Patents

Literature

278 results about "Curie" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The curie (symbol Ci) is a non-SI unit of radioactivity originally defined in 1910. According to a notice in Nature at the time, it was named in honour of Pierre Curie, but was considered at least by some to be in honour of Marie Curie as well.

Magnetocaloric element

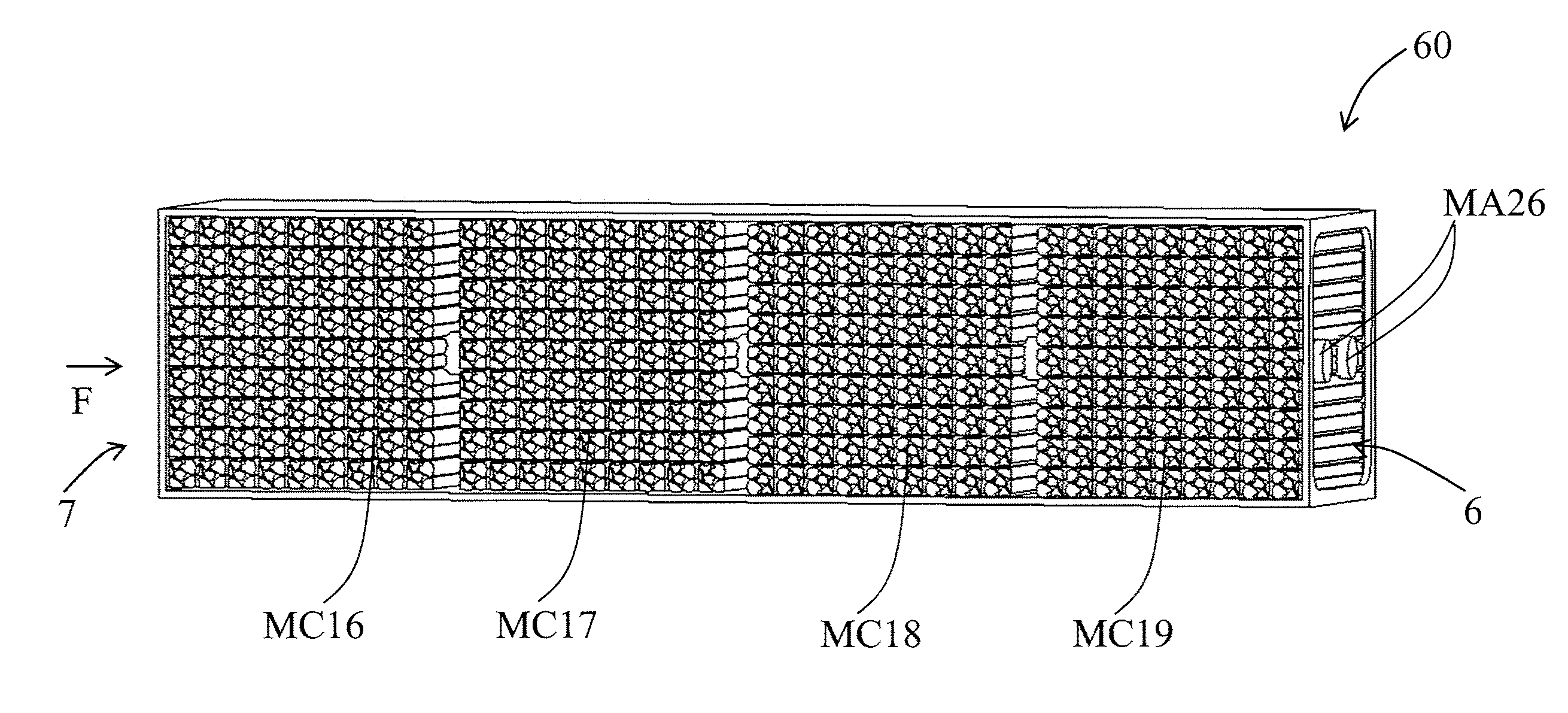

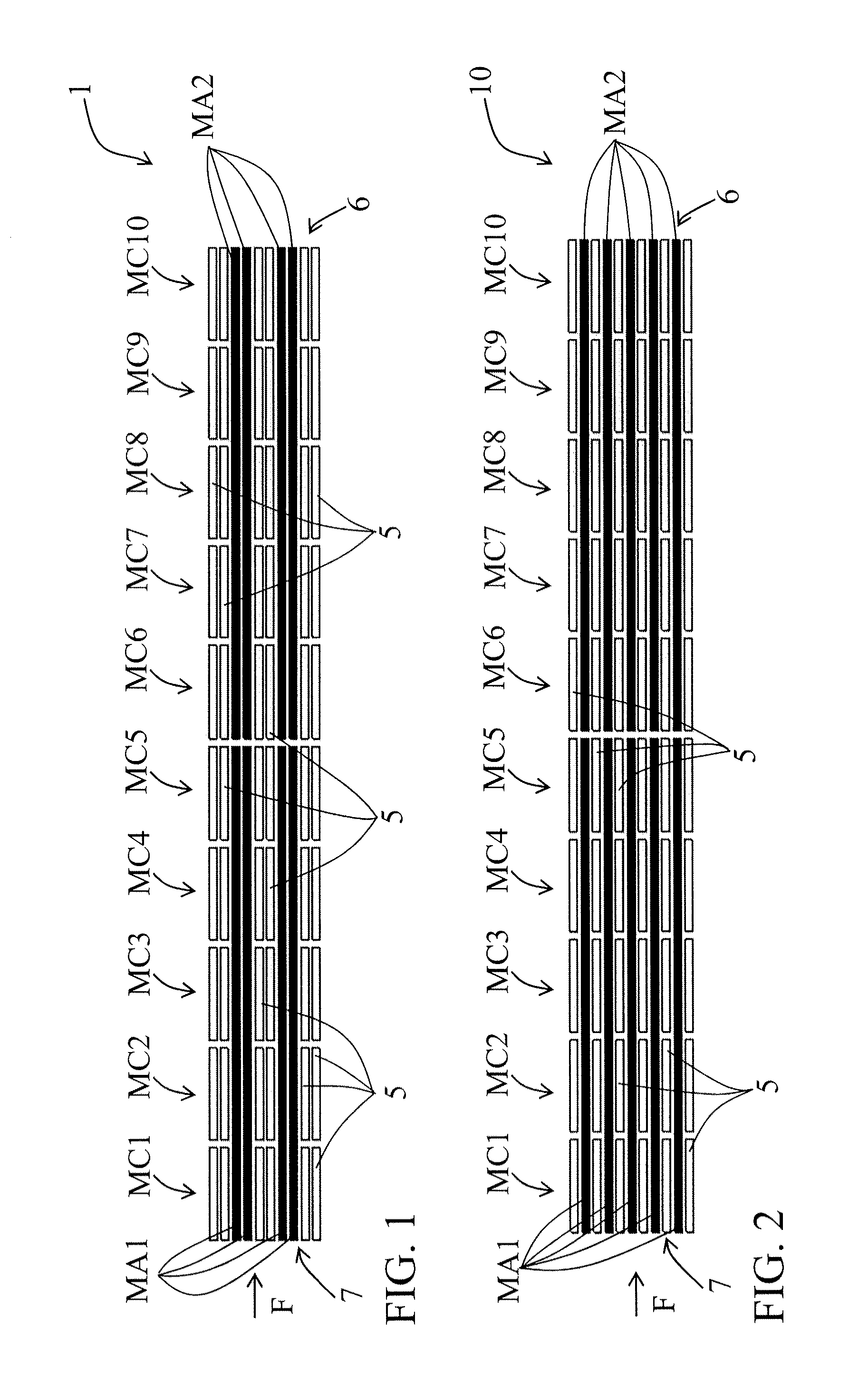

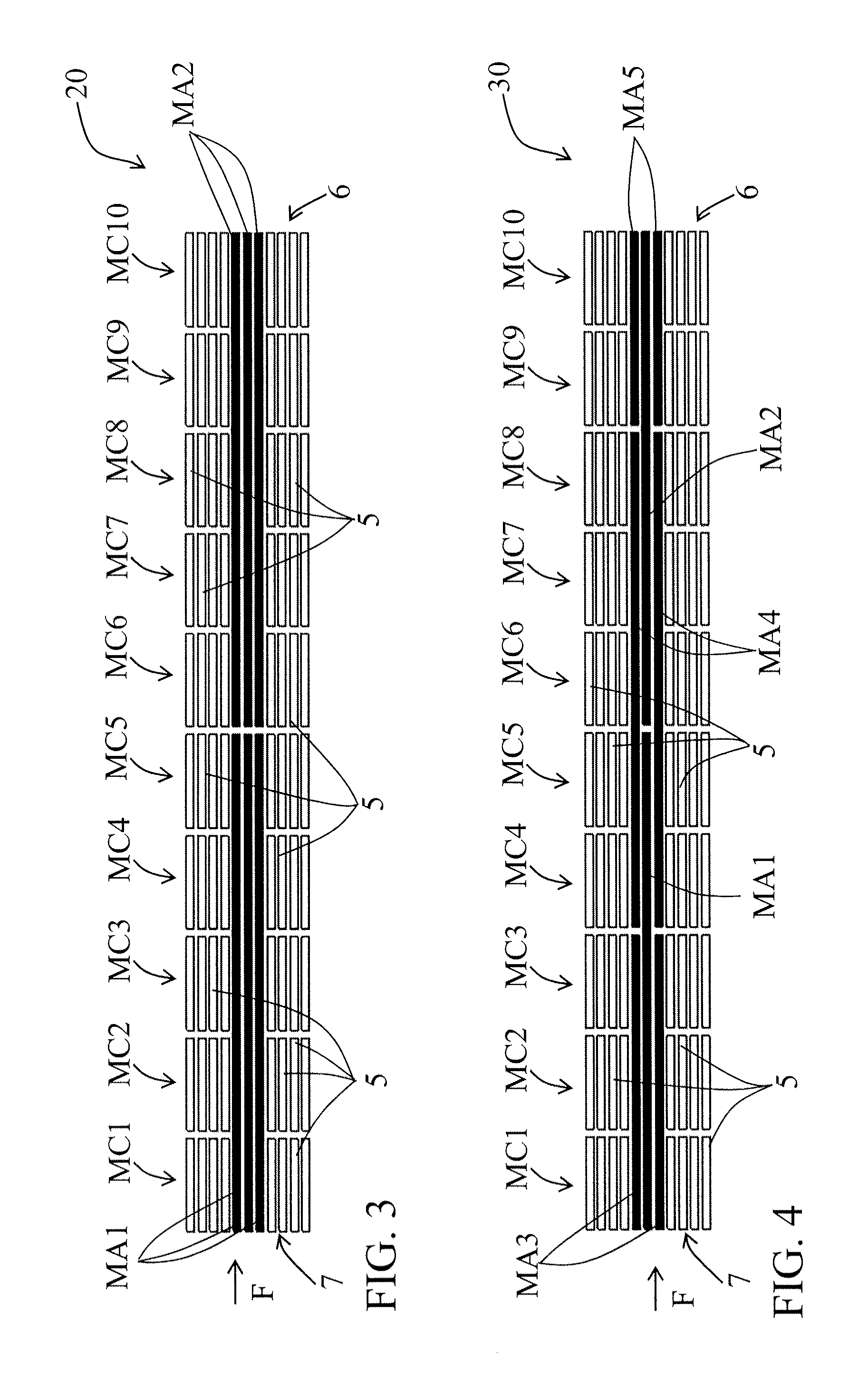

InactiveUS20110173993A1Speed up creationQuickly reachEnergy efficient heating/coolingMagnetic materialsTemperature gradientPhysics

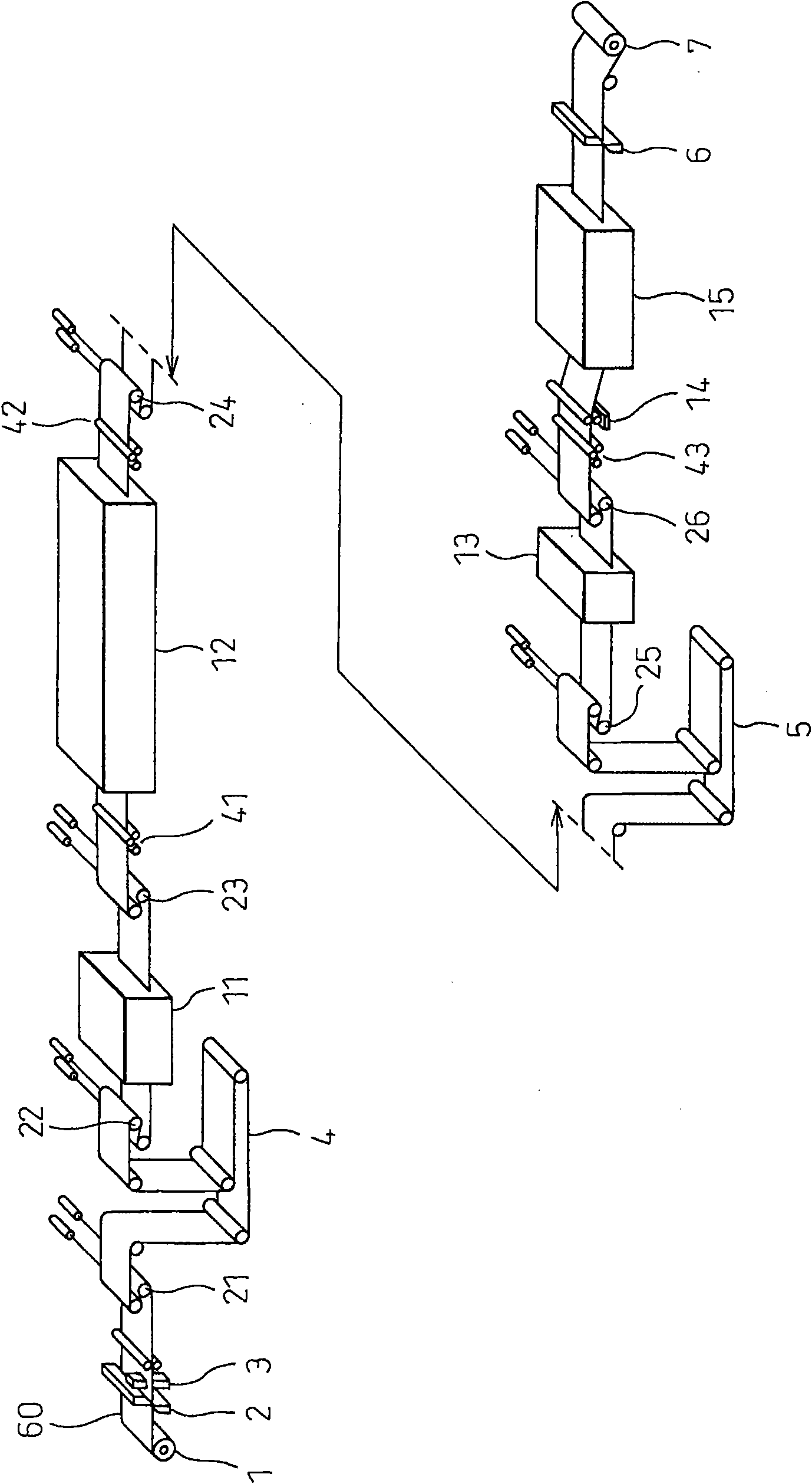

A magnetocaloric element (1) made by an alignment of at least two adjacent sets (MC1-10) of magnetocaloric materials having different Curie temperatures. The magnetocaloric materials within a same set (MC1-10) have the same Curie temperature. The sets (MC1-10) are arranged according to an increasing Curie temperature, and the magnetocaloric element (1) comprises elements (MA1-2) for initiating a temperature gradient between a hot end (6) and an opposed cold end (7) of the magnetocaloric element (1).

Owner:COOLTECH APPL S

Mn-Zn ferrite with broad temperature, broadband, high curie point and low loss and preparation method thereof

InactiveCN101620908AFulfil requirementsGuaranteed wide temperature characteristicsInorganic material magnetismHigh frequency powerNitrogen

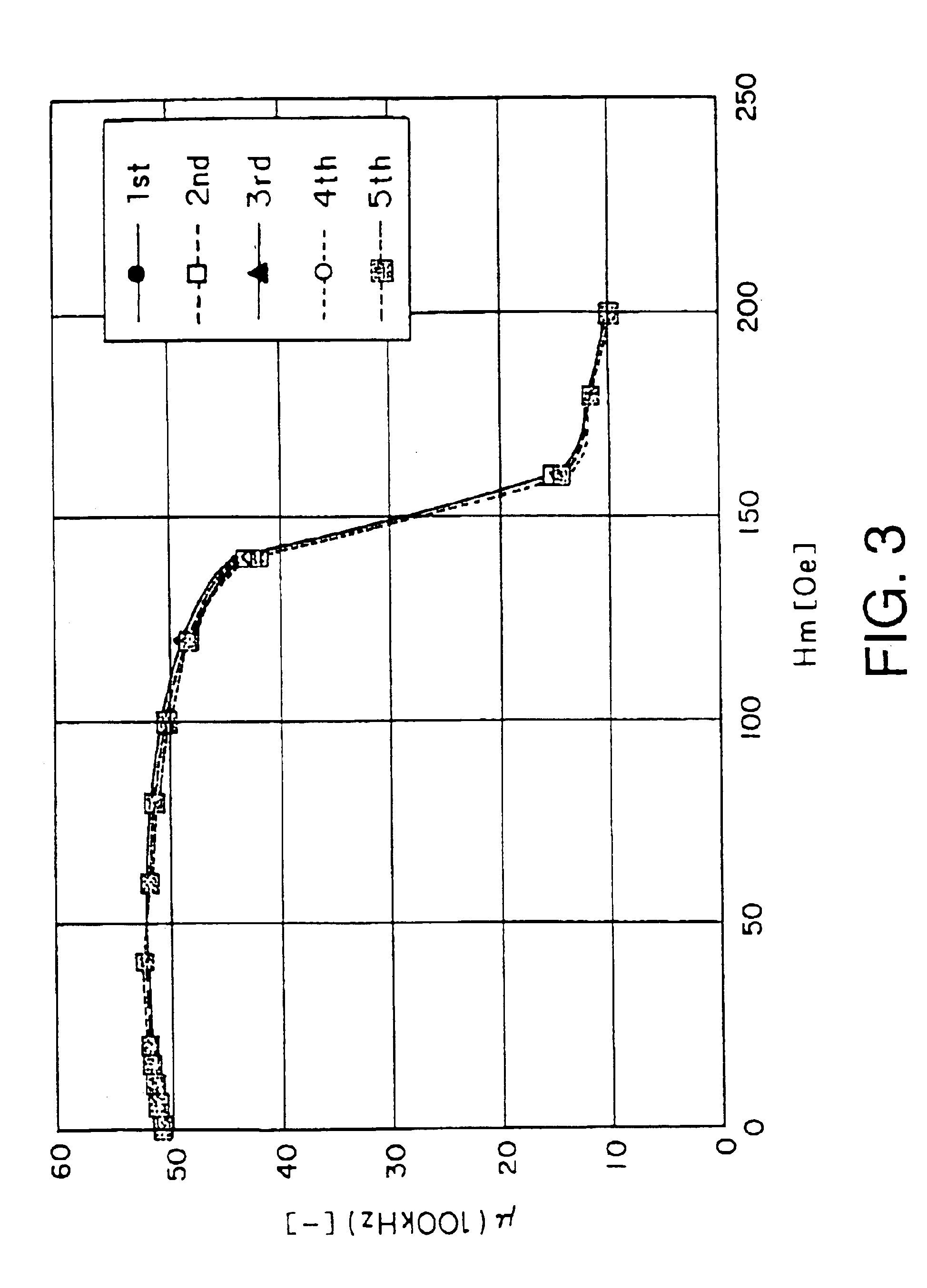

The invention discloses a Mn-Zn ferrite with broad temperature, broadband, high curie point and low loss and a preparation method thereof, the composition calculated by content of oxides is as follows: 52-57mol% of Fe2O3, 3-7mol% of ZnO and the balance of MnO; a first auxiliary component comprises 0.01wt%-0.1wt% of CaO and 0.005wt%-0.02wt% of SiO2; a second auxiliary component comprises one or more of V2O5, Nb2O5, Ta2O5, ZrO2, K2O and NiO, and the content is 0-0.2wt% by calculation, and a third auxiliary component comprises 0.04-0.075wt% of SnO2, 0.08-0.15wt% of TiO2 and 0.05-0.5wt% of Co2O3, wherein, the content of TiO2 is twice as much as that of SnO2. Pre-burning under the protection of nitrogen, sintering, the control of cooling atmosphere and the densification process are carried out, thereby leading the Mn-Zn ferrite with broad temperature, broadband and high curie point to not only meet the market demands of magnetic cores of electromagnetic couplers for electrodeless lamps, but also open up a vast world for new applications of a variety of high frequency power ferrite magnetic cores in communication and strong electric fields.

Owner:NANJING FINEMAG TECH

‘Thermal spring’ magnetic recording media for writing using magnetic and thermal gradients

InactiveUS6881497B2Avoid thermal instabilityRapid coolingSoldering apparatusRecord information storageMagnetic gradientMagnetic media

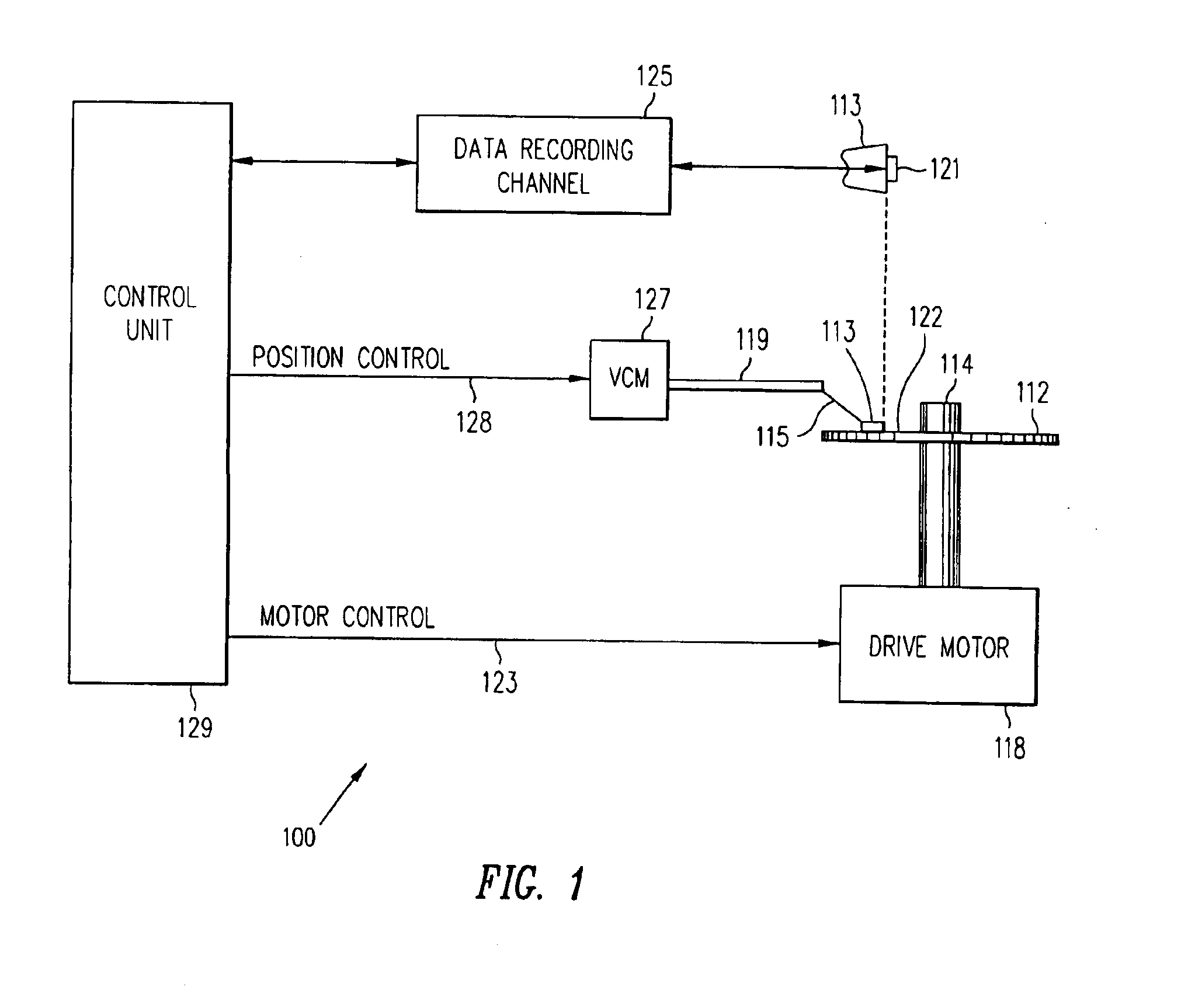

A thermal spring magnetic medium is provided having first and second stacks providing two exchange coupled ferromagnetic layers having different Curie temperatures. The first stack has a high magneto-crystalline anisotropy, a relatively low saturation magnetization and a low Curie temperature. The second stack has a relatively low magneto-crystalline anisotropy, a high saturation magnetization and a high Curie temperature. Preferably the first stack includes an alloy of Fe—Pt or Co—Pt, and the second stack includes an allow of Co—Pt or Co—Pd. A disk drive system having the novel medium is also provided.

