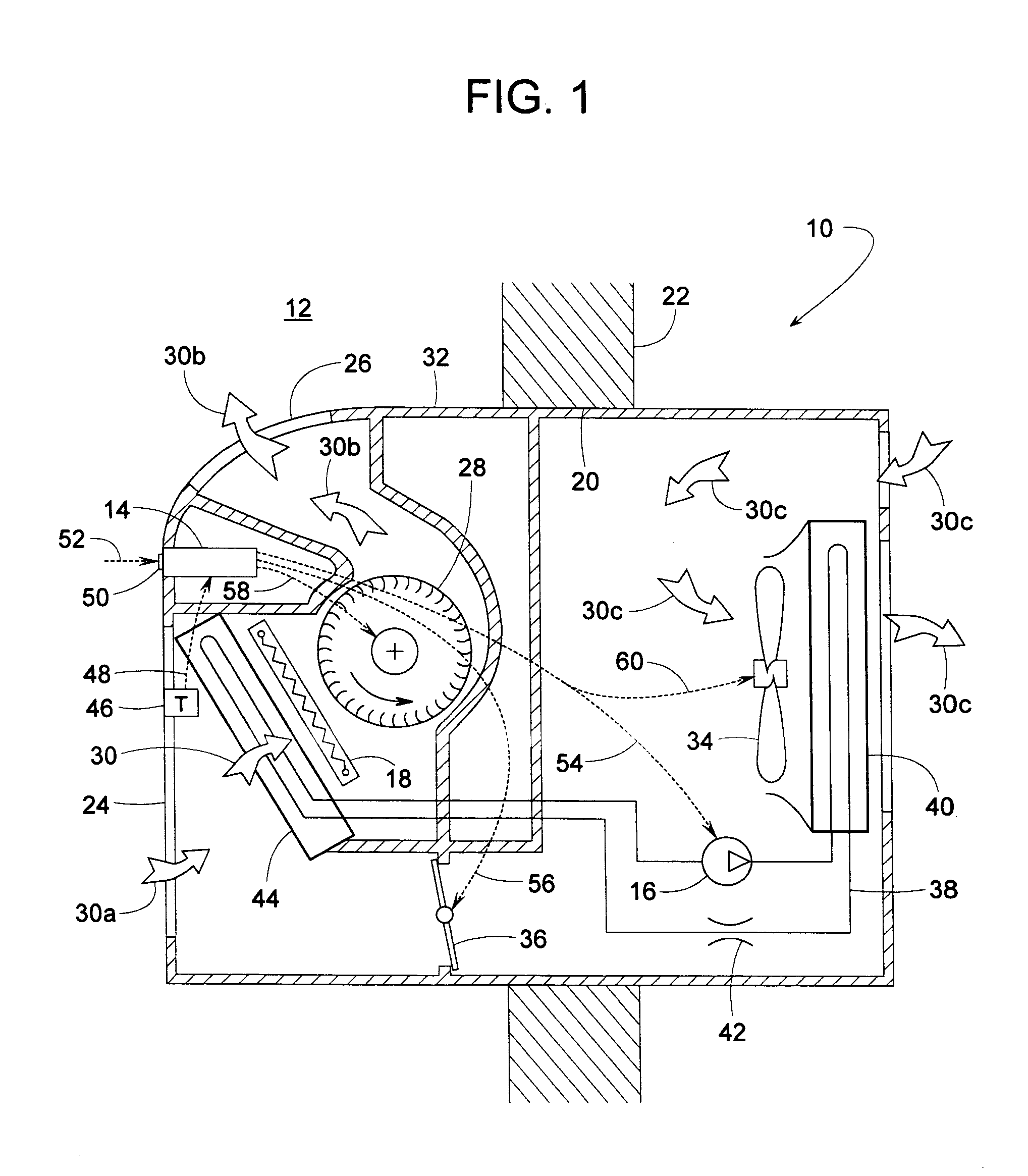

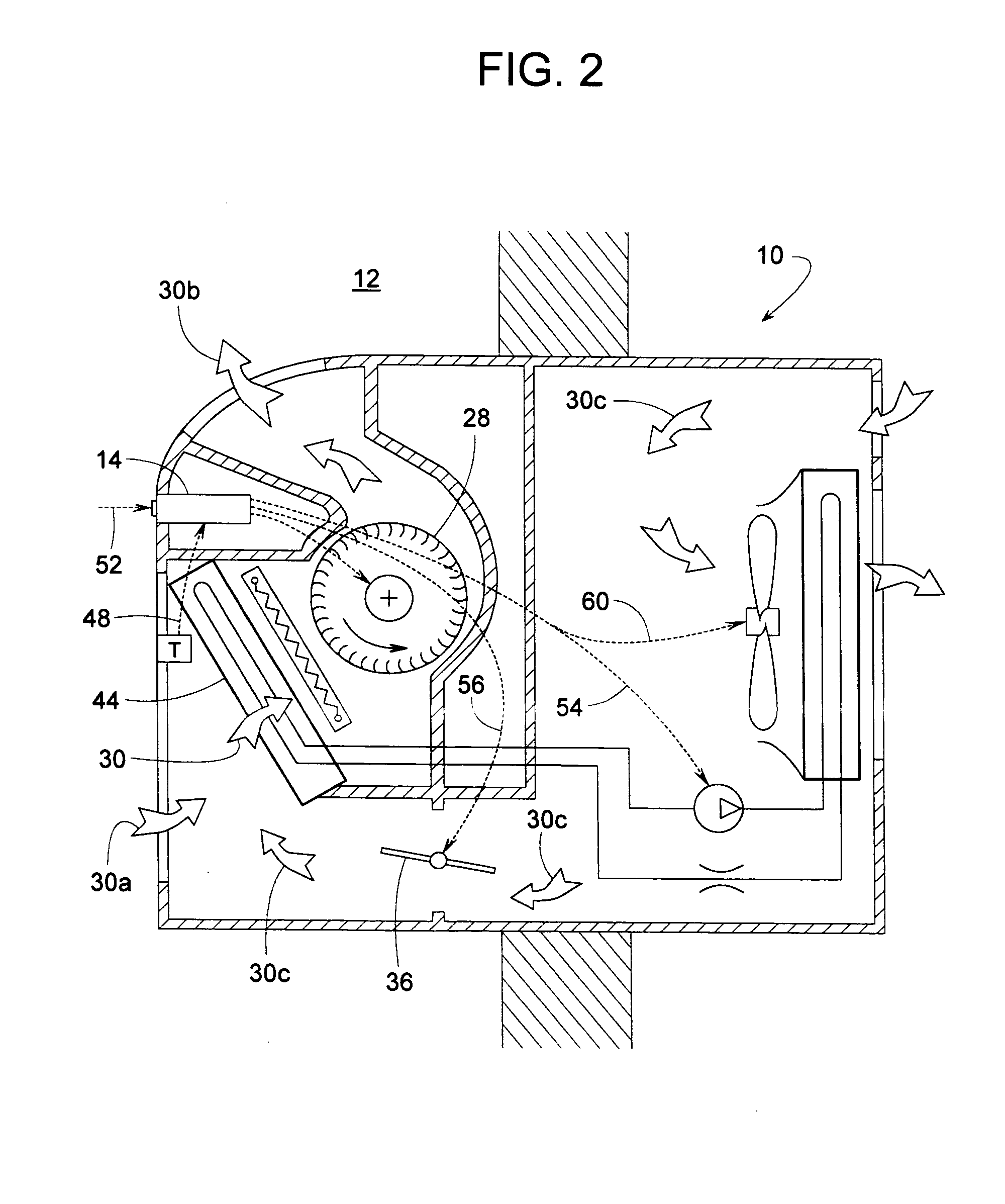

Method of extermination utilizing heated air

InactiveUS20050246942A1Conducive to pest controlUniform temperature distributionHot-air central heatingOther heat production devicesTemperature stratificationEngineering

A method of exterminating organisms is provided utilizing heated circulating air. First, a determination is made as to which enclosed areas of the building or other structure are to undergo extermination. This step defines an application zone. Next, a desired elevated temperature limit is established for heated air that is to be circulated through the application zone. Heaters are provided in airflow communication with the application zone, and circulation fans are positioned throughout the application zone to move the heated air for proper heat distribution. The heaters utilize an amount of recirculated air already present in the application zone to cut down on the amount of energy needed to raise the air temperature within the application zone towards the desired elevated temperature limit, and to eliminate the need for high CFM airflow heaters to achieve air temperature elevation. The temperature at various nodes within the application zone may be monitored to allow personnel to redirect circulating airflow within the application zone to balance out areas of higher air temperature with areas of lower air temperature. The method takes advantage of convection heat transfer to raise the temperature evenly within an application zone, minimizing temperature stratification which could result in ineffective pest extermination and / or damage to equipment and facilities.

Owner:IND FUMIGANT

Systems and methods for limiting joint temperature

ActiveUS8355799B2Reduce and eliminate temperature influenceReduce the risk of injuryDiagnostic recording/measuringSurgical instruments for heatingControl systemMonitoring and control

Joint temperature monitoring and control systems and methods are described herein in which the temperature of a fluid within a body or joint space is determined and / or monitored despite the energy generated during treatment by an ablation probe. One or more temperature sensors are positioned along the probe proximally of the electrode assembly and measure the temperature of an electrically conductive fluid without being overly influenced by the surgical effect occurring proximate the electrode assembly. The controller coupled to the probe can also be configured to set temperature limits and treatment times as well as moderating joint temperature by altering the electrically conductive fluid flow.

Owner:ARTHROCARE

System, method and apparatus for evaluating tissue temperature

InactiveUS20060030914A1Accurate assessmentReduce intensityStentsDiagnostic recording/measuringCapacitanceTemperature response

Owner:APSARA MEDICAL

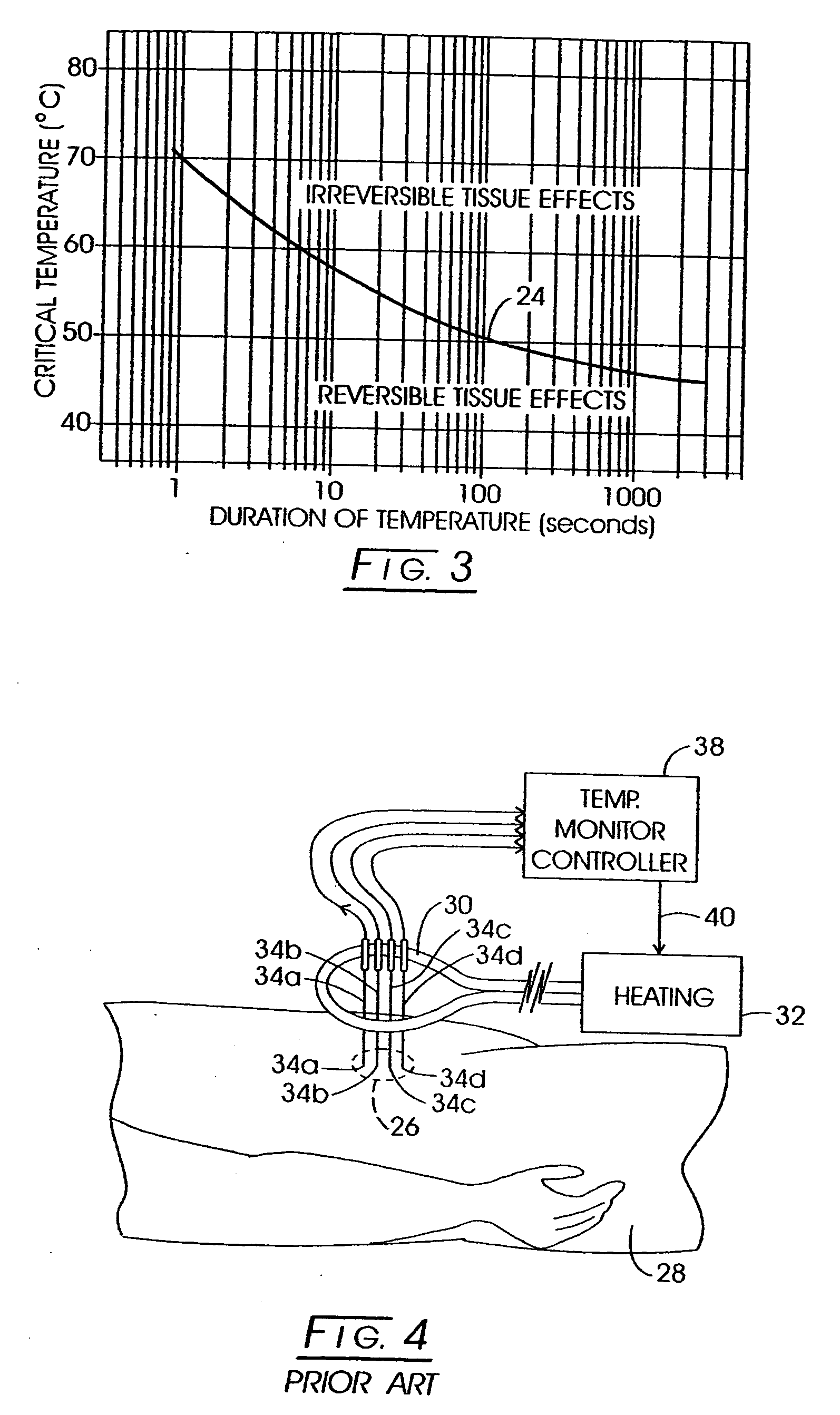

Self-temperature-limited polyurethane grouting material and preparation method thereof

The invention belongs to the technical field of materials and particularly relates to a self-temperature-limited polyurethane grouting material and a preparation method. The self-temperature-limited polyurethane grouting material is composed of three components, the component A includes isocyanate and prepolymer thereof and accounts for 30-50% of total mass of the grouting material, the component B includes polyether polyol and auxiliaries and accounts for 5-50%, preferably 30-50% of the total mass of the grouting material, and the component C includes self-temperature-limited additive with the boiling point adjustable within 66-130 DEG C and accounts for 5-55% of the total weight of the grouting material. By adding the self-temperature-limited additive into the isocyanate and the polyether polyol, heat storage temperature after the grouting material is solidified is lower than the boiling point of the self-temperature-limited additive, and accordingly, potential hazards of fire breaking due to overhigh storage heat of the grouting material are reduced, and fire disasters during grouting to underground engineering, especially coal mines are avoided.

