Patents

Literature

15966 results about "Fly ash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fly ash or flue ash, also known as pulverised fuel ash in the United Kingdom, is a coal combustion product that is composed of the particulates (fine particles of burned fuel) that are driven out of coal-fired boilers together with the flue gases. Ash that falls to the bottom of the boiler's combustion chamber (commonly called a firebox) is called bottom ash. In modern coal-fired power plants, fly ash is generally captured by electrostatic precipitators or other particle filtration equipment before the flue gases reach the chimneys. Together with bottom ash removed from the bottom of the boiler, it is known as coal ash. Depending upon the source and composition of the coal being burned, the components of fly ash vary considerably, but all fly ash includes substantial amounts of silicon dioxide (SiO₂) (both amorphous and crystalline), aluminium oxide (Al₂O₃) and calcium oxide (CaO), the main mineral compounds in coal-bearing rock strata.

Oil-based settable spotting fluid

InactiveUS6524384B2Increase displacementHigh gel strengthDrilling compositionCoatingsEmulsionWater source

Oil-based settable spotting fluid compositions and methods of using the compositions are provided. The oil-based settable spotting fluid compositions are basically comprised of oil, an emulsifying surfactant for emulsifying the oil with water whereby an oil-external emulsion is formed, a de-emulsifying surfactant which in time de-emulsifies said oil-external emulsion when the emulsion is contacted with external water, a hydraulic settable component selected from the group consisting of ASTM Class C or the equivalent fly ash and ASTM Class F or the equivalent fly ash together with a source of calcium and water selected from the group consisting of fresh water and salt water.

Owner:HALLIBURTON ENERGY SERVICES INC

Oil-based settable spotting fluid

InactiveUS6315042B1Increase displacementHigh gel strengthFlushingDrilling compositionEmulsionWater source

Oil-based settable spotting fluid compositions and methods of using the compositions are provided. The oil-based settable spotting fluid compositions are basically comprised of oil, an emulsifying surfactant for emulsifying the oil with water whereby an oil-external emulsion is formed, a de-emulsifying surfactant which in time de-emulsifies said oil-external emulsion when the emulsion is contacted with external water, a hydraulic settable component selected from the group consisting of ASTM Class C or the equivalent fly ash and ASTM Class F or the equivalent fly ash together with a source of calcium and water selected from the group consisting of fresh water and salt water.

Owner:HALLIBURTON ENERGY SERVICES INC

Methods of cementing high temperature wells and cement compositions therefor

Owner:HALLIBURTON ENERGY SERVICES INC

Siloxane polymerization in wallboard

ActiveUS20070022913A1Small expansionDimensional stabilitySolid waste managementWoven fabricsDihydrate Calcium SulfateSlurry

Polymerization of siloxane is improved using a gypsum-based slurry that includes stucco, Class C fly ash, magnesium oxide and an emulsion of siloxane and water. This slurry is used in a method of making water-resistant gypsum articles that includes making an emulsion of siloxane and water, then combining the slurry with a dry mixture of stucco, magnesium oxide and Class C fly ash. The slurry is then shaped as desired and the stucco is allowed to set and the siloxane polymerizes. The resulting product is useful for making a water-resistant gypsum panel having a core that includes interwoven matrices of calcium sulfate dihydrate crystals and a silicone resin, where the interwoven matrices have dispersed throughout them a catalyst comprising magnesium oxide and components from a Class C fly ash.

Owner:UNITED STATES GYPSUM CO

Composition and method for forming a sprayable materials cover

InactiveUS20050084334A1Improve performanceImprove adhesionSolid waste disposalLandfill technologiesWater dispersibleSlurry

An alternative cover for landfill may be formed from a slurry mixture of water, cementitious binder, adhesion enhancing admixture and fiber. These constituents may be mixed and applied to cover landfilled wastes, granular material piles or for soil erosion control. The cover will harden to minimize water infiltration, wind blown dust, odor and affinity to birds, flies and other insects. The water may include tap water, landfill leachate and wastewater. The binder may include Portland cement, blended cement, cement kiln dust, class C fly ash, and / or calcium sulphate hemihydrate. The adhesion enhancing admixture includes water-dispersible polymers. The fibers may comprise shredded paper or wood or plastic fibers.