Owner:WESTERN DIGITAL TECH INC

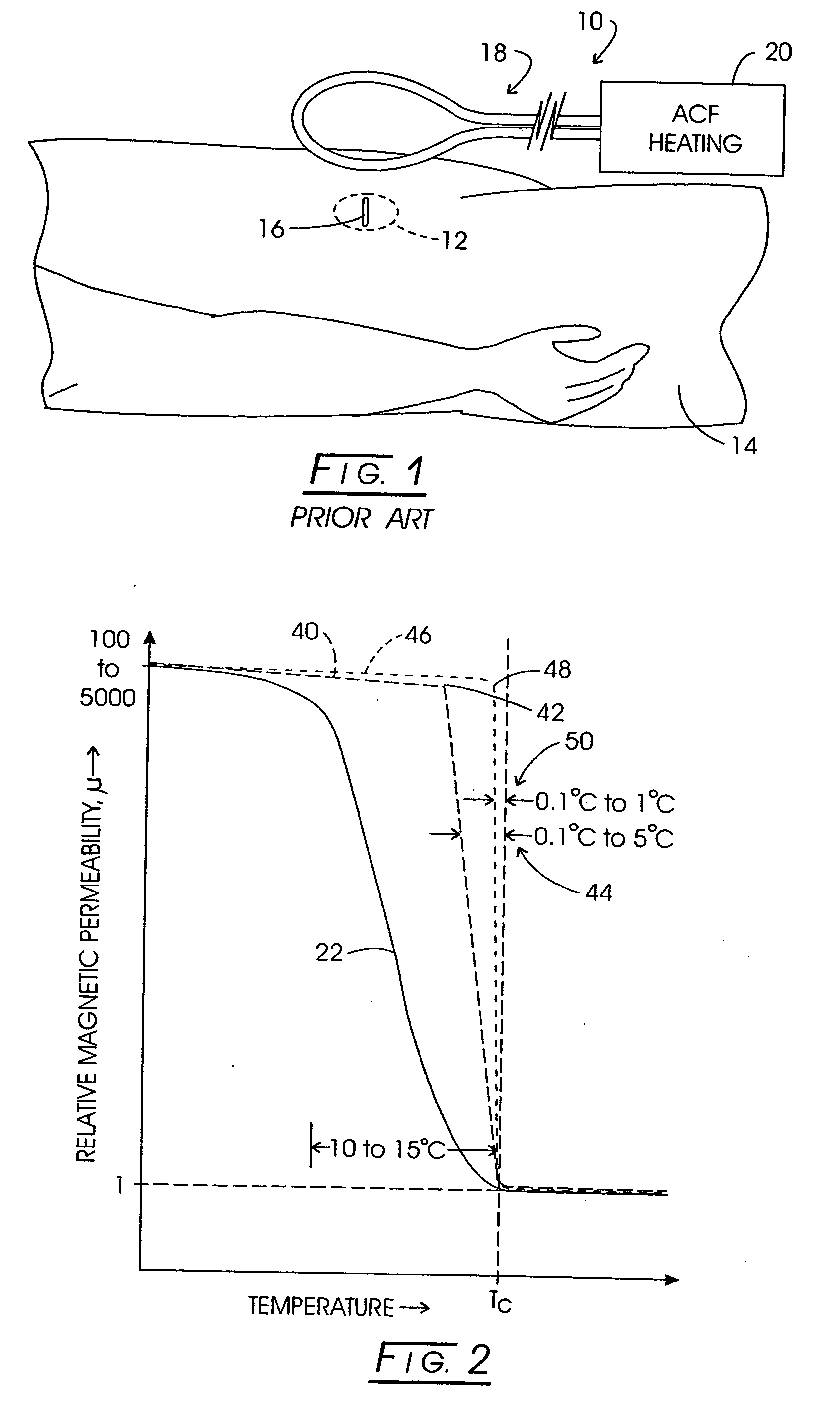

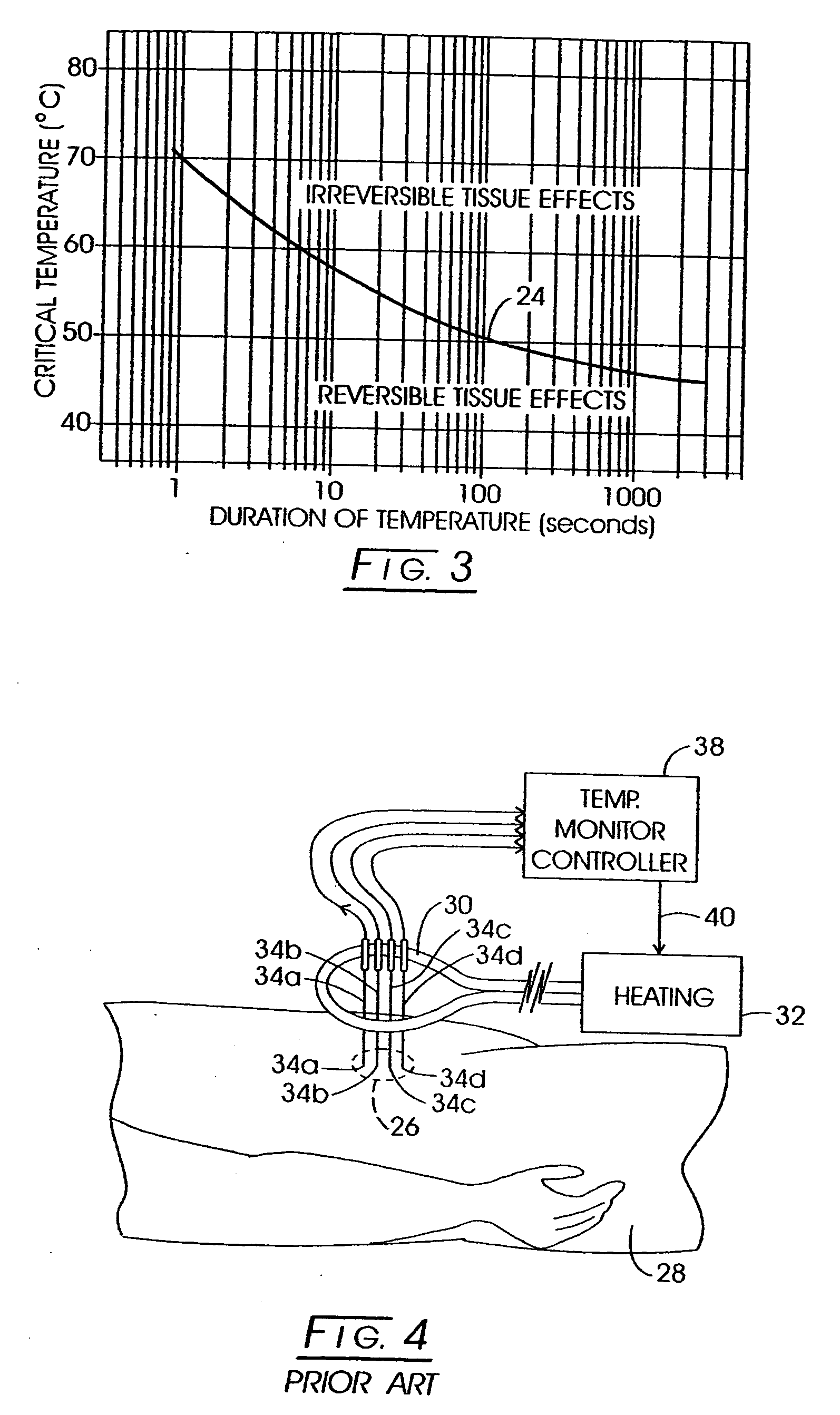

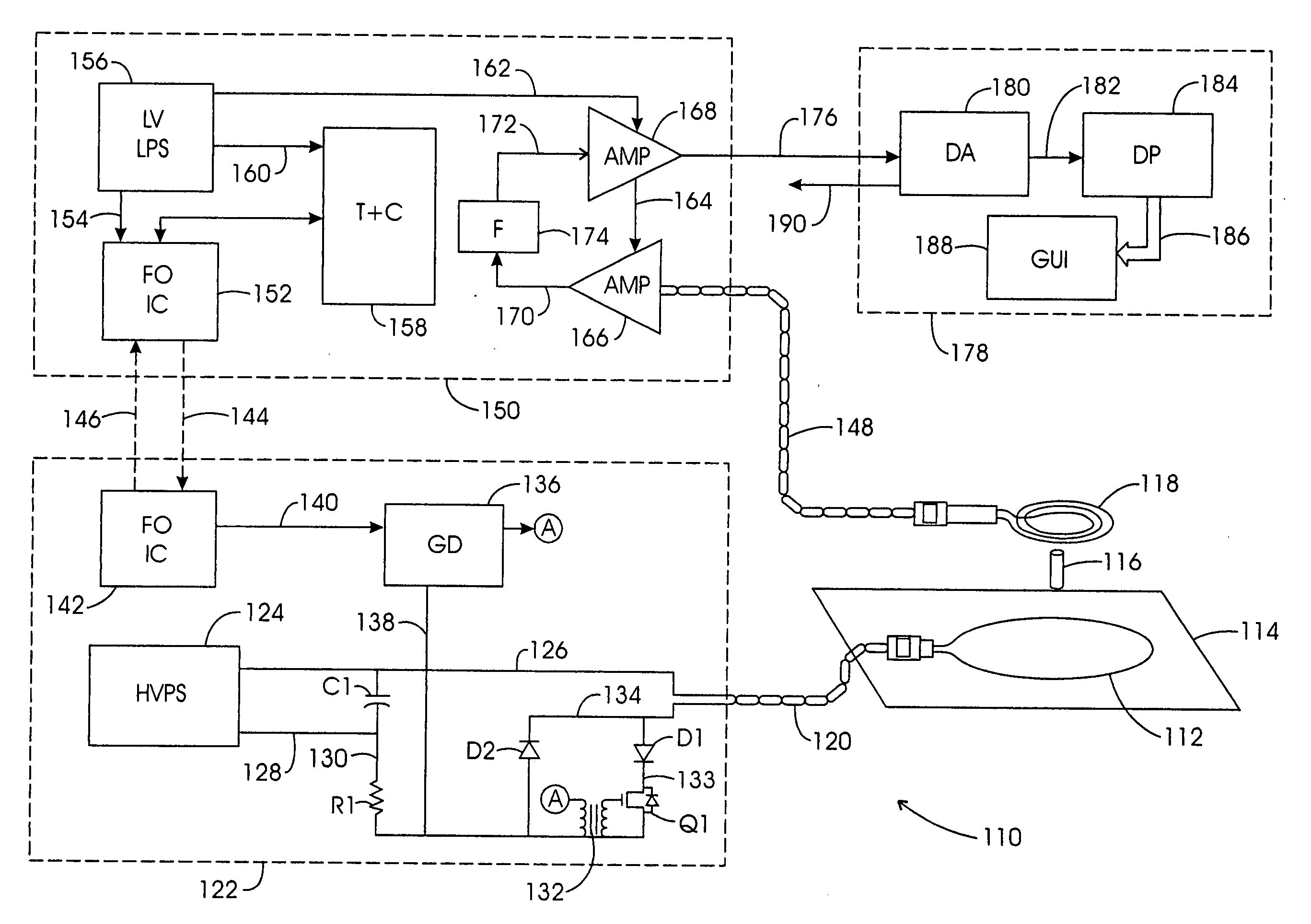

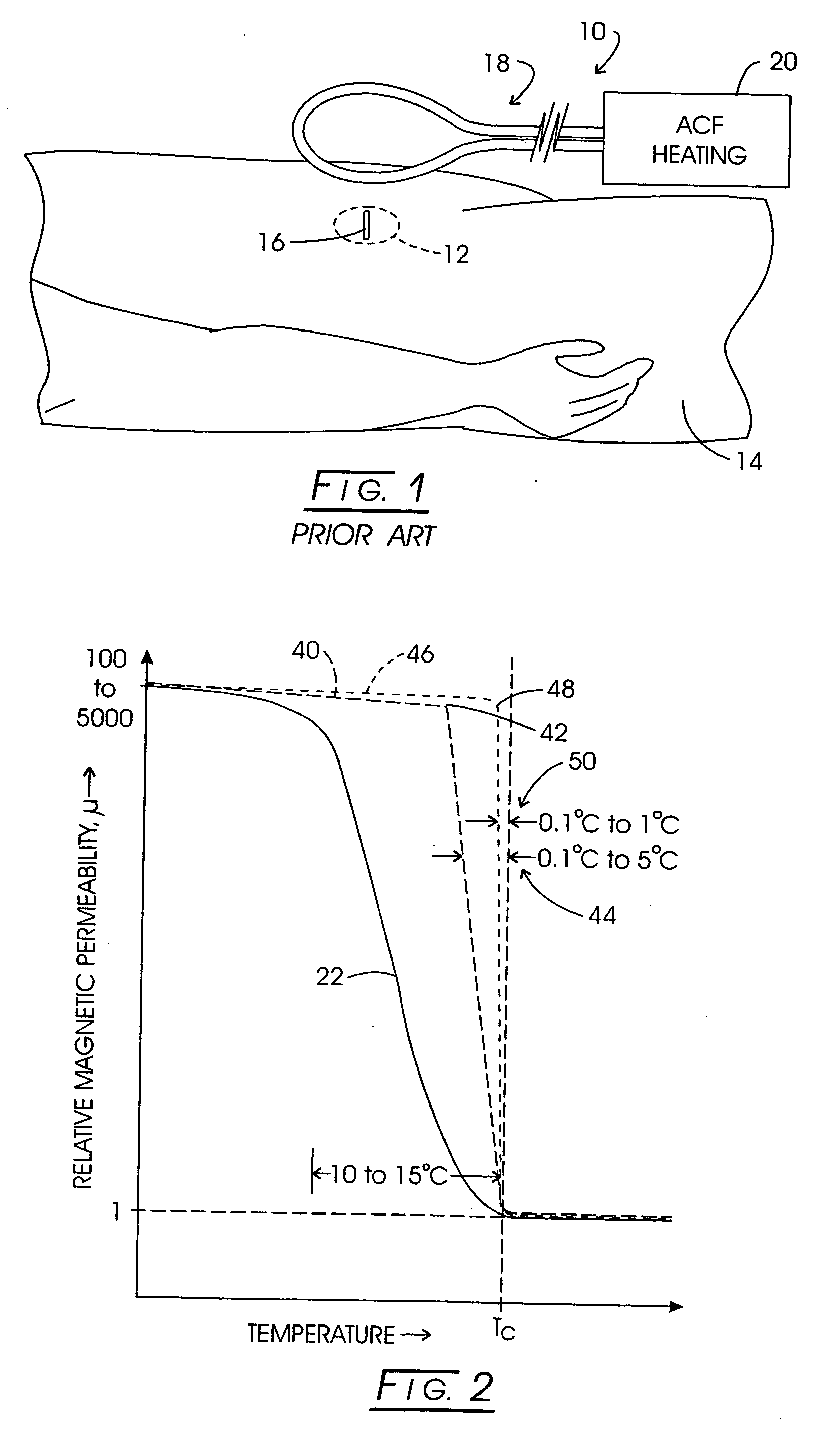

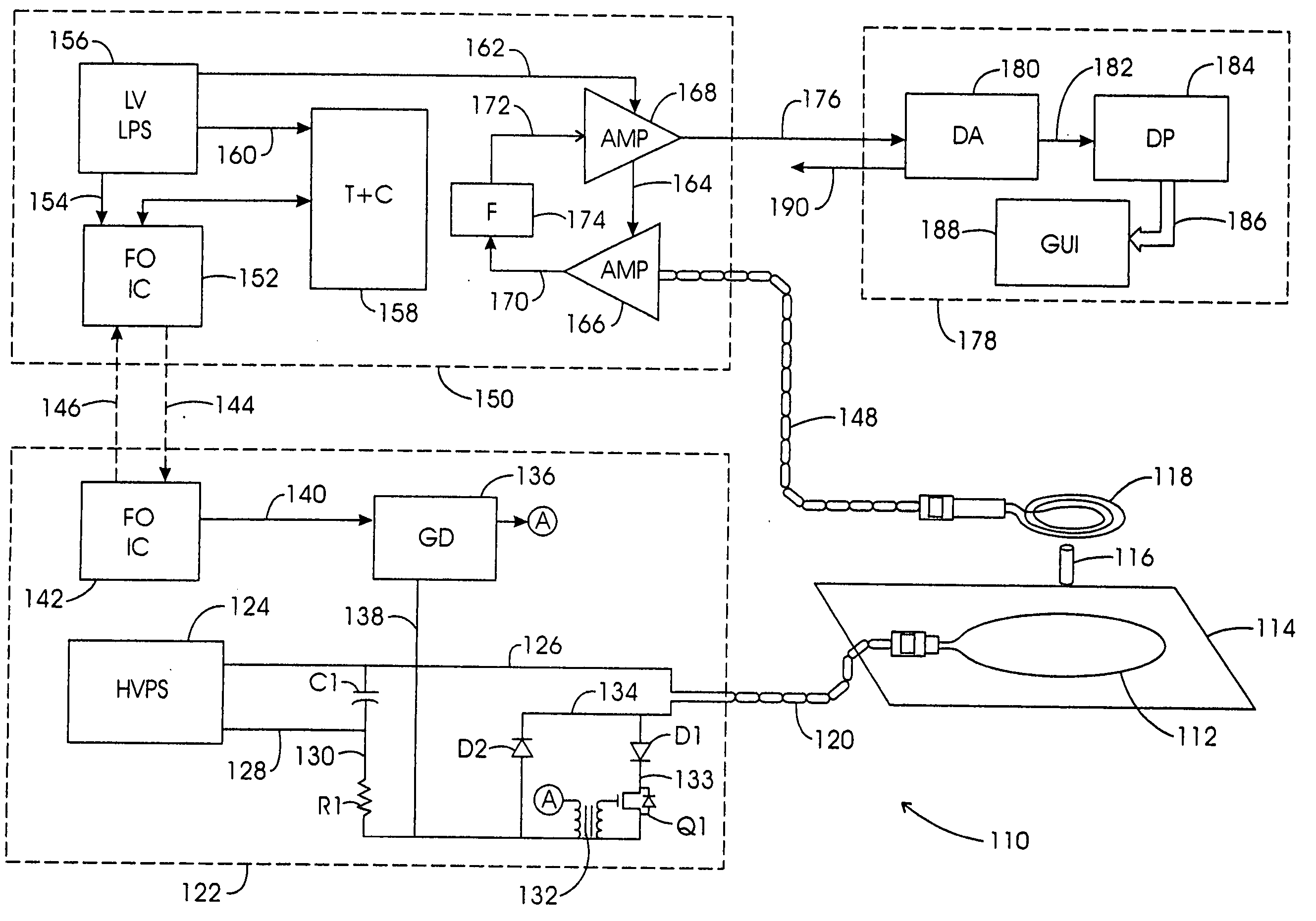

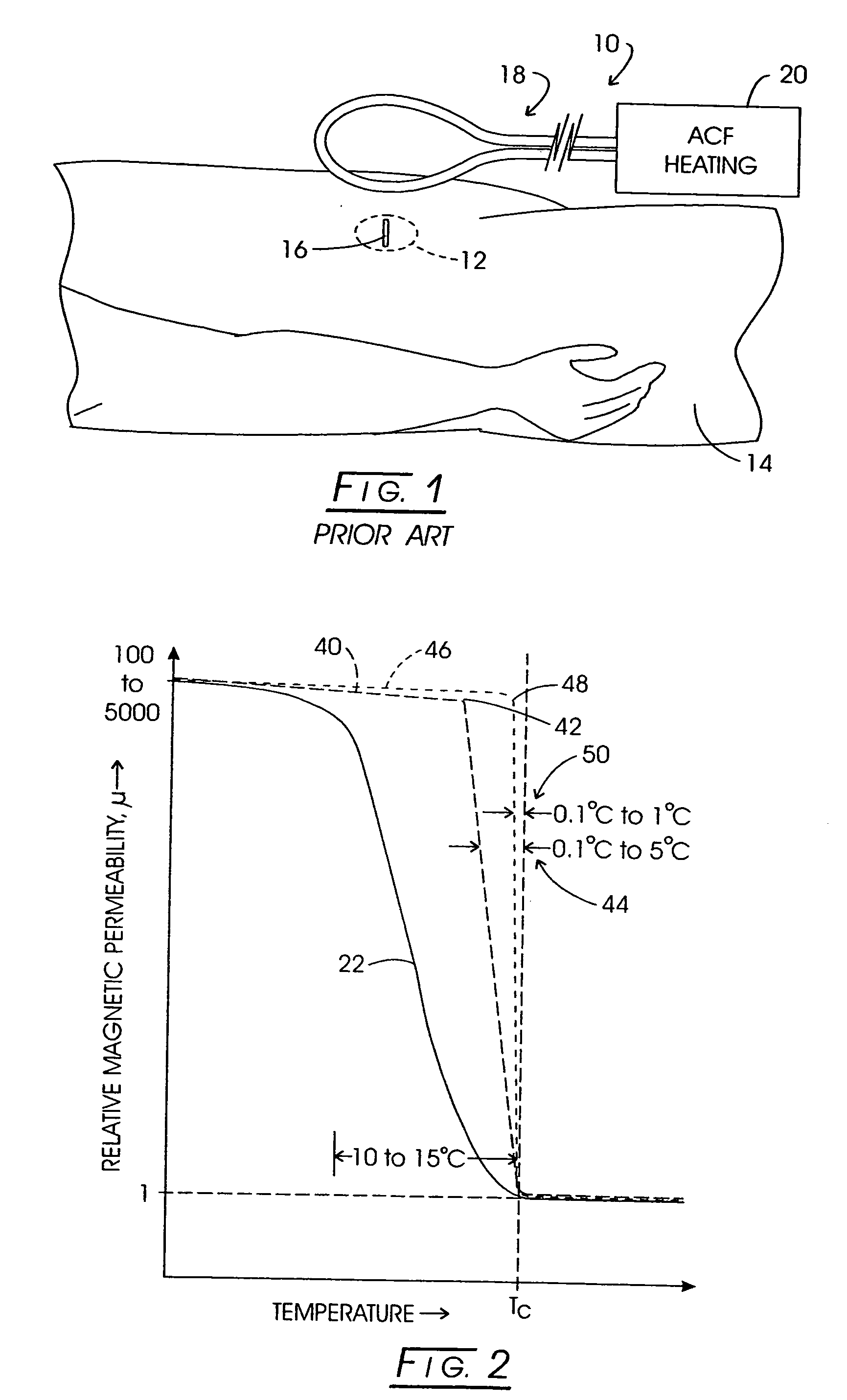

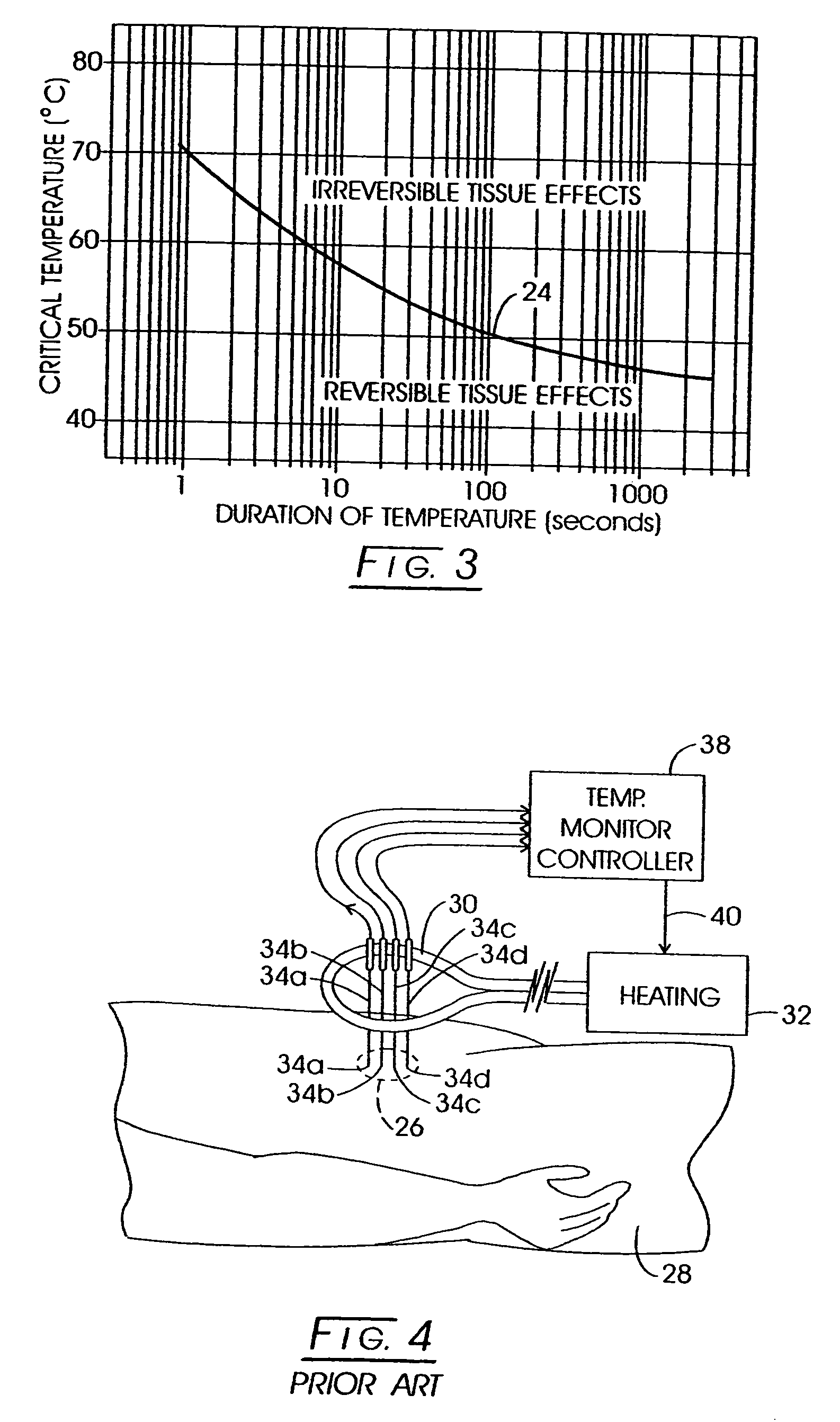

System, method and apparatus for evaluating tissue temperature

InactiveUS20060030914A1Accurate assessmentReduce intensityStentsDiagnostic recording/measuringCapacitanceTemperature response

Owner:APSARA MEDICAL

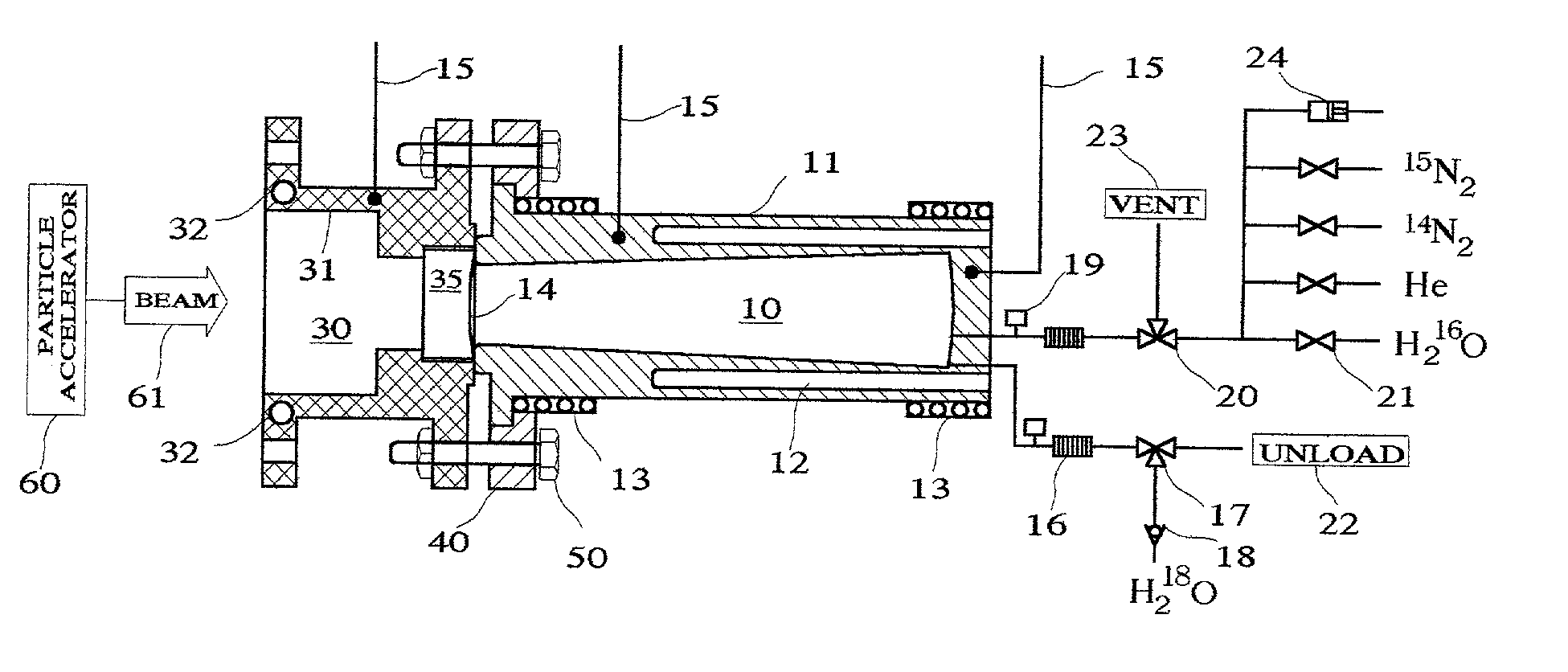

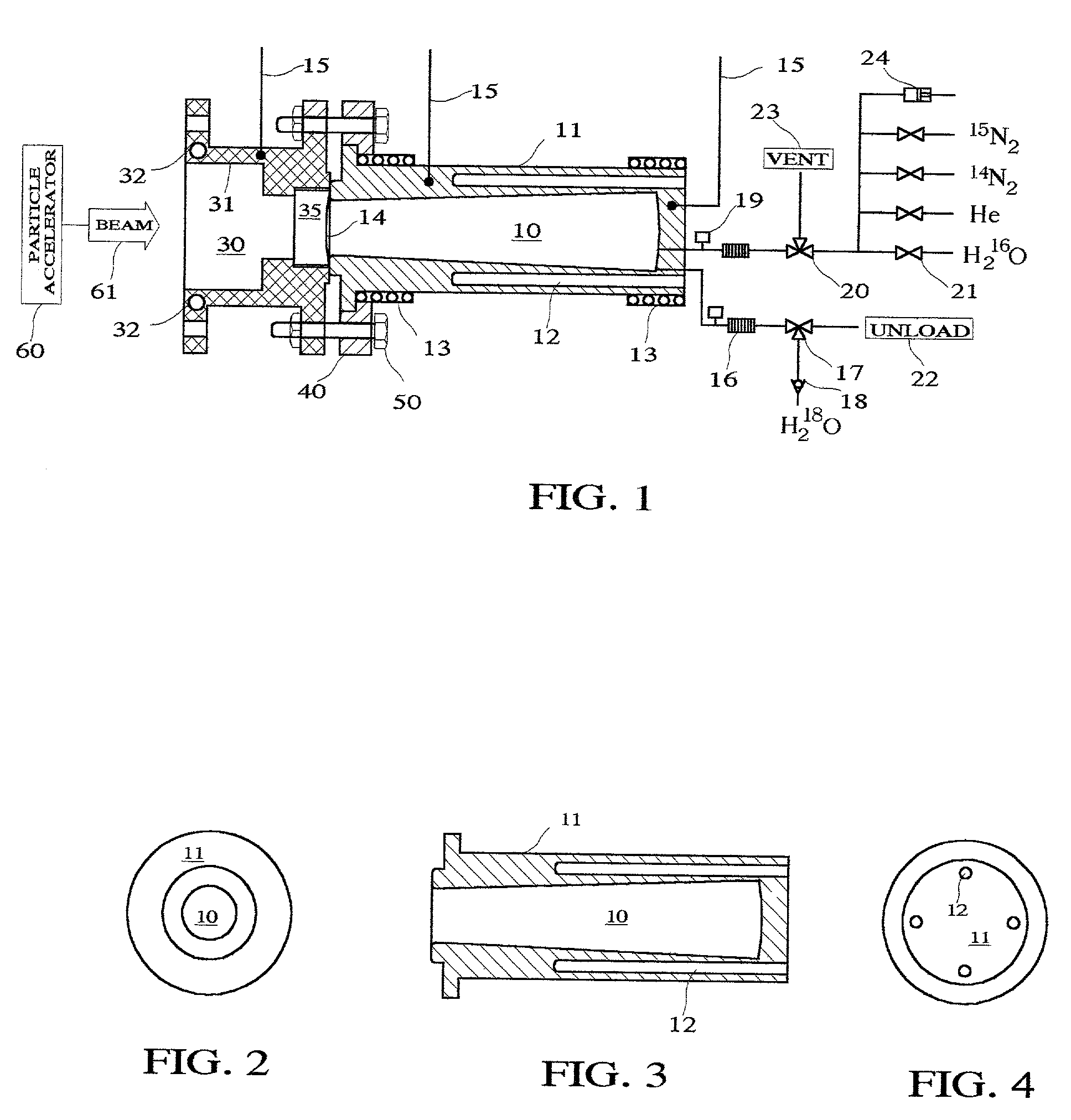

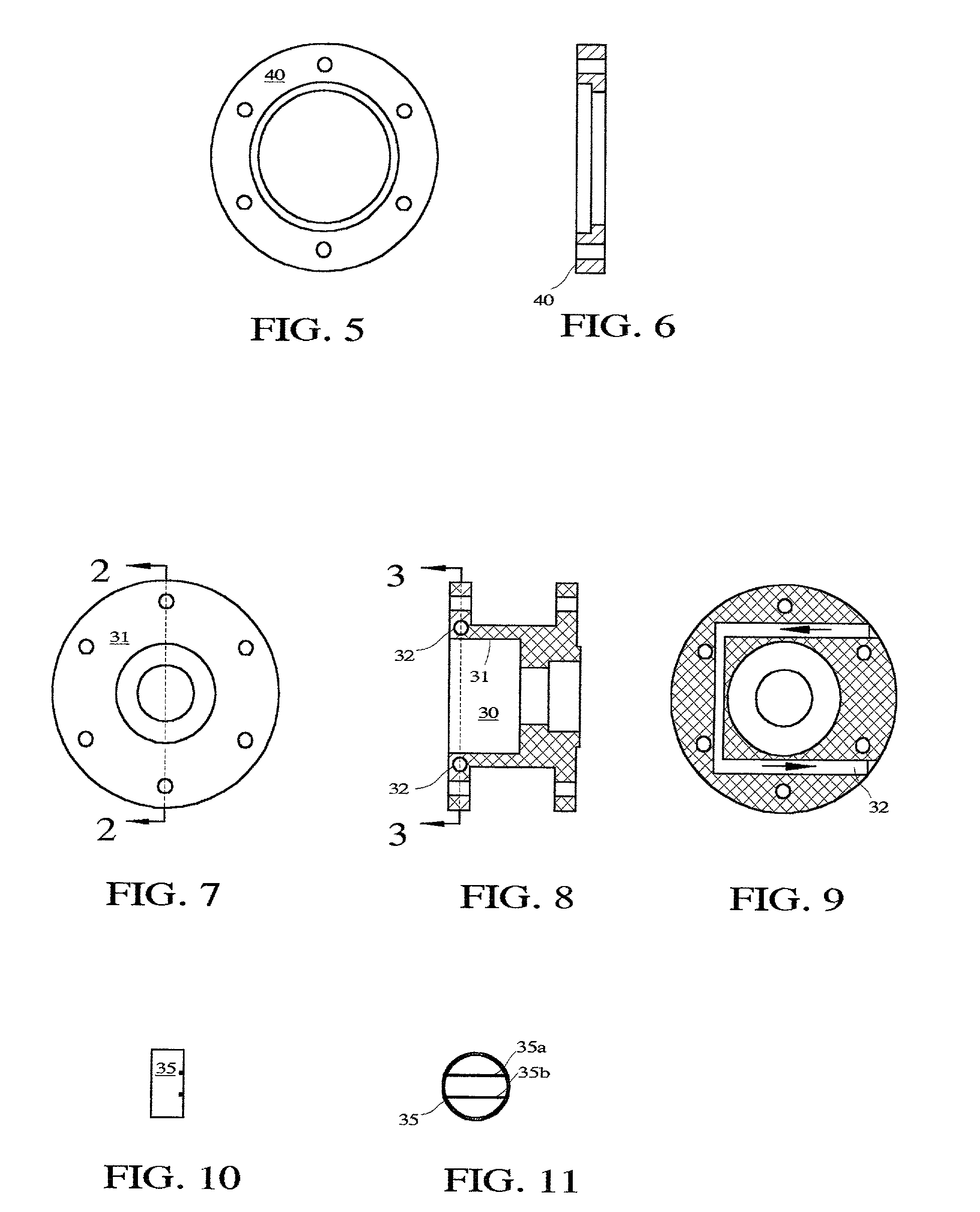

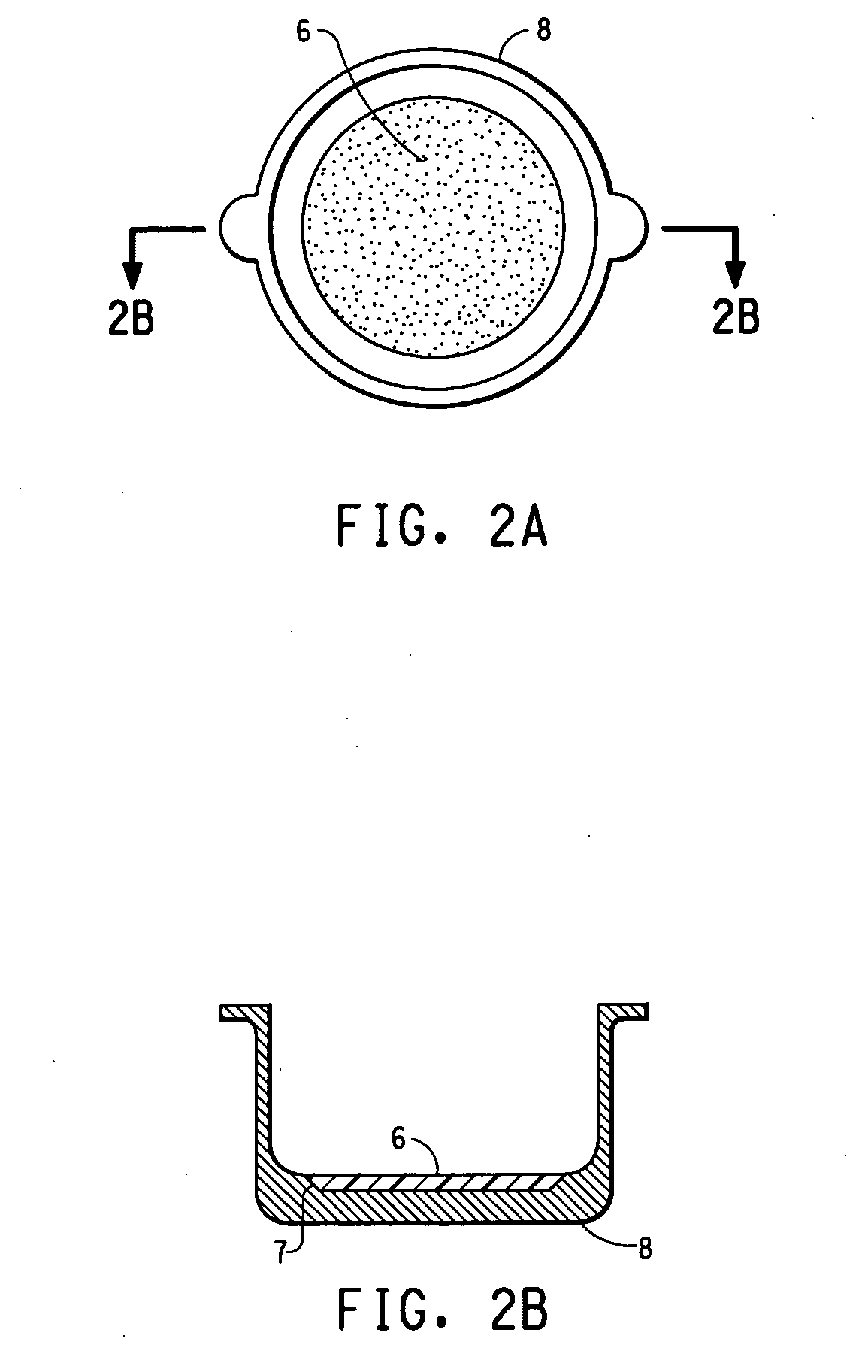

High power high yield target for production of all radioisotopes for positron emission tomography

InactiveUS20050061994A1Avoid low densitySuppress instabilityConversion outside reactor/acceleratorsNuclear monitoringCoolant flowInstability

