Patents

Literature

3180 results about "Polyvinyl acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

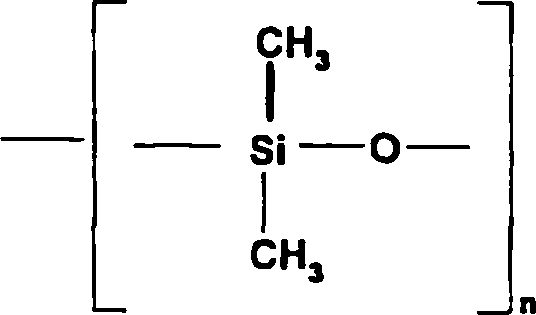

Poly(vinyl acetate) (PVA, PVAc, poly(ethenyl ethanoate): best known as wood glue, white glue, carpenter's glue, school glue, Elmer's glue in the US, or PVA glue) is an aliphatic rubbery synthetic polymer with the formula (C₄H₆O₂)ₙ. It belongs to the polyvinyl ester family, with the general formula -[RCOOCHCH₂]-. It is a type of thermoplastic. There is considerable confusion between the adhesive as purchased, an aqueous emulsion of mostly polyvinyl acetate, and the subsequently dried material, which is still polyvinyl acetate and chemically unchanged, that is erroneously thought of as the newly polymerized product.

Multilayer Films Or Plasticizer-Containing Polyvinyl Acetal With Sound-Absorbing Properties

ActiveUS20100028642A1Improve sound absorptionLow costSynthetic resin layered productsConstructions elementsPolyvinyl acetatePolyvinyl alcohol

An interlayer film for laminated glass with sound-absorbing properties contains at least two individual films, wherein the first individual film comprises a polyvinyl acetal with a portion of polyvinyl acetate groups of 0.1 to 11 mol % and a second individual film comprises a polyvinyl acetal with a portion of polyvinyl acetate groups of between 5 and 8 mol %.

Owner:KURARAY EURO GMBH

Cementitious article and method for preparing the same

ActiveUS20100247937A1Solid waste managementSynthetic resin layered productsAcetic acidPolymer science

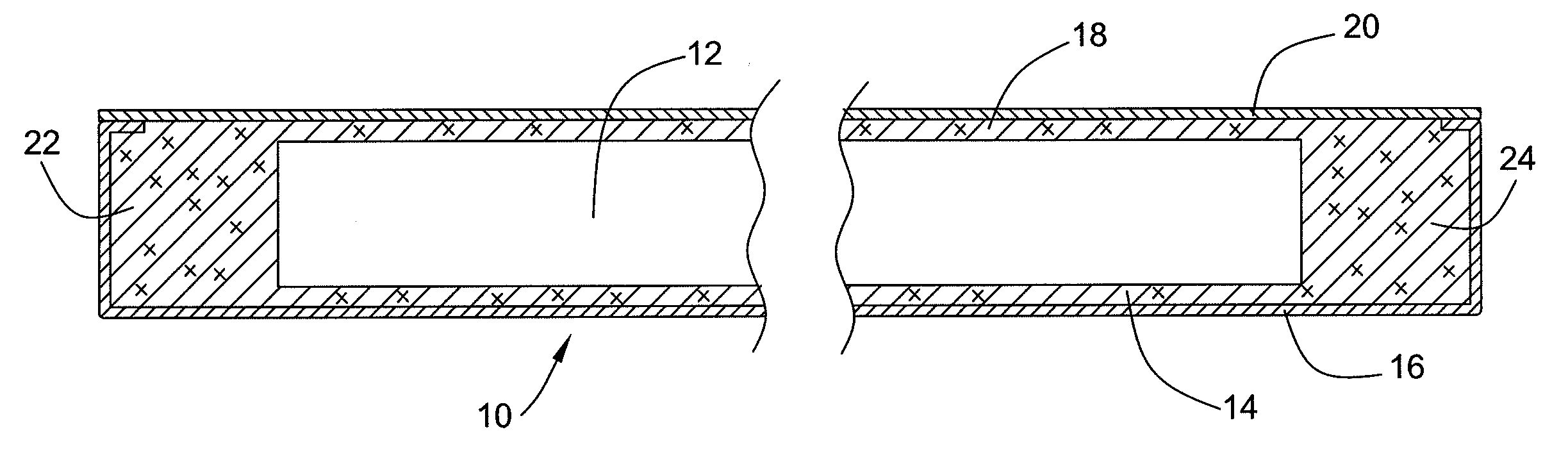

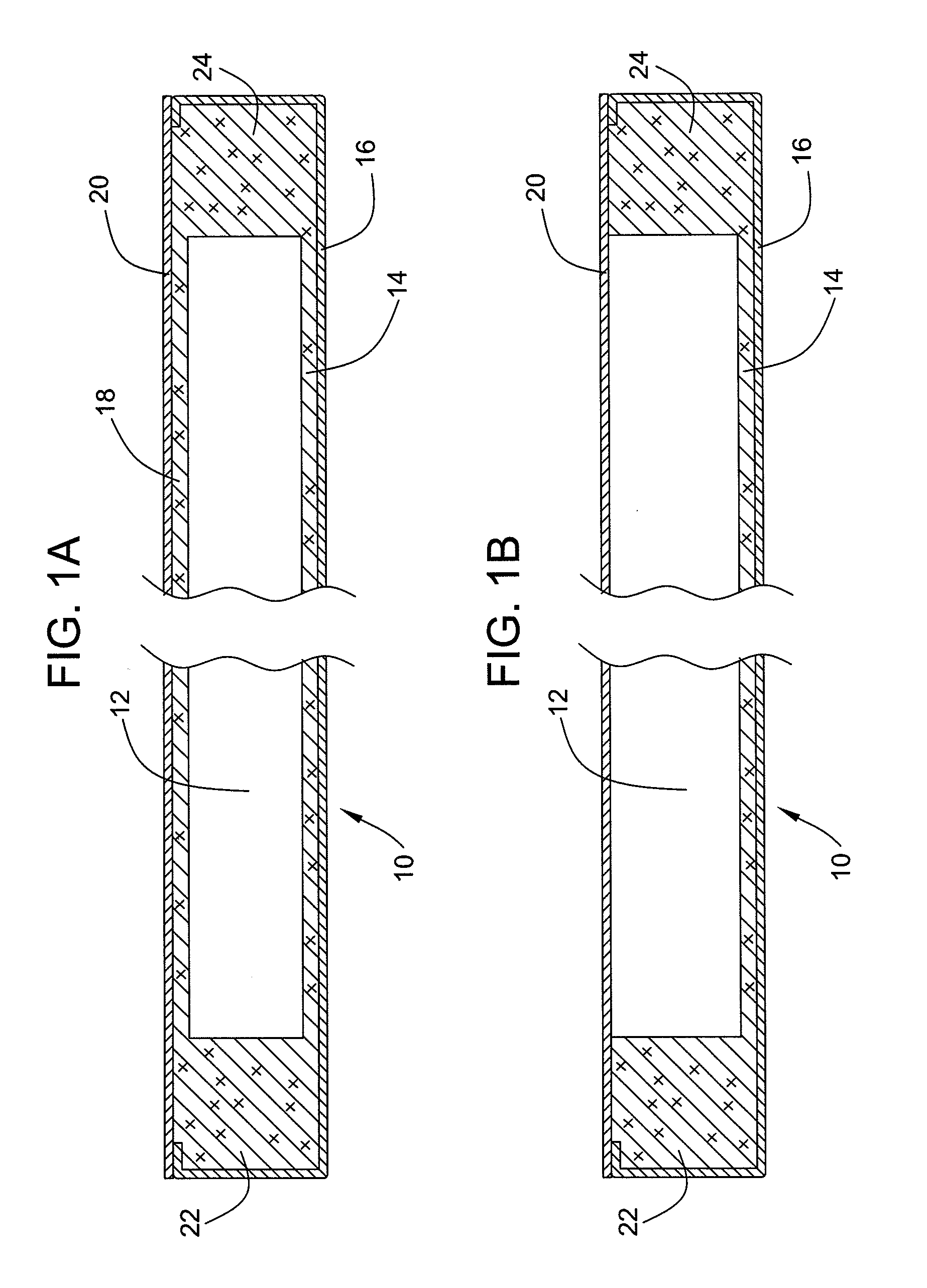

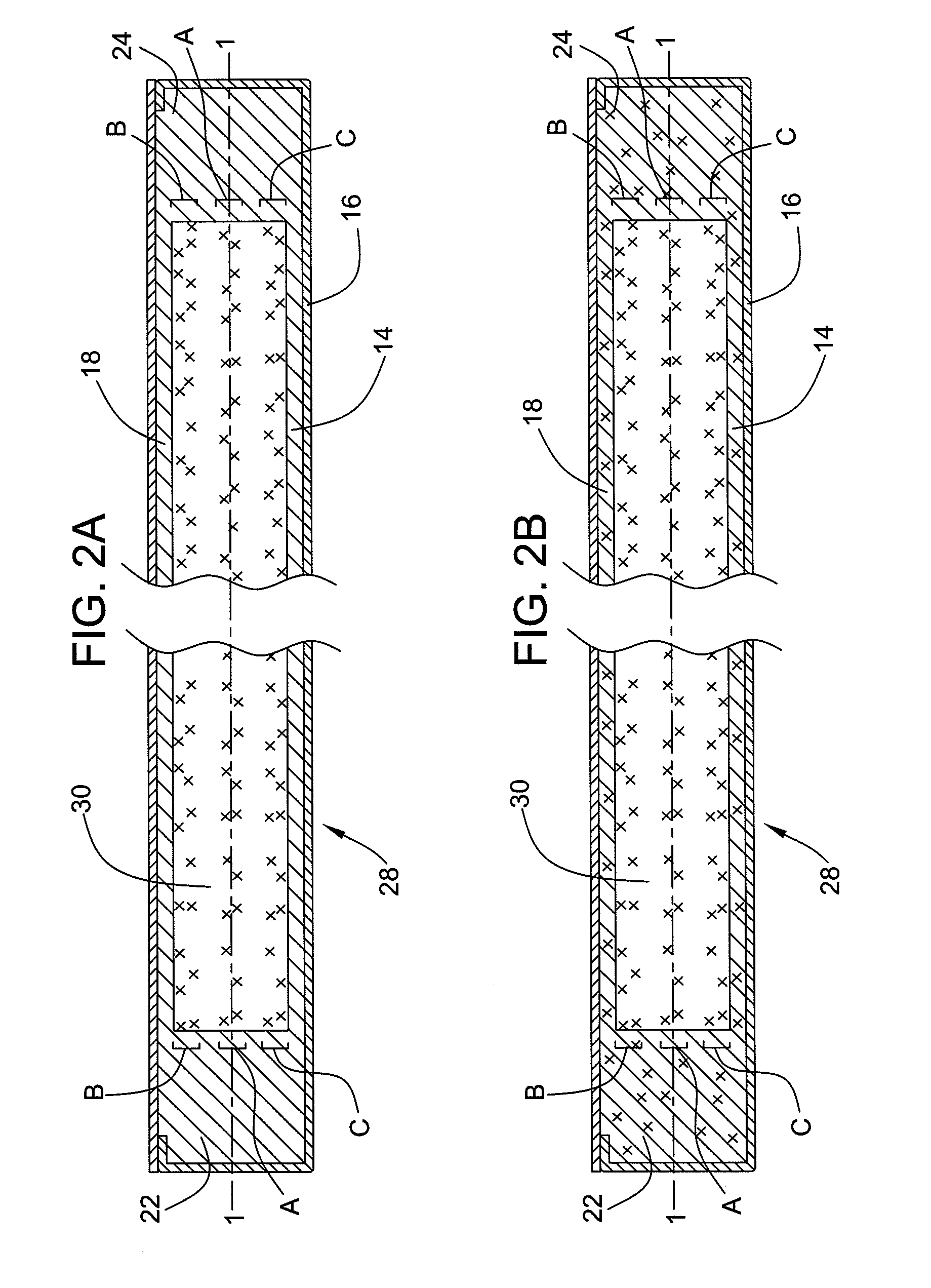

A cementitious article and a method of making a cementitious article are disclosed. The cementitious article comprises a cementitious component that comprises a polyvinyl acetate type polymer, a monobasic phosphate, and optionally boric acid. Cementitious articles, such as board, are prepared such that the polyvinyl acetate type polymer, the monobasic phosphate, and optionally boric acid can be present in the cementitious core, and / or in dense layers if present. The concentration of the polyvinyl acetate type polymer, monobasic phosphate, and optionally boric acid in the cementitious article can increase from a central region A to peripheral regions B and C, respectively. In some embodiments, the polyvinyl acetate type polymer is a polyvinyl alcohol and the monobasic phosphate is monoammonium phosphate.

