Patents

Literature

120results about How to "Reduce blasting vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

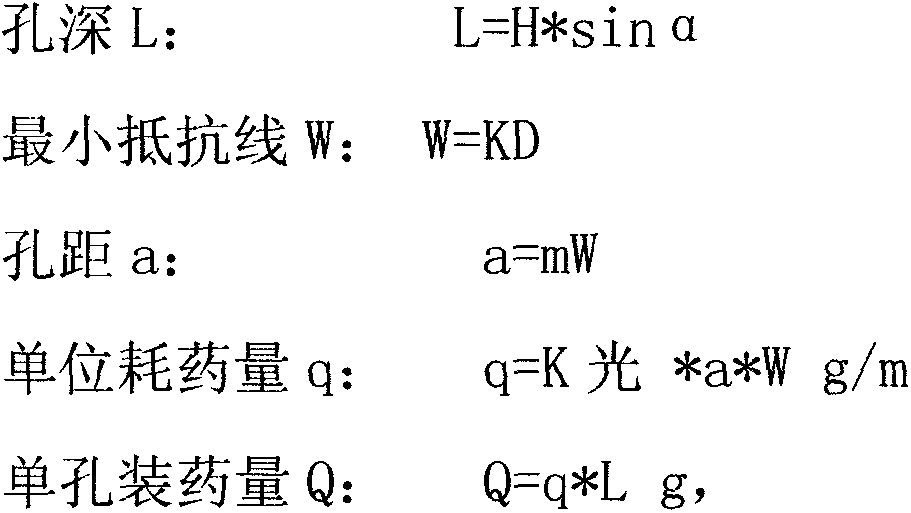

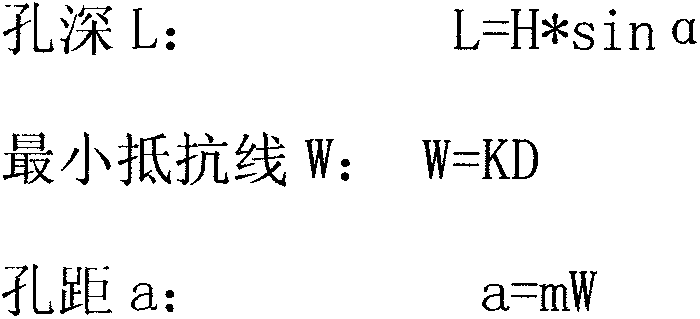

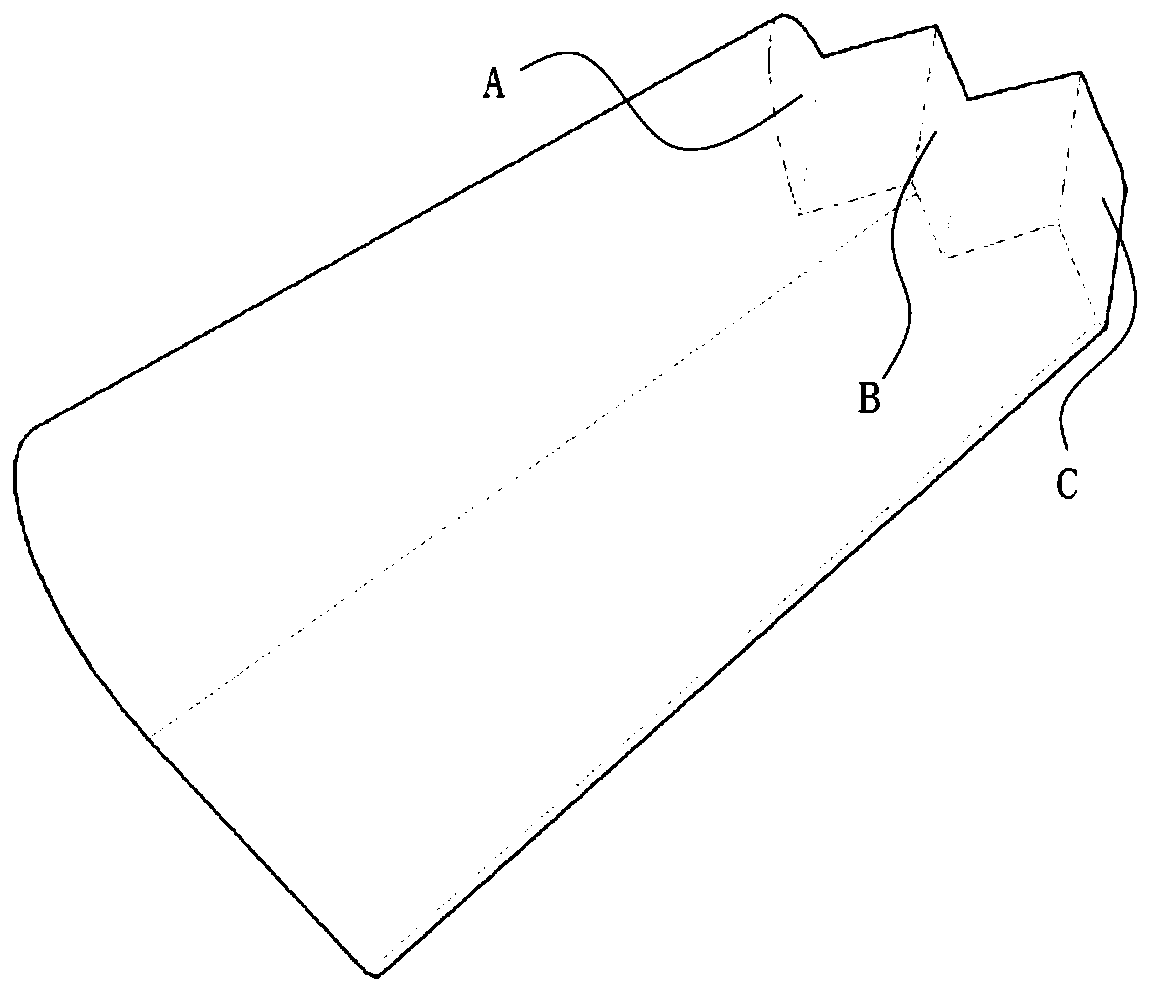

Multi-row micro-differential roadbed deep hole blasting construction method

The invention relates to a multi-row micro-differential roadbed deep hole blasting construction method, which comprises the following steps of: (1) selecting blasting parameters; (2) calculating security; (3) arranging a stair and a free face; (4) distributing holes and drilling holes; and (5) blasting. The blasting method is a multi-row deep hole millisecond micro-differential blasting method; and the blasting is performed by pull trough blasting and side slope blasting in a roadbed sequentially, wherein the pull trough blasting is loose blasting and the side slope blasting is precraking blasting. In the method, a shock conducting tube non-electric priming system micro-differential control blasting technology, a comprehensive blasting construction scheme of loose blasting, the deep hole millisecond micro-differential blasting technology and the roadbed side slope precraking blasting technology, and a wide-pitch and low-resistance hole distribution mode are adopted, so that explosivesand detonators are saved, the drilling mechanization degree is enhanced, the labor cost is reduced, the blasting effect is enhanced, the large rate of blast rocks is reduced, the material abandoning rate is reduced and harms of blasting vibration, impact waves, flying stones and the like are reduced; furthermore, when the blasting effect is enhanced and the stability of the blast roadbed side slope rocks is guaranteed, the absolute safety of blasting can be guaranteed.

Owner:HUITONG ROAD & BRIDGE CONSTR GROUP

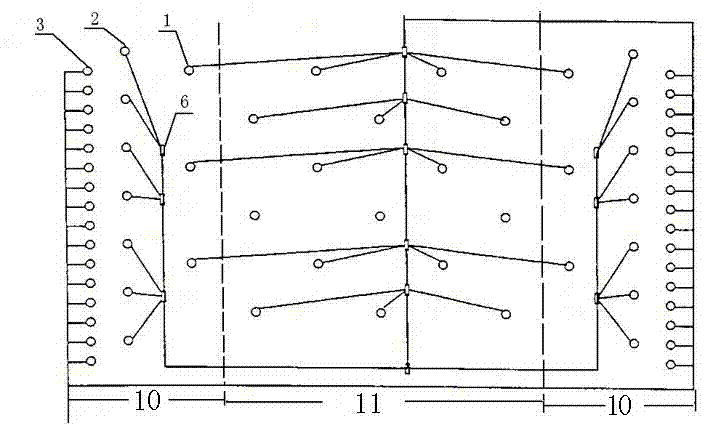

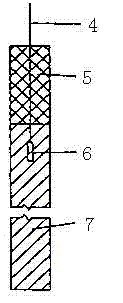

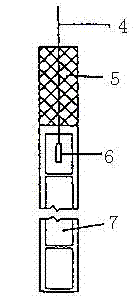

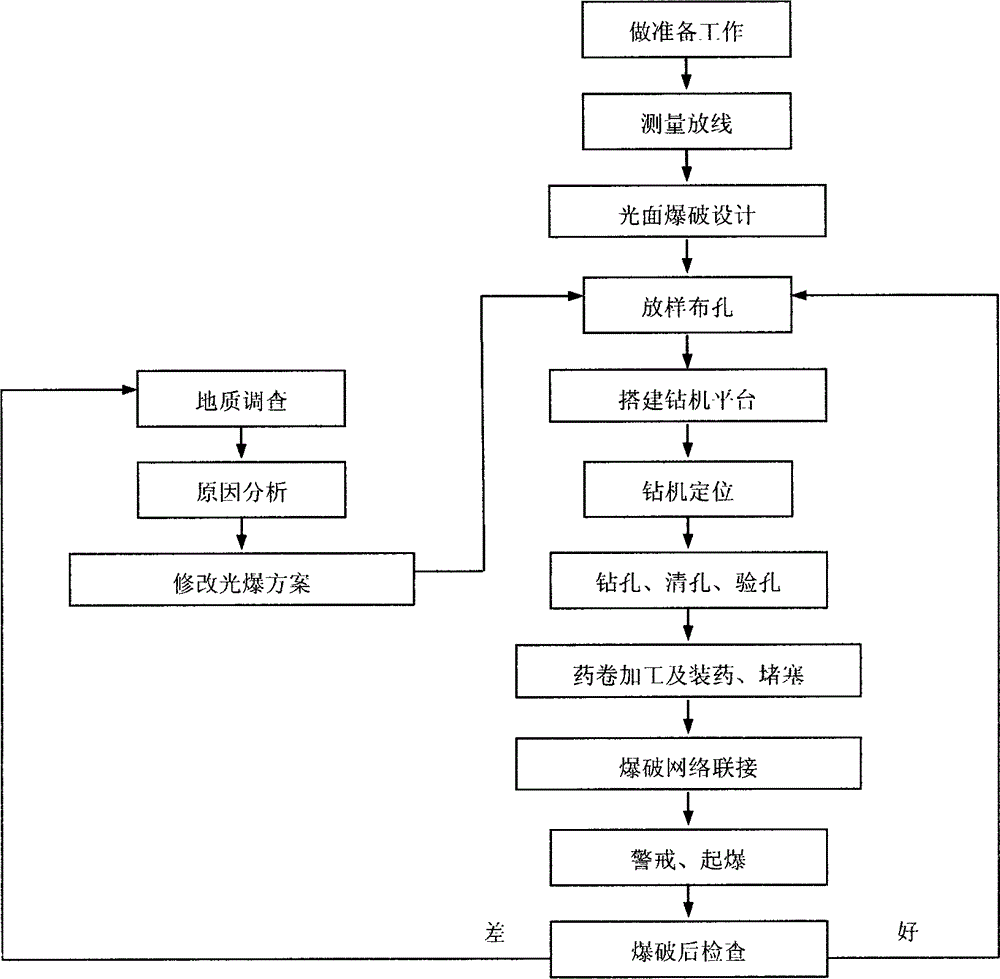

Side slope excavation smooth-surface blasting-method construction method

The invention discloses a side slope excavation smooth-surface blasting-method construction method. The side slope excavation smooth-surface blasting-method construction method comprises the steps of 1 researching a design drawing and geological information and cleaning a slope crest and the way leading to a mountain, 2 performing surveying and setting out, 3 designing smooth-surface blasting parameters, 4 performing setting out and hole arrangement, 5 establishing a drill machine platform and positioning the drill machine platform, 6 drilling holes, cleaning the holes and checking the holes, 7 performing cartridge processing and charging and blocking the top ends of the holes, 8 connecting a detonation network, 9 performing blasting and 10 performing checking after blasting. The side slope excavation smooth-surface blasting-method construction method is short in construction period, low in cost, high in efficiency, small in working amount, good in forming effect, high in safety and simple in construction.

Owner:浙江公铁建设工程有限公司

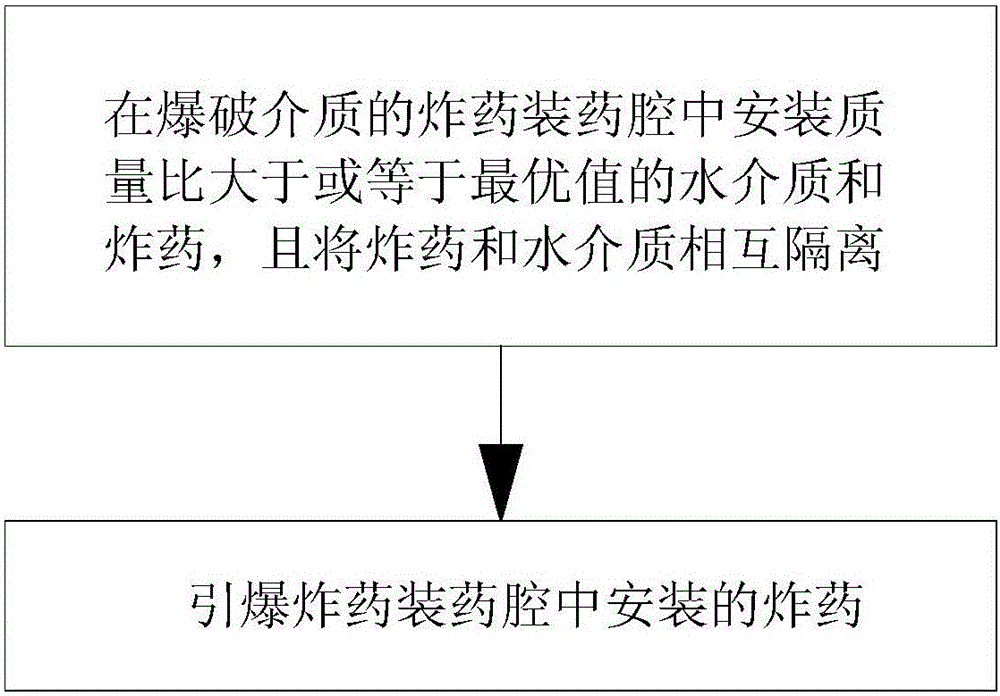

Aqueous medium energy transition blasting method and charging cavity

ActiveCN105674819ASolve the problem of insufficient effective utilization of energyAir Shock MitigationBlastingHydrogenMass ratio

The invention discloses an aqueous medium energy transition blasting method and charging cavity. The aqueous medium energy transition blasting method comprises the steps that firstly, an aqueous medium and explosives with the mass ratio larger than or equal to an optimal value are mounted in the explosive charging cavity of a blasting medium, and the explosives and the aqueous medium are isolated from each other; and then the explosives mounted in the explosive charging cavity are detonated. The aqueous medium and the explosives with the mass ratio larger than or equal to the optimal value M are mounted in the charging cavity, the explosives and the aqueous medium are isolated from each other, and the optimal value M is the ratio of explosion heat of the explosives adopted in the blasting process to heat energy released when water is synthesized by hydrogen and oxygen. The aqueous medium energy transition blasting method and charging cavity have the beneficial effects that the effective utilization rate of energy of the explosives can be increased, the blasting effect of the explosives on the blasting medium can be improved, blasting damage can be reduced, and blasting smoke is less.

Owner:秦健飞

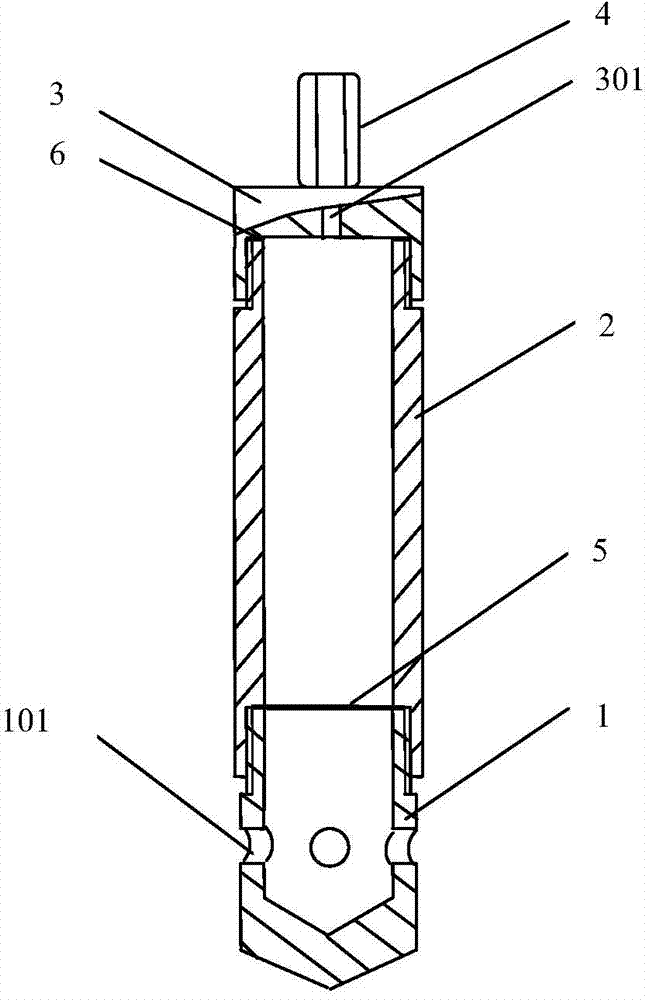

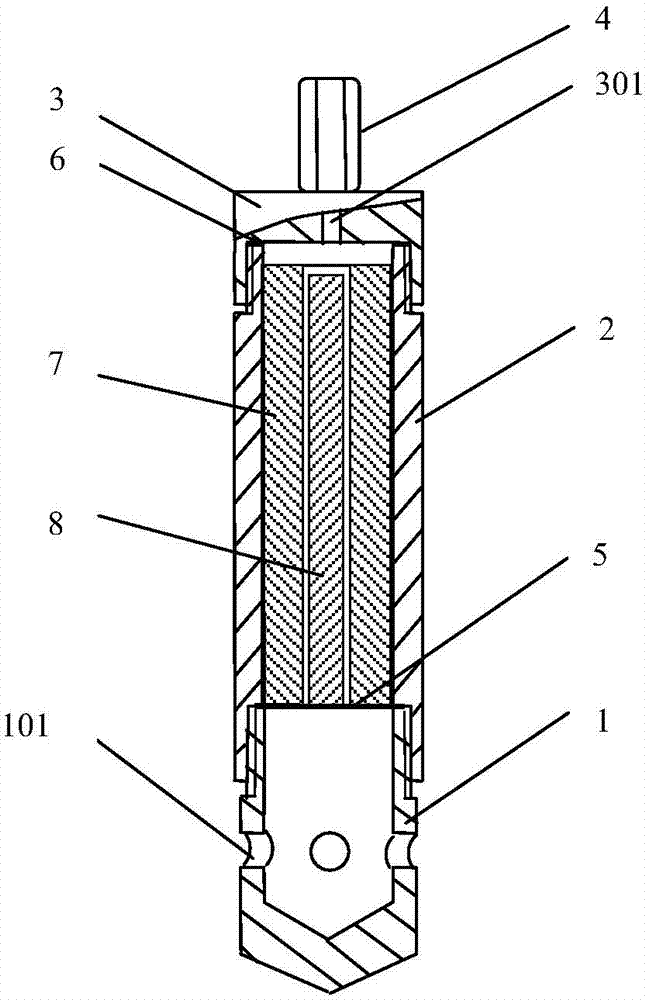

Dry ice blasting method and dry ice blasting device

InactiveCN104500068AOvercome potentially dangerous drawbacksWill not cause an explosionDisloding machinesUnderground miningToxic gasWater source

The invention relates to a dry ice blasting method and a dry ice blasting device, and belongs to the field of engineering blasting. The dry ice blasting device comprises a spray head, a cylinder body, a tail cover and a one-way valve, wherein the spray head is provided with an exhaust hole; the tail cover is provided with a water inlet hole; a sealing gasket is arranged between the cylinder body and the tail cover; a blasting sheet is arranged between the cylinder body and the spray head; and the tail cover is communicated with the one-way valve through the water inlet hole. The dry ice blasting method comprises the following steps: drilling in a coal bed; assembling the dry ice blasting device, and filling the dry ice blasting device with dry ice and a heating bag; connecting the dry ice blasting device with a water pipe, and placing into a blast hole; and communicating with a water source, and injecting water into the dry ice blasting device, wherein the heating bag inside the cylinder body fast releases heat when encountering water so as to urge the dry ice to be fast sublimated into carbon dioxide gas, when gas pressure exceeds the design pressure of the blasting sheet, the instant blasting of the blasting sheet is caused, and the carbon dioxide gas is fast discharged through the exhaust hole formed in the spray head to form impaction and expansion extrusion on the wall of the blast hole, so that the blasting is realized. The dry ice blasting method and the dry ice blasting device which are disclosed by the invention have the advantages of achieving the bursting at normal temperature, generating no flame or toxic gas and being suitable for a coal mine with gas and coal dust explosion risks.

