Partition control blasting method for tunnel rock drilling project

A partition control and engineering technology, applied in blasting and other directions, can solve the problems of weak drilling and blasting control, increase the amount of charge in the same section of the cutting hole, increase the amount of charge in the hole, etc., and achieve control of the distance of blasting flying stones, Reduce the negative effects of blasting and reduce the effect of blasting vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

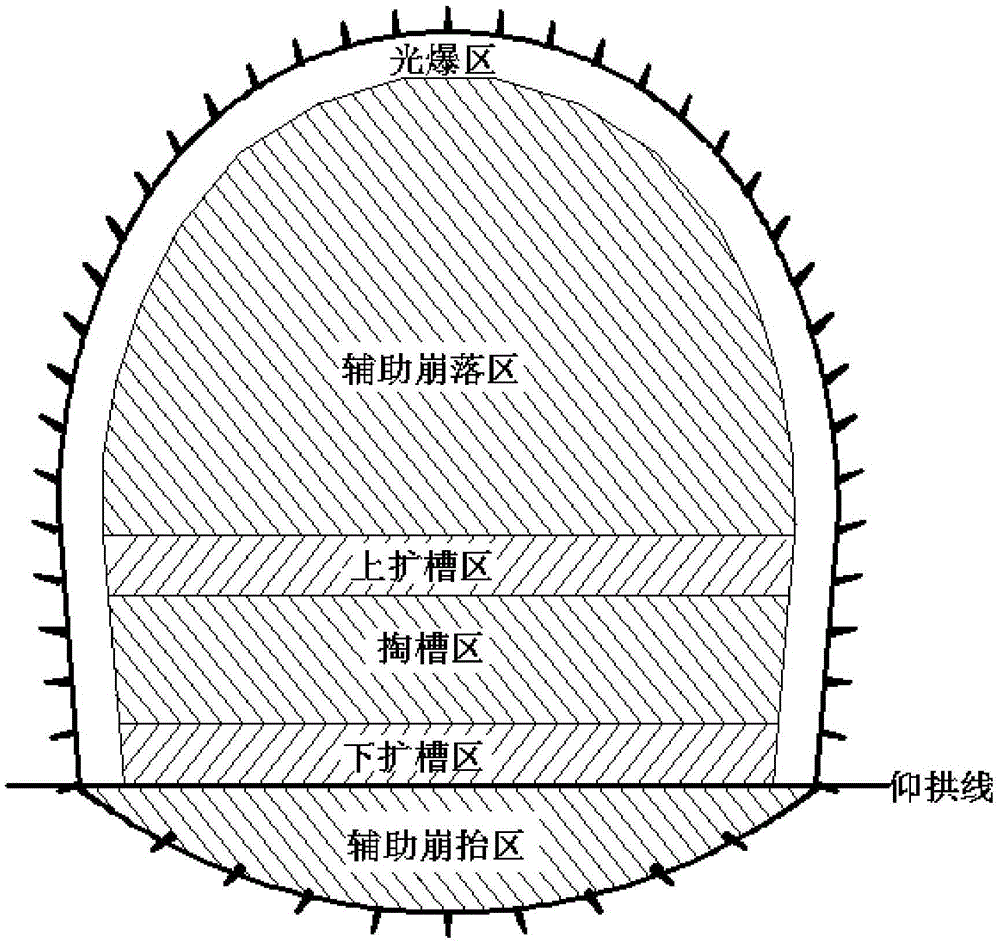

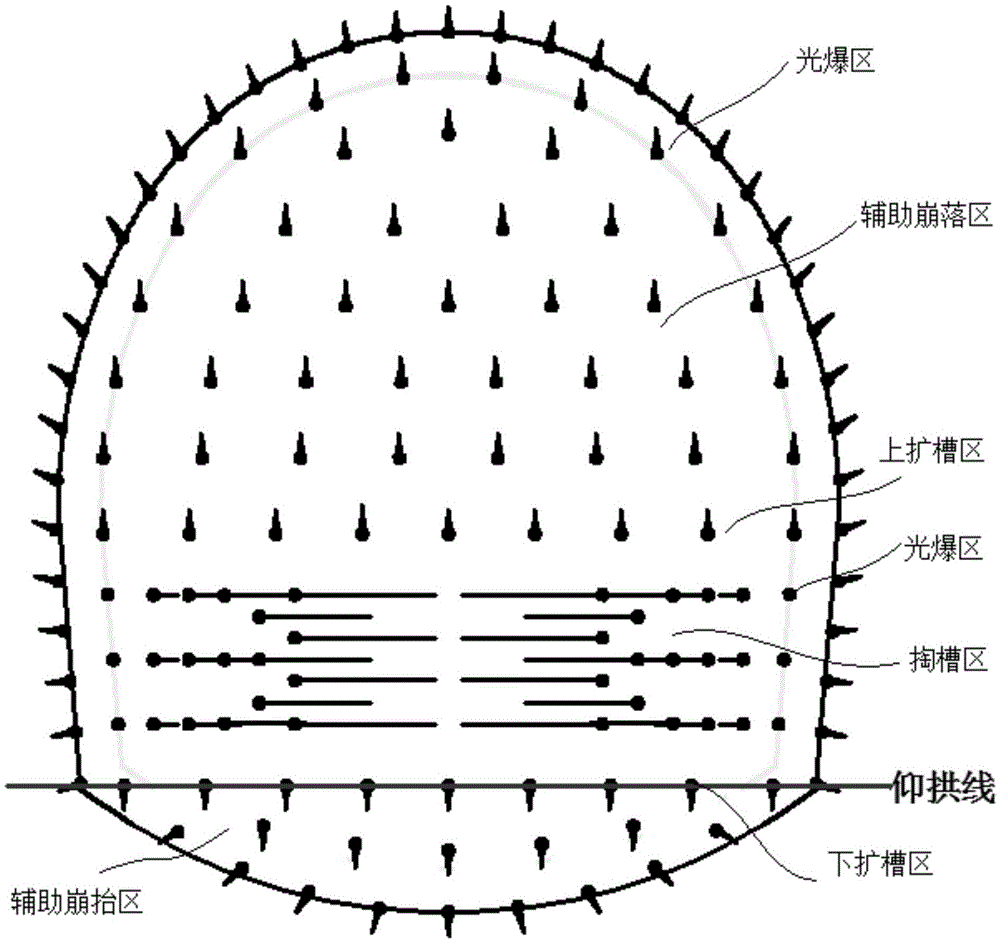

[0031] refer to figure 2 , 3 As shown, a tunnel rock drilling engineering partition control blasting method, the steps are as follows:

[0032] 1) Partitioned drilling: Divide the rock drilling face into the cutting area, the upper and lower expansion areas, the auxiliary caving area, the auxiliary caving area and the light explosion area, and drill holes in each area;

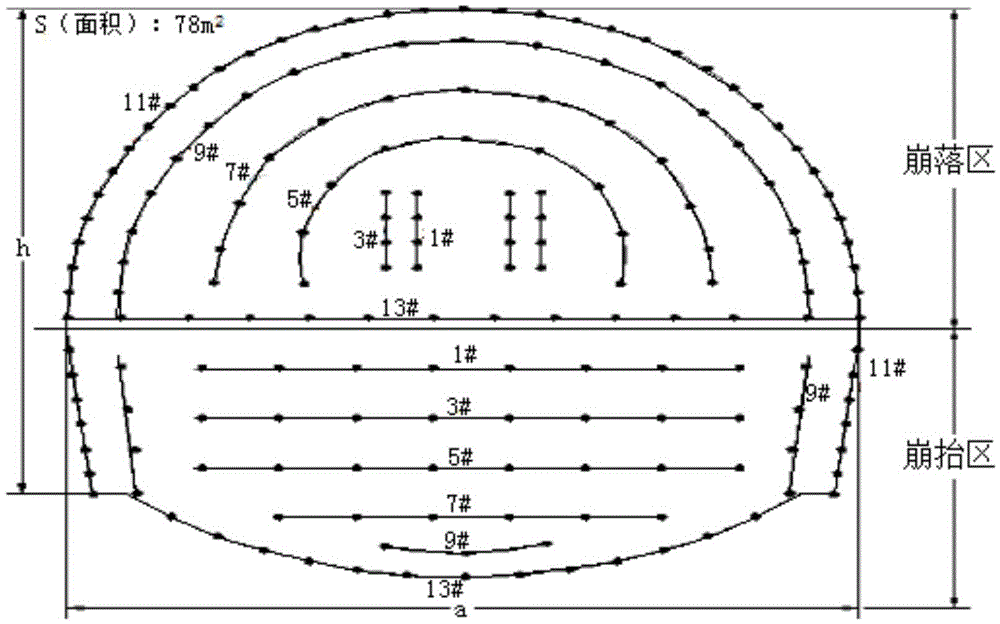

[0033] The lower middle area of the rock drilling face is the cutting area, which is composed of 3-4 rows and more than 10 rows of symmetrical horizontally inclined blastholes. The value of the resistance line between the holes is 75cm, the height of the cut is 1.5m, and the row spacing between the blastholes in the cut area is 400-750mm;

[0034] The upper and lower areas of the cutting area of the rock drilling face are the upper and lower expansion areas. The upper and lower expansion areas are the connection areas between the blastholes in the cutting area and the blastholes in the auxiliary caving ...

Embodiment 2

[0044] like figure 2 , 4 As shown, this embodiment is basically the same as Embodiment 1, and the difference is that it is applicable to high-speed rail double lines. like Figure 4 As shown, the schematic diagram of the layout of the blastholes on the double-line section of the high-speed railway, the cutout area is composed of 3 rows and 14 rows of horizontally inclined blastholes that are left and right symmetrical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com