Patents

Literature

1547 results about "High aluminum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

However, very high aluminum levels can. sometimes cause water to have a bluish color. The only way to know if your drinking water has. elevated levels of aluminum is to have it tested by a state-certified water testing laboratory.

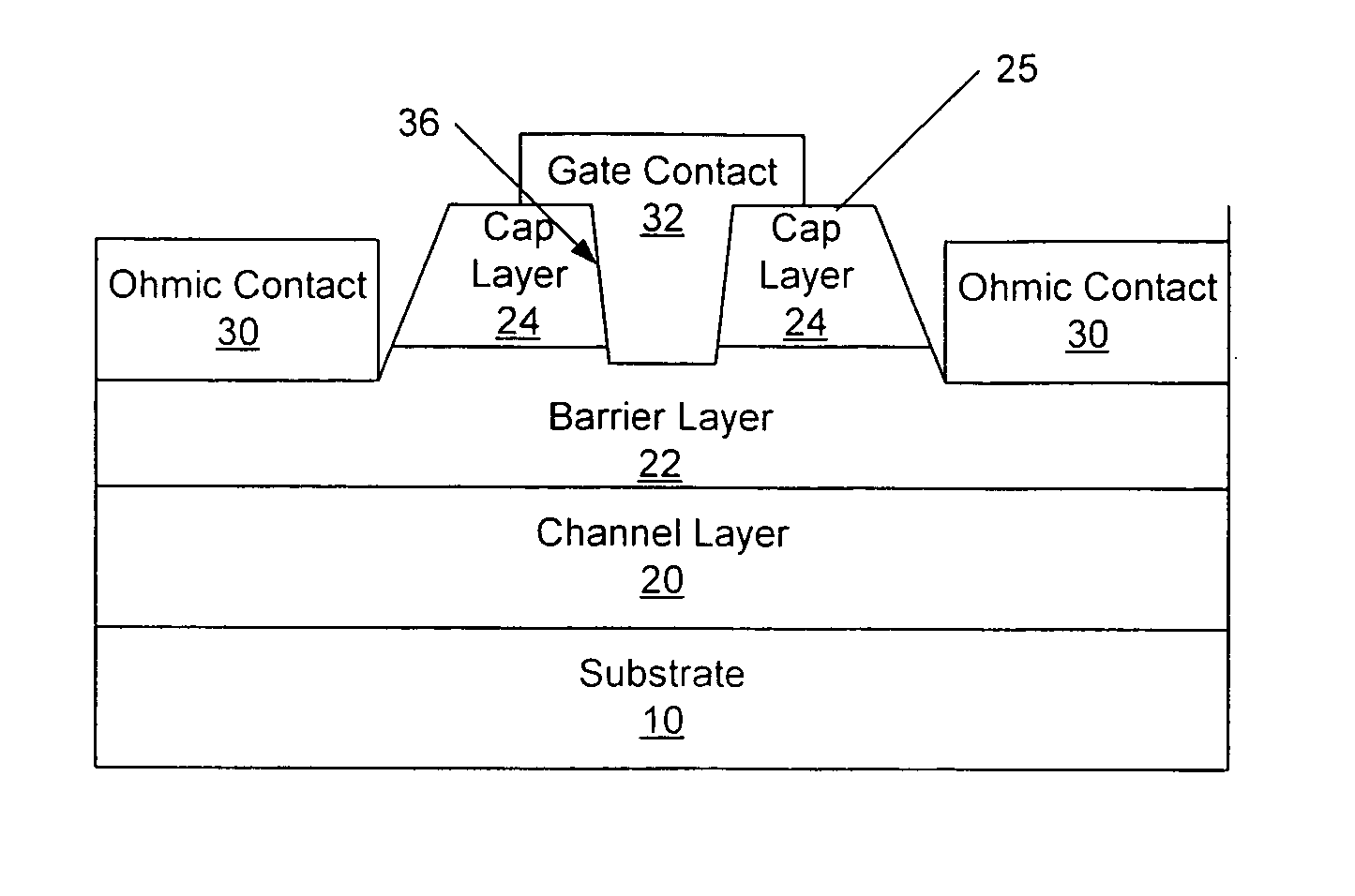

