Patents

Literature

1658results about "Positive temperature coefficient thermistors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High temperature thermocouple design and fabrication

ActiveUS20080205483A1Low neutron cross-sectionsHigh melting temperatureThermoelectric device manufacture/treatmentThermometers using electric/magnetic elementsEngineeringThermocouple

A method for fabricating a thermocouple capable of long-term operation in high temperature, hostile environments without significant signal degradation or shortened thermocouple lifetime due to heat induced brittleness.

Owner:BATTELLE ENERGY ALLIANCE LLC

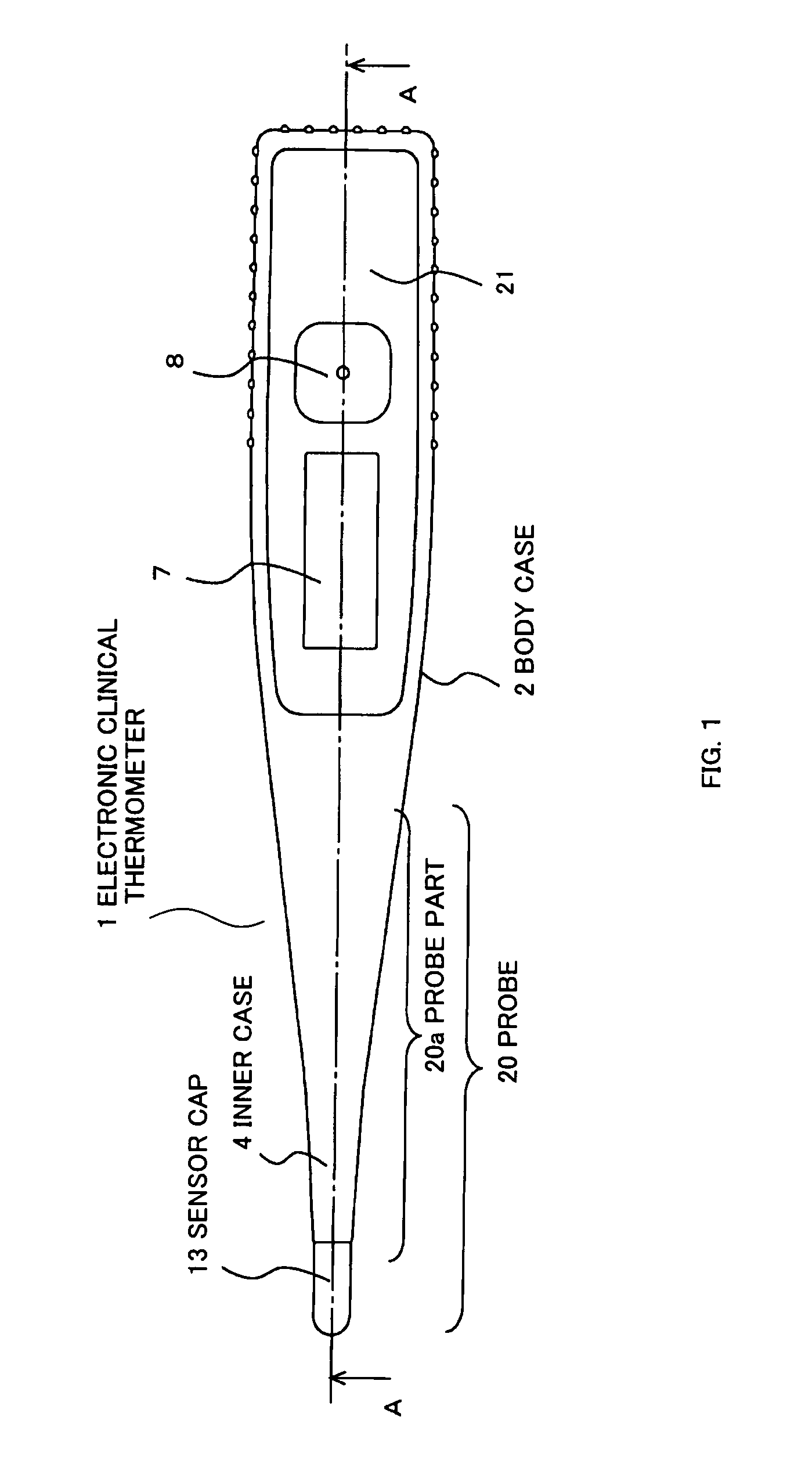

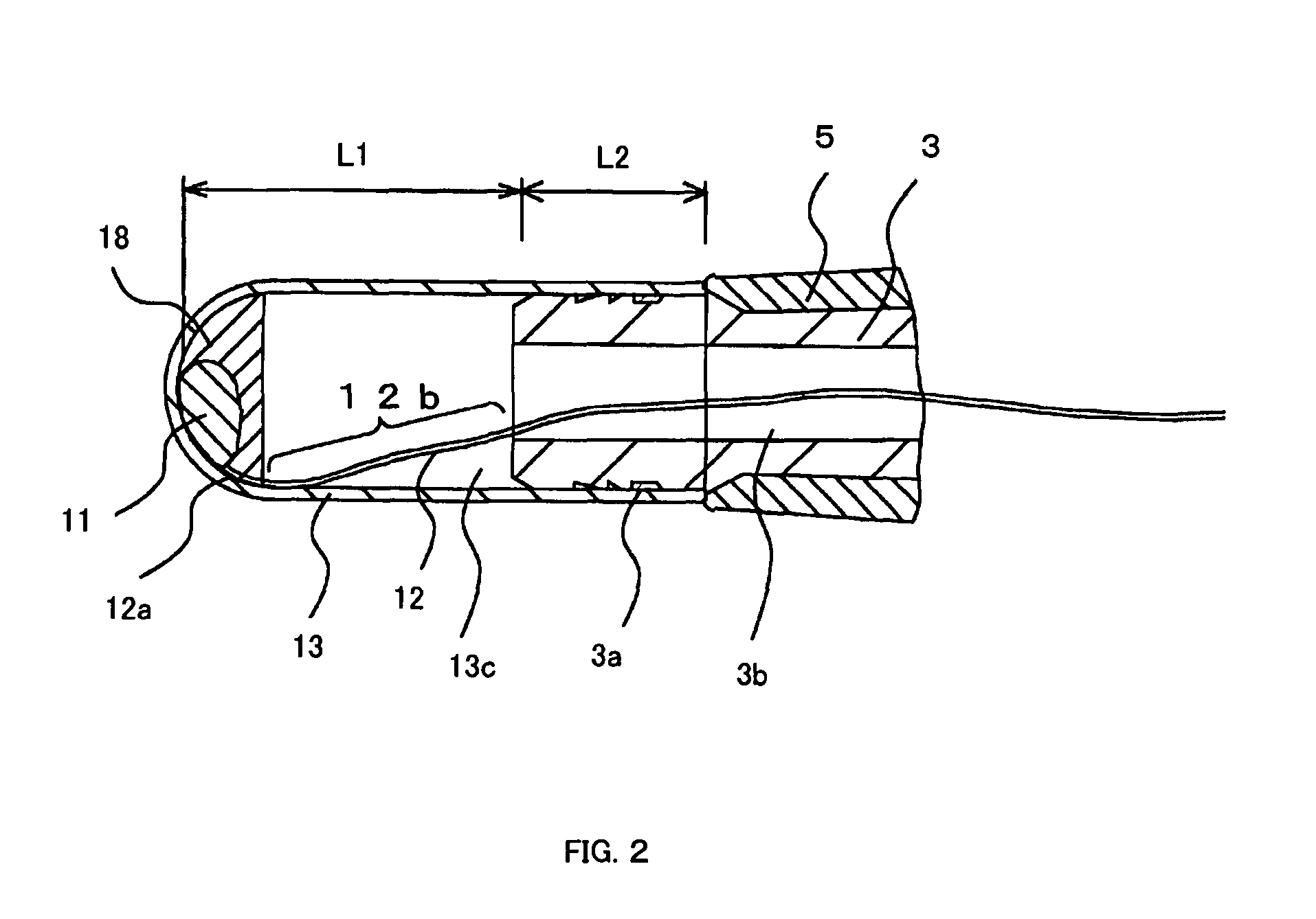

Electronic clinical thermometer and method of producing the same

InactiveUS7806587B2Thermometer detailsThermometers using electric/magnetic elementsBiomedical engineeringTemperature sensitive

A method of producing an electronic clinical thermometer is disclosed, the electronic clinical thermometer including a temperature-sensitive element, lead wire that is connected to the temperature-sensitive element, a body case having a probe part in which an insertion path for the lead wire to be inserted is formed, and a sensor cap having a cavity one end of which is opened and the other end is closed, both the lead wire projecting from the insertion path and the temperature-sensitive element being stored within the sensor cap, and the method includes a step for mounting the sensor cap on the probe part, in a state where the lead wire having the temperature-sensitive element mounted on the tip thereof projects from the insertion path of the probe part.

Owner:A STUCKI CO +1

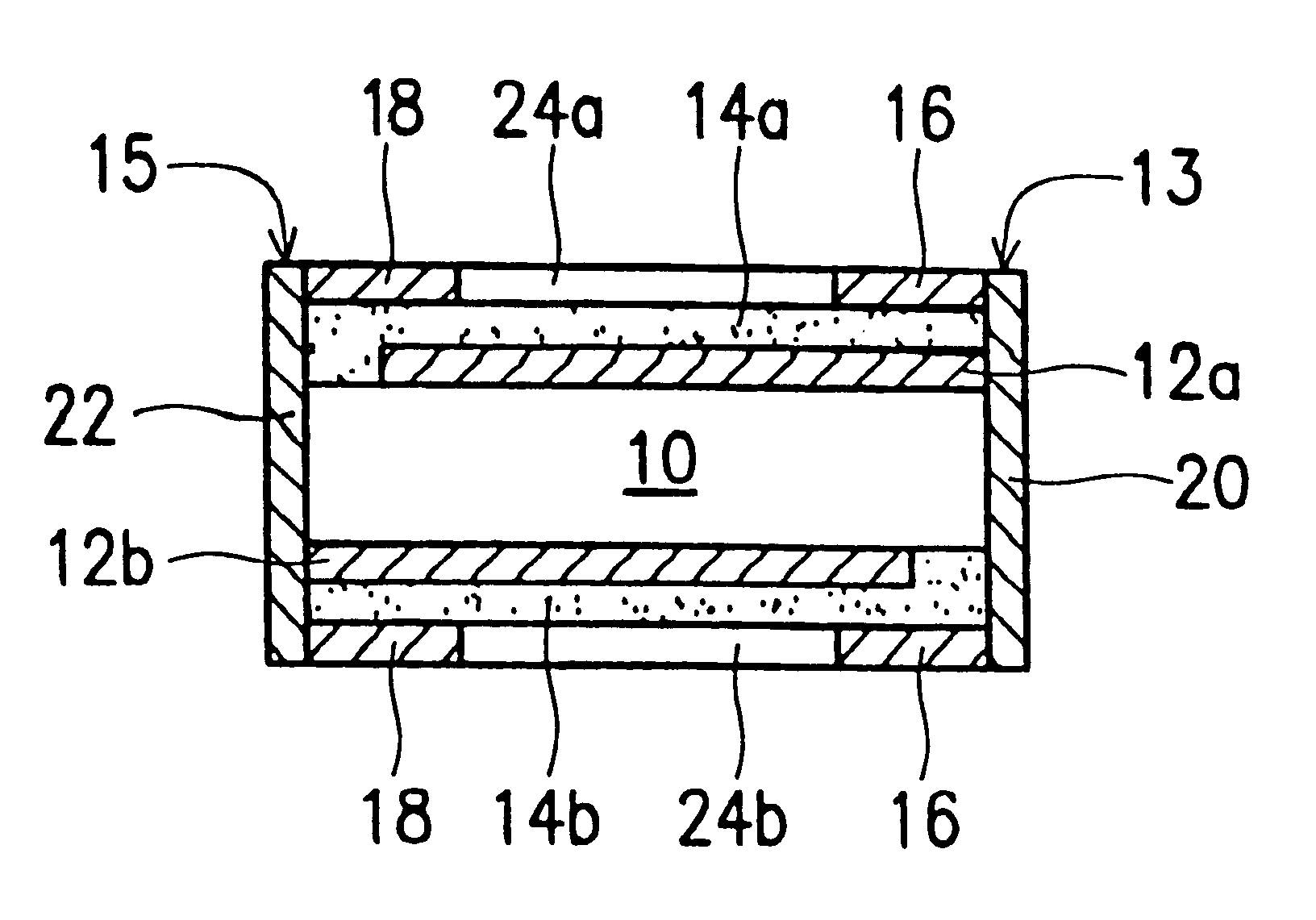

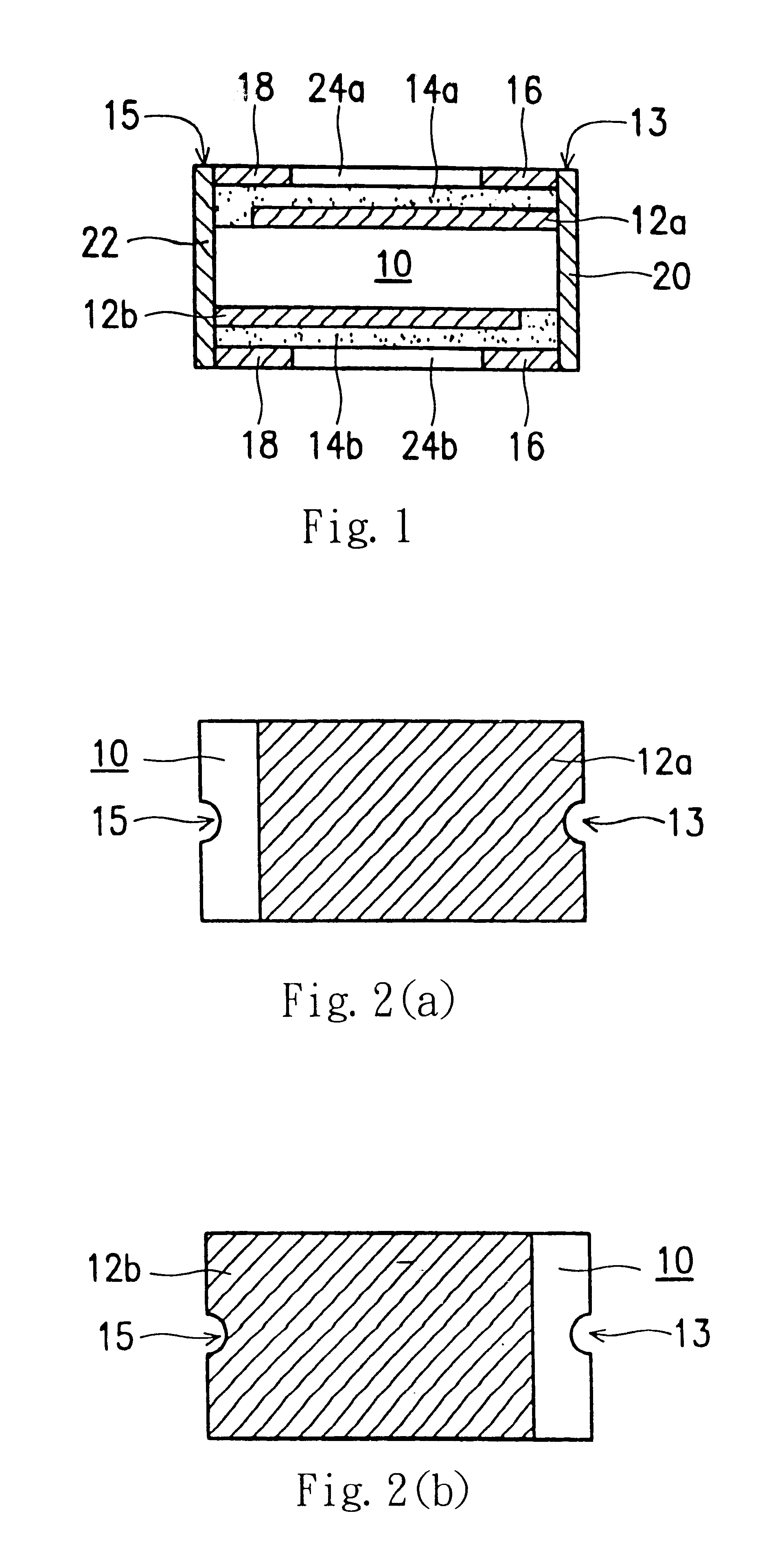

Surface mountable over-current protecting device

InactiveUS6377467B1Easy to installGood dimensional stabilityResistor terminals/electrodesNegative temperature coefficient thermistorsElectrical resistance and conductancePlanar electrode

The present invention relates to a novel thermal-sensitive resistive apparatus, such as PTC and NTC, which allocates planar electrode films on the top and bottom surfaces of a prior art thermal-sensitive resistive apparatus, such as a PTC apparatus, to laminate with an outer electrode layer. A plurality of interconnection vias are electroplated with conductive material to connect to any plane. It is convenient to surface mount the apparatus of the present invention on a printed circuit board. The present invention can largely increase the dimensional stability of components and overcome the disadvantage that thermal diffusion of the prior are surface mounted resistive apparatus is affected easily by line width and environments.

Owner:POLYTRONICS TECH

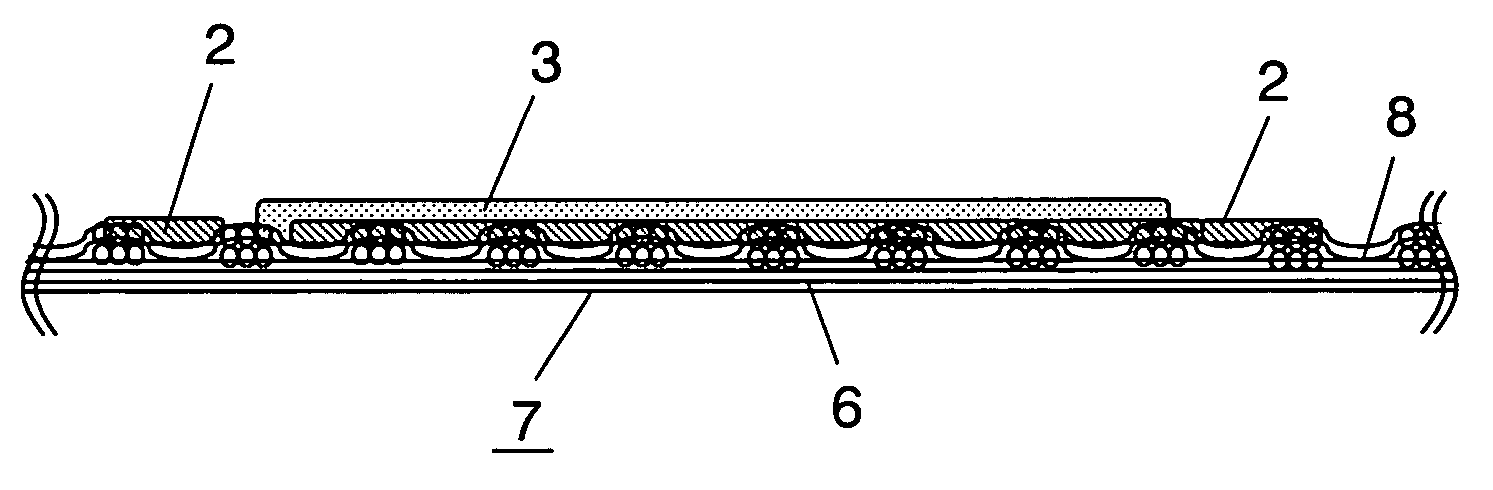

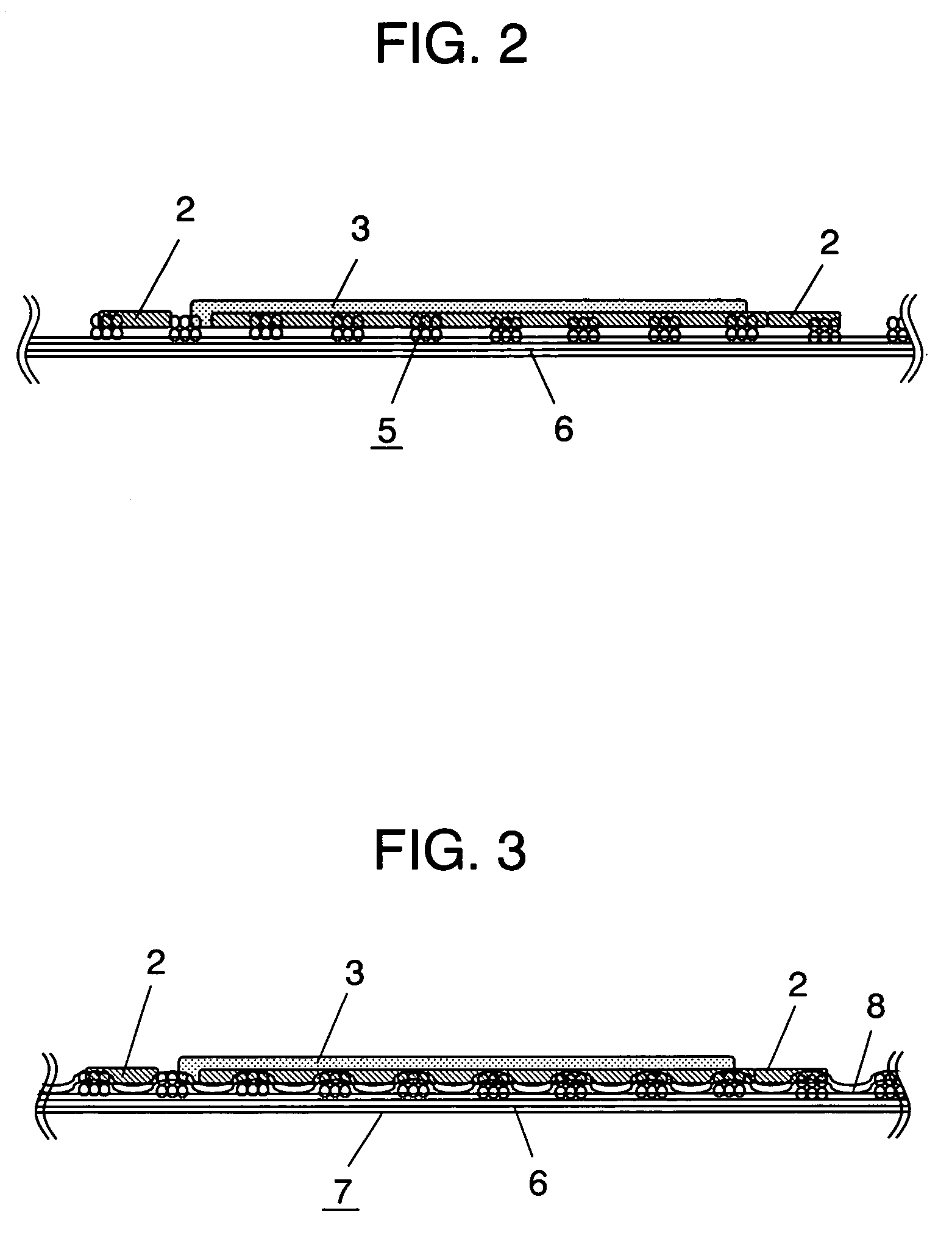

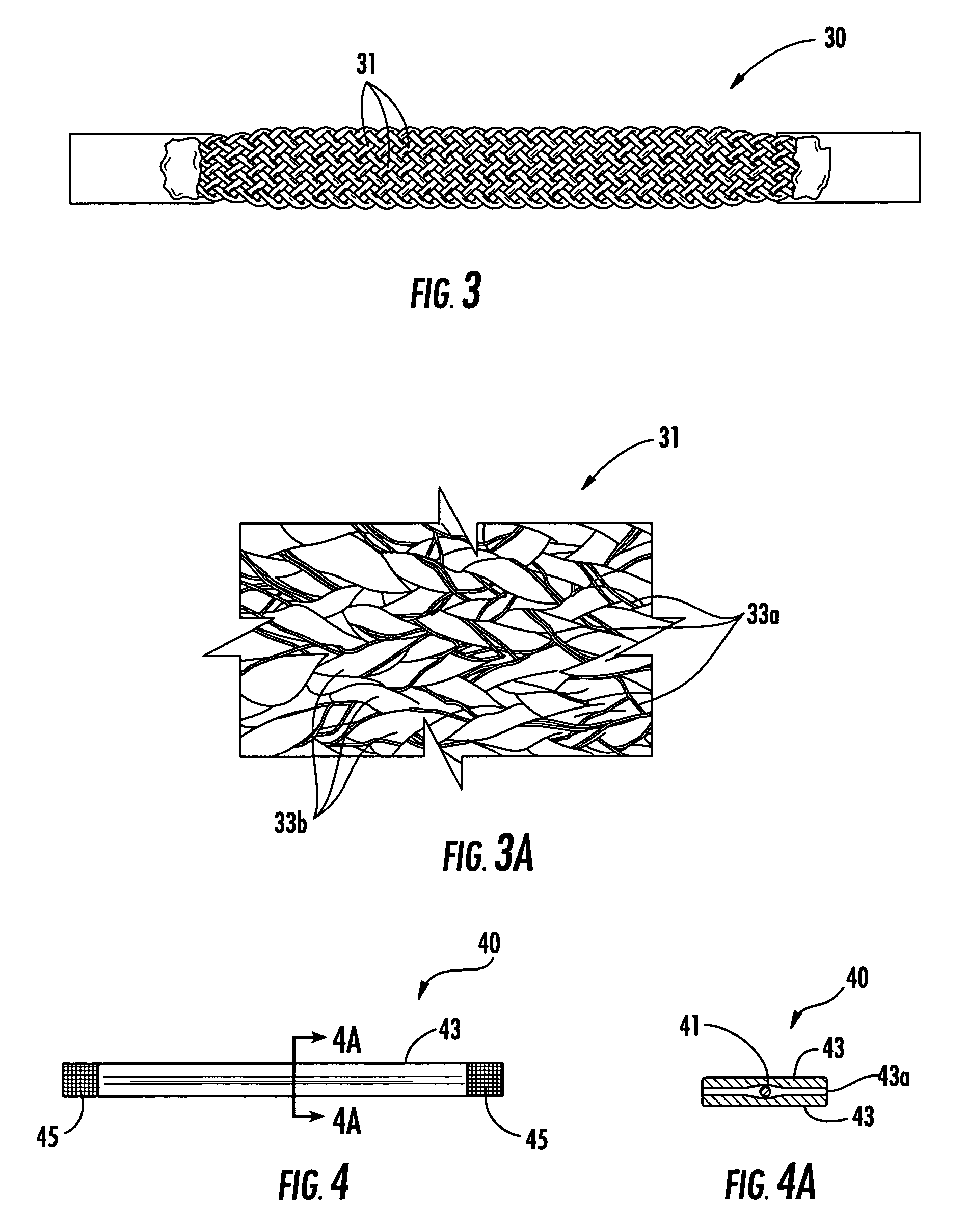

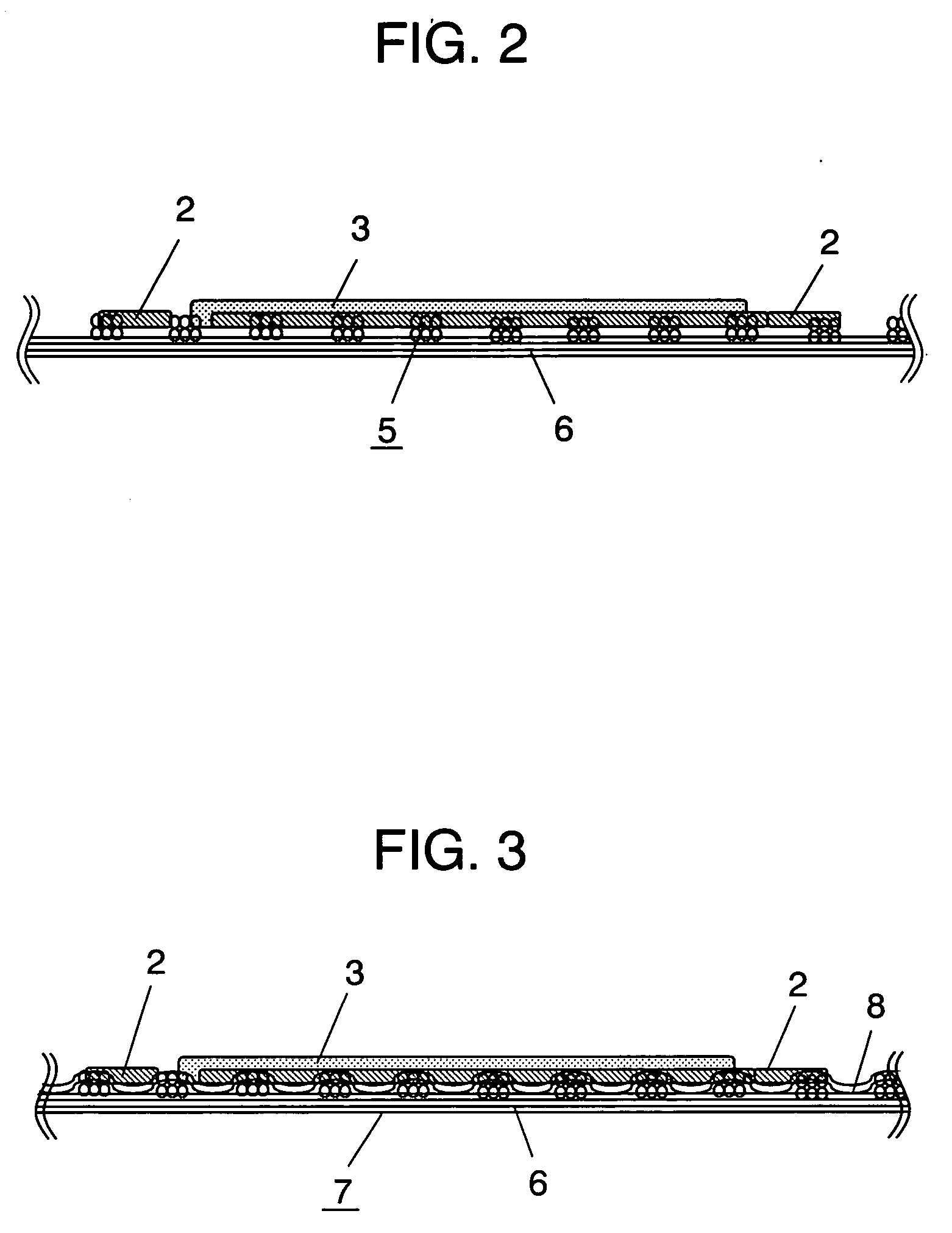

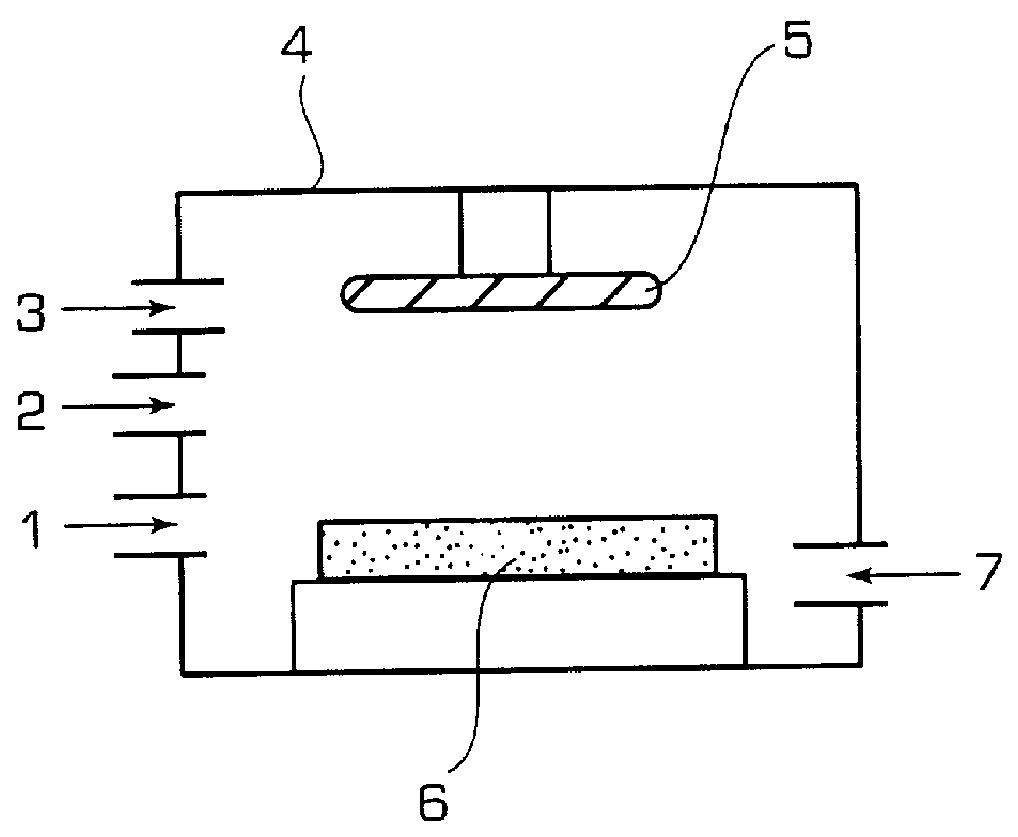

Flexible PTC heating element and method of manufacturing the heating element

InactiveUS7049559B2Resistor terminals/electrodesResistor mounting/supportingRubber materialEngineering

The flexible PTC heating element according to the invention has one of the following constitutions. A portion of an electrodes and a PTC resistor is impregnated into a flexible substrate. A flexible substrate is made of resin foam or rubber material having a concave / convex shape formed on the surface. The flexible PTC heating element has an elongation deformation portion disposed to at least one of an electrode and a PTC resistor. A flexible substrate has adhesiveness and either a flexible substrate or a flexible cover material has an elongation control portion. Therefore, the flexible PTC heating element is highly flexible and excellent in vibration durability.

Owner:PANASONIC CORP

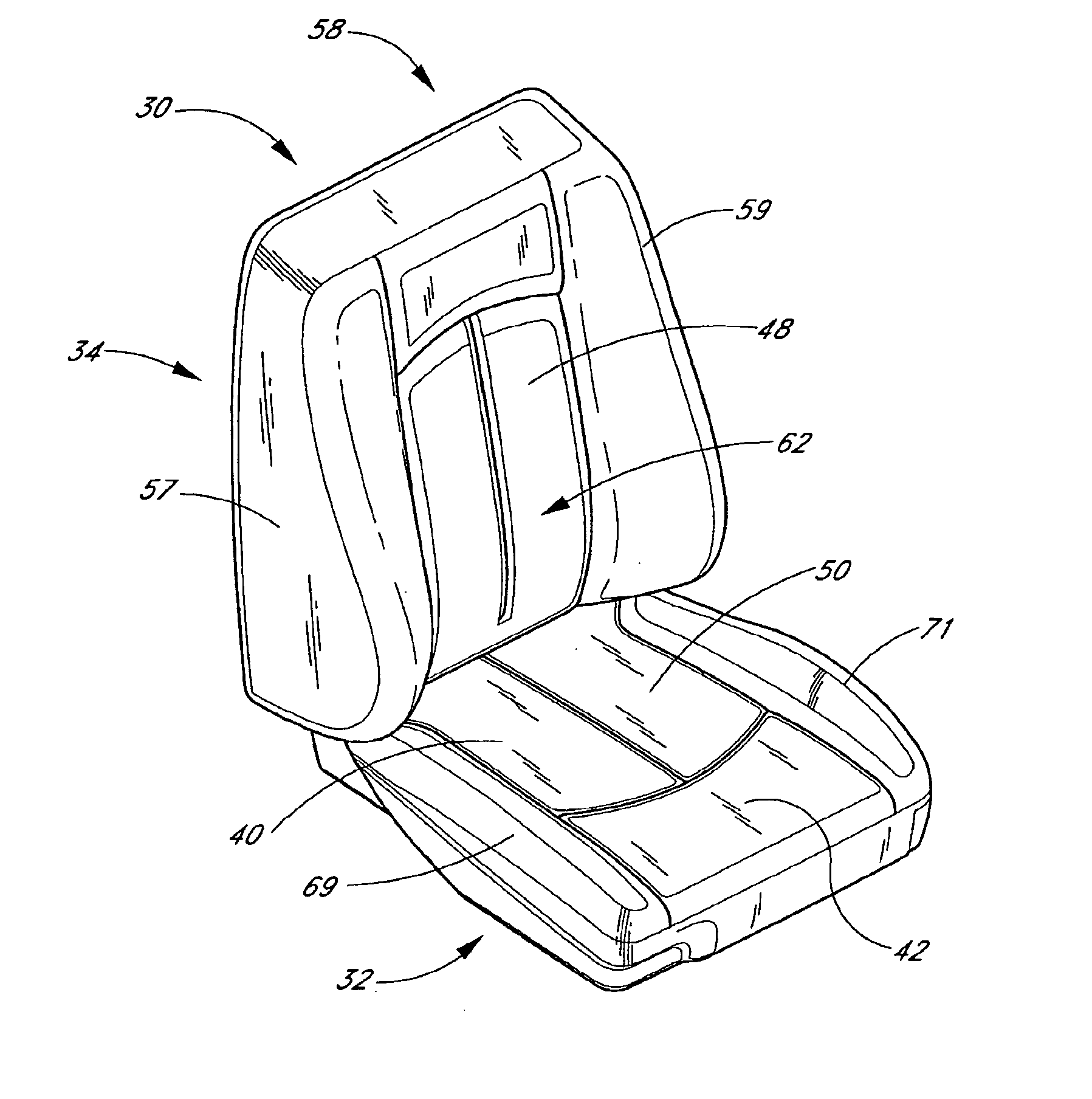

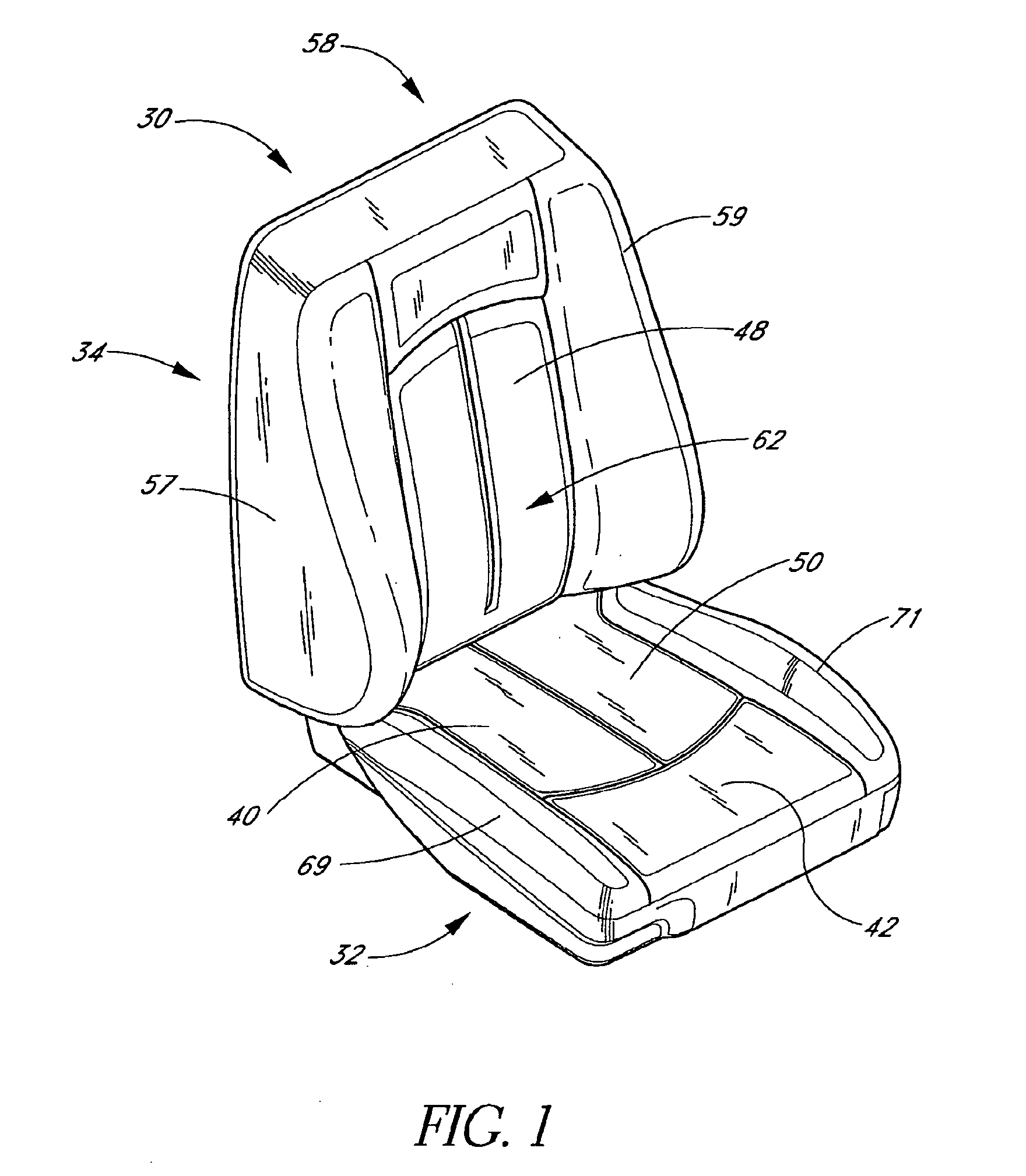

Seat climate control system

A method for thermally conditioning a space adjacent a seat assembly includes activating a heating element positioned within the seat assembly beneath a seat covering. A fluid module that includes a fluid supply device and a thermoelectric element is activated to direct heated air from the fluid module to a space adjacent the seat assembly through a distribution system formed at least partially in the seat cushion. After a period of time, the heating element is deactivated.

