Patents

Literature

92results about How to "Good fire and heat insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solvent-free expansion type fire-proof epoxy coating and its preparation method

The invention discloses the inflatable fire-resisting paint, comprising A and B. The A comprises epoxide resin, modified resin, catalyst, foamable agent, fire retarding agent, fluxing agent, color filler and smog inhibiting agent, and the B comprises color filler, curing agent and auxiliary agent. The fire-resisting paint has the advantages of good heat-insulating property, adhesion force and intensity. The coating has good water resistance, acid- alkali resistance, corrosion resistance and tenacity, and is not easy to drop. The paint can be used in rolled steel and aluminum products, especially the fireproof situation of oil factories.

Owner:MARINE CHEM RES INST

Low-smoke superthin expansion steel structure fireproof coating and its preparing method

The invention relates to a kind of new-style low smoke super thin inflating steel structure fire protection dope and its producing method. Its components have coordinated effect when encountering fire. It inflates and froths to isolate oxygen and has good heat insulation performance. It can slow down the speed of heat transmitting to protected basic material, and prevent flame fast overspreading. The dope of the invention is mainly comprised of basic material resin, carbon forming agent, vesicant and activator. It uses certain proportion of resin as main membrane forming substance, and improves height and intensity of frothing layer through adding china padding. The frothing height can get to over 50 times. It uses china padding and smoke inhibitor to have coordinated effect and reduce smoking quantity. Advantages: simple to smear, good fire protection performance, small smoking quantity, high frothing height and high frothing intensity.

Owner:FUDAN UNIV

Expansion type fire-retardant coating

ActiveCN102702962AOvercome the disadvantage of poor thermal stabilityGood fire and heat insulationFireproof paintsEpoxy resin coatingsAcrylic resinFireproofing

