Patents

Literature

52results about How to "Overcoming Process Defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

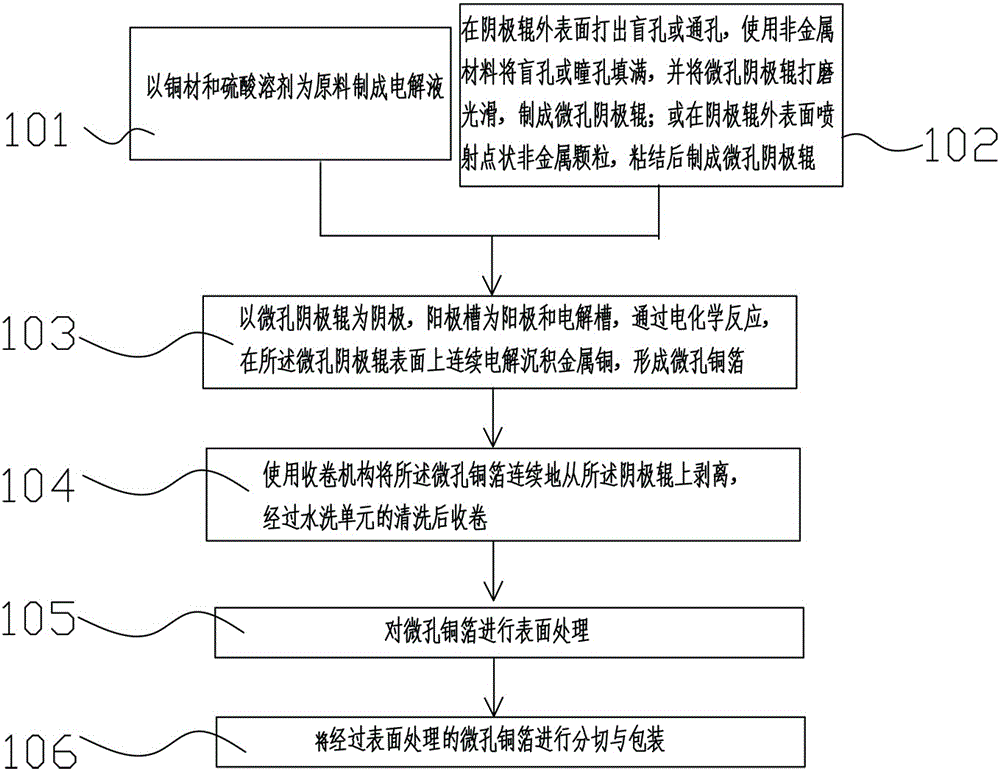

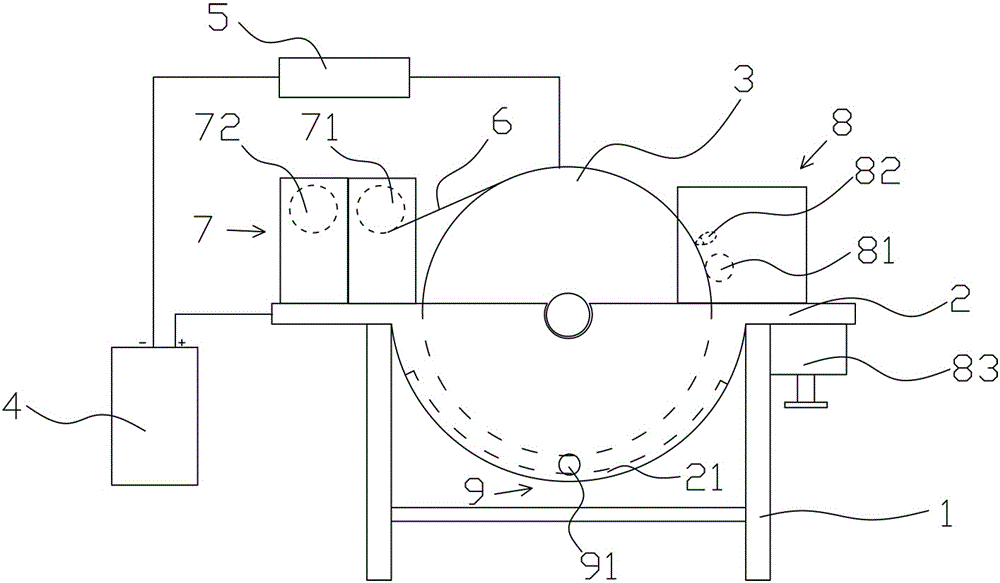

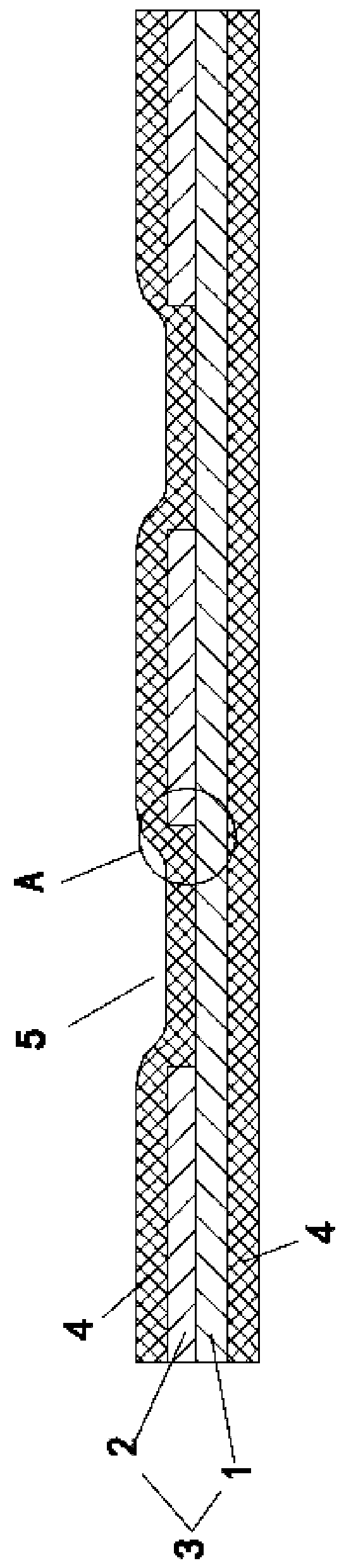

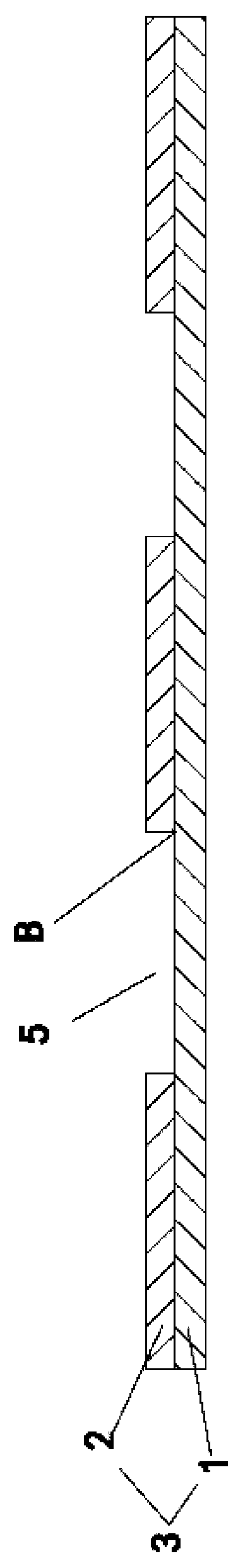

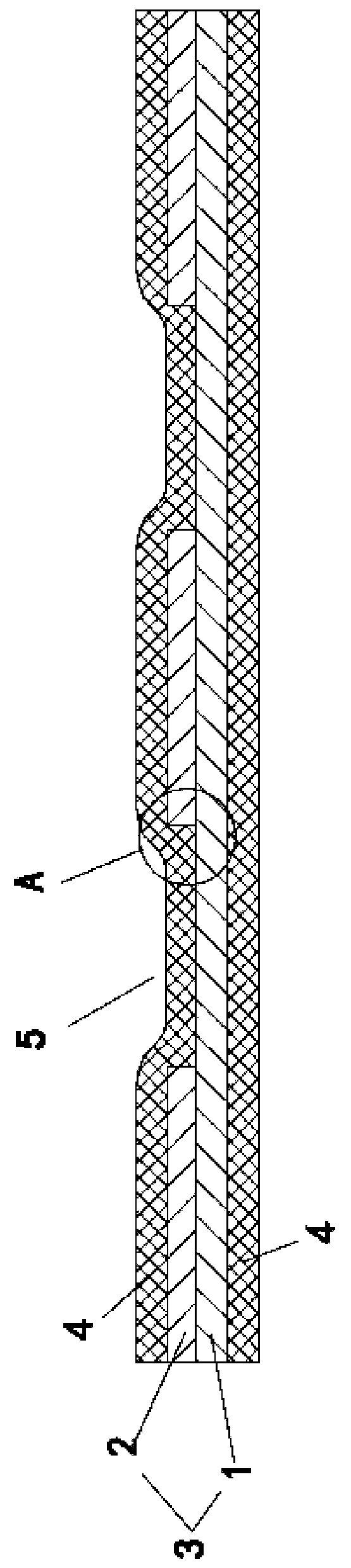

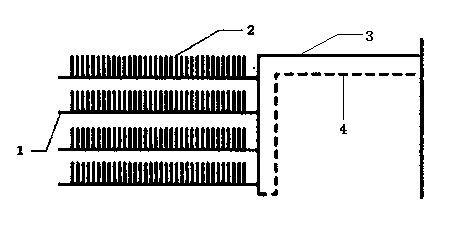

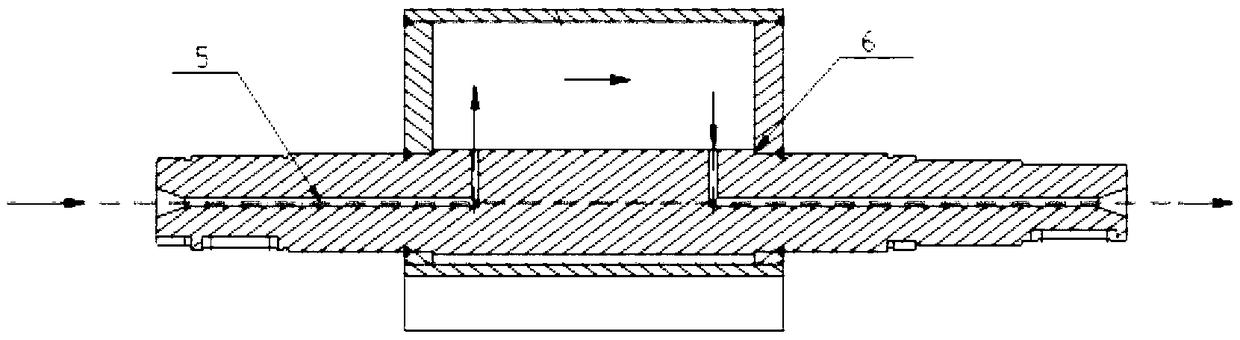

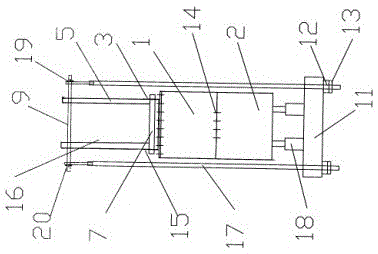

Production method of microporous copper foil, microporous copper foil and production device thereof

InactiveCN104993153AAppropriate thicknessNot easily deformedElectrode carriers/collectorsElectroforming processesIonElectrochemical response

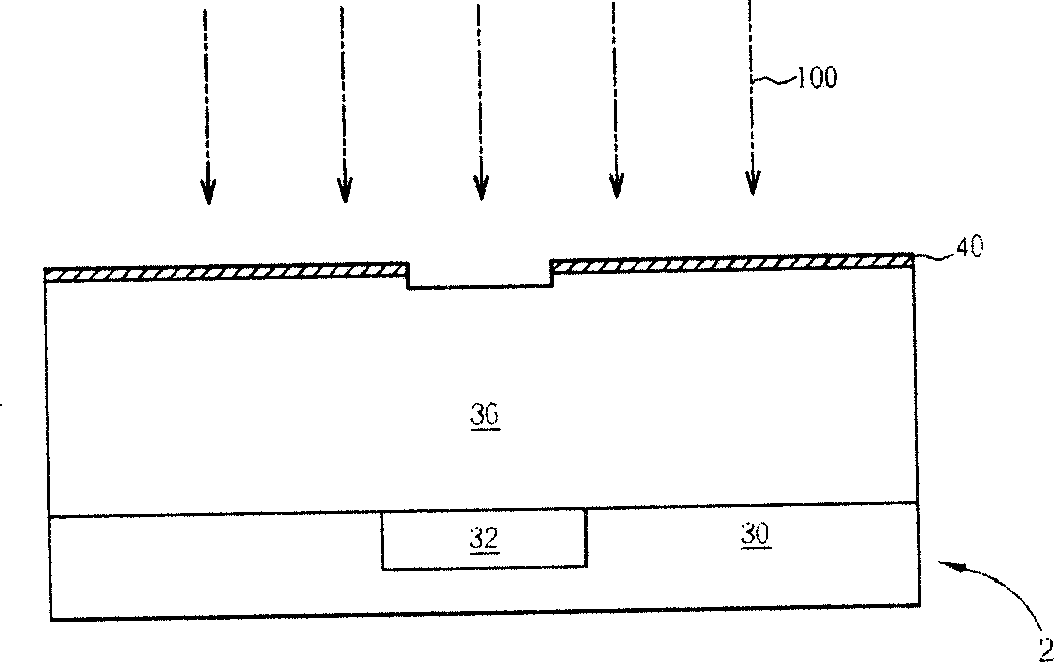

The invention provides a production method of a microporous copper foil, a microporous copper foil and a production device thereof. The production method comprises the following steps: taking a solution containing copper ions as an electrolyte, taking a prefabricated microporous cathode roll as a cathode, taking an anode cell as an anode, continuously electrolyzing depositing metal copper on the surface of the microporous cathode roll to form a microporous copper foil, wherein the microporous cathode roll is a cathode roll with a plurality of nonmetal dotted articles on a surface, contacting the electrolyte, of the cathode roll. The production device comprises a stander, wherein the stander is provided with the anode cell, the anode cell is connected with an anode of a power source by virtue of a copper bar, a cathode roll connected with a cathode of the power source is arranged above the anode cell, and the cathode roll is a microporous cathode roll. The microporous copper foil produced by adopting the production method is suitable for the smearing of a smearing machine, so that a cathode material is unlikely to drop; the microporous copper foil has advantages of being appropriate in thickness and not prone to deform and damage.

Owner:SHENZHEN XINYUREN TECH

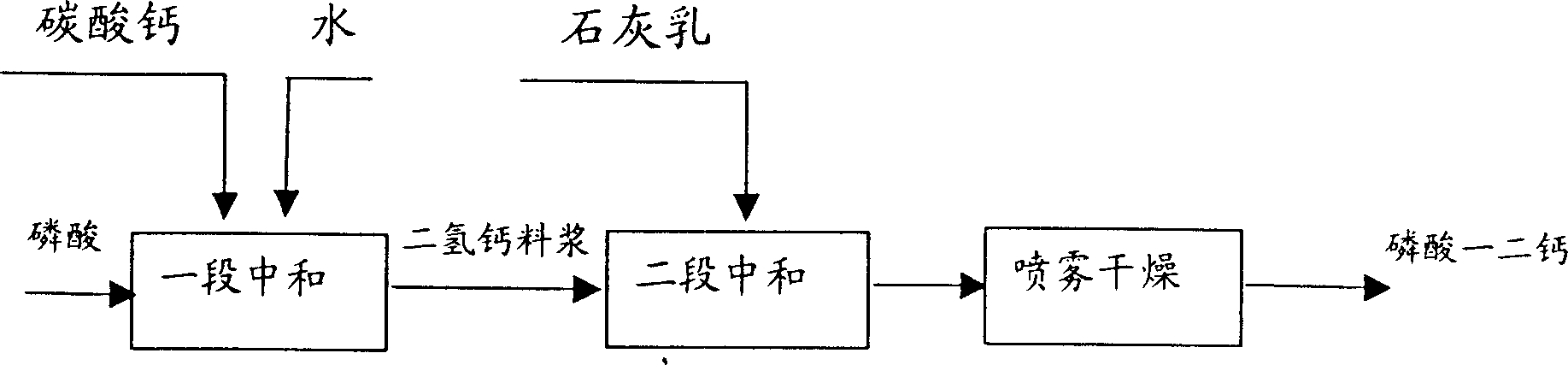

Method for producing feed grade dicalcium phosphate

InactiveCN1857997AIncrease profitReduce manufacturing costAccessory food factorsPhosphorus compoundsCalcium phosphate productO-Phosphoric Acid

The process of producing feed grade calcium phosphate features that the calcium phosphate producing process includes the first liquid phase neutralizing reaction between dilute phosphoric acid and calcium containing compound in the reactor to produce calcium dihydrogen phosphate slurry, the subsequent adding calcium containing compound for the second liquid phase neutralizing reaction to produce mixture slurry of calcium hydrogen phosphate and calcium dihydrogen phosphate, and the spray drying of the slurry to obtain the calcium phosphate product. The production process has no produced white fertilizer and waste water, high phosphorus utilization rate, low production cost, less environmental pollution and well preservation of crystalline water resulting in high biological potency.