Owner:CJS TECH

Very fast setting cementitious composition

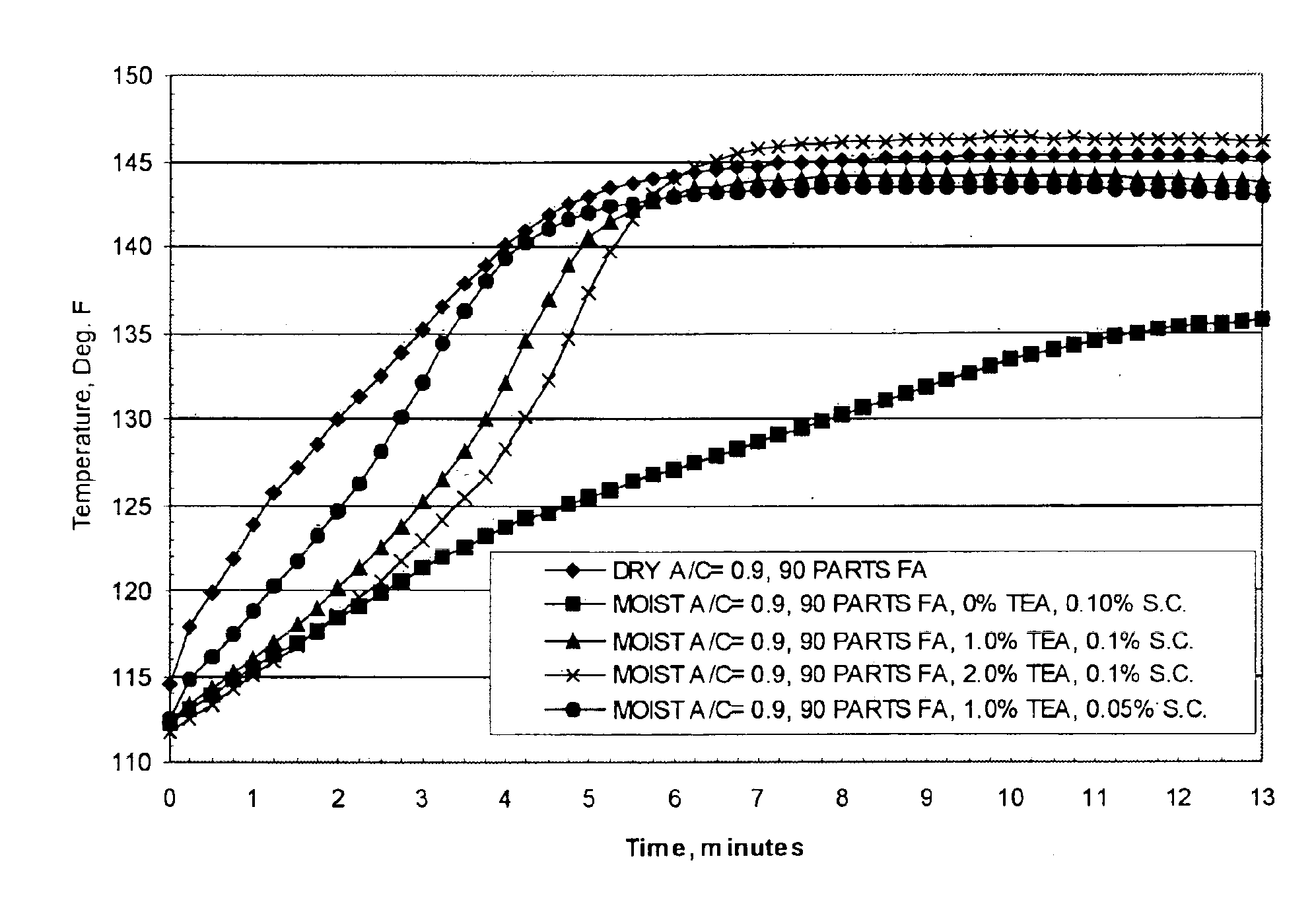

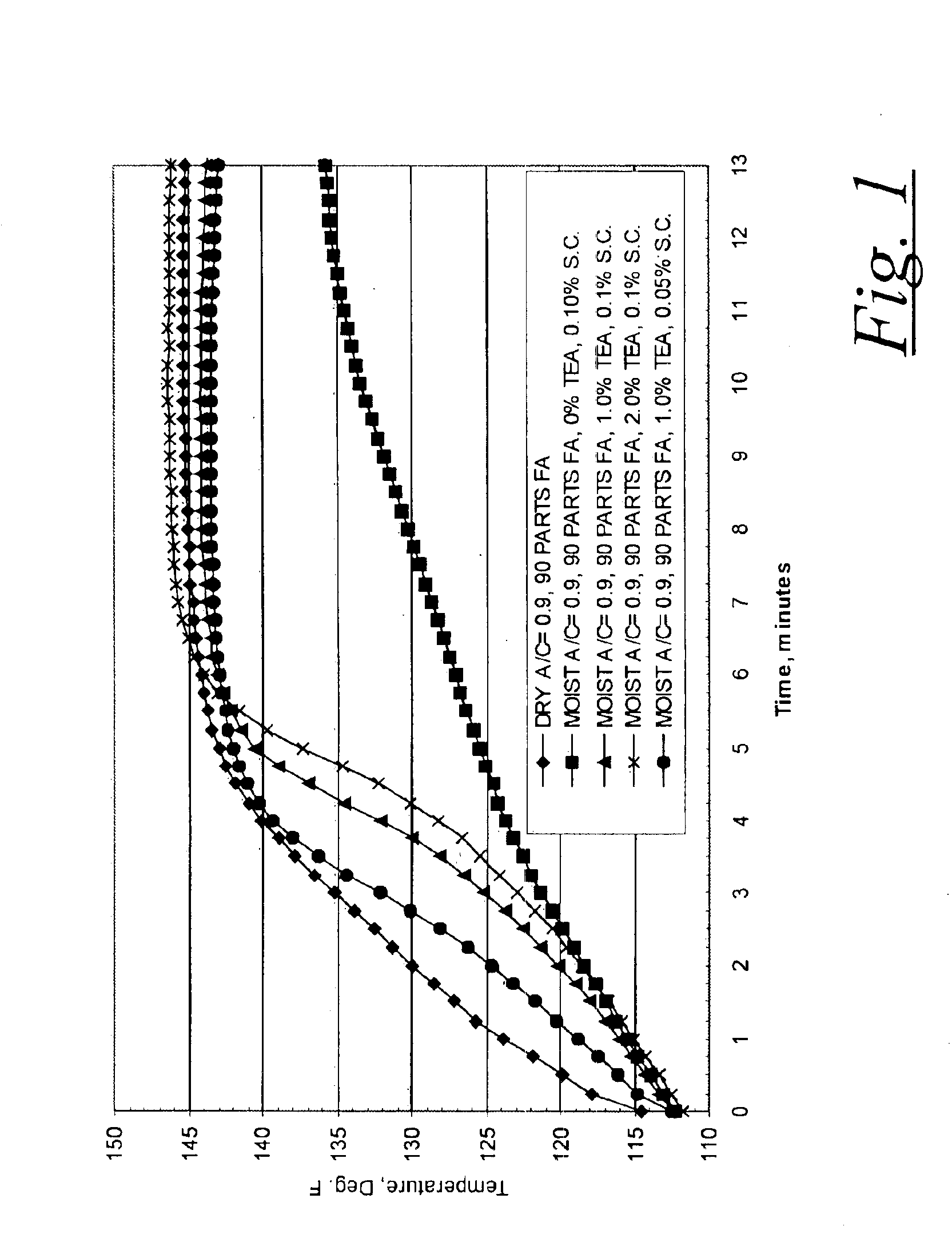

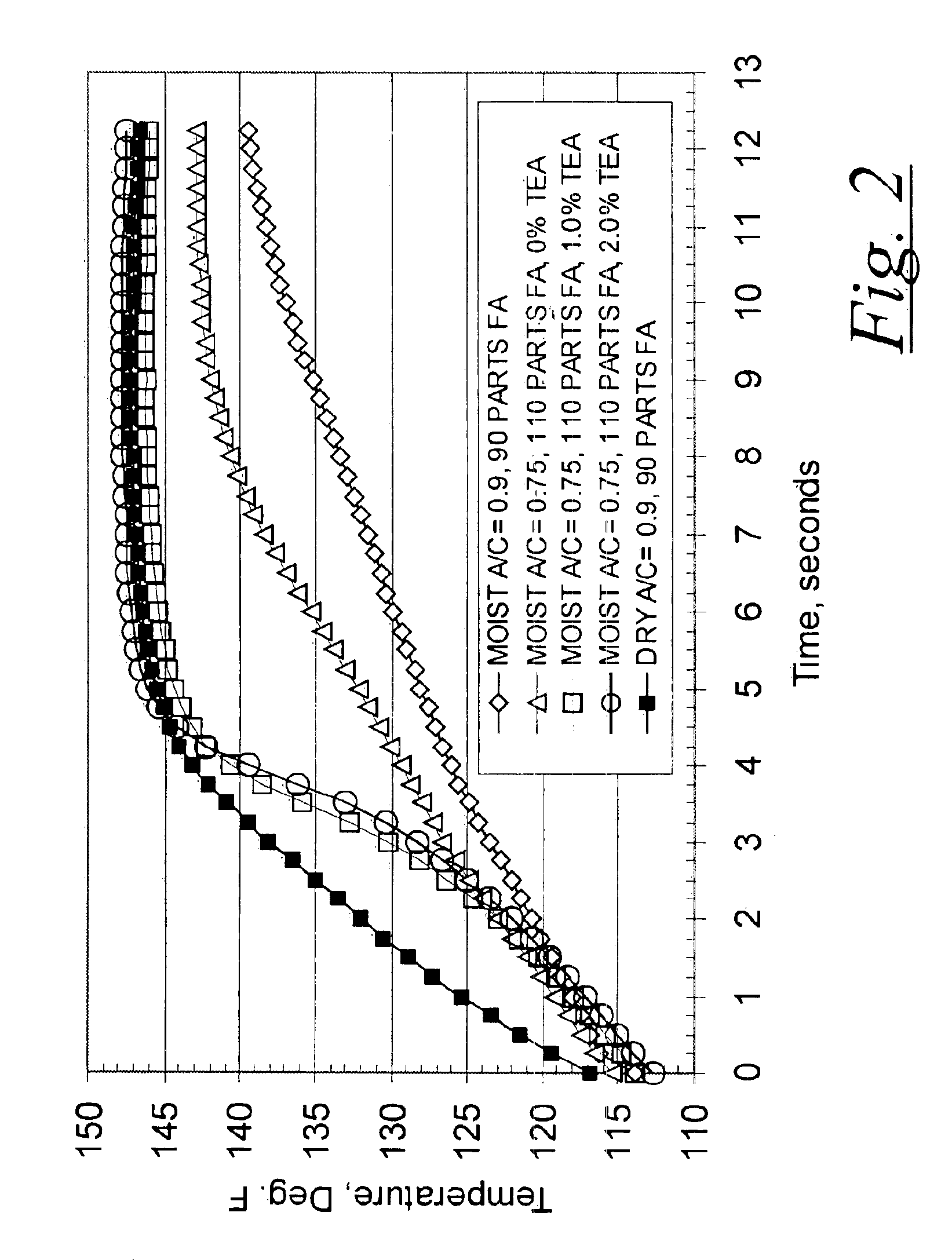

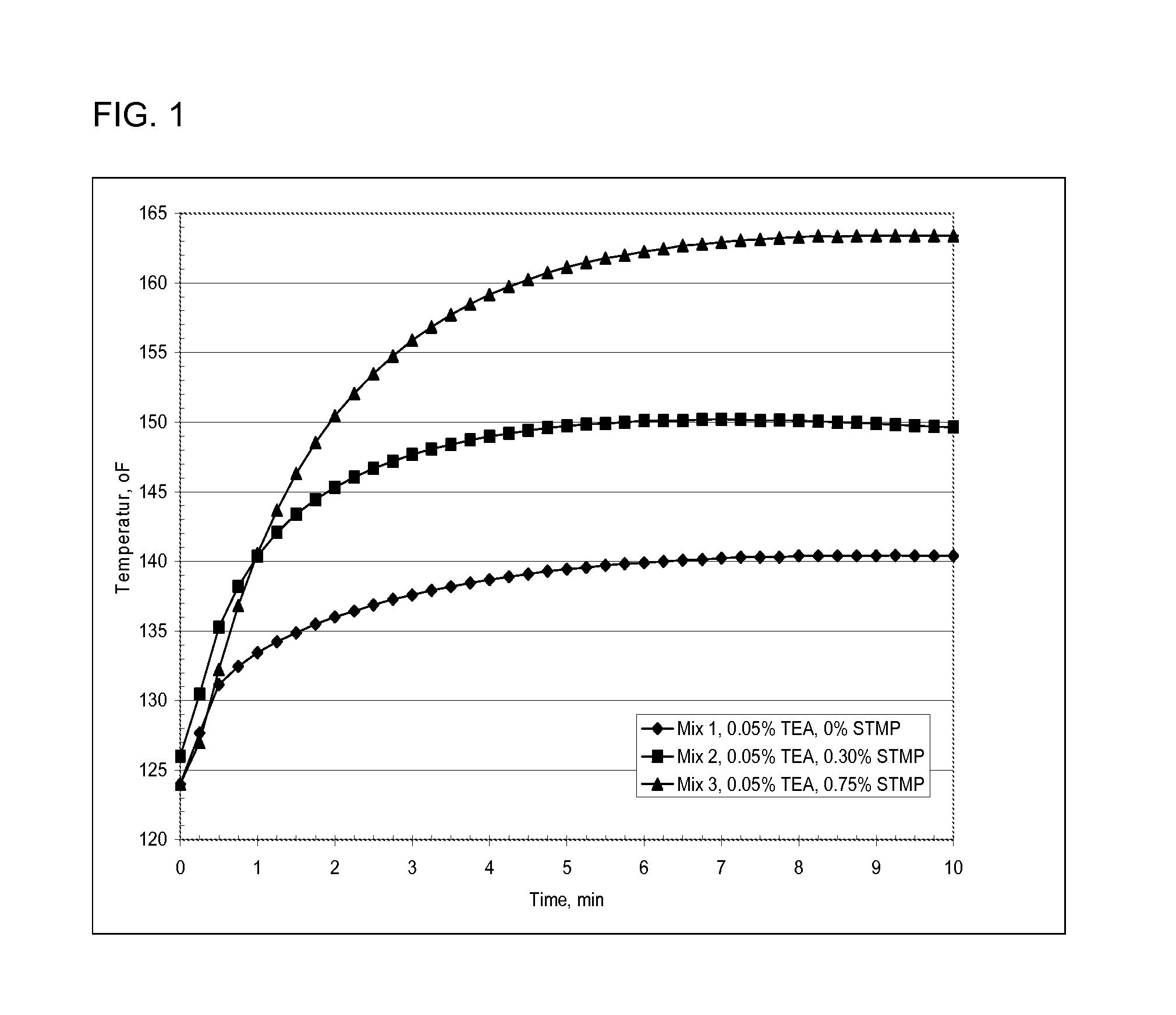

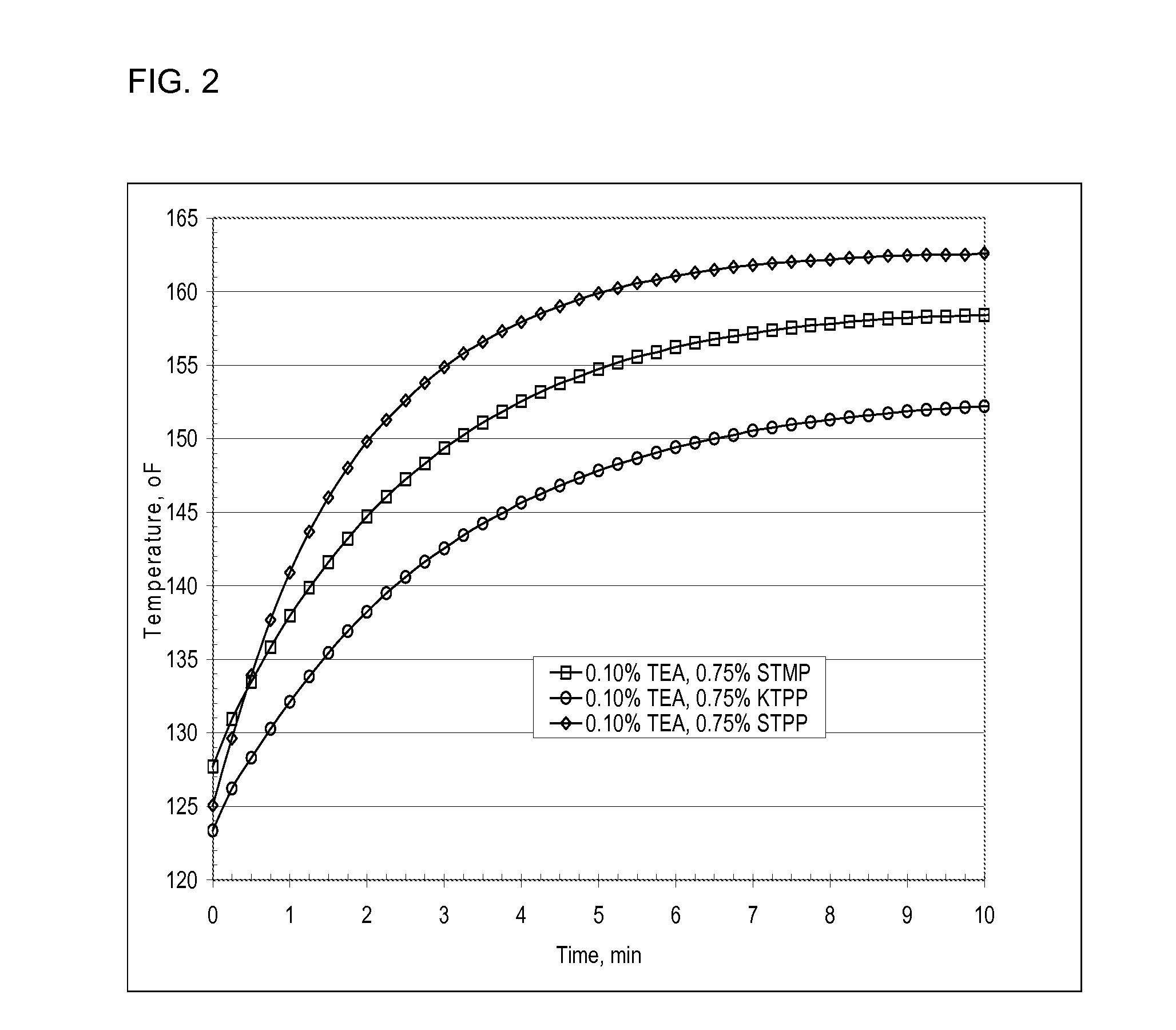

Extremely fast setting of cementitious compositions for producing cement-based products such as cement boards is made possible by adding an alkanolamine to a hydraulic cement such as portland cement, and forming a slurry with water under conditions that provide an initial slurry temperature of at least 90° F. Use of alkanolamine under conditions disclosed herein allows an extremely rapid setting of the cementitious composition. Additional reactive materials may be included such as high alumina cement, calcium sulfate and a pozzolanic material such as fly ash. The extremely fast rapid set permits rapid production of cementitious products.

Owner:UNITED STATES GYPSUM CO

Activated aluminosilicate binder

An activated aluminosilicate binder containing aluminosilicates, calcium sulphate and an activator containing alkali metal salts is disclosed. The aluminosilicates are selected from a group consisting of blast furnace slag, clay, marl and industrial by-products, such as fly ash, and has an Al2O3 content greater than 5% by weight. Blast furnace slag is present in an amount less than 35% by weight, and cement kiln dust, in an amount of from 1 to 20% by weight, is added to the mixture as an activator.

Owner:HOLCIM

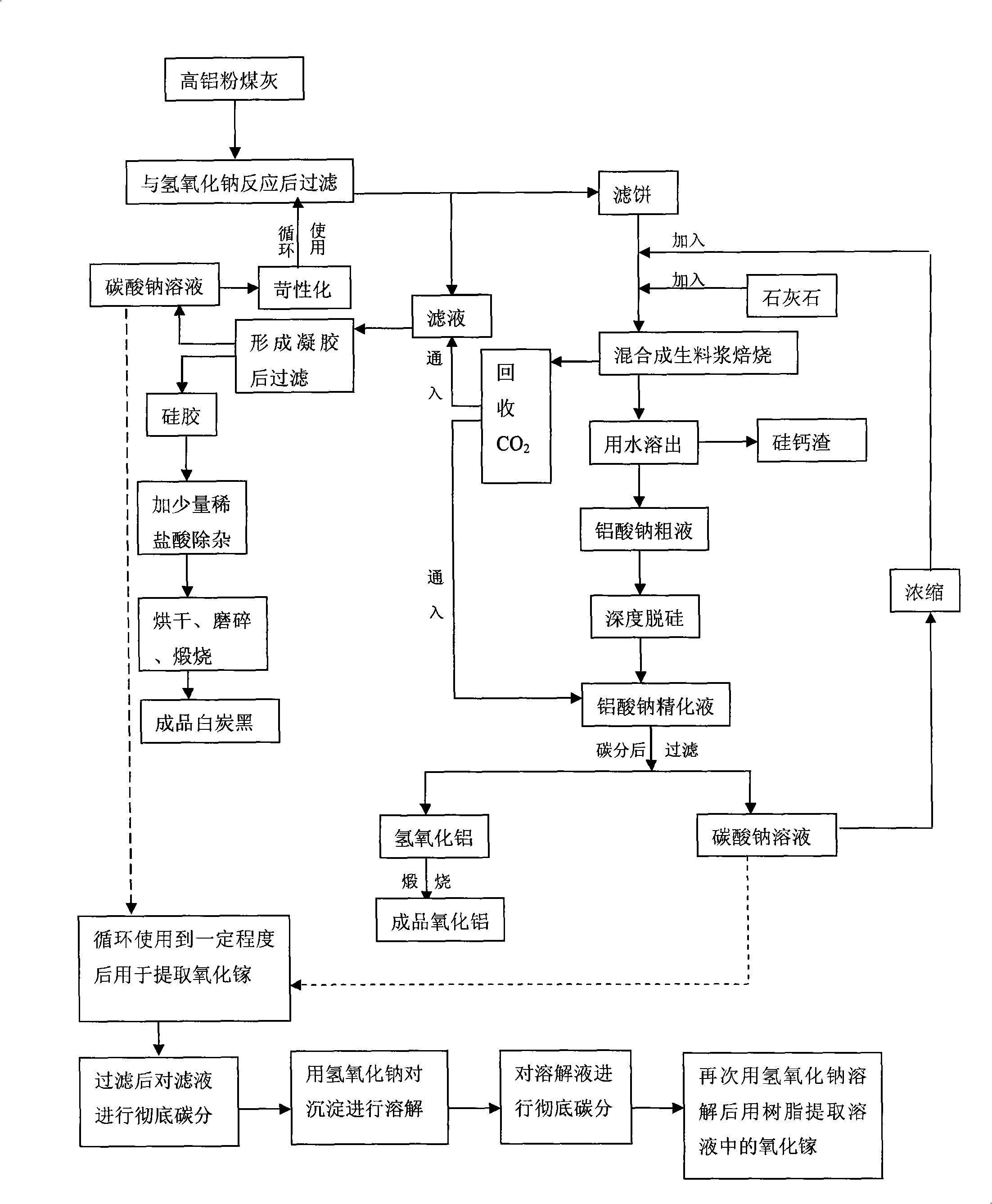

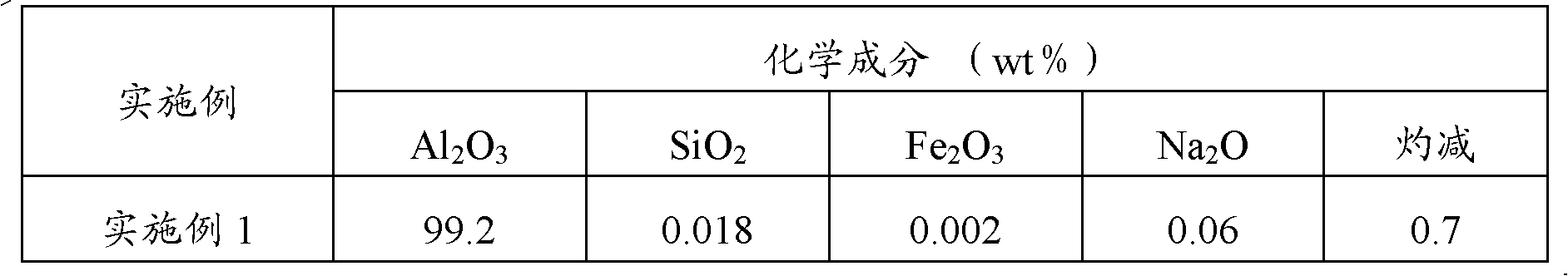

Process for abstracting earth silicon, oxide of alumina and gallium oxide from high-alumina flying ash

ActiveCN101284668AReduce the total massLow firing temperatureGallium/indium/thallium compoundsSilicon oxidesChemical industryFiltration

A method for extracting silicon dioxide, alumina and gallium oxide from high-alumina fly ash relates to the technology fields of environmental mineralogy and material, chemical industry and metallurgy. The method comprises the main steps as follows: causing the high-alumina fly ash to react with sodium hydroxide solution; filtering the solution; introducing CO2 to the filtrate for full gelation; cleaning, purifying, drying, grinding and calcining the silica gel after gel filtration to obtain finished white carbon black; adding limestone and a sodium carbonate solution into the filter mass after the reaction and filtration of the high-alumina fly ash and the sodium hydroxide solution; ball grinding the mixture into raw slurry; dissolving out the clinker obtained by baking the raw slurry; subjecting the filtrate to deep desiliconization to obtain sodium aluminate extraction liquid; filtrating the sodium aluminate extraction liquid after subjecting the sodium aluminate extraction liquid to carbon dioxide decomposition; baking the aluminum hydroxide after washing the filter mass to form the aluminum hydroxide product; and extracting the gallium oxide from the carbon dioxide decomposition mother solution and desiliconized solution. The method has the advantages of low material price, simple operating procedures, low investment, low production cost, low energy consumption and less slag.

Owner:TSINGHUA UNIV +1

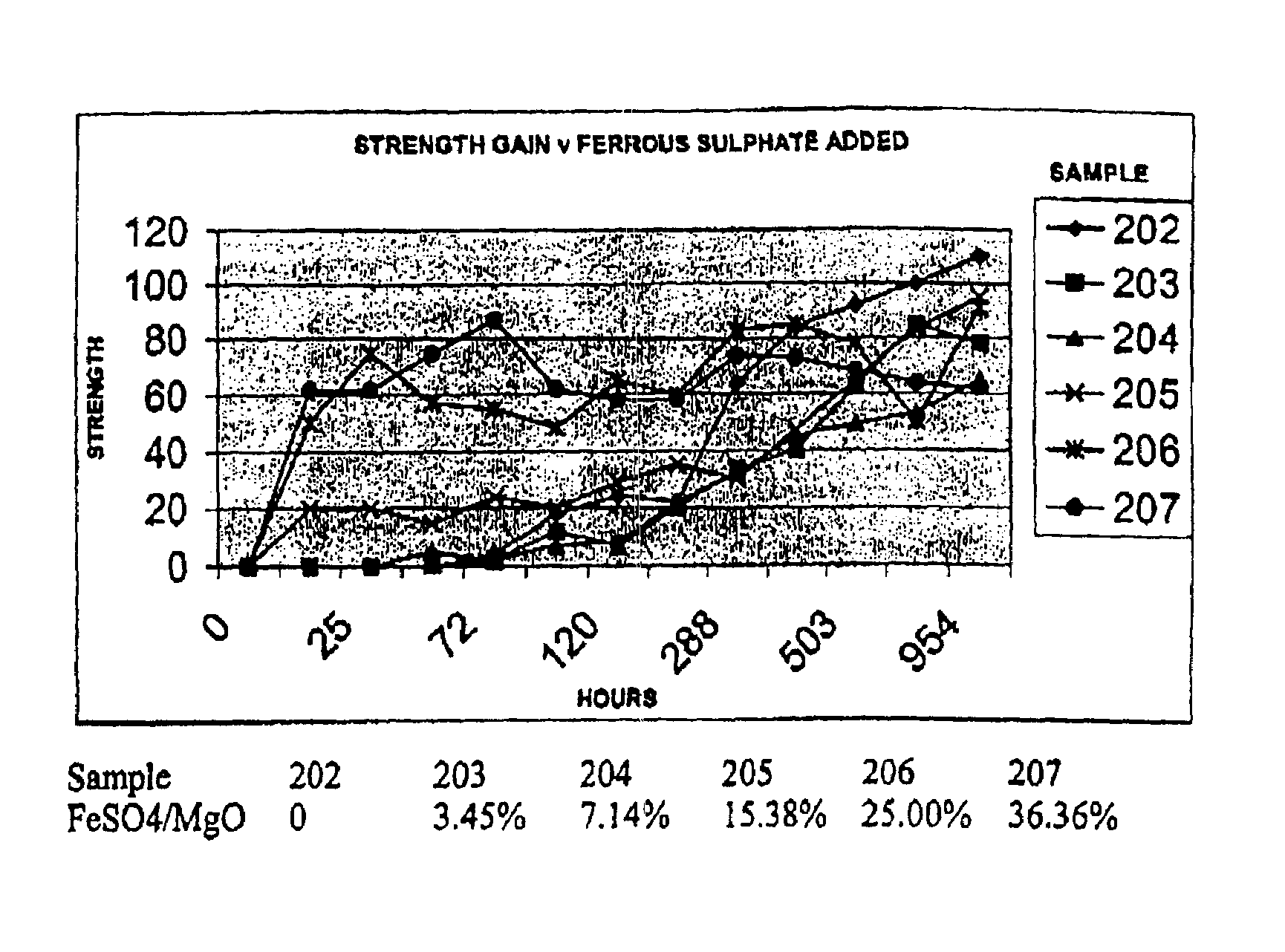

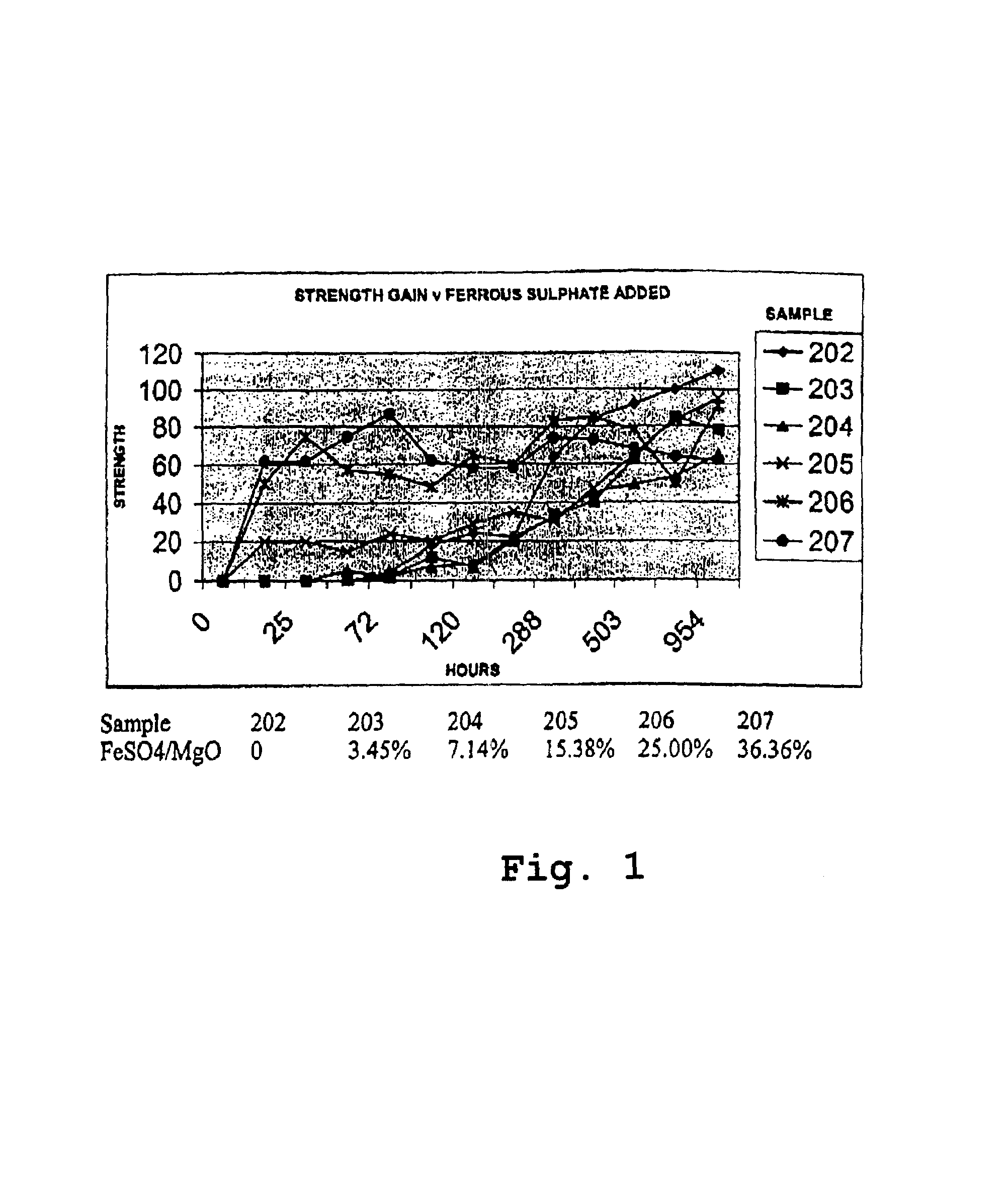

Reactive magnesium oxide cements

Novel hydraulic cements are disclosed that include reactive magnesium oxide prepared by low temperature calcination. The cements can be formulated to suit a large number of applications with various setting times, strength and levels of sustainability either by adding iron salts such as ferrous sulfate or blending with other compatible faster setting hydraulic cements such as Portland cement or by using both methods.The compositions are able to incorporate relatively large amounts of low cost pozzolans such as fly ash to advantage as well as wastes. Many excellent properties are exhibited and in particular good comprehensive strength and resistance to sulfates is able to be achieved.