Owner:LIAONING TECHNICAL UNIVERSITY

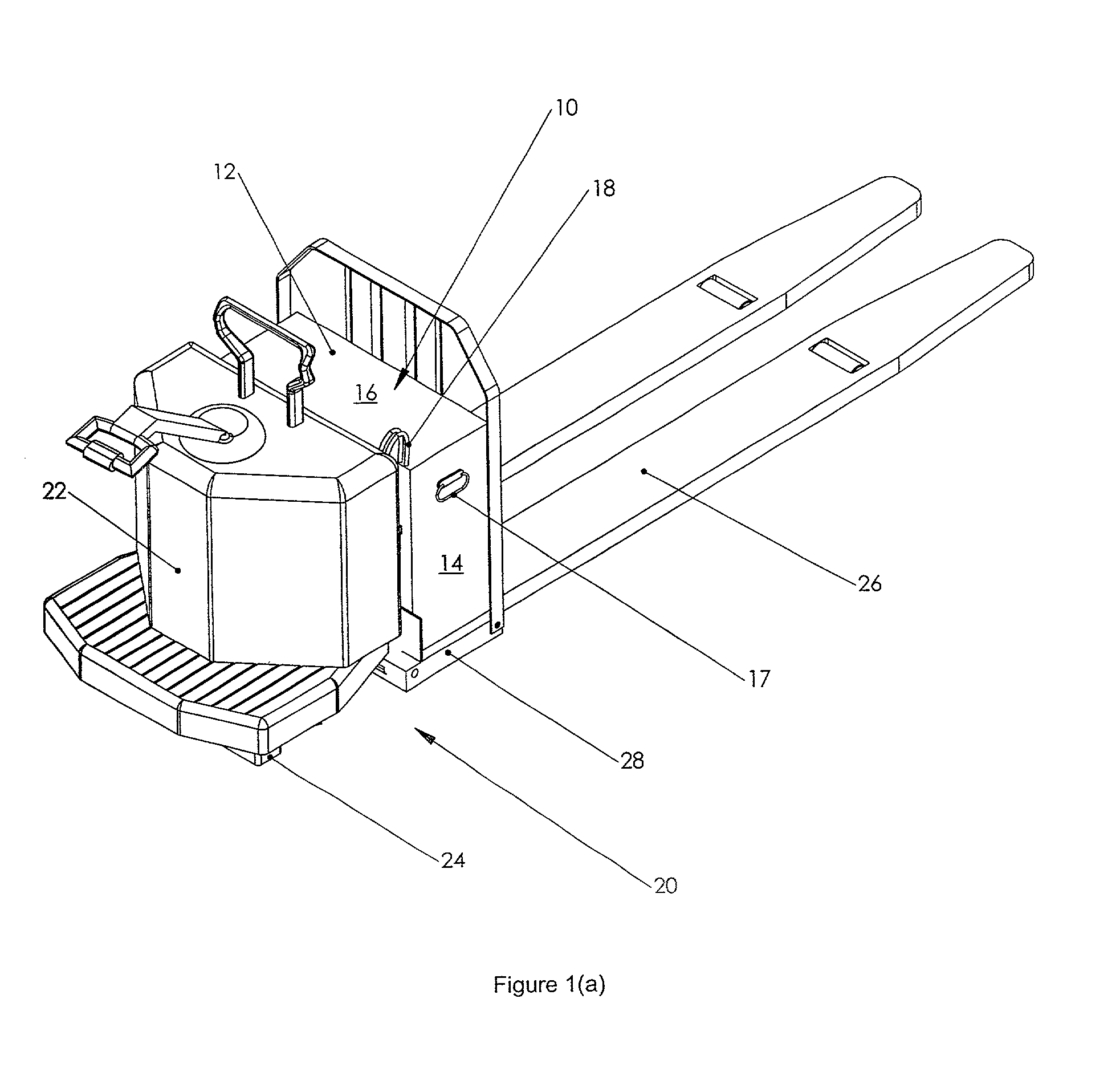

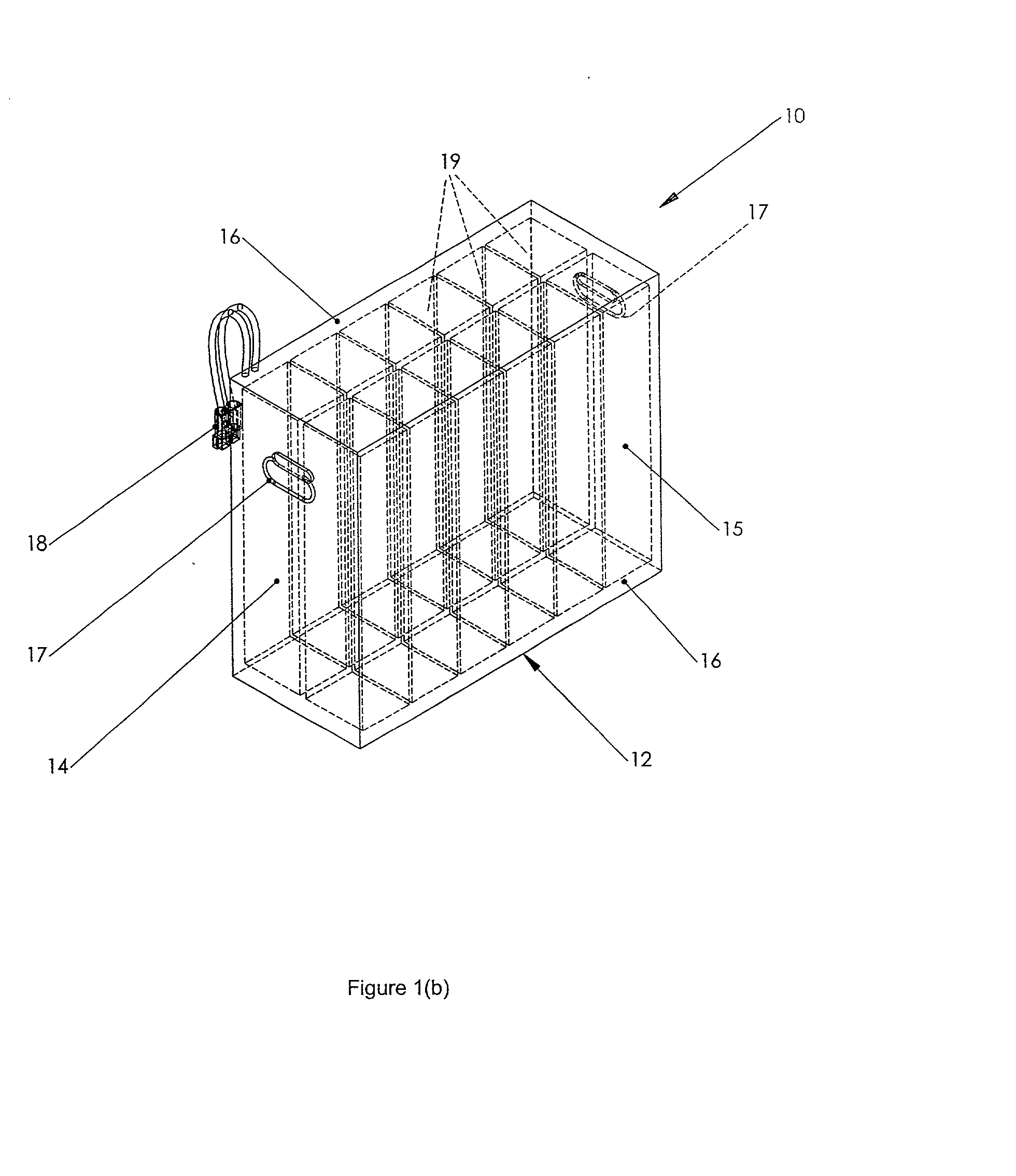

Hybrid power supply apparatus for battery replacement applications

InactiveUS20030070850A1Extended operating timeIncrease energy densityFuel cell heat exchangeCell temperature controlElectrical batteryElectric vehicle

This application relates to a hybrid power supply apparatus comprising a fuel cell and an energy storage device for use in off-road electric vehicles, such as lift trucks. The apparatus is a substitute for conventional lead acid batteries and is sized to fit within a conventional lift truck battery receptacle tray. The fuel cell and fuel processor systems are designed to meet the average load requirements of the vehicle, while the batteries and power control hardware are capable of responding to very high instantaneous load demands. The invention has a similar electrical interface as conventional battery systems and does not require vehicle modification. The apparatus is air-cooled to ensure that the hybrid power components operate within a preferred temperature range and to maintain the external surfaces of the apparatus and exhaust gases within safe temperature limits. Apart from vehicular applications, low power hybrid fuel cell products as exemplified by the present invention may also find application in uninterruptable power supply systems, recreational power, off-grid power generation and other analogous applications.

Owner:CELLEX POWER PRODS

Meltable ink for an inkjet printer and a method of selecting such an ink

InactiveUS6923853B2Specific visco-elastic propertyEffect print qualityMeasurement apparatus componentsDuplicating/marking methodsRoom temperatureEngineering

A meltable ink which is solid at room temperature, which ink is suitable for use in an indirect printing process, in which printing process the ink is transferred, by the use of an inkjet printhead, to a transfer element, whereafter the ink is transferred to a receiving material under pressure from the transfer element, the ink having a composition such that it is pressure-transferable at a temperature between a bottom temperature limit and a top temperature limit, wherein the ink has a deformation energy of less than 20×105 Pa.s at a temperature equal to said top temperature limit.

