Patents

Literature

59 results about "Square yard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The square yard (India: gaz) is an imperial unit of area, formerly used in most of the English-speaking world but now generally replaced by the square metre, however it is still in widespread use in the U.S., Canada, the U.K. and India. It is defined as the area of a square with sides of one yard (three feet, thirty-six inches, 0.9144 metres) in length.

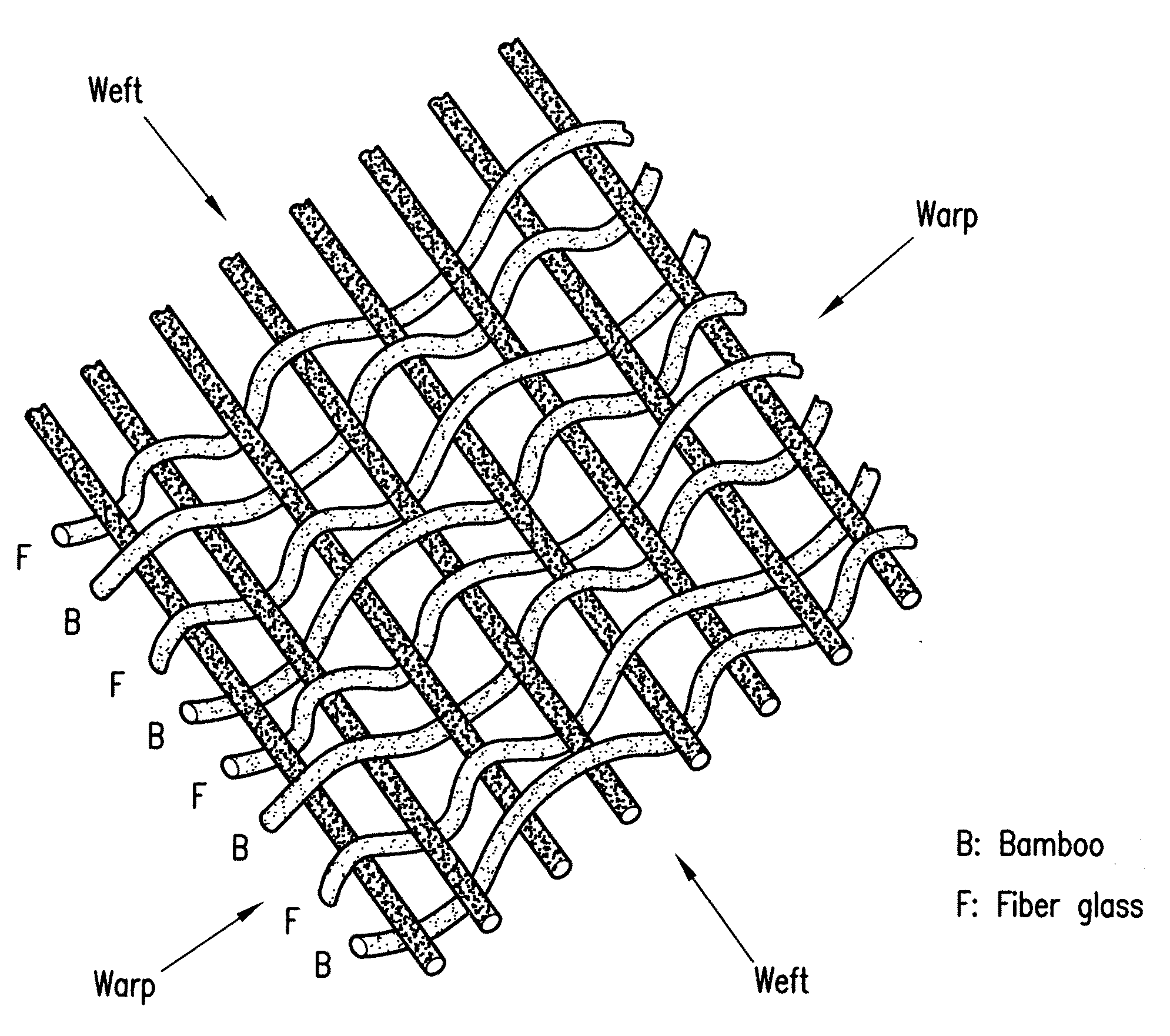

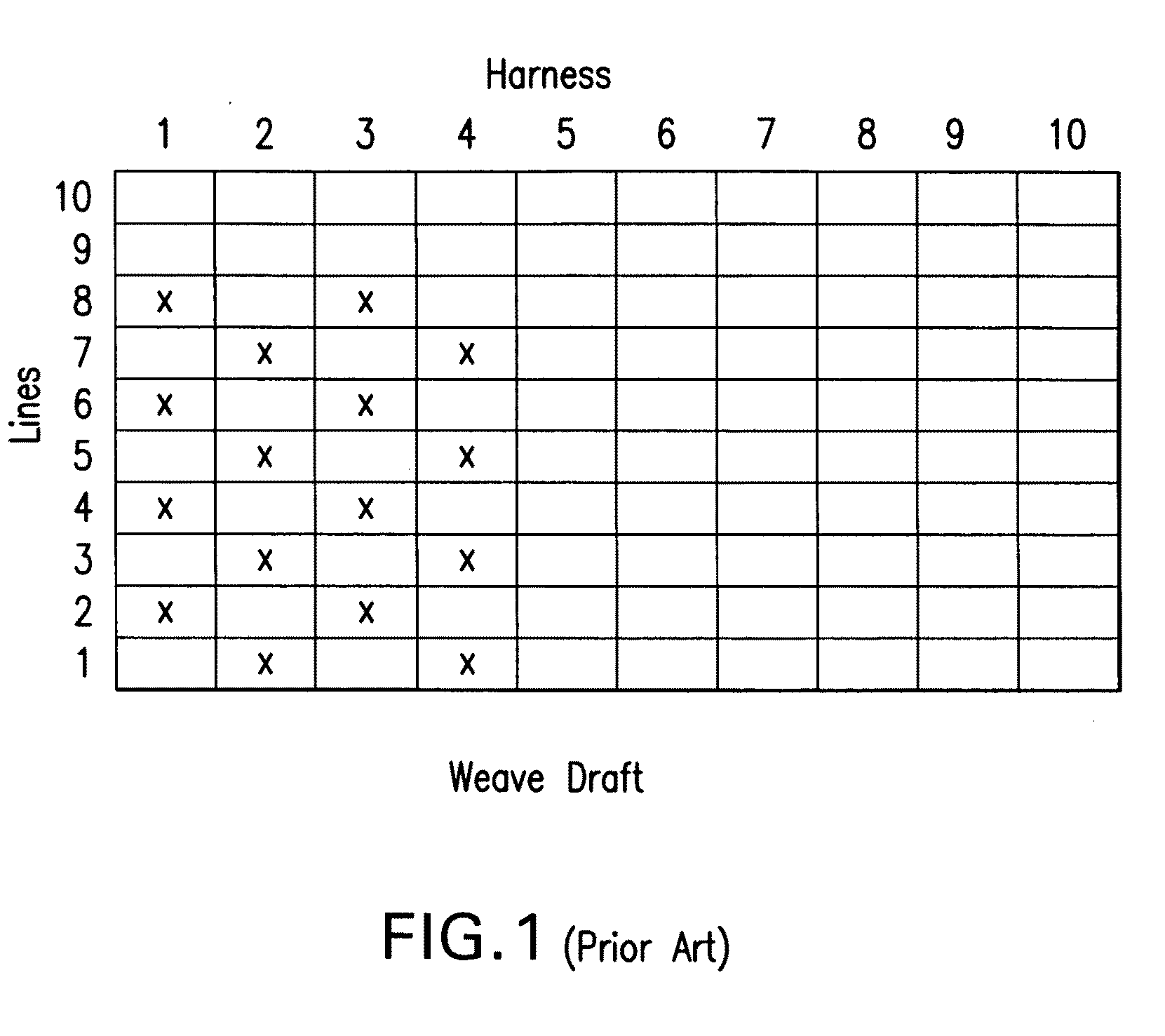

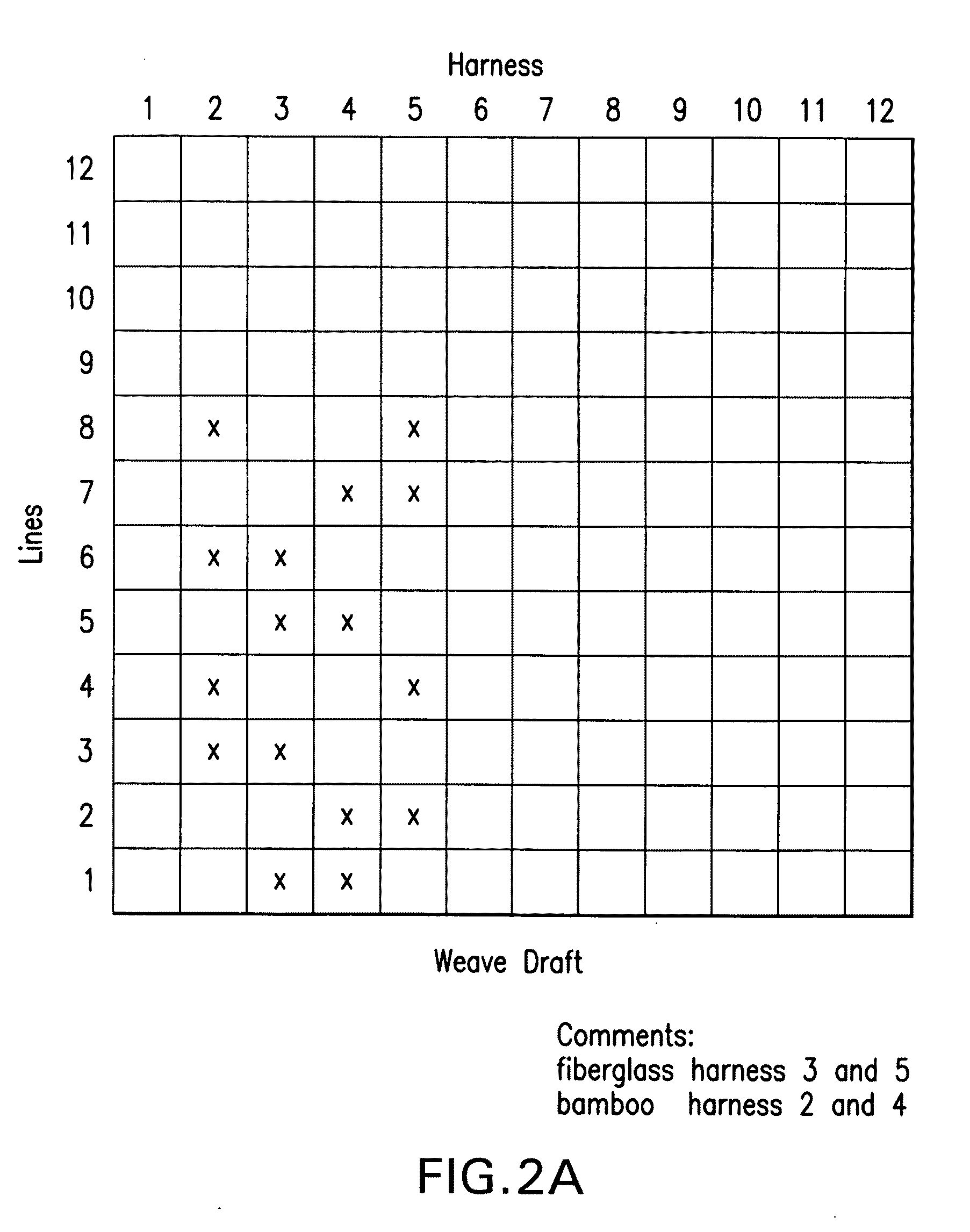

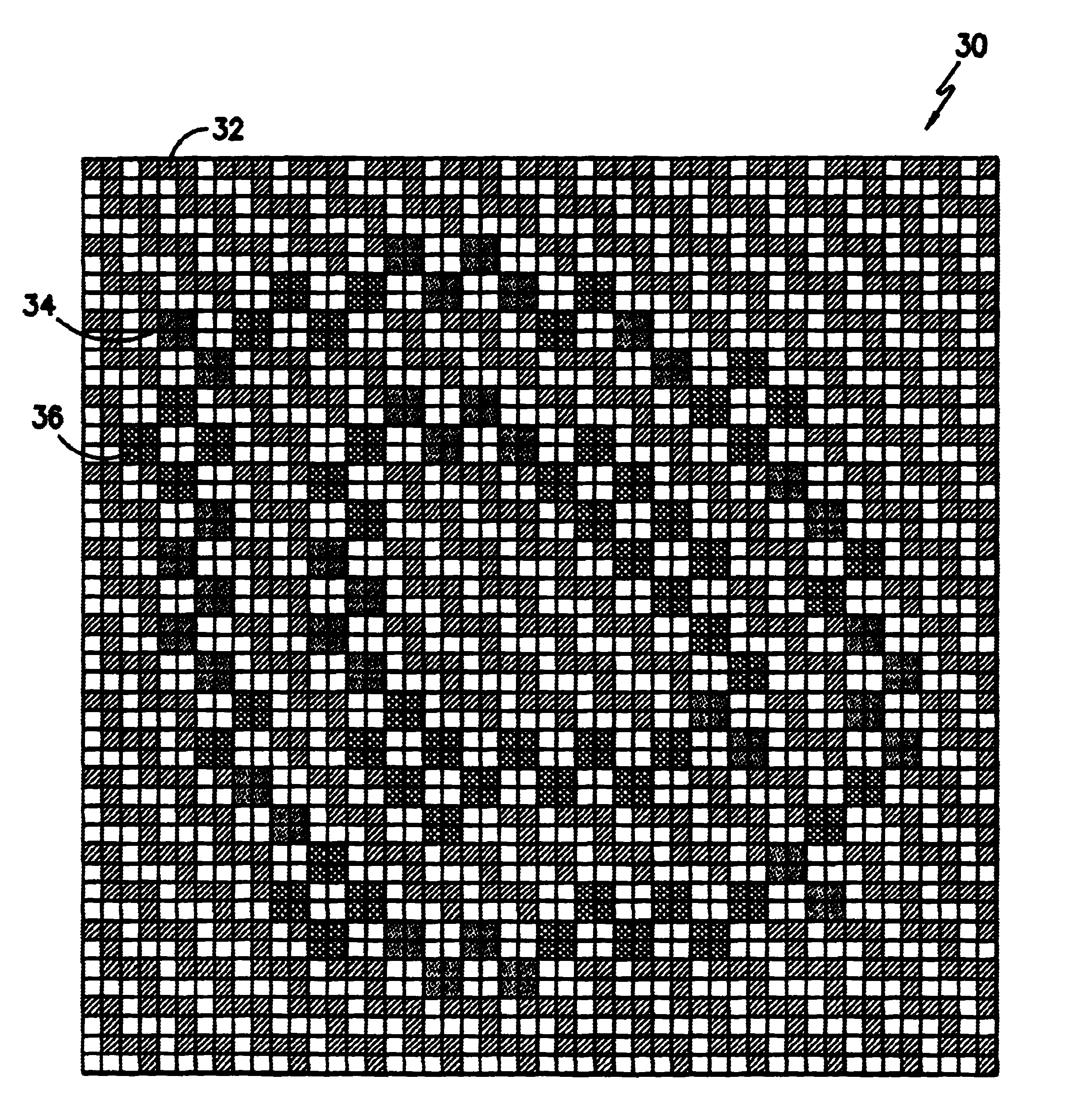

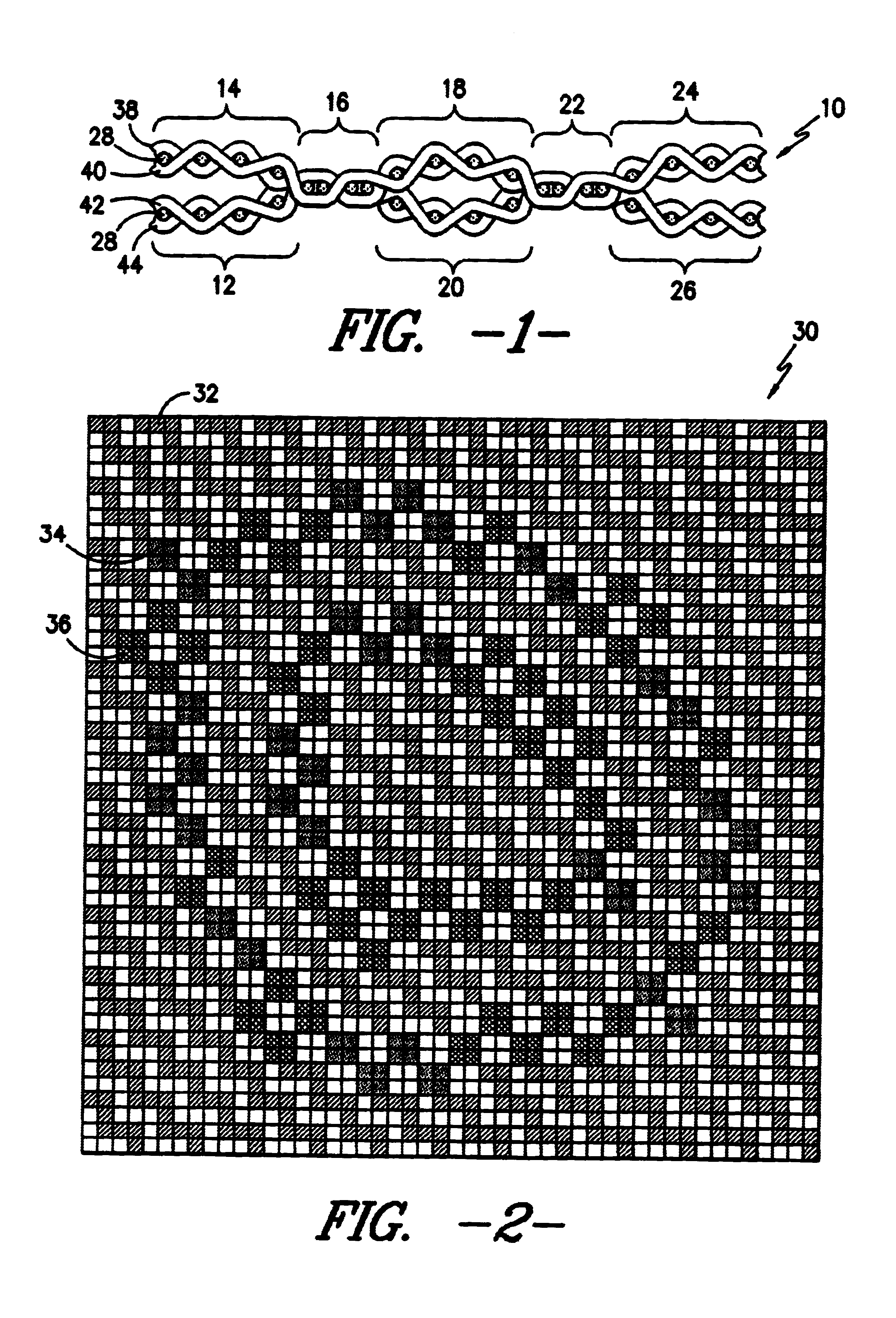

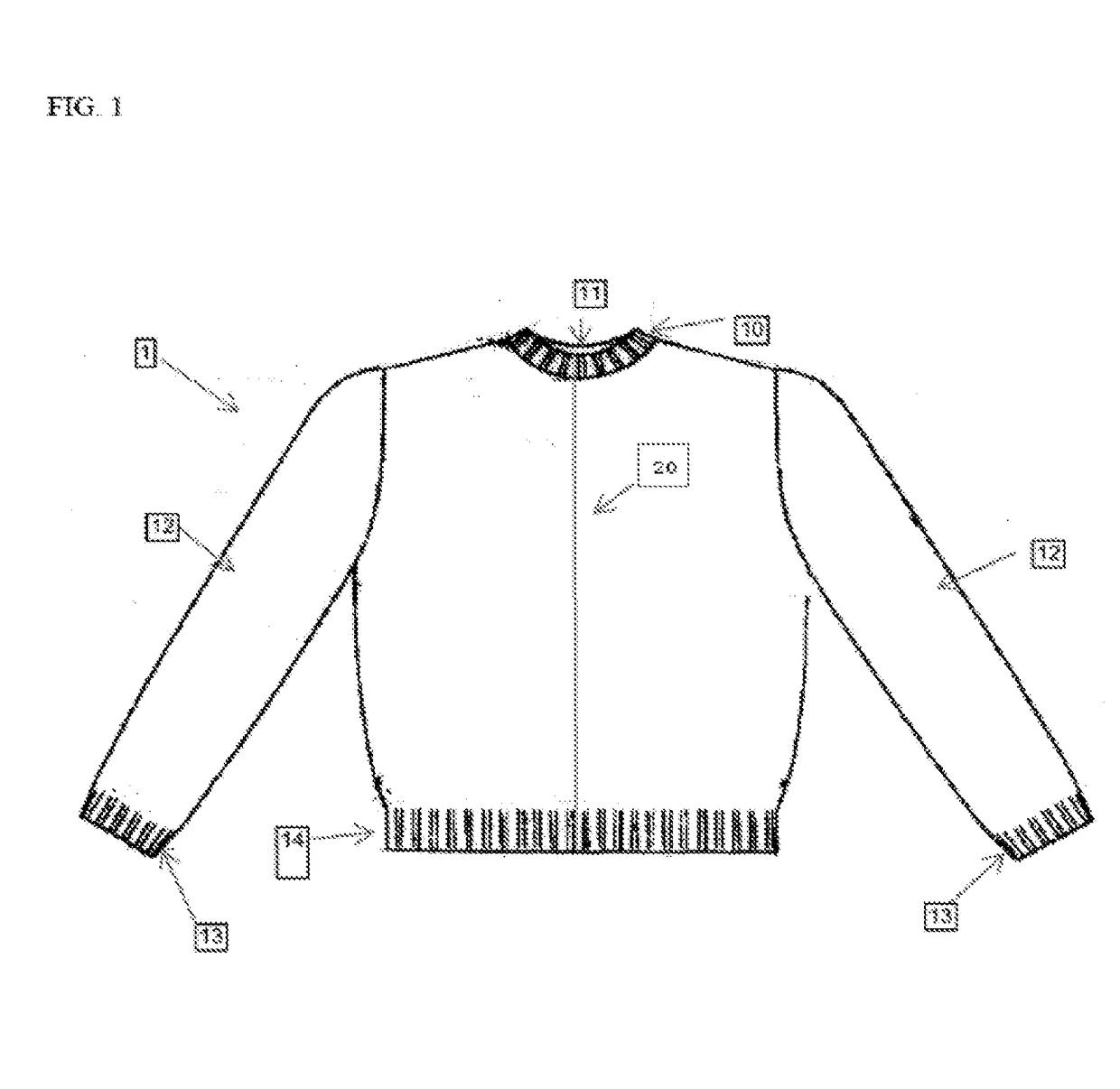

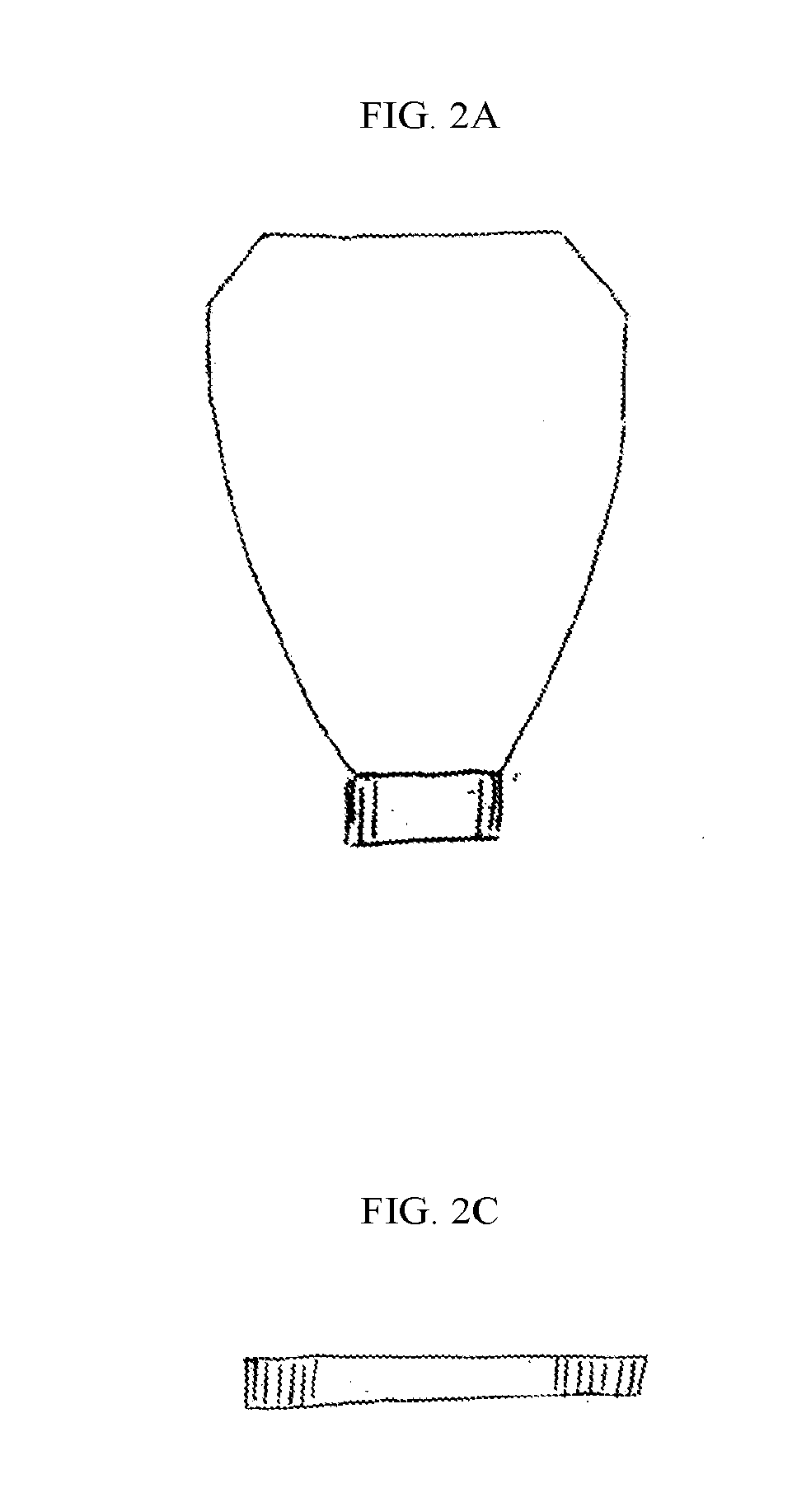

Hemostatic woven fabric

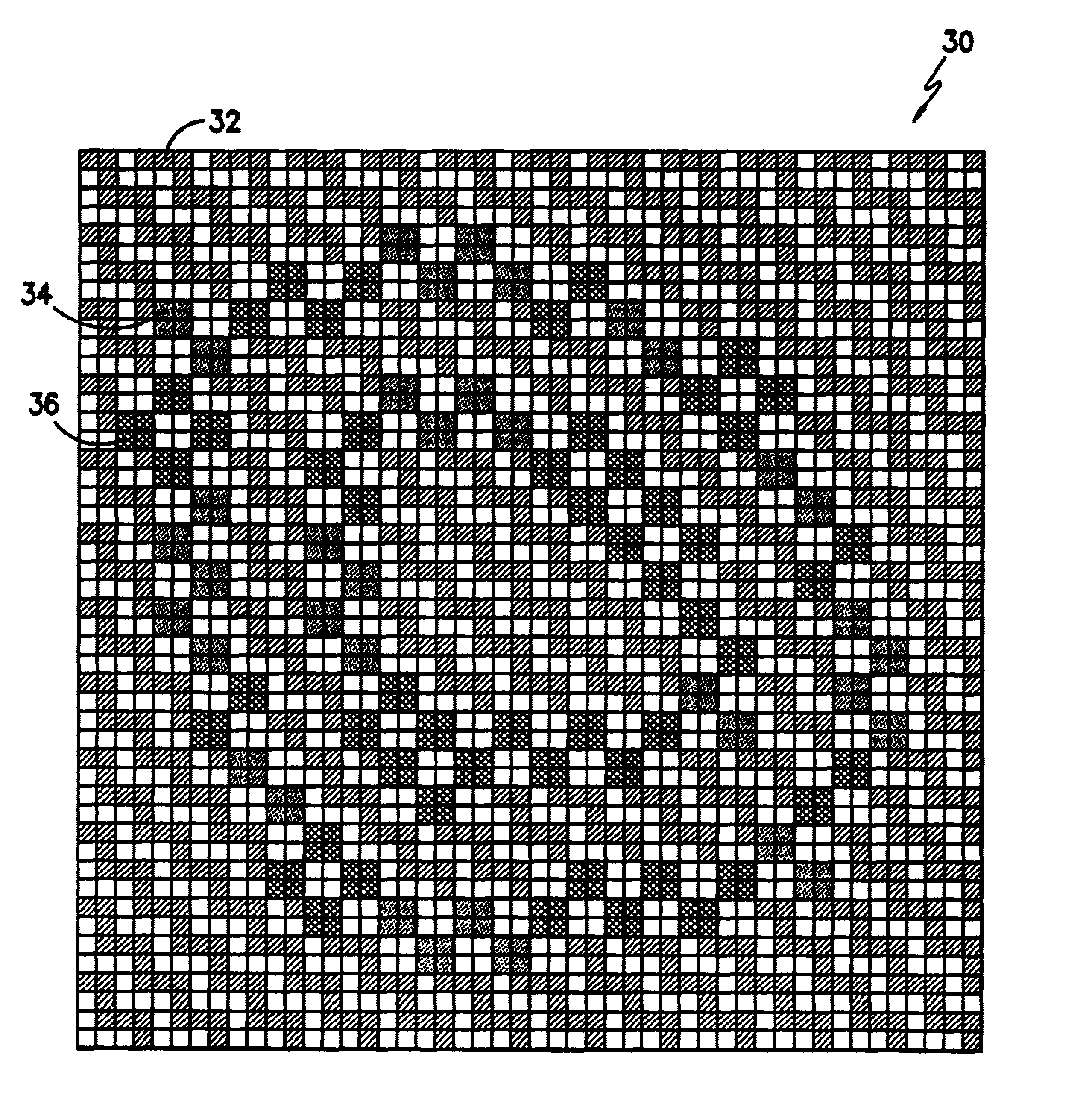

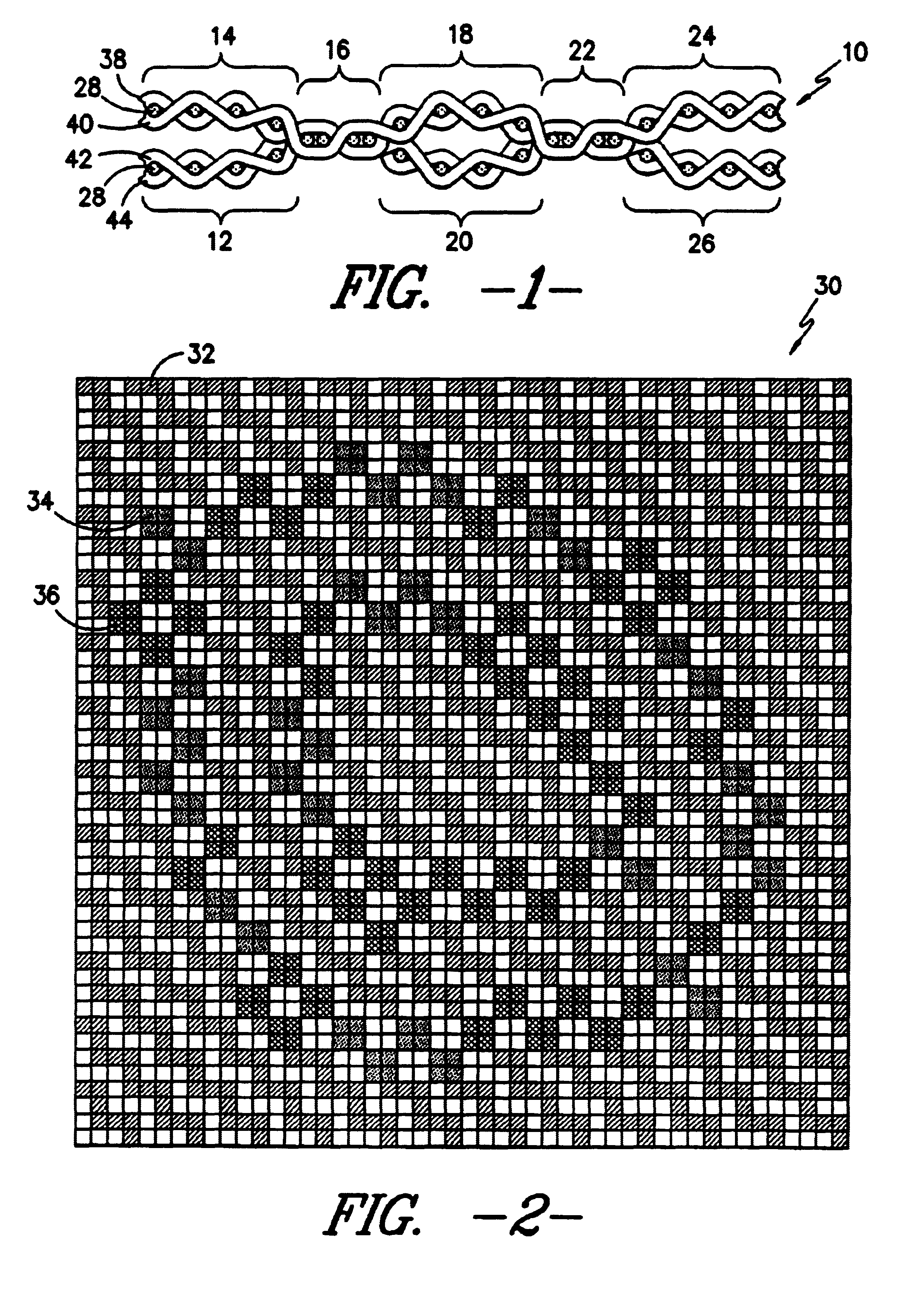