Owner:UNITED STATES GYPSUM CO

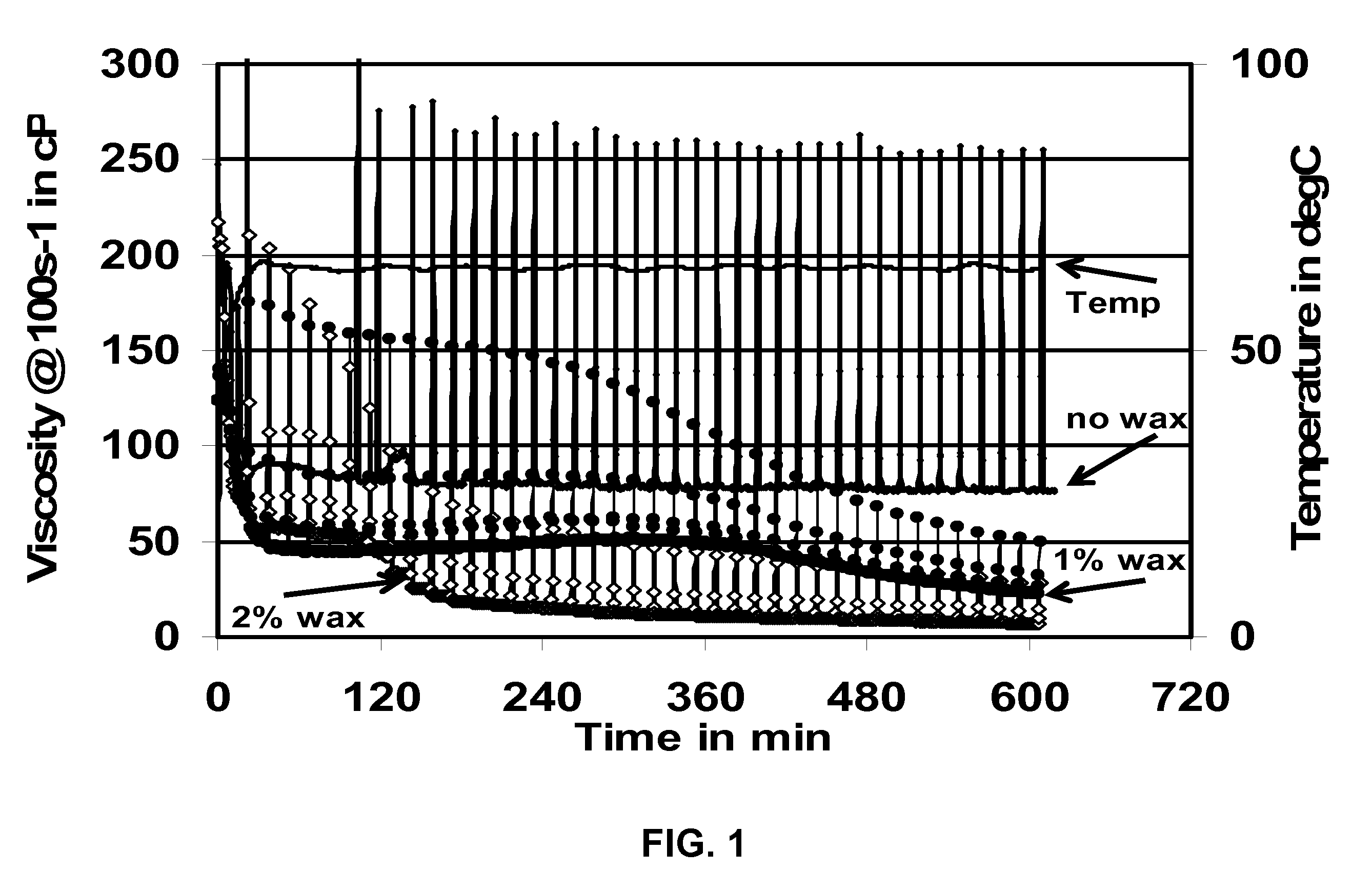

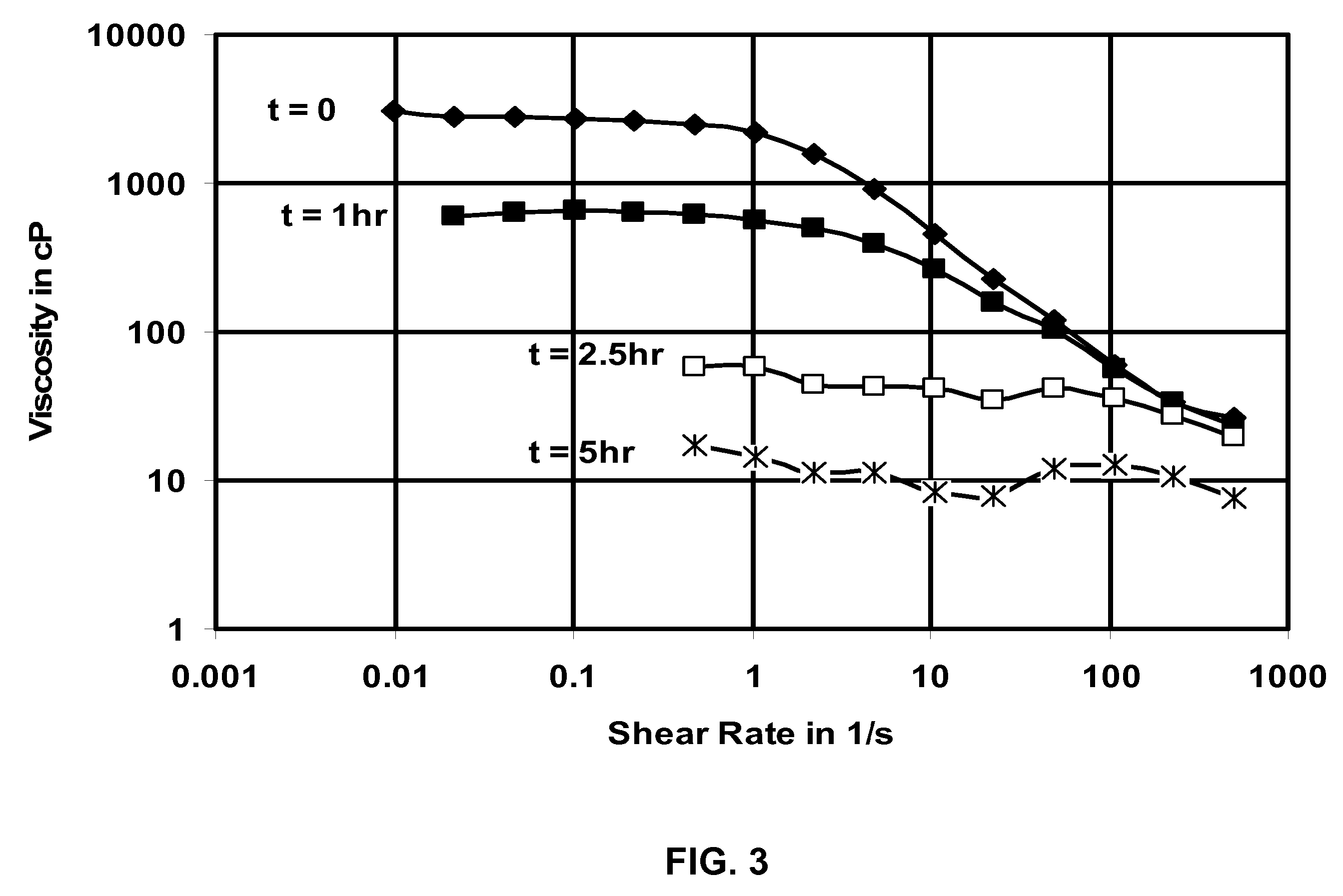

Internal Breaker for Oilfield Treatments

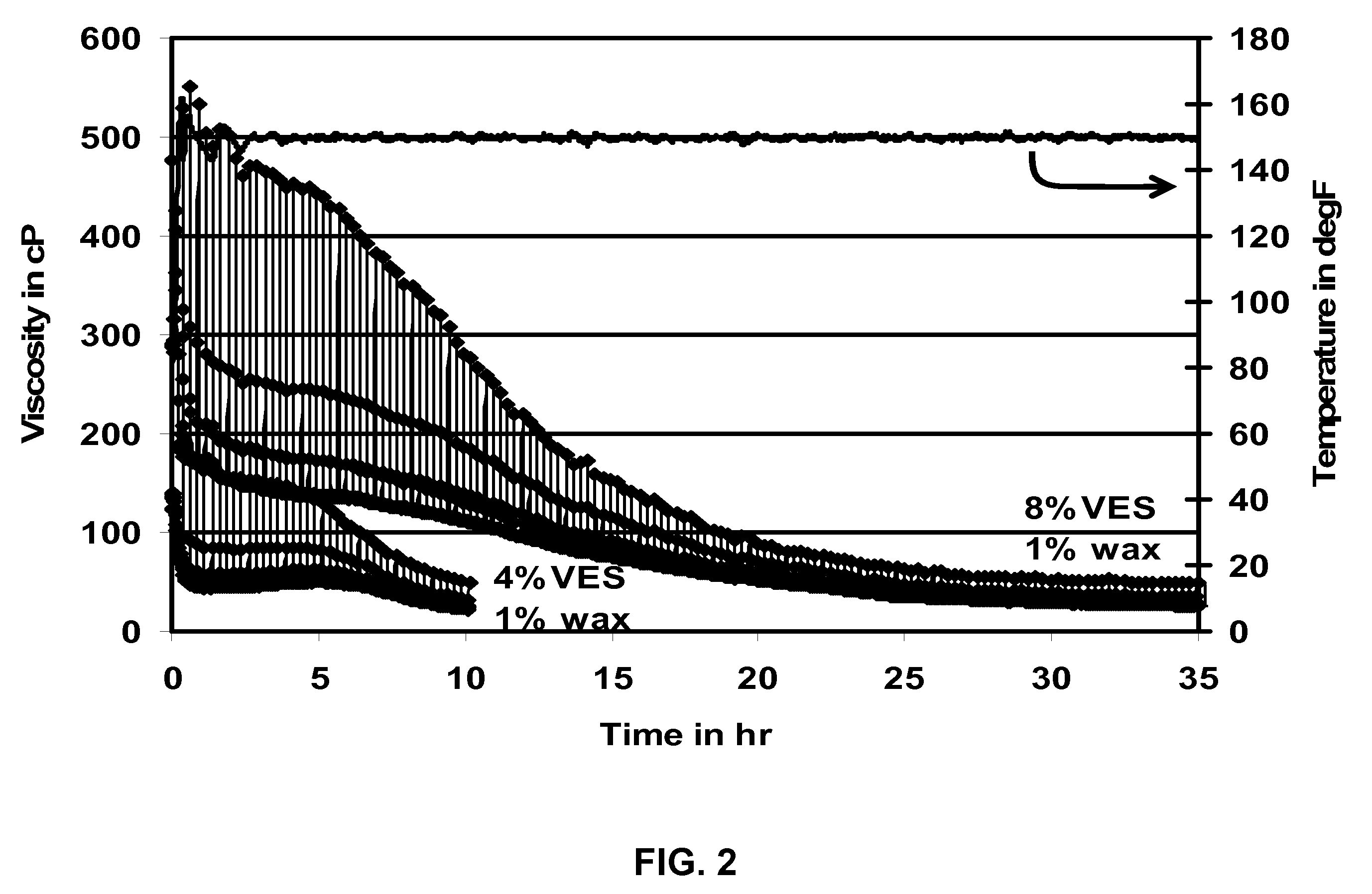

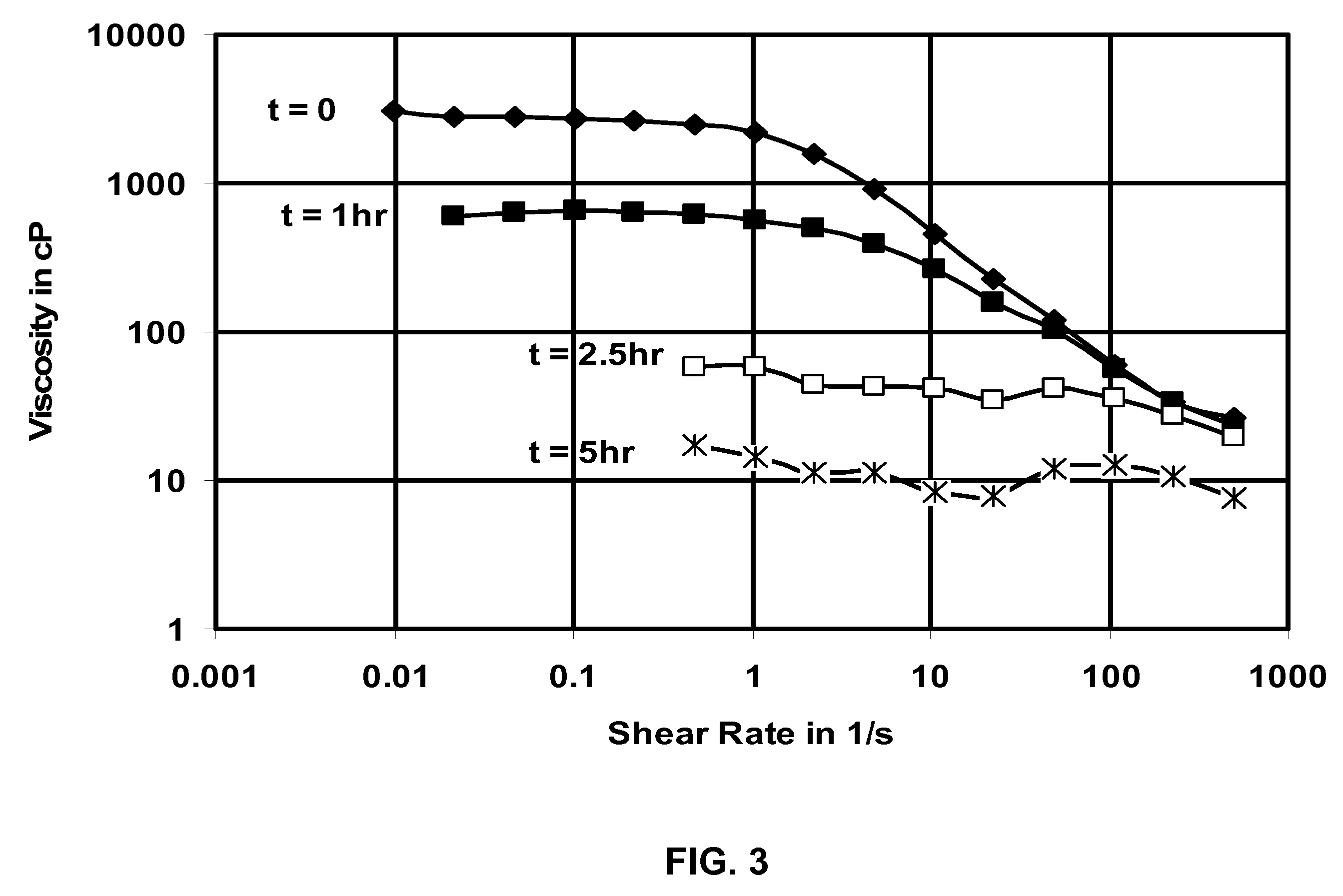

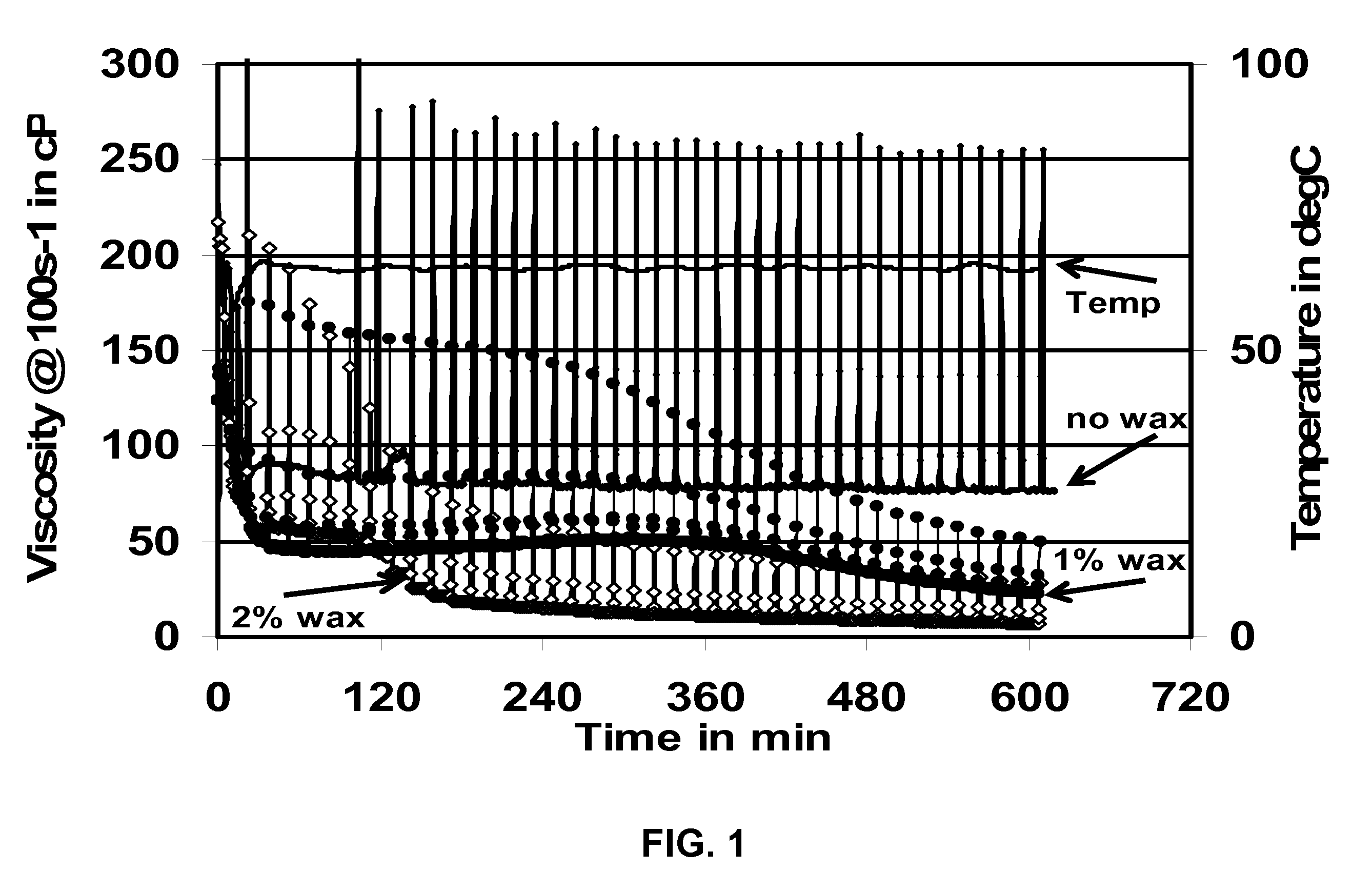

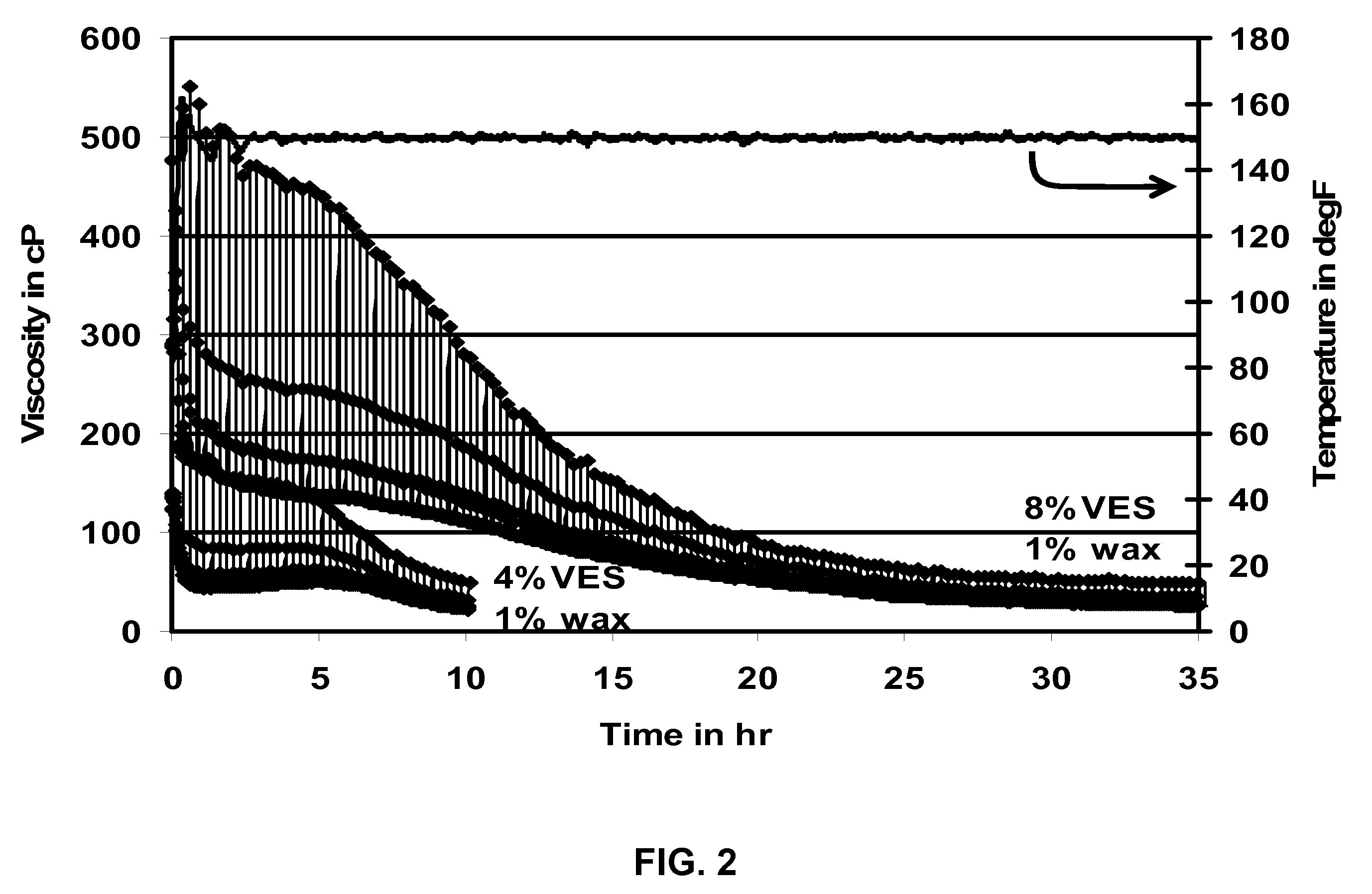

A composition and method for improving the fluid efficiency of many oilfield treatments is given. The composition is a solid additive, in a viscosified fluid, in a size range small enough that it enters formation pores; it optionally bridges there to form an internal filter cake, and then decomposes to provide a breaker for the viscosifying system for the fluid. Examples of suitable additives include waxes, polyesters, polycarbonates, polyacetals, polymelamines, polyvinyl chlorides, and polyvinyl acetates. Degradation of the additive may be accelerated or delayed.

Owner:SCHLUMBERGER TECH CORP

New type hot-melt adhesive and preparation method thereof

InactiveCN1687280ALow costHigh viscosityHydrocarbon polymer adhesivesPolyvinyl acetatePolymer science

The present invention relates to a new-type thermosol using attapulgite as additive and its preparation method. Its composition includes: main body resin ethylene and polyvinyl acetate copolymer EVA, etc. 20-50%, tackifying resin 20-50%, diluent 10-30%, attapulgite 2-40% and anti-oxidant 0.1-1%. Its preparation method includes the following steps: firstly, melting diluent, adding main body resin, when the main body resin basically molten, progressively adding tackifying resin and making reaction for 0.5-1.5 h at 130-180 deg.C, then adding attapulgite and anti-oxidant, further reacting for 0.5-1 hr., discharging material, forming and granulating so as to obtain the invented product.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Process for the manufacturing of an improved core for decorative laminates and a decorative laminate obtained by the process

InactiveUS6841023B2Improve brittlenessImprove the overall coefficientOrganic chemistryLamination ancillary operationsPolyesterFiber

A process for the manufacturing of a core forming a carrying structure for decorative laminates. The core comprises particles of cured, and optionally foamed, rigid, polyurethane, polyisocyanurate and / or phenolic resin. The particles are bonded to each other in a pressing procedure with a bonding agent comprising an adhesive such as a polymerizing monomer.i) The particles are achieved by grinding cured, and optionally foamed, rigid, polyurethane, polyisocyanurate and / or phenolic resin so that it passes through a 2 mm screen, preferably a 1 mm screen,ii) 100 parts per weight of particles is mixed with 1-100 parts per weight of fiber, the fiber additive having an average length in the range 1-15 mm.iii) The particle-fiber mixture is allowed to absorb a selected amount of water, the amount of water being in the range 1-15% by weight, The water is either added at any stage before the adding of bonding agent, and / or being used as a solvent in the bonding agent, and that,iv) 85 parts per weight of the particle mixture is mixed with 2-15 parts per weight of a bonding agent, the bonding agent selected from the group consisting of,a) A mixture of polyols, such as polyester or polyether, crude methylene diphenyl diisocyanate and possibly a small amount of