Owner:OCE TECH

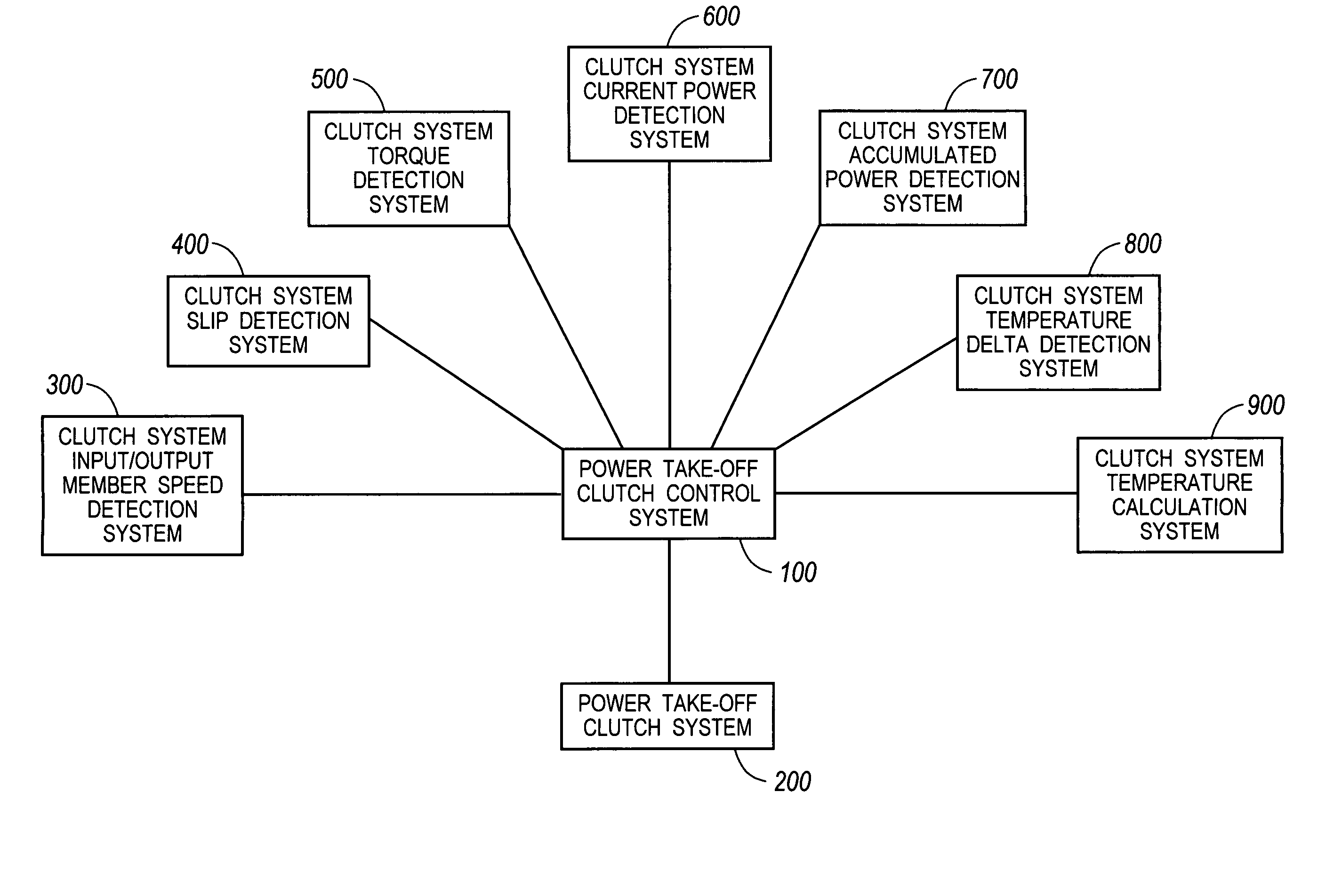

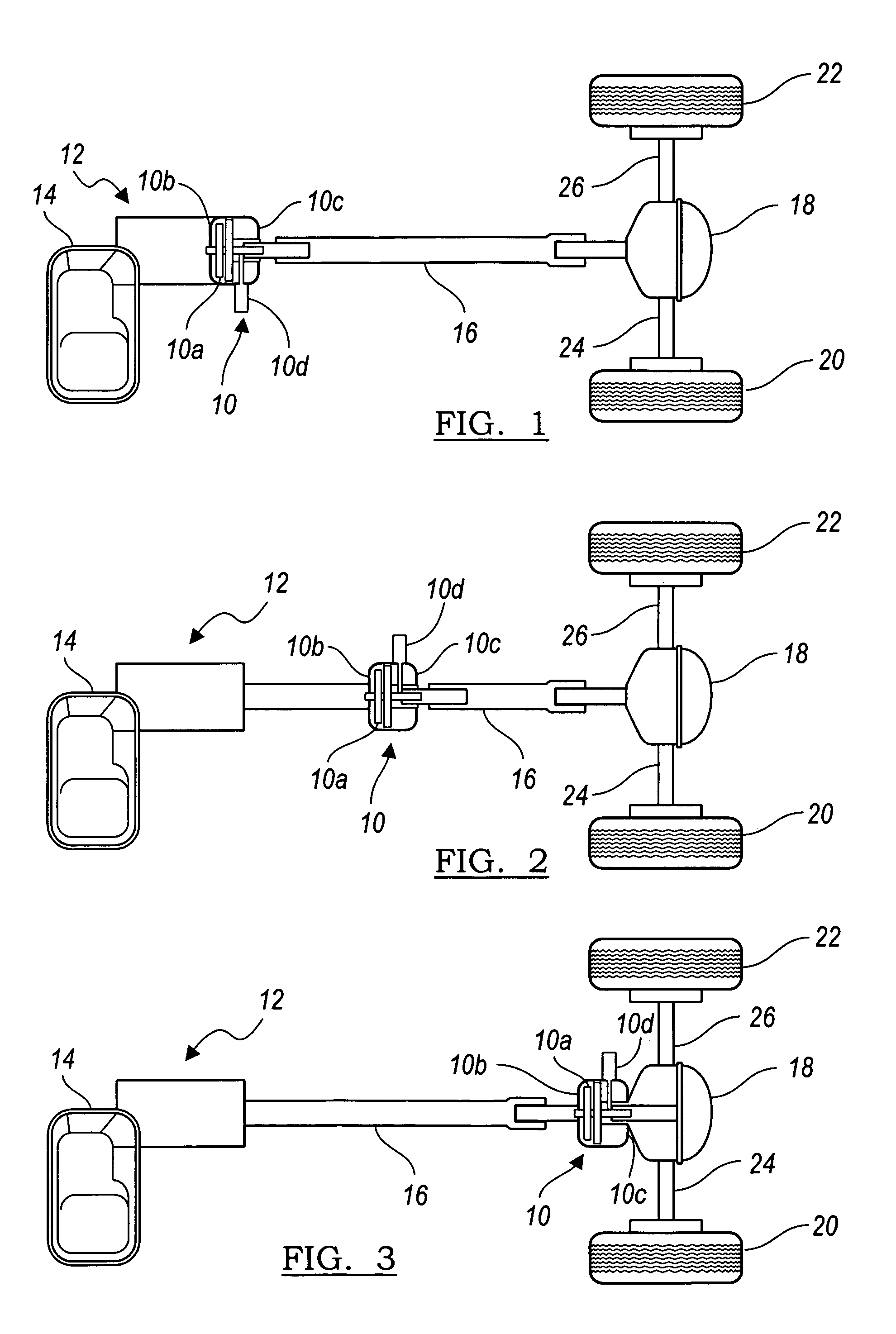

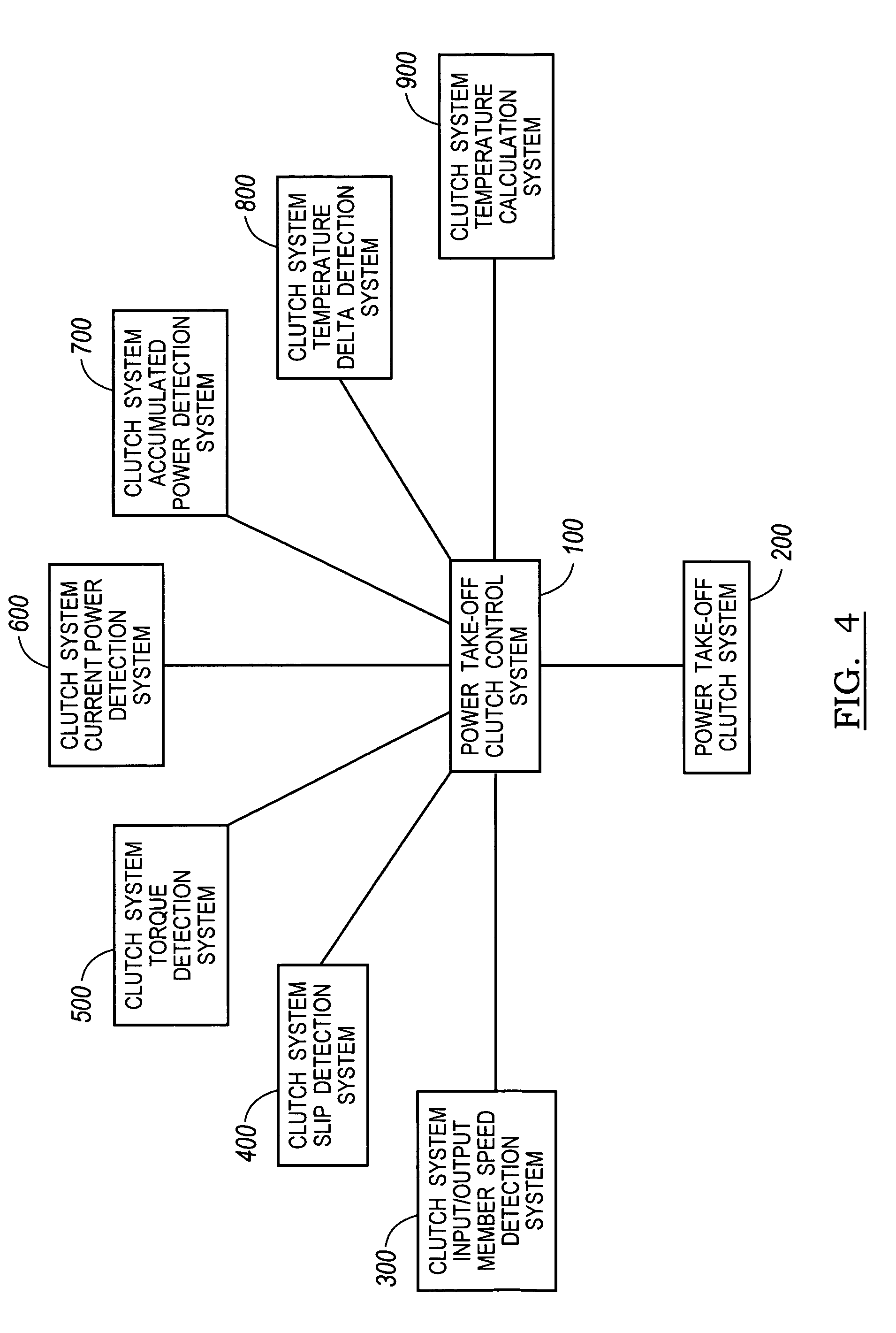

Power take-off clutch control system

Owner:BORGWARNER INC

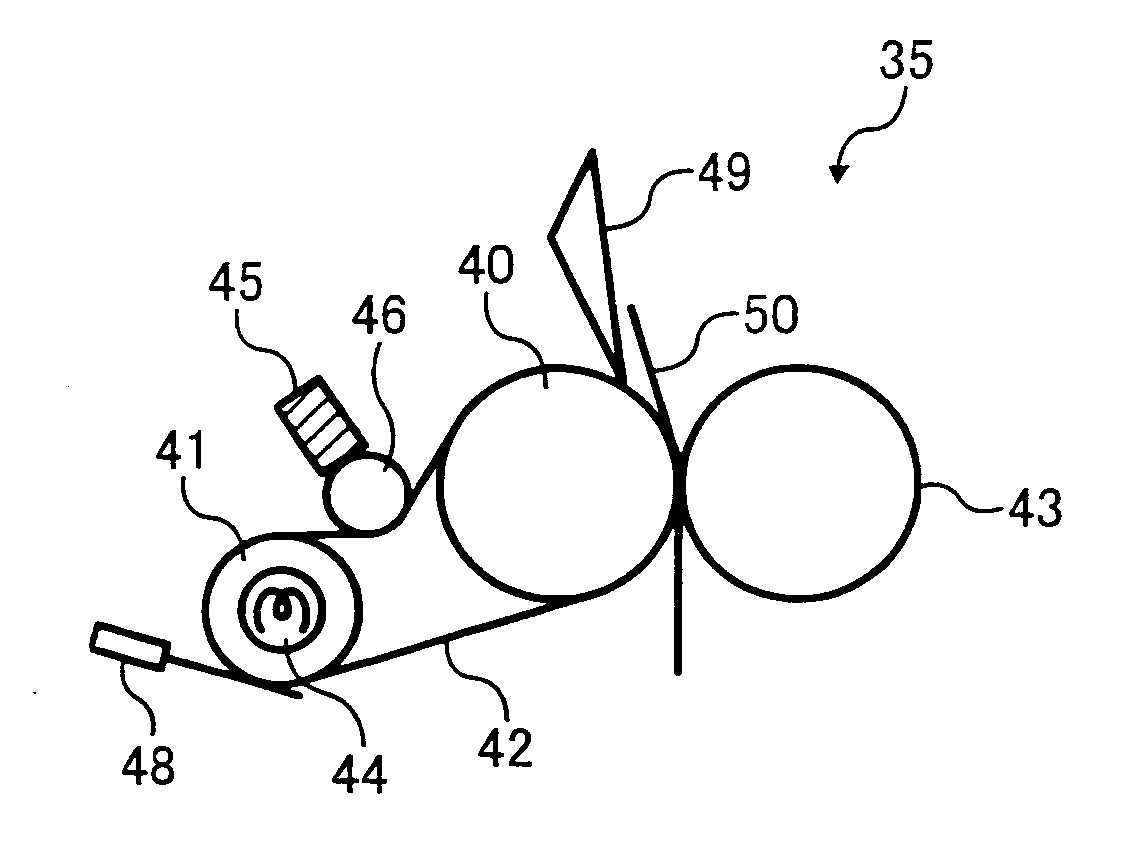

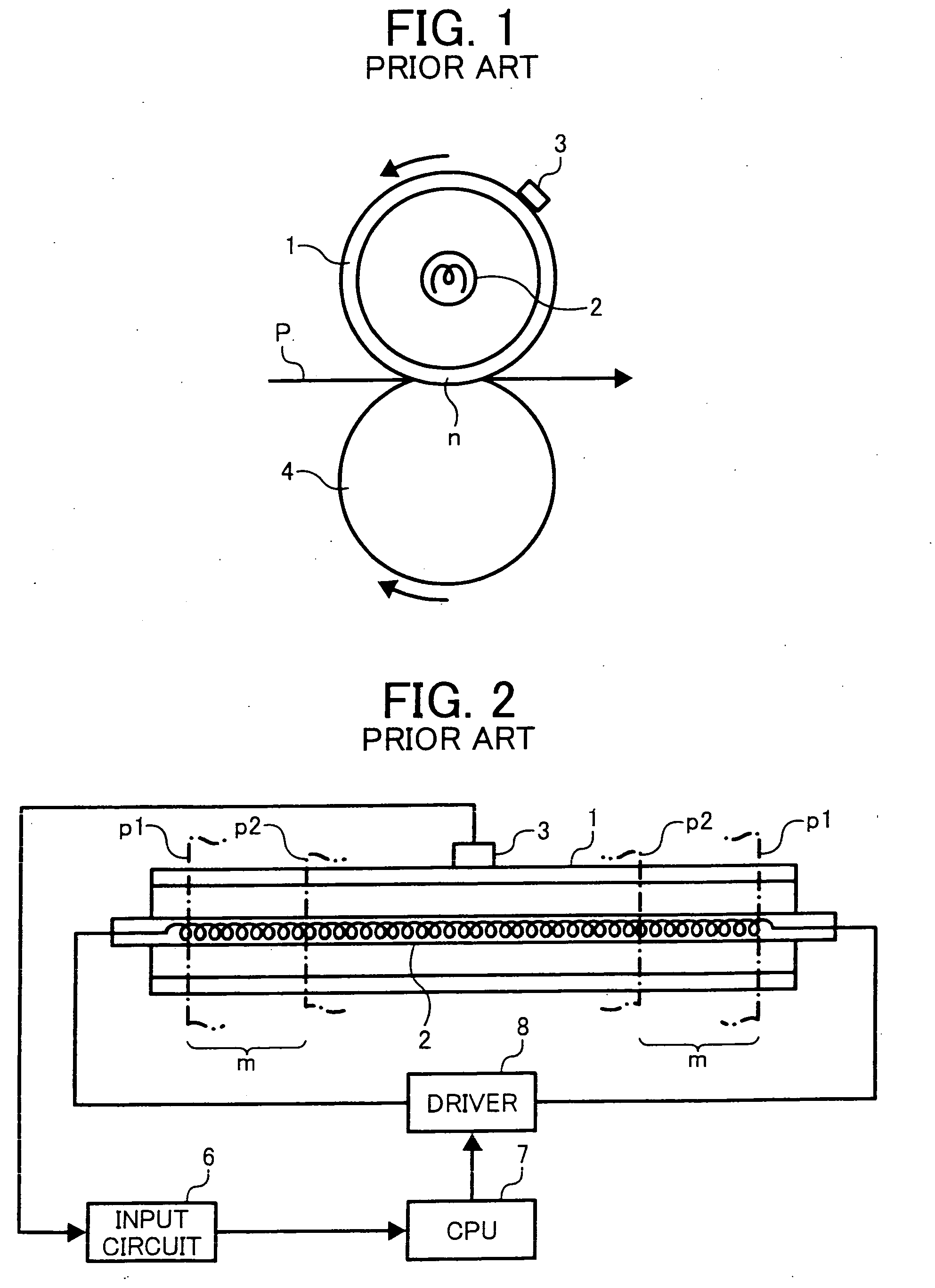

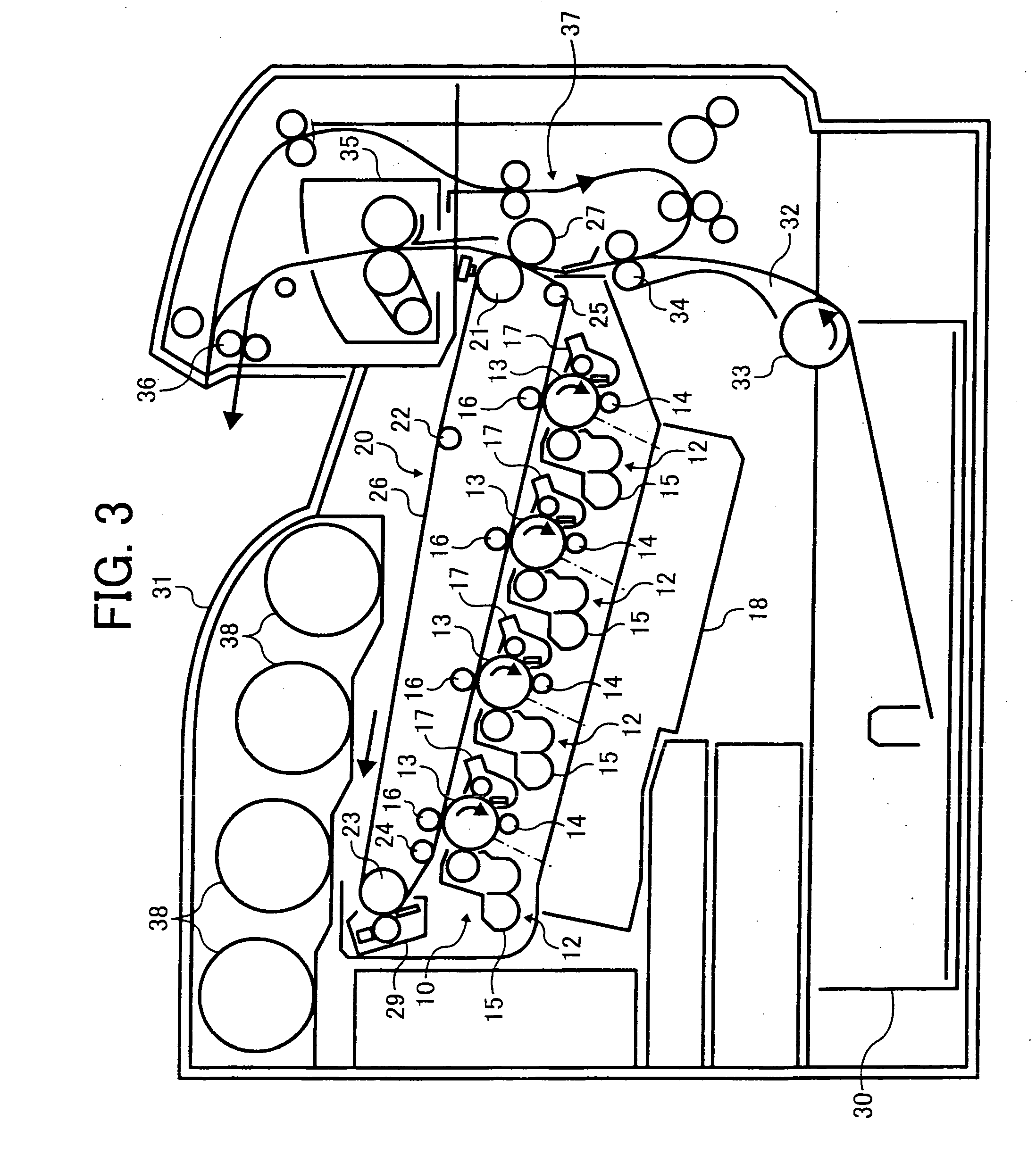

Image fixing apparatus, image forming apparatus, and image fixing method capable of effectively controlling an image fixing temperature

ActiveUS20070059003A1Longer gapIncrease blockingElectrographic process apparatusImage formationEngineering

Owner:RICOH KK

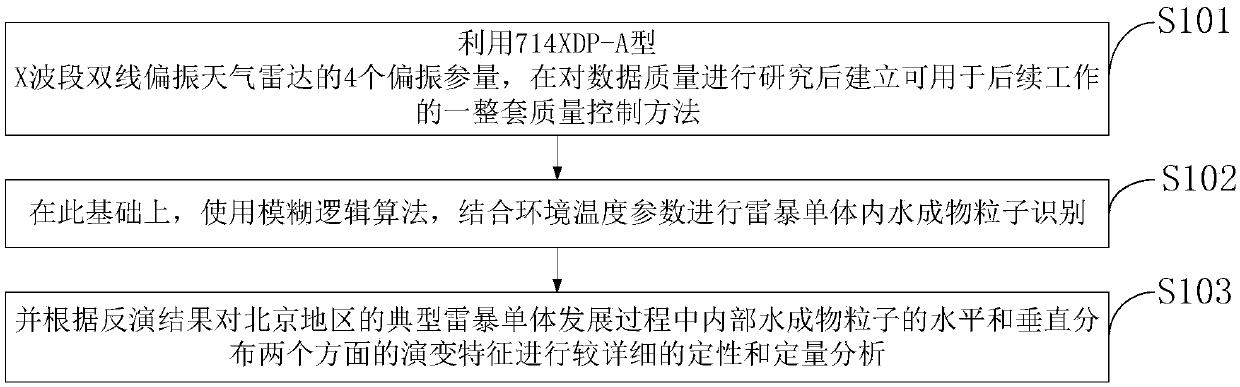

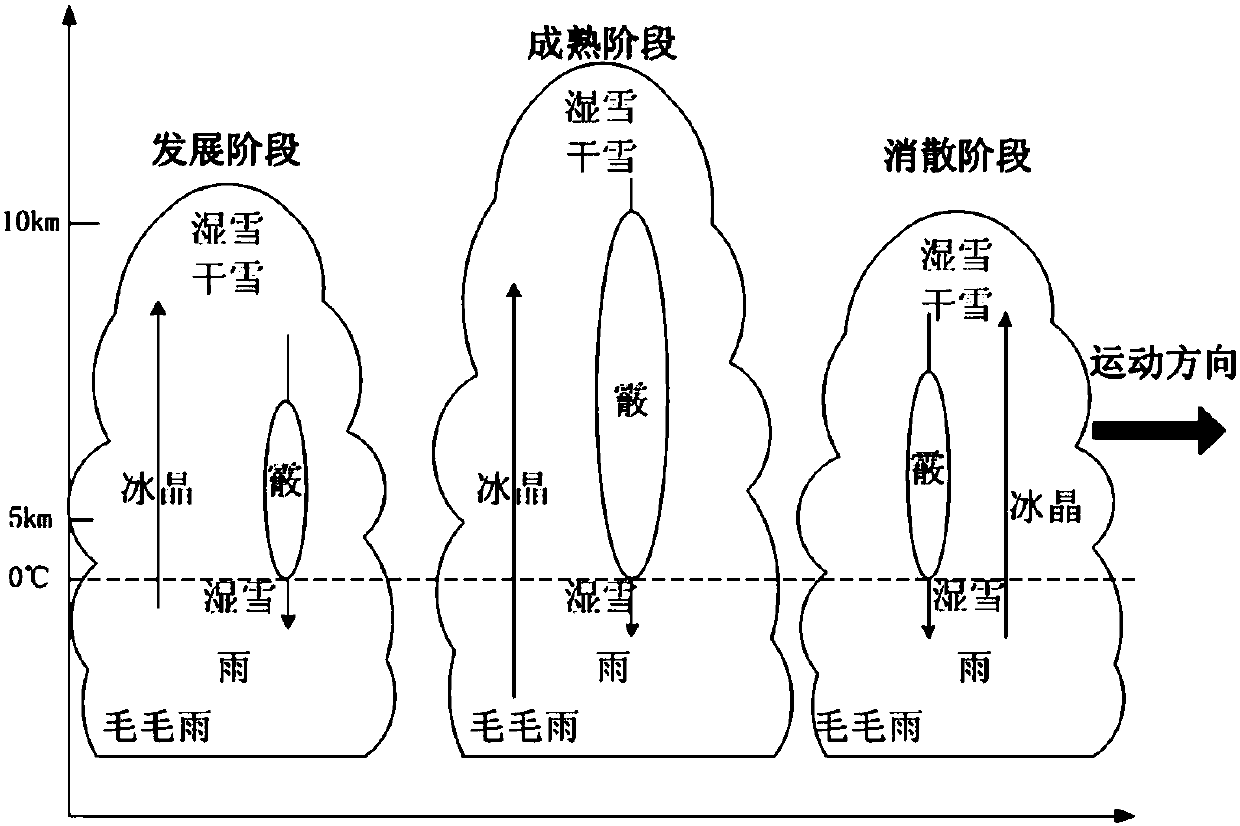

Dual-polarization radar observation based method for improving thunderstorm weather warning and forecasting accuracy