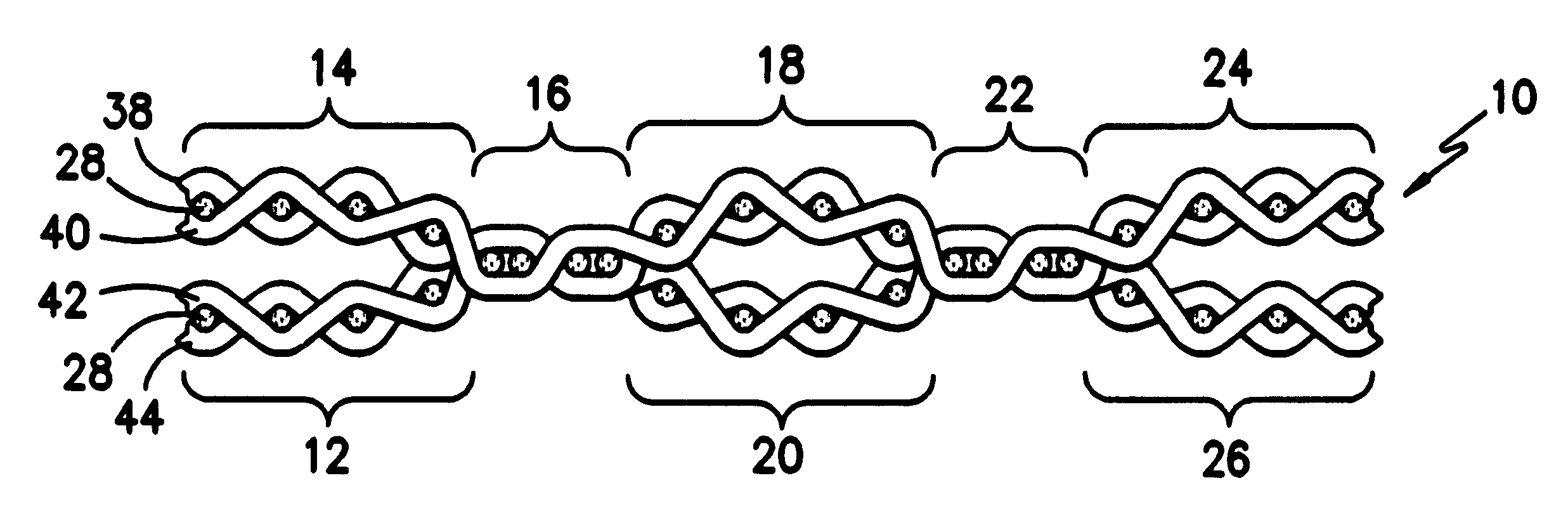

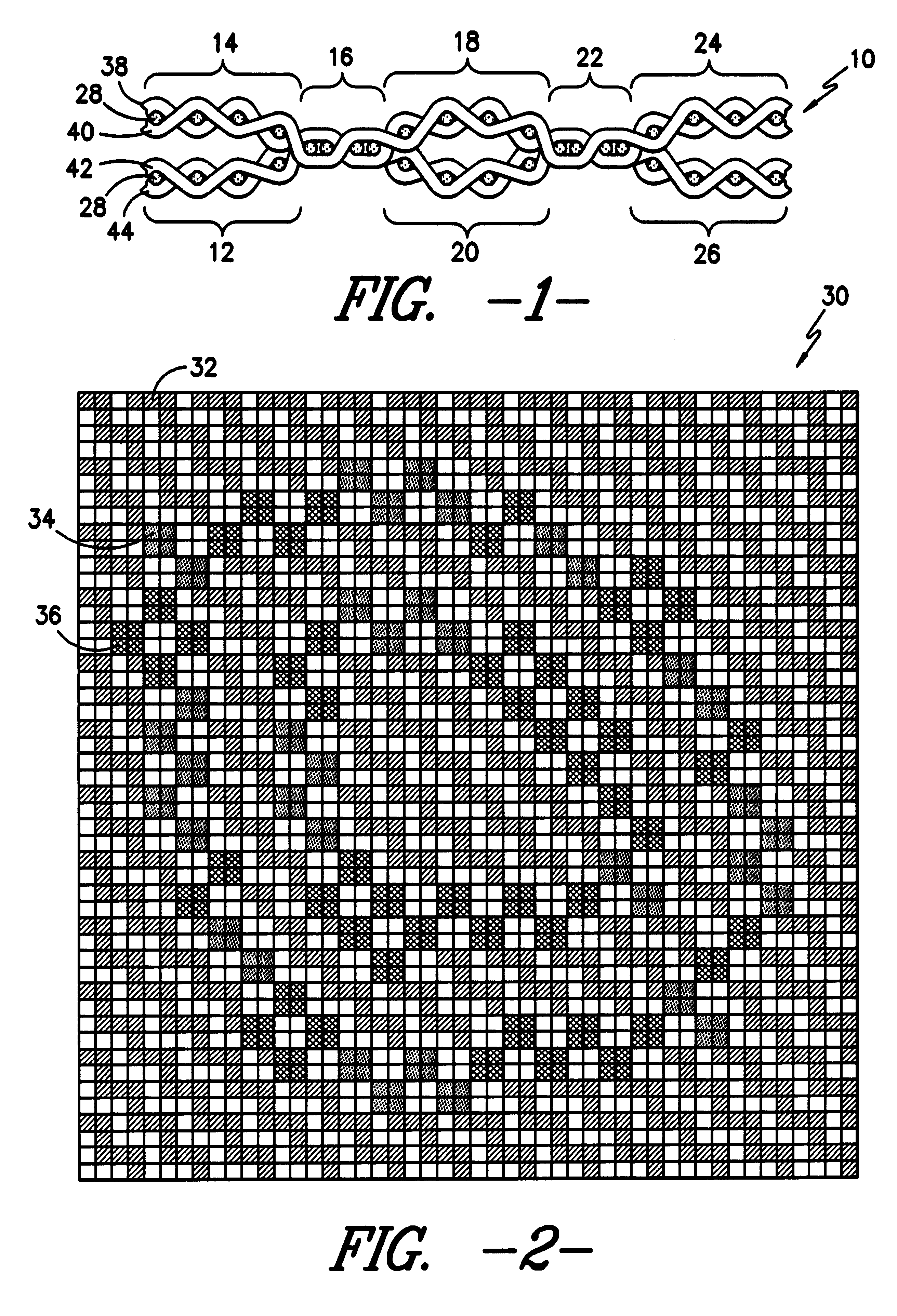

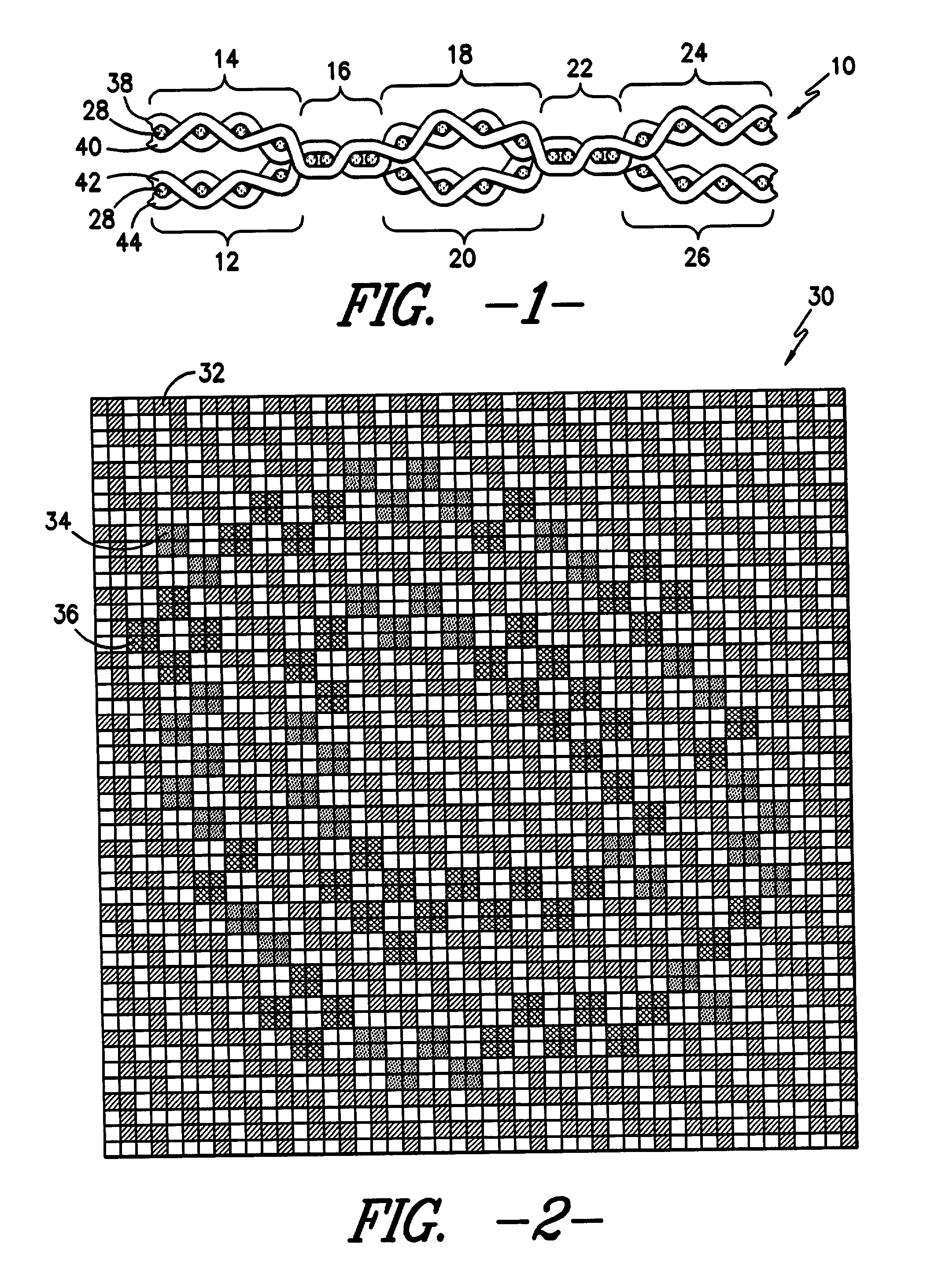

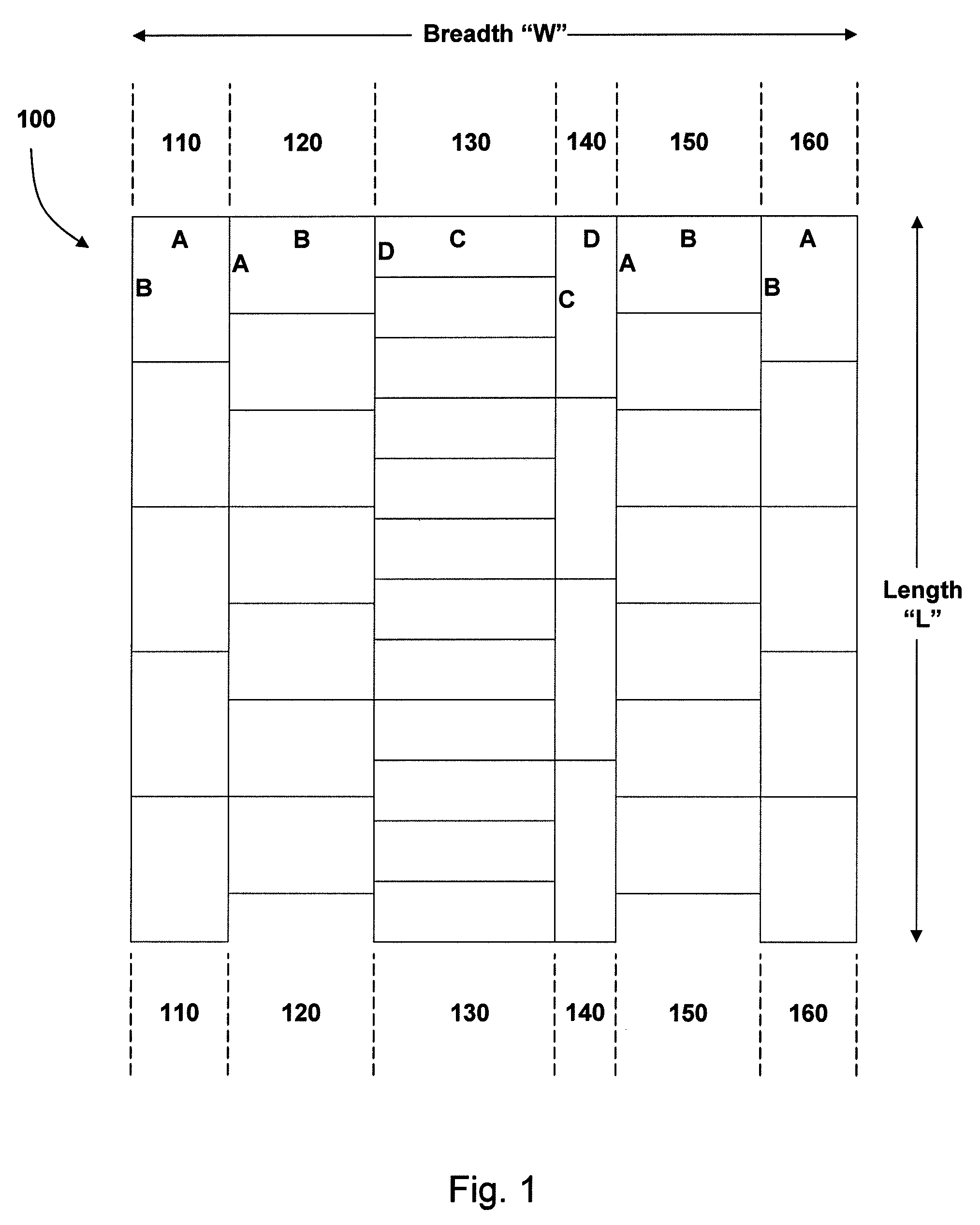

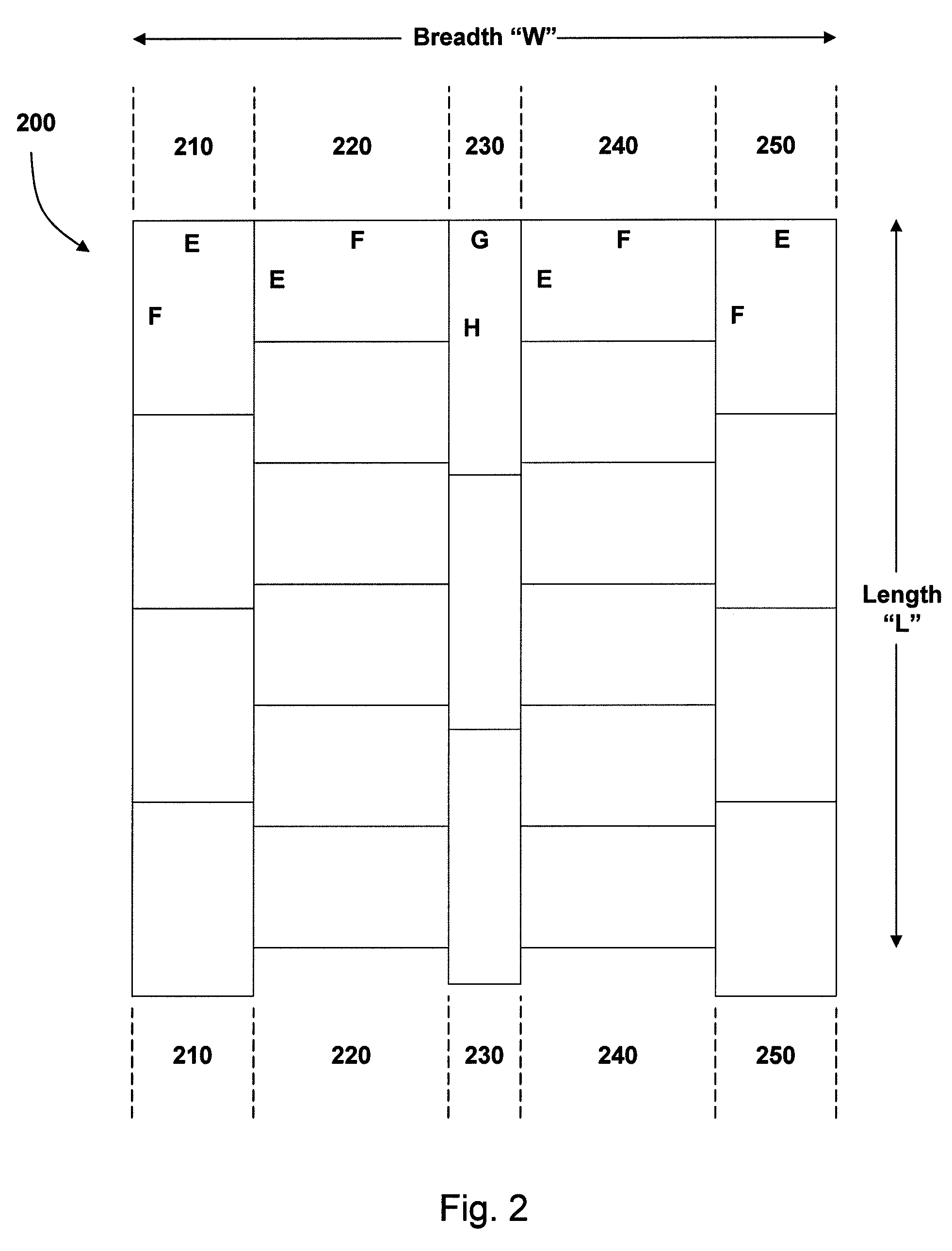

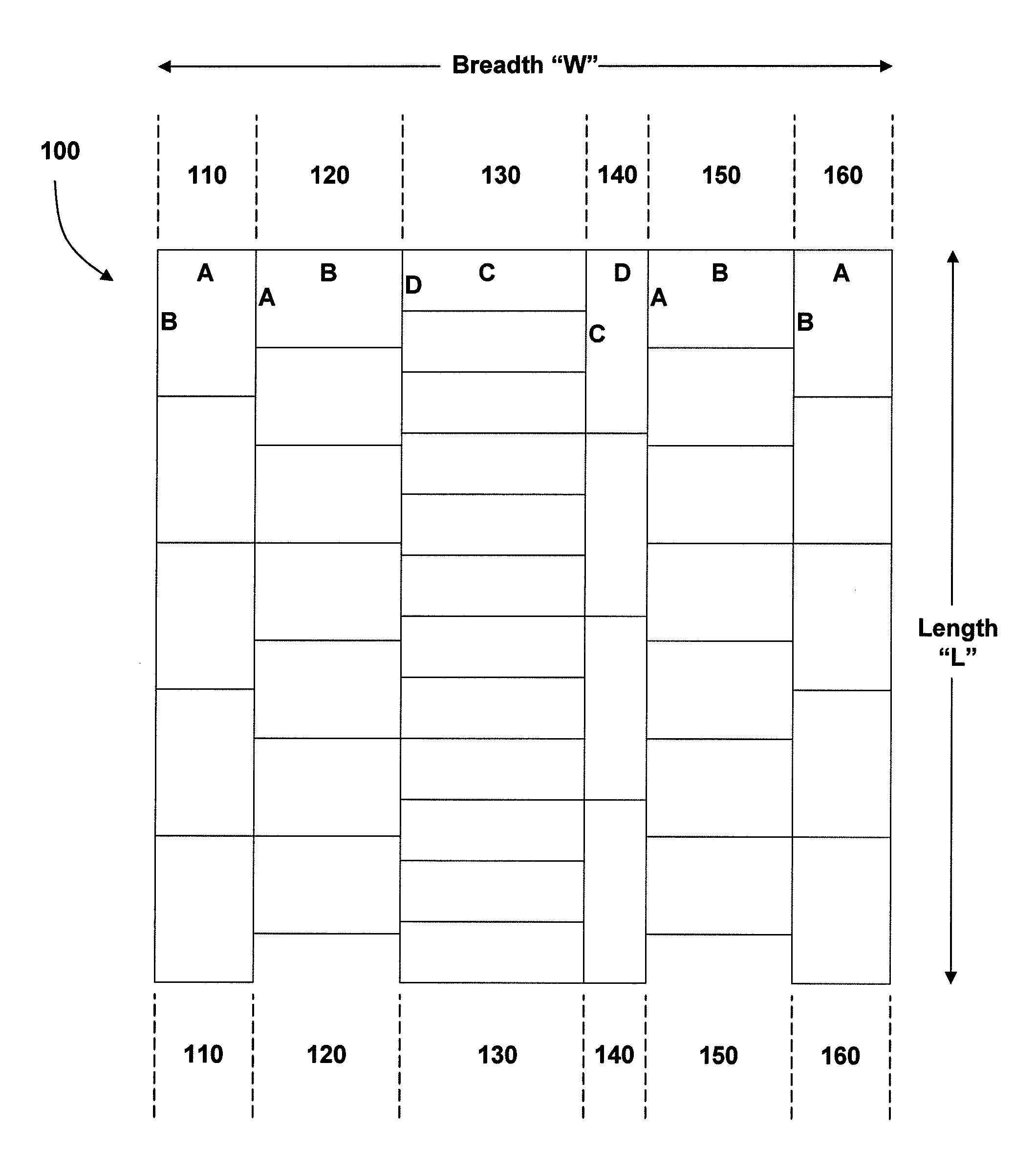

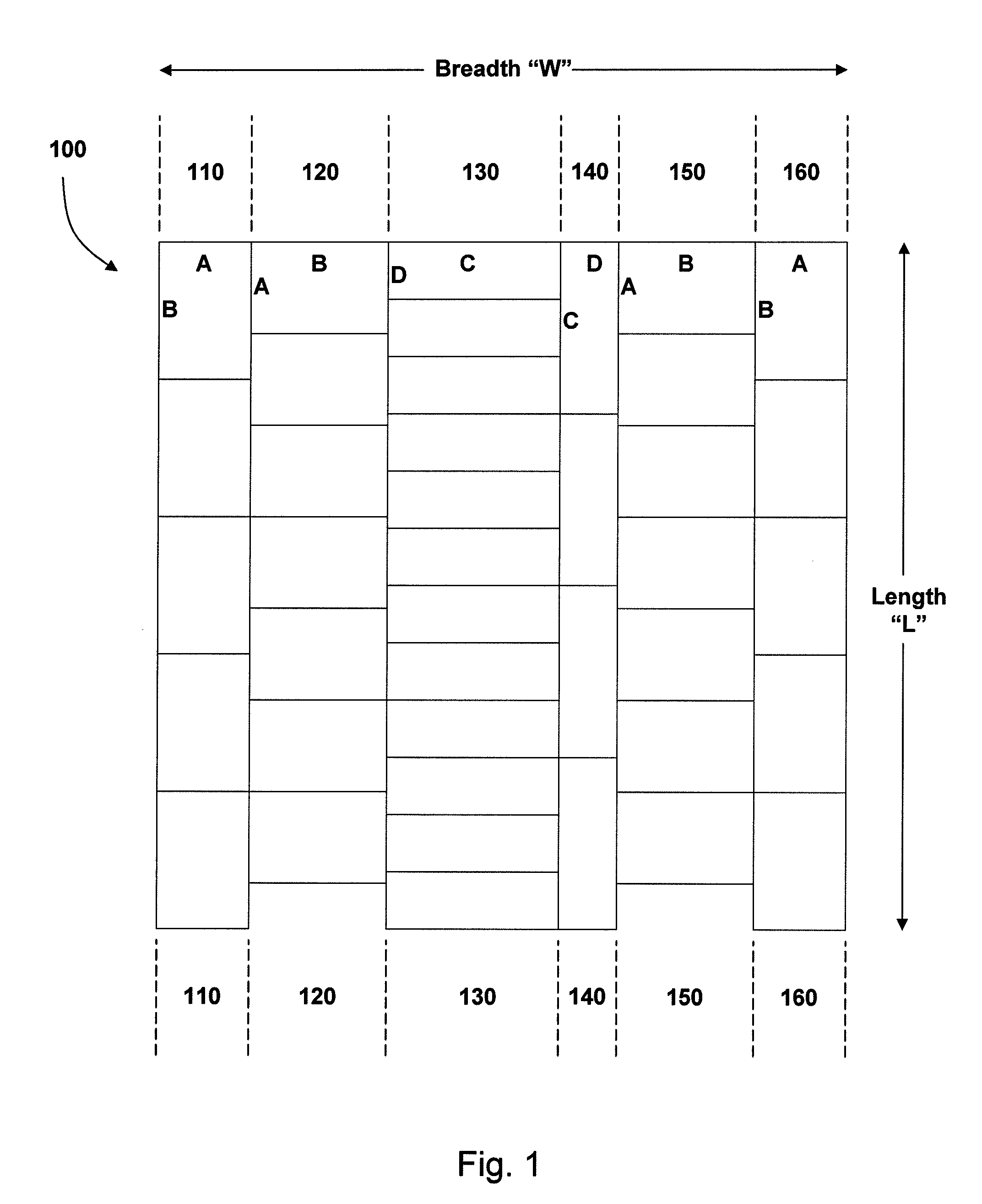

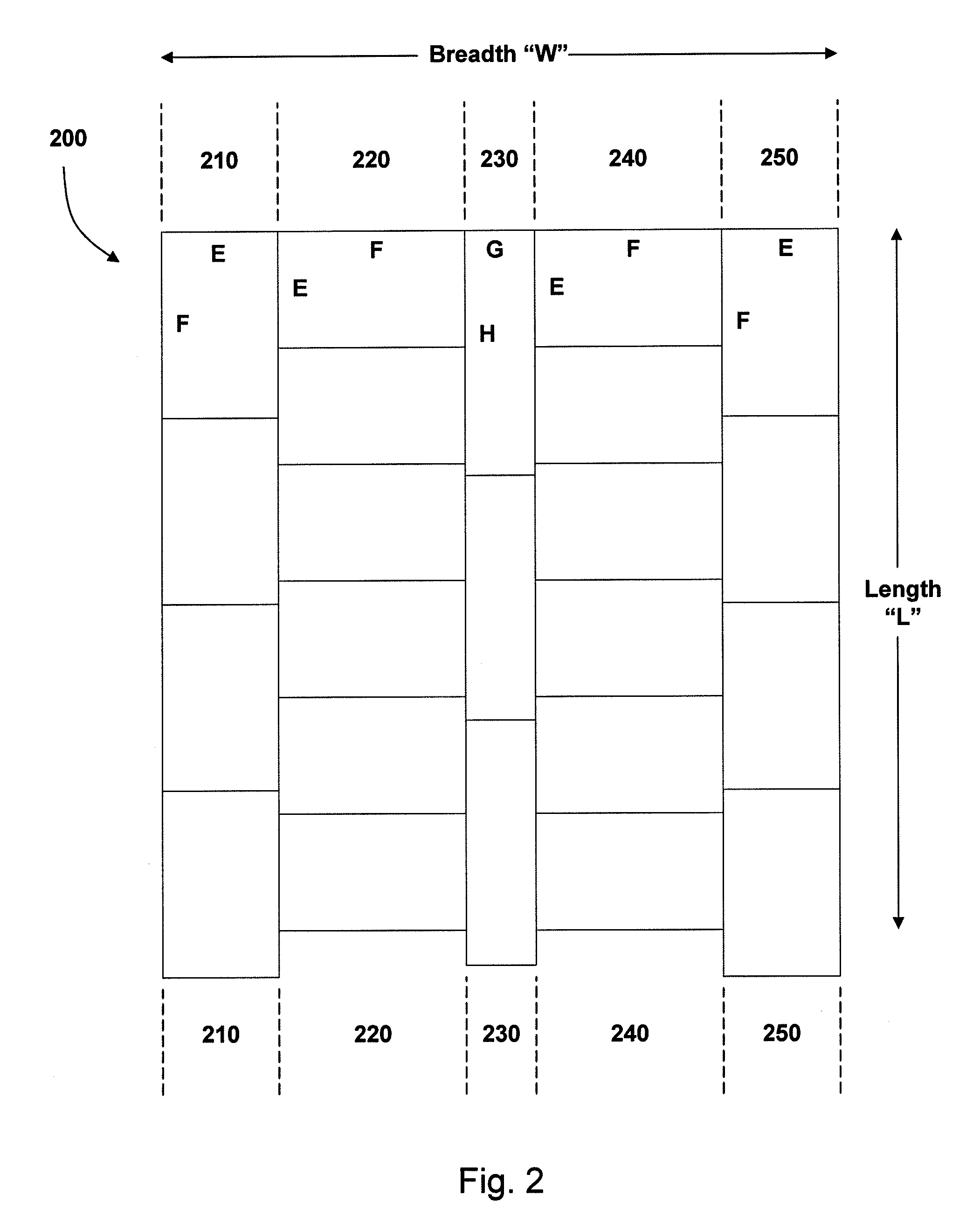

The present invention is directed to a woven fabric having the modified crowsfoot weave pattern shown in FIGS. 2A and 2B. The present invention is directed to a woven fabric comprising about 65 wt % fiberglass yarn and about 35 wt % bamboo yarn, the woven fabric (1) being about 15.0 ounces per square yard (OSY); (2) having a thread count of about 760; and (3) having the modified crowsfoot weave pattern shown in FIGS. 2A and 2B. Additional ingredients may also be added to the woven fabrics of the invention to enhance the hemostatic properties.