Owner:TECECO

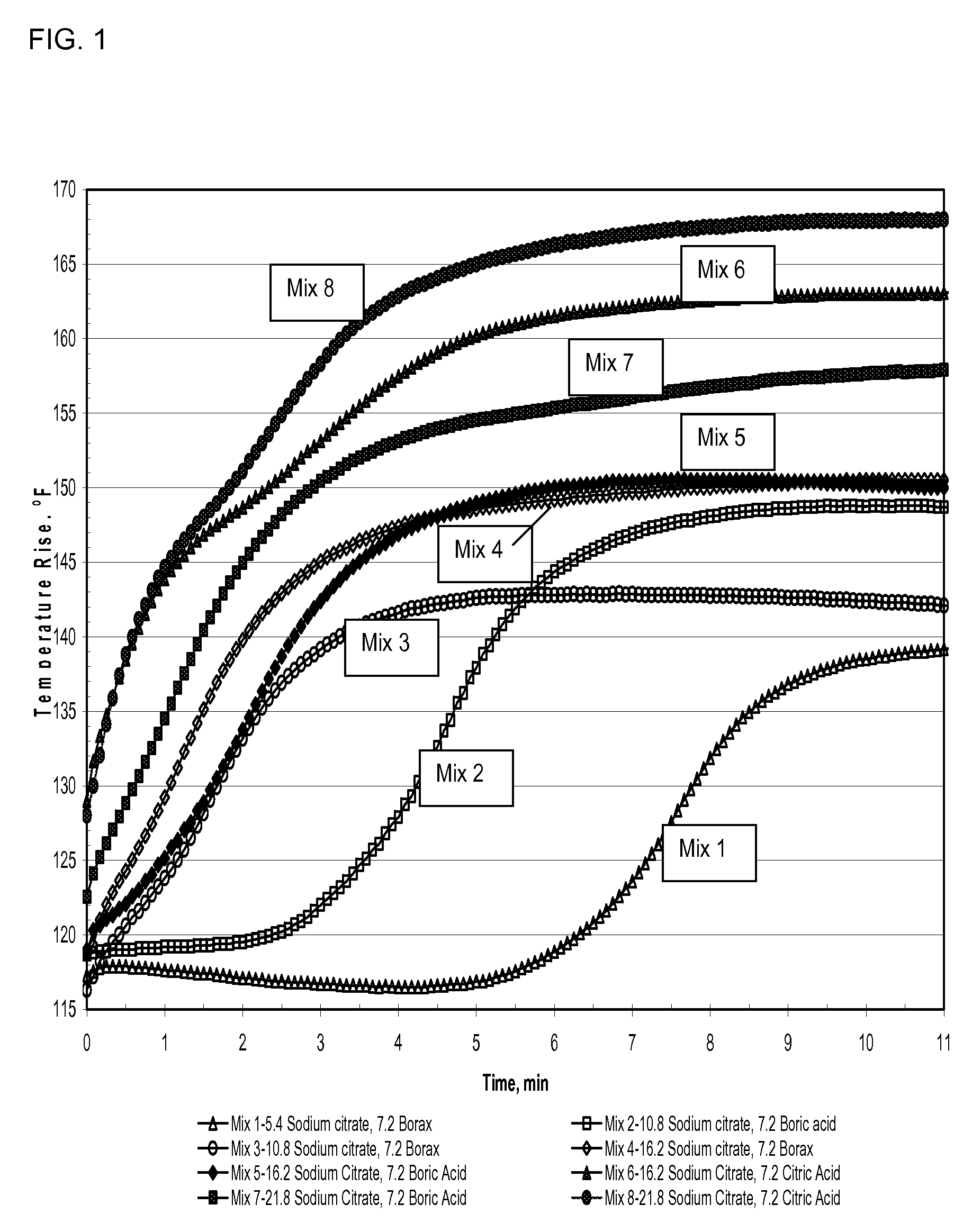

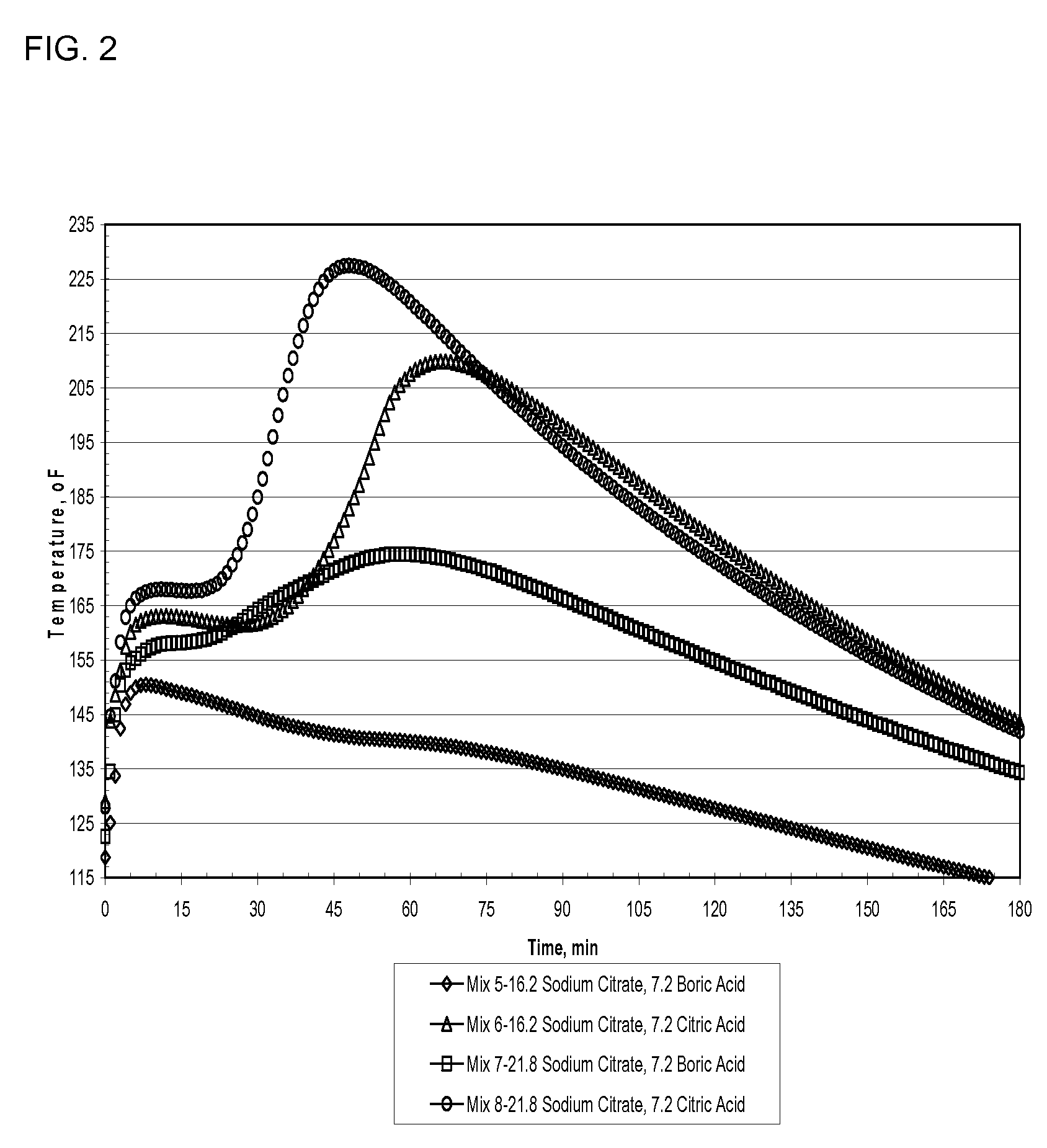

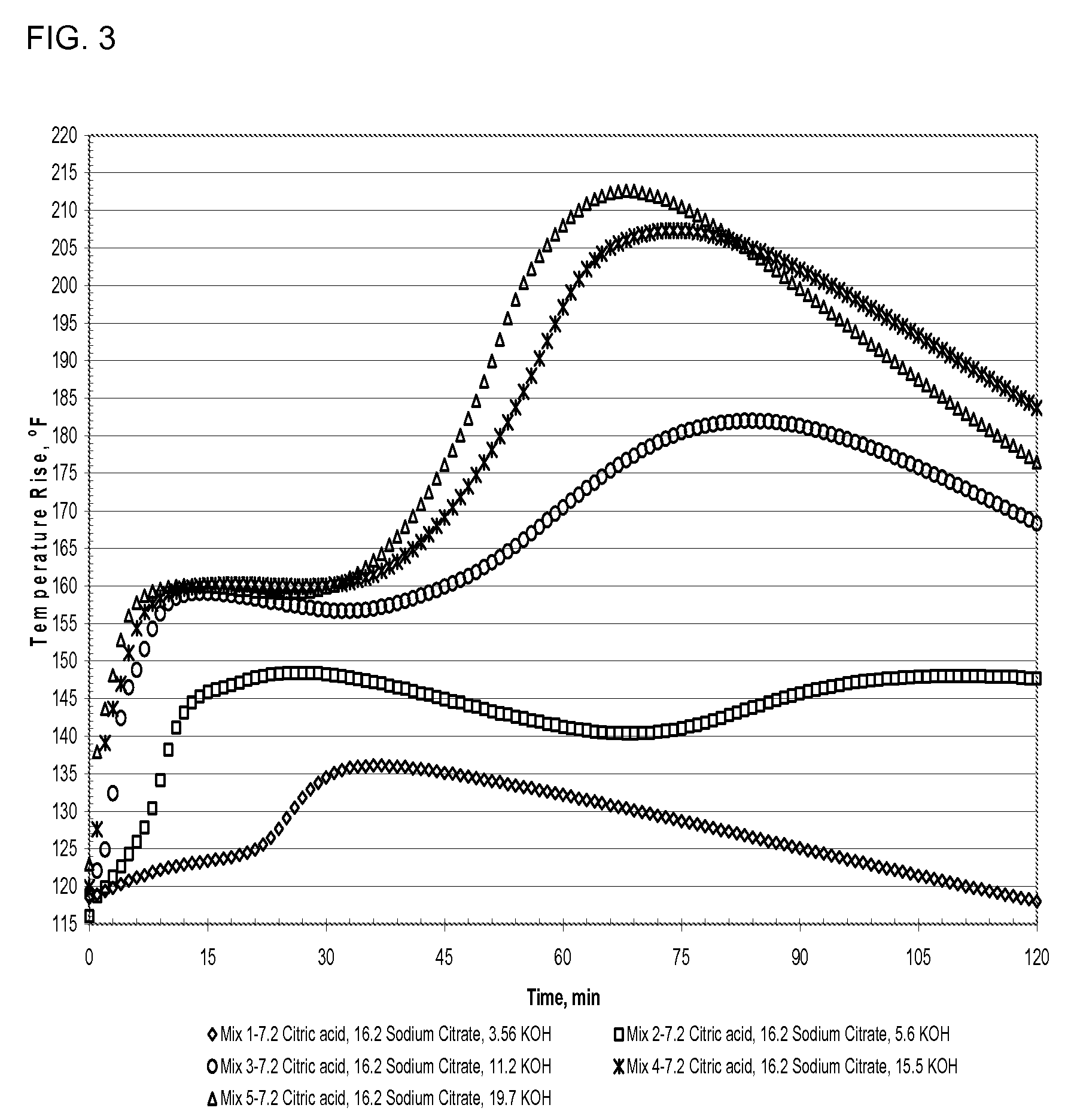

Fly ash based lightweight cementitious composition with high compressive strength and fast set

InactiveUS20100071597A1Quick SetupEnhanced early and final compressive strengthSolid waste managementPolymer scienceCompressive strength

A method of making a rapid setting lightweight cementitious composition with improved compressive strength for products such as boards is disclosed. The method mixes fly ash, alkali metal salt of citric acid and lightweight aggregate with water. Compositions which include fly ash, alkali metal salts of citric acid and lightweight aggregate are also disclosed.

Owner:UNITED STATES GYPSUM CO

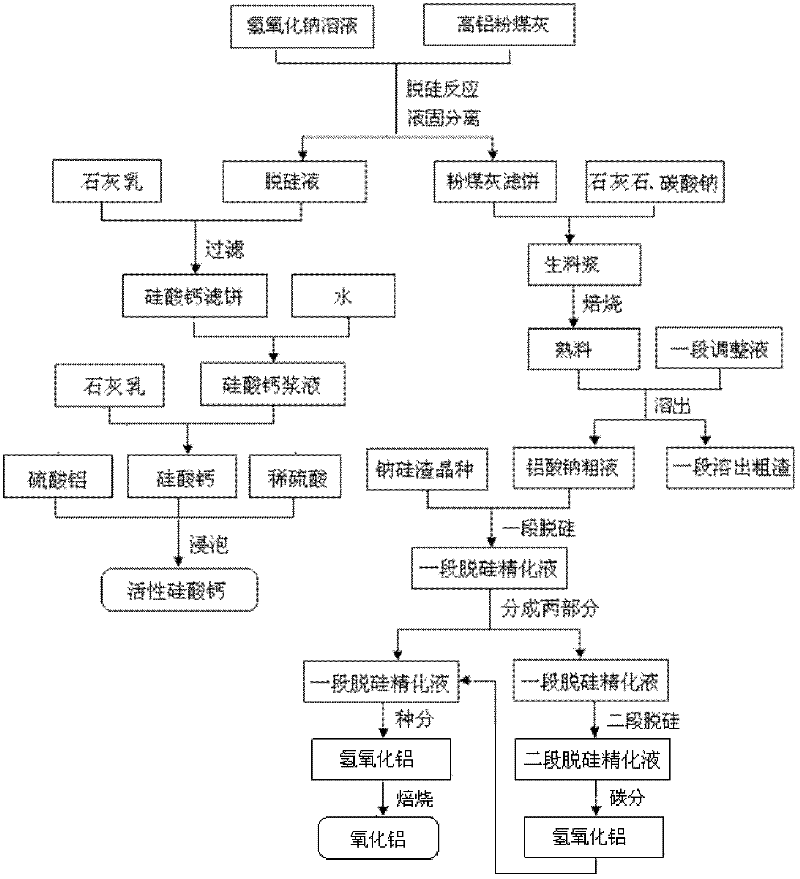

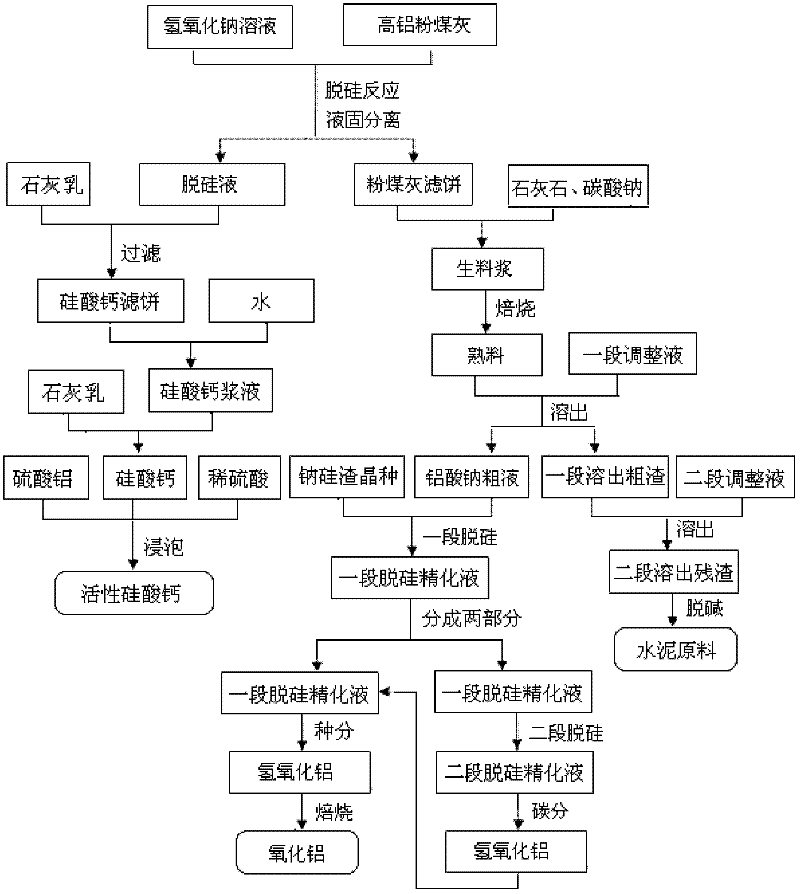

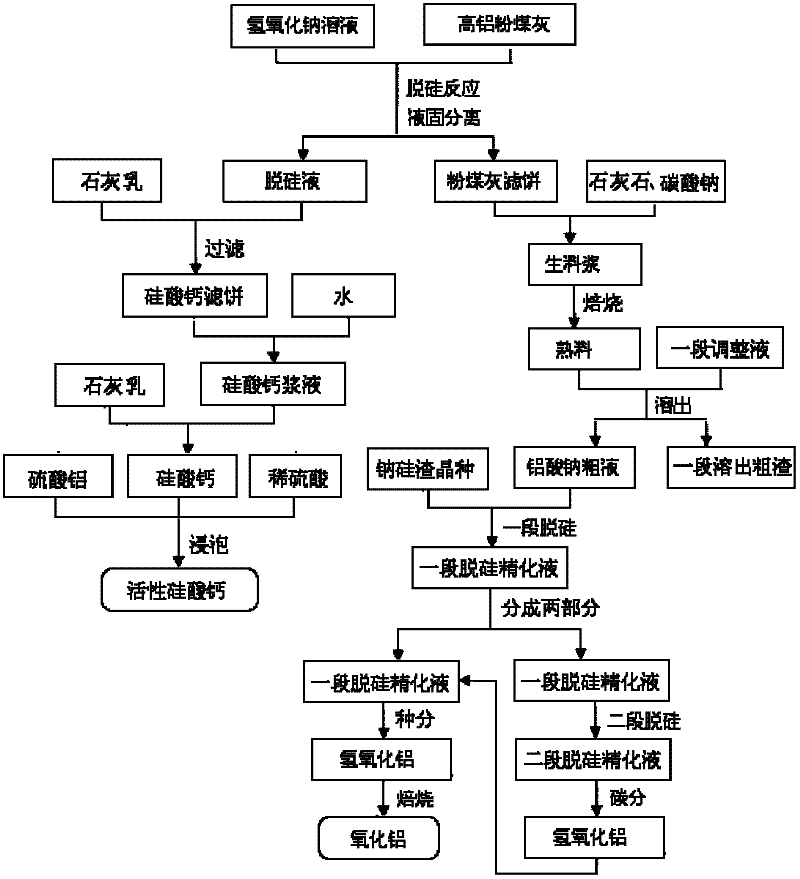

Method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash

ActiveCN102249253AExtraction is effective and cheapIncrease Al-Si RatioAlkaline-earth metal silicatesAluminium oxide/hydroxide preparationCalcium silicateSodium aluminate

