Device and method of automatic helical milling of hole

A technology of helical milling holes and mounting flanges, which is applied in the direction of automatic control devices, positioning devices, feeding devices, etc., can solve the problems of composite material processing delamination and large tool loss, so as to ensure processing accuracy, safety and high efficiency The effect of hole making and automatic hole making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

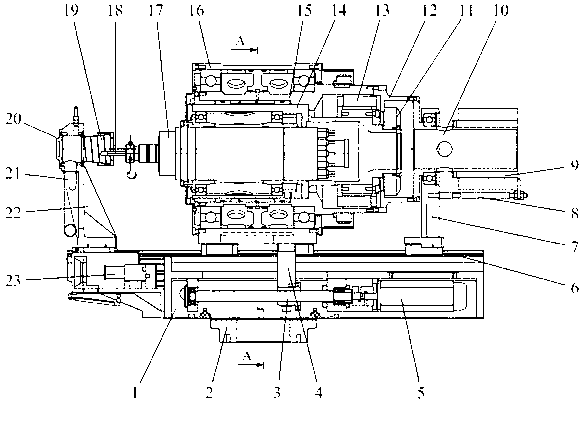

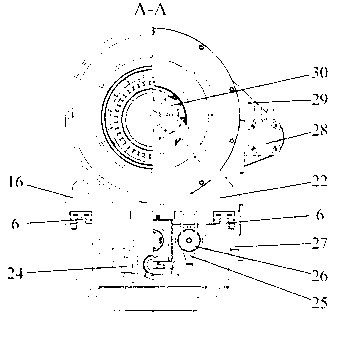

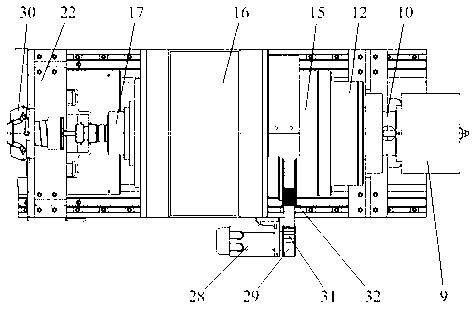

[0022] As shown in Figure 1, the automated screw milling device includes a base 1, a mounting flange 2, a ball screw pair 3, a nut seat 4, a first servo motor 5, a linear guide 6, an auxiliary support seat 7, an anti-rotation screw 8. Through hole slip ring 9, slip ring sleeve 10, circular grating 11, circular grating mounting plate 12, torque motor 13, inner eccentric sleeve 14, outer eccentric sleeve 15, spindle slide 16, electric spindle 17, tool 18, Spiral protective sleeve 19, presser foot 20, chip removal tube 21, presser foot 22, industrial camera 23, first linear grating 24, cylinder 25, cylinder adapter 26, second linear grating 27, second servo motor 28 , Timing belt 29, laser distance sensor 30, small timing belt wheel 31, large timing belt wheel 32; mounting flange 2, ball screw pair 3, first servo motor 5, cylinder 25, first linear grating 24, first The two linear grating 27 and the industrial camera 23 are installed on the base 1, the spindle slide 16 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com