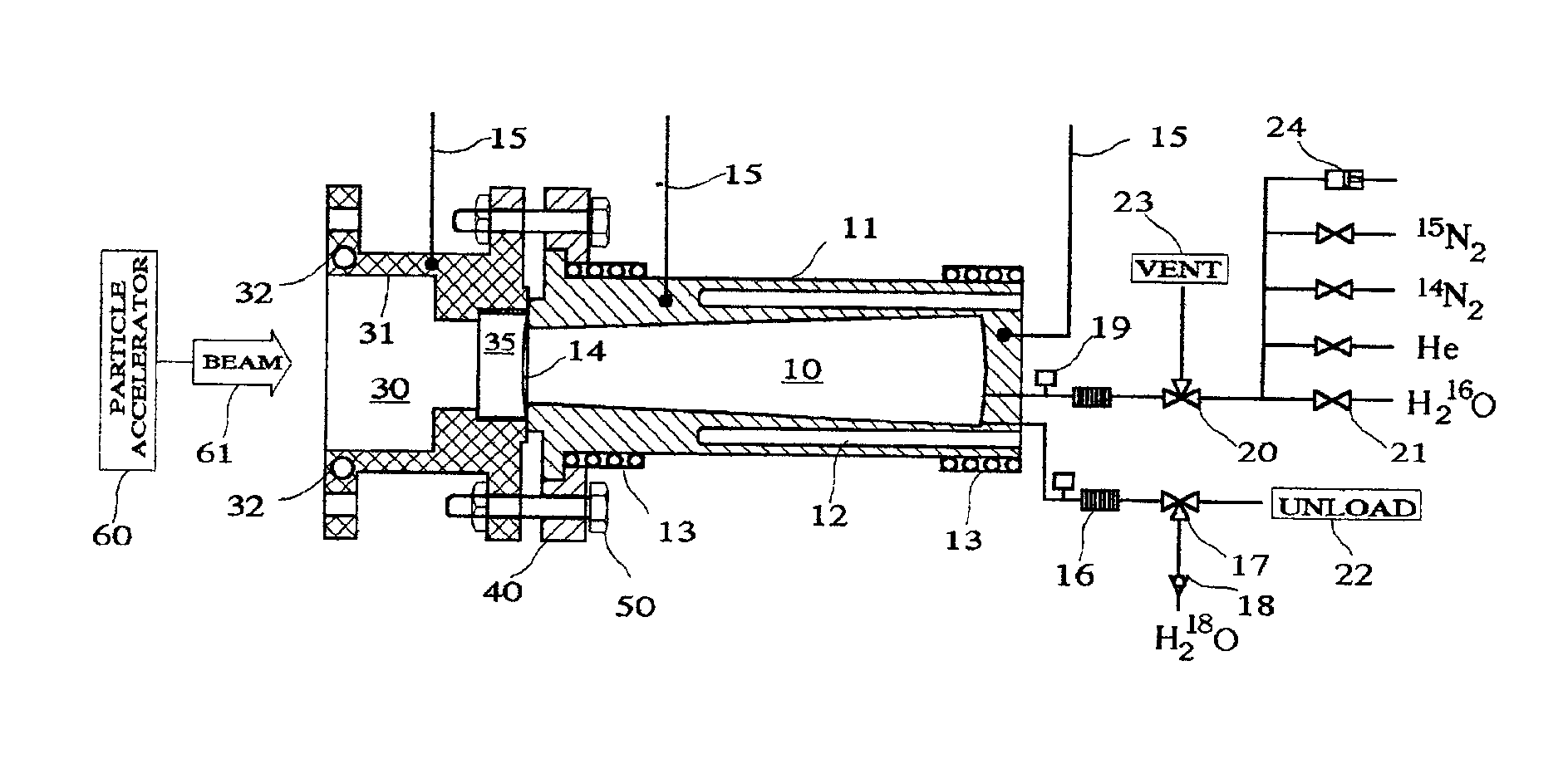

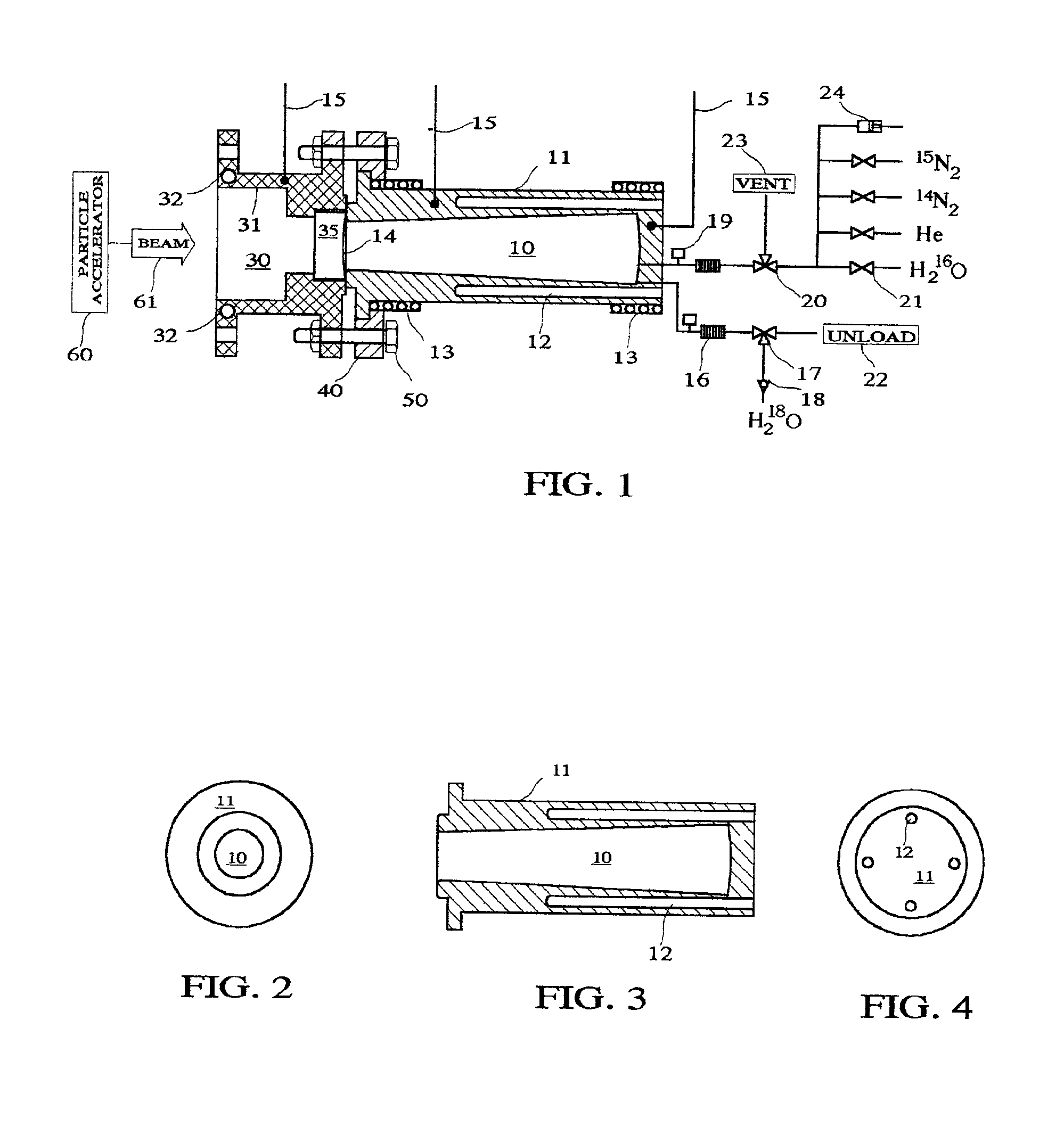

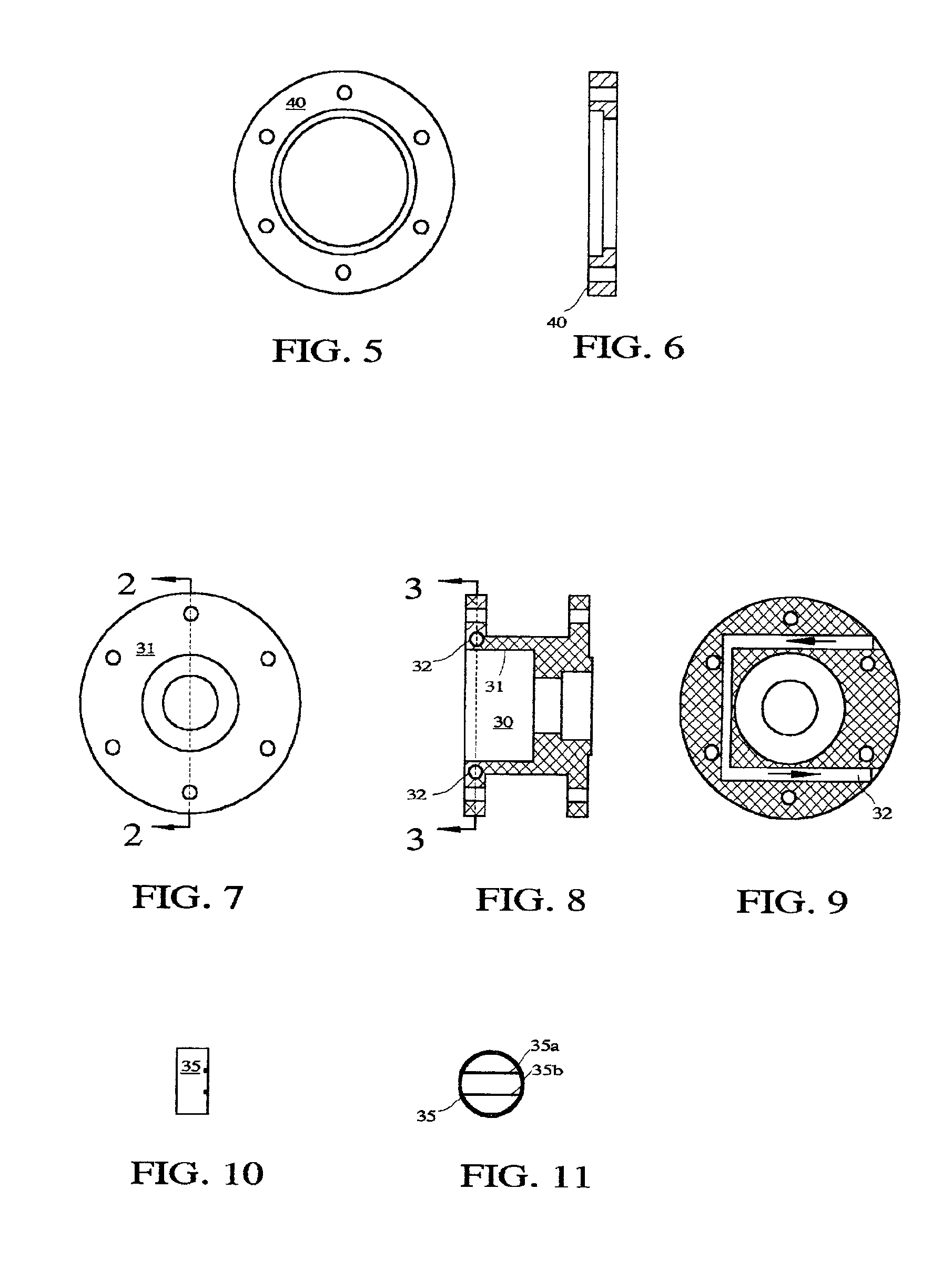

A high power high yield target for the positron emission tomography applications is introduced. For production of Curie level of Fluorine-18 isotope from a beam of proton it uses about one tenth of Oxygen-18 water compared to a conventional water target. The target is also configured to be used for production of all other radioisotopes that are used for positron emission tomography. When the target functions as a water target the material sample being oxygen-18 water or oxygen-16 water is heated to steam prior to irradiation using heating elements that are housed in the target body. The material sample is kept in steam phase during the irradiation and cooled to liquid phase after irradiation. To keep the material sample in steam phase a microprocessor monitoring the target temperature manipulates the flow of coolant in the cooling section that is attached to the target and the status of the heaters and air blowers mounted adjacent to the target. When the target functions as a gas target the generated heat from the beam is removed from the target by air blowers and the cooling section. The rupture point of the target window is increased by a factor of two or higher by one thin wire or two parallel thin wires welded at the end of a small hollow tube which is held against the target window. One or two coils are used to produce a magnetic filed along the beam path for preventing the density depression along the beam path and suppression of other instabilities that can develop in a high power target.

Owner:AMINI BEHROUZ

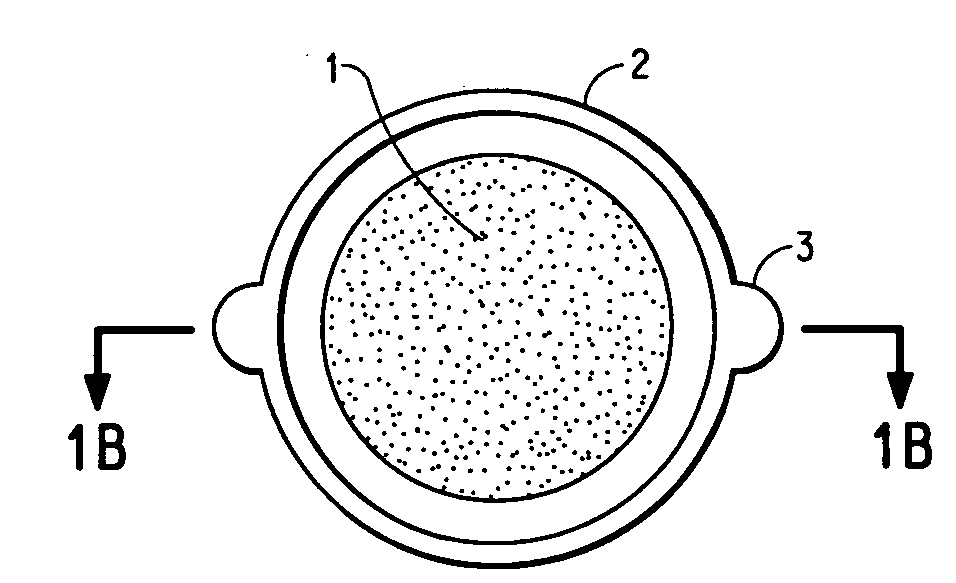

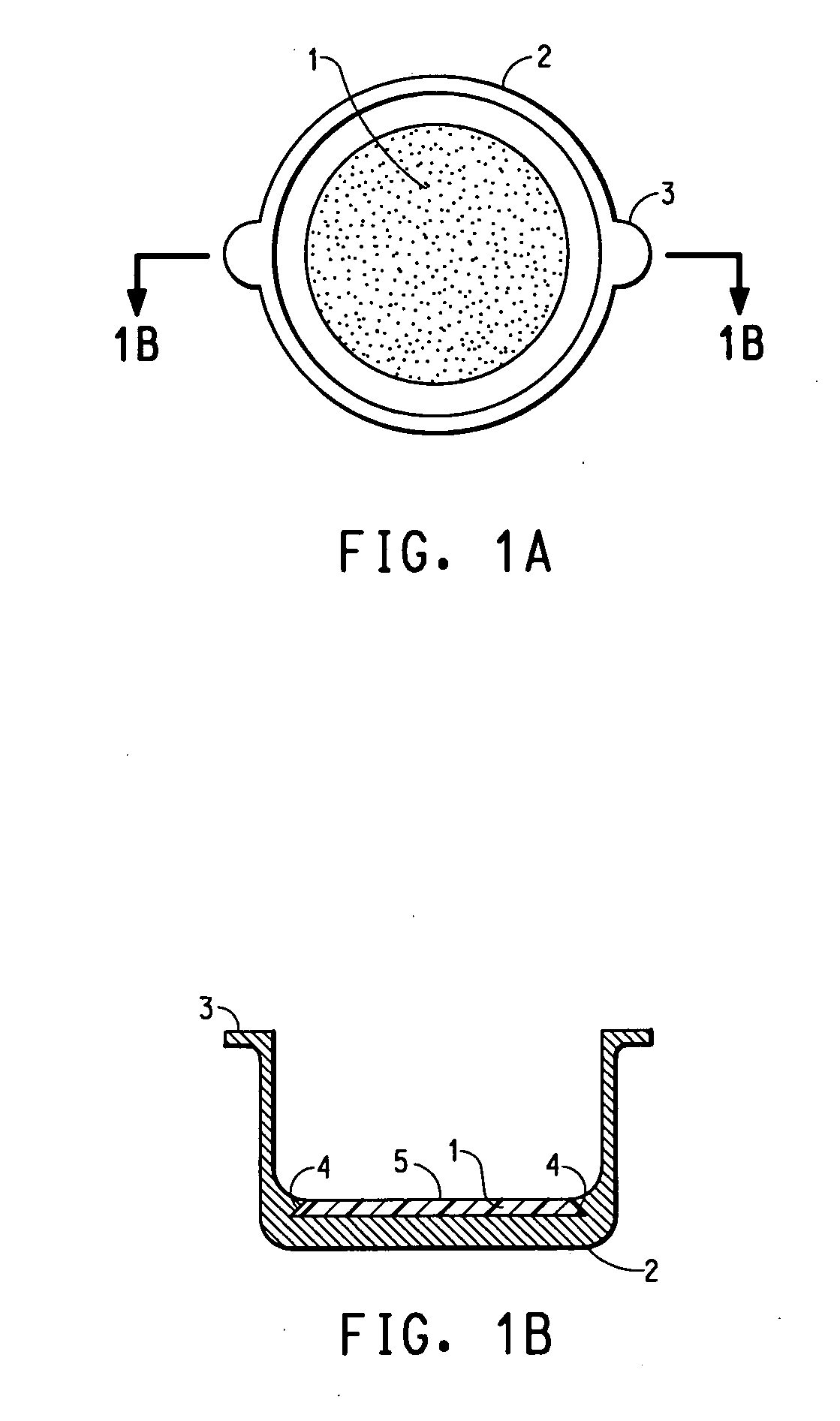

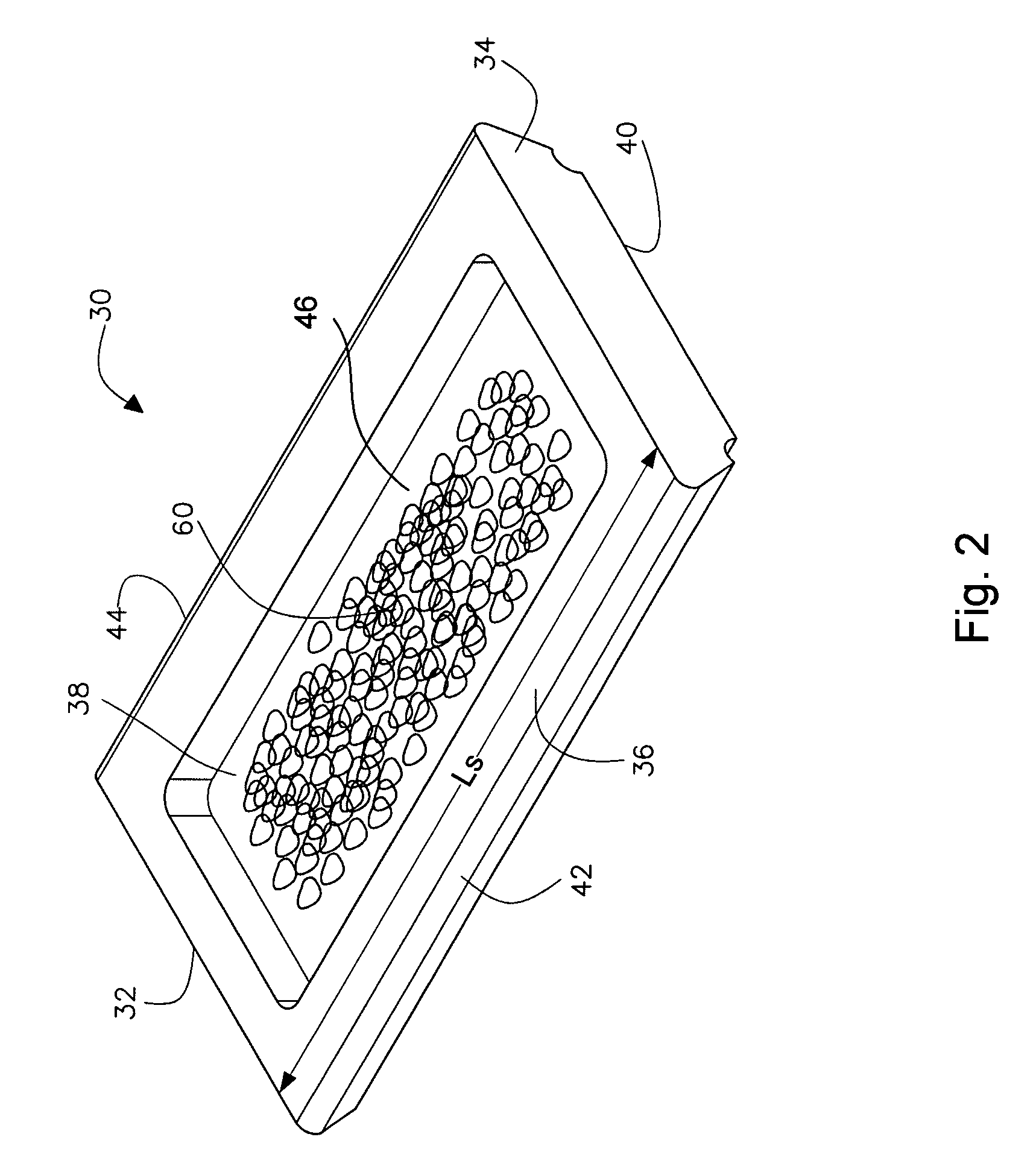

Ovenware for microwave oven

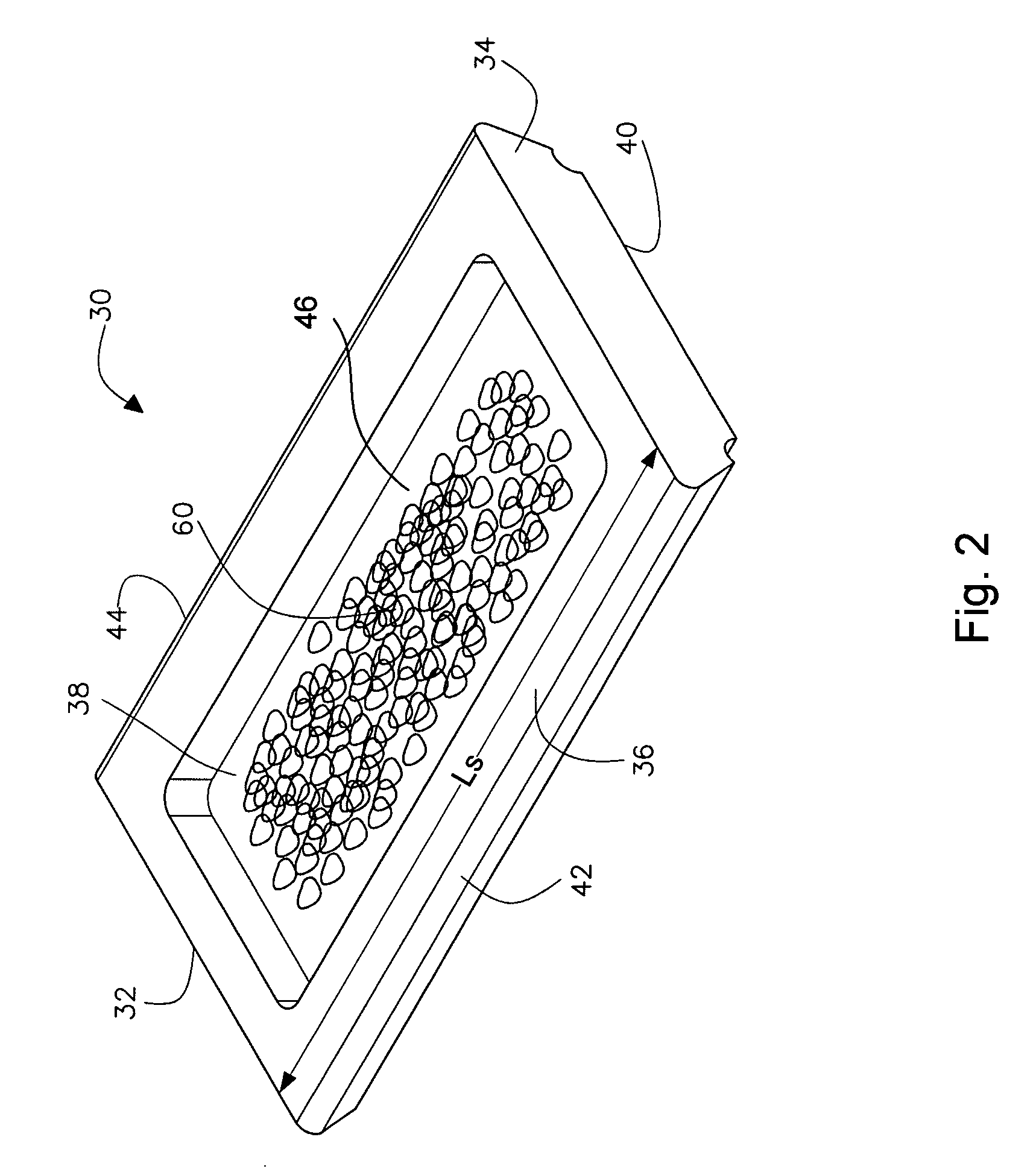

Ovenware for microwave ovens which contain a composition comprising a susceptor which has a Curie point temperature of about 100° C. to about 300° C. and a thermoplastic or thermoset polymer are improved and said composition is in contact with the food or drink to be heated or cooked, and / or composition has a thermal conductivity of about 0.7 W / m° K. or more. Heat generated by absorption of microwave radiation by the susceptor is more readily conducted to the food being cooked when the thermal conductivity of the composition is high, particularly when the part containing the susceptor is relatively thick. The relatively low Curie point of the susceptor prevent overheating of the ovenware and food being cooked. Also described are designs for various pieces of ovenware containing this composition.

Owner:TICONA LLC

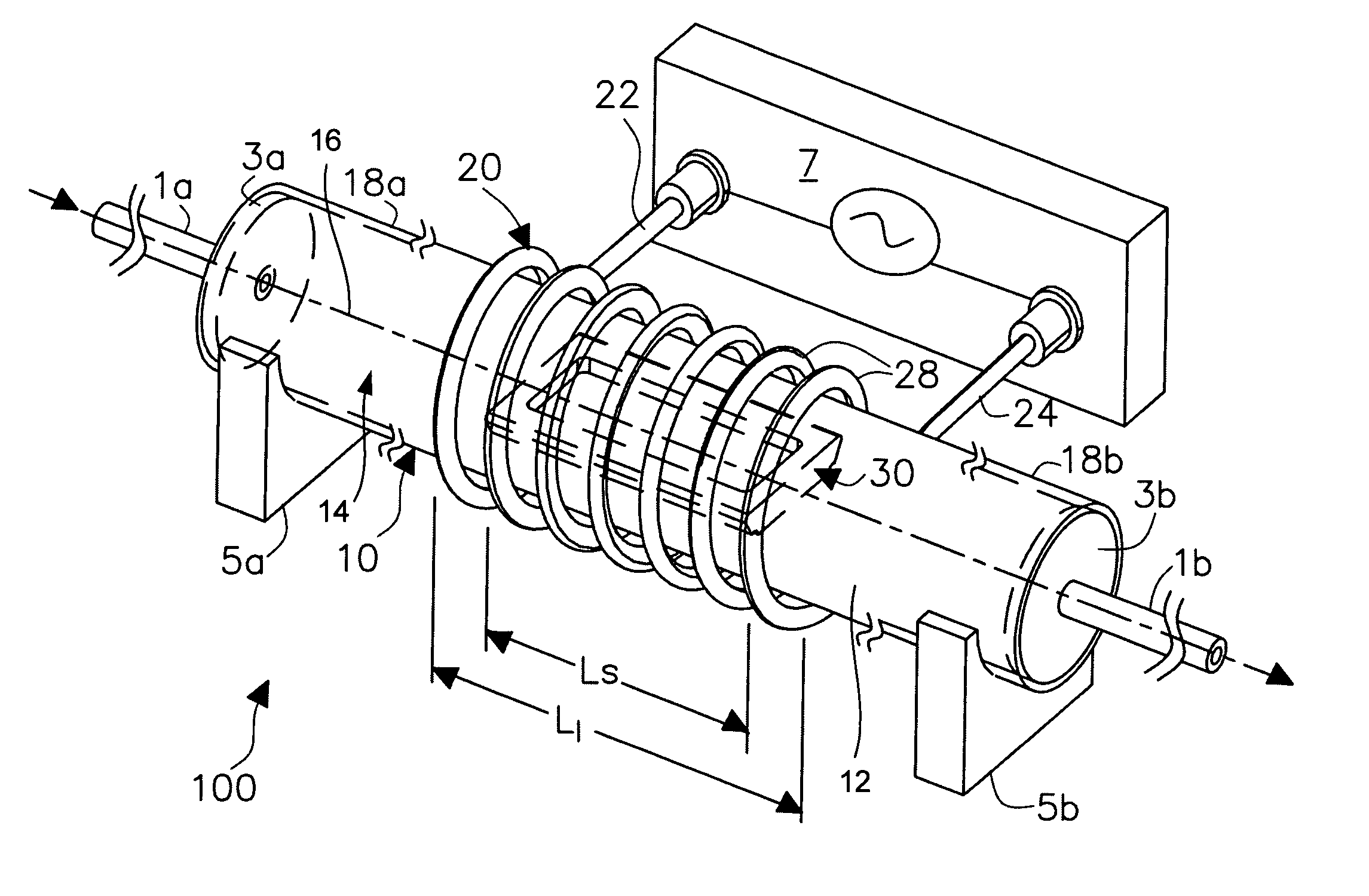

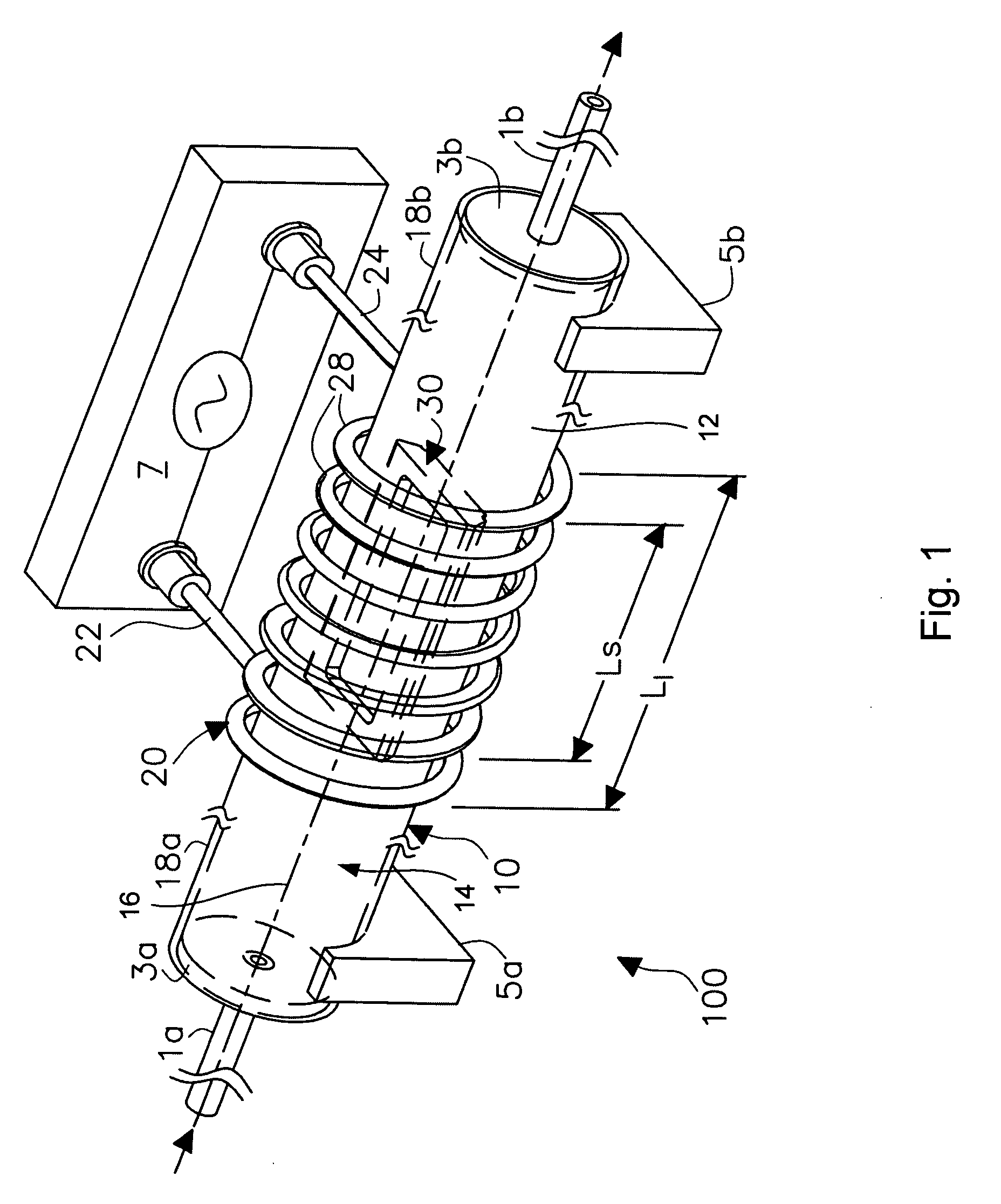

Production of nanostructures by curie point induction heating

An apparatus for synthesizing nanostructures. In one embodiment, the apparatus includes a heating device that defines a reaction zone therein and a susceptor made of a ferromagnetic material with a Curie temperature and placed in the reaction zone, where the Curie temperature substantially corresponds to a temperature at which the growth of desired nanostructures occurs and the heating device is capable of heating the susceptor substantially at the Curie temperature.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS +1

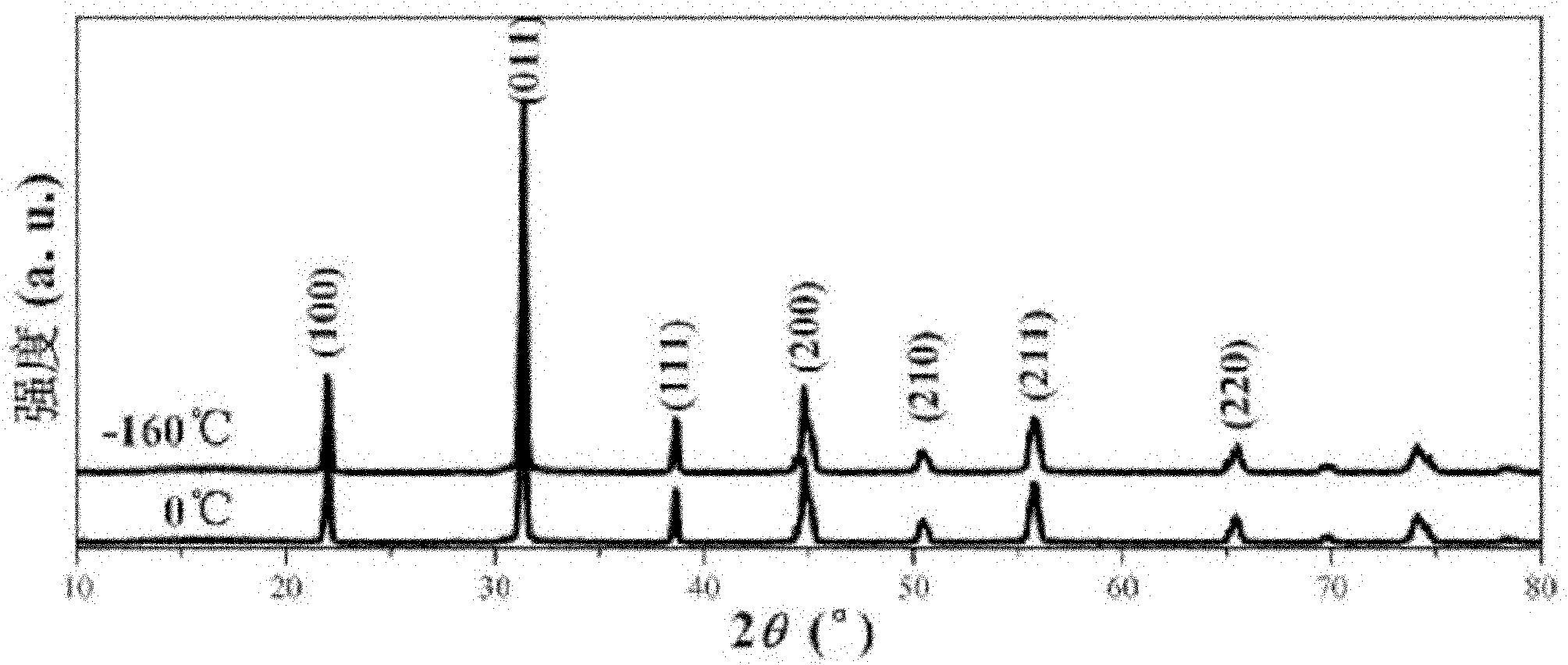

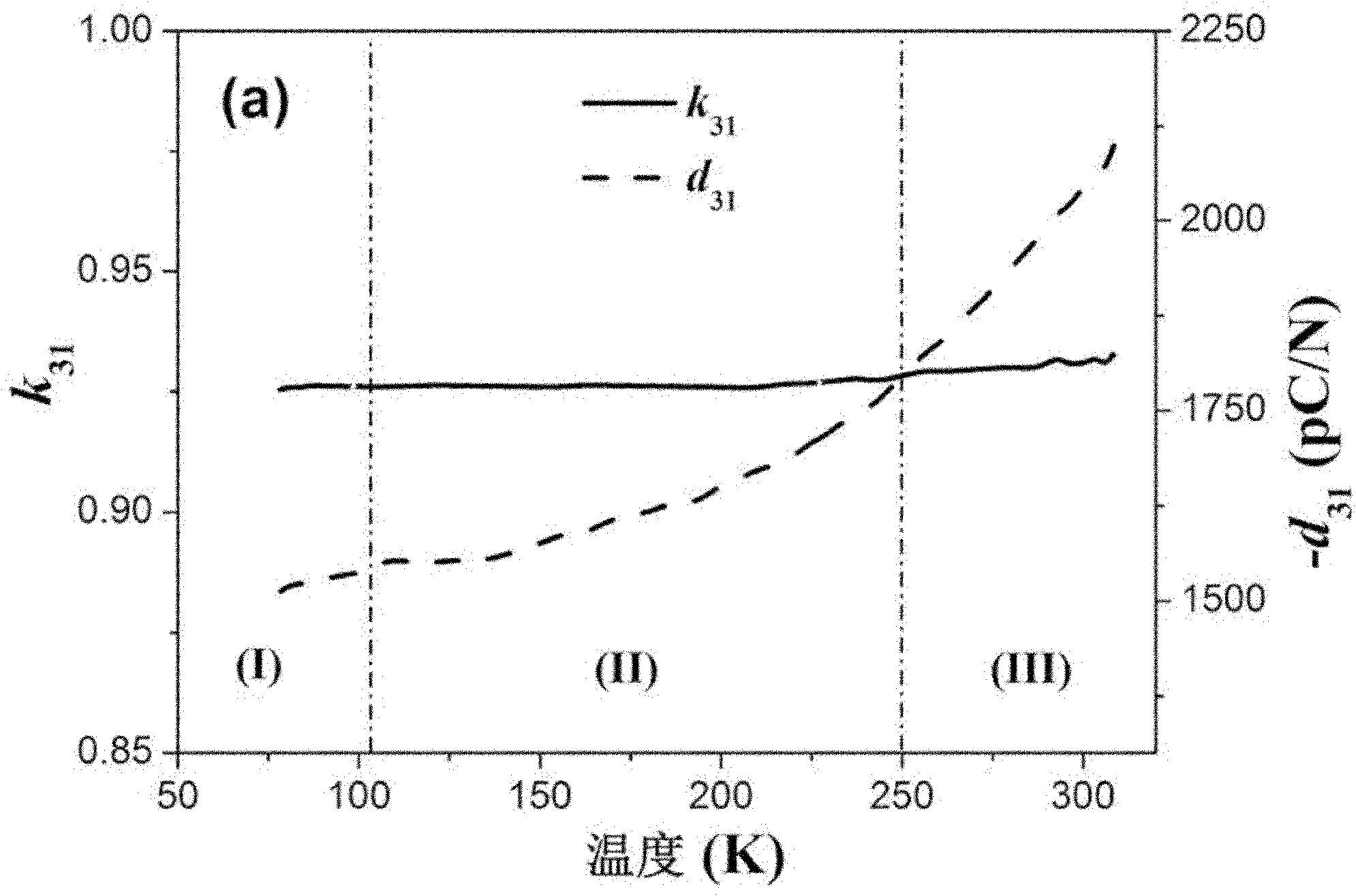

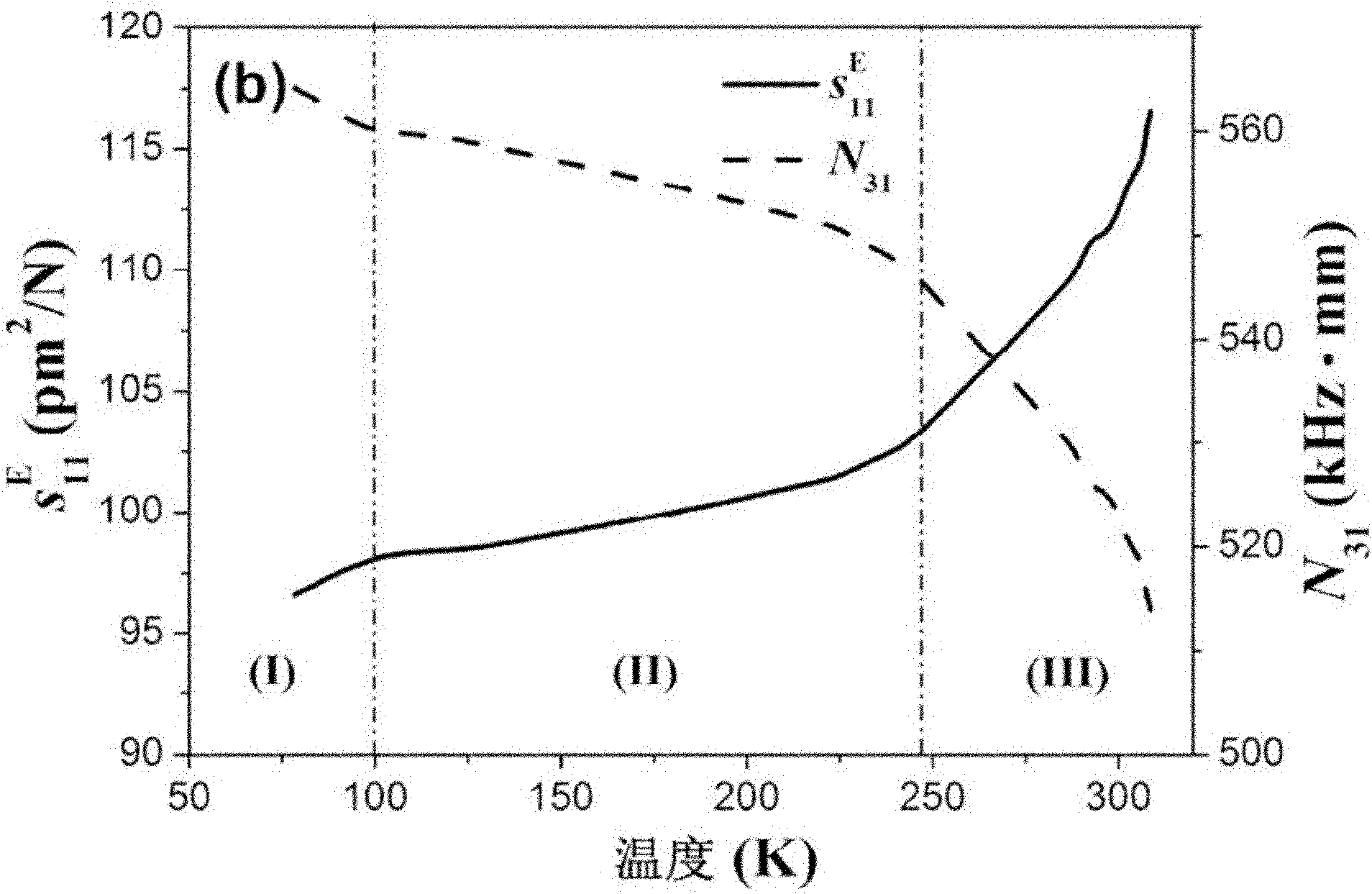

Ternary system relaxation ferroelectric single crystal material and preparation method thereof