Owner:四川川恒控股集团股份有限公司

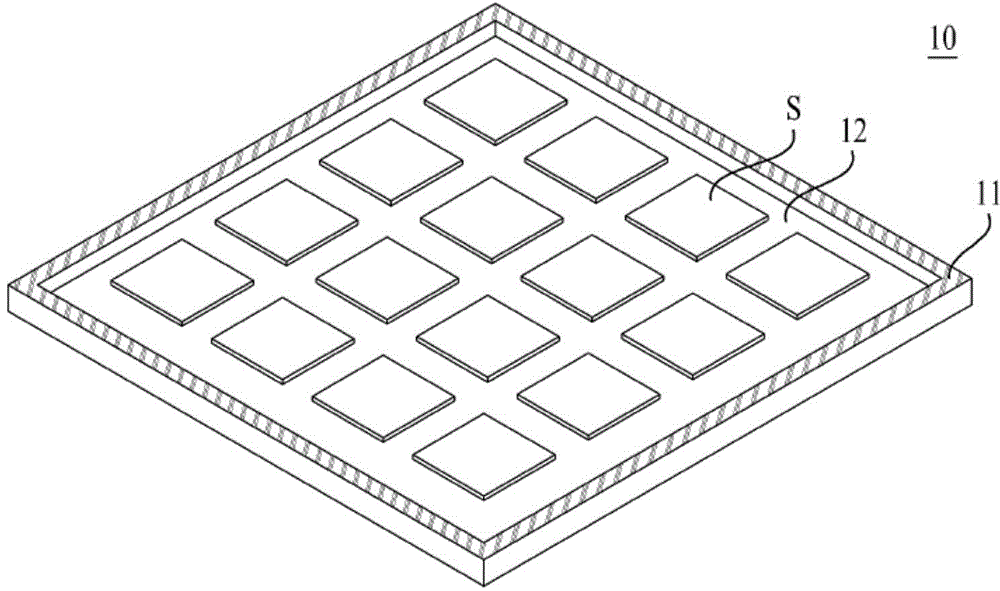

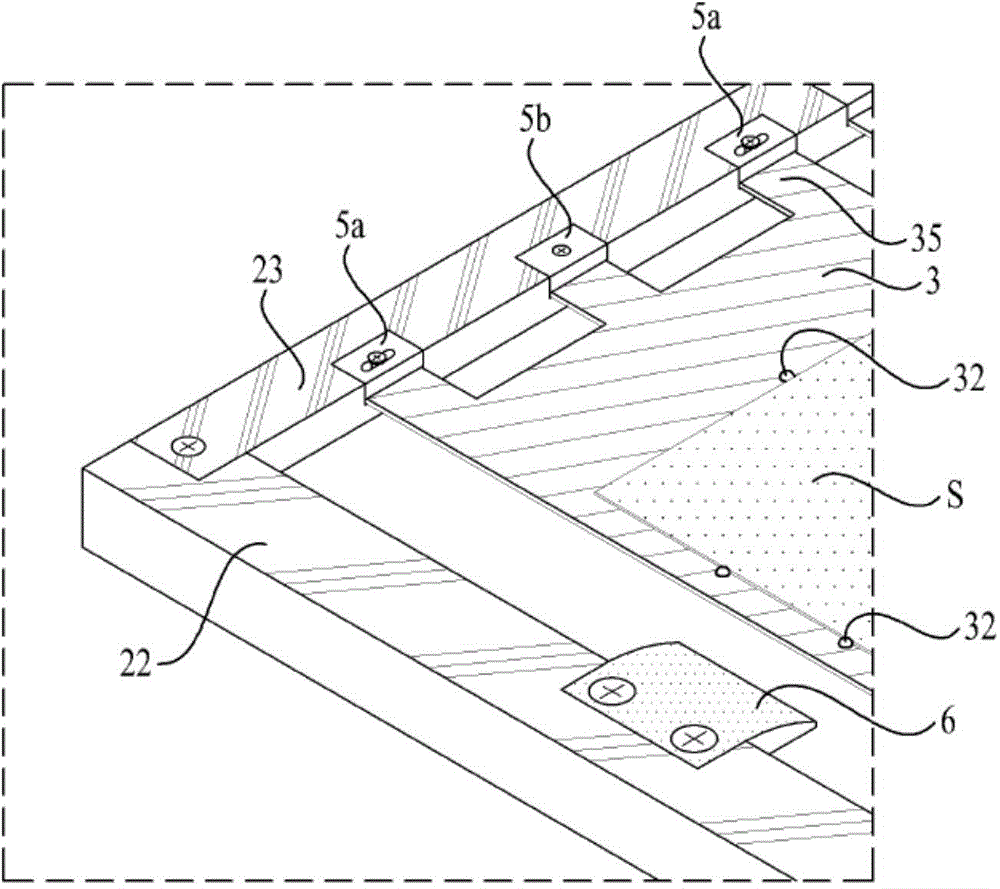

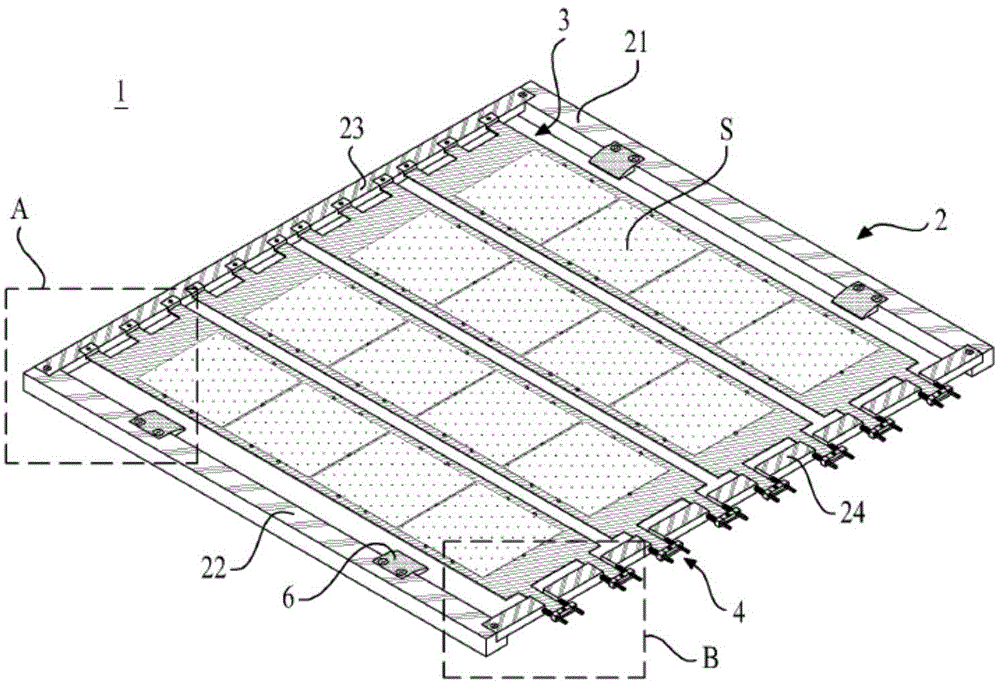

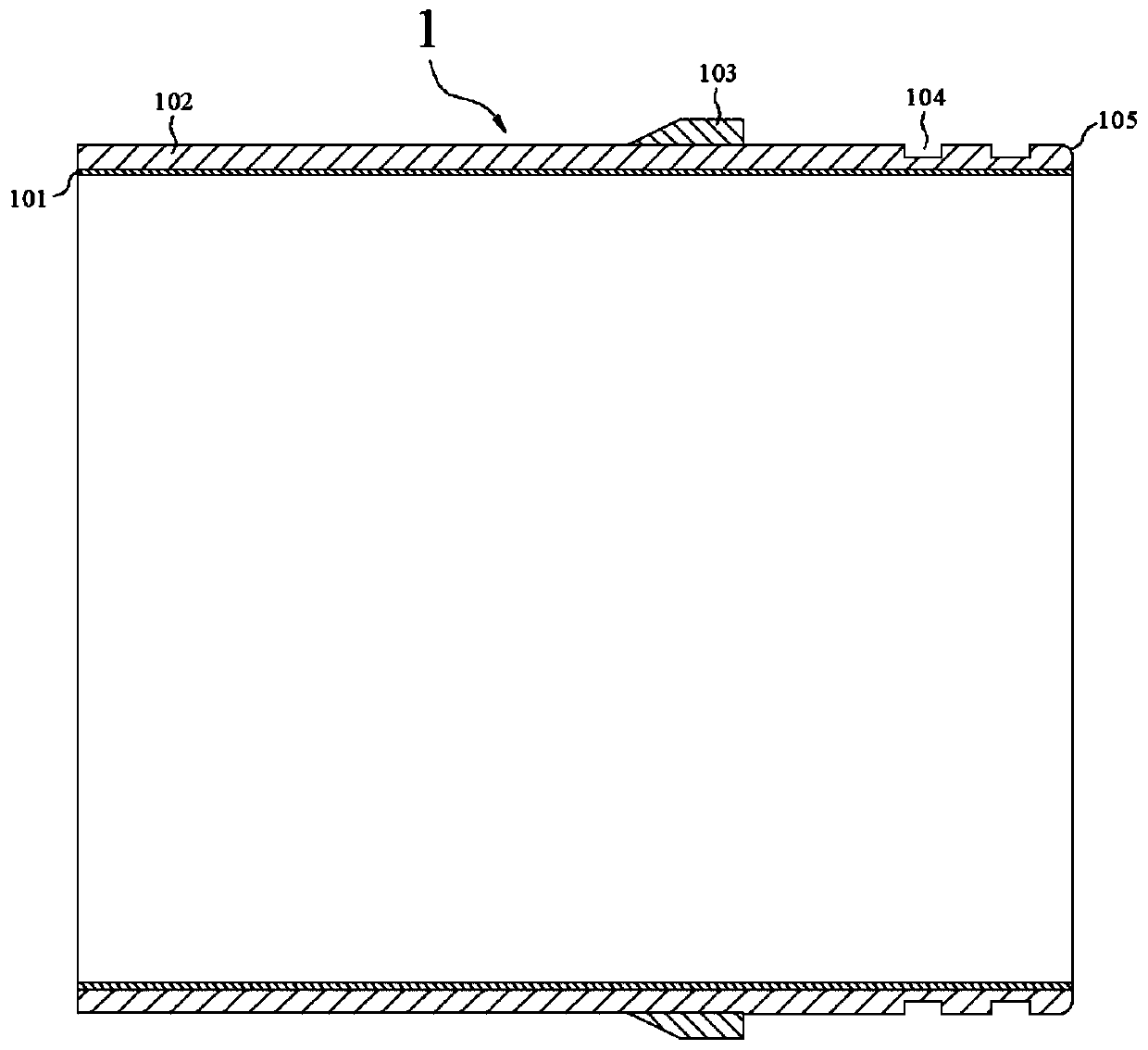

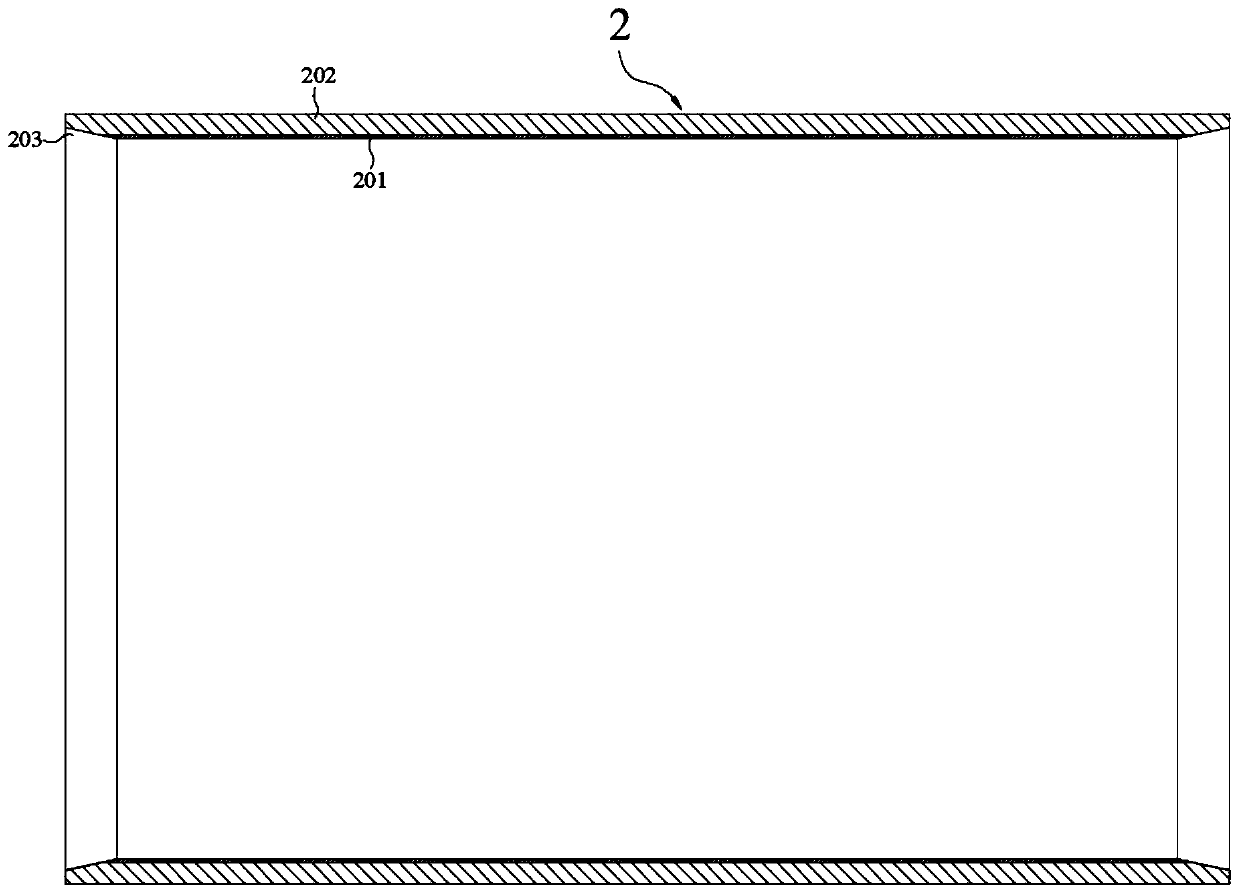

Substrate tray and substrate processing apparatus including same

ActiveCN104937707AEasy to handleIncrease productionElectric discharge tubesSemiconductor/solid-state device manufacturingEngineering

The present invention relates to a substrate tray and a substrate processing apparatus including same. The substrate tray includes: a plurality of straps for supporting a plurality of substrates arranged in a first axial direction; and a supporting frame to which a plurality of the straps is coupled in a second axial direction perpendicular to the first axial direction, wherein the straps are each formed in a length greater than the substrates in the second axial direction. According to the present invention, a plurality of straps are used to support a plurality of substrates, so that a substrate tray can easily be made large in size by increasing the number of straps.

Owner:JUSUNG ENG

SiC etching method for gentle and smooth side wall morphology

ActiveCN103715065ASolve the problem of widening and narrowingEasy accessSemiconductor/solid-state device manufacturingManufacturing technologyPhotoresist

The invention relates to the manufacturing technology of SiC devices, in particular to a SiC etching method for gentle and smooth side wall morphology. The method includes the steps of cleaning SiC materials, depositing a loose mask layer, photoetching, carrying out dry etching on the mask layer, carrying out wet etching on a smooth mask layer, removing photoresist and carrying out dry etching on the SiC materials. The key process improvement refers to that dry etching on the loose mask layer and wet etching on the smooth mask layer are combined. According to the method, the process of only adopting wet etching on the mask layer is changed, and therefore the problem that the mask bar width is decreased due to lateral erosion in the wet etching is solved. By means of the method, the SiC etching morphology of gentle and smooth side walls can be obtained effectively and conveniently.

Owner:STATE GRID CORP OF CHINA +1

Semiconductor technology

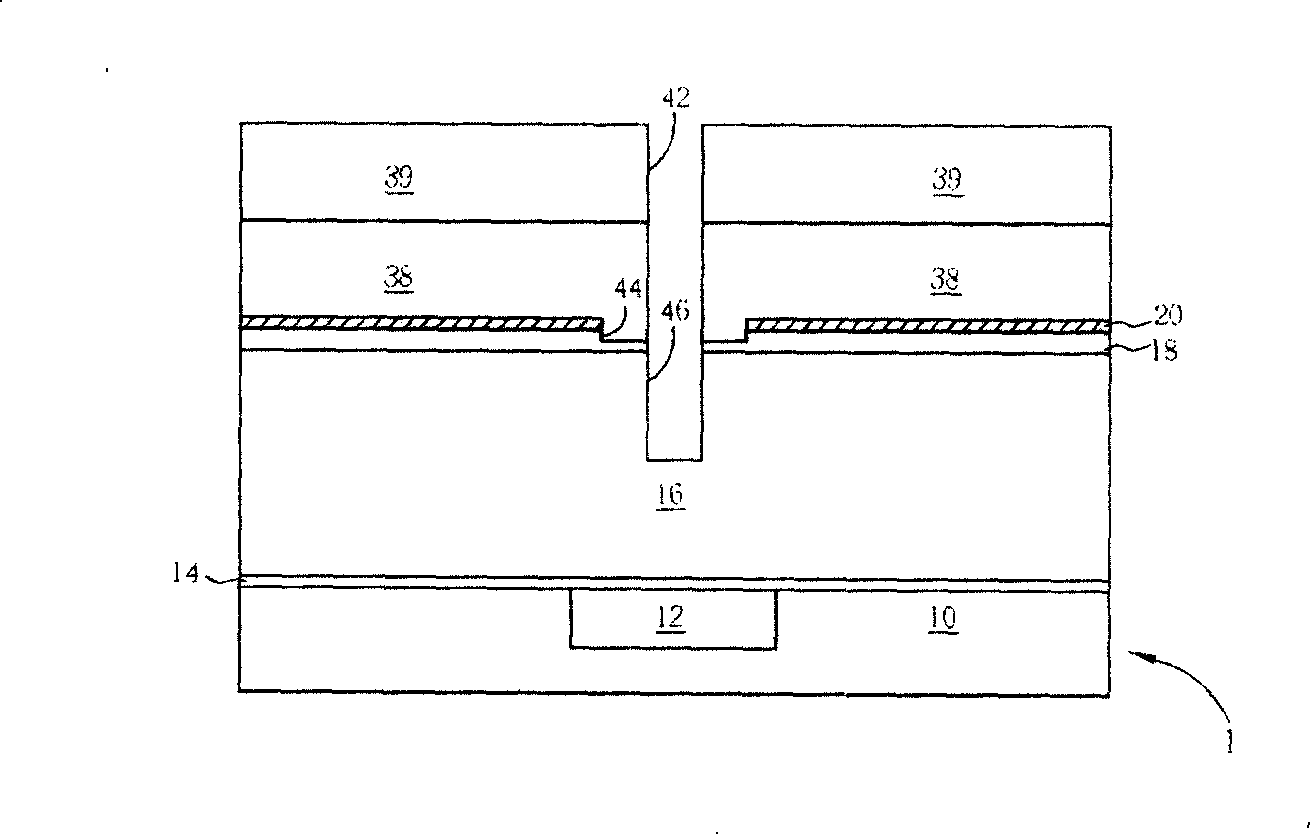

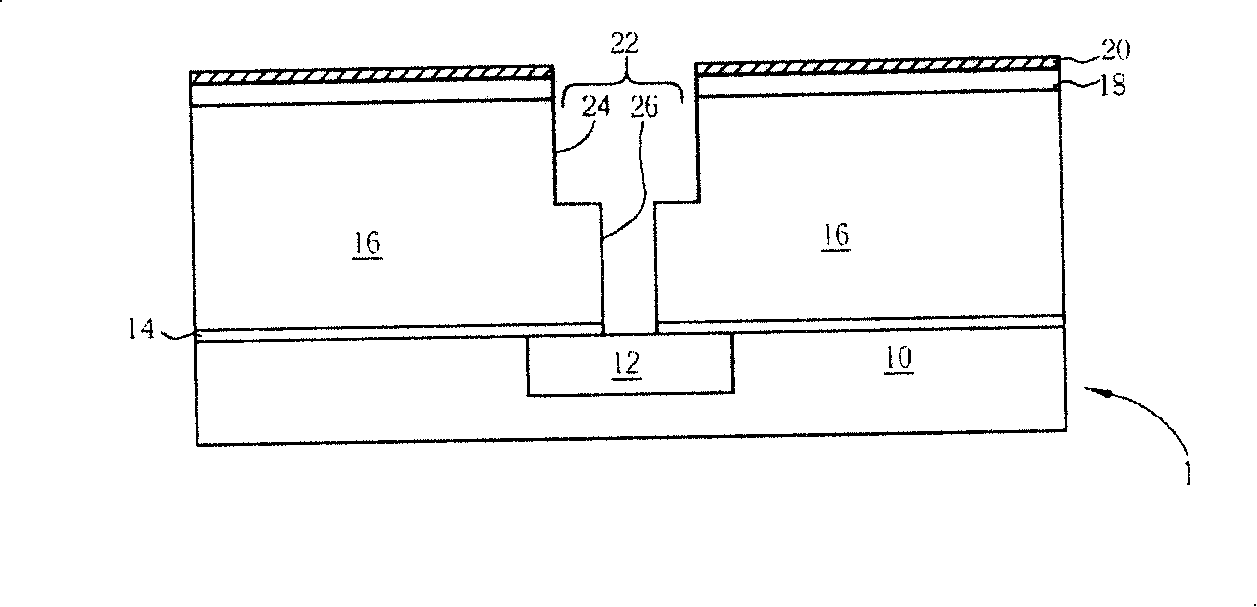

ActiveCN101211753AOvercoming Process DefectsSemiconductor/solid-state device manufacturingTitaniumCompounds of fluorine

The invention discloses a semiconductor process, which comprises the following steps: a plasma containing the fluorine free radicals is used for etching a characteristic pattern on a rigid mask and in a layer below the rigid mask, and a gas which can react with the fluorine free radicals is used for carrying out the treatment to ensure that the residual fluorine free radicals react with the gas so as to form the fluorine-contained compounds for the purpose of removal, thereby preventing the fluorine free radicals from reacting with the titanium compositions with forming the particles deposited on a substrate, which results in the process defect.