Owner:ENTEGRION INC

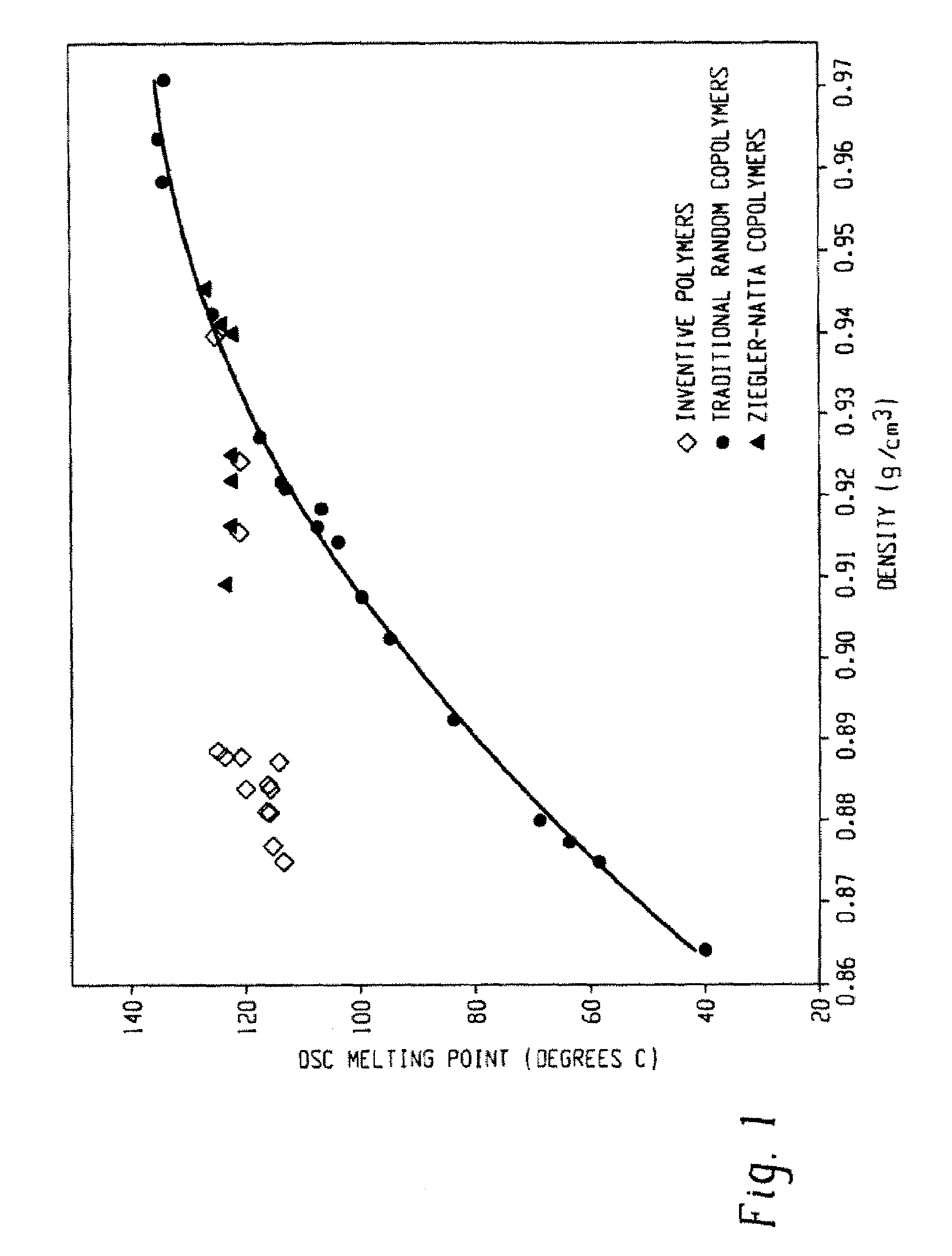

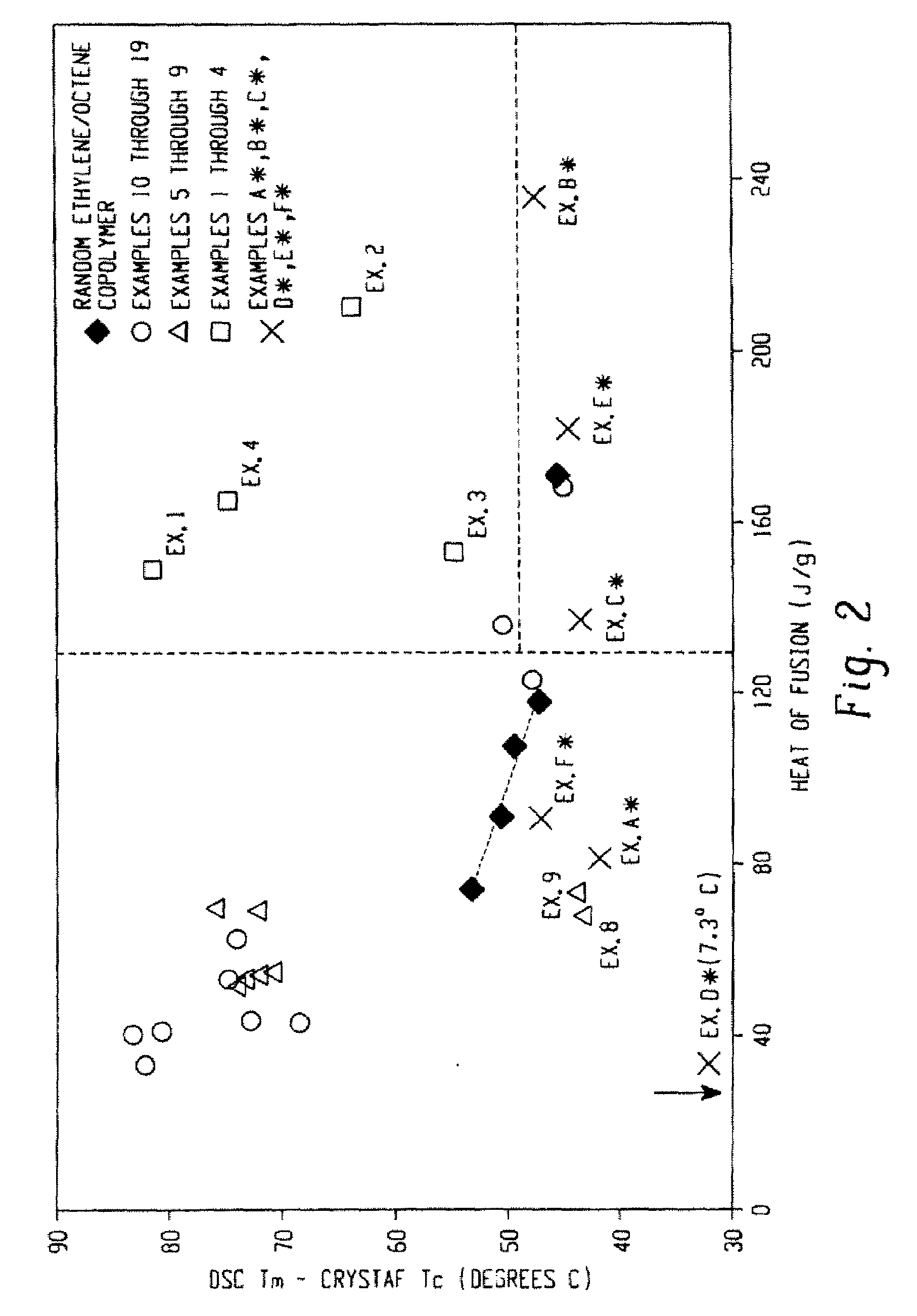

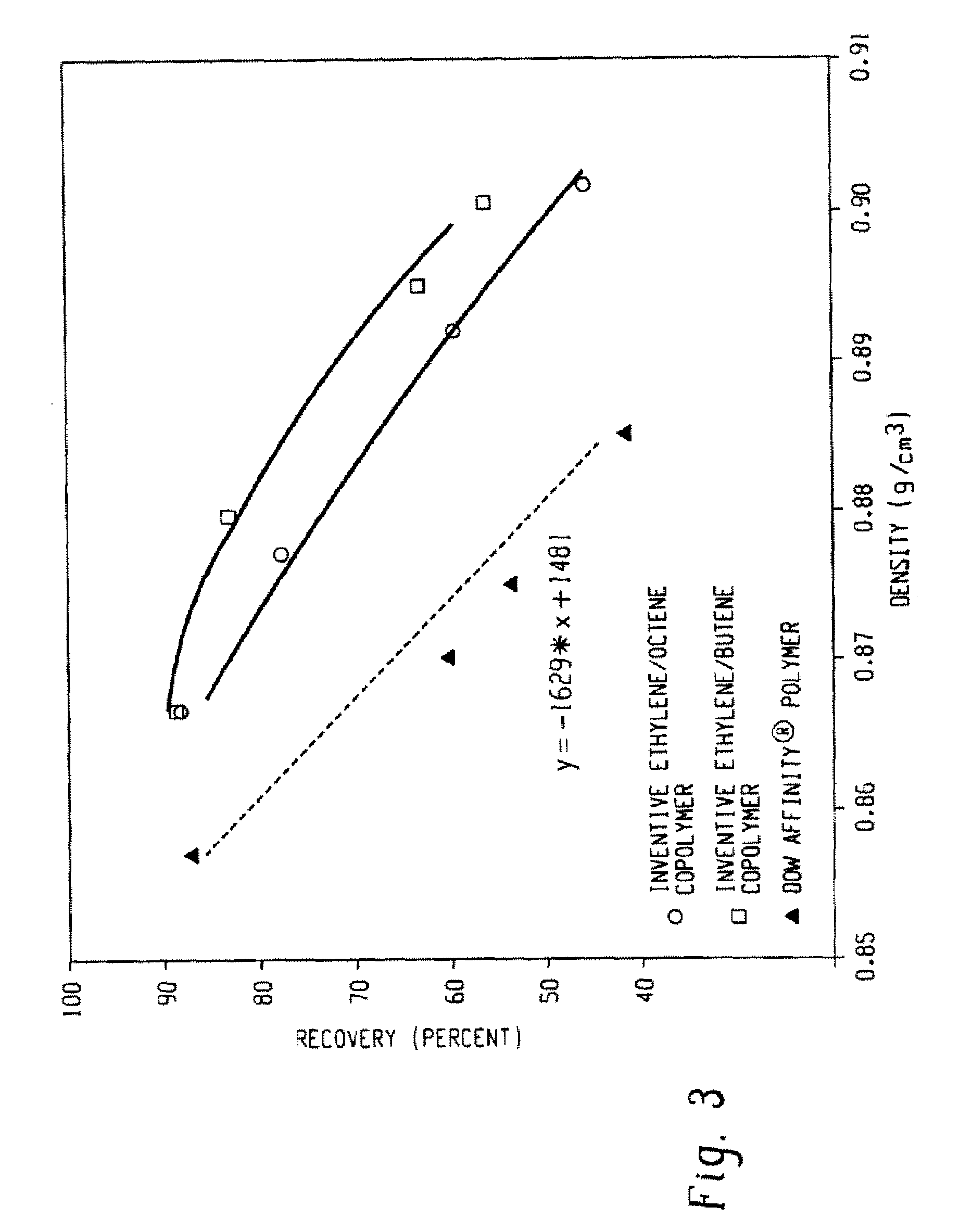

Olefin block compositions for heavy weight stretch fabrics

InactiveUS20080299857A1Improved ratio of stretch to growthHigh temperature toleranceMonocomponent synthetic polymer artificial filamentWoven fabricsSquare yardHeavy weight

Heavy weight stretch fabrics comprising ethylene / α-olefin interpolymer are described. The fabric often has a weight of at least 10 ounces per square yard measured according to ASTM 3776 and has a stretch of at least 10 percent measured according to ASTM D3107. These fabrics exhibit excellent chemical, resistance (for example chlorine or caustic resistance) and durability, that is they retain their shape and feel over repeated exposure to processing conditions, such as stone-washing, dye-stripping, PET-dyeing and the like, and industrial laundry conditions.

Owner:DOW GLOBAL TECH LLC

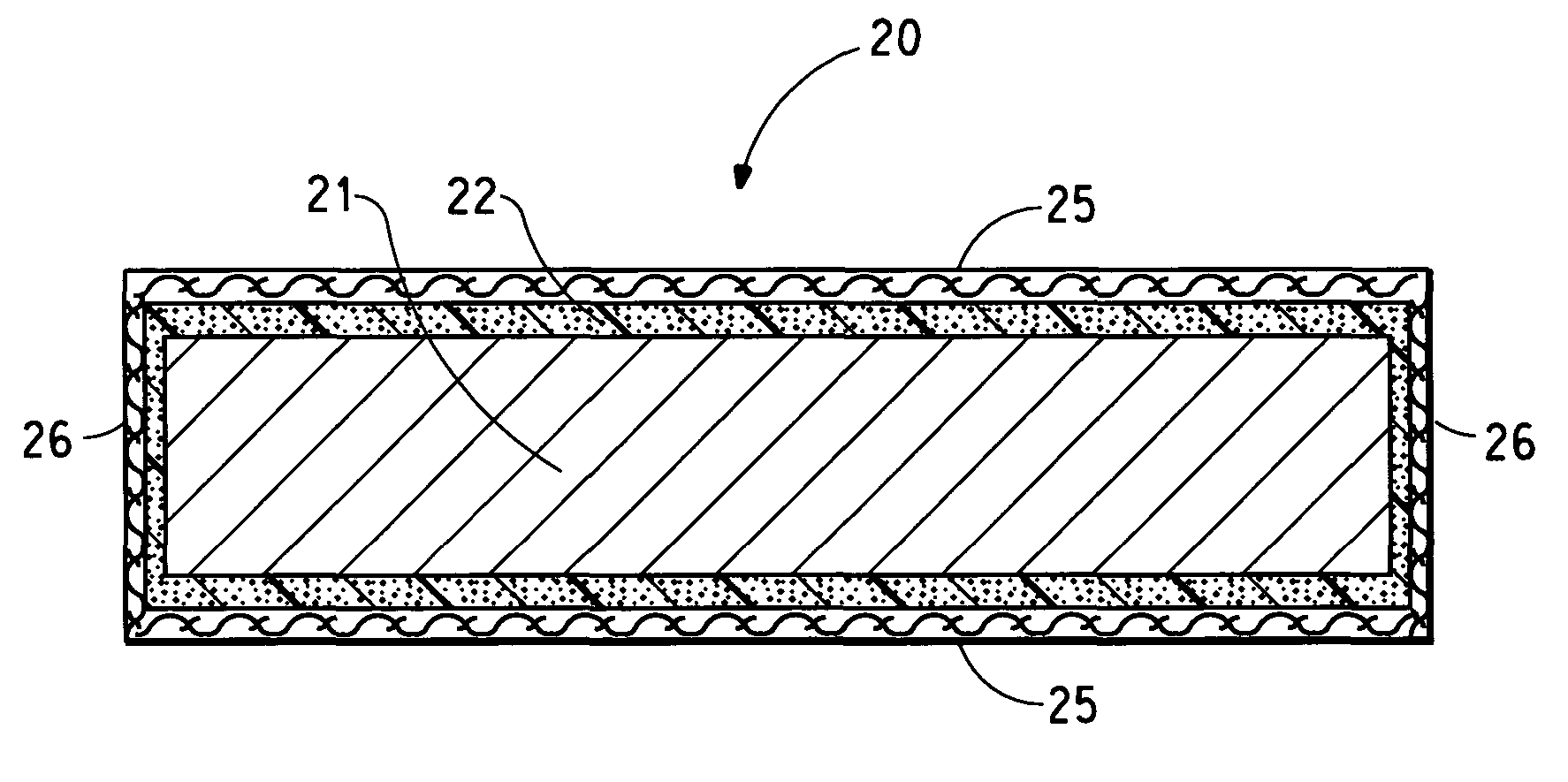

Fire resistant fabric composite, process for fire-blocking a mattress and mattress set, and a mattress and mattress set fire-blocked thereby

This invention relates to a fabric composite for use in fire-blocking a mattress, a fire-blocked mattress set, and a process for fire-blocking mattresses; the fabric composite comprising, in order, (a) sacrificial outer ticking, (b) sacrificial cushioning material, and (c) fire-blocking fabric, the fire-blocking fabric being a single layer of nonwoven fabric comprising at least 0.5 ounces per square yard (17 grams per square meter) of a cellulose fiber that retains at least 10 percent of its fiber weight when heated in air to 700 C at a rate of 20 degrees C. per minute, and at least 0.5 ounces per square yard (17 grams per square meter) of a heat-resistant fiber. Mattress sets fire-blocked with this fabric composite have a peak heat release rate of less than 150 kilowatts within 30 minutes, preferably less that 150 kilowatts within 60 minutes, and a total heat release of less than 25 megajoules within 10 minutes when tested according to Technical Bulletin 603 of the State of California.

Owner:EI DU PONT DE NEMOURS & CO

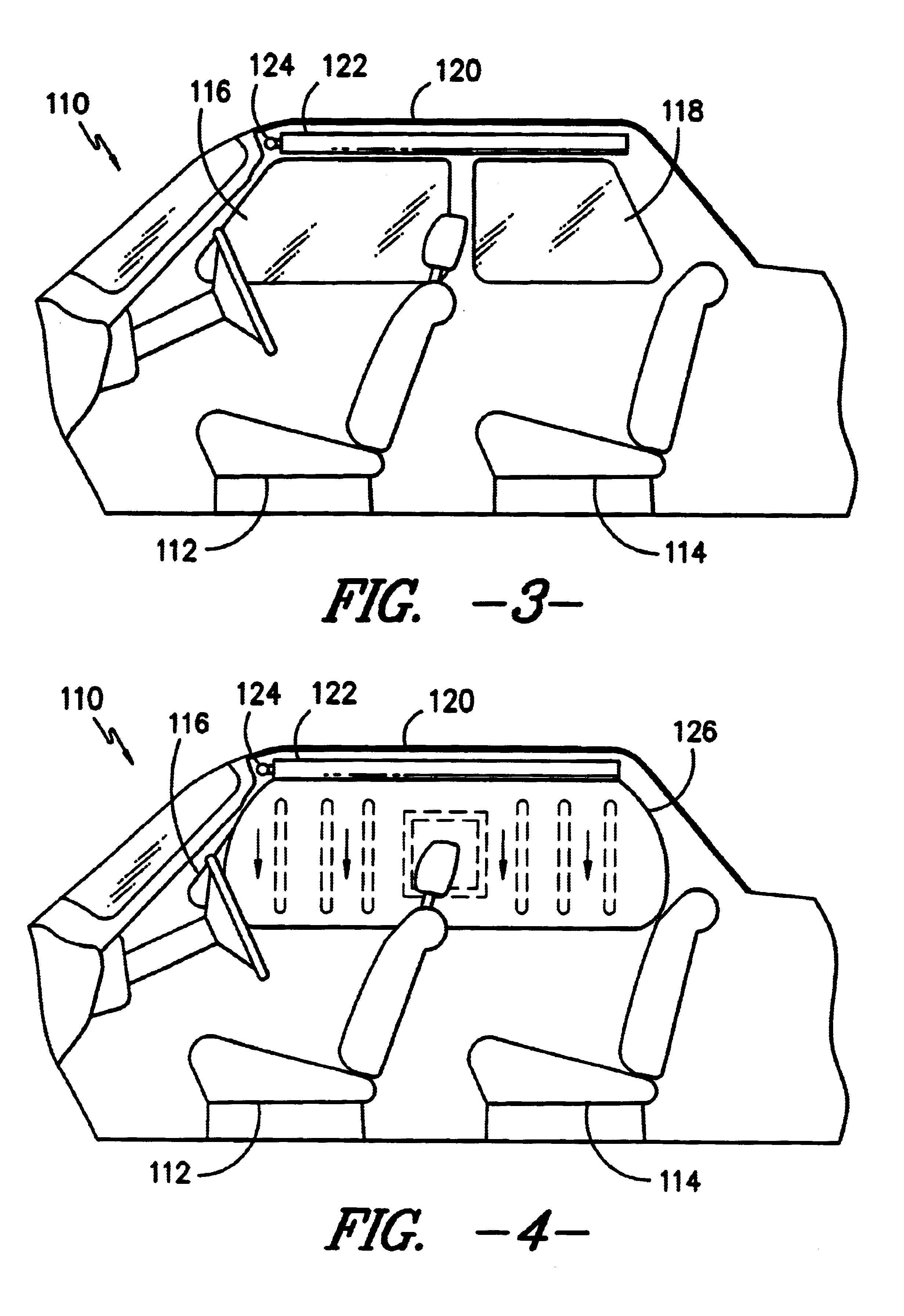

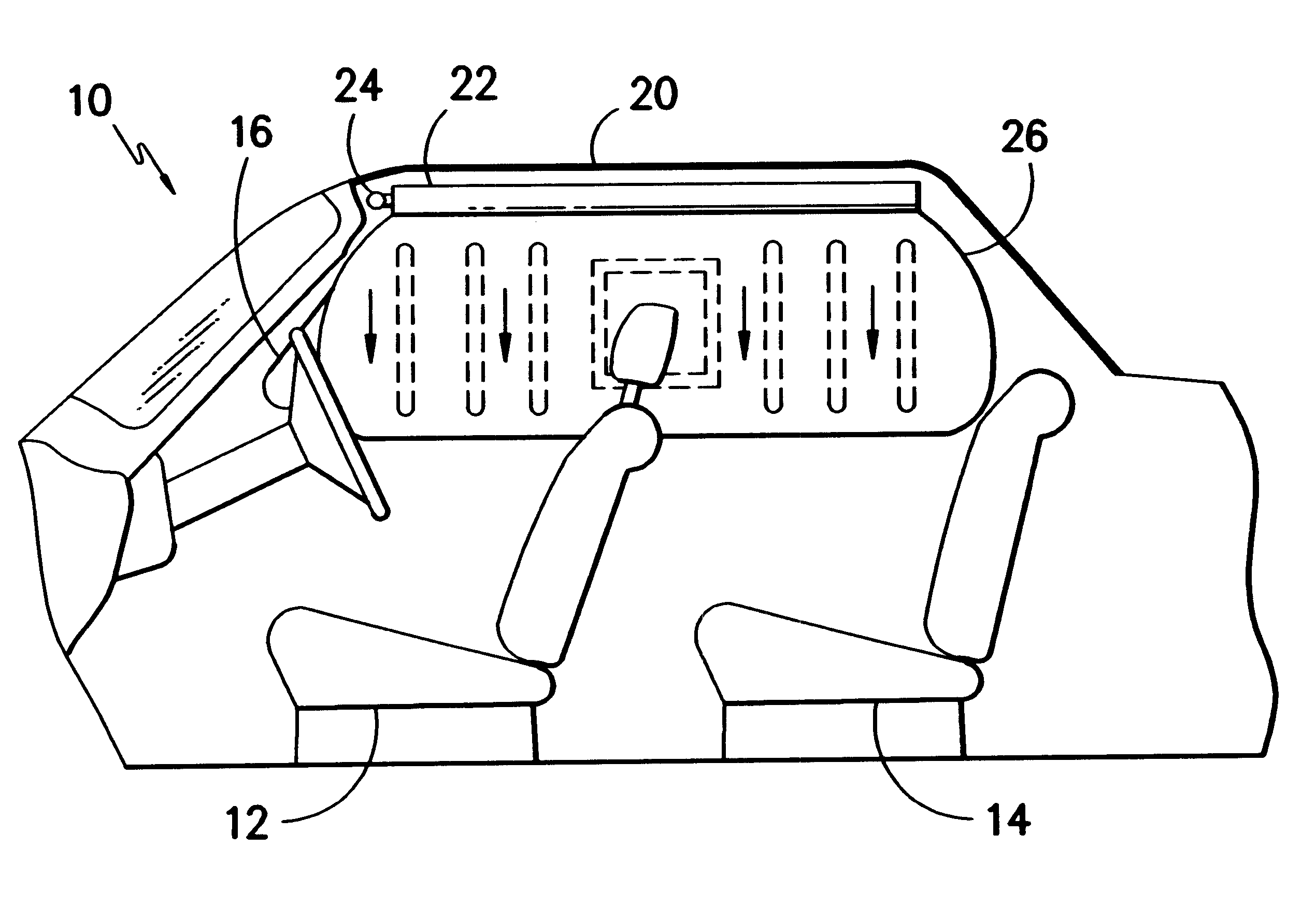

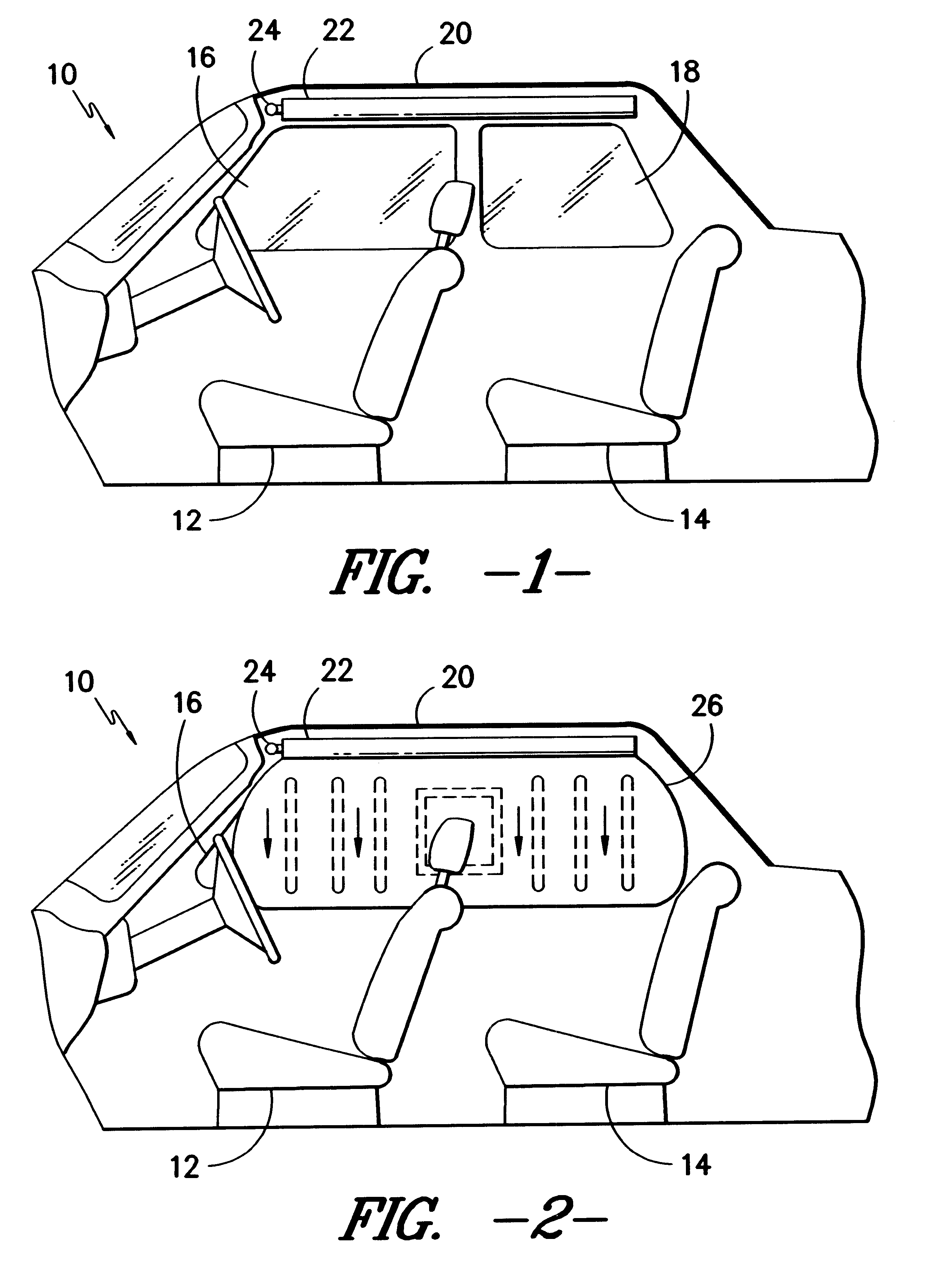

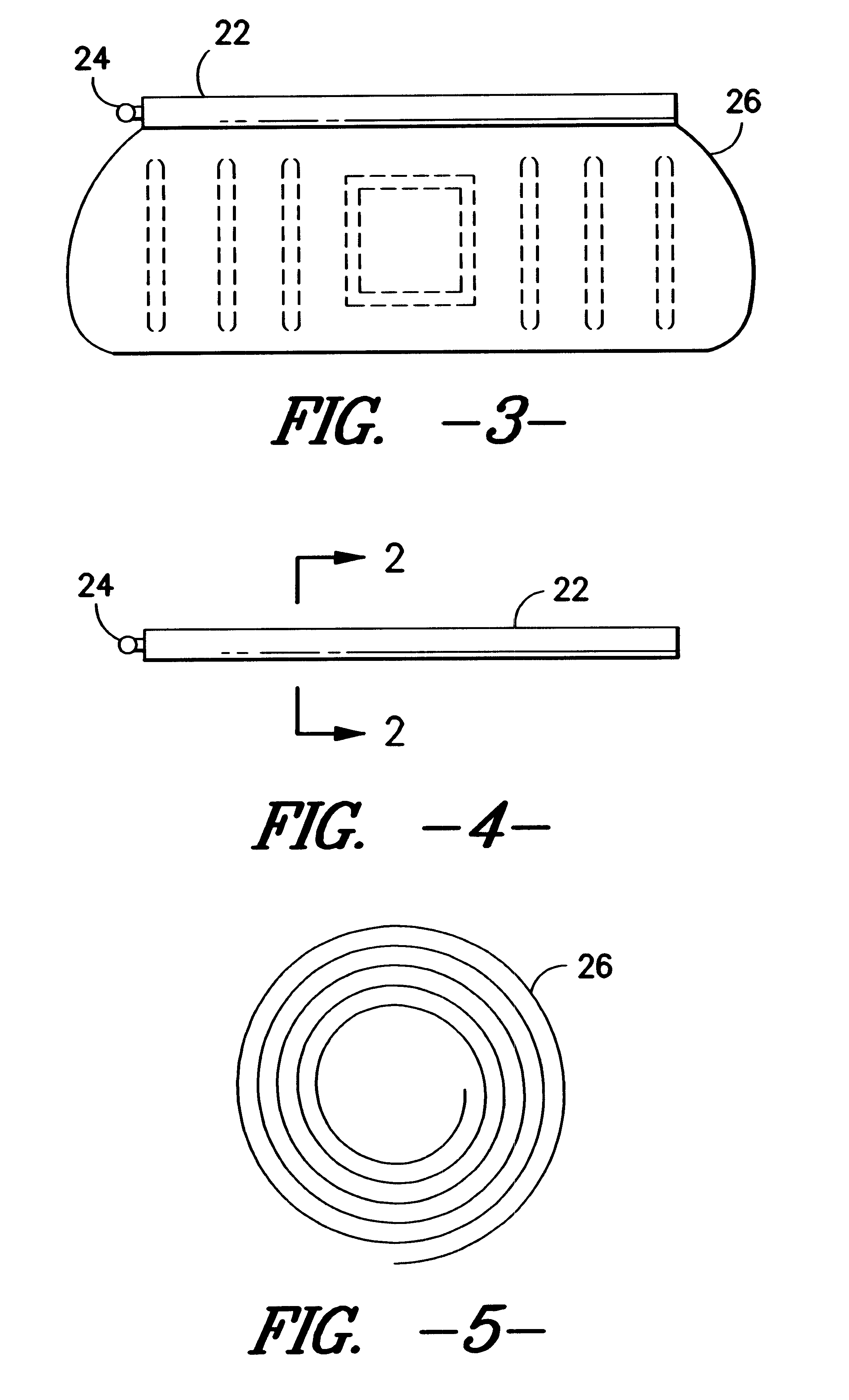

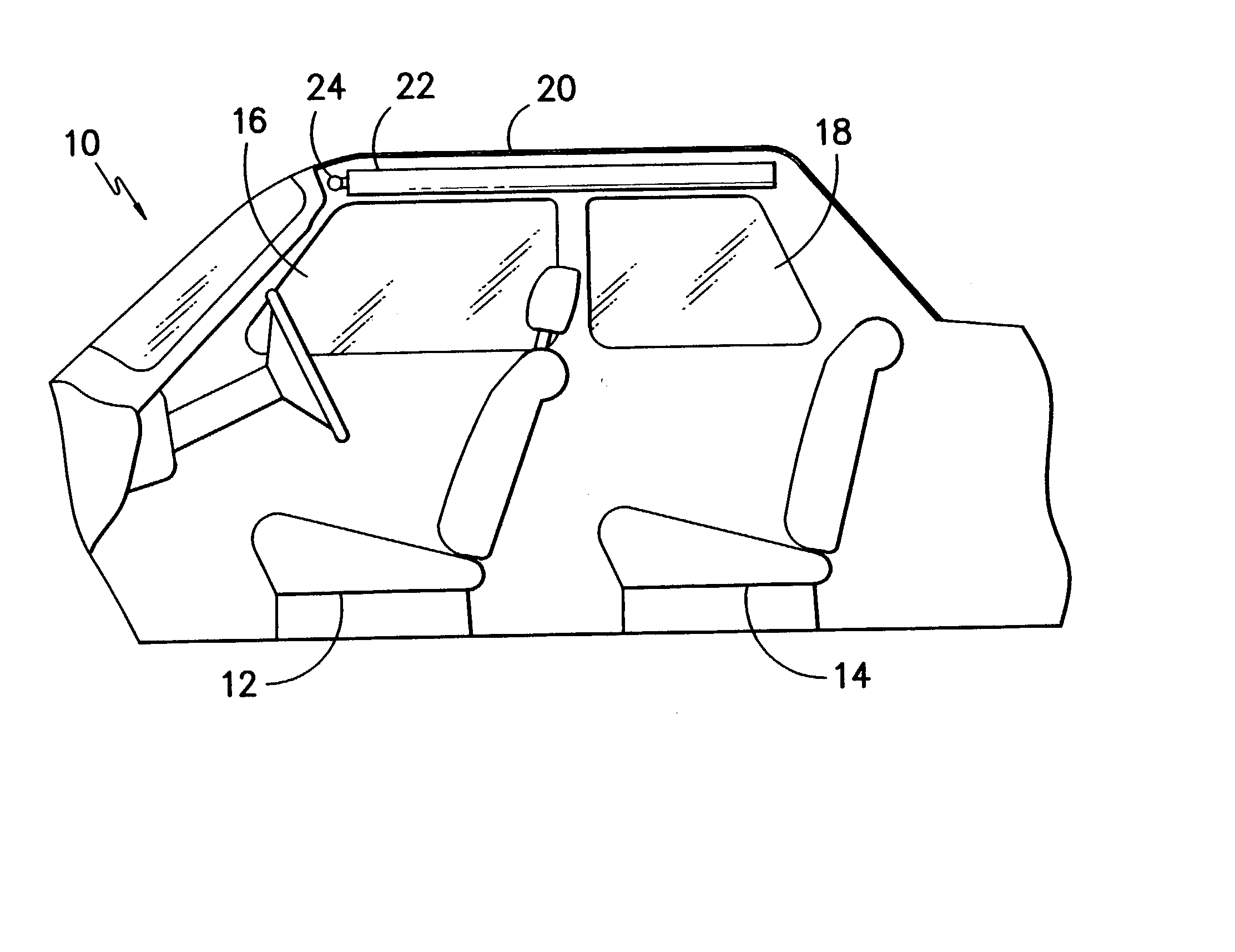

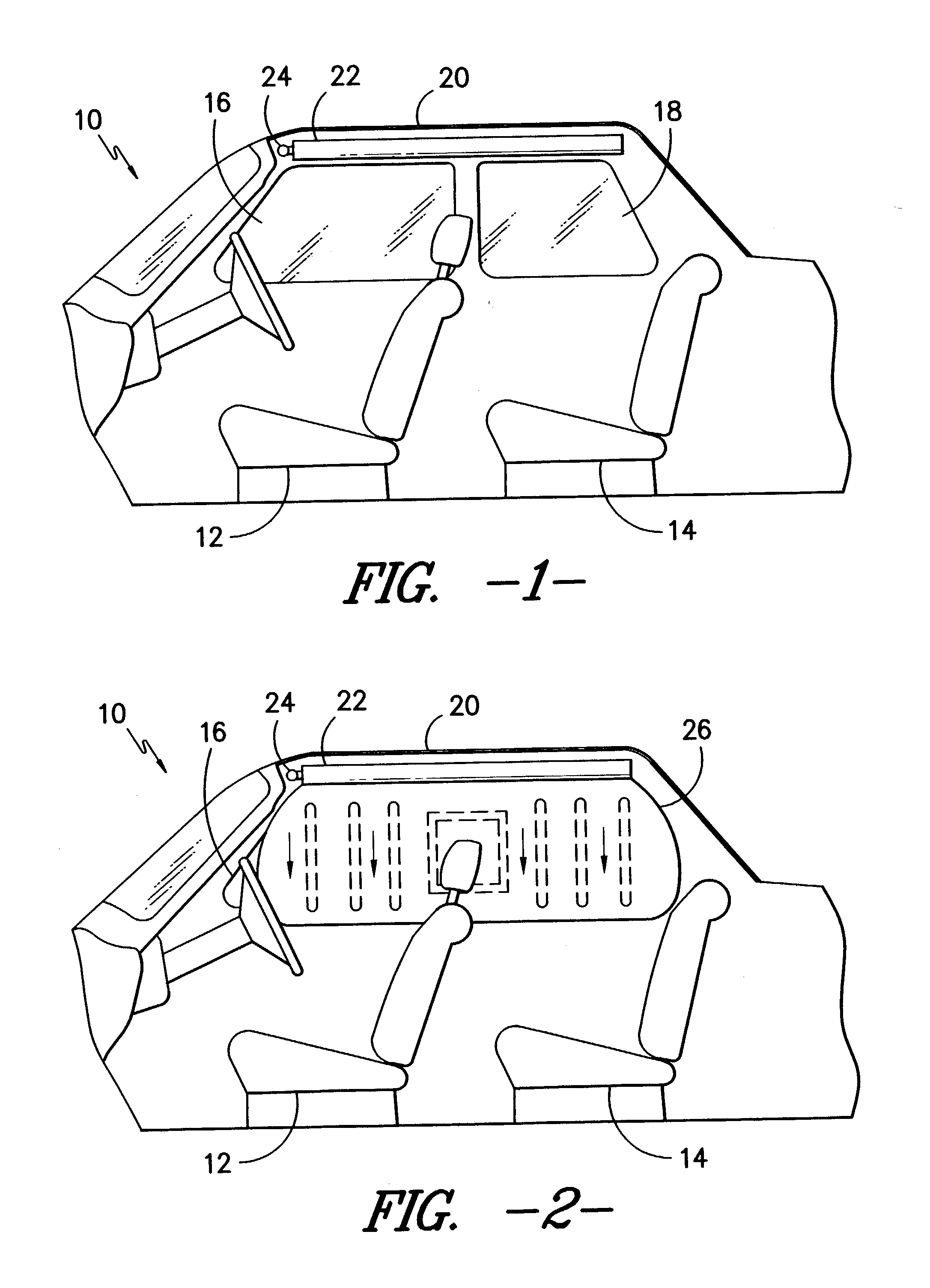

Low permeability airbag cushions having film coatings of extremely low thickness

InactiveUS6698458B1Beneficial and long-term low permeabilityExcellent long-term storage stabilityLeno shedding mechanismPreformed elementsNeopreneEngineering

