Patents

Literature

1981results about "Resistor manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

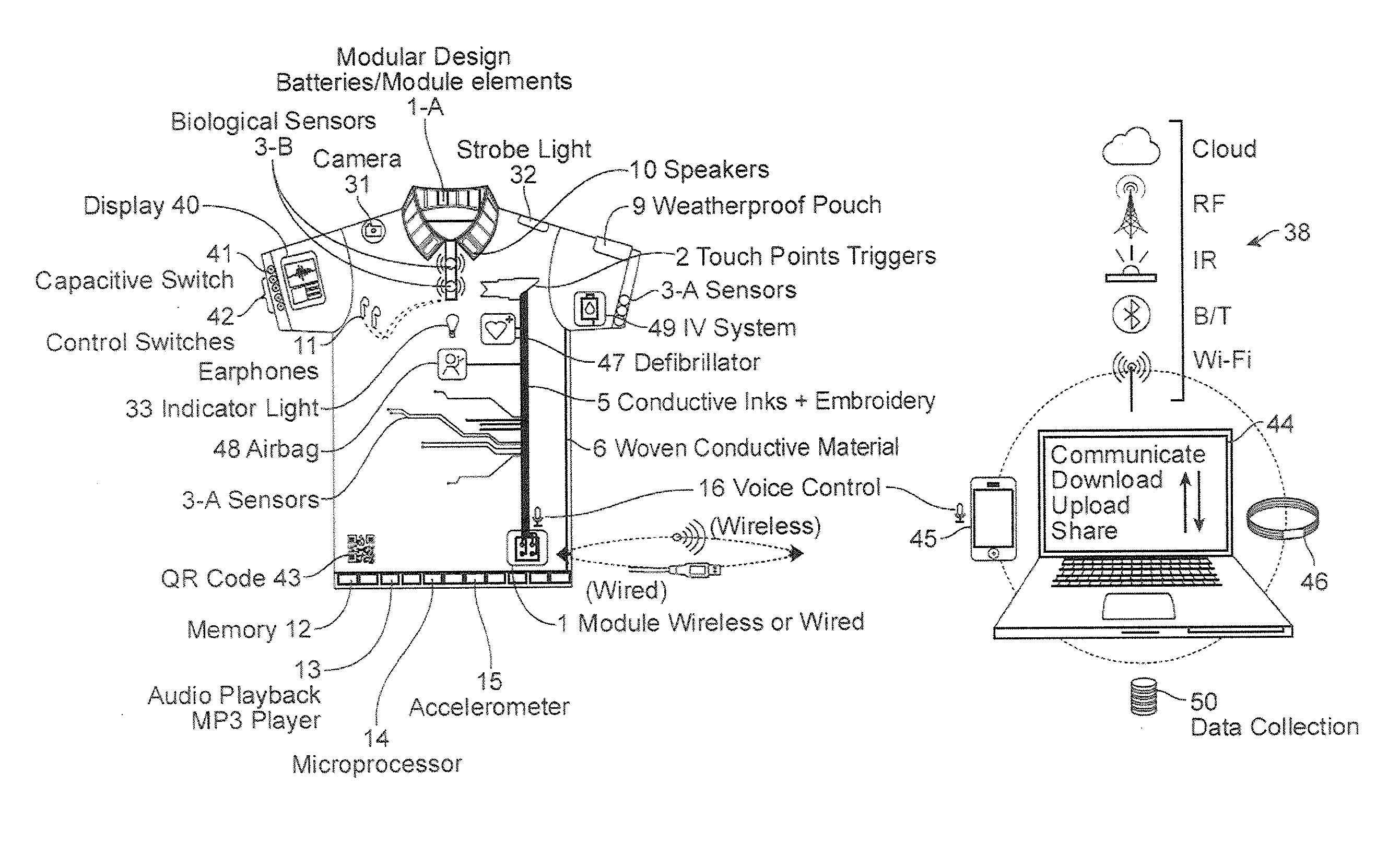

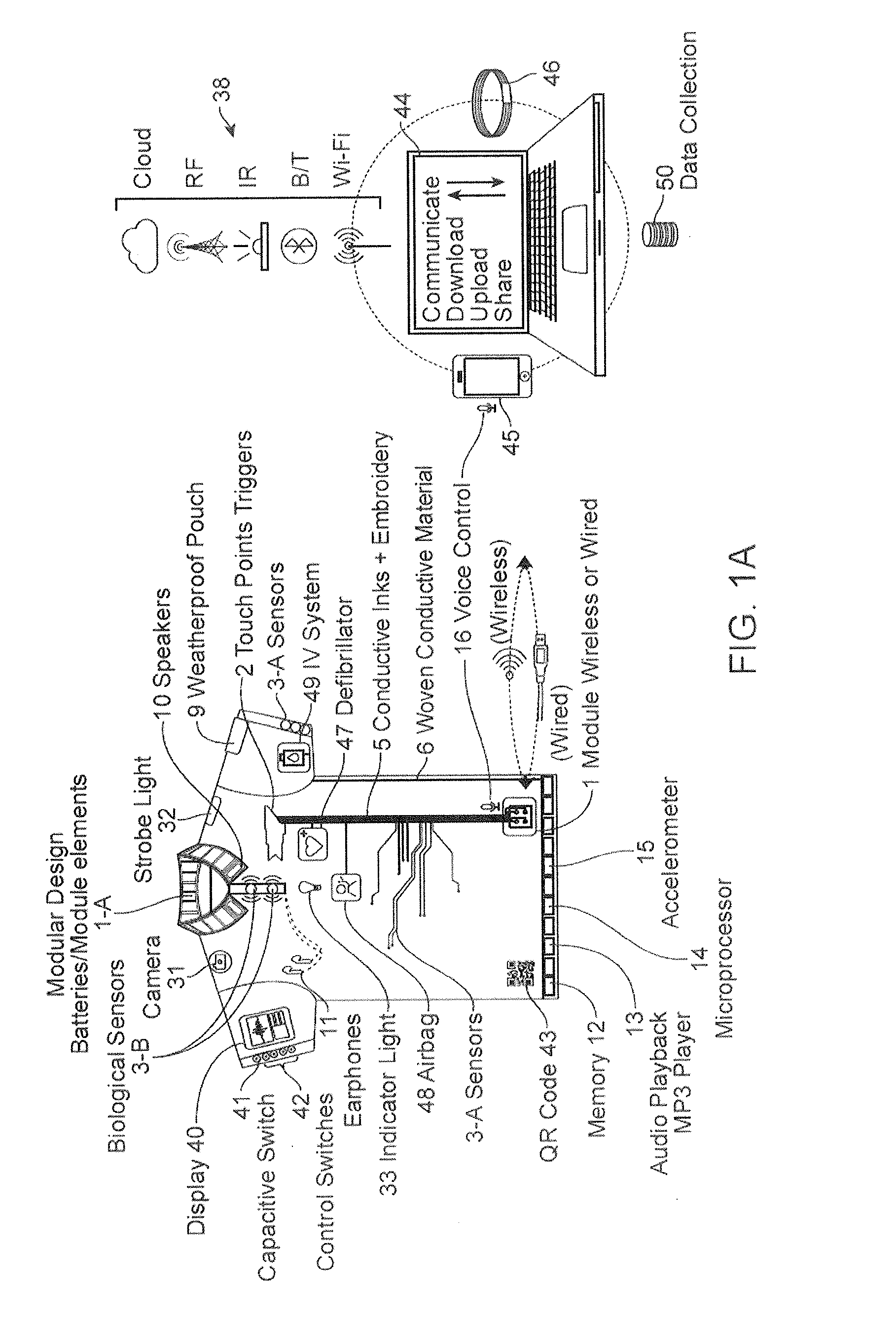

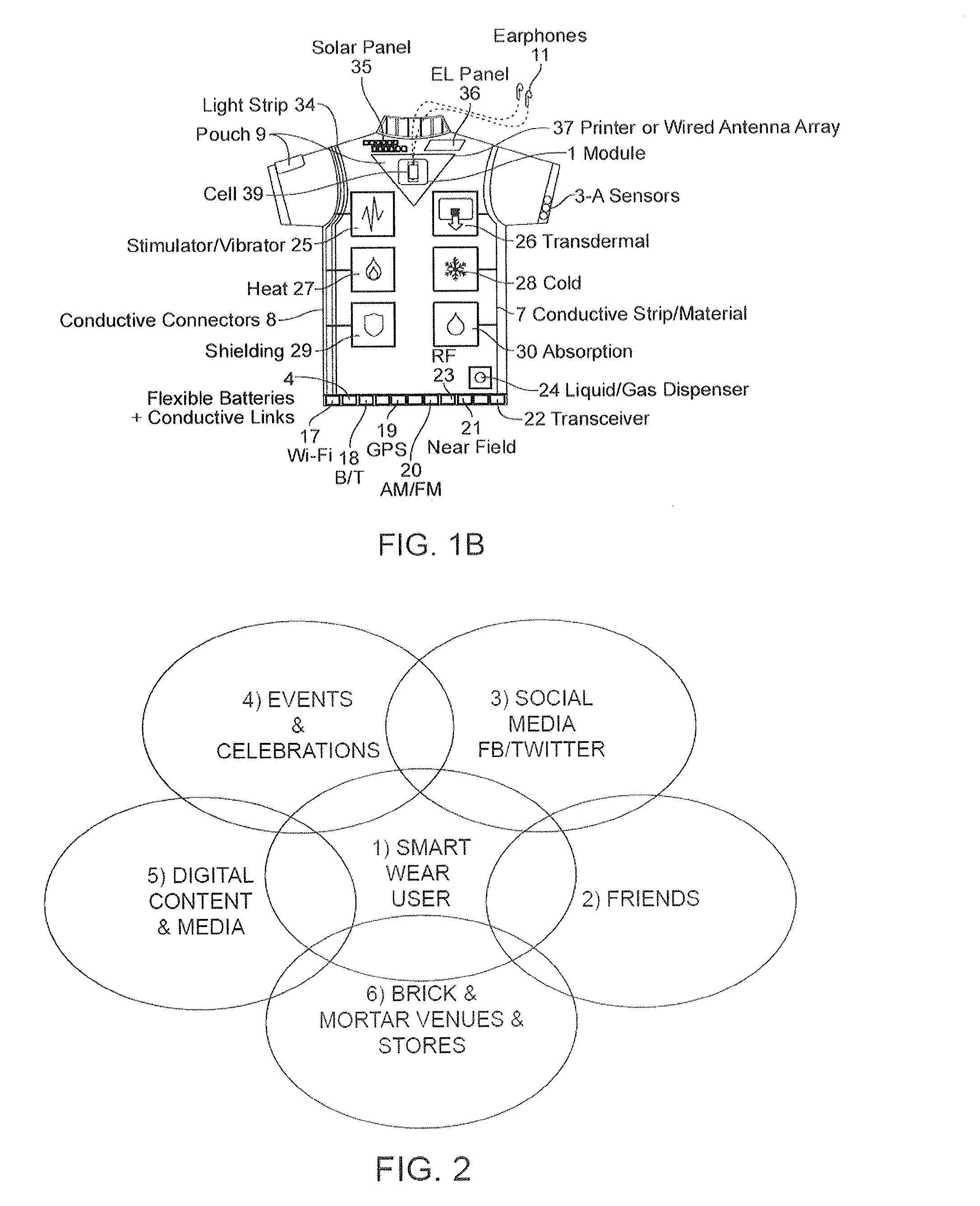

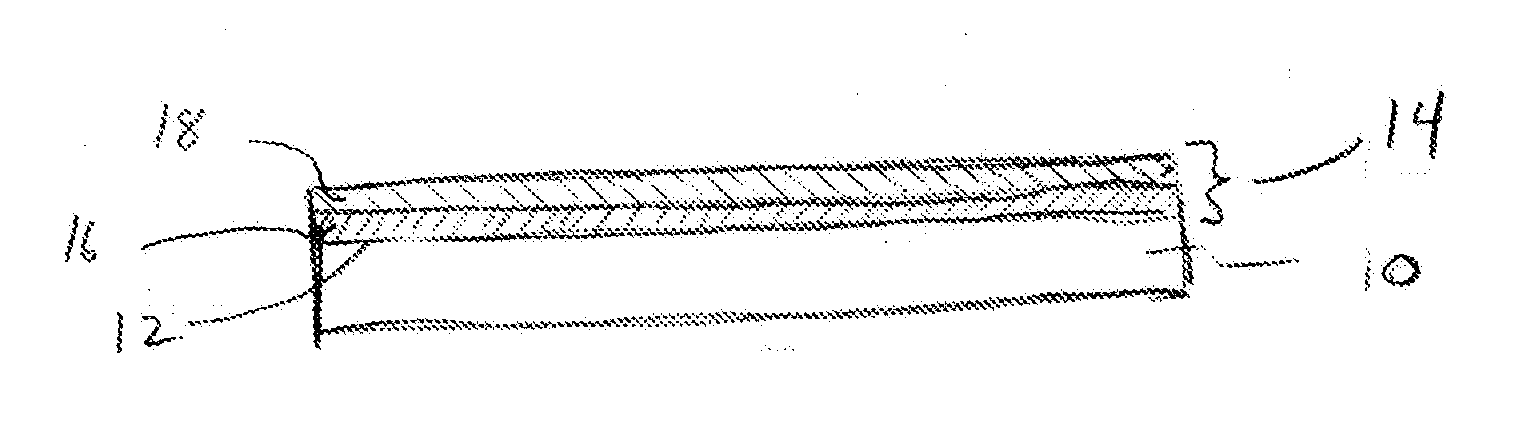

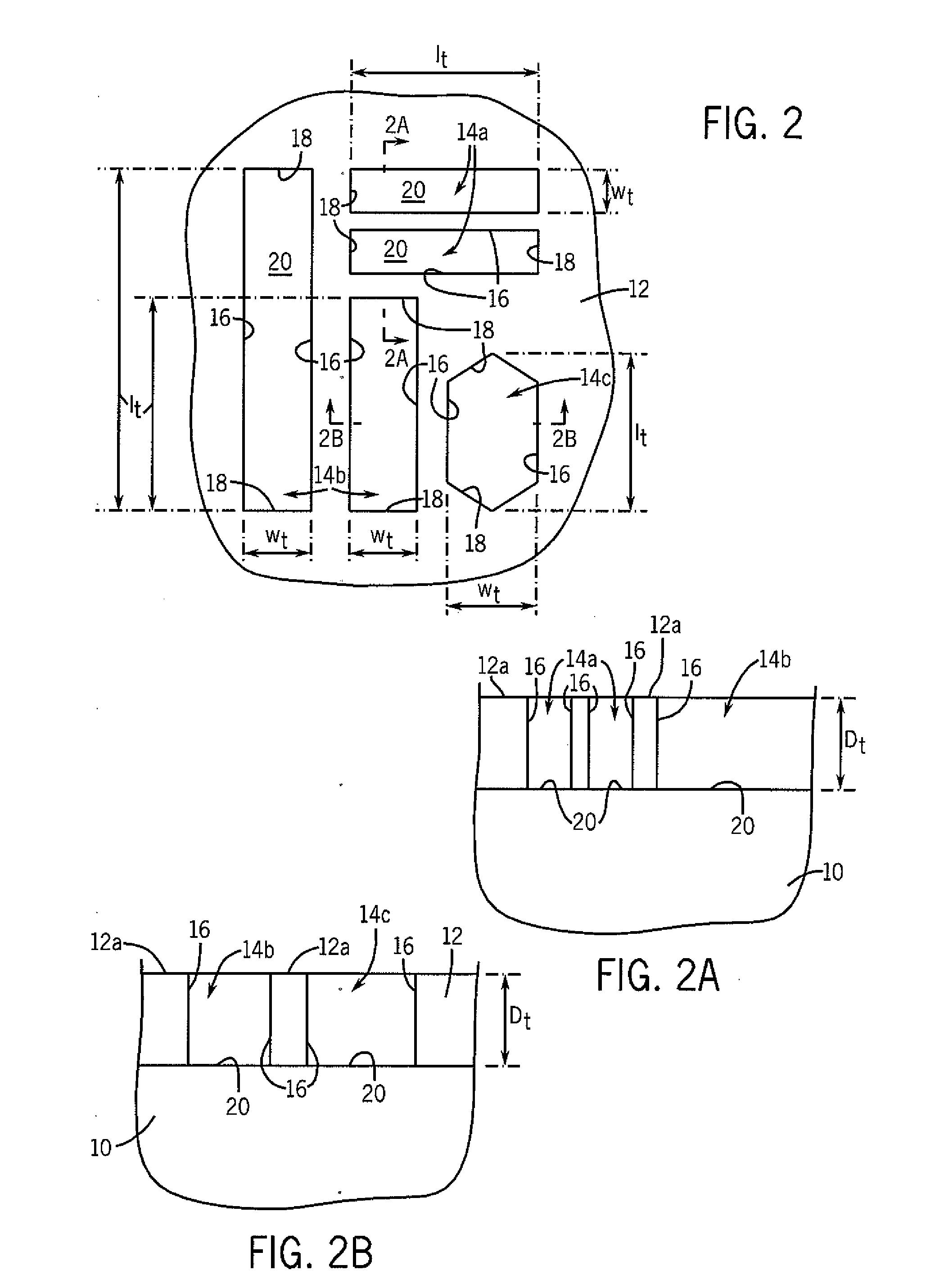

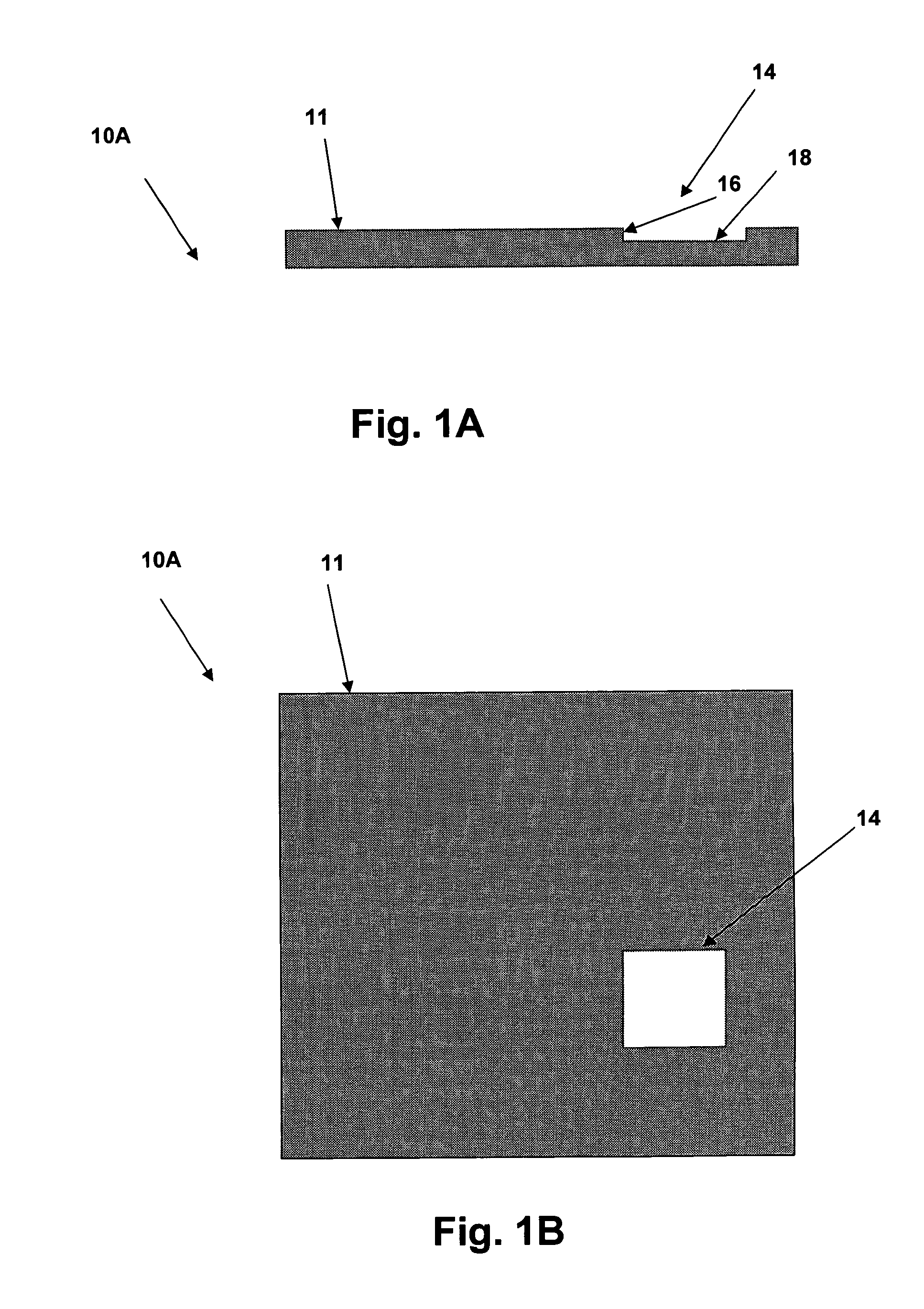

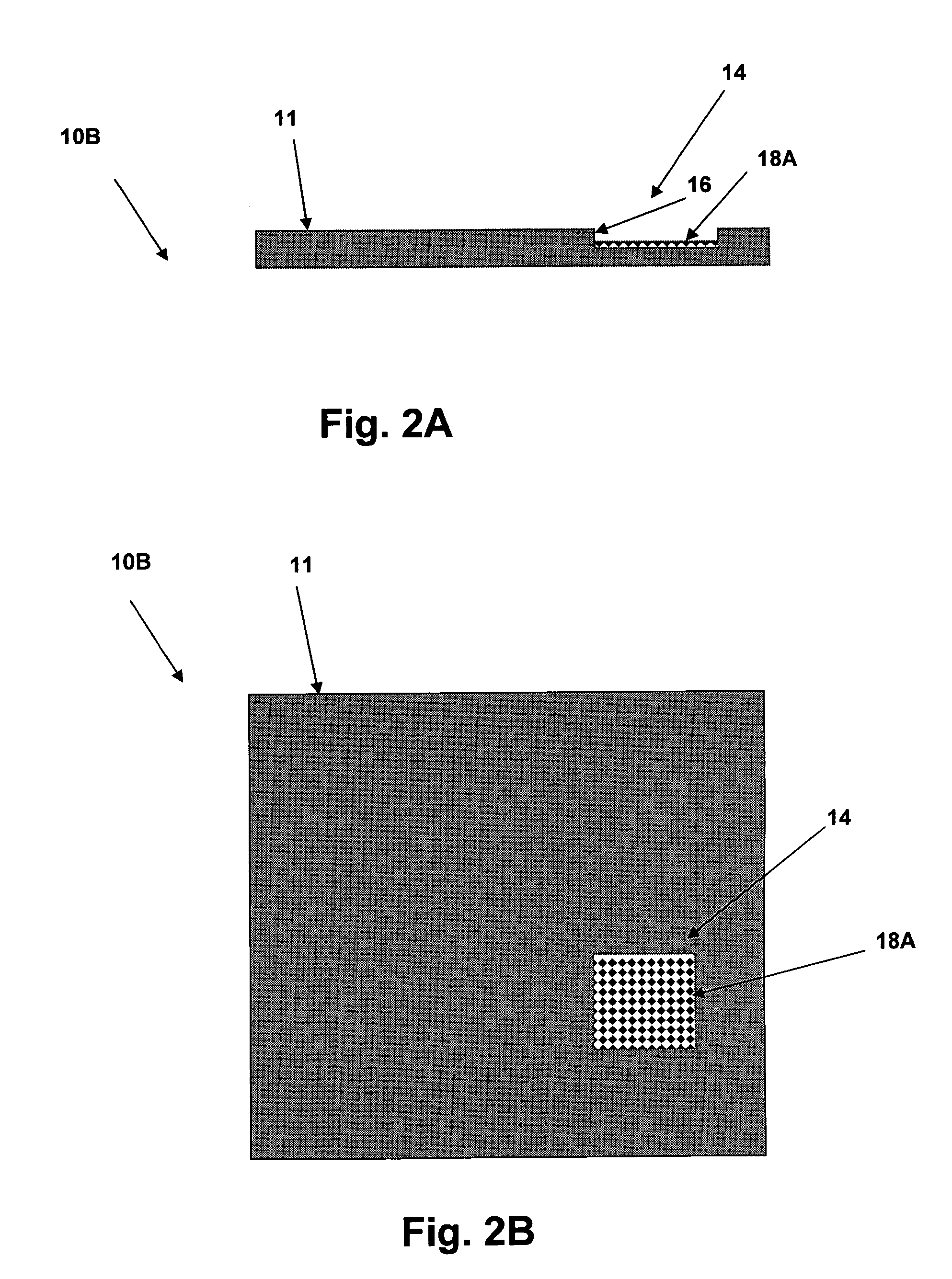

Methods of making garments having stretchable and conductive ink

InactiveUS20140318699A1Stable and continuous positioningRobust detectionPrinted circuit manufactureResistor manufactureAdhesiveSolvent

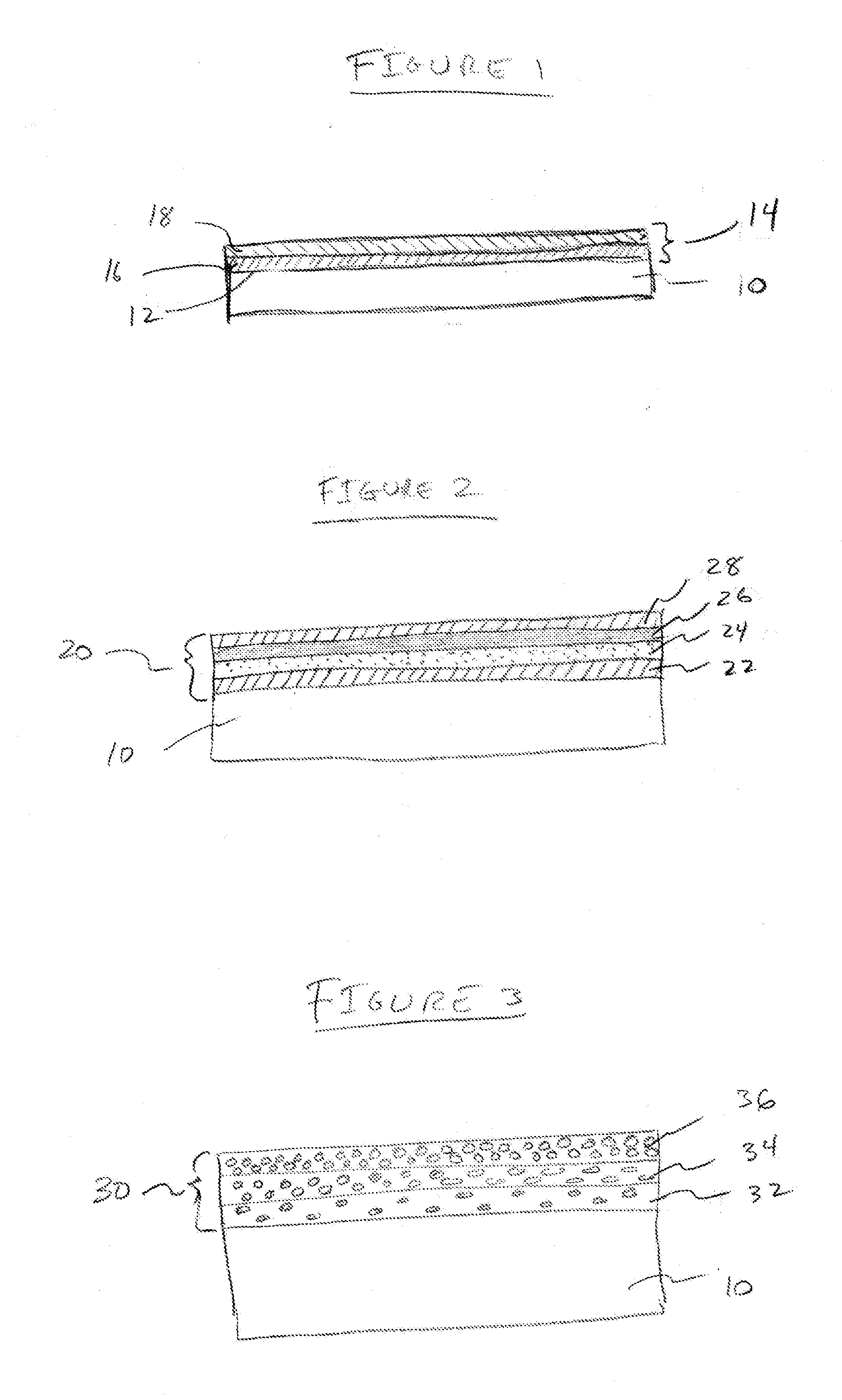

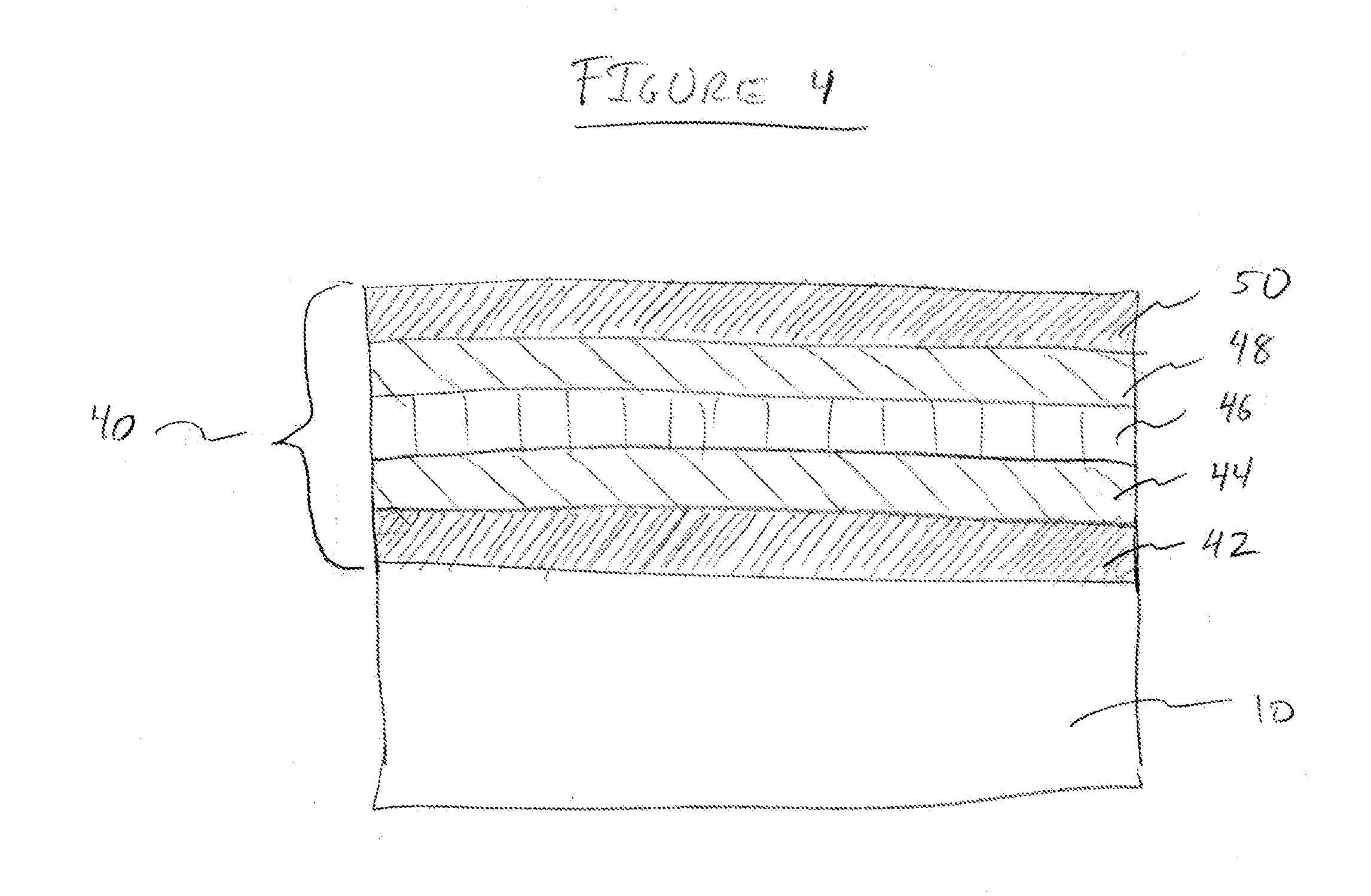

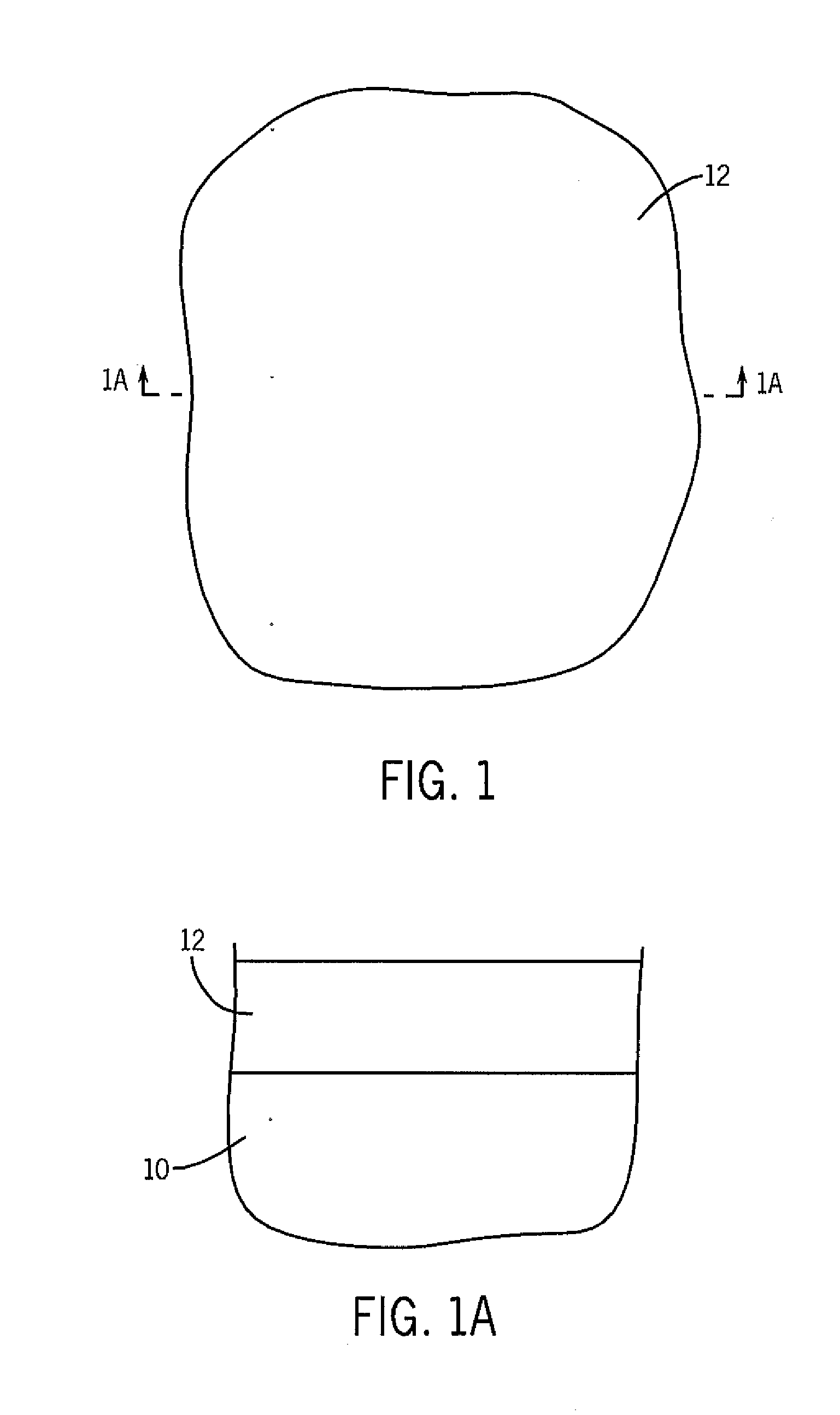

Methods of forming garments having one or more stretchable conductive ink patterns. Described herein are method of making garments (including compression garments) having one or more highly stretchable conductive ink pattern formed of a composite of an insulative adhesive, a conductive ink, and an intermediate gradient zone between the adhesive and conductive ink. The conductive ink typically includes between about 40-60% conductive particles, between about 30-50% binder; between about 3-7% solvent; and between about 3-7% thickener. The stretchable conductive ink patterns may be stretched more than twice their length without breaking or rupturing.