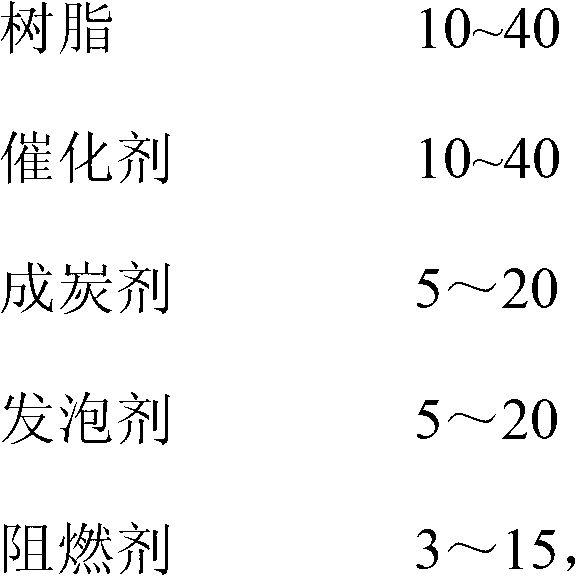

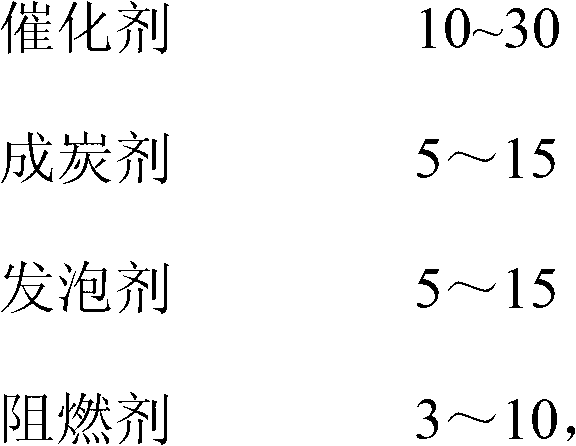

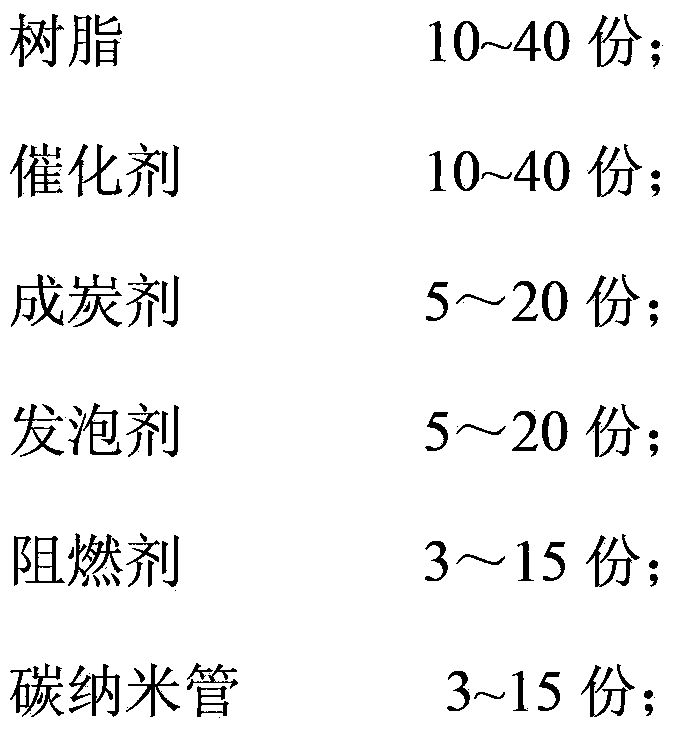

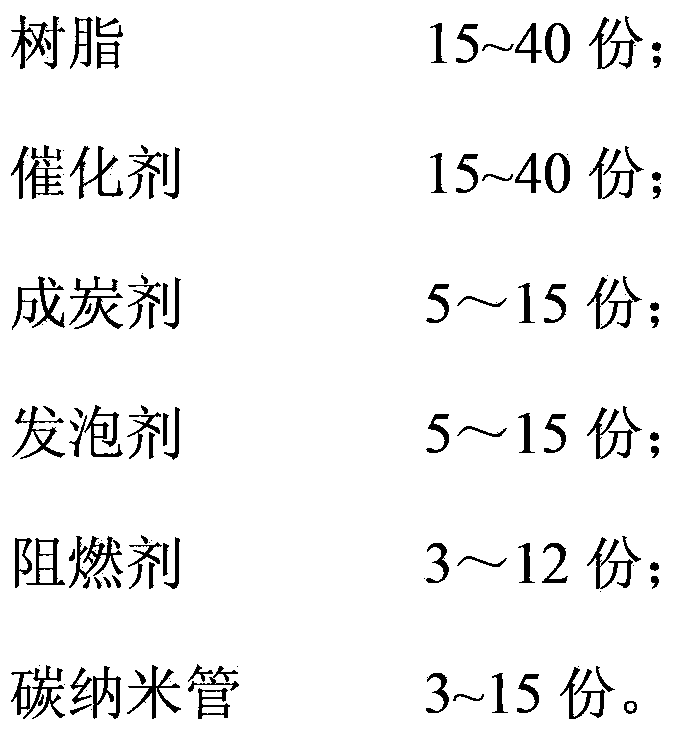

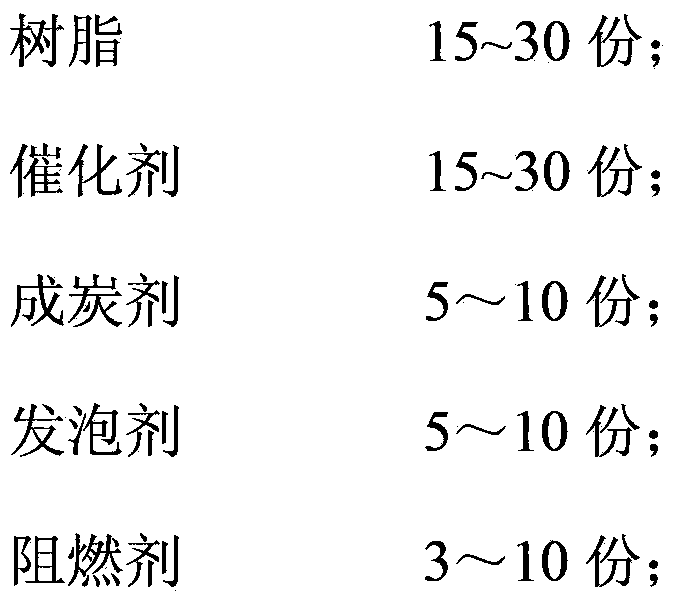

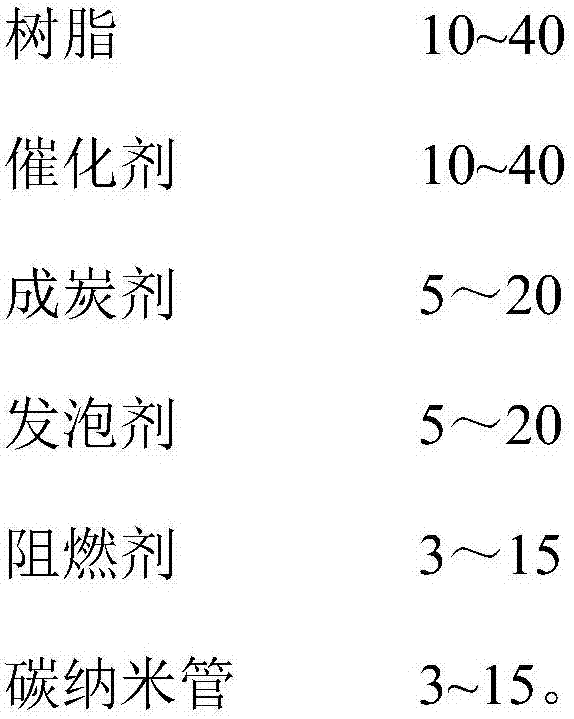

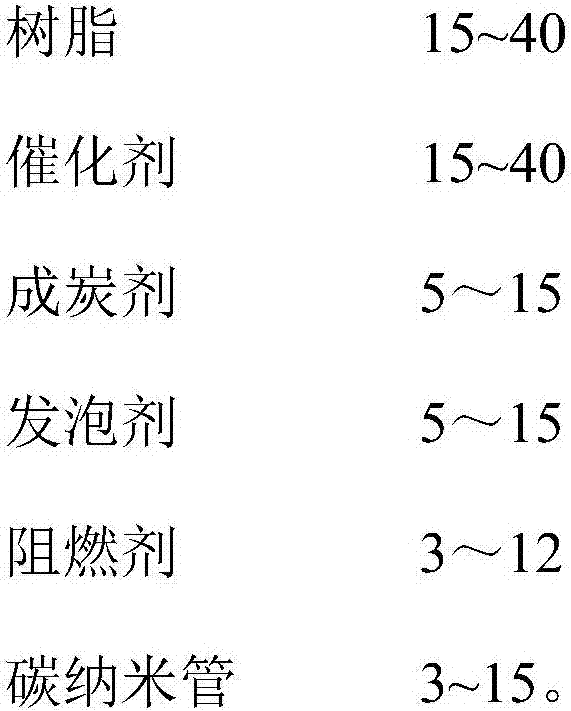

The invention relates to an expansion type fire-retardant coating which contains organic silicon resin, and particularly comprises the components in part by weight: 10-40 parts of resin, 10-40 parts of catalyst, 5-20 parts of charcoal forming agent, 5-20 parts of foaming agent, and 3-15 parts of flame retardant, wherein the resin is selected from one or more of epoxy resin, phenolic resin, and acrylic resin as well as organic silicon resin. According to the invention, the shortcoming that the traditional fire-retardant coating is poor in heat stability is overcome; the coating has the characteristics of good fireproofing heat-insulating property, good bonding force, high strength, capability of bearing high and low-temperature circulation influence, excellent water resistance, acid resistance and salt corrosion resistance of coating layer, difficult in falling, stability in storage, good decoration property, convenience for construction and the like; during combustion, no smog or little smog is generated; and the coating is particularly suitable to be used as a fire-resistant coating for ultra-thin steel structures, veneer type fire-retardant coating and cable fire-retardant coating.

Owner:TIANCHANG YINHU PAINT

Organic fireproofing plugging

A fire-proof organic blocking material for blocking the through hole and gap in fire accident is prepared from diethyl silica oil, light and / or heavy calcium carbonate, expanded pearlite (and / or vermiculite), filler chosen from diatomite, talc powder and bentone, and fire retarder chosen from aluminium hydroxide, hydrated zinc borate and magnesium hydroxide. Its advantages are high effect and durable plasticity and toughness.

Owner:应急管理部四川消防研究所

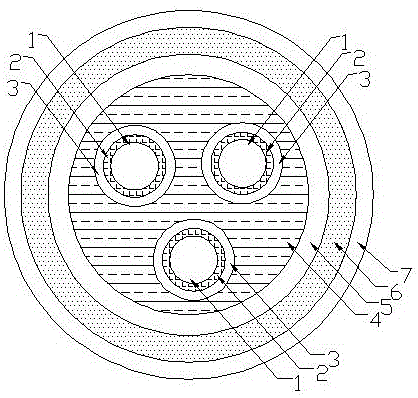

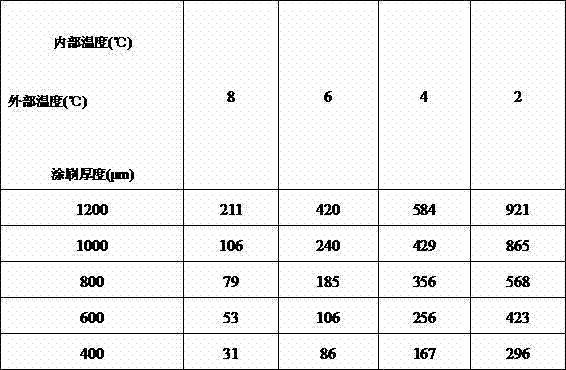

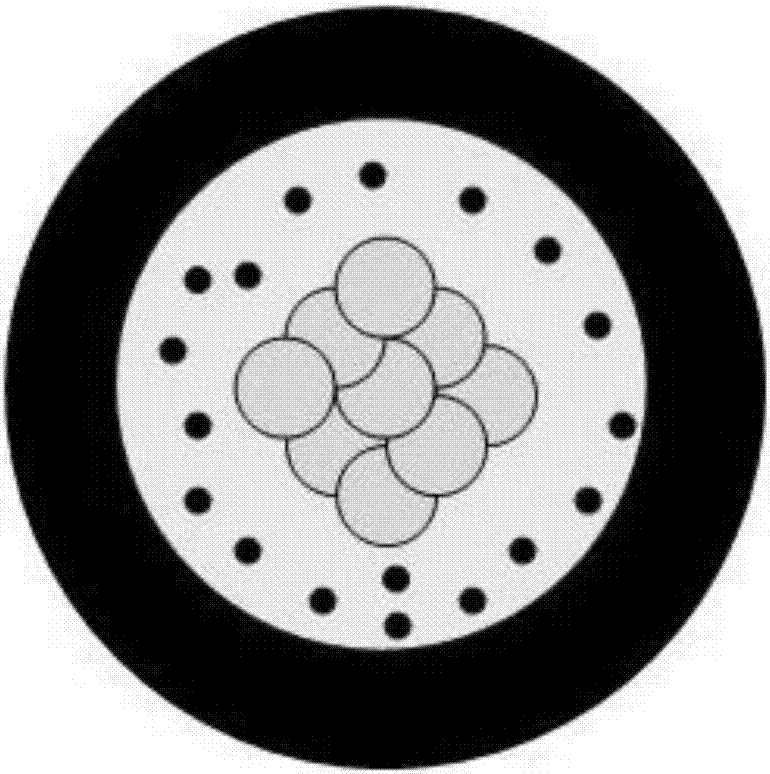

High-flexibility fireproof cable and preparation method thereof

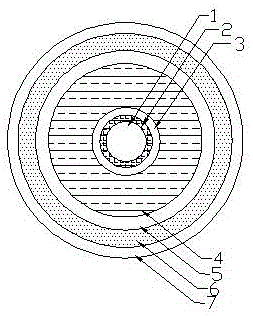

ActiveCN105761839AImprove flexibilityStrong fire resistanceFlexible cablesCable/conductor manufactureCopper conductorCeramic composite

The invention relates to the technical field of the cable, especially to a high-flexibility fireproof cable and a preparation method thereof. The preparation method comprises: wire drawing and annealing processing is carried out on a copper rod to obtain annealed copper wires, and the annealed copper wires are twisted to form a copper conductor; a ceramic composite belt wraps the external surface of the copper conductor obtained by pretreatment and a ceramic polyolefin material is arranged at the external surface of the ceramic composite belt in an extruding mode to obtain a cable core; the periphery of the cable core is filled with an organic fireproof mud material to obtain a filling layer; the external surface of the filling layer is wrapped by a mica tape to obtain a mica tape wrapping layer; the external surface of the mica tape wrapping layer is coated with a fine copper wire braiding layer; and the external surface of the fine copper wire braiding layer is coated with a sheath layer to obtain a high-flexibility fireproof cable. According to the invention, the process of the preparation method is simple and mature; the manufactured cable has high flexibility and excellent fireproof performance and can be applied to a control cabinet, an instrument connecting wire, and home installation with a high requirement; and the service life of the cable can reach 70 years.

Owner:DONGGUAN MINXING CABLES

Nuclear-grade high-temperature-resistance fireproof coating and preparation method thereof

ActiveCN104726020AEmission reductionBlocking exchange deliveryFireproof paintsShieldingPtru catalystNuclear power

Owner:HAILONG EMERSON ZHENJIANG ENERGY TECH

Fireproof coating for waterborne cable

InactiveCN103992708AGood fire and heat insulationGood adhesionFireproof paintsChemical industryAmmonium polyphosphate

The invention discloses a fireproof coating for a waterborne cable, belonging to the technical field of chemical industry. The fireproof coating is composed of the following components in parts by weight: 15-18 parts of acrylic resin, 10-15 parts of phenol formaldehyde resin, 20-26 parts of ammonium polyphosphate, 12-15 parts of pentaerythritol, 5-8 parts of tripolycyanamide, 5-9 parts of zinc borate, 3-7 parts of chlorinated paraffin, 0.1-0.5 part of flatting agent, 0.8-1.2 parts of defoaming agent, 2-3 parts of organic bentonite, 1-5 parts of inorganic pigment and 15-25 parts of water. The coating disclosed by the invention is good in fire resistance and heat insulation property, strong in binding power, high in strength, good in water resistance as well as acid and alkaline corrosion resistance, good in decoration and reduced in cost.