Owner:CHINA UNIV OF MINING & TECH

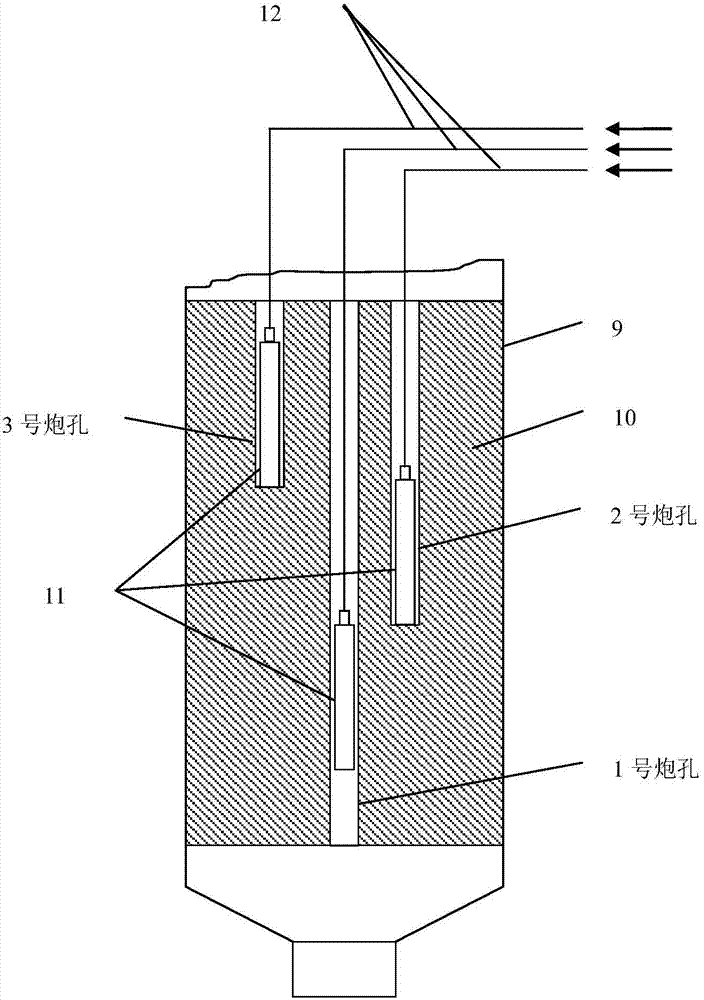

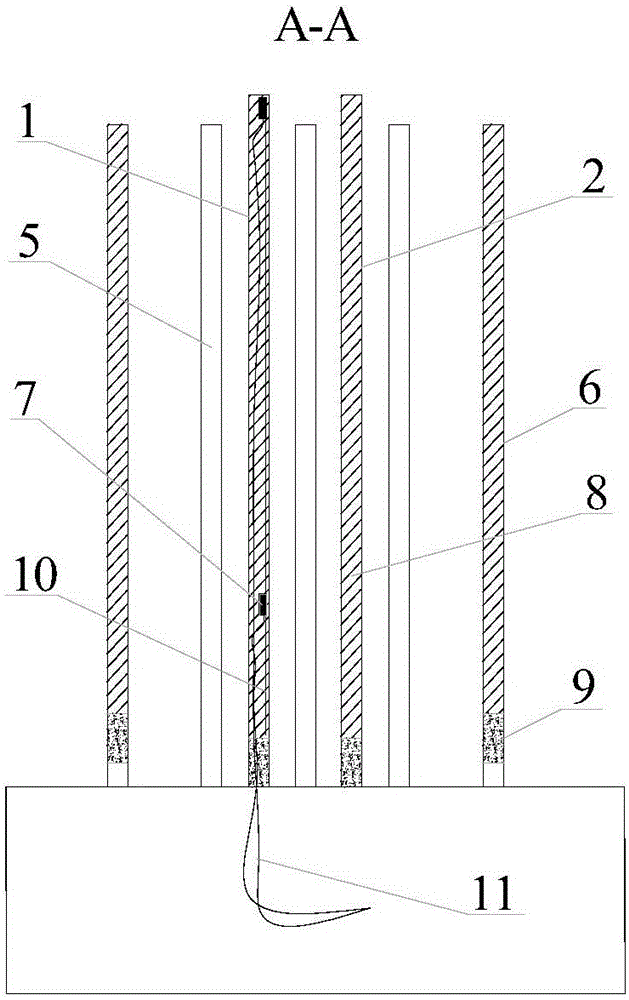

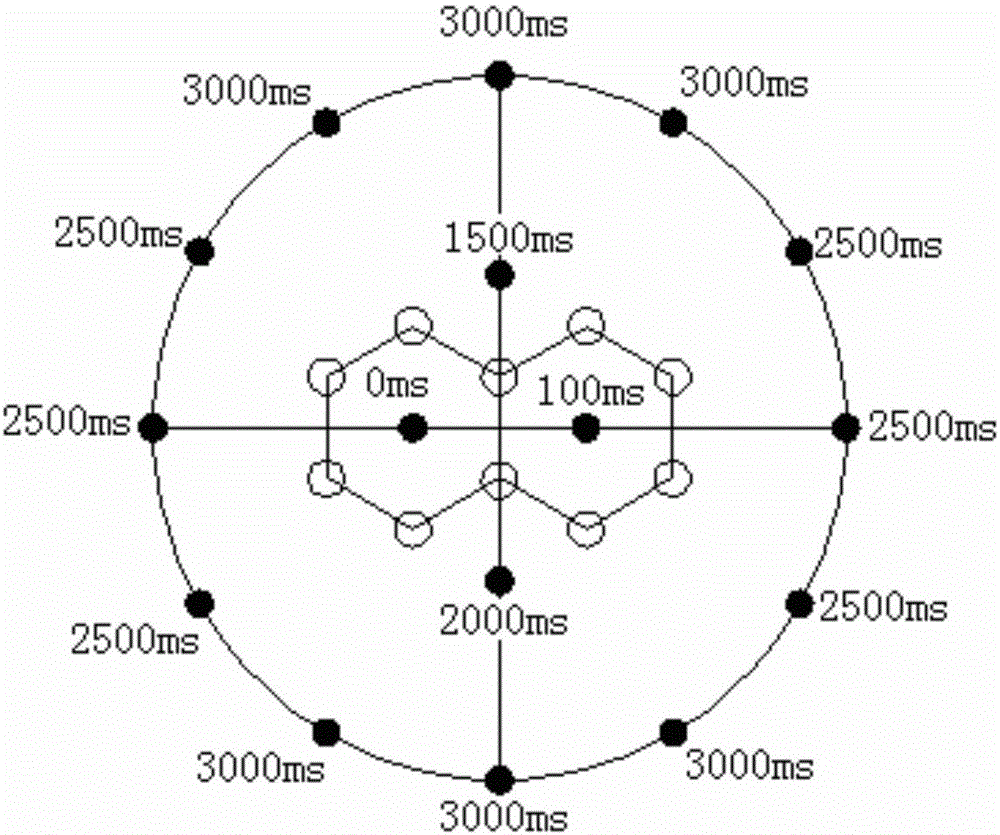

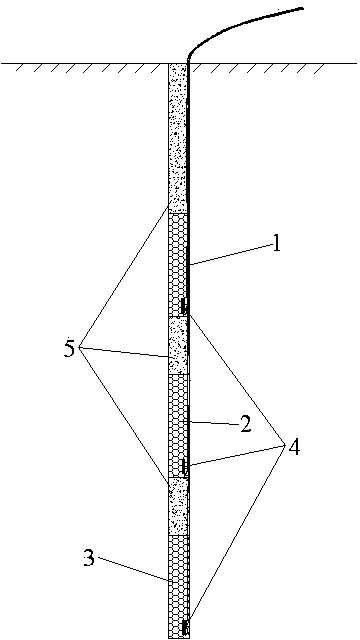

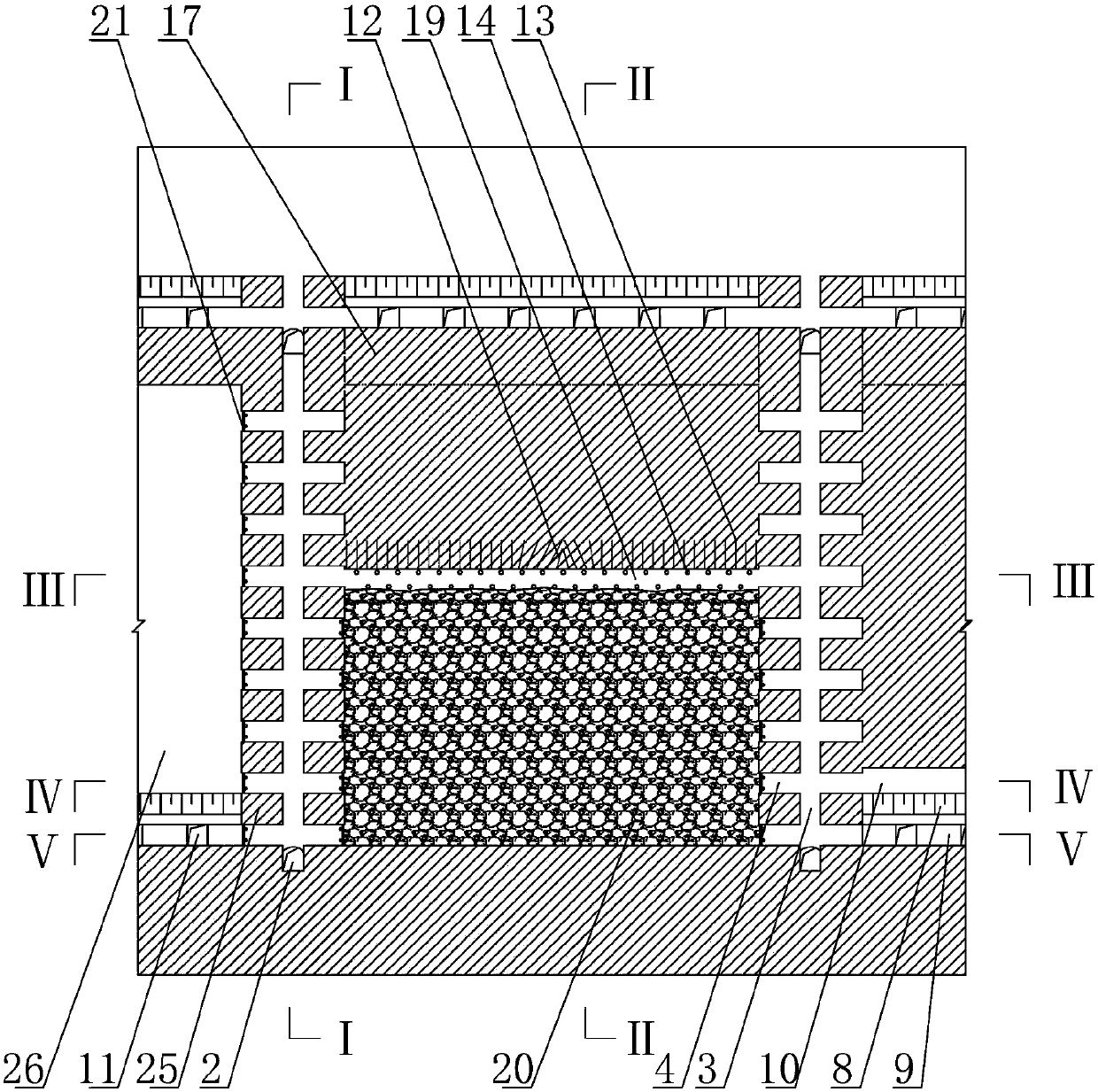

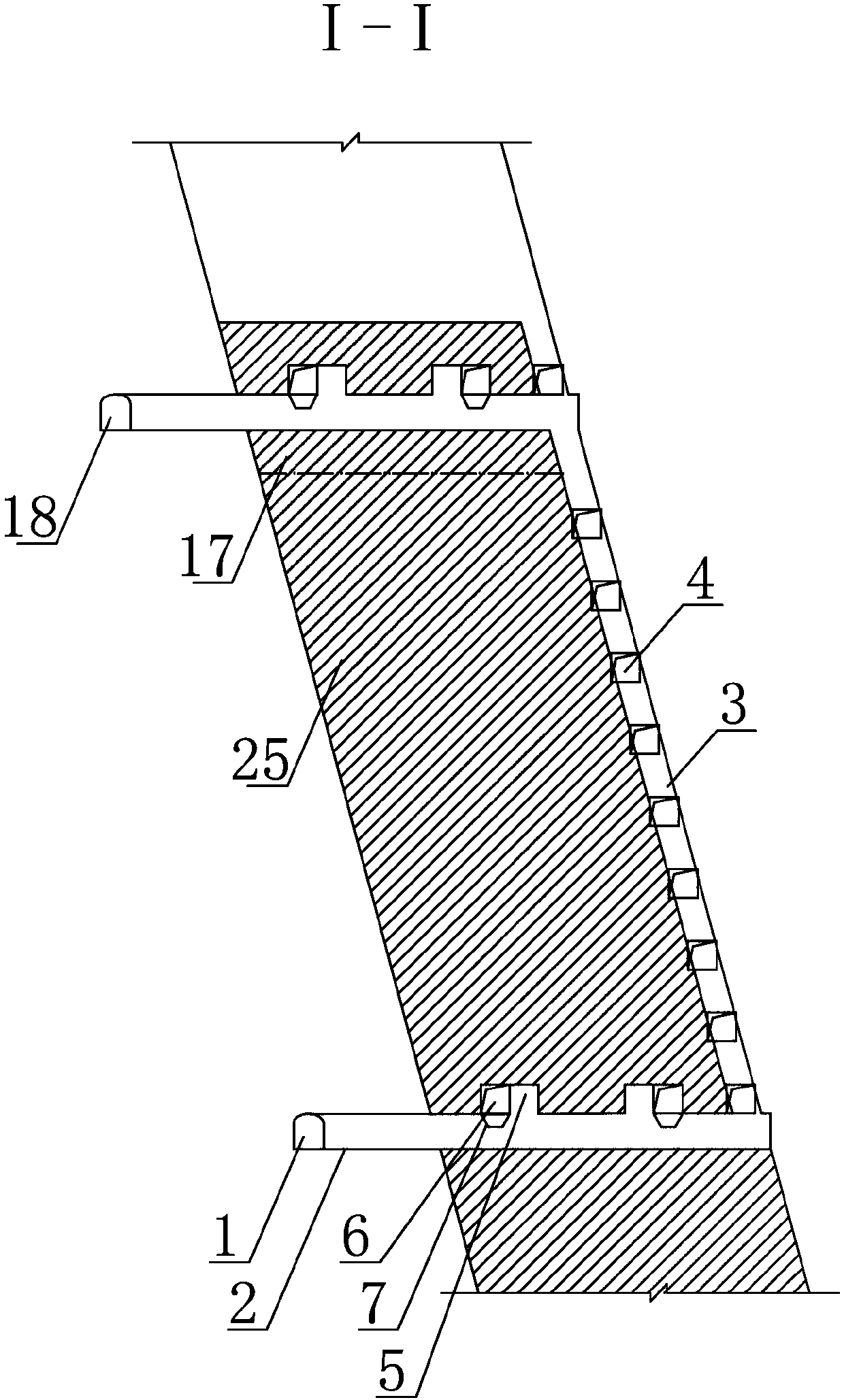

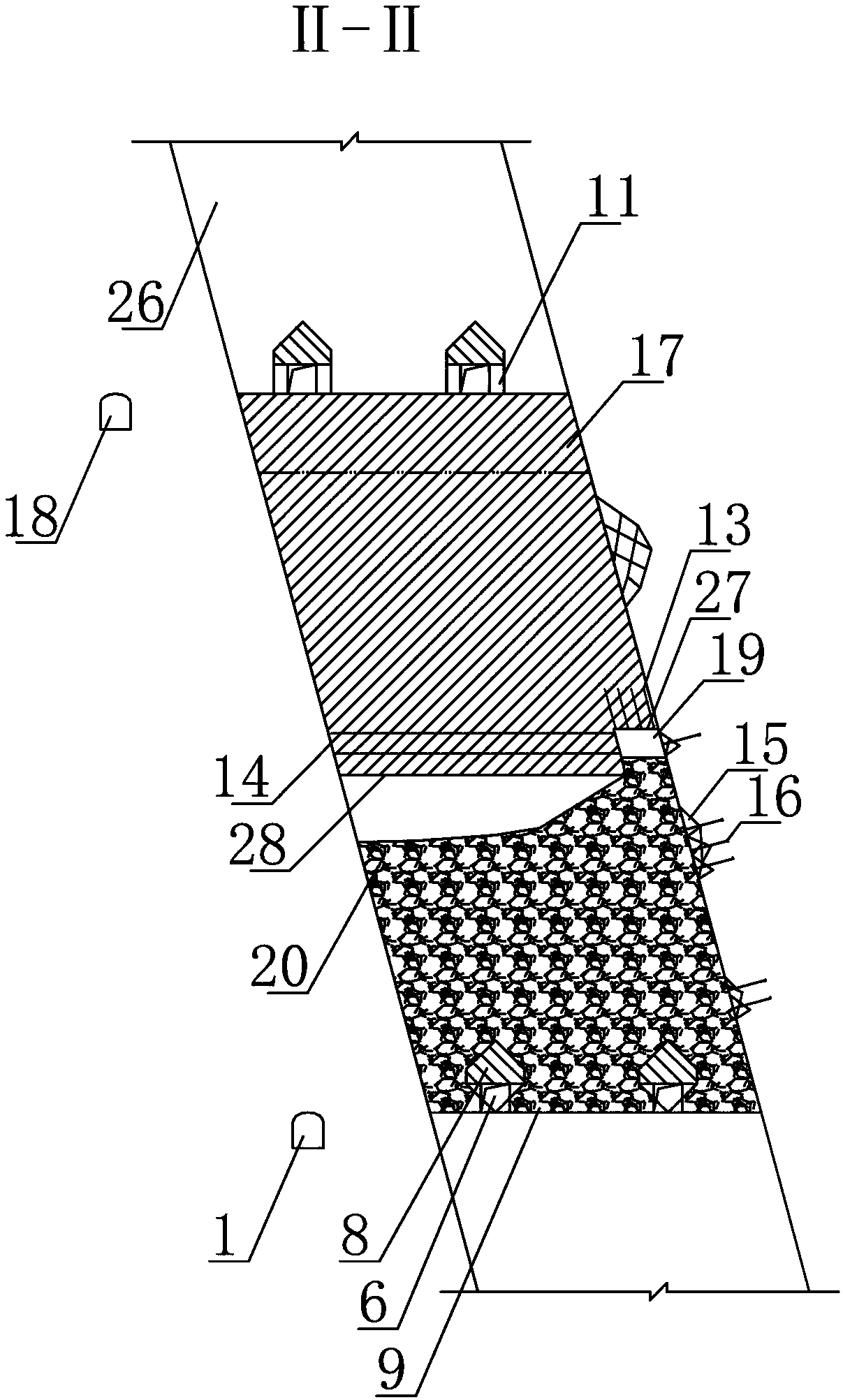

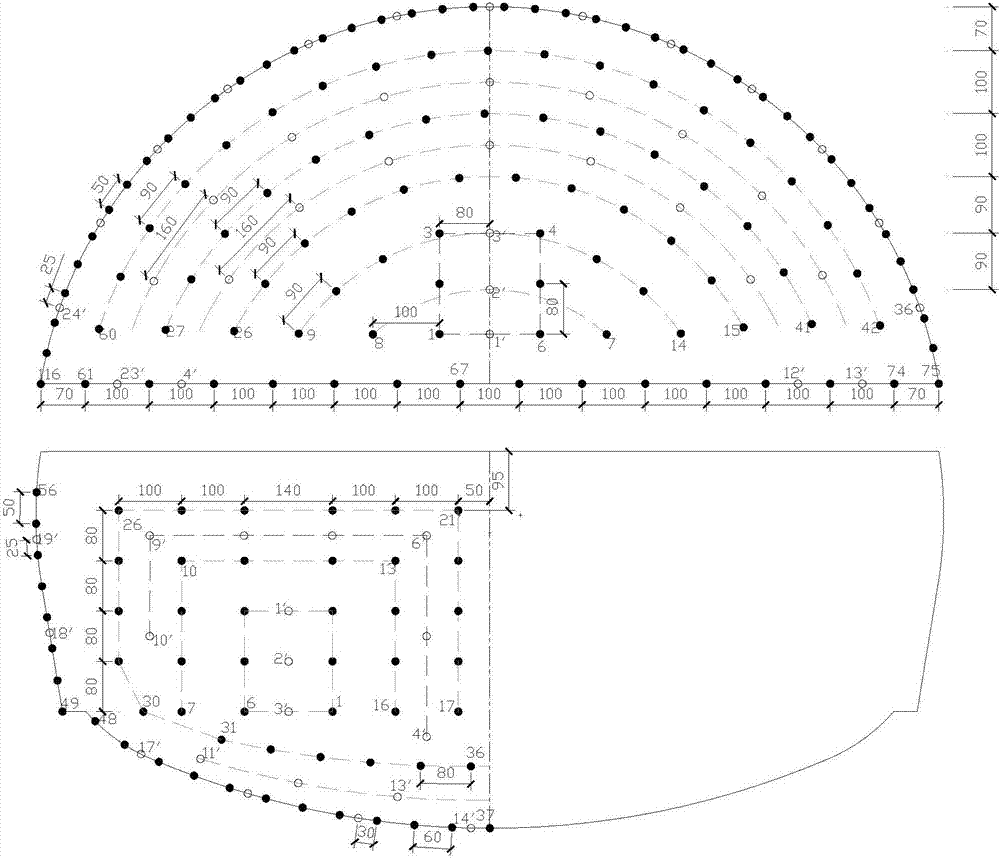

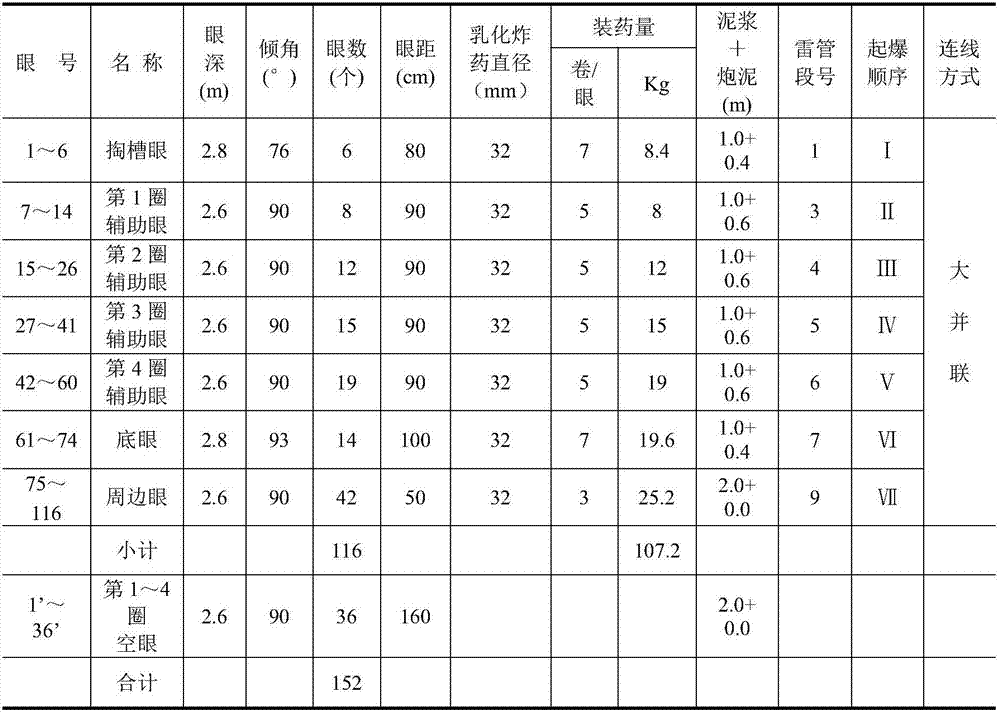

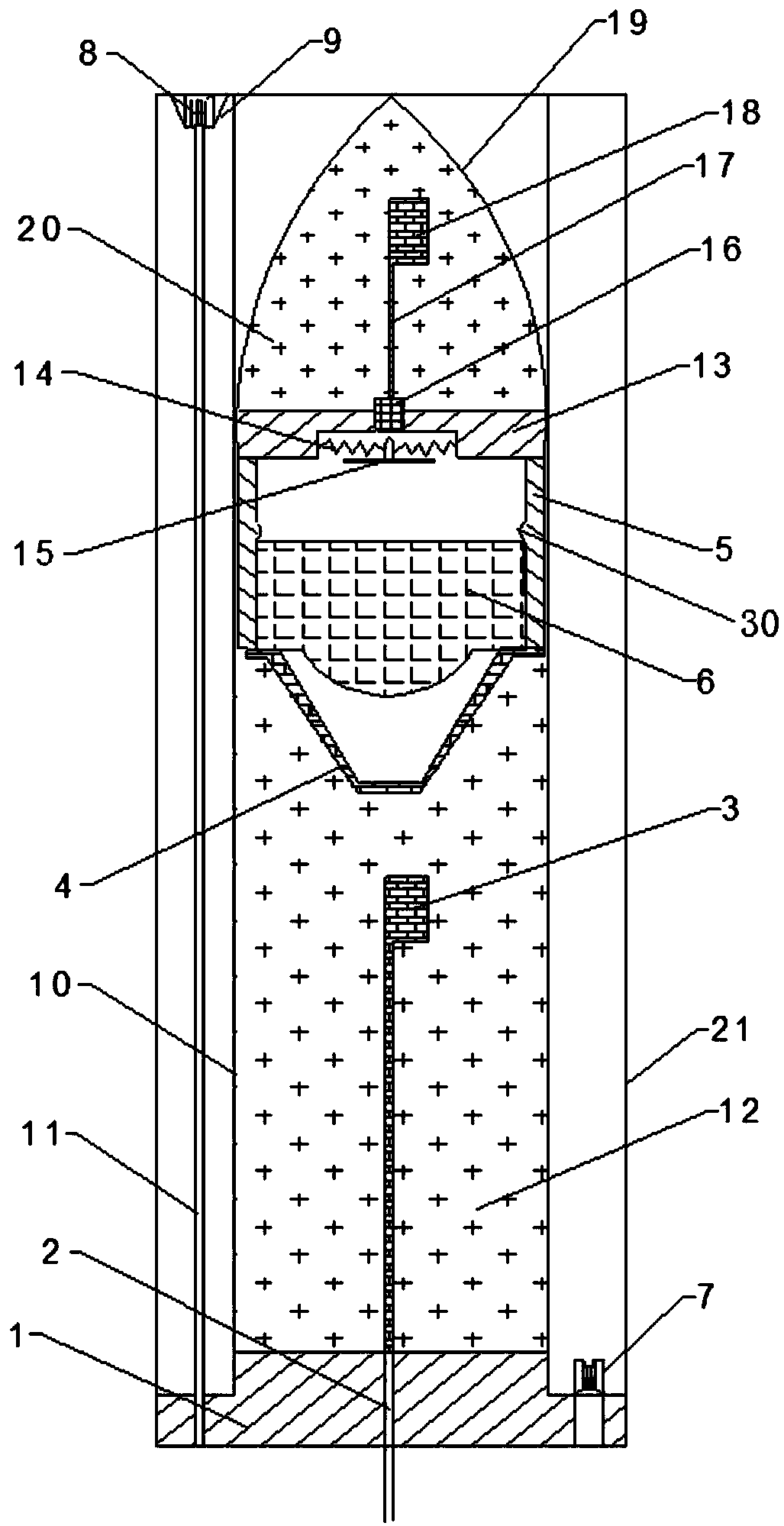

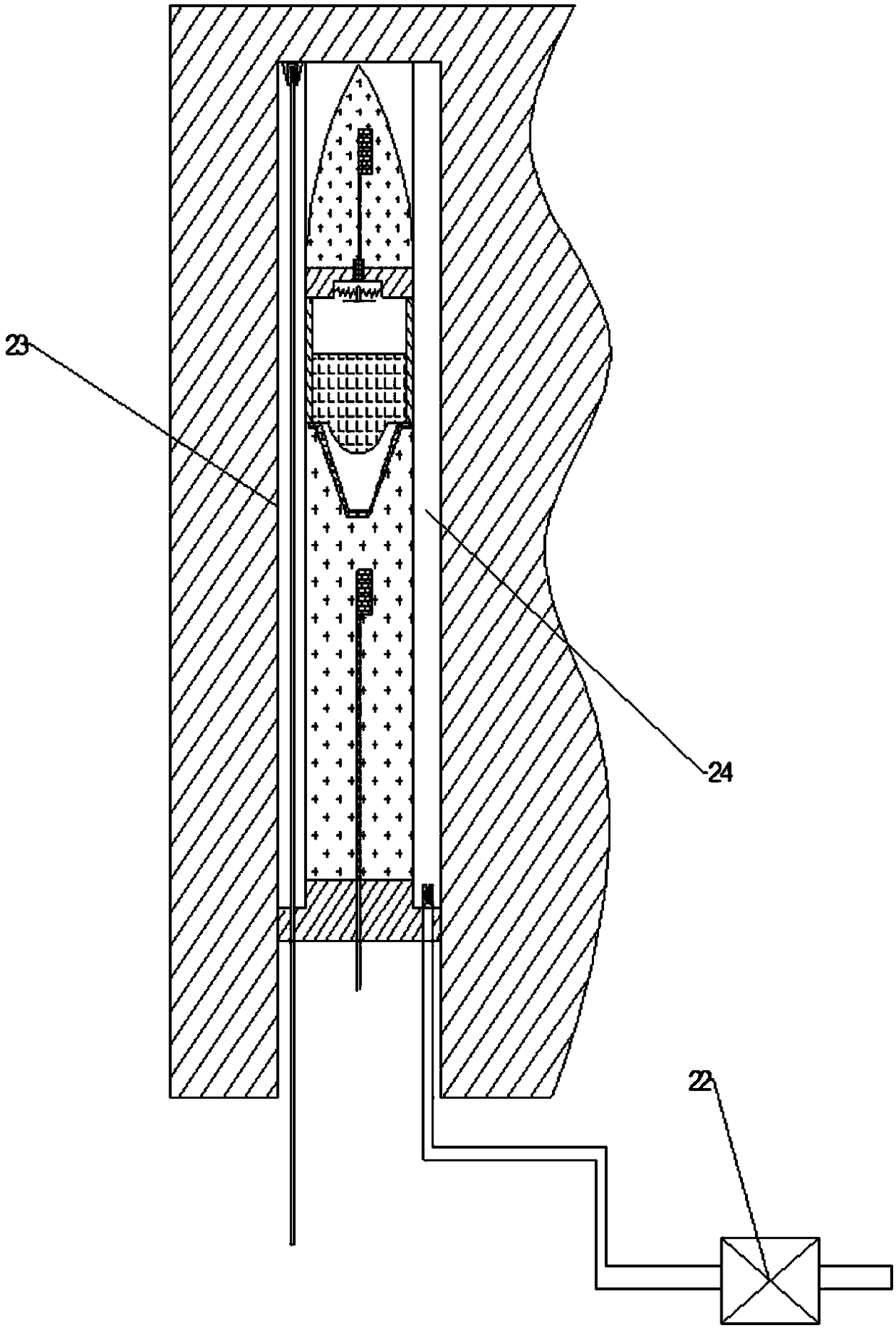

Gradient pre-splitting blasting method and device of lancing cartridges around vertical shaft