Owner:L I F E

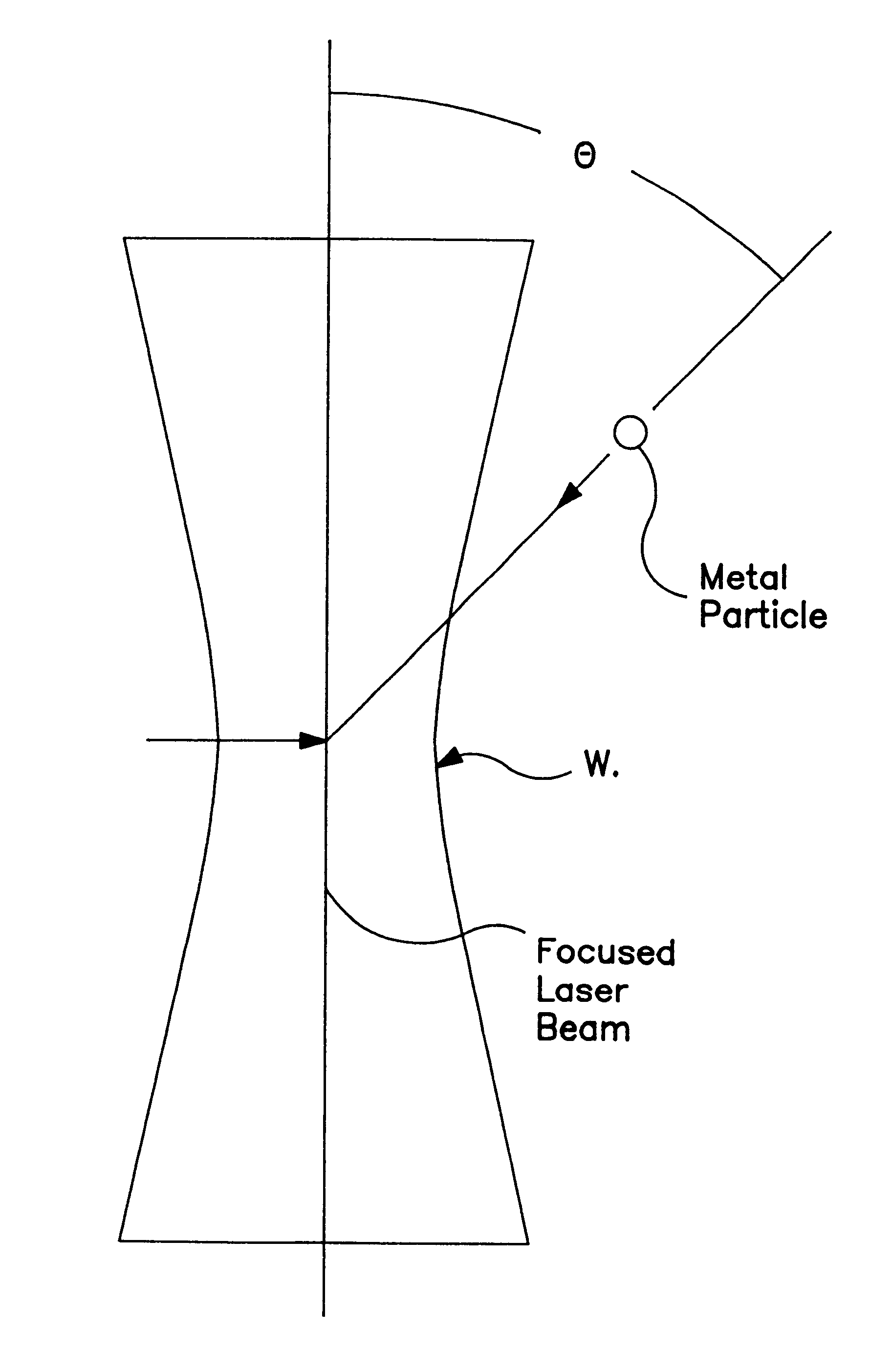

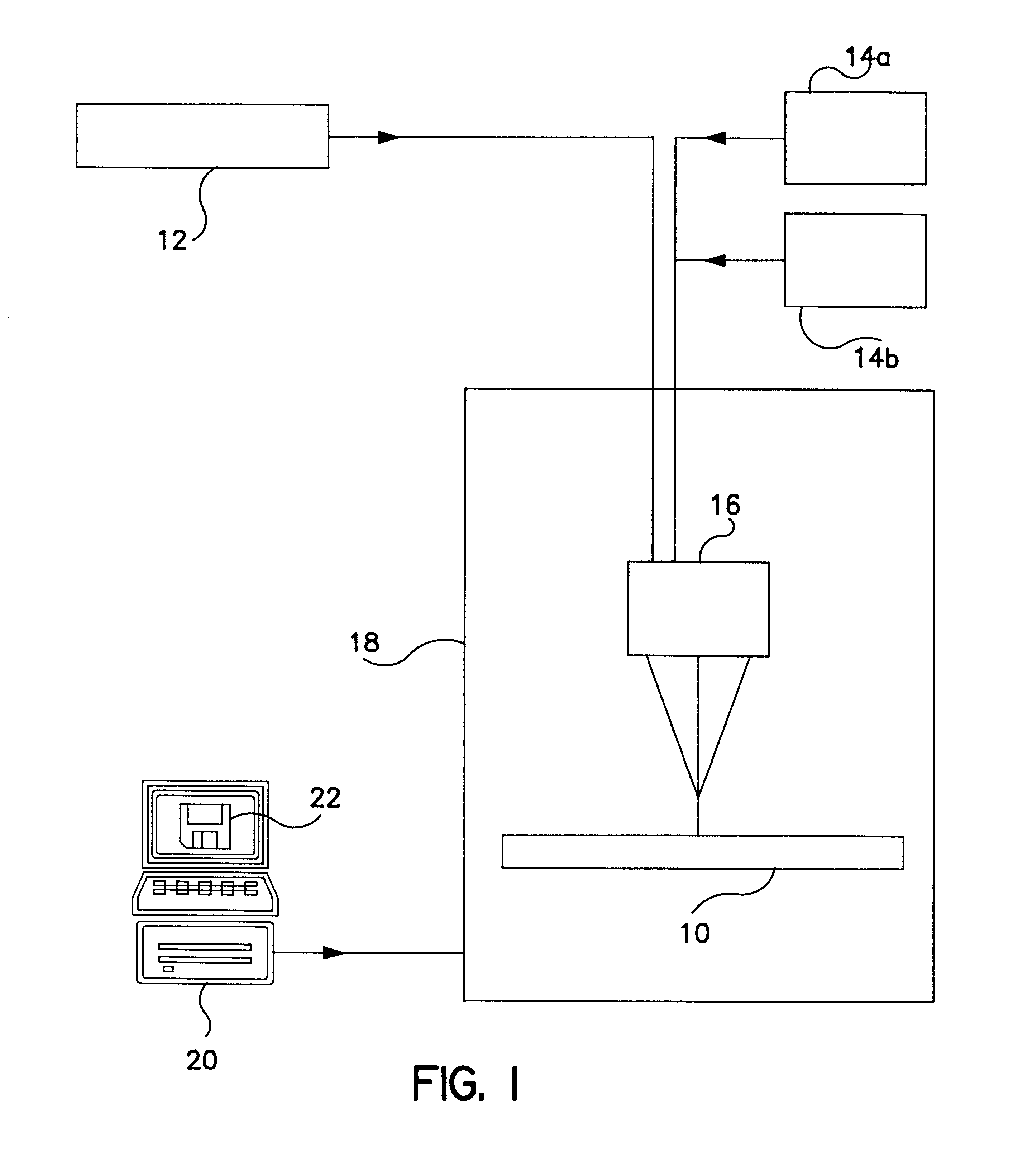

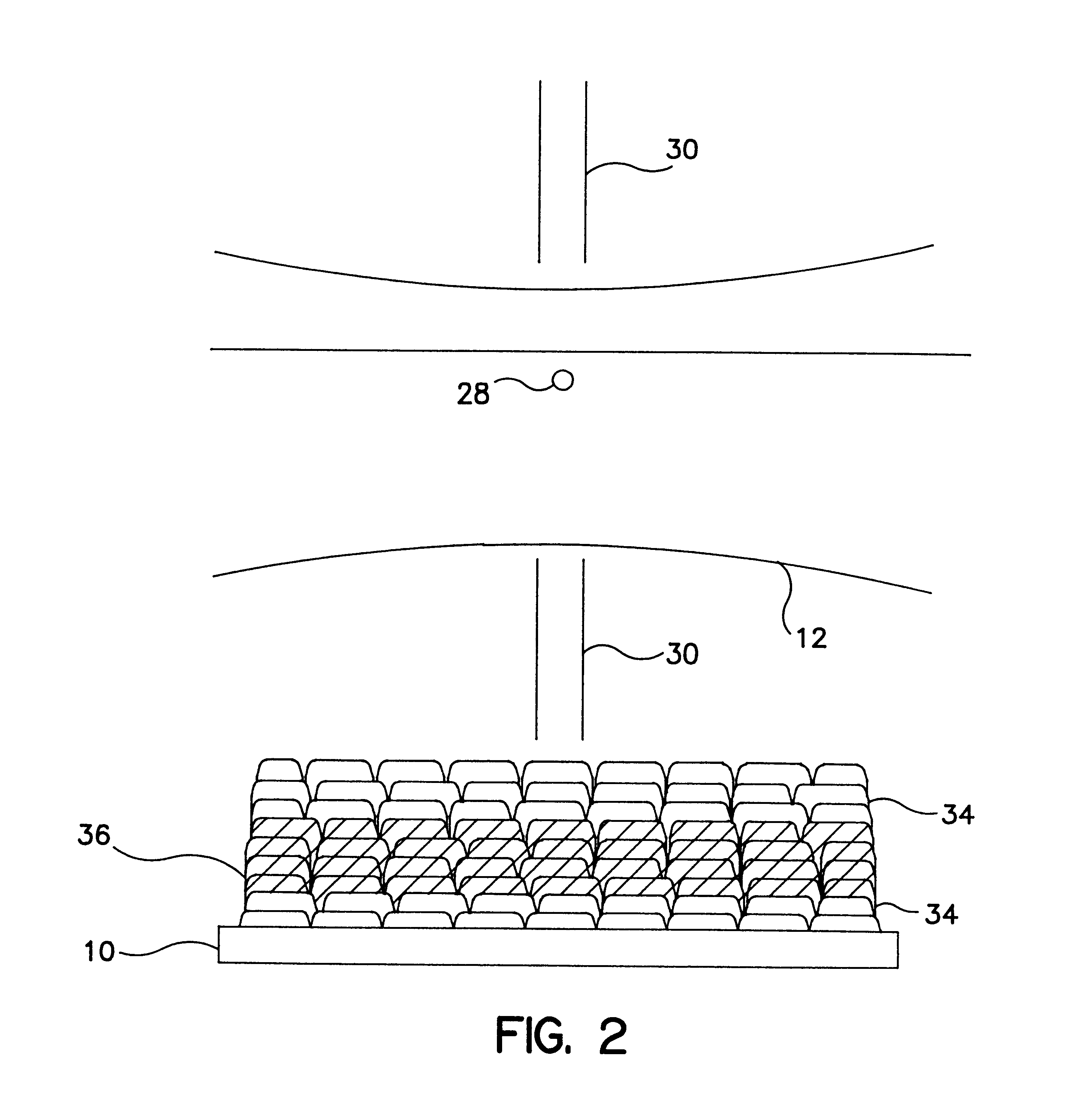

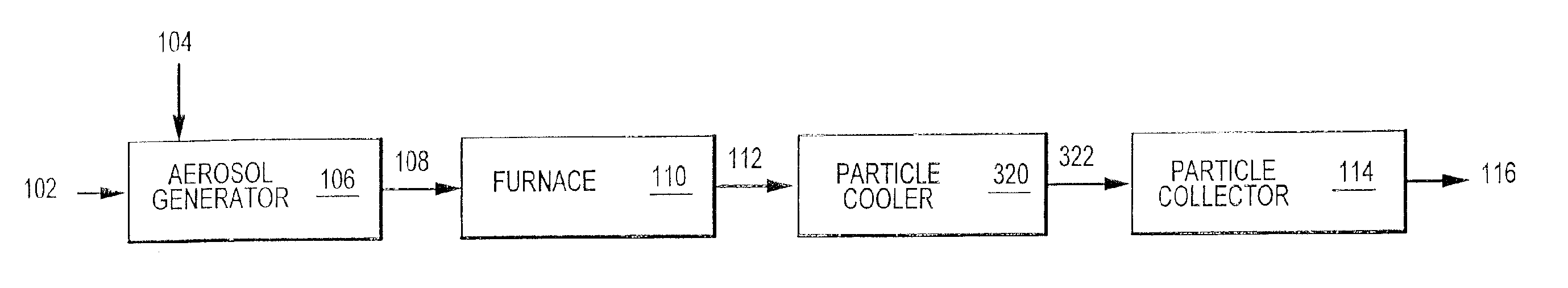

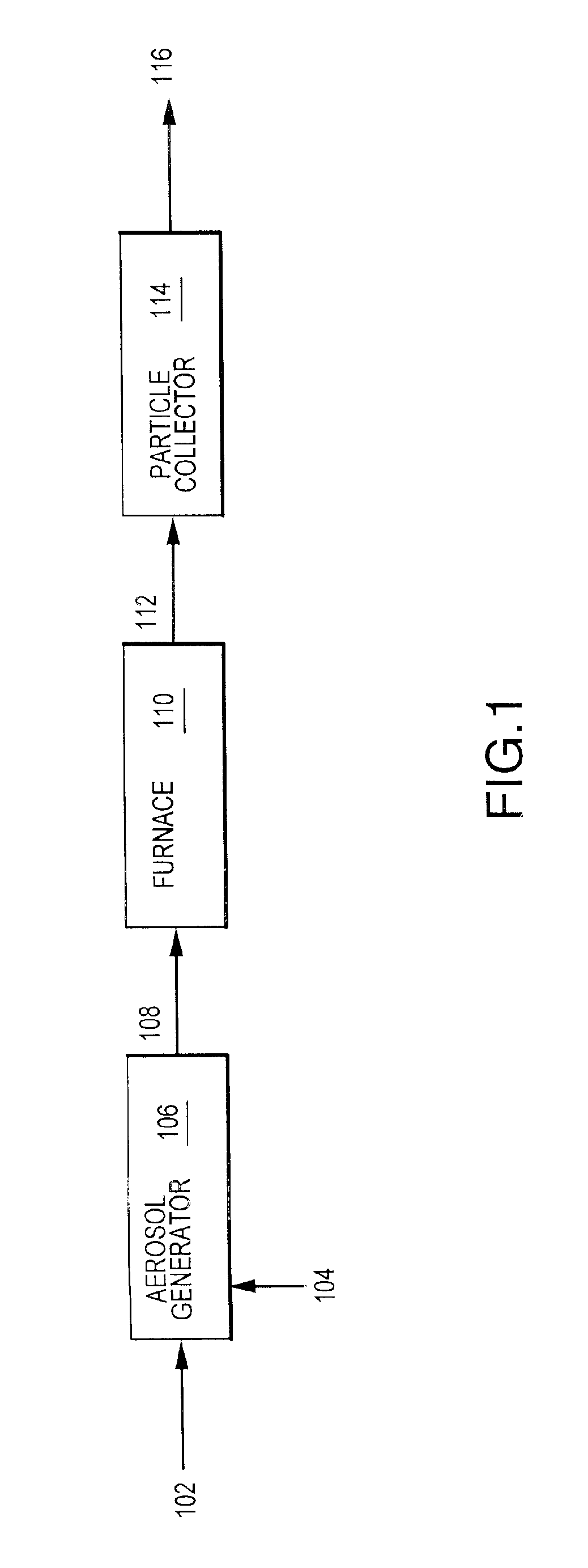

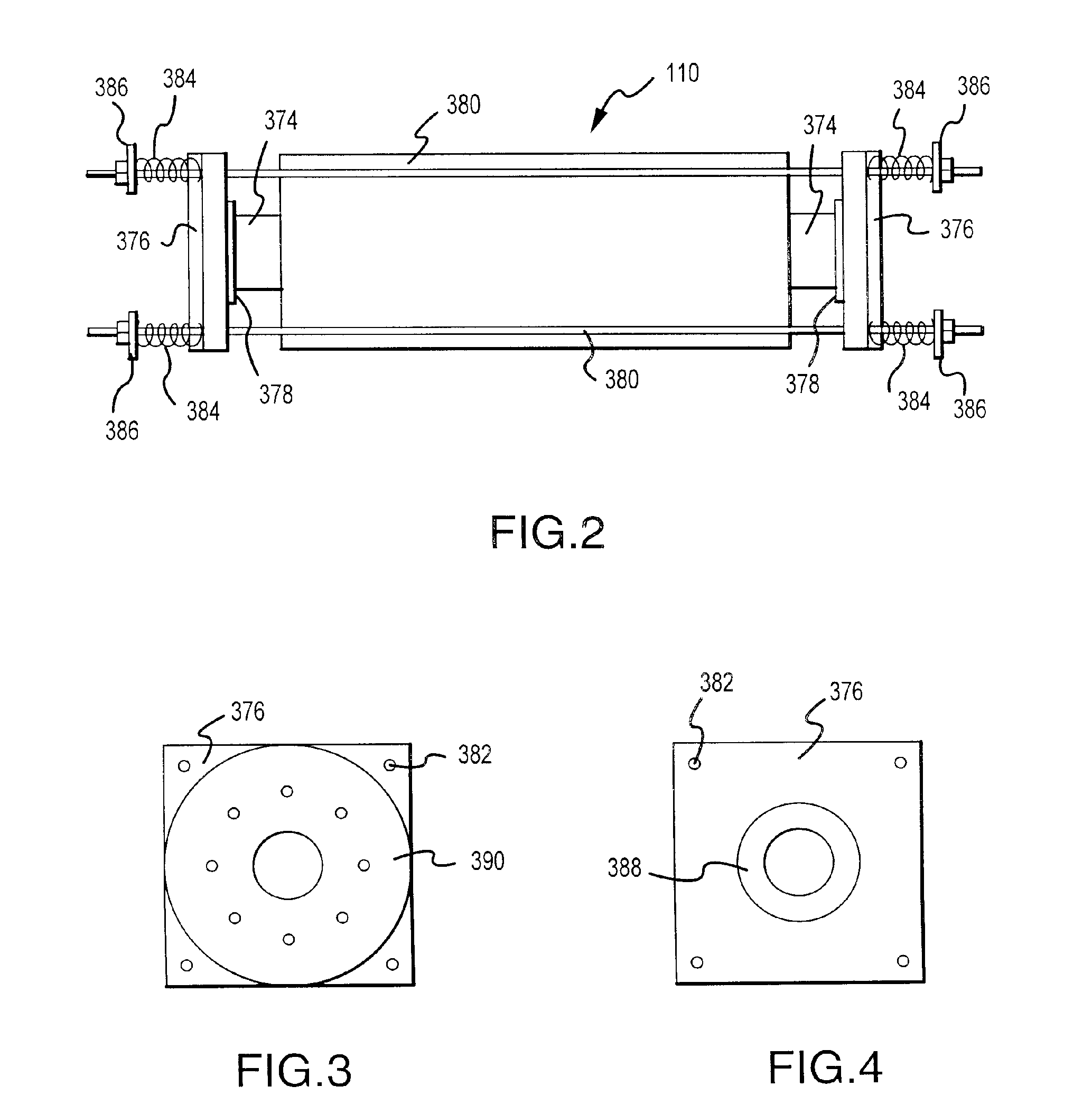

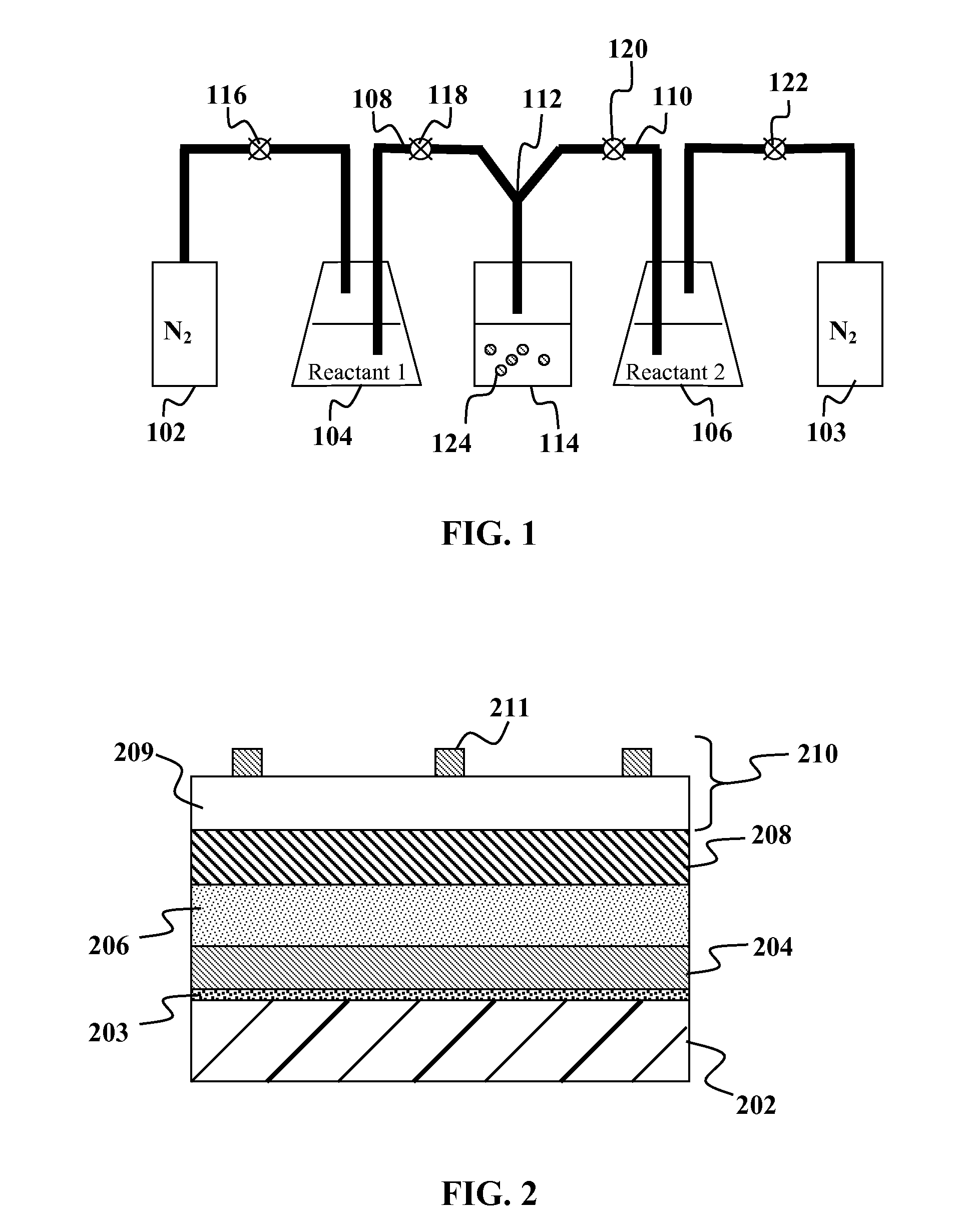

Precision spray processes for direct write electronic components

InactiveUS6251488B1Keep for a long timeIncrease probabilityMolten spray coatingVacuum evaporation coatingElectrical resistance and conductanceElectronic component

This invention combines the precision spray process with in-flight laser treatment in order to produce direct write electronic components. In addition to these components, the process can lay down lines of conductive, inductive, and resistive materials. This development has the potential to change the approach to electronics packaging. This process is revolutionary in that components can be directly produced on small structures, thus removing the need for printed circuit boards.

Owner:OPTOMEC DESIGN CO

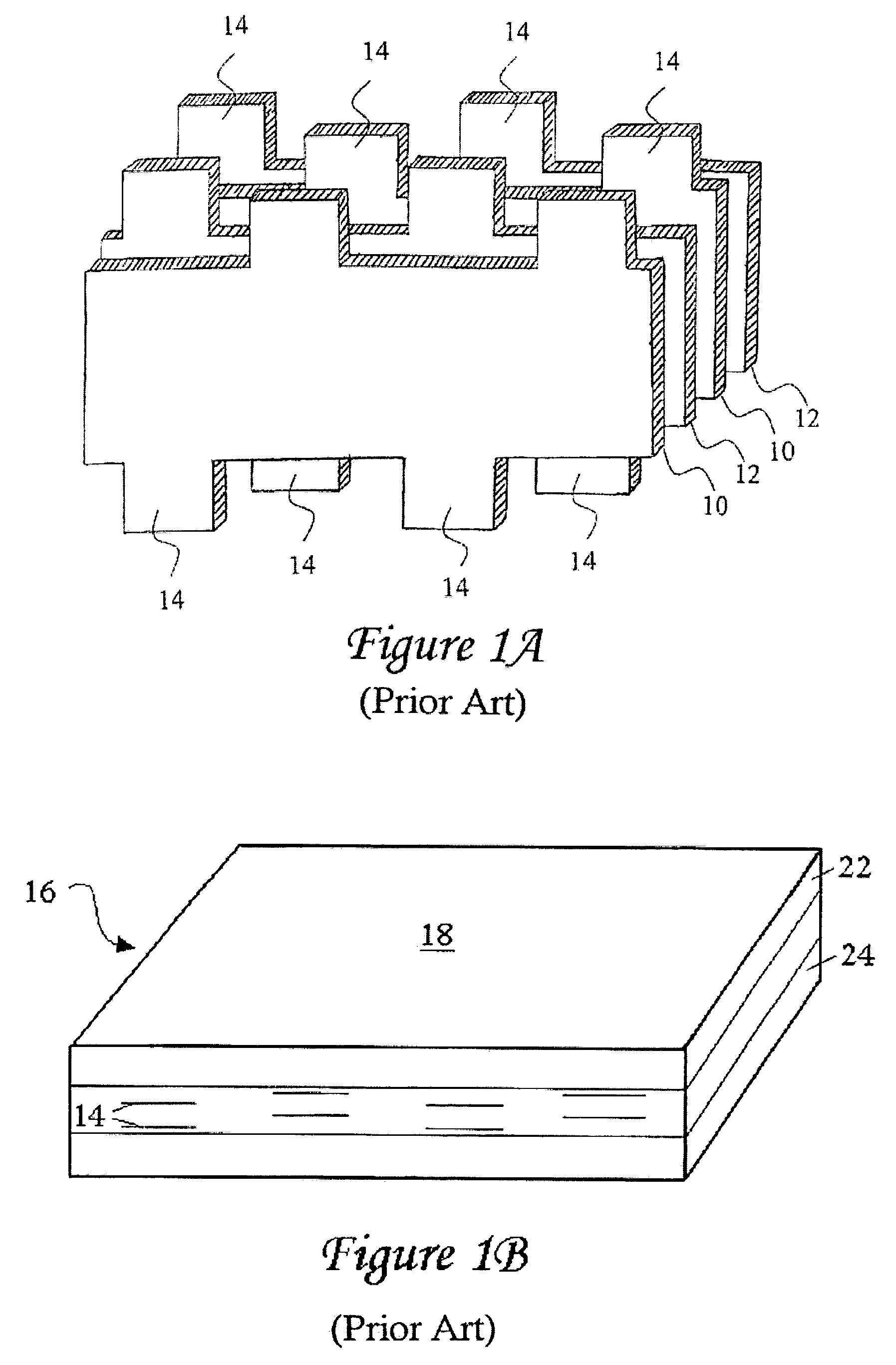

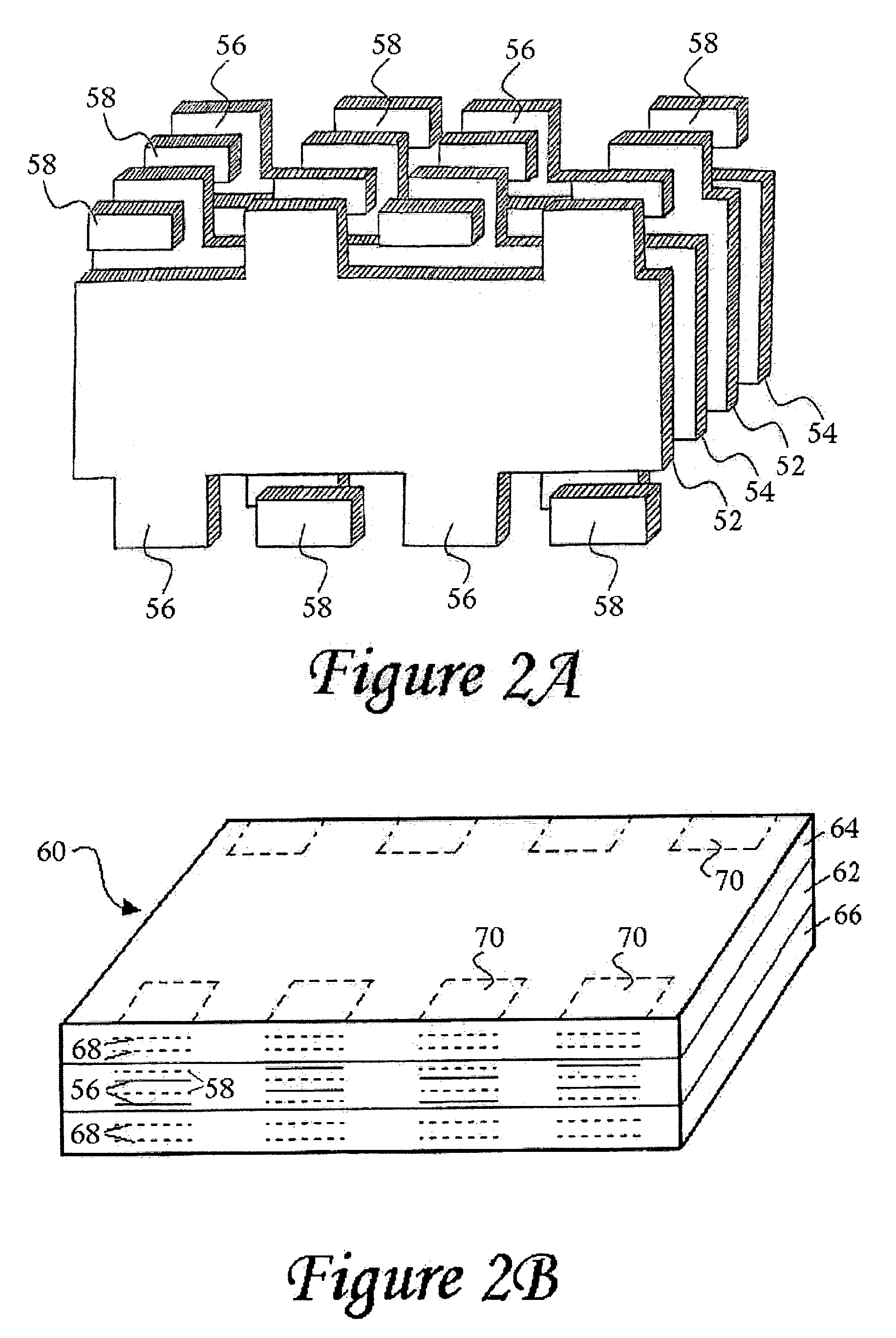

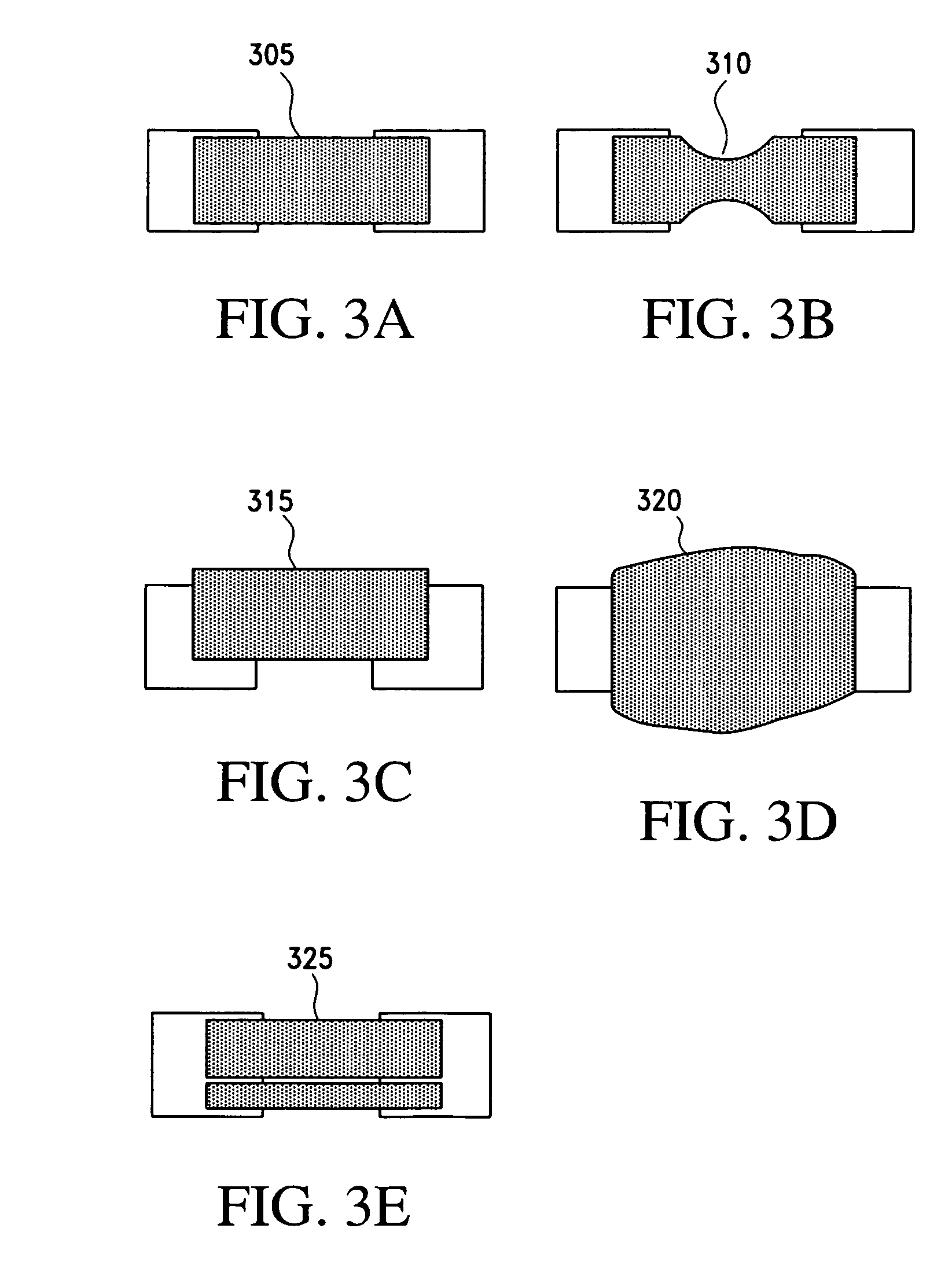

Method for forming plated terminations

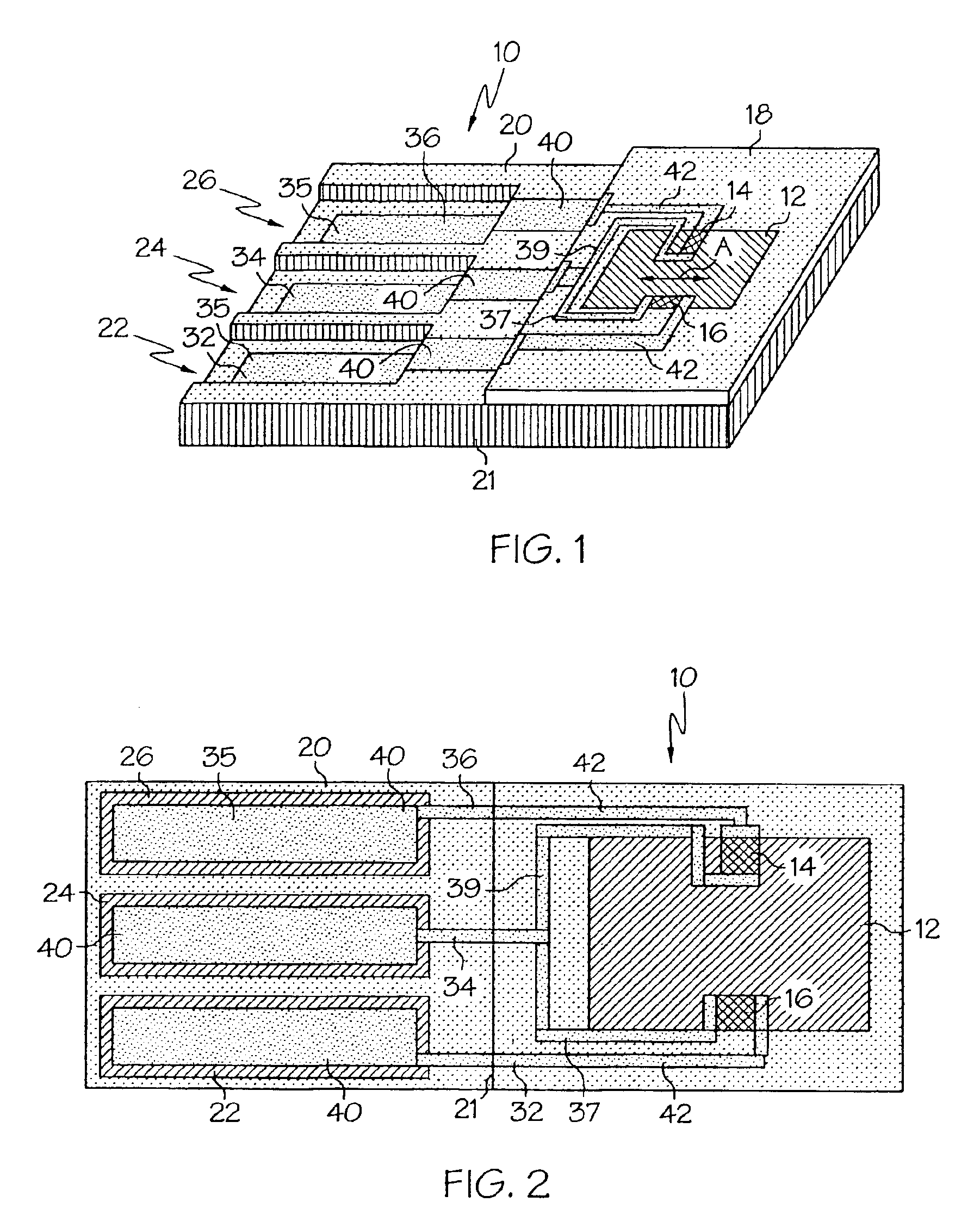

InactiveUS7152291B2Improved termination featureEliminate or greatly simplify thick-film stripesElectrolytic capacitorsSemiconductor/solid-state device detailsTermination problemEngineering

Improved method steps for terminating multilayer electronic components are disclosed. Monolithic components are formed with plated terminations whereby the need for typical thick-film termination stripes is eliminated or greatly simplified. Such termination technology eliminates many typical termination problems and enables a higher number of terminations with finer pitch, which may be especially beneficial on smaller electronic components. Electrode and dielectric layers are provided in an interleaved arrangement and selected portions of the electrode layers are exposed. Electrically isolated anchor tabs may optionally be provided and exposed in some embodiments. Termination material is then plated to the exposed portions of the electrode layers until exposed portions of selected such portions thereof are connected. A variety of different plating techniques and termination materials may be employed in the formation of the subject self-determining plated terminations.