Owner:ANHUI JIAMU RUBBLE & PLASTIC IND

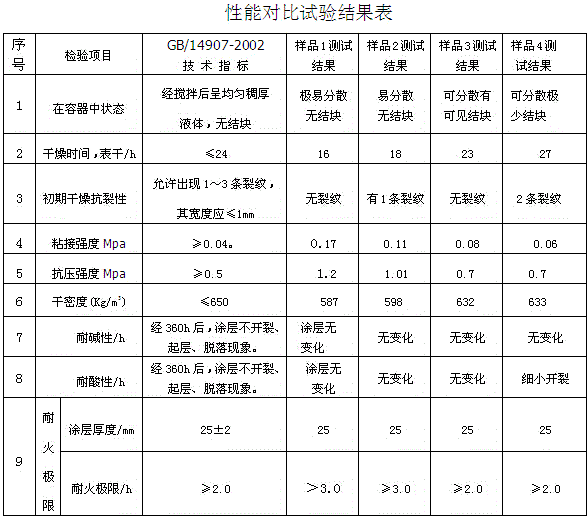

Heat-insulating fireproof interface agent for polystyrene heat-insulating plate

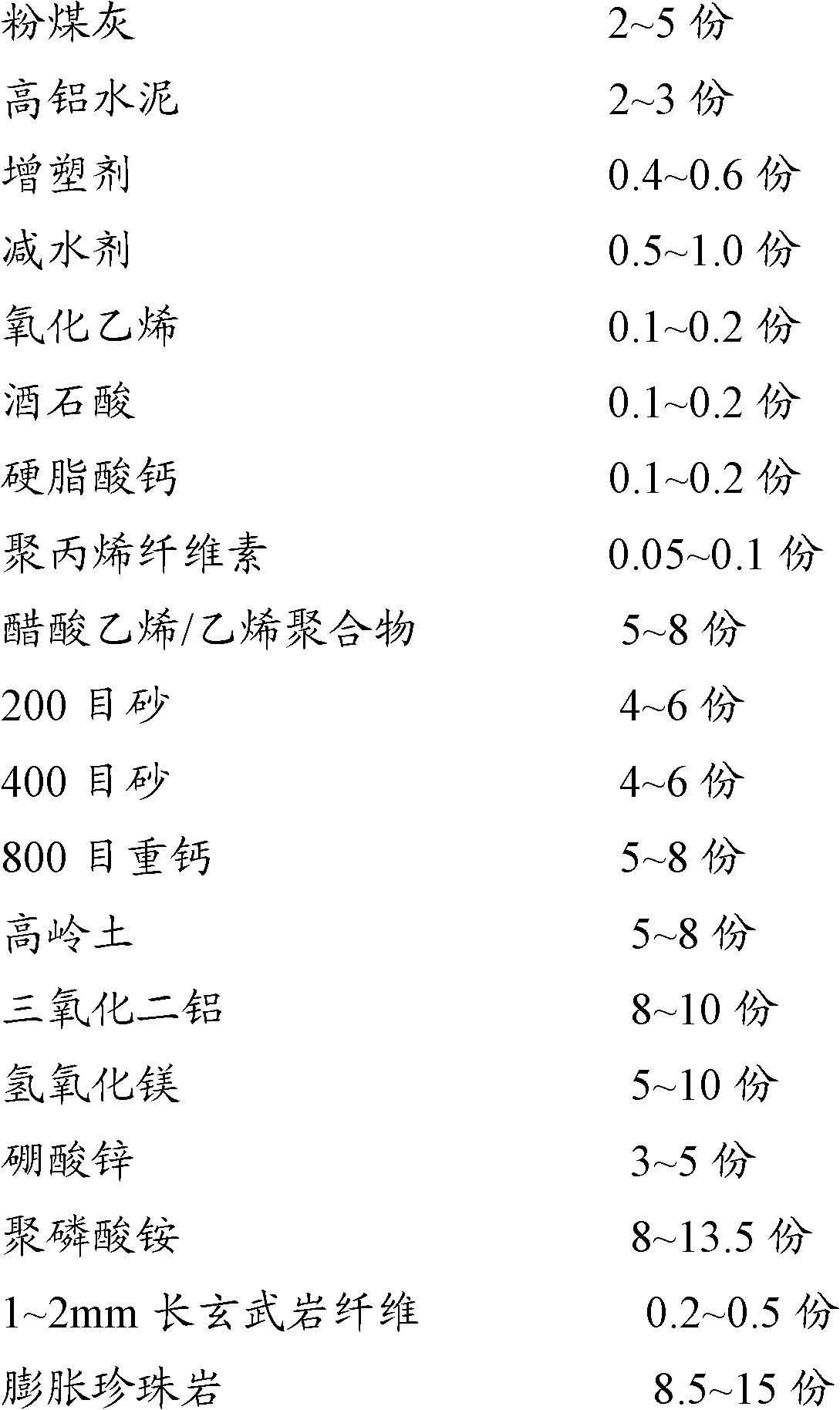

The invention relates to a heat-insulating fireproof interface agent for a polystyrene heat-insulating plate. The heat-insulating fireproof interface agent comprises 20-25 parts of silicate cement, 2-5 parts of coal ash, 2-3 parts of bauxite cement, 0.4-0.6 parts of plasticizer, 0.5-1.0 part of water reducer, 0.1-0.2 parts of ethylene oxide, 0.1-0.2 parts of tartaric acids, 0.1-0.2 parts of calcium stearate, 0.05-0.1 parts of polypropylene cellulose, 5-8 parts of vinyl acetate / ethylene polymer, 4-6 parts of 200 mesh sand, 4-6 parts of 400 mesh sand, 5-8 parts of 800 mesh coarse whiting, 5-8 parts of kaolin, 8-10 parts of aluminum oxide, 5-10 parts of magnesium hydroxide, 3-5 parts of zinc borate, 8-13.5 parts of ammonium polyphosphate, 0.2-0.5 parts of 1-2mm basalt fibers and 8.5-15 parts of expanded perlite. The heat-insulating fireproof interface agent for the polystyrene heat-insulating plate has the advantages of simple construction, excellent fireproof heat-insulating effect, excellent cracking resistance and high bonding strength with the polystyrene heat-insulating plate.

Owner:深圳市嘉达节能环保科技有限公司

High temperature-resistant fireproof coating and preparation method thereof

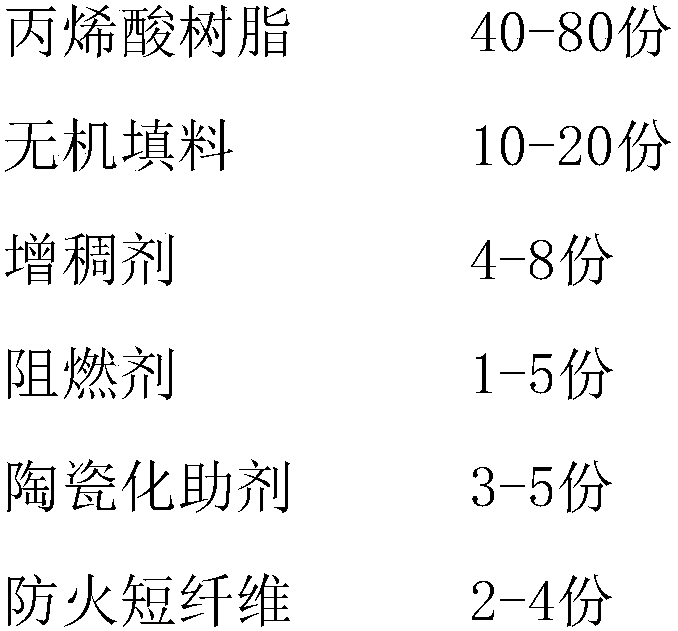

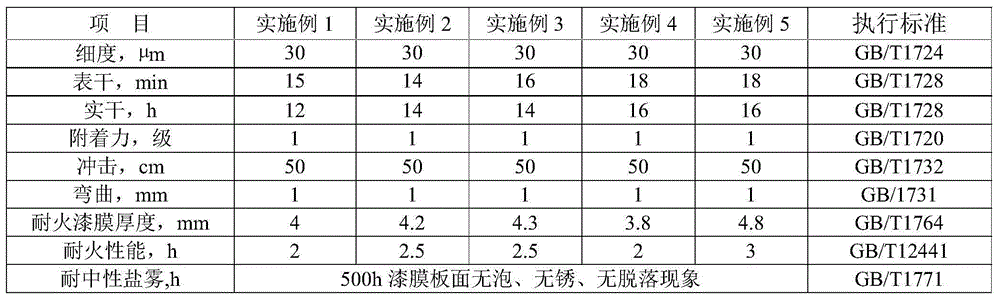

ActiveCN108504257AGood weather resistanceImprove performance such as salt spray resistanceFireproof paintsEpoxy resin coatingsFiberAcrylic resin