Owner:GENTHERM INC

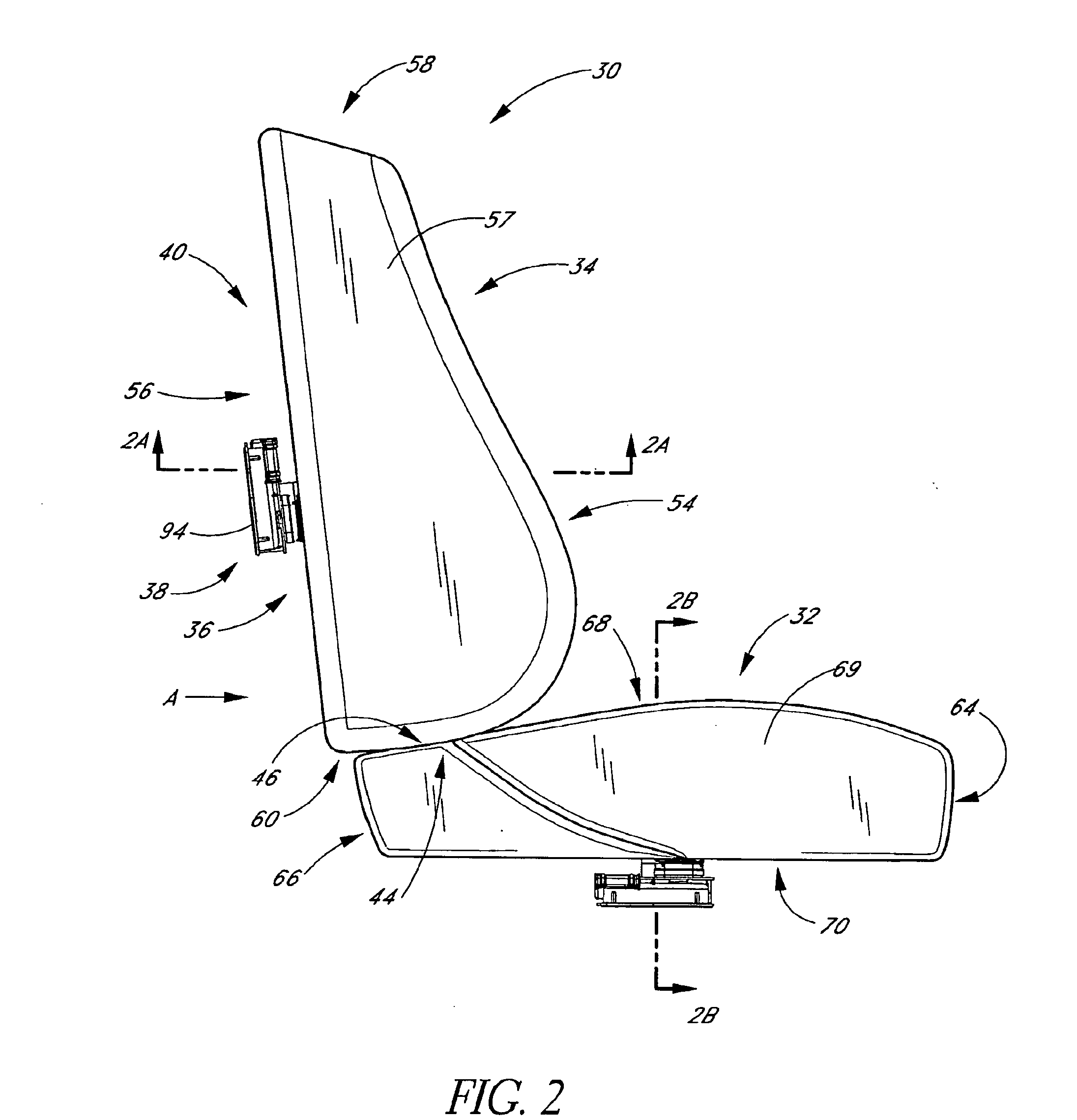

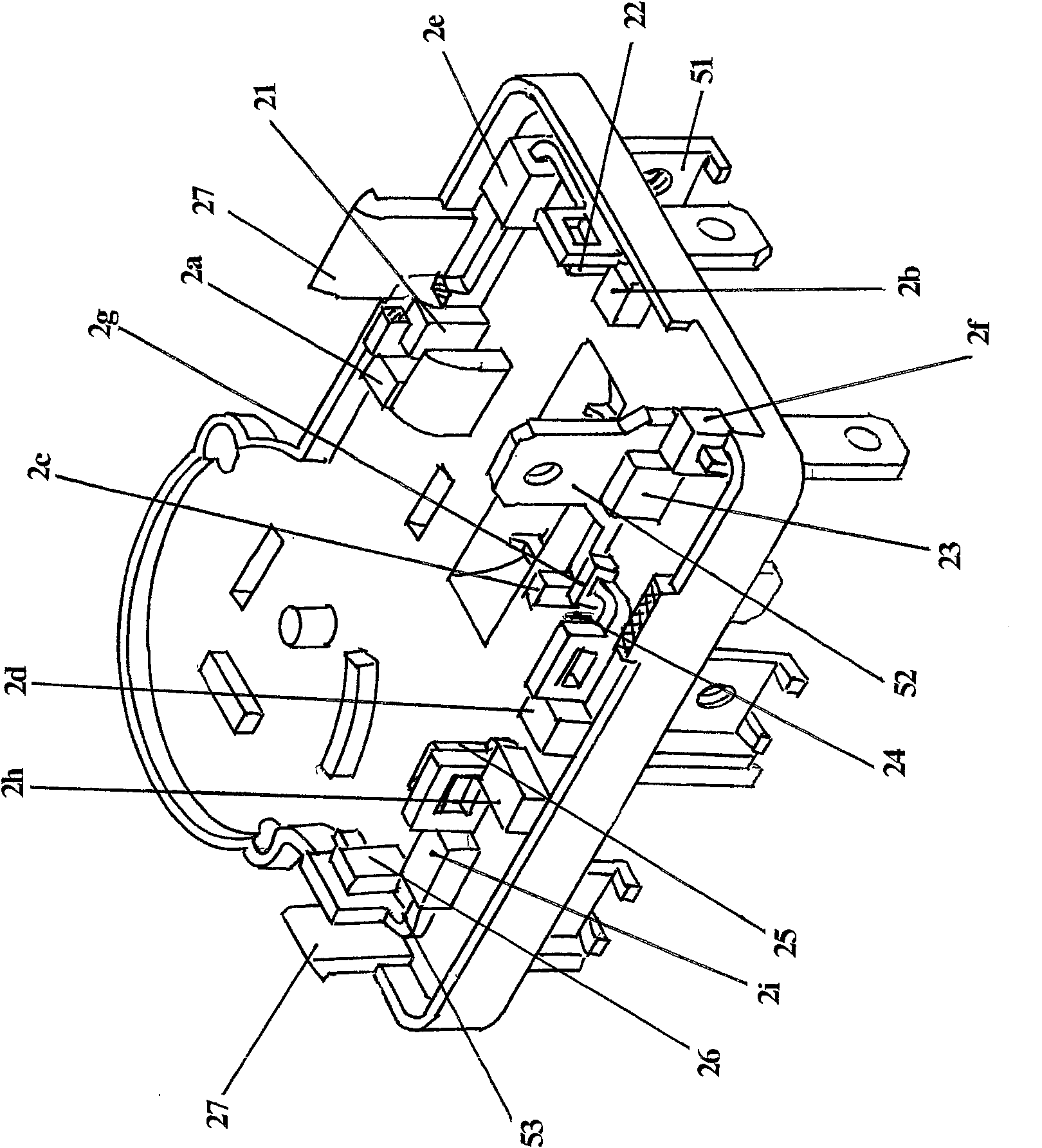

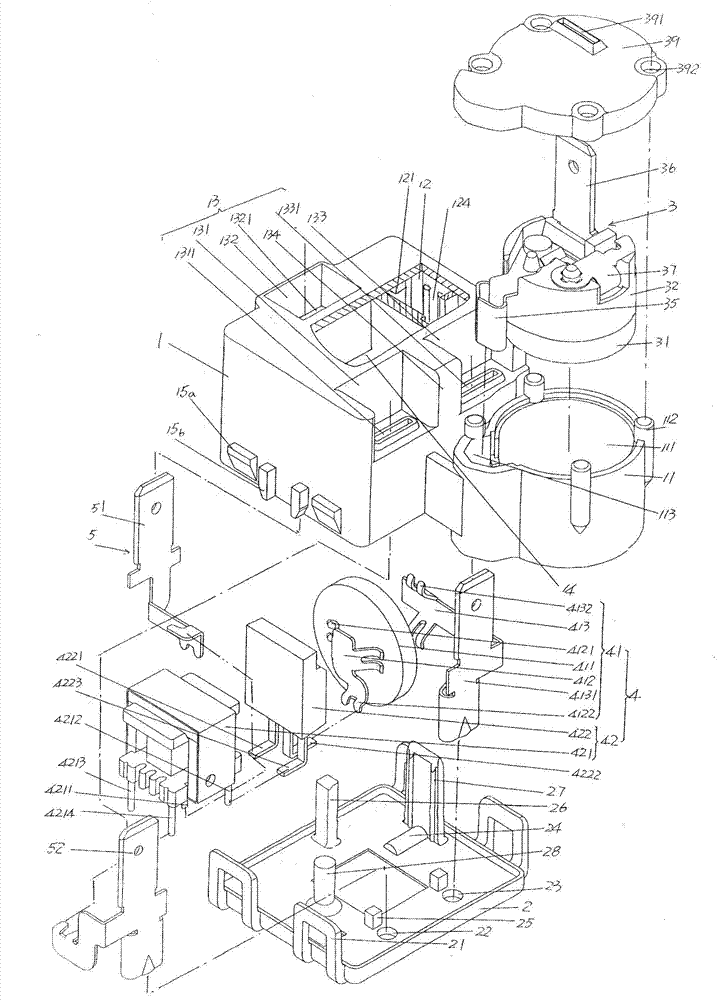

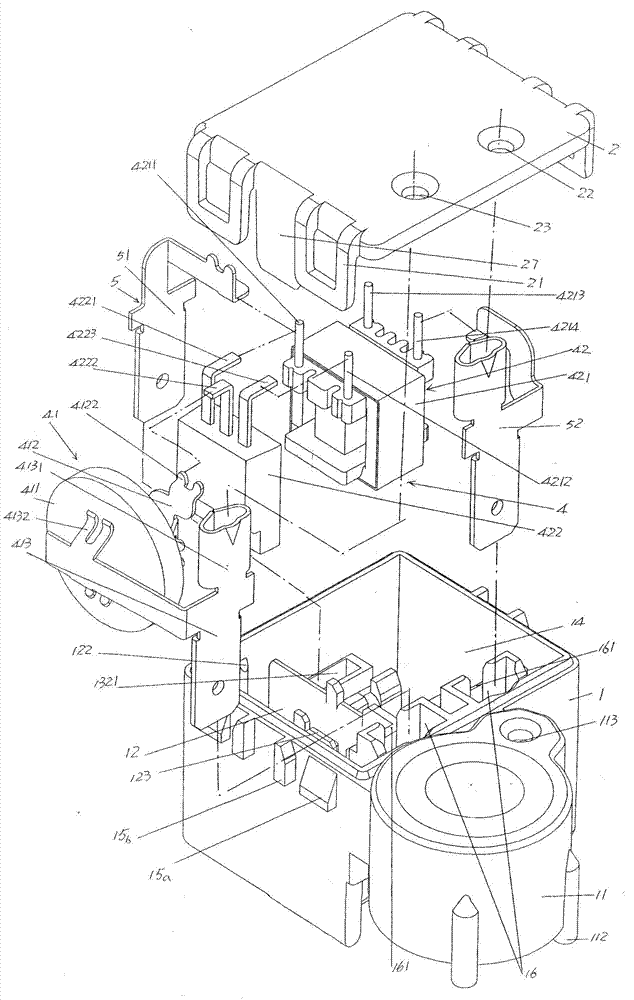

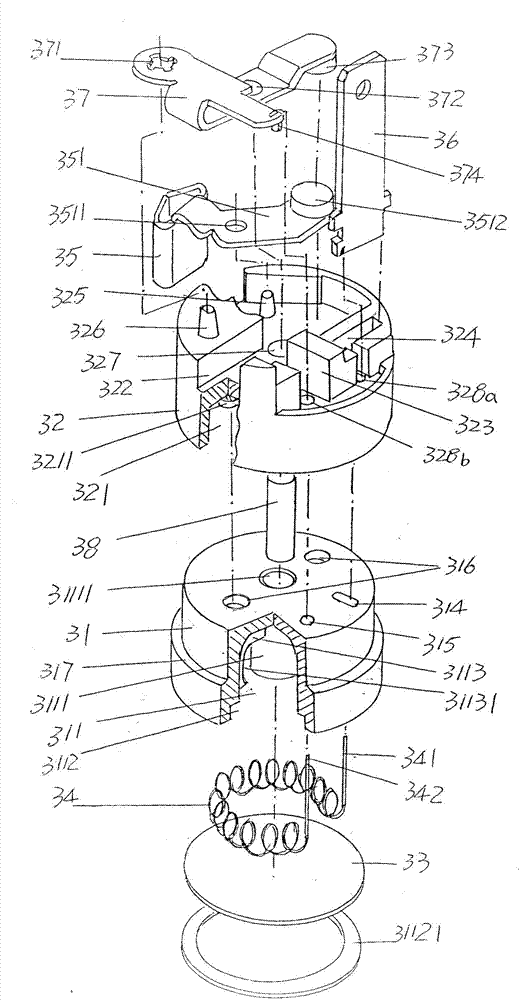

Energy-saving type integral single phase AC electric motor starting and protection device

ActiveCN100581043CReduce power consumptionReduce contact areaSingle-phase induction motor startersStarter detailsRefrigeration compressorElectric machine

An starter and protector for an energy-saving integral single-phase alternating current motor, belonging to cold compressor motor protecting equipment technology field, includes a housing, a cover, a motor protector mounted in the housing, a motor starter mounted on the housing, and a plug-in sheet mechanism composed of a L plug-in sheet, a N plug-in sheet and an earthing plug-in sheet. The motor starter includes a first pin, a second pin and a positive temperature coefficient thermistor, and is characterized in that the two ends of the positive temperature coefficient thermistor are equipped with a supporting wall separately, wherein the pair of the supporting walls being parallel with each other, a rostellum being arranged on the basic centered position of the upper side of each supporting wall, the two bottom sides of the positive temperature coefficient thermistor contacting the rostellum, and the two sides of the positive temperature coefficient thermistor holding with the first and the second pins separately. The invention has well energy-saving effect, and has substantial deflated volume, which being help to save the material for manufacturing the positive temperature coefficient thermistor.

Owner:CHANGSHU TIANYN ELECTROMECHANICAL

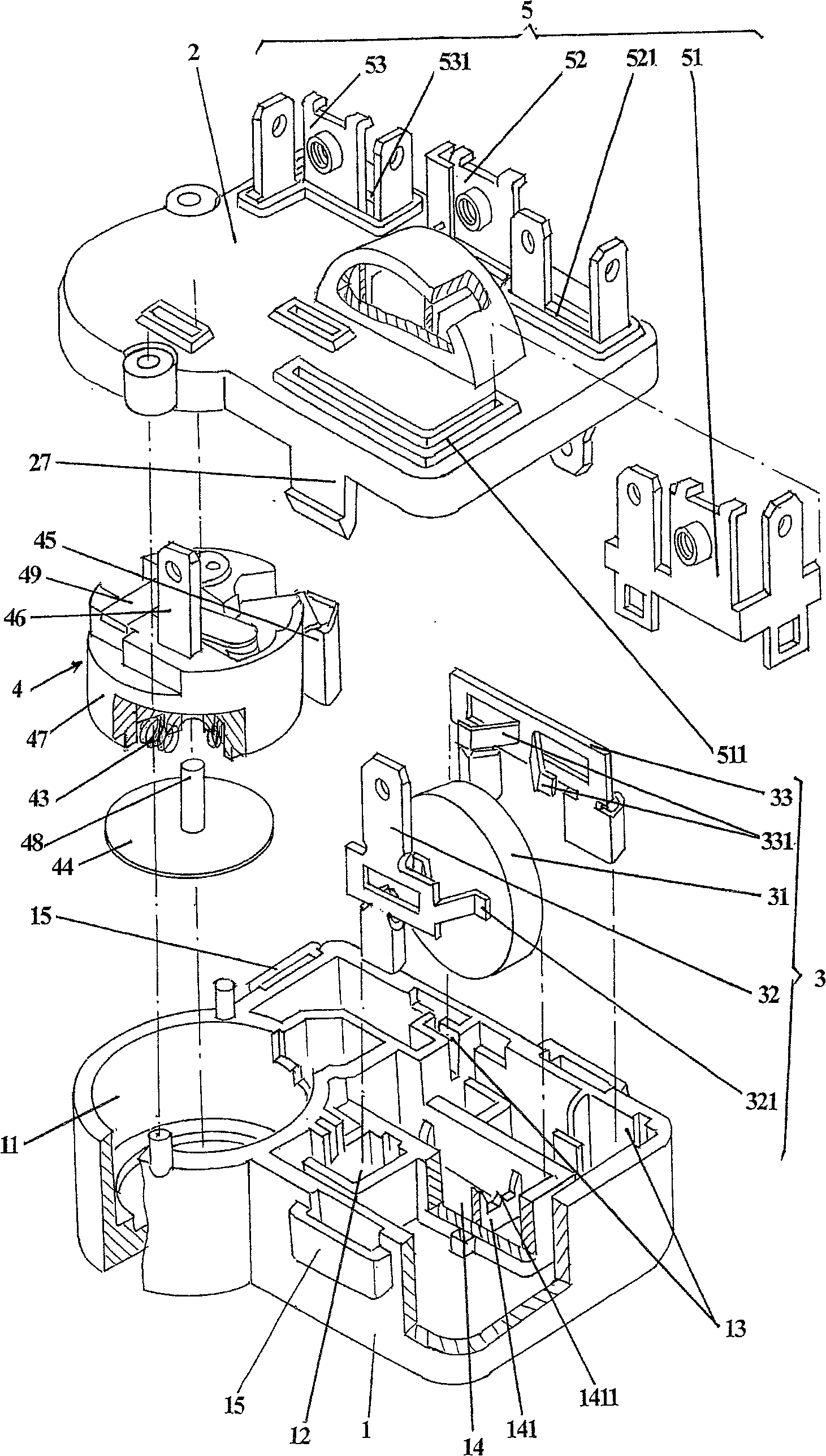

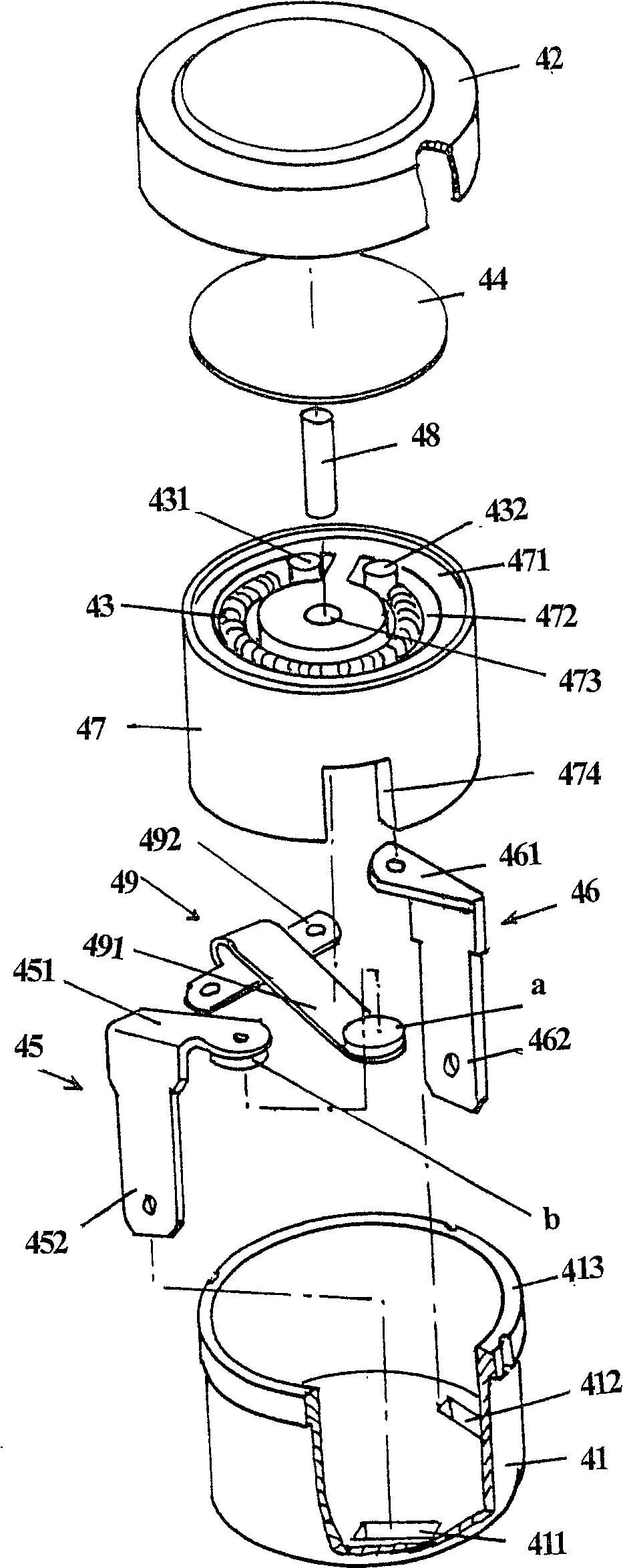

Power-dissipation-free and energy-saving type start protector of single phase AC motor

InactiveCN104734570AReduce volumeSmall footprintSingle-phase induction motor startersEmergency protective circuit arrangementsRefrigeration compressorEngineering

The invention provides a power-dissipation-free and energy-saving type start protector of a single phase AC motor and belongs to the technical field of refrigeration compressors. The power-dissipation-free and energy-saving type start protector comprises a shell, a shell cover, an overload protector, a power-dissipation-free starter and an external terminal mechanism. The shell is provided with an overload protector seat, a power-dissipation-free starter accommodation cavity, an external terminal mechanism cavity and a start controller accommodation cavity. The shell cover is provided with a first three-terminal jack and a second three-terminal jack. The overload protector is arranged in an overload protector accommodation cavity. The power-dissipation-free starter comprises a power-dissipation-free starter body and a start controller. The external terminal mechanism is matched with the external terminal mechanism cavity. The start protector is characterized in that the external terminal mechanism cavity comprises a first insertion cavity, a second insertion cavity and a third insertion cavity, the second insertion cavity is formed in the left side of the shell, and the bottom wall of the second insertion cavity is provided with a second shell insertion groove; the first insertion cavity and the third insertion cavity are formed in the right side of the shell, a first shell insertion groove is formed in the bottom wall of the first insertion cavity, and a third shell insertion groove is formed in the bottom wall of the third insertion cavity; the external terminal mechanism comprises a first insertion piece and a second insertion piece, the first insertion piece is matched with the second shell insertion groove in an inserted mode, and the second insertion piece is matched with the first shell insertion groove in an inserted mode.

Owner:CHANGSHU TIANYN ELECTROMECHANICAL

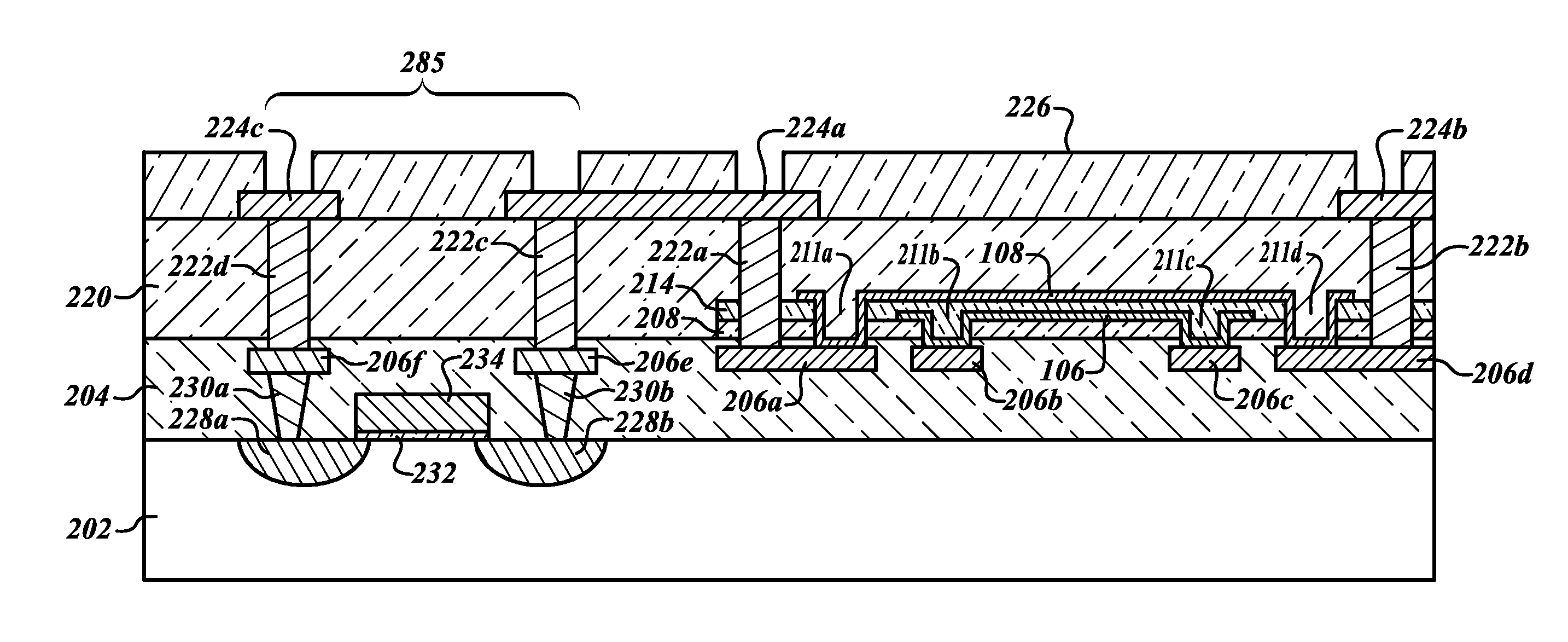

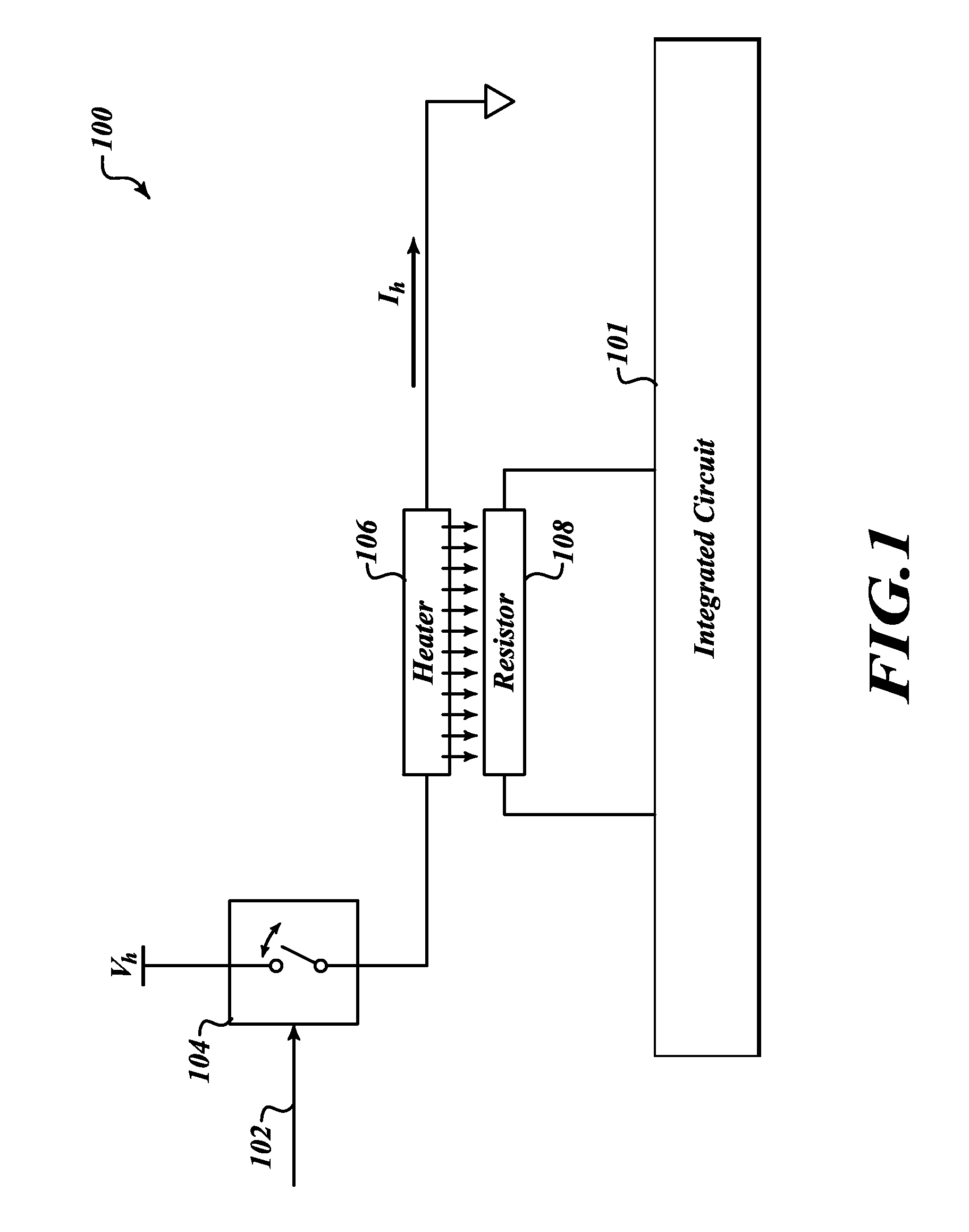

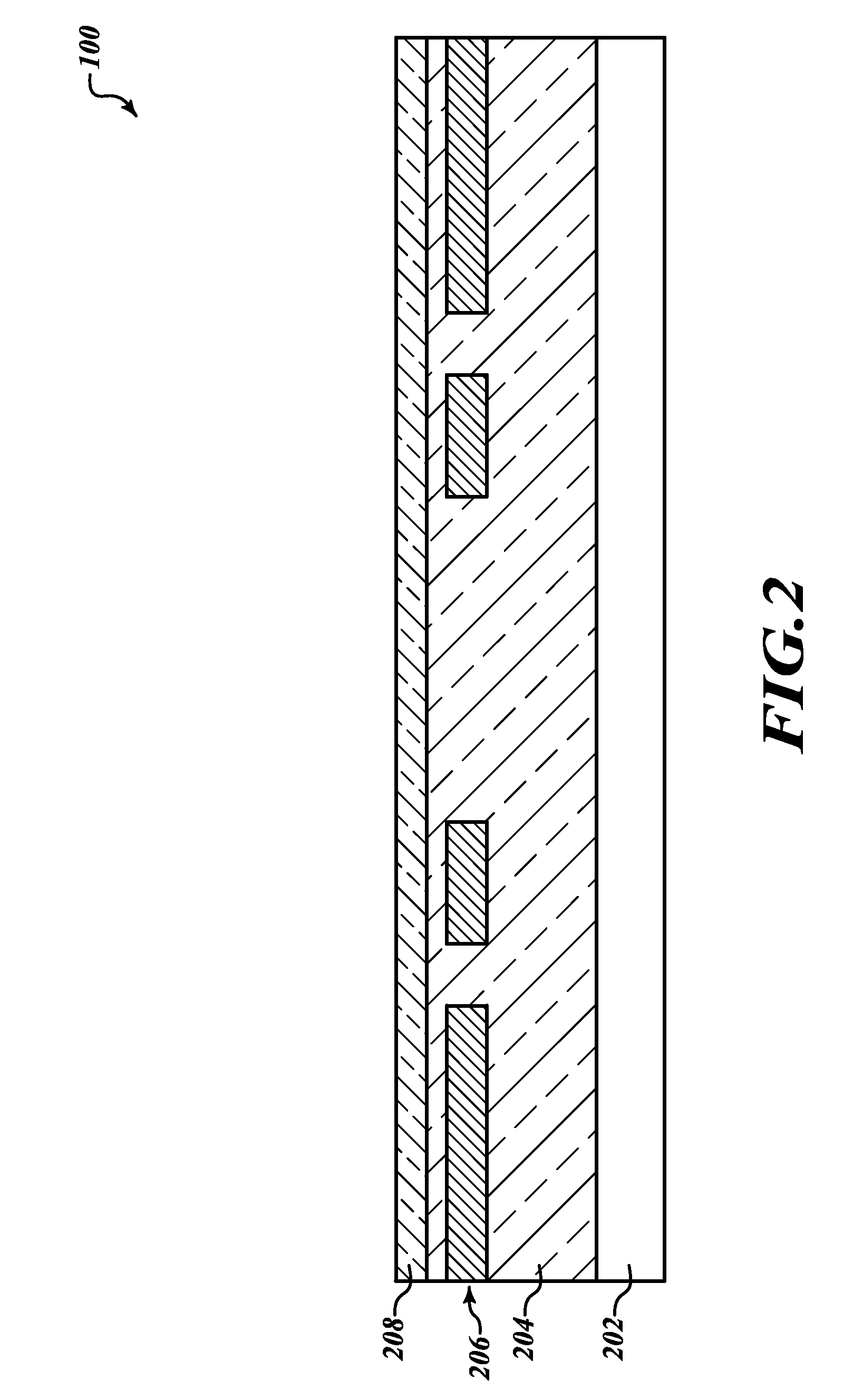

Dual thin film precision resistance trimming

ActiveUS20100073122A1Improve efficiencyIncrease resistanceSemiconductor/solid-state device detailsVacuum evaporation coatingElectrical resistance and conductanceEngineering

A trimmable resistor for use in an integrated circuit is trimmed using a heater. The heater is selectively coupled to a voltage source. The application of voltage to the heater causes the heater temperature to increase and produce heat. The heat permeates through a thermal separator to the trimmable resistor. The resistance of the trimmable resistor is permanently increased or decreased when the temperature of the resistor is increased to a value within a particular range of temperatures.