ActiveCN107843884AA method for perfecting particle identificationGood removal effectICT adaptationRadio wave reradiation/reflectionHorizontal distributionWeather radar

The invention belongs to the field of radar observation based weather forecasting and discloses a dual-polarization radar observation based method for improving thunderstorm weather warning and forecasting accuracy. X waveband dual-polarization weather radar parameters are utilized. On the basis of quality control on data including phase defolding, filtering and attenuation correction and based ona fuzzy logic algorithm, environment temperature limits of sounding data are introduced for identification of multiple hydrometeors in a thunderstorm body. Comparatively detailed analysis is performed on evolution characteristics of the hydrometeors in clouds in two aspects including horizontal distribution and perpendicular distribution during a typical thunderstorm body development process according to an inversion result. Finally, a micro-physical concept model during the thunderstorm body evolution process is established and the structure and the evolution features of the thunderstorm body are acquired. The method provided by the invention facilitates recognition of hydrometeor distribution and a microphysical process in the typical thunderstorm body and provides a quantitative and direct technical support for thunderstorm weather warning and forecasting.

Owner:CHENGDU UNIV OF INFORMATION TECH

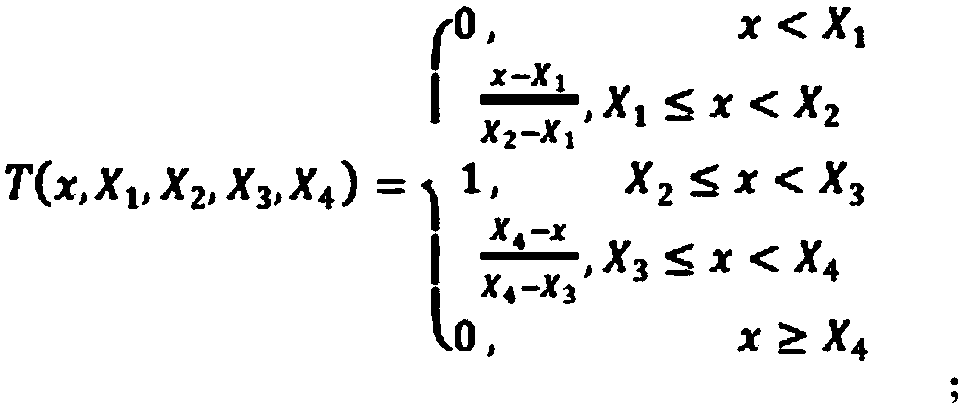

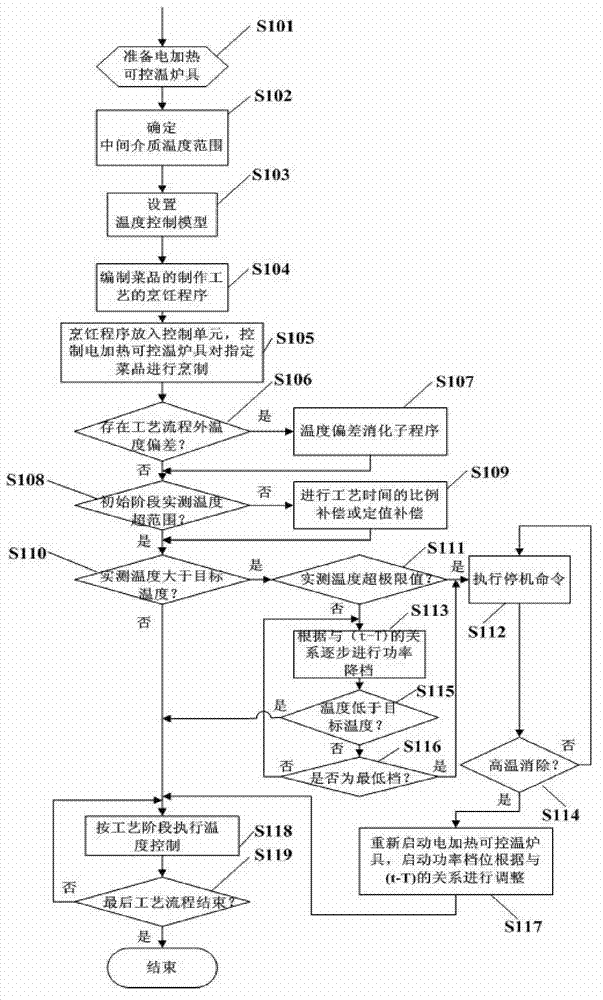

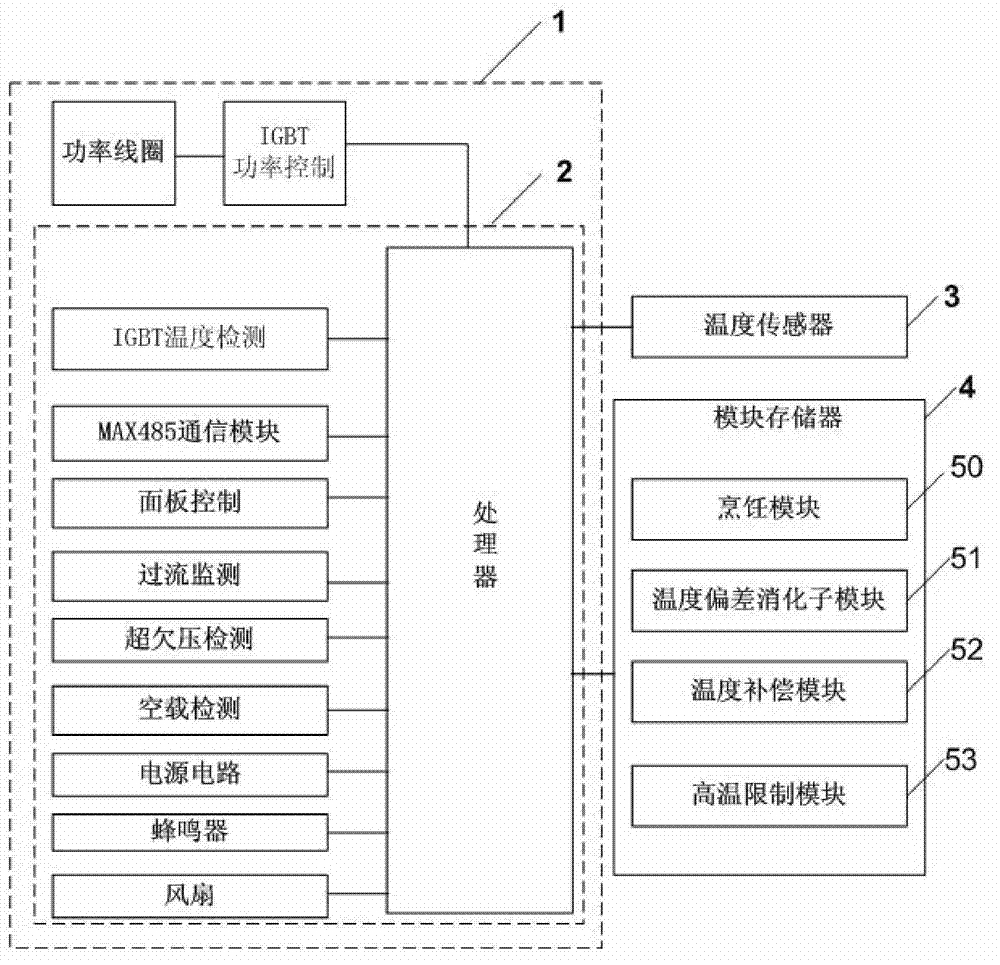

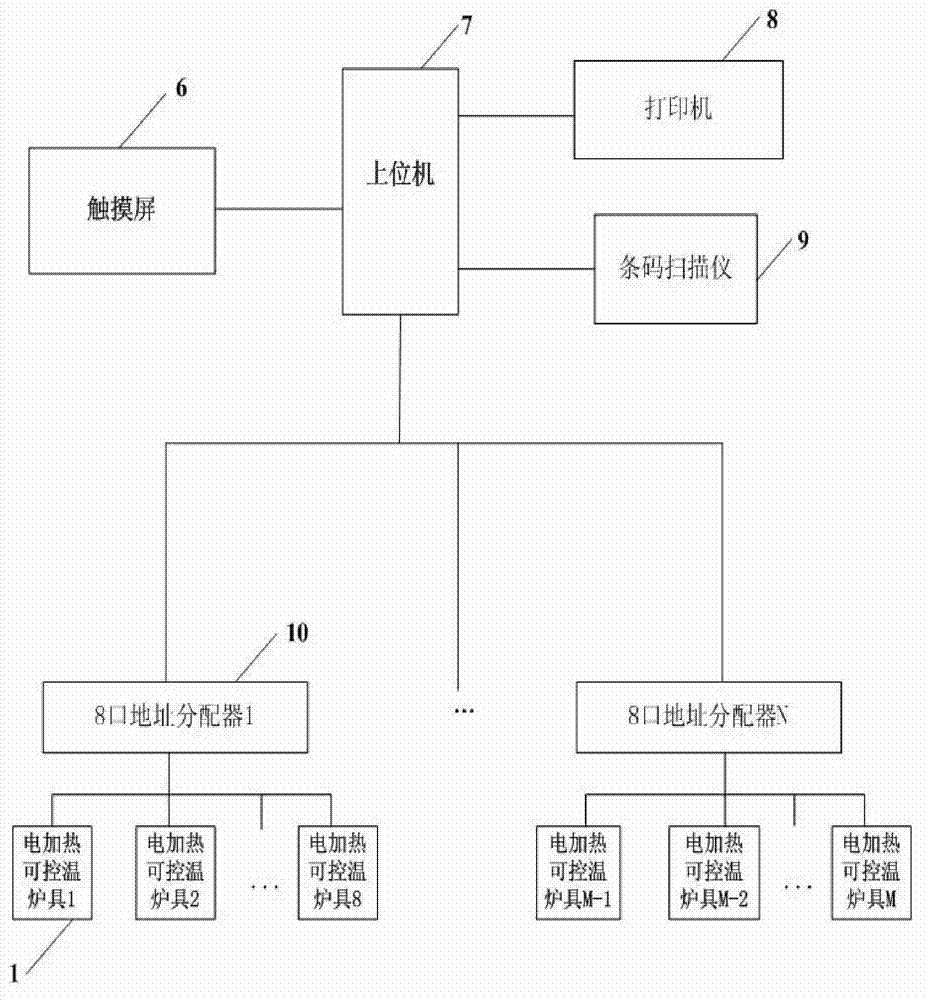

Method and system for realizing standardized cooking by using intelligent temperature control

InactiveCN102920309AGuaranteed tasteAchieve standardizationCooking vesselsElectricityTemperature control

The invention discloses a method and a system for realizing standardized cooking by using intelligent temperature control. According to the invention, operators failing to master cooking techniques also can make standardized dishes which are good and uniform in taste, and the method and system disclosed by the invention can be widely applicable to families and places of business. The system comprises an electric-heating temperature-controllable stove and a cooking container, wherein the electric-heating temperature-controllable stove is provided with a control unit, and the cooking container is placed on the electric-heating temperature-controllable stove. The system also comprises a temperature sensor, a cooking module, a temperature deviation digestion sub-module, a temperature compensation module and a high-temperature limit module, wherein the control unit is connected with the temperature sensor, the cooking module, the temperature deviation digestion sub-module, the temperature compensation module and the high-temperature limit module; and the cooking module compiles the technological process and the control program for each time node control temperature in the process of making each dish, and the like according to a preset temperature range for water, oil, water-oil mixtures and water vapor and a temperature control model of U = P-k (t-T).

