Patents

Literature

358results about How to "Warranty Strength Requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

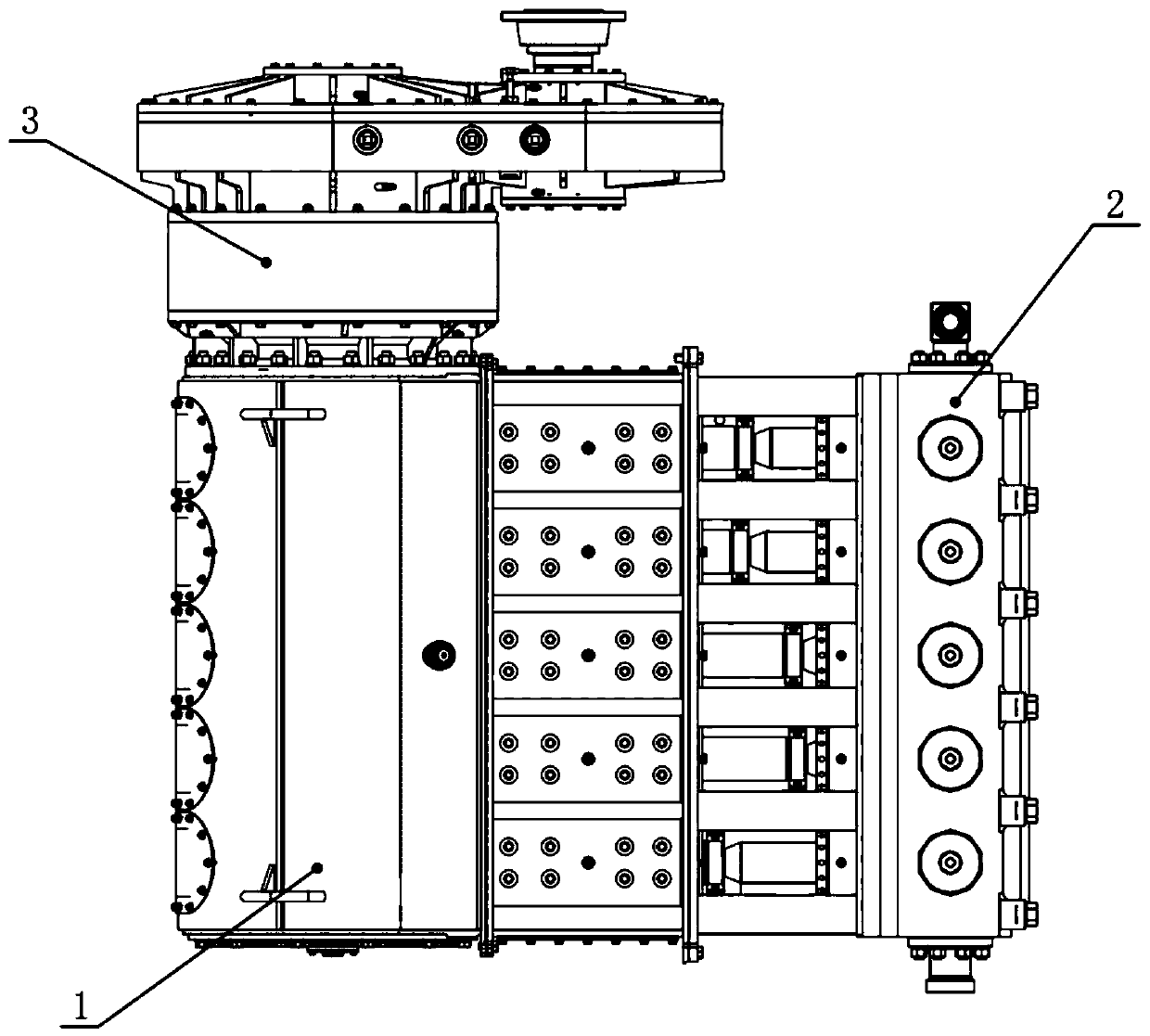

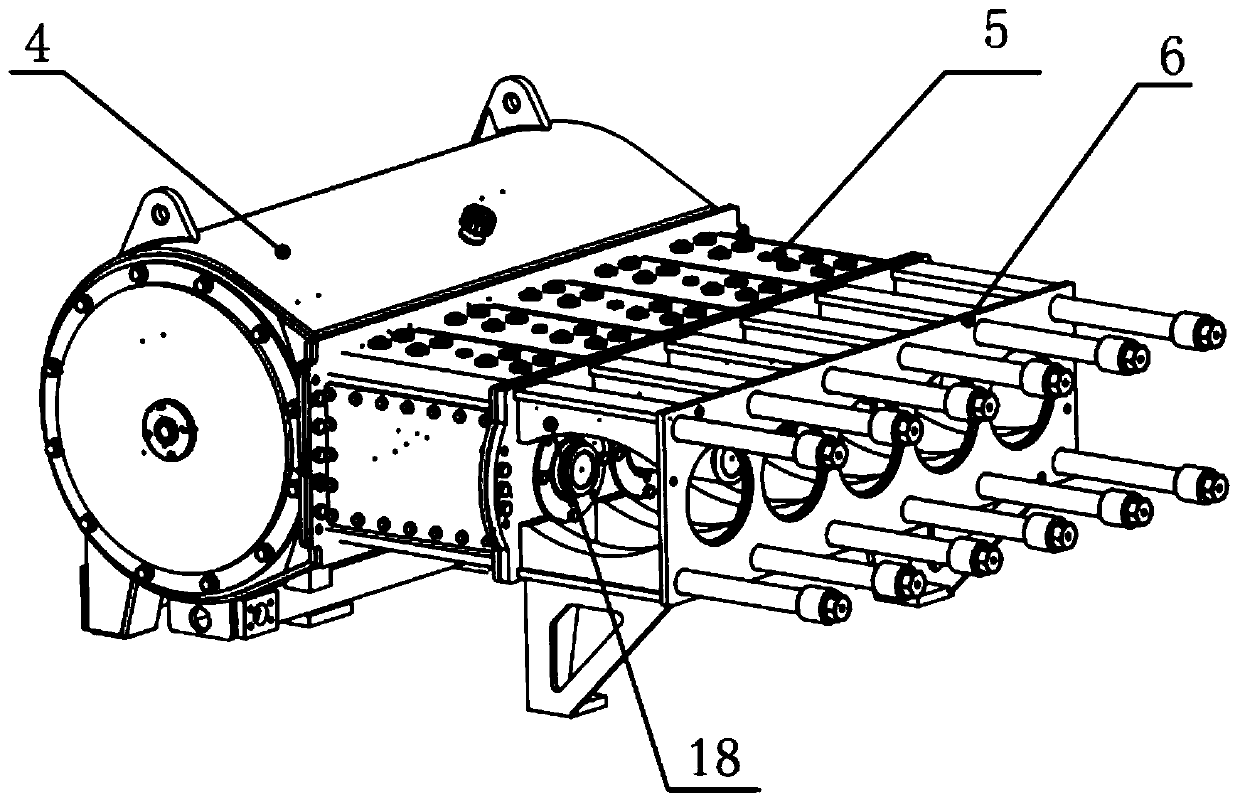

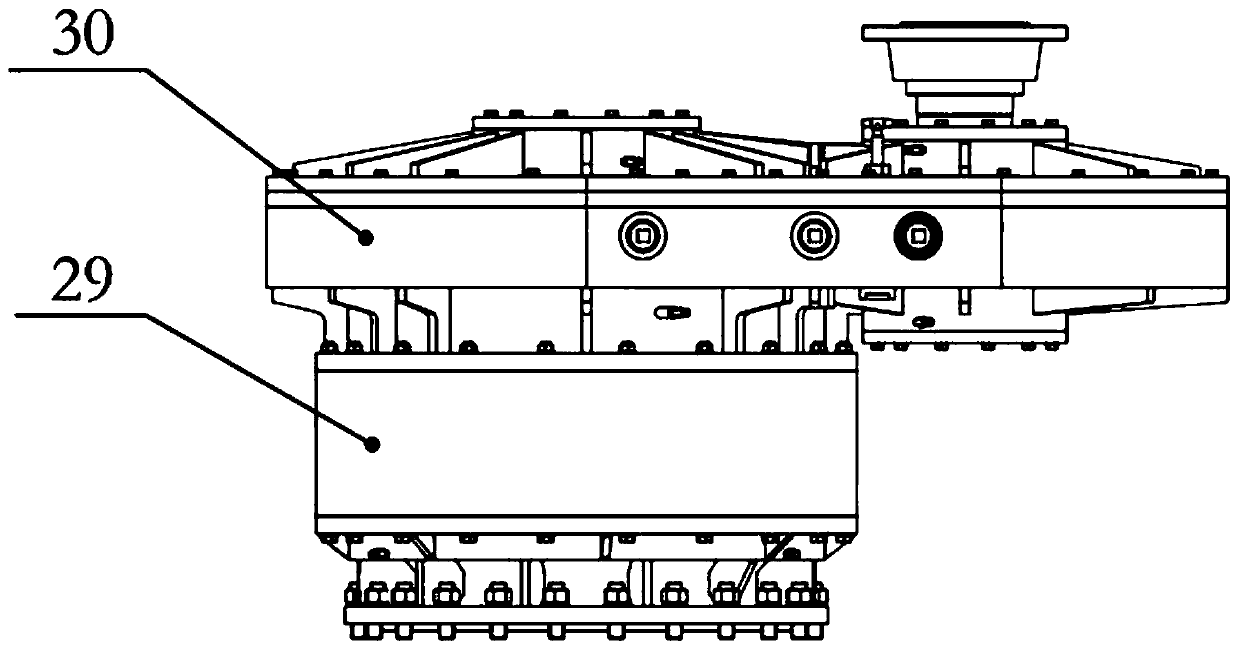

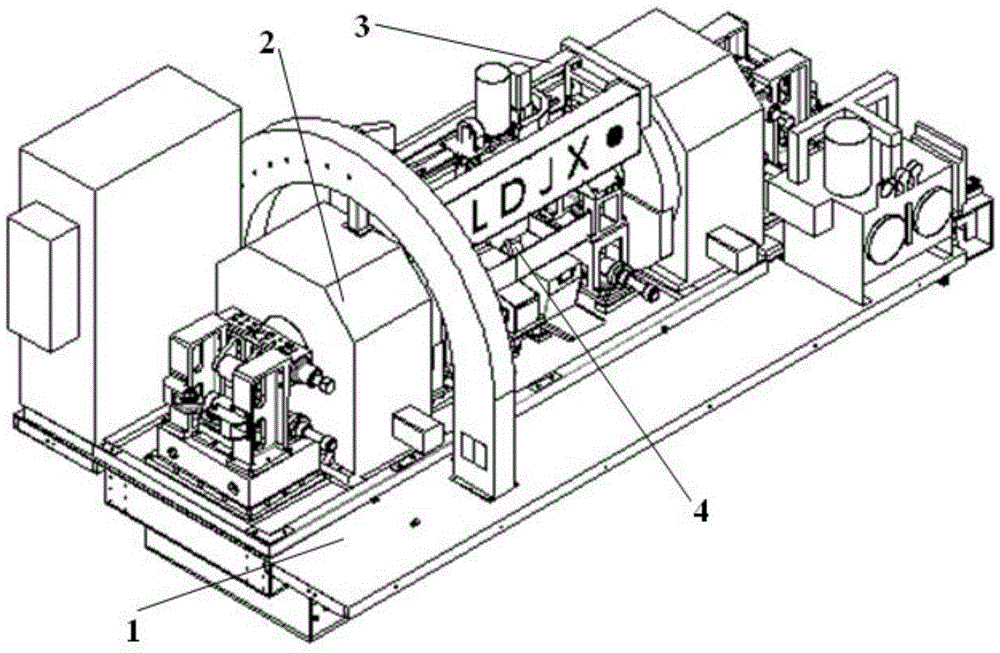

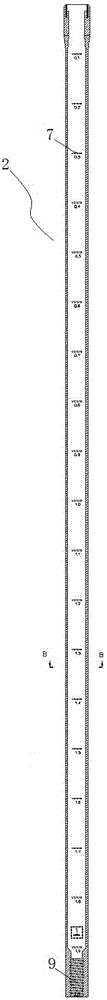

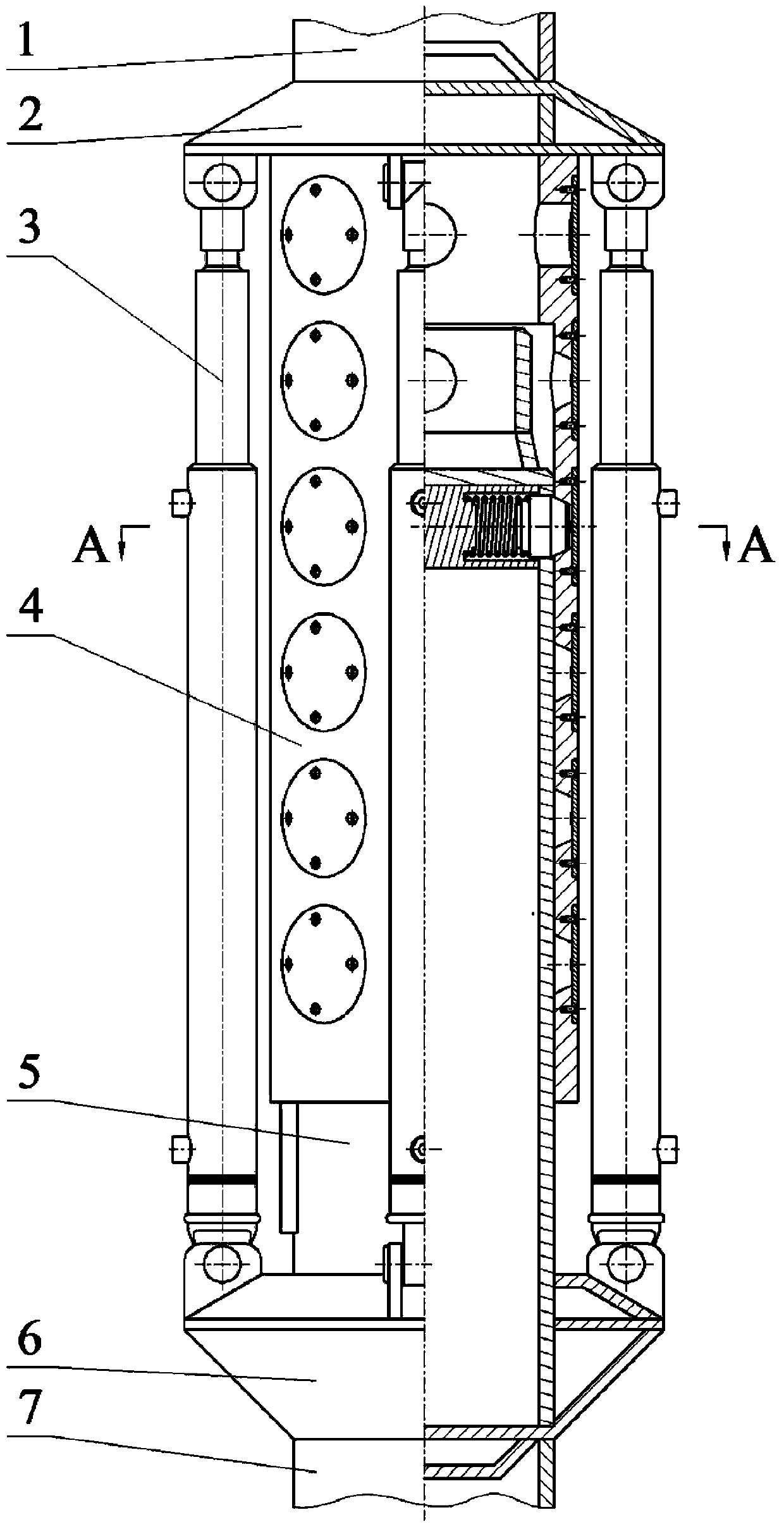

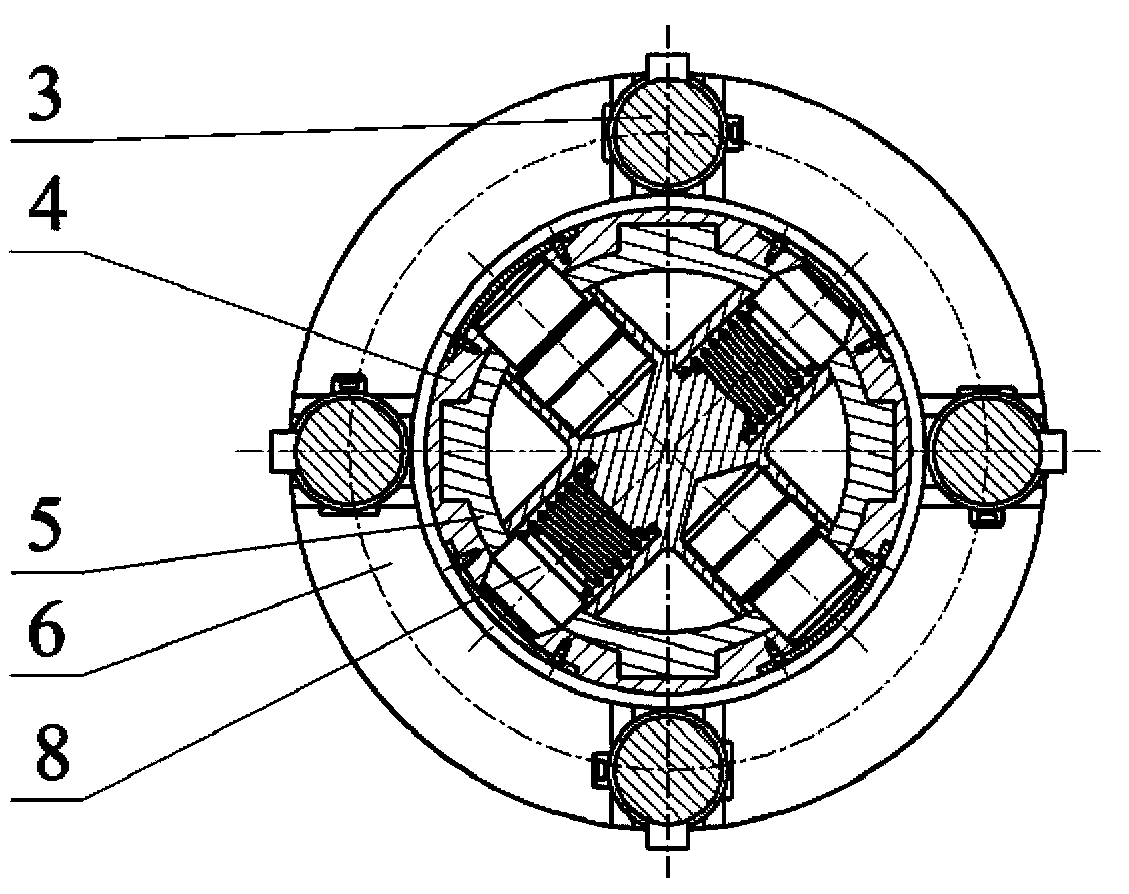

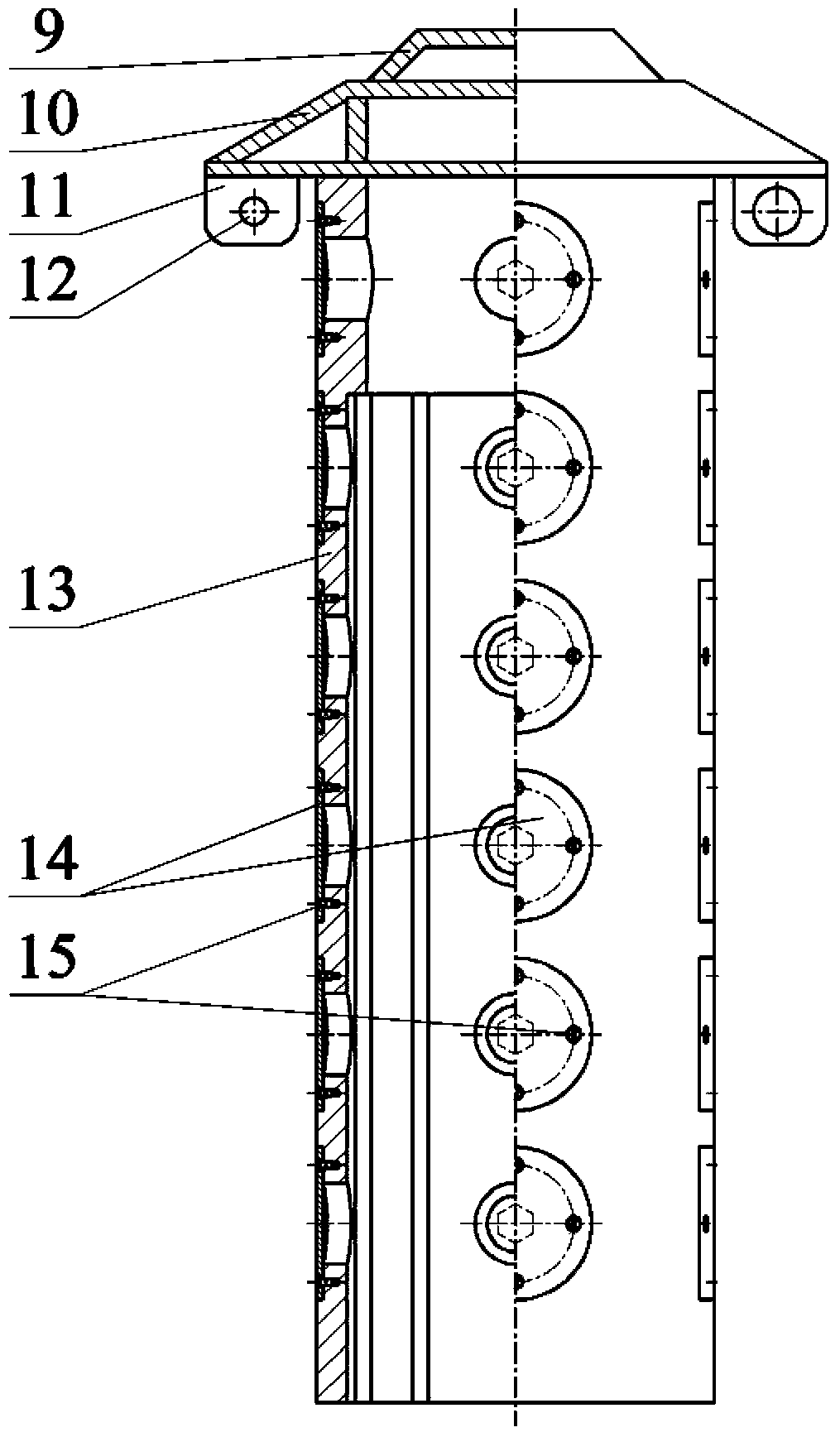

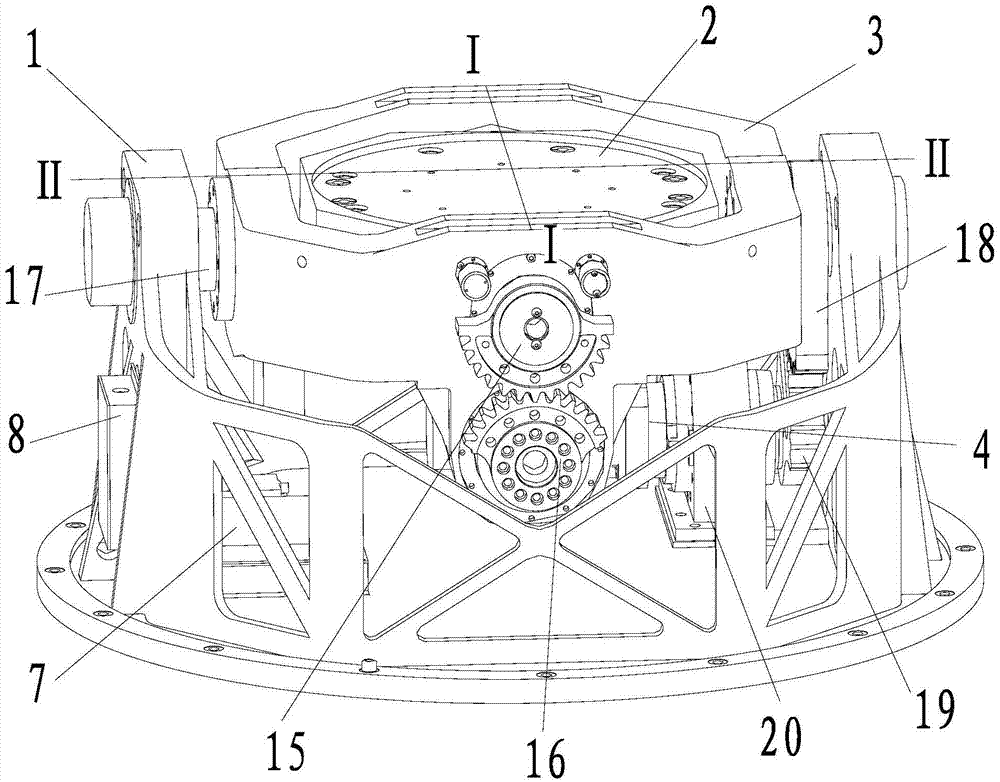

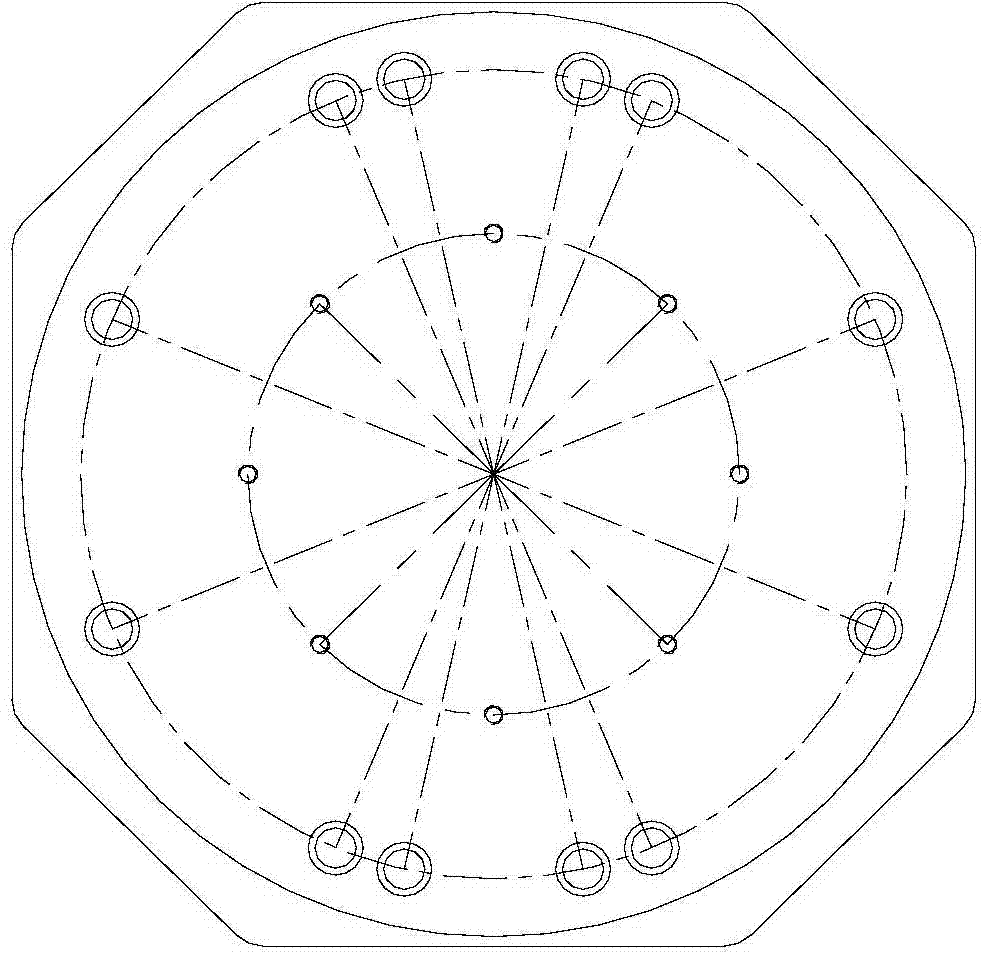

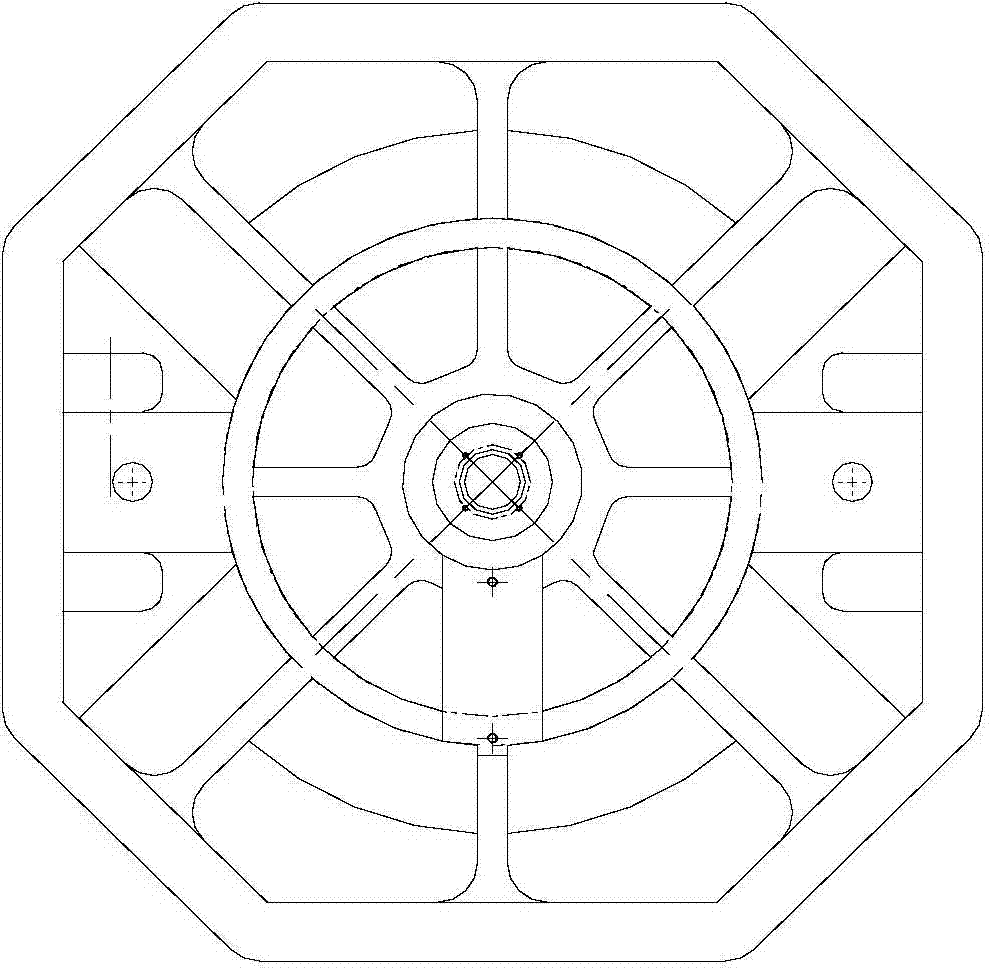

Super-power five-cylinder plunger pump

PendingCN109869294ALess equipmentSave on-site work spaceGearboxesPositive displacement pump componentsElectric driveCentre of rotation

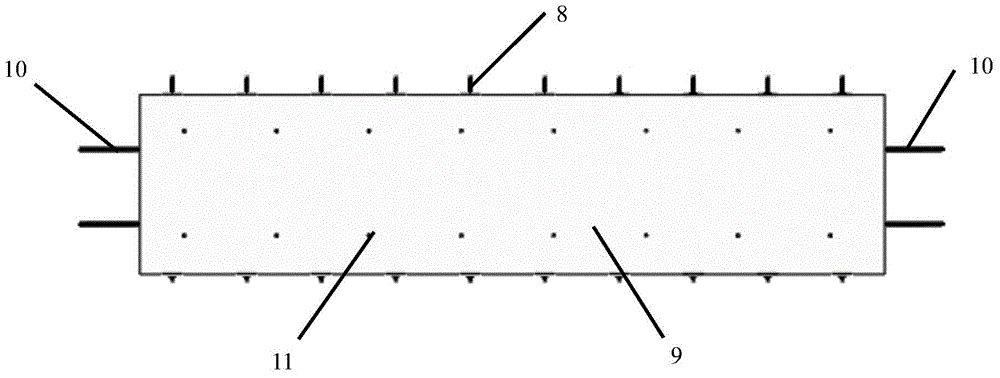

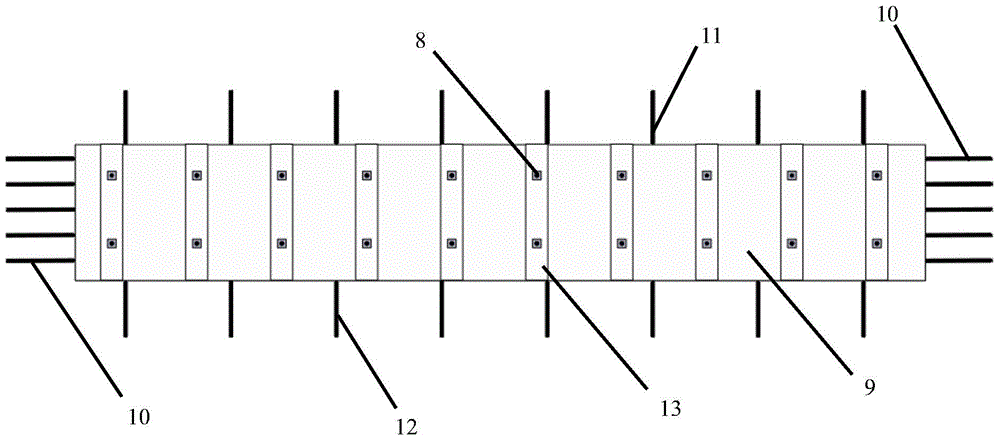

The invention discloses a super-power five-cylinder plunger pump. The super-power five-cylinder plunger pump comprises a power end assembly, a fluid-power end assembly and a reduction box assembly; the power end assembly adopting a sectional type structure design includes a crankshaft box body, a crosshead box body and a space-stop rack, one end of the crosshead box body is connected with the crankshaft box body, and the other end of the crosshead box body is connected with the space-stop rack; the fluid-power end assembly is arranged at one end of the space-stop rack, and the fluid-power endassembly passes through the space-stop rack and the crosshead box body in sequence and is connected with the crankshaft