Patents

Literature

8008 results about "Laser processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

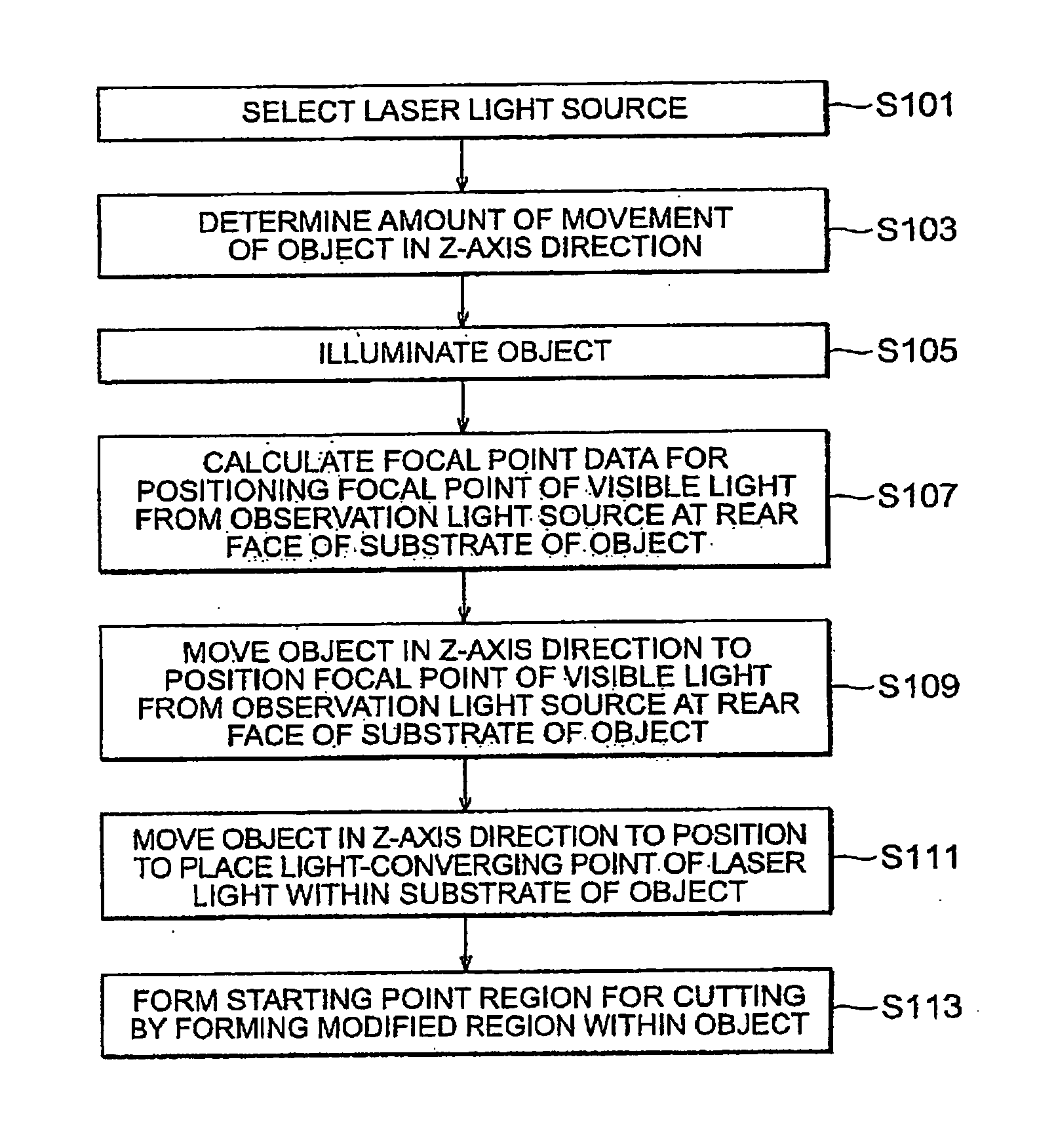

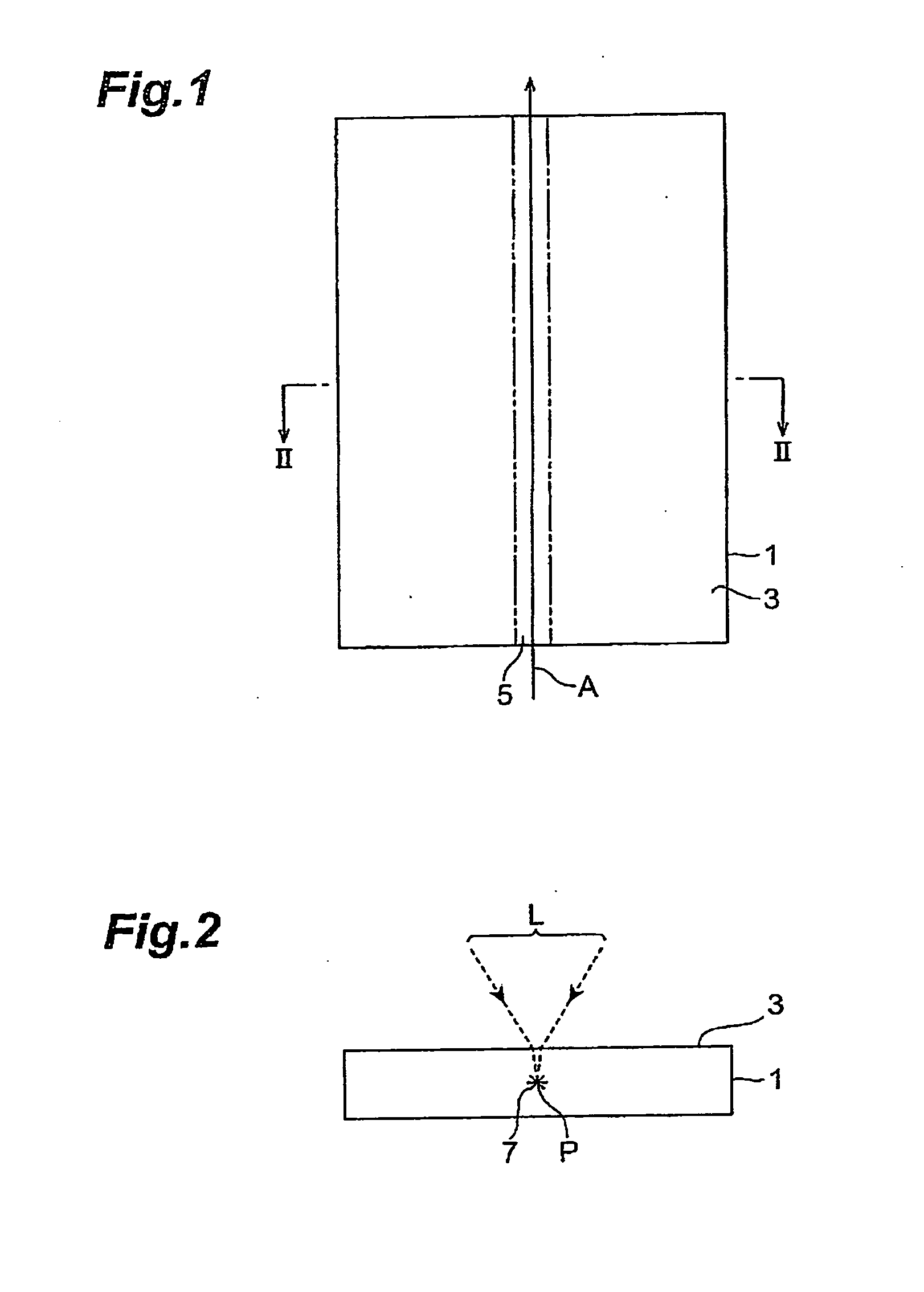

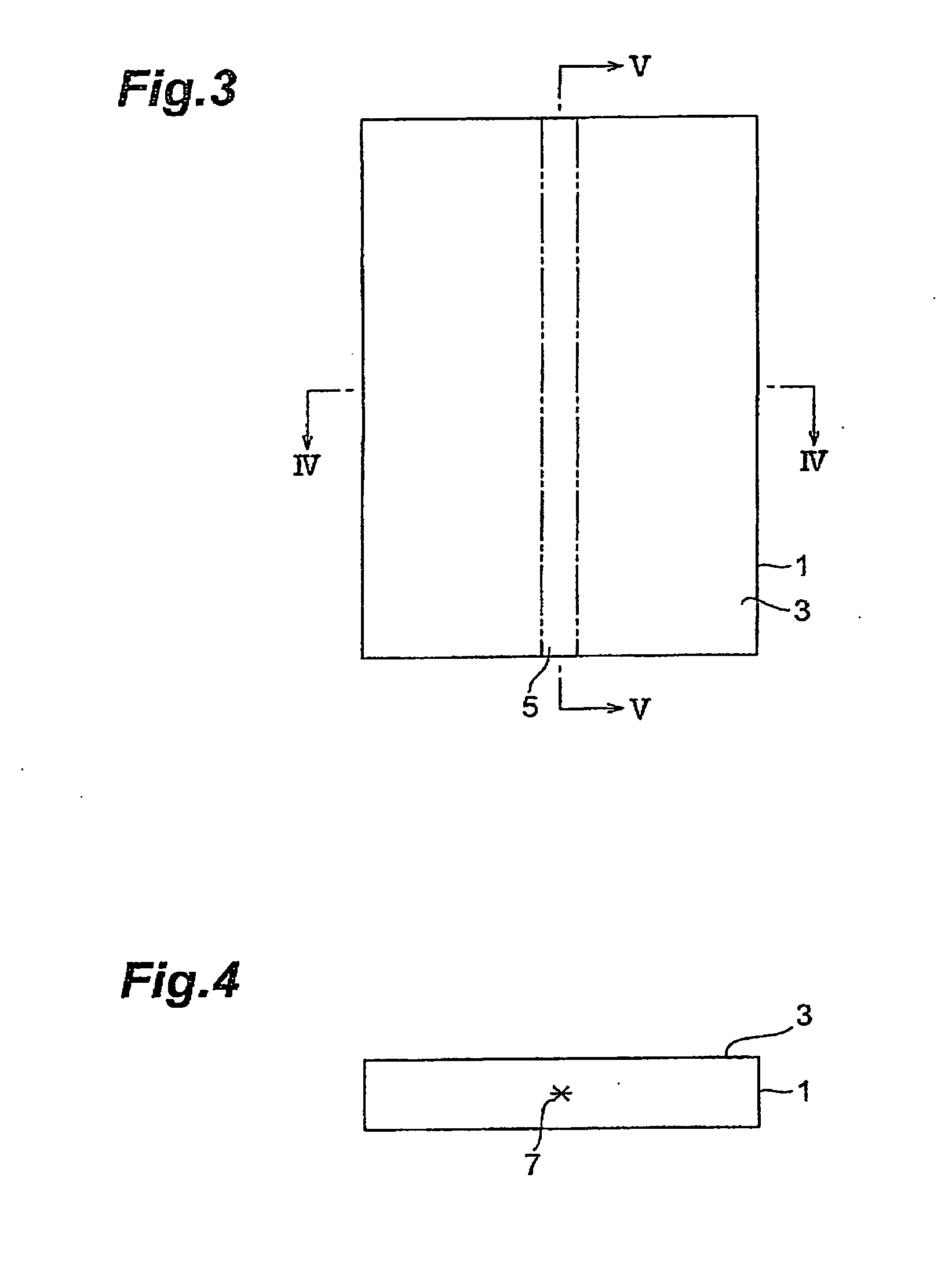

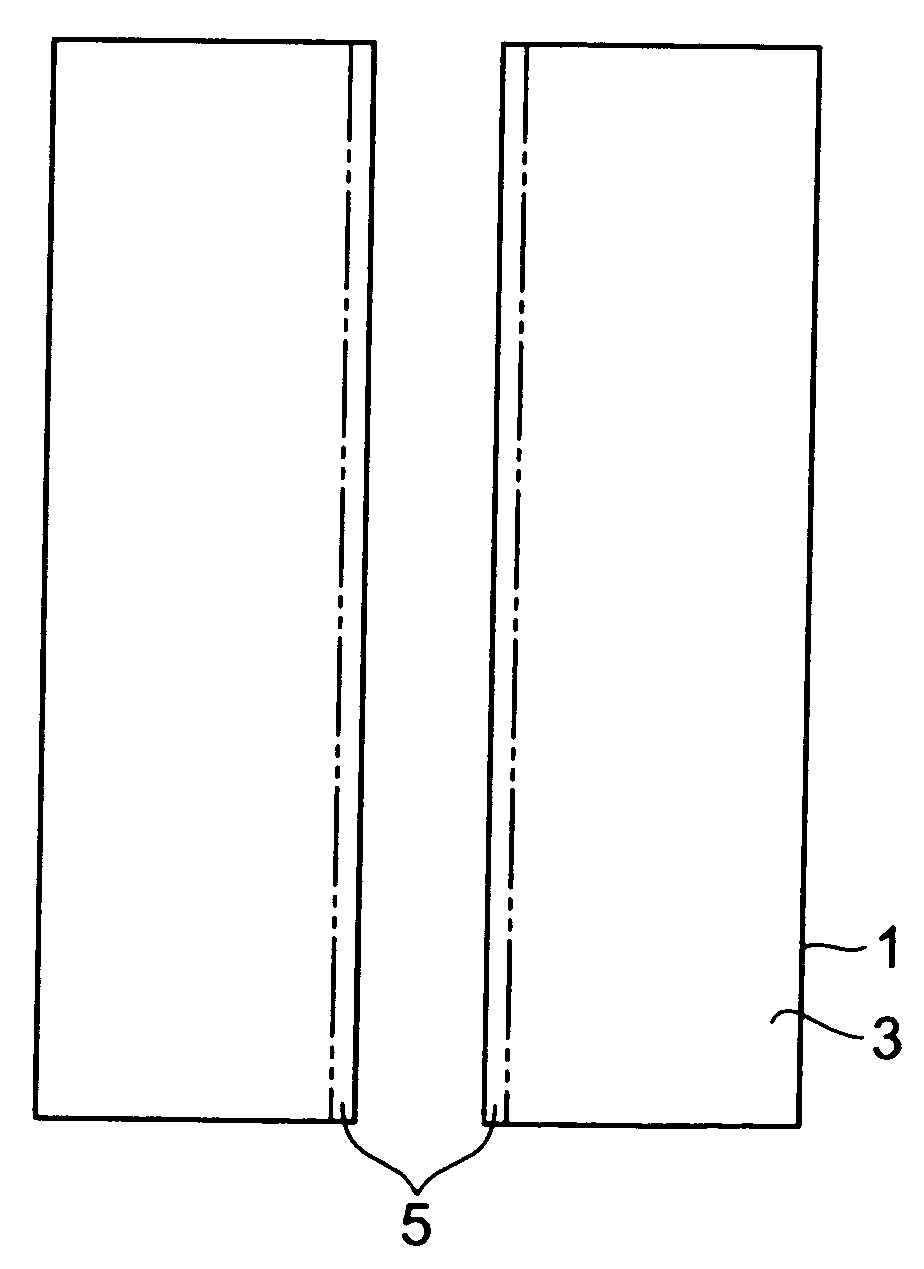

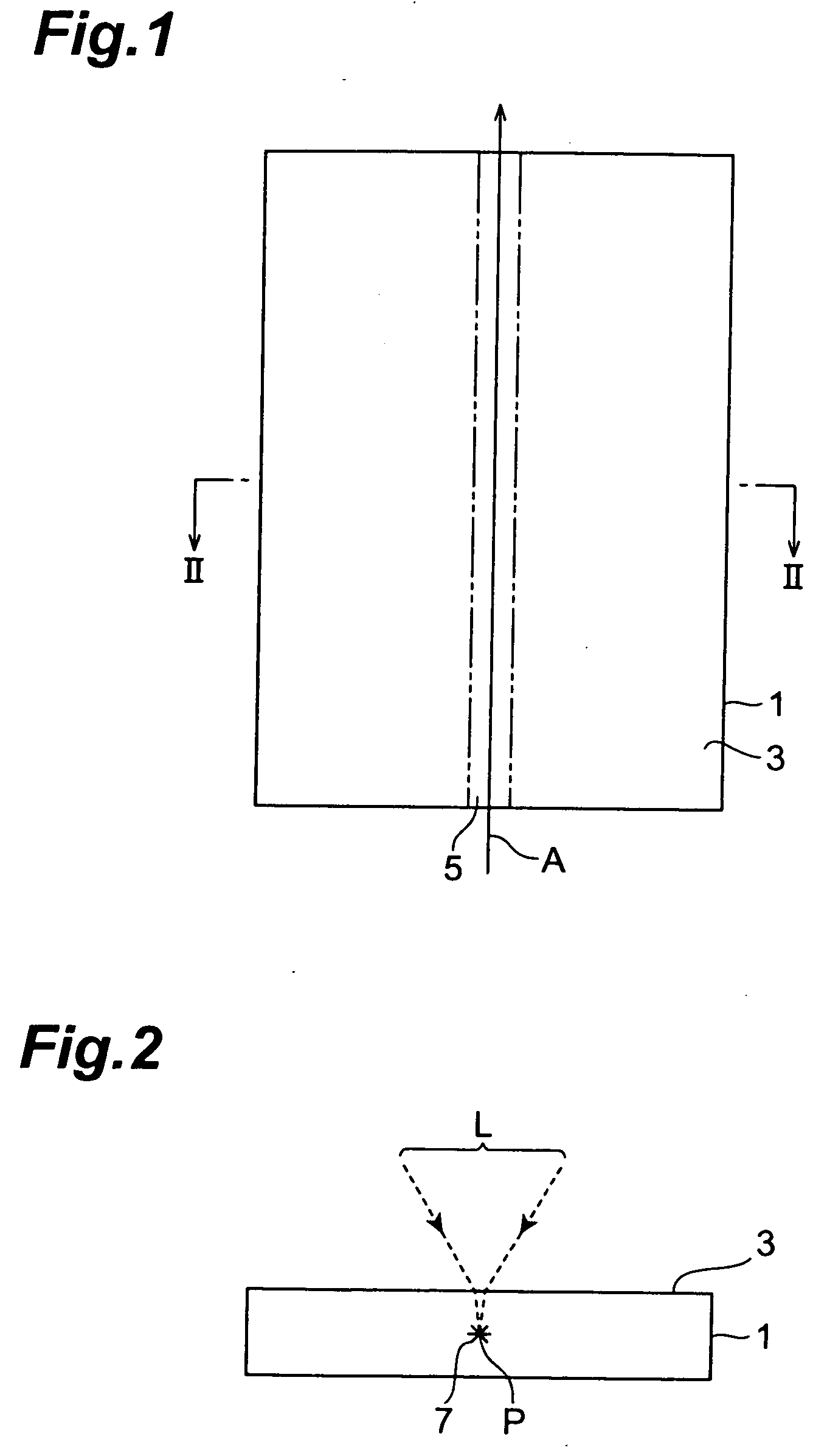

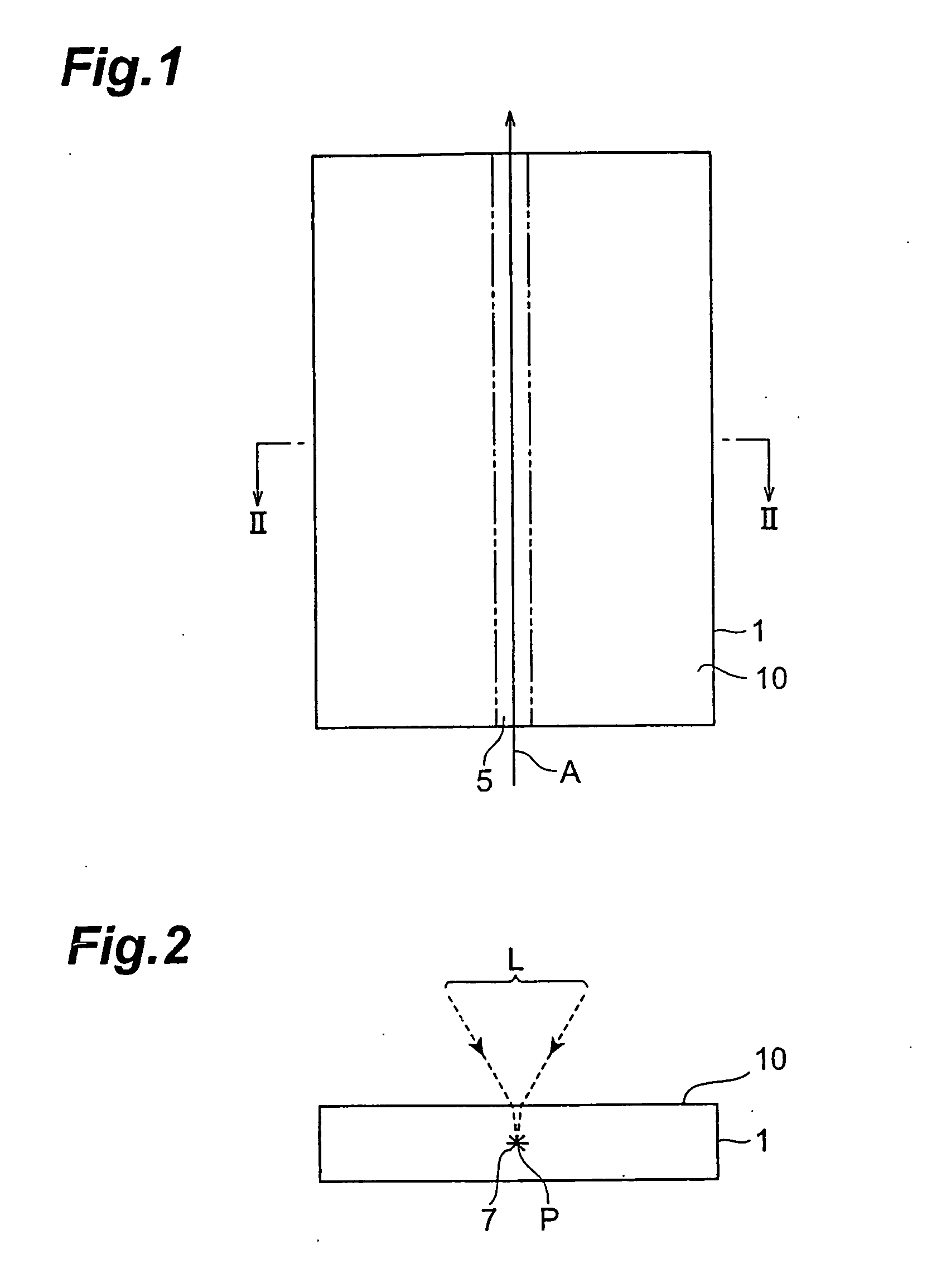

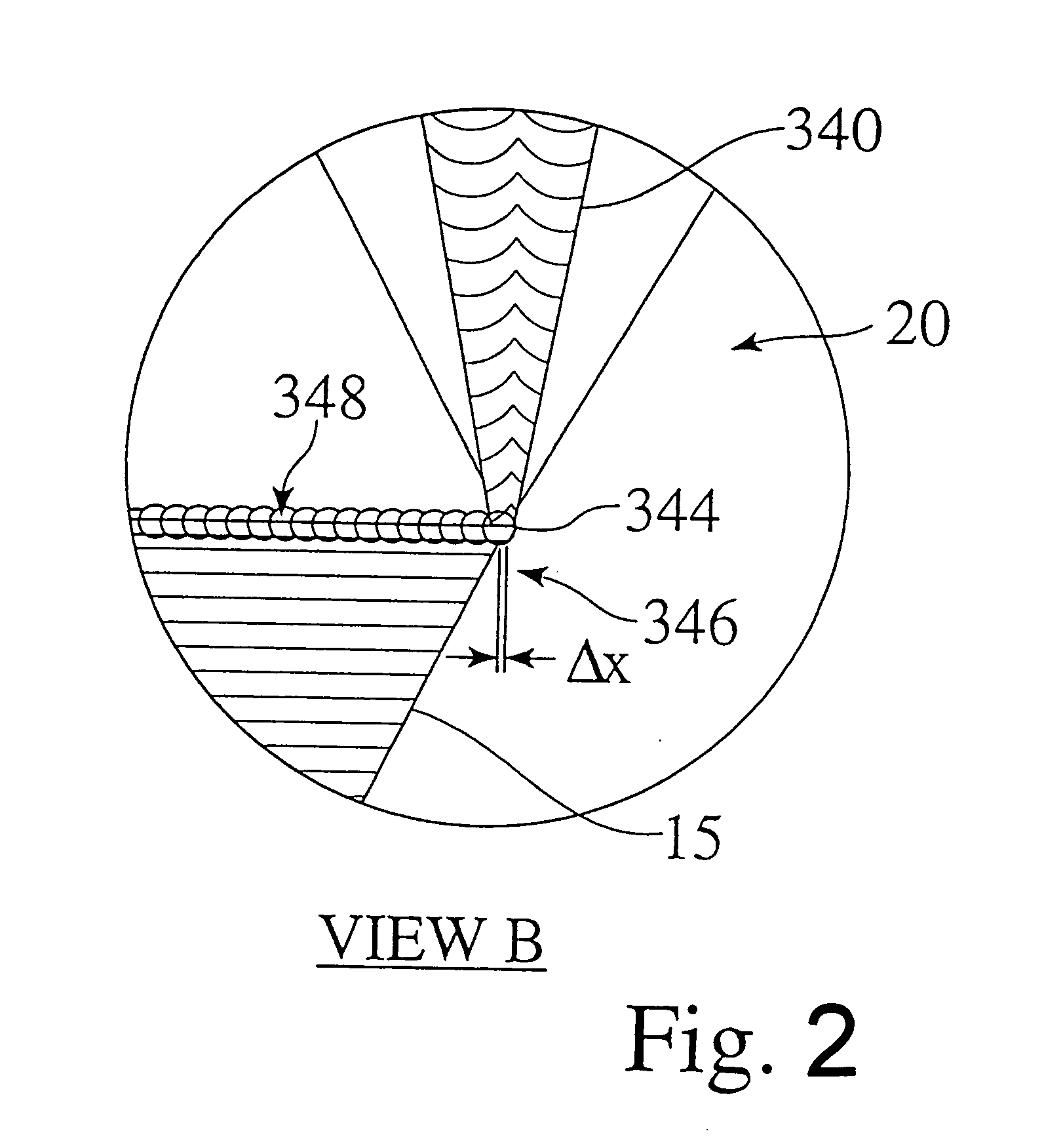

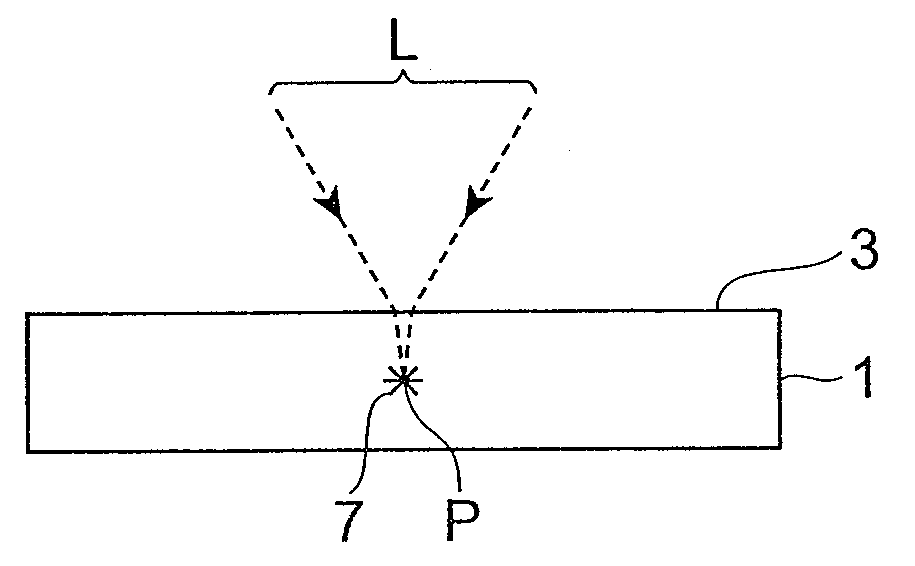

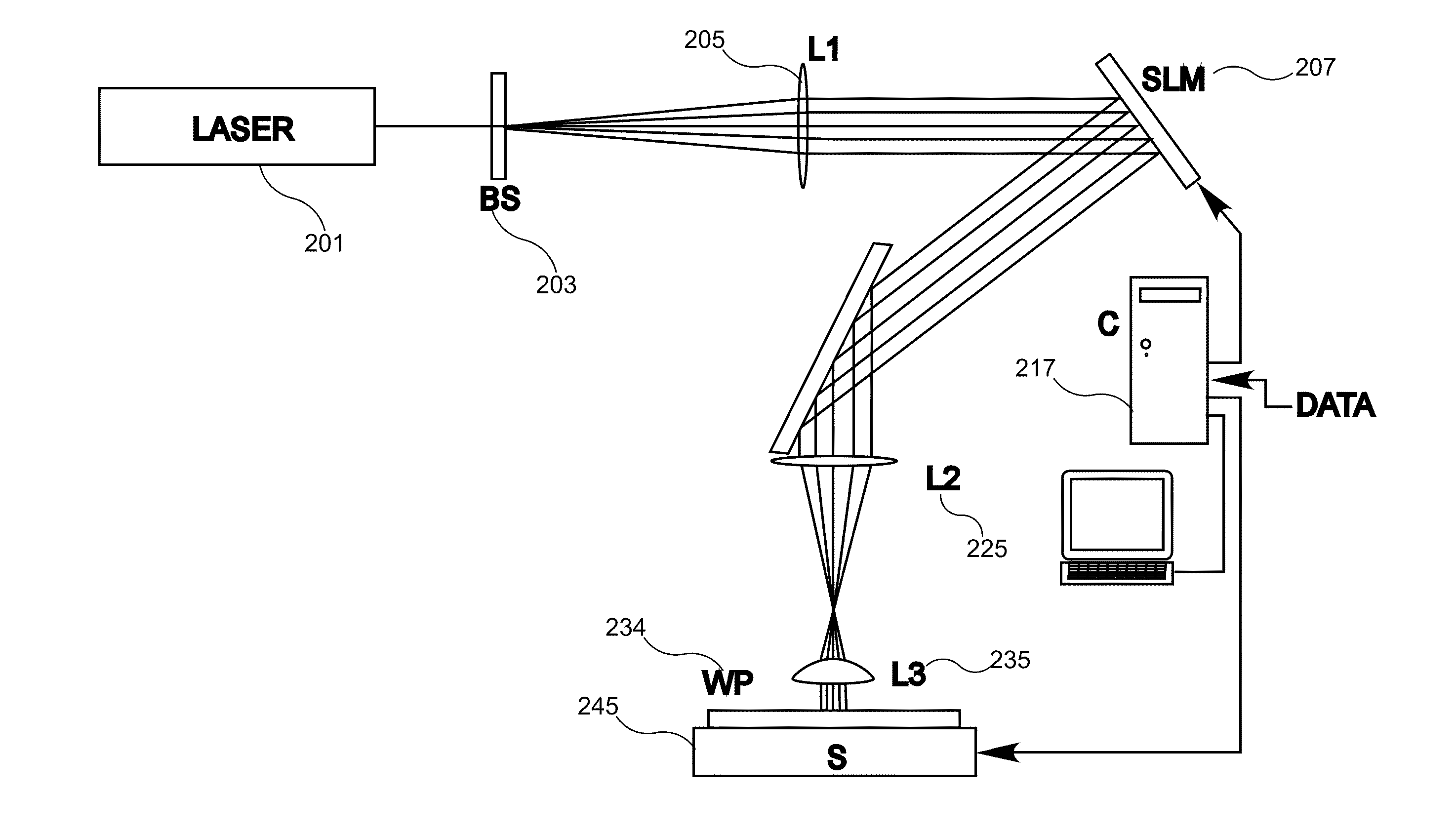

Laser processing method

ActiveUS20050202596A1Force is smallImprove accuracySolid-state devicesSemiconductor/solid-state device manufacturingLaser processingLaser light

