Patents

Literature

1864 results about "Torque motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A torque motor is a specialized form of electric motor which can operate indefinitely while stalled, that is, with the rotor blocked from turning, without incurring damage. In this mode of operation, the motor will apply a steady torque to the load (hence the name). A torque motor that cannot perform a complete rotation is known as a limited angle torque motor. Torque motors are DC motors. Torque motors sometimes avoid commutators and brushes called brushless dc motors, elimination of these parts allow dc motors or torque motors to work at higher speed...

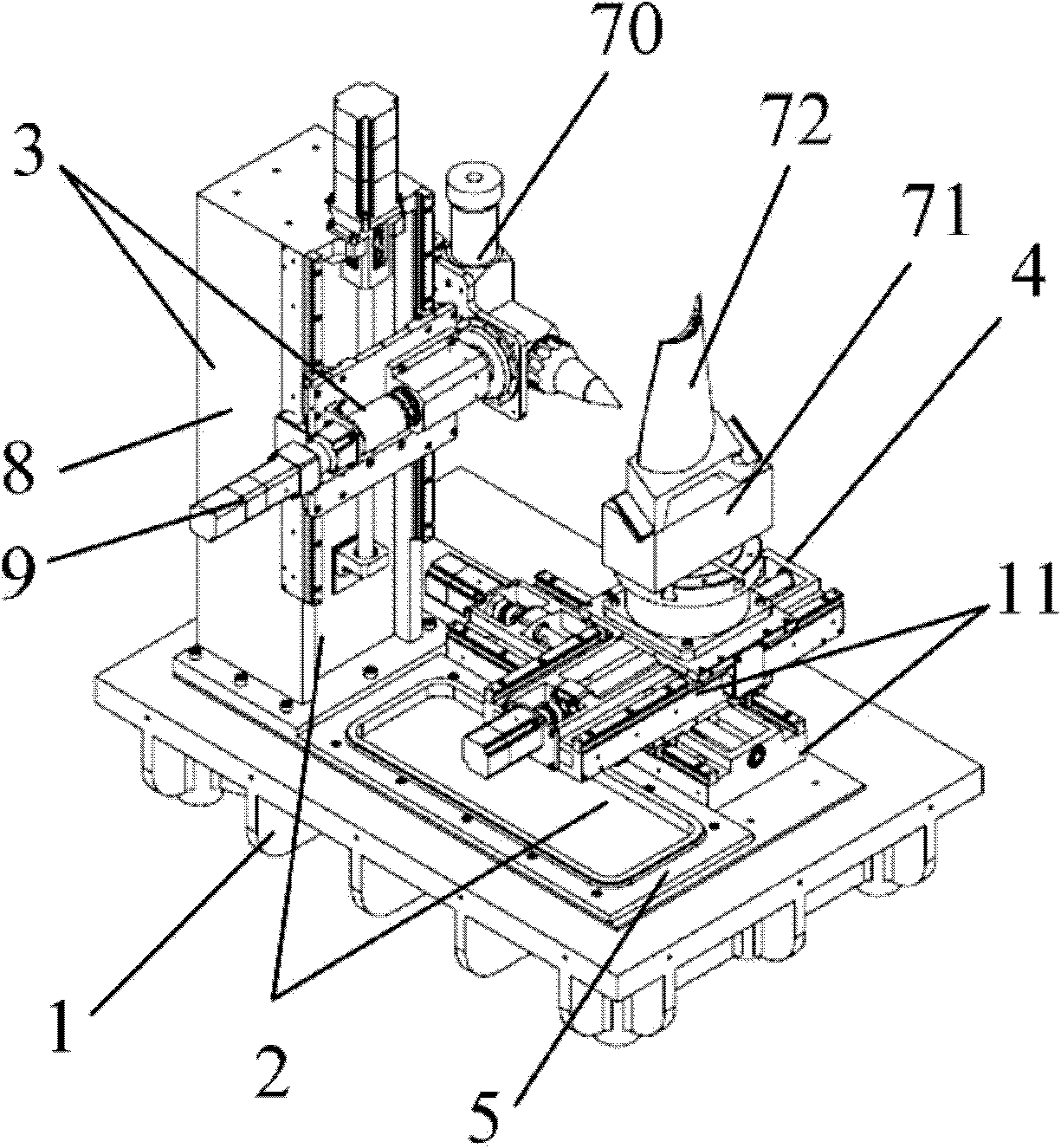

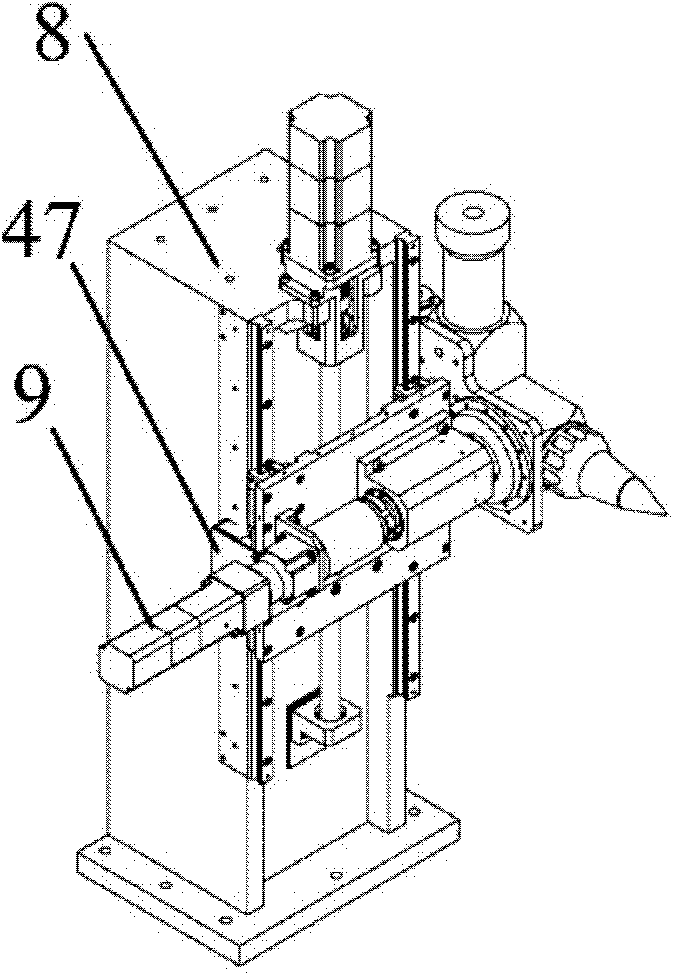

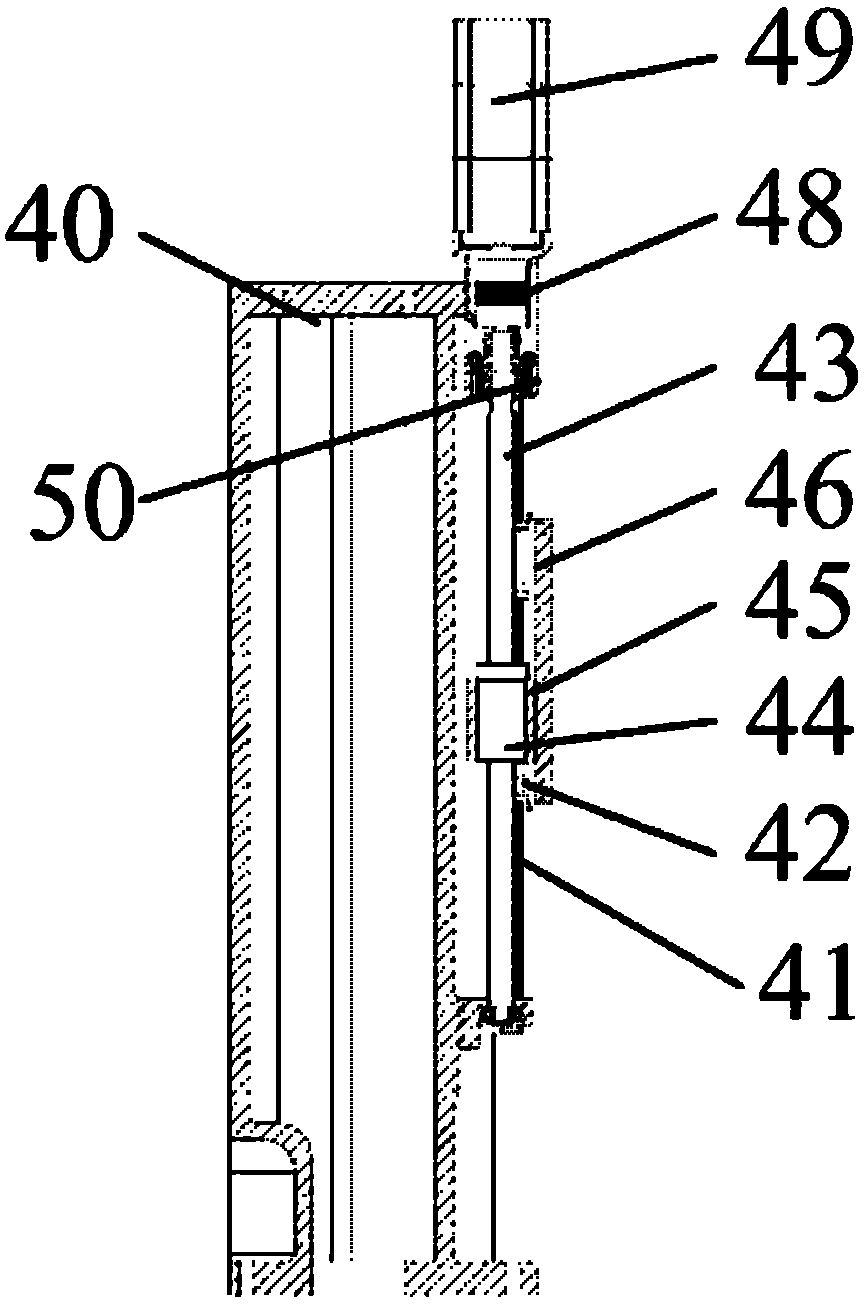

Five-axis linkage laser processing machine

InactiveCN102000911ASimple designEasy to processLarge fixed membersLaser beam welding apparatusLaser processingTorque motor

The invention discloses a five-axis linkage laser processing machine which comprises a base (1) and a machine body (2), wherein the machine body (2) comprises an upright column module (3) and a platform module (4) which are installed on the base (1), the upright column module (3) comprises a Z-axis submodule (8) and an A-axis rotary motion module (9), the Z-axis submodule (8) is provided with a Z-axis slide carriage (46) which moves in the vertical direction, the slide carriage is provided with the A-axis rotary motion module (9), a laser head (70) is installed at the end of an A axis and rotates along with the A axis, the platform module (4) consists of an XY workbench (11) and a C-axis rotary motion module (10) installed on the workbench, a C axis is driven by a torque motor (52) and is provided with a rotary workbench (53), and a workpiece is vertically installed on the rotary workbench through a special clamp. The invention has the advantages of novel structure layout, compact size and high processing accuracy and can also greatly enhance the processing efficiency.

Owner:XI AN JIAOTONG UNIV

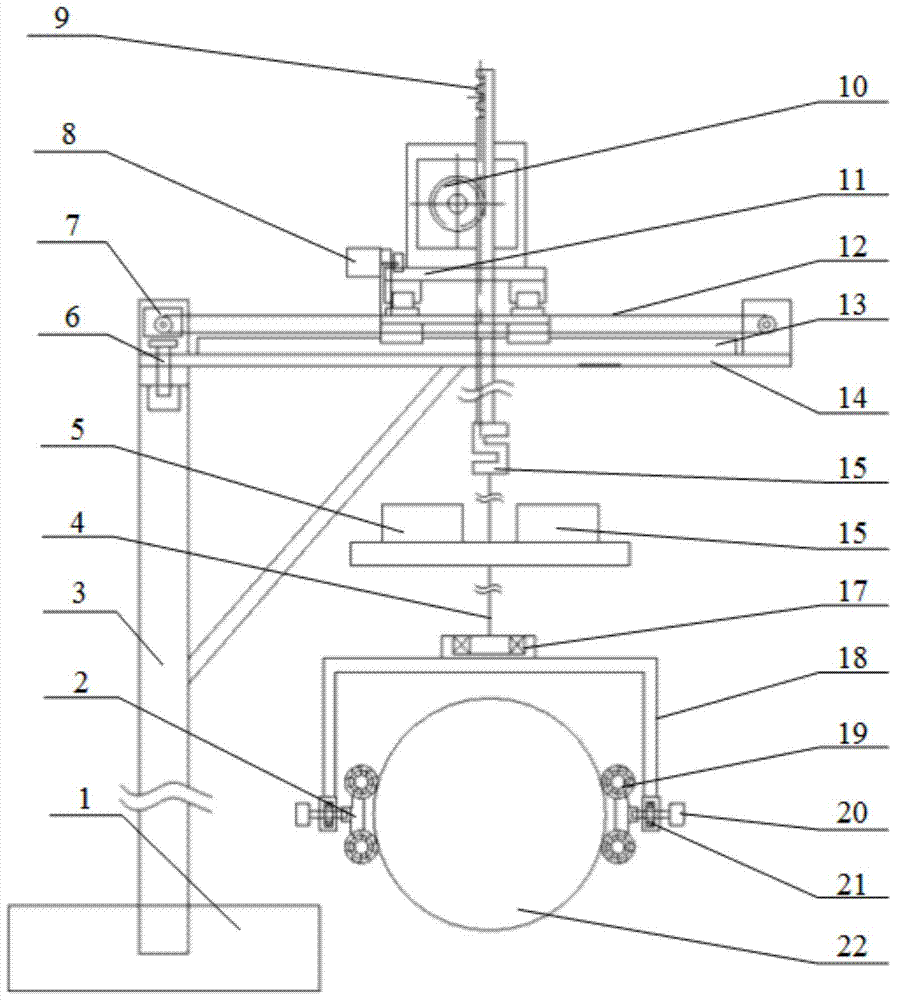

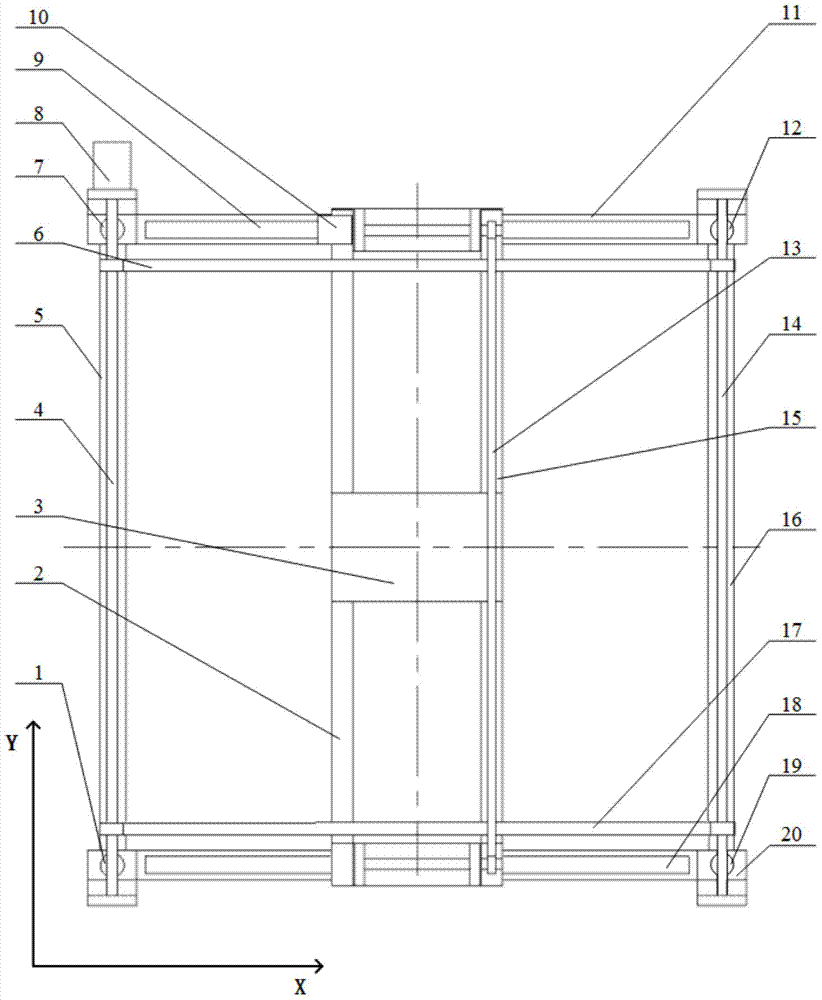

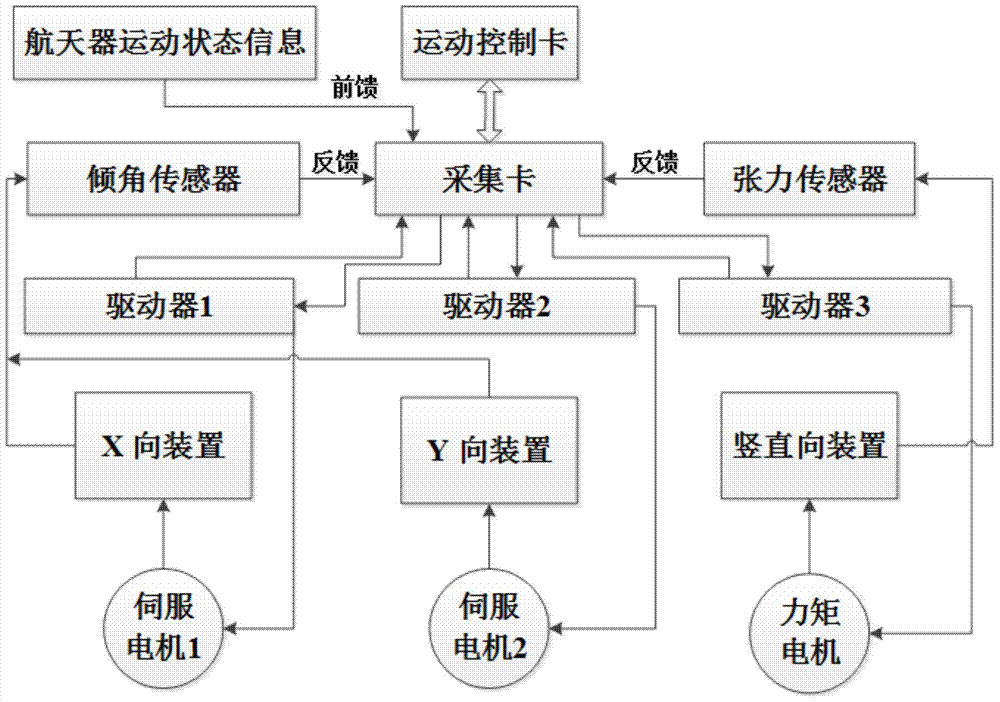

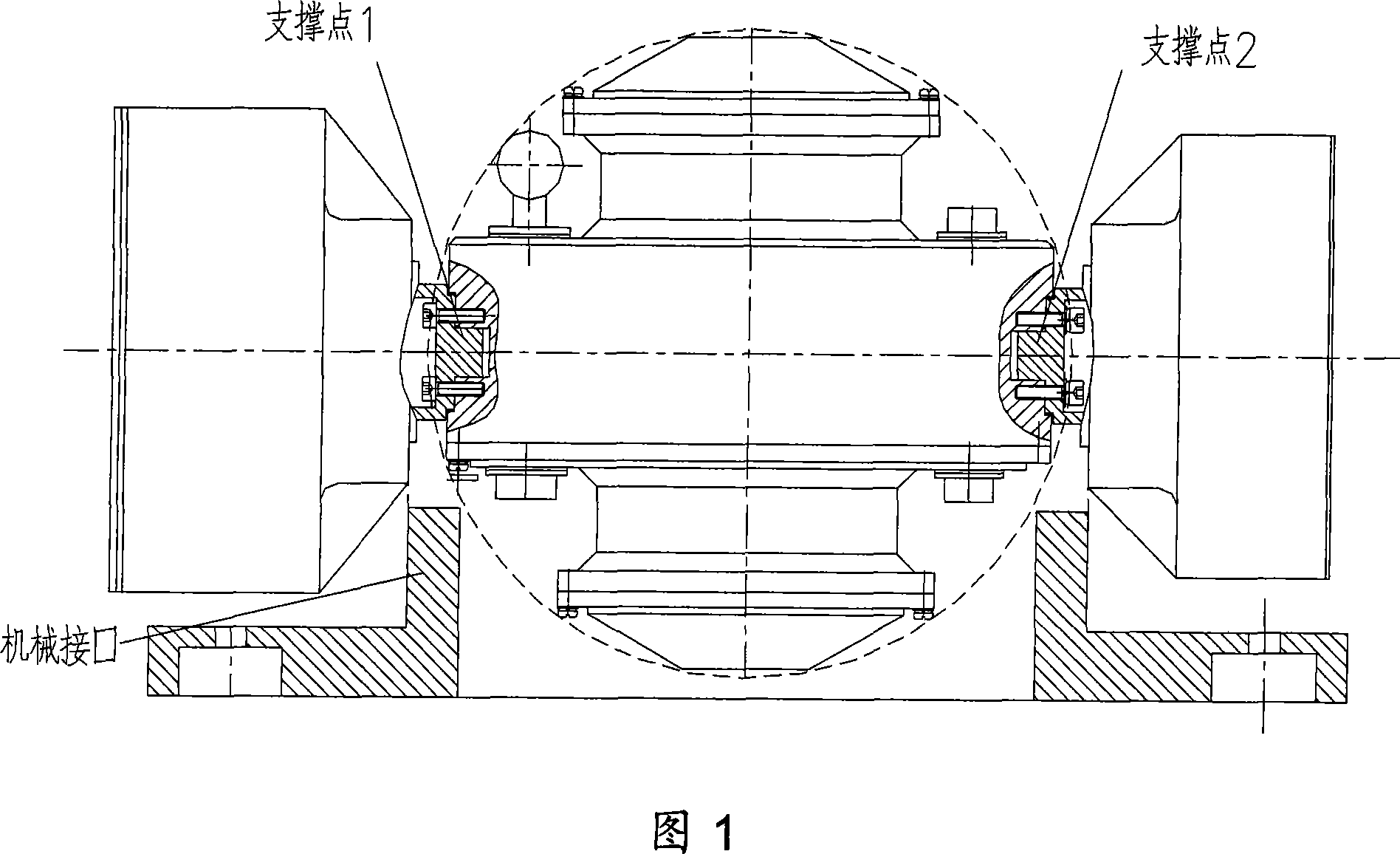

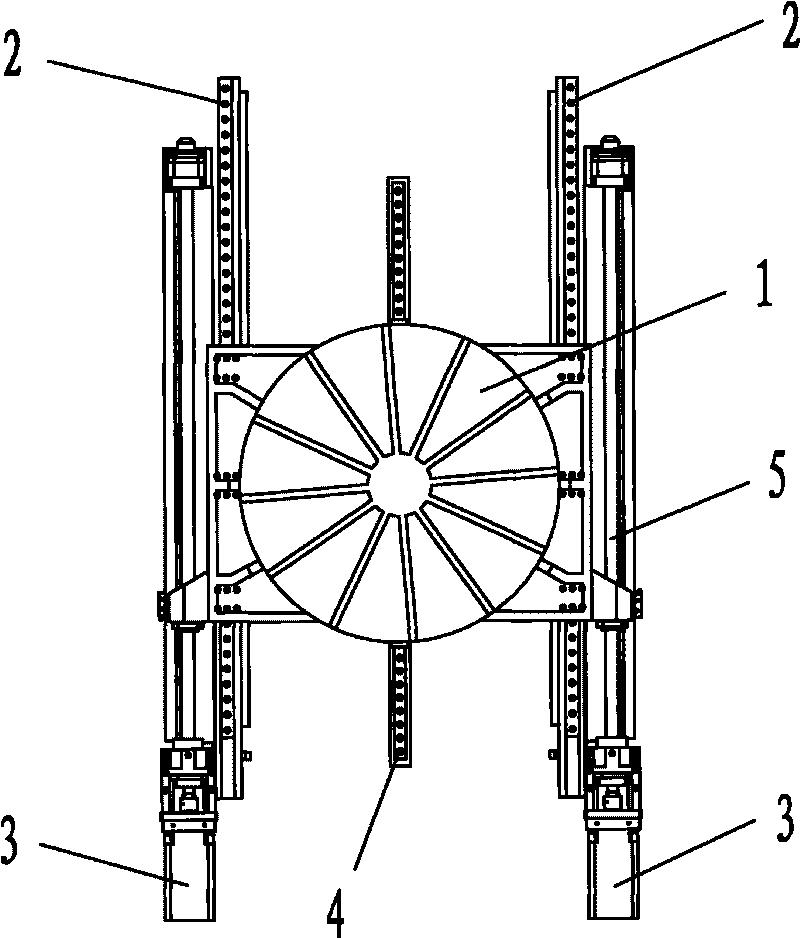

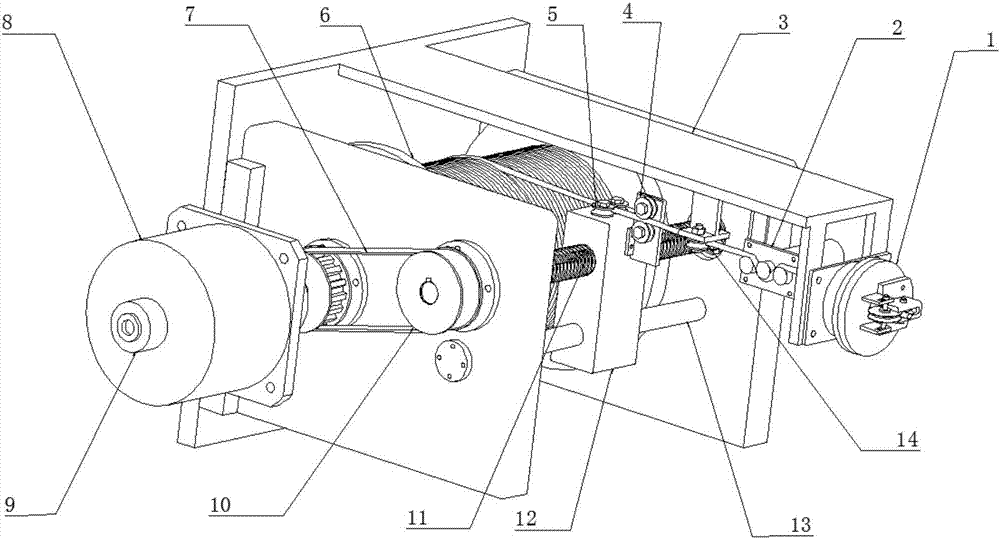

Design method of unrestricted suspension type initiative gravity compensation system

ActiveCN103482089AOvercome the influence of microgravity horizontal directionHigh compensation accuracyCosmonautic condition simulationsTorque motorEngineering

Provided is an unrestricted suspension type initiative gravity compensation system. The system is composed of an unrestricted connecting module, a vertical constant tension suspension module, a horizontal follow-up module and a control module. The unrestricted connecting module comprises a connecting sleeve, an outer mounting frame, a force applying piece and a low friction bearing, and enables a spacecraft to carry out approximate unrestricted rotation round a center of mass. The vertical constant tension suspension module comprises a torque motor, a pinion and rack, a suspension hanging spring and a tension sensor, and enable the tensile force borne by the spacecraft in movement is equal to gravity. The horizontal follow-up module comprises a servo motor, a guide rail, a synchronous belt and a tilt angle sensor, and the suspension module is made to carry out horizontal movement along with the spacecraft to guarantee that the hanging spring is in a vertical state. The control module comprises an acquisition card, a driver and a motion control card. The design method of the unrestricted suspension type initiative gravity compensation system can compensate the gravity of the spacecraft in a ground test environment, further is used for reproducing the real movement of the spacecraft in the interspace microgravity environment, has the advantages of being stable in running, through in compensation and the like, and can provide the approximate unrestricted microgravity environment for movements with six degrees of freedom.