Owner:UNITED MICROELECTRONICS CORP

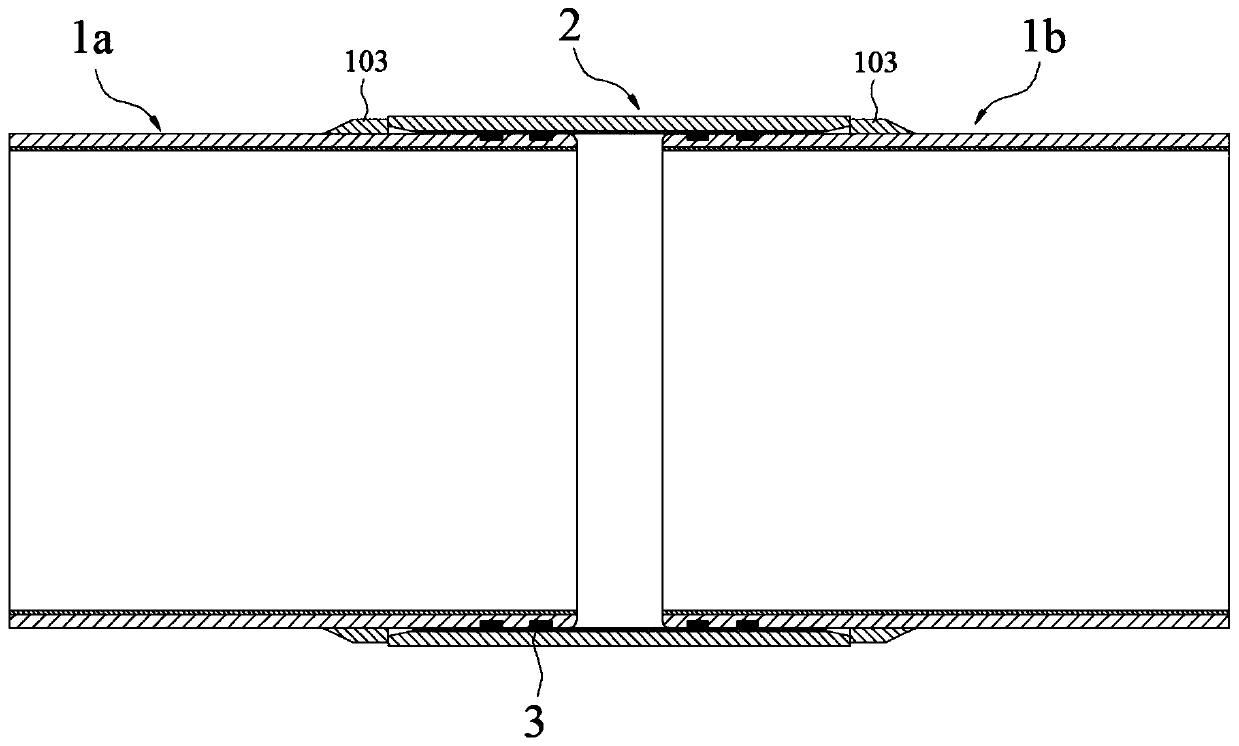

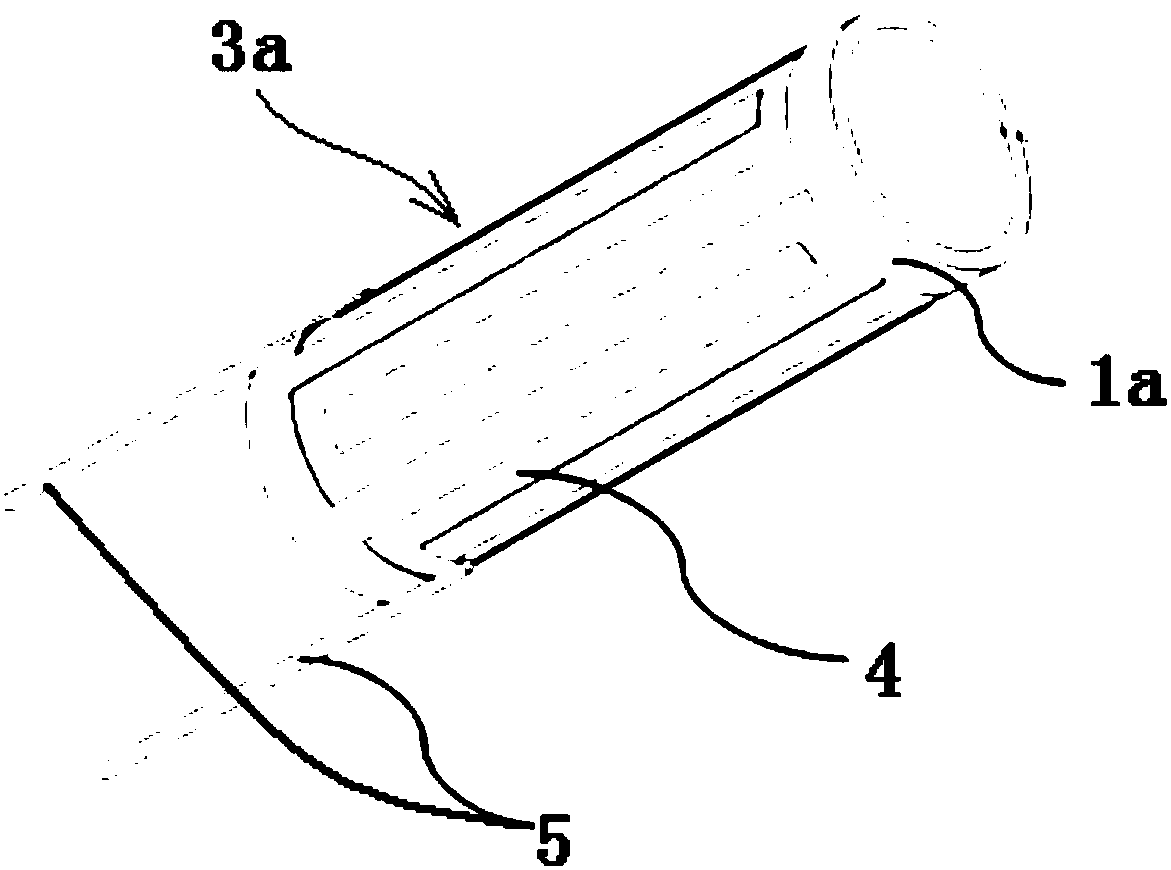

Bamboo composite pipe connecting structure and preparation method thereof

PendingCN110375134AImprove quality and efficiencyImprove forming efficiencyCouplingsRigid pipesWaste productEngineering

The invention discloses a bamboo composite pipe connecting structure and a preparation method thereof and belongs to the technical field of bamboo composite pipe connection. One end of each bamboo composite pipe is set as a pipeline socket with a blocking platform and a sealing groove, and the pipeline sockets on the two corresponding to-be-connected bamboo composite pipes are set as cylindrical bundle sections, so that the pipeline sockets of the two bamboo composite pipes are inserted at the two ends of the bundle sections and corresponding connection of the two bamboo composite pipes is realized. The bamboo composite pipe connecting structure provided by the invention is simple in structure and convenient and rapid in preparation process; the process defect in the existing bamboo composite pipe connecting structure forming process can be effectively overcome; waste products of forming parts are reduced; waste of materials are reduced; the preparation cost and the application cost ofthe bamboo composite connecting structure can be saved; and good application prospect and promotion value are achieved.

Owner:中林鑫宙竹缠绕发展有限公司

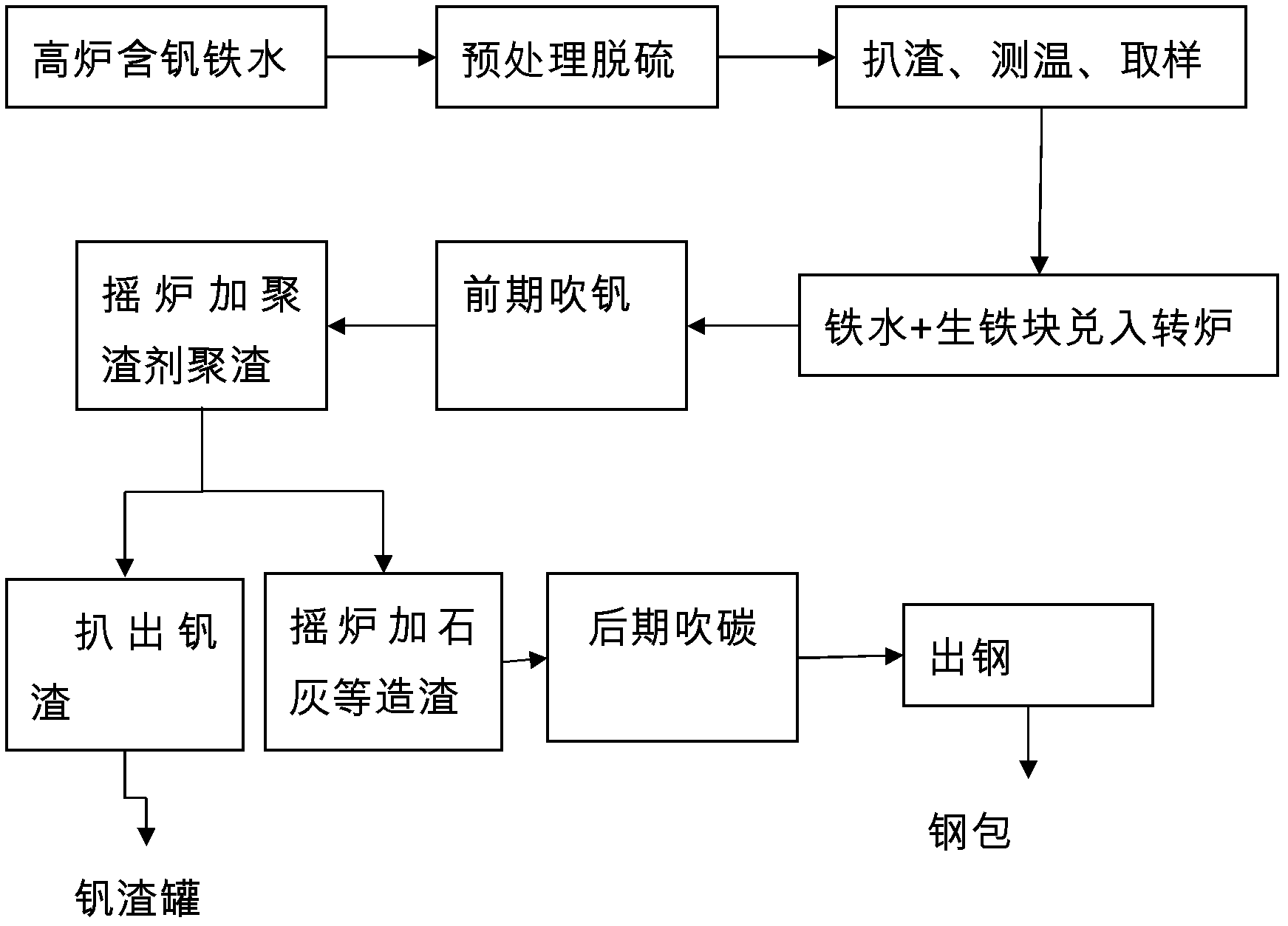

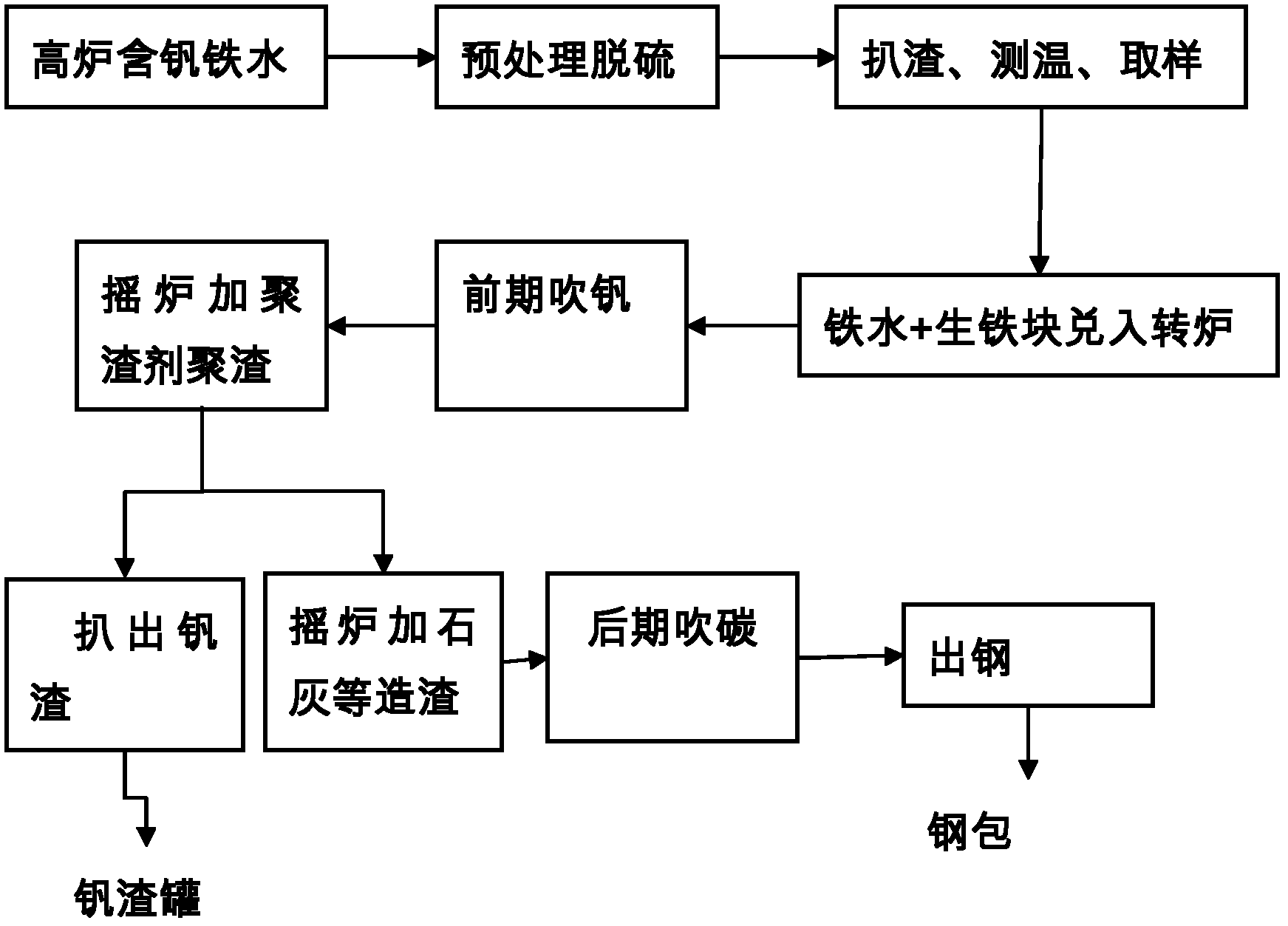

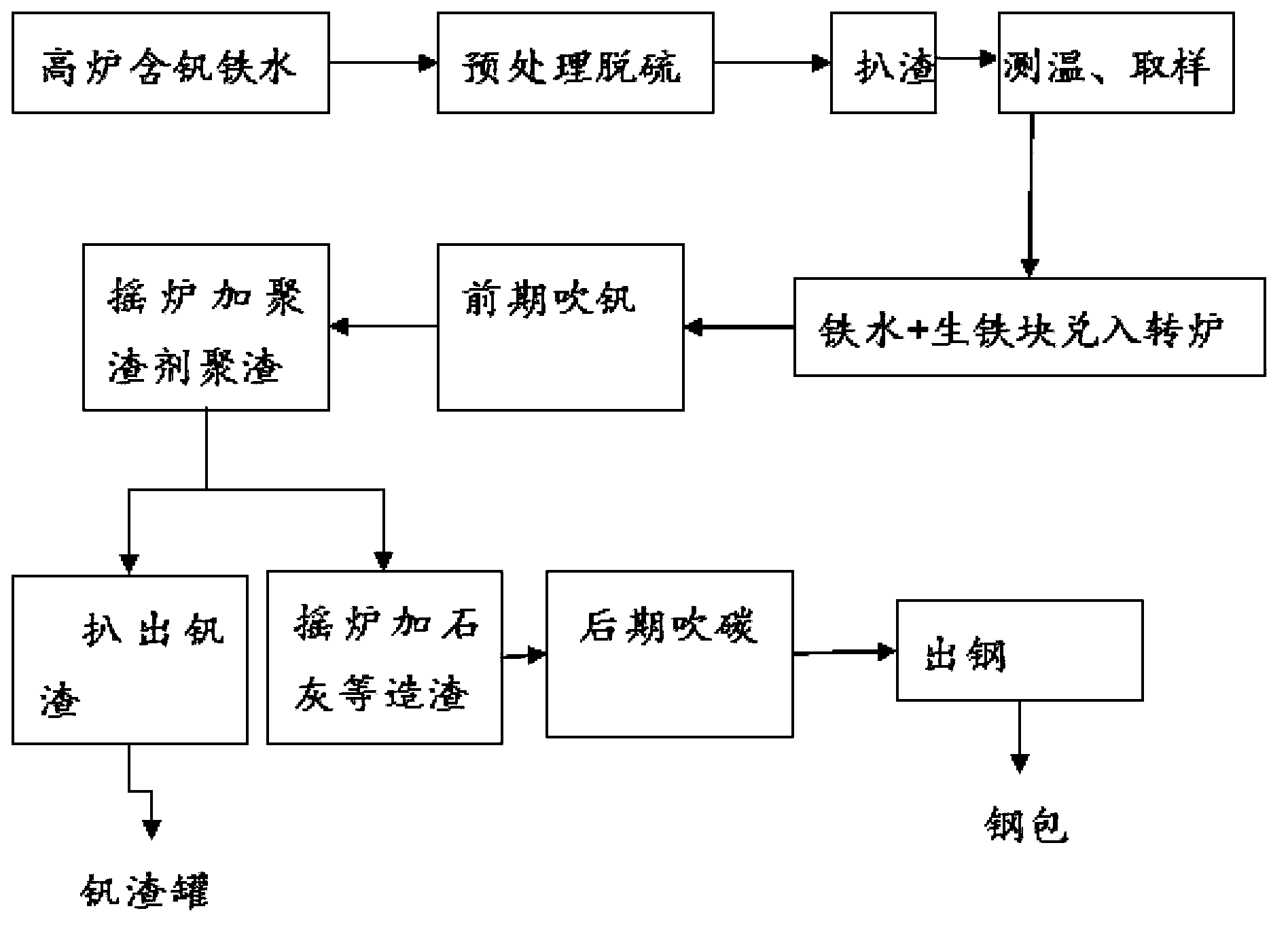

Method for single-stage vanadium extraction in same converter

ActiveCN102559986AOvercoming Process DefectsSolve the large heat lossManufacturing convertersSteelmakingSingle stage

The invention discloses a method for single-stage vanadium extraction in the same converter. In a blowing early stage, lime is not added for slagging, vanadium in molten iron is oxidized to enter slag, and silicon, manganese and titanium in the molten iron are oxidized to enter a slag phase; and blowing is stopped after the vanadium is oxidized, vanadium slag is discharged, lime and other slag formers are added for slagging and steelmaking, and qualified molten steel is produced. Compared with the prior art, the method for single-stage vanadium extraction in the same converter has the advantages of reducing temperature loss in the vanadium extracting process, improving the production efficiency of a converter workshop and reducing production cost.