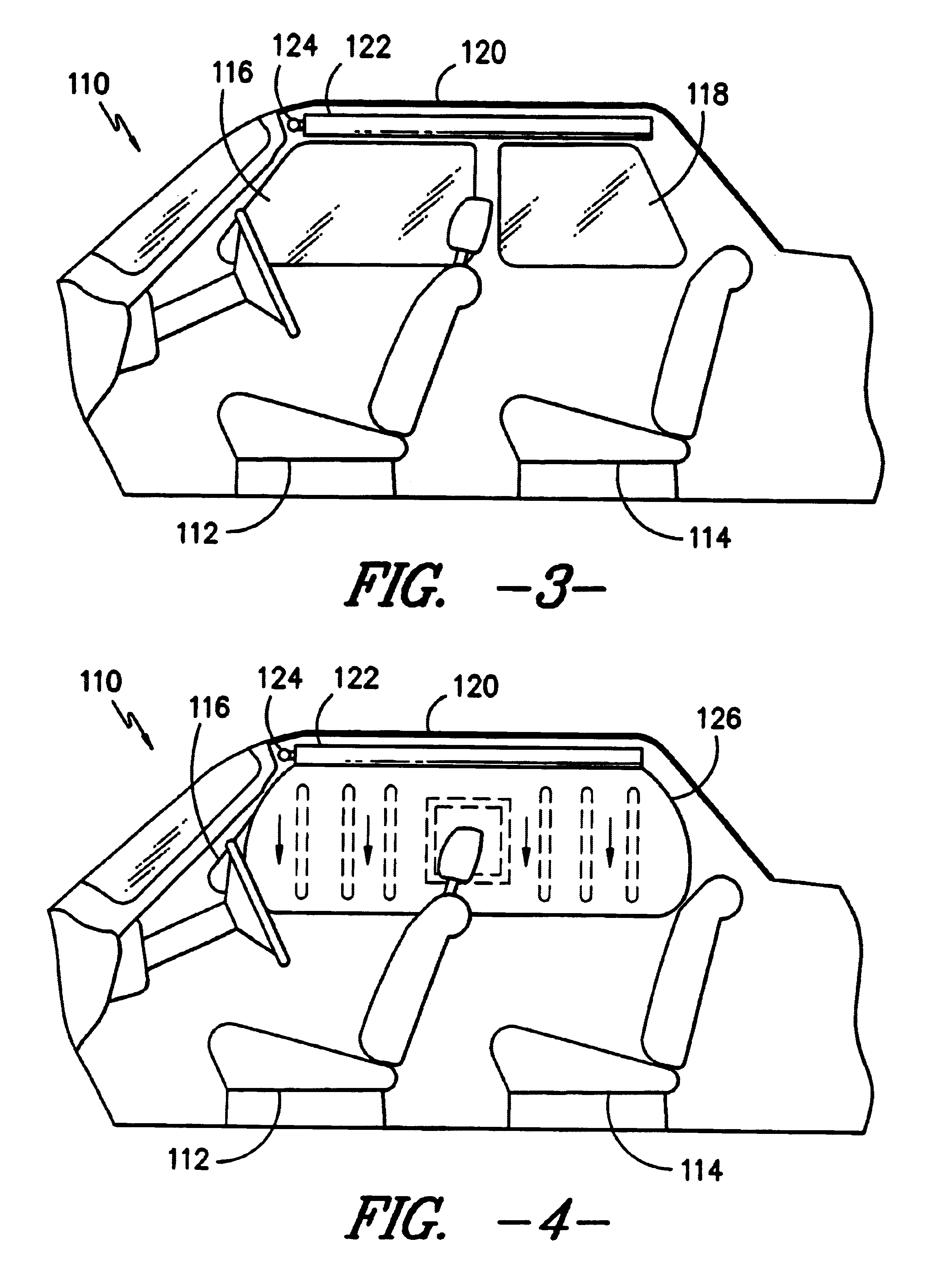

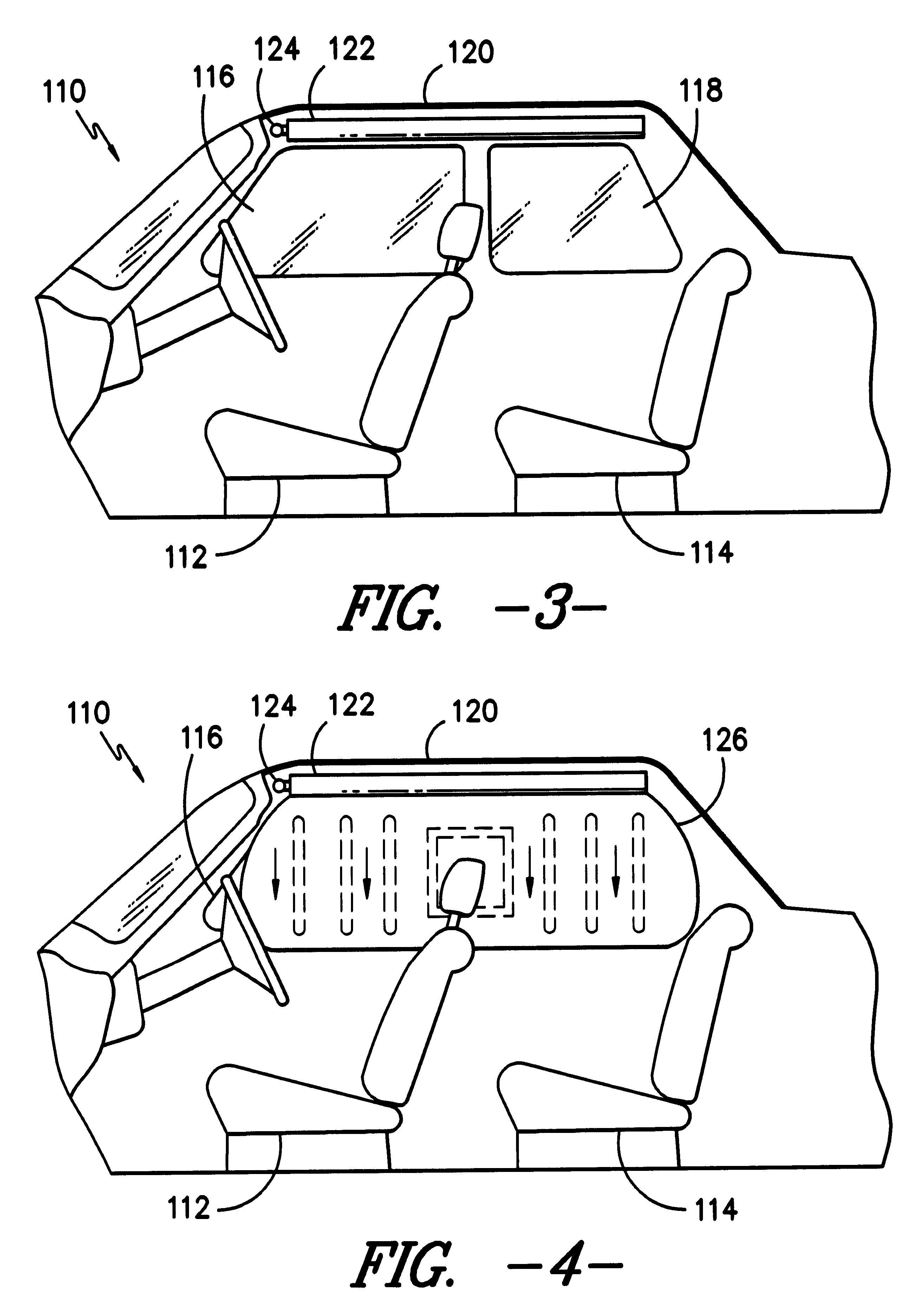

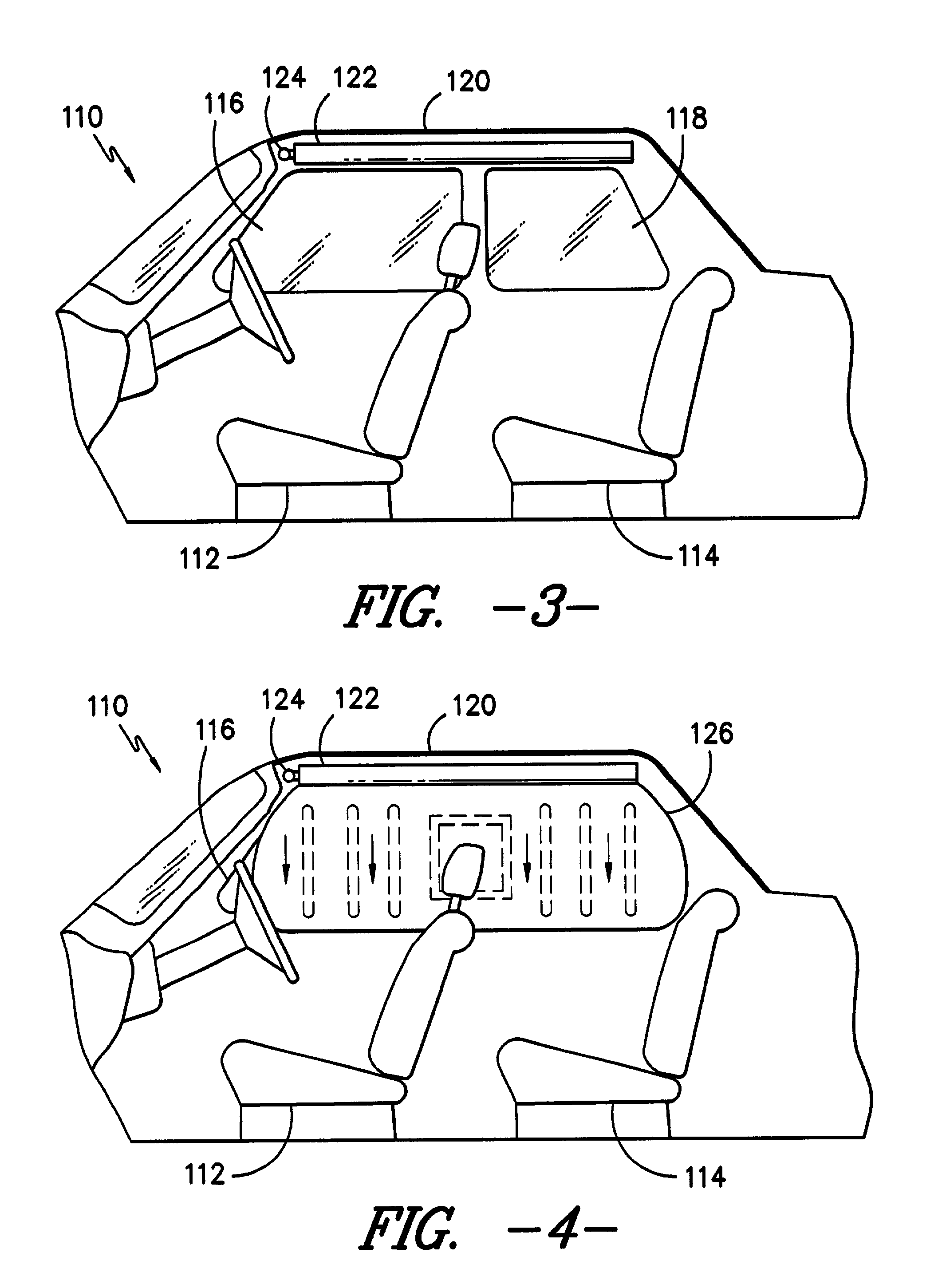

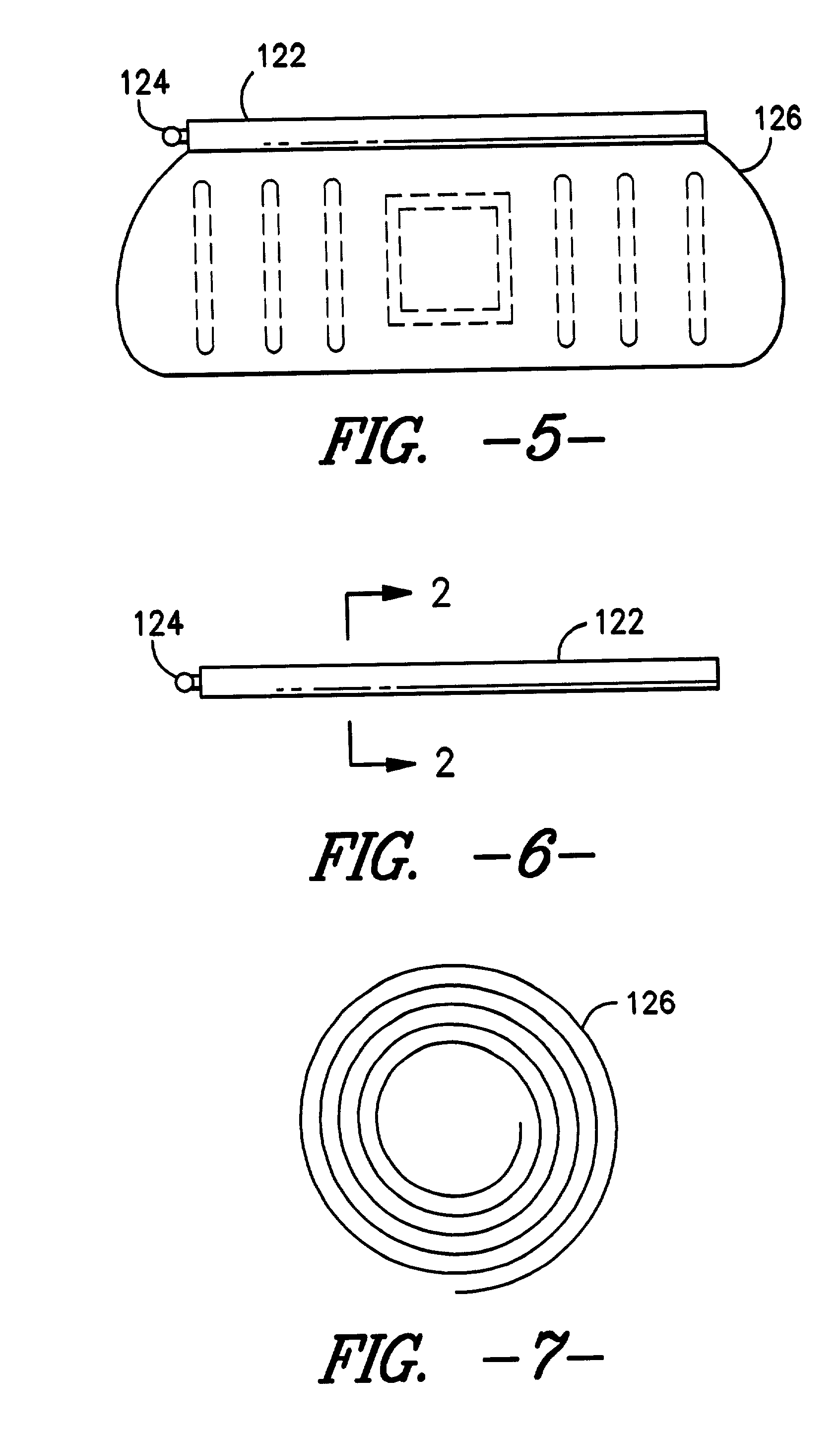

Coated inflatable fabrics, more particularly airbags to which very low add-on amounts of coating have been applied, are provided which exhibit extremely low air permeability. The inventive inflatable fabrics are primarily for use in automotive restraint cushions that require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin coating to provide such necessarily low permeability levels. Thus, the inventive coated inflatable airbag comprises a film laminated on at least a portion of the target fabric surface wherein the film possesses a tensile strength of at least 2,000 and an elongation at break of at least 180%. The film provides a low permeability airbag cushion exhibiting a leak-down time of at least 5 seconds wherein the film is present on the surface in an amount of at most 3.0 ounces per square yard of the fabric.

Owner:MILLIKEN & CO

Low permeability side curtain airbag cushions having extremely low coating levels

InactiveUS6451715B2Keep for a long timeReduce penetrationEnvelopes/bags making machineryPedestrian/occupant safety arrangementElastomerNeoprene

Coated inflatable fabrics, more particularly airbags to which very low add-on amounts of coating have been applied, are provided which exhibit extremely low air permeabilities. The inventive fabrics are primarily for use in automotive restraint cushions which require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin coating to provide such necessary low permeability levels. Thus, the inventive coated airbag possesses a coating of at most 3.0 ounces per square yard, most preferably about 0.8 ounces per square yard, and exhibits a leak-down time (a measurement of the time required for the entire amount of gas introduced within the airbag at peak pressure during inflation to escape the airbag at 10 psi) of at least 5 seconds as well as very low packing volumes (for more efficient use of storage space within a vehicle). All coatings, in particular elastomeric, preferably, though not necessarily, non-silicon coatings, and coated airbags meeting these criteria are intended to reside within the scope of this invention.

Owner:MILLIKEN & CO

Single layer fireblocking fabric for a mattress or mattress set and process to fireblock same

This invention relates to a single layer nonwoven fabric useful as a fireblocking component for mattresses, and a mattress or mattress set comprising the nonwoven fabric, and a process for fireblocking said mattress and mattress set; the nonwoven fabric comprising at least 0.5 ounces per square yard (17 grams per square meter) of a cellulose fiber that retains at least 10 percent of its fiber weight when heated in air to 700° C. at a rate of 20 degrees C. per minute, and at least 0.5 ounces per square yard (17 grams per square meter) of an organic fiber that retains 90 percent of its fiber weight when heated in air to 500° C. at a rate of 20 degrees C. per minute, the fabric having a basis weight having at least 2.5 ounces per square yard (85 grams per square meter), a density of at least 0.16 gram / cm3, and an air permeability of 70 meters / min (225 ft / min) or less.

Owner:EI DU PONT DE NEMOURS & CO

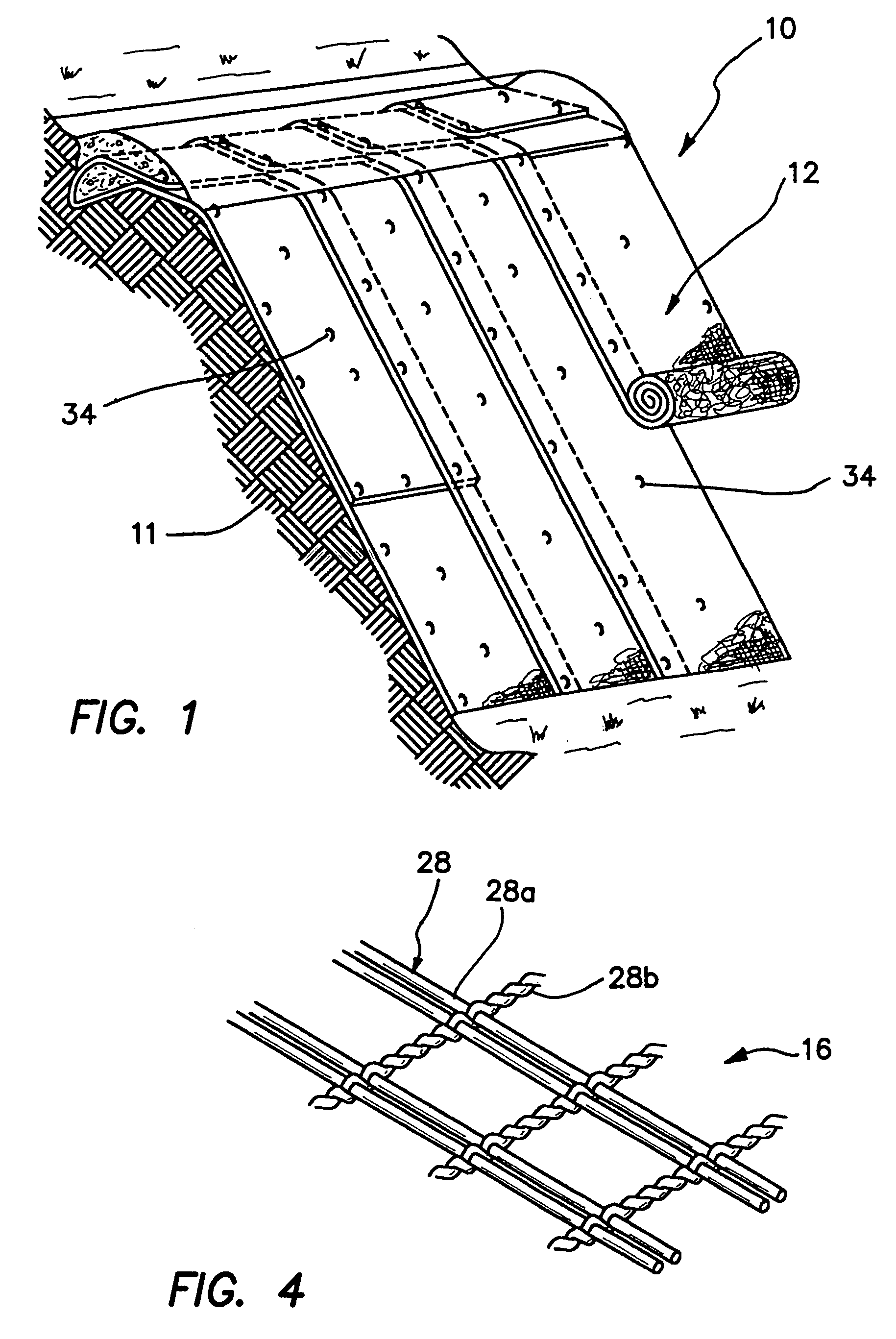

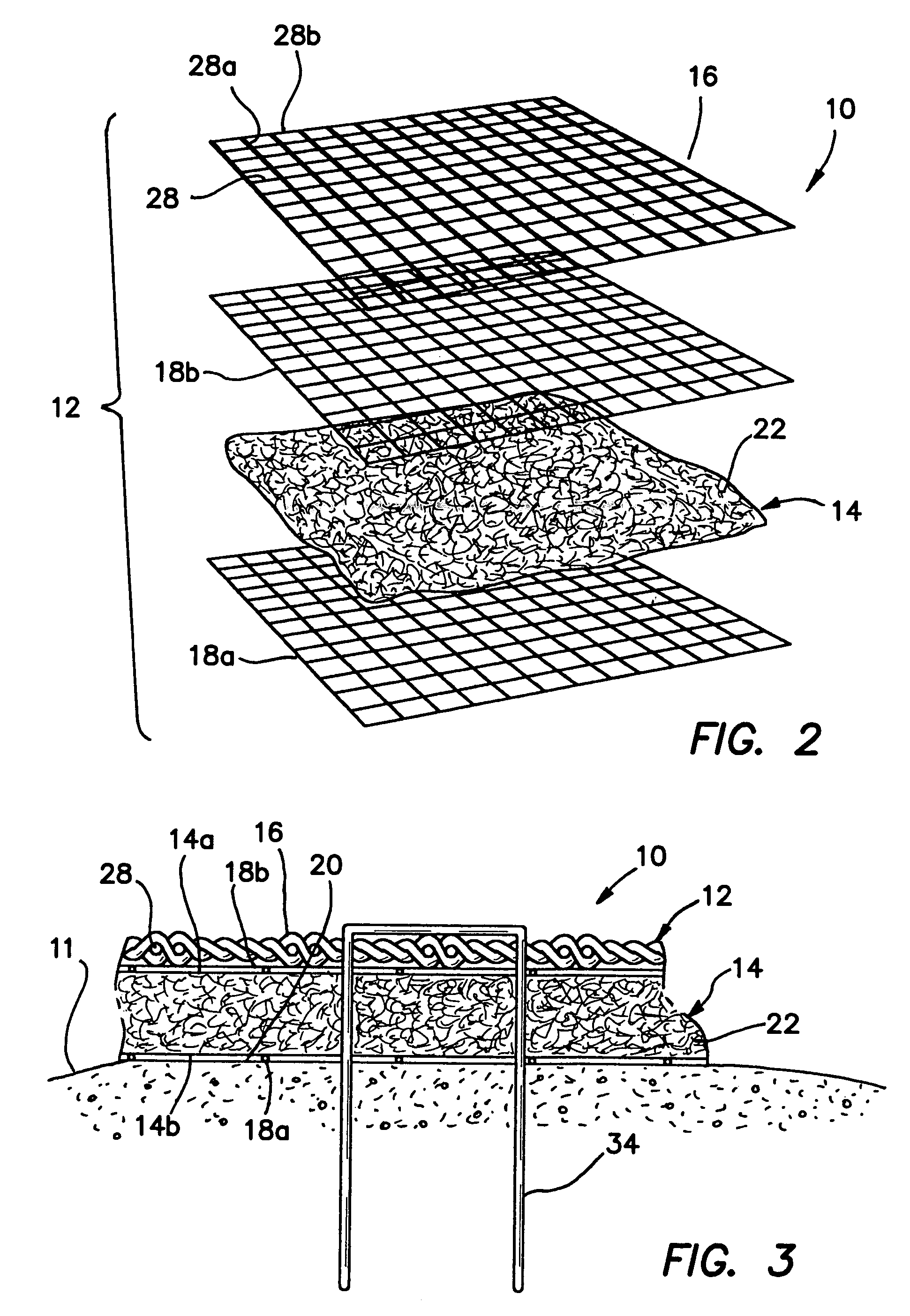

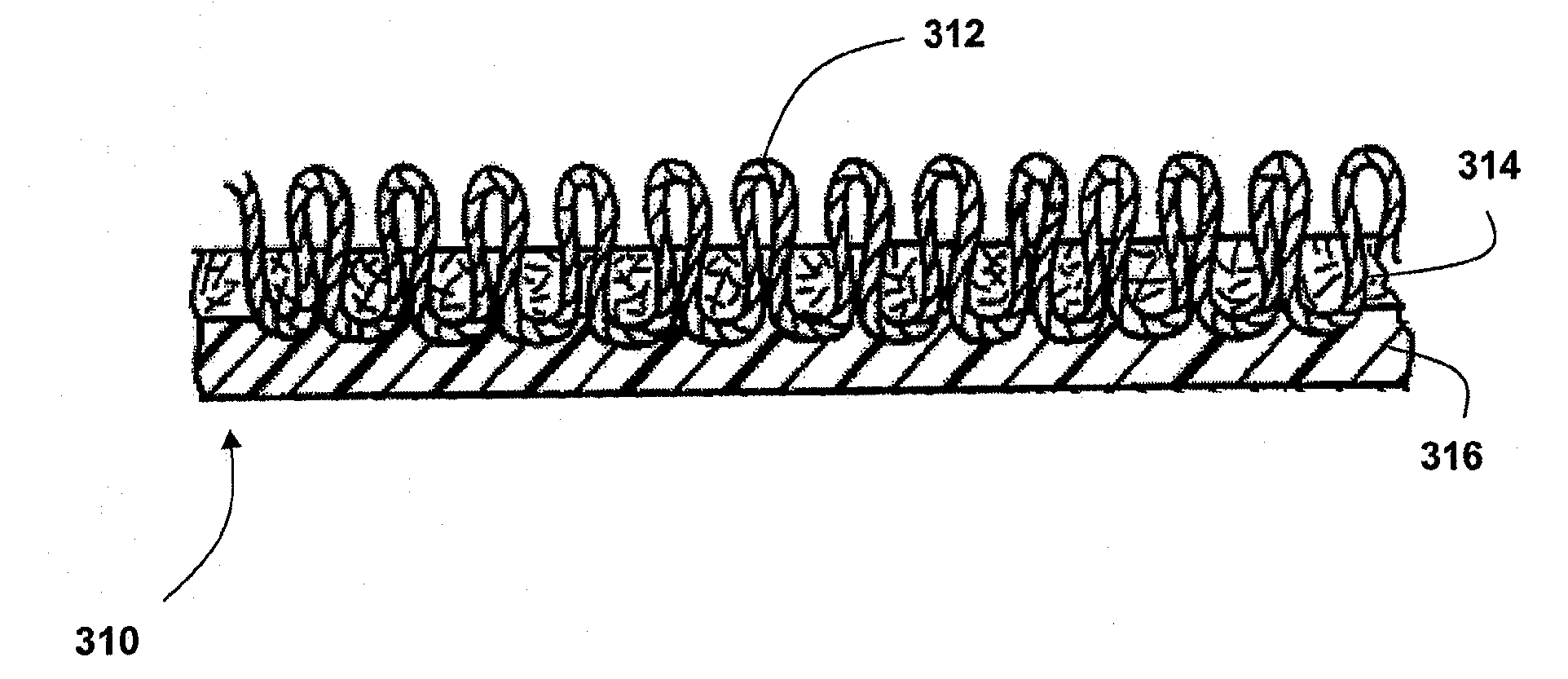

Erosion control reinforcement mat

InactiveUS6929425B1High mass unit densityIncrease shear stressExcavationsOrganic fertilisersControl systemEngineering

An erosion control system is provided which generally includes a flexible composite blanket or matting including a core layer bonded between an upper and a lower netting material, and an upper layer made of a biaxial geogrid. The matting has a flat upper surface without any substantial three dimensional features in which to trap sediment. The matting has a relatively high aerial density of about 0.7 pounds per square yard.

Owner:GREENFIX AMERICA

Low permeability side curtain airbag cushions having extremely low coating levels

InactiveUS20010005660A1Reduced packaging volumeLong leak-downEnvelopes/bags making machineryPedestrian/occupant safety arrangementElastomerEngineering

Coated inflatable fabrics, more particularly airbags to which very low add-on amounts of coating have been applied, are provided which exhibit extremely low air permeabilities. The inventive fabrics are primarily for use in automotive restraint cushions which require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin coating to provide such necessary low permeability levels. Thus, the inventive coated airbag possesses a coating of at most 3.0 ounces per square yard, most preferably about 0.8 ounces per square yard, and exhibits a leak-down time (a measurement of the time required for the entire amount of gas introduced within the airbag at peak pressure during inflation to escape the airbag at 10 psi) of at least 5 seconds as well as very low packing volumes (for more efficient use of storage space within a vehicle). All coatings, in particular elastomeric, preferably, though not necessarily, non-silicon coatings, and coated airbags meeting these criteria are intended to reside within the scope of this invention.