The invention provides a method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash. The method comprises the following steps that: the high-alumina fly ash firstly reacts with a sodium hydroxide solution to carry out pre-desilication to obtain a liquid-phase desiliconized solution and a solid-phase desiliconized fly ash; lime cream is added to the liquid-phase desiliconized solution to carry out a causticization reaction, the resulting solid phase is active calcium silicate which is prepared through carrying out filter pressing, flash evaporation and drying to obtain the finished product; limestone and a sodium carbonate solution are added to the desiliconized fly ash to blend qualified raw slurry, then the blend qualified raw slurry is subjected to baking into the clinker, the liquid phase generated from dissolution of the clinker is a crude solution of sodium aluminate; the crude solution of the sodium aluminate is subjected to processes of first-stage deep desilication, second-stage deep desilication, carbonation, seed precipitation, baking and the like to obtain the metallurgical grade aluminum oxide meeting requirements. According to the present invention, the defects in the prior art are overcome; purposes of less material flow and small amount of slaggling are achieved; energy consumption, material consumption and production cost are relative low; extraction rate of the aluminum oxide is high; the calcium silicate with high added value is co-produced; the method provided by the present invention can be widely applicable for the field of chemical engineering.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

Free flowing dry back-up insulating material

Disclosed is a free flowing dry back-up material which comprises:from 67 to 96% by weight of fly-ash;from 2 to 15% by weight of a heat sensitive binder such as boric acid;from 2 to 7% by weight of a non-wetting agent such as calcium fluoride;from 0 to 10% by weight of a heat expandable material, viz. a material expandable as a function of the temperature such as vermiculite or graphite; andfrom 0 to 1% by weight of a dust suppressant such as kerosene.This material which is useful in particular in the aluminum industry has the advantages of being water free and free flowing, such avoiding the use of vibrator to position it into a shell. It also has a low density and a low thermal conductivity. Moreover, it is organic free as compared to the existing materials which use an organic binder to ensure a low temperature set; and it sets at a temperature lower than 400° F.

Owner:LES PROD CHIMS INDS DE HAUTE TEMPERATURE PYROTEK

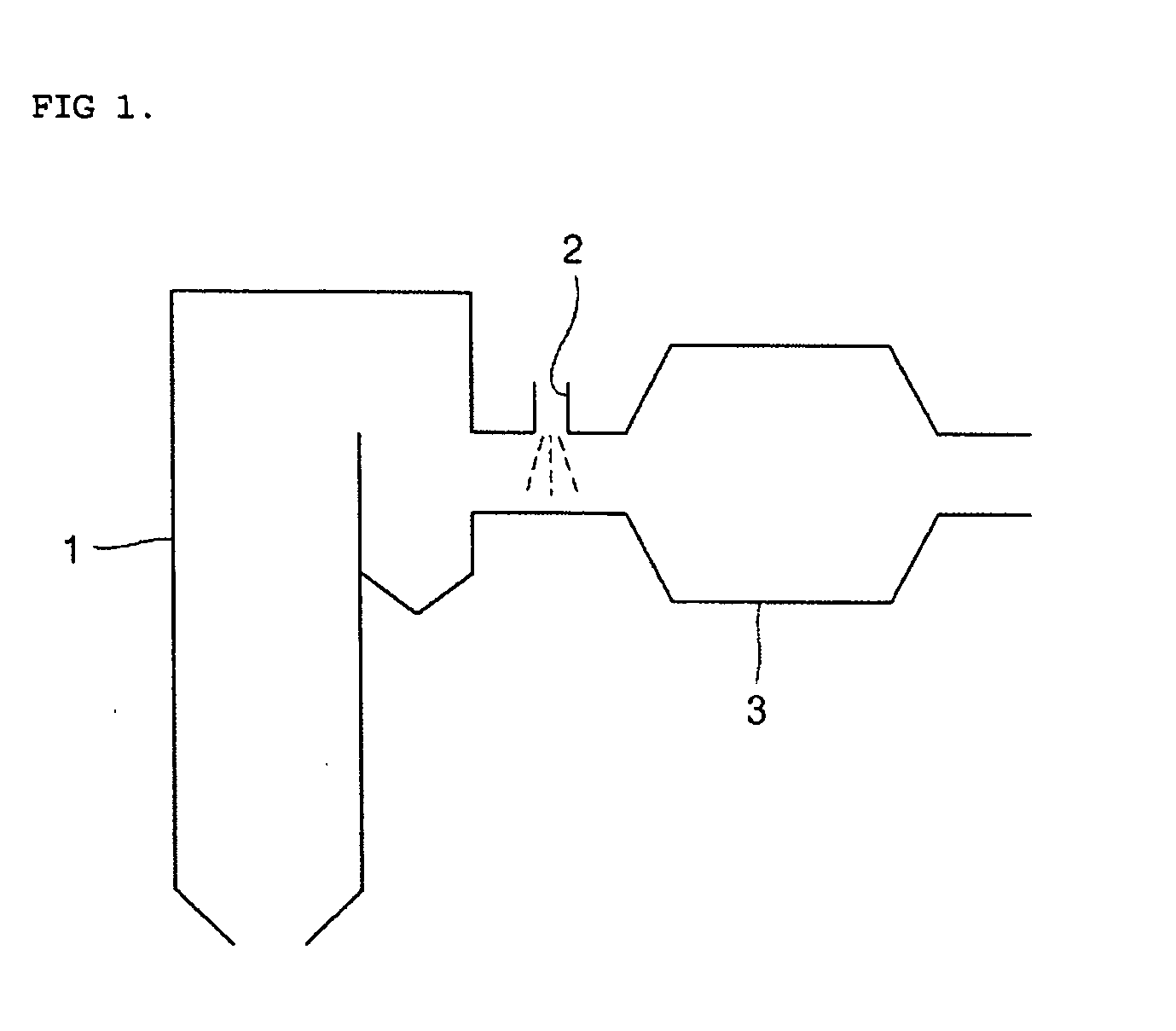

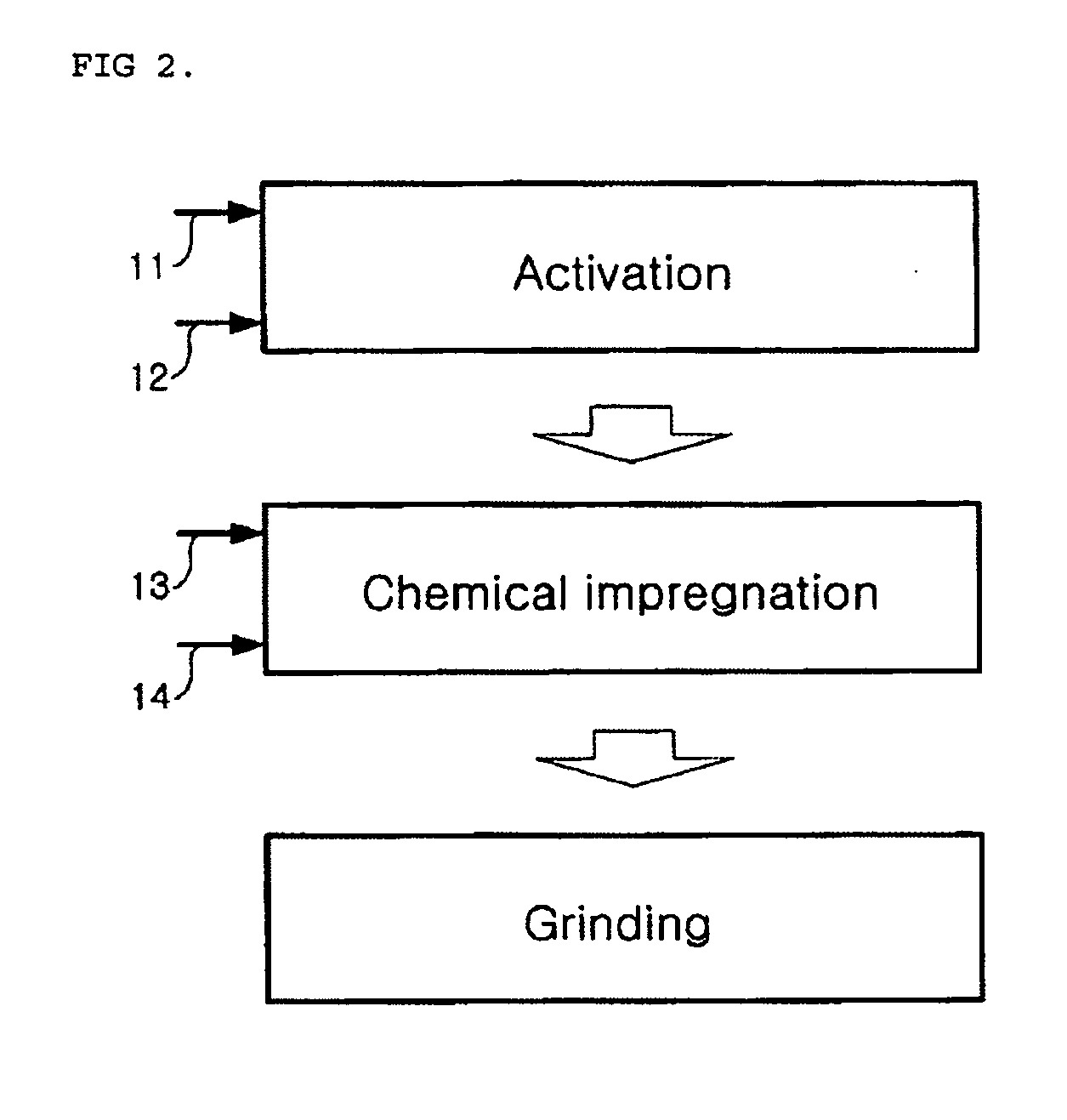

Sorbent for removal of trace hazardous air pollutants from combustion flue gas and preparation method thereof

InactiveUS20070179056A1Low costLow raw material costGas treatmentOther chemical processesSorbentToxic industrial waste

Disclosed is a sorbent for the removal of mercury from combustion flue gas and a preparation method thereof. The sorbent includes an activated heavy oil heavy ash impregnated with 0.1-30% by weight of any chemical substance selected from sulfur, iodine, bromine and chlorine. The sorbent is prepared in an economical manner using heavy oil fly ash, industrial waste generated from heavy oil-fired boilers, and has excellent sorption performance for mercury, so that a low concentration of mercury contained in combustion flue gas discharged from large-scale boilers can be removed by injection of a small amount of the sorbent. Thus, the invention can prevent a reduction in the recycling rate of coal fly ash in coal-fired power plants and minimize operation cost.

Owner:KOREA ELECTRIC POWER CORP

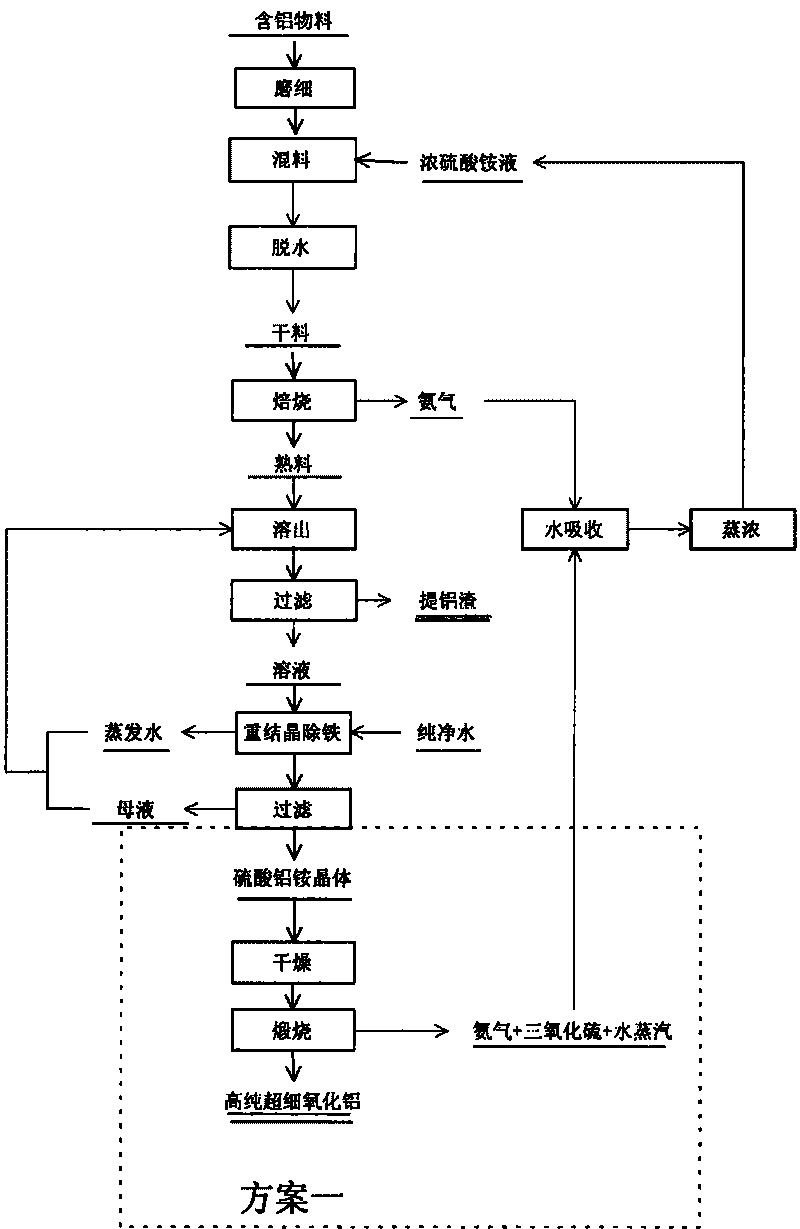

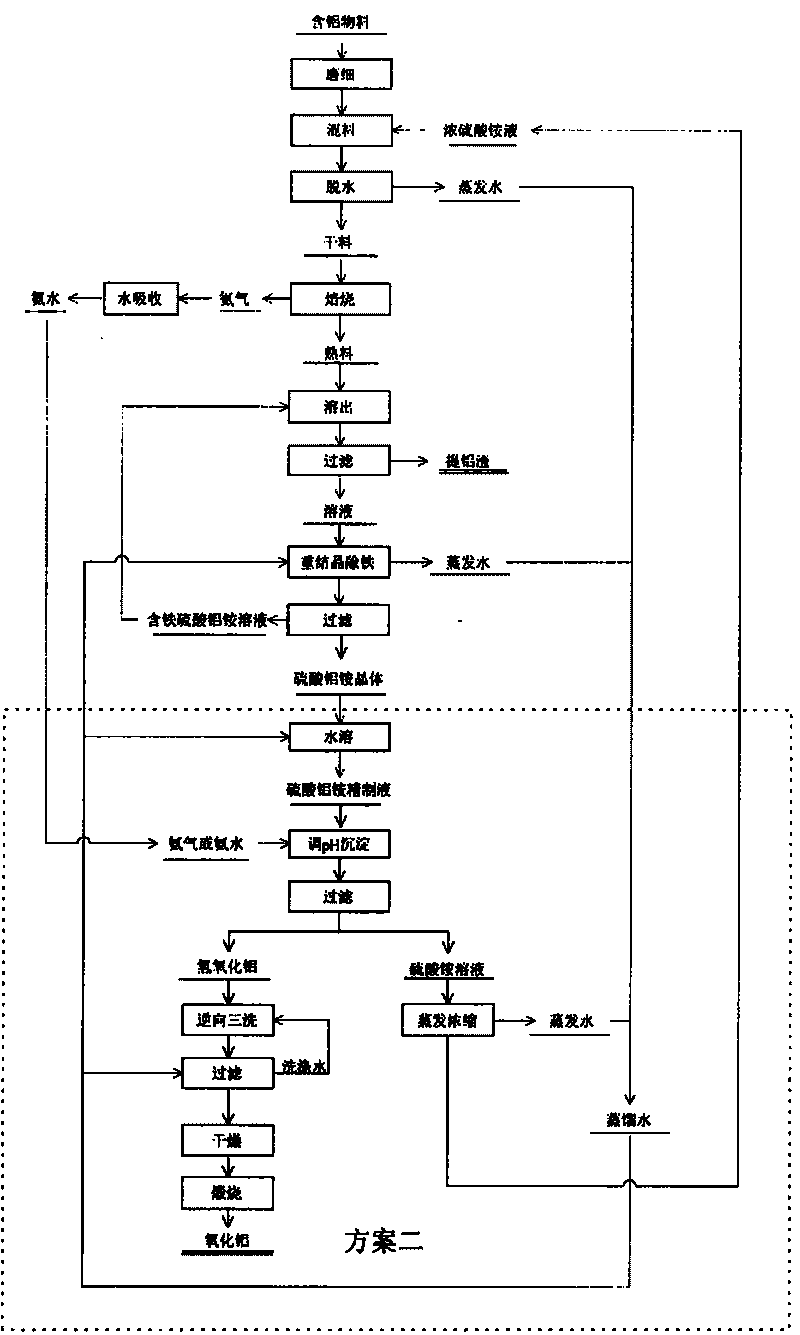

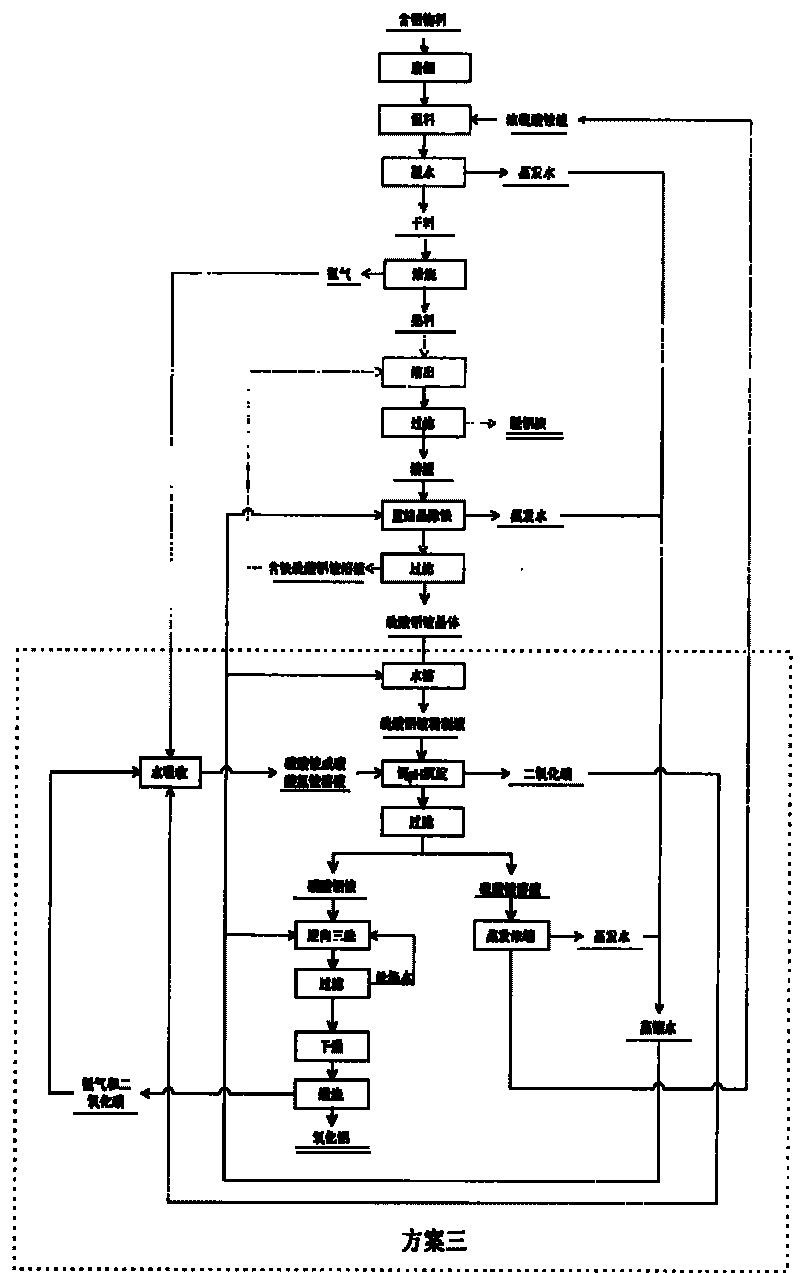

Method for preparing aluminum oxide from aluminiferous material

InactiveCN101734698AHigh value-added comprehensive utilizationCause secondary pollutionAluminium oxide/hydroxide preparationAluminium hydroxide preparationAluminum ammonium sulfateAlunite