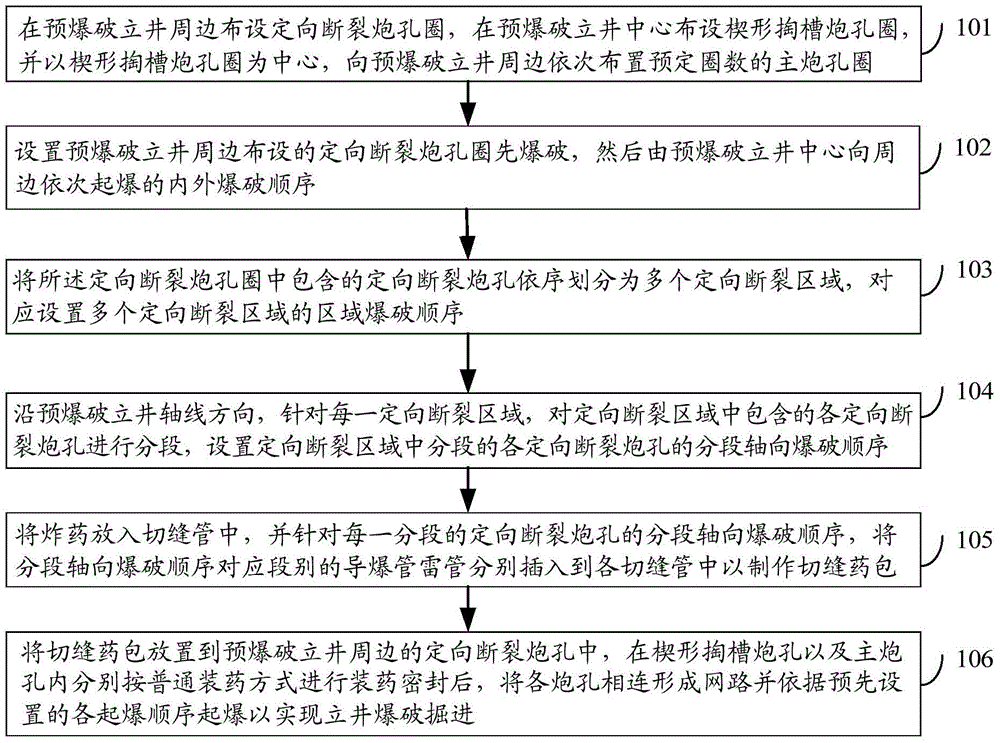

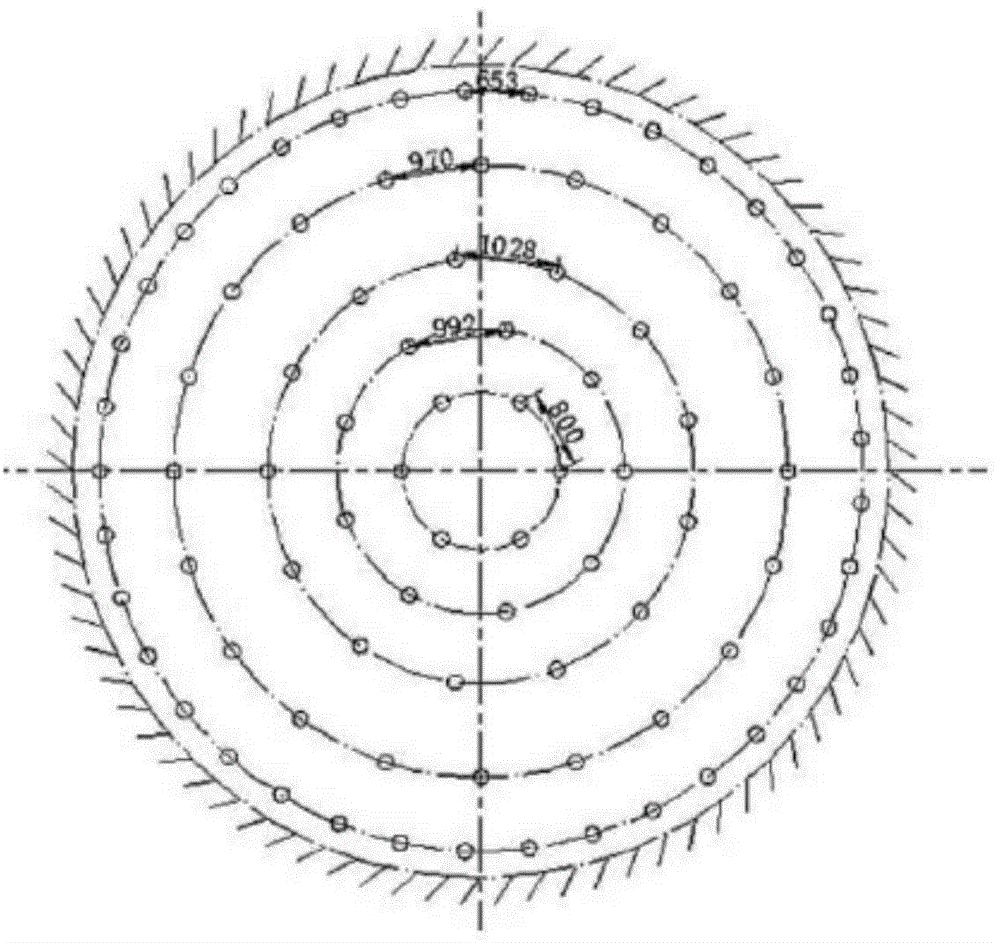

An embodiment of the invention discloses a gradient pre-splitting blasting method and device of lancing cartridges around a vertical shaft. The method includes distributing directional-breaking blasthole rings around the vertical shaft, distributing wedge-cut blasthole rings in the center and distributing main blasthole rings with preset ring number from the center to outside; setting a blasting sequence that the directional-breaking blasthole rings blast first, and the blasthole rings from the center to outside blast sequentially; sequentially dividing the directional-breaking blasthole rings into a plurality of directional-breaking areas and setting the corresponding area blasting sequence; subjecting the directional-breaking areas to segmentation and setting the corresponding segmental axial blasting sequence; putting explosive into lancing tubes and inserting nonel detonators corresponding to the segmental axial blasting sequence into the lancing tubes to make lancing cartridges; placing the lancing cartridges in directional-breaking blastholes around the vertical shaft, filling and sealing the wedge-cut blastholes and the main blastholes, and connecting the blastholes to form a detonating network. By the use of the gradient pre-splitting blasting method and device, blasting damage is reduced during the blasting, and blasting effect is improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

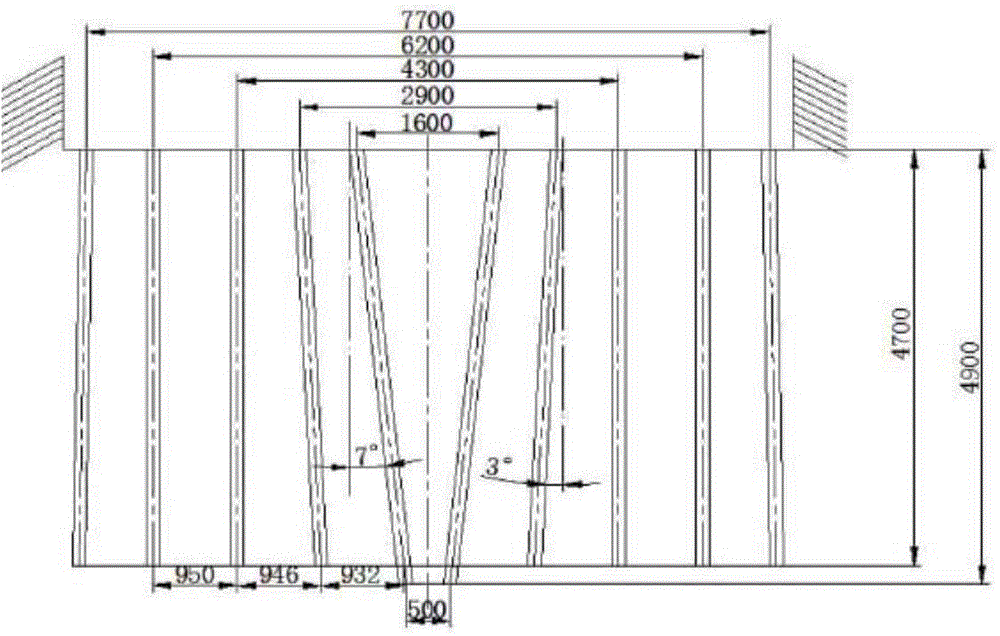

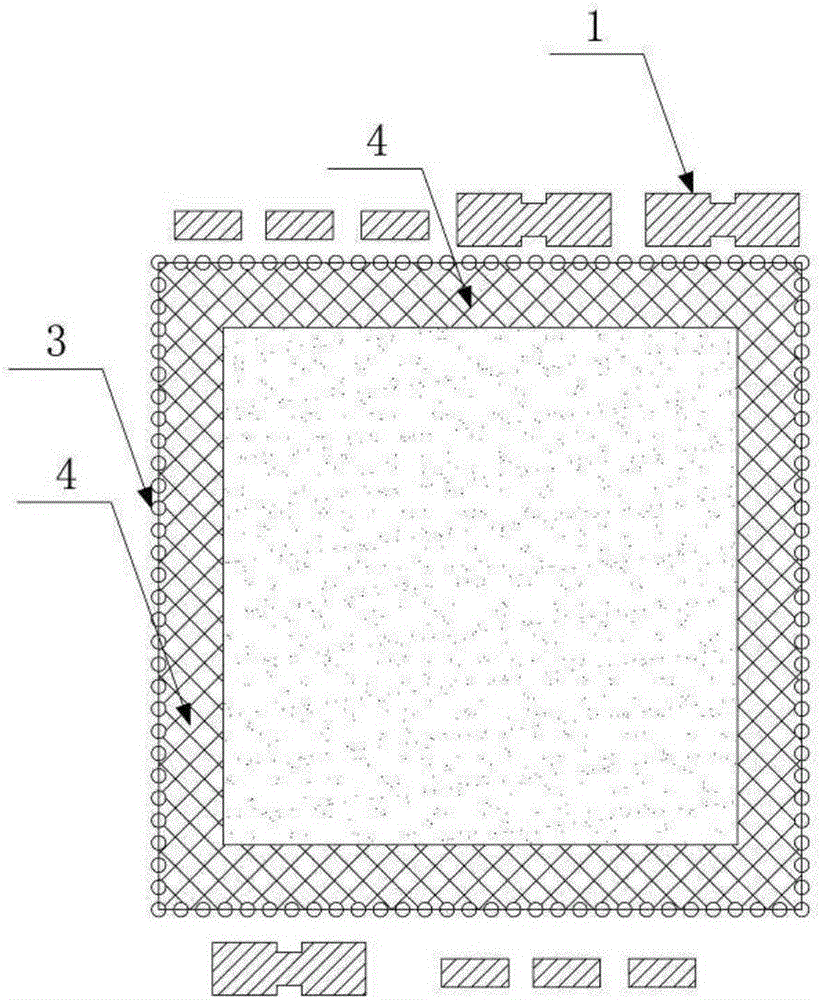

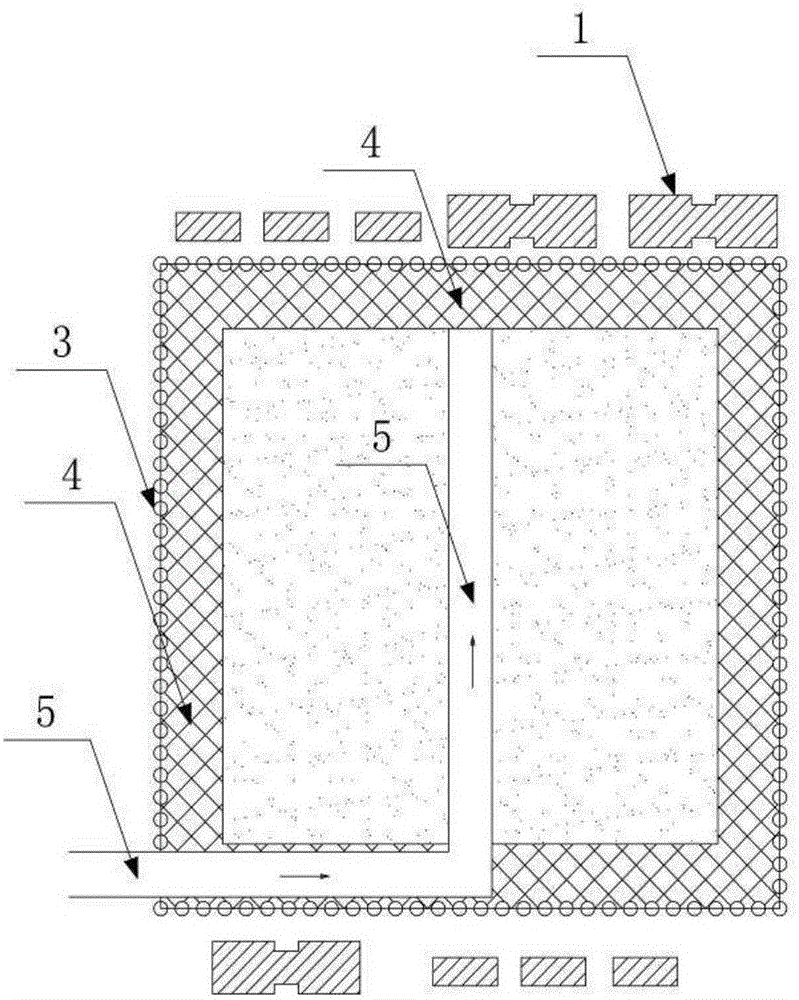

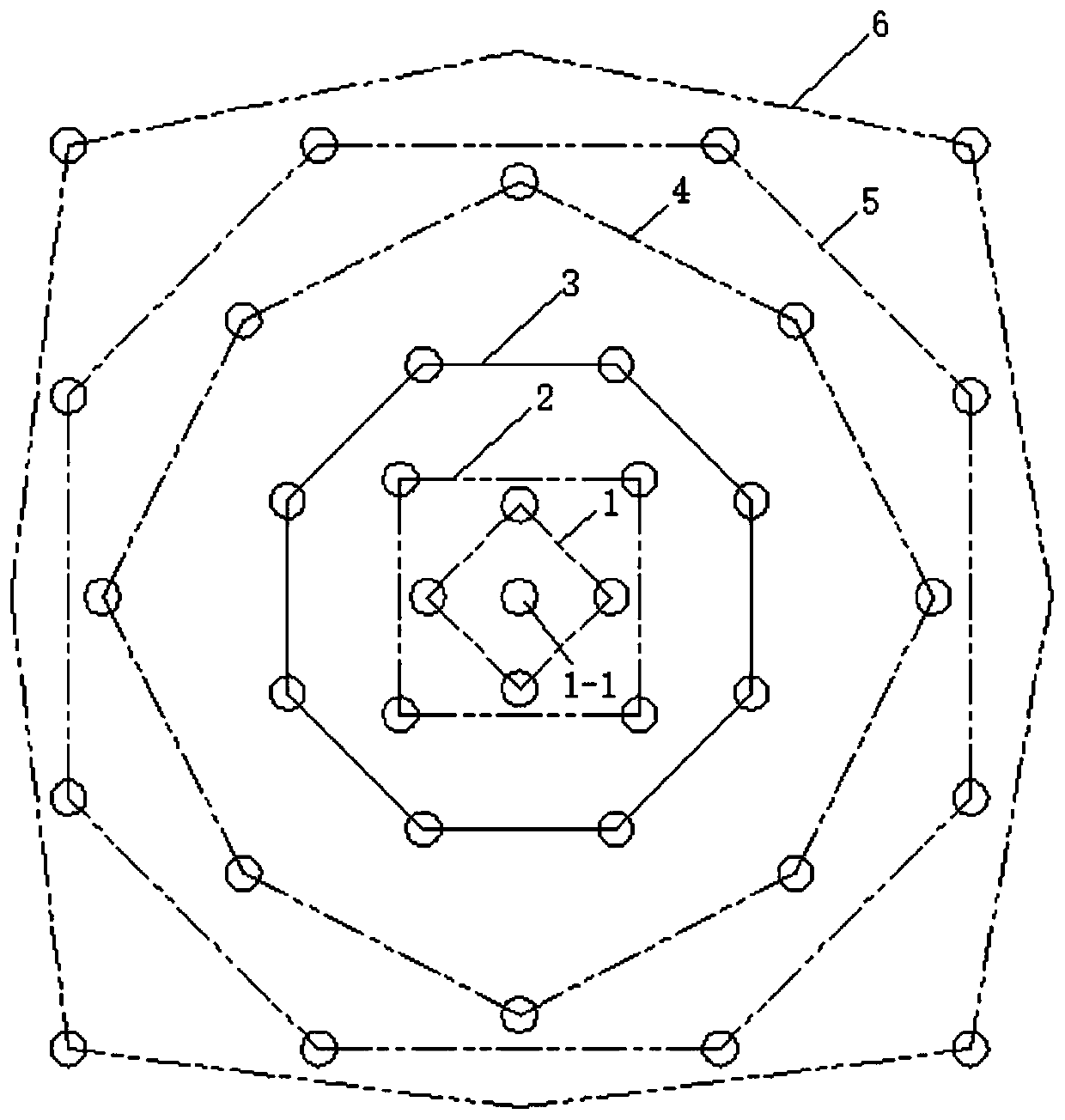

Dual-area slotting blast hole arrangement structure and blasting sinking method applied to structure

ActiveCN106767212AReduced precision requirementsIncrease heightBlastingEngineeringBlasting vibration

The invention discloses a dual-area slotting blast hole arrangement structure and a blasting sinking method applied to the structure. The structure comprises two blasting slotting hole areas symmetrically arranged with respect to the center of the free face of a courtyard, each blasting slotting hole area comprises a center charging hole and a plurality of empty holes arranged around the center charging hole; a ring of peripheral holes are formed in the periphery of each blasting slotting area, the center charging holes and the peripheral hoes are filled with explosive charges, and a plurality of auxiliary holes are formed between the blasting slotting areas and the peripheral holes and are filled with explosive charges. The method is simple in working procedure, operation is easy, the one-time sinking height is large, reliability is high, the sinking effect is good, the number of drilled holes is small, energy consumption is low, and the blasting vibration is small.

Owner:CENT SOUTH UNIV

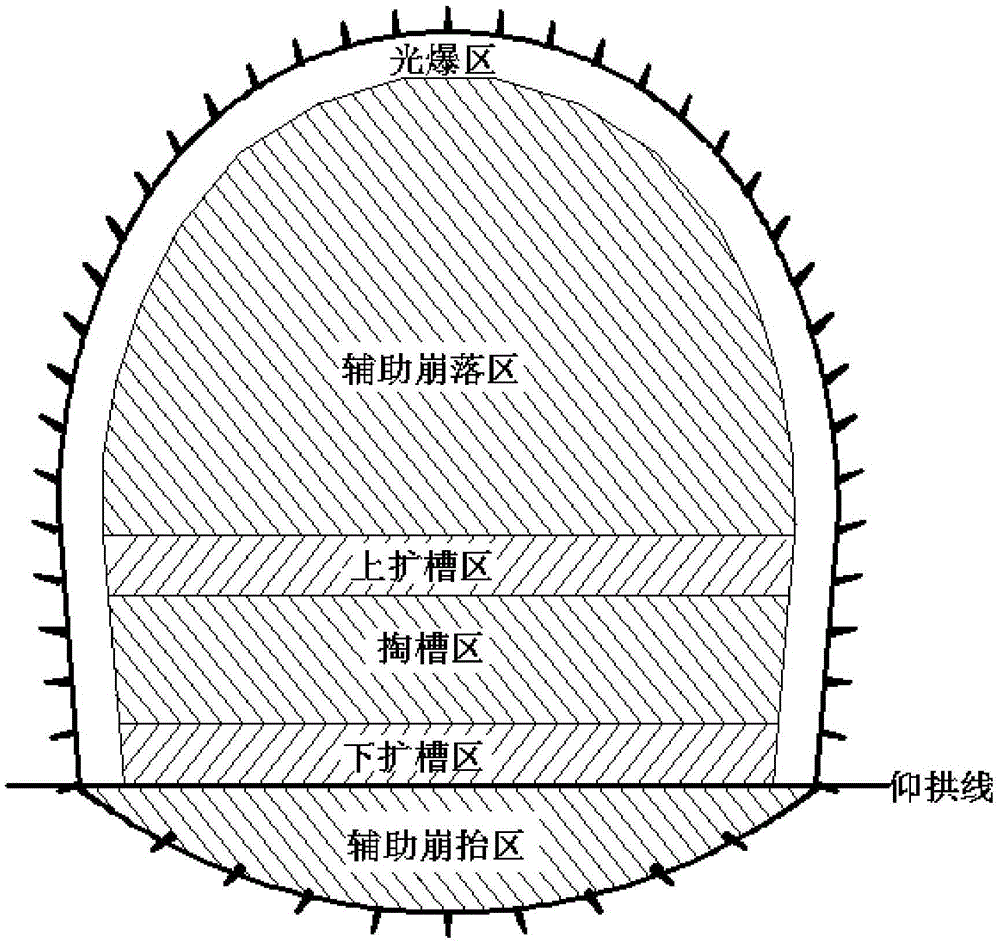

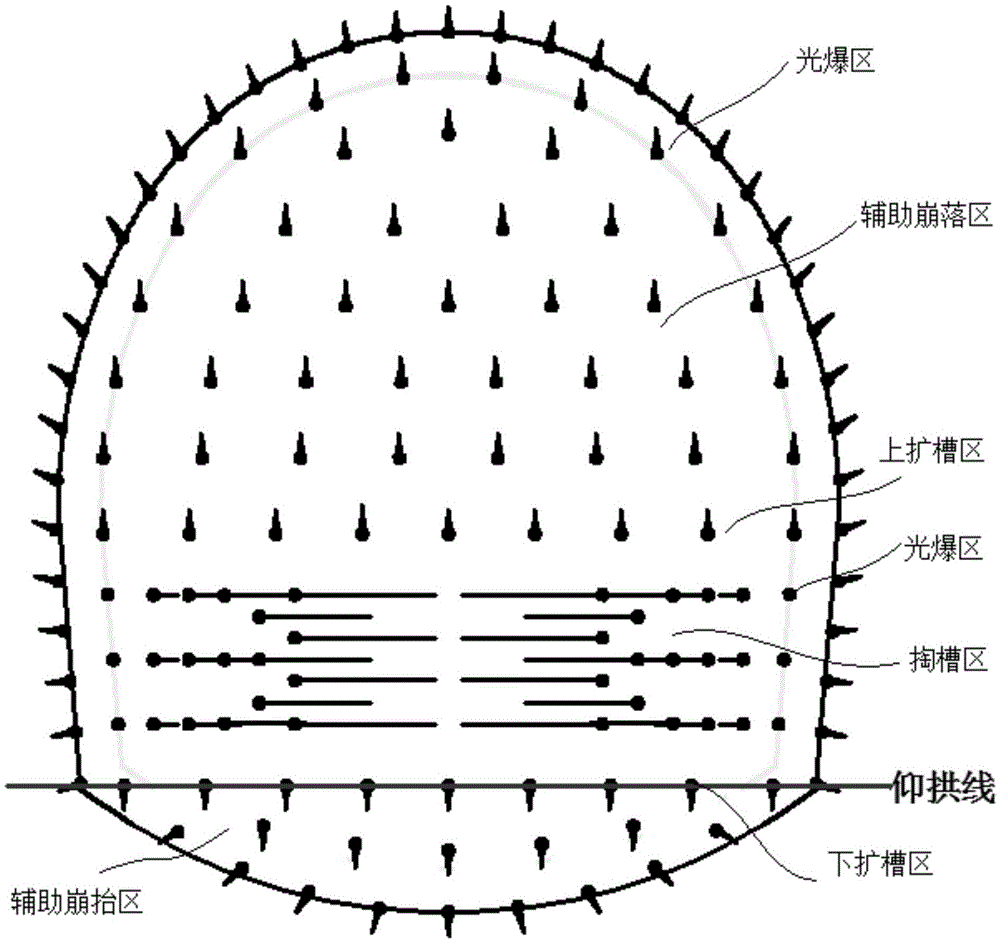

Partition control blasting method for tunnel rock drilling project

The invention discloses a partition control blasting method for a tunnel rock drilling project. The partition control blasting method sequentially comprises the steps that a rock drilling working surface is partitioned into a slotting partition, an upper and down slot expanding partition, an auxiliary collapsing partition, an auxiliary collapse lifting partition and a light blasting partition, and all the partitions are drilled to form holes; the blast holes are filled with explosives; rock drilling section blasting is started; the slotting partition and the upper and down slot expanding partition are blasted; then the auxiliary collapse lifting partition is blasted; the auxiliary collapsing partition is blasted; finally the light blasting partition is blasted. The partition control blasting method is a project blasting method used for underground rock drilling projects with large sections and has the advantages that the blasting vibration can be controlled, and the blasting effect can be improved.

Owner:坚兵(北京)工程技术有限公司

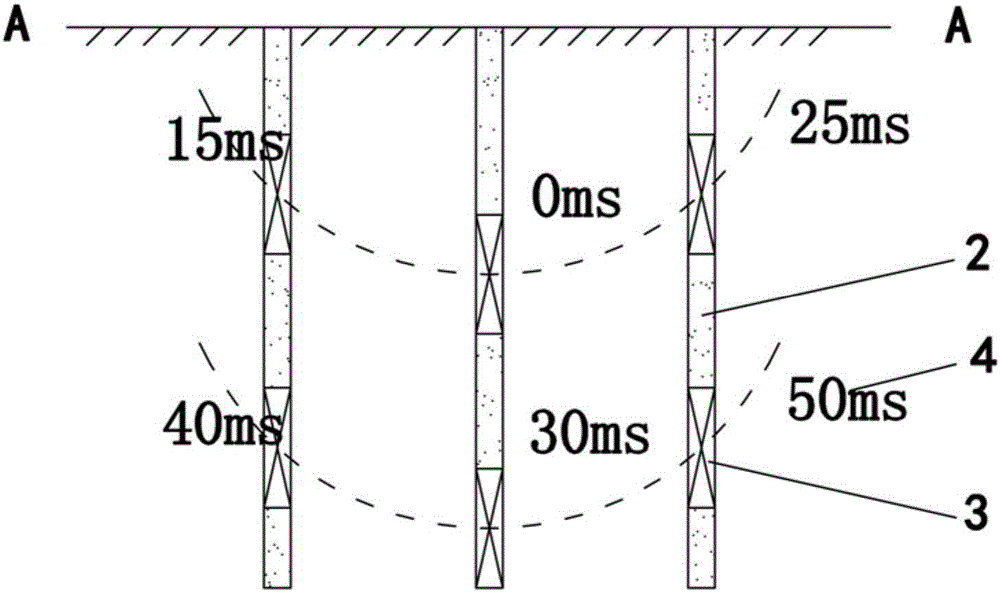

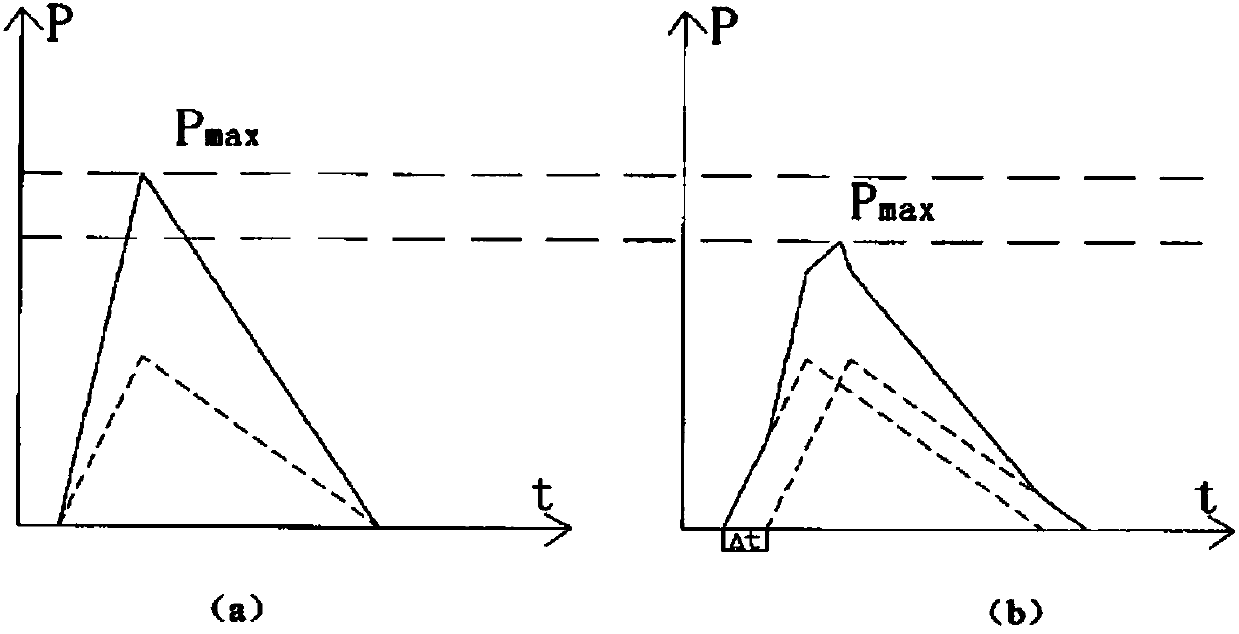

Subsection millisecond differential blasting method in blasthole

The invention discloses a subsection millisecond differential blasting method in a blasthole, which mainly comprises the following operating steps of filling explosives in a sectioned manner by using a spaced loading method in the blasthole, wherein the length of each subsection of filled explosives is equal; in the explosive filling process, enabling the distance between every two adjacent subsections of explosives is greater than an induced detonation distance; determining continuous coupling explosive loading parameters according to an empirical formula of medium-length hole parameters and further determining specific parameters of divided charge in the blasthole; and densely filling a space between every two adjacent subsections of explosives by using materials such as clay and rock powder, wherein each subsection of explosives is detonated by using a detonator, all ways of initiation are reverse initiation, namely all detonators are arranged at the bottoms of the subsections filled with the explosives after being arranged in igniting explosive packages, the energy-gathering caves of the detonators face to apertures, the differential interval time of the subsections filled with the explosives is 15-40 milliseconds, and the initiation sequence of the subsections filled with the explosives is from top to bottom. According to the subsection millisecond differential blasting method in the blasthole, blast vibration can be further reduced on the basis of the millisecond blasting among blastholes and the blasting crushing effect can be effectively improved.