box body through bolts; and the reduction box assembly is connected with the crankshaft box body, a crankshaft in the crankshaft box body is forging alloy steel, the crankshaft includes six shaft necks and five crank threw, each crank throw is arranged between two adjacent shaftnecks, and the distance between the crank threw and the rotating center of the crankshaft is 110mm to 160 mm. The super-power five-cylinder plunger pump has the beneficial effects that the rated inputpower of the super-power five-cylinder plunger pump is 5000 hp, so that the problem that high-power motors cannot be matched with the plunger pumps of corresponding specifications in electric drive fracturing is solved, and the contradictions that the conditions in oil and gas well fields are limited and the matching of fracturing equipment is much is further solved at the same time.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

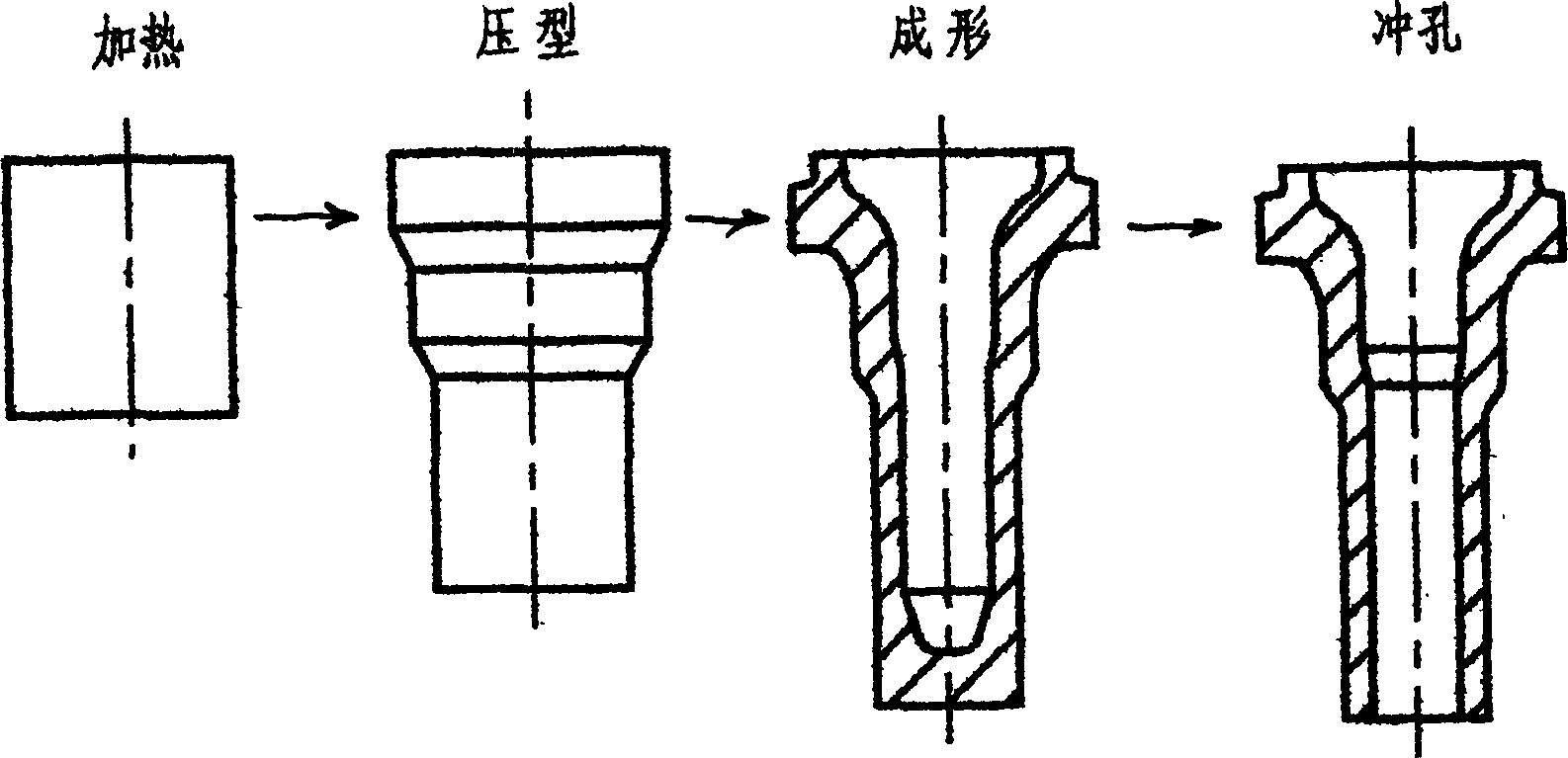

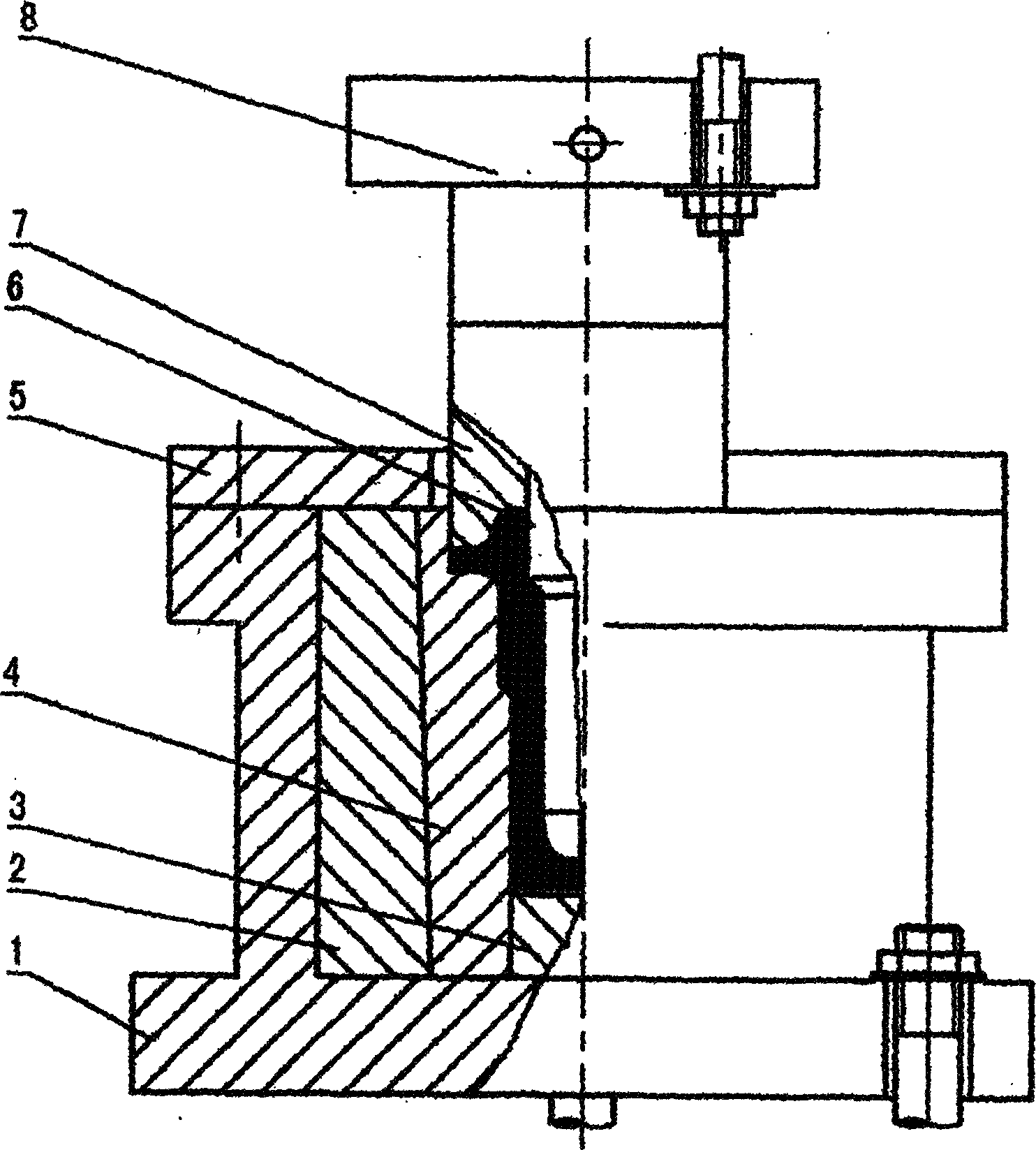

All fiber forging process for load-carrying vehicle hub axle and die therefor

InactiveCN1628921AHigh geometric accuracyGrain refinementForging/hammering/pressing machinesWheelsSurface finishFiber

This invention relates to a load automobile hub axle tube whole fiber forging and shaping process and its mould. It is characterized by the following: adopting solid material; finishing hub axle tube surface and deep hole extrusion shaping to get the whole fiber metal flow wire along axle direction and the inner hole is shaped by extrusion without process.