InactiveCN101985775ASmall sizeQuality improvementPolycrystalline material growthFrom frozen solutionsBridgman methodSingle crystal

The invention discloses a ternary system relaxation ferroelectric single crystal material. The material comprises the following chemical components: xPb(In1 / 2Nb1 / 2)O3-yPb(Mg1 / 3Nb2 / 3)O3-(1-x-y)PbTiO3, wherein the x is equal to 0.1-0.45, and the y is equal to 0.1-0.5. A preparation method of the single crystal material PIMNT is an improved Bridgman method and comprises the following steps of: processing raw materials, melting by raising the temperature, and performing crucible degrowth and crystal cooling growth. The prepared single crystal material overcomes the defects of over low Curie point of PMNT single crystals, difficult crystallization and difficult batch growth of the PINT single crystals in the prior art, has high piezoelectric performance and pyroelectric performance, higher temperature stability and wide application prospect and adds a new product in the field.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

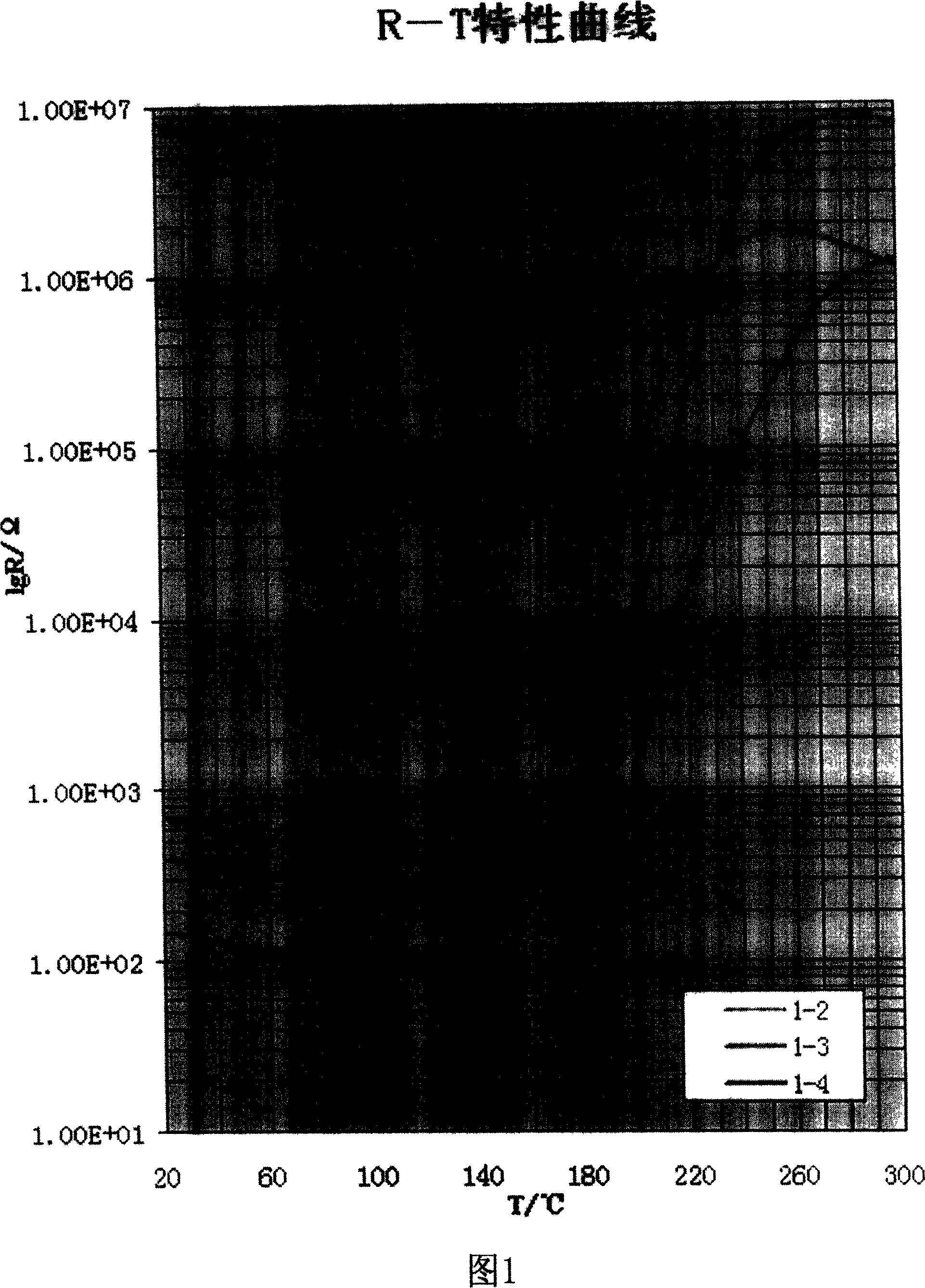

Leadless PTC thermistor material with high Curie point

InactiveCN101013618AAchieve lead-freeAchieve semiconductingCeramicsOxide conductorsElectrical resistance and conductanceSemiconductor materials

The invention relates to one semi-conductor materials to realize semi-conductive process meeting the high Curie piezoelectricity ceramics materials without lead, which comprises the following parts: (Na1 / 2Bi1 / 2)x(Ba1-x-y+z)TiO3+yM1+zM2O+0.02MnO2mol%, wherein, x=0.01-0.15; y=0.001-0.006; z=0.005-0.05; M1=0.0001-0.006; M2=0.005-0.05; Formula comprises micro semi-conductive element and additive components.

Owner:杨敬义 +1

High power high yield target for production of all radioisotopes for positron emission tomography

InactiveUS6917044B2Avoid low densityConversion outside reactor/acceleratorsNuclear monitoringInstabilityAir blower

A high power high yield target for the positron emission tomography applications is introduced. For production of Curie level of Fluorine-18 isotope from a beam of proton it uses about one tenth of Oxygen-18 water compared to a conventional water target. The target is also configured to be used for production of all other radioisotopes that are used for positron emission tomography. When the target functions as a water target the material sample being oxygen-18 or oxygen-16 water is heated to steam prior to irradiation using heating elements that are housed in the target body. The material sample is kept in steam phase during the irradiation and cooled to liquid phase after irradiation. To keep the material sample in steam phase a microprocessor monitoring the target temperature manipulates the flow of coolant in the cooling section that is attached to the target and the status of the heaters and air blowers mounted adjacent to the target. When the target functions as a gas target the generated heat from the beam is removed from the target by air blowers and the cooling section. The rupture point of the target window is increased by a factor of two or higher by one thin wire or two parallel thin wires welded at the end of a small hollow tube which is held against the target window. One or two coils are used to produce a magnetic filed along the beam path for preventing the density depression along the beam path and suppression of other instabilities that can develop in a high power target.

Owner:AMINI BEHROUZ

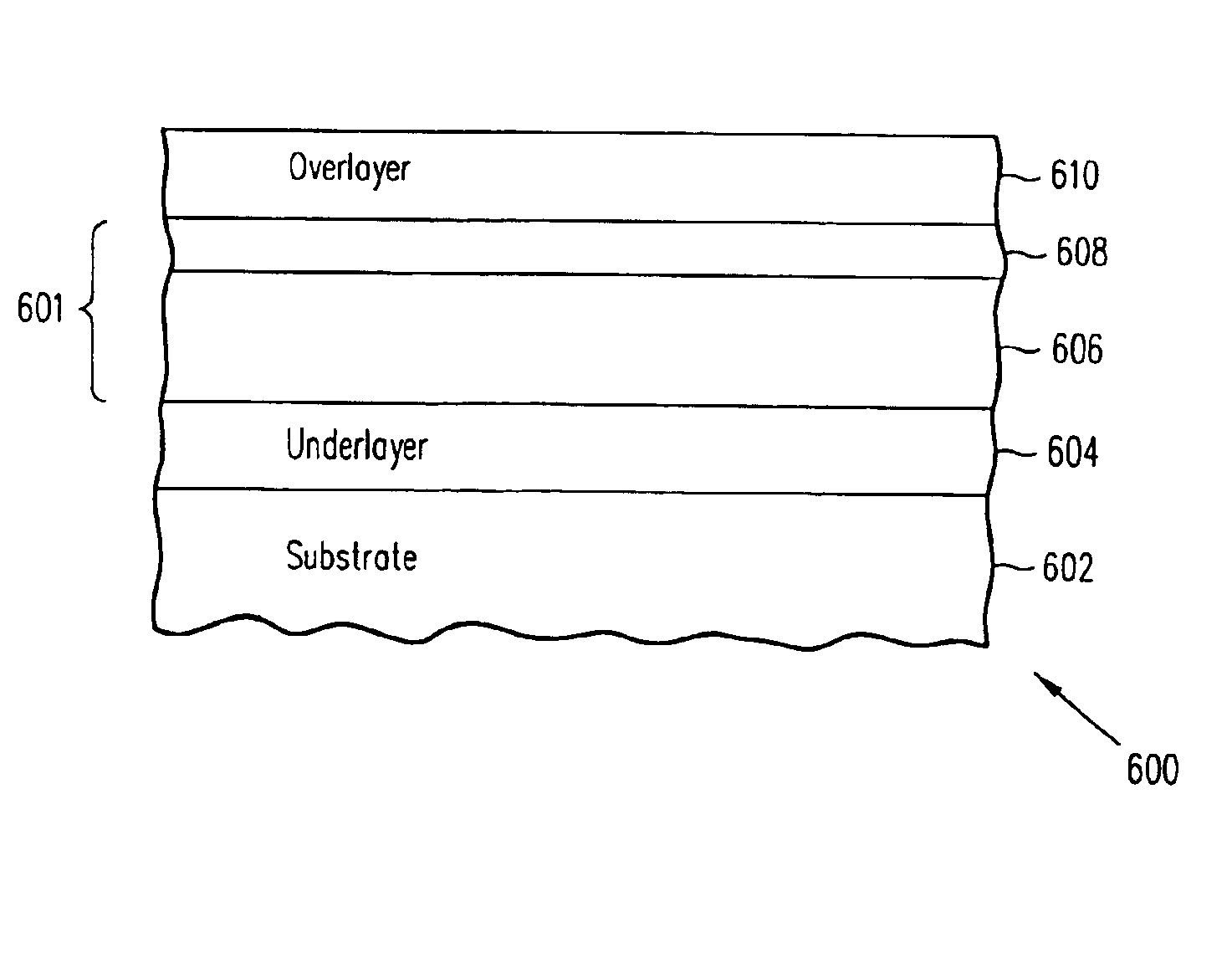

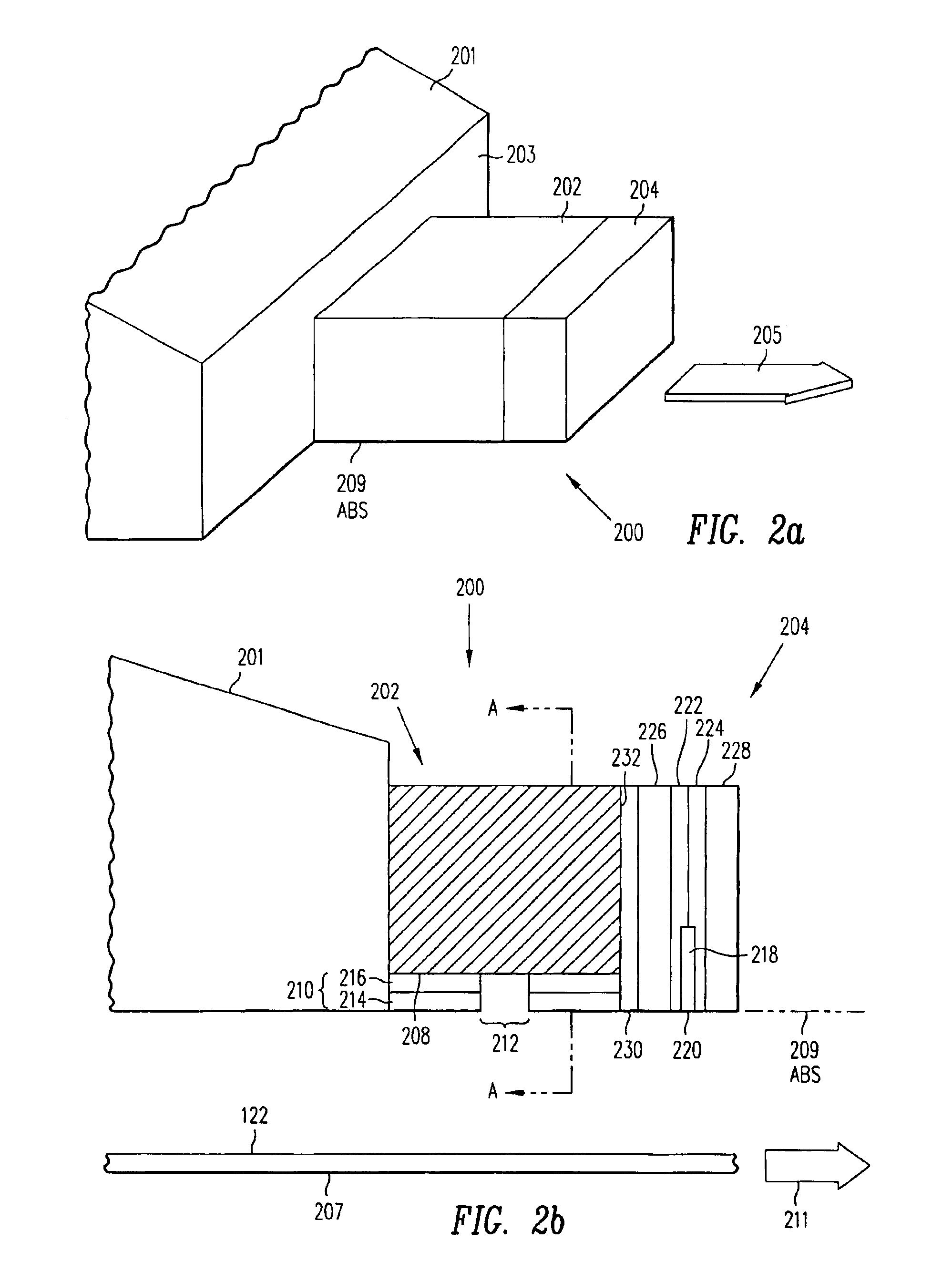

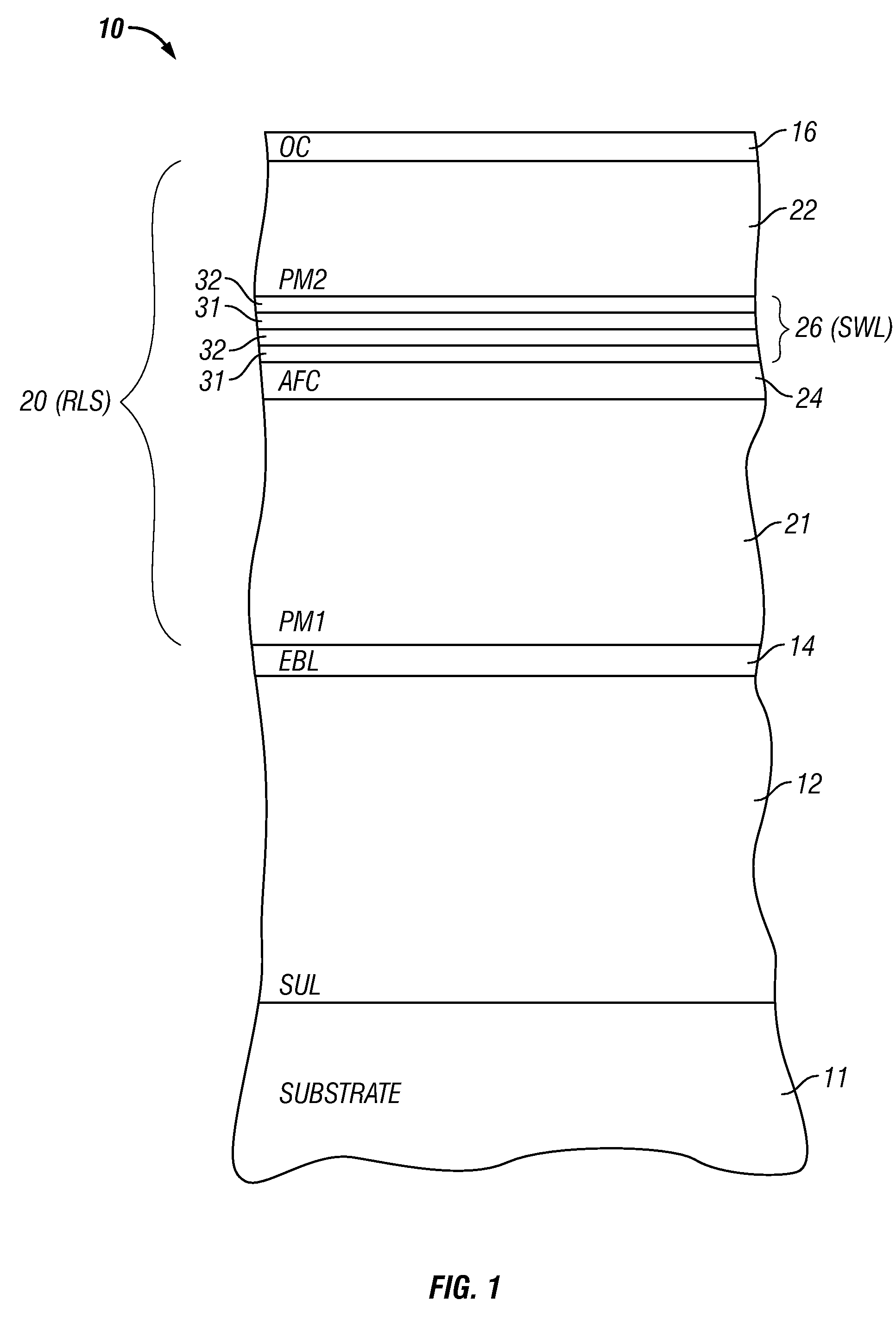

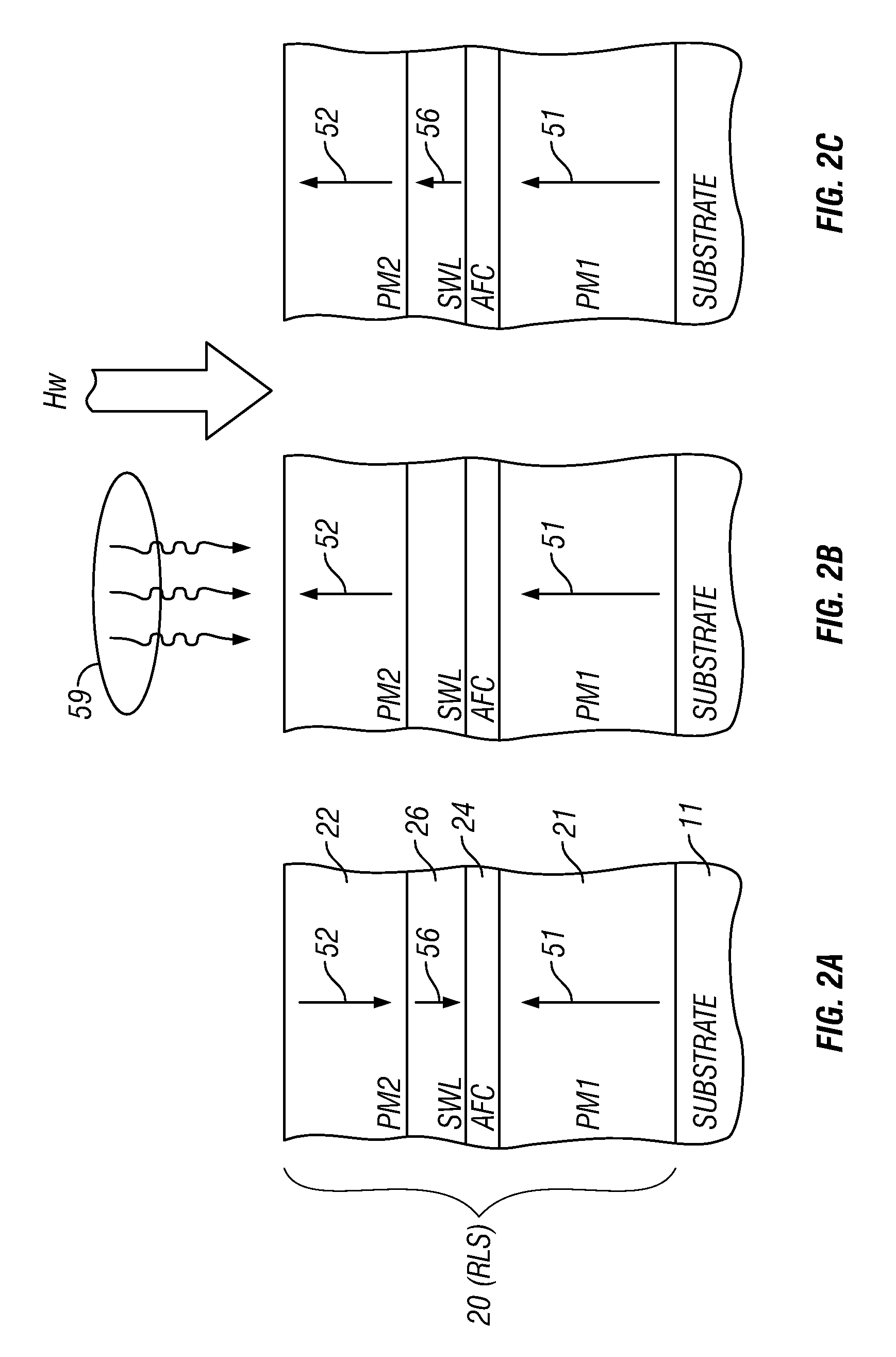

Perpendicular magnetic recording medium and system with low-curie-temperature multilayer for heat-assisted writing and/or reading

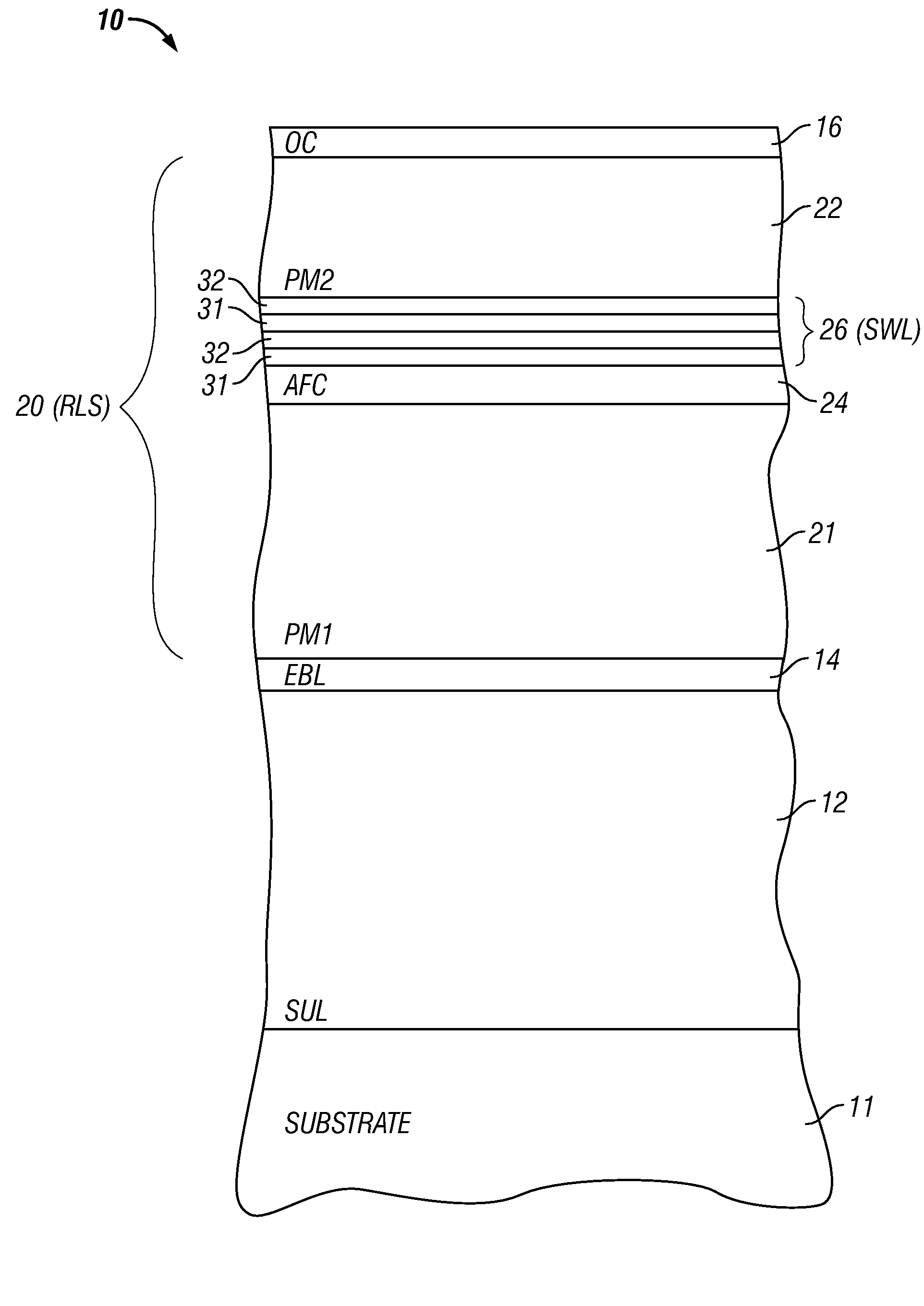

ActiveUS20090226762A1Strong readback signalData augmentationRecord information storageManufacture of flux-sensitive headsAntiferromagnetic couplingMagnetization

A perpendicular magnetic recording medium, usable for either continuous or patterned media, has a recording layer structure (RLS) of first and second perpendicular magnetic layers (PM1, PM2) and an antiferromagnetically coupling (AFC) layer and a ferromagnetic switching layer (SWL) between PM1 and PM2. The magnetic recording system uses heat to assist in the reading and / or writing of data. The SWL is a Co / Ni multilayer with a Curie temperature (TC-SWL) less than the Curie temperatures of PM1 and PM2. At room temperature, there is ferromagnetic coupling between SWL and the upper ferromagnetic layer (PM2) so that the magnetizations of SWL and PM2 are parallel, and antiferromagnetic coupling between SWL and the lower ferromagnetic layer (PM1) across the AFC layer so that the magnetization of PM1 is aligned antiparallel to the magnetizations of SWL and PM2. When the SWL is heated to above TC-SWL it is no longer ferromagnetic, there is no antiferromagnetic coupling between the SWL and PM1 across the AFC layer, and the magnetizations of PM1 and PM2 become aligned parallel.