Owner:MILLIKEN & CO

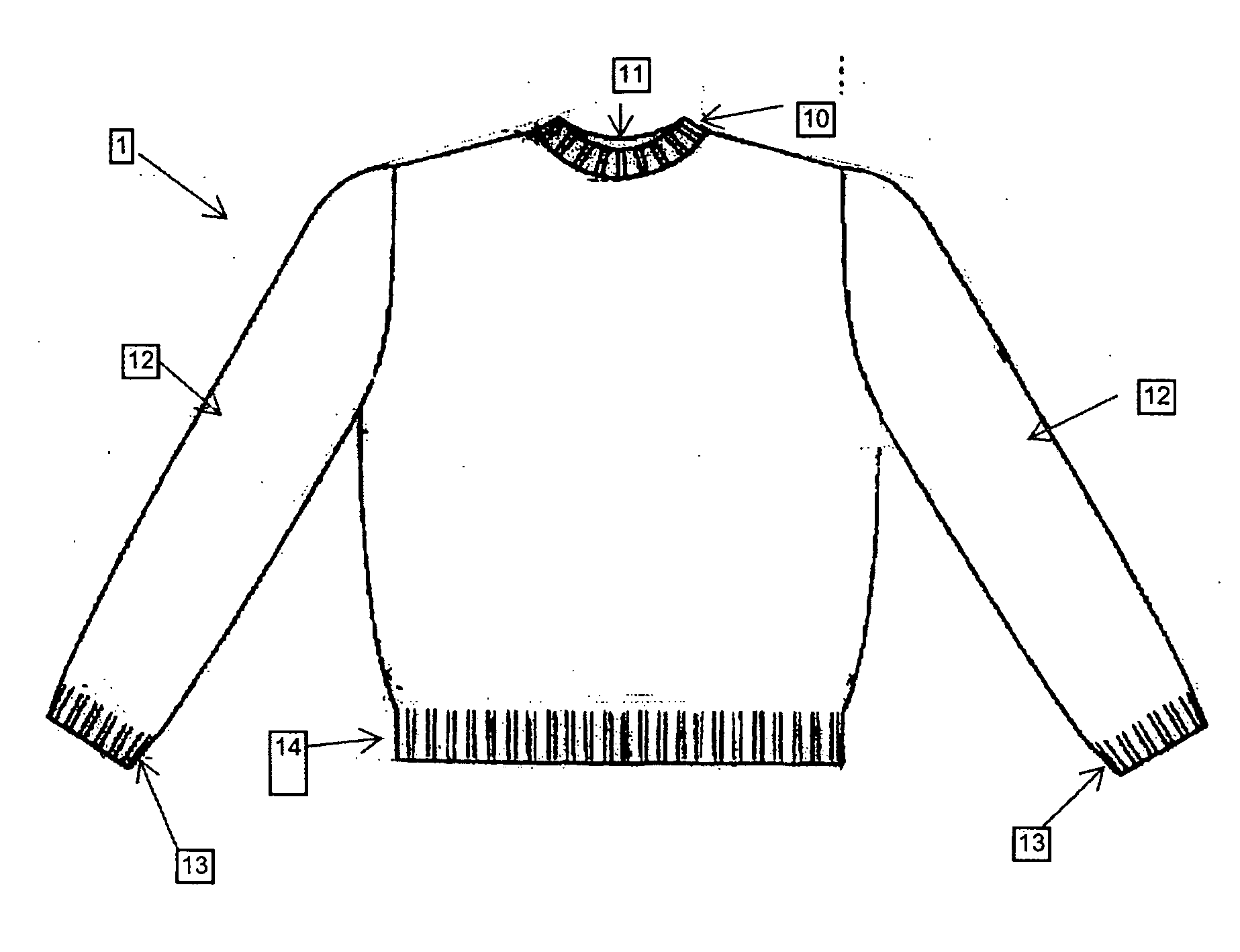

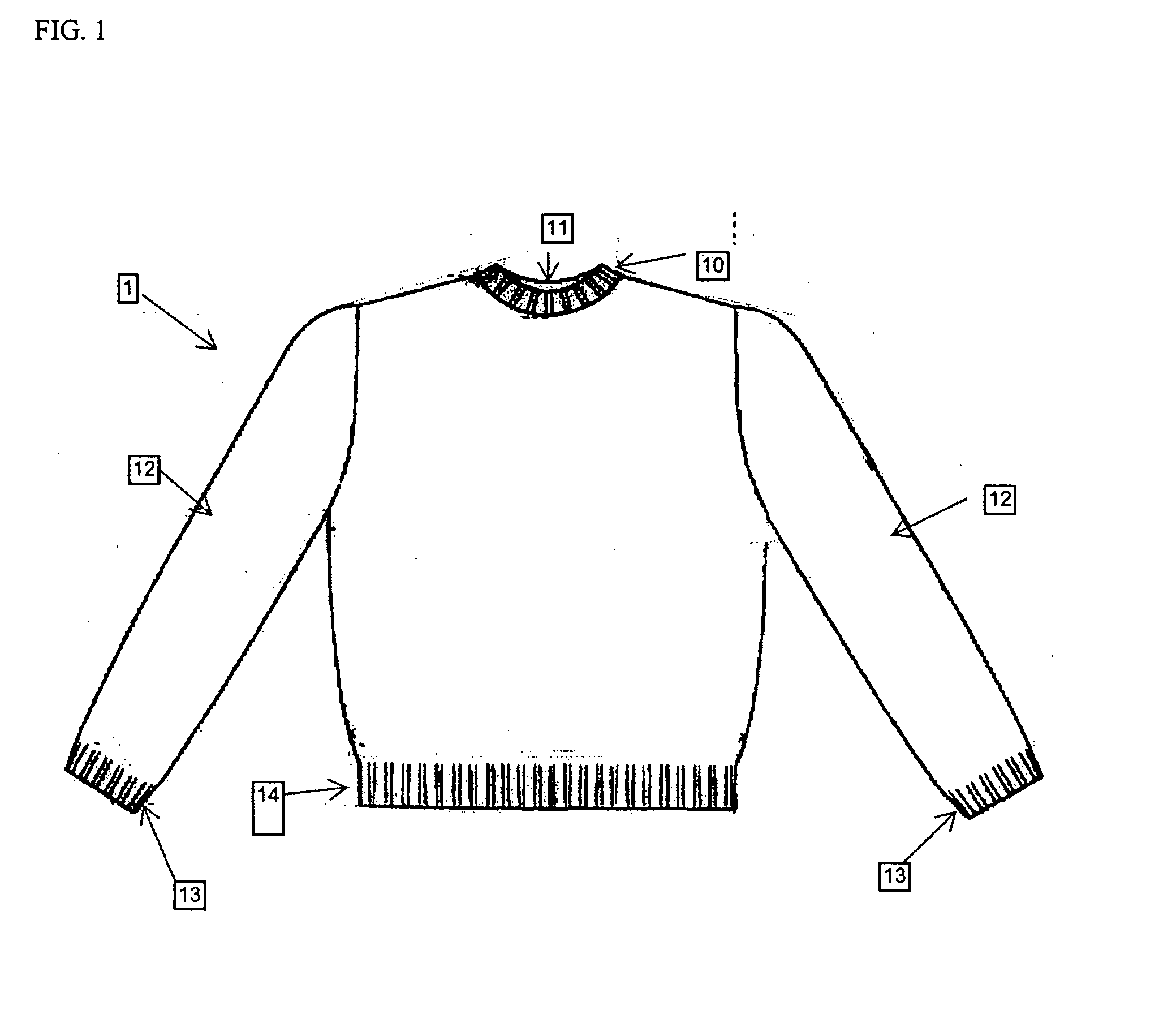

Cut, slash and/or abrasion resistant protective fabric and lightweight protective garment made therefrom

ActiveUS20070271965A1Satisfactory of slashSatisfactory level of cut and slashWeft knittingOrnamental textile articlesEngineeringSquare yard

A cut, slash and / or abrasion resistant fabric is provided having both high cut resistance and light fabric weight, preferably a cut resistance of at least 500 (as measured by ASTM-F1790-04) and a fabric weight of no more than 27.9 ounces / square yard (OPSY), which can be prepared, if desired, by shaped knitting into a shaped fabric panel, which is used to prepare cut, slash and / or abrasion resistant garments or coverings.

Owner:SUPREME CORQ

Multilayer spunlaced nonwoven fire blocking composite

This invention relates to a mulilayer spunlaced nonwoven composite useful as a fire blocking component for an article, an article such as furniture or a mattress comprising the nonwoven composite, and processes for making the nonwoven composite and fire blocking an article with the nonwoven composite. The multilayer nonwoven composite comprises a first layer comprising 75 to 25 weight percent regenerated cellulosic fiber that retains at least 10 percent of its fiber weight when heated in air to 700° C. at a rate of 20 degrees C. per minute and 25 to 75 weight percent heat-resistant fiber, said first layer having a basis weight of from 1 to 5 ounces per square yard (34 to 170 grams per square meter); and a second layer comprising up to 75 weight percent of a regenerated cellulosic fiber that retains at least 10 percent of its fiber weight when heated in air to 700° C. at a rate of 20 degrees C. per minute, and 25 to 100 weight percent of a modacrylic fiber, said second layer having a basis weight of from 1 to 5 ounces per square yard (34 to 170 grams per square meter), the nonwoven composite having a total basis weight of from 2 to 7 ounces per square yard (68 to 237 grams per square meter).

Owner:EI DU PONT DE NEMOURS & CO

Low permeability side curtain airbag cushions having extremely low coating levels

InactiveUS6701971B1Reduced packaging volumeLong leak-downLeno shedding mechanismPreformed elementsElastomerEngineering

Coated inflatable fabrics, more particularly airbags to which very low add-on amounts of coating have been applied, are provided which exhibit extremely low air permeabilities. The inventive fabrics are primarily for use in automotive restraint cushions which require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin coating to provide such necessary low permeability levels. Thus, the inventive coated airbag possesses a coating of at most 3.0 ounces per square yard, most preferably about 0.8 ounces per square yard, and exhibits a leak-down time (a measurement of the time required for the entire amount of gas introduced within the airbag at peak pressure during inflation to escape the airbag at 10 psi) of at least 7 seconds. All coatings, in particular elastomeric, non-silicon coatings, and coated airbags, meeting these criteria are intended to reside within the scope of this invention.

Owner:MILLIKEN & CO

Thermally protective flame retardant fabric

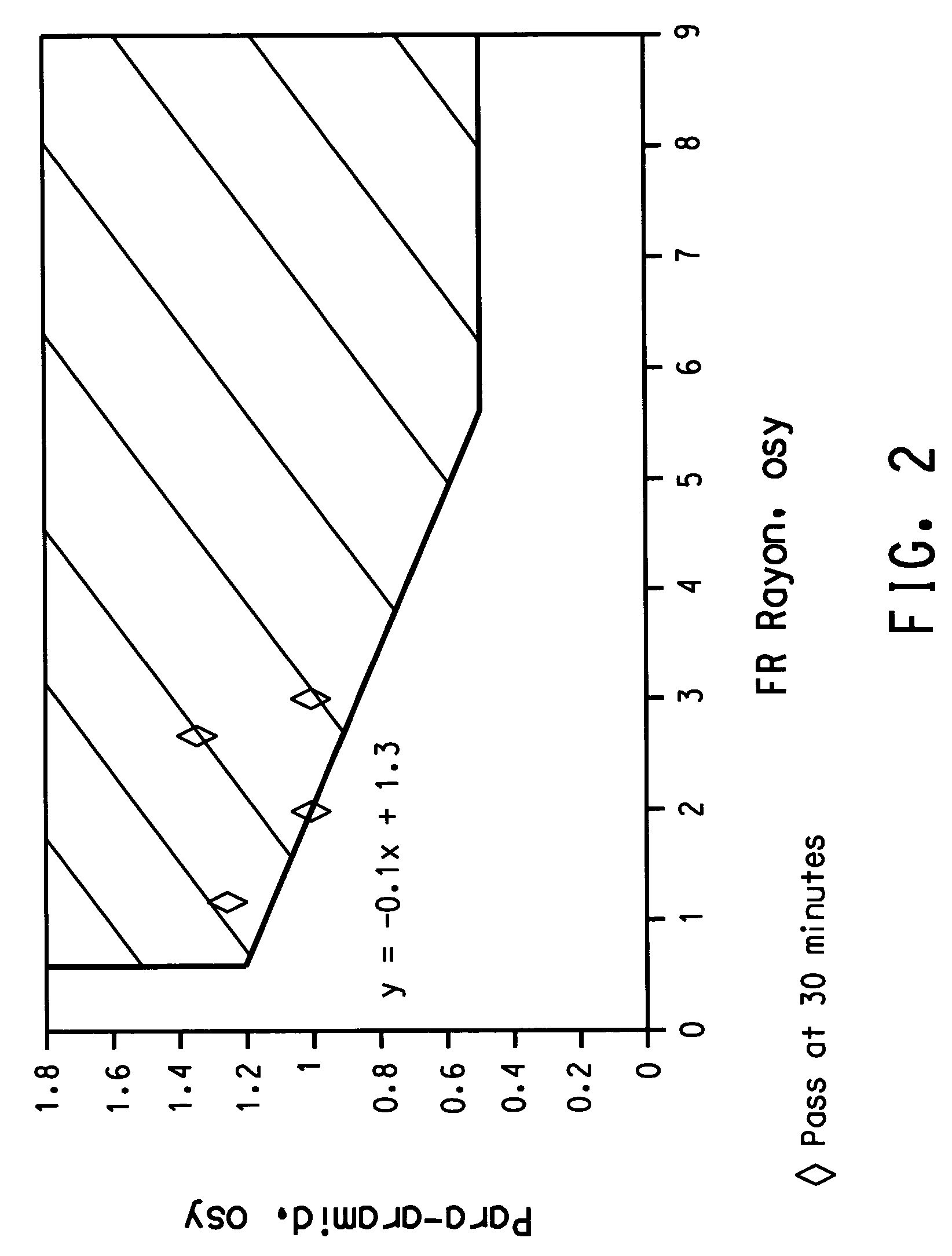

InactiveUS20090061131A1High protection levelLow costChemical protectionHeat protectionFiberEngineering

A thermally protective, flame retardant fabric includes a substrate treated with a combination of a flame retardant agent and an intumescent agent. The substrate includes non-thermoplastic fibers or a blend of non-thermoplastic fibers and thermoplastic fibers having a basis weight ranging from 2.0 to 15.0 ounces per square yard. The fabric has a contact thermal protective performance value of at least 4.5 and a contact thermal protective performance efficiency greater than 1.1. Applications of the fabric include protective garments, articles of furniture, vehicle components, building components, electrical components, decorative components, appliances, and containers.

Owner:PRECISION FABRICS GROUP

Low permeability airbag cushions having extremely low silicone-based coating levels

InactiveUS6569788B1Reduced packaging volumeHigh leak-down timePretreated surfacesPreformed elementsEngineeringNeoprene

Coated inflatable fabrics and more particularly concerns airbag cushions to which very low add-on amounts of silicone-based coating have been applied and which exhibit extremely low air permeability are provided. The inventive inflatable fabrics are primarily for use in automotive restraint cushions that require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones, and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin, substantially uniform silicone coating to provide such necessarily low permeability levels. Thus, the inventive coating comprises at least a single layer comprising a majority of silicone-based material, wherein the total thickness of the single layer is at most about 3.0 ounces per square yard as applied to a target fabric surface. The inventive airbag exhibits a characteristically long leak-down rate as compared to other coated airbags.

Owner:MILLIKEN & CO

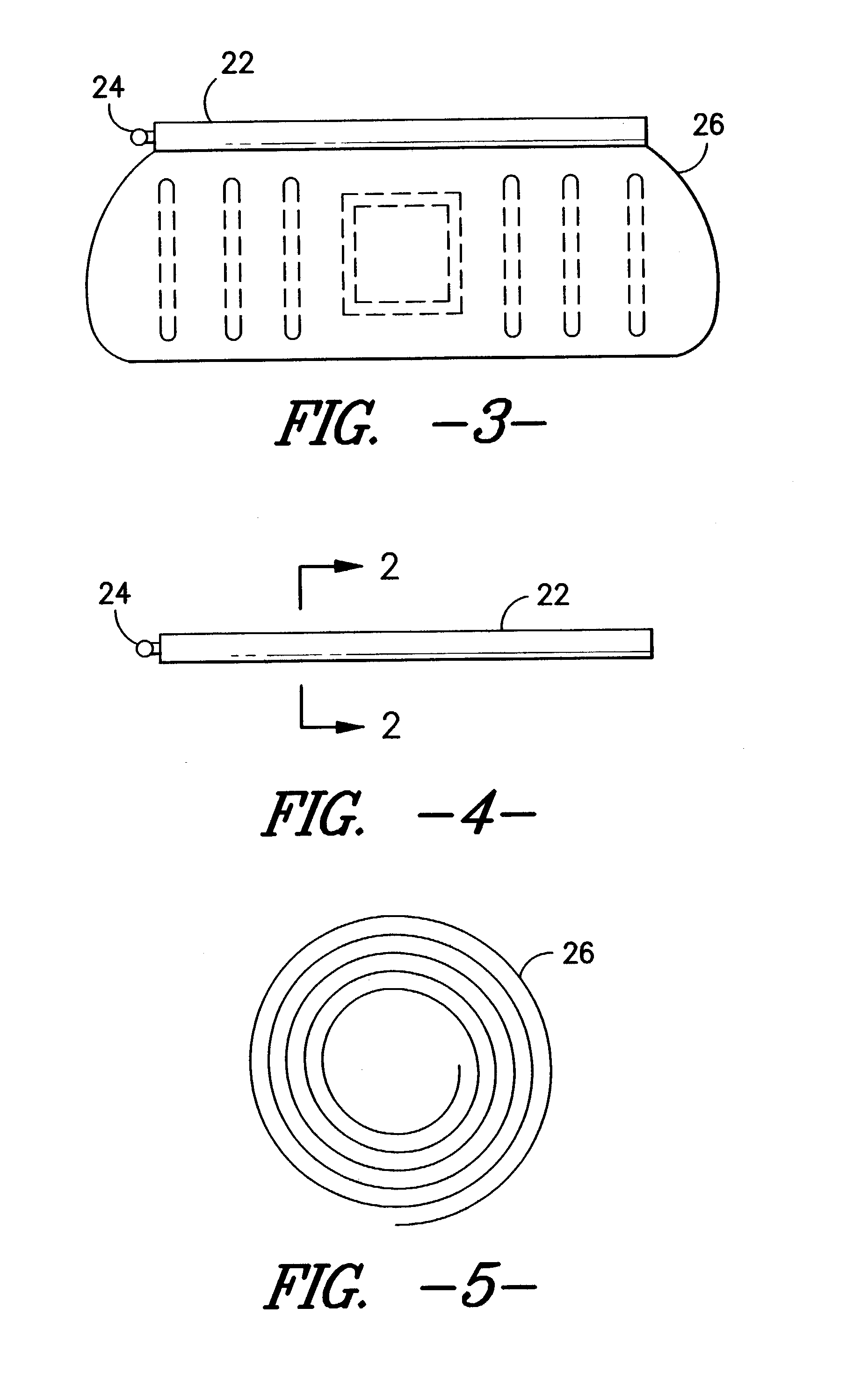

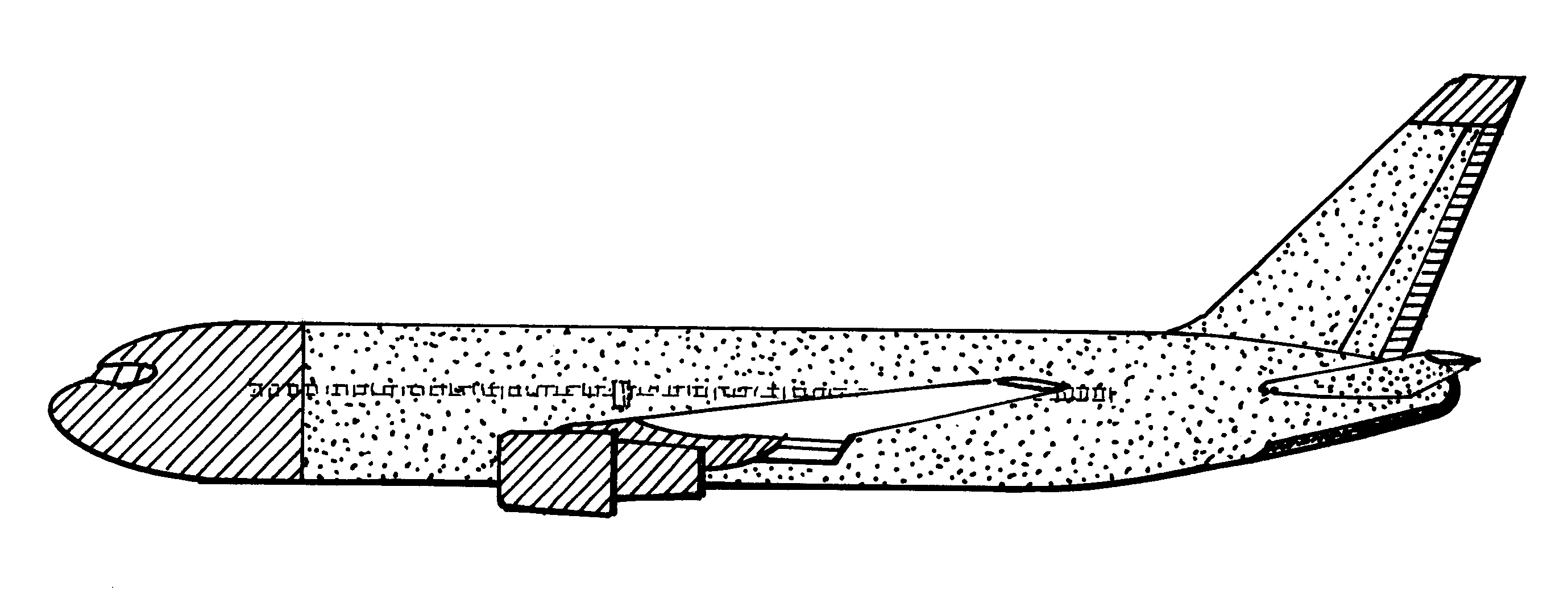

Low Weight Carpet Tile

ActiveUS20100170991A1Reduce weightMinimize the numberVehicle arrangementsLayered productsBrickFilling materials

Low weight and non-square carpet tile suitable for use in mass transit vehicles, particularly passenger aircraft. The carpet tile preferably weighs less than about 82 ounces per square yard. The carpet tile of this invention may have a carpet pile and at least one backing layer. The backing layer may use a low weight filler material. The carpet tiles satisfy transportation industry standards for flame, smoke and toxicity.

Owner:INTERFACE INC

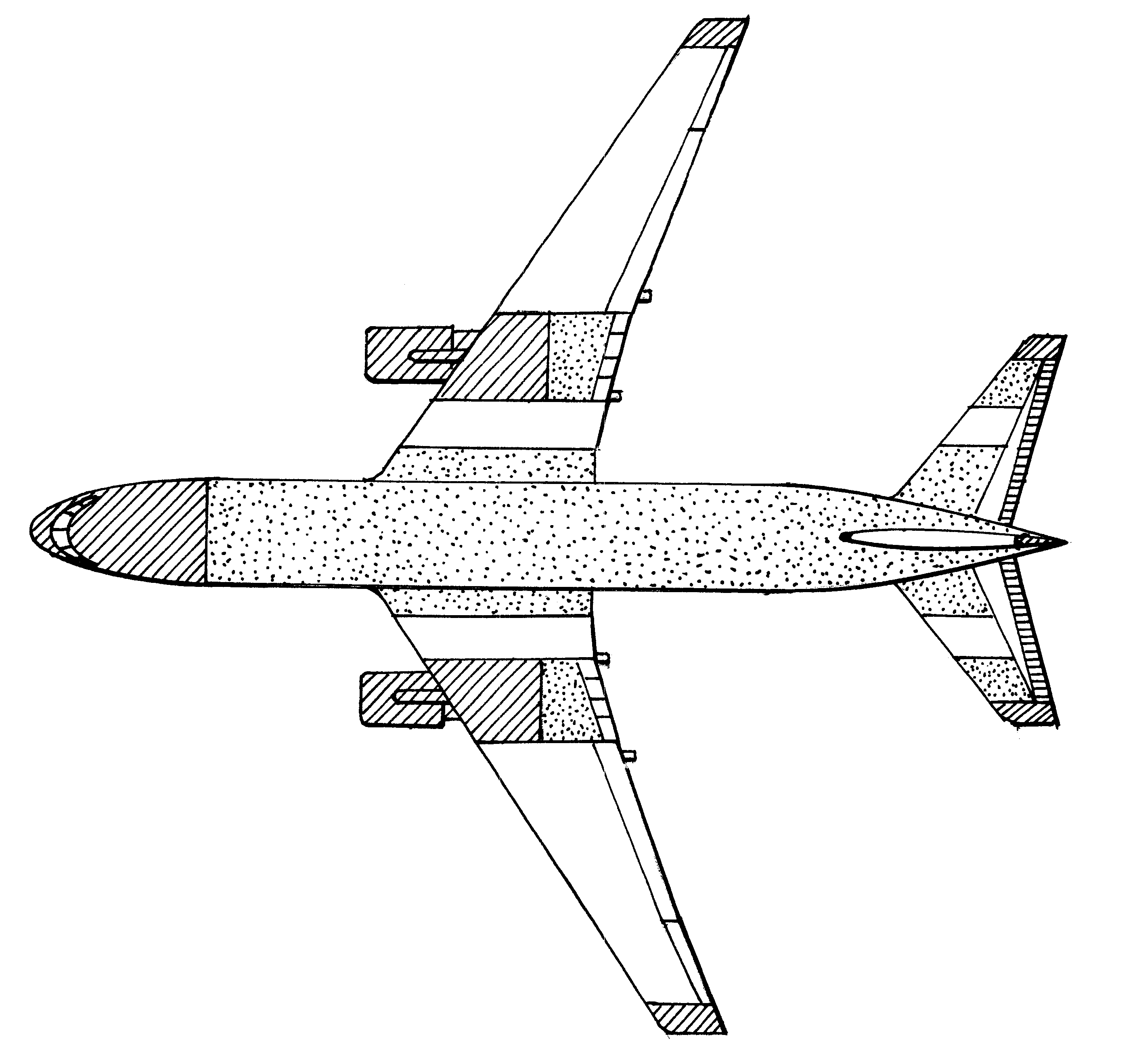

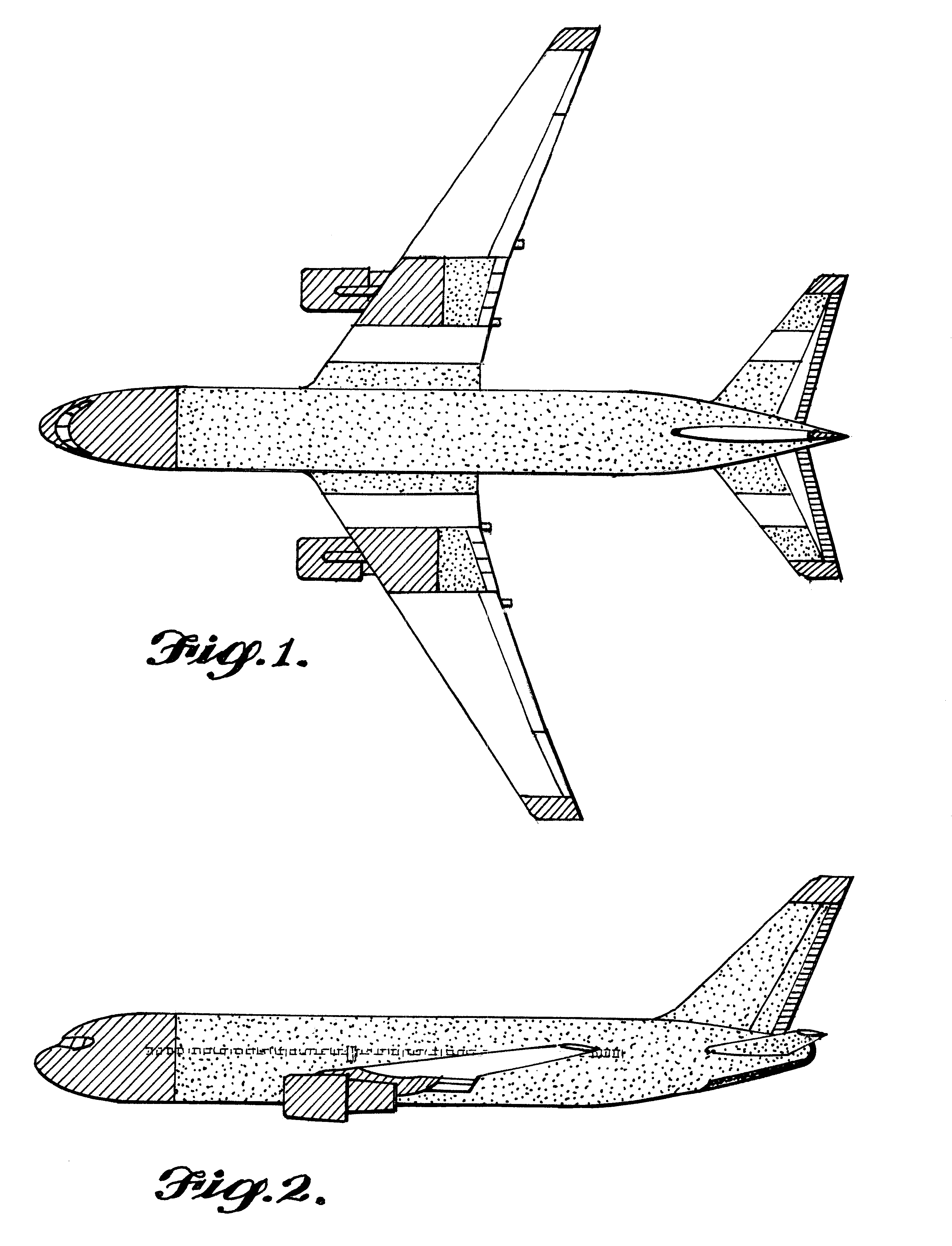

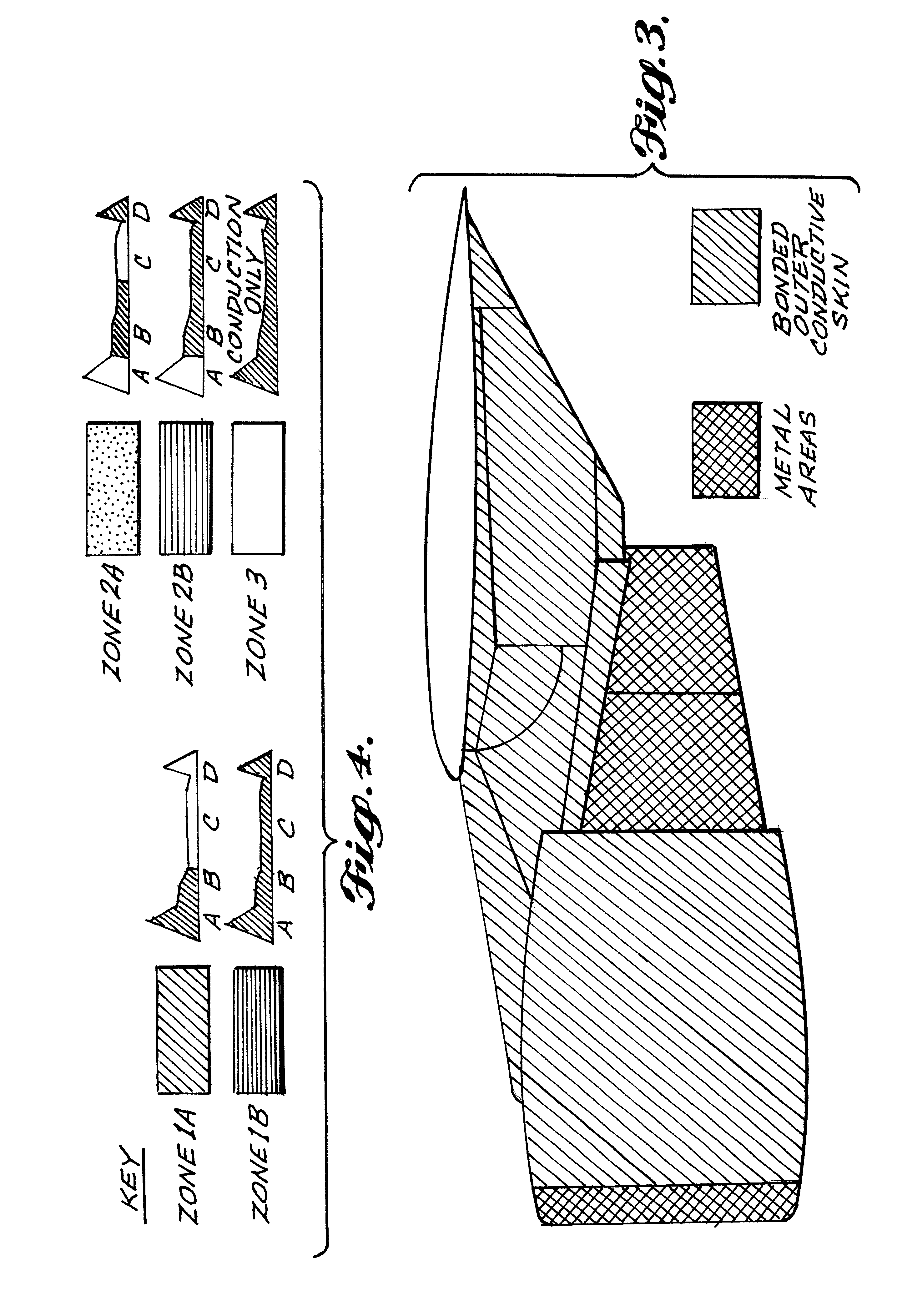

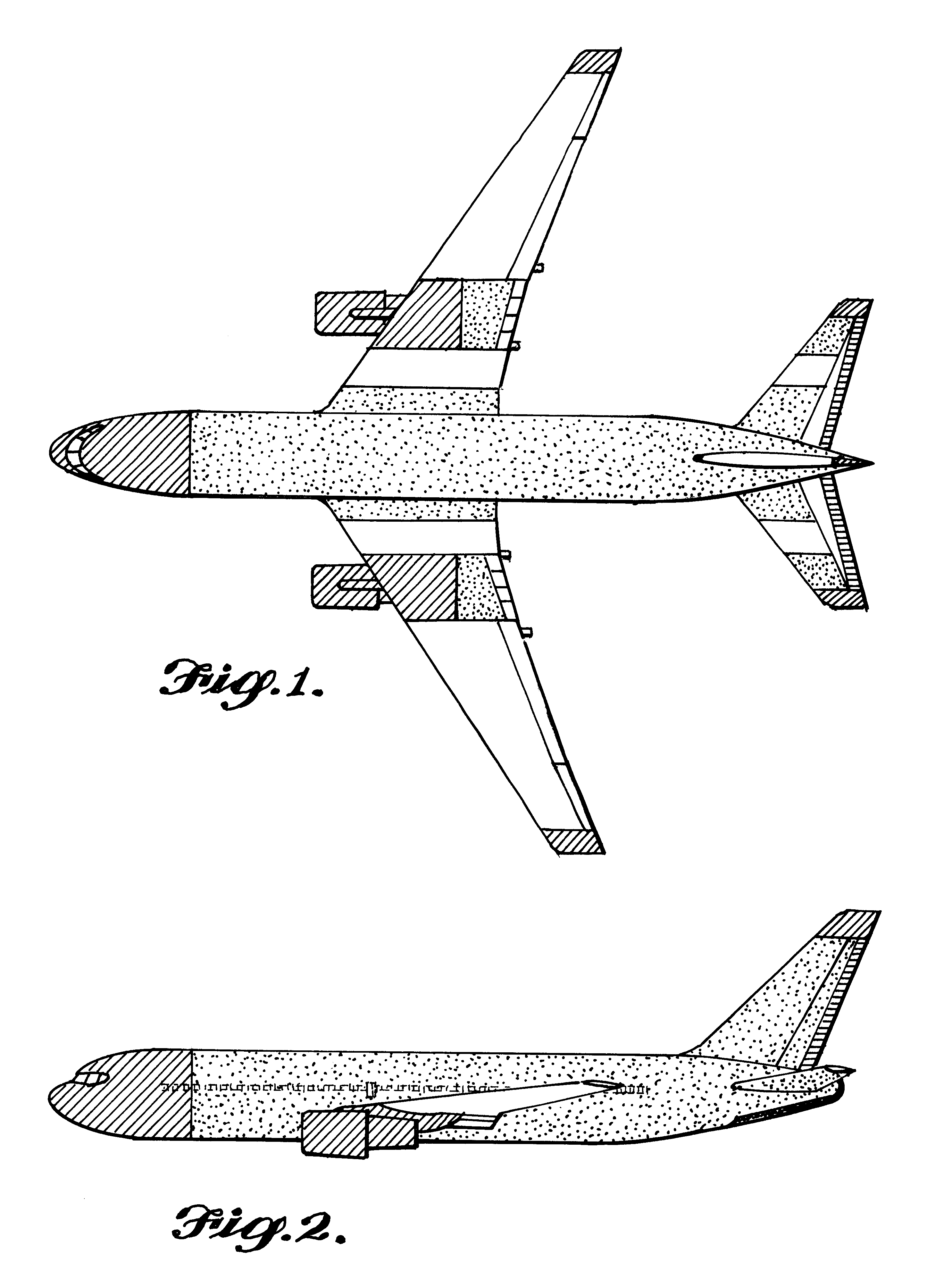

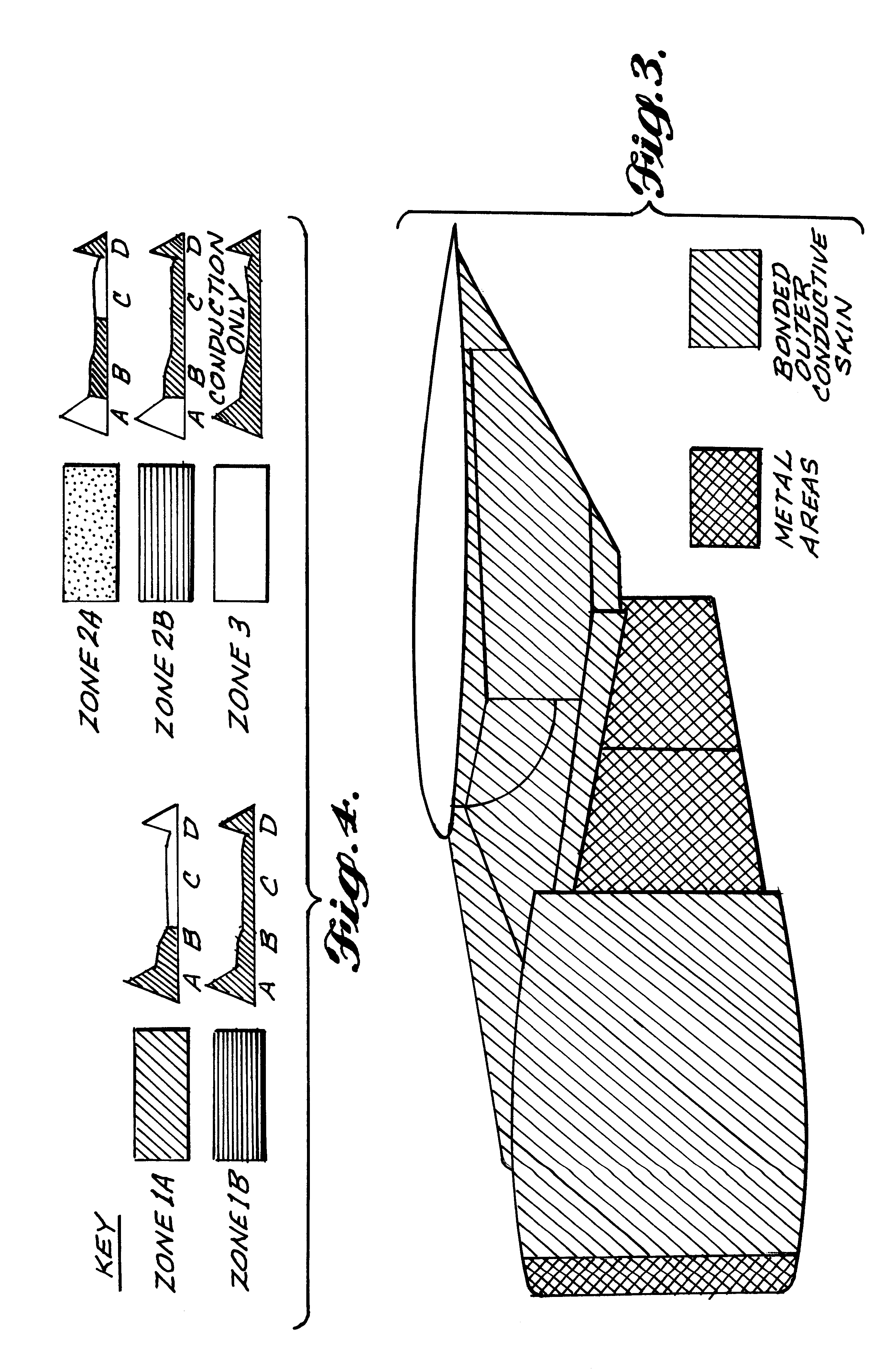

Lightning protection for electrically conductive or insulating skin and core for honeycomb structure

InactiveUS6432507B1Installation of lighting conductorsFuselage bulkheadsConductive coatingHoneycomb structure

Lightning protection utilizing lightweight electrically conductive coatings with a conductance of approximately 220 to 350 mhos per square co-cured or secondarily bonded to the outer surface of thin skin composite structure. Selection of either 2 to 3 ounces per square yard or aluminum mesh of 1 to 1.5 ounces per square yard, depending on corrosion compatibility, satisfy the conductance requirement and has shown superior lightning protection over heavier weight conductive coatings.