Owner:KYOCERA AVX COMPONENTS CORP

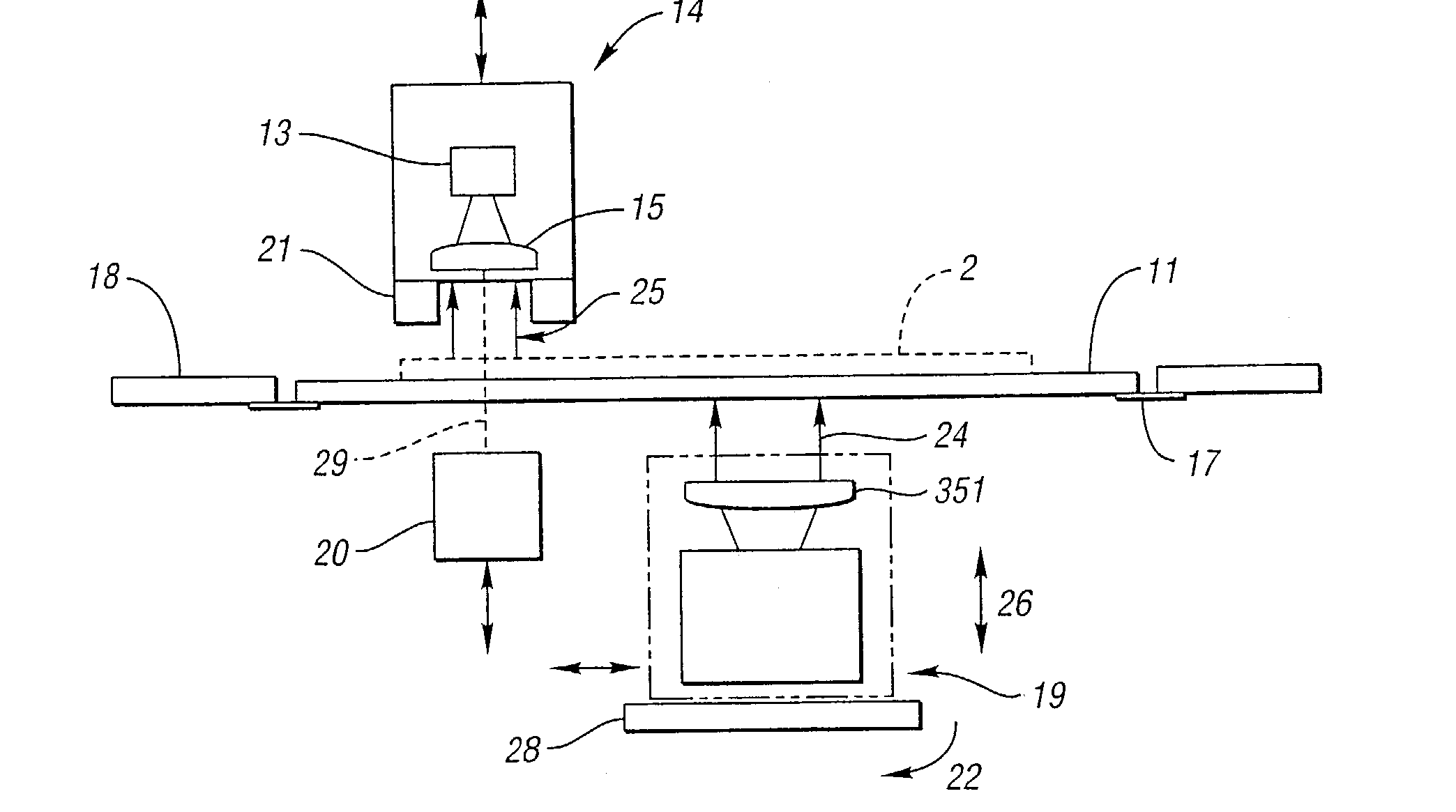

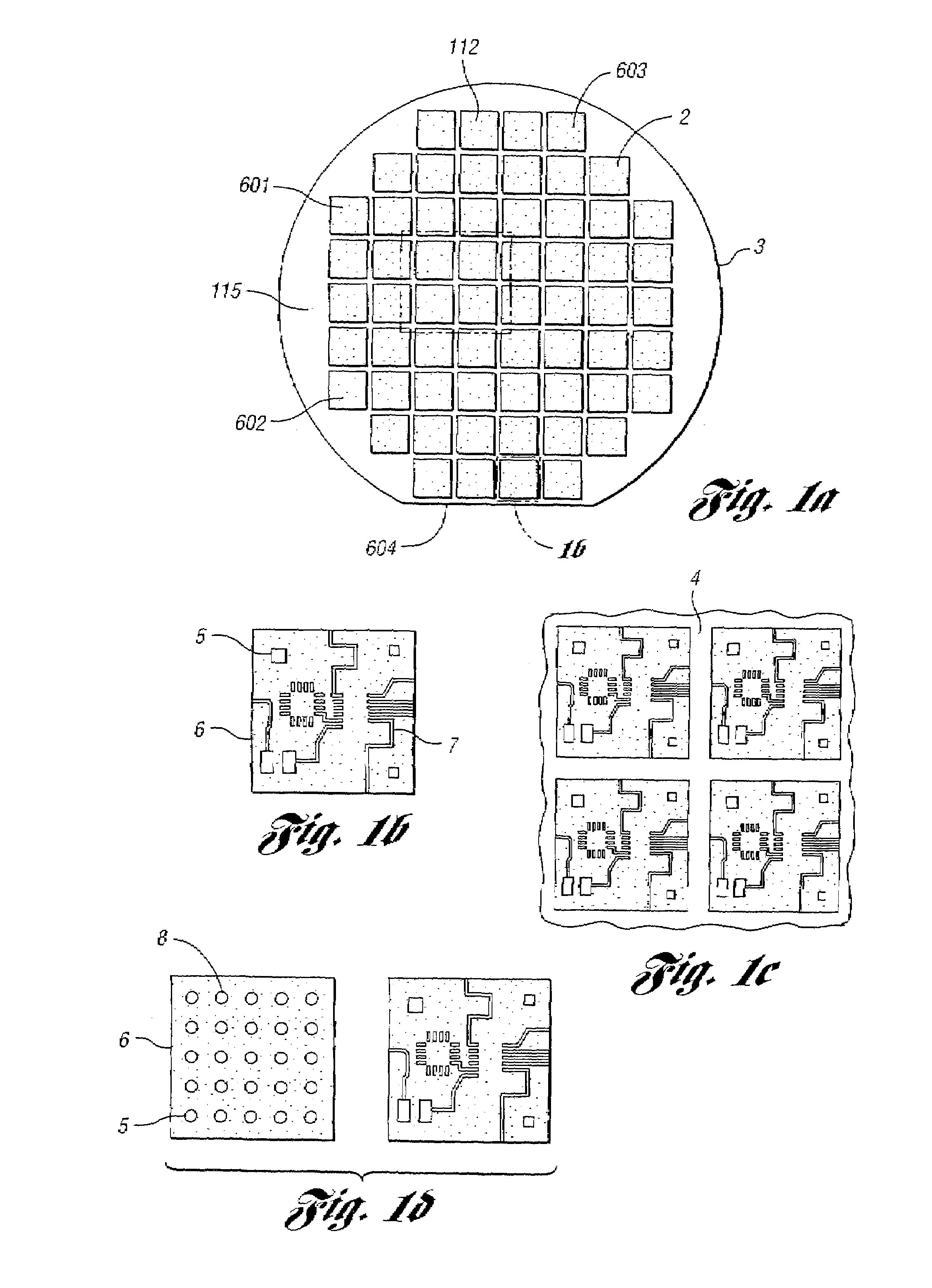

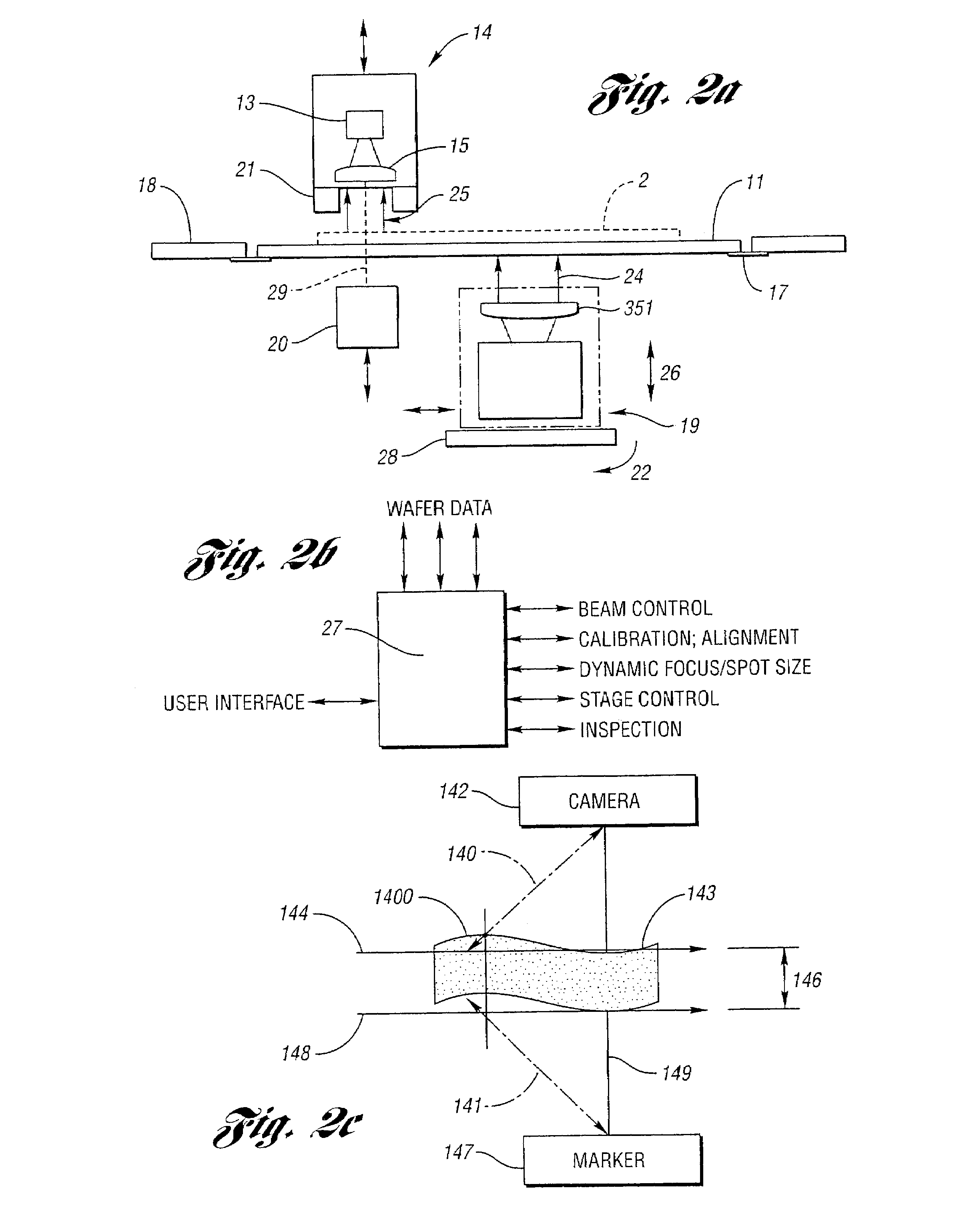

Method and system for calibrating a laser processing system and laser marking system utilizing same

InactiveUS7015418B2Mark accuratelyRecording apparatusSemiconductor/solid-state device detailsLaser processingThree degrees of freedom

A method of calibrating a laser marking system includes calibrating a laser marking system in three dimensions. The step of calibrating includes storing data corresponding to a plurality of heights. A position measurement of a workpiece is obtained to be marked. Stored calibration data is associated with the position measurement. A method and system for calibrating a laser processing or marking system is provided. The method includes: calibrating a laser marker over a marking field; obtaining a position measurement of a workpiece to be marked; associating stored calibration data with the position measurement; relatively positioning a marking beam and the workpiece based on at least the associated calibration data; and calibrating a laser marking system in at least three degrees of freedom. The step of calibrating includes storing data corresponding to a plurality of positions and controllably and relatively positioning a marking beam based on the stored data corresponding to the plurality of positions.

Owner:ELECTRO SCI IND INC

Porous Film and Multilayer Assembly Using the Same

InactiveUS20090008142A1Satisfactorily flexibleImprove porosityVacuum evaporation coatingSputtering coatingInterfacial delaminationPorous layer

[Object] To provide a multilayer assembly that excels in pore properties, is flexible, and is satisfactorily handled and processed; and a method of producing the multilayer assembly.[Solving Means] A multilayer assembly includes a base and, arranged on at least one side thereof, a porous layer and has a large number of continuous micropores with an average pore diameter of 0.01 to 10 μm. The multilayer assembly suffers from no interfacial delamination between the base and the porous layer when examined in a tape peeling test according to the following procedure:Tape Peeling TestA 24-mm wide masking tape [Film Masking Tape No. 603 (#25)] supplied by Teraoka Seisakusho Co., Ltd. is applied to a surface of the porous layer of the multilayer assembly and press-bonded thereto with a roller having a diameter of 30 mm and a load of 200 gf to give a sample; and the sample is subjected to a T-peel test with a tensile tester at a peel rate of 50 mm / min.

Owner:DAICEL CHEM IND LTD

Inorganic dopants, inks and related nanotechnology

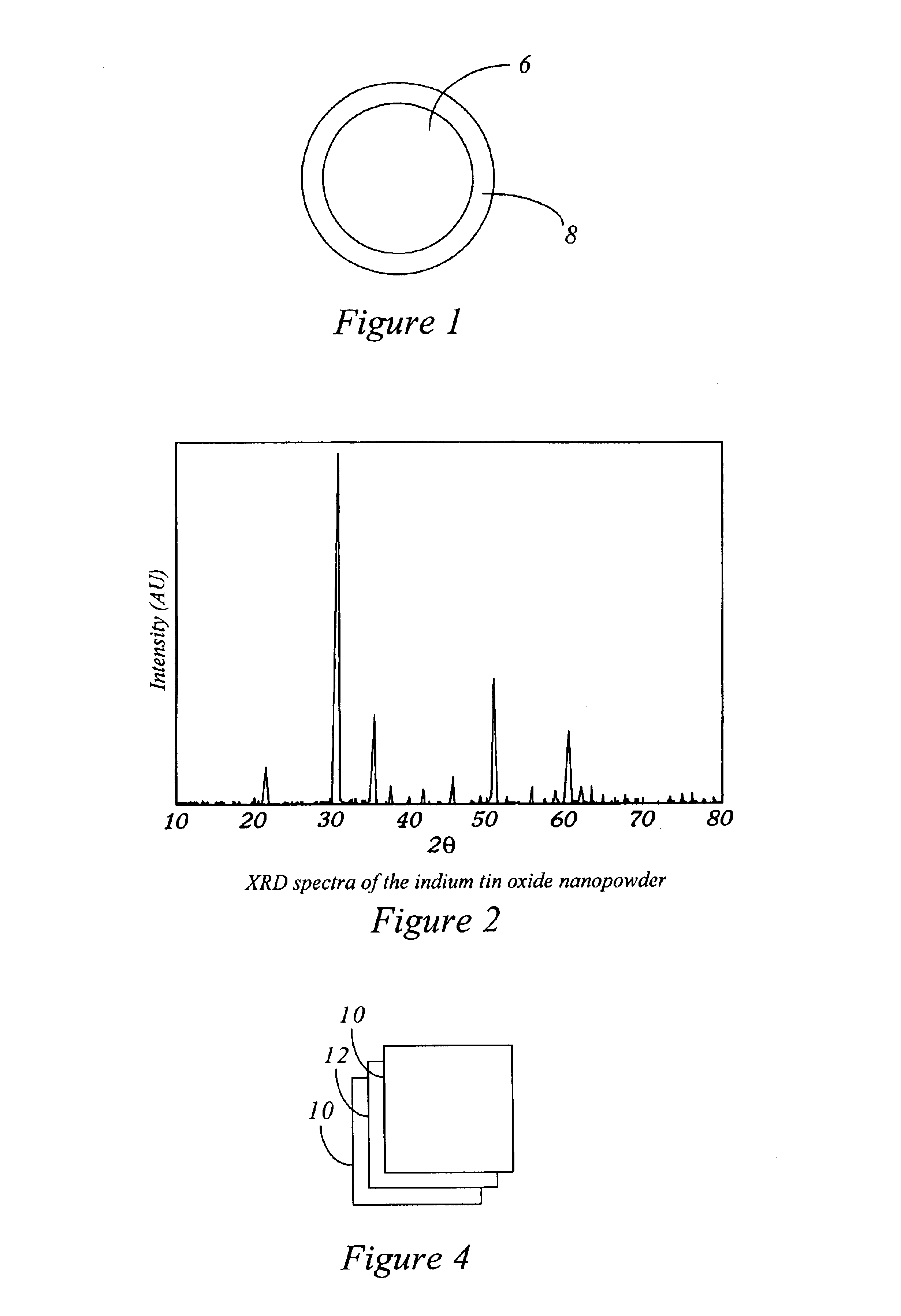

InactiveUS6849109B2Facilitated DiffusionLower transition temperatureSelenium/tellurium compundsCell electrodesIndiumCerium

Ink compositions with modified properties result from using a powder size below 100 nanometers. Colored inks are illustrated. Nanoscale coated, uncoated, whisker inorganic fillers are included. The pigment nanopowders taught comprise one or more elements from the group actinium, aluminum, antimony, arsenic, barium, beryllium, bismuth, cadmuim, calcium, cerium, cesium, chalcogenide, cobalt, copper, dysprosium, erbium, europium, gadolinium, gallium, gold, hafnium, hydrogen, indium, iridium, iron, lanthanum, lithium, magnesium, manganese, mendelevium, mercury, molybdenum, neodymium, neptunium, nickel, niobium, nitrogen, oxygen, osmium, palladium, platinum, potassium, praseodymium, promethium, protactinium, rhenium, rubidium, scandium, silver, sodium, strontium, tantalum, terbium, thallium, thorium, tin, titanium, tungsten, vanadium, ytterbium, yttrium, zinc, and zirconium.

Owner:PPG IND OHIO INC

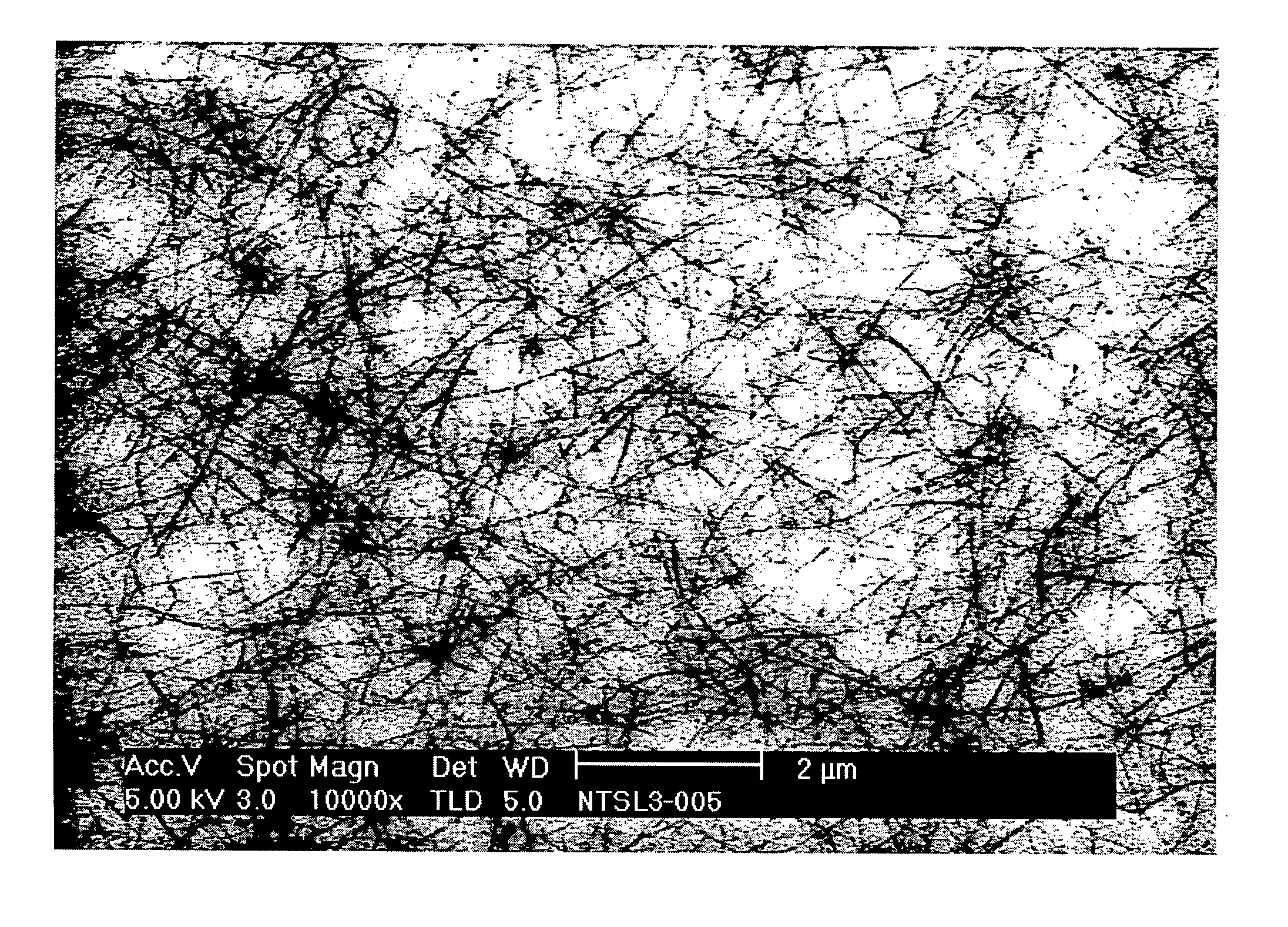

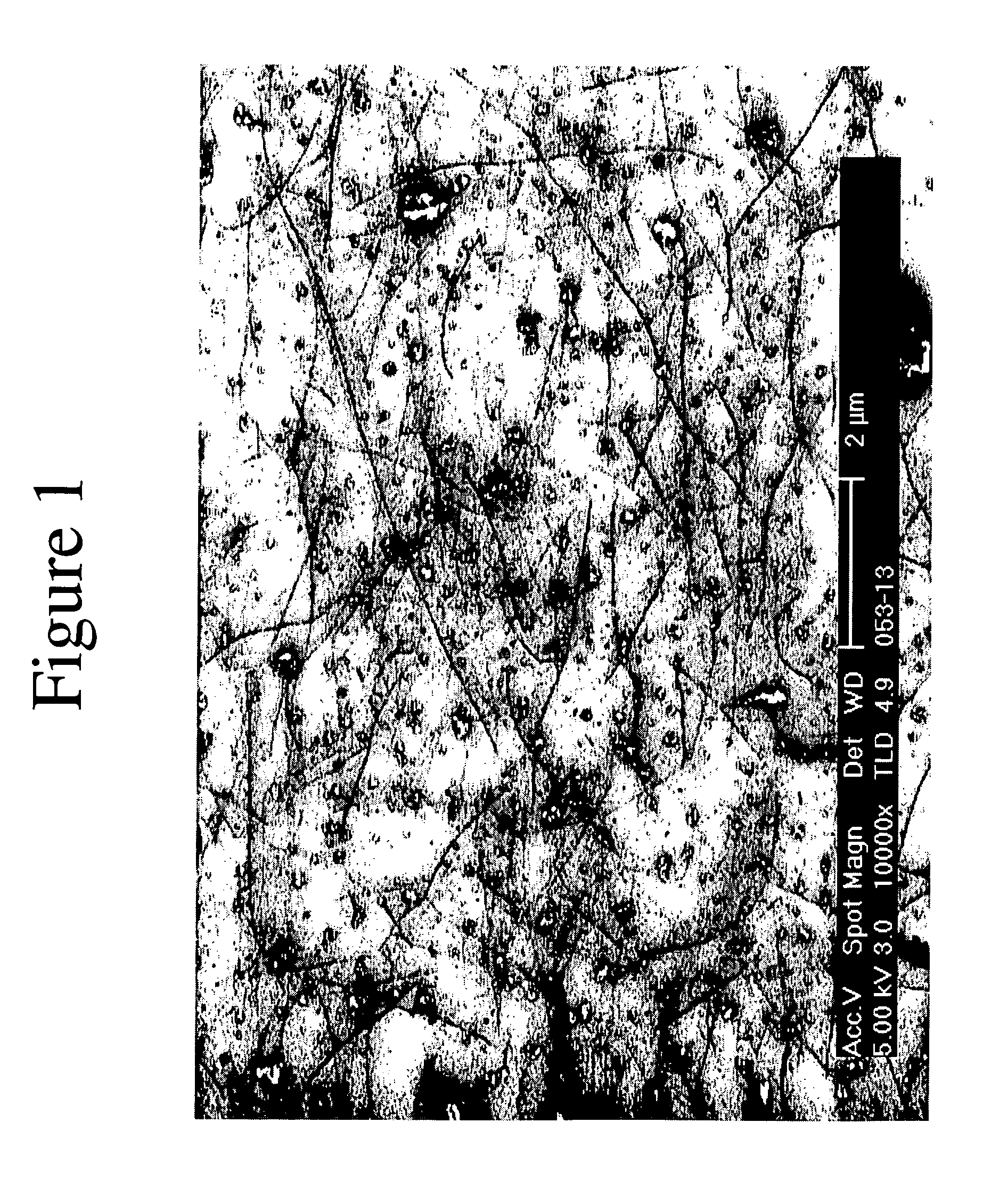

Nanotube articles with adjustable electrical conductivity and methods of making the same

InactiveUS20060276056A1Improve the immunityElectrical resistance increaseMaterial nanotechnologyFixed capacitor dielectricElectrical resistance and conductanceElectrical conductor

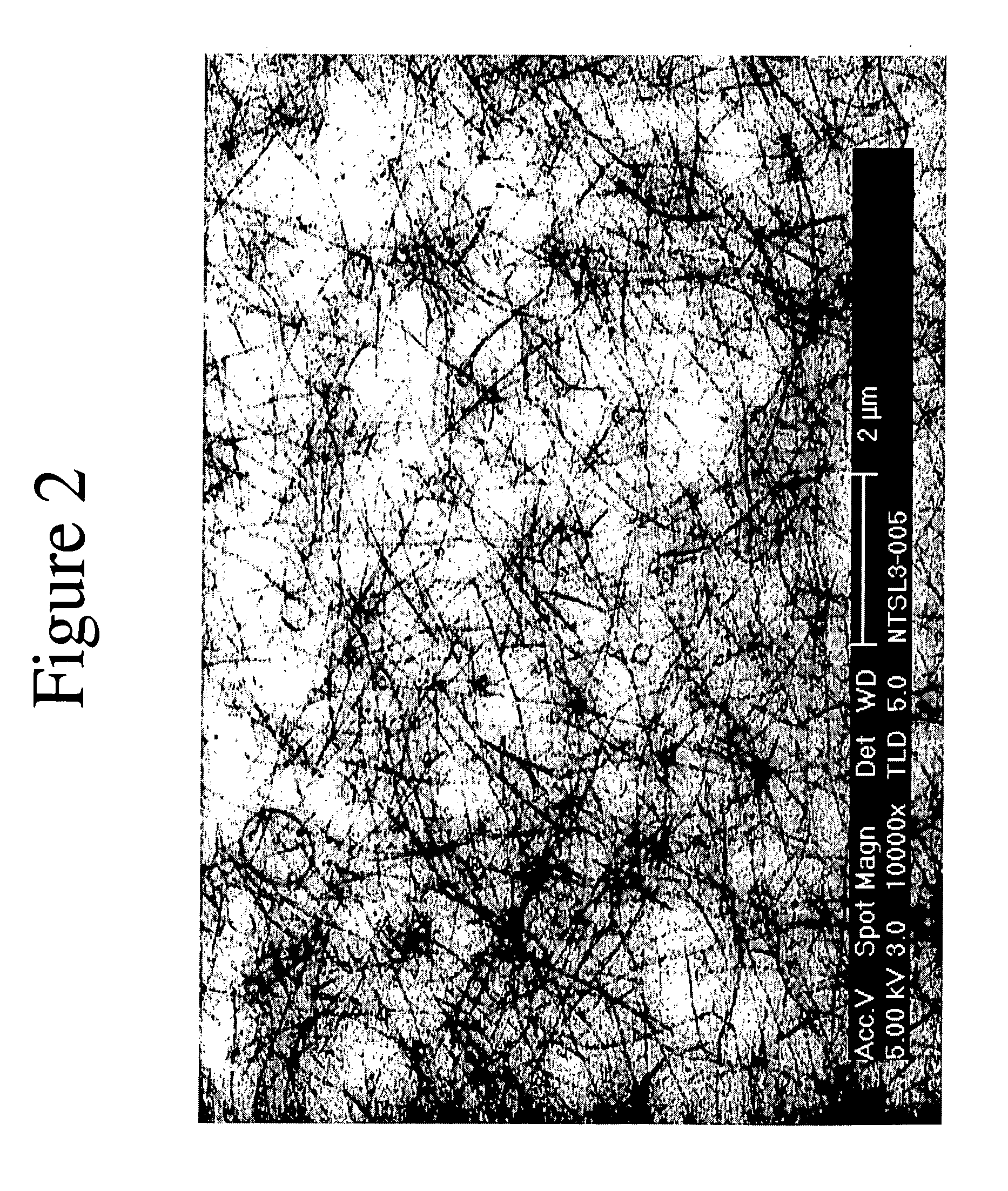

Nanotube articles having adjustable electrical conductivity, and methods of making the same. A patterned article includes conducting nanotubes that define a plurality of conductive pathways along the article, and also includes nanotubes of modified electrical conductivity. The modified nanotubes may electrically isolate the conducting nanotubes from other conductors. The nanotube segments may originally be semiconducting nanotubes, metallic nanotubes, nanotubes, single walled carbon nanotubes, multi-walled carbon nanotubes, or nanotubes entangled with nanotubes. The various segments may have different lengths and may include segments having a length shorter than the length of the article. A strapping material may be positioned to contact a portion of the plurality of nanotube segments. Such a strapping layer may also be used for making electrical contact to the nanotube fabric especially for electrical stitching to lower the overall resistance of the fabric.

Owner:NANTERO

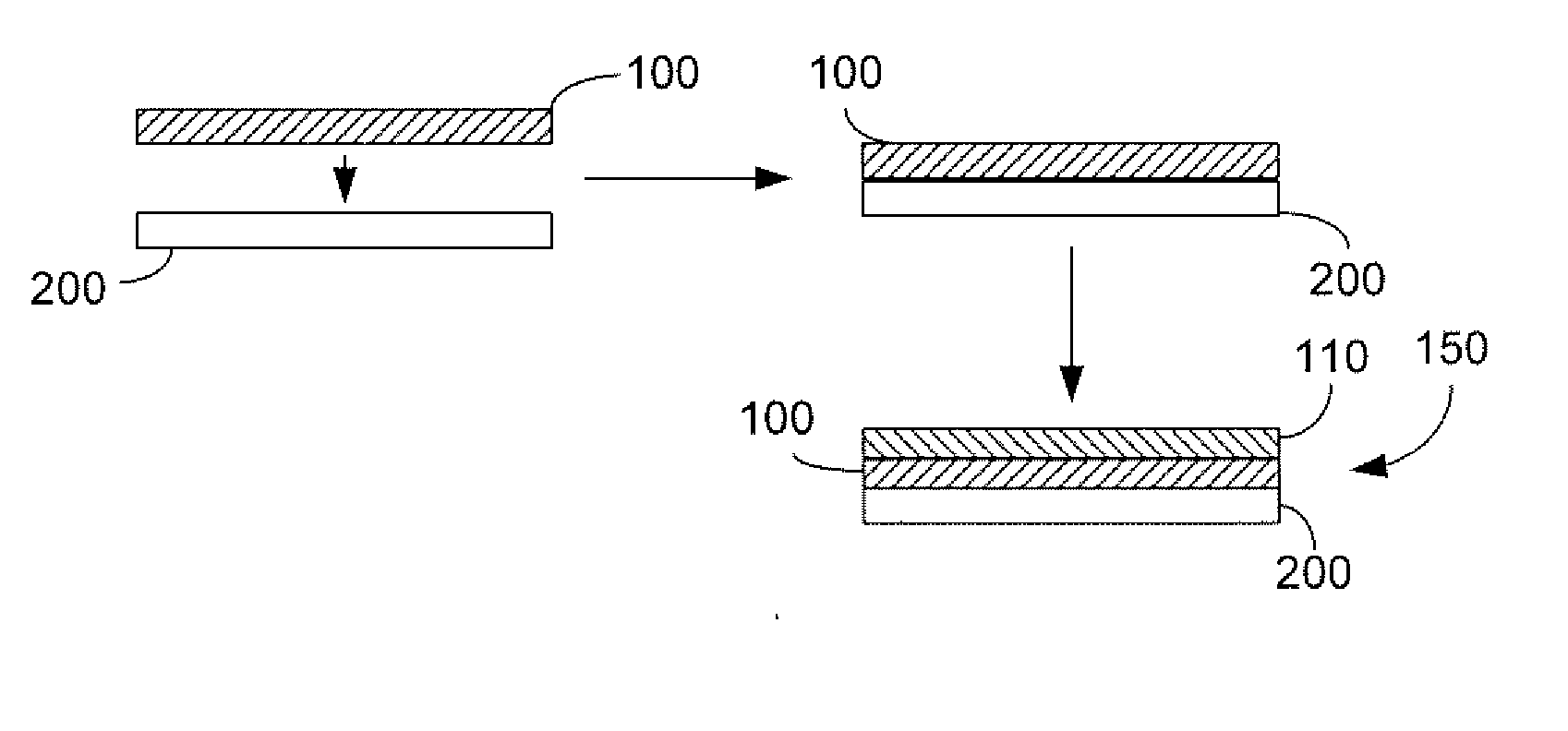

Patterning solution deposited thin films with self-assembled monolayers

InactiveUS6887332B1Low costMaterial nanotechnologyNanoinformaticsSelf-assembled monolayerDeposition process

The present invention provides a method of forming a patterned thin film on a surface of a substrate having thereon a patterned underlayer of a self-assembled monolayer. The method comprises depositing a thin film material on the self-assembled monolayer to produce a patterned thin film on the surface of the substrate. The present invention further provides processes for preparing the self-assembled monolayer. The present invention still further provides solution-based deposition processes, such as spin-coating and immersion-coating, to deposit a thin film material on the self-assembled monolayer to produce a patterned thin film on the surface of the substrate.

Owner:IBM CORP

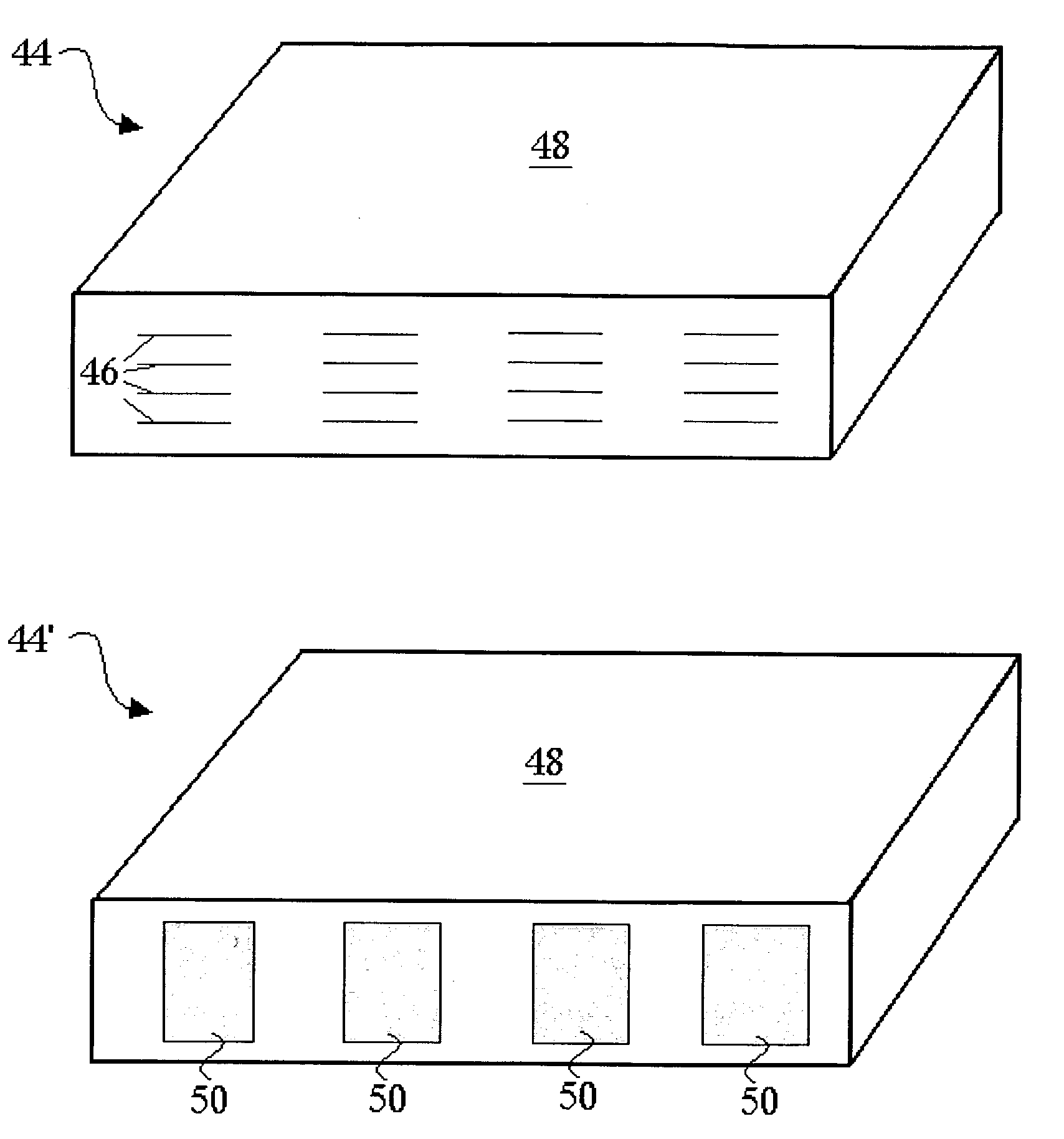

Alternating Self-Assembling Morphologies of Diblock Copolymers Controlled by Variations in Surfaces

ActiveUS20080311347A1Material nanotechnologySemiconductor/solid-state device manufacturingDevice formCopolymer

Methods for fabricating sublithographic, nanoscale microstructures arrays including openings and linear microchannels utilizing self-assembling block copolymers, and films and devices formed from these methods are provided. In some embodiments, the films can be used as a template or mask to etch openings in an underlying material layer.

Owner:MICRON TECH INC

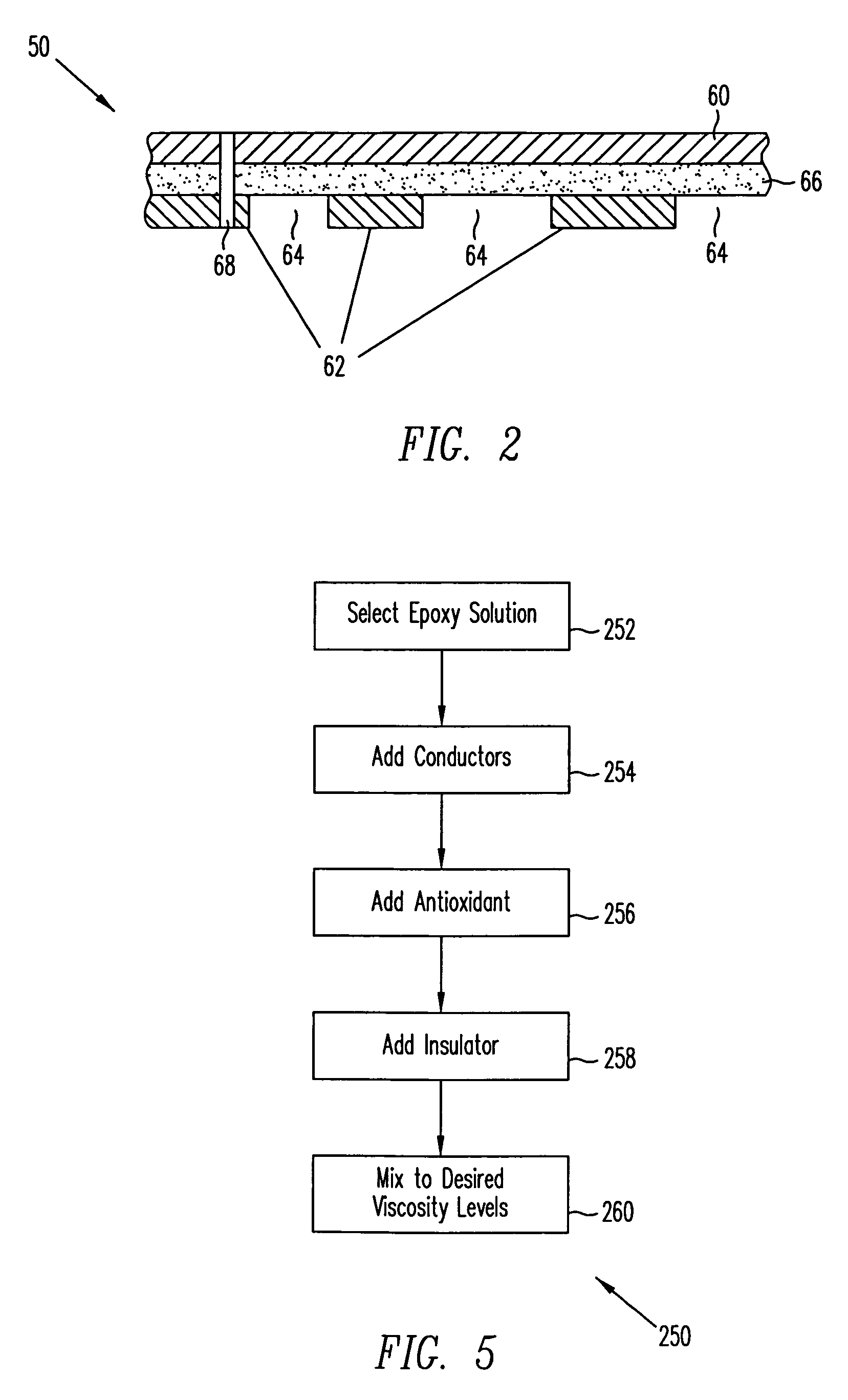

Methods and compositions for the formation of recessed electrical features on a substrate

InactiveUS20070122932A1Reduce settlementGood dispersionPrinted circuit aspectsConductive materialElectrical conductorMechanical property

Precursor compositions having a low conversion temperature and methods for the fabrication of recessed electrical features from the precursor compositions. The electrical features can be conductors, resistors and dielectric features. The precursor compositions are deposited into recessed features, such as trenches, formed in a substrate and are reacted at a low temperature to form electrical features having good electrical and mechanical properties. The substrate can be a low temperature substrate, such as an organic substrate.