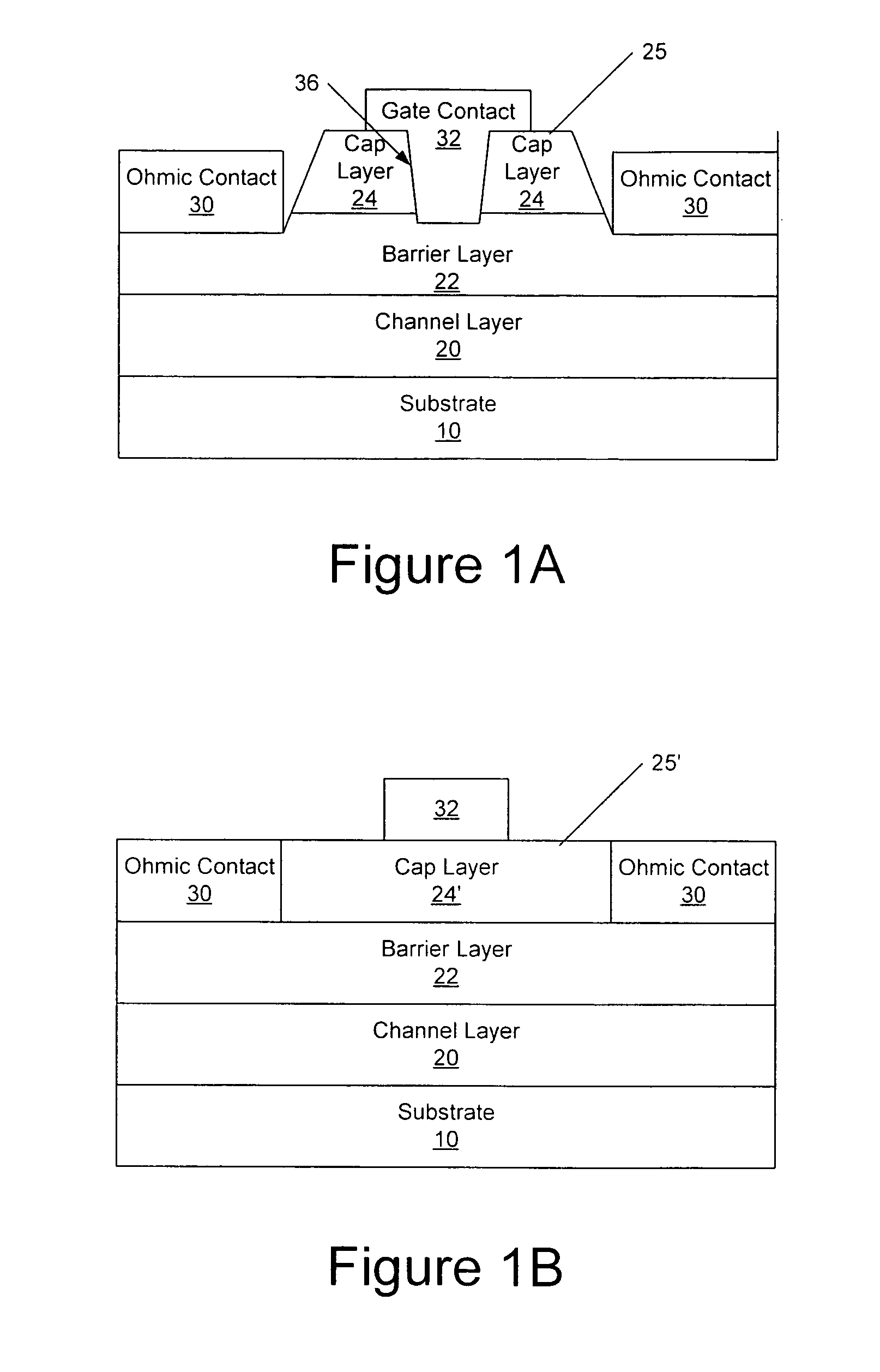

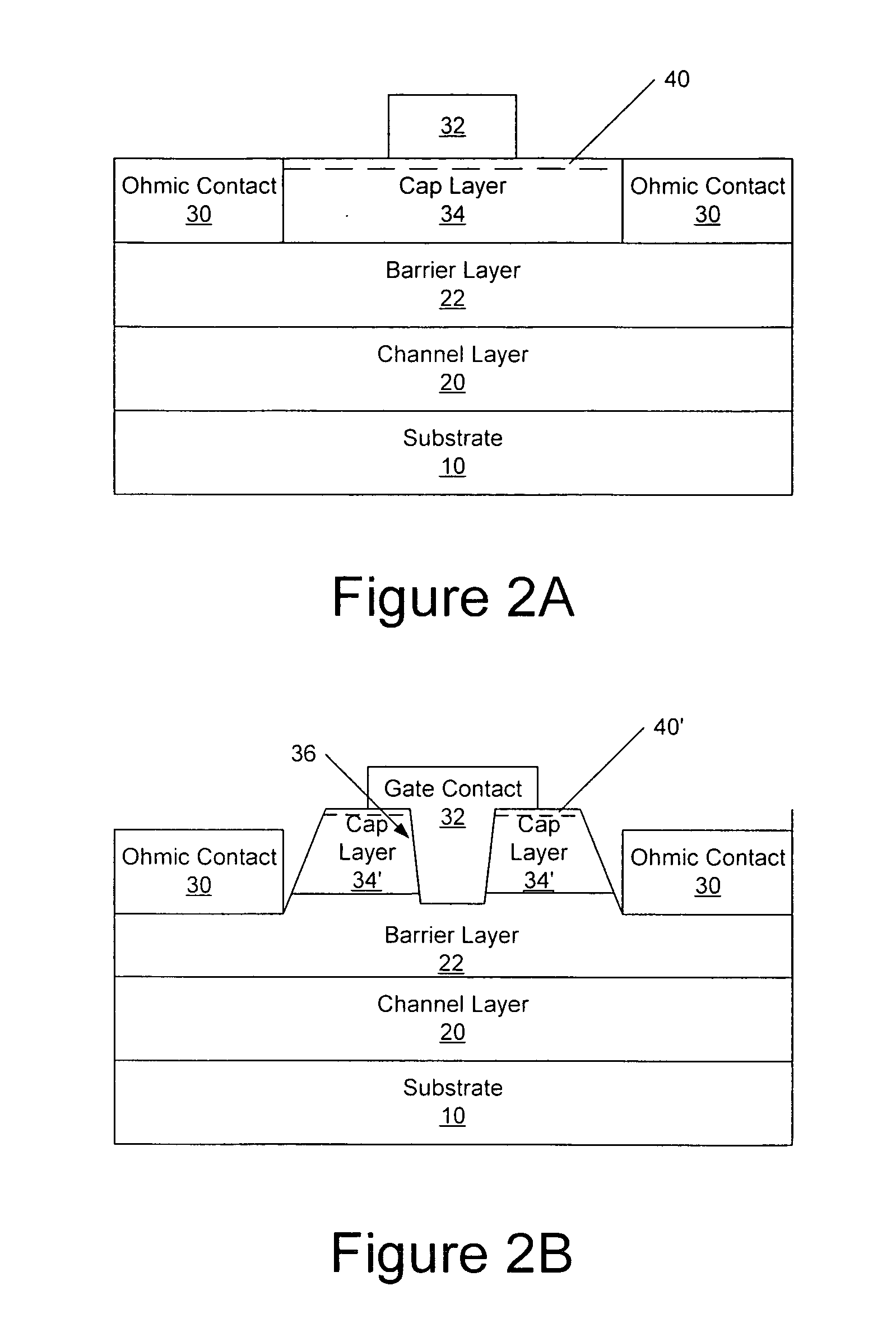

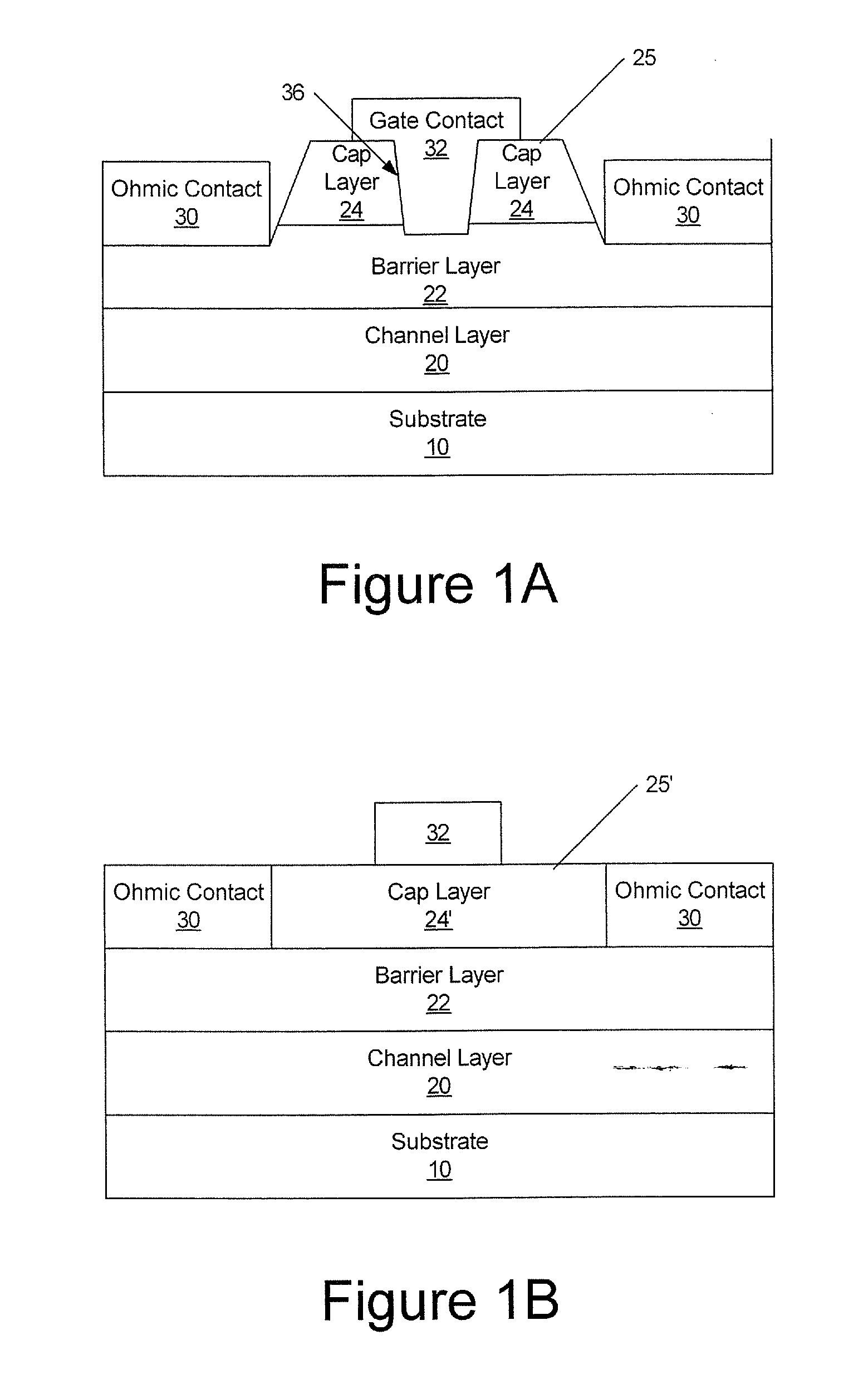