The invention provides a method for preparing aluminum oxide and other products from aluminiferous materials such as bauxite, high iron bauxite, alunite, kaoline, alumina, fly ash, coal gangue, aluminum ash, nepheline, clay and the like. The method comprises the following steps: (1) crushing, grinding and mixing the aluminiferous materials with ammonium sulfate and then roasting; (2) dissolving the roasted product (clinker aggregate) in water, and filtering to obtain aluminum ammonium sulfate solution and filter residues; (3) carrying out deferrization, aluminum deposition or recrystallization on the aluminium ammonum sulfate solution with ammonia to prepare aluminum oxide, and meanwhile, recycling the ammonium sulfate; (4) preparing silicon dioxide from the filter residues, and taking the remaining residues containing ferrum as the raw material for ironmaking. The method is suitable for treating various aluminiferous materials, has the advantages of simple technical process, simple equipment, no emission of solid, liquid and gas wastes, and no secondary pollution, and realizes the high-added-value green complex utilization of the aluminiferous materials such as bauxite, high ironbauxite, alunite, kaoline, alumina, fly ash, coal gangue, aluminum ash, nepheline, clay and the like.

Owner:NORTHEASTERN UNIV

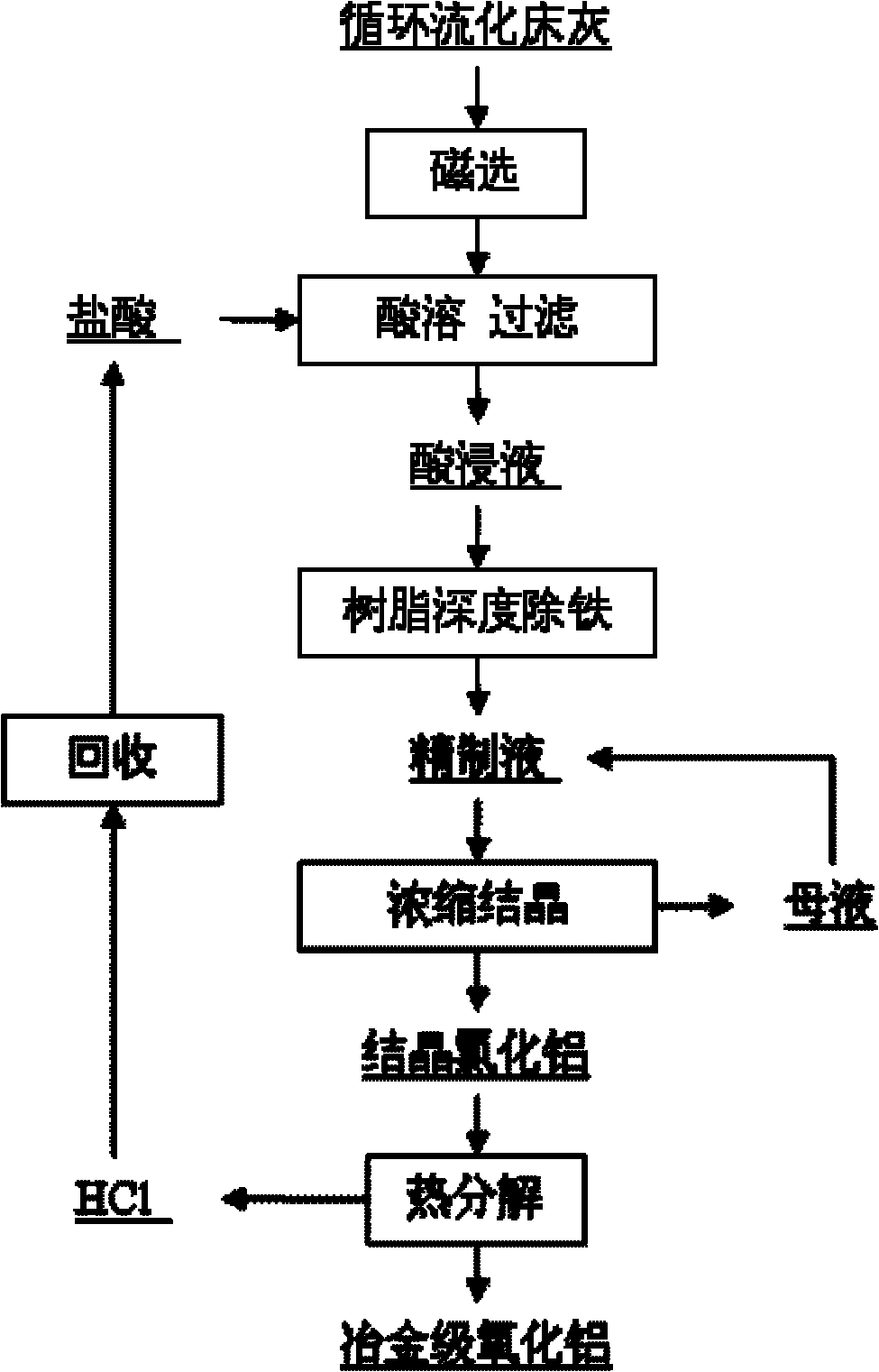

Method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash

ActiveCN102145905AHigh extraction rateReduce manufacturing costSolid waste disposalTransportation and packagingAluminium chloridePulverized fuel ash

The invention discloses a method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash as a raw material. The method comprises the following steps of: a) grinding the pulverized fuel ash, and removing iron by a wet magnetic separation method; b) reacting the pulverized fuel ash subjected to magnetic separation with hydrochloric acid to obtain hydrochloric acid immersion liquid; c) allowing the hydrochloric acid immersion liquid to pass through a large pore type cation resin column for further iron removal to obtain refined aluminum chloride solution; d) concentrating the refined aluminum chloride solution, and crystallizing to obtain an aluminum chloride crystal; and e) calcining the aluminum chloride crystal and decomposing to obtain the metallurgy-level aluminum oxide. The method has a simple process and an easily-controlled production process, and is high in aluminum oxide extraction efficiency, low in production cost and stable in product quality.

Owner:CHINA SHENHUA ENERGY CO LTD

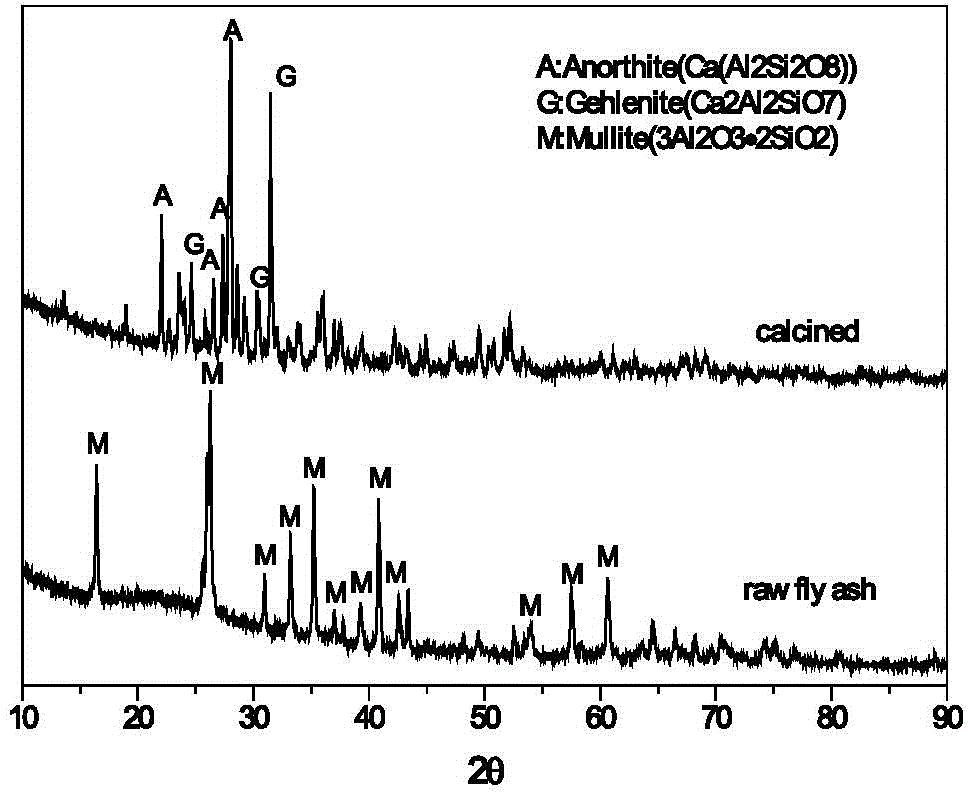

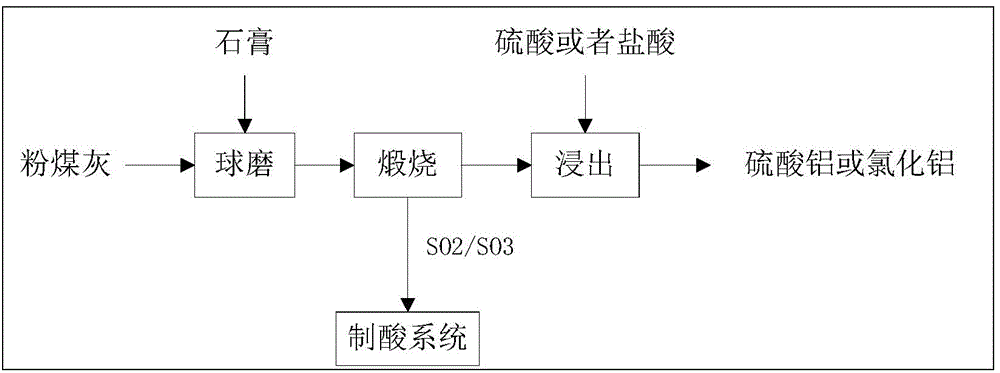

Method for cooperative activation of fly ash and decomposition of gypsum for recovery of sulfur resource

The invention provides a method for cooperative activation of fly ash and decomposition of gypsum for recovery of a sulfur resource. According to the method, solid waste, i.e., fly ash, discharged by a coal-fired power plant or coal-fired boiler is used as a raw material, a certain proportion of desulfurized gypsum discharged by the coal-fired power plant or waste phosphogypsum produced in the phosphorus chemical industry is added and mixed with the fly ash, then the obtained mixture is subjected to ball milling, and activation and calcination at a temperature of 950 to 1450 DEG C are carried out for 5 to 180 min; calcium sulfate in the gypsum are almost totally decomposed after calcination, and produced gas contains sulfur dioxide or sulfur trioxide which can be used as feed gas for preparation of sulfuric acid; and calcination enables solid fly ash to be activated, leaching with a sulfuric acid or hydrochloric acid solution is carried out at a temperature of 50 to 100 DEG C, and the leaching rate of alumina is greater than 80%. The method provided by the invention has the advantages that since all the raw materials are solid waste, the purpose of treating the waste by using the waste is achieved; elemental sulphur in the gypsum can be recovered; and the fly ash can be activated and activity of the fly ash can be improved, so a high alumina recovery rate at a low temperature can be realized. With the method, high-efficiency extraction of alumina in the fly ash is realized; the sulfur resource in the gypsum is recovered; shortage in industrial sulphur in the sulfuric acid industry in China is compensated; and the method has good economic benefits and wide industrial application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

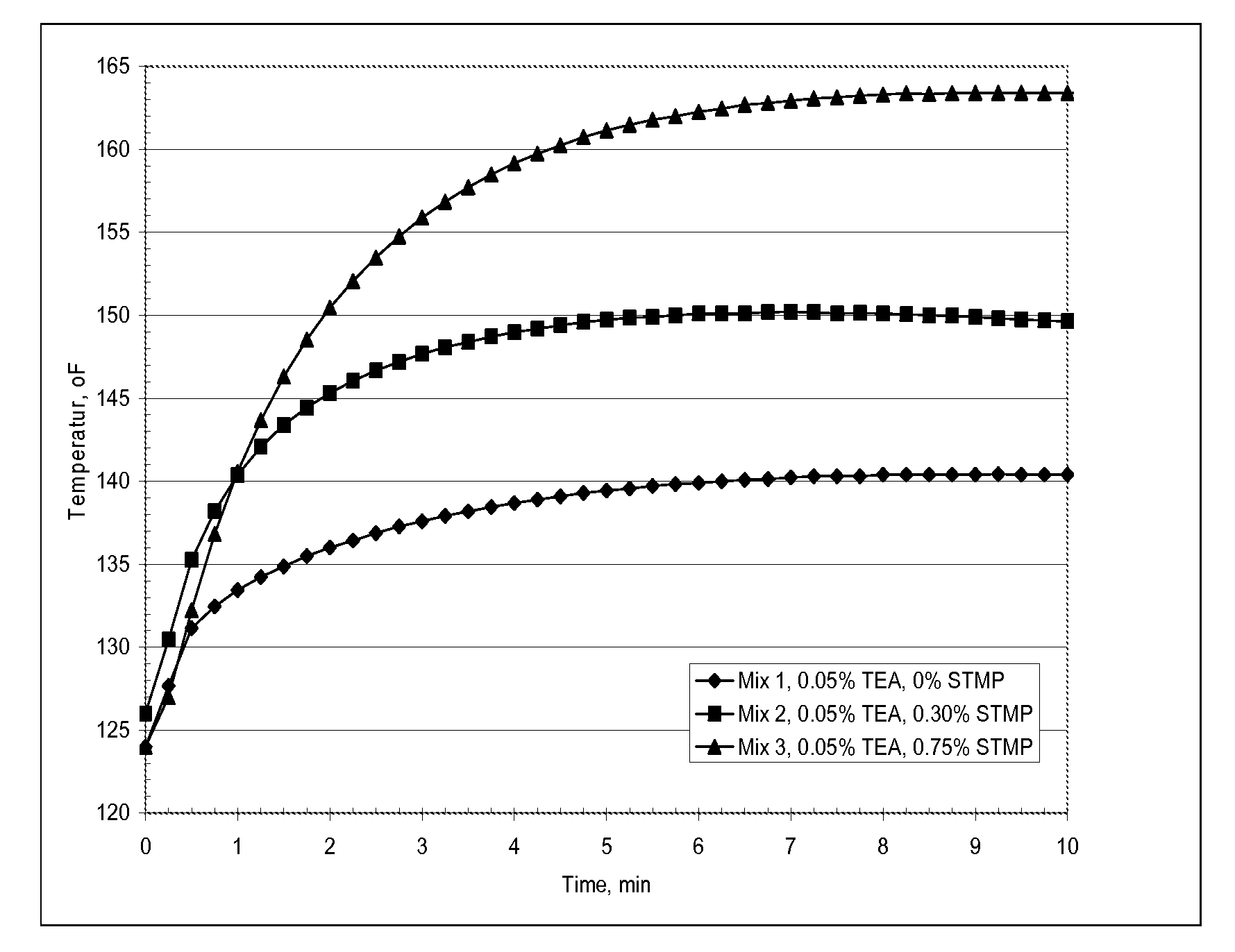

Very fast setting cementitious composition with high early-age compressive strength

ActiveUS7670427B2Addressing slow performanceHigh compressive strengthSolid waste managementPortland cementCement board

A method of making a rapid setting composition for cement boards is disclosed. Compositions including portland cement, fly ash, gypsum, alkanolamine and phosphate are disclosed. A synergistic interaction between the alkanolamine and phosphate increases the effectiveness of accelerating reactions thus allowing for quick setting and increased early-age compressive strength compositions.

