Patents

Literature

3648 results about "Acid resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

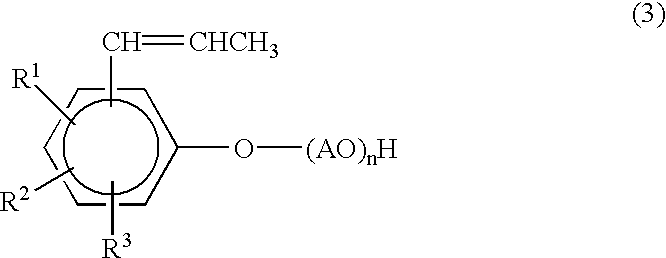

Raindrop fouling-resistant paint film, coating composition, film-forming method, and coated article

InactiveUS6013724ASatisfactory fouling resistanceHigh acid resistanceAntifouling/underwater paintsOther chemical processesCrack resistancePolymer chemistry

Owner:NIPPON PAINT CO LTD

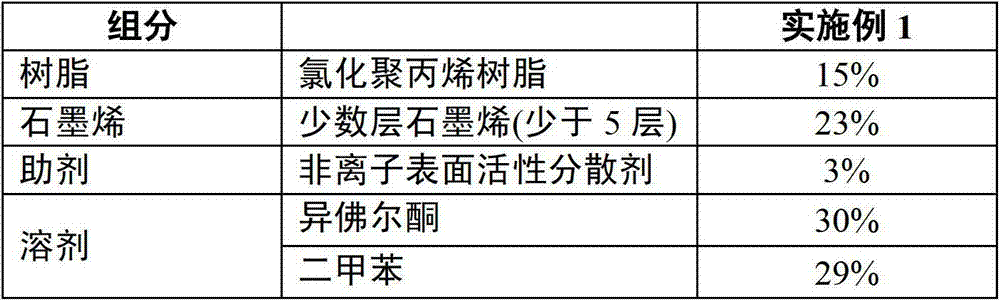

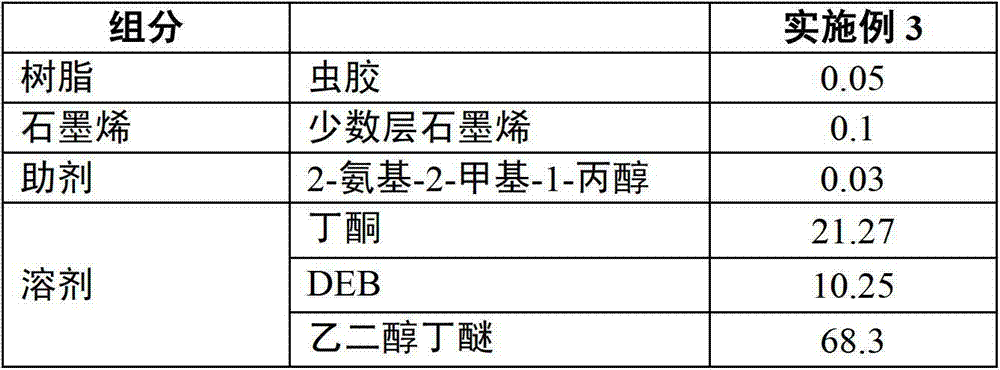

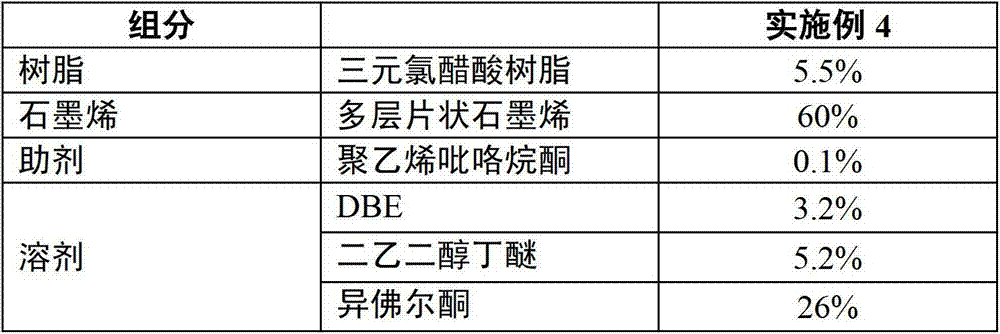

Graphene conductive ink and preparation method thereof

ActiveCN103113786AImprove thermal conductivityImprove mechanical propertiesInksConductive materialsSolvent

The invention relates to graphene conductive ink comprising the following components by weight percent: 0.01-25% of resin, 0.1-95% of graphene, 0.1-30.0% of assistant, and 5.0-99.79% of solvent. The two-dimensional conductive material graphene is used for the conductive ink; the graphene with special ratio is adopted as a conductive phase; the resin is taken as a binder; the assistant and the solvent are used for assisting; the prepared ink is good in anti-sedimentation property, and adjustable in viscosity and rheological behavior, and can be used for flexibly printing on the surfaces of a plurality of substrates; and the ink is stable in mechanical property, stable in electrical properties, oxidation resistance, acid resistance, alkali resistance and resistance to a chemical solvent after being cured.

Owner:SUZHOU NIUJIAN NEW MATERIAL

High-temperature thermal-insulation anticorrosive nano coating and its preparing method

InactiveCN1709988AImprove Radiation PerformanceGood heat insulationAlkali metal silicate coatingsPolymer scienceThermal insulation

The invention discloses a kind of new industry dope. It comprises such materials as 95 - 105 weight shares of Component A, and 1 - 3 weight shares of Component B; thereinto, Component A is made from following weight percents of materials: cementing agent 30-60%, pigment 12 - 30%, filling agent 10 - 30%, auxiliary agent 0.1 - 5%, compound nanometer dispersing agent 5 - 15% and solvent 10 - 25%; Component B is comprised of catalyzed membrane forming agent - nanometer Sb2O3 and mixed organic solvent carriers. The invention firstly brings nanometer Sb2O3 into high temperature heat preservation dope as catalyzer in dope membrane forming process. The dope of the invention has following advantages: it has high temperature heat preservation and heavy anticorrosion performances, and the coat has good acid resistance, alkali resistance, salt mist resistance, oil resistance, chemical reagent resistance, waiting resistance and ultraviolet resistance; it has excellent fire protection and waterproof performance; the clinging strength of smearing membrane is good, membrane forming speed is fast, and performance is stable.

Owner:孙启明

Boron-free glass

The invention discloses boron-free neutral glasses having the composition (in % by weight, based on oxide) 65-72 SiO2, 11-17 Al2O3, 0.1-8 Na2O, 3-8 MgO, 4-12 CaO and 0-10 ZnO, a ratio CaO / MgO of 1.4 to 1.6, and having a hydrolytic resistance in accordance with DIN ISO 719 in class 1 and an acid resistance in accordance with DIN 12116 and an alkali resistance in accordance with DIN ISO 695 at least in class 2.