Owner:THE BOEING CO

Low permeability airbag cushions having extremely low silicone-based coating levels

InactiveUS20030124929A1High leak-down timeReduce penetrationLayered productsPedestrian/occupant safety arrangementNeopreneEngineering

Coated inflatable fabrics and more particularly concerns airbag cushions to which very low add-on amounts of silicone-based coating have been applied and which exhibit extremely low air permeability are provided. The inventive inflatable fabrics are primarily for use in automotive restraint cushions that require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones, and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin, substantially uniform silicone coating to provide such necessarily low permeability levels. Thus, the inventive coating comprises at least a single layer comprising a majority of silicone-based material, wherein the total thickness of the single layer is at most about 3.0 ounces per square yard as applied to a target fabric surface. The inventive airbag exhibits a characteristically long leak-down rate as compared to other coated airbags.

Owner:PIONEER HI BRED INT INC

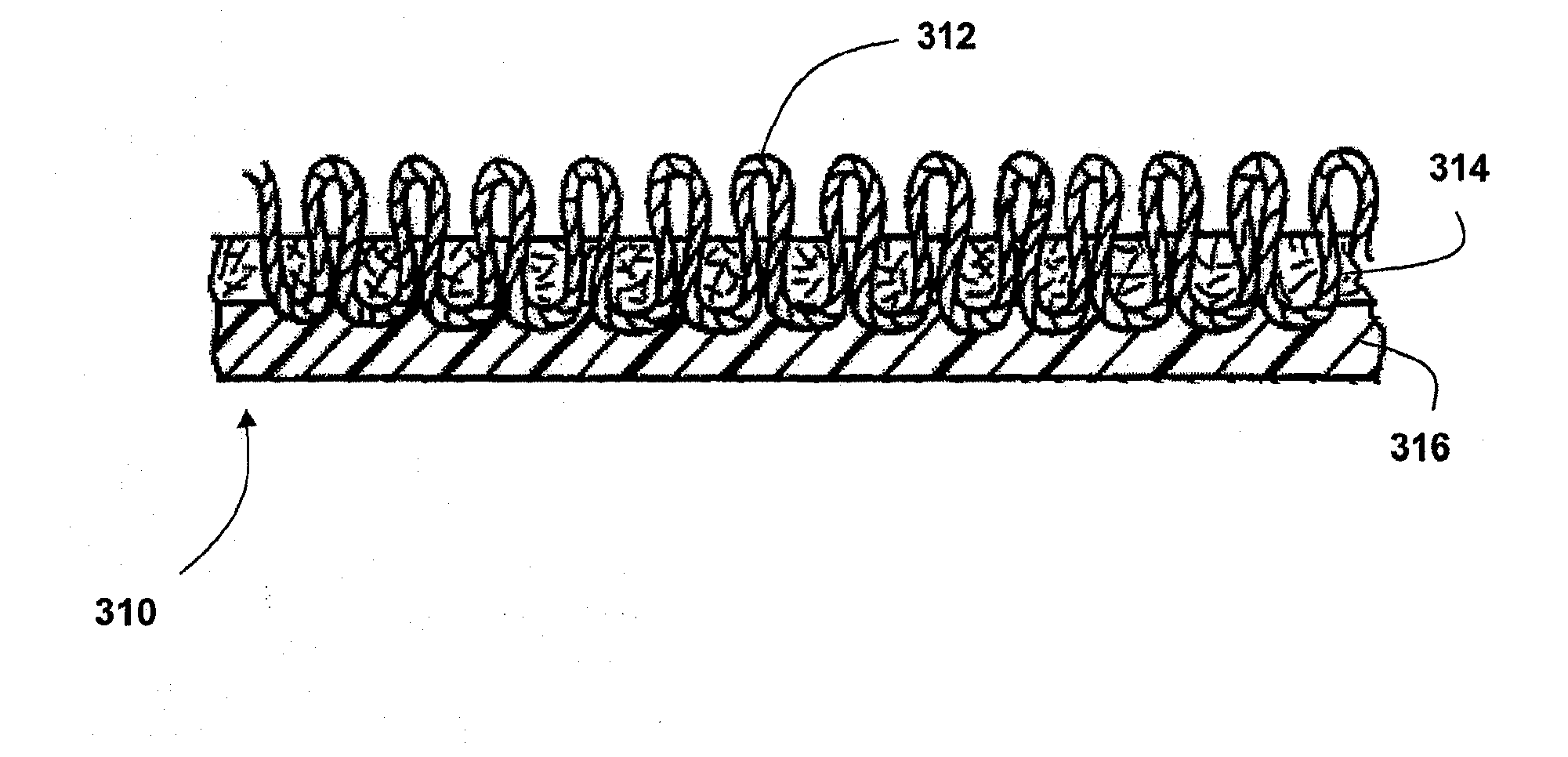

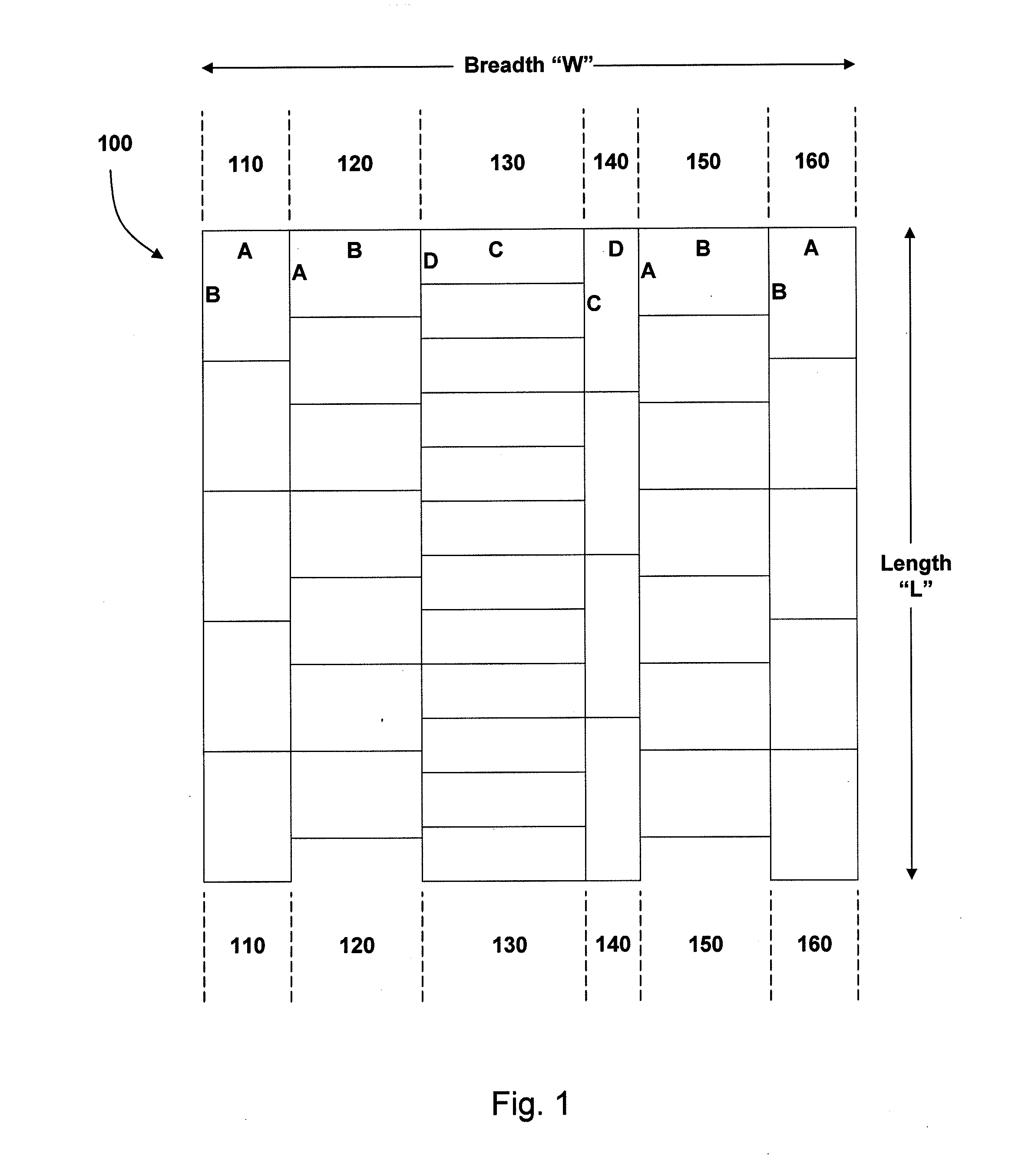

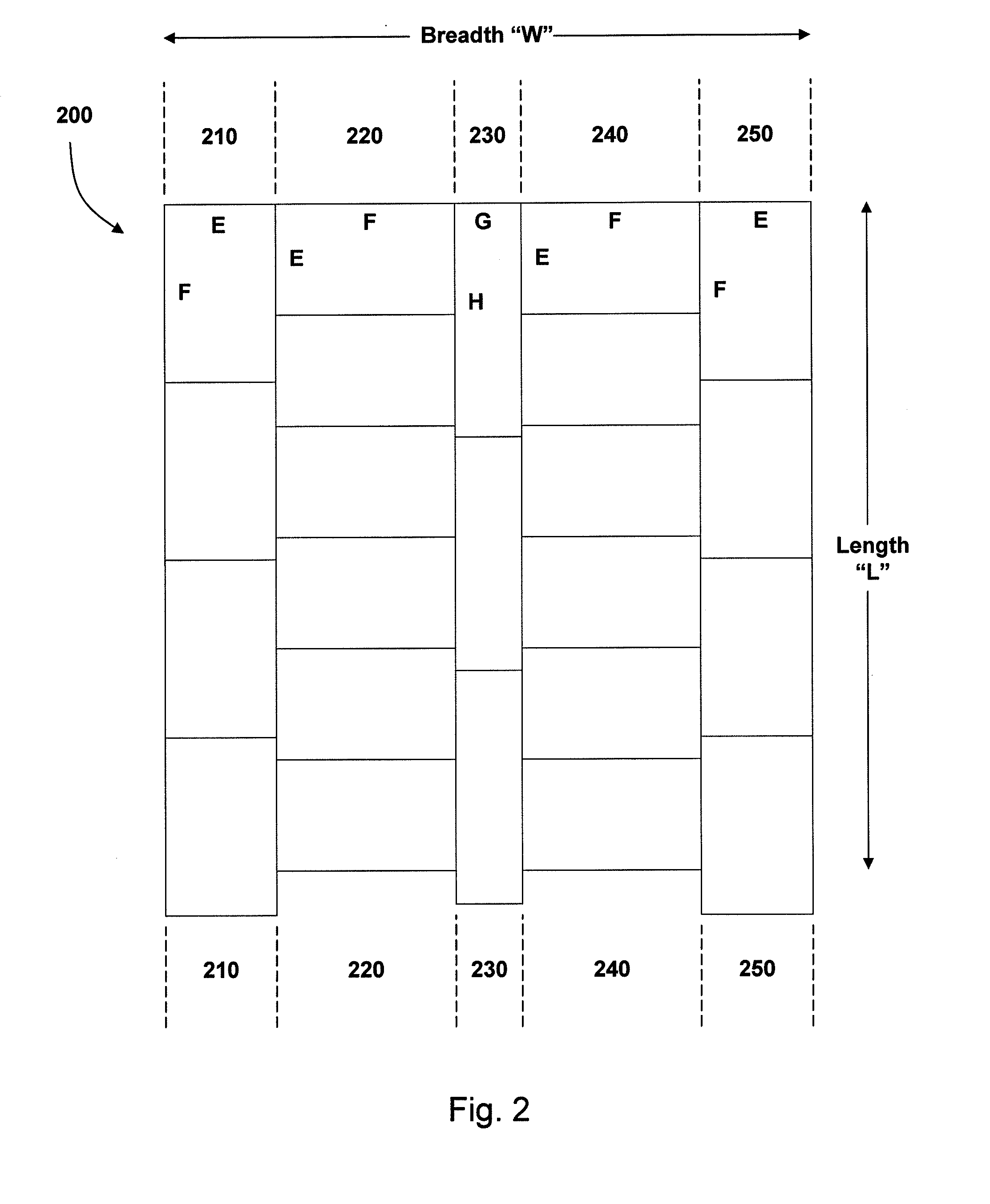

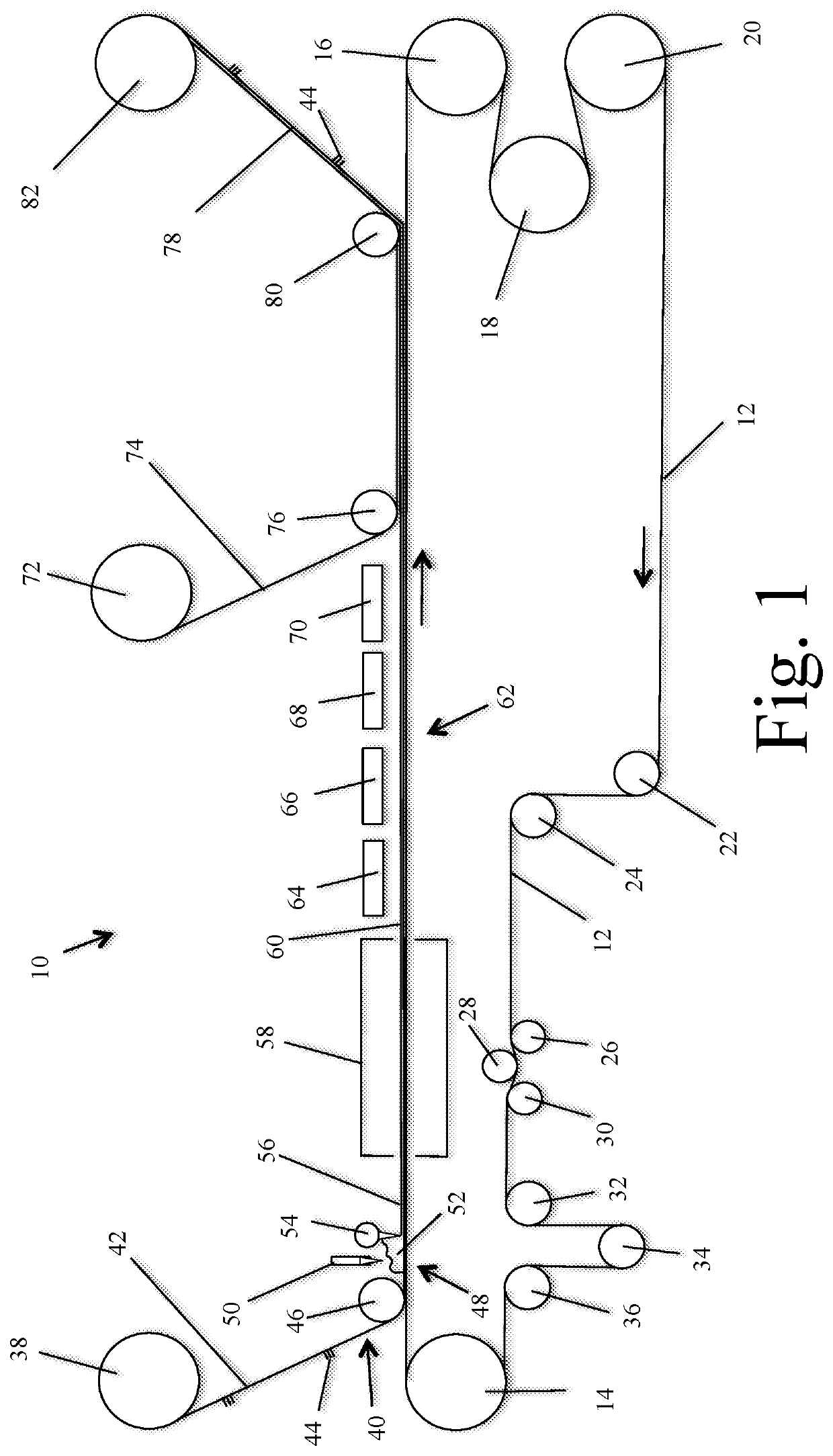

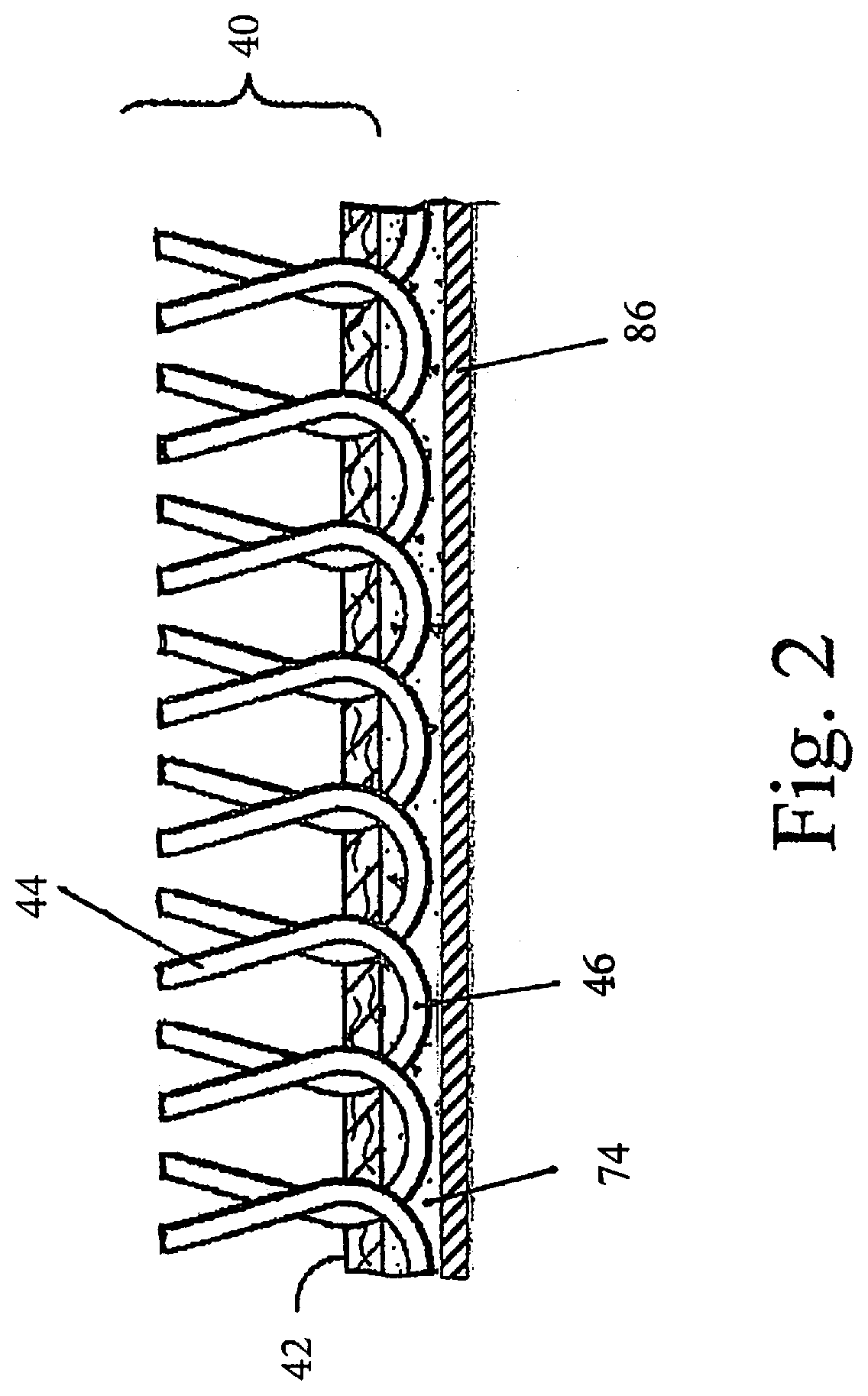

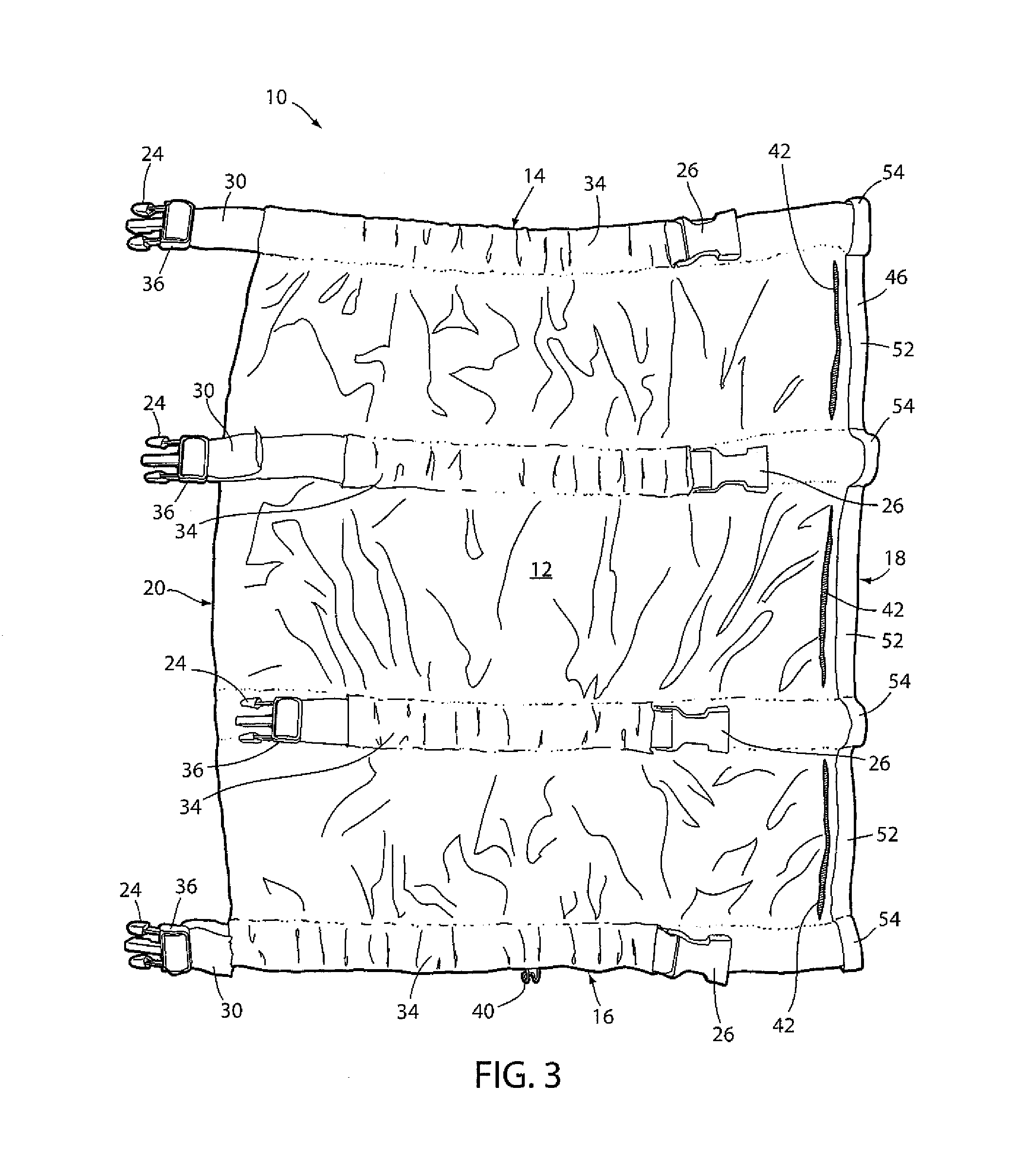

Low Weight Carpet and Carpet Tile and Methods of Manufacture

ActiveUS20100051169A1Reduce weightMinimize the numberVehicle arrangementsTufting apparatusProduction lineBrick

Low weight and non-square carpet tile suitable for use in mass transit vehicles, particularly passenger aircraft. The carpet tile preferably weighs less than about 82 ounces per square yard. The carpet tile of this invention may have a carpet pile and at least one backing layer. The backing layer may use low weight filler material. Secondary backing plastic material may be compressed into the tile structure with pressure rollers or other pressure applying process on an improved tile production line.

Owner:INTERFACE INC

Flame retardant fiber blends comprising flame retardant cellulosic fibers and fabrics and garments made therefrom