Owner:UNITED STATES GYPSUM CO

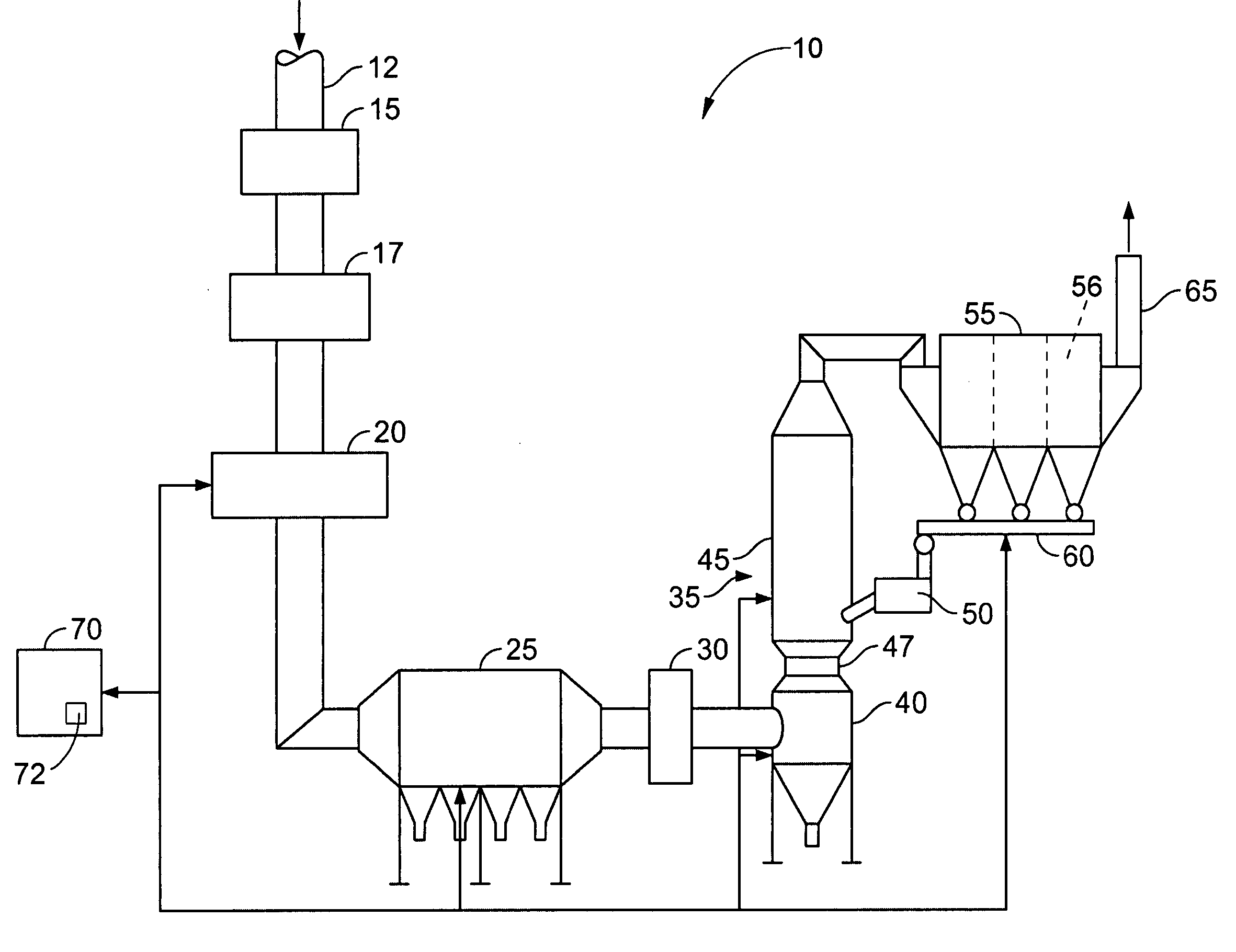

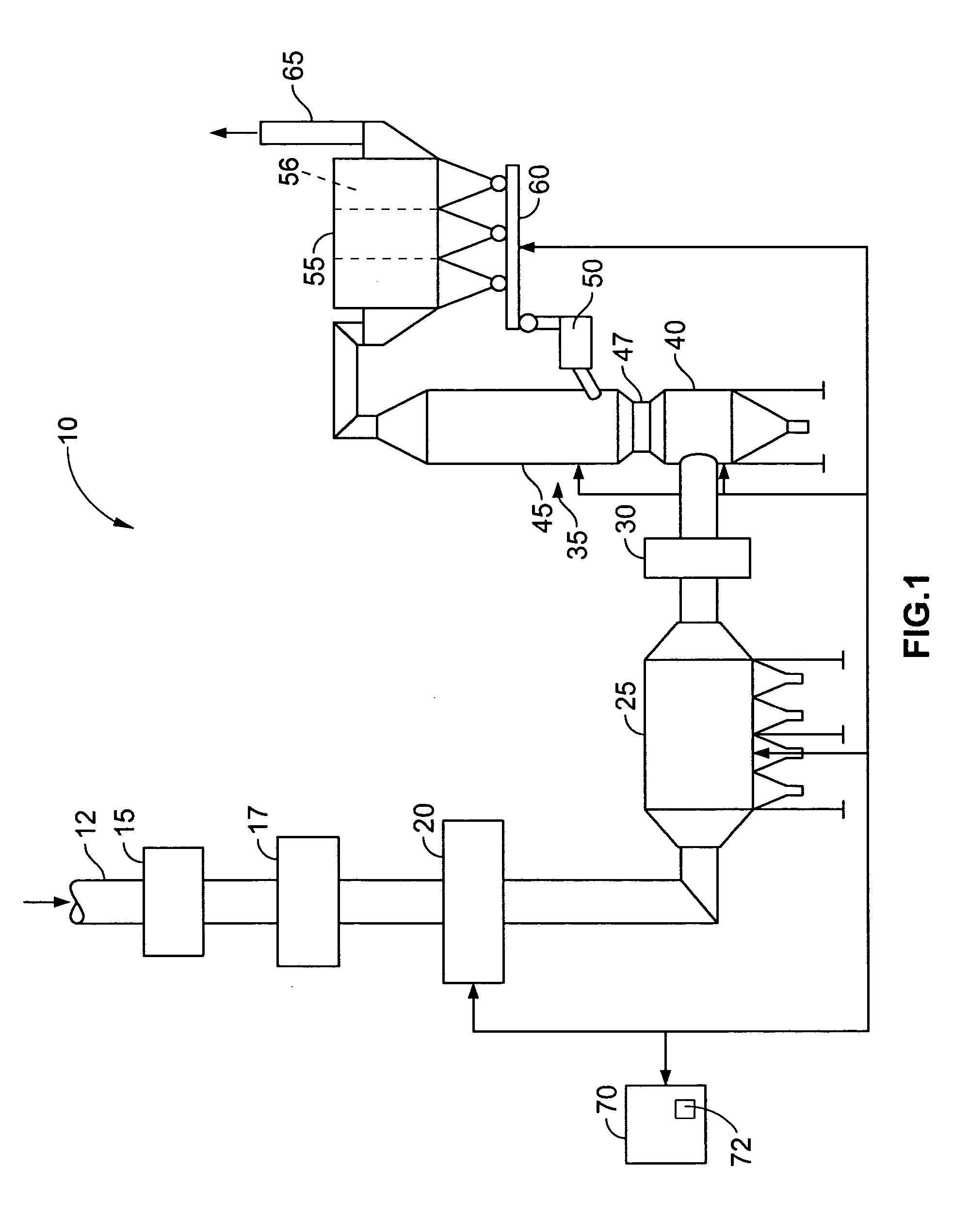

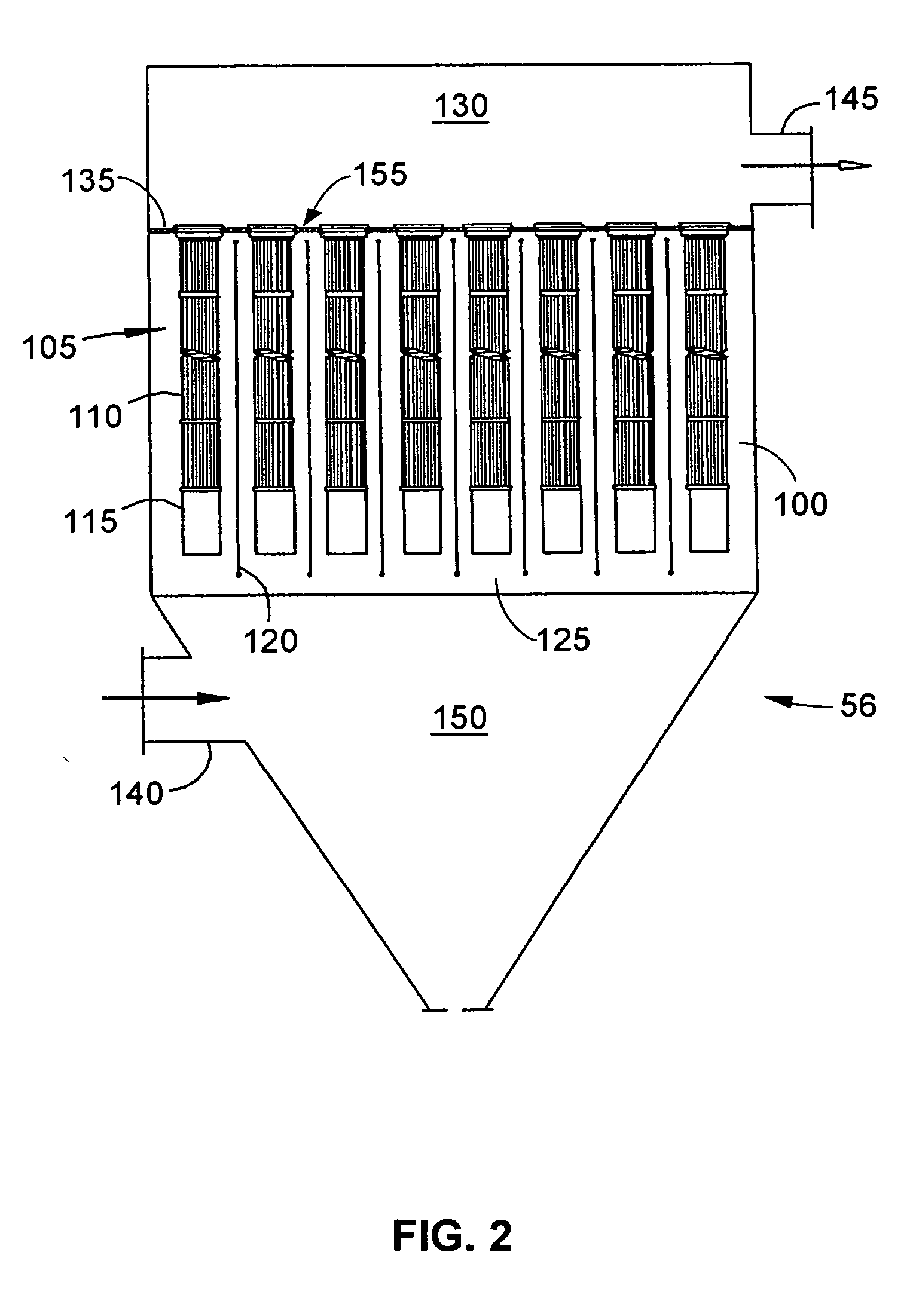

Method and apparatus for removing particulate and vapor phase contaminants from a gas stream

InactiveUS7141091B2Easy disposalAvoid pollutionIsotope separationExternal electric electrostatic seperatorParticulatesSorbent

Owner:ELECTRIC POWER RES INST INC

Composite tailing non-fired and non-steamed building block brick and preparation method thereof

InactiveCN102093004AHigh waste rateSolve the problem of excessive dosageSolid waste managementBrickSlag

The invention discloses a composite tailing non-fired and non-steamed building block brick and a preparation method thereof. The brick comprises the following raw materials in parts by weight or volume: 50-300 parts of tailing and 3-30 parts of cement; and at least two components are selected from the active wastes such as fly ash, coal gangue, shale slag, alkaline residue, carbide slag, chemical gypsum and the waste residue of metallurgical industry to be mixed with the raw materials. The preparation method comprises the following steps: mixing to stir, compressing and shaping, performing natural curing or utilizing the solar heaing hydrating maintenance to prepare the composite tailing building block brick. By adopting the preparation method of the invention, the single performances of the tailings and slags can be changed, thus the product can have higher strength and quality owning to the interaction of materials; the technology does not adopt firing and steaming, the cost is low; different sizes of solid bricks, perforated bricks, hollow blocks, floor tiles, grass planting bricks, roadside bricks and artistic rails can be prepared by changing the mould; and various harmful slags such as tailings can become good, the Chinese development direction of the comprehensive utilization of resources is satisfied and the brick of the invention has development and application prospect.

Owner:郭东京 +2

Burning-free block brick prepared from bulky industrial waste residues

The invention relates to a burning-free block brick prepared from bulky industrial waste residues. The burning-free block brick is characterized in that the block brick comprises the following raw materials in parts by weight or volume: 10-80 parts of at least one of tailing, magnesium slag, basic slag, mountain flour, cinder, fly ash, coal gangue, oil shale waste and sulfuric acid slag, 0-80 parts of at least one of gravel, waste sand, construction waste, garbage to be burnt, steel slag, mineral slag, copper slag, iron slag with gold, ardealite, phosphorous slag and carbide slag, 0-50 parts of active cementing material, 0-30 parts of cement clinker, 2-15 parts of cement and a defined amount of water. The preparation method of all types of burning-free and steaming-free standard bricks, perforated bricks, hollow blocks, paving tiles, road edge bricks and fence railings which have low cost and high strength, is as follows: proportioning, stirring for 1-6 minutes, adding a defined amount of water to stir, placing in moulds to form in a machine and performing natural curing for 7-28 days. The burning-free block brick has high raw material selectability, simple technology and wide development and application prospects, and is environmental-friendly.

Owner:司密花 +2

Lightweight high-performance foam concrete and preparation method thereof

ActiveCN104108912AHigh CaO contentHigh glass bead contentSolid waste managementCeramicwareFoam concreteFiber

The invention discloses a lightweight high-performance foam concrete, which is composed of the following components in parts by weight: 50 to 60 parts of cement, 20 to 35 parts of mineral slag, 15 to 20 parts of fly ash, 5 to 10 parts of gypsum, 60 to 80 parts of fine aggregate, 2.7 to 7.3 parts of additive, 0.1 to 0.2 part of fiber, 32 to 45 parts of water, and 5 to 25 parts of foam. The invention also discloses a preparation method of the foam concrete. The foam concrete has the advantages of small volume-weight, high strength, low water absorption, and small contraction rate, and has the waterproof and anti-cracking functions at the same time.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

Foam concrete and preparation method

The invention discloses a foam concrete and a preparation method, belonging to the technical field of building materials and construction, comprising the following components of cement, ore powder, fly ash and water, and further comprising a waterproof agent, fibers, an accessory and a foaming agent. The preparation method comprises the following steps of: adding 50-200 parts by weight of the cement, 10-100 parts by weight of the ore powder, 10-150 parts by weight of the fly ash, 60-250 parts by weight of the water, 0-3 parts by weight of the waterproof agent, 0.3-1 part by weight of fiber and 0.1-3 parts by weight of accessory to a container, evenly stirring the components by a stirring machine, adding 6-20 parts by weight of the foaming agent, mixing and stirring the mixture, quickly paving the obtained material on the construction surface for natural smoothing, standing for finishing foaming within 2-30min to obtain the desired strength after 24h, and maintaining to form the formed foam concrete. The invention has high strength, light quantity, low head conductivity coefficient, simple formula, convenient construction and low cost due to the utilization of industrial and mining waste materials, and the invention can partially replace polyvinyl benzene foam boards, extruded sheets and slurry particle insulating boards of a heat insulating system; in addition, the invention is applied to the field construction of a foam concrete heat insulating system of floors and roofs and the production of the foam concrete blocks and heat insulating slabs in a factory by using moulds.

Owner:CHENGDU XIYA TECH DEV

Mercury adsorbents compatible as cement additives

InactiveUS20080134888A1Efficient removalReduce distractionsGas treatmentOther chemical processesAluminateSorbent

Solid adsorbents, following their use for mercury removal from flue gas, that do not interfere with the ability of air-entraining additives (such as surfactants) to form stable bubbles when added to fly ash containing the adsorbents. The interference is overcome by heating the materials used in the manufacture of the adsorbent so that magnesium hydroxide and / or one or more alkali compounds containing one or more silicate, aluminate, and / or phosphate moiety, added or already present in the materials, binds multivalent cations present in the materials that could otherwise interfere with the surfactant activity.

Owner:PRAXAIR TECH INC

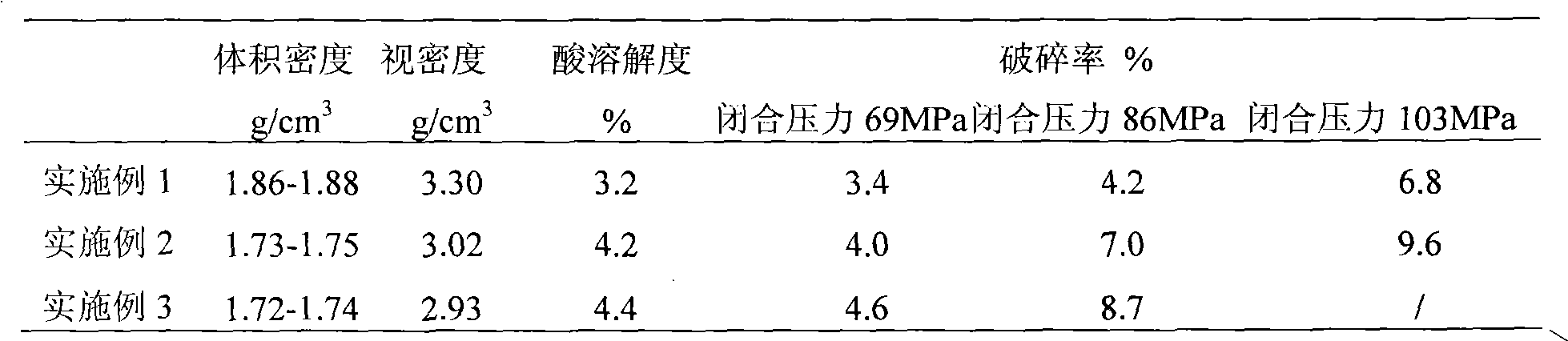

High-strength compress supporting agent for coarse oil and preparation method thereof

ActiveCN101575503AGood effectHas high strengthFluid removalDrilling compositionChemical compositionRed mud

The invention relates to a high-strength compress supporting agent for coarse oil and a preparation method thereof. The high-strength compress supporting agent for the coarse oil is prepared from the following raw materials by mass portion: 60 to 85 portions of ceramic roller waste, 1 to 20 portions of red mud, 0 to 20 portions of fly ash, 0 to 5 portions of manganese oxide or barium carbonate, 0 to 3 portions of dolomite and 5 to 10 portions of ceramic clay. The ceramic roller waste refers to corner waste or / and damaged and broken ceramic roller waste in the processing process of ceramic roller manufactures, and Al2O3 content of chemical compositions of the ceramic roller waste is not less than 68 percent. The high-strength compress supporting agent for the coarse oil prepared from the ceramic roller waste with high alumina content has the characteristics of high strength and acid resistance, and is used for oil fracturing in medium-deep wells; and the preparation method is simple and feasible, and is suitable for batch production.