Owner:SCHOTT AG

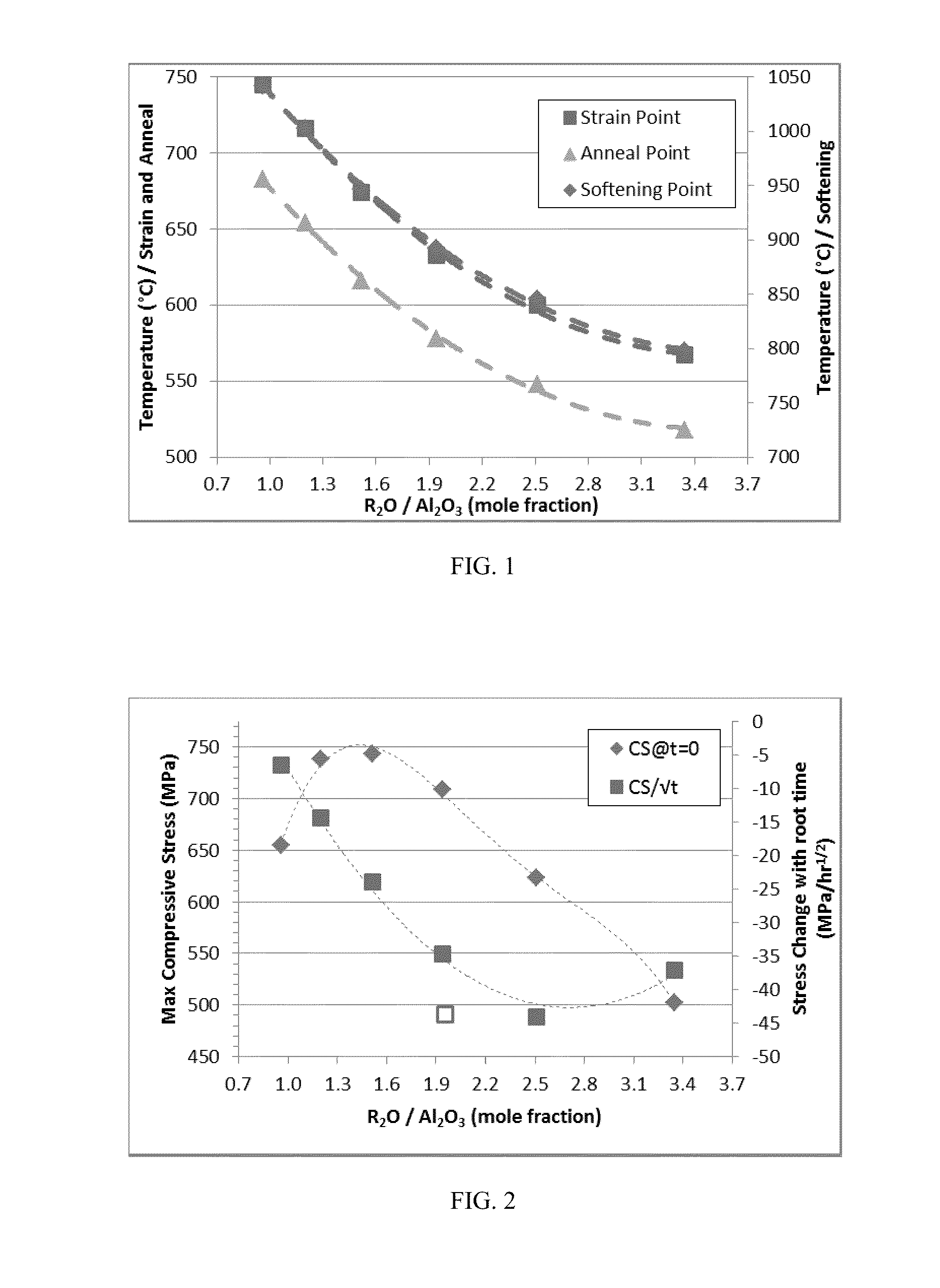

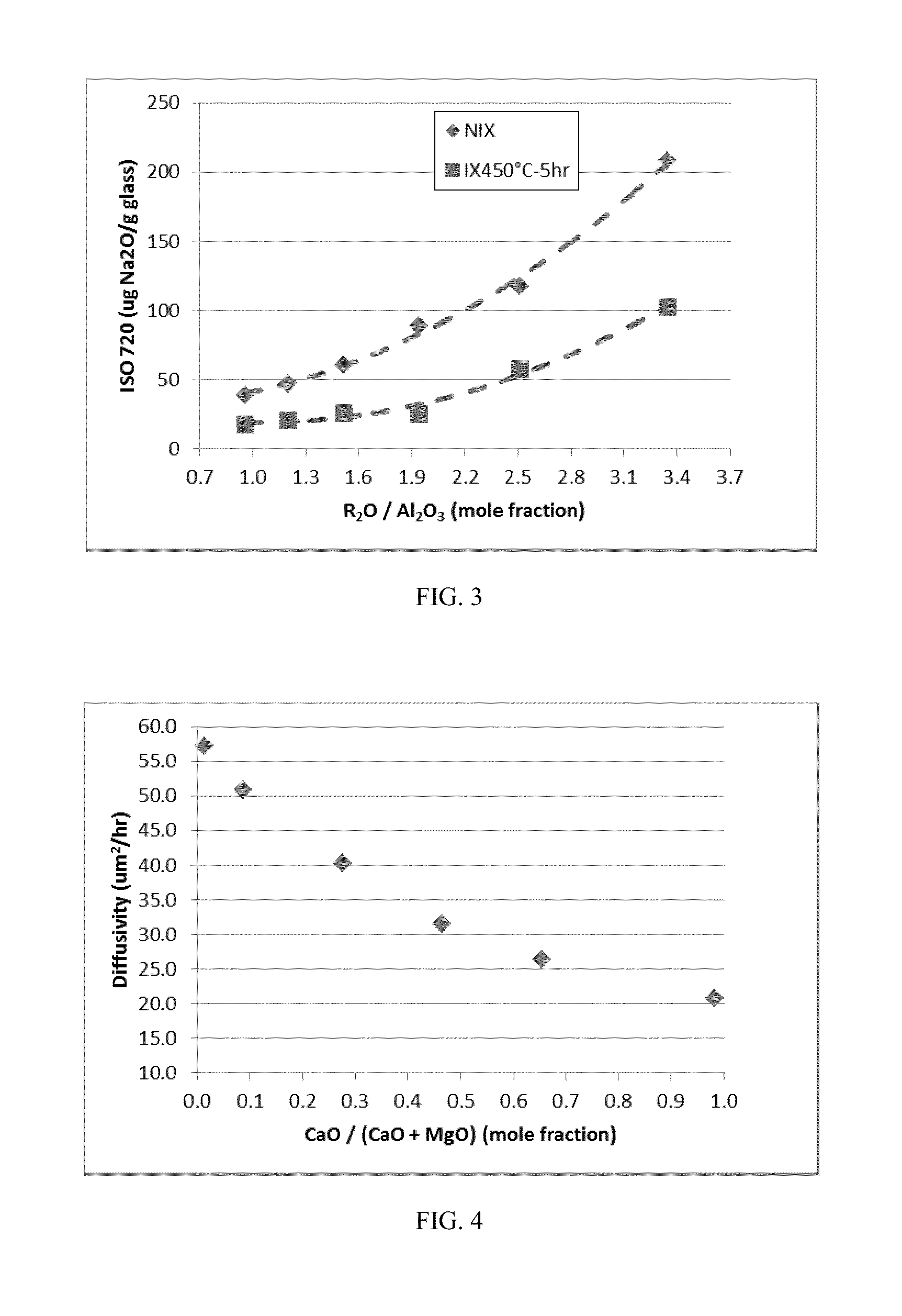

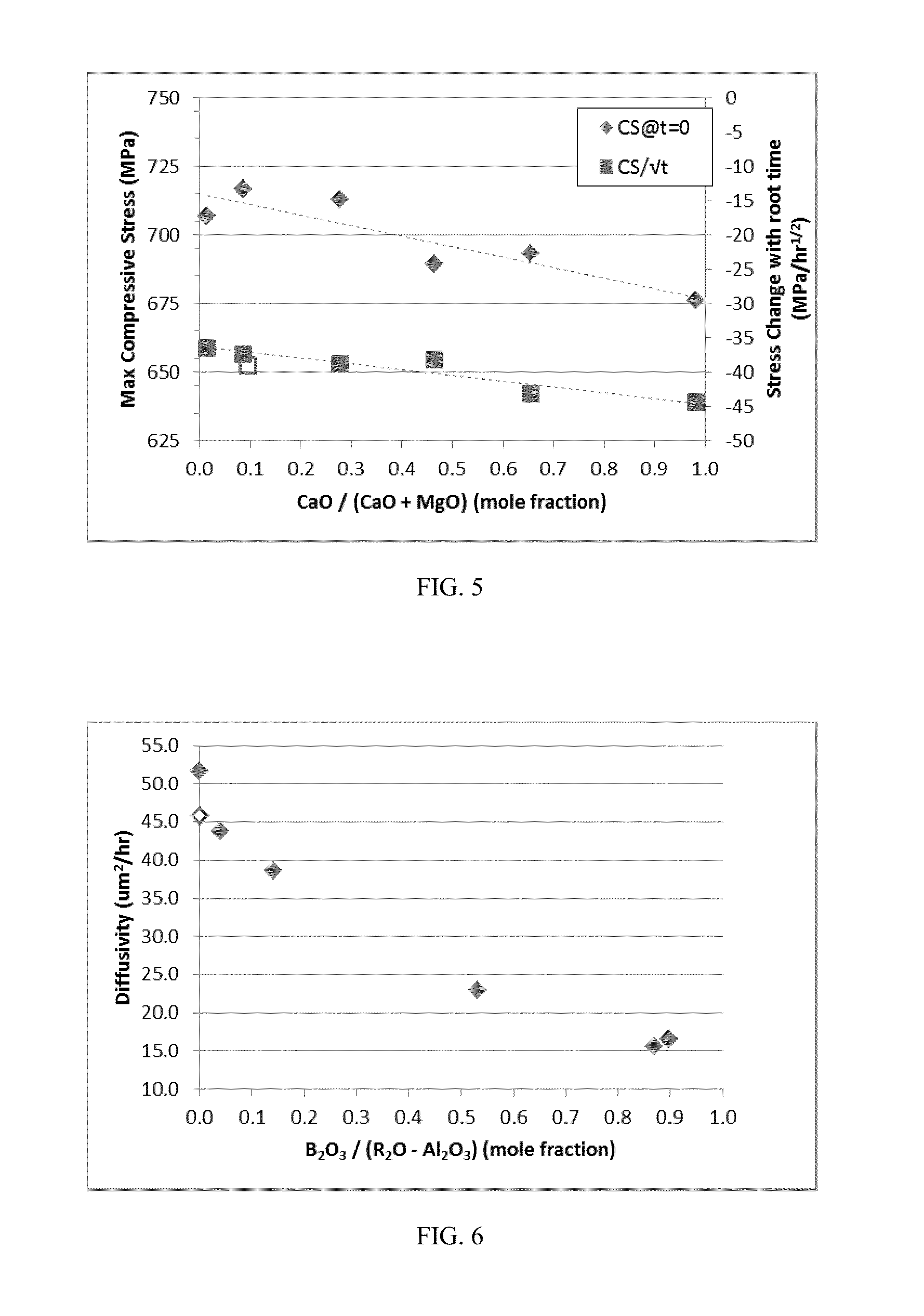

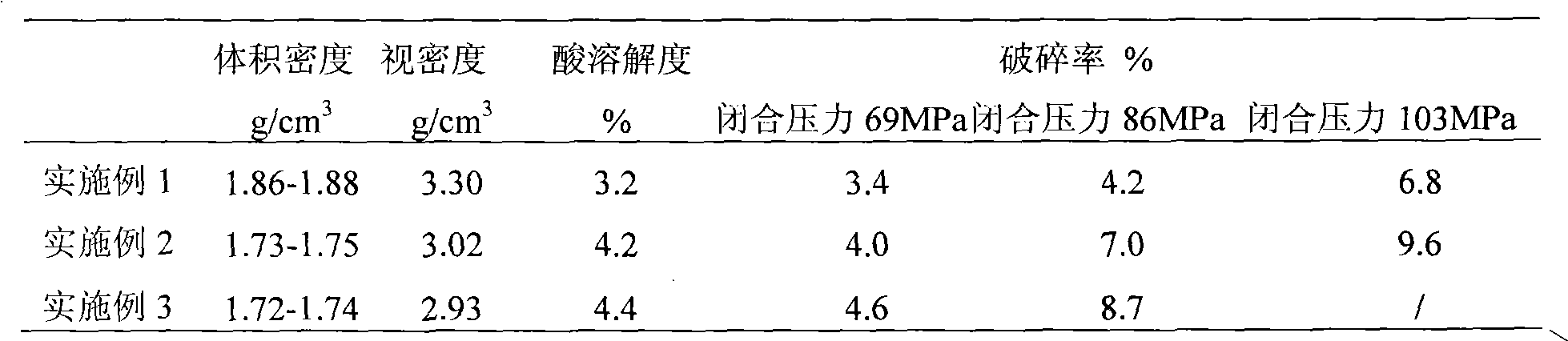

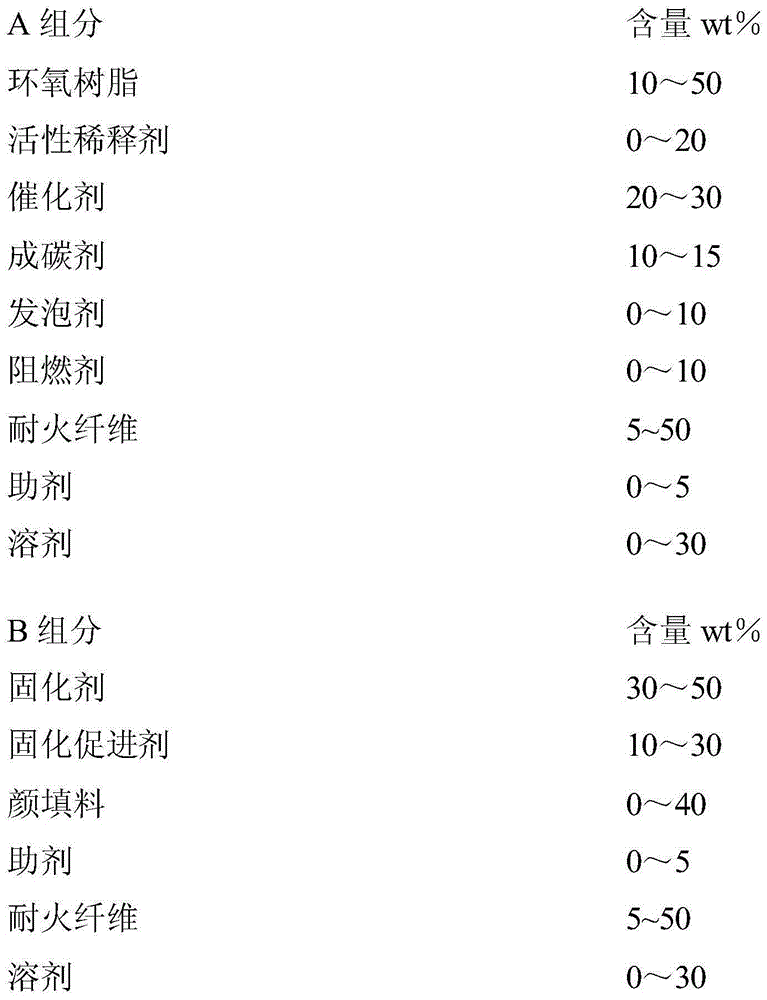

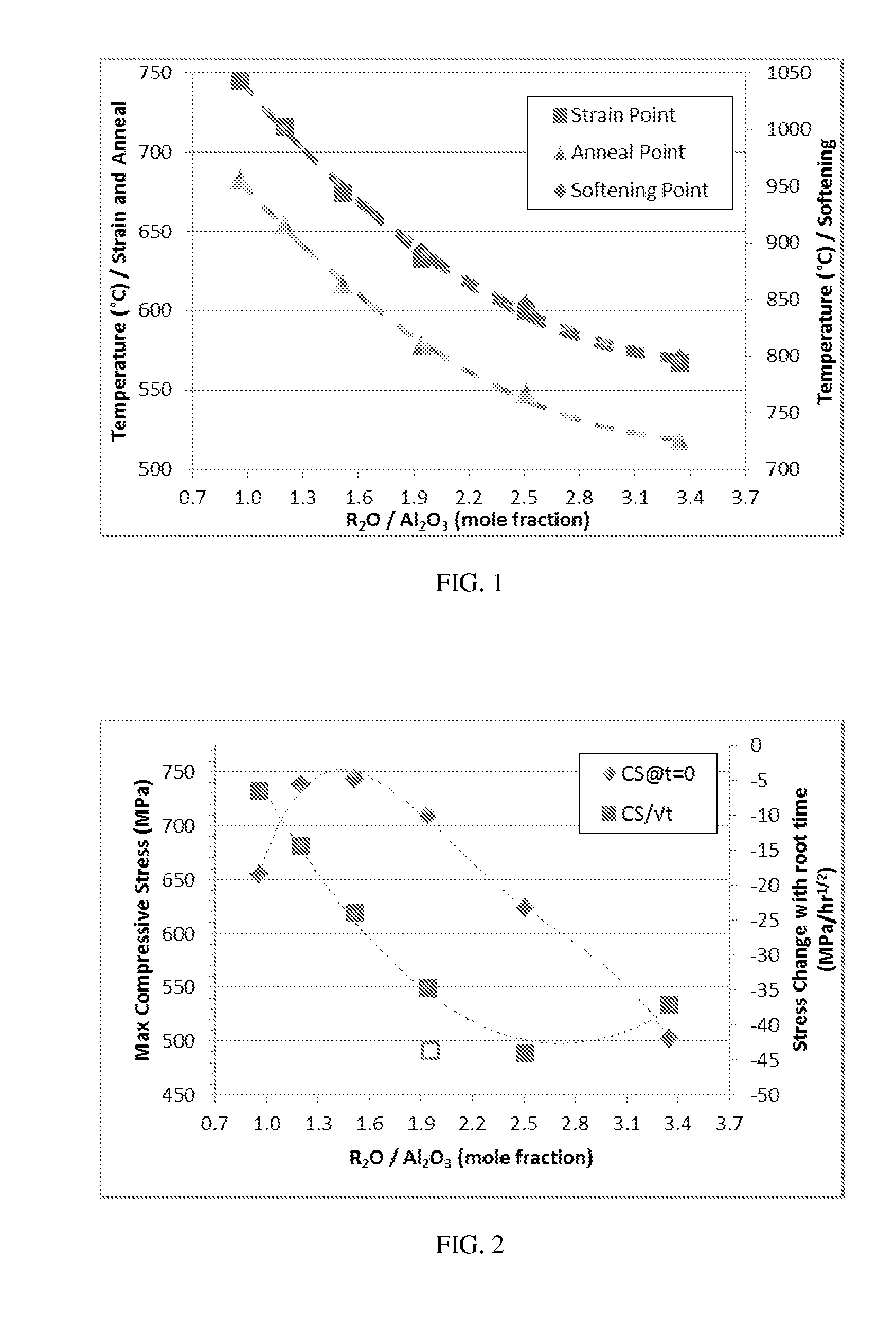

Glass compositions with improved chemical and mechanical durability

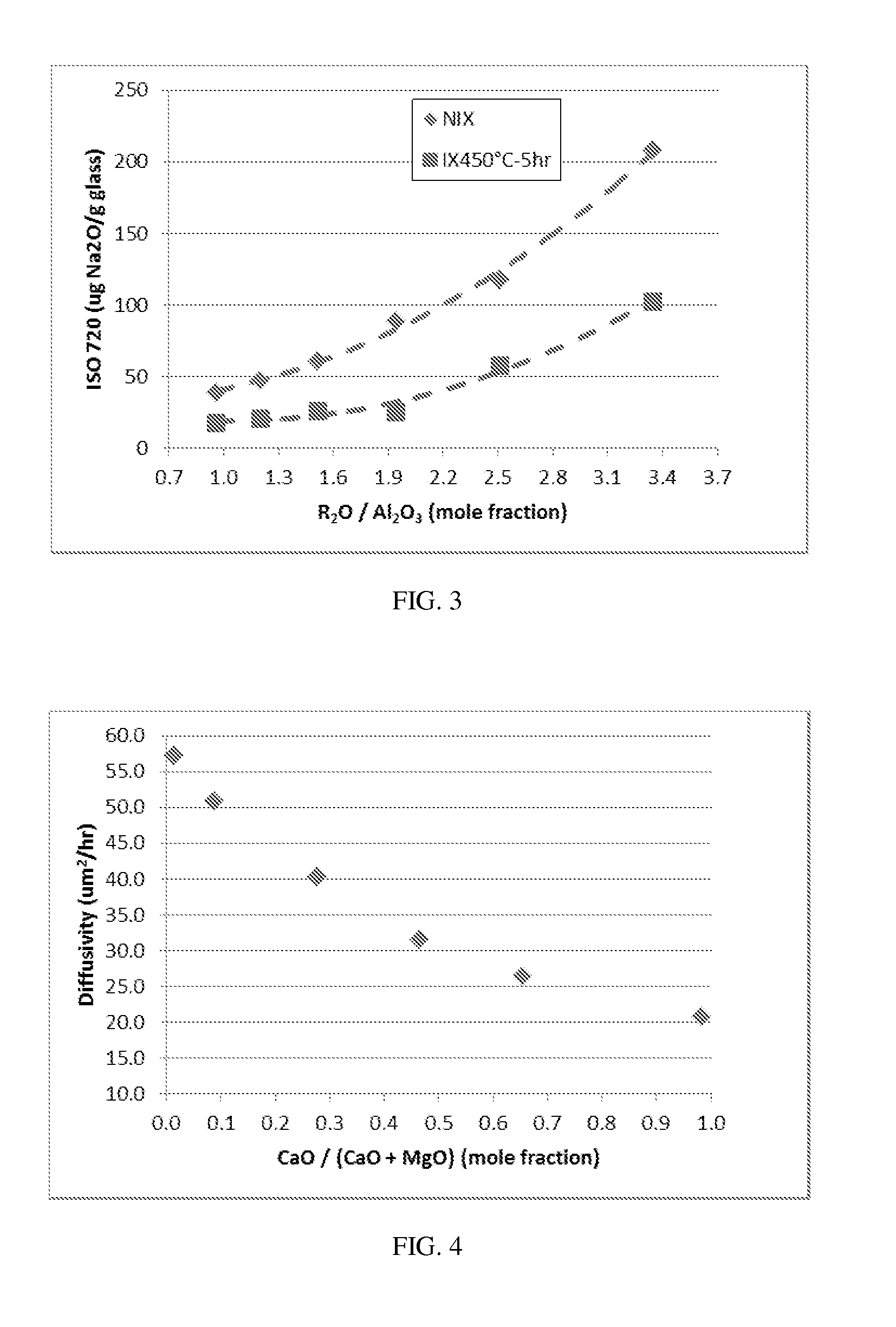

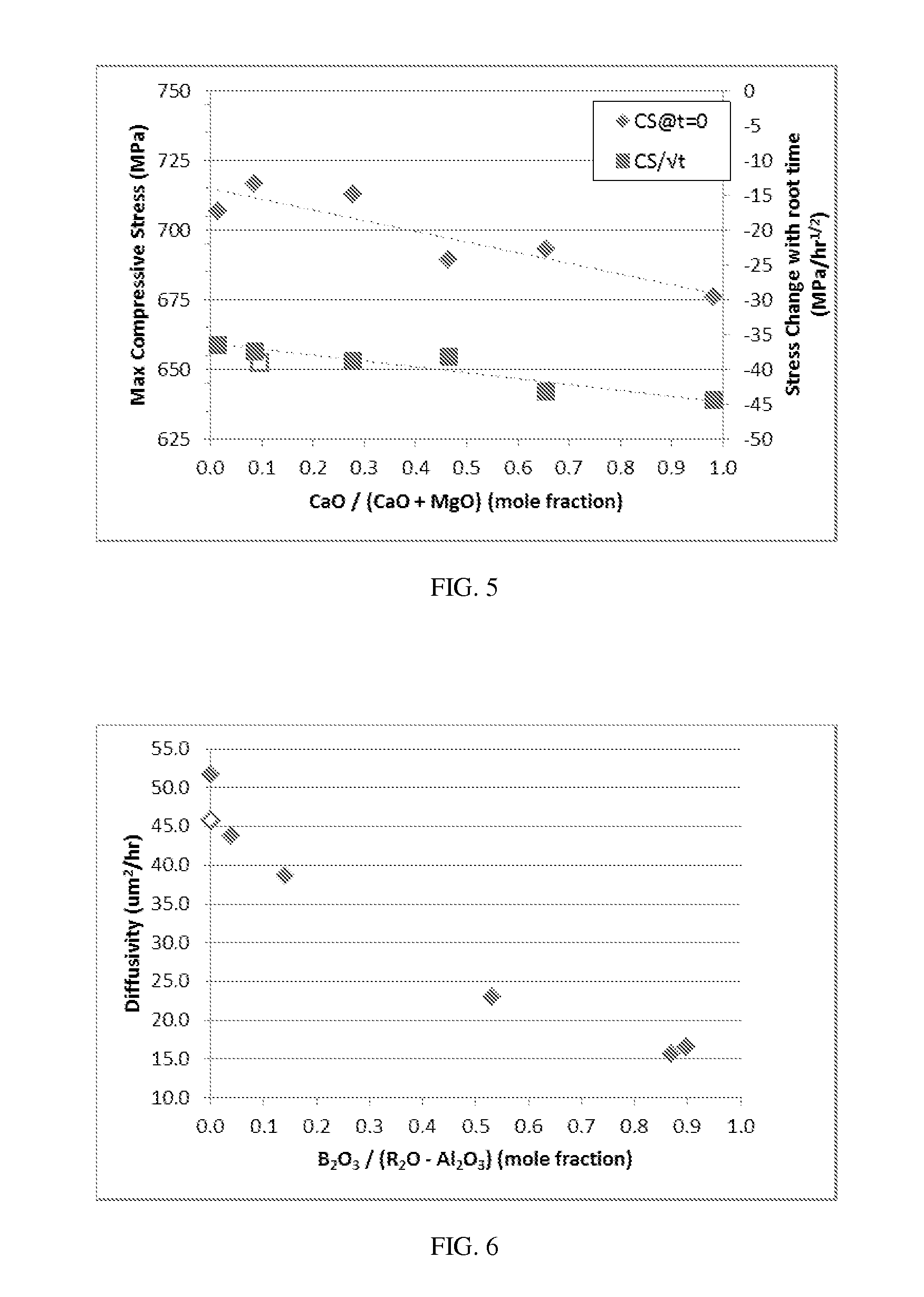

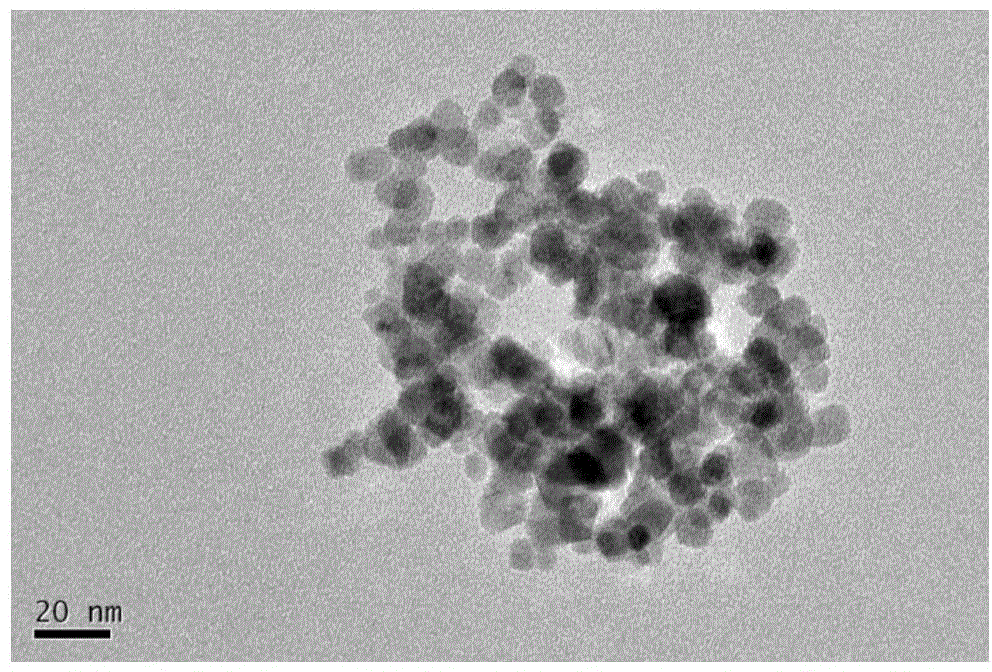

The embodiments described herein relate to chemically and mechanically durable glass compositions and glass articles formed from the same. In another embodiment, a glass composition may include from about 70 mol. % to about 80 mol. % SiO2; from about 3 mol. % to about 13 mol. % alkaline earth oxide; X mol. % Al2O3; and Y mol. % alkali oxide. The alkali oxide may include Na2O in an amount greater than about 8 mol. %. A ratio of Y:X may be greater than 1 and the glass composition may be free of boron and compounds of boron. In some embodiments, the glass composition may also be free of phosphorous and compounds of phosphorous. Glass articles formed from the glass composition may have at least a class S3 acid resistance according to DIN 12116, at least a class A2 base resistance according to ISO 695, and a type HGA1 hydrolytic resistance according to ISO 720.