Owner:STMICROELECTRONICS SRL +1

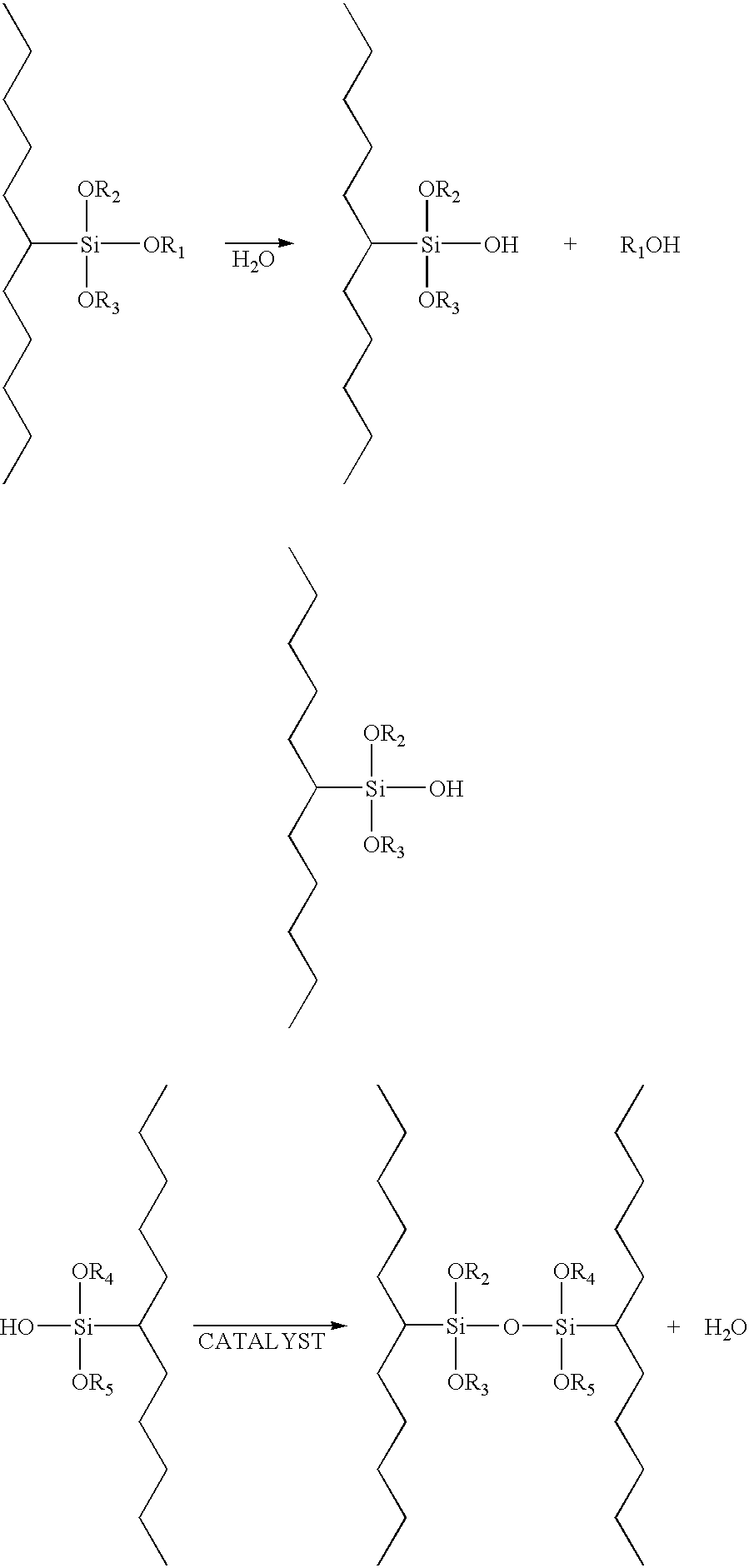

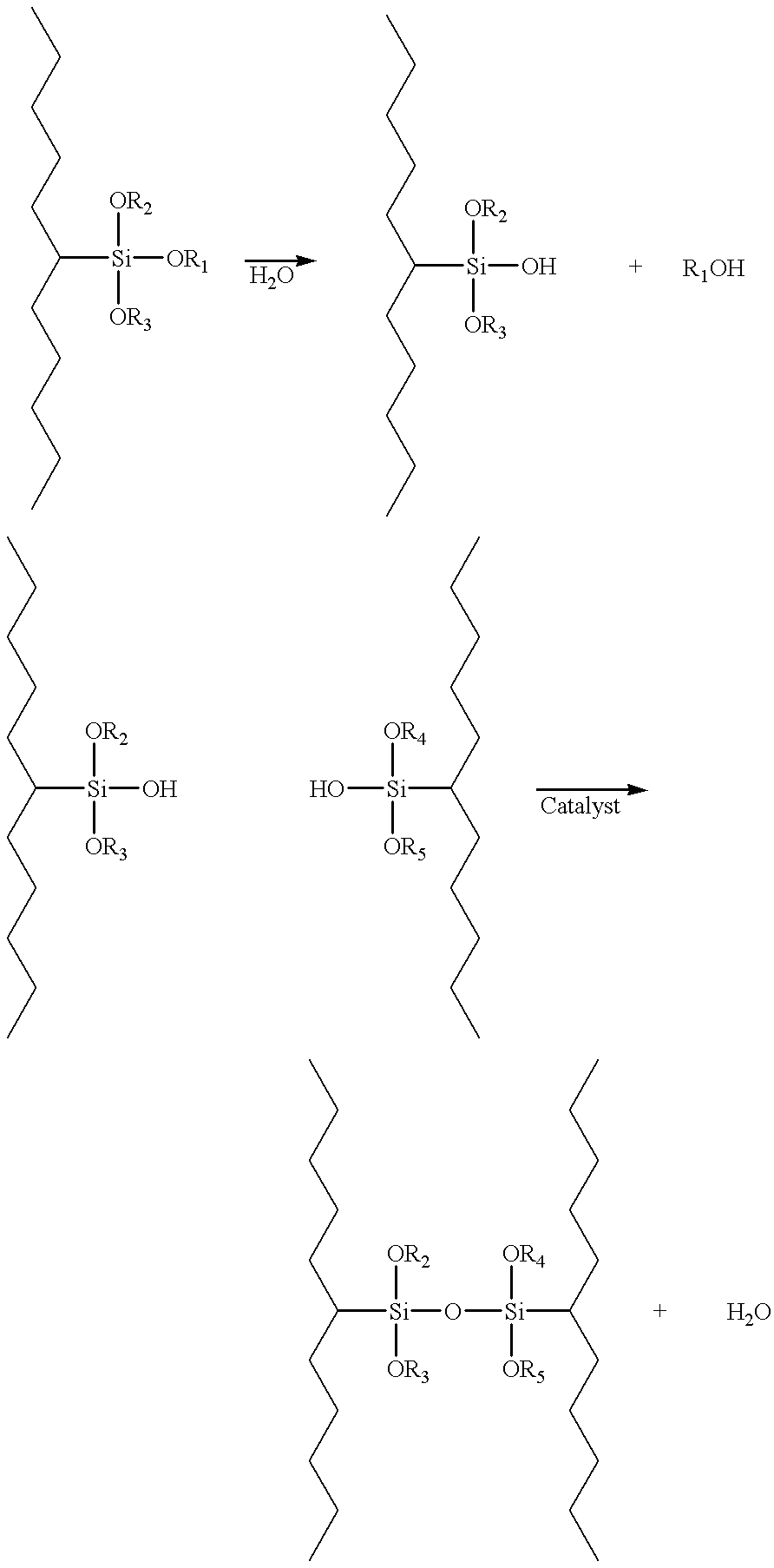

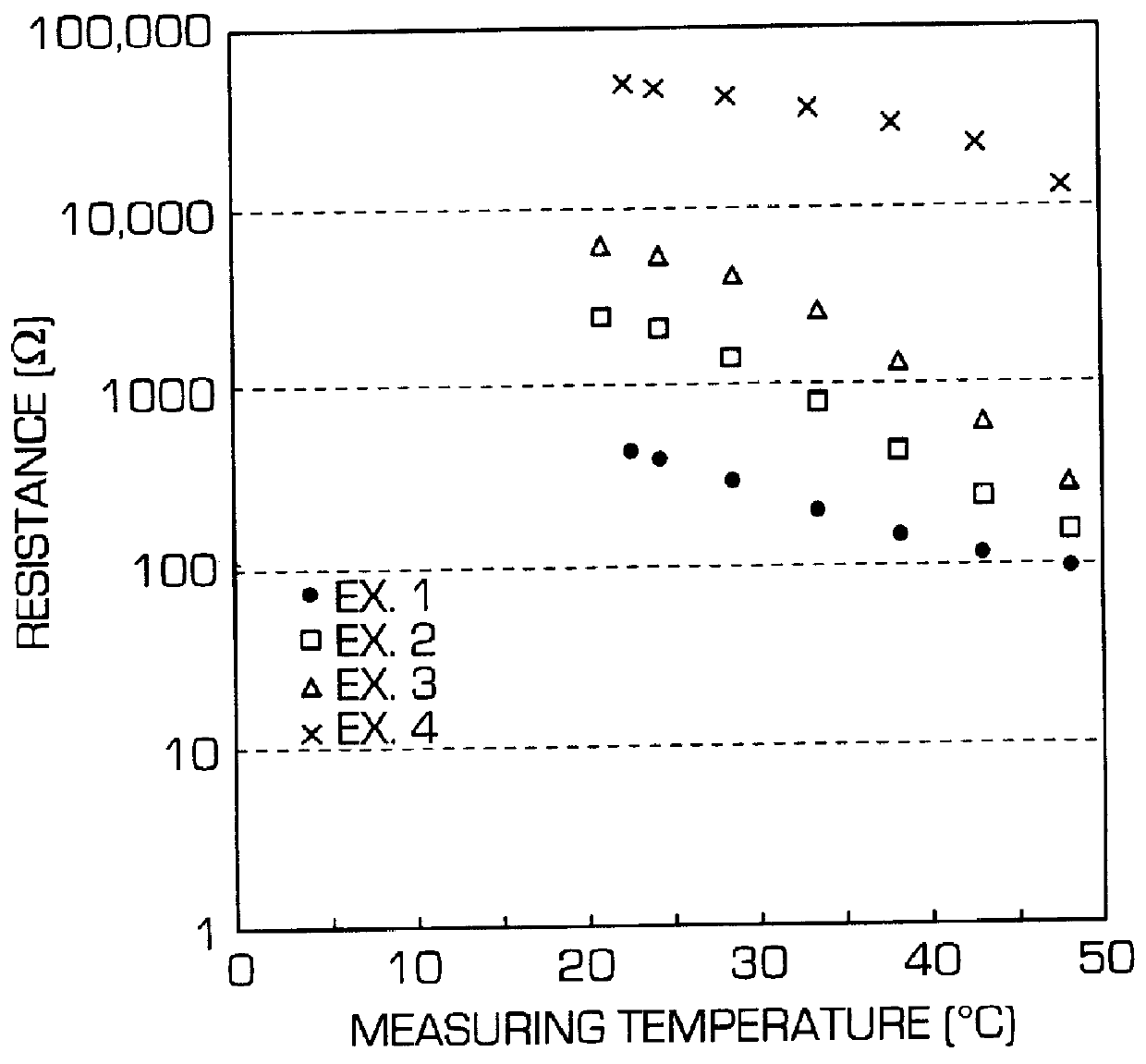

Organic positive temperature coefficient thermistor and manufacturing method therefor

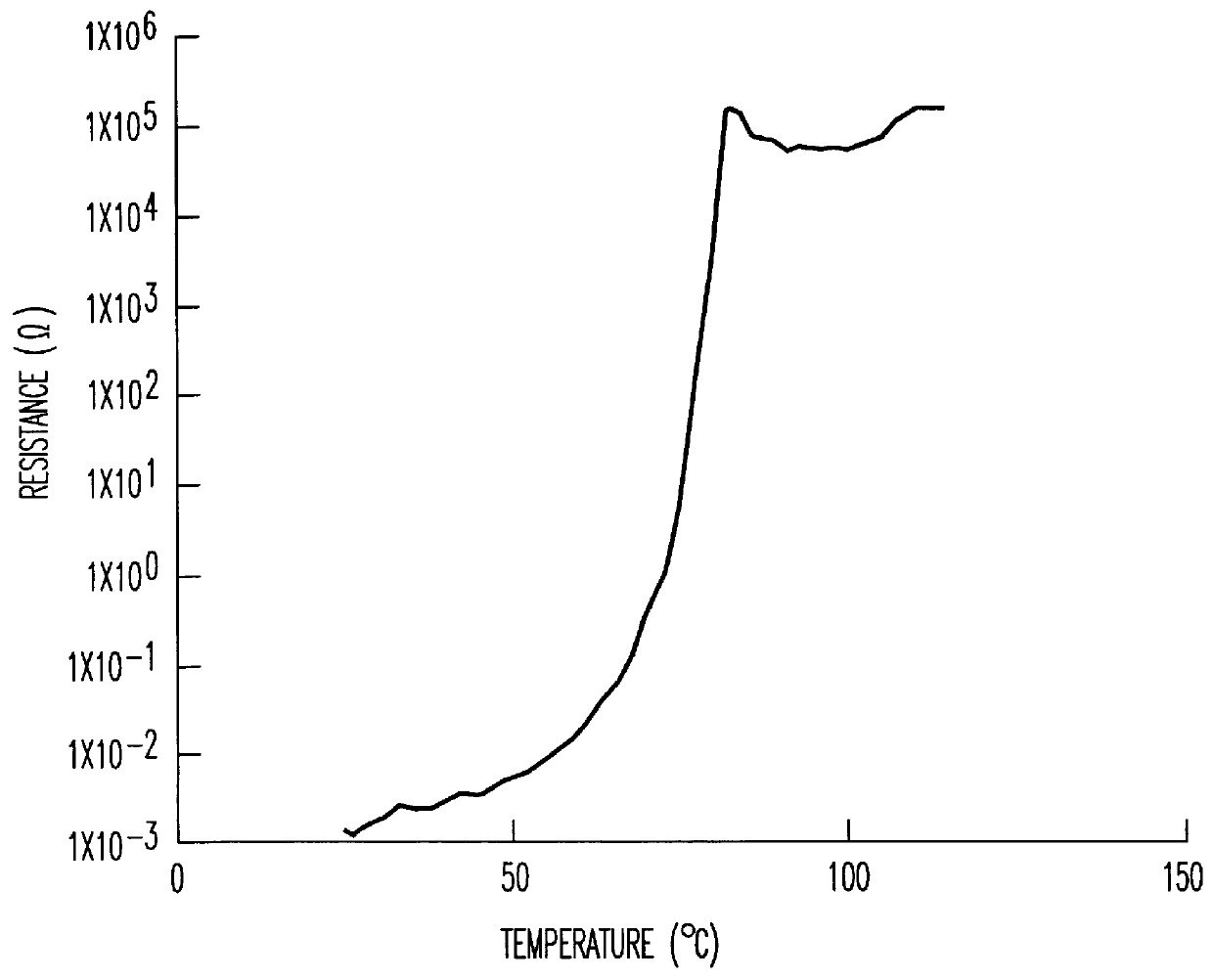

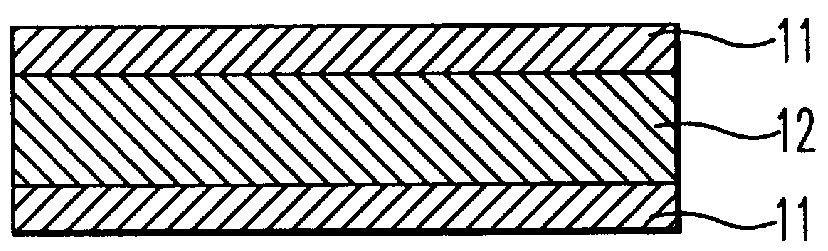

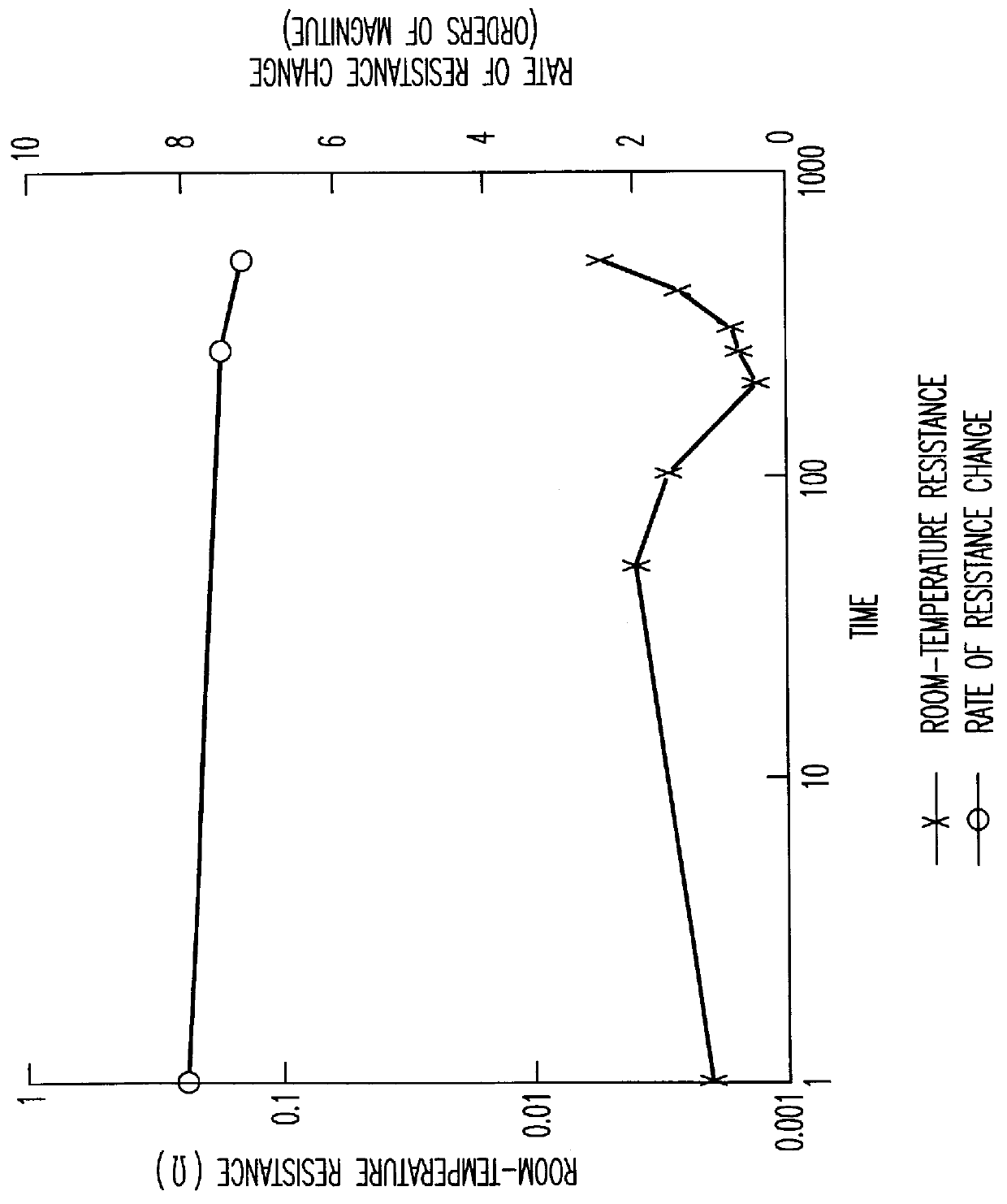

InactiveUS6143206ALower resistanceSignificant changeCurrent responsive resistorsConductive materialHysteresisMeth-

An organic positive temperature coefficient thermistor comprising a thermoplastic polymer matrix, a low-molecular organic compound having a melting point that is equal to or greater than 40 DEG C. and less than 100 DEG C. and conductive particles, each having spiky protuberances, is obtained by crosslinking a milled mixture of these components with a silane coupling agent comprising a vinyl group or a (meth)acryloyl group and an alkoxy group. This organic positive temperature coefficient thermistor has sufficiently low resistance at room temperature and a large rate of resistance change between an operating state and a non-operating state, and can be operated at less than 100 DEG C. with a reduced temperature vs. resistance curve hysteresis, ease of control of operating temperature, and high performance stability.

Owner:TDK CORPARATION

Nonaqueous electrolyte secondary battery and method for manufacturing the same

InactiveCN101276940AEnsure safetyCell seperators/membranes/diaphragms/spacersFinal product manufactureLithiumEngineering

Owner:PANASONIC CORP

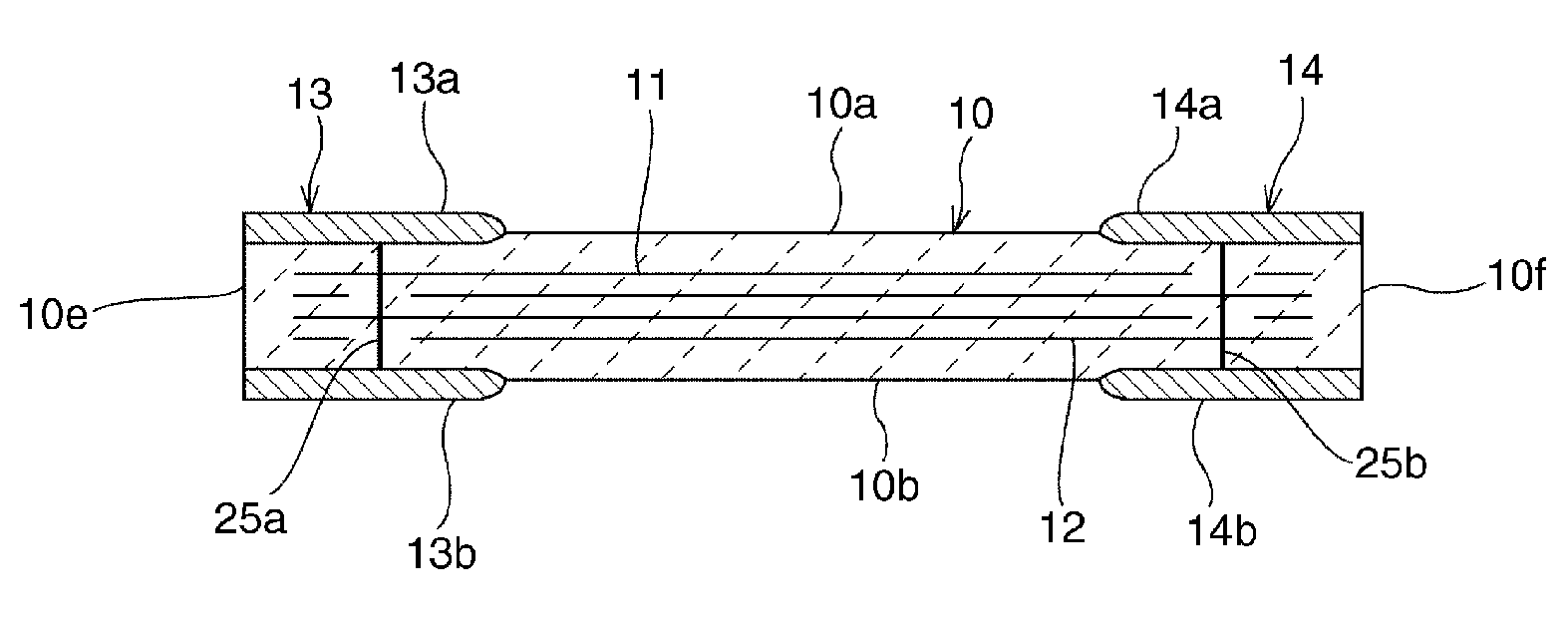

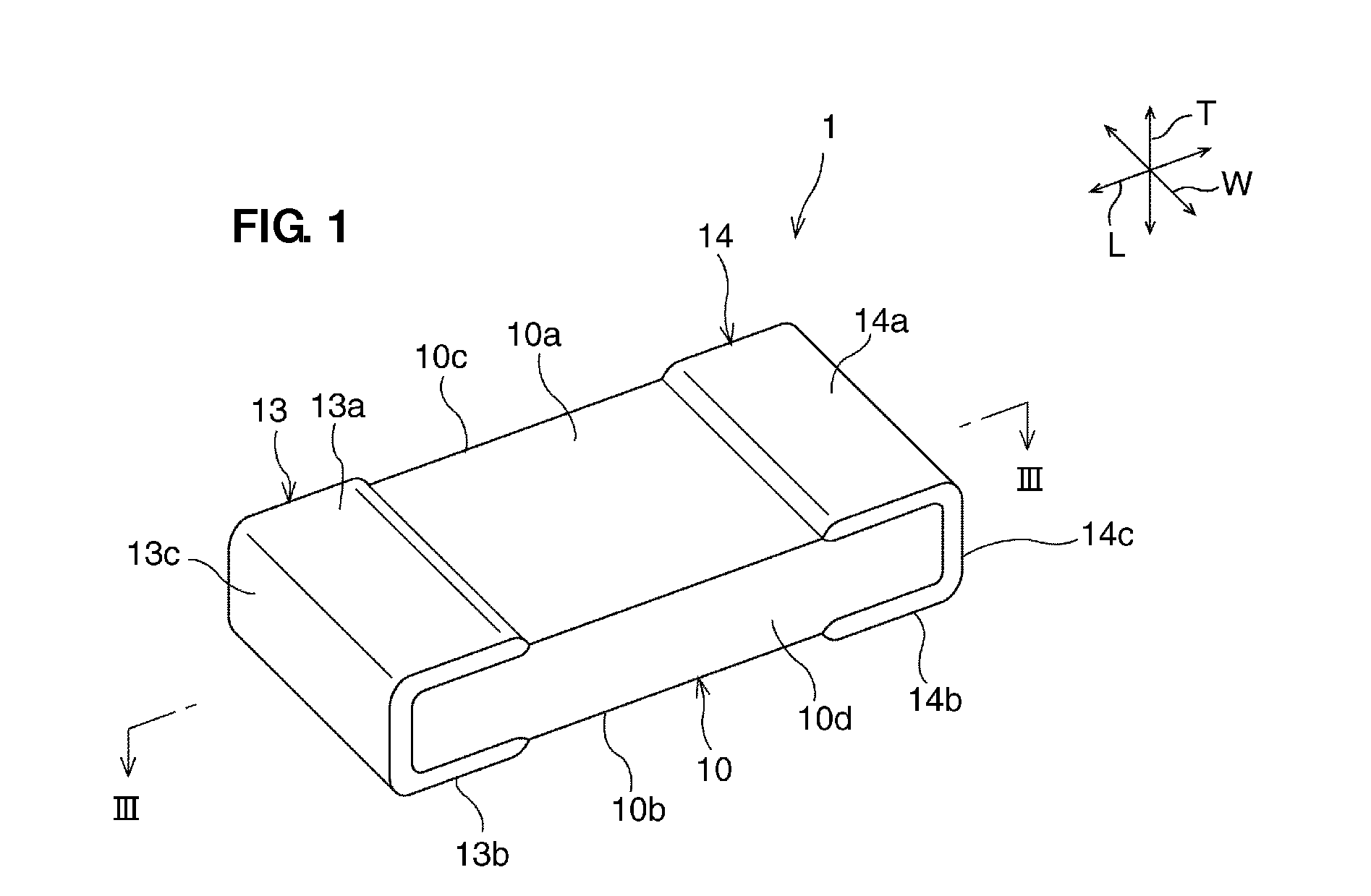

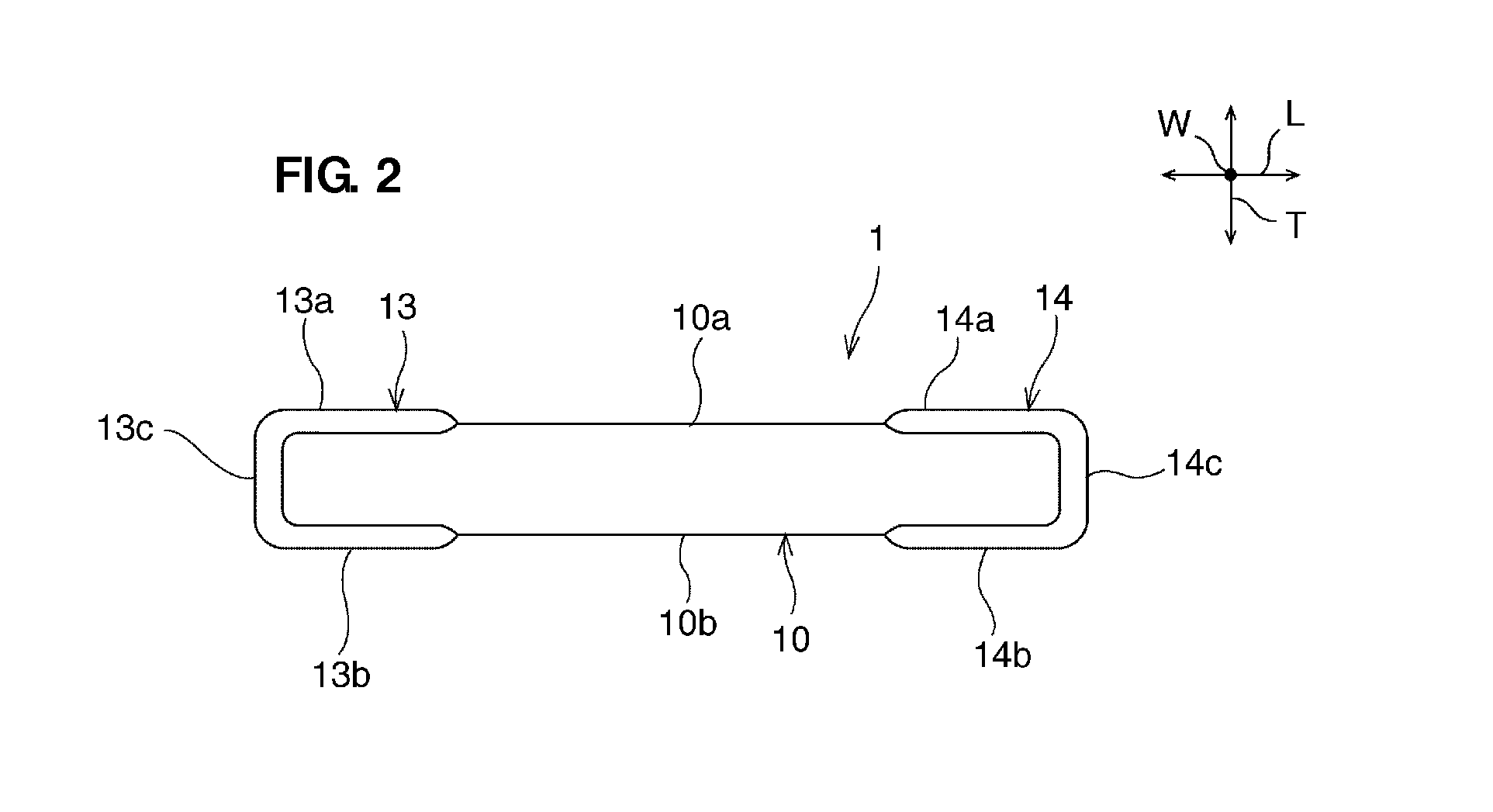

Method of manufacturing ceramic electronic component, ceramic electronic component, and wiring board

ActiveUS20120018205A1Minimize changesCharacteristic is prevented and minimizedResistor terminals/electrodesFinal product manufactureConductive pasteMetallurgy

A method of manufacturing a ceramic electronic component prevents variations in characteristics even when the ceramic electronic component is embedded in a wiring board. Ceramic green sheets containing an organic binder having a degree of polymerization in a range from about 1000 to about 1500 are prepared. A first conductive paste layer is formed on a surface of each of the ceramic green sheets. The ceramic green sheets are laminated to form a raw ceramic laminated body. A second conductive paste layer is formed on a surface of the raw ceramic laminated body. The raw ceramic laminated body formed with the second conductive paste layer is fired.

Owner:MURATA MFG CO LTD

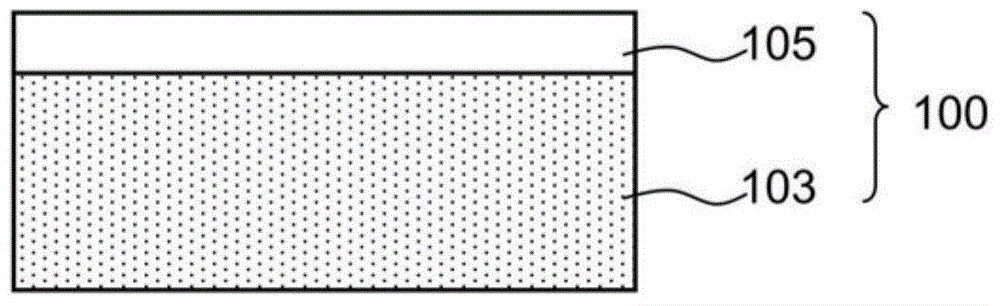

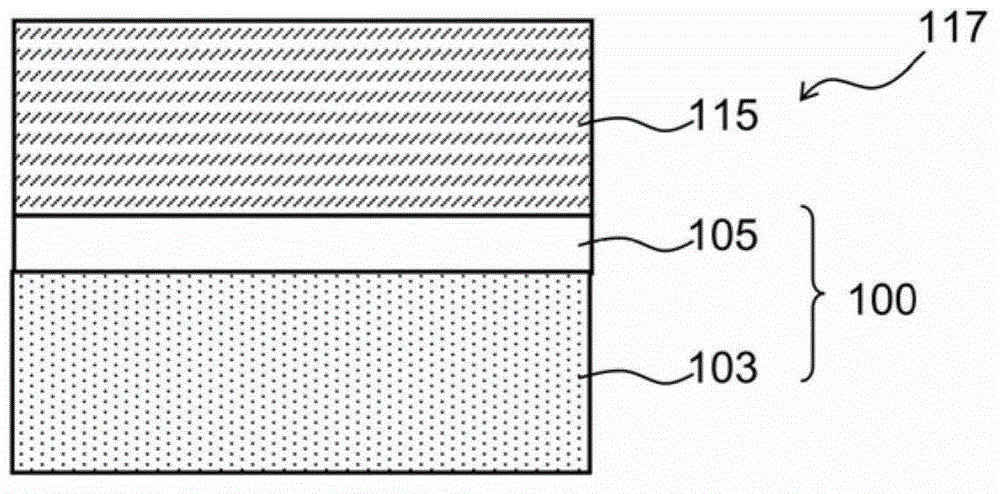

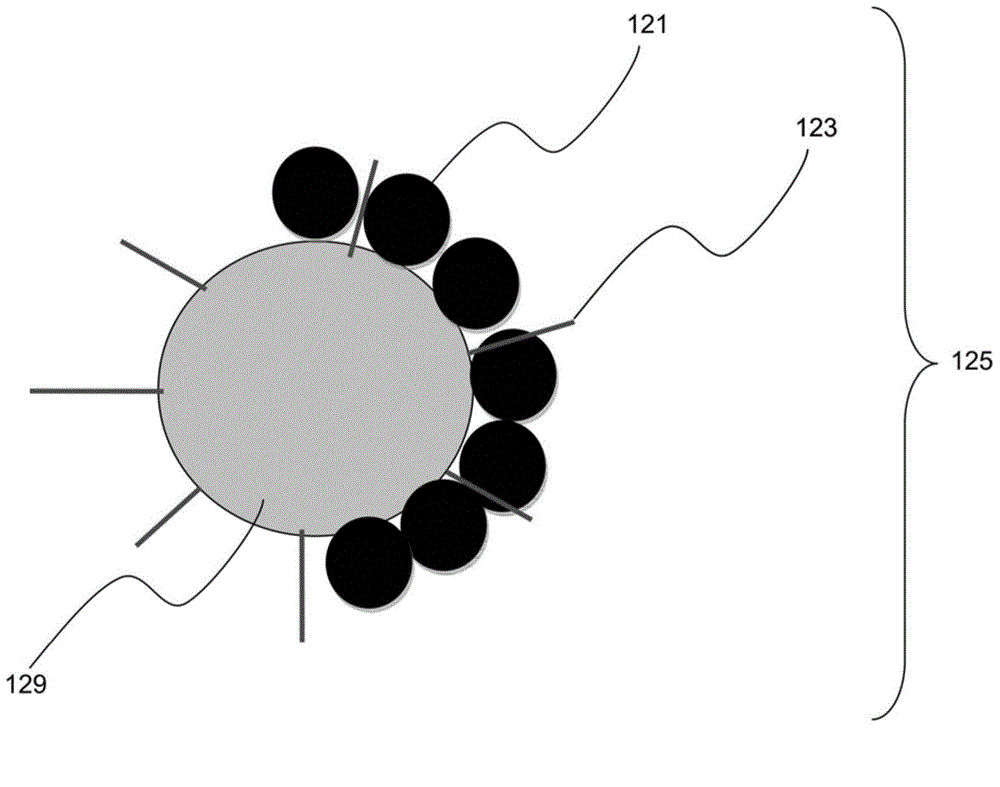

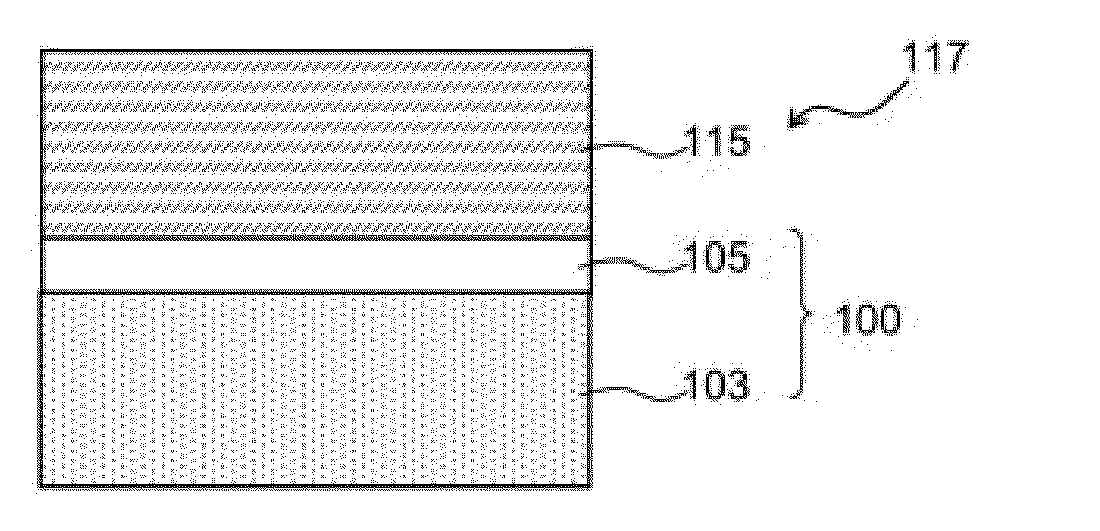

Collector, electrode structure, electricity storage component, and composition for collectors

Provided are: a highly safe collector which is capable of stably maintaining a PTC function even in cases where the temperature is further increased after the exhibition of the PTC function if used in an electrode structure of an electricity storage component such as a nonaqueous electrolyte battery, an electric double layer capacitor or a lithium ion capacitor; an electrode structure; an electricity storage component; and a composition for collectors. Provided is a collector (100) which is provided with a conductive base (103) and a resin layer (105) that is provided on at least one surface of the conductive base (103). The resin layer (105) is obtained by applying a paste, which contains polyolefin emulsion particles (125), a conductive material (121) and a crosslinking agent (131), onto the conductive base (103) and crosslinking the paste thereon. The polyolefin emulsion particles (125) contain a polyolefin resin (129) that is modified with a carboxylic acid or a carboxylic acid anhydride at both ends.

Owner:FURUKAWA SKY ALUMINUM CORP +2

Organic PTC thermistor

InactiveUS6607679B2Improve reliabilityImprove stabilityPrimary cell maintainance/servicingConductive materialThermoplastic elastomerThermistor

In an organic PTC thermistor comprising a matrix of at least two high-molecular weight compounds, a low-molecular weight organic compound, and conductive particles having spiky protuberances, a thermoplastic elastomer is contained in the matrix whereby the thermistor is improved in reliability and performance stability.