Owner:BEIHANG UNIV

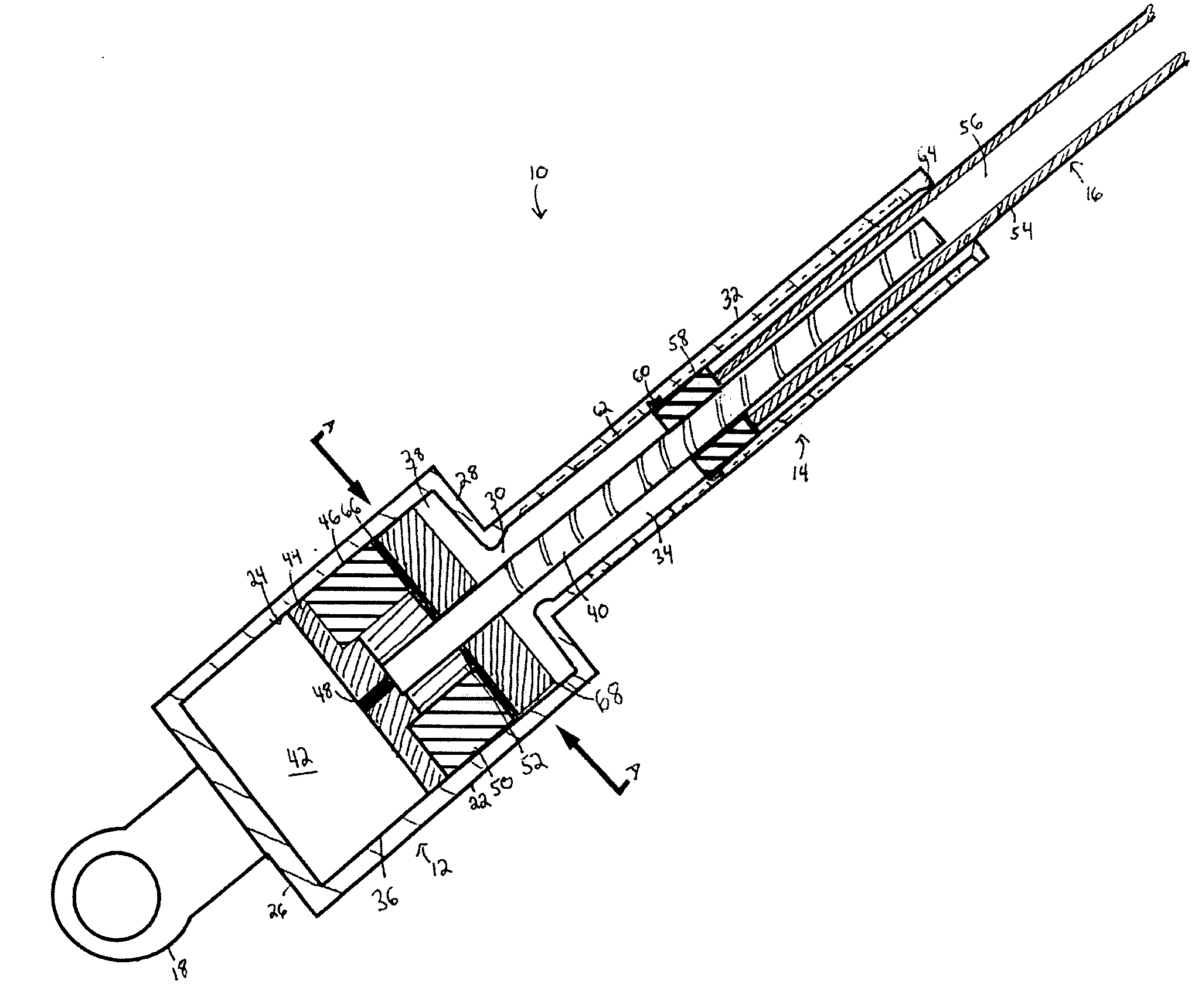

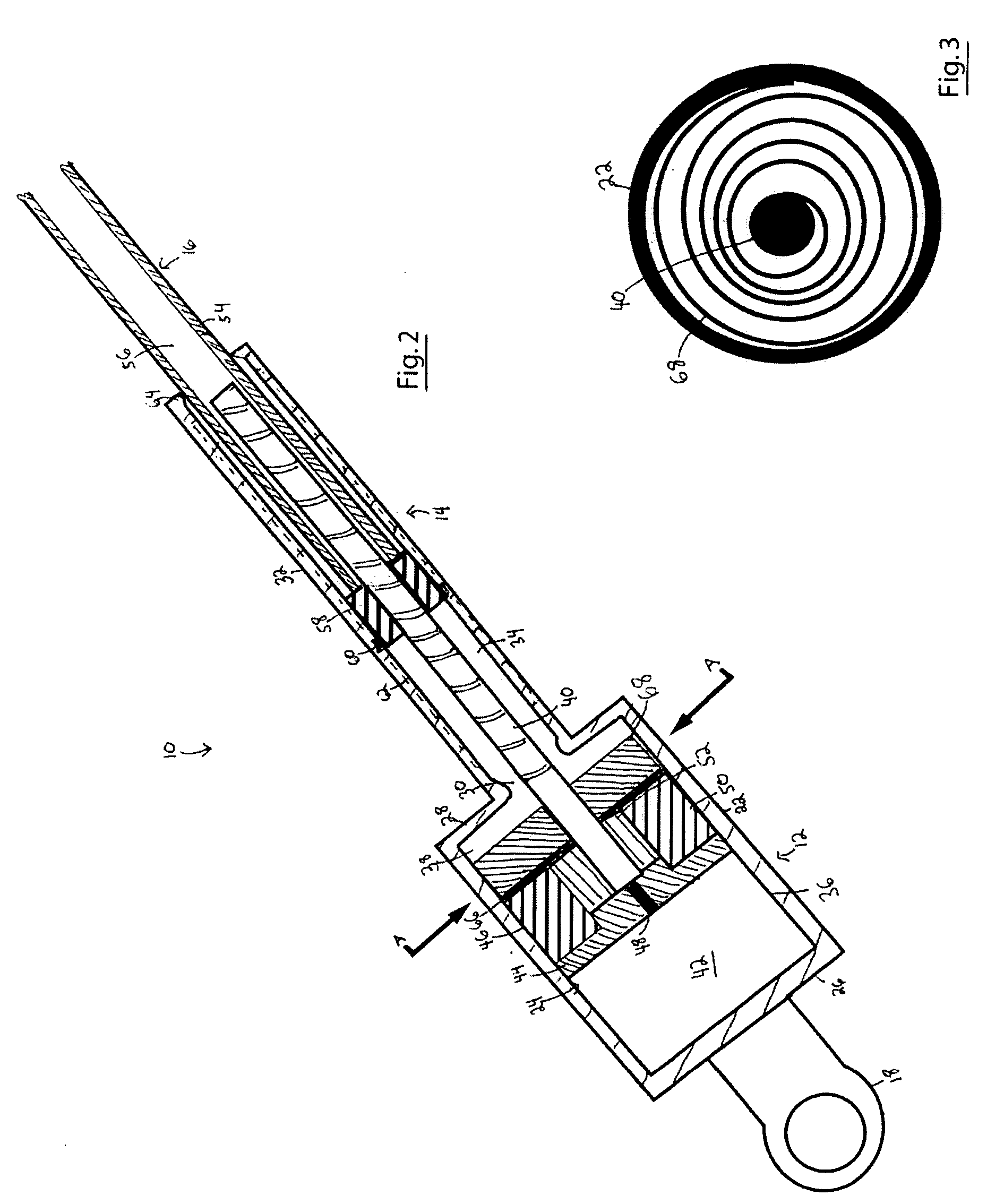

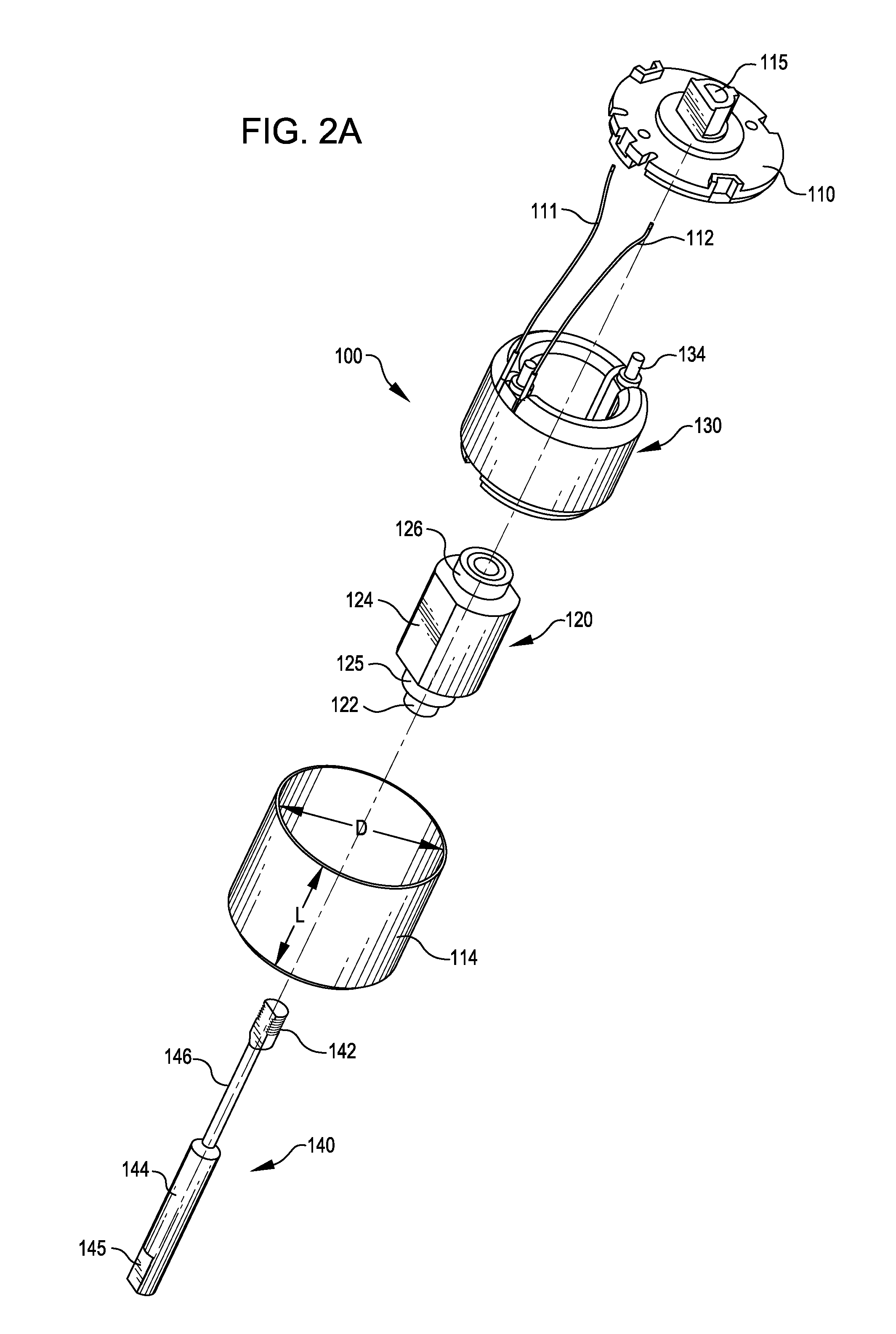

Electromechanical strut

ActiveUS20060082188A1Reduce the overall diameterStoring potential energyPower-operated mechanismSuperstructure subunitsTorque motorEngineering

An electromechanical strut using an inline motor coupled to an inline planetary gear that are both mounted in the lower housing. The motor-gear assembly drives a worm gear and nut screw in the upper housing, extending or retracting an extensible shaft. Additionally, a power spring mounted coaxially around the worm gear provides a mechanical counterbalance to the weight of a lift gate on the shaft. As the shaft extends, the power spring uncoils, assisting the motor-gear assembly in raising the lift gate. Retracting the shaft recoils the spring, storing potential energy. Thus, a lower torque motor-gear assembly can be used, reducing the diameter of the lower housing. Preferably, the power spring can also drive the power screw to extend the strut even when the motor-gear assembly is not engaged.

Owner:MAGNA CLOSURES INC

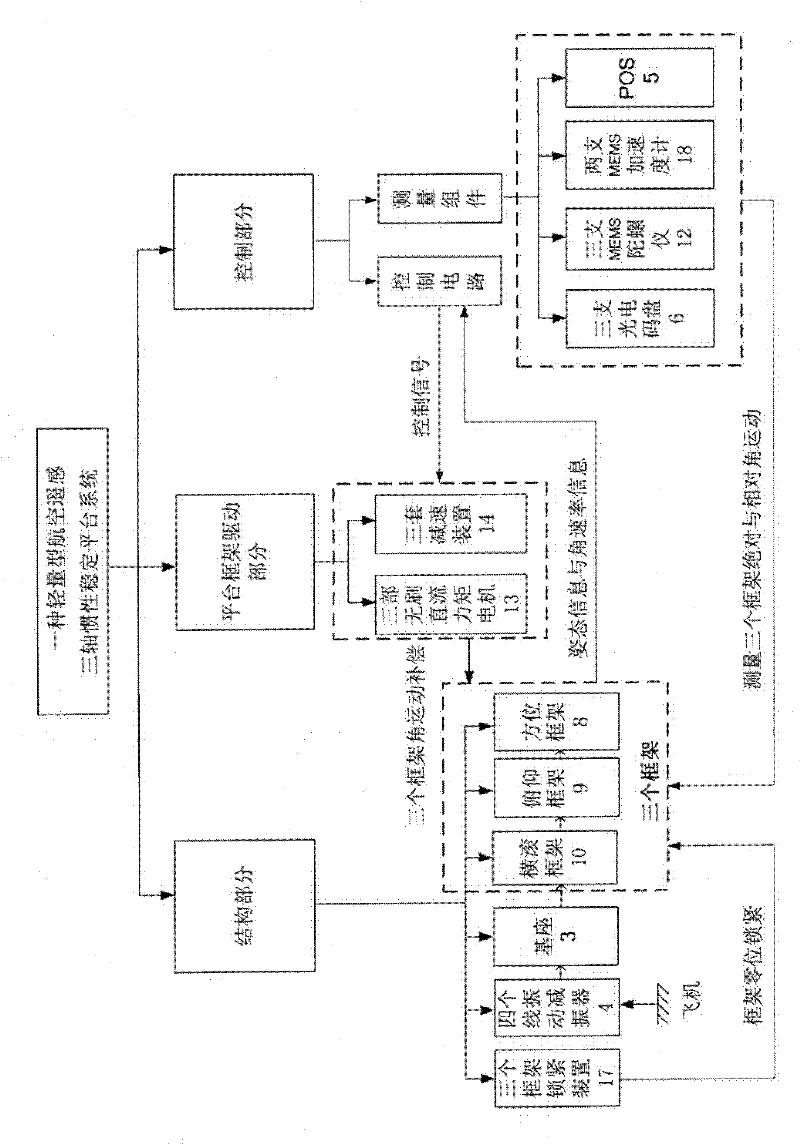

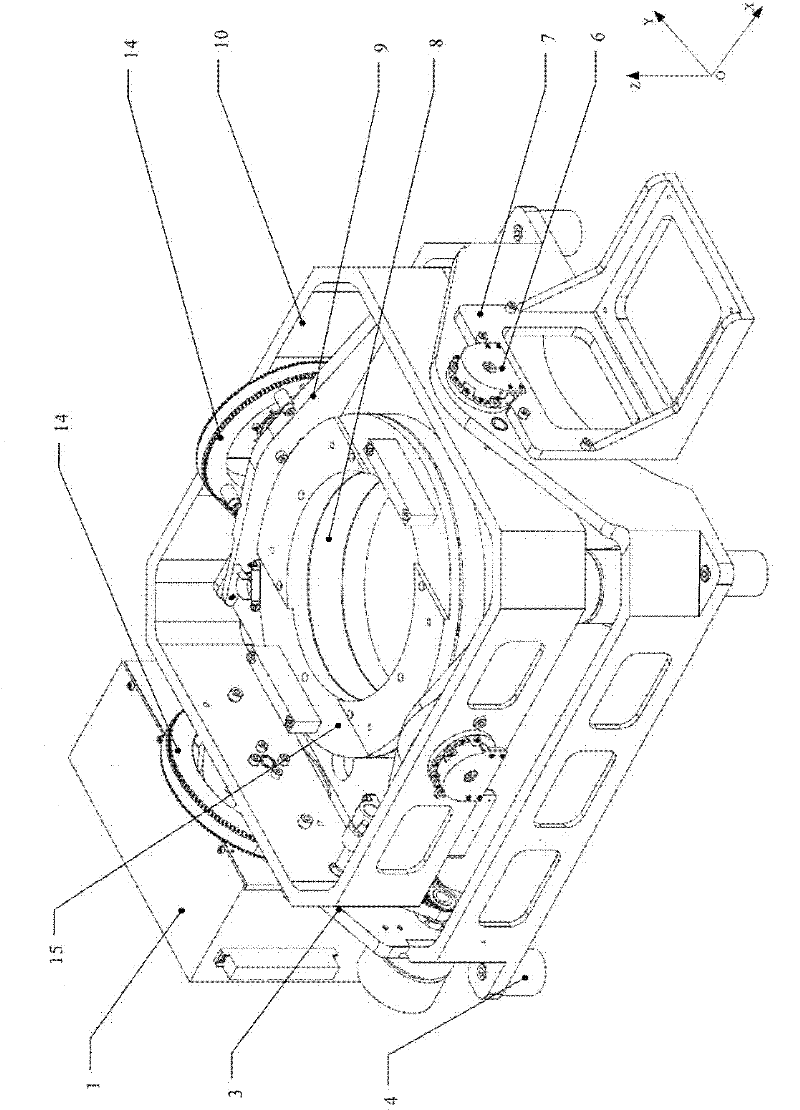

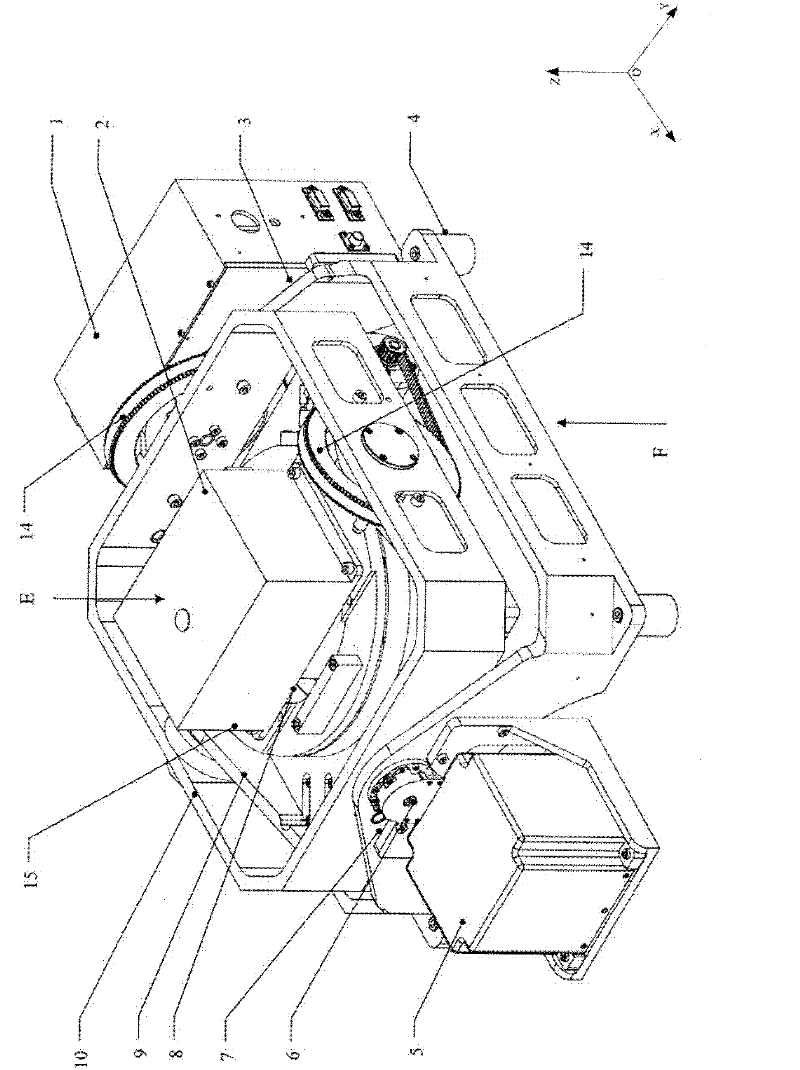

Light-type triaxial ISP (inertially stabilized platform) system using aerial remote sensing technology

ActiveCN102230801AReduce volumeReduce weightNavigation by speed/acceleration measurementsBrushless motorsAviation

The invention provides a light-type triaxial ISP (inertially stabilized platform) system using an aerial remote sensing technology, comprising a base, four linear vibration dampers, a rolling framework, a pitching framework, a direction framework, two MEMS (micro-electromechanical system) accelerometers, three MEMES gyroscopes, three DC (direct current) brushless torque motors, three sets of reduction gears, three photoelectric encoders and three framework servo control circuits, wherein the base is connected with a plane by the four linear vibration dampers so as to separate linear vibration; the rolling framework and the pitching framework are used for tracking the local geographical level and rotate around the X axis and the Y axis respectively; and the direction framework is used for tracking heading and rotates around the Z axis. The control part drives the three DC brushless motor frameworks to carry out compensation isolation on angular motion of the plane in accordance with angular rate information of the frameworks provided by the three MEMS gyroscopes and attitude information provided by a POS (position and orientation system) or the two EMES accelerators. The light-type triaxial ISP system has the characteristics of high accuracy, high load bearing / self weight ratio, wide stable range, small volume and light weight as well as self-attitude reference, and is suitable for stabilizing the camera visual axis in light-small type aerial remote sensing systems.

Owner:BEIHANG UNIV

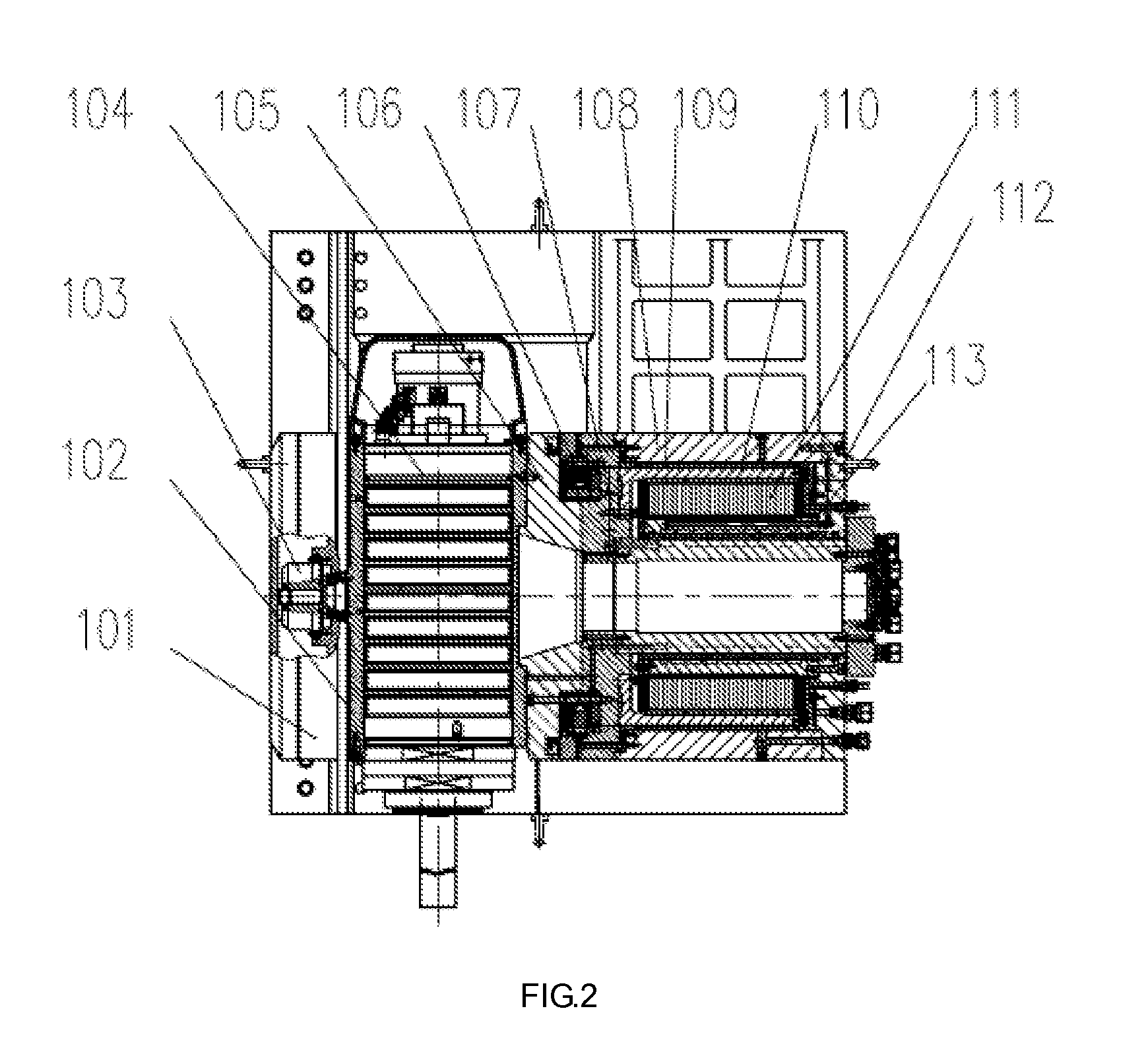

Device and method of automatic helical milling of hole

ActiveCN102794491AEasy to controlHigh control precisionAutomatic control devicesMeasurement/indication equipmentsNumerical controlGrating

The invention discloses a device and a method for automatic helical milling of a hole. The device comprises a base, a spindle slide base, an outer eccentric sleeve, an inner eccentric sleeve, a torque motor, a circular grating, an electric spindle, a presser foot, an industrial camera, a linear grating, four laser distance sensors, a servo motor, a ball screw assembly, a synchronous belt and the like, wherein axes of inner and outer contours of the inner and outer eccentric sleeves have offsets; the inner eccentric sleeve is installed in the outer eccentric sleeve; and the axis of the inner contour of the outer eccentric sleeve and the axis of the outer contour of the inner eccentric sleeve are coincident. The device and the method have the advantages that the tool radial offset is realized through control of a relative rotation angle between the inner eccentric sleeve and the outer eccentric sleeve; in spindle feeding, a double-grating feedback technology is adopted so that dimple depth accuracy is guaranteed; and a preset hole position on a workpiece is detected by the industrial camera and a normal vector of the preset hole position is detected by the four laser distance sensors and the industrial camera and the four laser distance sensors cooperate with automatic numerically-controlled devices such as an industrial robot, a numerically-controlled machine tool and the like and thus high-precision and high-efficiency automatic hole milling is realized.

Owner:ZHEJIANG UNIV

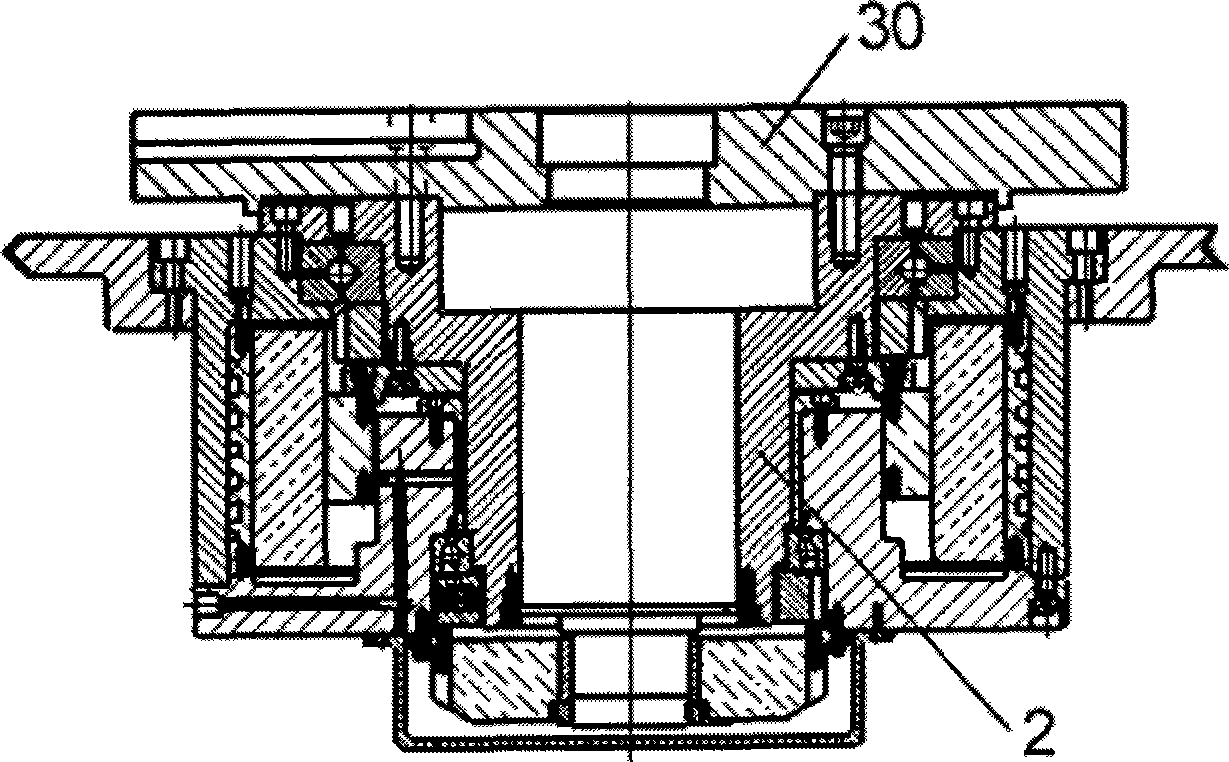

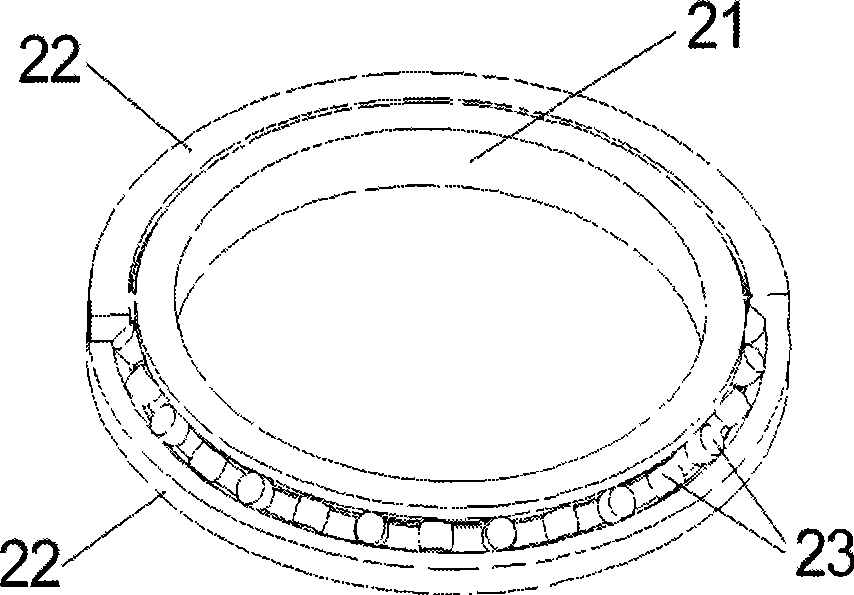

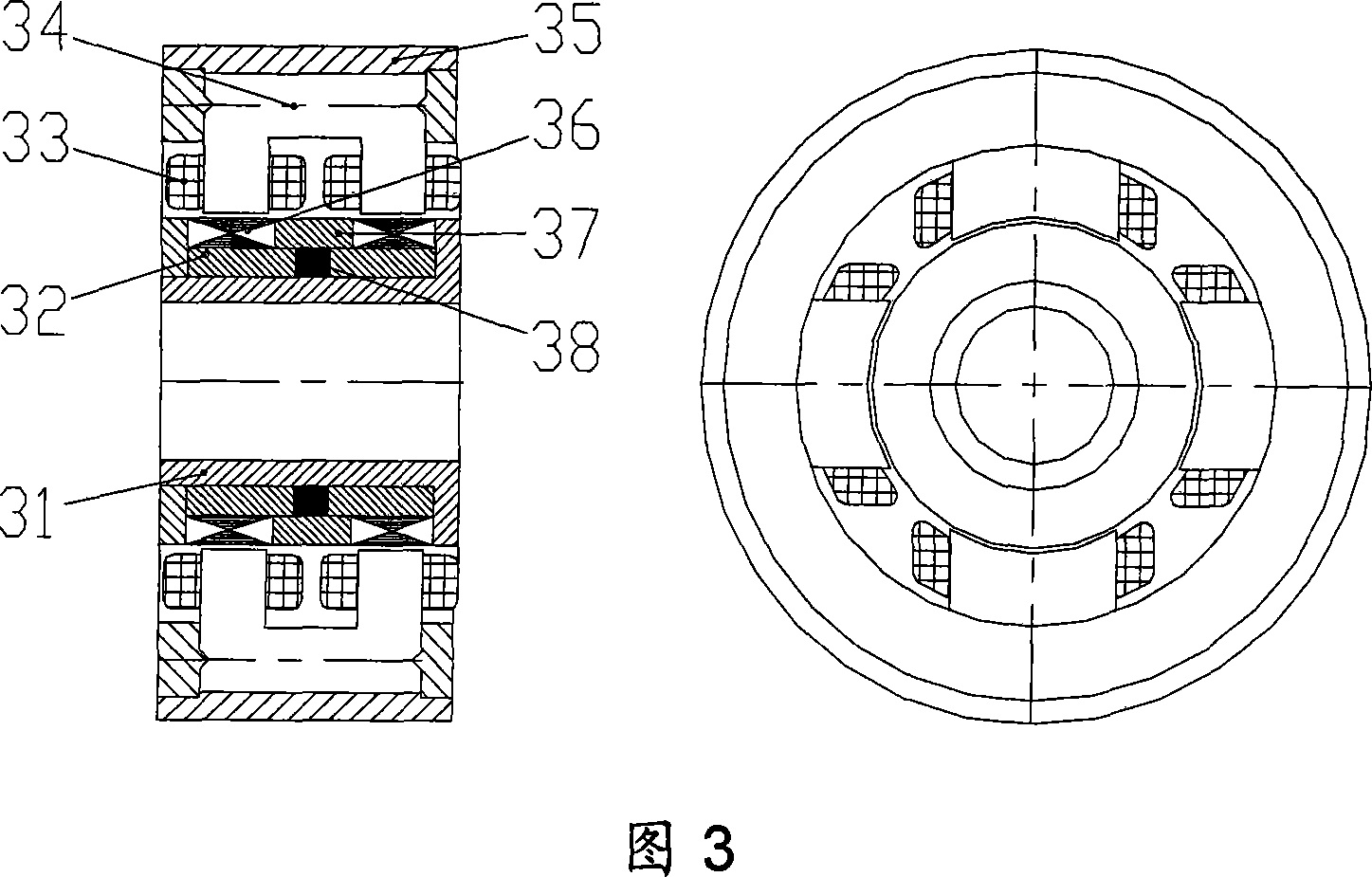

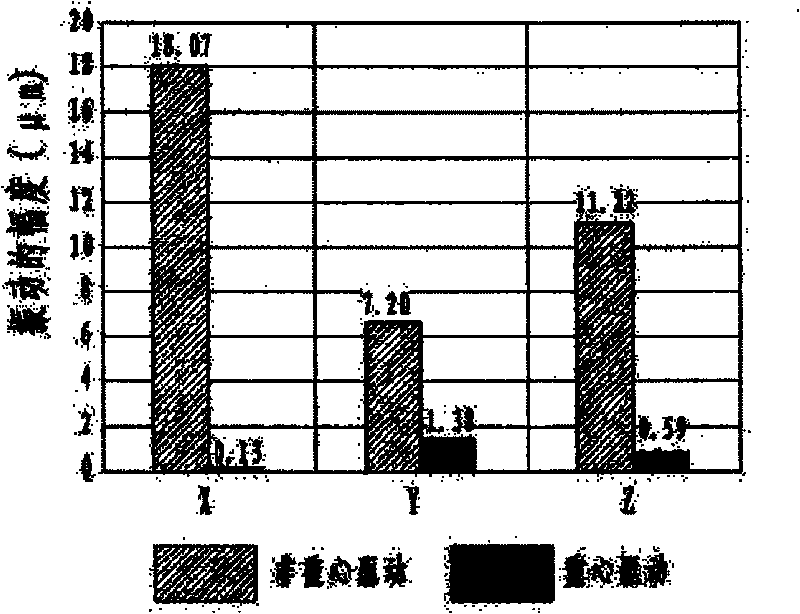

Direct driving type accurate turn plate

InactiveCN101480778ANo wearGood precision continuityRoller bearingsLarge fixed membersTorque motorDigital control

The invention discloses a direct driving type precise rotating table which comprises a working table (30) and a torque motor, wherein the torque motor comprises a motor shell (8), a main shaft (2), a stator (6) and a rotor (7), the motor shell (8) is fixedly connected with the stator (6) to form a static part, the main shaft (2) is fixedly connected with the rotor (7) to form a rotating part, and the working table (30) is directly and fixedly connected with the main shaft (2) of the torque motor. Furthermore, a circular arc crossing roller bearing (1) is arranged between the motor shell (8) and the main shaft (2) and comprises an inner ring (21), two outer rings (22) and a plurality of circular arc rollers (23) arranged among of the inner ring (21) and the outer rings (22), and the circular arc rollers (23) are sequentially crossed in an angle of 90 DEG. The invention has high radial and axial load capacity, good rigidity and high motion precision and stability, and can meet the integrated requirements of serving as a high-precision digital control rotating table.