Owner:CORNING INC

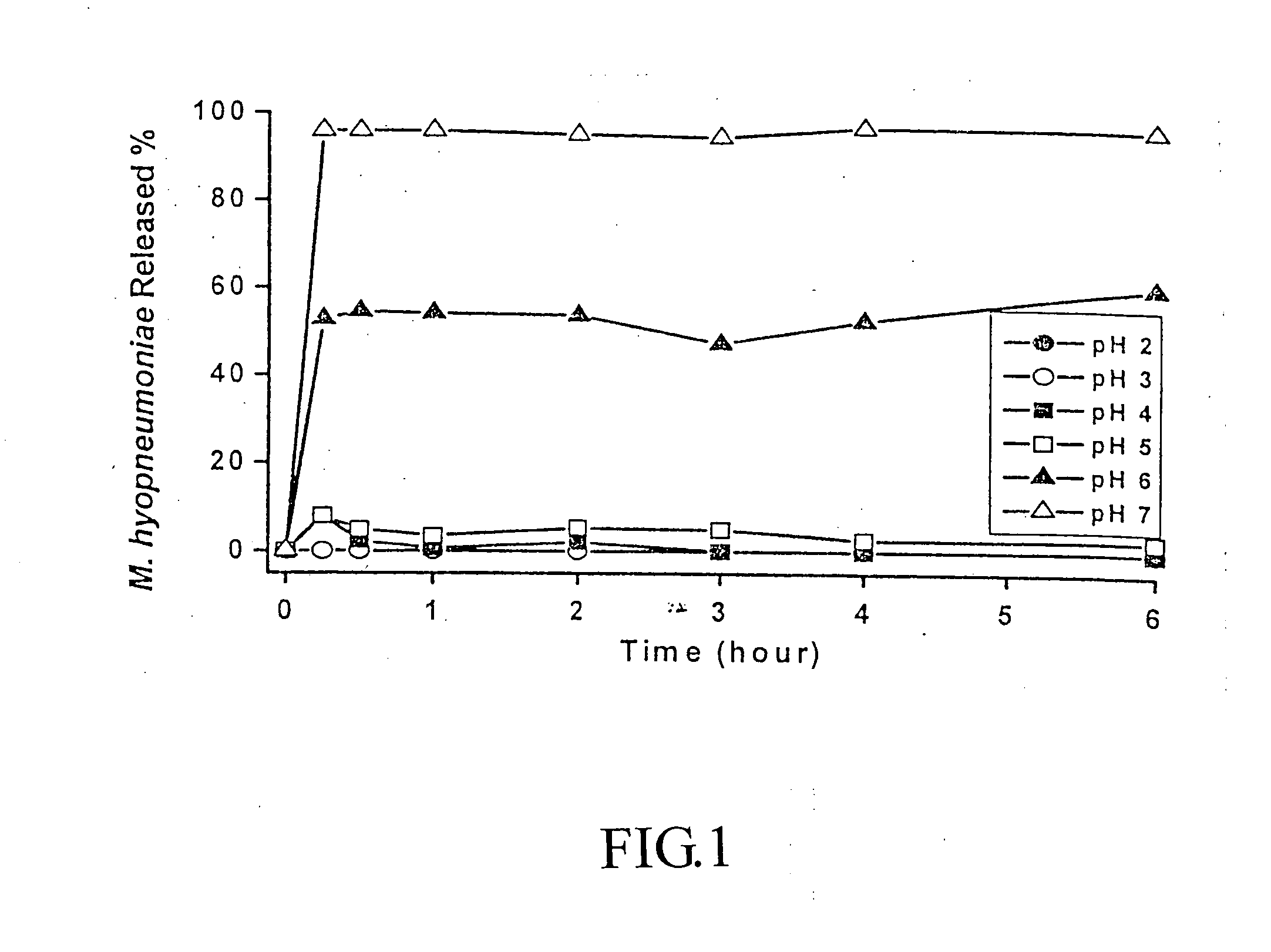

High-strength compress supporting agent for coarse oil and preparation method thereof

ActiveCN101575503AGood effectHas high strengthFluid removalDrilling compositionChemical compositionRed mud

The invention relates to a high-strength compress supporting agent for coarse oil and a preparation method thereof. The high-strength compress supporting agent for the coarse oil is prepared from the following raw materials by mass portion: 60 to 85 portions of ceramic roller waste, 1 to 20 portions of red mud, 0 to 20 portions of fly ash, 0 to 5 portions of manganese oxide or barium carbonate, 0 to 3 portions of dolomite and 5 to 10 portions of ceramic clay. The ceramic roller waste refers to corner waste or / and damaged and broken ceramic roller waste in the processing process of ceramic roller manufactures, and Al2O3 content of chemical compositions of the ceramic roller waste is not less than 68 percent. The high-strength compress supporting agent for the coarse oil prepared from the ceramic roller waste with high alumina content has the characteristics of high strength and acid resistance, and is used for oil fracturing in medium-deep wells; and the preparation method is simple and feasible, and is suitable for batch production.

Owner:JINGANG NEW MATERIALS

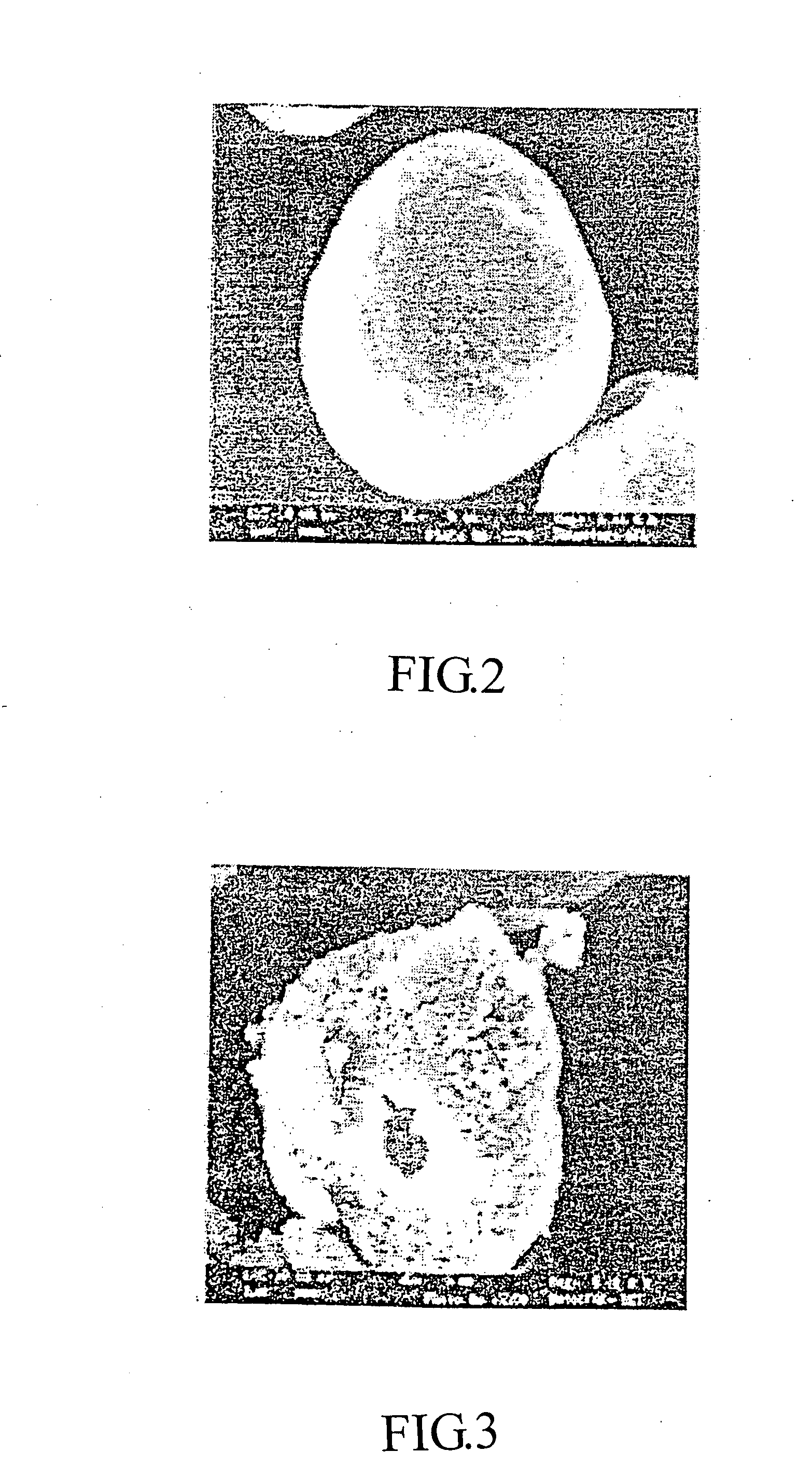

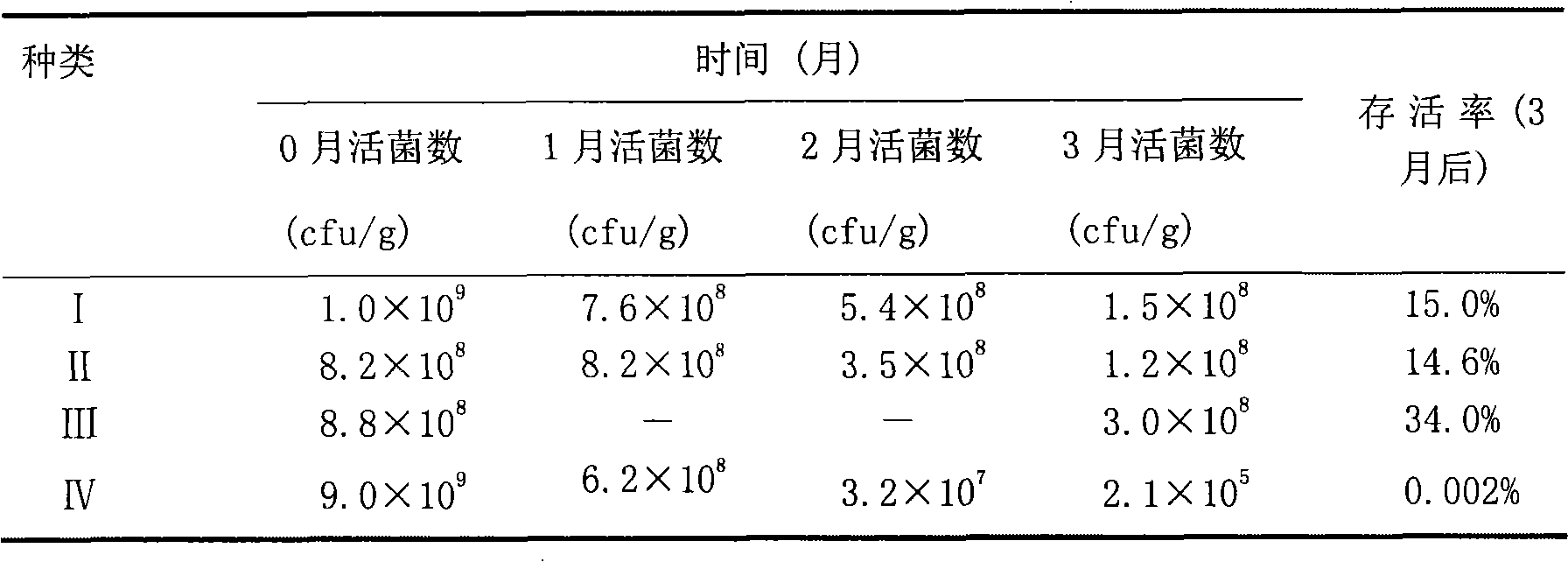

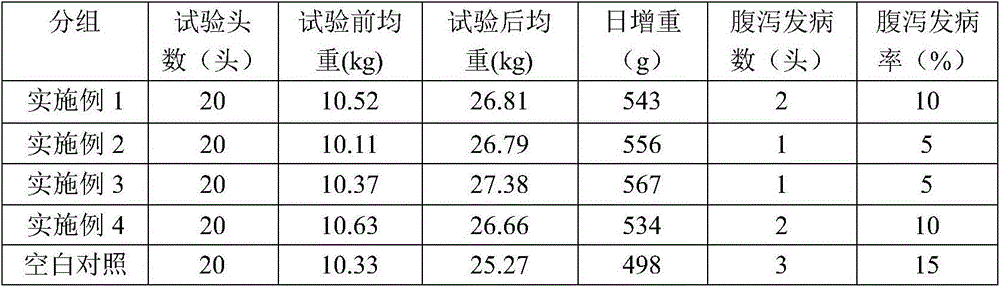

Probiotic composition having acid-resistant enteric coating

InactiveUS20070059296A1Improve digestibilityImproving resistance against diseaseOrganic active ingredientsBiocideBiotechnologyTalc

A probiotic composition essentially comprises 15 to 20 wt % of milk powder, 25 to 30 wt % of corn starch, 8 to 15 wt % of modified starch (capsul), 10 to 15 wt % of ethylcellulose, 5 to 15 wt % of bacterial broth, and 10 to 15 wt % of talc. The probiotic composition is microencapsulated to form a plurality of microencapsule coated with an acid-resistant enteric coating for improving the enteric acid-resistance, the probiotic survival rate, the antimicrobial property, the stability, the moisture-proof property, and the mobility of the probiotic composition preventing from coagulation in a moist environment and for being used as an additive applied to livestock feed.

Owner:BION TECH INC

Shale gas acid fracturing drag reducer and reparation method thereof

InactiveCN103694984AImprove acid resistanceImprove stabilityDrilling compositionEthylenediamineOil phase

The invention discloses a shale gas acid fracturing drag reducer and a reparation method of the shale gas acid fracturing drag reducer. The preparation method comprises the following steps: mixing monomer acrylic acid and 2-acrylamide-2 methyl propane sulfonic acid, dissolving in water, subsequently adding acrylamide, and finally adding ethylenediamine tetraacetic acid disodium to prepare into a water phase; mixing and dissolving a compounded surfactant with base oil to form an oil phase; performing inverse emulsion polymerization on the oil phase and the water phase to prepare the shale gas acid fracturing drag reducer. As a great amount of acid resistance monomers are introduced into the drag reducer, the acid resistance of the dreg reducer is greatly improved; the dreg reducer is milk white emulsion in appearance, is high in stability, non-ignitable, non-explosive, safe to transport and store, rapid to dissolve in water and free of fisheye; the requirements of continuous blending in shale gas acid fracturing can be met; the resistance reduction rate of a dreg reducer solution with the mass percentage of 0.2% can be greater than 70%.

Owner:SOUTHWEST PETROLEUM UNIV

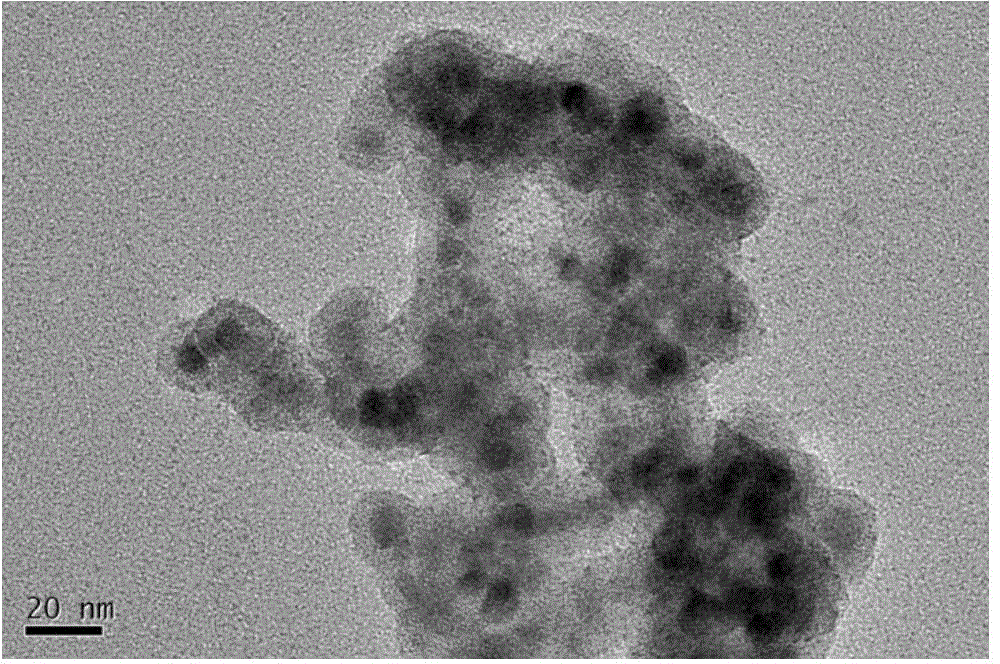

Method for preparing core-shell silicon dioxide coated nano calcium carbonate

InactiveCN101225245AImprove acid resistanceImprove qualityInorganic pigment treatmentCarbonizationHydrolysis

The invention provides a preparation method for core-shell type silicon dioxide-coated nanometer calcium carbonate, which comprises following steps: adding silicate in calcium carbonate suspension pulp; stirring and mixing using emulsion pump; introducing kiln gas with CO2 for carbonization until the pH is 6.5 to 7.0; heating to 60 to 90 DEG C; adding coating agent for coating treatment; the product is obtained after the coated pulp is filtered and the filter cake is dried. The preparation method for core-shell type silicon dioxide-coated nanometer calcium carbonate has the advantages of improving the acid resistance of nanometer calcium carbonate since silica sol precipitated through hydrolysis is coated on the surface of nanometer calcium carbonate, improving dispersion of the product in polymer due to surface treatment using coupling agent and organic acid, good acid resistance and dispersion, greatly improving physical and chemical properties, and felicitating industrial production with simple operation.