Owner:TDK CORPARATION

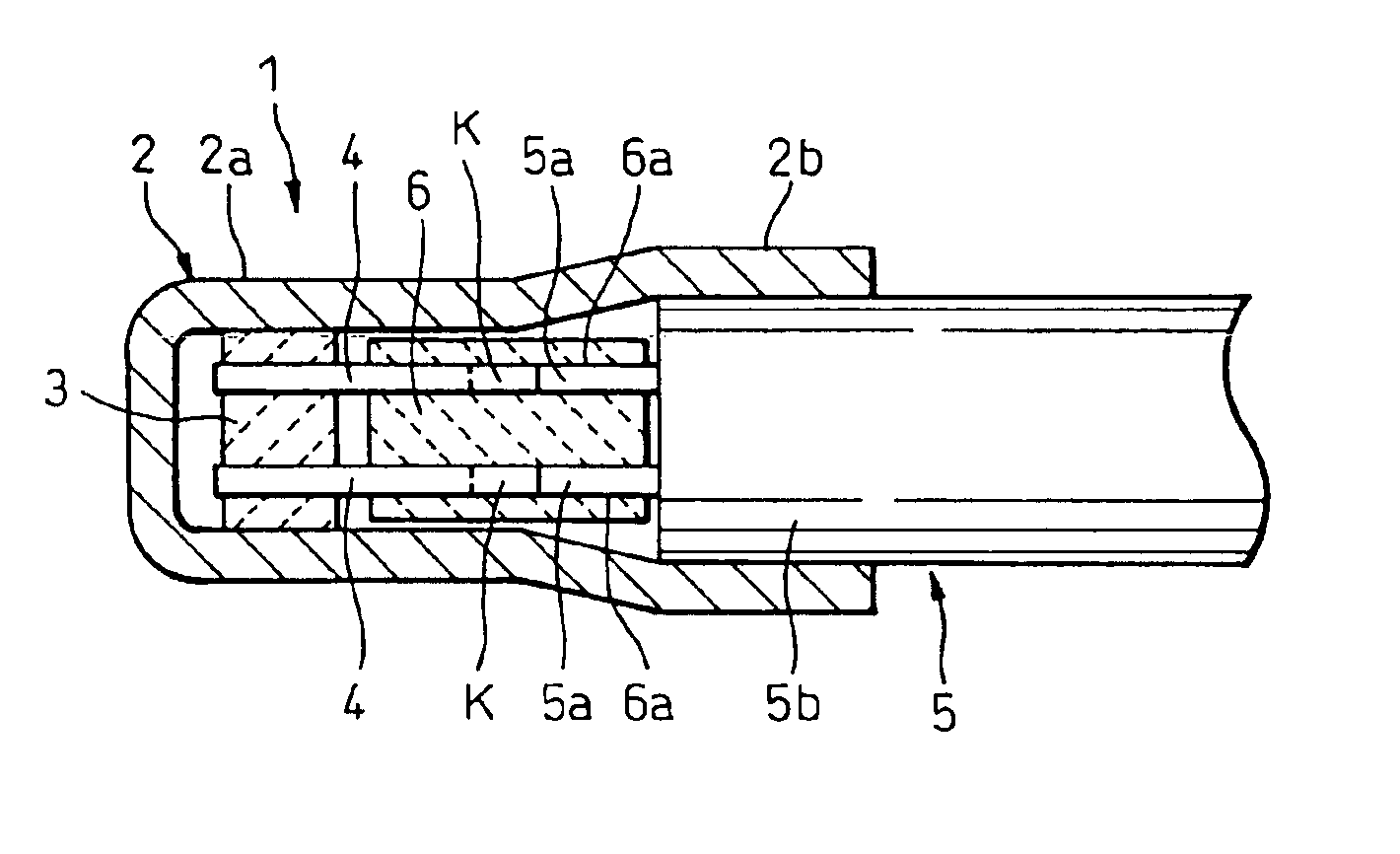

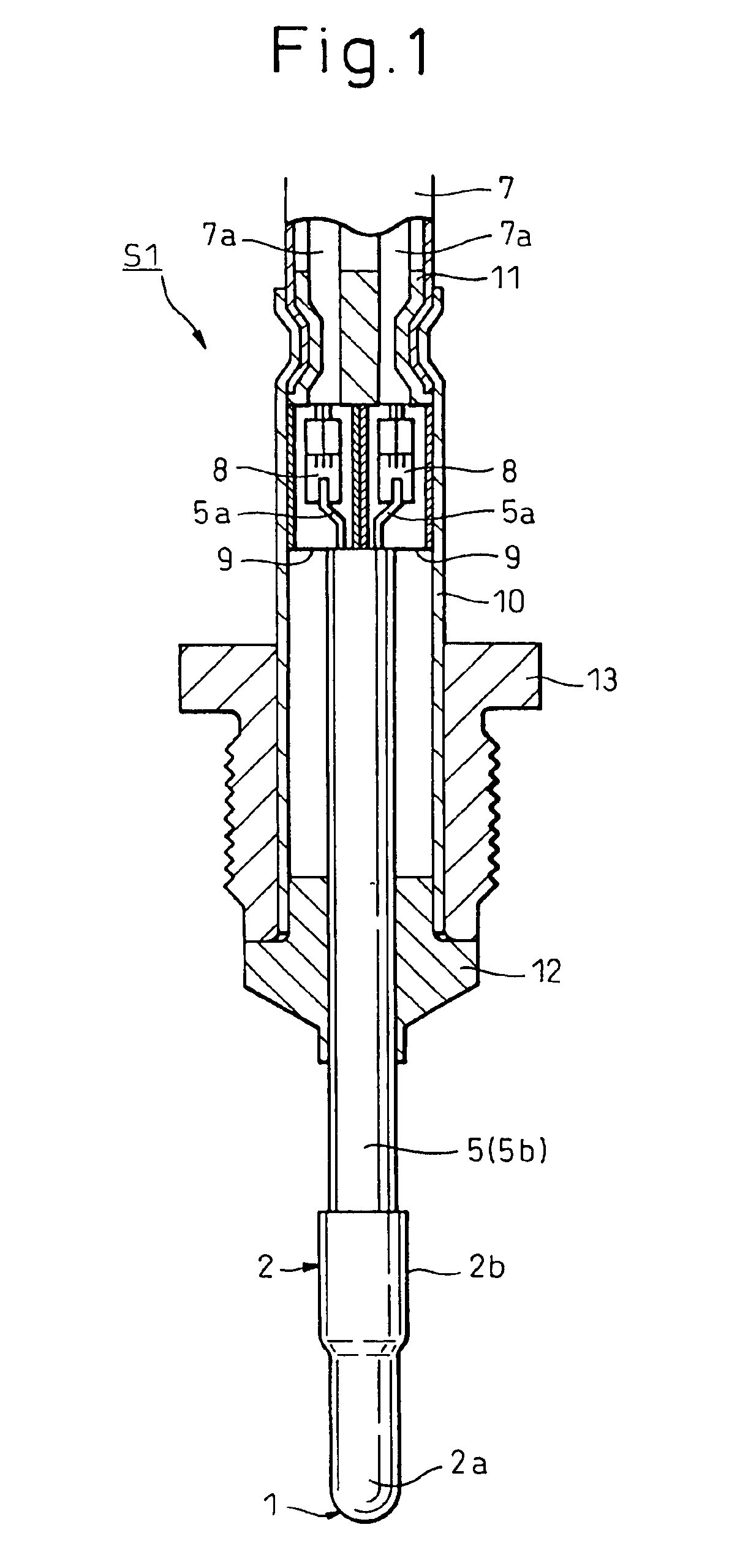

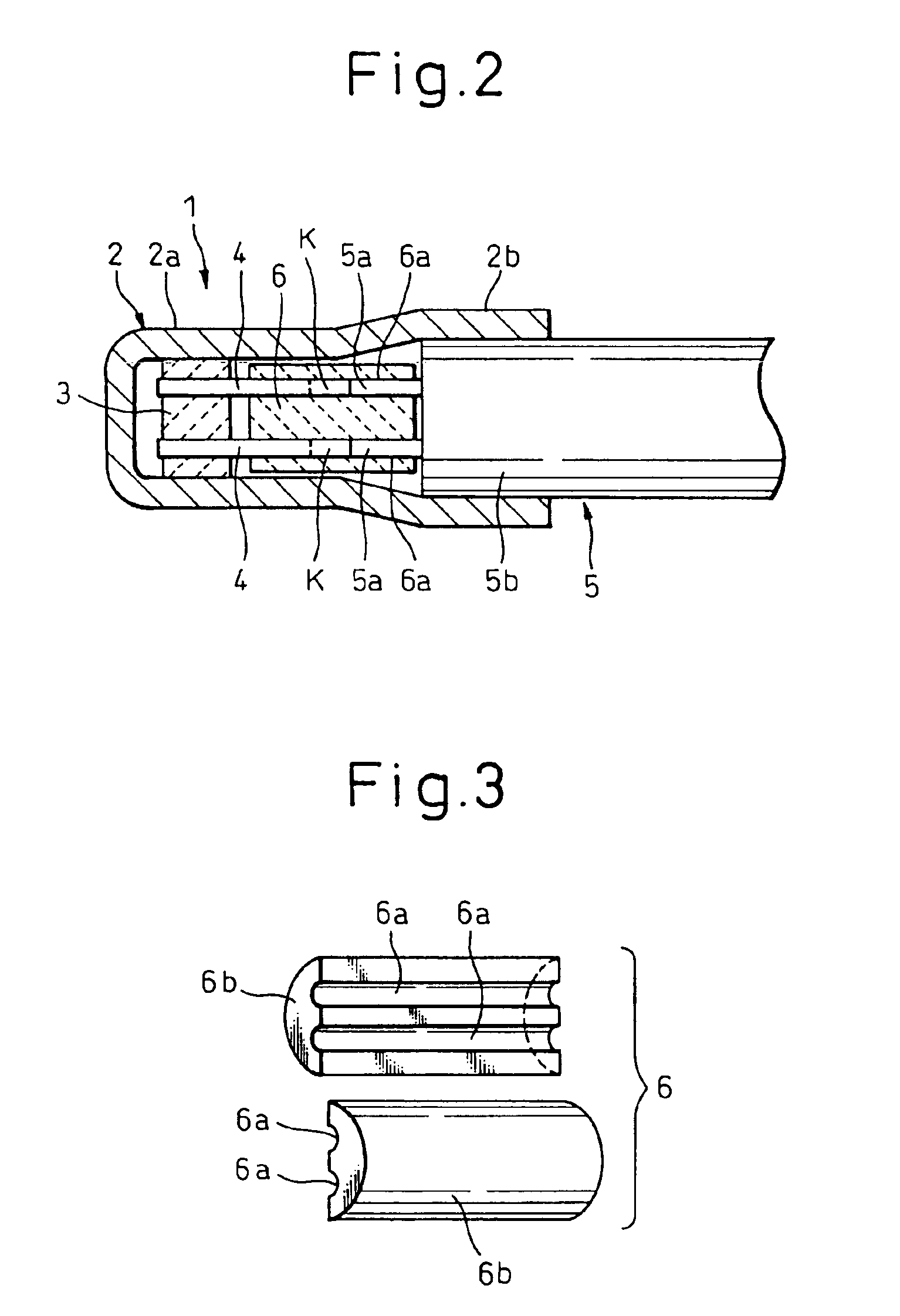

Thermistor temperature sensor

InactiveUS6899457B2Avoid breakingImprove vibrationThermometers using electric/magnetic elementsNegative temperature coefficient thermistorsEngineeringThermistor

An insulator 6 for holding electrode wires 4 is provided between a thermistor element 3 and a sheathed pin 5 which is a wiring, and the electrode wires 4, which are inserted into hole portions 6a of the insulator 6, are held therein not bonded to the insulator, whereby the vibration resistance of the electrode wires of the thermistor element is improved so that breaking of the electrode wires is prevented.

Owner:DENSO CORP

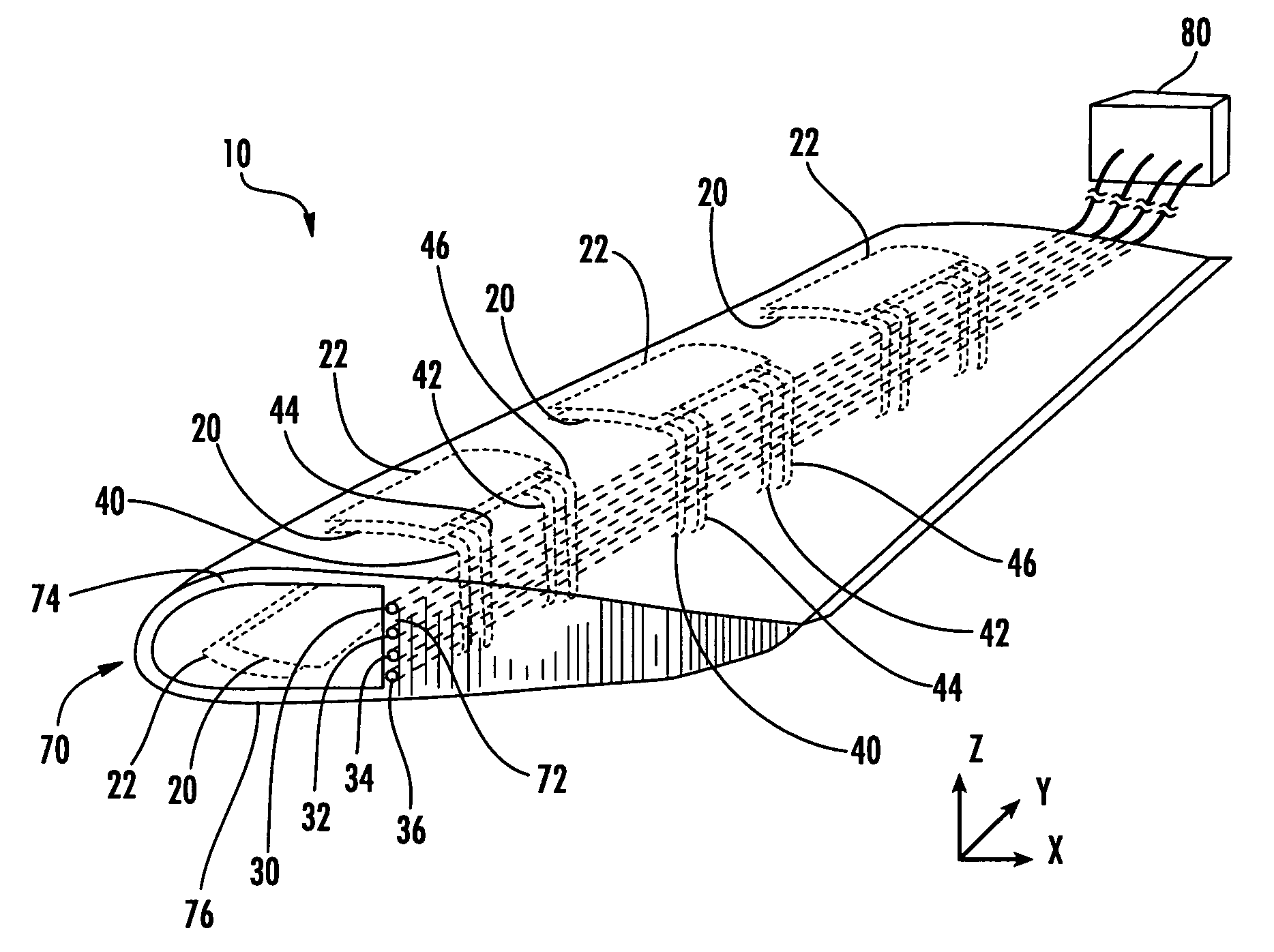

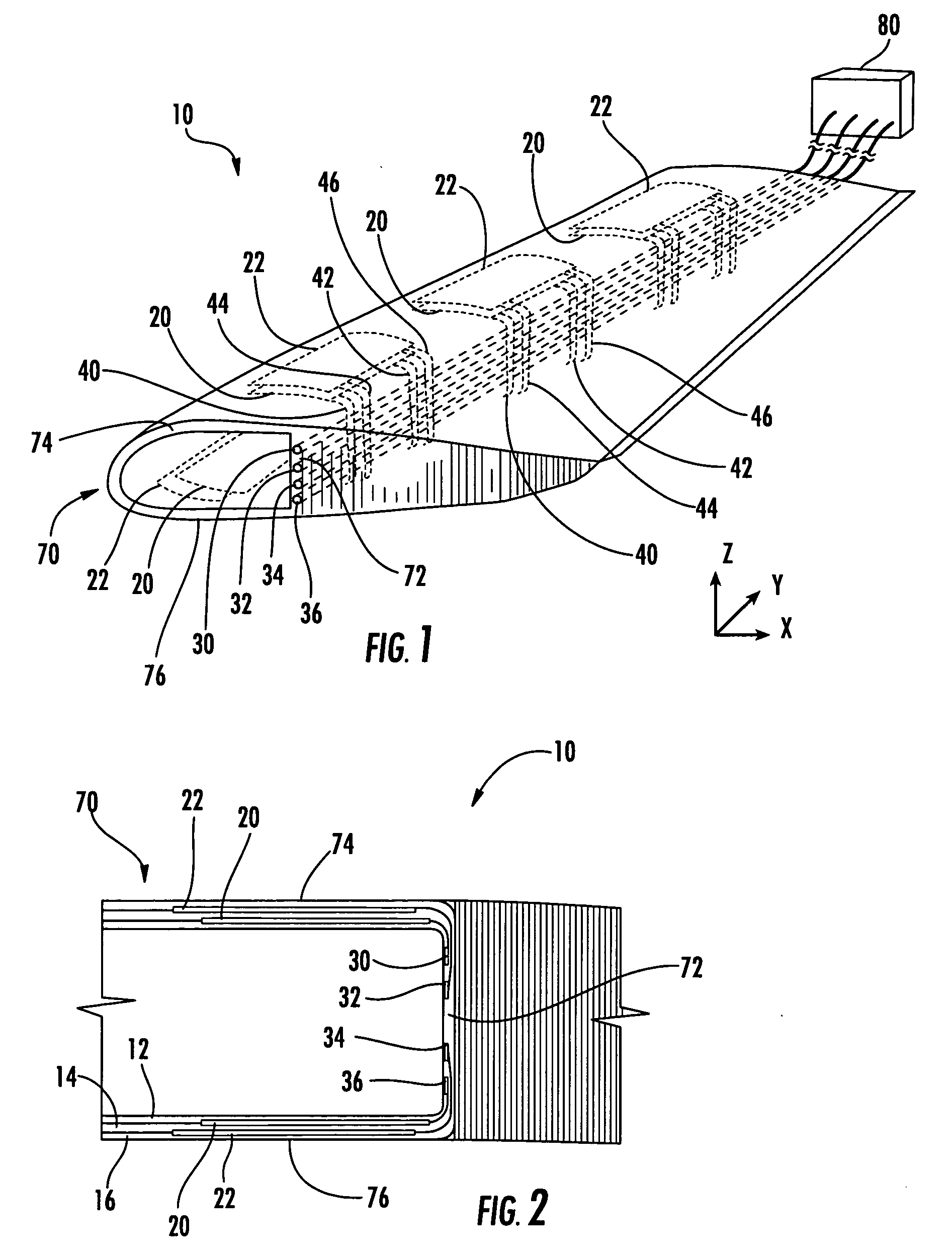

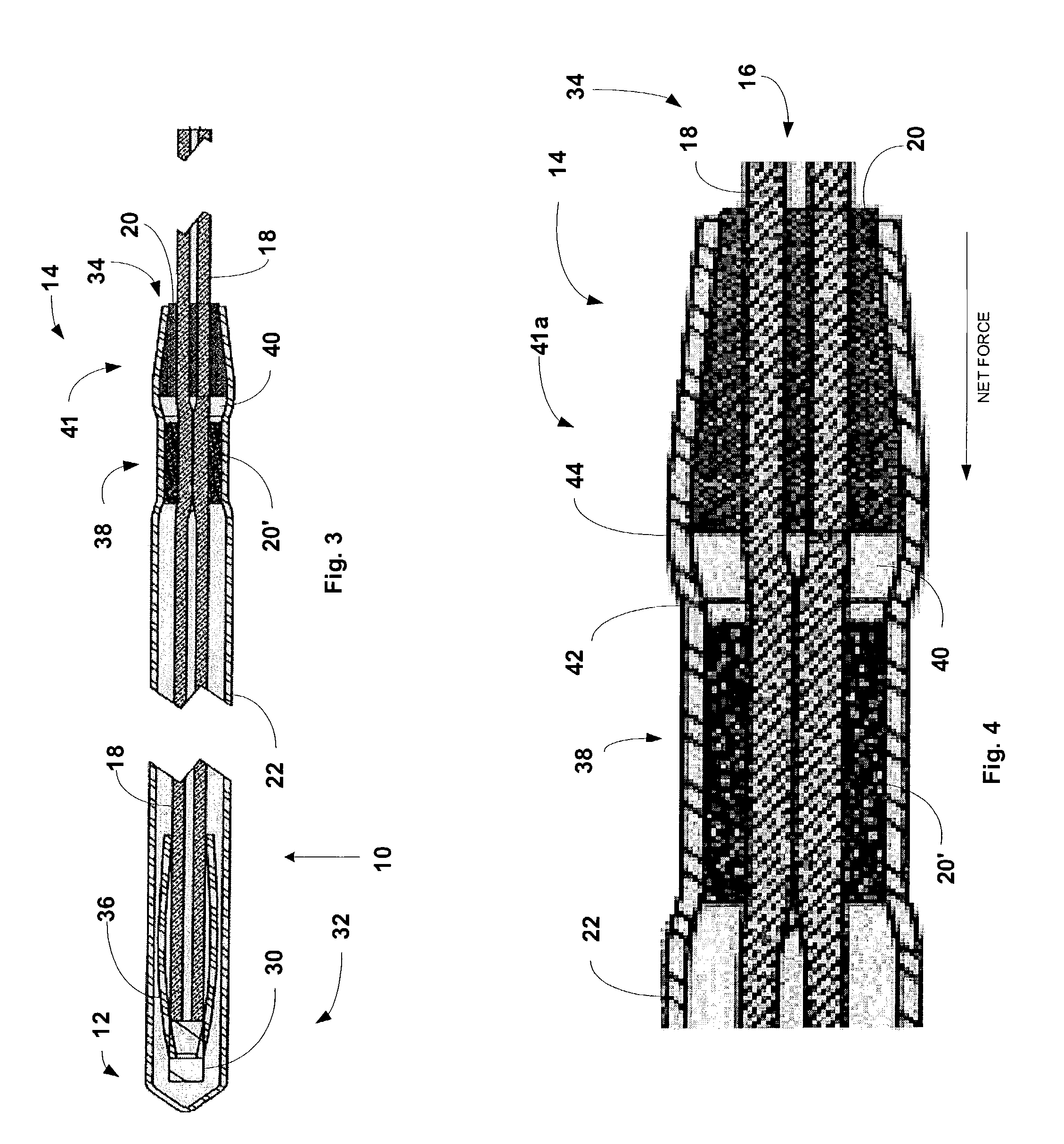

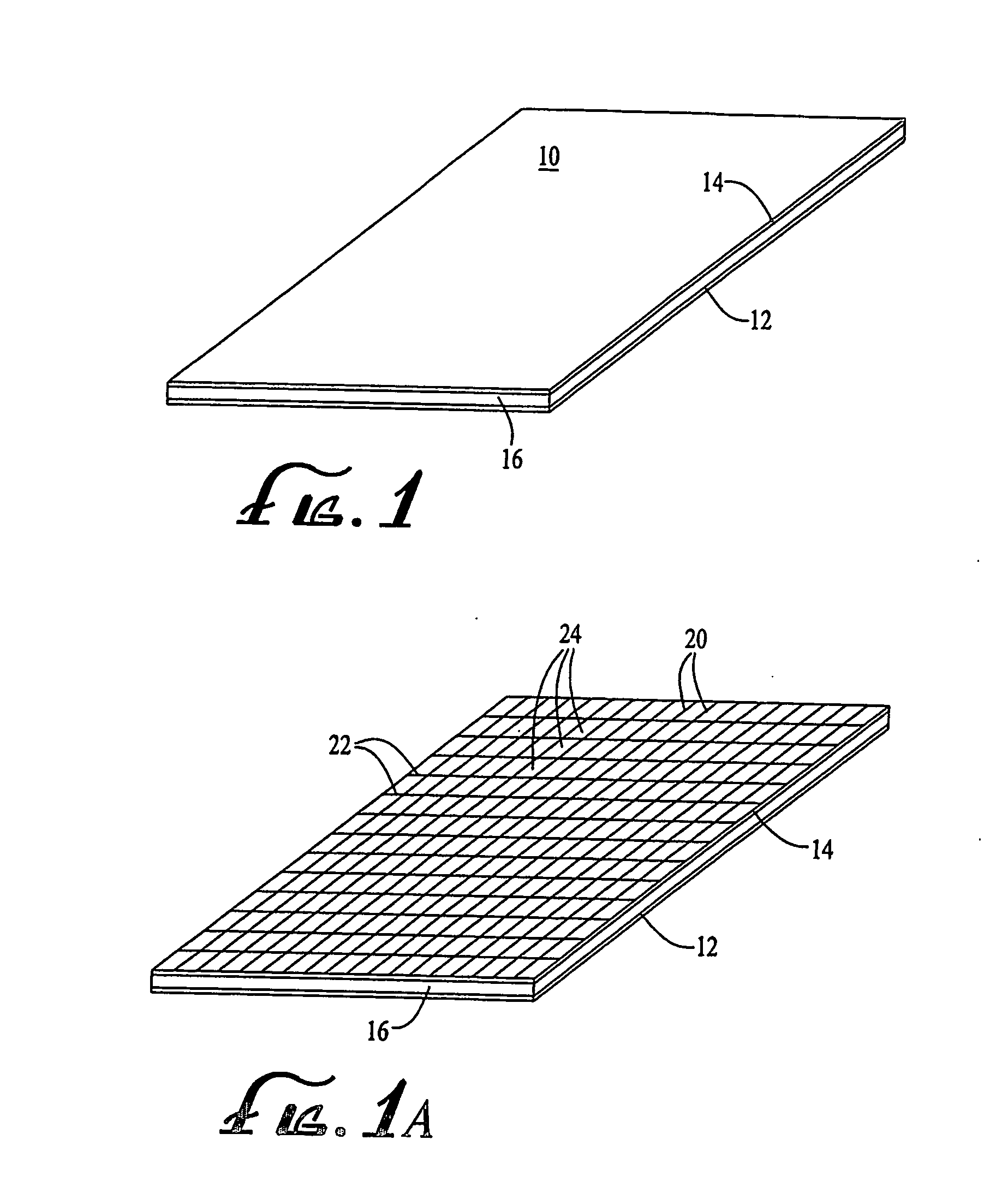

Structurally integrated circuit and associated method

ActiveUS20050257956A1Envelope/housing resistor manufactureLaminating printed circuit boardsElectrical devicesIntegrated circuit

A composite structural member with an integrated electrical circuit and an associated method of manufacture are provided. The structural member includes a plurality of layers of structural reinforcement material, and two or more electrical devices are disposed at least partially between the layers with an intermediate layer of the structural reinforcement material disposed between the electrical devices. At least one electrical bus is disposed in the structural member, and each electrical device is connected to the bus by a conductive electrode. Thus, the electrodes can extend through the intermediate layer of the structural reinforcement material to connect each of the electrical devices to one or more of the buses.

Owner:THE BOEING CO

Flexible ptc heating element and method of manufacturing the heating element

InactiveUS20050173414A1Resistor terminals/electrodesResistor mounting/supportingRubber materialEngineering

The flexible PTC heating element according to the invention has one of the following constitutions. A portion of an electrodes and a PTC resistor is impregnated into a flexible substrate. A flexible substrate is made of resin foam or rubber material having a concave / convex shape formed on the surface. The flexible PTC heating element has an elongation deformation portion disposed to at least one of an electrode and a PTC resistor. A flexible substrate has adhesiveness and either a flexible substrate or a flexible cover material has an elongation control portion. Therefore, the flexible PTC heating element is highly flexible and excellent in vibration durability.

Owner:PANASONIC CORP

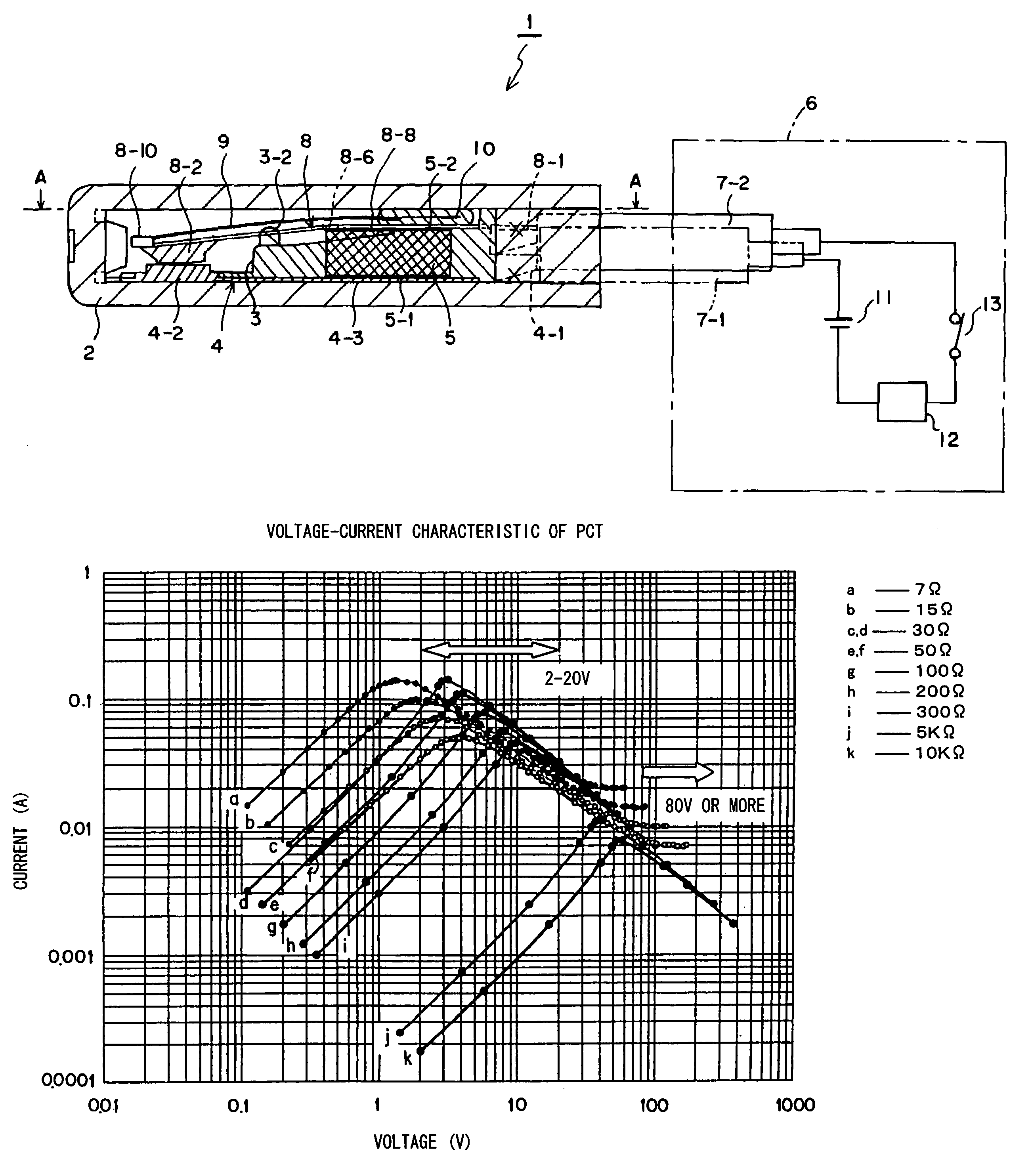

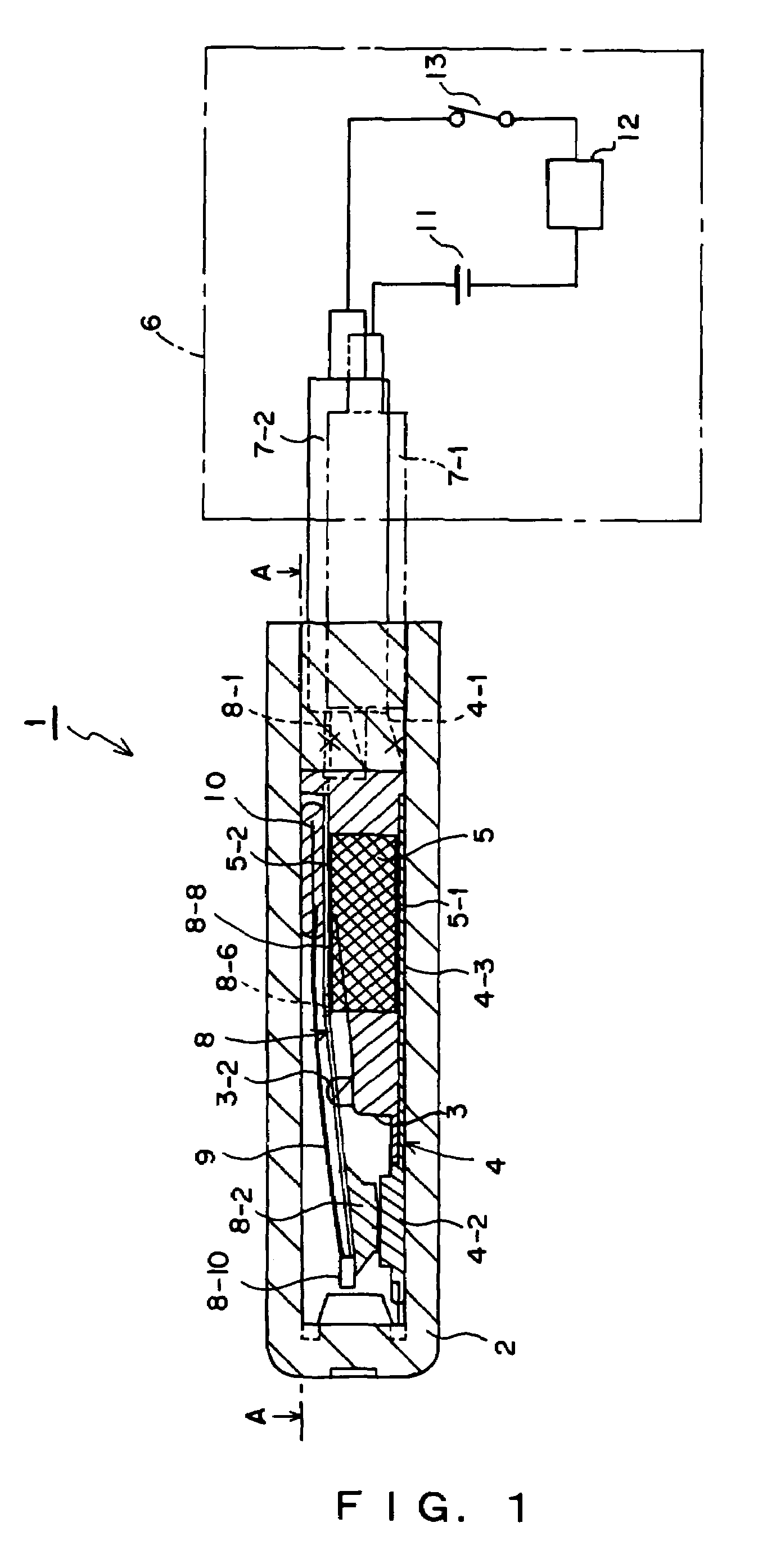

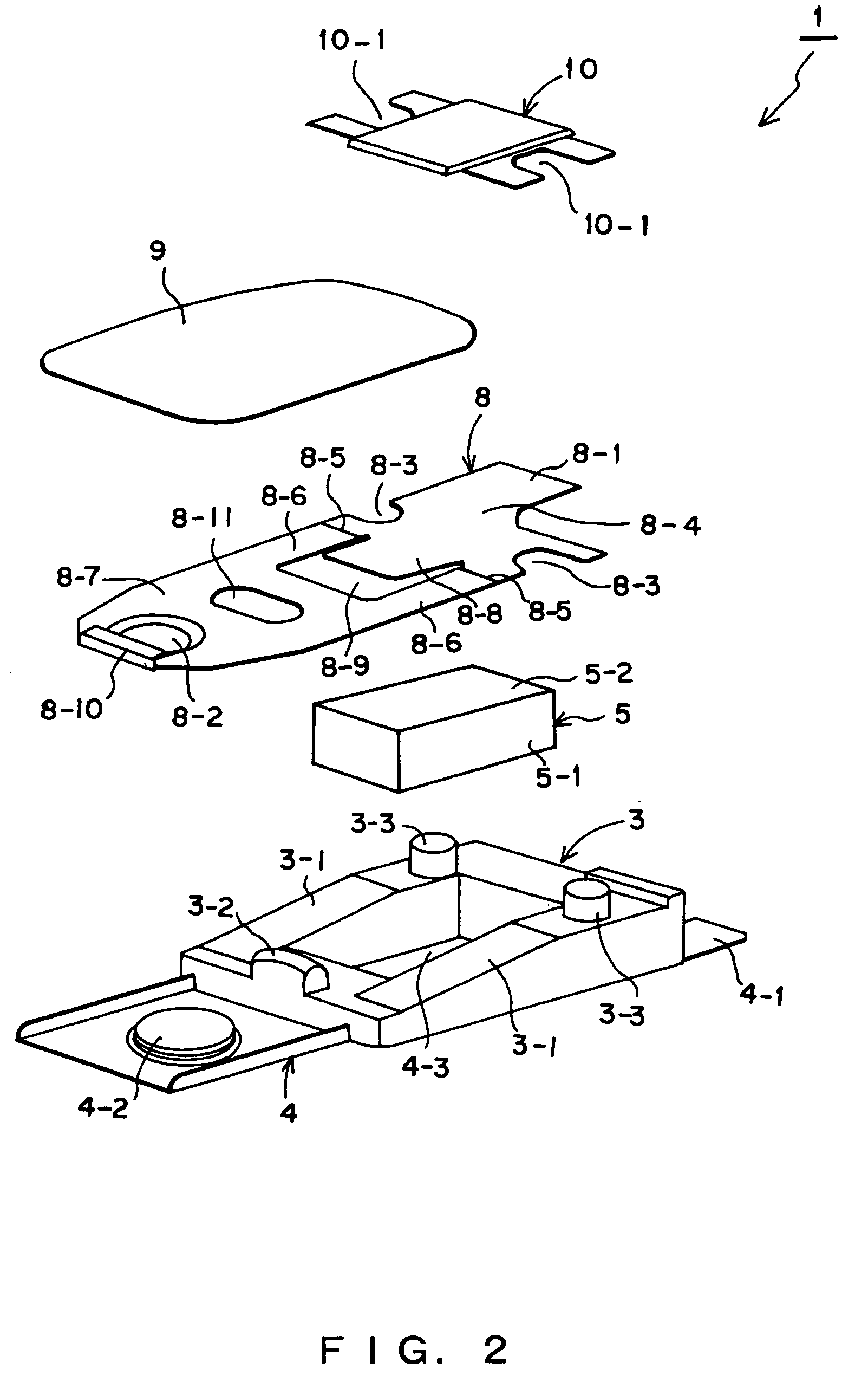

Direct current cutoff switch

ActiveUS7330097B2Inhibition continuesEasy to useProtective switch detailsElectrothermal relaysNonlinear resistorEngineering

In a direct current cutoff switch1, a PTC 5, which is a non-linear resistor, is parallel connected to a contact circuit composed of a fixed contact 4-2 and a movable contact 8-2 via electrodes 5-1. When the switch is closed, no current flows in the PTC 5 with a prescribed resistance value at 25° C., since voltage between both the electrodes 5-1 is almost “0”. When the switch is opened in order to cut off current, the contacts form a closed circuit since the PTC 5 is parallel inserted between the fixed contact 4-2 and the movable contact 8-2. For this reason, it is difficult for surge voltage to occur and an arc hardly occurs between both the contacts. The PTC 5 instantaneously heats due to passing current, reduces the resistance value and passes peak current. Then, the resistance value rises and becomes stable in a high value such that weak current which is negligible at 42V, which is rated voltage. Thus, current is substantially cut off.

