Patents

Literature

23004 results about "Dyeing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

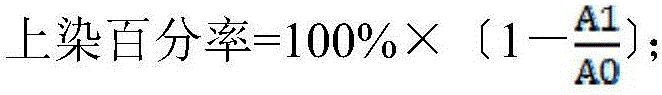

Dyeing is the application of dyes or pigments on textile materials such as fibers, yarns, and fabrics with the goal of achieving color with desired color fastness. Dyeing is normally done in a special solution containing dyes and particular chemical material. Dye molecules are fixed to the fibre by absorption, diffusion, or bonding with temperature and time being key controlling factors. The bond between dye molecule and fibre may be strong or weak, depending on the dye used. Dyeing and printing are different applications; in printing color is applied to a localized area with desired patterns and in dyeing it is applied to the entire textile.

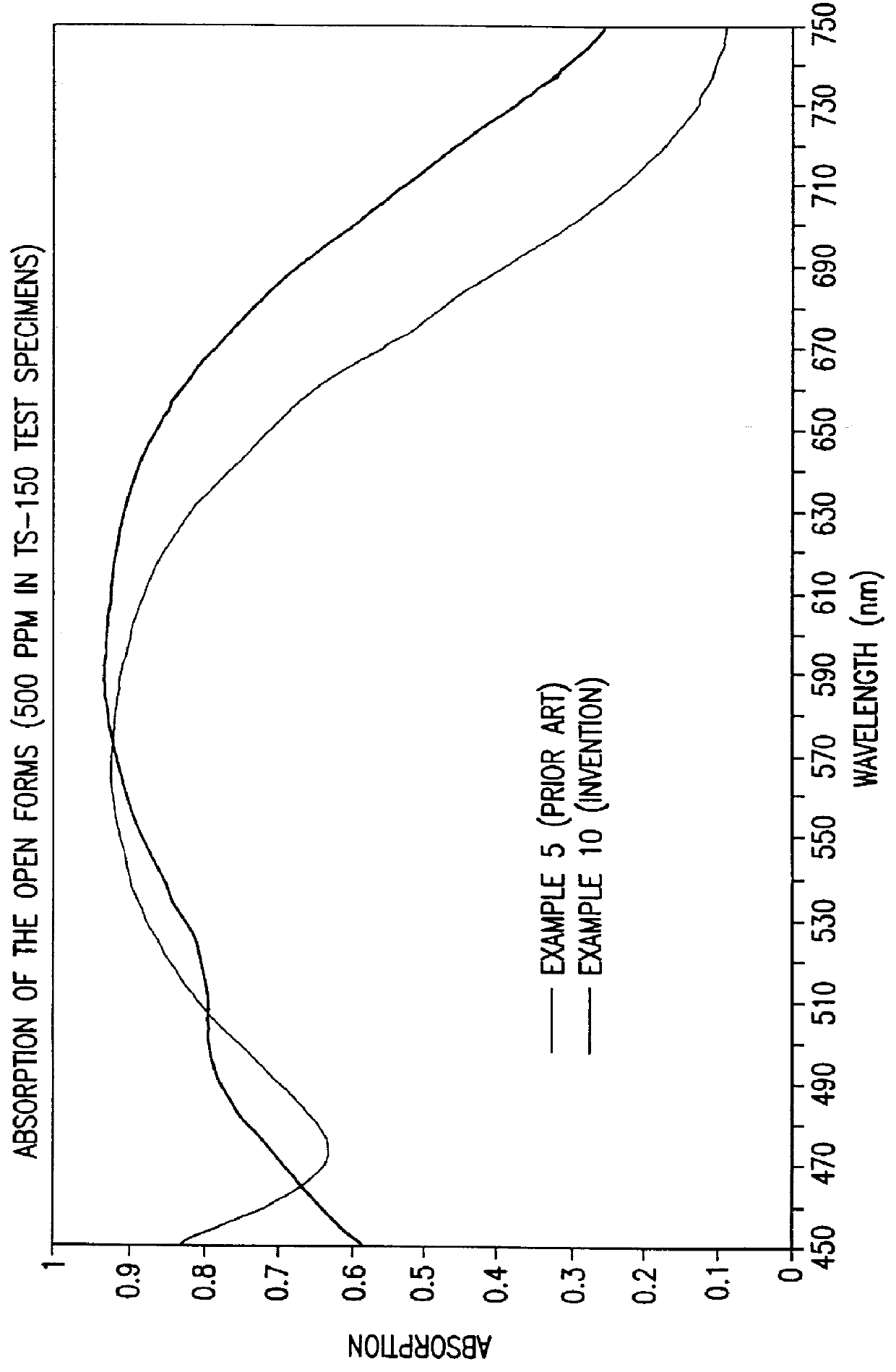

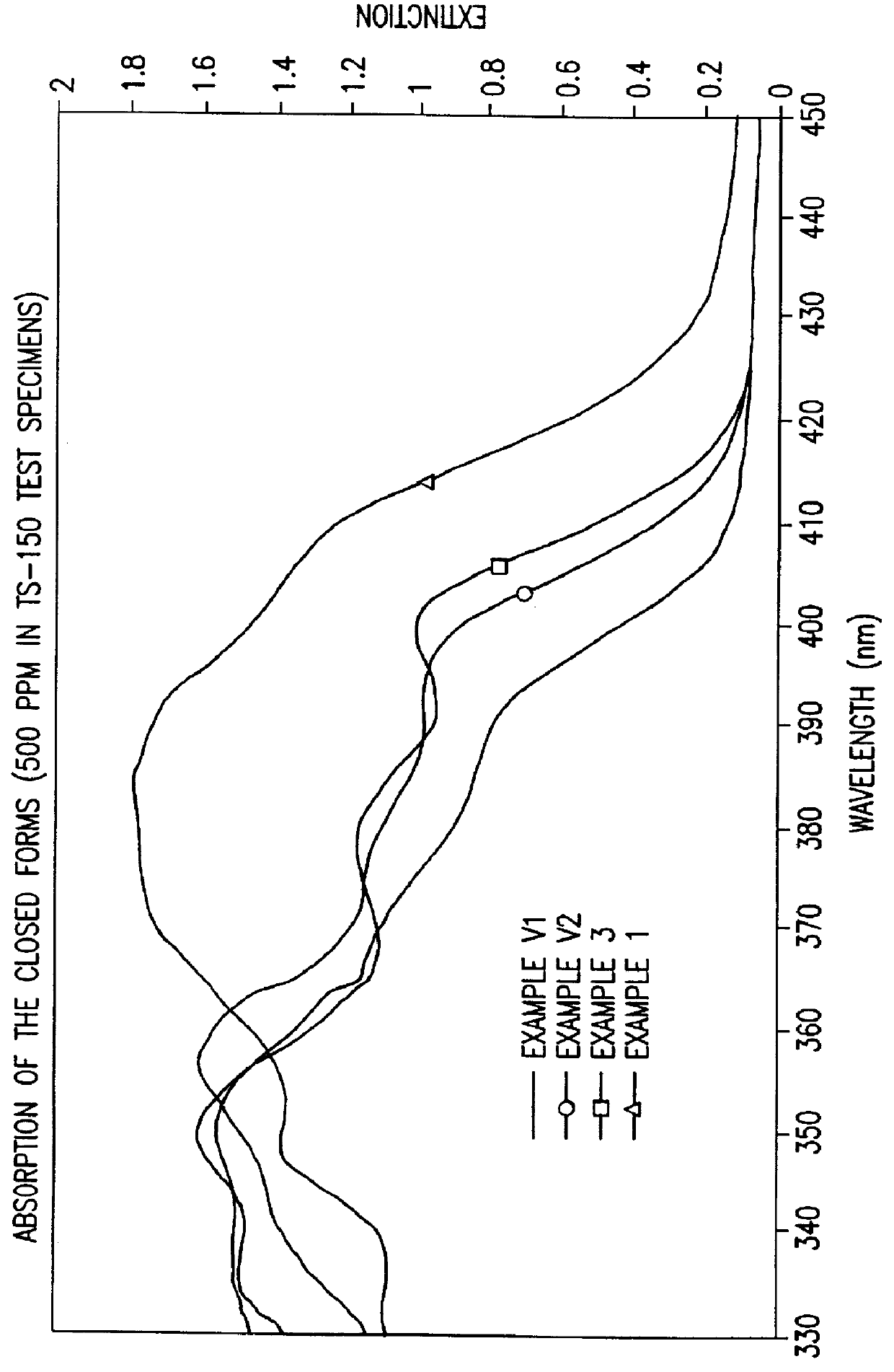

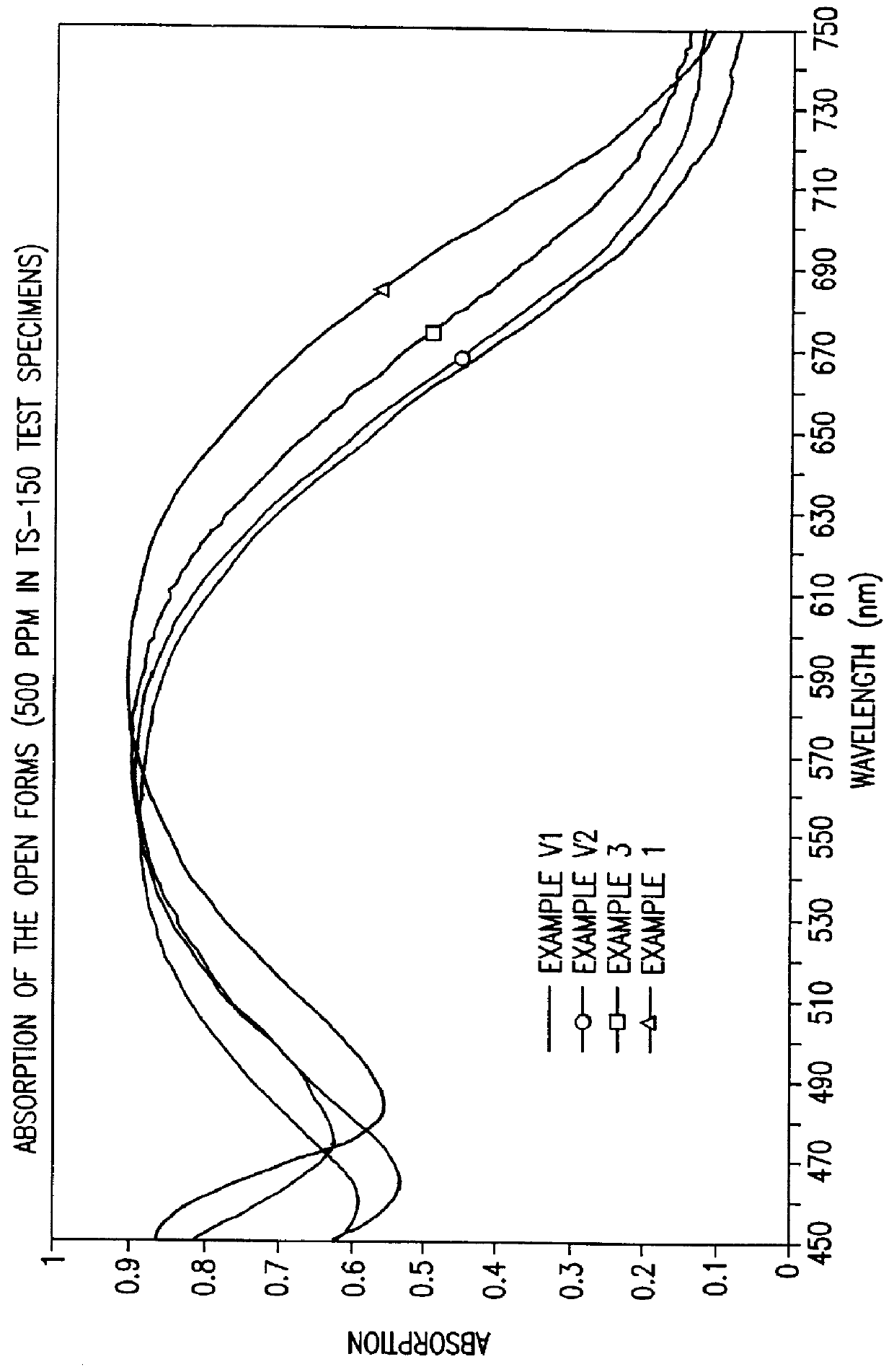

Photochromic naphtopyrane colorants, method for the production and use thereof, photochromic object

PCT No. PCT / DE98 / 02820 Sec. 371 Date May 21, 1999 Sec. 102(e) Date May 21, 1999 PCT Filed Sep. 22, 1998 PCT Pub. No. WO99 / 15518 PCT Pub. Date Apr. 1, 1999What is described here are photochromic naphthopyrane dyes with different substituents whose properties can be set by controlled selection of the substituents. In this manner it is possible to take an influence on the migration characteristics, the absorption characteristics and the brightening rate and kinetics. The inventive compounds display good darkening and brightening properties at a very good service life. The invention excels itself by the fact that a method is made available which is substantially improved over prior art, in addition to the surprising influence on specific properties of the inventive compounds. The described compounds are suitable for application in synthetic materials of any kind. A photochromic object is also the subject matter of the invention, which comprises one or several photochromic naphthopyrane dyes as well as at least one polymer material, with the photochromic object being producible by mass-dyeing or superficial dyeing.

Owner:RODENSTOCK GMBH

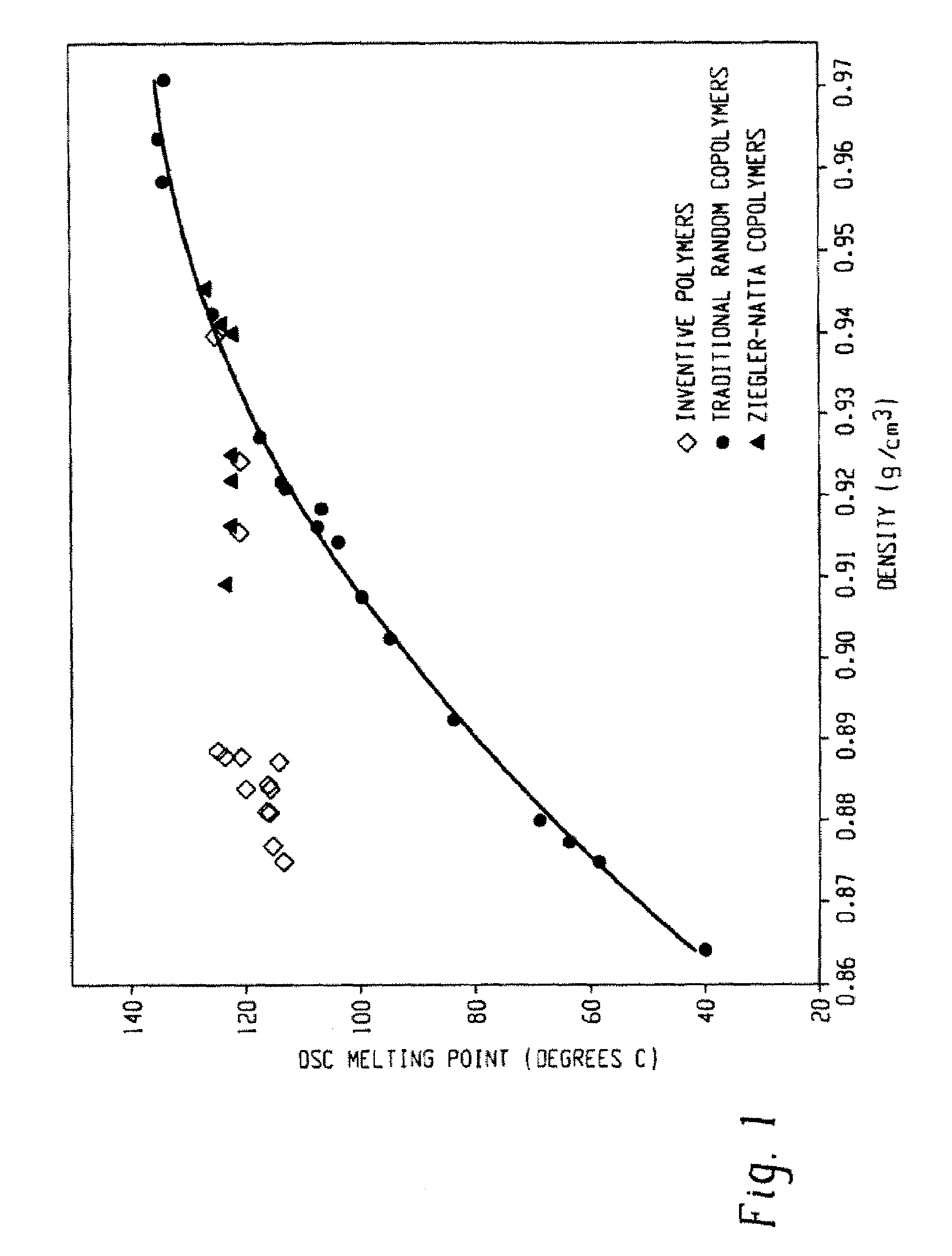

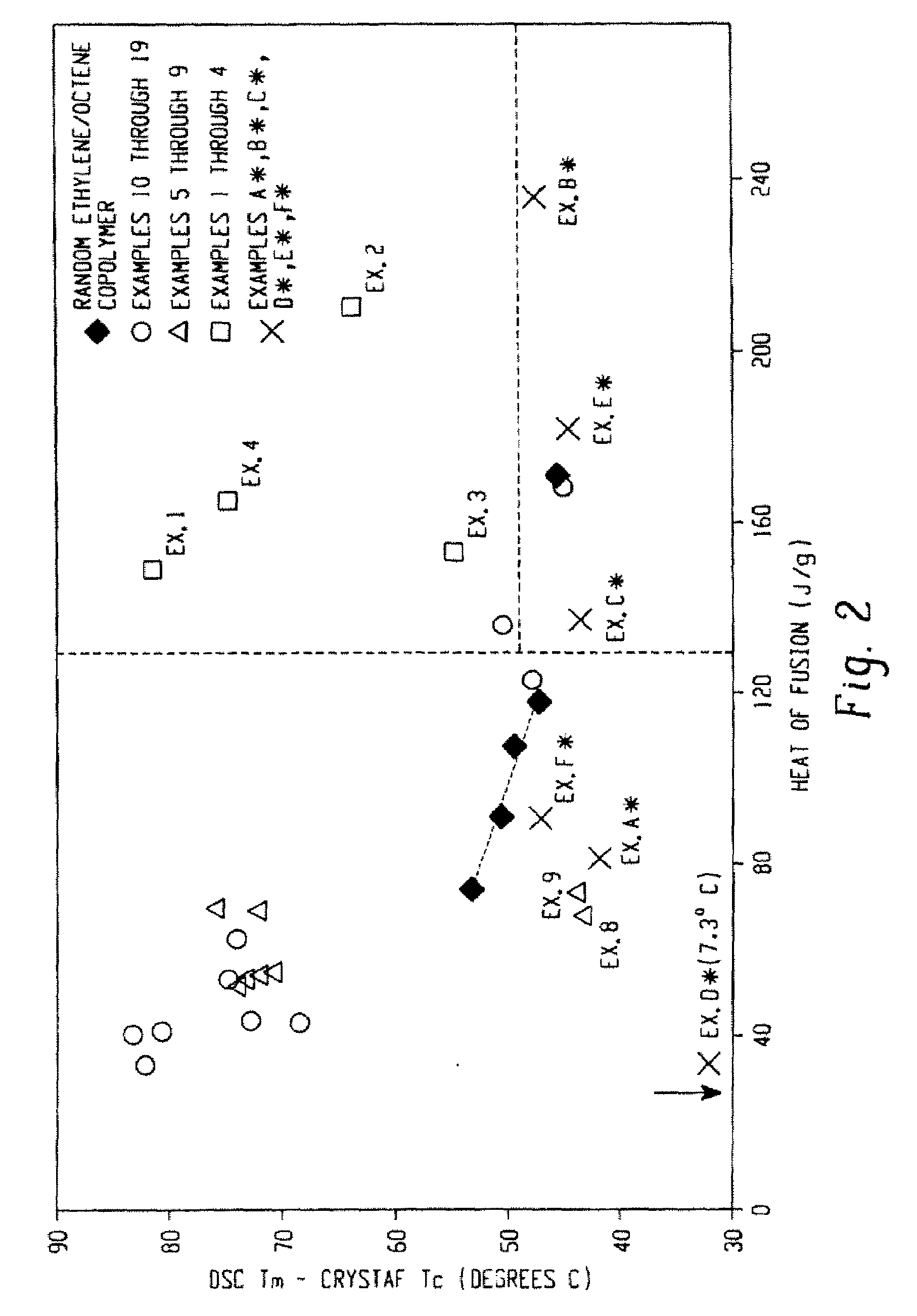

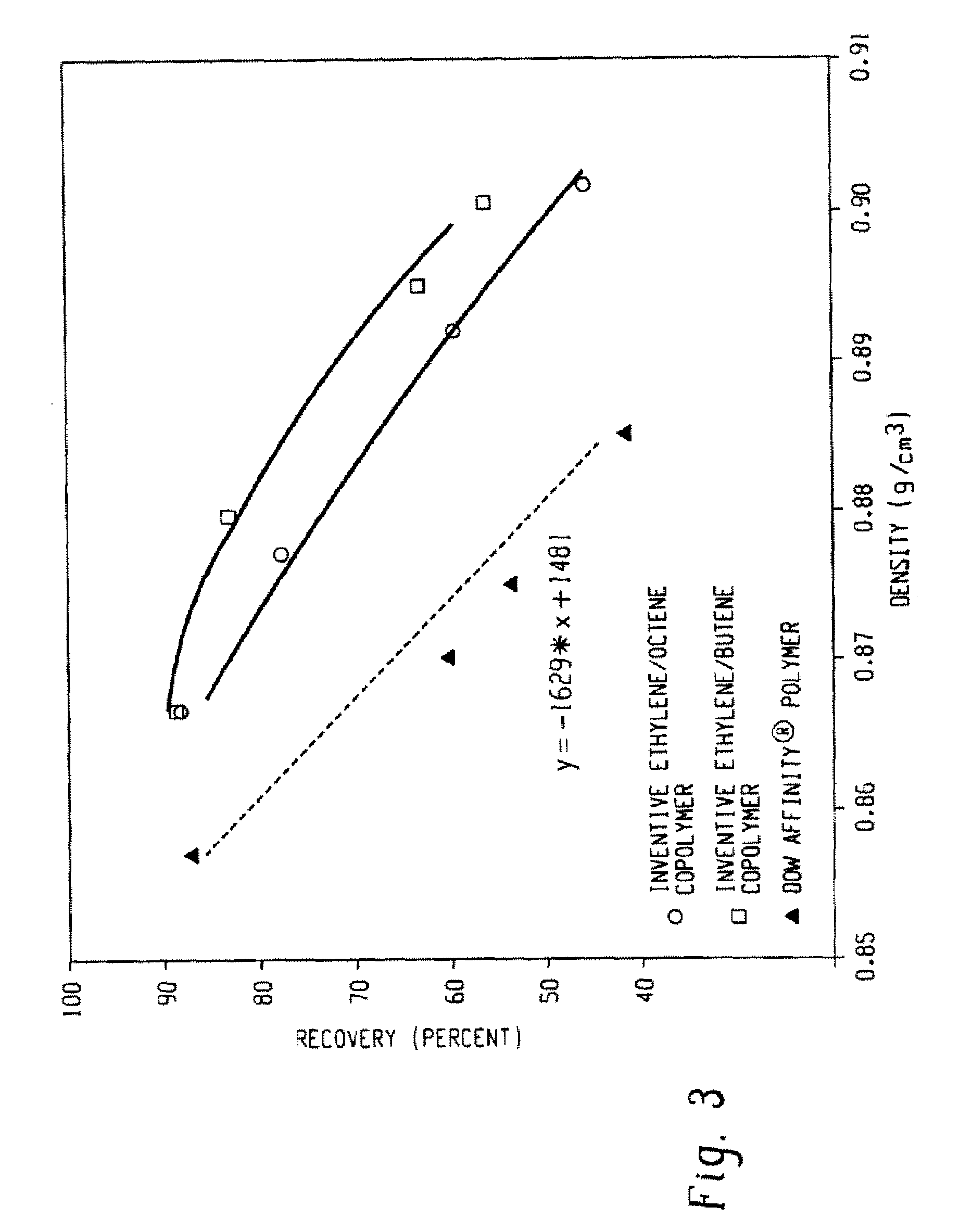

Olefin block compositions for heavy weight stretch fabrics

InactiveUS20080299857A1Improved ratio of stretch to growthHigh temperature toleranceMonocomponent synthetic polymer artificial filamentWoven fabricsSquare yardHeavy weight

Heavy weight stretch fabrics comprising ethylene / α-olefin interpolymer are described. The fabric often has a weight of at least 10 ounces per square yard measured according to ASTM 3776 and has a stretch of at least 10 percent measured according to ASTM D3107. These fabrics exhibit excellent chemical, resistance (for example chlorine or caustic resistance) and durability, that is they retain their shape and feel over repeated exposure to processing conditions, such as stone-washing, dye-stripping, PET-dyeing and the like, and industrial laundry conditions.