Owner:CABOT CORP

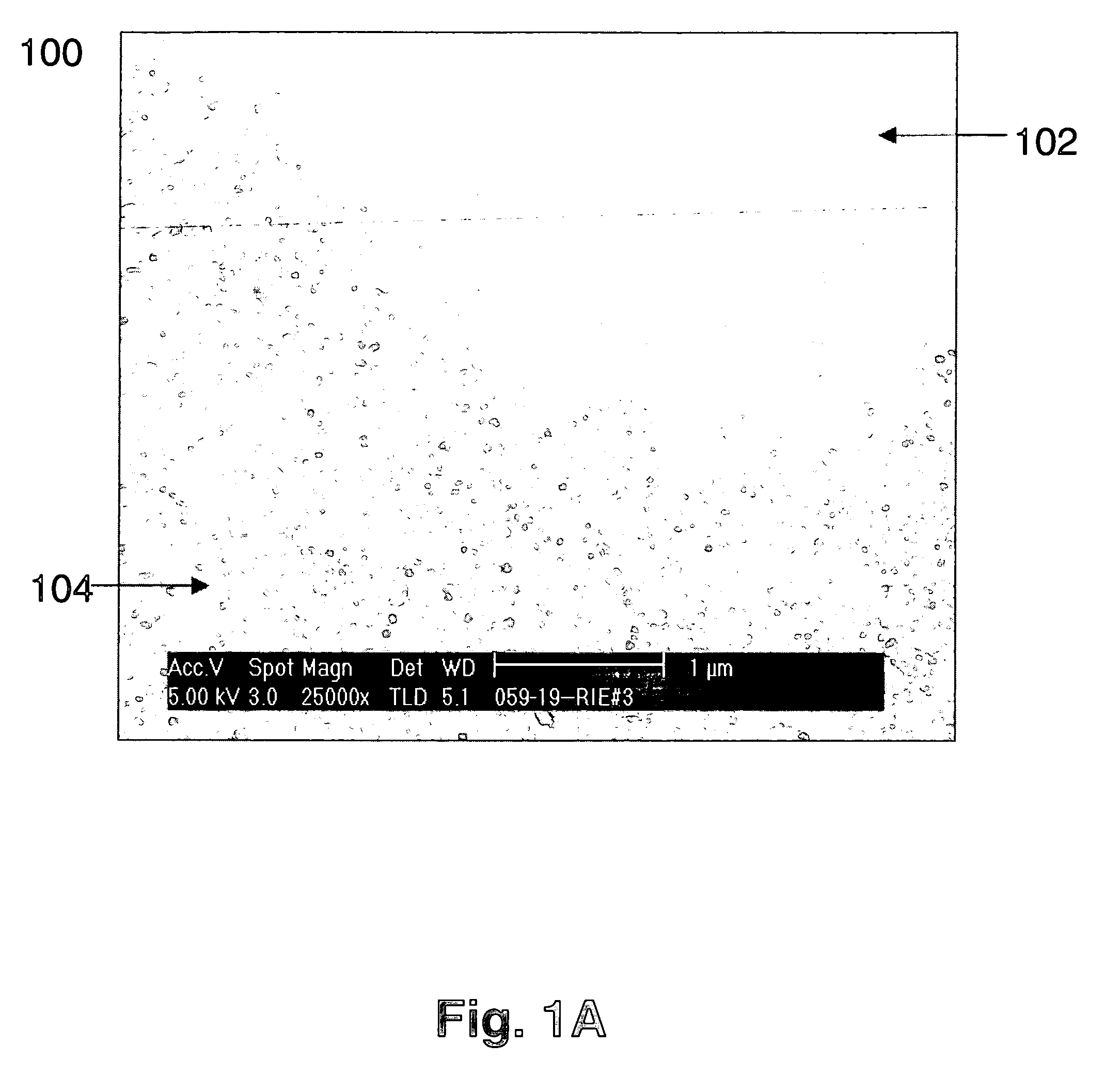

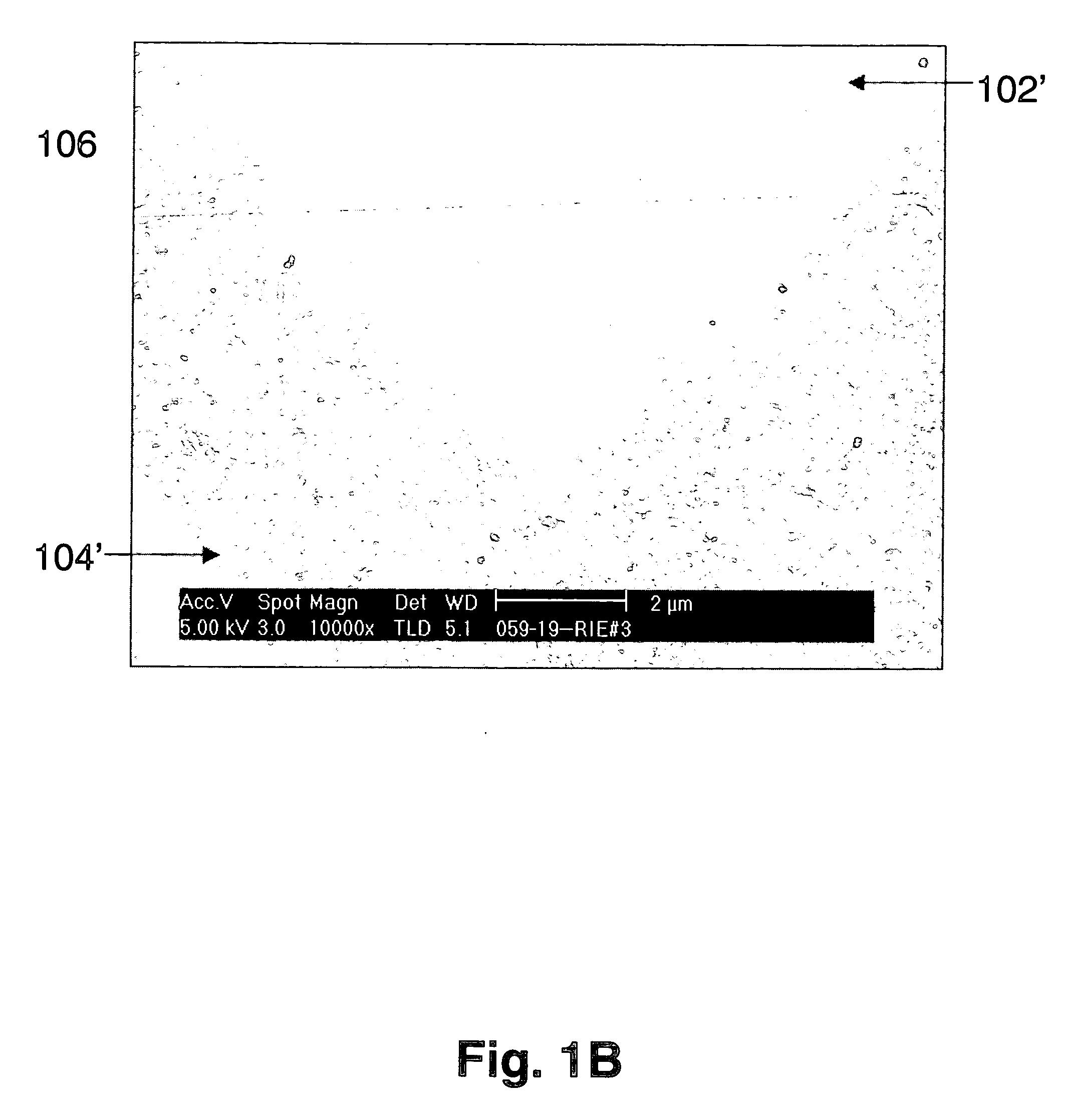

Spin-coatable liquid for use in electronic fabrication processes

Certain spin-coatable liquids and application techniques are described, which can be used to form nanotube films or fabrics of controlled properties. A spin-coatable liquid containing nanotubes for use in an electronics fabrication process includes a solvent containing a plurality of nanotubes. The nanotubes are at a concentration of greater than 1 mg / L. The nanotubes are pretreated to reduce the level of metallic and particulate impurities to a preselected level, and the preselected metal and particulate impurities levels are selected to be compatible with an electronics manufacturing process. The solvent also is selected for compatibility with an electronics manufacturing process.

Owner:ZEON CORP

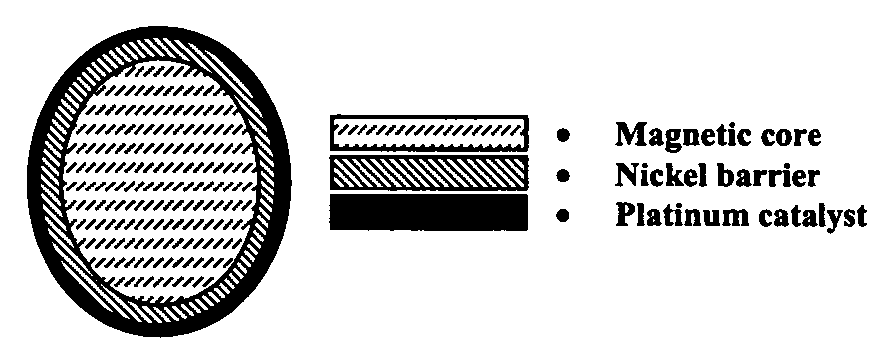

Coated nickel-containing powders, methods and apparatus for producing such powders and devices fabricated from same

InactiveUS20050097988A1High rateIncrease loadMaterial granulation and coatingGranule coatingSpherical morphologySmall particle

Nickel powder batches including coated nickel-containing particles and methods for producing the same. The coated nickel-containing particles having have a small particle size, narrow size distribution and a spherical morphology. The present invention is also directed to devices incorporating the coated nickel-containing particles.

Owner:CABOT CORP

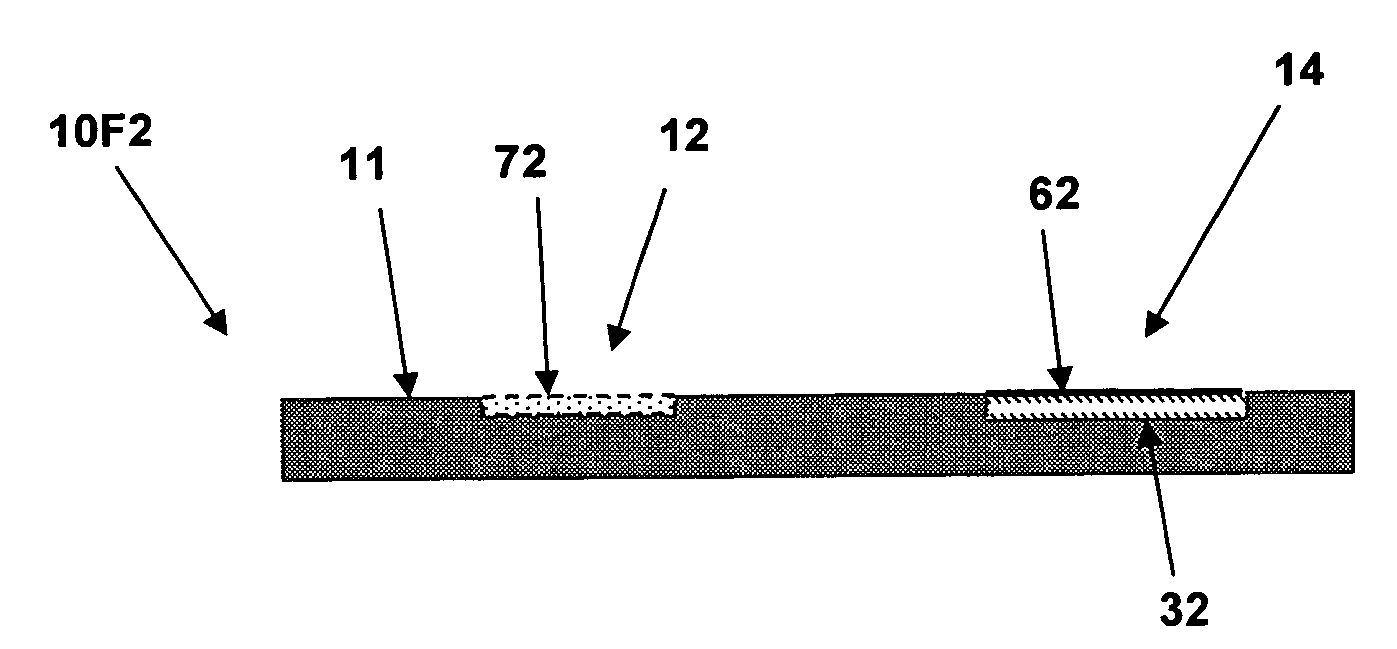

Flexible PTC heating element and method of manufacturing the heating element

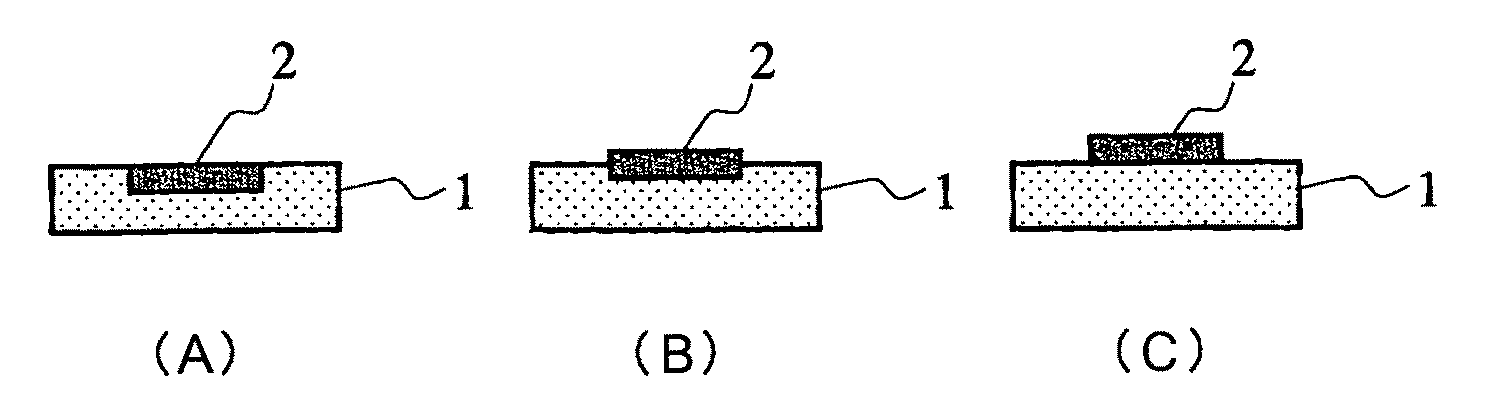

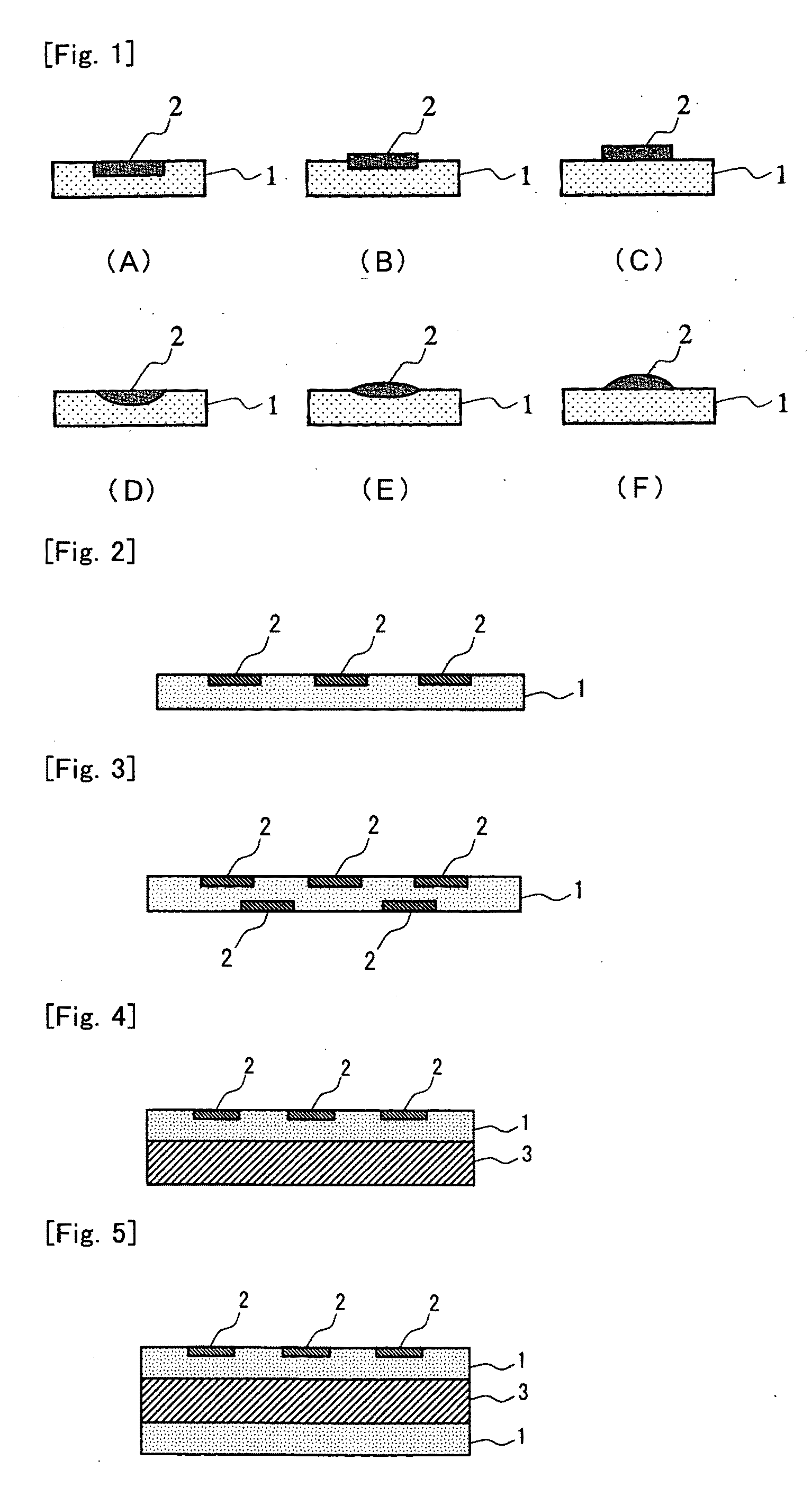

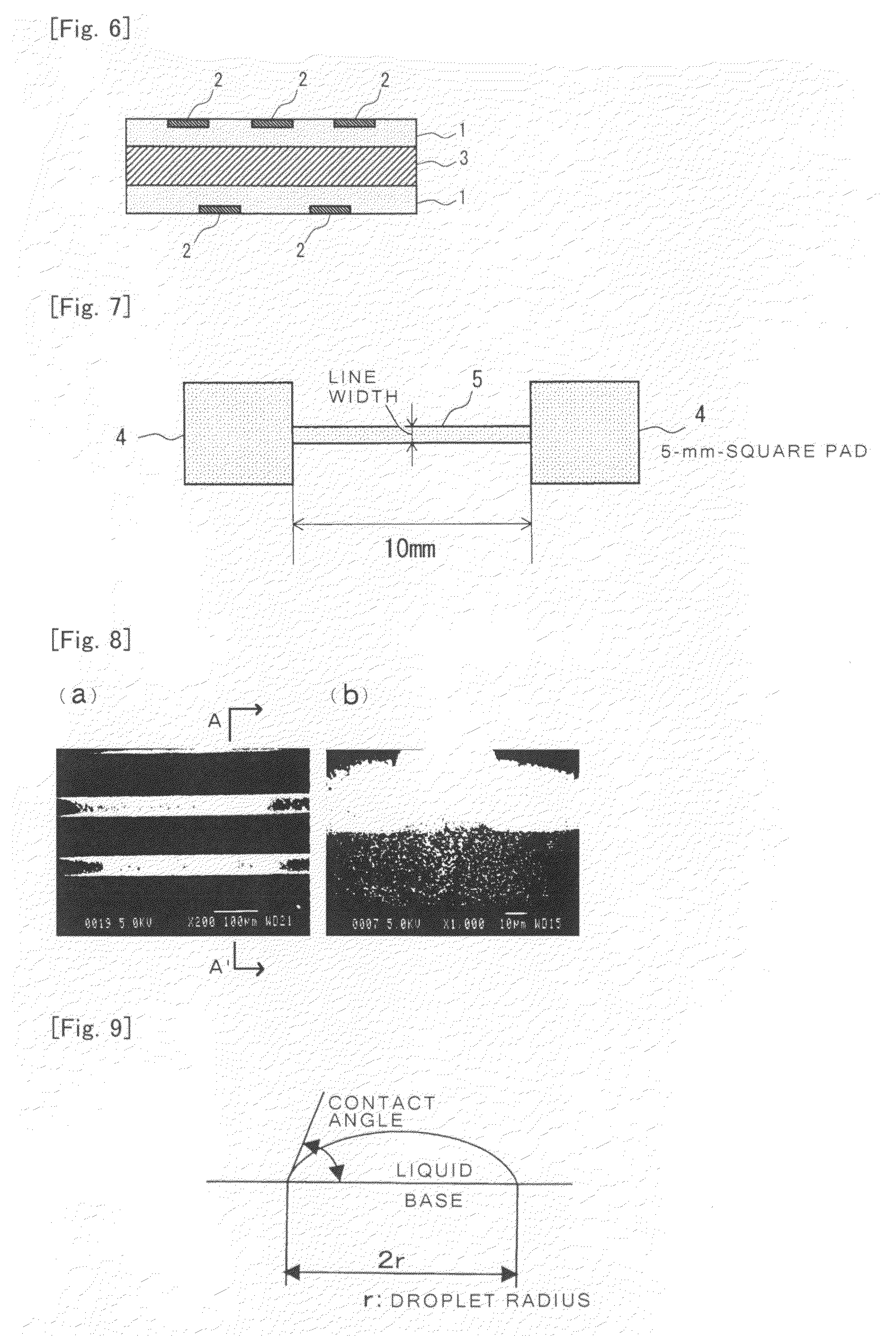

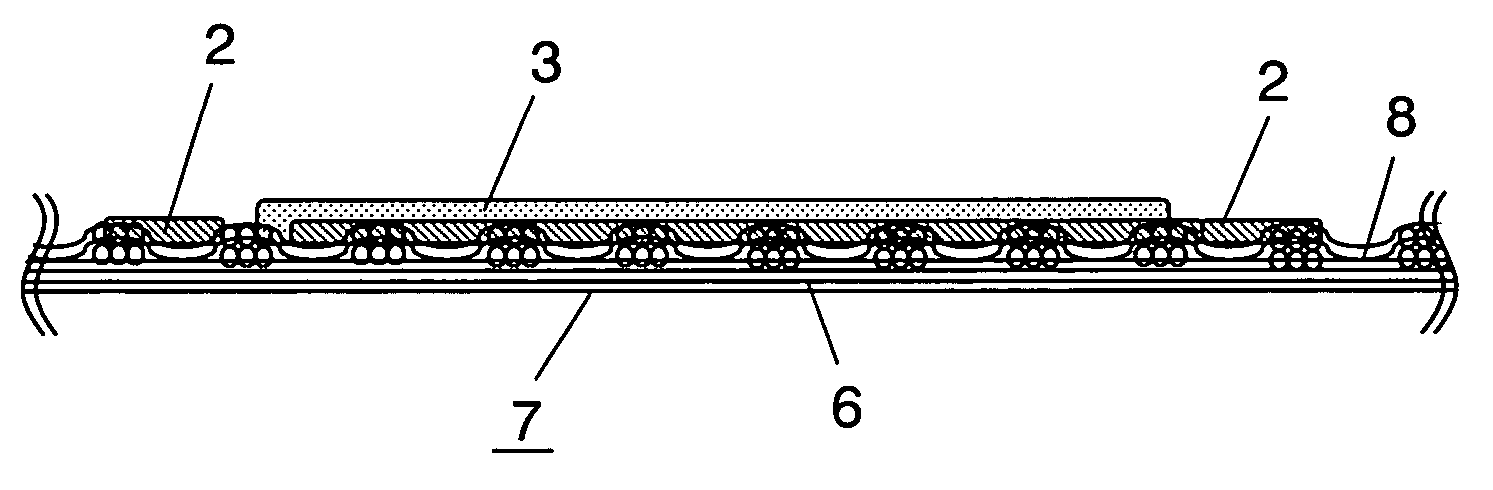

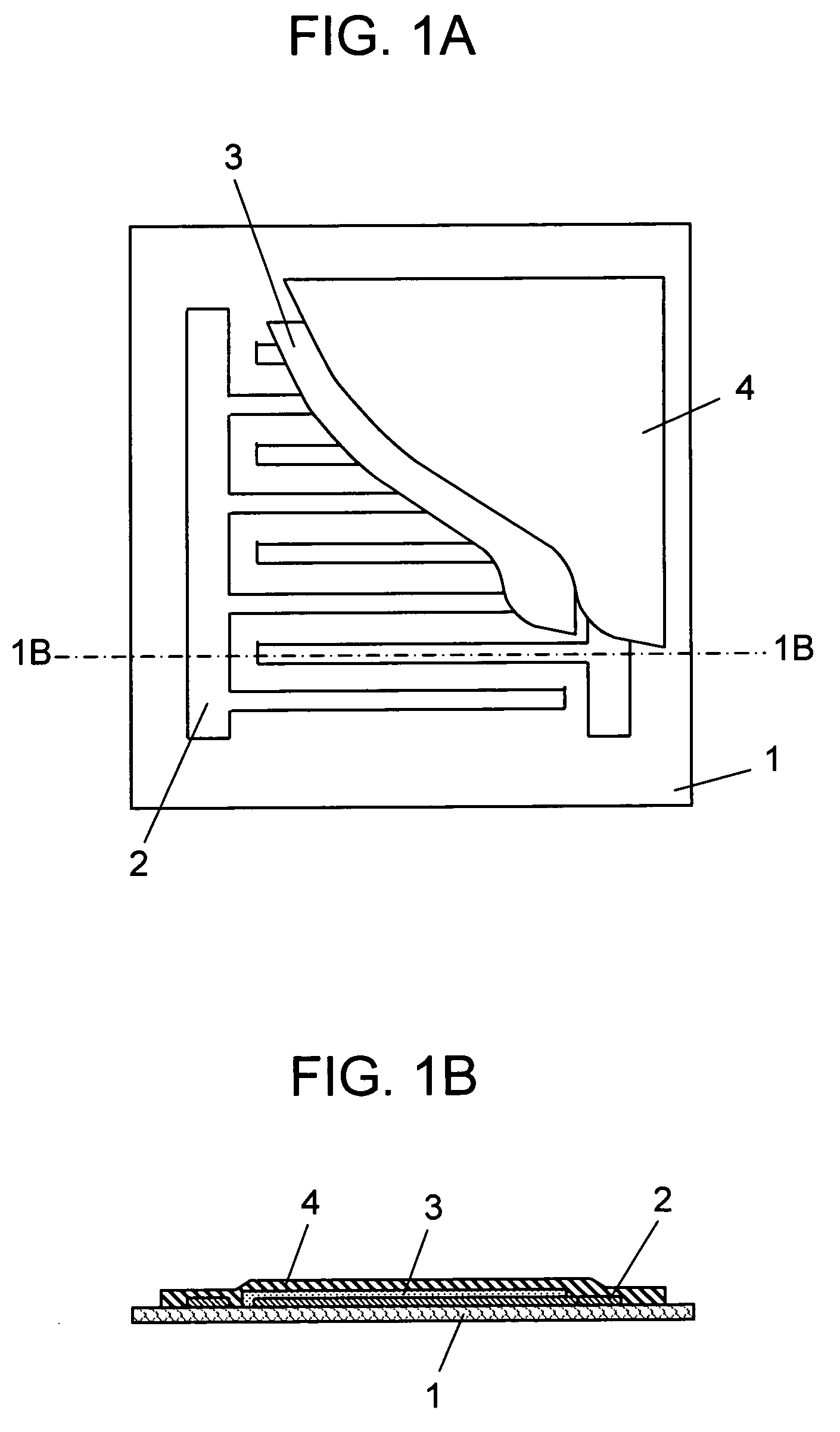

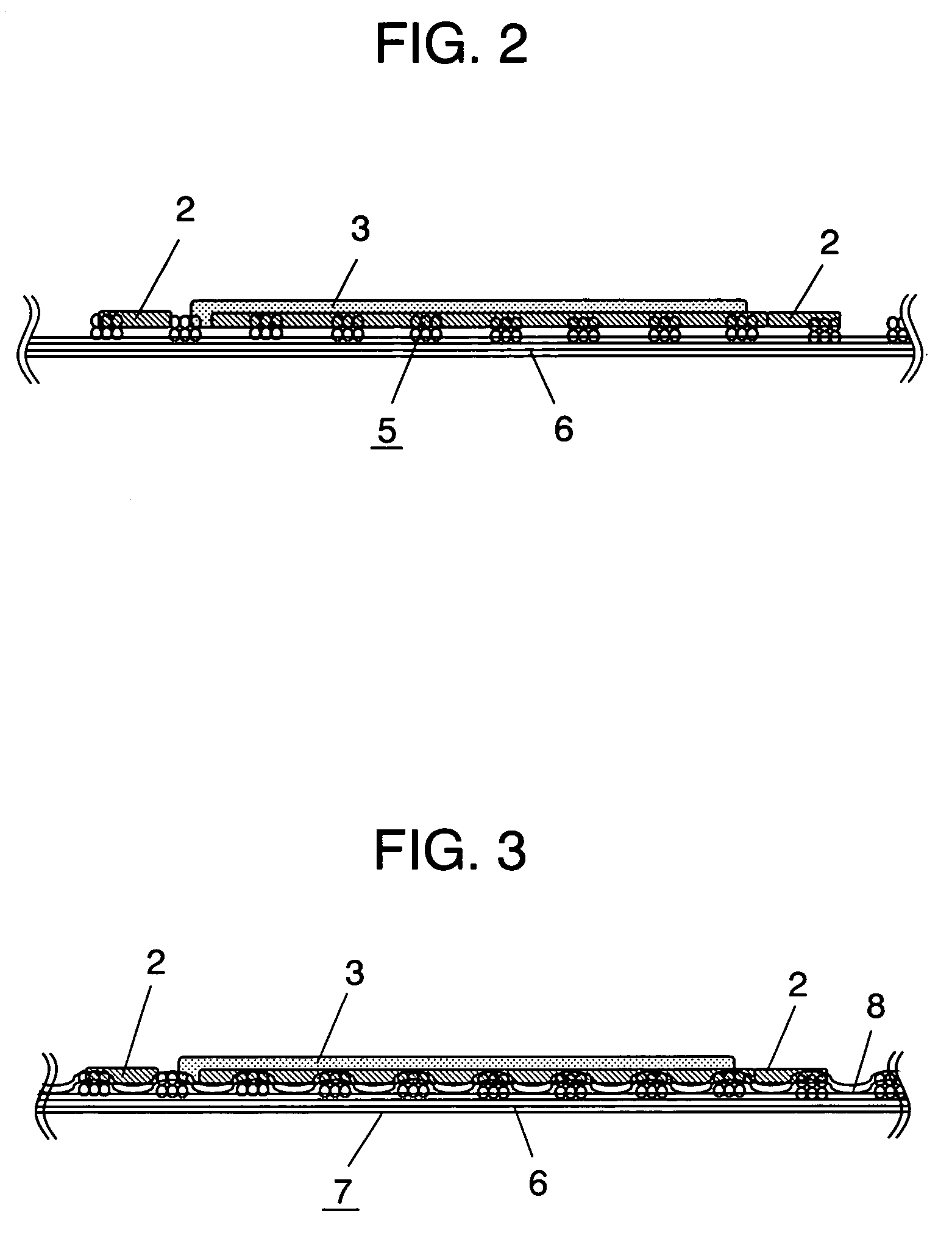

InactiveUS7049559B2Resistor terminals/electrodesResistor mounting/supportingRubber materialEngineering

The flexible PTC heating element according to the invention has one of the following constitutions. A portion of an electrodes and a PTC resistor is impregnated into a flexible substrate. A flexible substrate is made of resin foam or rubber material having a concave / convex shape formed on the surface. The flexible PTC heating element has an elongation deformation portion disposed to at least one of an electrode and a PTC resistor. A flexible substrate has adhesiveness and either a flexible substrate or a flexible cover material has an elongation control portion. Therefore, the flexible PTC heating element is highly flexible and excellent in vibration durability.

Owner:PANASONIC CORP

Electromagnetic Interference Shielding Structure Including Carbon Nanotubes and Nanofibers

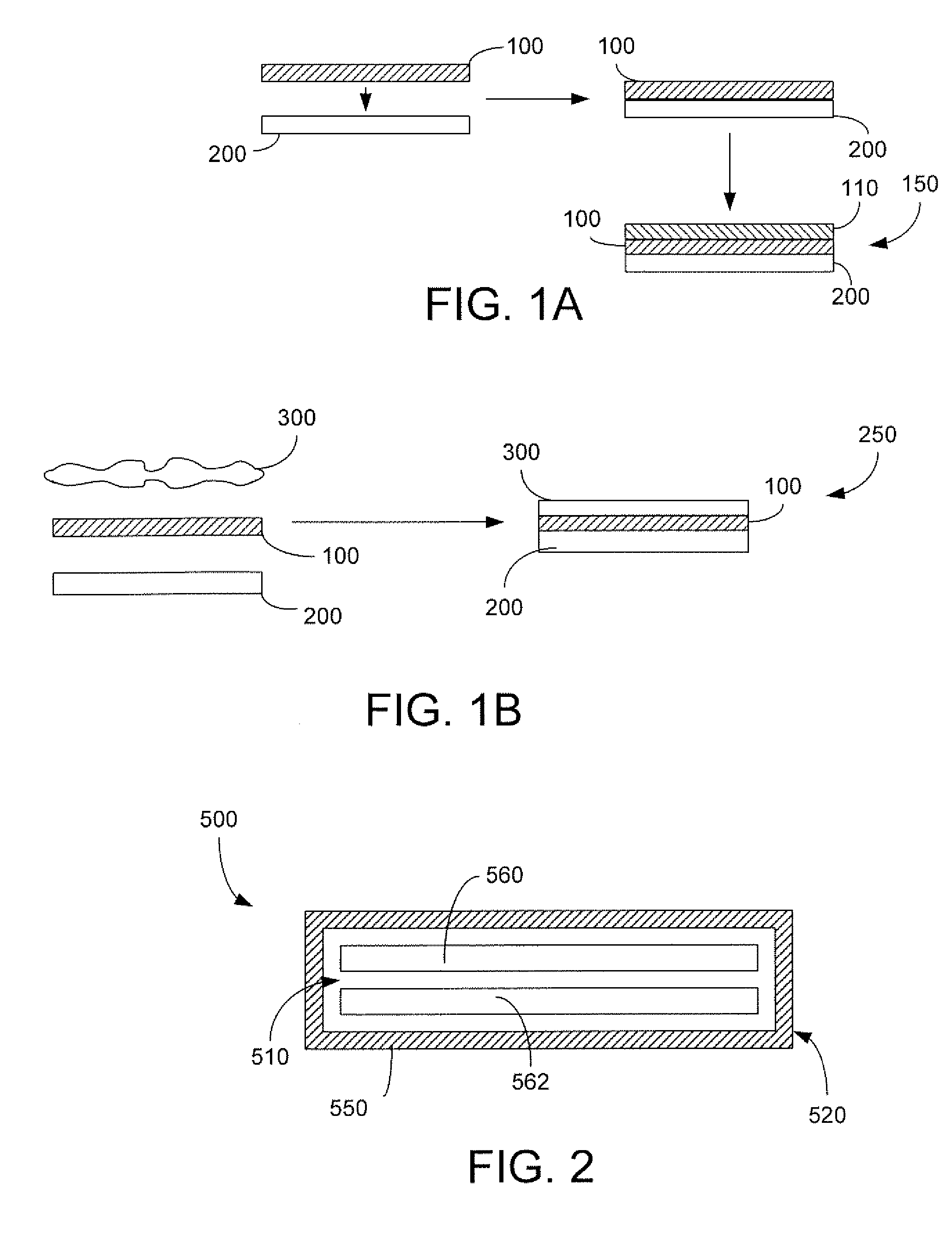

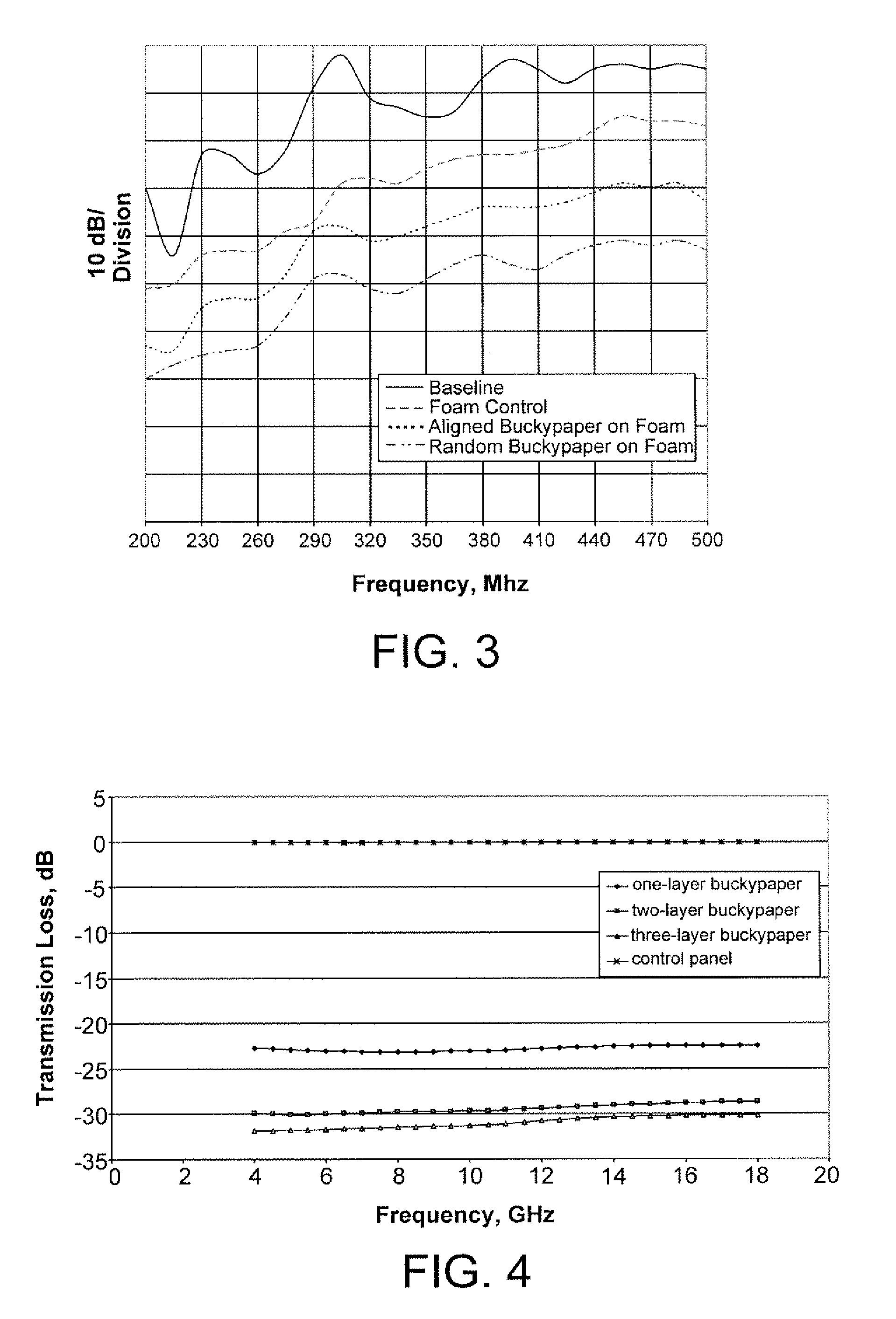

InactiveUS20080057265A1Shielding materialsRecord information storageFiberElectromagnetic interference

Electromagnetic interference (EMI) shielding structure and methods of making such structures are provided. In one case, a method is provided for making a lightweight composite structure for electromagnetic interference shielding, including the steps of providing a nanoscale fiber film which comprises a plurality of nanoscale fibers; and combining the nanoscale fiber film with one or more structural materials to form a composite material which is effective as an electromagnetic interference shielding structure. In another case, a method is provided for shielding a device which includes an electrical circuit from electromagnetic interference comprising the steps of providing a nanoscale fiber film which comprises a plurality of nanoscale fibers; and incorporating the nanoscale fiber film into an exterior portion of the device to shield an interior portion of the device from electromagnetic interference.