Owner:EI DU PONT DE NEMOURS & CO

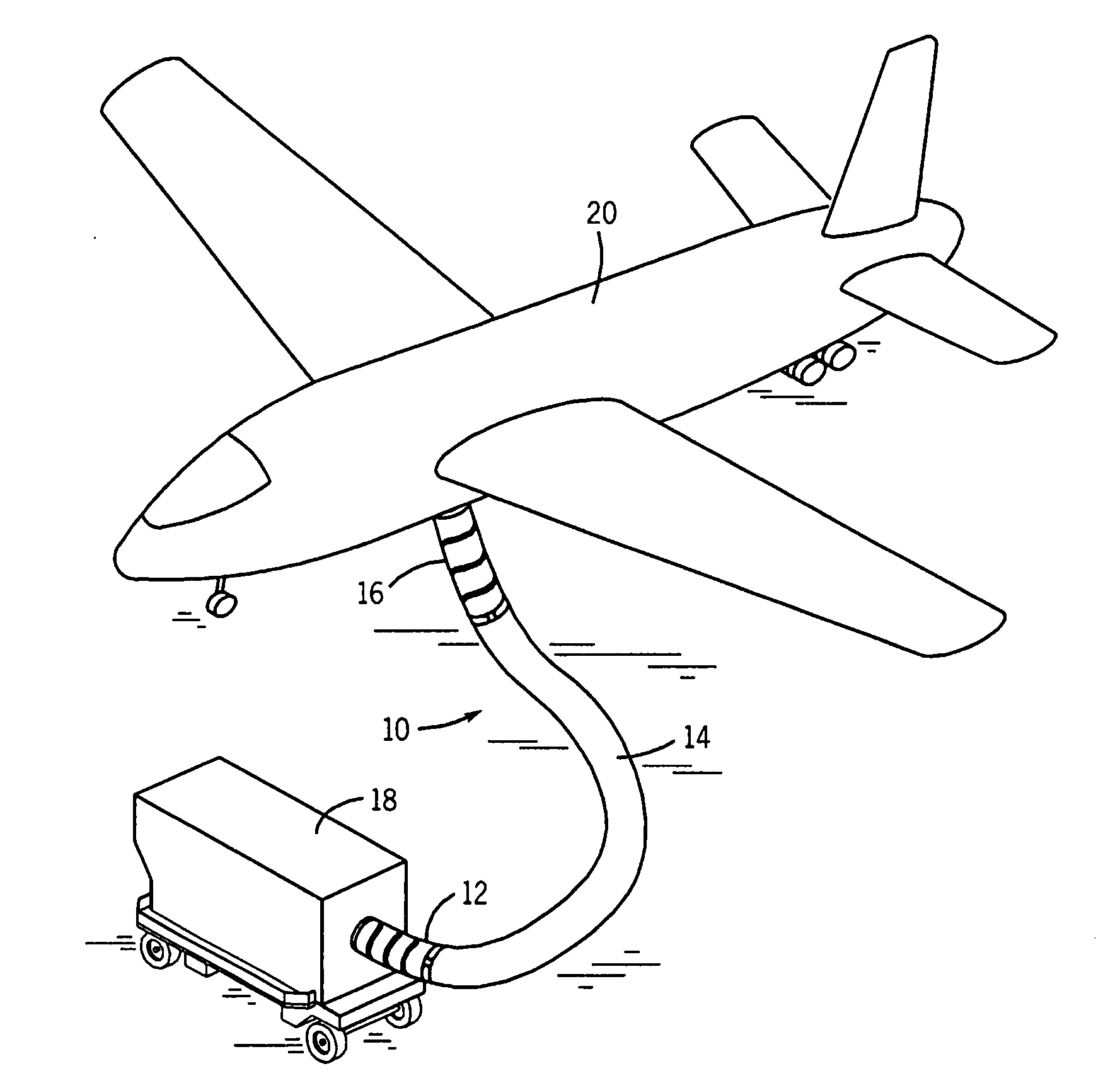

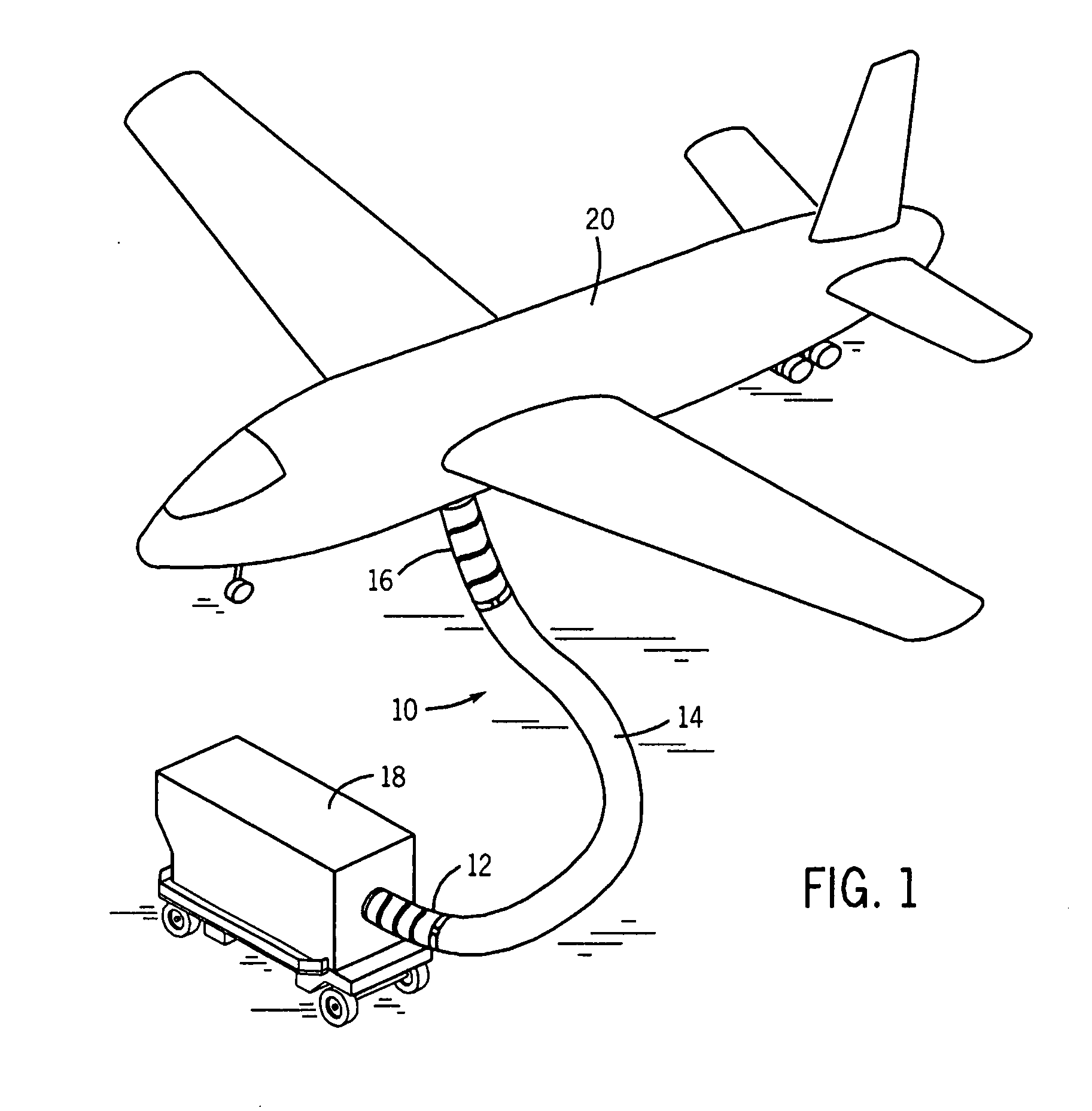

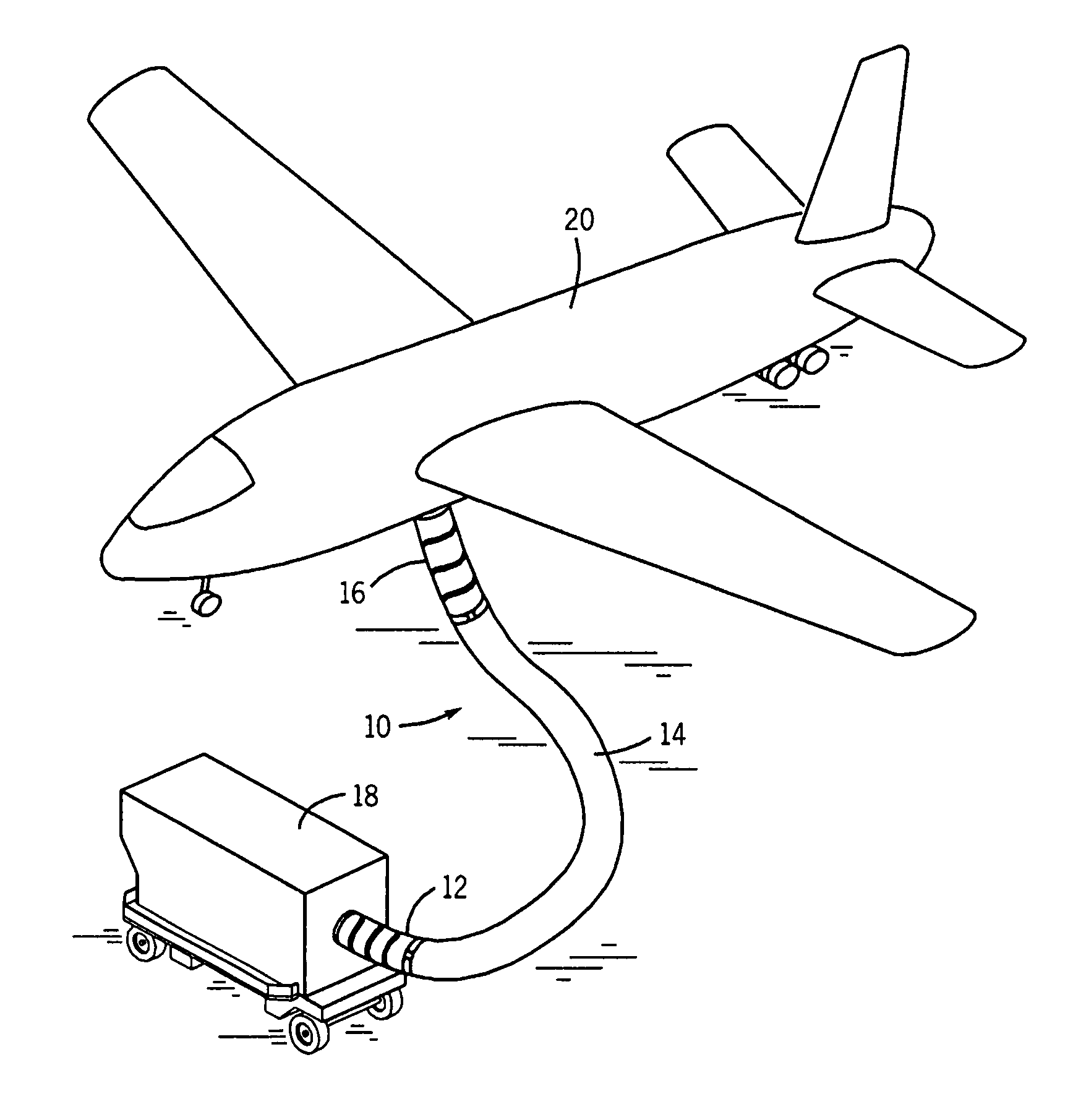

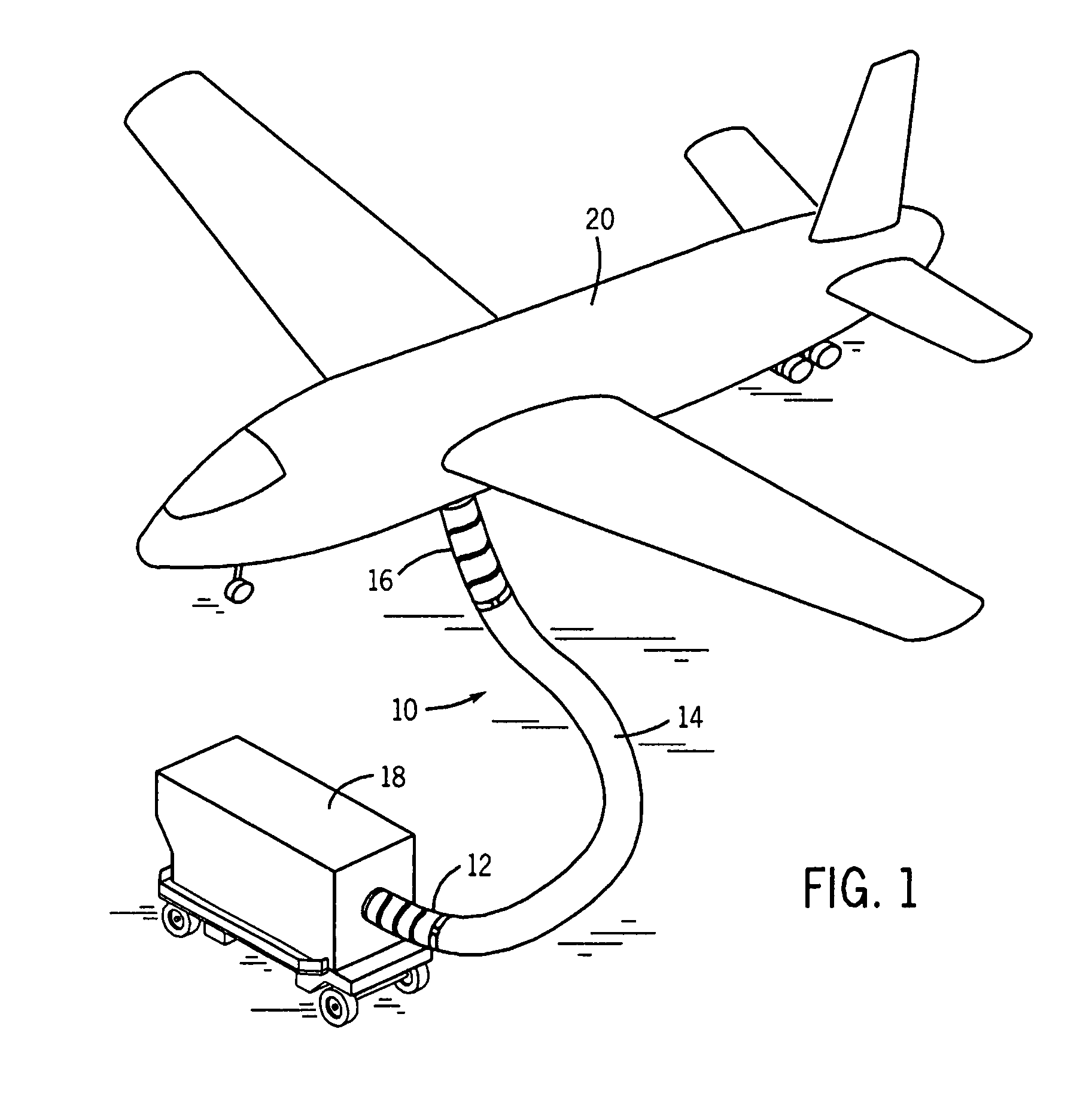

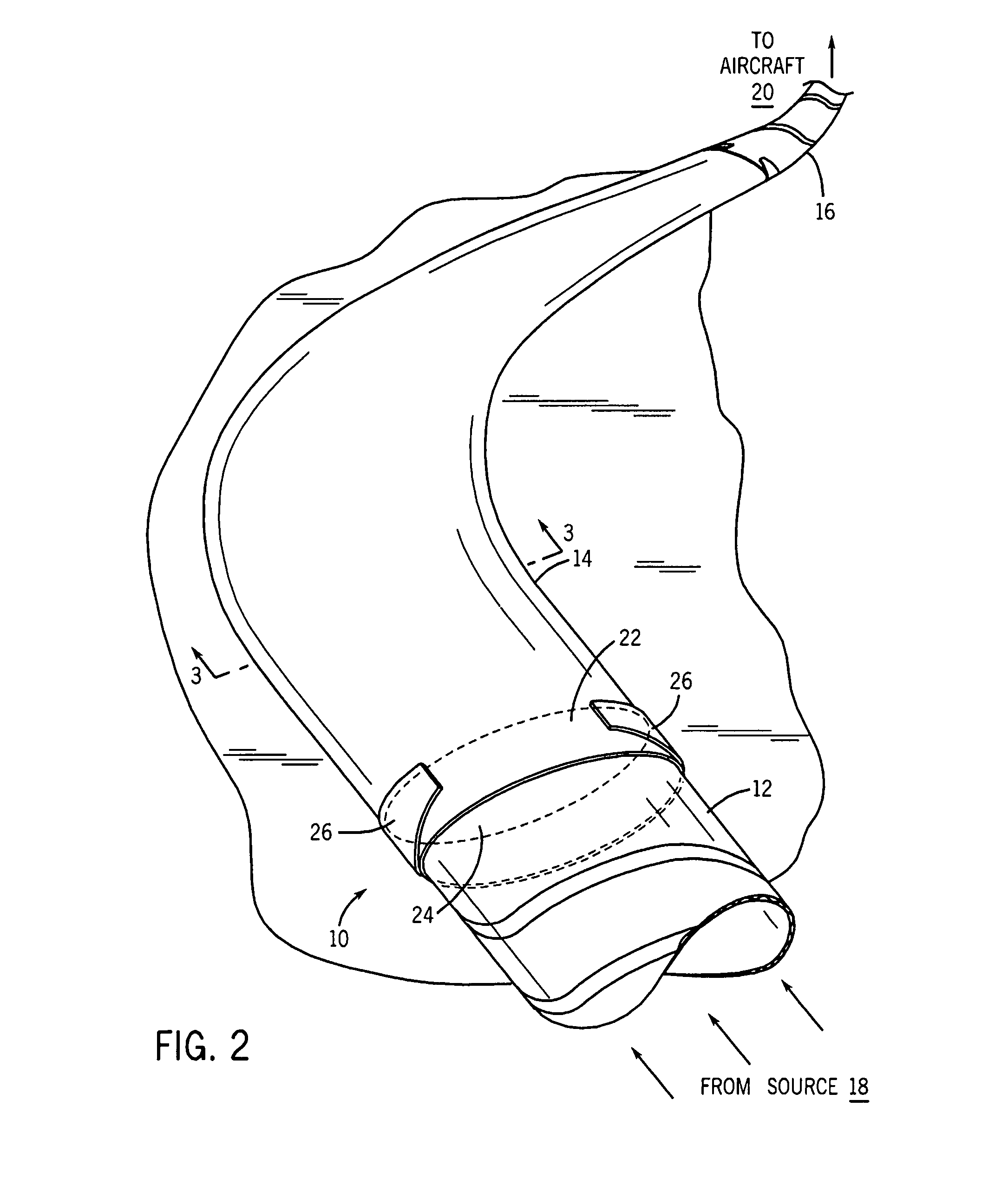

Robust preconditioned air hose

ActiveUS20080185064A1Thermal insulationSpace heating and ventilation detailsLinear densityPre treatment

A preconditioned air hose includes an abrasion-resistant external layer made of robust nylon, an insulating layer, and an inner layer. The robust external layer protects the air hose from wear and degradation due to abrasion. The external layer may be made of a fabric with an abrasion resistance of at least 22,000 cycles to failure as measured using the ASTM D 3884 standard. This external layer fabric may be composed of filaments having a linear density of about 1,000 denier. The external layer fabric may weigh about 10.8 ounces per square yard.

Owner:HOBART BROS

Low weight carpet and carpet tile and methods of manufacture

ActiveUS8083875B2Reduce weightMinimize the numberVehicle arrangementsAdhesive processes with surface pretreatmentProduction linePlastic materials

Low weight and non-square carpet tile suitable for use in mass transit vehicles, particularly passenger aircraft. The carpet tile preferably weighs less than about 82 ounces per square yard. The carpet tile of this invention may have a carpet pile and at least one backing layer. The backing layer may use low weight filler material. Secondary backing plastic material may be compressed into the tile structure with pressure rollers or other pressure applying process on an improved tile production line.

Owner:INTERFACE INC

Lightning protection for electrically conductive or insulating skin and core for honeycomb structure

InactiveUS6303206B1Installation of lighting conductorsFuselage bulkheadsConductive coatingHoneycomb structure

Lightning protection utilizing lightweight electrically conductive coatings with a conductance of approximately 220 to 350 mhos per square co-cured or secondarily bonded to the outer surface of thin skin composite structure. Selection of either 2 to 3 ounces per square yard or aluminum mesh of 1 to 1.5 ounces per square yard, depending on corrosion compatibility, satisfy the conductance requirement and has shown superior lightning protection over heavier weight conductive coatings.

Owner:THE BOEING CO

Robust preconditioned air hose

Owner:HOBART BROS

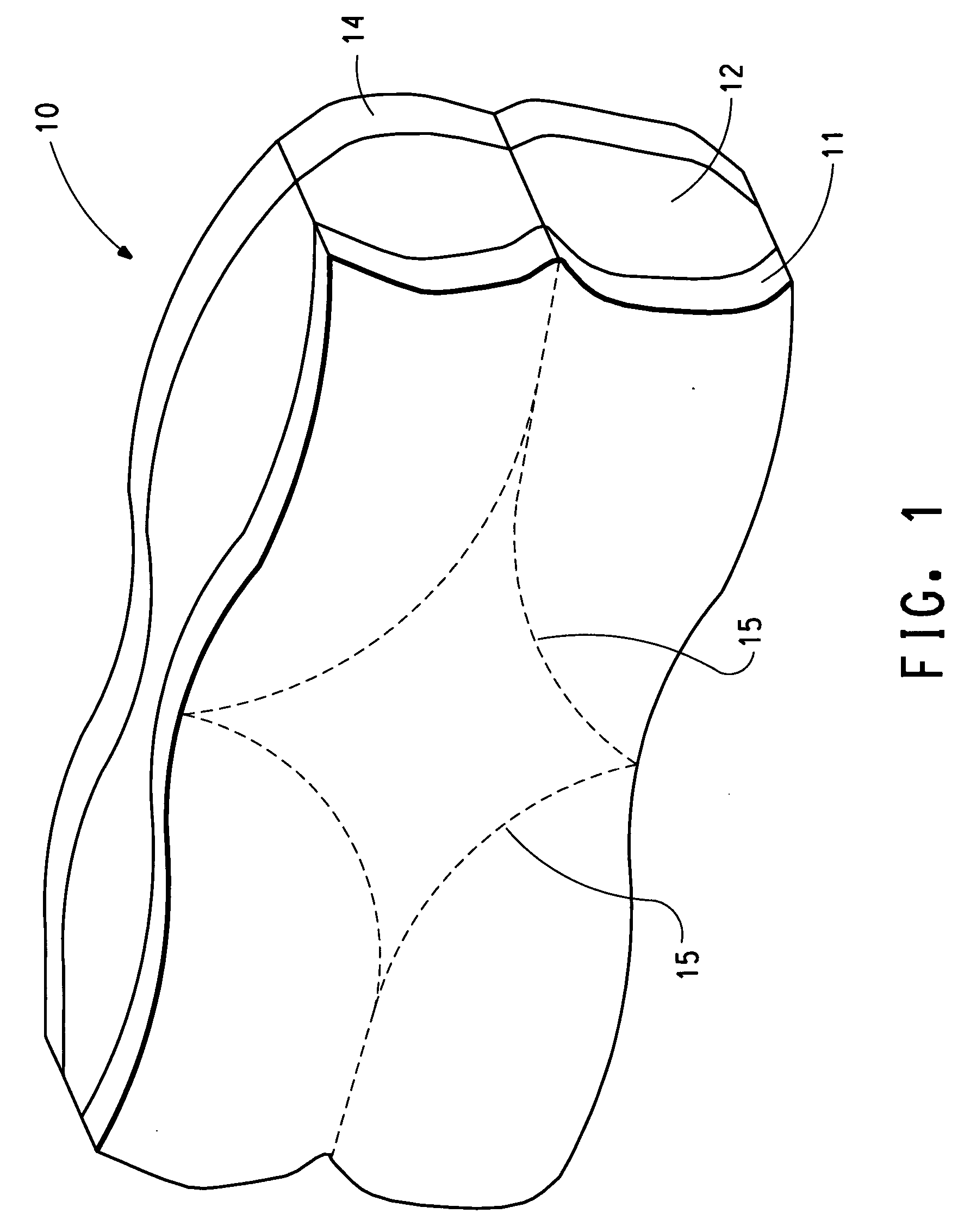

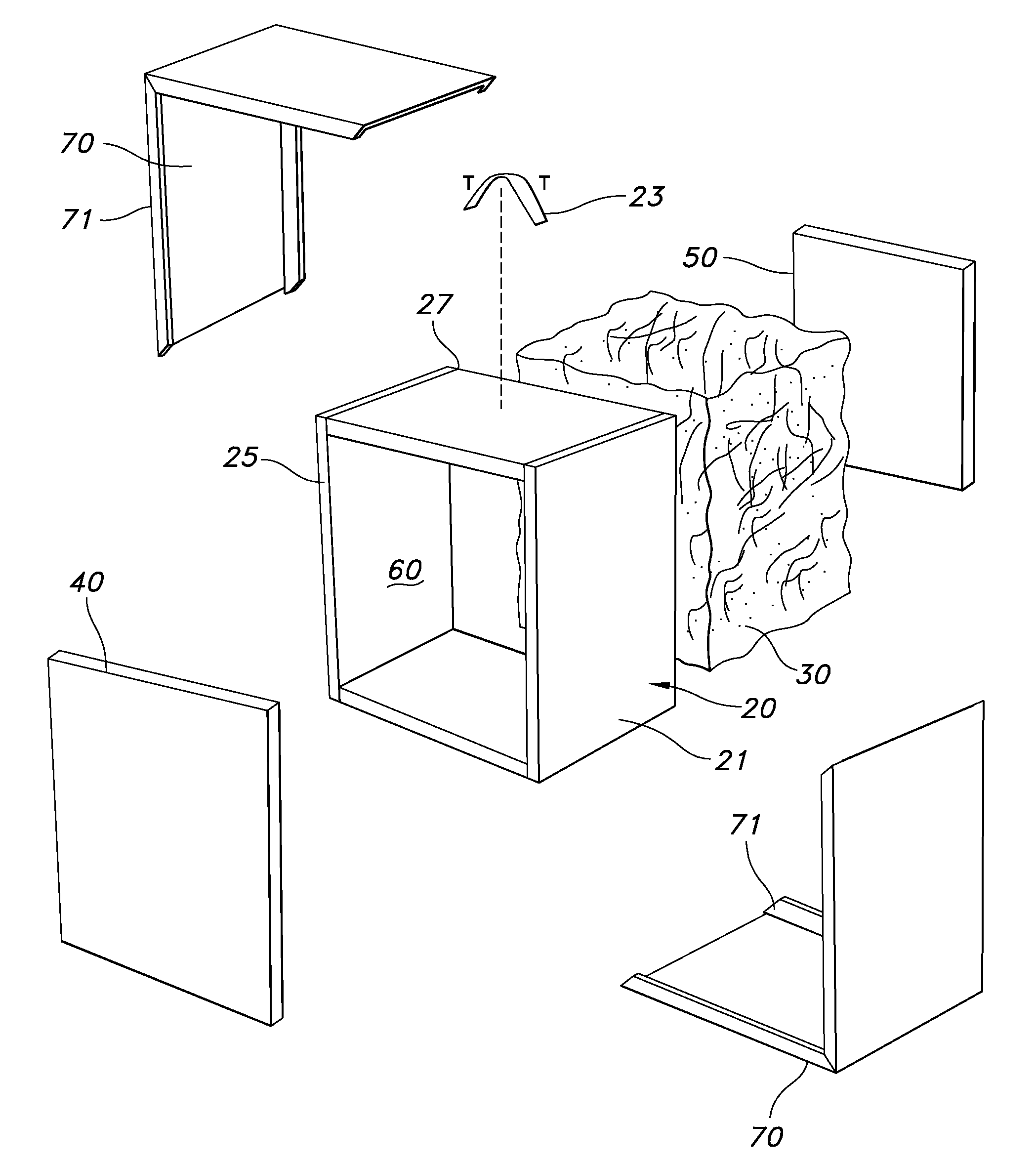

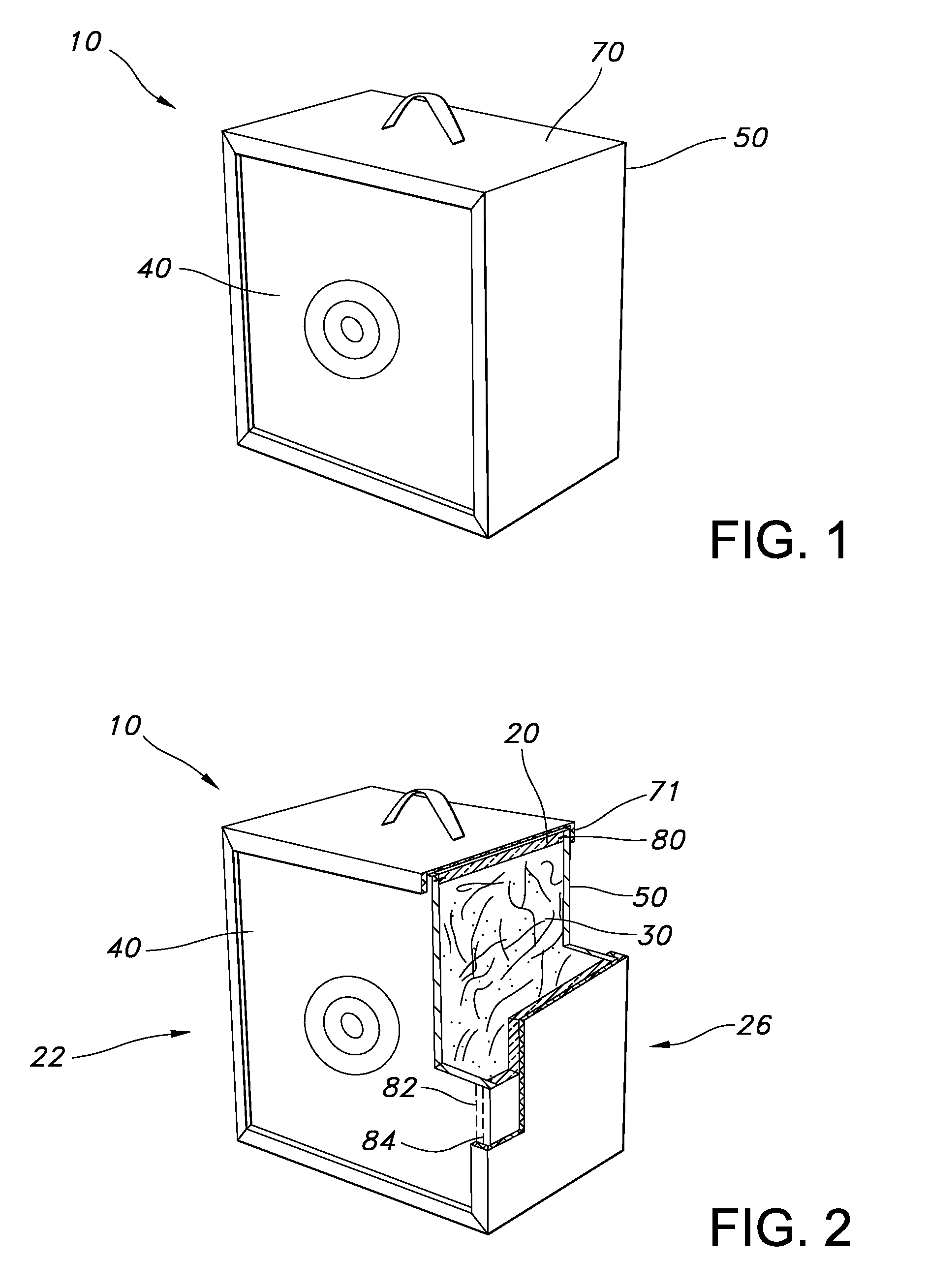

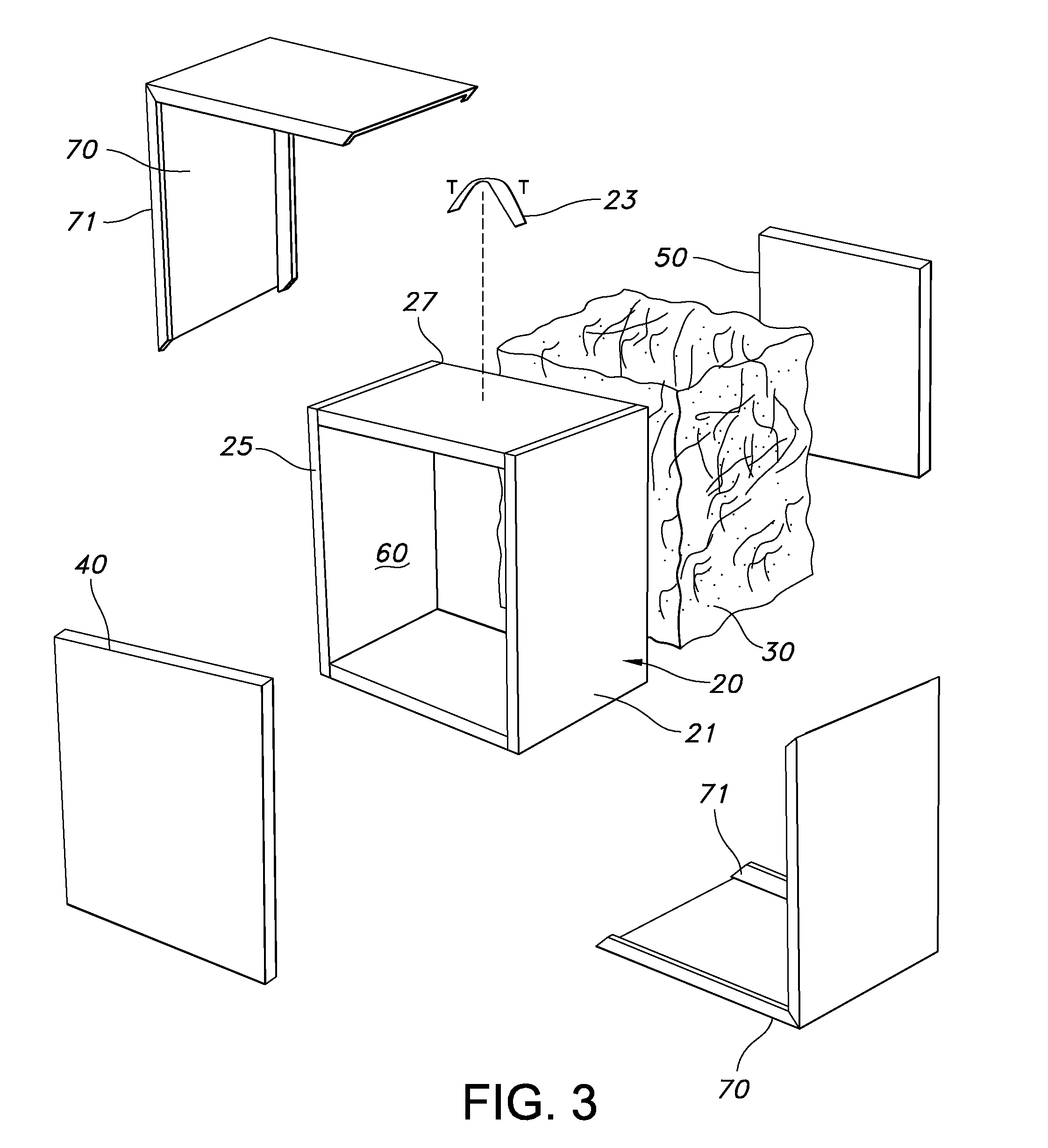

Archery target and related method of manufacture

An archery target including a rigid frame including a target side, a sheet secured to the frame on a target side to create an interior compartment bounded by the sheet and the frame, a compressed density material in the compartment and a backing. The sheet can be a filtration screen constructed from synthetic polymers, optionally polyamide fibers, and can have a weight of 13 to 16 ounces per square yard, and can include parallel warp yams formed from three pairs monofilament polyamide fibers, the three pairs of fibers twisted together to form a cable yarn, as well as parallel fill yam formed from a single monofilament polyamide fiber. A related method includes: providing a rigid frame; securing a sheet to the frame to create an interior compartment; compressing a density material; and securing a backing to the frame.

Owner:ALL SEASONS ARCHERY

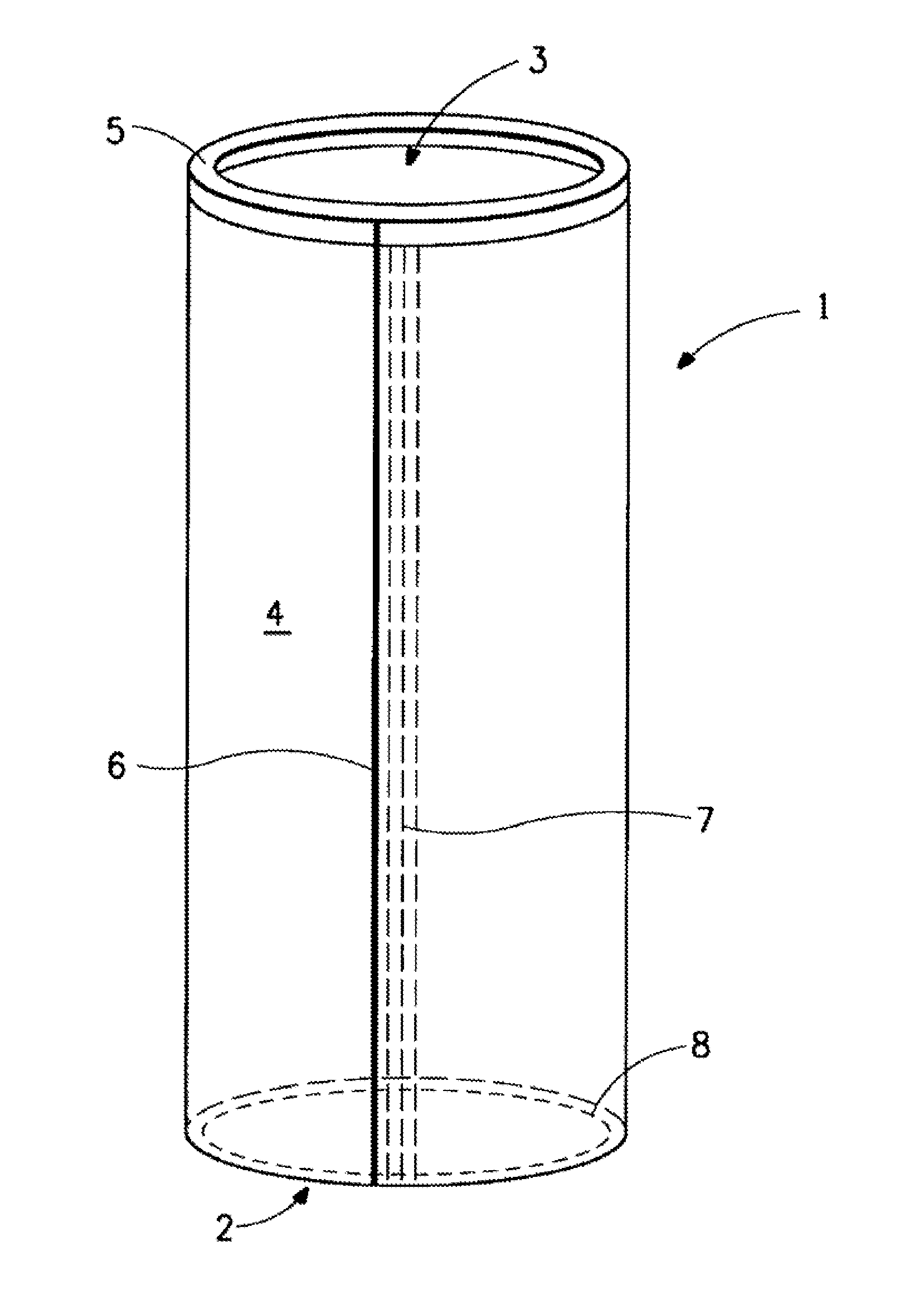

Low elongation structures for hot gas filtration

Structures containing a fiber mat inserted into a high modulus scrim of minimum basis weight 35 gsm. The structures have reduced tensile elongation at 50 N per 5 cm fabric strip in MD under ISO 9073-3 standard norm. The structure has a basis weight of at least 9 ounces per square yard (305 grams per square meter). The structure also has heat resistance of at least 150° to 190° C., preferably over 200 up to 260° C. to for service under typical hot flue gas filtration conditions. Filter bags made from these structures provide a controlled dimensional stability over their entire filter life time. In addition such stable structures are suitable for lamination with fragile membranes especially e-PTFE membranes where minimum amount of mechanical damage to the membrane occurs.