Owner:WESTERN DIGITAL TECH INC

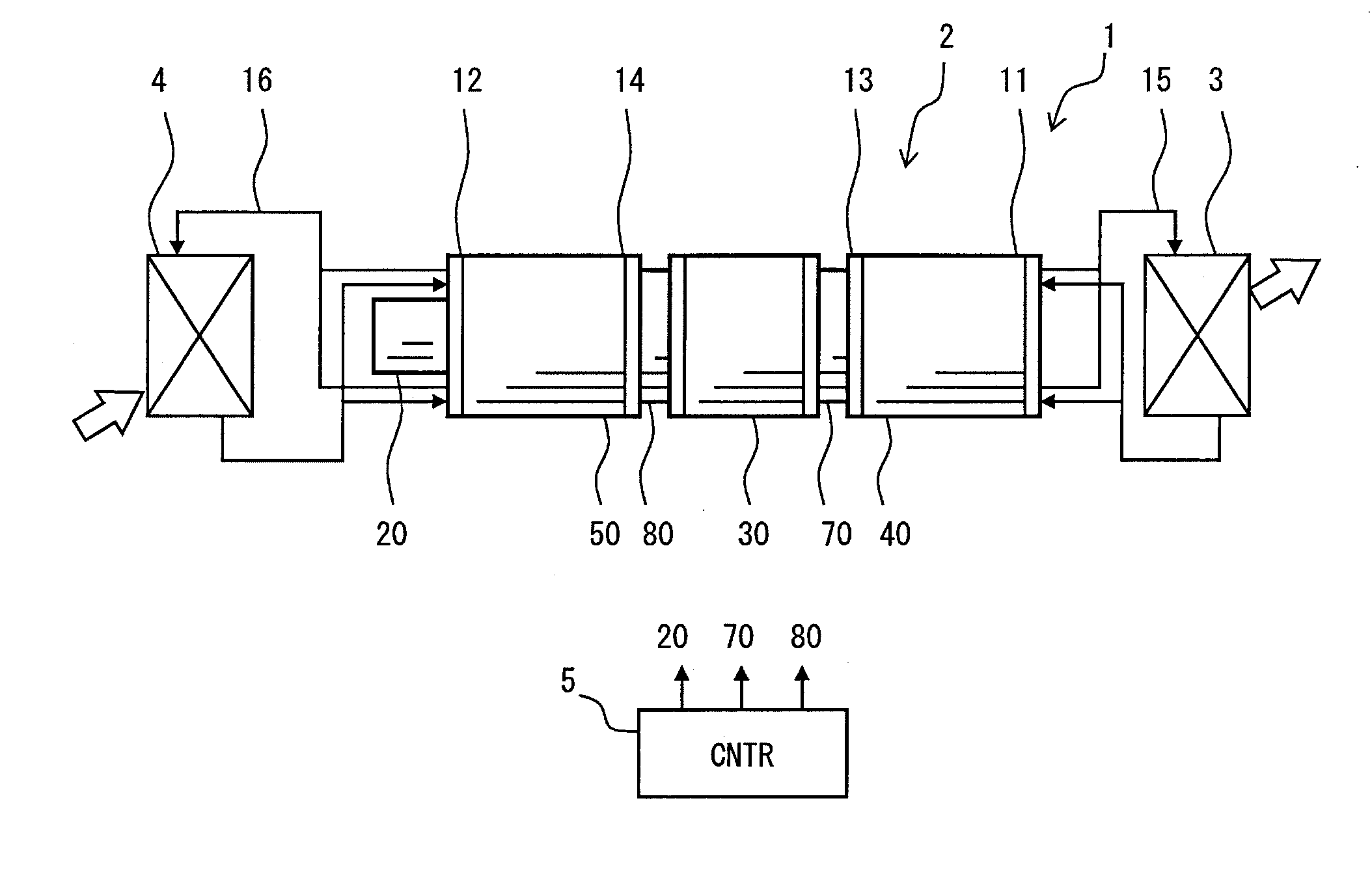

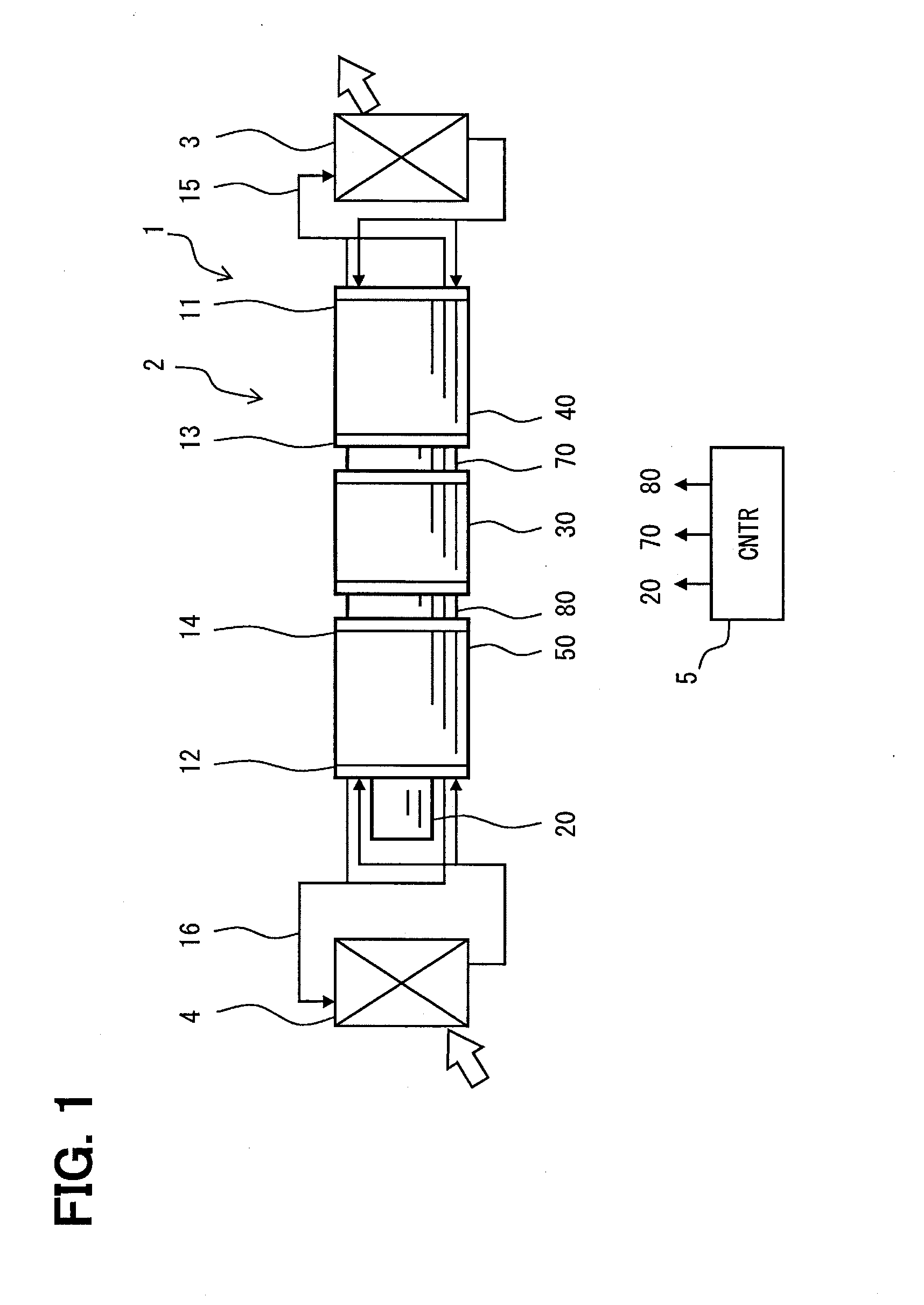

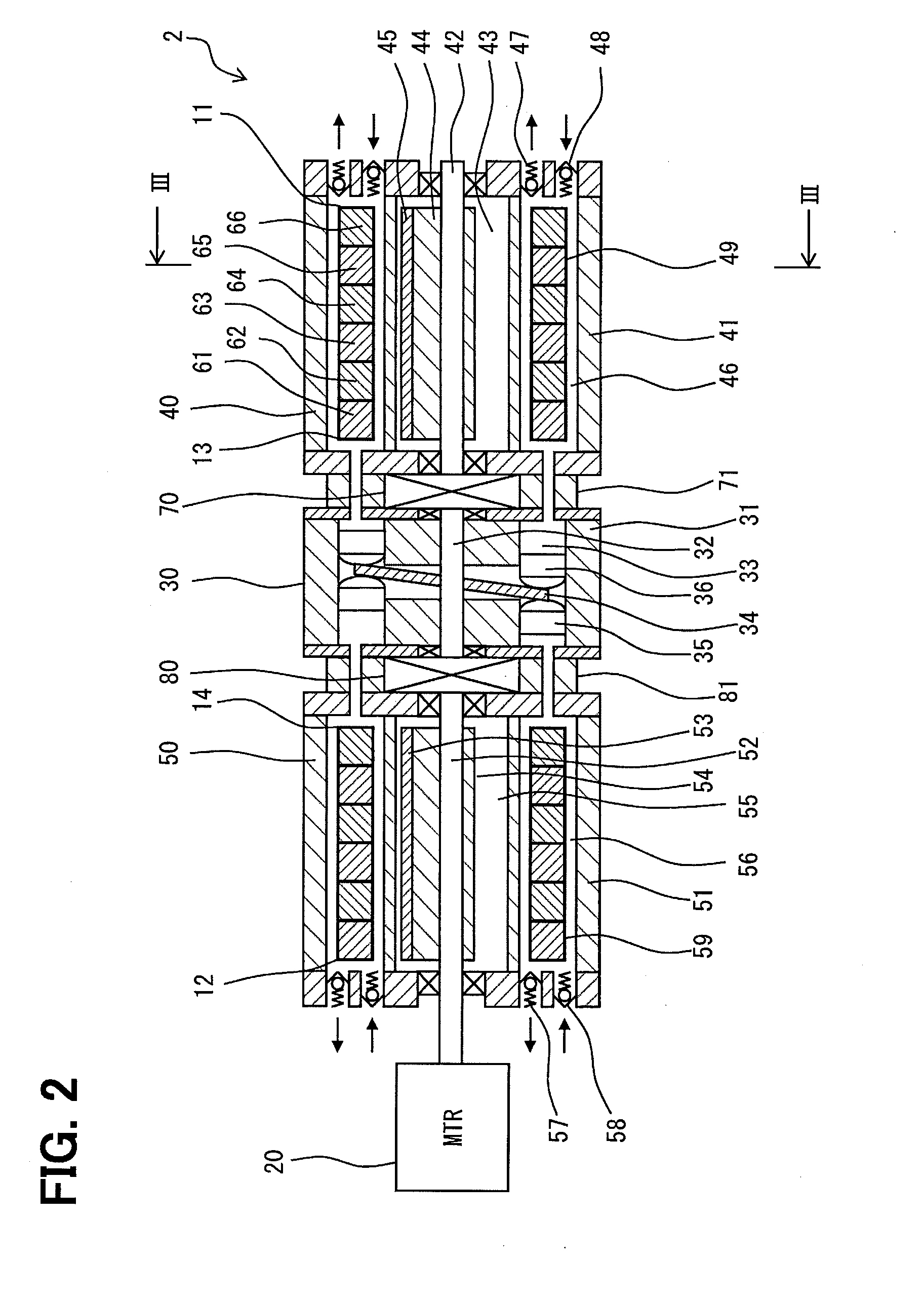

Magneto-caloric effect element and thermo-magnetic cycle apparatus

ActiveUS20150096307A1Improve efficiencyVehicle heating/cooling devicesMachines using electric/magnetic effectsBoundary temperatureEngineering

A magneto-caloric-effect element has a plurality of element units. The element units have lengths, respectively. The element units have different Curie temperatures, respectively. The element units demonstrate magneto-caloric effects. Two adjoining performance distribution crosses at a cross temperature. A temperature in the rated operational status between two adjoining element units is called a boundary temperature. The lengths and / or Curie temperatures are set so that the boundary temperatures and the cross temperatures coincide each other. Thereby, a plurality of element units can function at high effectiveness in the rated operational status.

Owner:DENSO CORP

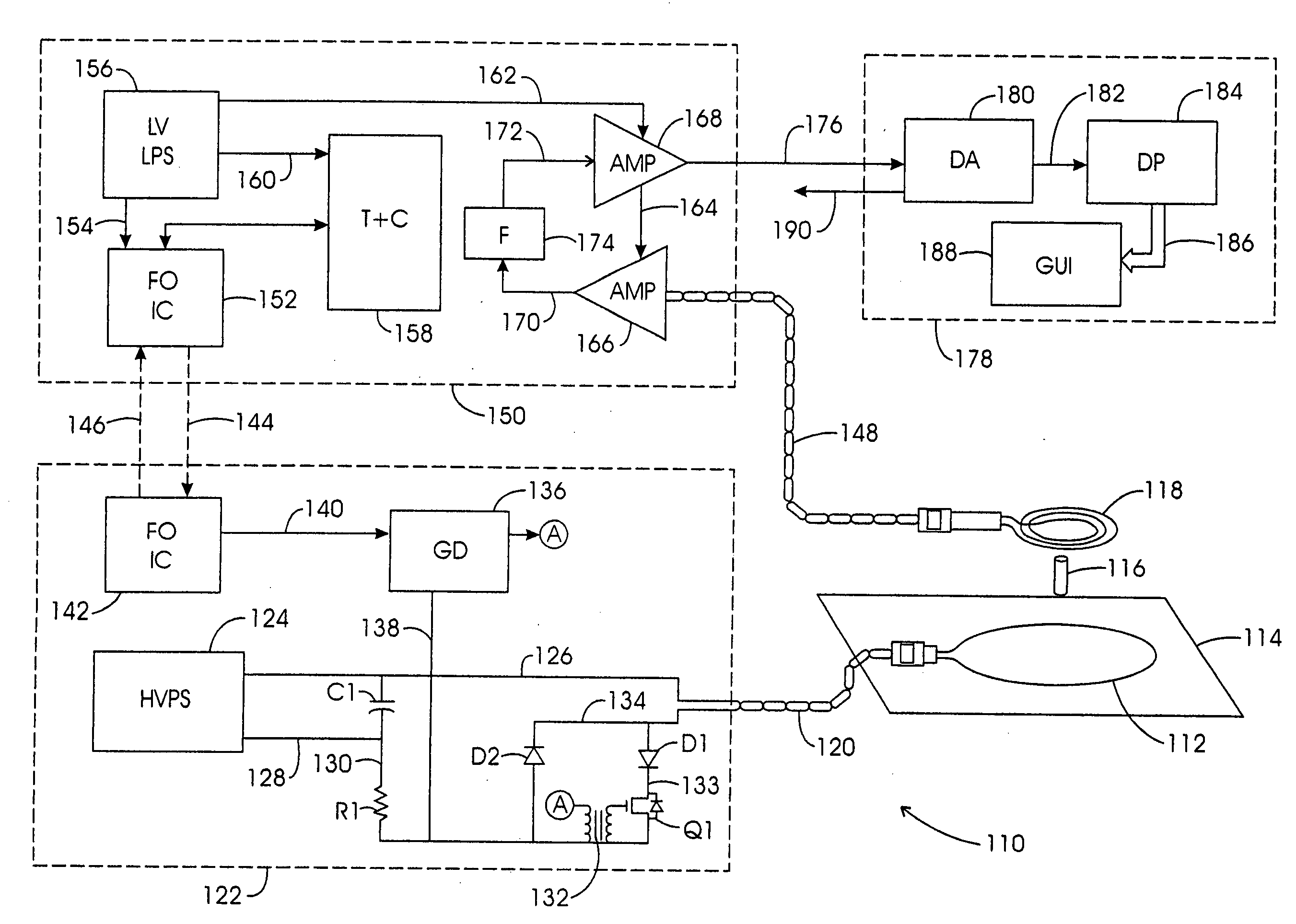

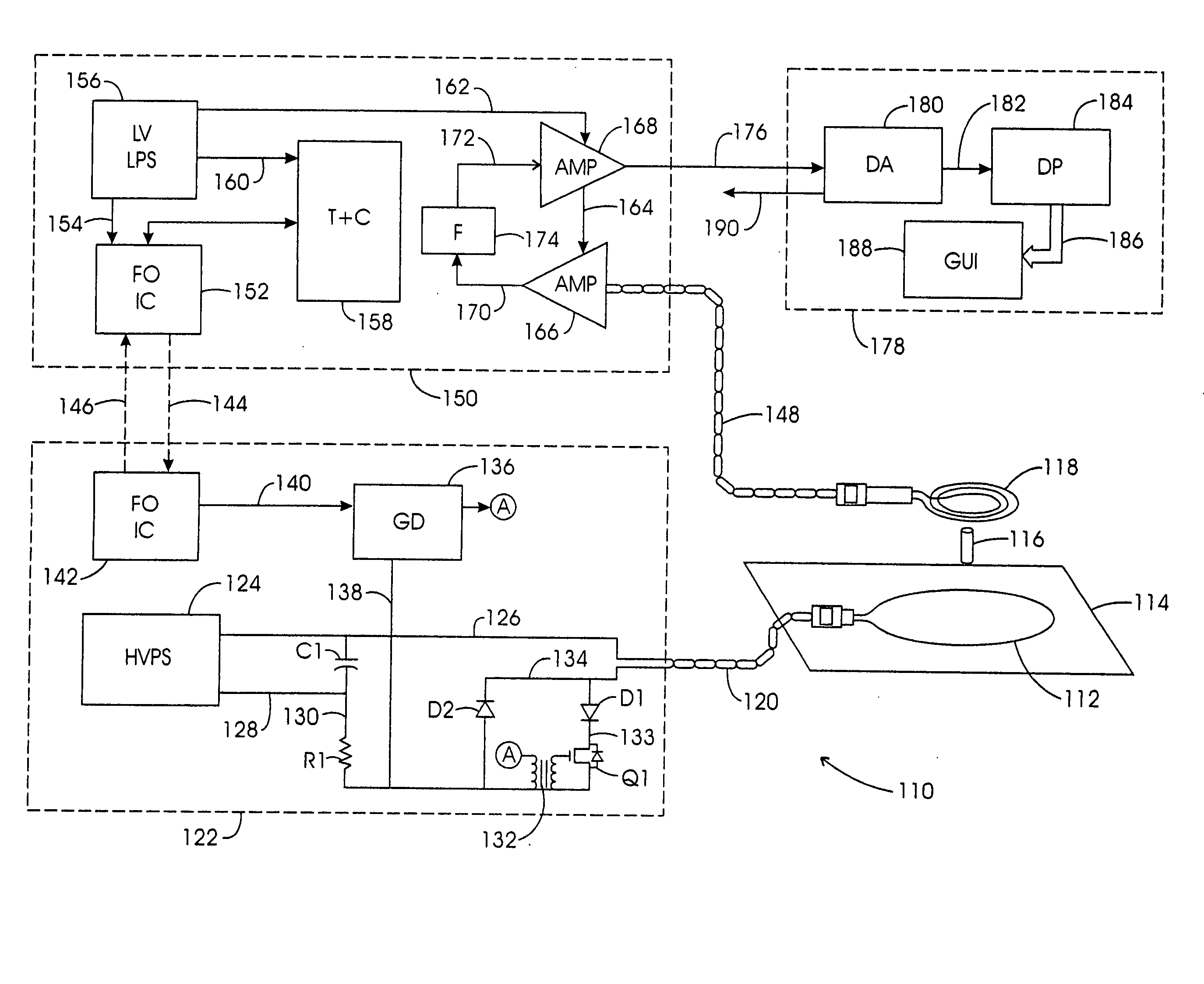

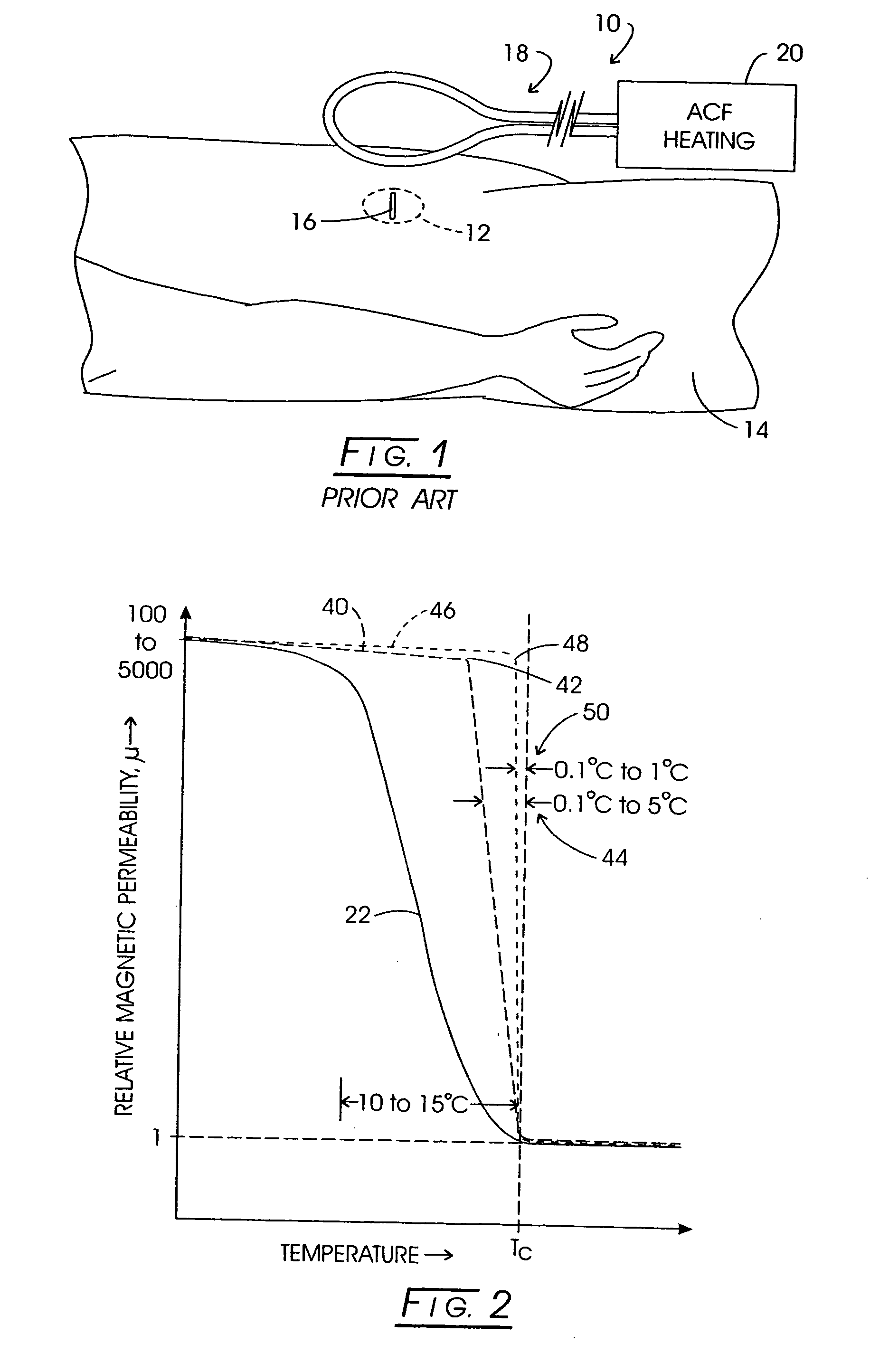

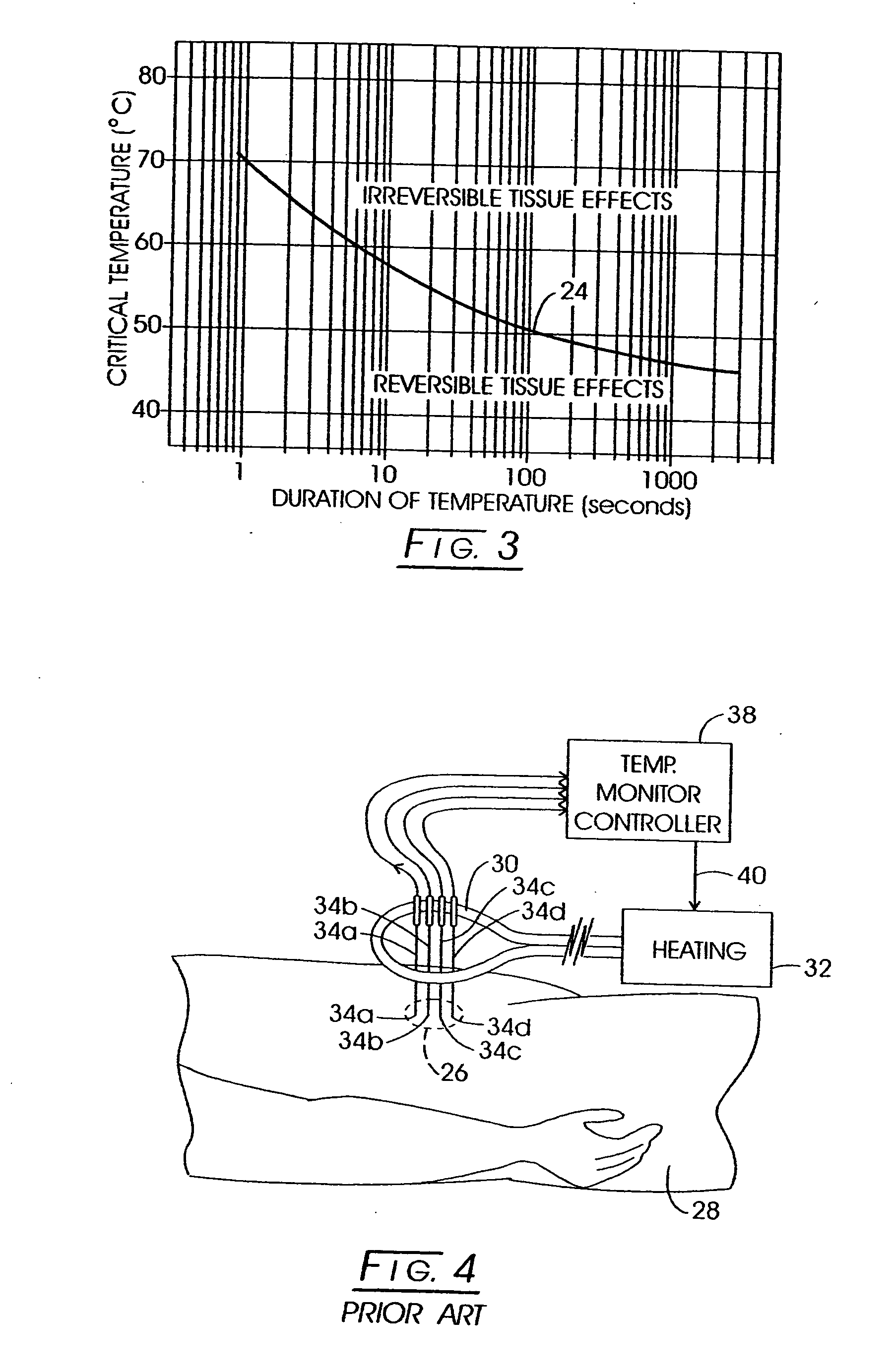

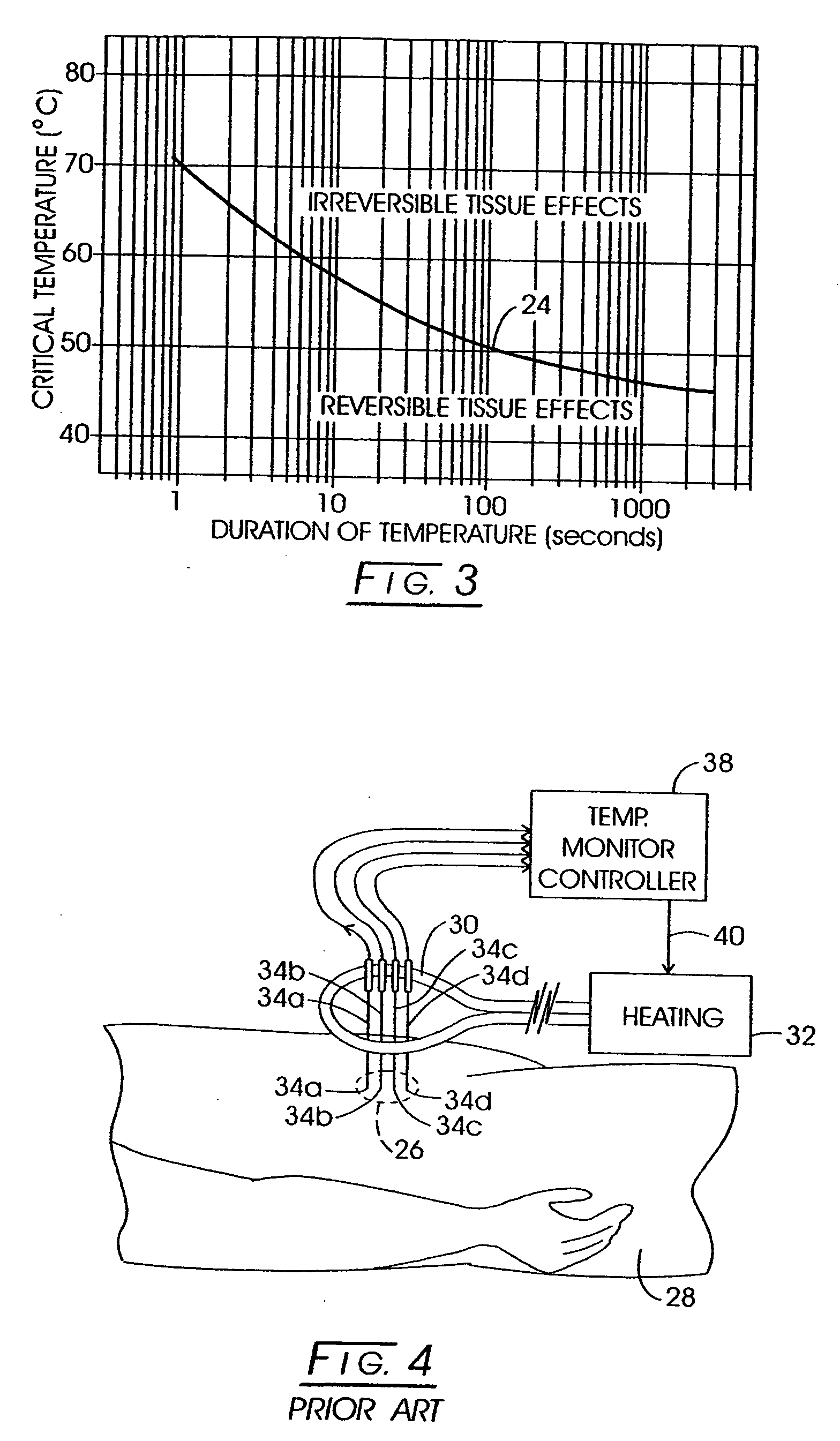

System, method and apparatus for evaluating tissue temperature

InactiveUS20060030912A1Accurate assessmentReduce intensityStentsElectrotherapyCapacitanceTemperature response

Method, system and apparatus for monitoring target tissue temperatures wherein temperature sensors are configured as passive resonant circuits each with a unique resonating signature at monitoring temperatures extending below a select temperature setpoint. The resonant circuits are configured with an inductor component formed of windings about a ferrite core having a Curie temperature characteristic corresponding with a desired temperature setpoint. By selecting inductor winding turns and capacitance values, unique resonant center frequencies are detectable. Temperature monitoring can be carried out with implants at lower threshold and upper limit temperature responses. Additionally, the lower threshold sensors may be combined with auto-regulated heater implants having Curie transitions at upper temperature limits.