Owner:FLORIDA STATE UNIV RES FOUND INC

Strip electrode with conductive nano tube printing

InactiveUS20050186333A1Accurate electronic readoutMinimizing strip to strip variationImmobilised enzymesBioreactor/fermenter combinationsSilver inkCarbon nanotube

A sensor system that detects a current representative of a compound in a liquid mixture features a multi or three electrode strip adapted for releasable attachment to signal readout circuitry. The strip comprises an elongated support which is preferably flat adapted for releasable attachment to the readout circuitry; a first conductor and a second and a third conductor each extend along the support and comprise means for connection to the circuitry. The circuit is formed with single-walled or multi walled nanotubes conductive traces and may be formed from multiple layers or dispersions containing, carbon nanotubes, carbon nanotubes / antimony tin oxide, carbon nanotubes / platinum, or carbon nanotubes / silver or carbon nanotubes / silver-cloride. An active electrode formed from a separate conductive carbon nanotubes layer or suitable dispersion, positioned to contact the liquid mixture and the first conductor, comprises a deposit of an enzyme capable of catalyzing a reaction involving the compound and preferably an electron mediator, capable of transferring electrons between the enzyme-catalyzed reaction and the first conductor. A reference electrode also formed from a conductive carbon nanotube layer or suitable dispersion is positioned to contact the mixture and the second conductor. The system includes circuitry adapted to provide an electrical signal representative of the current which is formed from printing conductive inks made with nano size particles such as conductive carbon or carbon / platinum or carbon / silver, or carbon nanotubes / antimony tin oxide to form a conductive carbon nanotube layers. The multiple-electrode strip is manufactured, by then applying the enzyme and preferably the mediator onto the electrode. Alternatively the electrode can have a carbon nanotubes / antimony tin oxide, carbon nanotubes / platinum, or carbon nanotubes / silver or carbon nanotubes / silver-cloride surface and or a conductive carbon or silver ink surface connecting leg. The carbon nanotube solution is first coated and patterned into electro shapes and the conductive carbon nanotubes, carbon or silver ink can be attached by printing the ink to interface with the carbon nanotube electro surface. A platinum electrode test strip is also disclosed that is formed from either nano platinum distributed in the carbon nanotube layer or by application or incorporation of platinum to the carbon nanotube conductive ink.

Owner:DOUGLAS JOEL S MR

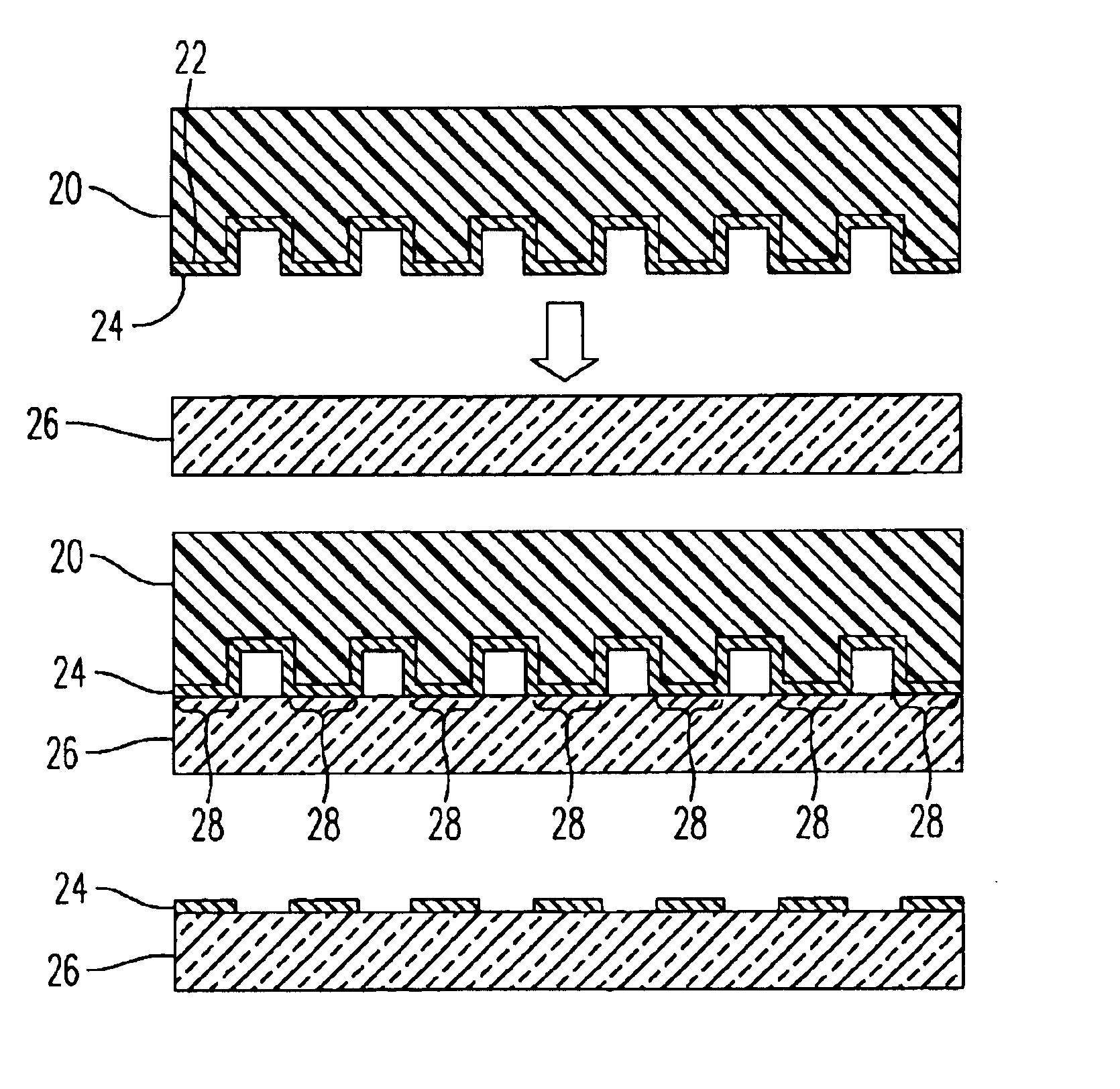

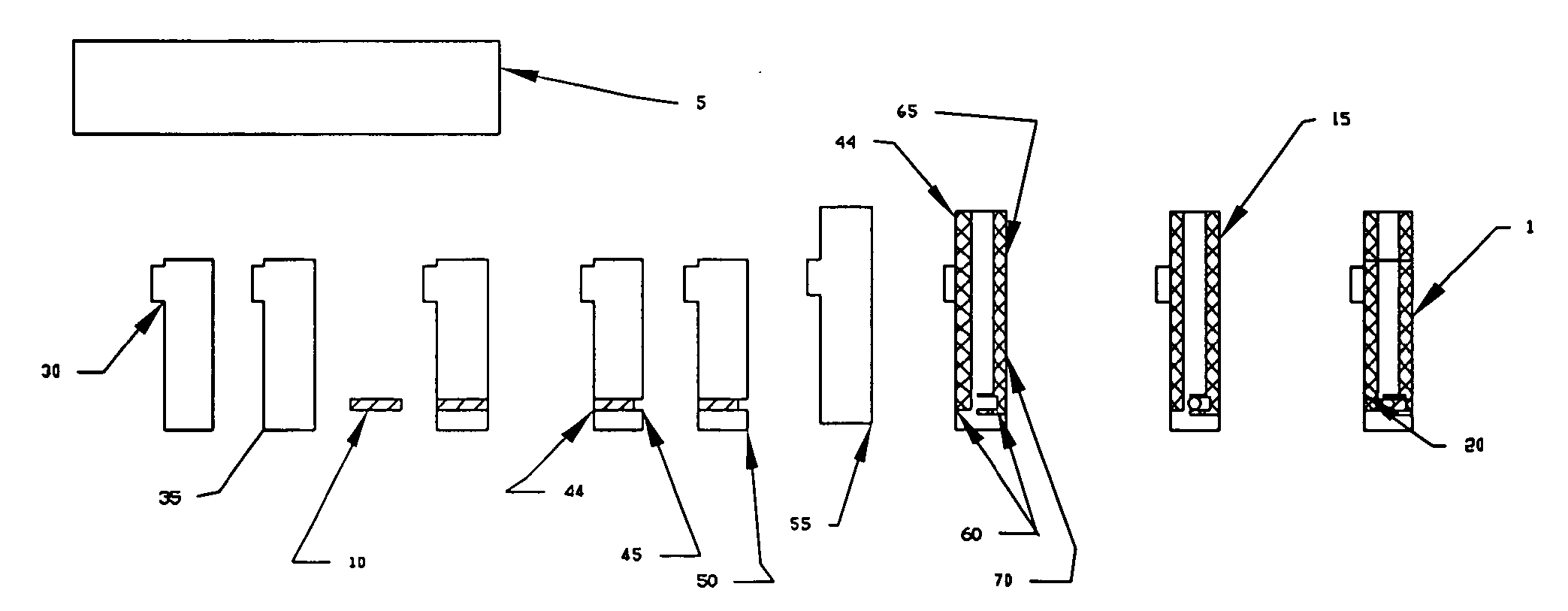

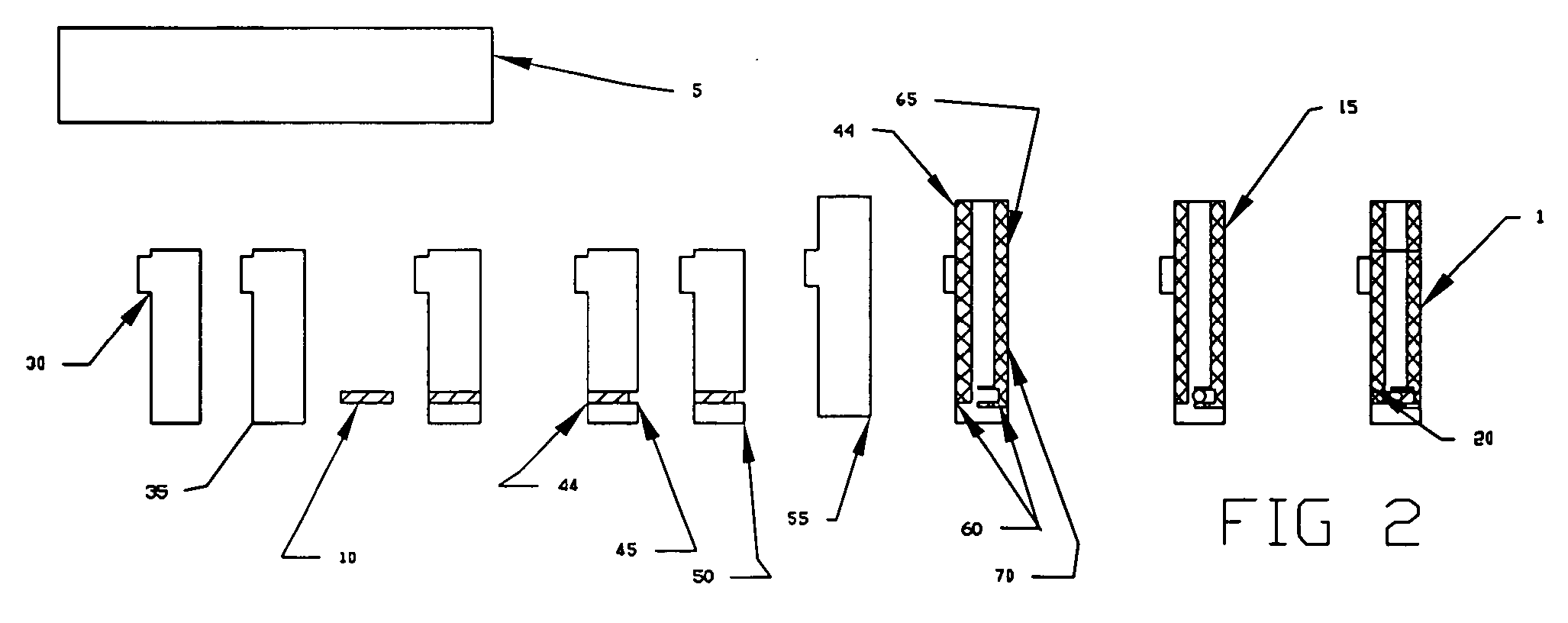

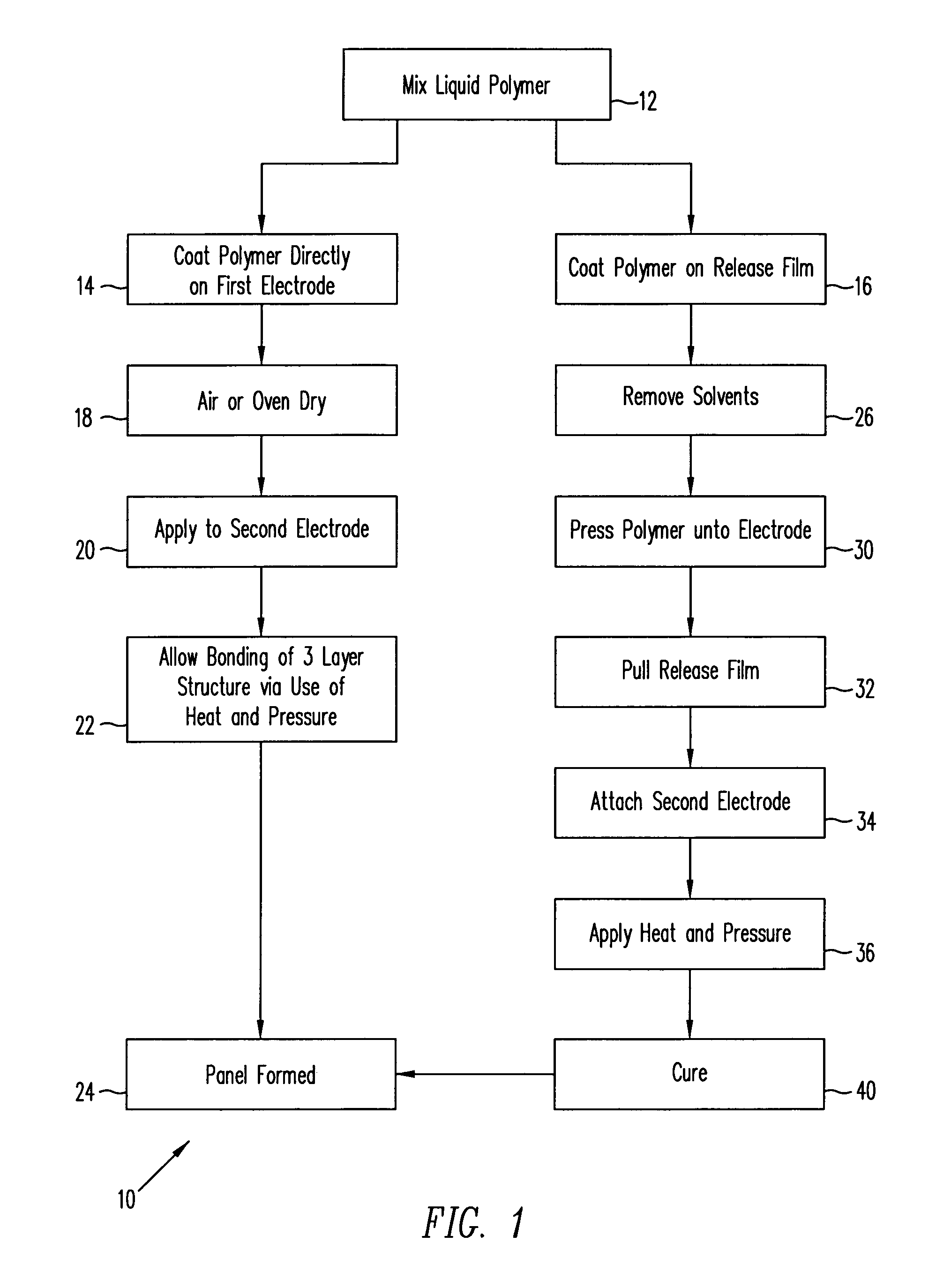

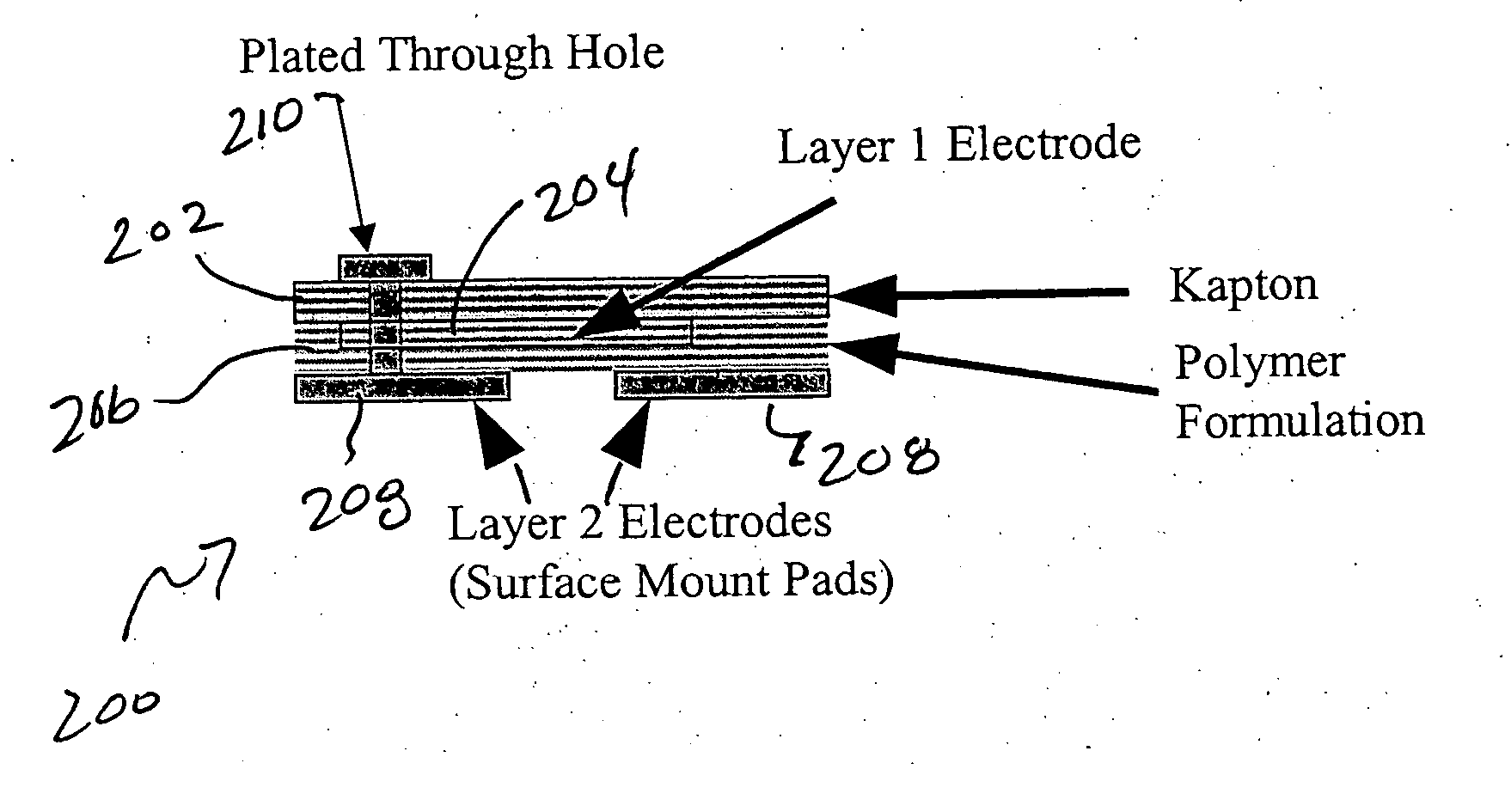

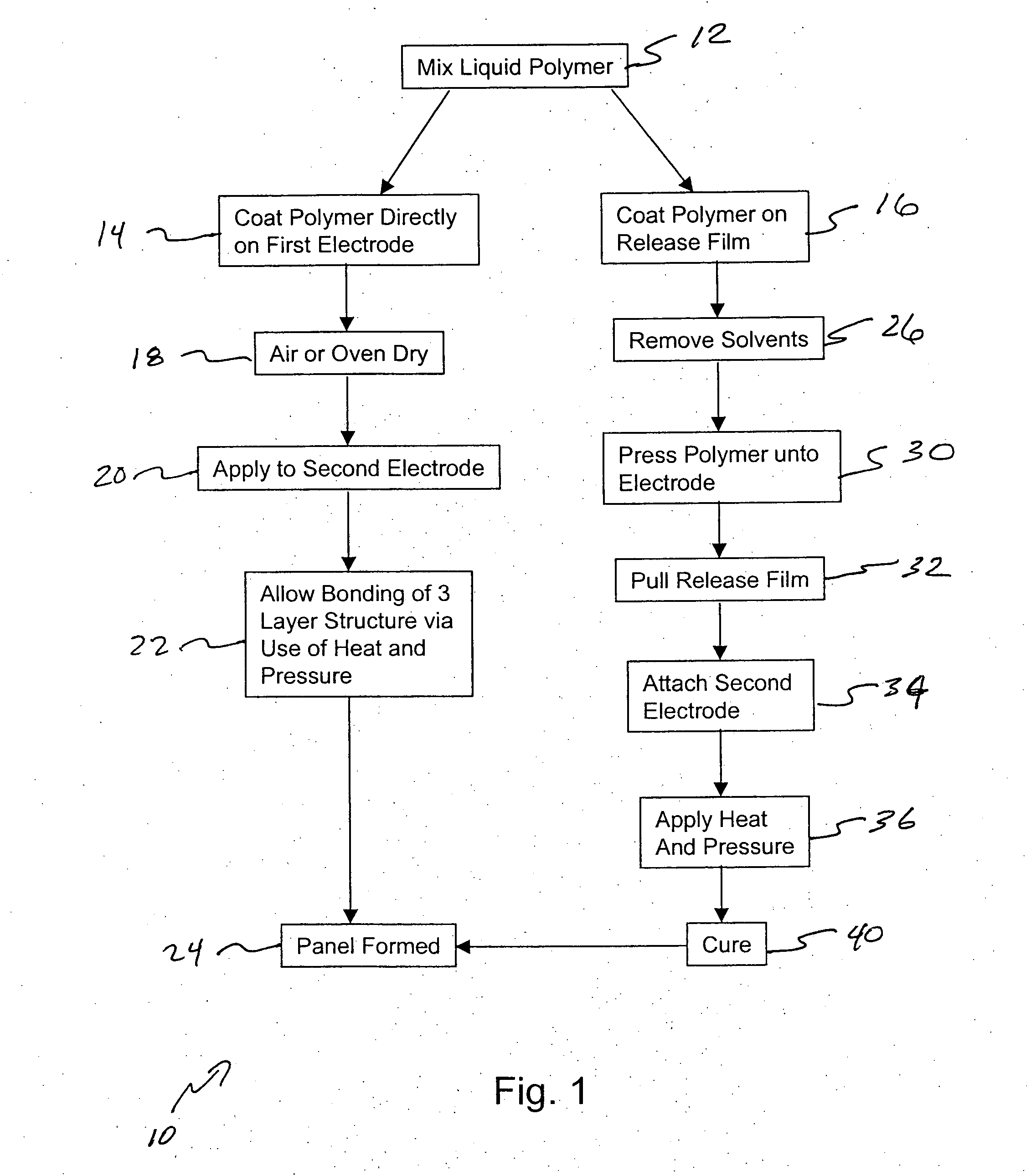

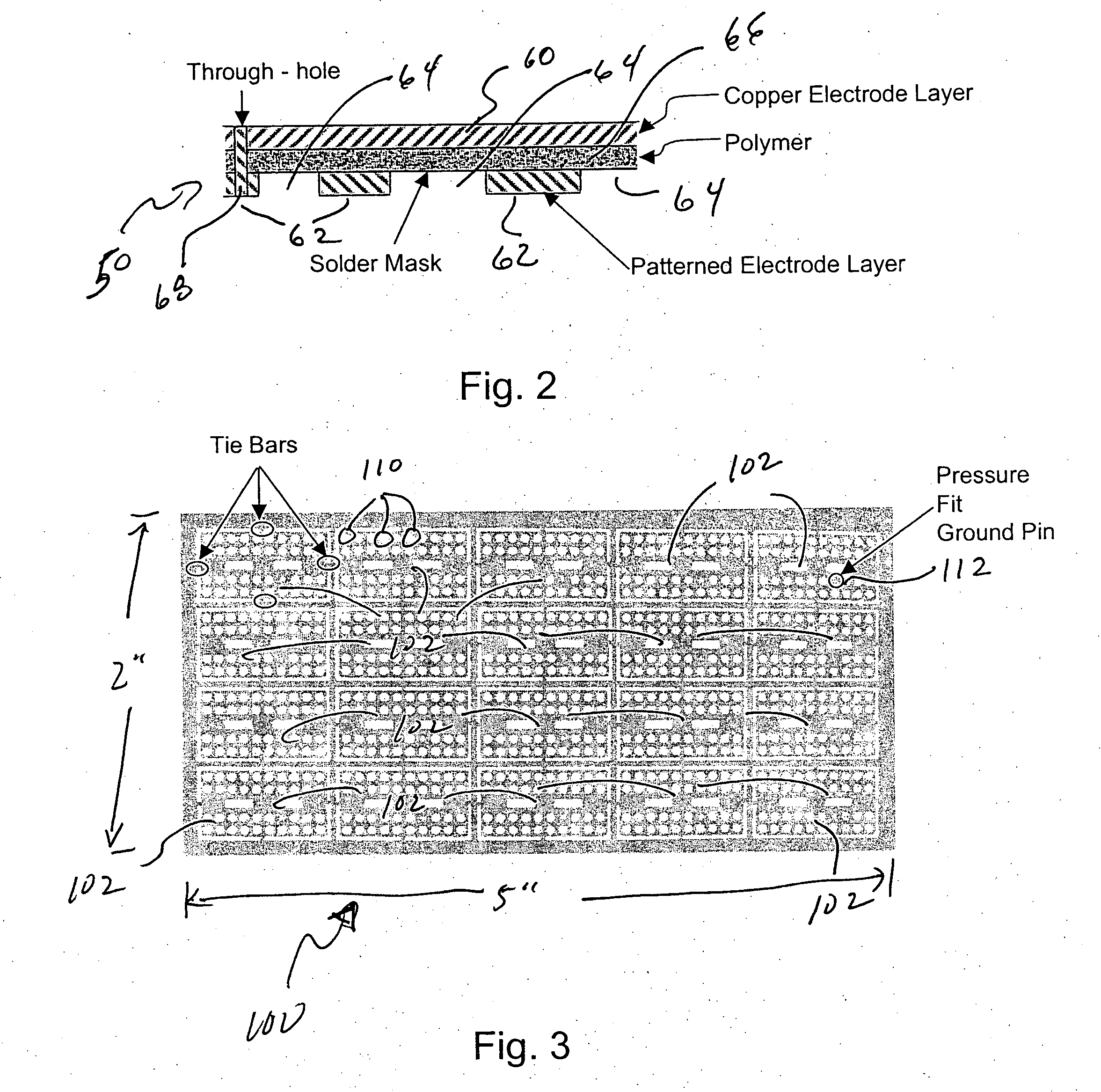

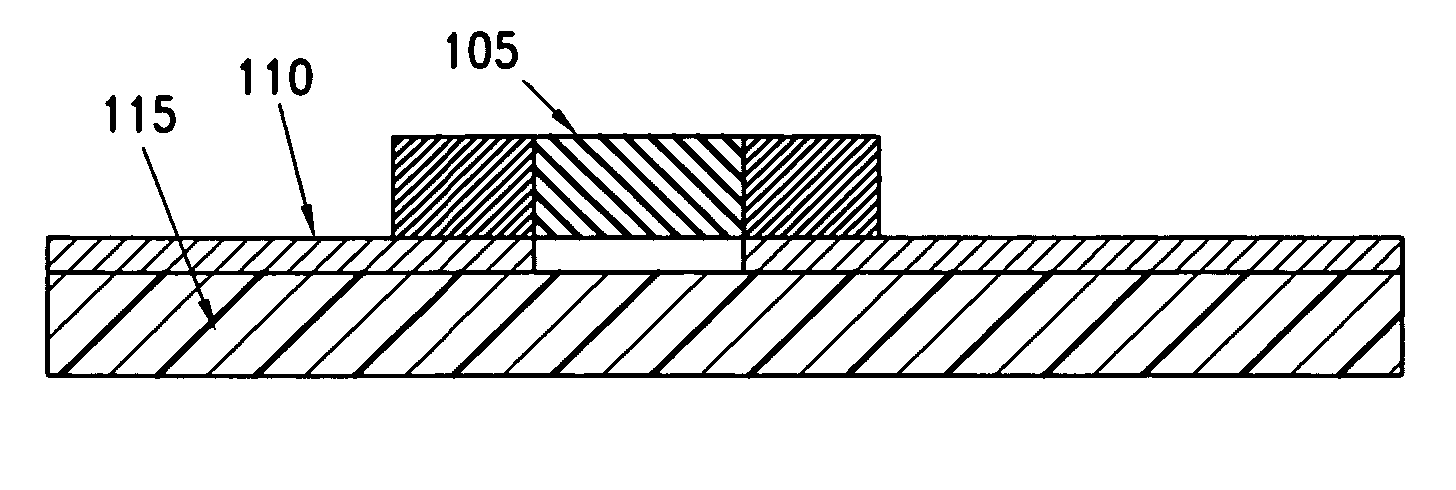

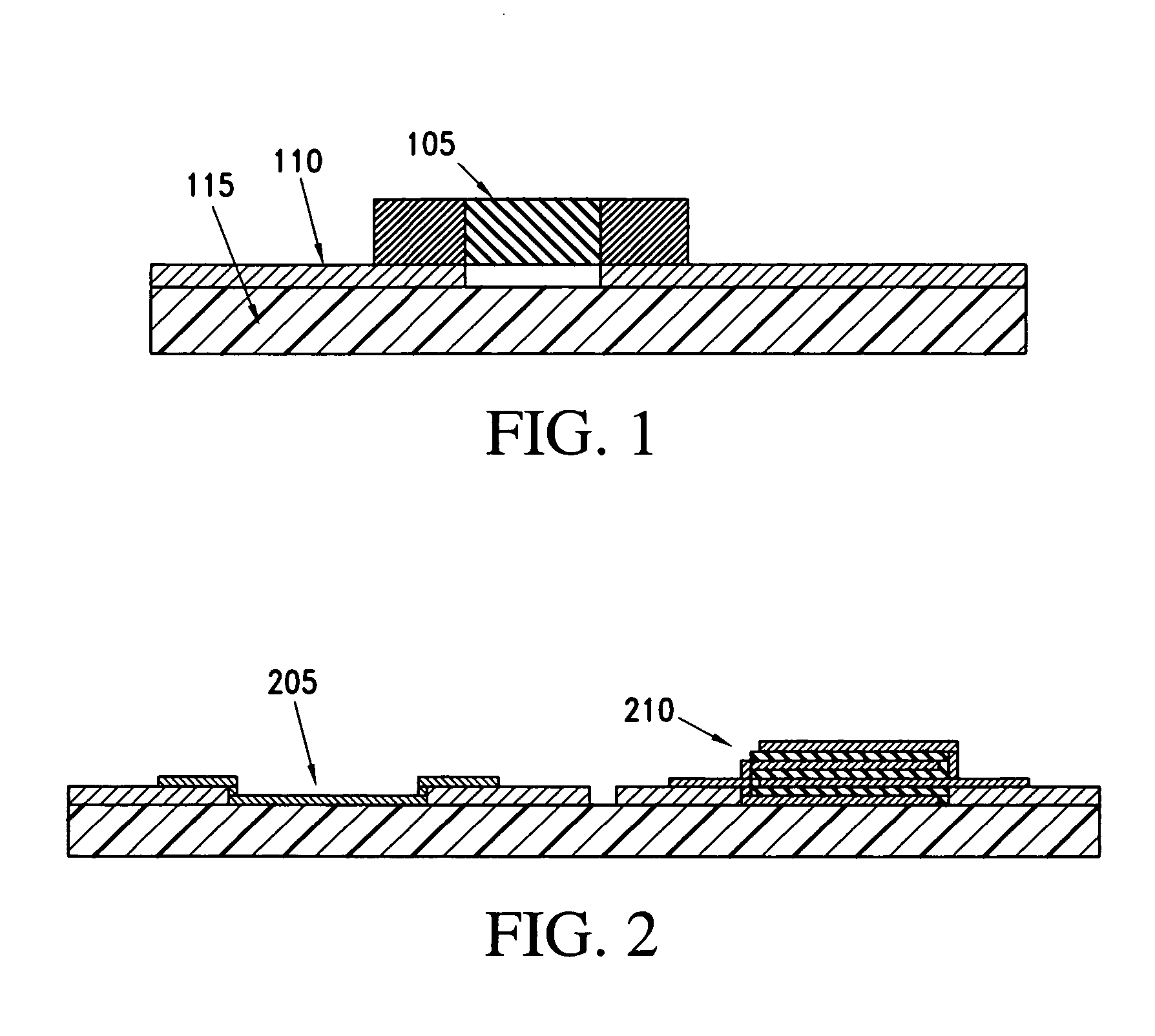

Method of manufacturing devices to protect election components

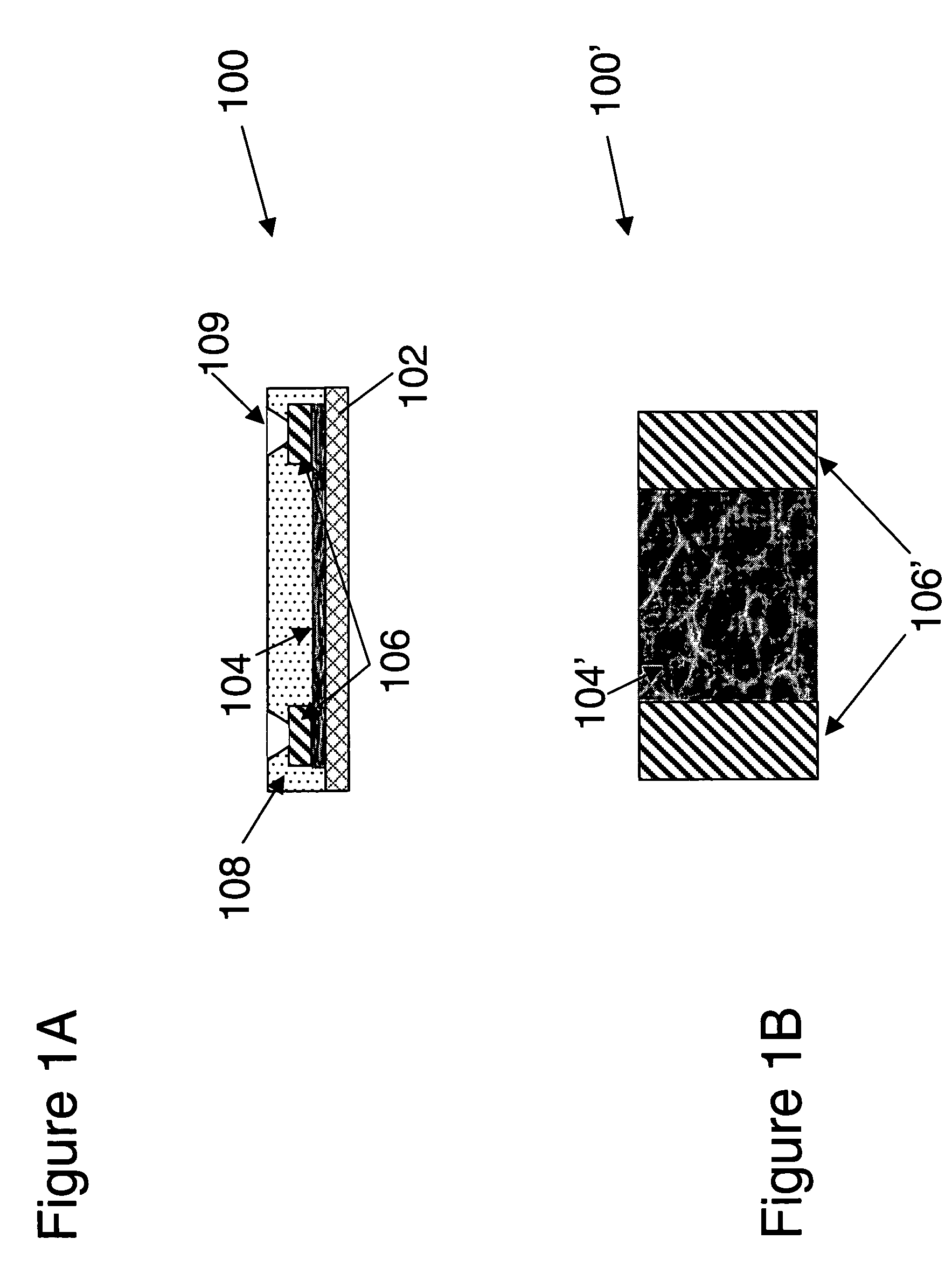

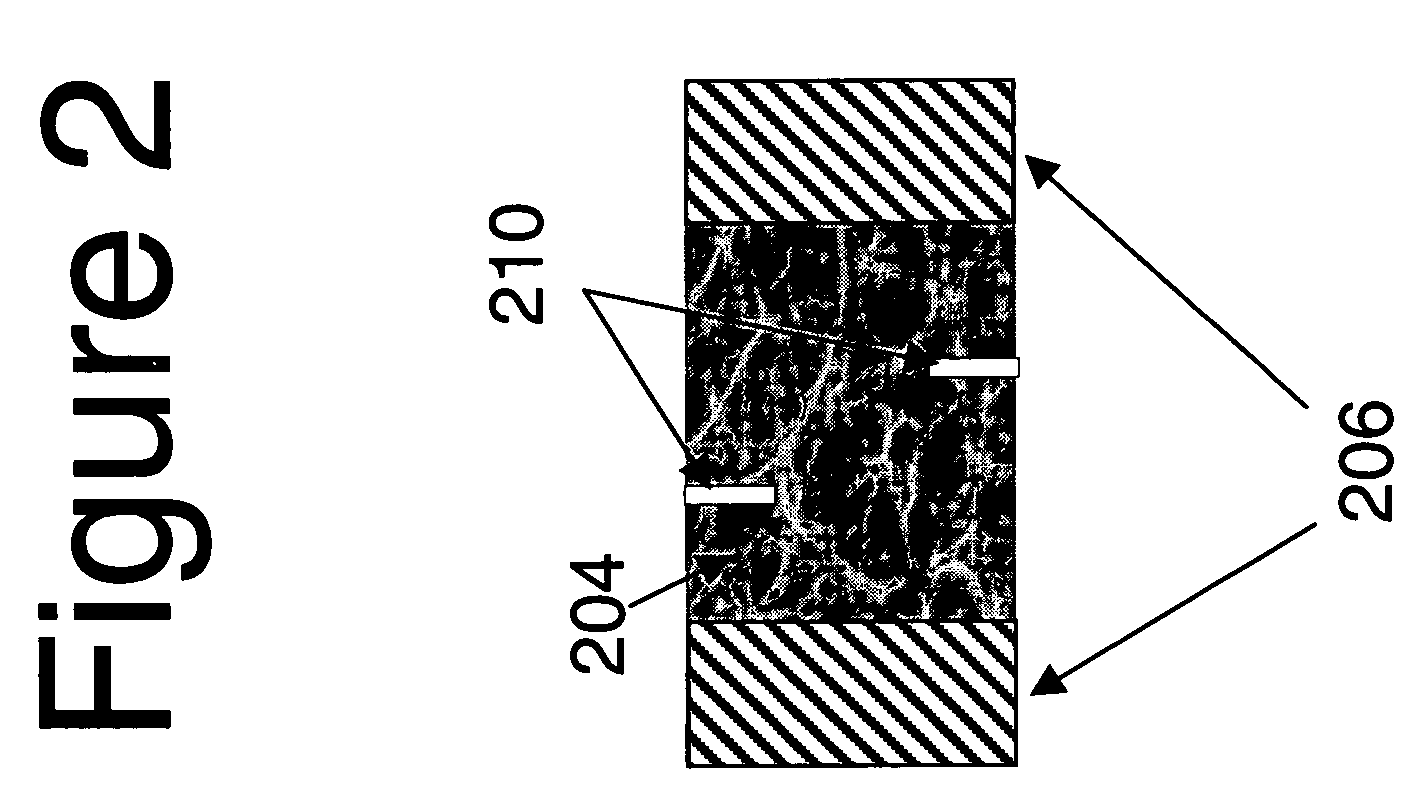

InactiveUS6981319B2Easy to customizeMake fastFuse device manufactureInsulating layers/substrates workingManufacturing technologyElectronic component

Devices capable of protecting electronic components during the occurrence of a disturbance event using printed circuit board manufacturing techniques. A three (3) layer structure is formed comprising a polymer-based formulation sandwiched between two electrode layers. The devices can be manufactured in panel form providing high quantities of devices which can be removed from the panel and applied directly to the component to be protected. Desired patterns can be formed on either one of the electrode layers by photo-etch techniques thereby providing a process that can be tailored to a large number of applications.