Owner:UCHIYA THERMOSTAT

High-temperature resistant PTC electroconductive composition, high-temperature resistant PTC device containing composition and manufacturing method thereof

ActiveCN101560325ALower resistanceImprove PTC StrengthCurrent responsive resistorsPositive temperature coefficient thermistorsMetallurgyOrganic polymer

The invention relates to a high-temperature resistant PTC electroconductive composition, which comprises 20 to 70 percent of organic polymers, 25 to 75 percent of electroconductive filler, 1 to 30 percent of inorganic filler and 0.1 to 10 percent of additive, wherein the preferred melting point of the organic polymers is more than 150 DEG C; the organic polymers are one or more crystalline or semi-crystalline polymers and made of one or more of nylon 11, nylon 12, polyvinylidene fluoride, soluble poly(tetrafluoroethylene), ethylene-tetrafluoroethylene copolymers, perfluoroethylene-propylene, ethylene-chlorotrifluoroethylene and copolymers thereof. The invention also provides a high-temperature resistant PTC device containing the composition and a manufacturing method thereof. The high-temperature resistant PTC device containing the composition has low resistance, high PTC strength and superior resistance stability, so that the high-temperature resistant PTC device can be used for overcurrent protection of circuits in high-temperature environments such as automobile motors and the like. Moreover, the high-temperature resistant PTC device is simple and convenient to manufacture and has high efficiency.

Owner:SHANGHAI KETER POLYMER MATERIAL

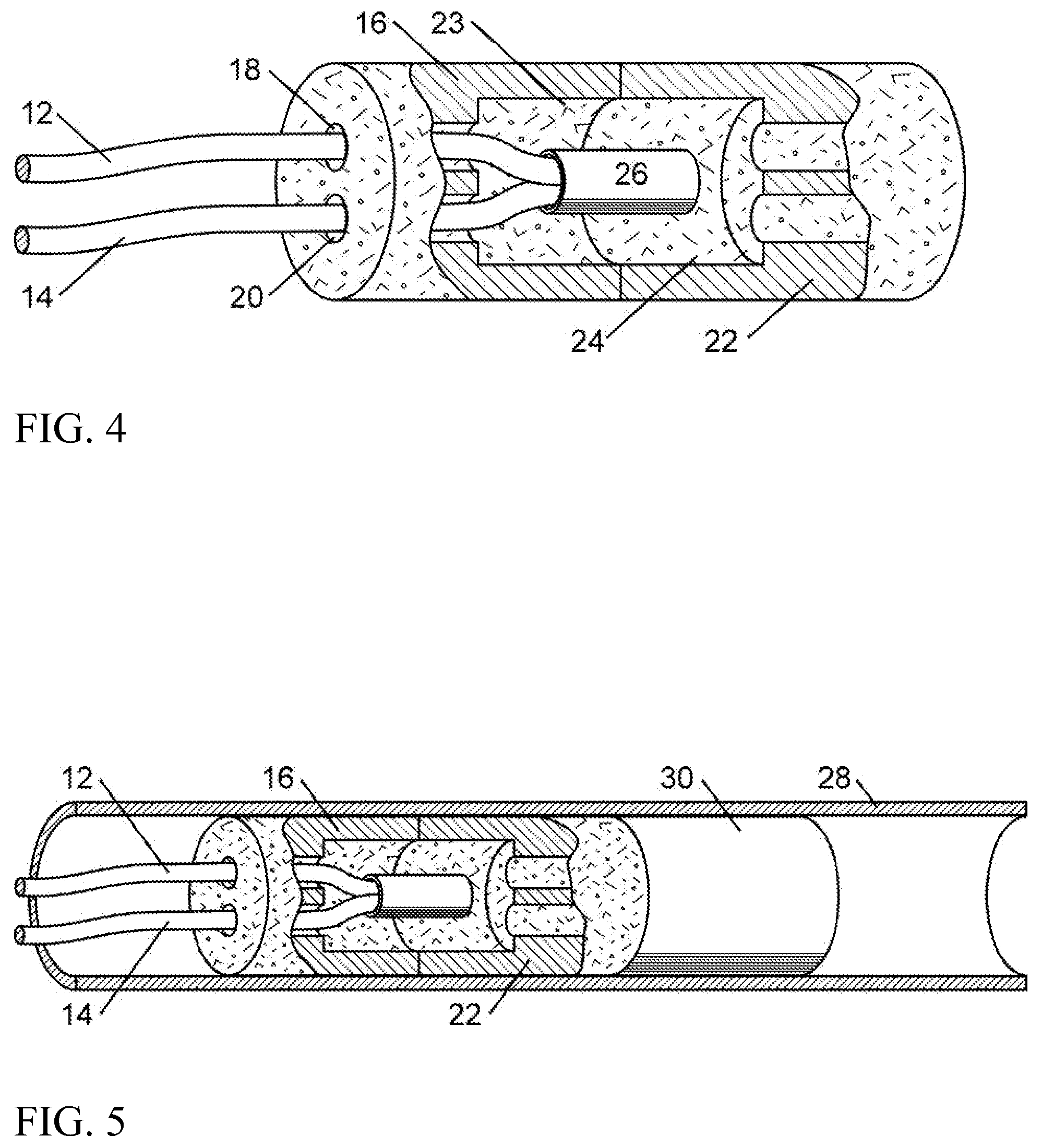

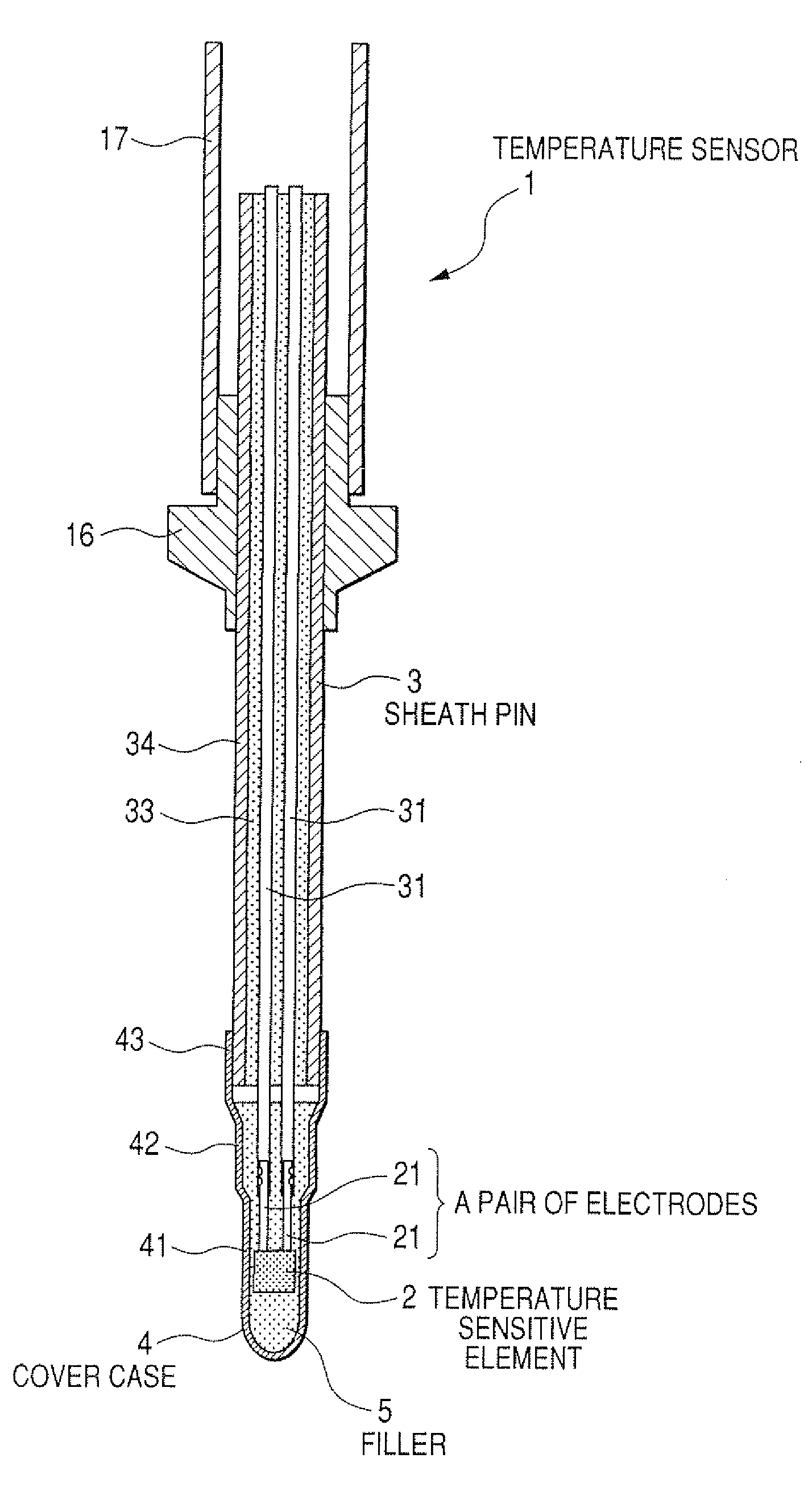

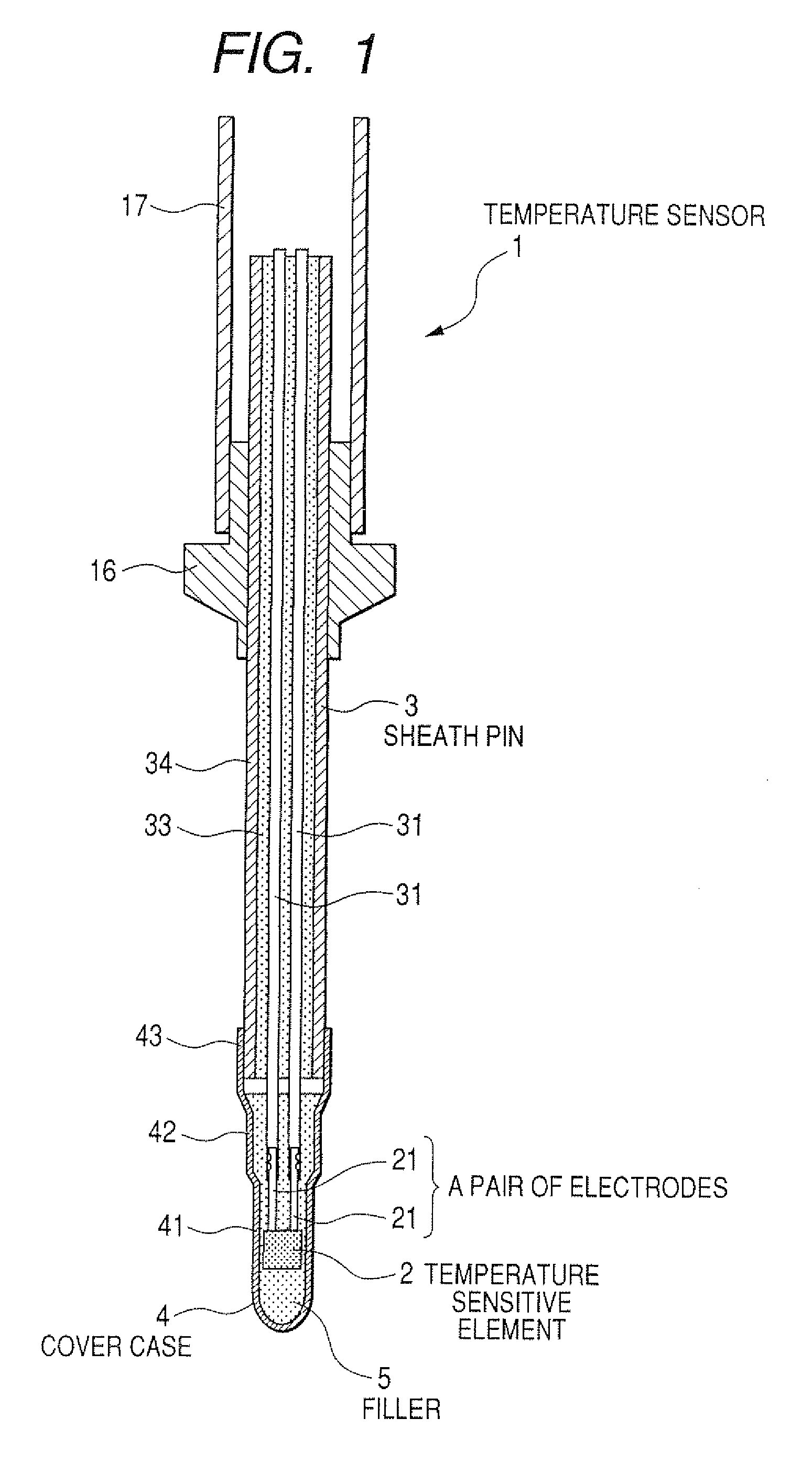

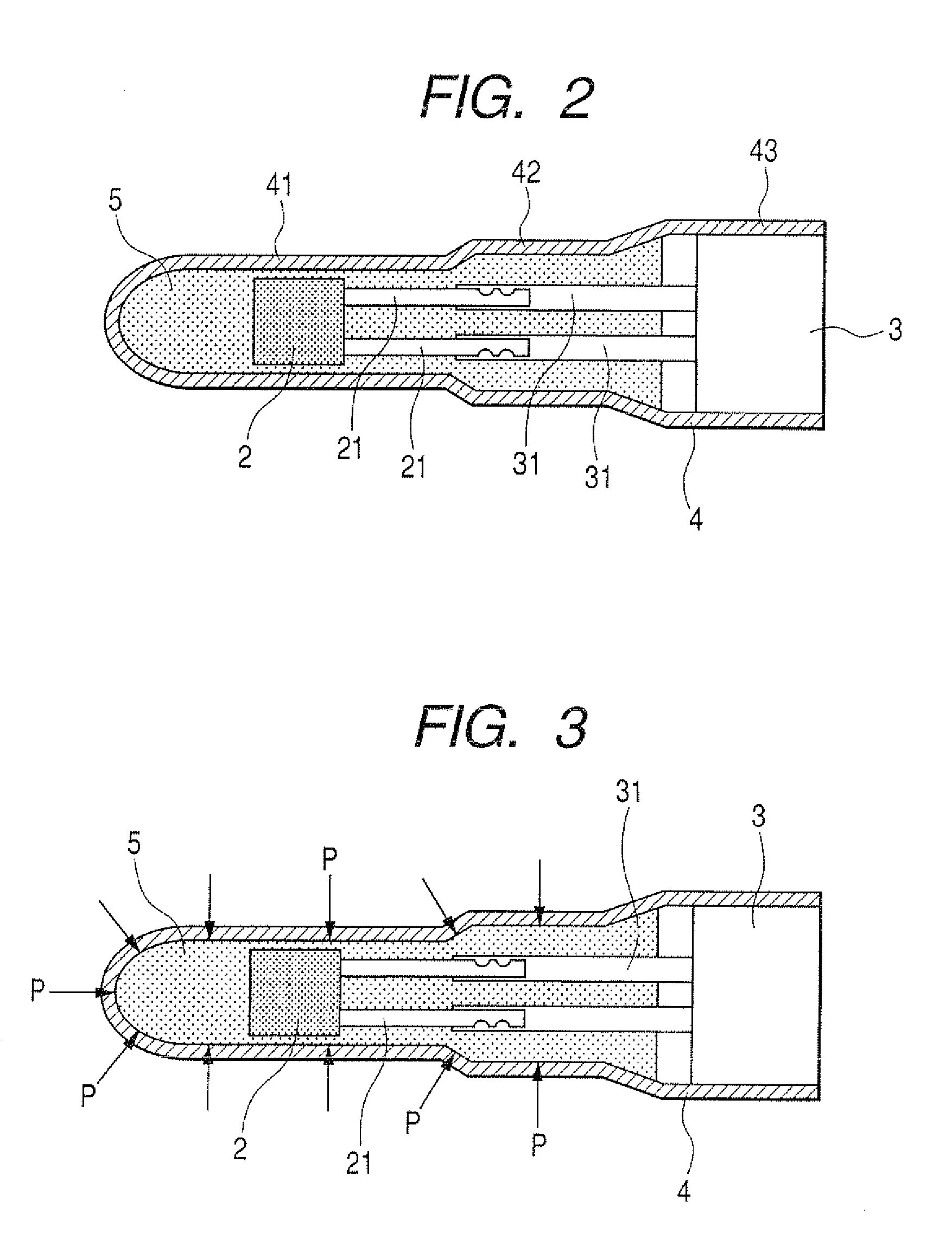

Temperature sensor and method of producing the temperature sensor

ActiveUS20080205484A1Avoid breakingImprove breathabilityThermometer detailsLine/current collector detailsPorosityElectrical resistance and conductance

In a temperature sensor having a temperature sensitive element, a sheath pin connected to the temperature sensitive element, and a cover case. The cover case, filled with a filler, accommodates the temperature sensitive element and the sheath pin. A hardening temperature of the filler is not less than an actual usage environment of the temperature sensor. Another temperature sensor has a temperature sensitive element exposed at a high temperature of not less than 750° C., a thermistor element, a sheath pin, an anti-vibration filler, and a metal cover case fixed to an end part of the sheath pin. The metal cover case accommodates the sheath pin and the thermistor element. The filler is made of a porous insulation material having a pore ratio within a range of 30 to 70% and filled around the thermistor element in the metal cover case.

Owner:DENSO CORP

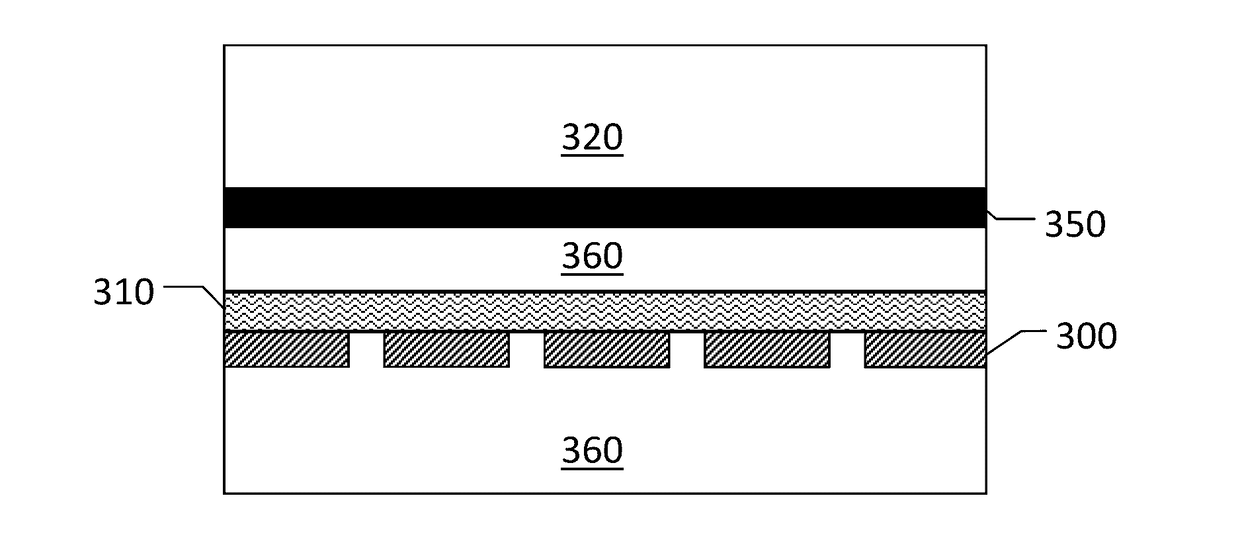

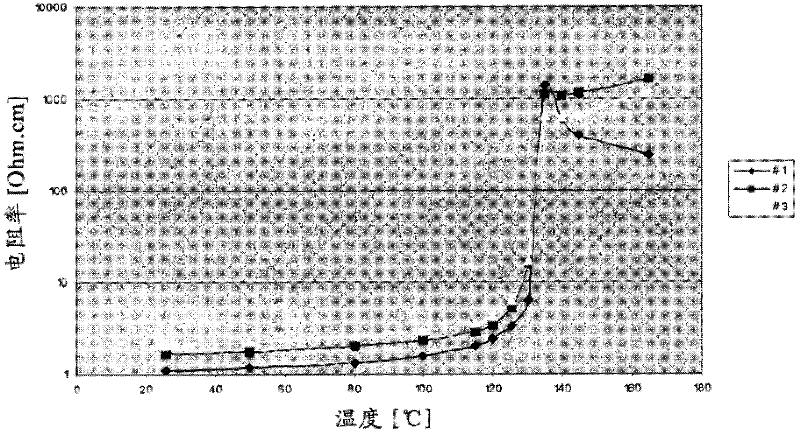

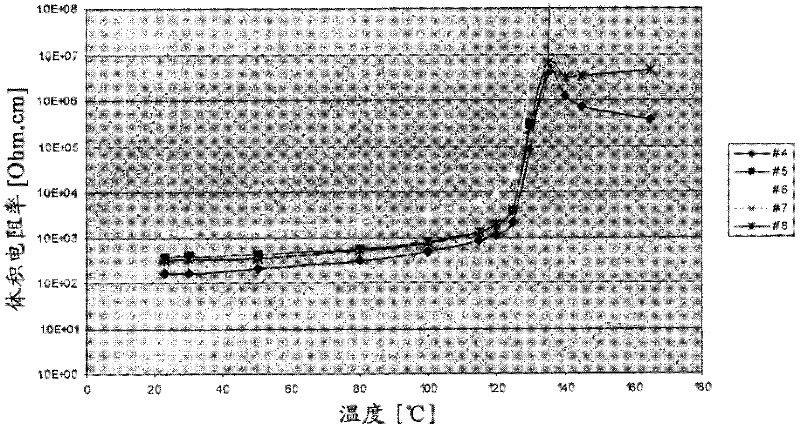

Electrically conductive PTC ink with double switching temperatures and applications thereof in flexible double-switching heaters

ActiveUS20170158898A1Eliminate the effects ofHigh PTC characteristicLighting and heating apparatusIce productionPolyesterCarbon composites

A double-switching heater includes a double-switching PTC ink deposited on a substrate to form one or more resistors. The double-switching PTC ink has a first resin that provides a first PTC effect at a first temperature range and a second resin that provides a second PTC effect at a second temperature range, where the second temperature range is higher than the first temperature range. The substrate may be a flexible substrate or a rigid substrate, and may bedeformable to generate a three-dimensional structure. The substrate may be: polyester, polyimide, polyamide, polypropylene, thermoplastic polyurethane, fiberglass, cement board, carbon composite materials, polyethylene terephthalate, polyethylene, aluminum, steel, glass composite, molded plastic, high-density polyethylene or styrene ethylene butylene styrene.

Owner:LMS CONSULTING GRP LLC

Organic positive temperature coefficient thermistor

InactiveUS6299801B1Suitable melting pointMelt viscosityHeater elementsConductive materialHysteresisPolymer science

The invention provides an organic positive temperature coefficient thermistor comprising at least two polymer matrices, a low-molecular organic compound and a conductive particle having spiky protuberances. For the polymer matrices, at least two thermoplastic polymer matrices having varying melting points or at least one thermoplastic polymer matrix and at least one thermosetting polymer matrix are used. It is thus possible to provide an organic positive temperature coefficient thermistor which has sufficiently low room-temperature resistance and a large rate of resistance change between an operating state and a non-operating state, and can operate with a reduced temperature vs. resistance curve hysteresis, ease of control of operating temperature, and high performance stability.

Owner:TDK CORPARATION

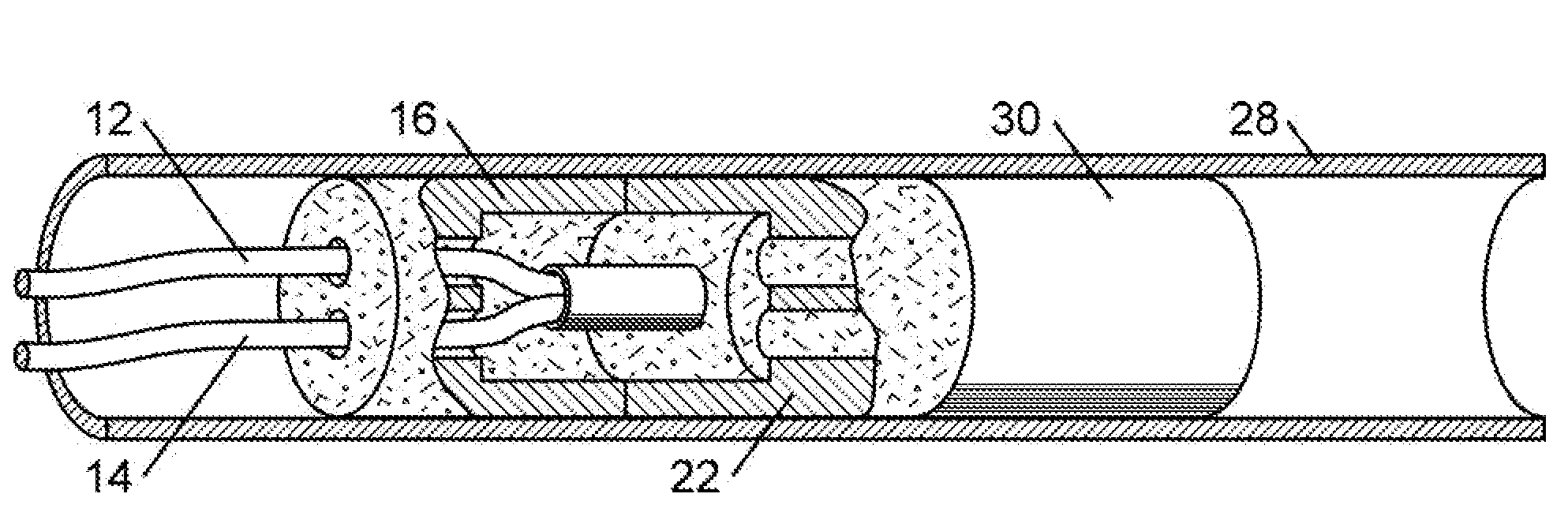

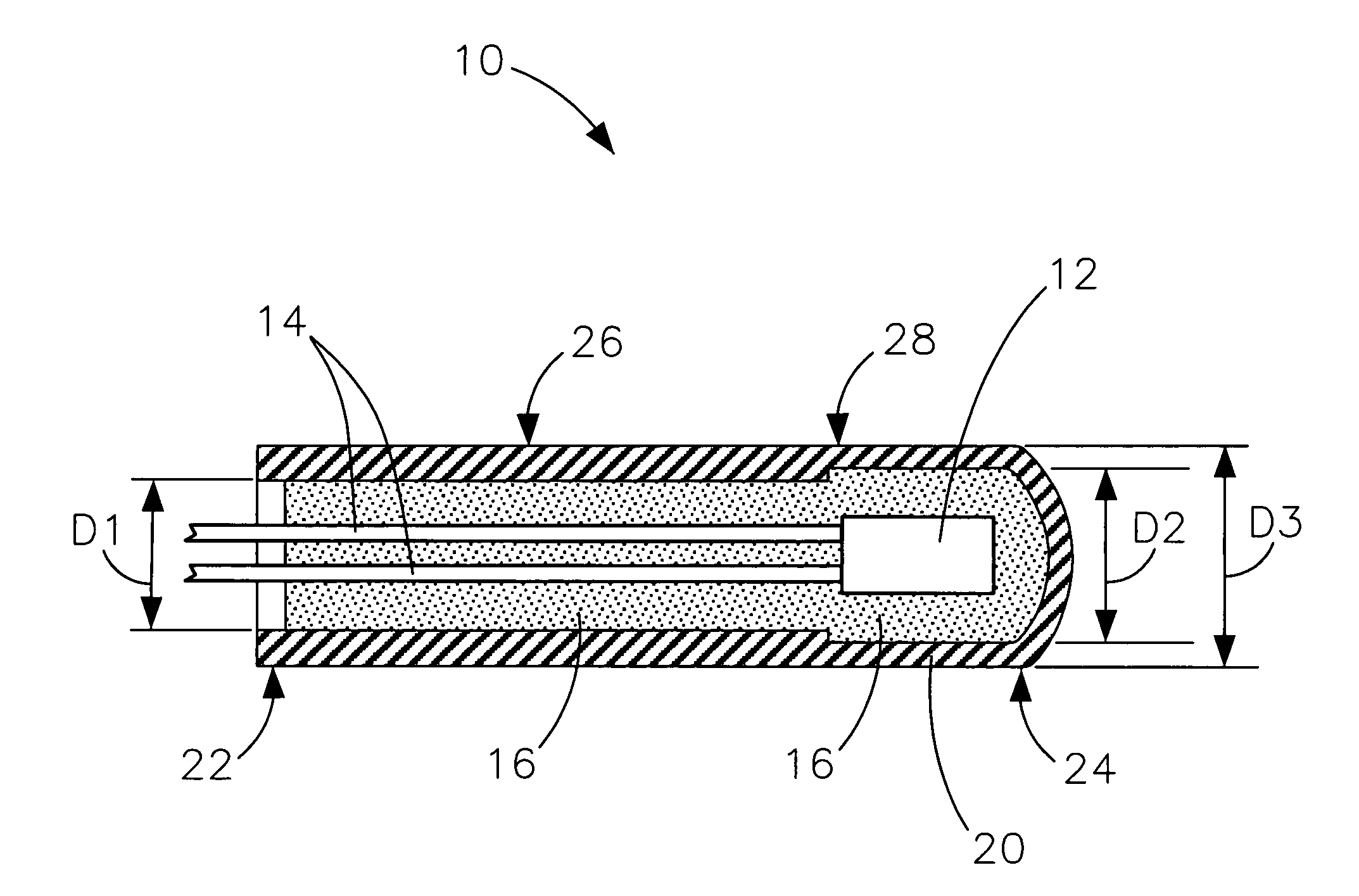

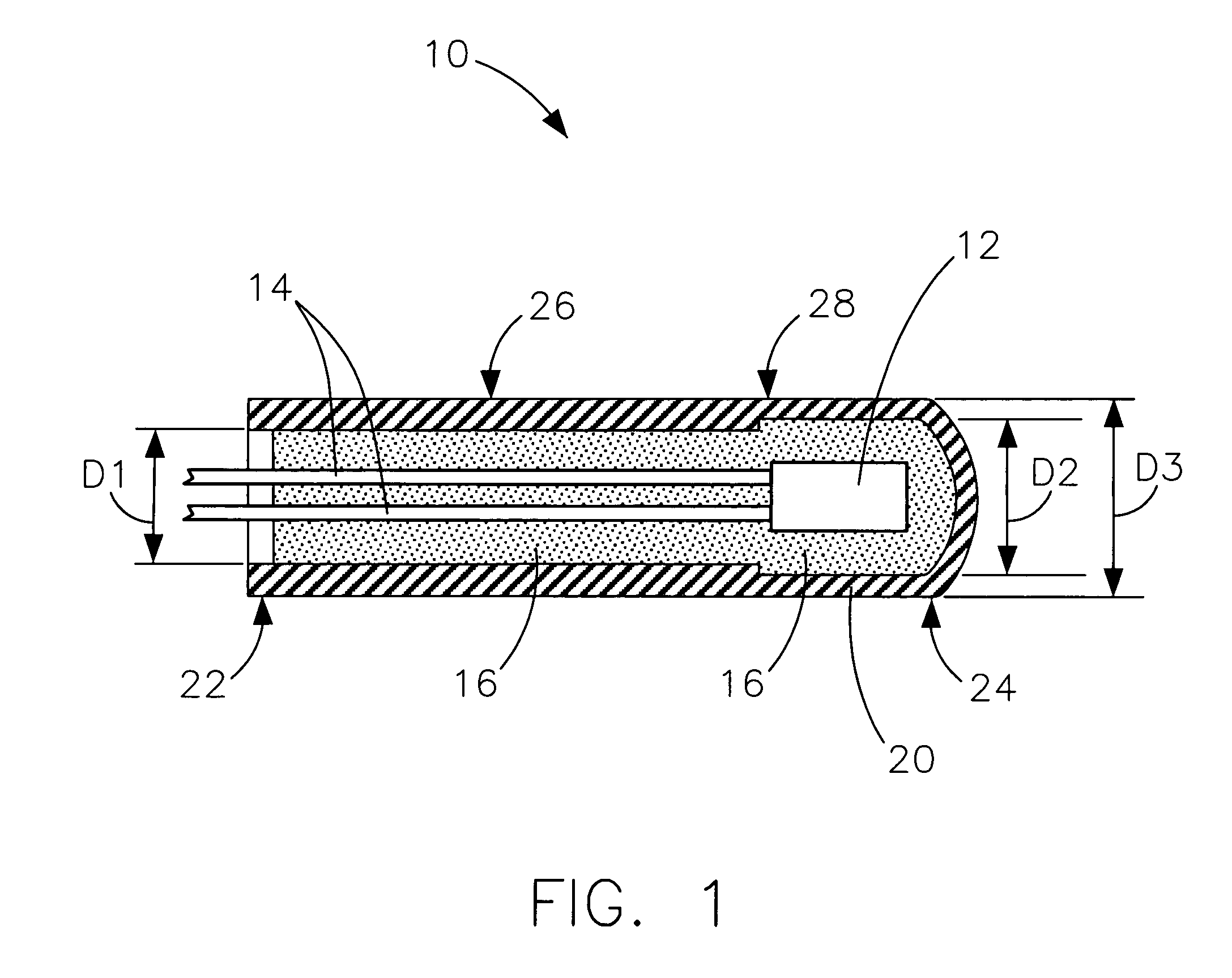

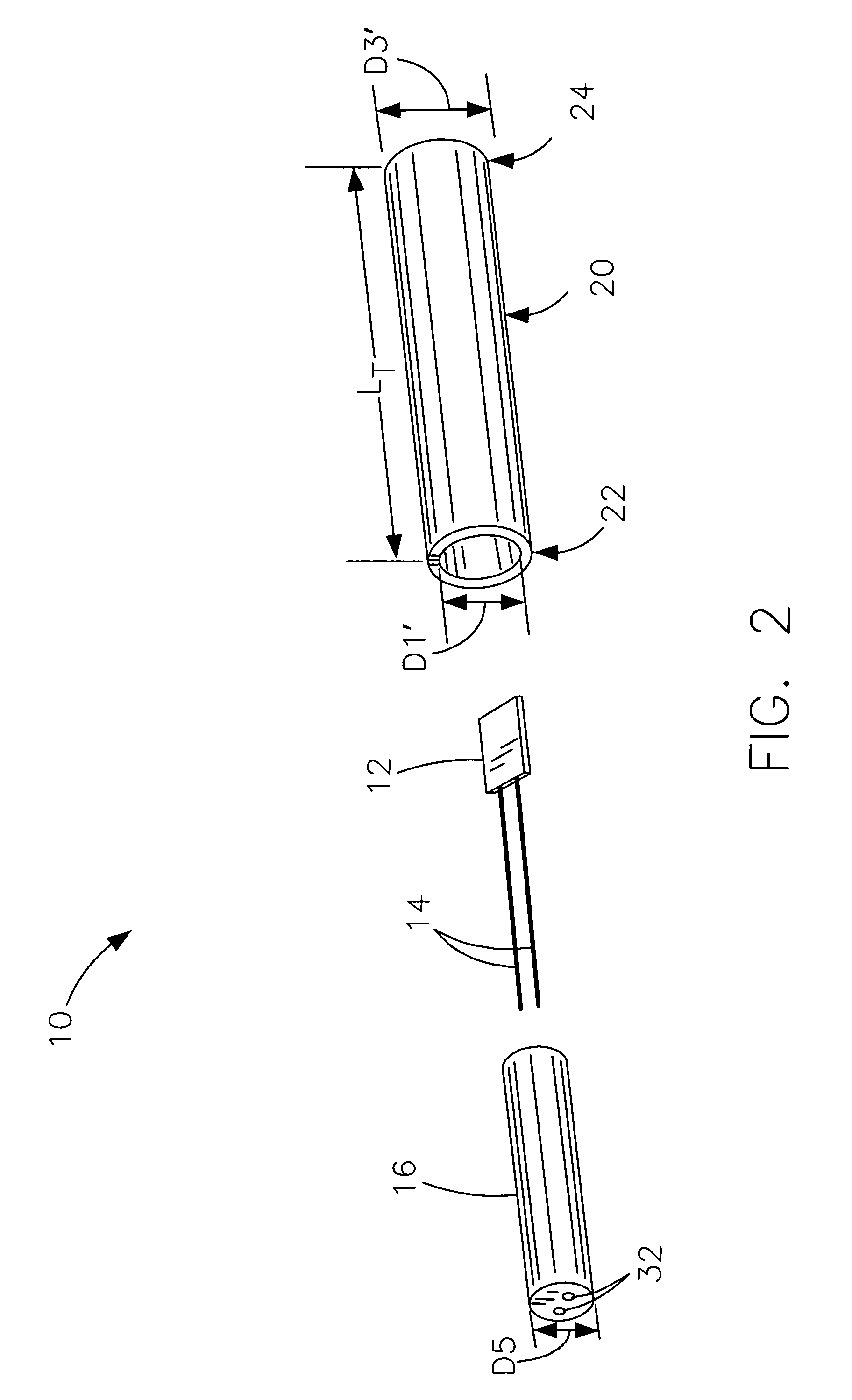

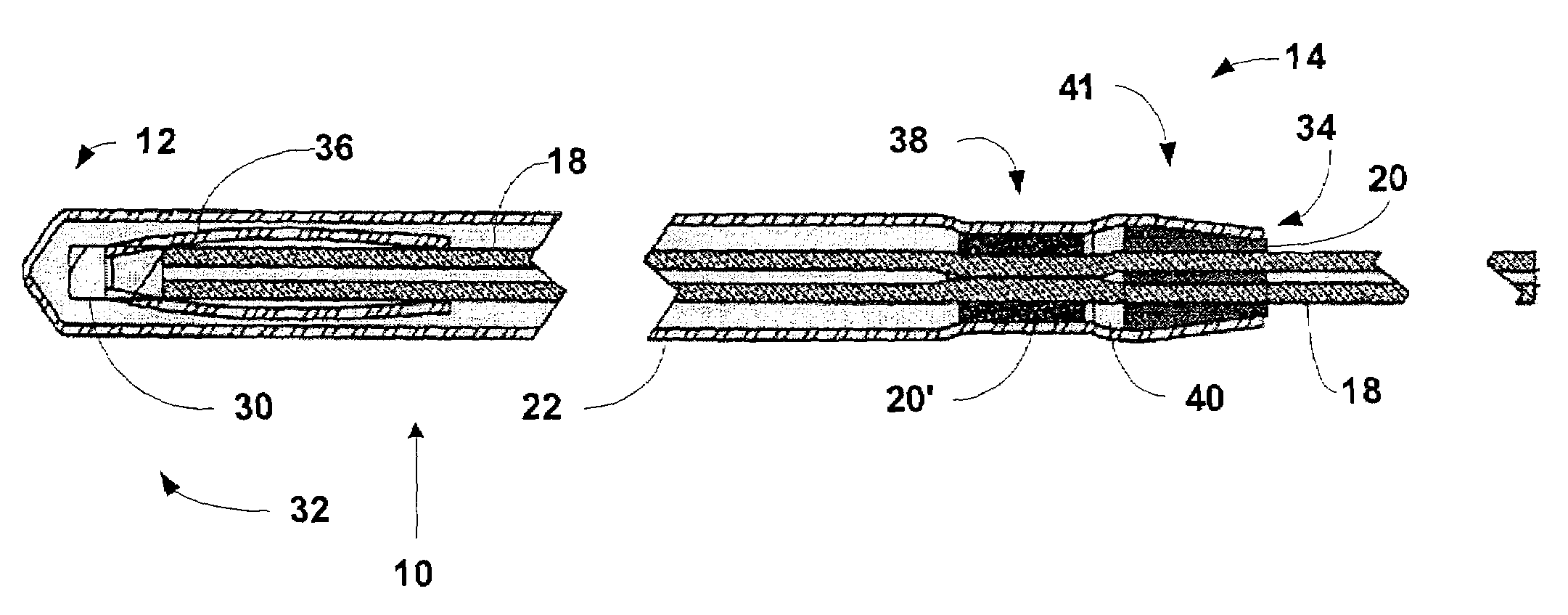

Temperature sensor and method of manufacturing

ActiveUS7855632B1Improved property against impactIncrease vibrationThermometer detailsThermometers using electric/magnetic elementsEngineeringElectrical and Electronics engineering

A temperature sensor includes an autonomous sensing element and a plurality of conductive wires connected to the sensing element. An electrical insulator surrounds the sensing element and the conductive wires for firmly holding the sensing element and conductive wires. The insulator includes substantially crushed and compacted powder insulation. A tube encases the insulator in a compressed manner and has a first end, a second end, a first portion having a first inside diameter located in the proximity of the first end and a second portion having a second inside diameter. The second inside diameter being greater than the first inside diameter. The sensing element is positioned within the second portion of the tube. Methods of manufacturing a temperature sensor are also included.