Owner:GUIZHOU XINLIAN BLAST ENG GRP

Efficient shock absorption blasting and excavation method adopting fishbone-shaped construction guide grooves for large rock deep foundation pit in dense building area

The invention discloses an efficient shock absorption blasting and excavation method adopting fishbone-shaped construction guide grooves for a large rock deep foundation pit in a dense building area. The efficient shock absorption blasting and excavation method is characterized in that excavation is conducted according to the following sequence: a, shock absorption holes are drilled in the outer rim of the foundation pit, and reserved protection belts are arranged; b, a main construction guide groove is excavated in the dense building direction through a shallow hole loosening and blasting method; c, in the positions perpendicular to the main construction guide groove, two or more auxiliary construction guide grooves are excavated facing the two sides of the main construction guide groove, and therefore the main construction guide groove and the auxiliary construction guide grooves form the fishbone shape; d, a middle-deep hole control blasting method is adopted, blasting and expanded-excavation are conducted on the rock among the auxiliary construction guide grooves; e, the reserved protection belts are excavated to the rim of the foundation pit by the adoption of the mechanical excavation method; f, support is conducted on the wall of the foundation pit; and h, layered excavation of the foundation pit is conducted by executing the steps of b to e in a looping manner. By the adoption of the efficient shock absorption blasting and excavation method, the excavation efficiency of the large foundation pit can be improved, and the influence of blasting and vibration on the surrounding buildings is lowered.

Owner:中铁二院重庆勘察设计研究院有限责任公司 +2

Efficient segmented blasting method in tunneling process

The invention relates to the technical field of tunnel gun hole blasting vibration, in particular to an efficient segmented blasting method in a tunneling process. Gun holes are distributed according to a tunneling section, geological conditions, circulating footage and the like; the in-hole segmented millisecond blasting is performed by a digital electronic detonator; the millisecond time precision is improved; the first blasting of explosives at the upper parts of the gun holes is realized; and a free surface is provided for blasting of explosives at the lower parts, so that the blasting effect is guaranteed. The method adopts the in-hole segmented millisecond blasting, reduces the blasting vibration speed, and increases the circulating footage.

Owner:3TH ENG CO LTD OF CHINA RAILWAY CONSTR 11TH BUREAU GRP +1

Ming method for stoping high-dipping thick orebody with medium and above stability in ore mass

ActiveCN107939402AAvoid collapsing intoReduce mix rateUnderground miningSurface miningMineralogyDeep hole

The invention discloses a mining method for stoping a high-dipping thick orebody with the medium and above stability in an ore mass. The method comprises the steps that an inverted-stepped mining faceis arranged in the thickness direction of the orebody in an ore room, mining is advanced from bottom to top, the mining face part close to a hanging wall is ahead of the mining face part close to a lying wall by a certain height, the advanced mining height of the mining face part close to the hanging wall is utilized to provide an operation space, a shallow hole is drilled upwards in the operation space, and a horizontally parallel medium-length hole is drilled in the direction of the lying wall to blast and break ores; and an anchor rod is used for anchoring partial unstable rocks on the hanging wall in the operation space, a part of the mined ores is temporarily left in the ore room to serve as a protective bottom column and a buffer layer of the hanging wall and provide a standing platform for upward operation and temporarily bearing hanging wall rocks, and a large quantity of ores are removed after ore room exploration is completed. The mining method is beneficial for reducing mixing of waste rocks in the mining process of the high-dipping thick orebody and improving the recycling ratio of resources, the blackness of the ores is even, the stope preparation work amount is less,and rock drilling and blast working are easy to organize.

Owner:KUNMING METALLURGY COLLEGE

Tunnel empty-hole mud vibration-reduction-control blasting method capable of reducing vibration and noise

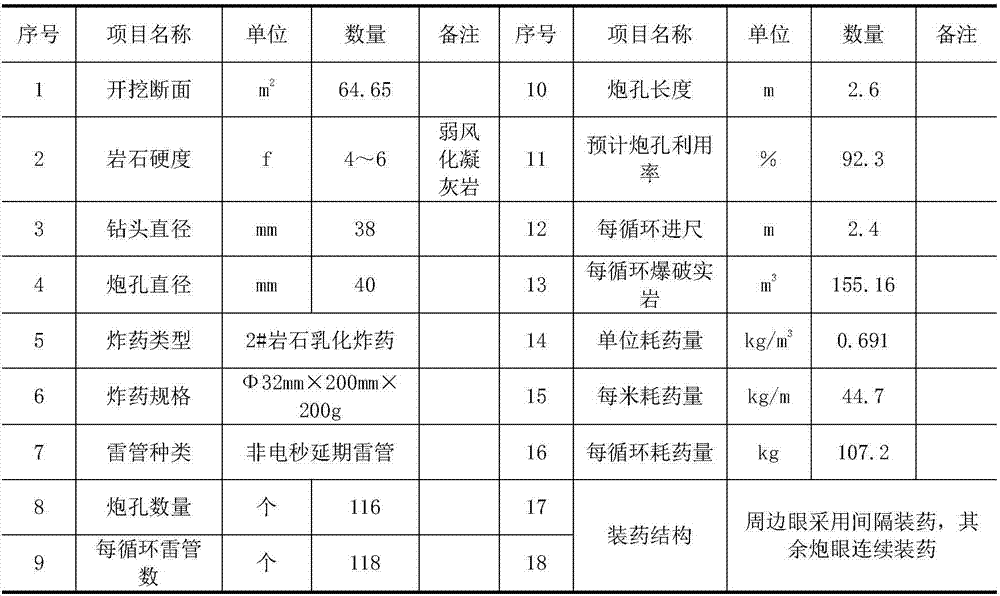

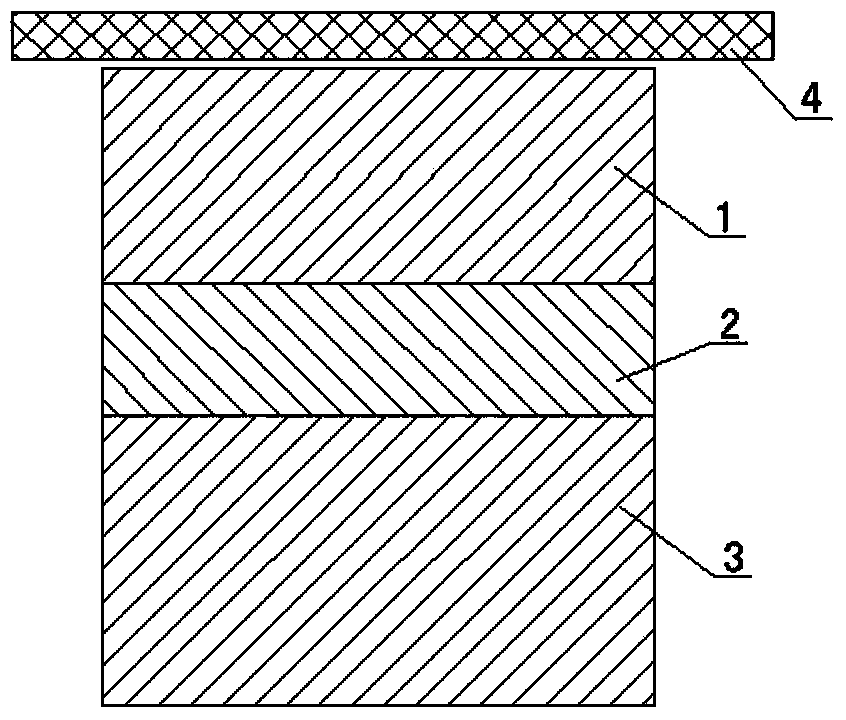

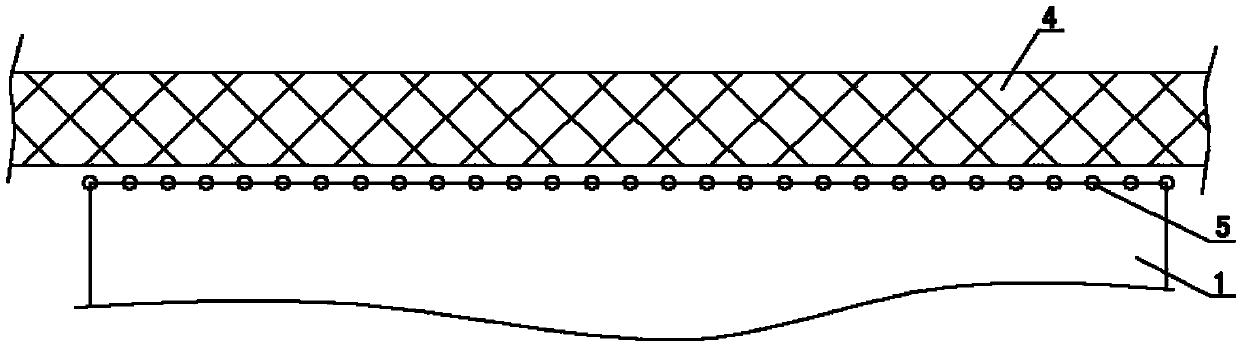

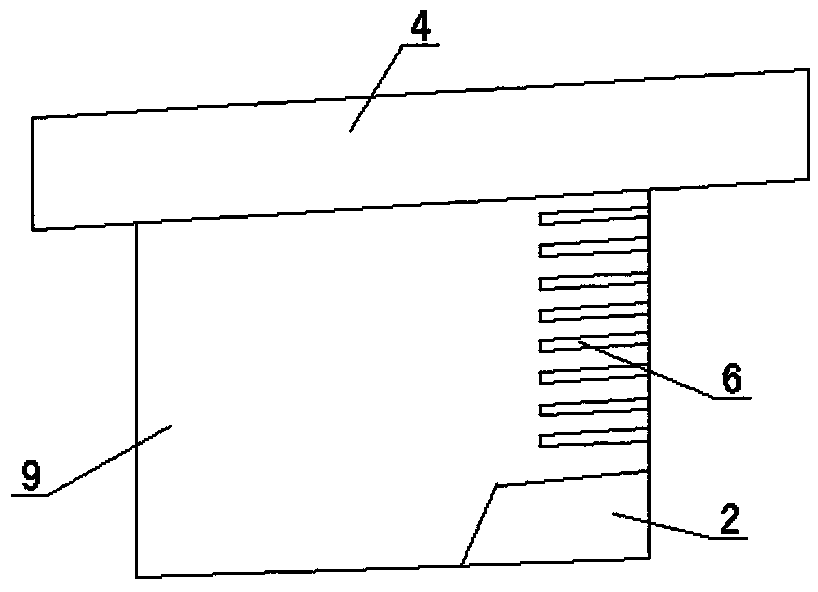

The invention relates to a tunnel empty-hole mud vibration-reduction-control blasting method capable of reducing vibration and noise. According to the method, hole drilling is positioned according to a drilling and blasting arrangement diagram; before powder charging, high-pressure air is used for sweeping holes, rock emulsion explosives and non-electric second-delay detonators are respectively selected, the powder charging holes are charged with powder according to a vibration reduction blasting parameter design list, the periphery holes are charged with the powder at intervals, the rest of the blastholes are continuously charged with the powder, the powder are charged to the bottoms of the holes, tamping is used for plugging the holes in place, and the empty holes are filled with plastic bags with mud; and the detonators are connected in place according to requirements, equipment and persons are all evacuated outside the safe distance, and detonation is carried out after the equipment and the persons are confirmed to be safe. The method has the advantages that the hole bottom blasting force can be enhanced, the blasting footage can be increased, particularly, reflection, refraction and absorption of the blasting shock waves can be strengthened, the process of shock wave->attenuating->stress wave->attenuating->seismic wave can be accelerated, the blasting vibration and noise can be greatly reduced, the blasting vibration speed is detected to be lees than 5cm / s, the phenomenon that people are disturbed can be greatly reduced, and the good technical economic effect can be obtained.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

Comprehensive damping method for mixed explosion of hard rock tunnel closely attaching to existing underground building

ActiveCN104180733AAvoid damageReliable blasting vibration speedBlastingShock waveStructure of the Earth

The invention discloses a comprehensive damping method mixed explosion of a hard rock tunnel closely attaching to an existing underground building. The method is characterized in that below the base plate of the existing structure of the existing building, an explosion working face is sequentially divided into a metal expansion explosion area, an emulsion explosive underholing area and an emulsion explosive explosion area towards the depth direction. By the method, explosion vibration speed during tunneling, attaching to the existing underground building, in a hard rock stratum can meet the requirements, the existing underground building is not damaged by explosion shock waves, and project progress is guaranteed.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

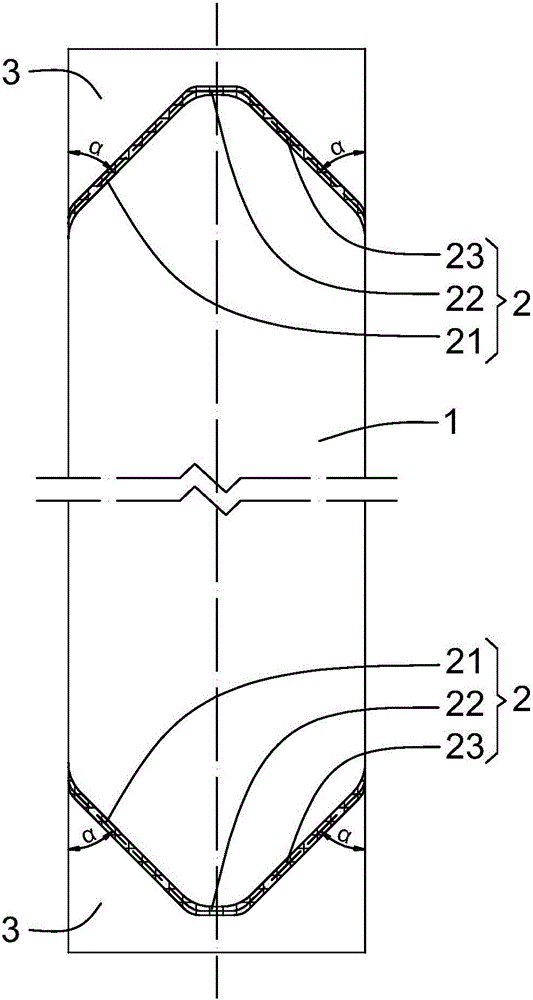

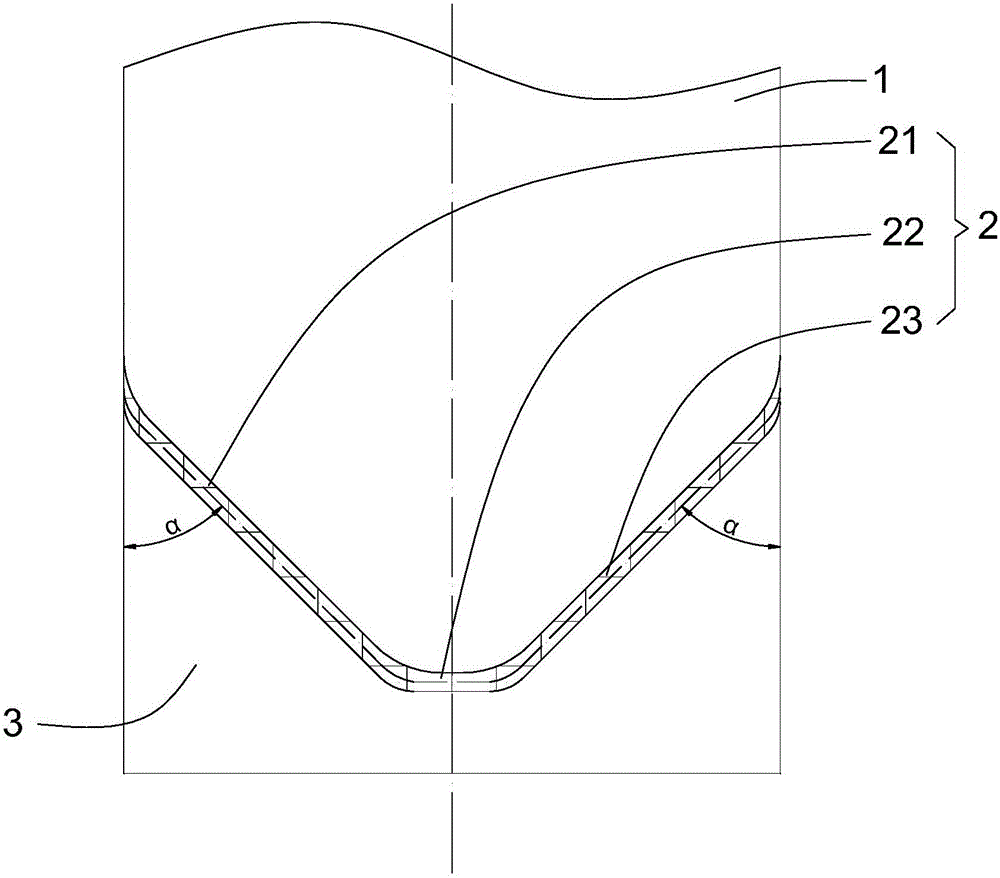

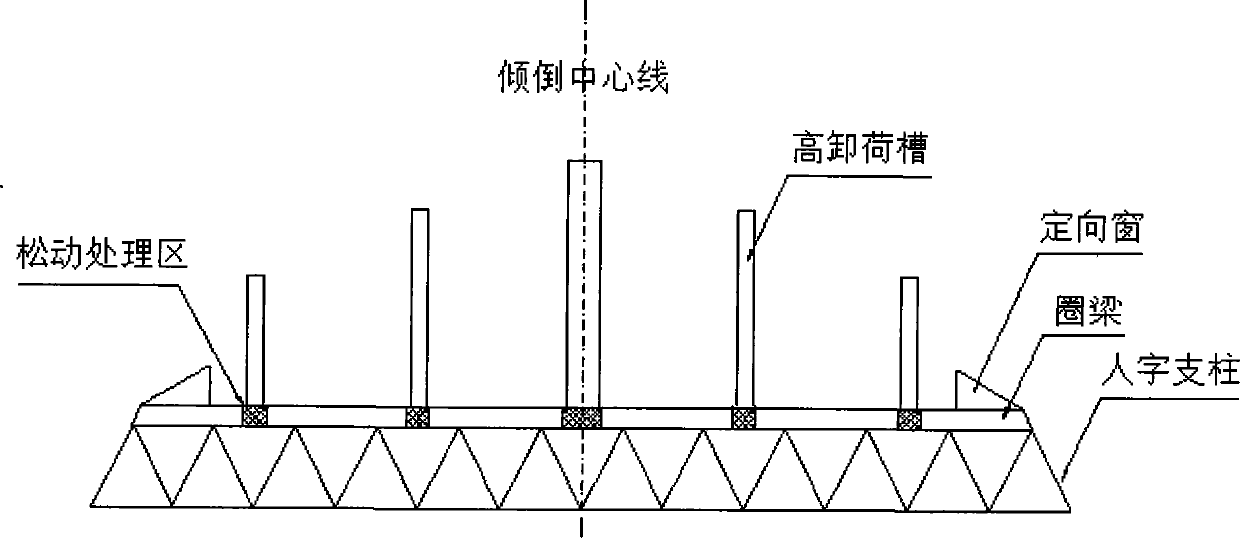

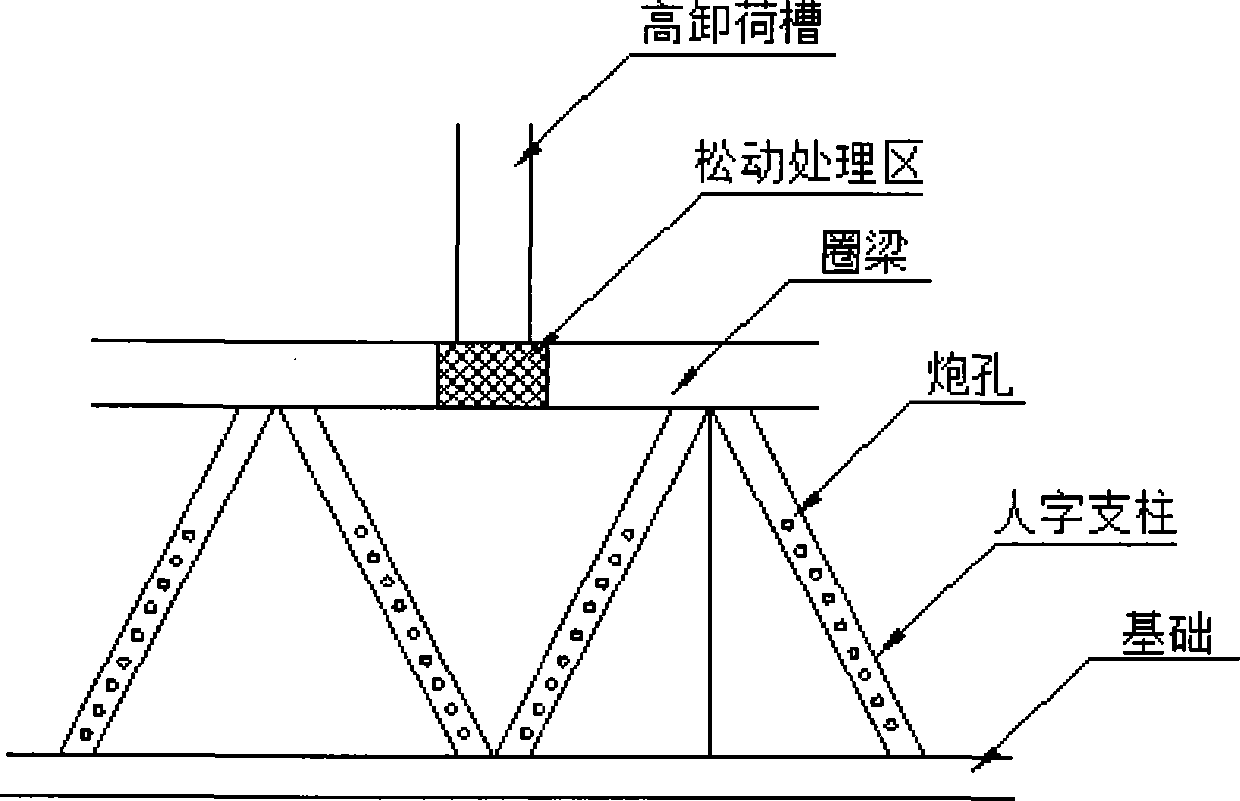

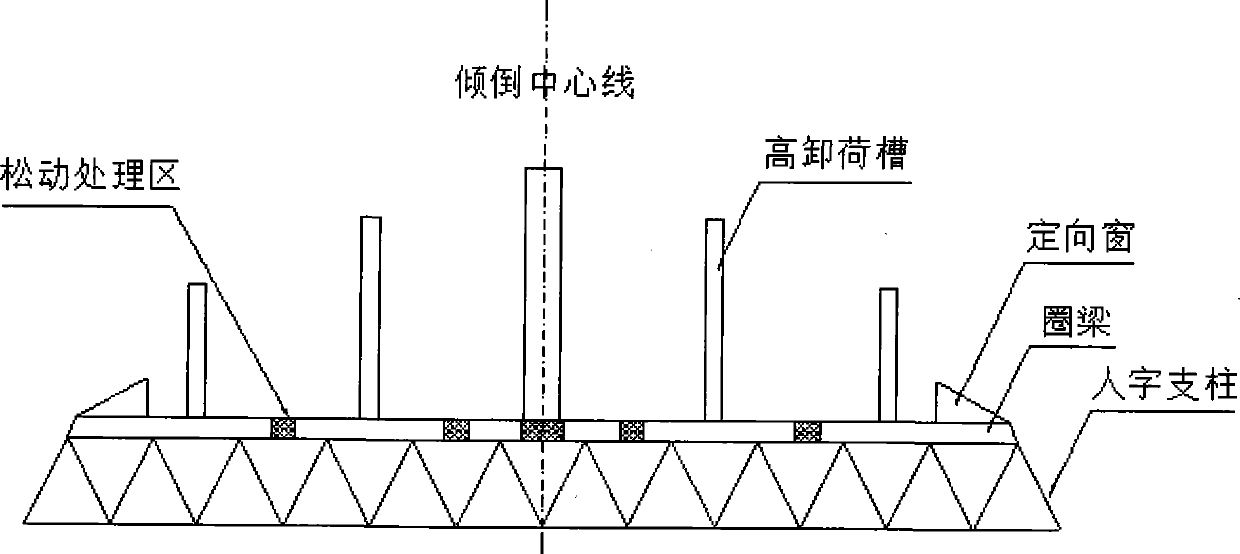

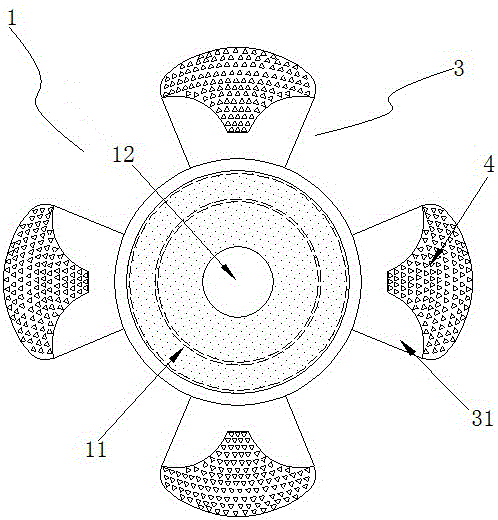

High-unloading slot composite-incision demolition blasting method for reinforced concrete cooling tower

InactiveCN104089550AReduce blasting vibrationReduce drilling workloadBlastingRebarReinforced concrete

The invention discloses a high-unloading slot composite-incision demolition blasting method for a reinforced concrete cooling tower, and relates to a demolition blasting method for the reinforced concrete cooling tower. The demolition blasting method comprises the following steps: pre-demolishing an internal sprinkling platform and an external ladder of the reinforced concrete cooling tower to be demolished by blasting; arranging a composite blasting incision including a rectangular herringbone pillar area, a trapezoidal ring beam area, an acute triangular directional window and a high unloading slot on the lower part of the tower body, wherein the high unloading slot and the directional window are mechanically arranged so as to ensure the construction precision; drilling at the herringbone pillar and a ring beam which is locally required to be loosened by blasting (a ring beam loosening area is constructed by a mechanical method and a blasting method), filling explosive, fencing, and strengthening blasting of a millisecond delay blasting network through non-electric bidirectional multi-point excitation. By the demolition blasting method, the falling direction can be accurately controlled, the number of boreholes and the amount of the explosive can be greatly reduced, the collapsing disintegration degree and the touchdown impact state of the tower body can be regulated and controlled, and the touchdown vibration can be effectively controlled.

