Five-axis linkage laser processing machine

A technology of laser processing and five-axis linkage, which is applied in the direction of metal processing machinery parts, laser welding equipment, metal processing equipment, etc., can solve the problems of affecting the drilling effect, inconvenient operation for workers, and affecting production efficiency, etc., to achieve excellent comprehensive performance, Improve the efficiency of clamping and ensure the effect of easy performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

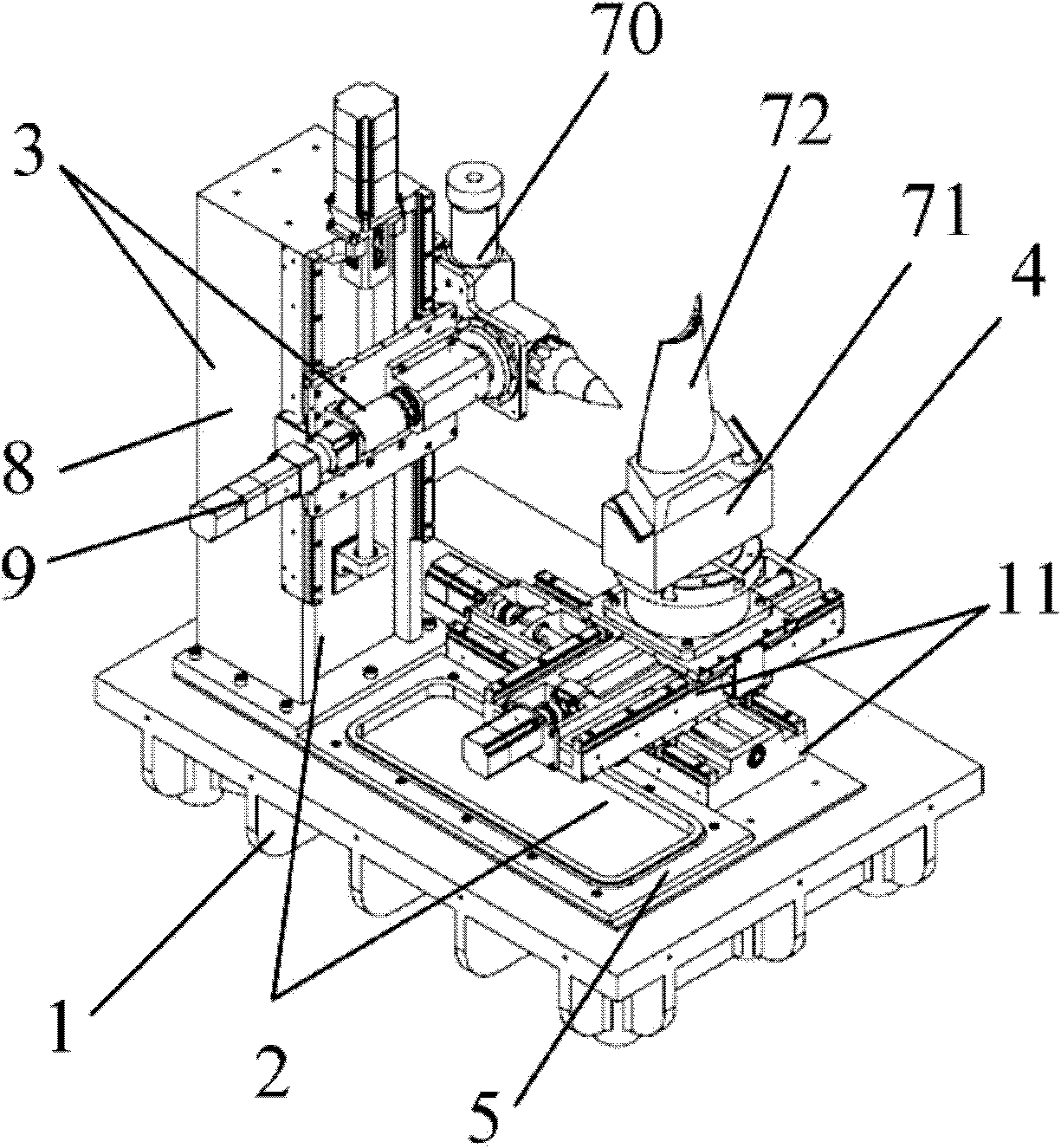

[0034] Such as figure 1 Shown: a five-axis linkage laser processing machine tool, which includes a base 1 and a bed 2. The base 1 is a flat workbench conforming to national standards, and the bed 2 includes such figure 2 Column modules shown in 3 and Figure 5 In the platform module 4 shown, both modules are installed on the base plane.

