Patents

Literature

66results about How to "Change impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

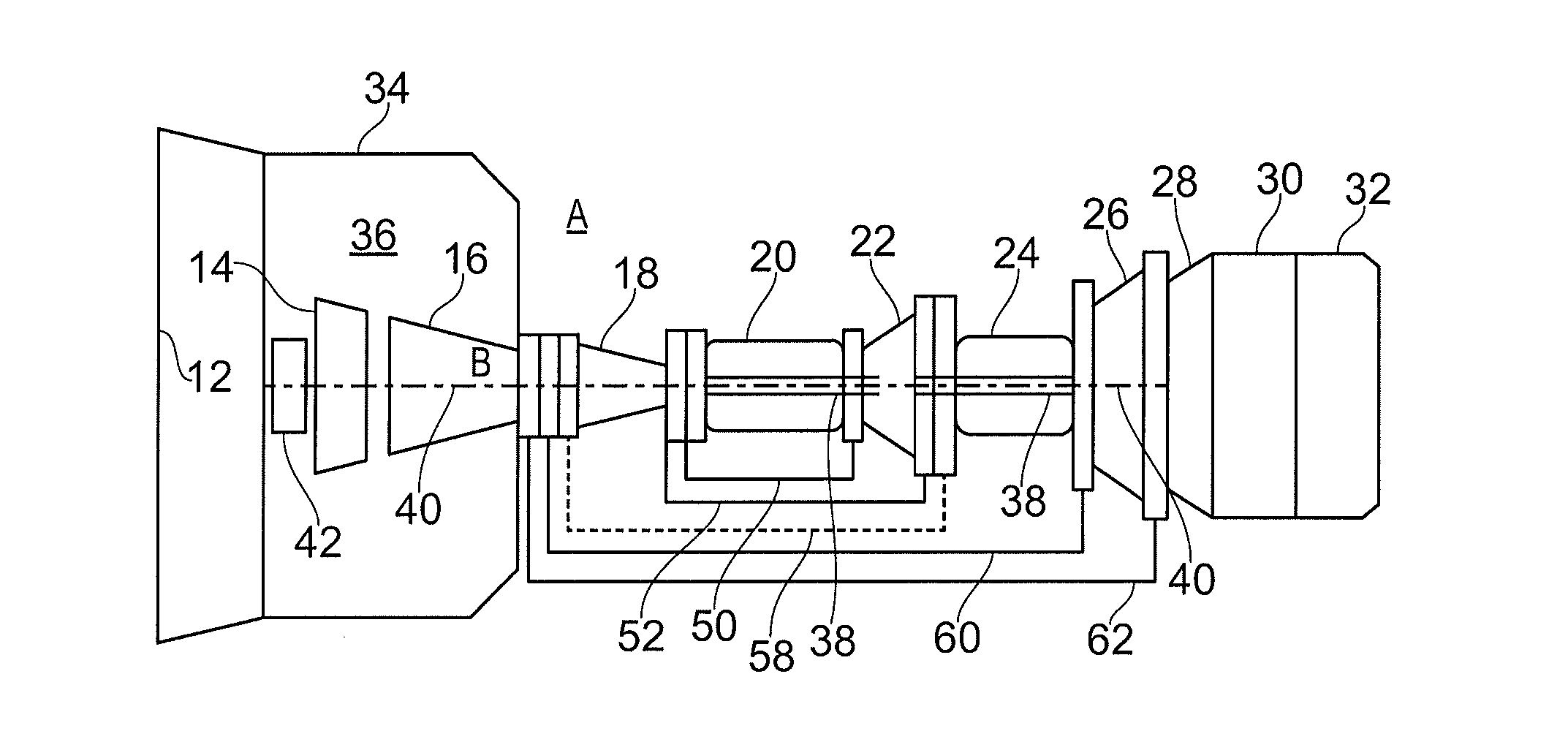

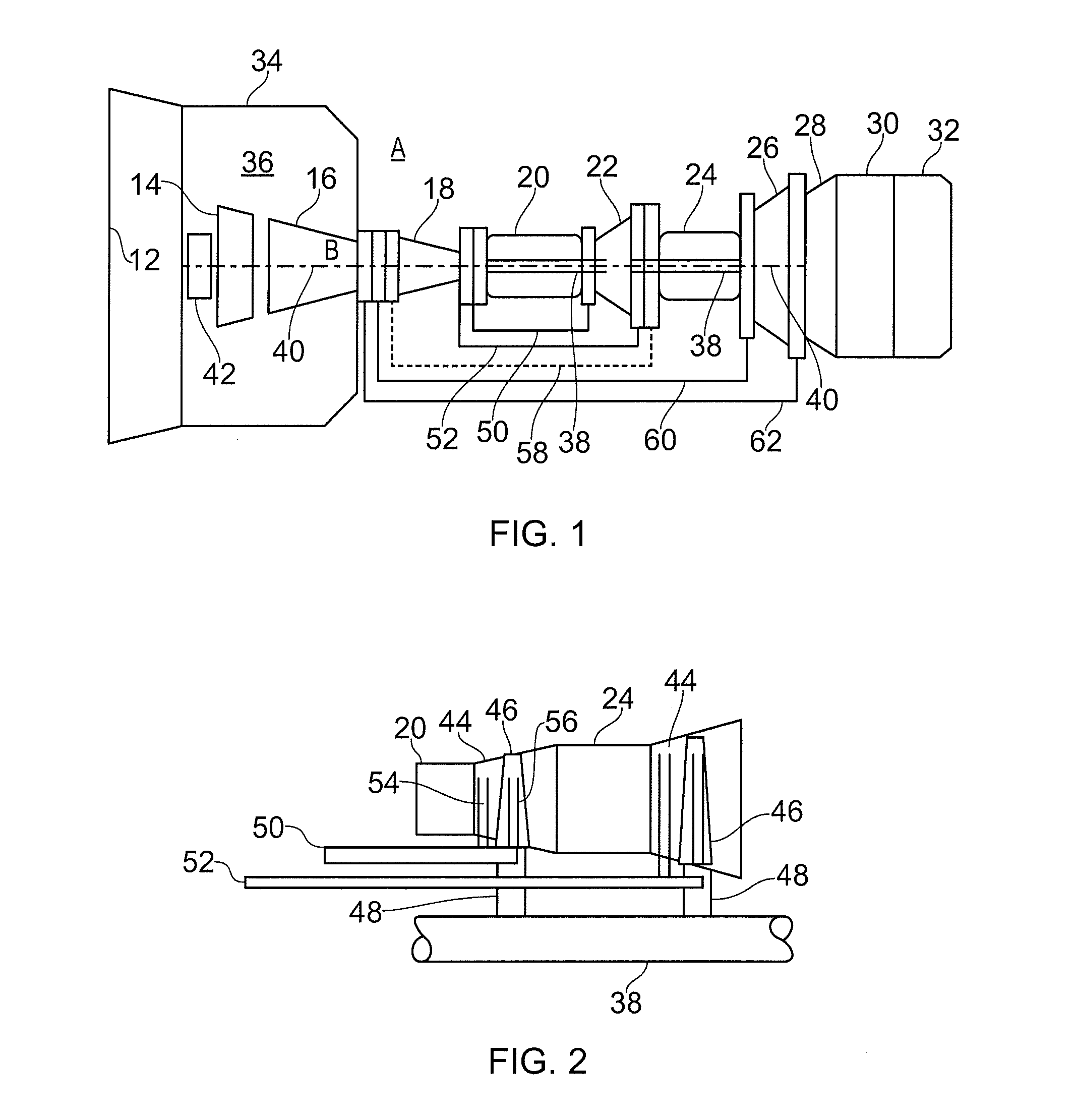

Gas turbine engine

ActiveUS20150292402A1Reduce fuel consumptionReduce weightContinuous combustion chamberTurbine/propulsion engine coolingCombustorTurbine

A gas turbine engine. The engine includes a first compressor coupled to a first turbine by a first shaft, the first turbine having first and second turbine stages. A first combustor is provided downstream of the first compressor and upstream of the first stage of the first turbine. A second combustor is provided downstream of the first stage of the first turbine, and upstream of the second stage of the first turbine. A further turbine is provided downstream of the first turbine, and is coupled to a further compressor by a further shaft.

Owner:ROLLS ROYCE PLC

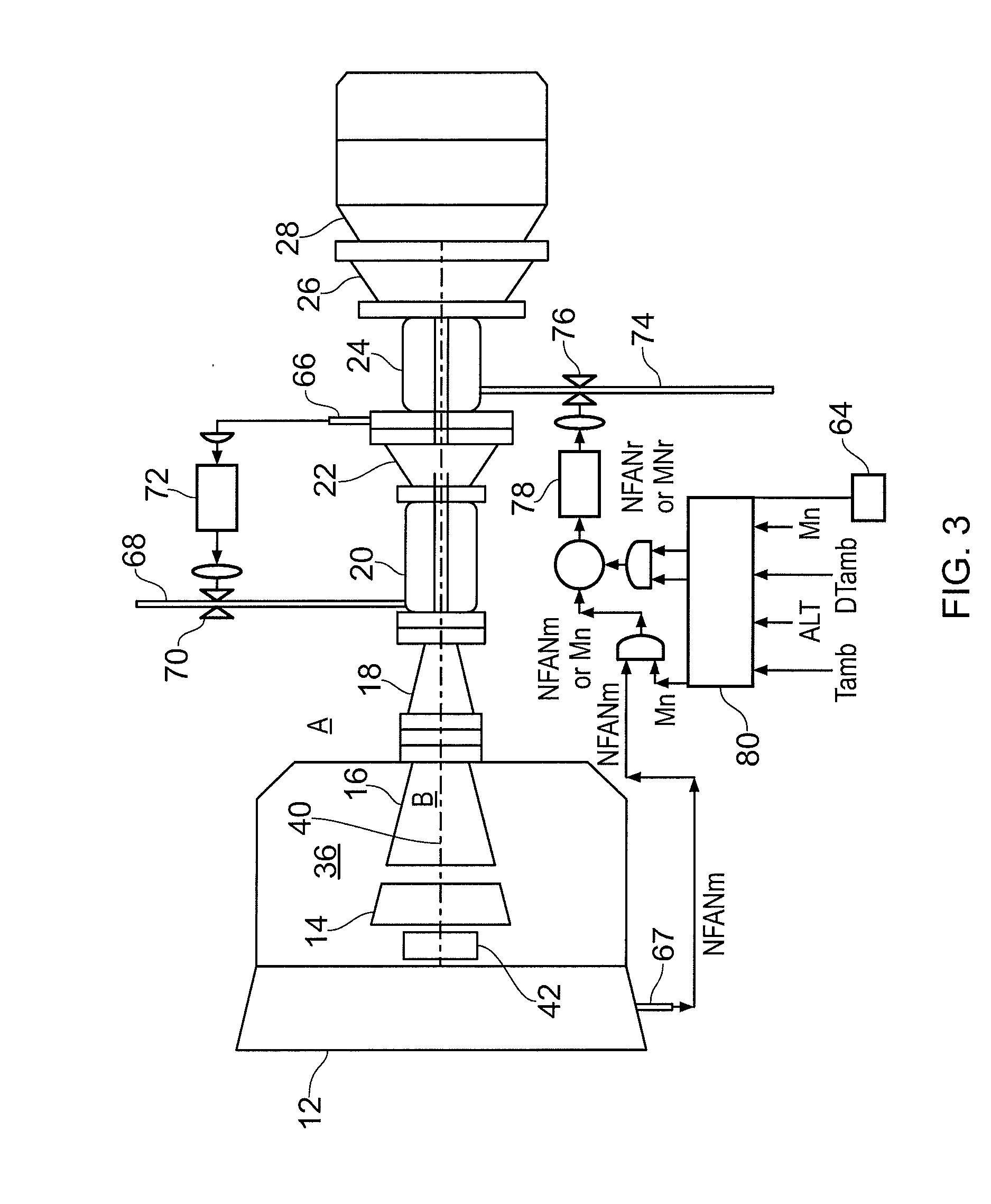

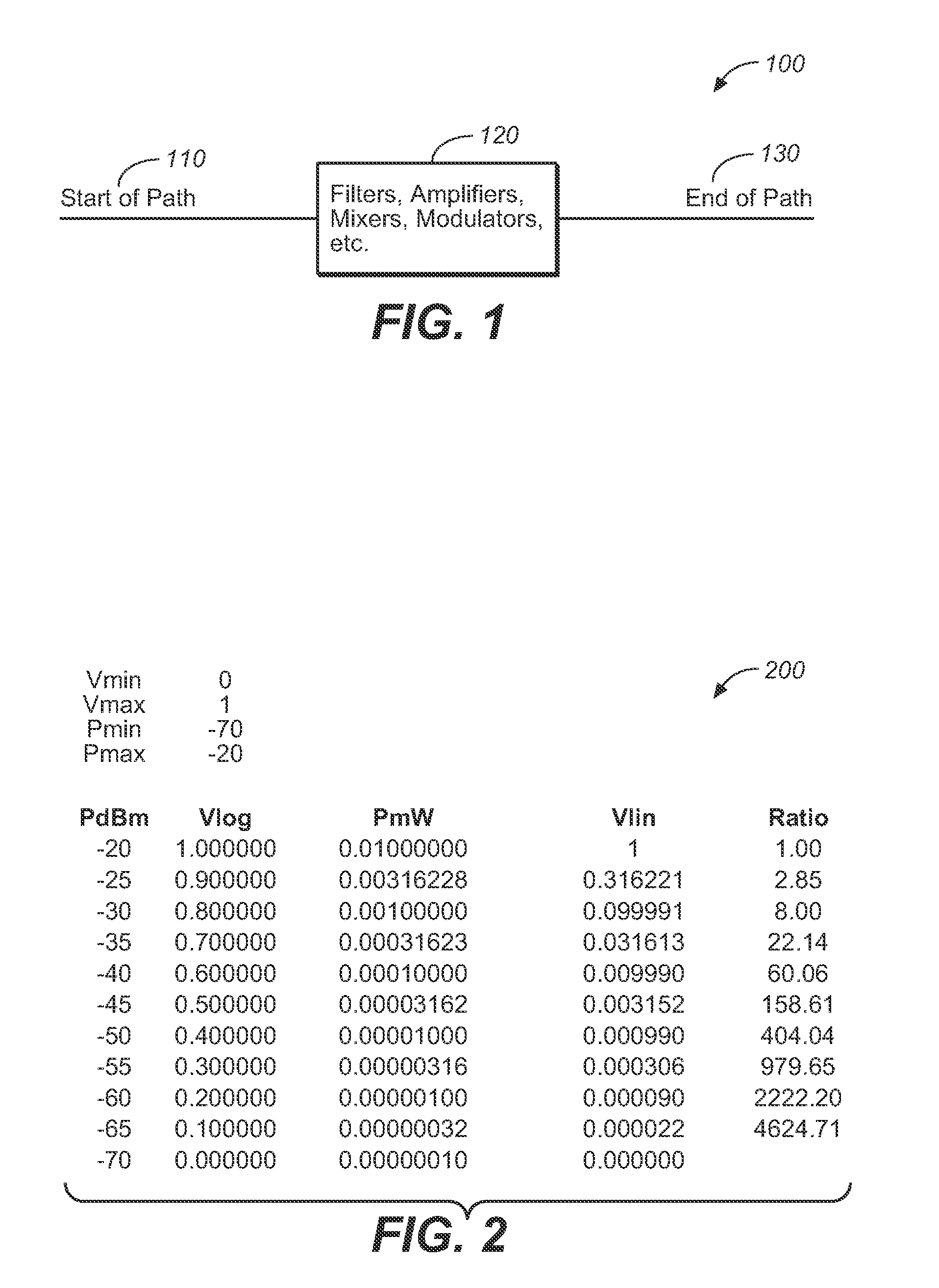

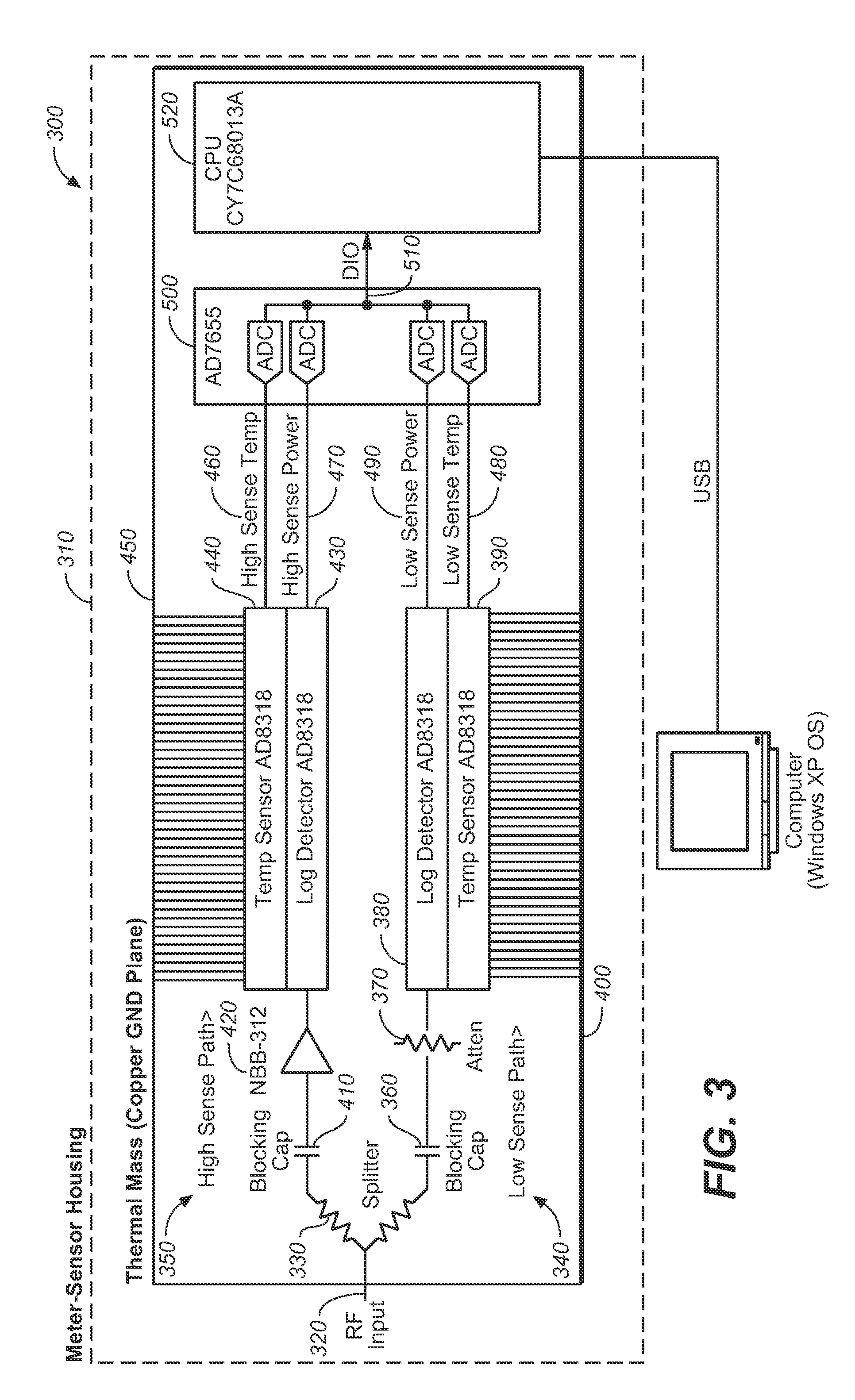

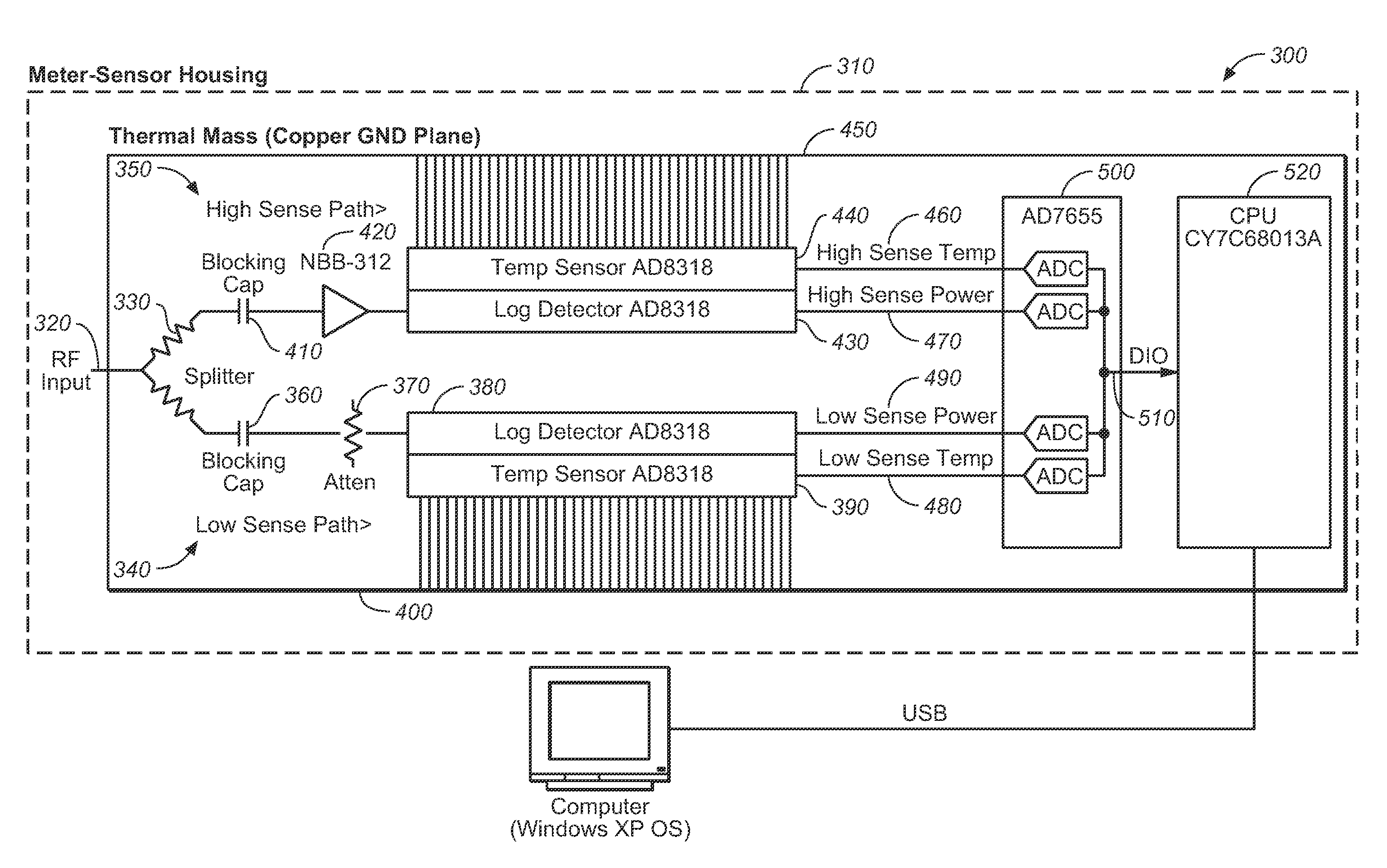

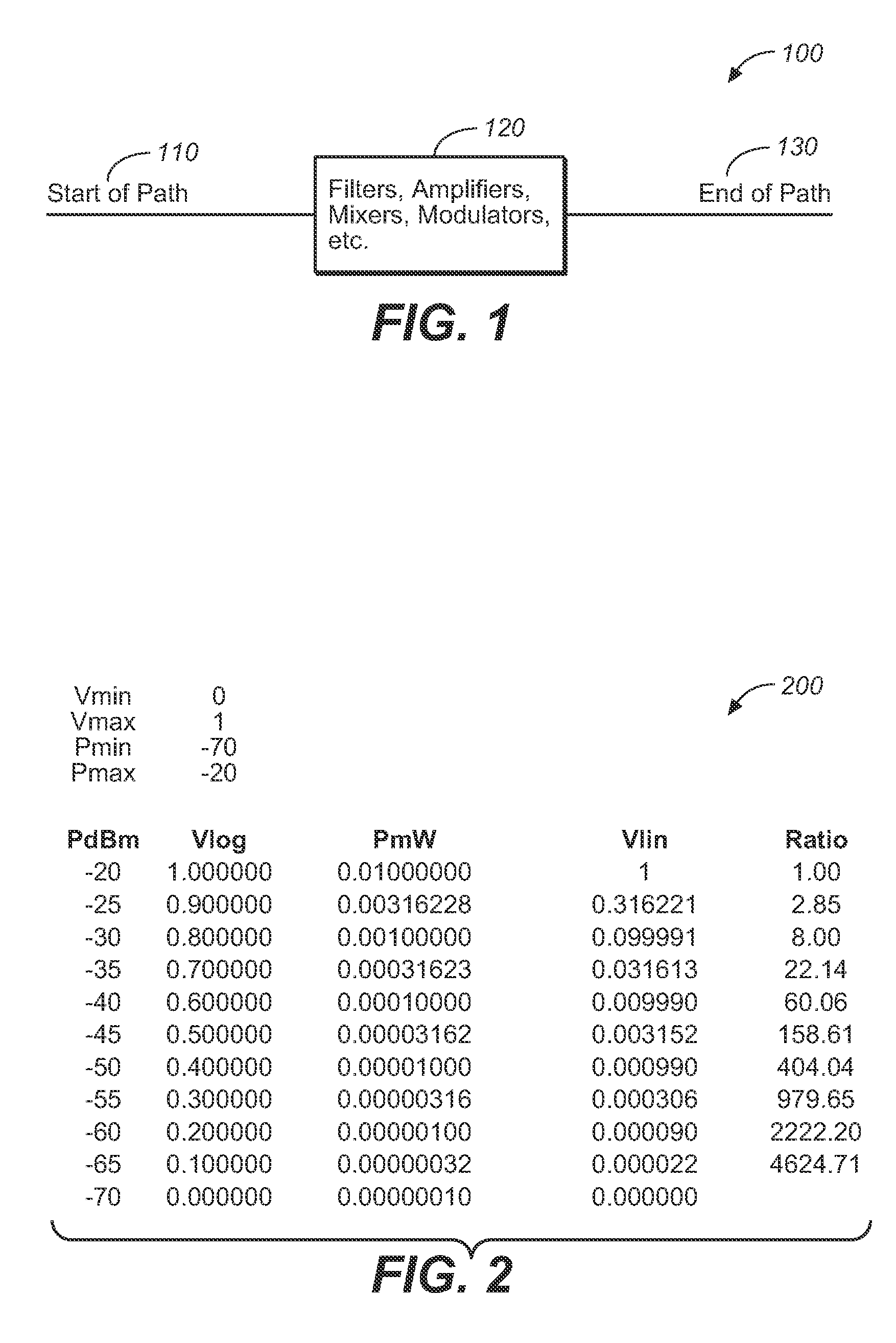

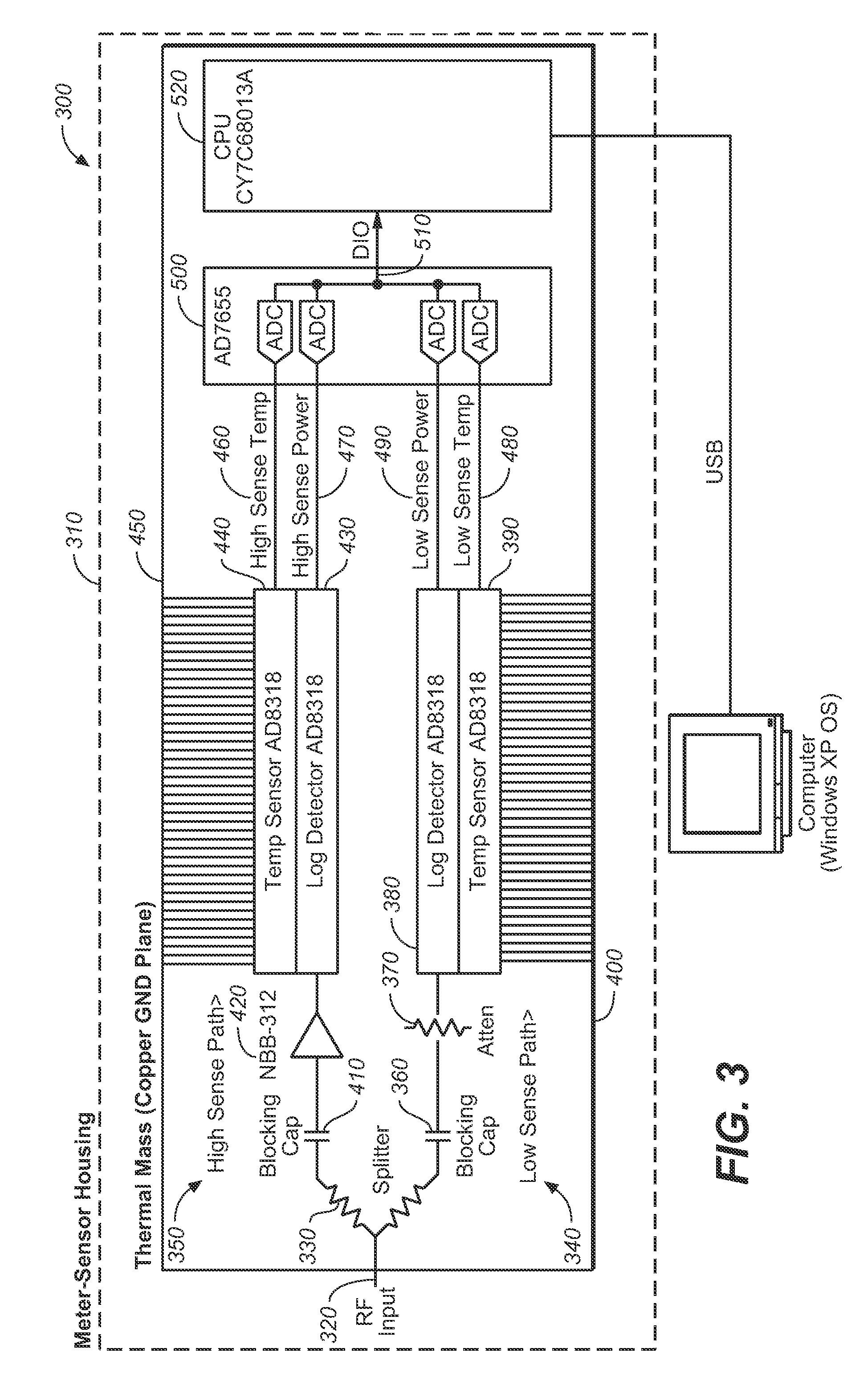

Method for eliminating the need to zero and calibrate a power meter before use

ActiveUS20080084199A1Impact of thermal changeLarge massResistance/reactance/impedenceElectrical measurement instrument detailsPower sensorAudio power amplifier

An improved power sensor having an input connector connected to an input port having a center pin and a ground side; an amplifier; first and second detectors; and a thermal stabilization system, including a thermal mass disposed between the ground side of the input connection and the detectors, a ground plane for holding the temperature of thermally sensitive components constant to within 2 degrees C., and a thermal impedance disposed between the center pin of the input port, preferably including a splitter and at least one DC capacitor, and a temperature sensor disposed on the ground plane.