Owner:上海卓越纳米新材料股份有限公司

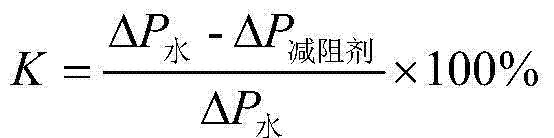

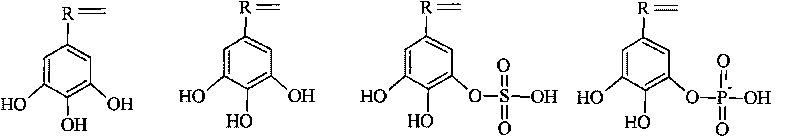

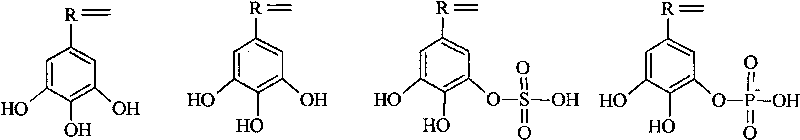

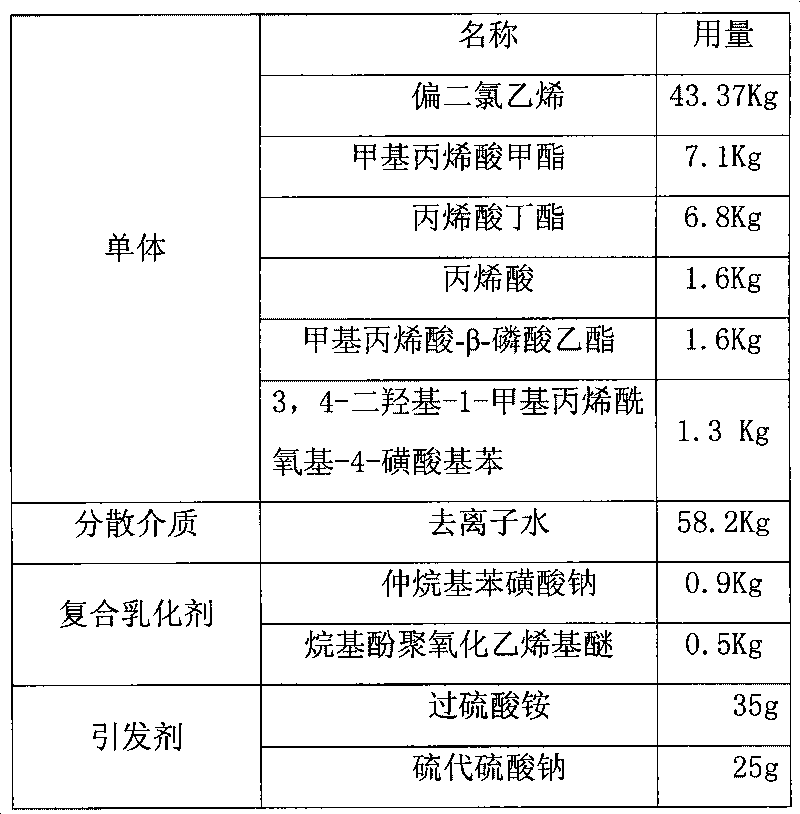

Waterborne rust conversion polymer emulsion, coating thereof and method for preparing same

The invention discloses a waterborne rust conversion polymer emulsion. The waterborne rust conversion polymer emulsion is prepared by the polyreaction of alkenyl halide monomers, monomers of (methyl)acrylic acid and esters of (methyl)acrylic acid, alkene phosphate ester monomers, a complexing agent, a compound emulsifying agent, an initiator and deionized water in an inert atmosphere at a pressure of 0.08 to 0.12MPa and a temperature of between 50 and 60 DEG C; and the percentages of dosages of all components on the basis of the total weight of all polyreaction monomers are: 75.0 to 95.0 percent of alkenyl halide monomers, 1.0 to 5.0 percent of alkene phosphate ester monomers, 5.0 to 10.0 percent of monomers of (methyl)acrylic acid and esters of (methyl)acrylic acid, 0.05 to 0.5 percent of initiator, 2 to 4 percent of compound emulsifying agent, 1.0 to 10.0 percent of complexing agent and 100 to 120 percent of deionized water. The coating prepared by the emulsion has the characteristics of good adhesive force, strong covering force, good stability, acid resistance, alkali resistance, salt spray corrosion resistance and long service life, and can be directly coated on the surfaces of metallic materials with a tight rusty layer without the rust removal treatment; and in a film-forming process, no volatile organic compounds are discharged, so that the coating of the invention is a green environmentally protected antirust coating.

Owner:深圳海润德添加剂有限公司

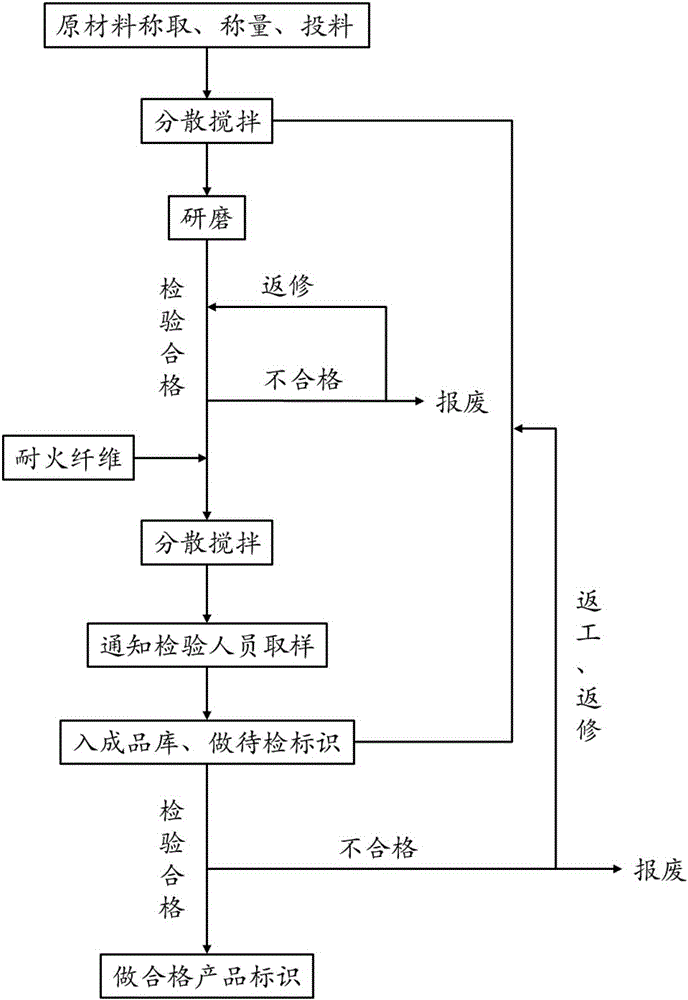

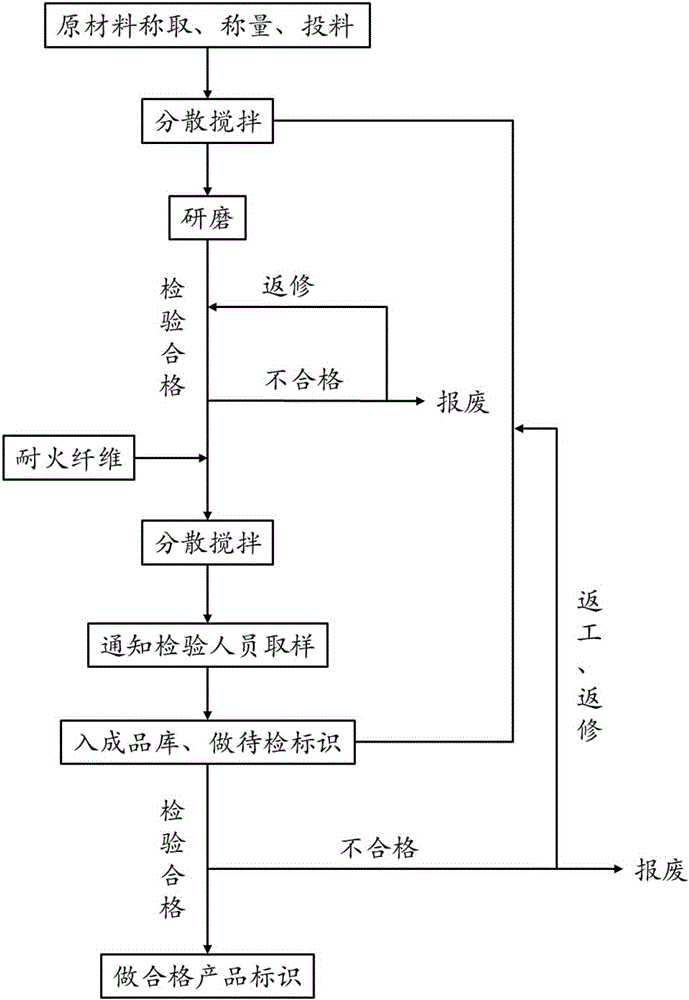

Environment-friendly epoxy intumescent fire-retardant coating and preparing method thereof

ActiveCN105238222AImprove acid resistanceGood alkali resistanceFireproof paintsEpoxy resin coatingsFiberAlkylphenol

The invention relates to an environment-friendly epoxy intumescent fire-retardant coating and a preparing method thereof, and belongs to the field of functional coatings. The environment-friendly epoxy intumescent fire-retardant coating is prepared from a component A and a component B, wherein the component A uses epoxy resin as a main film forming matter and is added with a reactive diluent, a catalyst, a carbon-forming agent, a foaming agent, fire retardant, auxiliaries and solvent, and the component B is composed of a curing agent, a curing accelerator, pigment filler, auxiliaries, refractory fibers and solvent. In the component A, the ratio of the epoxy resin to the reactive diluent is 1:1-5:1. In the component B, the ratio of the curing agent to the curing accelerator is 1:1-5:1, and the usage quantity of the refractory fibers accounts for 5-50% of the total mass. The environment-friendly epoxy intumescent fire-retardant coating is free of alkylphenol, or halogen compounds, or boron compounds or sulfocompounds. The prepared environment-friendly epoxy intumescent fire-retardant coating is good in acid resistance, alkali resistance, water resistance, ageing resistance and salt mist resistance and is particularly suitable for fire-retardant protection for maritime and severe outdoor environments, the petrochemical industry and places with hydrocarbon fire potential hazards.

Owner:MARINE CHEM RES INST

Glass compositions with improved chemical and mechanical durability

ActiveUS20130101766A1Record information storageLight beam reproducingAlkali metal oxideAlkaline earth oxides

The embodiments described herein relate to chemically and mechanically durable glass compositions and glass articles formed from the same. In another embodiment, a glass composition may include from about 70 mol. % to about 80 mol. % SiO2; from about 3 mol. % to about 13 mol. % alkaline earth oxide; X mol. % Al2O3; and Y mol. % alkali oxide. The alkali oxide may include Na2O in an amount greater than about 8 mol. %. A ratio of Y:X may be greater than 1 and the glass composition may be free of boron and compounds of boron. In some embodiments, the glass composition may also be free of phosphorous and compounds of phosphorous. Glass articles formed from the glass composition may have at least a class S3 acid resistance according to DIN 12116, at least a class A2 base resistance according to ISO 695, and a type HGA1 hydrolytic resistance according to ISO 720.

Owner:CORNING INC

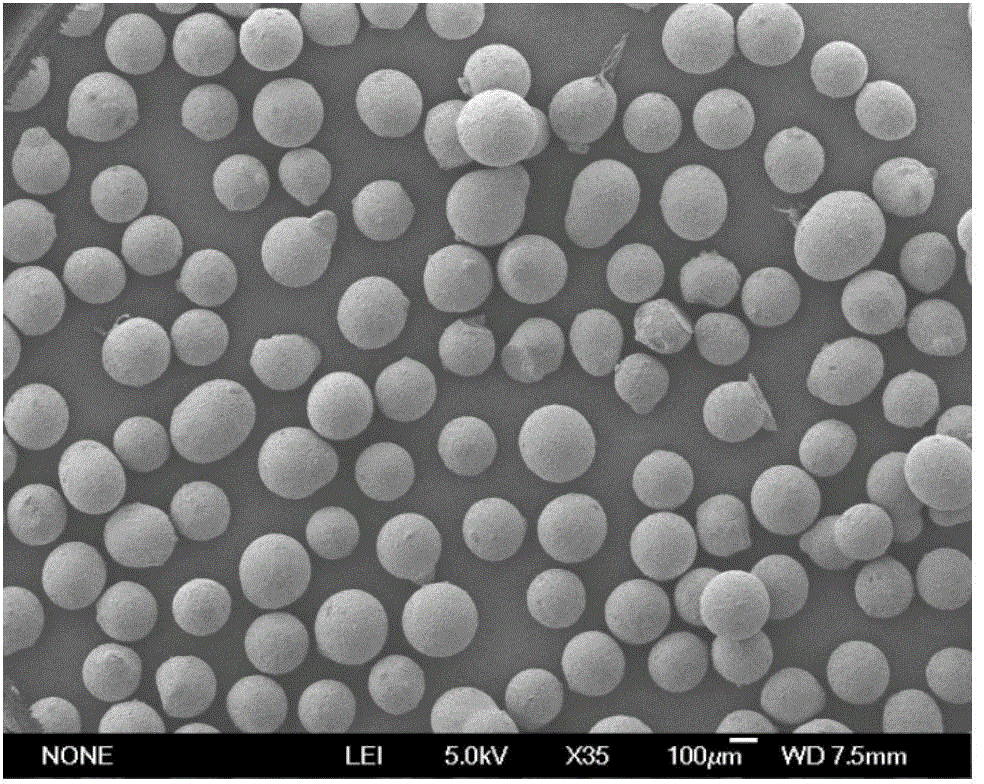

Acid-resistant magnetic chitosan microspheres as well as preparation method and application thereof

InactiveCN104437395AImprove acid resistanceHigh amino contentOther chemical processesWater contaminantsMicrosphereHydrolysis

The invention relates to an acid-resistant magnetic chitosan microsphere adsorbent as well as a preparation method and the application thereof, and in particular relates to acid-resistant magnetic chitosan microspheres which have the excellent absorption performance and recycling performance for acid waste water containing hexavalent chromium, a preparation method of the acid-resistant magnetic chitosan microspheres and the application of the acid-resistant magnetic chitosan microspheres. The preparation method of the acid-resistant magnetic chitosan microspheres comprises the following steps: (1) preparing Fe3O4 nano-particles modified by citric acid by using a coprecipitation method; (2) preparing single-coated magnetic SiO2 nano-particles by using a sodium silicate hydrolysis method or a sol-gel method; and (3) preparing the chitosan microspheres coated with magnetic SiO2 by taking chitosan powder as a raw material by adopting an emulsion crosslinking method. Furthermore, in order to further improve the adsorbing capacity of the microspheres, in the method, dendritic polyethylene imine is taken as a functional group for modifying the adsorbent, so that the modified chitosan microspheres can be obtained. The magnetic chitosan microspheres prepared by adopting the method not only have the excellent acid resistance, but also have the good absorption performance on Cr (VI) ions.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Polymer electrolyte fuel-cell separator sealing rubber composition

InactiveUS6875534B2Long-term serviceImprove permeabilitySpecial tyresCell component detailsFuel cellsWeather resistance

A rubber composition comprising (A) a polyisobutylene polymer having an allyl radical at an end, (B) an optional organpolysiloxane, (C) an organohydrogenpolysiloxane having at least two SiH radicals per molecule, and (D) a platinum group metal catalyst forms a seal member on a periphery of one side of a polymer electrolyte fuel-cell separator. Due to improved acid resistance, weather resistance, creep resistance and gas permeability, the seal member remains effective for a long period of time.