Owner:HENAN POLYTECHNIC UNIV

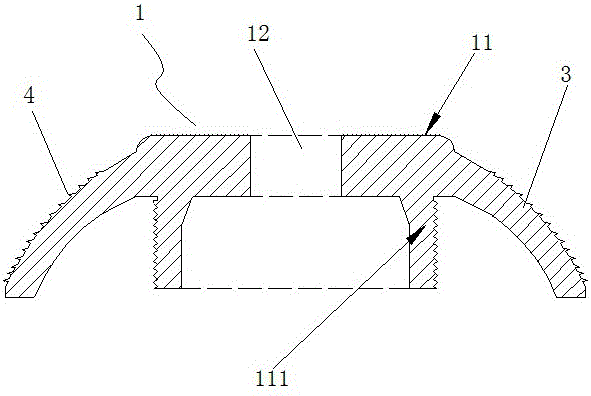

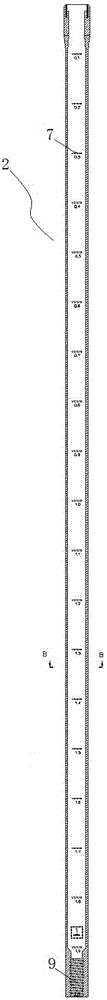

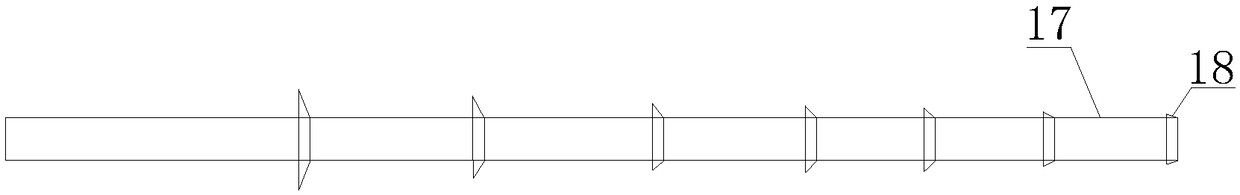

Gun hole charging and plugging device

The invention discloses a gun hole charging and plugging device which comprises a disc and a head rod detachably connected with the disc. The disc comprises a tray, fins and a center through hole. The fins are arranged in the mode of surrounding the outer wall of the tray and have elasticity and toughness, and the center through hole is formed in the center of the tray. The fins can be inserted into a gun hole, and the outer diameter of the fins is larger than that of the gun hole. The fins are provided with anti-skid structures capable of being clamped and fixed to the wall of the gun hole. The bottom of the tray is provided with a connection port in butt connection with the head rod. The problem that a cartridged explosive slides when being charged into an upward hole is effectively solved, the non-coupling charging structure is actually achieved, interval charging can be achieved, accordingly, the oversized fragment output rate is effectively reduced, blasting vibration is reduced, and safety and stability of sinking and driving engineering are maintained. In addition, the explosive consumed cost is reduced, the workload of workers is reduced, and the device plays a quite important role in developing enterprises, reducing the operation cost and improving productivity.

Owner:湖南华楚项目管理有限公司

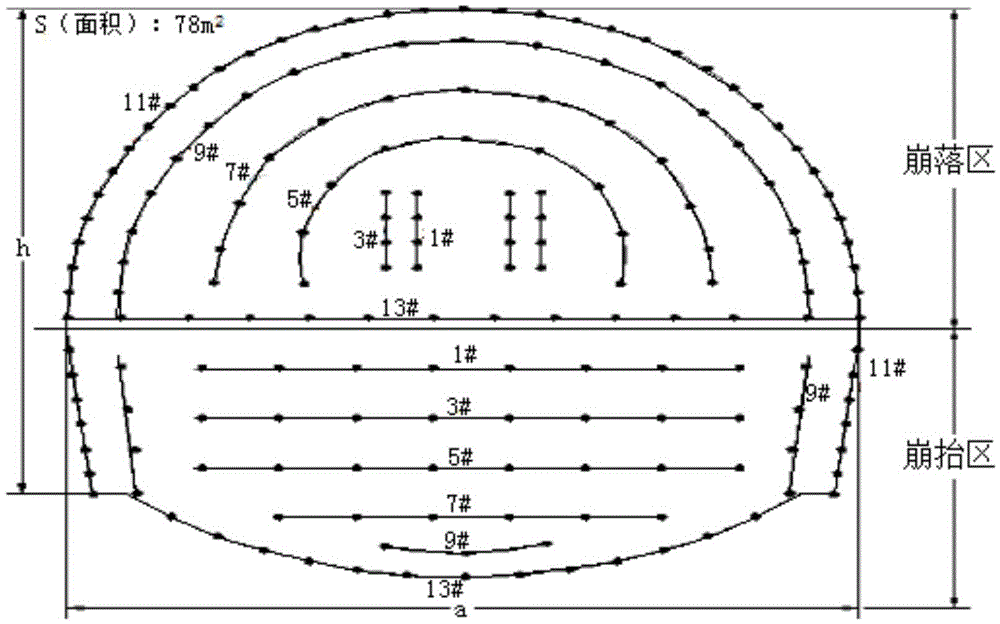

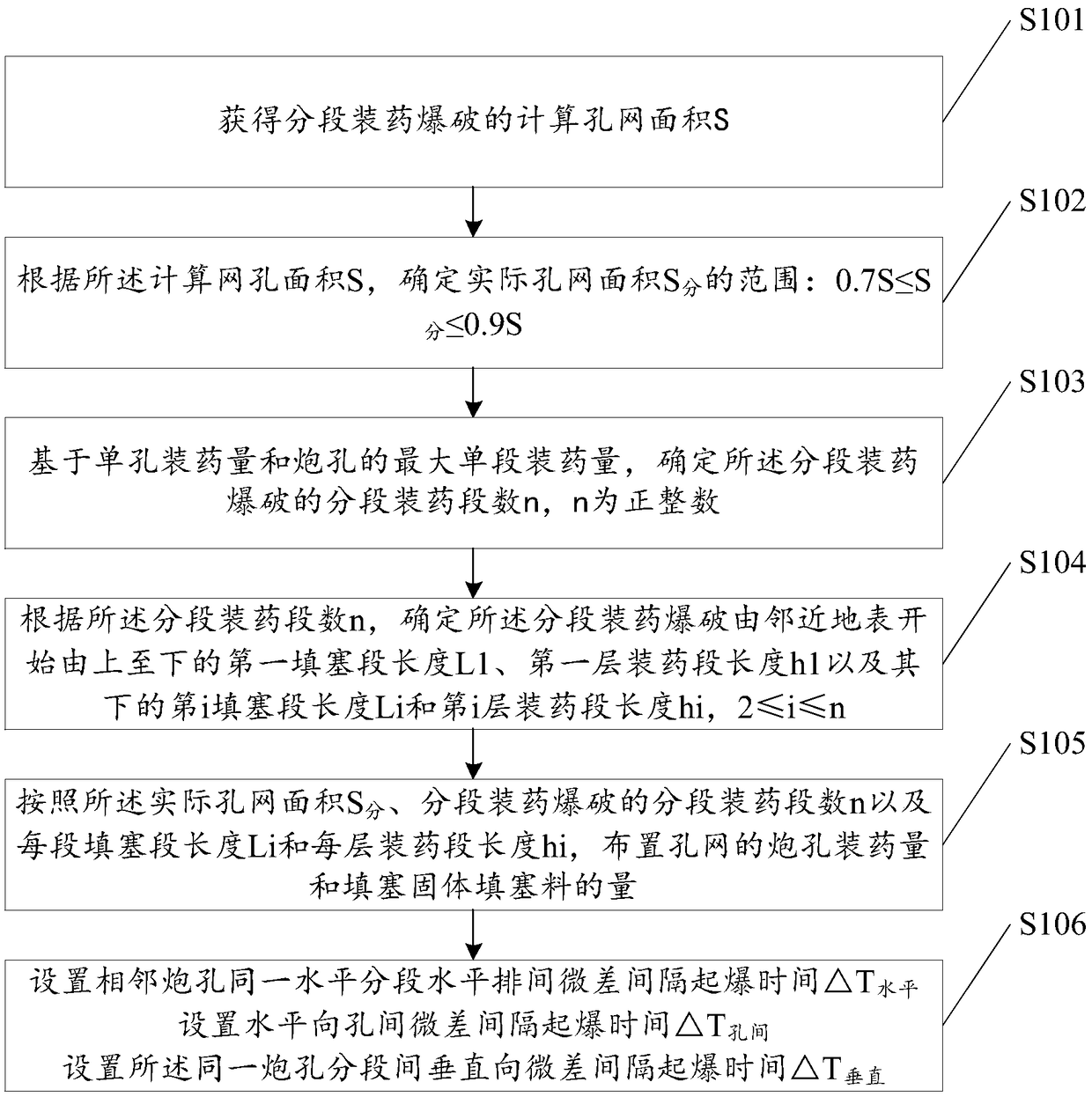

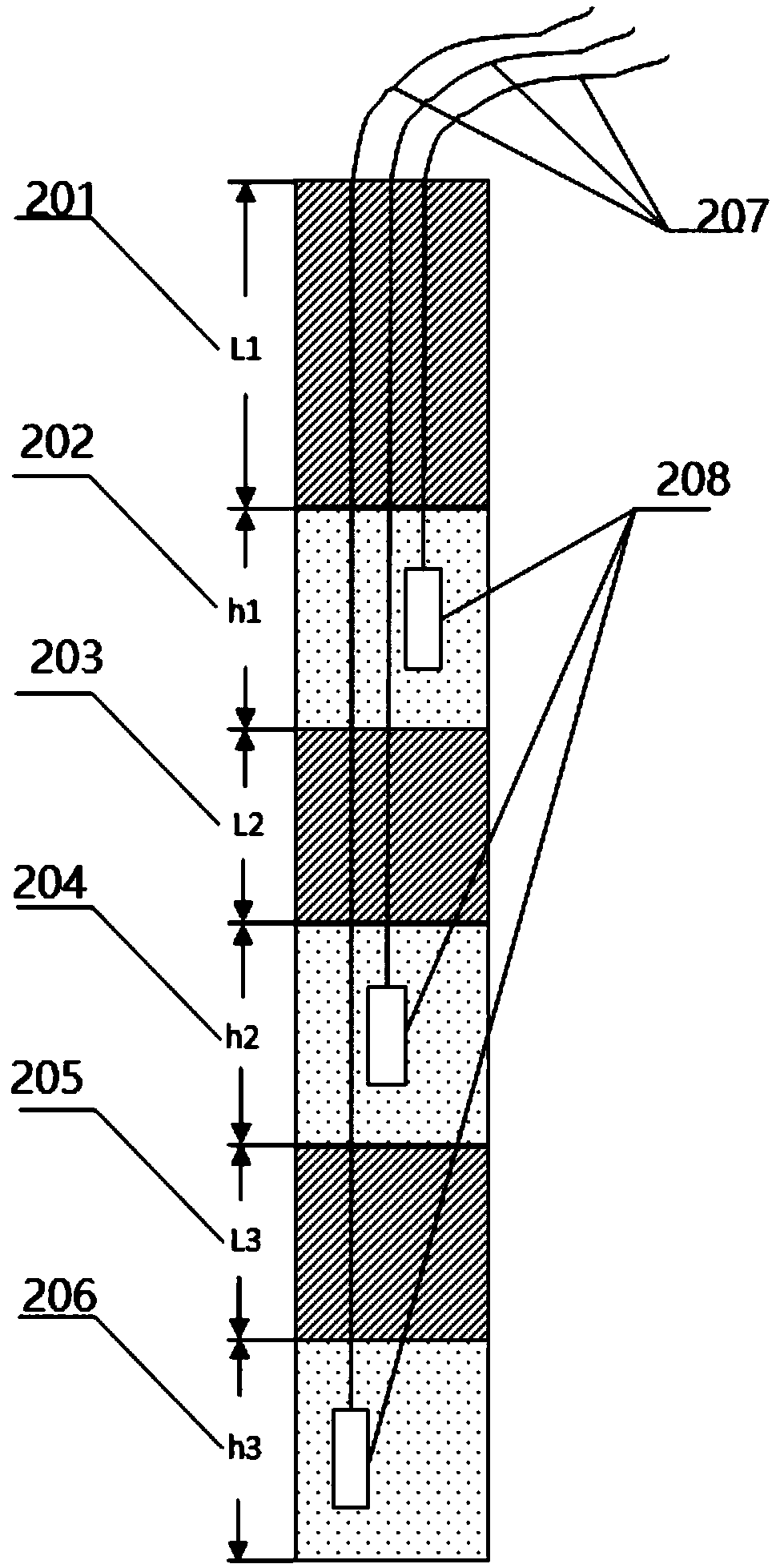

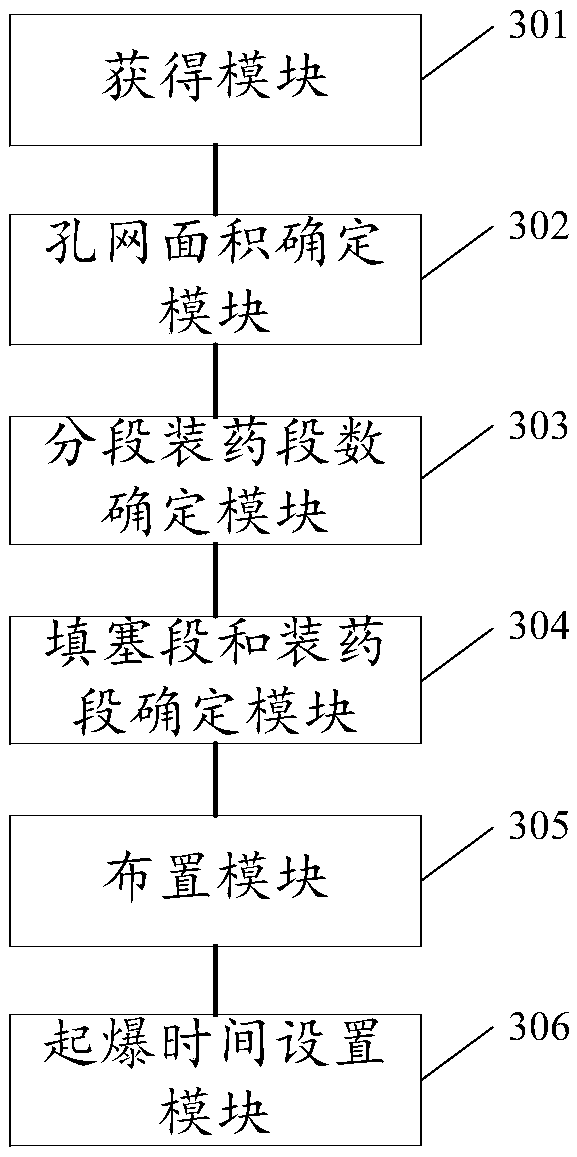

Segmented blasting method and device for medium-depth holes

The invention relates to the technical field of blasting processes, in particular to a segmented blasting method and device for medium-depth holes. The method includes the steps of determining the range of an actual hole net area S, wherein S is equal to or greater than 0.7 S and equal to or smaller than 0.9 S; on the basis of the single-hole explosive payload and the maximum single-segment explosive payload of a blasthole, determining the segmented explosive loading segment number of segmented explosive loading and blasting, and according to the segmented explosive loading segment number, determining the length L1 of a first filling segment, the length h1 of a first layer explosive loading segment, the length Li of the ith filling segment under the first layer explosive loading segment and the length hi of the ith layer explosive loading segment during segmented explosive loading and blasting, wherein the first filling segment, the first layer explosive loading segment, the ith filling segment and the ith layer explosive loading segment are sequentially disposed at the position close to the earth surface from top to bottom; setting the blasthole explosive payload of a hole net andthe quantity of solid fillers for filling according to the parameters above and setting short-delay interval blasting time of every two adjacent blastholes in each horizontal segment among horizontalrows and the short-delay interval blasting time among horizontal holes; according to the calculation value of the short-delay interval blasting time of one blasthole segment in the vertical direction, setting the actual value of the short-delay interval blasting time of the blasthole segment in the vertical direction to be 1.2-1.3 times higher than the calculation value. Therefore, the blasting quality is improved.

Owner:SHOUGANG CORPORATION

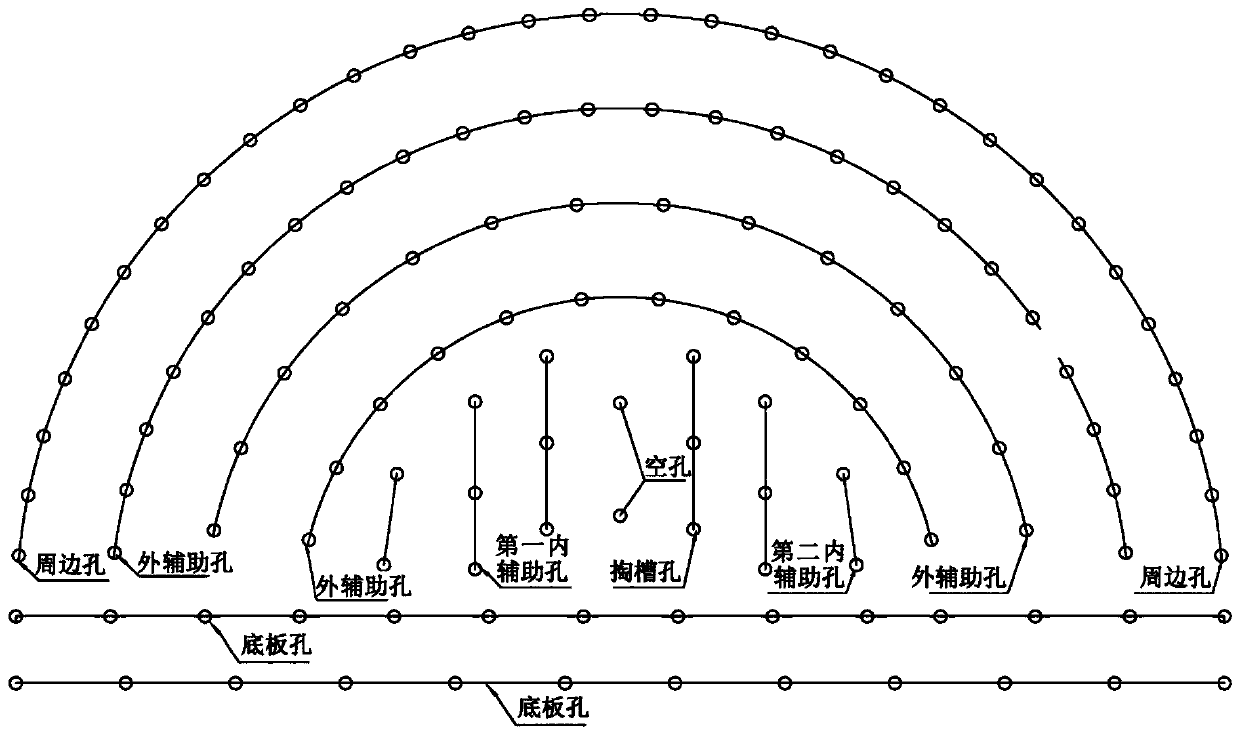

Tunneling method for improving explosion driving rate and lowering explosion vibration

ActiveCN104596372AOvercoming the disadvantage of strong vibrationExcavation by blastingBlastingDetonationEngineering

The invention provides a tunneling method for improving explosion driving rate and lowering explosion vibration. The tunneling method comprises the following steps: firstly, arranging an empty slot in a tunnel face; then, respectively arranging peripheral blast holes, slot expansion blast holes, auxiliary blast holes and bottom plate blast holes in the outline periphery of the section of a tunnel to be excavated, between the outline periphery and the empty slot, and in the bottom edge of the section of the tunnel, wherein the slot expansion blast holes and the auxiliary blast holes are arranged in a turn-by-turn way; carrying out time delay detonation in the turn-by-turn way from an inner turn to an outer turn from the slot expansion blast holes in the inner turn to the periphery blast holes in the outmost turn, and finally detonating the bottom plate blast holes; setting the slot expansion blast holes and auxiliary blast holes in the same turn to carry out hole-by-hole time delay detonation. Since the empty slot is arranged in the tunnel face in advance, the defect of big vibration strength caused by a traditional explosion method is overcome; in addition, a good free face for all blast hole explosion is realized, so that deeper blast holes can be drilled in one time to realize one-time deeper explosion drilling footage and smaller explosion vibration, big-drilling-footage explosion excavation under a complex environment can be favorably realized, and excavation efficiency is improved.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Wall protecting device and hole-wall pressure testing method

ActiveCN108061495AAvoid damageReserve damageBlastingMeasurement of explosion forceDetonationCoupling

The invention discloses a wall protecting device and a hole-wall pressure testing method. The wall protecting device comprises an energy-gathered wall protecting semicircular sleeve, a strain gauge stripping, a dynamic stress sensor and a data line. The energy-gathered wall protecting semicircular sleeve mainly protects a reserved rock mass and reduces the situation that the reserved rock mass isextruded and damaged due to the fact that detonation gas is wedged into primary and secondary cracks of the hole wall; the stripping is mainly used for supporting the energy-gathered wall protecting semicircular sleeve and increasing the non-coupling property between the energy-gathered wall protecting semicircular sleeve and the hole wall; and the dynamic stress sensor is mainly used for monitoring the hole wall pressure in the blasting process and providing a reference for later optimization design of the spacing between the energy-gathered wall protecting semicircular sleeve and the hole wall and the explosive charging spacing. According to the wall protecting device and the hole-wall pressure testing method, smooth blasting of different lithology can be achieved, through feedback of data, an explosive charging structure and the spacing between the energy-gathered wall protecting semicircular sleeve and the hole wall are continuously subjected to optimization design, and under the condition of ensuring the excavation rock mass, the purpose of effectively reducing blasting vibration and reserved rock mass damage can be achieved.

Owner:CHINA UNIV OF MINING & TECH

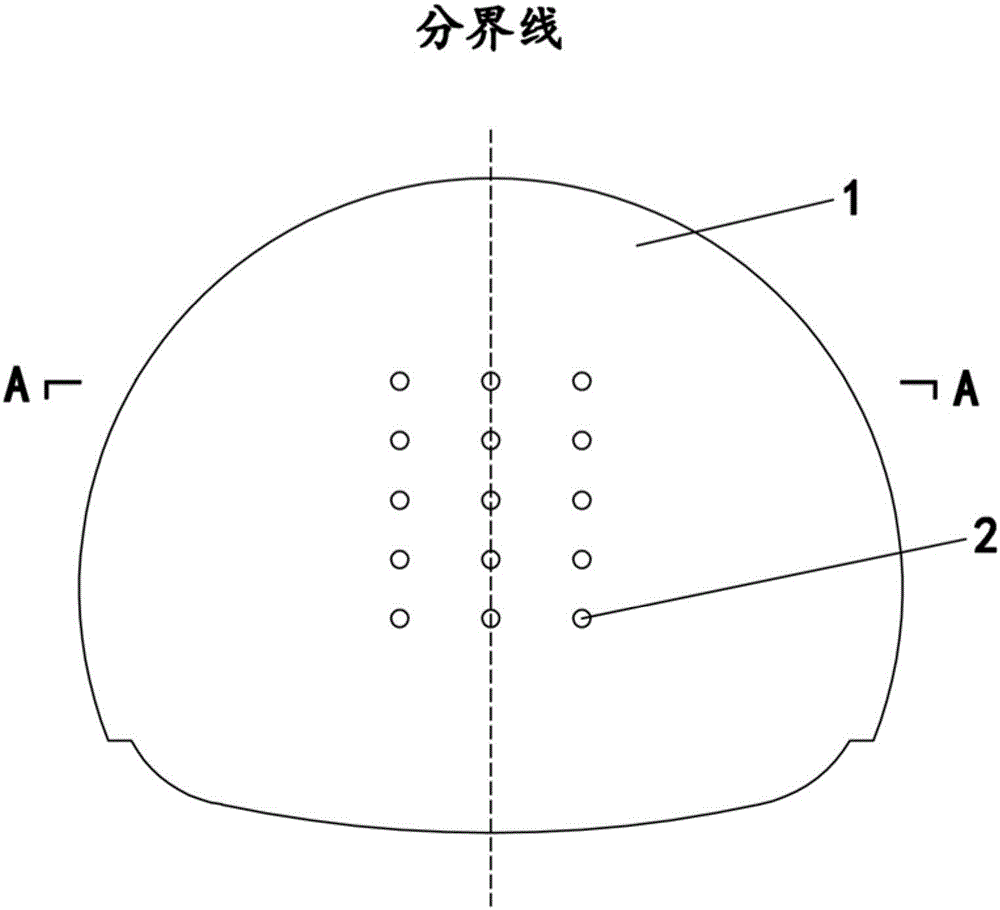

Tunneling blasting method comprehensively utilizing detonator short time difference and empty hole vibration reduction technique

InactiveCN108592725AGuaranteed blasting effectAvoid the disadvantage of large blasting vibrationBlastingDetonatorEngineering

The invention discloses a tunneling blasting method comprehensively utilizing the detonator short time difference and an empty hole vibration reduction technique. The center line of a tunnel face of ablasted tunnel serves as the boundary, and the blasted area is divided into a left region and a right region, wherein the left region and the right region are symmetrical to each other; the two sidesof the center line are provided with a plurality of slotting holes, auxiliary holes and peripheral holes correspondingly, wherein the slotting holes, the auxiliary holes and the peripheral holes aresymmetrical to one another, a vibration reduction hole linear array is arranged on the ground between the blasted area and a building, and in the implementation process, the same row of holes are blasted hole by hole in a symmetrical and delayed manner. Hole-by-hole sequential blasting is performed through electronic detonators, and targeted to different types of blastholes, through the setting ofthe optimal delay time of the electronic detonators, vibration waves transferred to the ground interfere with one another and are counteracted partially; and meanwhile, vibration reduction holes of optimized design are formed on the ground, and 50% of blasting vibration can be effectively lowered. Through the combined measure, the blasting effect of a constructed smooth surface can be guaranteed,the defect that traditional smooth surface blasting is large in vibration can also be overcome, and finally influences on the surface buildings are reduced.