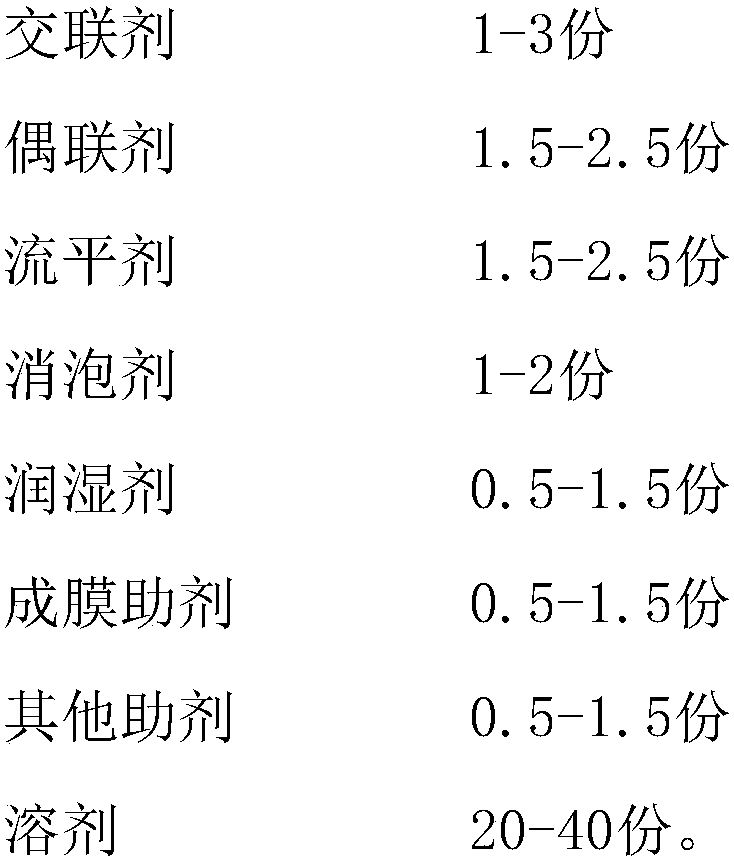

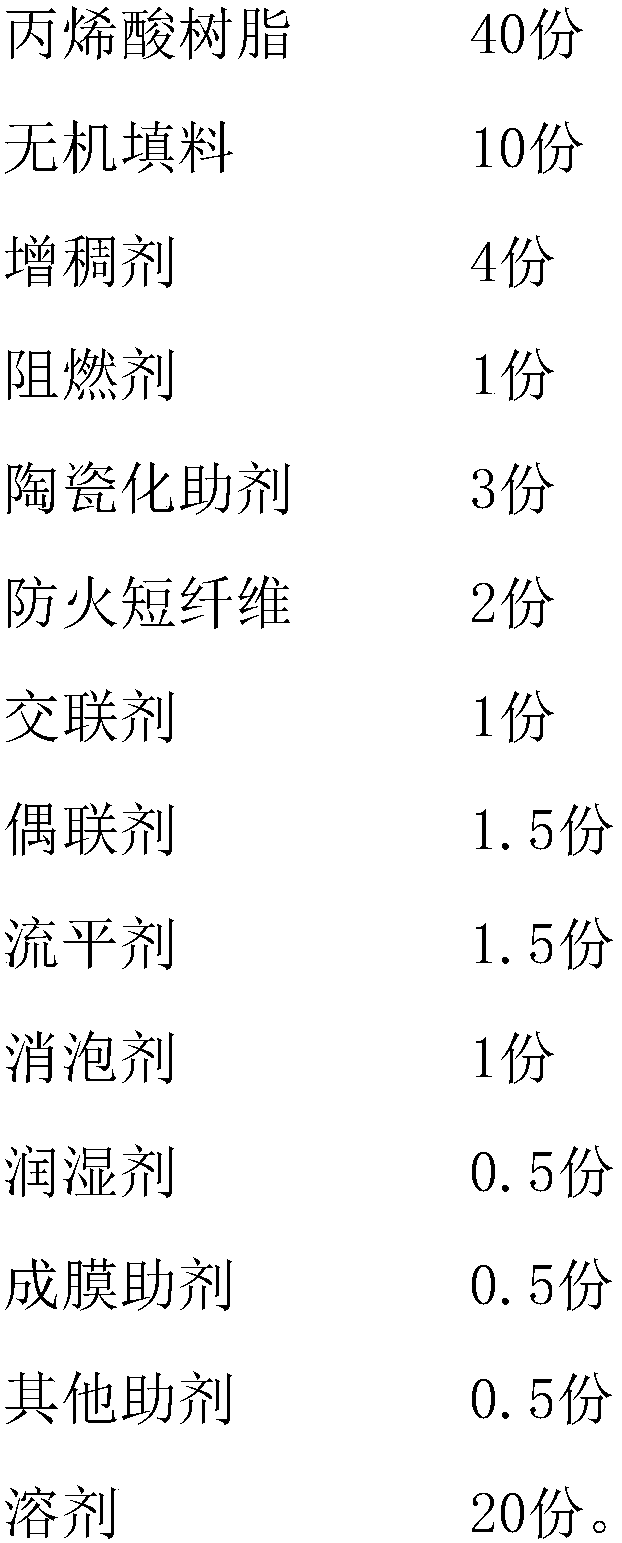

The invention relates to the technical field of coatings, in particular to a high temperature-resistant fireproof coating and a preparation method thereof. The high temperature-resistant fireproof coating is prepared from the following raw materials in parts by weight: acrylic resin, inorganic filler, a thickener, a flame-retardant agent, a ceramic additive, fireproof short fibers, a crosslinkingagent, a coupling agent, a flatting agent, a defoaming agent, a wetting agent, a film forming additive, other additives and solvents. The high temperature-resistant fireproof coating has the advantages that high temperature can be endured, the flame-retardant property is good, the propagation of fire condition is well blocked, and the fireproof property is excellent; the effect of resisting long-time impact by 1100 DEG C hydrocarbon high-temperature fire hazard is realized; the weather-resistant property and waterproof property are realized, the shrinkage is avoided, the coating strength is high, and the surface is flat.

Owner:GUANGDONG ZHICHENG CHEM +1

Expansion-type fireproof coating

InactiveCN103351815AGood fire and heat insulationGood adhesionFireproof paintsStarch coatingsFoaming agentCarbon nanotube

The invention relates to an expansion-type fireproof coating. The coating comprises, by weight, 10-40 parts of resins, 0-40 parts of catalysts, 5-20 parts of charring agents, 5-20 parts of foaming agents, 3-15 parts of fire retardants and 3-15 parts of carbon nanotubes. The expansion-type fireproof coating has good fire proofing and heat insulating properties, good bonding force and high intensity, and can endure high low temperature cycling. The coating has advantages of good water resistance, good acid resistance, good salt corrosion resistance, stable storage, good decoration and convenient construction, and is not easy to fall off. The coating solves the problems of low expansion rate of fireproof coatings and low compactness of charring layers in the prior art, and has excellent fireproof performance.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Water-based fireproof coating

InactiveCN103911025AGood fire and heat insulationGood adhesionFireproof paintsHeat stabilitySmoke Emission

The invention provides a water-based fireproof coating which is prepared from the following components in parts by weight: 40 parts of titanium dioxide powder, 40 parts of lithopone, 40 parts of silicon ash powder, 40 parts of ash calcium powder, 440 parts of water, 400 parts of silica sol, 60 parts of milk ester, 2 parts of fire retardant, 1 part of defoaming agent, 2.5 parts of multifunction additive and 1.5 parts of thickening agent. According to the water-based fireproof coating provided by the invention, the defects of the existing fireproof coating that the heat stability is poor and the phenomenon of the increasing of smoke generating quantity is caused due to a large quantity of organic resins existing in the existing fireproof coating are overcome. The water-based fireproof coating is good in fireproof and heat-insulating performance, good in bonding force and high in strength, and is not influenced by the cycling of high and low temperatures. A coating layer obtained by the water-based fireproof coating has the characteristics of being good in water resistance, acid resistance and salt corrosion resistance, difficult to fall off, stable to store, good in decoration, convenient to construct and the like; smoke is not generated or small amount of smoke is generated during the burning of the coating layer.