Owner:LADYBUG TECH

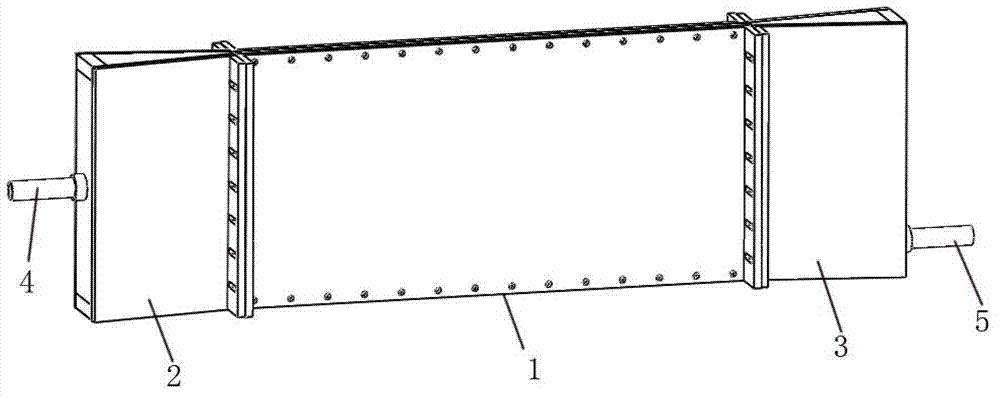

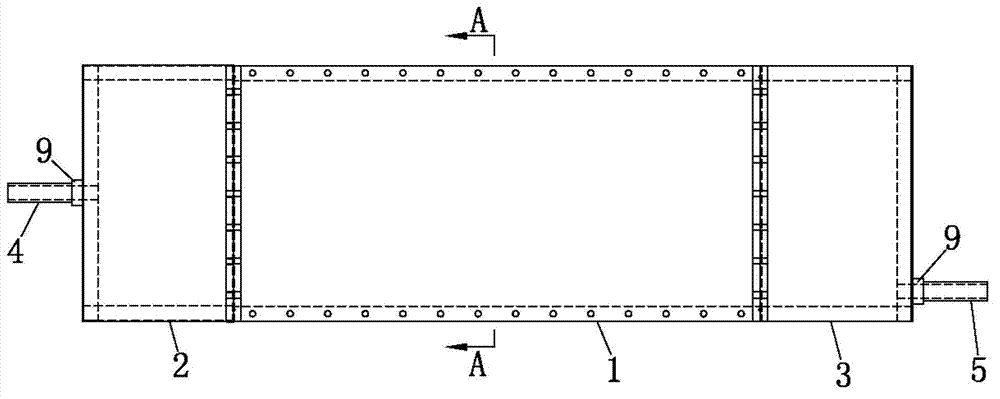

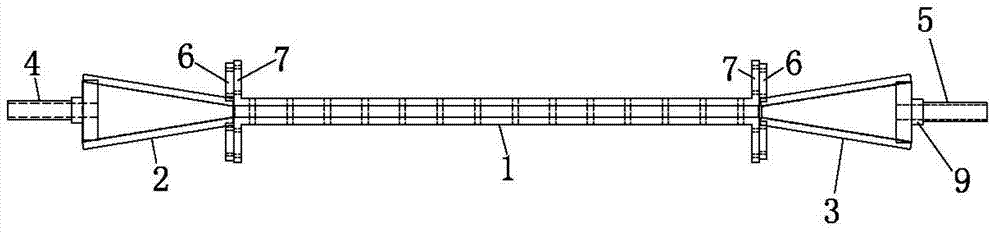

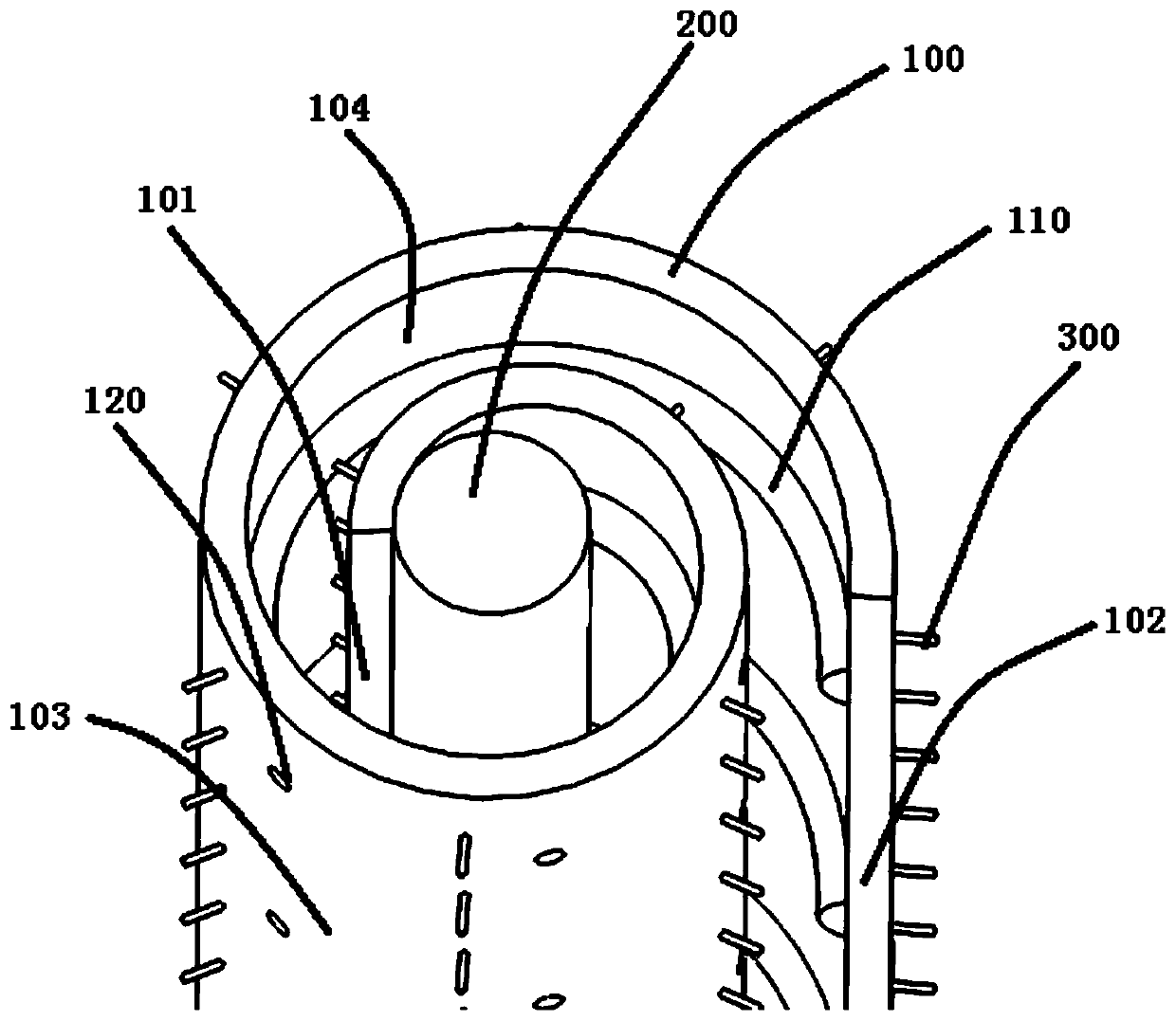

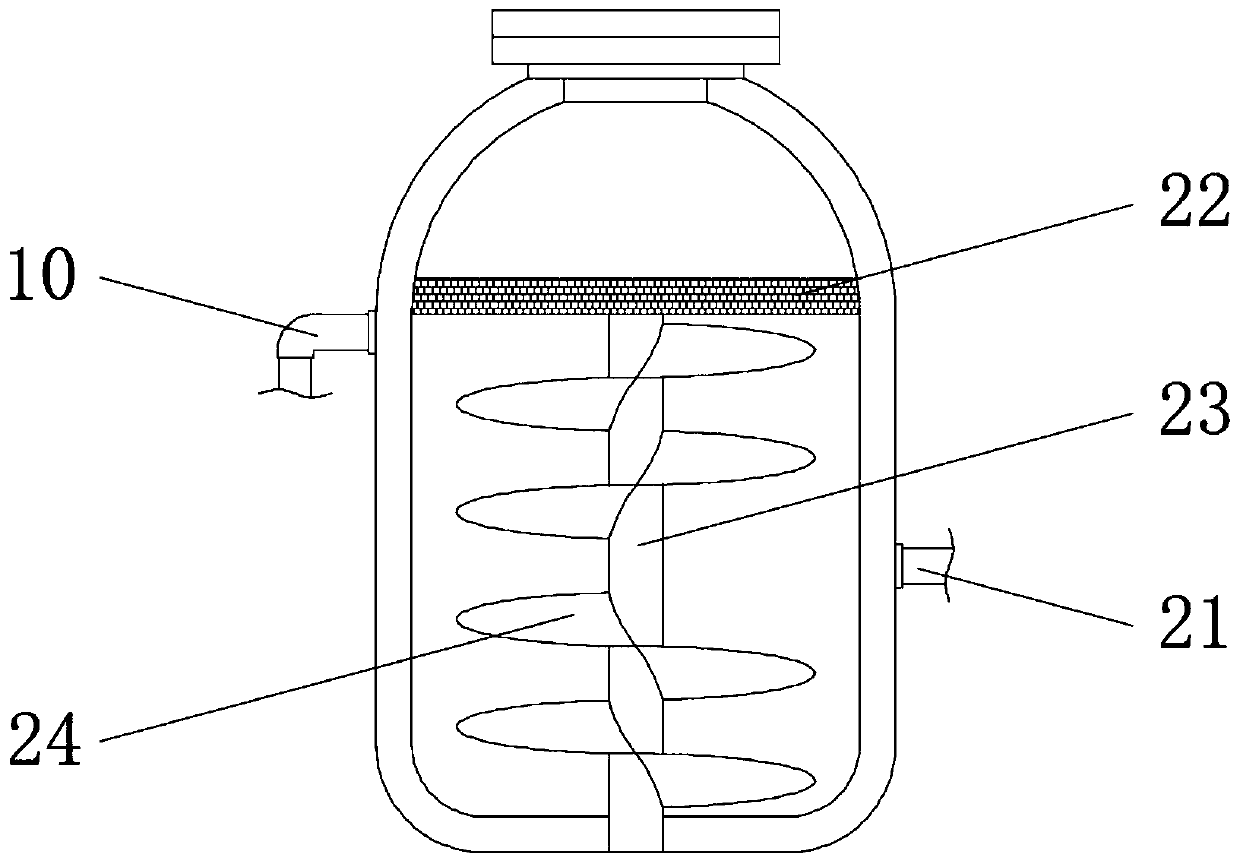

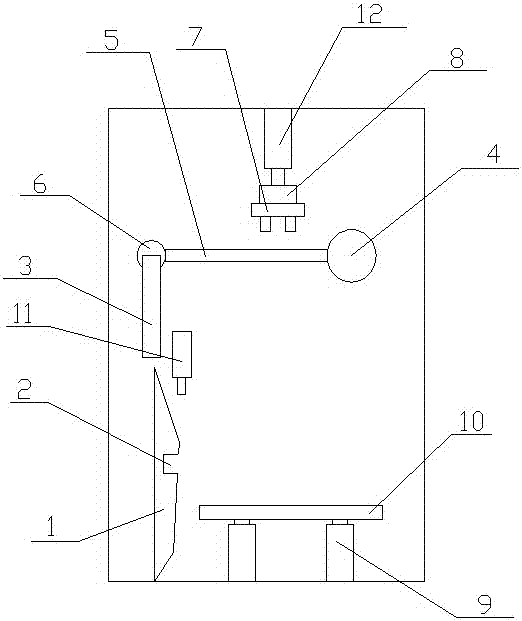

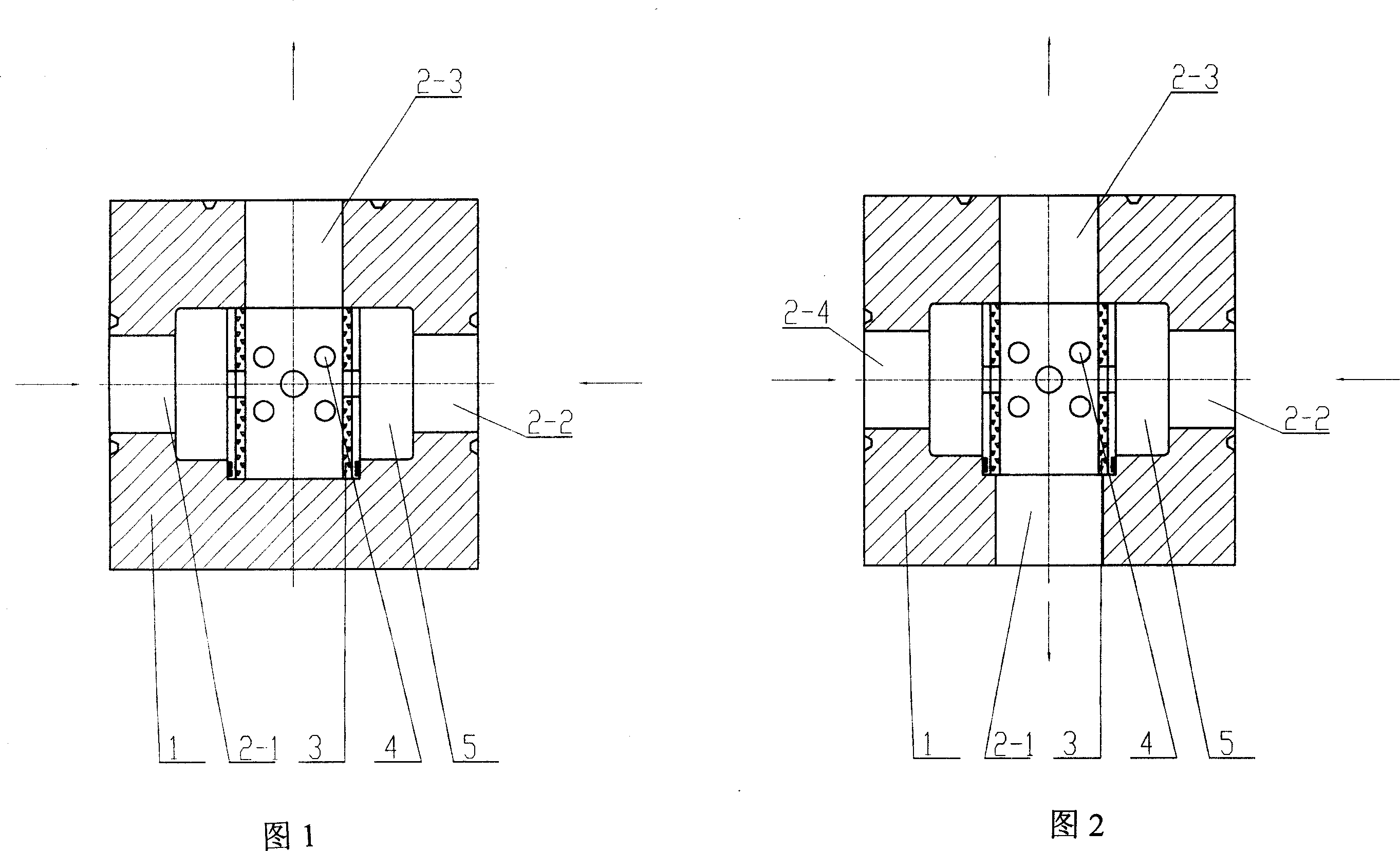

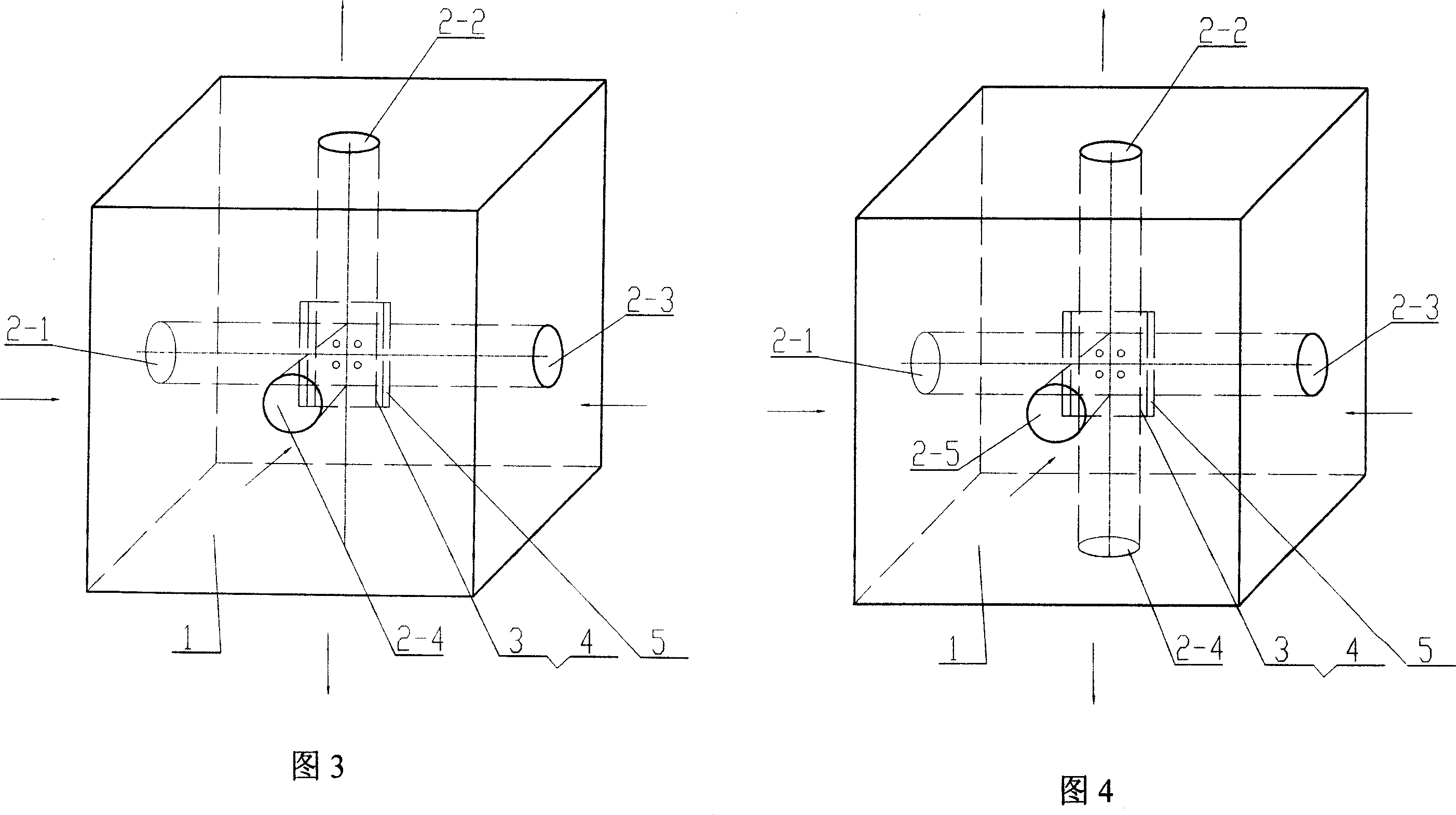

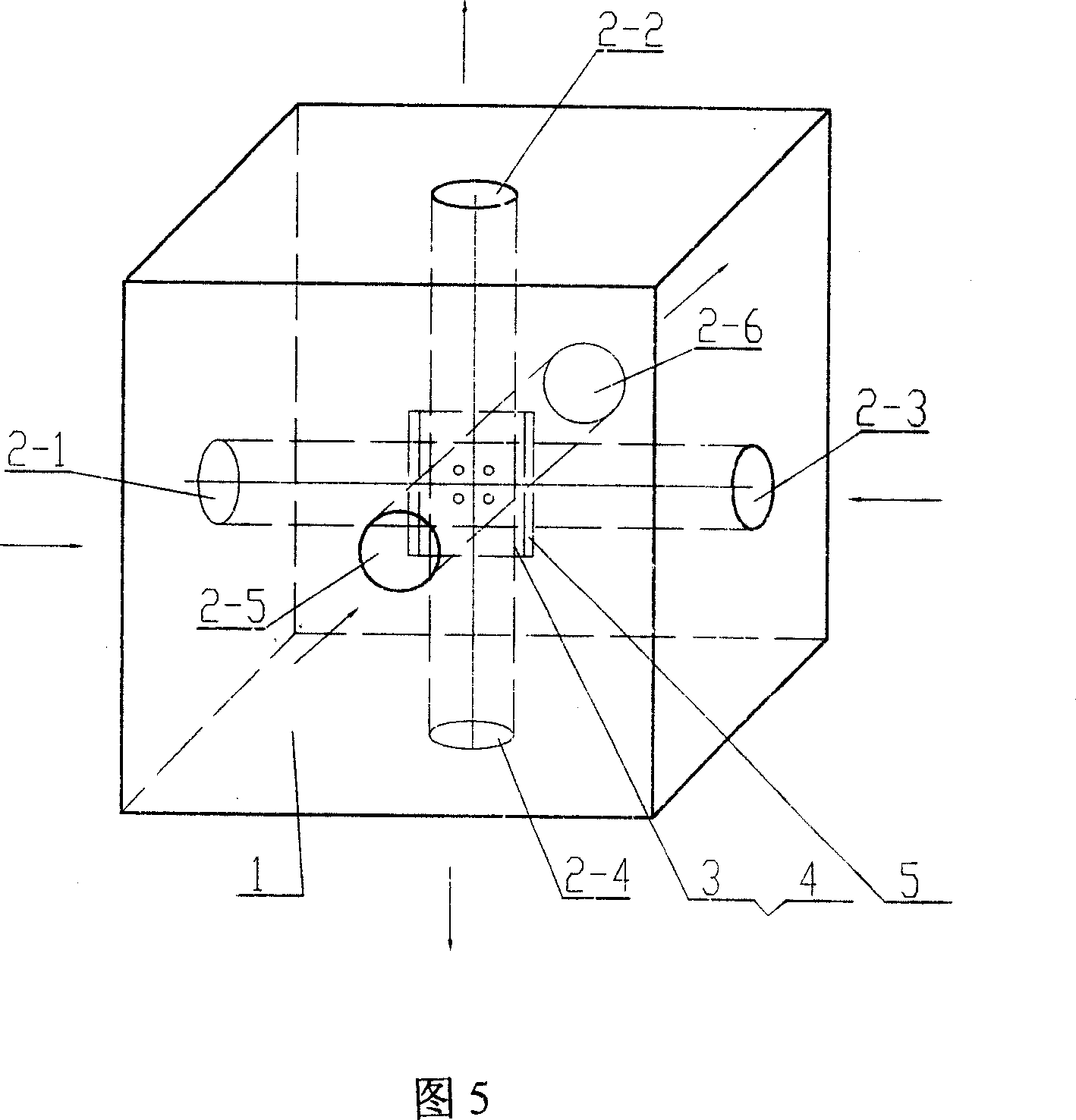

Visualization experiment device and method for transport law of coal dust in cracks

The embodiment of the invention discloses a visualization experiment device and a visualization experiment method for a transport law of coal dust in cracks. The visualization experiment device comprises a middle crack assembly, a left transition joint and a right transition joint, wherein a first pipeline is connected to one end of the left transition joint, and the other end of the left transition joint is connected to the left end of the middle crack assembly; one end of the right transition joint is connected to the right end of the middle crack assembly, and the other end of the right transition joint is connected with a second pipeline; the middle crack assembly has a transparent structure; and the width adjustable cracks are reserved in the middle crack assembly. According to the visualization experiment device, the widths of the cracks can be regulated, so that the cracks of different widths can be simulated, the manufacturing cost of the device is reduced greatly, and the comprehensiveness of physical simulation experiments is increased greatly.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