Owner:WATLOW ELECTRIC MFG

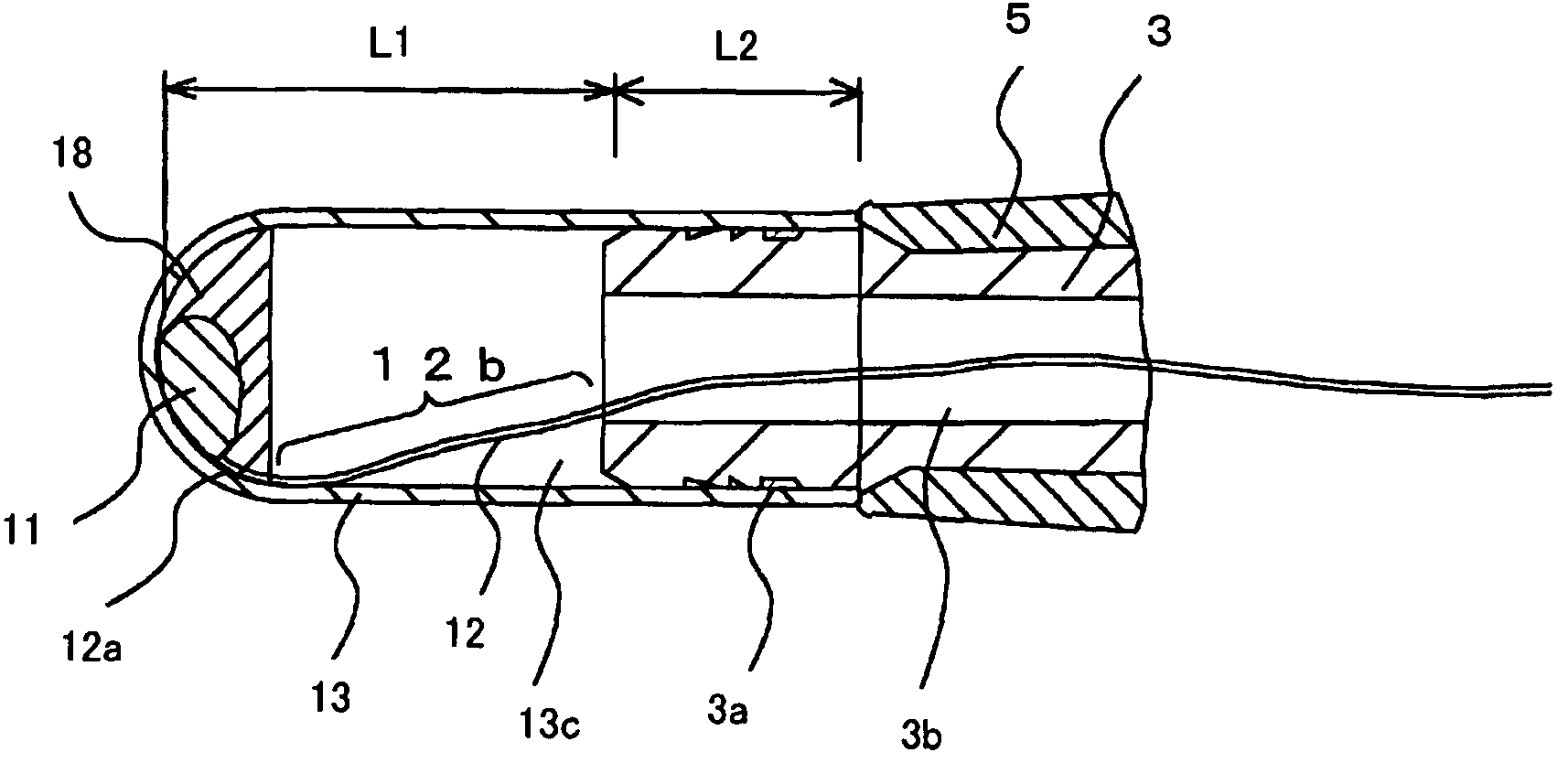

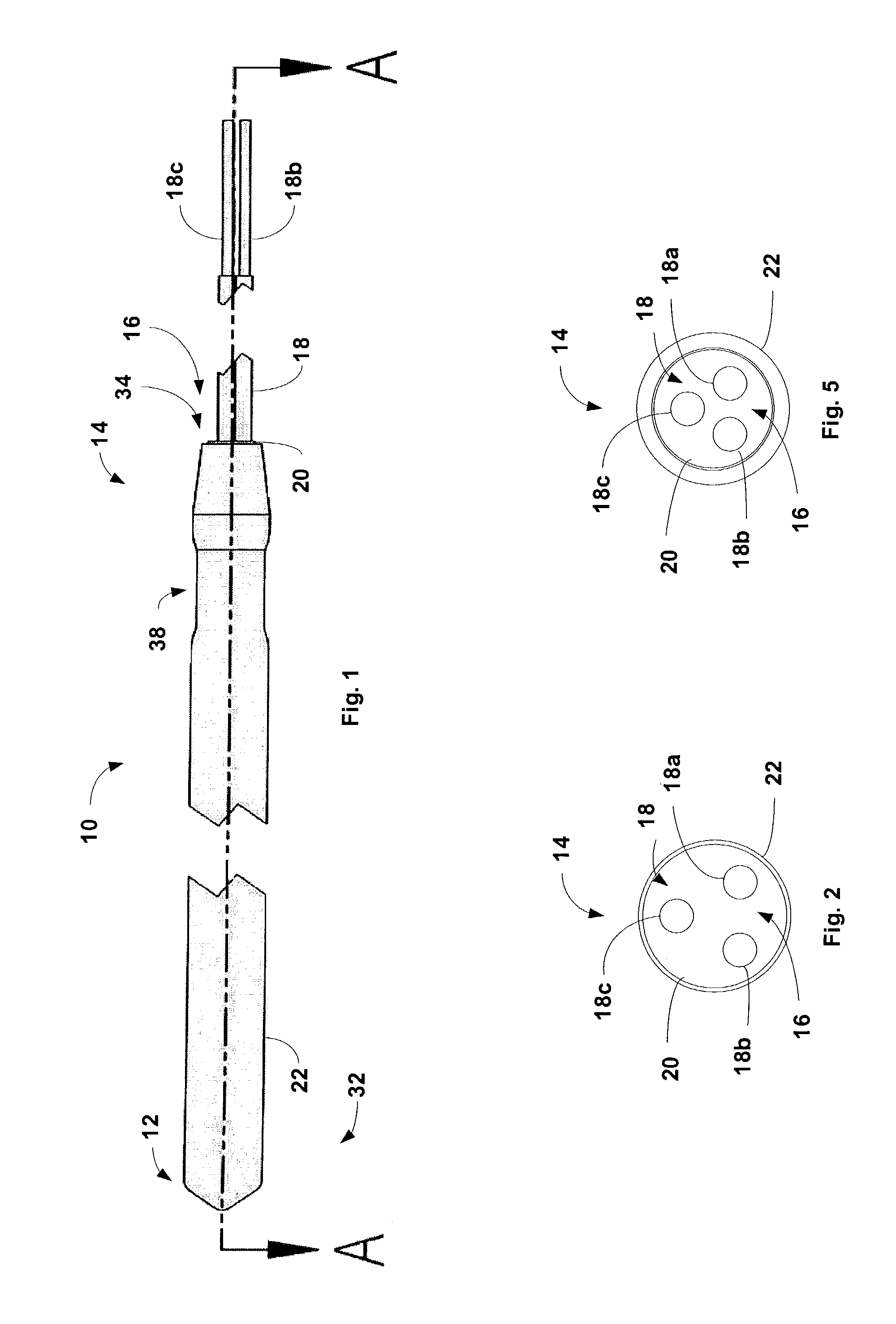

End seal design for temperature sensing probes

InactiveUS7060949B1Efficiently provideThermometer detailsOhmic-resistance waterproof/air-tight sealsEngineeringHeating element

An end seal for a temperature sensing probe. Electrical interface wiring is passed through a restraining element and is operatively coupled to a temperature sensing element or heater element mounted in the sheath. The sheath is formed around the restraining element in a shape that provides a net force inward as temperature variations expand and contract the restraining element.

Owner:WATLOW ELECTRIC MFG

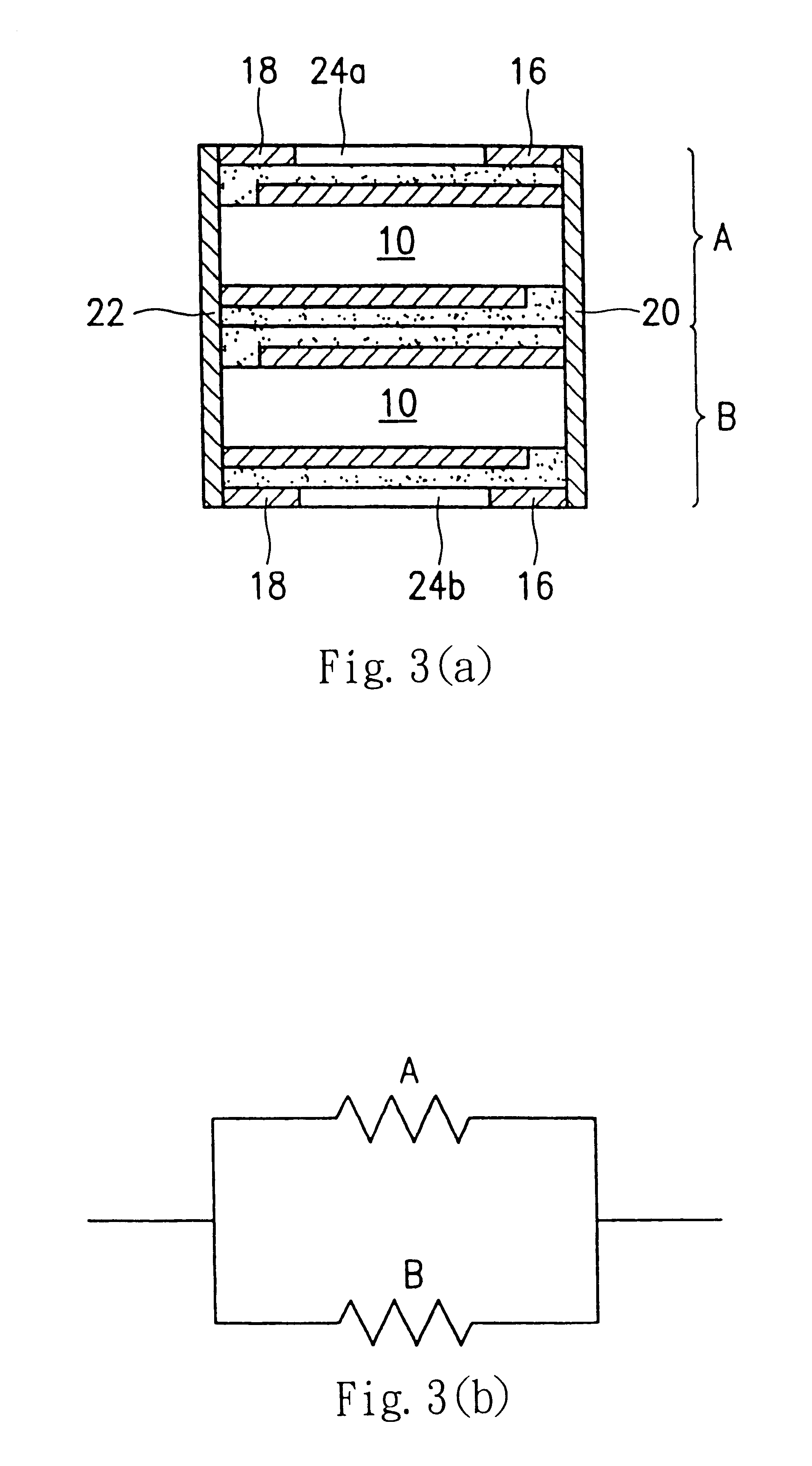

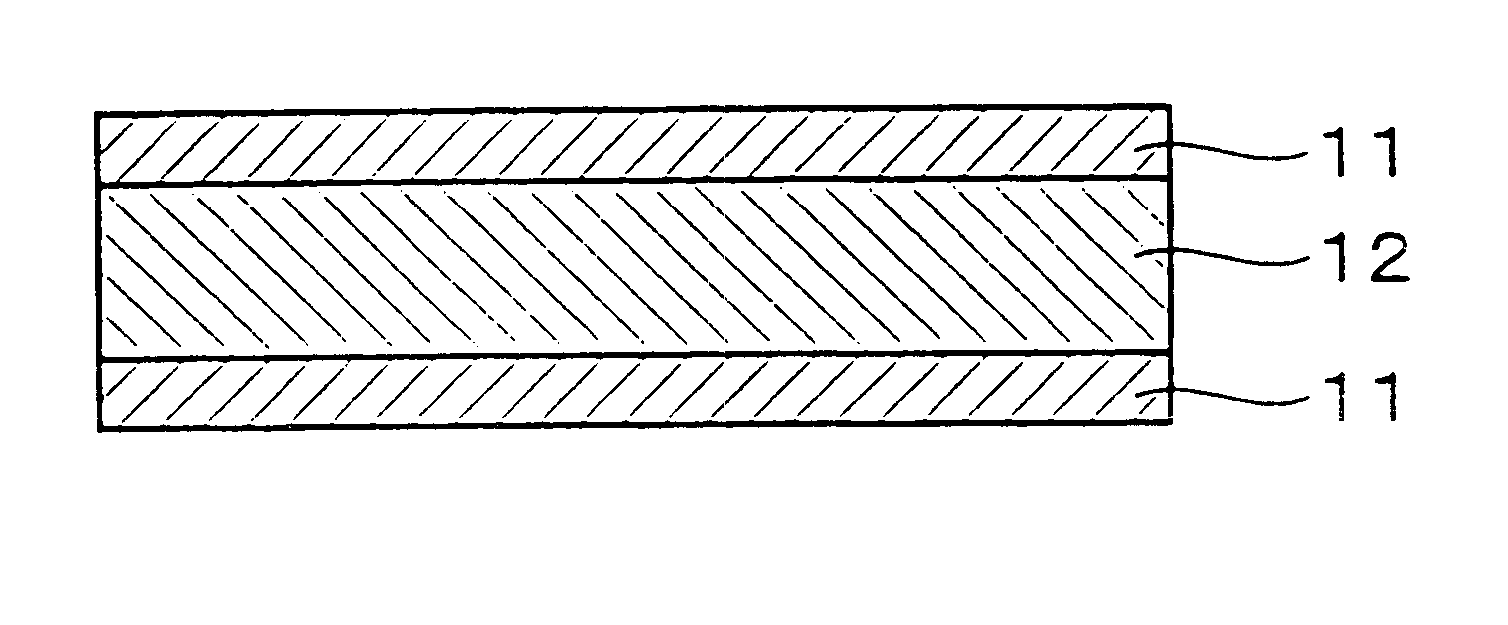

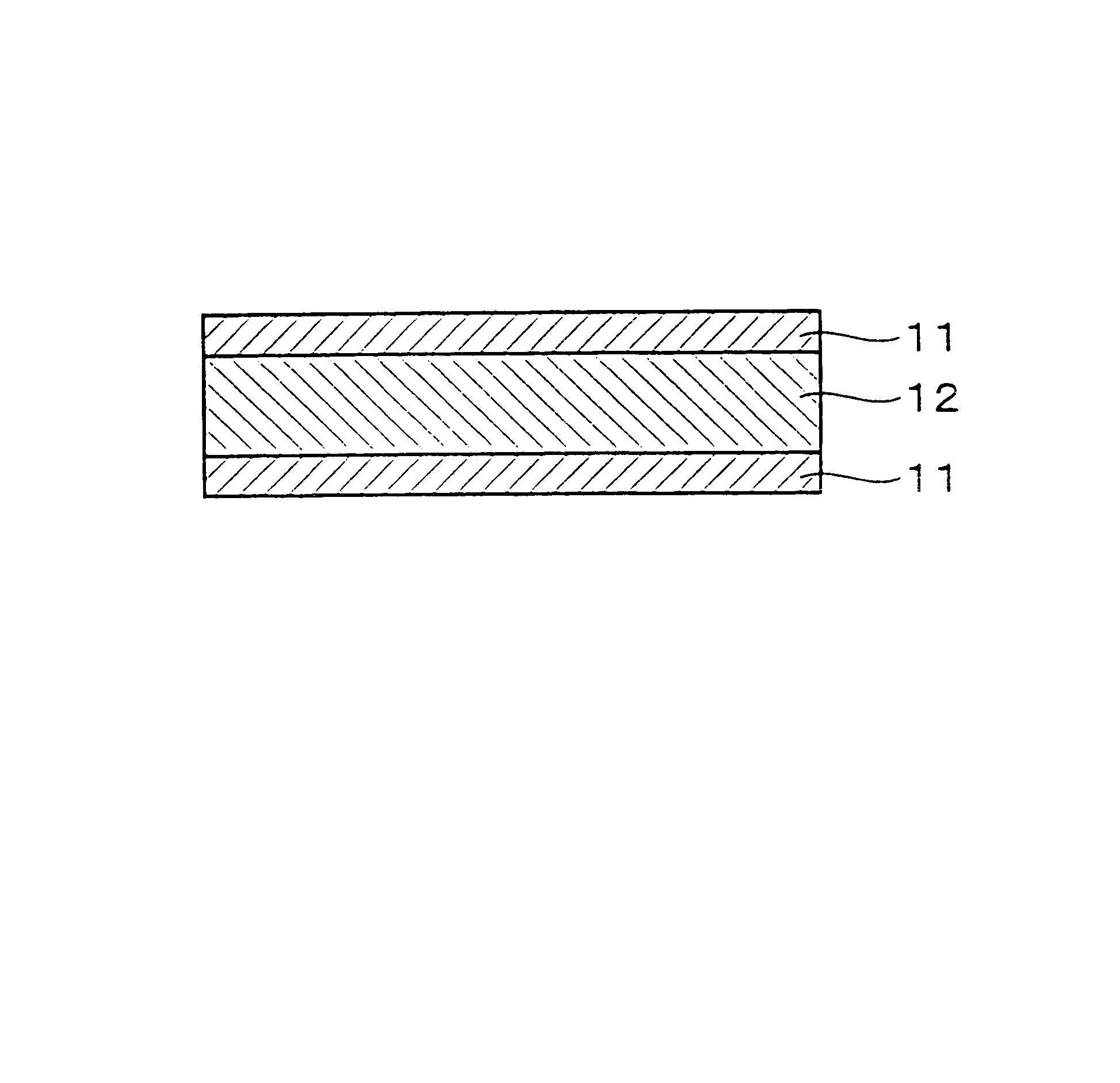

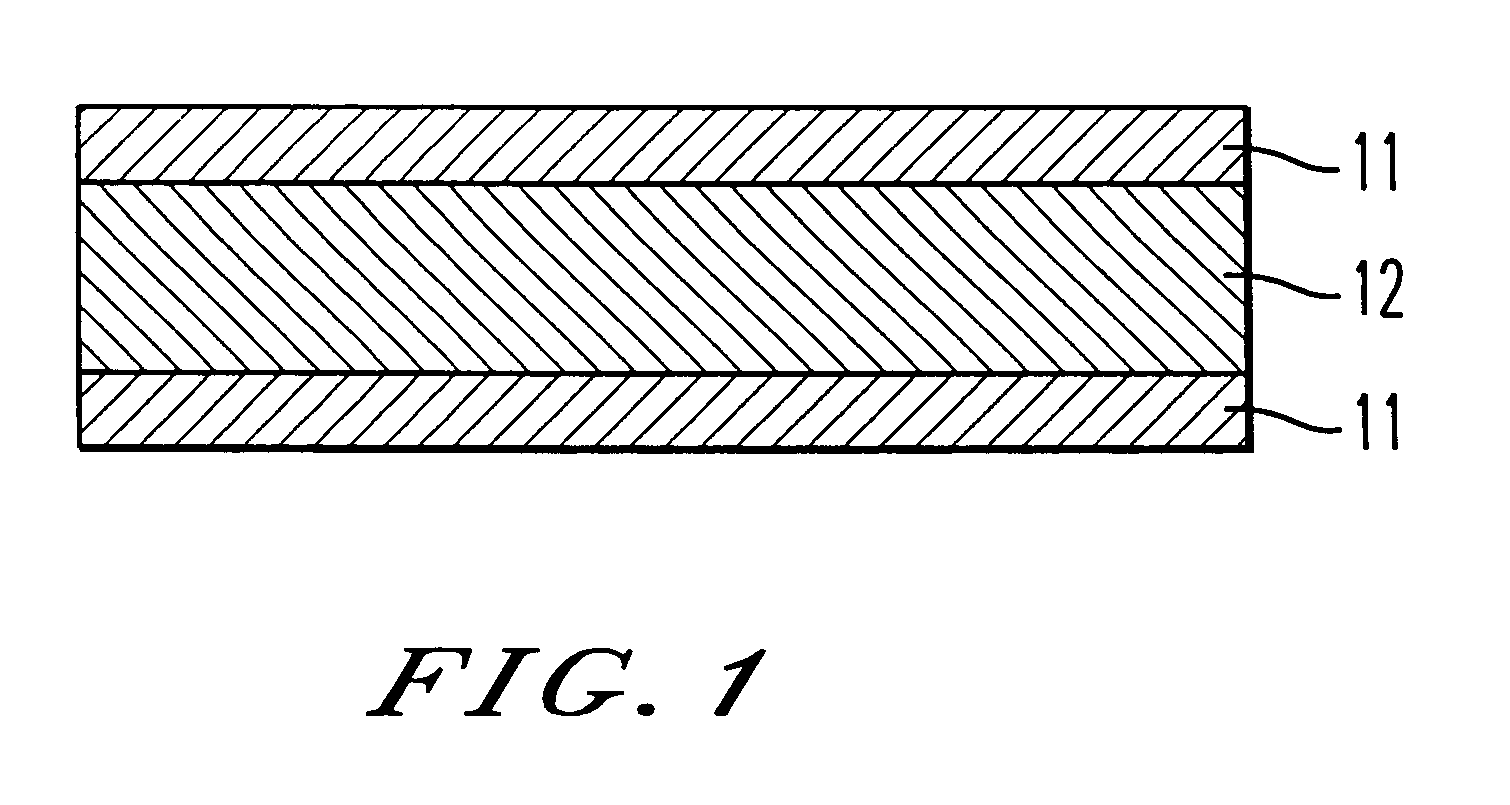

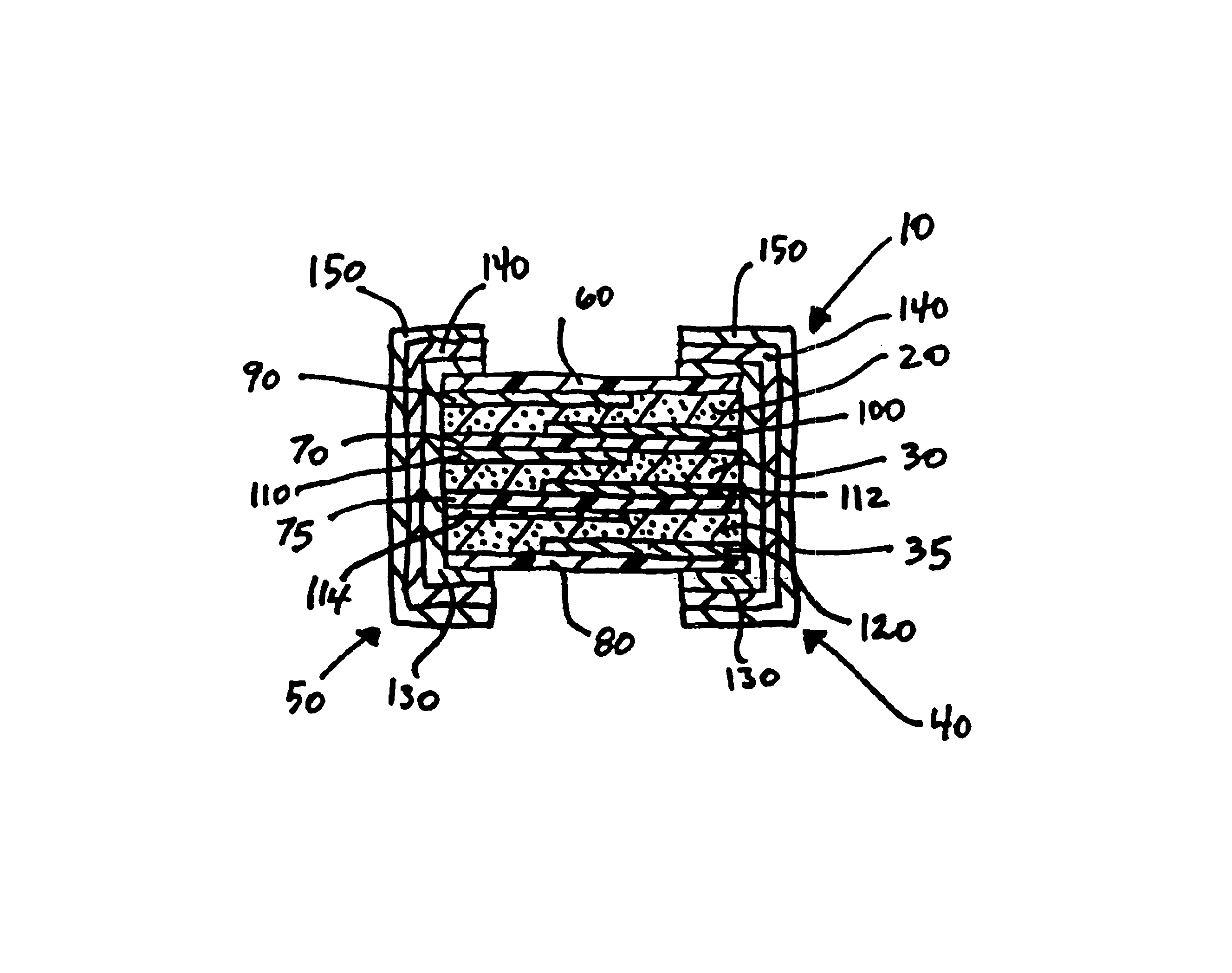

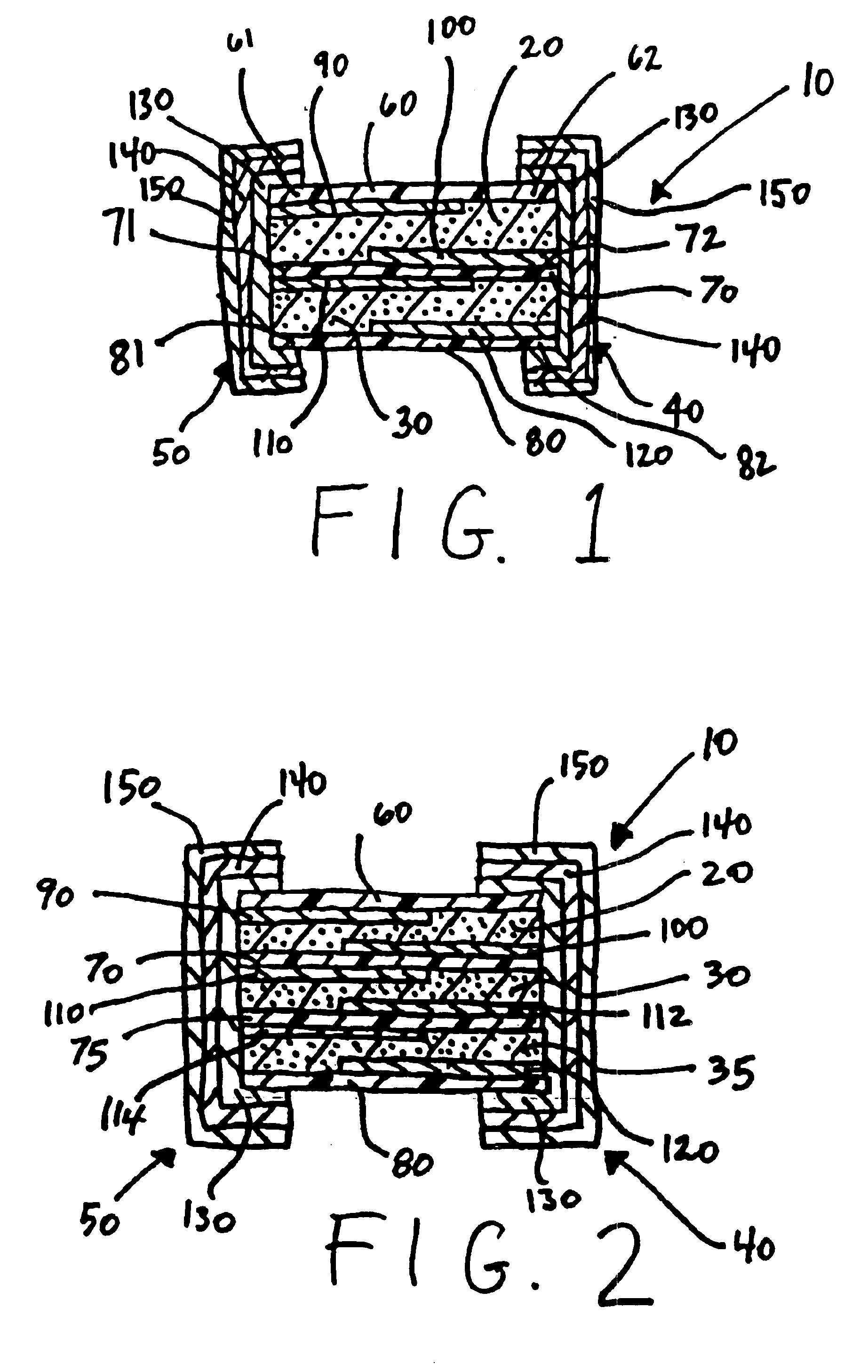

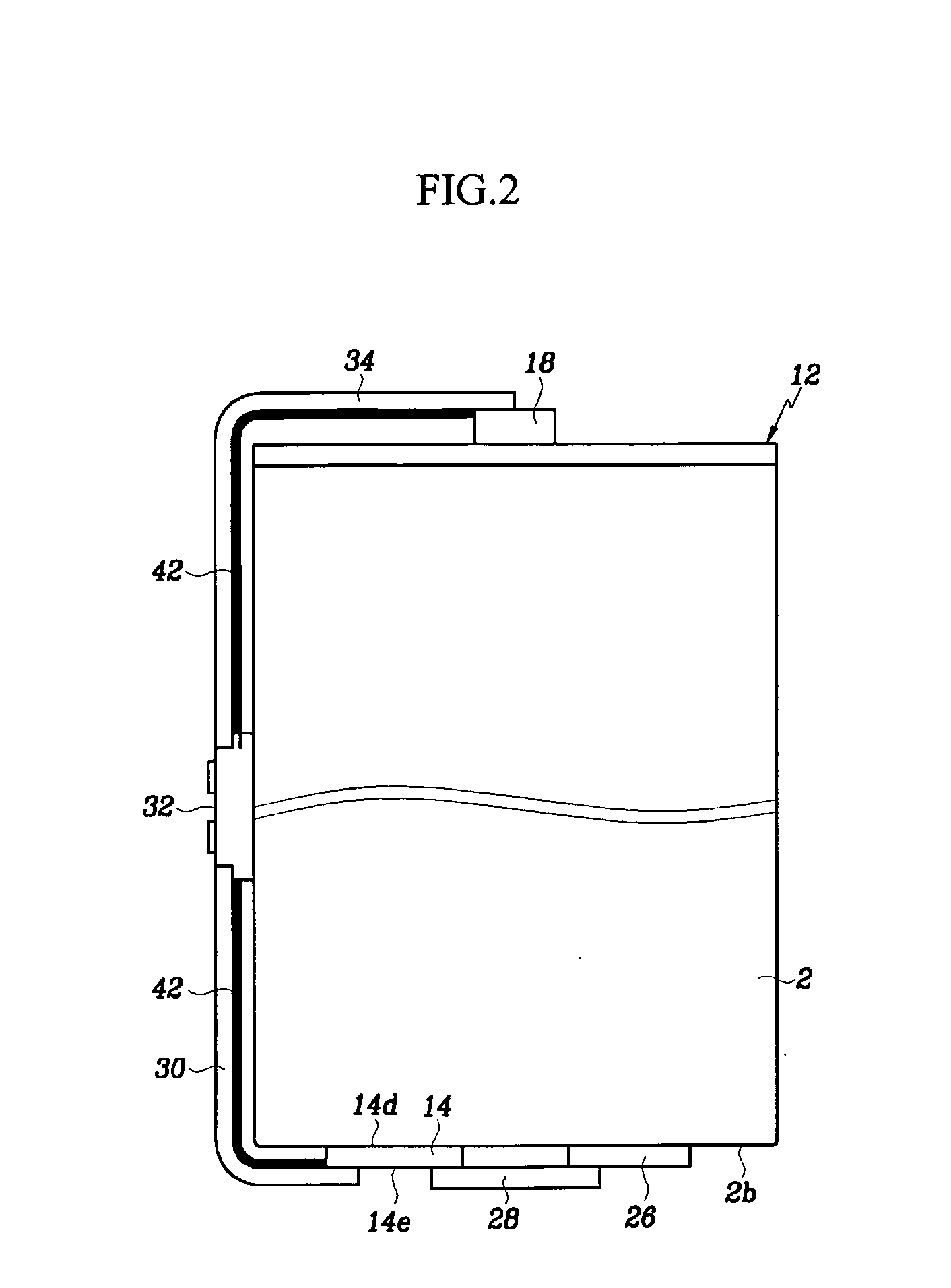

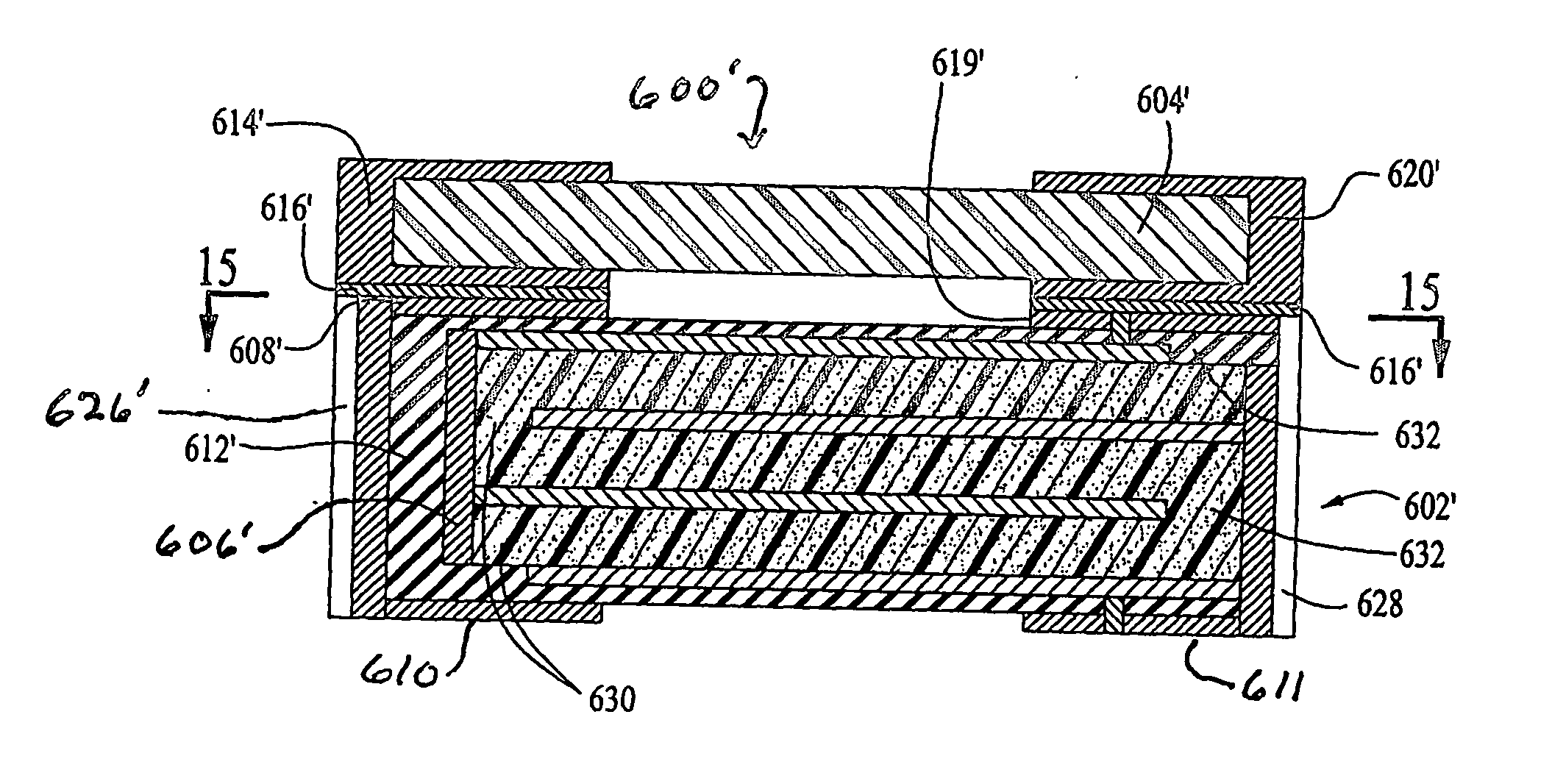

PTC circuit protection devices

InactiveUS6838972B1Large capacityIncrease ratingsResistor chip manufactureResistor terminals/electrodesEngineeringElectrical contacts

An electrical circuit protection device with three supporting substrates, two PTC elements, and first and second end terminations. The first and third substrates have an electrode formed on a first surface thereof. The second substrate has electrodes formed on both surfaces thereof. The first PTC element is laminated between the first and second substrates, electrically connecting thefirst electrodes formed on the first and second substrates. The second PTC element is laminated between the second and third substrates, electrically connecting the second electrode formed on the second substrate and the first electrode formed on the third substrate. The end terminations wraps around opposite ends of the device. The first end termination is in electrical contact with the first electrodes formed on the second and third substrates and the second end termination is in electrical contact with the first electrode formed on the first substrate and the second electrode formed on the second substrate. The PTC elements are electrically connected in parallel between the end terminations. The multi-layered configuration allows for an increased electrical rating without increasing the overall footprint, i.e., length and width, of the device.