Owner:三六零安全科技股份有限公司 +2

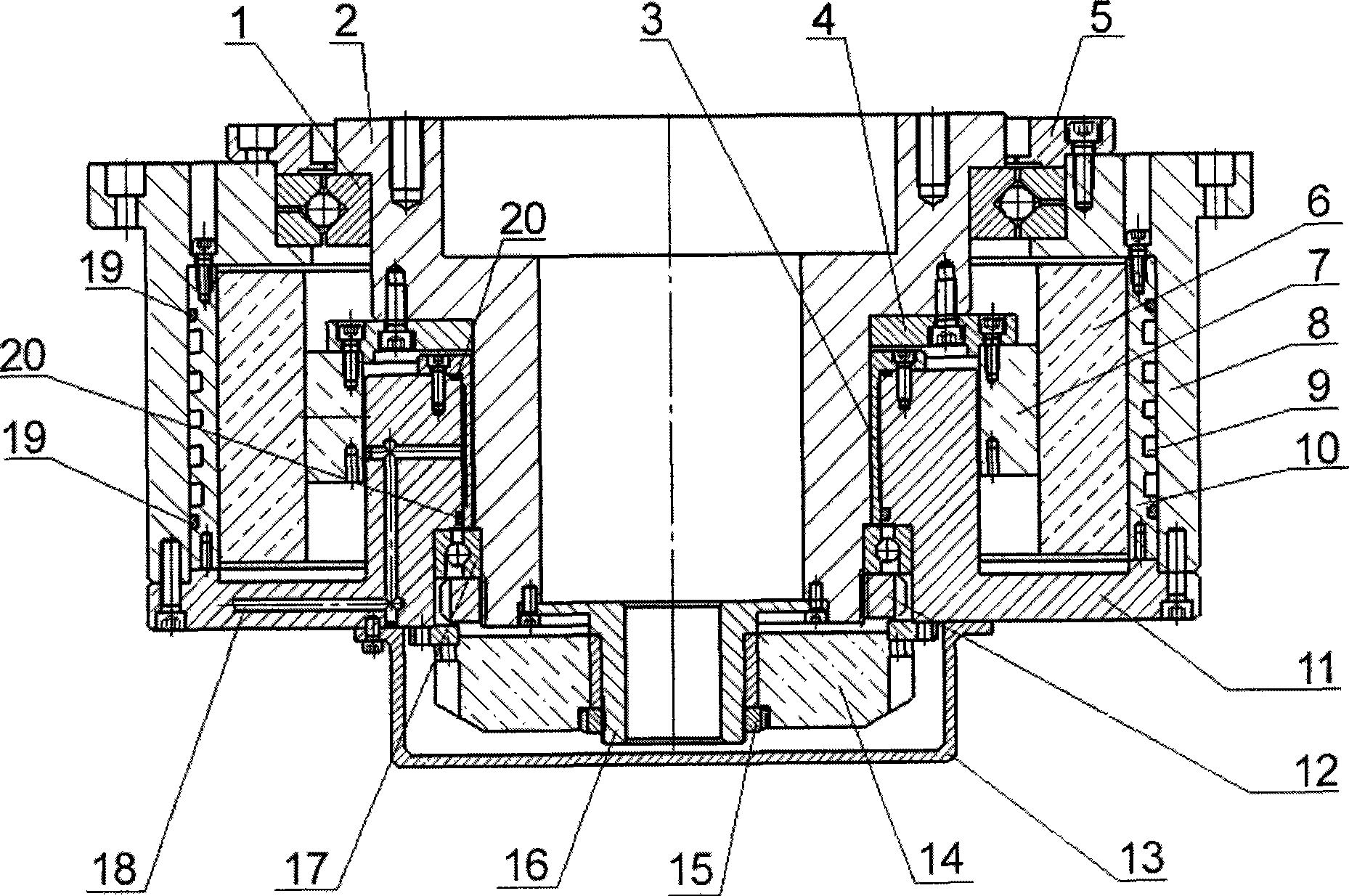

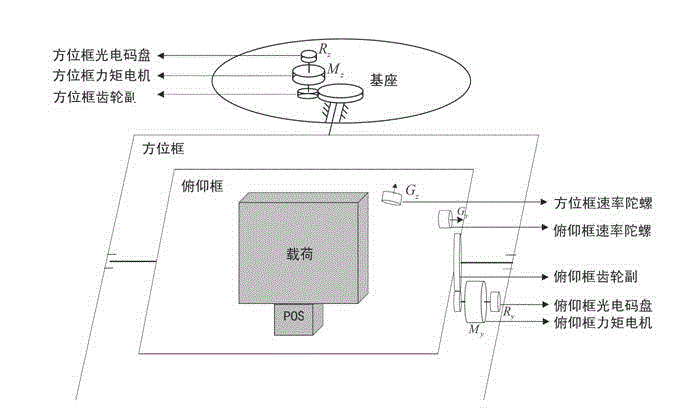

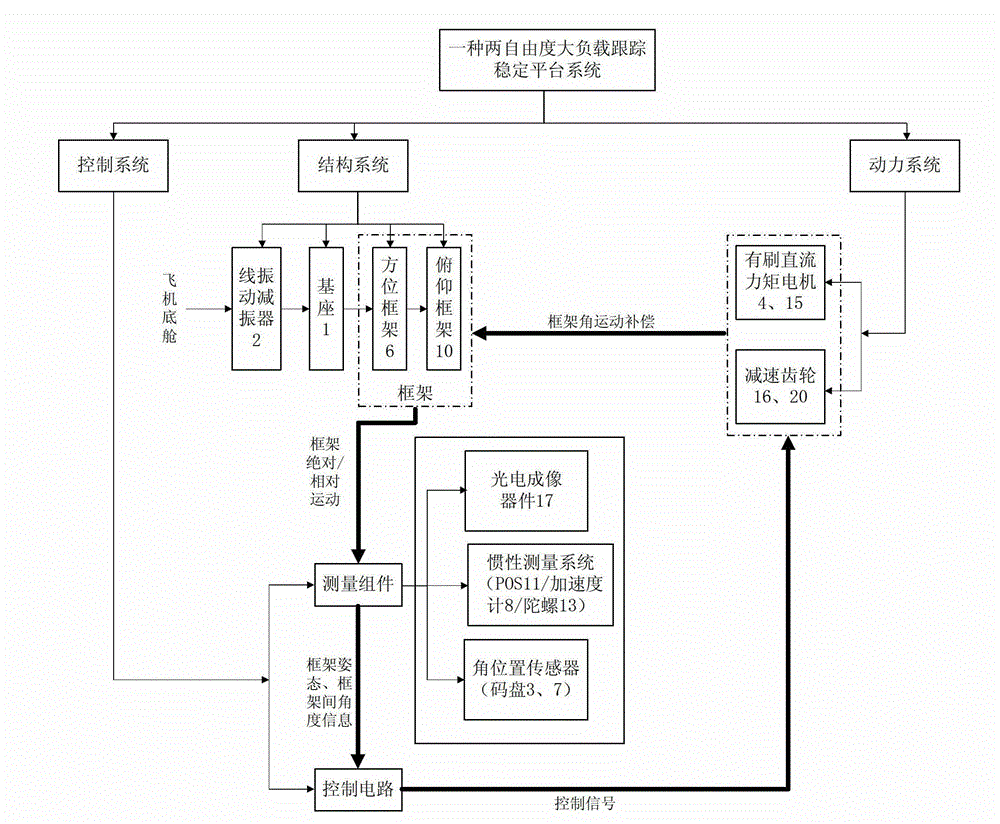

Two-freedom-degree heavy-load tracking stabilized platform system

ActiveCN103149948AOvercome the disadvantages of large load volumeLoad largeNavigation by speed/acceleration measurementsControl using feedbackAviationGyroscope

The invention relates to a two-freedom-degree heavy-load tracking stabilized platform system which comprises a base, four line vibration dampers, a position framework, a pitching framework, external loads (a photoelectric imaging device, two micro-electromechanical system (MEMS) accelerometers two MEMS gyroscopes and a position orientation system (POS)), two direct current (DC) torque motors with brushes, two photoelectric coded discs and two framework control circuits. The base is connected with an airplane through line vibration dampers for isolating airplane line vibration. The position framework is supported by the base and carries a pitching frame component to achieve gyration within 0 degree to 360 degrees. The pitching framework is supported by a position frame and carries external loads to achieve gyration within -90 degrees to 0 degree. A control part drives a motor to enable the framework to rotate according to frame angular rate information which is provided by the gyroscopes and attitude information which is provided by the POS or the accelerometers, so that airplane angular motion is compensated and isolated. The two-freedom-degree heavy-load tracking stabilized platform system has the advantages of being high in precision, large in ration between load and self weight, standard in self attitude, and suitable for camera boresight stability in light small air monitoring systems.

Owner:BEIHANG UNIV

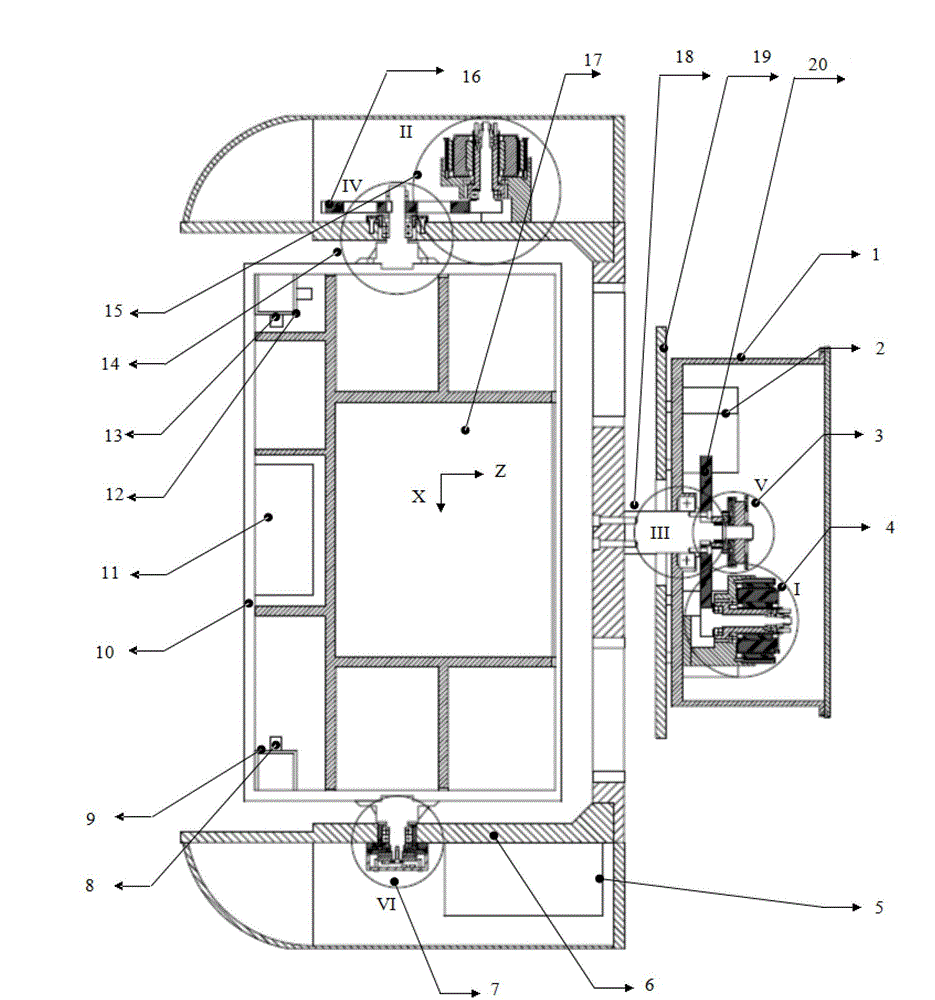

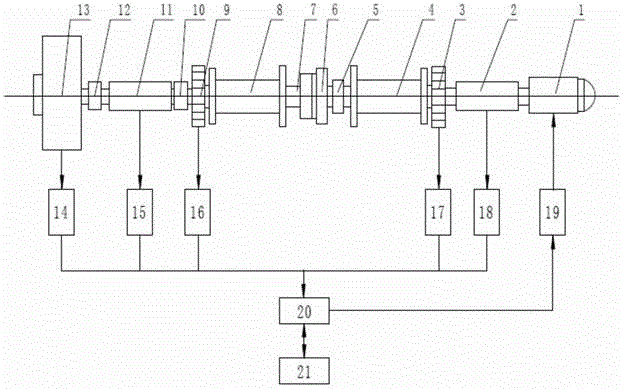

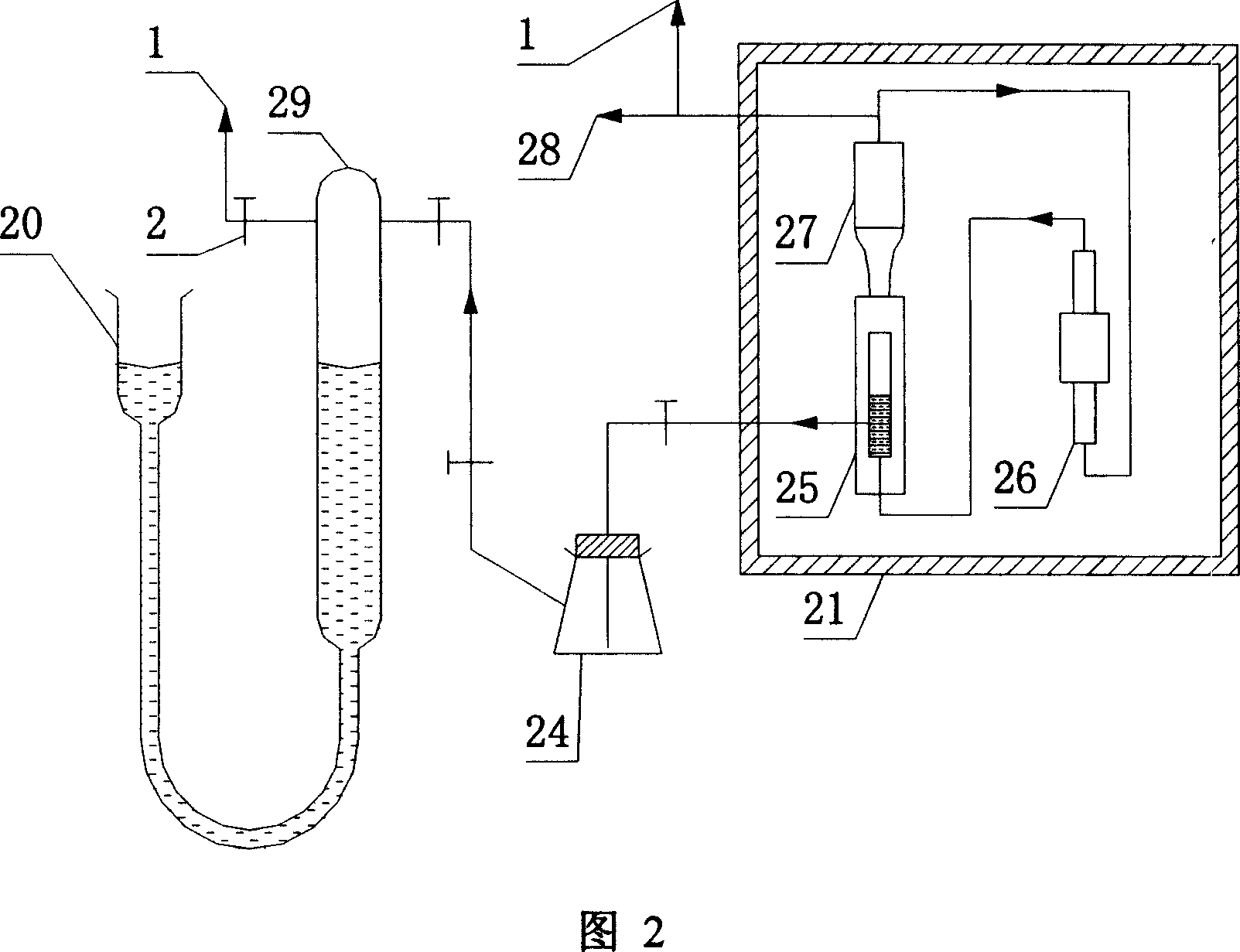

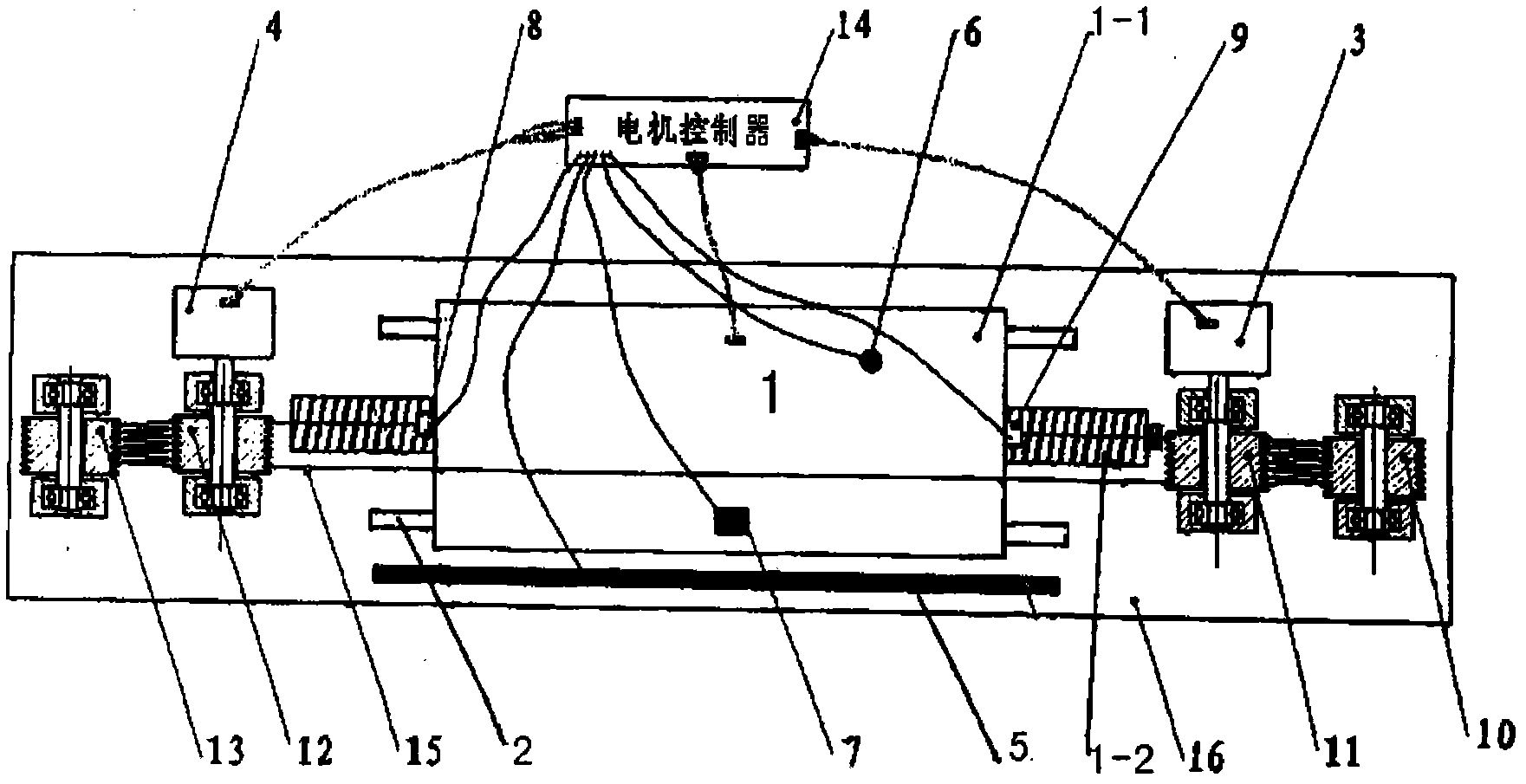

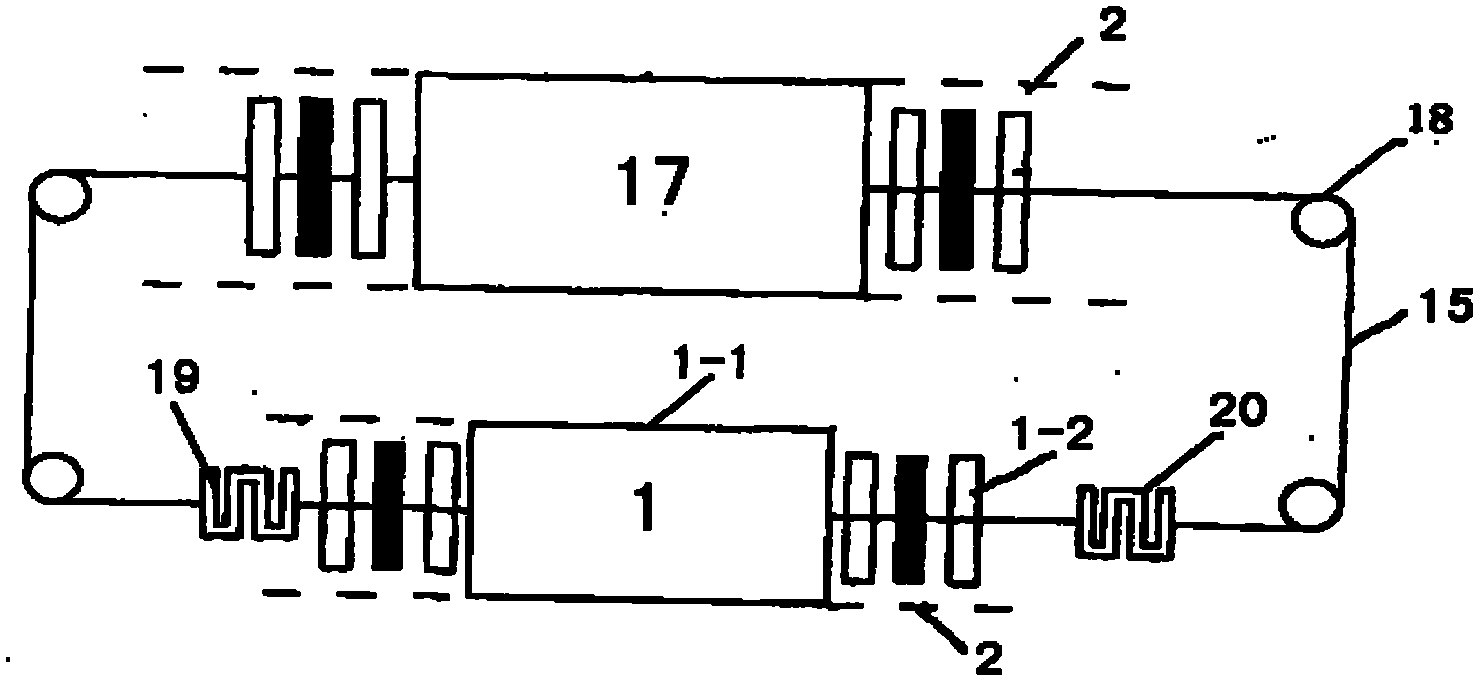

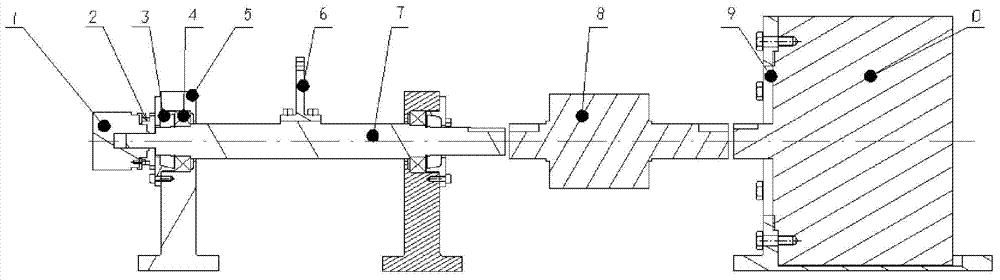

Vacuum high/low temperature environmental simulation electromechanical transmission mechanism comprehensive performance experimental system

InactiveCN101886978AReduce volumeLow costMachine gearing/transmission testingStands/trestlesTorque motorOptical table

The invention discloses a vacuum high / low temperature environmental simulation electromechanical transmission mechanism comprehensive performance experimental system, which comprises an experimental platform, a driving assembly, a vacuum high / low temperature experimental assembly, a normal temperature and normal pressure experimental assembly and a loading assembly. The driving assembly comprises a servo motor, an input end torque and speed sensor and an input end angle encoder; the vacuum high / low temperature experimental assembly comprises vacuum high / low temperature environmental simulation equipment, an optical platform, and input and output end magnetic fluid sealing shafts; and the loading assembly comprises an output end angle encoder, an output end torque and speed sensor and a torque motor. The vacuum high / low temperature environmental simulation equipment has low cost, the installation of the driving assembly and the loading assembly is performed outside a vacuum tank, and the installation and debugging are convenient. Due to the adoption of a modular design, the experimental system can test the comprehensive performance of a speed reducer and other rotating mechanisms under the conditions of space environment and normal temperature and normal pressure environment on the same experimental system, and has the advantages of strong adaptability of the equipment and high detection accuracy.

Owner:SICHUAN UNIV +1

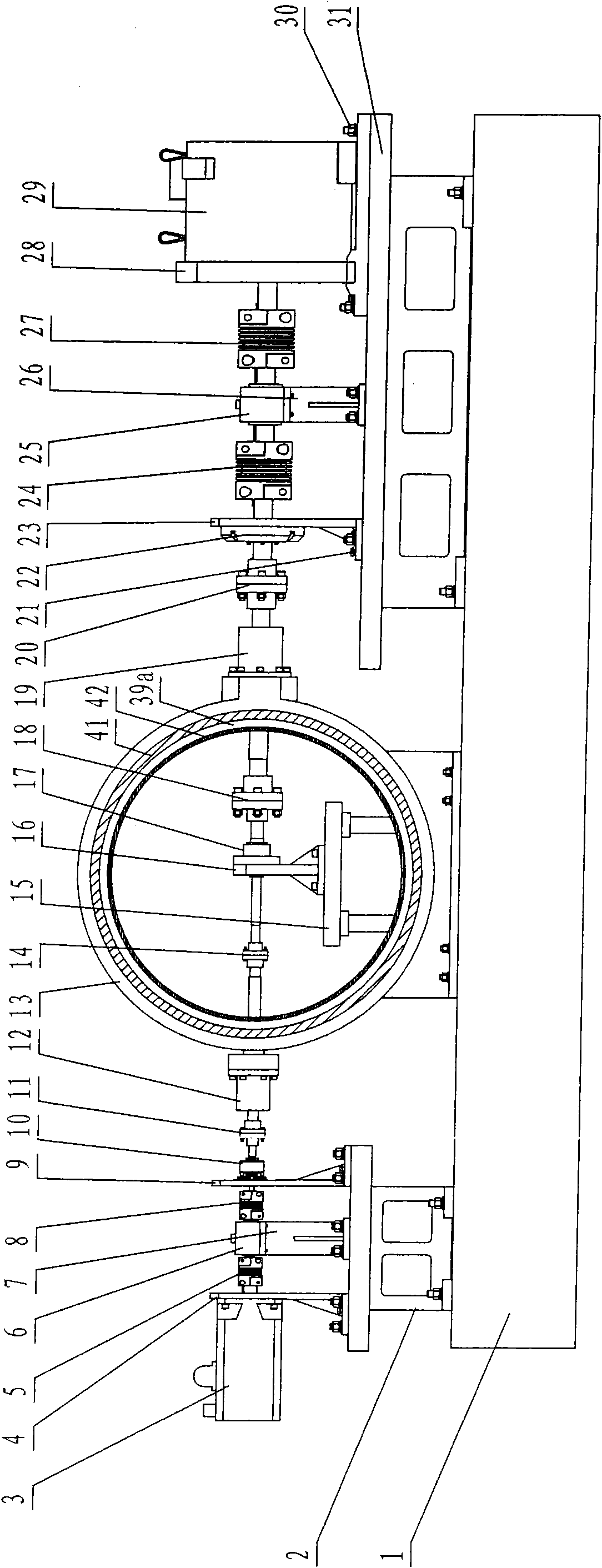

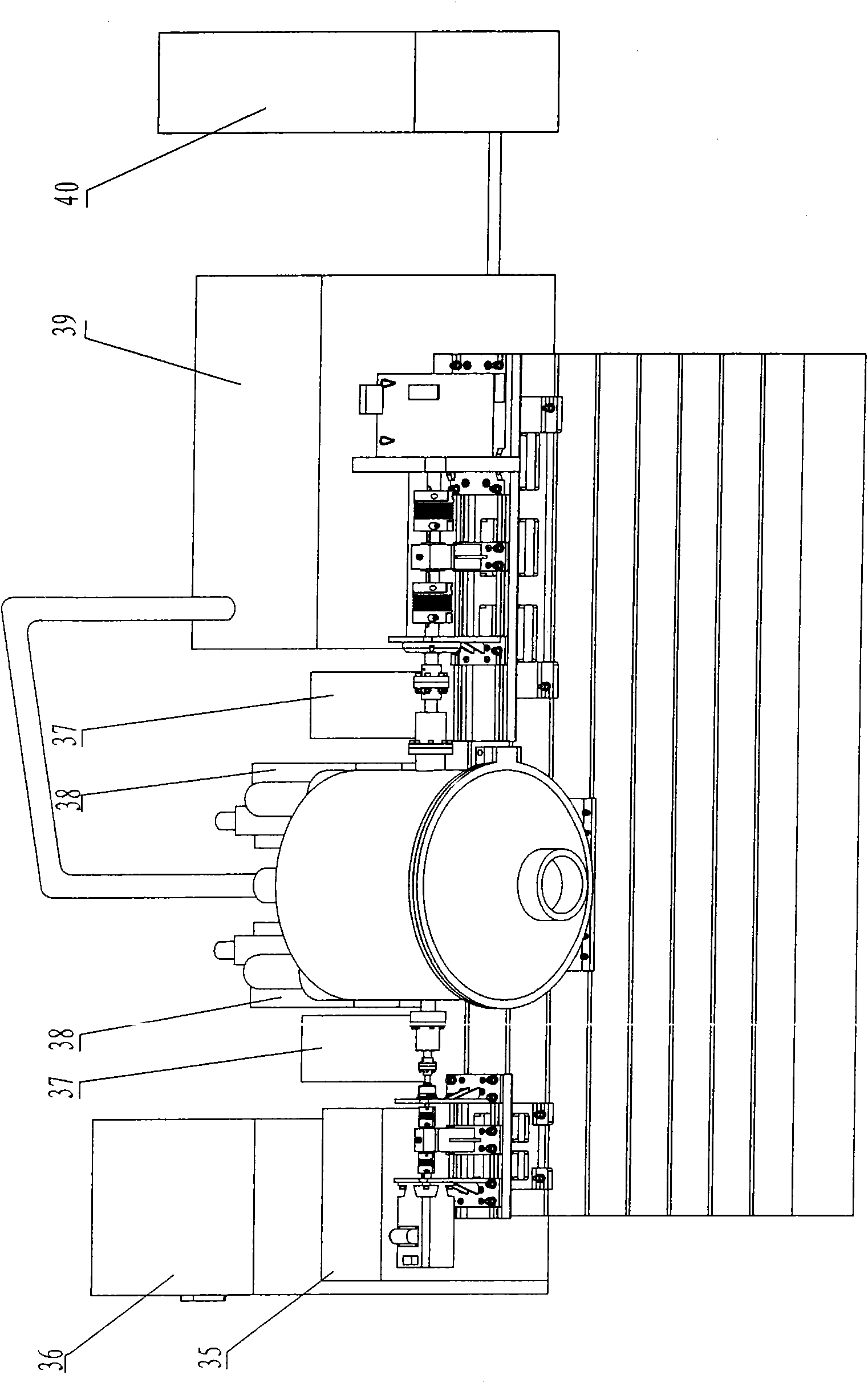

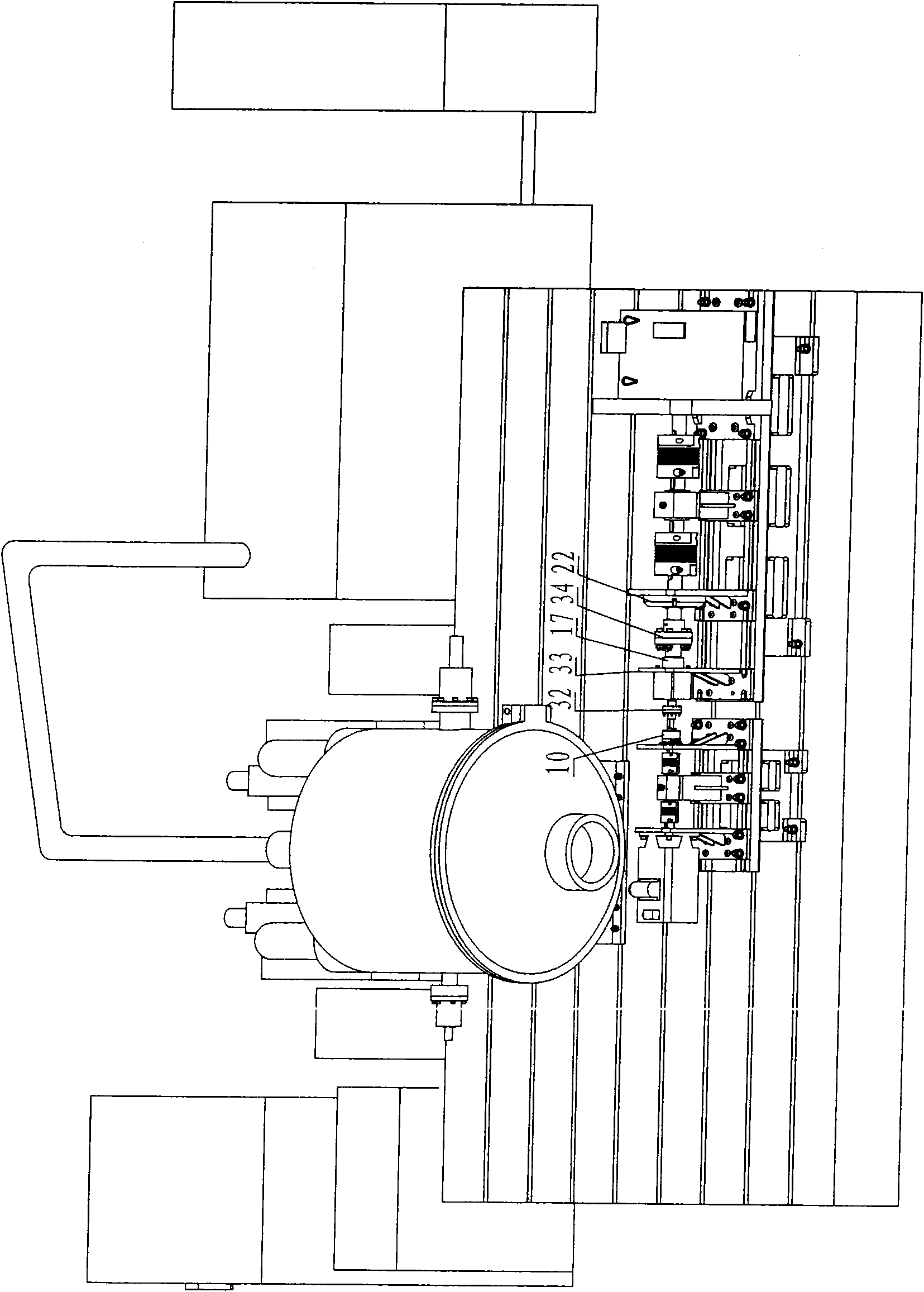

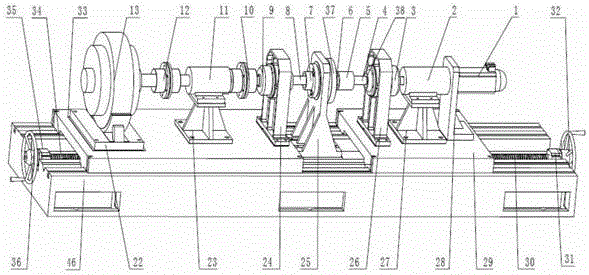

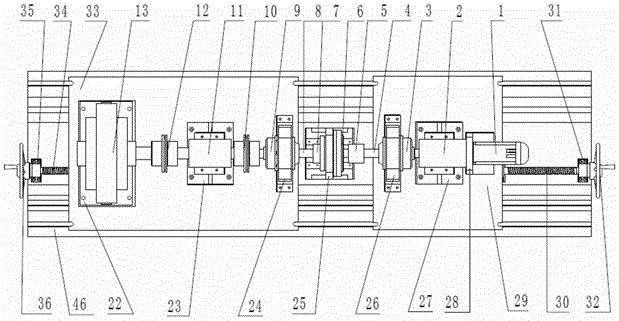

Measuring instrument for comprehensive performances of RV (rot-vector) reducer

InactiveCN104568428ASimplified installation stepsMachine gearing/transmission testingMeasuring instrumentTorque motor

The invention relates to a measuring instrument for comprehensive performances of an RV (rot-vector) reducer and belongs to the technical field of precision testing and metering. The measuring instrument comprises two major parts, wherein a mechanical part mainly comprises a precision mounting support of the RV reducer, an input shaft system, an output shaft system, a torque motor, a shaft coupling, a torque sensor, a magnetic powder brake and a brake mounting support; a measuring and controlling part mainly comprises the torque motor, a controller, a driver, an encoder, a subdivision device, a DSI (digital speech interpolation) card, a data acquisition card and an industrial personal computer. The measuring instrument provided by the invention fills in the blank in testing tables for the comprehensive performances of the RV reducers at home and abroad, and has the advantages of reliable performances, good measurement repeability and accurate measured parameters.