Owner:李克敏 +3

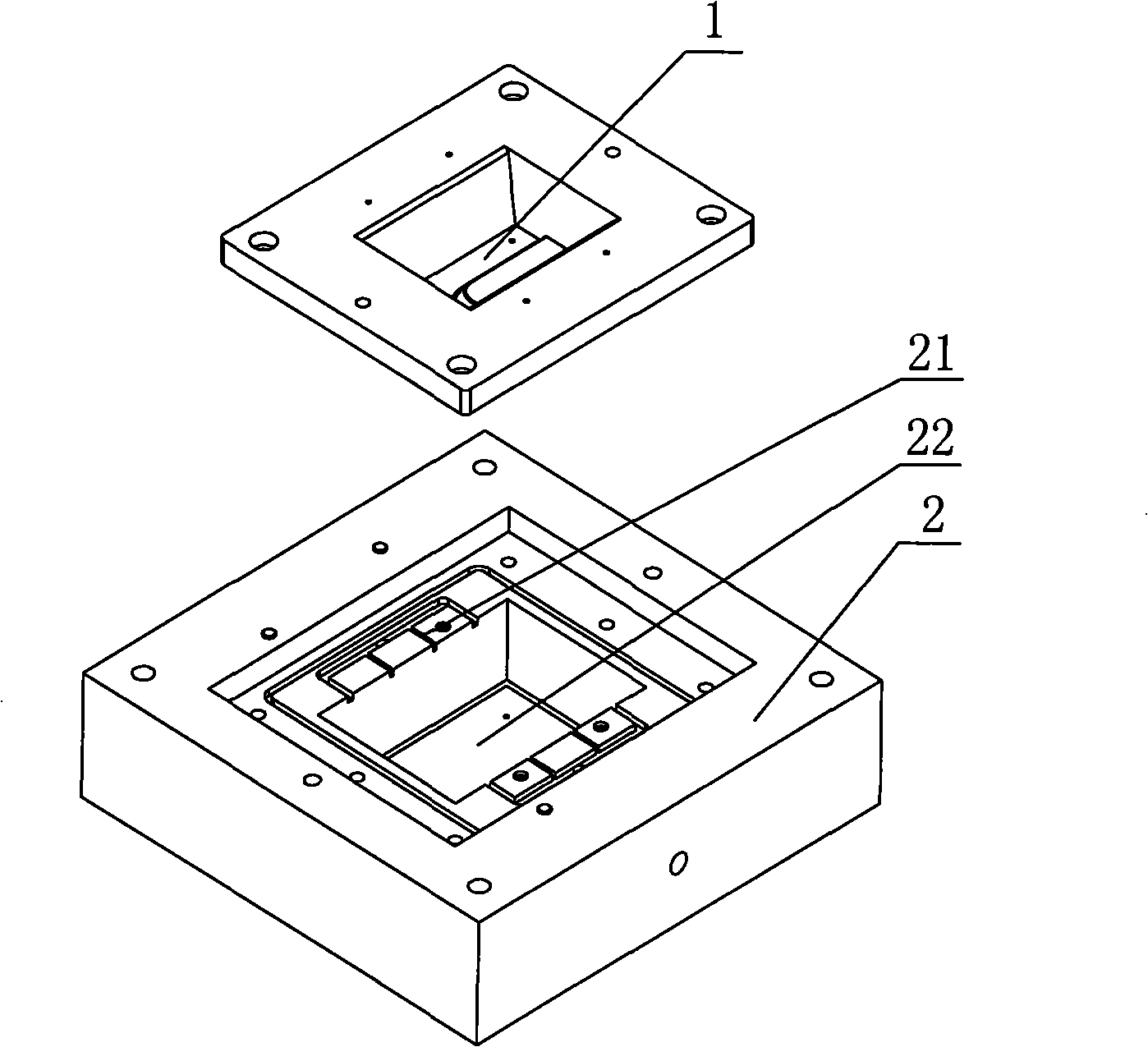

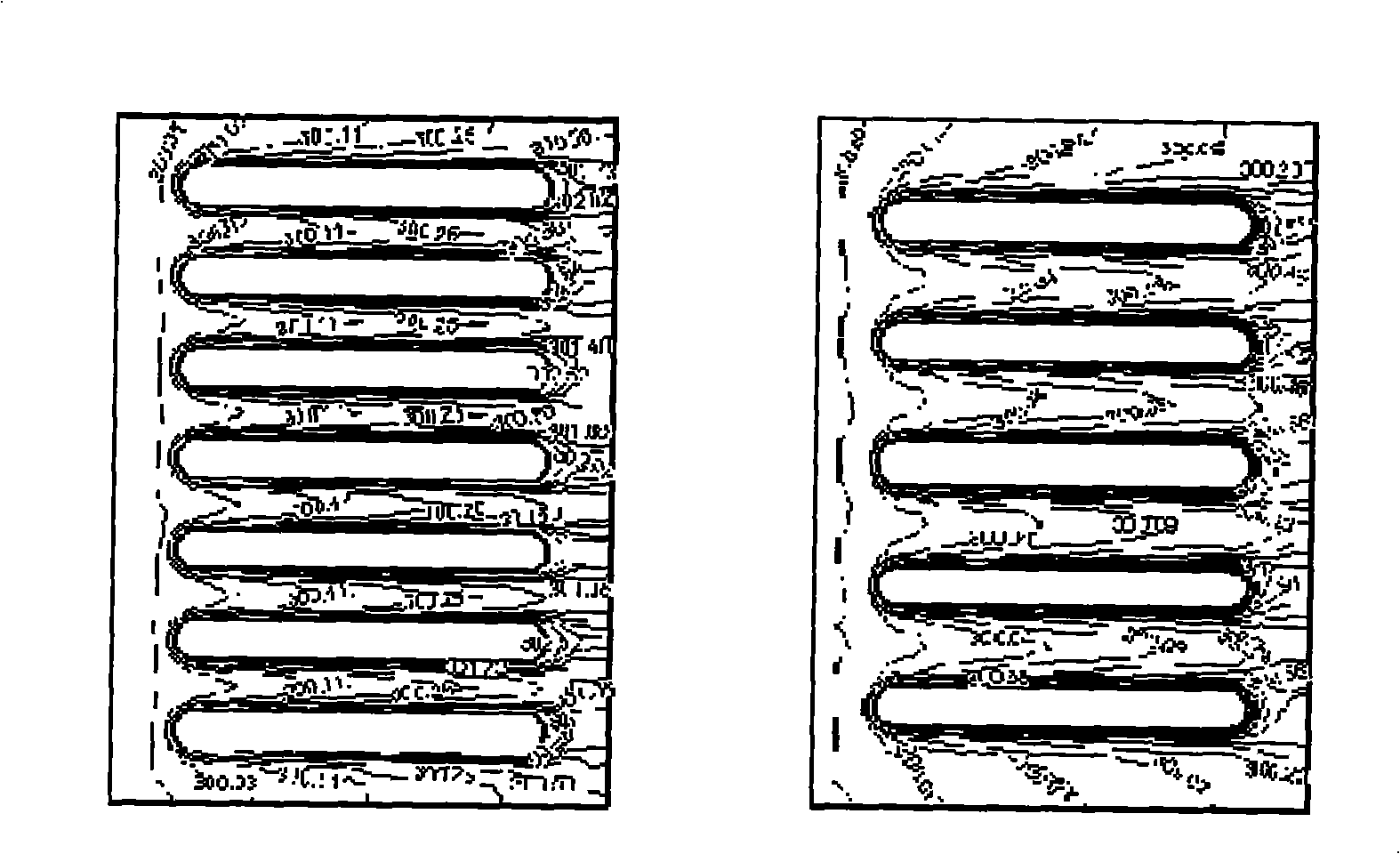

Cooling system of ultra-high strength steel hot stamping forming die

InactiveCN101288890AImprove cooling effectWarranty Strength RequirementsShaping toolsHot stampingSheet steel

The invention discloses a cooling system used for an ultra-high strength steel plate thermal die cutting and forming die. The die comprises a concave die and a concave die seat; a water chamber is arranged between the concave die and the concave die seat; the water chamber is communicated with a water inlet and a water outlet. The water chamber is arranged between the concave die and the concave die seat of the invention; after cooled water is inlet in the water chamber, a steel plate workpiece can be quickly cooled by the thermal conduction between the die and the steel plate so as to meet the quenching condition of the steel plate. Especially, the water chamber is also internally provided with a supporting column; the upper end of the supporting column is contacted with the lower bottom surface of the concave die; the lower end of the supporting column is contacted with the upper bottom surface of the concave die seat; therefore, the structural strength of the concave die is ensured, the flowing direction of the water flow can be guided, flow perturbation conditions can be provided, meanwhile, the heat transfer area is increased, and the heat exchange efficiency between the cooled water and the die is improved.

Owner:TONGJI UNIV +1

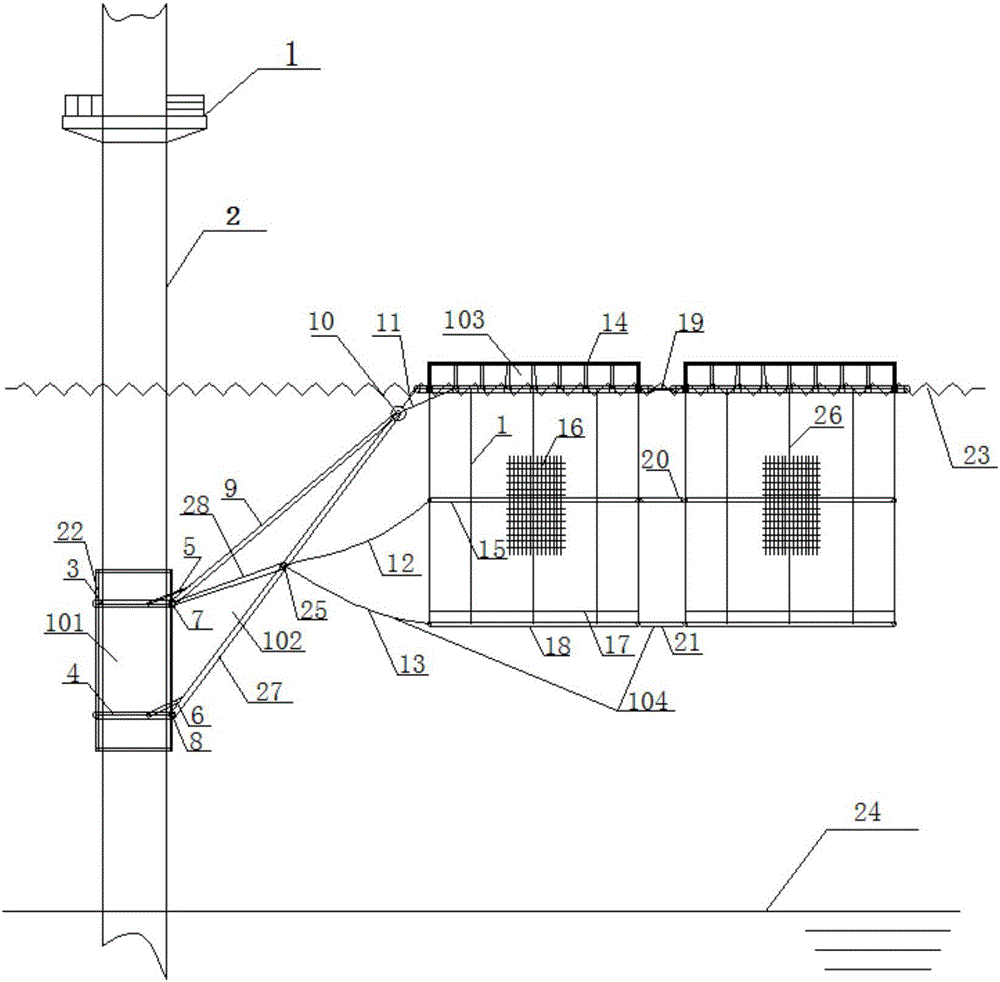

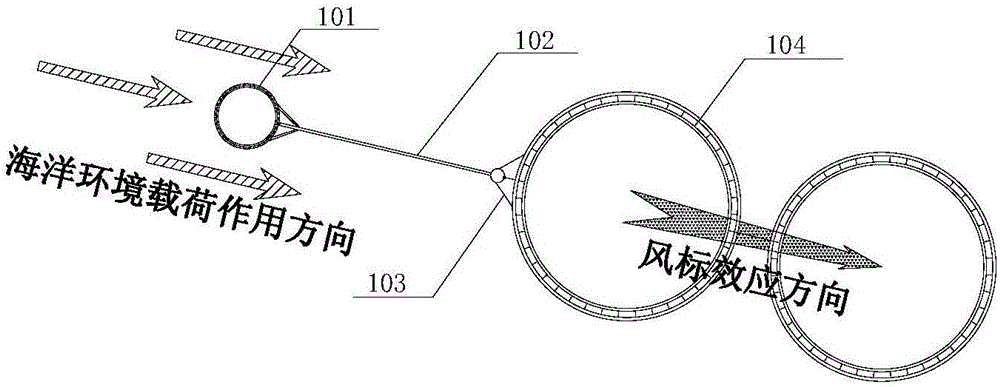

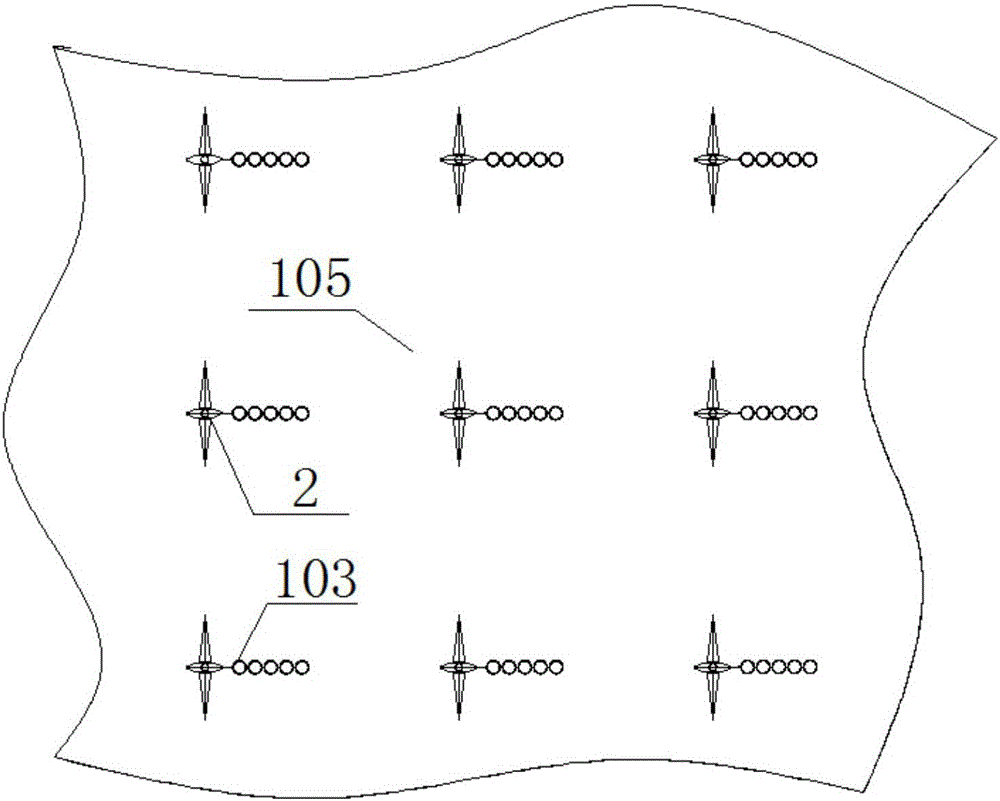

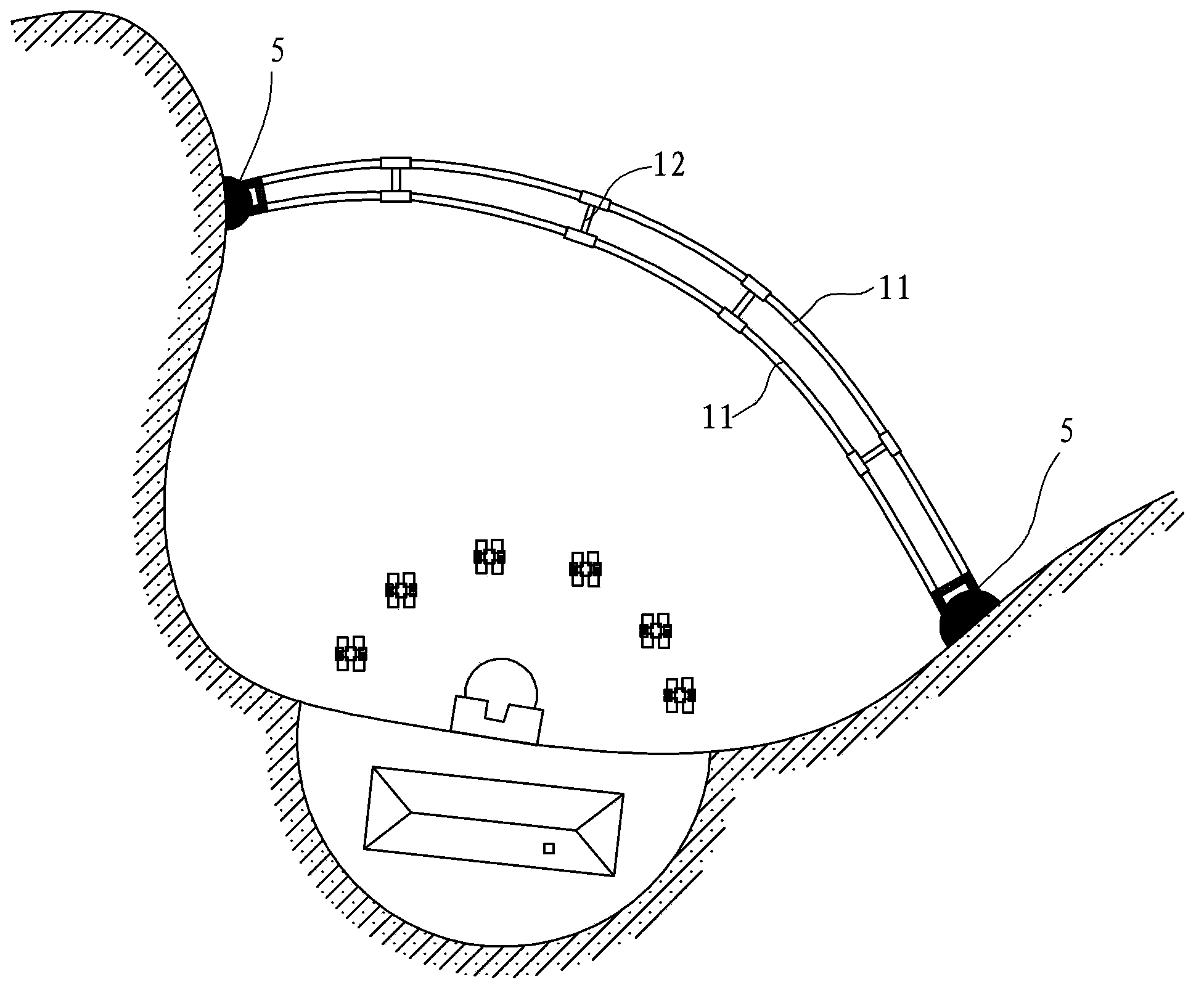

Deep sea net box cultivating apparatus for offshore wind field

ActiveCN105104271AReduces the effects of oxidation and corrosionIncrease stiffnessClimate change adaptationAgricultural fishingWind forceElectric energy

The invention discloses a deep sea net box cultivating apparatus for offshore wind field, which comprises an offshore wind turbine foundation, wherein an operation platform is mounted on the top portion of the offshore wind turbine foundation; a rotary sleeve ring fixing system is mounted on a lower end of the offshore wind turbine foundation; the rotary sleeve ring fixing system is connected to a rotary arm mechanism; the rotary arm mechanism is connected to an offshore net box module through a cable connecting rod component; the rotary sleeve ring fixing system comprises a reinforced cylinder sleeve; an upper rotary sleeve ring and a lower rotary sleeve ring are respectively mounted on an upper end and a lower end of the reinforced cylinder sleeve; and the upper rotary sleeve ring and the lower rotary sleeve ring are respectively connected to the rotary arm mechanism through an upper connecting buckle and a lower connecting buckle. According to the utility model, by adopting the apparatus provided herein, the offshore wind field can be applied with various purposes; organic combination between the offshore wind power generation and the offshore net box cultivation is realized; the space of the offshore wind field and the offshore wind power are fully utilized, thus improving the overall economy benefits.