blowing agent in a ratio forming a polymeric resin with a density in the range 600-1400 kg / m3.b) A formaldehyde based resin such as phenol-formaldehyde resin, urea-formaldehyde resin, melamine-urea-formaldehyde resin, melamine-urea-phenol-formaldehyde resin or phenol-resorcinol-formaldehyde resin, orc) Polyvinyl acetate resin.v)The mixture is applied between the belts of the continuos belt press or the press plates of a static press, optionally with at least one intermediate carrier web, the belts or press plates allowing a mainly uniform and specified material thickness to form. A slightly porous and preconditioned core with a selected water content in the range 0.8-12% is hereby achieved. The invention also relates to a decorative laminate achieved through the process.

Owner:PERGO

Internal breaker for oilfield treatments

A composition and method for improving the fluid efficiency of many oilfield treatments is given. The composition is a solid additive, in a viscosified fluid, in a size range small enough that it enters formation pores; it optionally bridges there to form an internal filter cake, and then decomposes to provide a breaker for the viscosifying system for the fluid. Examples of suitable additives include waxes, polyesters, polycarbonates, polyacetals, polymelamines, polyvinyl chlorides, and polyvinyl acetates. Degradation of the additive may be accelerated or delayed.

Owner:SCHLUMBERGER TECH CORP

Modified release formulations containing drug-ion exchange resin complexes

ActiveUS20100166858A1Convenient coatingMinimizes fracturePowder deliveryNervous disorderPolyvinyl acetatePlasticizer

A coated drug-ion exchange resin complex comprising a core composed of a drug complexed with a pharmaceutically acceptable ion-exchange resin is provided. The drug-ion exchange resin complex is in admixture with a release retardant. The coating is a polyvinyl acetate polymer and a plasticizer. Methods of making and products containing this coated complex are described.

Owner:TRIS PHARMA

Protein-based wood adhesive and preparation method thereof

InactiveCN102719217ANo health damageAvoid decompositionNon-macromolecular adhesive additivesProtein adhesivesPolyvinyl alcoholAdhesive

The invention discloses a protein-based wood adhesive which is characterized by being made of the following raw materials in part by weight: 100 parts of water, 5 to 50 parts of protein-containing raw materials, 10 to 14 parts of polyamide epichiorobydrin (PAE), 5 to 15 parts of modifier, 1 to 15 parts of acidity regulator, 0 to 15 parts of stabilizer, 0 to 10 parts of humectant, 0 to 10 parts of anti-freeze, 0.1 to 10 parts of preservatives, 0 to 10 parts of mold inhibitor, 0 to 10 parts of enzyme inhibitor, and 0 to 10 parts of filling. The protein-containing raw materials contain over 10% of coarse protein, and the modifier is one of or a mixture of several of polyacrylamide, polyvinyl alcohol, polyvinyl acetate, borax, ammonium thiosulfate, carbamide and isocyanate. The invention also discloses a preparation method of the protein-based wood adhesive. The invention adopts common chemical materials and adopts a break-through normal-temperature material-mixing technique, which uses water as solvent. The adhesive has the advantages of high stickiness, evenness and convenience in adhesive application and stable product quality.