Owner:SHIN ETSU CHEM IND CO LTD

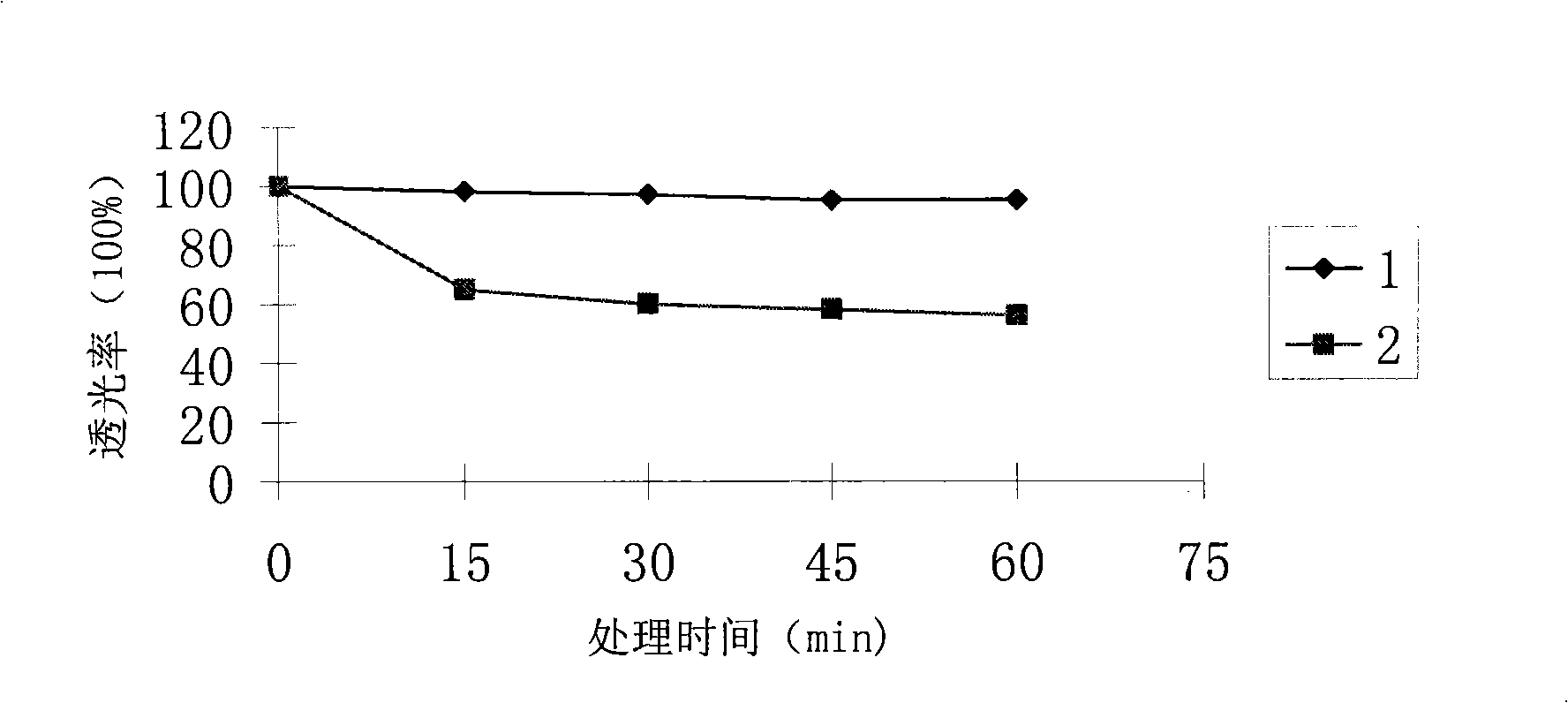

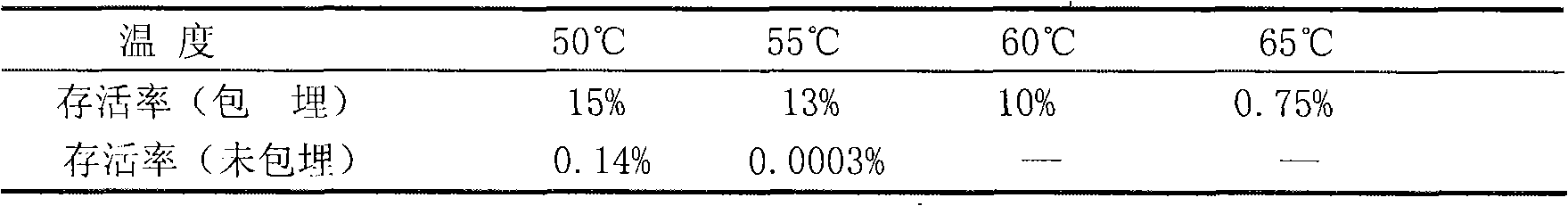

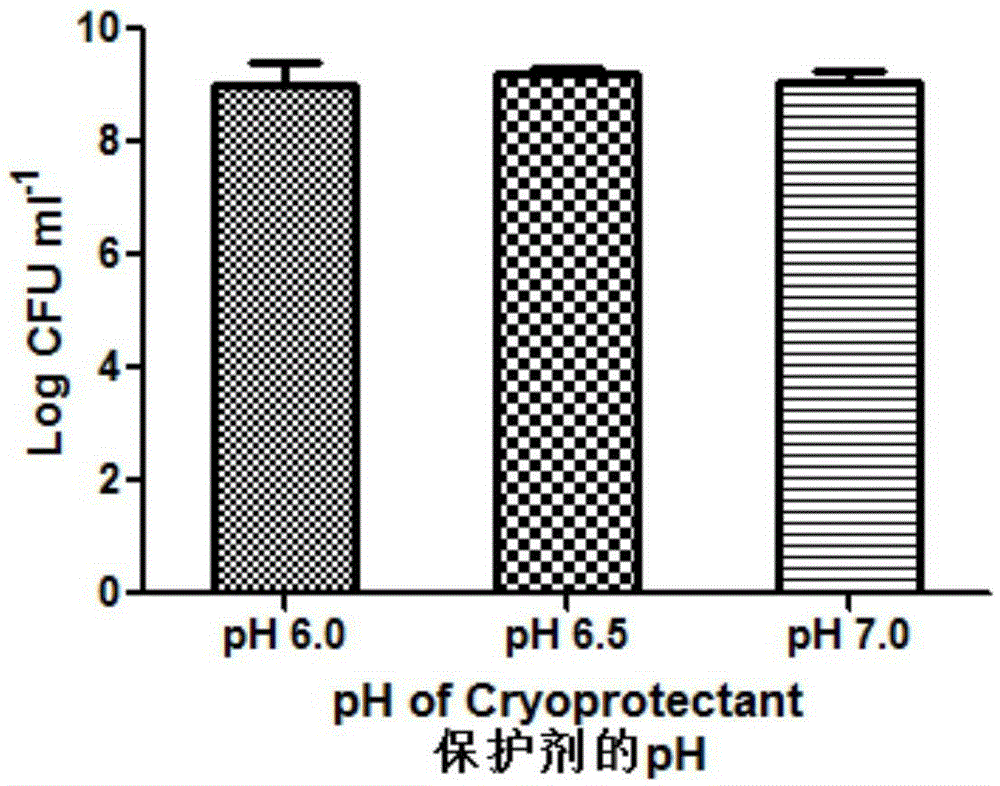

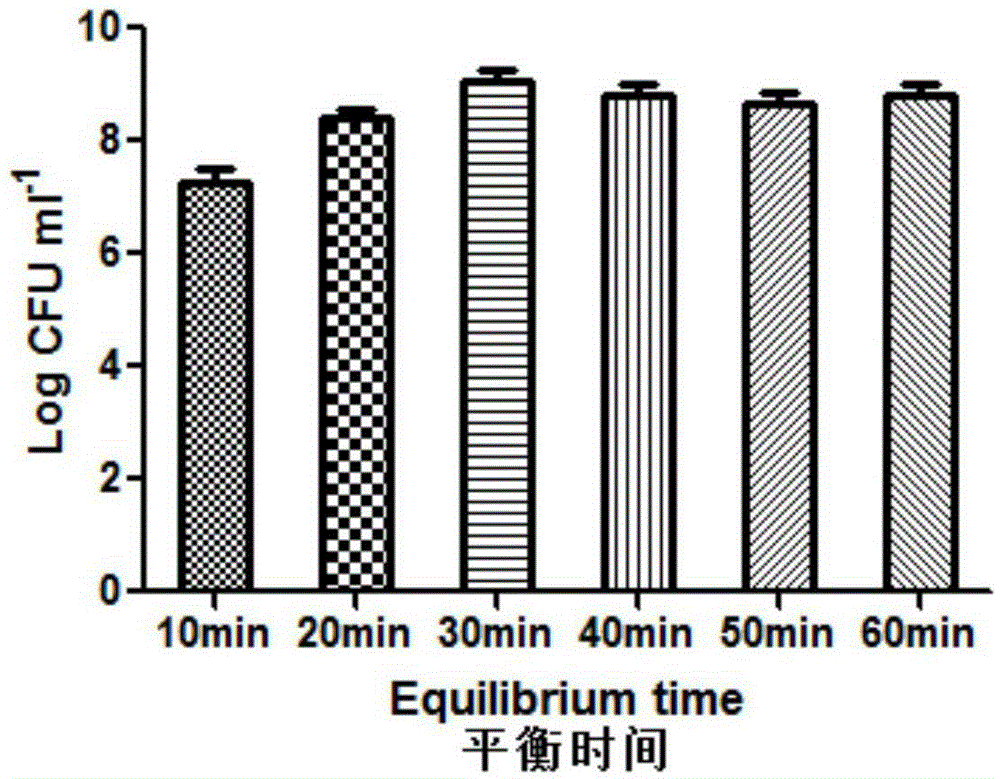

Lactobacillus helveticus microcapsule, preparation and use thereof

InactiveCN101323850AOvercoming the problem of low survival rate of freeze-dryingImprove efficiencyMilk preparationMetabolism disorderFreeze-dryingDietary supplement

The invention provides a lactobacillus helveticus microcapsule as well as the preparation and application thereof, pertaining to the embedding technology of lactobacillus helveticus and aiming at microencapsulating the lactobacillus helveticus so as to solve the problems of low embedding efficiency and embedding yield in single-layer or double-layer embedment. The technical proposal adopted by the invention is that isolated soy protein, microporous starch and sodium alginate are respectively taken as the first, the second and the third layers of wall materials for microencapsulation; the three-layer embedment is carried out to the lactobacillus helveticus for the first time, wherein, in the process of preparing bacterial suspension, an orthogonal optimization protective agent is adopted to improve the livability after freeze drying. The microcapsule of the invention has strong heat resistance and acid resistance, solves the inactivation problem caused by gastric acid, digestive enzyme and antibiotic, etc. to active bacillus, is capable of releasing when reaching large intestine, and balances intestinal flora. The reusability of fermented milk is good. The lactobacillus helveticus used by the invention enriches the variety of probiotic bacteria microcapsule and is a good dietary supplement.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Efficient probiotics microcapsule as well as preparation method and application thereof

The invention discloses an efficient probiotics microcapsule which comprises a core material and a wall material, wherein the core material comprises 90-95wt% of probiotics and 5-10wt% of a protector; the wall material is of a double-layer structure, wherein the inner layer is made from sodium alginate and the outer layer is made from whey protein or gelatin. The invention also discloses a preparation method and application of the efficient probiotics microcapsule. The microcapsule is coated by double layers of the sodium alginate and the gelatin or whey protein, so that the acid resistance, cholate resistance and storage resistance of the probiotics are improved. The microcapsule disclosed by the invention is added into the feed, so that the host intestinal microenvironment equilibrium can be regulated, the harmful bacteria can be restrained and the disease resistance of the host can be improved.

Owner:NANJING YOUFAN BIOTECH

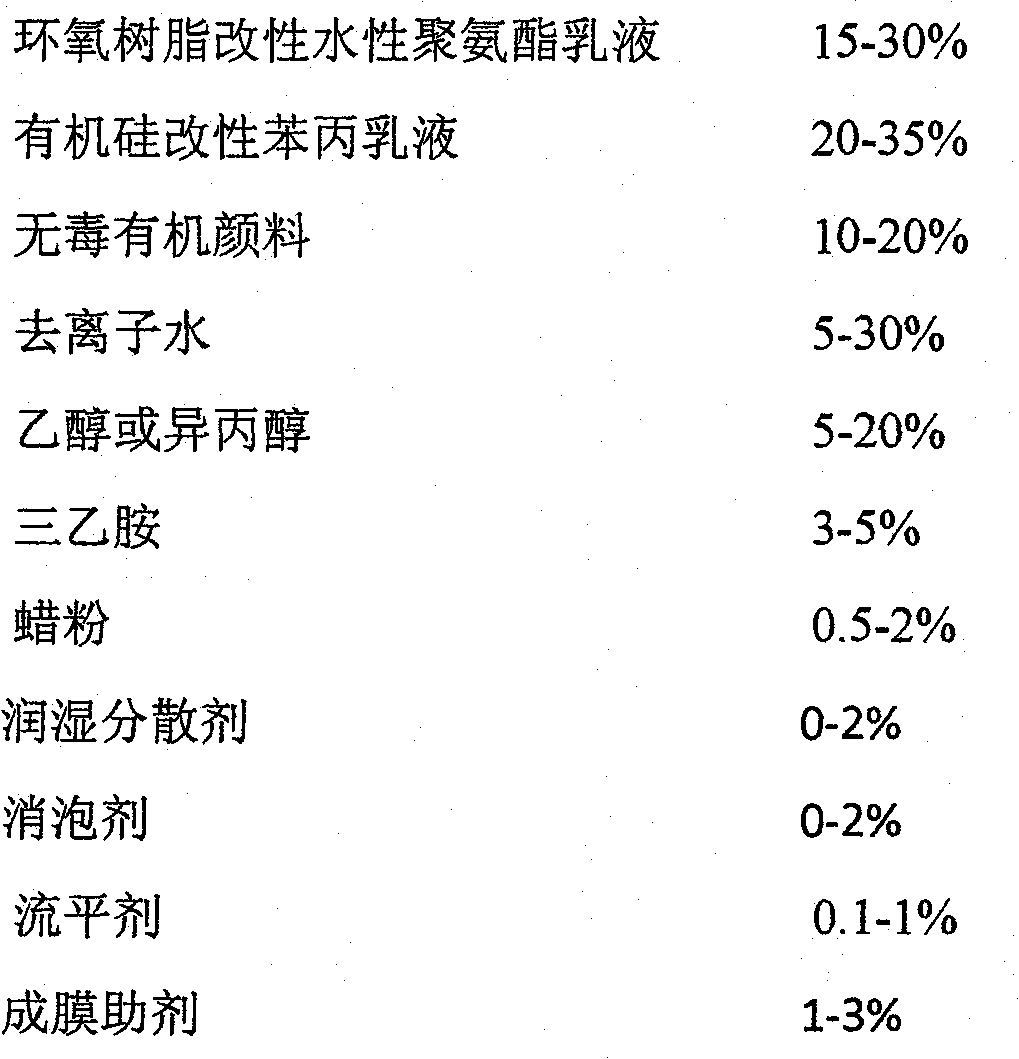

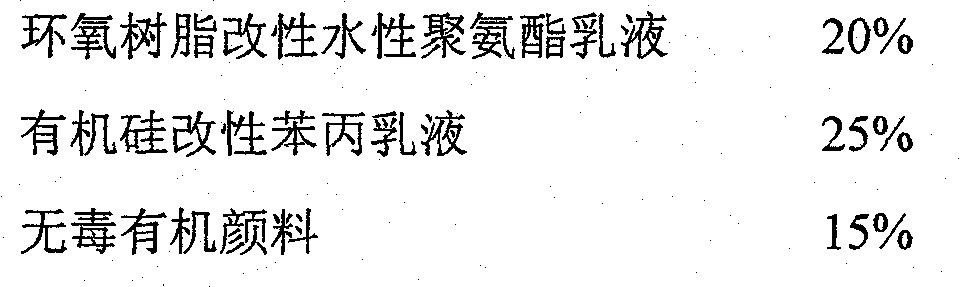

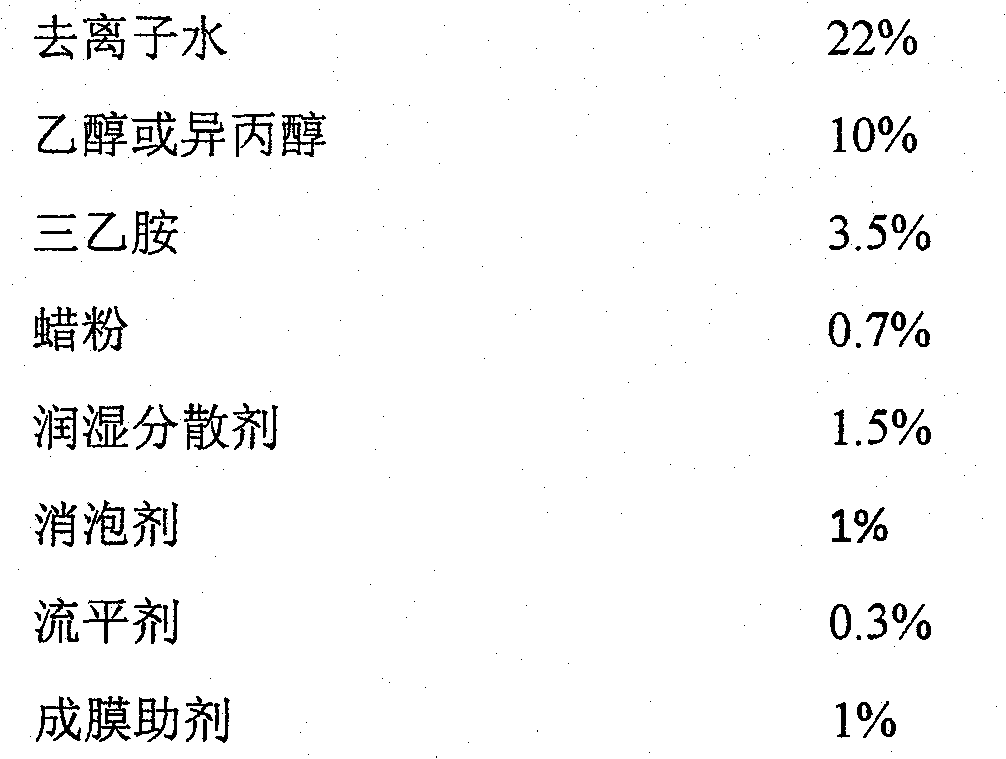

Water-based ink for plastic printing and preparation method thereof

The invention discloses a water-based ink for plastic printing and a preparation method thereof. The water-based ink is prepared by using epoxy resin modified water-based polyurethane emulsion and organic silicon modified styrene-acrylic emulsion as base materials and using deionized water and alcohol as solvents. The water-based ink comprises the following components by weight percent: 15-30% of epoxy resin modified water-based polyurethane emulsion, 20-35% of organic silicon modified styrene-acrylic emulsion, 10-20% of non-toxic organic pigment, 5-30% of deionized water, 5-20% of ethanol or isopropanol, 3-5% of triethylamine and 1.6-10% of additive. The water-based ink does not contain the volatile organic solvent, is incombustible, nonexplosible and non-toxic and has high attachment fastness on the plastic film and good printing effect; the ink has high chemical resistance, acid resistance and alkali resistance; and the ink has good water resistance, heat resistance, freezing resistance and oil resistance. The ink can be widely used in the packaging and printing of the industries such as grain, vegetables, alcohol and tobacco, and food; and the safety and non-toxicity of the ink can be ensured, and the ink is a green and environmentally-friendly product and has considerable market potential.