Owner:佛山市榕岸海洋工程装备有限公司

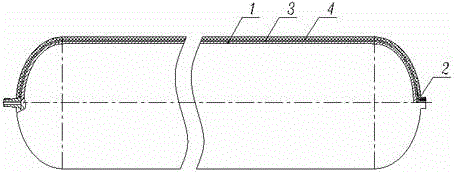

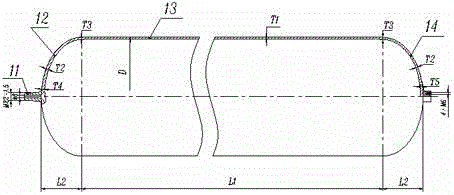

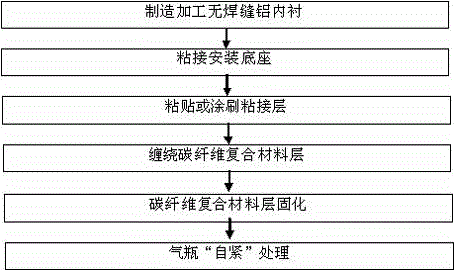

100 L carbon fiber wrapped aluminum-lined composite cylinder and manufacture method thereof

The present invention provides a 100 L carbon fiber wrapped aluminum-lined composite cylinder, including a weldless aluminum liner, a mounting base, an adhesive layer and a carbon fiber composite layer. The mounting base and the weldless aluminum liner form a smooth flattening winding mandrel; the external part of the mandrel is wound by the carbon fiber composite layer; and the adhesive layer is arranged between the mandrel and the carbon fiber composite layer and is used for firmly connecting the weldless aluminum liner and the carbon fiber composite layer. The composite cylinder has the advantages of large volume, high pressure resistance, high efficiency, light weight, high security, low cost and short manufacturing cycle. The present invention also provides a manufacture method of the carbon fiber wrapped aluminum-lined composite cylinder.

Owner:SHANGHAI INST OF SPACE PROPULSION

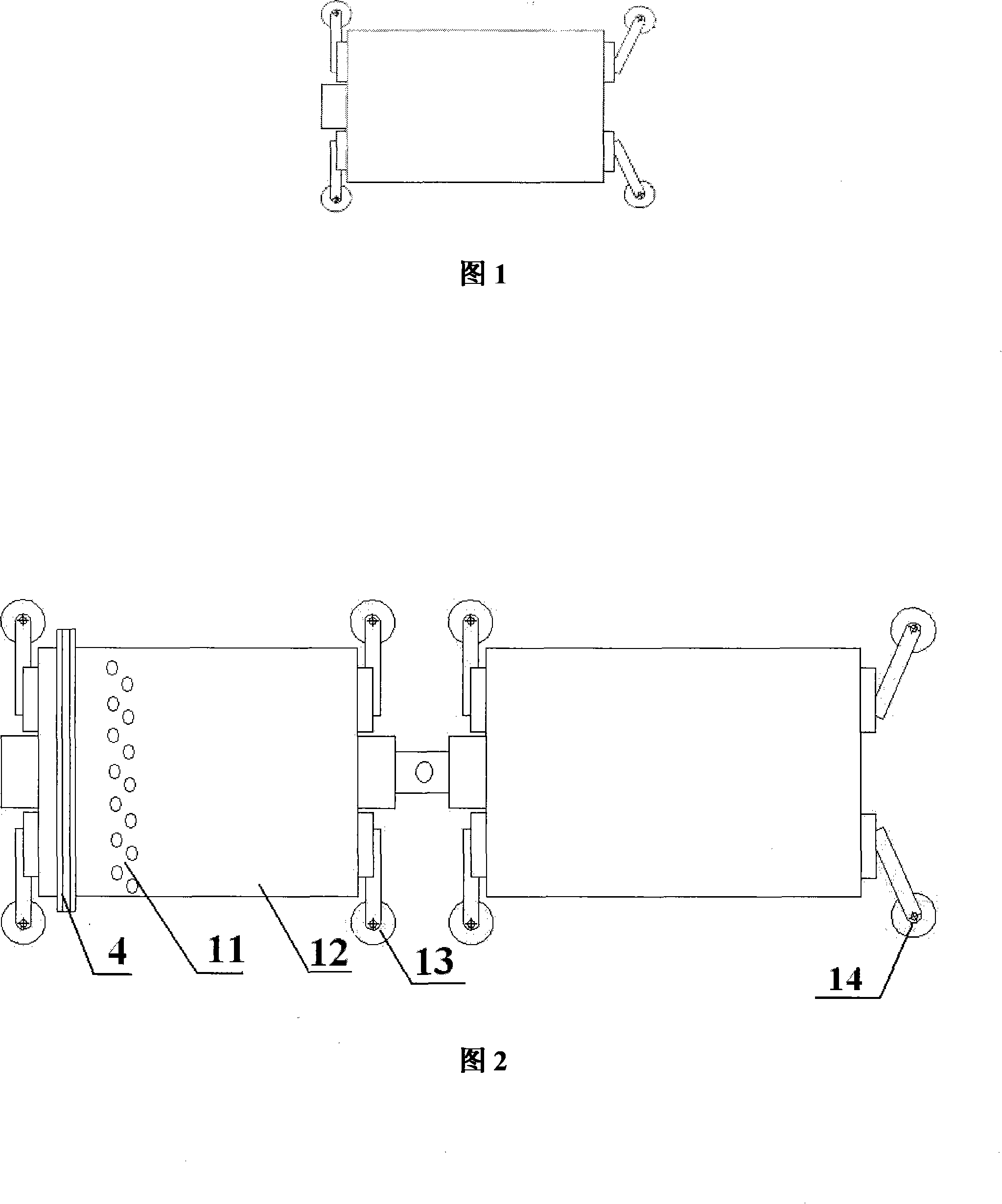

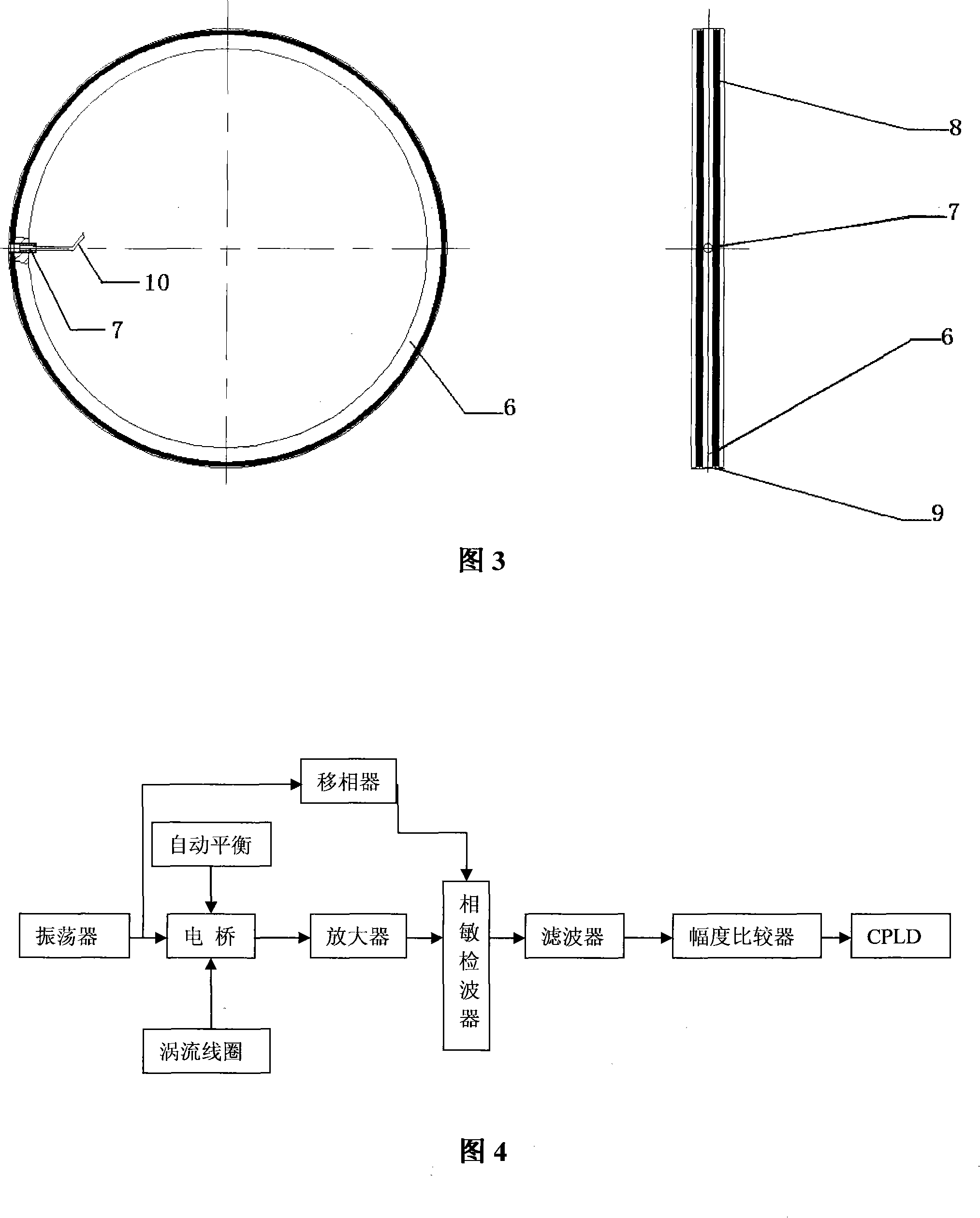

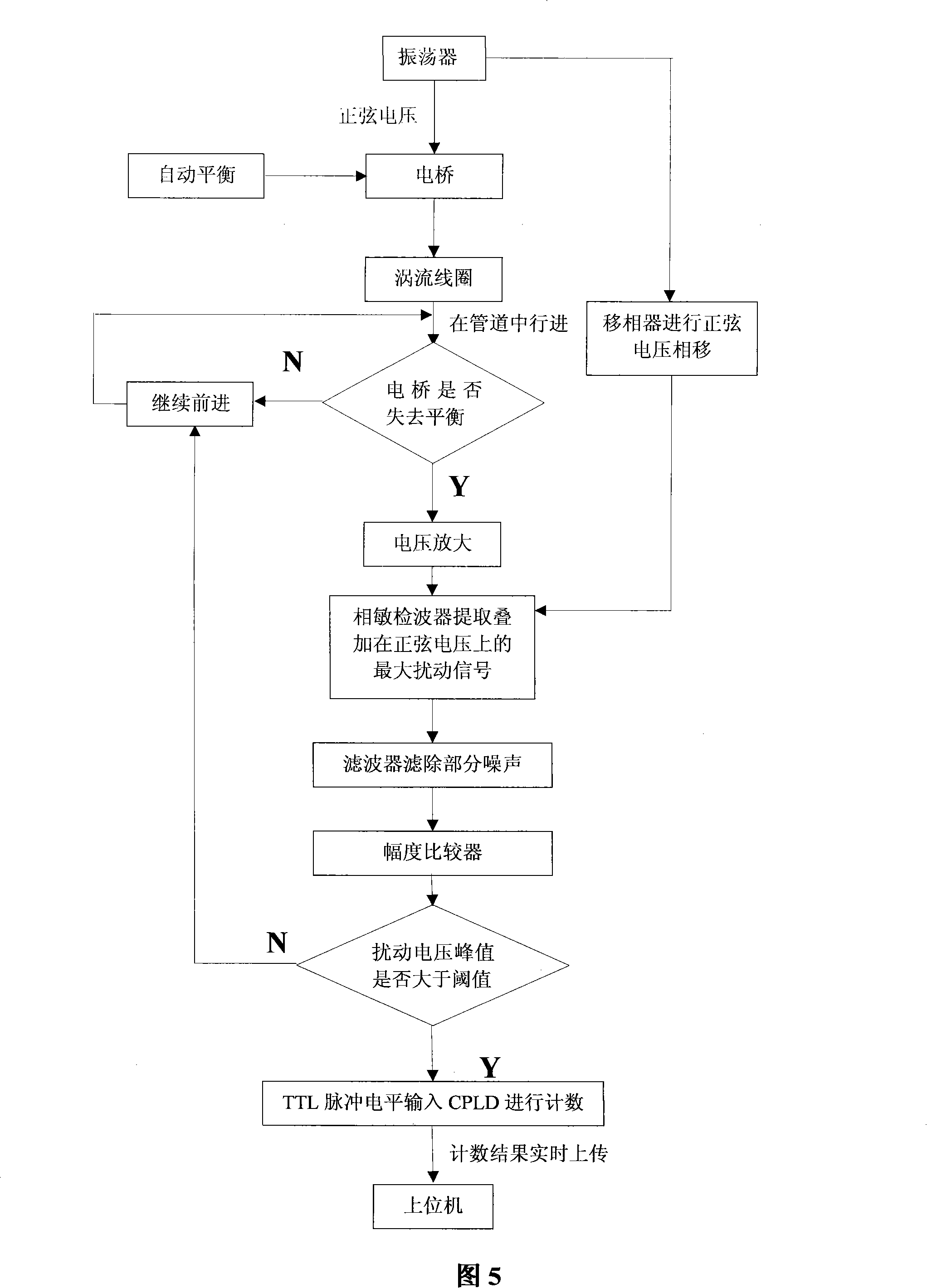

Long conveyance pipe defect positioning method and positioning system

ActiveCN101169225AAccurate seam countReduce in quantityPipeline systemsLocalization systemEddy current

The invention relates to a positioning method and a positioning system for a long-distance pipeline defect. In the method for locating defects of long-distance pipelines according to the present invention, a series of butt girth welds are formed in the long-distance pipelines during installation, and wheel-type odometers are used for mileage measurement and positioning in long-distance pipelines. When the wheel-type mileage While the meter is advancing and measuring the mileage in the long-distance pipeline, the eddy current testing device is used to detect when the butt girth weld has passed. This information is analyzed simultaneously with the mileage data of the wheel odometer to determine the pipeline defect s position. The long-distance pipeline defect location system of the present invention includes a wheel odometer and an eddy current detection device; the eddy current detection device includes an eddy current coil and an eddy current detection processing module connected with the eddy current coil. The positioning method and system of the invention can avoid the increase of the accumulative distance error of the wheel odometer, improve the positioning accuracy, and fully meet the positioning requirements.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

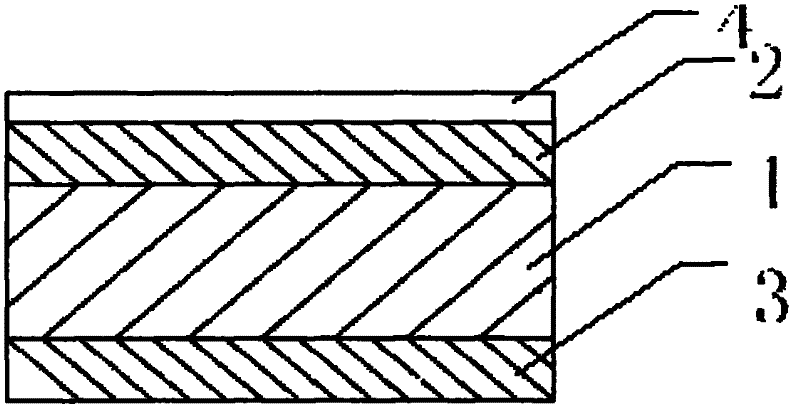

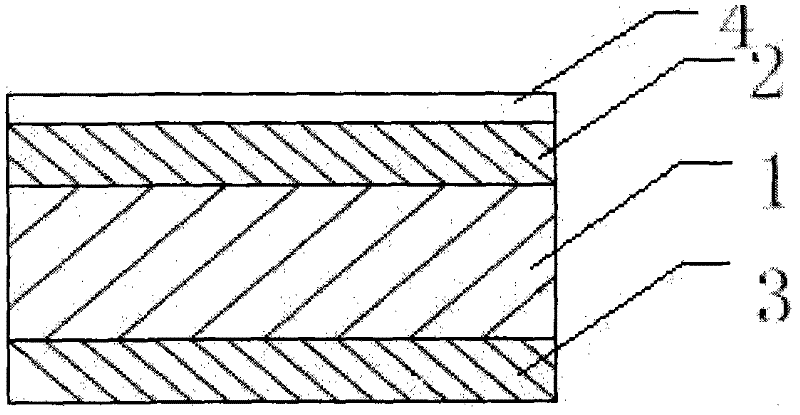

Interior decorative composite board for automobile roof panel

ActiveCN102431228AHigh strengthImprove breathabilityLayered productsSuperstructure subunitsFiberUltimate tensile strength

The invention specifically relates to an interior decorative composite board for automobile roof panel comprising an intermediate non-woven layer, an upper non-woven layer composited with the upper surface of the intermediate non-woven layer and a lower non-woven layer composited with the lower surface of the intermediate non-woven layer. Weight percentage of the materials used by the intermediate non-woven layer is as follows: jute fiber 48-80%, low melting point fiber 20-52%, and other fiber 0-20% such that the interior decorative composite board for automobile roof panel comprising the intermediate non-woven layer has great strength and excellent breathability and sound-proof effect.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

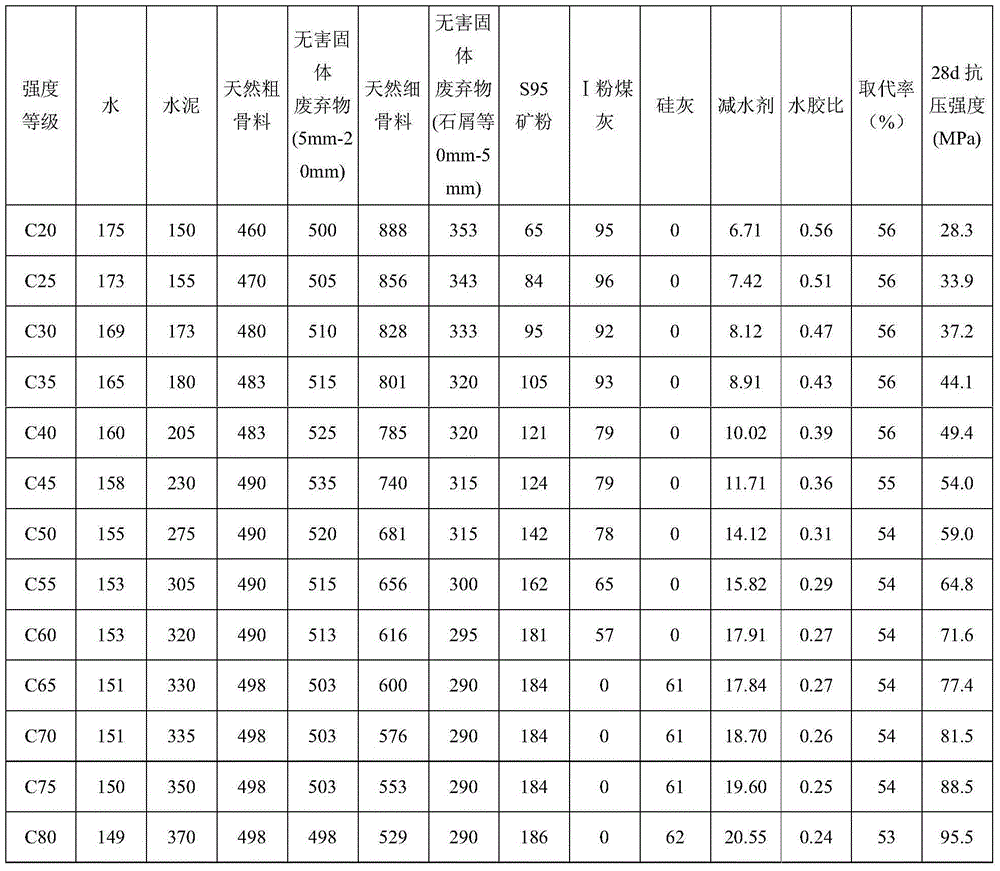

Harmless solid waste high-performance concrete

ActiveCN104692729ARealize the purpose of resource recyclingImprove the level of effective utilizationSolid waste managementReinforced concreteEnvironmental engineering

The invention provides harmless solid waste high-performance concrete. The strength grade of the concrete is C20-C80 grade; the volume-weight of the harmless solid waste high-performance concrete is 2300-2600kg / m<3>; and the harmless solid waste high-performance concrete comprises the following components in a set ratio: water, cement, natural coarse aggregate, harmless solid waste, natural fine aggregate, 0-5m harmless solid waste, a mineral admixture and a water reducing gent. The harmless solid wastes (recycled aggregate, industrial derivatives and the like) are applied to concrete, so that the effective utilization level of the solid wastes can be improved. The required work performance, strength, requirements, endurance quality and the like of the concrete can be ensured; and the harmless solid waste high-performance concrete can be suitable for concrete structures, reinforced concrete structures and the like, so that the targets of recycling and utilizing of the harmless solid wastes are reached.