Owner:张杭生

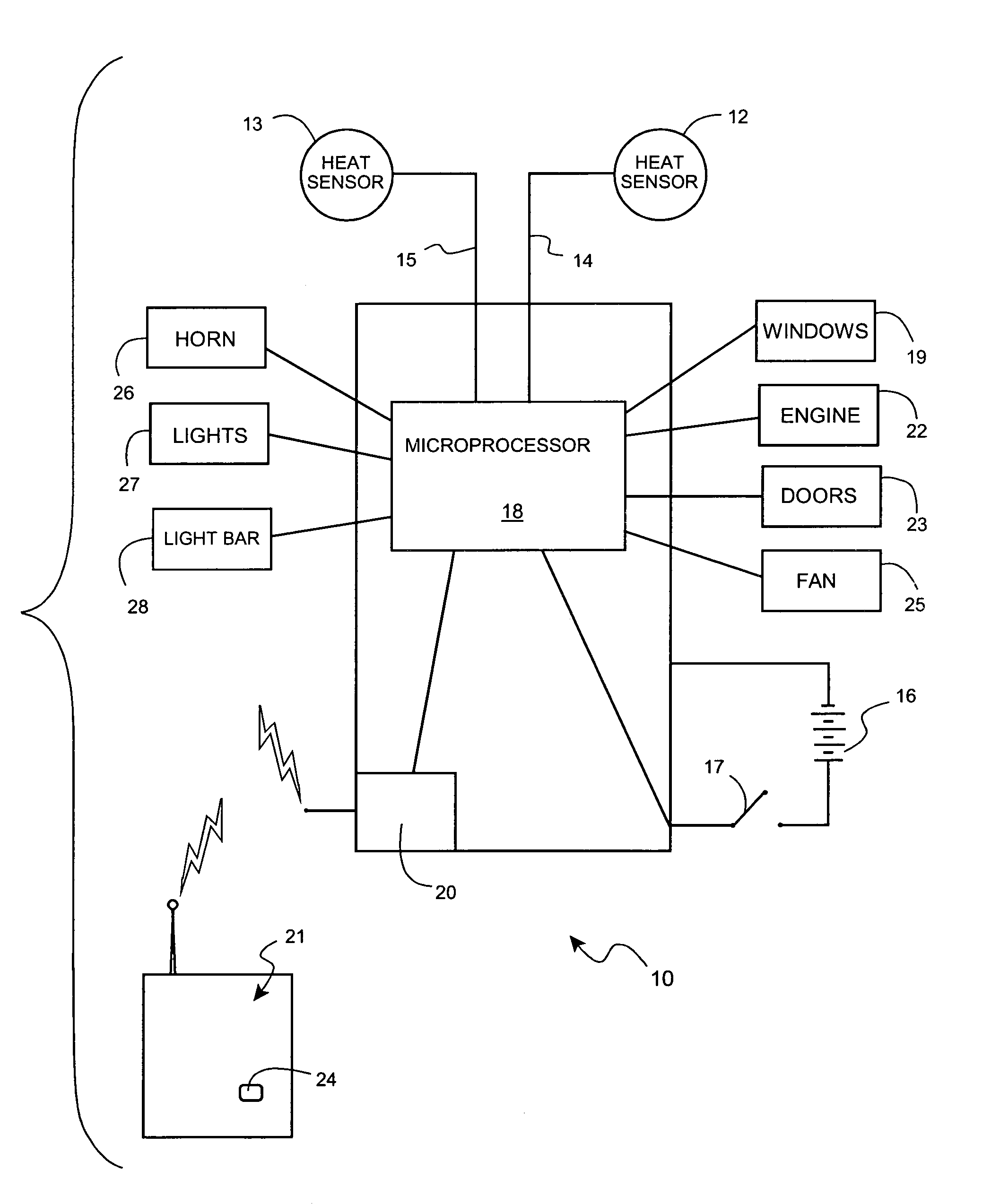

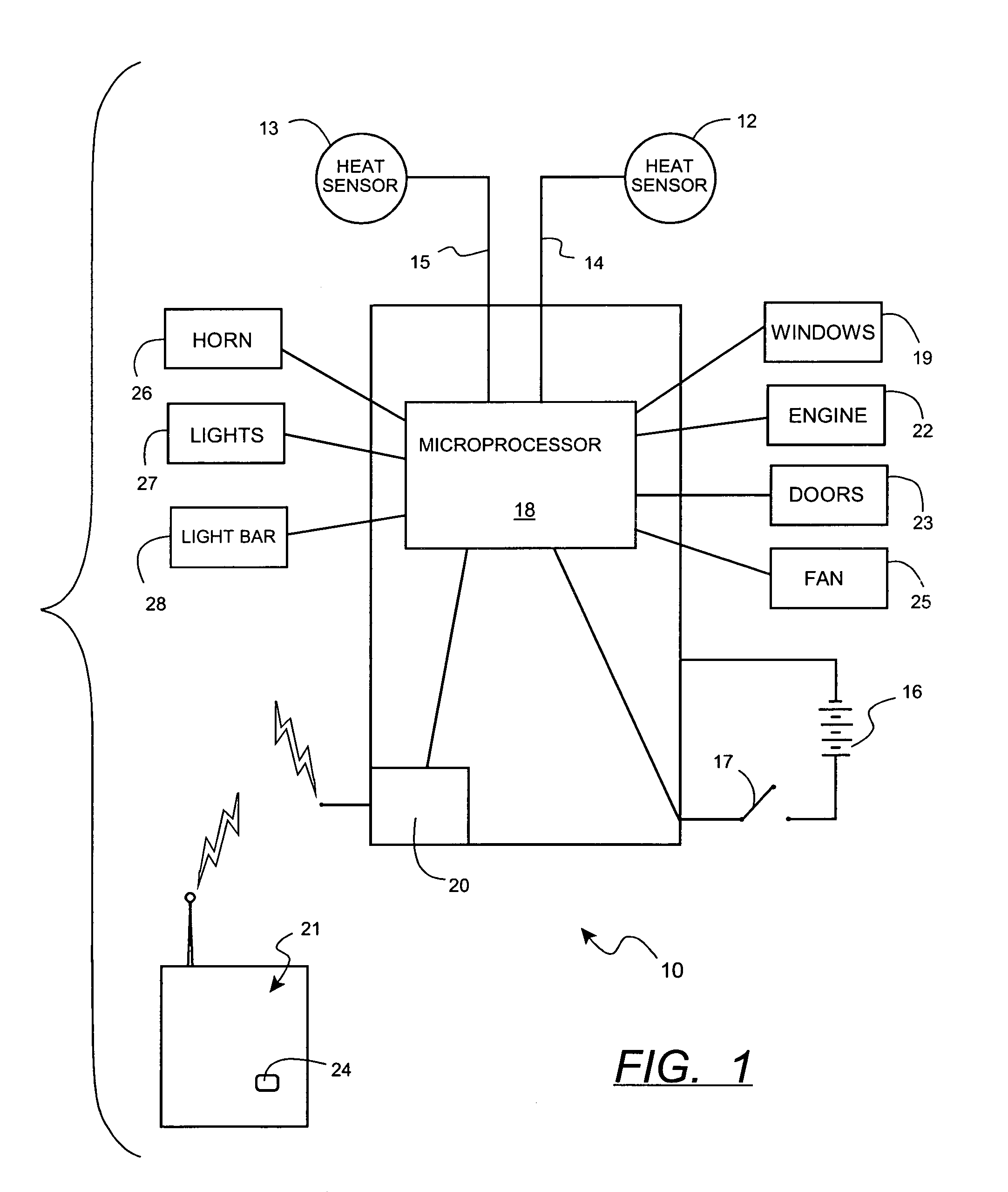

Multiple sensor heat alarm

Owner:JOHN JOHNSTON +2

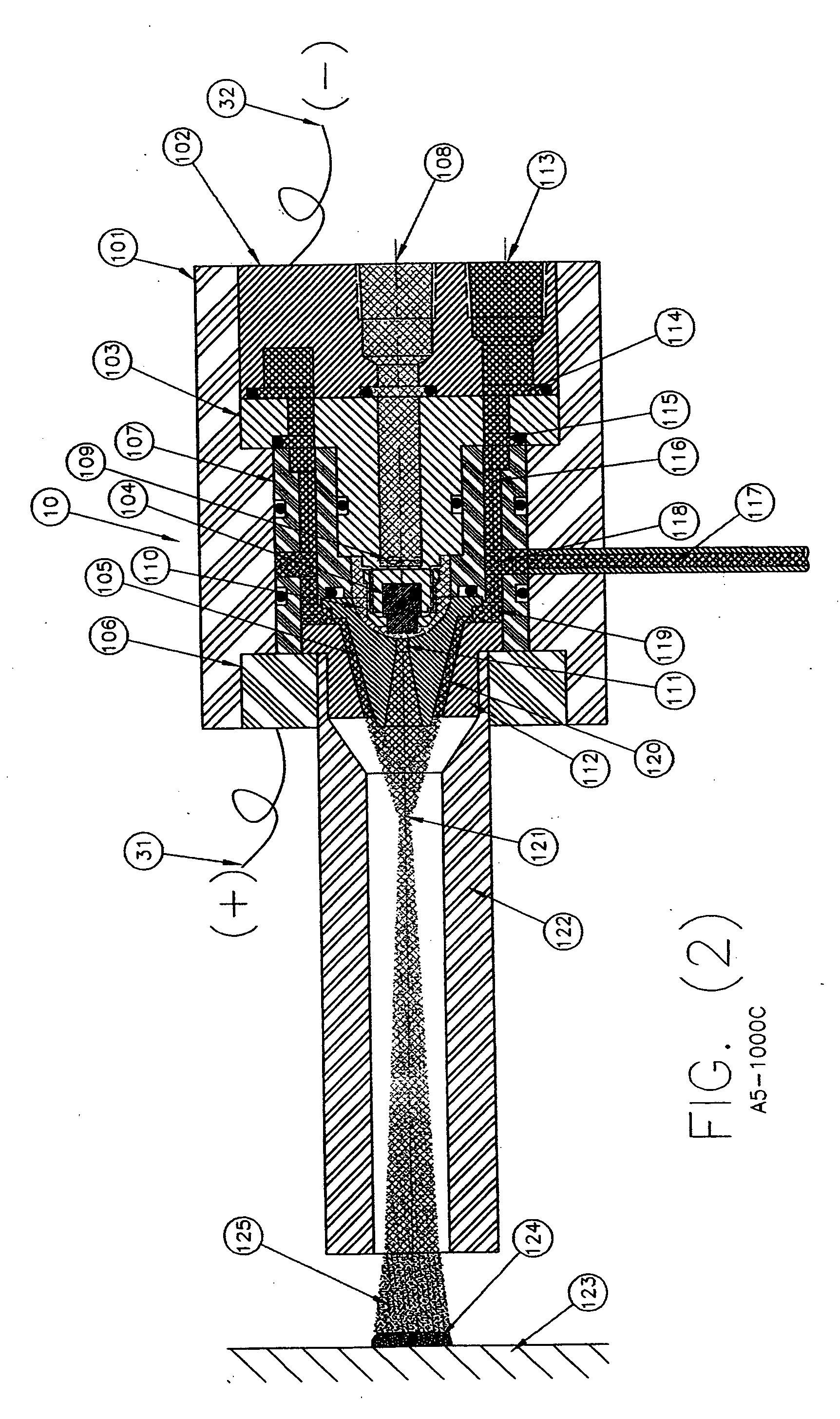

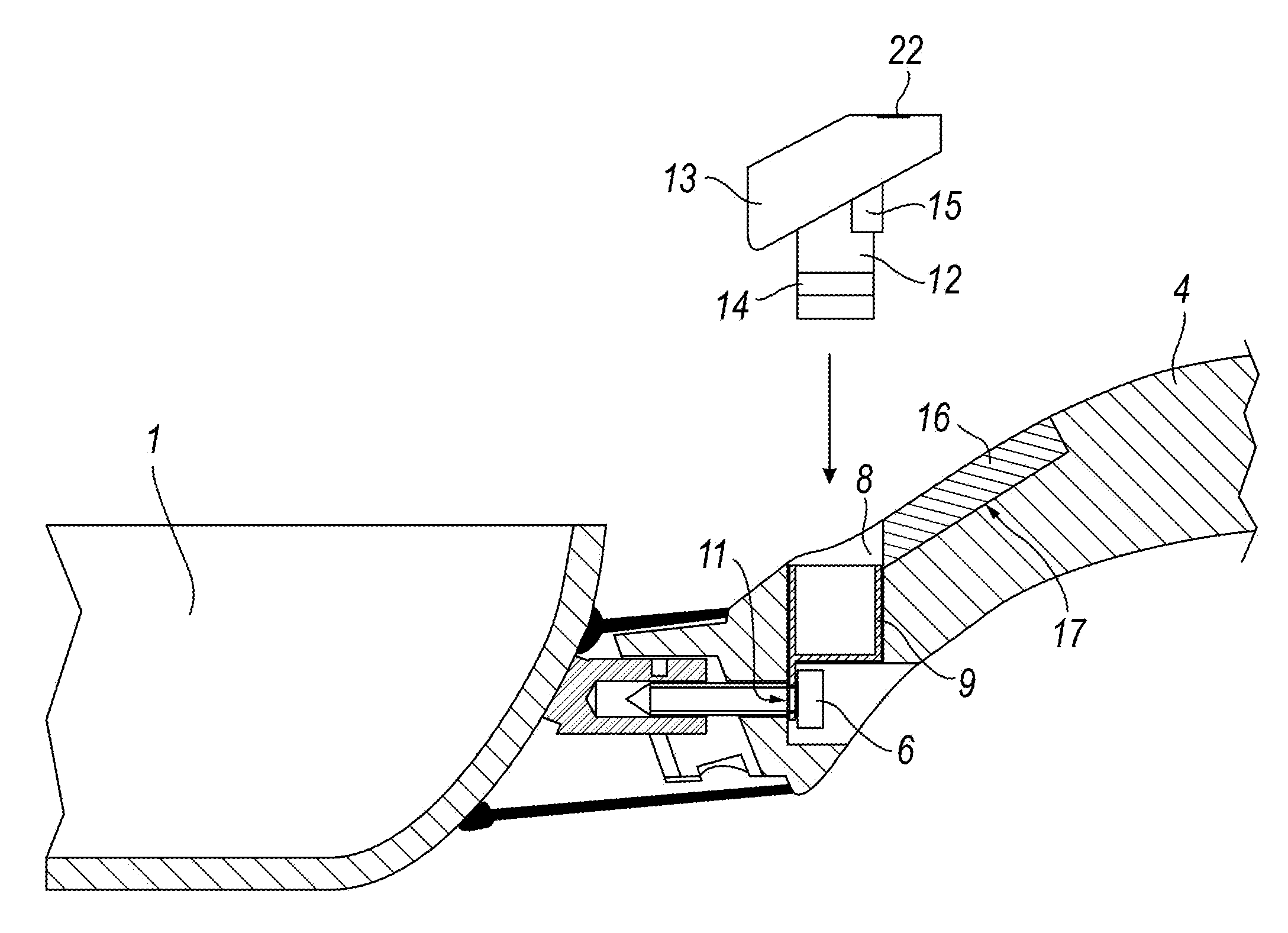

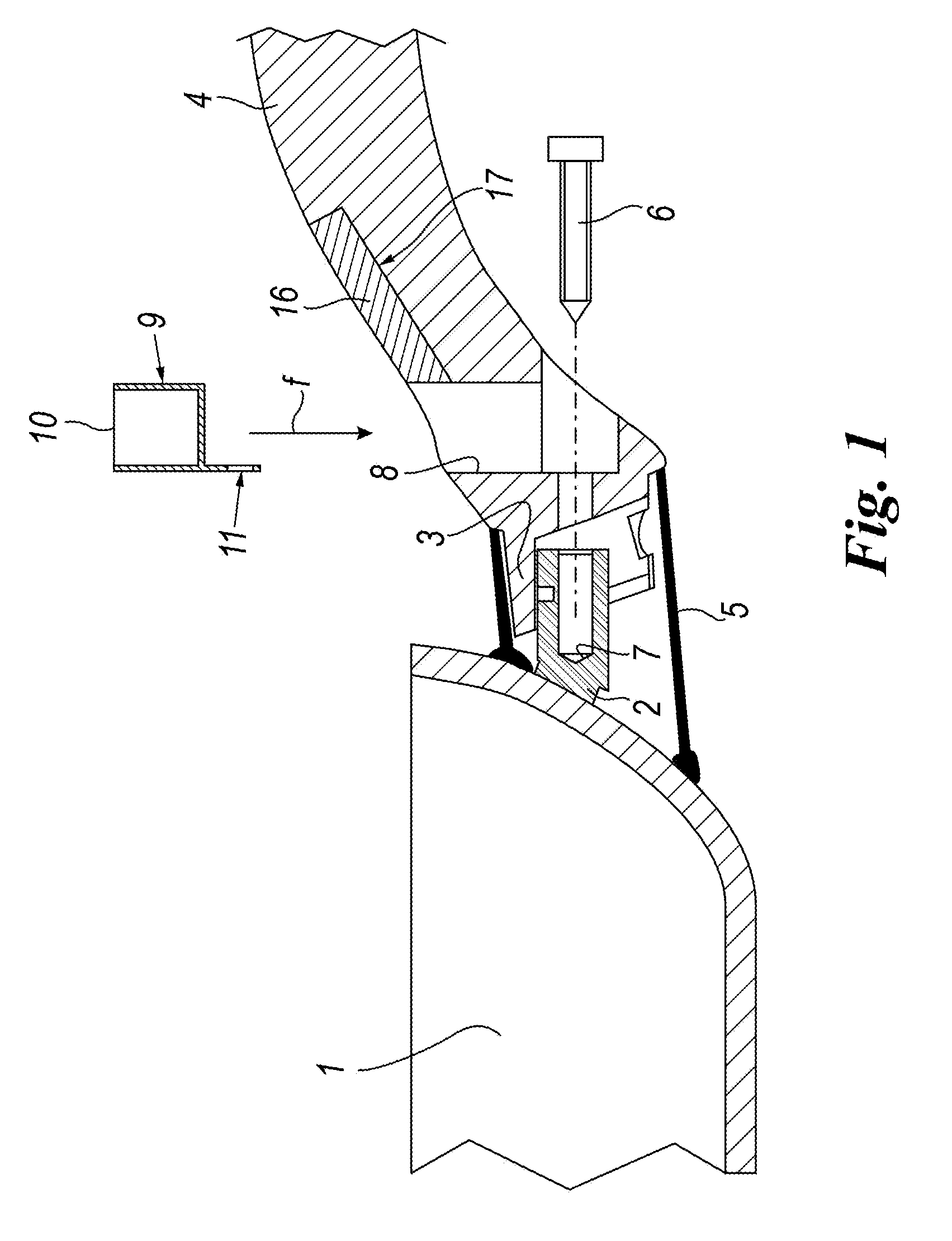

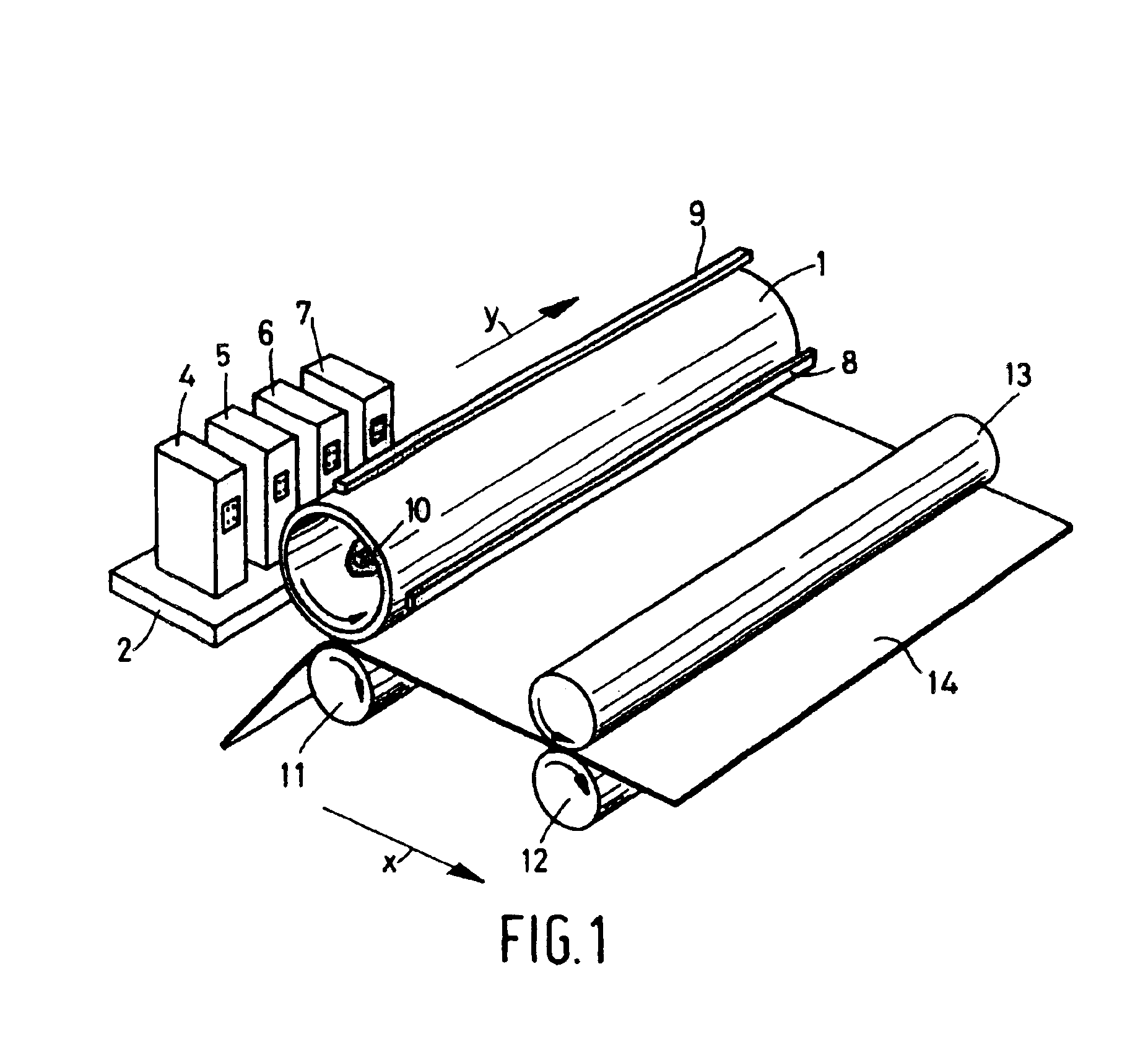

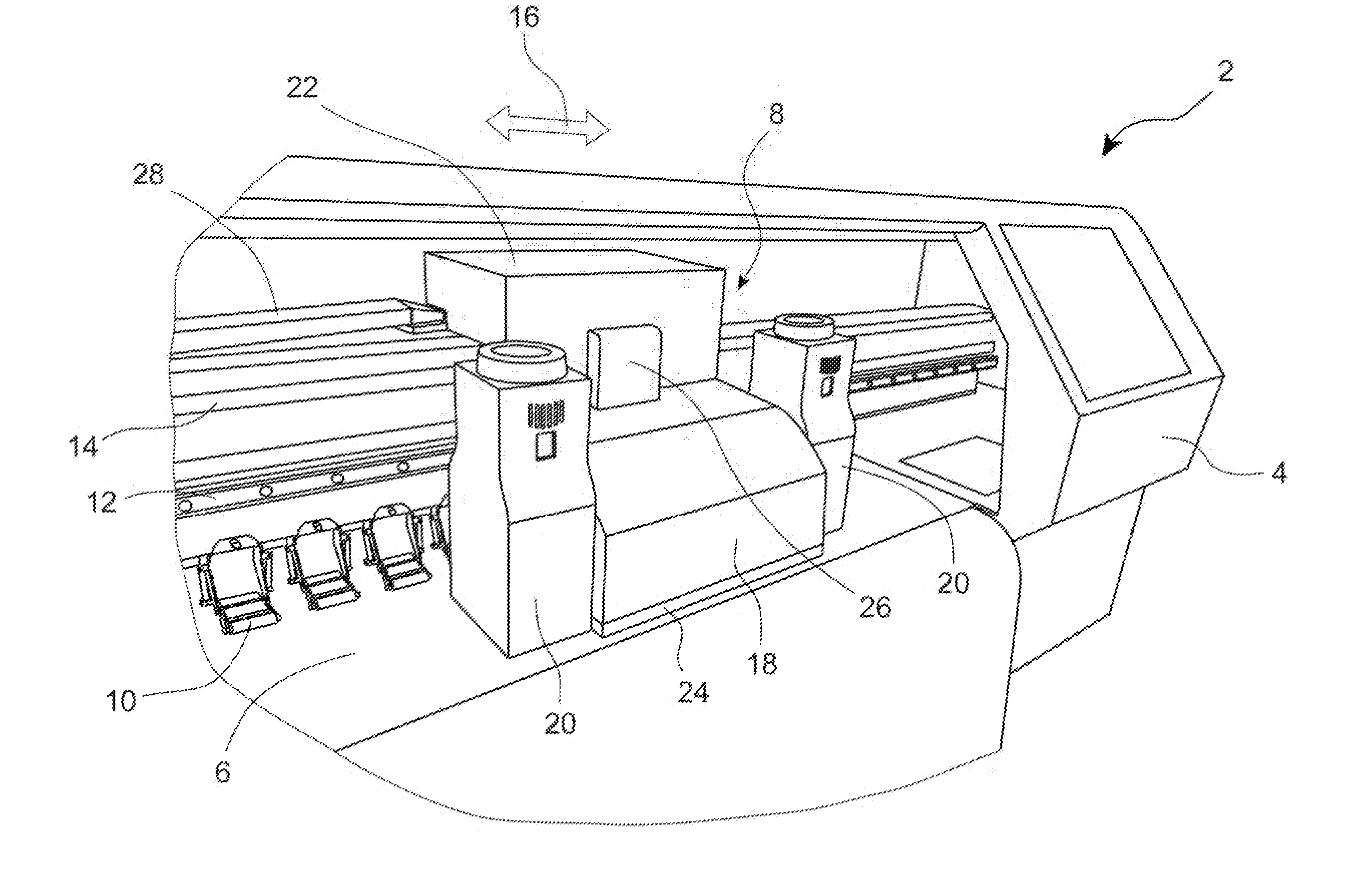

Rotary plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS6986471B1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorMaterials science

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns. The system also includes a rotating member for coating concave surfaces and internal bores or other such devices which can be better coated using rotation.

Owner:FLAME SPRAY IND