Owner:马晓平

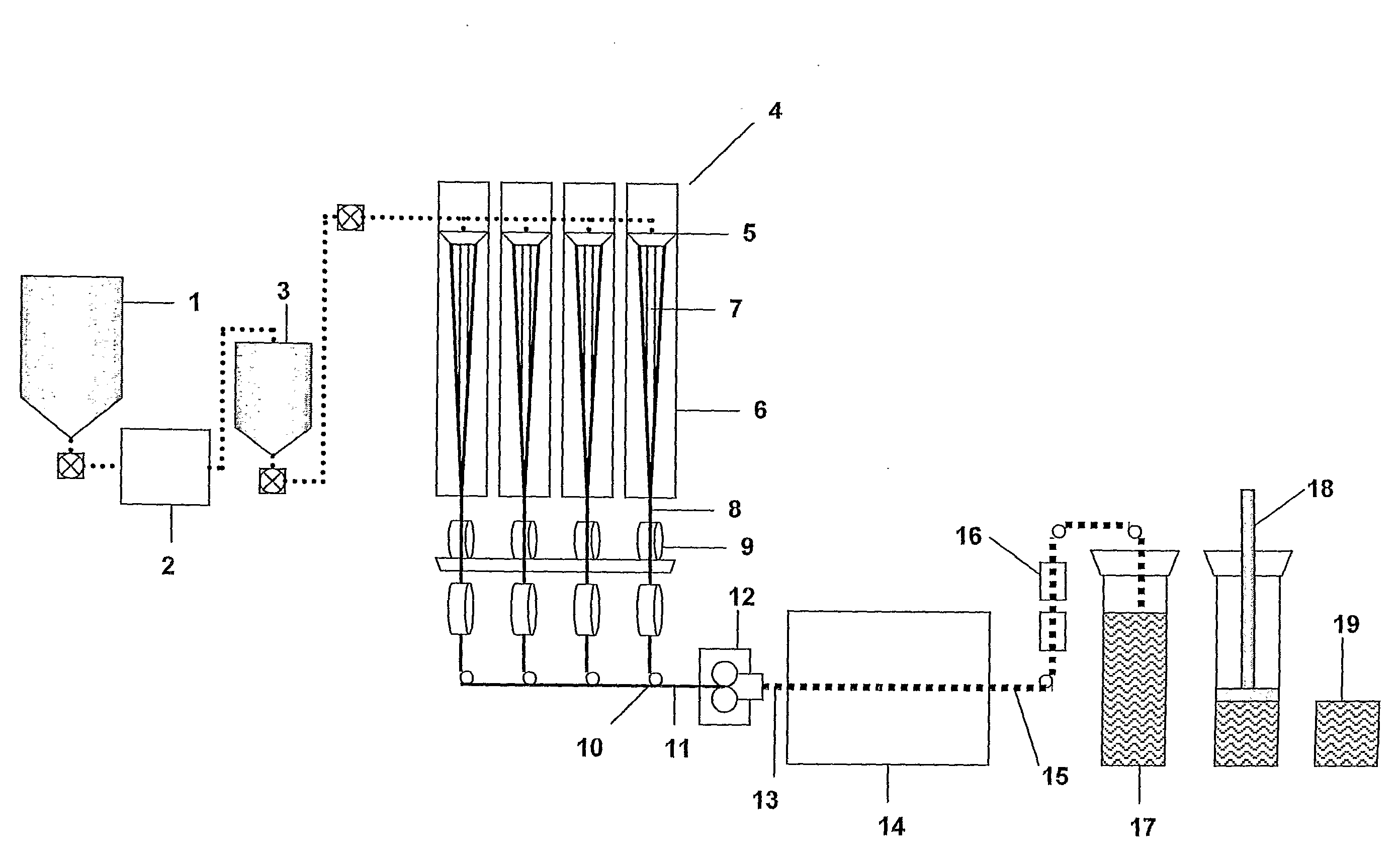

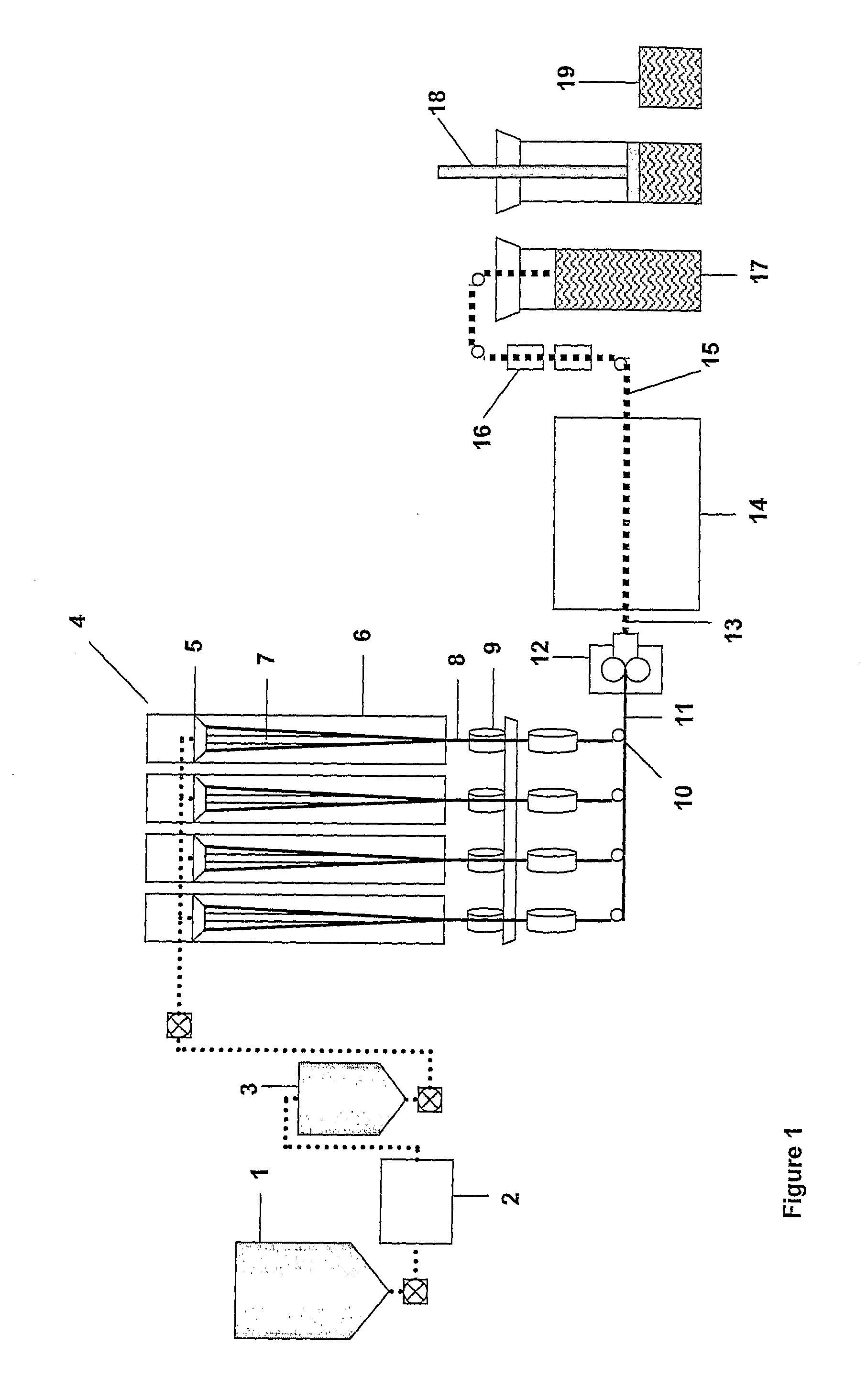

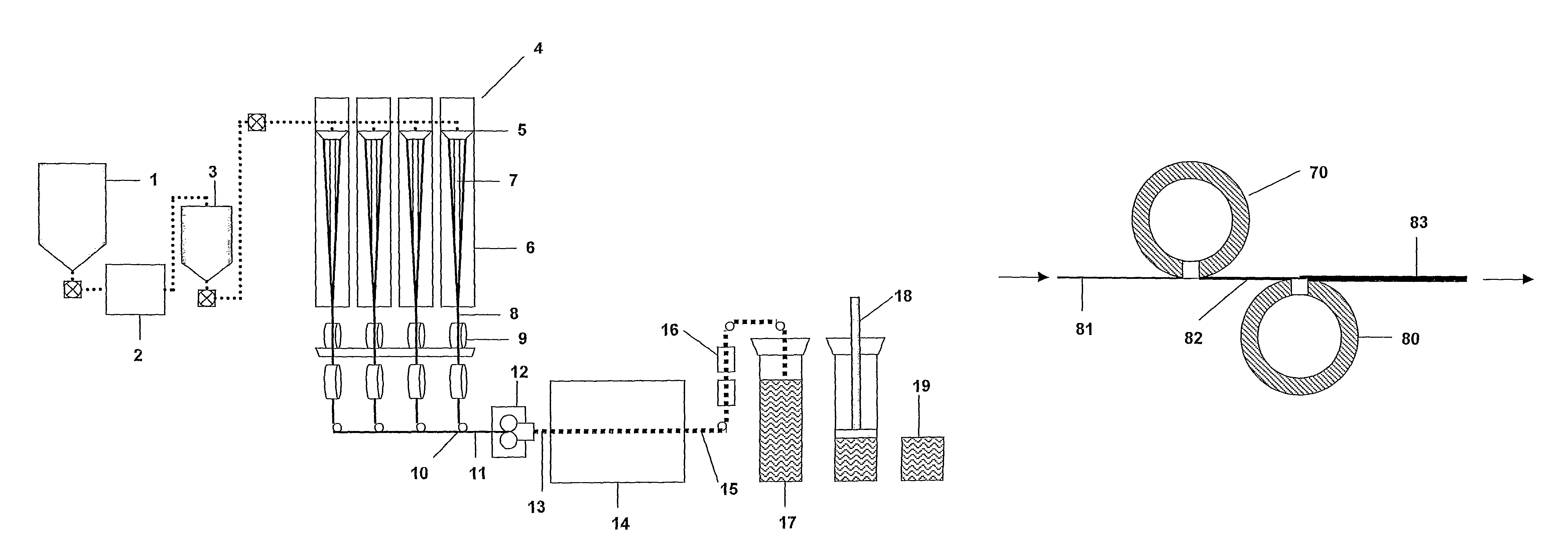

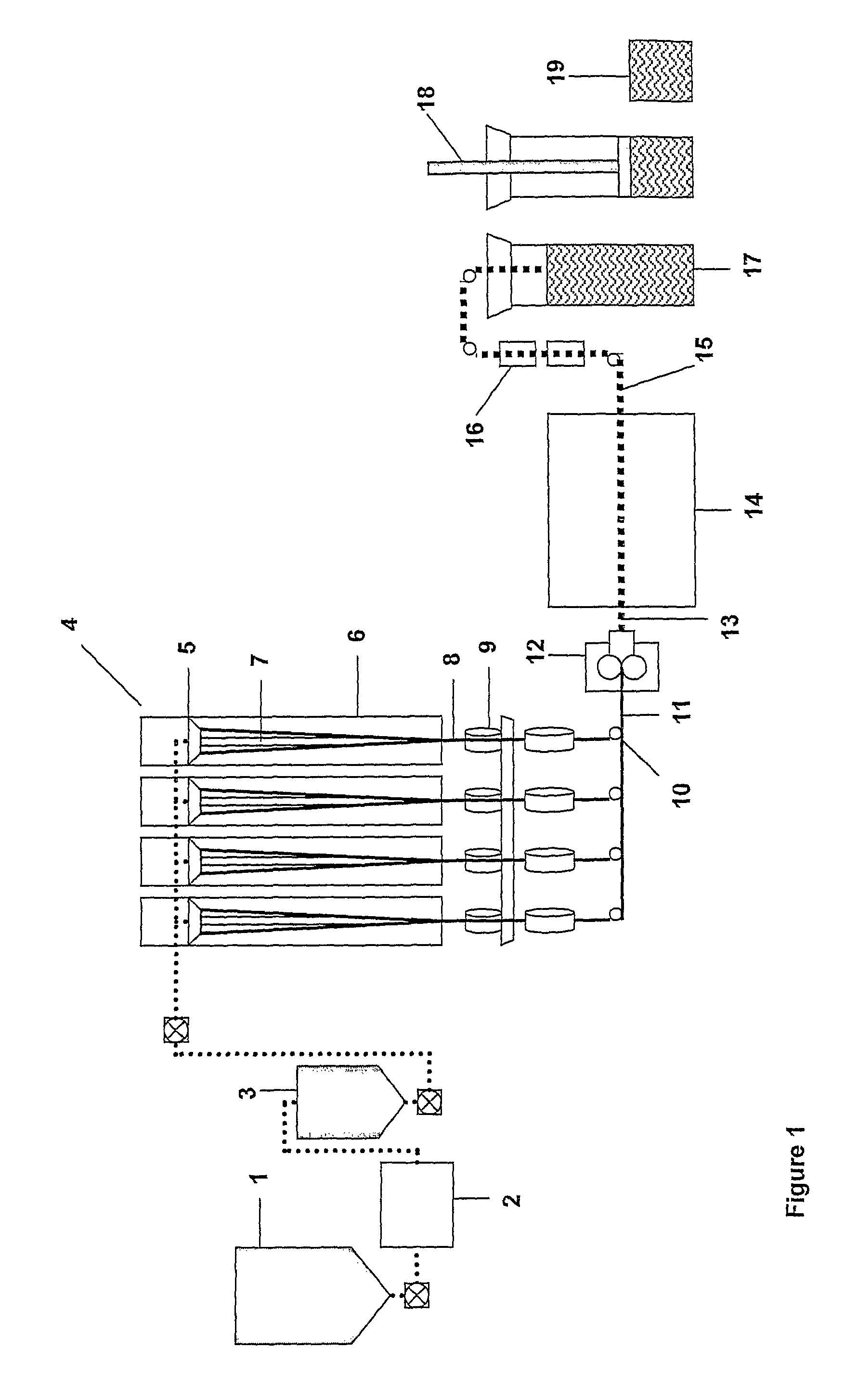

Process For Making Filter Tow

InactiveUS20080245376A1Consistent amountReduce concentrationCigar manufacturePaper/cardboard wound articlesCellulose acetateCyclodextrin

A method of preparing a crimped tow of cellulose acetate filaments comprising the steps of: a) providing cellulose acetate dope b) forming filaments (23) from the dope c) applying at least one additive to the filaments d) crimping the filaments to form a crimped tow wherein the at least one additive is capable of removing a component from cigarette smoke. Preferably, the component is a Hoffmann analyte. The additive may comprise a solution, liquid, emulsion or particulate material or combinations thereof. Preferably, the additive comprises an acidic compound or an alkaline compound. The additive may comprise malic acid, potassium carbonate, citric acid, tartaric acid, lactic acid, ascorbic acid, polyethyleneimine, cyclodextrin, sodium hydroxide, sulphamic acid, sodium sulphamate, polyvinyl acetate and carboxylated acrylate, carbon, silica, zeolite, clay, alumina, metal, molecular sieves or an ion exchange resin. The product tow can be processed on standard equipment to make efficient filter rods from which cigarette filter tips can be made which give significantly increased and selective retention of key smoke constituents.

Owner:CELANESE ACETATE LLC

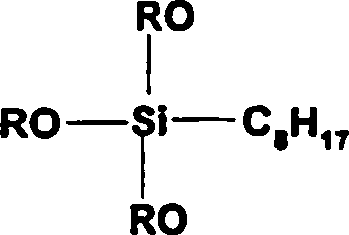

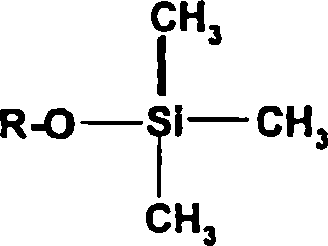

Basalt fiber surface modification impregnating compound and preparation method thereof

The invention discloses a basalt fiber surface modification impregnating compound and a preparation method thereof, and belongs to a basalt fiber impregnating compound. The impregnating compound comprises the following components in percentage by weight: 0.2-0.6% of organic silane coupling agent, 0.05-0.3% of pH (potential of hydrogen) conditioning agent, 3.0-10.0% of polyvinyl acetate emulsion, 0.2-2.0% of polyurethane emulsion, 0.5-3.0% of water-borne epoxy resin film forming matter, 1.0-5.0% of polyolefin emulsion, 0.1-1.0% of organic silicon emulsion, 0.1-1.0% of antistatic agent and the balance of water. The basalt fiber surface modification impregnating compound prepared according to the rated mass ratio is directly coated on the surface of basalt fiber in the basalt producing and wiredrawing process, and the surface modification is finished after the basalt fiber surface modification impregnating compound is dried, thereby being convenient to use. Meanwhile, the preparation method for the basalt fiber surface modification impregnating compound, which is disclosed by the invention, is simple, is suitable for industrial production and is easy for popularizing.