Owner:BEIJING UNIV OF TECH

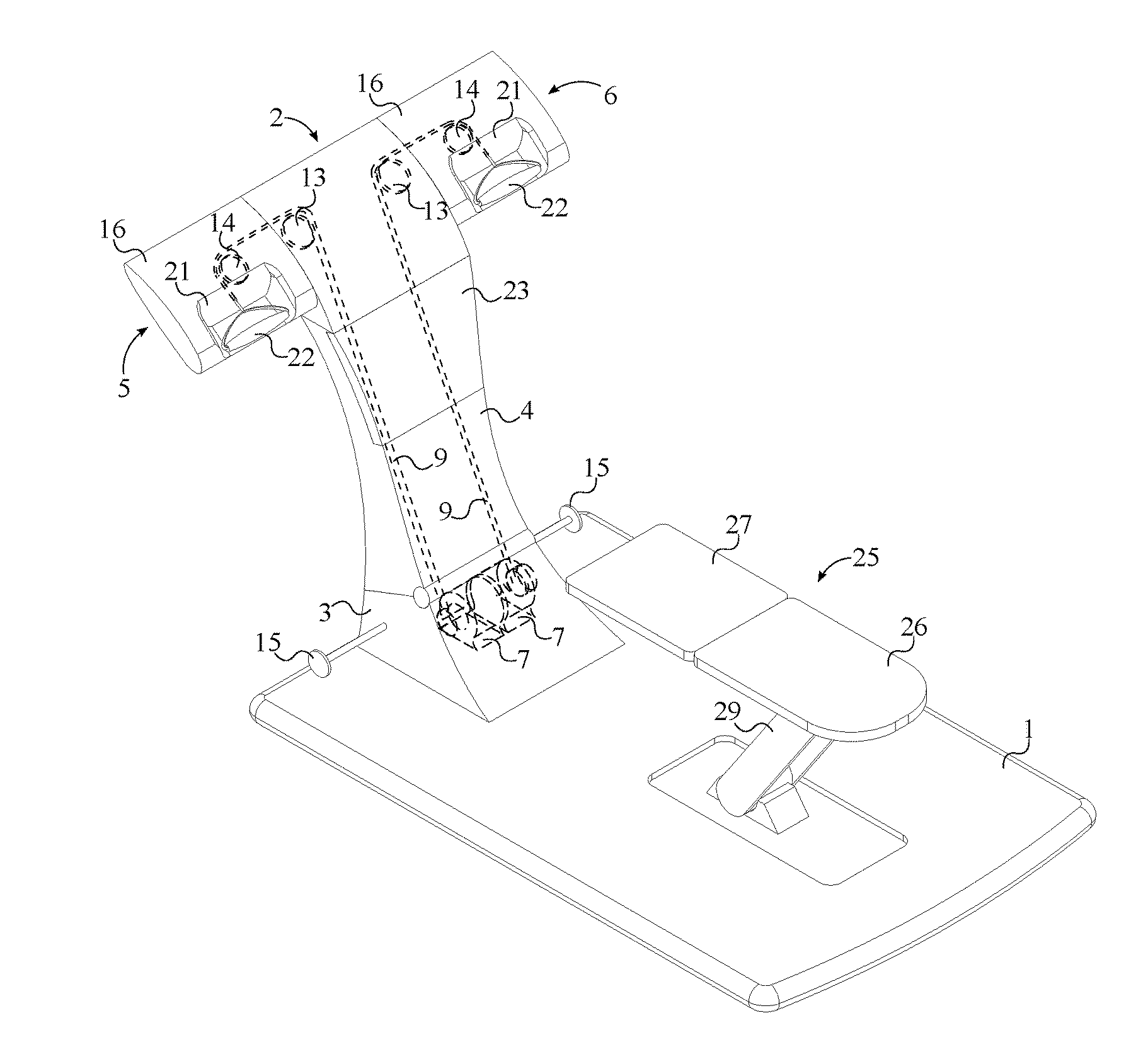

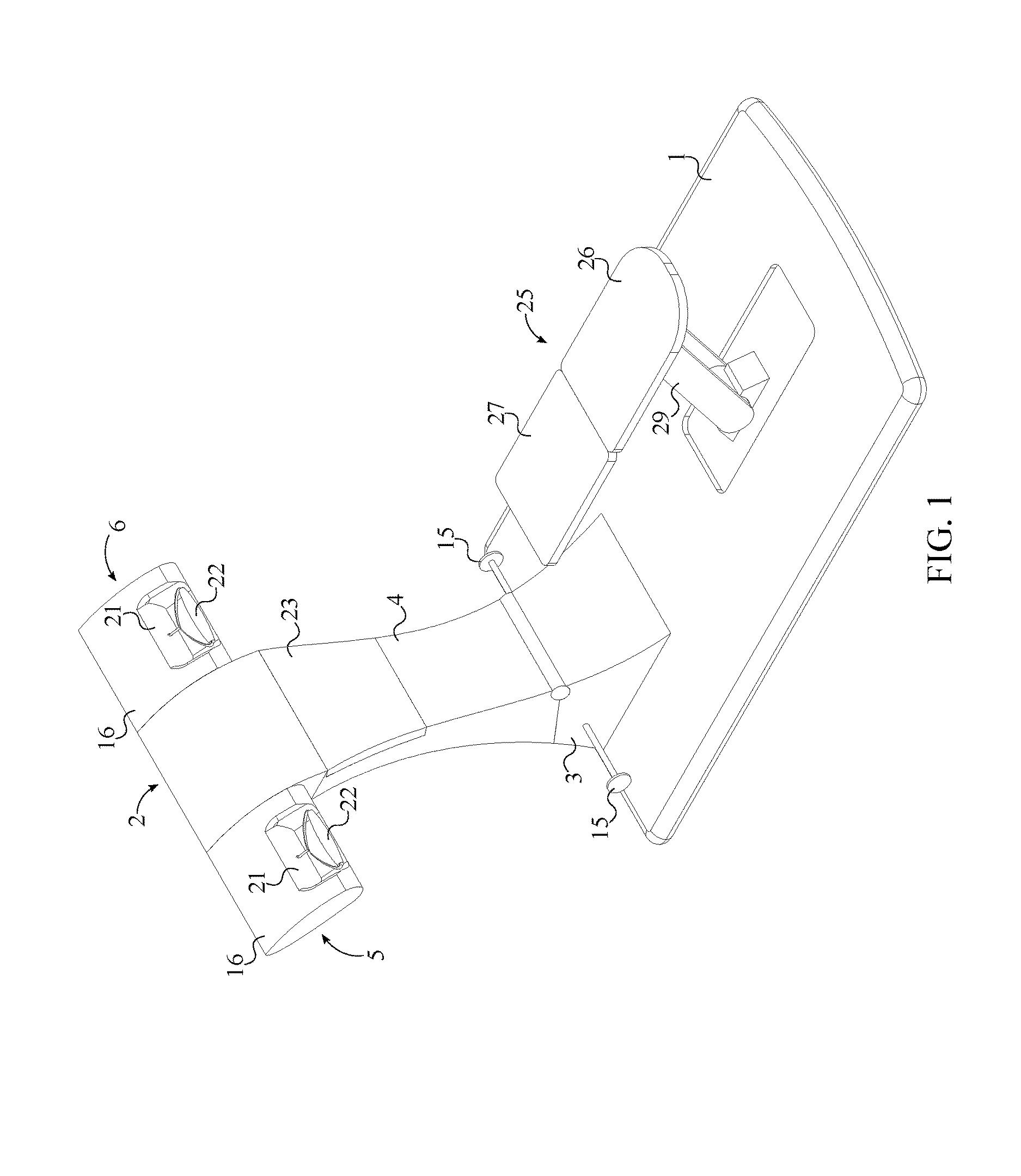

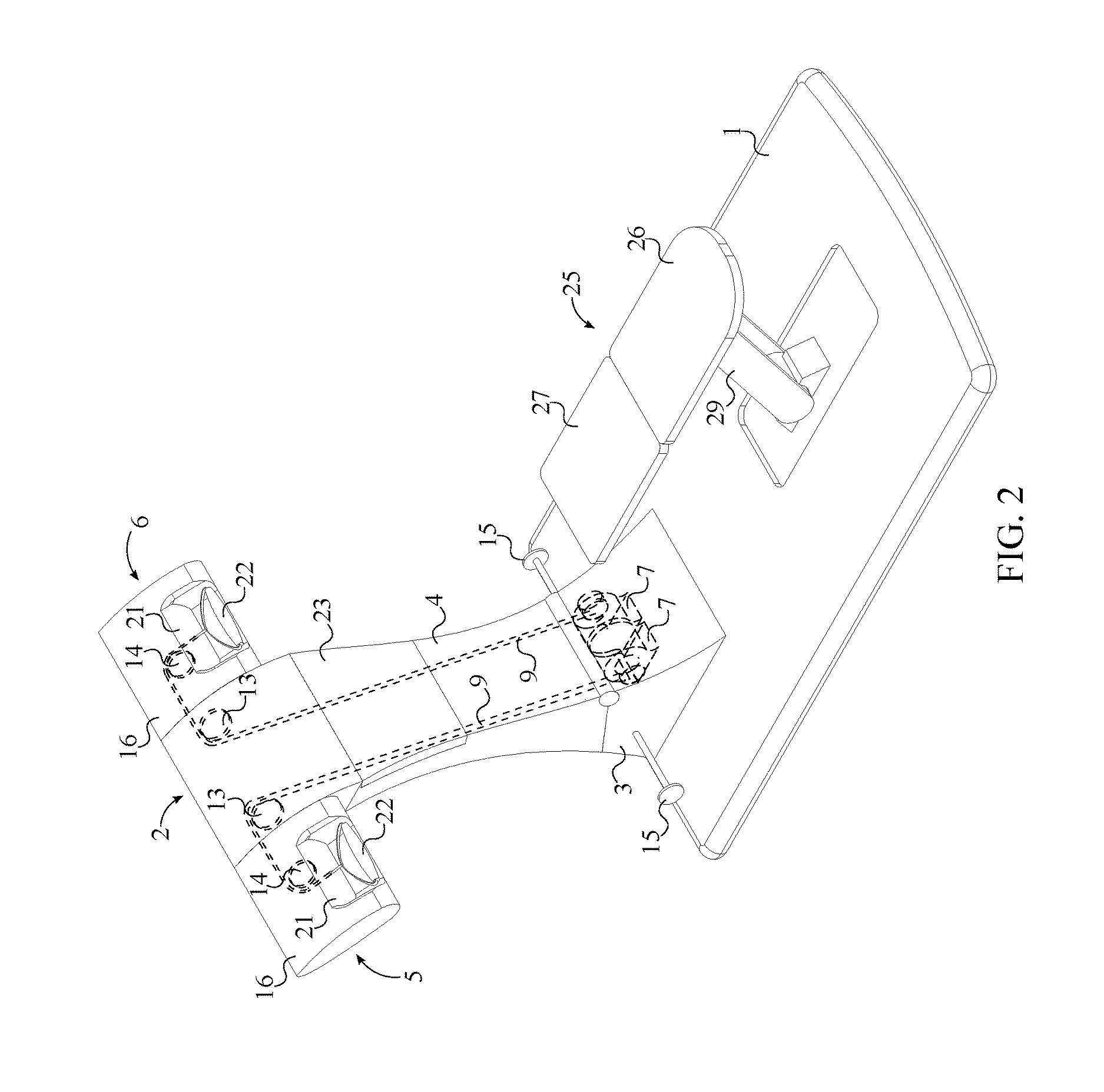

Multi-positioning exercise machine with dynamic resistance

An exercise machine which allows a user to perform a variety of exercises using dynamic resistance. The exercise machine includes a platform base, a housing tower, an upper-left exercise module, an upper-right exercise module, and a control console. The upper-left exercise module and the upper-right exercise module each comprise a primary torque motor, a primary cable, a pulley system, a structural arm, and a primary handle. The housing tower is connected onto the platform base. The upper-left exercise module and the upper-right exercise module are integrated into the housing tower and provide a means for applying a resistance force onto the extremities of the user. The primary cable tensionably engages the pulley system and connects the primary handle to the primary torque motor. The primary handle rests within and against the structural arm, attached to the housing tower. The control console allows for external device compatibility.

Owner:XOMETRICS INC

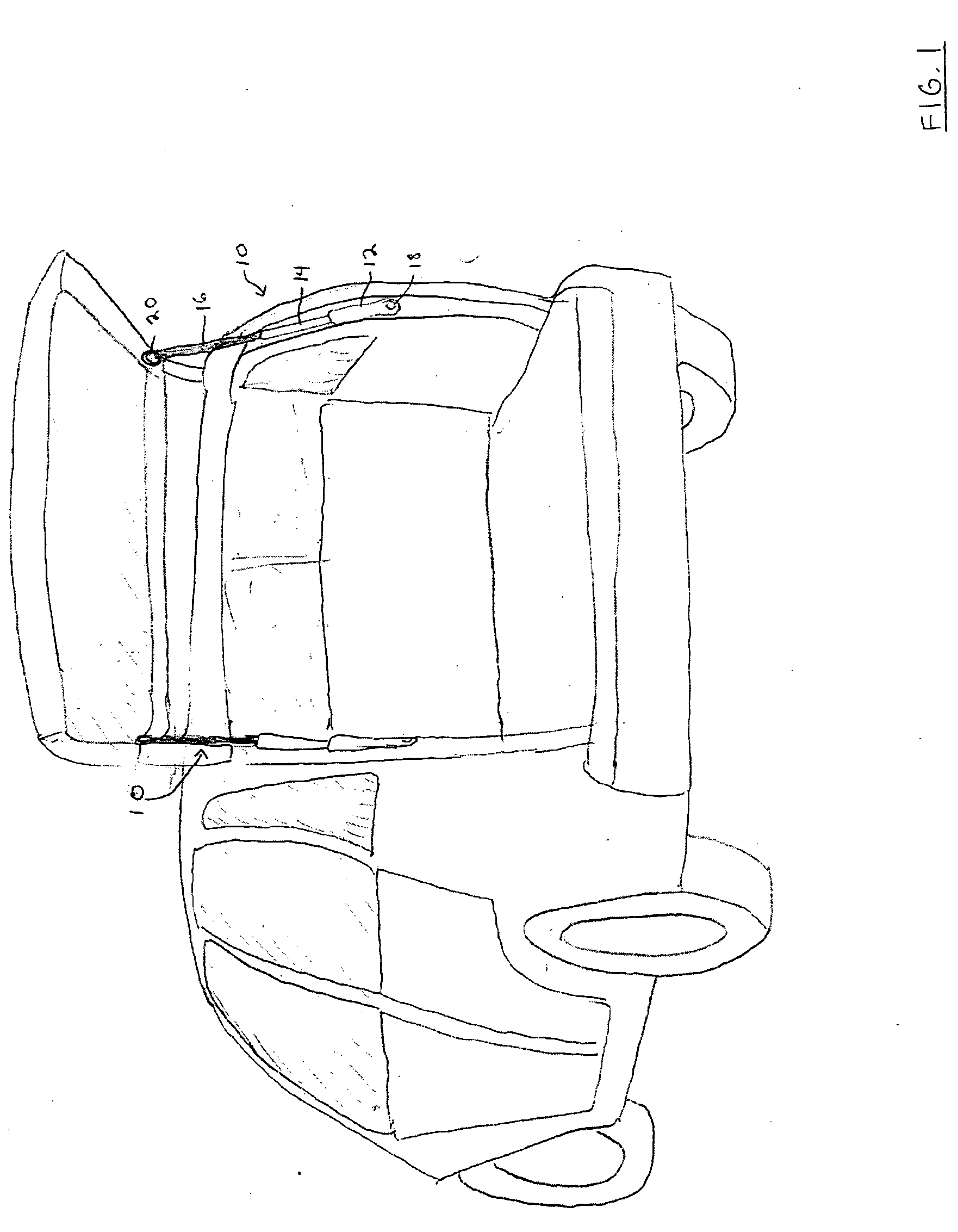

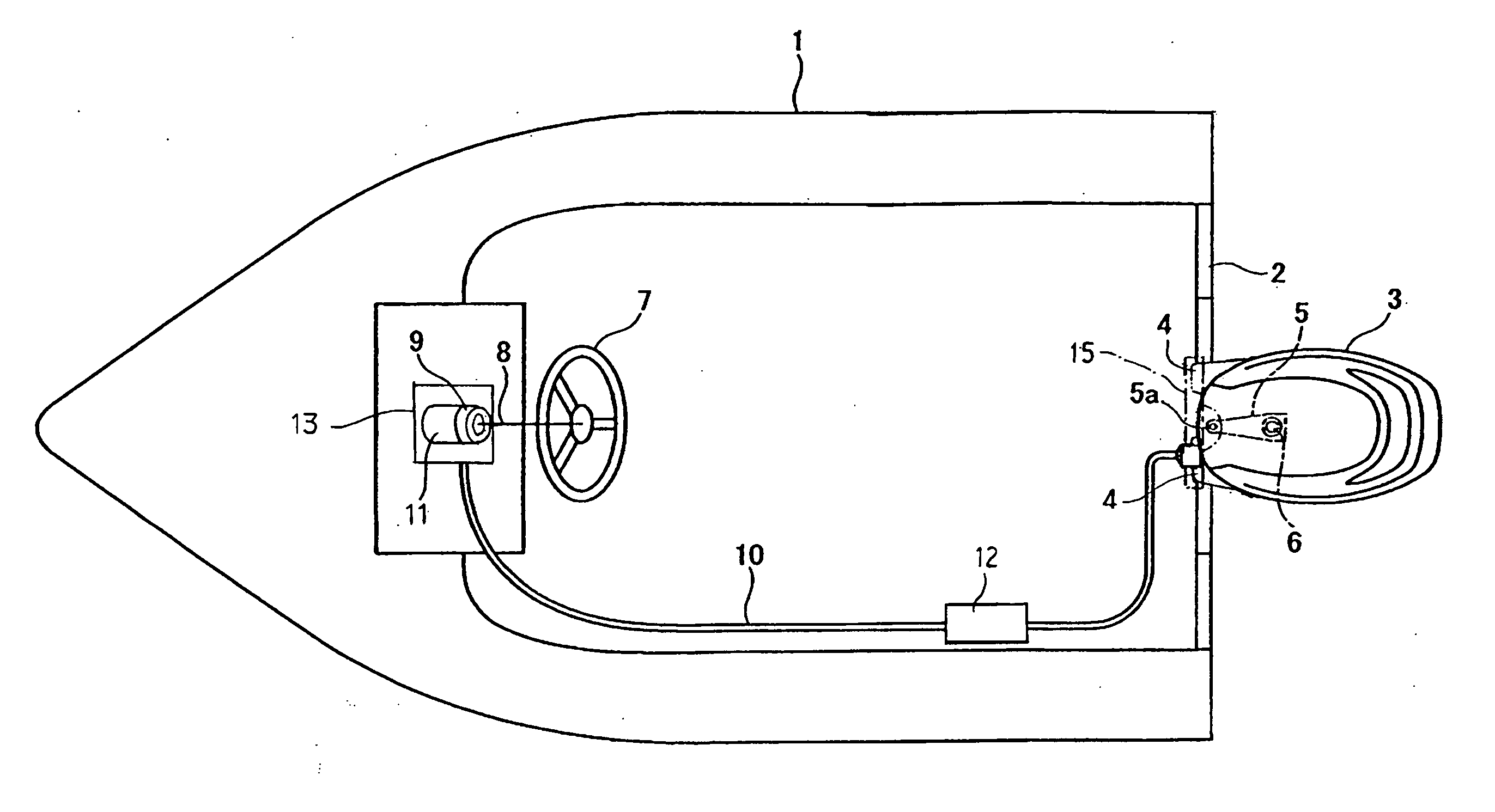

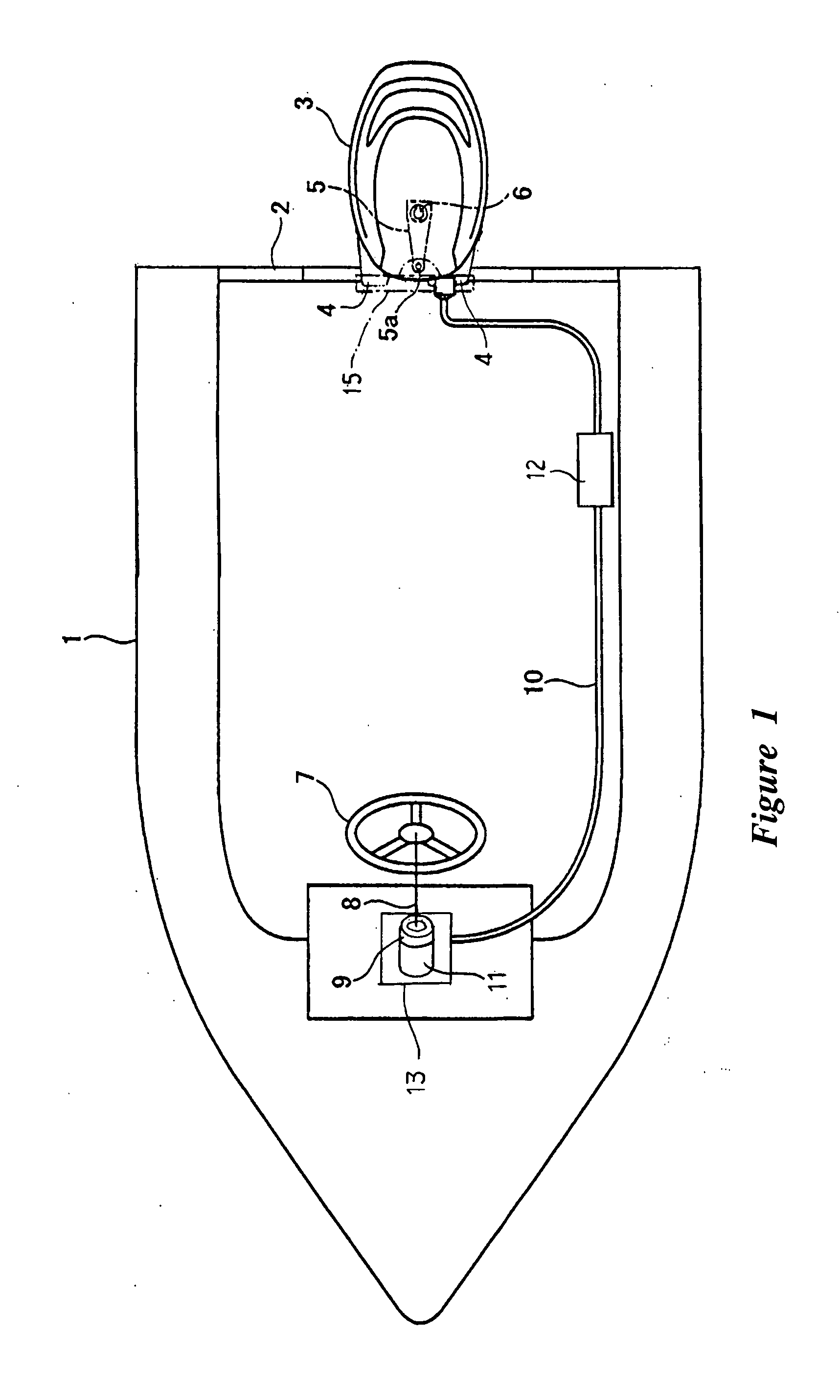

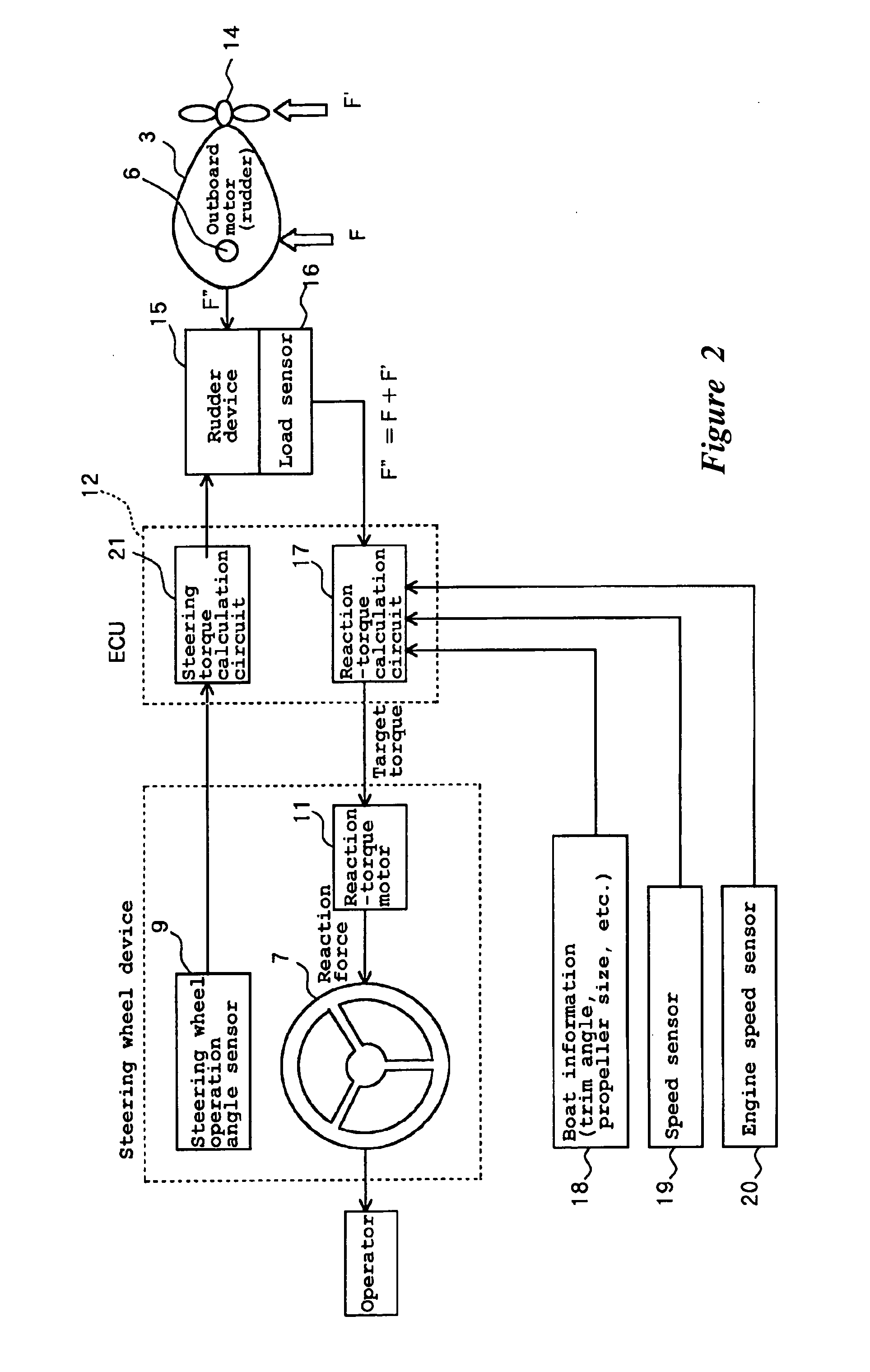

Electric steering apparatus for watercraft

InactiveUS20050199168A1Quick responseEnhanced advantageSteering ruddersPropulsion power plantsSteering wheelTorque motor

An electric steering apparatus can include a rudder device driven by an electric motor, a steering wheel for operation by an operator to control the angle of the rudder device, a reaction torque motor for applying a reaction force to the steering wheel, a load sensor for detecting an external force acting on a boat or the rudder during steering, and a reaction torque calculator circuit for calculating a target torque for the reaction motor according to an input of the load sensor.