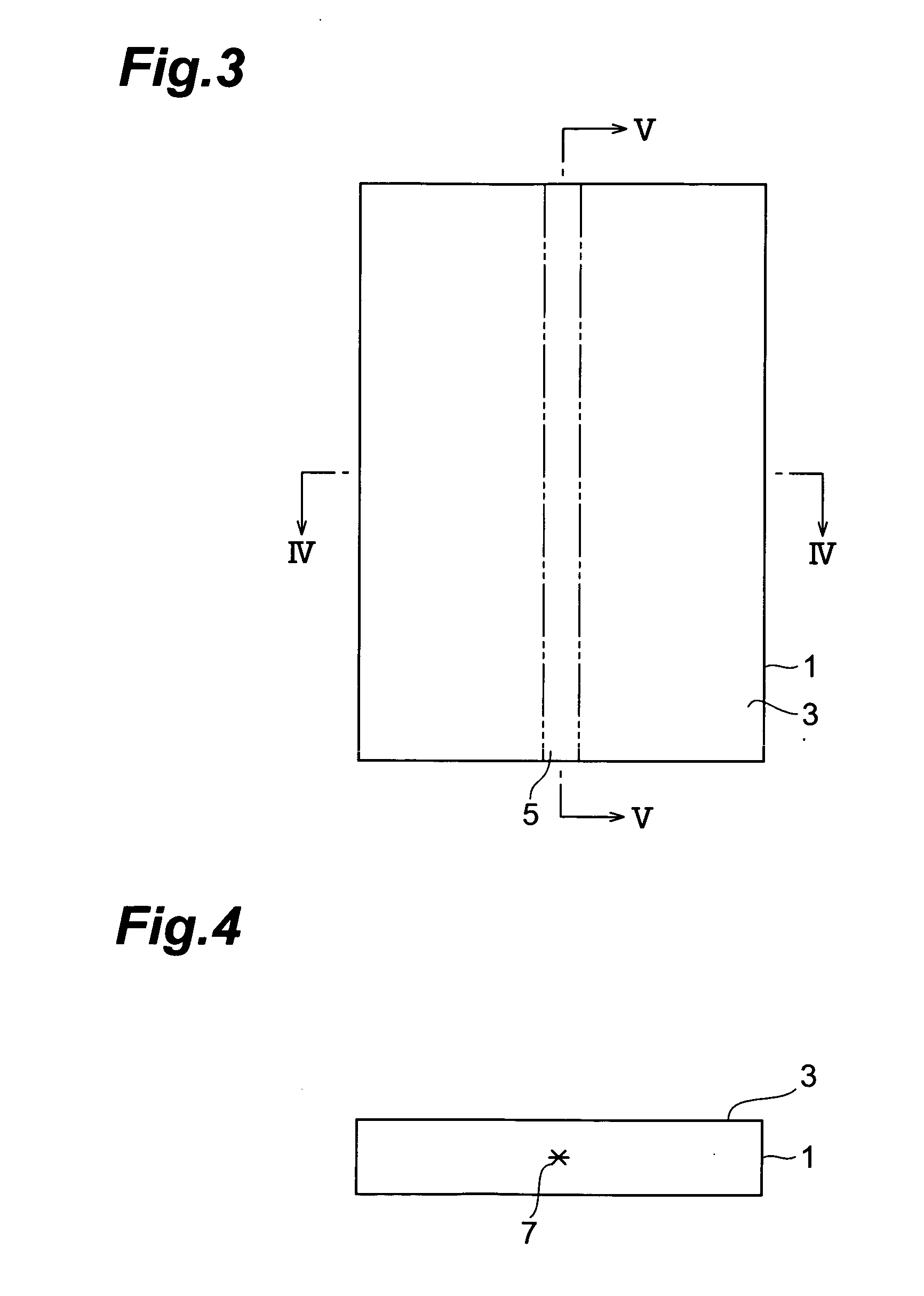

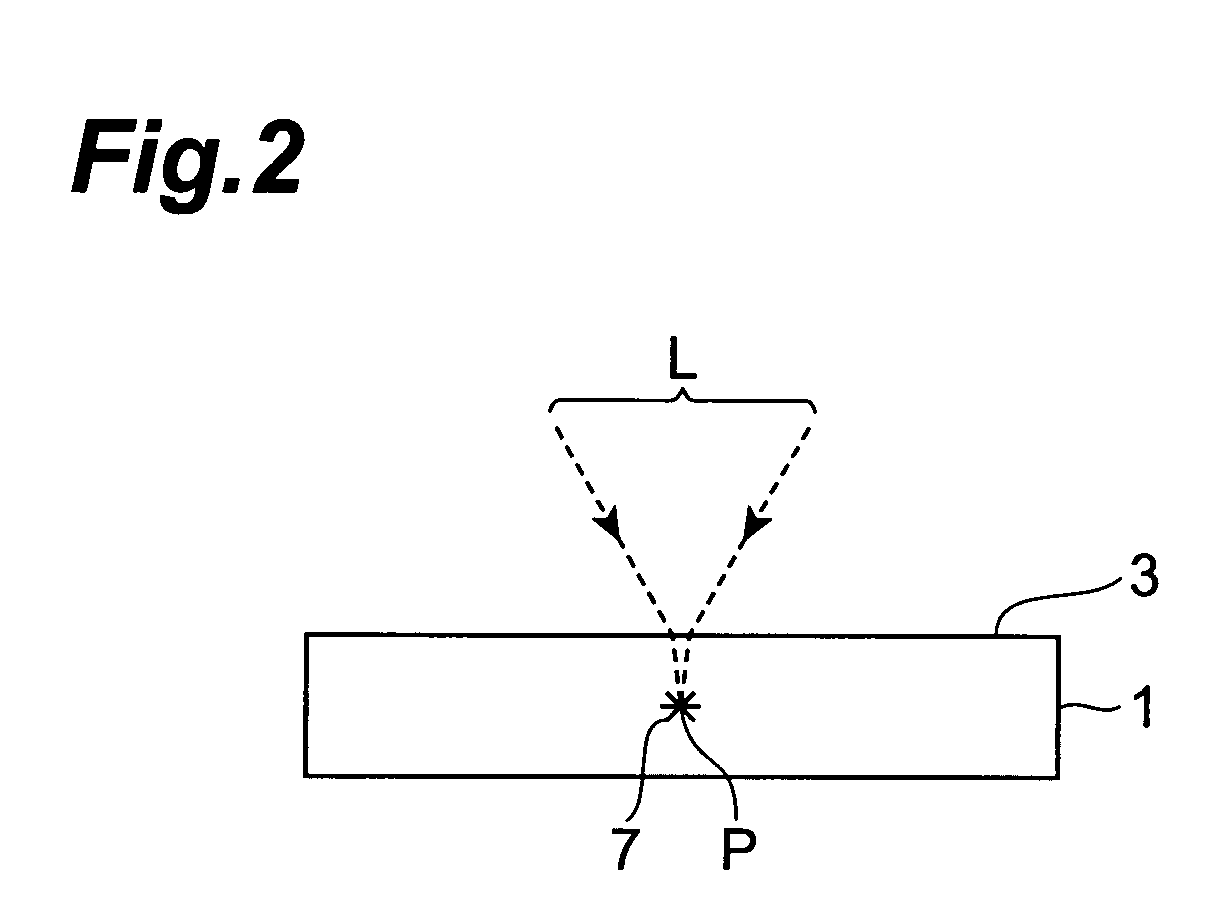

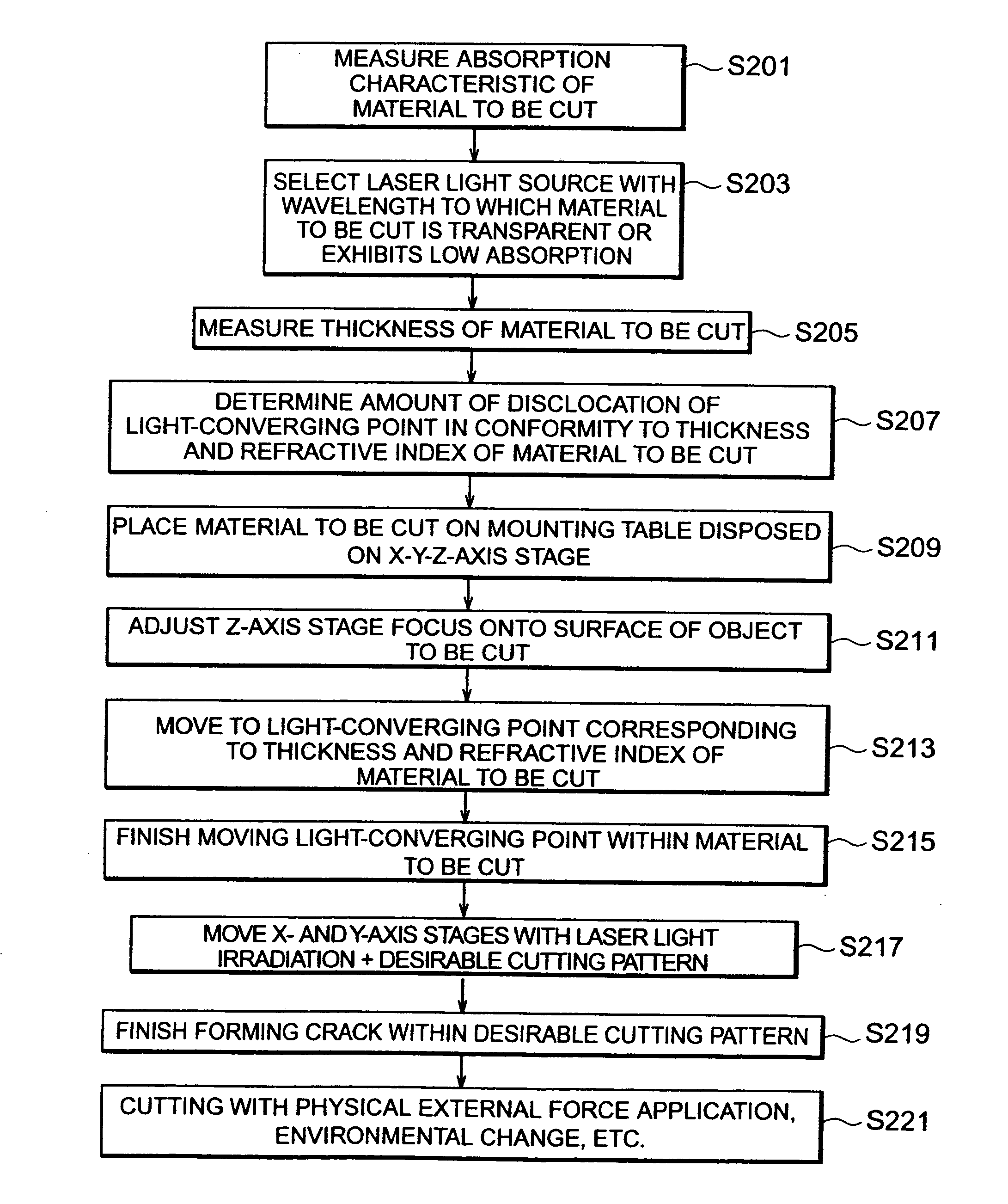

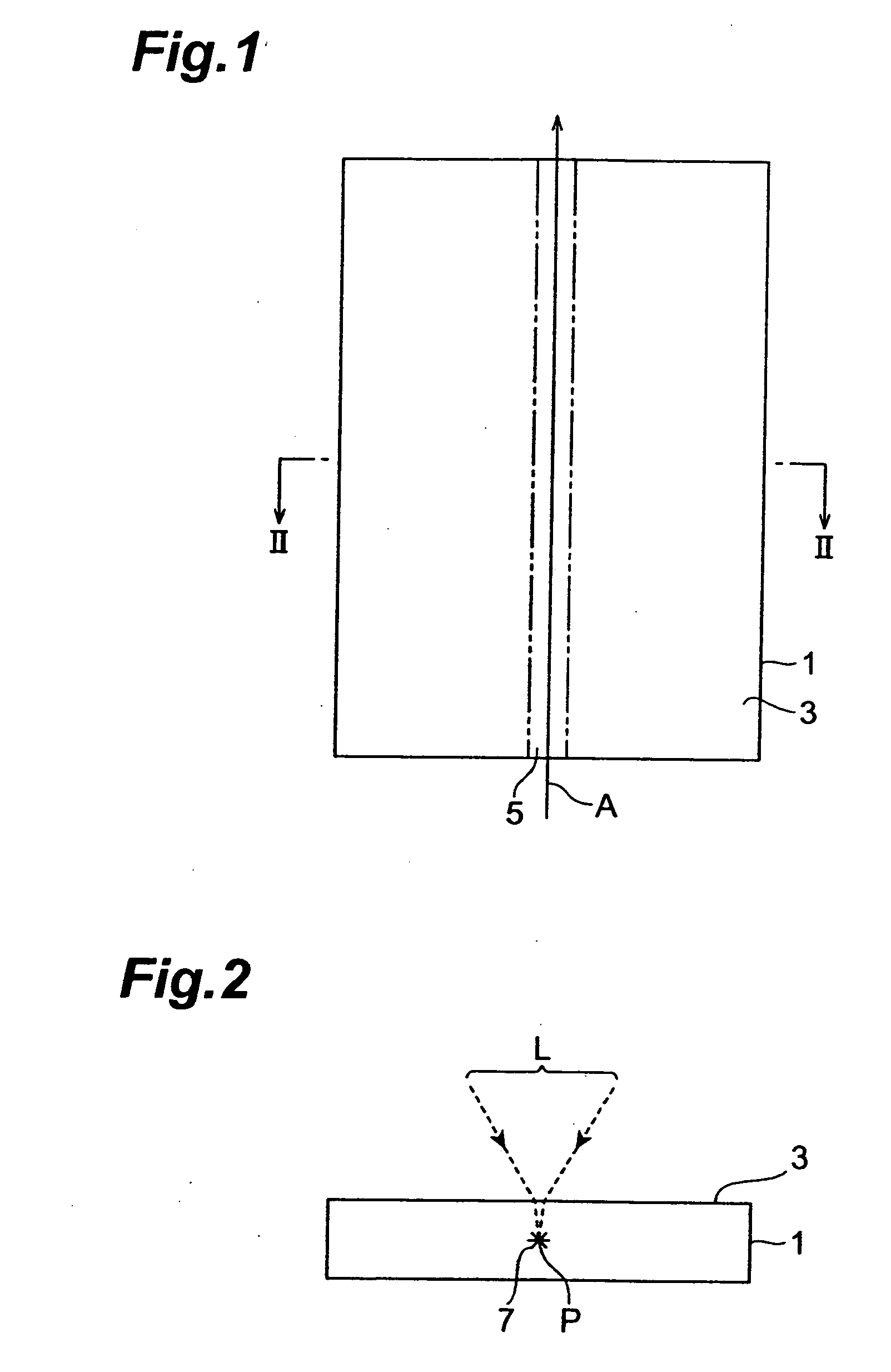

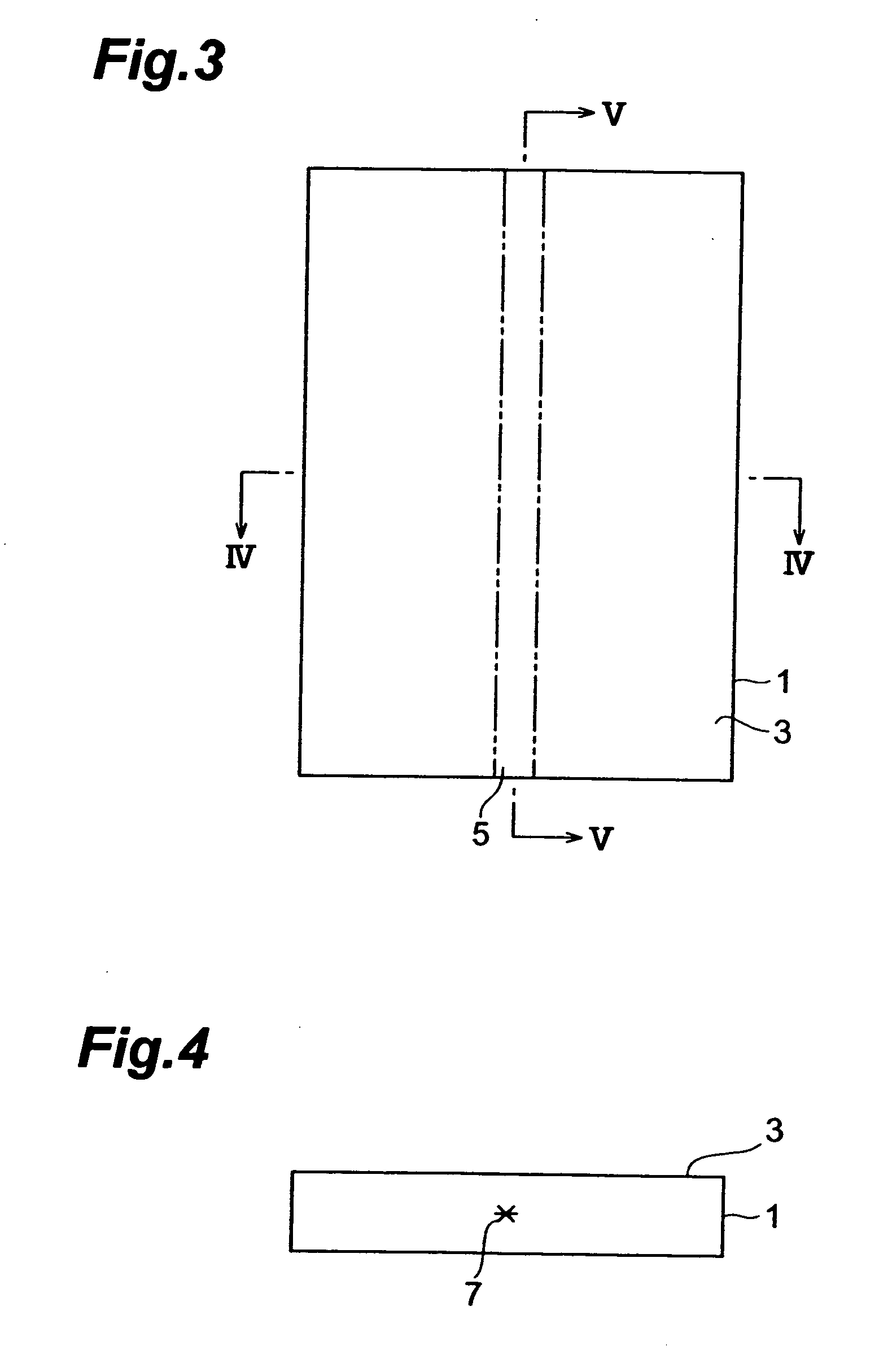

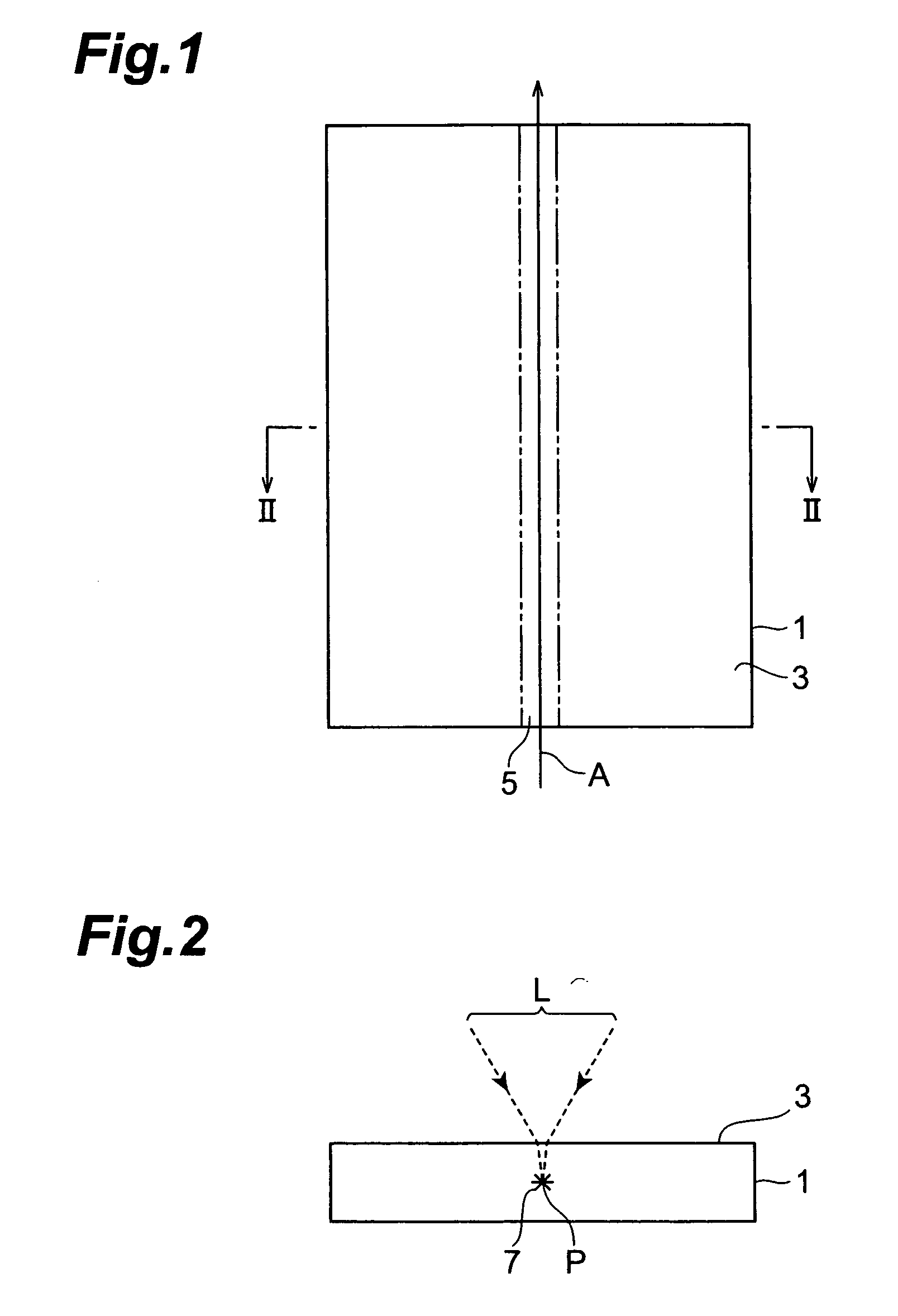

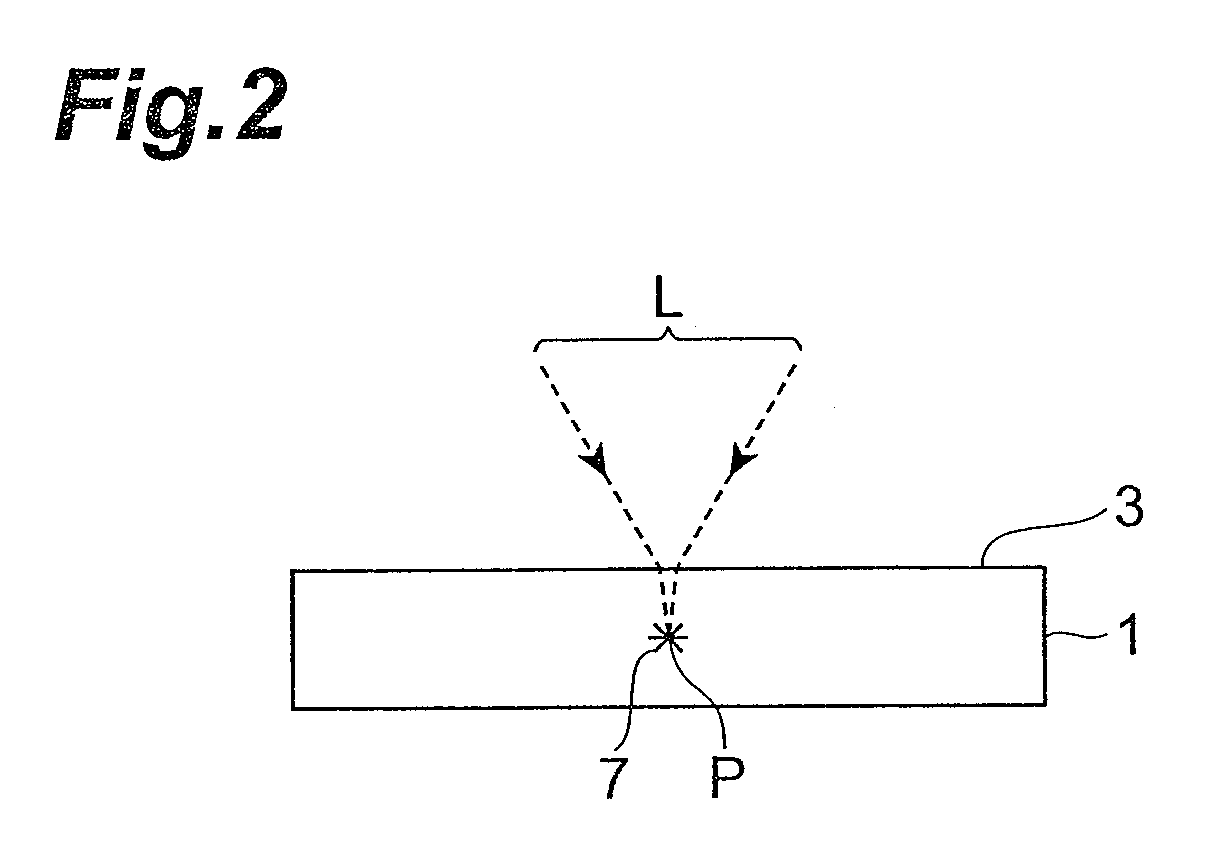

A laser processing method which can highly accurately cut objects to be processed having various laminate structures is provided. An object to be processed comprising a substrate and a laminate part disposed on the front face of the substrate is irradiated with laser light L while a light-converging point P is positioned at least within the substrate, so as to form a modified region due to multiphoton absorption at least within the substrate, and cause the modified region to form a starting point region for cutting. When the object is cut along the starting point region for cutting, the object 1 can be cut with a high accuracy.

Owner:HAMAMATSU PHOTONICS KK

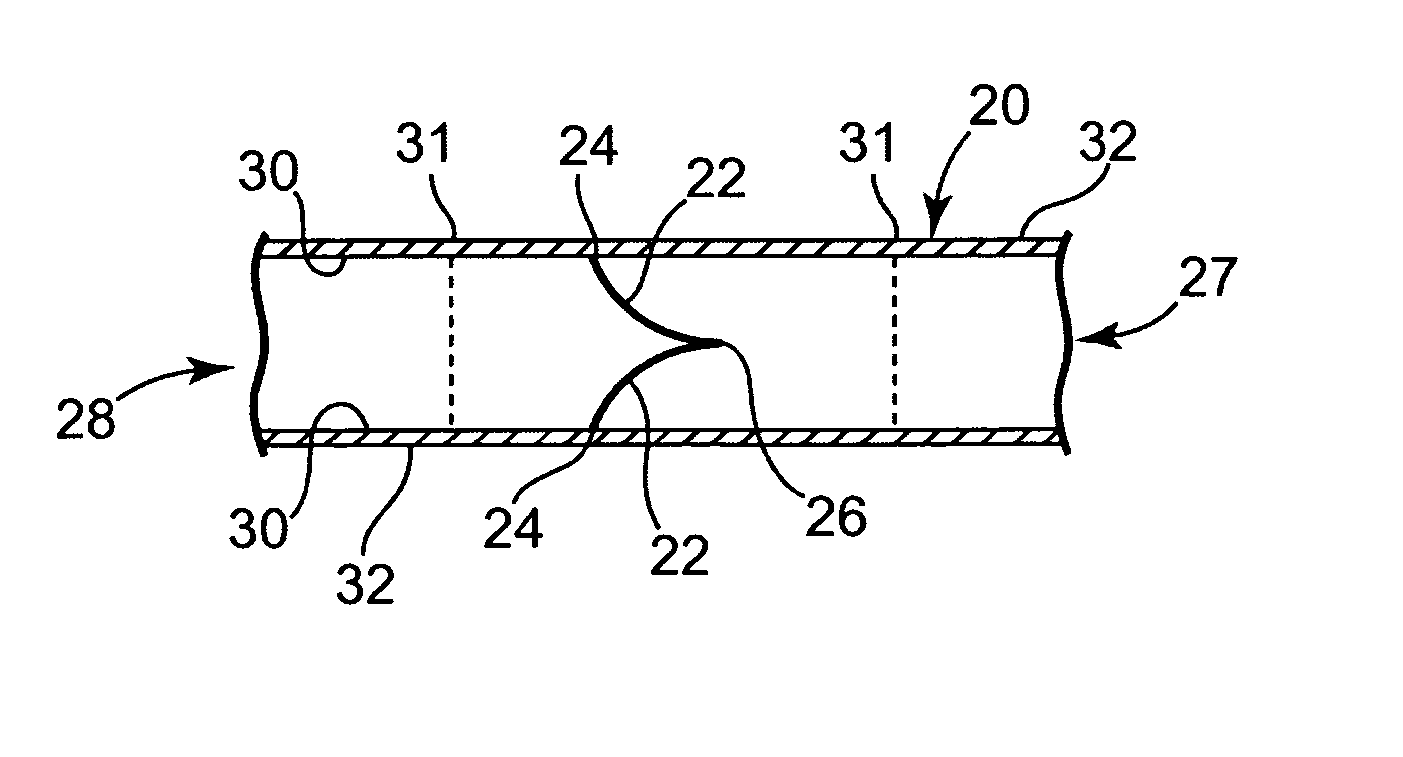

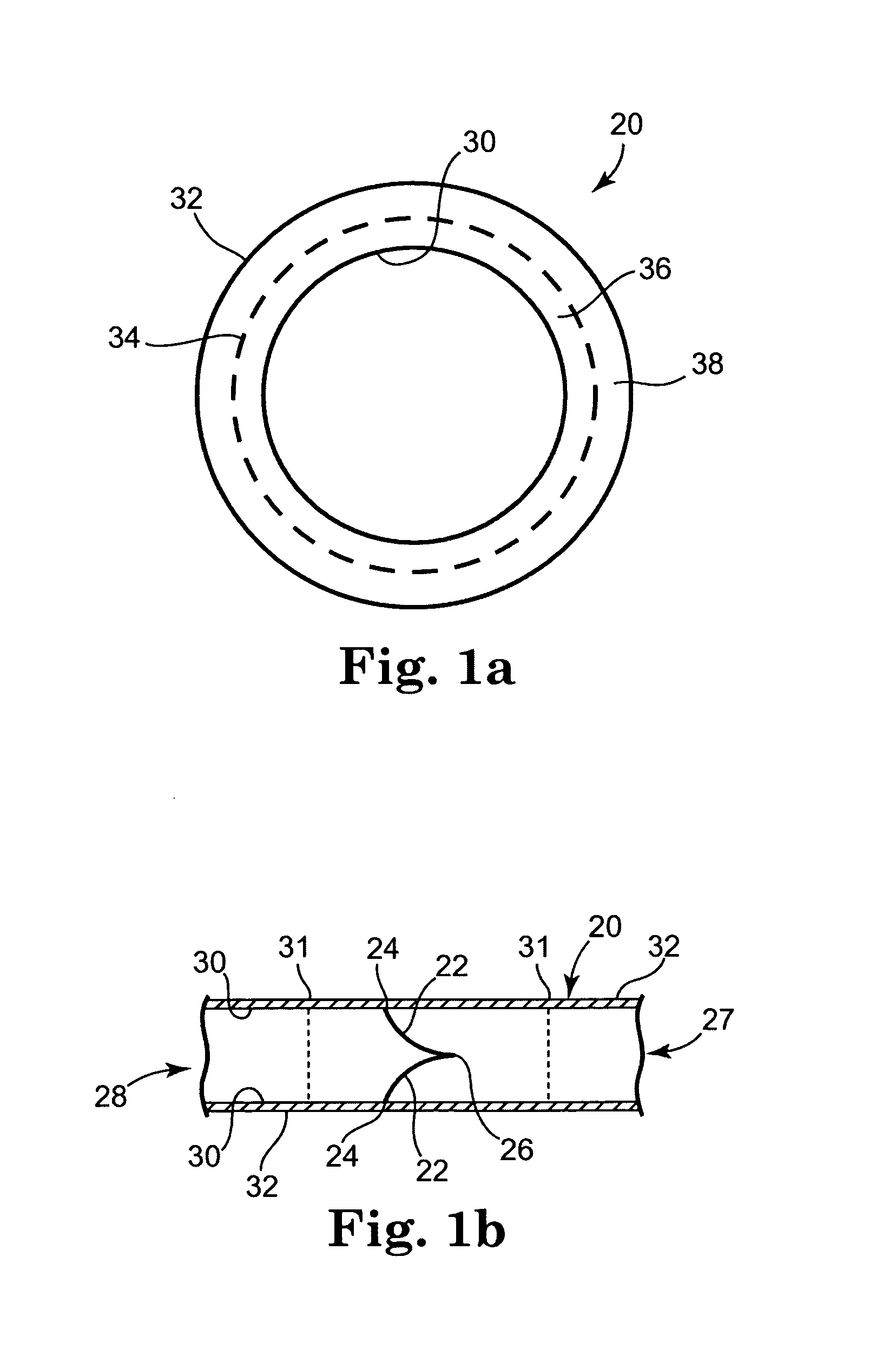

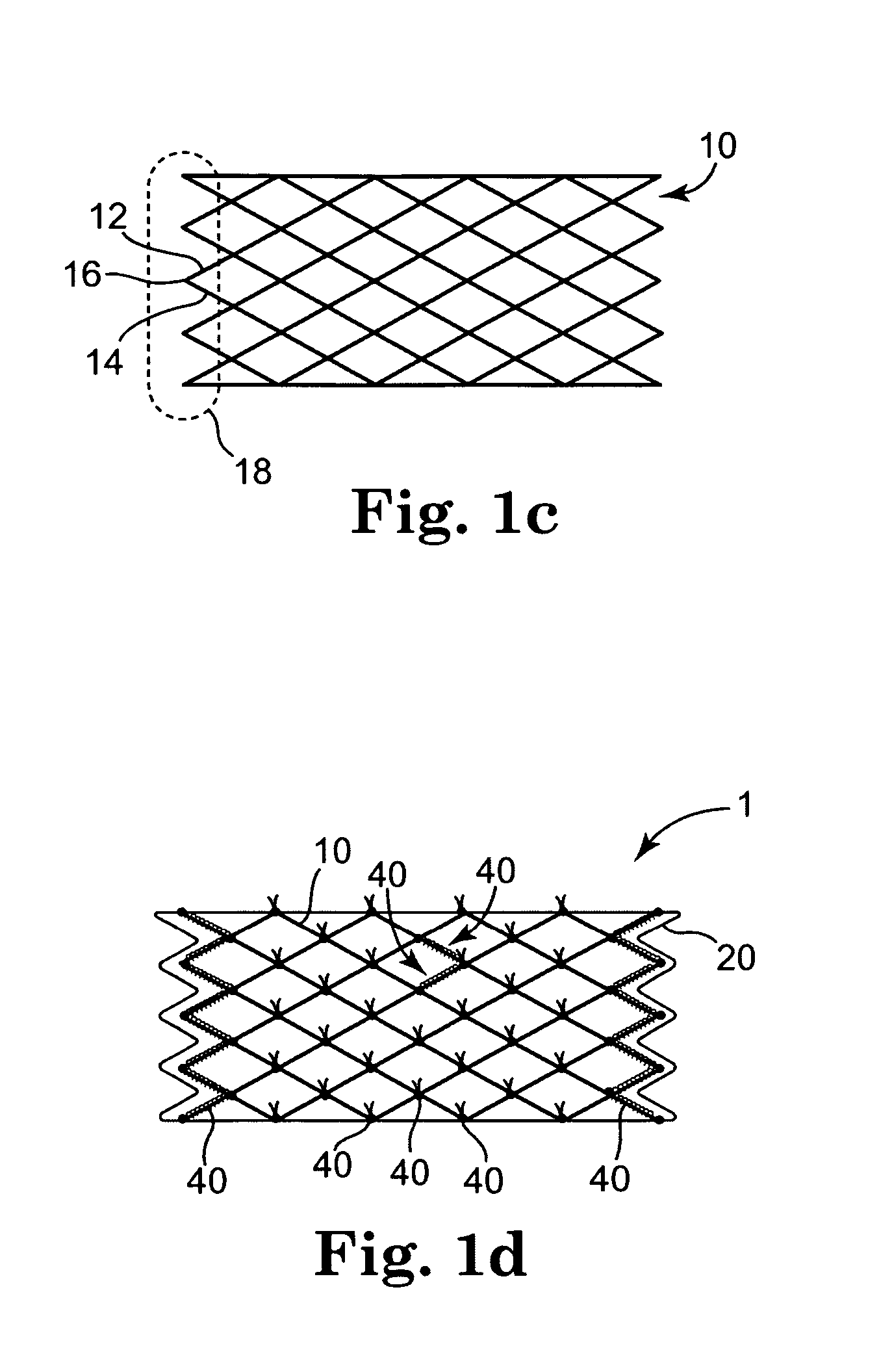

Composite heart valve apparatus manufactured using techniques involving laser machining of tissue

ActiveUS20070073392A1Modifies tissue much fasterLow scrap rateTubular organ implantsVenous valvesVeinLaser processing

Methodology for using laser machining techniques to modify a tissue for use in a medical device. In a representative mode of practice, relatively low energy laser machining is used to thin down at least a portion of a valved jugular vein. The thinned down vein may then be sutured to, or otherwise integrated with, a corresponding stent to make a percutaneous heart valve.

Owner:MEDTRONIC INC

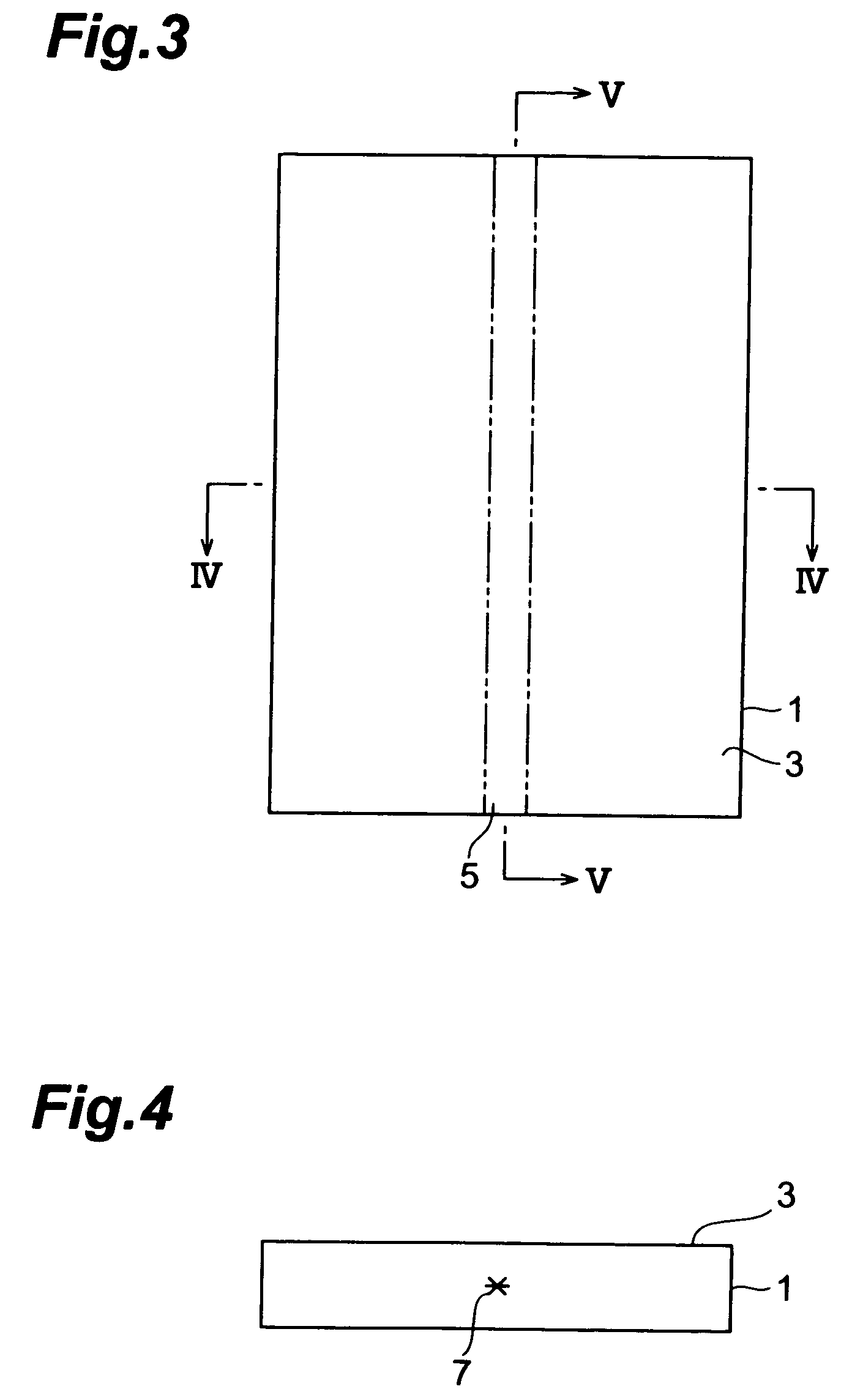

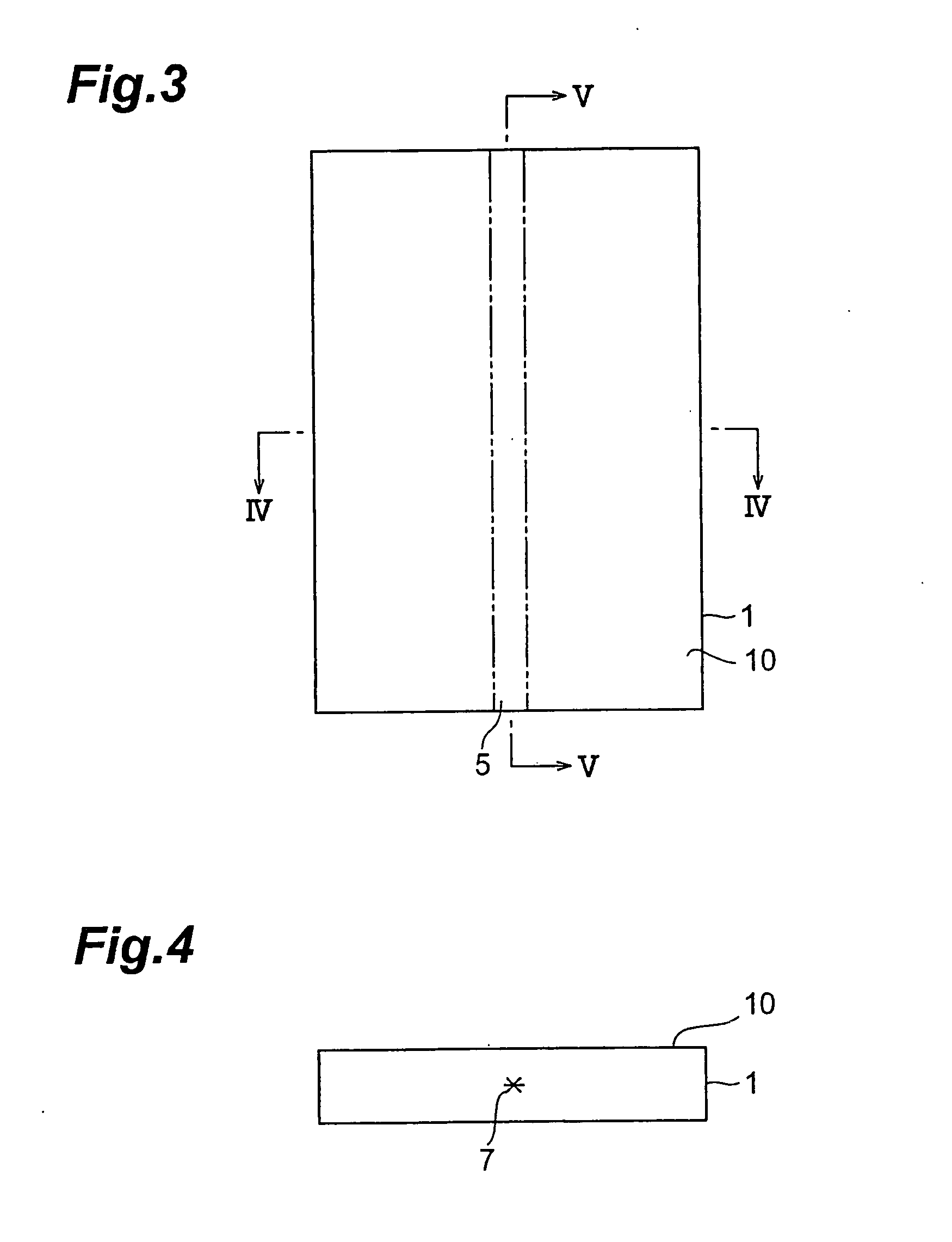

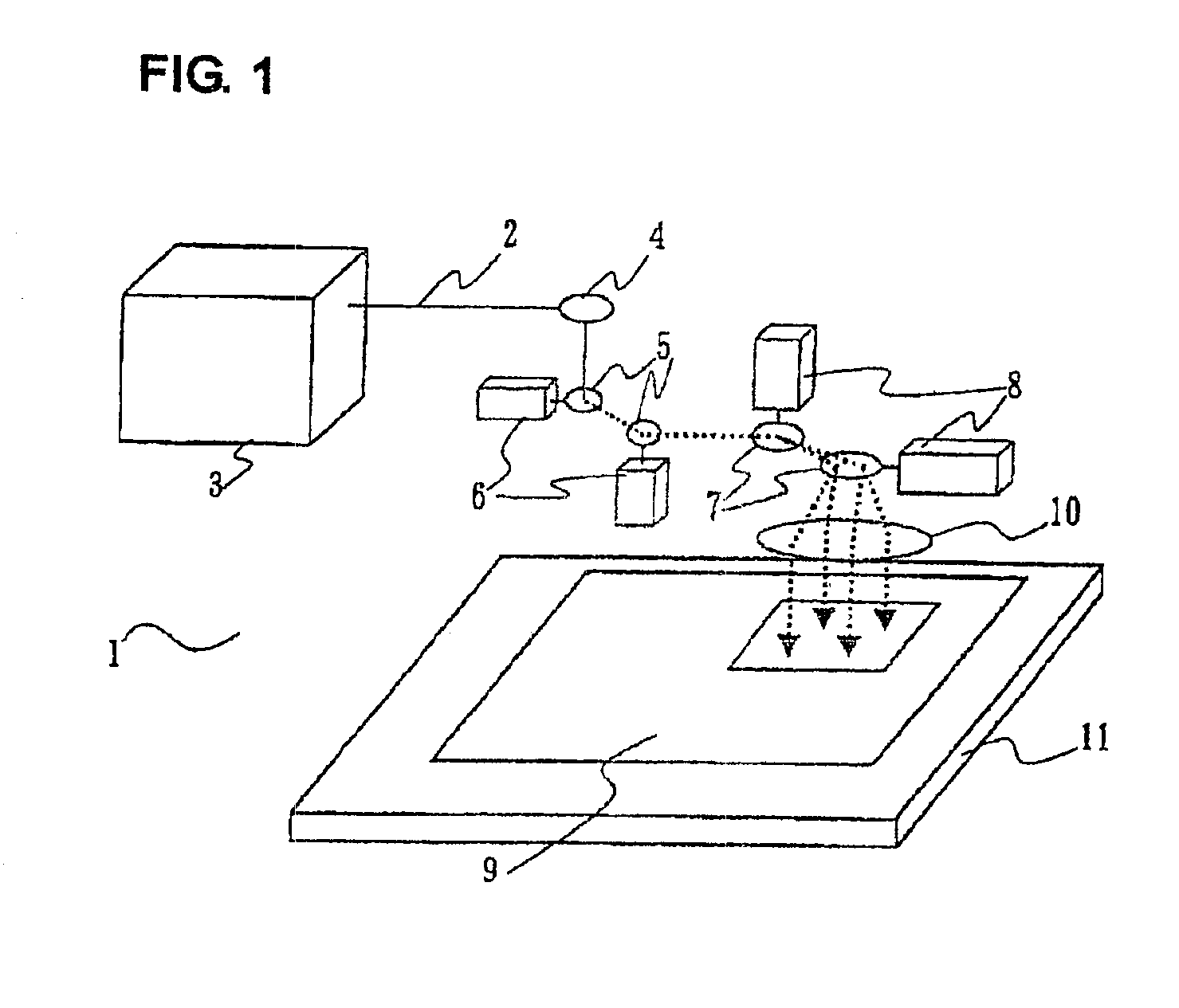

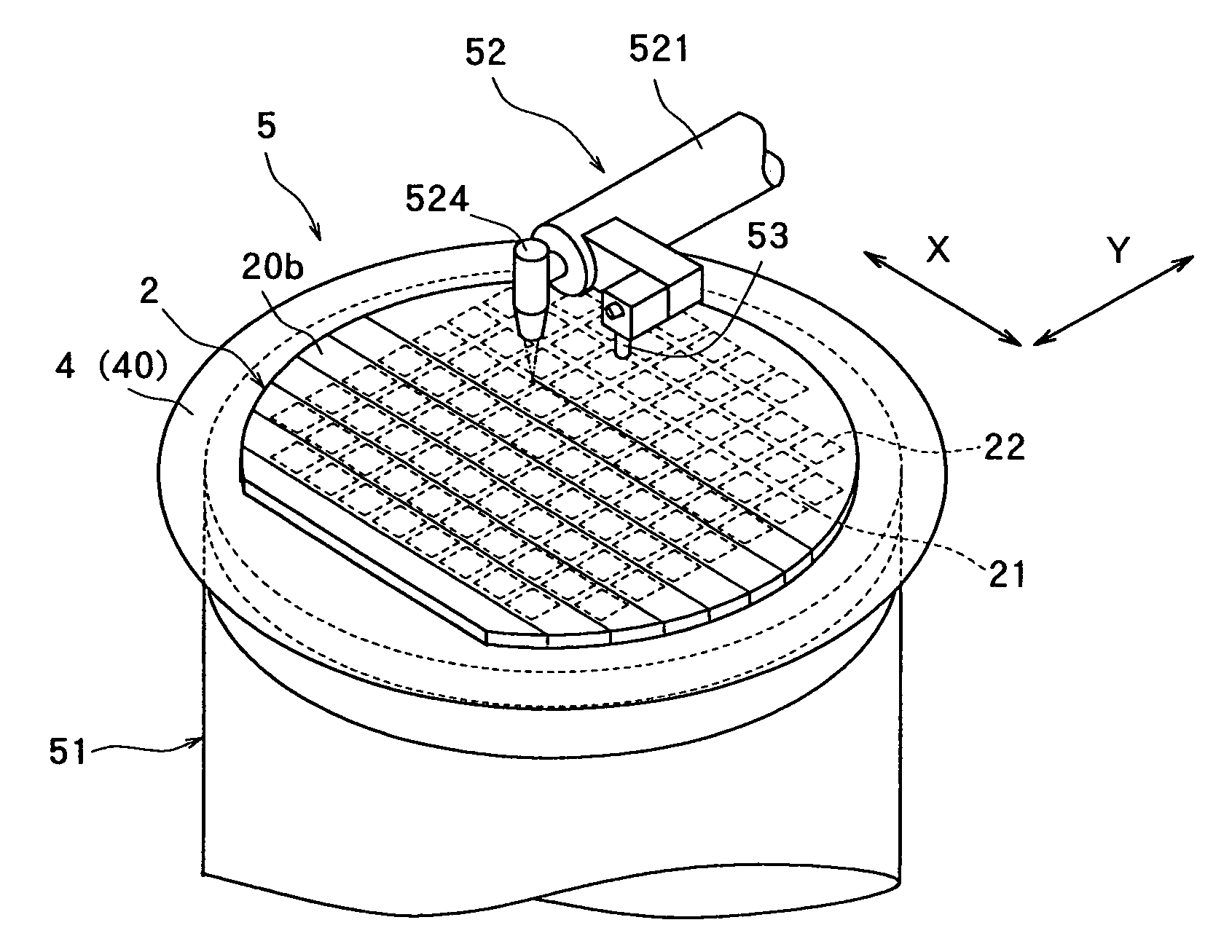

Laser processing method and laser processing apparatus

InactiveUS20050173387A1No unnecessary fracture in surfaceNo unnecessary fractureSolid-state devicesSemiconductor/solid-state device manufacturingLaser processingLaser beam machining