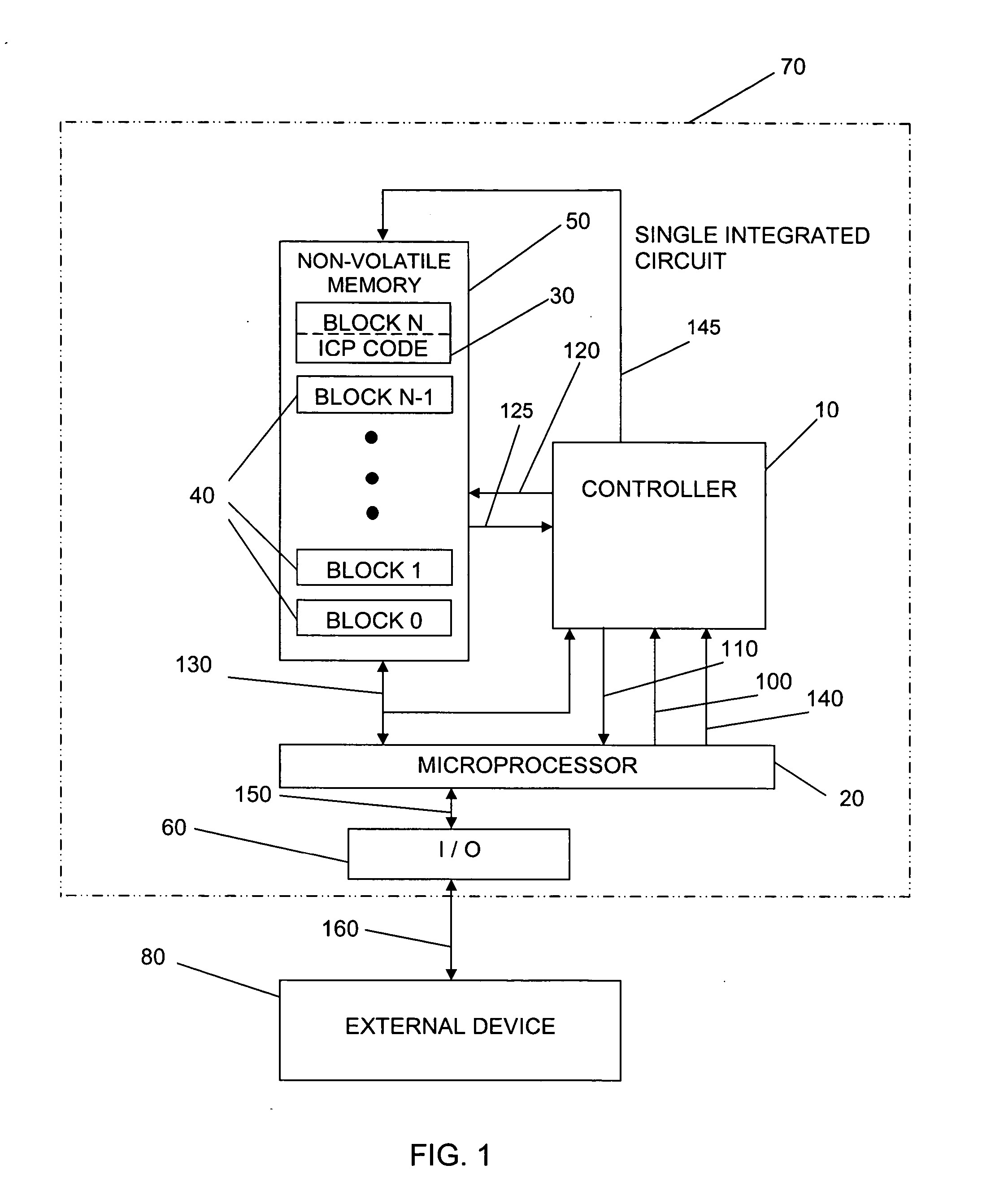

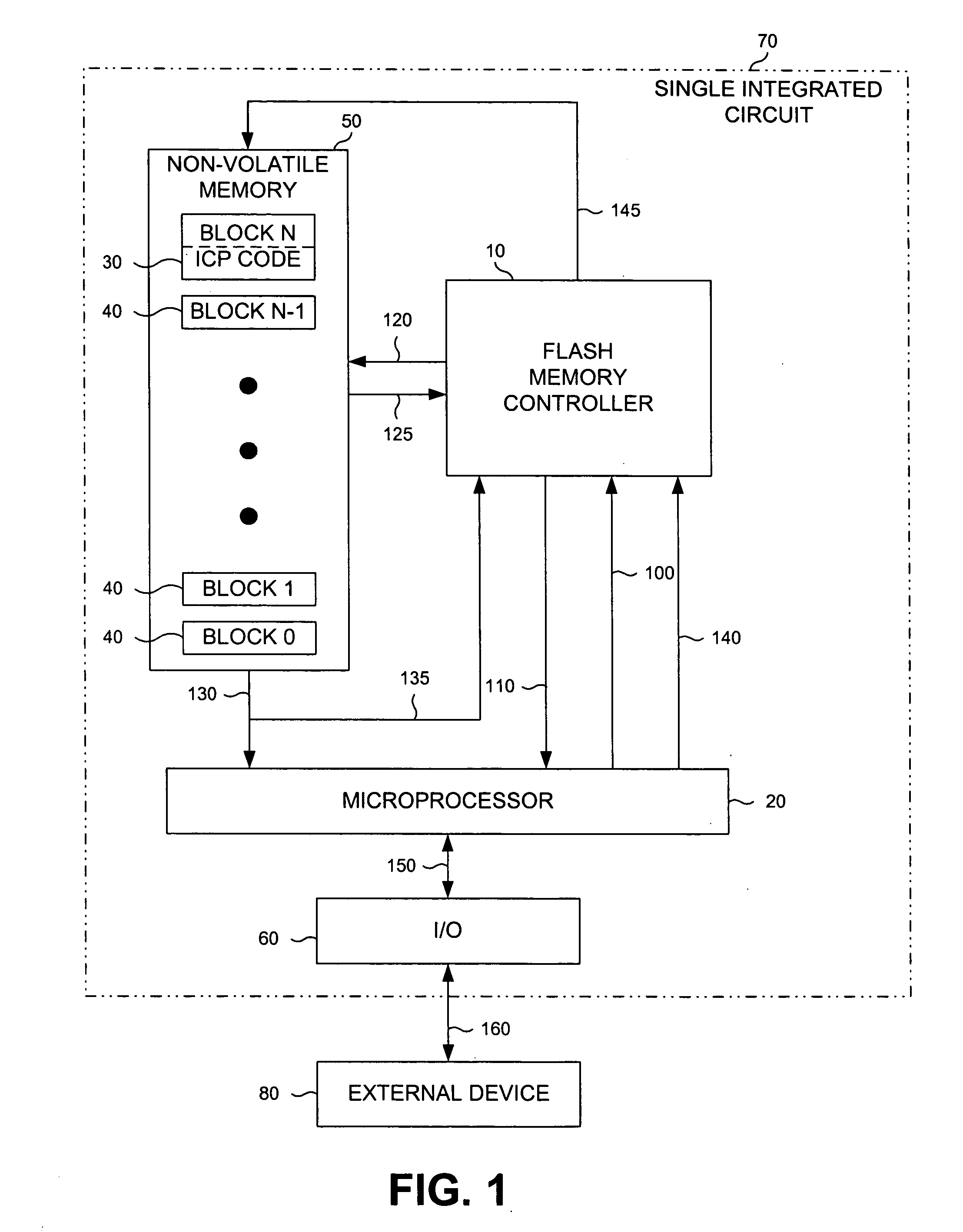

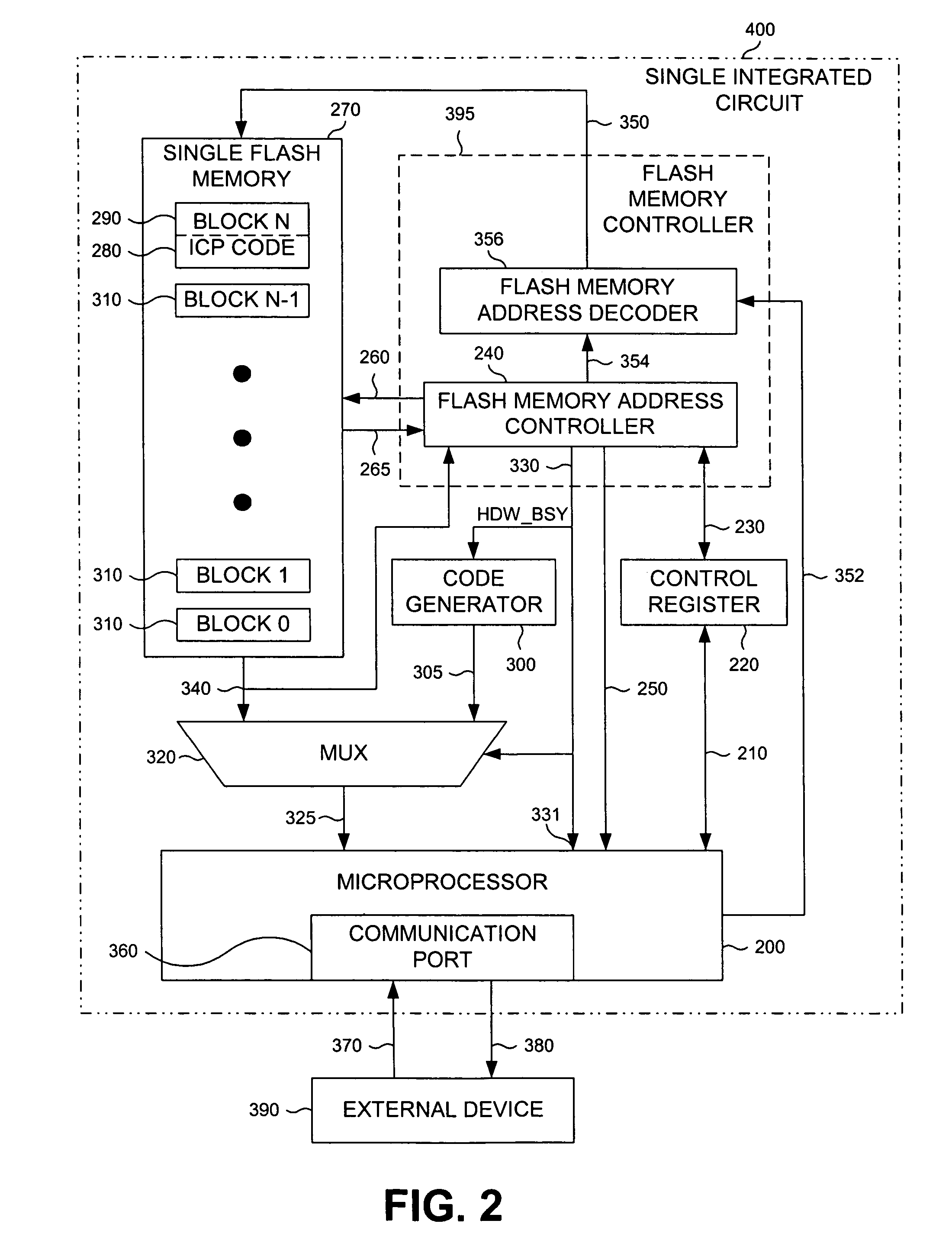

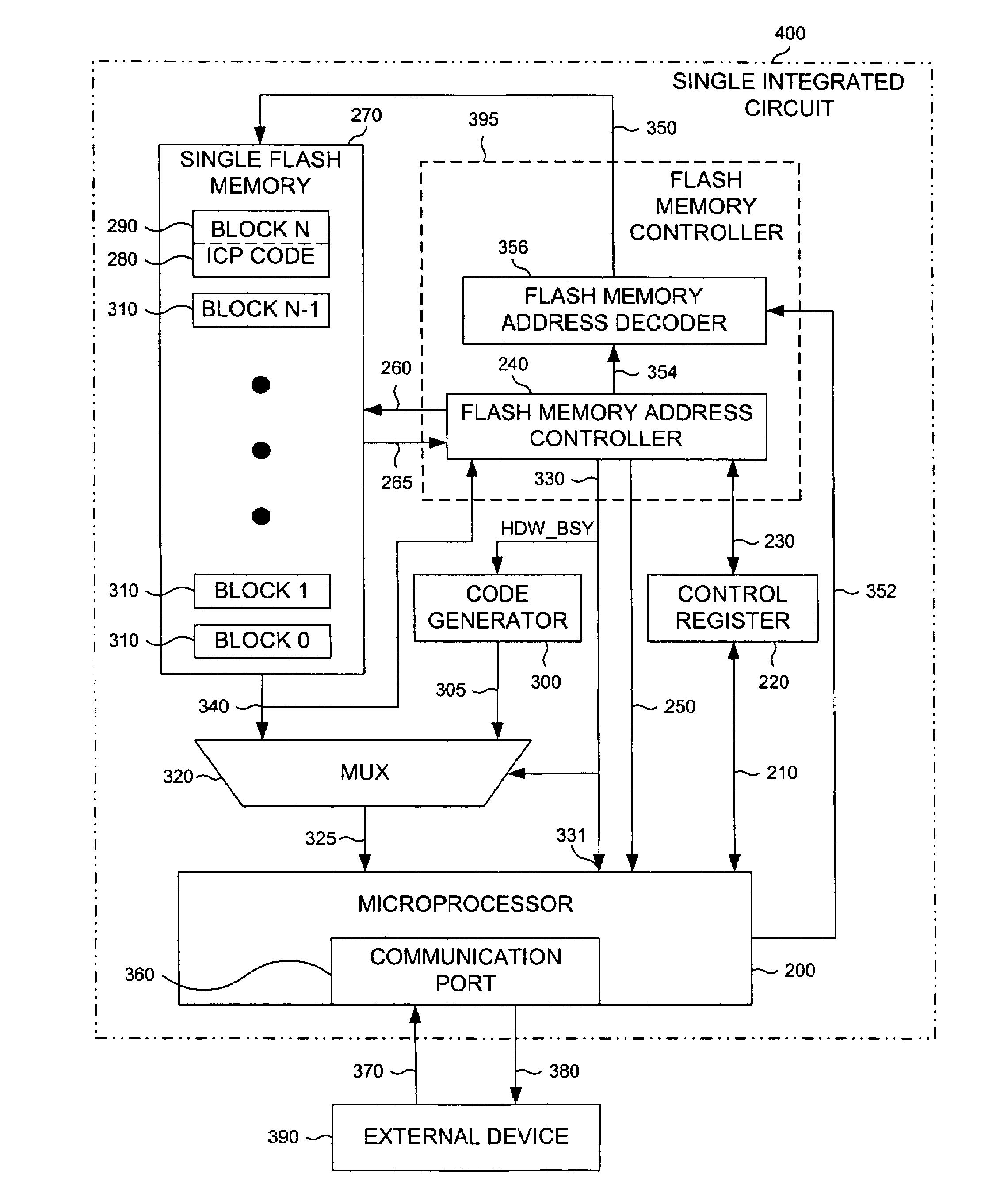

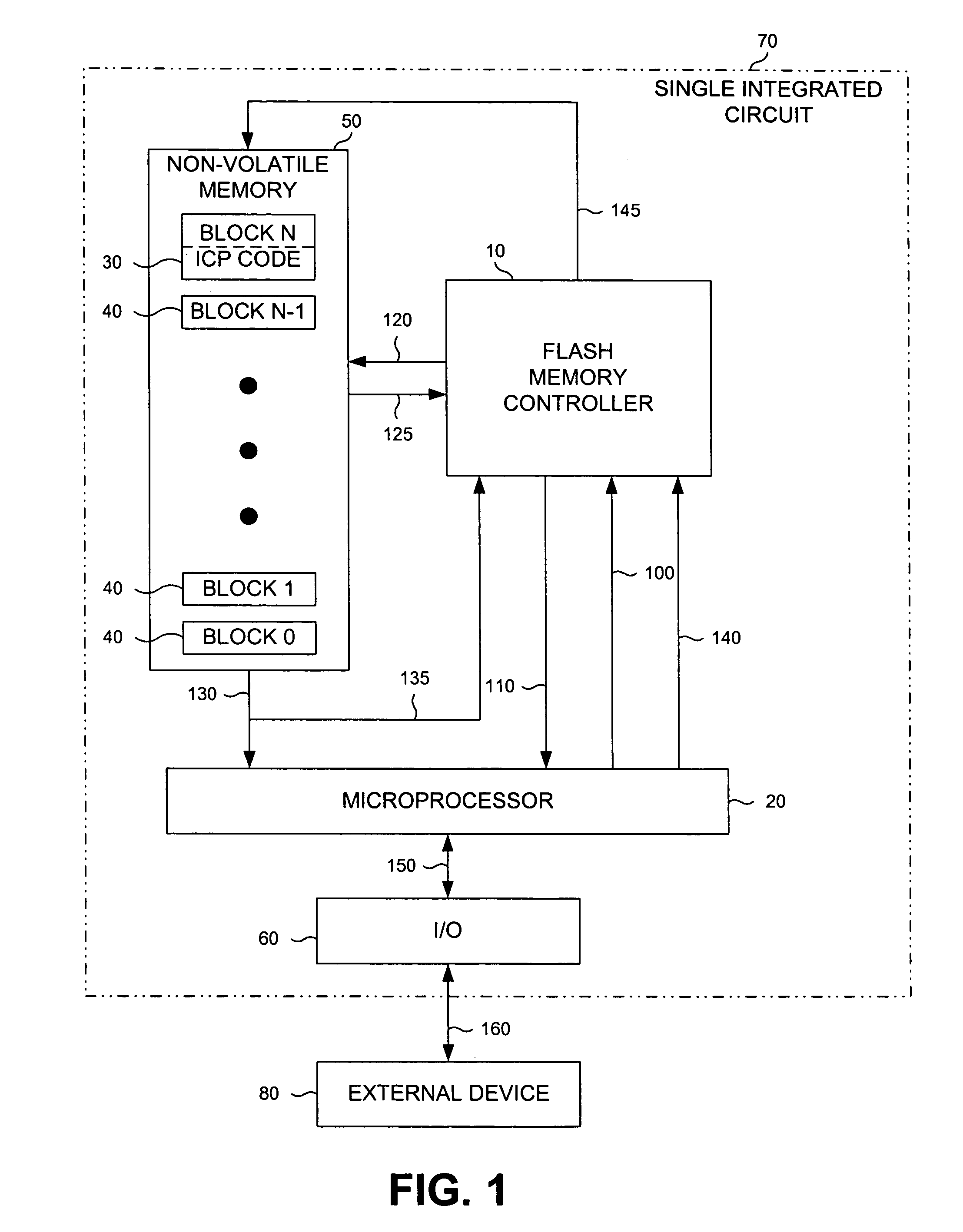

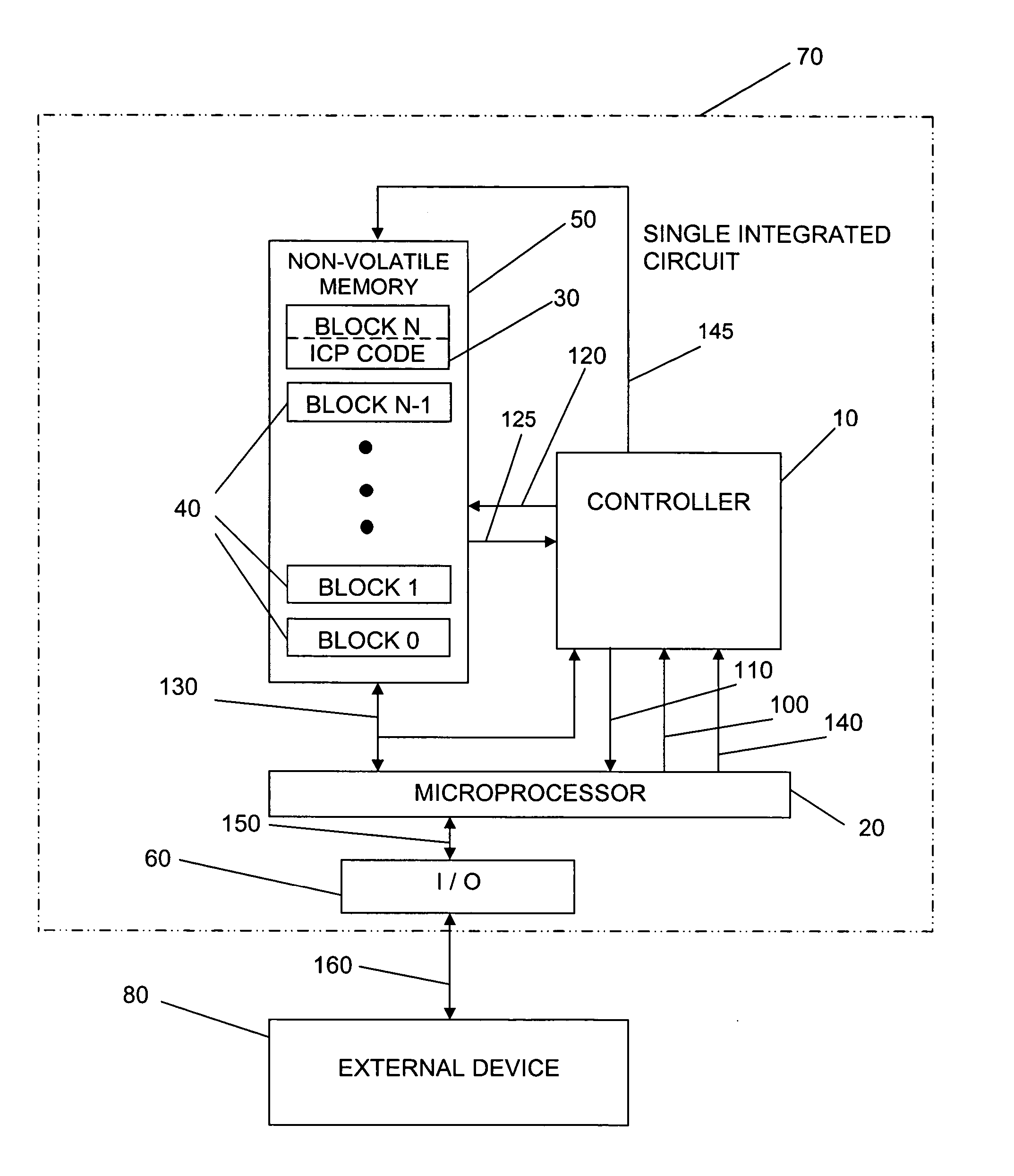

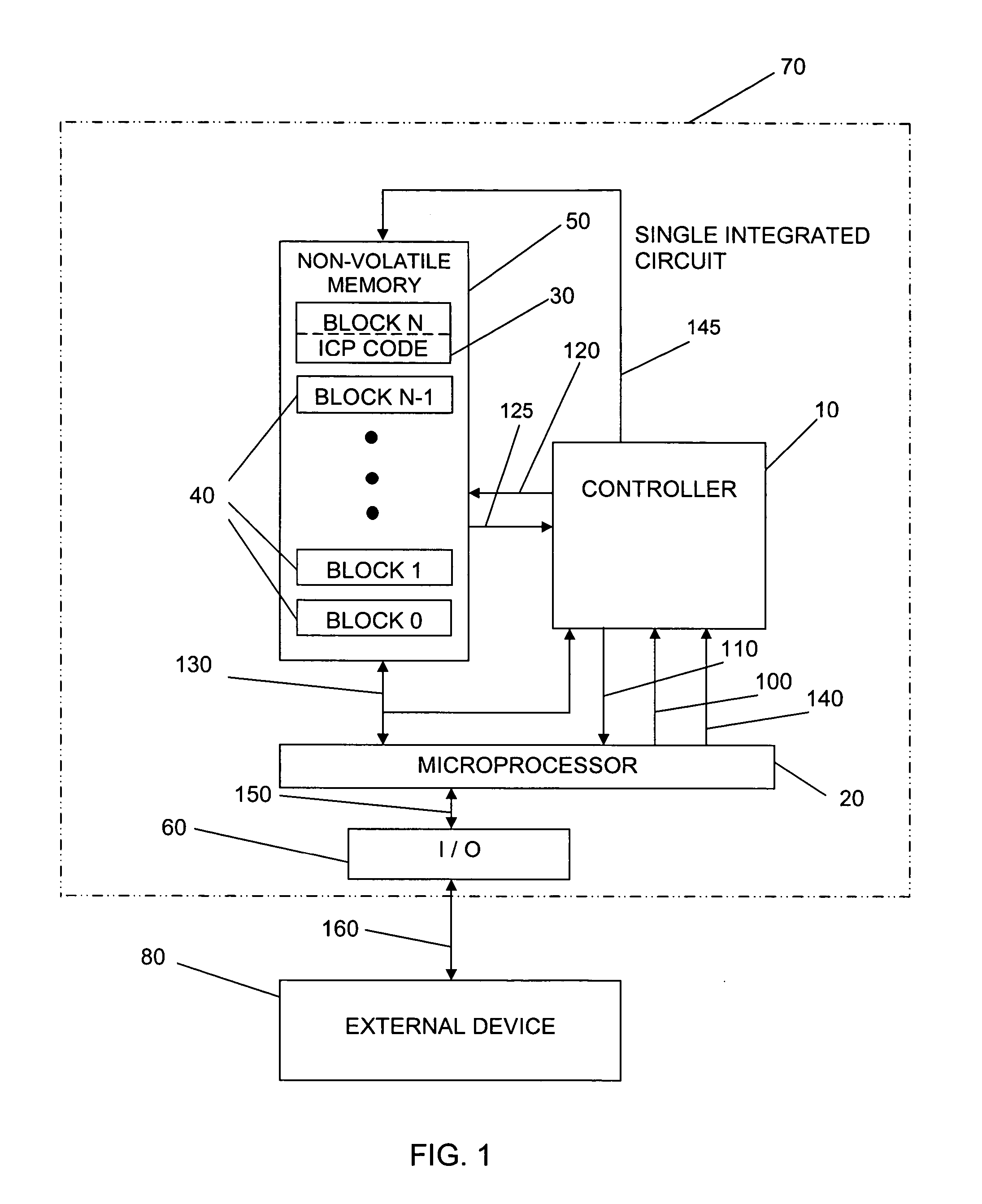

In-circuit programming architecture with processor and delegable flash controller

ActiveUS20050289290A1Improve reliabilityReduce power consumptionRead-only memoriesProgram loading/initiatingFlash memory controllerMemory controller

An architecture for an integrated circuit with in-circuit programming allows real-time modification of the in-circuit programming code and other code stored on the chip. The architecture utilizes a microprocessor and control logic on an integrated circuit having a single non-volatile memory that stores instructions and data, such as in-circuit programming and user code, and input / output ports and related structure for exchanging data with an external device. Using in-circuit programming code stored on the chip, the chip interactively establishes an in-circuit programming exchange with an external device to update data and instructions including the in-circuit programming code. Input / output conflicts during in-circuit programming can be avoided by employing a memory controller to handle at least part of the in-circuit programming operations. The memory controller allows the in-circuit programming code to be updated in real time.

Owner:MACRONIX INT CO LTD

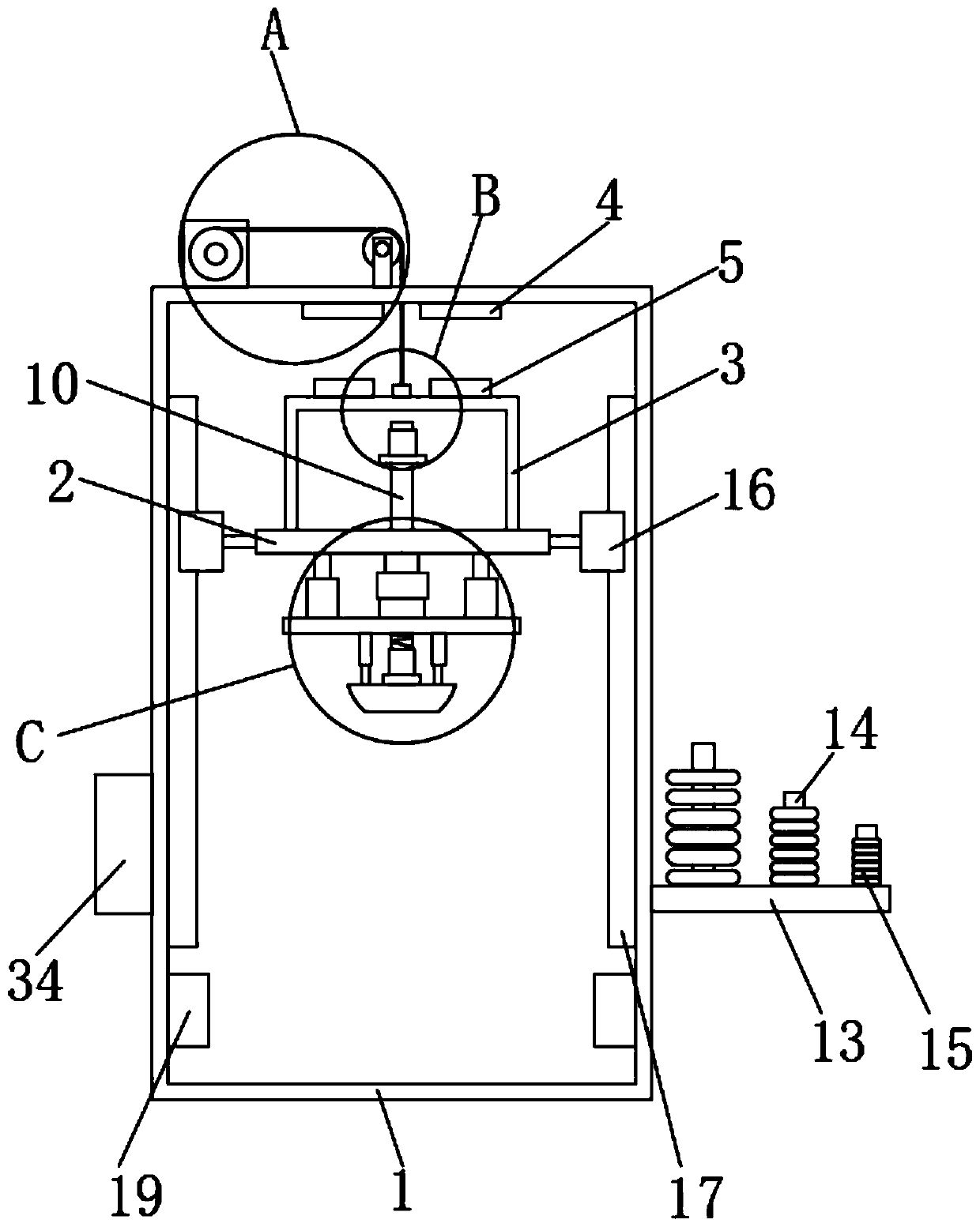

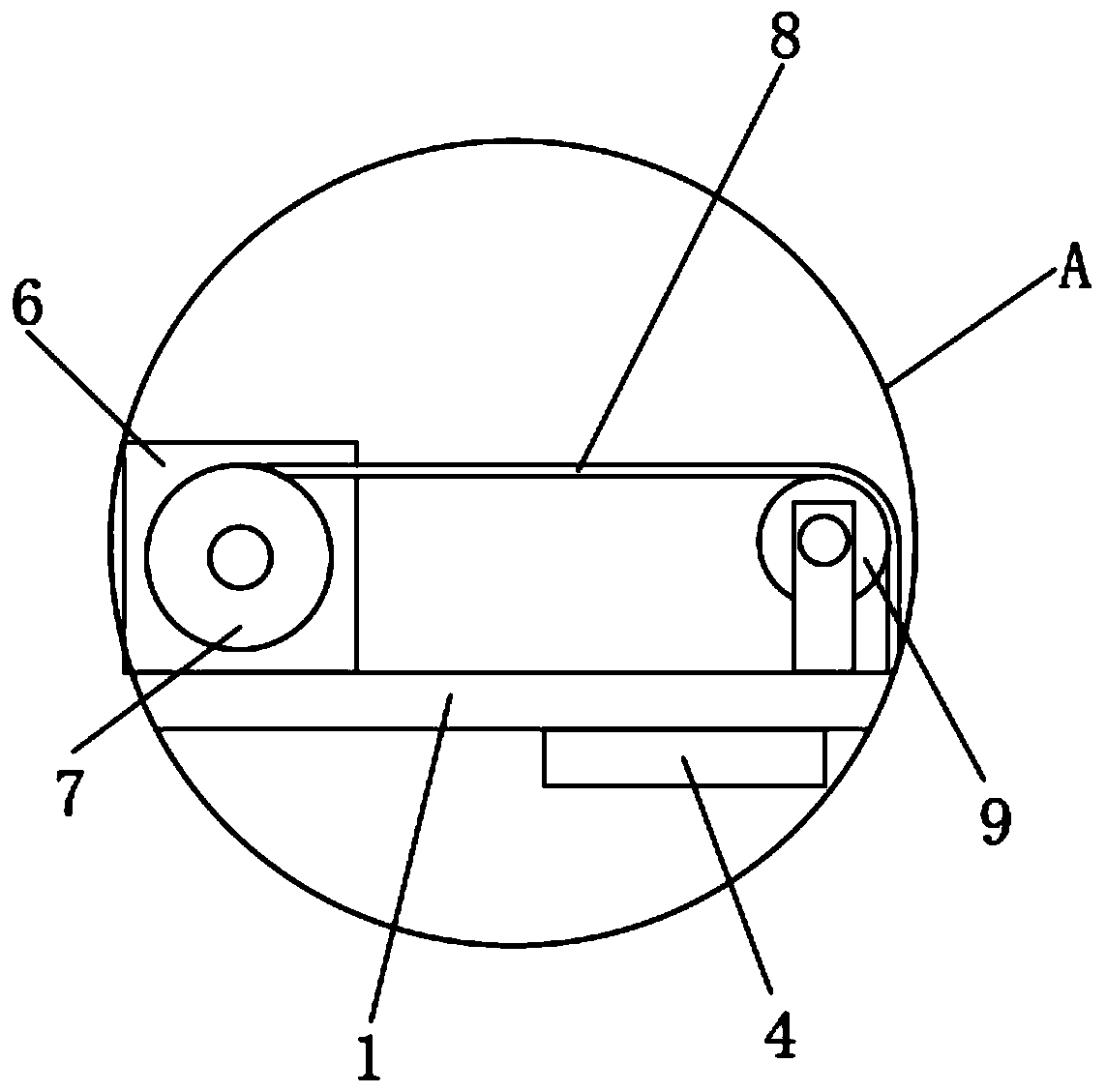

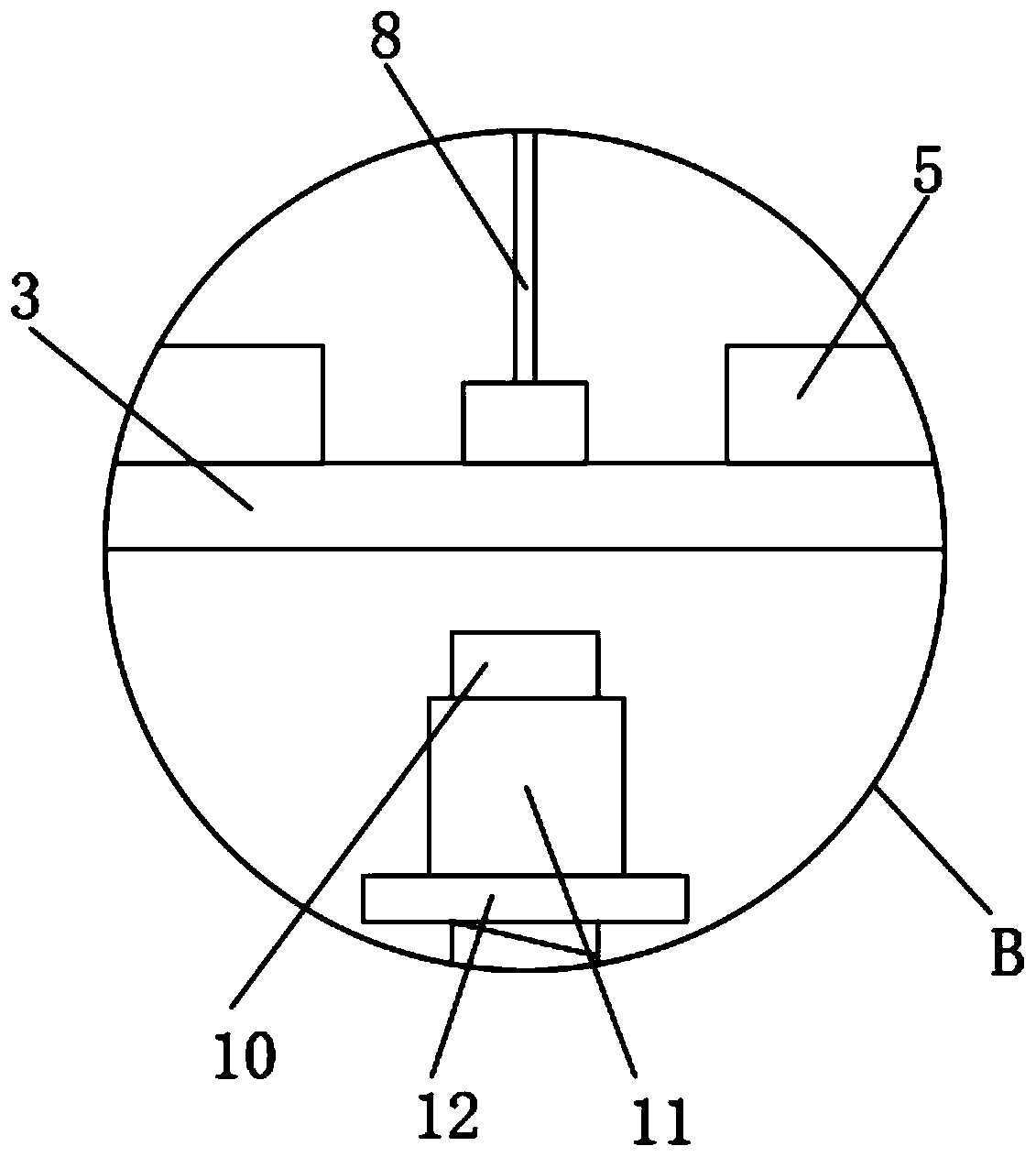

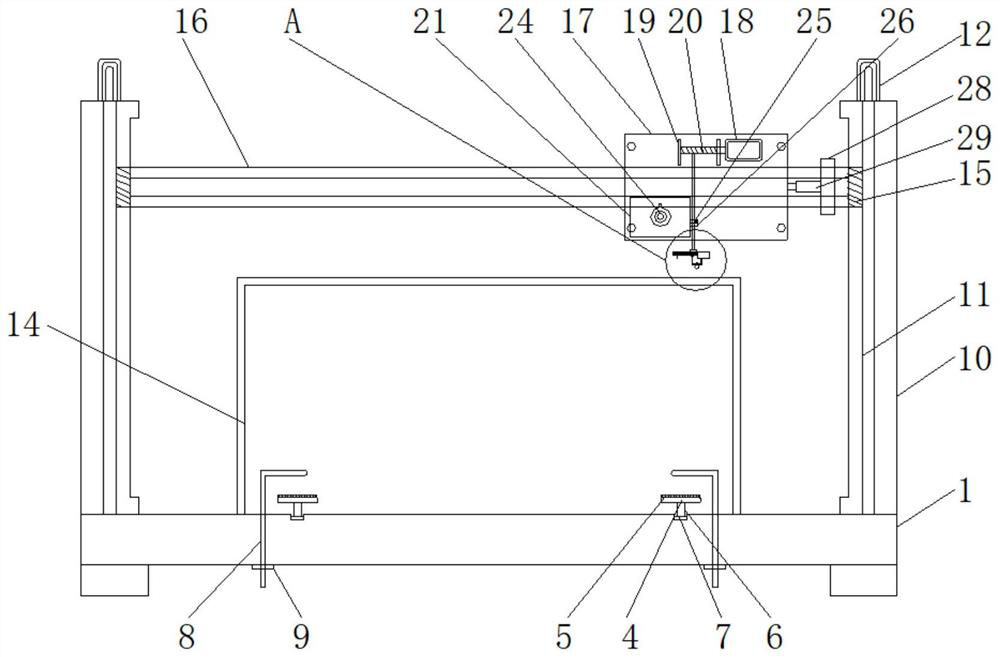

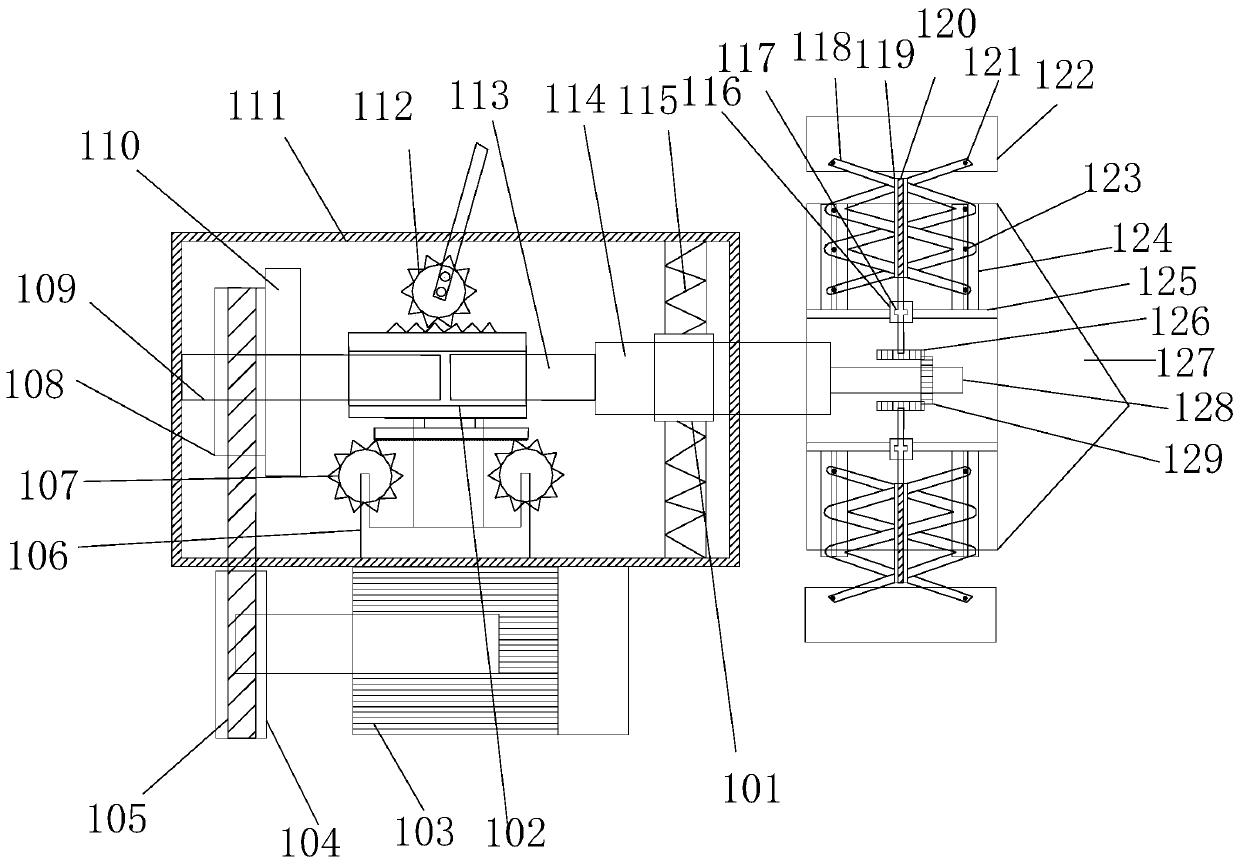

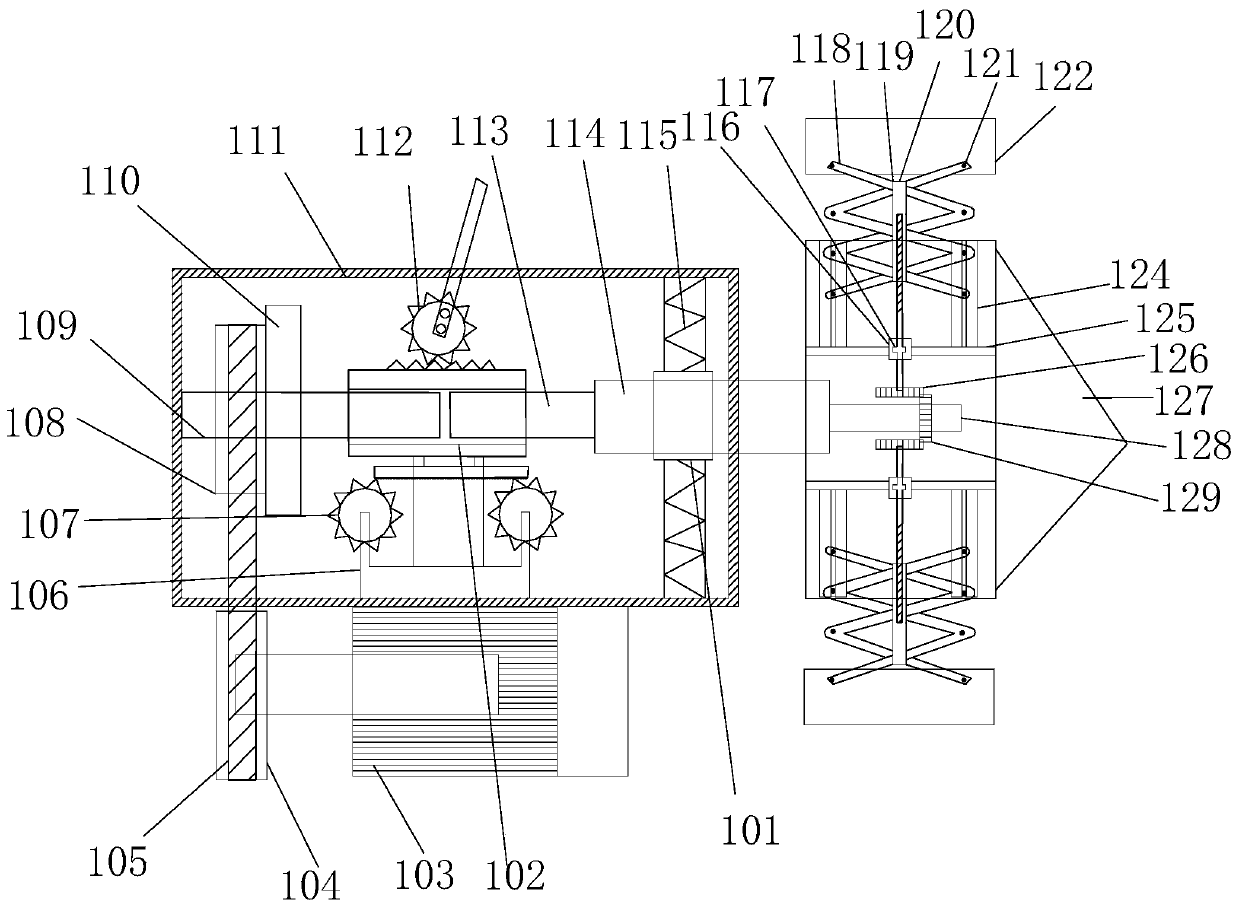

Device and method for testing impact resistance of plastic pipe

InactiveCN111504813AComprehensive test functionComprehensive test resultsMaterial strength using repeated/pulsating forcesBobbinElectric machine

The invention discloses a device and a method for testing the impact resistance of a plastic pipe. The invention belongs to the technical field of pipe performance testing. The device comprises a device frame, and a supporting plate is movably mounted in the device frame; the top end of the supporting plate is fixedly connected with a C-shaped hanging rod; two electromagnets are fixedly mounted on the inner wall of the top of the device frame; two iron blocks are fixedly connected to the top of the hanging rod, a driving motor is fixedly installed at the top of the device frame, a bobbin is fixedly connected to the output end of the driving motor, a hanging rope is wound around the outer wall of the bobbin, a fixed pulley is fixedly installed on one side of the driving motor, and the hanging rope is in transmission connection with the fixed pulley. According to the invention, diversified test functions can be realized, adaptive adjustment can be carried out according to use scenes andimpact resistance requirements of different pipes, the test result is comprehensive, the structure is simple, the operation is convenient, and the test method is convenient to implement.