Owner:APSARA MEDICAL

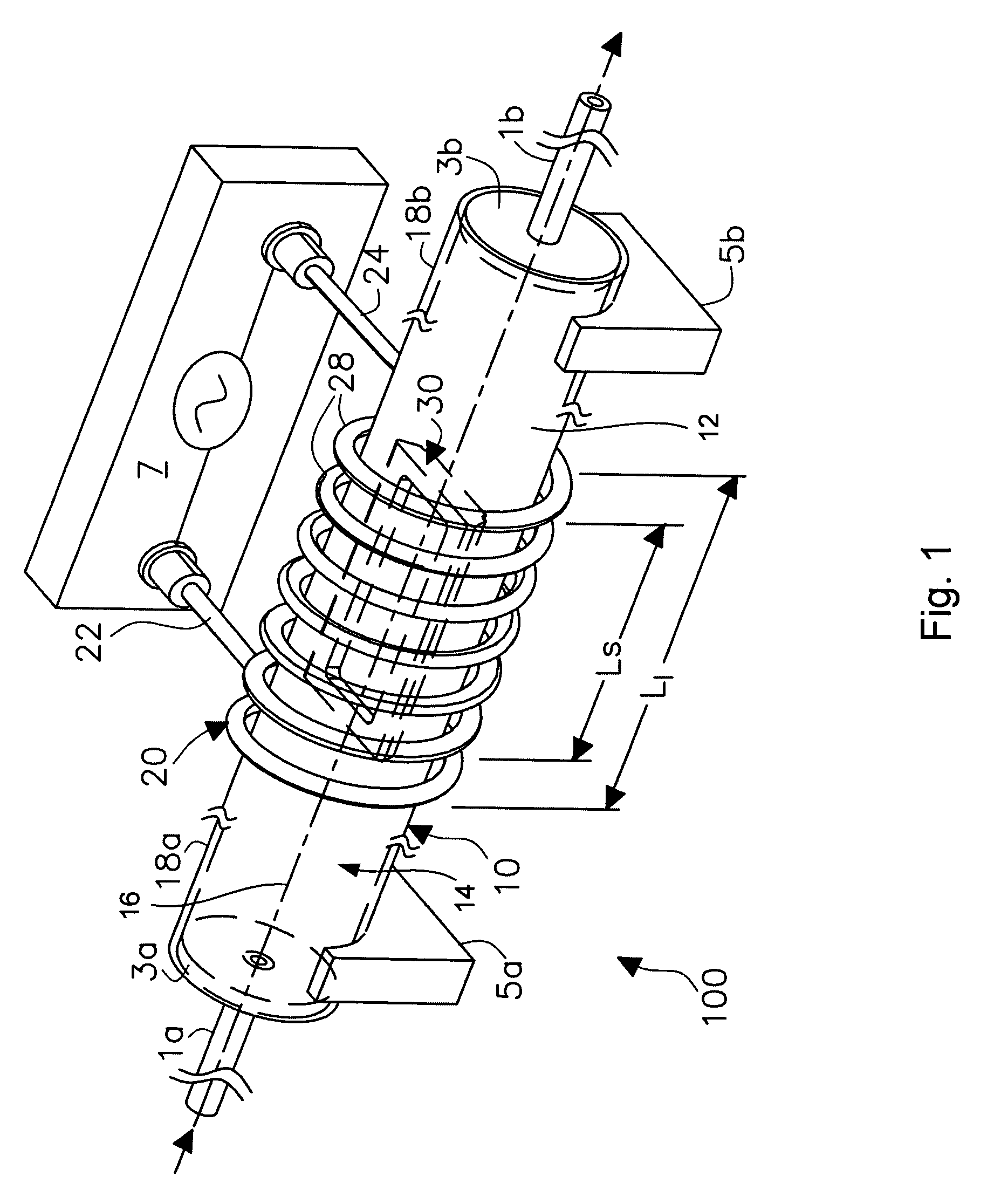

Localized stress relief by induction heating

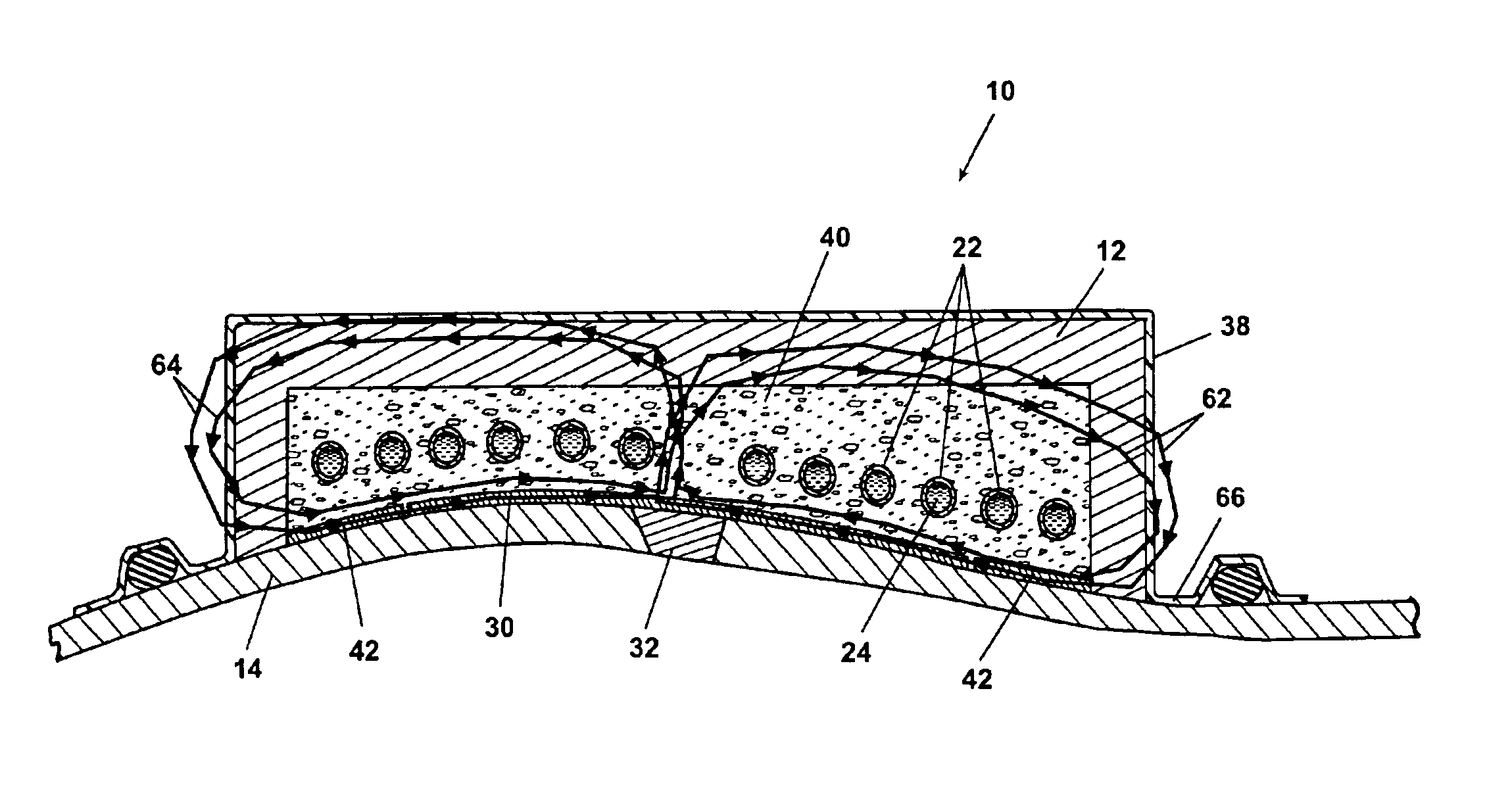

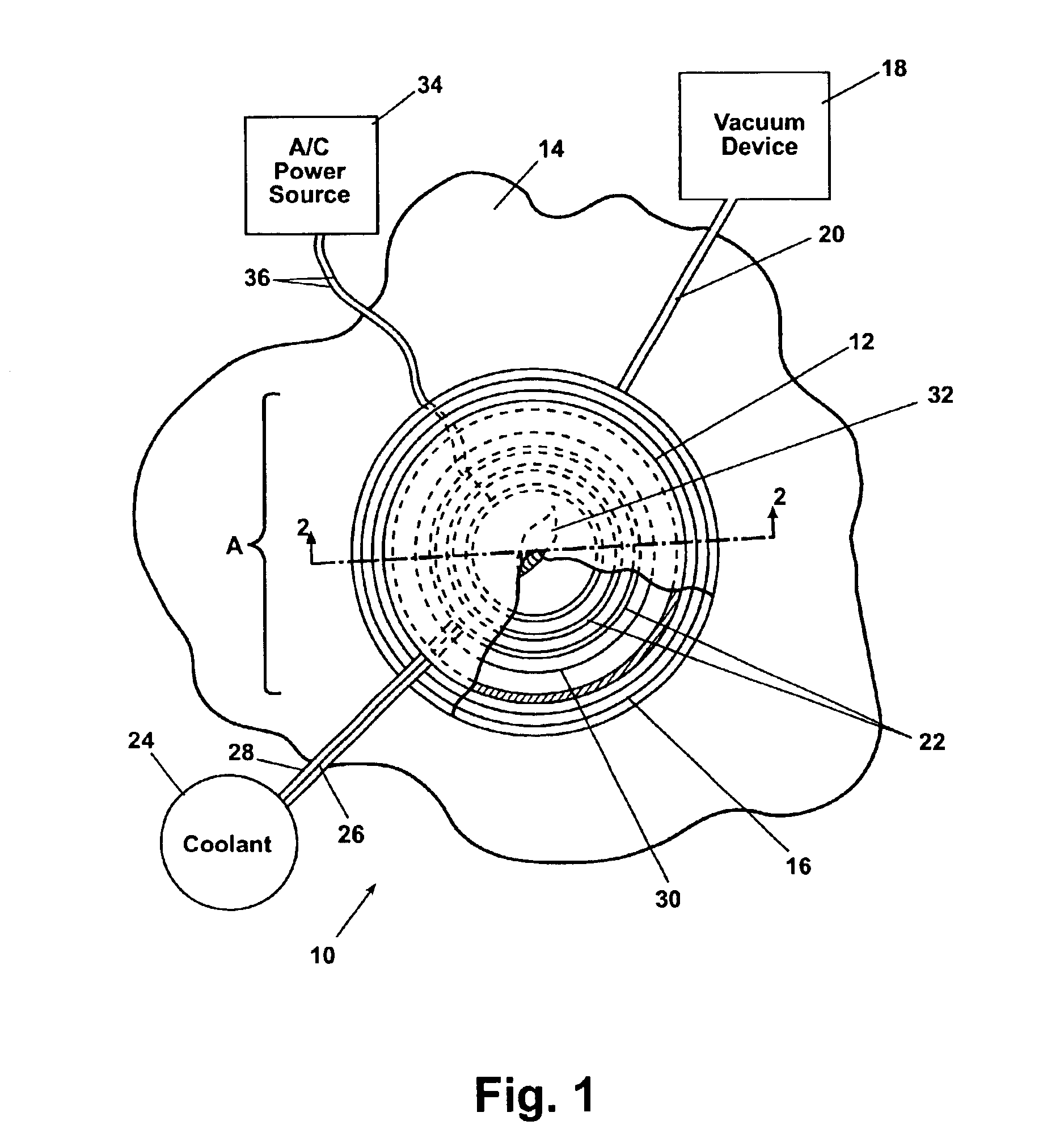

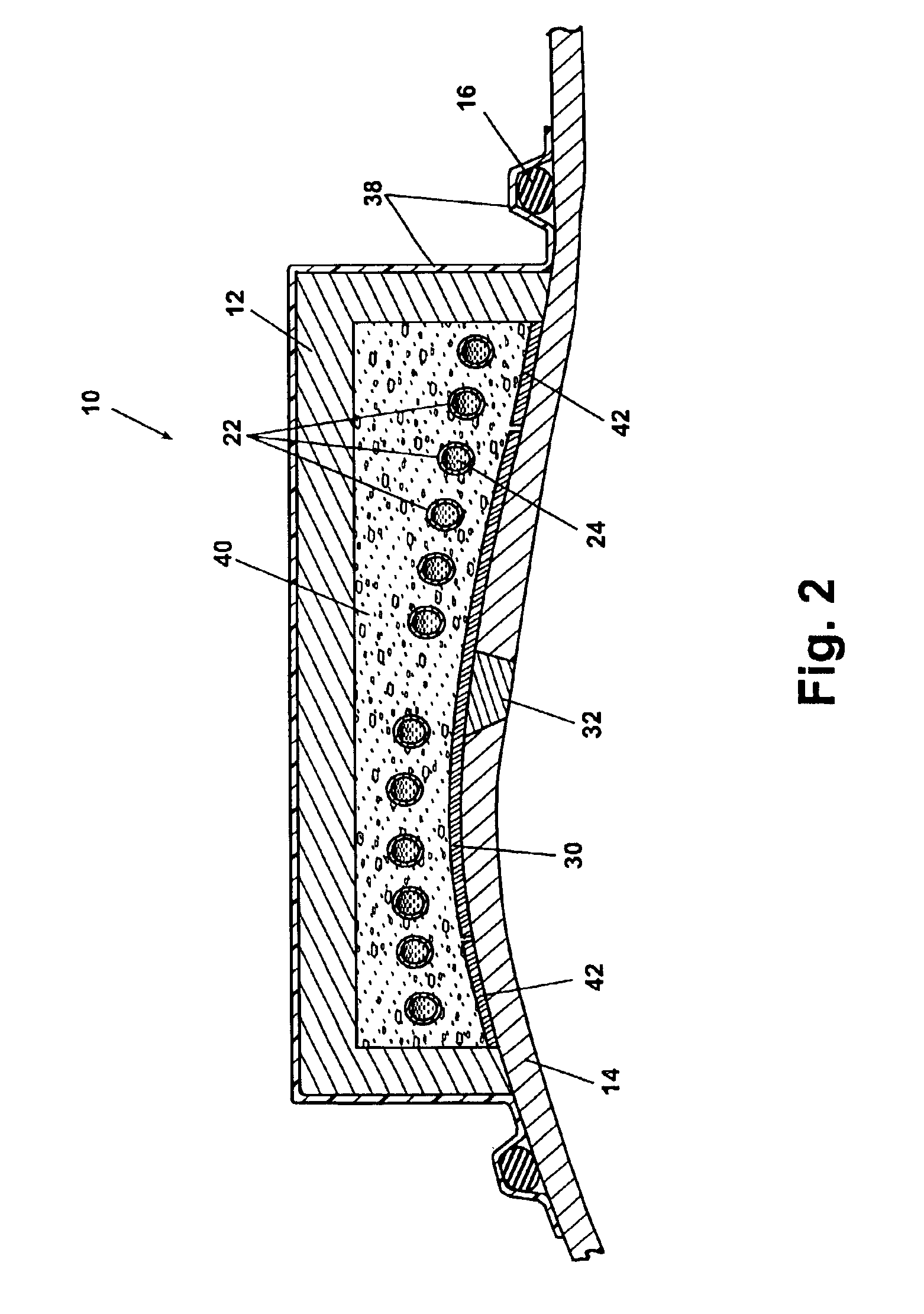

InactiveUS6884975B2Improve permeabilityRelieve a metal plate areaFurnaces without endless coreCoil arrangementsStress inducedSusceptor

A system and method inductively heats and stress relieves a weld joint area having a stress induced zone. A susceptor assembly is positioned over the stress induced zone. The susceptor assembly includes susceptor sheets manufactured to operate at different, preselected Curie temperatures. A housing is mounted over the susceptor assembly including an induction coil positioned adjacent to the susceptor assembly. An alternating electric current is applied to the induction coil. The alternating electric current causes the induction coil to generate a plurality of magnetic flux lines. The invention provides the advantage that the magnetic flux lines passing through the susceptor assembly heat the susceptor assembly providing localized and controlled temperature heat to the weld joint area to stress relieve the stress induced zone.

Owner:THE BOEING CO

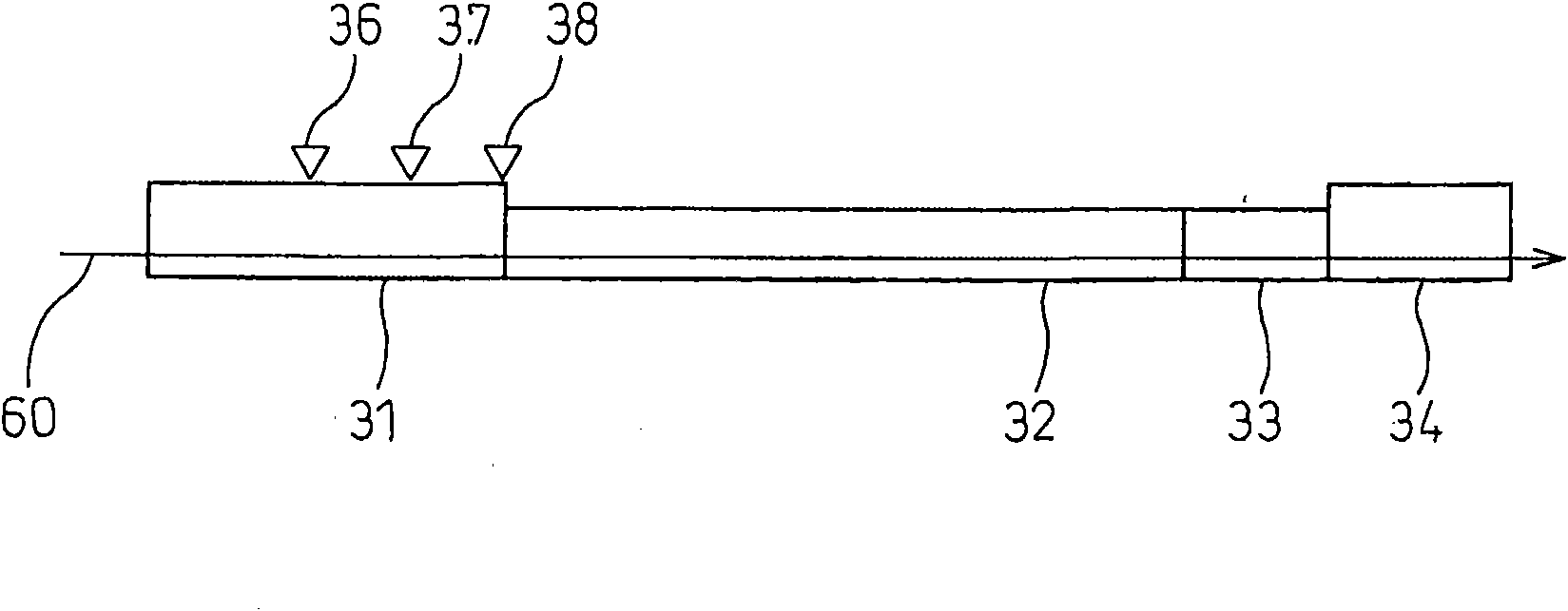

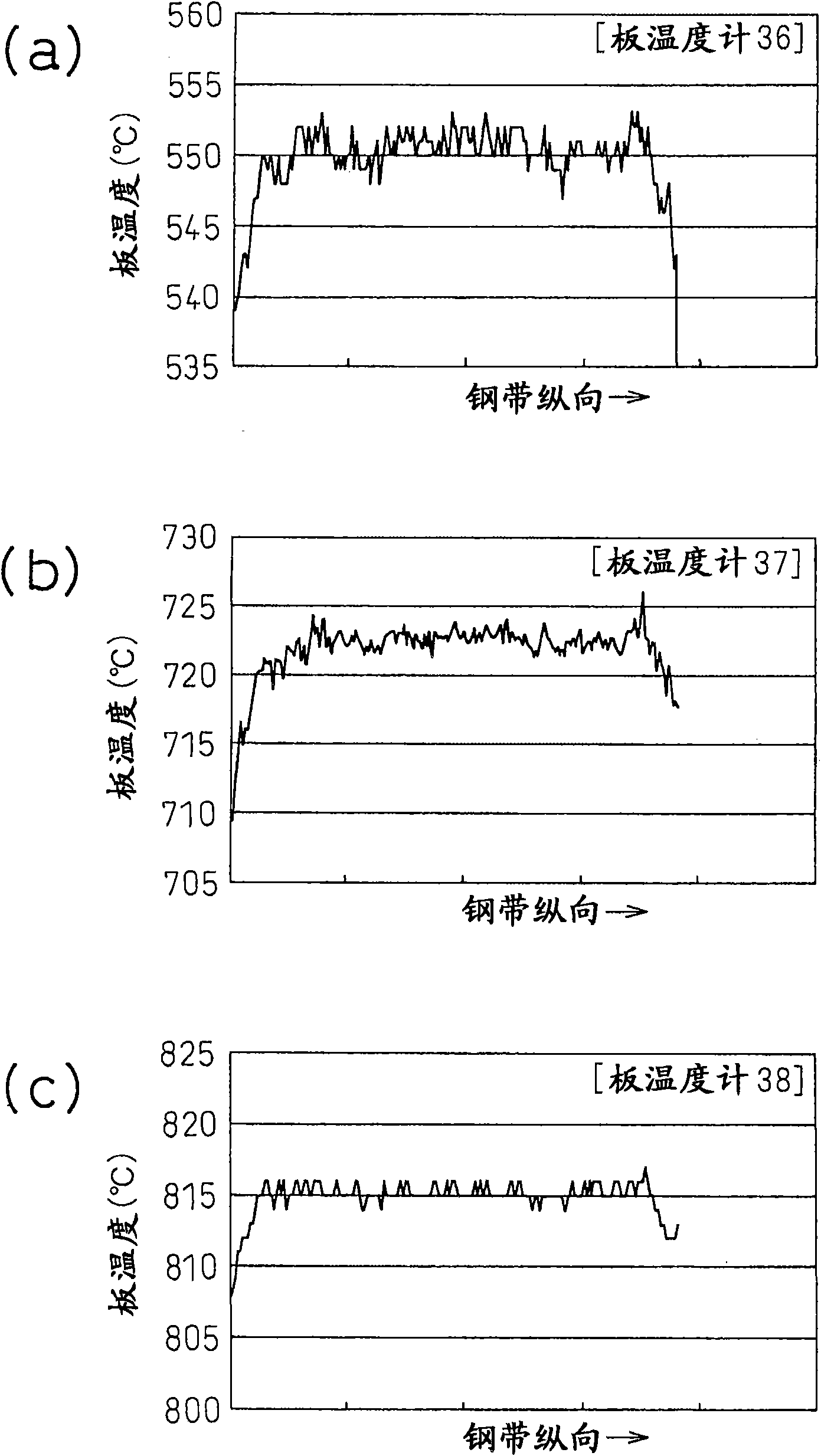

Method of continuous annealing for steel strip with curie point and continuous annealing apparatus therefor

ActiveCN101652485AHeating evenlyBig quality improvementIncreasing energy efficiencyFurnace typesContinuous annealingGas heating

In the continuous annealing of a steel strip with Curie point (Tc) at an annealing temperature exceeding Tc with the use of a continuous annealing equipment composed of a heating area, a soaking areaand a cooling area, the heating treatment in the heating area is divided into three regions. In the first heating area, the steel strip is heated to below Tc-50 DEG C by radiant heating means by gas heating and / or radiant heating means by an electric heater. In the subsequent second heating area, the heated steel strip is heated to the region of Tc-30 DEG C to Tc-5 DEG C by solenoid coil high-frequency induction heating means. In the final third heating area, the heated steel strip is heated to a treatment target temperature exceeding Tc by radiant heating means by gas heating and / or radiant heating means by an electric heater. Accordingly, there can be attained uniform annealing in the longitudinal direction of the steel strip with Curie point.

Owner:NIPPON STEEL CORP

Production of nanostructures by curie point induction heating

InactiveUS20070068933A1Increase temperatureSufficient amountCatalytic gas-gas reactionMaterial nanotechnologySusceptorReaction zone

An apparatus for synthesizing nanostructures. In one embodiment, the apparatus includes a heating device that defines a reaction zone therein and a susceptor made of a ferromagnetic material with a Curie temperature and placed in the reaction zone, where the Curie temperature substantially corresponds to a temperature at which the growth of desired nanostructures occurs and the heating device is capable of heating the susceptor substantially at the Curie temperature.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS +1

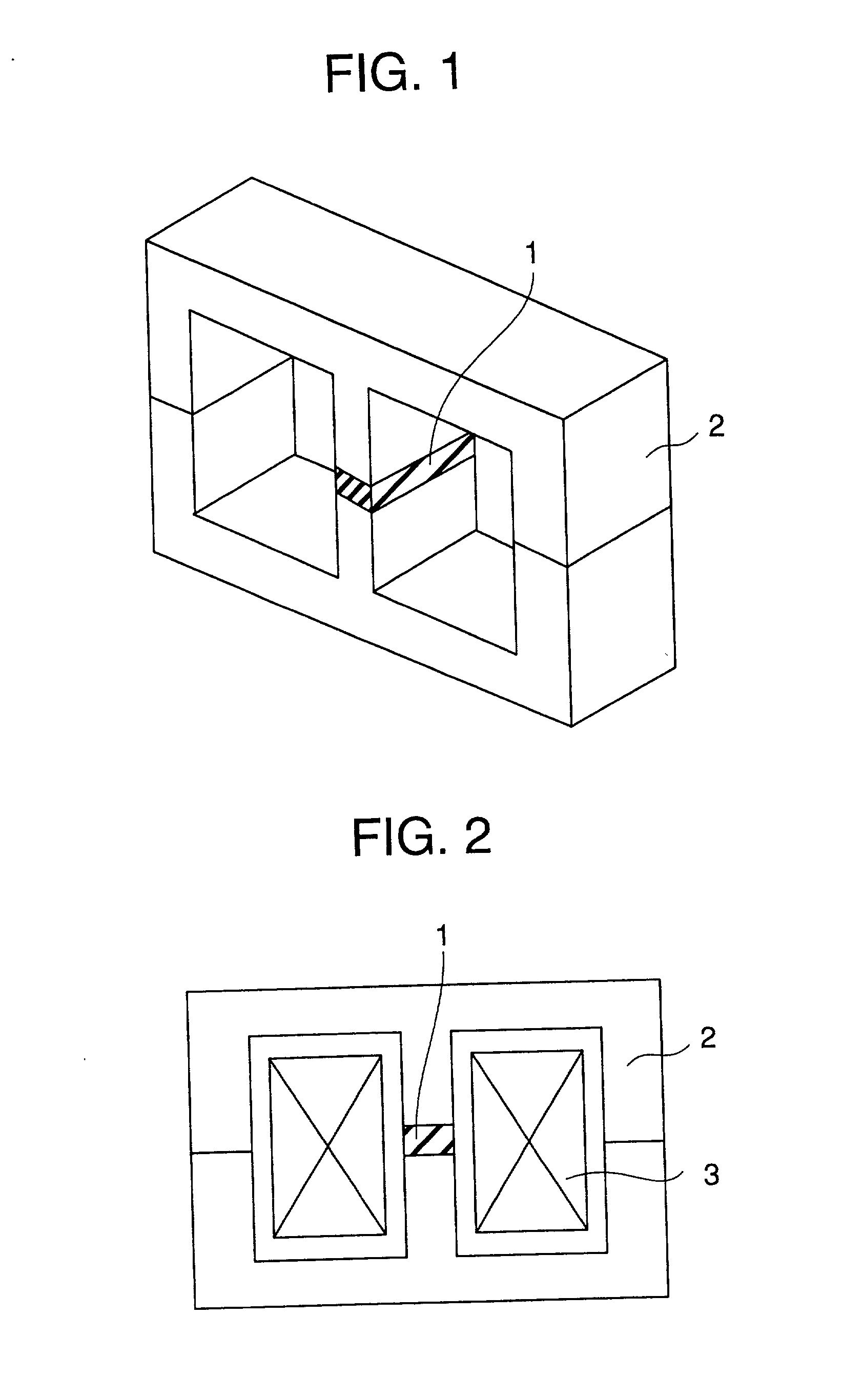

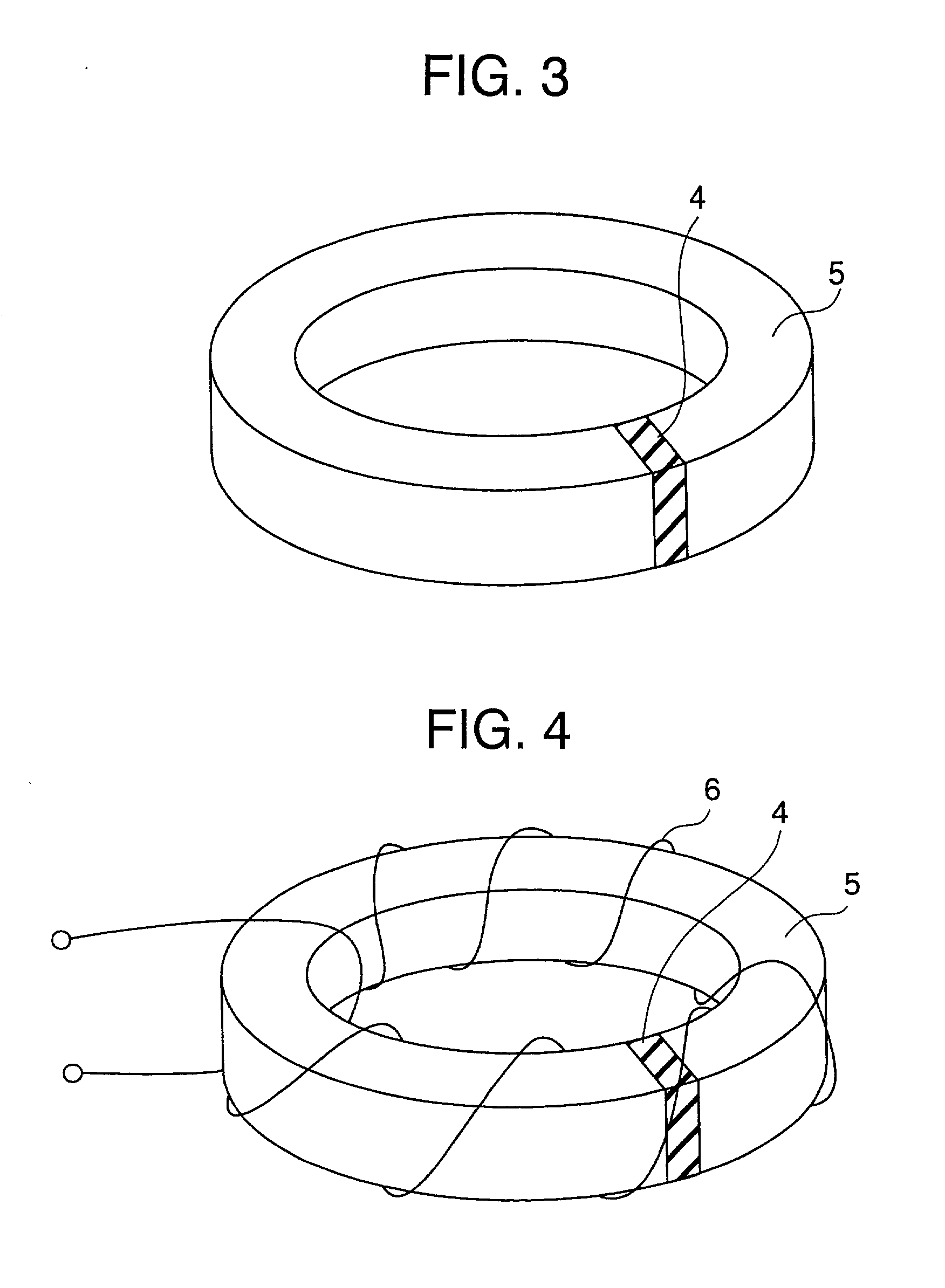

Magnetic core including magnet for magnetic bias and inductor component using the same

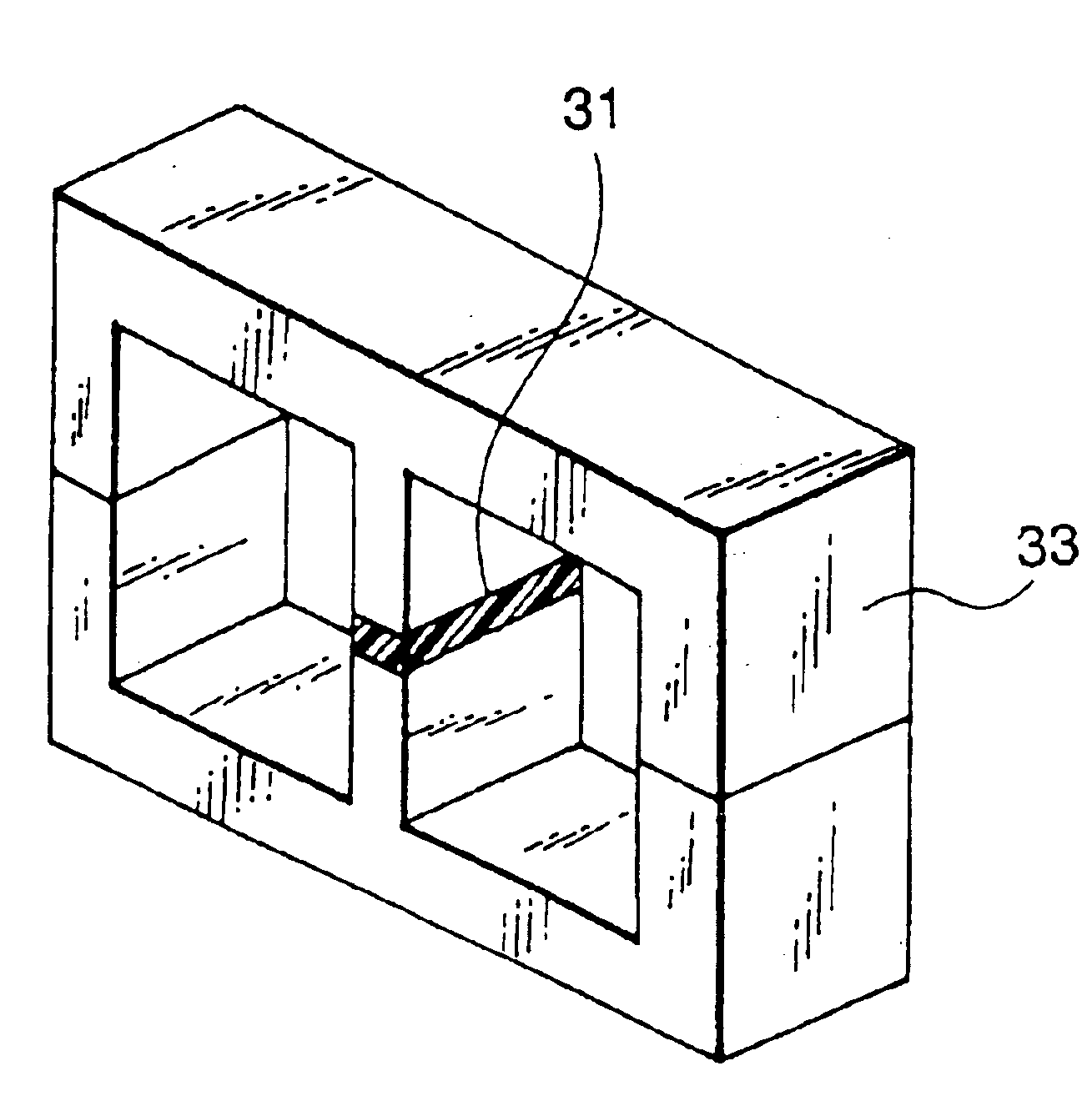

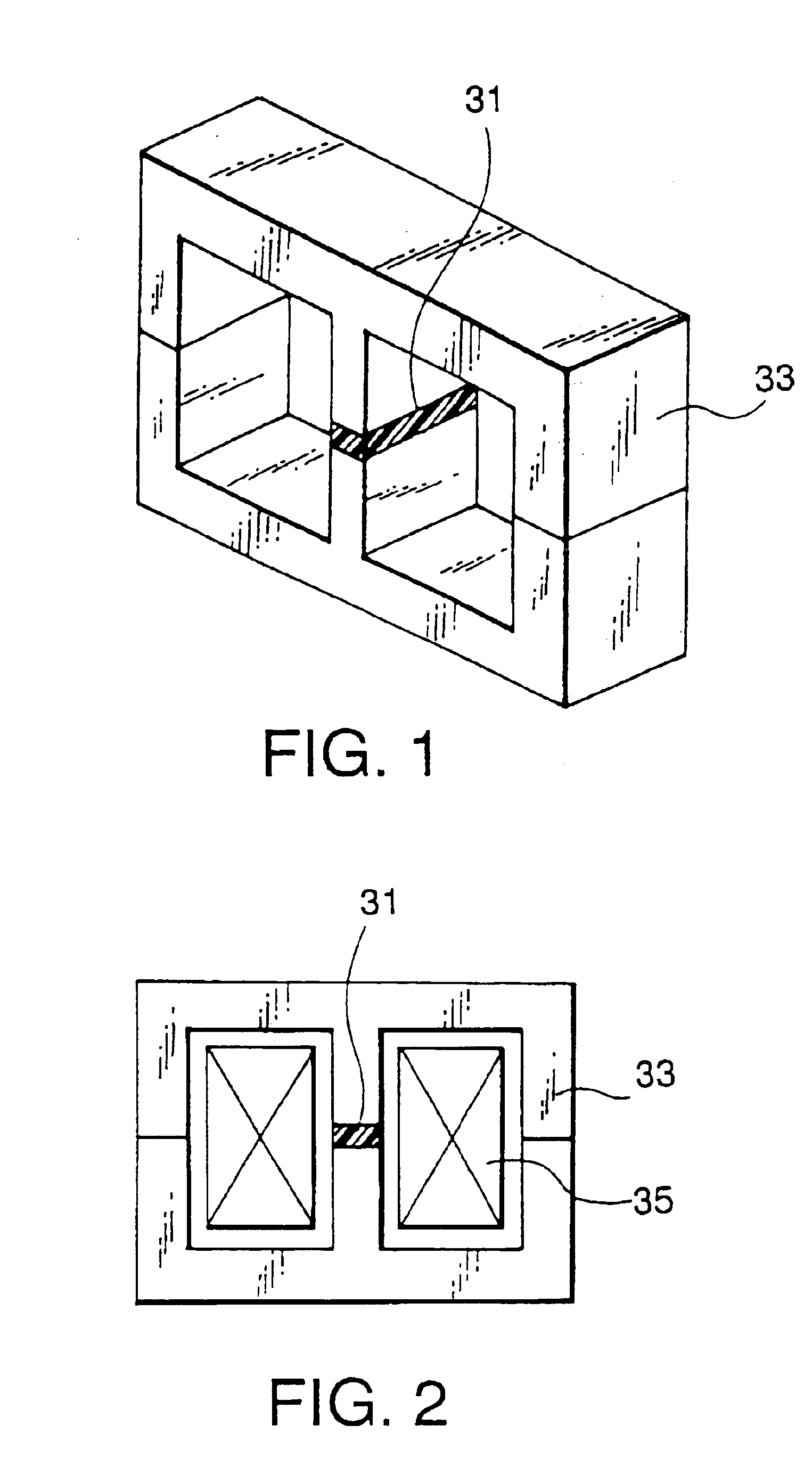

InactiveUS6906608B2Improve DC Superposition CharacteristicsReduce thicknessTransformers/inductances casingsVariable inductancesInductorRare-earth magnet

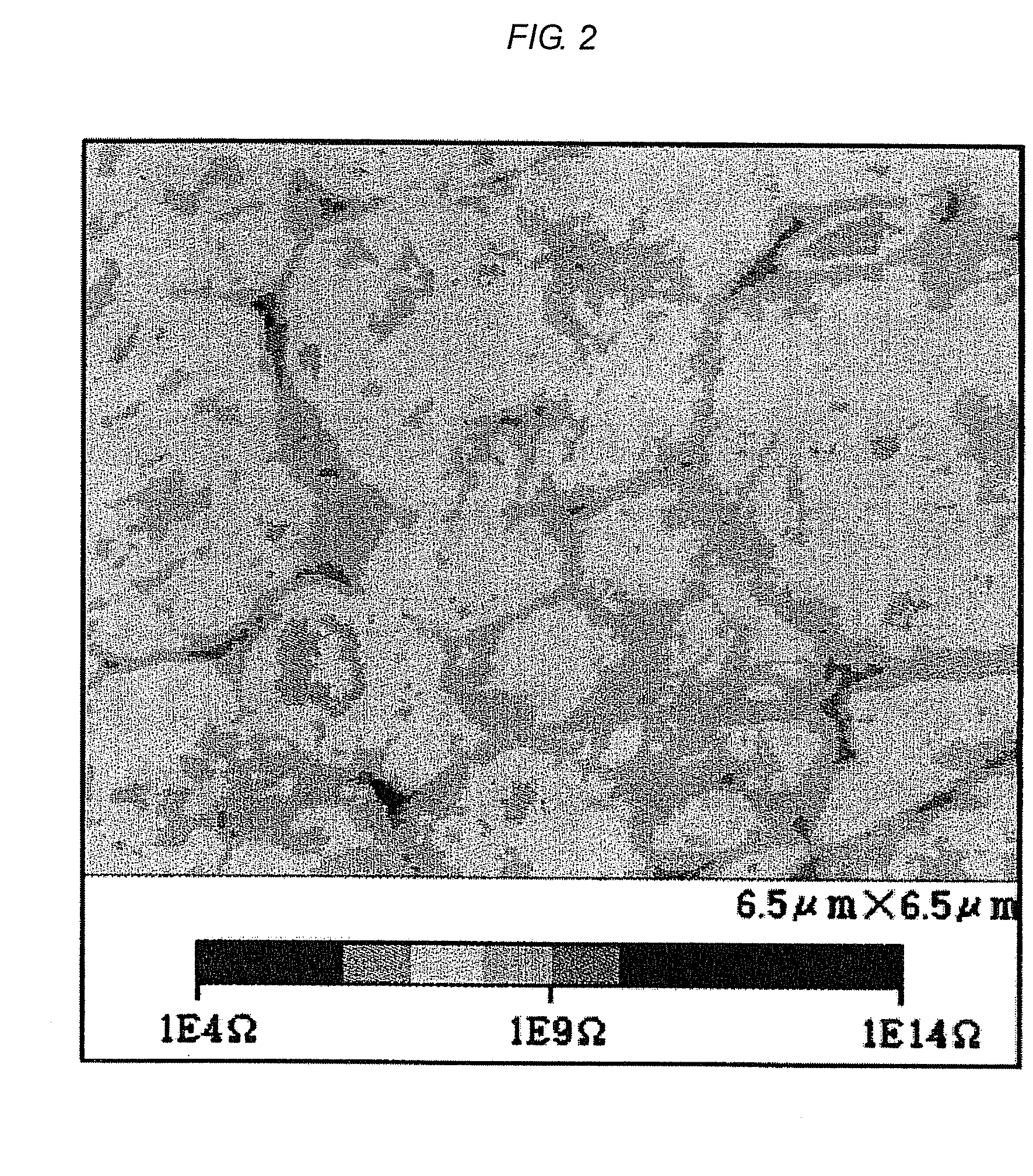

An inductor component according to the present invention includes a magnetic core including at least one magnetic gap having a gap length of about 50 to 10,000 μm in a magnetic path, a magnet for magnetic bias arranged in the neighborhood of the magnetic gap in order to supply magnetic bias from both sides of the magnetic gap, and a coil having at least one turn applied to the magnetic core. The aforementioned magnet for magnetic bias is a bonded magnet containing a resin and a magnet powder dispersed in the resin and having a resistivity of 1 Ω·cm or more. The magnet powder includes a rare-earth magnet powder having an intrinsic coercive force of 5 KOe or more, a Curie point of 300° C. or more, the maximum particle diameter of 150 μm or less, and an average particle diameter of 2.0 to 50 μm m and coated with inorganic glass, and the rare-earth magnet powder is selected from the group consisting of a Sm—Co magnet powder, Nd—Fe—B magnet powder, and Sm—Fe—N magnet powder.