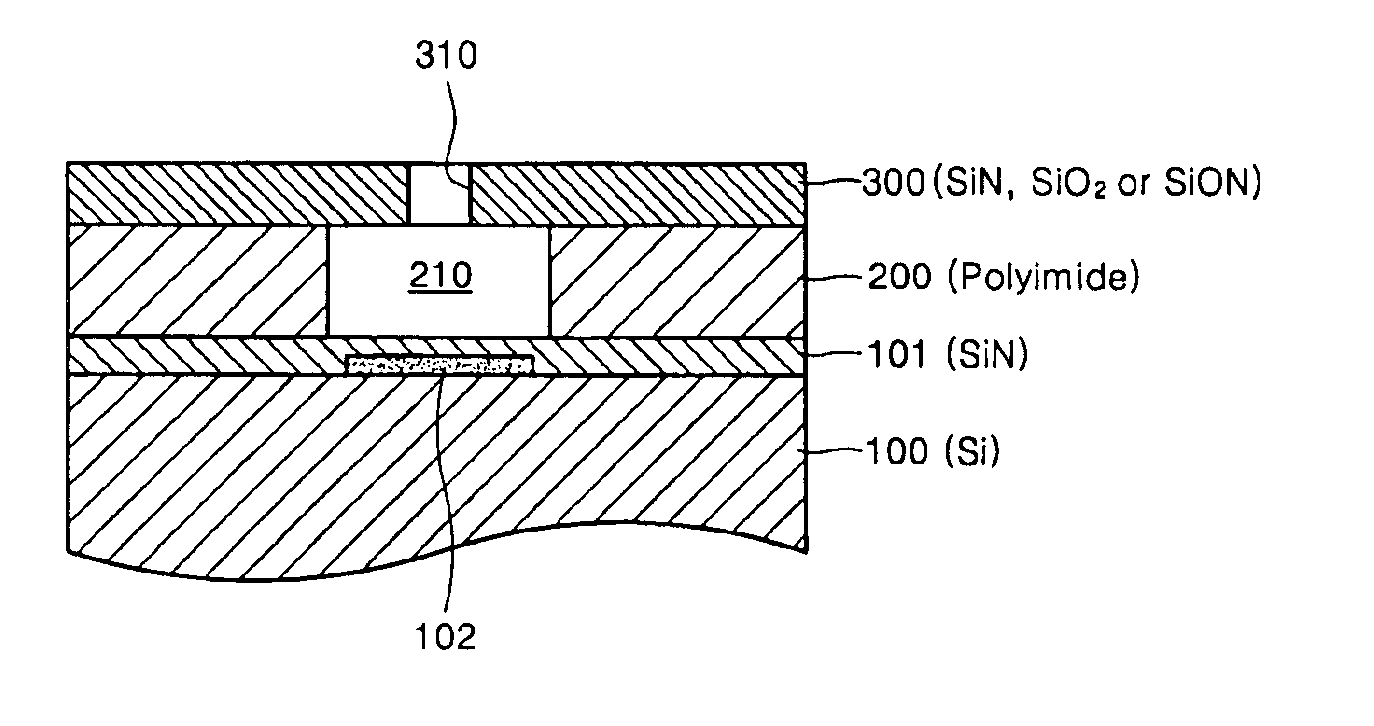

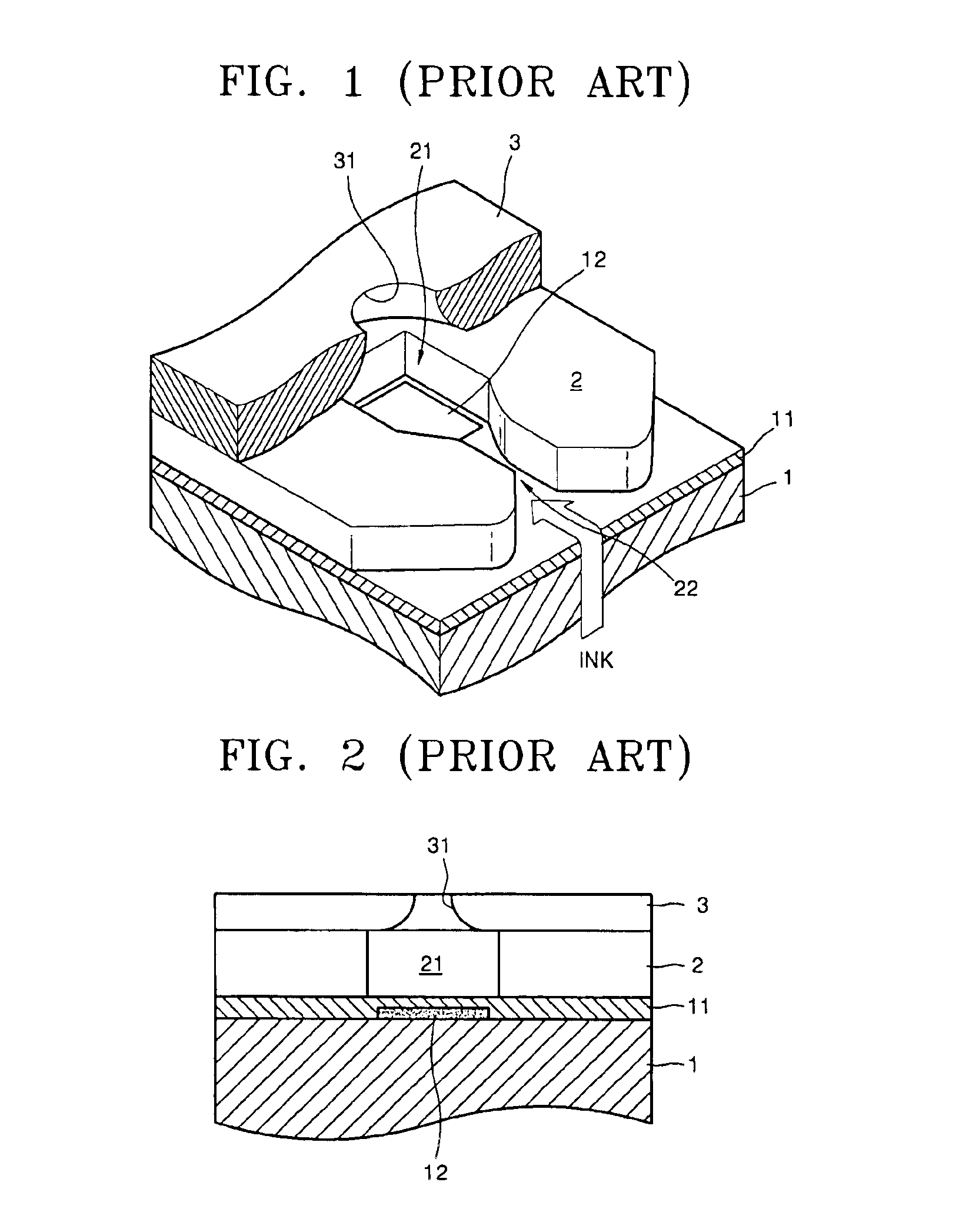

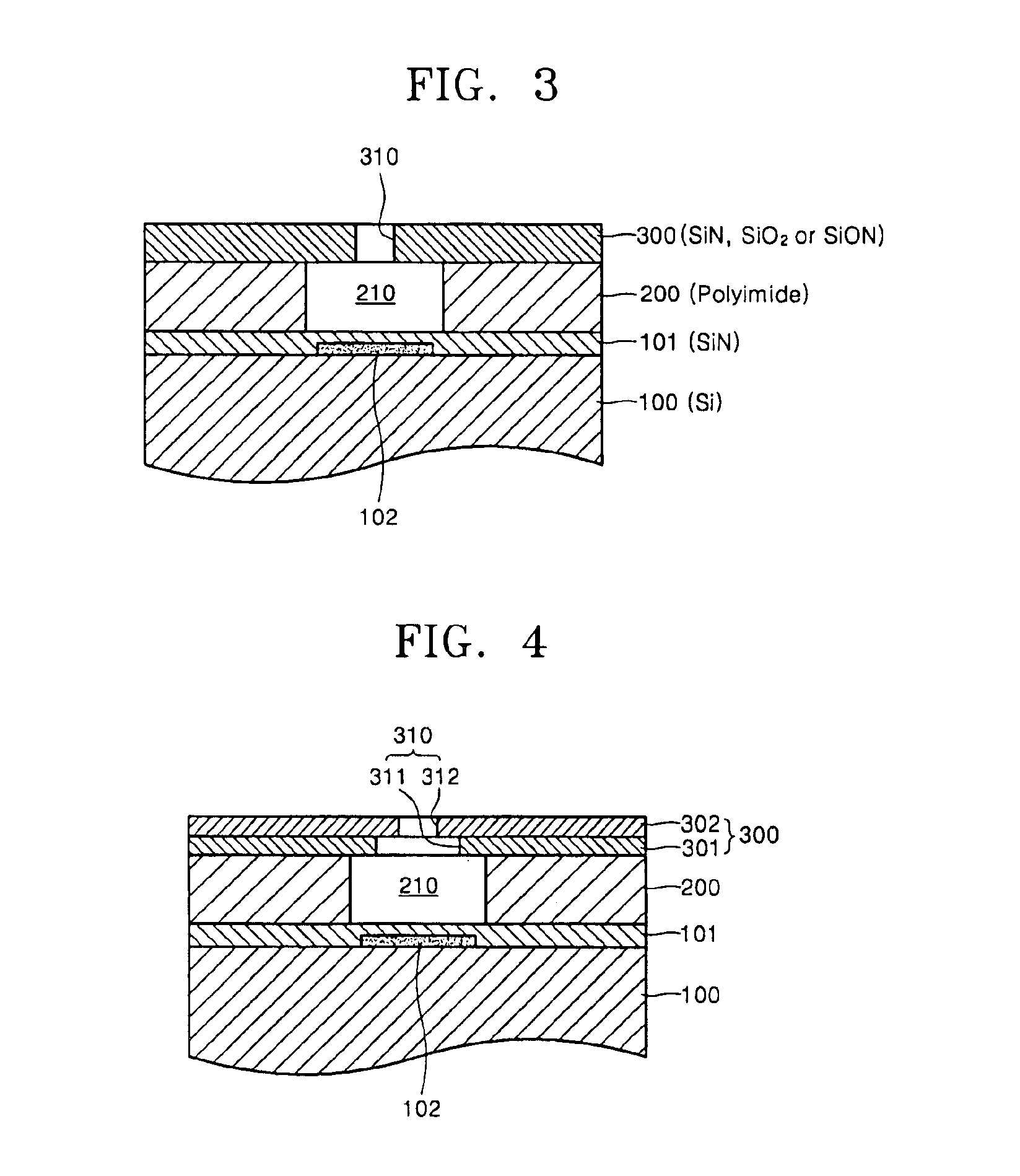

Ink-jet printhead and method of manufacturing the same

An ink-jet printhead and a method of manufacturing the ink-jet printhead include a substrate on which at least one heater and a passivation layer protecting the at least one heater are formed, a passage plate formed on the substrate to provide a chamber corresponding to the at least one heater, and a nozzle plate in which an orifice corresponding to the chamber is formed. The passage plate is formed of photoresist, and the nozzle plate is formed of a silicon-family material at a temperature limited by characteristics of the passage plate.