Owner:DOW GLOBAL TECH LLC

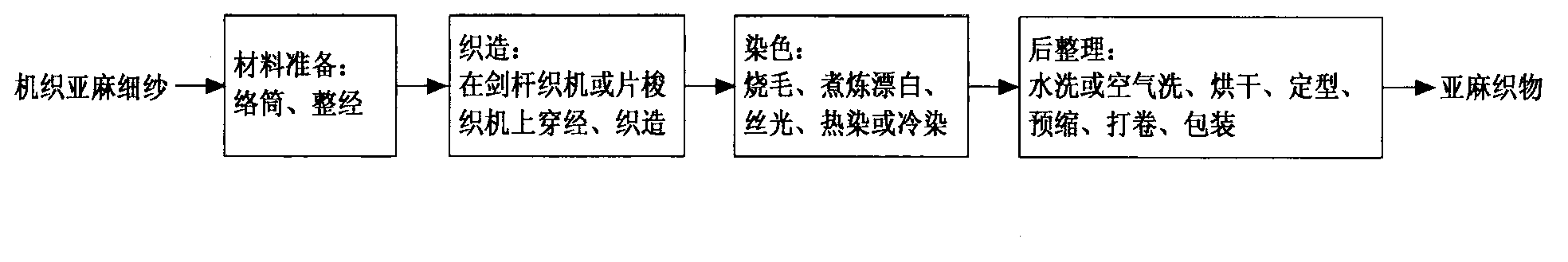

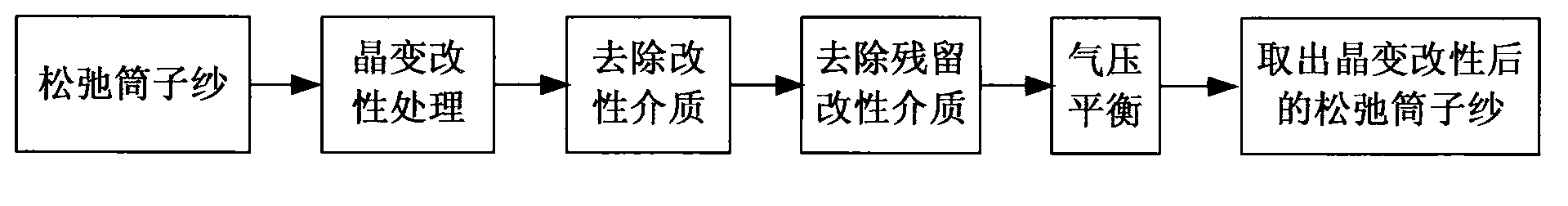

High-grade flax fabric weaving method based on crystallized and modified flax yarns

InactiveCN102839508ASoft textureImprove evennessLiquid/gas/vapor treatment of definite length materialsWoven fabricsAir-jet loomPulp and paper industry

The invention provides a high-grade flax fabric weaving method based on crystallized and modified flax yarns. The method comprises the following steps: in the material preparing stage, woven flax spun yarns are subjected to relaxation and winding, so as to form relaxed yarns on cones; the relaxed yarns on cones are subjected to crystallization and modification treatment; the crystallized and modified relaxed yarns on cones are simultaneously subjected to winding, electronic yarn clearing and waxing, so that weaving yarns on cones are obtained; the weaving yarns on cones are subjected to warping according to the quantity of warp yarns; in the weaving stage, flax grey cloth is woven by taking the weaving yarns on cones as weft yarns, the warp yarns after warping as warp yarns, and drawing weft and warp yarns in an air jet loom; in the dyeing stage, the woven flax grey cloth is subjected to hot dyeing or cold dyeing; in the after finishing stage, the dyed flax grey cloth is rinsed, dried, finalized, preshrunk, wound and packaged to form the high-grade flax fabric. According to the high-grade flax fabric weaving method, the bottleneck of wearability of traditional flax fabric is solved, the flax fabric is enabled to obtain the sense of cotton, the production efficiency is improved, the production cost is reduced, and the energy conservation and emission reduction in the production process are realized.

Owner:DONGHUA UNIV +1

Graphene blend regenerated cellulose fiber and preparation method thereof

ActiveCN103046151AImprove conductivityImprove thermal performanceArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentMoisture absorptionCellulose fiber

The invention relates to a graphene blend regenerated cellulose fiber. The graphene blend regenerated cellulose fiber is prepared by mixing an oxidized graphene solution and a regenerated cellulose solution, molding a mixture through a viscose wet spinning process and reducing the mixture; the dry breaking strength of the graphene blend regenerated cellulose fiber is not less than 1.8 cN / dtex, the wet breaking strength of the graphene blend regenerated cellulose fiber is not less than 0.9 cN / dtex, the dry breaking elongation of the graphene blend regenerated cellulose fiber is not less than 16%, the mass specific resistance of the fiber is 1-9X106 omega.g / cm2, and the thermal decomposition temperature of the fiber is not lower than 400 DEG C; and with the regenerated cellulose fiber as a matrix, the prepared graphene blend regenerated cellulose fiber has the advantages of good moisture absorption, good air permeability, soft handle and good dyeing performance and has the characteristics of ultrahigh strength, thermal conductivity, electric conductivity, antibacterial property and the like of the graphene; the conductive and thermal properties of the fiber are both improved by being compared with those of the traditional regenerated cellulose fiber; the antibacterial property of the fiber is additionally provided; and the graphene blend regenerated cellulose fiber provided by the invention has the advantages of simple production process, easiness in operation, and higher yield. People estimate that the developed graphene blend regenerated cellulose fiber can be widely applied to the field of costumes, industrial textiles and the like.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG +1

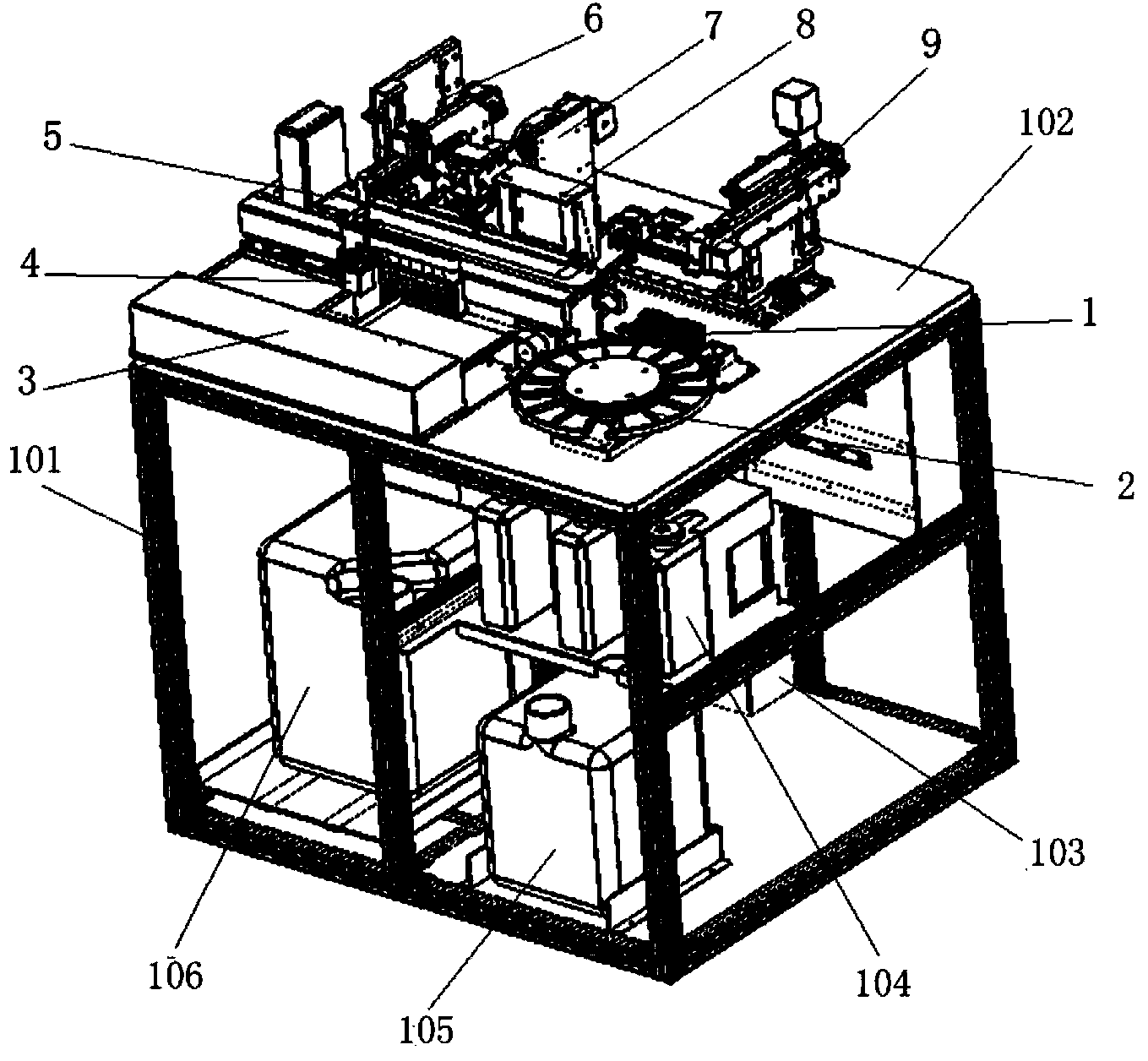

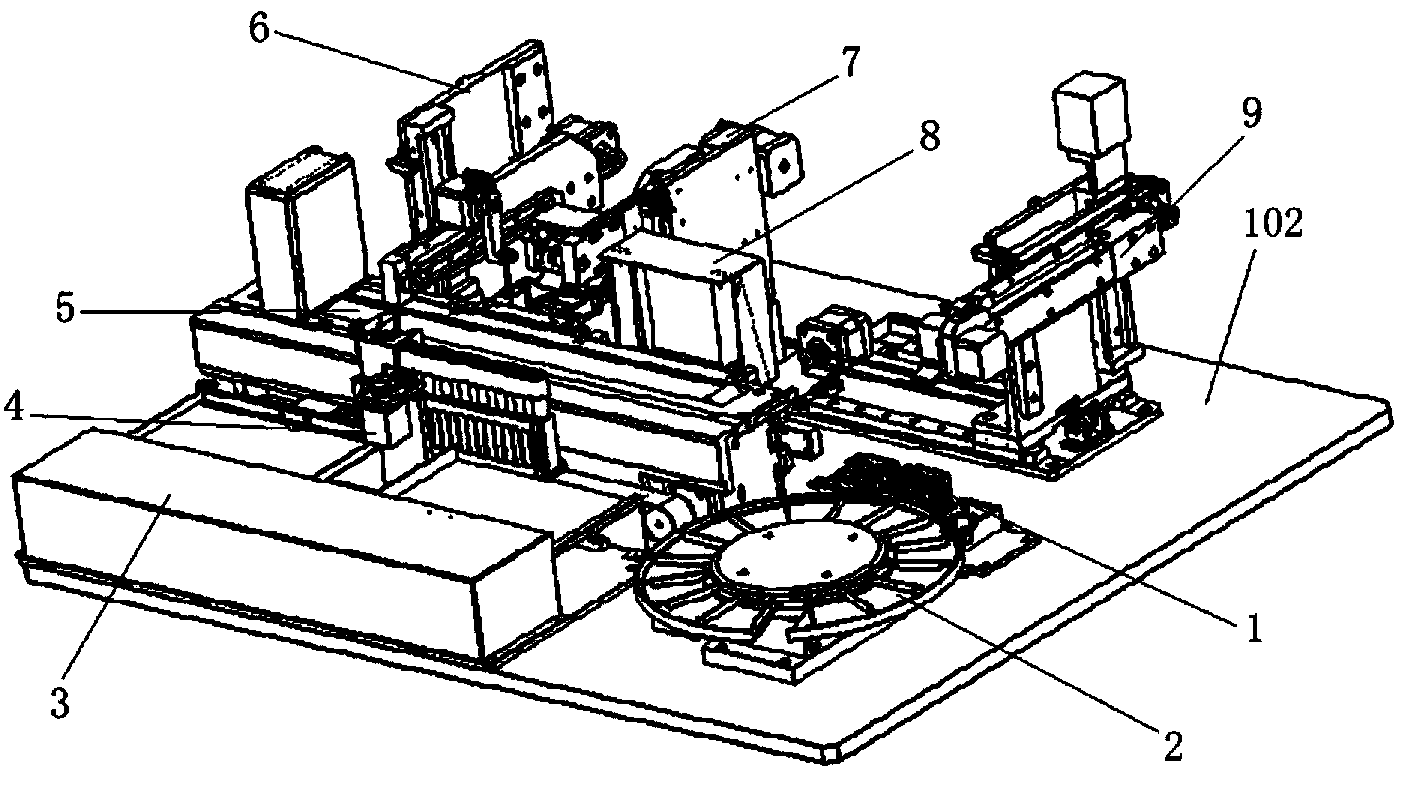

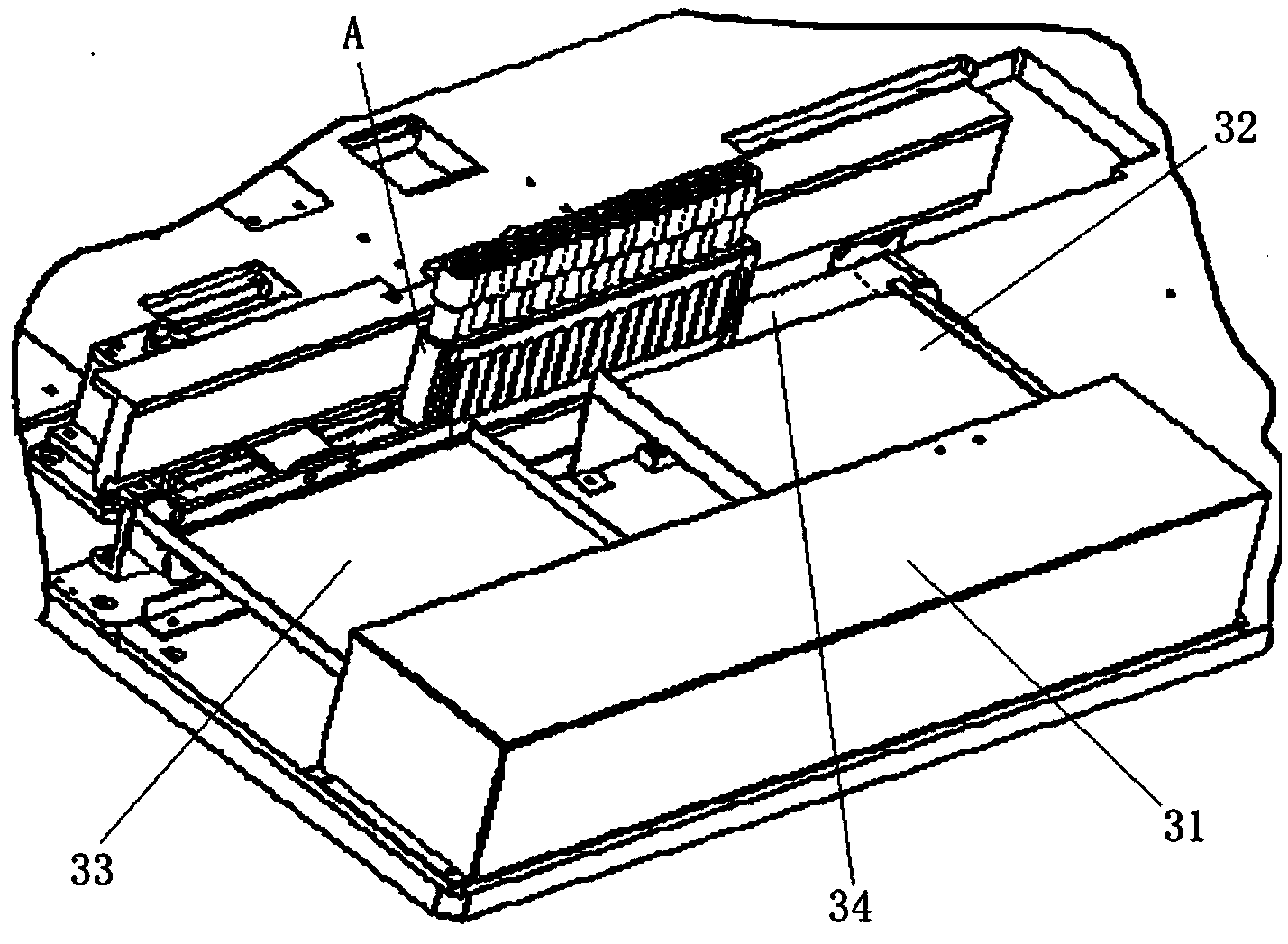

Full-automatic medical examination blood piece pushing and dyeing machine

ActiveCN103364242AAvoid confusionGuaranteed reliabilityPreparing sample for investigationControl systemBarcode

The invention provides a full-automatic medical examination blood piece pushing and dyeing machine to solve the problems of a medical examination blood piece pushing and dyeing technology in the prior art that the manual operation ratio is high, the labor intensity is great, the confusion is easy to cause, the examination quality is difficult to completely guarantee and the like. The full-automatic medical examination blood piece pushing and dyeing machine comprises a rack, a base plate, a test tube conveying device, a barcode reading device, a glass slide conveying device, a sample coating device, a piece pushing device, a printing device, a glass slide transferring device, a dyeing device, a glass slide collecting device, a control system, a dyeing solution container, a washing solution container and a waste solution container. The full-automatic medical examination blood piece pushing and dyeing machine disclosed by the invention has the beneficial technical effects that a flow line of test tube conveying, barcode reading, glass slide conveying, blood sample coating, barcode information printing, sample dyeing and glass slide collection is formed so that the operations of uniform mixing, coating, piece pushing, dyeing and collection of a blood sample can be automatically finished, samples can be prevented from being confused and the detection reliability is guaranteed.

Owner:四川丹诺迪科技有限公司

Fabric coating dyeing process

InactiveCN1936148ASimple pad dyeing processSave energyHeating/cooling textile fabricsDyeing processAdhesiveSurface-active agents

The invention relates to a fabric pigment dyeing technology. The dye liquor is made up of dope color paste, anode ion modifying agent, surface active agent, pH regulator and adhesive. After mixing equal according to certain order, the dye liquor would be used to take pad dyeing, and the pigment dyeing fabric product would be gained after drying and fixation. The invention has the advantages of good color deepness and vividness, low consumption of adhesive and improved handle of fabric.

Owner:SUNVIM GROUP

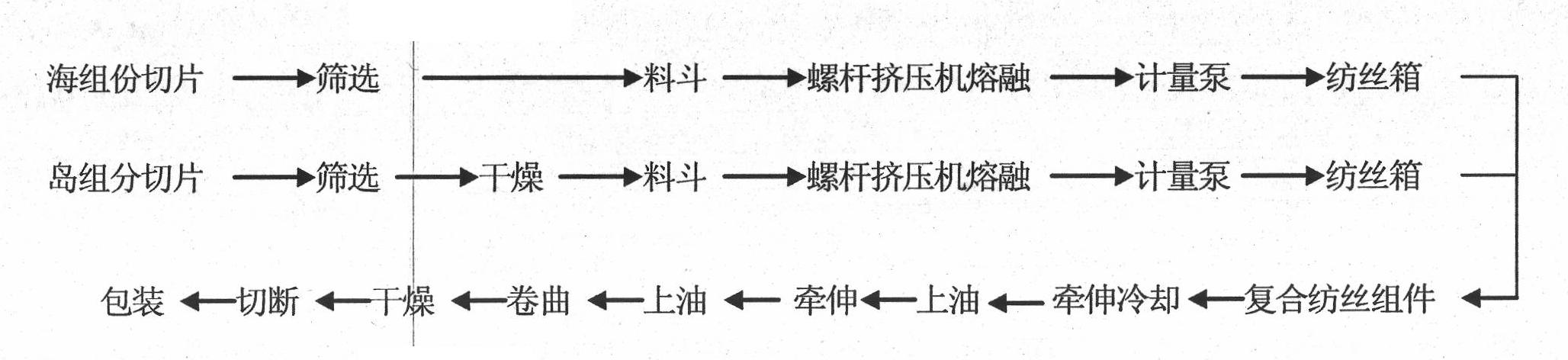

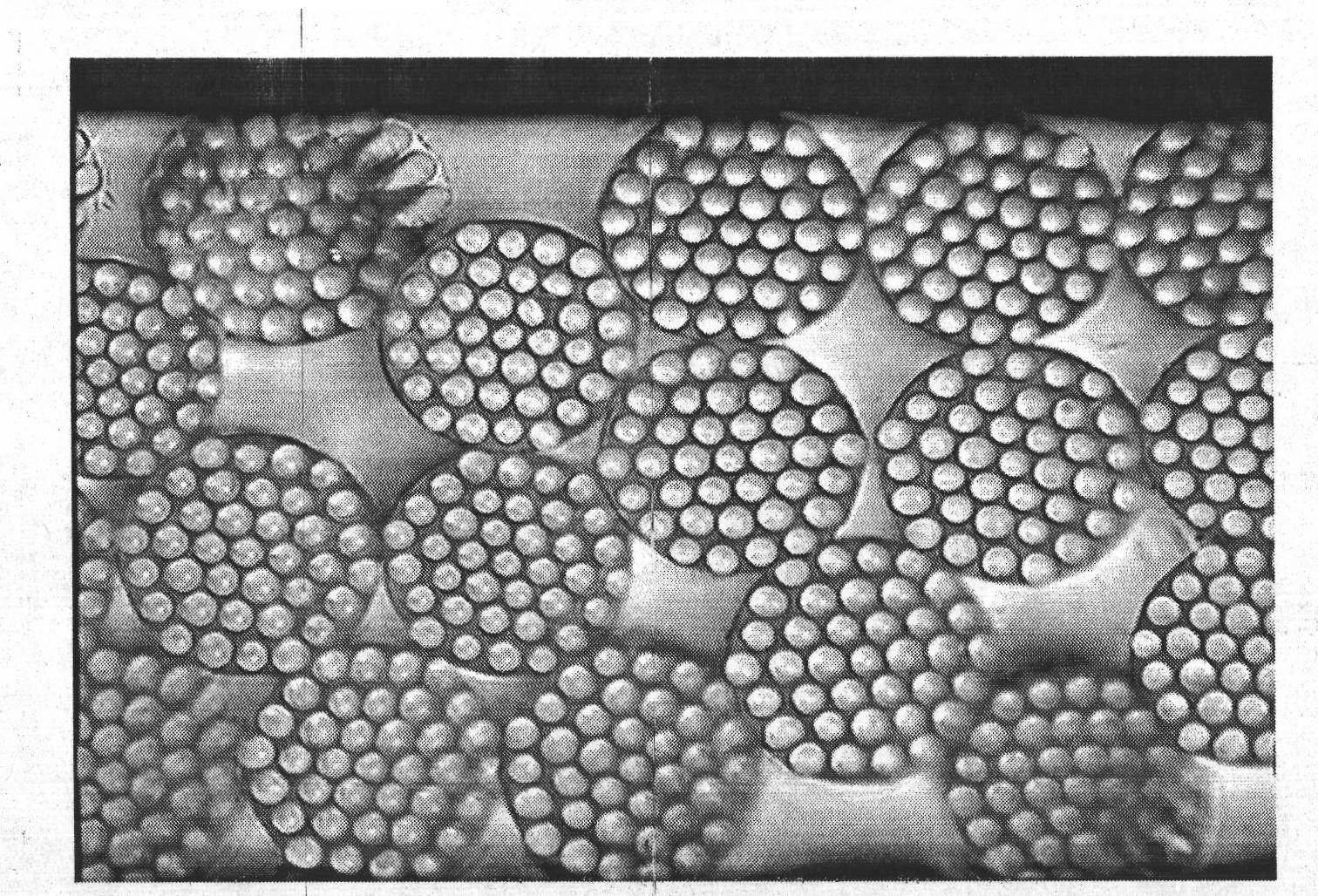

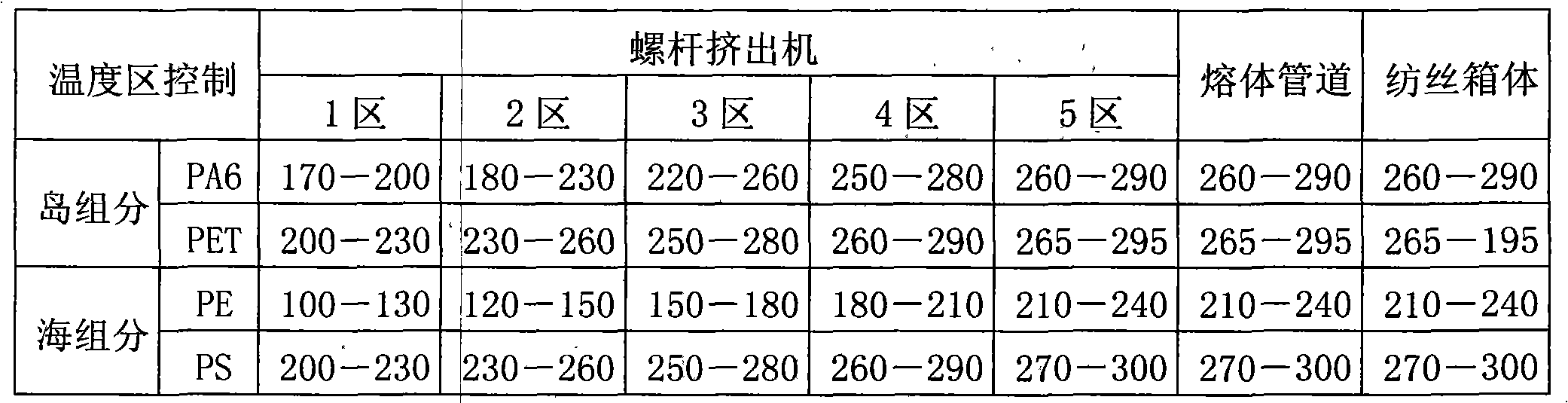

Sea-island typed conjugate multi filament comprising dope dyeing component and a process of preparing for the same