Owner:SHENZHEN WEIHAI BUILDING MATERIAL

Production method of 350 MPa grade cold rolled magnetic pole steel

InactiveCN1904114ACooperate wellExcellent overall performanceRoll mill control devicesHeat treatment process controlChemical compositionUltimate tensile strength

This invention relates to a process of producing 350MPa cold rolled steel magnet. It includes steps as follows: (1)to heat plate body to 1160-1230DEG C;(2)hot

Owner:WUHAN IRON & STEEL (GROUP) CORP

Production method of 250 MPa grade cold rolled magnetic pole steel

InactiveCN1904113ACooperate wellExcellent overall performanceRoll mill control devicesHeat treatment process controlChemical compositionMetallurgy

This invention relates to a process of producing 250MPa cold rolled steel magnet. It includes steps as follows: (1)to heat plate body to 1160-1230DEG C;(2)hot rolling steps: the start rolling temperature 1050-1100DEG C,end rolling temperature 840-880DEG C,cooling to 640-700DEG C for coiling. (3)cooling to 70DEG C below for acid picking. (4)cold rolling steps; (5) bell furnace anneal; controlling temperature 660-680DEG C (6) temper rolling, then the products. Account to weight the main chemical composition is: C 0.03-0.09%,Si 0.10-0.30%,Mn 0.30-0.70%,Nb 0.015-0.025 %,Als 0.01-0.07%,P <=0.025%,S <=0.010%, Fe the rest.

Owner:WUHAN IRON & STEEL (GROUP) CORP

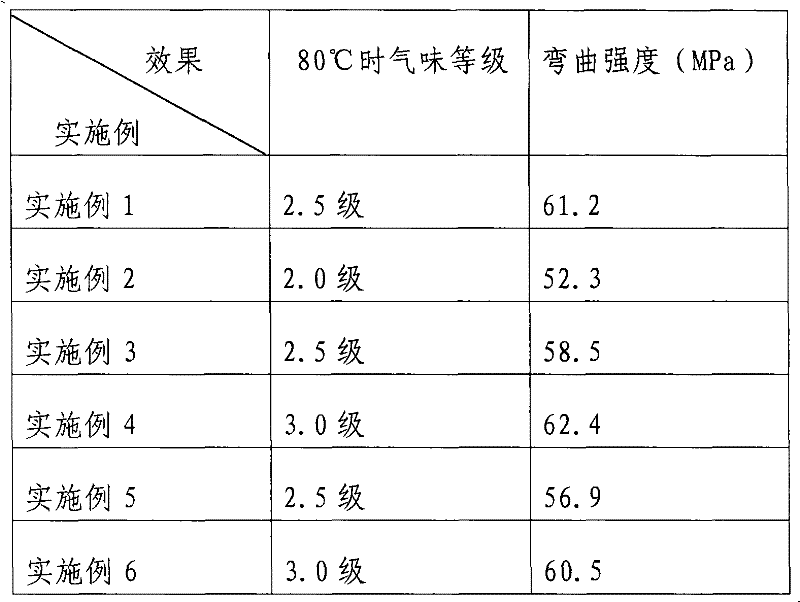

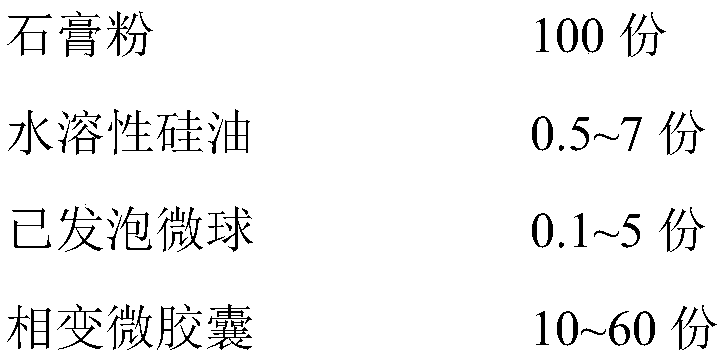

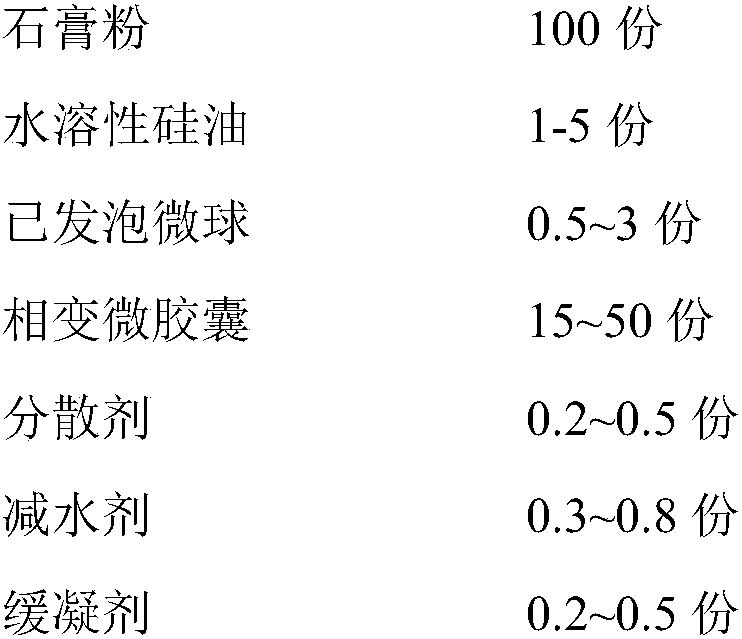

Ultra-light energy-storing gypsum board and preparation method thereof

The invention discloses an ultra-light energy-storing gypsum board and a preparation method thereof. The ultra-light energy-storing gypsum board is prepared from the following components in parts by weight: 100 parts of gypsum powder, 0.5 to 7 parts of water soluble silicon oil, 0.1 to 5 part of foamed microsphere and 10 to 60 parts of phase change microcapsule. By adopting the ultra-light energy-storing gypsum board, the weight of the gypsum board is lowered remarkably; meanwhile, the heat-insulation performance is achieved; under the synergistic effect with phase change microcapsules, the temperature control effect is improved further, and the dispersion property, the flowing performance and the combination strength of foamed microspheres in the gypsum powder are improved; meanwhile, thefoamed microspheres are very light, and can be premixed with the phase change microcapsules, so that subsequent machining operation is facilitated; moreover, the foamed microspheres have certain strength, and the dispersing property in the gypsum powder of the phase change microcapsules and interface action force with the gypsum powder are improved by hydrophilic long-chain monomers in the phasechange microcapsules, so that the requirement on the strength of the gypsum board product is met; gaps in the gypsum board can be filled with the foamed microspheres, so that the water absorbing rateis lowered; the ultra-light energy-storing gypsum board can be applied to a high-moisture environment.

Owner:NANOSPHERE SHANGHAI +1

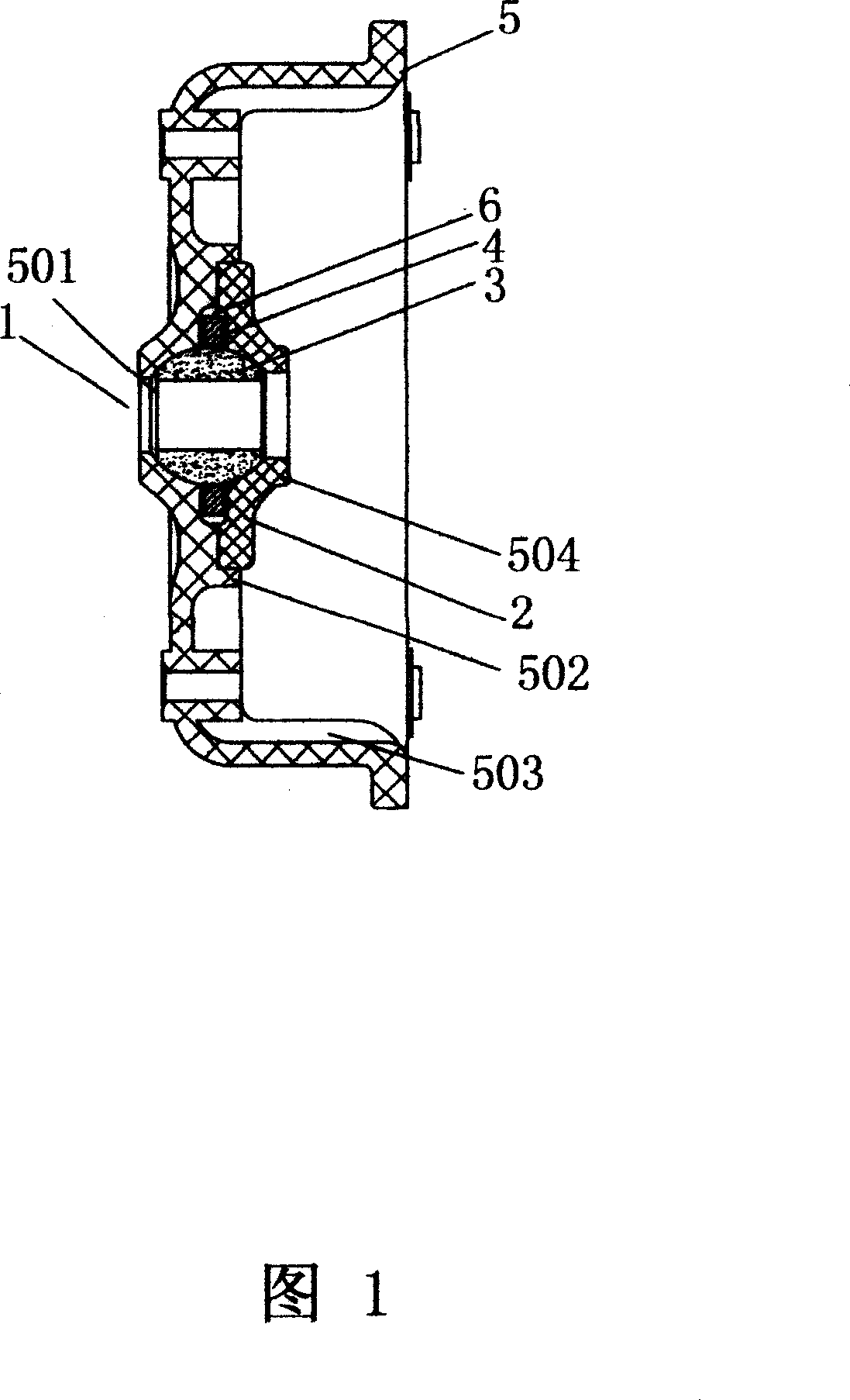

Method for mounting plastic electric machine casing and bearing device

InactiveCN1949632AHigh shaft positioning accuracyExcellent matching adjustment performanceManufacturing dynamo-electric machinesEngineeringInjection moulding

Owner:罗世明

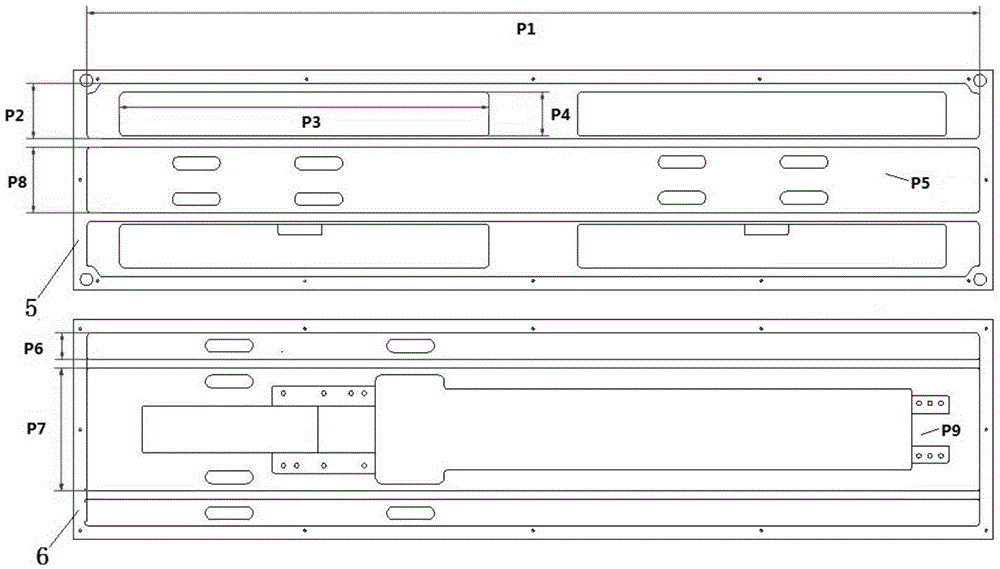

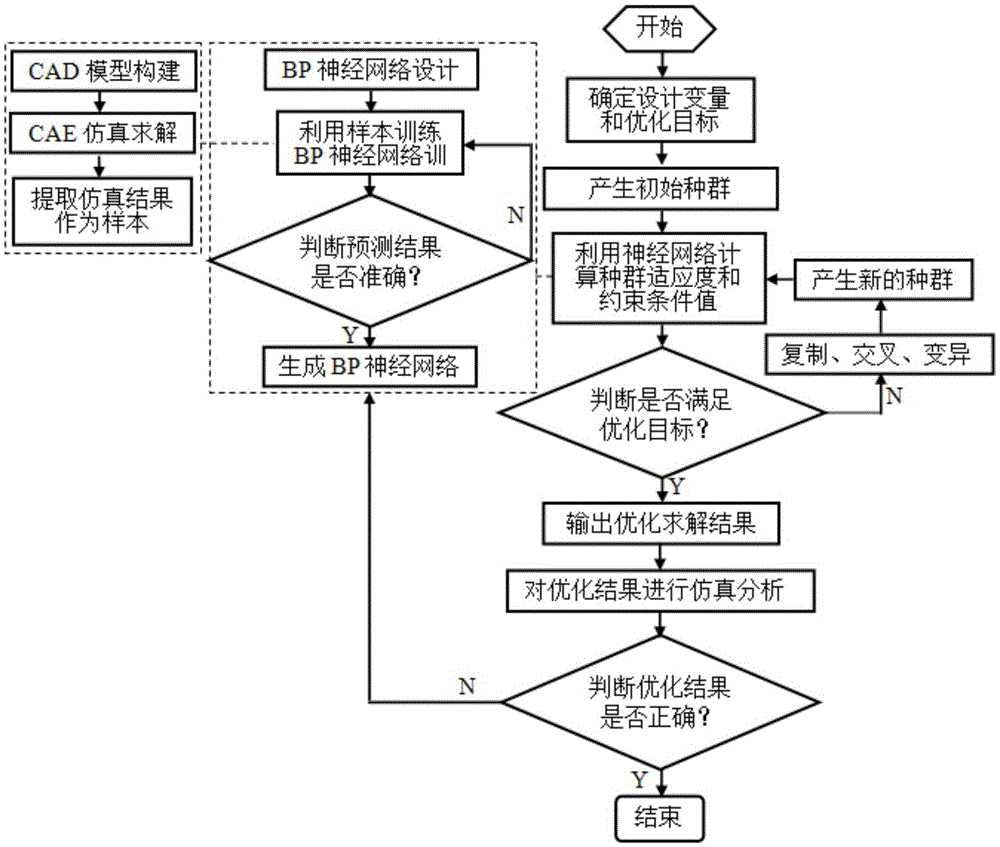

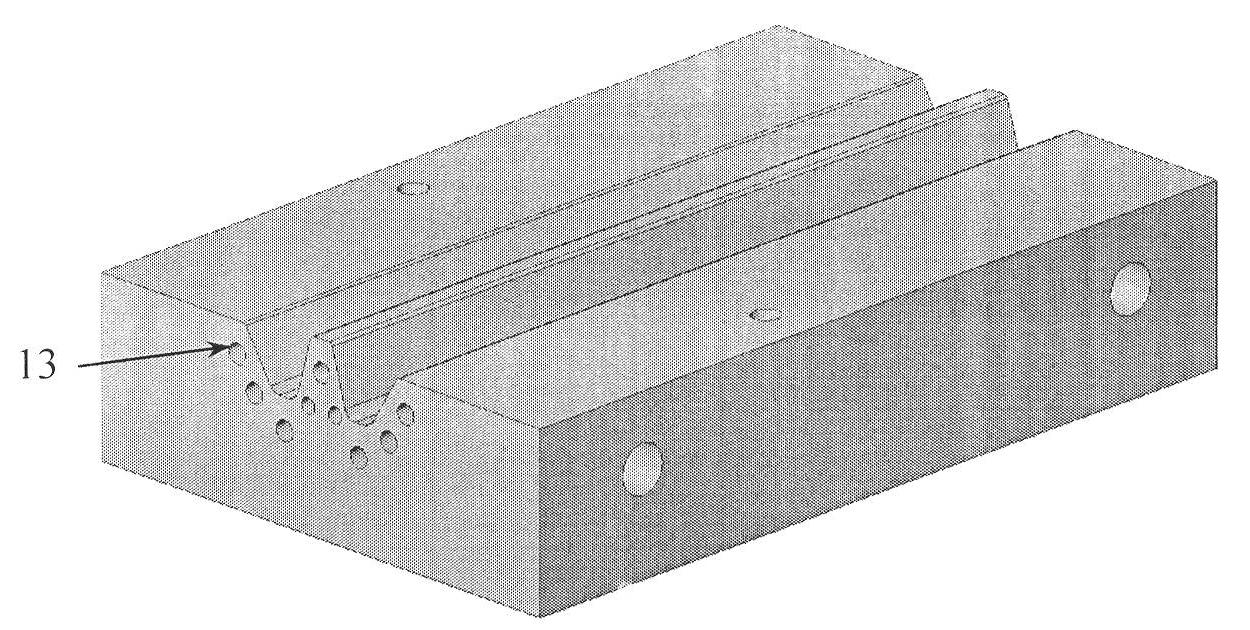

Optimum design method for steel rail weld seam finish-milling machine tool beam body based on BP neural network and genetic algorithm

ActiveCN105574300AImprove performanceImprove the design levelGeometric CADNeural learning methodsWeld seamEngineering

The invention discloses an optimum design method for a steel rail weld seam finish-milling machine tool beam body based on a BP neural network and a genetic algorithm. The optimum design method includes the steps that firstly, the size of an auxiliary structure for supporting or reinforcing a whole in the beam body is selected as a design variable, and the optimization criterion of the beam body is to improve rigidity and reduce total weight on the premise of ensuring structural strength; secondly, the strength, rigidity and weight of the beam body are obtained by adopting an orthogonal test method to serve as sample data; thirdly, the neural network is designed and is trained with the sample data until the difference between a predicted value and a sample value is defined within an allowance error range; fourthly, a population is generated, and population fitness and constraint condition values are calculated by using the neural network so that genetic algorithm optimization solution can be conducted; fifthly, optimum obtained parameters are analyzed in a simulation mode to determine optimization result feasibility. On the premise of ensuring the structural strength, the structural rigidity is effectively improved, the structural weight is effectively reduced, and therefore the overall structural performance of a finish-milling machine tool is promoted.