Owner:厦门爆破工程有限公司 +1

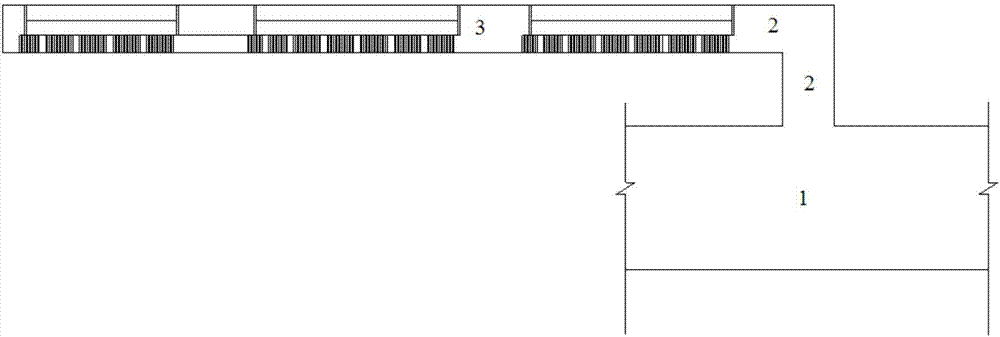

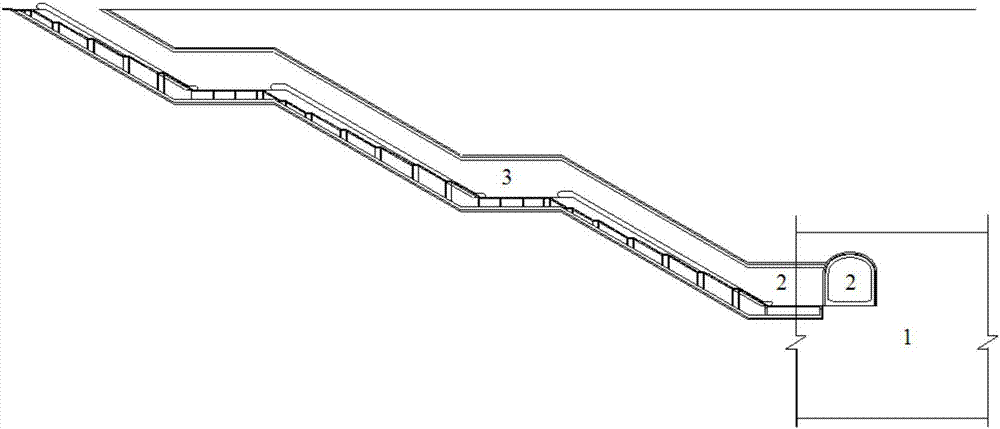

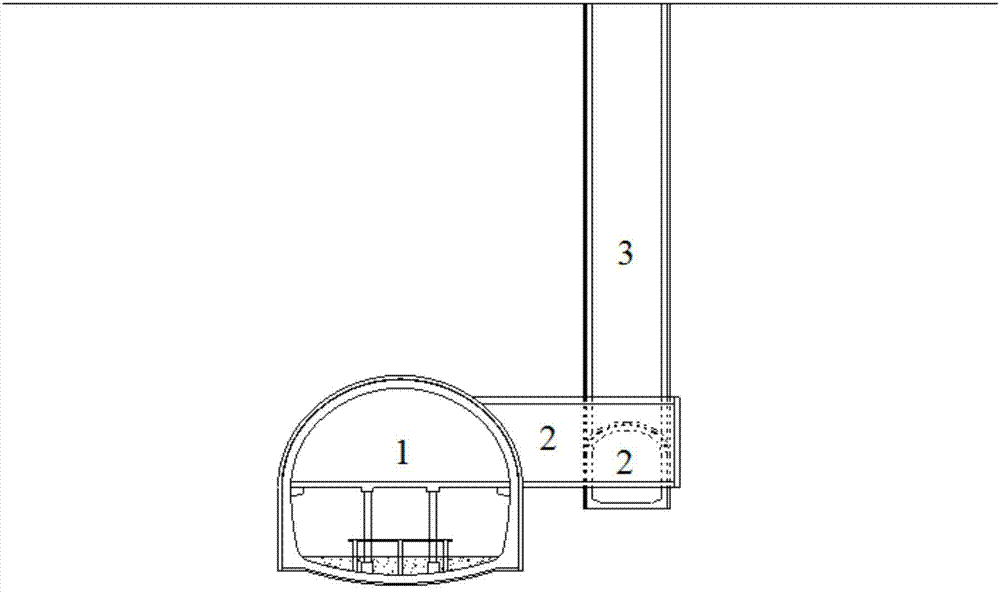

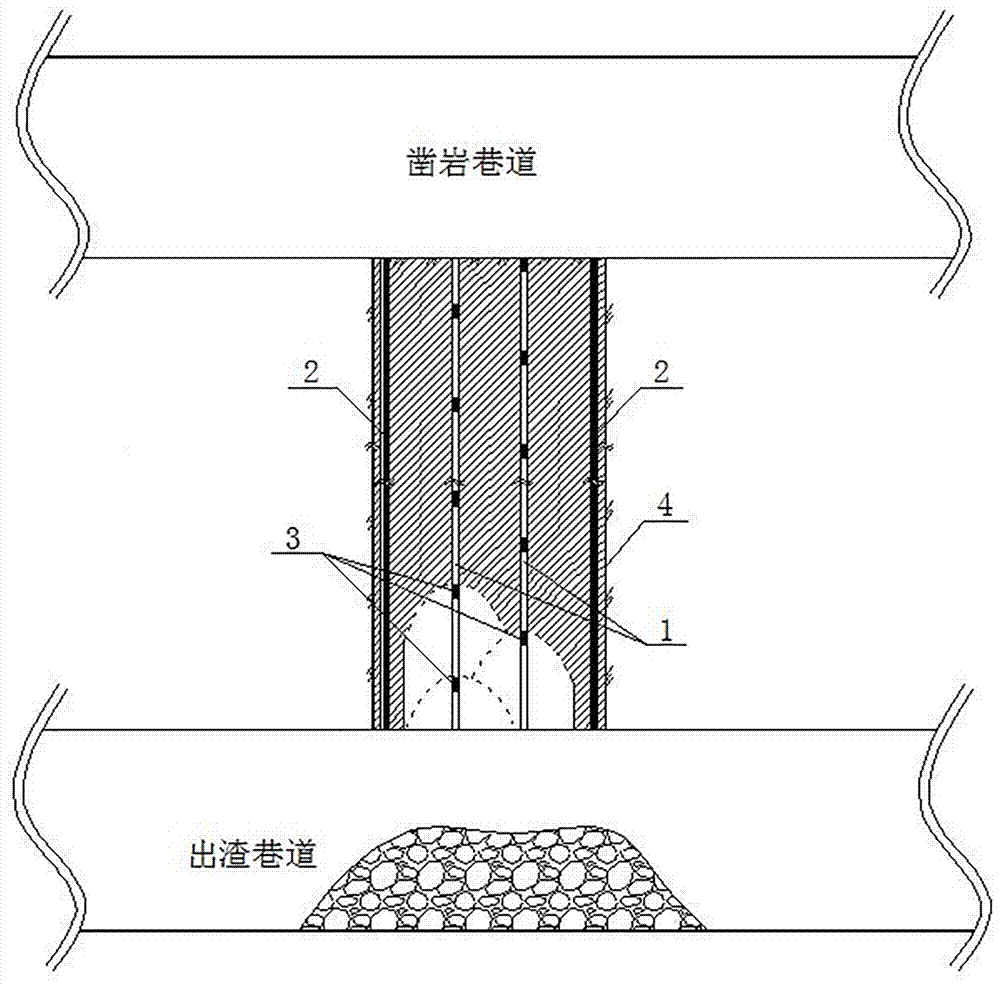

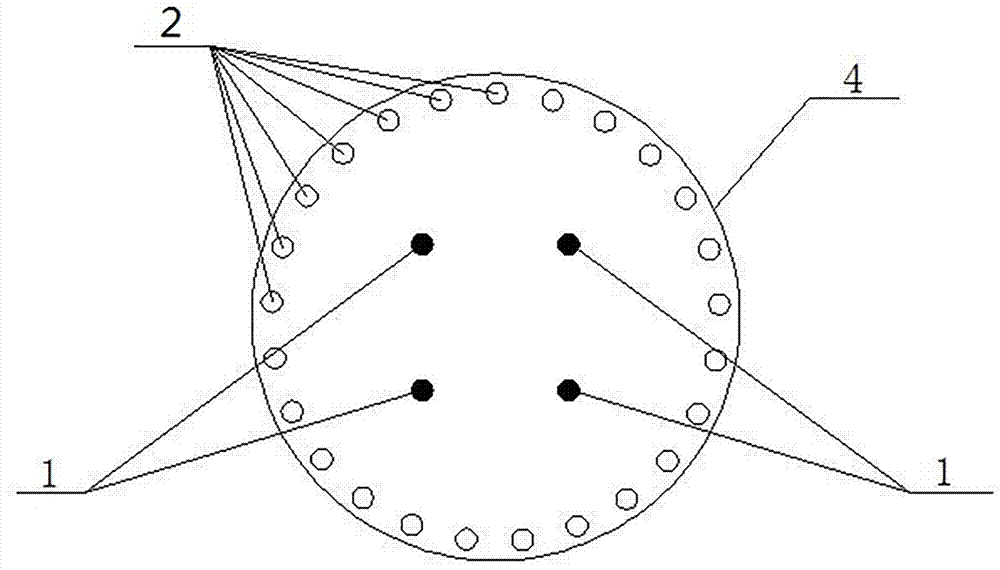

Rapid construction method for subsurface section of passageway of subsurface subway station in rock stratum

The invention discloses a rapid construction method for a subsurface section of a passageway of a subsurface subway station in a rock stratum. The rapid construction method comprises the following steps: taking a small-cross-section inclined pilot tunnel which is constructed in advance and connects an open excavation section to a station as a slag discharge channel; constructing a subsurface section from the open excavation section to the subway station; conveying residue soil generated in an operation process of the subsurface section into the slag discharge channel by using an excavator or a forklift; conveying the residue soil to a tunnel position of a connection section between the station and the passageway by great gradient of the slag discharge channel; and conveying the residue soil to the ground via a station construction channel by a slag car. The problems are solved that in the traditional method for constructing the subsurface section of the passageway of the subsurface subway station in the rock stratum, risks are high and the efficiency is low in a process of excavating from the open excavation section to the station and discharging slag, and the profile cannot be controlled easily when a tunnel is excavated from the station to the open excavation section; construction safety, construction progress and construction quality are guaranteed.

Owner:CRRC CONSTR ENG CO LTD

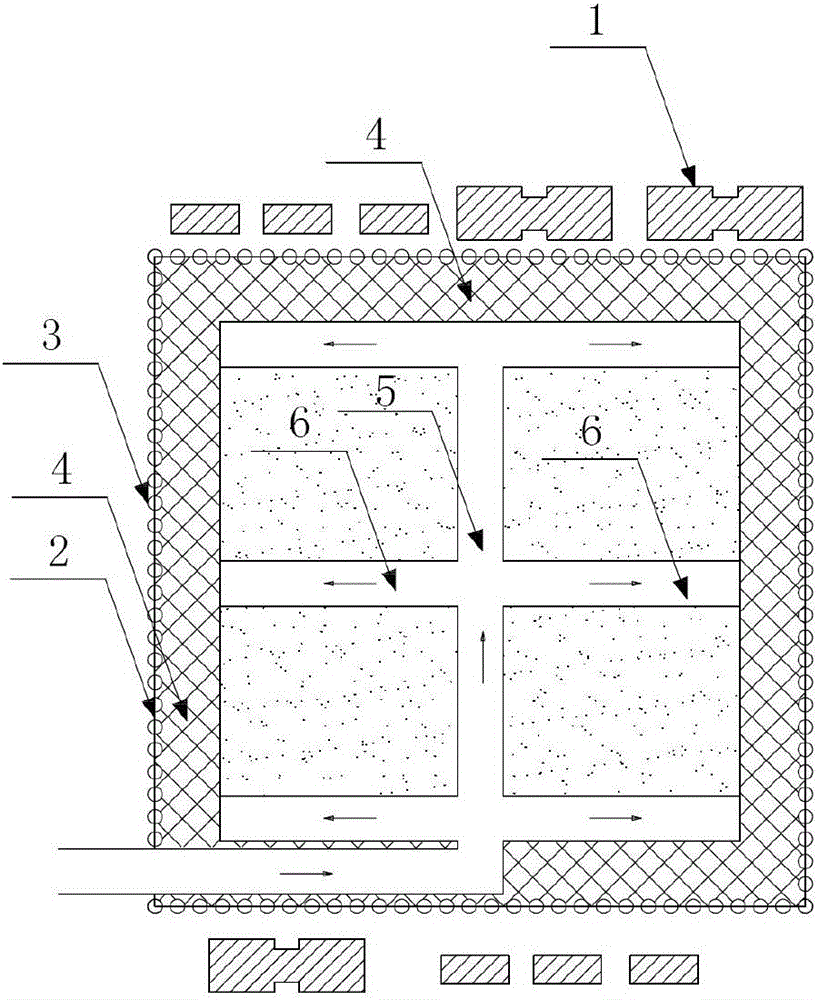

Subway foundation pit blasting method

The invention provides a subway foundation pit blasting method. The subway foundation pit blasting method comprises the steps that a small shallow hole diameter blasting area is arranged in a foundation pit within the range away from the underground continuous wall side boundary by 5.0 m, and a large deep hole diameter blasting area is arranged in the foundation pit outside the range away from the underground continuous wall side boundary by 5.0 m; a row or multiple rows of damping holes are formed in the position, away from the underground continuous wall side boundary by 0.5 m, of the periphery of the foundation pit, and PVC tubes are arranged in the damping holes. The damping holes and difference holes are adopted, the earthquake wave strength can be reduced by 30%, through the millisecond elementary error delay detonation technology, the blasting vibration is reduced, the blasting vibration strength is controlled to the maximum limit, the damage effect on the foundation pit bottom plate rock layer can be reduced, the blasting damage to the surrounding building can be prevented, the harm to the public facilities and vehicle pedestrians can be prevented, and safety of the surrounding environment is protected.

Owner:CCCC TUNNEL ENG

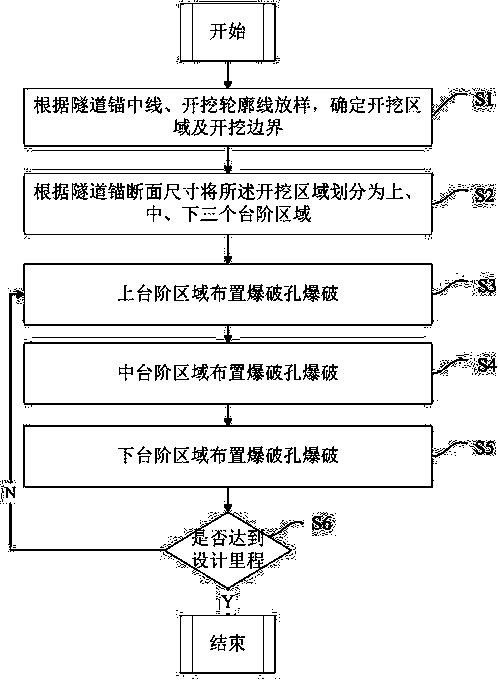

Soft rock and large-dip-angle tunnel anchor digital detonator blasting excavation method

The invention belongs to the field of tunnel anchor excavation construction, and provides a soft rock and large-dip-angle tunnel anchor digital detonator blasting excavation method. After the method is adopted for conducting tunnel anchor blasting excavation, a smooth and flat interface is formed on the excavated boundary, blasting vibration is reduced, influences on surrounding construction buildings are reduced, soft rock and large-dip-angle tunnel anchor micro-disturbance construction is achieved, integrity of surrounding rock is improved, environment damage is reduced, and accordingly integral stability and durability of a tunnel anchor are enhanced. Thus, the soft rock and large-dip-angle tunnel anchor digital detonator blasting excavation method has the obvious advantages that the vibration rate is small, surrounding rock disturbance is reduced, the blasting effect can be effectively improved, tunnel anchor construction and later operation safety is ensured, and influences on thesurrounding construction buildings can be reduced as well.