InactiveUS6838172B2Improve shrinkageImprove fastnessFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterYarn

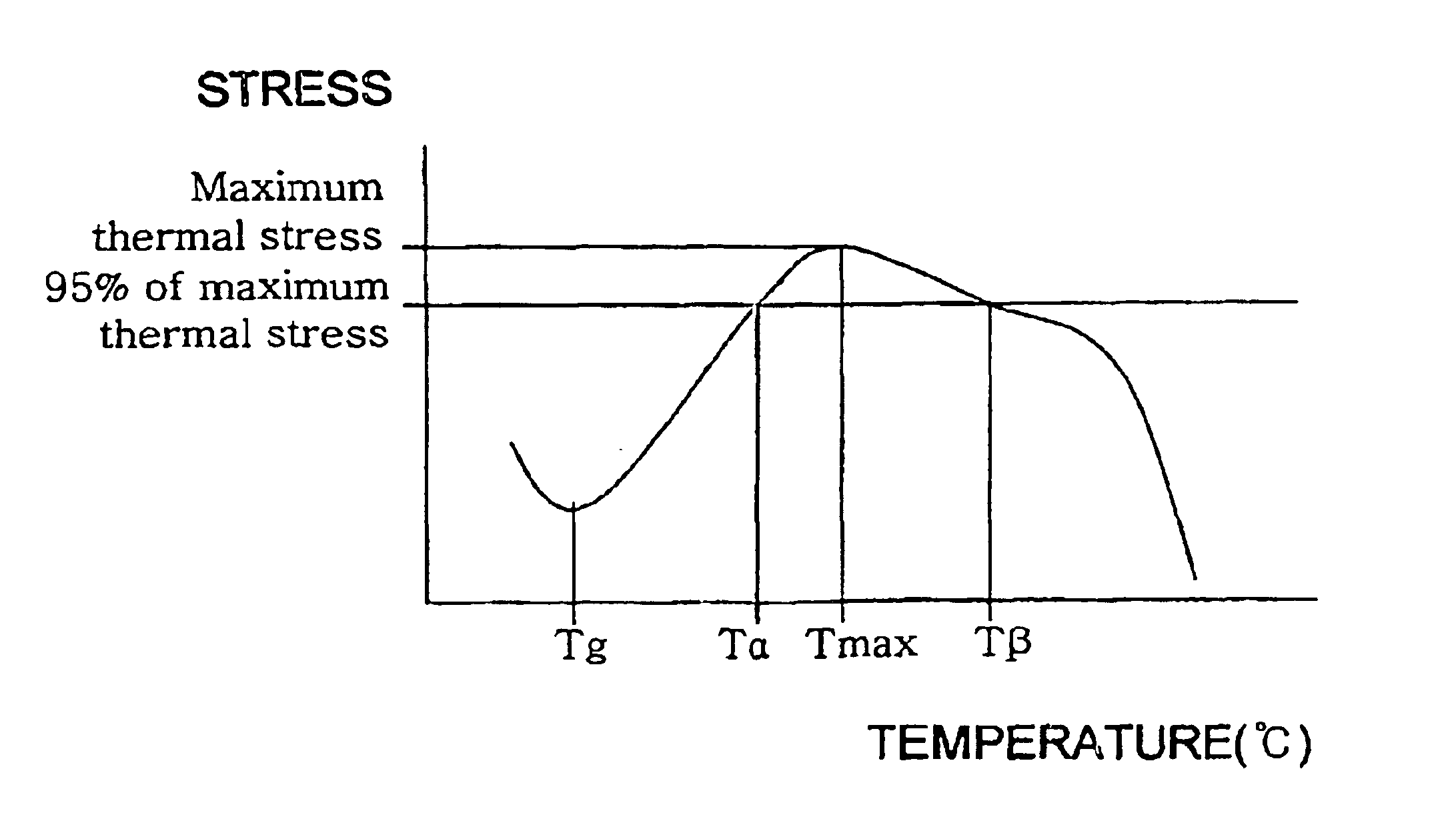

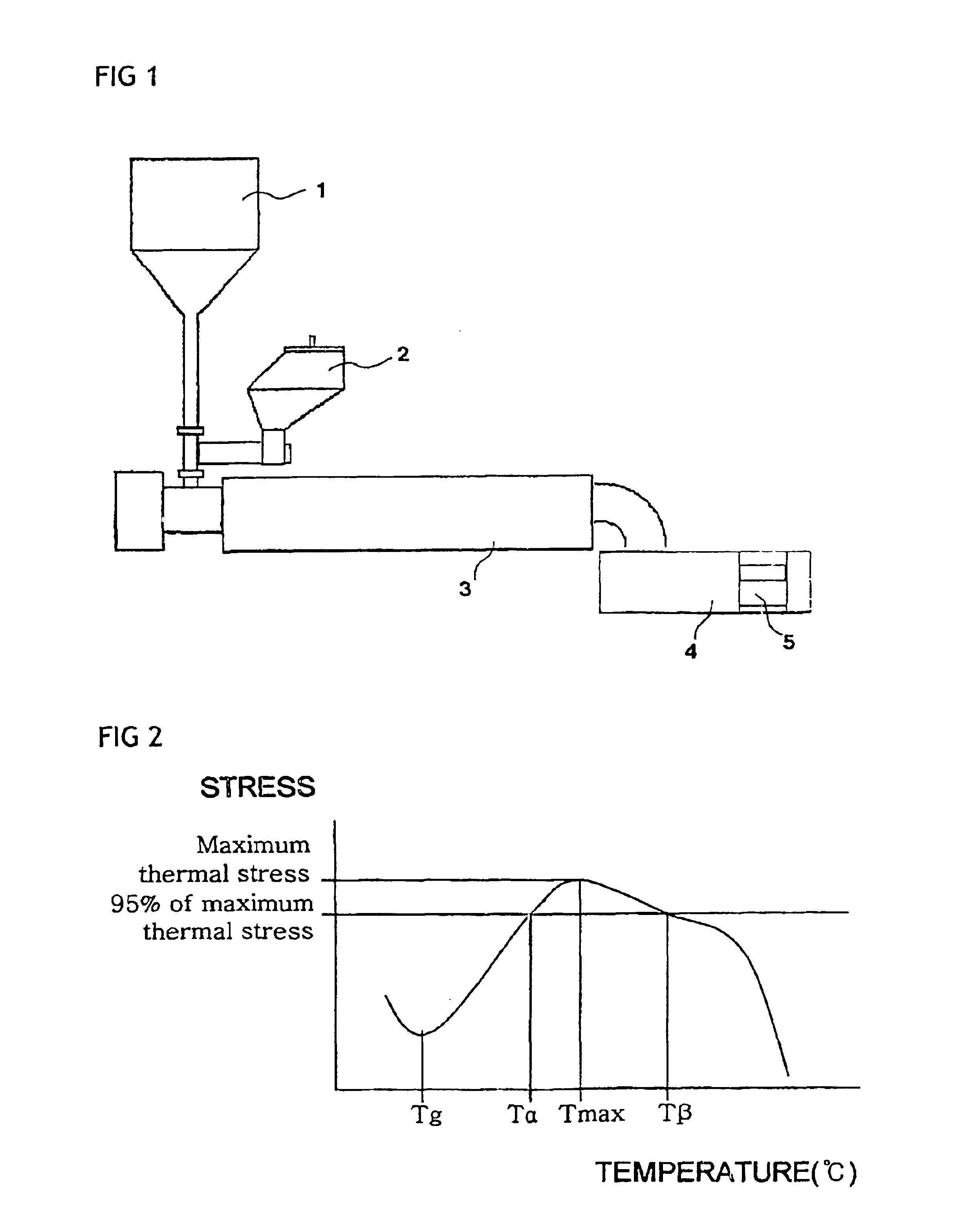

The present invention relates to a dope dyed sea-island type conjugate multifilament. In the dope dyed sea-island type conjugate multifilament, which comprises easy soluble polymer as a sea component and polyester as an island component, the island component contains a dope dyed component selected from the group consisting of carbon black, pigments and dyestuffs and the temperature range (Tα-Tβ) showing more than 95% of the maximum thermal stress of yarns is from 120° C. to 210° C. The dope dyed sea-island type conjugate multifilament of the present invention has an excellent thermal shrinkage property and excellent wash fastness and light fastness, and the dyeing process thereof can be omitted after producing a woven or knitted fabric because a dope dyed component is contained in the island component (ultra fine yarn). The dope dyed sea-island type conjugate multifilament of the present invention is useful as yarns for warp knit fabrics used in production of women's apparel.

Owner:KOLON IND INC

Waterborne polyurethane resin superfiber leather and manufacturing method thereof

ActiveCN101725052ASimple production processReduce pollutionFibre treatmentSynthetic resin layered productsPolyvinyl alcoholSolvent

The invention relates to polyurethane resin superfiber leather and a manufacturing method thereof, belonging to the technical field of manufacturing methods. The manufacturing method is characterized by comprising the steps of sea-island fiber, non-woven fabrics, polyvinyl alcohol impregnation or hot-pressing and ironing out, original cloth processing, impregnation and coating of polyurethane, thermal coagulation, reduction amount of base, basic cloth, dyeing or embossment of grinding surfaces and inspection and warehousing. The polyurethane resin superfiber leather can be obtained by using the method. Compared with solvent type polyurethane, the waterborne polyurethane resin superfiber leather has equivalent physical properties, accords with application requirement, uses the environment-friendly polyurethane resin and has no organic solvent harmful to the environment; a DMF reclamation step is required by solvent type products in the production process so as to simplify the production process; and the polyurethane resin superfiber leather is energy-saving and environment-friendly, meets the limiting requirement on an environment-friendly polyurethane synthetic leather at abroad, reduces the demand quantity of producers, the harm to the producers as well as the production cost and has strong market competitiveness.

Owner:烟台万华超纤股份有限公司 +1

High-strength stretch-proof flame-retardant textile

InactiveCN101748549ASolve the difficulty of weavingSolve not easy to dyeWoven fabricsYarnCompound aEngineering

The invention provides a high-strength stretch-proof flame-retardant textile. The flame-retardant textile is formed by weaving a flame-retardant composite yarn, wherein the flame-retardant composite yarn is formed by compounding a core yarn and a leather yarn and is one of a covering yarn and a fasciated yarn; the core yarn adopts a flame-retardant filament yarn as a raw material; the leather yarn adopts a flame-retardant short fiber as a raw material; and the weight ratio of the flame-retardant filament yarn to the flame-retardant short fiber is 30-90:10-70. Compared with the conventional flame-retardant textile, the high-strength stretch-proof flame-retardant textile has higher strength and overcomes the defects of difficult weaving, difficult dyeing and uncomfortableness of the high-strength fiber; the high-strength stretch-proof flame-retardant textile has permanent flame retardance which cannot decrease after the textile is washed, and better textile strength; the textile has soft and comfortable handfeel, rich color and good strength, meets the requirements of various flame-retardant clothes and related standards; the product has rich and varied appearances and is durable; and the combustion performance of the textile can meet the national standards of flame-retardant products.

Owner:汕头市奥山服饰有限公司

Microcapsules of essential oil from fragrant plants and preparation thereof

InactiveCN1680519AEasy to useEasy to storeEssential-oils/perfumesMicroballoon preparationOil phaseAromatic plants

The invention opened a process to produce the micro-capsule of aromatic plant essential oil. The micro-capsule is made up of aromatic plant essential oil and capsule material. The particle size is 10-30um; the process is: first to dissolve the capsule material, then to dissolve the surface activator in the water phase or the oil phase, next to stir to get the latex emulsion, last to get the product by the spray drier. The product can be used to food, medicine, cosmetic, printing and dyeing and coatings.

Owner:新疆芳香植物科技开发股份有限公司 +1

Ultraviolet light curing printing ink for digital printing and dyeing preparation thereof

UV solidified printing ink for digital code printing and dyeing is composed of polyurethane acrylate, prepolymer, activity monomer, dyestuff, light initiator, dispersant agent and other addition agents. The prepolymer has the character of low viscosity and good flexibility. The ink doesn't contain organic solvent and has wide material adaptation, storage stability and softness.

Owner:DONGHUA UNIV

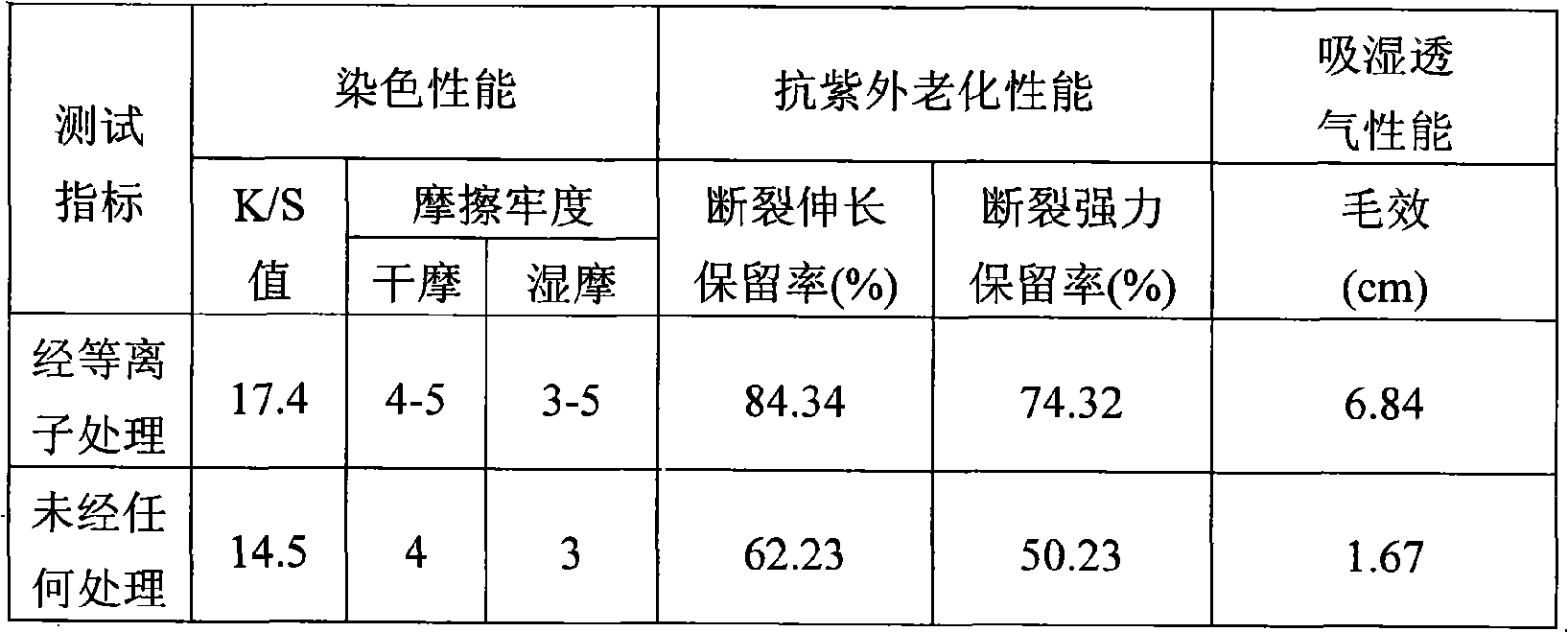

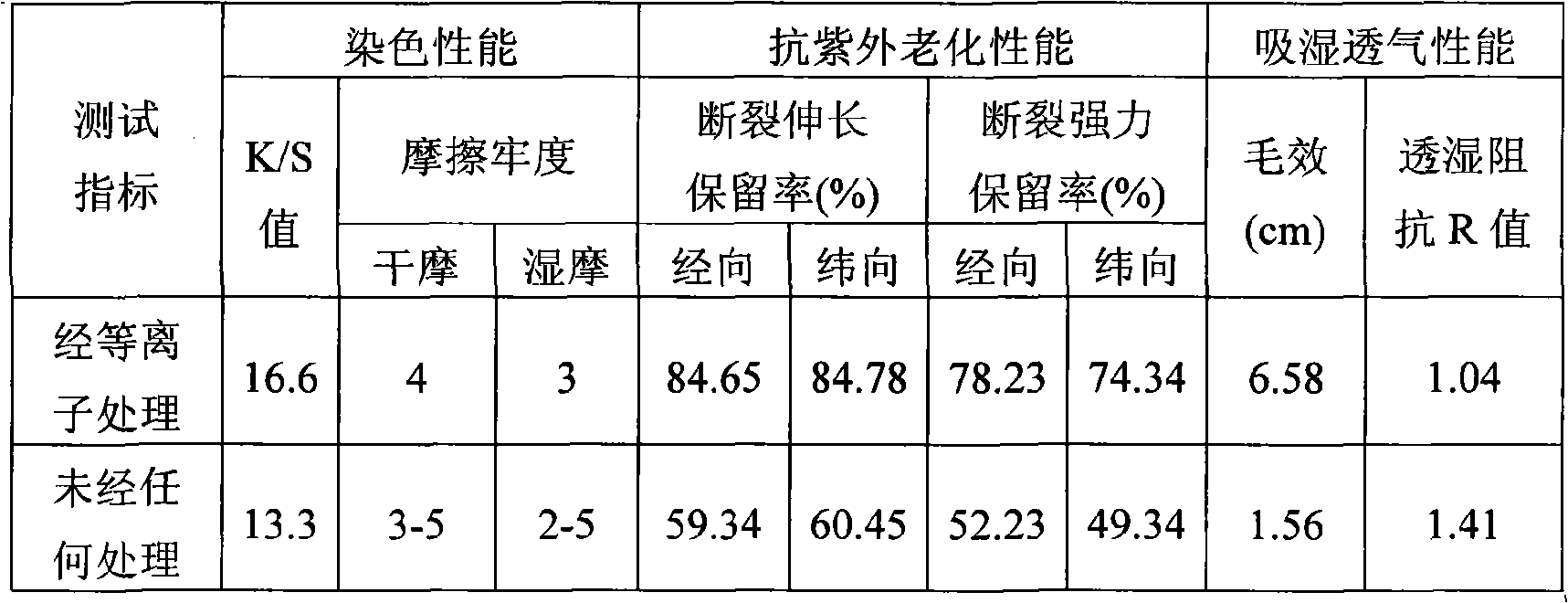

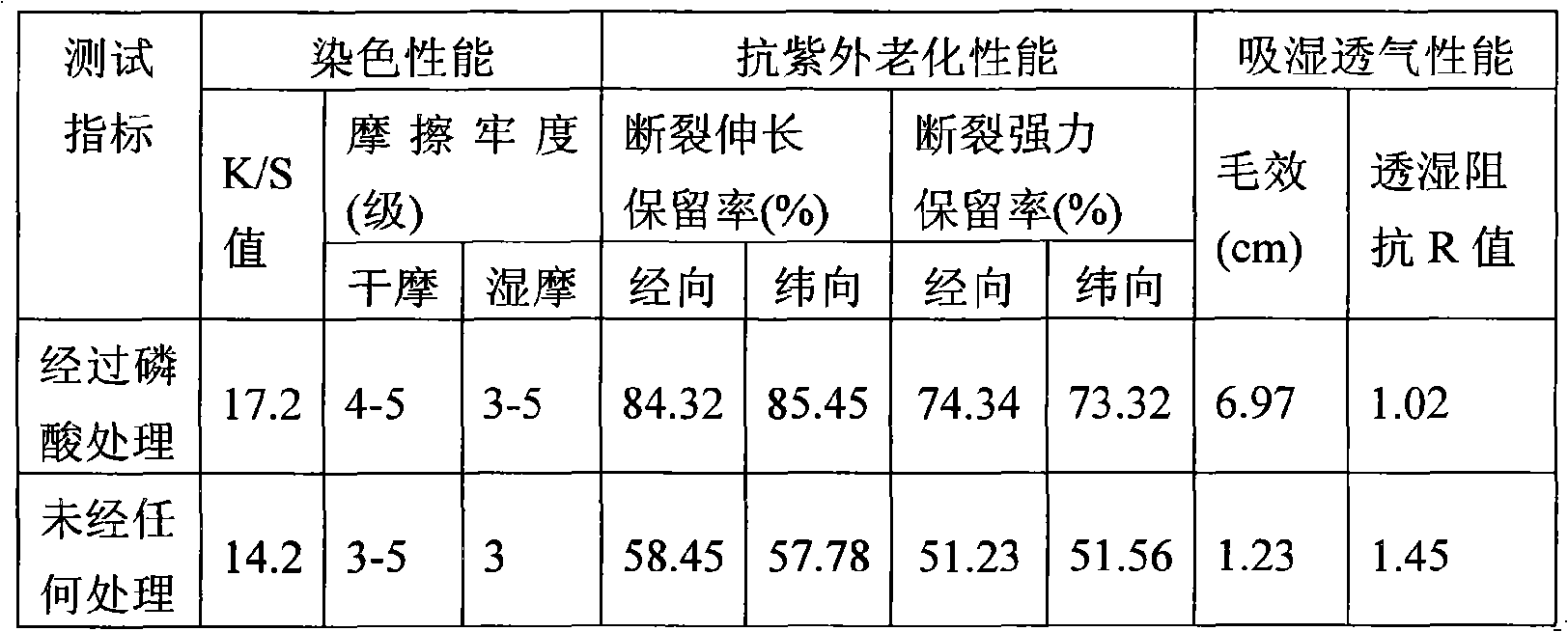

Method for modification, dyeing and multifunctional composite finishing of aramid fiber

InactiveCN101570940ALittle impact on physical and mechanical properties such as strengthEnhanced interactionPhysical treatmentDyeing processChemical industryMoisture permeability

The invention discloses a method for modification, dyeing and multifunctional composite finishing of aramid fiber, and belongs to the technical field of textile chemical industry. Through surface physical and chemical modification for the aramid fiber, the method improves the physical and chemical states of the aramid fiber surface and is favorable for the dyeing and after finishing of the aramid fiber. The specific process flow comprises the following steps of cleaning before the dyeing of the aramid fiber, pretreatment of the aramid fiber, dyeing of the aramid fiber, and multifunctional composite finishing of the aramid fiber. Not only the dyeing property of the aramid fiber treated by the method is remarkably improved, but also the dyeing fastness is good, the aramid fiber has good moisture permeability particularly, and simultaneously the aramid fiber is endued with good anti-ultraviolet ageing function. Moreover, the aramid fiber is subjected to composite finishing by adopting a nano composite sol, and the method has wide applicability, simple process, relatively low treatment cost, and low requirements on the applied technology and equipment.

Owner:JIANGNAN UNIV

Processing method for mercerized knitted bedding fabric

InactiveCN102433678AMoisturize evenlySoft touchMercerising of indefinite length fabricsSingeingTextile printerPolymer science

The invention discloses a processing method for a mercerized knitted bedding fabric. The processing method mainly adopts a production technology of double-calcination single yarn, first refining and then mercerizing, and grey yarn is sequentially subjected to yarn singeing, yarn steaming, knitting, grey cloth singeing, refining, dewatering, cylinder drying, mercerizing, dyeing, dewatering, scutching, drying, printing, forming and pre-shrinking and finally is checked and stored in a cabin. The mercerized knitted bedding fabric has the advantages of high conformality, low shrinkage, wide width and the like, and can meet the requirement on the knitted bedding fabric; compared with a woven fabric, the mercerized knitted bedding fabric has higher elasticity, water absorption and air permeability, is more smooth and fine in handfeel, and has better comfortableness.