Owner:WUHAN UNIV OF TECH

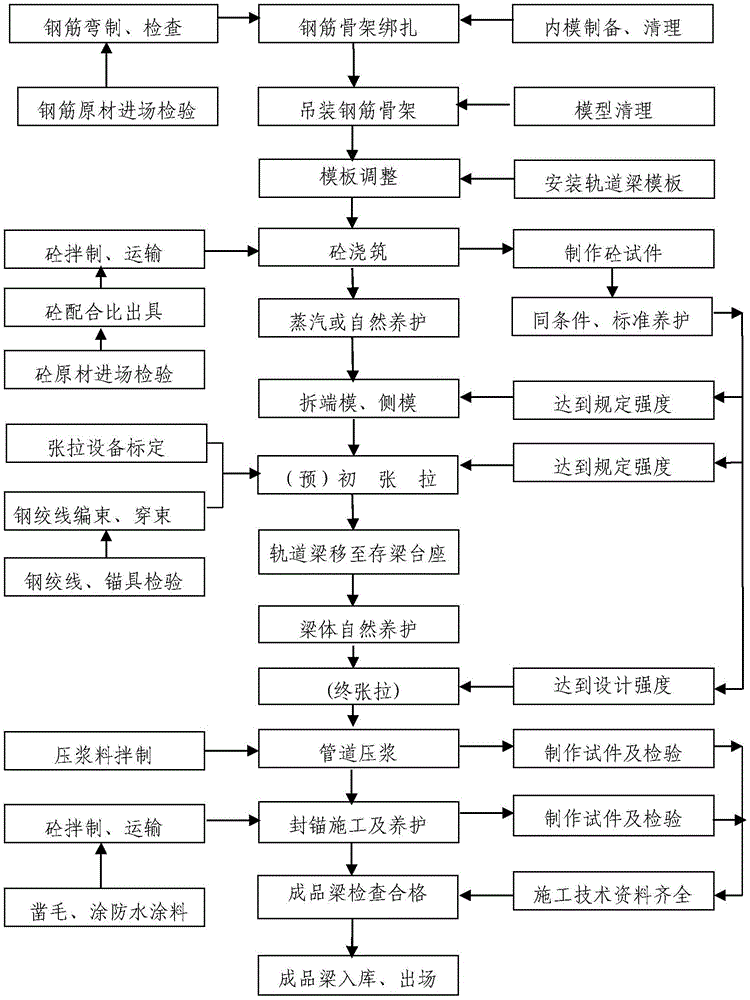

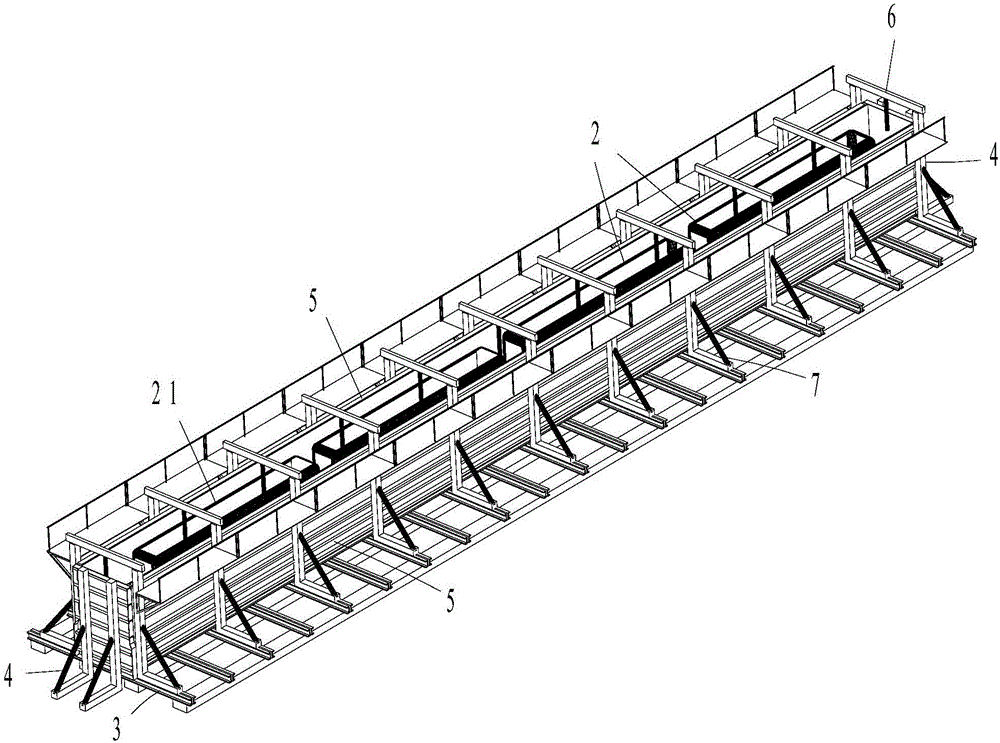

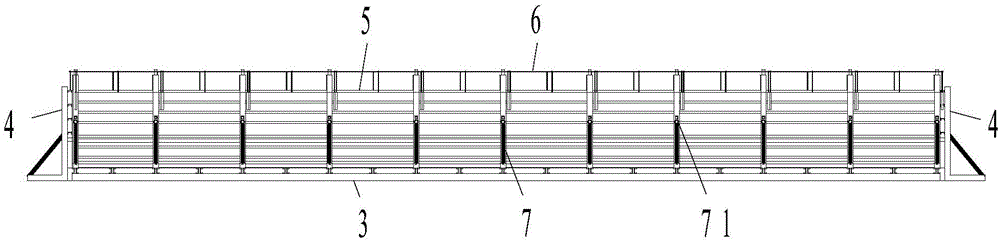

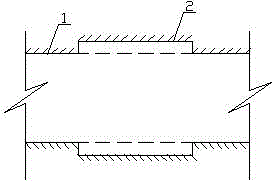

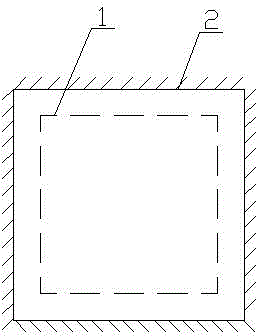

Manufacture method for maglev track beam

ActiveCN105014786AImprove prefabrication efficiencyHigh adjustment accuracyMouldsRailway tracksEngineeringVertical displacement

The invention discloses a manufacture method for a maglev track beam. The manufacture method comprises the following steps: tying a framework of steel reinforcement, manufacturing an internal mold, putting the internal mold in the framework of steel reinforcement, mounting a formwork of track beam, and regulating the formwork of track beam so as to meet the required linearity. The lateral displacement relative to the track beam and the perpendicularity relative to a bottom mold of the side mold of the formwork of track beam can be regulated through a regulating component, and a translating component arranged outside end molds is used for regulating the longitudinal movement relative to the side mold of each end mold. The manufacture method has the advantages of being easy to operate, high in regulating precision and simple to assemble and disassemble the molds. A control component can respectively regulate the transverse displacement, the longitudinal displacement and the vertical displacement of the track beam, the linearity precision can achieve the range of + / -5, and the precast quality of a curved track beam is ensured. The intelligent control can realize high regulating precision, high efficiency and good reliability of a formwork system, and the manufacture method is particularly applicable to precasting of medium-low-speed maglev linear or curved track beams.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD

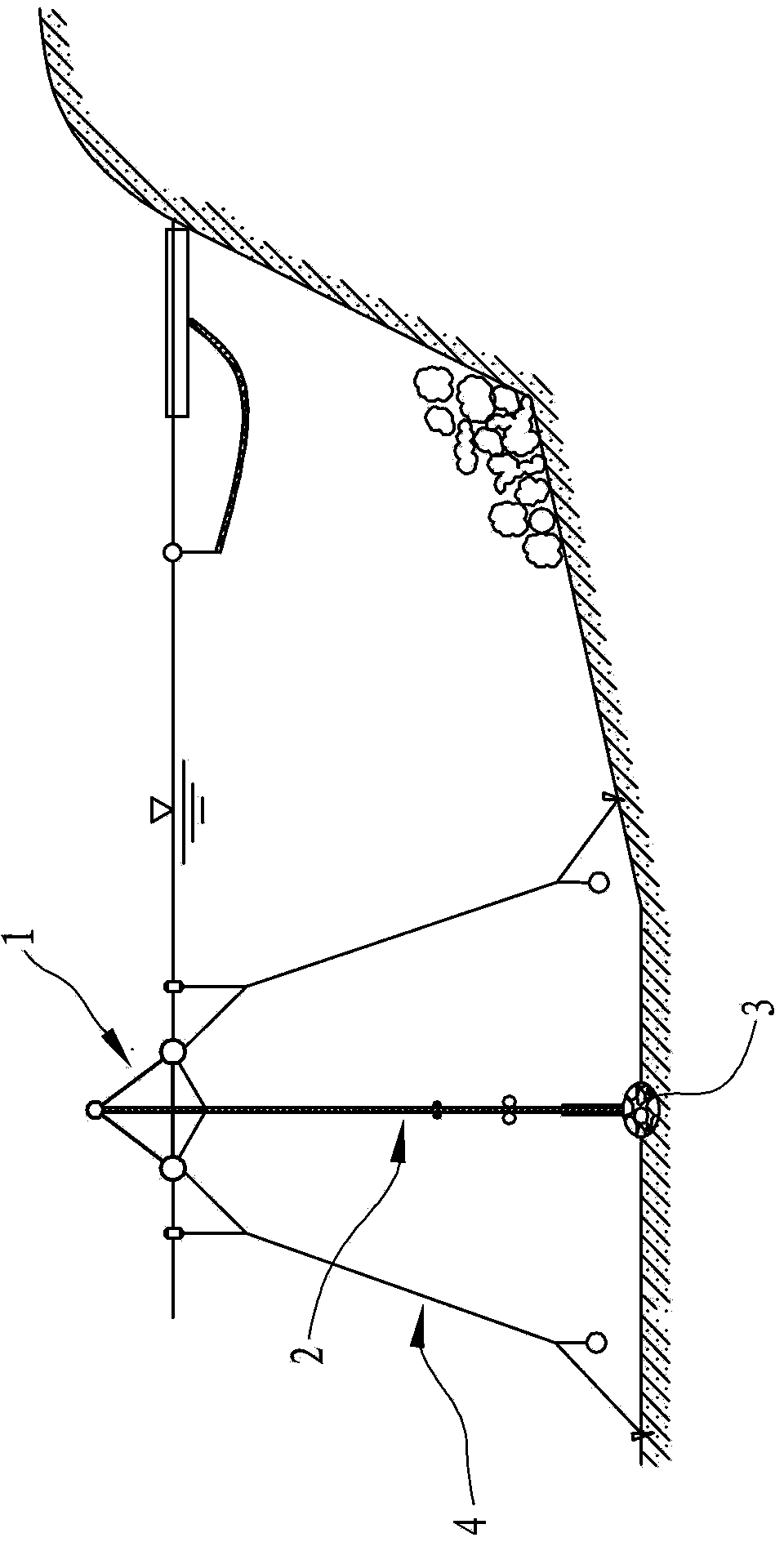

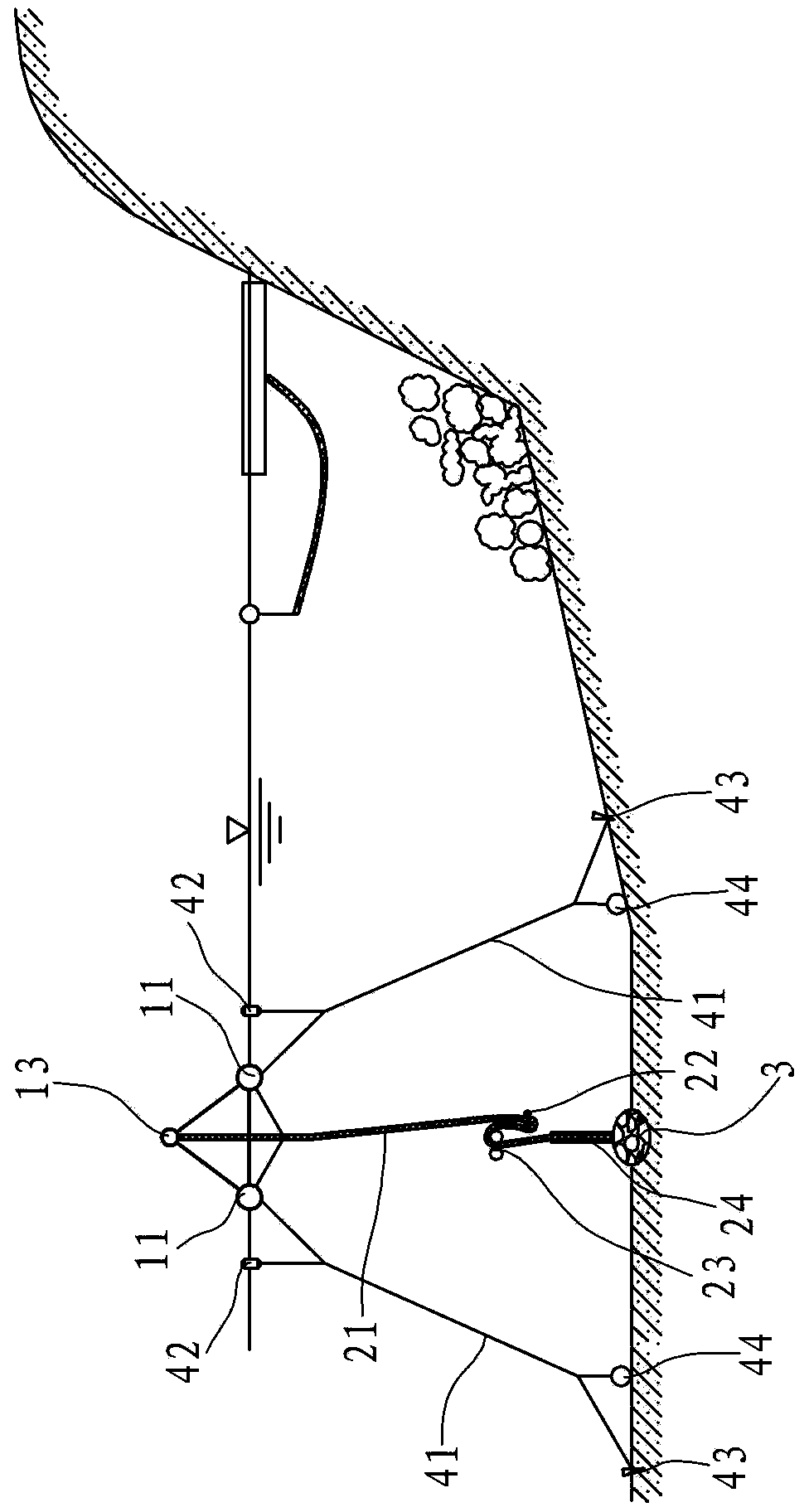

A shallow sea large-scale ecological seine culture device

InactiveCN103053449BAvoid entanglementWarranty Strength RequirementsClimate change adaptationPisciculture and aquariaShallow seaEnvironmental engineering

The invention discloses a large-scale ecological purse seine breeding device in shallow sea. The large-scale ecological purse seine breeding device in the shallow sea comprises a buoyancy system, a netting system, a dragon-shaped sandbag and an anchoring system, wherein the buoyancy system comprises double-row main floating pipes which are arranged in a parallel mode at intervals and a shore connecting structure which is fixedly arranged on the shore; two ends of the main floating pipes are respectively connected to the shore connecting structure and can longitudinally move up and down relative to the shore connecting structure; the netting system comprises a purse seine and the upper end of the purse seine is fixedly connected with the main floating pipes; the dragon-shaped sandbag is arranged at the bottom of the netting system; the anchoring system comprises a main anchor rope, the upper end of the main anchor rope is connected to the main floating pipes, and the lower end of the main anchor rope is fixedly arranged at the bottom of the sea through a piled anchor or an anchor block. The large-scale ecological purse seine breeding device in the shallow sea has the advantages of meeting the strength requirement of the buoyancy system of the purse seine by utilizing a mode of fixing the purse seine under the HDPE (high-density polyethylene) main floating pipes; ensuring a purse seine system to be always connected closely with a coastal connecting section and avoiding escape of the fish due to the fact that a buoy which is arranged in the shore connecting structure changes along with water levels; and being capable of avoiding the purse seine winding under different tide levels by arranging a chain and a floating ball string in the purse seine.

Owner:ZHEJIANG OCEAN UNIV

Gob-side entry three-dimensional reinforcement filled wall structure and filling method thereof

InactiveCN103603688AWarranty Strength RequirementsImprove integrityMaterial fill-upLocking mechanismEngineering

Owner:ANHUI UNIV OF SCI & TECH

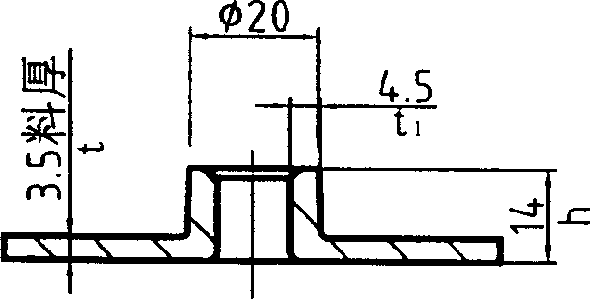

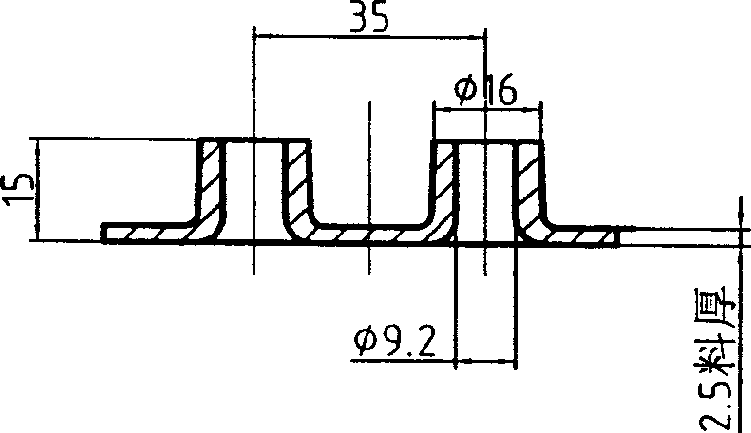

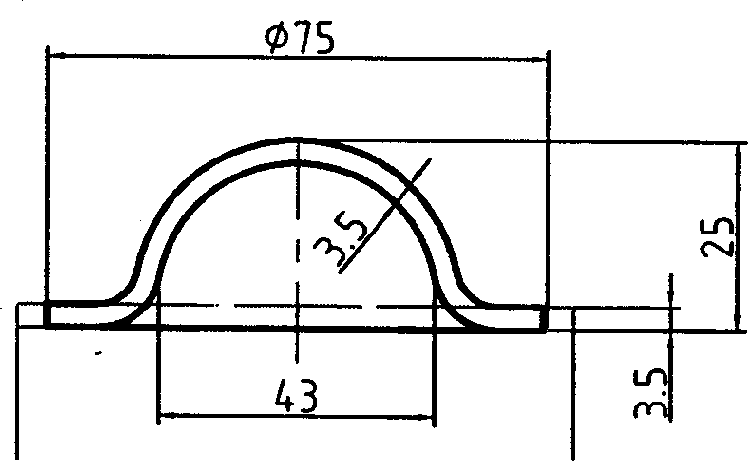

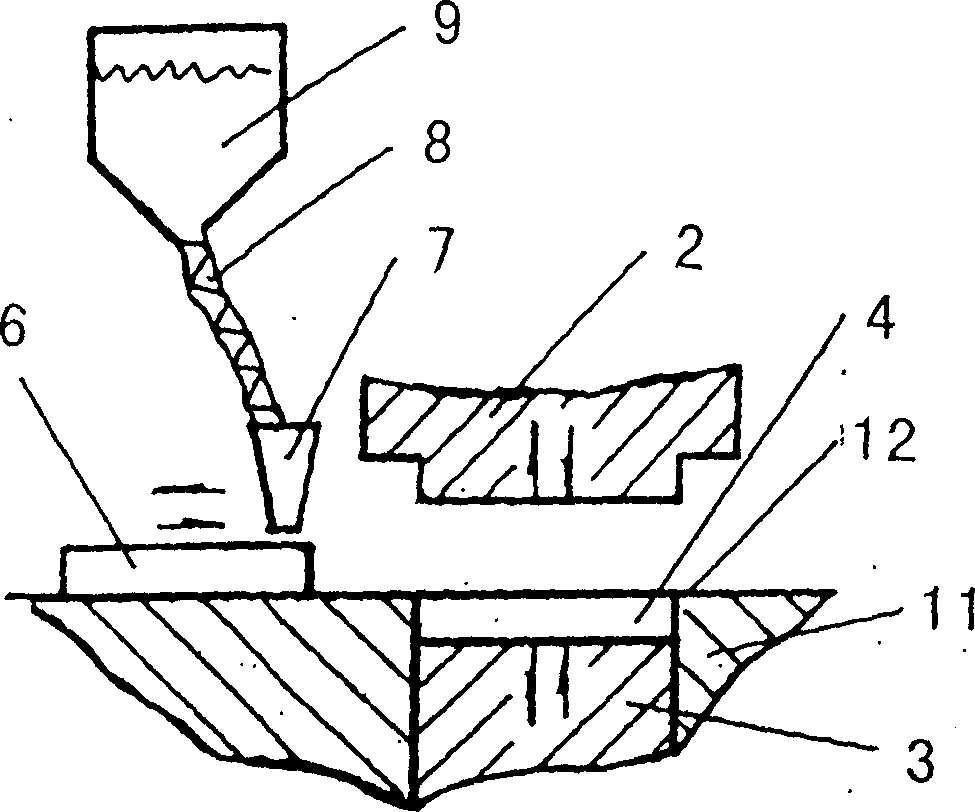

Method for processing panel into protuberant drum wall-thickening part by utilizing stamping process

The invention provides a method for using punch technique to process the plate into wall-thickened work-piece. Via pre-molding the plate of work-piece into protruded shape, the differential volume is equal to the protruded part; using concave and protruding moulds to punch and shorten diameter of protruding part to make the height of work-piece equal to the pre-molded height; using one group of concave moulds whose diameters are constant-height continuous arranged to punch the outer diameter of protruding part and shorten the diameter of protruding part, therefore, the outer diameter of protruding part is the diameter of protruding cylinder of final product; using composite mould with expanding diameter and molding functions to make the diameter to the inner diameter of cylinder and compressing molding to reach the height of final product to attain the final product. The invention can solve the defects of present technique and integrate the plate chassis and the protruding cylinder, to confirm the strength demand of work-piece when in working, and improve service life of work-piece.