Owner:JINGANG NEW MATERIALS

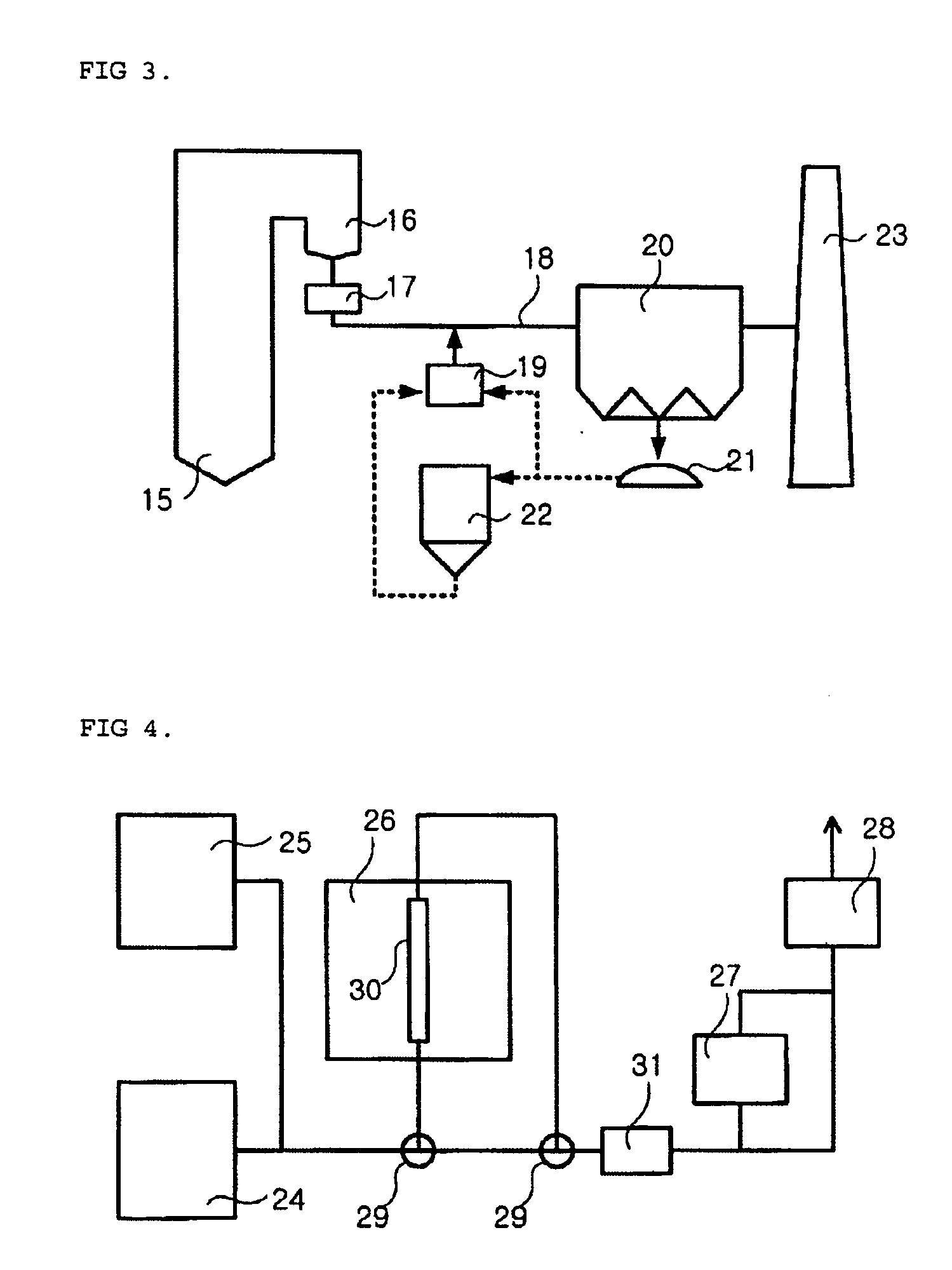

Method and system for removing mercury from combustion gas

A method for continuously removing mercury from a supply of combustion gas is provided. The method includes adjusting a power input to an electrostatic precipitator to control a quantity of fly ash emitted from the electrostatic precipitator. A turbulent flow of combustion gas is produced to suspend particulate matter including the quantity of fly ash contained in the supply of combustion gas. A substantial portion of the mercury is absorbed within the particulate matter including the quantity of fly ash. The supply of combustion gas is filtered to remove the particulate matter from the mercury. A quantity of absorption sites available for absorbing mercury is controlled by monitoring an emission of fly ash from the electrostatic precipitator.

Owner:GENERAL ELECTRIC CO

Method of preparing aluminum oxide from fly ash

ActiveCN1923695AHigh dissolution rateFewer separation stepsAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium sulfateSlag

The invention discloses a preparing method of alumina through fly ash, which comprises the following steps: grinding fly ash; sintering; activating; stirring with H2SO4 evenly to sinter into dried slag; immersing through hot water; stripping aluminum sulfate; condensing; cooling to evolve aluminum sulfate; crystallizing; heating; dehydrating to obtain anhydrous aluminum sulfate; heating; decomposing to obtain gamma-Al2O3.

Owner:PINGSHUO INDAL

Inorganic-organic microbial compound fertilizer and preparation method thereof

ActiveCN102001870AAvoid competitionPromote growthOrganic fertilisersBacillus licheniformisHigh concentration

The invention relates to an inorganic-organic microbial compound fertilizer and a preparation method thereof. The inorganic-organic microbial compound fertilizer is characterized by comprising ordinary high-concentration three-element compound fertilizer, humic acid, fly ash, microbial compound bacteria powder and other elements, wherein the microbial compound bacterial powder is obtained by mixing bacterial powders which are prepared by respectively fermenting and culturing photosynthetic bacteria, yeast, lactic acid bacteria, bifidobacterium, bacillus subtilis, bacillus licheniformis, bacilluslaterosporus, bacillus megaterium, bacillus mucilaginosus, azotbacteria chroococum and actinomycetes. In the inorganic-organic microbial compound fertilizer, the microbial content of the yeast is no less than 2.0*108cfu / g, and the microbial contents of the other strains are all no less than 2.0*109cfu / g. The inorganic-organic microbial compound fertilizer can centralize the advantages of an organic fertilizer, an inorganic fertilizer and microorganisms, thereby enhancing the stress resistance and the disease resistance of crops, enhancing the fertilizer absorption ability of the crops, lowering the soil hardening degree and improving the soil ecological environment and the quality of the crops.

Owner:山西晨雨晋中肥业有限公司

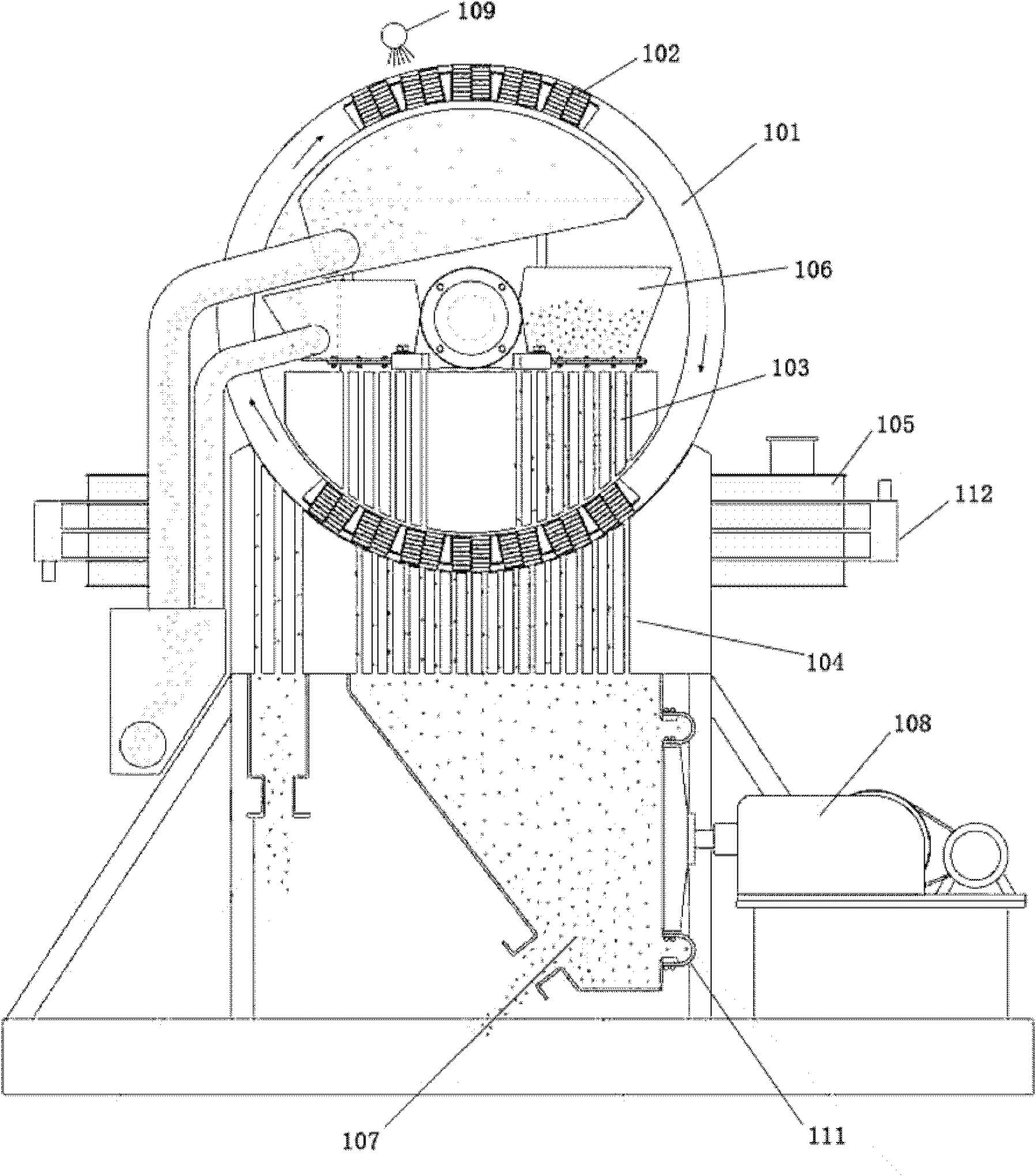

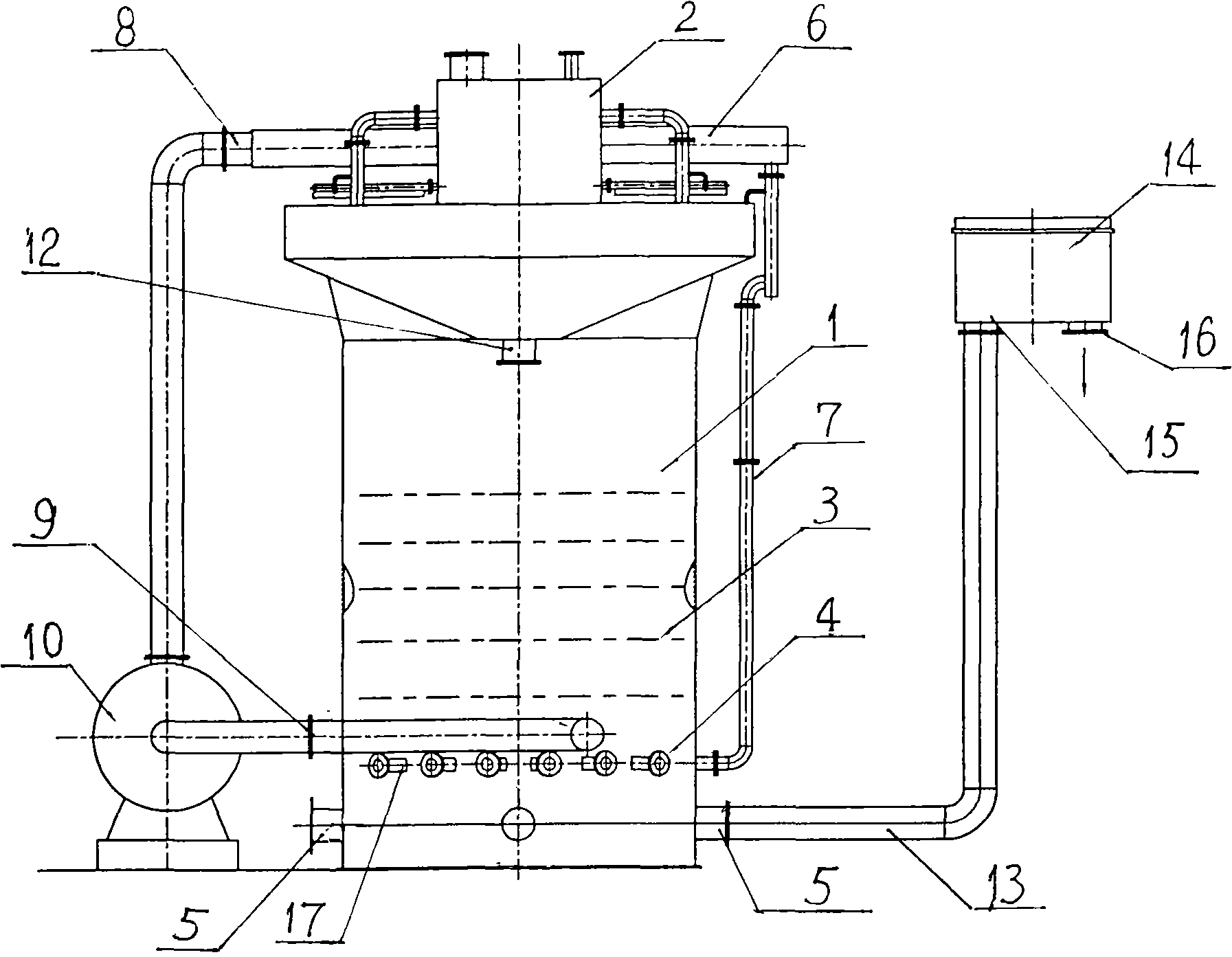

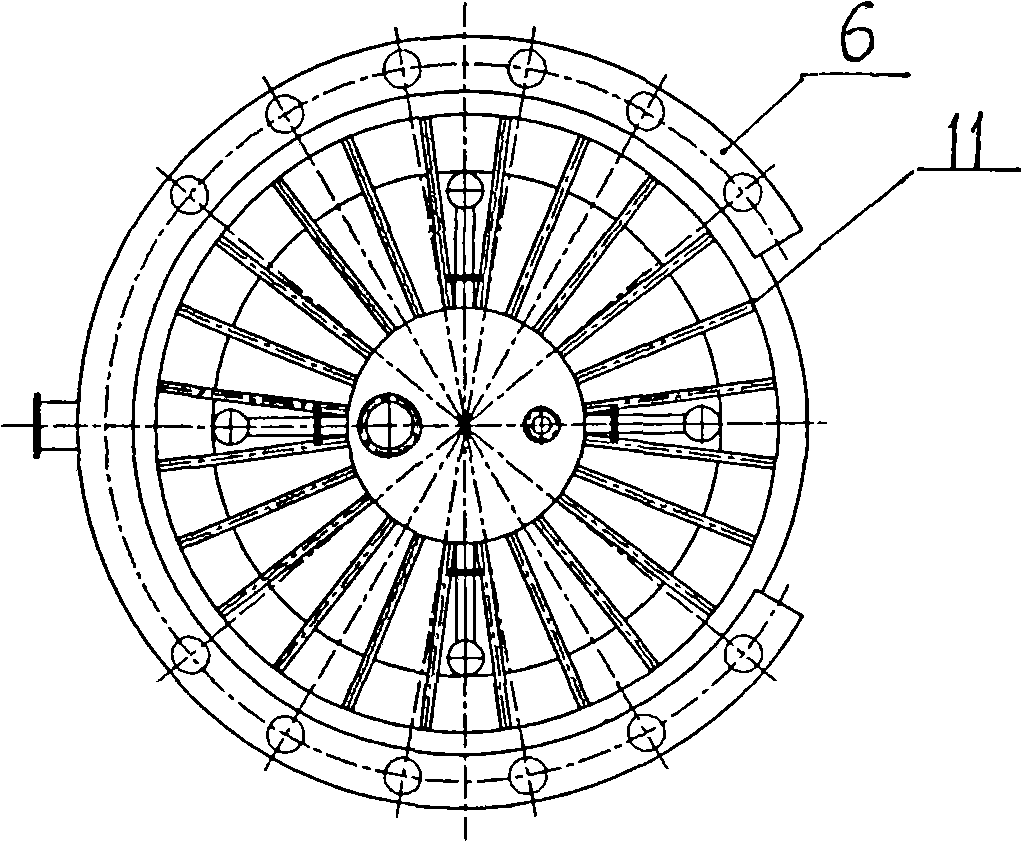

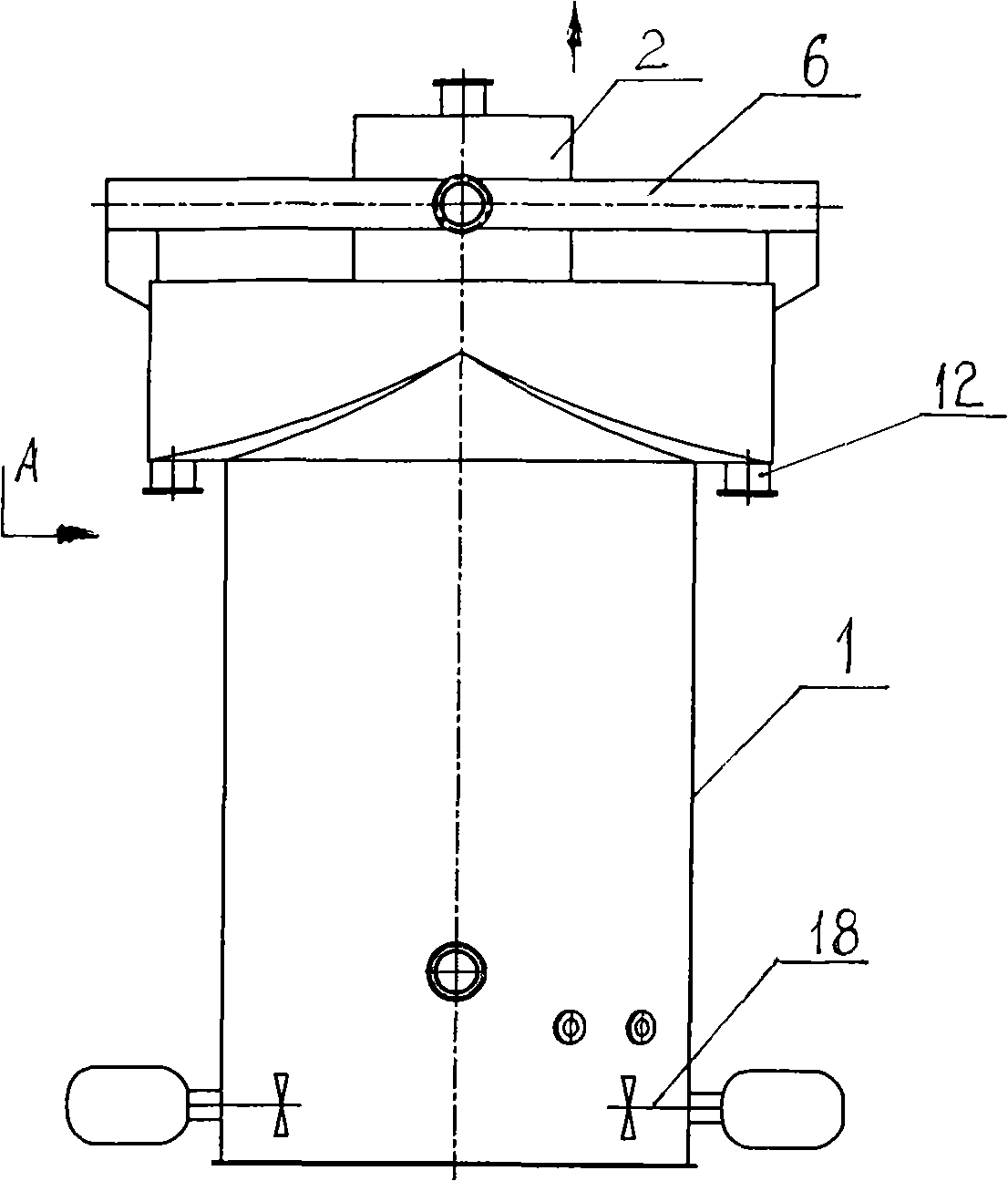

Flotation pillar special for fly ash

The invention relates to a special flotation column of coal fly ash, an ore pulp distributor is arranged at the top part of a cylinder body of the special flotation column, a plurality of layers of bubble plates are arranged in the cylinder body, a multi-point rotary flow device and a multi-point fly ash overflow hole are arranged at the lower part of the cylinder body, an ore pulp distributing pipe is arranged at the periphery of the ore pulp distributor, a circulating pipeline is arranged at the periphery of the cylinder body, the upper end of the circulating pipeline is connected and communicates with the ore pulp distributing pipe, the lower end is connected and communicates with the rotary flow device, an interface of the ore pulp distributing pipe and a feed and discharge port are respectively connected with the both ends of a circulating pump, a high carbon ash balance overflow plate and a high carbon ash overflow collection port are further arranged at the upper part of the flotation column, and the fly ash overflow hole is provided with a fly ash automatic regulation box by the connection of the pipeline. The special flotation column is applicable to various requirements, the decarburization effect is good, the continuous operation is stable and reliable, the quality of fine coal is high and the processing ability is great, thus saving energy, increasing efficiency and saving investment.