Owner:WUHU SHENGLUO TEXTILE INDAL

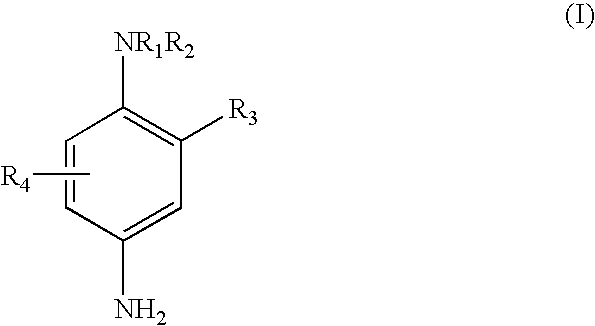

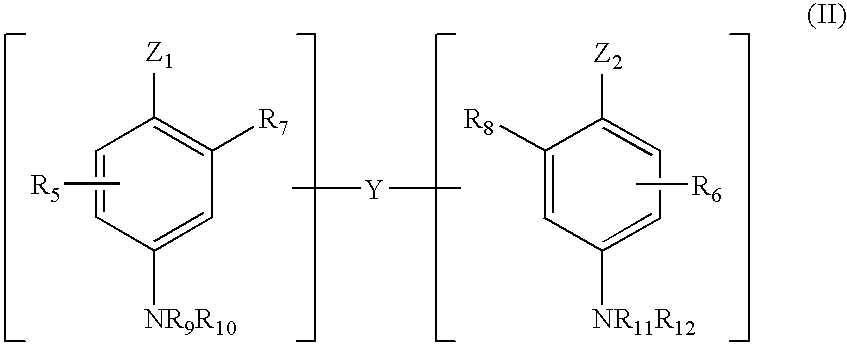

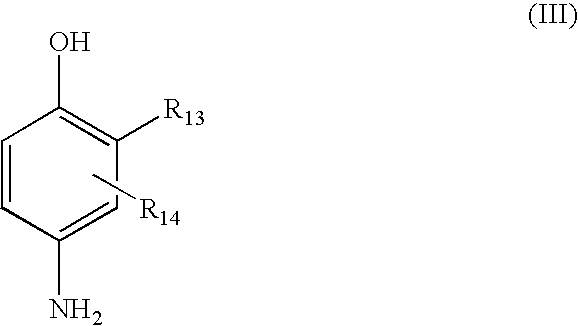

Composition useful for the oxidation dyeing of human keratinous fibres

A composition useful for the oxidation dyeing of human keratinous fibers and in particular hair containing, in a cosmetically acceptable medium based on water and at a basic pH, at least one oxidation dye and an alkalinizing agent containing at least one alkali metal, alkaline-earth metal or ammonium metasilicate and at least one alkanolamine, and the dyeing method using this composition.

Owner:LOREAL SA

Figured sea-island super-fine fiber, and preparation method thereof and synthetic leather preparing process method using same

ActiveCN102071495AGood mechanical propertiesImprove dyeing effectNew-spun product collectionFilament/thread formingPhospholambanPolyolefin

The invention relates to a figured sea-island super-fine fiber, and a preparation method and a synthetic leather preparing process method using the same, which belong to the technical field of leather and leather manufacture methods. The figured sea-island super-fine fiber is characterized in that the weight percentage ratio of island components of the fiber to sea components of the fiber is 50 percent to 80 percent / 50 percent to 20 percent, wherein the island components are polyamide (PA) 6 or polyethylene terephthalate (PET), and the sea components are polyolefins or phospholamban (PLB) or polyvinyl alcohol (PVOH). The preparation method comprises the steps of slice drying and melting, composite spinning, oiling and falling into a barrel, drafting curling and drying cutting. The synthetic leather preparing method comprises the following steps that: 1. the components are sequentially prepared into a single-layer fiber net, a composite layer fiber net, needle-punched non-woven cloth and needle-punched non-weaving cloth; 2.soakage and coagulation are sequentially carried out on the non-weaving cloth, the non-weaving cloth is washed, so that a synthetic leather impregnated substrate is formed, repeated soaking squeezing, azeotropic distillation and drying are sequentially carried out, so the synthetic leather is obtained. The synthetic leather produced by the invention has the advantages of excellent mechanical performance, excellent dyeing performance, excellent dyefastness, better production controllability, economy and environment protection. Compared with natural leather and products of the natural leather, the synthetic leather has the advantages that use performance such as durability, weatherability, antibacterium mothproofing, dyefastness and the like of products is much superior to that of the natural leather and the products of the natural leather.

Owner:烟台万华超纤股份有限公司

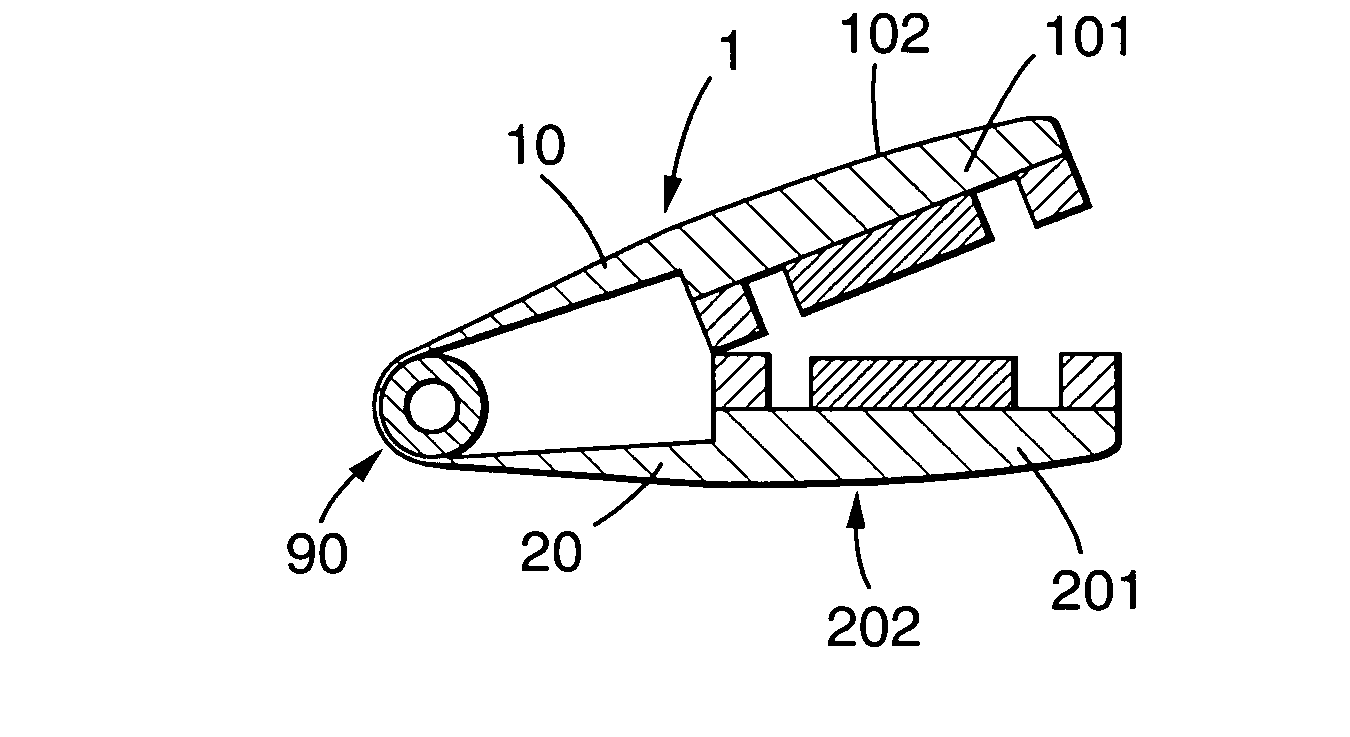

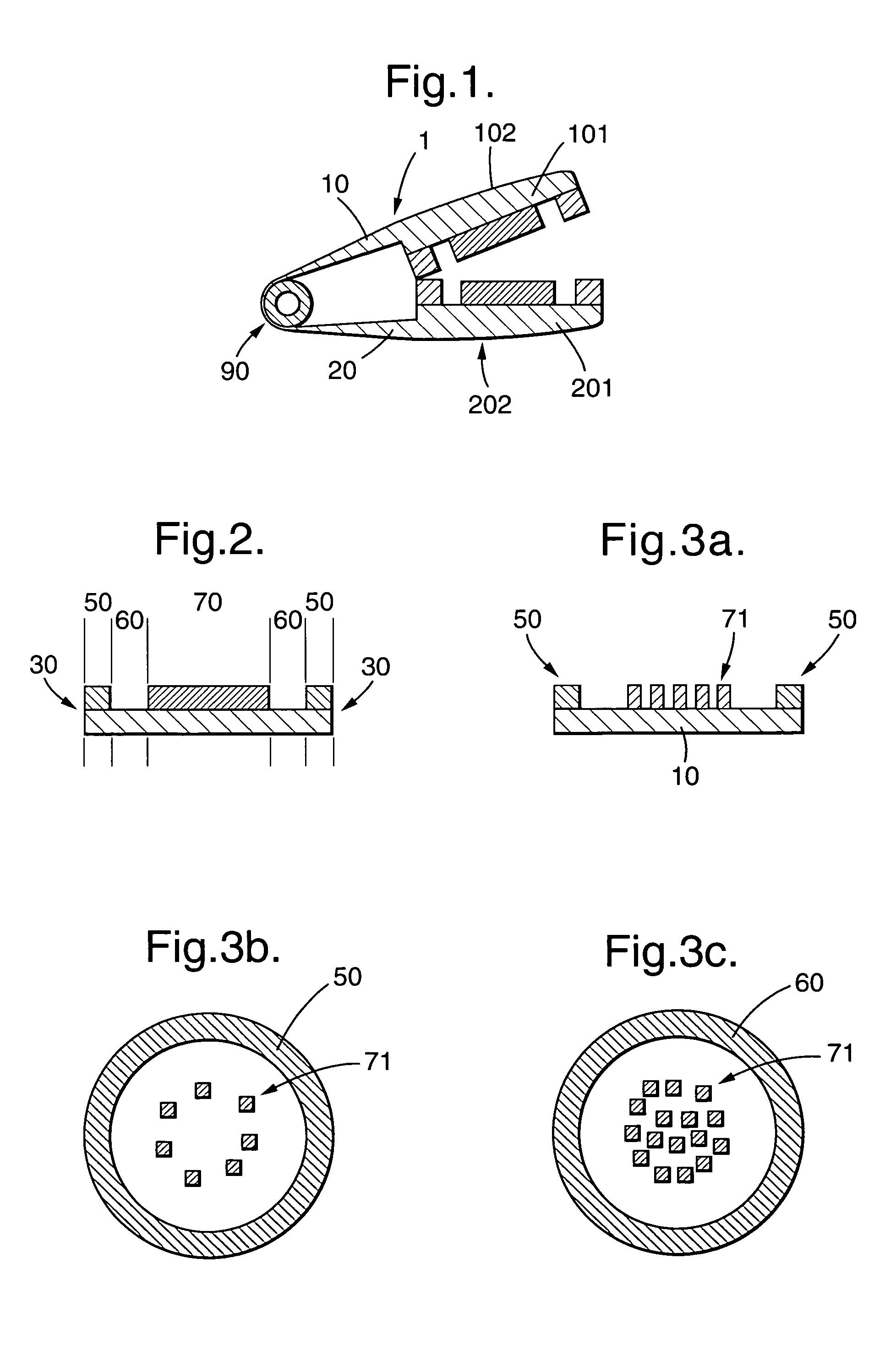

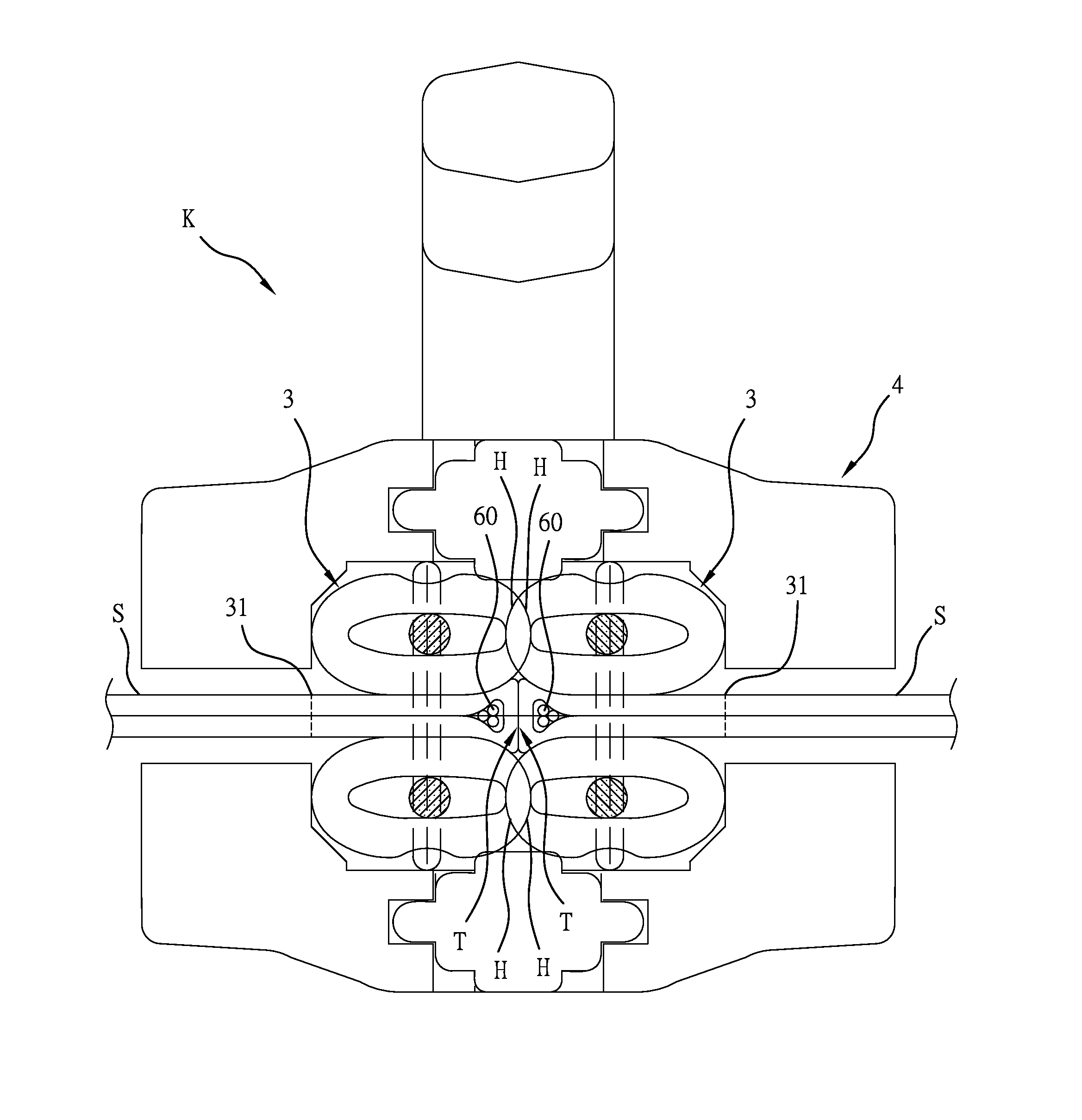

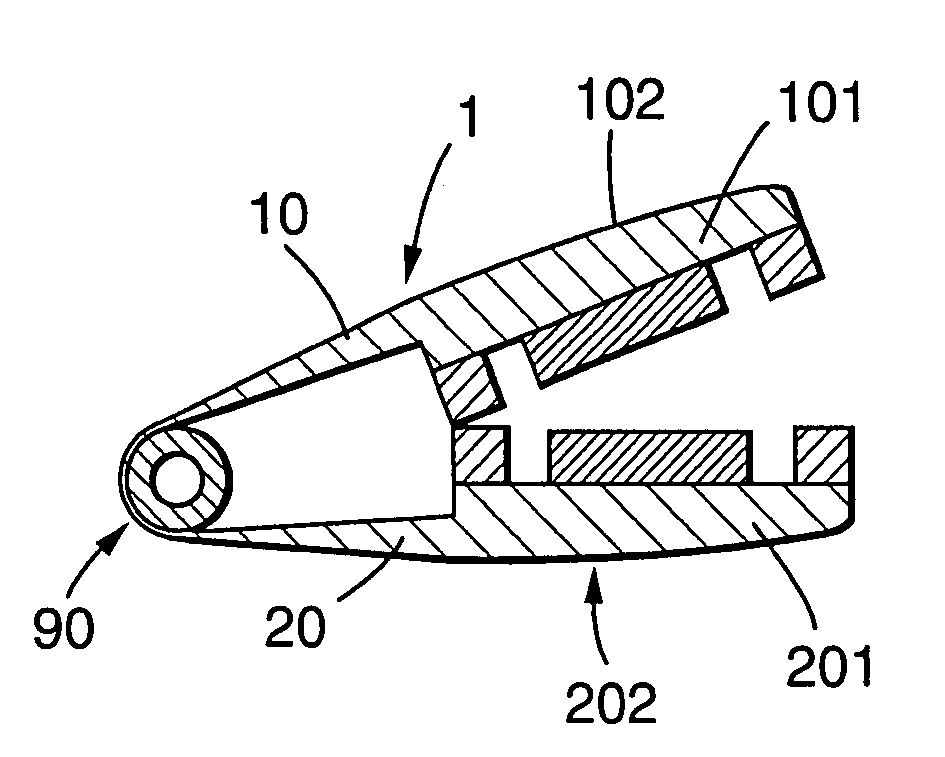

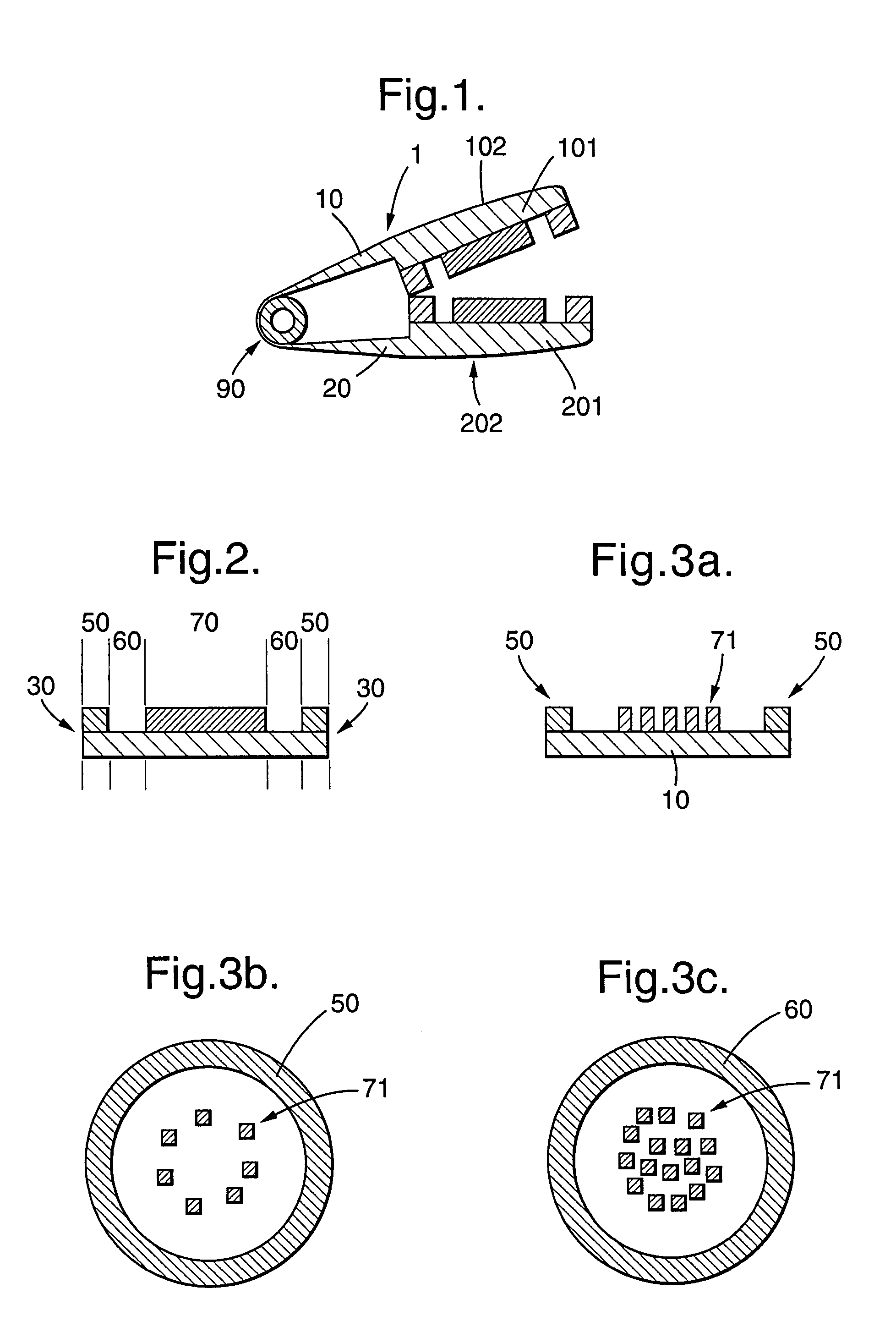

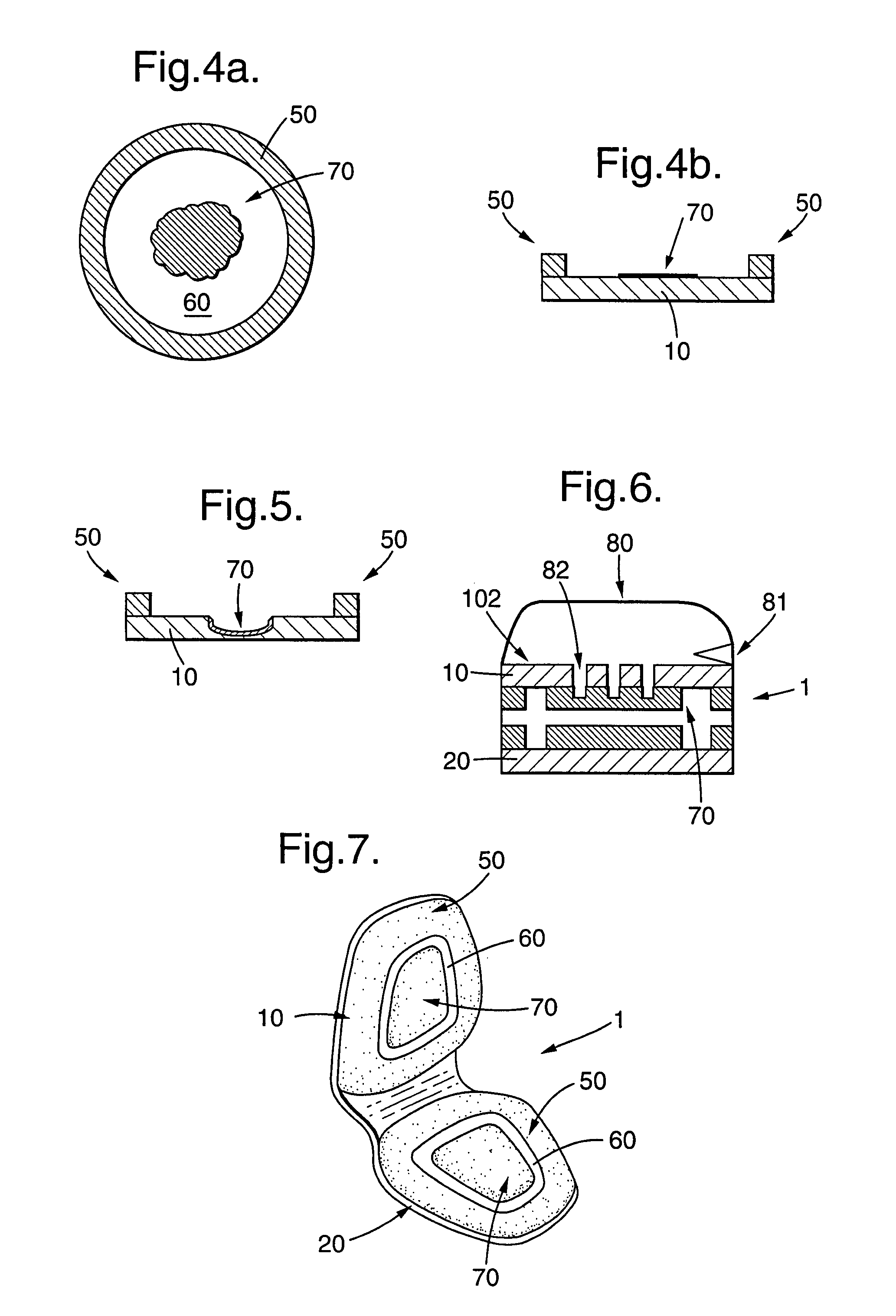

Hair highlighting application tool

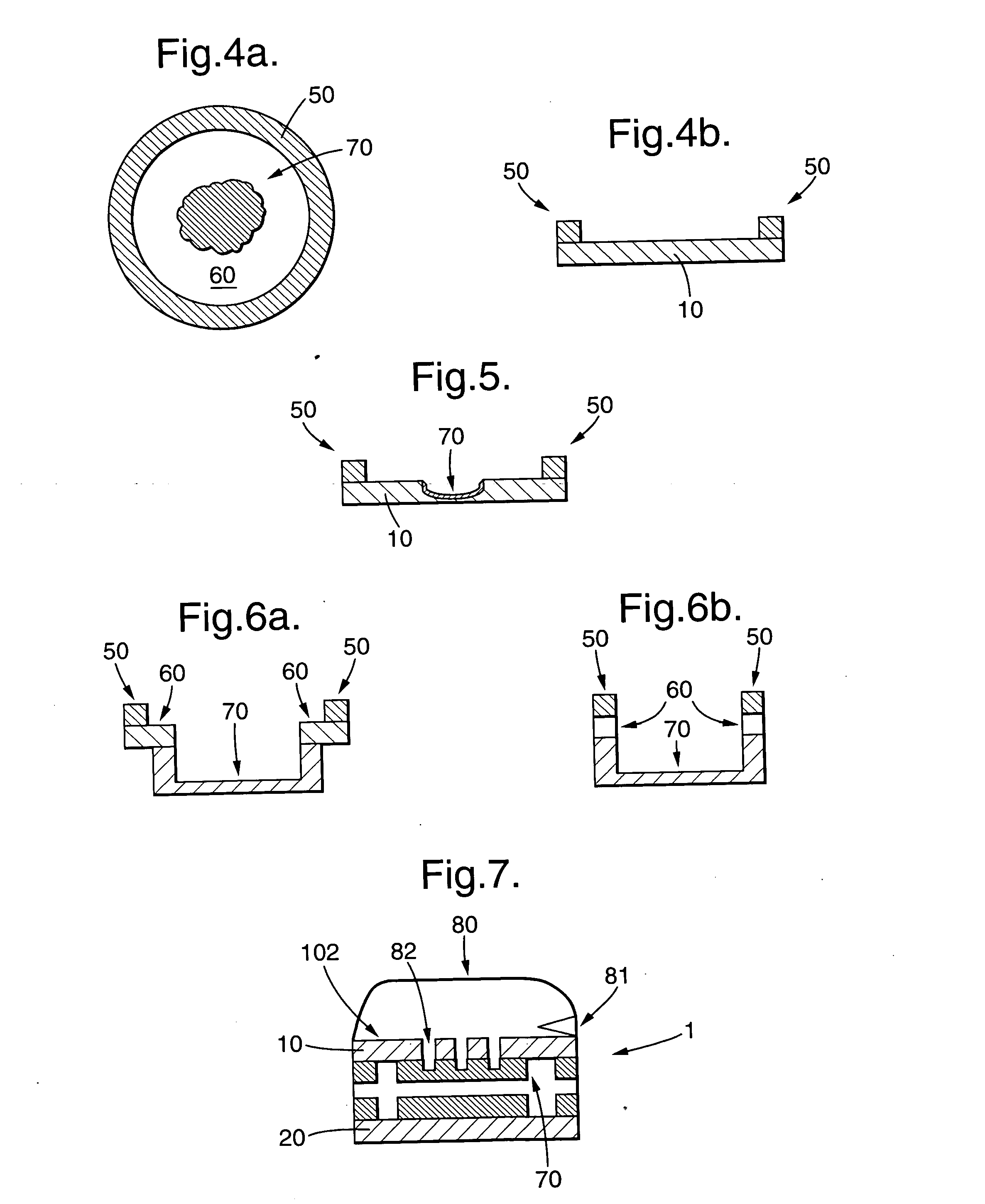

Disclosed herein is an application tool (1) and methods to use the same. The application tool (1) comprises two plates (22), connected together. At least one of said two plates (22) comprises a fluid control zone (50), which run along the perimeter edge (30) of said at least one plate (22), a displacement zone (60), which at least partially separate said fluid control zone (50) from a containment zone (70). A hair treatment composition may be loaded in the containment zone (70) Application of hair treatment compositions through the application tool (1) according to the invention allows for a precise, non-messy and clean targeting of the hair treatment composition on a hair strand and it is especially useful for highlighting and dyeing compositions.