Owner:S PRINTING SOLUTION CO LTD

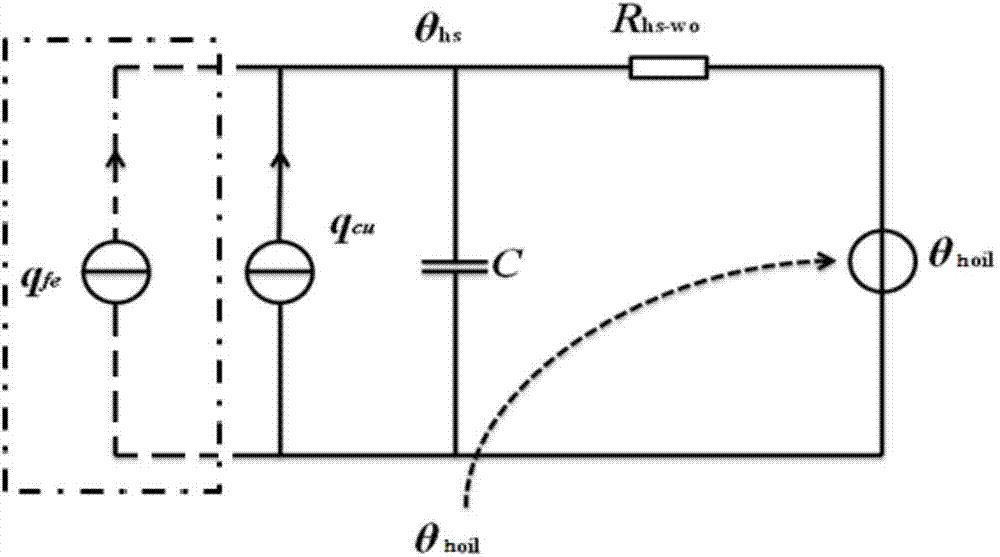

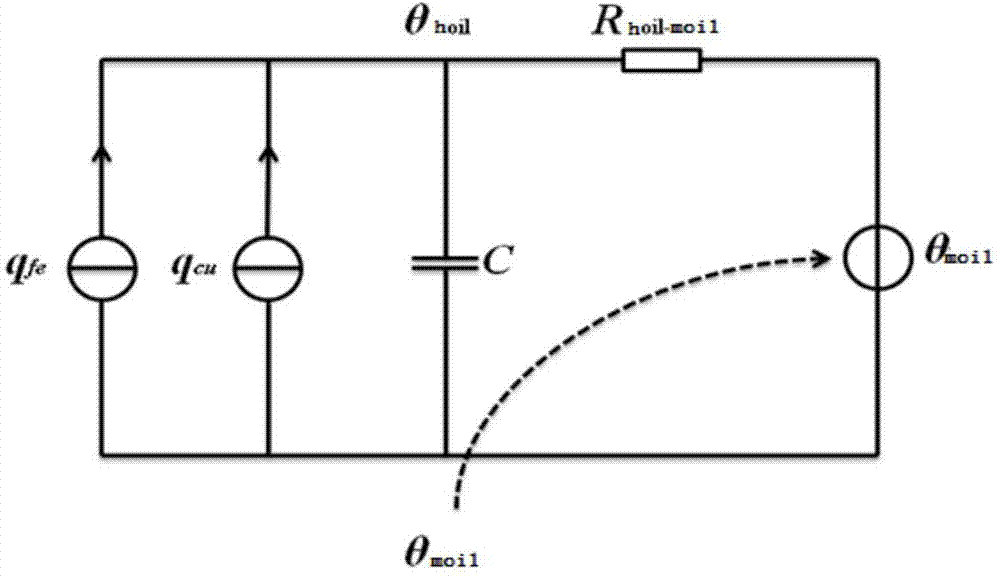

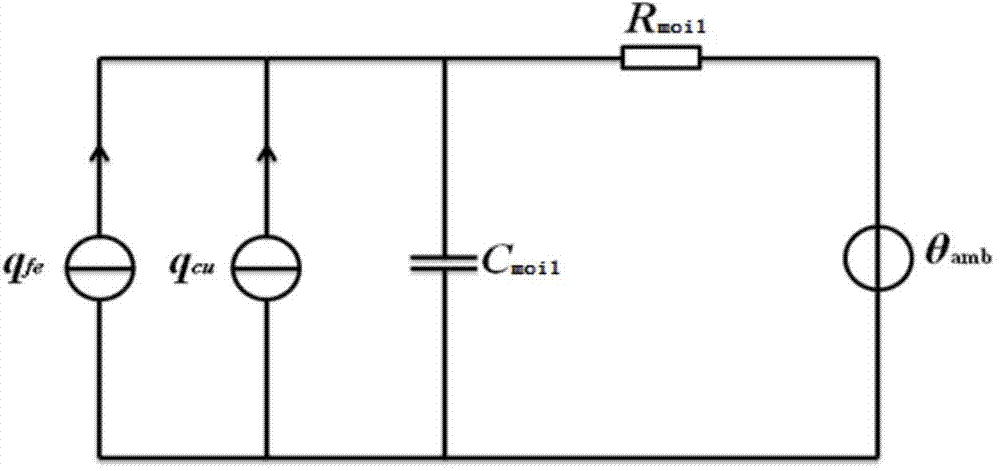

Dynamic capacity increasing method for oil-immersed transformer

ActiveCN103779059ADynamic capacity increase real-time monitoringAvoid overall overheatingInductances/transformers/magnets manufactureThermometer applicationsSteady state temperatureTime delays

The invention relates to a dynamic capacity increasing method for an oil-immersed transformer, and belongs to the field of transformers. The method includes the steps that heat conduction process in the transformer is simplified into a circuit model; winding hot-spot temperature, top oil temperature, average oil temperature, average winding temperature of the transformer under the current load condition are calculated; according to the limit that the winding hot-spot temperature does not exceed 140 DEG C, whether temperature in the transformer will exceed the limit temperature or not under the current load and environment conditions is calculated, whether a temperature limit value is reached or not if long-term emergency loads or short-term emergency loads occur at the moment is calculated, and if the temperature in the transformer possibly exceeds the limit value of the short-term emergency loads, the time for reaching the limit value and the finally reached steady state temperature are calculated to serve as alarm signals; if it is monitored that the temperature will exceed the standard within t minutes, an early-warning signal is sent out, certain time delay is set, and if the loads are not reduced within the set time delay, a cooling fan of the transformer is turned on. Long-term continuous operation of cooling equipment can be avoided, and operation life of the cooling equipment is prolonged.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

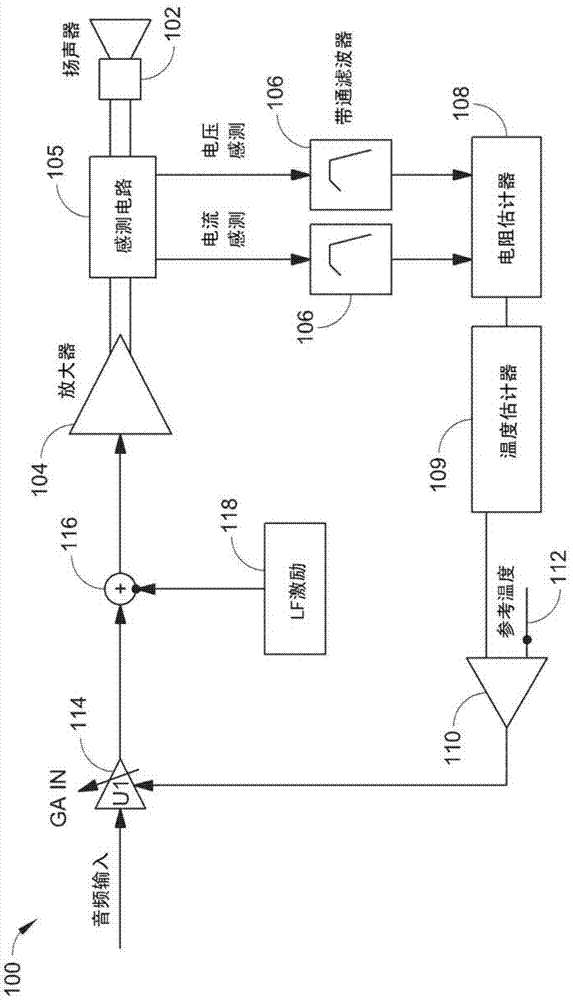

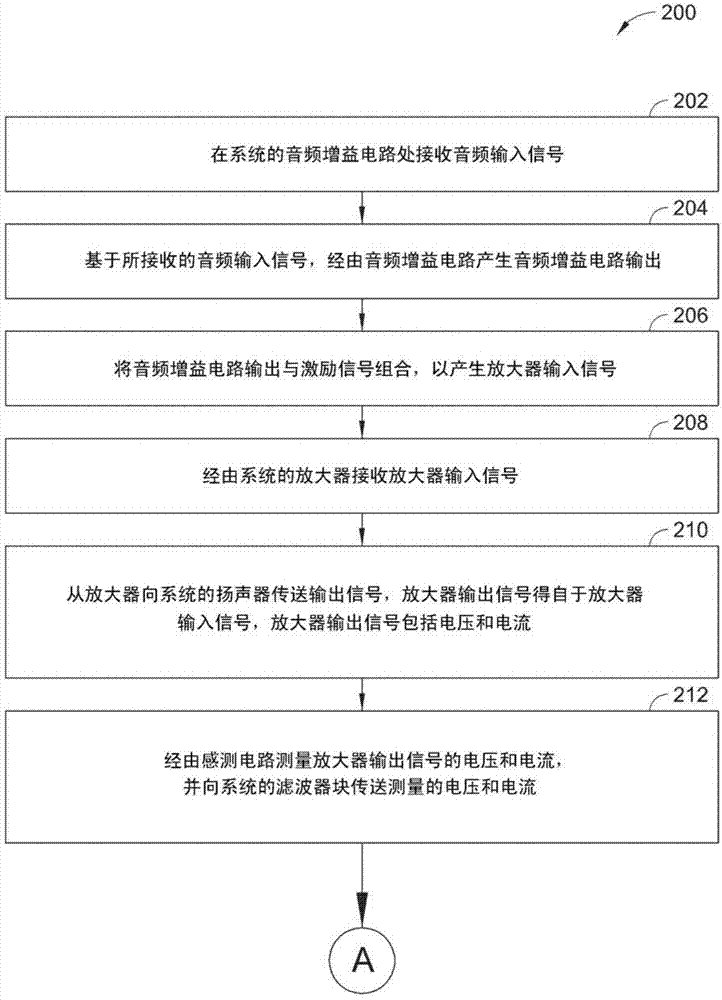

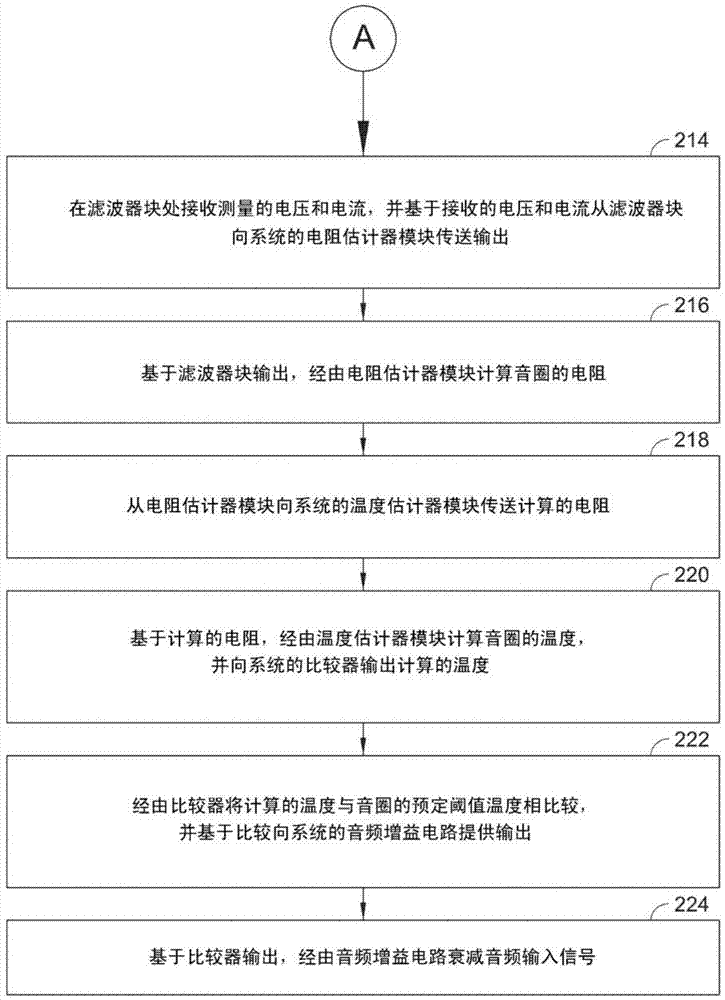

Direct measurement of input signal to loudspeaker to determine and limit temperature of voice coil of the loudspeaker

Aspects of the disclosure pertain to a system and method for providing temperature limiting for a voice coil of a speaker. The system and method provide the aforementioned temperature limiting based upon monitoring (e.g., measurement) of an amplifier output signal provided to the speaker. Providing the aforementioned temperature limiting promotes improved protection for the speaker.