Owner:LITTELFUSE INC

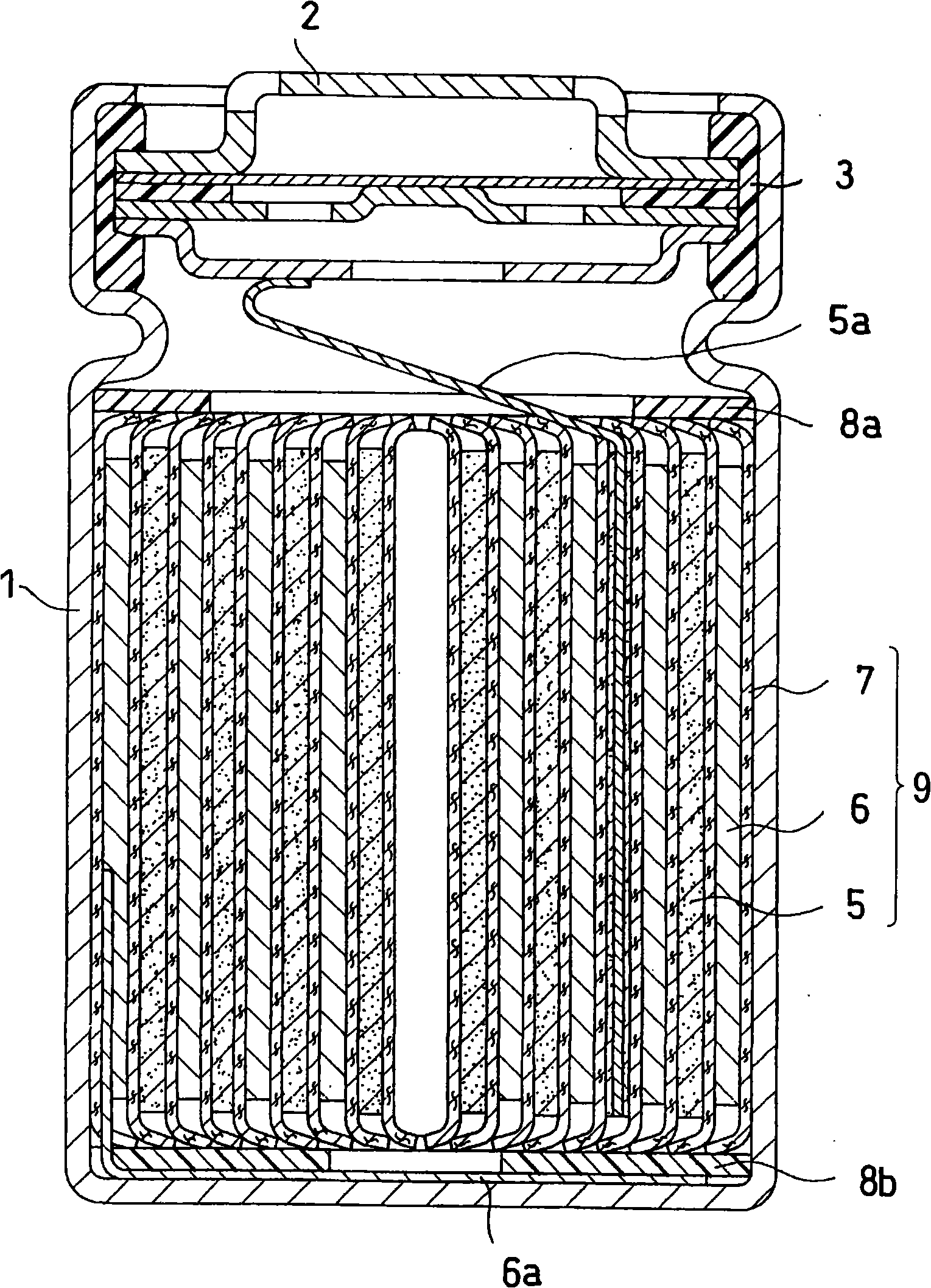

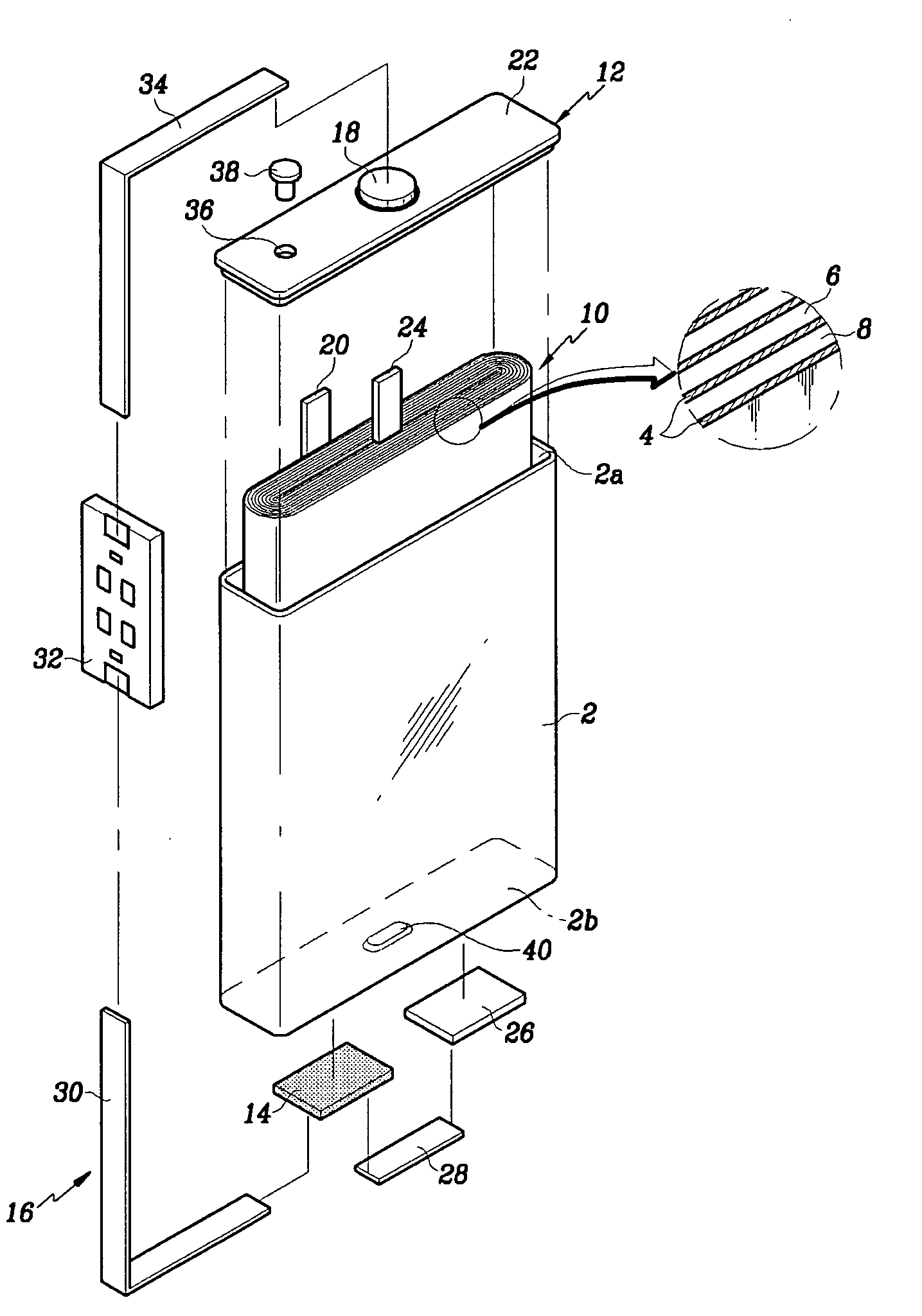

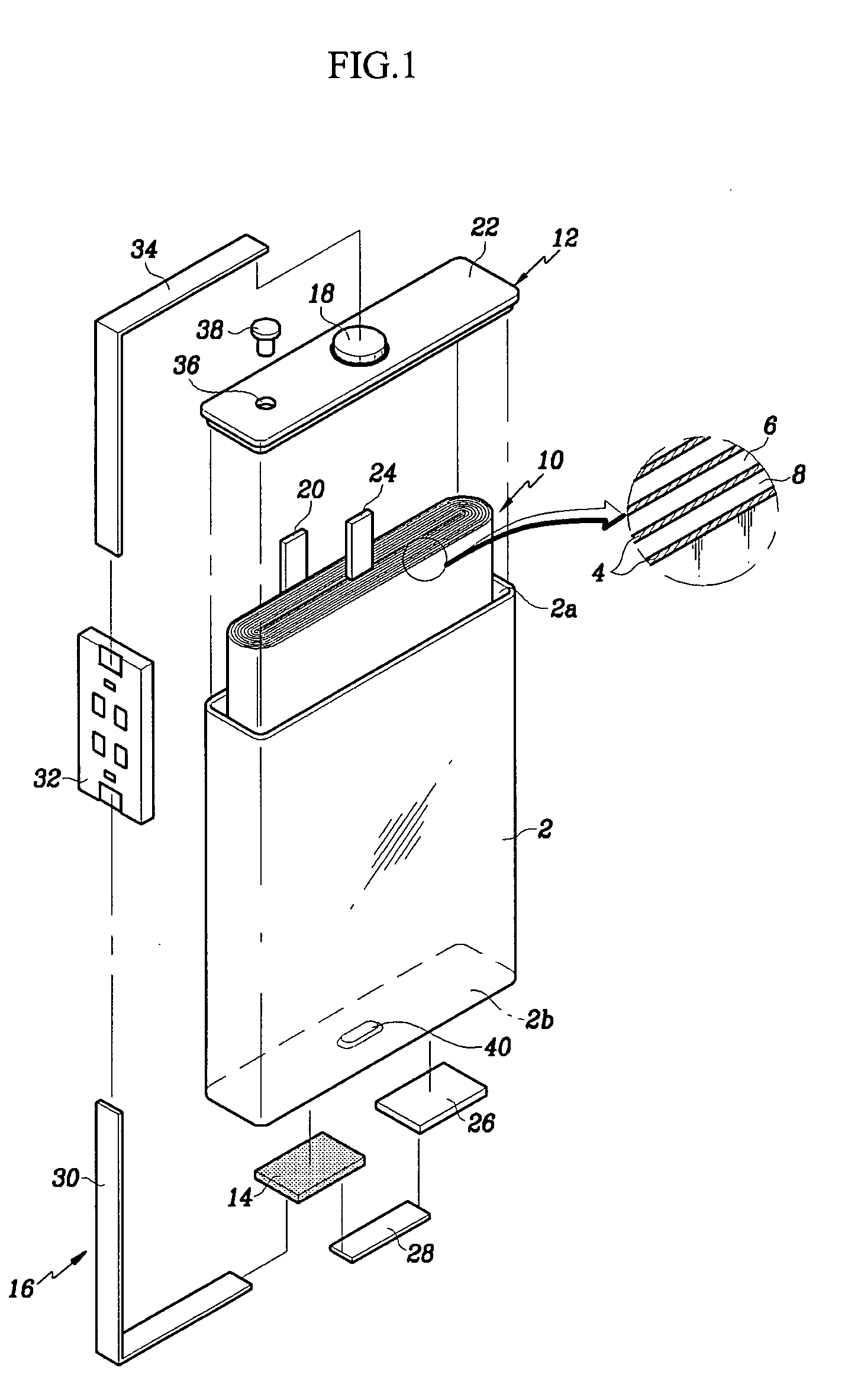

Secondary battery

ActiveUS20040257036A1Batteries circuit arrangementsPrimary cell maintainance/servicingPositive temperatureElectrolyte

A secondary battery includes an electrode assembly having a separating plate interposed between an anode plate and a cathode plate. A container receives the electrode assembly together with an electrolyte. The container is electrically connected to one of the anode plate and the cathode plate. Also, the secondary battery includes a cap assembly having an electrode terminal electrically connected to one of an end of the anode plate and the cathode plate. The cap assembly is fixed to an opening of the container to seal the same. Also included is a safety device having a PTC (positive temperature coefficient) element contacting the container without an element interposed therebetween.

Owner:SAMSUNG SDI CO LTD

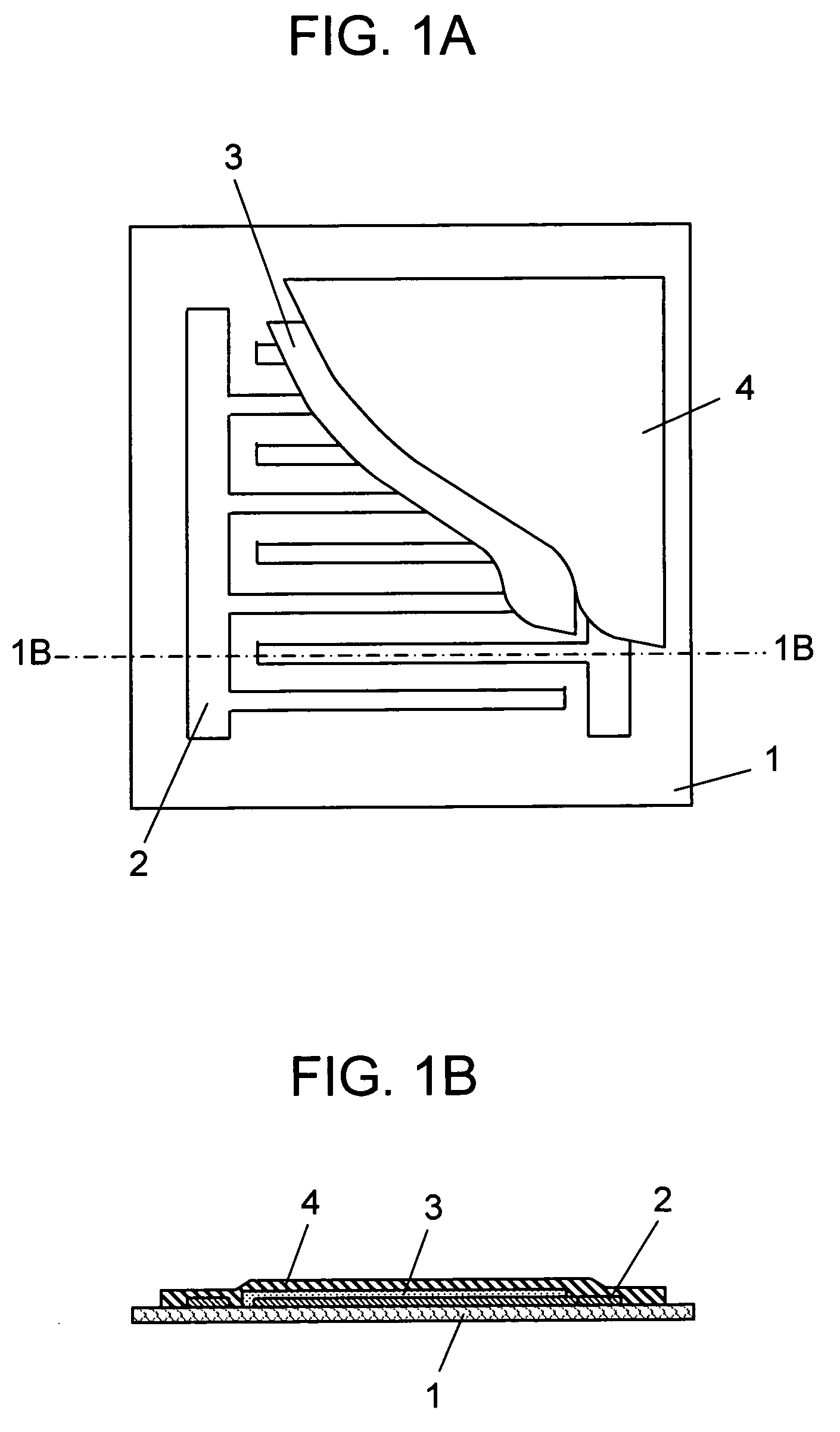

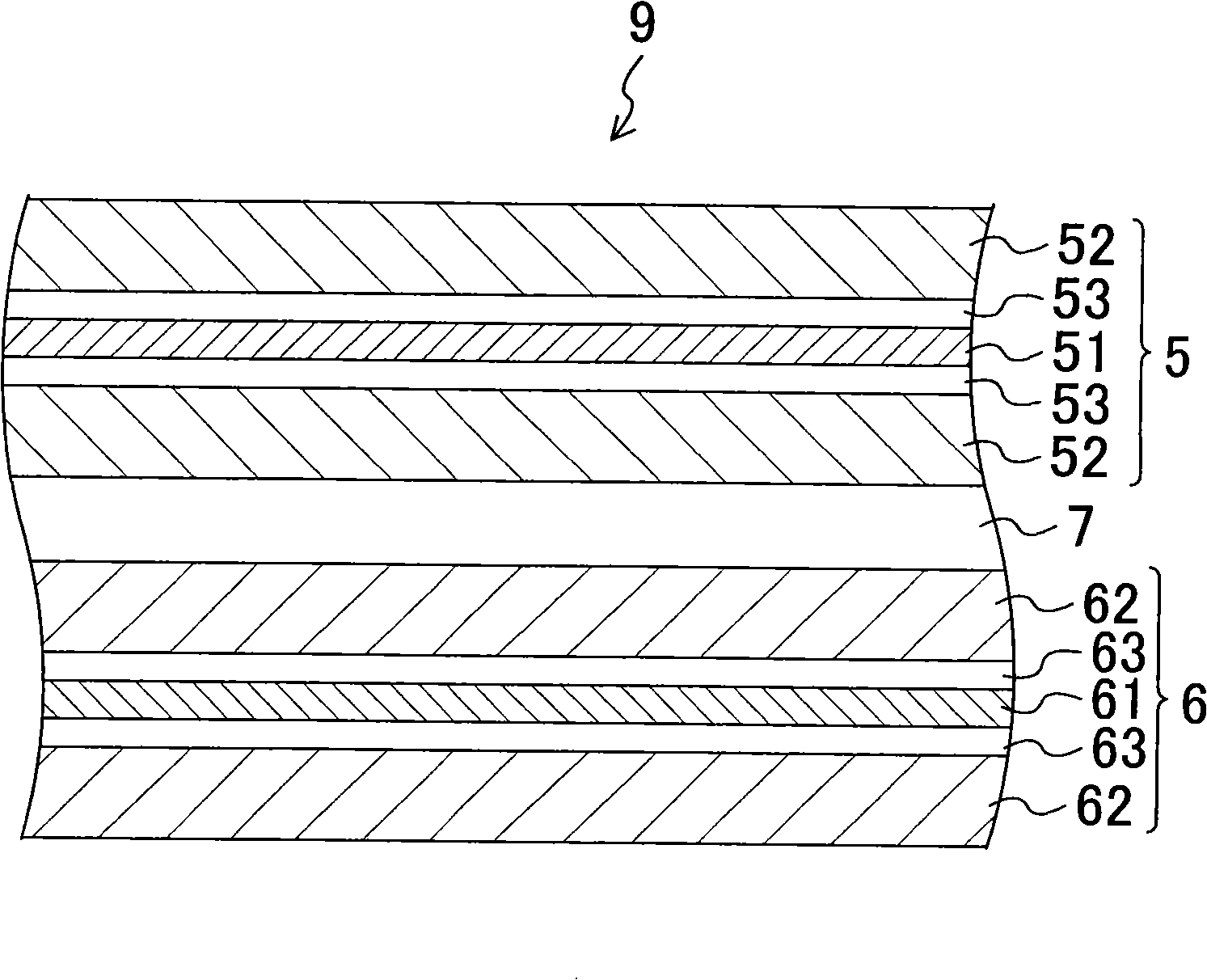

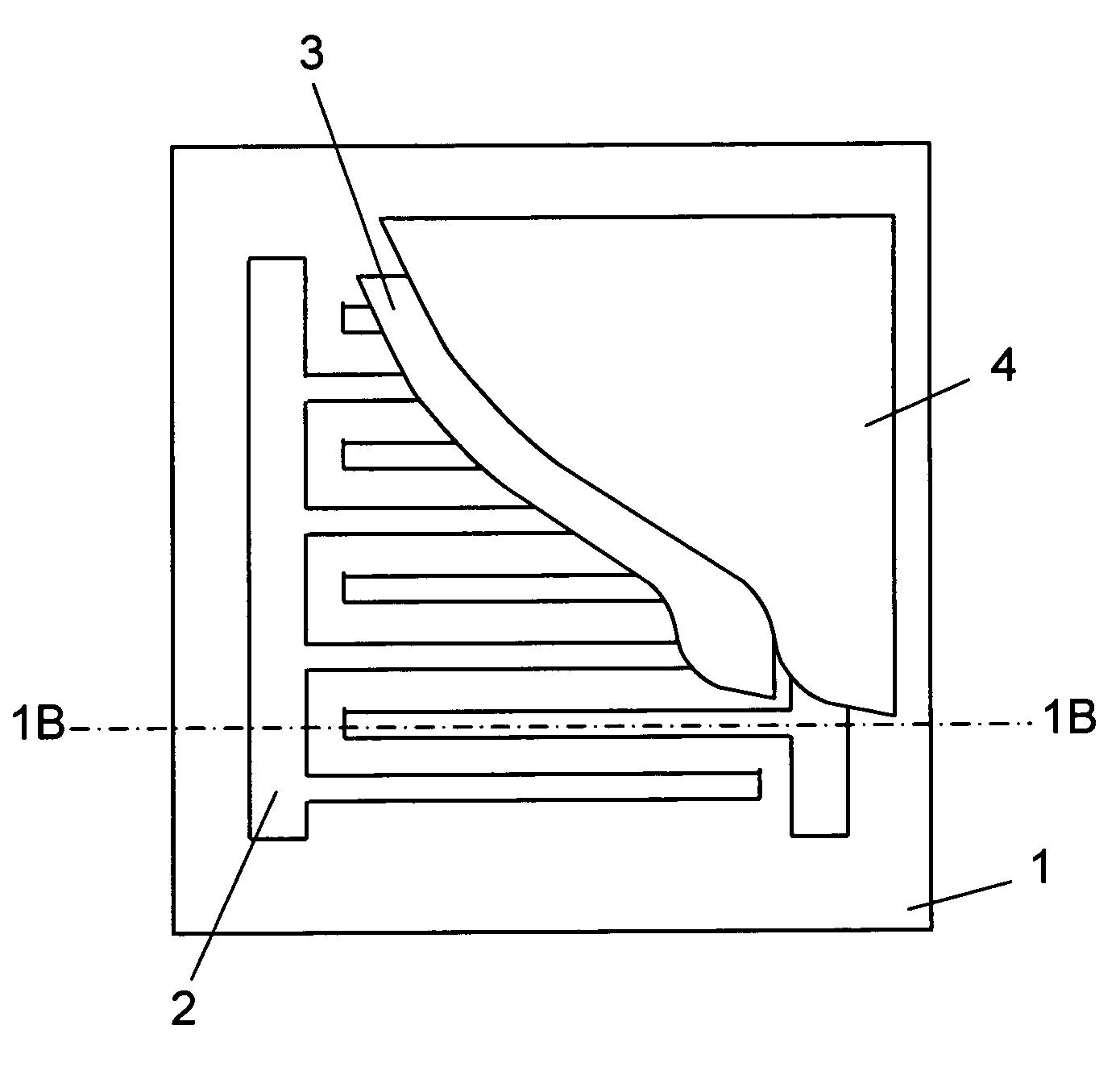

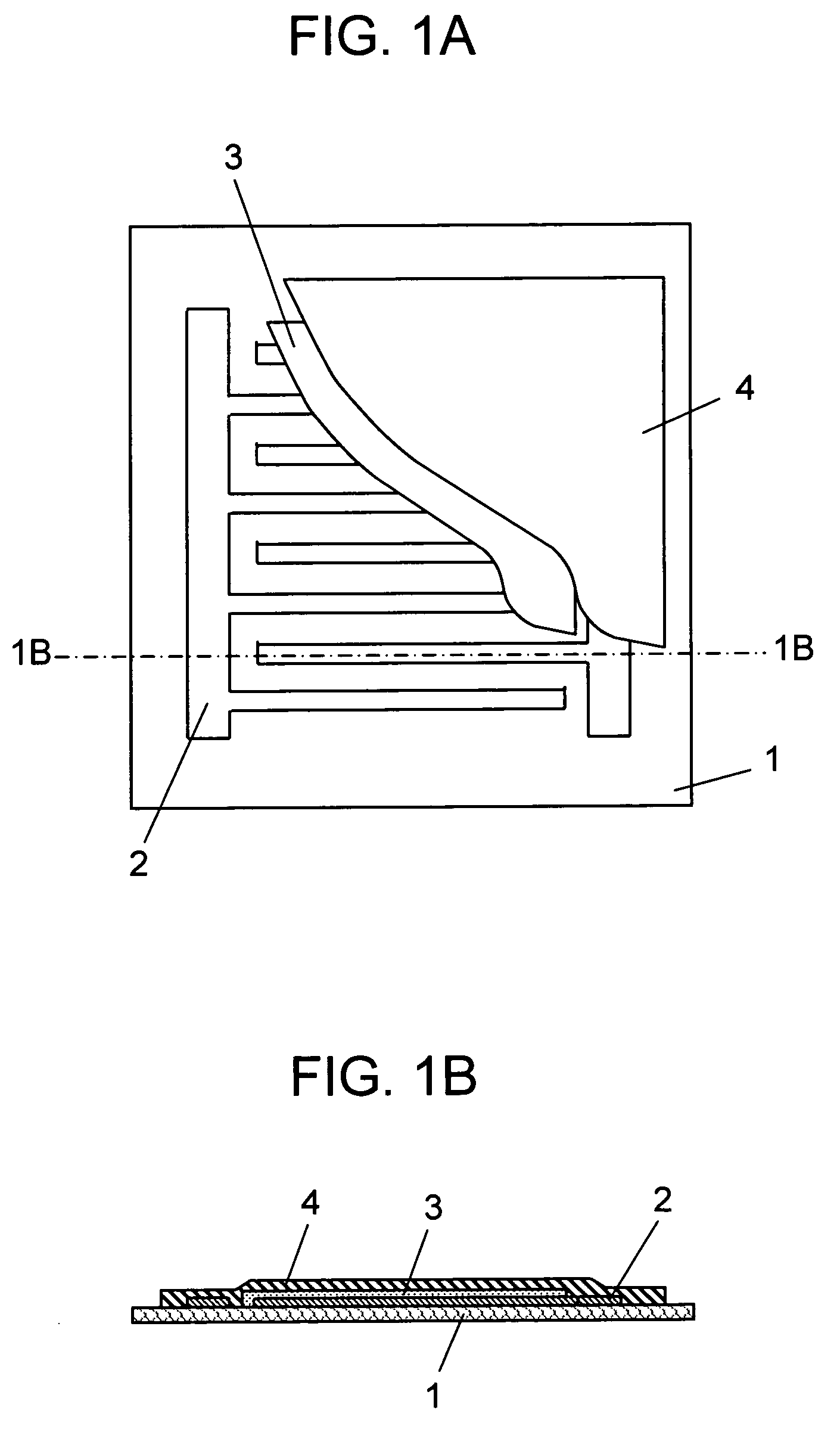

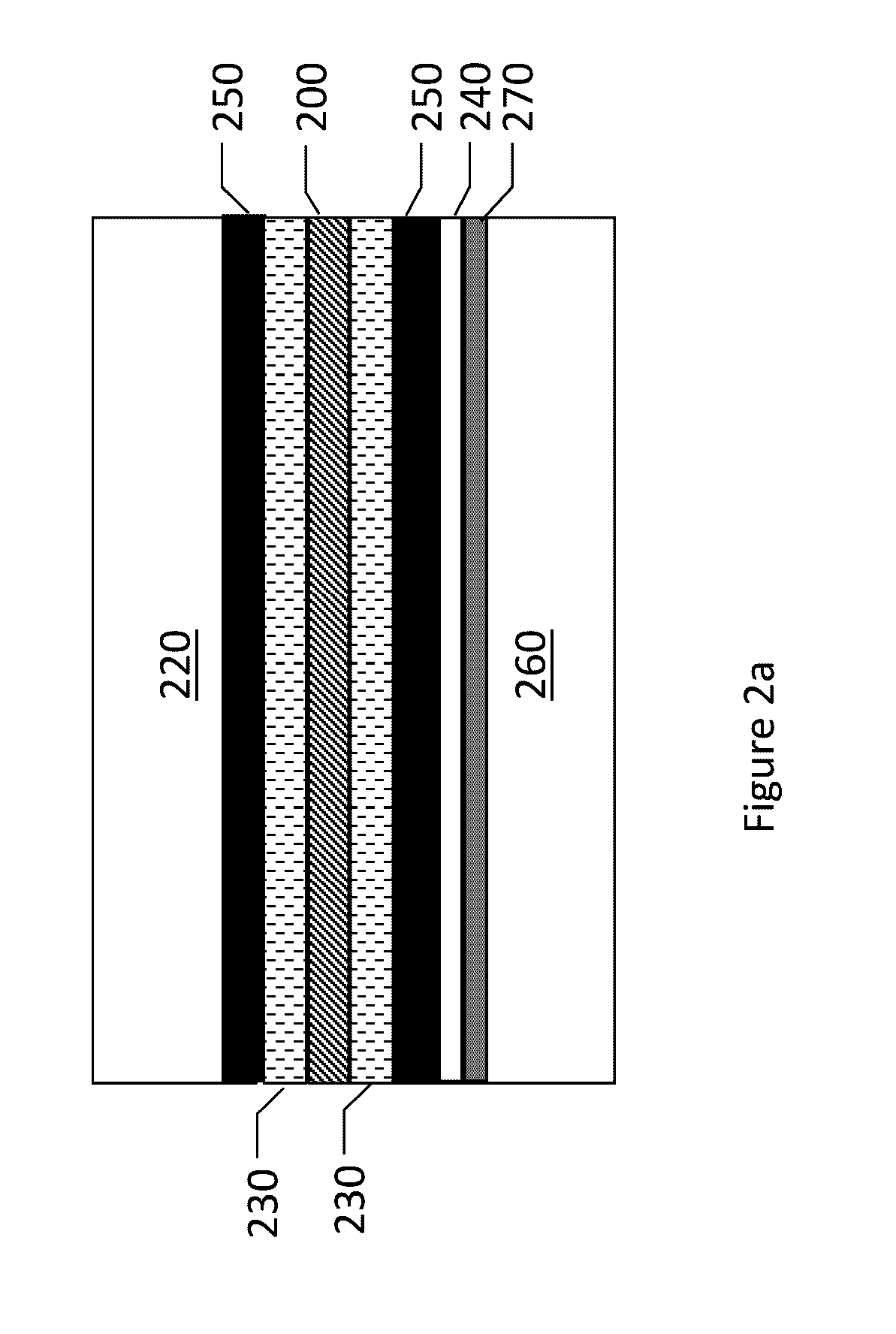

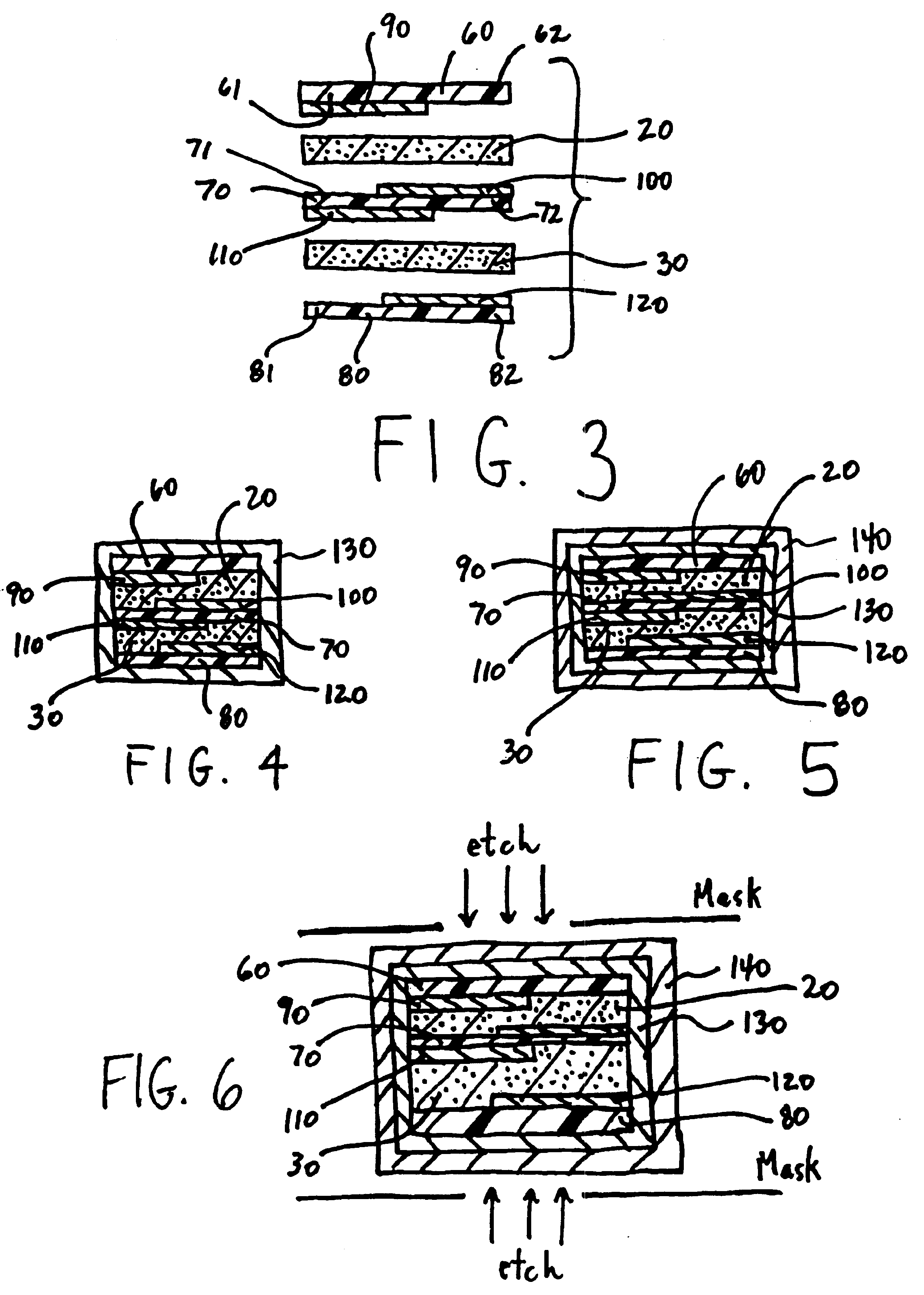

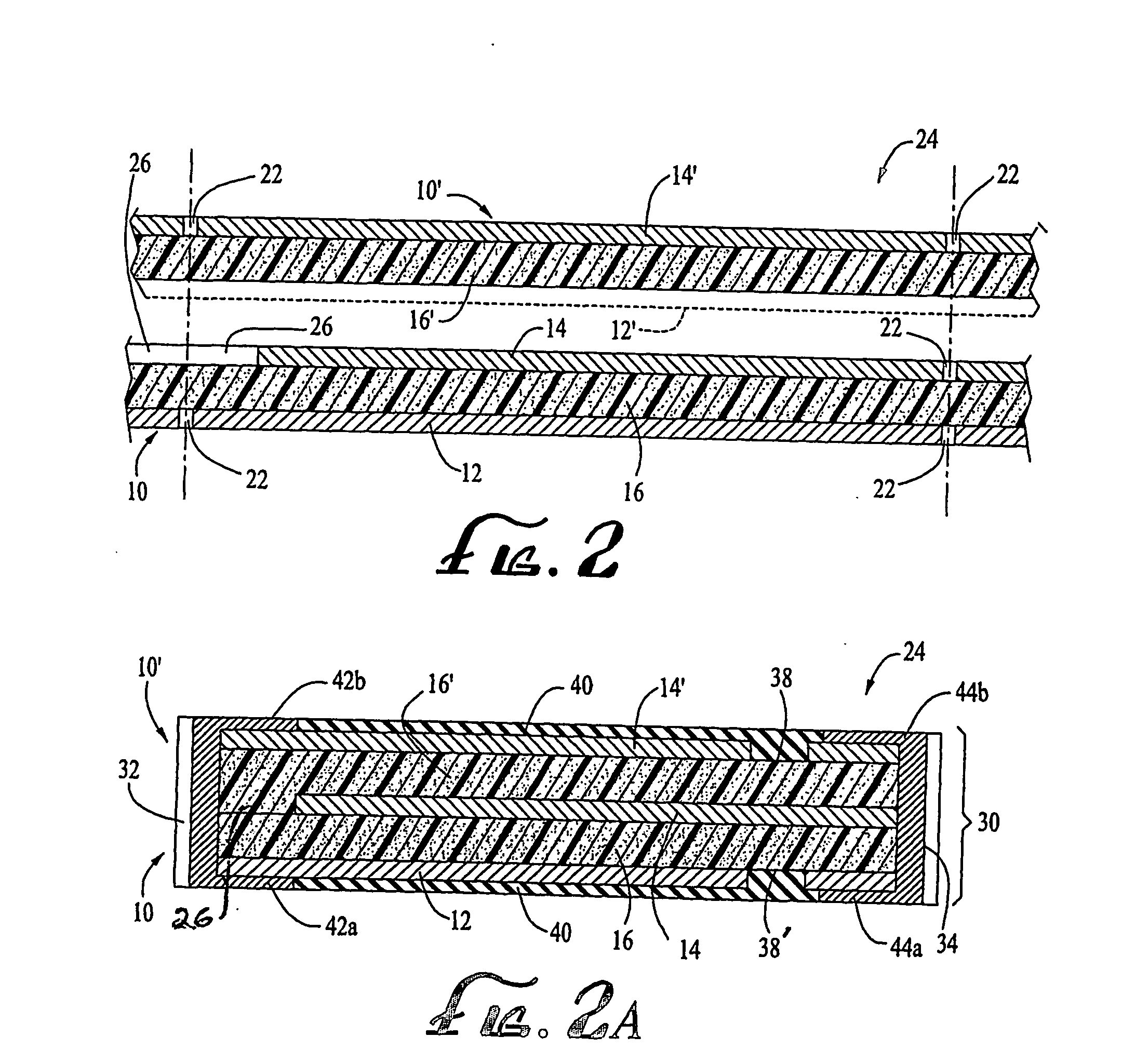

Multi-layer polymeric electronic device and method of manufacturing same

InactiveUS20060176675A1Improve space efficiencyCost efficient to manufactureOther resistor networksPrinted circuit assemblingElectrical conductorMetal foil

An electronic device is formed of multiple, alternating layers of conductive polymer and metal foil electrodes, in which electrical connections between selected electrodes are provided by cross-conductors formed by plated through-hole vias. More specifically, the device includes a first cross-conductor that electrically connects a first set of electrodes, and a second cross-conductor electrically connects a second set of electrodes. Correspondingly, the first cross-conductor is electrically and physically isolated from the second set of electrodes, while the second cross-conductor is electrically and physically isolated from the first set of electrodes. The electrodes are etched to form an isolation gap that isolates that electrode from either the first or second cross-conductor. The first and second cross-conductors, in turn, are formed by plating the through-hole vias, so as to establish electrically-conductive contact with those electrodes not separated from the via by an isolation gap. Thus, a device may be formed with N non-metallic (e.g. polymeric) layers and N+1 electrodes, where N is an integer greater than 1, wherein a first cross-conductor electrically contacts a first set of electrodes, and a second cross-conductor electrically contacts a second set of electrodes, whereby the non-metallic layers are connected in parallel.