Owner:THE PROCTER & GAMBLE COMPANY

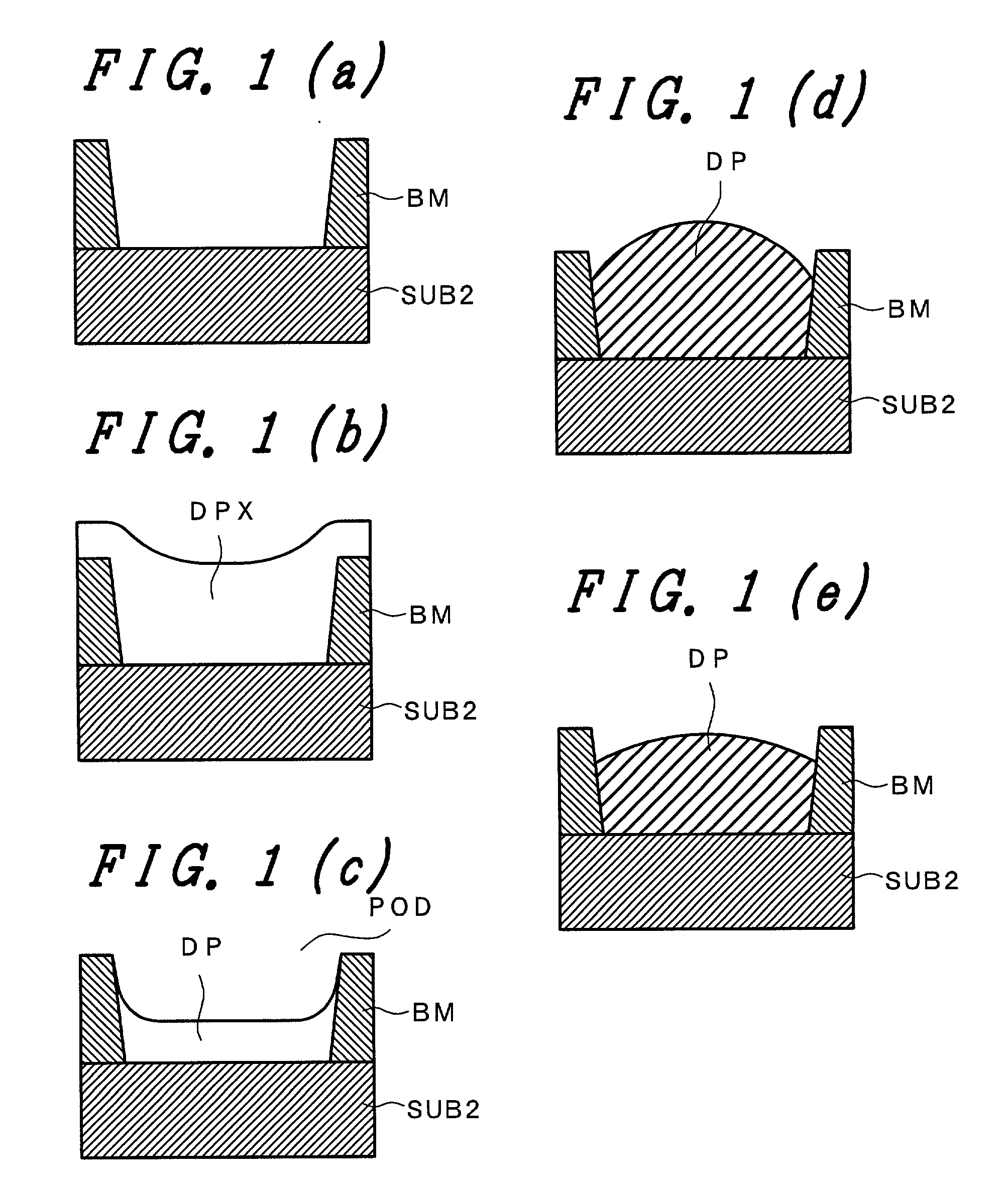

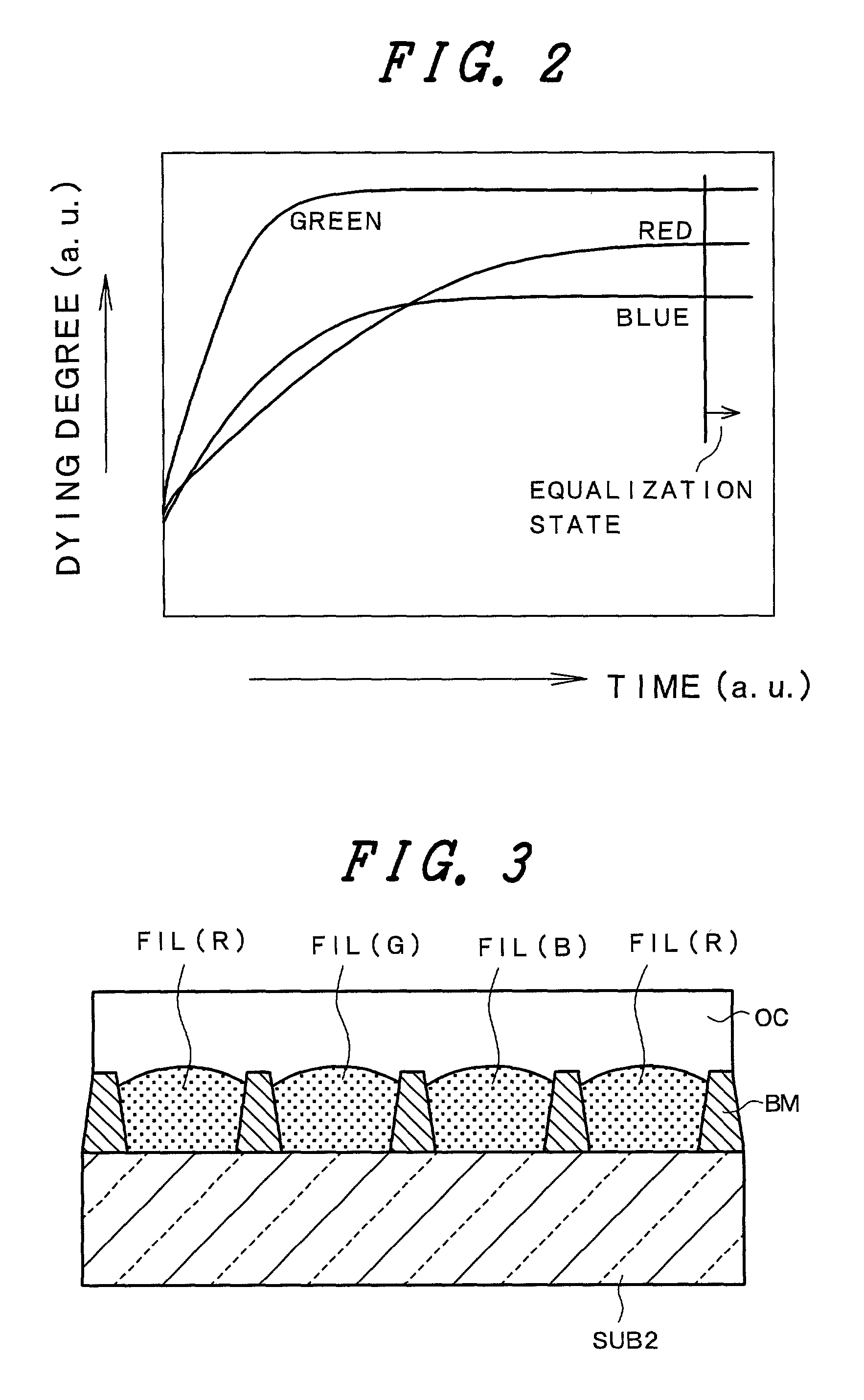

Method of manufacturing color filters and liquid crystal display device using these color filters

InactiveUS20010007733A1Improve flatnessImprove display qualityOptical filtersTypewritersUltravioletEngineering

After forming a black matrix which defines pixel regions on a substrate, dyed substrate layers of photo hardening property are formed. By irradiating ultraviolet rays to the dyed substrate layers from the back of the substrate and by developing, ink reservoirs which use the black matrix as partition walls are formed. The dyeing material such as the dye is supplied to these ink reservoirs by an ink jet system. Due to these partition walls, there is no possibility that the dyeing material scatters to the neighboring or adjacent pixel regions to cause the mixed color. Further, since the filters having a sufficient thickness can be formed in the ink reservoirs, the surface flatness of the color filters can be sufficiently ensured without coating the thick overcoat layer.

Owner:HITACHI LTD +1

Device for drying fabric and method

ActiveCN101726165ADry evenlyControlled dryingDrying solid materials with heatDrying chambers/containersYarnProduction line

The invention discloses a device for drying fabric and a method, belonging to the field of drying the fabric. The device comprises a roller way, a drying support pan, a box body part, an on-line detection system and a PLC control system. The box body part comprises a plurality of heating boxes, the drying power of which are gradually reduced; the heating boxes are communicated with each other; and the inner walls of the heating boxes are provided with magnetic control pipes. The method comprises the steps of: leading the fabric to sequentially pass through the heating boxes with the function of microwave drying, and the drying power of the heating boxes are gradually reduced according to the pass sequence of the fabric. By adopting the technology of microwave drying, the device has high efficiency; is even, energy-saving and environment-friendly; can controllably dry the fabric; has high automation; can gradually and continuously dry the fabric by leading the fabric to sequentially pass through the heating boxes, the drying power of which are gradually reduced; leads the dried fabric to be evenly dried and have good quality; and is suitable for an unmanned automatic yarn dyeing and finishing production line.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

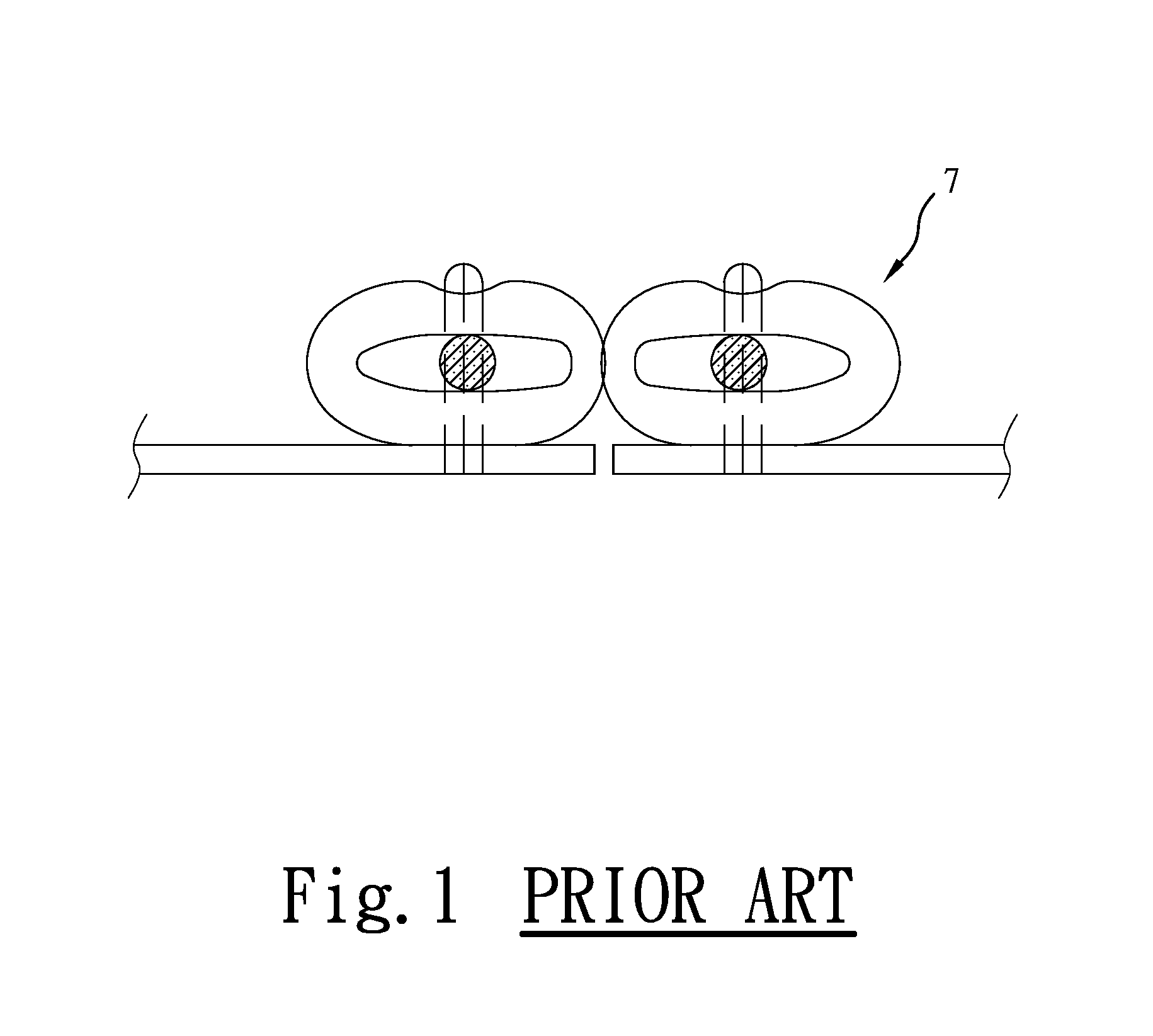

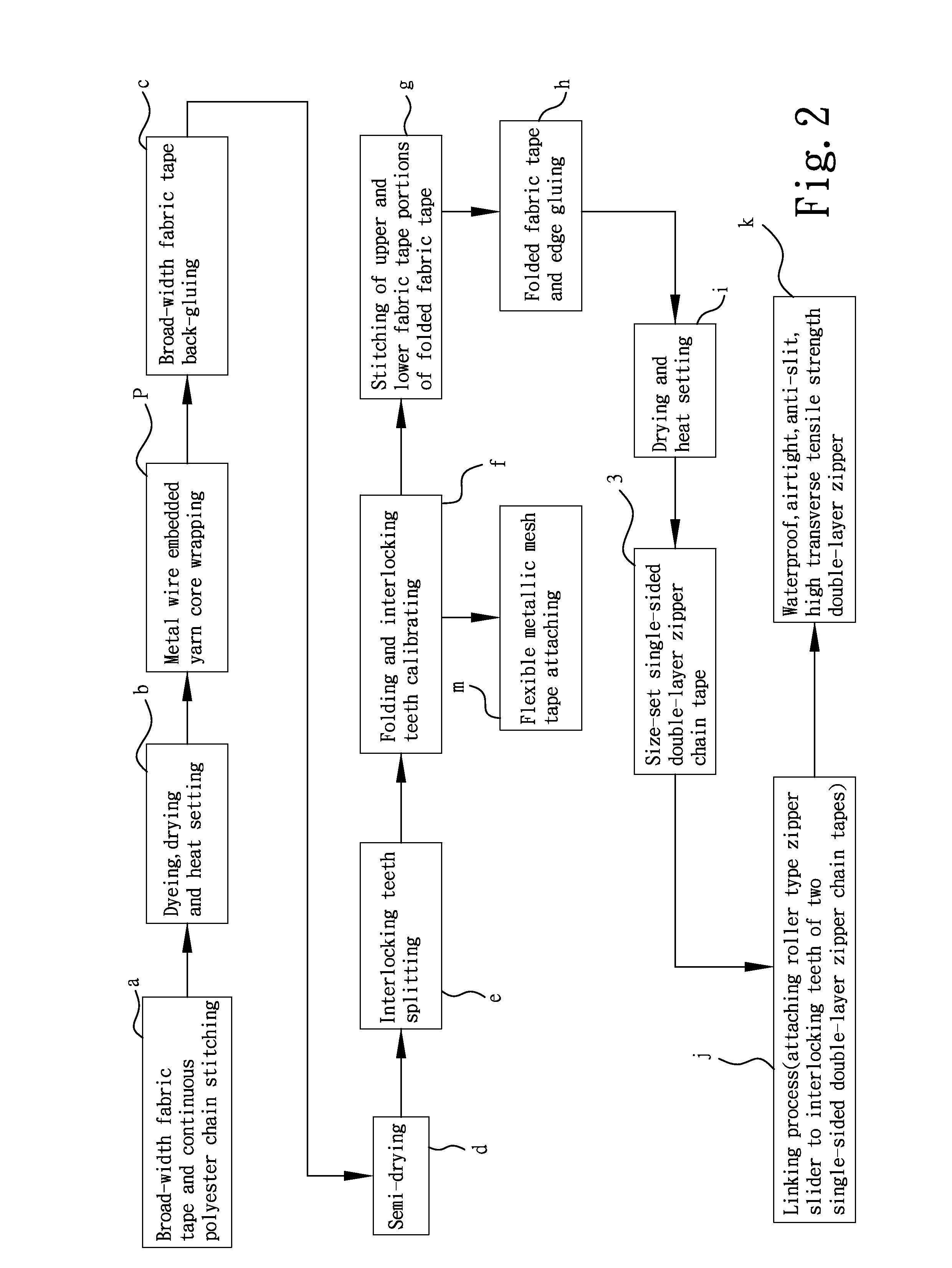

Waterproof, Anti-Split, High Transverse Tensile Strength Double-Layer Zipper and its Fabrication Method

ActiveUS20140359978A1Good for stable movementHigh strengthSnap fastenersWire articlesPolyesterHigh intensity

A waterproof, airtight, anti-slit, high transverse tensile strength double-layer zipper made by: stitching a continuous polyester chain to a middle part of a broad-width fabric tape and then separating the continuous polyester chain into left and right series of interlocking teeth after zipper chain tape dyeing and drying and gluing processes, and then folding up the zipper chain tape and stitching up the open side of the folded zipper chain tape so as to obtain a single-sided double-layer zipper chain tape, and then using a zipper slider to couple two single-sided double-layer zipper chain tapes, thereby obtaining a waterproof, airtight, anti-slit, high transverse tensile strength double-layer zipper. Alternatively, the continuous polyester chain can be stitched to the broad-width fabric tape near its one lateral side for making a high-strength double-layer zipper with less fabric consumption.