Owner:SICHUAN AEROSPACE TUOXIN BASALT IND

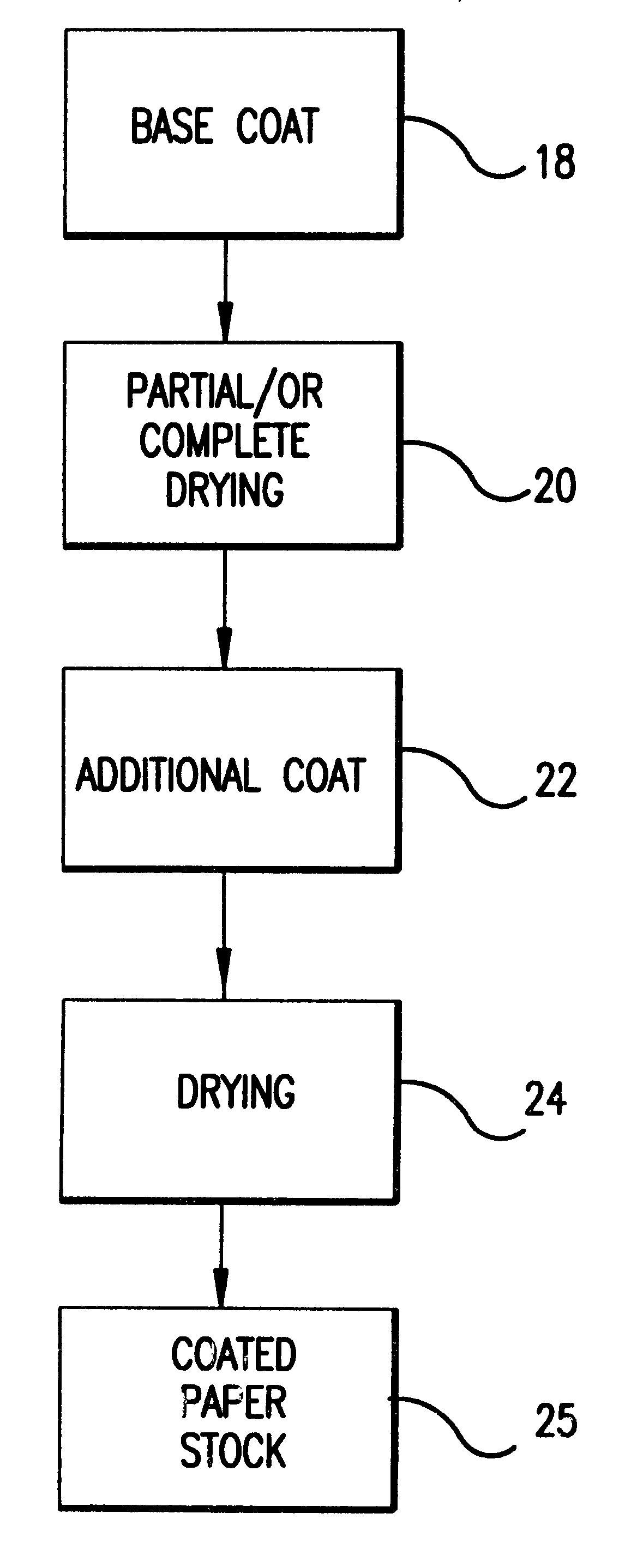

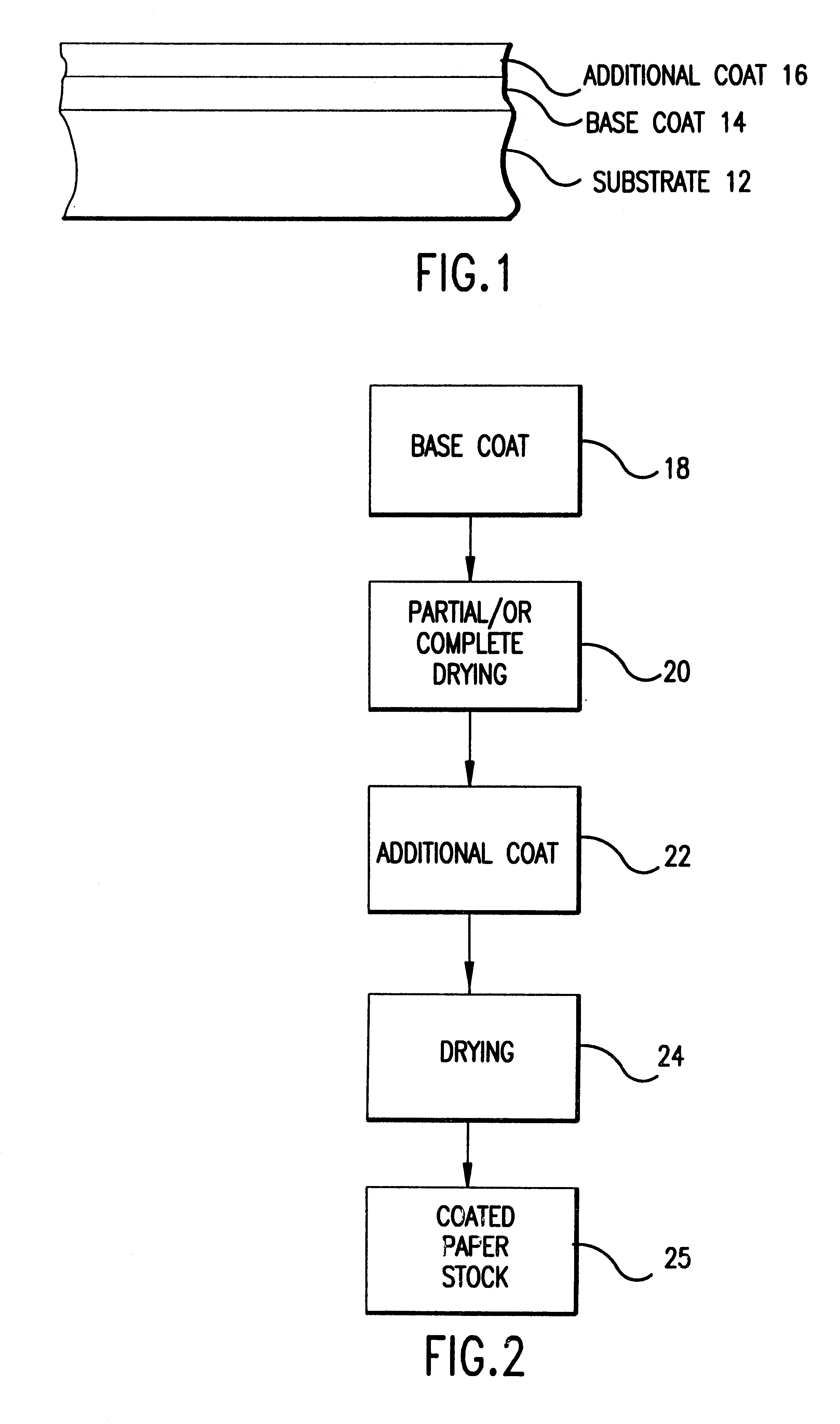

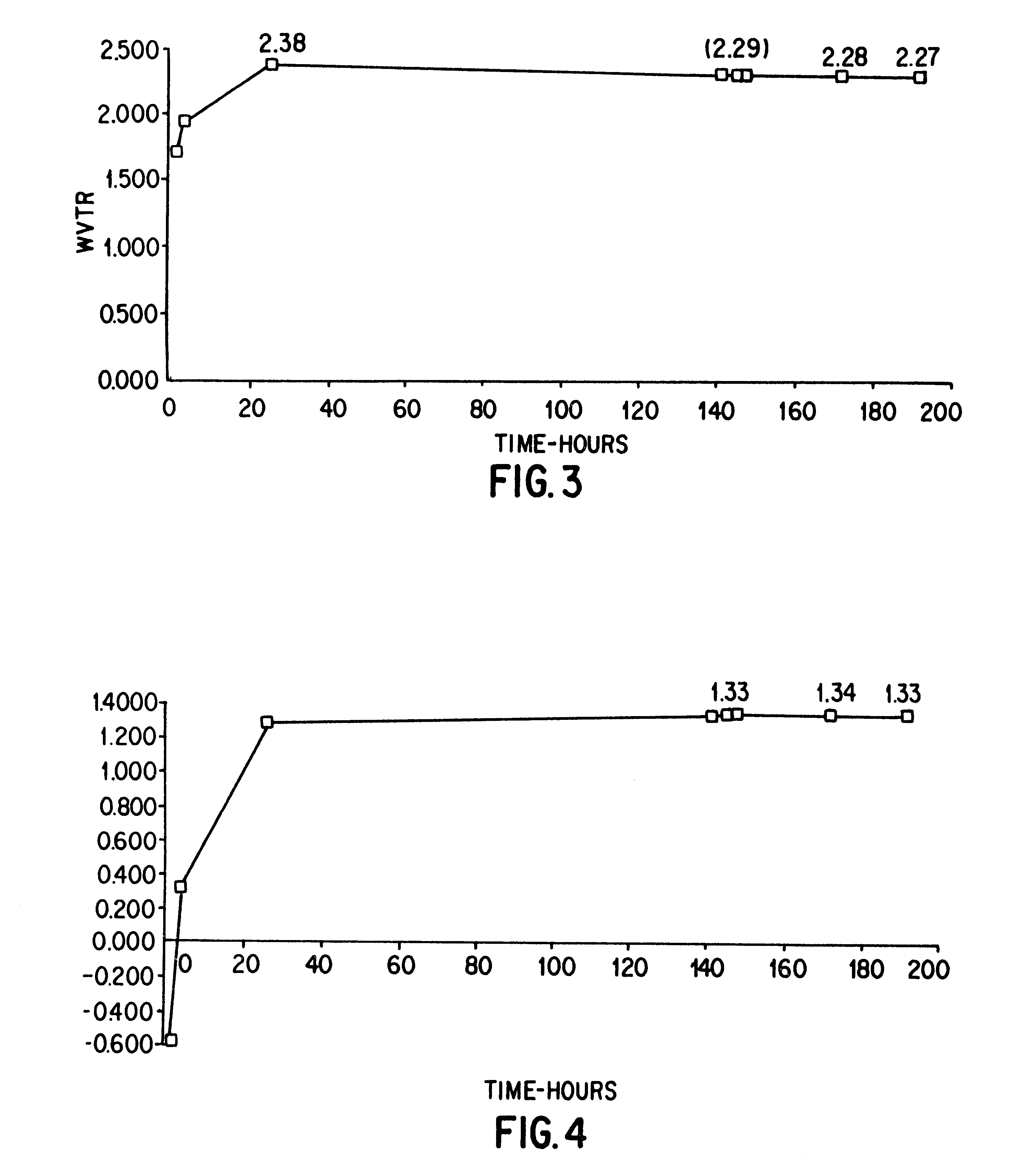

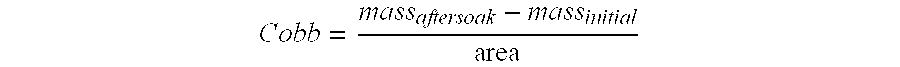

Recyclable and repulpable ream wrap and related methods of manufacture

InactiveUS6548120B1Reduce penetrationReduce drying demandFlexible coversWrappersWater basedPolymer science

Recyclable and repulpable coated paper stock, preferably for use as ream wrap, comprising a substrate coated on at least one surface with a base coat and at least one additional coat over said base coat. Both coats are water based dispersions of a polymer selected from the group consisting of acrylic polymers, acrylic copolymers, polyvinyl acetate, polyvinyl alcohol, ethylene-vinyl acetate, polyvinyl chloride, styrene butadiene copolymers, polyvinylidiene chloride and its copolymers, or starch. The wax free coating forms a pin-hole free continuous film on the substrate which is resistant to water and water vapor. The invention also includes processes for making and recycling the invented coated paper stocks.

Owner:COATING EXCELLENCE INT

Process for making filter tow

InactiveUS8308624B2Consistent amountReduce concentrationCigar manufacturePaper/cardboard wound articlesCellulose acetateCyclodextrin

A method of preparing a crimped tow of cellulose acetate filaments comprising the steps of: a) providing cellulose acetate dope b) forming filaments (23) from the dope c) applying at least one additive to the filaments d) crimping the filaments to form a crimped tow wherein the at least one additive is capable of removing a component from cigarette smoke. Preferably, the component is a Hoffmann analyte. The additive may comprise a solution, liquid, emulsion or particulate material or combinations thereof. Preferably, the additive comprises an acidic compound or an alkaline compound. The additive may comprise malic acid, potassium carbonate, citric acid, tartaric acid, lactic acid, ascorbic acid, polyethyleneimine, cyclodextrin, sodium hydroxide, sulphamic acid, sodium sulphamate, polyvinyl acetate and carboxylated acrylate, carbon, silica, zeolite, clay, alumina, metal, molecular sieves or an ion exchange resin. The product tow can be processed on standard equipment to make efficient filter rods from which cigarette filter tips can be made which give significantly increased and selective retention of key smoke constituents.

Owner:CELANESE ACETATE LLC

Modified release oral dosage form using co-polymer of polyvinyl acetate

Once a day modified release oral dosage form comprising of granules or pellets which are either compressed into tablet or filled inside the capsule, wherein the pellet has a core of active ingredient coated on non pareil seeds with a rate controlling functional coating of co-polymer of polyvinyl acetate optionally with an intermediate separating coating between the core and the functional coating layer.

Owner:ASTRON RES LTD

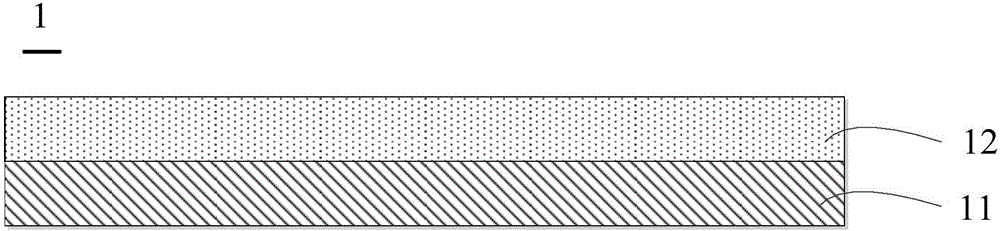

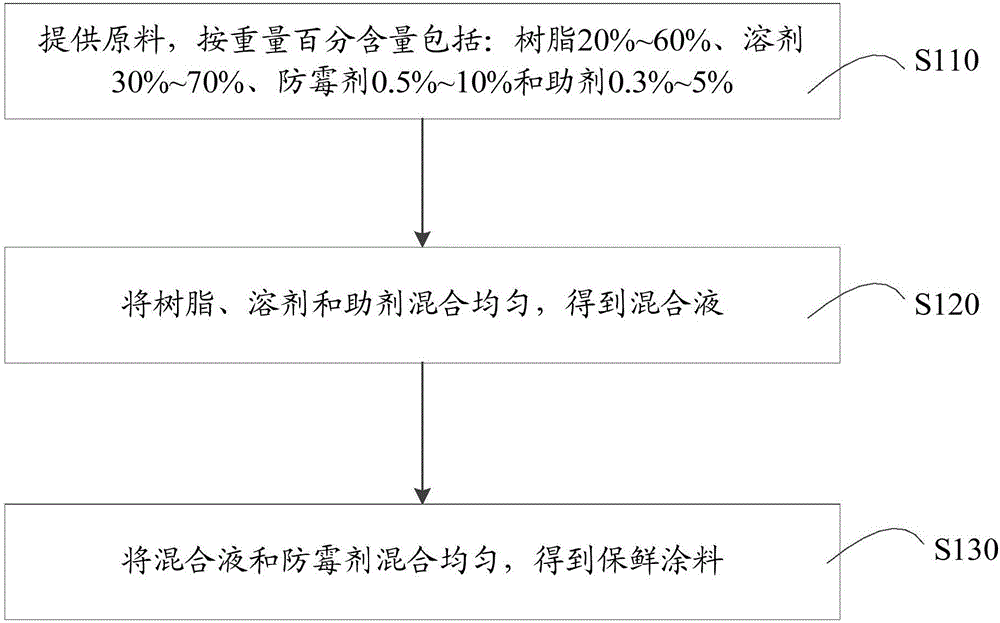

Mildewproof preservative film and preparation method thereof

InactiveCN106634129AIncrease contactNo porosityAntifouling/underwater paintsPaints with biocidesCarvacryl acetateSolvent

The invention discloses a mildewproof preservative film and a preparation method thereof. The mildewproof preservative film comprises a base layer and a mildewproof preservative coating arranged on the base layer, wherein the mildewproof preservative coating is prepared from a mildewproof preservative paint. The mildewproof preservative paint comprises the following components in percentage by weight: 20-60% of resin, 30-70% of solvent, 0.5-10% of mildew preventive and 0.3-5% of aid. The resin is composed of at least one of polyurethane, an acrylate copolymer, polyvinyl alcohol, polyvinylidene chloride, modified polyvinylidene chloride, an ethylene-vinyl acetate copolymer, a polyvinyl acetate copolymer and a vinyl acetate-butyl ester copolymer; and the solvent is composed of at least one of water and ethanol. The mildewproof preservative coating of the mildewproof preservative film has the advantages of compact surface and no void; and by adding the mildew preventive, the mildewproof preservative coating has the favorable effects of keeping the moisture constant and preventing mildewing. The mildewproof preservative film is especially suitable for preserving fruits, bread, tobacco and other foods which have shorter storage period, can easily mildew in a short time and need to be eaten in time.