Owner:YAMAHA MARINE KK

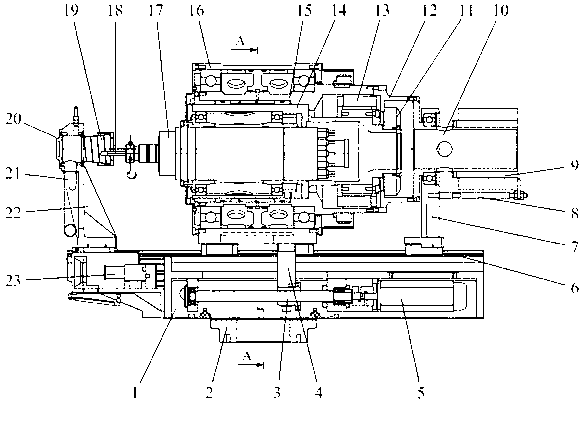

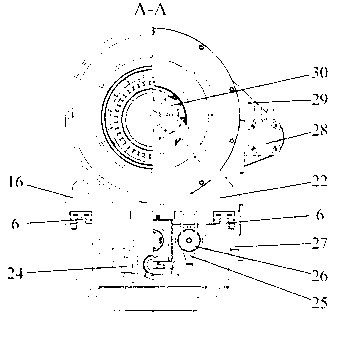

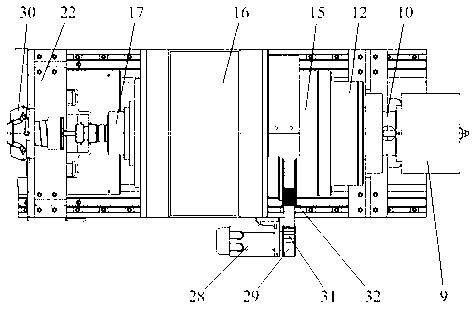

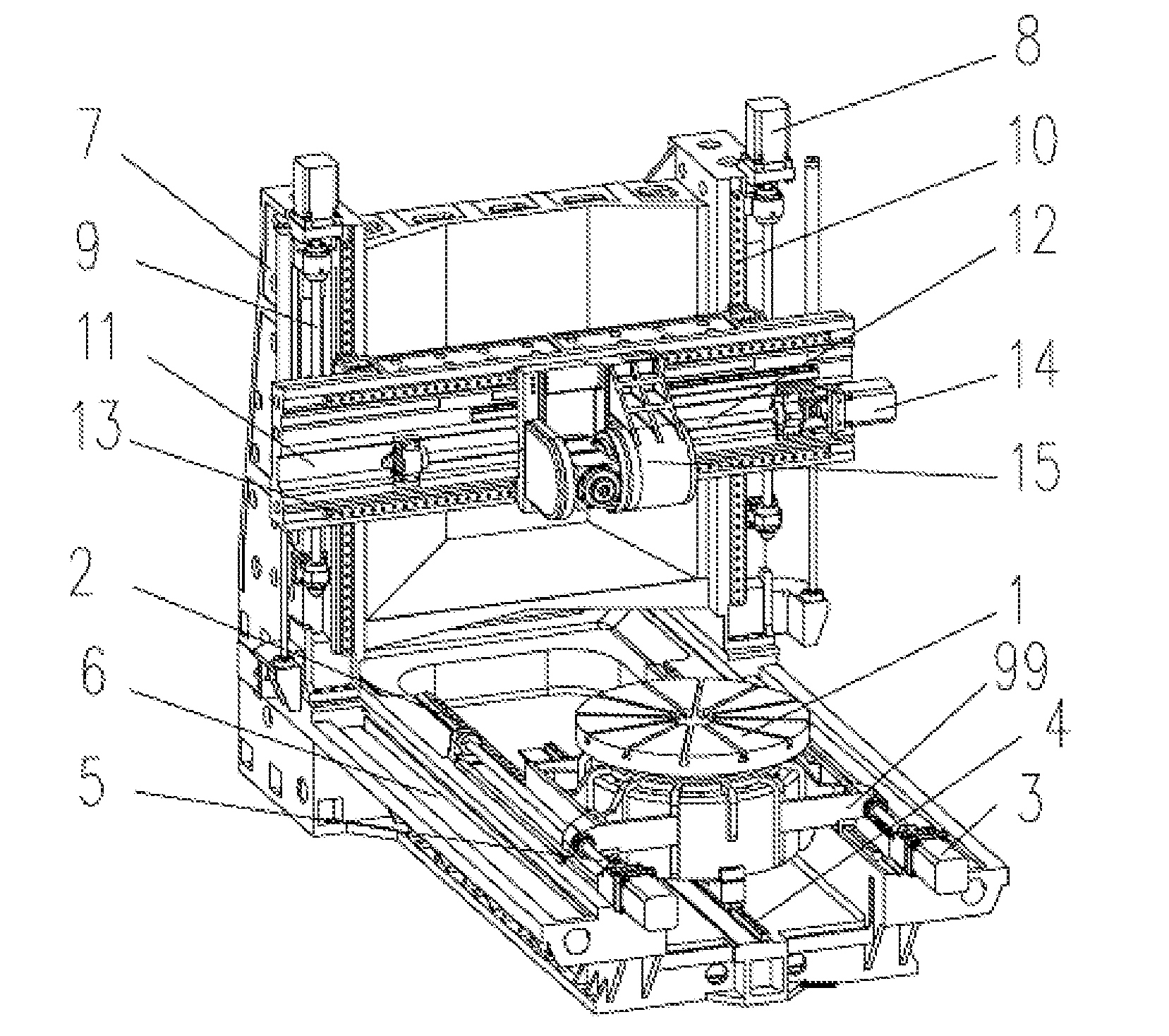

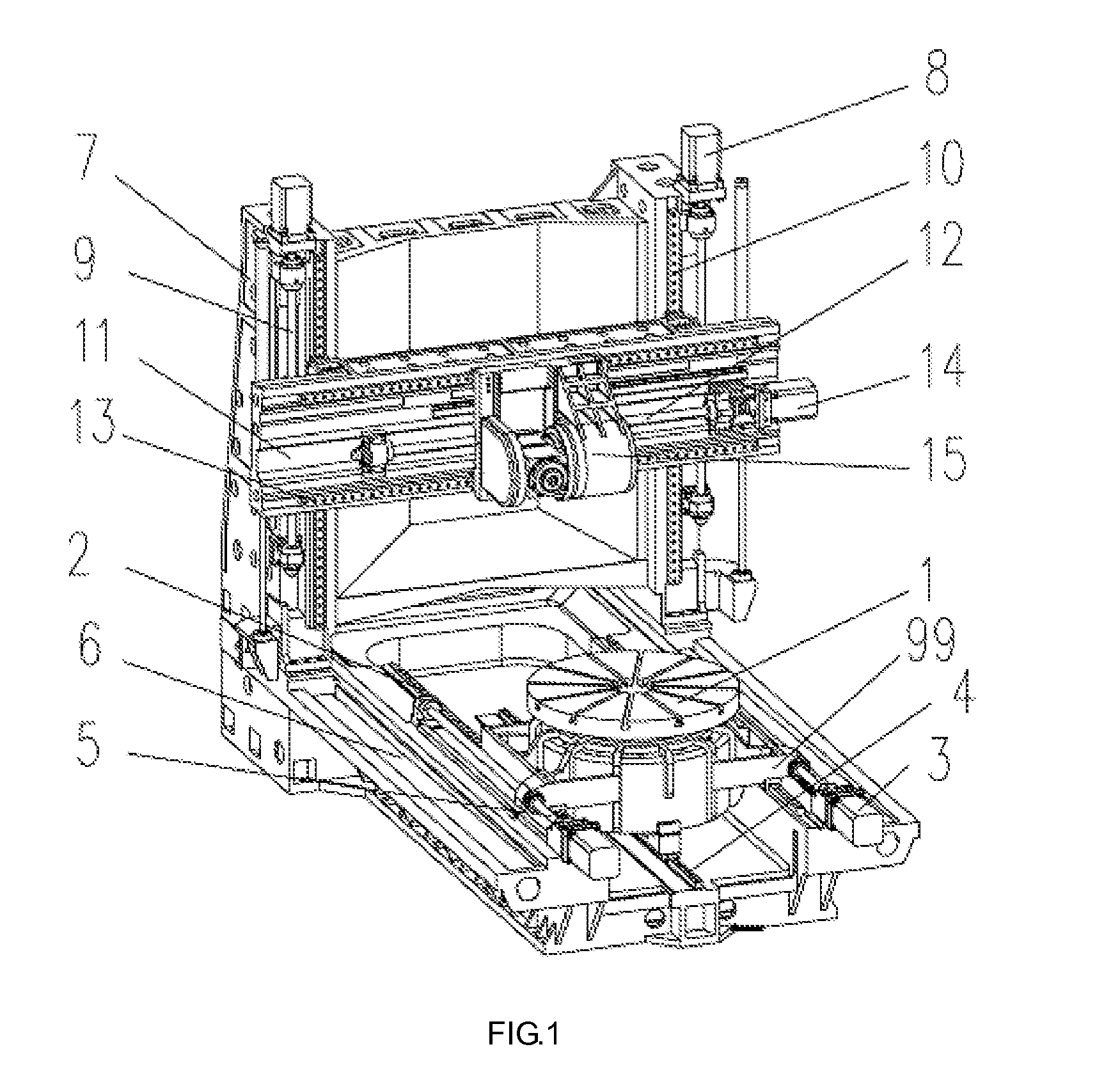

Vertical turning-milling complex machining center

ActiveUS20120210551A1Avoid vibrationDeformation MinimizationLathesAutomatic/semiautomatic turning machinesReciprocating motionTorque motor

A vertical turning-milling complex machining center comprises a horizontally-arranged bed body (6) and a vertically-arranged column (7). The bed body (6) is provided with an X-axis lateral supporting linear track (2) and an X-axis guide screw (5). The bed body (6) is also provided with a uniaxial rotating table (1) which can reciprocate and is driven directly by a first external rotor torque motor. The column (7) is vertically provided with a Z-axis lateral supporting linear track (10), a Z-axis guide screw (9) and a crossbeam (11) that reciprocates up and down. The crossbeam (11) is provided with a transverse Y-axis linear track (13), a Y-axis guide screw (12) and a single-pendulum milling head seat frame that can reciprocate along the Y-axis guide screw (12). The single-pendulum milling head is driven directly by a second external rotor torque motor. The vertical turning-milling complex machining center uses direct-drive technology applied to a B-axis and a C-axis, the motor torque is greatly increased and functional parts can stably operate, therefore the integral rigidity and stability of the machining center are improved.

Owner:KEDE NUMERICAL CONTROL CO LTD

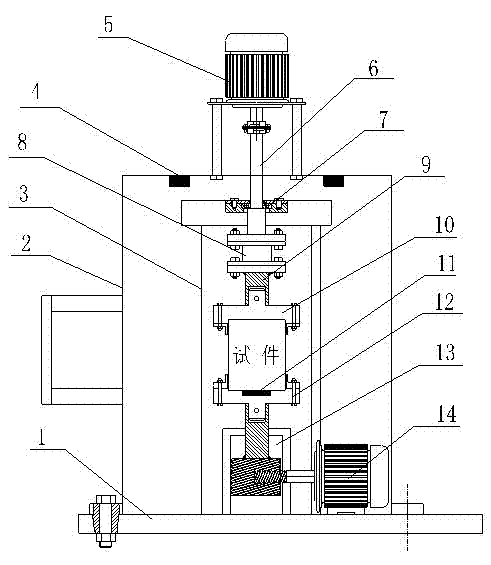

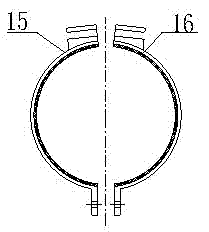

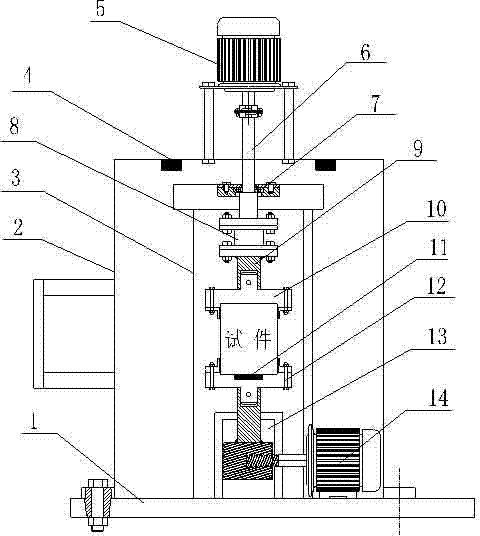

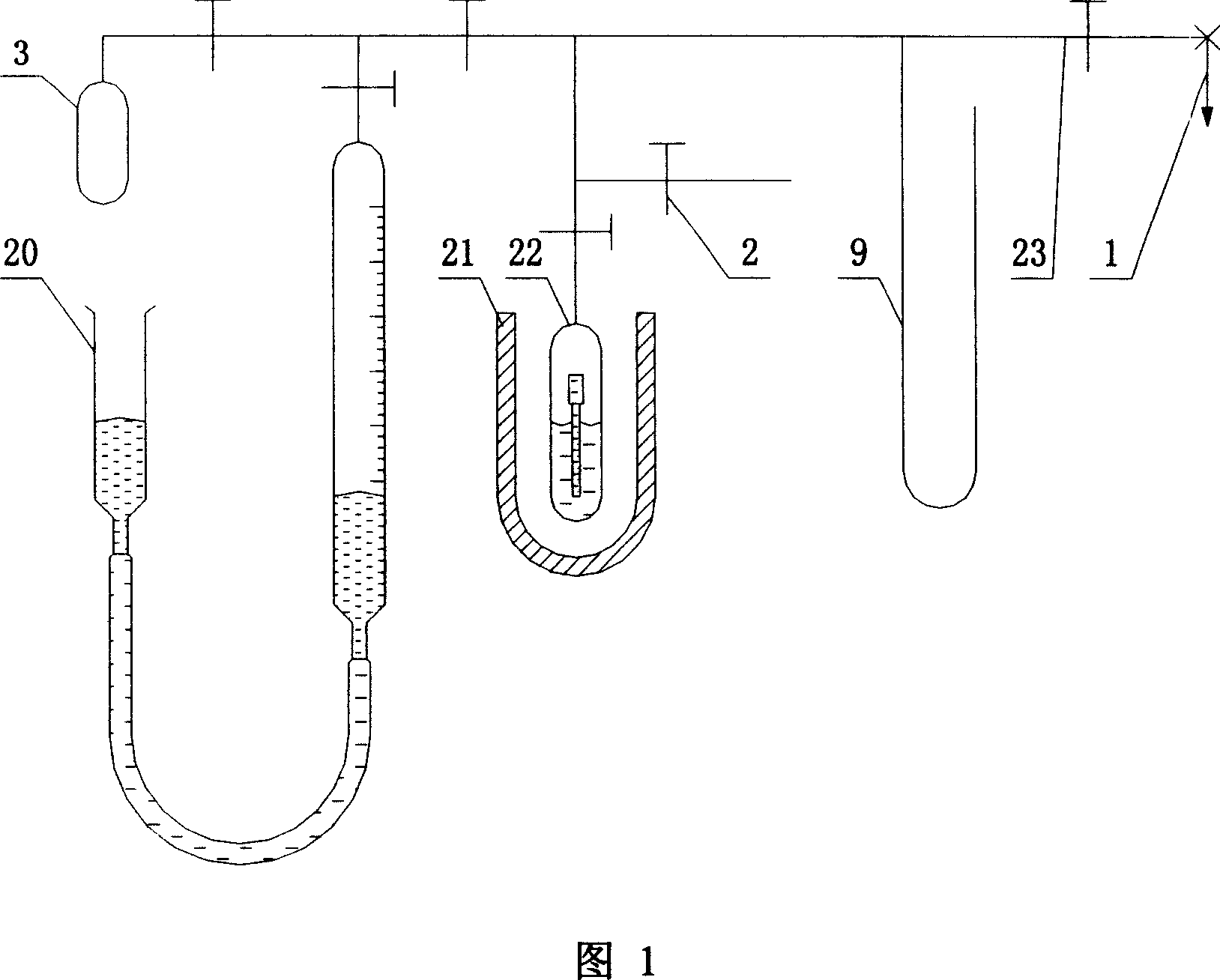

A torsional shear test device for asphalt pavement materials and structures

InactiveCN102297812AAccurately reflect the torsional shear deformation processPrevent deviationInvestigating material ductilityTorque motorClassical mechanics

The invention relates to the research field of asphalt pavement materials and structures in highway engineering, and discloses a torsional shear test device for asphalt pavement materials and structures, which is characterized in that it includes a machine base, a reaction force frame arranged on the machine base, and a The worm gear mechanism at the bottom of the reaction force frame, the worm input end of the worm gear mechanism is connected to the pressure motor, the output end of the worm gear is connected to the lower support plate for clamping the test piece, and the pressure sensor is arranged on the lower support plate; the reaction force frame A torque motor is arranged on the top, and the output shaft of the torque motor is connected downwards to the disc torque sensor and the upper support plate for clamping the specimen in turn.

Owner:CHANGAN UNIV

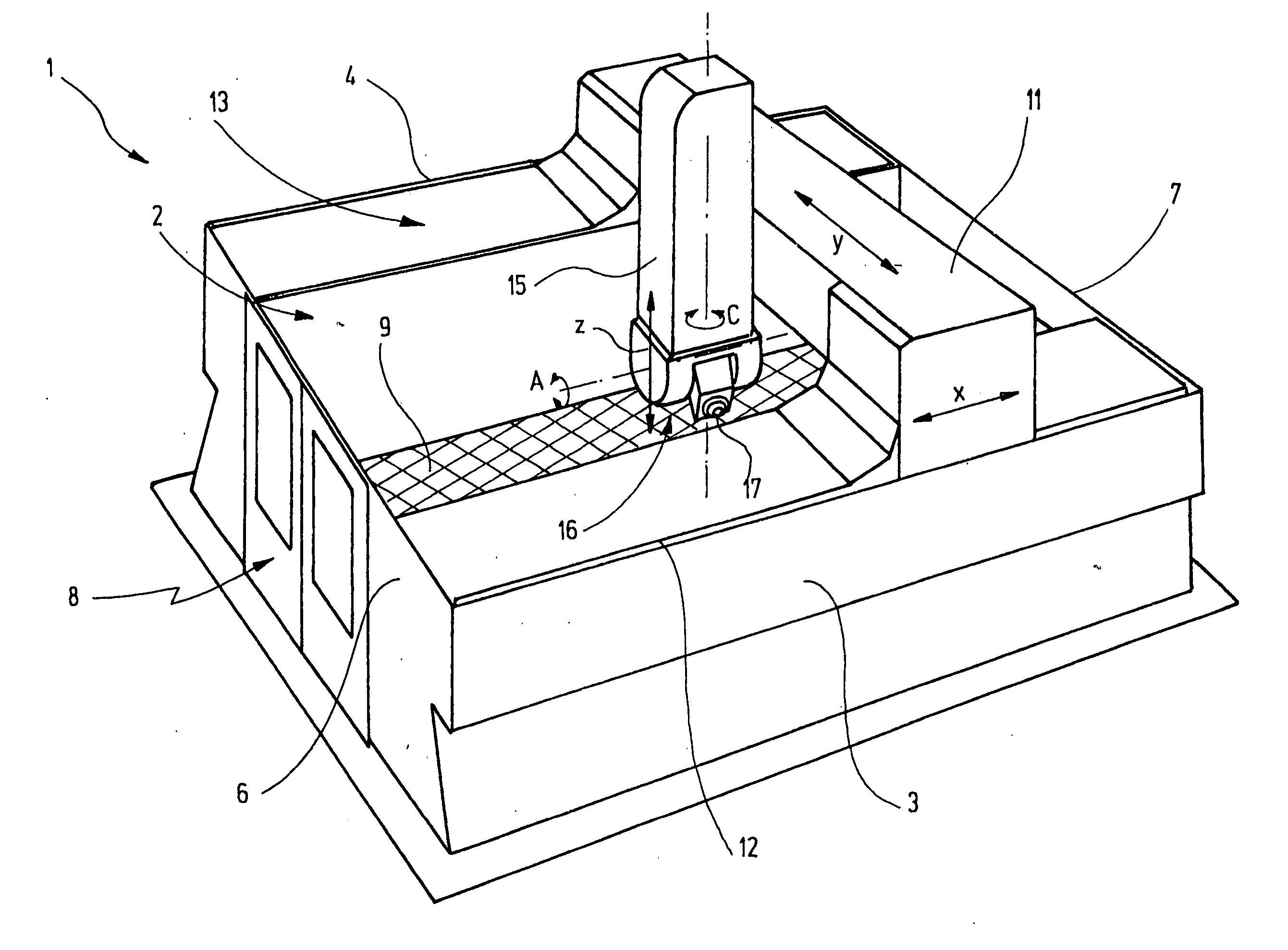

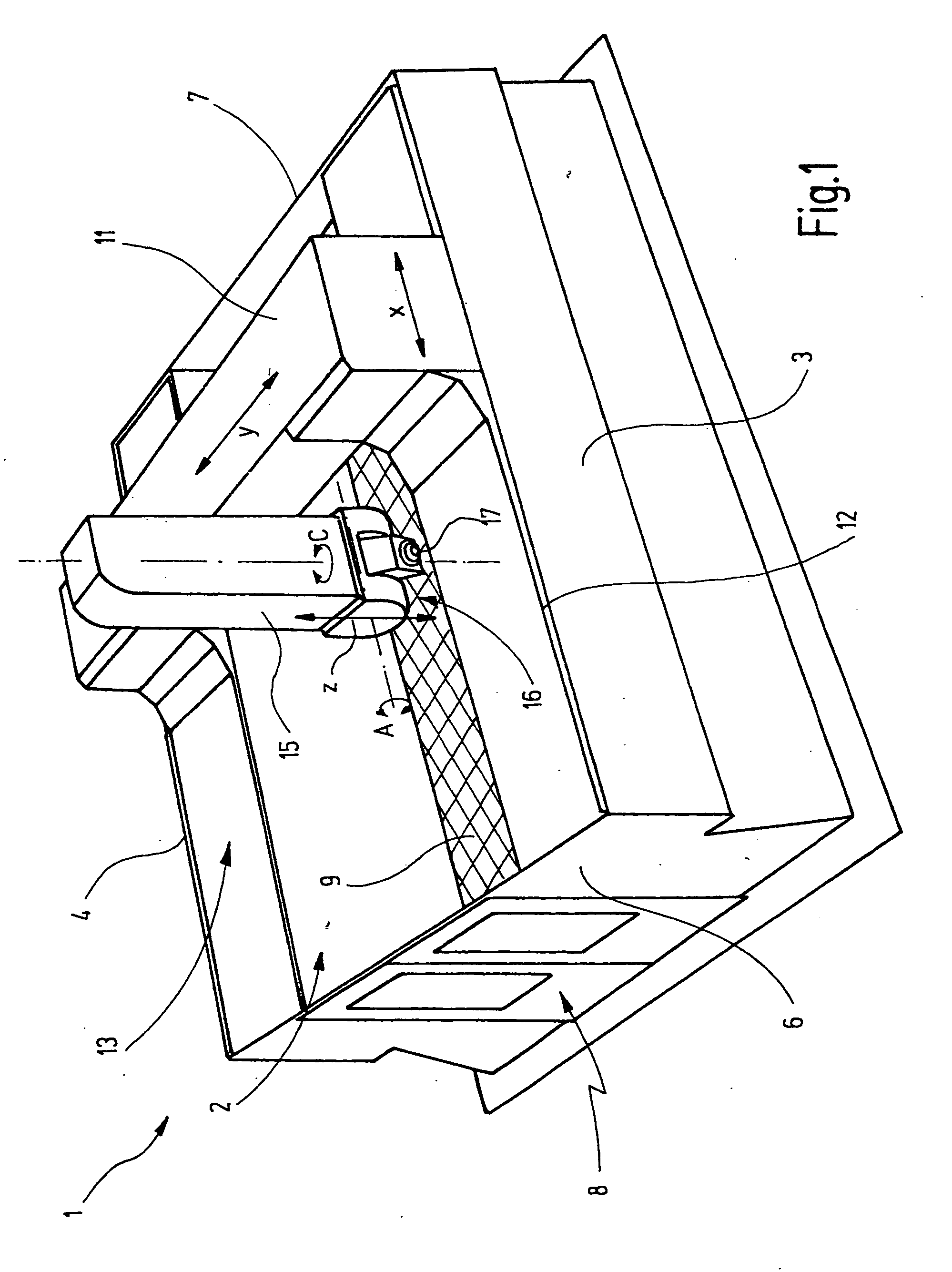

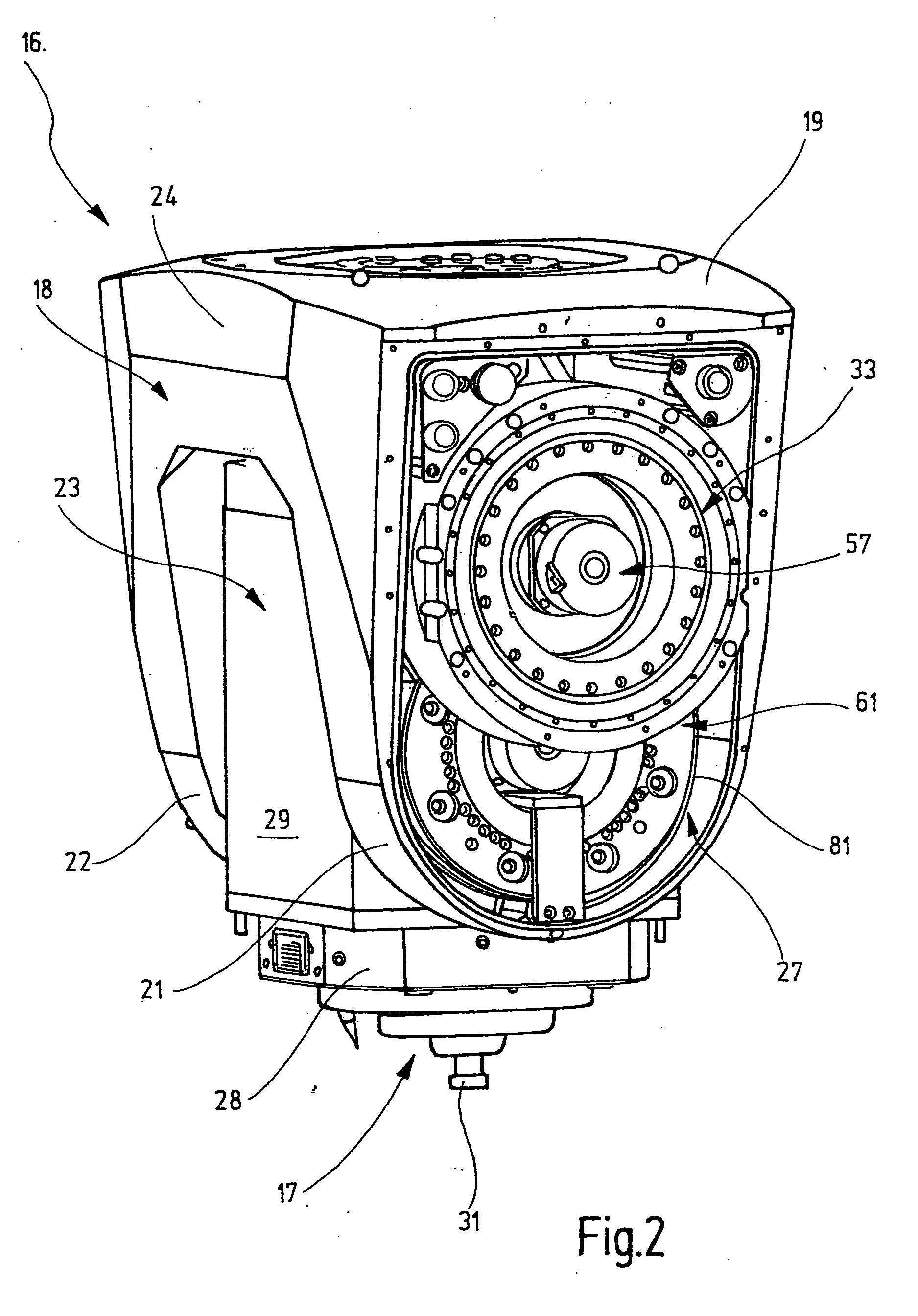

Mobile milling head with torque motor drive

InactiveUS20070059116A1Improve surface qualityPrecise positioningMachine tool componentsWorkpiecesDynamic stiffnessGear drive

A milling head (16) for a milling machine (1) arranged for machining large-size workpieces comprises a fork 18, which is rotatably arranged around a first axis (C) and demonstrates a pair of fork arms (21, 22), which are separated from one another, a spindle device (23), which is arranged between the fork arms and rotatable around a second axis A, a first torque motor (42), which is coupled to the fork 18 for directly driving and controlling of the rotation of the fork around the first axis (C), and a second torque motor (57) for driving and controlling the rotation of the spindle around the second axis (A), said second torque motor being coupled to the spindle device (23) by means of a one-stage toothed gearing (61), which is mechanically clamped free of backlash. The configuration according to the invention is arranged to achieve high torque with high dynamic stiffness and small interference contour of the milling head (16).

Owner:FA F ZIMMERMANN

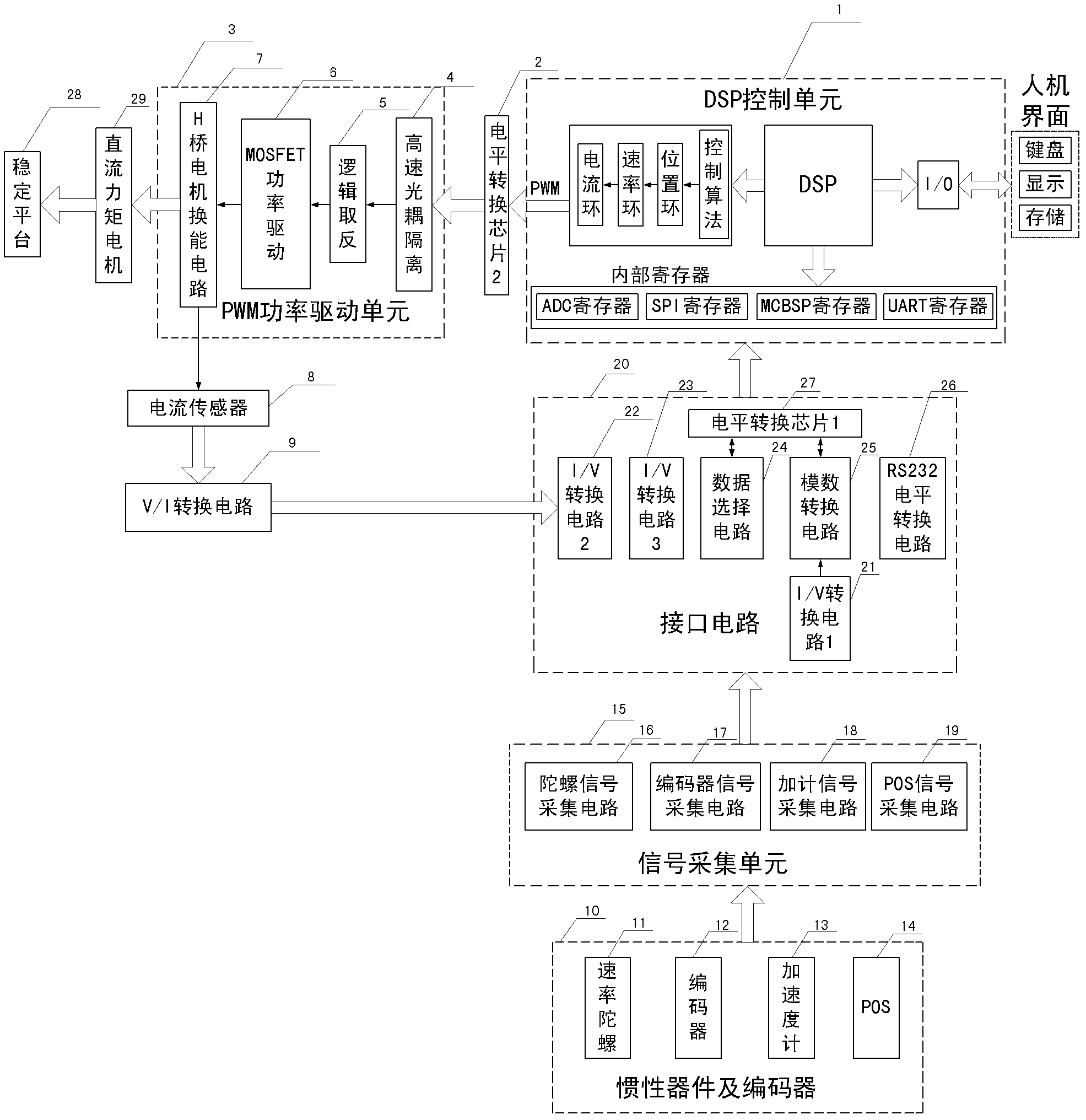

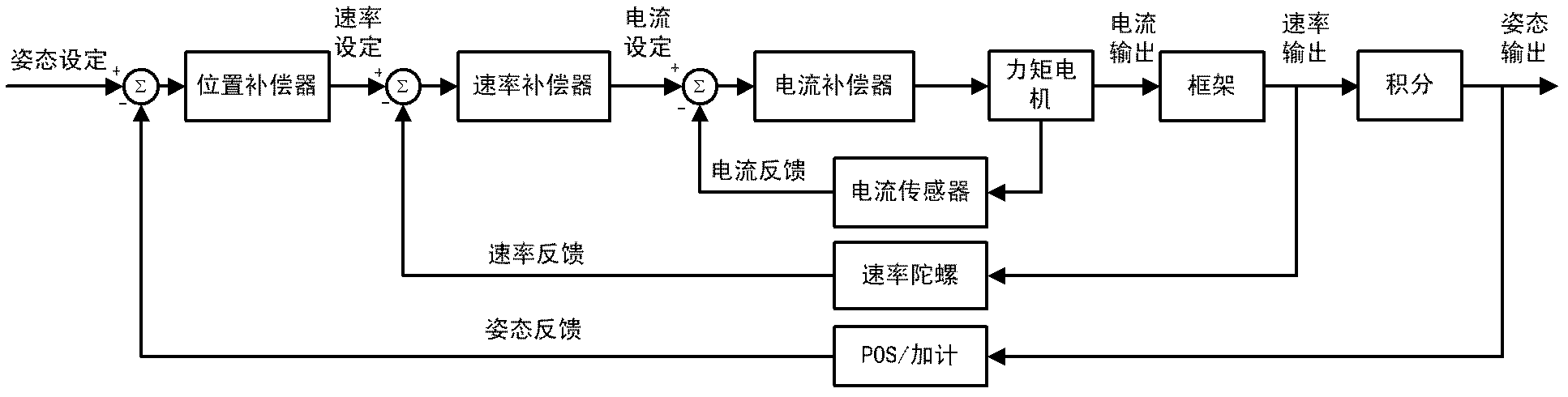

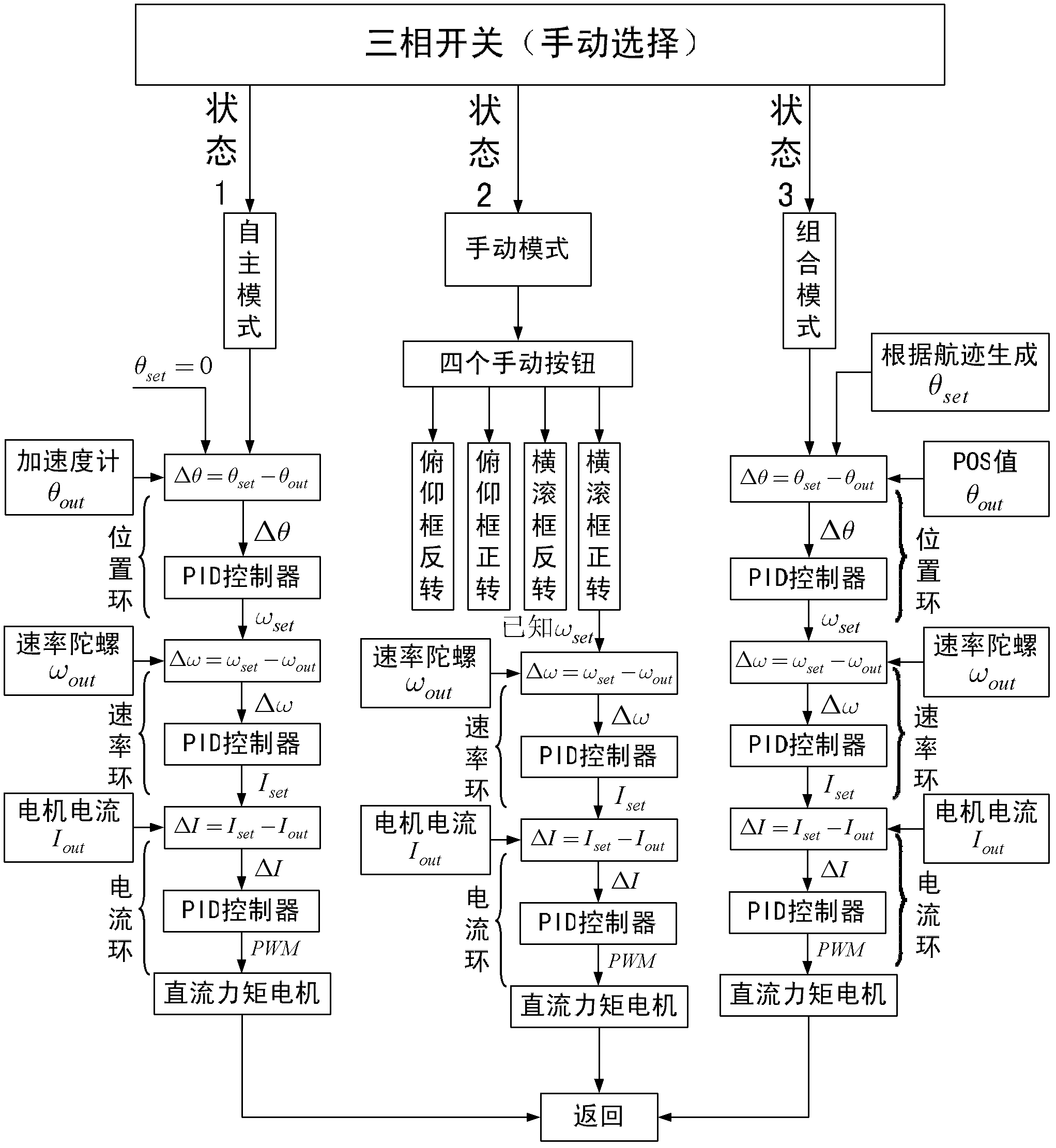

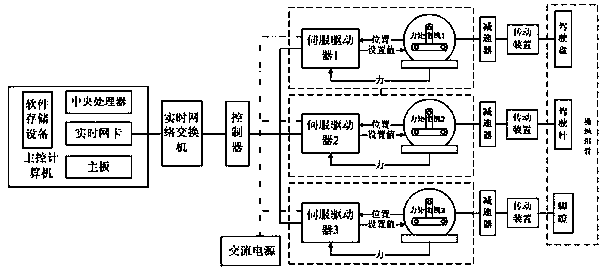

High-precision and large-load control system and method of three-axis inertially stabilized platform for airborne remote sensing