Owner:WANG LIEN CHOU

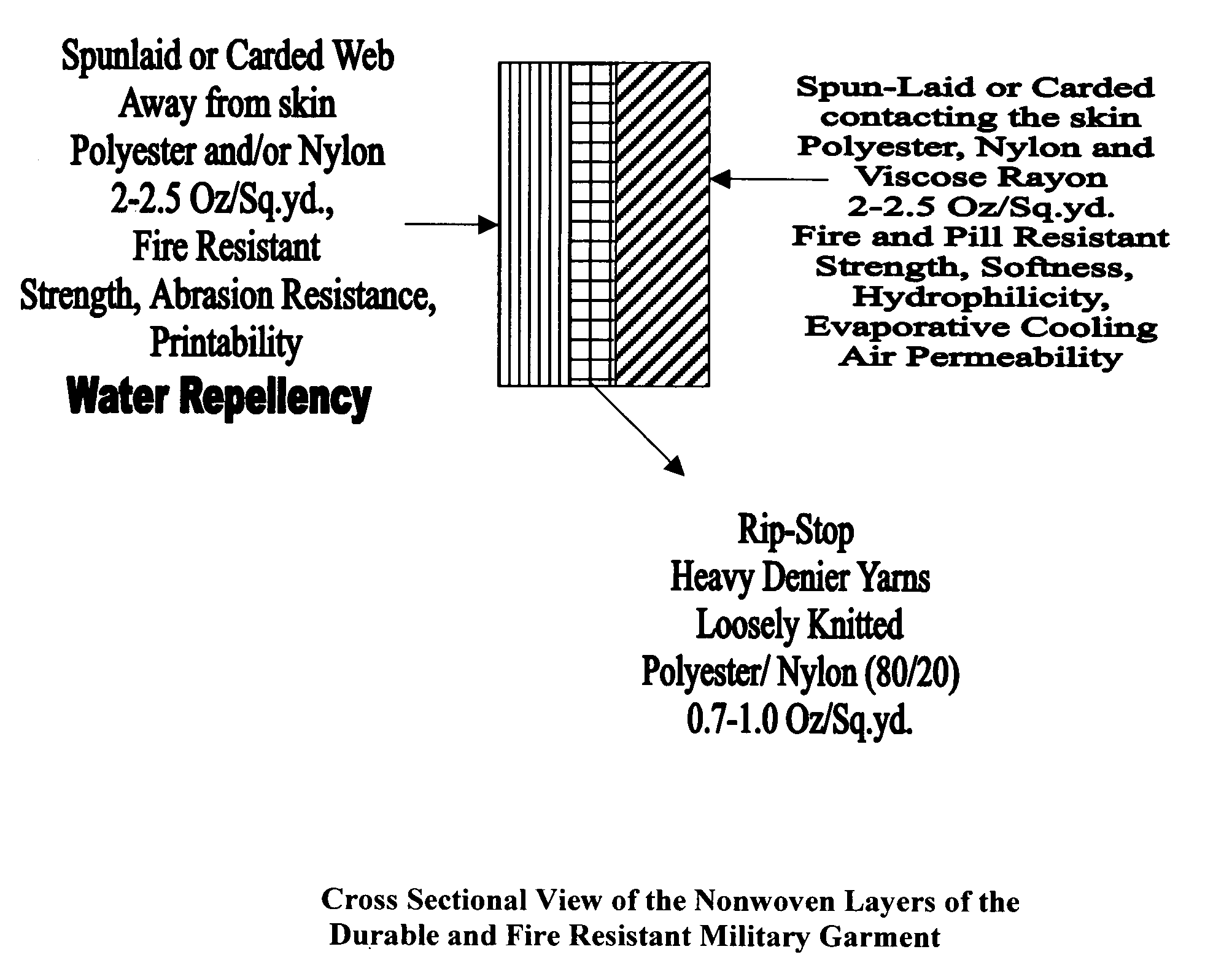

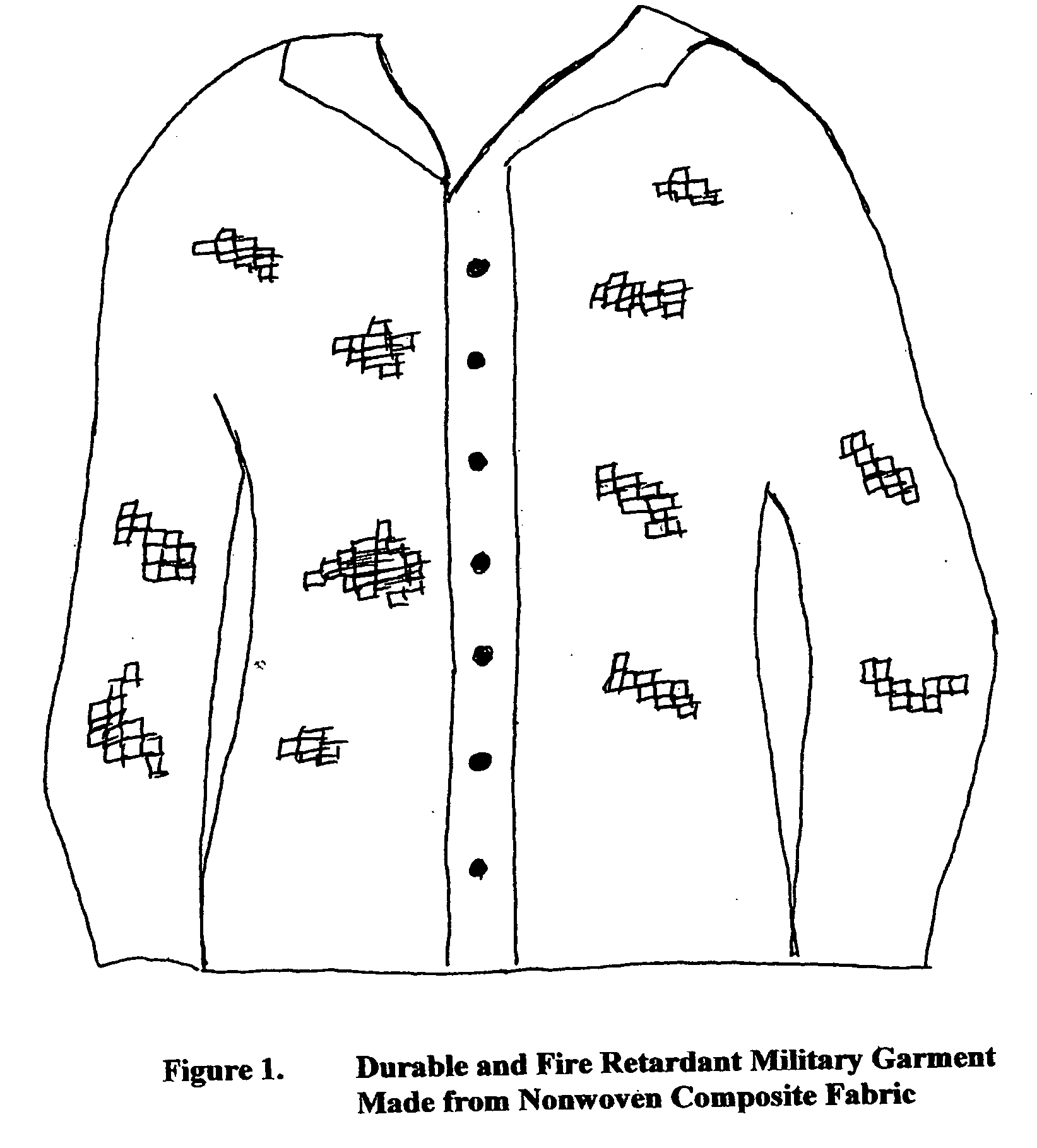

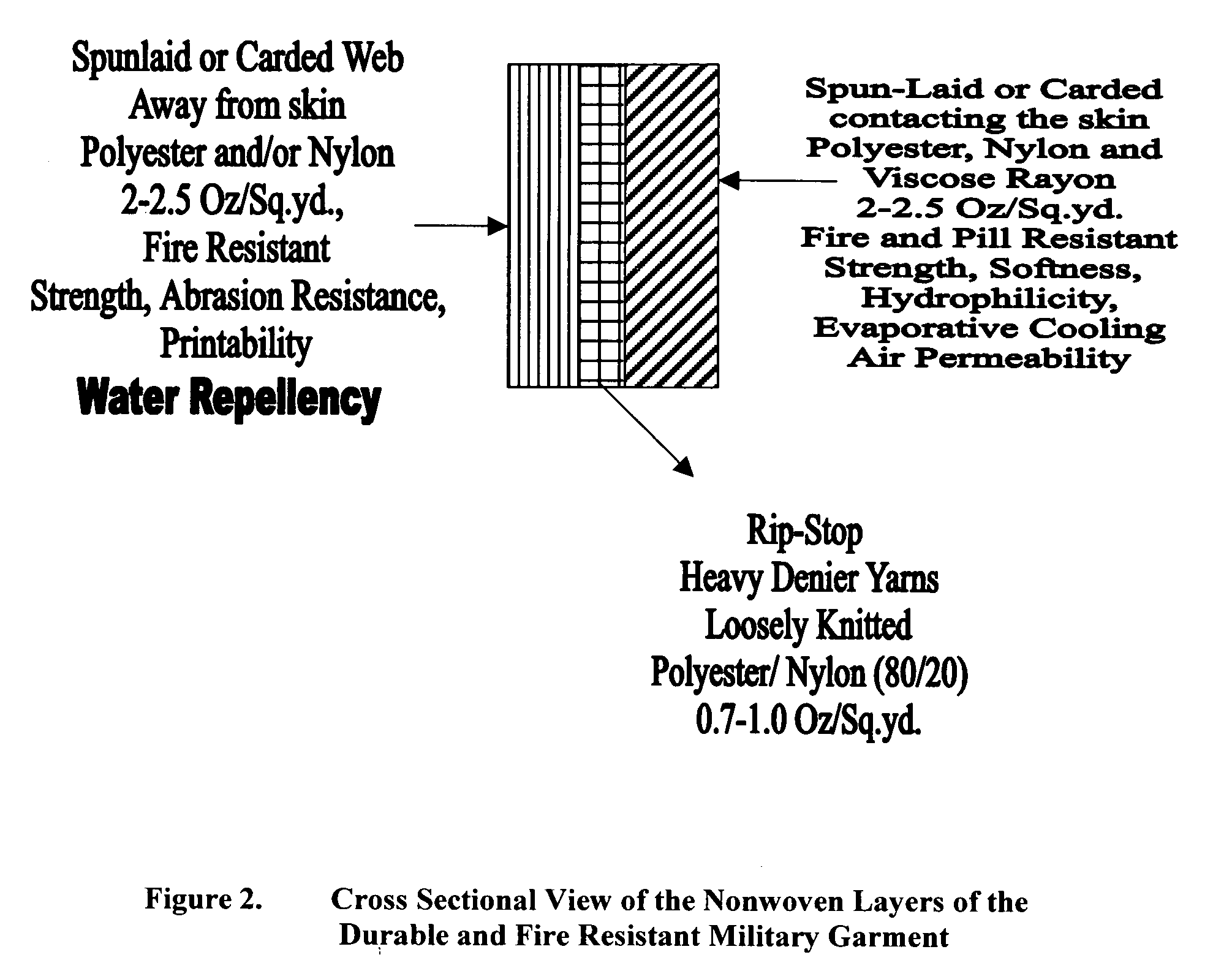

Durable and fire resistant nonwoven composite fabric based military combat uniform garment

InactiveUS20060035555A1Durable/wash resistant fire retardant chemicalImprove wear resistanceProtective equipmentLayered productsPunchingMilitary Uniforms

The present invention is directed to the design and manufacture of a durable, fire resistant, comfortable and economical nonwoven composite fabric based garment, which meets the stringent requirements of military combat uniform clothing. The nonwoven based garment is designed to replace the traditional woven textile fabric used in the military and outdoor sporting garments today. The novel garment of the current invention is constructed using a unique nonwoven composite fabric that exhibits mechanical, physical, durability and comfort characteristics similar to or better than that of the current woven military uniform fabric. In particular, the present invention contemplates the nonwoven composite fabric used to make the garment is prepared by combining at least two separate fire resistant nonwoven webs forming the inside and outside layers of the garment. An optional rip-stop element such as a loosely knitted fabric may be sandwiched between the two nonwoven webs to improve the tear resistance of the entire garment. Hydroentangling or needle-punching processes and subsequent thermal calendering / embossing techniques combine the individual nonwoven webs of the garment before dyeing, printing and finishing with traditional textile chemicals to form a composite fabric for stitching to make the garment.

Owner:NARAYANAN VASANTHAKUMAR +2

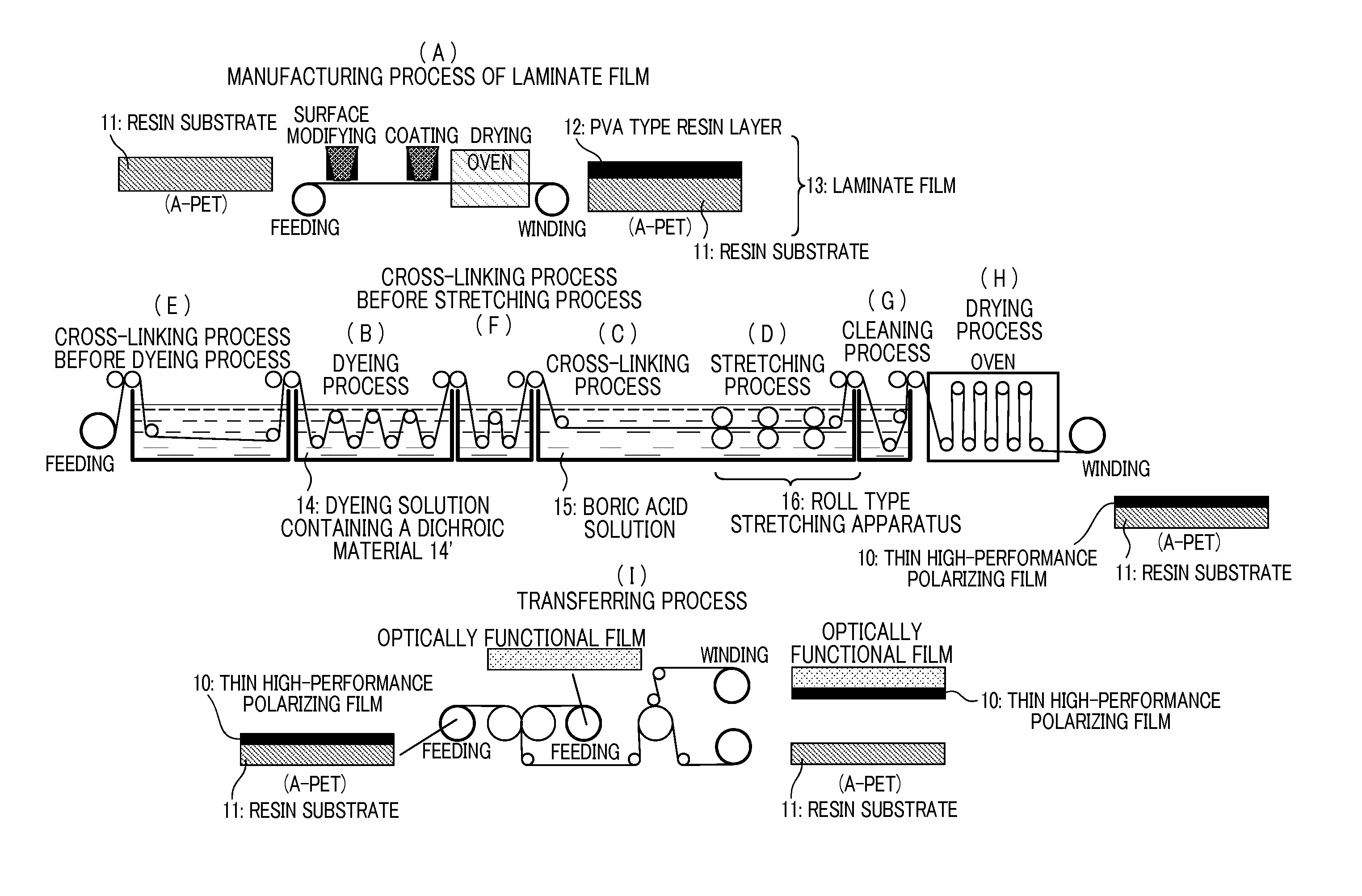

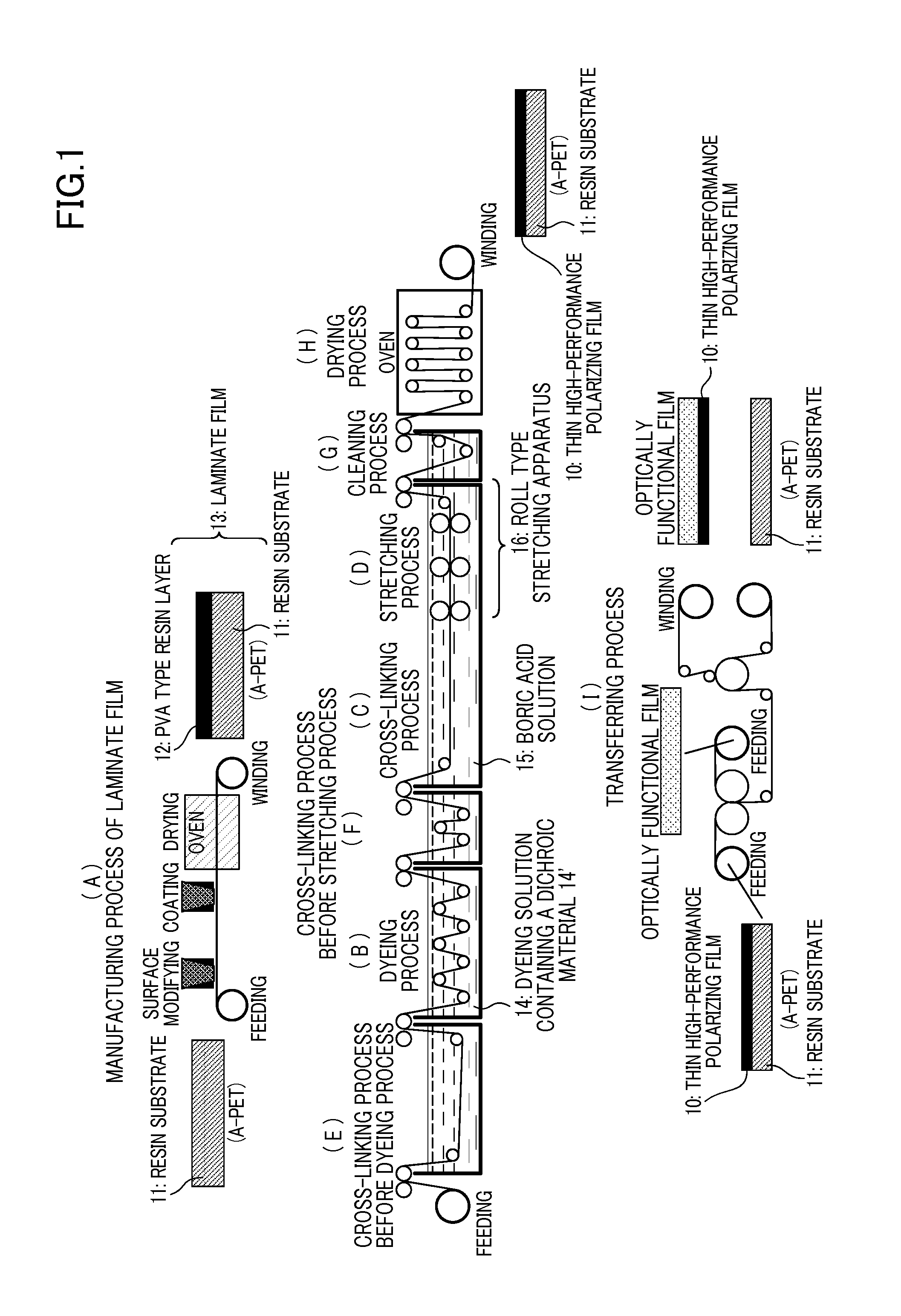

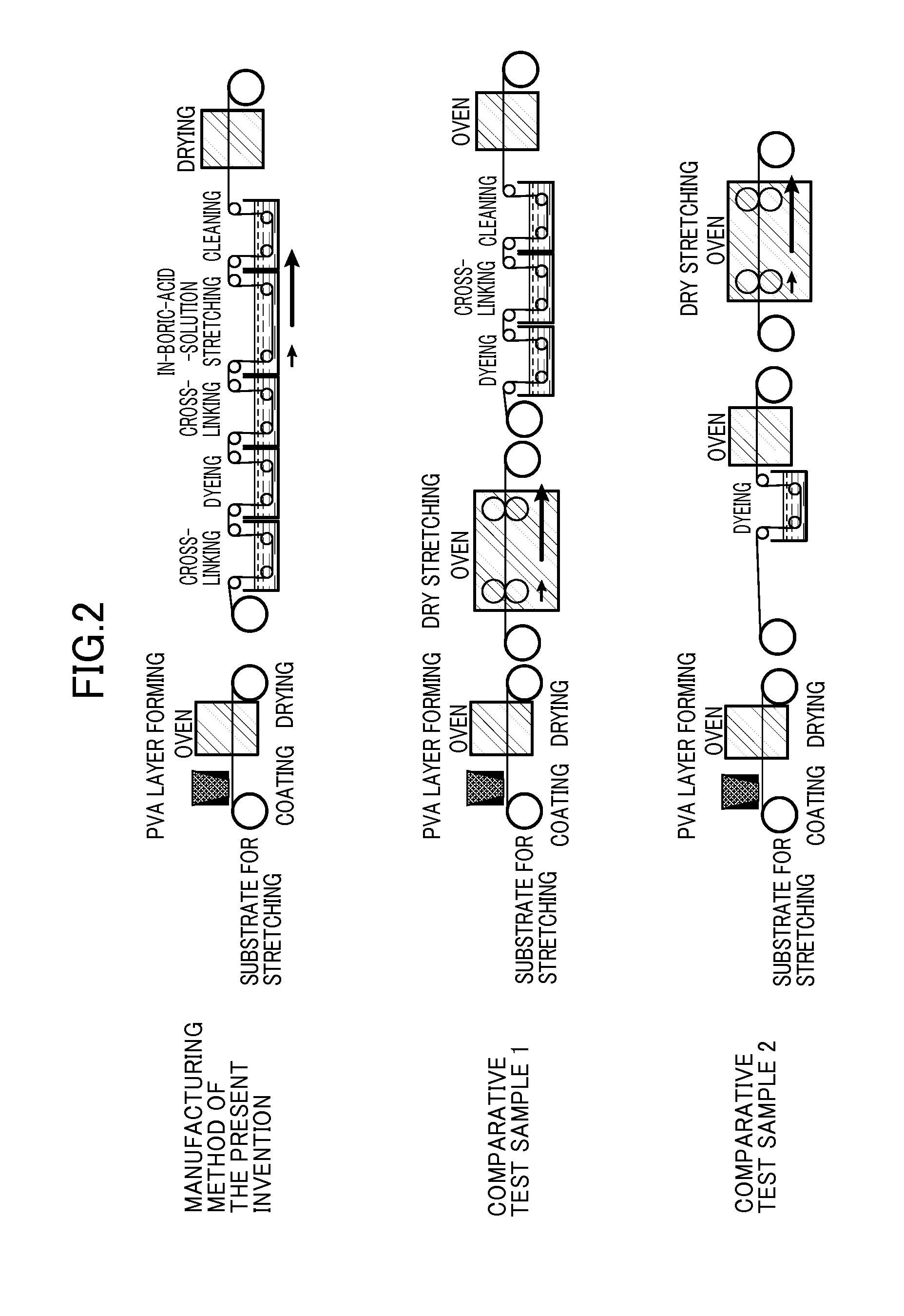

Thin high-performance polarizing film and method for manufacturing the same

InactiveUS20110315306A1High magnificationReduced optical performanceMonocomponent cellulose artificial filamentPolarising elementsStretch ratioBoric acid

A method for manufacturing a thin high-performance polarizing film includes coating a polyvinyl alcohol type resin on a resin substrate having a thickness of at least 20 μm and then drying the resin to thereby form a polyvinyl alcohol type resin layer, immersing thus produced polyvinyl alcohol type resin layer in a dyeing solution including a dichroic material to thereby have the dichroic material impregnated in the polyvinyl alcohol type resin layer, stretching the polyvinyl alcohol type resin layer having the dichroic material impregnated therein together with the resin substrate in a boric acid solution such that a total stretching ratio of 5.0 or more of the original length is achieved.