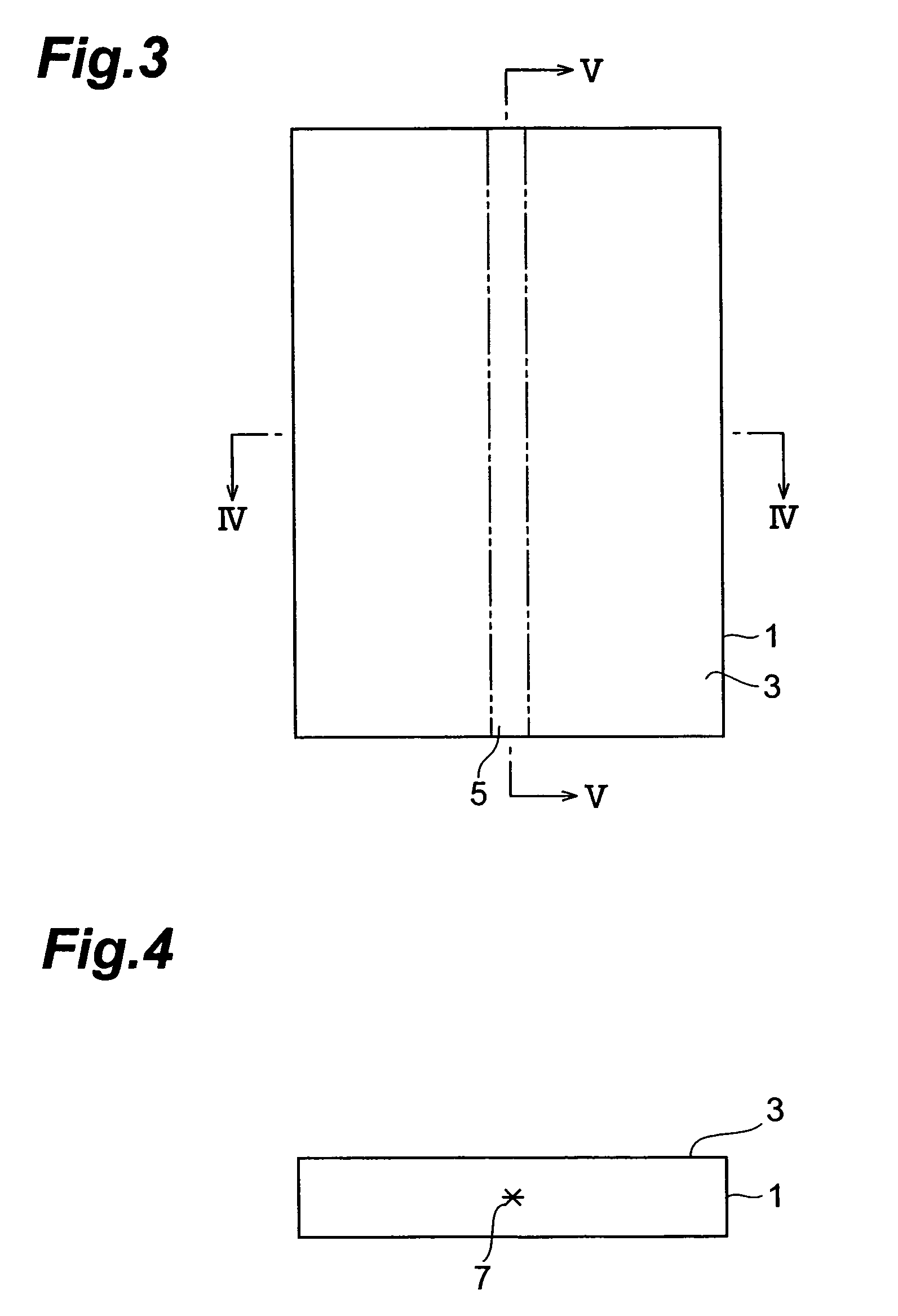

A laser beam machining method and a laser beam machining device capable of cutting a work without producing a fusing and a cracking out of a predetermined cutting line on the surface of the work, wherein a pulse laser beam is radiated on the predetermined cut line on the surface of the work under the conditions causing a multiple photon absorption and with a condensed point aligned to the inside of the work, and a modified area is formed inside the work along the predetermined determined cut line by moving the condensed point along the predetermined cut line, whereby the work can be cut with a rather small force by cracking the work along the predetermined cut line starting from the modified area and, because the pulse laser beam radiated is not almost absorbed onto the surface of the work, the surface is not fused even if the modified area is formed.

Owner:HAMAMATSU PHOTONICS KK

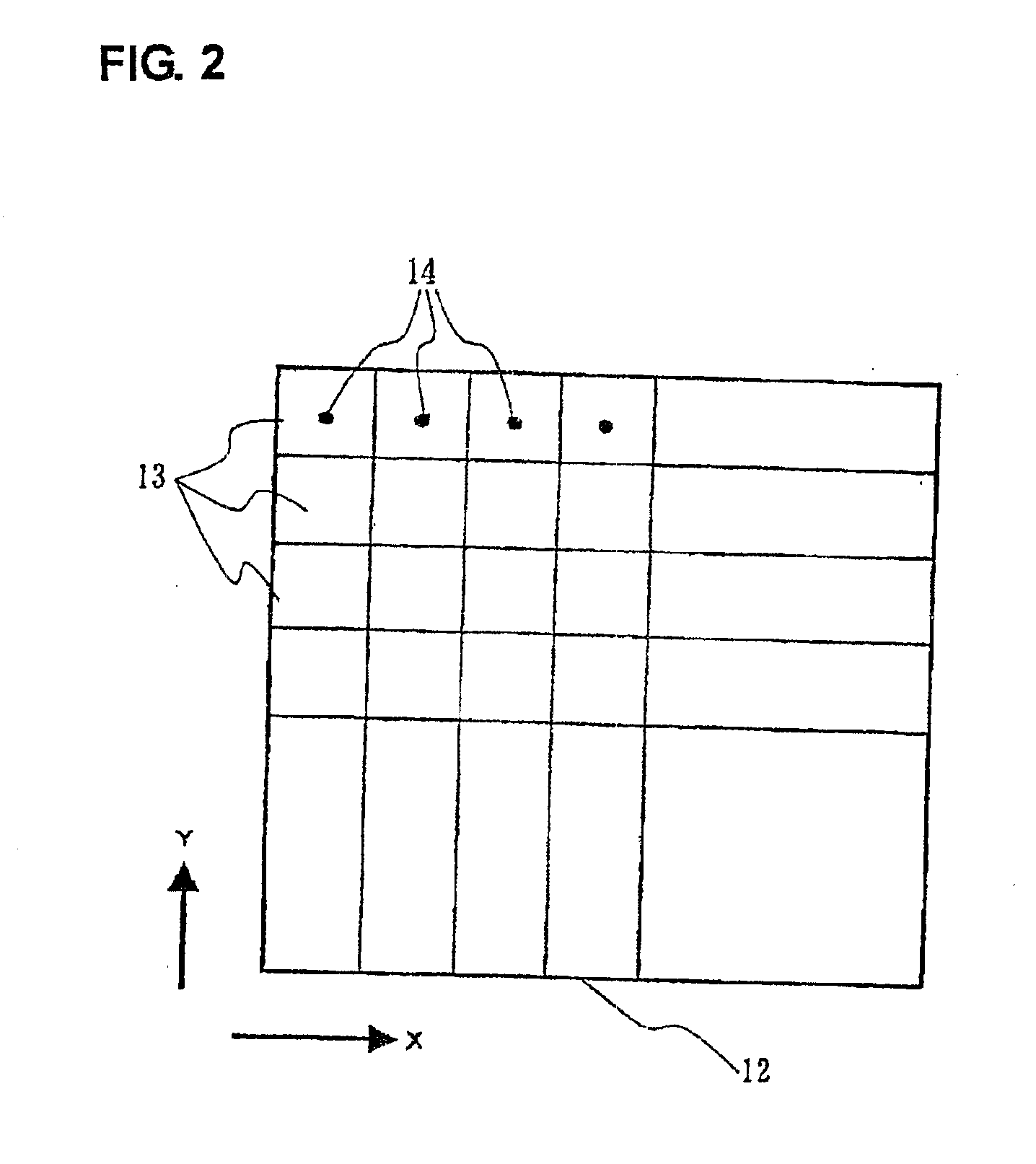

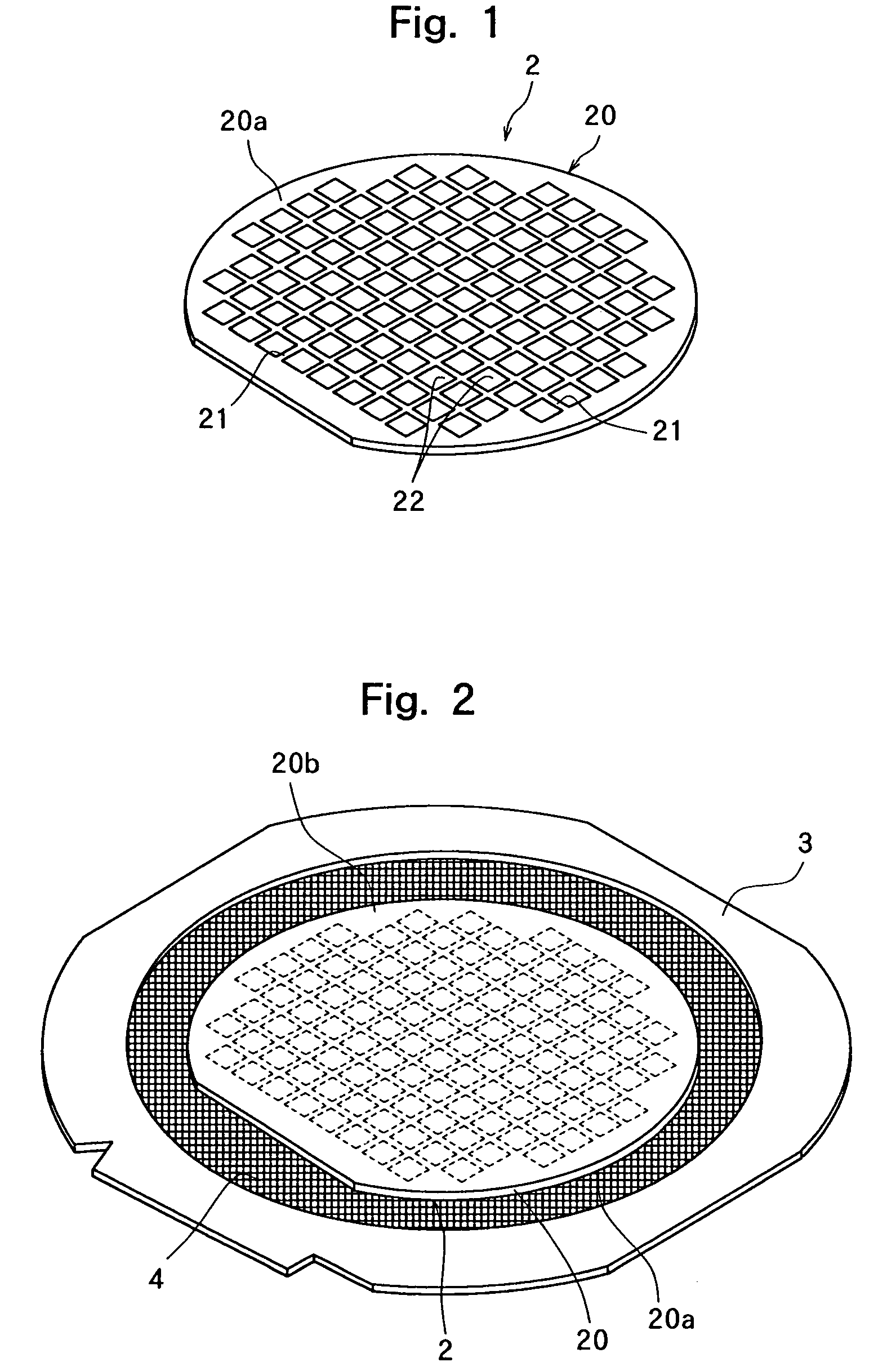

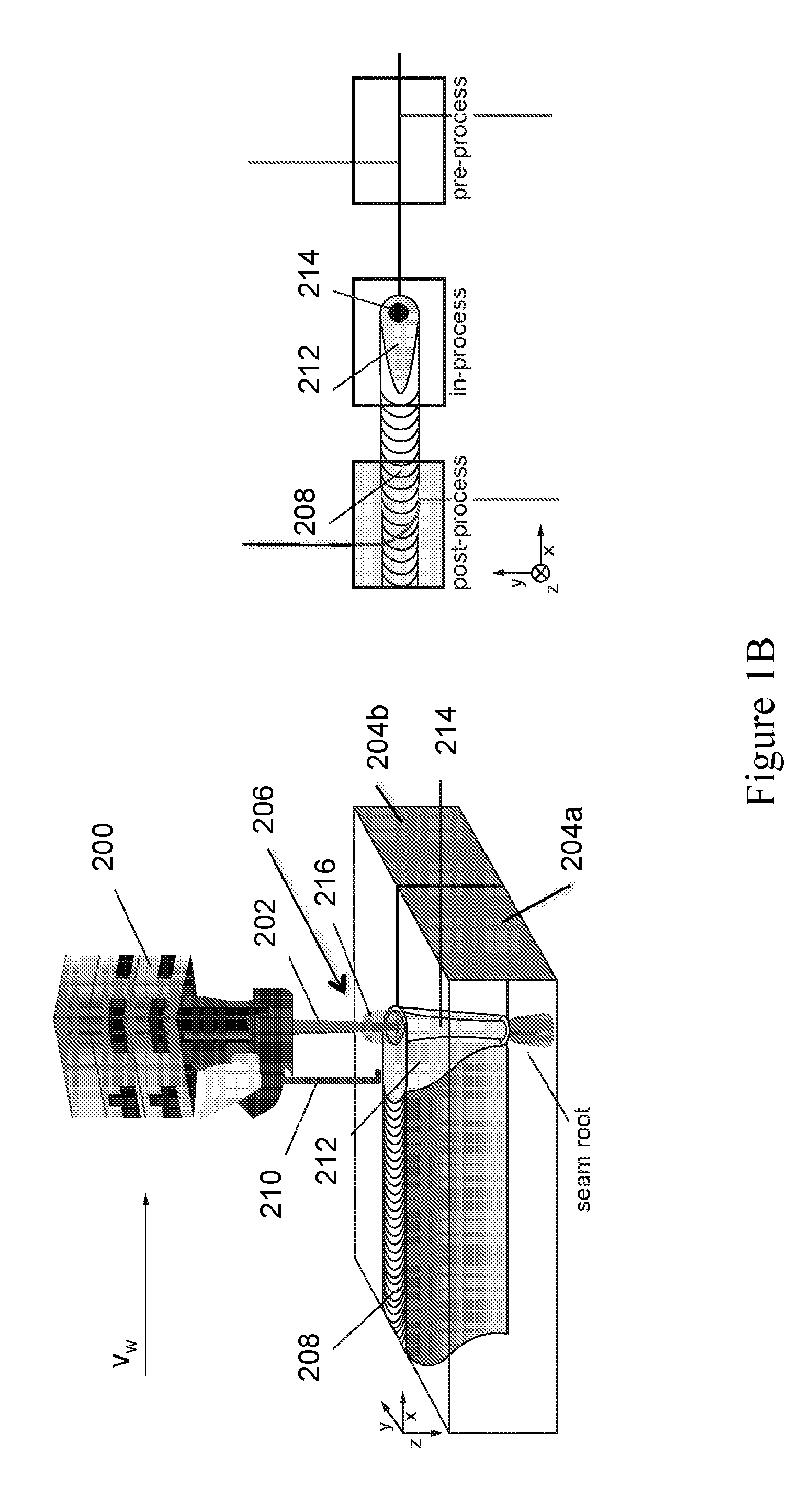

Laser processing method

ActiveUS20070158314A1Reduce manufacturing stepsImprove accuracyFine working devicesWelding/soldering/cutting articlesLaser processingProcess region

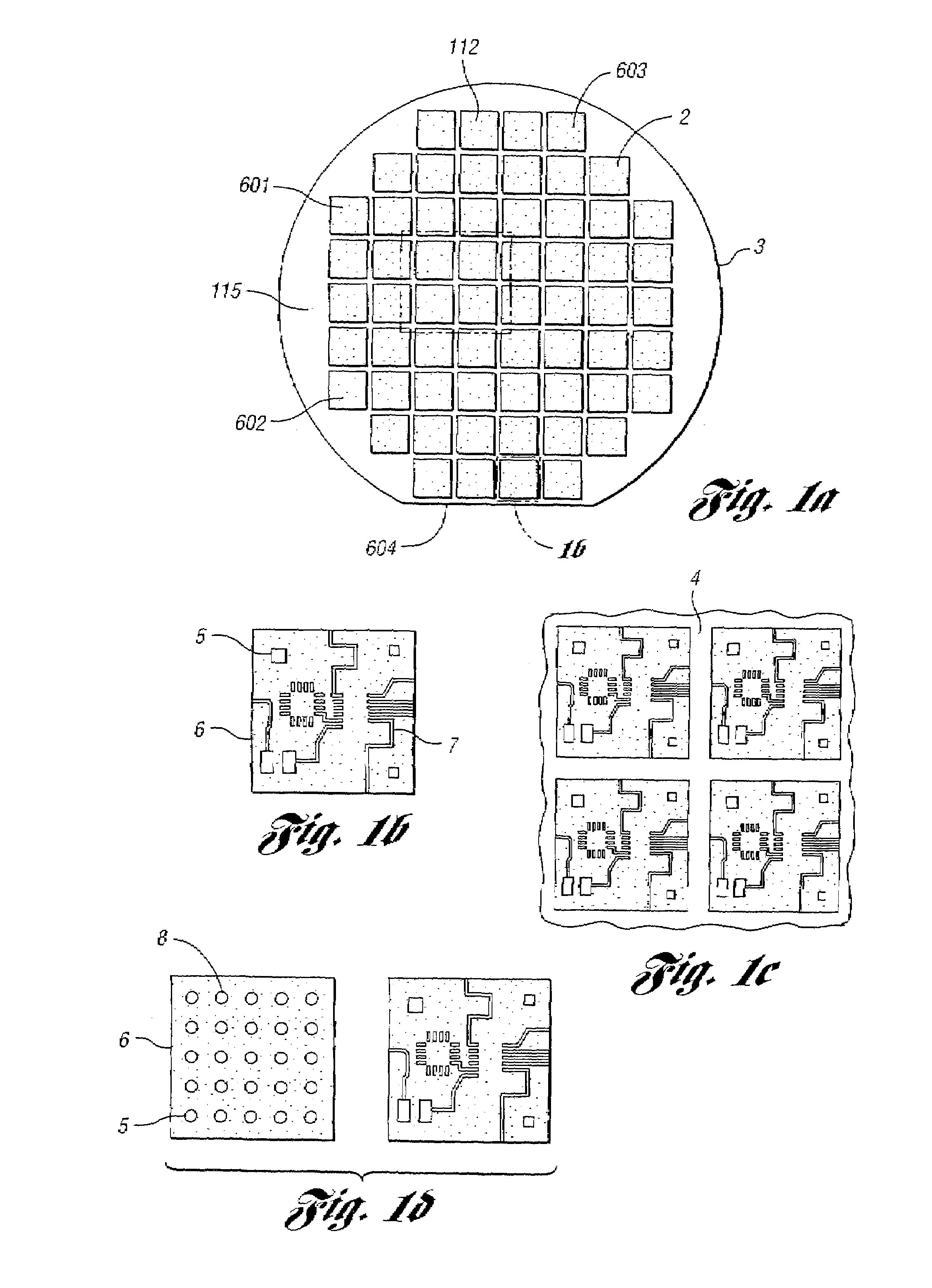

The present invention provides a laser processing method comprising the steps of attaching a protective tape 25 to a front face 3 of a wafer 1a, irradiating a substrate 15 with laser light L while employing a rear face of the wafer 1a as a laser light entrance surface and locating a light-converging point P within the substrate 15 so as to form a molten processed region 13 due to multiphoton absorption, causing the molten processed region 13 to form a cutting start region 8 inside by a predetermined distance from the laser light entrance surface along a line 5 along which the object is intended to be cut in the wafer 1a, attaching an expandable tape 23 to the rear face 21 of the wafer 1a, and expanding the expandable tape 23 so as to separate a plurality of chip parts 24 produced upon cutting the wafer 1a from the cutting start region 8 acting as a start point from each other.

Owner:HAMAMATSU PHOTONICS KK

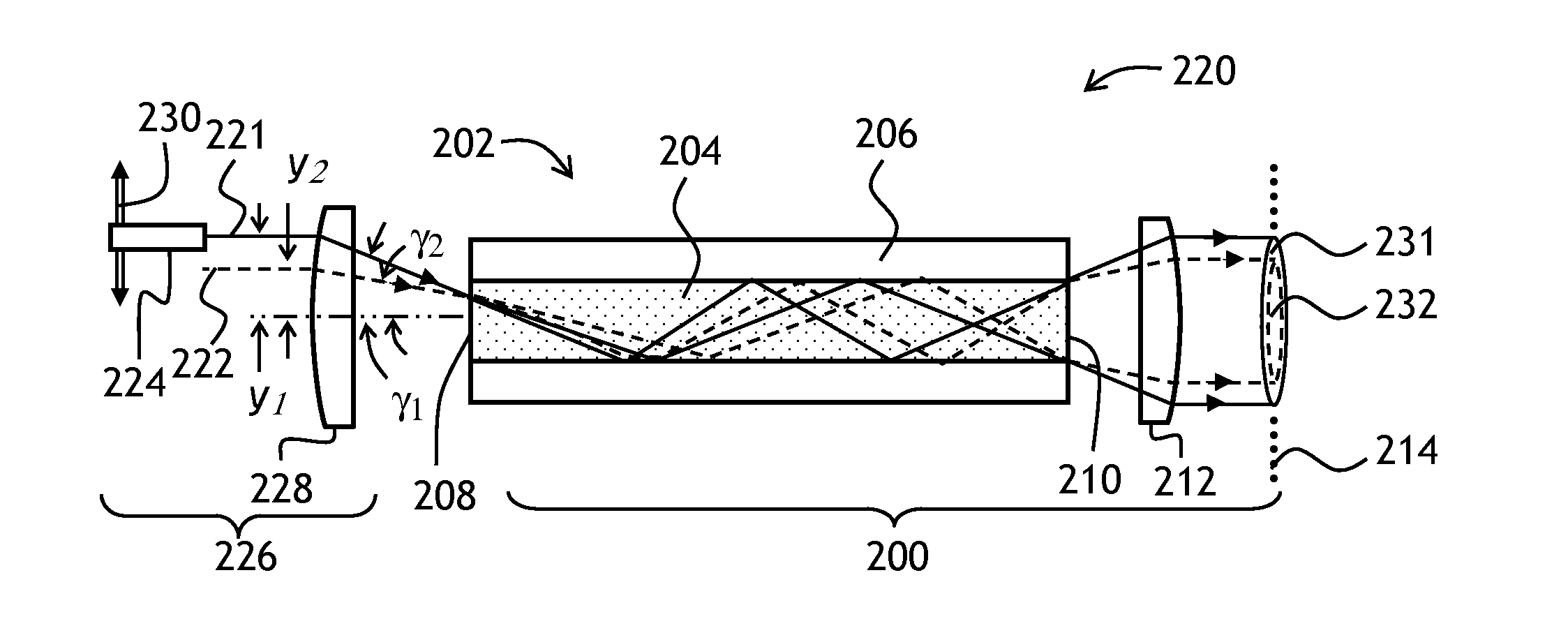

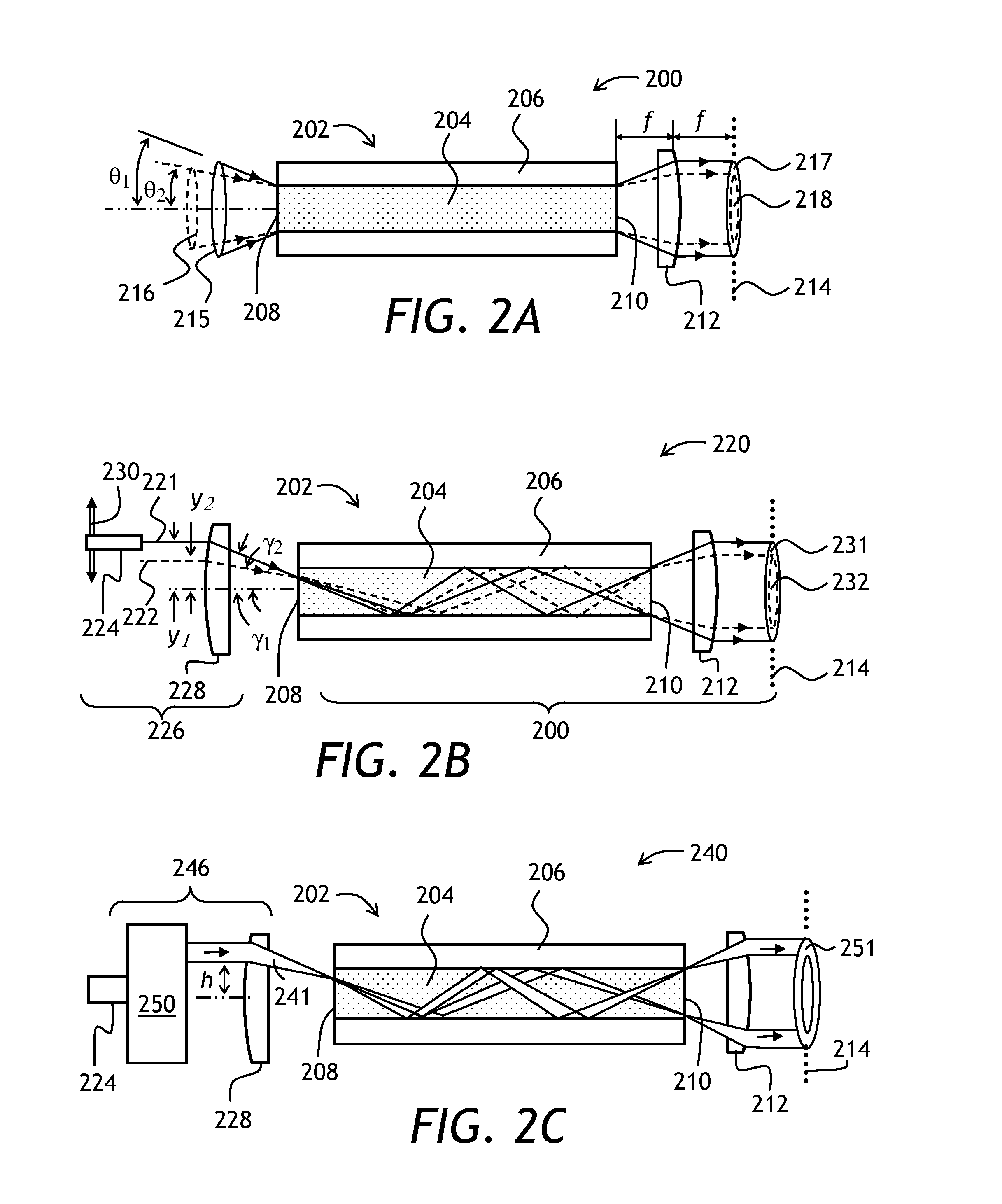

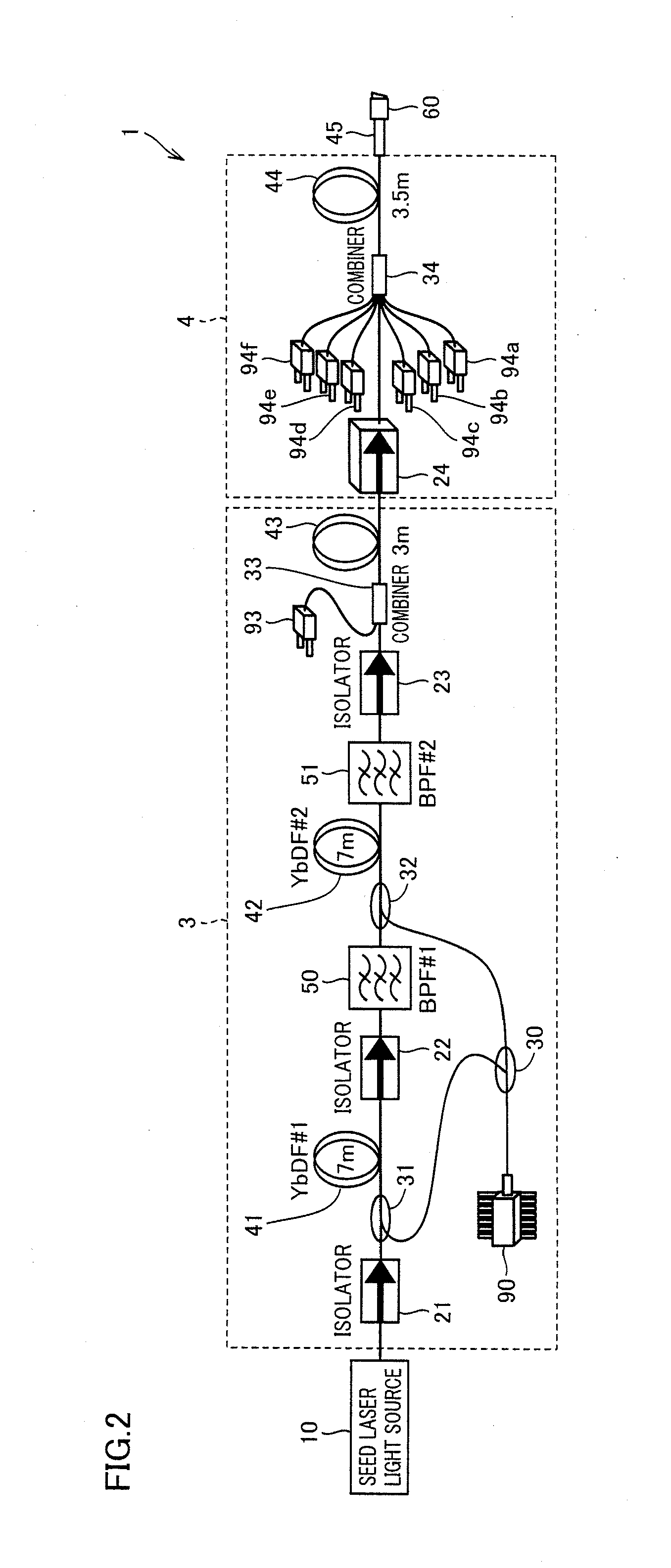

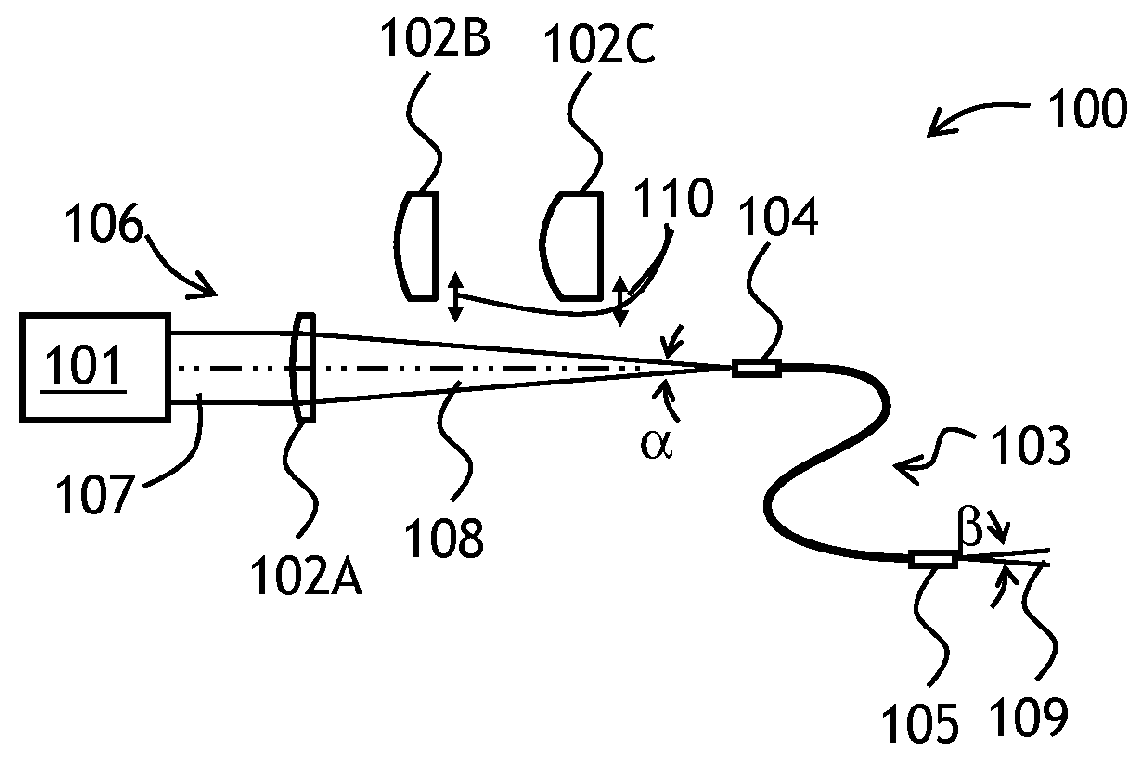

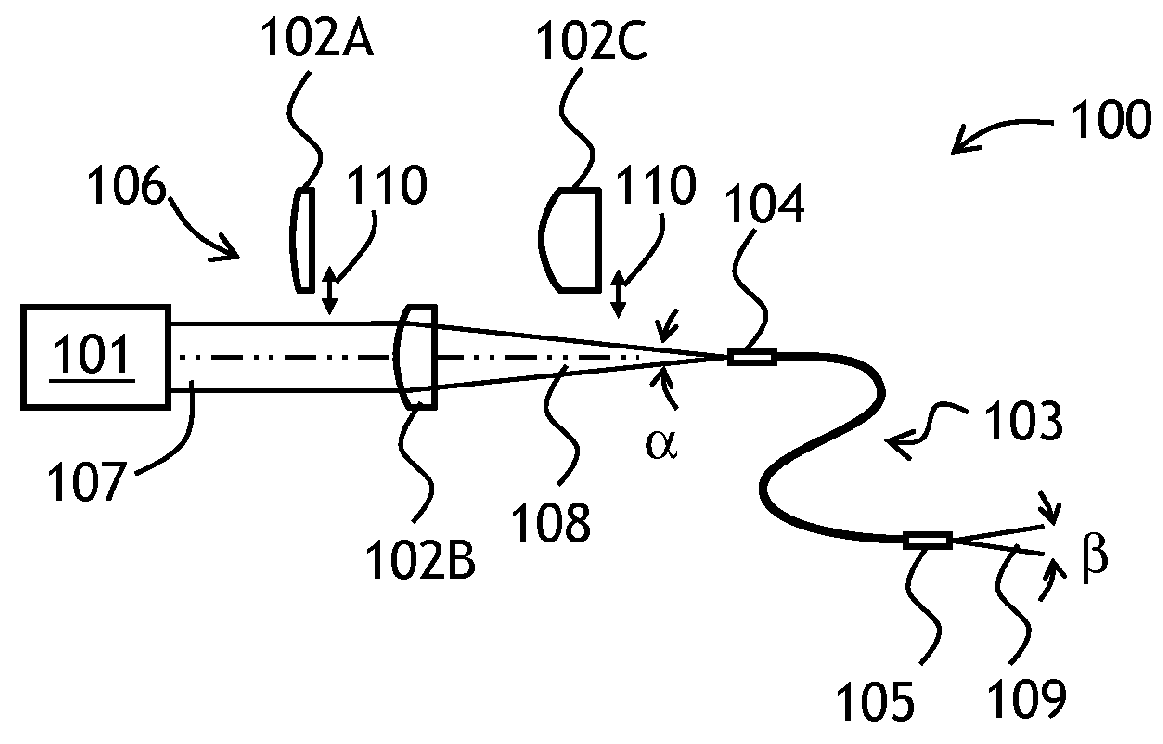

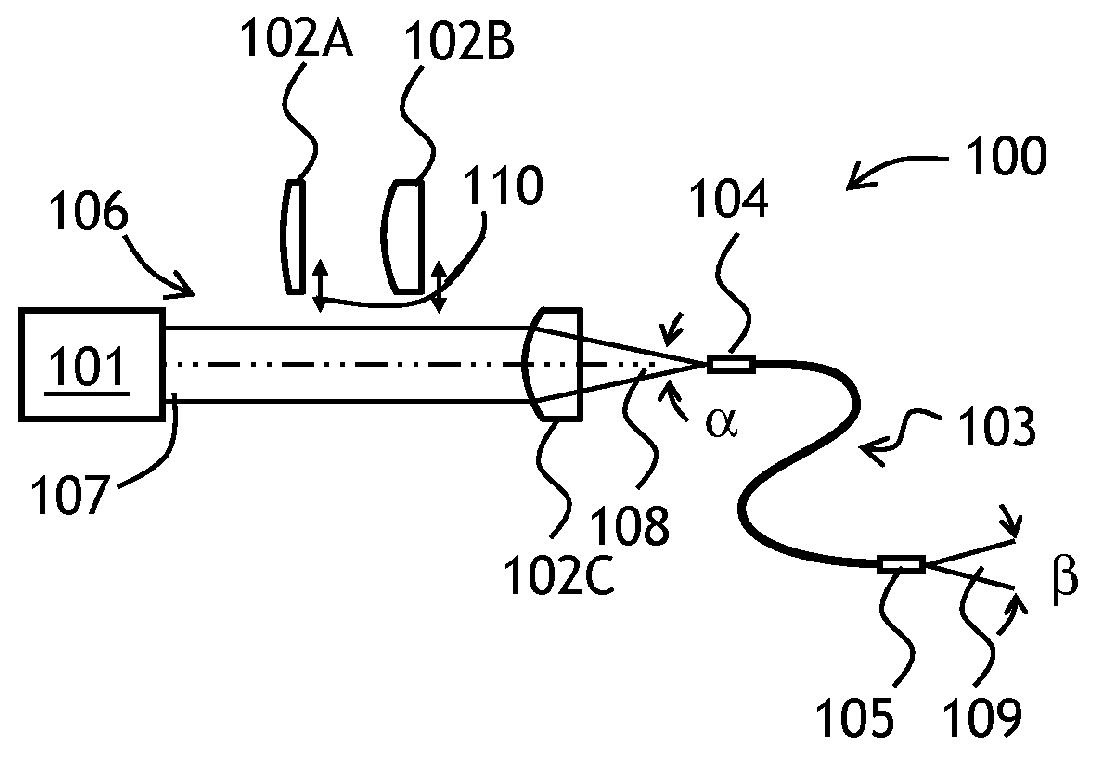

Varying beam parameter product of a laser beam

ActiveUS20130148925A1Short focal lengthClear processLaser detailsCoupling light guidesLaser processingLight beam

An optical delivery waveguide for a material laser processing system includes a small lens at an output end of the delivery waveguide, transforming laser beam divergence inside the waveguide into a spot size after the lens. By varying the input convergence angle and / or launch angle of the laser beam launched into the waveguide, the output spot size can be continuously varied, thus enabling a continuous and real-time laser spot size adjustment on the workpiece, without having to replace the delivery waveguide or a process head. A divergence of the laser beam can also be adjusted dynamically and in concert with the spot size.