Owner:夏勤三

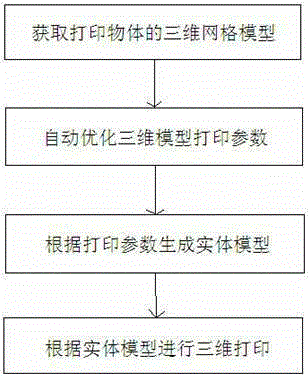

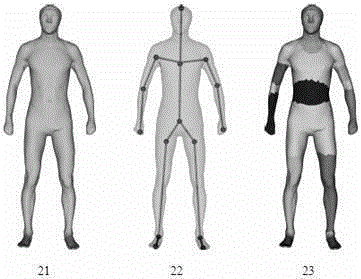

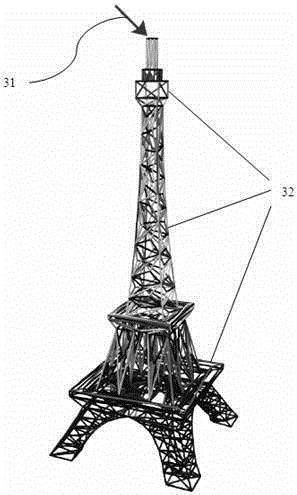

Three-dimensional printed object structure optimizing algorithm based on stress analysis

ActiveCN105204791AWarranty Strength RequirementsHigh strengthDigital output to print unitsStress minimizationObject structure

The invention discloses a three-dimensional printed object structure optimizing algorithm based on stress analysis. The algorithm comprises steps as follows: a three-dimensional network model of a printed object is acquired, and a user sets force distribution and printed material size constraints; printing parameters of the three-dimensional model are optimized automatically, a heterogeneous frame structure is generated automatically through input by the user, and initial parameters are determined and optimized; a solid model is generated according to optimized printing parameters; three-dimensional printing is performed on the generated solid model, and a three-dimensional printing model is established with physical properties of a printed material, printing conditions and material sizes of the printed object used as constraints and stress minimization of the printing model used as the target. With the adoption of the algorithm, adaptive optimization of the scaling ratio and the number in a frame can be realized, the strength requirement for the object is guaranteed under the condition that the regulated material size is used, and besides, the model can be simplified; the strength of the printed object is improved through parameter optimization and the topology structure of the object is simplified.

Owner:GUANGDONG SANWEIJIA INFORMATION TECH CO LTD

Diving casting cast-in-place pile construction method for constructing in scree layer and sand layer

ActiveCN101196004AWarranty Strength RequirementsMeet strength requirementsBulkheads/pilesSlurry wallImmersed tube

The invention relates to a construction method for an immersed tube compaction cast-in-place concrete pile in the construction in a pebble bed, a puddingstone bed, a sand bed, and a strong weathered mudstone. Double casing pipes are hammered, simultaneously, the inner pipe is extracted from the stratum, then concrete is cast into the outer pipe, the inner pipe is positioned into the outer pipe and presses the surface of the concrete, then the outer pipe is pulled up at uniform speed, and the formation of the cast-in-place concrete pile is completed. Earth is not carried out when the hole is formed, therefore the degree of compaction of the earth among the piles is greatly enhanced, simultaneously, when the pile body concrete is cast, no hole collapse phenomenon of the outer pipe appears in the hole, even slurry wall protection is not required to be adopted, in addition, no bottom settlings exists at the bottom of the pile, thereby the characteristic that the bearing capacity of a single pile is high is ensured, and the invention has the advantages of no pollution on site and quick construction speed.

Owner:刘清洁

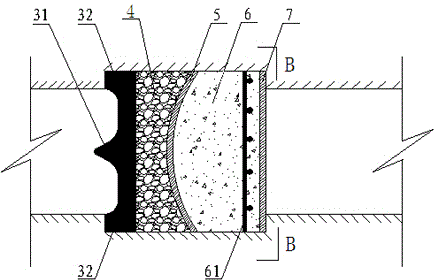

Mining cambered anti-impact sealing wall and construction method of mining cambered anti-impact sealing wall

InactiveCN104314614AKinetic energy offsetReduce shockMining devicesUnderground chambersEngineeringTunnel wall

The invention relates to a mining cambered anti-impact sealing wall. Before the wall is manufactured, a slot is formed in a position where a tunnel is needed to be sealed; the slot is continuously distributed along left and right tunnel walls of the tunnel, a top plate and a bottom plate; the slot is 500 mm in depth and 500-800 mm in width. According to a direction where air billows come, the mining cambered anti-impact sealing wall comprises a stream guide layer, a filling layer, a cambered steel plate layer, a concrete sealing wall and a plane steel plate layer from inside to outside in sequence, wherein each layer reaches to the slotting borders of the left and right tunnel walls, the top plate and the bottom plate.

Owner:SHANDONG UNIV OF SCI & TECH

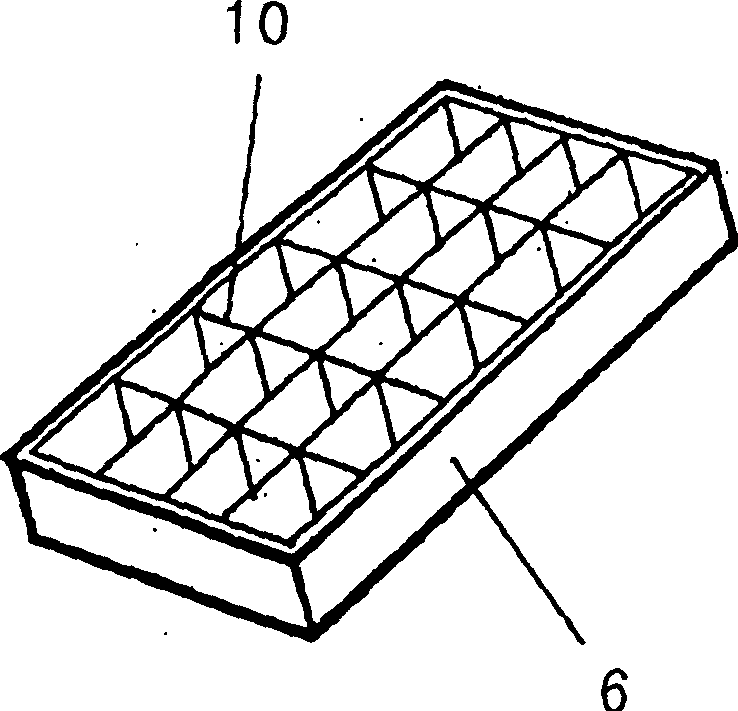

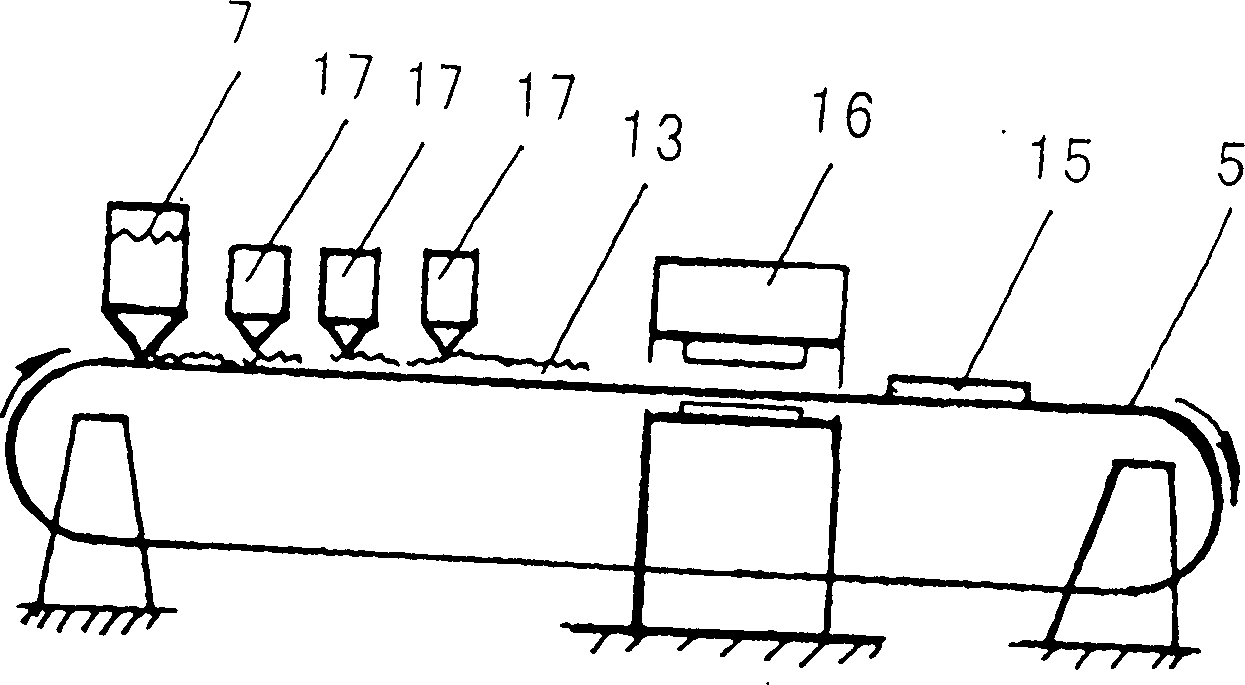

Ceramic tile forming equipment and forming method

InactiveCN1511688ARegular shapeReduce cutting processShaping conveyorsCeramic tilesMaterials science

The present invention is ceramic tile forming equipment and method. The equipment has material feeder to feed material to the belt conveyer; press with upper and lower punching heads; belt conveyer set between the upper and the lower punching heads; and sliding mold frame of rigid material set between the upper and the lower punching heads. The sliding mold frame may be made to move in the axial direction of the punching heads. The present invention makes it possible to produce ceramic tiles of different thickness for different decoration methods.