Owner:CHANGDE JINRUN NEW MATERIAL TECH CO LTD

Semi-synthetic platelet gel and method for the preparation thereof

A semi-synthetic platelet gel comprising a platelet-rich plasma, at least one platelet activator, and a biocompatible polymer selected from the group comprising carbomers, polyalkylene glycols, poloxamers, polyesters, polyethers, polyanhydrides, polyacrylates, polyvinyl acetates, polyvinyl pyrrolidones, polysaccharides, and derivatives thereof. A method for preparing a semi-synthetic platelet gel comprising the steps of (a) mixing a platelet-rich plasma with at least one platelet activator, and, before the start of clot formation, (b) adding the mixture thus obtained to a biocompatible polymer selected from the group comprising carbomers, polyalkylene glycols, poloxamers, polyesters, polyethers, polyanhydrides, polyacrylates, polyvinyl acetates, polyvinyl pyrrolidones, polysaccharides, and derivatives thereof.

Owner:LECTIO PHARMAENTWICKLUNGS UND VERW

Energy-saving type concrete crack repairing agent

The invention discloses an energy-saving type concrete crack repairing agent which comprises the following components in parts by weight: 12-18 parts of sand, 5-10 parts of a quartz powder, 20-35 parts of ordinary portland cement, 10-18 parts of sulphoaluminate cement, 6-12 parts of sodium silicate, 5-9 parts of a polyvinyl acetate emulsion powder, 3-7 parts of silica fume, 7-10 parts of a slag powder, 6-9 parts of fly ash, 8-10 parts of an expansive agent, 0.4-0.6 part of a polycarboxylic acid type high-efficiency water-reducing agent, and 0.2-0.4 part of polypropylene fiber. The concrete repairing agent has high bonding strength, and significantly improves the binding force between a new concrete interface and an old concrete interface; the concrete repairing agent is short in congealing curing time, fast in development of strength after congealing, and suitable for rapid repairing; the concrete repairing agent has the advantages of environmental protection, no toxicity, no smell, harmlessness to human bodies, single-component construction, and no pollution to the environment; and the concrete repairing agent can be used for repairing of concrete cracks, holes, honeycombs and pock marks, and drawing repairing of seams of face bricks and mosaic.

Owner:HUNAN CONSTR ENG GRP COR +1

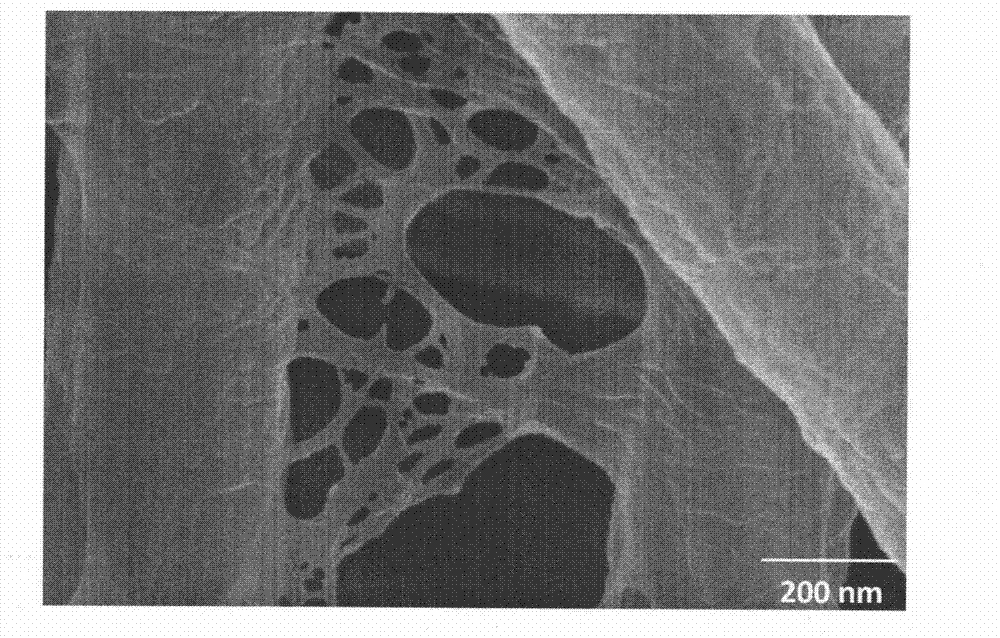

Method for preparing cellulose nanocrystal/electrostatic spinning nanofiber filter film

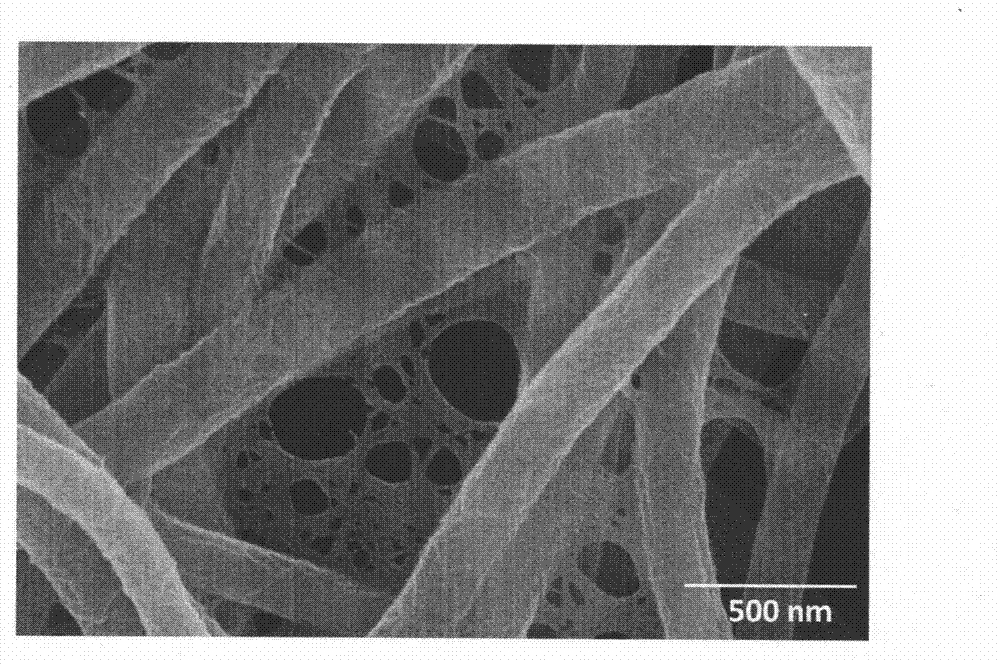

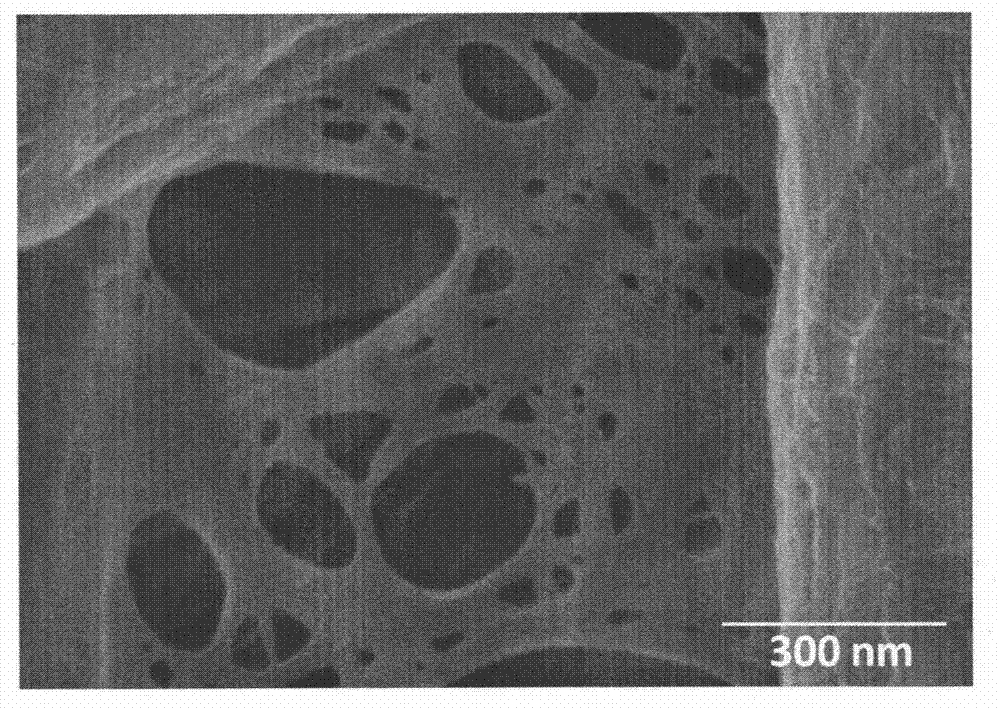

InactiveCN102806021AImprove adsorption capacityPurify waterSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiberPolymer science

The invention provides a method for preparing a cellulose nanocrystal / electrostatic spinning nanofiber filter film. The method is characterized in that the prepared cellulose nanocrystals of which the diameter is 3 to 10nm are coated on the surface of an electrostatic spinning nanofiber film to form a network structure so as to filter out impurities in raw water, intercept suspended solids, colloid, bacteria and the like in the water and effectively adsorb residual chlorine and heavy metal in the water; and therefore, the aim of purifying water quality can be fulfilled. Moreover, due to the adoption of a multi-layer compounded mode, the mechanical strength of the nano fiber film can be improved by the cellulose nanocrystals, so that the filter film has the advantages of simple structure, high mechanical strength, good filtering effect, low cost and the like, and has wide application prospect in the fields of drinking water purification, textile dyeing wastewater treatment, polyvinyl acetate (PVA) slurry recycling and the like.

Owner:DONGHUA UNIV

Novel Treated Mineral Pigments for Aqueous Based Barrier Coatings

InactiveUS20110046284A1Improve sealingImprove barrier propertiesWood working apparatusInksCellulosePolyvinyl acetate

This invention is directed to novel pigments, pigment systems (including components not classified as pigments) and formulations for use in an aqueous coating system applied onto cellulosic (paper and / or paperboard) and non-cellulosic substrates (polyethylene (PE), polylactic acid (PLA), polyvinyl acetate (PVAc), etc.) to impart barrier properties.

Owner:BASF CORP

Elastomer compositions for use in a hydrocarbon resistant hose

InactiveUS20050059764A1Improve impermeabilityGood oil resistanceSynthetic resin layered productsSpecial tyresElastomerPolymer science

A heat tolerant, pressure resistant elastomeric composition comprising a blend of a first ethylene-vinyl ester copolymer and a second copolymer selected from the group consisting of chlorosulfonated polyethylene (CSM), chlorinated polyethylene (CPE), polychloroprene (CR), ethylene-acrylic elastomer (AEM), alkyl-acrylate copolymer (ACM), polyvinyl acetate (PVA), nitrile-butadiene rubber (NBR), hydrogenated nitrile-butadiene rubber (HNBR), and mixtures thereof, a hose manufactured therefrom; and a method for preparing the hose are described.

Owner:FLUID ROUTING SOLUTIONS

Pyromellitic dianhydride catalyst and preparation method thereof

InactiveCN102008971ASolve the problem of selectivityPhysical/chemical process catalystsOrganic chemistryAlkali metal oxideSlurry

The invention provides a pyromellitic dianhydride catalyst and a preparation method thereof, relates to a catalyst and the preparation method and solves the problems of low catalyst yield and low selectivity of the conventional gaseous oxidation method for preparing pyromellitic dianhydride. The catalyst consists of an active ingredients and a carrier, wherein the active ingredients consist of V2O5, TiO2, P2O5, Sb2O3 and alkali metal oxides. The method comprises the following steps of: 1, weighing; 2, adding an antimony source and a vanadium source into oxalic acid solution with stirring to obtain vanadyl oxalate solution; 3, adding a phosphorus source, the antimony source and alkali metal salt into the vanadyl oxalate solution, uniformly mixing, then adding a titanium source, adding polyvinyl acetate emulsion and then pulping and grinding to obtain size; and 4, adding the carrier into a revolving drum of spray painting equipment, heating and spraying the size on the carrier, putting into a Muffle furnace to carry out air purge and cooling to obtain the catalyst. The catalyst is used for catalysis and preparation of pyromellitic dianhydride.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Adhesive and sealant systems

Adhesive and sealant systems based on epoxy resins, polyurethane, silane-terminated polymers, silicones, unsaturated polyester resins, vinyl ester resins, acrylates, polyvinyl acetate, polyvinyl alcohol, polyvinyl ether, ethylene vinyl acetate, ethylene-acrylic acid copolymers, polyvinyl acetates, polystyrene, polyvinyl chloride, styrene-butadiene rubber, chloroprene rubber, nitrile rubber, butyl rubber, polysulfide, polyethylene, polypropylene, fluorinated hydrocarbons, polyamides, saturated polyesters and copolyesters, phenol-formaldehyde resins, cresol- / resorcinol-formaldehyde resins, urea-formaldehyde resins, melamine-formaldehyde resins, polyimides, polybenzimidazoles, polysulfones, which contain 1 wt.% to 15 wt.% of a compacted, hydrophobic pyrogenic silica.