Owner:LUMENTUM OPERATIONS LLC

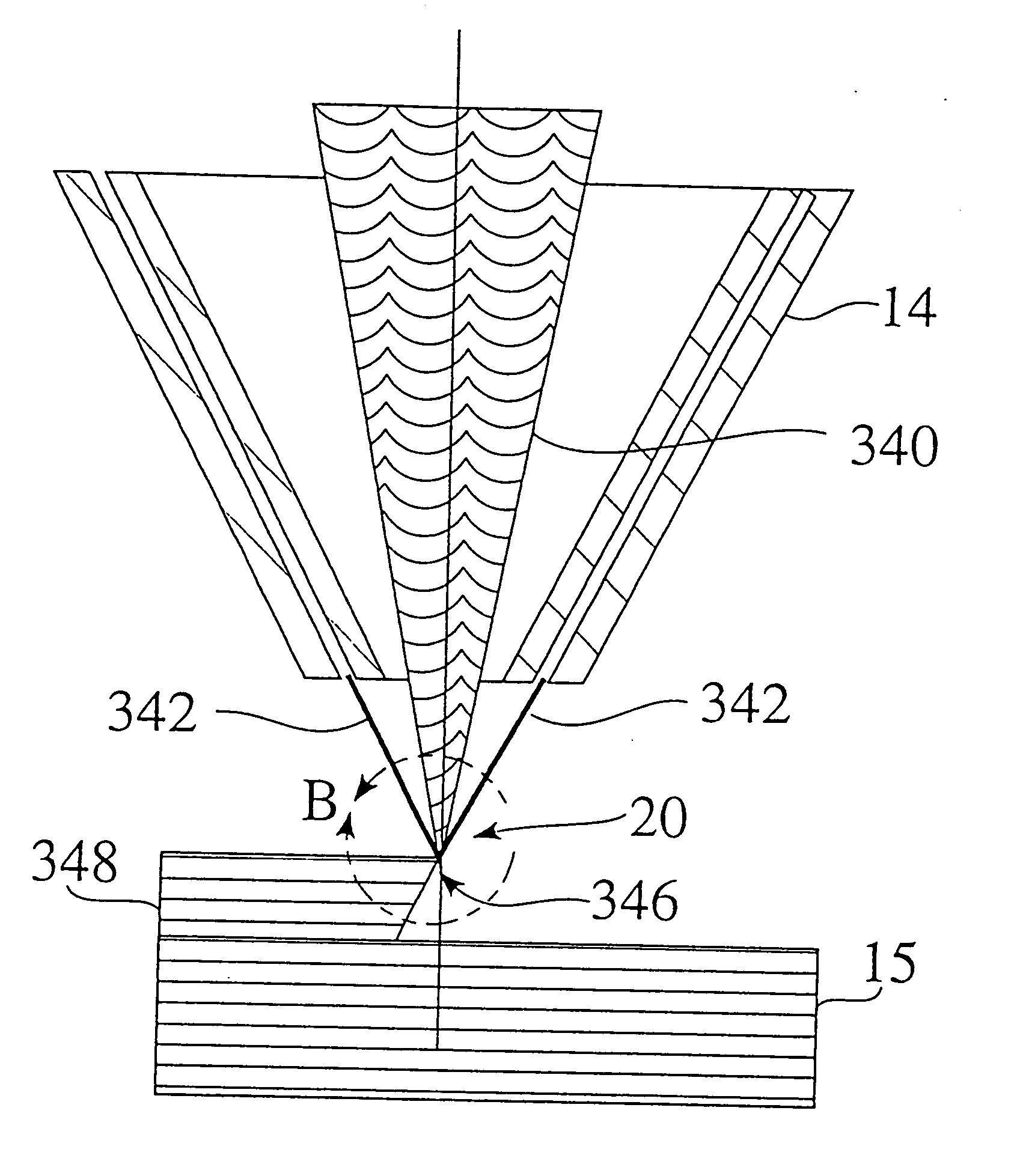

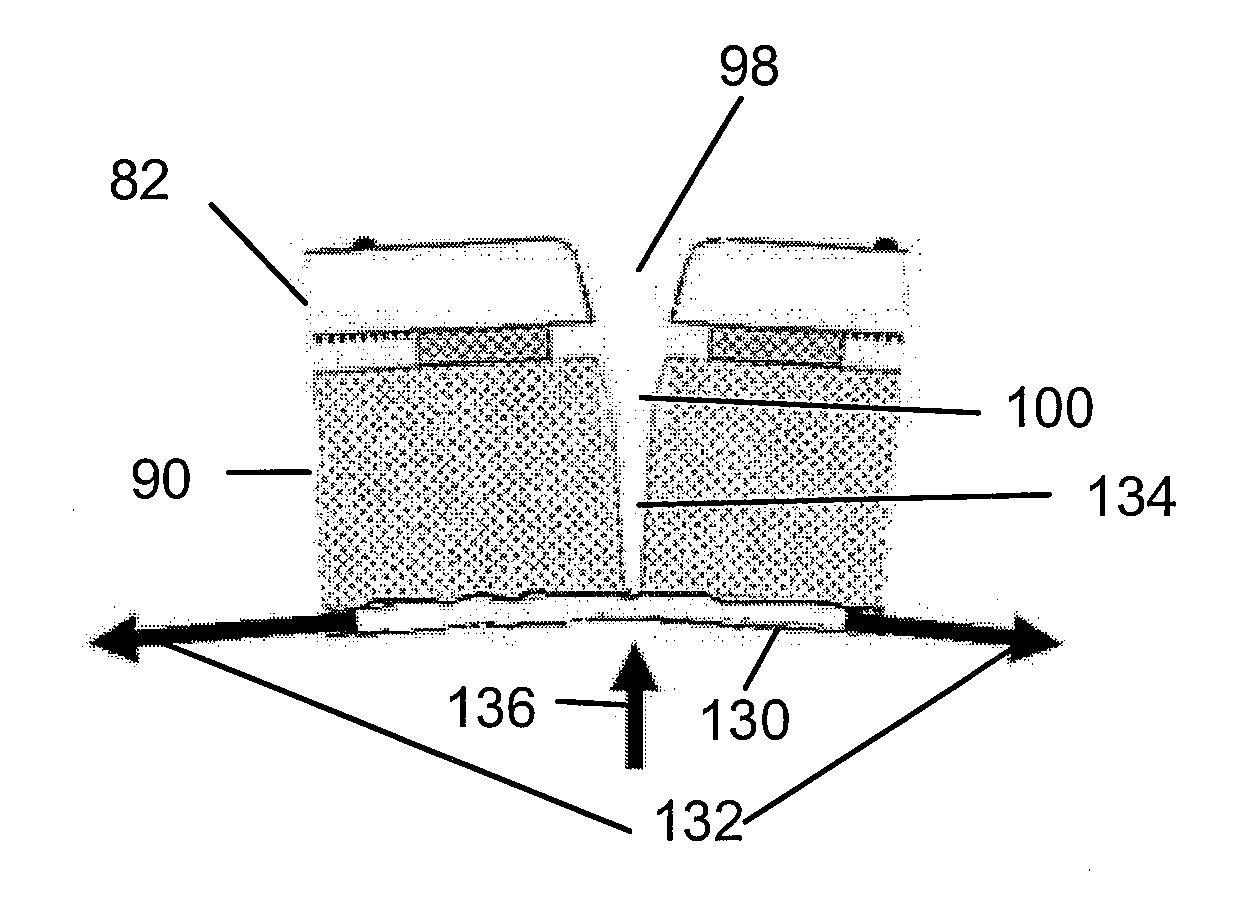

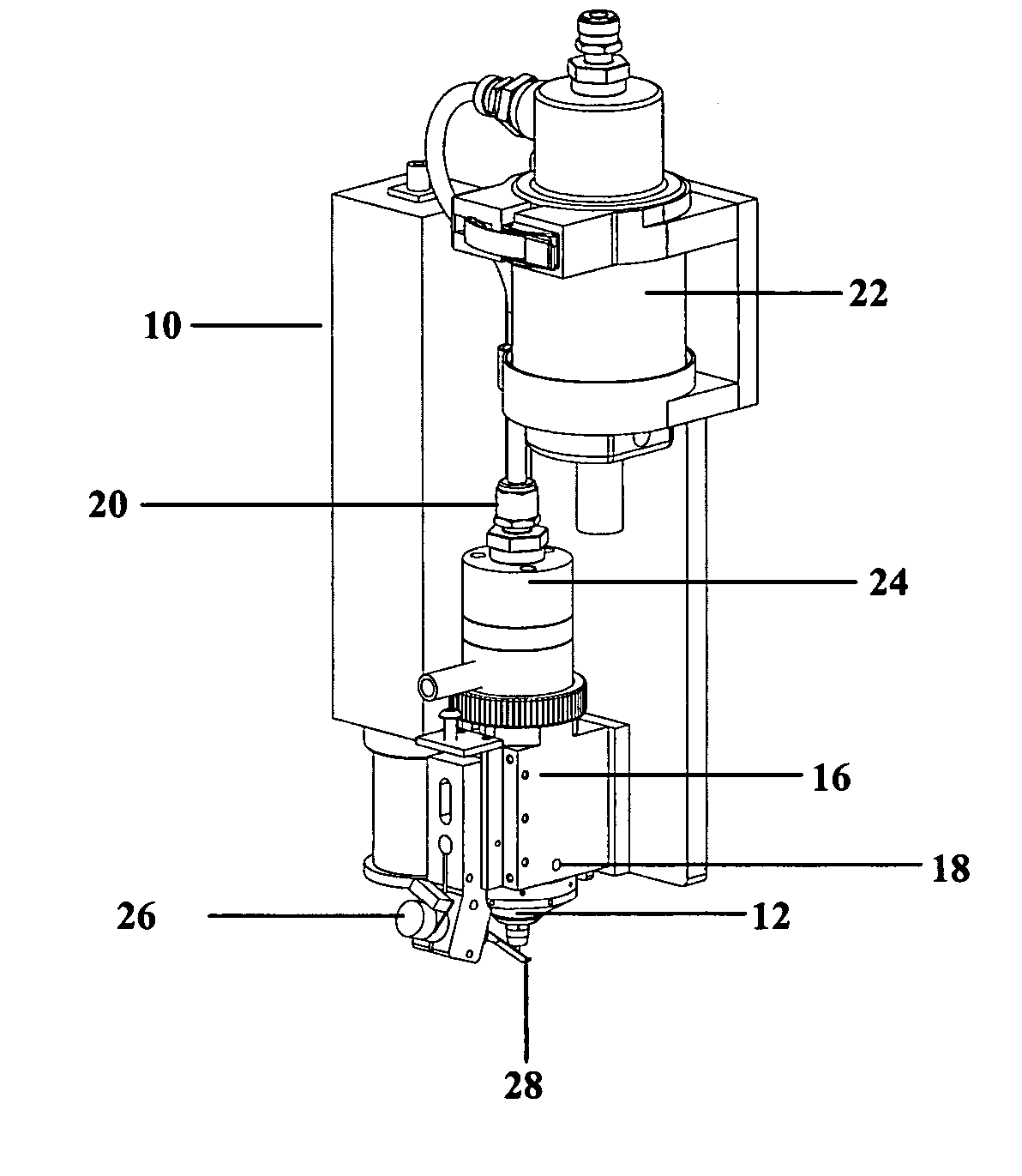

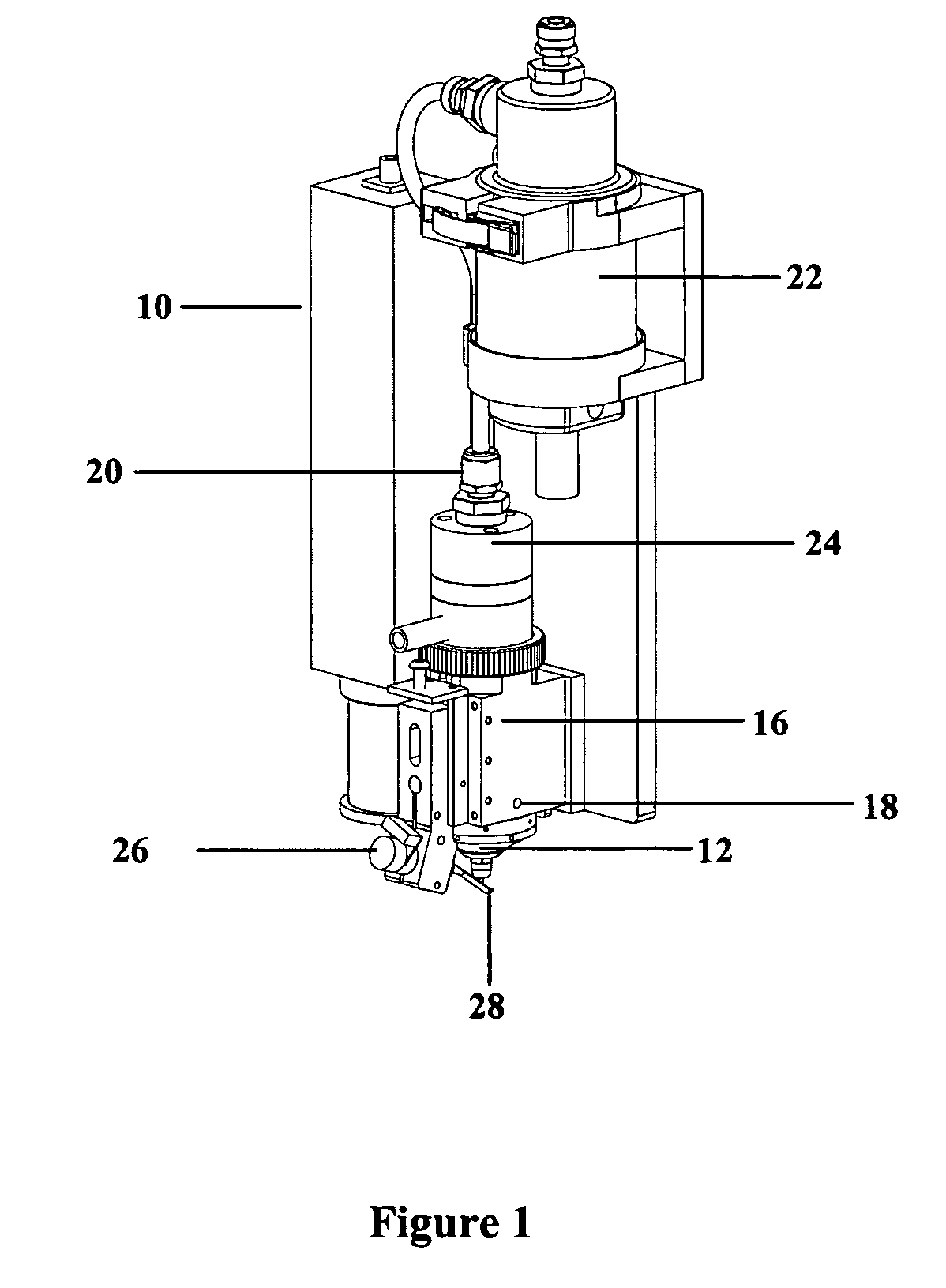

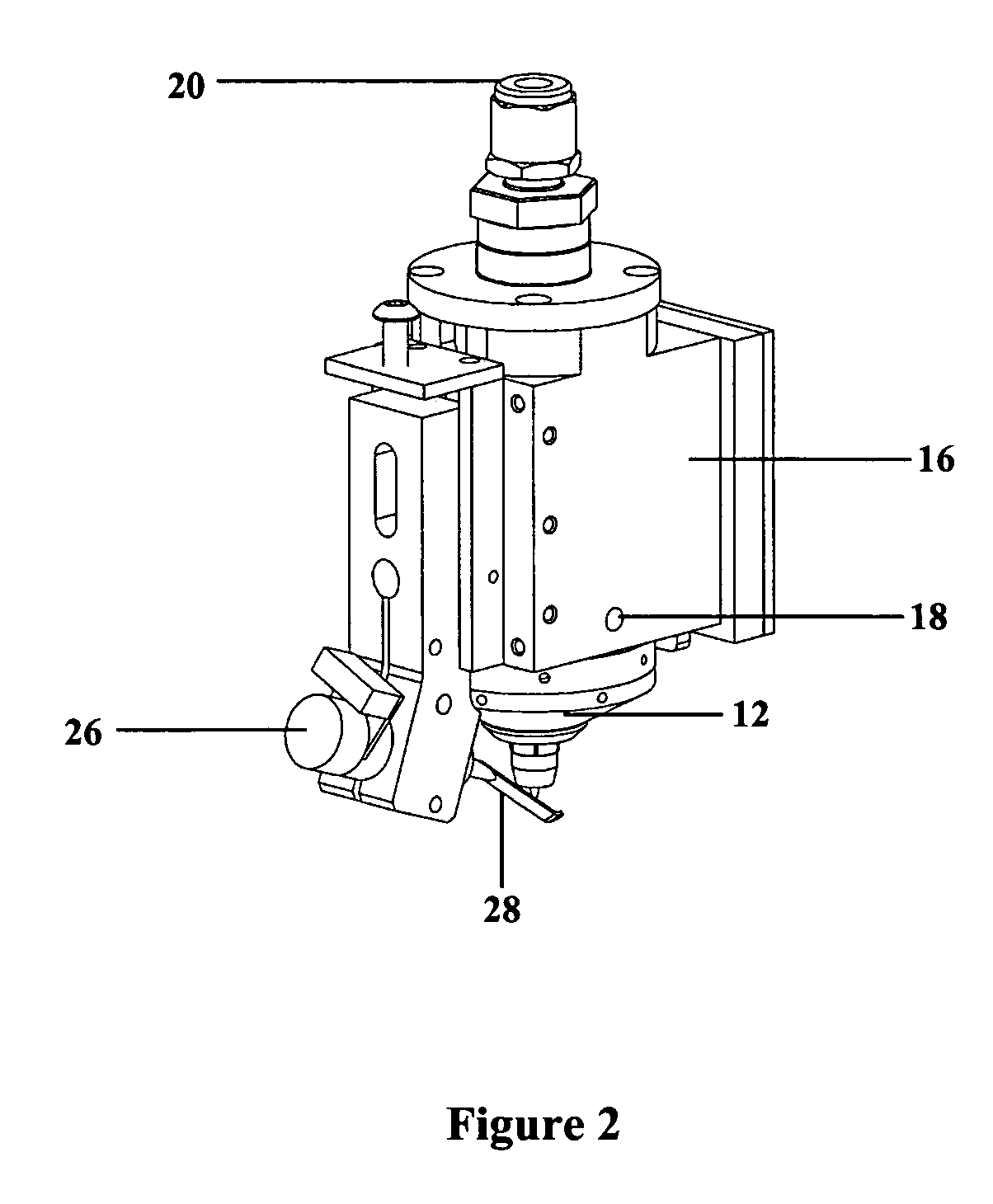

Greater angle and overhanging materials deposition

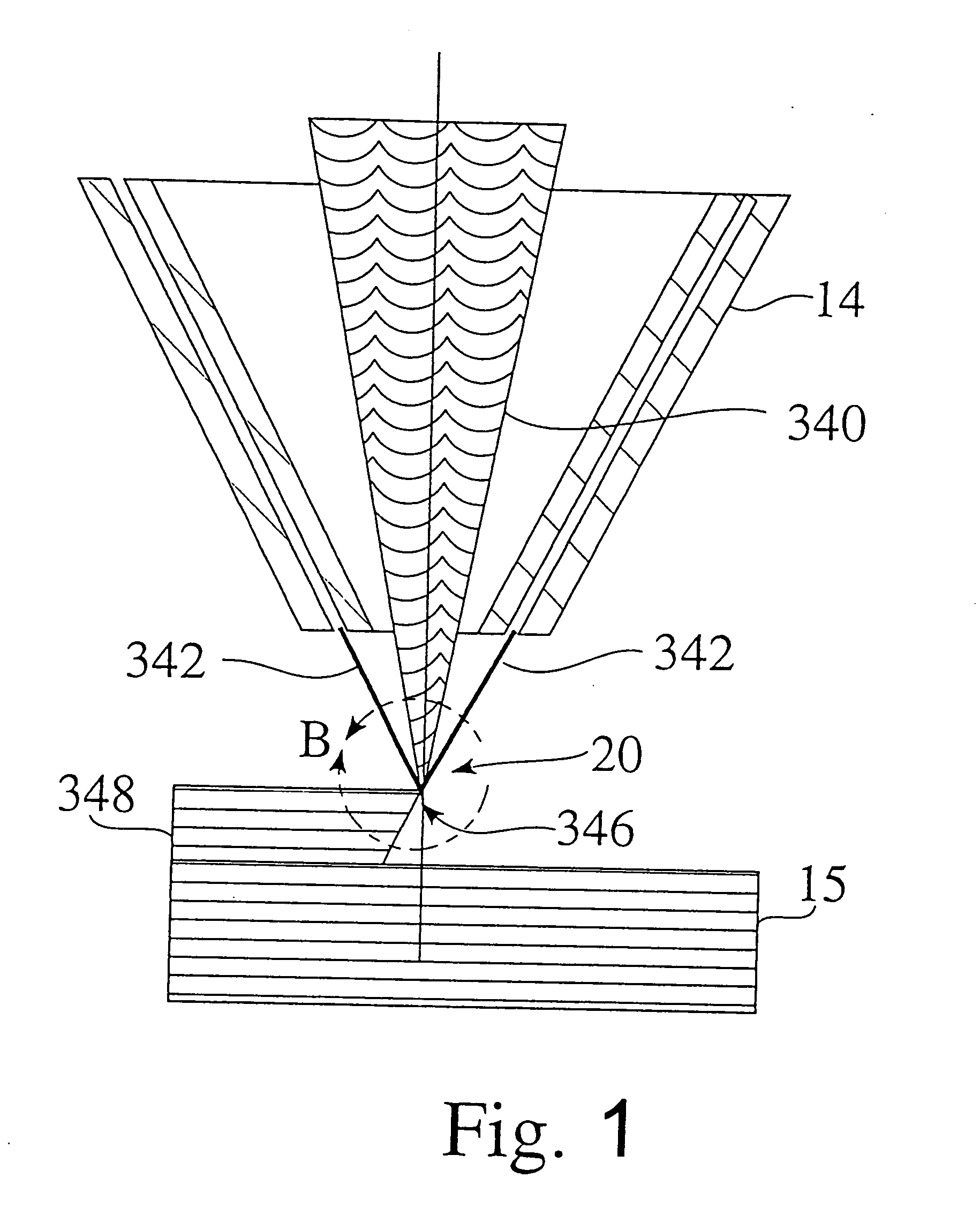

InactiveUS20060003095A1Easy to collectAdditive manufacturing apparatusMolten spray coatingLaser processingSpray nozzle

Apparatuses and methods for producing greater angle or overhanging deposits on a structure. Nozzles for propelling powder at a target or structure for subsequent laser processing are preferably at a greater angle of powder entry than currently used. The nozzles are arranged around the laser beam and can be individual or disposed around an annular ring. The individual nozzles can be interchangeable with the annular ring. Discrete nozzles can be used in addition to or in place of the other nozzles, allowing angles of powder entry up to approximately 180°. The nozzles may be translated or rotated with respect to the target along or about multiple axes. Also a method for temporarily supporting an overhang using weaker material under the overhang. The weaker material can be removed after the overhang is fabricated and solidified.

Owner:OPTOMEC DESIGN CO

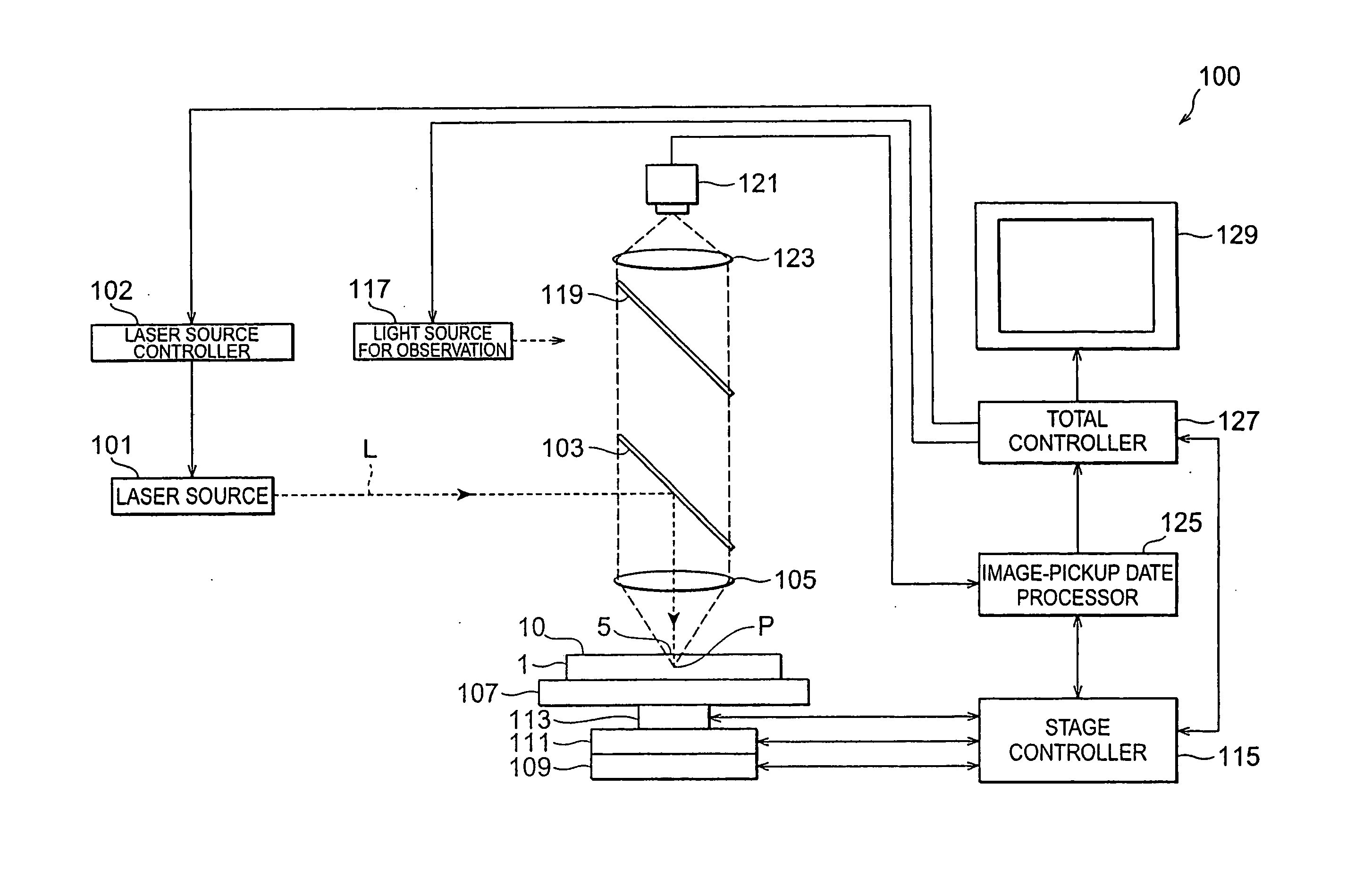

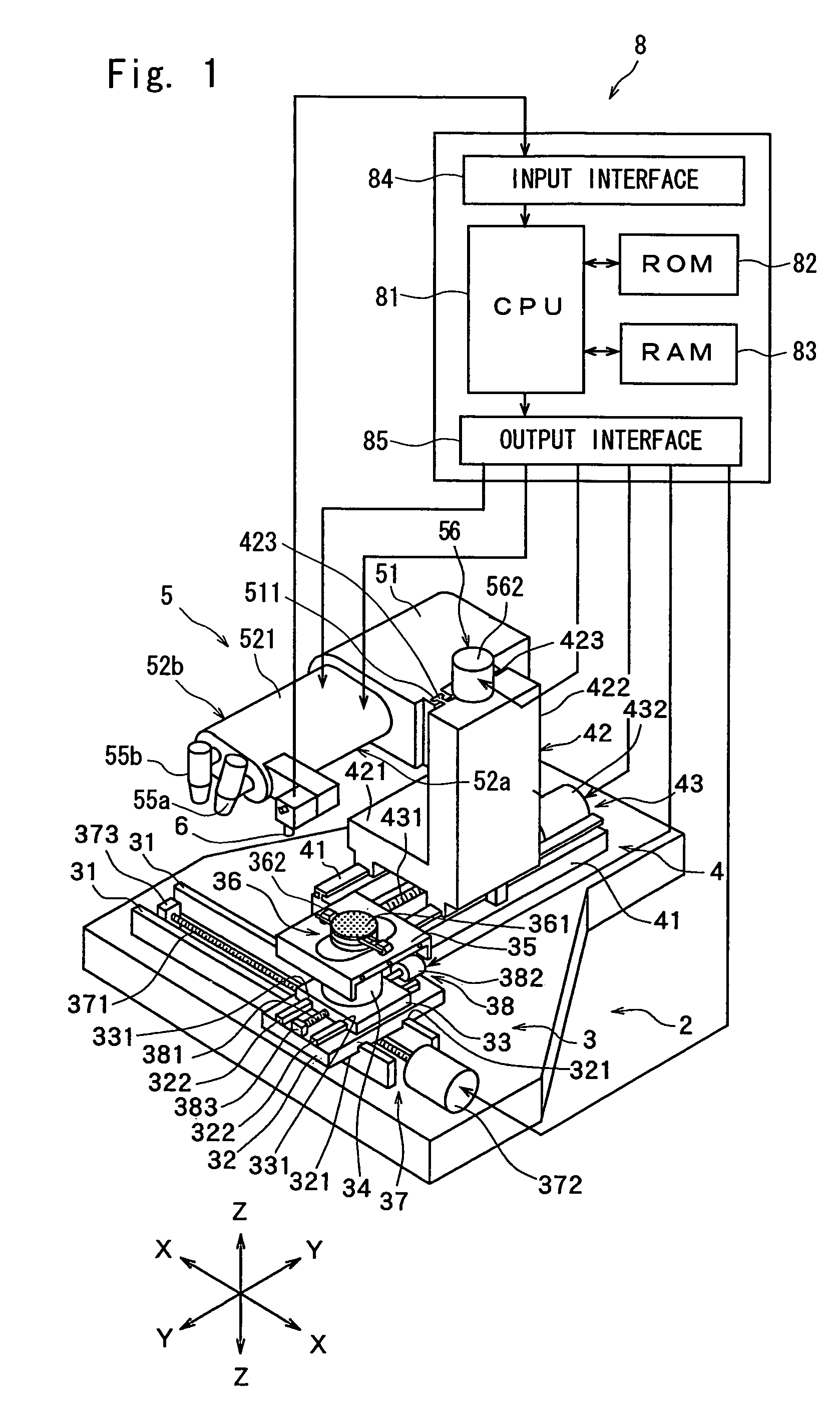

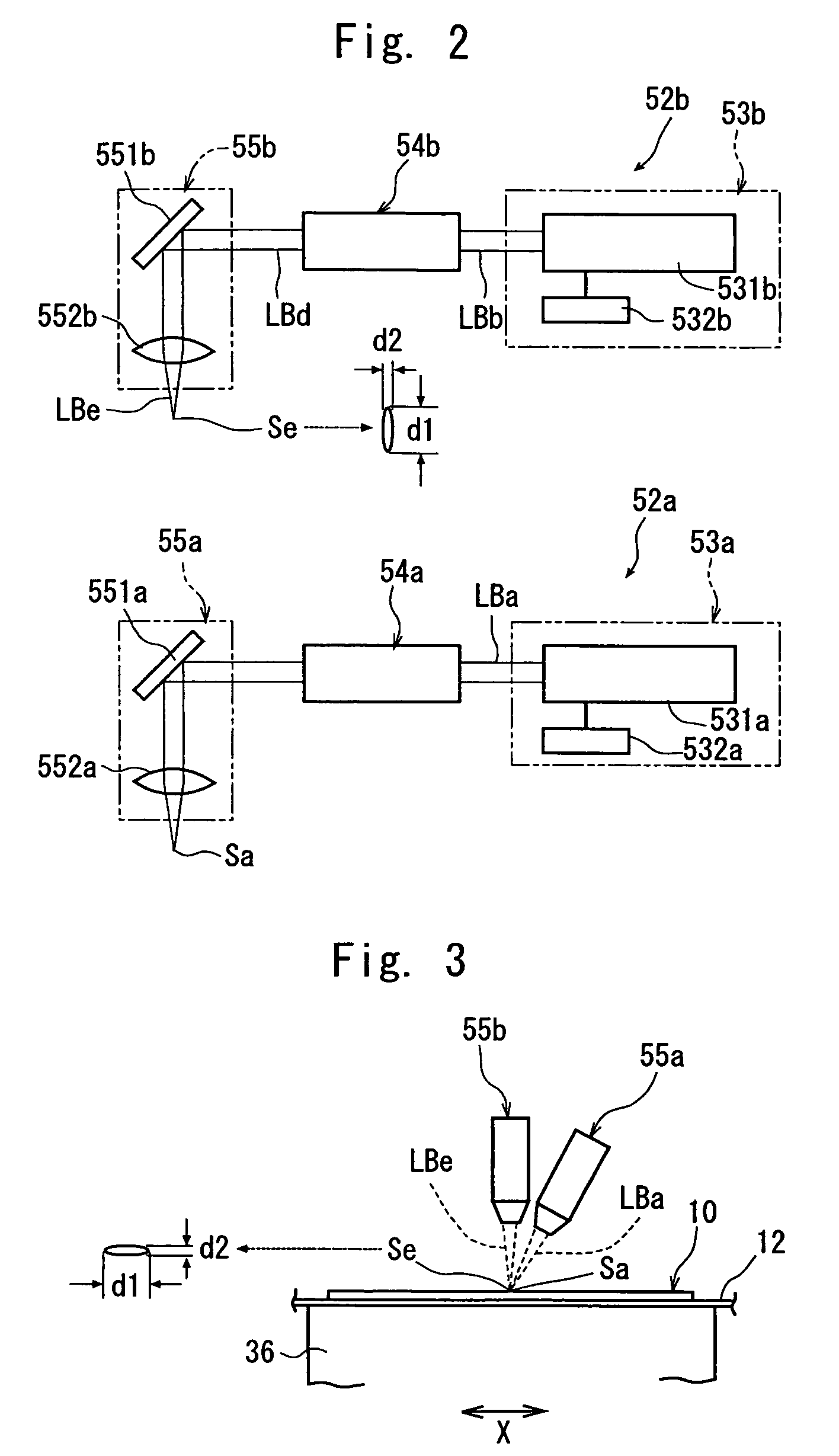

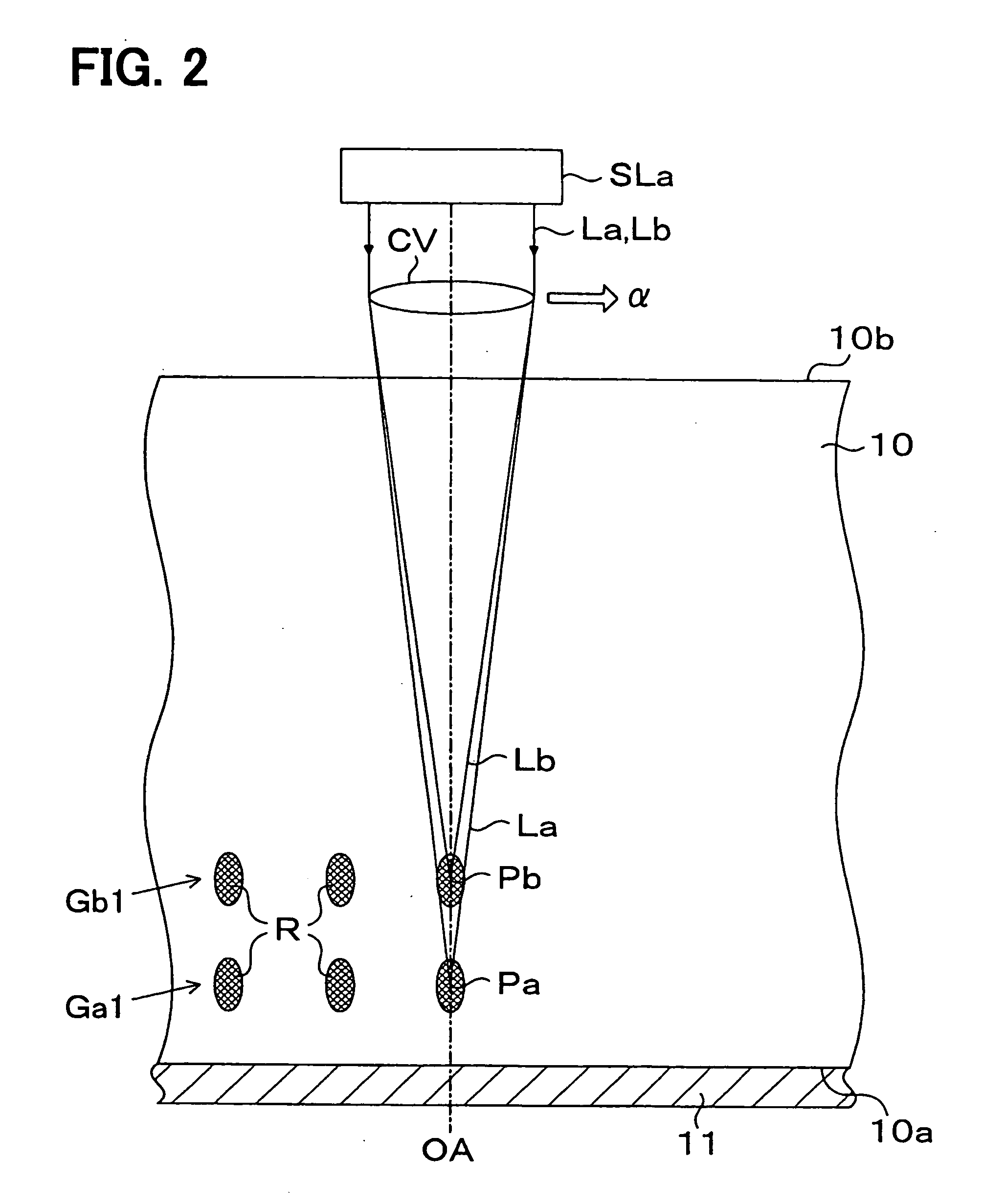

Device and method for laser processing

InactiveUS20060144828A1Prevent movementImprove accuracyLaser detailsSemiconductor/solid-state device manufacturingLaser processingLaser light