Owner:宜兴市官林镇政宇涂料厂

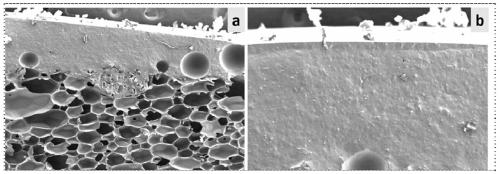

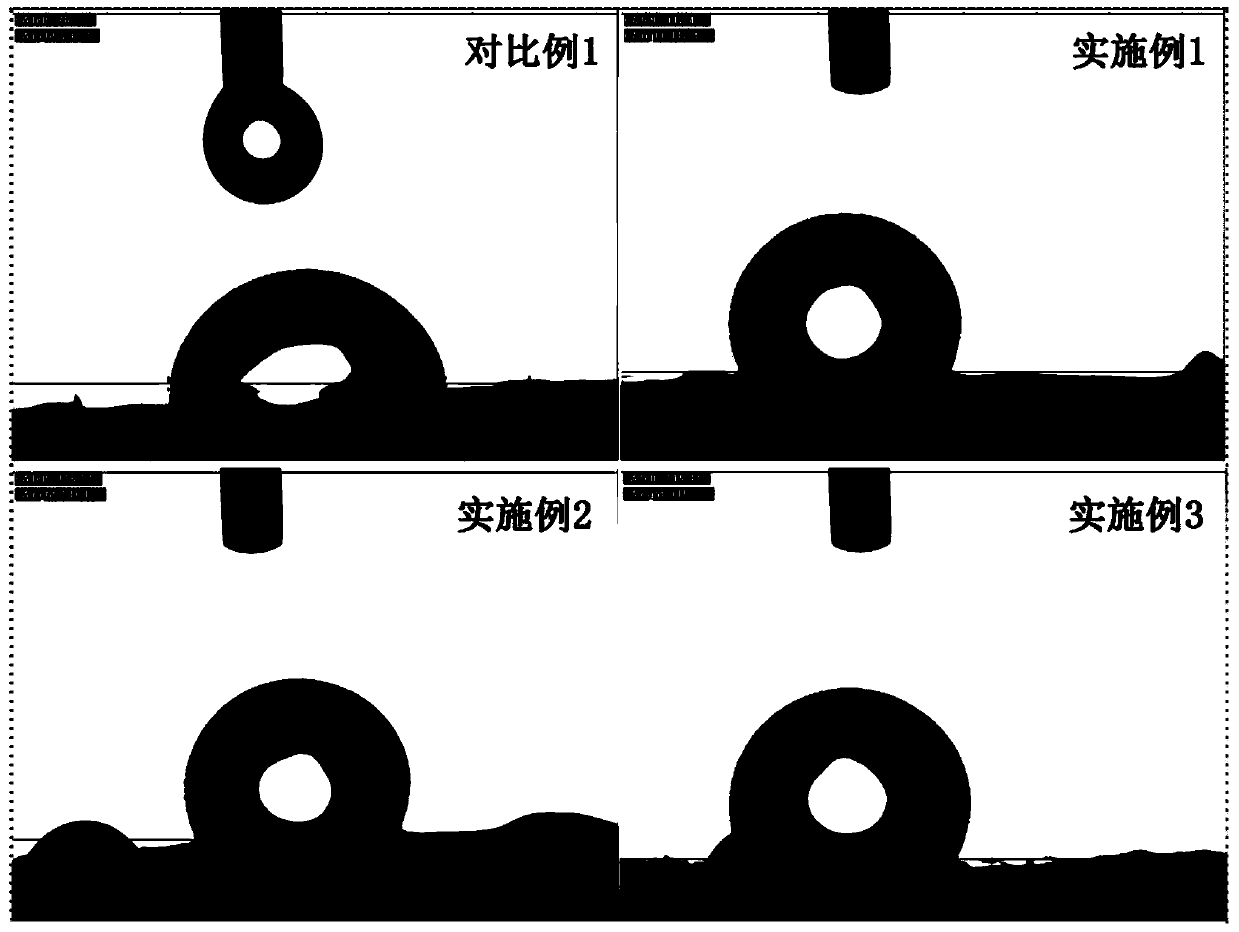

Flame-retardant rigid polyurethane foam of hydrophobic graphene aerogel coating and preparation method of flame-retardant rigid polyurethane foam

ActiveCN109912837AIntegrity guaranteedGood fire and heat insulationFireproof paintsDimethyl siloxaneBall mill

The invention discloses flame-retardant rigid polyurethane foam of a hydrophobic graphene aerogel coating and a preparation method of the flame-retardant rigid polyurethane foam. The flame-retardant rigid polyurethane foam comprises the following raw materials: polyether polyol, isocyanate, silicone oil, a catalyst A33, tetraethylortho silicate, ethanol, distilled water, poly-dimethyl siloxane, reduced graphene oxide and trimethylchlorosilane. The preparation method of the flame-retardant rigid polyurethane foam of the hydrophobic graphene aerogel coating specifically comprises the following steps: (1) preparing graphene aerogel with tetraethylortho silicate, ethanol, distilled water and reduced graphene oxide according to a certain process; (2) performing ball-milling on graphene aerogel,mixing the ball-milled graphene aerogel with poly-dimethyl siloxane, and stirring the mixture to obtain a coating; (3) coating rigid polyurethane foam with the coating, and drying to obtain the flame-retardant rigid polyurethane foam. The flame-retardant rigid polyurethane foam disclosed by the invention is simple and convenient in preparation process, green and non-toxic and simple in coating method, easy to operate, good in mechanical property and obvious in flame-retardant effect.

Owner:SOUTH CHINA UNIV OF TECH

Expanding fire-proof paint

InactiveCN1164701CGood fire and heat insulationGood adhesionFireproof paintsFoaming agentAcrylic resin

Owner:MARINE CHEM RES INST CO LTD

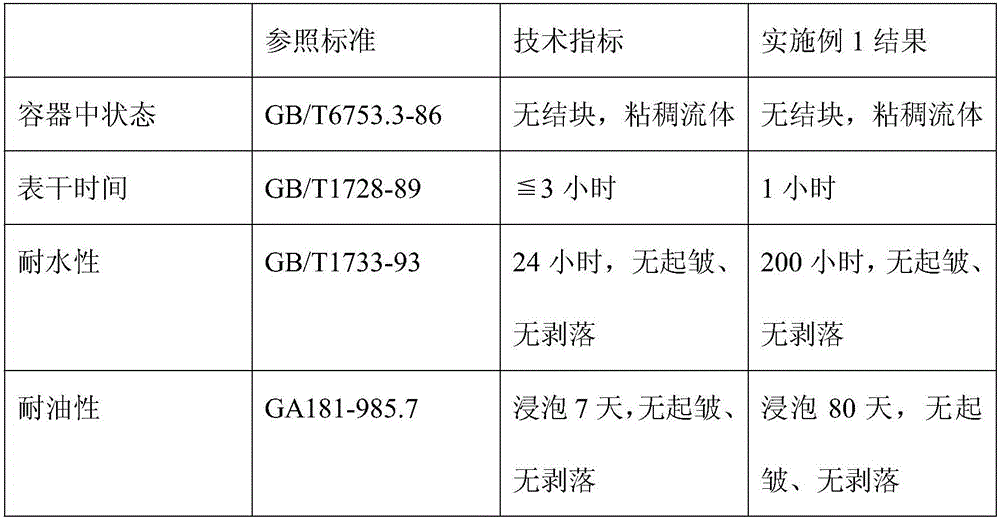

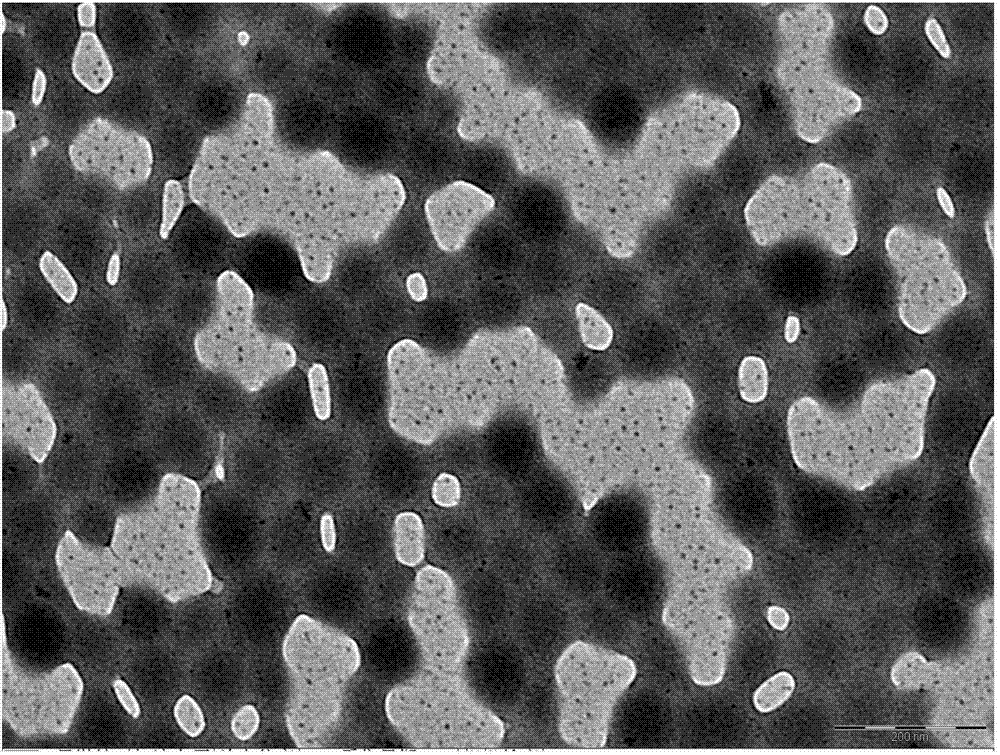

Micro-arc oxidation composite aqueous fire retardant coating and preparation method thereof

ActiveCN107815196AProvides comprehensive fire protectionNovel methodFireproof paintsSpecial surfacesMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a micro-arc oxidation composite aqueous fire retardant coating and a preparation method thereof. A micro-arc oxidization film layer is formed on the surface of a valve metallicmatrix by using a micro-arc oxidation method by adopting alkaline electrolyte, and then an aqueous fire retardant coating is compounded on the surface of the micro-arc oxidization film layer, whereinthe coating takes ammonium polyphosphate, pentaerythritol and melamine as a flame-retardant system, titanium dioxide as a pigment filler, and water as a solvent. When meeting fire, the flame-retardant system of the aqueous fire retardant coating on the outer layer achieves concerted reaction to form a dense spongy expanded carbonaceous layer, a two-dimensional lamellar structure of graphene oxideundergoes multilayer stacking in the carbonaceous layer to form a dense physically blocked layer so as to isolate transfer of outside heat to the inner layer, while the heat conductivity of the micro-arc oxidization film layer on the inner layer is low, so as to further isolate transfer of the heat to the matrix. The micro-arc oxidation composite aqueous fire retardant coating has excellent fireretardant and heat insulating performances, is applicable to valve metals of aluminum, magnesium, titanium and the like, and is strong in binding force, simple and environment-friendly in processing technology and low in cost.