Owner:陈辉

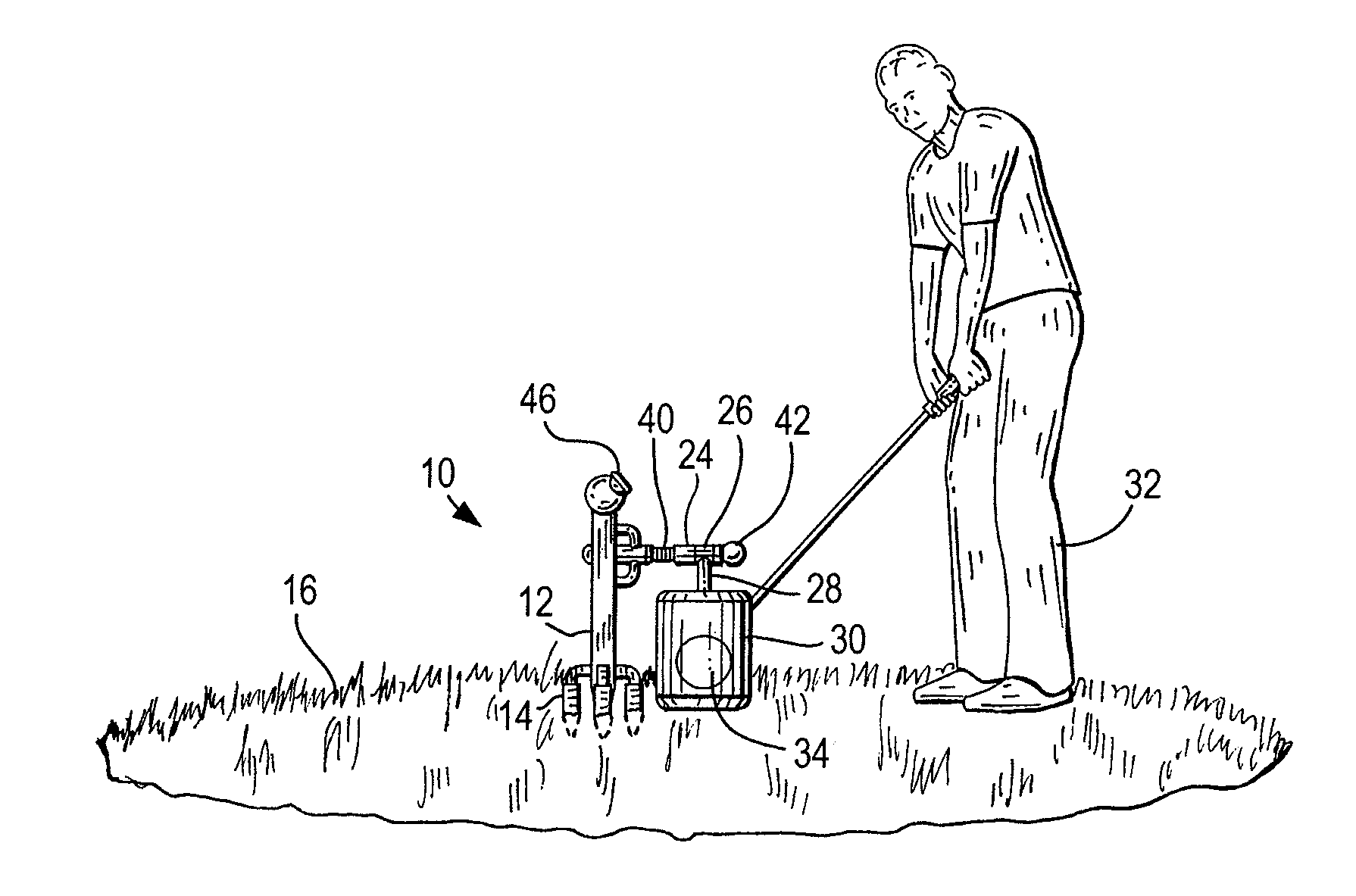

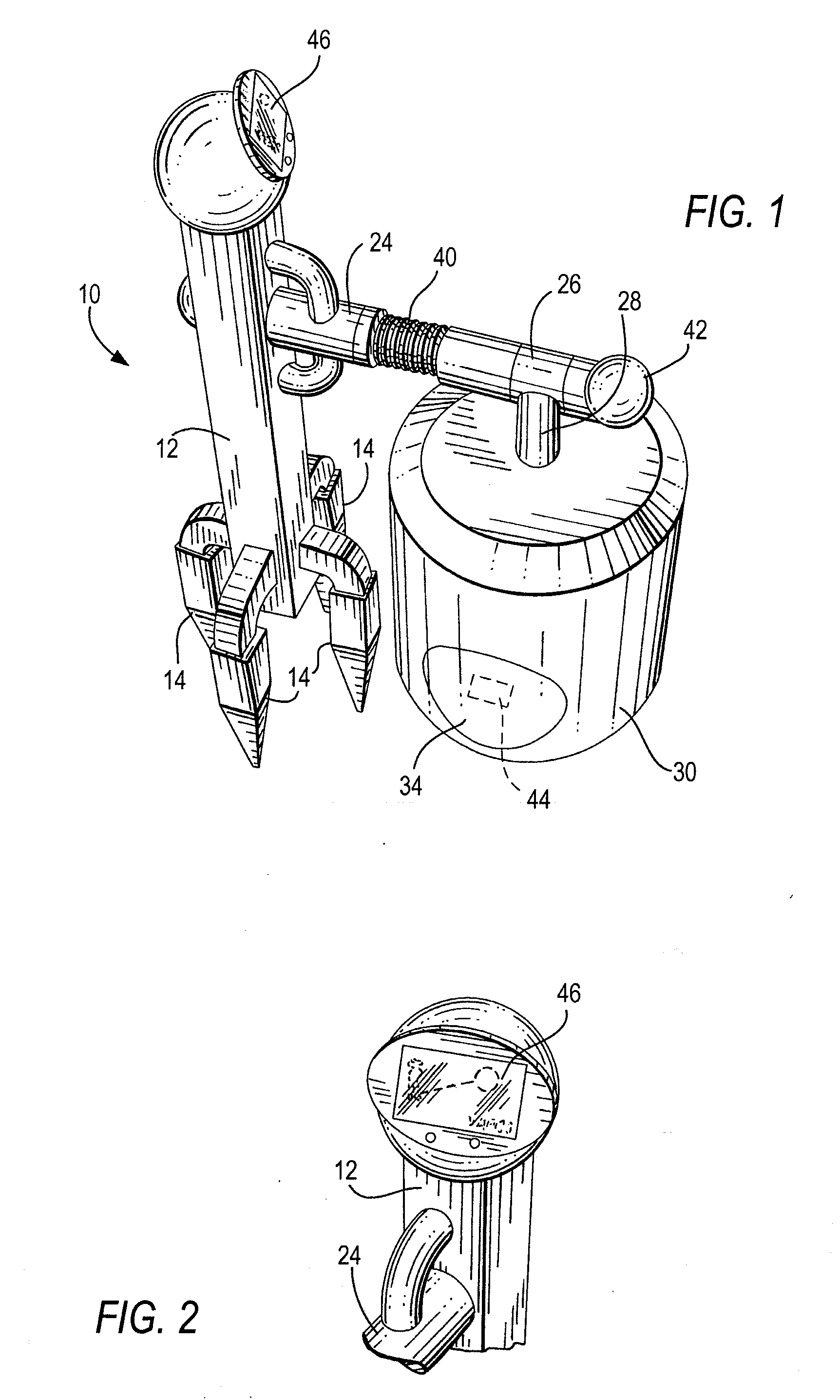

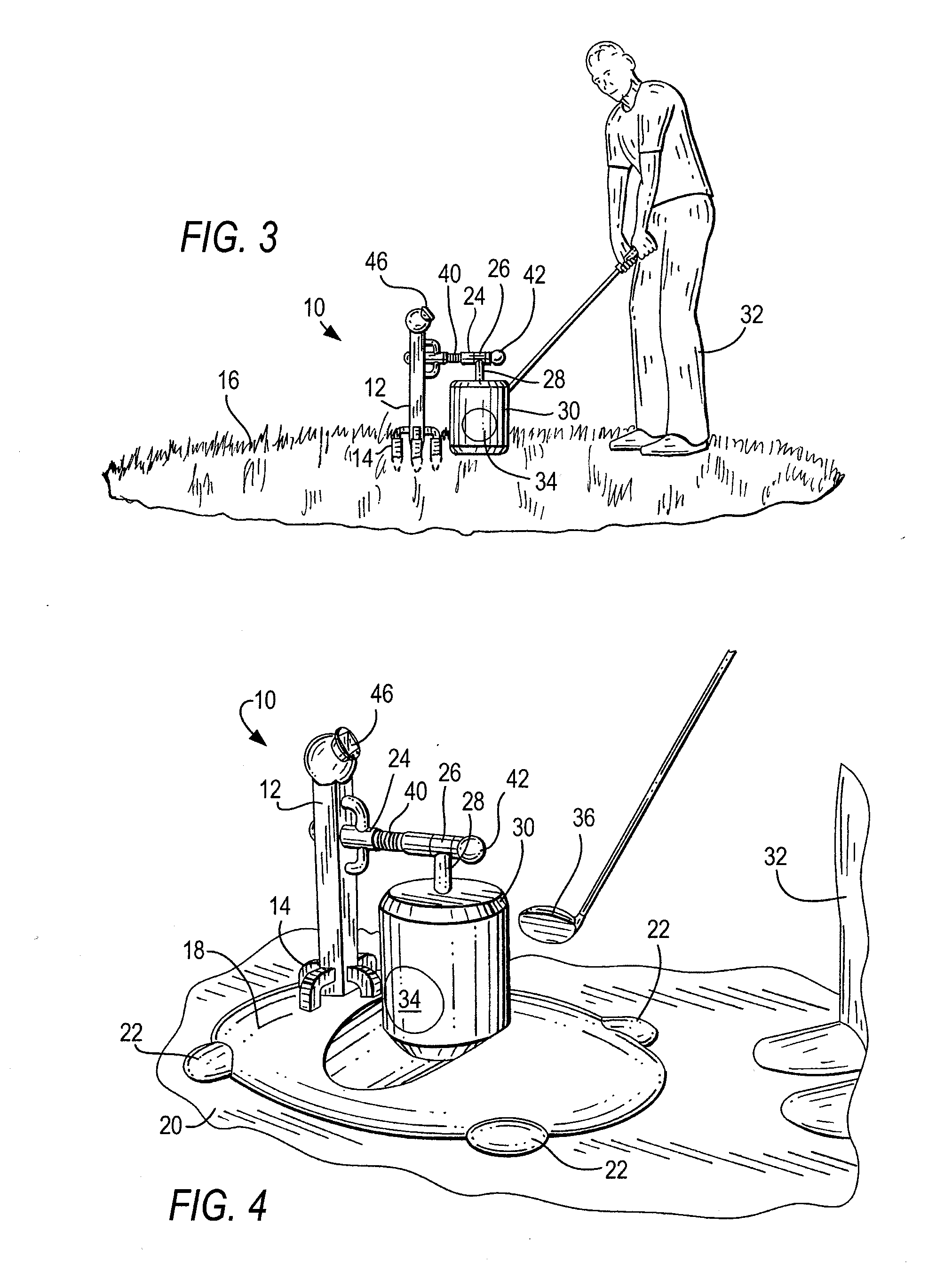

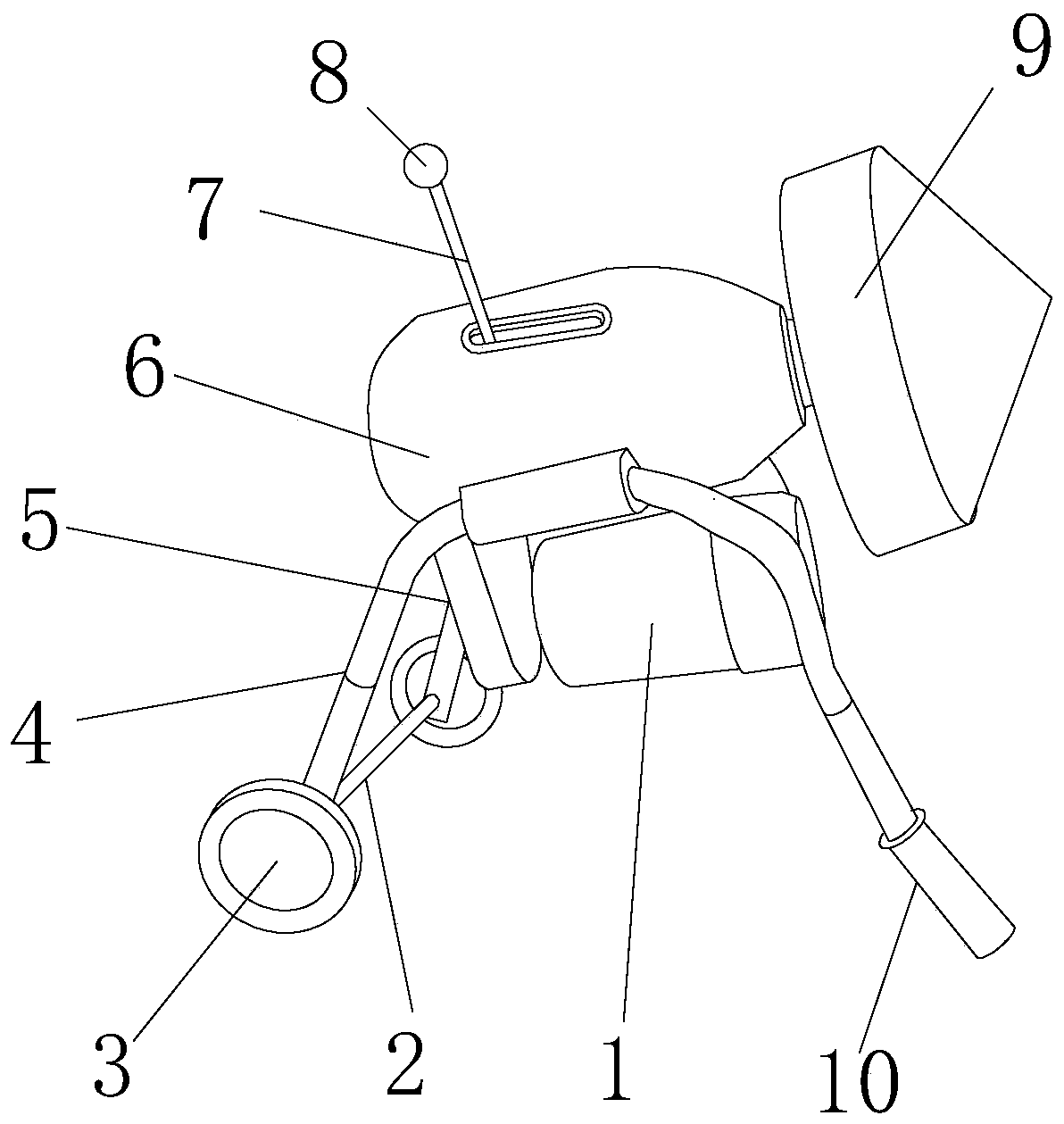

Golf swing trainer

A golf practice and exercise device has an elevated arm from which an impact object is suspended for swinging movement. The object is positioned with a clubhead impact target in position for striking by the clubhead of a golf club swung by a golfer. The resistance to the impact of the golf club is adjustable. A sensor detects the magnitude and velocity of the striking force, and a display displays an indication as to how far a golf ball would have gone after being struck with a force and velocity of the detected magnitude.

Owner:MURRAY JAMES

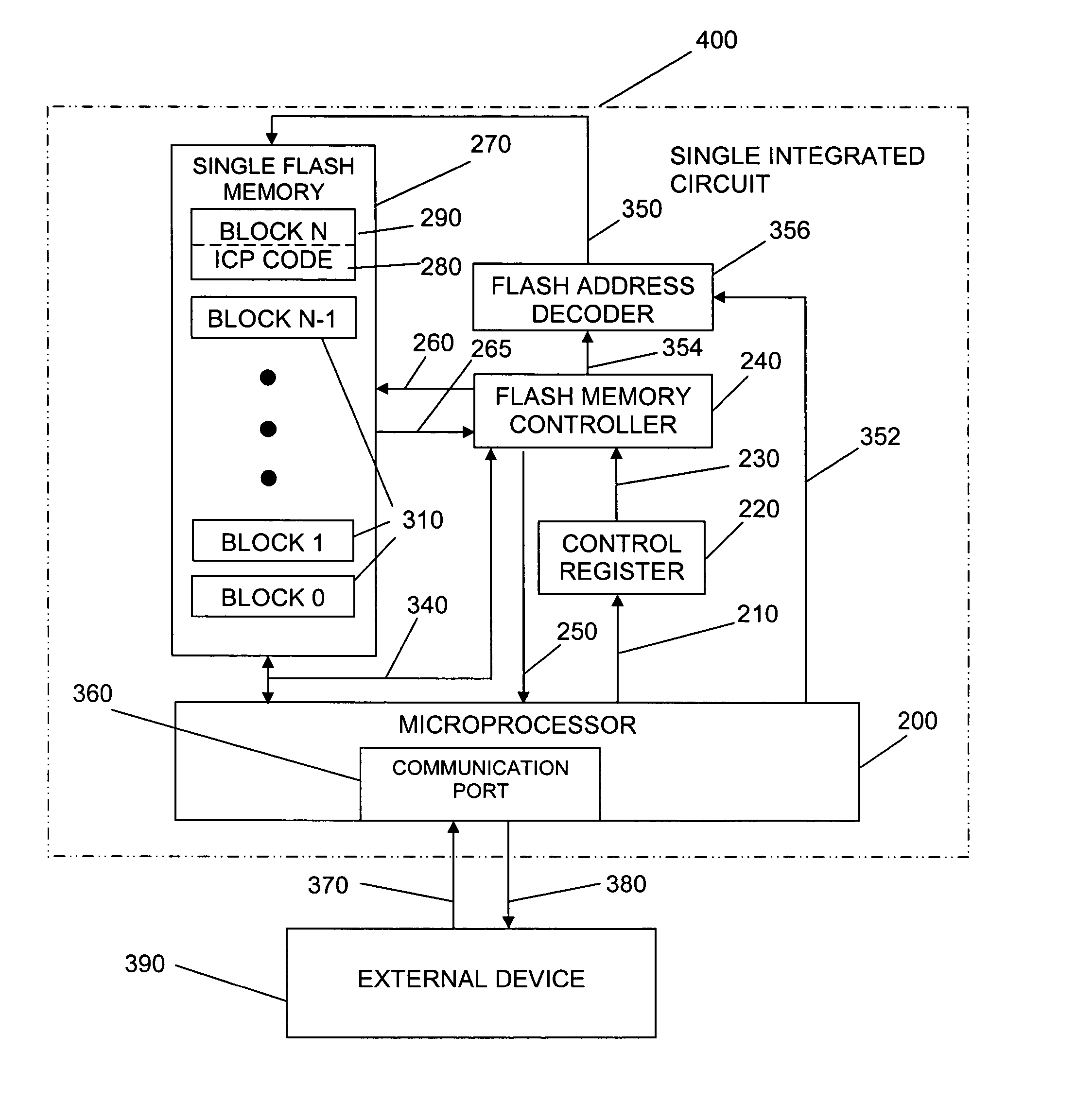

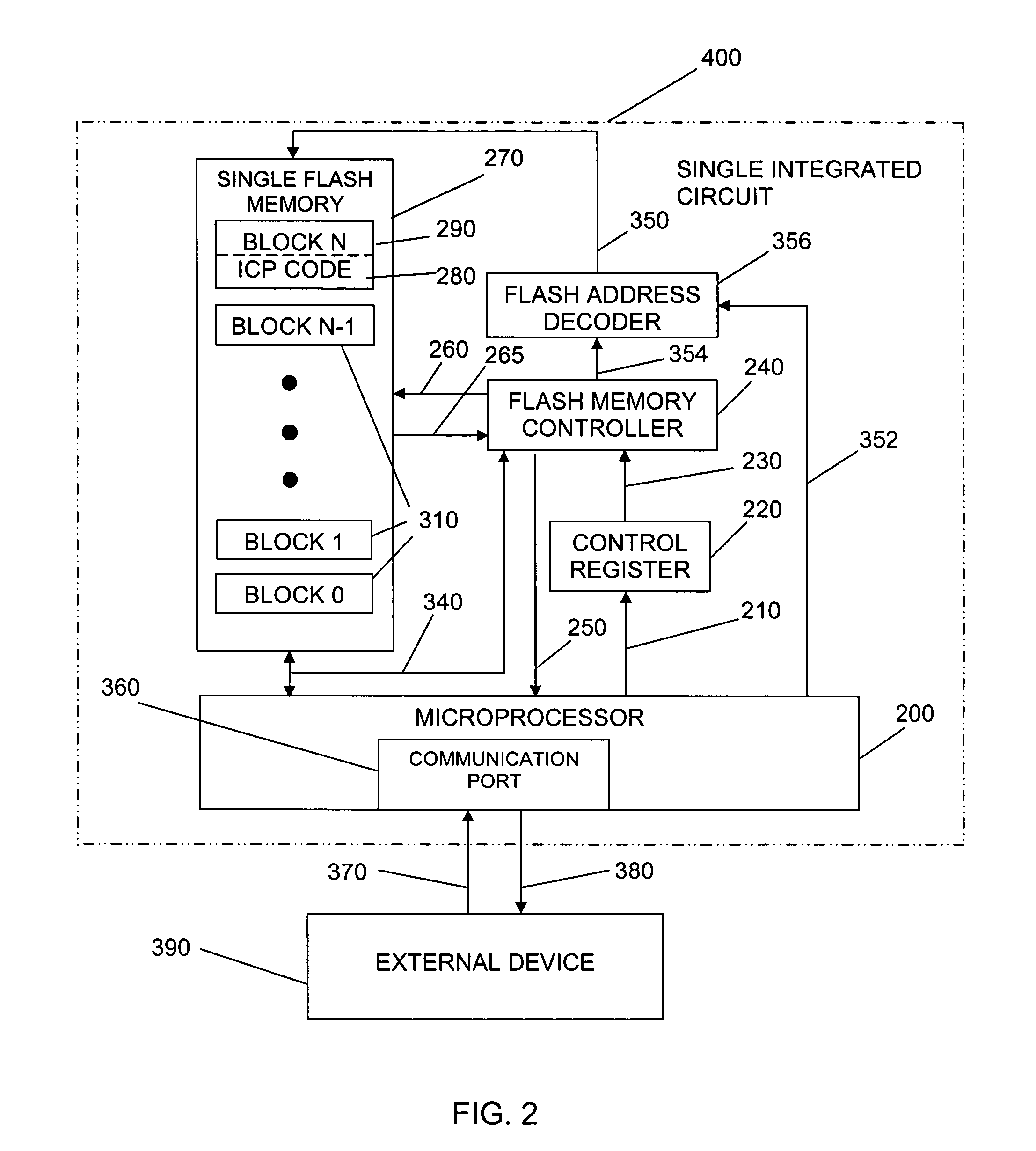

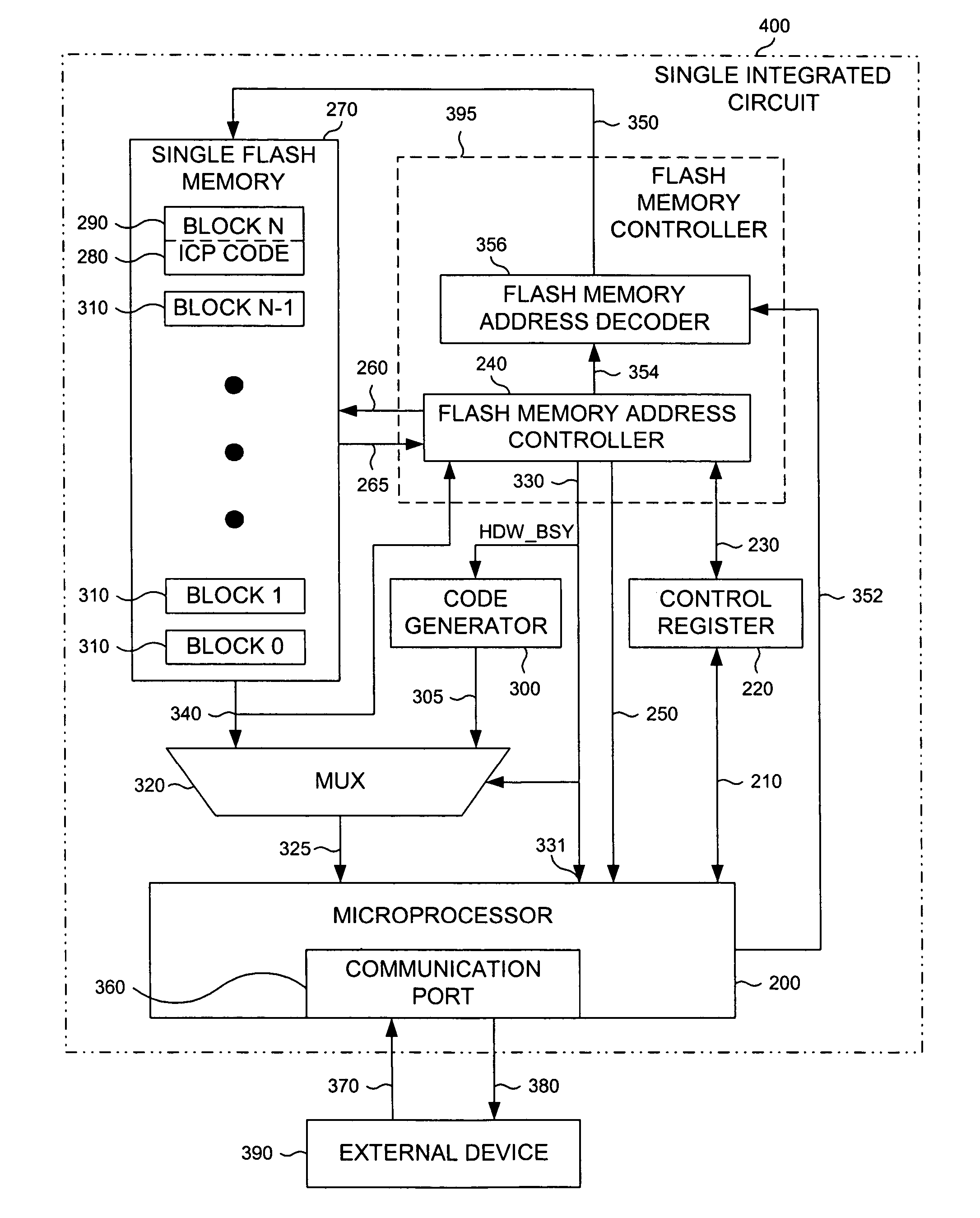

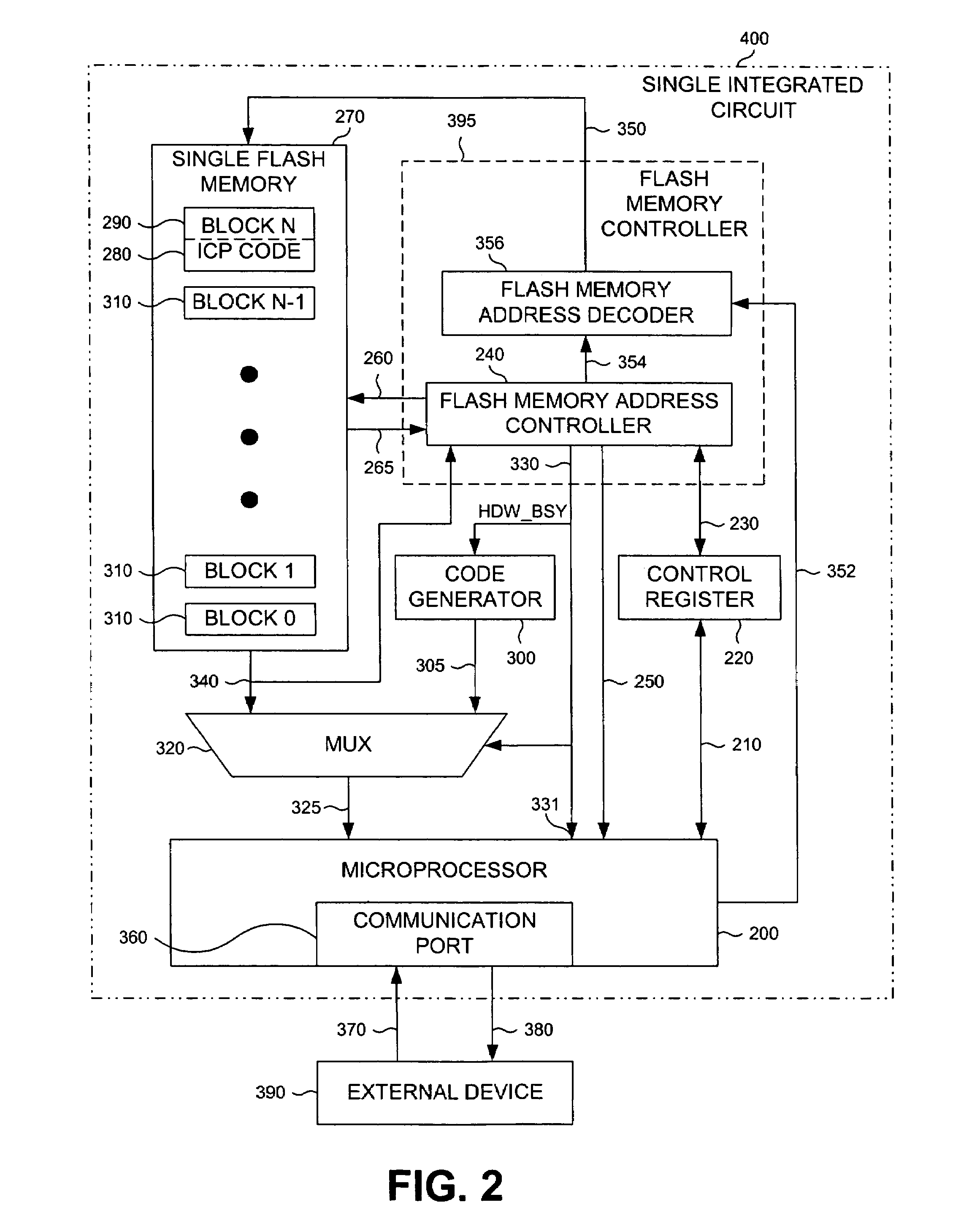

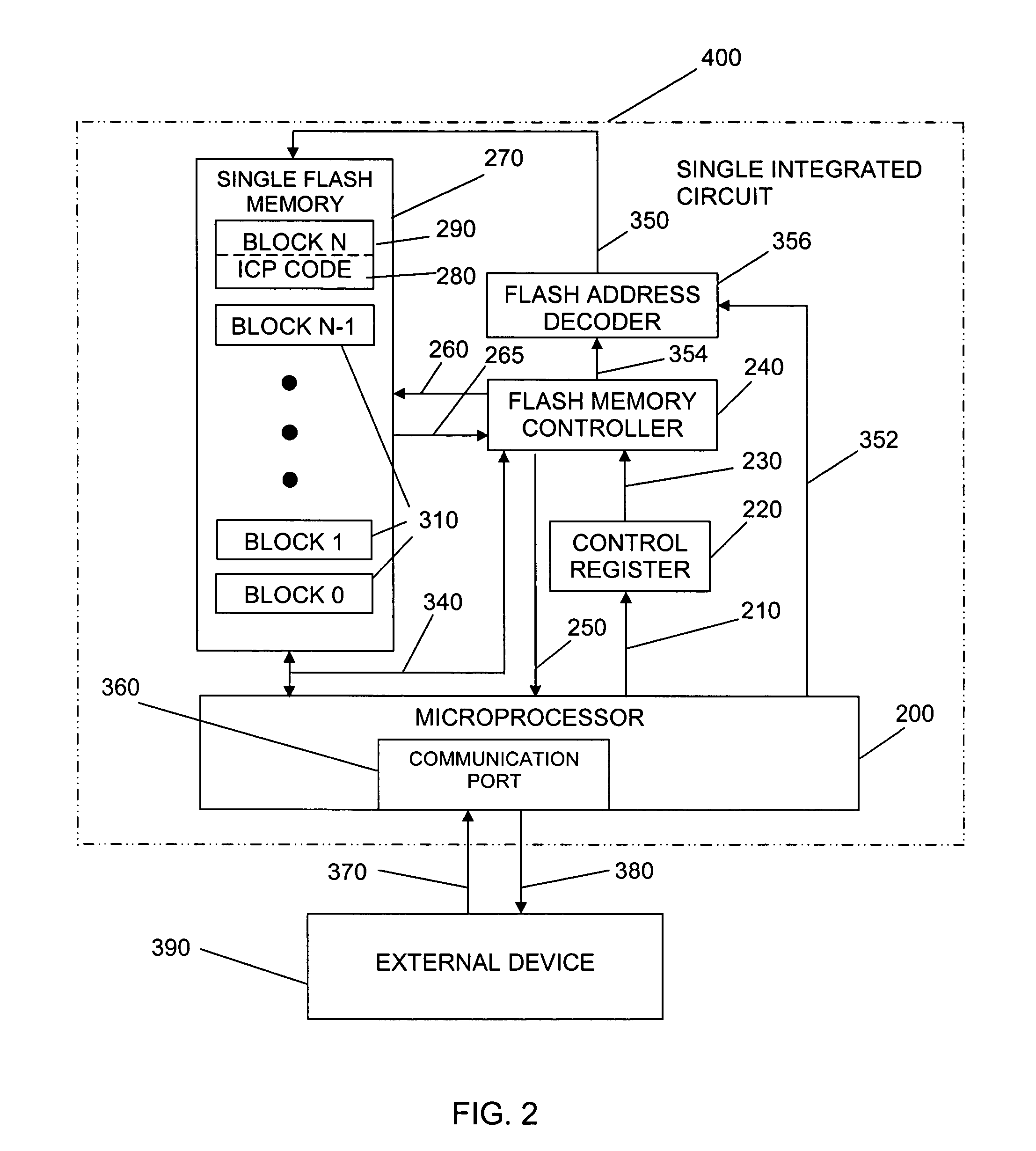

In-circuit programming architecture with processor, delegable flash controller, and code generator

ActiveUS20060041712A1Change impactImprove reliabilityGeneral purpose stored program computerMultiple digital computer combinationsFlash memory controllerUser code

An architecture for an integrated circuit with in-circuit programming allows real-time modification of the in-circuit programming code and other code stored on the chip. The architecture utilizes a microprocessor and control logic on an integrated circuit having a single non-volatile memory that stores instructions and data, such as in-circuit programming and user code, and input / output ports and related structure for exchanging data with an external device. Using in-circuit programming code stored on the chip, the chip interactively establishes an in-circuit programming exchange with an external device to update data and instructions including the in-circuit programming code. Input / output conflicts during in-circuit programming can be avoided by employing a code generator that supplies control routines to the microprocessor during at least part of the in-circuit programming operations. The code generator allows the in-circuit programming code to be updated in real time.

Owner:MACRONIX INT CO LTD

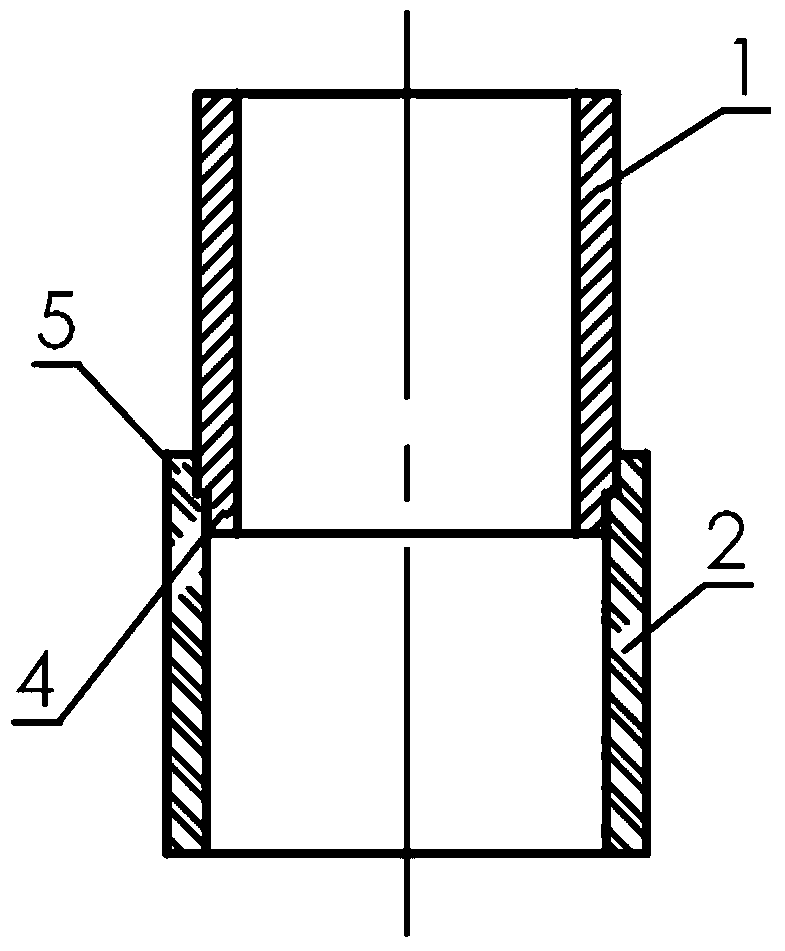

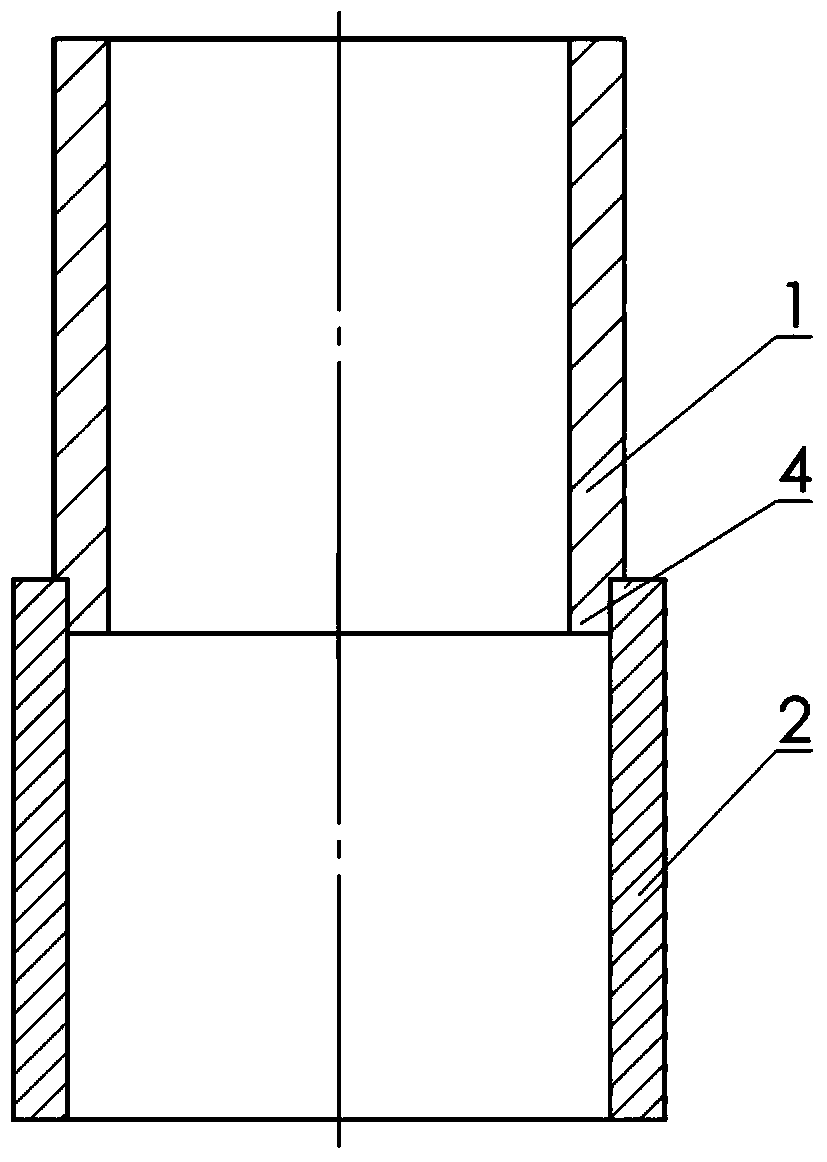

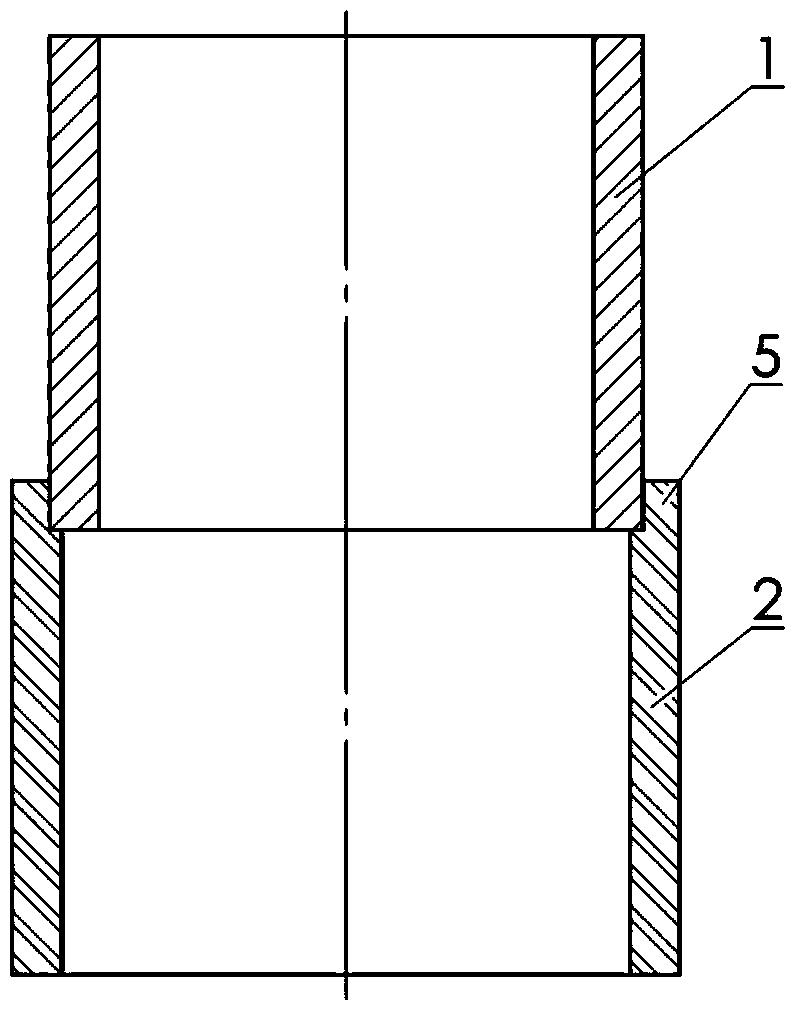

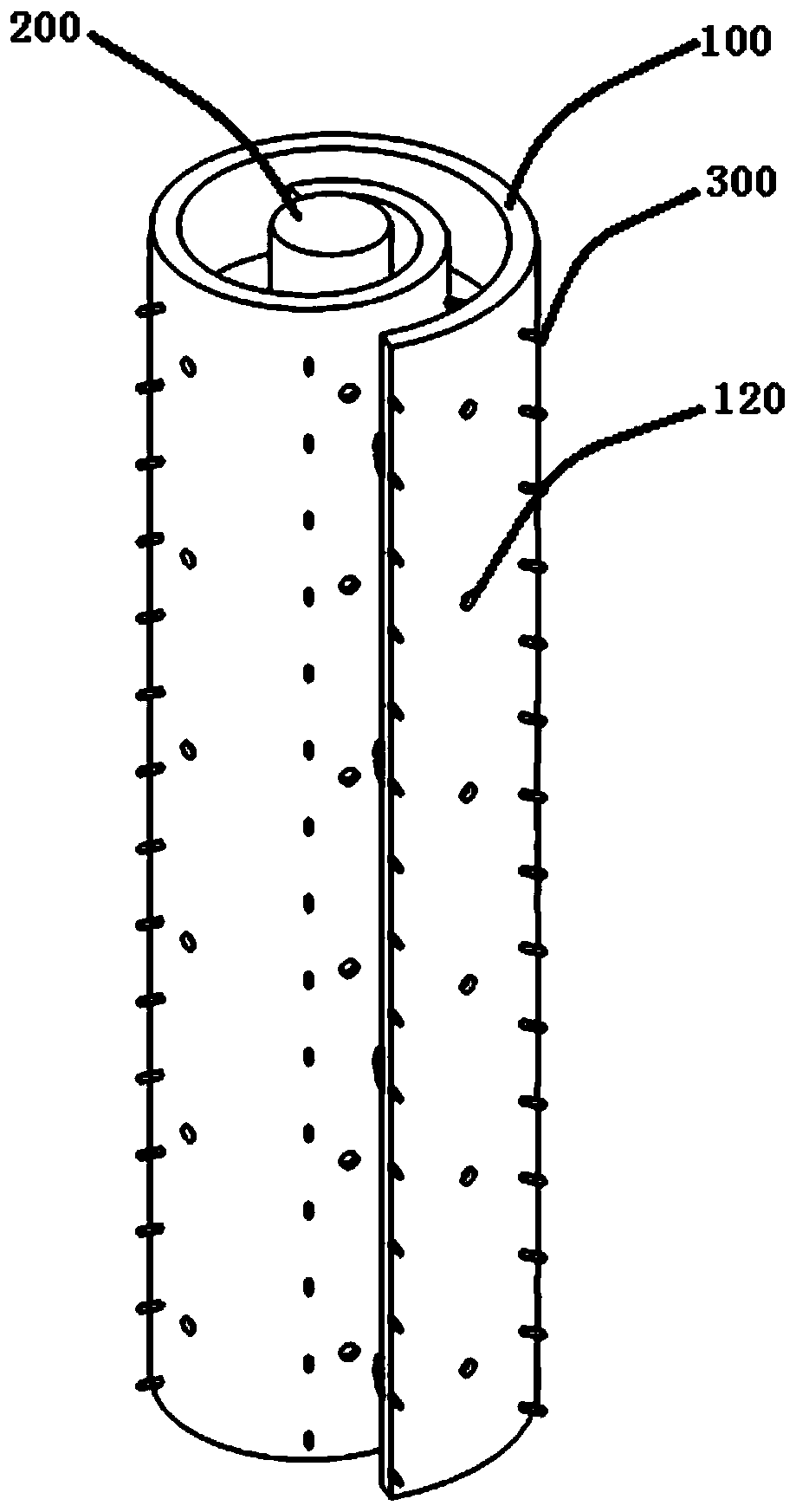

Round tube combination buffering device

InactiveCN103410904AImprove protectionHigh energy absorption per unit volumeElastic dampersEnergy absorptionAbsorbed energy