Owner:ELECTRONICS POLYMERS NEWCO

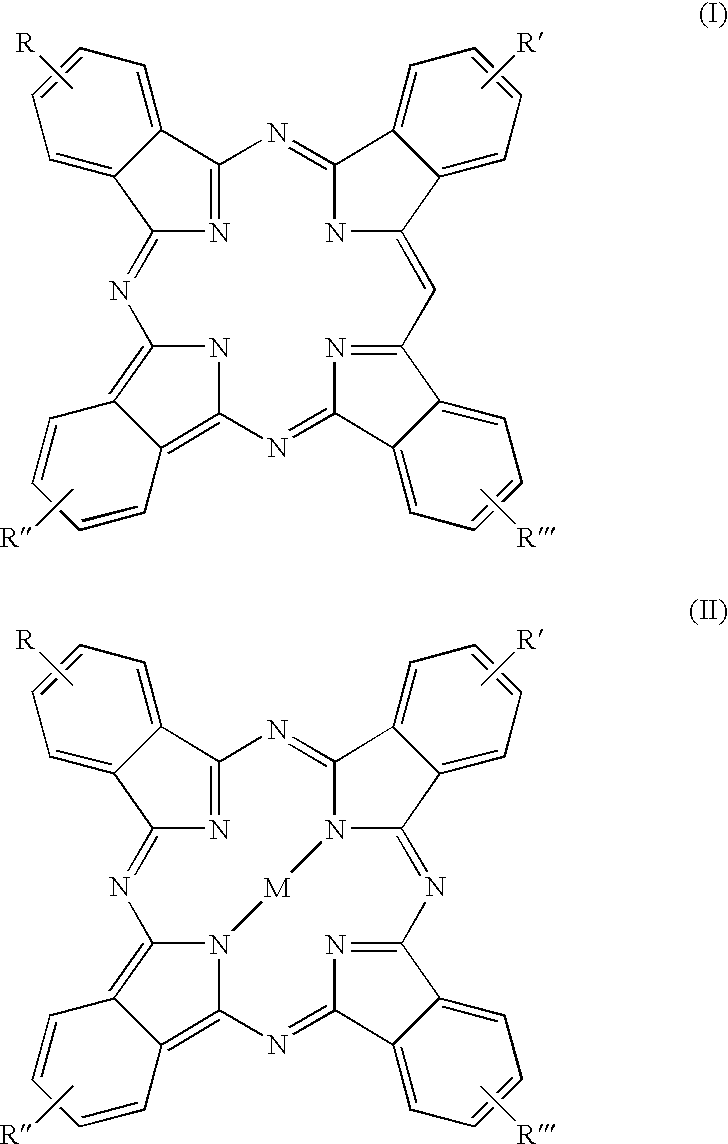

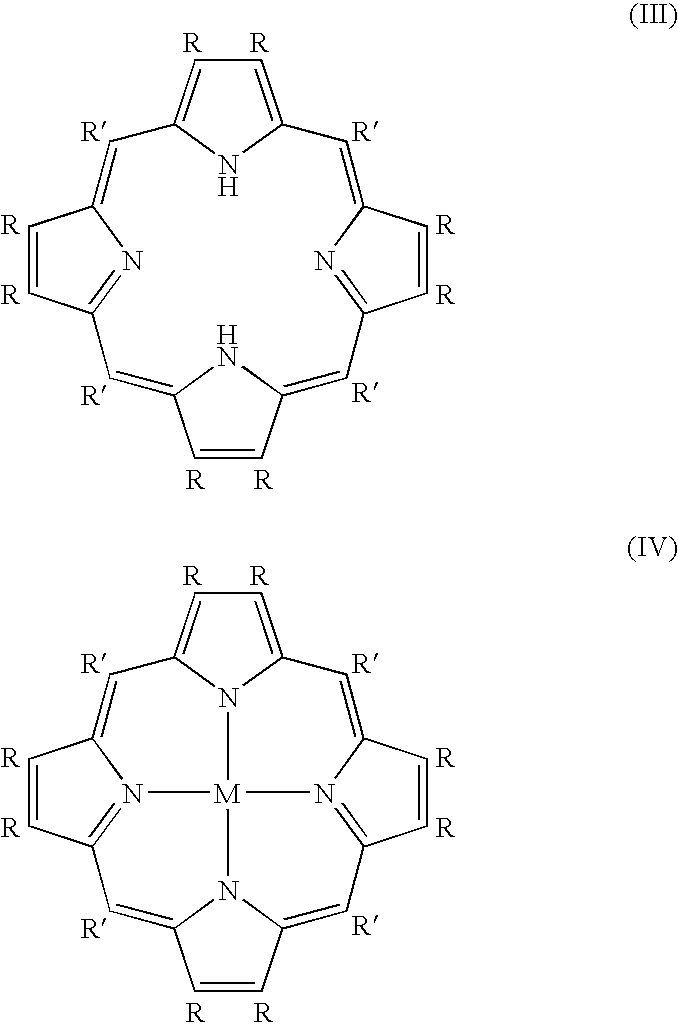

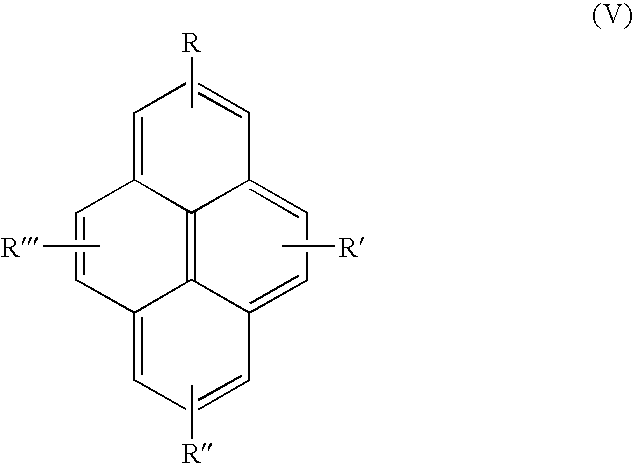

Conductive thermoplastic composites and methods of making

InactiveUS20040016912A1Improve conductivityImprove mechanical propertiesMaterial nanotechnologyConductive materialPolymer resinPolymer composites

A polymeric composite comprises a polymeric resin; an electrically conductive filler; and a polycyclic aromatic compound, in an amount effect to increase the electrical conductivity of the polymeric composition relative to the same composition without the polycyclic aromatic compound. The addition of the polycyclic aromatic compound in addition to a conductive filler imparts improved electrical and mechanical properties to the compositions.

Owner:SHPP GLOBAL TECH BV

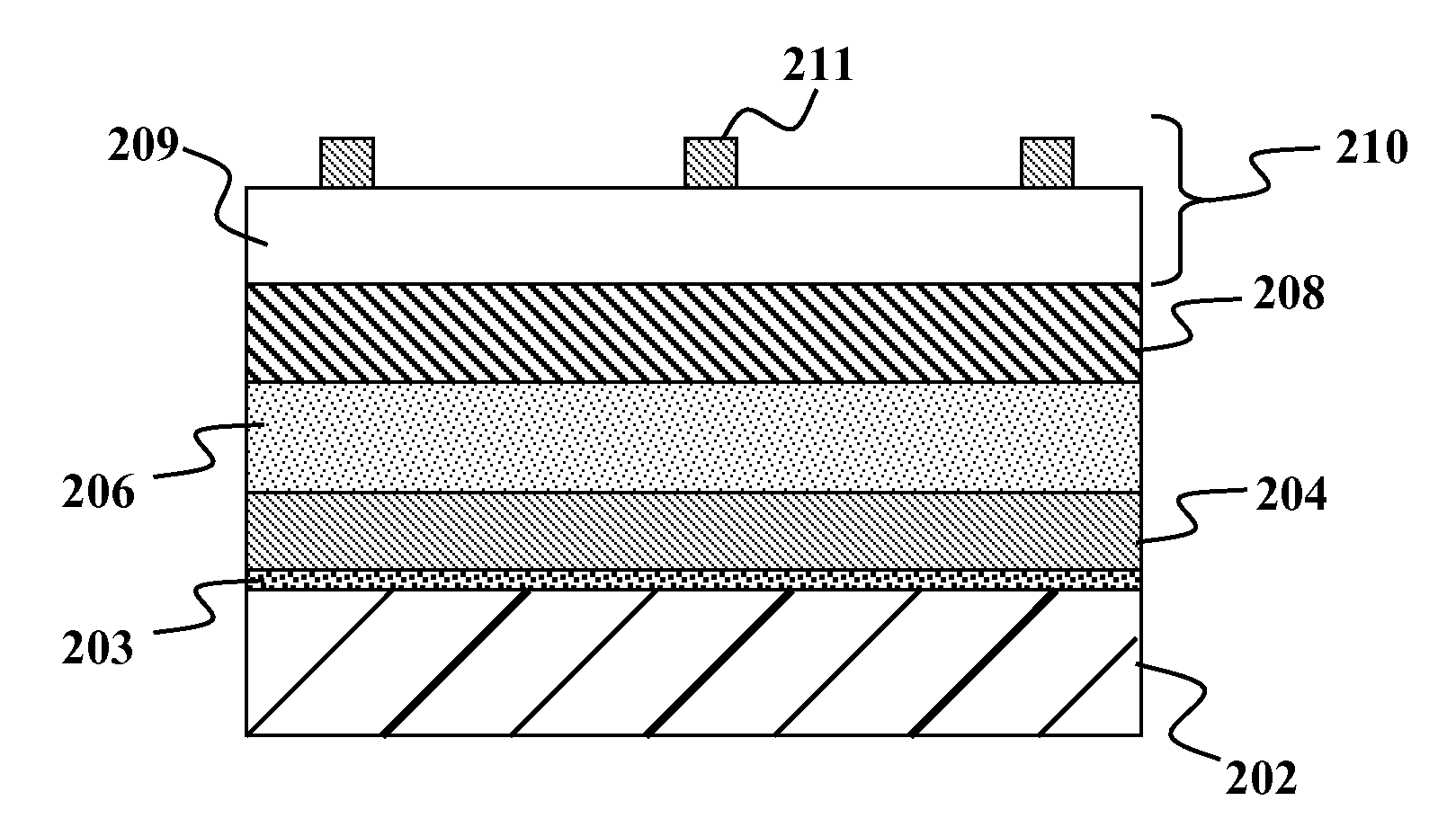

Solution-based fabrication of photovoltaic cell

InactiveUS20080135812A1Improve overall utilizationLow costMaterial nanotechnologyNanostructure manufactureNanoparticleSolar cell

An ink for forming CIGS photovoltaic cell active layers is disclosed along with methods for making the ink, methods for making the active layers and a solar cell made with the active layer. The ink contains a mixture of nanoparticles of elements of groups IB, IIIA and (optionally) VIA. The particles are in a desired particle size range of between about 1 nm and about 500 nm in diameter, where a majority of the mass of the particles comprises particles ranging in size from no more than about 40% above or below an average particle size or, if the average particle size is less than about 5 nanometers, from no more than about 2 nanometers above or below the average particle size. The use of such ink avoids the need to expose the material to an H2Se gas during the construction of a photovoltaic cell and allows more uniform melting during film annealing, more uniform intermixing of nanoparticles, and allows higher quality absorber films to be formed.

Owner:AERIS CAPITAL SUSTAINABLE IP

ESD protection devices and methods of making same using standard manufacturing processes

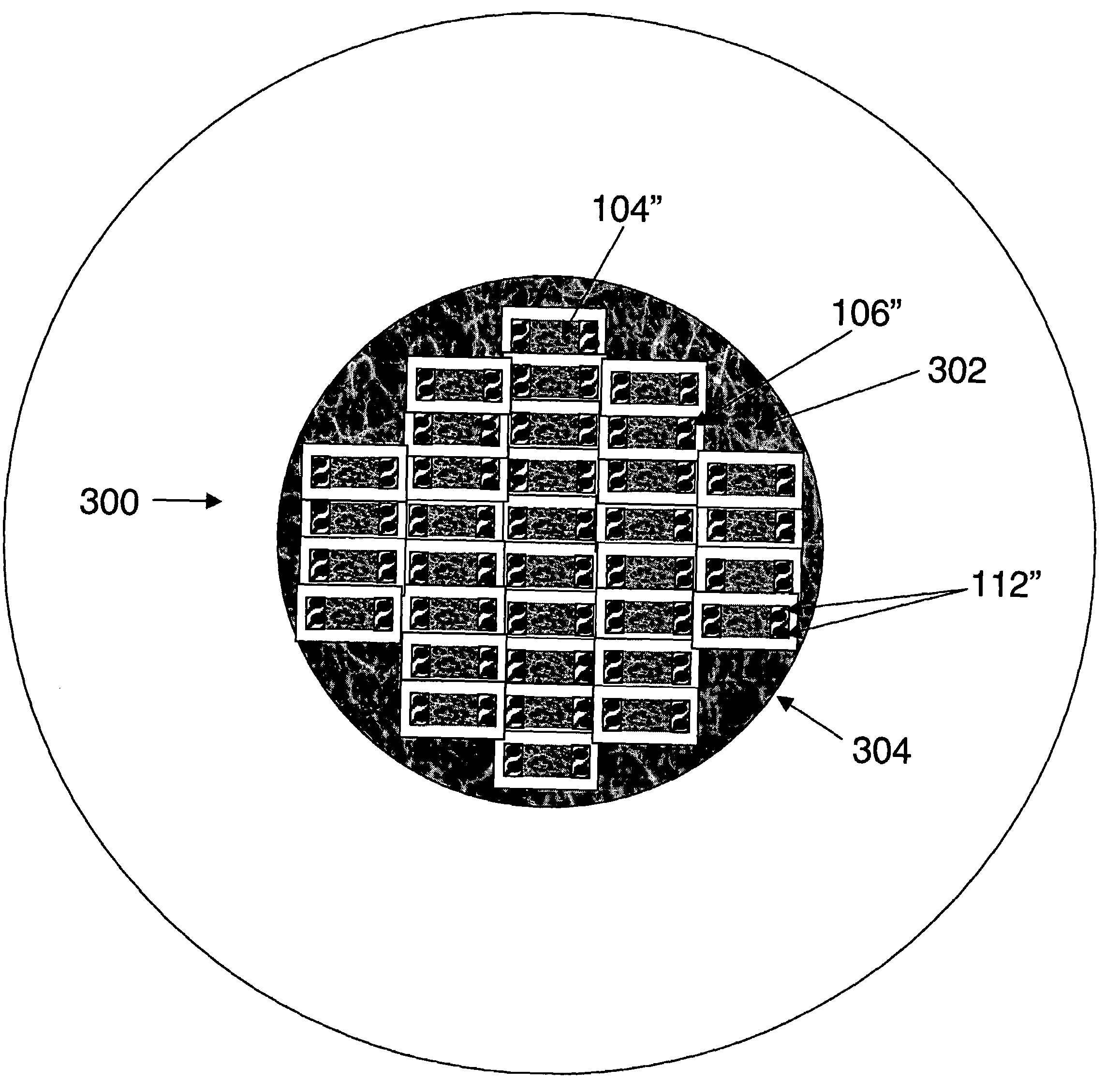

ActiveUS20050083163A1Easy to customizeMinimal effortInsulating layers/substrates workingPrinted resistor incorporationManufacturing technologyElectronic component

Devices capable of protecting electronic components during the occurrence of a disturbance event using printed circuit board manufacturing techniques. A three (3) layer structure is formed comprising a polymer-based formulation sandwiched between two electrode layers. The devices can be manufactured in panel form providing high quantities of devices which can be removed from the panel and applied directly to the component to be protected. Desired patterns can be formed on either one of the electrode layers by photo-etch techniques thereby providing a process that can be tailored to a large number of applications.

Owner:ELECTRONICS POLYMERS NEWCO

Method of manufacturing a thin piezo resistive pressure sensor

InactiveUS6912759B2Small widthReduce thicknessPiezoelectric/electrostrictive device manufacture/assemblyPaper/cardboard articlesEngineeringPiezoresistive pressure sensors

A method for forming a sensor including the steps of providing a base wafer and forming a sensor cavity in the base wafer. The method further includes the step of coupling a diaphragm wafer to the base wafer, the diaphragm wafer including a diaphragm portion and a sacrificial portion. The diaphragm wafer is coupled to the base wafer such the diaphragm portion generally covers the sensor cavity. The method further includes the steps of reducing the thickness of the diaphragm wafer by removing the sacrificial portion, and forming or locating at least one piezo resistive portion on the diaphragm portion.

Owner:ROSEMOUNT AEROSPACE

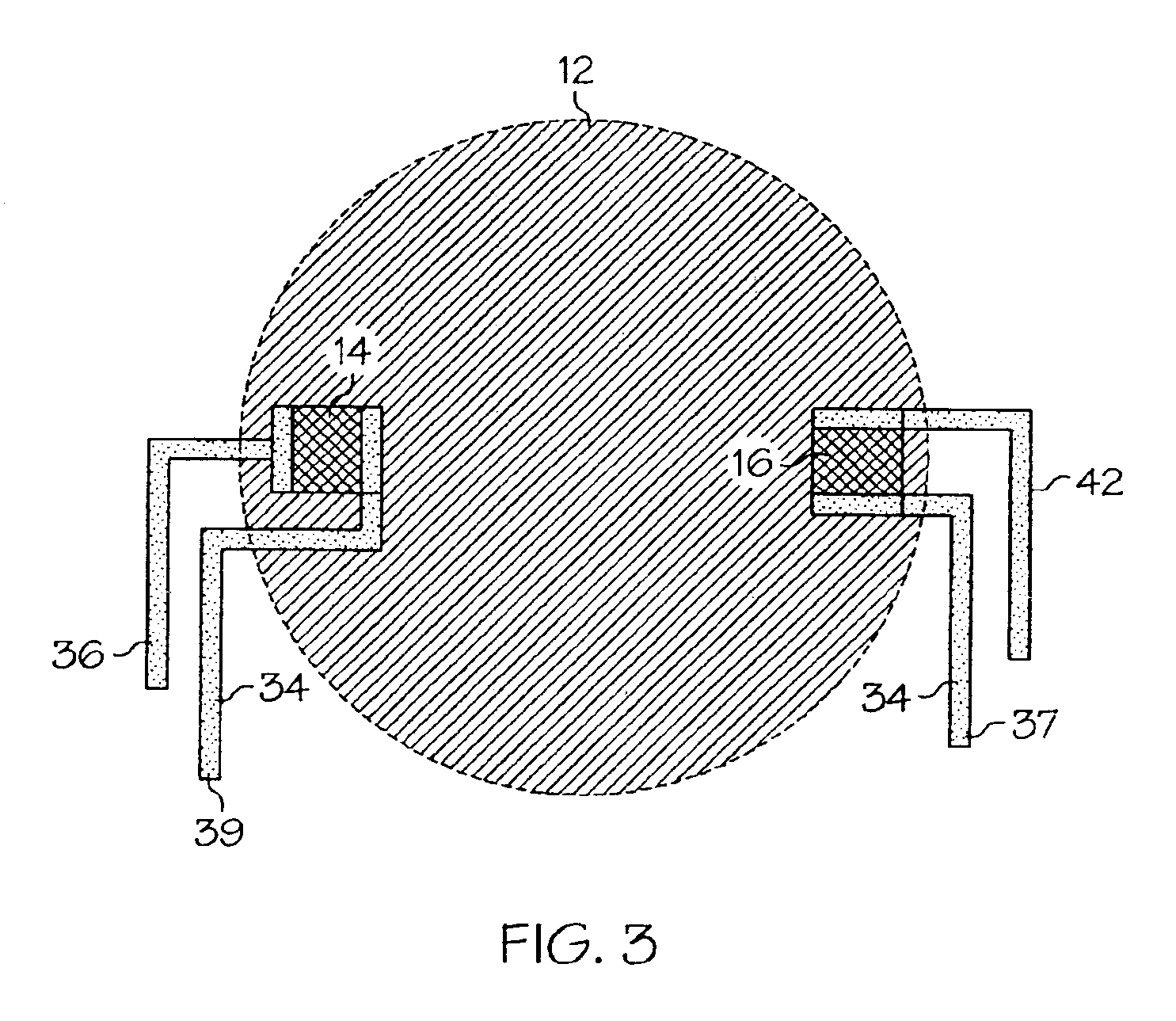

Coated and magnetic particles and applications thereof

InactiveUS20040115340A1Easy to controlImprove catalytic performanceNon-insulated conductorsVolume/mass flow measurementAlloyMaterials science

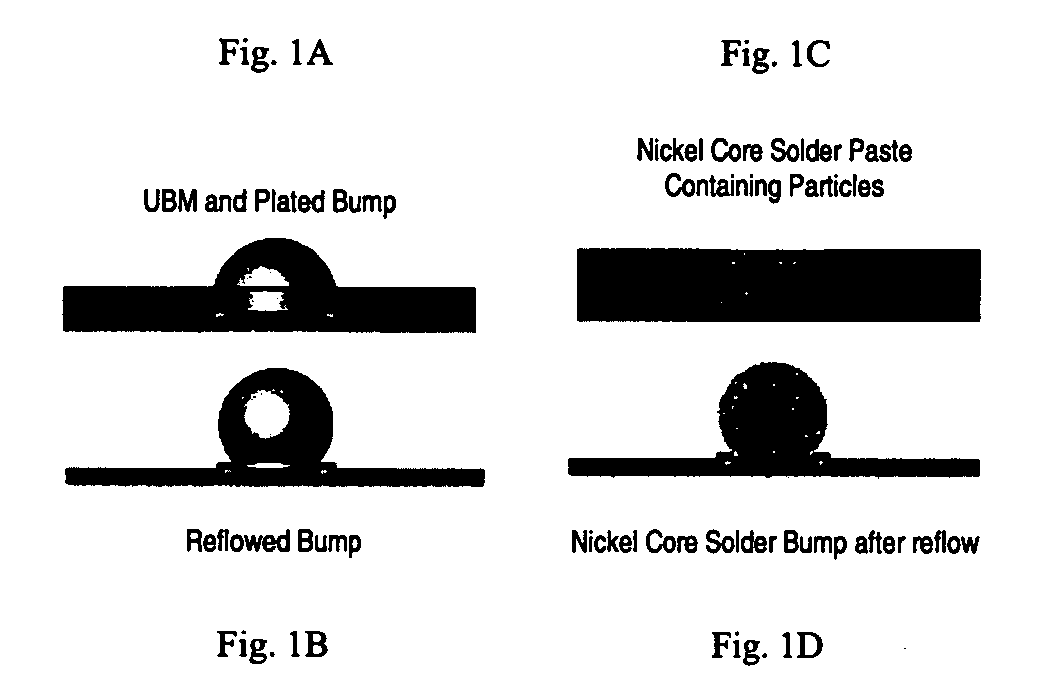

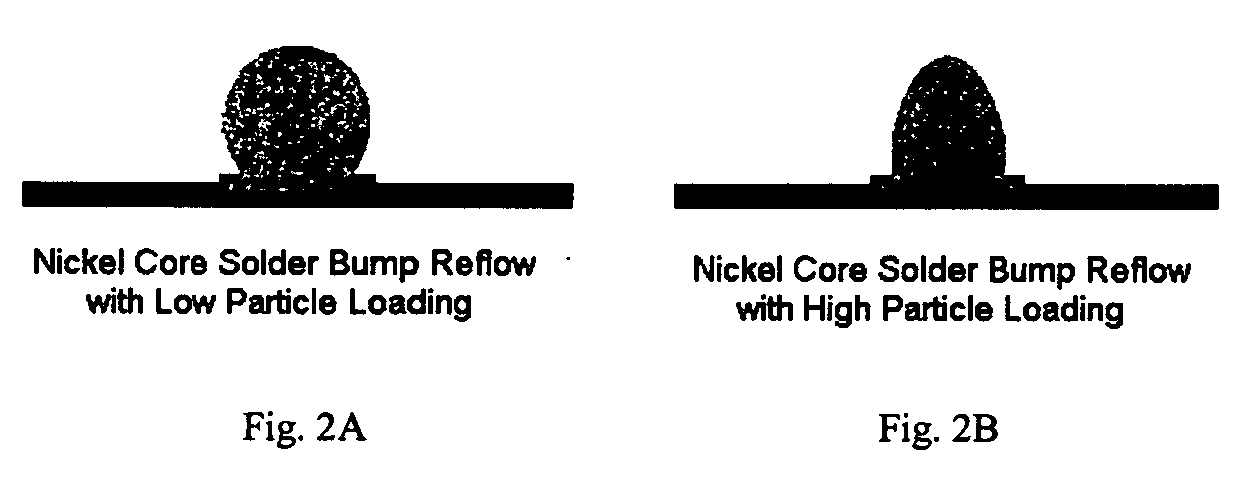

A method of using coated and / or magnetic particles to deposit structures including solder joints, bumps, vias, bond rings, and the like. The particles may be coated with a solderable material. For solder joints, after reflow the solder material may comprise unmelted particles in a matrix, thereby increasing the strength of the joint and decreasing the pitch of an array of joints. The particle and coating may form a higher melting point alloy, permitting multiple subsequent reflow steps. The particles and / or the coating may be magnetic. External magnetic fields may be applied during deposition to precisely control the particle loading and deposition location. Elements with incompatible electropotentials may thereby be electrodeposited in a single step. Using such fields permits the fill of high aspect ratio structures such as vias without requiring complete seed metallization of the structure. Also, a catalyst consisting of a magnetic particle coated with a catalytic material, optionally including an intermediate layer.

Owner:SURFECT TECH

Dual thin film precision resistance trimming

ActiveUS20100073122A1Improve efficiencyIncrease resistanceSemiconductor/solid-state device detailsVacuum evaporation coatingElectrical resistance and conductanceEngineering

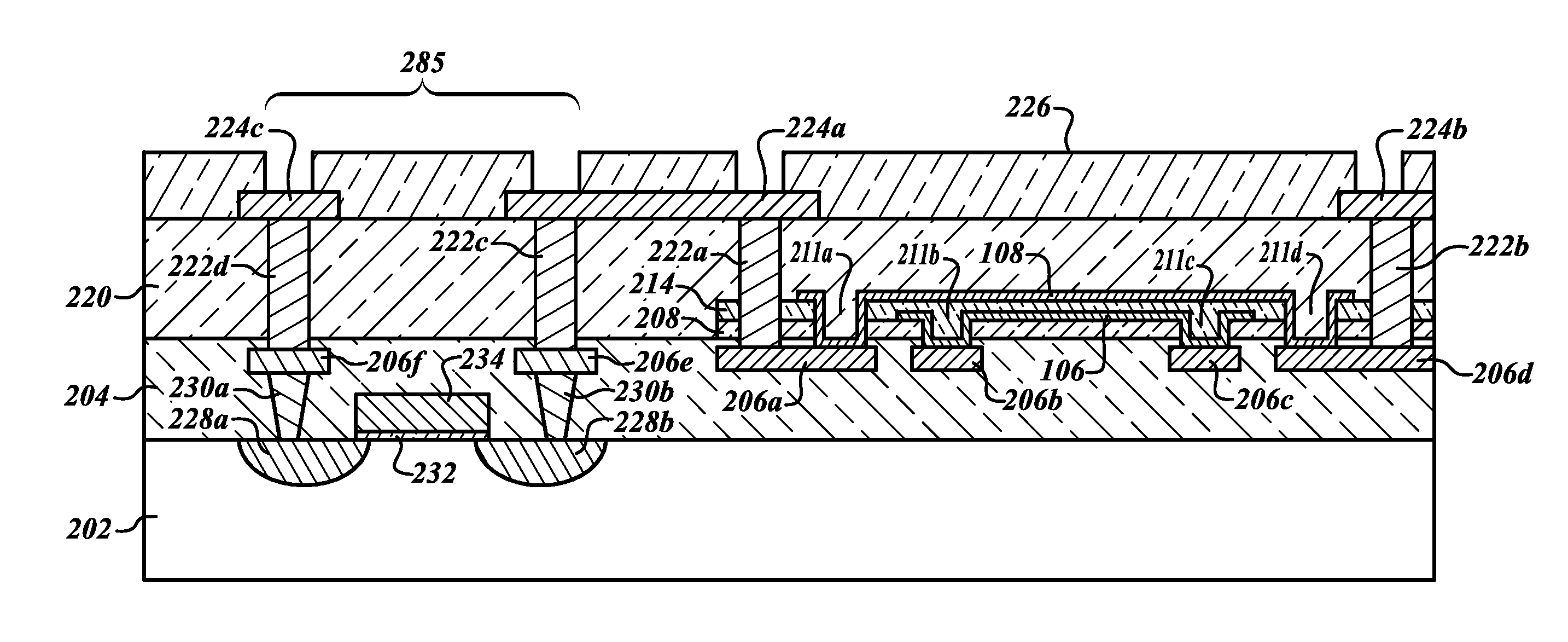

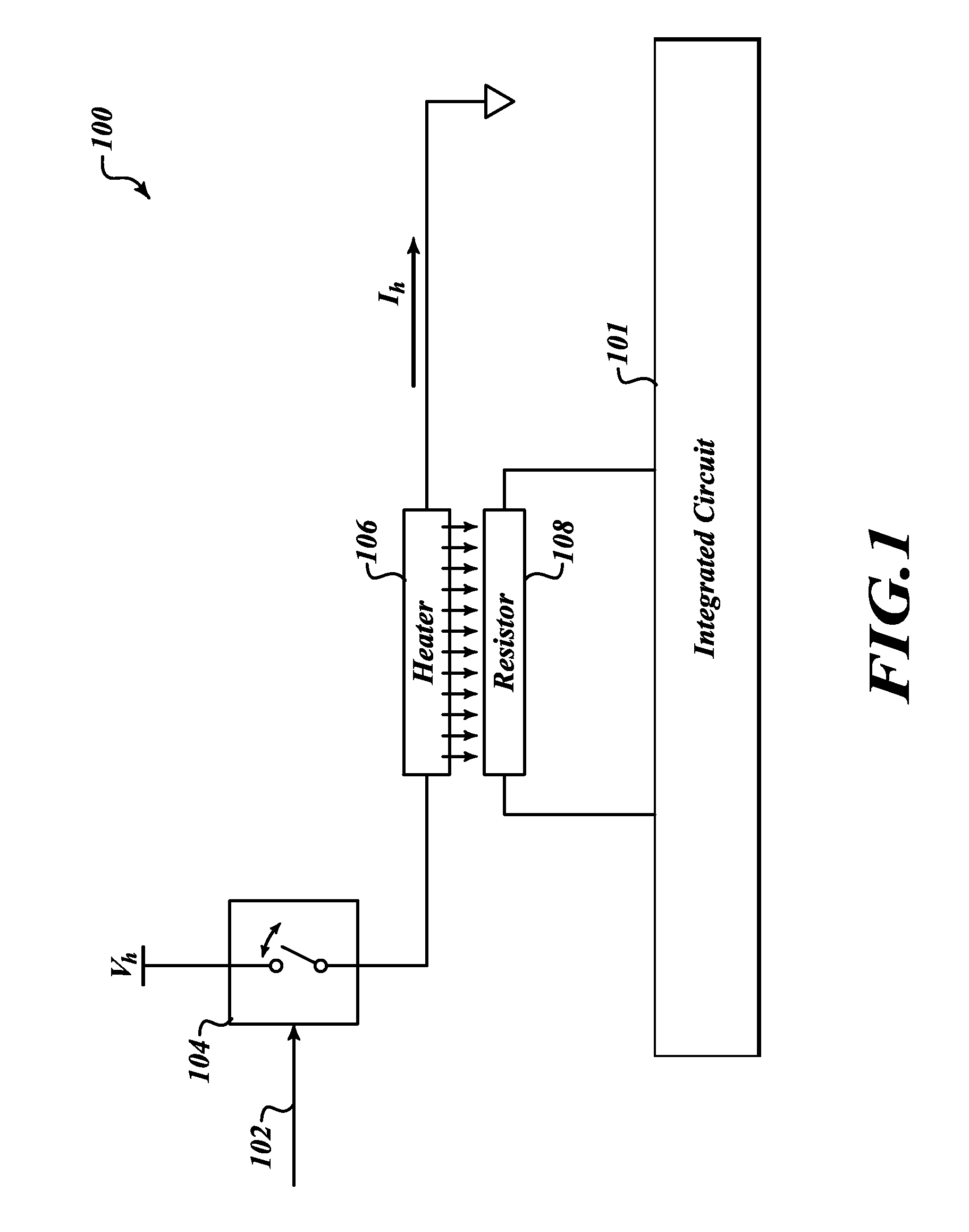

A trimmable resistor for use in an integrated circuit is trimmed using a heater. The heater is selectively coupled to a voltage source. The application of voltage to the heater causes the heater temperature to increase and produce heat. The heat permeates through a thermal separator to the trimmable resistor. The resistance of the trimmable resistor is permanently increased or decreased when the temperature of the resistor is increased to a value within a particular range of temperatures.