InactiveCN102436262AInhibition effectEnhanced inhibitory effectAttitude controlPosition/course control in three dimensionsDigital signal processingTorque motor

The invention provides a high-precision and large-load control system and method of a three-axis inertially stabilized platform for airborne remote sensing. The system comprises a DSP (digital signal processing) control unit, a PWM (pulse-width modulation) power drive unit, an interface circuit, a signal acquisition unit, an inertial device, an encoder and a direct current (DC) torque motor. The method comprises the following steps: acquiring data such as the attitude angle and angular speed of frameworks relative to an inertial space, coil current and relative corners among the frameworks through the signal acquisition unit; transferring the data into an internal register of the DSP control unit through the interface circuit so that the data is read by the DSP control unit; taking the data as signals to be input into the DSP control unit, and generating PWM controlled quantity by adopting a three-loop (a current loop, a speed loop and a position loop) compound control algorithm; and transferring PWM signals into an energy conversion circuit of an H-bridge DC motor through the power drive unit so as to drive the DC torque motor to change with reference instructions, and finally realizing active control of the inertially stabilized platform. The high-precision and large-load control system and method provided by the invention have the advantages that control precision and loading capability of the system are improved, the control algorithm is completed, and diversity and intellectualization of a platform operating mode are improved.

Owner:BEIHANG UNIV

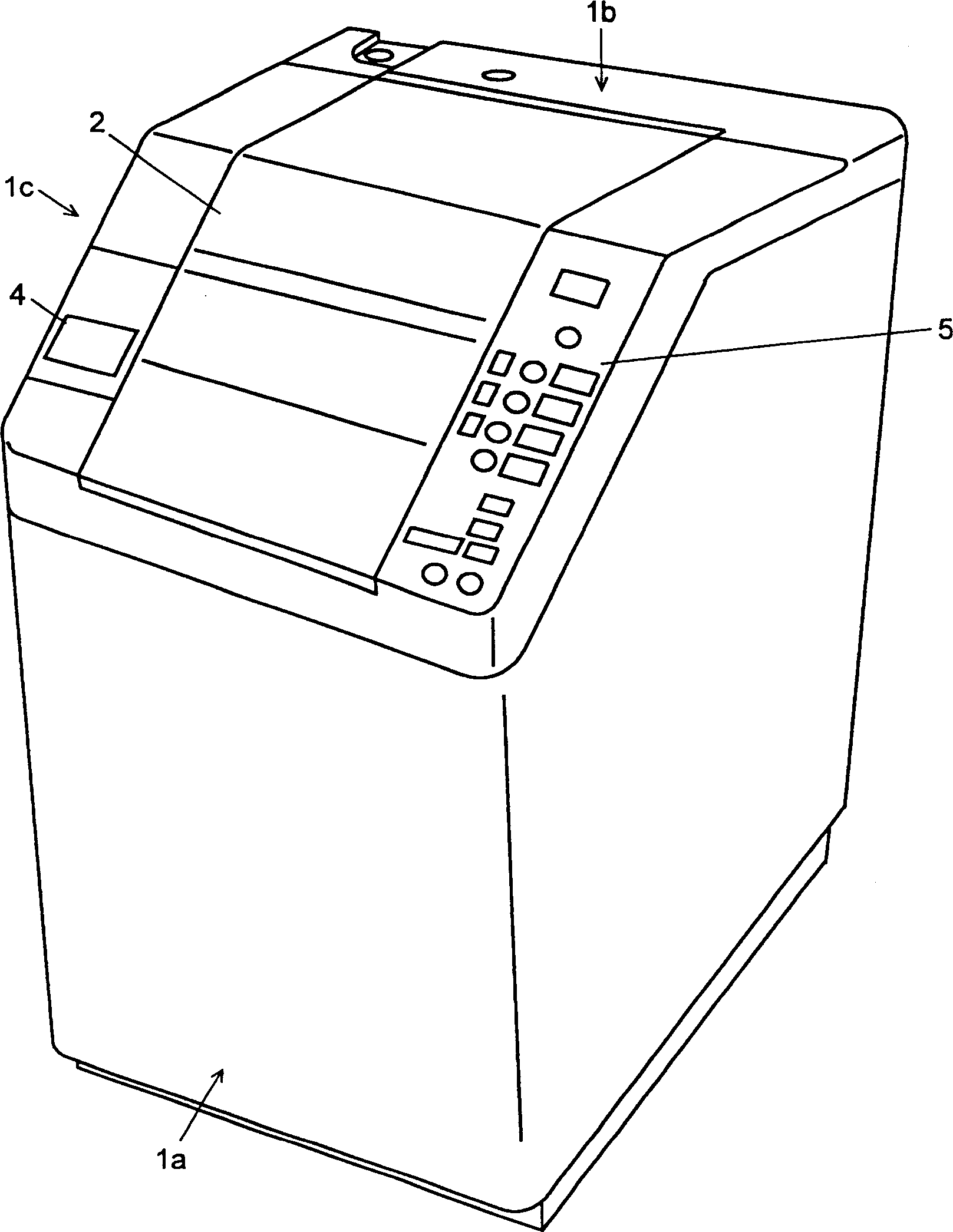

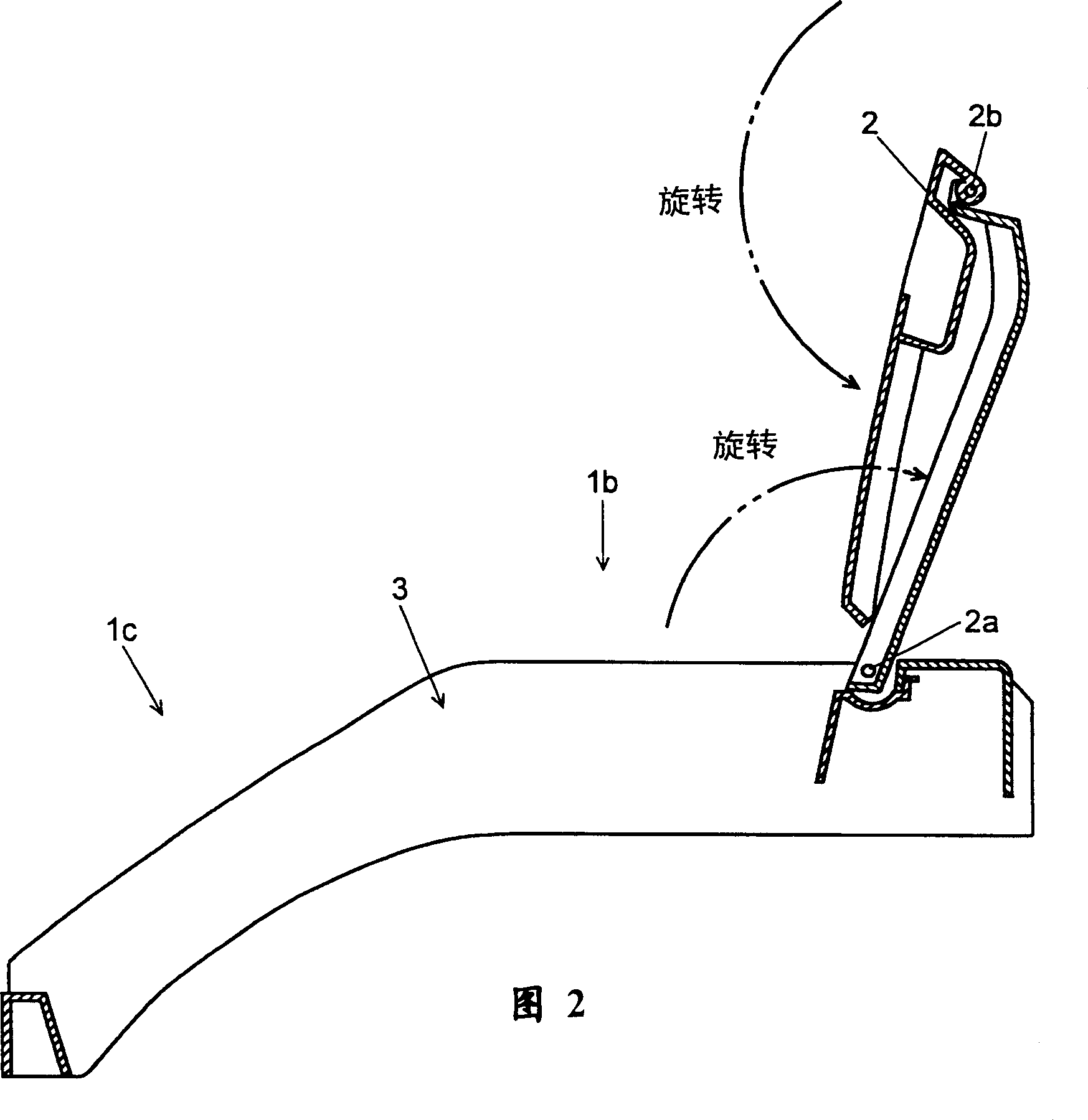

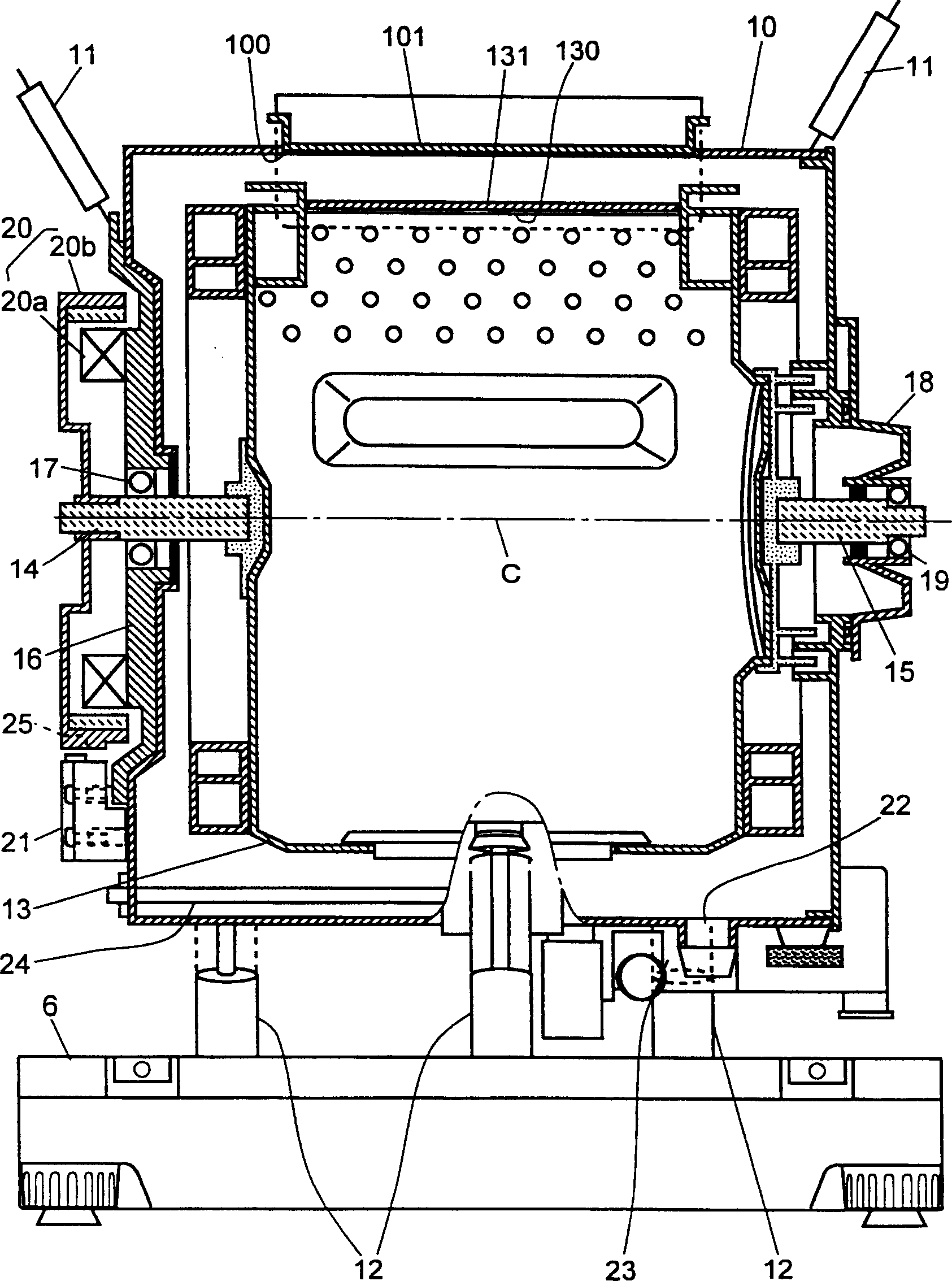

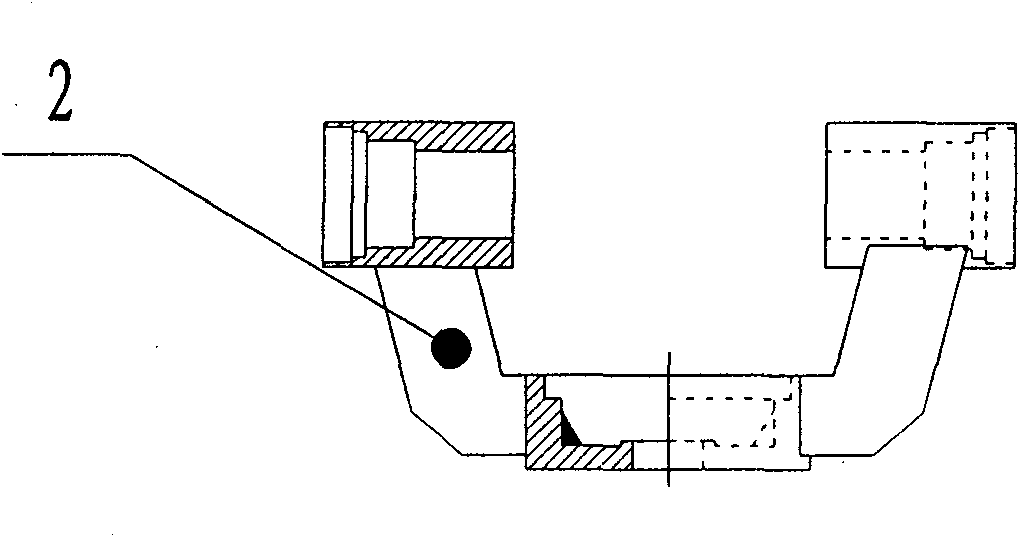

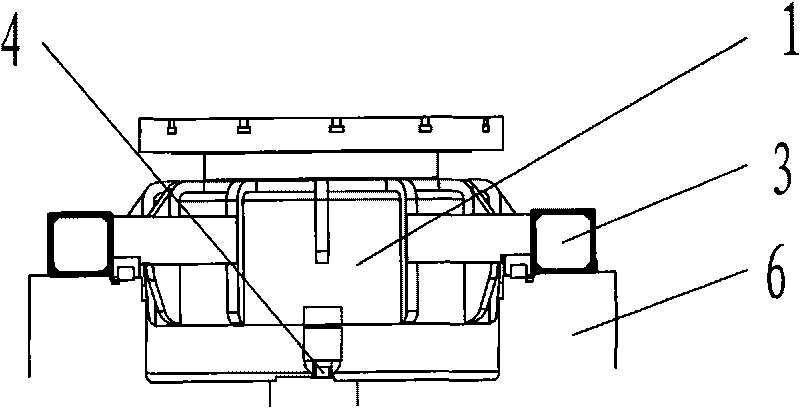

Drum type laundry machine

InactiveCN1442533AReliable lockingOther washing machinesWashing machine with receptaclesTorque motorEngineering

The present invention relates to a drum type washing machine which fixes the rotational position of the drum with a simple structure. An engagement groove (25) is provided on the outer periphery of the rotor (20b) of the external gear motor directly connected to the main shaft (14) of the drum (13), and a drum locking device (21) is provided directly below the shaft. . The drum locking device (21) has a structure to move the lock pin vertically with the rotation of the torque motor, and the position of the drum (13) is fixed when the lock pin advances to fit in the groove of the engagement groove (25).