Owner:MAXIM INTEGRATED PROD INC

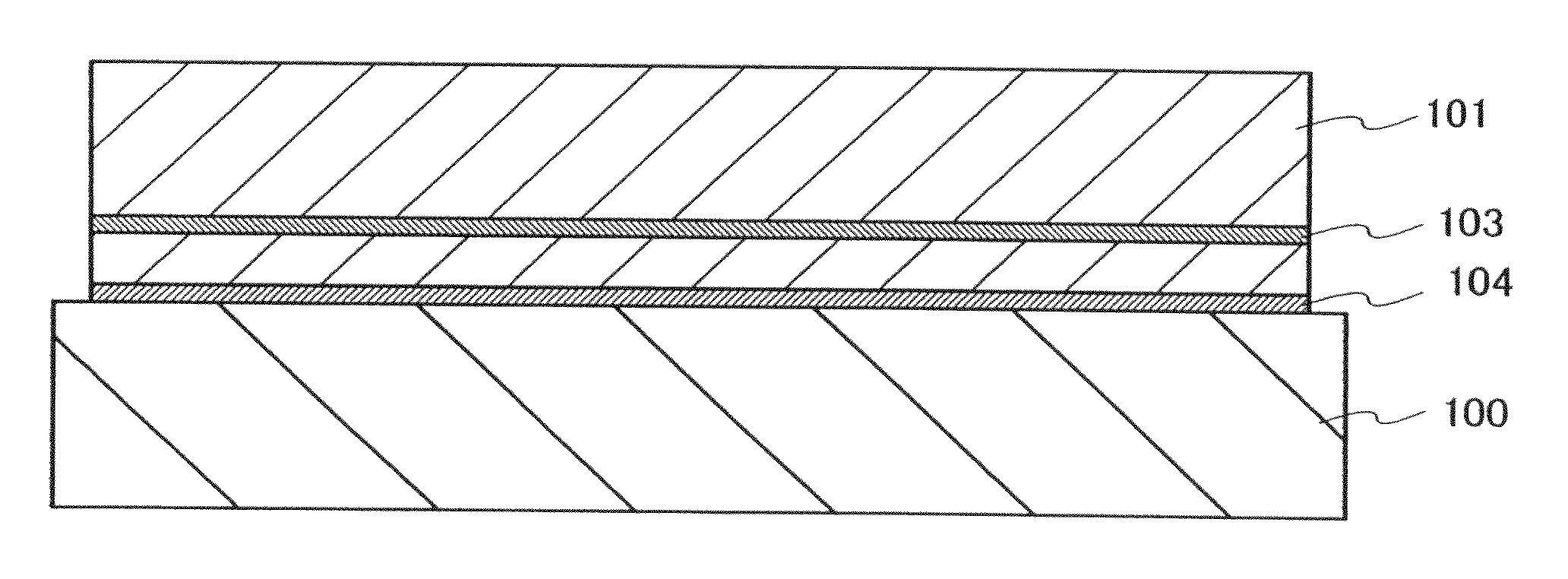

Method of manufacturing SOI substrate

InactiveUS20080261376A1Reduce planarityImprove flatnessTransistorSemiconductor/solid-state device manufacturingSilanesSource material

To provide an SOI substrate with an SOI layer that can be put into practical use, even when a substrate with a low allowable temperature limit such as a glass substrate is used, and to provide a semiconductor substrate formed using such an SOI substrate. In order to bond a single-crystalline semiconductor substrate to a base substrate such as a glass substrate, a silicon oxide film formed by CVD with organic silane as a source material is used as a bonding layer, for example. Accordingly, an SOI substrate with a strong bond portion can be formed even when a substrate with an allowable temperature limit of less than or equal to 700° C. such as a glass substrate is used. A semiconductor layer separated from the single-crystalline semiconductor substrate is irradiated with a laser beam so that the surface of the semiconductor layer is planarized and the crystallinity thereof is recovered.

Owner:SEMICON ENERGY LAB CO LTD

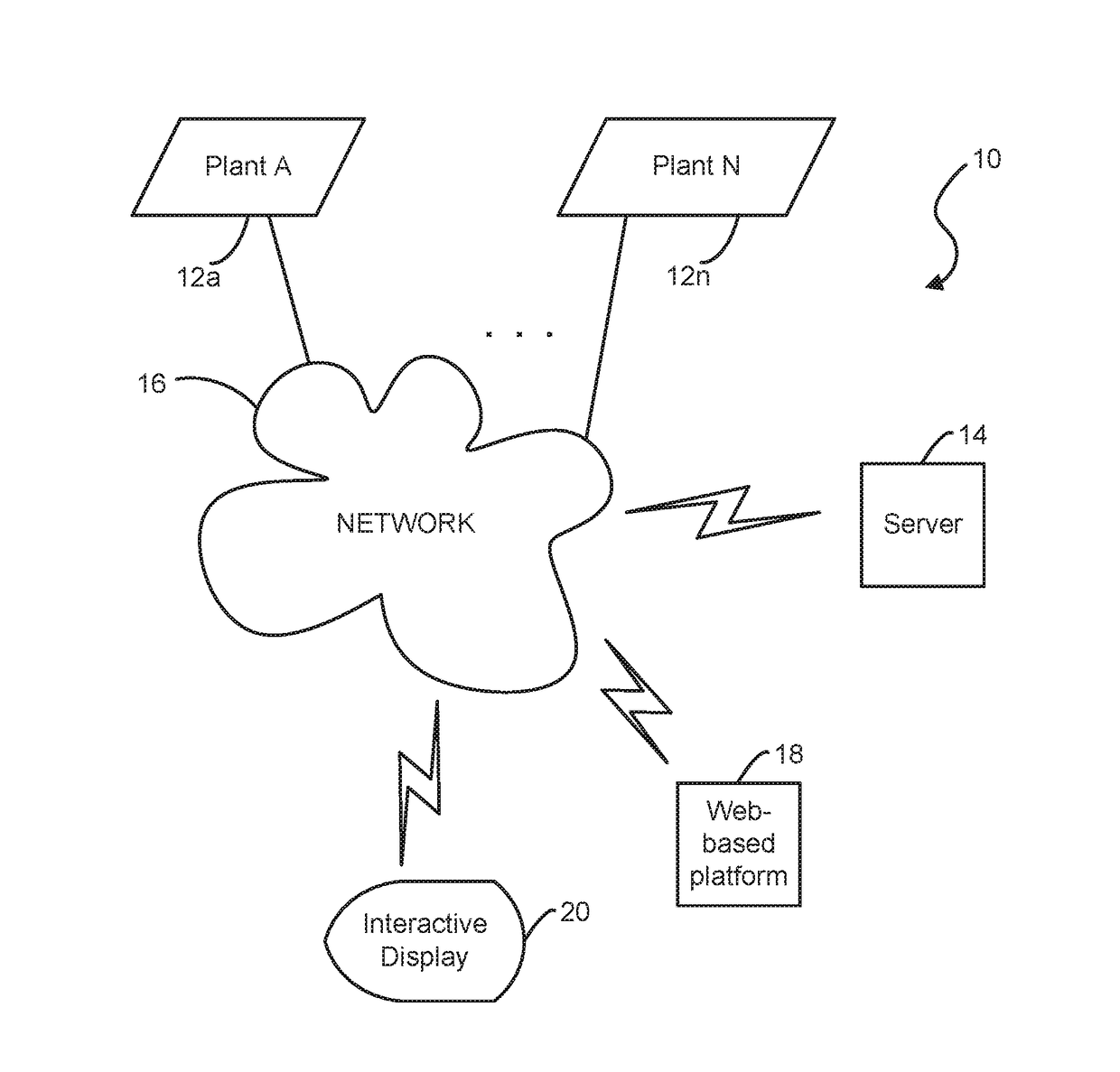

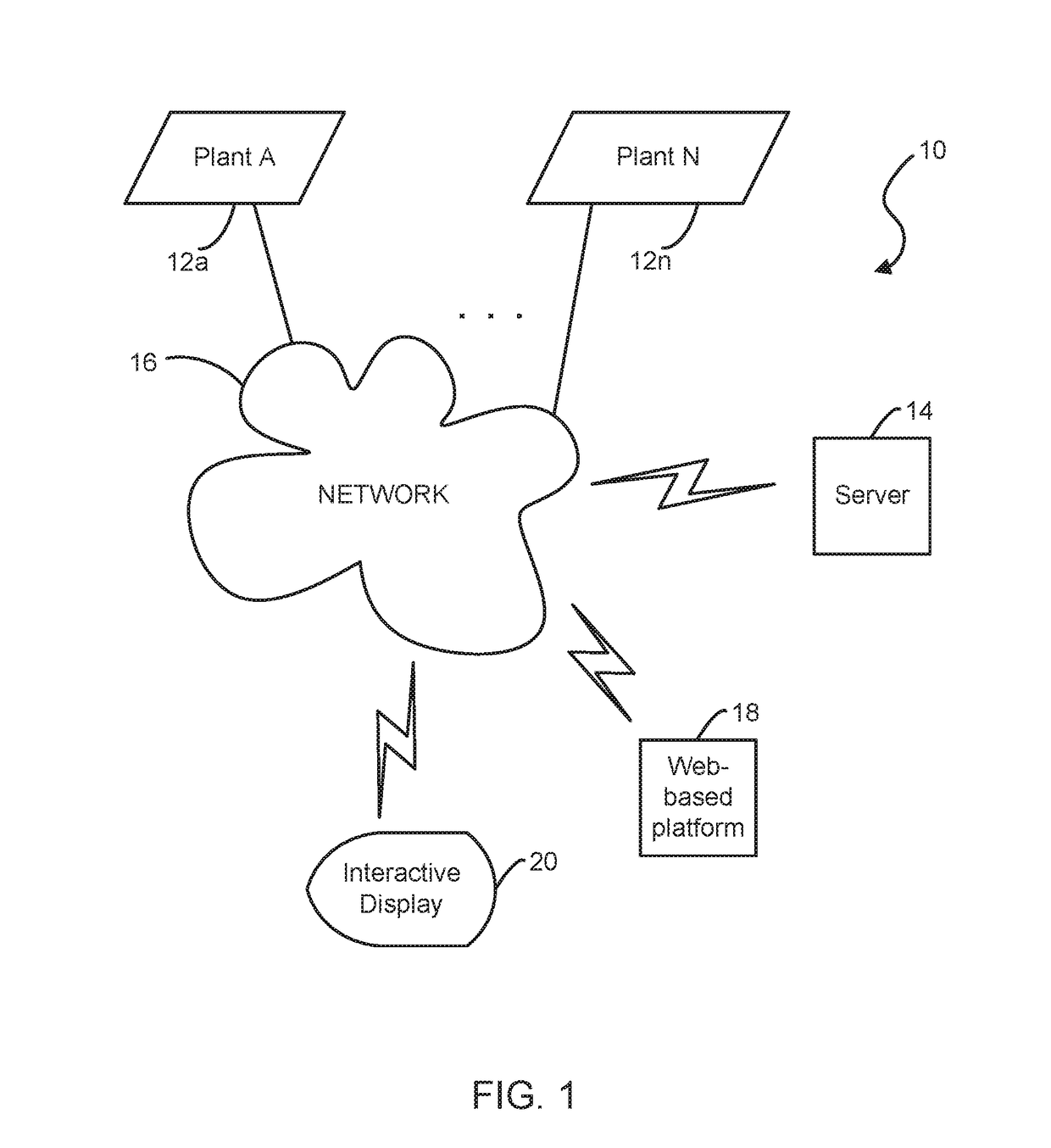

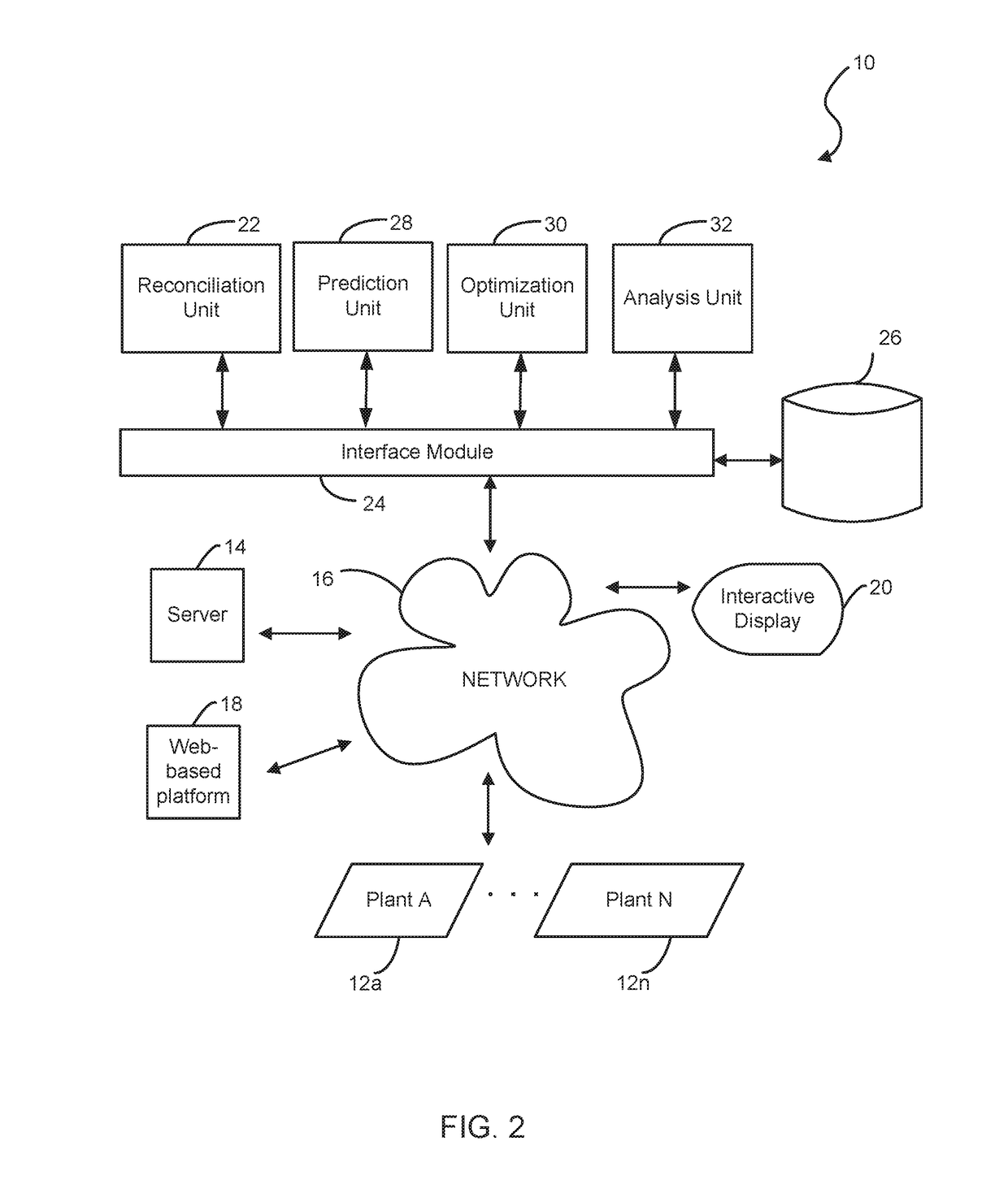

Identifying and implementing refinery or petrochemical plant process performance improvements

ActiveUS20180046155A1Operation efficiency can be improvedEasy to operateHydrocarbon distillation control/regulationCatalytic naphtha reformingReboilerFractionation

A refinery or petrochemical plant may include a fractionation column and related equipment, such as one or more condensers, receivers, reboilers, feed exchangers, and pumps. The equipment may have boundaries or thresholds of operating parameters based on existing limits and / or operating conditions. Illustrative existing limits may include mechanical pressures, temperature limits, hydraulic pressure limits, and operating lives of various components. There may also be relationships between operational parameters related to particular processes. For example, the boundaries on a naphtha reforming reactor inlet temperature may be dependent on a regenerator capacity and hydrogen-to-hydrocarbon ratio, which in turn may be dependent on a recycle compressor capacity. Operational parameters of a final product may be determined based on actual current or historical operation, and implemented in one or more models to determine adjustments for enhanced operational efficiency.

Owner:UOP LLC

Apparatus and method for printing sharp image in an inkjet printer

InactiveUS20130215203A1Cost advantagePrevent coalescenceOther printing apparatusImaging qualityEngineering

An apparatus and method to heat media in order to achieve rapid ink drying for sharp image quality is disclosed. The apparatus comprises a media heating means to heat media approximate the print zone to prevent coalescence and inter-color bleeding, and a printhead cooling means to cool the printhead so that the printhead temperature is maintained below an upper printhead temperature limit to minimize clogged nozzles. The preferred embodiment includes a hot air blower attached to the movable carriage to impinge heated air directly on to the media surface, and circulating a liquid coolant in a fluid channel built in a printhead plate conductively connected to the printhead.

Owner:MEIJET COATING & INKS

PTAC dehumidification without reheat and without a humidistat

ActiveUS20080156891A1Avoid OverloadingShorten speedSpace heating and ventilation safety systemsSpace heating and ventilation control systemsControl mannerRoom temperature

A refrigerant system includes a controller that enables the system to dehumidify the air in a room without relying on a humidistat and without having to operate the system's compressor and electric heater at the same time. To dehumidify the air, the system's compressor, supply air fan, and outside air damper are controlled in a manner similar to other systems operating in a cooling mode when the room temperature is above a certain setpoint temperature. When the room temperature falls below the setpoint, however, the operation changes significantly. The controller closes the outside air damper, decreases the speed of the fan, and continues operating in this manner until the room temperature decreases to a subcooling temperature limit. The subcooling temperature limit is less than a predetermined limit that is used during the system's normal cooling mode.

Owner:TRANE INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com