Owner:THE THIRD CONSTR CO LTD OF CHINA CONSTR THIRD ENG BUREAU

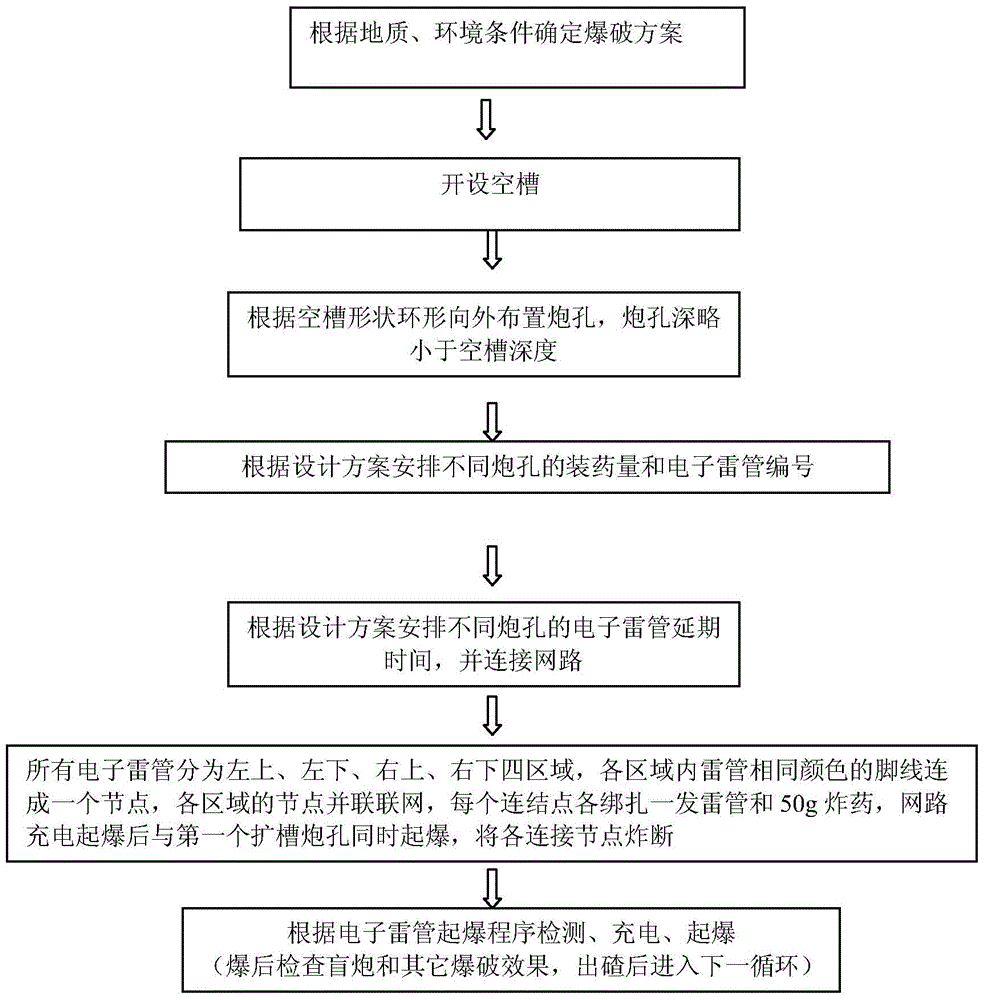

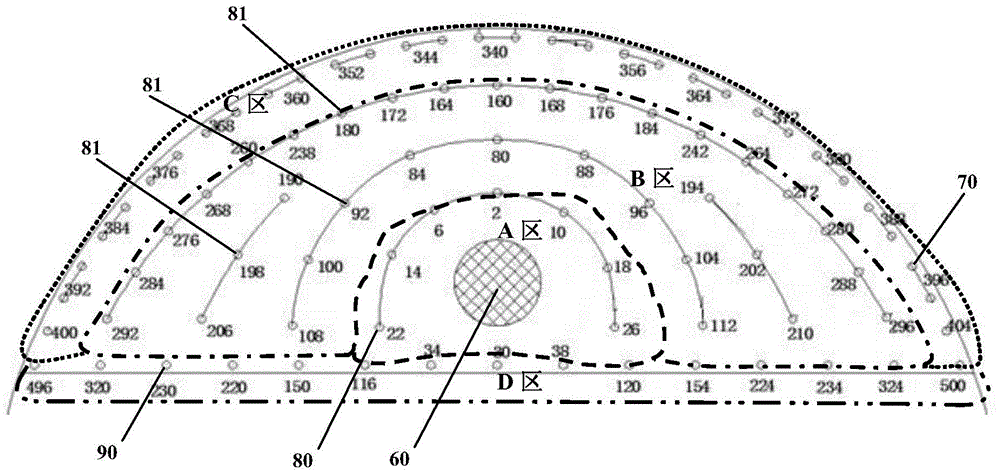

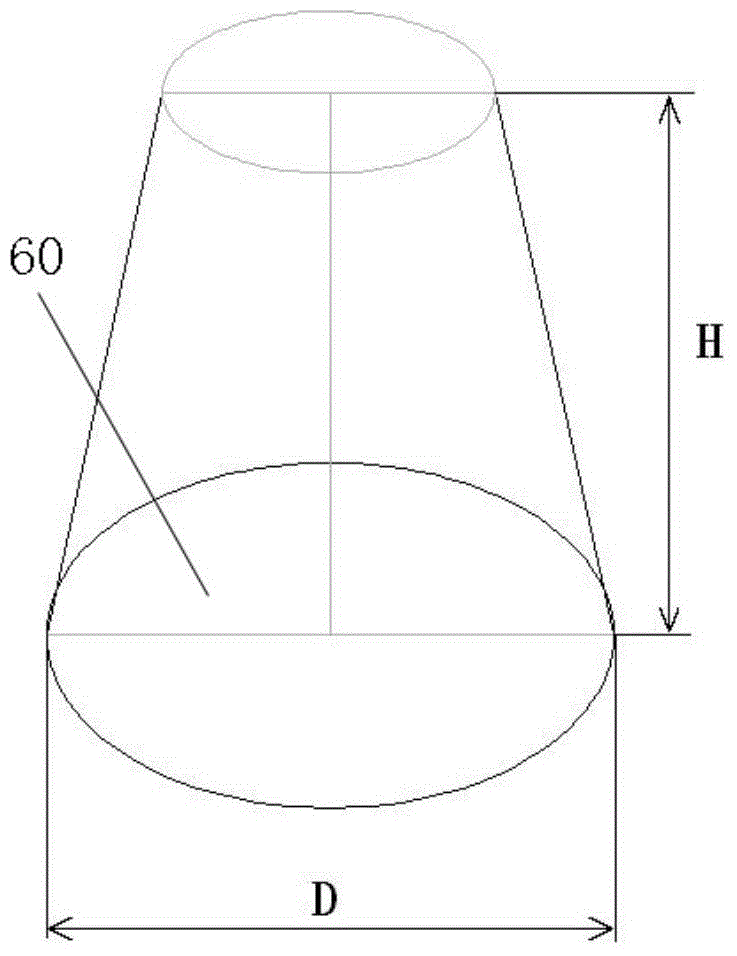

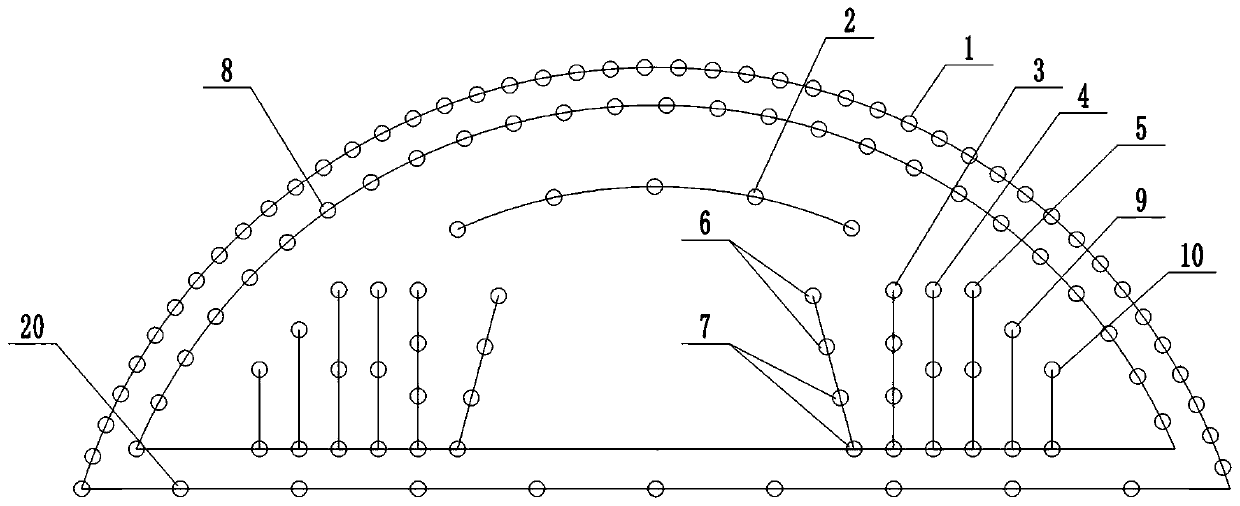

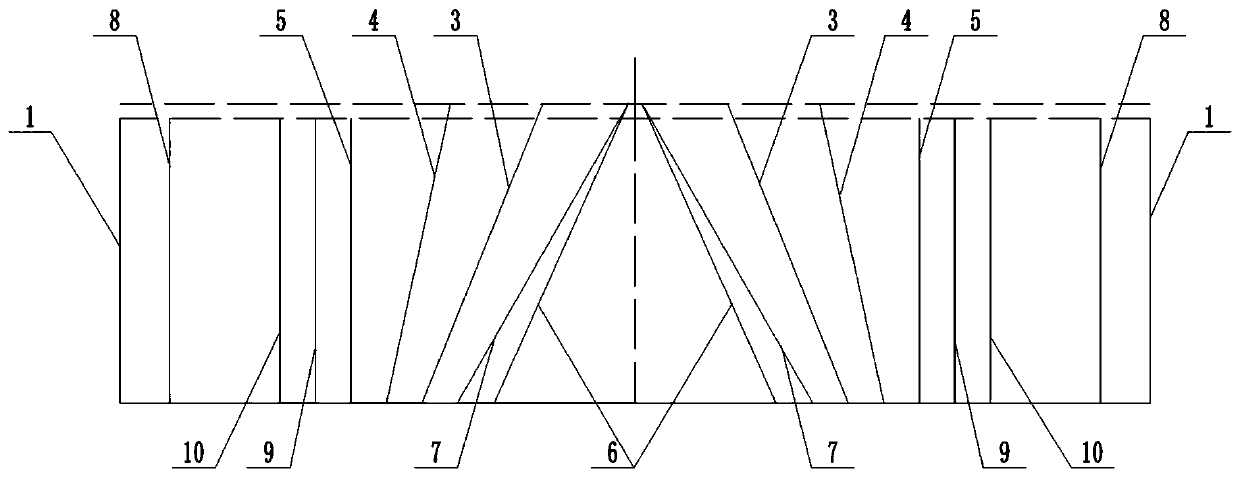

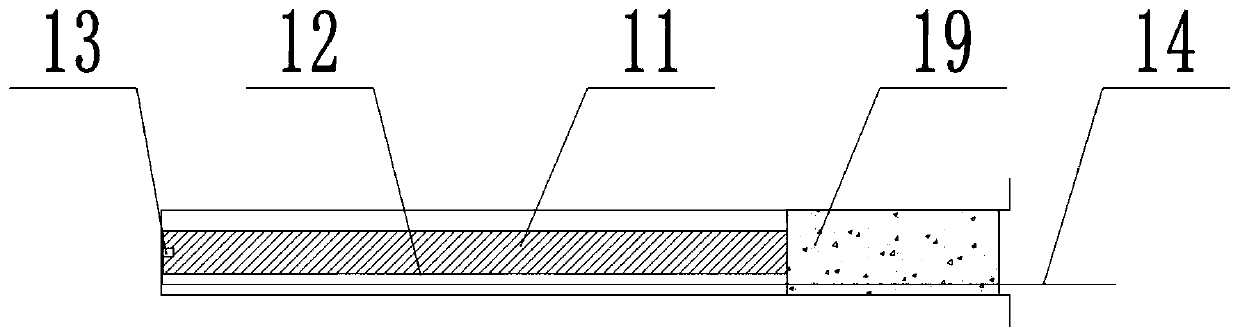

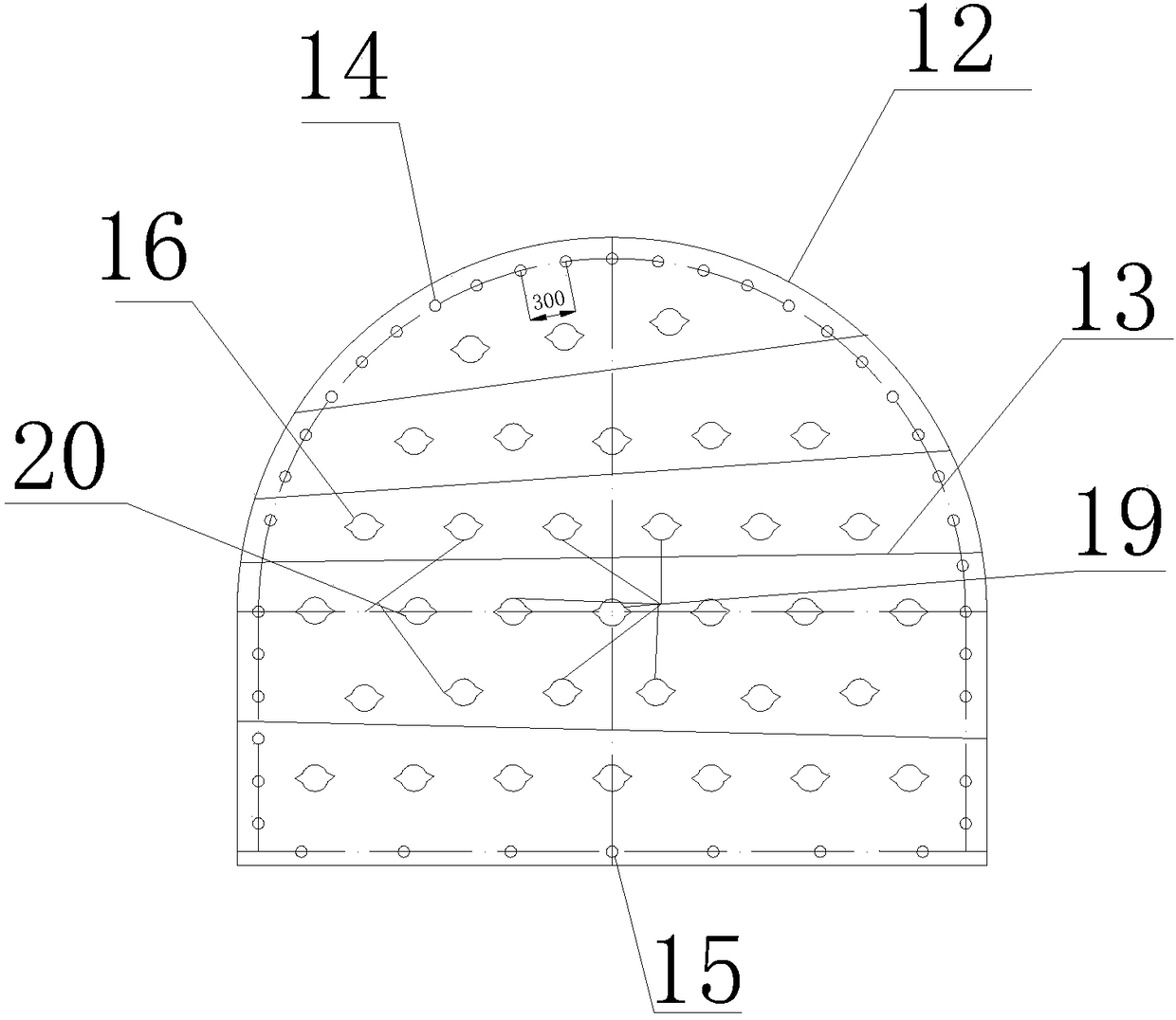

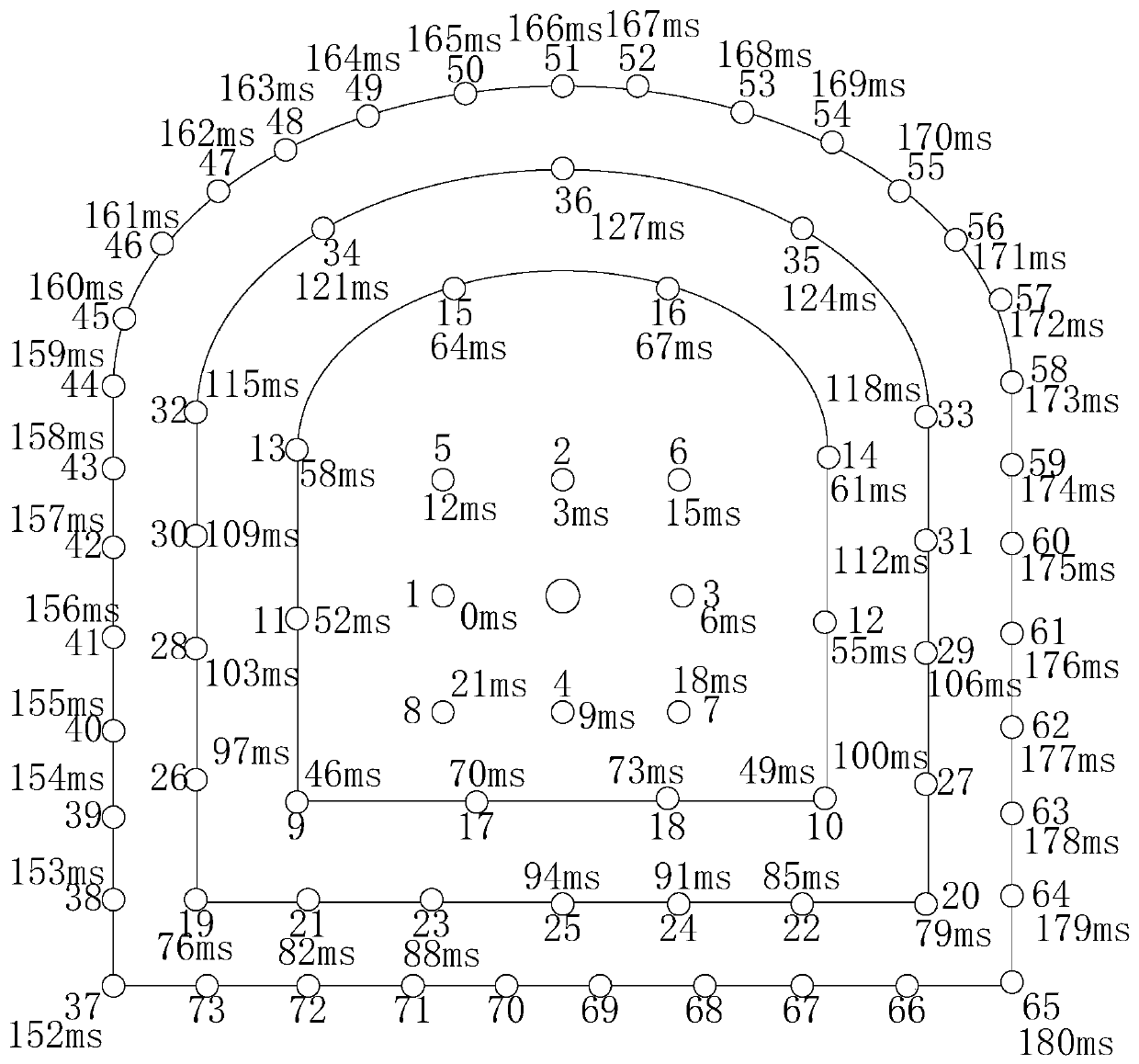

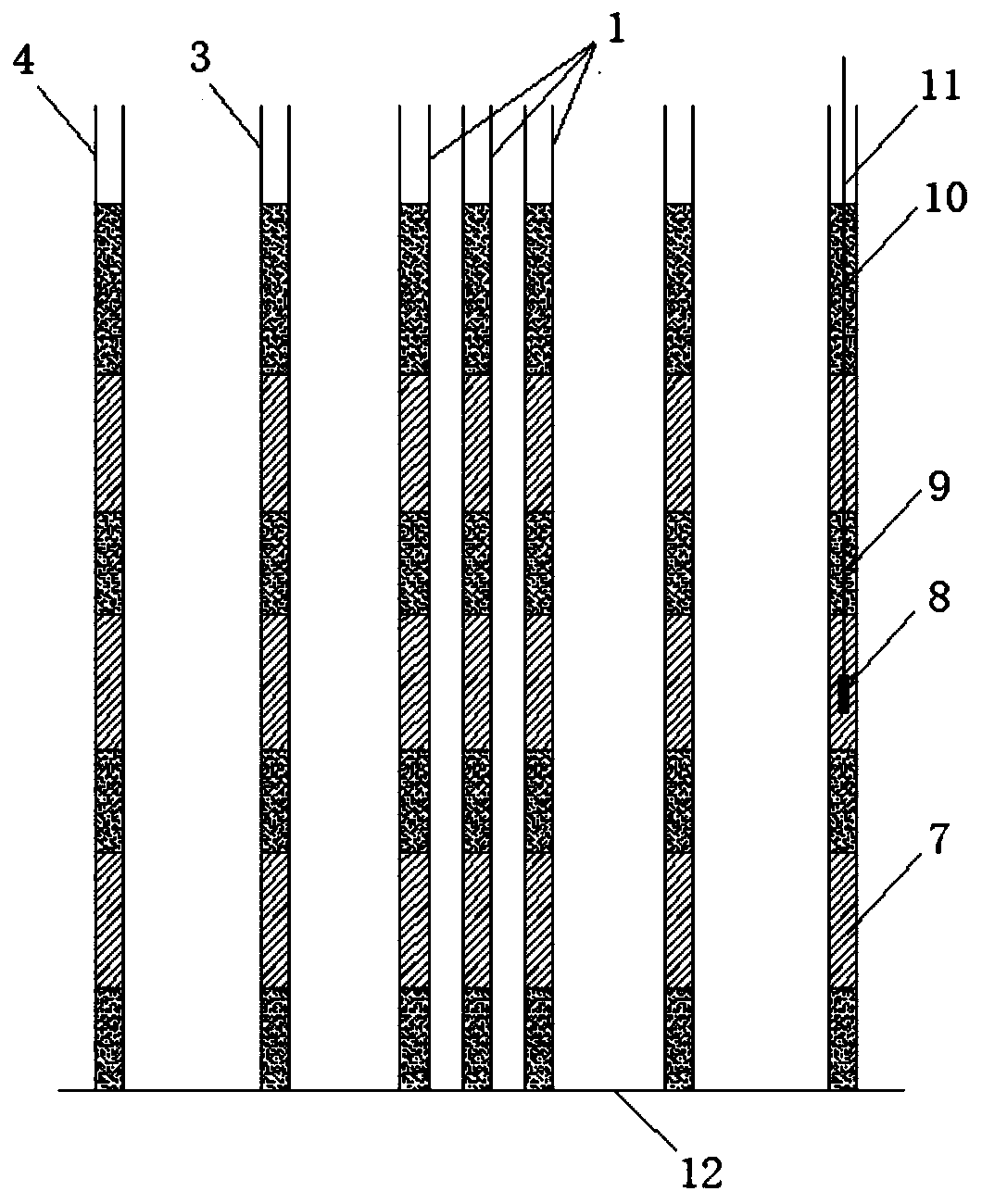

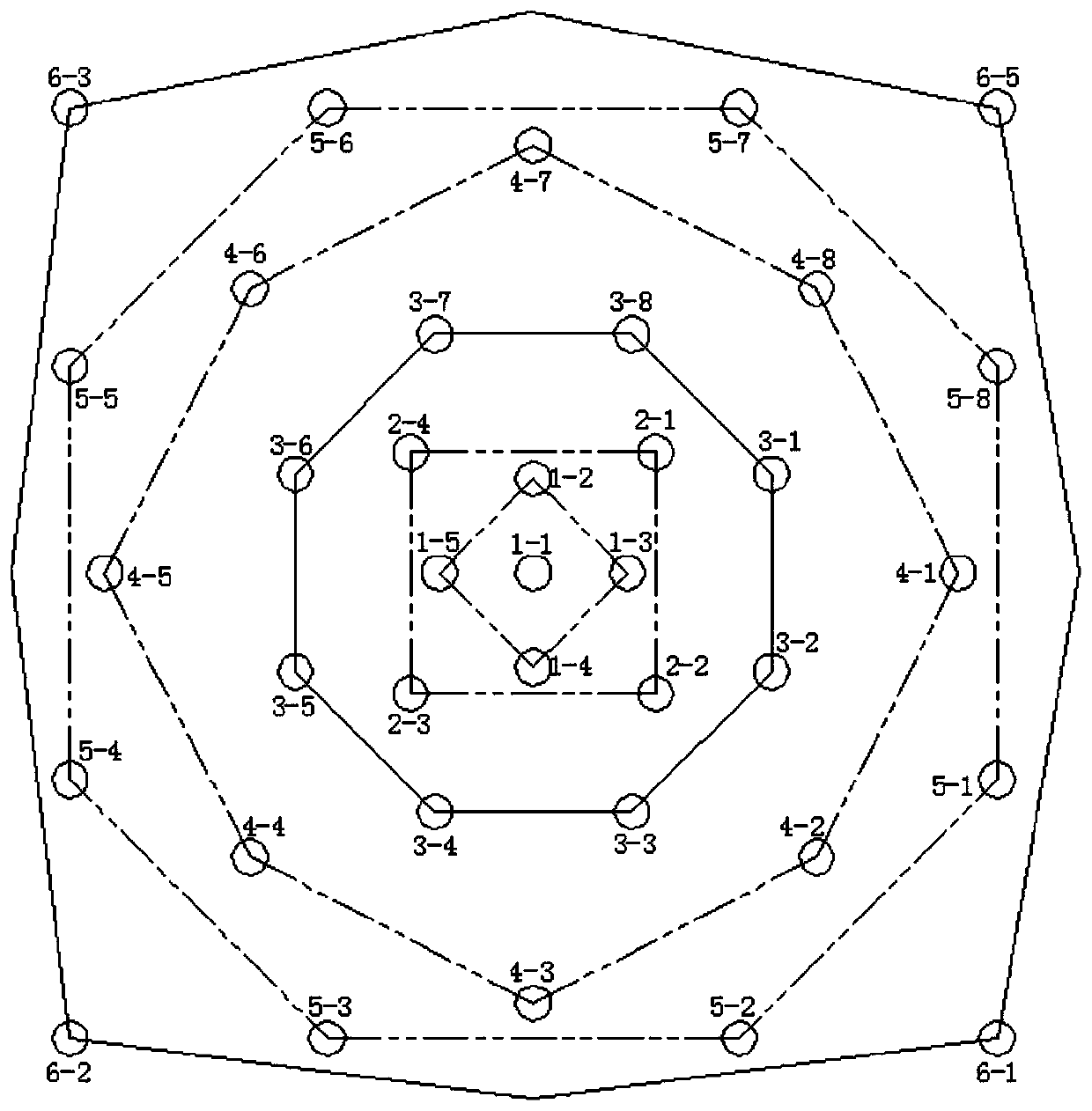

Well formation method adopting vertical shaft blasting for mines

ActiveCN107270791AGuaranteed blasting effectLower drug doseBlastingStructural engineeringBlasting vibration

The invention belongs to the technical field of mining and blasting, and relates to a well formation method adopting a vertical shaft blasting for mines. According to the method disclosed by the invention, explosive charges in a cutting hole are detonated sequentially so as to produce inverted funnel structures which are overlapped to form a blasting hole free surface, and the explosive charges in blasting control holes are synchronously detonated so as to form the vertical shaft of mines; when the blasting effect is ensured, the segment explosive charge can be reduced, the blasting vibration and clamping effects are reduced, the height of well formation by once blasting is improved, and the construction quality and the construction efficiency are improved.

Owner:JINCHUAN GROUP LIMITED

Soft rock single-step deep hole slotting, vibration attenuation, bottom flattening and smooth blasting structure in tunnel

ActiveCN111023927AImprove self-stabilityBreaking rock time extendedBlastingTunnelsVibration attenuationDetonation

The invention discloses a soft rock single-step deep hole slotting, vibration attenuation, bottom flattening and smooth blasting structure in a tunnel. Multiple blast holes are formed in the tunnel tobe blasted, and explosives are arranged in the multiple blast holes. The blast holes include peripheral holes, groove expanding holes, slotting holes, auxiliary holes and bottom plate holes. The groove expanding holes, the slotting holes, the auxiliary holes and the bottom plate holes are internally provided with explosives of continuous loaded structures. Explosives of spaced loading structuresare arranged in the peripheral holes, and the blast holes are blocked through stemming. According to the soft rock single-step deep hole slotting, vibration attenuation, bottom flattening and smooth blasting structure in the tunnel, due to the arrangement of the positions of the blast holes and due to the fact that the explosives of the different structures are arranged in the blast holes, the explosives are blocked in the blast holes through the stemming, the explosive blasting stress and detonation gas are blocked in the blast holes, the rock breaking time is prolonged, the blasting energy utilization rate is increased, the footage is increased, the blasting vibration is reduced, the self-stabilization capability of surrounding rock is improved, and the construction speed is greatly increased.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

Horizontal joint fissure tunnel-smooth-excavation blasting method

PendingCN108469209AReduce usageReduce the number of peopleBlastingBlasting vibrationUtilization rate

The invention belongs to the field of tunnel engineering for horizontal joint development of rock mass, and particularly relates to a horizontal joint fissure tunnel-smooth-excavation blasting method.The method comprises the steps that a grooving control blasting device and a smooth blasting axial uncoupled rapid explosive transfer device are used; slotting blasting of blastholes outside peripheral holes of a tunnel and uncoupling charge of the peripheral holes are carried out; and through millisecond blasting, the requirements of footage and the smooth effect of tunnel excavation blasting are realized. According to the horizontal joint fissure tunnel-smooth-excavation blasting method, the advantages of the slotting blasting and axial uncoupled blasting are fully combined, the influence of horizontal joint fissure on blasting construction is reduced, the blasting energy utilization rate and blasting tunneling footage of the horizontal joint tunnel are improved, the smooth blasting effect of the tunnel is improved, the use of peripheral hole explosives is reduced, blasting vibration is reduced, the surrounding rock stability is improved, the construction risk is reduced, the tunnelconstruction environment is improved, the number of operators is reduced, and the charge efficiency is improved.