Owner:SICHUAN DAZHOU IRON & STEEL GROUP

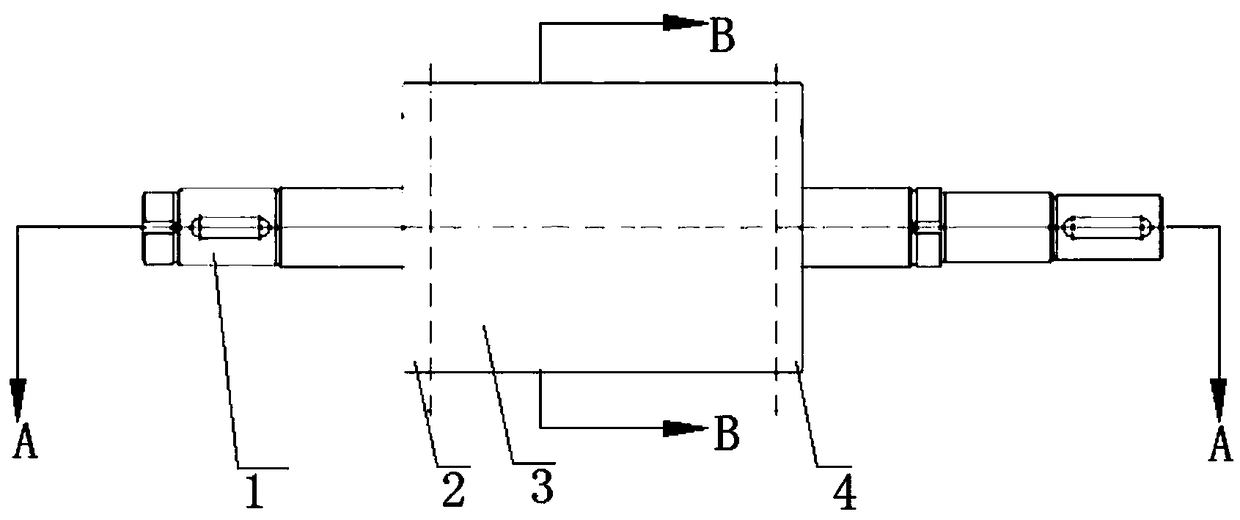

Method for welding cold-expansion tube production line draw rod

The invention provides a method for welding a pull rod for a production line of cold expansion pipes, which comprises the following steps: preparing before welding; preparing a short joint end of the pull rod; preparing of a long joint end of the pull rod; welding; detecting after the welding, namely, carrying out ultrasonic and dye penetration inspection for the welded joint after the pull rod is welded. The method has the advantages that by adopting an unconventional method to weld and repair the pull rod for the production line of the cold expansion pipes, the method solves the technical problems of integral preheating of the pull rod, heat treating after the welding and welding at low temperature, avoids multiple technical defects, shortens repair time, and reduces loss of oil fields. The pull rod is a key component of production line equipment for the cold expansion pipes in the oil fields, and directly influences production operation after the pull rod is damaged, then the downtime loss is 320, 000 Yuan per hour, and if spare parts are bought abroad, several months are needed. The method generates certain social benefit and larger economic benefit, and provides scientific repair method for guiding production practice for projects in the same field.

Owner:TIANJIN PIPE GROUP CORP

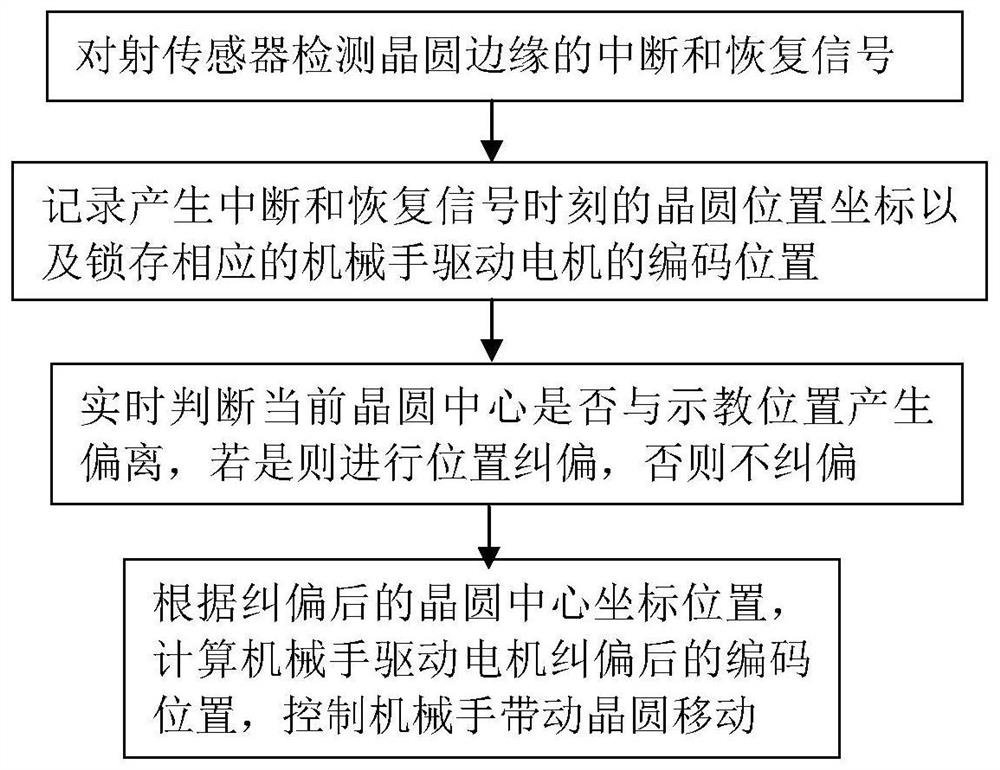

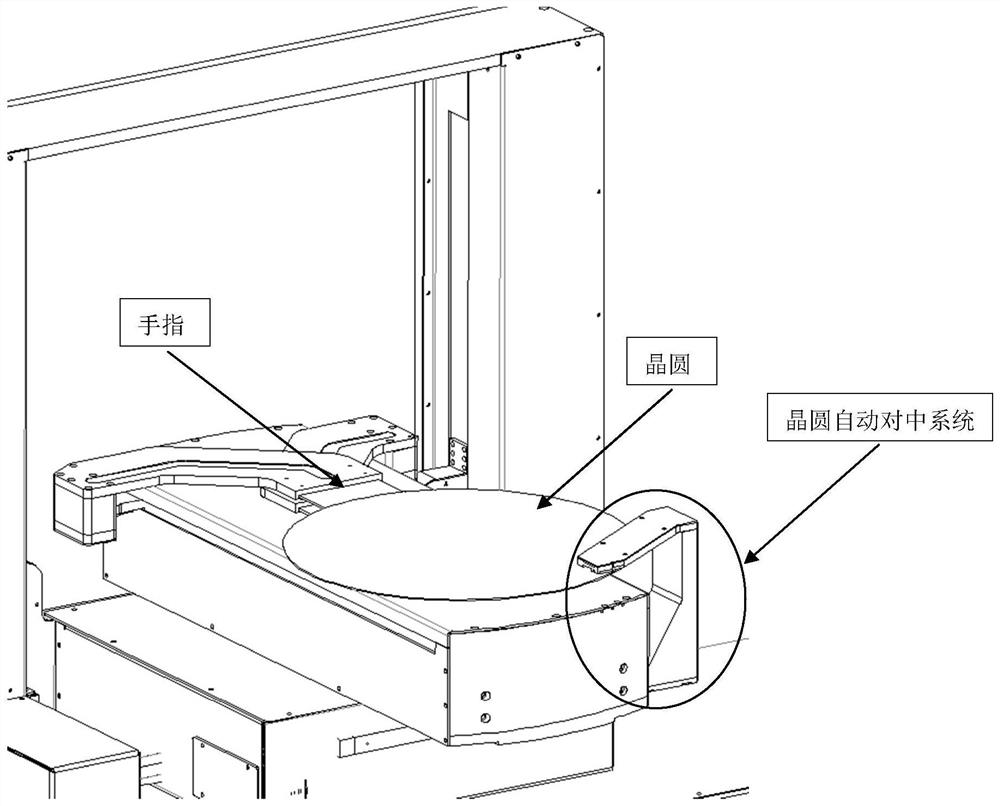

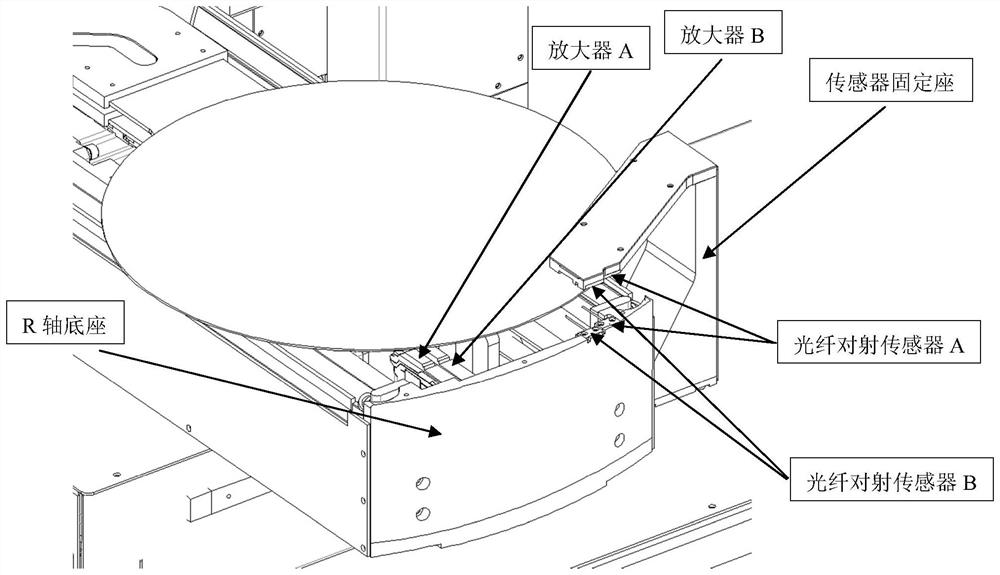

Automatic wafer centering method

PendingCN113380686AIncrease production capacityHigh precisionSemiconductor/solid-state device manufacturingConveyor partsWaferMachine

The invention discloses an automatic wafer centering method, which comprises the following steps of: acquiring a wafer edge signal by a sensor in the process of taking back a wafer by a manipulator, obtaining the current center position of the wafer through an algorithm, comparing the current center position of the wafer with the teaching center position of the wafer, and compensating in the process of sending out the wafer next time by the manipulator if a deviation exists; and when the wafer gap just falls in one sensor detection area, rejecting the measurement result of the sensor in the gap area through an algorithm. According to the method, a machine table does not need to additionally increase stations, a mechanical arm can measure and compensate the wafer offset in the wafer conveying process, the equipment productivity is not affected at all, and the cost is far lower than that of a traditional mechanical centering unit and an optical centering unit.

Owner:SHENYANG KINGSEMI CO LTD

Direct dry-film adhering process for hollowed-out region of hollowed-out flexible circuit board

ActiveCN109714904AAvoid bitesOvercoming Process DefectsConductive material chemical/electrolytical removalNon-metallic protective coating applicationEmulsionFlexible circuits

The invention provides a direct dry-film adhering process for a hollowed-out region of a hollowed-out flexible circuit board. The direct dry-film adhering process is characterized by comprising the steps of: A, acquiring a semi-finished copper-clad flexible board; B, selecting a dry film with the thickness of a photosensitive emulsion layer greater than that of a cover film; C, heating double sides of the semi-finished copper-clad flexible board separately, and then adhering dry films on the double sides; D, allowing the semi-finished copper-clad flexible board adhered with the dry films to standby, pushing the semi-finished copper-clad flexible board into an oven for baking, and allowing the semi-finished copper-clad flexible board to standby after baking; E, aligning the semi-finished copper-clad flexible board obtained in the step D by using a film, wherein the exposed part of photosensitive emulsion completes polymerization and film hardening after being exposed to ultraviolet light, the unexposed part is developed to expose copper foil, the exposed copper foil is etched away and then the dry films of the film hardening part is removed to obtain the flexible circuit board. Thedirect dry-film adhering process eliminates the process defect that the hollowed-out flexible circuit board needs to print printing oil in the hollowed-out region and then be adhered with the dry films, reduces the cost, improves the production efficiency, and reduces the printing ink pollution.