The invention discloses a round tube combination buffering device which comprises a large round tube and a small round tube which have different strengths and are contacted in sequence in the load direction. Wherein the inner diameter of large round pipe is slightly smaller than the outer diameter of the small round pipe; the round tubes with different strengths and different sizes are overlapped coaxially; under the condition that the volume of a plurality of layers of round tube buffering device is not changed, a manner of absorbing energy by single circular tube flexion deformity is changed into a manner of absorbing energy by shear failure among the round tubes; the device has the advantages that the energy absorption amount in unit volume is large, impact force is stable, and the ratio value of a mean load / a peak load is relatively high, so that a protected object can be well protected.

Owner:NORTHWEST INST OF NUCLEAR TECH

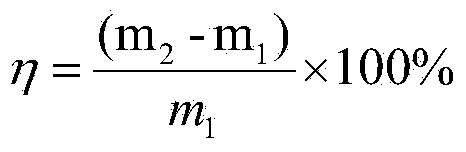

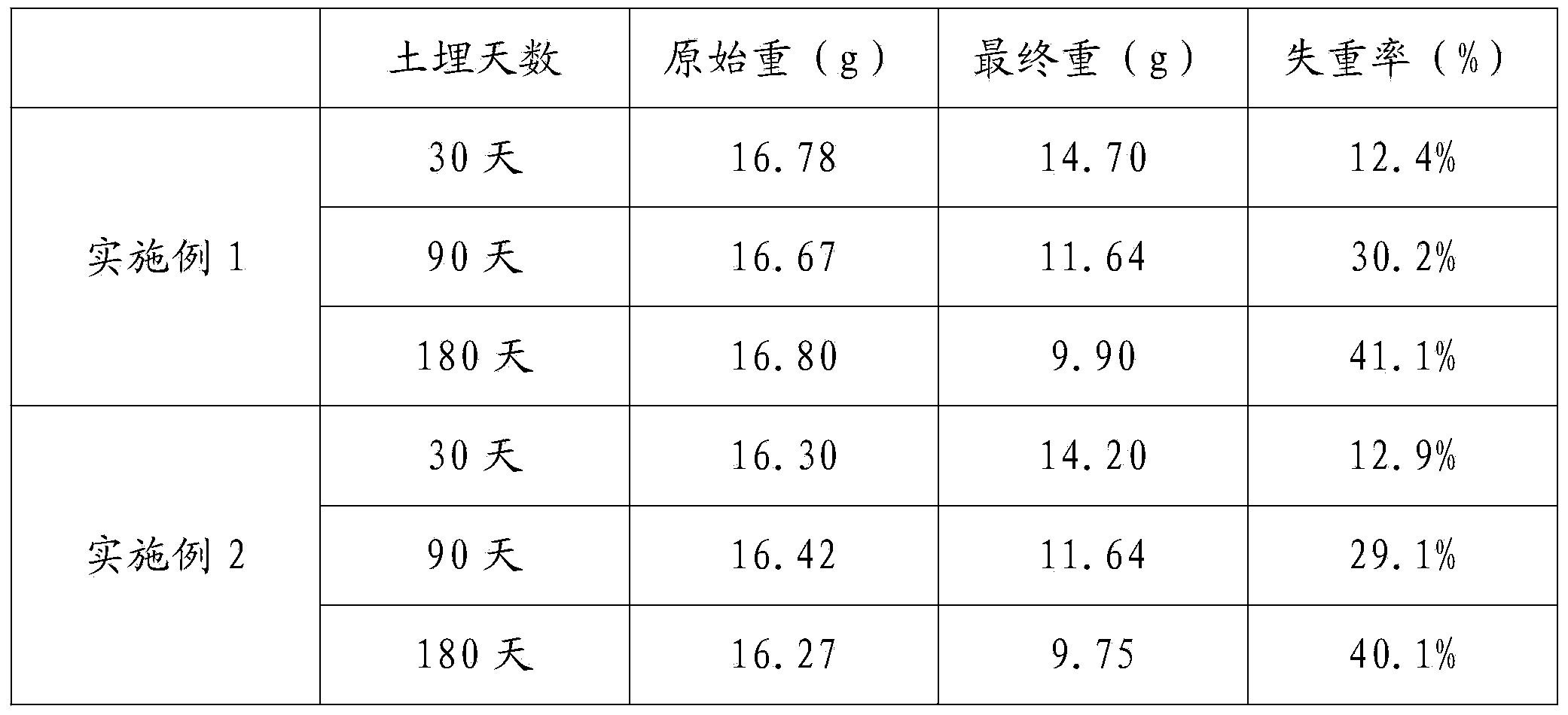

Preparation method of potato starch-based degradable plastic film

The invention discloses a preparation method of a potato starch-based degradable plastic film. The preparation method of the potato starch-based degradable plastic film comprises the following steps: mixing 60-80 parts of potato starch and 300-400 parts of deionized water to form a starch aqueous solution, and pasting at the temperature of 85-90 DEG C; at the temperature of 60-70 DEG C, adding 3-4 parts by weight of an initiating agent, stirring for 15 minutes, and then adding 120-180 parts of vinyl acetate and 8-12 parts of acrylic amide and reacting for 2-2.5 hours to obtain grafted copolymer emulsion; then adding 30-40 parts of a 10% poly(vinyl alcohol) solution and 10-20 parts of a 4% epoxy chloropropane solution into the grafted copolymer emulsion, reacting at the temperature of 60-70 DEG C for 1.5-2 hours, carrying out suction filtration at reduced pressure, and drying to obtain a solid mixture, carrying out hot melting extrusion-blown molding on the solid mixture by virtue of a single screw extrusion film blowing machine to obtain a plastic film, and finally cutting, carrying out roll dividing, and packaging. The prepared plastic film has good water resistance and biodegradability.

Owner:GUANGXI UNIV

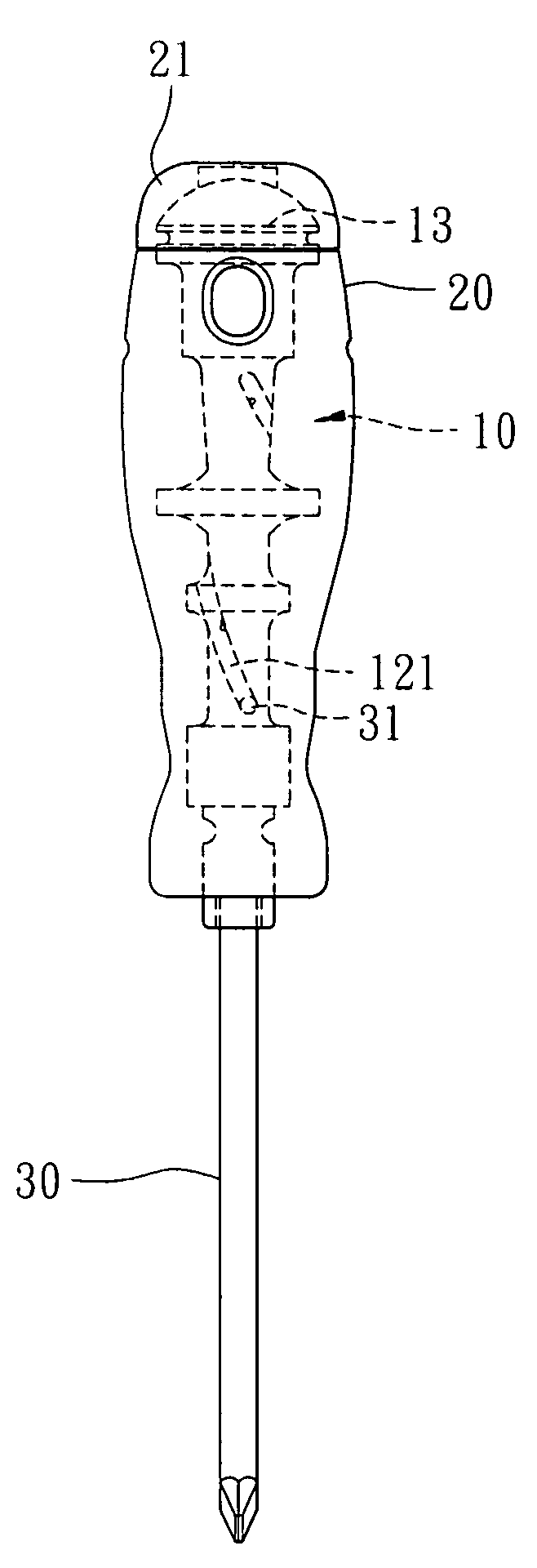

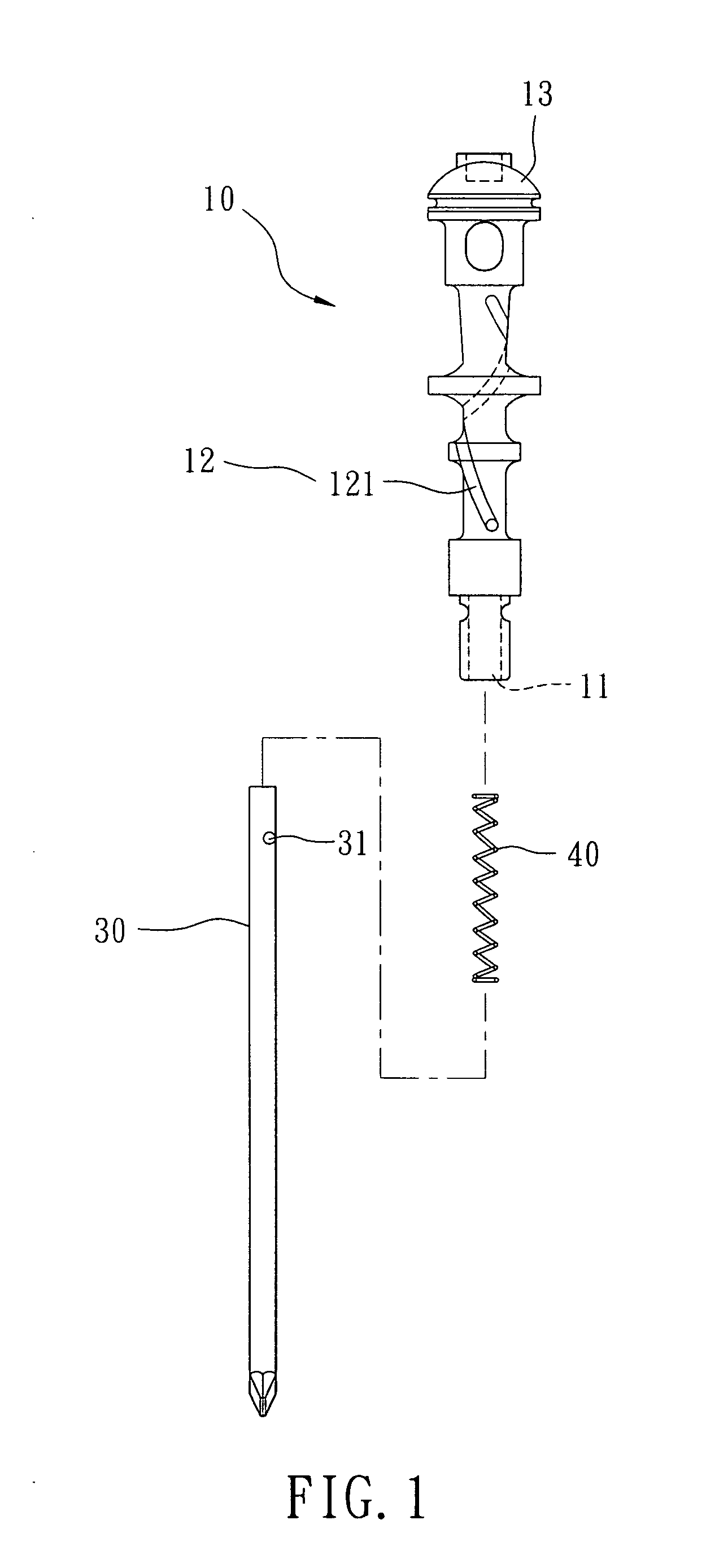

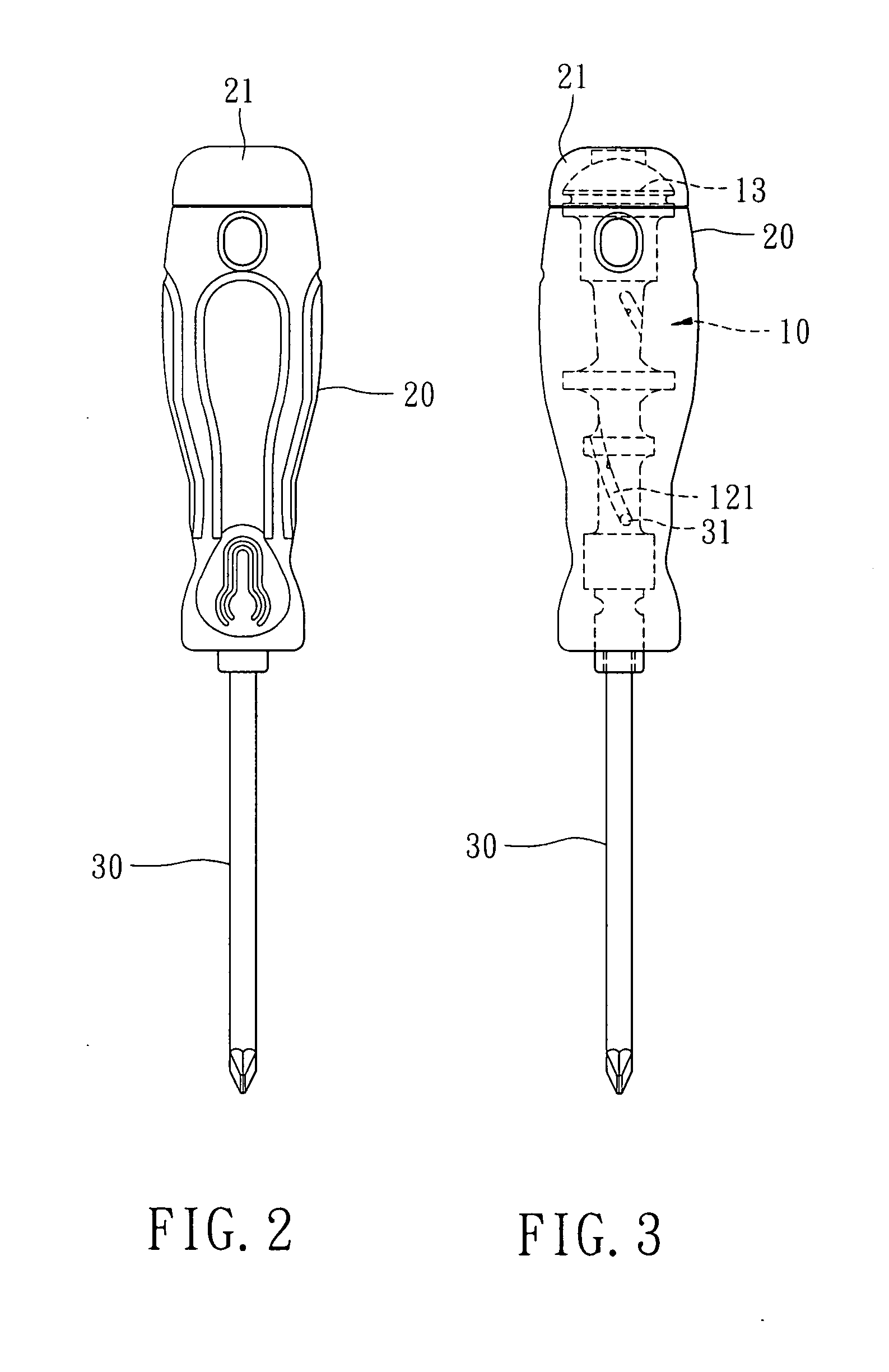

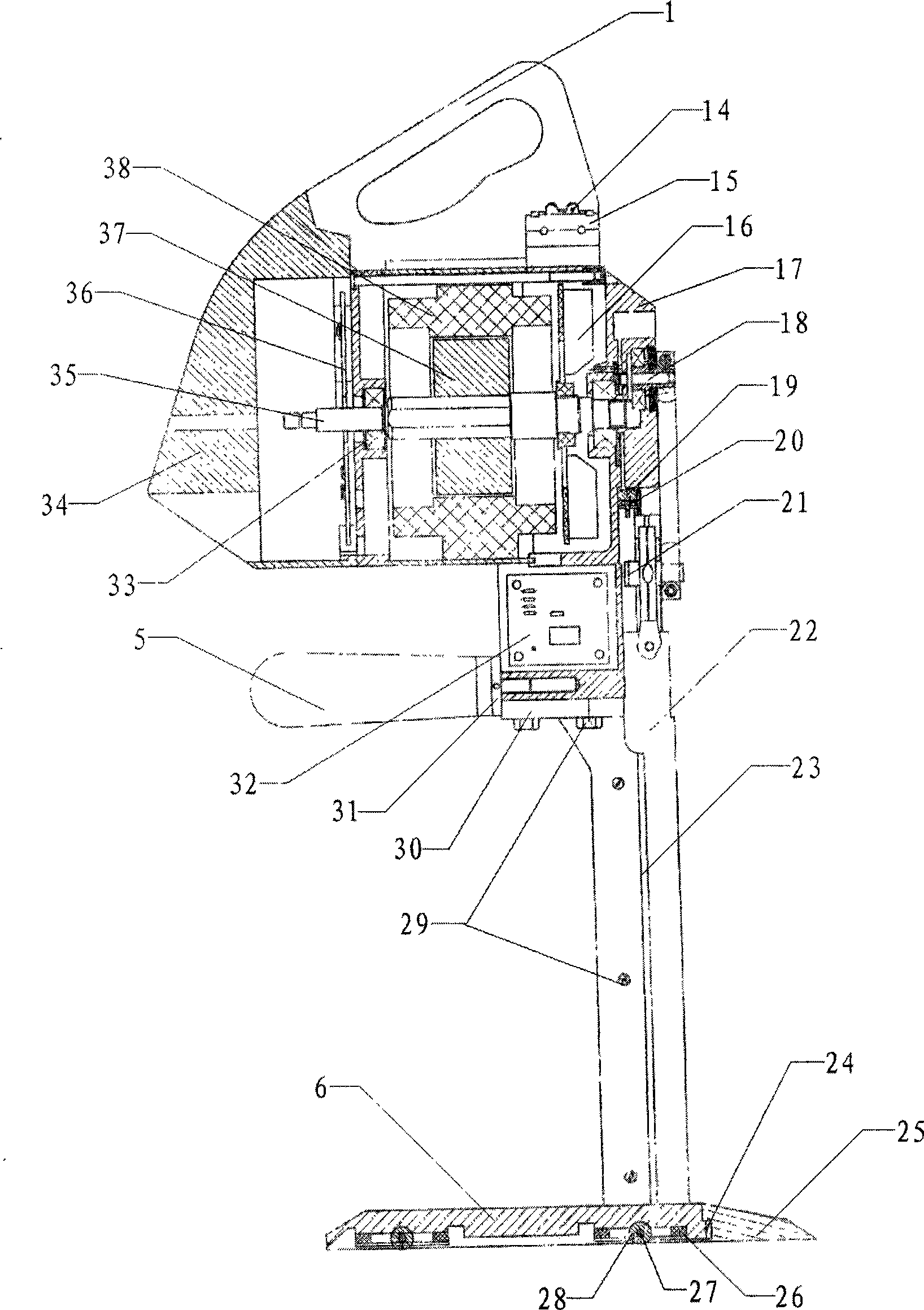

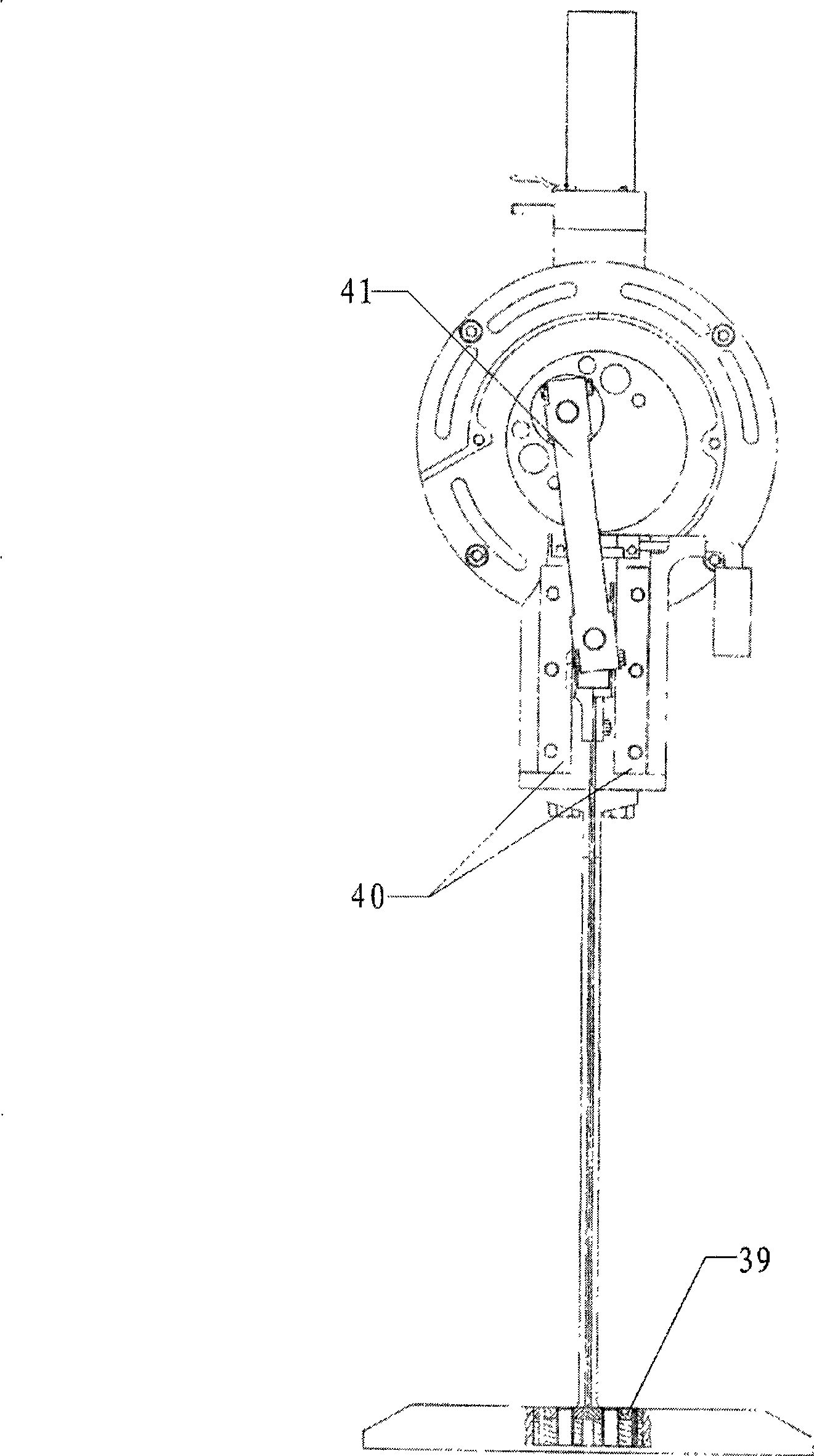

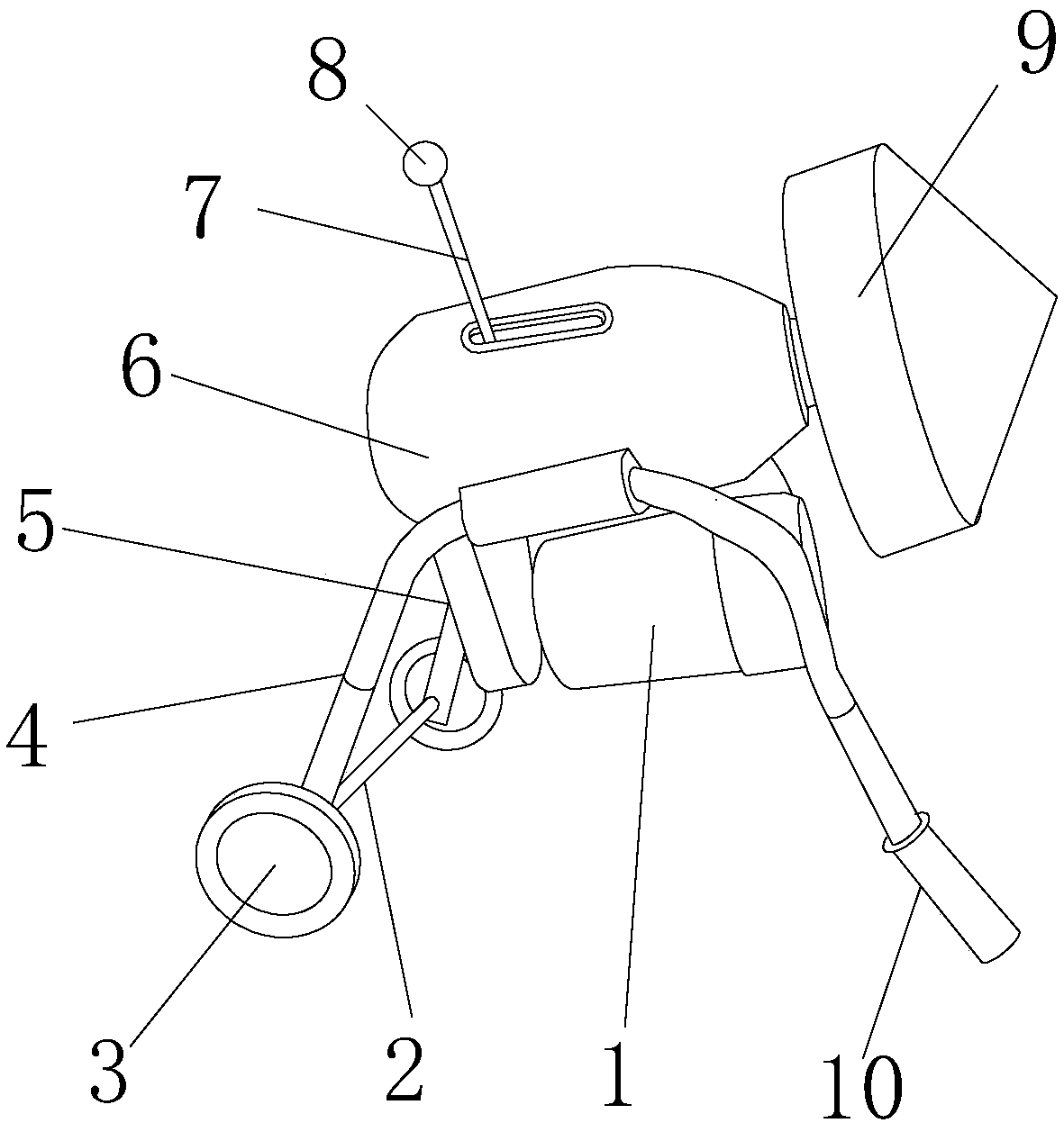

Impact screwdriver

An impact screwdriver includes: a handle has a spindle mounted therein. The spindle has a first end and a second end extending to an outer surface of the handle, a percussion portion is mounted on the first end of the spindle for loading impact, a tank is axially defined in the spindle from the second end of the spindle, a guiding structure is defined in an inner periphery of the tank, an elastic member and a driving shank is sequentially mounted in the tank for cooperating each other, a boss is positioned on the driving shank and installed into the guiding structure to make the guiding structure drive the driving shank when the percussion portion is impacted.