Owner:EI DU PONT DE NEMOURS & CO

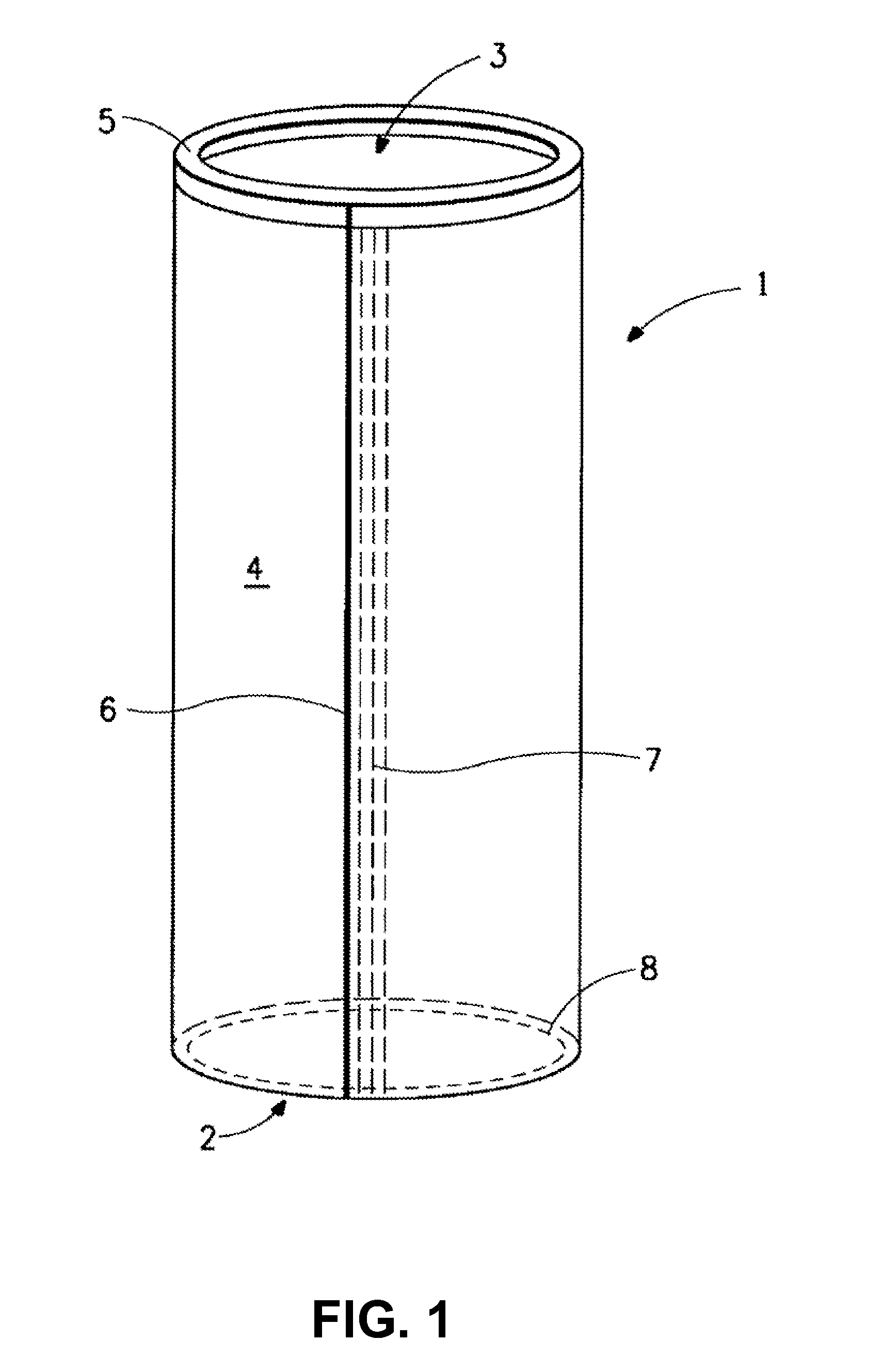

Container for preservation of perishable food items

A container for preserving food items includes a sidewall extending from a sidewall base, the sidewall defining an open interior space and a rim of the sidewall defining an opening in the container, the opening providing access to the open interior space. The container is constructed of an organic cotton fabric having a density of about 6-10 ounces per square yard (oz. / sq. yd.).

Owner:NOLAN JULIANNE L

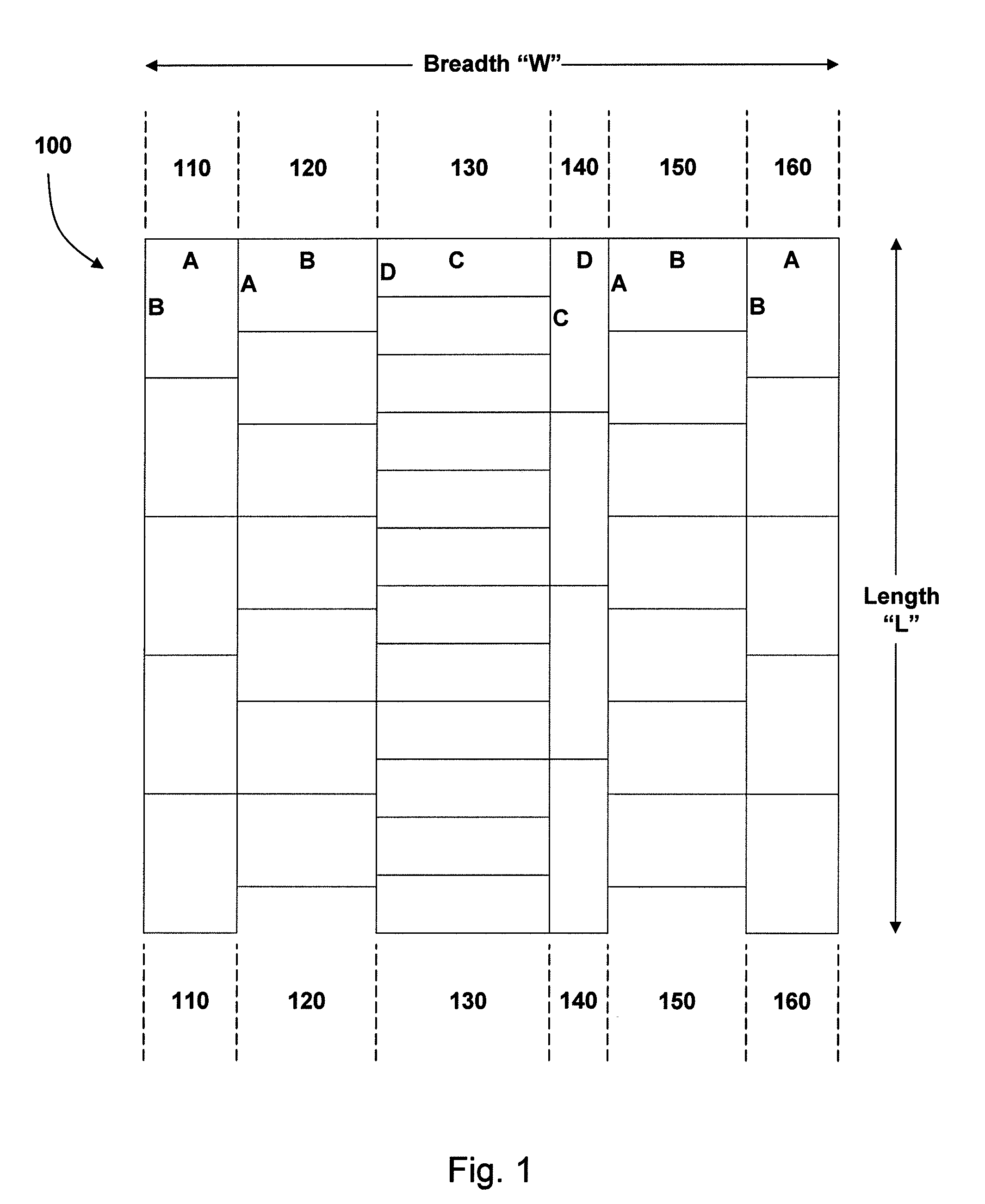

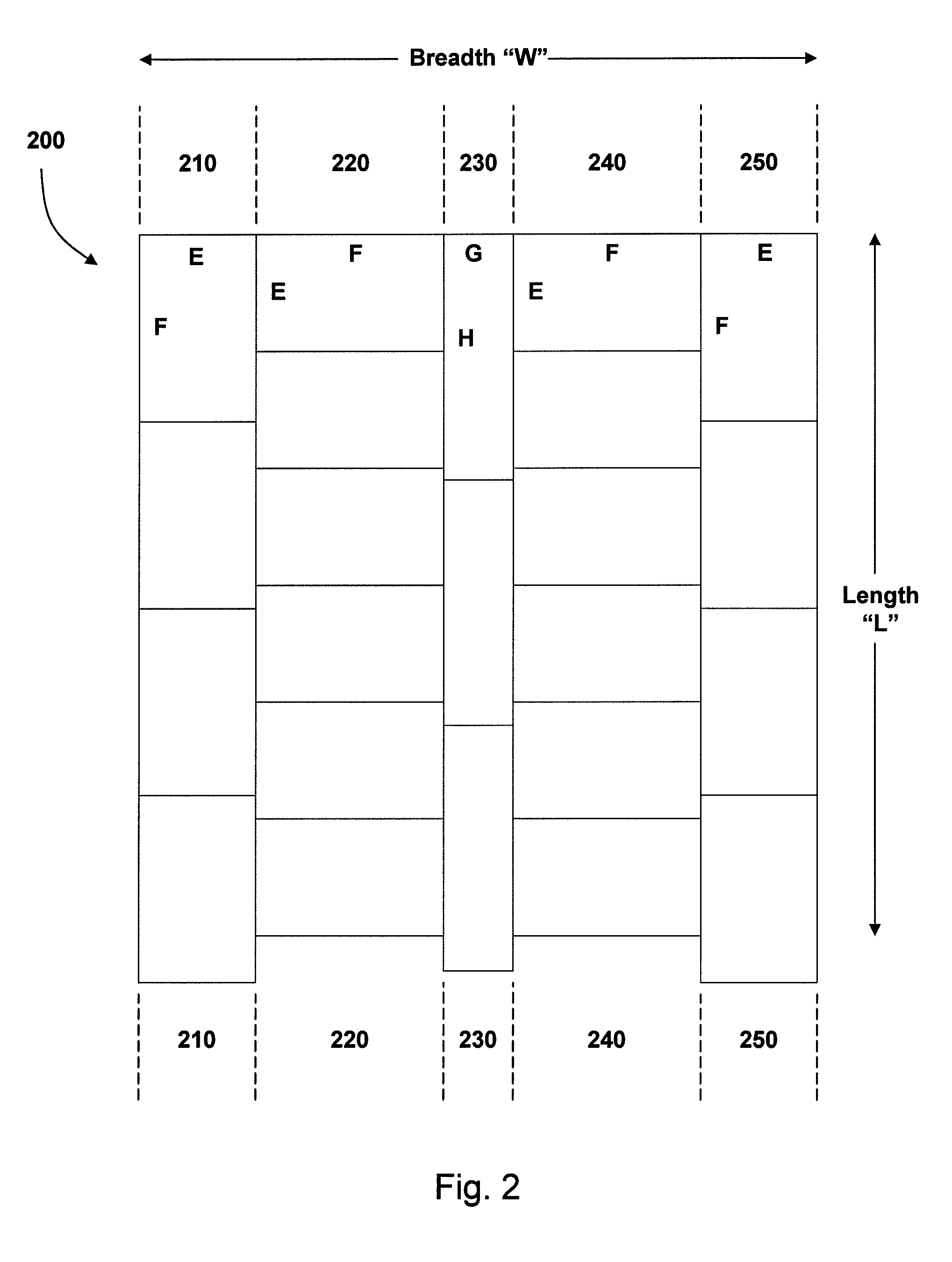

Low Weight Carpet and Carpet Tile and Methods of Sizing and Installation

ActiveUS20100051745A1Reduce weightMinimize the numberVehicle arrangementsCoatingsBrickFilling materials

Low weight and non-square carpet tile suitable for use in mass transit vehicles, particularly passenger aircraft. The carpet tile preferably weighs less than about 82 ounces per square yard. The carpet tile of this invention may have a carpet pile and at least one backing layer. The backing layer may use a low weight filler material. The carpet tiles satisfy transportation industry standards for flame, smoke and toxicity. Tiles may be sized during manufacture and installed in configurations that minimize the number of tile sizes needed and minimize the need for cutting tiles during installation. The patterns used for such tiles may be orthogonally ambiguous or otherwise suitable for “random” installation. In other embodiments, a passenger aircraft cabin includes a floor having rectangular carpet tiles installed thereon, and the carpeting can be installed in the aircraft without removing seats from the aircraft.

Owner:INTERFACE INC

Cut, slash and/or abrasion resistant protective fabric and lightweight shaped knit garment made therefrom having improved appearance and cut resistance

InactiveUS20170340038A1Satisfaction level is loweredSatisfactory level of cut and slashWeft knittingTrousersEngineeringSquare yard

A cut, slash and / or abrasion resistant shaped knit garment having both high cut resistance and preferably light fabric weight, a cut resistance of at least 4, preferably at least 5 (as measured by ASTM-F1790-97) and preferably a fabric weight of no more than 27.9 ounces / square yard (OPSY).

Owner:SUPREME CORQ

Water permeable artificial turf and method of making same

InactiveUS20190360160A1Reduce manufacturing costArtificial flowers and garlandsGround pavingsArtificial turfThermosetting polymer

The invention comprises a method. The method comprises applying to a primary backing and loop backs of a tufted synthetic turf a plurality of solid polymer particles having a particle size less than or equal to 1,000 microns such that a layer of solid polymer particles is formed across the width and length of the primary backing, wherein the polymer particles are applied to the primary backing at a rate of approximately 10 to approximately 18 ounces of polymer per square yard and wherein the solid polymer particles are thermoplastic polymer particles or a mixture of thermoplastic polymer particles and thermosetting polymer particles. The method also comprises heating the polymer particles on the primary backing and loop backs to a temperature at or above the melting temperature of the polymer particles and allowing the heated polymer particles to cool below their melting temperature wherein the tufted synthetic turf has bundle lock of at least 6.8 pounds and the tufted synthetic turf has a water permeability of at least 10 inches of water per hour.

Owner:TEXTILE RUBBER & CHEM CO INC

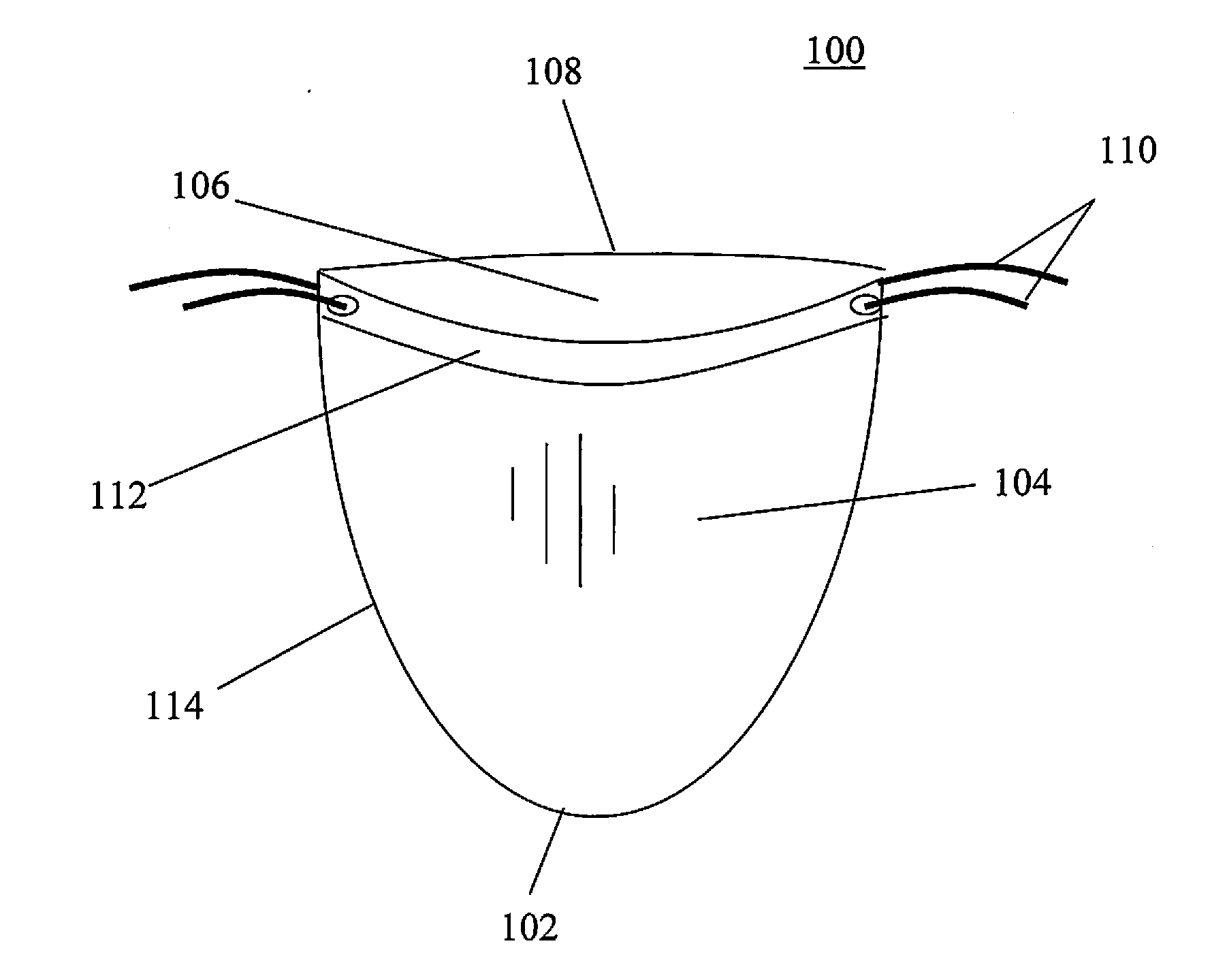

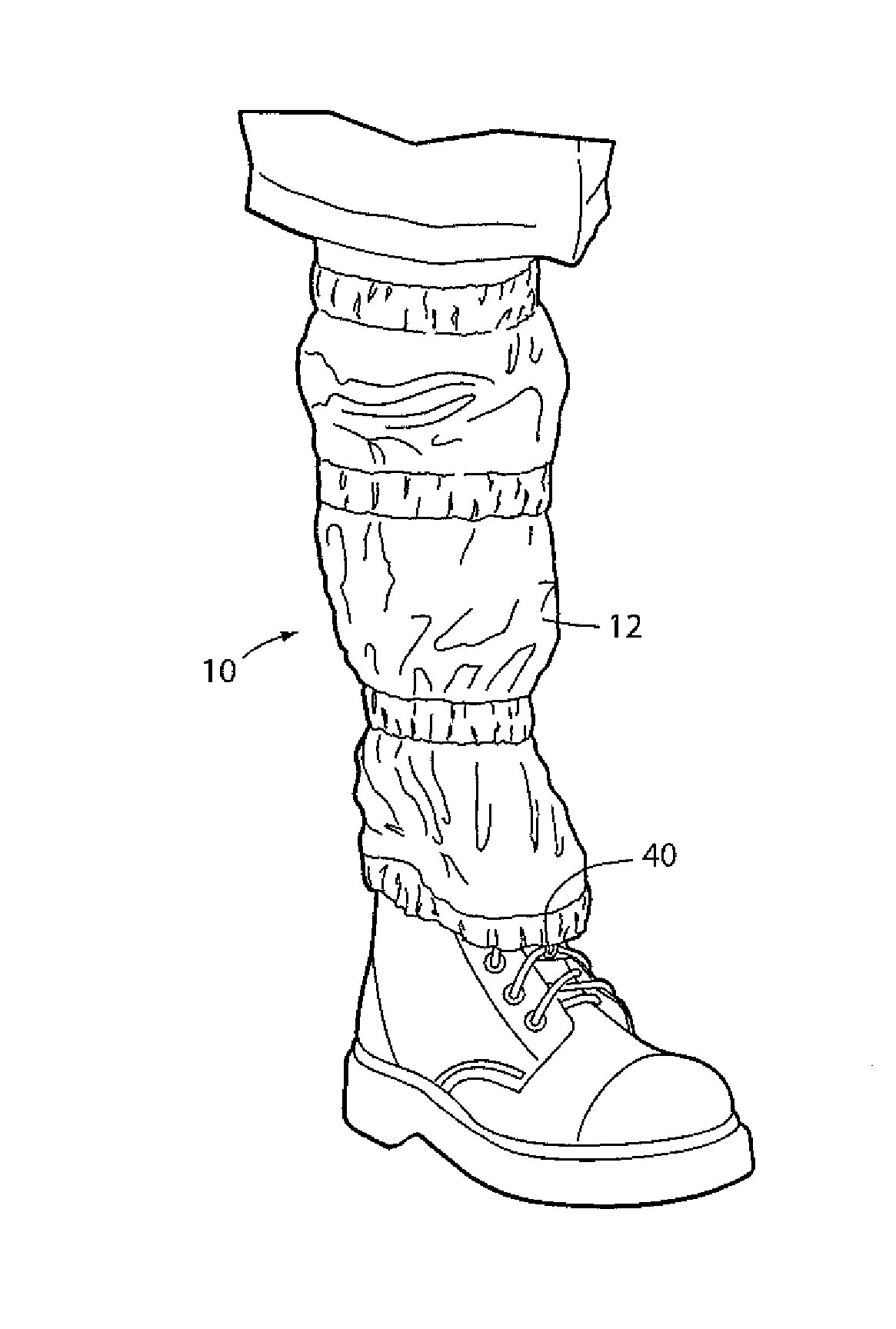

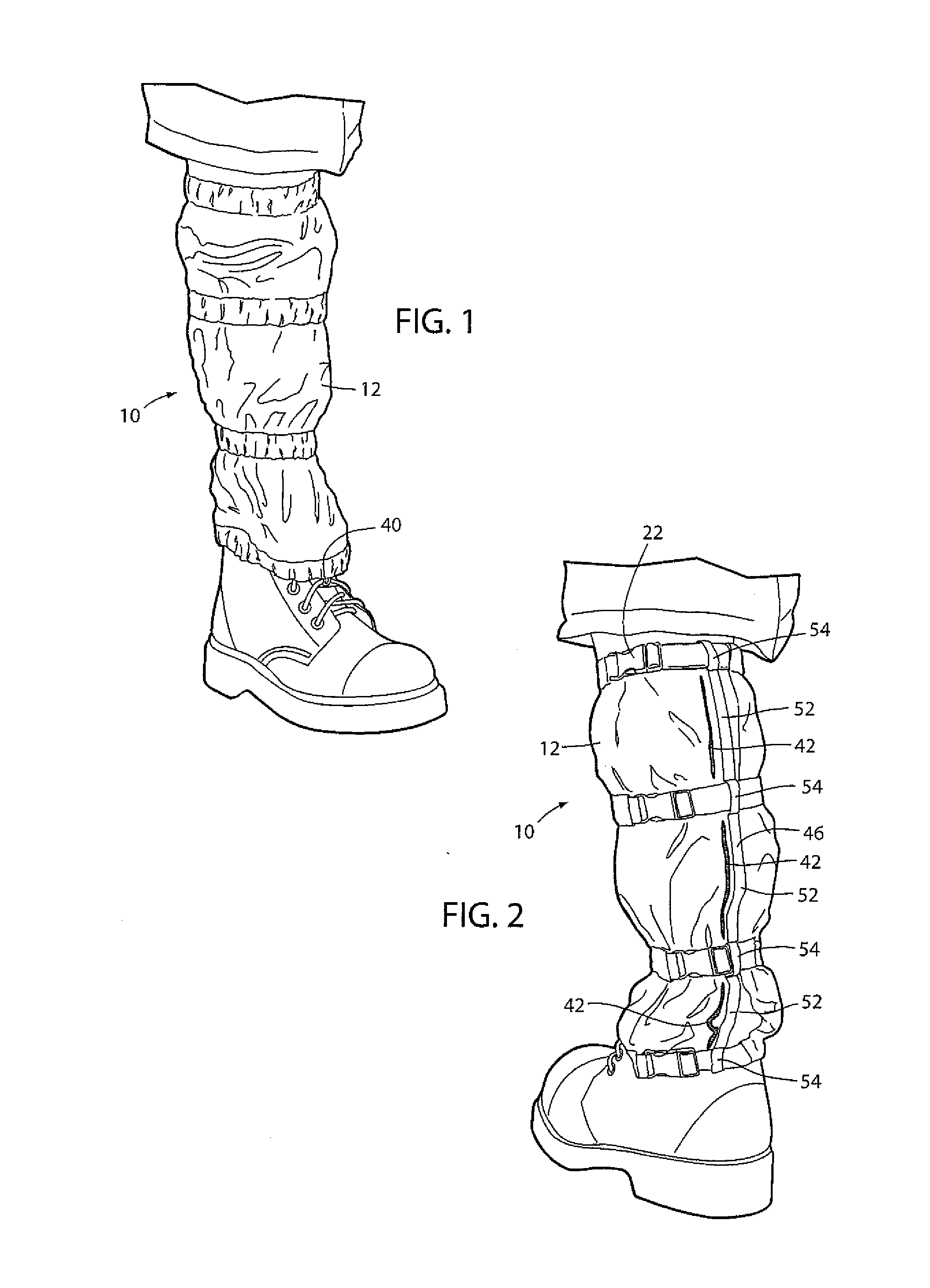

Lower leg covering for lawn care professionals

A protective leg covering for preventing grass clippings or other lawn or garden debris from impinging directly upon a lower leg, clothing covering a lower leg, or footwear, of a human operating a power tool that tends to propel grass clippings or other yard or garden debris toward the lower legs of the user includes a fabric panel having an upper edge, a lower edge and opposite side edges; a plurality of buckles that each have a first piece and a corresponding second piece that extend from opposite side edges and which cooperate to secure the leg covering over a lower leg of the human; and wherein the fabric panel is made of a fabric having a weight of from 2 to 10 ounces per square yard.

Owner:CALLAWAY ROBERT

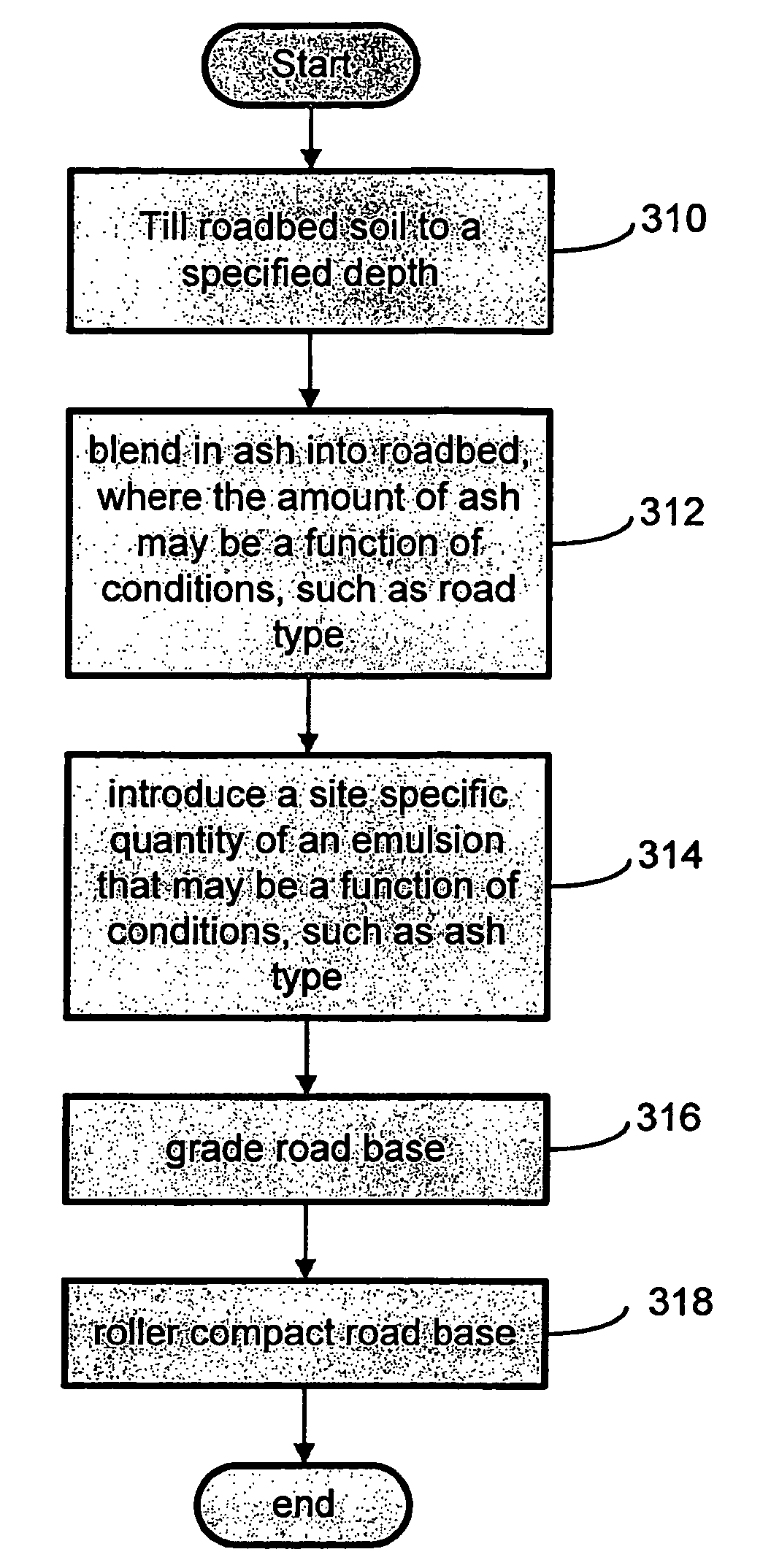

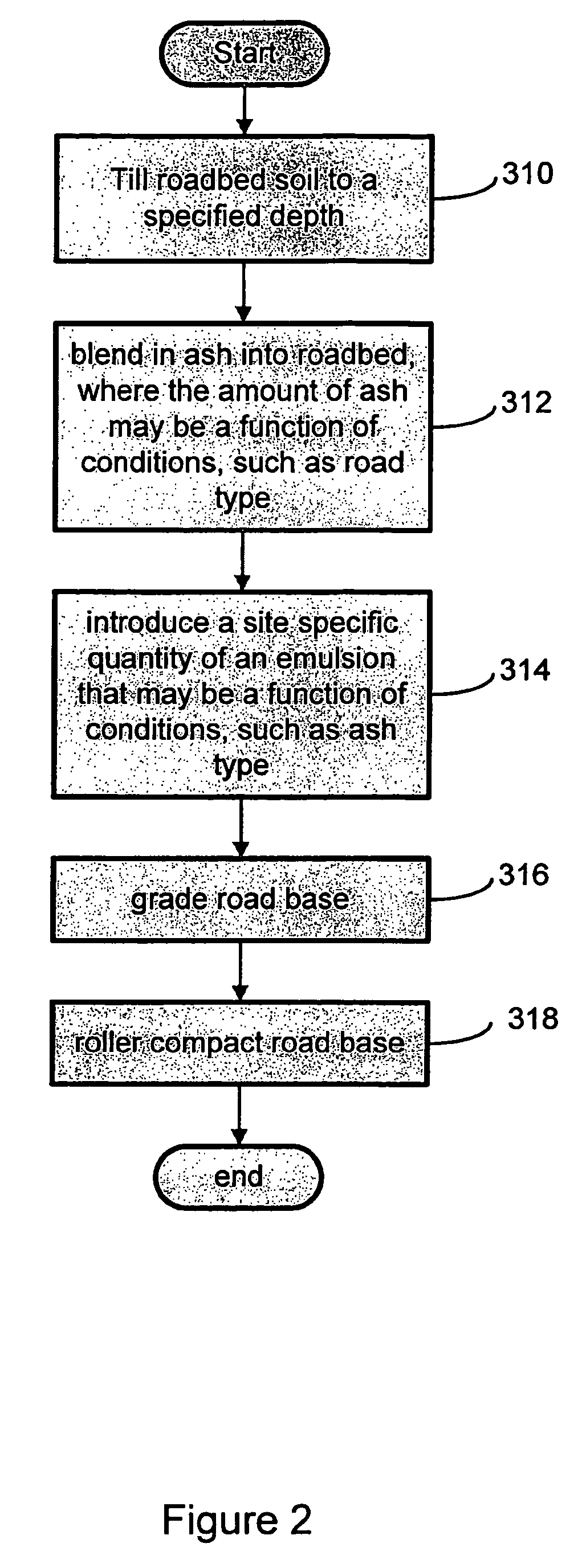

Composition and method for stabilizing road base

InactiveUS20060011105A1Strengthened road baseReduce the amount requiredRoadwaysSolid waste managementEmulsionFly ash

A mixture, comprising of fly ash and an emulsion, where said emulsion is mixed with said fly ash in a range of 5% to 50% of fly ash per an area of a square yard and 0.5 gallons to 2.5 gallons per square yard of the emulsion to said area.

Owner:ENVIROAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com