Owner:GUANGXI UNIV +1

Fireproof coating with black mica powder

ActiveCN103773170AGood fire and heat insulationGood adhesionFireproof paintsRubber derivative coatingsStyreneSodium

The invention discloses a fireproof coating with black mica powder. The fireproof coating with the black mica powder is prepared from the following raw materials in parts by weight: 10-15 parts of black mica powder, 5-8 parts of mullite powder, 8-10 parts of nano-montmorillonite, 3-5 parts of dimethyl phosphate, 10-15 parts of acrylic resin, 15-30 parts of amino resin, 2-4 parts of chlorinated rubber, 2-3 parts of carbamide phosphate, 1-3 parts of silane coupling agent, 5-6 parts of sorbitol, 7-9 parts of aluminium oxide, 3-5 parts of sodium borate, 8-10 parts of vermiculite, 3-4 parts of semi-hydrated gypsum, 3-5 parts of graphite powder, 2-3 parts of titanium dioxide powder, 8-13 parts of organic silicon modified styrene-acrylic emulsion, 5-6 parts of cellulose ether, 2-3 parts of glass powder, 6-8 parts of butyl latex, 2-3 parts of sodium fluosilicate and 3-5 parts of wood fiber. The fireproof coating has the advantages of being excellent in fireproof heat insulation property, excellent in adhesive strength, excellent in water resistance, acid-alkaline resistance and salt corrosion resistance, not easy to fall off, stable in storage, non-toxic and environmental-friendly.

Owner:ANHUI WILLY PAINT SCI & TECH LTD

Adsorbing odor-removing environment-friendly fireproof coating and preparation method thereof

InactiveCN106634082AImprove the function of absorbing odorPrevent air conditioning diseaseFireproof paintsAntifouling/underwater paintsAmmonium polyphosphateEmulsion

The invention discloses an adsorbing odor-removing environment-friendly fireproof coating which is prepared from, by weight parts, 30-50 parts of portland cement, 10-15 parts of polyvinyl acetate emulsion, 8-10 parts of forsterite powder, 5-7 parts of high aluminum powder, 5-7 parts of modified attapulgite clay, 5-6 parts of white carbon black, 3-4 parts of epoxidized soybean oil, 10-15 parts of acrylic resin, 15-30 parts of polytetrafluoroethylene emulsion, 5-6 parts of ammonium polyphosphate, 5-6 parts of pentaerythritol, 6-7 parts of porous starch, 6-8 parts of butyl latex, 2-3 parts of sodium fluorosilicate, 3-5 parts of sisal fiber, 5-8 parts of medical stone powder, 3-5 parts of bamboo powder and 5-7 parts of nanocomposite emulsion. The adsorbing odor-removing environment-friendly fireproof coating is good in fireproof and heat-insulating performance, good in water resistance, oil resistance and stain resistance and easy to clean, has a function of purifying air and removing odor, and is nonhazardous, green and environmentally friendly.

Owner:TONGLING XIANGYUN FIRE FIGHTING TECH

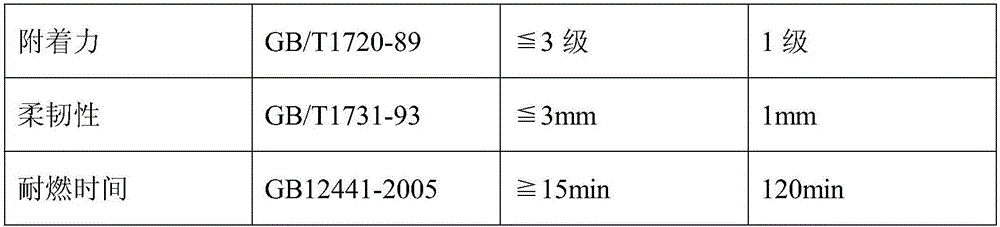

Decorative expansive-type waterborne styrene-acrylic emulsion-containing fireproof and heat-insulating coating

InactiveCN108384338ALow thermal conductivityReduce stress crackingFireproof paintsPentaerythritolDefoaming Agents

The invention provides a decorative expansive-type waterborne styrene-acrylic emulsion-containing fireproof and heat-insulating coating. The decorative expansive-type waterborne styrene-acrylic emulsion-containing fireproof and heat-insulating coating comprises the following raw material components in parts by weight: 20-30 parts of a styrene-acrylic emulsion, 2-4 parts of hollow glass microbeads,8-12 parts of titanium dioxide, 20-30 parts of ammonium polyphosphate, 8-12 parts of tripolycyanamide, 5-8 parts of pentaerythritol, 0.2-0.5 part of a silane coupling agent, 3-6 parts of a dispersingagent, 2-4 parts of a thickening agent, 0.2-0.5 part of a defoaming agent, 1.0-2.5 parts of a film-forming aid, 0.1-0.3 part of a wetting agent, 0.2-0.5 part of an OP-10 emulsifying agent and 20-30 of deionized water.

Owner:FOSHAN KANGDONG LIGHTING TECH CO LTD

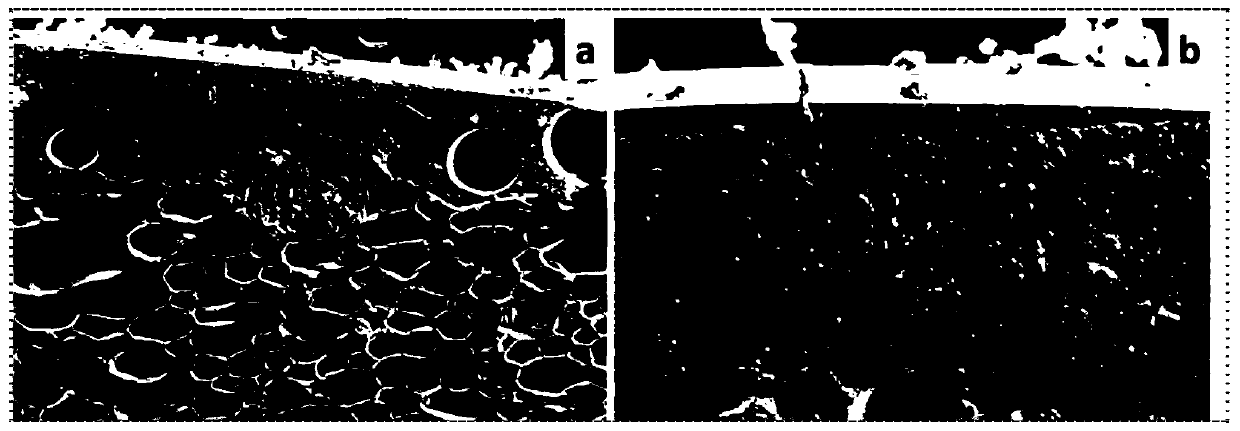

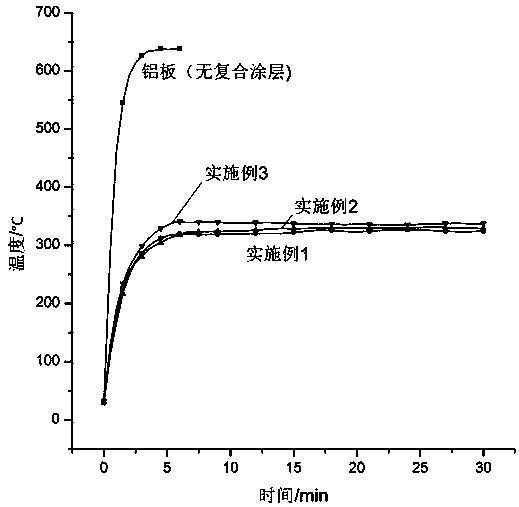

Thick-thin composite fireproof coating and preparation method thereof

InactiveCN110183884AComposite goodBlock deliveryFireproof paintsLiquid surface applicatorsEnvironmental resistanceComposite effect

The invention belongs to the technical field of fireproof heat insulation coatings and discloses a thick-thin composite fireproof coating and a preparation method thereof. The thick-thin composite fireproof coating is composed of a thick non-expansive fireproof coating on a metal plate substrate and a thin expansive fireproof coating. The preparation method comprises the following steps: applyingthe thick non-expansive fireproof coating to a polished metal plate substrate in a brush coating or roller coating manner, and performing curing to prepare the thick non-expansive fireproof coating; and applying the thin expansive fireproof coating on the thick non-expansive fireproof coating in a brush coating or roller coating or spraying manner, and performing curing, so as to obtain the thick-thin composite fireproof coating. The two fireproof coatings can achieve an excellent composite effect, the binding force between composite layers is high, the raw materials are cheap and environment-friendly, and construction is simple. The fireproof effect of the fireproof coating can be greatly improved, and the cost can be reduced to make certain economic benefits.