Owner:HSIEH CHIH CHING

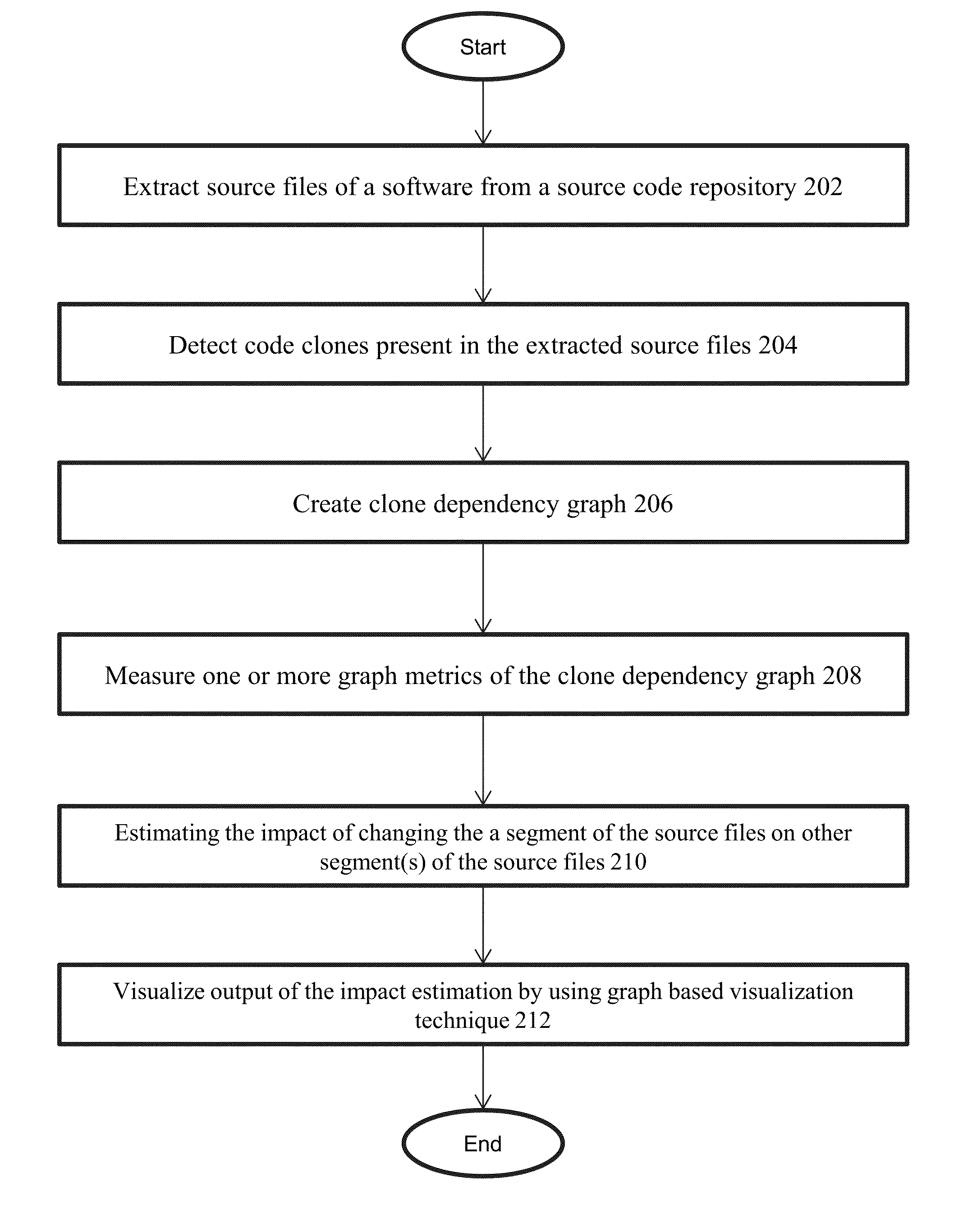

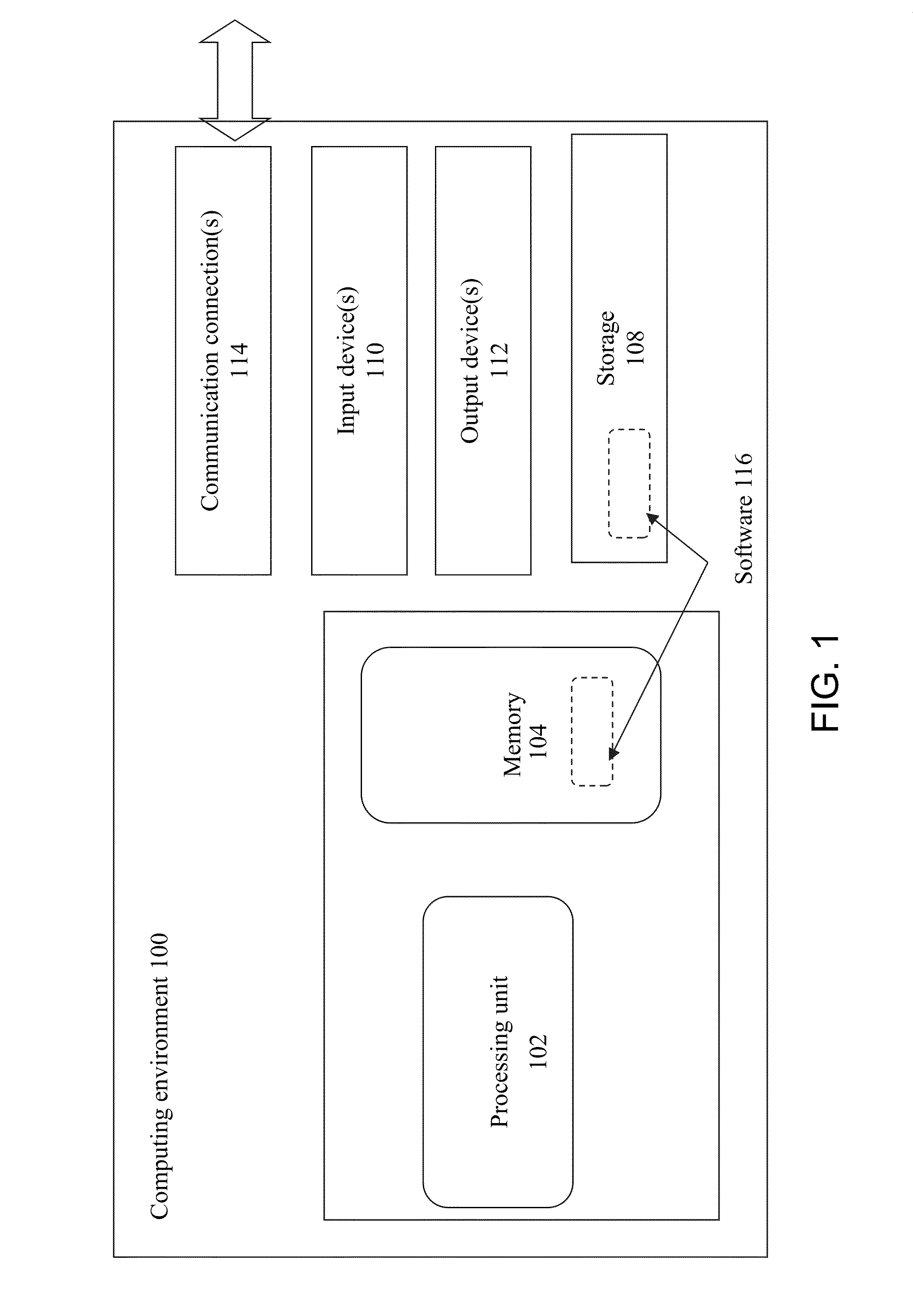

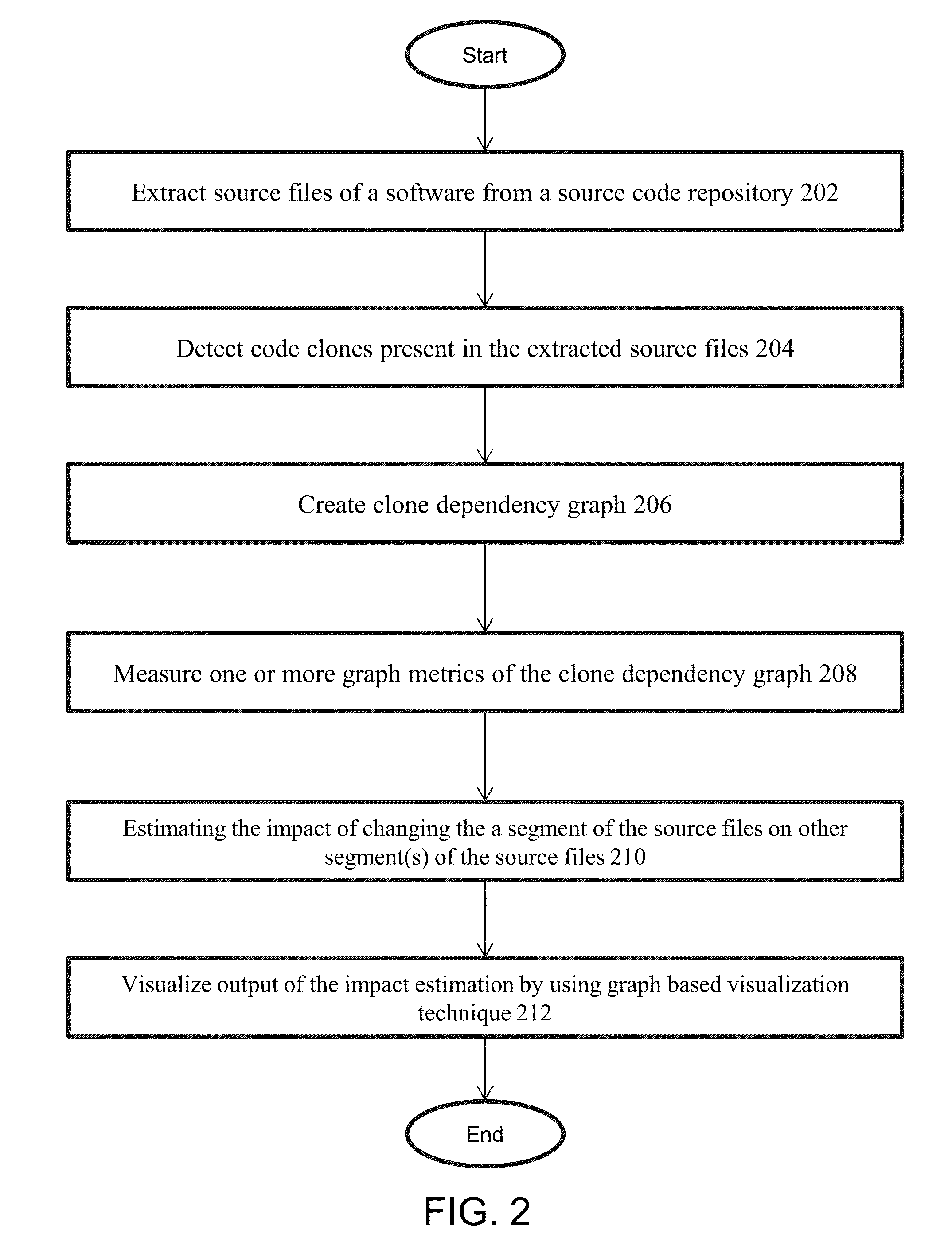

Systems and methods for estimating an impact of changing a source file in a software

ActiveUS9201649B2Reduce effortSave maintenance costError detection/correctionReverse engineeringDependency graphSoftware

The technique relates to a system and method for estimating an impact of changing one or more source files in a software based on a clone dependency graph. This technique involves extracting the source files from a repository and detecting code cones present in the source files. After detecting the code clones the clone dependency graph is created. Several graph metrics are calculated and applied to the clone dependency graph to estimate the impact of changing a source file on other source files of the software. Finally, the output is visualized with the help of graph visualization technique.

Owner:INFOSYS LTD

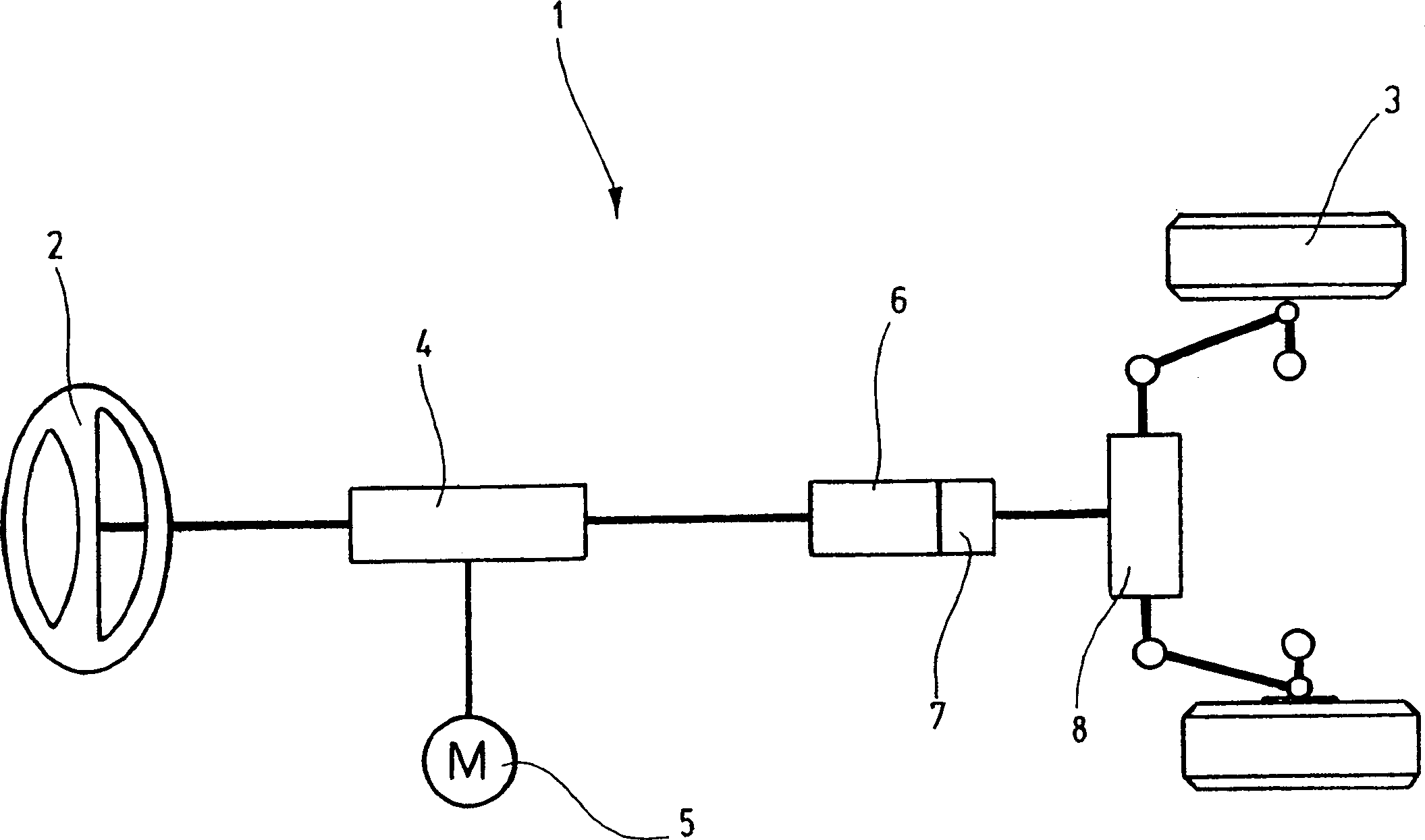

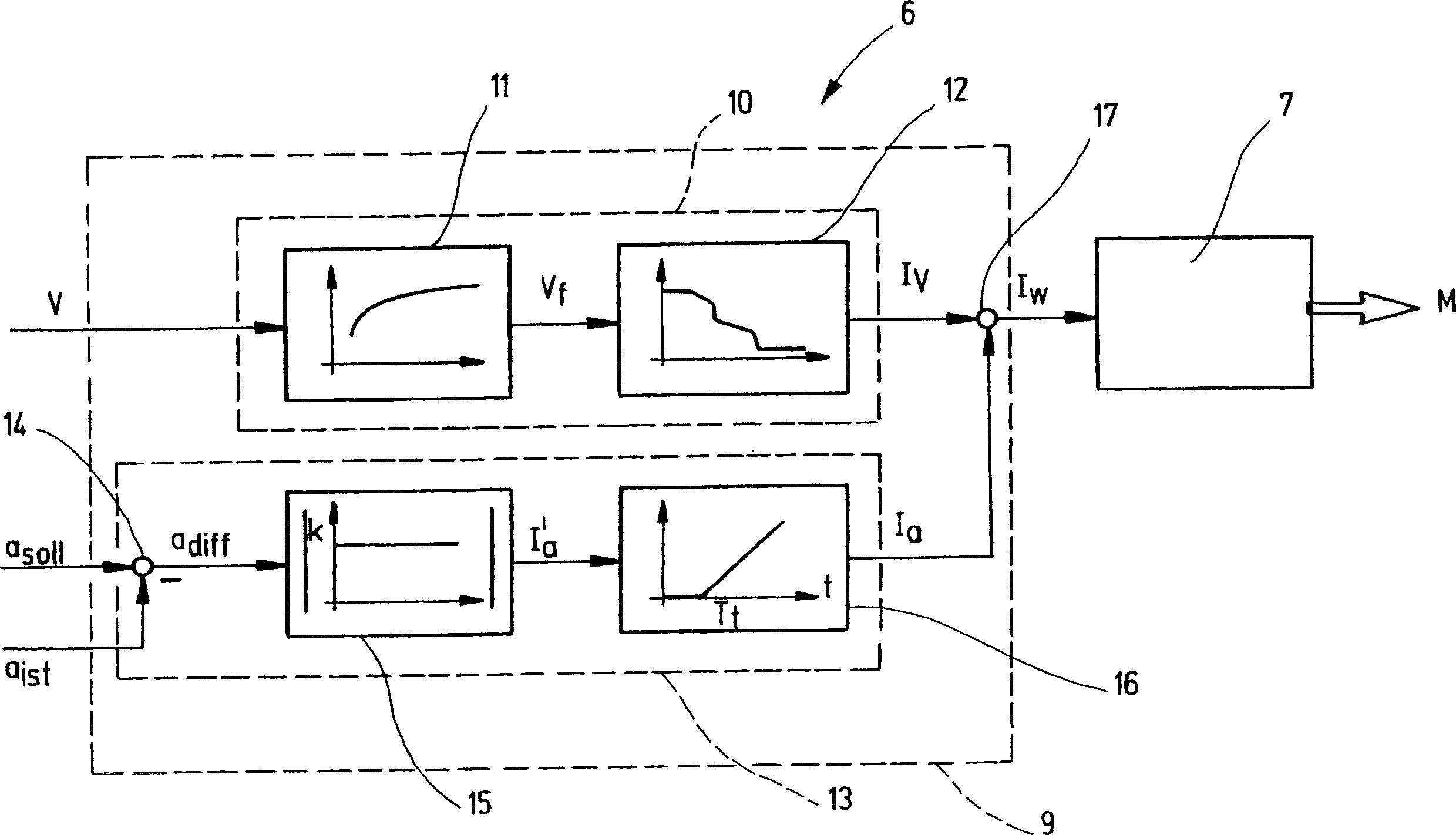

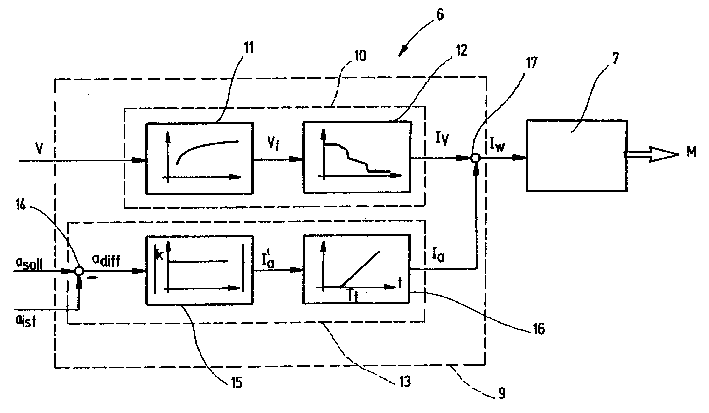

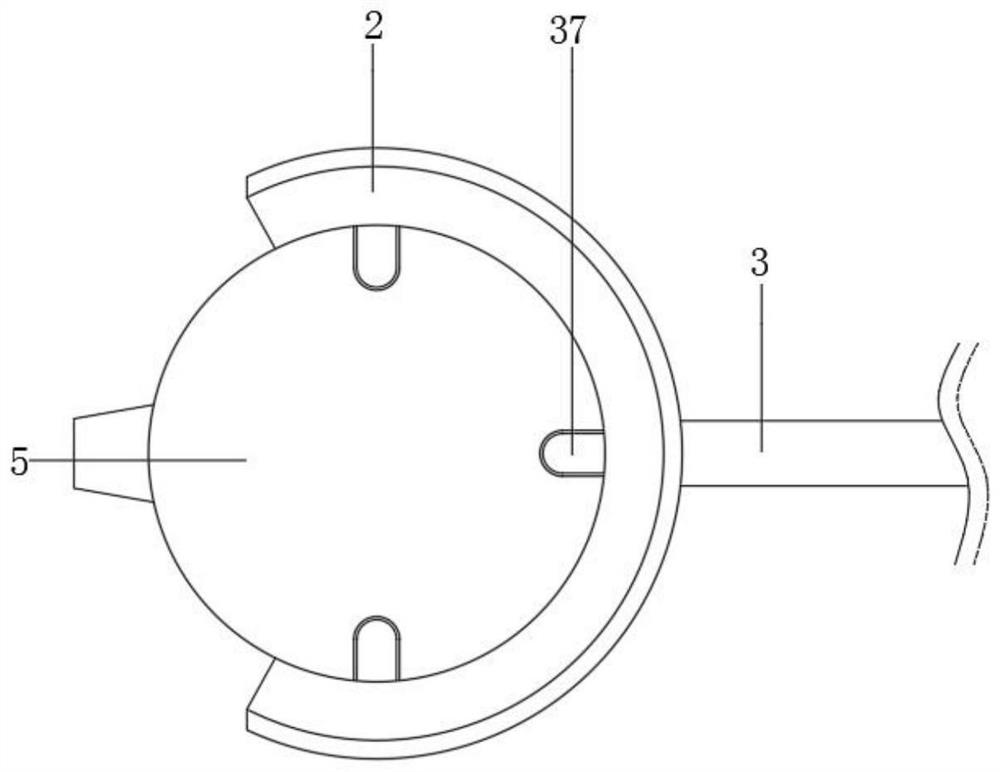

Power-assisted steering system of an automobile

InactiveCN1419507AImprove driving stabilityRapid responseElectric motor controlSteering linkagesEffective powerSteering angle

The present invention relates to a power-assisted automobile steering system (1). Said steering system (1) has a steering wheel (2) for providing the desired steering angle of the automobile wheels (3), driving dynamics elements (4) for superimposing a correction angle onto the steering angle, said correction angle being determined with a view to increasing the driving stability and / or driving comfort of the automobile, and a power assist drive device (6). The power assist drive device (6) is configured as a variable torque booster in order to keep the performance of the driving dynamics elements (4) approximately constant throughout the speed range of the vehicle, the degree of torque boost (M) depending on the automobile speed (V) and at least one value of the driving dynamics elements (4) that characterises the correction angle.

Owner:ROBERT BOSCH GMBH

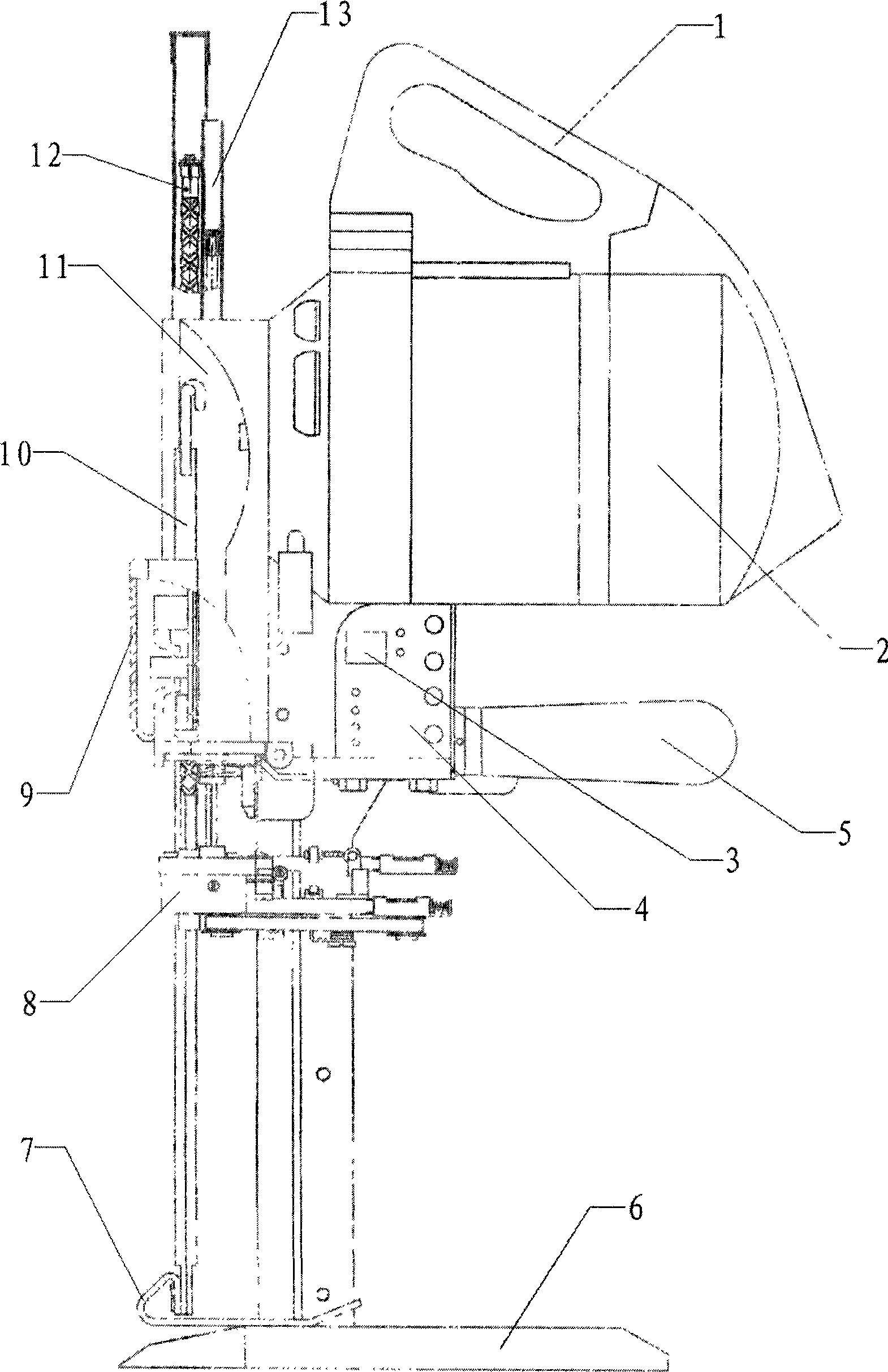

Numerical control electric cloth cutter

InactiveCN101386085AChanges are affected by dustChange impactShearing machinesShearing machine accessoriesNumerical controlSynchronous motor

The invention relates to a numerical control electric cutting machine, comprising a holding handle, a driving mechanism, a chassis and an adjusting mechanism; the lower part of the holding handle is provided with the driving mechanism; the lower part of the driving mechanism is provided with a control panel which is provided with an indicator screen; one side of the adjusting mechanism is provided with a guiding column which is connected with the driving mechanism; a front cover abrading component, a pressing foot rod, a cam cover and an abrasive belt wheel grinding component are sequentially arranged at the lower part of the guiding column from top to bottom; the lower part of the whole device is provided with the chassis. The numerical control electric cutting machine has the beneficial effects that the driving mechanism adopts an AC permanent magnetic synchronous motor and has the advantages of high efficiency and large torque; the digital operation panel has the functions of adjustable gears and speed; a HALL element is taken as a motor rotor sensor, thus avoiding the defect that an optical coupling sensor is affected by dusts; stable output power an be kept at different speeds and different resistance.

Owner:阮剑光

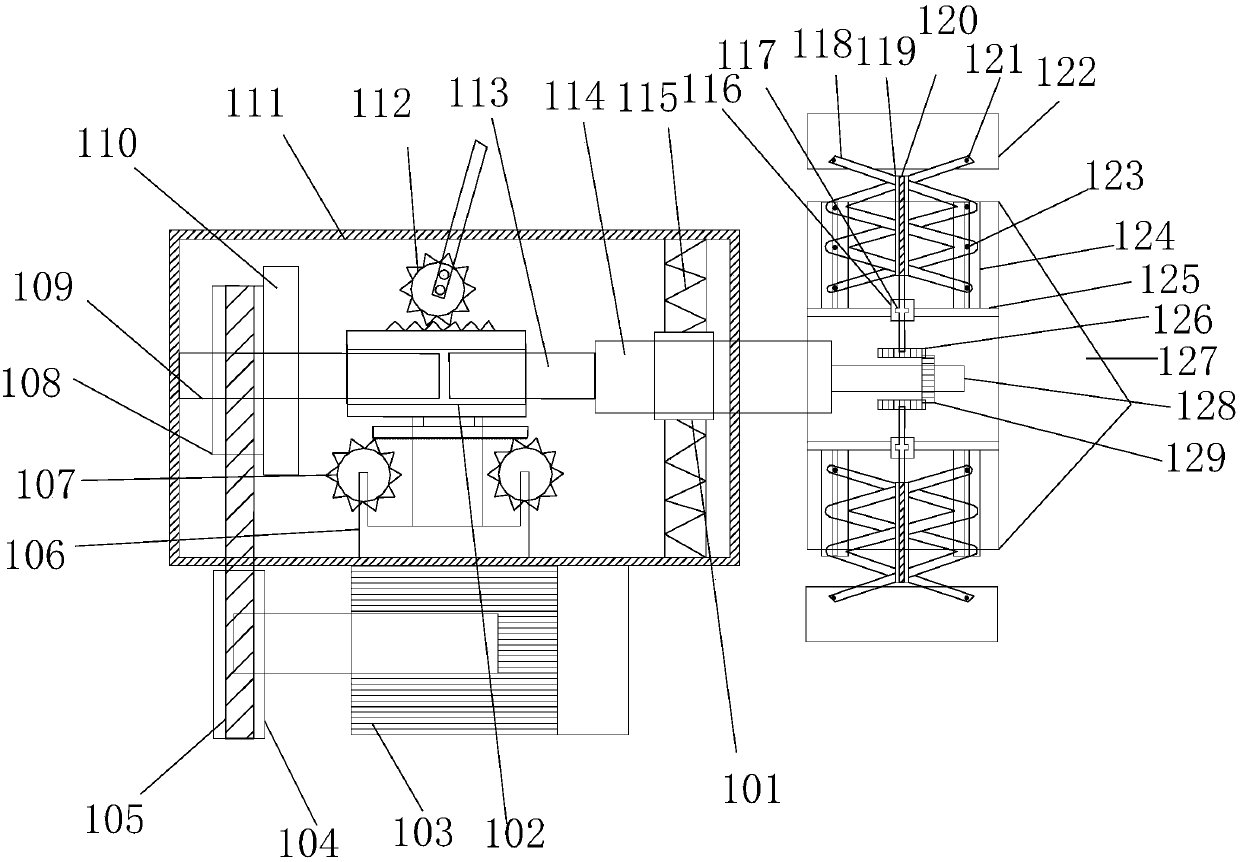

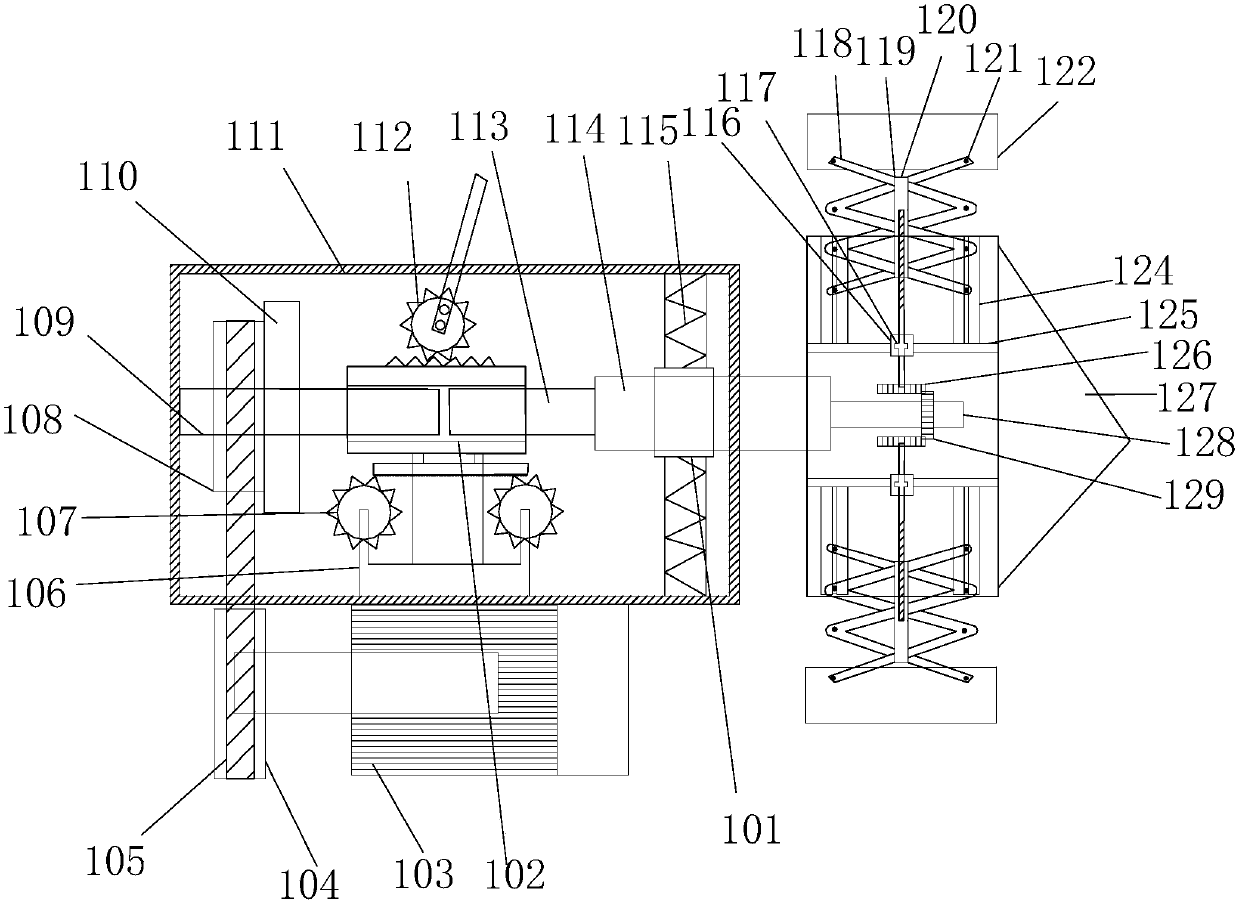

Gravure-based aqueous ink light source curing device

PendingCN110744921AImprove curing efficiencyVery good curing efficiencyPrinting press partsPhysicsPrint-through

The invention discloses a gravure-based aqueous ink light source curing device. According to the device, a driving motor is fixedly connected with a driving plate through bolts, power is transferred to a transmission shaft through a reduction gearbox, and the transmission shaft drives a second gear and a third gear to rotate synchronously, so that a mounting cover is driven to communicate with a curing light source to move up and down while a first screw rod and a second screw rod are enabled to rotate, in this way, the curing light source can adjust the height in the vertical direction and further adjust an illumination area therein while moving up and down, and therefore the curing light source can meet the curing requirements of aqueous ink prints of different specifications, and the curing efficiency is greatly improved; and in addition, the curing light source can adjust the distance between the curing light source and the aqueous ink prints through up-down movement of the curinglight resource, the influence of heat generated by the curing light source on the aqueous ink prints is further changed, so that the curing requirements of the aqueous ink prints are met, and the curing efficiency of the aqueous ink prints is greatly improved.

Owner:SHANGHAI PUBLISHING & PRINTING COLLEGE

Stamping module and working method thereof

The invention discloses a stamping module and a working method thereof. The stamping module comprises a stamping barrel connected to a drive mechanism, wherein a mould cavity of a mould is arranged below the stamping barrel; the mould cavity is used for stamping and manufacturing a housing; a board is arranged on the surface of the mould cavity; an upper pressure plate and a lower pressure plate,which are connected through a rope, are arranged in the inner cavity of the stamping barrel; the upper pressure plate and the lower pressure plate can slip back and forth in the stamping barrel; an accommodating tank is arranged on the upper surface of the lower pressure plate; non-Newtonian fluid is filled in the accommodating tank; the lower surface of the lower pressure plate is connected to astamping head; at least two groups of pump machines are arranged on the lower surface of the lower pressure plate; while the stamping head is in contact with the board, materials can be pumped into the accommodating tank or out of the accommodating tank to change a component proportion of the non-Newtonian fluid, so that force of the stamping head is regulated, and the board can be quickly formedin a case of not breaking. According to the stamping module disclosed by the invention, the non-Newtonian fluid is arranged in the part of the stamping equipment for effectively buffering, so that a bristle board and equipment are protected, and therefore, regulating precision of a punch is improved.

Owner:广州麦迪水谷汽车模具有限公司

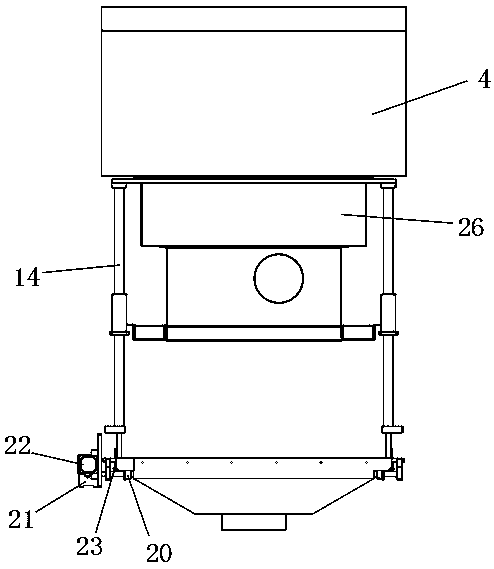

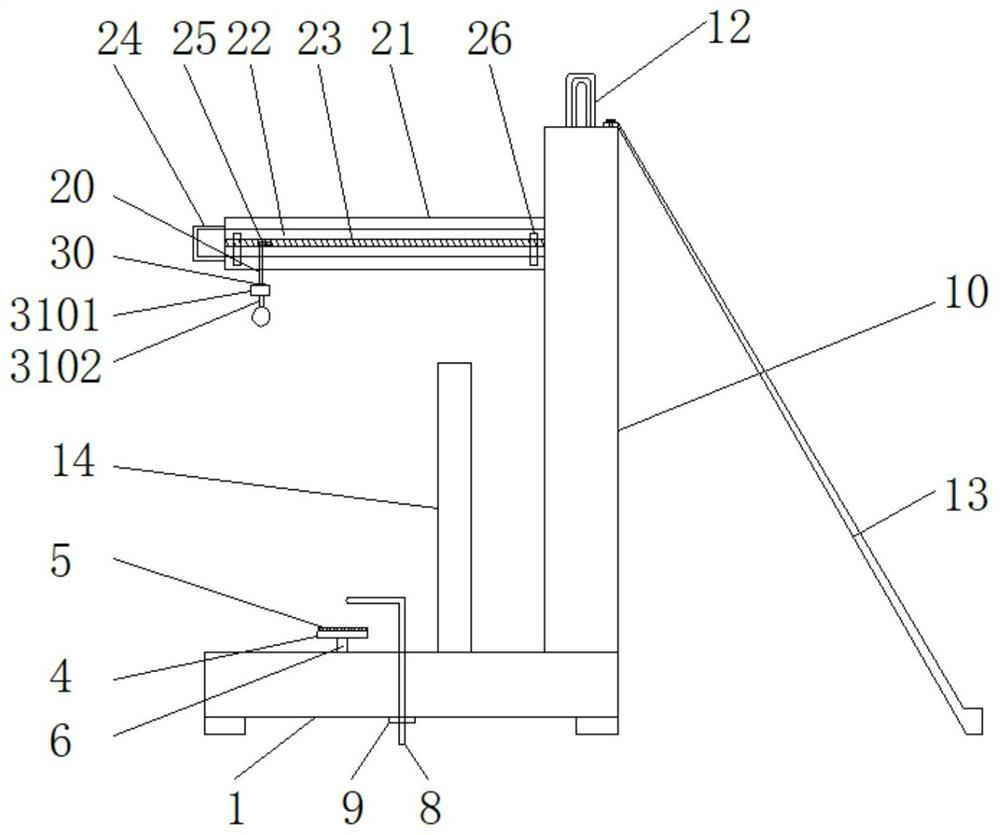

Single fireproof glass detection device

PendingCN112485101AChange distanceUniform impact dataStrength propertiesElectric machineScrew thread

The invention discloses a single-piece fireproof glass detection device. The device comprises a base, a supporting block, a threaded rod, a first screw rod, a mounting plate, a second screw rod and adischarging mechanism, a sliding groove is formed in the top end of the base, a rubber pad is embedded and fixed to the top end of the supporting block, a connecting rod is fixed to the bottom of thesupporting block, and the threaded rod penetrates through a mounting hole; the bottom of the first lead screw penetrates through the top end of the mounting frame, a winding motor is fixed to the right side above the mounting plate, the right side of the second lead screw penetrates through the top end of the left side of the transverse plate, a concave block is fixed to the top end of the right side of the back face of the sliding rail, a telescopic motor is fixed to the left side of the concave block, the output end of the telescopic motor is fixedly connected with the right end of a secondsliding block, the telescopic motor is electrically connected with a controller, and a connecting block is welded and fixed to the bottom of a wire rope. The single fireproof glass detection device isprovided with the threaded rod, and the fireproof glass is fixed through the threaded rod, so the situation that the fireproof glass is stressed to bounce upwards, and consequently impact resistancedata of the fireproof glass is inaccurate is prevented.