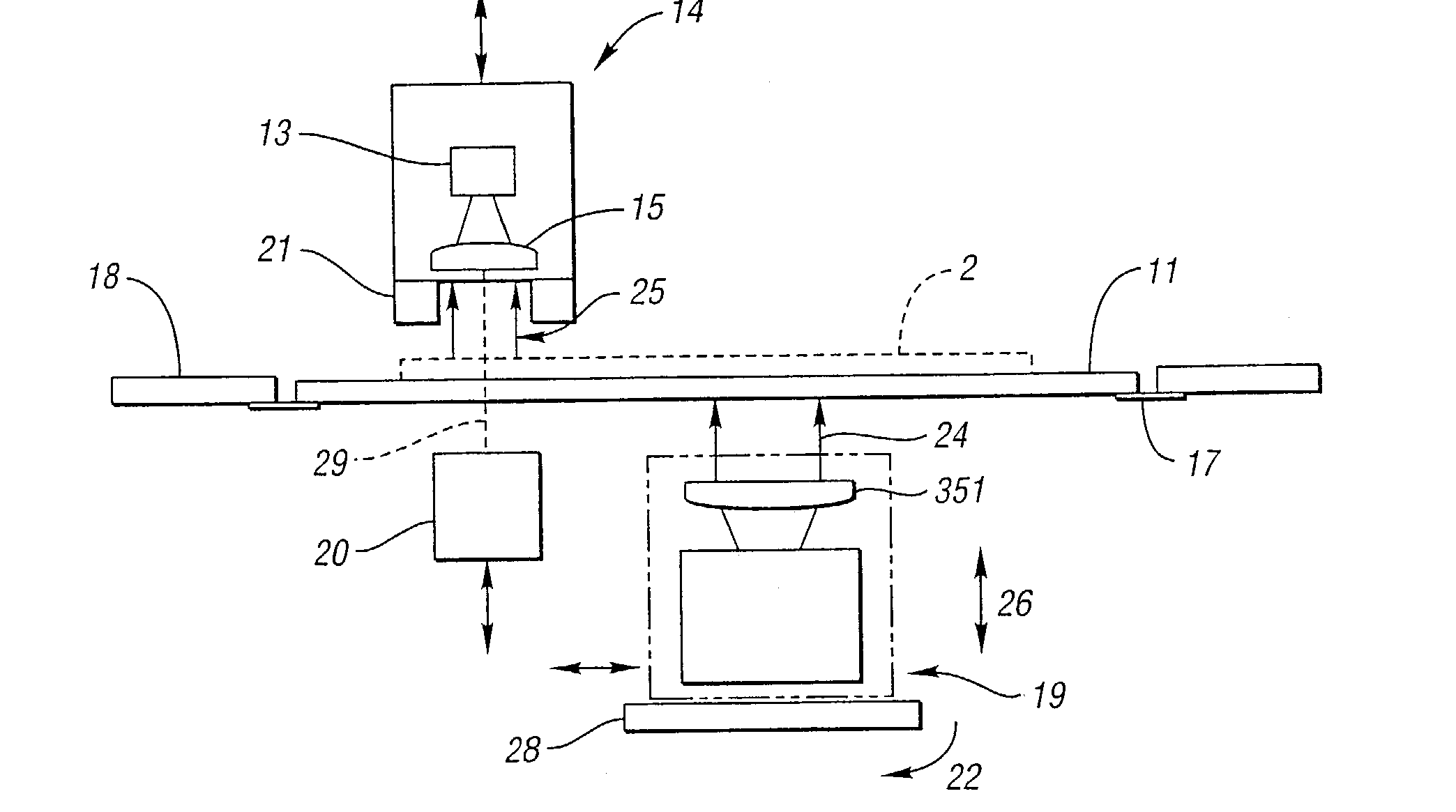

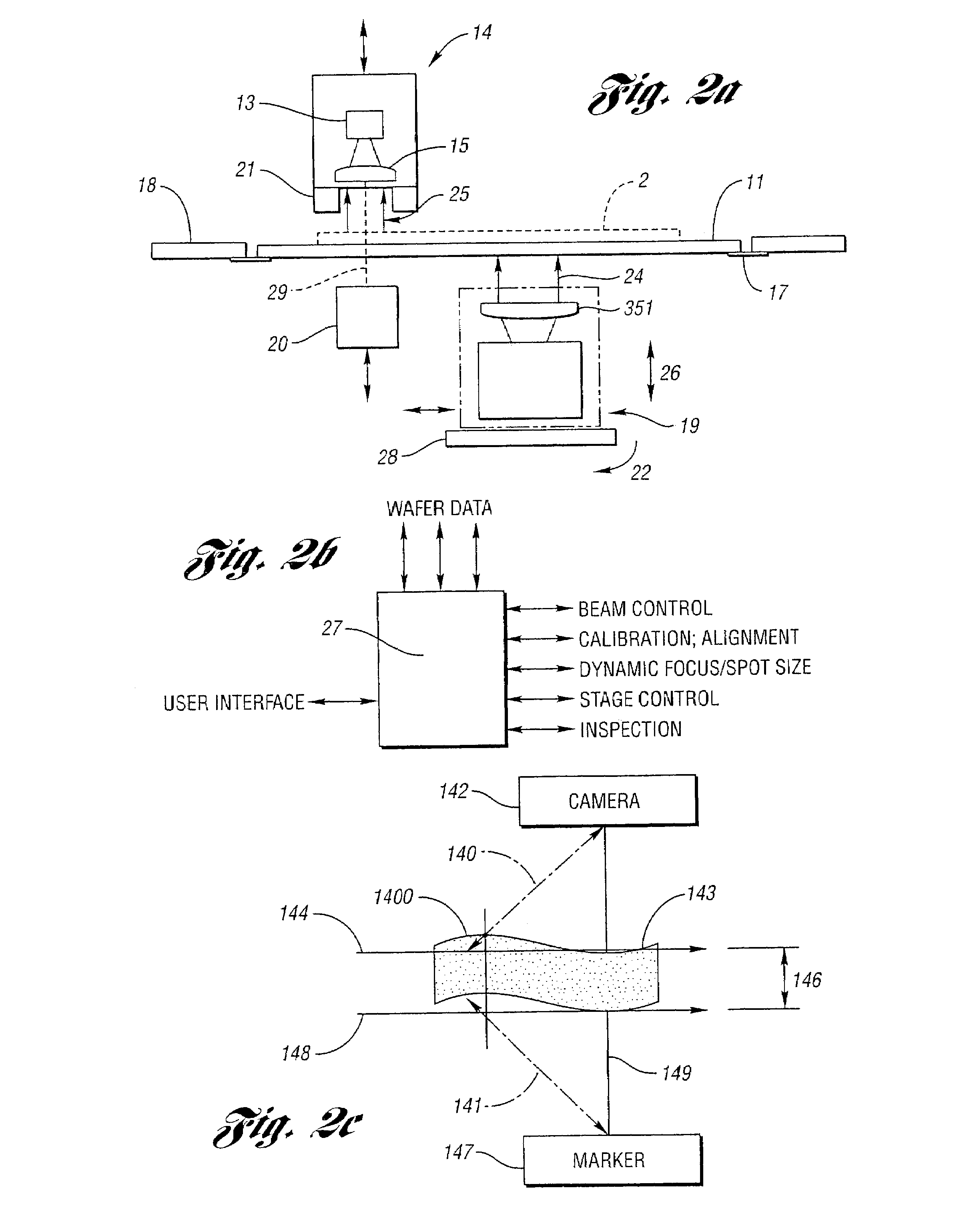

A laser processing apparatus and a laser processing method which can accurately converge processing laser light at a predetermined position are provided. In the laser processing apparatus, a condenser lens 31 converges processing laser light L1 and rangefinding laser light L2 onto an object to be processed 1 on the same axis. Here, light-converging point position control means40 detects reflected light L3 of the rangefinding laser light reflected by the front face 3 of the object 1, and places a light-converging point P1 of the processing laser light L1 at a predetermined position. Since the processing by the processing laser light L1 and the measurement of displacement of the front face 3 by the rangefinding laser light L2 are carried out on the same axis as such, the light-converging point P1 of processing laser light L1 can be prevented from shifting from the predetermined position because of vibrations of the stage 21 and the like. Therefore, the processing laser light L1 can accurately be converged at the predetermined position.

Owner:HAMAMATSU PHOTONICS KK

Method and system for calibrating a laser processing system and laser marking system utilizing same

InactiveUS7015418B2Mark accuratelyRecording apparatusSemiconductor/solid-state device detailsLaser processingThree degrees of freedom

A method of calibrating a laser marking system includes calibrating a laser marking system in three dimensions. The step of calibrating includes storing data corresponding to a plurality of heights. A position measurement of a workpiece is obtained to be marked. Stored calibration data is associated with the position measurement. A method and system for calibrating a laser processing or marking system is provided. The method includes: calibrating a laser marker over a marking field; obtaining a position measurement of a workpiece to be marked; associating stored calibration data with the position measurement; relatively positioning a marking beam and the workpiece based on at least the associated calibration data; and calibrating a laser marking system in at least three degrees of freedom. The step of calibrating includes storing data corresponding to a plurality of positions and controllably and relatively positioning a marking beam based on the stored data corresponding to the plurality of positions.

Owner:ELECTRO SCI IND INC

Method for Laser Singulation of Chip Scale Packages on Glass Substrates

InactiveUS20100248451A1Preclude creationMinimized in sizeSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesLaser processingOptoelectronics

An improved method for singulation of compound electronic devices is presented. Compound electronic devices are manufactured by combining two or more substrates into an assembly containing multiple devices. Presented are methods for singulation of compound electronic devices using laser processing. The methods presented provide fewer defects such as cracking or chipping of the substrates while minimizing the width of the kerf and maintaining system throughput.

Owner:ELECTRO SCI IND INC

Laser machining device

InactiveUS6875951B2Low costSmall sizeWelding/soldering/cutting articlesLaser beam welding apparatusLaser processingGalvanometer

A laser machining device according to the invention is provided with a laser oscillator for generating a laser beam, a main deflecting galvannometer mirror, an Fθ lens, and a sub-deflecting means arranged in an optical path between the laser oscillator and the main deflecting galvanometer mirror. A means for splitting a laser beam is provided, and the sub-deflecting means is inserted into the optical path of one of the split laser beams. At the same time, both the split laser beams are incident from the same main deflecting galvannometer mirror to the Fθ lens, and a numerical aperture in the optical system constituted by the main deflecting galvannometer mirror, the Fθ lens, and an object is set to be not more than 0.08.

Owner:MITSUBISHI ELECTRIC CORP

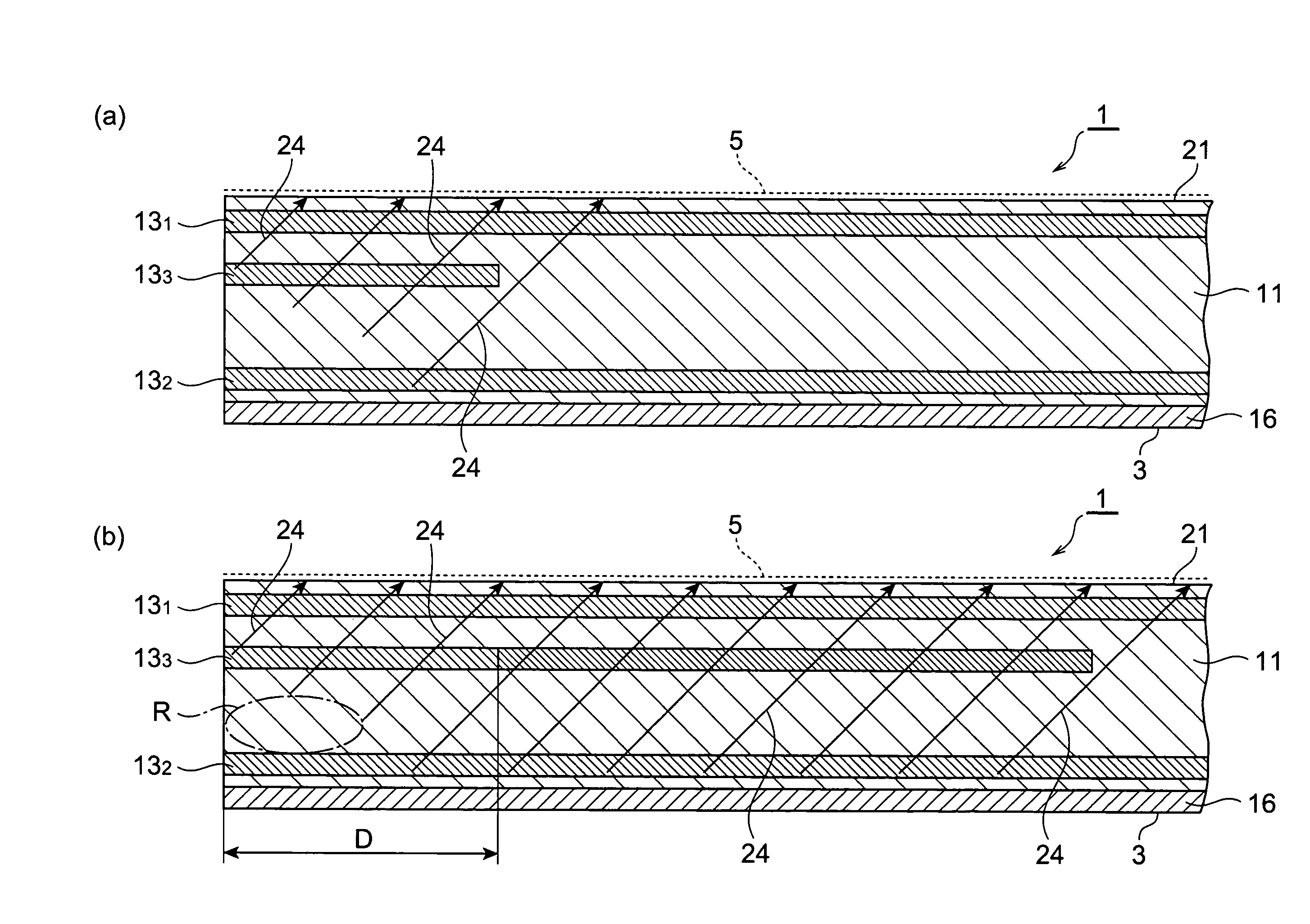

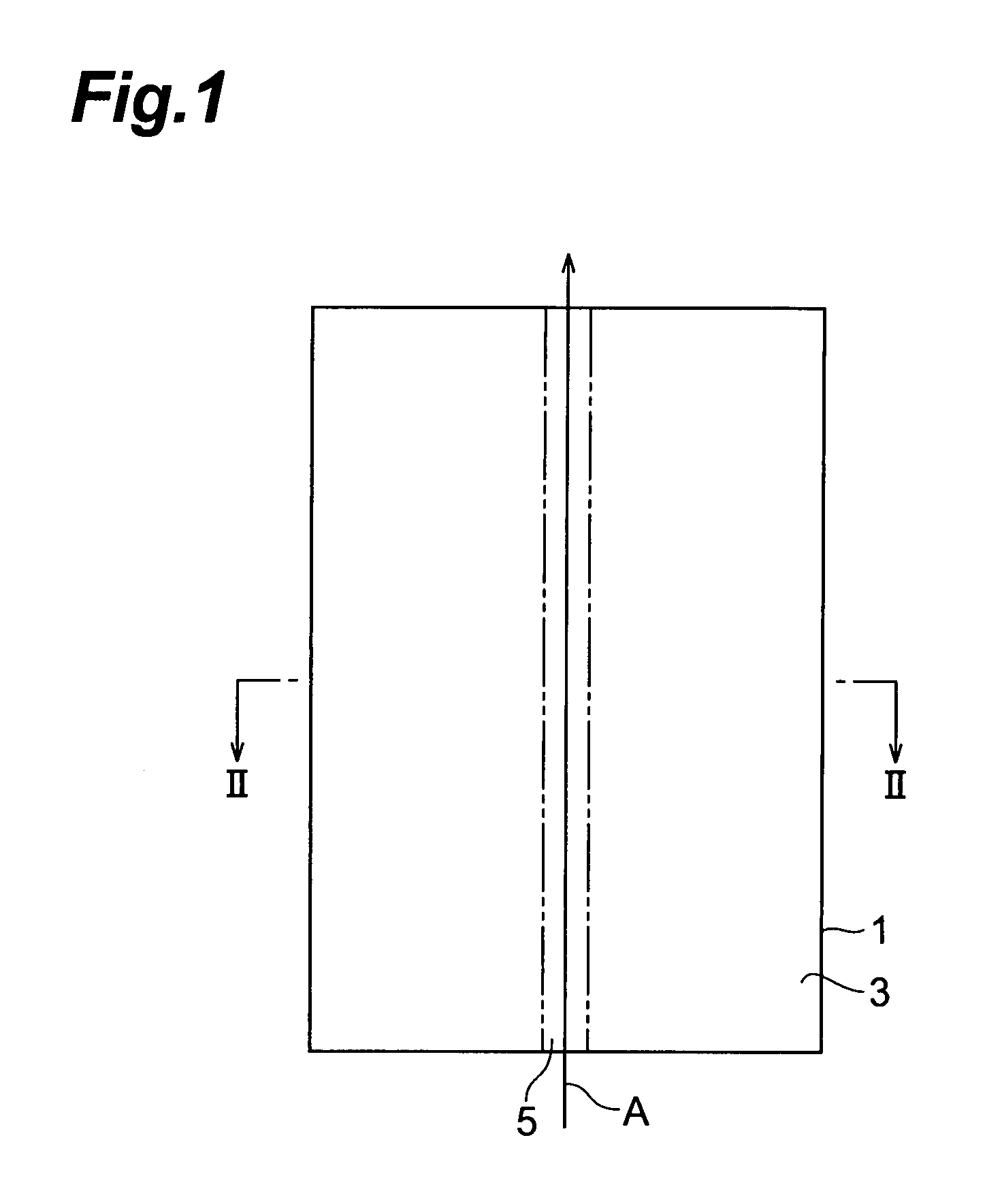

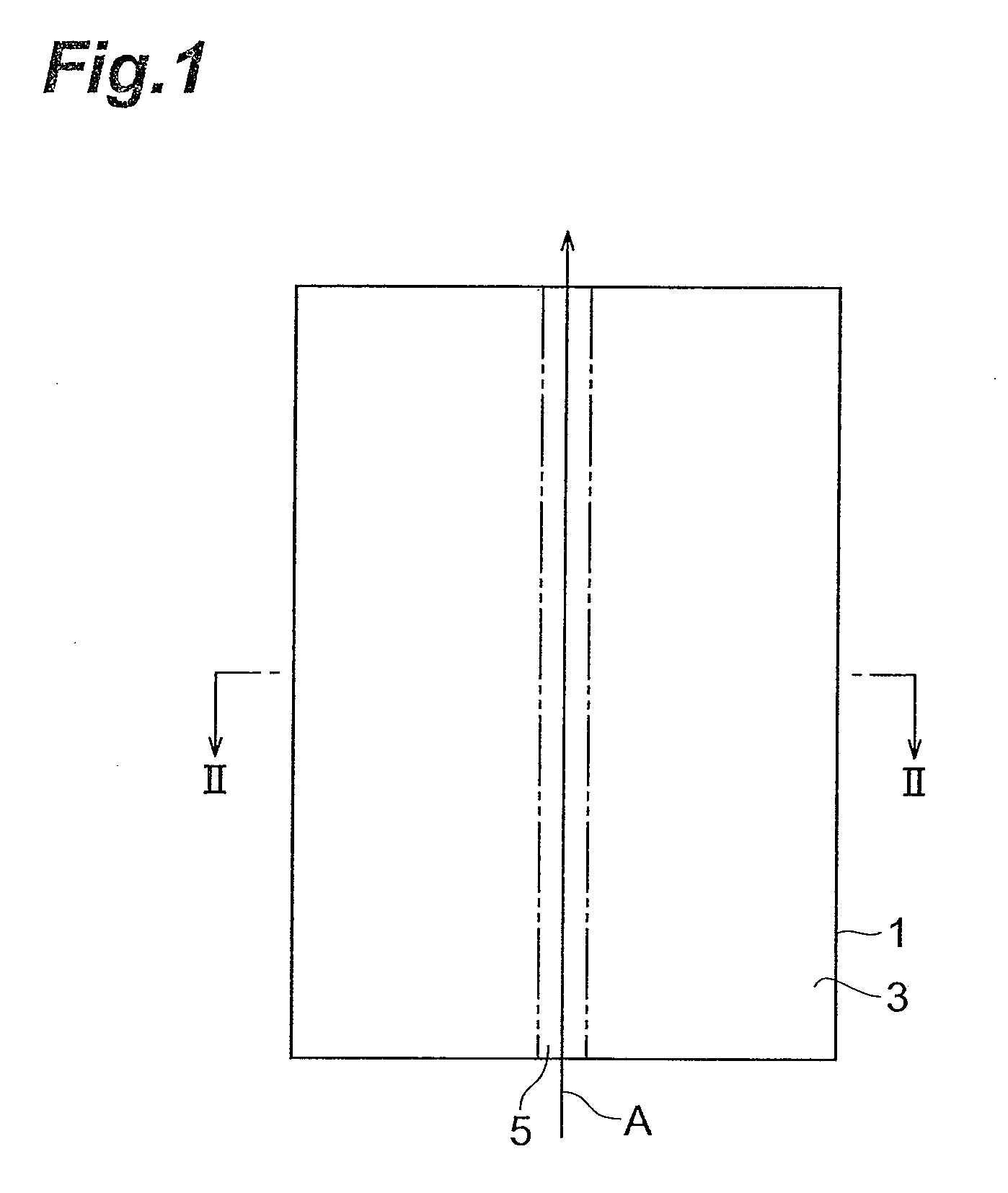

Laser processing method and chip

ActiveUS7897487B2High precision cuttingPrecise cuttingSemiconductor/solid-state device manufacturingFine working devicesLaser processingLaser light

An object to be processed can be cut highly accurately along a line to cut.An object to be processed 1 is irradiated with laser light while locating a converging point within a silicon wafer 11, and the converging point is relatively moved along a line to cut 5, so as to form modified regions M1, M2 positioned within the object 1 along the line to cut 5, and then a modified region M3 positioned between the modified regions M1, M2 within the object 1.

Owner:HAMAMATSU PHOTONICS KK

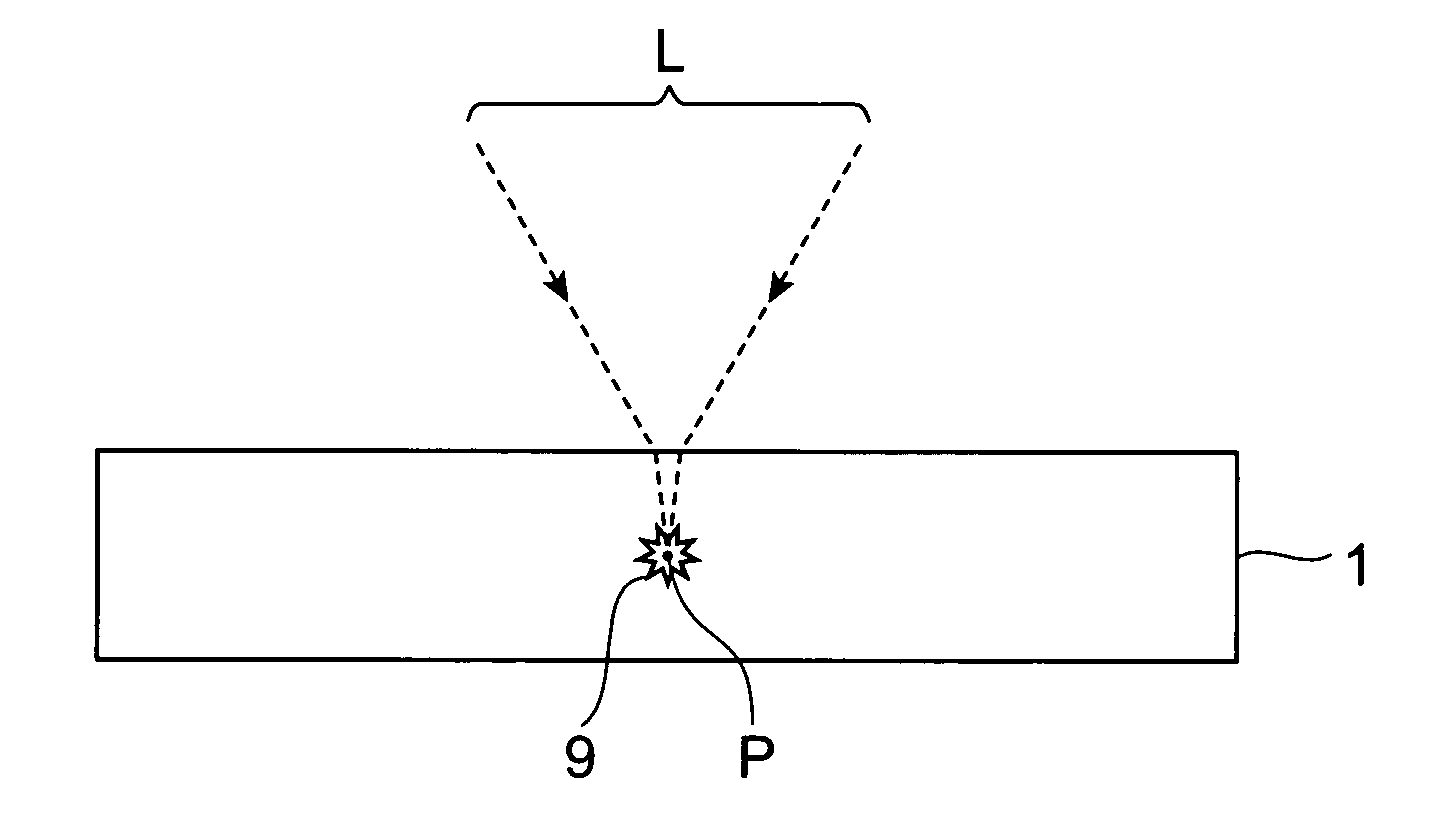

Laser processing method and laser processing apparatus

InactiveUS20050181581A1No unnecessary fractureSolid-state devicesSemiconductor/solid-state device manufacturingLaser processingLaser beam machining

A laser beam machining method and a laser beam machining device capable of cutting a work without producing a fusing and a cracking out of a predetermined cutting line on the surface of the work, wherein a pulse laser beam is radiated on the predetermined cut line on the surface of the work under the conditions causing a multiple photon absorption and with a condensed point aligned to the inside of the work, and a modified area is formed inside the work along the predetermined determined cut line by moving the condensed point along the predetermined cut line, whereby the work can be cut with a rather small force by cracking the work along the predetermined cut line starting from the modified area and, because the pulse laser beam radiated is not almost absorbed onto the surface of the work, the surface is not fused even if the modified area is formed.

Owner:HAMAMATSU PHOTONICS KK

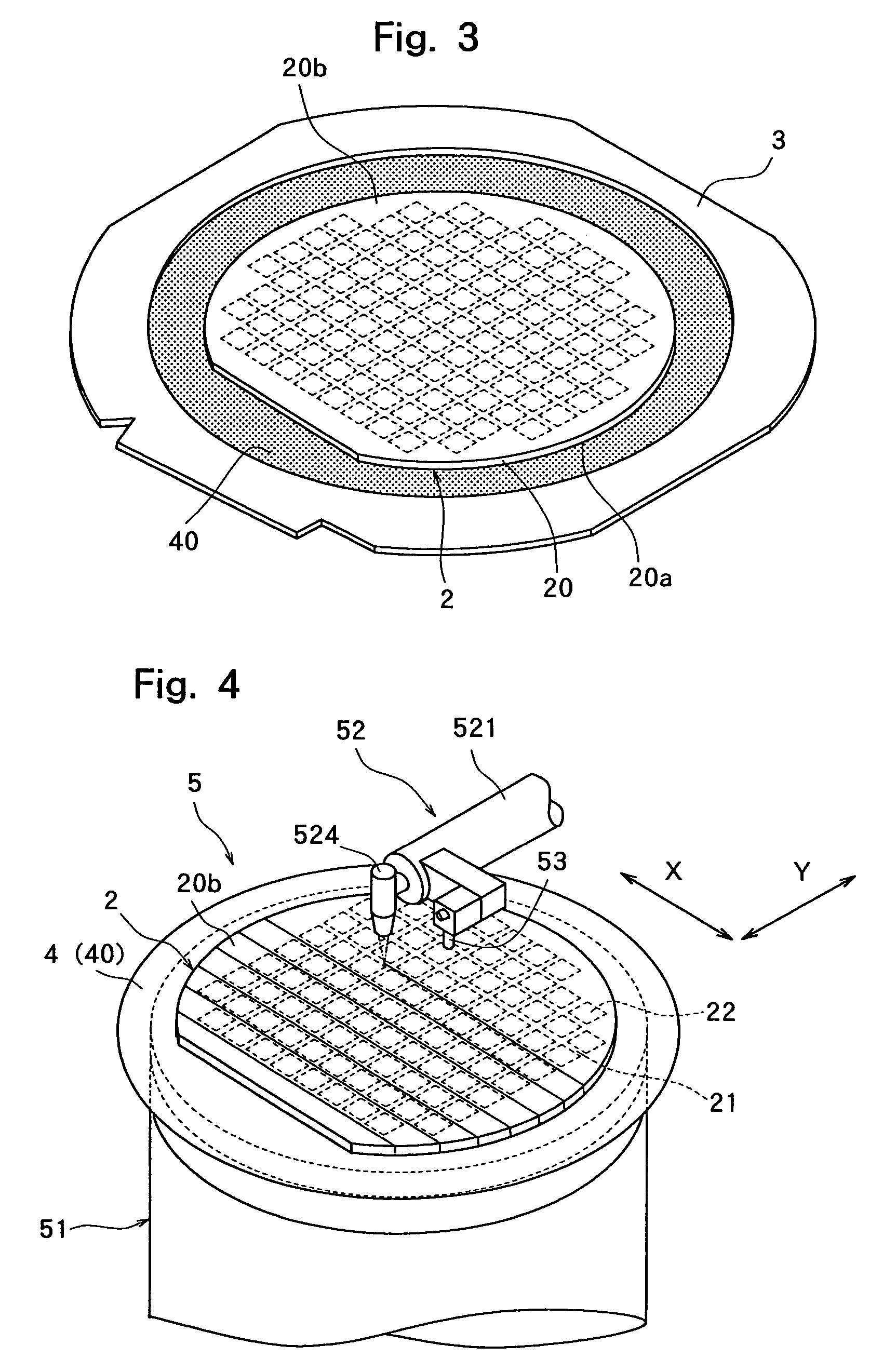

Laser processing apparatus

ActiveUS7473866B2Soften the processing area of the workpieceProcessing area is softenedPhotometrySemiconductor/solid-state device manufacturingLaser processingLight beam

A laser processing apparatus comprising a chuck table, laser beam irradiation means for irradiating a workpiece held on the chuck table with a laser beam, and processing feed means for processing-feeding the chuck table and the laser beam irradiation means relative to each other. The laser beam irradiation means includes first laser beam irradiation means for throwing a first pulsed laser beam having a wavelength in the intermediate-infrared radiation region, and second laser beam irradiation means for throwing a second pulsed laser beam having a wavelength in the ultraviolet radiation region. The first laser beam irradiation means and the second laser beam irradiation means are set such that at least a part, in the processing feed direction, of the focus spot of the second pulsed laser beam overlaps the focus spot of the first pulsed laser beam.

Owner:DISCO CORP

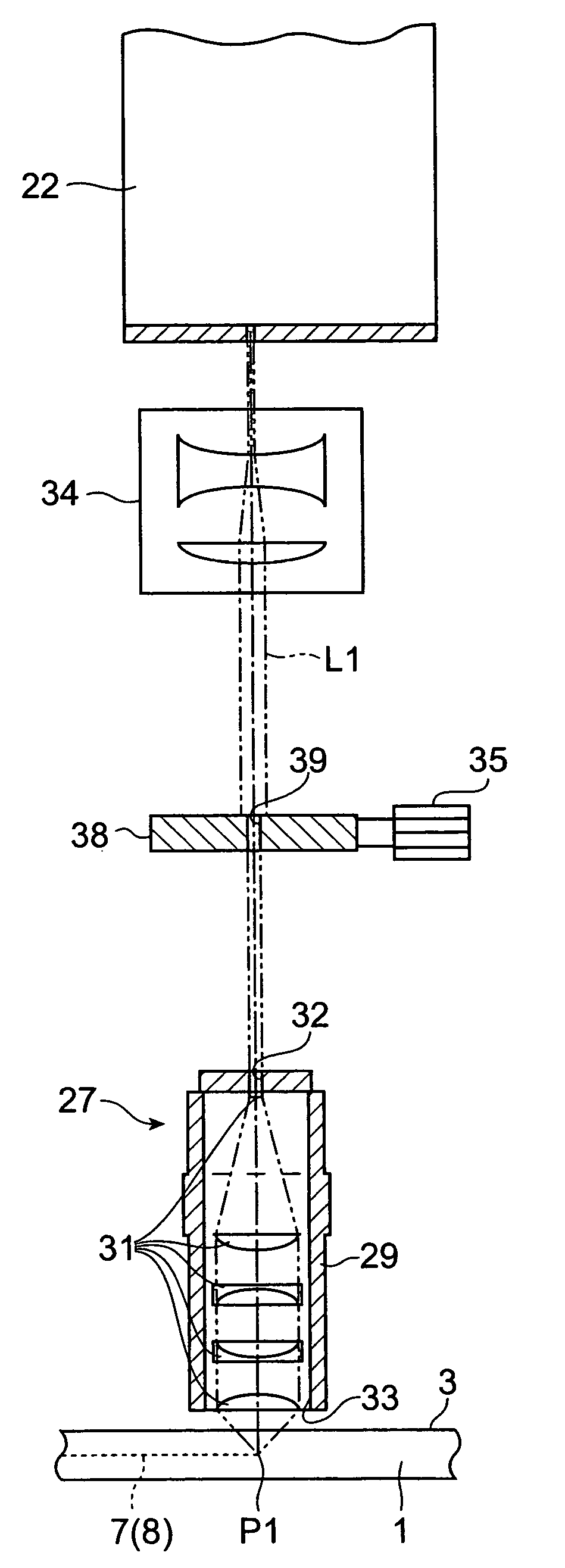

Laser processing device

ActiveUS7489454B2Suppress positional fluctuationReduce lightLaser detailsFine working devicesBeam expanderLaser processing

A laser processing apparatus which can suppress the positional fluctuation in light-converging point of laser light during laser processing is provided. On an optical path of laser light L1 connecting a beam expander 34 and a first light-transmitting hole 32 of a lens holder 29 to each other in a laser processing apparatus 20, a stop member 38 including a second light-transmitting hole 39 having the same diameter as that of the first light-transmitting hole 32 is disposed. Hence, the amount of laser light L1 cut by the surrounding part of the first light-transmitting hole 32 can substantially be eliminated, whereby the lens holder 29 can be prevented from being heated upon irradiation with the laser light L1. Also, even when the stop member 38 is heated by the laser light L1 cut by the surrounding part of the second light-transmitting hole 39, heat is prevented from being transmitted from the stop member 38 to the lens holder 29, since the stop member 38 is separated from the lens holder 29. Therefore, the positional fluctuation in light-converging point P1 of the laser light L1 during laser processing can be suppressed to a low level.

Owner:HAMAMATSU PHOTONICS KK

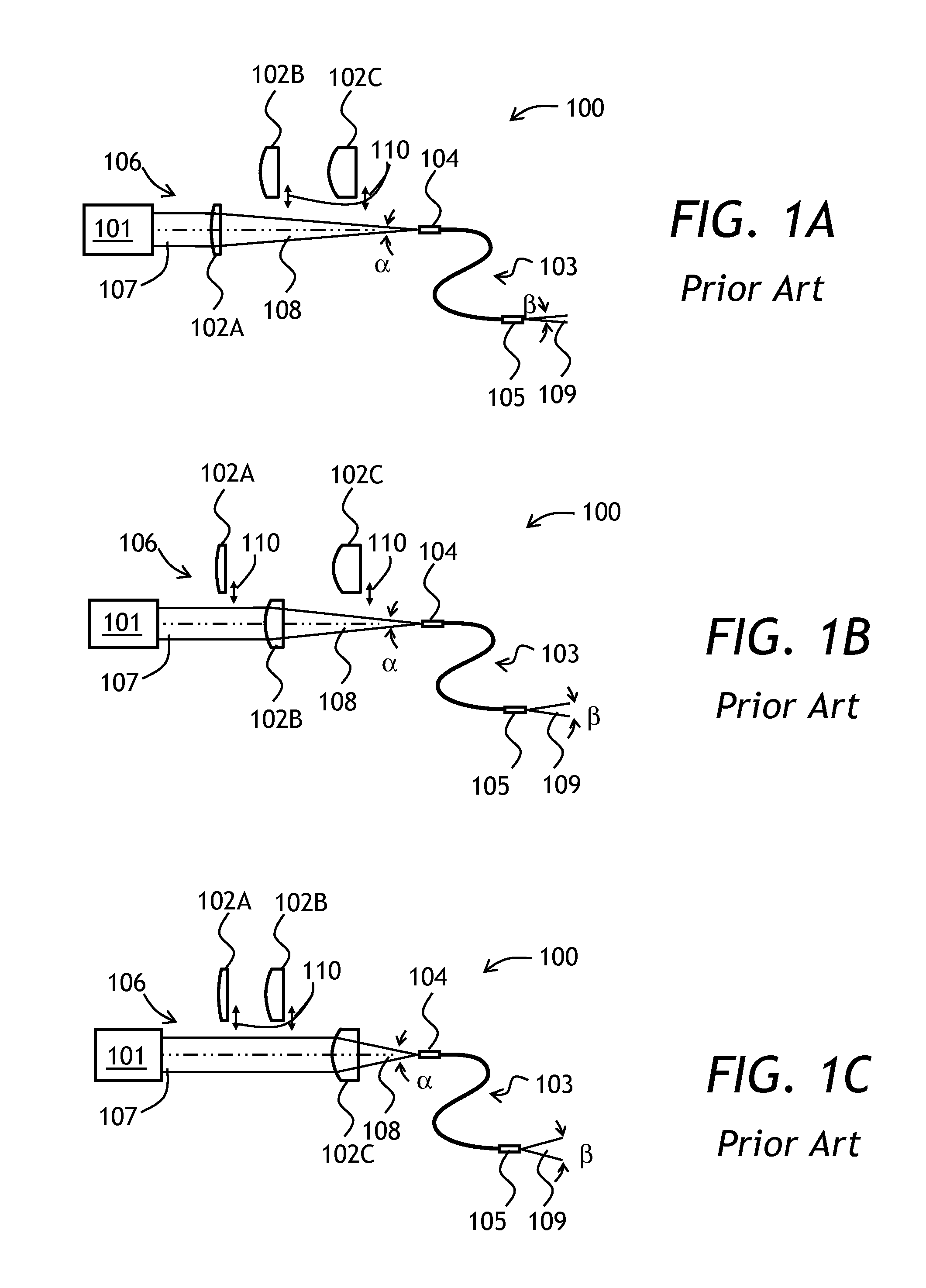

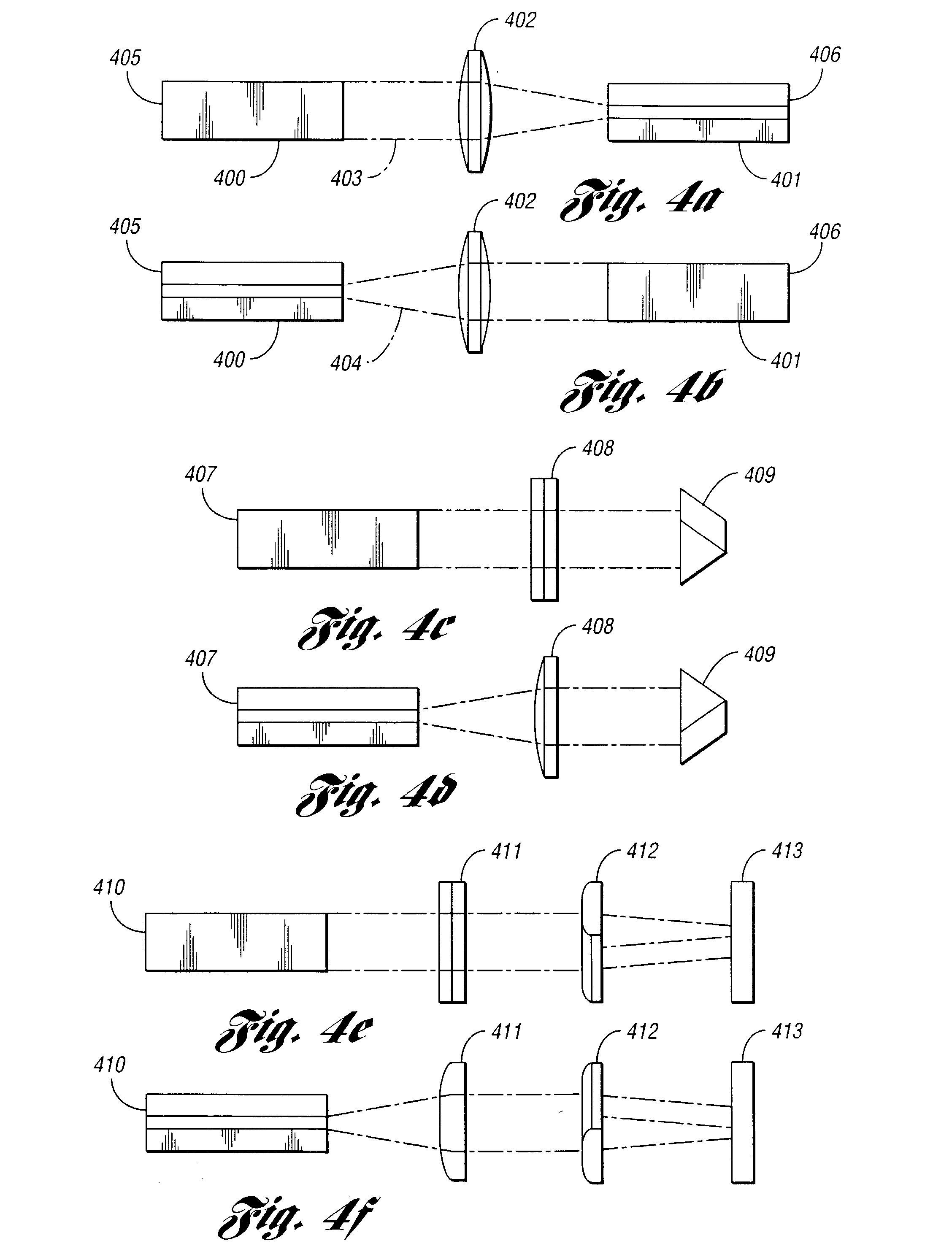

Waveguide architecture, waveguide devices for laser processing and beam control, and laser processing applications