Owner:SOUTH CHINA UNIV OF TECH

Anti-corrosion anti-permeability fire-retardant coating

InactiveCN104860604AGood fire and heat insulationGood acid and alkali resistanceEnvironmental resistanceCoal

The invention discloses an anti-corrosion anti-permeability fire-retardant coating comprising the following raw materials by weight: 50-80 parts of Portland cement, 10-15 parts of polymer emulsion, 15-20 parts of expanded perlite, 10-20 parts of talcum powder, 3-6 parts of granite, 10-15 parts of graphite powder, 5-7 parts of magnesium hydroxide, 5-7 parts of aluminum hydroxide, 0.3-1.5 parts of silicon alkyl powder, 3-5 parts of pentaerythritol, 2-3 parts of a concrete expansion agent, 6-8 parts of mica powder, 1-3 parts of aluminum dihydrogen tripolyphosphate and 1-3 parts of zinc borate. The anti-corrosion anti-permeability fire-retardant coating is used for under coal mine well coal seams, has the advantages of excellent fire-retardant heat-insulating property, good coal adhesion, good anti-permeability waterproof property, good antistatic property, good water, acid and alkali and salt corrosion resistance, storage stability, no toxicity and environmental protection, and the like, and can meet the requirements of irregularity of the surface of the coal seams and self deformation of the coal seams, and crack phenomenon is not easy to cause.

Owner:TONGLING XIANGYUN FIRE FIGHTING TECH

High-wear-resistant and high-oil-resistant fireproof coating and preparation method thereof

InactiveCN106497169AGood fire and heat insulation performanceGood oil resistanceFireproof paintsAntifouling/underwater paintsAmmonium polyphosphateKaolinite

The invention discloses a high-wear-resistant and high-oil-resistant fireproof coating and a preparation method thereof. The high-wear-resistant and high-oil-resistant fireproof coating comprises, by weight, 30-50 parts of silicate cement, 10-15 parts of alundum powder, 5-8 parts of carbon monofluoride, 10-15 parts of kieselguhr, 8-10 parts of rice hull ash, 5-6 parts of talcum powder, 8-10 parts of tung oil, 3-5 parts of partial kaolinite, 3-5 parts of modified electric powder, 5-7 parts of aluminum dihydrogen phosphate, 10-15 parts of acrylic resin, 5-6 parts of ammonium polyphosphate, 1-3 parts of a titanate coupling agent, 5-6 parts of pentaerythritol, 6-7 parts of porous starch, 2-3 parts of zinc borate, 3-5 parts of palm fiber and 10-12 parts of chlorohydrin rubber viscosity resin. The high-wear-resistant and high-oil-resistant fireproof coating is good in fireproof and heat insulation performance, good in oil resistance, wear resistance, freezing resistance and fireproofness, high in adhesion and less prone to falling off.

Owner:TONGLING XIANGYUN FIRE FIGHTING TECH

Facing expansion type silica solution water-based fireproof coating for woodware

InactiveCN108441003AImprove the blending effectOvercoming poor thermal stabilityFireproof paintsAmmonium polyphosphateDefoaming Agents

The invention provides a facing expansion type silica solution water-based fireproof coating for woodware. The paint comprises the following raw materials in parts by weight: 100-180 parts of silica solution, 60-90 parts of hydroxyl polymer, 20-30 parts of ammonium polyphosphate, 8-12 parts of melamine, 5-8 parts of pentaerythritol, 8-12 parts of titanium dioxide, 10-20 parts of talcum powder, 3-6parts of dispersing agent, 0.1-0.3 part of rheological agent, 0.1-0.3 part of defoaming agent, 2-4 parts of thickening agent, 0.1-0.3 part of preservative, 1.0-2.5 parts of filming additive, 0.3-0.6part of grinding additive, 0.1-0.3 part of wetting agent, 0.8-1.5 parts of silane coupling agent, 0.8-1.5 parts of PH conditioning agent, and 20-50 parts of deionized water.

Owner:FOSHAN KANGDONG LIGHTING TECH CO LTD

Environment-friendly high-temperature-resistant fireproof paint

InactiveCN104726017AEmission reductionBlocking exchange deliveryFireproof paintsPtru catalystOrganosolv

The invention discloses an environment-friendly double-component high-temperature-resistant fireproof paint which is composed of a component A and a component B, wherein the component A contains a hydroxy silicon oil flame retardant, a magnetic filler, a ceramic assistant and other thermal-insulation fillers; and the component B contains a crosslinking agent, a coupling agent and a catalyst. When the paint is in use, the component A and component B are mixed according to the mass ratio of 10:1, and cured to form the film. The paint is free of any organic solvent, and has the characteristics of favorable expansion character when meeting fire, high strength of the expanded carburization layer, long fireproof time and the like. The coating has the advantages of favorable heat insulation property and favorable high temperature resistance, and can resist the high temperature of 800 DEG C above.

Owner:HAILONG EMERSON ZHENJIANG ENERGY TECH

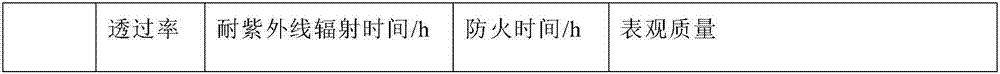

Fireproof glue liquid matrix and preparation method thereof, and fireproof glue liquid and preparation method thereof

ActiveCN106883797AImprove thixotropyLow viscosityNon-macromolecular adhesive additivesConstructions elementsPolymer scienceHardness

The invention provides a fireproof glue liquid matrix and a preparation method thereof, and a fireproof glue liquid and a preparation method thereof. The fireproof glue liquid matrix is prepared from silicon dioxide and a lubricating matter, wherein the lubricating matter is a copolymer of aromatic olefin and / or acrylate. The fireproof glue liquid is prepared from the fireproof glue liquid matrix. The prepared fireproof glue liquid has the advantages that the viscosity is only 50 to 1000cp, and the fireproof glue liquid can be used for preparing composite fireproof glass with fireproof layer thickness less than 1mm. A fireproof layer prepared by the fireproof glue liquid has the advantages of good fireproof and heat isolation properties, high hardness, high transmittance and good anti-ultraviolet property.

Owner:CHINA BUILDING MATERIALS ACAD

Solvent-free expansion type fire-proof epoxy coating and its preparation method

ActiveCN100487070CGood fire and heat insulationGood adhesionFireproof paintsCarboxyl rubber coatingsFuranHydantoin derivatives

The intumescent fireproof coating disclosed by the present invention is composed of two components A and B. The component A uses epoxy resin as the main film-forming substance, and is added with modified resin, catalyst, char-forming agent, foaming agent, flame retardant, Flux, pigments and fillers, smoke inhibitors, component B is composed of pigments and fillers, curing agent, auxiliary agent; the epoxy resin is selected from bisphenol A type epoxy resin, bisphenol F type epoxy resin, TDE- 85 epoxy resin, hydantoin epoxy resin, etc.; the modified resin is selected from polyurethane, furan resin, amino resin, bisphenol F resin, etc.; the dosage ratio of components A and B is 2-4:1. The fireproof coating has good fireproof and heat insulation performance, good adhesion, high strength, and can withstand the influence of high and low temperature cycles. The coating has good water resistance, acid and alkali resistance, salt corrosion resistance, excellent flexibility, and is not easy to fall off. Stable storage, convenient construction, etc., suitable for indoor and outdoor steel, aluminum, etc., especially suitable for fire prevention occasions in offshore oil platforms, oil fields, refineries and petrochemical plants.

Owner:MARINE CHEM RES INST CO LTD

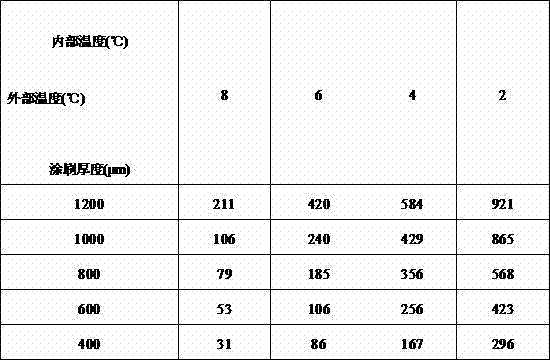

Outdoor thick steel structure fire-retardant coating

InactiveCN104529346ALow thermal conductivityGood fire and heat insulationCrack resistanceWeather resistance

The invention relates to an outdoor thick steel structure fire-retardant coating and belongs to the field of building materials. The fire-retardant coating is prepared by mixing the following raw materials in percentage by weight: 10-20% of natural sepiolite fabric, 4-6% of light calcium carbonate, 20-30% of hole-closed perlite, 1-1.4% of high-strength water-resistant rubber powder, 1.6-2% of a hydrophobic agent, 40-44% of Portland cement and 8.0-12% of refractory cement. Since the fire-retardant coating is prepared by mixing natural sepiolite fabric, hole-closed perlite, light calcium carbonate and high-strength water-resistant rubber powder, polymer long chains in high-strength water-resistant rubber powder form continuous network structures which are interspersed one another, the bonding strength of the final product is significantly improved, and meanwhile, the water resistance, crack resistance, weather resistance and impact resistance of the cement-based products can also be improved and the fire-retardant coating has good chemical resistance and water resistance and hardly falls off.