Owner:江苏金桥玻璃科技有限公司

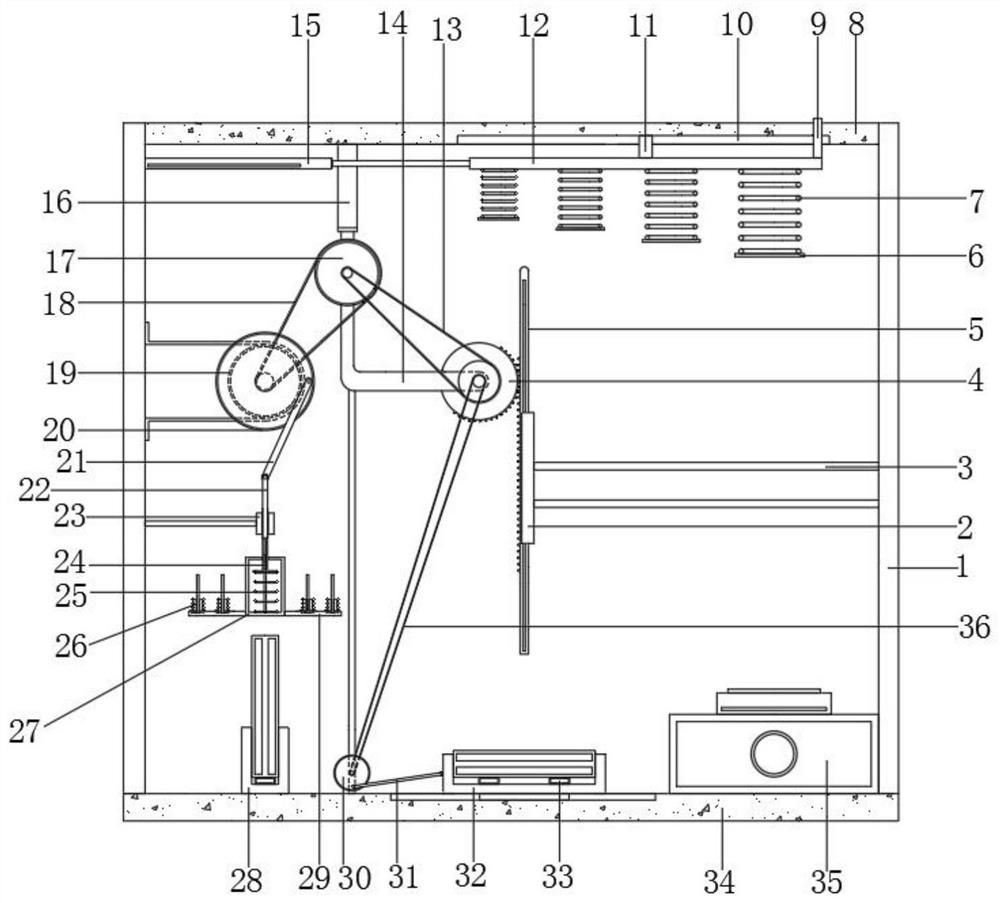

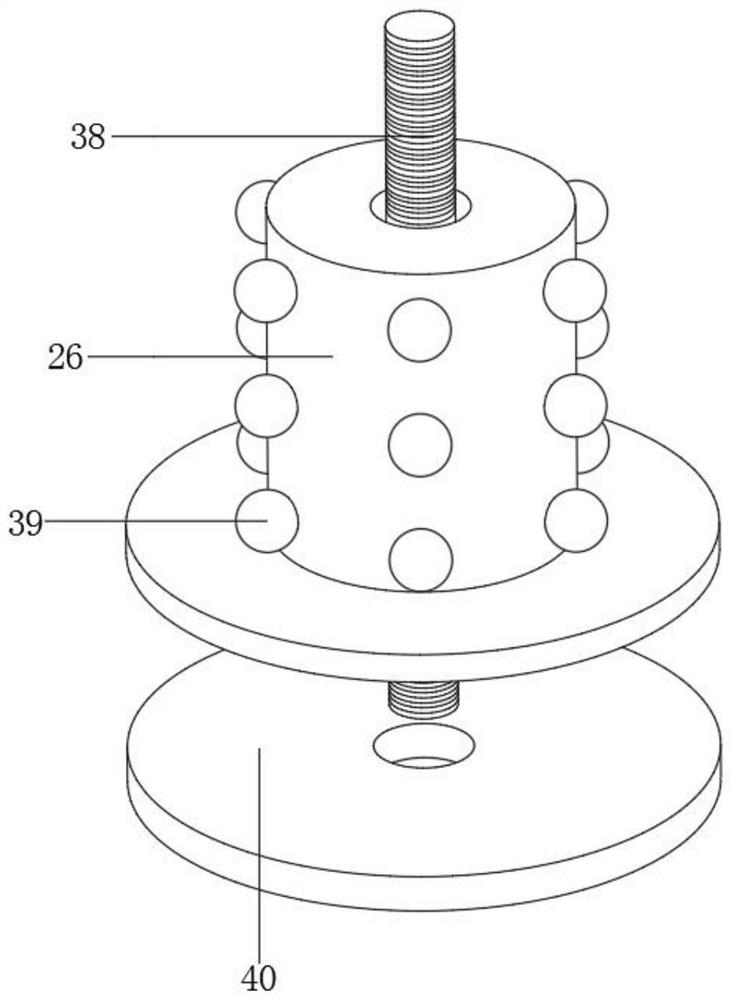

Impact resistance detection equipment for automobile shock absorber support production

ActiveCN112284672AIncrease the counterweightImprove stabilityVehicle suspension/damping testingShock testingImpactShock absorber

The invention belongs to the technical field of automobile detection, particularly relates to impact resistance detection equipment for automobile shock absorber support production, and provides the following scheme for solving the problems that impact detection equipment of a traditional automobile shock absorber support is generally simple in structural design and single in detection mode. The detection equipment comprises a base plate, side supporting plates are vertically welded to the two sides of the outer wall of the top of the base plate, the same top plate is welded to the top ends ofthe side supporting plates, and the two sides of the outer wall of the top of the base plate are fixedly provided with a first tool and slidably connected with a second tool correspondingly. By arranging side ball bodies, the balance weight of a threaded balance weight table block can be further increased, a good anti-skid effect is achieved at the same time, and therefore the threaded balance weight table block can be conveniently disassembled and assembled; a magnetic ring can be in magnetic adsorption fit with the threaded balance weight table block, so that the mounting stability of the threaded balance weight table block is improved, and the safety of detection operation is ensured.

Owner:玉环九峰机械有限公司

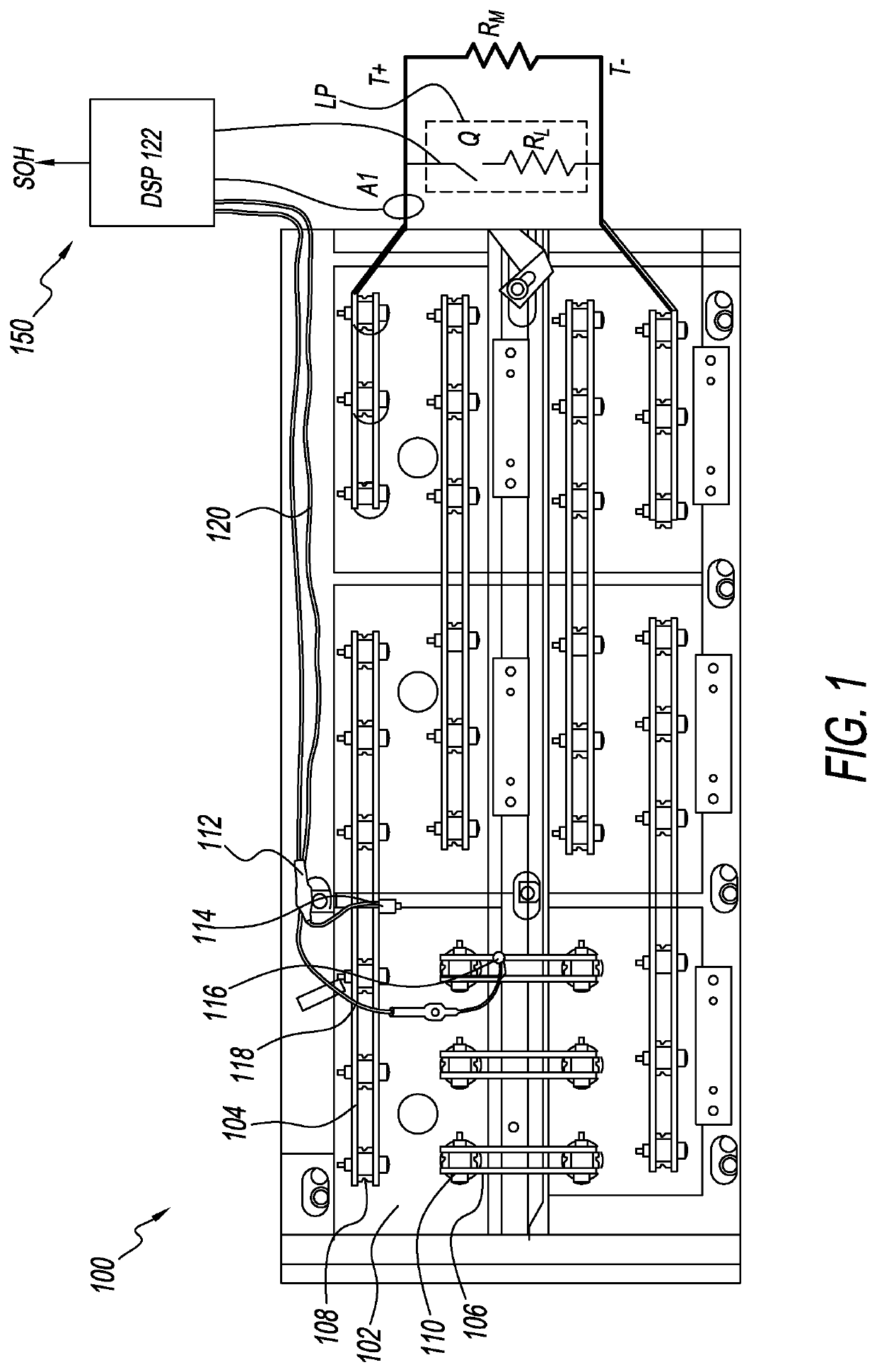

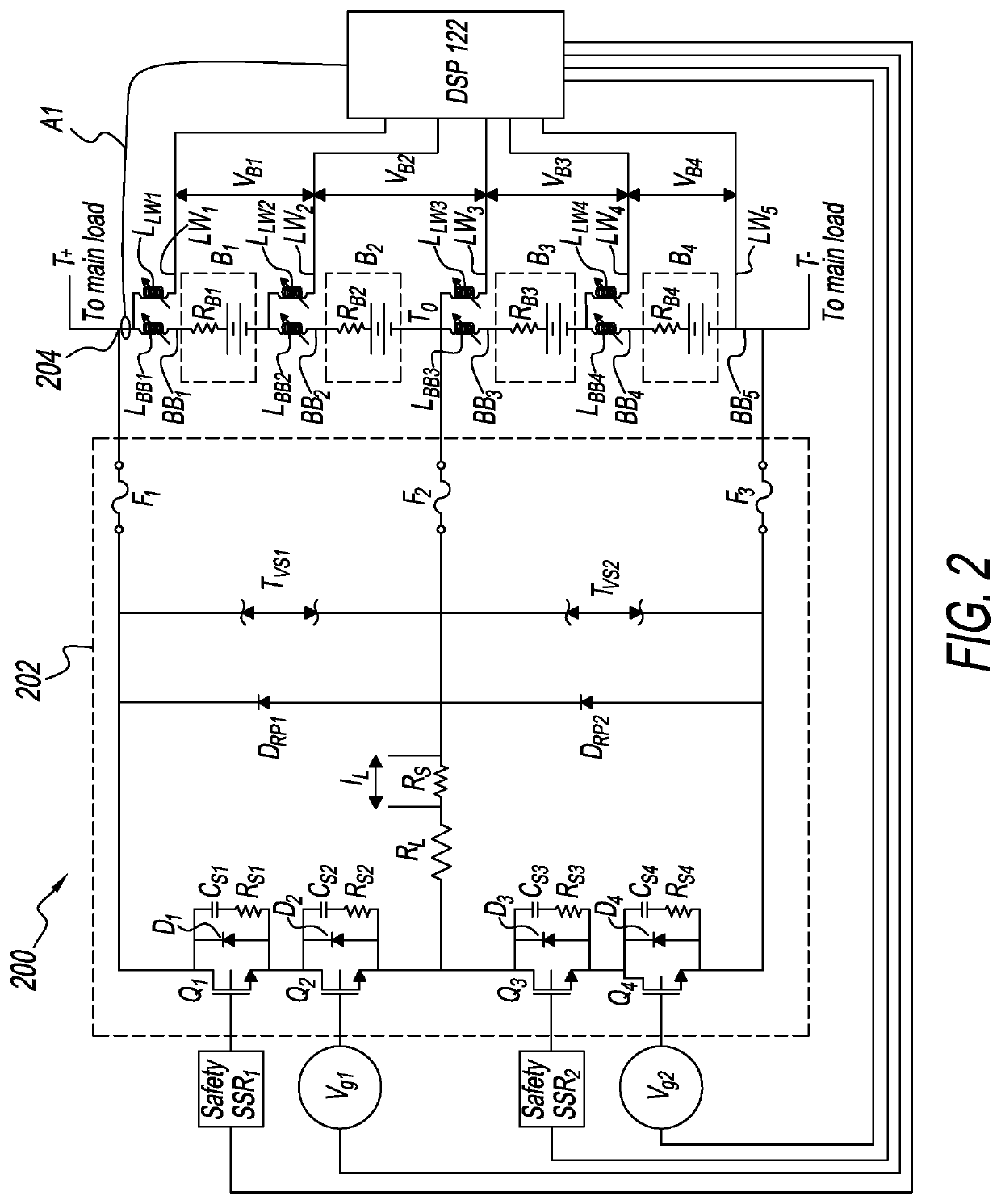

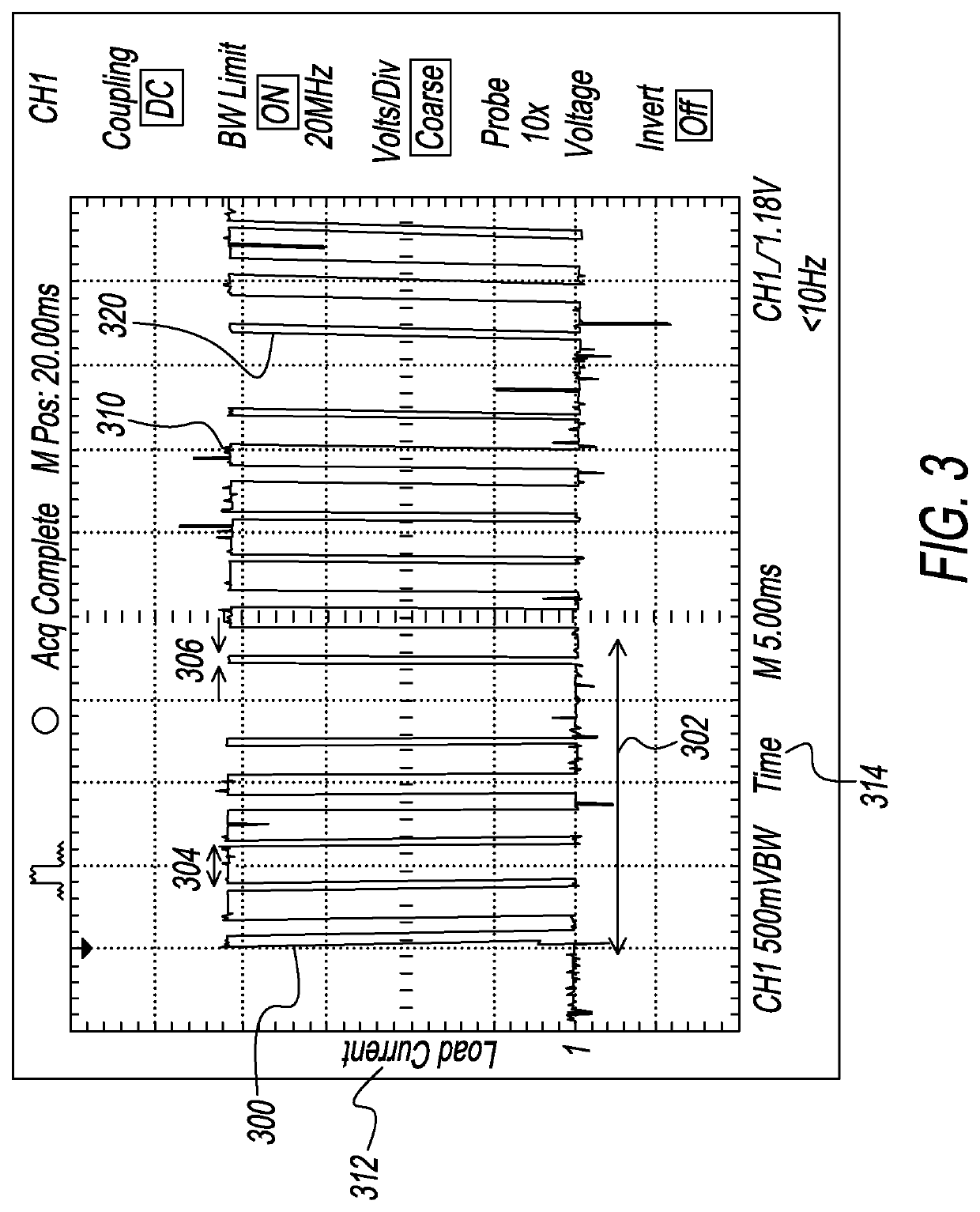

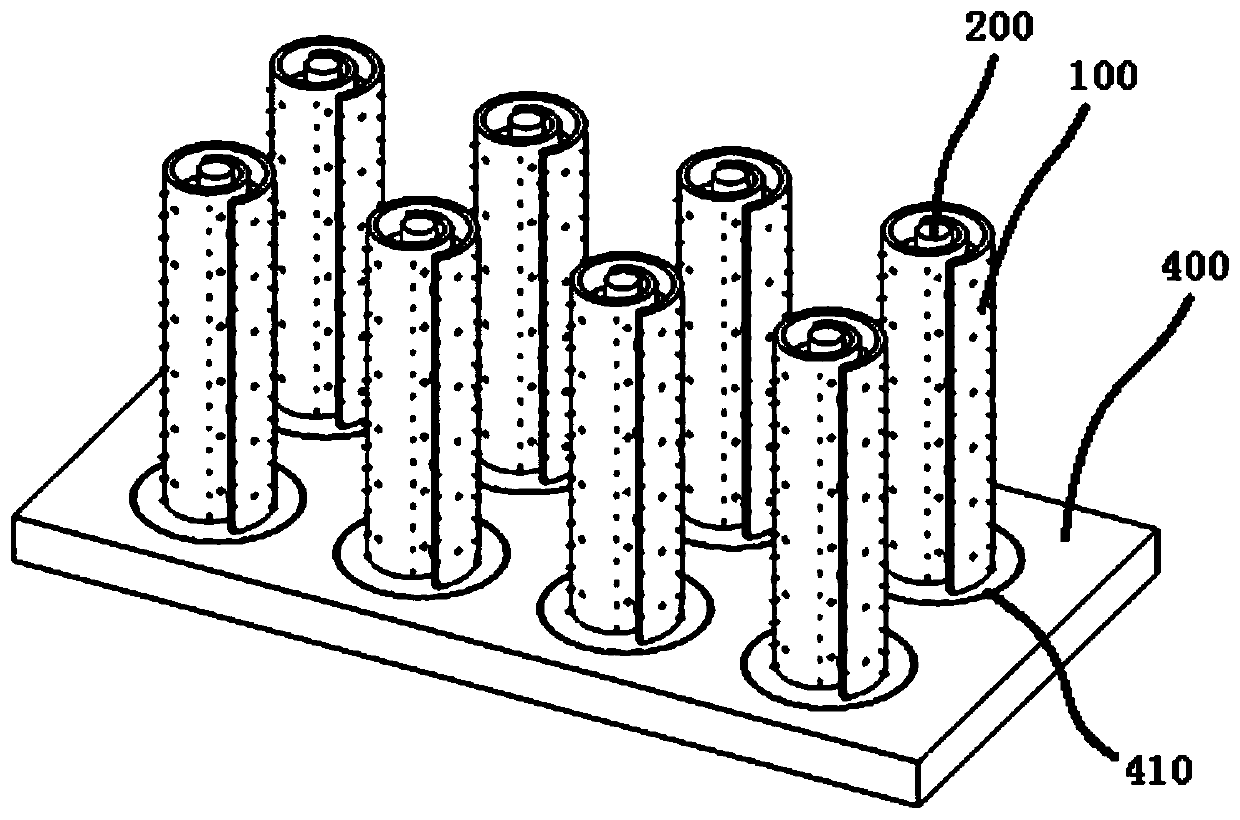

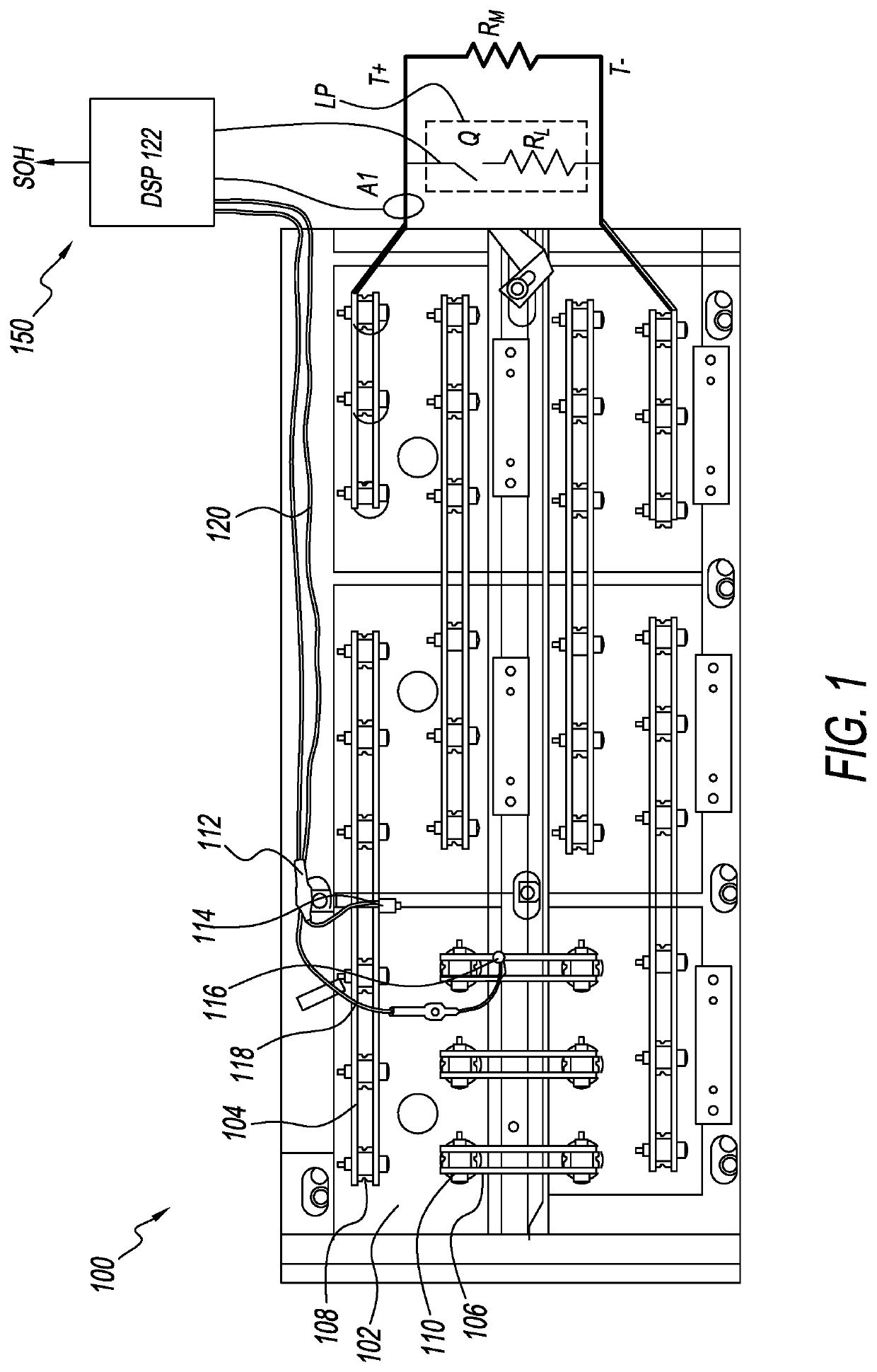

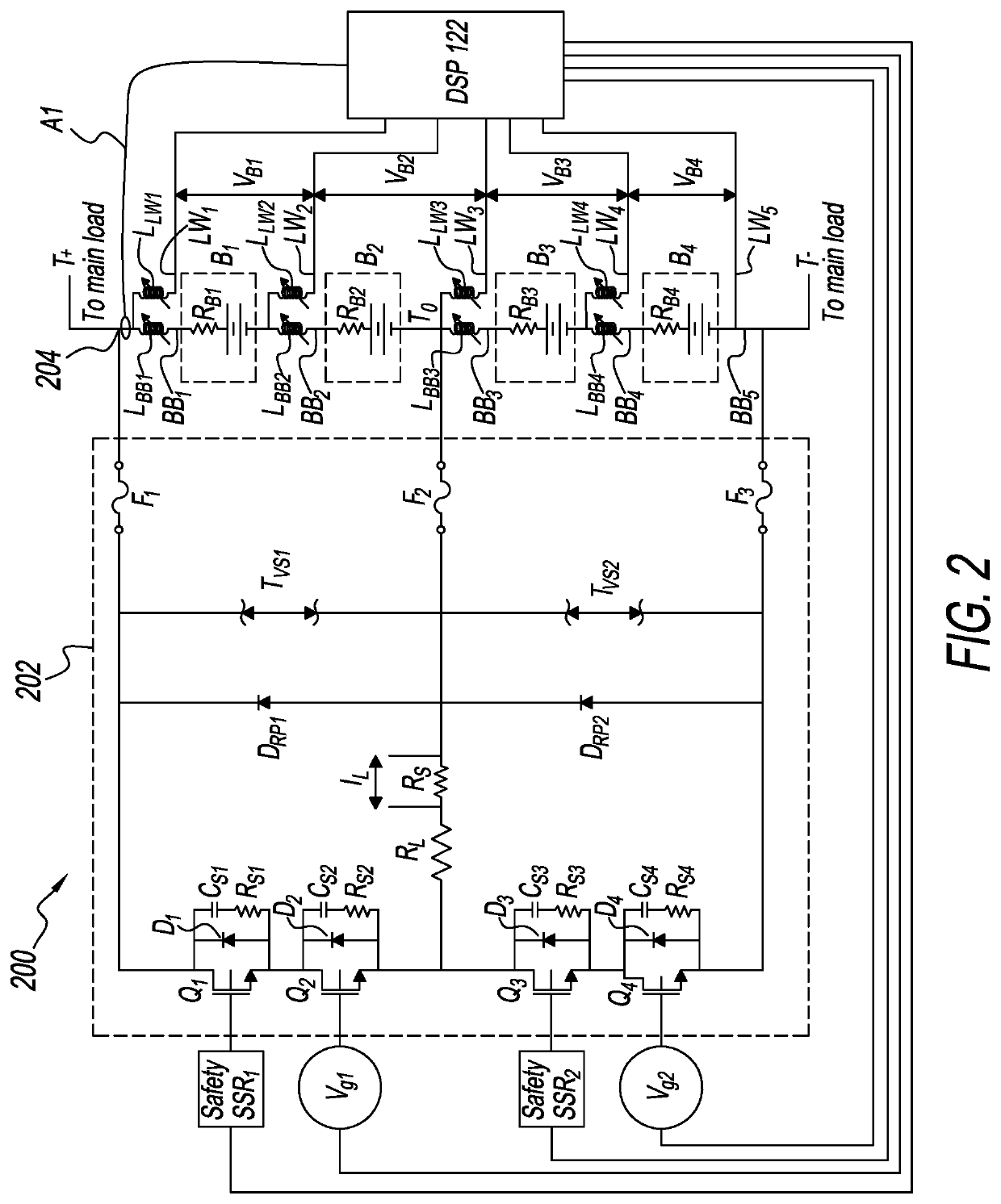

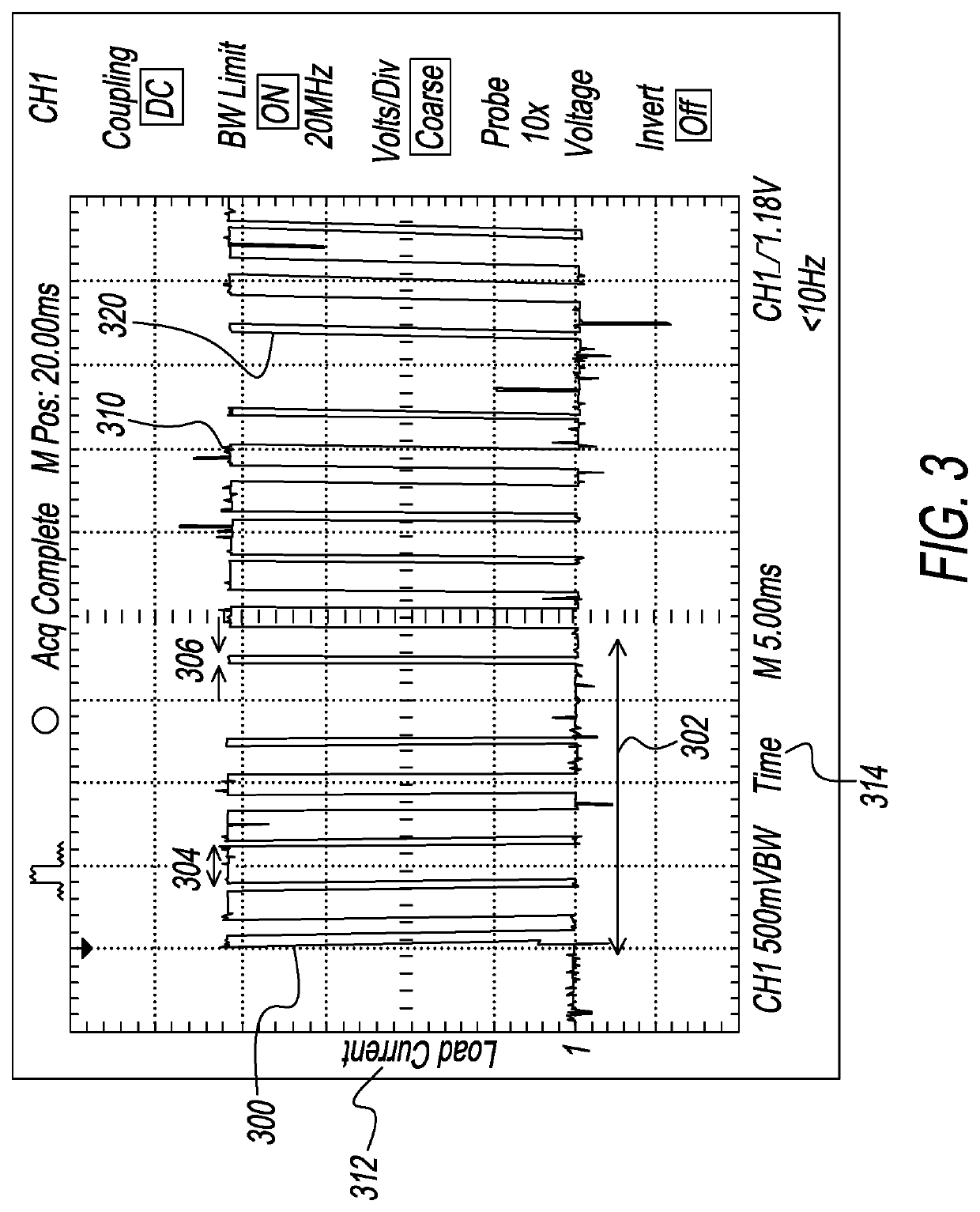

Battery Monitor Control System

ActiveUS20200132744A1Accurate measurementHeat dissipationCharge equalisation circuitResistance/reactance/impedenceLoad resistanceElectrical battery

A battery monitor control system has a load plate, two or more lead wires connected to two or more busbars in a string of batteries, and a digital signal processor. The load plate has one or more primary switches connected to two or more terminals of the batteries in the string of batteries. The load plate also has a load resistor and a current sensor. The primary switches are turned on and off to produce a ripple current in the string of batteries. The digital signal processor determines the real portion of the complex impedance of at least one of the batteries by analyzing the voltage and current waveform of the ripple current. The primary switches may be turned on and off with a sin wave modulation.