Owner:TOKIN CORP

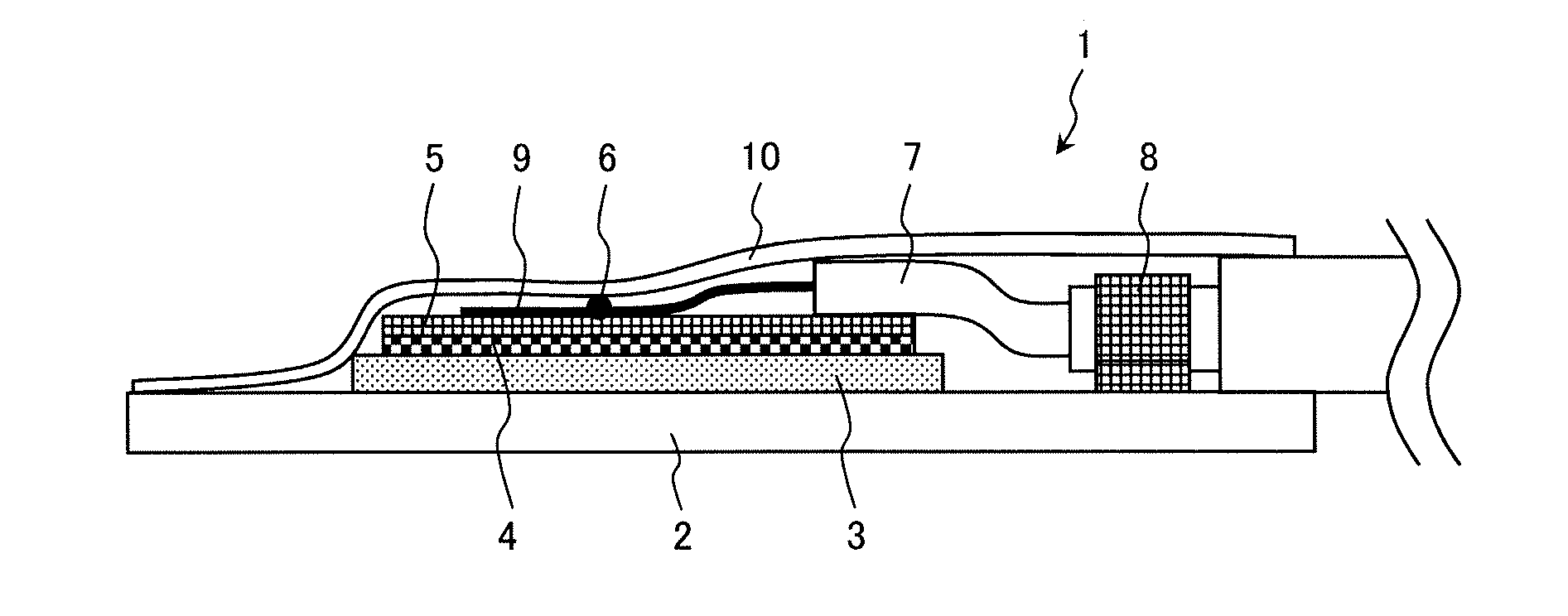

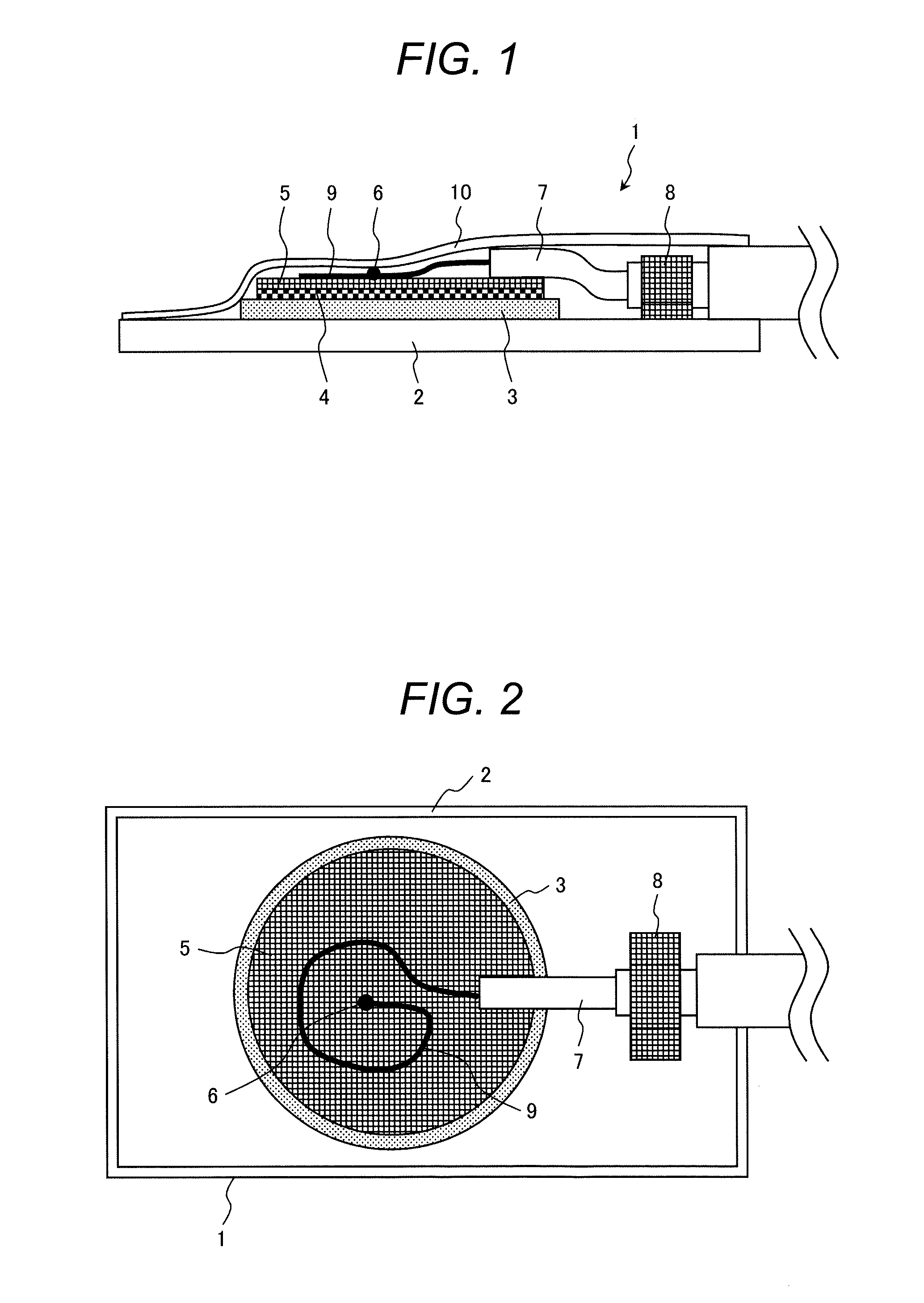

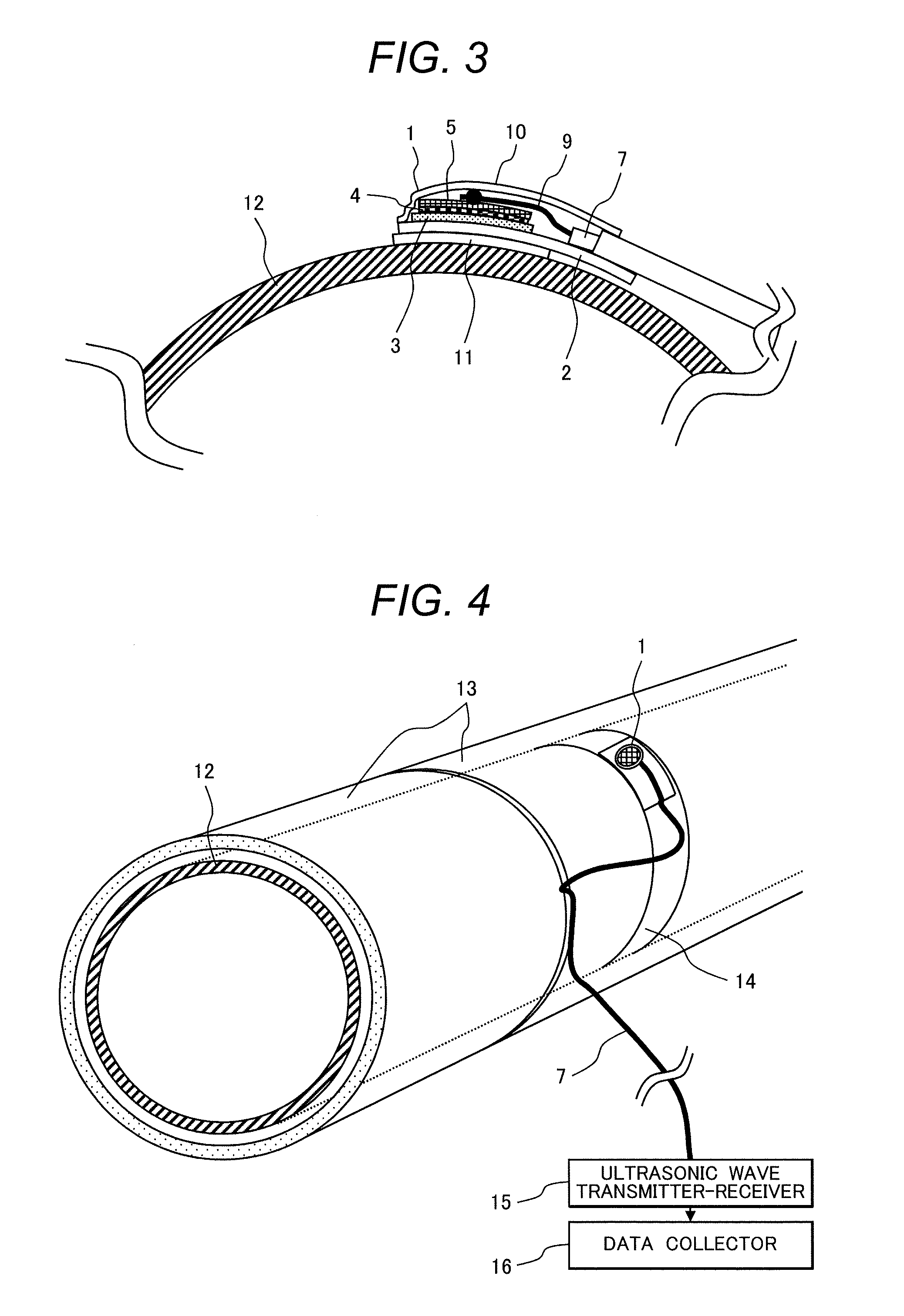

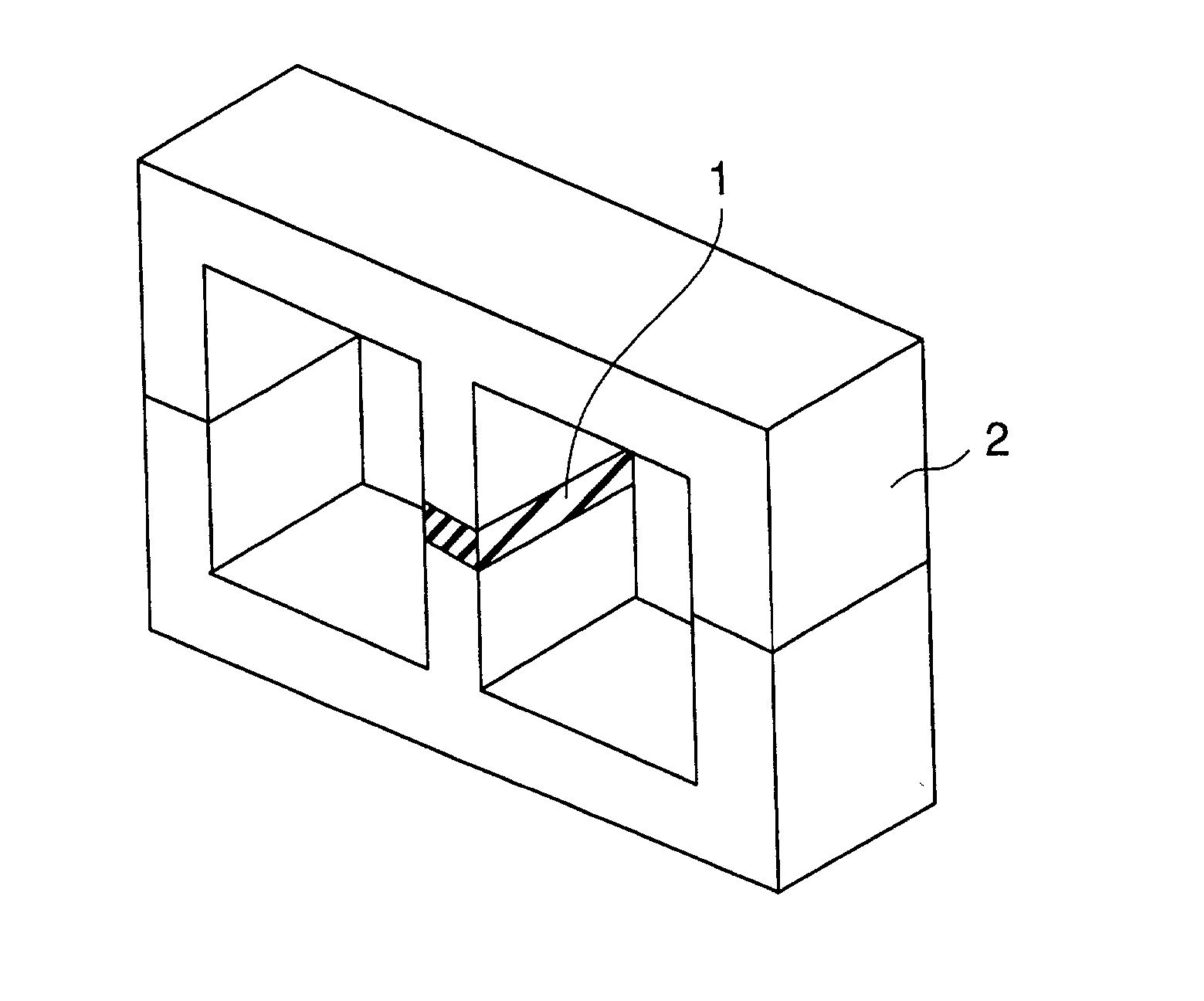

Heat-Resistant Ultrasonic Sensor and Installation Method Thereof

ActiveUS20120291554A1Accurate detectionPiezoelectric/electrostrictive device manufacture/assemblyMaterial analysis using sonic/ultrasonic/infrasonic wavesElectricityCoaxial cable

A heat-resistant ultrasonic sensor forms a piezo-electric ceramics film with a thickness of 0.5 mm or smaller and a Curie point of 200° C. or higher on a flexible metal plate. A thin metal film that is an electrode is attached to a top surface of the piezo-electric ceramics film and a metal wire mesh covers the thin metal film and is attached to a top surface of the thin metal film. A core of a heat-resistant coaxial cable is connected to the metal wire mesh at a connection point. The heat-resistant coaxial cable is fixed to the thin metal plate with a metal fixing member that is a ground portion. An electric insulating cover is attached to the thin metal plate and covers the piezo-electric ceramics film, the thin metal film, the metal wire mesh, the connection point, the fixing member, and the core of the coaxial cable.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

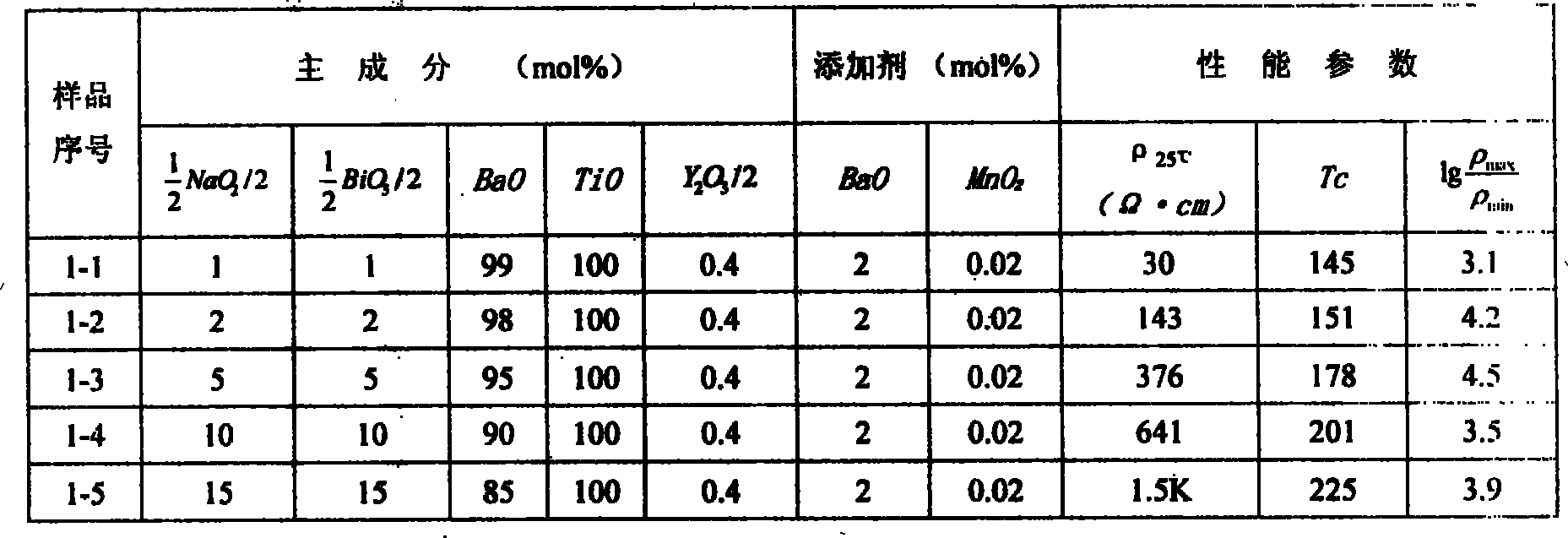

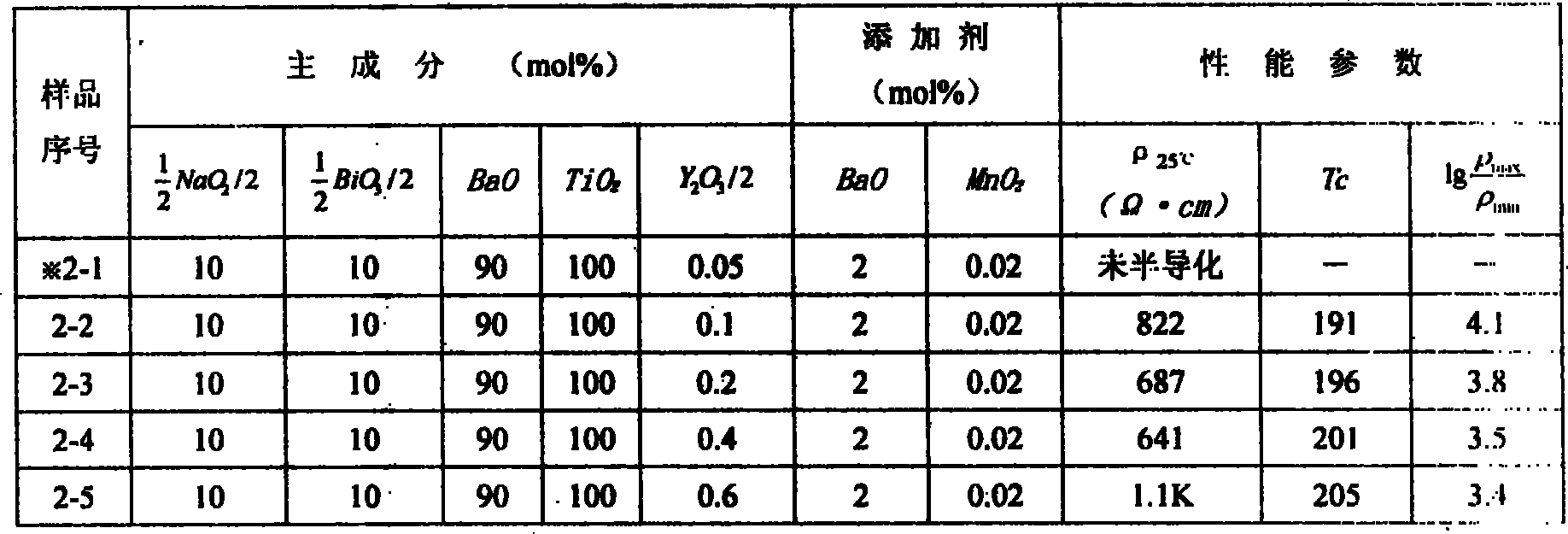

Method for preparing high Curie point leadless PTC ceramic resistance material

InactiveCN101224979ASolve the technical problems of semiconductorizationAvoid pollutionCeramicsPositive temperature coefficient thermistorsElectrical resistance and conductanceCompound a

A preparation method of a lead-free high-Curie temperature PTC varistor ceramic material, the Na2Co3, Bi2O3 and TiO2 are mixed into a compound A while the TiO2 and BaCO3 are mixed into a compound B, the Na0.5Bi0.5TiO3 powder and the BaTiO3 powder are synthesized respectively through ball milling of the compound A and B; the synthesis Na0.5Bi0.5TiO3 powder and BaTiO3 powder, the semi-derived element and the TiO2 are ball milled, dried, granulated, and molded; the body molded is sintered to obtain a semi-derived ceramic sample which is oxidized for the lead-free high-curie temperature PTC varistor ceramic material. The invention fulfills unleaded requirements, avoids environmental pollution and human harm caused by lead application in manufacturing of resistance material, and solves the technical difficulties for the semi-derived lead-free high-curie temperature PTC varistor ceramic material.

Owner:SHAANXI UNIV OF SCI & TECH

Magnetically biasing bond magnet for improving DC superposition characteristics of magnetic coil

InactiveUS20020149458A1Improve propertiesExcellent in magnetic property and core-loss characteristicPermanent magnetsVariable inductancesRare earthInductance

In order to provide an inductance part having excellent DC superposition characteristic and core-loss, a magnetically biasing magnet, which is disposed in a magnetic gap of a magnetic core, is a bond magnet comprising magnetic powder and plastic resin with the content of the resin being 20% or more on the base of volumetric ratio and which has a specific resistance of 0.1 OMEGA.cm or more. The magnetic powder used is rare-earth magnetic powder having an intrinsic coercive force of 5 kOe or more, Curie point of 300° C. or more, and an average particle size of 2.0-50 mum. A magnetically biasing magnet used in an inductance part that is treated by the reflow soldering method has a resin content of 30% or more and the magnetic powder used therein is Sm-Co magnetic powder having an intrinsic coercive force of 10 kOe or more, Curie point of 500° C. or more, and an average particle size of 2.5-50 mum. A thin magnet having a thickness of 500 m or less can be realized for a small-sized inductance part.

Owner:TOKIN CORP

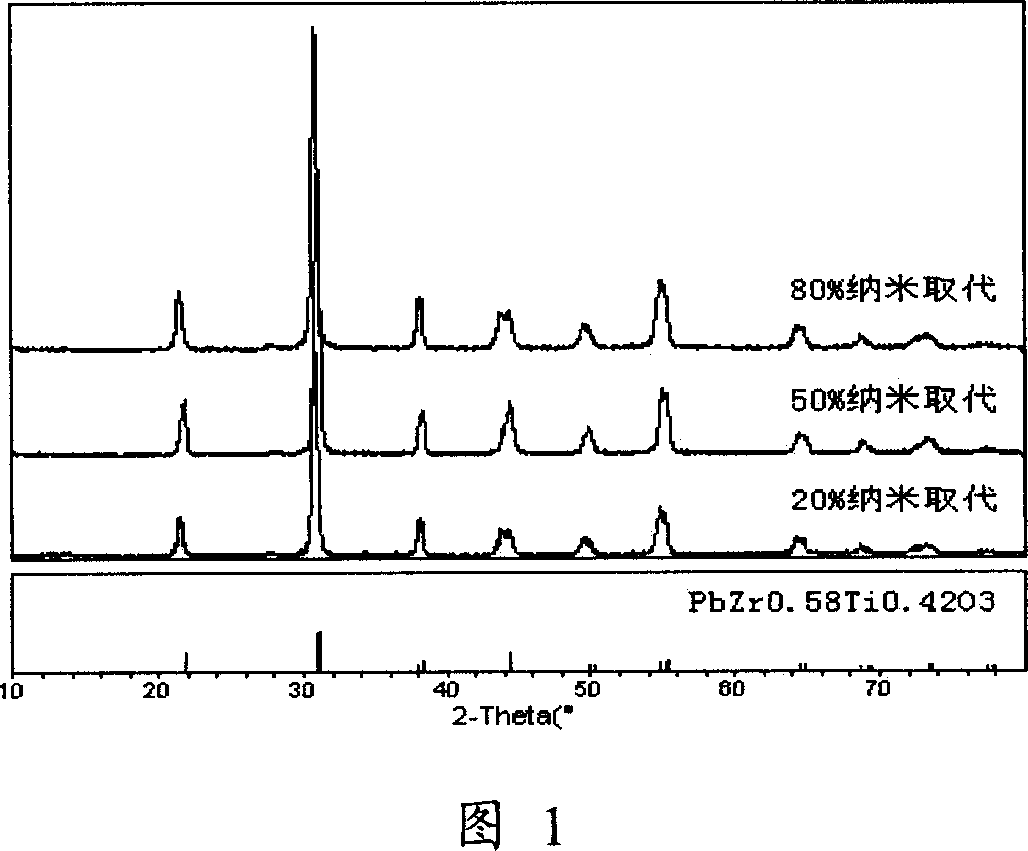

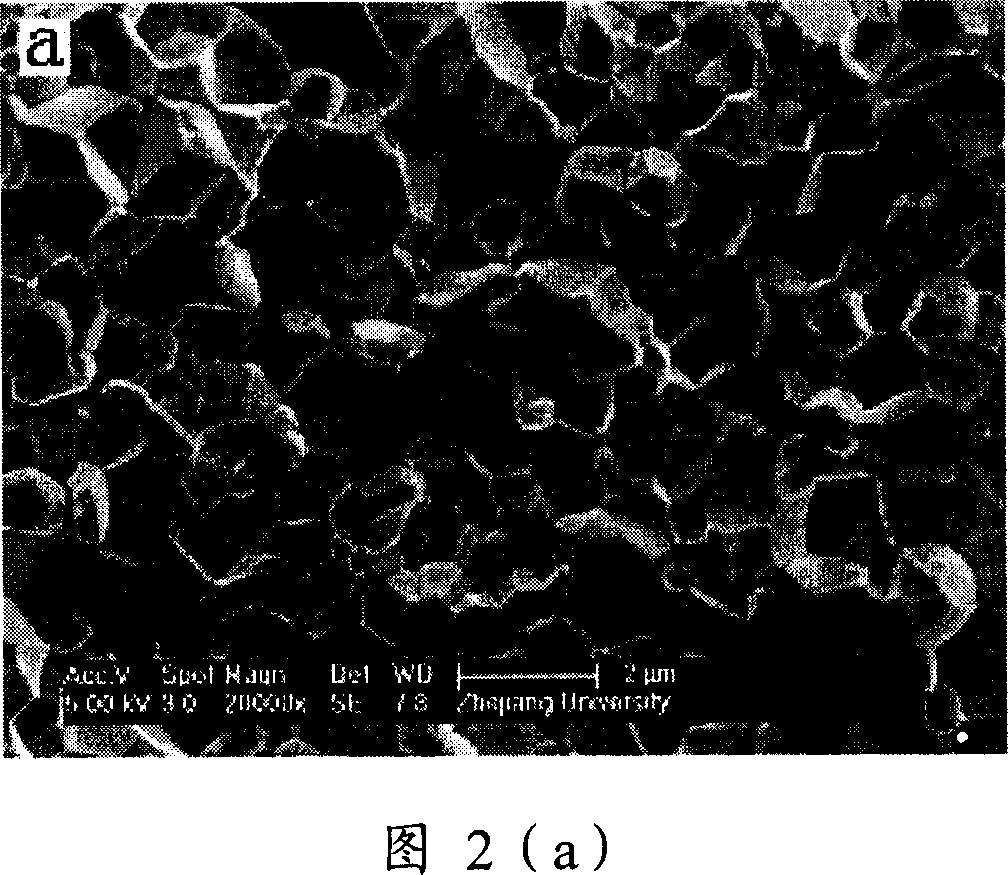

Modified PZT piezoelectric ceramics with Nano powder being added directly, and preparation method

ActiveCN1958509AProcess stabilityExcellent dielectric propertiesPiezoelectric/electrostrictive/magnetostrictive devicesLead zirconate titanateNanometre

This invention relates to a method for preparing nanopowder-modified lead zirconate titanate piezoelectric ceramic. The method directly adds nanopowder as a substitute for micropowder into the mixed raw materials, which can reduce pre-sintering temperature by 50-200 deg.C and final-sintering temperature by 50-100 deg.C, and can adjust the crystalline and properties of pre-sintered sample as well as the electrical properties of the sintered piezoelectric ceramic. Nanopowder-modified piezoelectric ceramic sintered at 1200 deg.C has a Curie point increased by 50-100 deg.C. Besides, the piezoelectric ceramic has excellent impact stability (TC = 350-400 deg.C; epsiv = 350-800; KP = 0.48-0.60), adjustable piezoelectric constant, stable process and good repeatability. The piezoelectric ceramic can be used to produce ceramic frequency discriminator and ceramic filter.

Owner:ZHEJIANG JIAKANG ELECTRONICS CO LTD +1

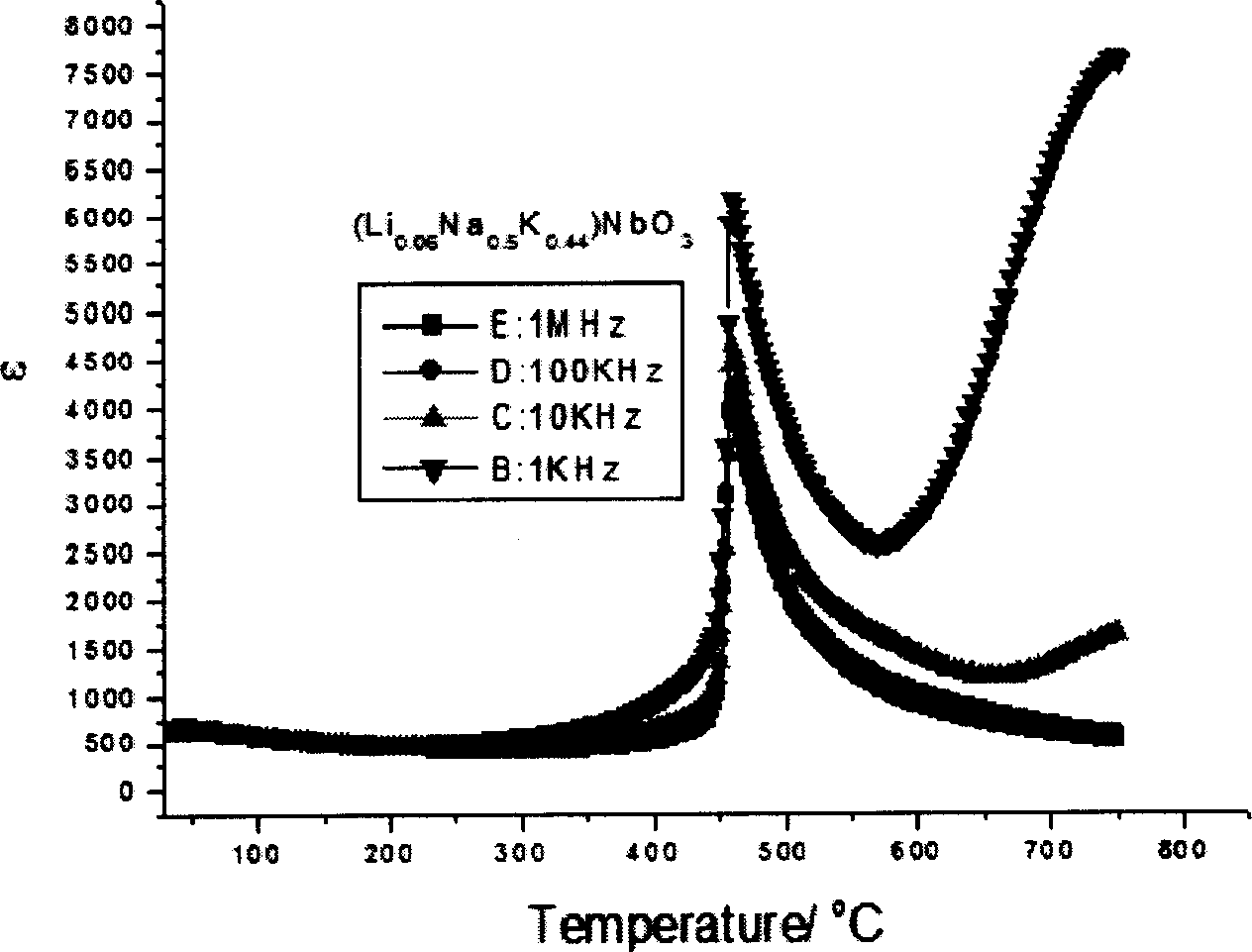

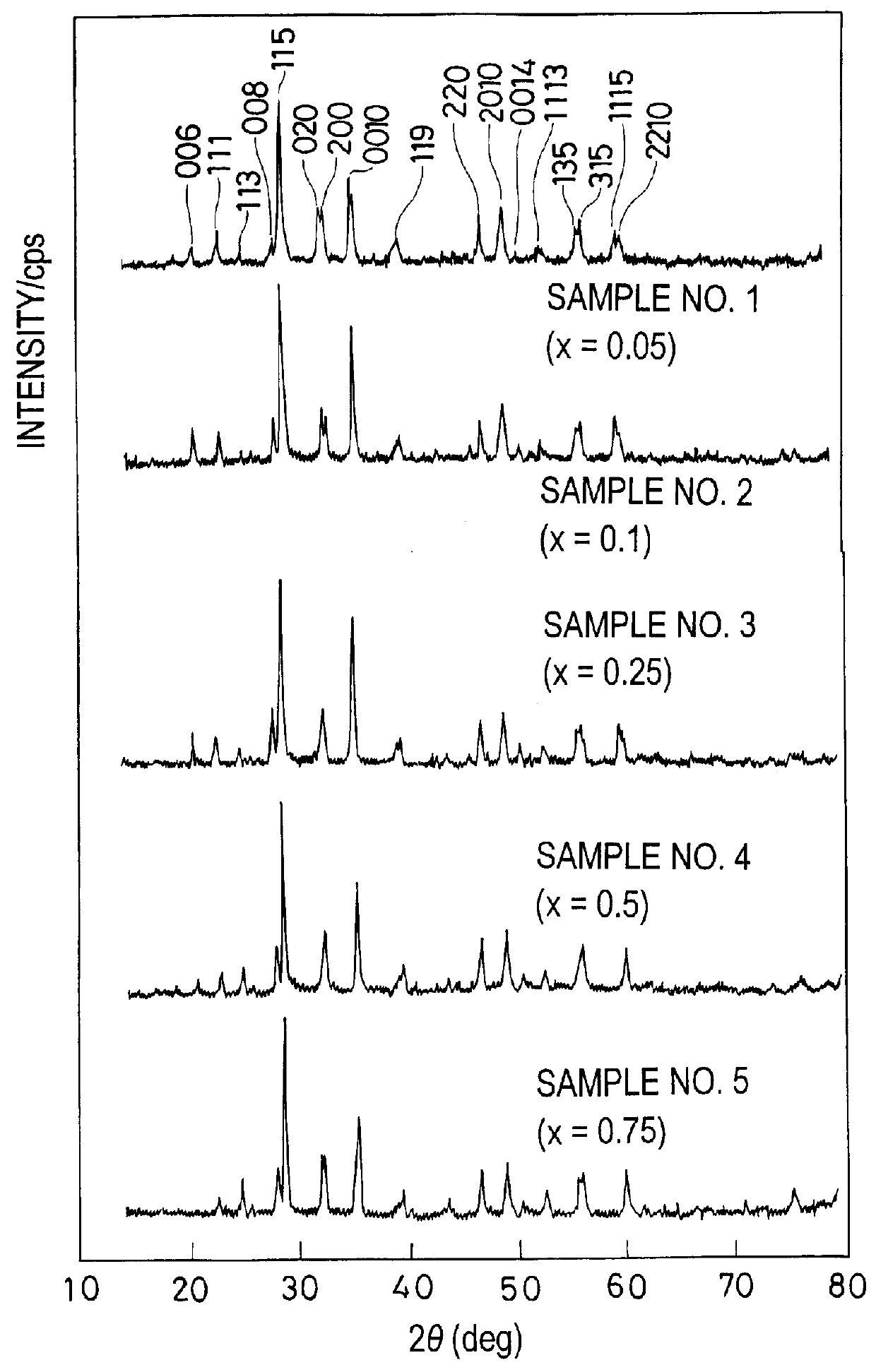

Lead-less lithium sodium potassium niobate piezoelectric ceramic with high curie point and its prepn

InactiveCN1810711AExcellent piezoelectric propertiesOvercoming the Drawbacks of Lead PollutionPiezoelectric/electrostrictive/magnetostrictive devicesLithiumElectricity

The present invention relates to lead-less piezoelectric ceramic composition and is especially one kind of lead-less Li-Na-K niobate piezoelectric ceramic and its preparation process. The lead-less piezoelectric ceramic composition of the present invention is expressed in the general expression of (1-u)[(1-z)(LixNayK1-x-y)NbO3+zMTiO3]+uMnO2, where, x, y and z are atom percentages of corresponding elements, x is 0.01-0.2, y is 0.2-0.7, z is 0.01-0.25, x+y+z=1, u is 0-0.05, and M is one bivalent metal ion selected from Ca, Mg, Ba and Sr. The lead-less piezoelectric ceramic composition is prepared through sintering at relatively low temperature, say, 1190 deg.c or even lower, and has good piezoelectric characteristic, practical plane electromechanical coupling coefficient kp, high Curie point and no lead and lead compound contained.

