Preparation method of potato starch-based degradable plastic film

A technology of potato starch and plastic film, applied in the direction of flat products, applications, household appliances, etc., can solve the problems of little research, achieve the effects of changing damage and impact, wide application range, and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Prepare the polyvinyl acetate emulsion according to the method of the present invention in advance: the initiator that the vinyl acetate emulsion adopts is ammonium persulfate, protective colloid is polyvinyl alcohol, emulsifier is anionic emulsifier sodium lauryl sulfate and nonionic Emulsifier Tween-80 and system. Reacting while stirring at a temperature of 70-80° C., a milky white product with a solid content of 25% to 30% and a viscosity of 600 to 700 mpa·s is obtained.

[0029] Prepare the polyvinyl alcohol solution in advance according to the method of the present invention: add deionized water into the container, start the mixer, and then throw in polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 99%. The weight of the polyvinyl alcohol and water The ratio is 1:9, heat up to 90-95°C and keep it warm for 1h, then cool to room temperature.

[0030] The specific process of preparing potato starch-based degradable plastic film ...

Embodiment 2

[0032] Prepare polyvinyl acetate emulsion according to the method of the present invention in advance: the initiator that prepares vinyl acetate emulsion adopts is ammonium persulfate, and protective colloid is polyvinyl alcohol, and emulsifier is anionic emulsifier sodium lauryl sulfate and nonionic Emulsifier Tween-80 and system. Reacting while stirring at a temperature of 70-80° C., a milky white product with a solid content of 25% to 30% and a viscosity of 600 to 700 mpa·s is obtained.

[0033] Prepare the polyvinyl alcohol solution in advance according to the method of the present invention: add deionized water into the container, start the mixer, and then throw in polyvinyl alcohol with a degree of polymerization > 1700 and a degree of alcoholysis of 99%. The weight of the polyvinyl alcohol and water is The ratio is 1:9, heat up to 90-95°C and keep it warm for 1.5h, then cool to room temperature.

[0034]The specific process of preparing potato starch-based degradable p...

Embodiment 3

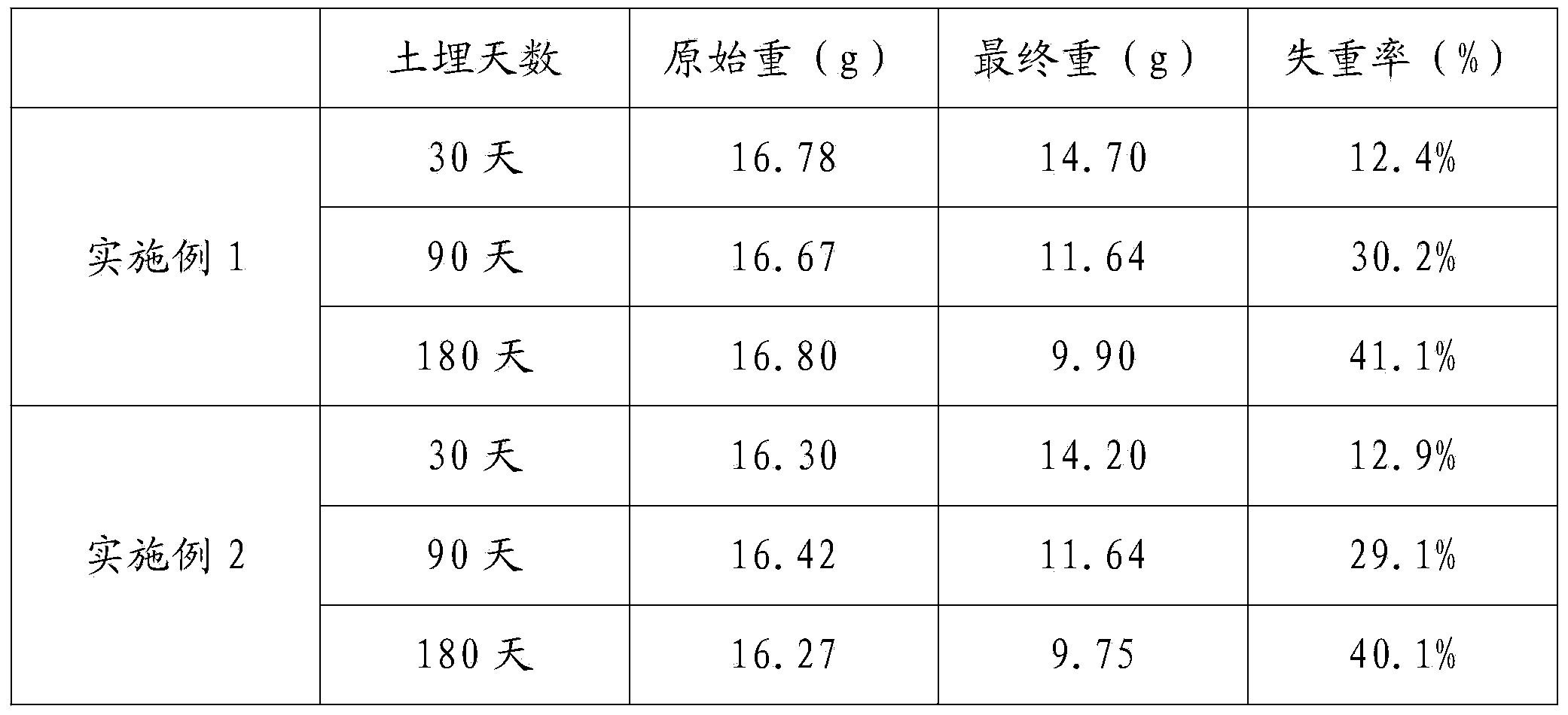

[0035] Embodiment 3 performance test

[0036] The plastic film made by embodiment 1 and 2 is made stretchability and water resistance test respectively:

[0037] (1) Water resistance test

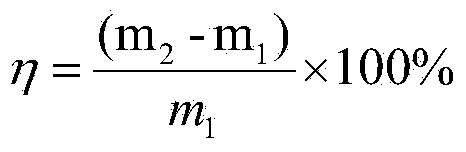

[0038] Water resistance is reflected by the water absorption rate of the plastic film. The lower the water absorption rate, the better the water resistance. The test method for water absorption rate is: cut a sample with a size of 50cm×50cm, weigh it as m1, and place it in clean tap water at room temperature Soak for 24 hours, take out the sample and dry it with filter paper and weigh it as m2. For each sample to be tested, 3 samples were taken for measurement, and the results were averaged. The calculation formula of water absorption η is:

[0039] η = ( m 2 - m 1 ) m 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com