Owner:贵州安顺惠海粉煤灰开发有限公司

Filled polymer composite and synthetic building material compositions

ActiveUS20050163969A1Improve mechanical propertiesLow costSolid waste managementLayered productsPolyesterFiber

The invention relates to composite compositions having a matrix of polymer networks and dispersed phases of particulate or fibrous materials. The polymer matrix contains a polyurethane network formed by the reaction of a poly- or di-isocyanate and one or more saturated polyether or polyester polyols, and an optional polyisocyanurate network formed by the reaction of optionally added water and isocyanate. The matrix is filled with a particulate phase, which can be selected from one or more of a variety of components, such as fly ash particles, axially oriented fibers, fabrics, chopped random fibers, mineral fibers, ground waste glass, granite dust, or other solid waste materials. The addition of water can also serve to provide a blowing agent to the reaction mixture, resulting in a foamed structure, if such is desired.

Owner:BORAL IP HLDG

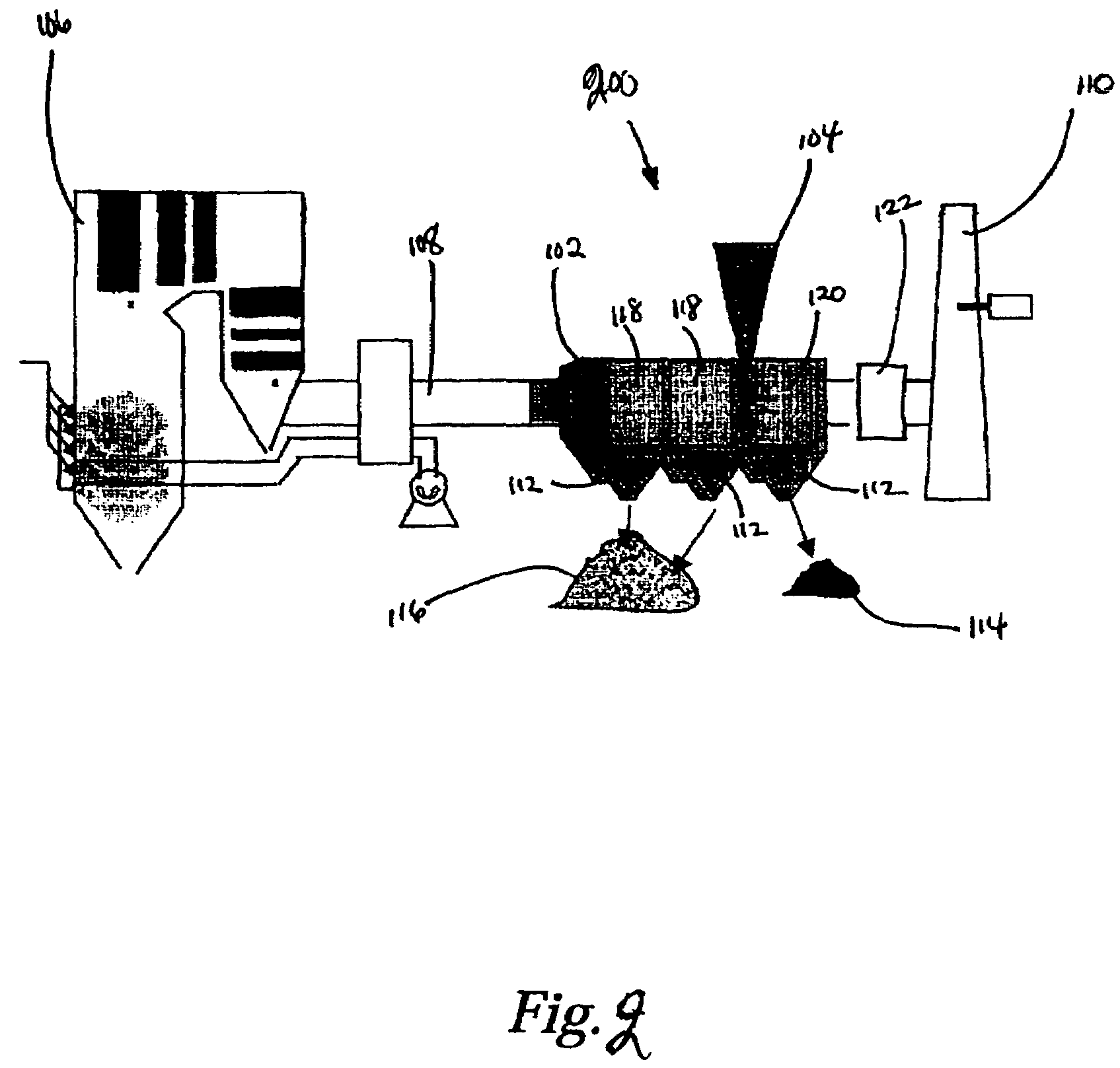

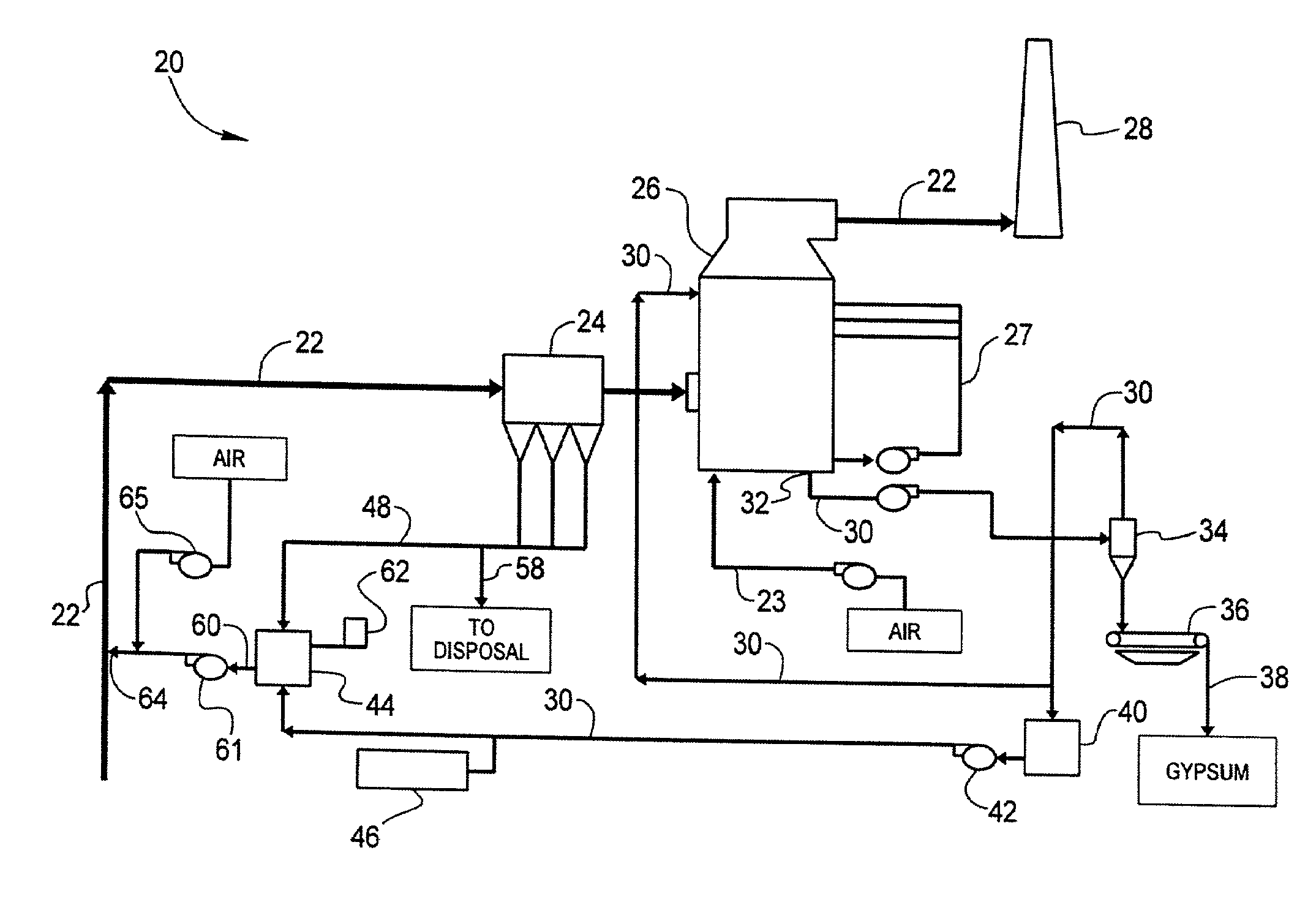

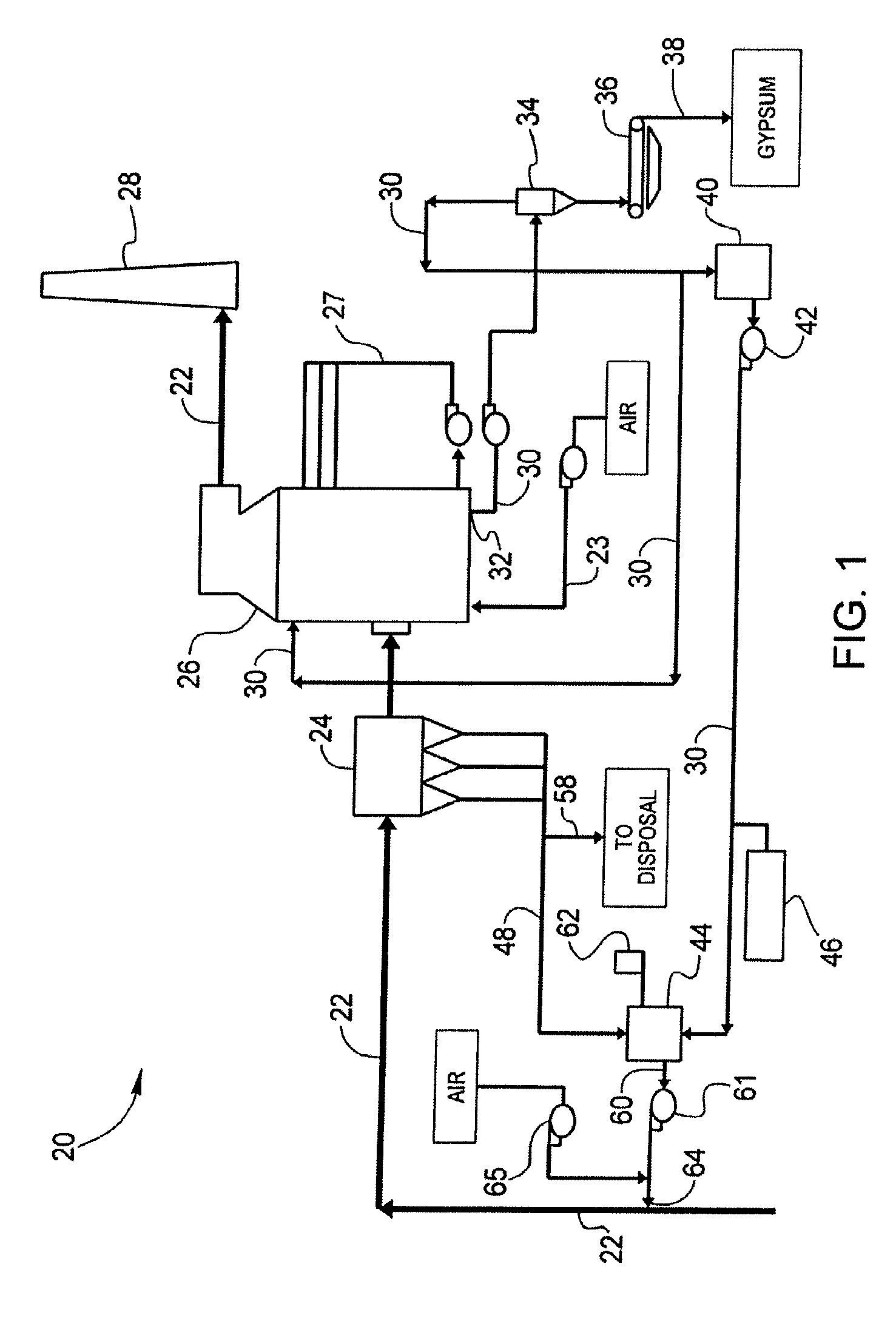

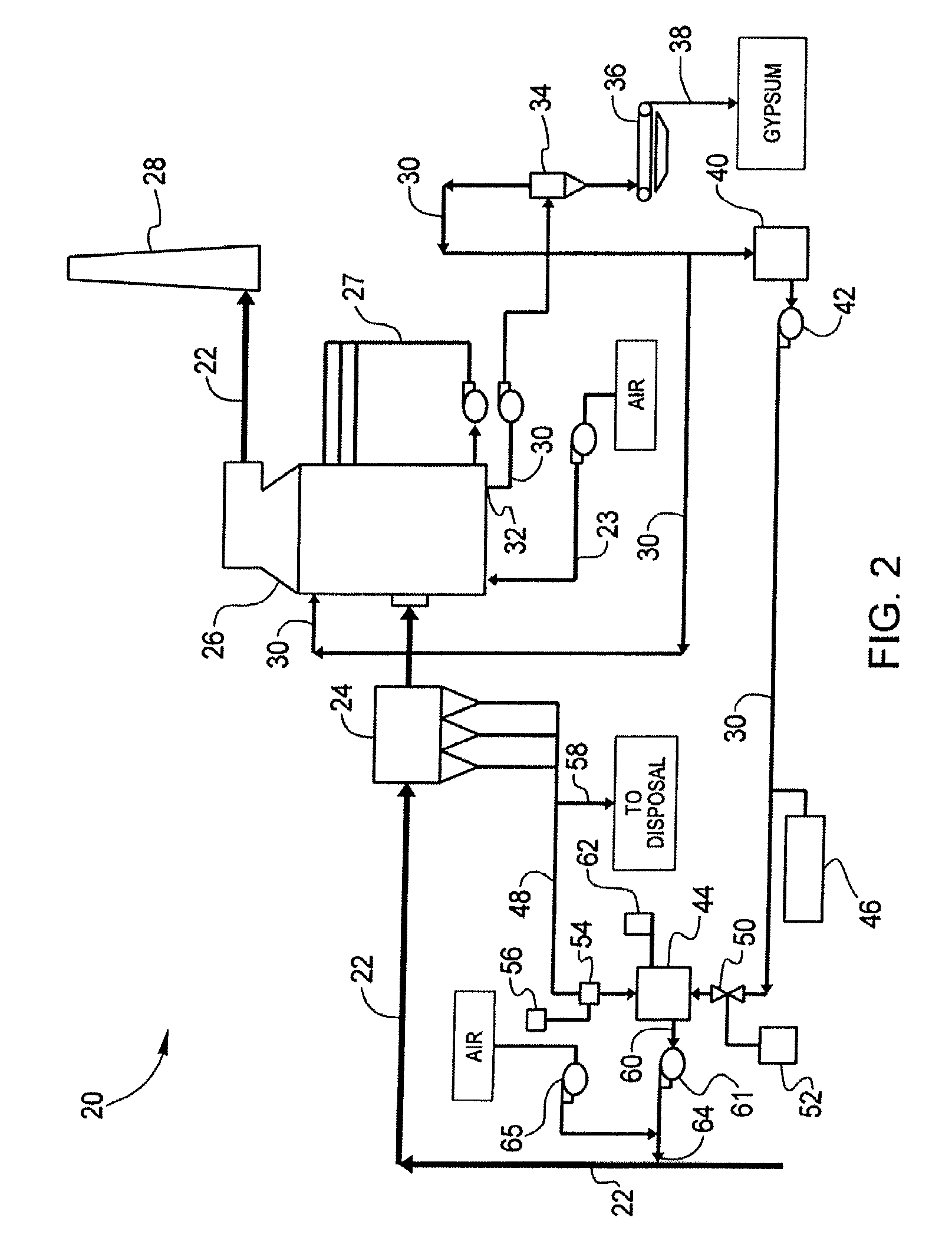

Reduced liquid discharge in wet flue gas desulfurization

One aspect of the invention relates to a method for removing contaminants from a flue gas stream (22). The method includes: removing fly ash from a flue gas stream (22) utilizing a particle collector (24); contacting the flue gas stream with an alkaline reagent in a wet scrubber (26); discharging a purge liquid (30) from the wet scrubber (26); and, combining at least a portion of the purge liquid with at least a portion of fly ash circulating within a dry circulating fluid bed scrubber (48) to form moistened fly ash (60).

Owner:GENERAL ELECTRIC TECH GMBH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com