Owner:SICHUAN UNIV

Piezoelectric ceramic composition

InactiveUS6080327AAvoid environmental pollutionHigh curie pointPiezoelectric/electrostrictive device material selectionElectromechanical coupling coefficientLead oxide

A lead-oxide-free piezoelectric ceramic composition having an electromechanical coupling coefficient greater than a predetermined value and having a Curie point of at least 500.degree. C., whose main component is a two-component-based solid solution of the formula of (1-x)Bi.sub.a Ti.sub.b Nb.sub.c O.sub.9 -xNa.sub.p Bi.sub.q Nb.sub.r O.sub.9, and which has a bismuth layer structure in the range of 0<x<1, the solid solution of the above formula satisfying 2.4<(1-x)a+xq<3.1, 0<b<1.1, 0.9<(1-x)c+xr<2.1, and 0<p<0.6.

Owner:TDK CORPARATION

System, method and apparatus for evaluating tissue temperature

InactiveUS20060030913A1Accurate assessmentReduce intensityStentsDiagnostic recording/measuringCapacitanceTemperature response

Method, system and apparatus for monitoring target tissue temperatures wherein temperature sensors are configured as passive resonant circuits each with a unique resonating signature at monitoring temperatures extending below a select temperature setpoint. The resonant circuits are configured with an inductor component formed of windings about a ferrite core having a Curie temperature characteristic corresponding with a desired temperature setpoint. By selecting inductor winding turns and capacitance values, unique resonant center frequencies are detectable. Temperature monitoring can be carried out with implants at lower threshold and upper limit temperature responses. Additionally, the lower threshold sensors may be combined with auto-regulated heater implants having Curie transitions at upper temperature limits.

Owner:APSARA MEDICAL

Semiconductor ceramic composition

InactiveUS20090036293A1Improve featuresLess subject to thermorunawayAlkaline earth titanatesPositive temperature coefficient thermistorsRoom temperatureControl room

It is intended to provide a semiconductor ceramic composition containing no Pb, which is capable of shifting the Curie temperate to a positive direction as well as of controlling room temperature resistivity and having an excellent jump characteristic. Since the semiconductor ceramic composition in which a portion of Ba of BaTiO3 is substituted by Bi—Na has a crystal in which a central part and an outer shell part of a crystal grain are different from each other in composition, the composition is capable of improving control of room temperature resistivity and a jump characteristic, and therefore it is optimum as a material for a PTC thermistor, a PTC heater, a PTC switch, a temperature detector, and the like.

Owner:HITACHI METALS LTD

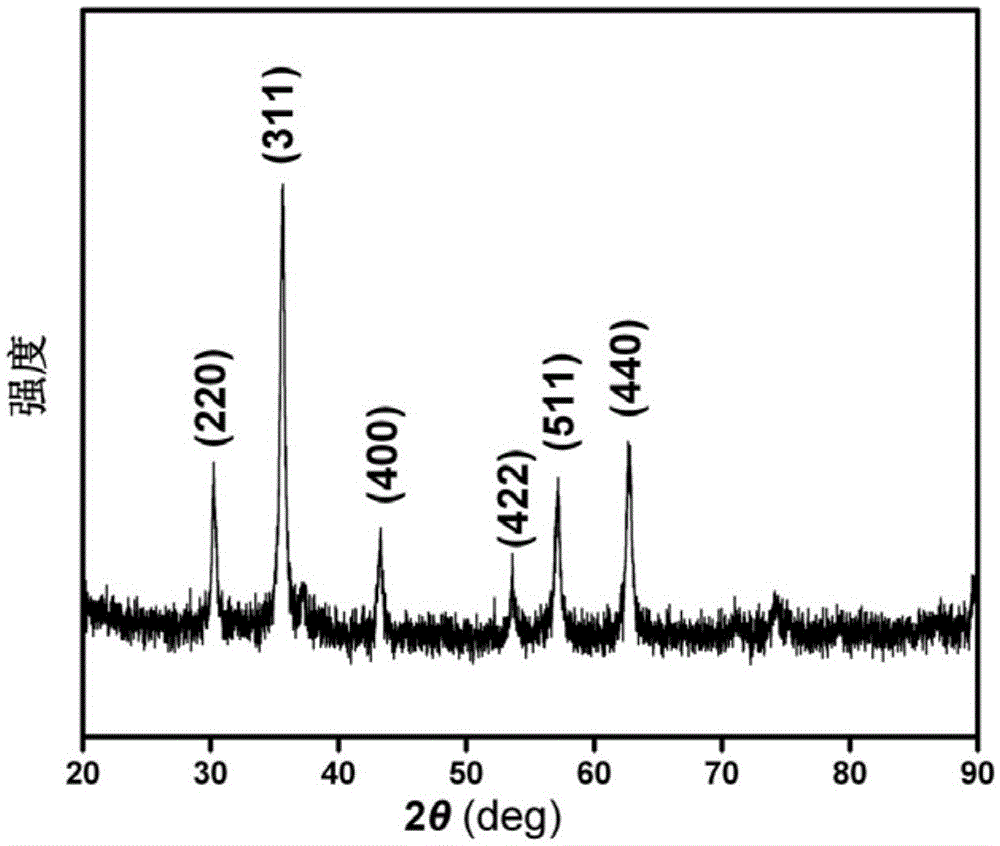

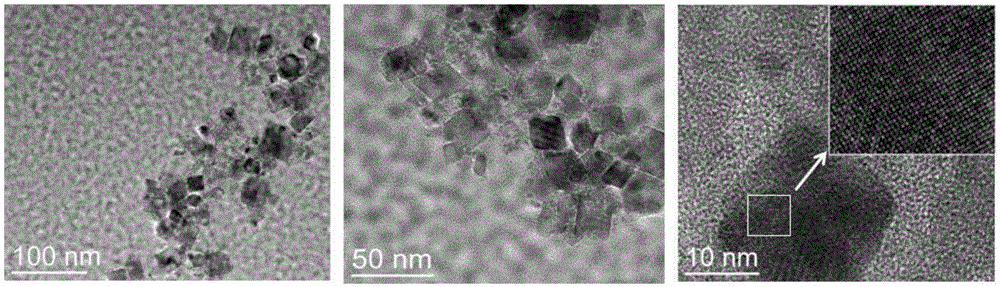

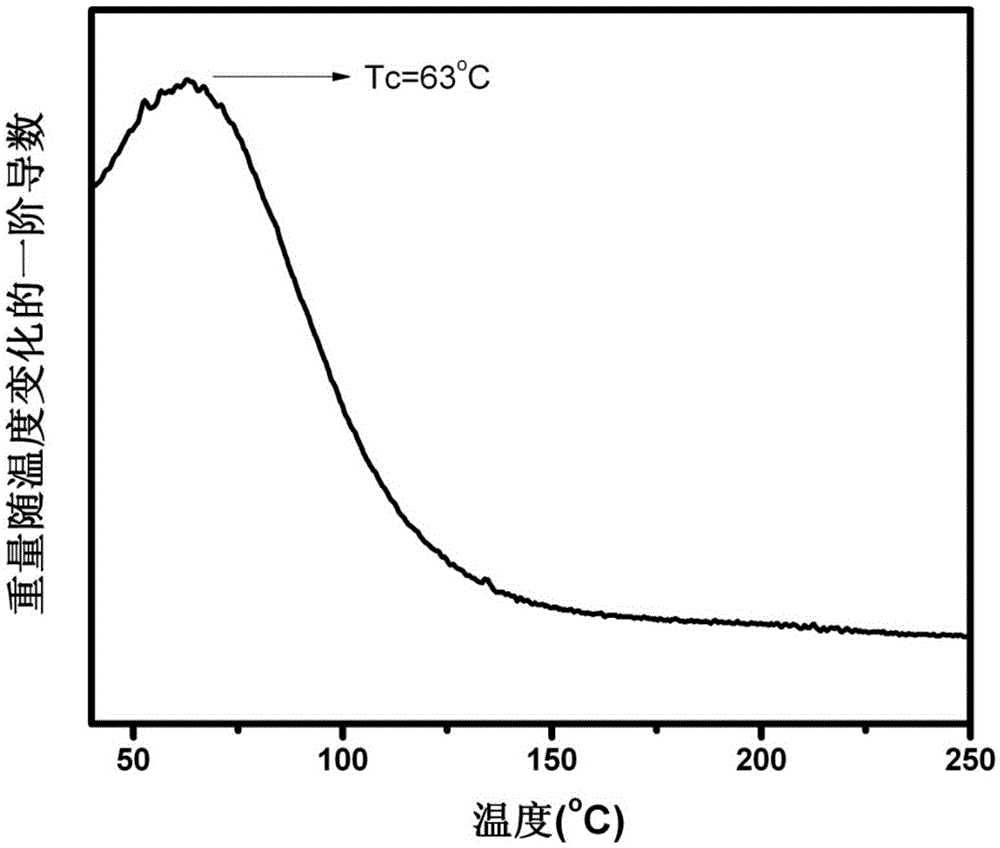

Preparation method of nanoparticles for self-controlled temperature magnetic-induction hyperthermia

ActiveCN105457025AChemically stableChemically stable spinel ferrite with stable structurePowder deliveryEnergy modified materialsNanoparticleCobalt

The invention discloses a preparation method of nanoparticles for self-controlled temperature magnetic-induction hyperthermia, and belongs to the technical field of magnetic-induction hyperthermia for treating tumors. In a spinel cobalt ferrtte structure, sublattices are divided into tetrahedral sites and octahedral sites, and all Co2+ and one half of Fe3+ are on octahedral sites while the other half of Fe3+ is on the tetrahedral sites; the level of a Curie point is directly determined by the strength of an exchange interaction between the tetrahedral sites and the octahedral sites. According to the method, Cr3+ and Zn2+ are doped into cobalt ferrtte by virtue of a hydrothermal method, so that the number of magnetic ions on the tetrahedral sites and the octahedral sites in the spinel structure is reduced, and subsequently the exchange interaction is weakened; therefore, the Curie point is lowered. By virtue of the spinel structure, the stable chemical properties of the obtained product are guaranteed, and the product, due to the property of low Curie point, is applicable to the self-controlled temperature magnetic-induction hyperthermia. The preparation method is economic and convenient and is easy for popularization.

Owner:DALIAN UNIV OF TECH

System, method and apparatus for evaluating tissue temperature

InactiveUS20060020313A1Accurate assessmentReduce intensityStentsElectrotherapyTemperature responseCapacitance

Method, system and apparatus for monitoring target tissue temperatures wherein temperature sensors are configured as passive resonant circuits each with a unique resonating signature at monitoring temperatures extending below a select temperature setpoint. The resonant circuits are configured with an inductor component formed of windings about a ferrite core having a Curie temperature characteristic corresponding with a desired temperature setpoint. By selecting inductor winding turns and capacitance values, unique resonant center frequencies are detectable. Temperature monitoring can be carried out with implants at lower threshold and upper limit temperature responses. Additionally, the lower threshold sensors may be combined with auto-regulated heater implants having Curie transitions at upper temperature limits.

Owner:APSARA MEDICAL

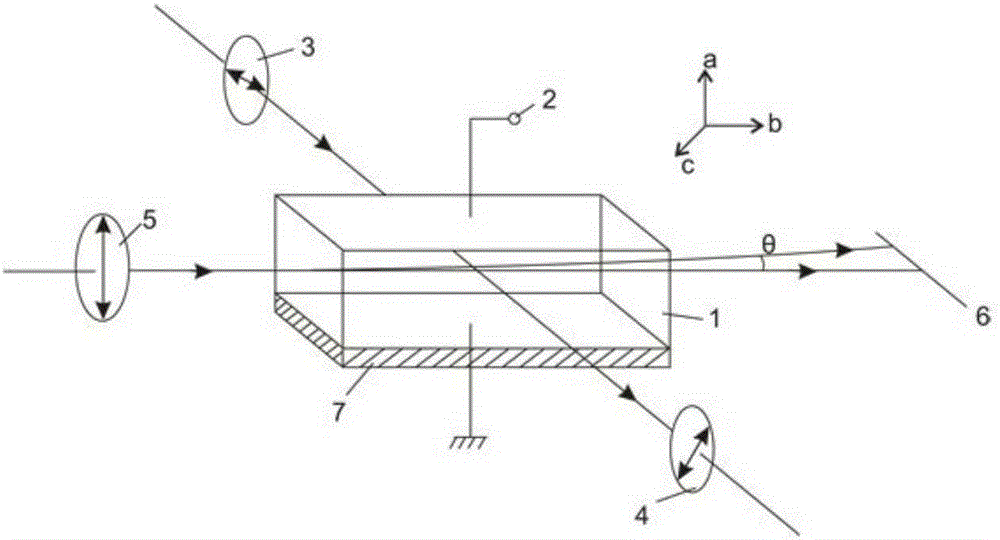

Secondary electro-optic crystal with gradient refractive index effect as well as preparation method and application method of secondary electro-optic crystal

ActiveCN105220232ALarge refractive index gradientRealize functional compoundPolycrystalline material growthBy pulling from meltRefractive indexCrystal growth

The invention specifically relates to a secondary electro-optic crystal with a gradient refractive index effect as well as a preparation method and an application method of the secondary electro-optic crystal. The secondary electro-optic crystal is an ion doped electro-optic crystal with a general formula of M: KTa[1-x]NbxO3, and has a perovskite structure, wherein M=Cu<2+>, Fe<3+>, Sn<4+>, Ni<2+>, Ti<4+>, Na<+> and Li<+>, and the content of M is 0-5at%; the content x of Nb in a crystal component is more than or equal to 0 and less than or equal to 5, a curie point is positioned between -241 and 90 DEG C, the crystal above the curie point is a cubic phase and an m3m point group; and the crystal below the curie point becomes a tetragonal phase and a 4mm point group, a matrix component Ta / Nb is uniformly distributed in the crystal, doped ions M are in non-uniform distribution in the crystal, and the concentration distribution changes linearly along the growth direction of the crystal. The invention realizes functional combination of an electro-optic effect and a gradient refractive index effect of the crystal, and respectively realizes modulation of propagation direction and intensity of laser in different directions of the same modulation sample.

Owner:山东山科智晶光电科技有限公司

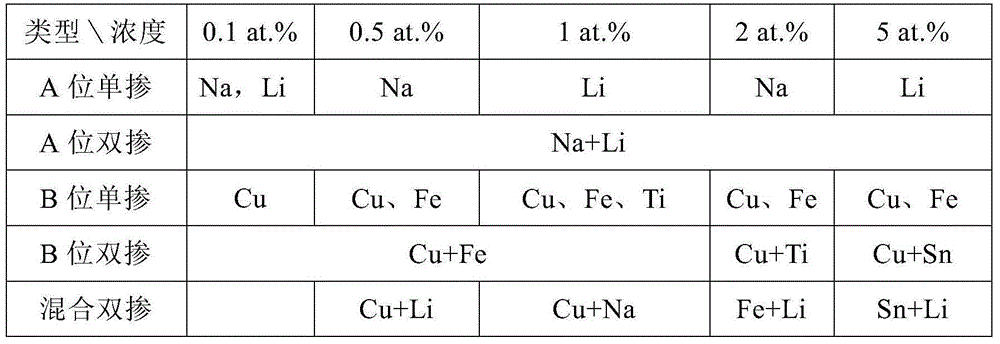

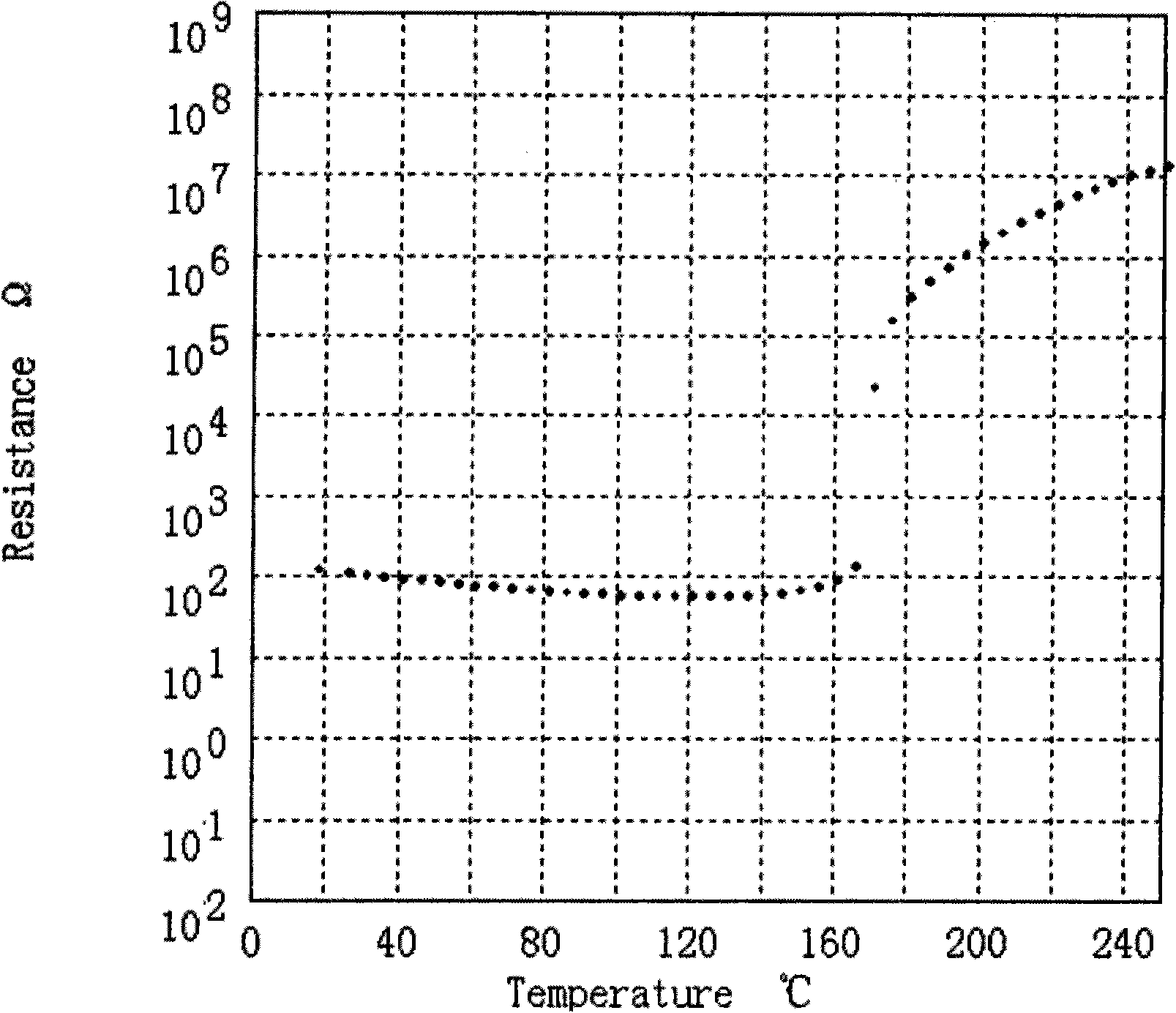

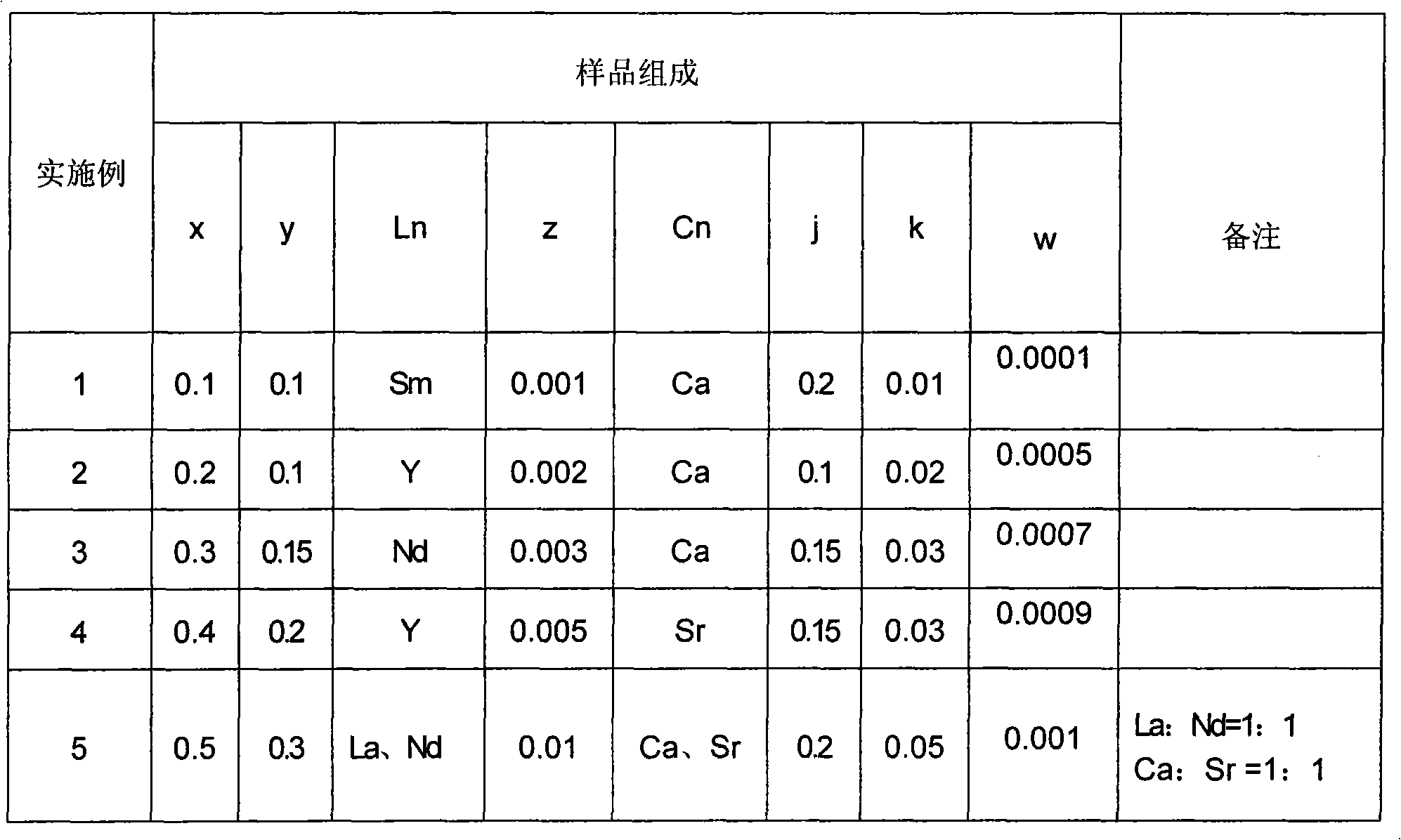

High-Curie-point low-resistivity lead-free PTCR (Positive Temperature Coefficient of Resistance) ceramic material and preparation method thereof

InactiveCN101830698AAvoid churnDoes not affect componentsTemperature coefficientPositive temperature

The invention discloses a high-Curie-point low-resistivity lead-free PTCR (Positive Temperature Coefficient of Resistance) ceramic material with a constitution formula (1): [Bi0.5(Na1-xKx)0.5]y[Ba1-y-z-j]TiO3+zLn3++jCn2++kSi2++wMn(NO3)2. In the formula, x is equal to 0.1-0.5, y is equal to 0.1-0.3, z is equal to 0.001-0.01, j is equal to 0.1-0.2, k is equal to 0.01-0.05, w is equal to 0.0001-0.001, Ln comprises one or two elements of Sm, Nd, Y and La, and Cn comprises at lest one of Ca and Sr. The preparation method comprises the following steps of: (1) respectively preparing solutions containing Bi, Na, K, Ba, Ti, Ln, Cn, Si and Mn ions and preparing a mixed solution according to a mol ratio given in formula (1); (2) mixing the mixed solution, organic monomers and a crosslinking agent according to a proportion of 100ml: (6-20)g: (0.5-8)g and crosslinking and polymerizing the organic monomers and the crosslinking agent in the solution to obtain gel; (3) calcining at 700-800 DEG C for 1-3h to obtain ceramic powder; and (4) granulating the powder, drily pressing to form and calcining at a high temperature of 1200-1300 DEG C for 1-2h. The ceramic material has the advantages of high Curie point and low resistivity.

Owner:HUAZHONG UNIV OF SCI & TECH +1

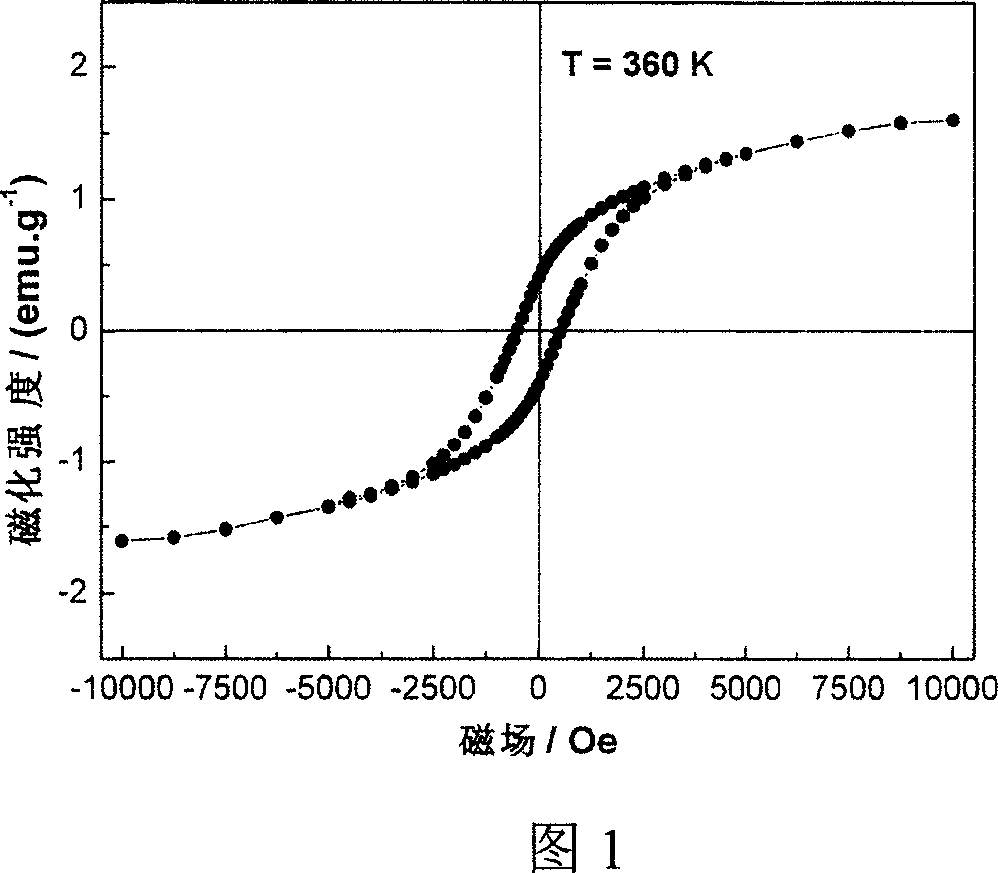

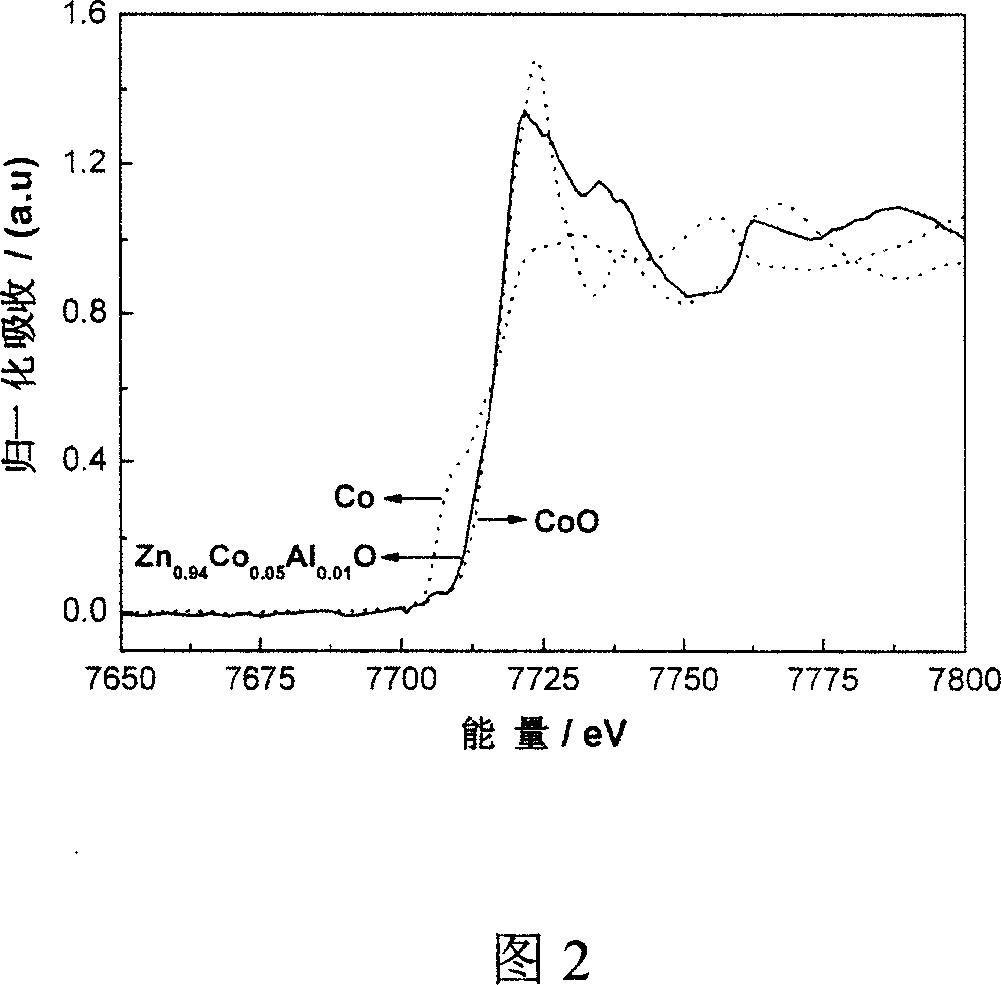

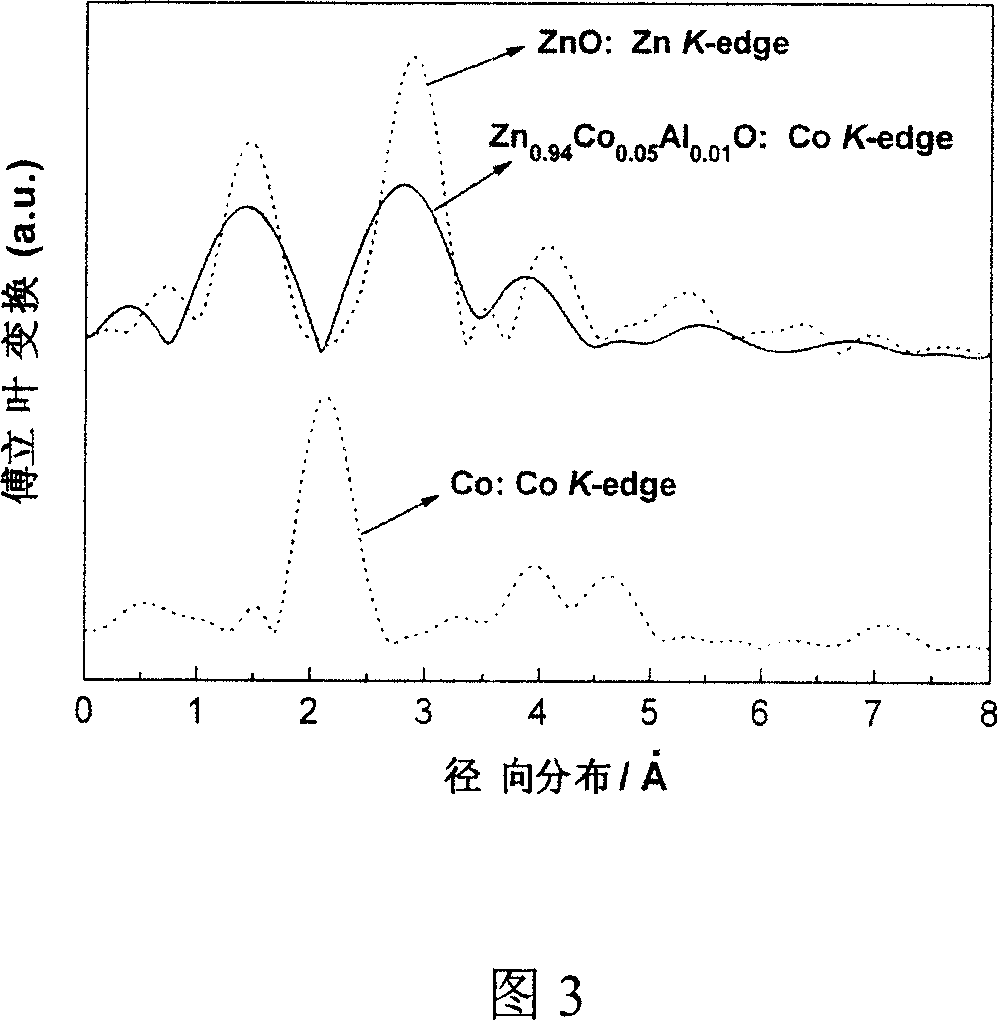

Method of preparing high temperature ferromagnetism ZnO:(Co,Al) nano-material using sol-gel method

The present invention relates to a sol-gel method for preparing ZnO:(Co, Al) nano powder body and film with ferromagnetism, its Curie point is above 360 K. Said sol-gel method includes the following steps: firstly, preparing Co and Al codoped ZnO colloid solution, drop-adding colloid on the precleaned Si chip or other substrate (quartz glass, sapphire and SiC, etc.), utilizing the mode of rotating substrate to make the colloid solution be uniformly coated on the substrate surface, preheating said substrate on which the colloid solution is uniformly coated for a period of time, making heat treatment at 300-350 deg.C, then making annealing treatment at 600-800 deg.C under the condition of argon atmosphere so as to obtain the invented product.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com