Owner:DEGUSSA AG

Solid pharmaceutical compositions containing pregabalin

InactiveUS20070269511A1Absorption windowPromote undesirable lactam formationBiocideOrganic active ingredientsCross-linkOral medication

Owner:WARNER-LAMBERT CO

Process for producing laminated glass composites with embedded electrically conductive structures

Production of glass laminates containing electrically conductive structures is facilitated by including the electrically conductive structures on a first polyvinyl acetate film with low or no plasticizer content, and employing a second polyvinyl acetal film with a high plasticizer content.

Owner:KURARAY EURO GMBH

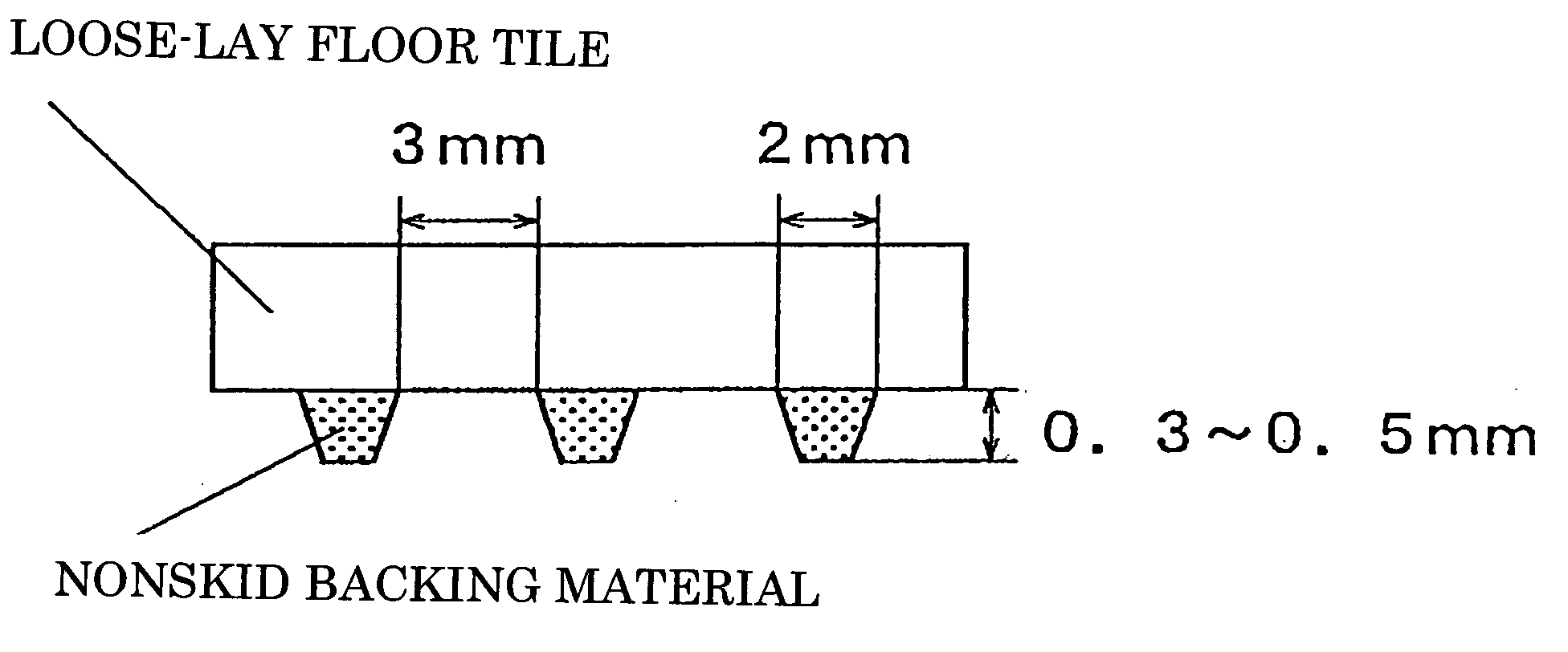

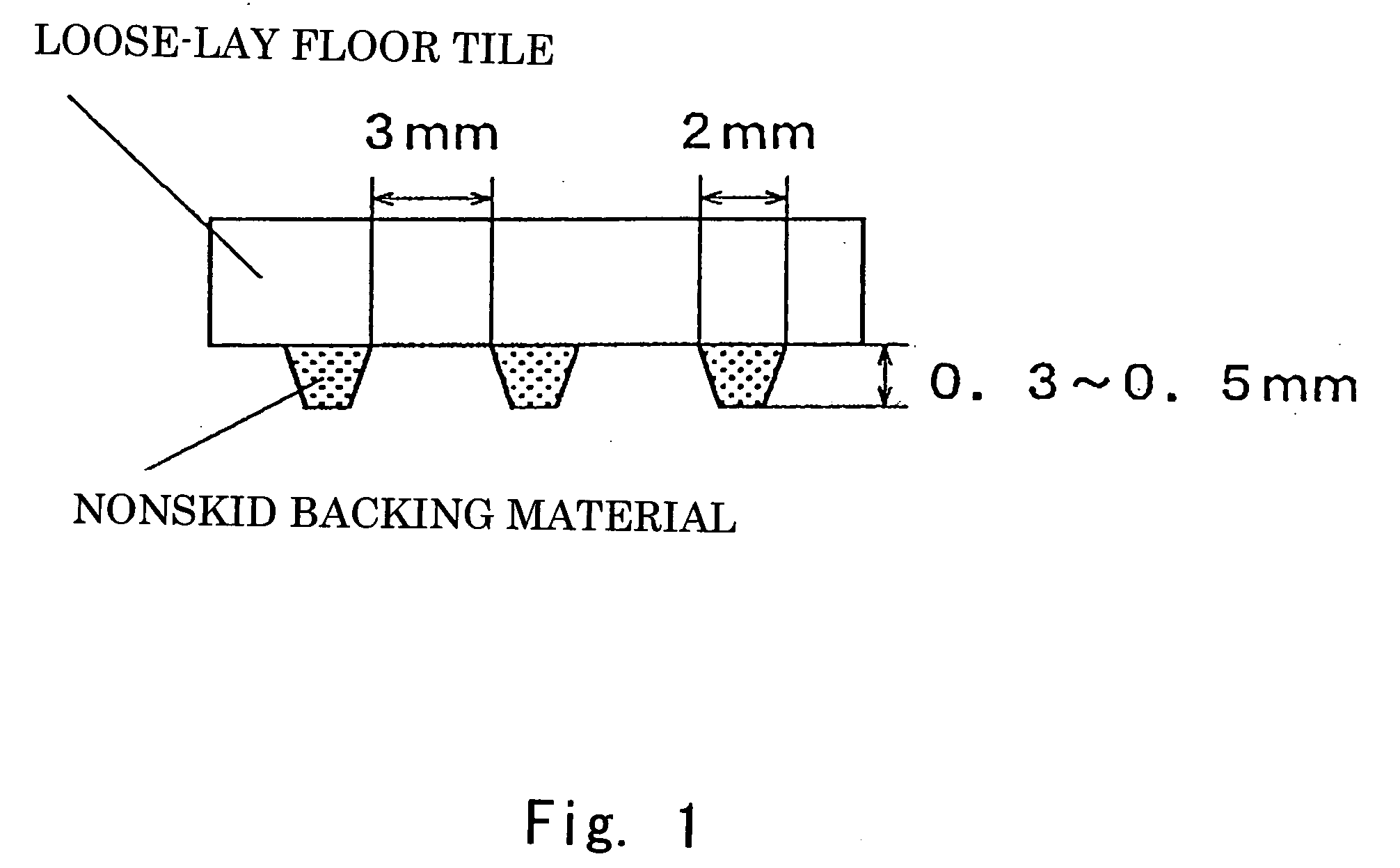

Free laying floor tile having pvc based backing material for preventing tile from slipping provided on back surface thereof

A loose-lay floor tile which has on a back face a nonskid backing material obtained by solidifying a paste sol containing a plasticizer and one of polyvinyl chloride, copolymers of vinyl chloride and vinyl acetate and mixtures of polyvinyl chloride and polyvinyl acetate. Drawbacks of conventional acrylic mechanically foamed materials such as water absorption, resistance to water, resistance to alkali and strength of a foamed material are improved.

Owner:TAJIMA +1

Polyvinyl acetal resin composition

ActiveUS20110049434A1Sufficient flexibilityNot easy to damageConductive materialOrganic conductorsConductive pastePolyvinyl acetate

It is an object of the present invention to provide a polyvinyl acetal resin composition capable of giving a ceramic green sheet which has sufficient flexibility and is hardly damaged even when being formed into a thin film, when the polyvinyl acetal resin composition is used as a binder for a ceramic green sheet. It is another object of the present invention to provide a ceramic slurry, a ceramic paste, a ceramic green sheet, a conductive paste and an interlayer film for laminated glass for automobiles, each produced by using the polyvinyl acetal resin composition.The present invention pertains to a polyvinyl acetal resin composition containing a polyvinyl acetal resin A and a polyvinyl acetal resin B incompatible with the polyvinyl acetal resin A, which is formed by acetalizing a mixed polyvinyl alcohol containing two or more kinds of polyvinyl alcohols having different saponification degrees, and wherein the mixed polyvinyl alcohol contains main two kinds of polyvinyl alcohols in which X and Y satisfy the relationship of the following equation (1):[Formula 1]|X−Y|≧10 (1)in which X represents the saponification degree of any one polyvinyl alcohol a of the polyvinyl alcohols contained in the mixed polyvinyl alcohol and Y represents the saponification degree of a polyvinyl alcohol b other than the polyvinyl alcohol a, andwherein in denoting, by M, the polymerization degree of one polyvinyl alcohol having a higher polymerization degree of the main two kinds of polyvinyl alcohols and denoting the polymerization degree of the other polyvinyl alcohol by N, M and N have the relationship of the following equation (2):[Formula 2]M / N≦3 (2)and a phase composed of the polyvinyl acetal resin A and a phase composed of the polyvinyl acetal resin B form a sea-island structure.

Owner:SEKISUI CHEM CO LTD

Water-insoluble medicine sustained-release pellet, sustained-release orally disintegrating tablet thereof and preparation method thereof

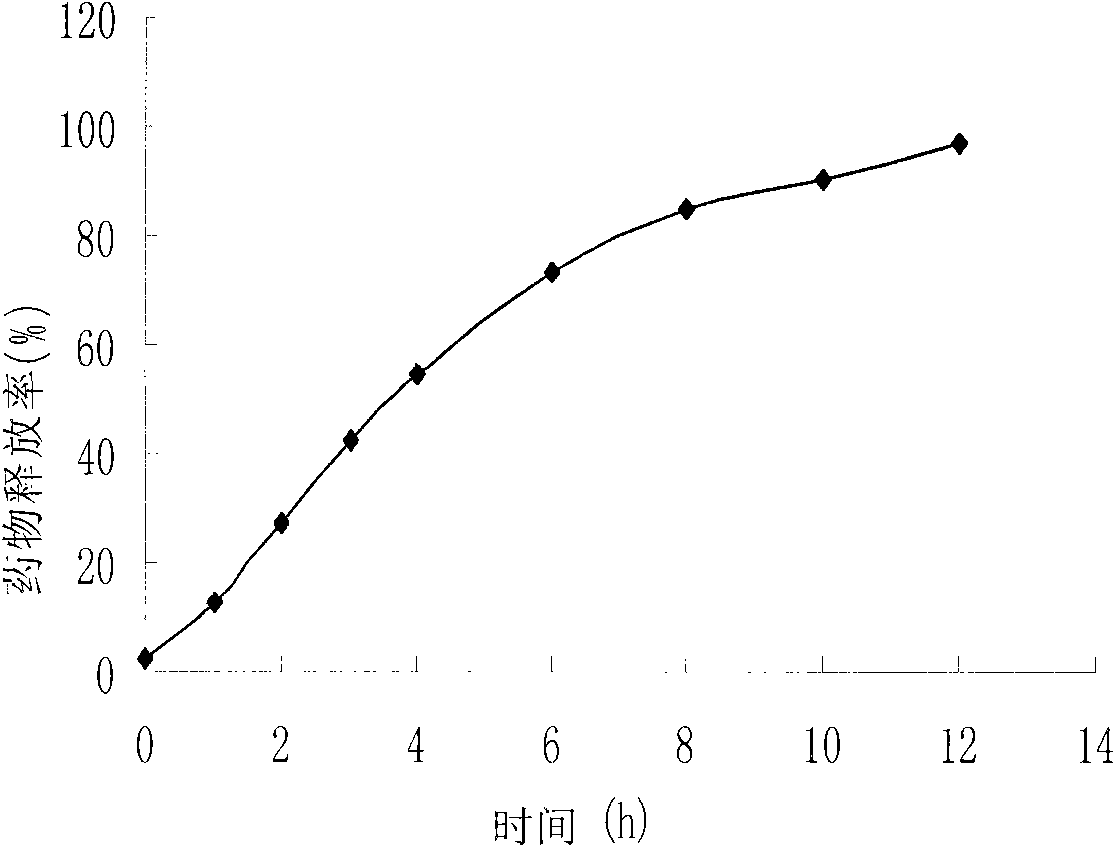

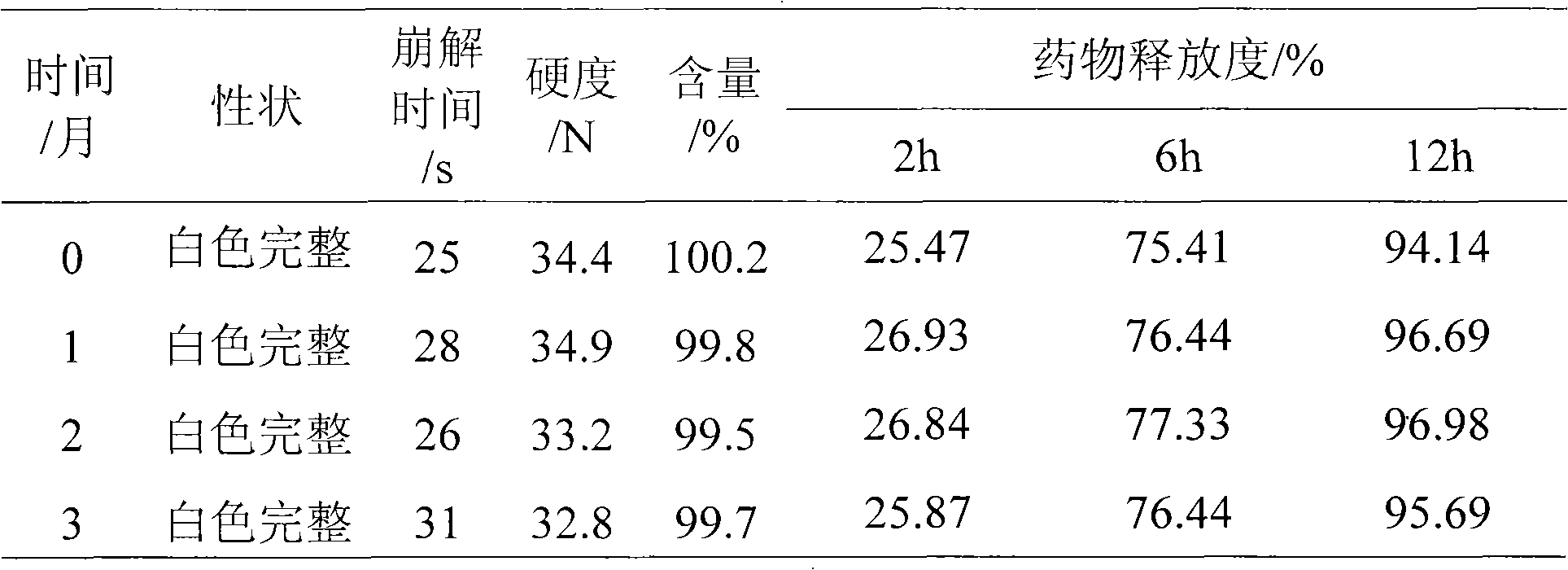

InactiveCN101862297ASmall particle sizeHigh strengthOrganic active ingredientsAntipyreticSustained release pelletsSide effect