Owner:NITTO DENKO CORP

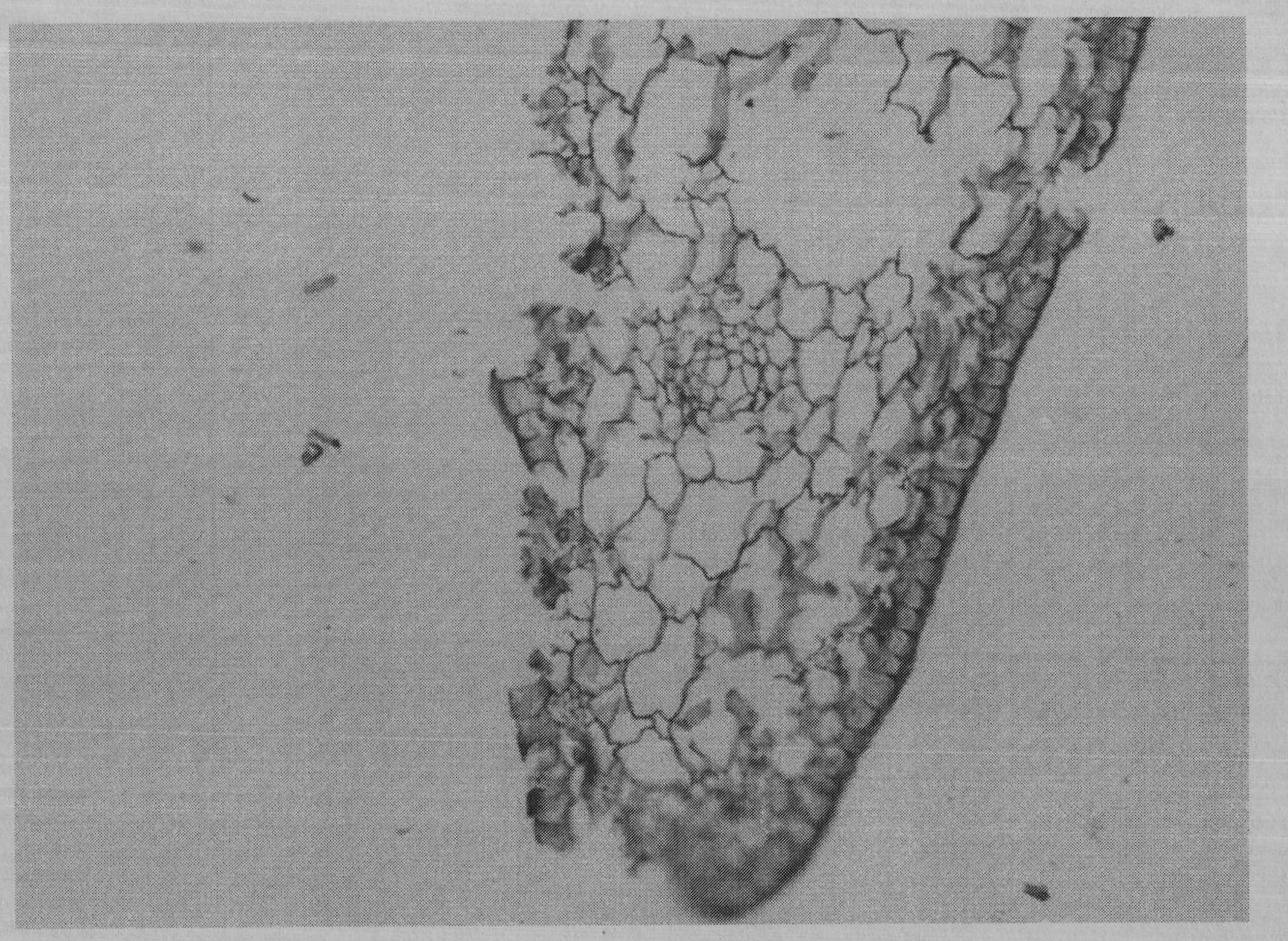

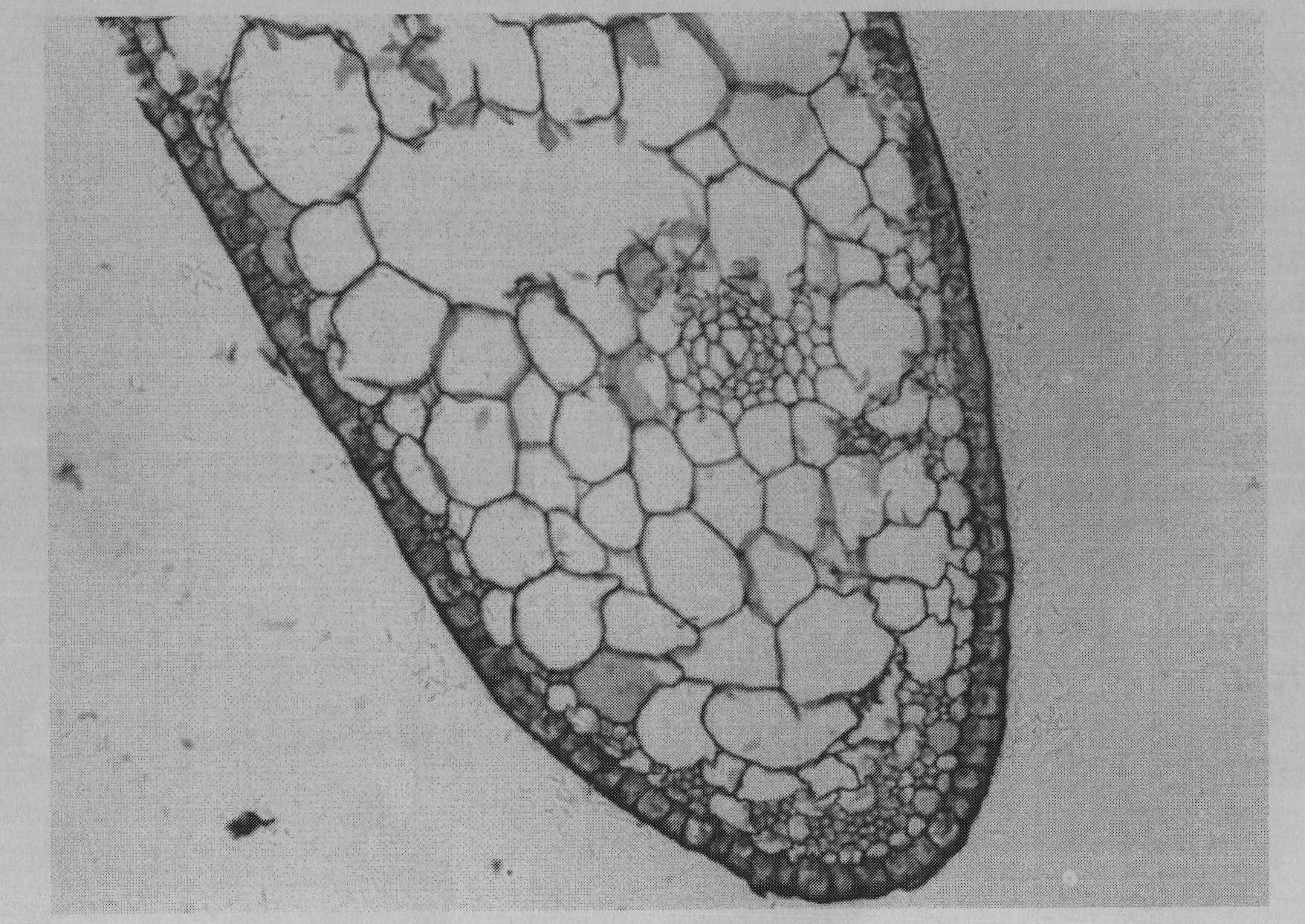

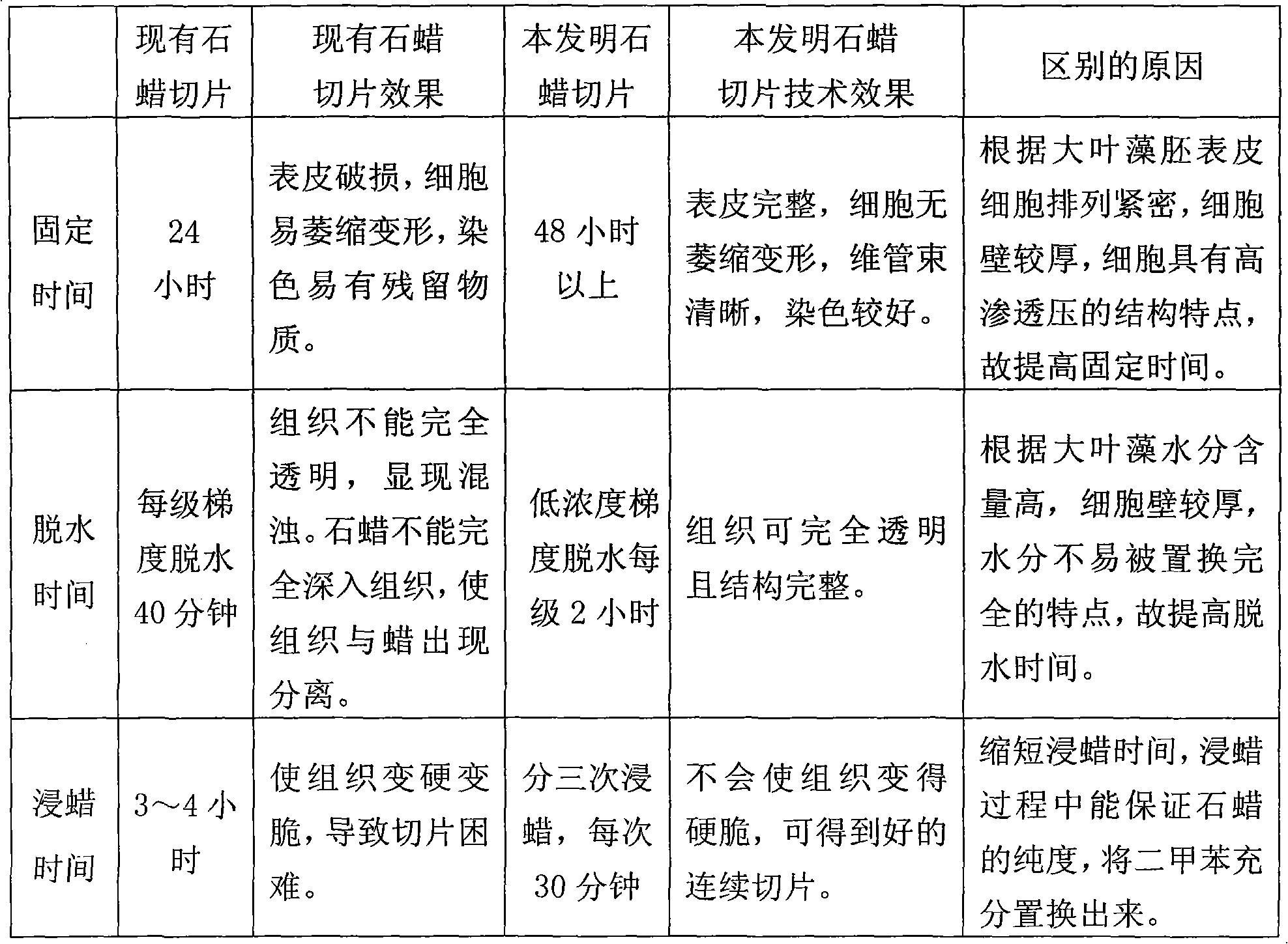

Manufacturing method of paraffin sections of zostera marina embryo

ActiveCN102116711AAvoid deformationModerate hardnessWithdrawing sample devicesPreparing sample for investigationParaffin waxEmbryo

The invention discloses a manufacturing method of paraffin sections of zostera marina embryo, comprising the following steps: (1) material drawing and fixation: zostera marina seeds are taken and the fruit skin is stripped, and after endosperm is removed, an integral zostera marina embryo is soaked in FAA (free amino acids) fixing solution and is fixed for more than 48 hours; (2) dehydration: the zostera marina embryo is taken out from the fixing solution and is soaked in alcohol for dehydration; (3) waxing and embedding: paraffin is added gradually in a vessel containing the zostera marina embryo and dimethylbenzene, and conventional paraffin embedding is carried out to obtain the wax blocks containing the zostera marina embryo; (4) slicing, spreading and drying: the wax blocks coated with the zostera marina embryo is fixed on a wheel rotation type slicing machine for carrying out continuous slicing of the paraffin, so as to obtain wax bands and enable the wax bands to be attached to an object slide; (5) dewaxing, rehydration and dyeing of hematoxylin dye solution; (6) slicing, dehydration and dyeing of eosin and alcohol; and (7) transparence and mounting are carried out to manufacture a permanent section. In the manufacturing method disclosed by the invention, the paraffin sections of the zostera marina embryo, which have clear dyeing and an integral texture structure, can be obtained.

Owner:SHANDONG ORIENTAL OCEAN SCI TECH

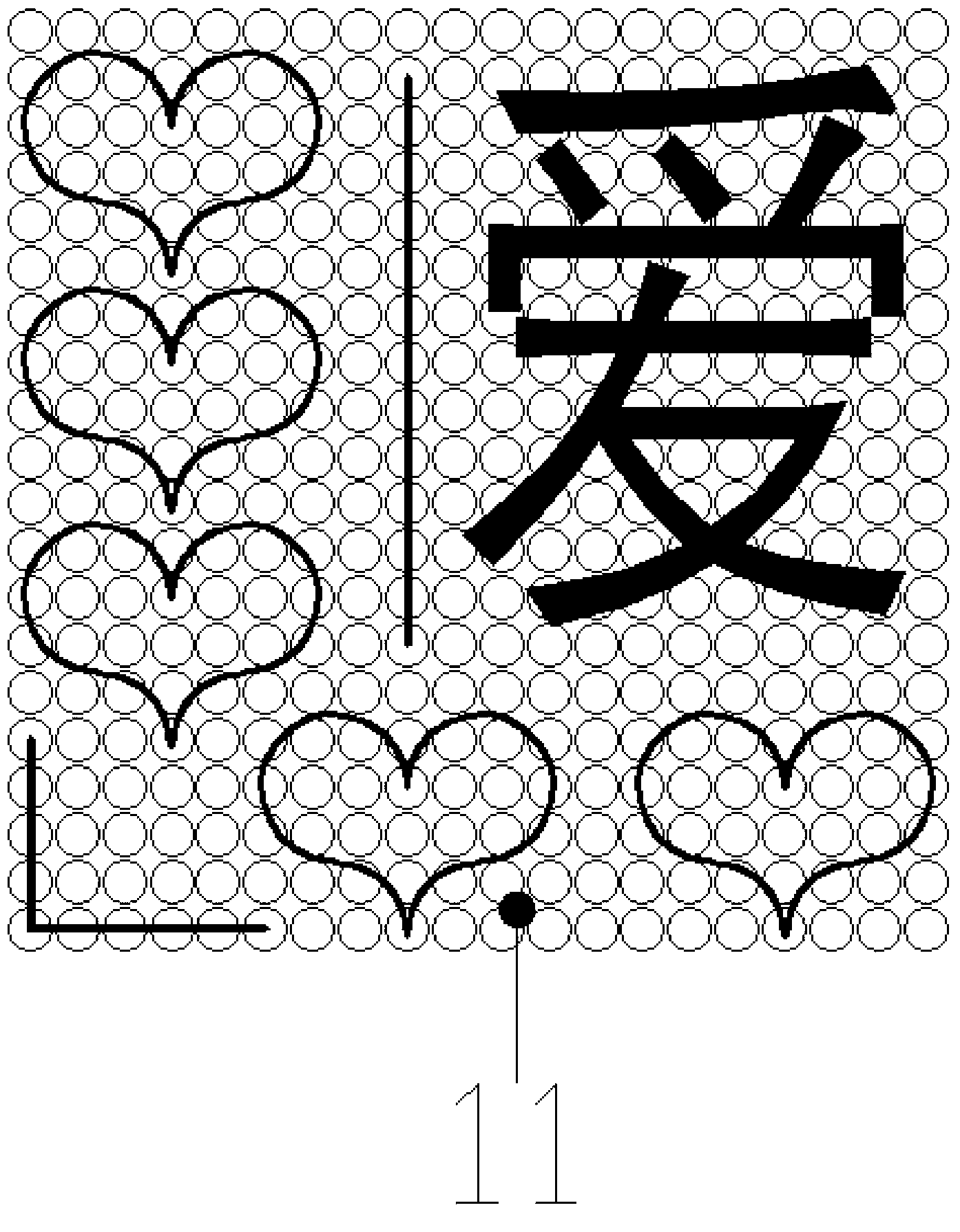

Image-text firework production method with users dyeing partial preset part

ActiveCN103234396AGuaranteed eleganceGuaranteed consistent specificationsFireworksGraphicsText display

The invention discloses an image-text firework production method with users dyeing a partial preset part. The image-text firework production method is characterized in that an image-text firework carrier, dyeing articles and a dyeing image-text production method are adopted. The image-text firework carrier is provided with a lift-off rocket, a lattice structural body, preset image-text display flames, flame primary color powder, simultaneous propellant powder and a simultaneous ignition device, wherein the lift-off rocket is connected with the lattice structural body, and the simultaneous propellant powder, the preset image-text display flames and the flame primary color powder are filled in the lattice structural body. The dyeing articles include a dyeing saline solution and a dyeing device. The dyeing image-text production method includes image-text sample manuscript design, dyeing saline solution application, flame primary color powder penetrating staining, liquid component removing for sufficient drying and the like. According to the image-text firework production method, the displayed picture part of set off fireworks is preset and can be randomly combined according to free expressing of users, and accordingly the users can experience pleasure brought by personal participation and can directly express affection. In addition, the image-text firework production method is simple to implement, low in cost and suitable for volume production.

Owner:SUZHOU ZZH INTPROP SERVICES

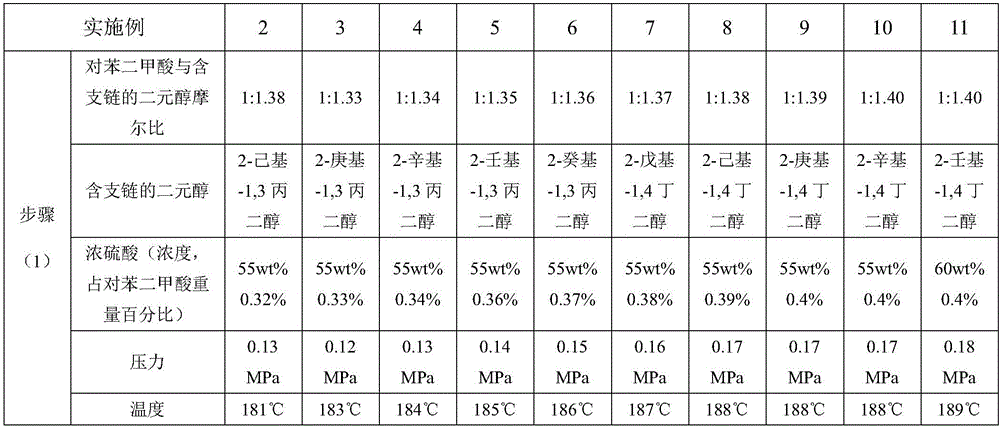

Polyester fibres and preparation method thereof

ActiveCN106367835AImprove dyeing effectEasy to processSpinnerette packsMonocomponent copolyesters artificial filamentSlurryLow vacuum

The invention relates to polyester fibres and a preparation method thereof. The raw material of the polyester fibres is modified polyester which consists of a terephthalic acid chain segment, an ethylene glycol chain segment and a branched chain-containing dihydric alcohol chain segment. The preparation method of the polyester fibres comprises the following steps: performing esterification reaction on terephthalic acid and branched chain-containing dihydric alcohol under the catalysis of concentrated sulphuric acid to obtain terephthalic acid dihydric alcohol ester; then, preparing the terephthalic acid and the ethylene glycol into slurry, and performing the esterification reaction on the slurry to obtain the terephthalic acid ethylene glycol ester; finally, stirring and mixing the terephthalic acid dihydric alcohol ester and the terephthalic acid ethylene glycol ester, and performing condensation polymerization in a low vacuum stage and a high vacuum stage under the action of a catalyst and a stabilizing agent to obtain modified polyester; metering, extruding, cooling, oiling, stretching, heat-setting and winding the polyester to prepare the polyester fibres. The increasing amplitude of the spatial gaps of the polyester fibres is much higher than that of branched chain-free polyester fibres at the same temperature, which is beneficial to the degree of micro particles, such as a dye, that enter the polyester; the dyeing rate is improved.

Owner:JIANGSU HENGLI CHEM FIBER

Viscose fiber with mint antibacterial function and preparation method thereof

InactiveCN101525777AImprove antibacterial functionPrevent adverse side effectsArtificial filaments from viscoseSocial benefitsAntibacterial agent

The invention provides a viscose fiber with mint antibacterial function and a preparation method thereof. The viscose fiber is characterized in that a natural mint extractive is used as an antibacterial agent agent, superfine powder grains or solution of the natural mint extractive are added to viscose spinning solution, and the superfine powder grains are molded to obtain the viscose fiber with the mint antibacterial function according to the traditional wet spinning and spraying technology, wherein the additive quantity (or the additive quantity of the superfine powder grains of the natural mint extractive in the solution) of the superfine powder grains of the natural mint extractive is 1 percent to 10 percent of the weight of the viscose spinning solution. The viscose fiber adopts the natural mint extractive as the antibacterial agent which is evenly distributed in the fiber, and the antibacterial agent has persistent antibacterial function and dyeing effect and does not have side effects on human body. The viscose fiber with the mint antibacterial function is suitable for preparing underdress, other clothes and bed textiles and has wide application range and large economic and social benefit. The preparation method has reasonable and simple process and is suitable for industrialization production.

Owner:张永堂

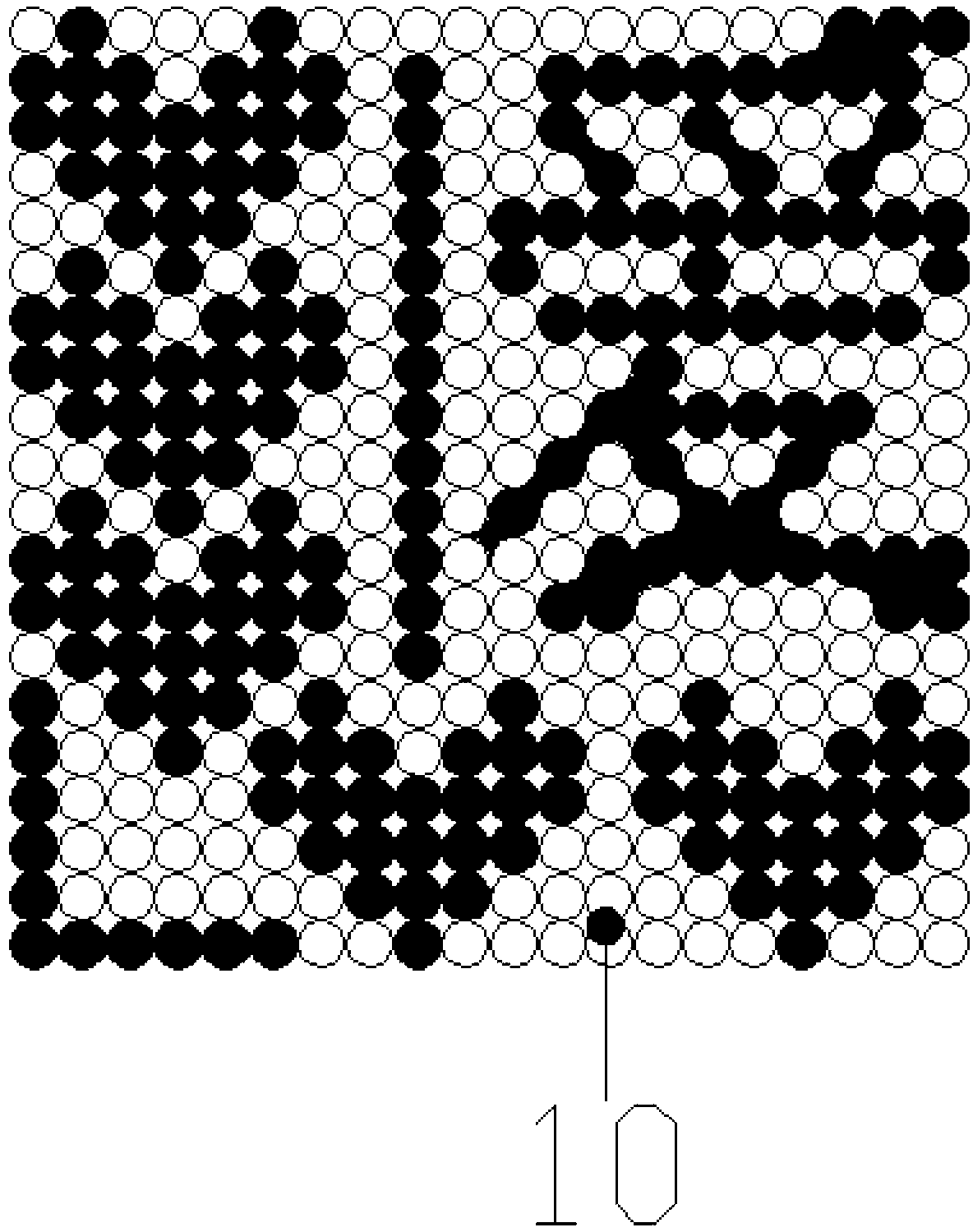

Production method of partitioned independent powder-charged post-dyed graphic fireworks

ActiveCN103234394AEasy to produceFlexible dyeing and moldingSpecial ornamental structuresFireworksFireworksEngineering

The invention discloses a production method of partitioned independent powder-charged post-dyed graphic fireworks. A graphic firework structure and a post-dyed graphic firework production method are included. The graphic firework structure comprises lattice structural bodies, the lattice structural bodies are filled with firework base color powder and connected with simultaneous launchers, the simultaneous launchers are connected with a simultaneous ignition bin, and the simultaneous ignition bin is filled with simultaneous ignition powder and connected with a lift-off rocket. The post-dyed graphic firework production method comprises a dyeing salt solution, a dyeing device and a dyeing method, wherein the dyeing method comprises designing graphic sample manuscripts, contacting the dyeing salt solution with the firework base color powder through the dyeing device, enabling the dyeing salt solution to permeate into the firework base color powder according to rule limitation, mixing, removing liquid components, performing full drying, and displaying desired colors after the original firework base color powder is lighted. The production method is simple in implementation and convenient to produce, inventory is not needed, and the graphic fireworks can be dyed before leaving factories and be dyed by users through free combination after being purchased.