Owner:STMICROELECTRONICS SRL +1

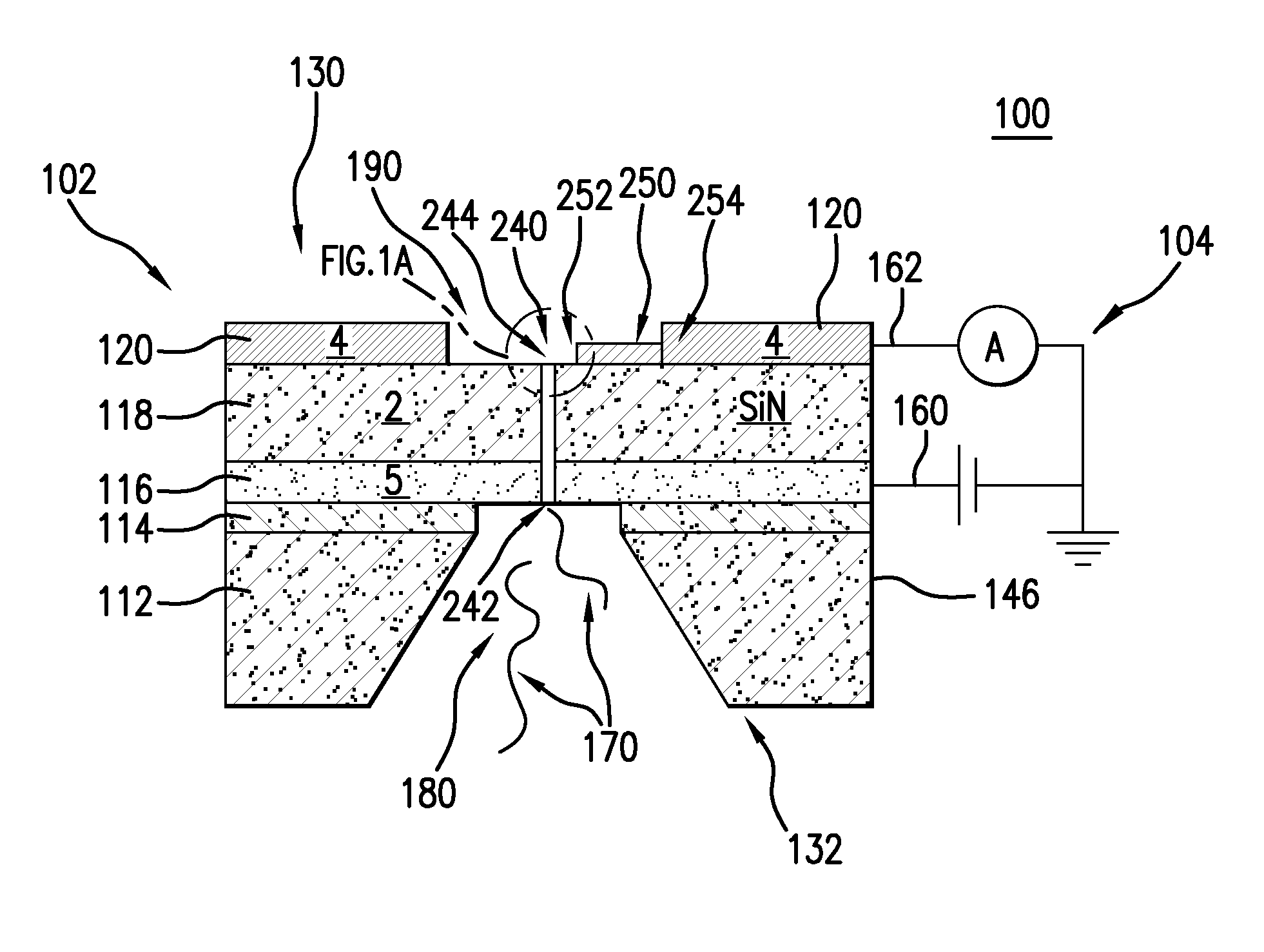

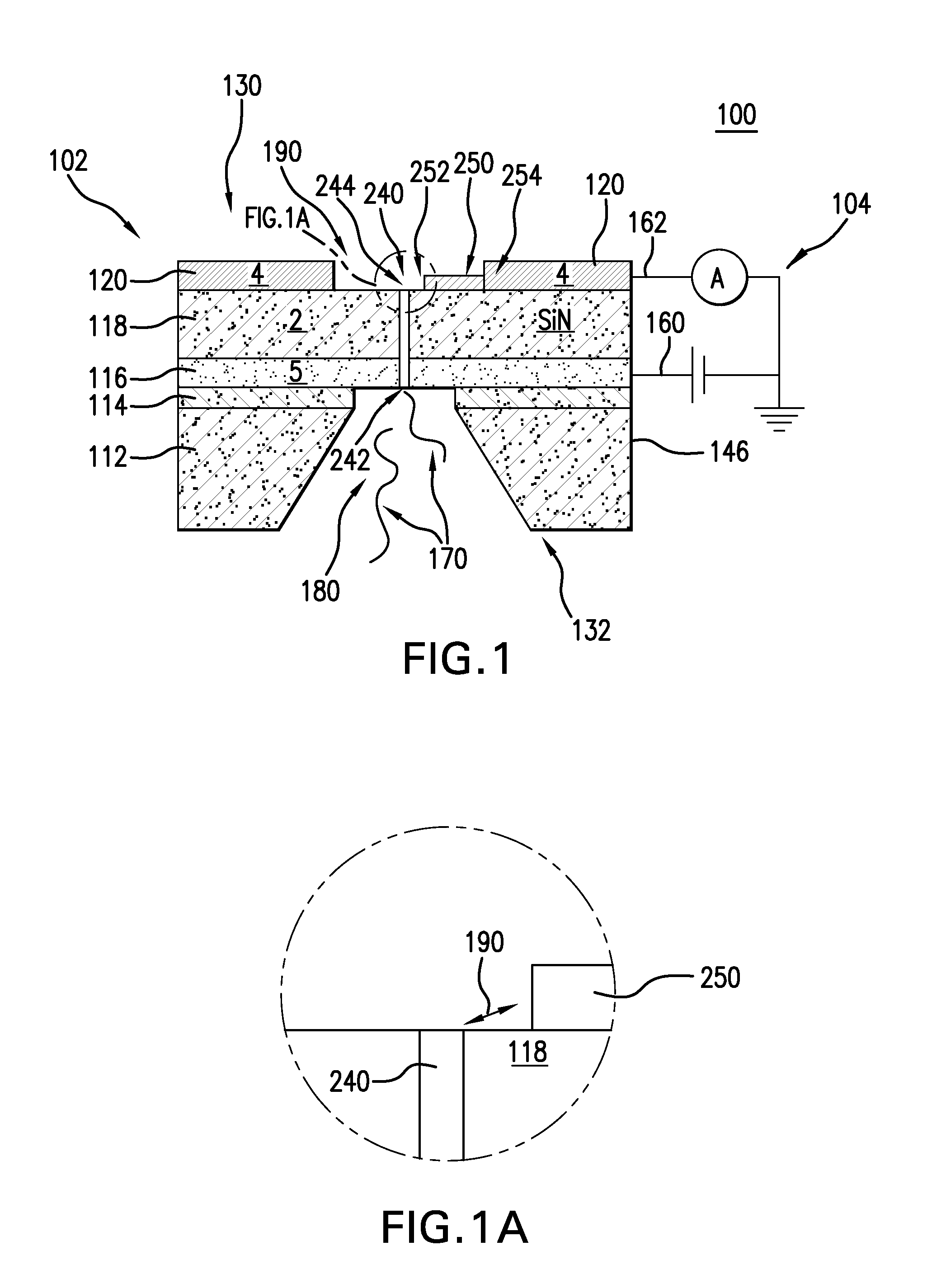

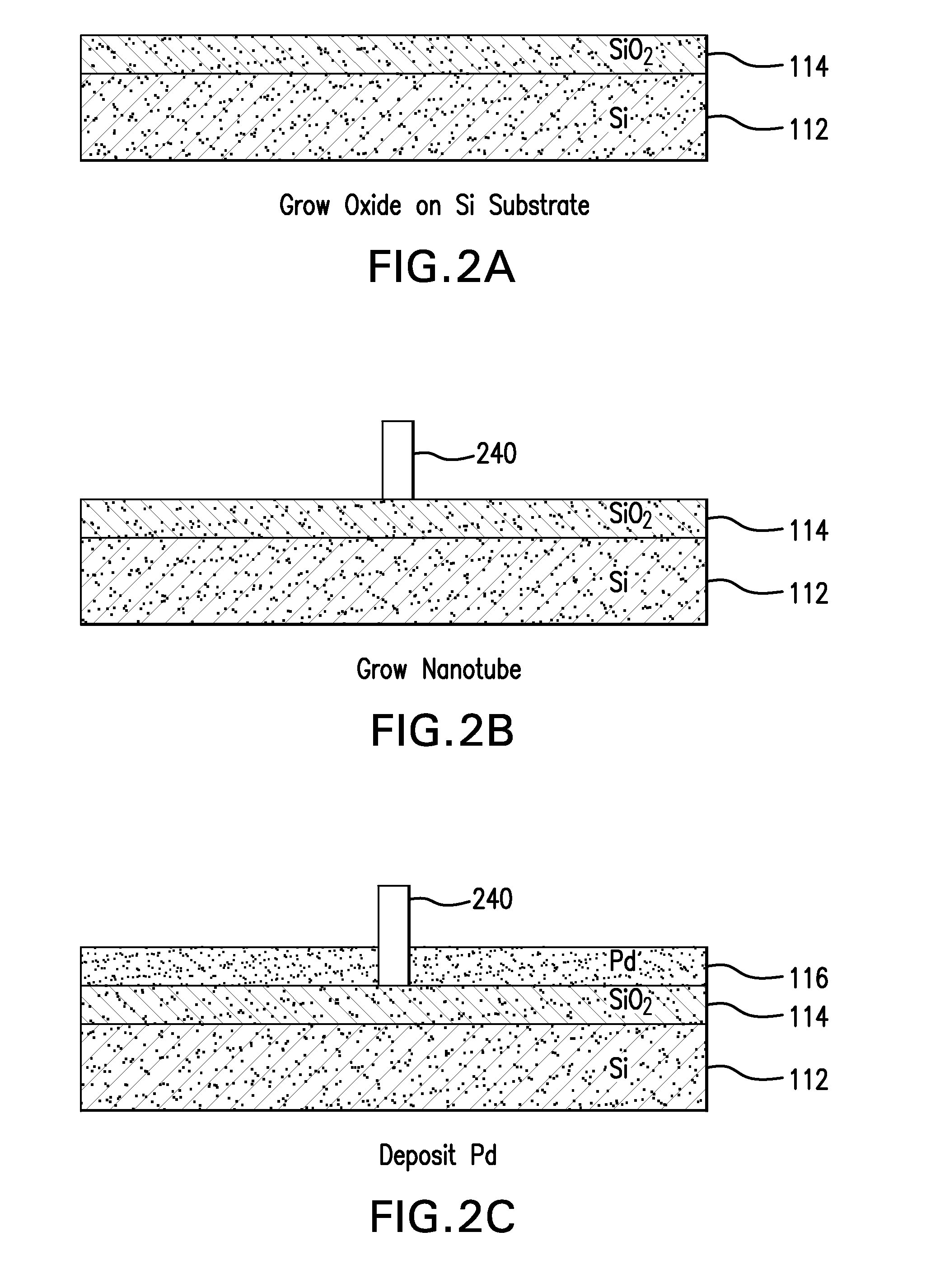

Nanopore and Carbon Nanotube Based DNA Sequencer and a Serial Recognition Sequencer

ActiveUS20110120868A1Volume/mass flow measurementFluid pressure measurement by electric/magnetic elementsBiopolymerDNA sequencer

The present invention is directed to systems, devices and methods for identifying biopolymers, such as strands of DNA, as they pass through a constriction such as a carbon nanotube nanopore. More particularly, the invention is directed to such systems, devices and methods in which a newly translocated portion of the biopolymer forms a temporary electrical circuit between the nanotube nanopore and a second electrode, which may also be a nanotube. Further, the invention is directed to such systems, devices and methods in which the constriction is provided with a functionalized unit which, together with a newly translocated portion of the biopolymer, forms a temporary electrical circuit that can be used to characterize that portion of the biopolymer.

Owner:ARIZONA STATE UNIVERSITY

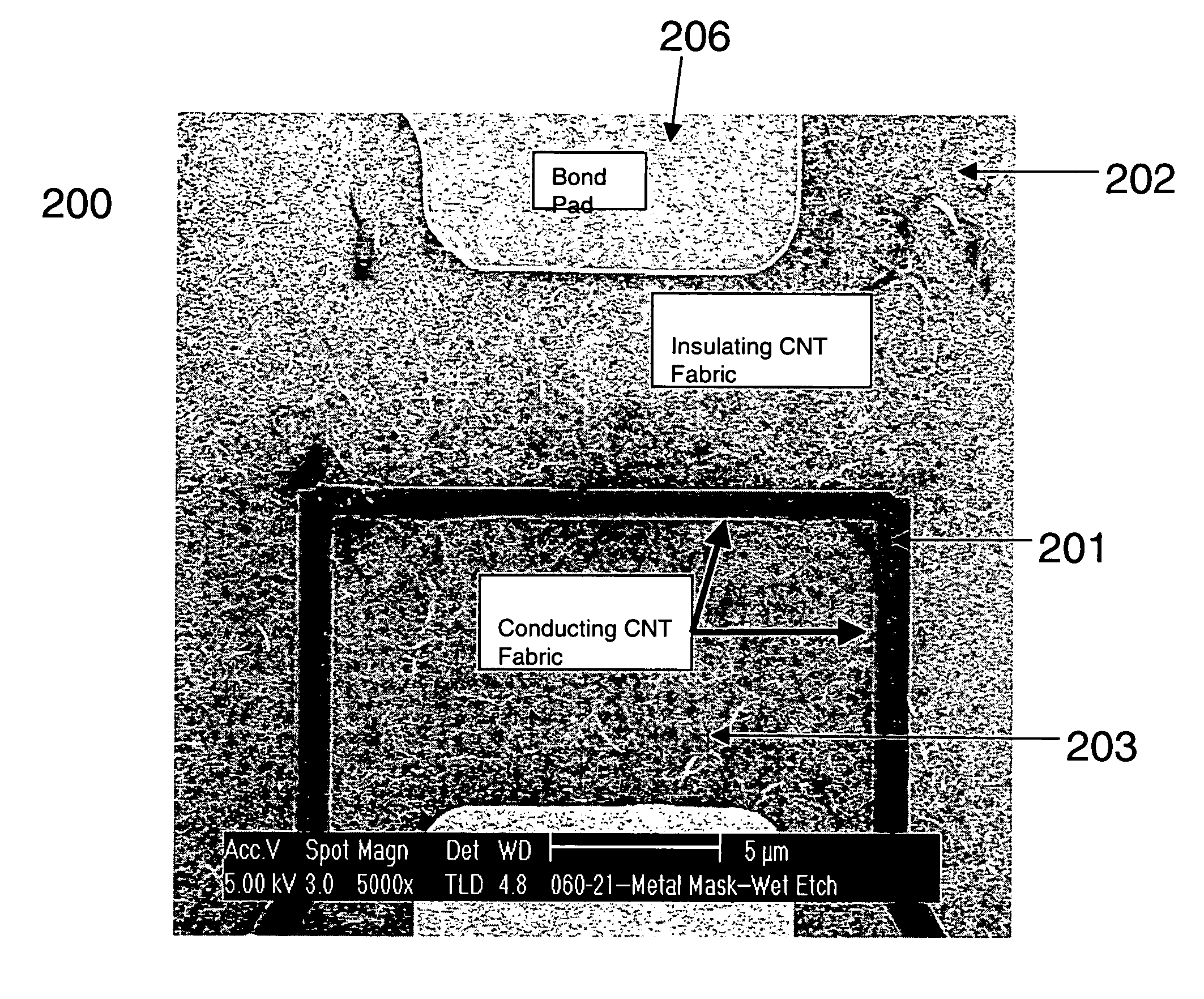

Resistive elements using carbon nanotubes

ActiveUS7365632B2Function increaseEasy parameter controlCurrent responsive resistorsSolid-state devicesBulk resistanceCarbon nanotube

Resistive elements include a patterned region of nanofabric having a predetermined area, where the nanofabric has a selected sheet resistance; and first and second electrical contacts contacting the patterned region of nanofabric and in spaced relation to each other. The resistance of the element between the first and second electrical contacts is determined by the selected sheet resistance of the nanofabric, the area of nanofabric, and the spaced relation of the first and second electrical contacts. The bulk resistance is tunable.

Owner:NANTERO

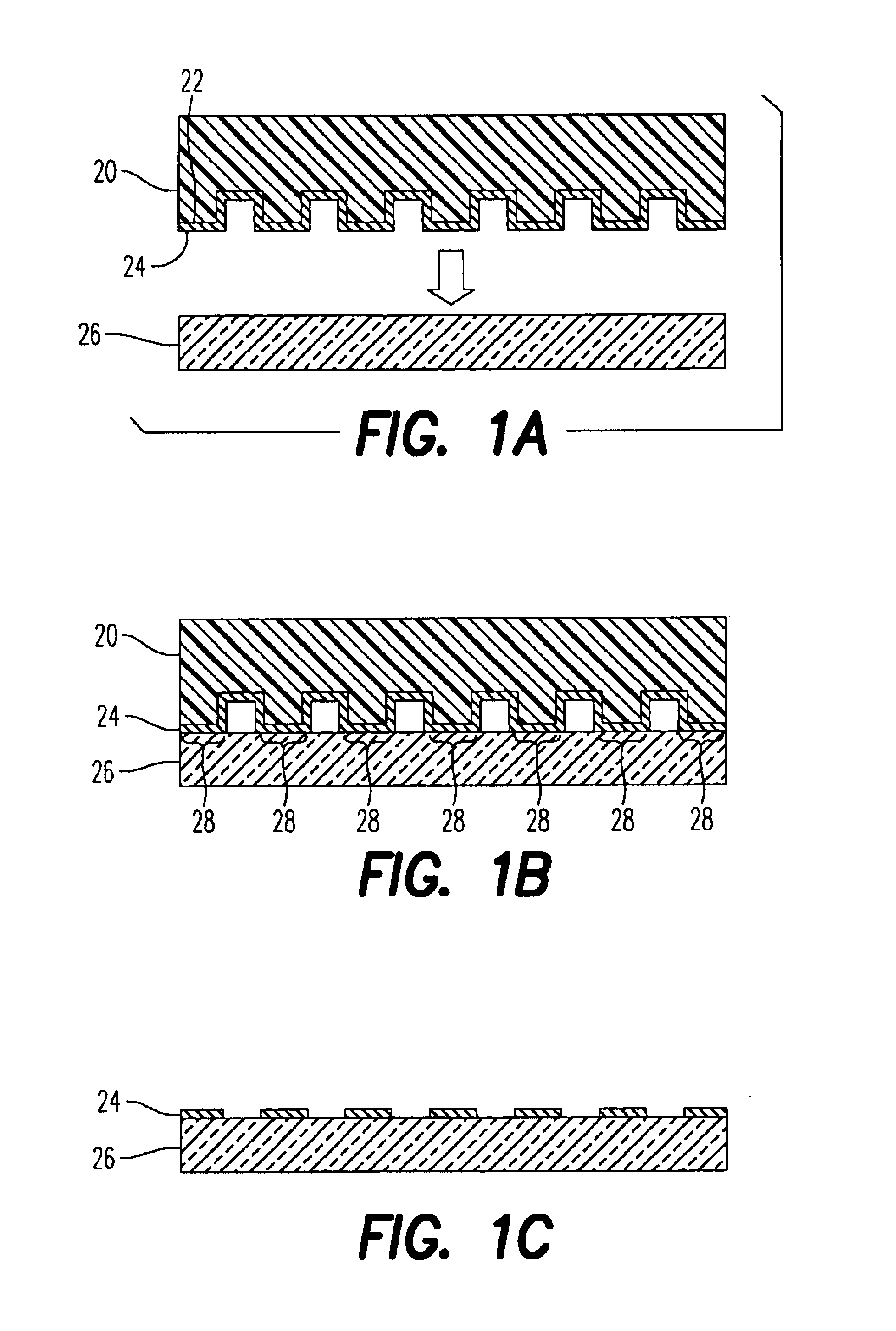

Method for making an integrated circuit substrate having embedded passive components

InactiveUS7334326B1Low incremental costIncremental costPrinted circuit assemblingElectrolytic capacitorsConductive pasteConductive materials

A method for making an integrated circuit substrate having embedded passive components provides a reduced cost and compact package for a die and one or more passive components. An insulating layer of the substrate is embossed or laser-ablated to generate apertures for insertion of a paste forming the body of the passive component. A resistive paste is used to form resistors and a dielectric paste is used for forming capacitors. A capacitor plate may be deposited at a bottom of the aperture by using a doped substrate material and activating only the bottom wall of the aperture, enabling plating of the bottom wall without depositing conductive material on the side walls of the aperture. Vias may be formed to the bottom plate by using a disjoint structure and conductive paste technology. Connection to the passive components may be made by conductive paste-filled channels forming conductive patterns on the substrate.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

Replacement of passive electrical components

A process of fabricating a passive electrical component, such as a resistor, a capacitor, or an inductor, is provided. The process includes the step of ink-jet printing at least one electronic ink onto a substrate in a predetermined pattern. The step of ink-jet printing may include the steps of: a) selecting at least one electronic ink having at least one electrical characteristic when cured; b) determining a positional layout for a plurality of droplets of the at least one electronic ink such that, when the at least one electronic ink has been cured, the positional layout provides a desired response for the electrical component; c) printing each of the plurality of droplets of the at least one electronic ink onto the substrate according to the positional layout using an ink-jet printing process; and d) curing the at least one electronic ink.

Owner:CABOT CORP

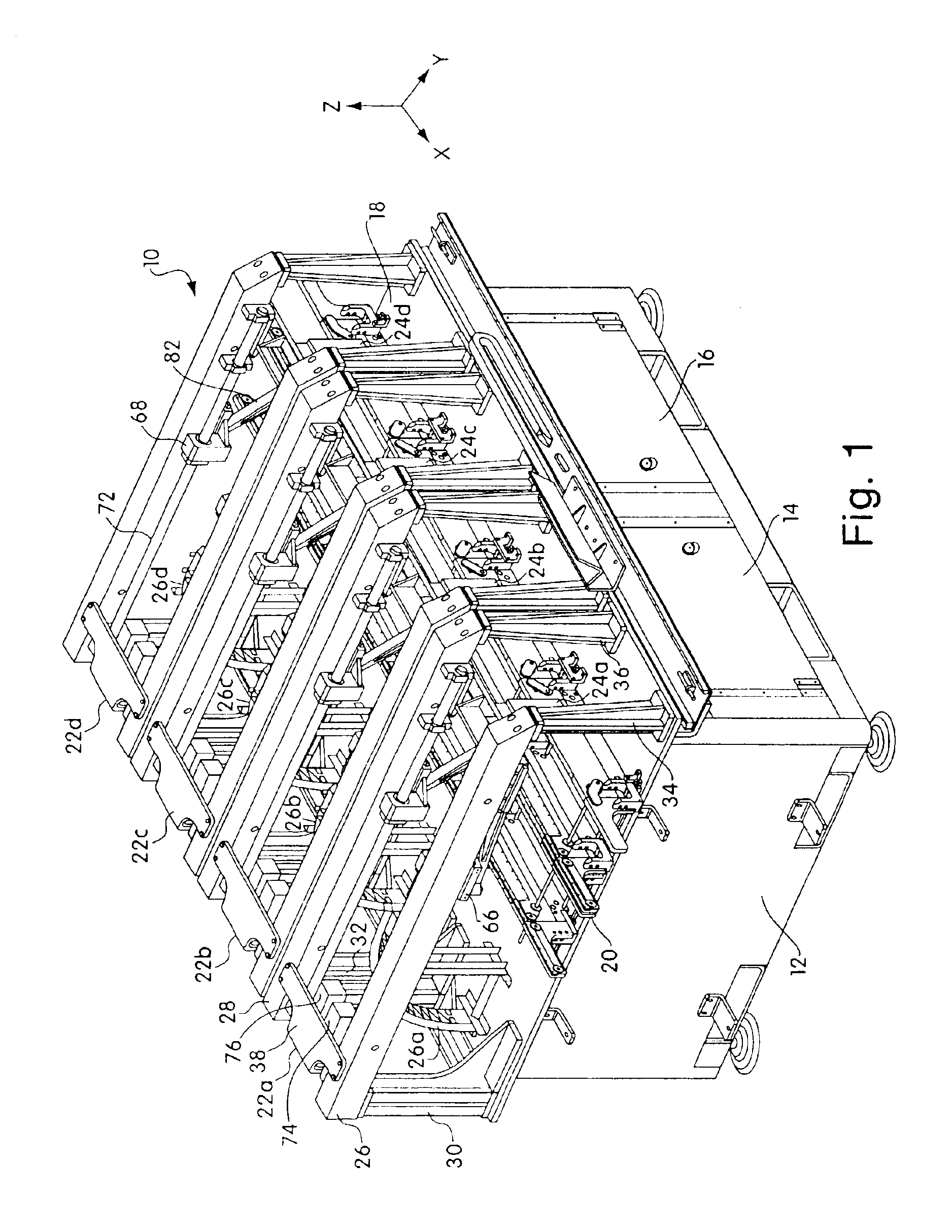

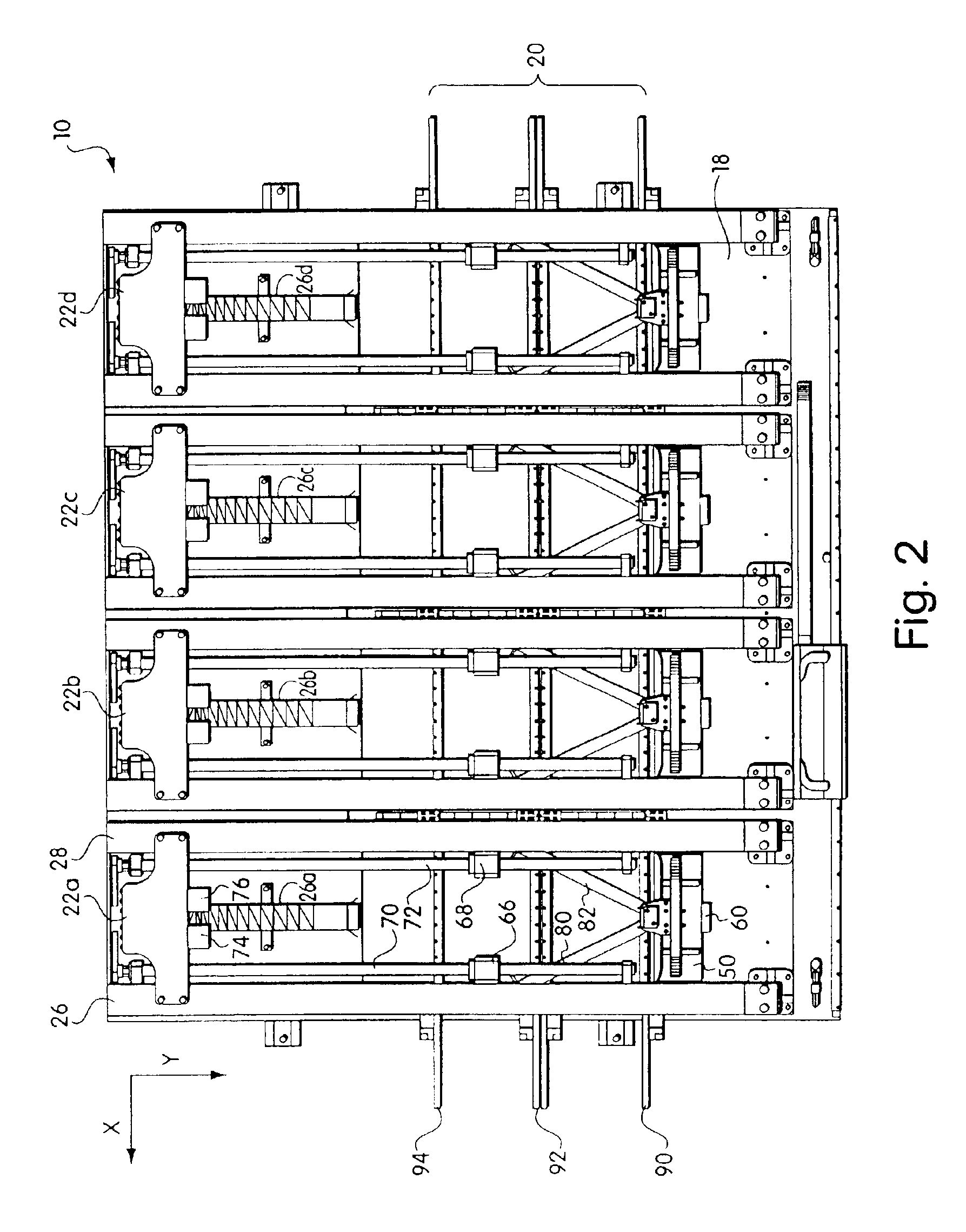

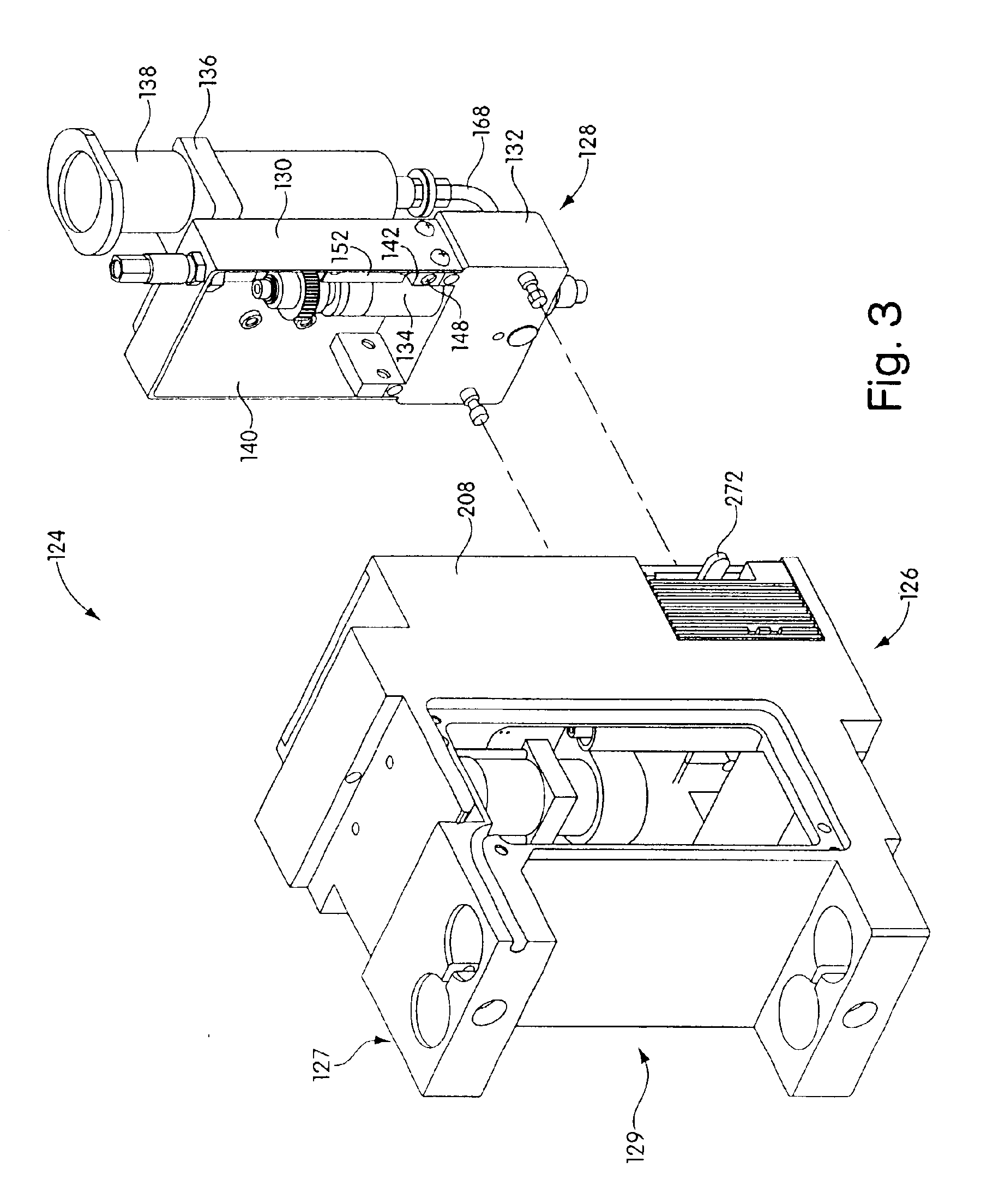

Dispensing system and method

InactiveUS6866881B2Increase the number ofReduce gear ratioLarge containersPretreated surfacesMotor unitElectric motor

A dispensing system and method for dispensing material onto a substrate. The dispensing system includes a frame, a support, coupled to the frame, that supports the substrate at a dispensing position in the dispensing system, and a dispensing head, coupled to the frame, that dispenses the material onto the substrate. The dispensing head includes a motor unit having a first motor coupled to an output drive mechanism, and a dispensing unit, removably coupled to the motor unit, having a material outlet from which the dispensing material is dispensed, the dispensing unit having a dispensing mechanism coupled to the material outlet and coupled to the output drive mechanism of the motor unit such that operation of the first motor causes the dispensing mechanism to dispense material through the outlet. The dispensing head may be controlled for deposition of dots of material having diameters smaller than a dispensing needle of the dispensing unit.