Owner:哈尔滨绿科科技有限公司

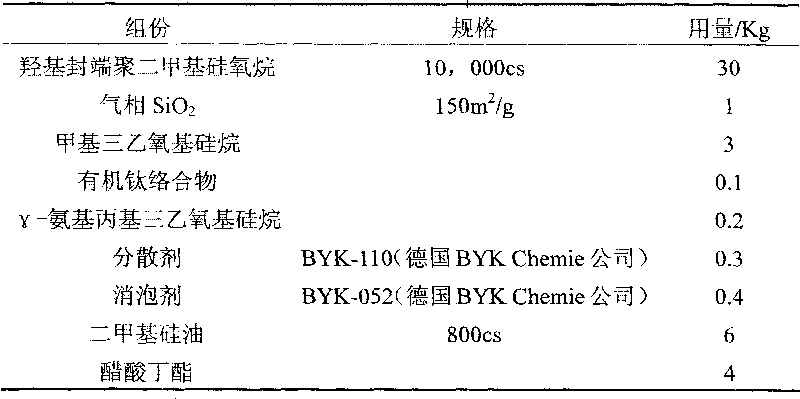

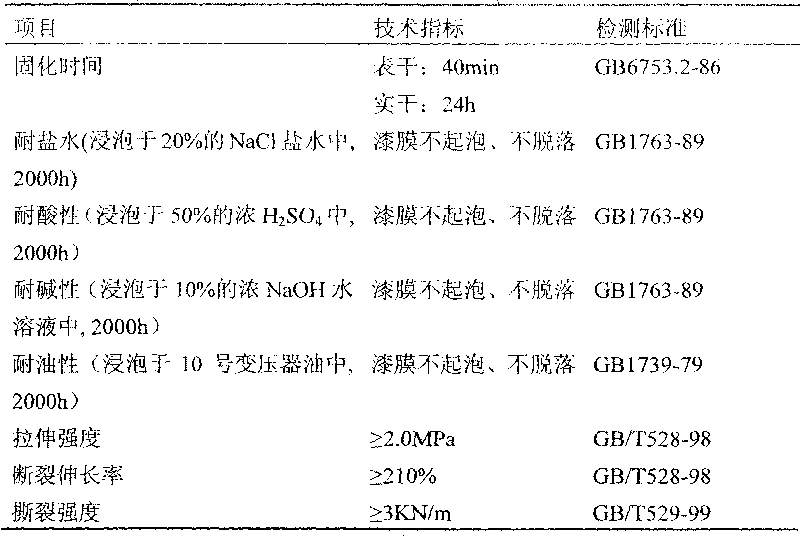

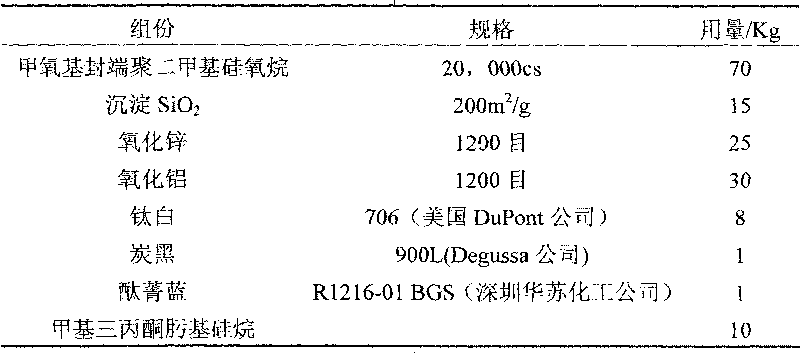

Elastic anti-corrosion coating

InactiveCN101747835AGood weather resistanceImprove water resistanceAnti-corrosive paintsRoom temperatureSolvent

The invention relates to an elastic anti-corrosion coating, which is a room-temperature silicon sulfide-based functional compound with high property. The formula of the coating comprises(in part by weight): 30 to 70 parts of polyorganosiloxane, 1 to 80 parts of pigments and fillers, 30 to 10 parts of crosslinking agent, 1 to 10 parts of auxiliary agent and 10 to 80 parts of thinning agent. The elastic anti-corrosion coating has high weathering resistance, water resistance, acid resistance, solvent resistance and oil resistance and alkali resistance; the paint film can be desirably adhered onto glass, ceramics, steel structural members, concrete, various resin primers and the like, and the paint film is good in elasticity and hydrophobicity and high in tensile strength and breaking elongation, can be widely used for the corrosion prevention of bridges, tanks and various steel structural members and the corrosion and leakage protection of ground, drainage channels and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

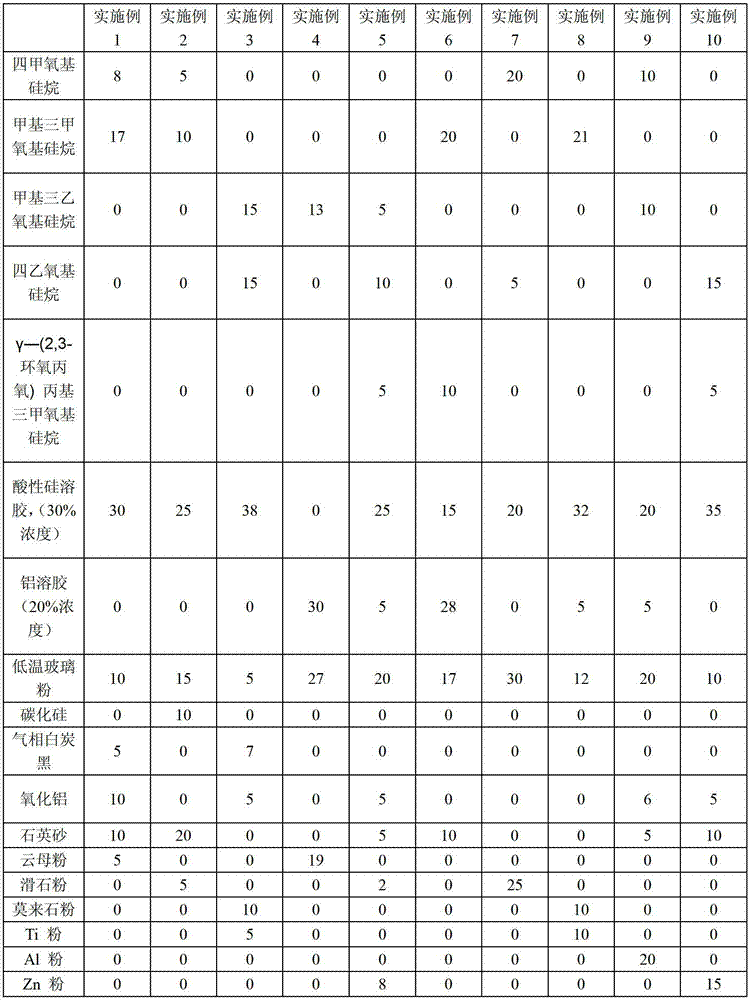

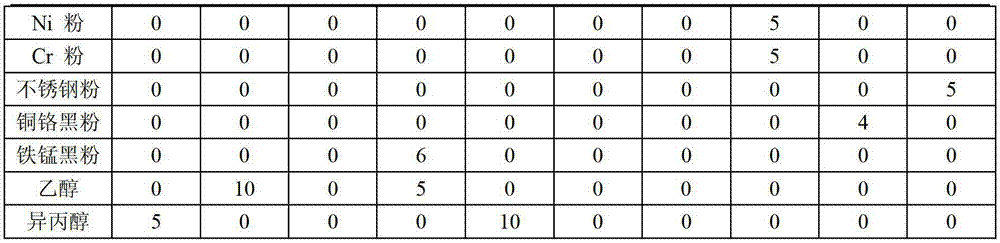

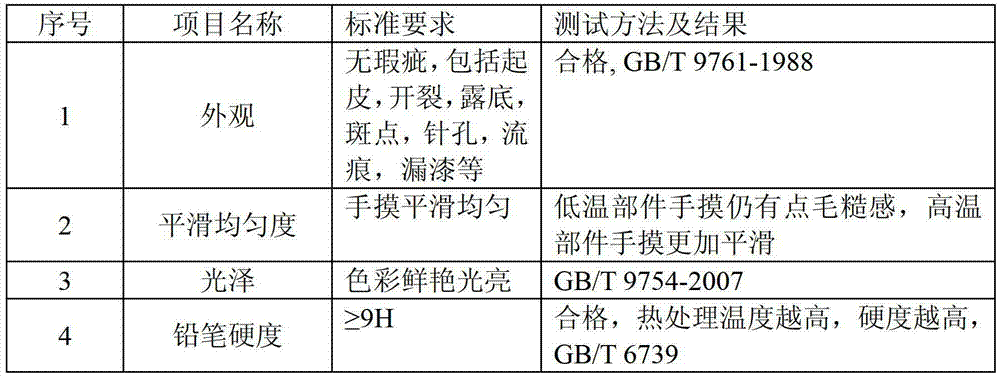

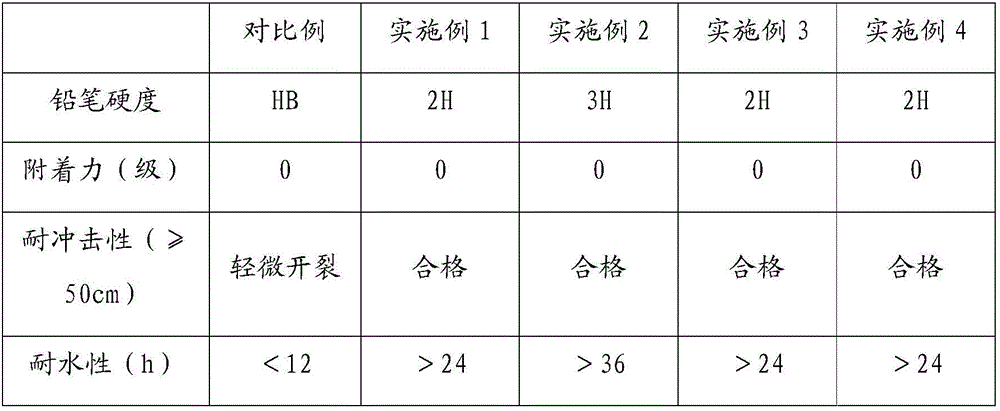

High temperature resistant coating for engine exhaust system

The invention relates to a high temperature resistant coating for an engine exhaust system. The high temperature resistant coating is characterized by being prepared through at least one step by mixing the following raw materials in parts by weight: 10-80 parts of base materials, 10-80 parts of ceramic materials and 5-30 parts of low-temperature glass powder, wherein the base materials include 10-50 parts by weight of silicon sol and 0-30 parts by weight of aluminum sol; and the ceramic materials include at least one of quartz sand, aluminum oxide, silicon carbide, talcum powder, kaolin powder, mullite powder and mica powder.Compared with an organic silicon coating, the high temperature resistant coating disclosed by the invention has better high temperature resistance because the silicon sol or the mixture of the silicon sol and the aluminum sol is used as the base material in the raw materials; the high temperature resistant coating disclosed by the invention is compact in structure, can be used at a temperature higher than 600 DEG C, has the advantages of anti-corrosive properties, namely salt-fog resistance, acid resistance, and the like, higher rigidity and abrasion resistance because various raw materials are mixed in appropriate proportion and synergistically play a role; and the high temperature resistant coating is matched with an engine material in thermal expansion coefficient, has good temperature and denaturalization resistance and is particularly suitable for engine anticorrosion.

Owner:SUZHOU NANODISPERSIONS

Preparation method of nano-silicon-dioxide-modified water-based polyurethane

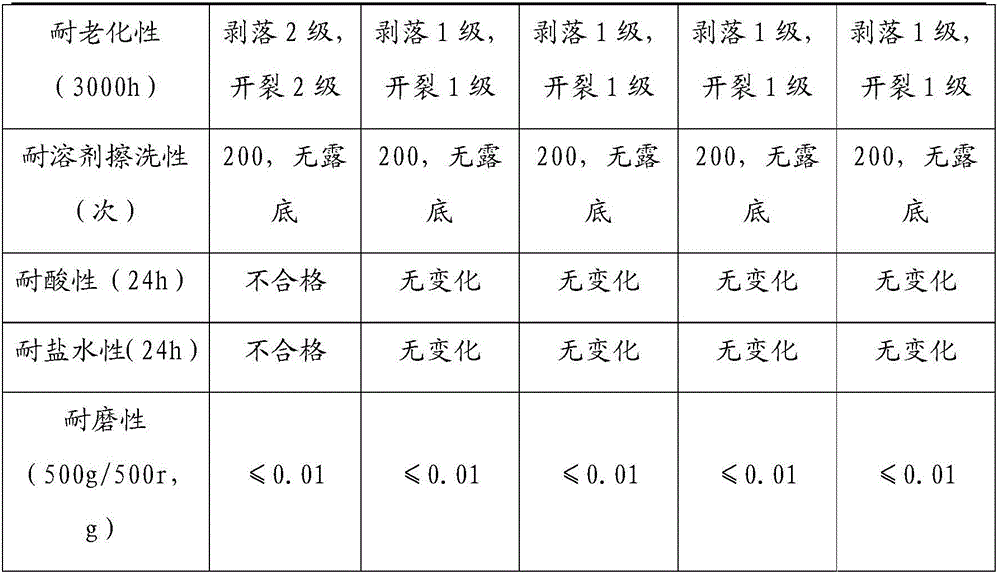

The invention discloses a preparation method of nano-silicon-dioxide-modified water-based polyurethane. The method comprises the following steps: (1) preparing a water-based polyurethane prepolymer by a conventional process; (2) silane-coupling-agent-modified nano silica sol: diluting nano silica sol with a small amount of isopropanol, mixing with a silane coupling agent, and stirring to react at normal temperature for 30 minutes, thereby obtaining the silane-coupling-agent-modified nano silica sol; and (3) adding the water-based polyurethane prepolymer obtained in the step (1) into the silane-coupling-agent-modified nano silica sol obtained in the step (2), adding deionized water and a small-molecule amine chain extender, carrying out high-speed shear emulsification and dispersion at normal temperature for 15-30 minutes, and carrying out reduced pressure distillation to remove the solvent, thereby obtaining the nano-silicon-dioxide-modified water-based polyurethane. The film formed by the resin prepared by the method has excellent hardness, adhesion, impact resistance, water resistance, aging resistance, solvent scrubbing resistance, acid resistance, saline water resistance, wear resistance and the like.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

Antibacterial property imparting glass composition

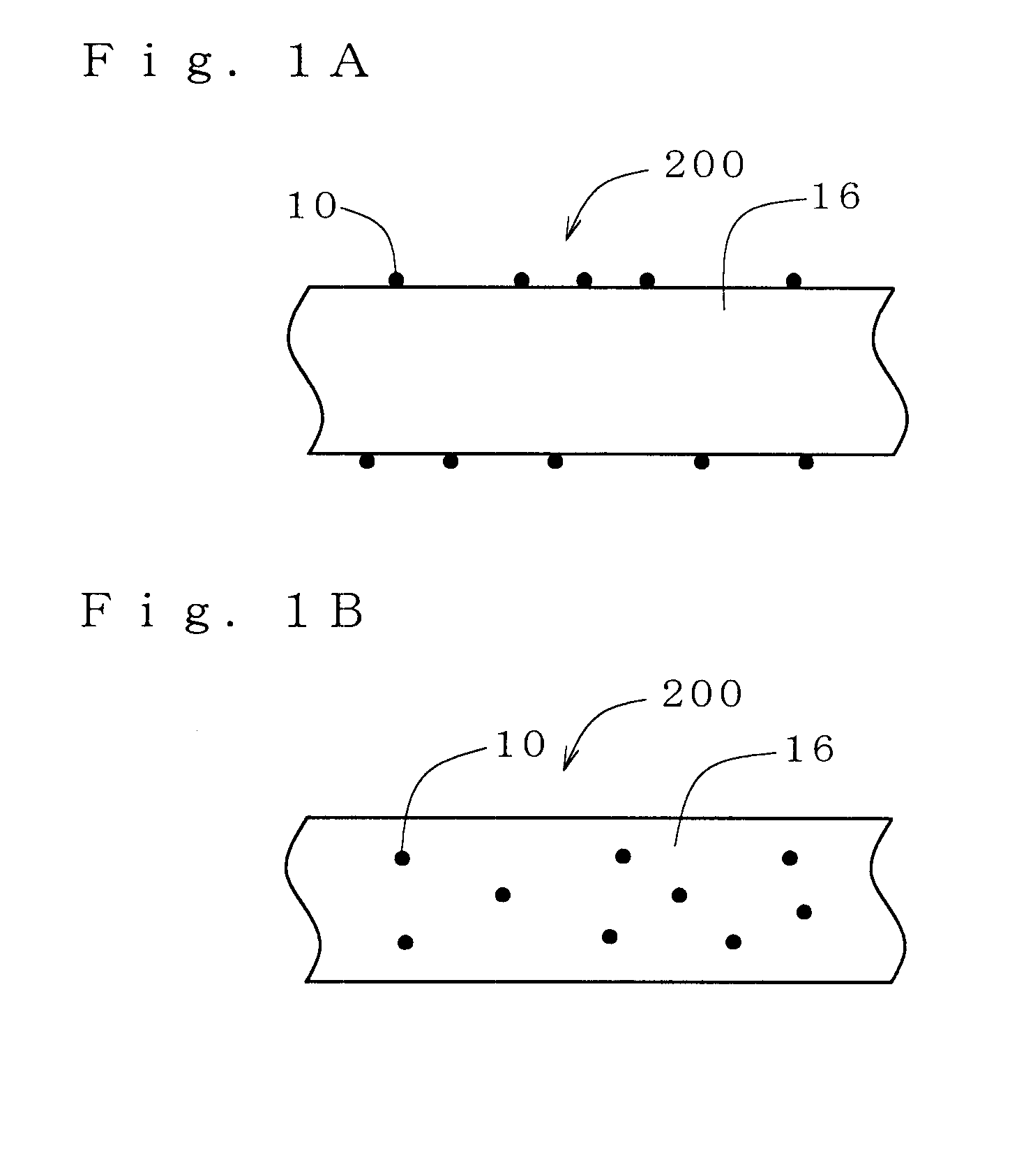

An antibacterial property imparting glass composition is provided, which may be fixed in a form of, for example, a particle on the surface of a fiber substrate and / or dispersed and complexed in the fiber substrate. Such an antibacterial property imparting glass composition comprises 0.1 to 5.0% by weight of Ag2O in a composition containing 45-67 mol % of P2O5, 5 to 20 mol % of Al2O3, 1 to 40 mol % of 1 or 2 or more selected from MgO, CaO and ZnO, and 20 mol % or less of B2O3. An antibacterial fiber containing such an antibacterial property imparting glass composition at a ratio of, for example, 0.1 to 5.0% by weight shows high water resistance, acid resistance, alkali resistance and detergent resistance in antibacterial property.