Owner:GUIZHOU HIGHWAY ENG GRP +1

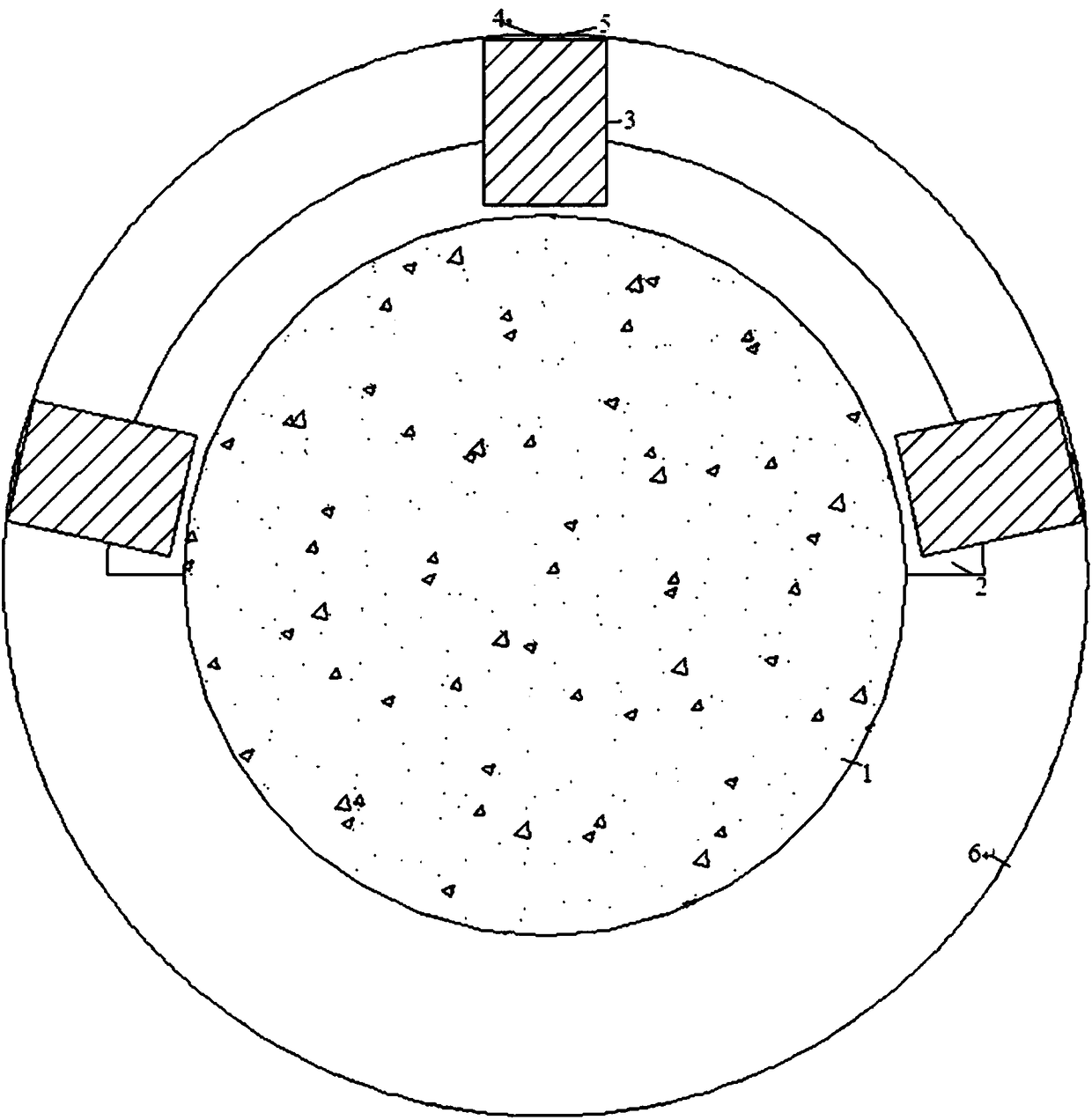

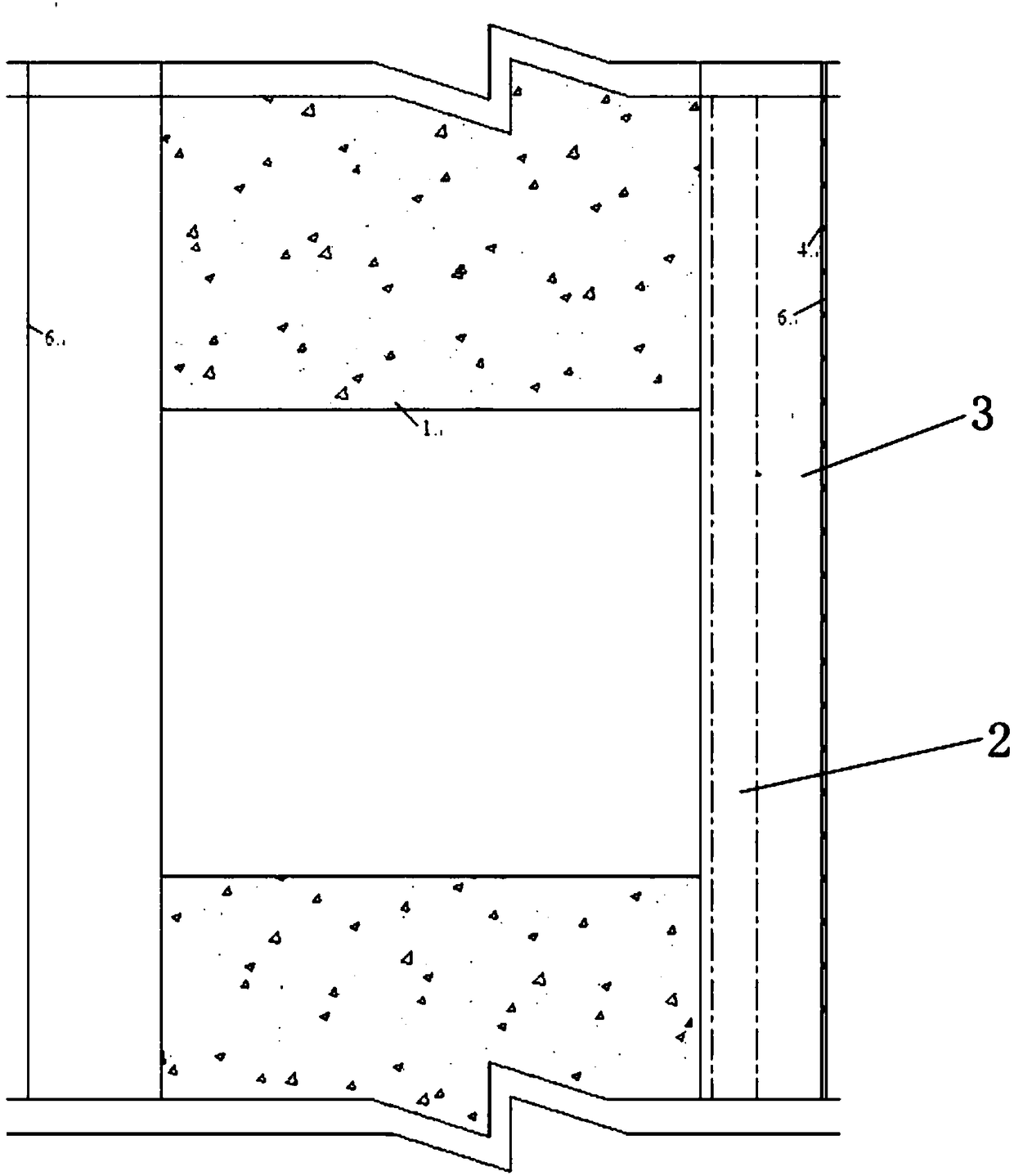

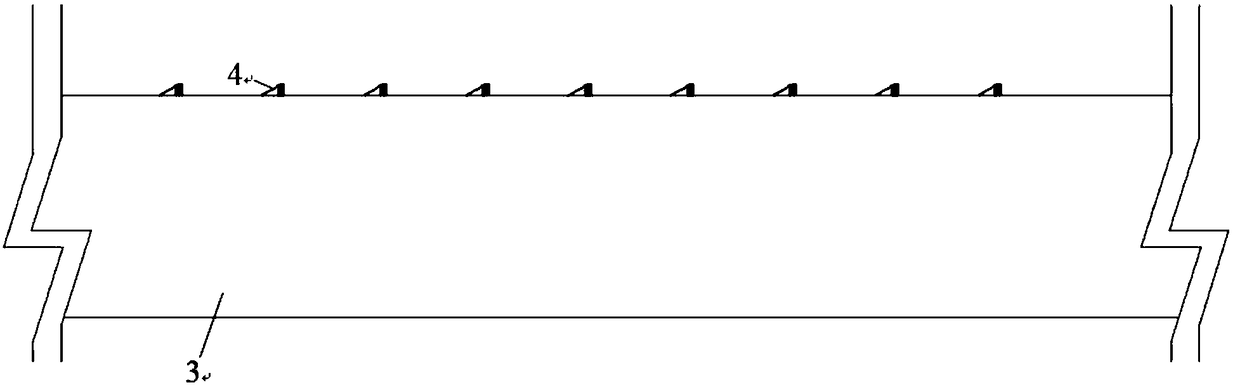

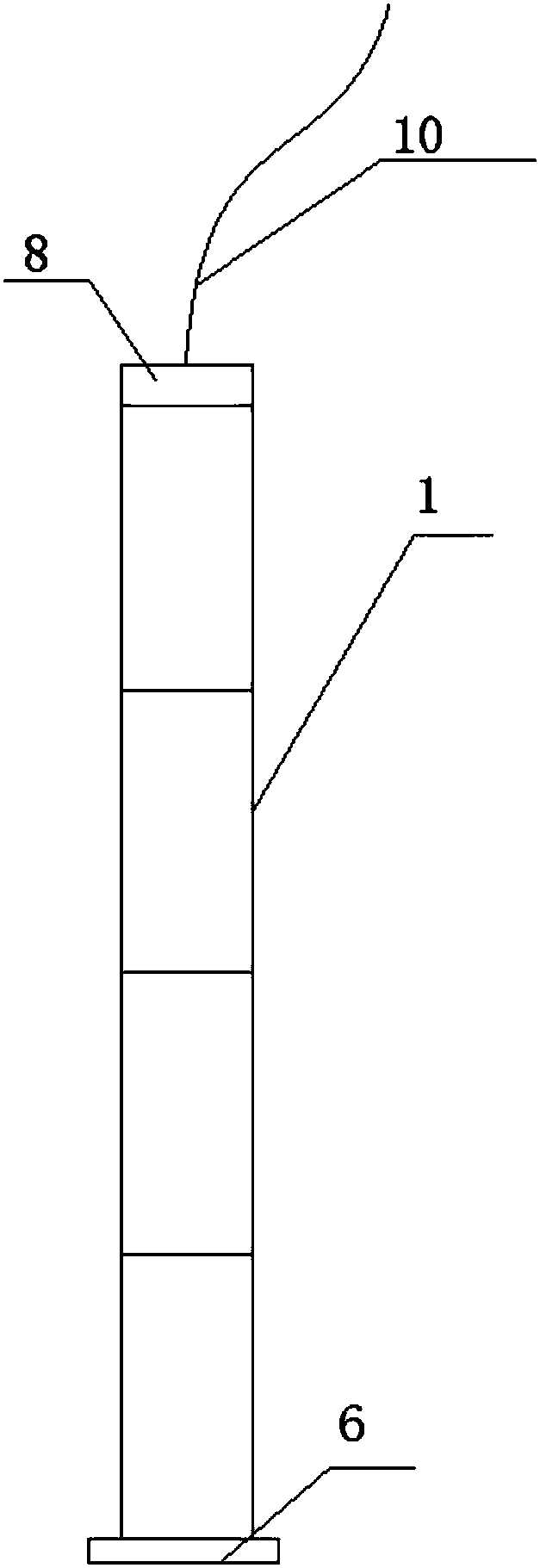

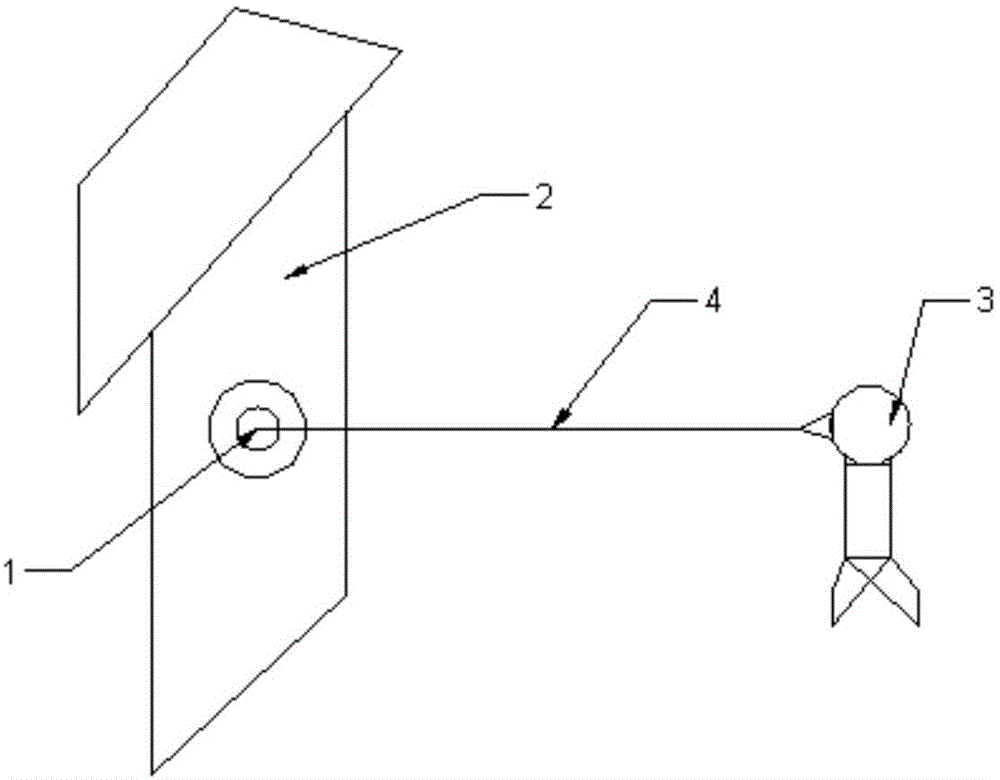

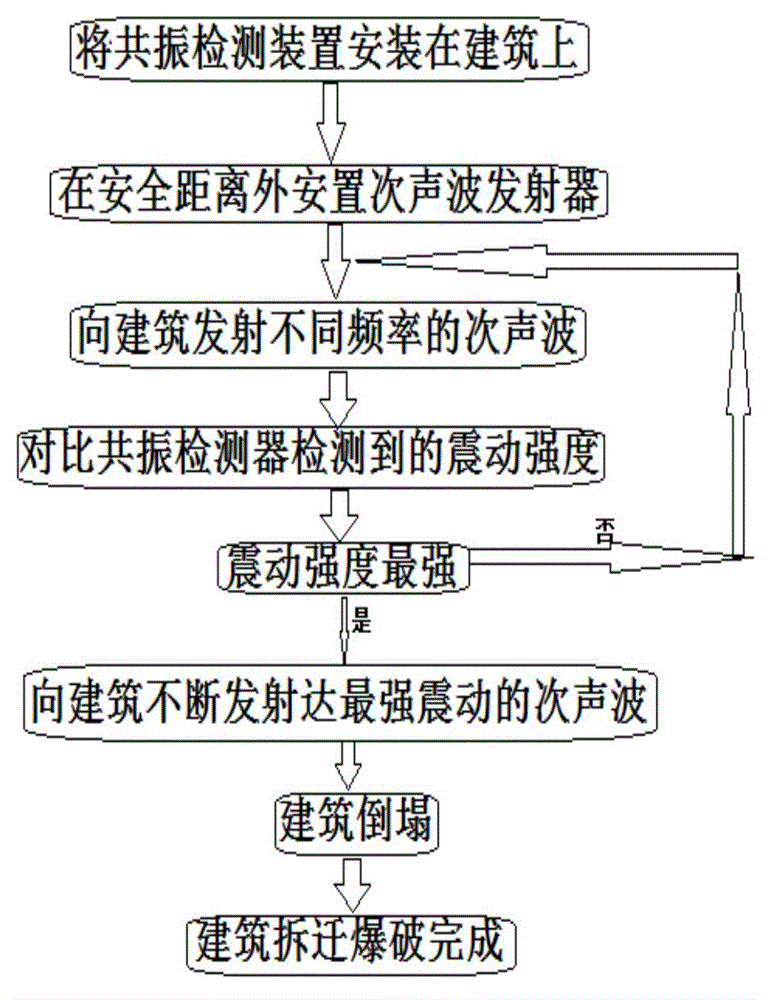

Building blasting device based on infrasonic wave resonance technology

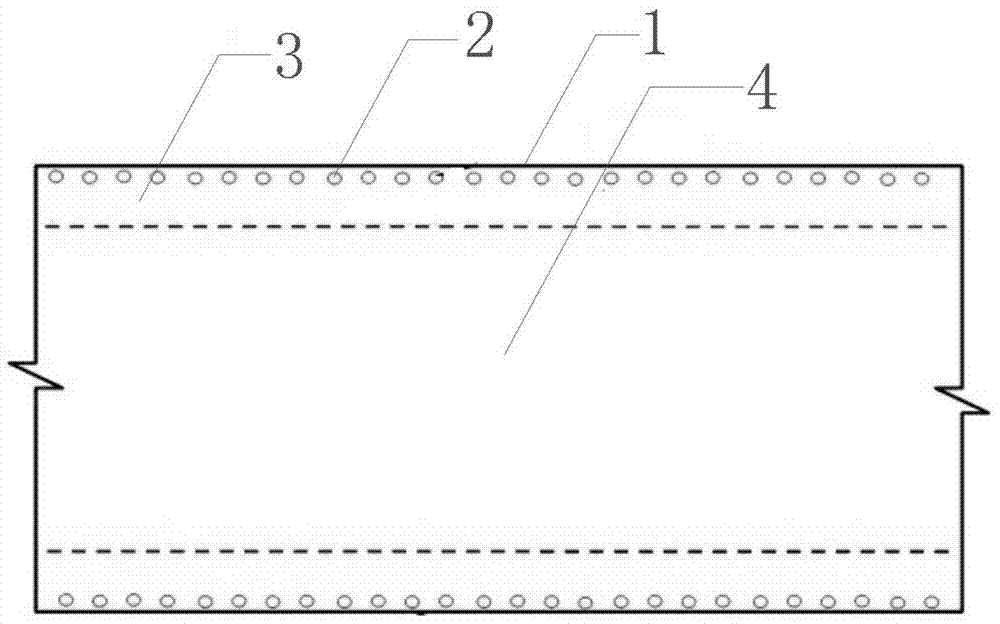

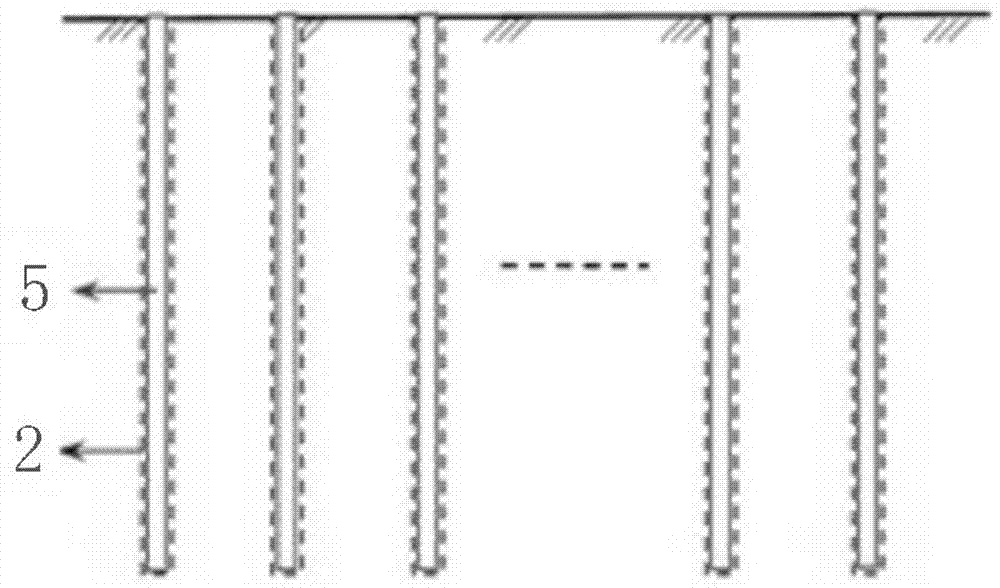

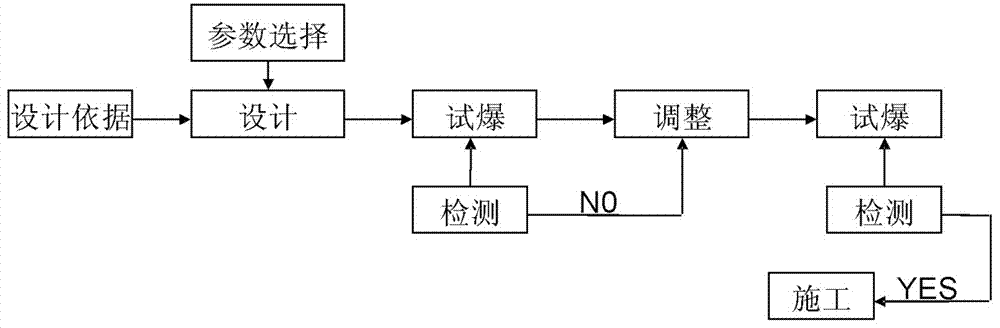

InactiveCN105091681AFormation range is smallImprove shielding effectBlastingInfrasonic wavesEngineering

The invention discloses a building blasting device based on an infrasonic wave resonance principle. The building blasting device comprises a resonance detector (1), a building (2) subjected to demolition blasting , an infrasonic wave emitter (3) and infrasonic waves (4); the resonance detector (1) is mounted on the demolition blasting building (2), and the infrasonic wave emitter (3) is placed on the ground away from the building over the collapsing safety distance; the infrasonic wave emitter is turned on and emits the infrasonic waves (4), gradually enhanced with 1Hz as the beginning, to the building in an orientation manner; the resonance detector (1) continuously detects and records the vibration frequency and the vibration strength of the building; the vibration strength and the vibration state of the building (2) obtained after the infrasonic wave are emitted every time are compared, and demolition blasting begins; and the infrasonic wave emitter (3) is used for emitting the infrasonic waves (4) to the building, and vibration of the demolition blasting building (2) is more and more strenuous till demolition blasting is achieved. The collapse direction can be accurately controlled, the blasting vibration can be effectively reduced, and the collapse length range of the building can be reduced.

Owner:NANJING DAWU EDUCATION TECH

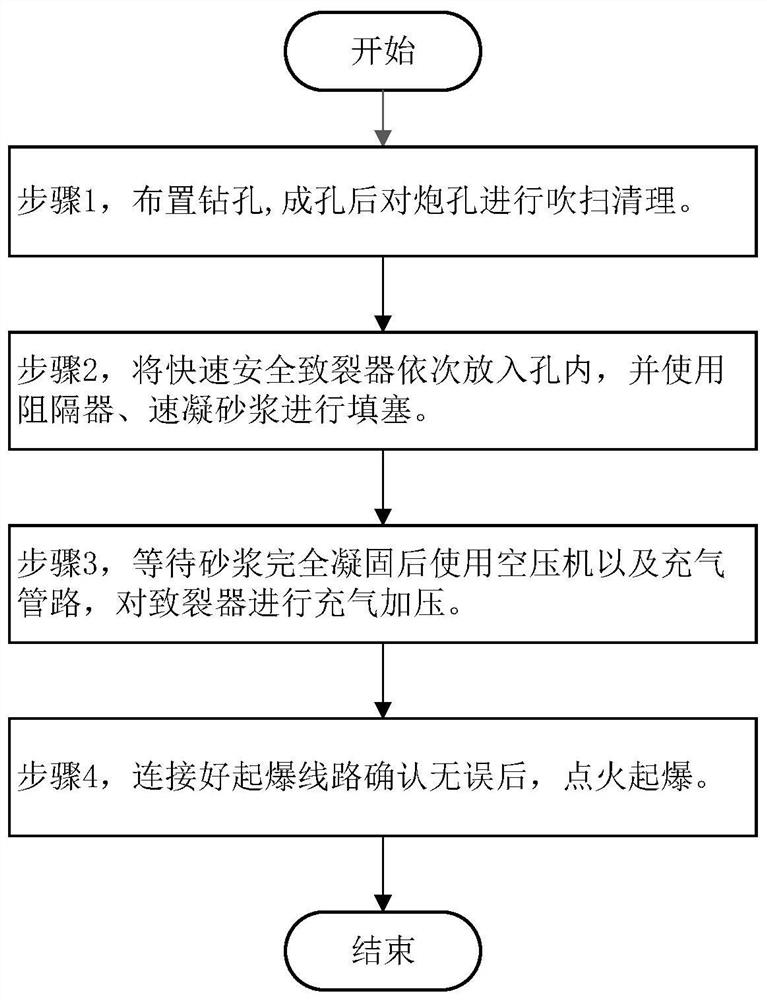

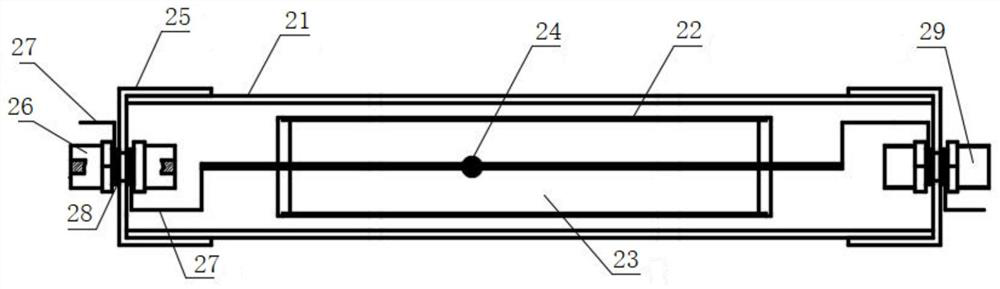

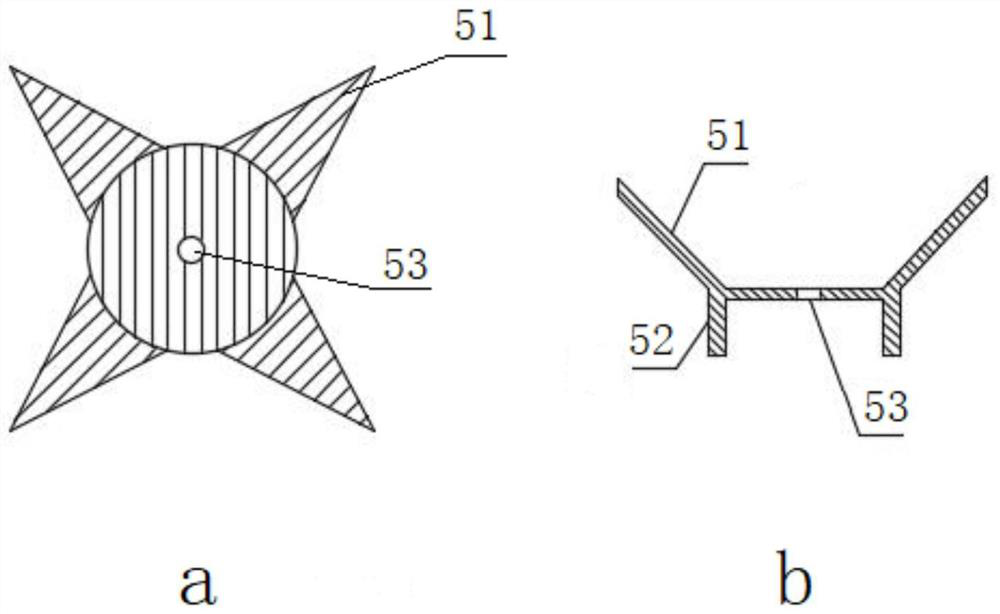

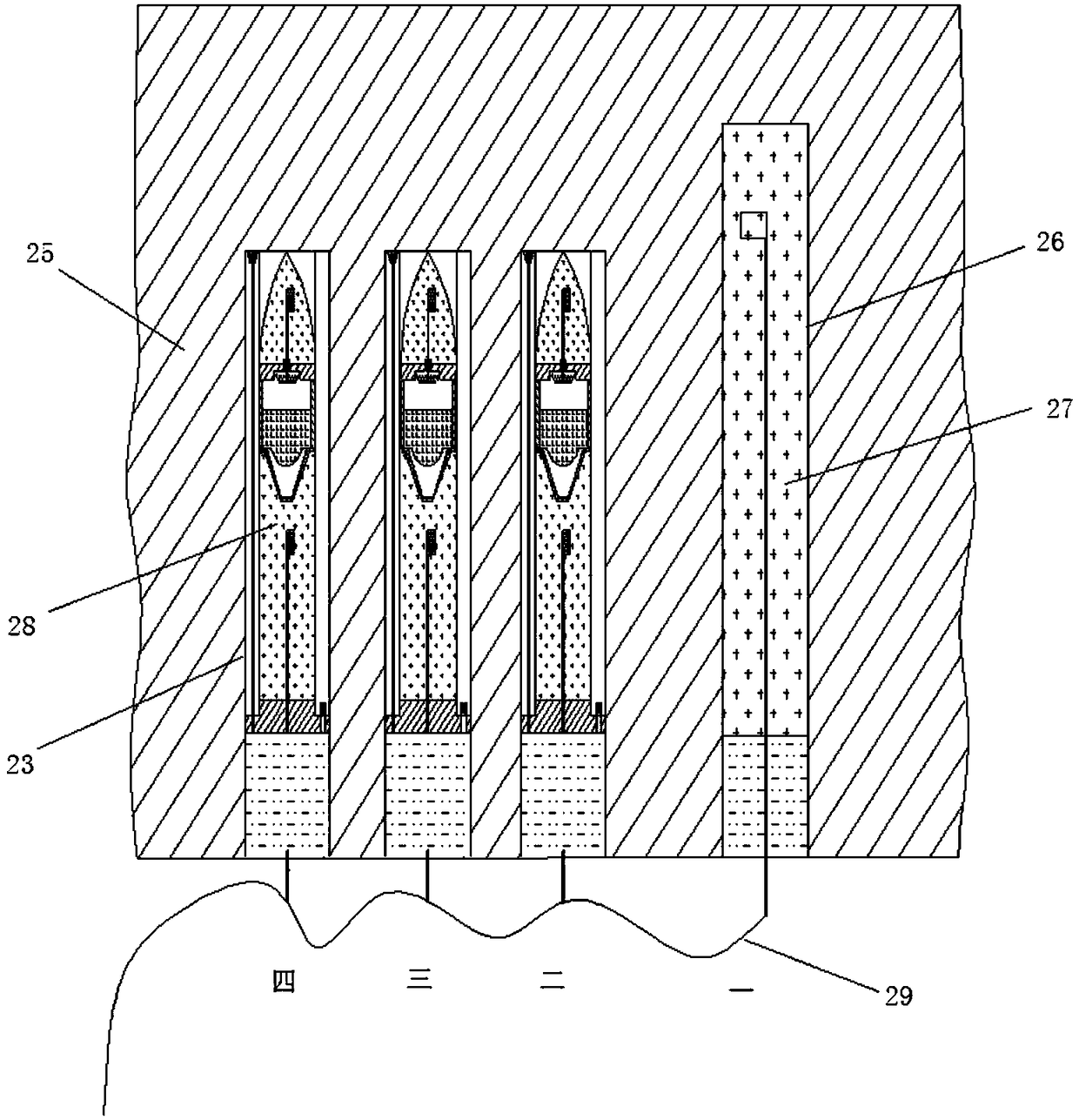

Blasting construction method for blasting equipment

PendingCN111692935AThe blasting implementation process is convenientStrong blasting controllabilityBlasting cartridgesBlastingDetonationArchitectural engineering

The invention discloses a blasting construction method for blasting equipment. The blasting construction method comprises the steps: firstly a hole net is arranged, a first row of holes is formed in the direction of a free face, the hole diameter is larger than 90 mm, the hole distance is 500-1000 mm, the row distance between a second row of holes and the first row of holes is 500-1000 mm, and inthe same way, after hole forming, purging clearing is conducted on the blast holes; then the blasting equipment is sequentially put into the holes, the blast holes are stuffed with barriers, the blasting equipment is sealed in the blast holes, and the exteriors of the barriers are stuffed with quick-setting mortar; after the mortar is solidified, the blasting equipment is inflated and pressurizedthrough an air compressor and an inflating pipeline, and a pressure value reaches the initiation pressure; and finally after connection of an initiation circuit is completed and confirmed, ignition detonation is conducted. According to the method provided by the invention, the blasting implementation process is convenient, blasting controllability is high, blasting vibration can be reduced, greatprotection effect on the construction ambient environment can also be achieved, and meanwhile the blasting effect is ensured.

Owner:马铭泽

Blasting structure of efficient blasting device

The invention discloses a blasting structure of an efficient blasting device. The blasting structure of the efficient blasting device comprises a geological part needing to be exploded, wherein a mainblast hole is formed in the geological part needing to be exploded, an auxiliary blast hole is formed in the periphery of the main blast hole in sequence, an explosive is placed in the main blast hole, a blasting device is arranged in the auxiliary blast hole, and the main blast hole and the auxiliary blast hole are connected in sequence through a detonation line. According to the blasting structure of the efficient blasting device, the method is mainly designed by utilizing a micro-differential blasting technology, a bottom-bottom blasting technology and a water interval blasting technology,the explosion vibration is reduced, the large block amount is reduced, the single-consumption amount and the dust concentration of the explosive are reduced, the utilization rate of a blast hole is increased, the blasting effect is increased, and the explosion safety is improved.

Owner:GUIZHOU UNIV

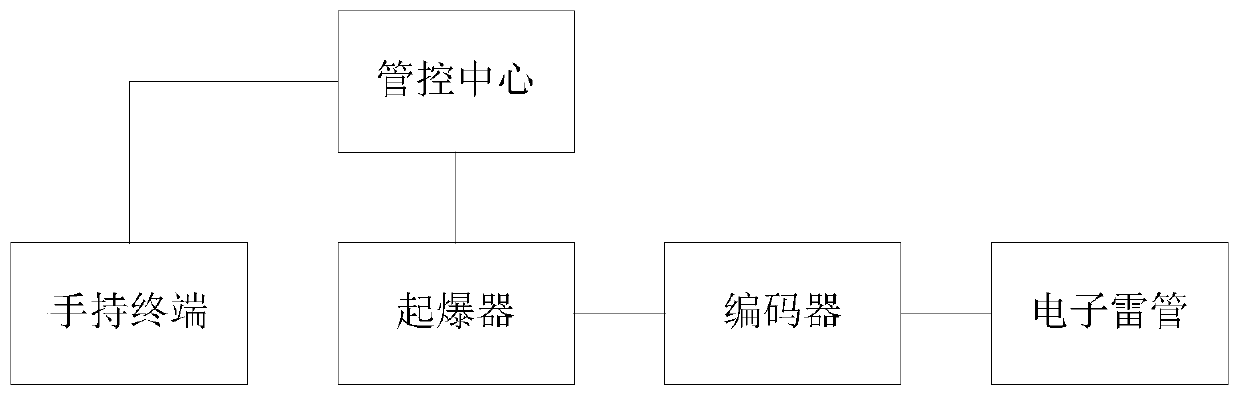

Electronic detonator initiation system for tunnel blasting

InactiveCN111023921AReduce the chance of occurrenceReduce handlerBlastingTunnelsMechanical engineeringEmbedded system

The invention relates to the field of blasting, and discloses an electronic detonator initiation system for tunnel blasting. The electronic detonator initiation system is used for reducing the generation probability of blind shots during tunnel blasting and managing the blind shots. The electronic detonator initiation system comprises a handheld terminal, a control center, an initiator, an encoderand an electronic detonator, wherein the handheld terminal communicates with the control center through a wireless network; bar codes corresponding to equipment IDs are arranged on the outer portionsof the encoder and the electronic detonator; the handheld terminal is provided with a camera for scanning the bar codes; if the initiation of the electronic detonator fails and the line of the electronic detonator is intact, the handheld terminal is used for scanning the bar code of the electronic detonator failing to initiate and the bar code of the corresponding encoder, acquiring the ID of theelectronic detonator failing to initiate and the ID of the encoder, and reporting the acquired IDs to the control center for blind shot management; and the blind shot management comprises secondary initiation authorization and destruction authorization, so that the blind shots are conveniently recycled or placed to run into the society. The electronic detonator initiation system is suitable for tunnel blasting.

Owner:PANZHIHUA UNIV +1

Single-free-surface combined blast hole broaching blasting method

InactiveCN110332866AIncreased stress durationUniform fragmentation by blastingBlastingEngineeringSingle section

The invention discloses a single-free-surface combined blast hole broaching blasting method. The method comprises the steps that a blasting center hole and a plurality of circles of combined blast holes around the blasting center hole with different distances are arranged, the blast holes are charged in a sectioned mode and independently controlled to detonate, all the blast holes are subjected tosubsection delay blasting from bottom to top according to the explosive sections, and the delay blasting of the same section of explosive is completed by all the combined blast holes in a mode from inside to outside by taking the center blast hole as a starting point within blasting delay of the two sections of explosive in the center blast hole. According to the method, the combined delay initiation between the blast holes and in the blast holes is adopted, so that a common blasting funnel is formed, the broaching blasting effect is guaranteed, the action time of the pressure of the blastinggas in the combined blast holes is prolonged, more energy can be applied to the subsequent rock pushing and throwing, the explosive quantity of a single section of blasting can be greatly reduced, and the defect of large vibration of a traditional cut blasting in the same section is avoided.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com