Owner:福建世卓电子科技有限公司

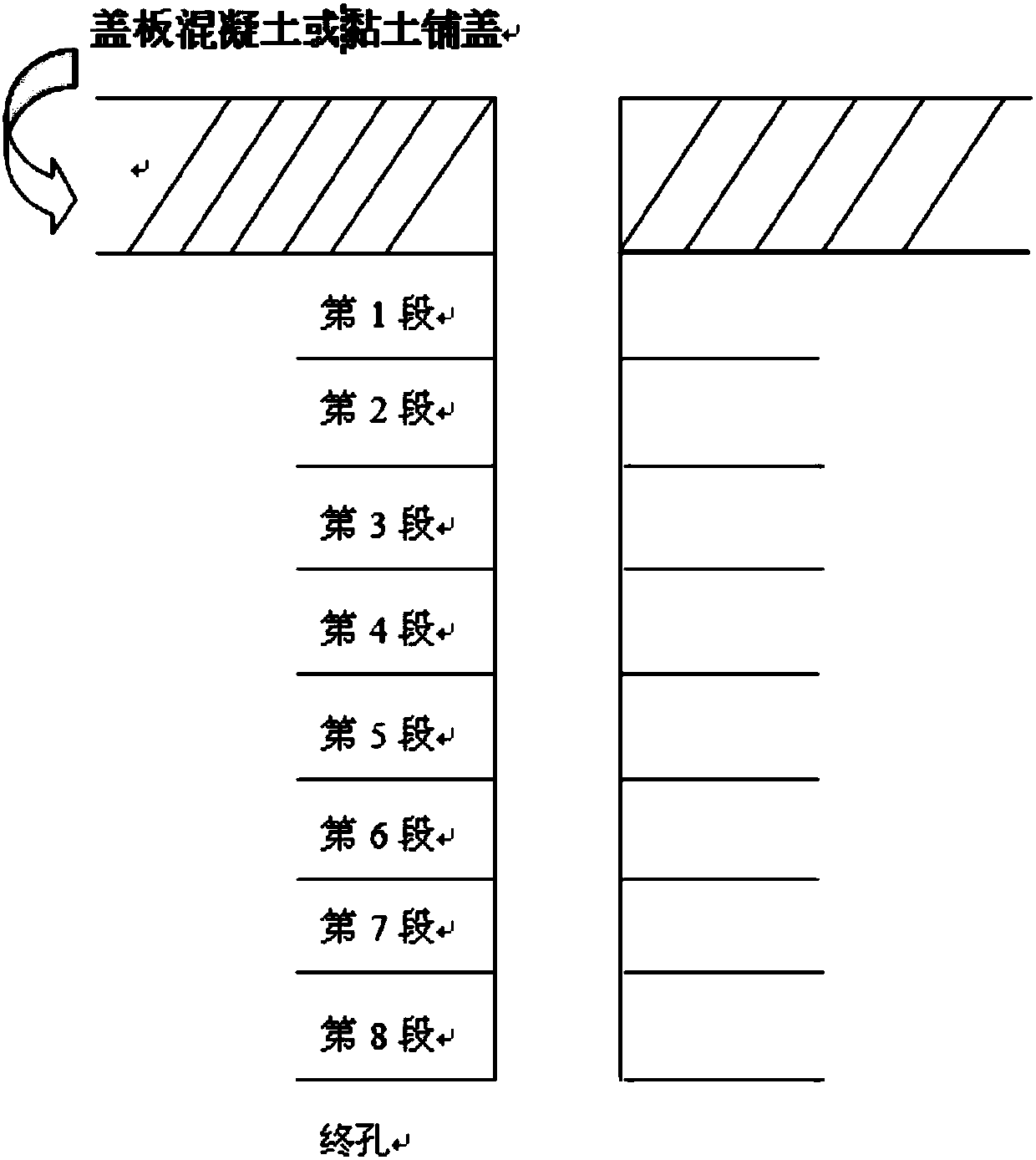

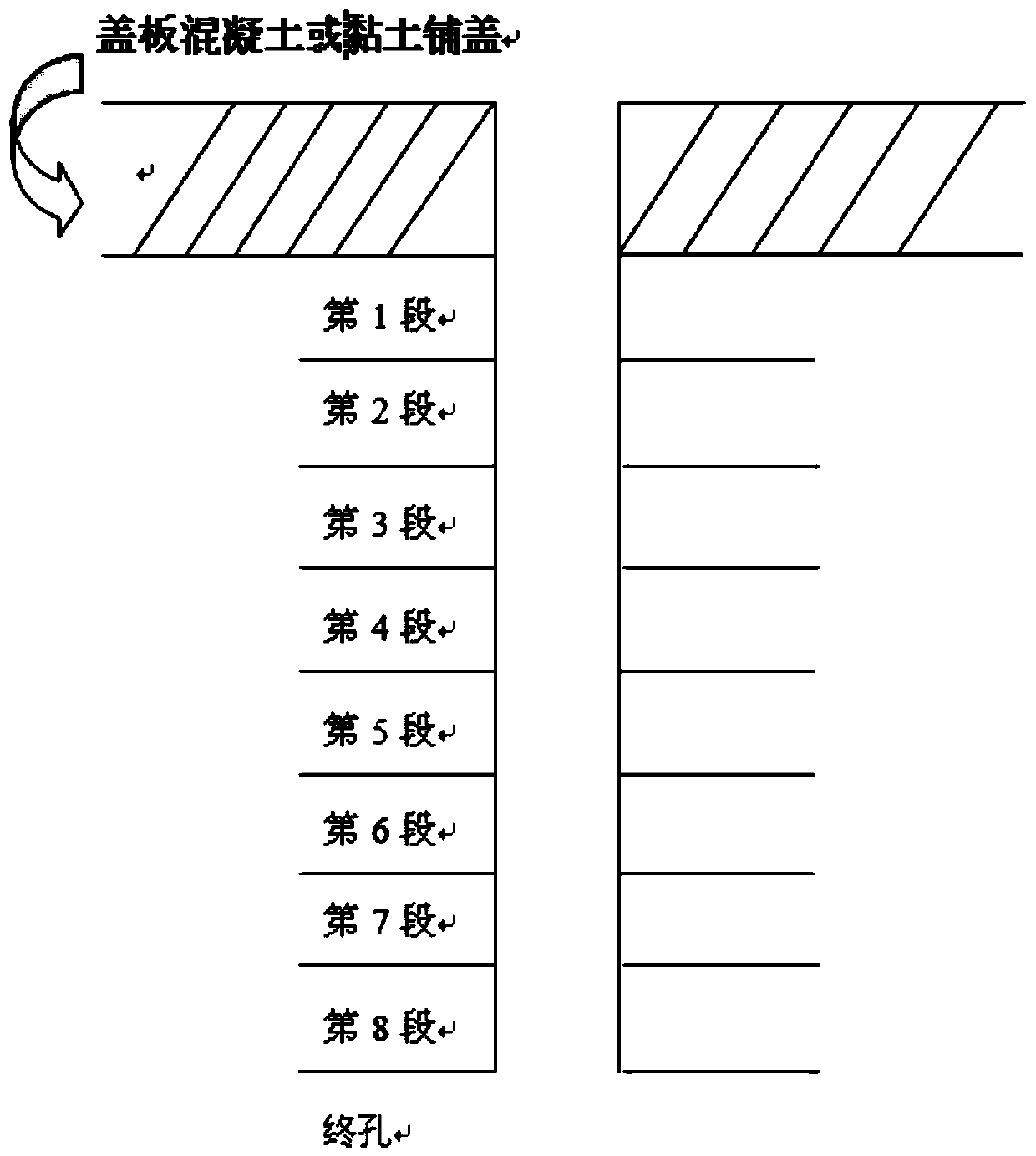

Drilling and grouting construction method for sand gravel stratum

ActiveCN107747312ASimplify the difficulty of installation and operationAvoid enteringBulkheads/pilesGroutEnvironmental geology

The invention belongs to the technical field of civil engineering, and relates to a drilling and grouting construction method for a sand gravel stratum. The drilling and grouting construction method for the sand gravel stratum comprises the following steps that firstly, hole drilling is carried out, and pipe following drilling is conducted for downward feeding of a wall protection casing pipe; secondly, a grout pipe line is downwards fed; thirdly, an orifice blocking device is installed; fourthly, according to grouting procedures, a proper water cement ratio is adopted for grouting and grout proportioning changing till grouting completion; and fifthly, grouting construction is carried out. The drilling and grouting construction method for the sand gravel stratum has the beneficial effectsthat the problems caused when a perforated pipe enters the sand gravel stratum are solved; the setting depth is controllable, and compared with an inserting and beating method, the drilling and grouting construction method is easy to conduct; the problem that in the process of pulling out the casing pipe, the sand gravel stratum collapses, and consequently the perforated pipe is blocked is prevented, and the problem that slip casting cannot be effectively conducted in the sand gravel stratum is solved; the installation and operation difficulty of a stop-grouting plug is lowered; the effect onthe grouting diffusion radius is relatively small; the process defects are overcome, and the grouting quality is reliable; and the drilling and grouting construction method is suitable for any sand gravel stratum, can be implemented without process tests and has very obvious beneficial effects for a region where the stratum is complex.

Owner:SINOHYDRO BUREAU 11 CO LTD

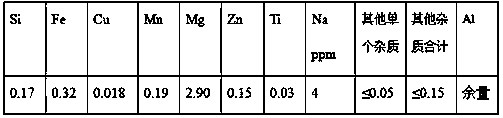

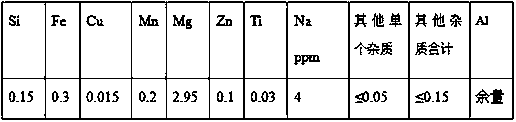

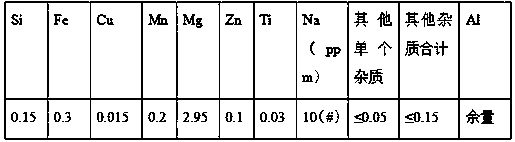

Preparation method of aluminum alloy for aerosol bottle cap

ActiveCN108642344AOvercoming technical deficienciesSolve problems such as slag inclusionSlagImpurity

The invention provides a preparation method of an aluminum alloy for an aerosol bottle cap. The method comprises the steps of S1, preparing a cast ingot through alloy components based on the mixing ratio; S2, milling the cast ingot; S3, uniformly thermally processing the cast ingot; S4, performing hot rolling on the cast iron to obtain a blank; S5, performing cold rolling to the blank which is subjected to hot rolling until the intermediate annealing thickness is reached; S6, washing the surface with weak alkali; S7, completely recrystallizing and annealing the middle; S8, performing pass rolling on a finished product; S9, stably chemically processing the finished product; and S10, stretching and bending and correcting back roll. According to the method, the Na content is effectively decreased based on the component mixing ratio and the technical method; the range of Na element which easily causes Na embrittlement in a high-magnesium alloy is avoided, and thus the problem of Na embrittlement is solved; and meanwhile, the component fluctuation is well controlled, and the problem that the magnesium element easily results to slag inclusion is solved; and meanwhile, the problem of liquid leaking caused by impurities adhering to the surface can be solved by a special weak alkali washing technology in the middle process; and the produced aluminum alloy for the aerosol bottle cap is high in stability in batch.

Owner:RUYUAN DONGYANG UACJ PRECISION FOIL CO LTD

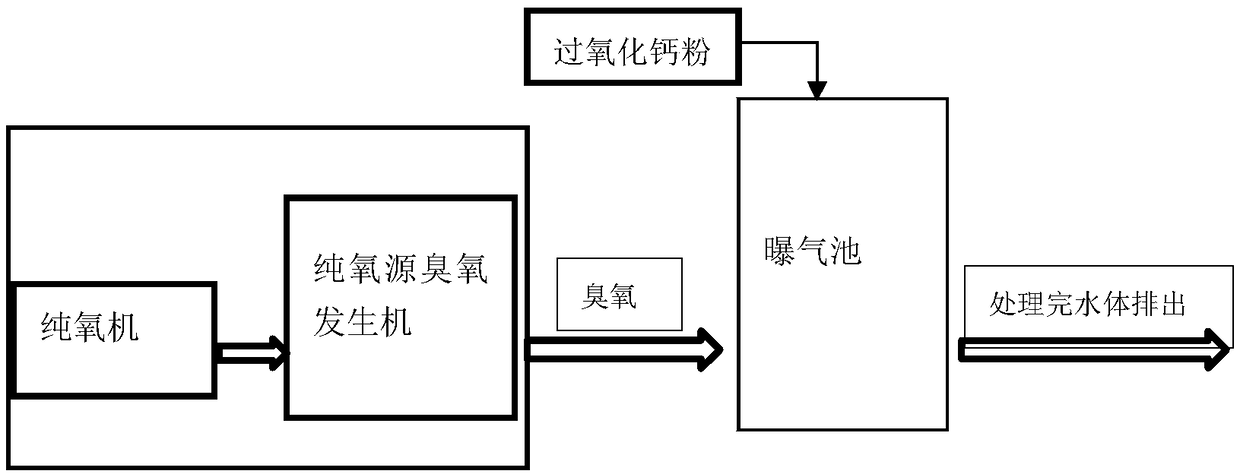

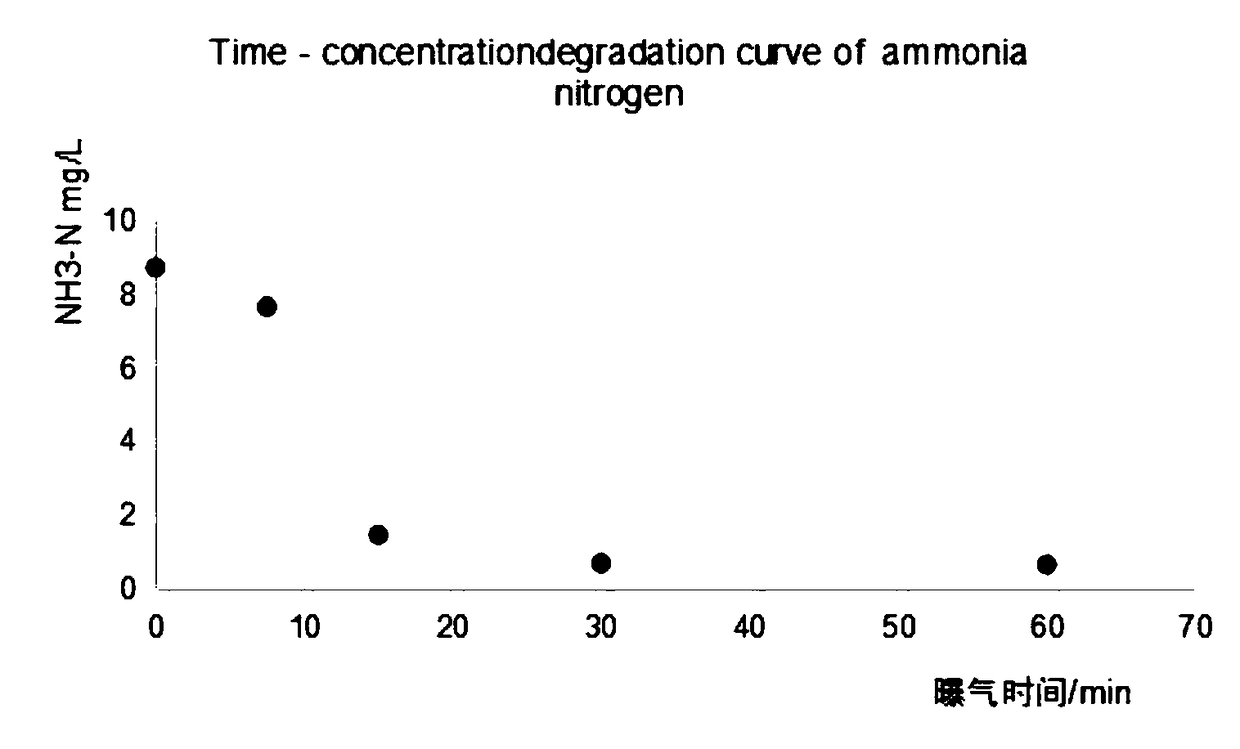

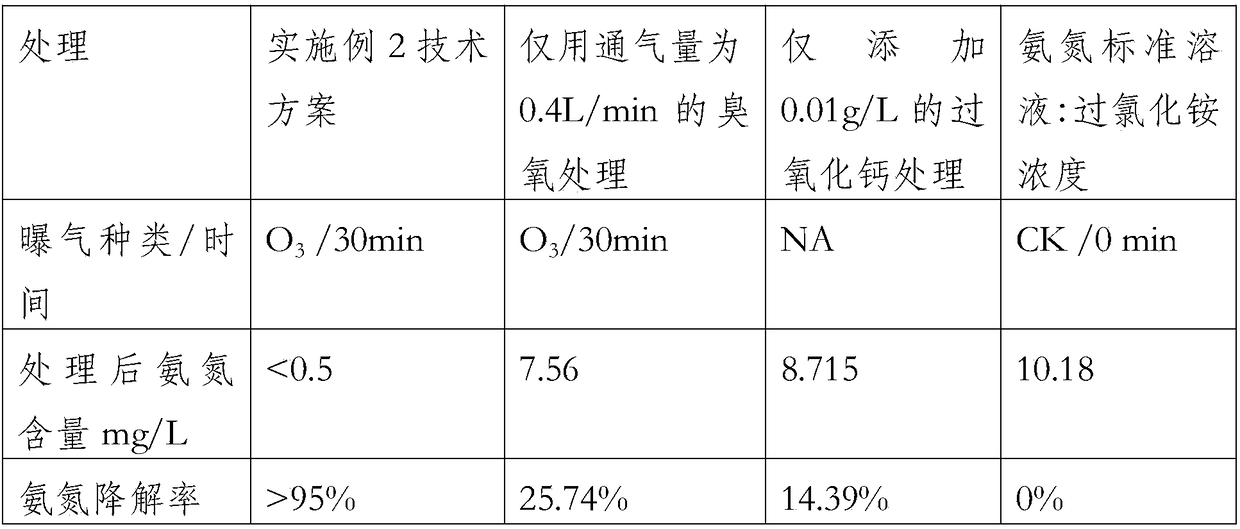

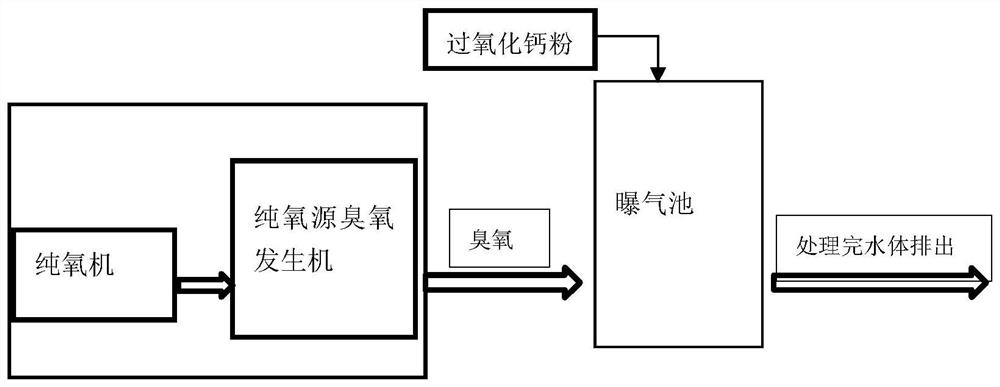

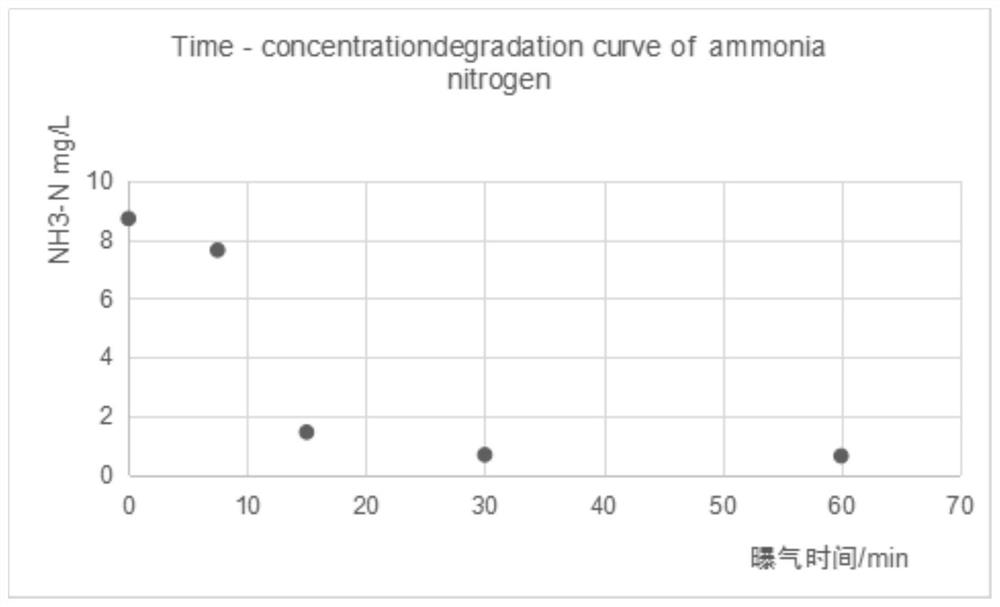

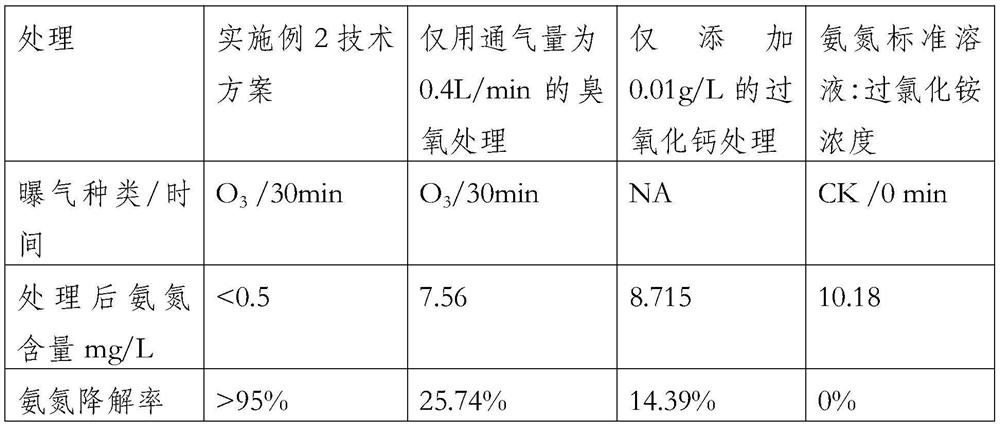

Method of using ozone and trace calcium peroxide to remove low-concentration ammonia nitrogen in water

ActiveCN109081422AIncrease dissolved oxygen contentOvercoming Process DefectsWater contaminantsWater/sewage treatment using germicide/oligodynamic-processOzone generatorAmmonia nitrogen

The invention discloses a method of using ozone and trace calcium peroxide to remove low-concentration ammonia nitrogen in water. The method comprises: adding 0.001-0.01 g / L of calcium peroxide into water; using a pure oxygen generator to make pure oxygen, placing the pure oxygen generator in an ozone generator, and using the pure oxygen from the pure oxygen generator as an oxygen source to the ozone generator, thereby producing ozone; introducing the water into an aerating tank and through the ozone generated by the ozone generator. The trace calcium peroxide can cooperate with the ozone so as to degrade ammonia nitrogen in water within a short time, the removal rate is up to 99%, the treatment time may shorten to 15 min, no secondary pollution is caused to the water, and the concentration of calcium peroxide may decrease to 0.001 g / L. The method herein is good in safety and reliability and very low in cost; the method helps evidently reduce the stink of black and odorous water and evidently increase the content of dissolved oxygen in the water.