Owner:KPS SPECIAL SITUATIONS FUND II LP

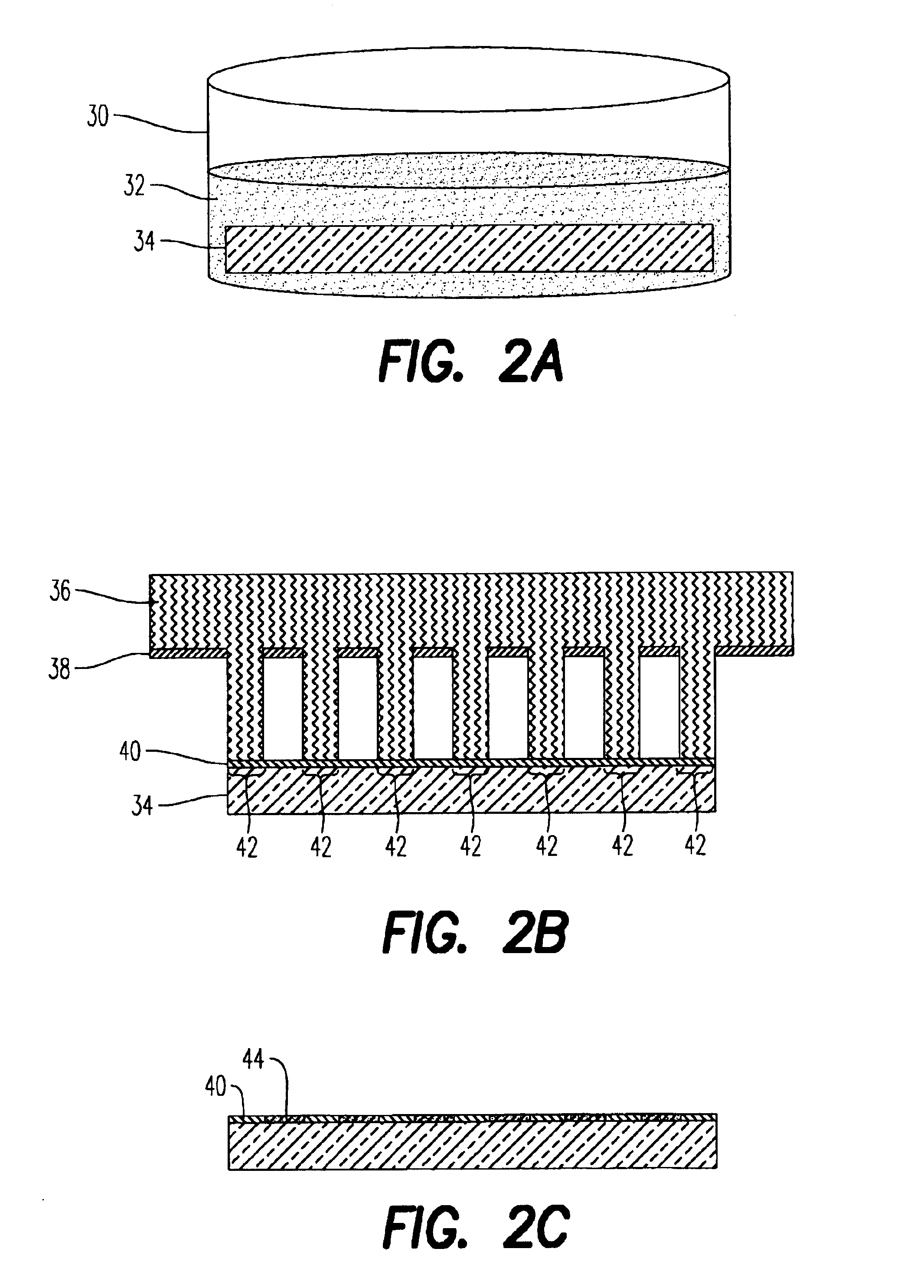

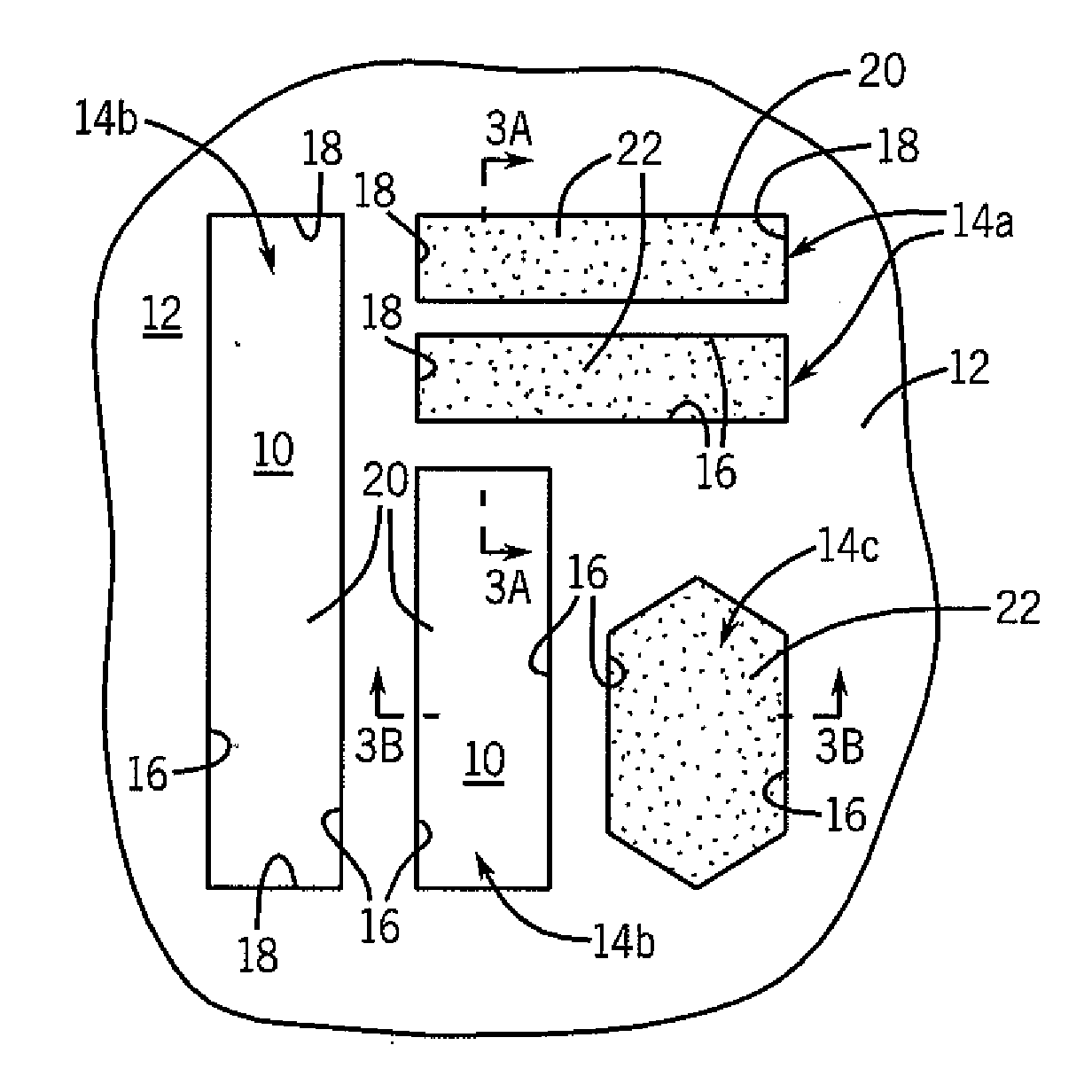

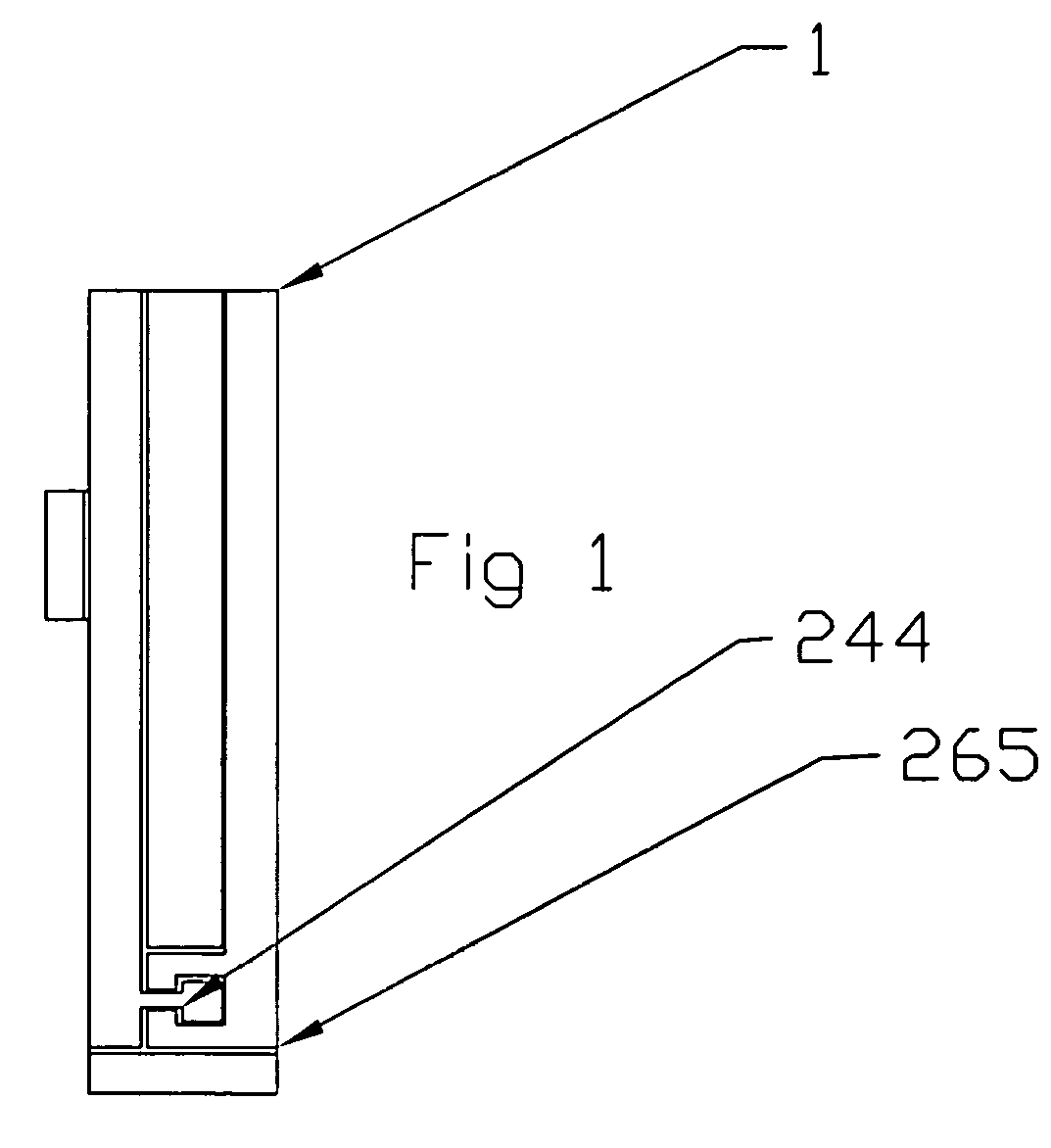

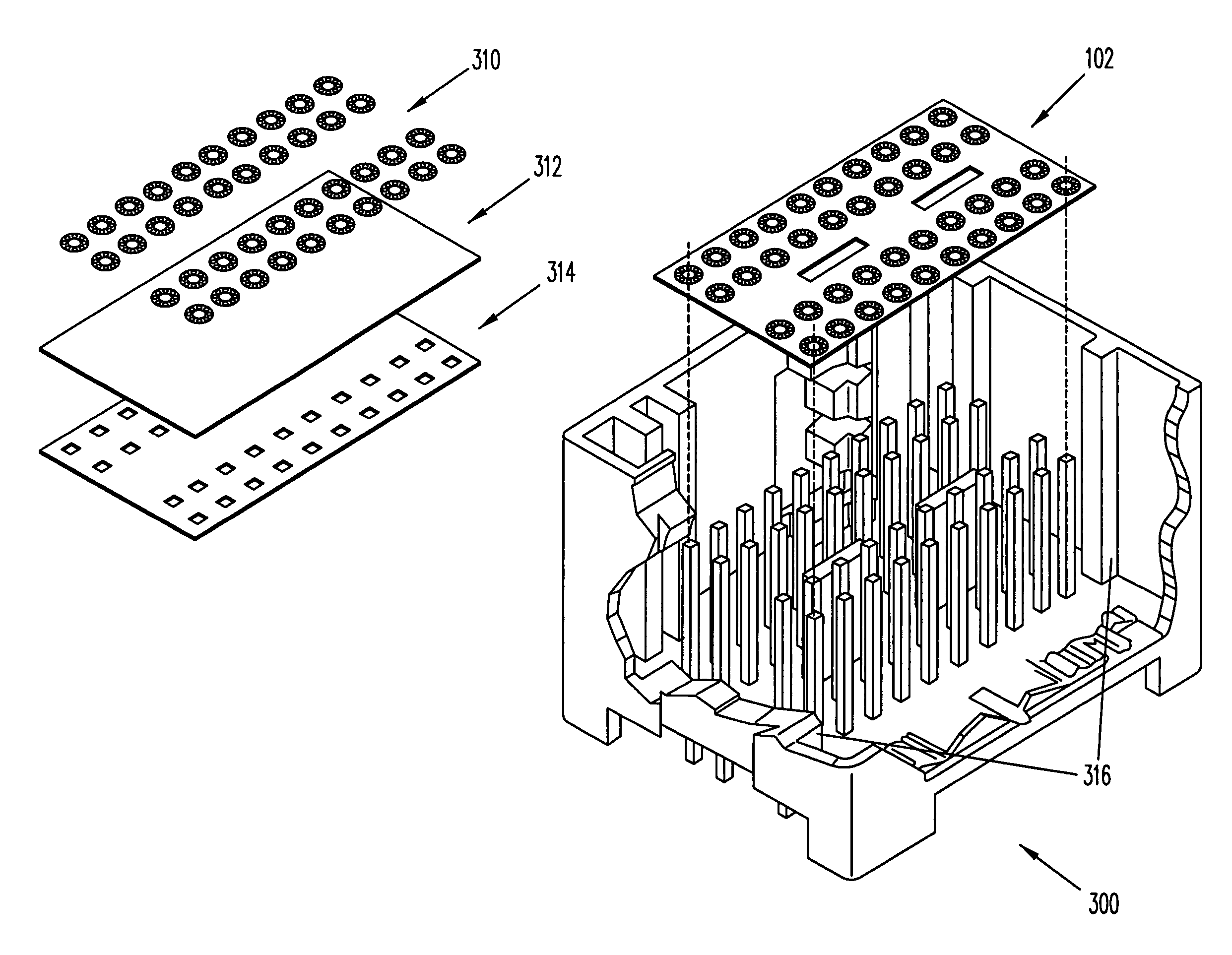

Thin film surface mount components

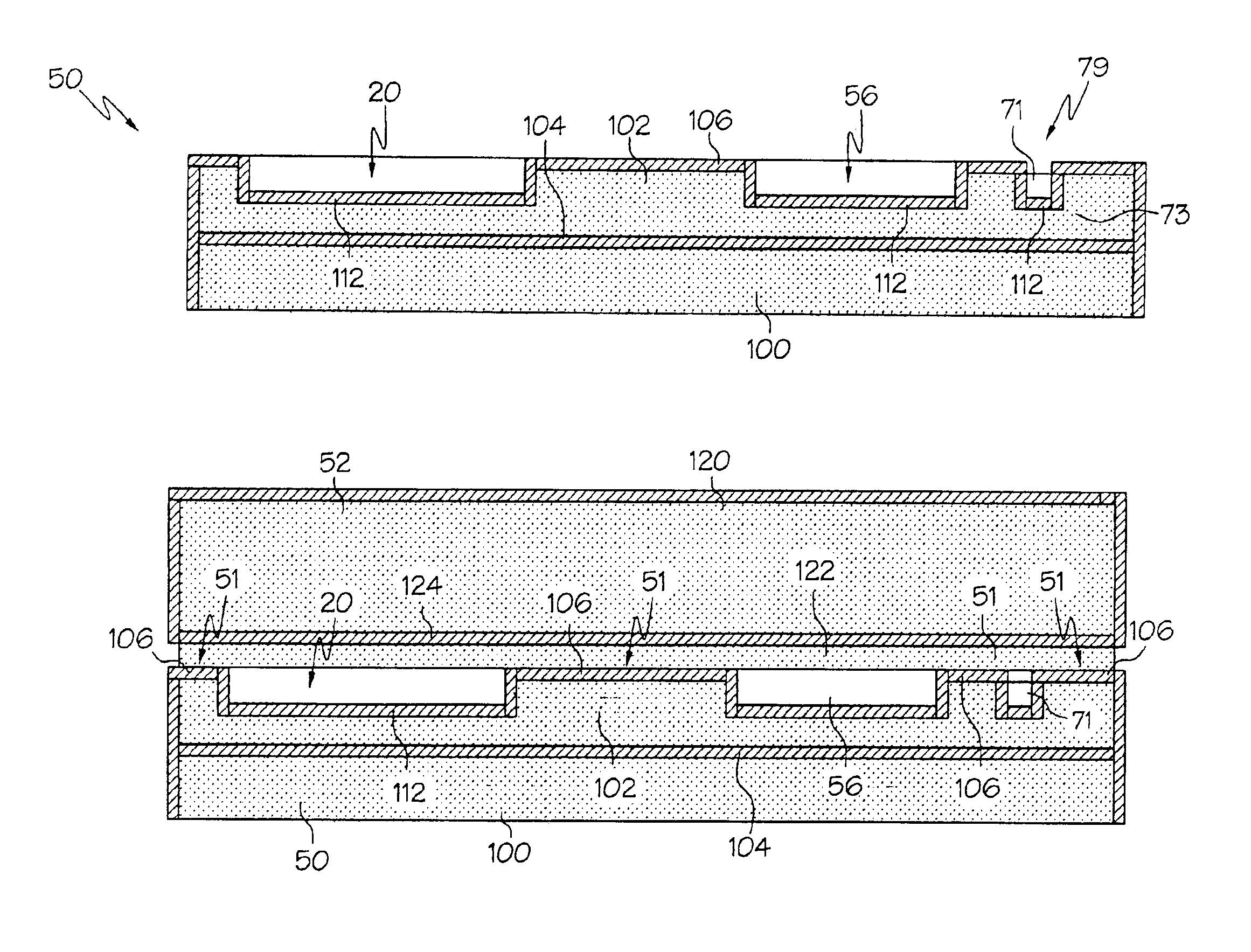

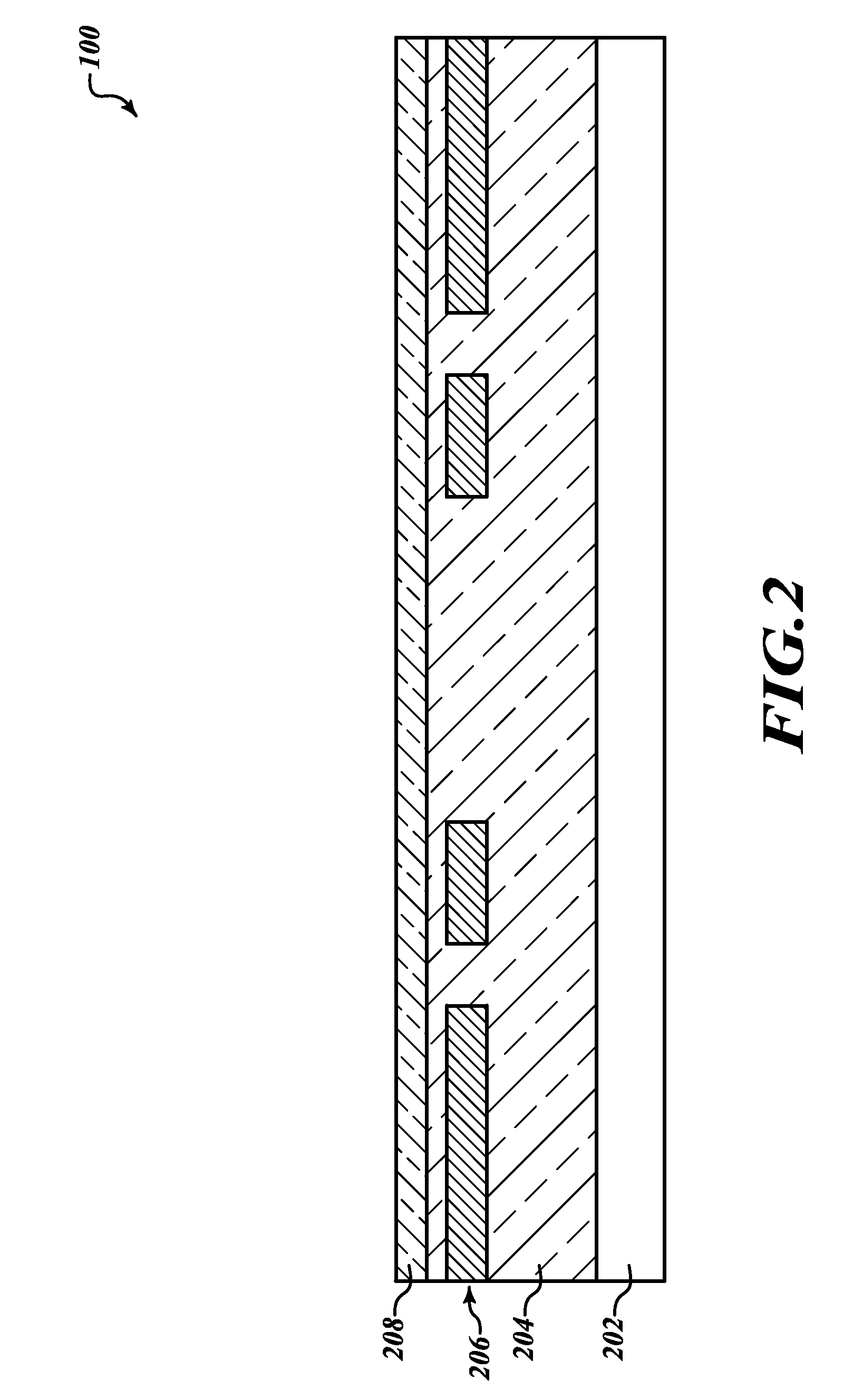

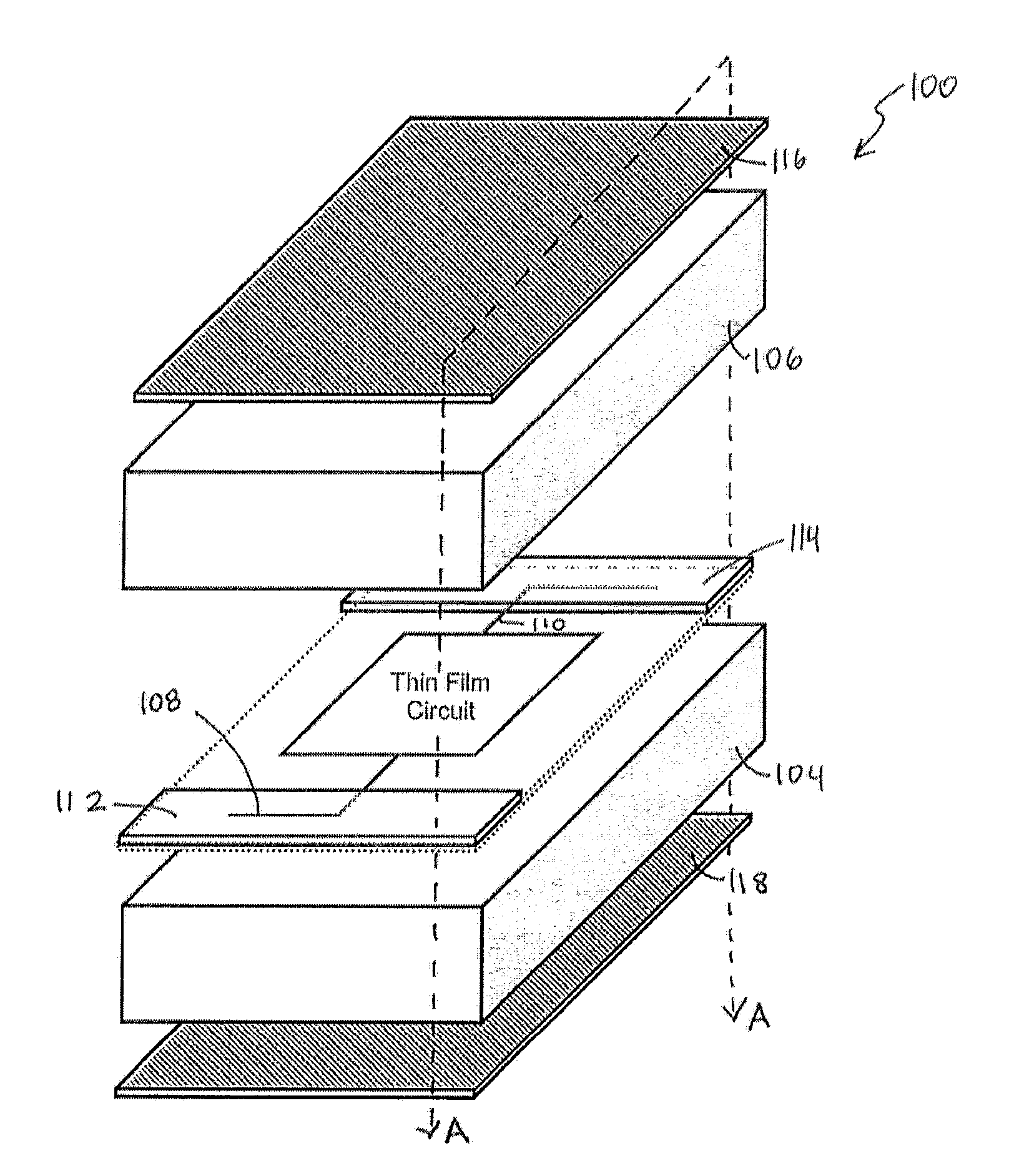

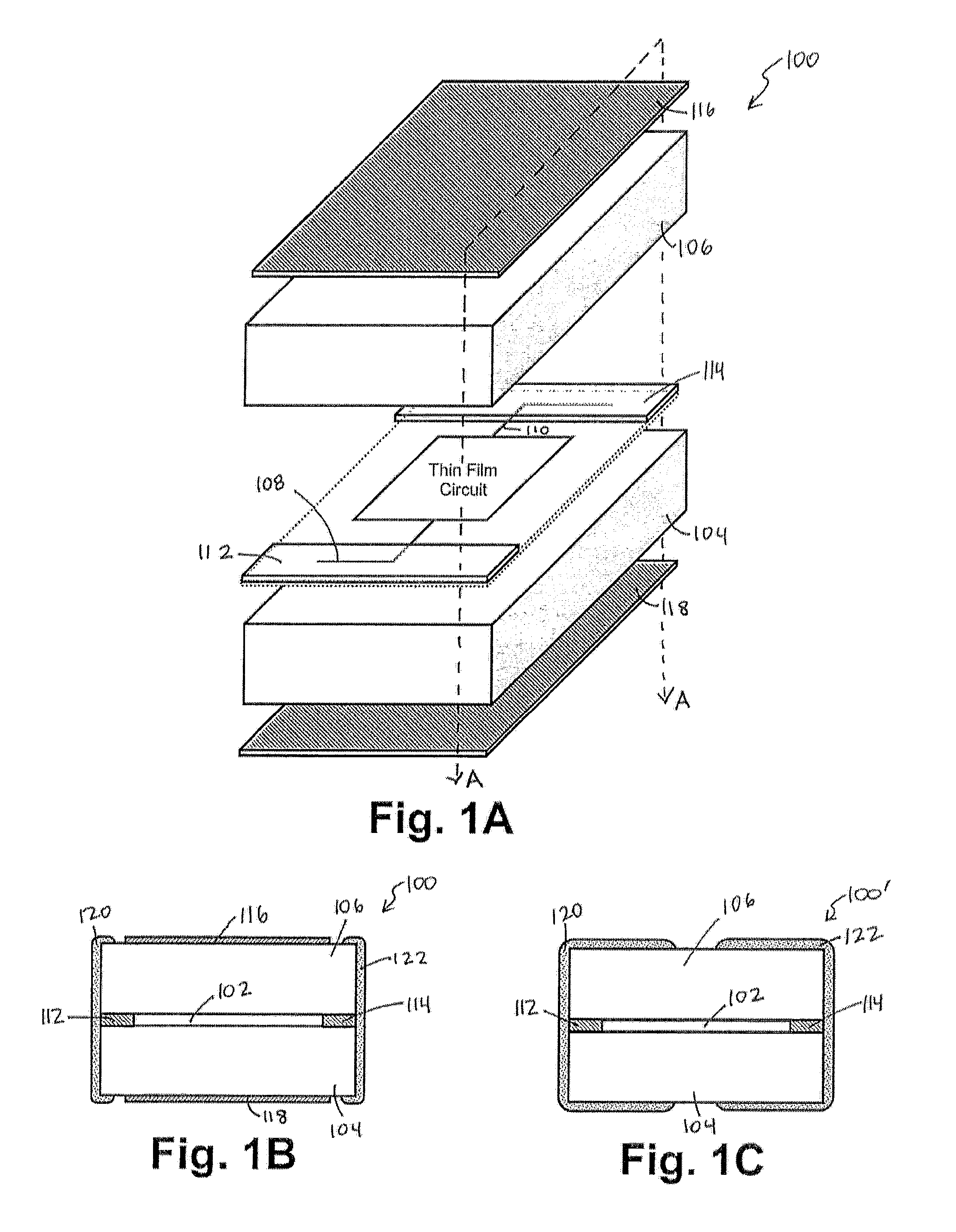

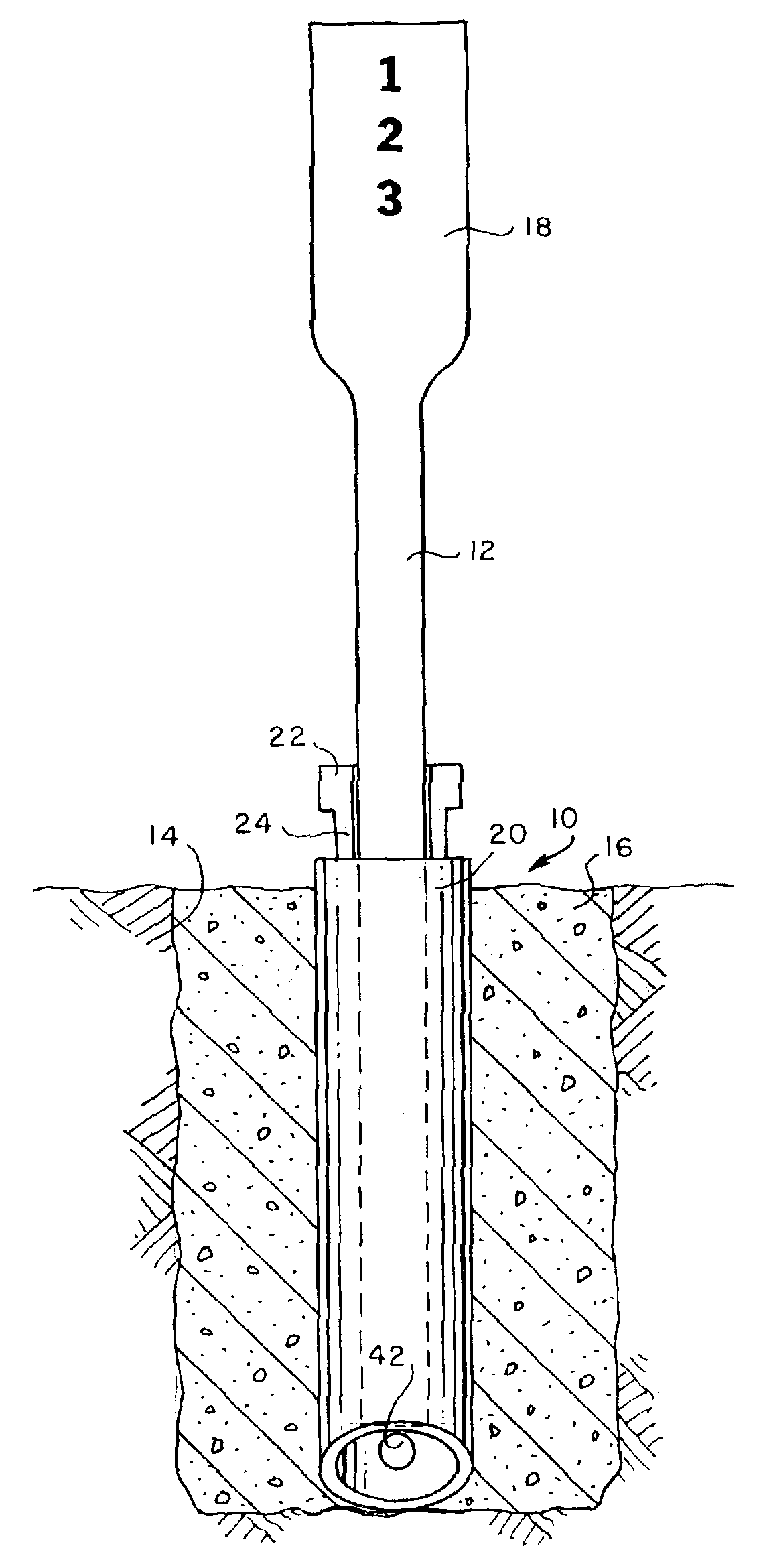

ActiveUS20110090665A1Lowering termination costImprove functionalityMultiple-port networksDigital data processing detailsSurface mountingConductive polymer

Surface mount components and related methods of manufacture involve one or more thin film circuits provided between first and second insulating substrates. The thin film circuits may include one or more passive components, including resistors, capacitors, inductors, arrays of one or more passive components, networks or filters of multiple passive components. Such thin film circuit(s) can be sandwiched between first and second insulating substrates with internal conductive pads being exposed between the substrates on end and / or side surfaces of the surface mount component. The exposed conductive pads are then electrically connected to external terminations. The external terminations may include a variety of different materials, including at least one layer of conductive polymer and may be formed as termination stripes, end caps or the like. Optional shield layers may also be provided on top and / or bottom device surfaces to protect the surface mount components from signal interference. For embodiments where one or more thin film circuits are provided between insulating base and cover substrates, such thin film circuit(s) can be formed with conductive pads that extend to and are initially exposed along one or more surfaces of the resultant component. The cover substrate is formed with a plurality of conductive elements (e.g., internal active electrodes, internal anchor electrodes and / or external anchor electrodes) that are designed to generally align with the conductive pads formed on the base substrate such that conductive element portions are exposed in groups along one or more peripheral surfaces of a device. External plated terminations are then formed directly to the exposed portions of the conductive elements.

Owner:KYOCERA AVX COMPONENTS CORP

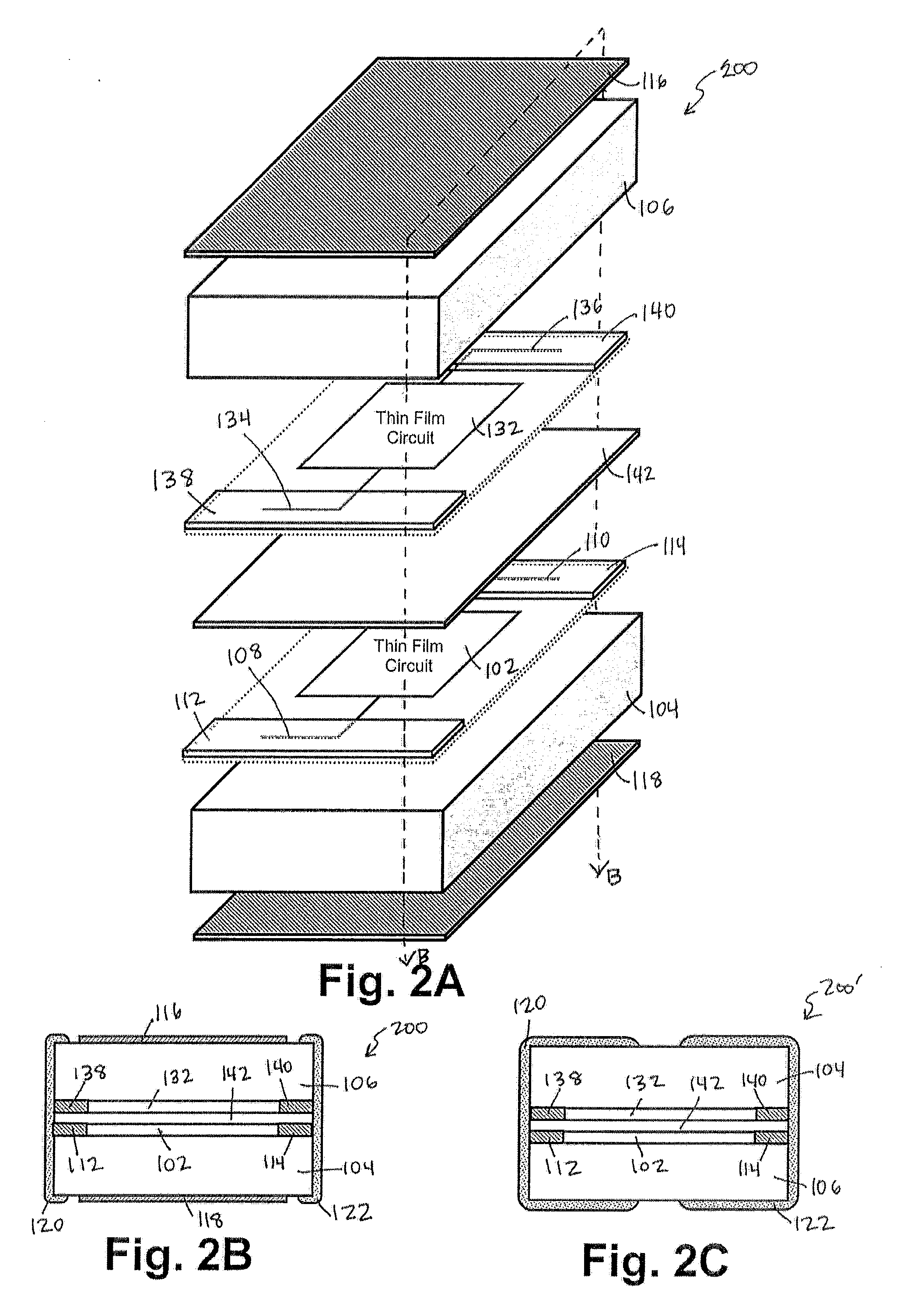

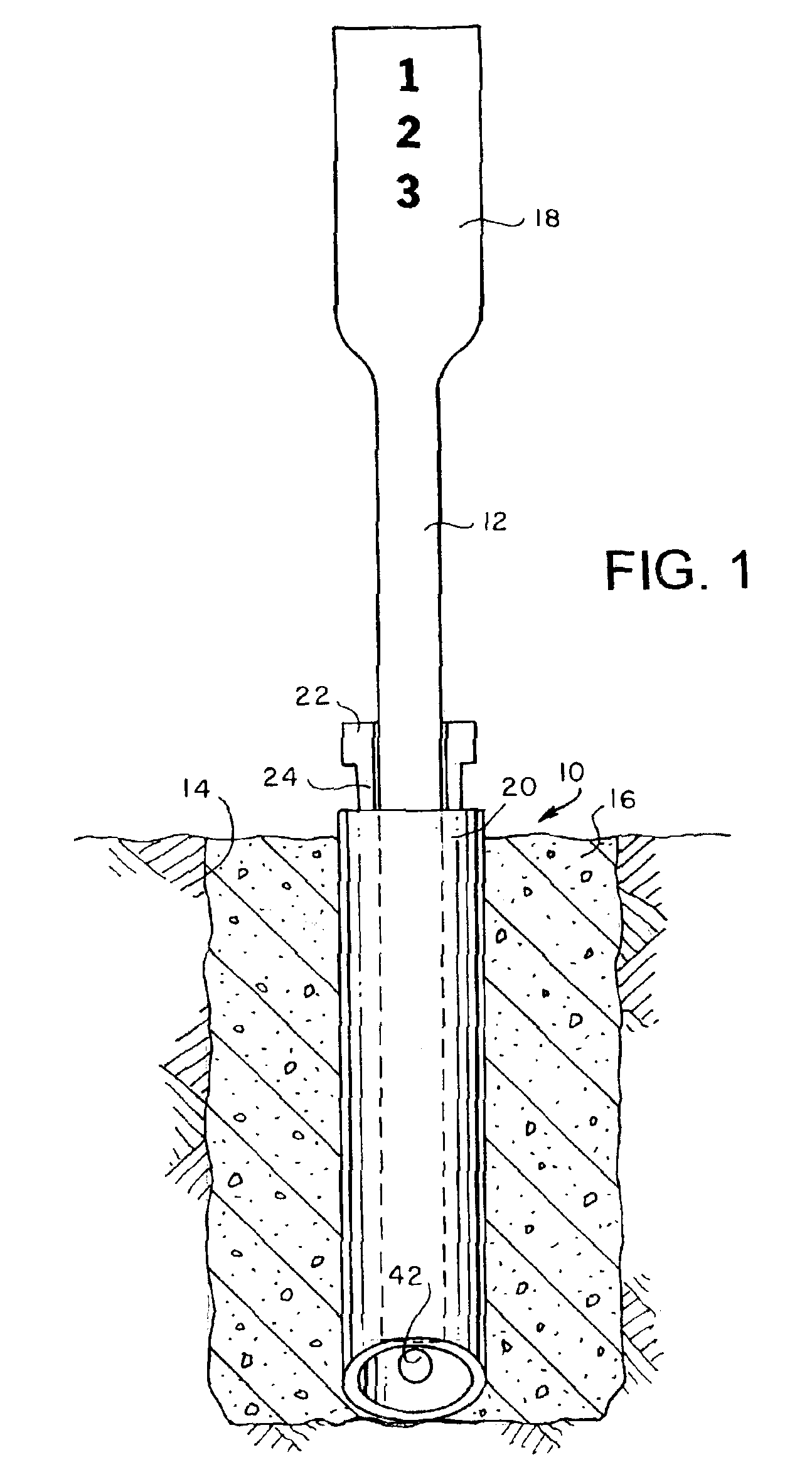

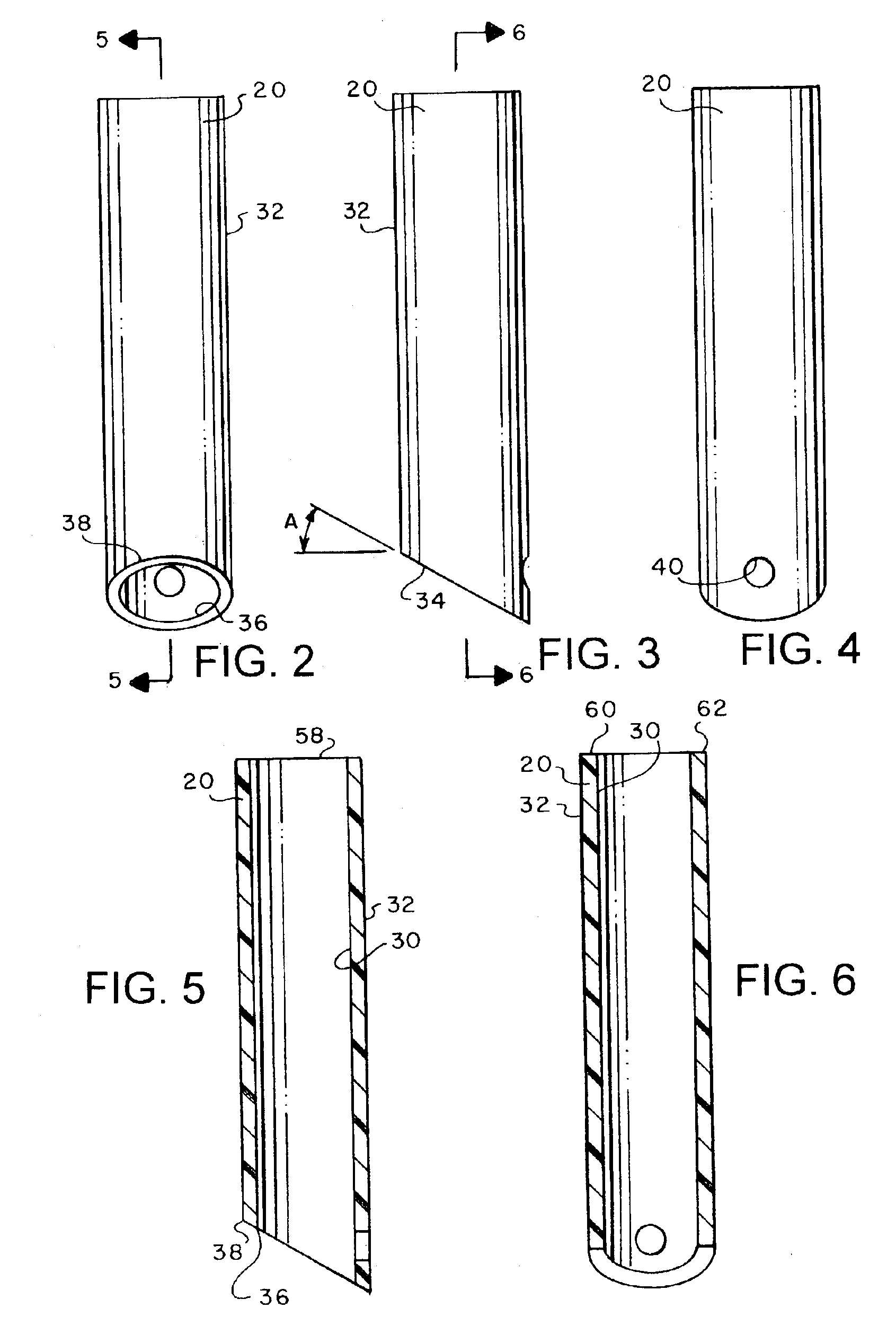

Post mount assembly

ActiveUS7003919B2Non-conductive material with dispersed conductive materialFoundation engineeringEngineeringMechanical engineering

Owner:CAMINOVERDE II

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com