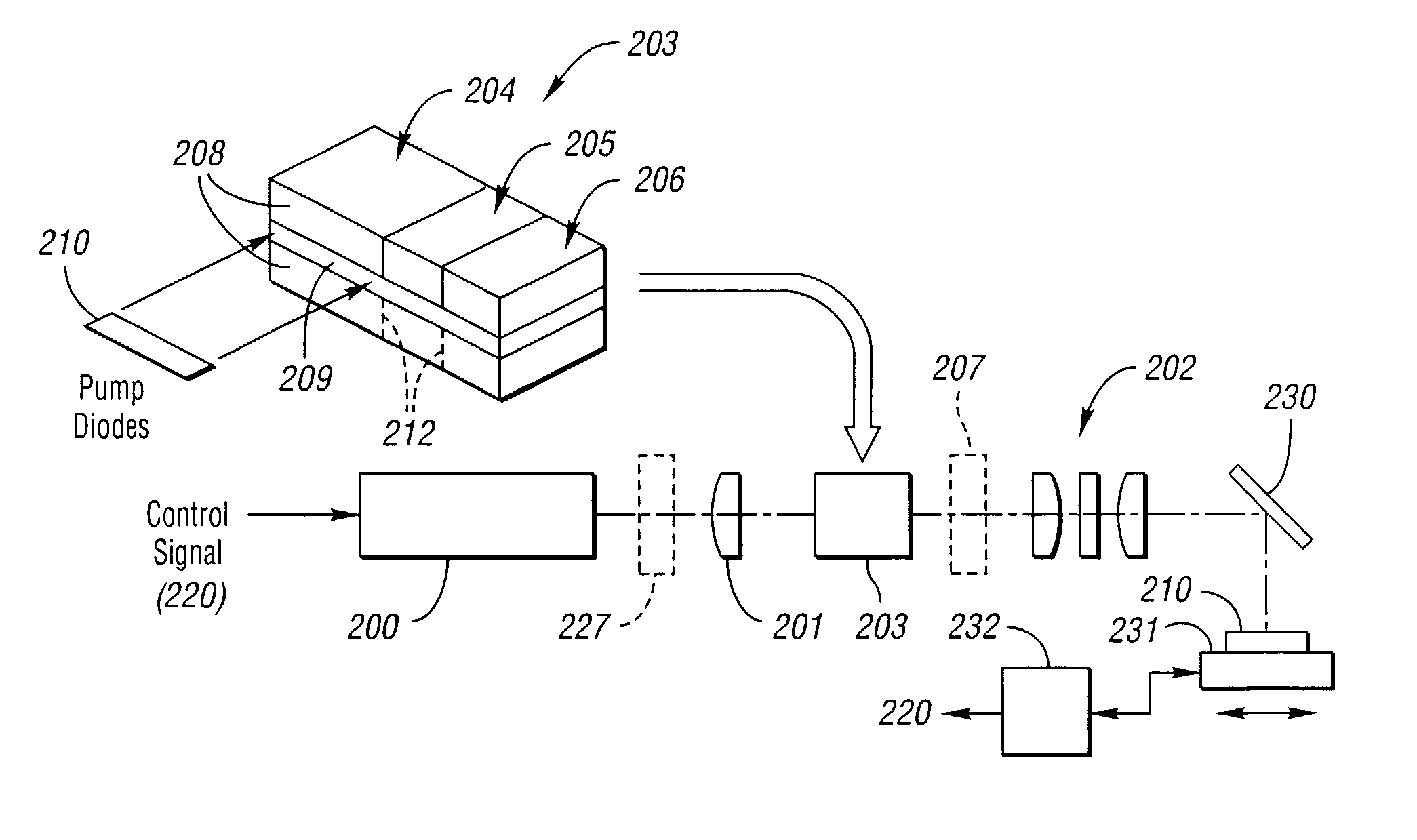

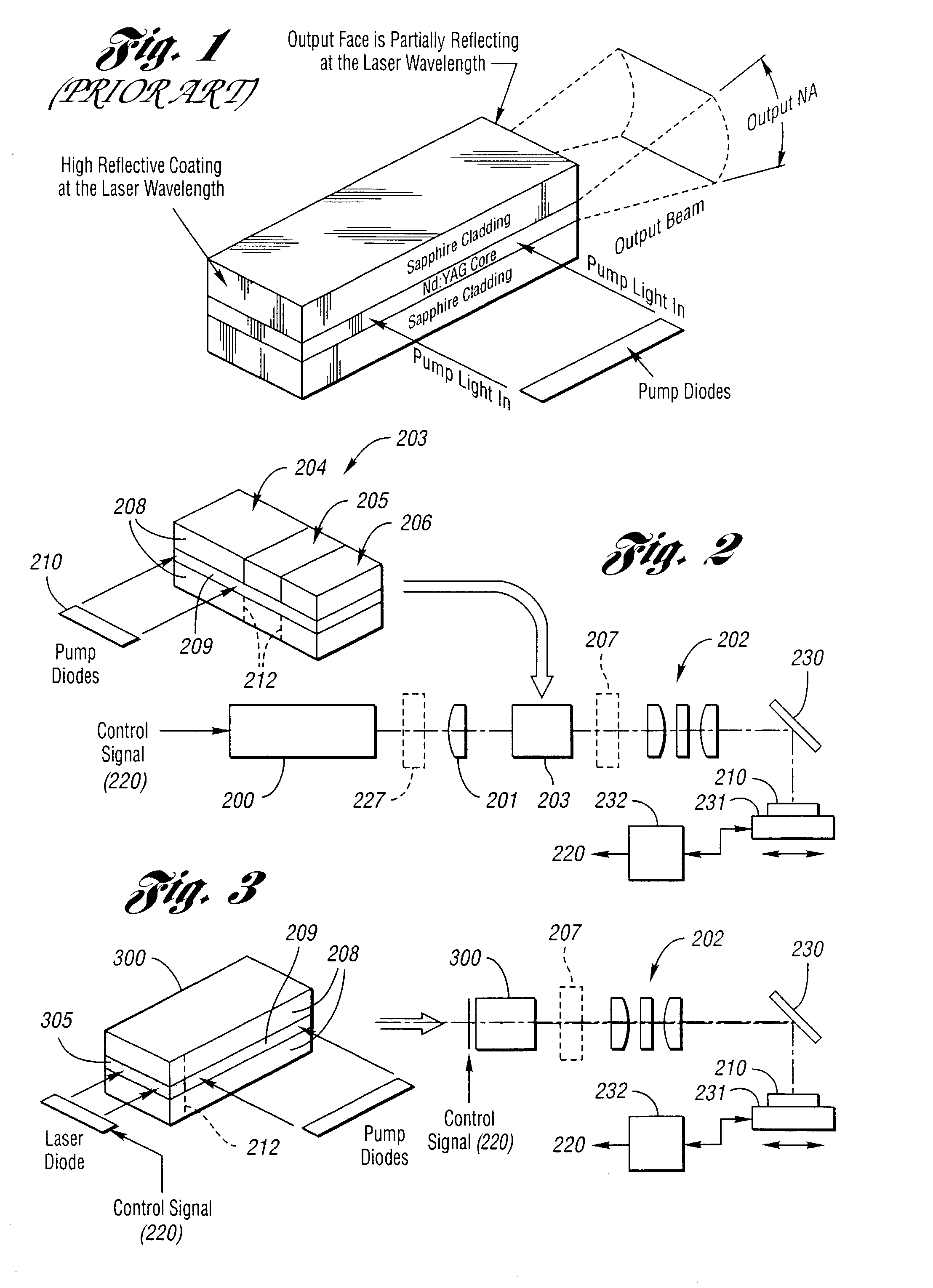

InactiveUS20030161375A1Optical resonator shape and constructionActive medium shape and constructionEngineeringWaveguide

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:GSI LUMONICS LTD

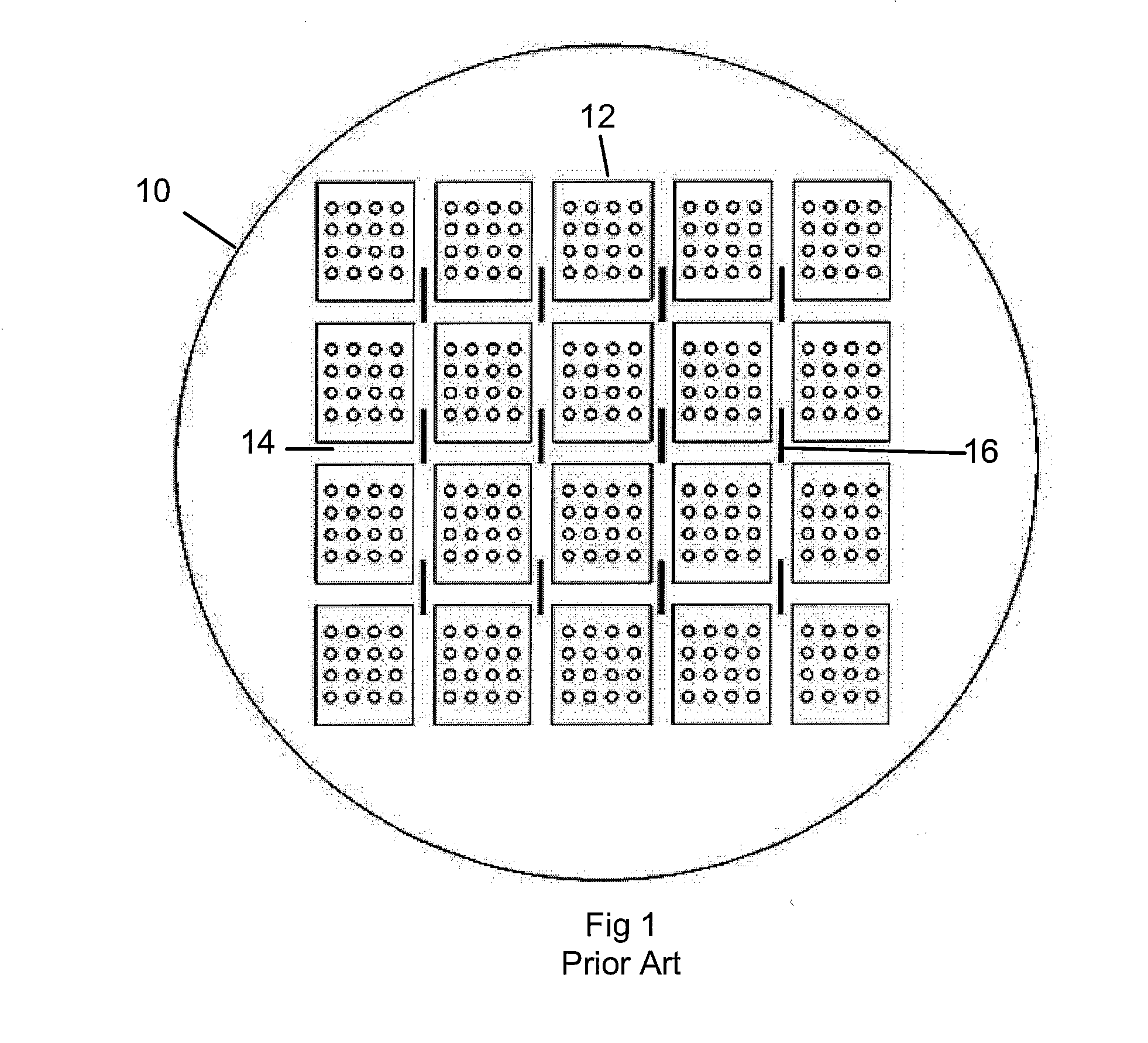

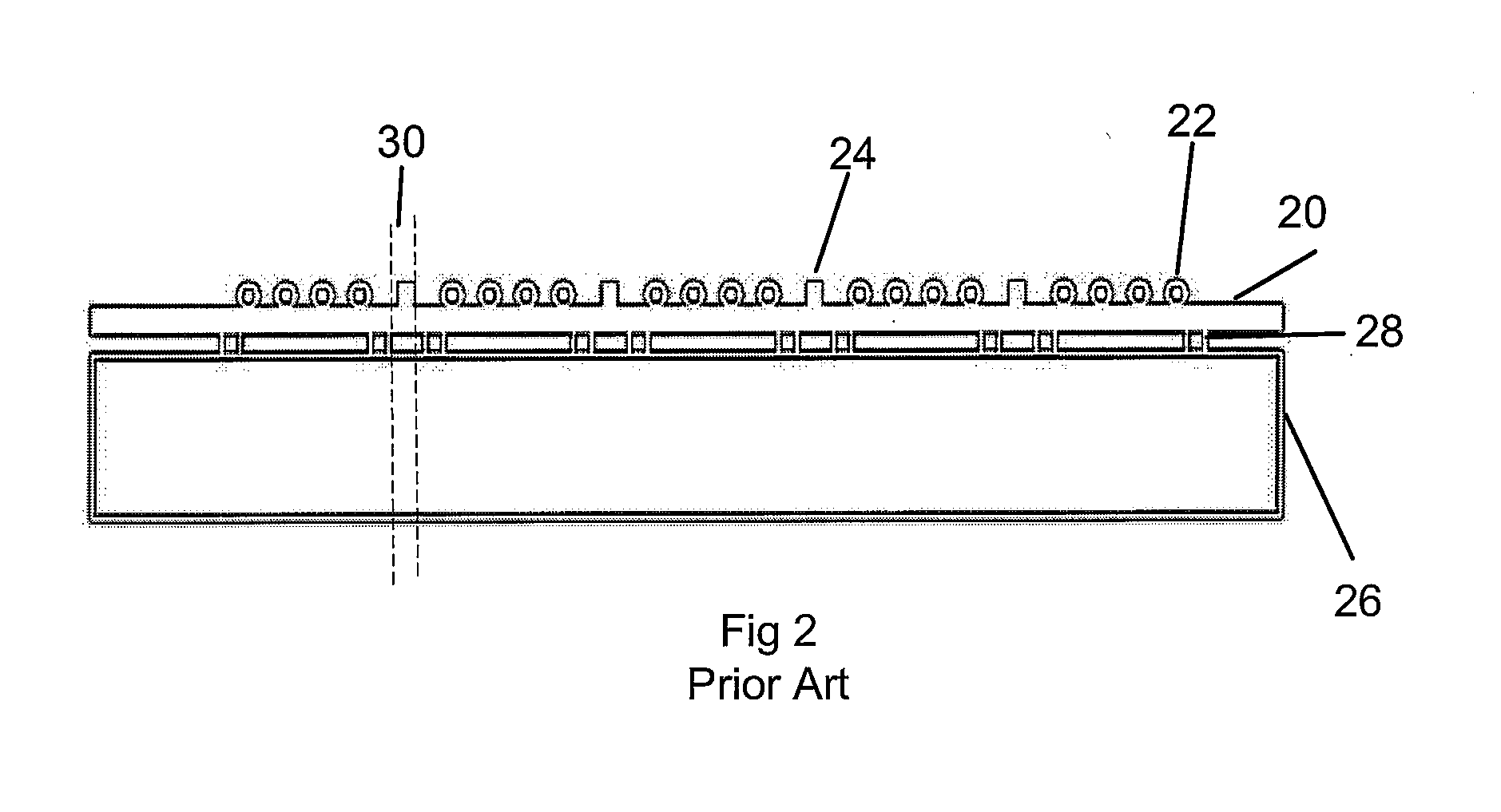

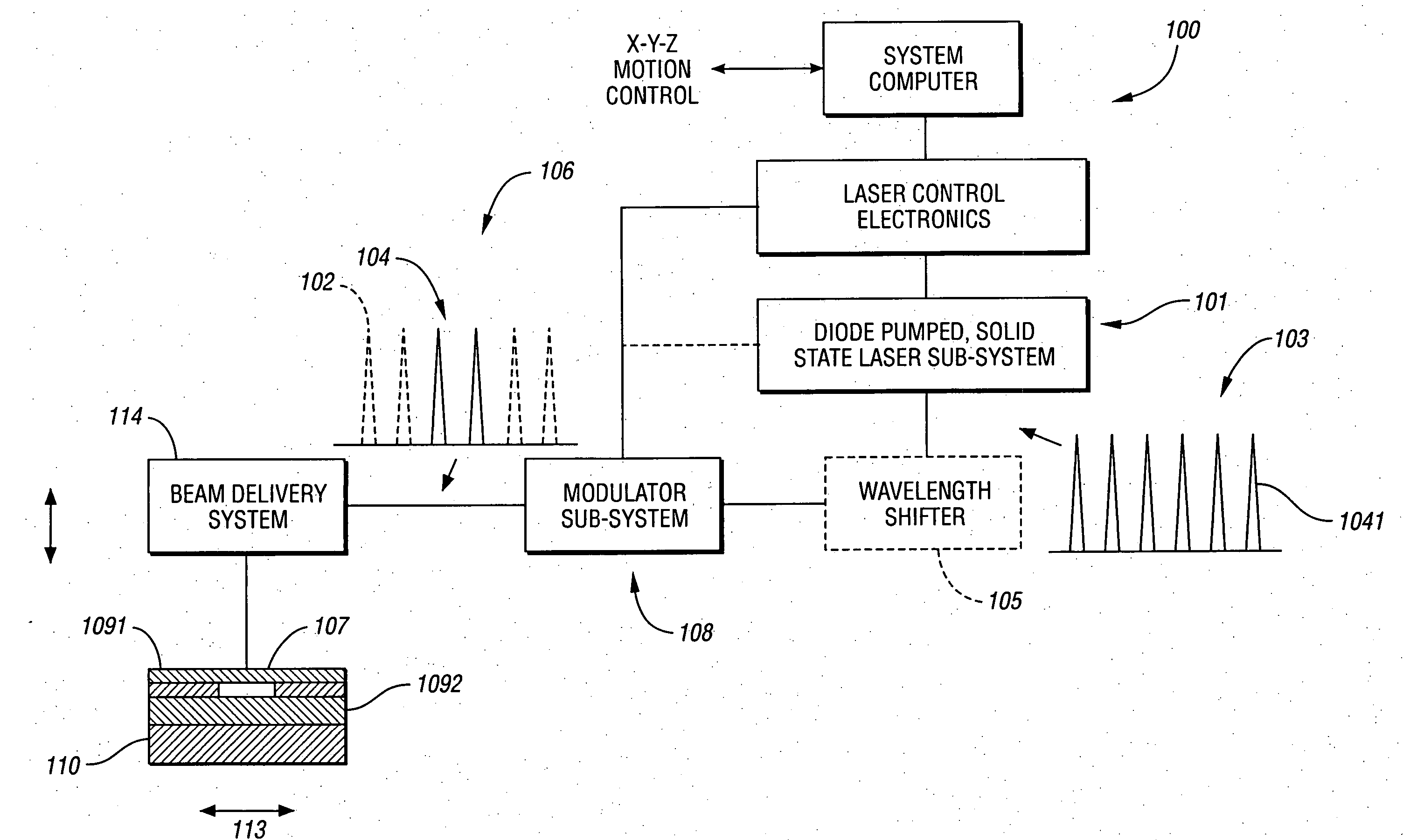

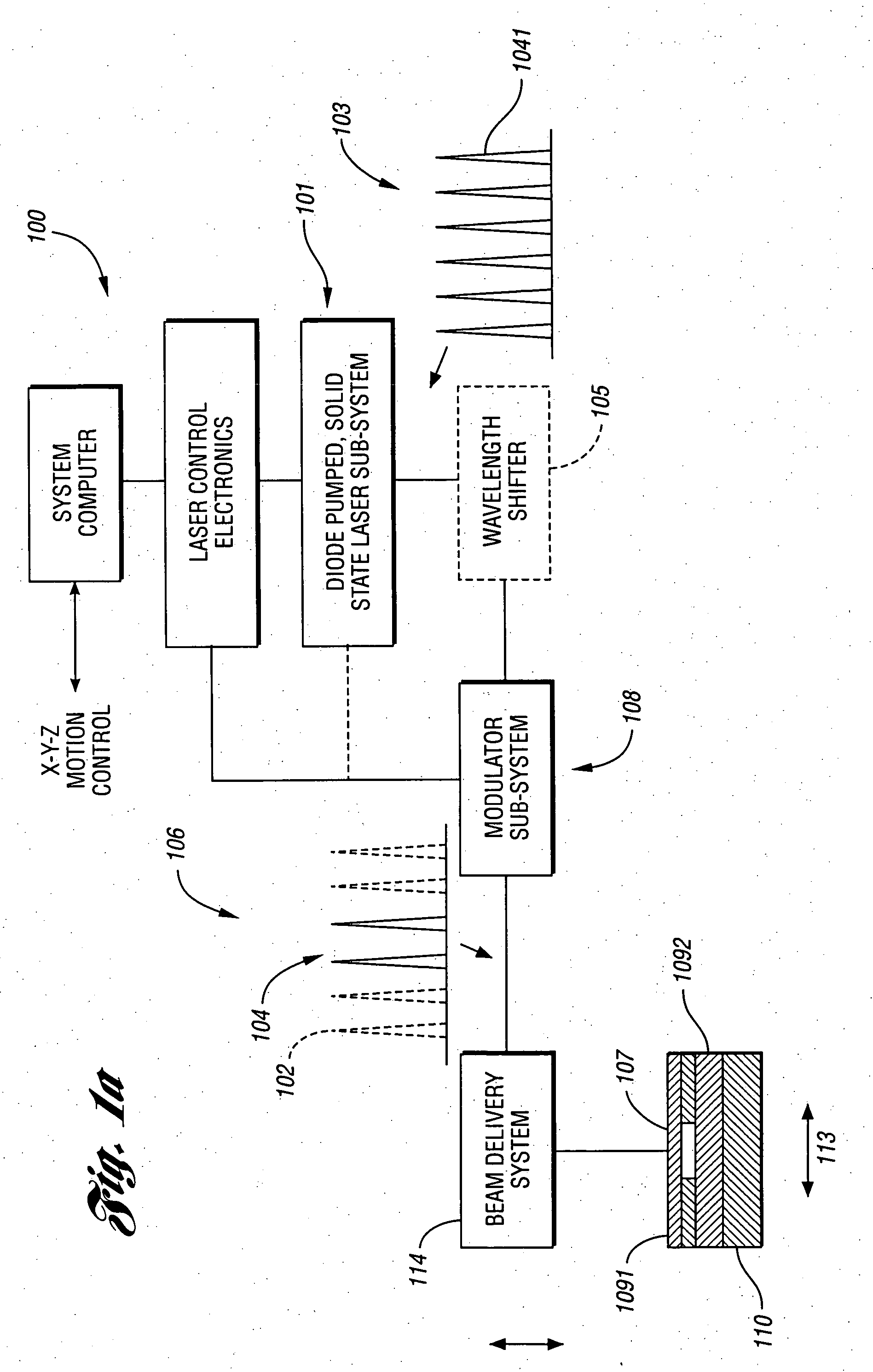

Laser-based method and system for memory link processing with picosecond lasers

InactiveUS20040134896A1Quality improvementSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsPicosecond laserNanosecond

A laser-based method of removing a target link structure of a circuit fabricated on a substrate includes generating a pulsed laser output at a pre-determined wavelength less than an absorption edge of the substrate. The laser output includes at least one pulse having a pulse duration in the range of about 10 picoseconds to less than 1 nanosecond, the pulse duration being within a thermal laser processing range. The method also includes delivering and focusing the laser output onto the target link structure. The focused laser output has sufficient power density at a location within the target structure to reduce the reflectivity of the target structure and efficiently couple the focused laser output into the target structure to remove the link without damaging the substrate.

Owner:ELECTRO SCI IND INC

Method of wafer laser processing using a gas permeable protective tape

ActiveUS7435607B2Exclude influenceDecline in wafer holding force is eliminatedSolid-state devicesSemiconductor/solid-state device manufacturingLaser processingPulsed laser beam

A laser processing method for forming a deteriorated layer, which has been once molten and then re-solidified, in the inside of a wafer by applying a pulse laser beam capable of passing through the wafer to the wafer along a dividing line formed on the wafer, comprising: a protective tape affixing step for affixing a protective tape having gas permeability to one side of the wafer; a wafer holding step for holding the wafer having the protective tape affixed thereto on the chuck table of a laser beam machine in such a manner that the surface side onto which the protective tape has been affixed comes into contact with the chuck table; and a laser beam application step for applying a pulse laser beam capable of passing through the wafer from the other surface side of the wafer held on the chuck table with its focusing point set to a position near the one surface of the wafer to form the deteriorated layer exposed to the one surface along the dividing line in the inside of the wafer.

Owner:DISCO CORP

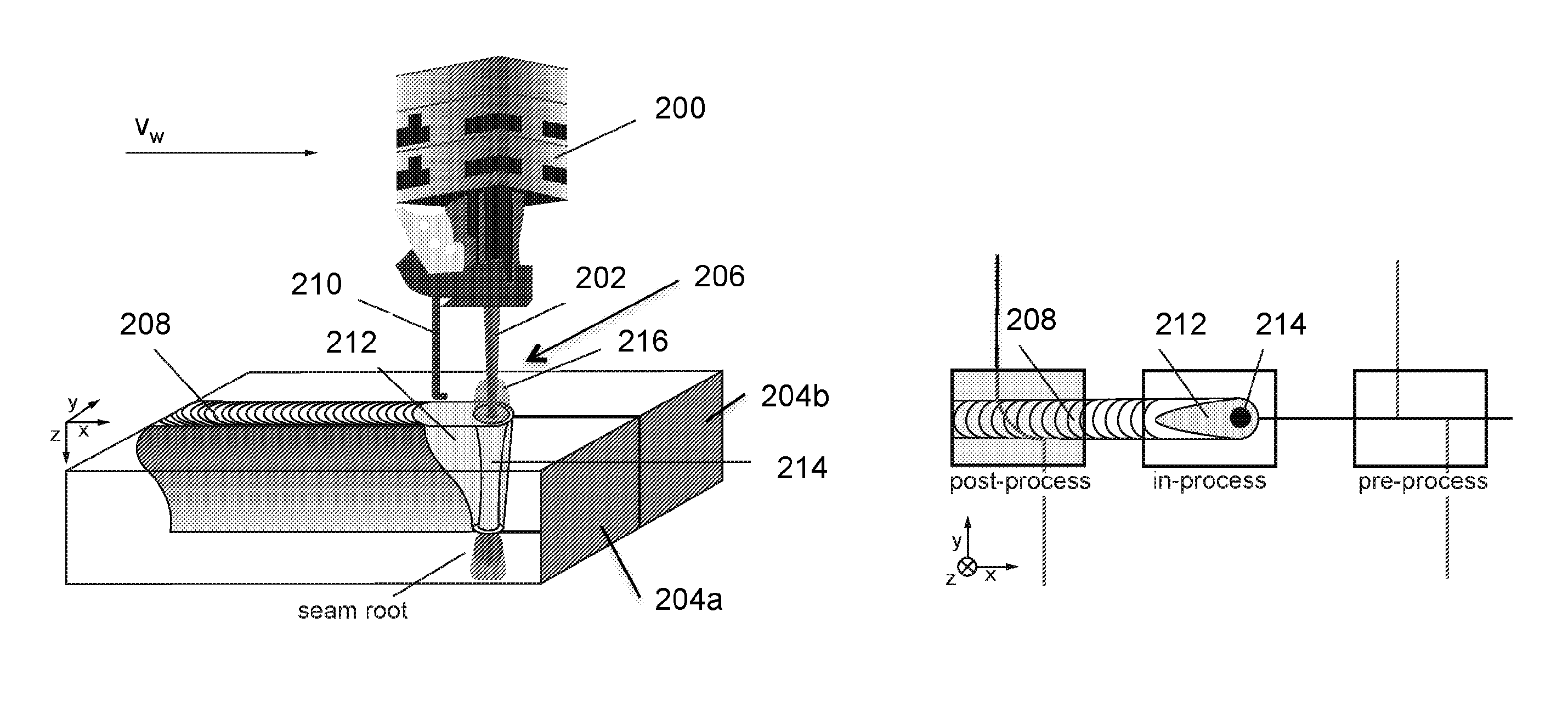

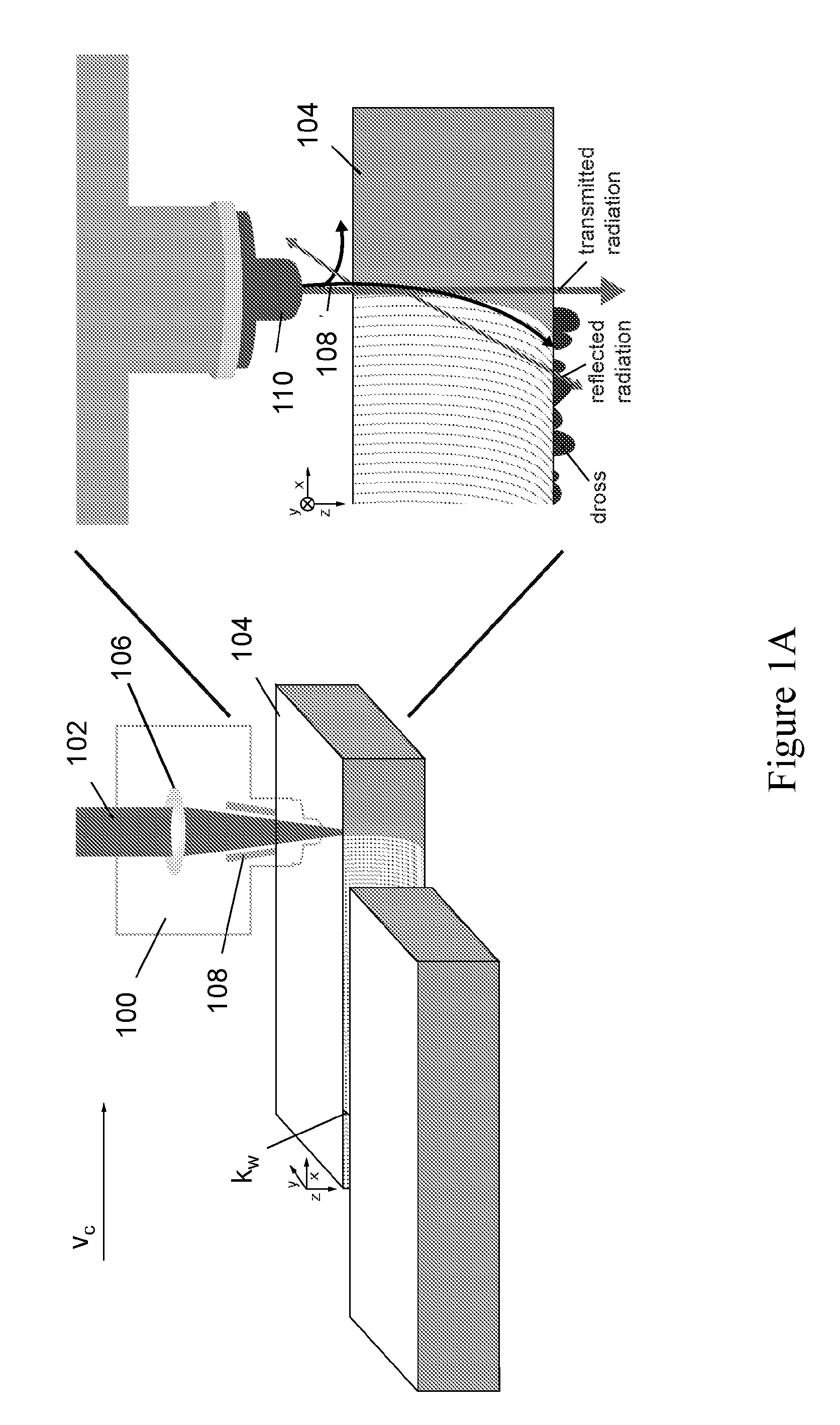

Method for closed-loop controlling a laser processing operation and laser material processing head using the same

ActiveUS20130178952A1Reliable detectionSimilar levelImage analysisSoldering apparatusLaser processingAlgorithm

The present invention relates to a method for closed-loop controlling a processing operation of a workpiece, comprising the steps of: (a) recording a pixel image at an initial time point of an interaction zone by means of a camera, wherein the workpiece is processed using an actuator having an initial actuator value; (b) converting the pixel image into a pixel vector; (c) representing the pixel vector by a sum of predetermined pixel mappings each multiplied by a corresponding feature value; (d) classifying the set of feature values on the basis of learned feature values into at least two classes of a group of classes comprising a first class of a too high actuator value, a second class of a sufficient actuator value and a third class of a too low actuator value at the initial time point; (e) performing a control step for adapting the actuator value by minimizing the error et between a quality indicator ye and a desired value; and (f) repeating the steps (a) to (e) for further time points to perform a closed-loop controlled processing operation.

Owner:PRECITEC GMBH +1

Laser processing method and chip

ActiveUS20100184271A1High precision cuttingPrecise cuttingSemiconductor/solid-state device manufacturingFine working devicesLaser processingLaser light

An object to be processed can be cut highly accurately along a line to cut.An object to be processed 1 is irradiated with laser light while locating a converging point within a silicon wafer 11, and the converging point is relatively moved along a line to cut 5, so as to form modified regions M1, M2 positioned within the object 1 along the line to cut 5, and then a modified region M3 positioned between the modified regions M1, M2 within the object 1.

Owner:HAMAMATSU PHOTONICS KK

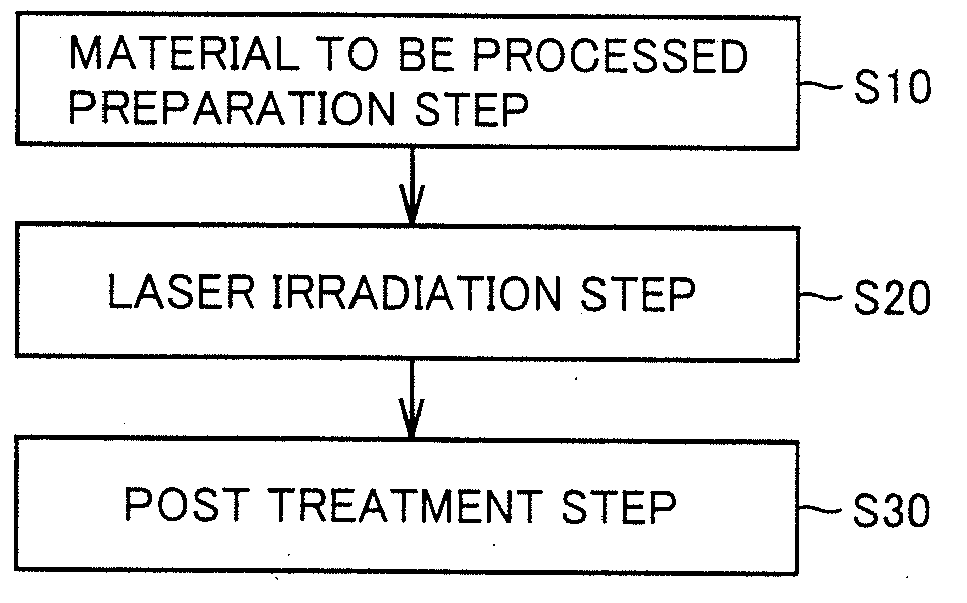

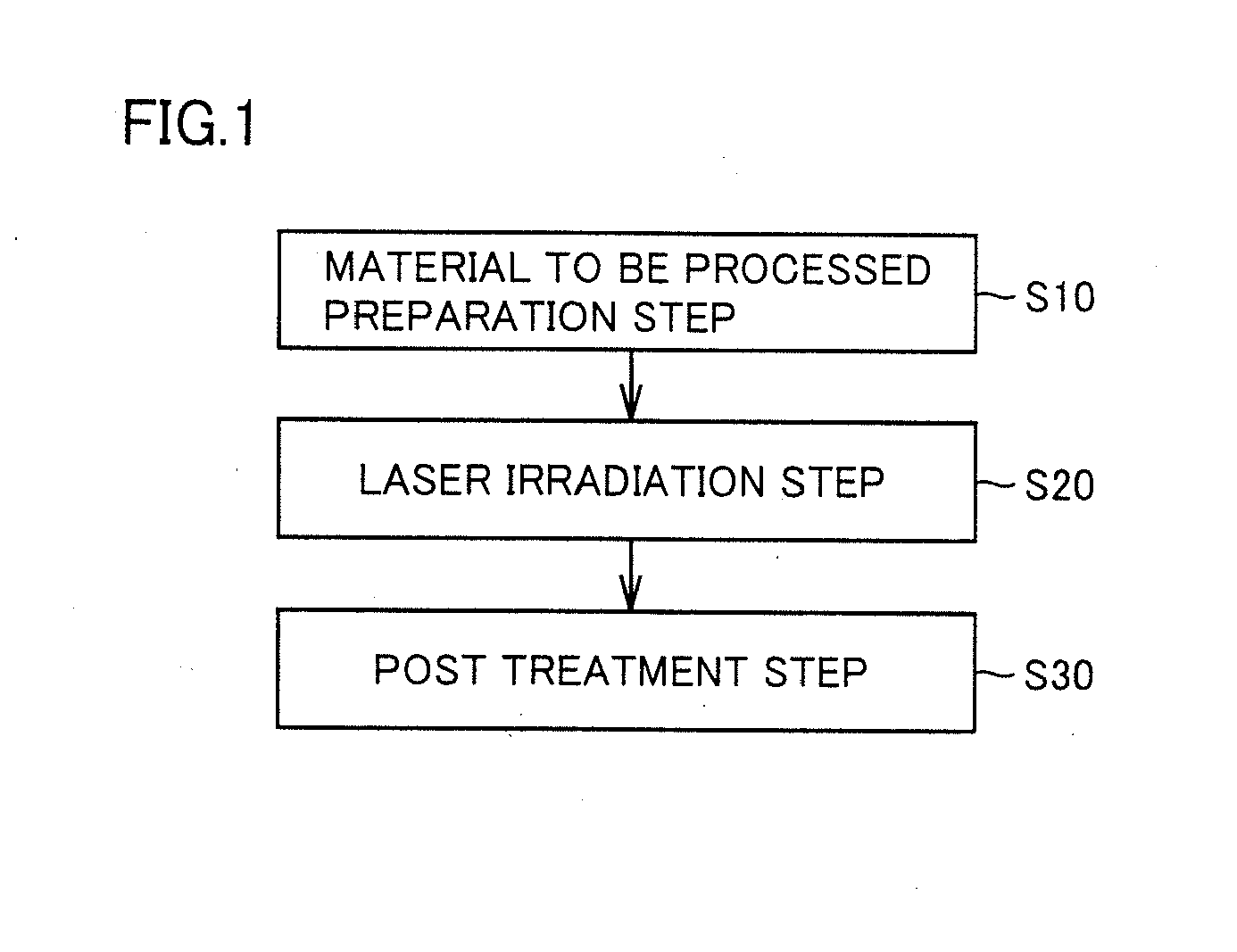

Laser processing method

ActiveUS20120255935A1Good body shapeReduce processing costsSemiconductor/solid-state device manufacturingFine working devicesLaser processingOptoelectronics

There is obtained a laser processing method by which an excellent shape of a cut surface can be achieved and an increase in cost can be suppressed. A laser processing method includes the steps of: preparing a material to be processed; and forming a modified area in the material to be processed, by irradiating the material to be processed with laser beam. In the aforementioned step, pulsed laser beam having a continuous spectrum is focused with a lens, thereby forming a focusing line constituted by a plurality of focuses that are obtained by predetermined bands forming the continuous spectrum of the laser beam, and the material to be processed is irradiated with the laser beam such that at least a part of the focusing line is located on a surface of the material to be processed, thereby forming the modified area on an axis of the focusing line.