Owner:佛山市灵海陶瓷科技有限公司

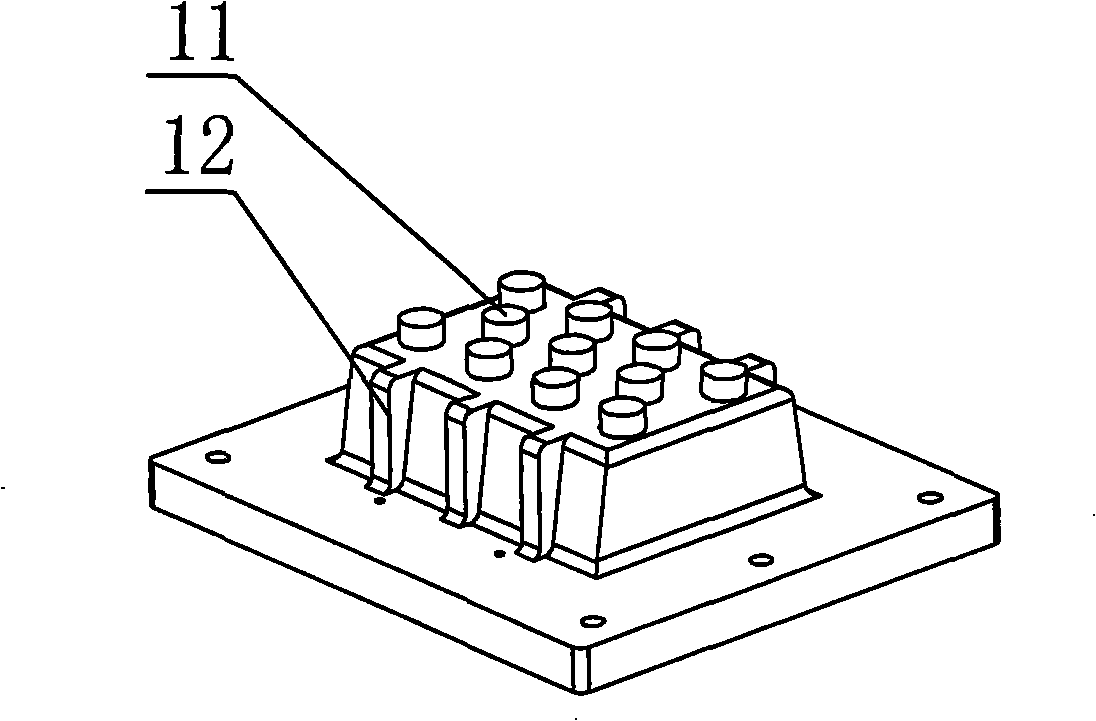

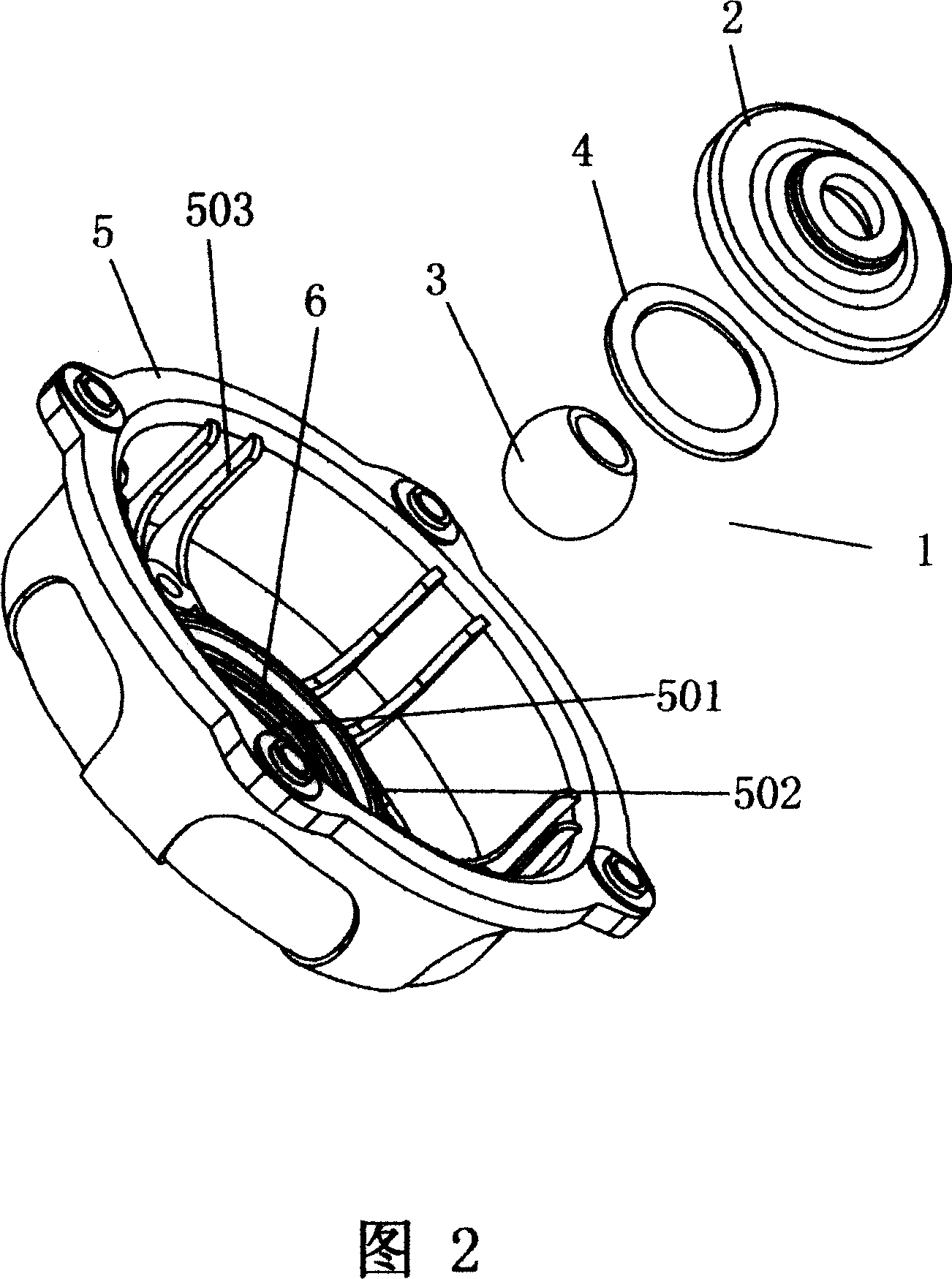

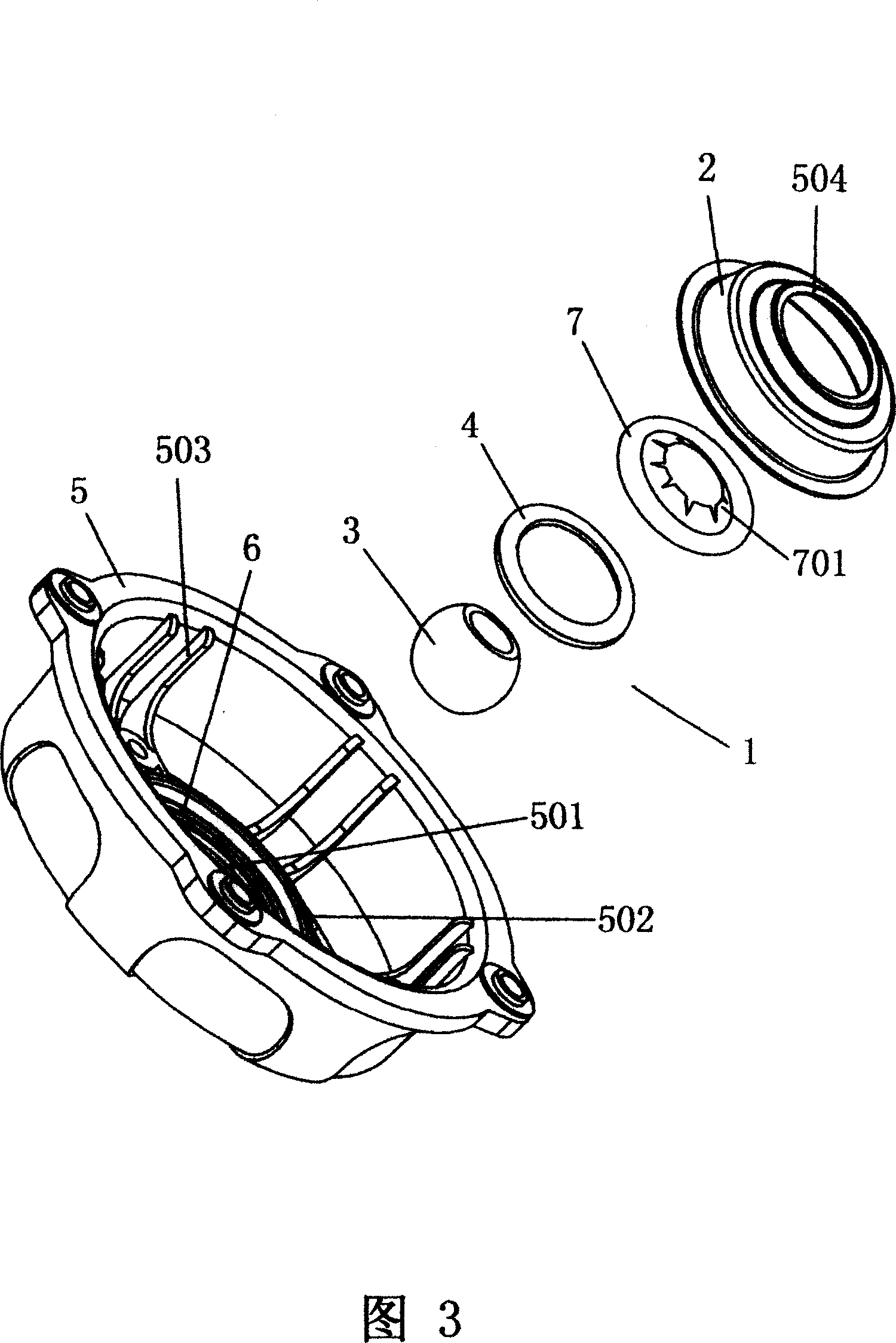

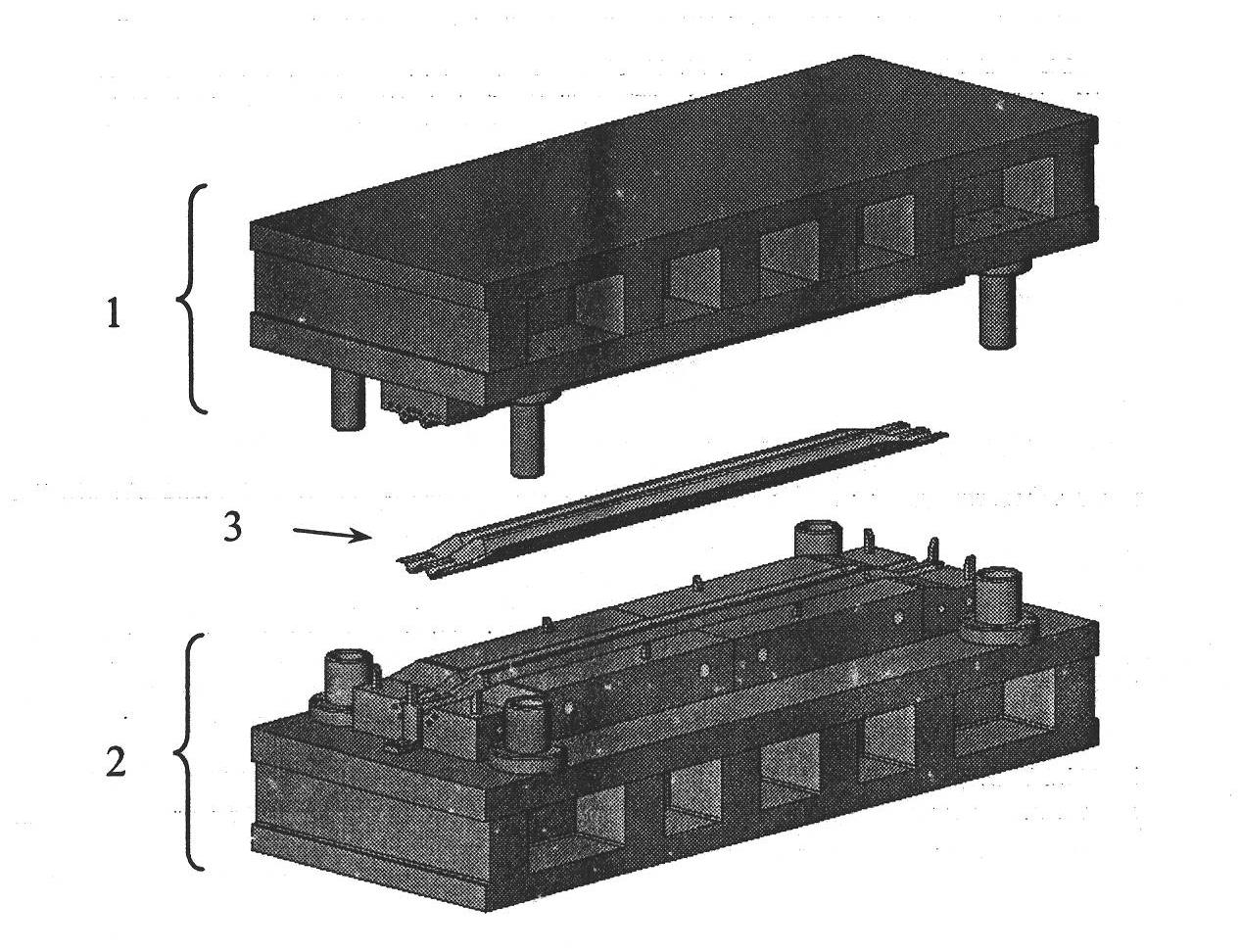

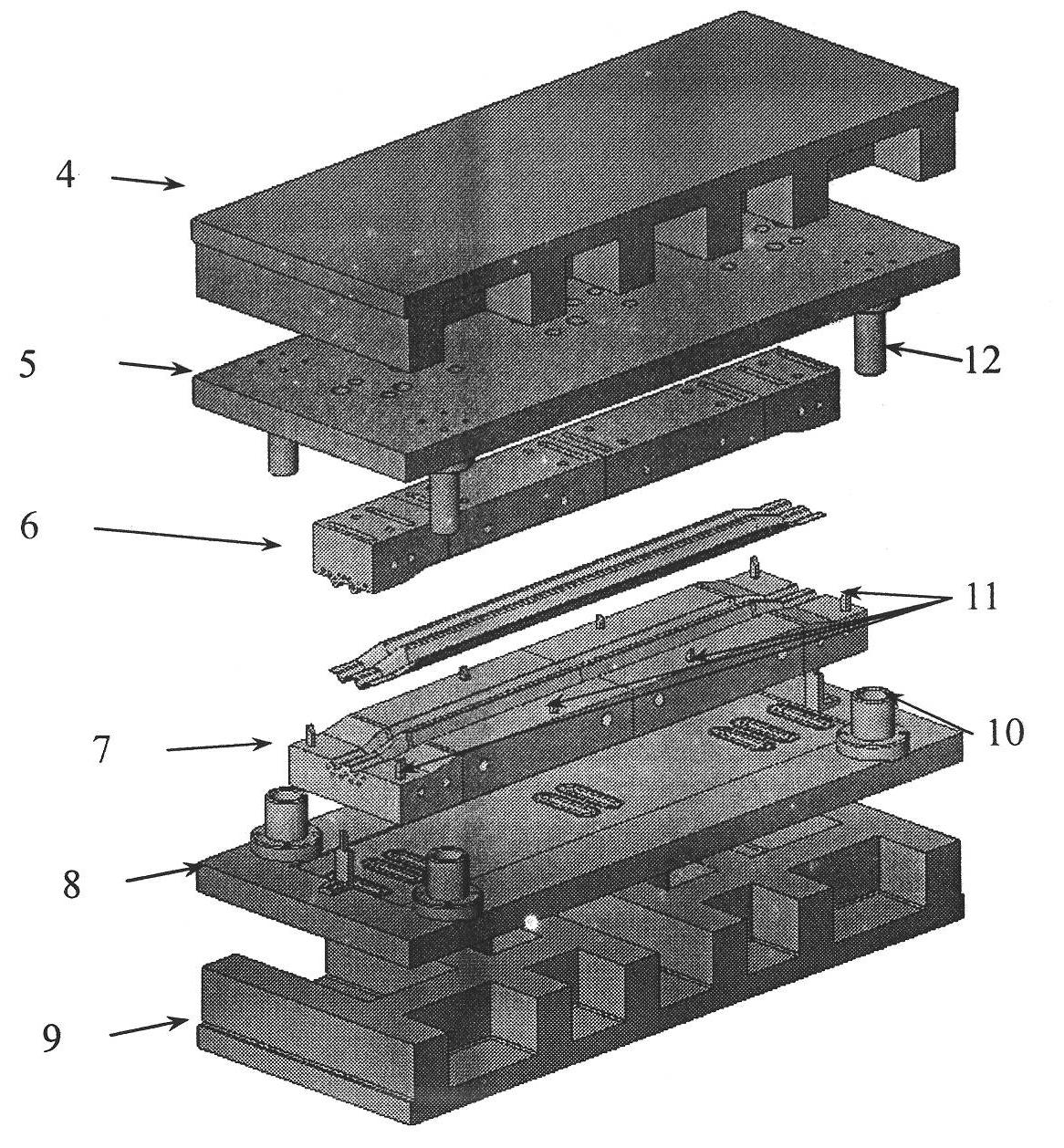

Ultra-high strength steel hot-stamping die for car door anticollision beam

InactiveCN101972814AHigh strengthReduce weightShaping toolsLoad-supporting pillarsHot stampingEngineering

The invention provides a hot-stamping die for an anticollision beam, comprising an upper die and a lower die, wherein the upper and lower dies mainly comprise combined convex / concave dies, cooling systems and a cooling seal ring. The blocks of the combined convex / concave dies avoid the corners and are staggered relatively. The cooling systems adopt drill holes, wherein the diameter of the holes is 8-30mm and the peaks of the holes are 3-10mm distant from the profiles; the two ends of the holes are sealed after hole drilling; runway type water troughs are processed near the places where the block dies are 10-50mm distant from the two end faces; the cooling water enters from one water trough and flows out of the other water trough; and seal grooves are arranged on the cooling water troughs and the cooling water troughs are provided with the seal ring and are externally connected with cooling water pipes.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Method for preparing silicon carbide honeycomb ceramics

ActiveCN102503533AImprove temperature conditionsLower sintering temperatureCeramicwarePolyvinyl alcoholHoneycomb

The invention discloses a method for preparing silicon carbide honeycomb ceramics. The method comprises the following steps of: 1) mixing bamboo charcoal micro-powder, silica sol, aluminum oxide, yttrium oxide and organic matter starch at a weight ratio of 70: 20: (1-5): (1-5): (1-8), so as to obtain honeycomb ceramics powder; 2) mixing and pugging: mixing water, polyvinyl alcohol and polyhydroxyethanol according to a weight ratio of 70: (10-20): (10-20), and uniformly stirring the components to obtain a solution; and mixing the solution with the honeycomb ceramics powder according to a weight ratio of 100: (65-80), fully mixing the mixture in a mixing machine at a normal pressure and temperature for 0.5-1 hour, and then aging the mixture at the normal pressure and temperature for 2-3 hours, so as to obtain slurry material; 3) carrying out extrusion molding; 4) drying; and 5) sintering. The silicon carbide honeycomb ceramics produced by the preparation method disclosed by the invention has the characteristics of controllable holes, high specific surface area, intensity meeting requirements, and the like.

Owner:ZHEJIANG UNIV

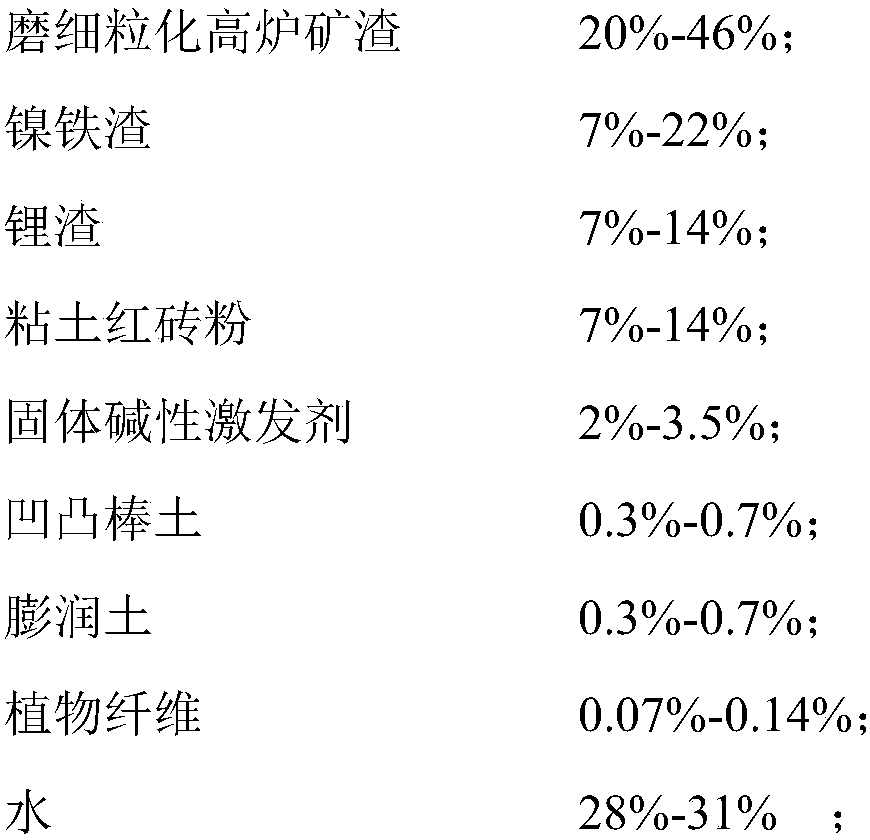

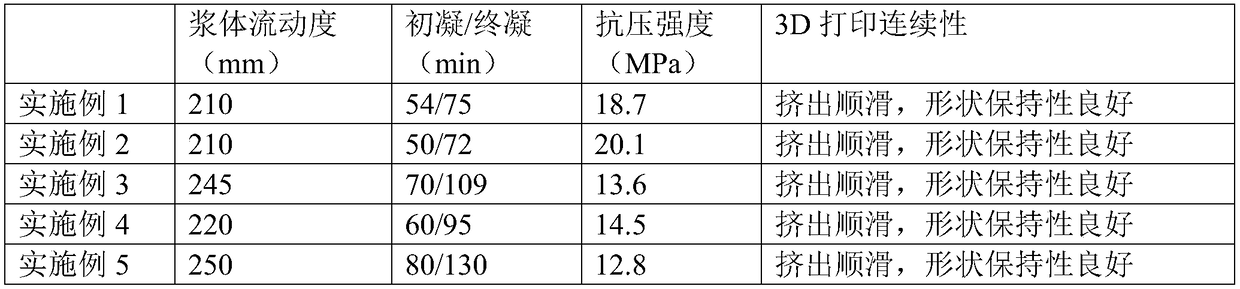

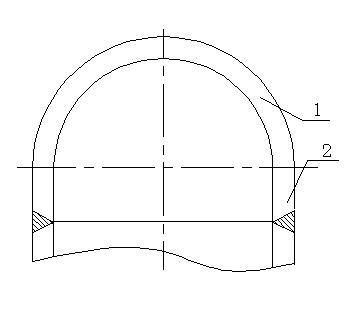

Alkali-activated cementitious material for 3D printing

InactiveCN109336475AStrength mentionedMeet the printing process requirementsAdditive manufacturing apparatusFiberLithium

The invention discloses a novel alkali-activated cementitious material for 3D printing. The novel alkali-activated cementitious material for the 3D printing is prepared from following raw materials inpercentage by weight: 20%-46% of ground granulated blast furnace slag, 7%-22% of nickel iron slag, 7%-14% of lithium slag, 7%-14% of red brick powder, 2%-3.5% of a solid alkali activator, 0.3%-0.7% of attapulgite, 0.3%-0.7% of bentonite, 0.07%-0.14% of plant fiber and 28%-31% of water. The novel alkali-activated cementitious material for the 3D printing has good workability, has good cohesive property and high stability due to the characteristics of quick setting, rapid hardening and early strength and completely meets the material performance requirement of the 3D printing technology.

Owner:SOUTHEAST UNIV

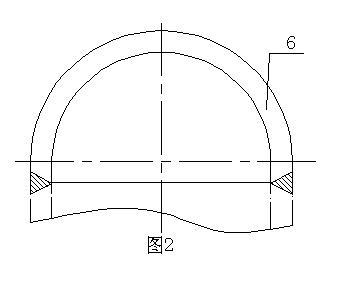

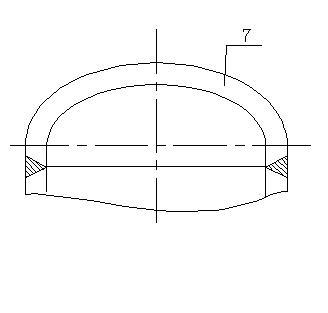

Reusable welded hydraulic cover of boiler and pressure vessel and manufacturing method of reusable welded hydraulic cover

ActiveCN102155538AIncrease material consumptionReduce utilizationPressure vesselsSingle useSteel plates

The invention discloses a reusable welded hydraulic cover of a boiler and a pressure vessel and a manufacturing method of the reusable welded hydraulic cover. In a hydraulic test in the conventional product factory for the boiler and the pressure vessel, the hydraulic cover which is formed by assembled welding of large-diameter welding pipes of a welding groove on a construction site serves as a welding temporary pressed element; the hydraulic cover is generally formed by oxygen-acetylene cutting of a steel plate; the stressed condition of a flat welding structure of the steel plate is poor; and the steel plate is thick and heavy and usually disposable so as to cause great waste. The welded hydraulic cover of the boiler and the pressure vessel comprises a cover (1), wherein hydraulic allowance (2) is formed at the lower end of the cover. The invention is applied to manufacturing of the boiler and the pressure vessel.

Owner:HARBIN BOILER

Oil bushing steel and manufacturing process thereof

ActiveCN101153373AImprove hardenabilityImprove toughnessTemperature control deviceHeat treatment process controlChemical compositionHeating furnace

The invention relates to an oil bushing steel and the manufacturing process thereof, wherein, the chemical composition of the steel is as follows: 0.28wt percent to 0.35wt percent of C, 0.1wt percent to 0.4wt percent of Si, 0.8wt percent to 1.6wt percent of Mn, 0.4wt percent to 0.6wt percent of Mo, 0.8wt percent to 1.2wt percent of Cr, 0.05wt percent to 0.10wt percent of V, less than or equal to 0.005wt percent of S, 0.01wt percent to 0.04wt percent of Al and the rest, Fe and other inevitable impurities; the manufacturing process of the steel is as follows: the tube blank made by continuous casting or continuous rolling is perforated by a perforator after heating in a heating furnace and is under tube rolling under 950 DEG C to 1,050 DEG C; the tube blank is fed into a reheating furnace after releasing from a rod and then is fed into a tension-reducing mill or a stretcher after holding under 800 DEG C to 1,000 DEG C for air cooling after rolling; finally, after holding under 860 DEG C to 1,000 DEG C and quenching, the tube blank is under tempering under 600 DEG C to 660 DEG C holding to be made into production tube. The steel has excellent hardenability and higher structural stability and can ensure that an oil well oil bushing not only can obtain 1,000MPa to 1,200MPa yield strength, but also can meet the requirements of more than 70J transverse ballistic work and more than 90J ballistic work.

Owner:BAOSHAN IRON & STEEL CO LTD

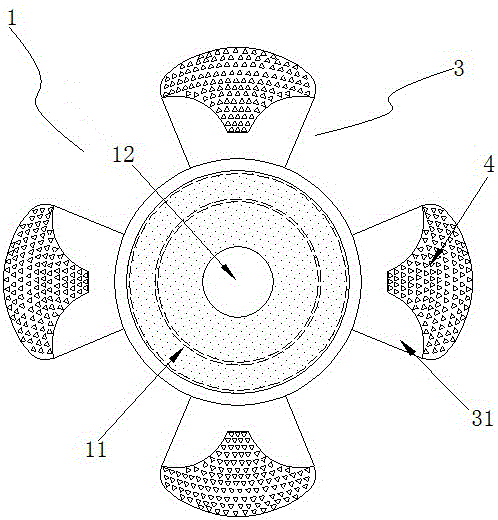

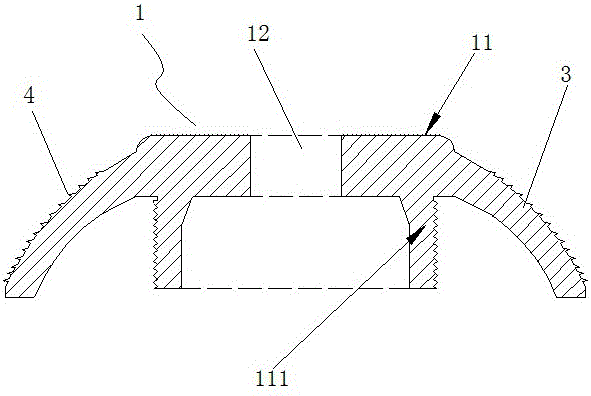

Gun hole charging and plugging device

The invention discloses a gun hole charging and plugging device which comprises a disc and a head rod detachably connected with the disc. The disc comprises a tray, fins and a center through hole. The fins are arranged in the mode of surrounding the outer wall of the tray and have elasticity and toughness, and the center through hole is formed in the center of the tray. The fins can be inserted into a gun hole, and the outer diameter of the fins is larger than that of the gun hole. The fins are provided with anti-skid structures capable of being clamped and fixed to the wall of the gun hole. The bottom of the tray is provided with a connection port in butt connection with the head rod. The problem that a cartridged explosive slides when being charged into an upward hole is effectively solved, the non-coupling charging structure is actually achieved, interval charging can be achieved, accordingly, the oversized fragment output rate is effectively reduced, blasting vibration is reduced, and safety and stability of sinking and driving engineering are maintained. In addition, the explosive consumed cost is reduced, the workload of workers is reduced, and the device plays a quite important role in developing enterprises, reducing the operation cost and improving productivity.

Owner:湖南华楚项目管理有限公司

Processing method for engineering machinery wheel assembly

The machining process of engineering machinery wheel assembly includes the following steps: cutting strip material in the width of even number times the required assembly width; rolling to form the required sizes and shape; rounding to form cylinder; butt welding; and cutting to form even number assemblies. The symmetrical machining process has balanced outer forces, no torque and good forming effect as well as high production efficiency and low cost, and is especially suitable for mass production.

Owner:张振寰

Offshore platform hydraulic self-lifting device

ActiveCN103469777AQuick lockAvoid shockArtificial islandsUnderwater structuresHydraulic cylinderStructural engineering

The invention discloses an offshore platform hydraulic self-lifting device which comprises an upper support, a lower support, a sleeve assembly, a body, support body and a hydraulic system. The sleeve assembly comprises a sleeve. A plurality rows of circular holes are axially formed on the wall of the sleeve. Each row of circular holes comprises two symmetrical circular holes. At least two keyways are axially formed on the inner wall of the sleeve. The top of the sleeve is connected with the upper support. The body comprises a base pipe nested into a cavity of the sleeve. At least two guide grooves are formed on the outer wall of the base pipe. Wire guide grooves matched with the keyways can slide along the guide grooves. The bottom of the base pipe is connected with the lower support. The support body comprises a base block disposed on the upper portion of the base pipe and two support pins. The base blocks disposed in a cavity of the base pipe is connected with the base pipe. The support pins are connected with the base blocks. The pin bodies of the support pin penetrate the base pipe to be matched with the circular holes of the sleeve. The hydraulic system comprises at least two symmetric hydraulic cylinders which are connected to a main oil pump through multi-path reversing valves. The bottom of each hydraulic cylinder is connected with the lower support, and the top thereof is connected with the upper support.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Ship-based heavy stabilizing platform

ActiveCN103760811AImprove carrying capacityHigh stability and precisionNumerical controlControl theoryEngineering

The invention belongs to the field of machinery manufacturing, and relates to a ship-based heavy stabilizing platform, in particular to structural design of stabilizing platforms with the load being more than 250 kg. The ship-based heavy stabilizing platform comprises a main support, an installation platform, an inner frame, a rolling servo gear motor, a servo control box, a pitching servo gear motor, a spinning top plate, a spinning top A, a spinning top B, an angle sensor A, an angle sensor B, an inclination angle sensor, an inner ring shaft A, an inner ring shaft B, an inner ring gear, an inner ring servo motor gear, an outer ring shaft, a gear shaft, an outer ring servo motor gear and a motor support. The ship-based heavy stabilizing platform has the advantages of being high in bearing capacity, high in stabilizing precision and quick in response. The ship-based heavy stabilizing platform can realize stabilization without a counter weight. Due to the fact that the ship-based heavy stabilizing platform is provided with the inclination angle sensor, drift generated by the spinning tops can be corrected in appropriate time, and the stabilizing precision can be improved.

Owner:HEBEI HANGUANG HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com