Owner:BTECH INC

An automatic cleaner for natural gas pipelines

Owner:温岭市红坤鞋业有限公司

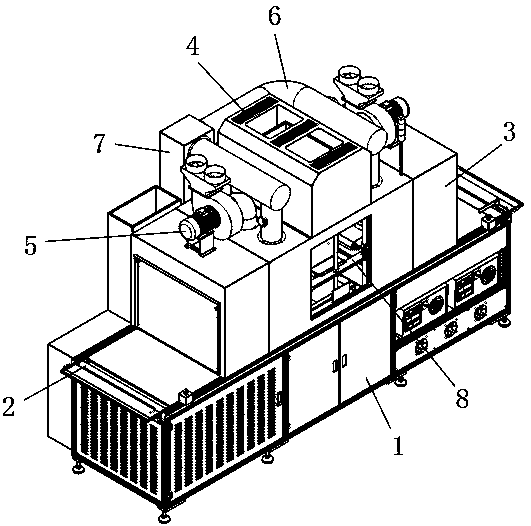

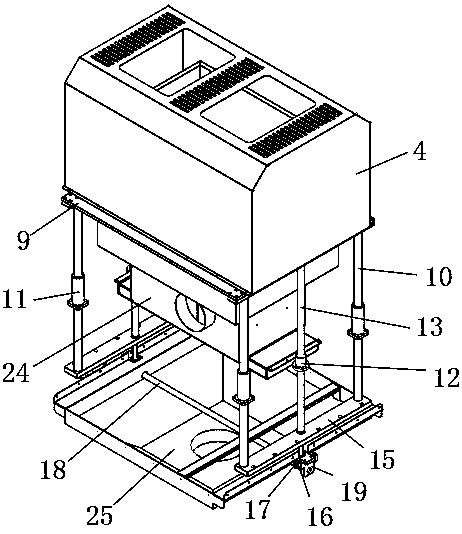

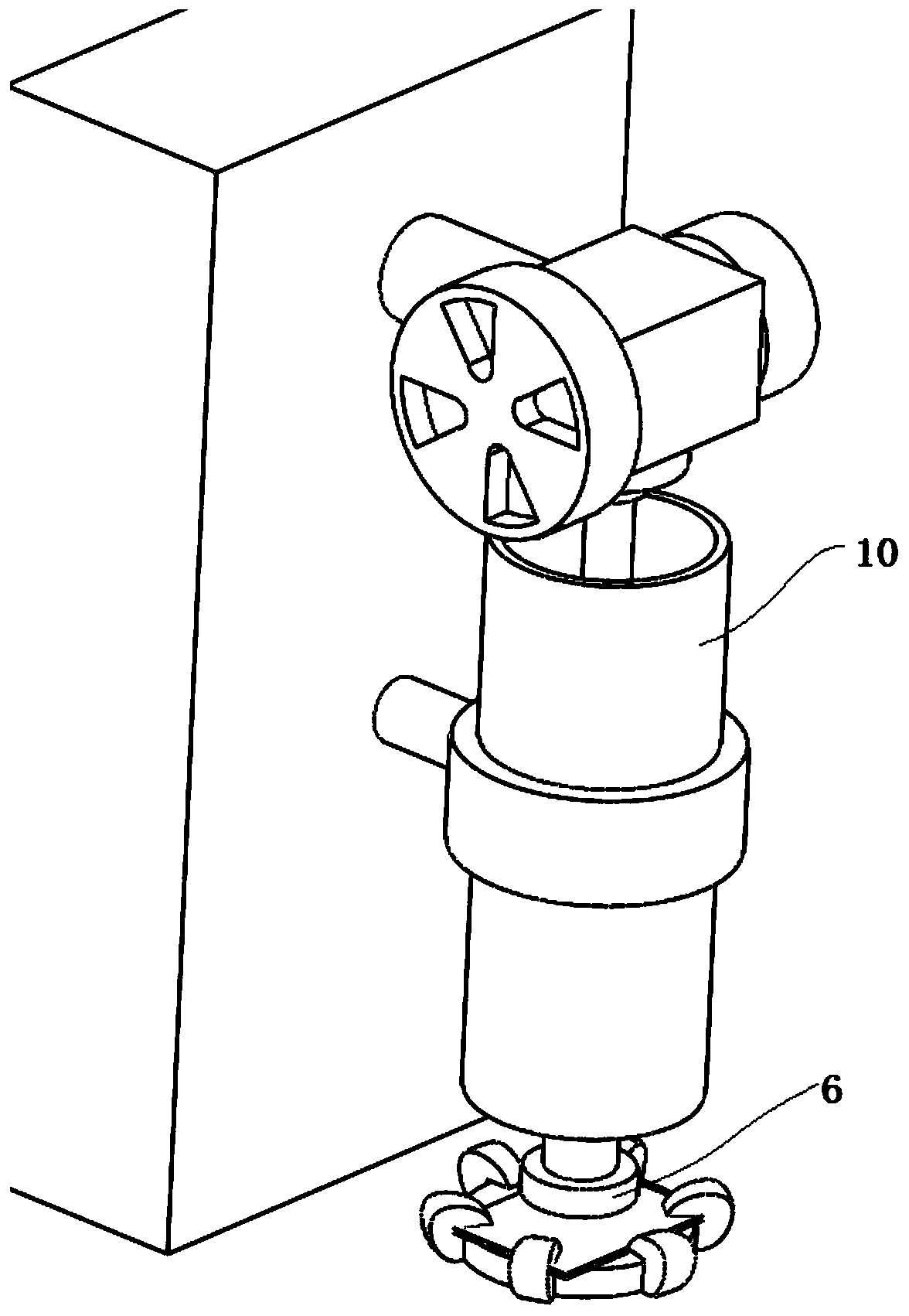

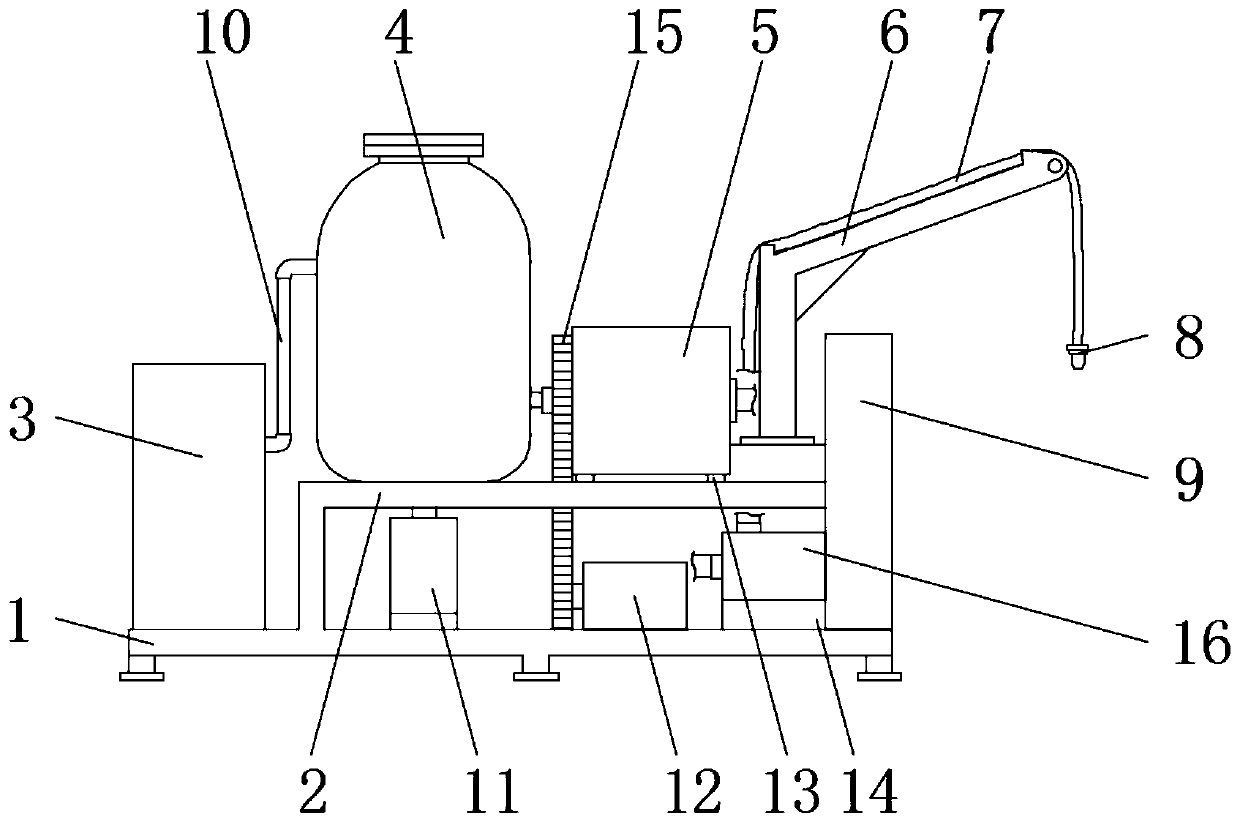

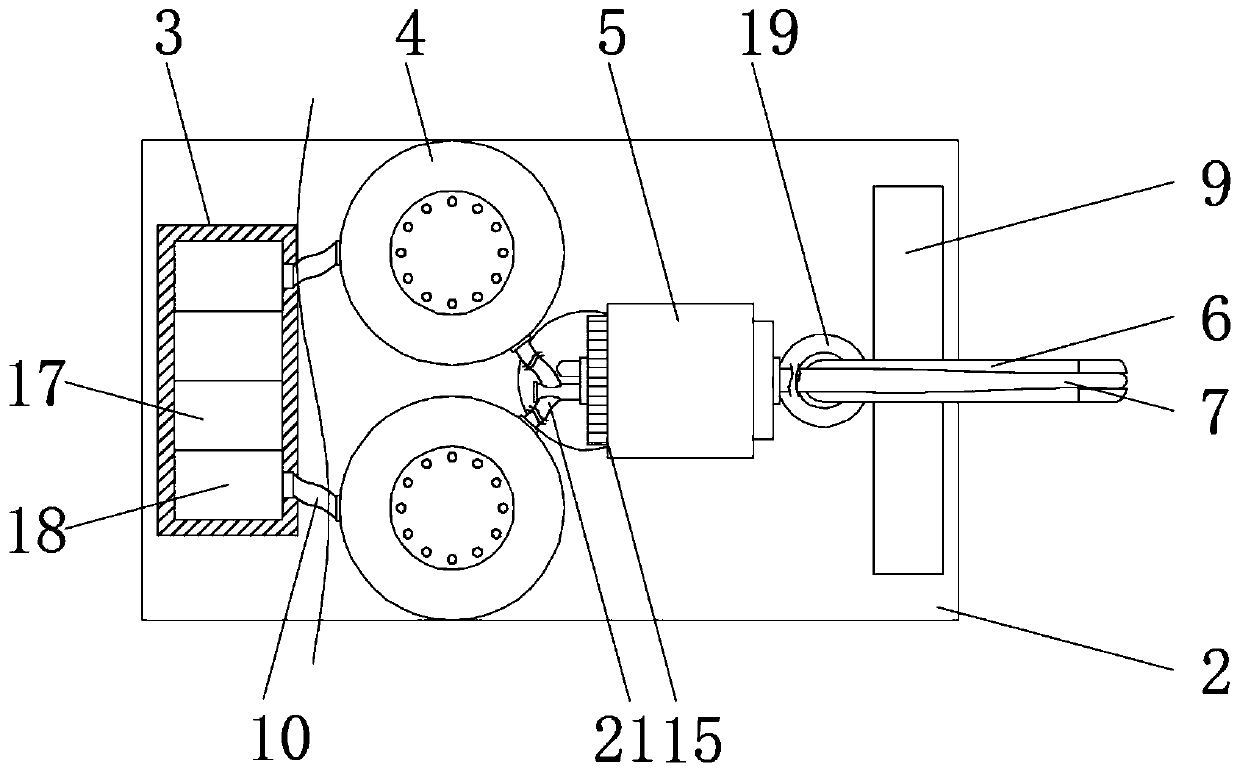

Natural gas pipe automatic cleaner

ActiveCN107931278AHigh practical valueIncrease lateral distanceHollow article cleaningHand shakesEngineering

The invention discloses a natural gas pipe automatic cleaner. The natural gas pipe automatic cleaner comprises a linkage device, a connecting rod, a moving wheel, a height extension adjusting supportleg, a protective cover, a machine body, a rocking rod, a handle, a cleaning head and a leg cover; the side surfaces of the top end of the height extension adjusting support leg are respectively fixedon the two sides of the machine body; the two ends of the connecting rod penetrate through the bottom of the left end of the height extension adjusting support leg to connect into the moving wheel; and the bottom of the protective cover is welded with the bottom of the machine body. The linkage device of the natural gas pipe automatic cleaner can control the cleaning diameter of a fixed brush through an internal mechanical structure to finally adapt to the internal diameter of a natural gas pipe; meanwhile, the height extension adjusting support leg can be automatically adjusted under the condition of external force, so that the practical value of the cleaner can be improved, and meanwhile, the working efficiency is improved; and the transverse distance of the fixed brush can be adjustedunder the condition of hand shaking by a middle connecting device, so that the use convenience is improved.

Owner:温岭市红坤鞋业有限公司

Chemical container inner side wall cleaning device and cleaning method thereof

InactiveCN111346888AImprove general performanceAchieve brush cleaningHollow article cleaningFlexible article cleaningRotational axisBristle

Owner:FOSHAN GAOMING XILUO TECH CO LTD

Method for eliminating the need to zero and calibrate a power meter before use

ActiveUS20090315534A1Eliminate needChange impactElectric devicesCurrent/voltage measurementPower sensorAudio power amplifier

An improved power sensor having an input connector connected to an input port having a center pin and a ground side; an amplifier; first and second detectors; and a thermal stabilization system, including a thermal mass disposed between the ground side of the input connection and the detectors, a ground plane for holding the temperature of thermally sensitive components constant to within 2 degrees C., and a thermal impedance disposed between the center pin of the input port, preferably including a splitter and at least one DC capacitor, and a temperature sensor disposed on the ground plane.

Owner:LADYBUG TECH

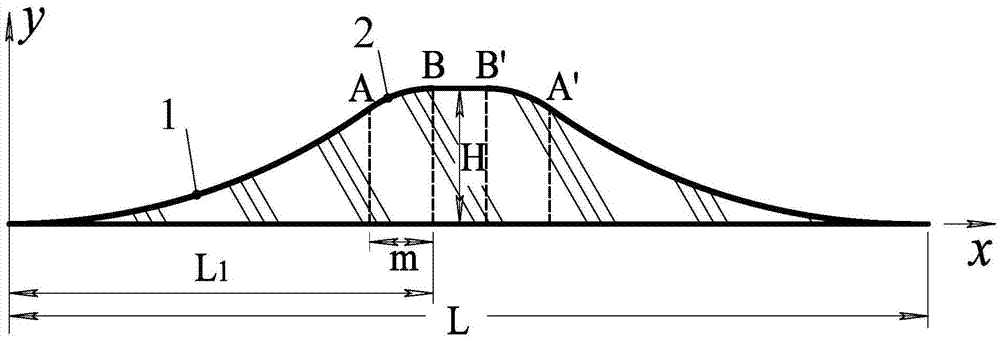

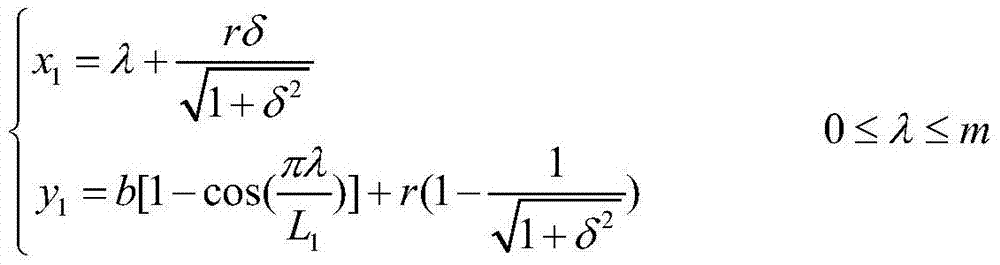

Deceleration strip capable of clear punishment on different vehicle speeds

ActiveCN105442469AImprove ride comfort performanceEnsure comfortTraffic signalsRoad signsSpeed bumpLow speed

The invention provides a deceleration strip capable of achieving clear punishment on different vehicle speeds. The upper end and the lower end of the cross section of the deceleration strip are provided with horizontal straight lines, and the two sides of the cross section are provided with a left curve and a right curve which are symmetrical; each curve is composed of a first cosine curve section (1) and a second cosine curve section (2), the first cosine curve section (1) is tangent to the lower-end horizontal straight line, the second cosine curve section (2) is tangent to the upper-end horizontal straight line, and the first cosine curve section (1) is tangent to the second cosine curve section (2). The deceleration strip has the advantages that strong bumping vibration punishment is applied to high-speed vehicles, the higher the vehicle speed is, the higher the punishment intensity is, and therefore a driver is reminded to learn a lesson and dares not to overspeed next time; low-speed vehicles can flatly drive through, and the riding comfort of the driver and passengers is better; the condition that an existing deceleration strip uniformly generates boring vehicle jumping bump and vibration impact no matter the vehicle speed is high or low is changed, induced noise is low, and the service life of vehicle parts and the deceleration strip is prolonged.

Owner:上海一起送网络科技有限公司

In-circuit programming architecture with processor, delegable flash controller, and code generator

ActiveUS7406559B2Change impactImprove reliabilityGeneral purpose stored program computerMultiple digital computer combinationsFlash memory controllerUser code

An architecture for an integrated circuit with in-circuit programming allows real-time modification of the in-circuit programming code and other code stored on the chip. The architecture utilizes a microprocessor and control logic on an integrated circuit having a single non-volatile memory that stores instructions and data, such as in-circuit programming and user code, and input / output ports and related structure for exchanging data with an external device. Using in-circuit programming code stored on the chip, the chip interactively establishes an in-circuit programming exchange with an external device to update data and instructions including the in-circuit programming code. Input / output conflicts during in-circuit programming can be avoided by employing a code generator that supplies control routines to the microprocessor during at least part of the in-circuit programming operations. The code generator allows the in-circuit programming code to be updated in real time.

Owner:MACRONIX INT CO LTD

Battery monitor control system

ActiveUS10705128B2Heat dissipationGenerated loadCharge equalisation circuitResistance/reactance/impedenceElectrical batteryBusbar

A battery monitor control system has a load plate, two or more lead wires connected to two or more busbars in a string of batteries, and a digital signal processor. The load plate has one or more primary switches connected to two or more terminals of the batteries in the string of batteries. The load plate also has a load resistor and a current sensor. The primary switches are turned on and off to produce a ripple current in the string of batteries. The digital signal processor determines the real portion of the complex impedance of at least one of the batteries by analyzing the voltage and current waveform of the ripple current. The primary switches may be turned on and off with a sine wave modulation.

Owner:BTECH INC

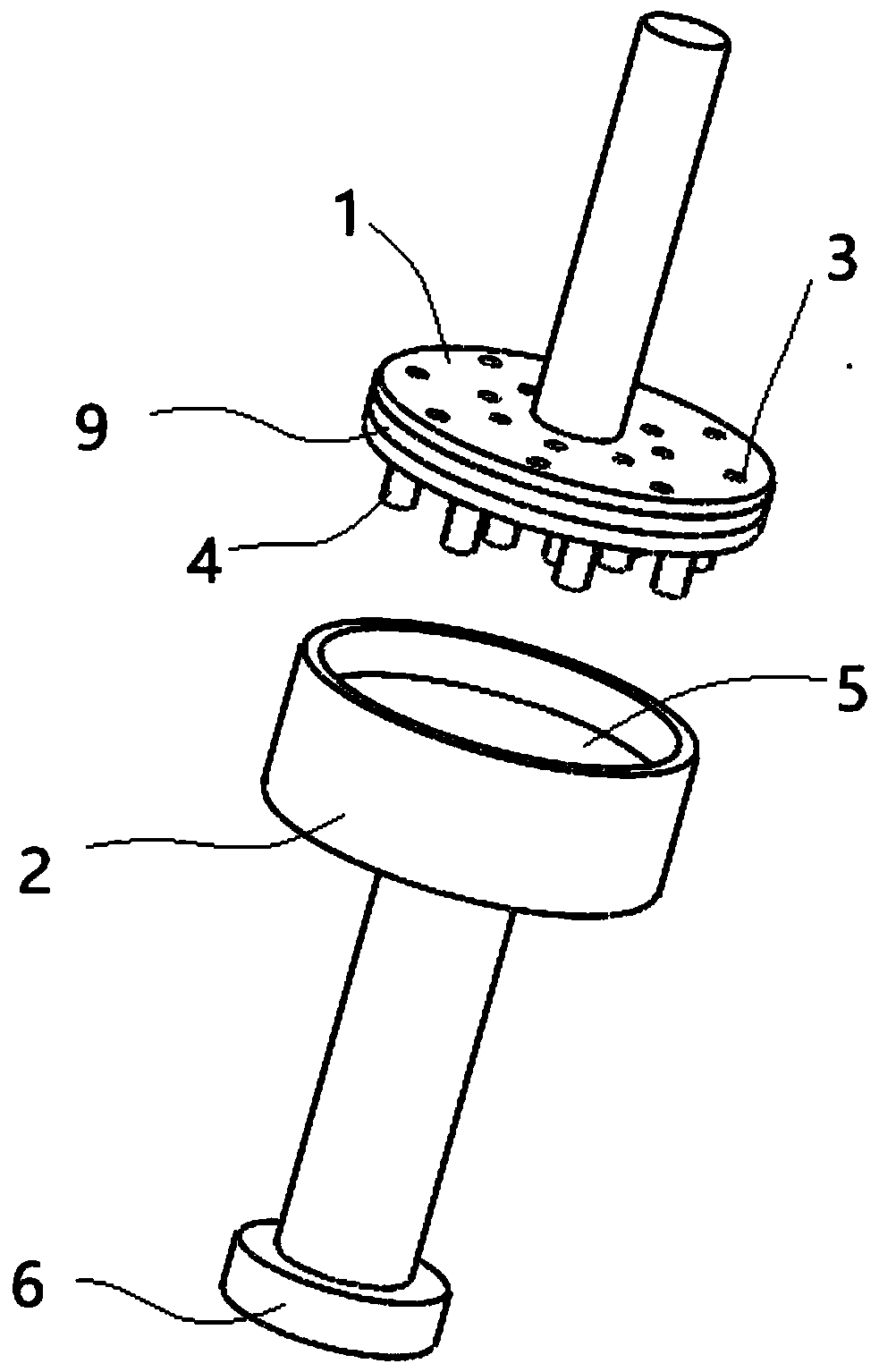

Precise high-pressure polyurethane foaming machine

The invention discloses a precise high-pressure polyurethane foaming machine. The foaming machine comprises a base, material bins and a mixing box; a first support is mounted at the top of the base; acontrol box is mounted at the top of the base; and the material bins are mounted at the top of the first support. According to the foaming machine, by the aid of a first pressure pump and a first pressure gauge which communicate with the mixing box as well as second pressure pumps and second pressure gauges which communicate with the two material bins, raw materials in the mixing box and the material bins can be stirred and pressurized respectively, the raw materials in the two material bins are stirred and pressurized preliminarily, are fluffy due to the internal gas, are conveyed into an inner barrel of the mixing box and are mixed for stirring and pressurizing again, the volumes of the two groups of fluffy raw materials are enlarged, the contact area of the raw materials is increased,mixing of the raw materials is promoted, meanwhile, the secondary pressure can be adjusted according to the state of the raw materials after preliminary pressurizing, by the aid of the foaming procedure of secondary pressurizing, the phenomenon of insufficient foaming can be avoided, the raw materials are ensured to be foamed completely, foam is fine and uniform, and the machine is suitable for wide popularization and use.

Owner:WENZHOU FEILONG POLYURETHANE ENG

In-circuit programming architecture with processor and delegable flash controller

ActiveUS8090916B2Change impactImprove reliabilityRead-only memoriesProgram loading/initiatingFlash memory controllerMemory controller

An architecture for an integrated circuit with in-circuit programming allows real-time modification of the in-circuit programming code and other code stored on the chip. The architecture utilizes a microprocessor and control logic on an integrated circuit having a single non-volatile memory that stores instructions and data, such as in-circuit programming and user code, and input / output ports and related structure for exchanging data with an external device. Using in-circuit programming code stored on the chip, the chip interactively establishes an in-circuit programming exchange with an external device to update data and instructions including the in-circuit programming code. Input / output conflicts during in-circuit programming can be avoided by employing a memory controller to handle at least part of the in-circuit programming operations. The memory controller allows the in-circuit programming code to be updated in real time.

Owner:MACRONIX INT CO LTD

Simulation bumping deformation detection device for vehicle handle when vehicle installation

InactiveCN108007698AImprove detection accuracyChange impactVehicle shock testingGravity effectAutomotive engineering

The present invention provides a simulation bumping deformation detection device for a vehicle handle when vehicle installation. The device comprises an installation bench configured to simulate a vehicle body, the installation bench is provided with an installation groove, a hanging rack is arranged above the installation bench, the hanging rack is provided with a bumping hammer, the bumping hammer is connected with the hanging rack through a connection rod, a rotation connection block is arranged between the hanging rack and the connection rod, a fixed clamp is arranged beside the hanging rack, the lifted bumping hammer is fixed through the fixed clamp, the fixed clamp is provided with a control motor, and the control motor automatically loosens the fixed clamp. The installation bench configured to simulate the vehicle body is employed to simulate a vehicle installation condition and is fell down under the gravity effect of the bumping hammer on the hanging rack to simulate the impact on the door handle when an accident happens, a shooting camera is employed to record a deformation condition to improve the detection precision, a regulation cylinder is lifted to regulate the height of the bumping hammer to change the impact force.

Owner:FENGYE TIMS WUHU AUTO PARTS CO LTD

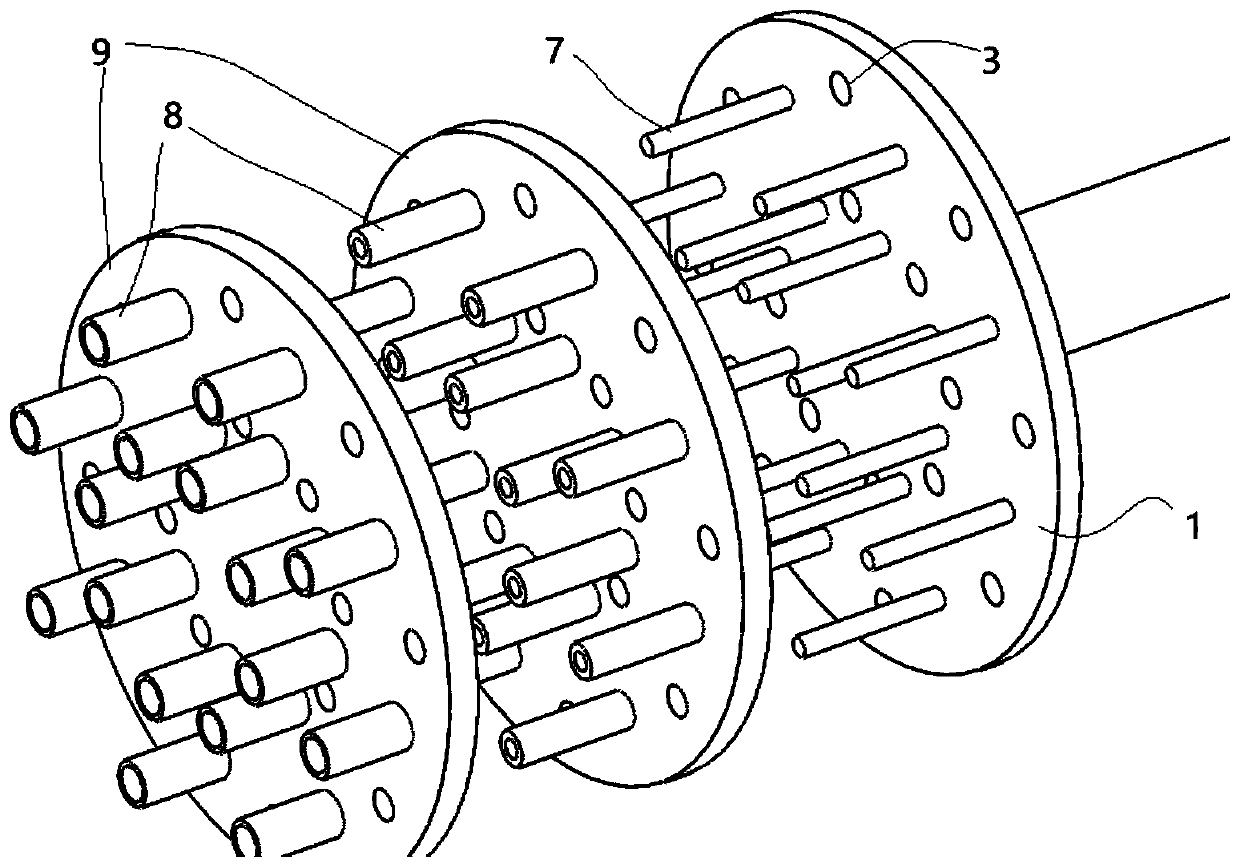

Ablation-resistant pipe joint

InactiveCN101016968AReduce shockReduce impactPipe elementsBranching pipesEngineeringMechanical engineering

The invention provides an anti-abrasion tube connector, wherein its body is arranged with 3-6 through holes. The invention is characterized in that the collected part of the through holes is arranged with a chamber for buffering working medium, while the chamber contains a screen tube made from rigid alloy, the axis of the screen tube is vertical to the through hole via which the working medium enters in, the side of the screen tube is arranged with several screen holes. Therefore, the invention can reduce the impact of working medium on the inner wall of the body, to reduce abrasion and improve safety or the like.

Owner:JIANHU COUNTY HONGDA VALVE FITTINGS CO LTD

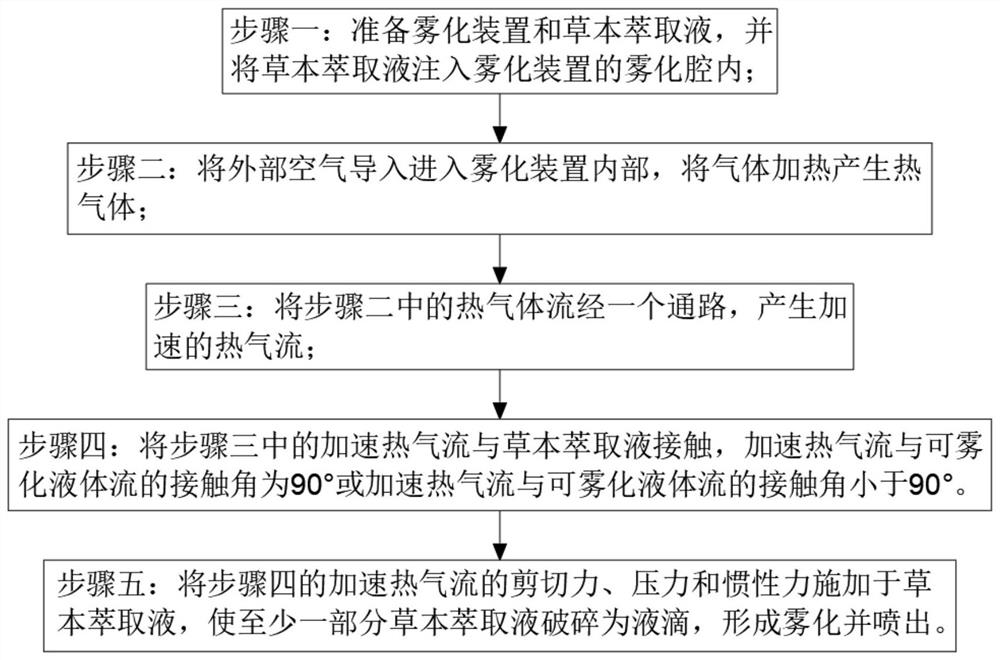

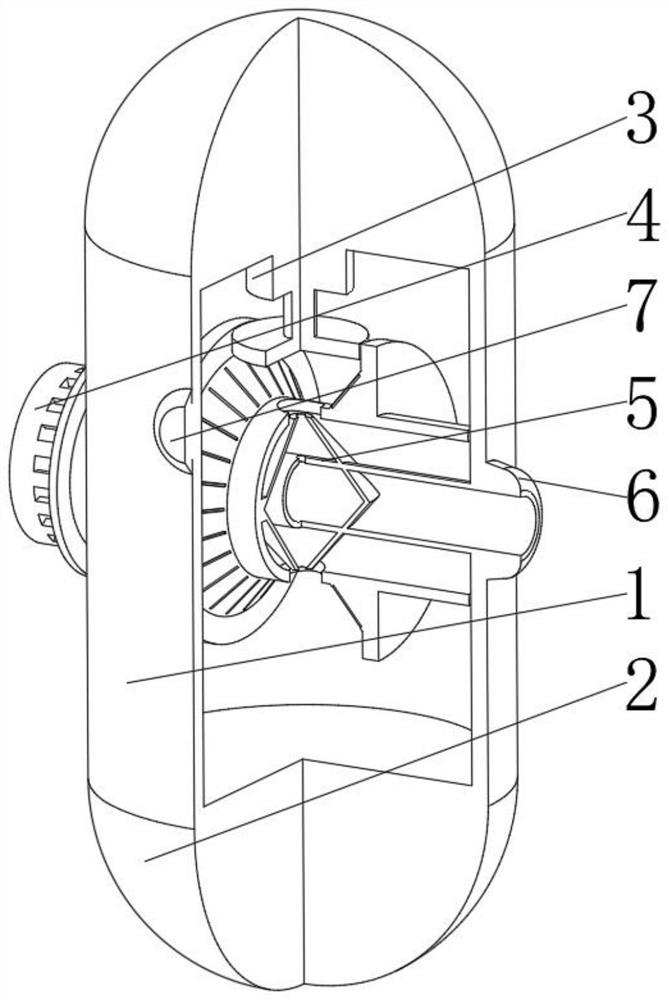

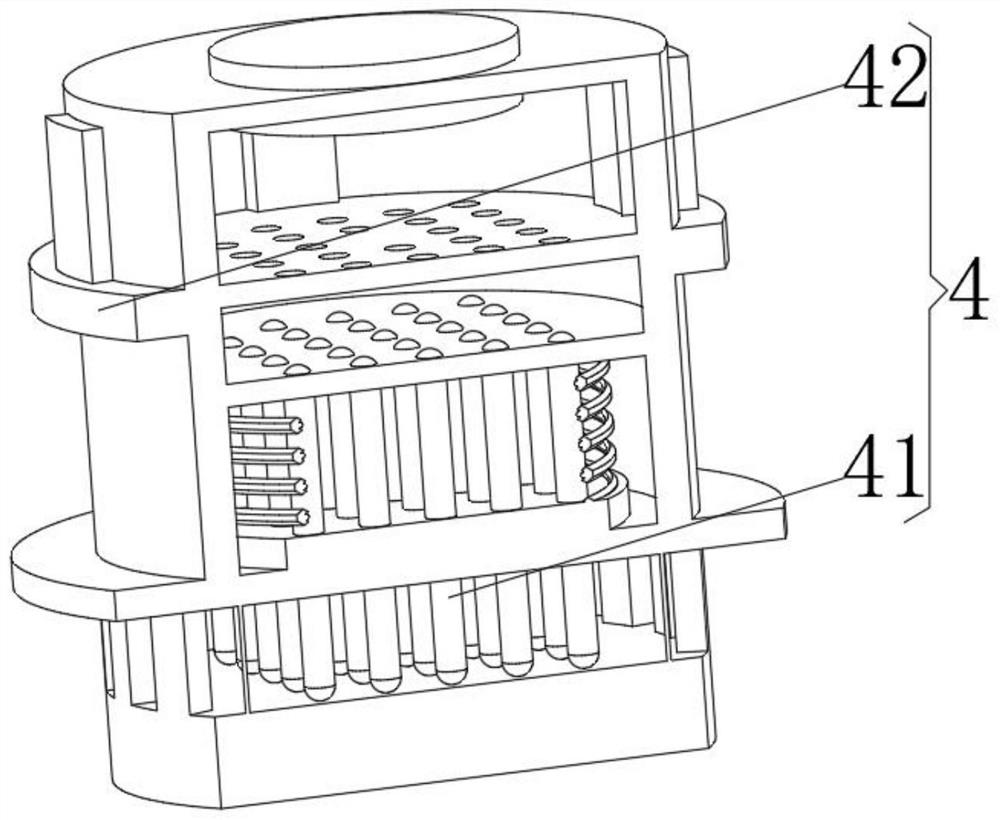

Herbal extract atomization method and atomization device

ActiveCN113182108AEasy temperature controlControl flow rateLiquid spraying apparatusThermodynamicsTurbulent heat flux

The invention discloses a herbal extract atomization method. The method comprises the following steps that secondly, outside air is introduced into an atomization device, and the air is heated through a plasma and vortex heating dual-heating mechanism to generate hot air; thirdly, the hot air in the second step flows through a channel, and accelerated hot air flow is generated; and fourthly, the accelerated hot air flow in the third step makes contact with a herbal extract, the contact angle between the accelerated hot air flow and liquid flow capable of being atomized is 90 degrees or the contact angle between the accelerated hot air flow and the liquid flow capable of being atomized is smaller than 90 degrees. The invention relates to the technical field of atomization. Plasma and vortex heating dual-heating methods can be mutually replaced during use, so that the temperature of atomized air can be conveniently regulated and controlled, air expansion is controlled through heat, the air pressure of the air is regulated and controlled, the flow speed of the air is conveniently controlled, the impact force of the air after atomization is changed through wires, and an atomization receptor is protected.

Owner:广州雾普康生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com