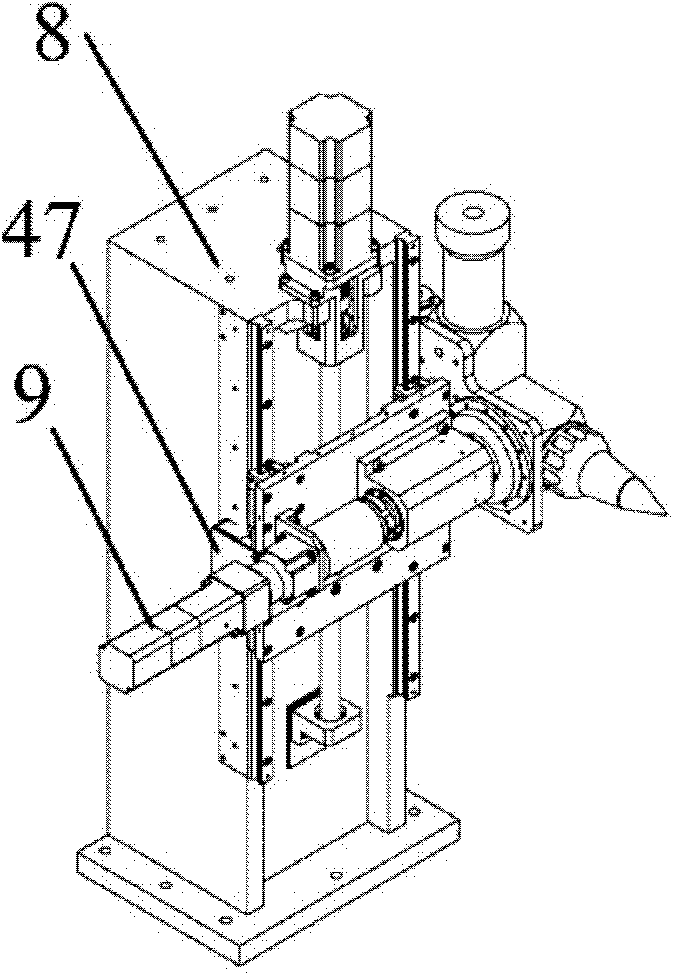

[0035] figure 2 Column modules shown include image 3 shown in the Z-axis submodule 8 and Figure 4 A-axis submodule 9 shown. There is a Z-axis slide plate 46 moving vertically on the column module, and an A-axis rotary motion module 9 is installed on the slide plate, and the laser head is installed at the end of the A-axis and rotates with the A-axis.

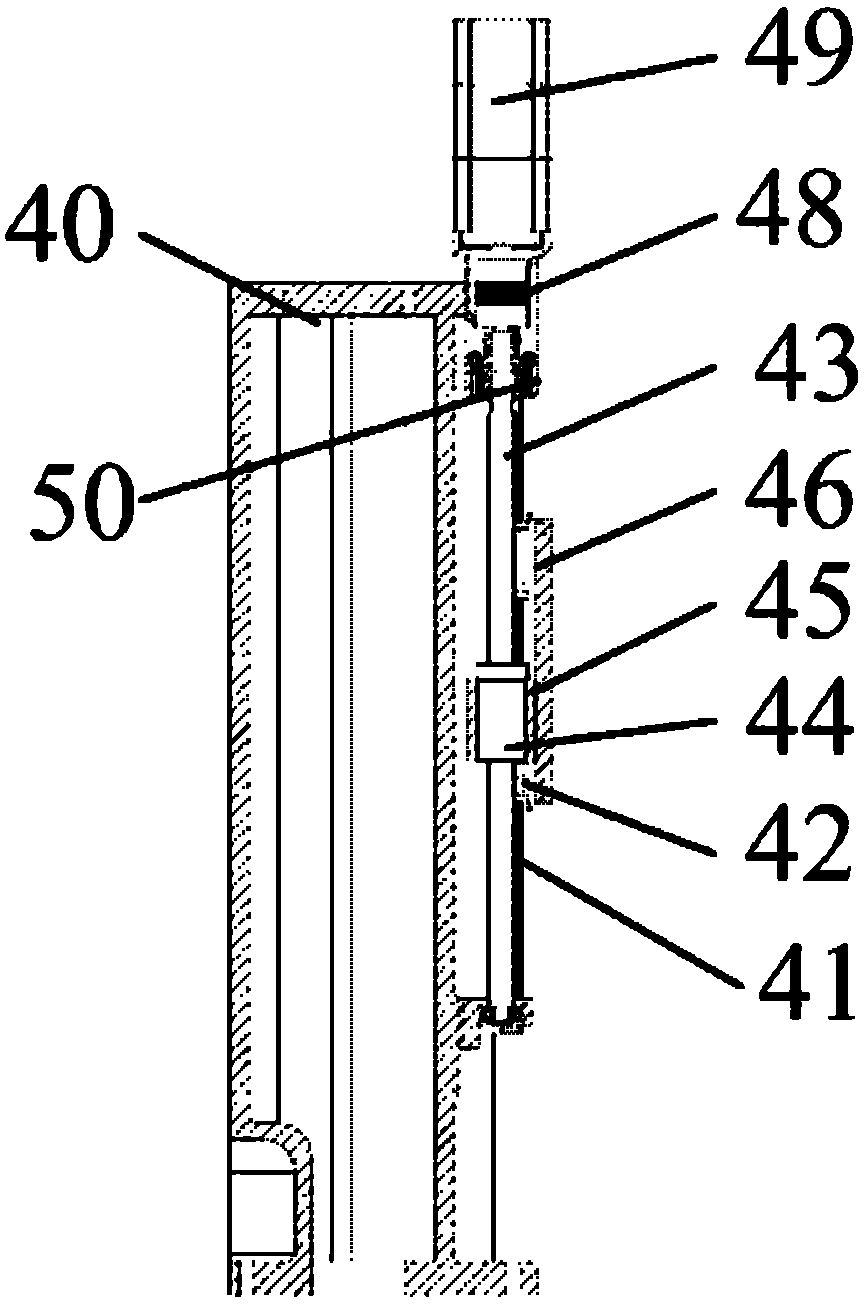

[0036] image 3The Z-axis sub-module shown is provided with a column 40, on which there is a guide rail installation surface and a screw support installation surface; the Z-axis guide rail 41 is installed on the guide rail installation surface, and the screw support 50 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com