Owner:BOURNS INC

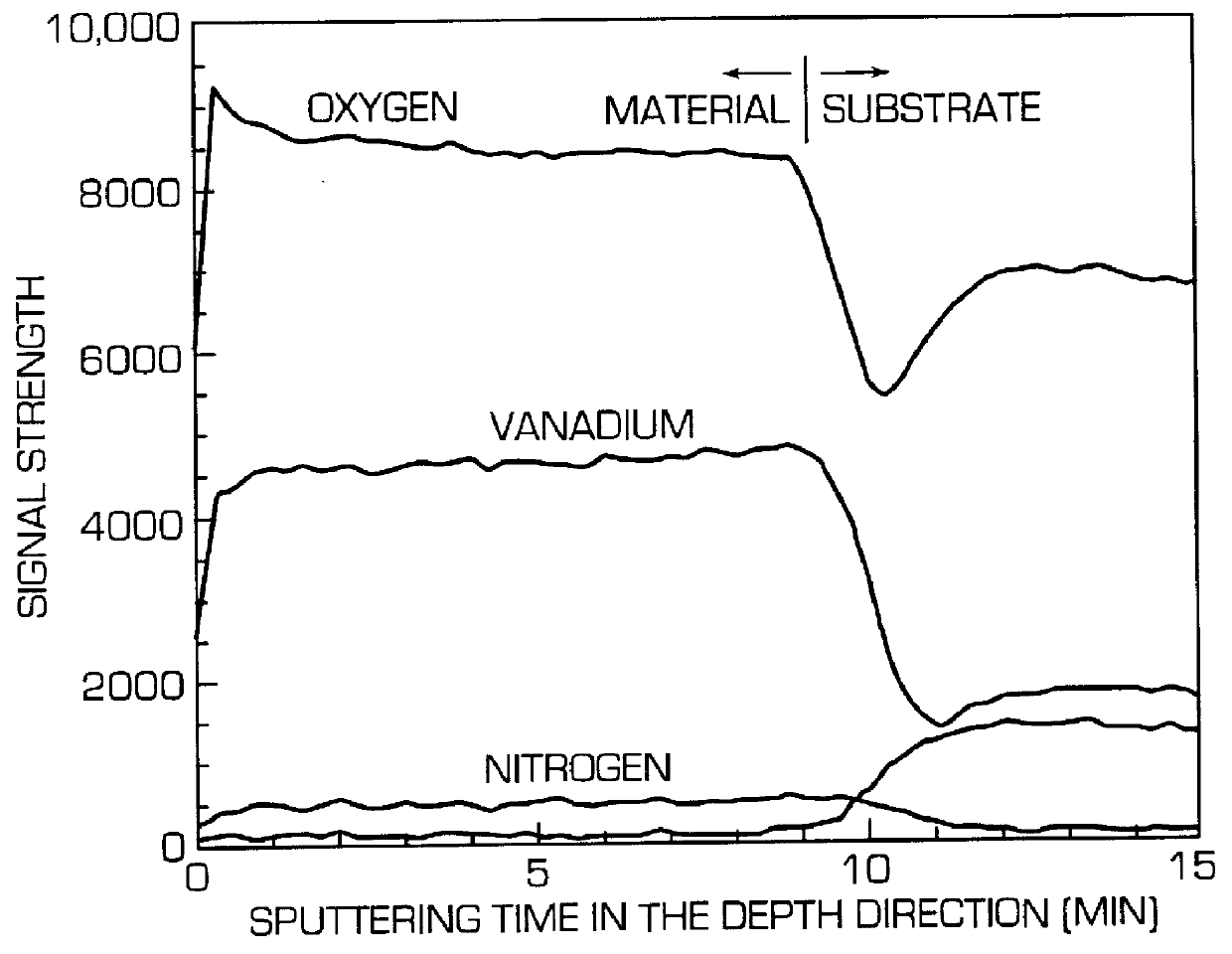

Thin-film temperature-sensitive resistor material and production process thereof

Described are a thin-film temperature-sensitive resistor material which comprises, at a temperature-sensitive resistor portion, a mixed crystal of a nitride and oxide of a transition metal such as vanadium preferably, that represented by the formula: MNxOy wherein 0<x<1, and 2< / =y< / =13 / 6, simultaneously exhibits a high temperature coefficient of resistance and a low specific resistance at about room temperature, and has excellent sensitivity at about room temperature; and a process for the production of a thin-film temperature-sensitive resistor material, which comprises forming its temperature-sensitive resistor portion by using a gas-atmosphere composed mainly of a nitrogen gas preferably, a mixed gas composed of nitrogen, argon and oxygen, and has a flow rate ratio of nitrogen to oxygen (nitrogen / oxygen) of 14 / 1 to 23 / 1.

Owner:NEC CORP

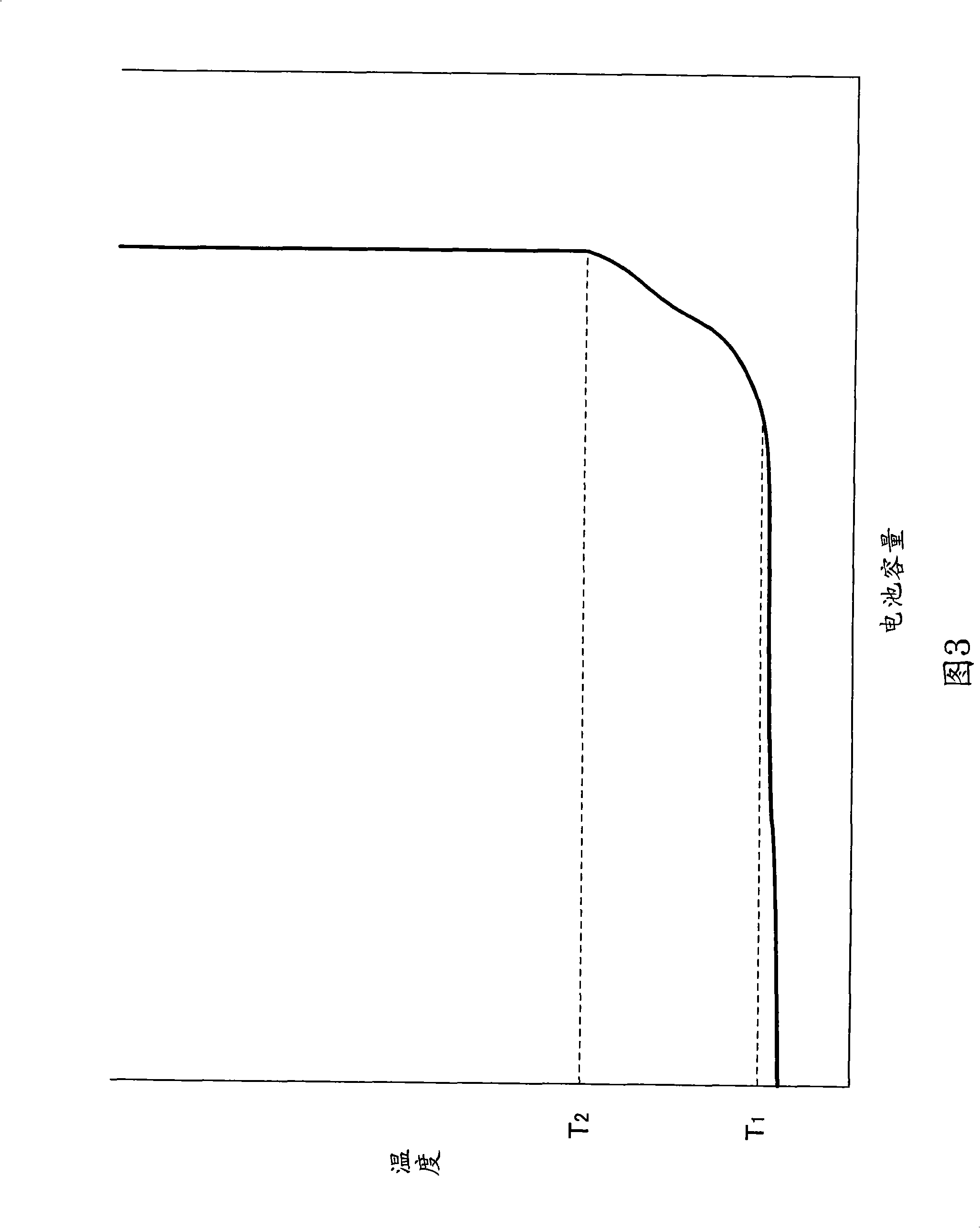

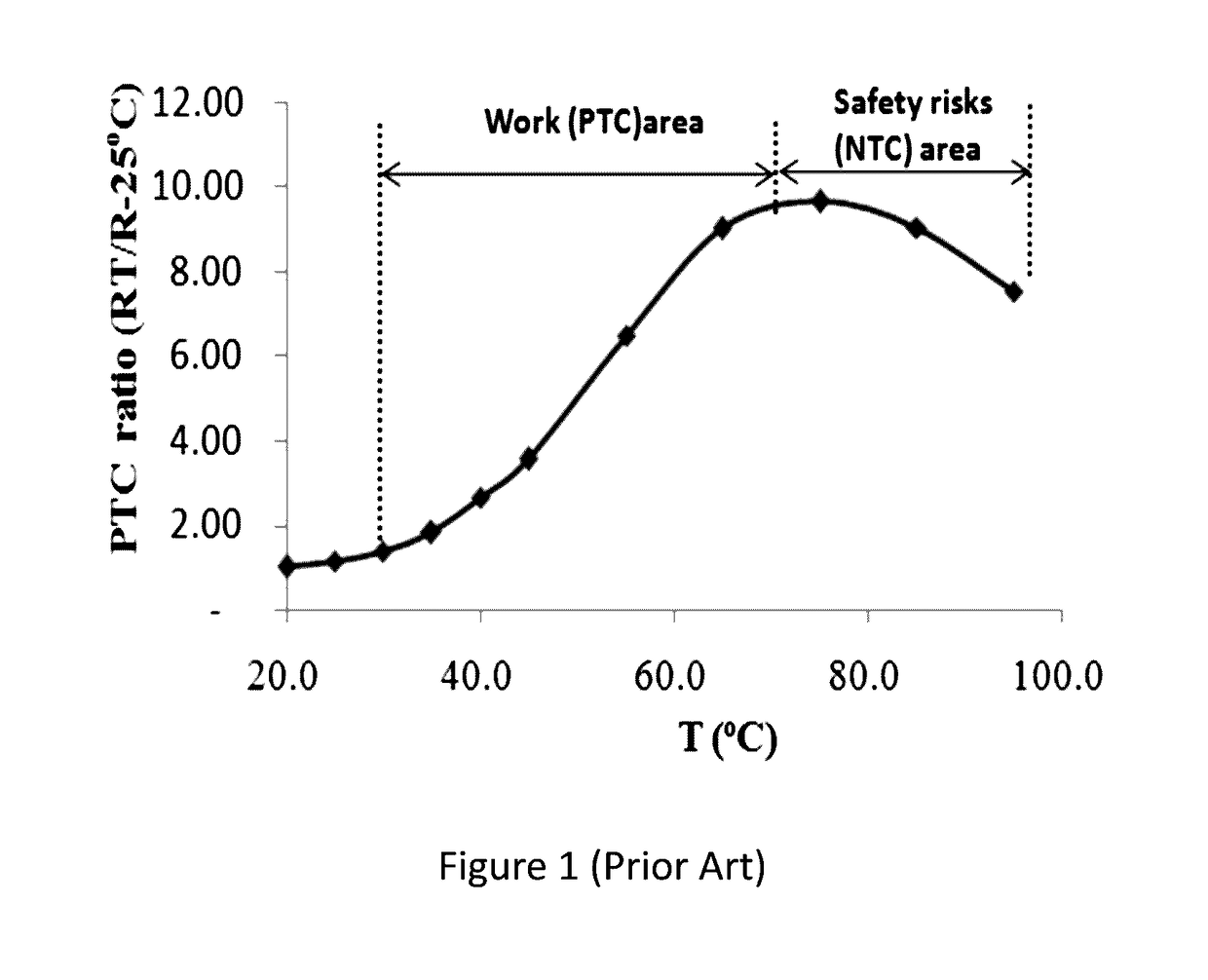

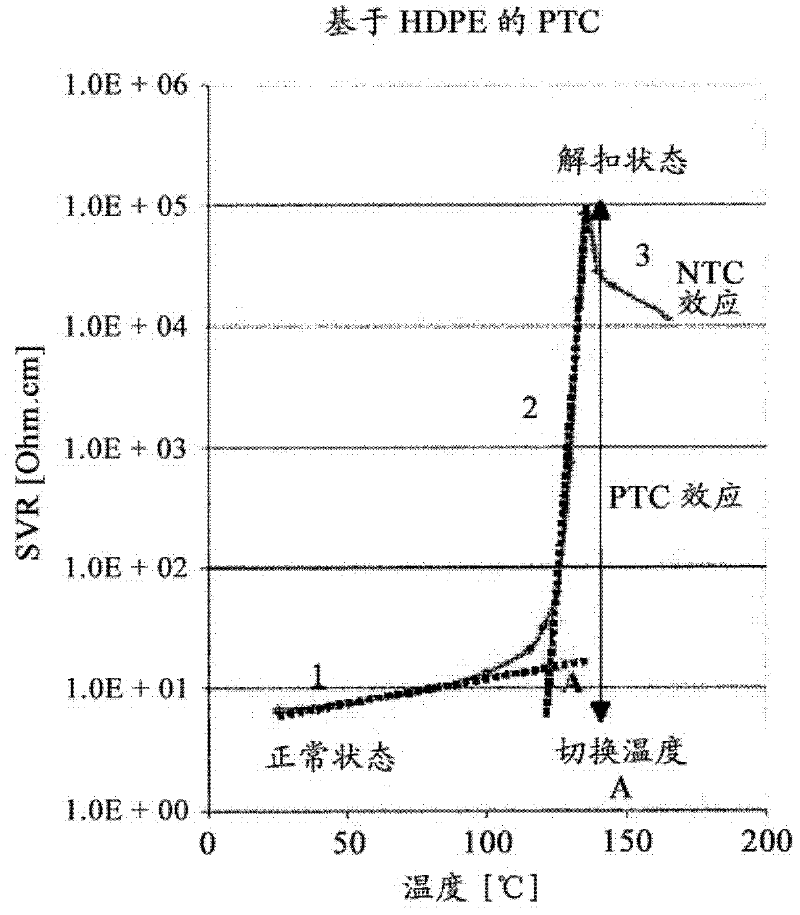

Positive temperature coefficient materials with reduced negative temperature coefficient effect

InactiveCN102598162AImprove featuresResistor manufacturePositive temperature coefficient thermistorsNegative temperatureTemperature coefficient

Positive temperature coefficient (PTC) compositions having a reduced negative temperature coefficient effect (NTC) are provided that are achieved without crosslinking the thermoplastic base material. The PTC compositions include a thermoplastic base resin, an electrically conductive filler and particles of a polymeric additive dispersed in the PTC composition.

Owner:SABIC GLOBAL TECH BV

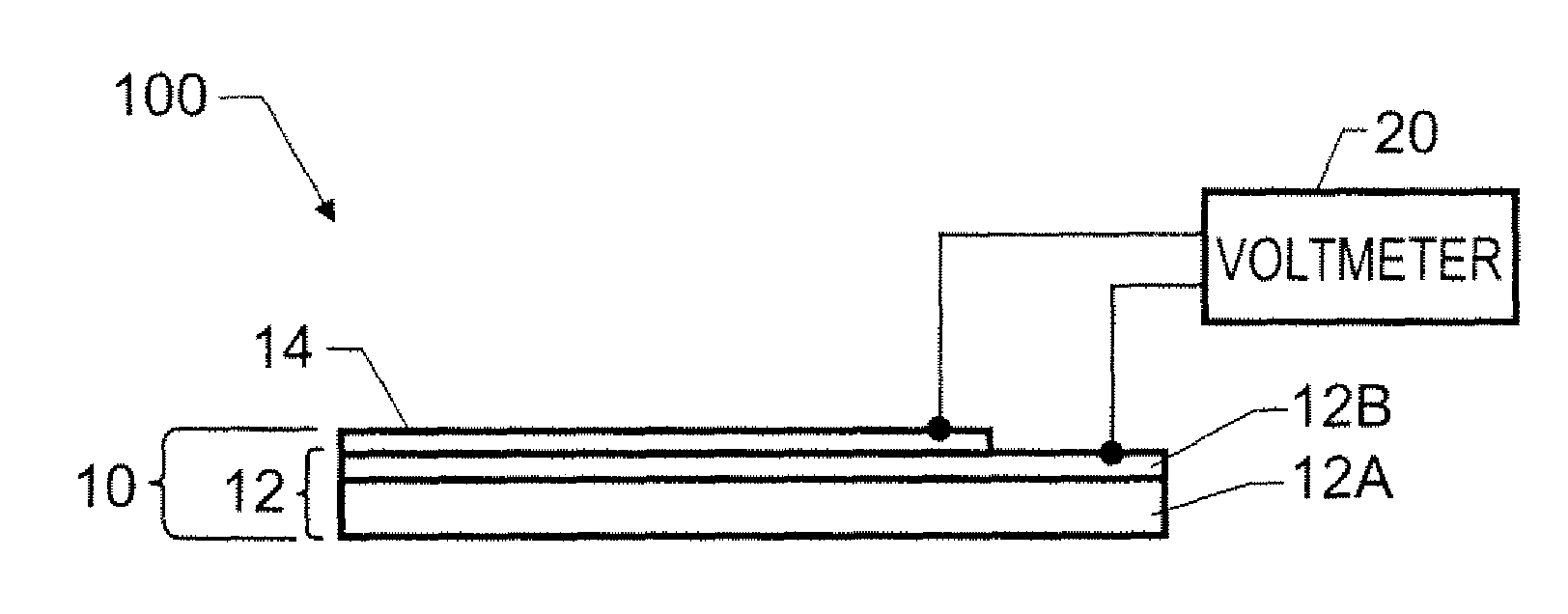

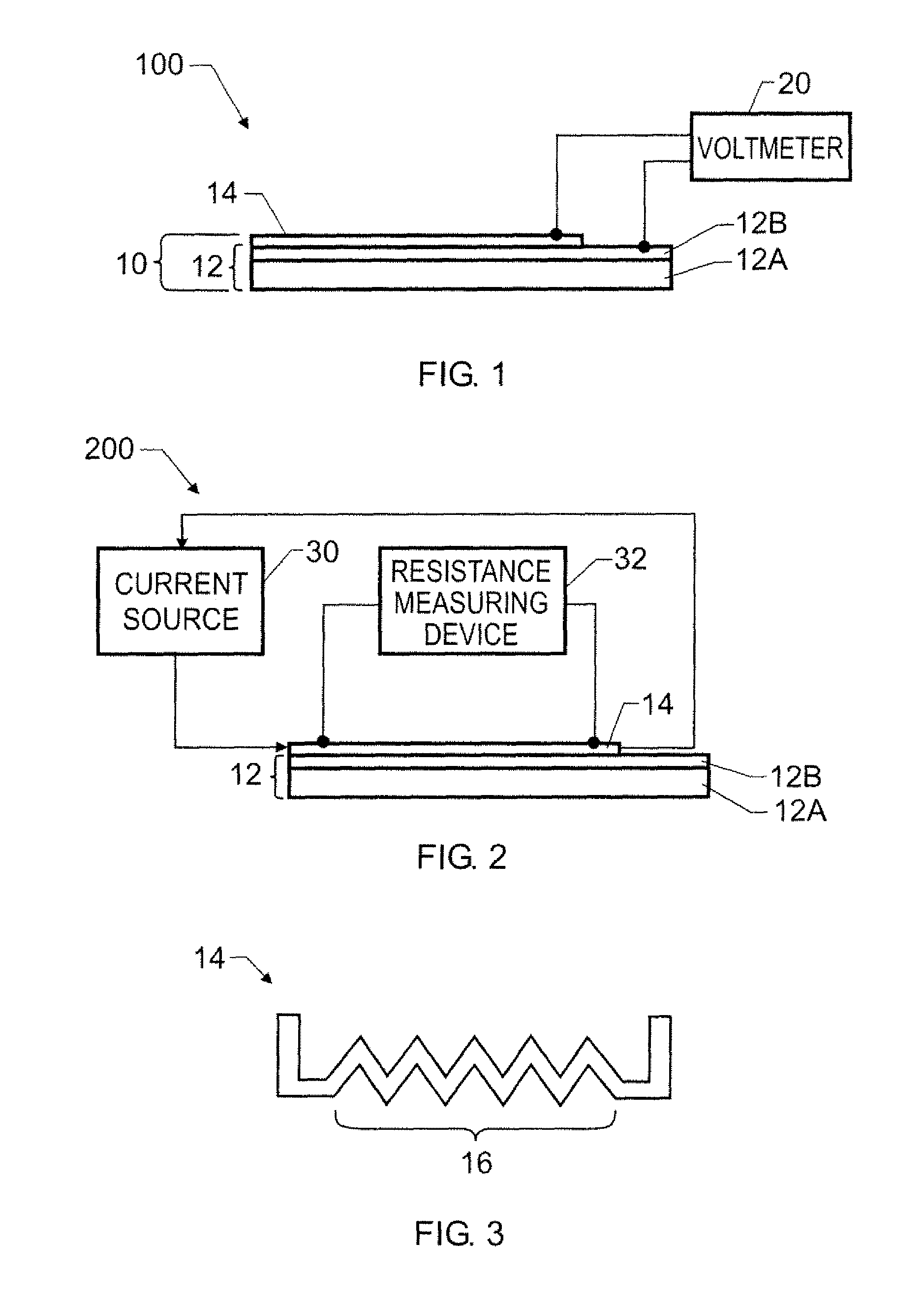

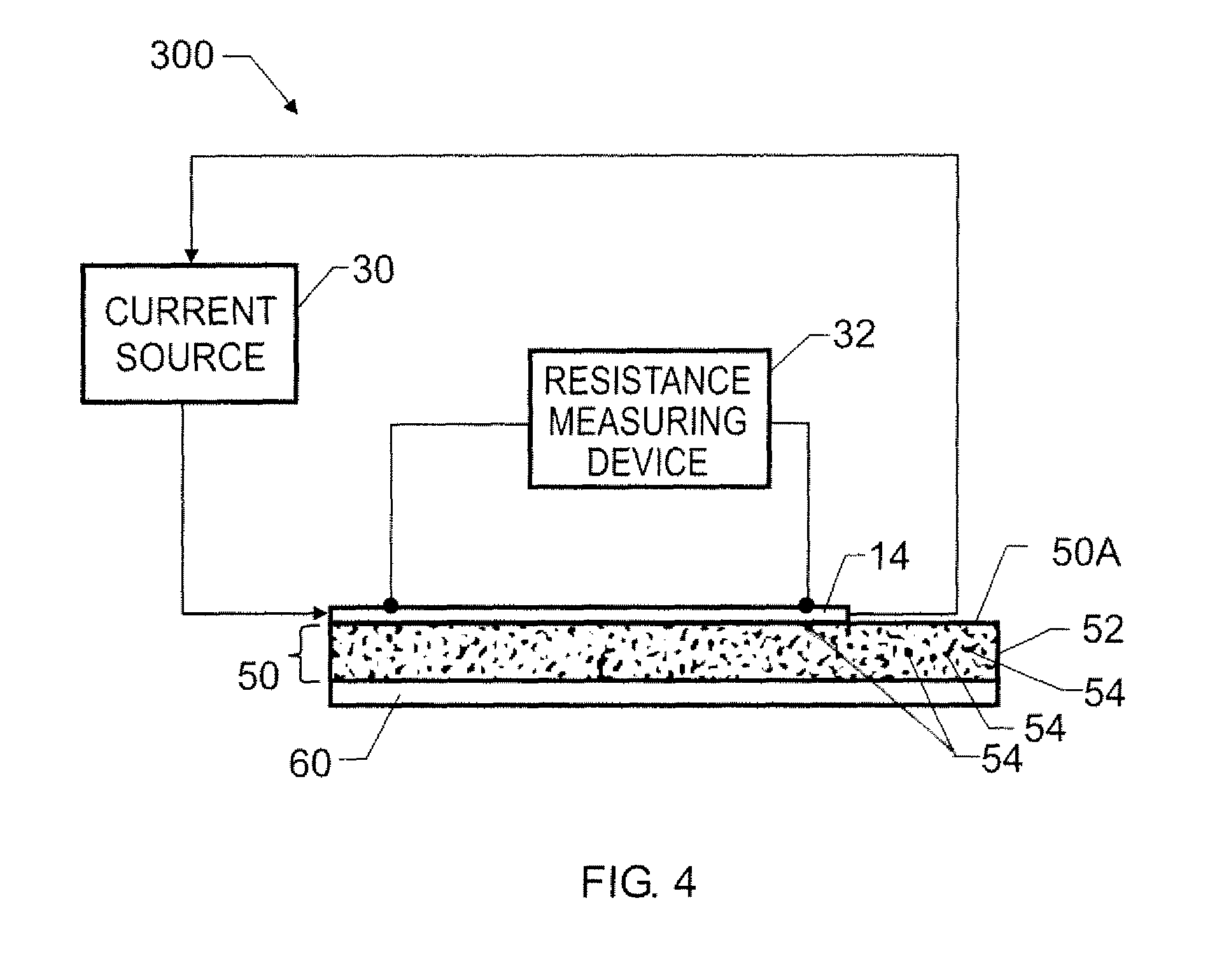

Flexible Thin Metal Film Thermal Sensing System

InactiveUS20100118916A1Current responsive resistorsThermometers using electric/magnetic elementsThin metalConductive materials

A flexible thin metal film thermal sensing system is provided. A thermally-conductive film made from a thermally-insulating material is doped with thermally-conductive material. At least one layer of electrically-conductive metal is deposited directly onto a surface of the thermally-conductive film. One or more devices are coupled to the layer(s) to measure an electrical characteristic associated therewith as an indication of temperature.

Owner:NASA

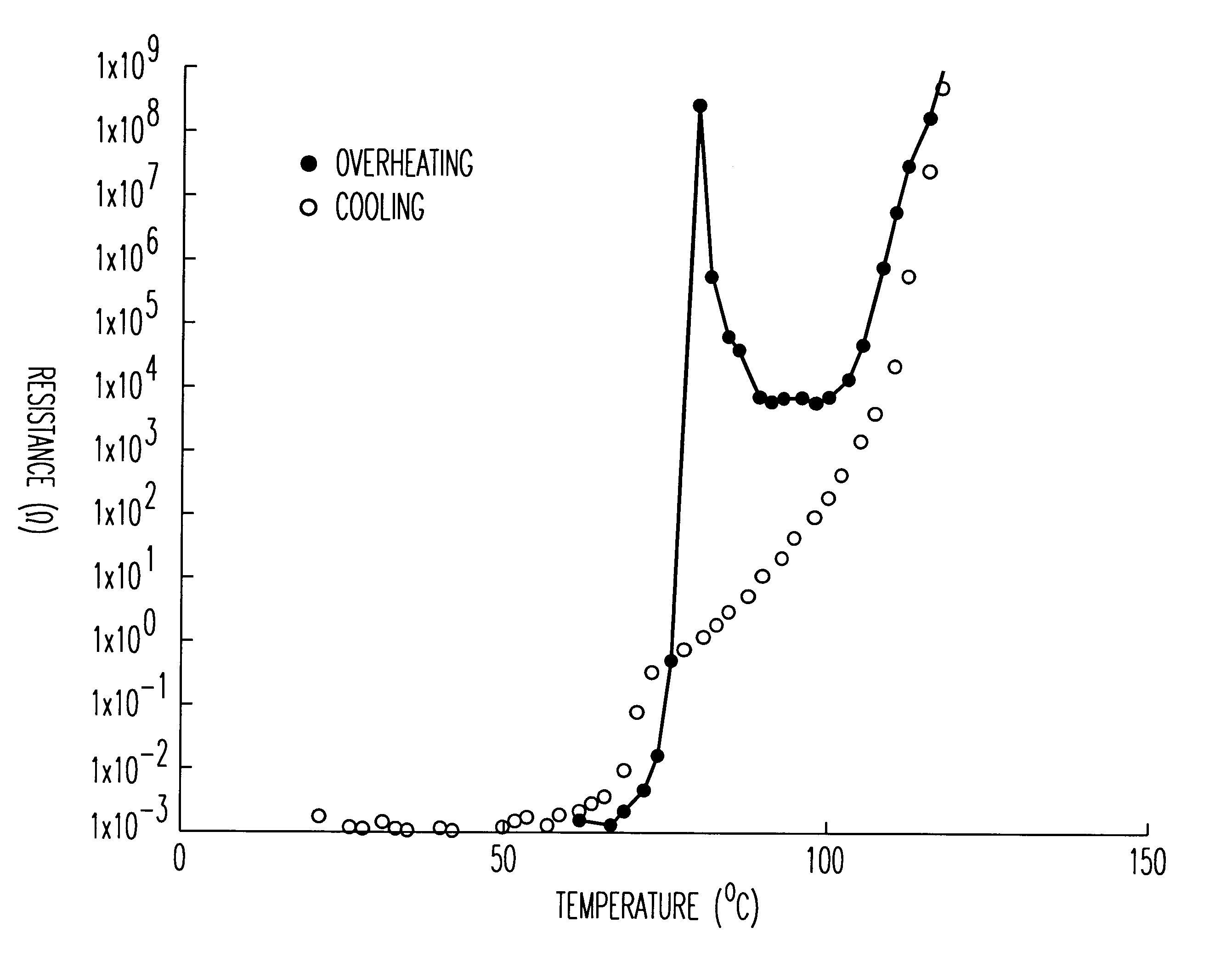

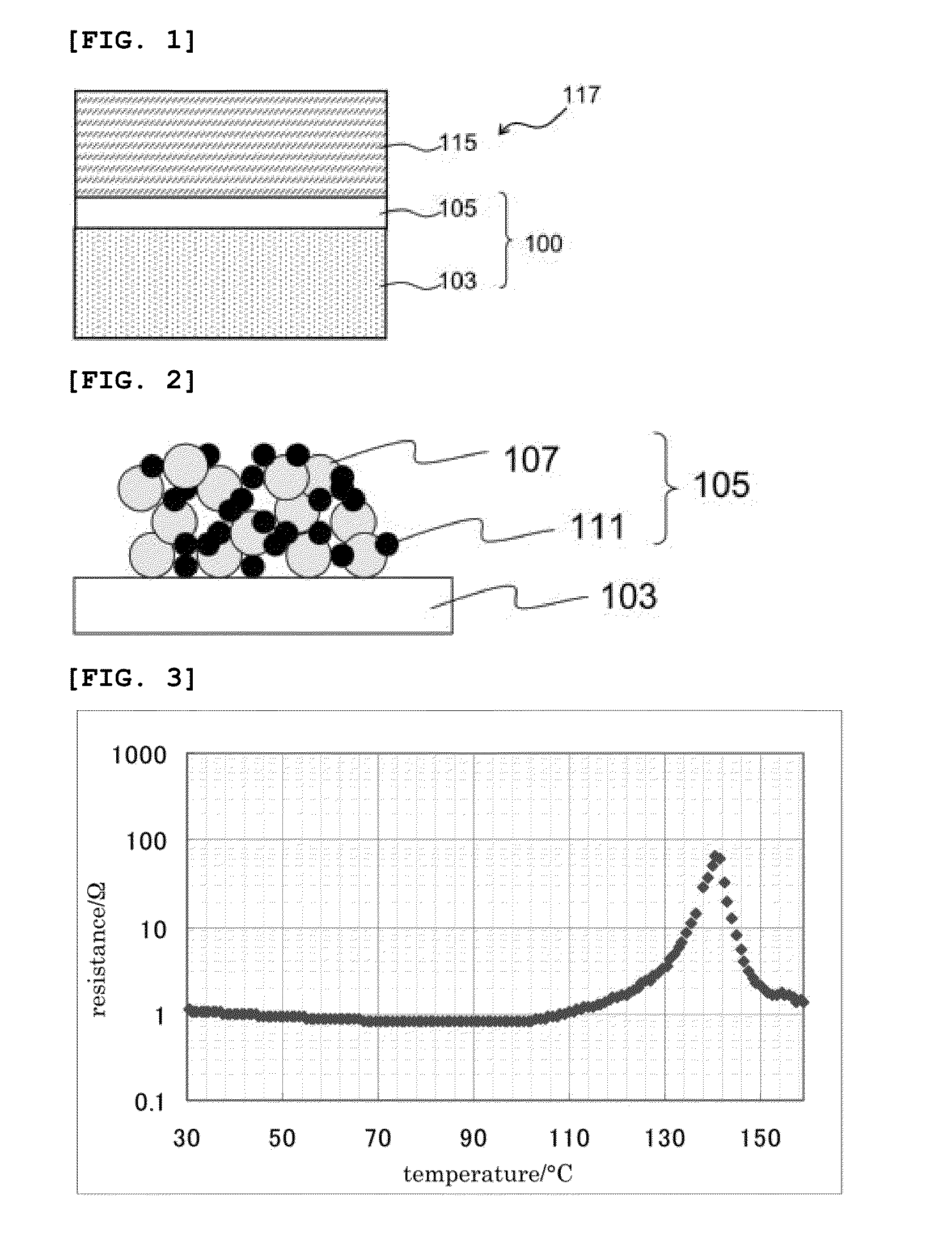

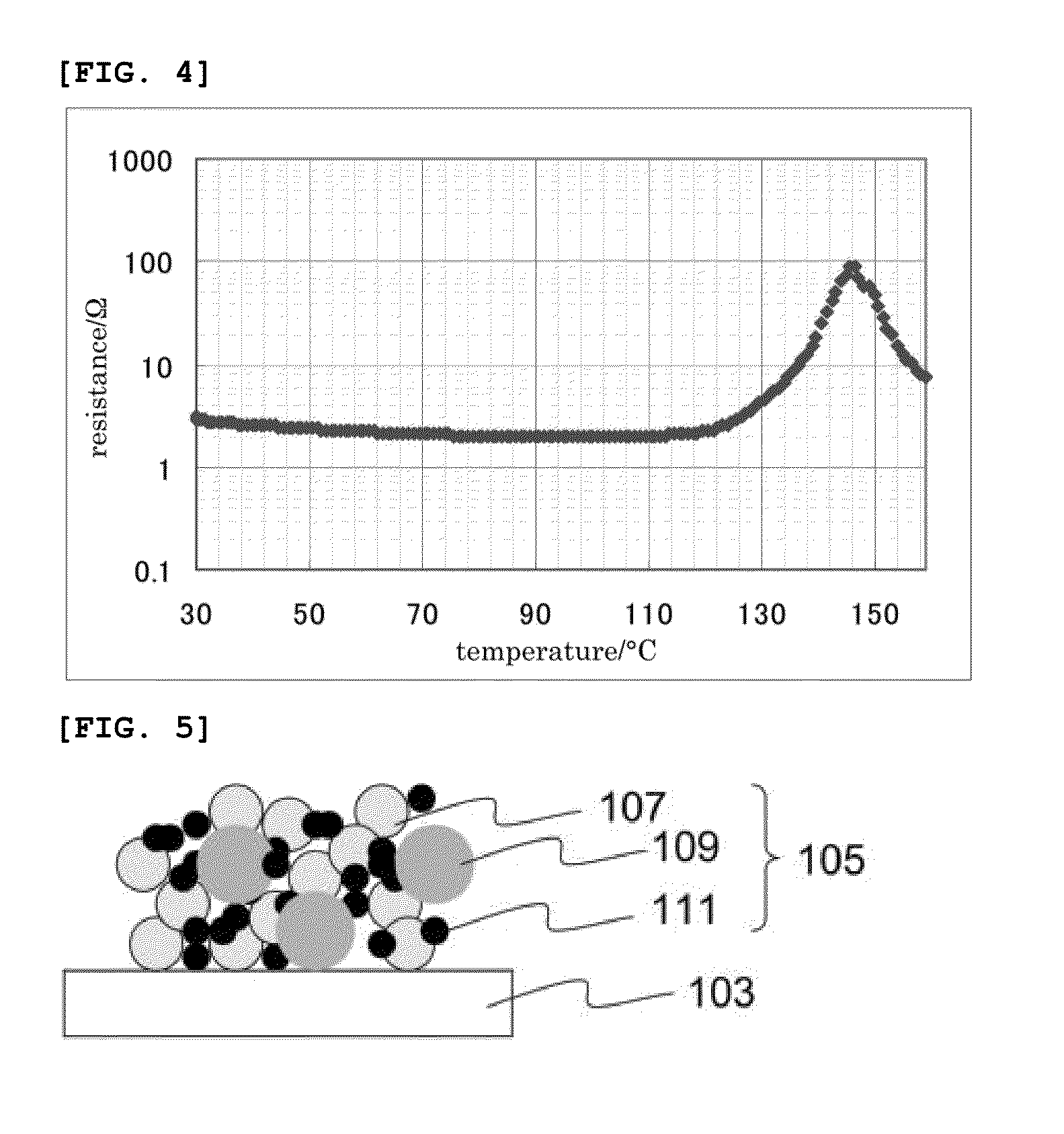

Current collector, electrode, secondary battery, and capacitor

InactiveUS20150303484A1Sufficient safety functionHigh operating requirementsHybrid capacitor electrodesElectrolytic capacitorsElectrical resistance and conductanceInternal pressure

A current collector which can realize sufficient safety function even when the cell is deformed by external force or when the internal pressure is increased; and an electrode, a secondary battery, and a capacitor using the current collector; are provided. A current collector, including: a metal foil; and a conductive layer formed on a surface of the metal foil; is provided. Here, regarding the current collector, a temperature-resistance curve of the current collector obtained by sandwiching the current collector in between brass electrodes of 1 cm diameter, the measurement of resistance being performed with conditions of 15N of load between the electrodes and temperature being raised from ambient temperature at a rate of 10° C. / min satisfies a relation of R(Ta+5) / R(Ta−5)≧1, R(Ta+5) being resistance at temperature Ta+5° C. and R(Ta−5) being resistance at temperature Ta−5° C., Ta being a temperature higher than a temperature satisfying a relation of (R(T) / R(T−5))>2.0 and first satisfying a relation of (R(T) / R(T−5))<2.0.

Owner:FURUKAWA ELECTRIC CO LTD +2

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com