Owner:SUZHOU ZZH INTPROP SERVICES

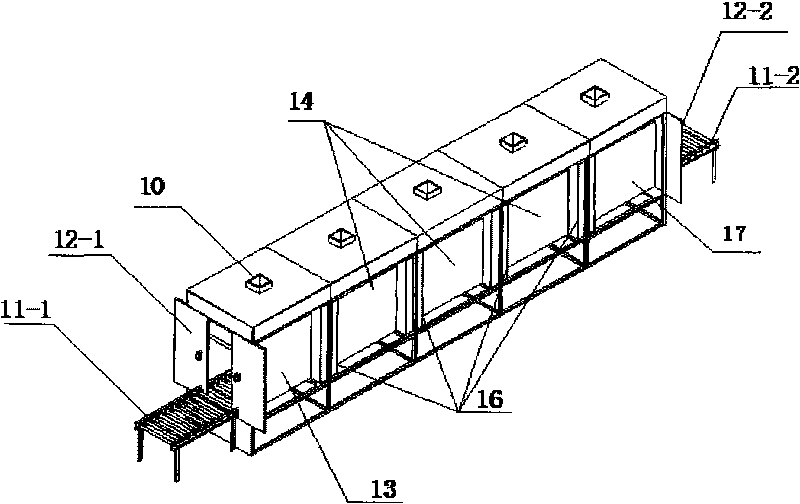

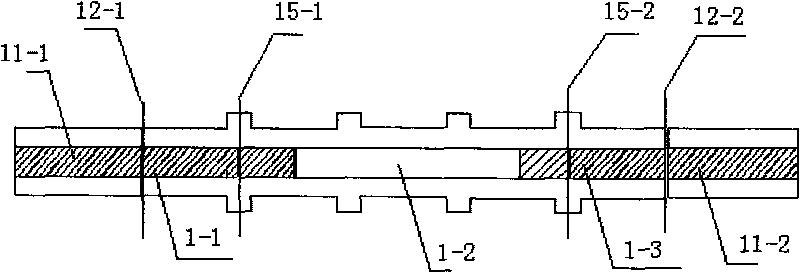

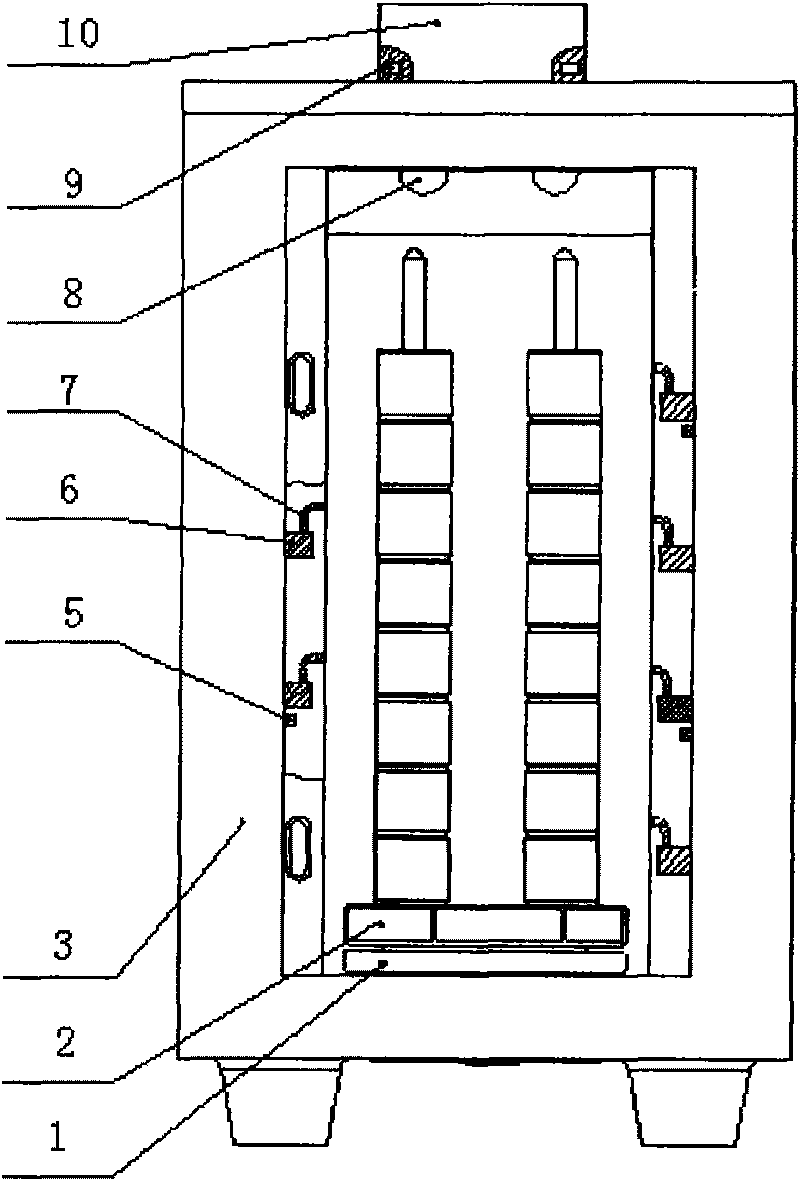

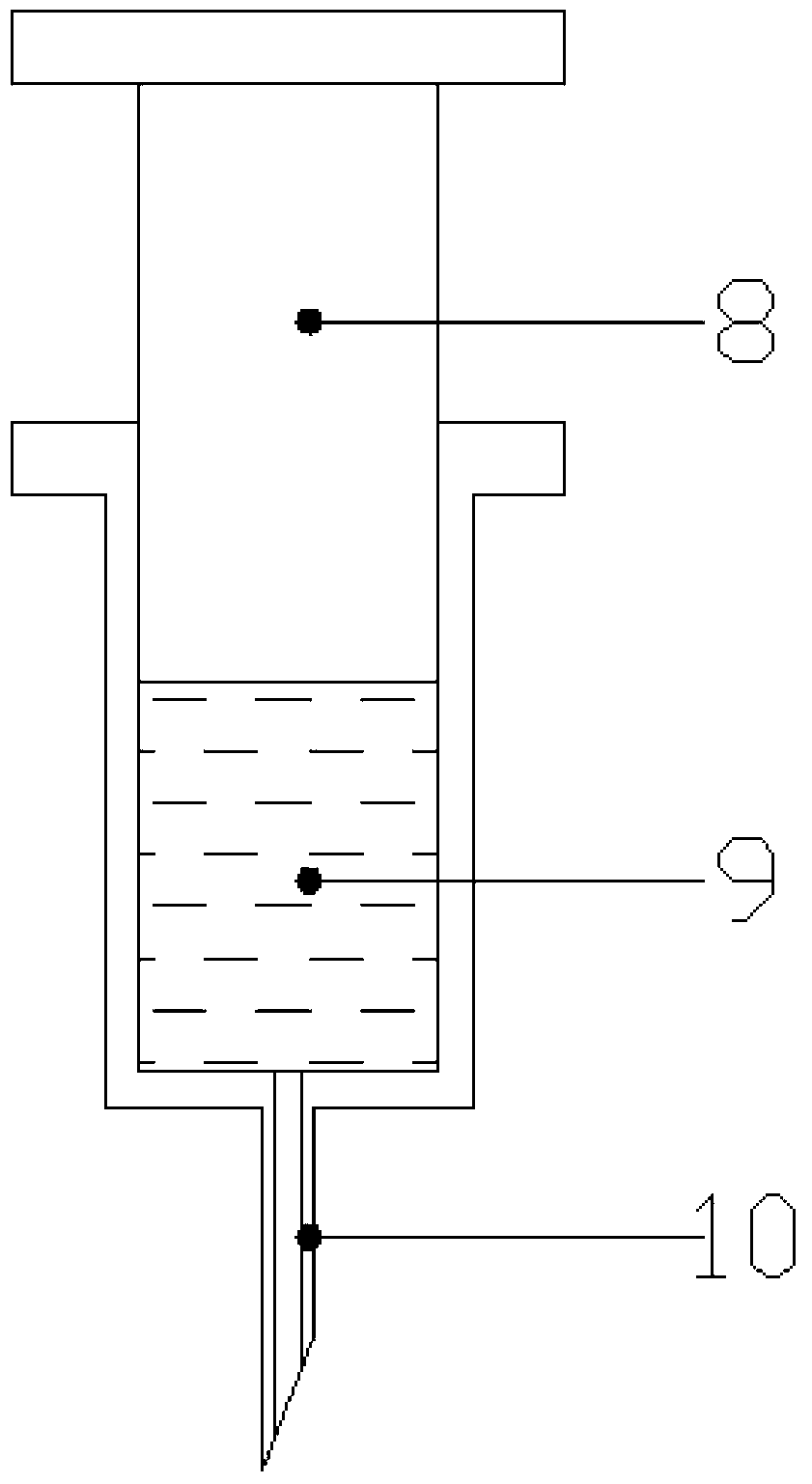

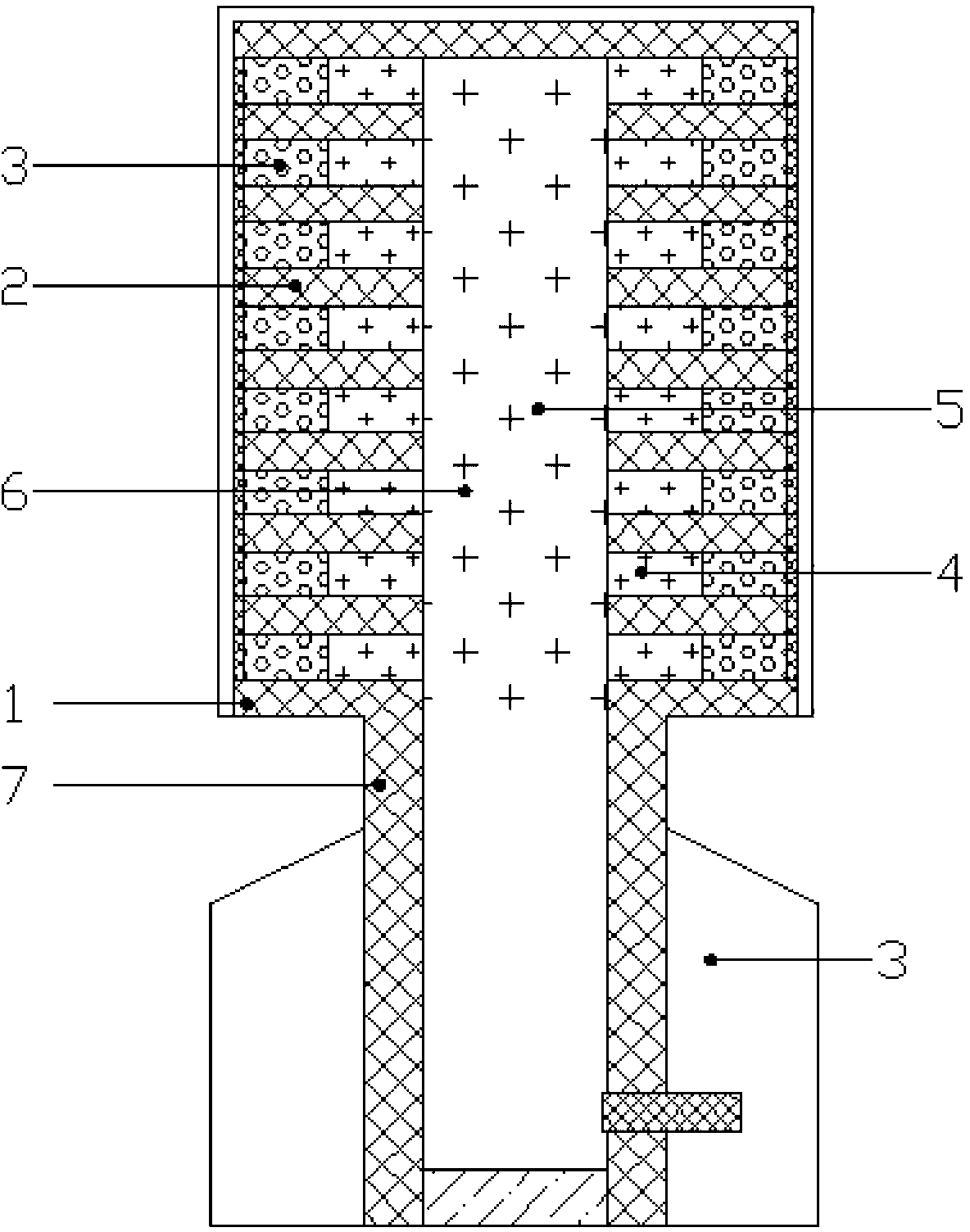

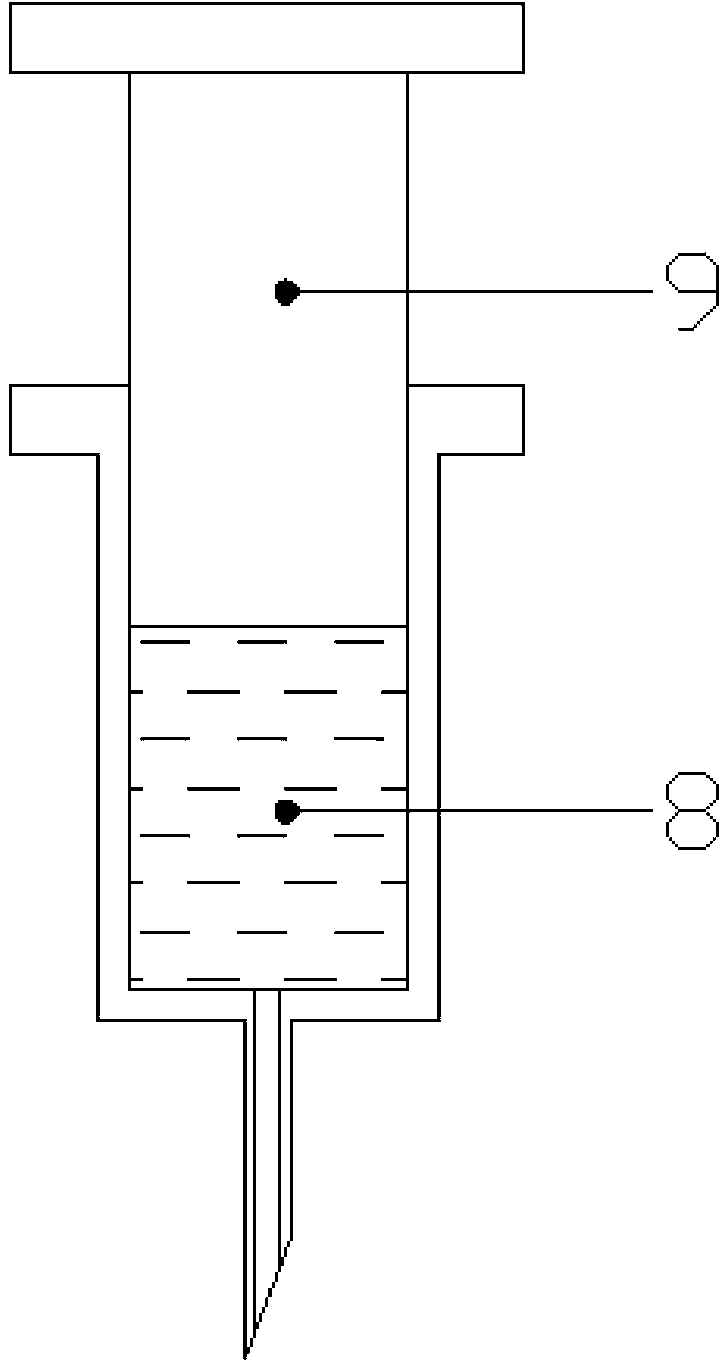

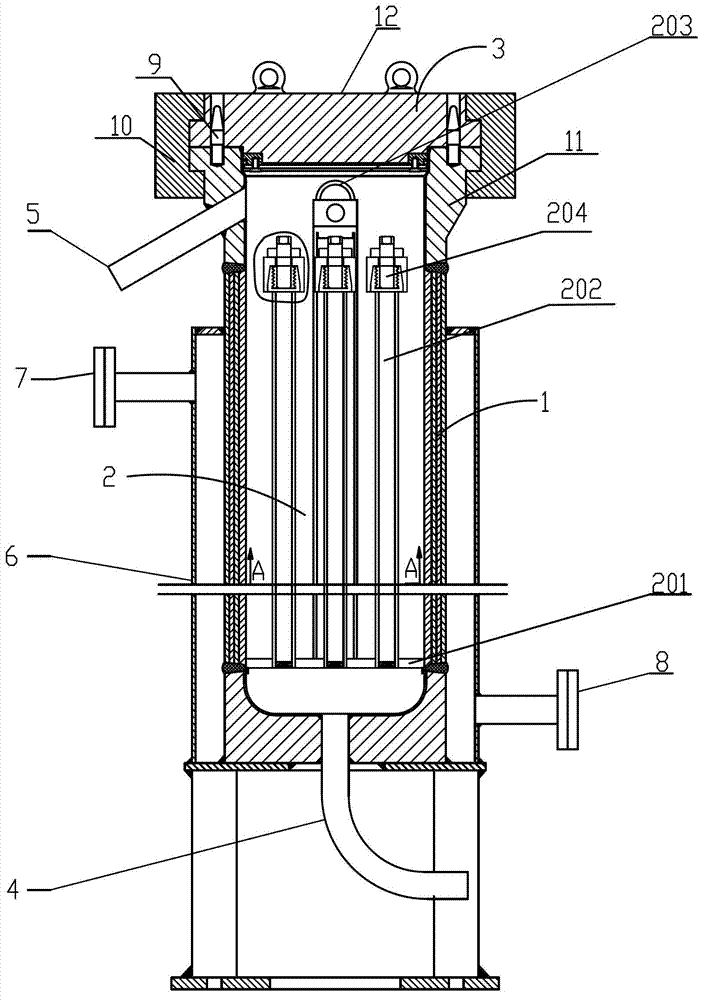

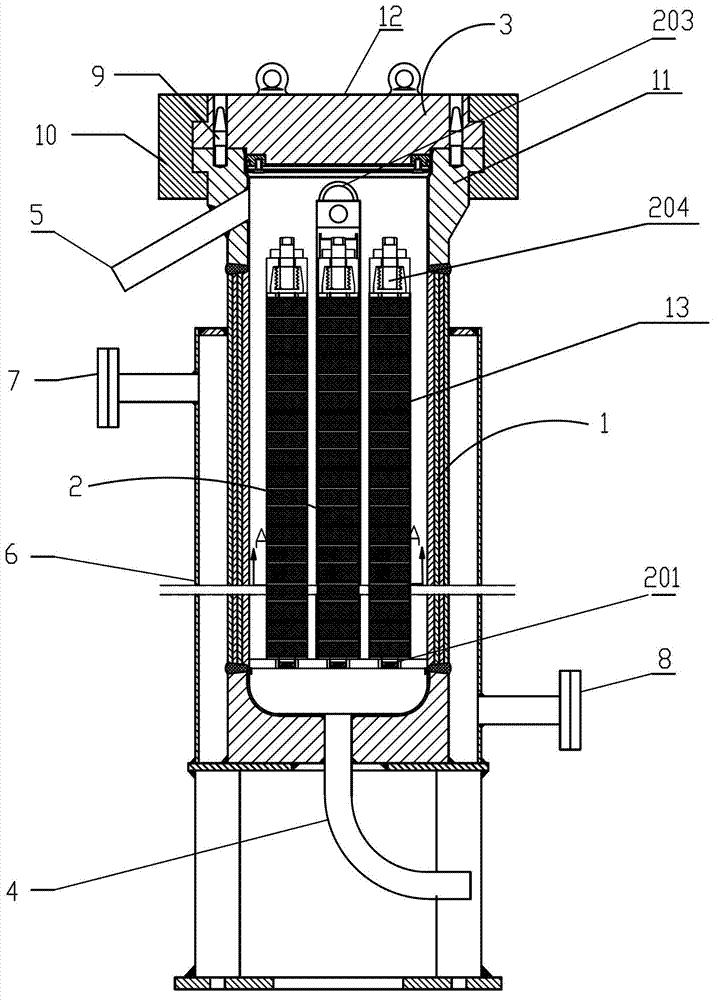

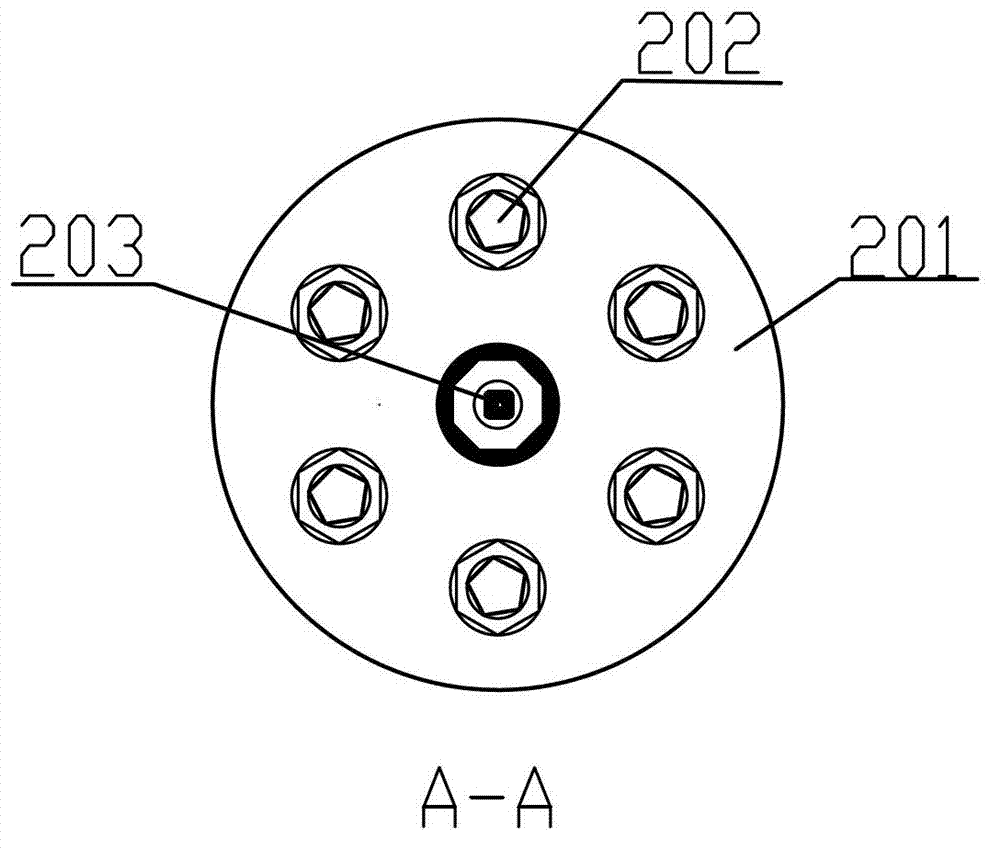

Supercritical carbon dioxide cheese dyeing kettle and waterless supercritical carbon dioxide cheese dyeing method

ActiveCN102787459ATextile treatment containersSolvent treatment with solvent recoveryEngineeringDrill

The invention relates to a supercritical carbon dioxide cheese dyeing kettle and a waterless supercritical carbon dioxide cheese dyeing method. In the dyeing kettle, when carbon dioxide fluid enters a distribution tray from an inlet, blades start rotating clockwise under the effect of pressure; inserted drill rods are driven to rotate by a rotation part; and the rotating speed of the inserted drill rods is increased along with the increase of pressure in a cylinder body. When a cheese is dyed, the cheese on the inserted drill rods is dyed at a speed of 0.2-0.5 r / s. When the rotating cheese is dyed, the cheese is subjected to the pressure of the fluid flowing out from a central shaft; the rotation and bicirculation of the cheese dyeing are realized; the uniform dyeing effect of the dyed cheese can be improved; and the migration ability and the diffusibility can be improved.

Owner:晋江国盛新材料科技有限公司

Modacrylic Shrinkable Fiber and Method for Manufacturing The Same

A modacrylic shrinkable fiber according to the present invention is containing a polymer composition obtained by mixing 50 to 99 parts by weight of a polymer (A) containing 40 wt % to 80 wt % of acrylonitrile, 20 wt % to 60 wt % of a halogen-ontaining monomer and 0 wt % to 5 wt % of a sulfonic-acid-containing monomer, and 1 to 50 parts by weight of a polymer (B) containing 5 wt % to 70 wt % of acrylonitrile, 20 wt % to 94 wt % of an acrylic ester and 1 wt % to 40 wt % of a sulfonic-acid-containing monomer containing a methallylsulfonic acid or metal salts thereof or amine salts thereof, in which a total amount of the polymer (A) and the polymer (B) is 100 parts by weight. In this way, a modacrylic shrinkable fiber that has a favorable color development property after dyeing and a high shrinkage ratio even after dyeing is obtained.

Owner:KANEKA CORP

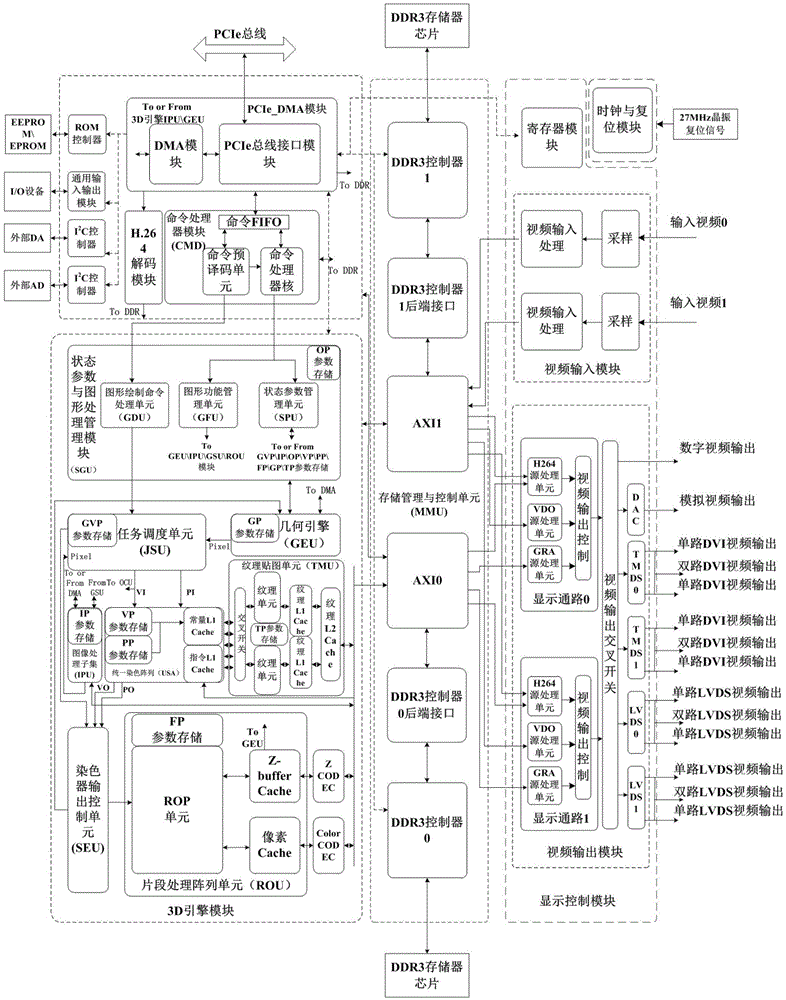

GPU (Graphics Processing Unit) system architecture based on uniform dyeing technology

ActiveCN105630441ARealize the effect of time division multiplexingIncrease profitProcessor architectures/configurationDigital output to display deviceGraphicsComputer module

The invention relates to a GPU (Graphics Processing Unit) system architecture based on a uniform dyeing technology. The architecture comprises a host interface module based on a PCIe (Peripheral Component Interface Express), a 3D (Three-Dimensional) engine module based on a uniform dyeing architecture, a storage control and management module based on AXI (Automatic X-ray Inspection) and two paths of independent display control modules, wherein the host interface module is connected with the 3D engine module, and, the host interface module, the 3D engine module and the display control module are all connected with the storage control and management module. The GPU system architecture can realize the hardware acceleration of an OpenGL API (Open Graphics Library) (Application Program Interface).

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

Hair highlighting application tool

Disclosed herein is an application tool (1) and methods to use the same. The application tool (1) comprises two plates (22), connected together. At least one of said two plates (22) comprises a fluid control zone (50), which run along the perimeter edge (30) of said at least one plate (22), a displacement zone (60), which at least partially separate said fluid control zone (50) from a containment zone (70). A hair treatment composition may be loaded onto the containment zone (70). Application of hair treatment compositions through the application tool (1) according to the invention allows for a precise, non-messy and clean targeting of the hair treatment composition on a hair strand and it is especially useful for highlighting and dyeing compositions.

Owner:NOXELL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com