Owner:HAIER GRP CORP +1

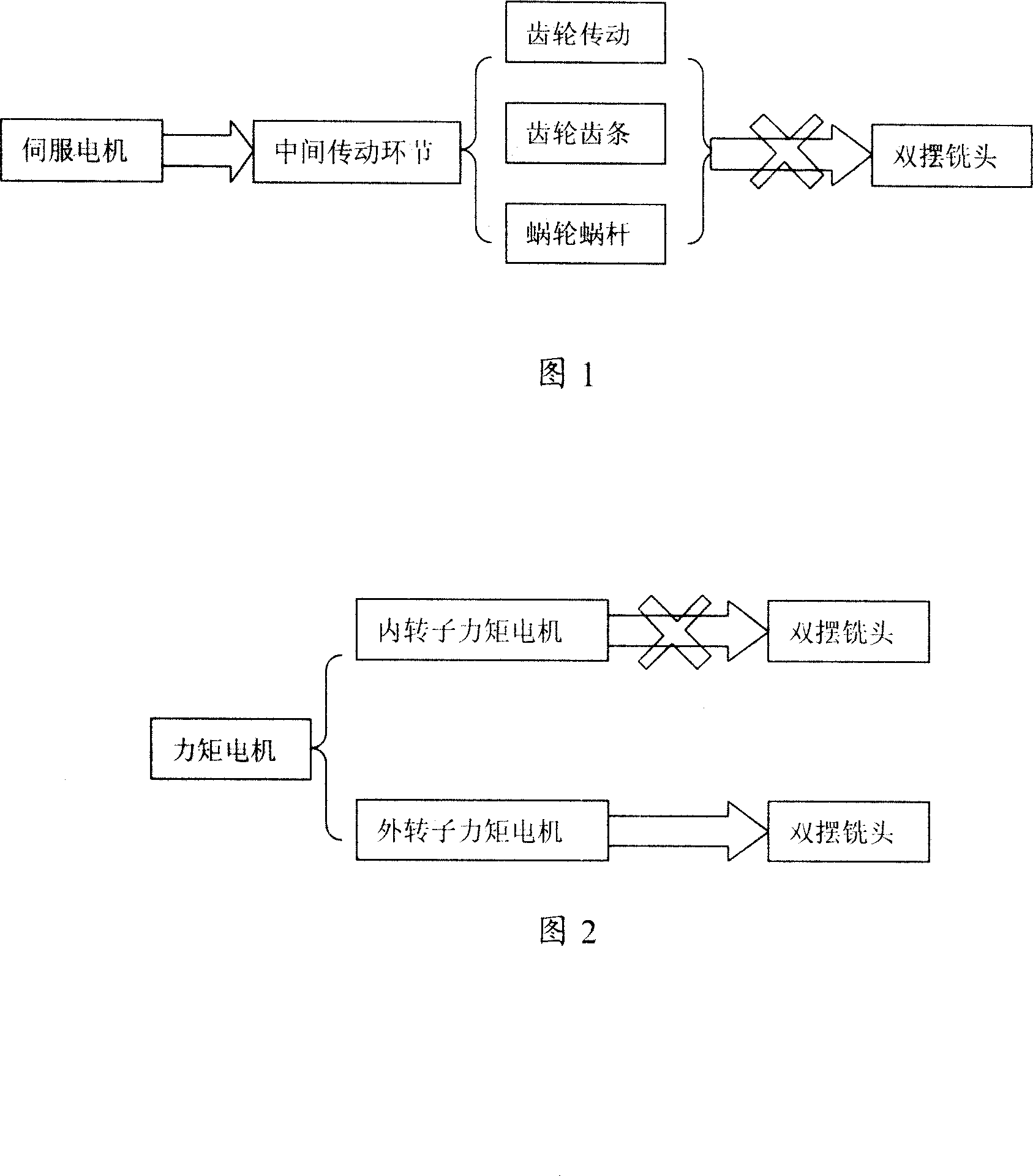

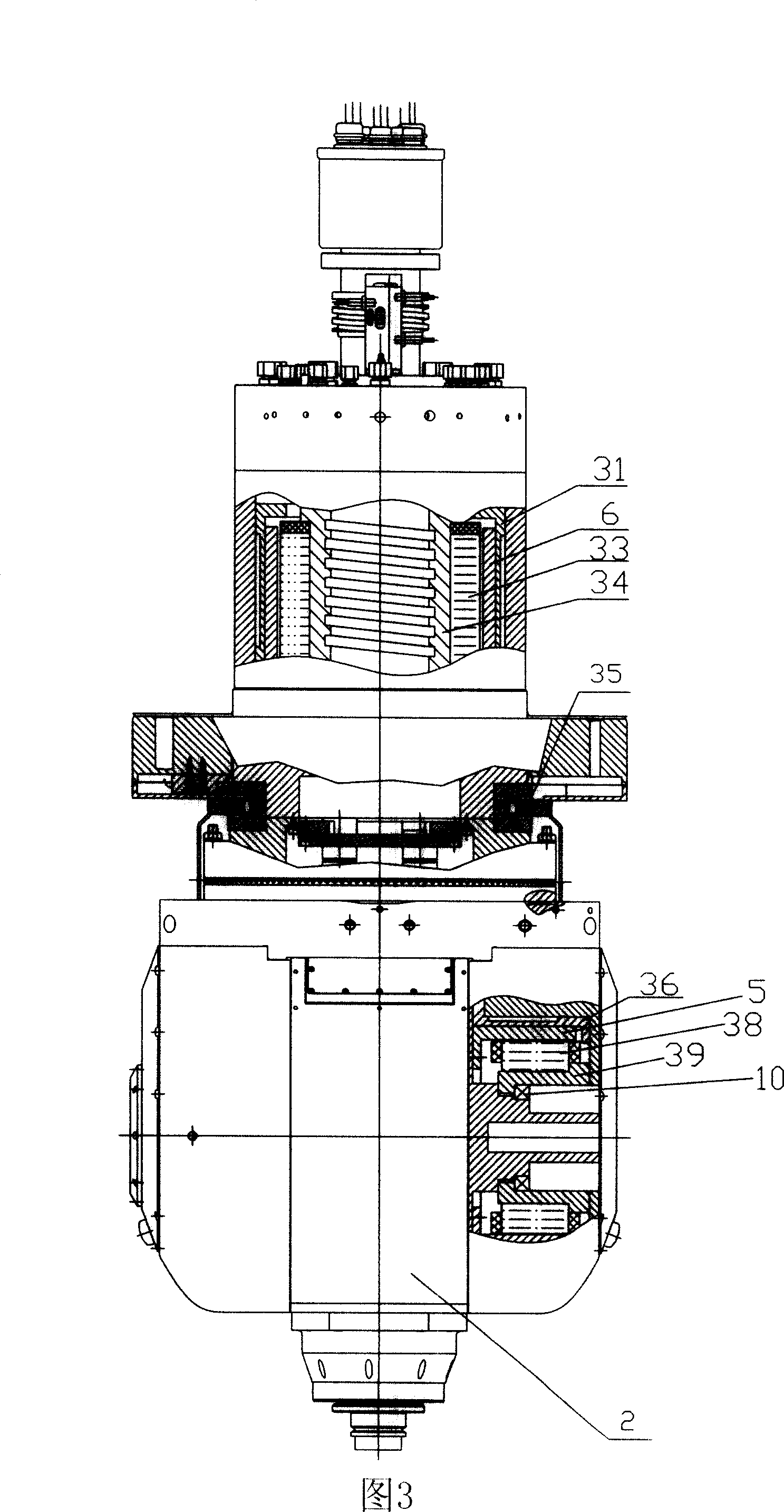

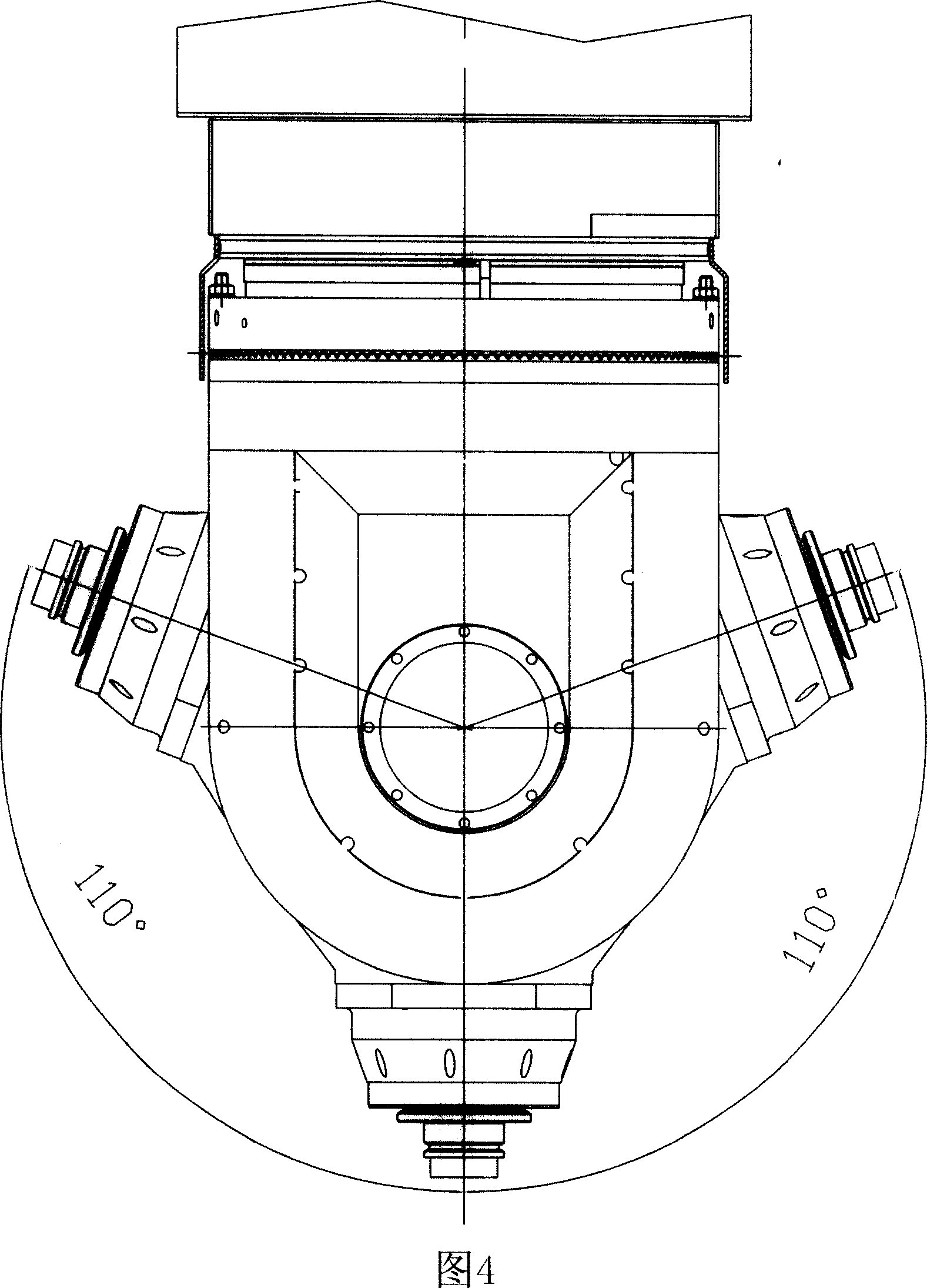

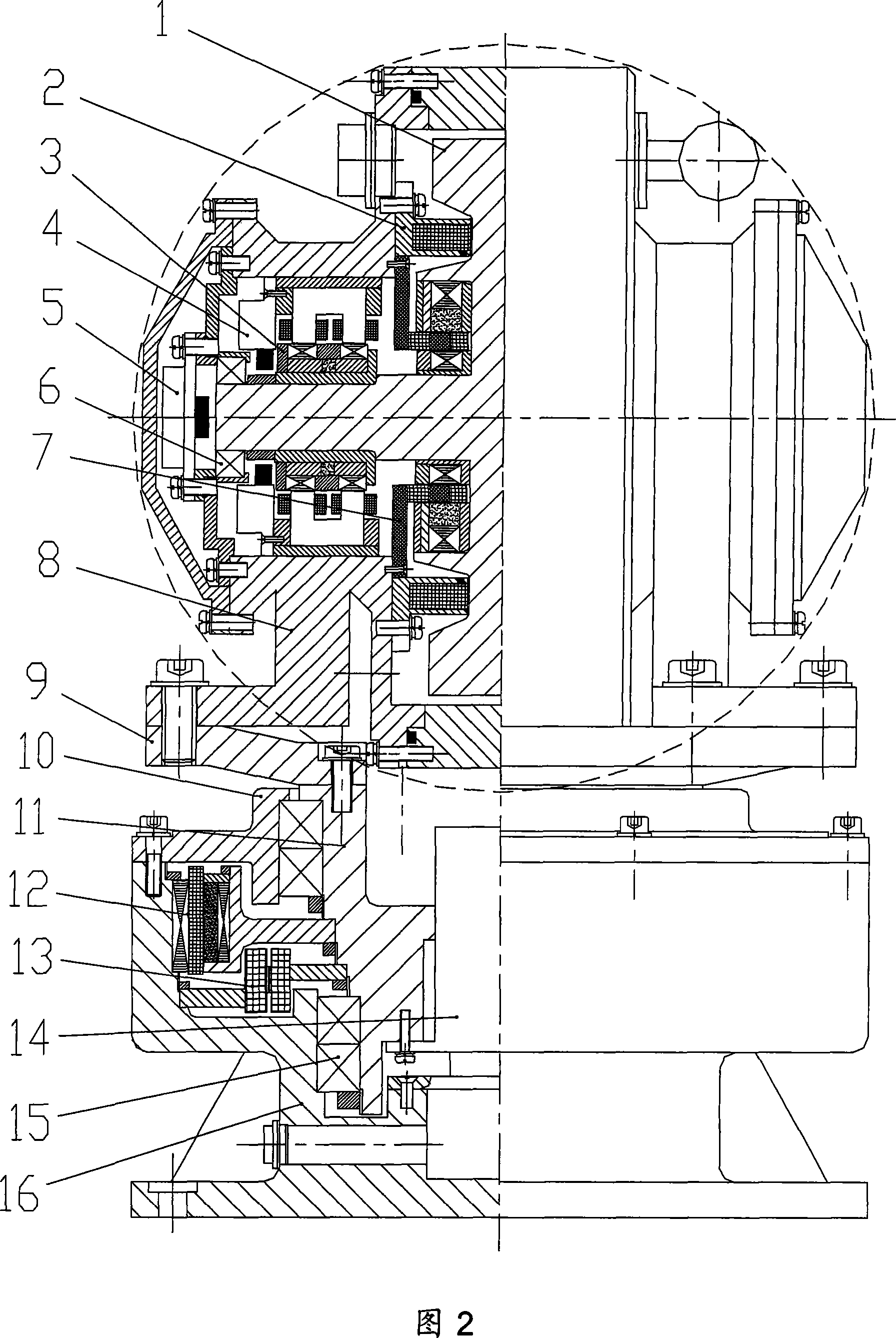

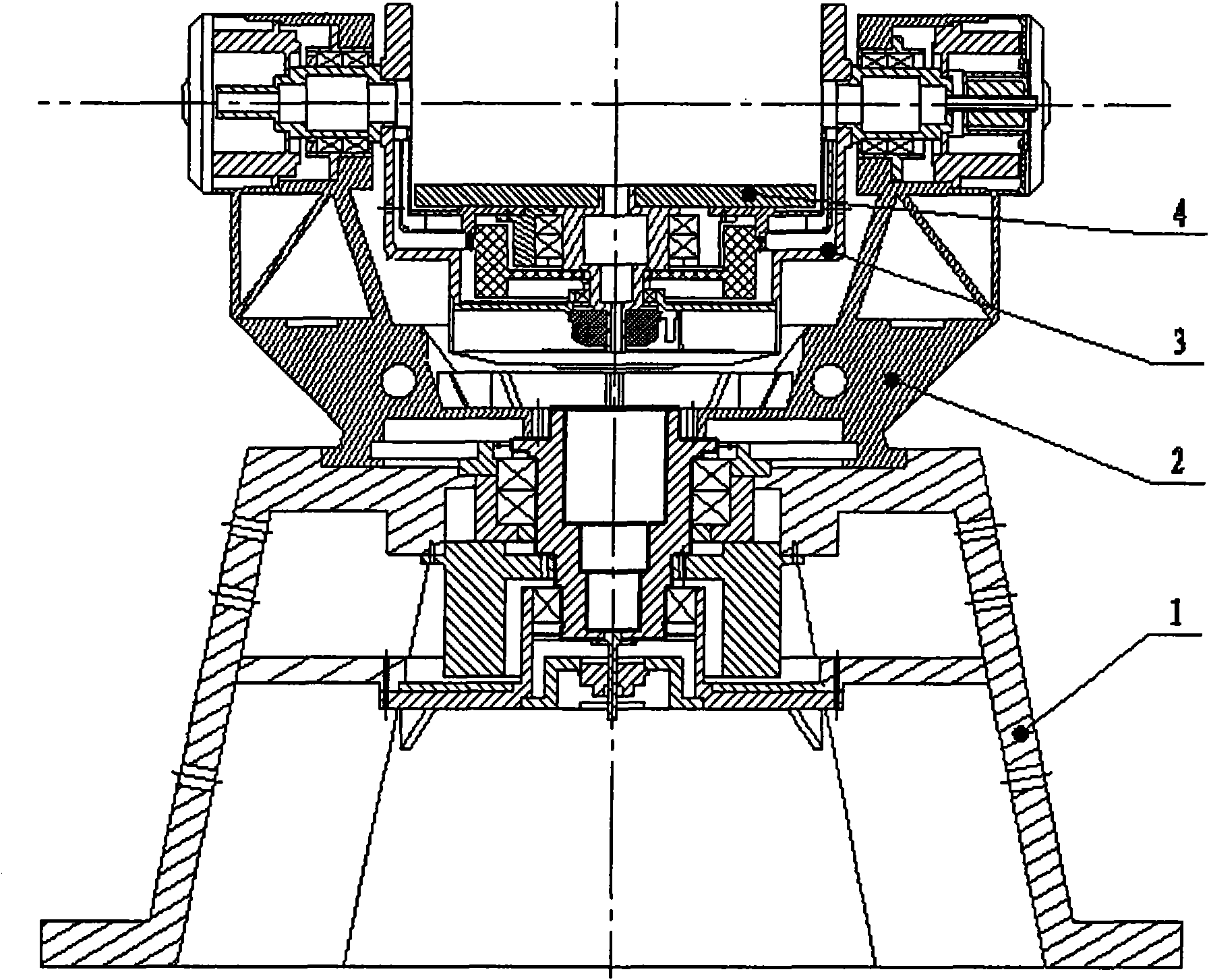

Double pendulum milling head of AC permanent magnetic synchronization external-rotor-type force moment motor drive

ActiveCN101011795AImprove running accuracyImprove stabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectricityNumerical control

The double pendulum milling head driven by the AC permanent syntactic rotor torque motor having a cross hollow shaft, whose both ends fixed on the rotor of the horizontal torque motor at both ends of the A shaft. Acting as an integral, they are fixed on the rotor of the vertical torque motor of C shaft. In this way, vertical motor driving the milling head to rotate around C shaft, and A shaft horizontal motor driving the pendulum of milling head around A shaft. It complete the complex machining of the working piece through compound motion in two directions matching the high speed revolution of the shaft itself. It is compact in structure, simple of drive, good in rigidity, smaller in mechanical components quantity, higher reaction sensitivity, free from wear and reverse gap, being able to machining for a five-face body with high precision.

Owner:KEDE NUMERICAL CONTROL CO LTD

Single end support type magnetic suspension control moment gyro of single framework

InactiveCN101049860AEliminate frictional momentIncrease speedSpacecraft guiding apparatusUltra high speedAxial displacement

A single end supported single-frame magnetic-levitation torque-controlling gyro is composed of magnetically levitated rotor system and frame system. Said magnetically levitated rotor system consists of gyro rotor, axial and radial magnetic bearings, and axial and radial displacement sensors, protecting bearing, drive motor and gyro room. Said frame system comprises frame jointer, end covers, mandrel, torque motor, angular position sensor, electrically conductive slide ring, mechanical bearing, and base. It has high rotation speed and long service life.

Owner:BEIHANG UNIV

Aircraft attitude-simulating 3-degree-of-freedom electrical turntable

InactiveCN101794524ASimple structureCompact assemblyCosmonautic condition simulationsSimulatorsElectric machineTorque motor

The invention relates to an aircraft attitude-simulating 3-degree-of-freedom electrical turntable, belonging to the technical field of simulation. The aircraft attitude-simulating 3-degree-of-freedom electrical turntable is characterized in that: the 3-degree-of-freedom electrical turntable comprises an inner frame, a middle frame, an outer frame and a turntable pedestal, wherein the turntable pedestal is equipped with the outer frame, the outer frame is equipped with the middle frame, and the middle frame is equipped with the inner frame; a rotating shaft of the outer frame is provided with a driving DC torque motor, and the motor is coaxially installed with a coded disc; a shaft of the middle frame is arranged on the outer frame and provided with two parallel driving DC torque motors, and the motors and the coded discs are arranged at both ends; the inner frame is provided with one driving DC torque motor, the coded disc and the motor are coaxially installed, and the shafts of the outer frame, the middle frame and the inner frame are spatially vertical to each other and intersect at one point. The aircraft attitude-simulating 3-degree-of-freedom electrical turntable has the advantages of: simple structure, compact assembly, low cost and good practicability, accurate data, high simulation degree, high precision and good dynamic performance in simulating the aircraft attitude, etc.

Owner:CIVIL AVIATION UNIV OF CHINA

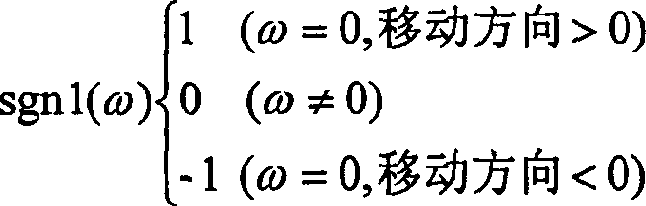

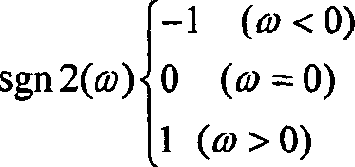

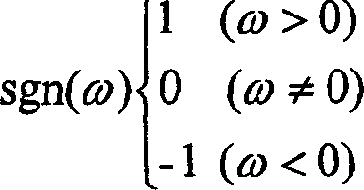

Robot arm control method and control device

By appropriately selecting a command value or an actually measured value as the angular velocity used for friction torque calculation, friction compensation can be effective in both cases when actively operating according to the angular velocity command and passively operating, that is, when being pushed by an external force . Also, after a collision is detected, when the motor rotation direction is opposite to the collision direction, the position control is switched to current control so that the motor generates torque in the opposite direction to the motor rotation direction, thereby reducing the motor rotation speed and weakening the collision energy. Thereafter, when the motor rotation speed becomes the set value or lower, the mode is set to flexible control, thereby eliminating deformation of the speed reduction device or the like caused by the collision. On the other hand, when the motor rotation direction and the collision direction are the same, the position control is directly transferred to the flexibility control without going through the current control. By performing operations according to the collision force, it is possible to weaken the collision torque.

Owner:PANASONIC CORP

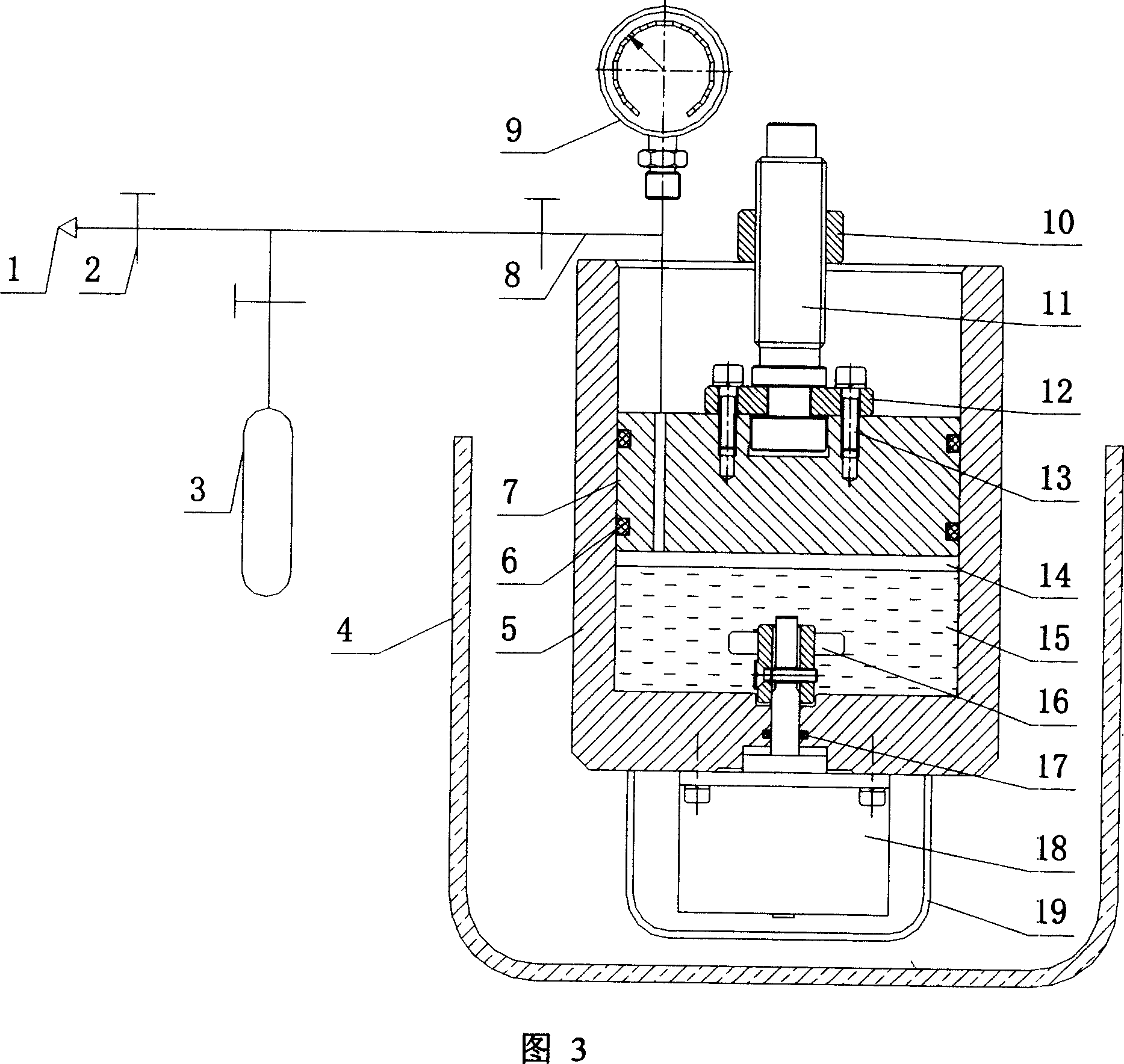

Detector for gas solubility in liquid

The present invention is instrument for gas solubility in liquid. The instrument has stirring blades soaked in test liquid and connected to the shaft of torque motor, one cylinder with piston connected to a lead screw, one precise constant temperature water bath with temperature display for the cylinder to be set in, and one gas source connected to gas pipe and precise manometer, with the precise manometer being connected to the inner cavity of the cylinder through the axial hole in the piston. The present invention converts the rotation of the lead screw into the axial motion of the piston inside the cylinder to control the gas pressure in the liquid inside the cylinder cavity, and has precise measurement of temperature, piston displacement and in-cavity gas pressure. The gas amount over the liquid may be calculated based on the gas state equation and the dissolved gas amount may be obtained. The present invention is used in measuring gas content and solubility in liquid.

Owner:ZHEJIANG UNIV

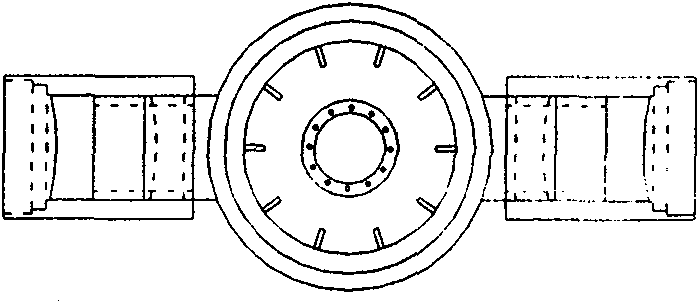

Vertical milling lathe complex machining center

ActiveCN101722419AIncrease productivityReduce wearOther manufacturing equipments/toolsLarge fixed membersTorque motorEngineering

The invention discloses a vertical milling lathe complex machining center which comprises a horizontally arranged lathe body (6) and a vertically arranged upright post (7). The lathe body (6) is provided with an X-axis lateral supporting line track (2) and an X-axis guide screw (5) and configured with a uniaxial rotating table (1) which reciprocates and is driven by a first outer rotor torque motor in a direct driven mode. The upright post (7) is vertically provided with a Z-axis lateral supporting line track (10) and a Z-axis guide screw (9) and configured with a crossbeam which reciprocates up and down. The crossbeam (11) is provided with a transverse Y-axis line track (13) and a Y-axis guide screw (12) and configured with a single pendulum milling head seat frame which can reciprocate along the Y-axis guide screw (12); and a single pendulum milling head is driven by a second outer rotor torque motor at the rear part in the direct driven mode. Since a direct driven technology is applied to a B axis and a C axis, the motor torque is greatly increased and a functional part can stably operate; therefore the integral rigidity and the stability of a lathe are improved.

Owner:KEDE NUMERICAL CONTROL CO LTD

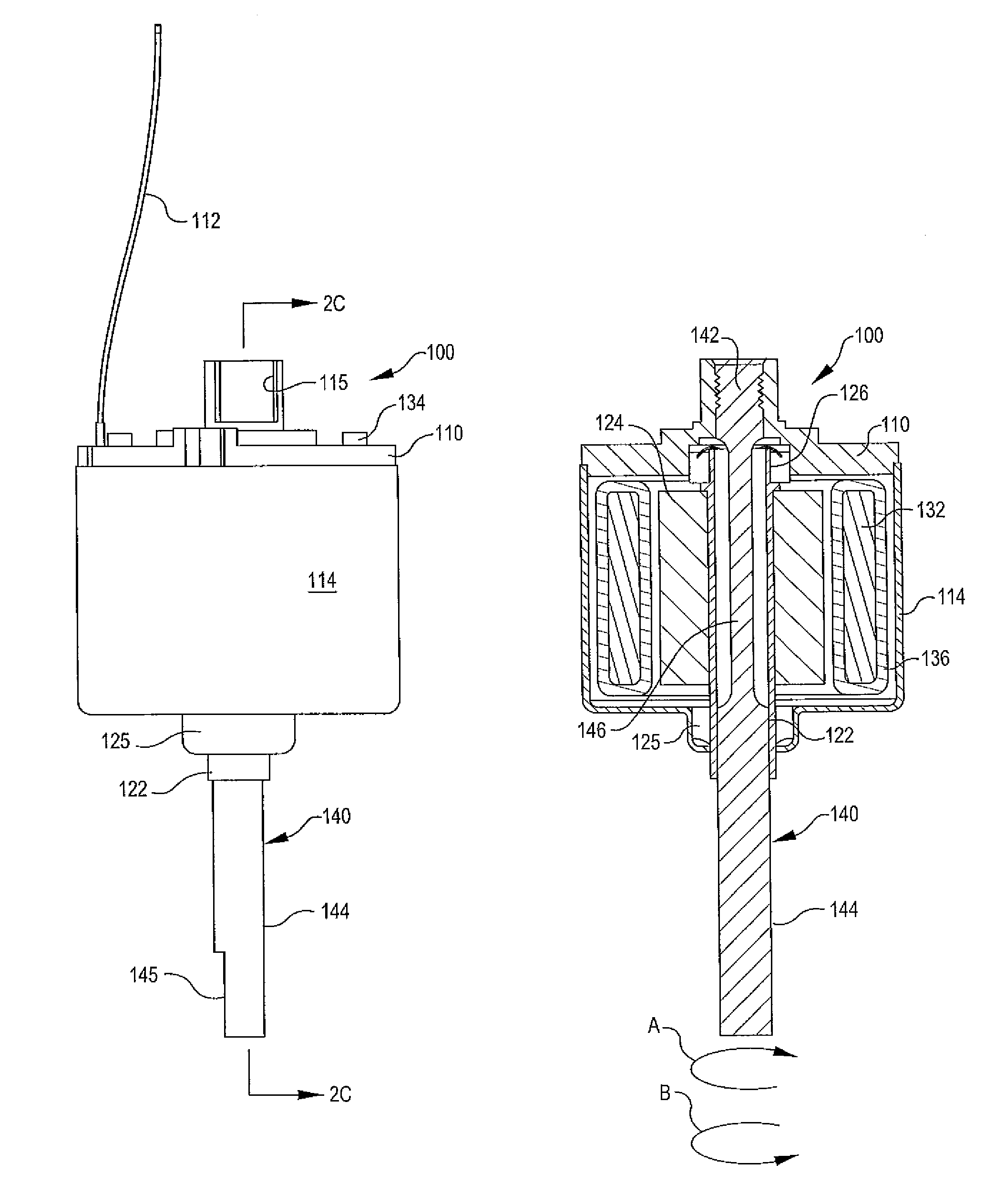

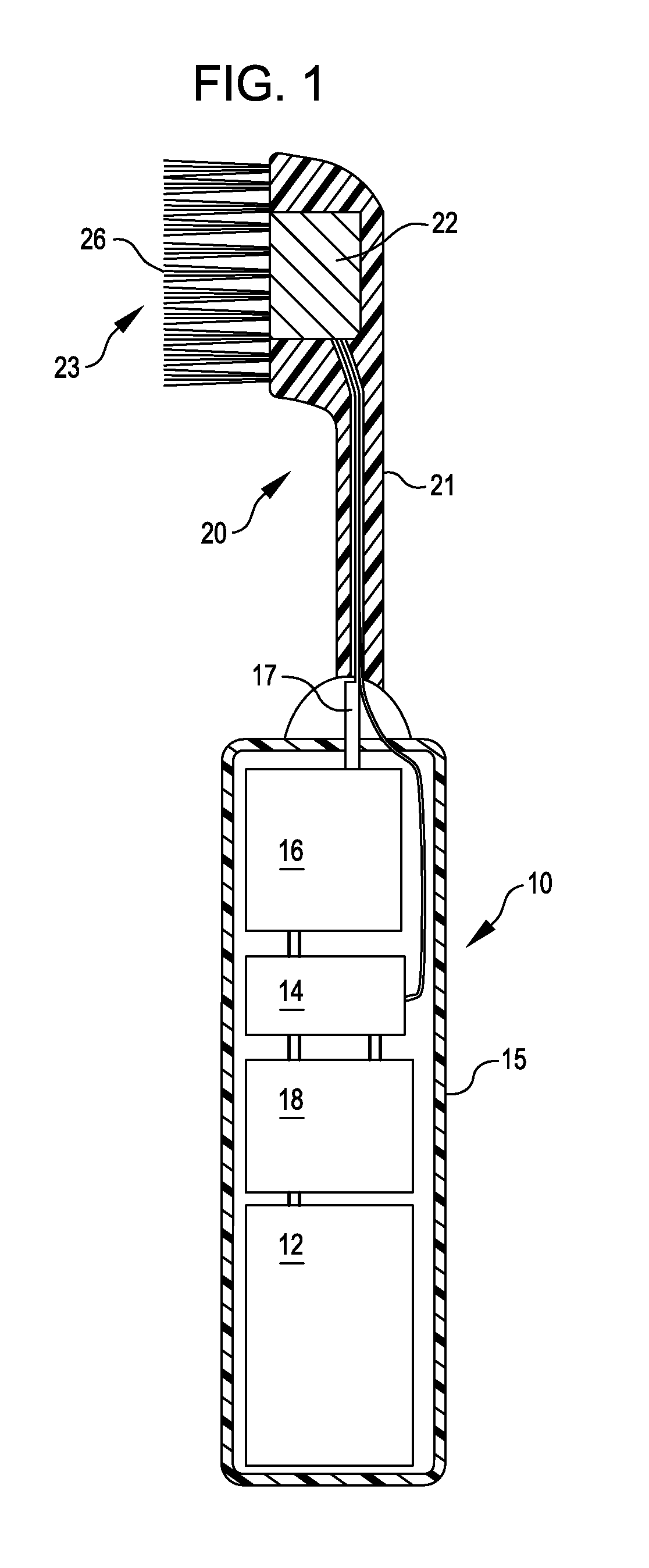

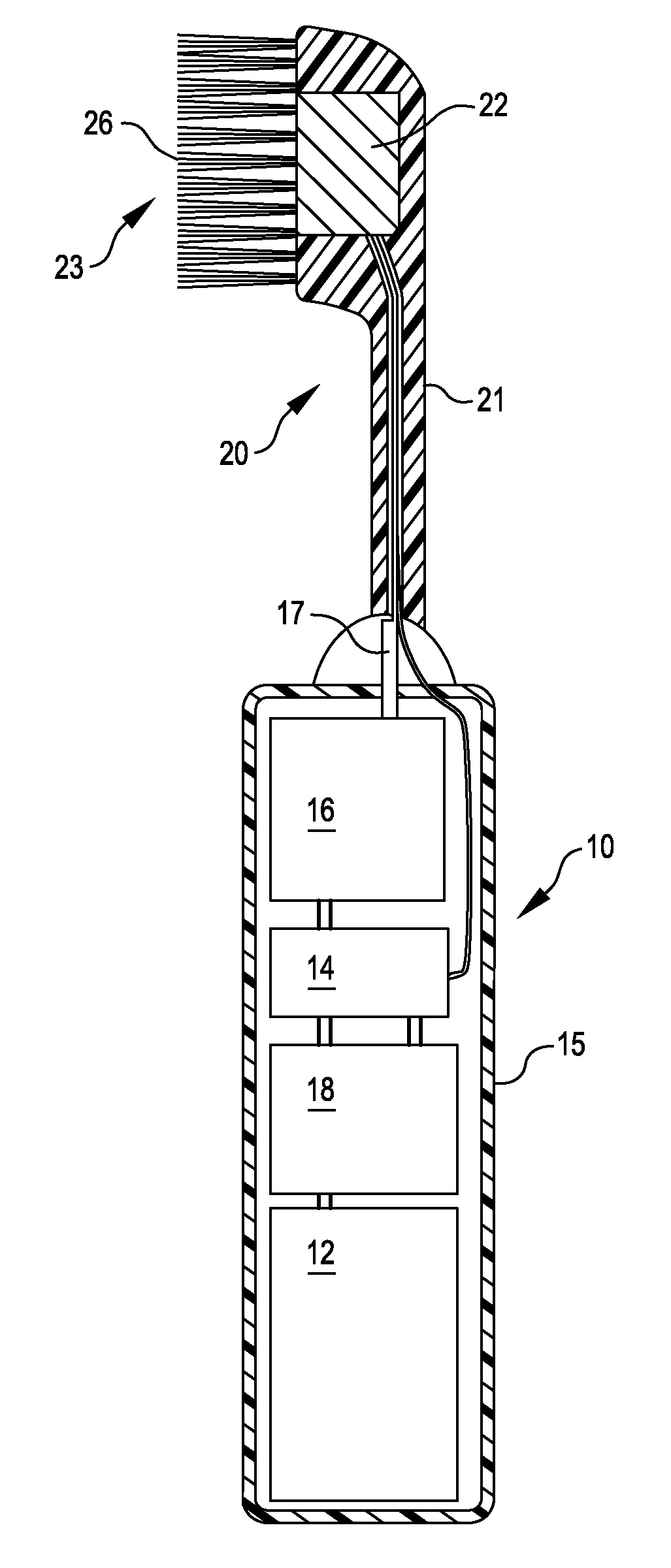

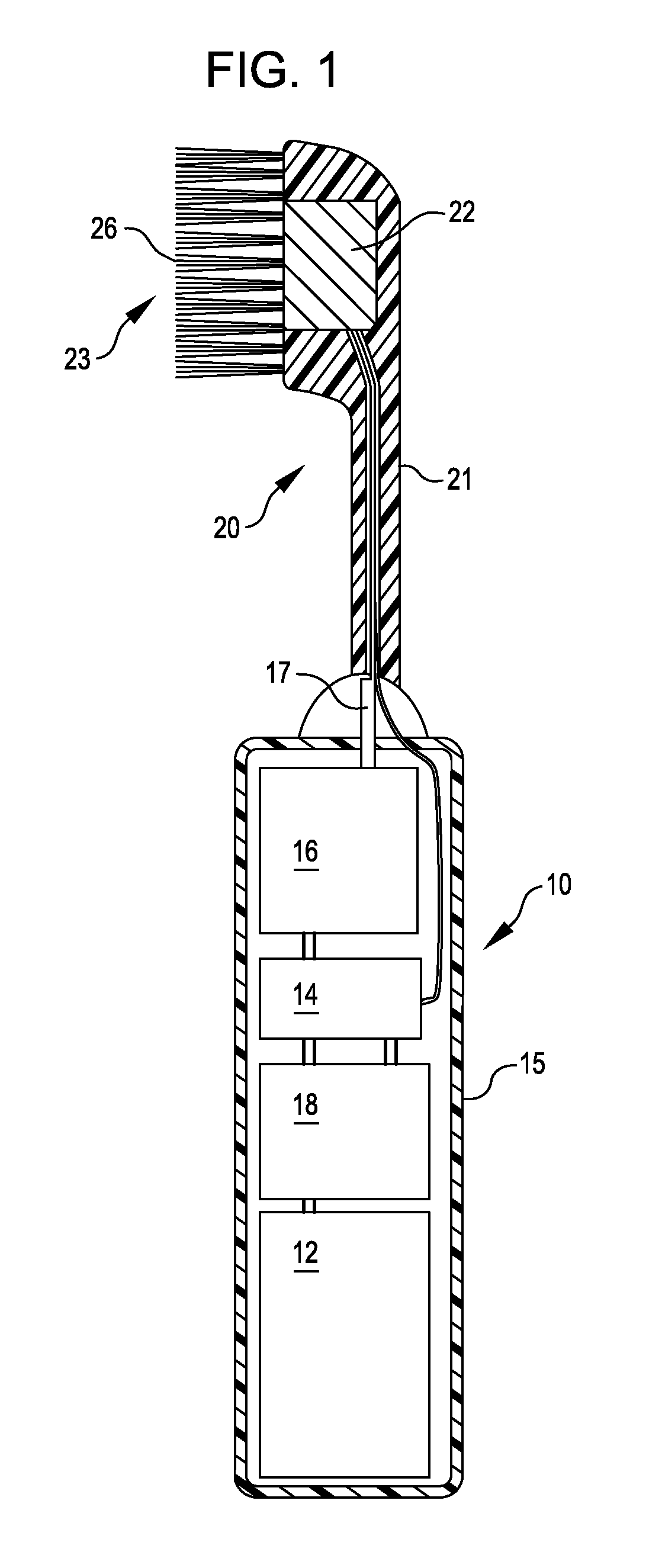

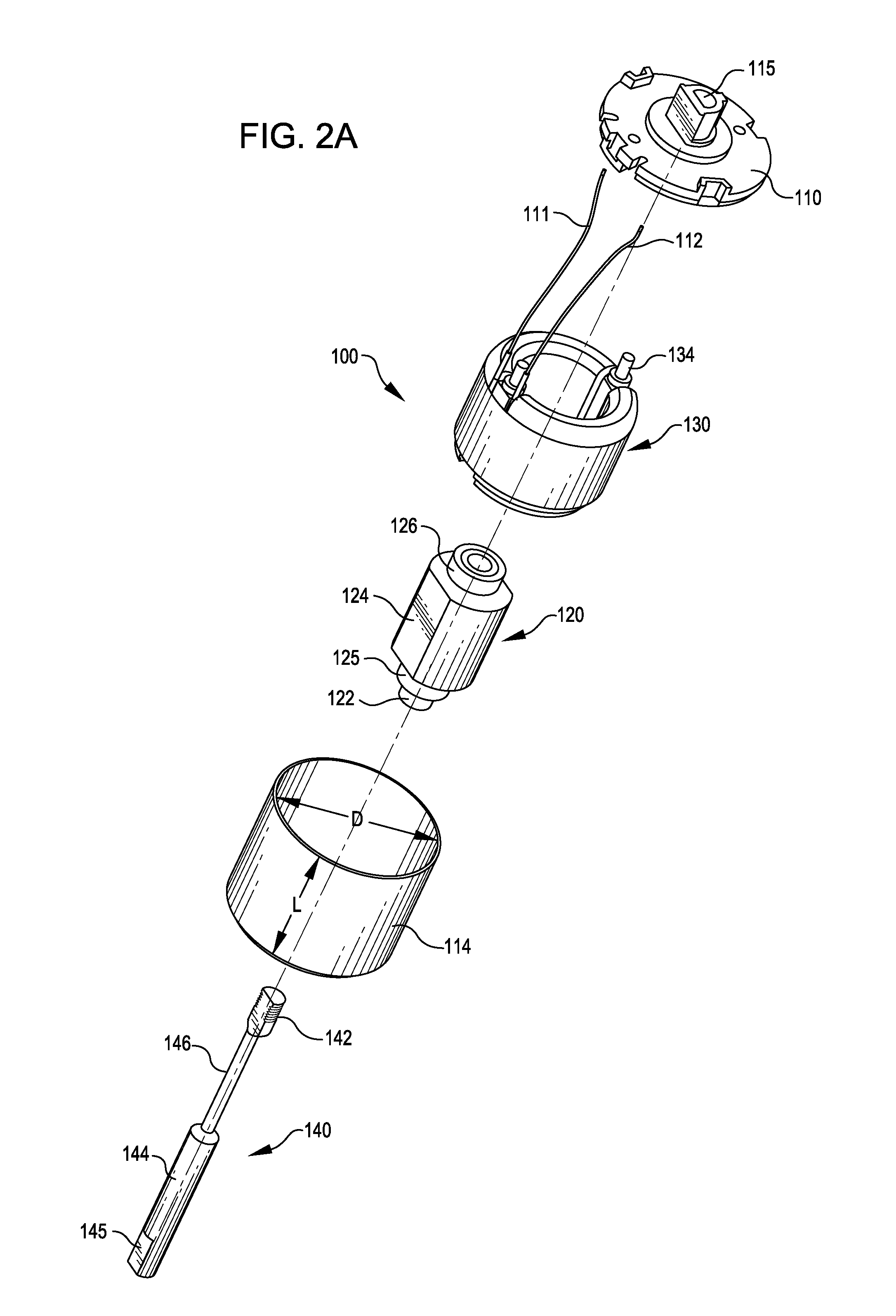

Oscillatory motors and devices incorporating them

InactiveUS7732952B1Suitable for useAssociation with control/drive circuitsCarpet cleanersUltrasonic sensorElectric machine

An oscillatory device incorporating a limited angle torque motor capable of oscillating one or more end effector(s) is provided. The device may additionally incorporate an ultrasound transducer and / or a waveguide structure.