Owner:SUMITOMO ELECTRIC IND LTD +1

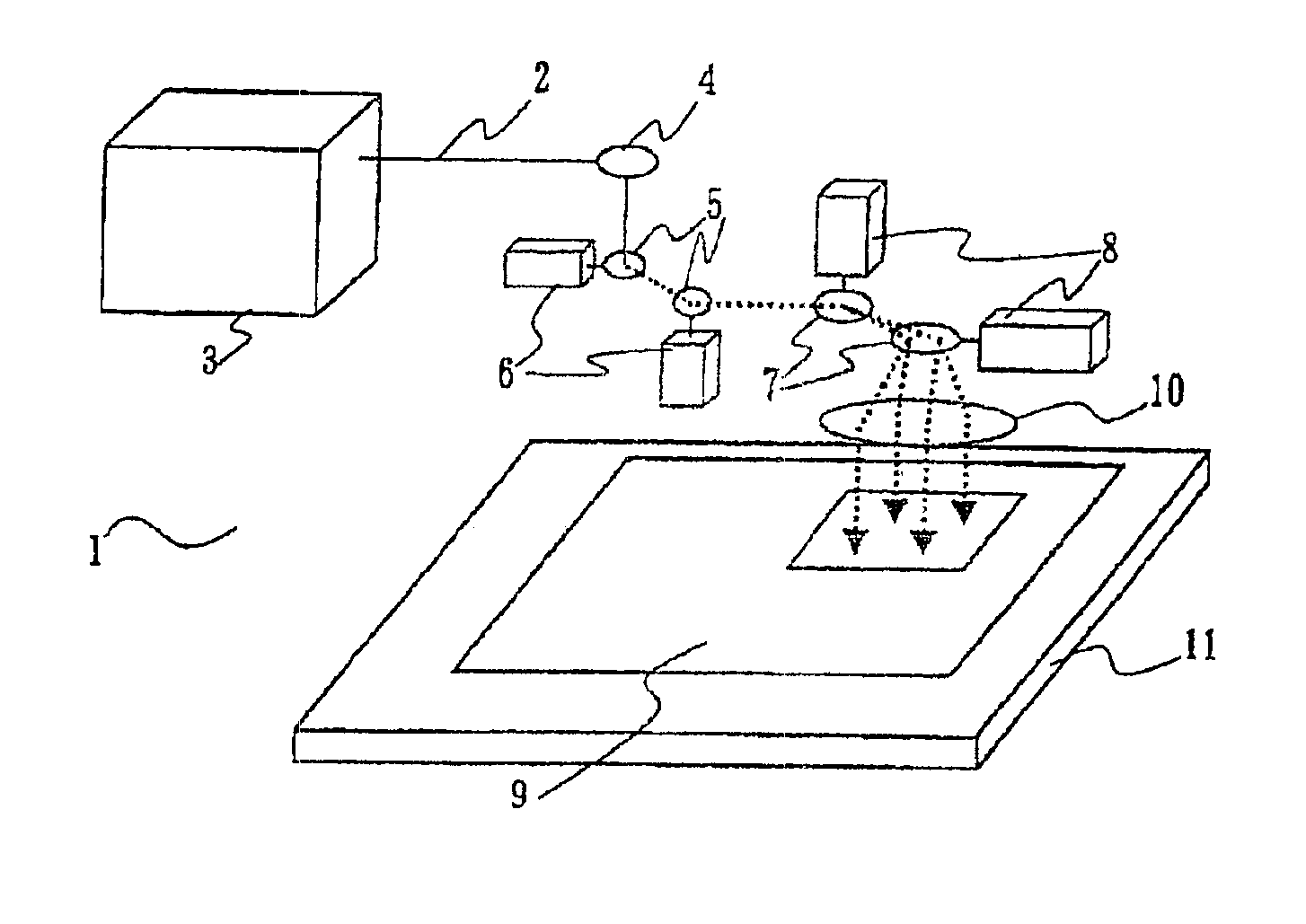

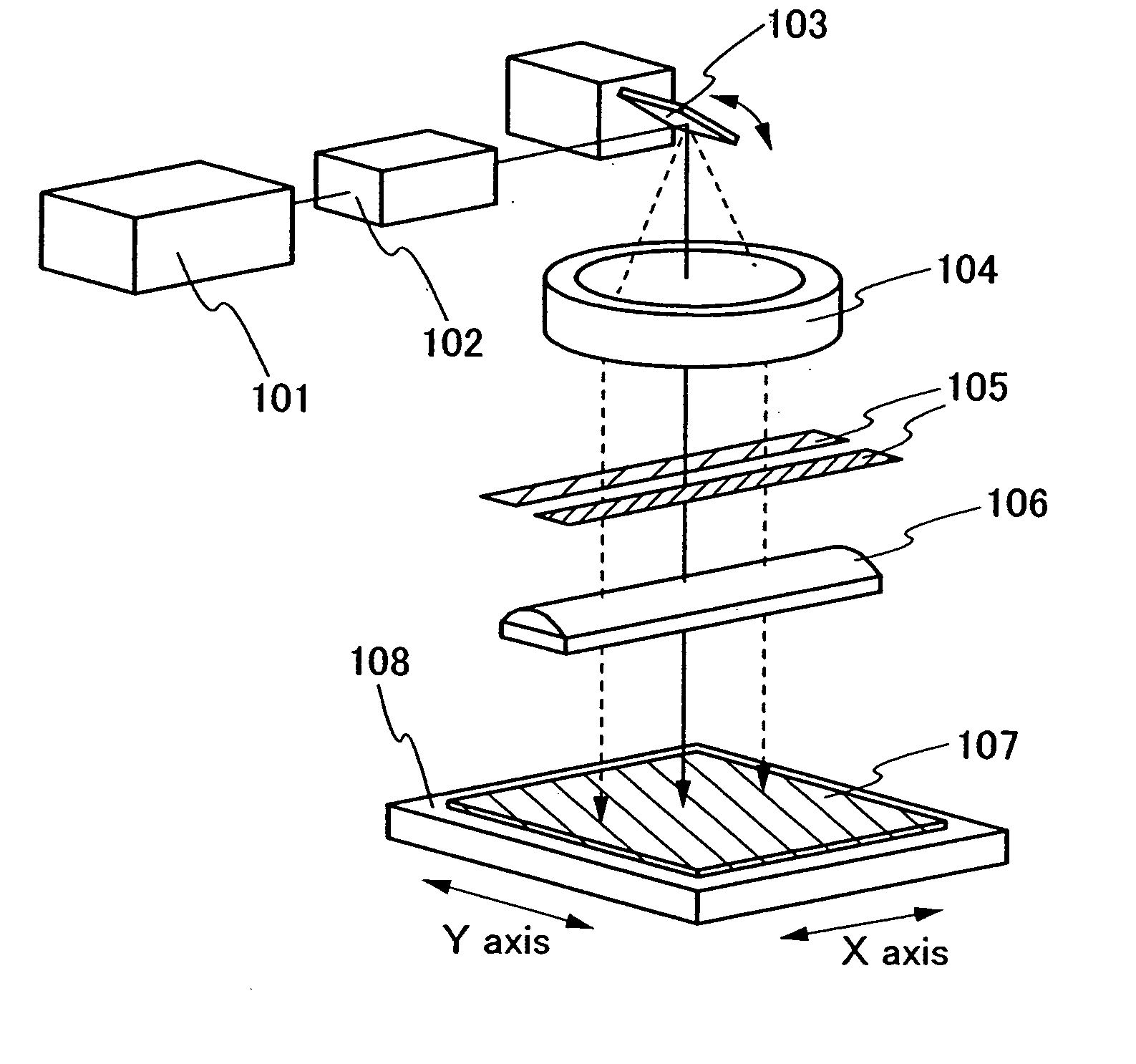

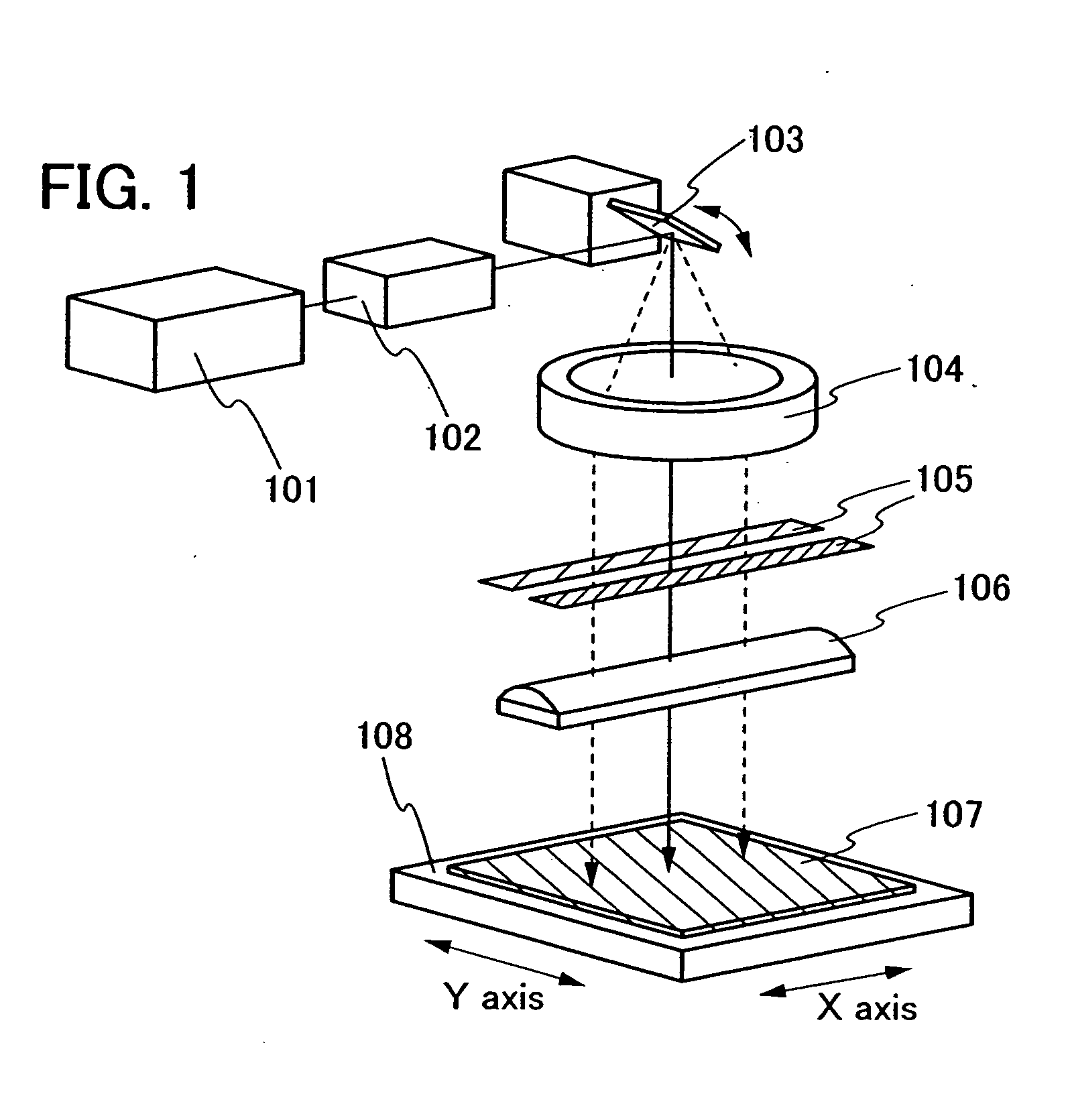

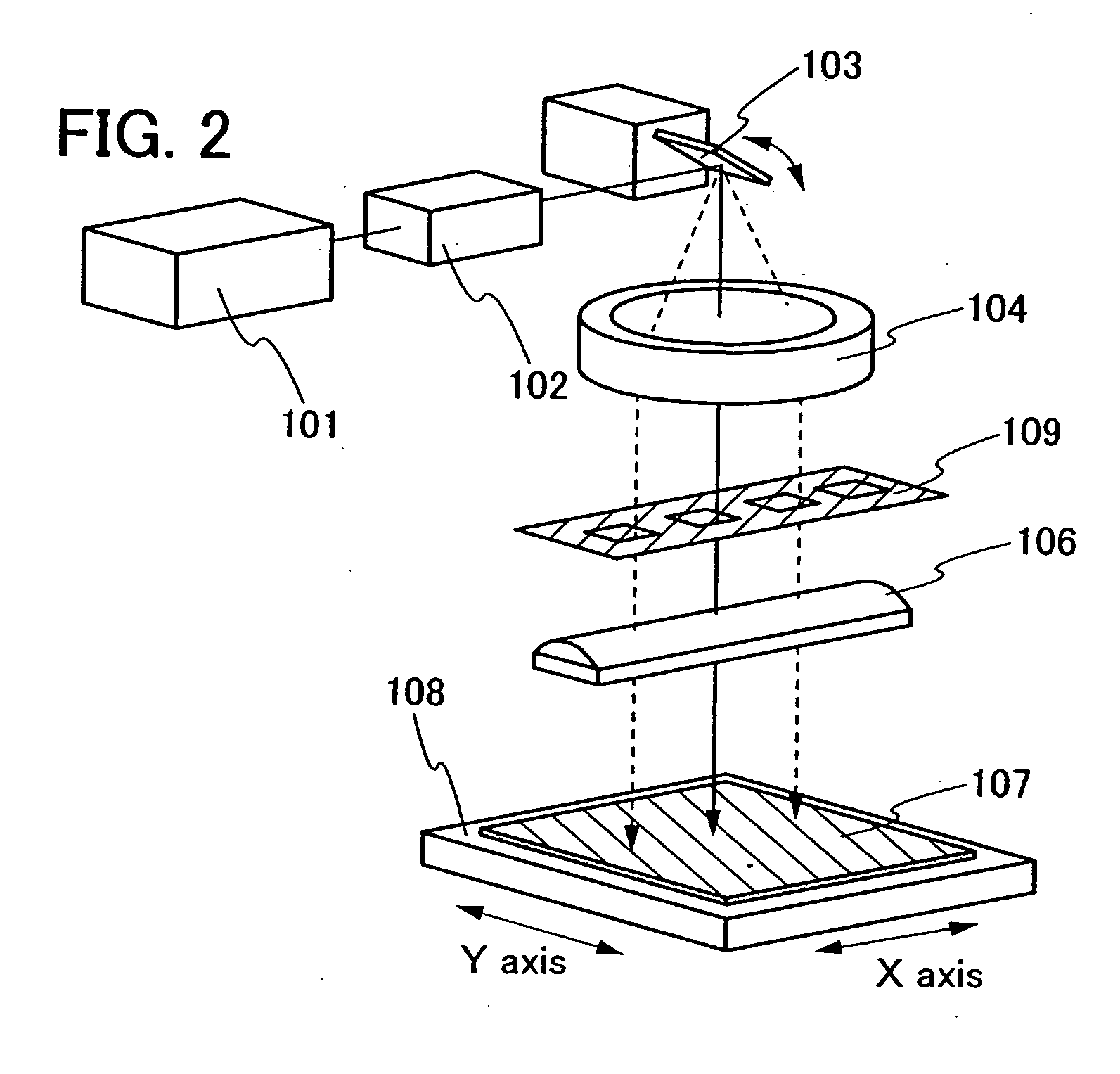

Laser irradiation apparatus, laser irradiation method, and manufacturing method of semiconductor device

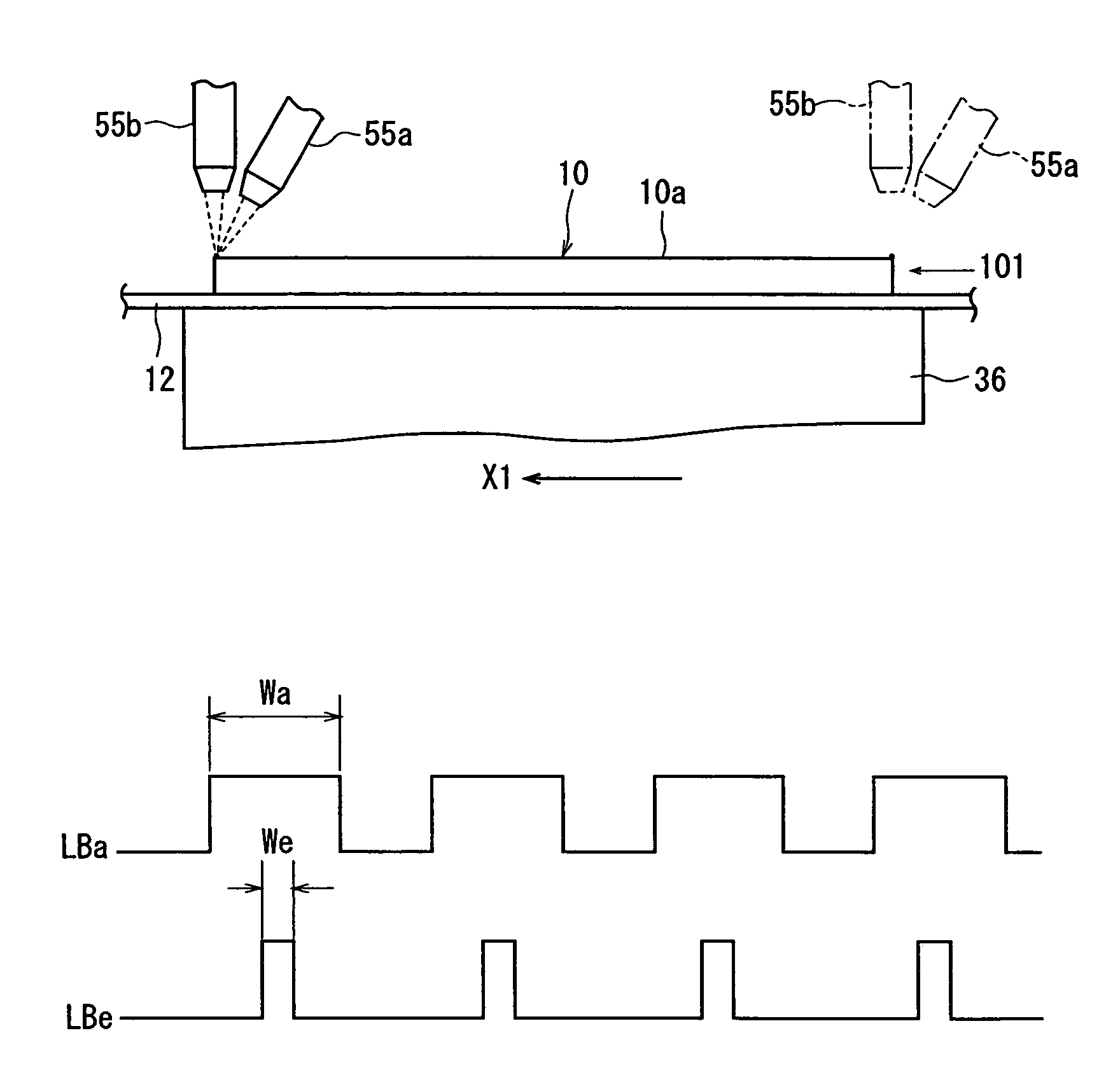

ActiveUS20070138151A1Facilitate conductionEasily projectedSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesLaser processingDevice material

To provide a laser irradiation apparatus and a laser irradiation method in which a region formed with microcrystals in a region irradiated with laser beams is decreased by disposing a slit in an optical system using a deflector, and laser processing can be favorably conducted to a semiconductor film. Further to provide a semiconductor manufacturing apparatus using the above-described laser irradiation apparatus and the laser irradiation method. In the optical system, an f-θ lens having an image space telecentric characteristic or a slit the shape of which is changed in accordance with the incidence angle of a laser beam, is used. The slit is disposed between the f-θ lens and an irradiation surface, and an image at a slit opening portion is projected onto the irradiation surface by a projection lens. By the above-described structure, laser irradiation can be uniformly conducted to a whole region scanned with laser beams.

Owner:SEMICON ENERGY LAB CO LTD

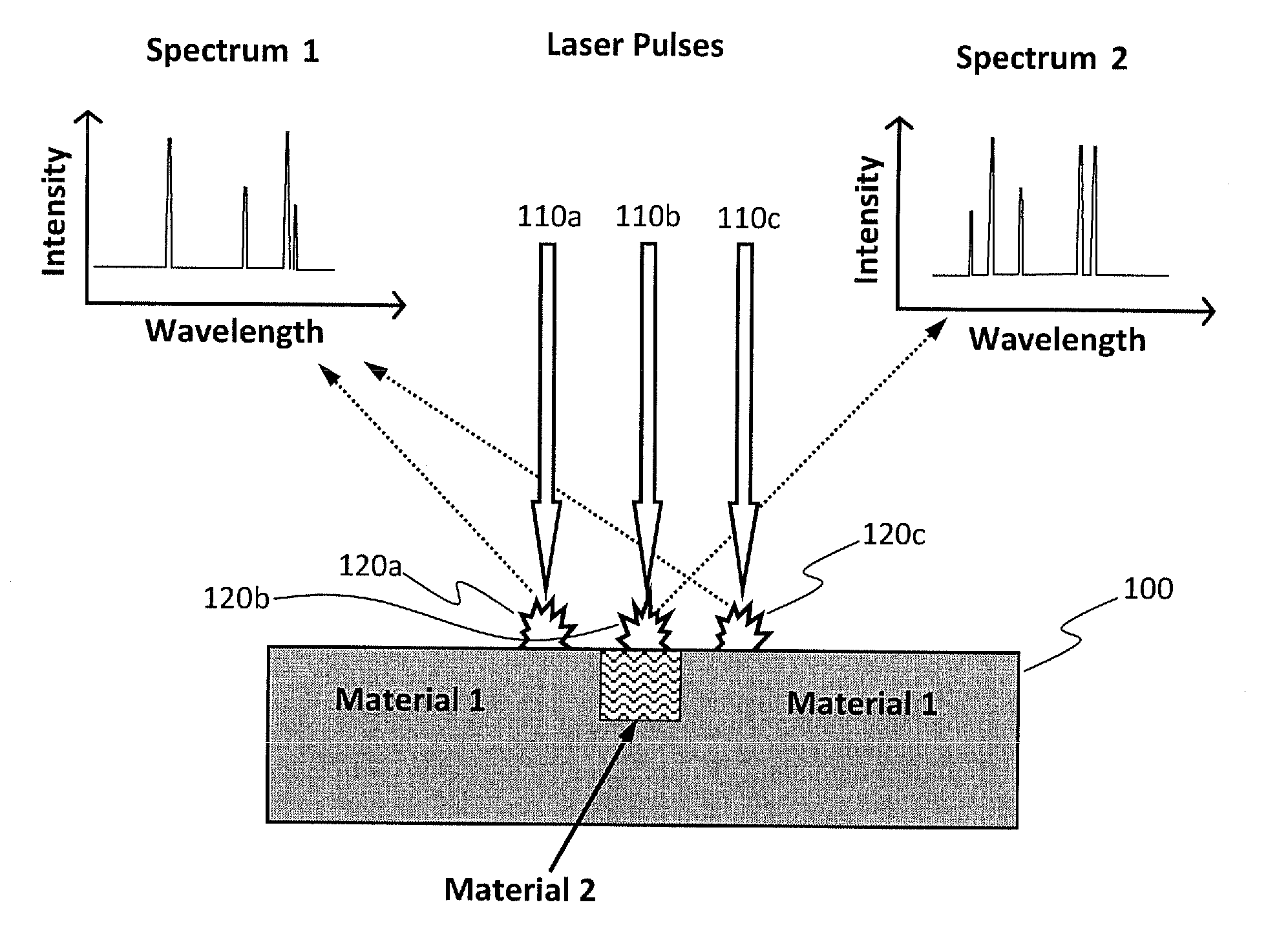

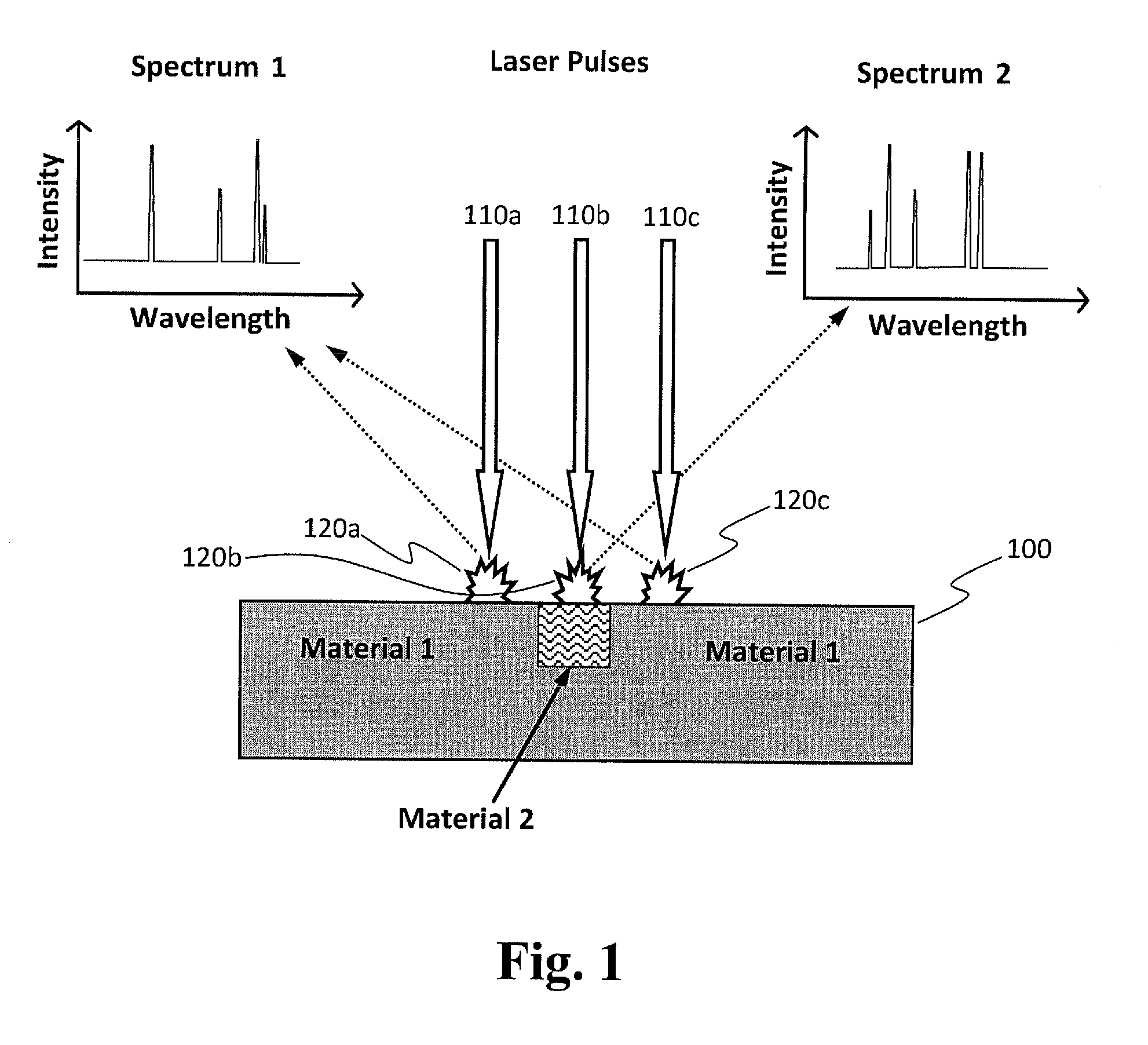

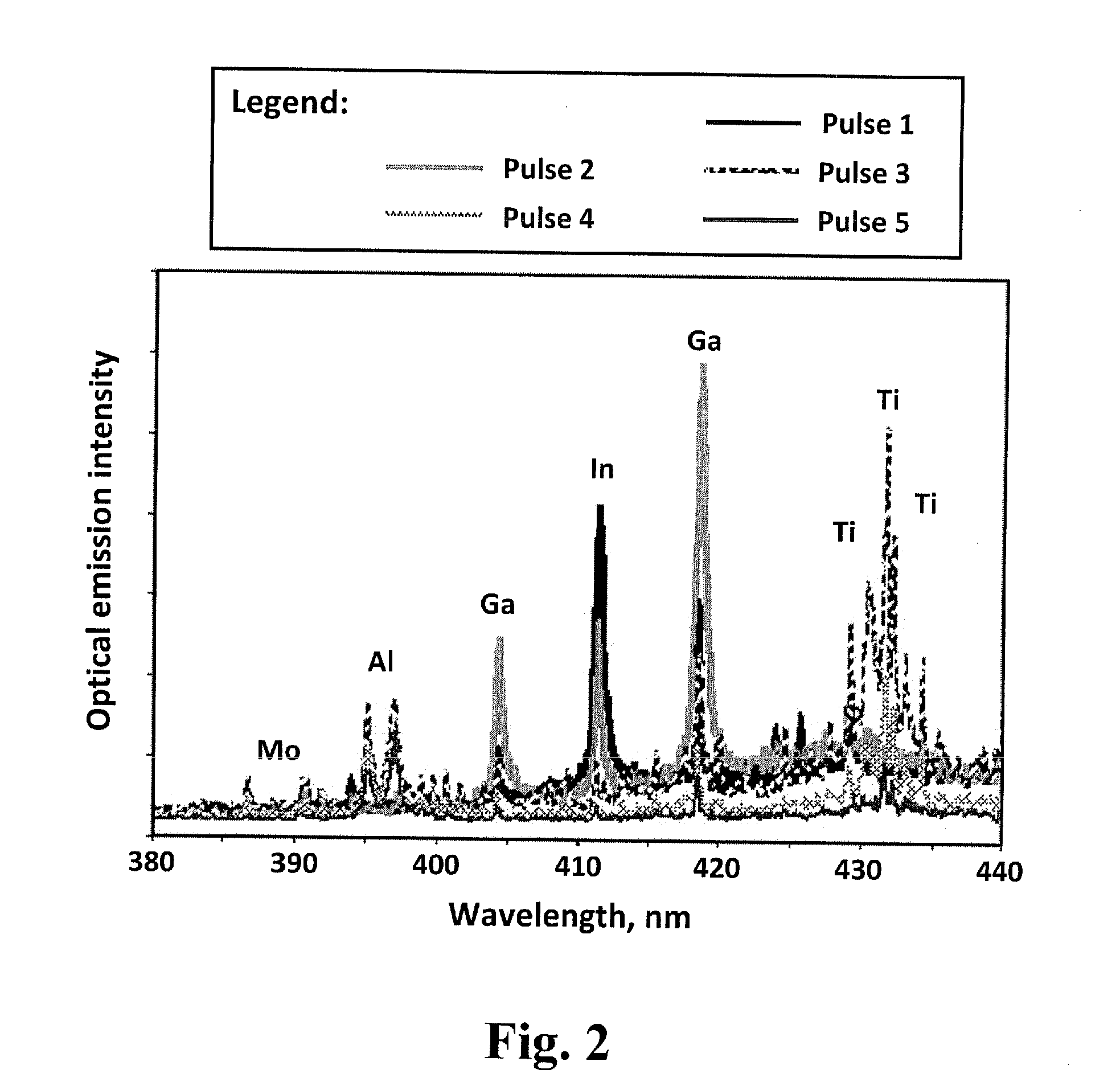

Method for real-time optical diagnostics in laser ablation and laser processing of layered and structured materials

ActiveUS20110100967A1Strong specificityImprove efficiencyMaterial analysis by electric/magnetic meansLaser beam welding apparatusLaser processingOptical diagnostics

A method for real-time optical diagnostics in laser ablation and laser processing of layered or structured materials or material structures. Diagnostics is provided during laser ablation that is utilized regularly in laser processing and / or chemical analysis of structured materials, by means of measuring optical emission generated as a result of the pulsed laser-material interaction in real time. The method can involve a single-layer-film or a stack of multiple layers or a structure of different domains. The method is particularly beneficial in fabrication of thin-film structures, such as photovoltaic and electronic devices or circuits of devices.

Owner:APPLIED SPECTRA

Varying beam parameter product of a laser beam

An optical delivery waveguide for a material laser processing system includes a small lens at an output end of the delivery waveguide, transforming laser beam divergence inside the waveguide into a spot size after the lens. By varying the input convergence angle and / or launch angle of the laser beam launched into the waveguide, the output spot size can be continuously varied, thus enabling a continuous and real-time laser spot size adjustment on the workpiece, without having to replace the delivery waveguide or a process head. A divergence of the laser beam can also be adjusted dynamically and in concert with the spot size.

Owner:LUMENTUM OPERATIONS LLC

Laser processing for heat-sensitive mesoscale deposition

InactiveUS7294366B2Low damage thresholdElectric discharge heatingRadiation applicationsLaser processingHeat sensitive

A method of depositing various materials onto heat-sensitive targets. Heat-sensitive targets are generally defined as targets that have thermal damage thresholds that are lower than the temperature required to process a deposited material. The invention uses precursor solutions and / or particle or colloidal suspensions, along with optional pre-deposition treatment and / or post-deposition treatment to lower the laser power required to drive the deposit to its final state. The present invention uses Maskless Mesoscale Material Deposition (M3D™) to perform direct deposition of material onto the target in a precise, highly localized fashion. Features with linewidths as small as 4 microns may be deposited, with little or no material waste. A laser is preferably used to heat the material to process it to obtain the desired state, for example by chemical decomposition, sintering, polymerization, and the like. This laser processing may be performed in an ambient environment with laser powers of less than 100 milliwatts.

Owner:OPTOMEC DESIGN CO

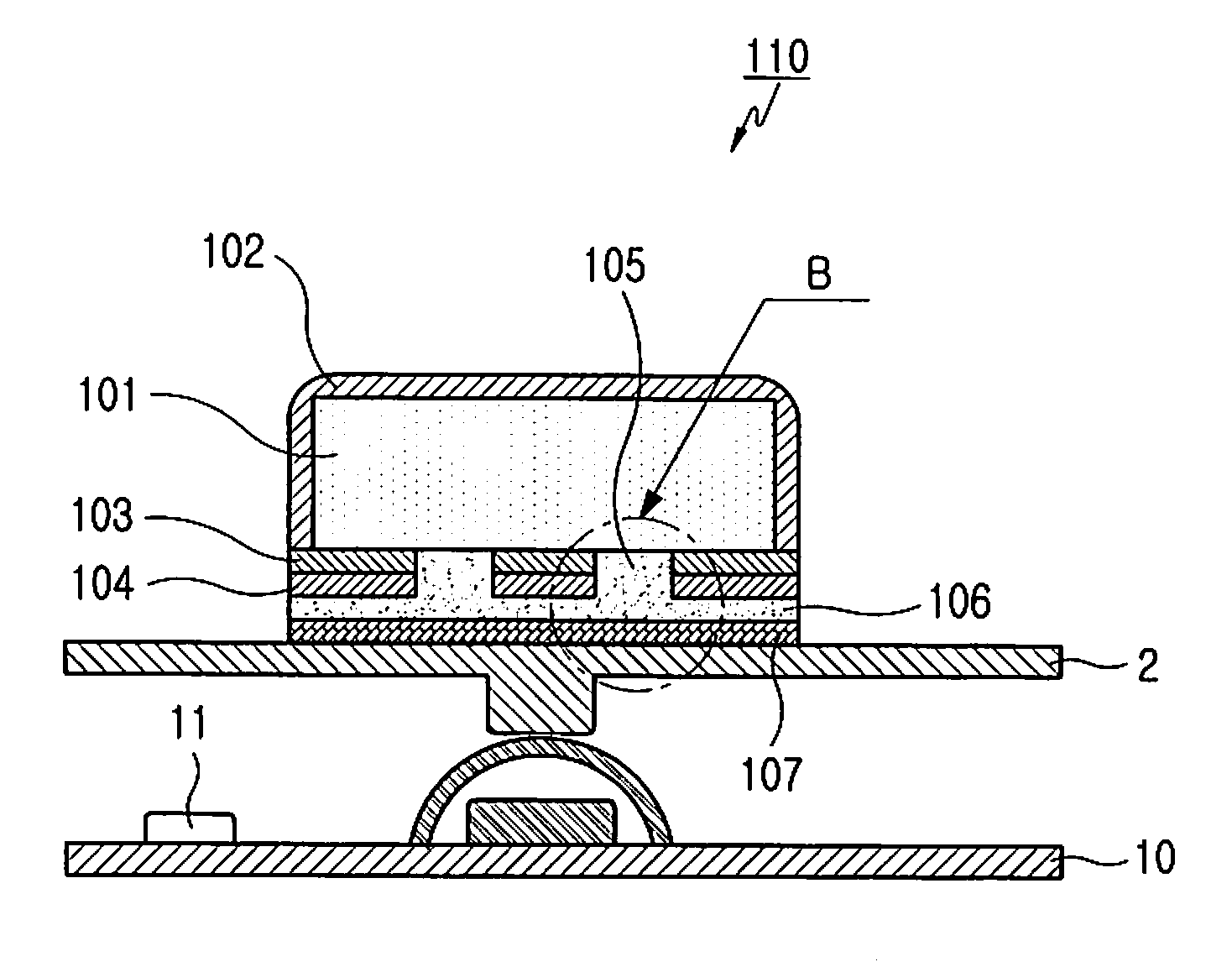

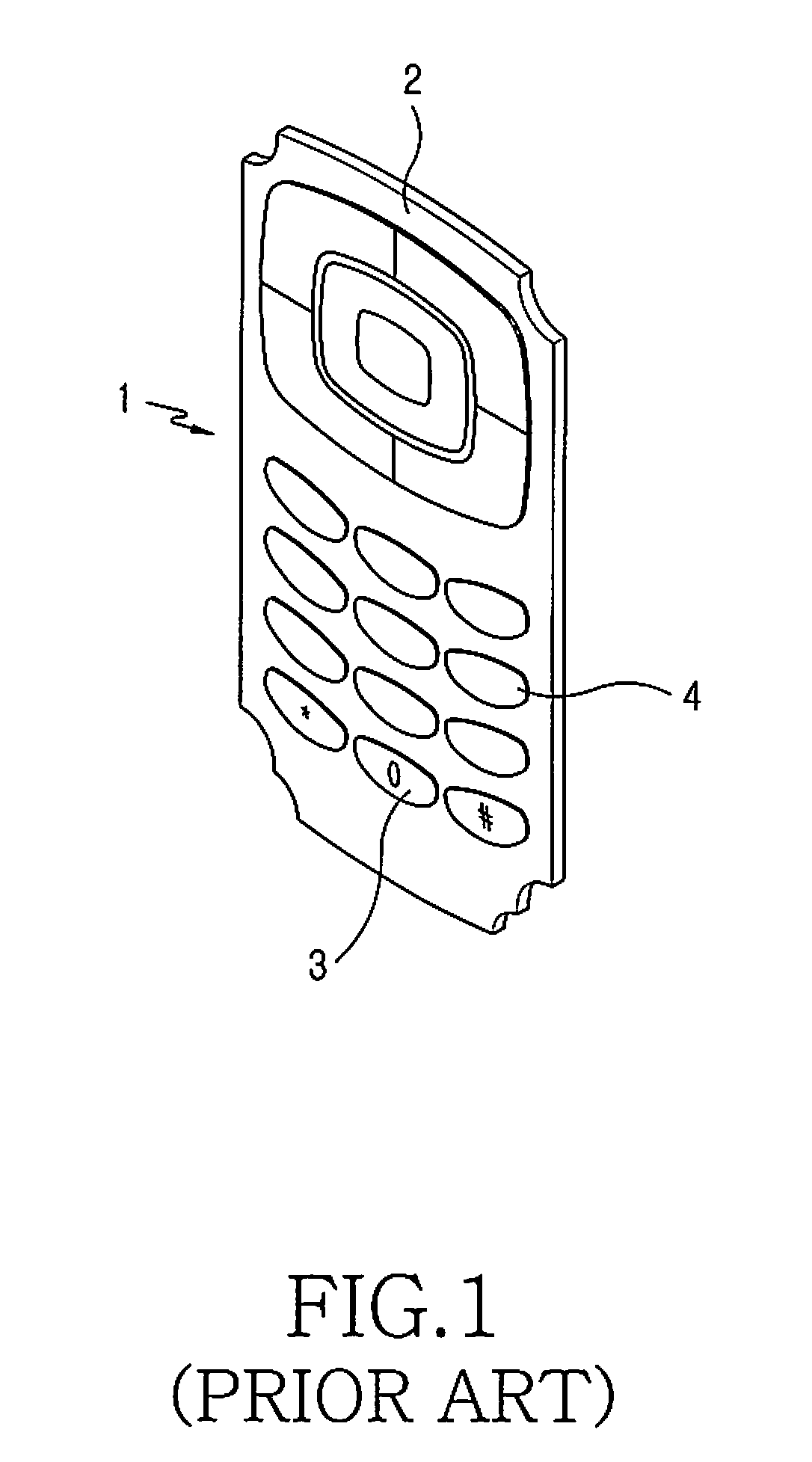

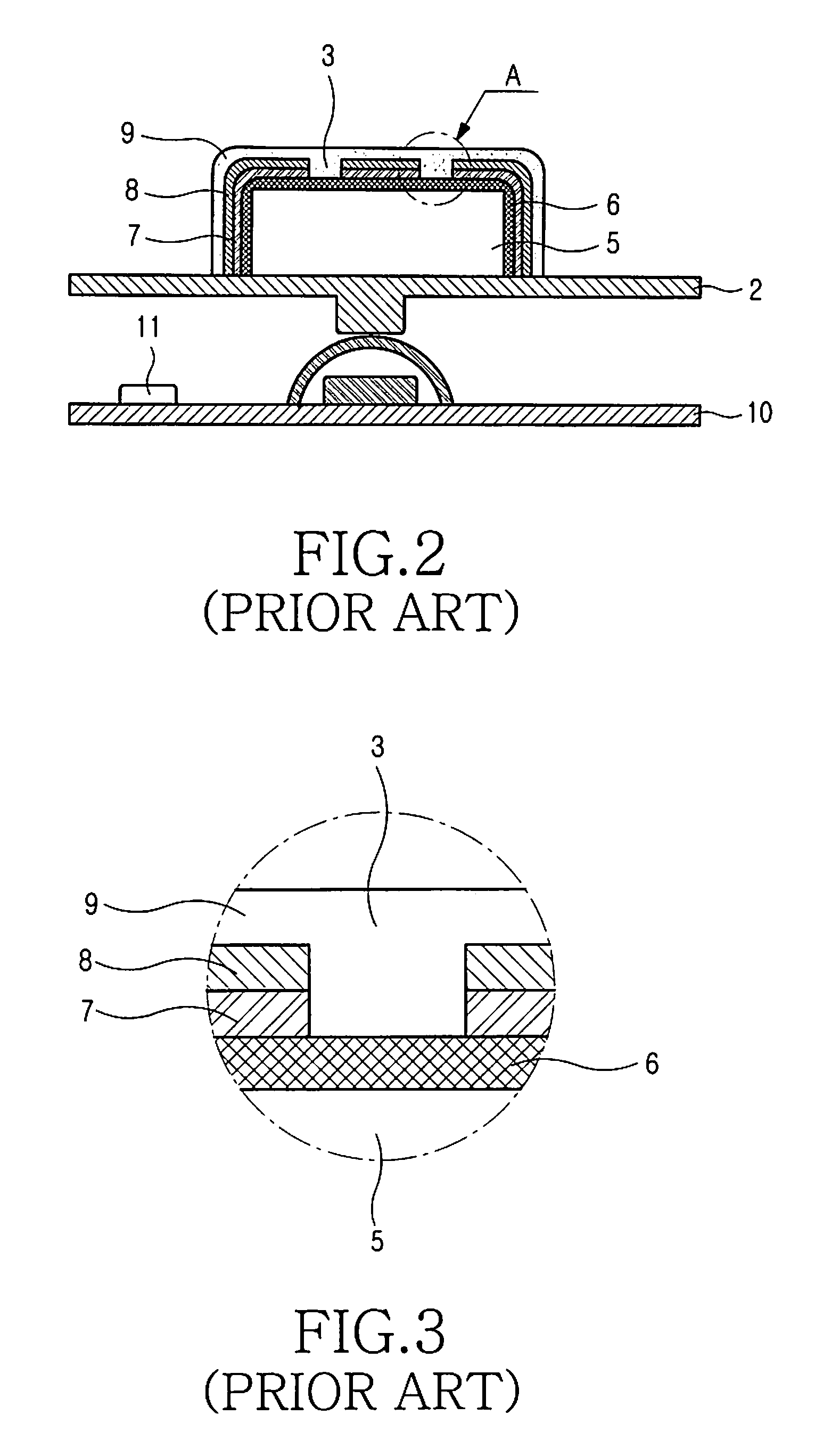

Manufacturing method of keypad for mobile phone and keypad manufactured thereby

ActiveUS7414213B2Increase resistanceHigh hardnessInput/output for user-computer interactionEmergency actuatorsLaser processingLacquer

Disclosed is a manufacturing method of a keypad for a mobile phone and the keypad manufactured thereby, in which a vacuum deposition layer and a cellophane paper are attached to a lower surface of a key in the keypad. The keypad for a mobile phone includes a plurality of keys, each key includes a key body of a transparent resin material and a high-hardness transparent coating layer coated onto a surface of the key body in order to increase hardness, and each key comprises a key background color paint layer for color presentation, coated onto a lower surface of the key body; an opaque paint layer coated onto a lower surface of the key background color paint layer; a transparent marking portion formed by performing a laser processing according to a shape of a numeral, a character, or a symbol with respect to the lower surface of the key body so as to remove the color paint layer and the opaque paint layer; a metallic vacuum deposition layer formed on the lower surface of the key body and a lower surface of the opaque paint layer; and a transparent color-printed layer or a cellophane paper attached to a lower surface of the metallic vacuum deposition layer so as to present various colors.