Owner:南京清中环境技术有限公司

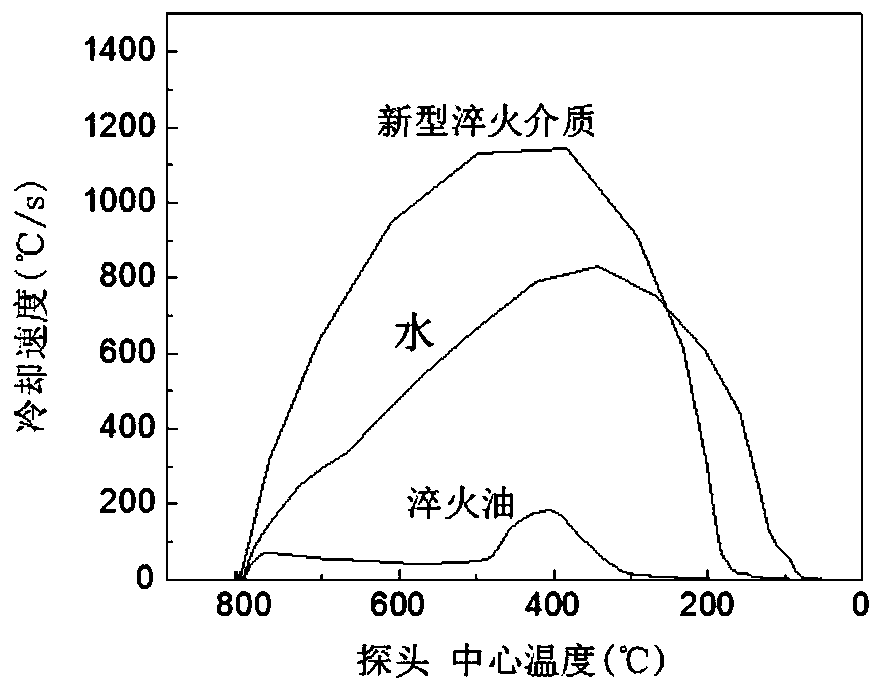

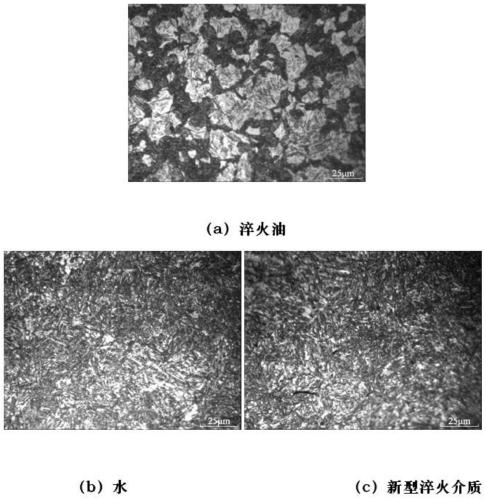

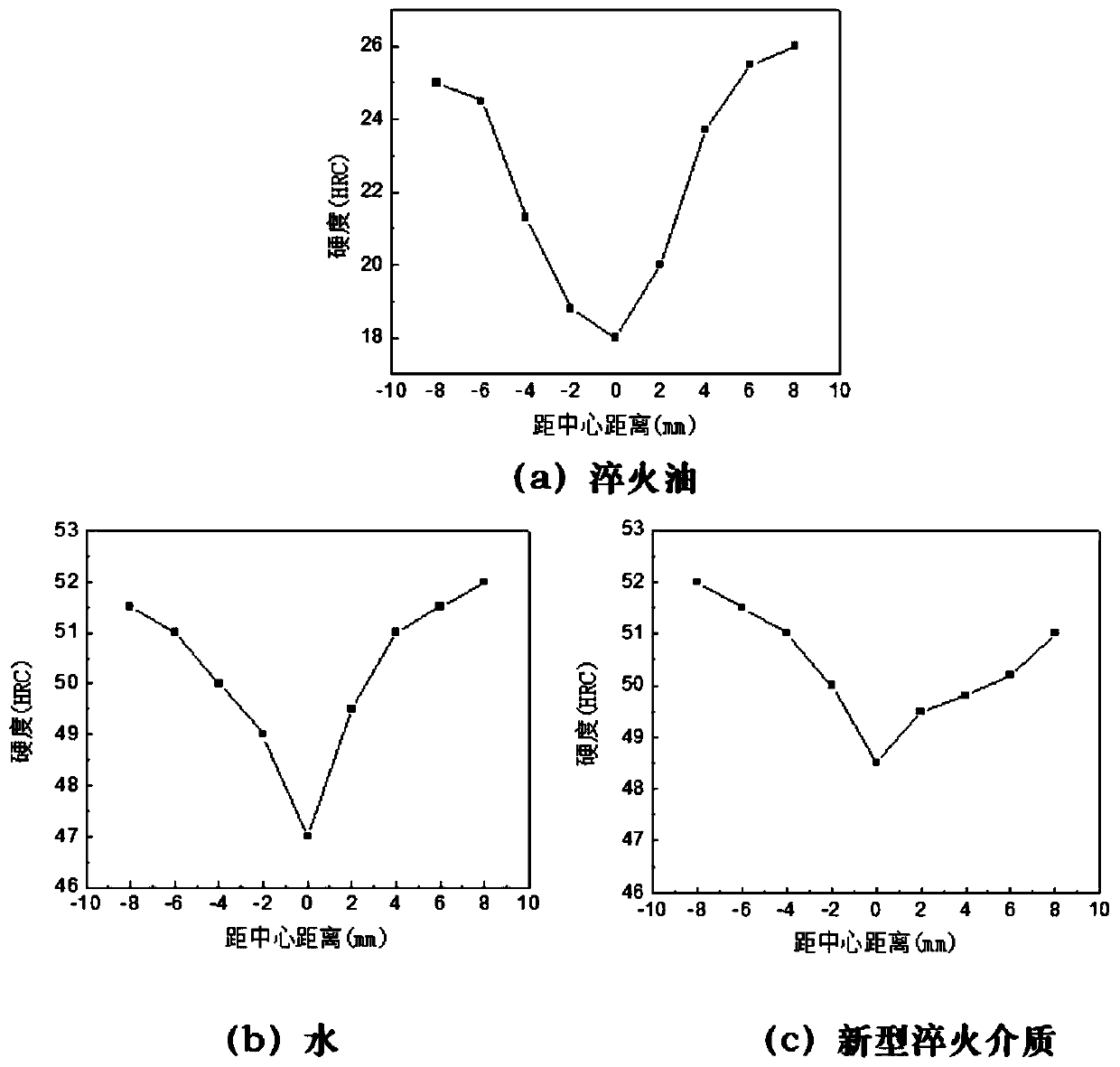

Water-based inorganic quenching medium

PendingCN110079648AReduce quenching stressEasy to manufactureQuenching agentsWater basedCarbon steel

The invention relates to the field of metal heat treatment, in particular to a water-based inorganic quenching medium. According to the water-based inorganic quenching medium, the raw materials are simple; preparation and quenching operation technologies are simple and convenient; the quenching cooling characteristic is more close to an ideal quenching medium; on the basis that quenching structureand performance of a low-hardenability material such as ordinary carbon steel and the like are satisfied, quenching stress of a workpiece with a complex shape is effectively lowered; and deformationand cracking of the workpiece are avoided.

Owner:FUJIAN UNIV OF TECH

Improvement method for air use of vertical disk filter

InactiveCN103537140AOvercoming Process DefectsGuaranteed normal use of windFiltration separationAir volumeFilter system

In production, the air pressure of a vertical disk filter system is relatively lowered to affect the normal production along with the increase of yield of aluminum oxide; in addition, a low-pressure machine frequently stops to interrupt air supply, so that a material is precipitated in the vertical disk filter and an air pipe is blocked to cause production accidents. An improvement method provided by the invention comprises the following steps: 1, increasing the air supply pipe diameter of a vertical disk, namely, additionally connecting a pipe to the vertical disk filter on a main pipeline; 2, additionally arranging a high and low-pressure air intercommunication valve, connecting a pipeline to a low-pressure air master pipeline on a high-pressure air pipe with relatively massive sufficient air supply and mounting an electric valve at the junction of the pipeline and the low-pressure air master pipeline, connecting a controller to an operating room, immediately starting the electric valve in the operating room to connect high-pressure air into a low-pressure air supply pipe network to supply air for 5-10min when the low-pressure machine abruptly stops, closing after a standby low-pressure machine is started to supply the air normally so as to guarantee that a stirring air pipe of the vertical disk is not blocked and guarantee the stable operation of production. The method can solve the technological problem of air supply of a single low-pressure machine, guarantees the normal air use of the vertical disk filter and guarantees the stable and high production.

Owner:洛阳宝诺重型机械有限公司

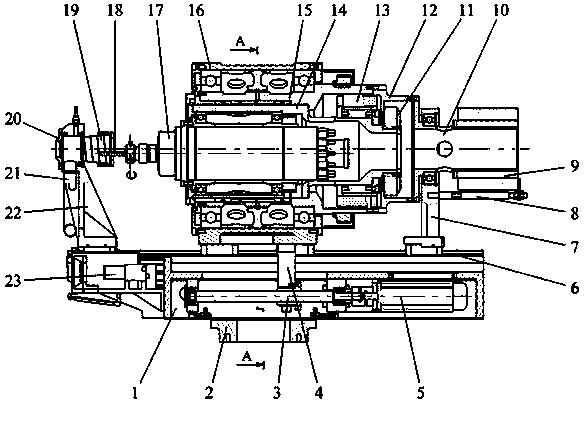

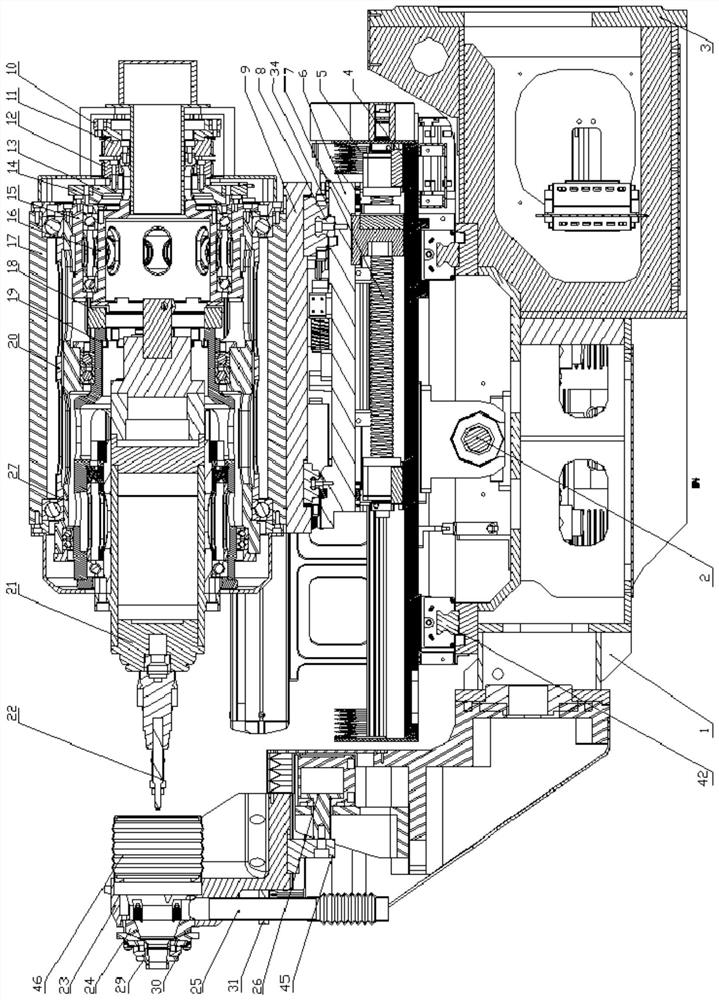

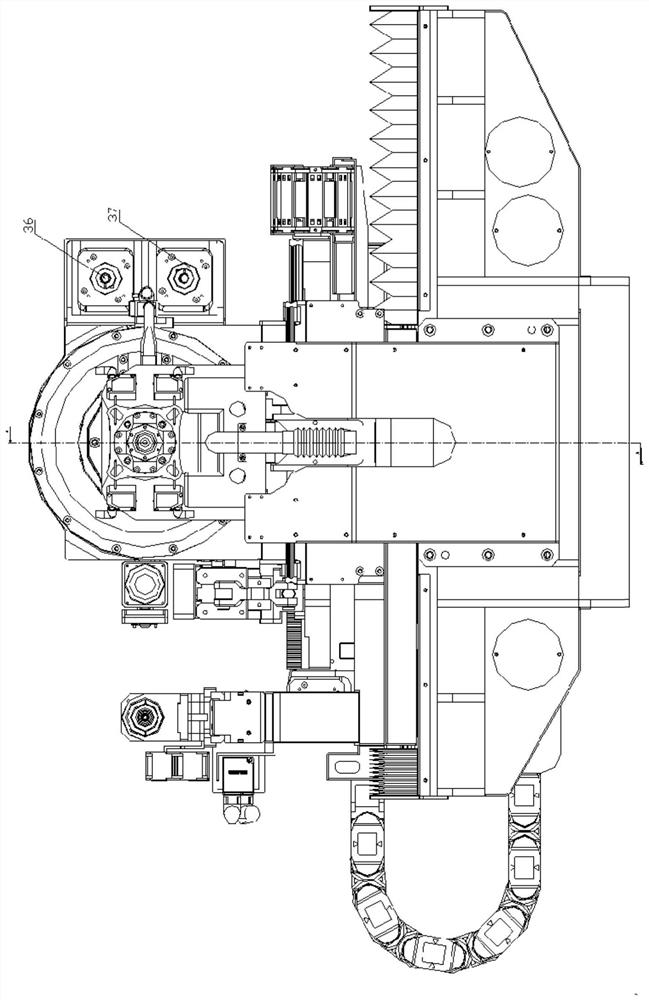

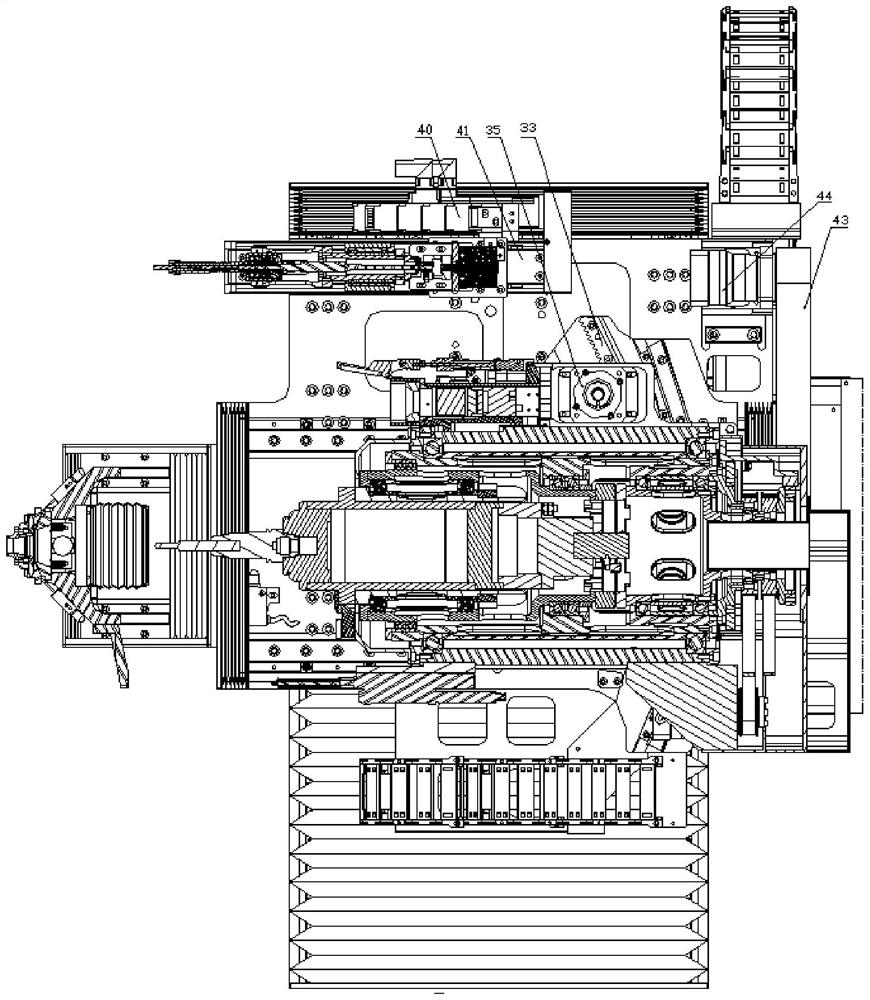

Device and method of automatic helical milling of hole

ActiveCN102794491BEasy to controlHigh control precisionAutomatic control devicesMeasurement/indication equipmentsNumerical controlGrating

The invention discloses a device and a method for automatic helical milling of a hole. The device comprises a base, a spindle slide base, an outer eccentric sleeve, an inner eccentric sleeve, a torque motor, a circular grating, an electric spindle, a presser foot, an industrial camera, a linear grating, four laser distance sensors, a servo motor, a ball screw assembly, a synchronous belt and the like, wherein axes of inner and outer contours of the inner and outer eccentric sleeves have offsets; the inner eccentric sleeve is installed in the outer eccentric sleeve; and the axis of the inner contour of the outer eccentric sleeve and the axis of the outer contour of the inner eccentric sleeve are coincident. The device and the method have the advantages that the tool radial offset is realized through control of a relative rotation angle between the inner eccentric sleeve and the outer eccentric sleeve; in spindle feeding, a double-grating feedback technology is adopted so that dimple depth accuracy is guaranteed; and a preset hole position on a workpiece is detected by the industrial camera and a normal vector of the preset hole position is detected by the four laser distance sensors and the industrial camera and the four laser distance sensors cooperate with automatic numerically-controlled devices such as an industrial robot, a numerically-controlled machine tool and the like and thus high-precision and high-efficiency automatic hole milling is realized.