Owner:ULTREOTECH

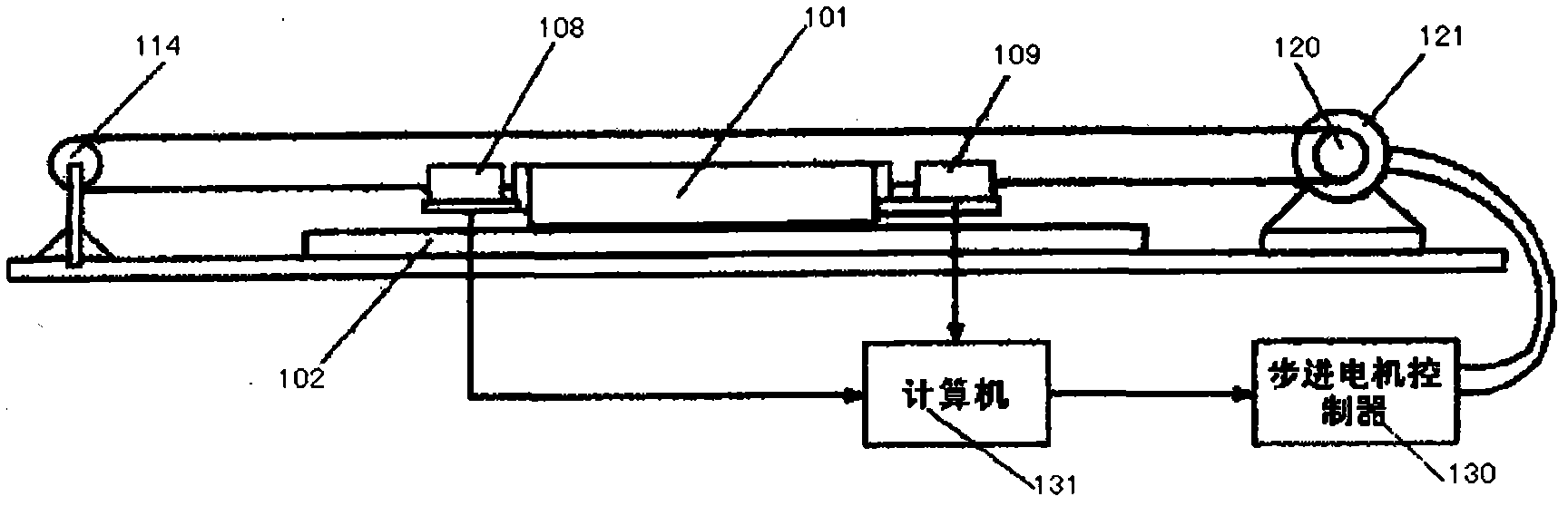

Comprehensive test device for linear motor motion system

InactiveCN101980037APrecise positioningConducive to the study of the limit output stateDynamo-electric machine testingLow speedTorque motor

The invention discloses a comprehensive test device for a linear motor motion system, which belongs to the field of motor test equipment. The comprehensive test device consists of a tested linear motor, a rotating servo motor, a torque motor, a sensor module and a transmission mechanism. Linear motion guide rails and a linear position sensor are fixed on a workbench; a linear motor primary section is arranged on the linear motion guide rails; the output of a controller is connected with each sensor through one communication interface; the sensors transmit position, acceleration, tensile forceand temperature measurement signals obtained in a test process through the communication interfaces; and the rotating servo motor, the torque motor and the linear motor realize coordinated motion with the controller through communication interfaces. The test device can finish the plurality of tests of dynamic stiffness tests, thrust coefficient determination, temperature rise tests, low-speed motion characteristic tests and the like on a linear motor-driven machine tool feeding system, and solve the problems of absence of a complete set of test device, low test accuracy and low repeatability of the linear motor-driven machine tool feeding system.

Owner:TSINGHUA UNIV

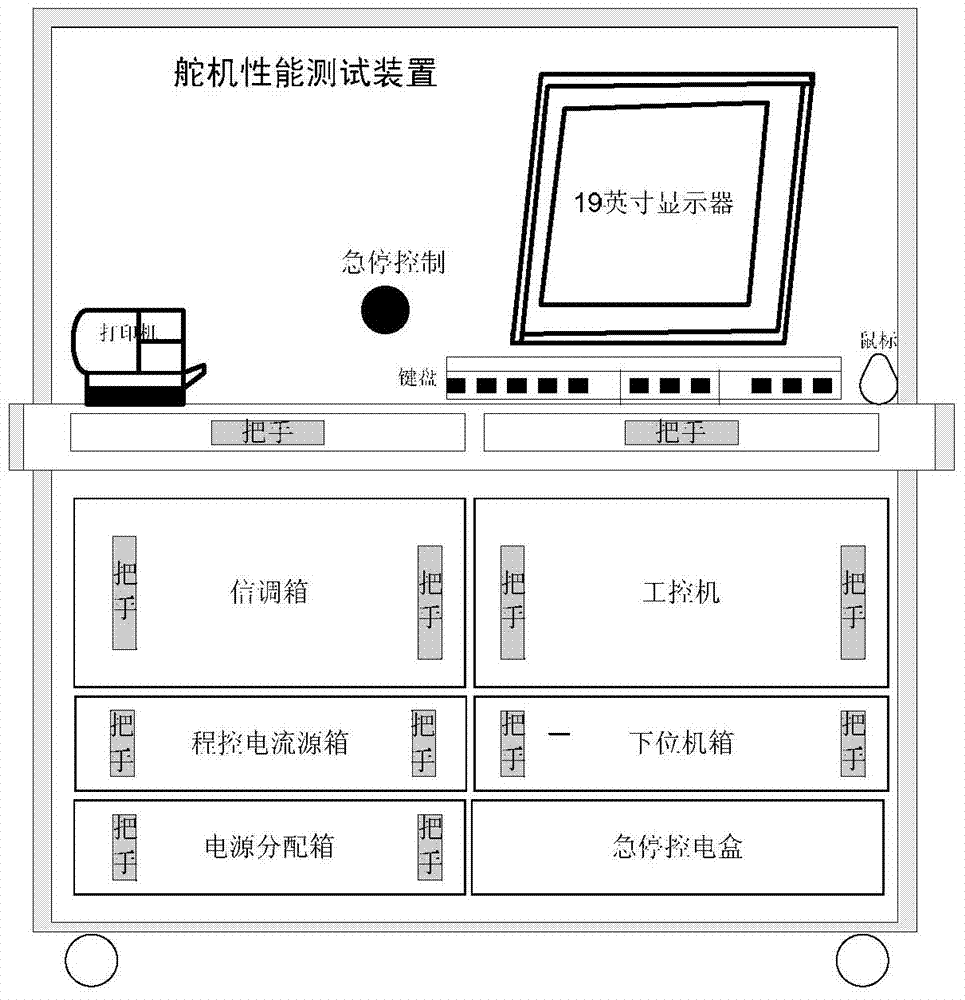

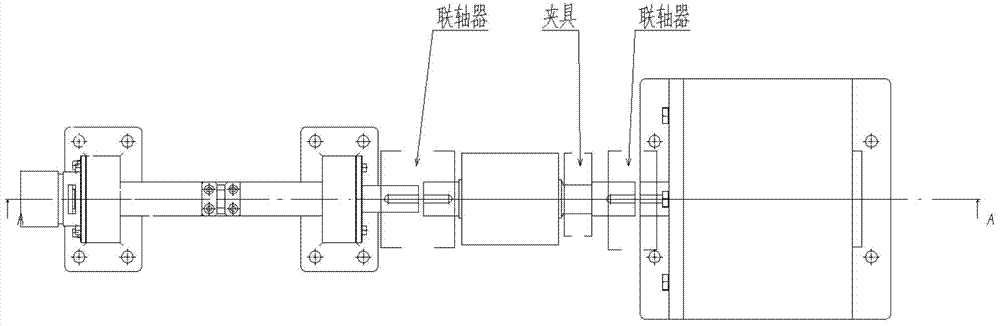

Actuator performance tester

ActiveCN103499444AMeet the testCompact structureProgramme controlMachine gearing/transmission testingTorque motorDisplay device

An actuator performance tester comprises a measurement and control console and an electric loading platform, which are connected through cables; the measurement and control console comprises a display, a printer, a signal conditioning case, an industrial personal computer, a program-controlled current source case, a power distribution case, a scram control box, a mouse and keyboard suite, a lower computer case and a rack; the electric loading platform comprises a position encoder, a flexible connecting plate, two bearing caps, two swivel bearings, two shaft system supports, a rocker, a transmission shaft, a torque / rotational speed sensor, a motor support, a torque motor, a bed, two couplings and a fixture. The actuator performance tester can carry out static and dynamic performance tests on a universal gas actuator in order to obtain the performance of the actuator in real time, and can store and manage performance data.

Owner:BEIHANG UNIV

Oscillatory motors and devices incorporating them

InactiveUS20100237720A1Suitable for useAssociation with control/drive circuitsBatteries circuit arrangementsUltrasonic sensorTransducer

Owner:ULTREO

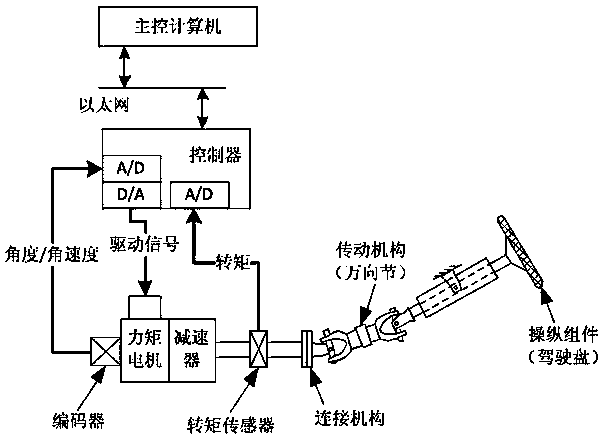

Airplane simulation manipulator with operating force feel

ActiveCN103473967ASatisfy force-displacement curveManipulation force changes in real timeCosmonautic condition simulationsSimulatorsTorque motorControl channel

The invention discloses an airplane simulation manipulator with an operating force feel, and belongs to the technical field of digital simulation operation of airplane cockpits. The airplane simulation manipulator comprises a control channel, a master control computer, a network switch, and a controller, wherein the control channel corresponds to each manipulating component and provides the operating force feel to each manipulating component; the master control computer generates a control instruction of the control channel via flight aerodynamic data; the network switch converts the control instruction and then transmits to the control channel; the controller obtains the control instruction output by the master control computer through the network switch; the control channel comprises a servo motor composed of a servo driver and a torque motor; a torque sensor is arranged coaxially with a rotating shaft of the output end of the servo motor; the rotating shaft of the servo motor is connected with a transmission gear through a link mechanism. By adopting the airplane simulation manipulator, simulation of the operating force feel is achieved through the torque motor; a force feel-displacement curve of a real airplane can be accurately met; the operating force can change in real time along with the change of a flight state; the follow-up function under an automatic driving connection state is also achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

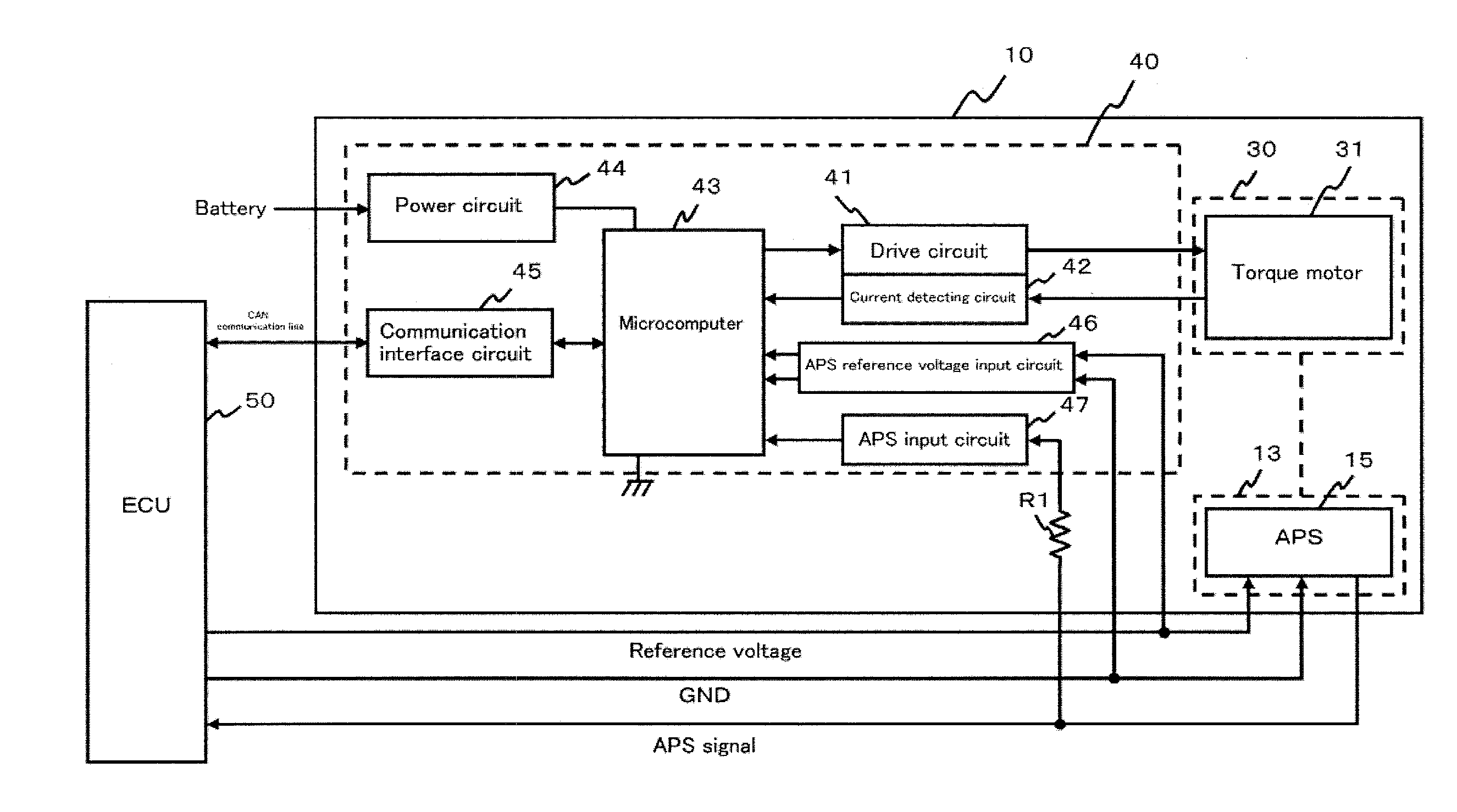

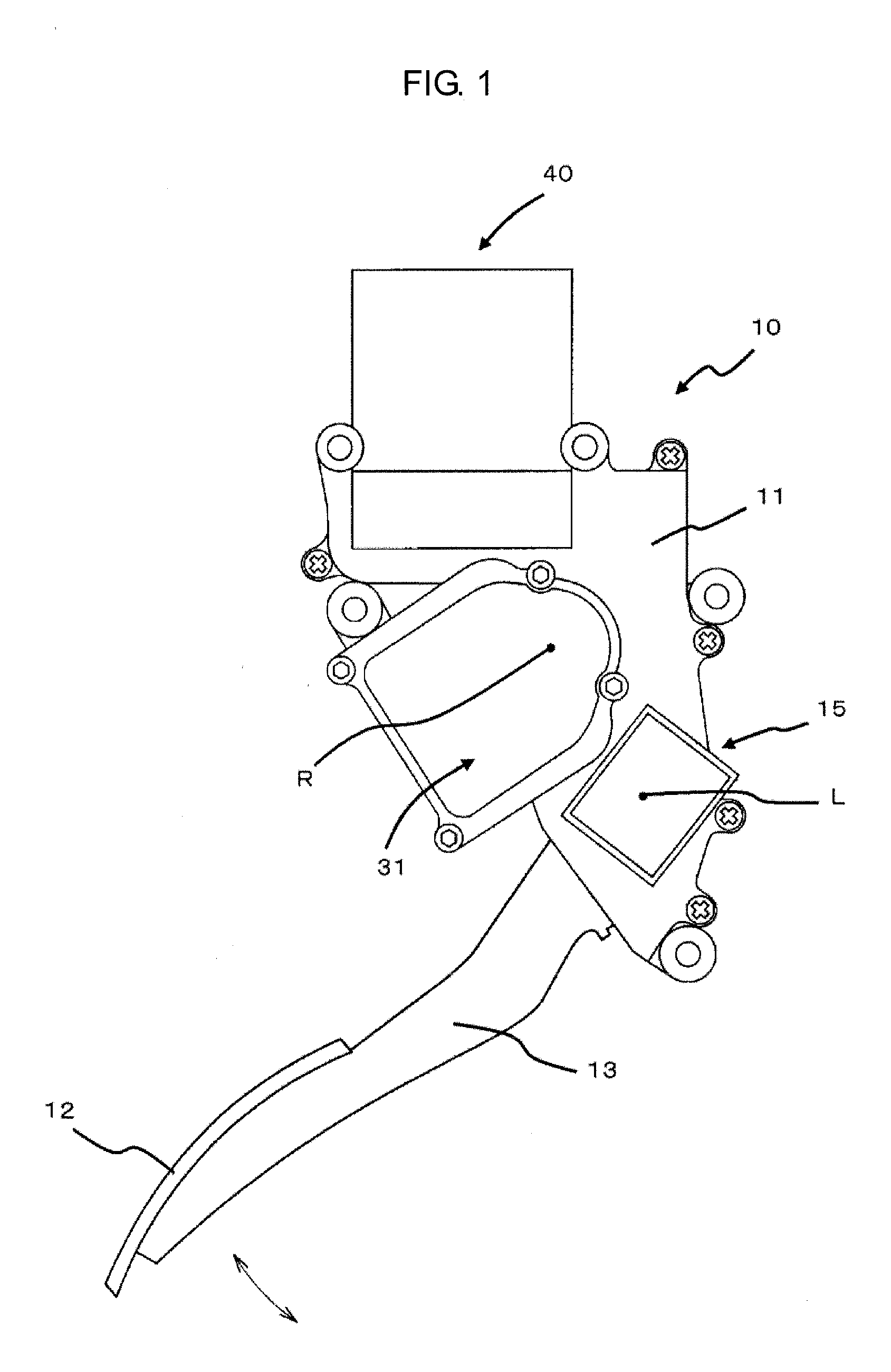

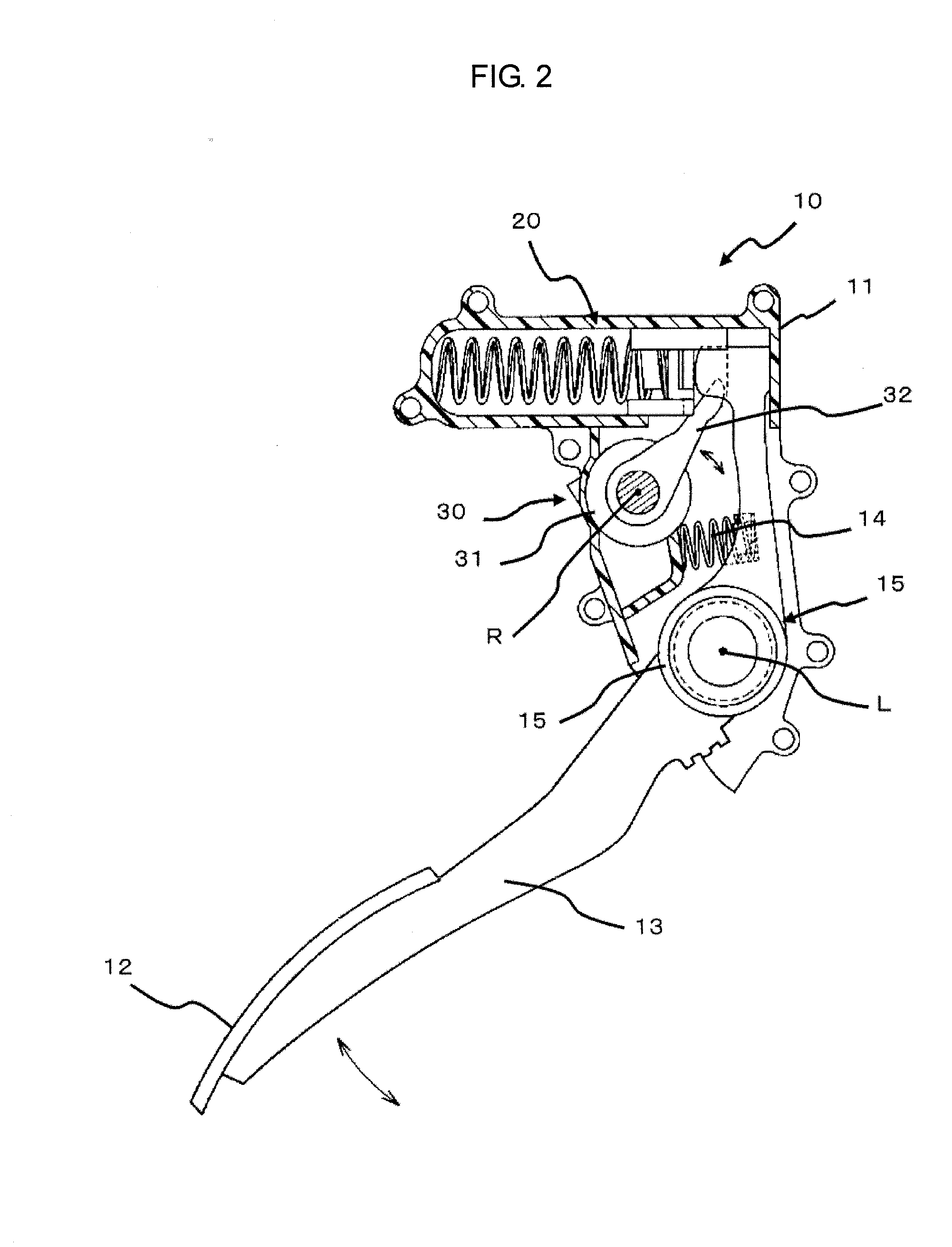

Accelerator pedal apparatus

ActiveUS20120143441A1Easy to controlLow costControlling membersMechanical apparatusTorque motorEngineering

An accelerator pedal apparatus includes a torque motor which generates operational reaction force corresponding to operation of an accelerator pedal, an accelerator pedal position sensor (APS) which detects an accelerator opening rate of an accelerator pedal and outputs the accelerator opening rate to an engine control unit (ECU) being an upper device, and a control unit which applies the operational reaction force as controlling driving of the torque motor. The control unit applies the operational reaction force as controlling driving of the torque motor based on the accelerator opening rate when being commanded to apply the operational reaction force by the ECU.

Owner:MIKUNI CORP

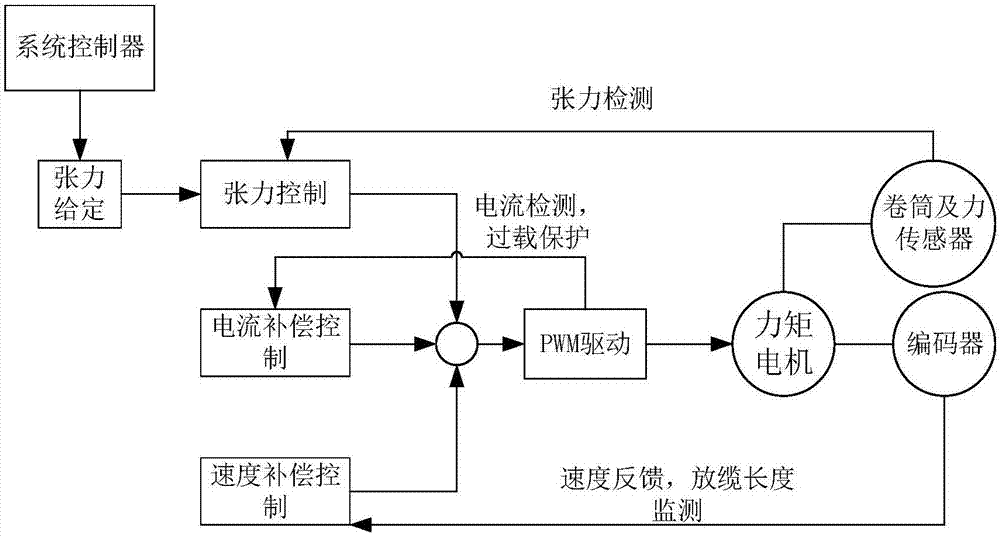

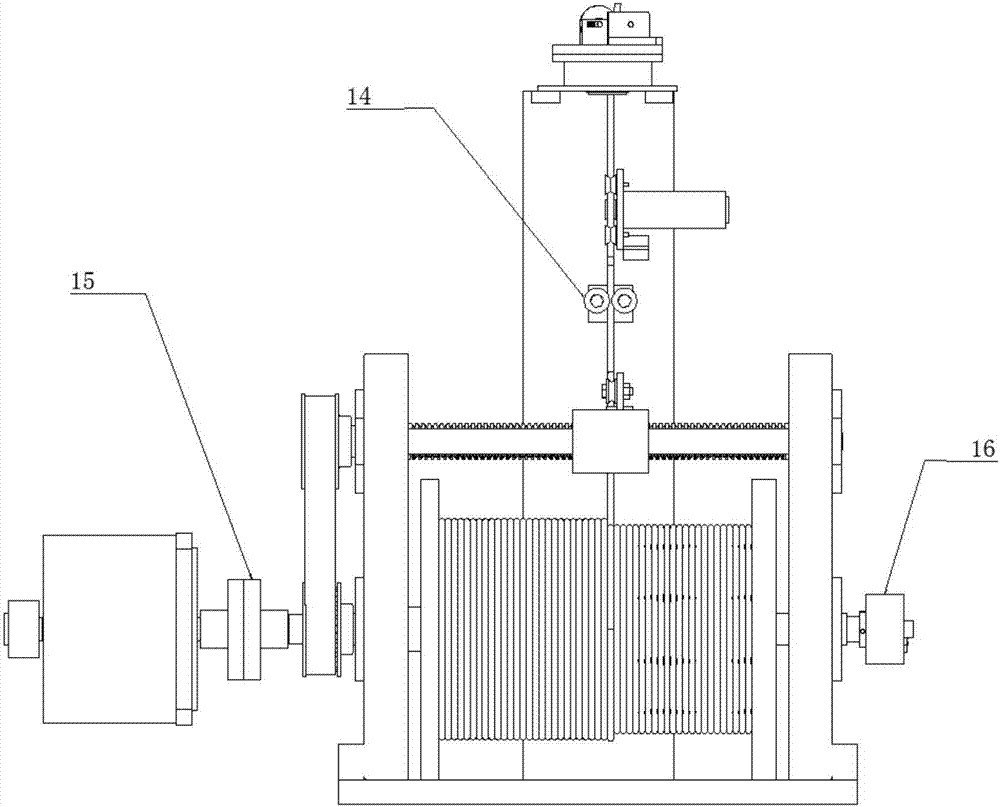

Cable winding and unwinding device of mooring unmanned aerial vehicle and control system

ActiveCN107161808AReduce the effect of tensionSolve the constant tension problemControl systemTorque motor

The invention provides a cable winding and unwinding device of a mooring unmanned aerial vehicle and a control system. A driving unit comprises a torque motor and a synchronous belt; a cable arrangement device consists of a two-way lead screw, a spiral pair and a guide rail; the torque motor directly drives a cable storage cylinder to wind cables, and drives a reciprocating lead screw to rotate by a synchronous belt transmission mechanism to realize reciprocating wire arrangement actions of the spiral pair; and optical cables penetrate through three sets of fixed free wheels and force sensors in sequence by a wire arrangement device, and are finally connected to the unmanned aerial vehicle through a guide mechanism. The torque motor directly drives the cable storage cylinder, so that the power consumption caused by such factors as mechanical friction in the transmission process is reduced; compared with single guide wheel in a traditional cable winding and unwinding device on the aspect of guiding and fixing the optical cables, three sets of free wheels are adopted; two sets of free wheels are mounted on the spiral pair to horizontally move along with rotation of the lead screw in an axis perpendicular manner; and the other set of free wheels are mounted on the bracket to guarantee invariable direction of feeding the optical cables into the force sensor so as to guarantee the measurement accuracy.

Owner:HARBIN ENG UNIV

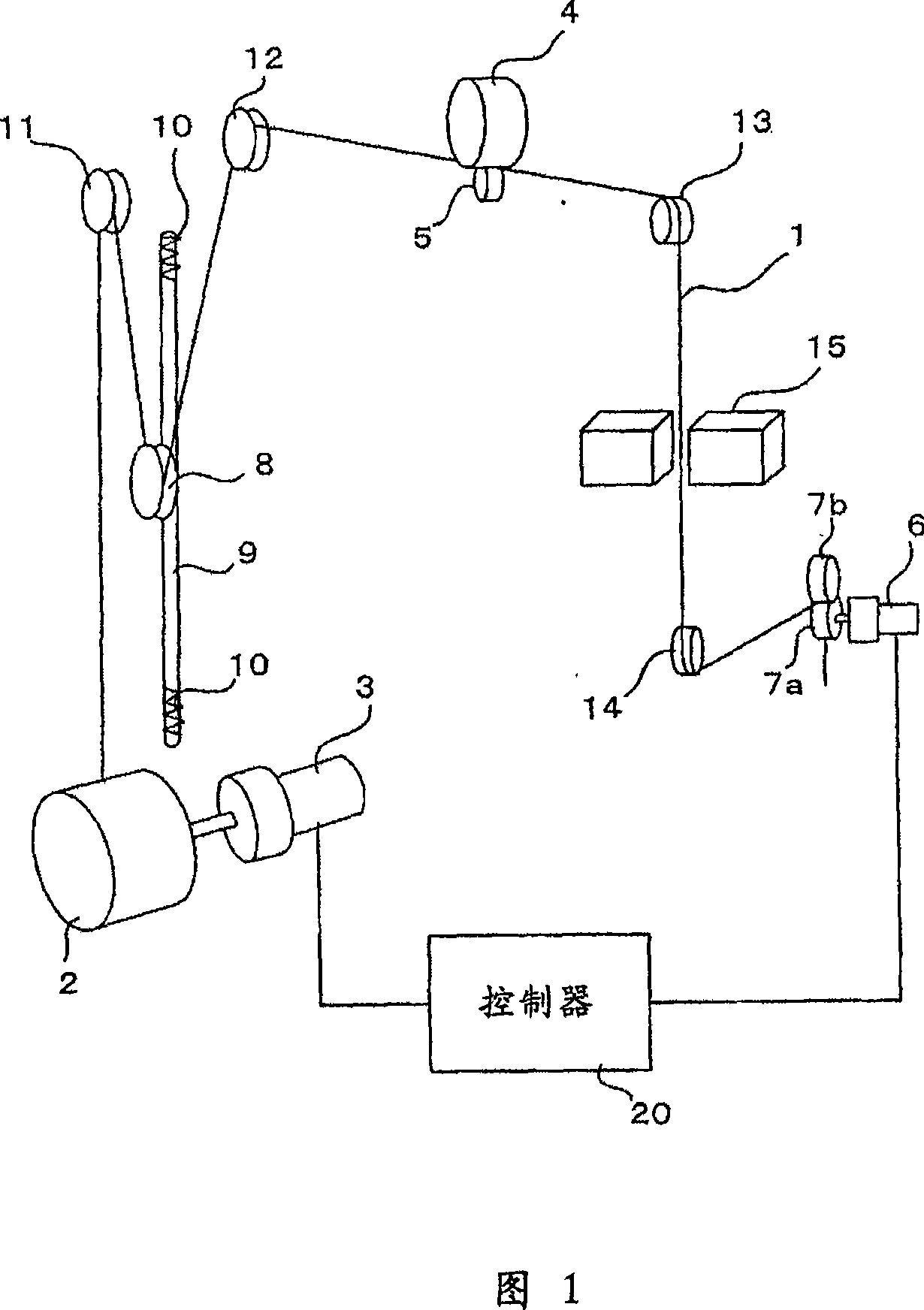

Wire electrode supply device for wire-cut electric discharge machine

InactiveCN101045262APrevent deviationFilament handlingElectrical-based machining electrodesElectric dischargeBobbin

A wire electrode supply device capable of preventing slack and snapping of a wire electrode even using a heavy wire bobbin without using a wire electrode tension detector. A pulley is provided between the wire bobbin driven by a torque motor and a brake roller. The wire electrode unwinds from the wire bobbin, passes through the pulley, brake roller and a workpiece work area, and is taken up by a wind-up roller. When the wire electrode traveling speed is changed from fast to slow, the pulley descends to prevent the wire electrode from slackening between the wire bobbin and the brake roller. When the traveling speed is changed from slow to fast, the back tension from the torque motor is reduced for a predetermined period of time, reducing tension on the wire electrode and preventing it from snapping. Also, the pulley descends, rotating the wire bobbin in the feeding direction and quickening tracking of the shift to fast feed speed, enabling snapping of the wire electrode to be prevented even when a heavy wire bobbin is used.

Owner:FANUC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com