Owner:ROVI GUIDES INC

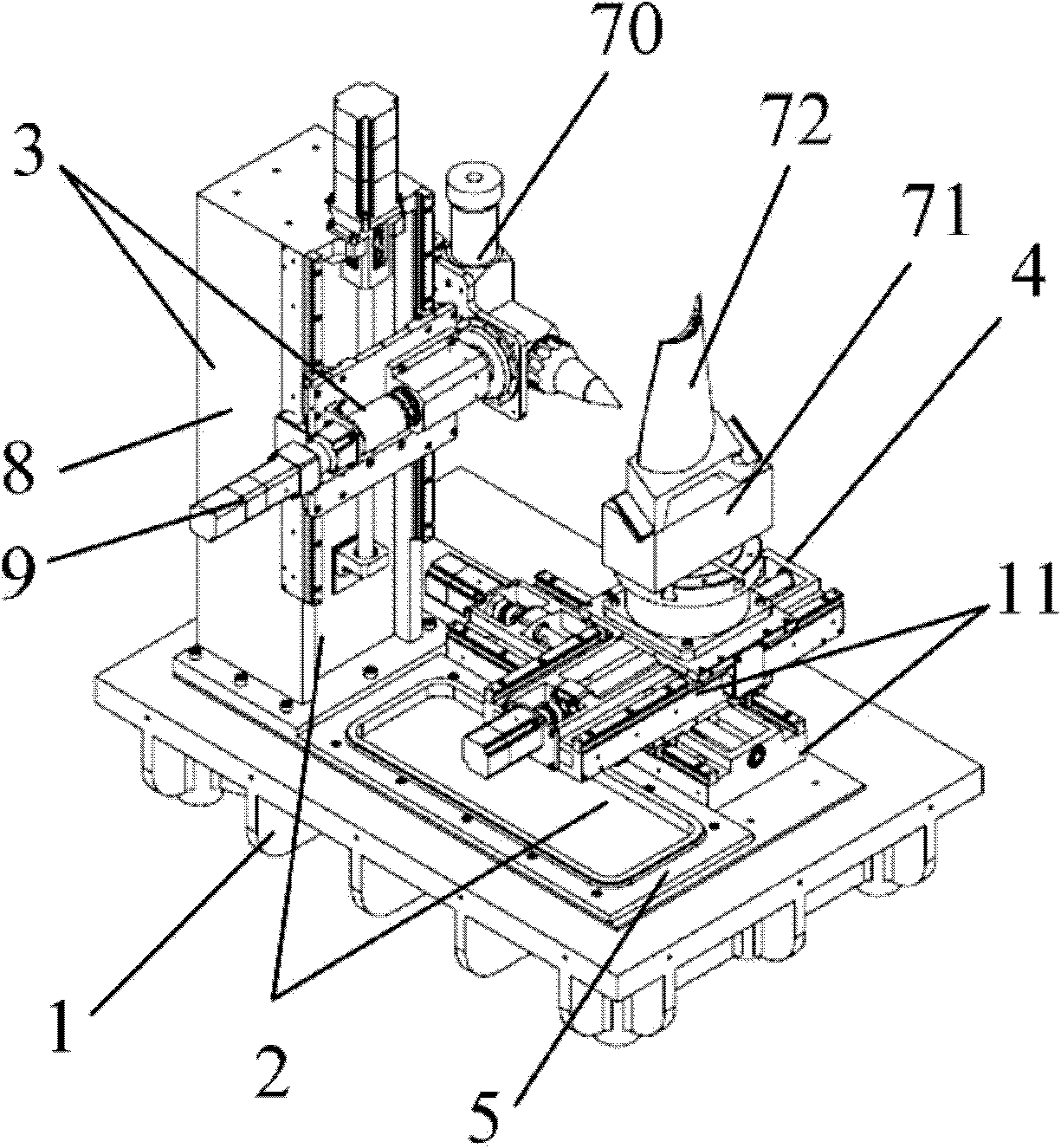

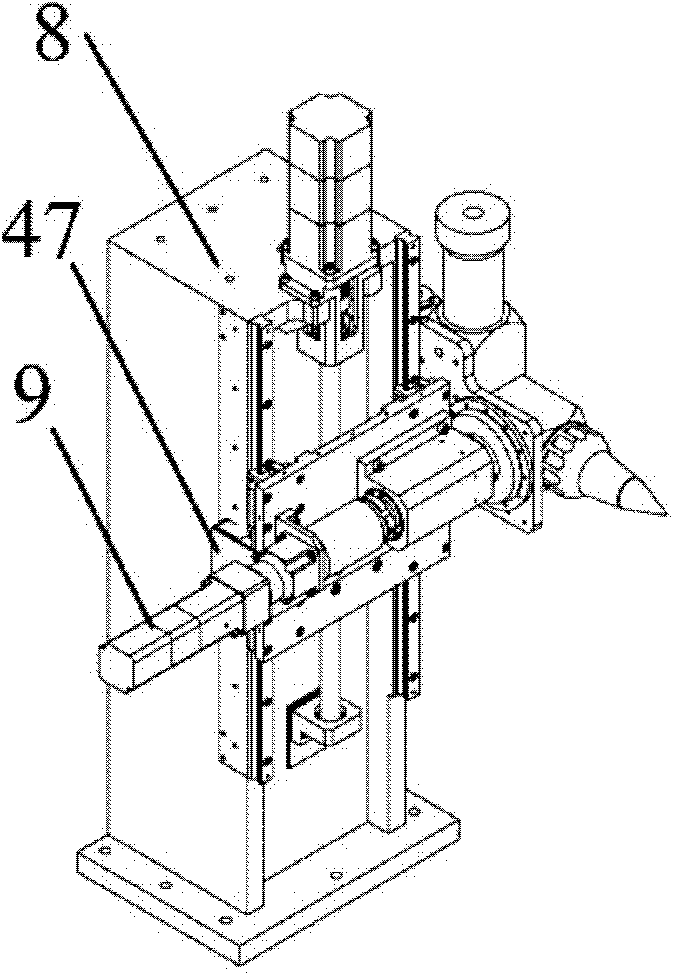

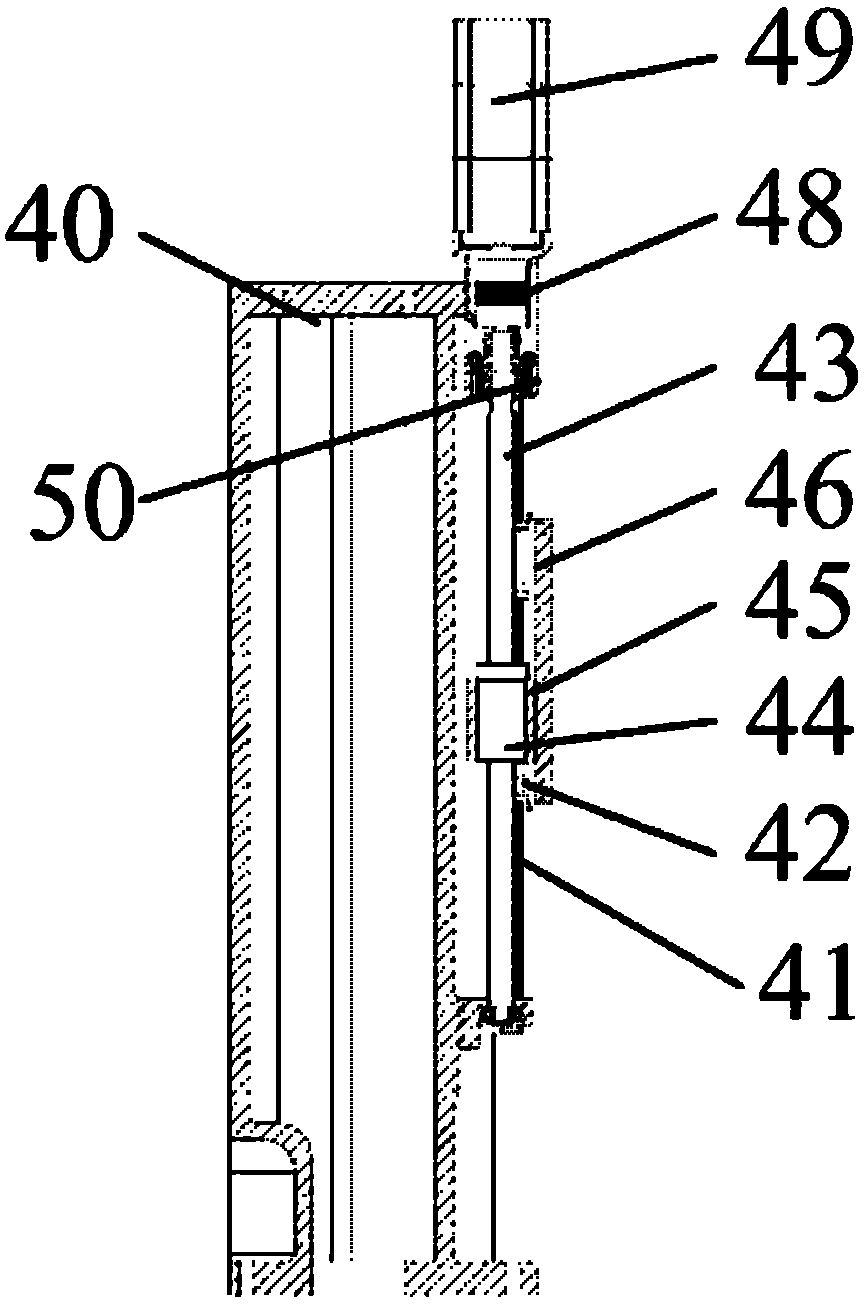

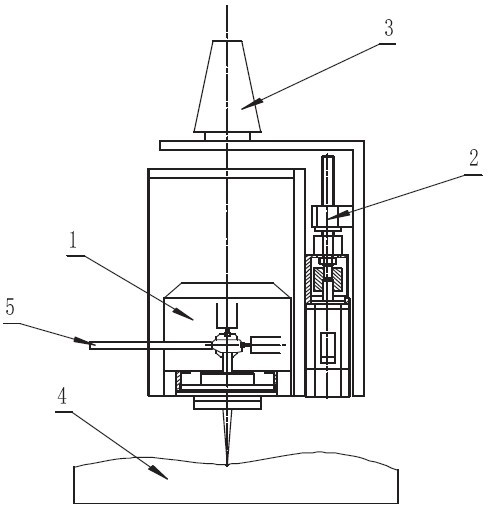

Five-axis linkage laser processing machine

InactiveCN102000911ASimple designEasy to processLarge fixed membersLaser beam welding apparatusLaser processingTorque motor

The invention discloses a five-axis linkage laser processing machine which comprises a base (1) and a machine body (2), wherein the machine body (2) comprises an upright column module (3) and a platform module (4) which are installed on the base (1), the upright column module (3) comprises a Z-axis submodule (8) and an A-axis rotary motion module (9), the Z-axis submodule (8) is provided with a Z-axis slide carriage (46) which moves in the vertical direction, the slide carriage is provided with the A-axis rotary motion module (9), a laser head (70) is installed at the end of an A axis and rotates along with the A axis, the platform module (4) consists of an XY workbench (11) and a C-axis rotary motion module (10) installed on the workbench, a C axis is driven by a torque motor (52) and is provided with a rotary workbench (53), and a workpiece is vertically installed on the rotary workbench through a special clamp. The invention has the advantages of novel structure layout, compact size and high processing accuracy and can also greatly enhance the processing efficiency.

Owner:XI AN JIAOTONG UNIV

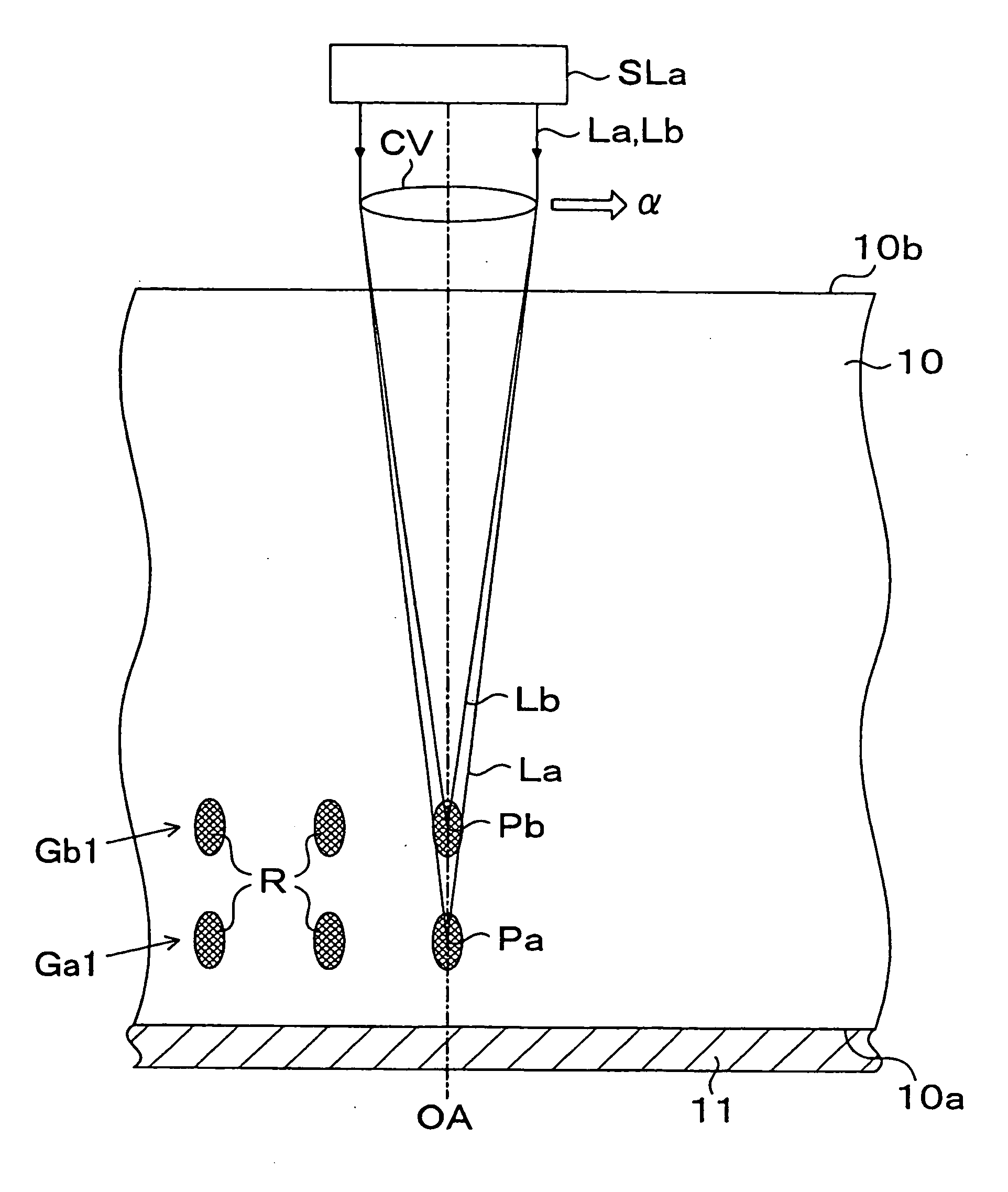

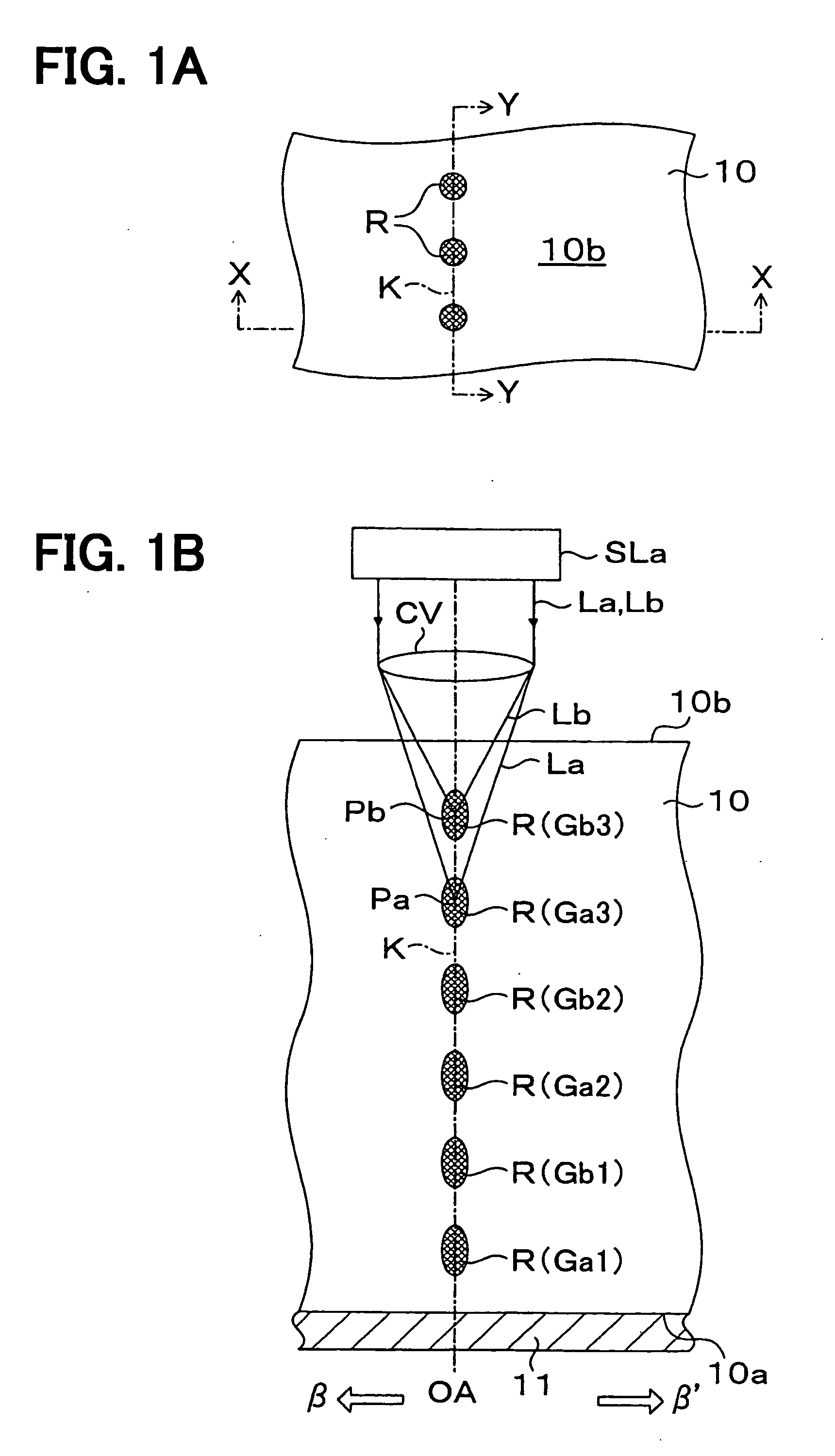

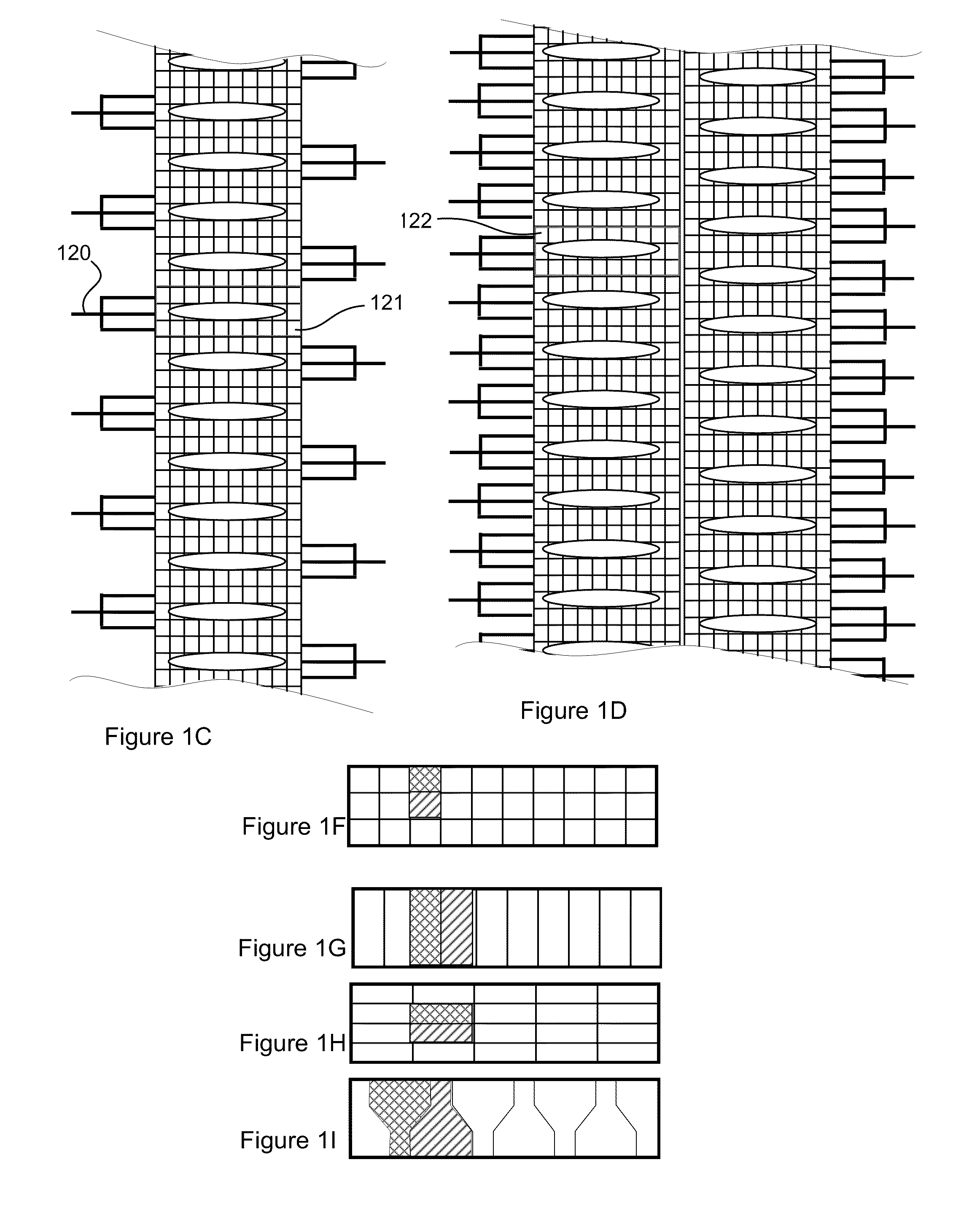

Laser processing apparatus and laser processing method

InactiveUS20070202619A1Reliable formingLaser detailsSemiconductor/solid-state device manufacturingLaser processingOptoelectronics

A laser processing apparatus has one laser light source that simultaneously radiates laser beams with two wavelengths. Depth positions of focusing points for laser beams are gradually changed in a wafer. Three sets of modifying region groups, i.e., six layers of modifying region groups, are successively formed. One set of modifying region groups constitutes two layers and is formed at a time. The modifying region groups are separated, adjoined, or overlapped with each other along an estimated cut line of the wafer in a depth direction from a surface thereof.

Owner:DENSO CORP

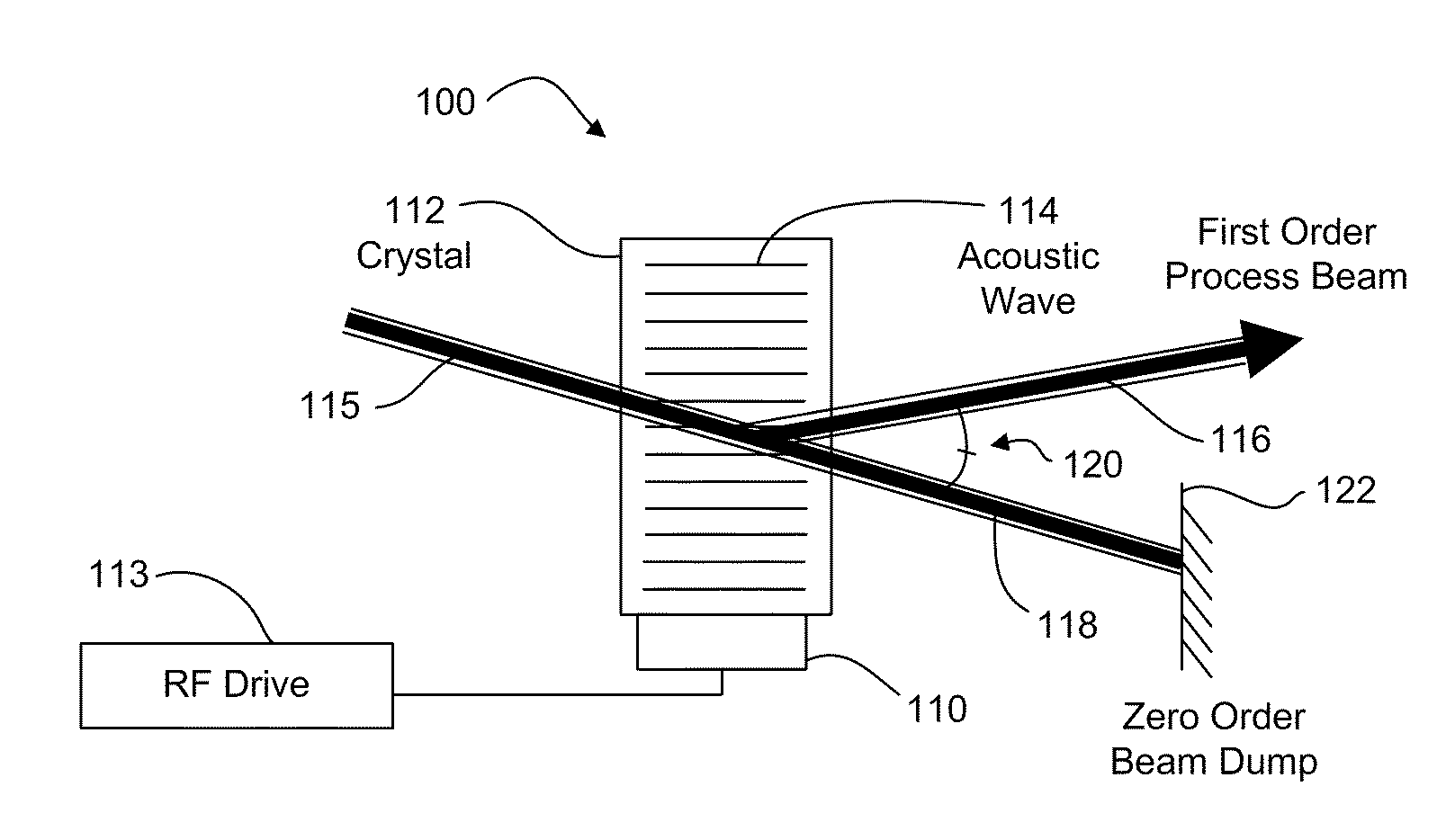

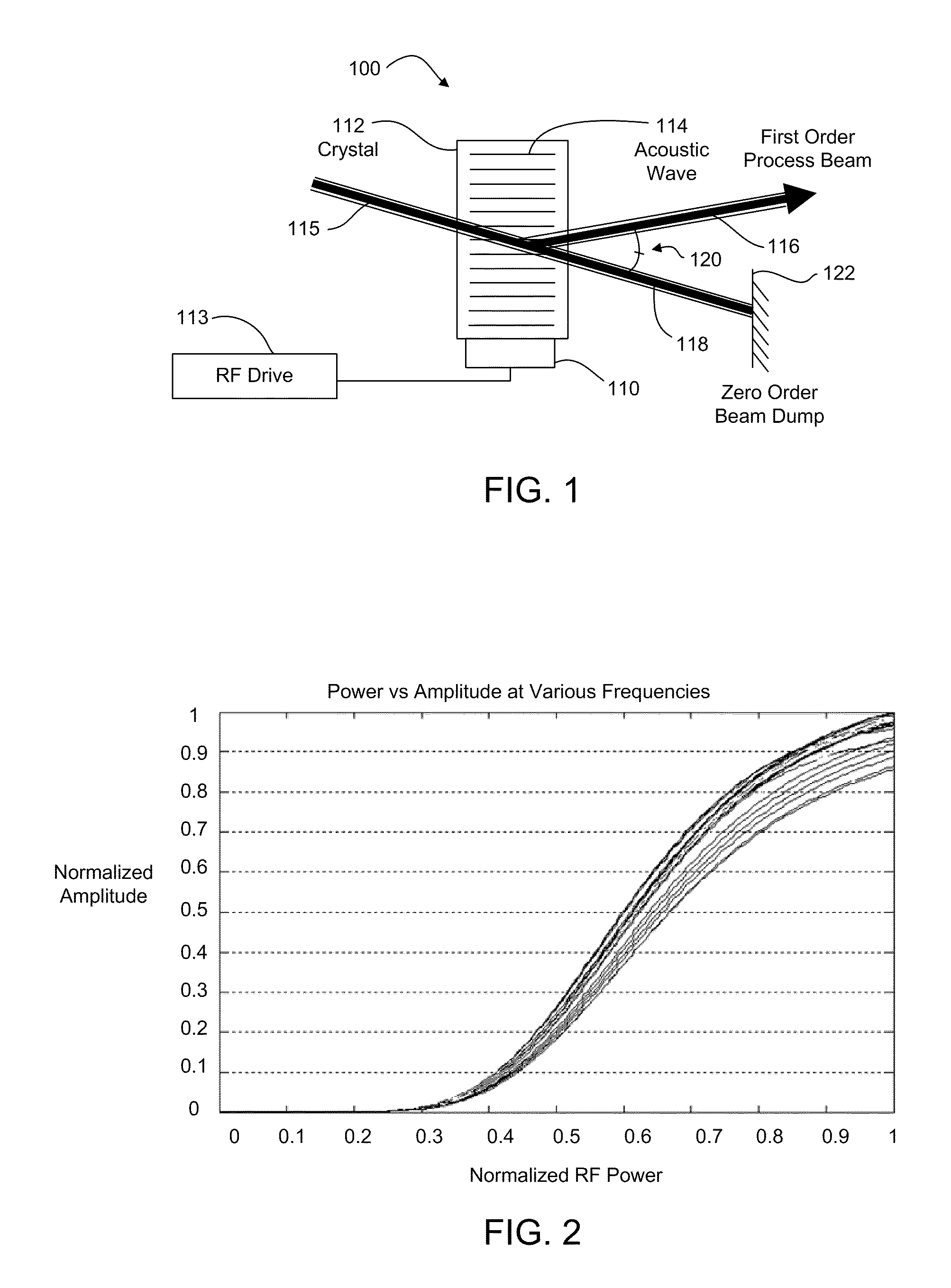

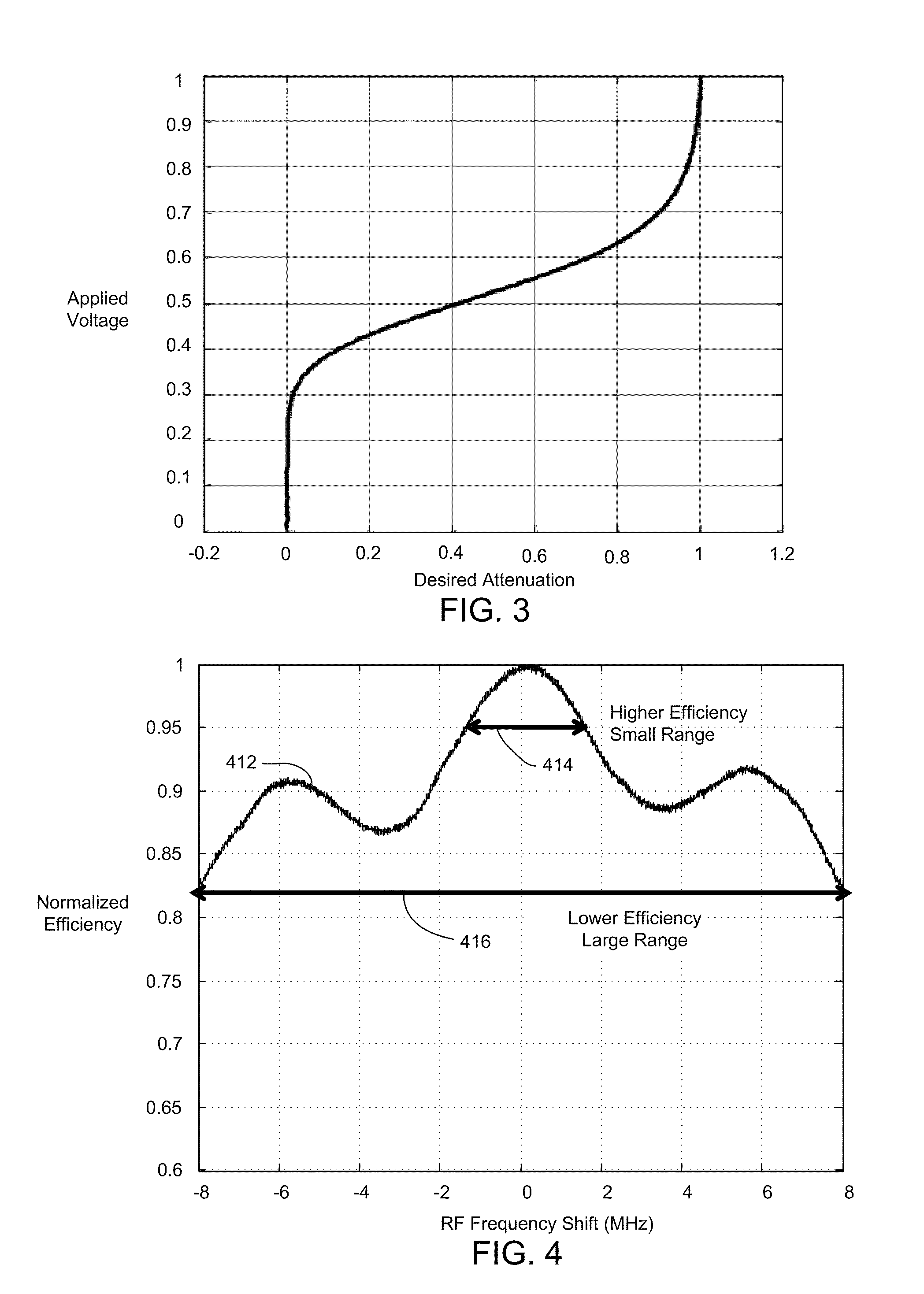

Acousto-optic deflector applications in laser processing of dielectric or other materials

ActiveUS20100301023A1Effective expansionIncrease speedWelding/soldering/cutting articlesMetal working apparatusPower modulationAcousto optic deflector

A laser processing system for micromachining a workpiece includes a laser source to generate laser pulses for processing a feature in a workpiece, a galvanometer-driven (galvo) subsystem to impart a first relative movement of a laser beam spot position along a processing trajectory with respect to the surface of the workpiece, and an acousto-optic deflector (AOD) subsystem to effectively widen a laser beam spot along a direction perpendicular to the processing trajectory. The AOD subsystem may include a combination of AODs and electro-optic deflectors. The AOD subsystem may vary an intensity profile of laser pulses as a function of deflection position along a dither direction to selectively shape the feature in the dither direction. The shaping may be used to intersect features on the workpiece. The AOD subsystem may also provide rastering, galvo error position correction, power modulation, and / or through-the-lens viewing of and alignment to the workpiece.

Owner:ELECTRO SCI IND INC

Laser machining method and device applicable for complicated curved surface

ActiveCN102151984AReduce the overall heightImprove energy consumptionLaser beam welding apparatusLaser etchingLaser processing

The invention provides a laser machining method applicable for a complicated curved surface. By adopting processing steps of dividing the complicated curved surface into curved surface sheets and establishing a coordinate system of each curved surface sheet, the subsequent processing steps of dividing sub blocks and machining pattern parallel projection can be implemented according to the coordinates of the curved surface sheets respectively, so the limit that a machining molded surface backing to a laser incident direction or a steep surface parallel to an optical axis direction cannot be machined because only one coordinate system is adopted to perform whole injection in the prior art can be overcome, the machining efficiency is improved and the machining applicable range is extended. The invention also provides a laser machining device. The laser machining device has a three-axis laser machining head structure provided with a two-axis laser polarization mirror and a Z-axis mobile mechanism, so the problem that the conventional system depends on a three-axis lathe is solved; therefore, a machining unit is independent and compact, and is easy to assemble and disassemble; the conventional five-axis linkage milling machine can be changed into a laser-etching machining lathe so that the functions are compatible; and the laser machining device has a significant practical value.

Owner:武汉飞能达激光技术有限公司

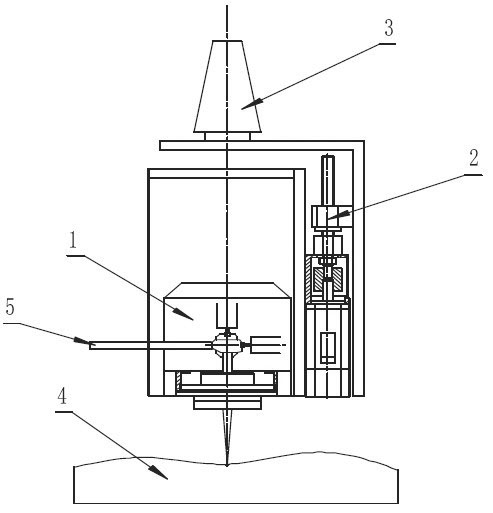

Methods and Device for Laser Processing

InactiveUS20110240611A1Facilitates laser ablationNot to damagePhotomechanical apparatusSemiconductor/solid-state device manufacturingLaser processingLaser ablation

The present invention relates to laser ablation microlithography. In particular, we disclose a new SLM design and patterning method that uses multiple mirrors per pixel to concentrate energy to an energy density that facilitates laser ablation, while keeping the energy density on the SLM mirror surface at a level that does not damage the mirrors. Multiple micro-mirrors can be reset at a very high frequency, far beyond current DMD devices.

Owner:MICRONIC LASER SYST AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com