Owner:ISHIZUKA GARASU

Thermosetting paint composition

PCT No. PCT / EP96 / 05160 Sec. 371 Date Jul. 21, 1998 Sec. 102(e) Date Jul. 21, 1998 PCT Filed Nov. 22, 1995 PCT Pub. No. WO97 / 22672 PCT Pub. Date Jun. 26, 1997To offer thermosetting paint compositions resistant to yellowing to brass, which give paint films of excellent resistance to yellowing due to brass, low-temperature curability, weather resistance, resistance to yellowing after stoving, acid resistance, scratch resistance, solvent resistance, adhesion and appearance. Thermosetting paint compositions, which are thermosetting paint compositions which are resistant to yellowing due to brass, characterized in that the paint-film-forming components include (A) a compound which has per molecule at least 2 functional groups which can react with an isocyanate group, at 49.6-90 wt %, (B) a blocked isocyanate which has par molecule at least 2 isocyanate groups blocked by an azole blocking agent, at 9.6-50 wt %, (C) an ultraviolet absorber and / or free radical scavenger, at 0.2-5 wt %, (D) an organotin compound at 0.1-3 wt %, and (E) an amino resin at 0.1-30 wt %.

Owner:BASF COATINGS AG

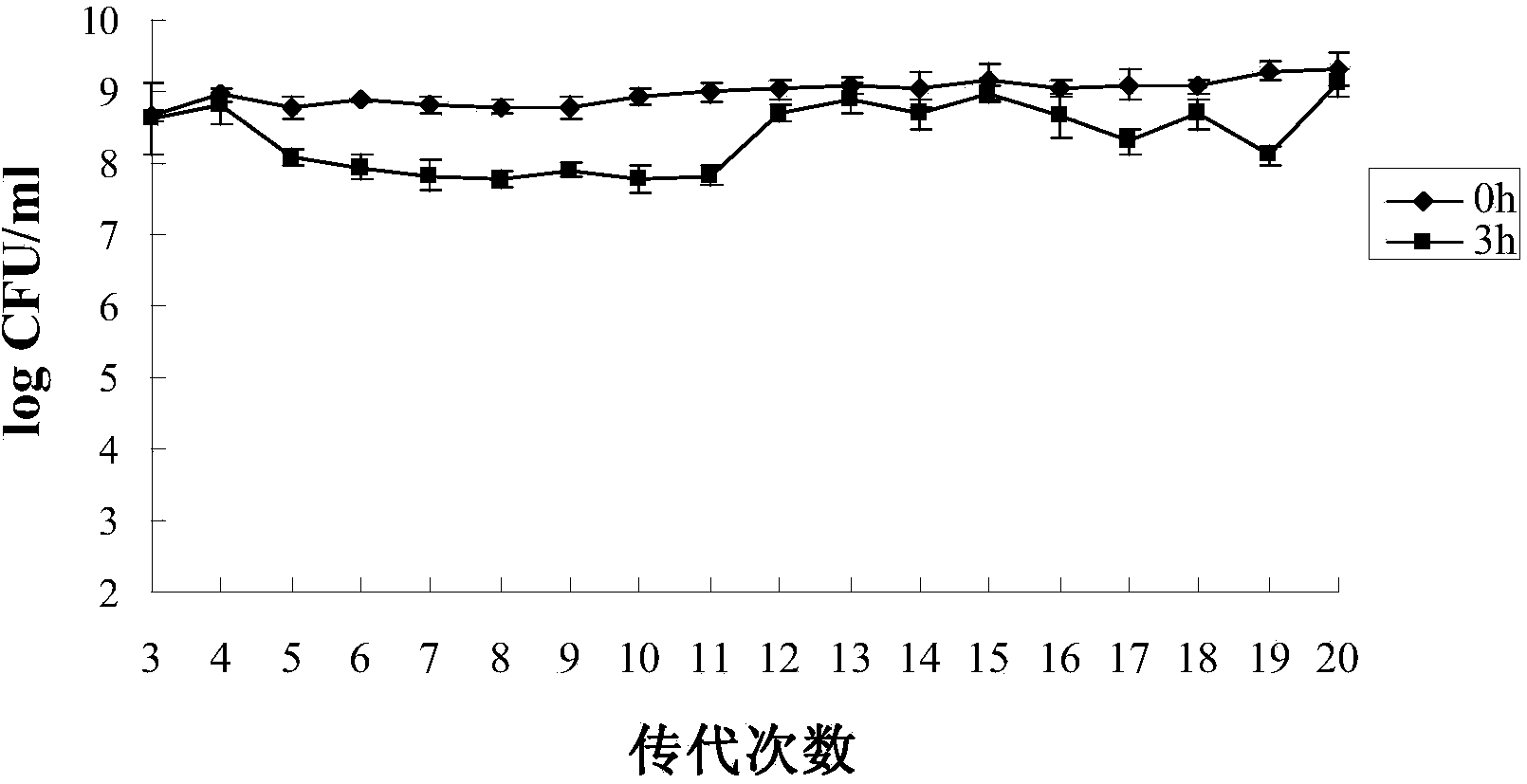

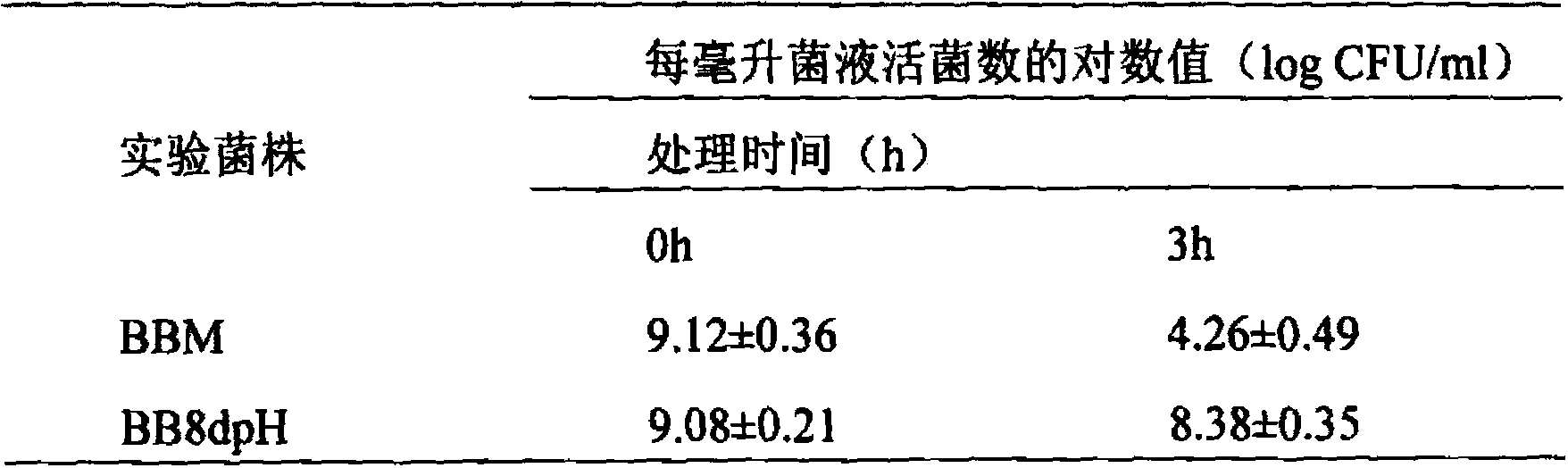

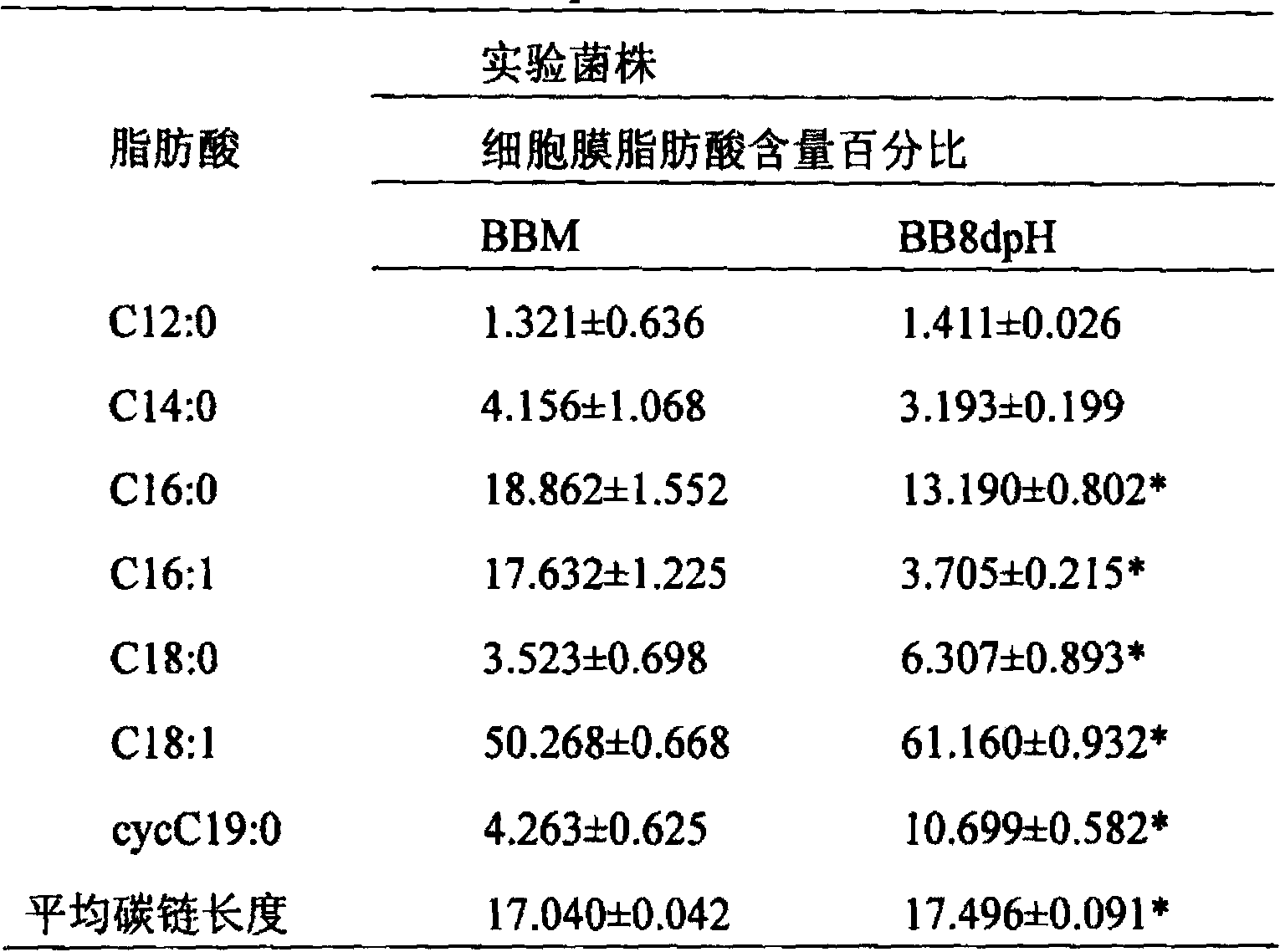

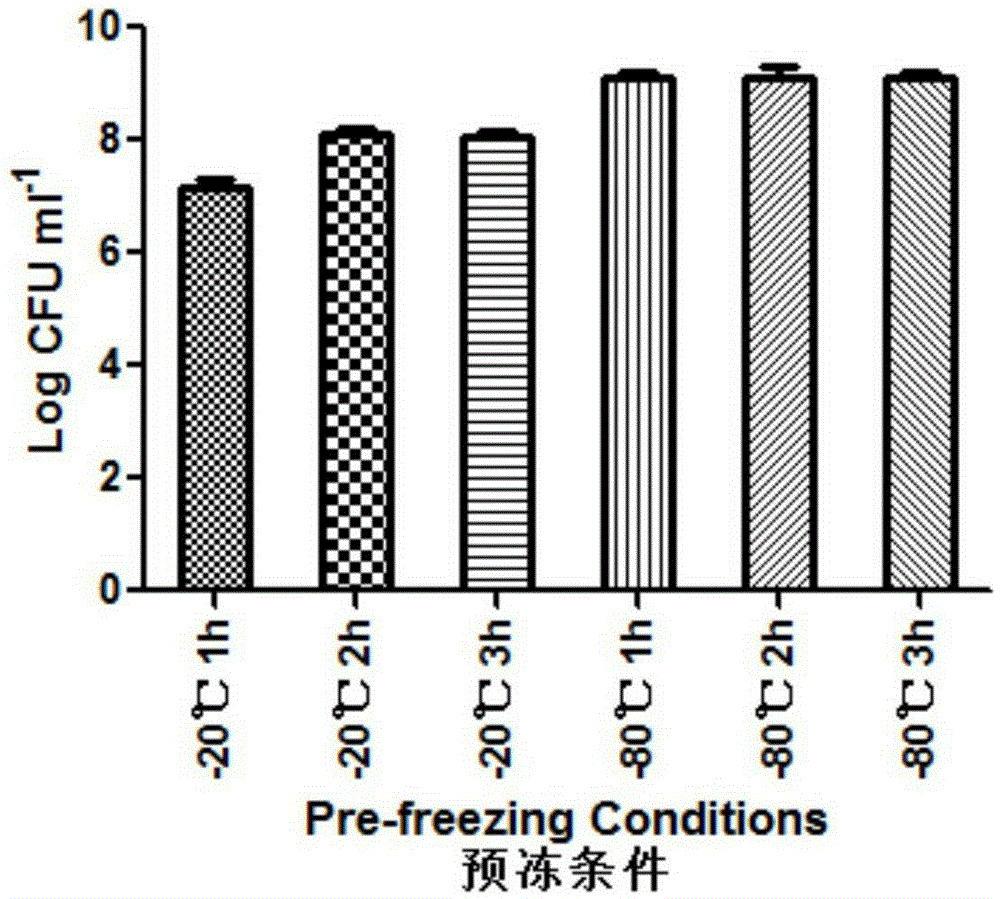

Acid-resistant bifidobacterium breve BB8dpH and application thereof

InactiveCN103849590AExcellent acid resistanceGenetically stableBacteriaMicroorganism based processesFecesCell membrane

The invention provides an acid-resistant bifidobacterium breve BB8dpH and an application thereof. The nucleotide sequence of the 16SrRNA gene part of the bifidobacterium breve BB8dpH is shown in SEQ ID NO.1, and is stored with the preservation number of CGMCCNo.8370. The bifidobacterium breve BB8dpH is a strain obtained by separating from the dejecta of healthy young people and further screening under the pH 3.2 acid condition. According to the fermentation and culturing process, anaerobic culture at 37 DEG C is carried out in a BL liquid substrate (containing 0.05% cysteine hydrochloride) for 24 hours. The bifidobacterium breve BB8dpH has remarkably better acid resistance than the common strains, and the acid resistance has genetic stability; the bifidobacterium breve BB8dpH has different percent contents of cell membrane fatty acids from the common strains, the average carbon chain length of the bifidobacterium breve BB8dpH is remarkably longer than that of the common strains, and the cell membrane fluidity of the bifidobacterium breve BB8dpH is remarkably lower than that of the common strains; and the bifidobacterium breve BB8dpH is used in the production field of daily fermented food, health-care food and medicines.