The invention discloses a water-insoluble medicine sustained-release pellet, a sustained-release orally disintegrating tablet thereof and a preparation method thereof. The water-insoluble medicine sustained-release pellet comprises a hollow pellet core, a medicine layer, an insulation layer and a sustained-release layer, wherein the sustained-release layer comprises the following ingredients: 54 to 88 percent of sustained-release materials, 2 to 30 percent of antitackiness agents and 1 to 30 percent of pore-foaming agents, wherein the percentage is the mass percentage in the sustained-release layer, wherein the sustained-release materials are one kind or several kinds of materials selected from ethyl acrylate and methyl methacrylate copolymers, polyvinyl acetate and ethyl cellulose. Through regulating the coating combinations and filling auxiliary materials to be pressed into orally disintegrating tablets, the medicine can be slowly released for more than 8 to 13 hours, so the stable blood medicine concentration can be maintained, the side effect is reduced, the medicine taking times can be reduced, and the medicine taking is convenient. The invention conforms to zero-grade release, has the advantages of high final accumulated medicine release amount, high efficacy, strong selectivity, good mouth feeling, simple production steps and high efficiency, and can be applied to large-scale production.

Owner:SHANGHAI INST OF PHARMA IND +1

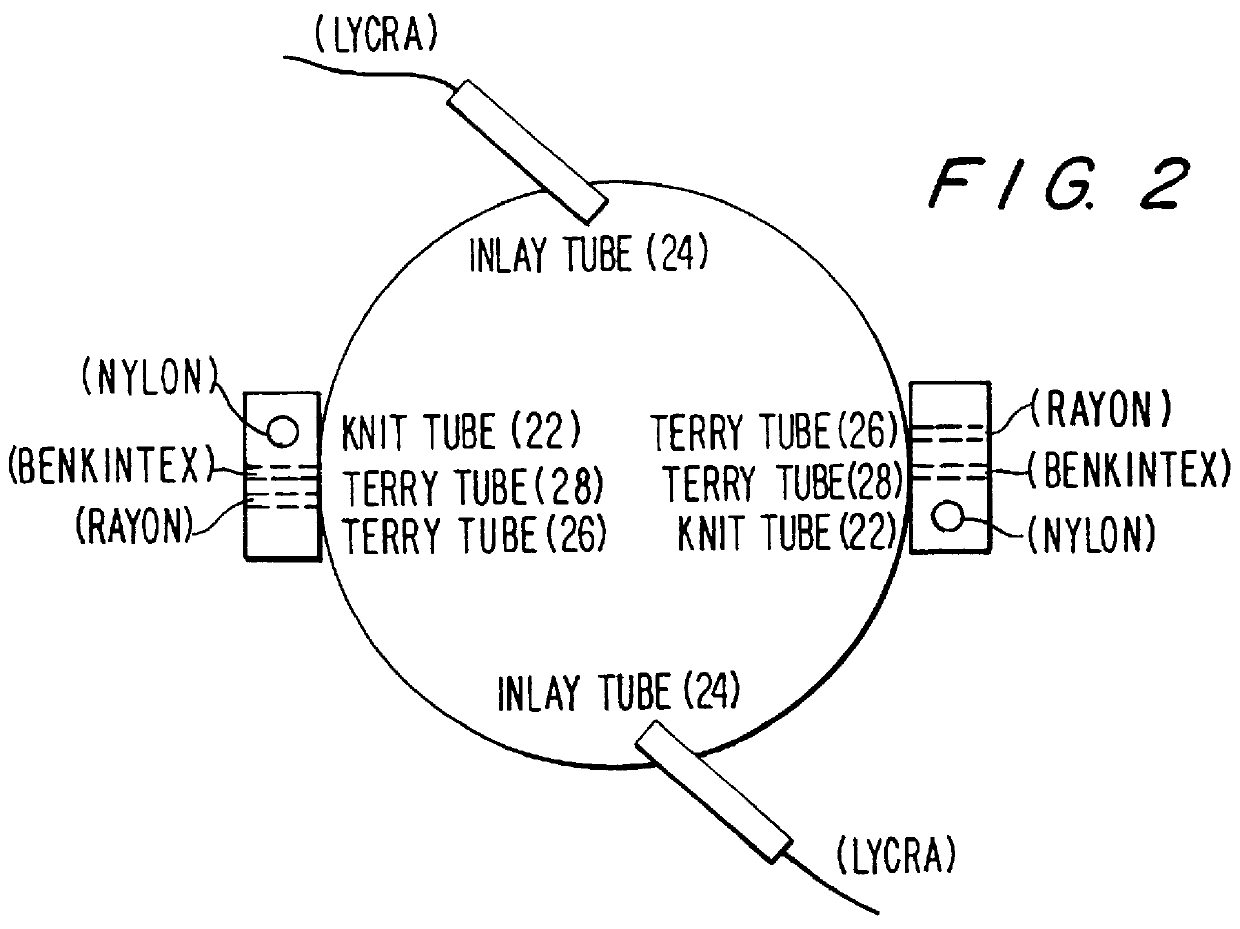

Anti-static roll cover

InactiveUS6120864AEasy to installInexpensive and disposablePhotosensitive materialsSemiconductor/solid-state device manufacturingYarnPolyvinyl acetate

A transfer roll cover has an inner surface made of conductive and elastic material to fit snugly around and make conductive contact with a transfer roll, and an outer surface made of looped yarns which are attached to the inner surface and have outer looped ends which make light rolling contact with a sheet transported over the transfer roll. The looped yarns are a composite of a cleaning yarn for cleaning particulate contaminants and an antistatic yarn for removing static charges from the transported sheet. In a preferred embodiment, the transfer roll cover has an inner surface made of nylon knitted yarn as a base yarn that holds the cover together and a LYCRA TM inlayed yarn which has an elasticity that allows the cover to stretch over and fit snugly onto the transfer roll. As an alternative, a heat-shrinkable polyvinyl acetate (PVA) yarn may be used as the elastic material. The preferred outer surface includes rayon knitted yarn with looped outer ends as the cleaning yarn, and BEKINTEX TM conductive knitted yarn with looped outer ends as the antistatic yarn.

Owner:BBA NONWOVENS SIMPSONVILLE

Hot-pressed veneer adhesive and preparation method thereof

ActiveCN102585736ALow costShort curing timeMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesiveCarvacryl acetate

The invention discloses a hot-pressed veneer adhesive and a preparation method thereof. The hot-pressed veneer adhesive mainly comprises the following components: deionized water, polyvinyl alcohol, an emulsifier, an initiator, methacrylic acid, N-methylol acrylamide, vinyl acetate, a plasticizer, a buffering agent, cassava starch, borax, a dispersing agent, aqueous rosin, a defoaming agent and a corrosion inhibitor. When the hot-pressed veneer adhesive is prepared, the preparation method comprises the following steps of: firstly synthesizing a self-crosslinked polyvinyl acetate copolymerization modified emulsion, then adding 20-35% of raw cassava starch, a crosslinking agent, waterborne tackifying resin and other auxiliaries for mixing and finally preparing the hot-pressed veneer adhesive with excellent performances. Compared with a traditional urea resin veneer adhesive, the adhesive prepared by the invention has the advantages of convenience in use, low curing temperature, short curing time and no harm to an environment and a human body.

Owner:顶立新材料科技股份有限公司

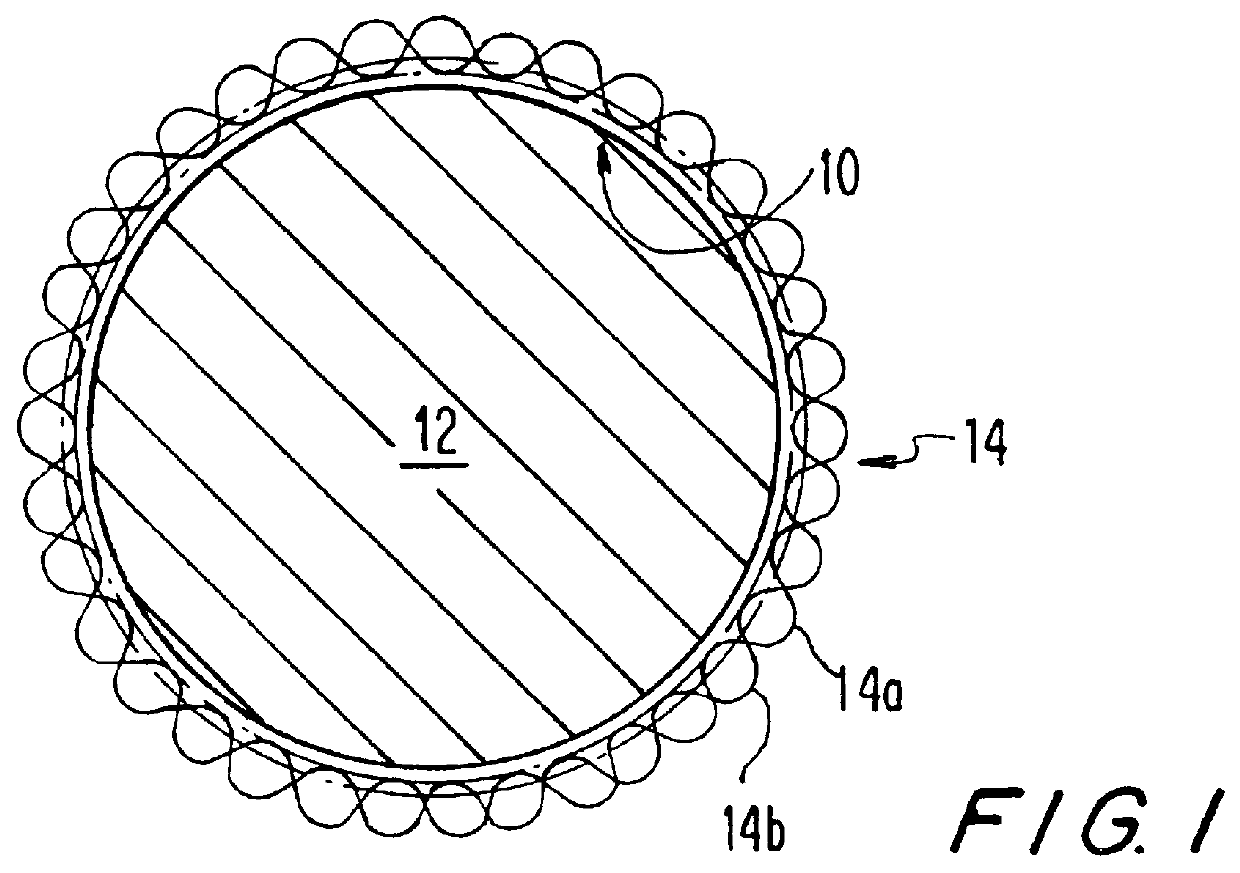

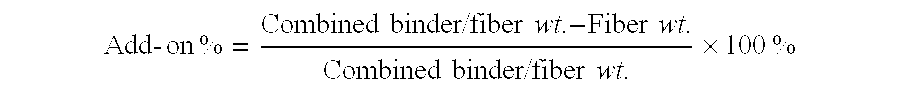

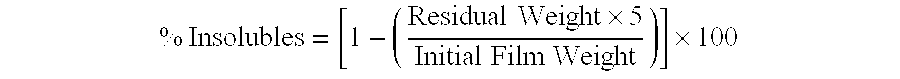

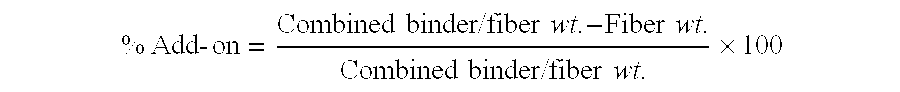

High strength polyvinyl acetate binders

InactiveUS20070184732A1Excellent tensile strength performanceEasy curingFibre treatmentSynthetic resin layered productsMonomer compositionEmulsion

A binder composition for fibrous substrates that includes a low-pressure polymerized emulsion resin comprising vinyl acetate monomer units and post-crosslinking monomer composition. The inventive compositions enable fibrous substrates with high tensile strengths and excellent curability, and are particularly useful as binders in synthetic fiberfill applications.

Owner:CELANESE INT CORP

Polymer lithium ion battery core outer package forming material

InactiveCN102431239AImprove shielding effectNot easy to peel offSynthetic resin layered productsMetal layered productsHigh resistancePolyvinyl alcohol

The invention provides a polymer lithium ion battery core outer package forming material, and aims at providing a battery core outer package forming material with the advantages that the blocking performance is very high, the cold punching forming performance is good, and puncture resistance, electrolyte resistance stability and organic solvent and high-volatile substance resistance can be realized. An outer resistance layer lamination layer body is formed by at least one layer of heat resistance resin film: any one material from polyethylene glycol terephthalate (PET), biaxially oriented polyamide (BOPA) and polyethylene naphthalate (PEN) or coexistence of two materials from PET, BOPA and PEN through co-extrusion compounding, aluminum foils in a resistance permeation layer lamination body at least comprise 0.9 weight percent to 1.5 weight percent of Fe, a high-resistance layer lamination body comprises a base layer, a function layer and a hot sealing layer, the base layer is a co-polymer film formed by paired compounding or the combination of at least two kinds of film substrates in polystyrene (PP), chlorinated polypropylene (CPP), polyurethane (PE), PET, polyamide (PA) or metaxylylene diamine (MPE) elastic body polymer blends, polyvinyl dichloride (PVDC), ethylene vinyl silane (EVOH), PEN and transpeptidase (GT), and a high-resistance water-resistance modified polyvinyl acetate (PVA) coating film is respectively coated on the co-polymer film substrate. The polymer lithium ion battery core outer package forming material revolutionarily solves the electrolyte resistance stability problem.

Owner:刘继福

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com