Owner:LUOYANG DAYU IND

Preparation method for fireproof board

The invention relates to a preparation method for a fireproof board. The preparation method comprises the following steps: subjecting cement, phosphoric acid and magnesium sulfate to full stirring, adding a flame retardant into the above-mentioned mixed material, and carrying out uniform stirring so as to obtain a mixed material A; quartering the mixed material A by weight, adding bentonite into a quarter of the mixed material A, and carrying out uniform stirring so as to obtain a mixed material B; adding diatomite, expanded perlite and slag into remained three quarters of the mixed material A, and carrying out uniform stirring so as to obtain a mixed material C; subjecting the mixed material B and the mixed material C to full stirring at 40 to 50 DEG C so as to obtain a fireproof material slurry; injecting the obtained slurry into a mold, then carrying out compaction, carrying out curing at normal temperature and normal pressure for 2 to 3 days, carrying out demolding, then carrying out curing at normal temperature and normal pressure for 7 to 9 days, and carrying out cutting into a required size according to needs. The method provided by the invention is simple; and the obtained fireproof board has the advantages of low density, high hardness, light weight, good fireproof performance, strong processibility, safety, environmental protection and no pollution, and meets the needs of the development of the industry.

Owner:LUOYANG MINGLI TECH DEV

Intumescence fire-retardant coating

InactiveCN107254258AGood fire and heat insulationGood adhesionFireproof paintsAnti-corrosive paintsFoaming agentCarbon nanotube

The invention relates to an intumescence fire-retardant coating which comprises carbon nanotubes, wherein the carbon nanotubes are multi-wall carbon nanotubes or / and single-wall carbon nanotubes. The coating comprises the following components in parts by weight: 10-40 parts of a resin, 0-40 parts of a catalyst, 5-20 parts of a carbonizing agent, 5-20 parts of a foaming agent, 3-15 parts of a flame retardant and 3-15 parts of carbon nanotubes. The intumescence fire-retardant coating provided by the invention has the characteristics of being high in fireproof and thermal-insulating property, good in bonding force, high in strength, high in high / low temperature circulation resistance, high in water resistance, acid resistance and salt corrosion resistance, not liable to drop off, stable to store, high in decoration property, convenient to construct and the like, is capable of overcoming the defects that a conventional fireproof coating is low in intumescence multiplying power and poor in carbonized layer density, and is very high in fireproof property.

Owner:过春明

Water-based ultra-thin fireproof coating and preparation method thereof

InactiveCN104449106AImprove bindingImprove anti-corrosion performanceFireproof paintsAnti-corrosive paintsWater basedAluminum silicate

The invention provides a water-based ultra-thin fireproof coating, which comprises the following components in percentage by weight: 20-30% of chloroethylene-vinylidene chloride polyemulsion, 5-15% of benzene acrylic emulsion, 5-8% of expandable graphite powder, 5-10% of rutile type titanium dioxide, 2-4% of environment-friendly zinc phosphate, 4-5% of precipitated barium sulphate, 2-4% of corrosion inhibitor, 5-8% of aluminum hydroxide, 2-4% of antimonous oxide, 2-4% of water-based chlorinated paraffin, 1-3% of aluminum silicate fiber, 5-10% of ammonium polyphosphate (APP), 3.5-7% of pentaerythritol (PER), 1.5-2.4% of melamine (MEL), 0.2-0.3% of water-based disperser, 0.1-0.2% of water-based defoamer, 0.1-0.2% of water-based foam inhibitor, 1-2% of hydrated magnesium silicate, 0.5-1% of water-based thickening agent, 0.5-1% of neutralizer, 0.5-1% of flash-rust inhibitor, 1-2% of coalescing agent, 0.1-0.2% of water-based wetting agent, and 7.0-9.0% of deionized water. The dry speed of the water-based ultra-thin fireproof coating disclosed by the invention is rapid; the fireproof ability can be above 2 h; and the water-based ultra-thin fireproof coating has very excellent binding force and antiseptic property to rusty substrates.

Owner:成都拜迪新材料有限公司

Preparation method of environment-friendly double-component high-temperature-resisting fireproof coating

InactiveCN104726018AEmission reductionBlocking exchange deliveryFireproof paintsCross-linkOrganic solvent

The invention discloses a preparation method of an environment-friendly double-component high-temperature-resisting fireproof coating. The preparation method comprises the following steps: adding hydroxyl silicone oil, a flame retarding agent, magnetic filler and a ceramic additive into a grinding machine D under the stirring condition until the mixture is gradually and uniformly dispersed; grinding to a specified fineness to obtain a component A; adding a cross-linking agent, a coupling agent and a catalyst into a high-speed disperser; uniformly mixing to obtain a component B; when in use, uniformly mixing the prepared component A and the prepared component B in a mass ratio of 10 to 1; curing at the temperature of 10 to 50 DEG C to form a film namely high temperature-resisting fireproof coating, wherein the component A contains a hydroxyl silicone oil flame retarding agent, the magnetic filler, the ceramic additive and other heat insulating fillers, the component B contains the cross-linking agent, the coupling agent and the catalyst; when in used, mixing the component A and the component B in a mass ratio of 10 to 1 and curing at the temperature of 10 to 50 DEG C to form a film. The environment-friendly double-component high-temperature-resisting fireproof coating disclosed by the invention is free of an organic solvent and has the characteristics of good expansion performance when meeting fire, high expansion carbonization layer strength, long fire retarding time and the like; the coating is good in heat insulation property and high temperature resistance; the temperature resistance is 800 DEG C or more; the operation is convenient.

Owner:HAILONG EMERSON ZHENJIANG ENERGY TECH

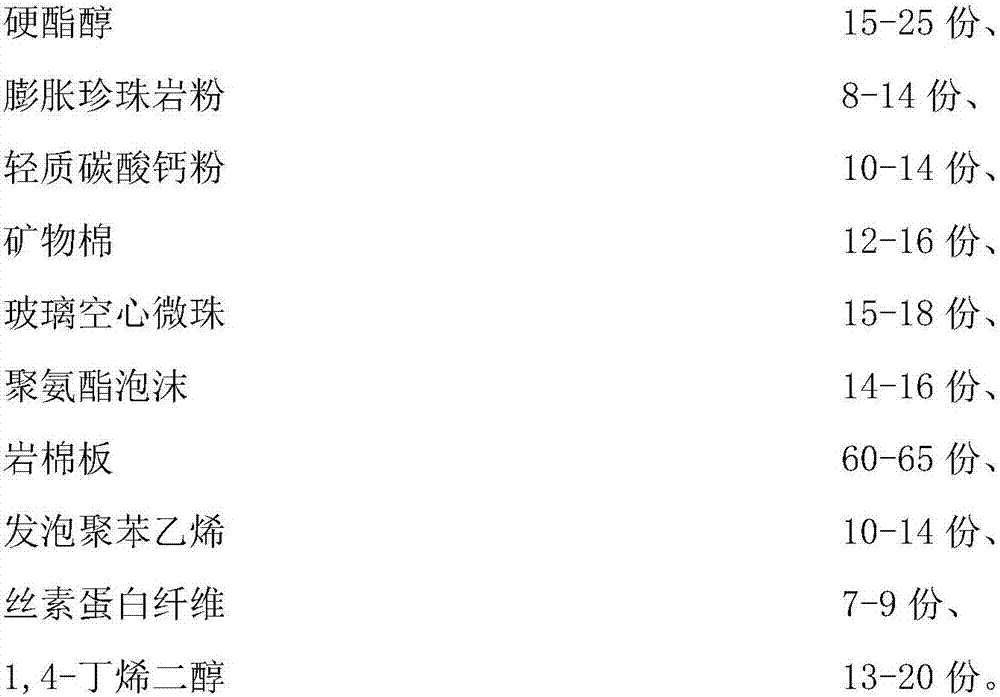

Novel fireproof heat-insulating building material and preparation method thereof

The invention provides a novel fireproof heat-insulating building material and a preparation method thereof, and relates to the field of building materials. The building material is prepared from the following raw materials in parts by weight: 15 to 30 parts of stearyl alcohol, 8 to 15 parts of expanded perlite powder, 10 to 15 parts of light calcium carbonate powder, 12 to 18 parts of mineral wool, 15 to 20 parts of glass hollow microbeads, 14 to 18 parts of polyurethane foam, 60 to 70 parts of rock wool board, 10 to 15 parts of foamed polystyrene, 7 to 9 parts of silk fiber and 13 to 22 parts of 1,4-butylene glycol. The preparation method of the building material comprises the following steps: smashing, stirring, casting and cooling. By adopting the building material, the problems of poor fireproofing and heat-insulating effects and high cost of a conventional fireproof heat-insulating building material are solved.

Owner:肥西县碧涛建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com