Owner:ZHEJIANG UNIV

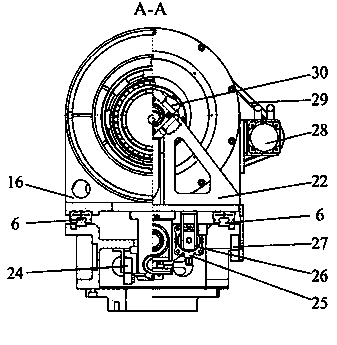

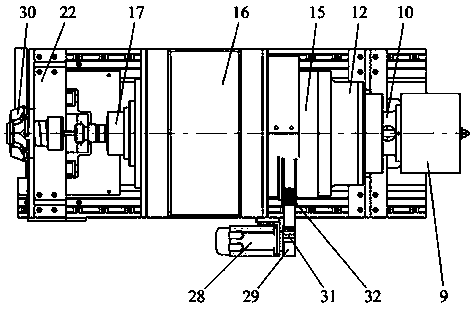

Spiral milling actuator

ActiveCN113084535ACompact designGuaranteed machining accuracyFeeding apparatusLarge fixed membersClassical mechanicsControl theory

The invention discloses a spiral milling actuator. The spiral milling actuator is characterized by comprising a base, a cutter, a feeding mechanism arranged on the base and used for driving the cutter to do feeding motion, a swinging mechanism arranged on the feeding mechanism and used for driving the cutter to do arc swinging, an eccentric adjusting mechanism used for controlling the radial offset distance of the cutter and and a rotating shaft driving mechanism; the eccentric adjusting mechanism comprises an inner eccentric sleeve, an inner shaft barrel connected with the inner eccentric sleeve through a sliding connecting piece, an outer eccentric sleeve arranged outside the inner eccentric sleeve and an outer shaft barrel fixed to the outer eccentric sleeve; the axes of the inner contours and the outer contours of the inner eccentric sleeve and the outer eccentric sleeve are designed in an offset mode; and the rotating shaft driving mechanism is used for driving the cutter to rotate and comprises a main shaft sleeve, an electric main shaft, an outer eccentric driving assembly for driving the outer shaft barrel to rotate and an inner eccentric driving assembly for driving the inner shaft barrel to rotate.

Owner:杭州艾美依航空制造装备有限公司

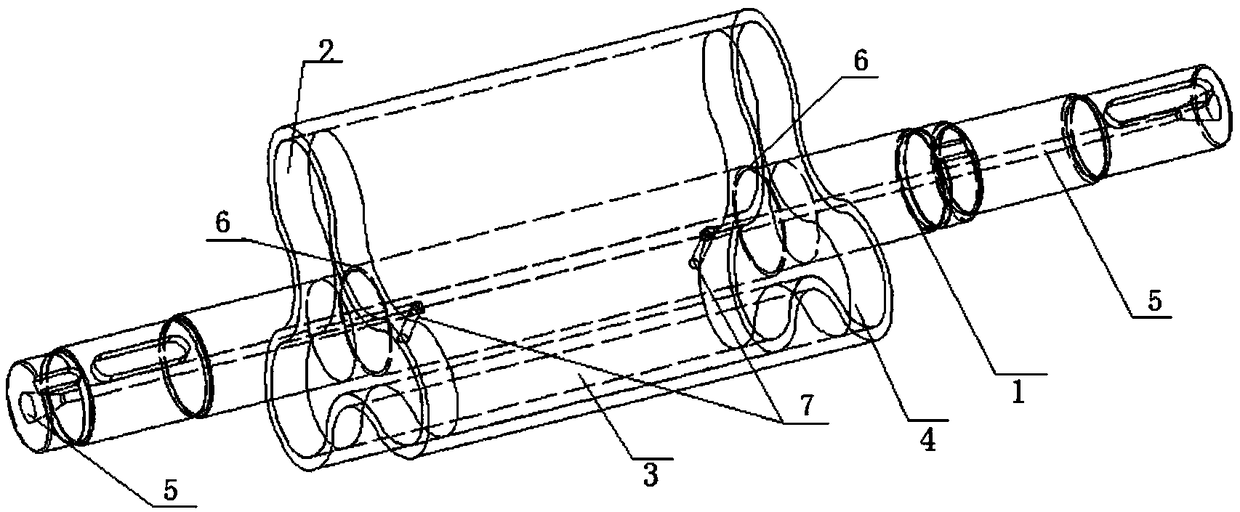

Novel structure of rotor and manufacturing technology thereof

InactiveCN109026682AOvercoming Process DefectsImprove blank qualityFoundry mouldsRotary piston pumpsManufacturing technologyMachining

The invention discloses a novel structure of a rotor and a manufacturing technology of the novel structure of the rotor. The manufacturing technology comprises the following steps that the step (1), parts are manufactured, specifically, a rotor blade is manufactured through a mold, a rotor front cover plate and a rotor rear cover plate are manufactured in a machining mode, and a rotor shaft is manufactured in a machining mode; the step (2), the parts are assembled, specifically, the rotor blade sleeves the rotor shaft in an empty mode, and then the rotor front cover plate and the rotor rear cover plate are connected to the rotor shaft and the rotor blade in an expanded mode or welded on the rotor shaft and the rotor blade, so that the whole rotor is formed; and the step (3), finish machining is conducted, specifically, the shaft neck, the excircle and the end face of the whole rotor obtained in the step (2) are subjected to precision machining, the profile of the whole rotor is subjected to precision milling or planing machining, and finally the novel precise structure of the rotor is obtained. The novel structure of the rotor and the manufacturing technology of the novel structureof the rotor well overcome the defects that in the prior art, the rotor weight is large, materials are not uniform, the manufacturing technology is relatively complex, the quality is poor, and the cost is high.

Owner:江阴爱尔姆真空设备有限公司

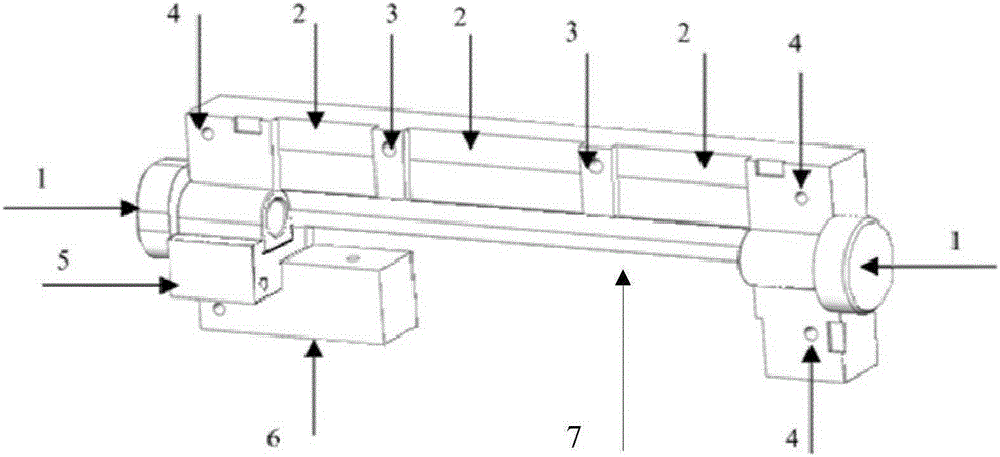

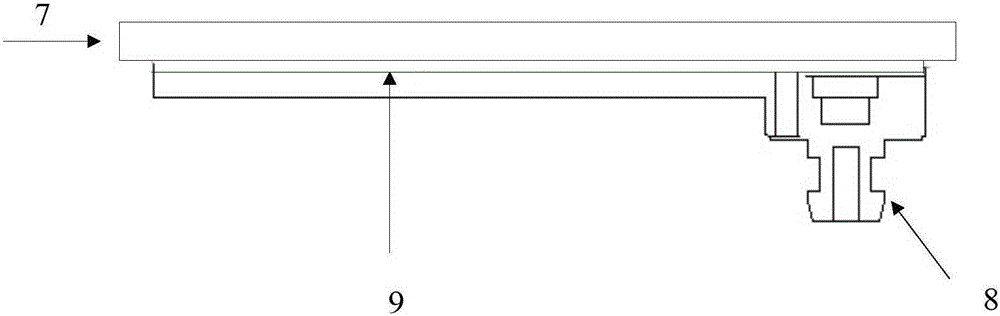

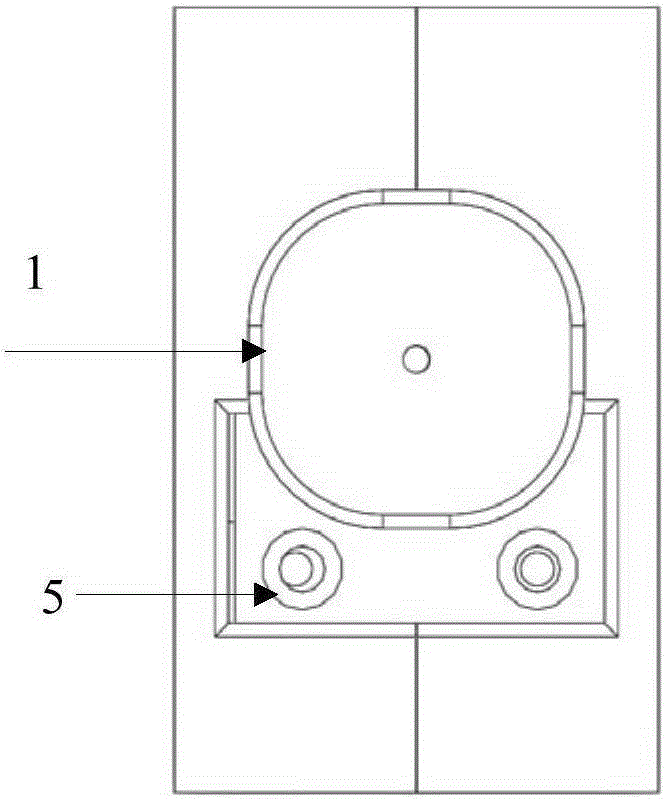

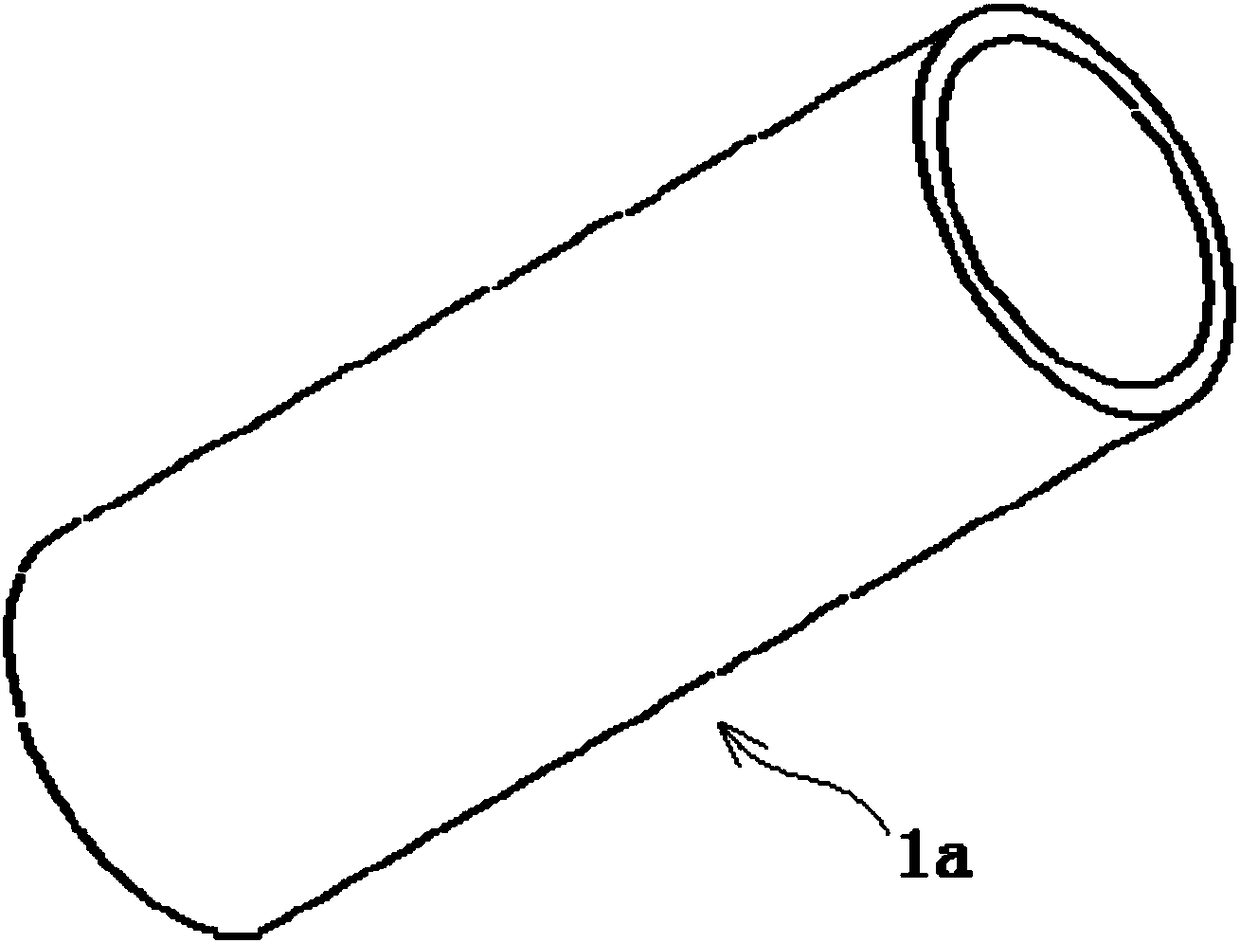

Universal three-electrode conductance cell integrated forming die and using method

The invention provides a universal three-electrode conductance cell integrated forming die. The universal three-electrode conductance cell integrated forming die comprises a die body, a positioning and sealing plugs, glue filling grooves, positioning pin holes, connecting holes and controllable sliding blocks. The die body comprises two symmetrical die parts. The controllable sliding blocks are connected with the two die parts in a sliding mode respectively through bolts. Grooves are formed in the upper portions of the controllable sliding blocks. The positioning and sealing plugs are used for fixing a conductance cell tube. The positioning and sealing plug at one end is in the shape that the upper portion of the positioning and sealing plug is round and the lower portion of the positioning and sealing plug is square, is assembled at the groove formed in the corresponding controllable sliding block and is connected with the corresponding controllable sliding block in a matched mode. The positioning and sealing plug at the other end is cylindrical. The glue filling grooves are formed in the die body. The positioning pin holes are formed in the corresponding positions of the die parts. The connecting holes are formed in the two ends of each die part. An insertion groove is formed below the die parts. According to the universal three-electrode conductance cell integrated forming die, a conductance cell is integrally packaged, human factors are reduced, the packaging process is simplified, the packaging dimension is guaranteed, the manufacturing cycle is greatly shortened, and production efficiency is improved.

Owner:STATE OCEAN TECH CENT

Processing device and processing method for heating body

ActiveCN108263080AHigh degree of automationOvercoming Process DefectsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSlurry

The invention provides a processing device and a processing method for a heating body. The method comprises: when manufacturing a heating body, firstly, adding molten metal into a slurry box, until aprinting surface of a segment of a conveyor belt being immersed in the molten metal, the segment of the conveyor belt contacting with a compaction roller, coaxially fixing a cylindrical heating film carrier on a printing shaft, then starting a driving device to make a driving roll rotate, the driving roll rotating to make the printing surface which is soaked by the molten metal move to the heatingfilm carrier and abut against the heating film carrier, the molten metal in a banded printing structure being adhered to the surface of the heating film carrier, to form a heating film band. Thus, aprocess defect in the prior art of first printing and then rolling is prevented, the heating film band can be reliably attached on the heating film carrier. The processing device for a heating body ishigh in automation degree, and can improve processing efficiency.

Owner:SHANGHAI TOBACCO GRP CO LTD

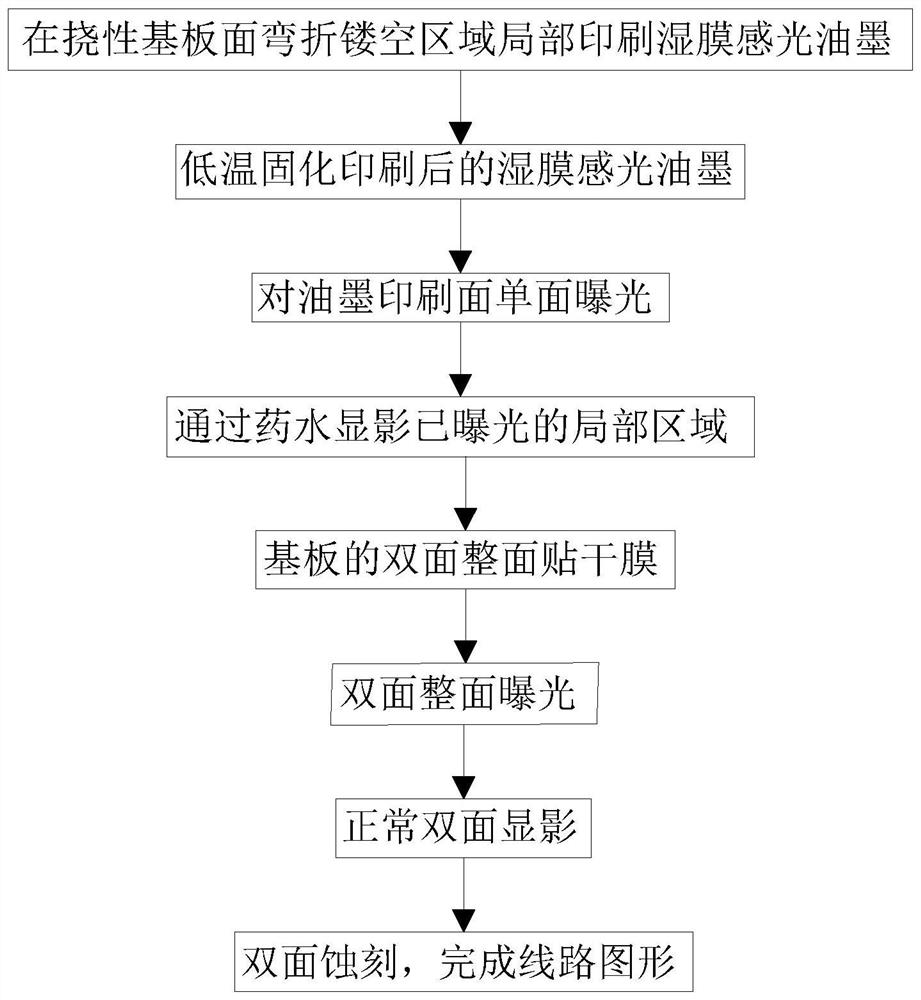

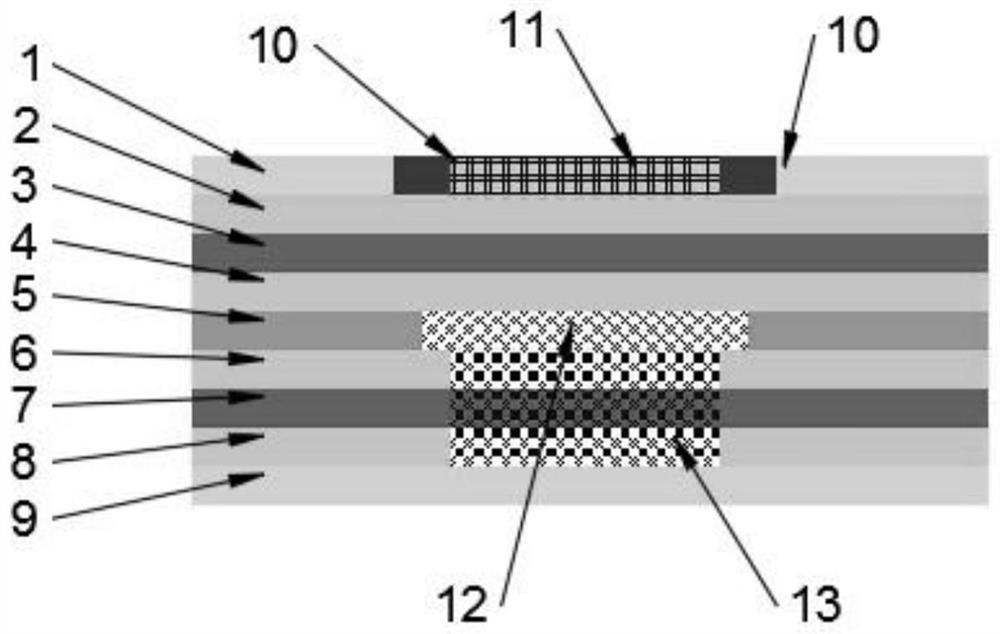

Manufacturing process of circuit pattern of outer-layer flexible rigid-flex circuit board