Owner:SHANGHAI JIAO TONG UNIV

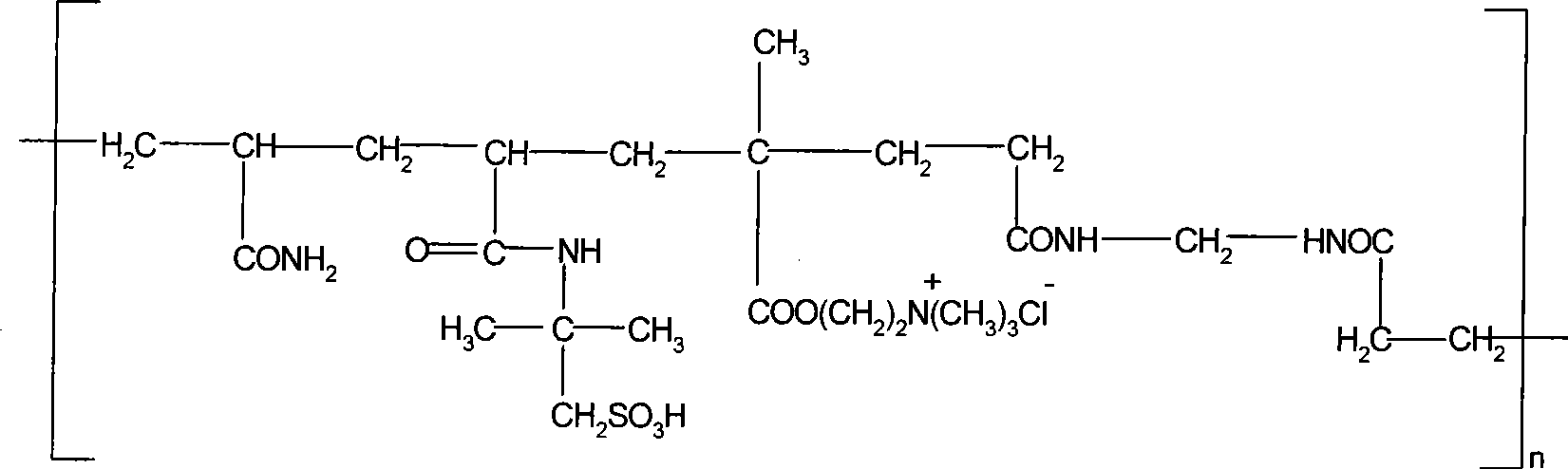

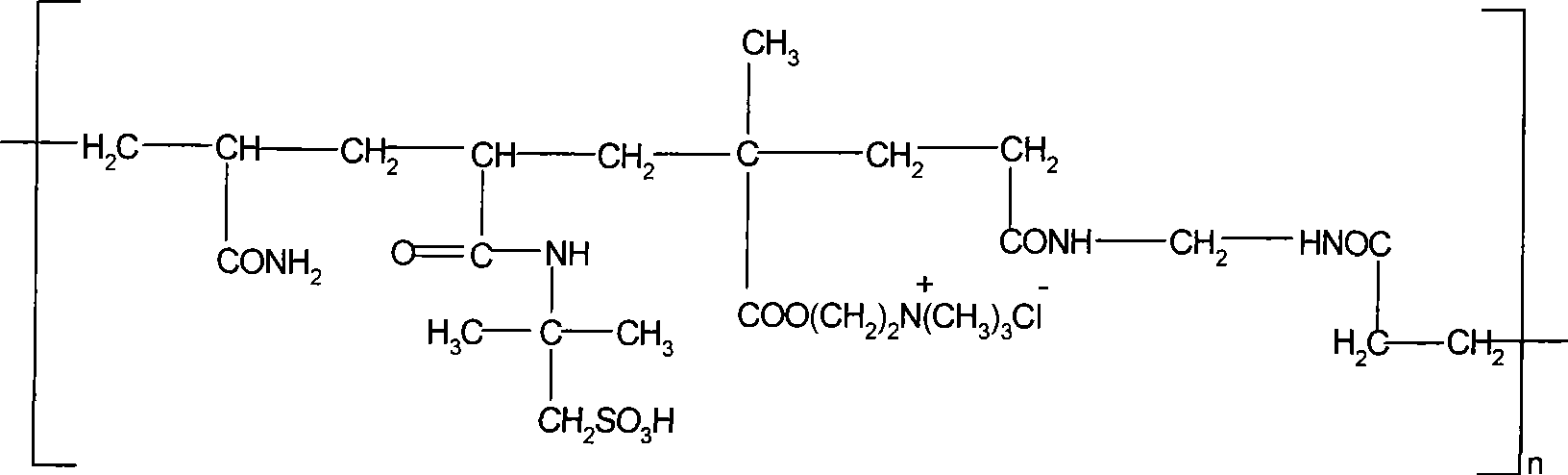

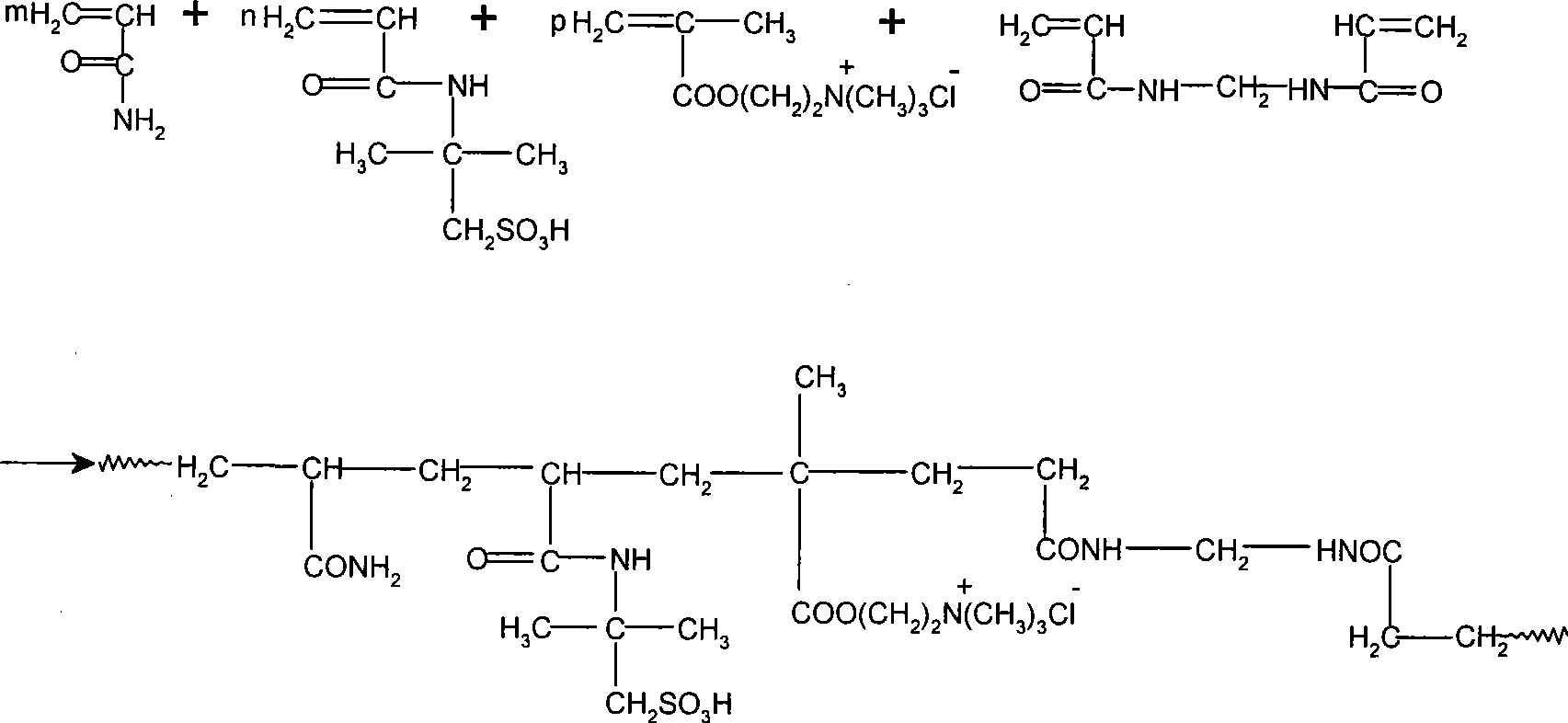

Acid fracturing thickening agent and preparation thereof

InactiveCN101412906AHigh viscosityImprove high temperature resistanceDrilling compositionTemperature resistancePetroleum

The invention discloses a novel acidified fractured thickening agent and a preparation method thereof, and belongs to the field of macromolecular synthesis. The thickening agent is prepared by the method comprising the following steps: adopting a water solution polymerizing method, oxidizing and reducing an evocating agent, adding proper amount of chain extender into a sealed system, and copolymerizing the mixture by the reaction of methacryloyloxy trimethyl-ammonium chloride (DMC), acrylamide (AM) and 2-acrylamido-2-methyl propane sulfonic acid (AMPS). The thickening agent has the advantages of acid resistance and high temperature resistance, has favorable thickening effect, and is applied to the fields of acidified fracturing construction, strengthening oil extraction work and the like in petroleum extraction.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

Inorganic powder capillary crystalline waterproof coating material

InactiveCN101362867AImprove impermeabilityImprove permeabilityAntifouling/underwater paintsPaints with biocidesWater reducerQuartz

The invention discloses an inorganic powder infiltration crystalline water-proof material which consists of 45 to 55 portions of 600#silicate cement, 20 to 25 portions of ultra-thin quartz sands, 25 to 30 portions of master batches, 1 to 5 portions of effective retarding water reducers and 1 to 5 portions of macromolecular tougheners and is manufactured by feeding the materials into a stirrer to be uniformly stirred. The inorganic powder infiltration crystalline water-proof material is characterized by having the advantages of secondary anti-permeability capacity, durable water-proof performance, high sticking performance, acid resistance and alkali matter resistance; besides, the inorganic powder infiltration crystalline water-proof material have the capacity of growing an insoluble crystal in the pores and the micro cracks of a concrete substrate to plug the pores and the micro cracks, thereby improving the anti-permeability capacity of the concrete and achieving the goals of anti-permeability and anti-leakage. The inorganic powder infiltration crystalline water-proof material can be broadly applied to the water-proof projects of railways, roads, ports and docks, culverts, dams and pools as well as large underground projects.

Owner:天津市耀新科技发展有限公司

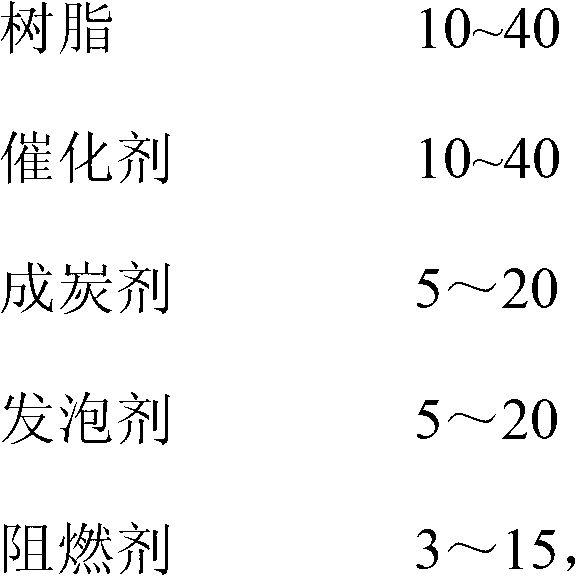

Expansion type fire-retardant coating

ActiveCN102702962AOvercome the disadvantage of poor thermal stabilityGood fire and heat insulationFireproof paintsEpoxy resin coatingsAcrylic resinFireproofing

The invention relates to an expansion type fire-retardant coating which contains organic silicon resin, and particularly comprises the components in part by weight: 10-40 parts of resin, 10-40 parts of catalyst, 5-20 parts of charcoal forming agent, 5-20 parts of foaming agent, and 3-15 parts of flame retardant, wherein the resin is selected from one or more of epoxy resin, phenolic resin, and acrylic resin as well as organic silicon resin. According to the invention, the shortcoming that the traditional fire-retardant coating is poor in heat stability is overcome; the coating has the characteristics of good fireproofing heat-insulating property, good bonding force, high strength, capability of bearing high and low-temperature circulation influence, excellent water resistance, acid resistance and salt corrosion resistance of coating layer, difficult in falling, stability in storage, good decoration property, convenience for construction and the like; during combustion, no smog or little smog is generated; and the coating is particularly suitable to be used as a fire-resistant coating for ultra-thin steel structures, veneer type fire-retardant coating and cable fire-retardant coating.

Owner:TIANCHANG YINHU PAINT

Surface treatment method of aluminum alloy and treatment liquid

InactiveCN101709459AImprove anti-corrosion performanceUniform thicknessLiquid/solution decomposition chemical coatingSalt resistanceChemical plating

The invention relates to a surface treatment method of aluminum alloy, which comprises the following steps of: pre-treating: removing oil stains on the aluminum alloy surface by adopting an alkali degreasing solution; alkali washing: purifying the aluminum alloy surface at 50-60 DEG C by adopting alkali wash to remove a natural oxide film on the aluminum alloy surface; acid pickling: treating the aluminum alloy surface at room temperature for 1-5 minutes by adopting a pickling solution to further remove residual spots left on the aluminum alloy surface after alkali washing; and chemically plating Ni-P: forming a Ni-P plating layer on the aluminum alloy surface by adopting a pre-prepared chemical plating Ni solution with pH value of 5-6.5 at 85-90 DEG C for 90-240 minutes. By adopting a chemical plating Ni-P layer process to form a uniform favorable plating layer with good acid resistance, alkali resistance and salt resistance outside an aluminum alloy shell, the invention avoids the phenomena of uneven thickness of a protective layer and spraying missing on a complex structure part, and remarkably improves the anticorrosion performance of the aluminum alloy.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Probiotic microcapsules as well as preparation method and application thereof

ActiveCN105310080AImprove the situation of low freeze-drying survival rateImprove stabilityFood freezingFood shapingFreeze-dryingK carrageenan

The invention relates to probiotic microcapsules as well as a preparation method and application thereof. The probiotic microcapsules comprise a core material and a wall material, wherein the core material is probiotics; the outer layer of the wall material is coated with chitosan; the wall material is prepared from an aqueous solution containing a natural polymer material and a freeze-drying protection agent; the freeze-drying protection agent comprises one or more of glucose, fructose, sucrose, lactose, trehalose, soluble starch, glycerin, mannitol, Arabic gum, dextran 40 and skim milk; the natural polymer material comprises one or more of gellan gum, xanthan gum, k-carrageenan, sodium alginate, cellulose acetate phthalate or gelatin; in the aqueous solution, the volume fraction of the freeze-drying protection agent is 4.0%-20.0% and the volume fraction of the polymer material is 0.5%-5.0%. The probiotic microcapsules can keep excellent acid resistance and storage stability before and after being freeze-dried.

Owner:SUN YAT SEN UNIV

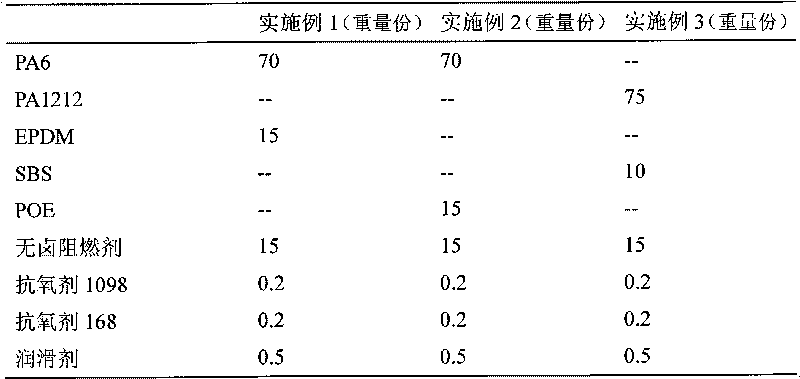

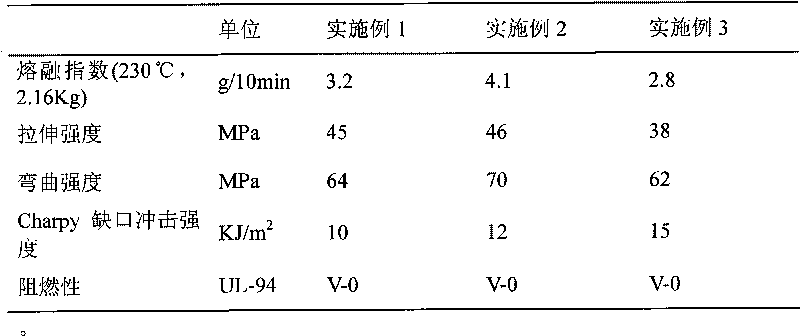

High-viscosity halogen-free flame-retardant polyamide composition

The invention relates to a high-viscosity halogen-free flame-retardant polyamide composition which comprises the following components in parts by weight: 60-92 of polyamide, 3-20 of plasticizer, 5-20 of halogen-free flame retardant and 0.1-2 of other assistants. After the polyamide composition prepared by the invention is formed and processed, a product has good flexibility, twisting resistance and good bending property and can bear a heavier load; the product has acid resistance and friction resistance, has resistance to lubricating oil and cooling liquid and has luster at the surface; the product can bear the stress of foot tread, has no rupture and no deformation, can be quickly restored and has no any damage per se; and the appearance of the product is smooth, black and bright, and the product has no broken fragments and has uniform color. The invention can be used for the finished pieces of a corrugated pipe and the like of a high-grade automobile.

Owner:HEFEI GENIUS NEW MATERIALS

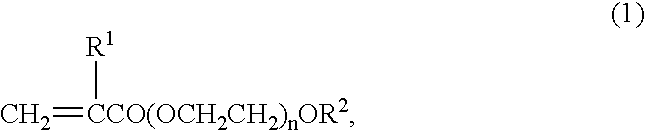

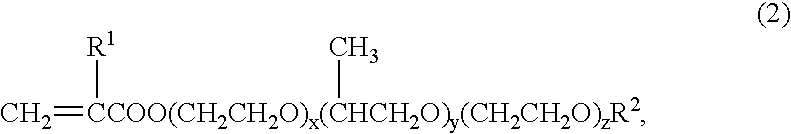

Water-based surface-treating agent for metallic material

InactiveUS6447620B1Raise the ratioIncreased insolubilityOther chemical processesSolid state diffusion coatingWater basedMetallic materials

A water-based surface-treating agent for metallic materials which gives a film highly satisfactory in corrosion resistance, blackening resistance, wet secondary adhesion to topcoatings, low-pollution characteristics (amount of fixed chromium), chemical resistance (especially acid resistance and alkali resistance), etc., while retaining the intact practical liquid stability of conventional chromate-containing resinous coating agents. The water-based surface-treating agent comprises a synthetic resin emulsion and hexavalent chromium ions and has a pH of 5 or lower, the synthetic resin emulsion being one obtained by emulsion-polymerizing the following ingredients using a nonionic polymerizable emulsifier and a nonionic nonpolymerizable emulsifier: (1) an ethylenic carboxylic acid, (2) a functional acrylic monomer having at least one of N-((un)substituted methylol)carbamoyl, phosphonate, alkoxy, cyano, and carbamoyl groups, and (3) a third monomer which is different from the ingredients (1) and (2) and forms the skeleton of the copolymer to be obtained.

Owner:HENKEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com