ActiveCN114615814ASolve the phenomenon that cannot be compacted and crackedReach process flowConductive material chemical/electrolytical removalMultilayer circuit manufactureEngineeringPrinting ink

A process for manufacturing a circuit pattern of an outer-layer flexible rigid-flex circuit board comprises the following steps of: printing ink, namely locally printing wet film photosensitive ink in a bent hollow area of a flexible substrate surface; curing the printed wet film photosensitive ink at low temperature; performing single-side exposure on the ink printing surface; developing the exposed local area through liquid medicine; dry films are pasted on the whole double surfaces of the substrate; double-sided whole-surface exposure is performed, a wet film is exposed, and a developing area is not repeatedly exposed any more, so that developing and film removal are facilitated; normal double-sided development; and finally finishing the circuit pattern. Through the wet film and dry film process method, the phenomenon that the dry film cannot be compacted and broken due to the fact that the outer layer flexible substrate is sunken due to the fact that the prepreg is hollowed out is solved; according to the wet ink printing process method, a concave area can be completely coated, a dry film is pasted for secondary exposure after exposure and development of a circuit pattern, meanwhile, exposure avoids a wet film area, and the technological process of combining the dry film with the wet film is achieved.

Owner:信丰迅捷兴电路科技有限公司

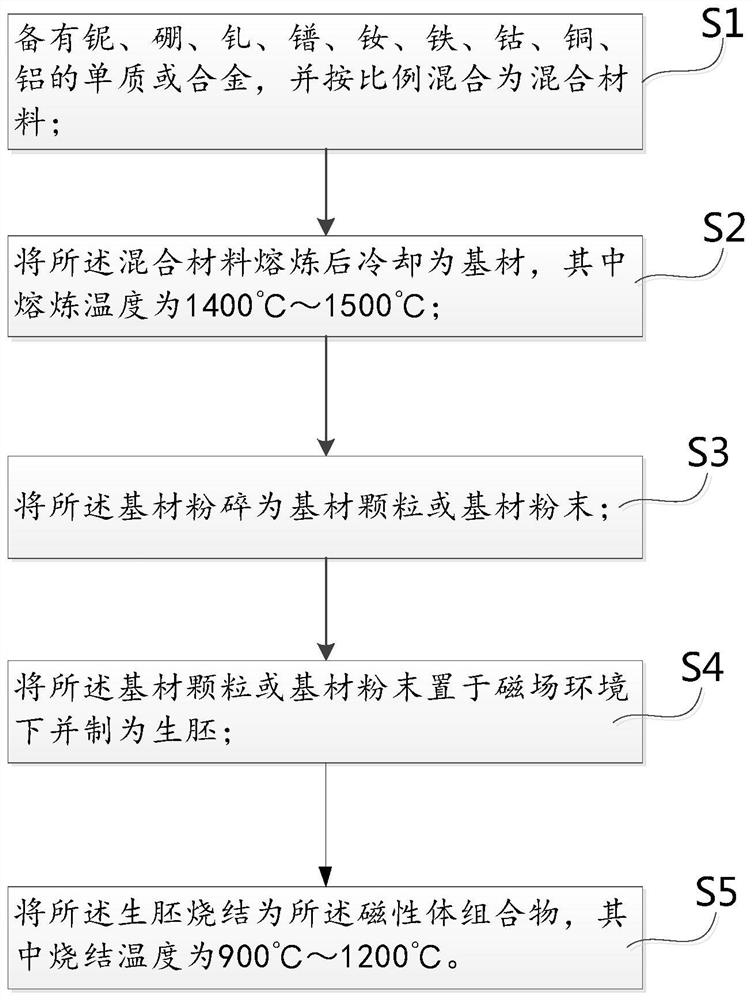

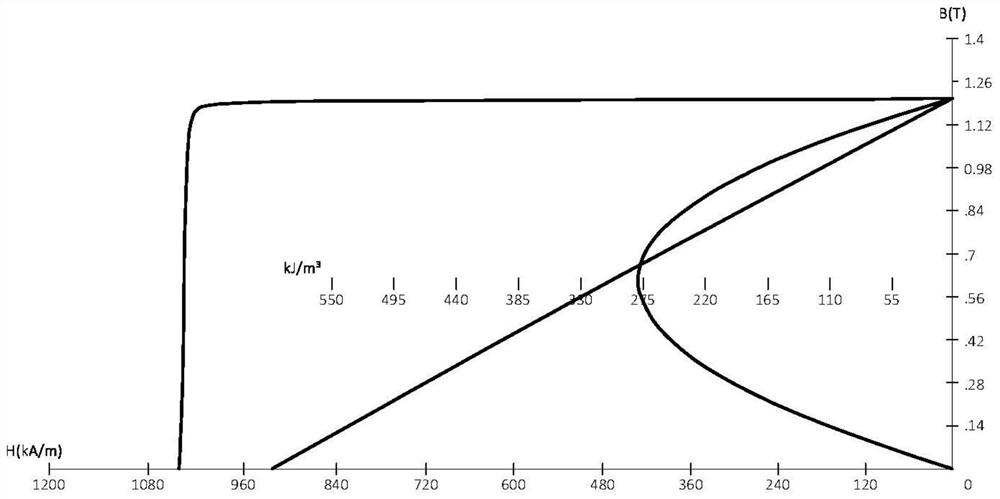

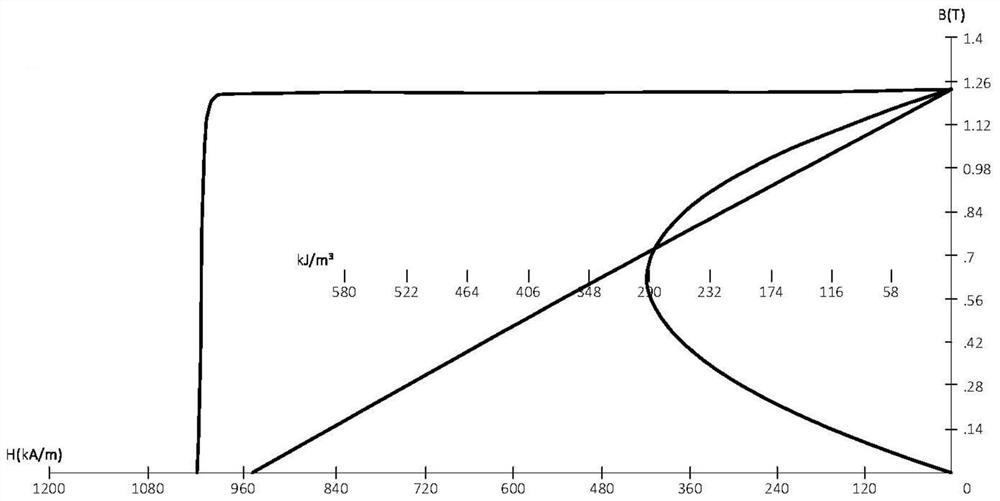

Magnetic body composition and its preparation method

ActiveCN110875112BImprove magnetic propertiesAvoid uneven process defectsMagnetic materialsPermanent magnet manufactureNiobiumPhysical chemistry

The invention discloses a magnetic body composition, which comprises the following components: 0.0%-80.0% of iron; 10.0%-40.0% of neodymium; 0.10%-10.0% of praseodymium; 0.10%-10.0% of gadolinium; ; Aluminum 0.01% to 10.0%; Niobium 0.01% to 10.0%; Cobalt 0.01% to 10.0%; Copper 0.01% to 10.0%. The present invention also provides a method for preparing a magnetic body composition. The steps of the preparation method at least include: preparing single substances or alloys of niobium, boron, gadolinium, praseodymium, neodymium, iron, cobalt, copper, and aluminum, and mixing them in proportion to form Mixed material; the mixed material is smelted and then cooled to form a base material, wherein the melting temperature is 1400°C to 1500°C; the base material is pulverized into base material particles or base material powder; the base material particle or base material powder is Place in a magnetic field environment and make a green body; sinter the green body to form the magnetic body composition, wherein the sintering temperature is 900°C-1200°C. The magnetic body composition has good magnetic properties and mechanical properties. The preparation method has the advantages of simplicity, high efficiency, energy saving and excellent process.

Owner:伊亜伦

A method for removing low-concentration ammonia nitrogen in water by using ozone and trace amounts of calcium peroxide

ActiveCN109081422BIncrease dissolved oxygen contentOvercoming Process DefectsWater contaminantsWater/sewage treatment using germicide/oligodynamic-processAmmoniacal nitrogenOxygen content

Owner:南京清中环境技术有限公司

Method for single-stage vanadium extraction in same converter

ActiveCN102559986BOvercoming Process DefectsSolve the large heat lossManufacturing convertersSteelmakingSingle stage

The invention discloses a method for single-stage vanadium extraction in the same converter. In a blowing early stage, lime is not added for slagging, vanadium in molten iron is oxidized to enter slag, and silicon, manganese and titanium in the molten iron are oxidized to enter a slag phase; and blowing is stopped after the vanadium is oxidized, vanadium slag is discharged, lime and other slag formers are added for slagging and steelmaking, and qualified molten steel is produced. Compared with the prior art, the method for single-stage vanadium extraction in the same converter has the advantages of reducing temperature loss in the vanadium extracting process, improving the production efficiency of a converter workshop and reducing production cost.

Owner:SICHUAN DAZHOU IRON & STEEL GROUP

Method for welding cold-expansion tube production line draw rod

The invention provides a method for welding a pull rod for a production line of cold expansion pipes, which comprises the following steps: preparing before welding; preparing a short joint end of the pull rod; preparing of a long joint end of the pull rod; welding; detecting after the welding, namely, carrying out ultrasonic and dye penetration inspection for the welded joint after the pull rod is welded. The method has the advantages that by adopting an unconventional method to weld and repair the pull rod for the production line of the cold expansion pipes, the method solves the technical problems of integral preheating of the pull rod, heat treating after the welding and welding at low temperature, avoids multiple technical defects, shortens repair time, and reduces loss of oil fields.The pull rod is a key component of production line equipment for the cold expansion pipes in the oil fields, and directly influences production operation after the pull rod is damaged, then the downtime loss is 320, 000 Yuan per hour, and if spare parts are bought abroad, several months are needed. The method generates certain social benefit and larger economic benefit, and provides scientific repair method for guiding production practice for projects in the same field.

Owner:TIANJIN STEEL PIPE MFG CO LTD

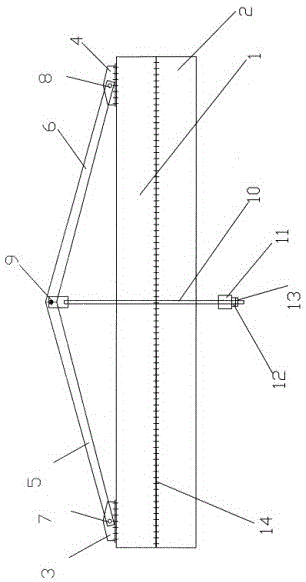

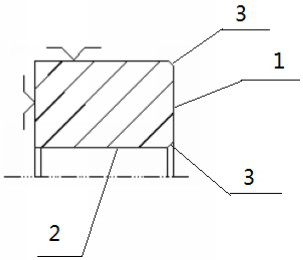

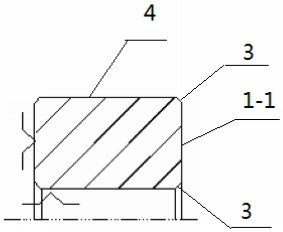

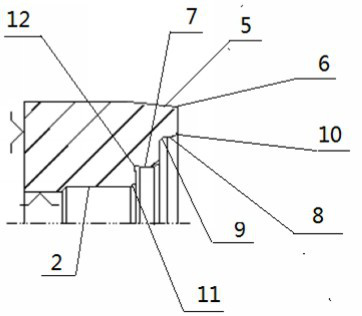

Mounting device for laminated beams of main girder

ActiveCN105066100AOvercoming Process DefectsControl installation qualityBoiler supporting/setting arrangementsEngineeringLaminated beam

The invention discloses a mounting device for laminated beams of a main girder, and solves the technical problem of clearance leakage in connection of upper and lower laminated beams, which possibly causes joint gaping on the upper and the lower laminated beams. The mounting device comprises an upper laminated beam (1) arranged on a lower laminated beam (2), two left connecting frames are fixedly arranged at the left end of the upper laminated beam (1), two right connecting frames are fixedly arranged at the right end of the upper laminated beam (1), the other end of a left front frame girder (5) and the other end of a right front frame girder (6) are hinged together through a top connecting pin (9), the upper end of a front suspender (10) is connected to the front end of the top connecting pin (9), the upper end of a rear suspender (17) is connected to the rear end of the top connecting pin (9), a horizontal supporting beam (11) is connected between the front suspender (10) and the rear suspender (17), a jack (18) is arranged on the horizontal supporting beam (11), and the upper end of the jack (18) is connected to the lower bottom surface of the lower laminated beam (2) in a propping manner. The mounting device provided by the invention ensures entire quality of boiler installation.

Owner:SHANXI ELECTRIC POWER CONSTR CO LTD CEEC

A method for drilling and grouting construction in sand and gravel formation

The invention belongs to the technical field of civil engineering, and relates to a method for drilling and grouting construction in sand and gravel formations, comprising: (1) drilling and following pipes to drill into a wall casing; (2) running into a grouting pipe; 3) Install the orifice blocker; (4) According to the grouting procedure, adopt the appropriate water-cement ratio to start grouting and change the grout until the grouting is completed; (5) Grouting construction. The invention has the beneficial effects of solving the problem that the flower tube enters the gravel formation. The embedding depth is controllable, which is easier than the plugging method; it prevents the sand and gravel strata from collapsing during the process of pulling out the casing, which causes the flower tube to be blocked, and solves the problem that the sand and gravel stratum cannot be effectively grouted; simplifies the grout stopper It is difficult to install and operate; it has little effect on the grouting diffusion radius; it overcomes the process defects and the grouting quality is reliable; it is suitable for any sand and gravel stratum and can be implemented without process tests, especially in areas with complex strata.

Owner:SINOHYDRO BUREAU 11 CO LTD

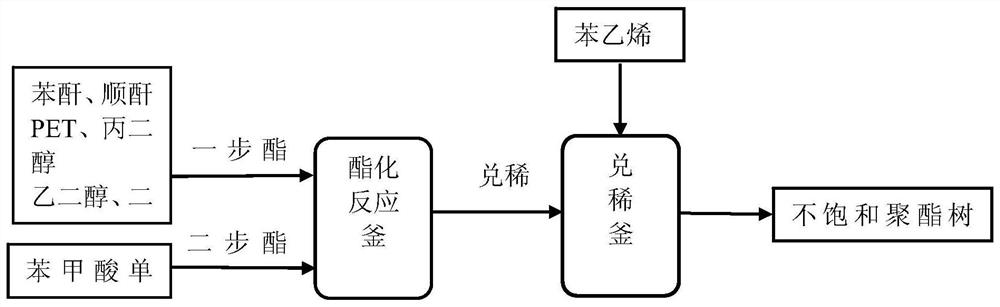

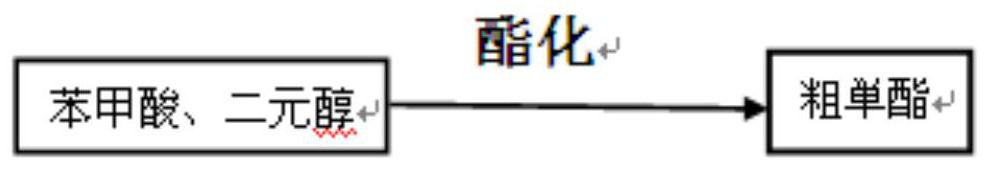

A kind of production method of unsaturated polyester resin

ActiveCN109824874BGuaranteed presenceOvercoming Process DefectsBenzoic acidHeat deflection temperature

The invention discloses a production method of unsaturated polyester resin. By improving the end-capping process—by using benzoic acid monoester as the end-capping agent, the energy consumption generated in the heating and cooling process in the secondary feeding is avoided, so as to improve its durability. Properties of corrosion resistance, tensile strength and heat deflection temperature.

Owner:XIAMEN HAIWAN CHEM

A kind of processing technology of backstop spare parts of heavy-duty bearing of railway wagon

The invention relates to a processing technology for bearing spare parts, in particular to a processing technology for backstop spare parts of heavy-duty bearings for railway wagons, and belongs to the technical field of bearing processing. It includes the following steps: (1) Select the forging of the back stop of the bearing, and use a lathe to sequentially process the end face, the first inner hole, and the safety angle of the forging; (3) Turning the end face of the forging, the slope of the large diameter, and the fillet of the large diameter in sequence; (4) Turning the side opposite to the position of the forging where the large inner hole and the third inner hole are located The forgings are processed by turning; the continuous processing process is adopted, and the positioning reference is reasonably selected to ensure that the positioning reference is unified; the CNC machine tool is used to replace the equipment used in the original process, and the digital processing advantage of the CNC machine tool is used to give full play to its unique transmission and execution mechanism. , so as to overcome the process defects in the process of processing.

Owner:WAFANGDIAN BEARING GRP STATE BEARING ENG TECH RES CENT CO LTD

A kind of pelletizing method of pellets used in rotary hearth furnace direct reduction production process

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com