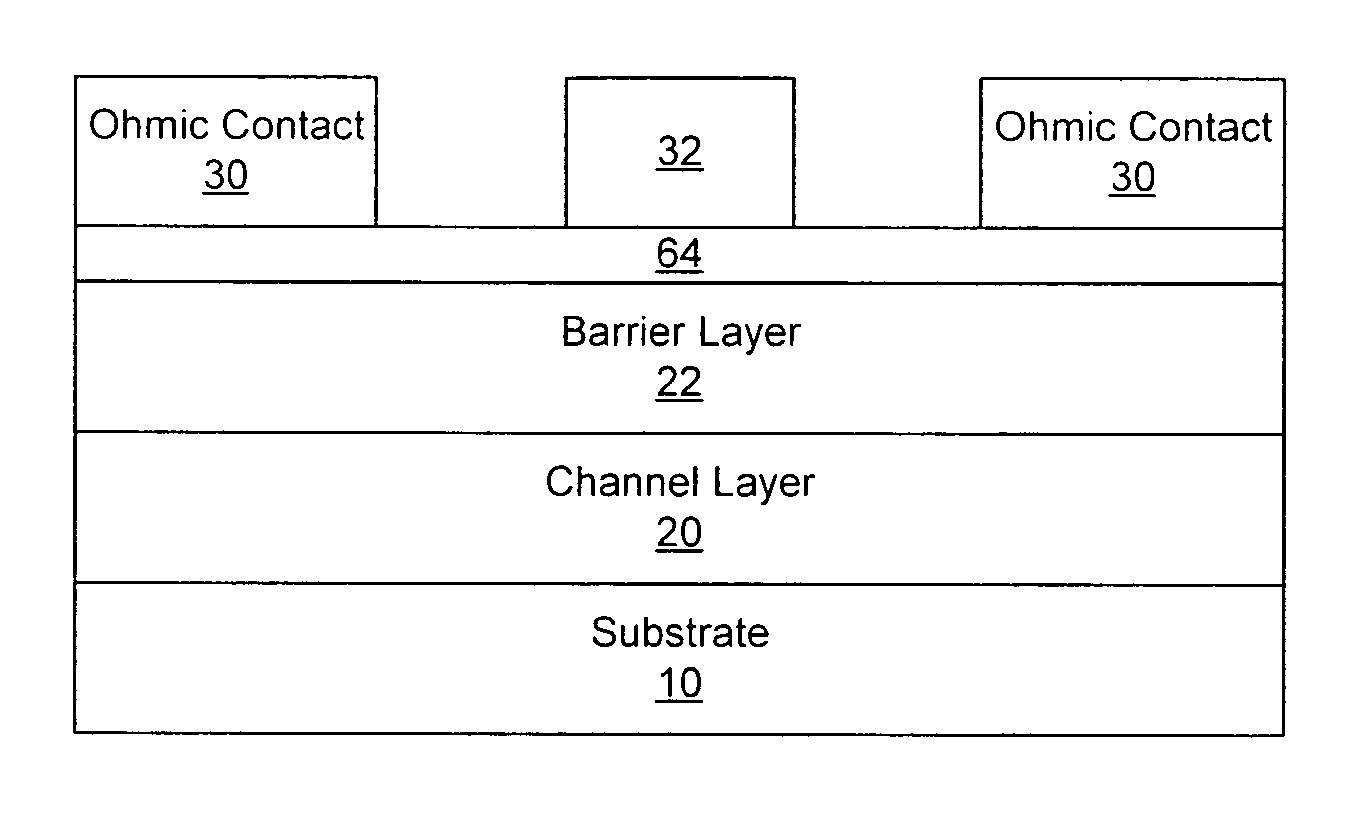

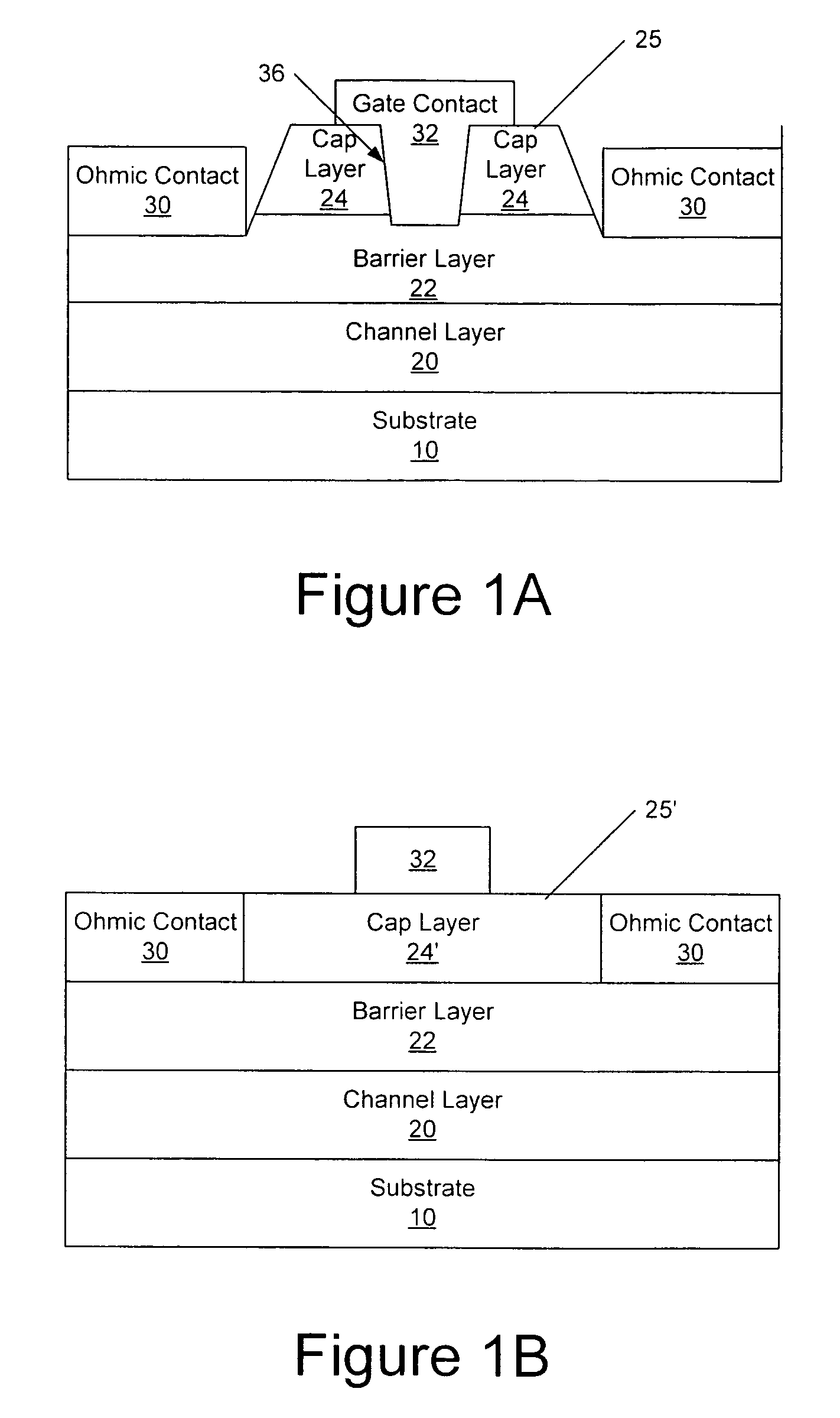

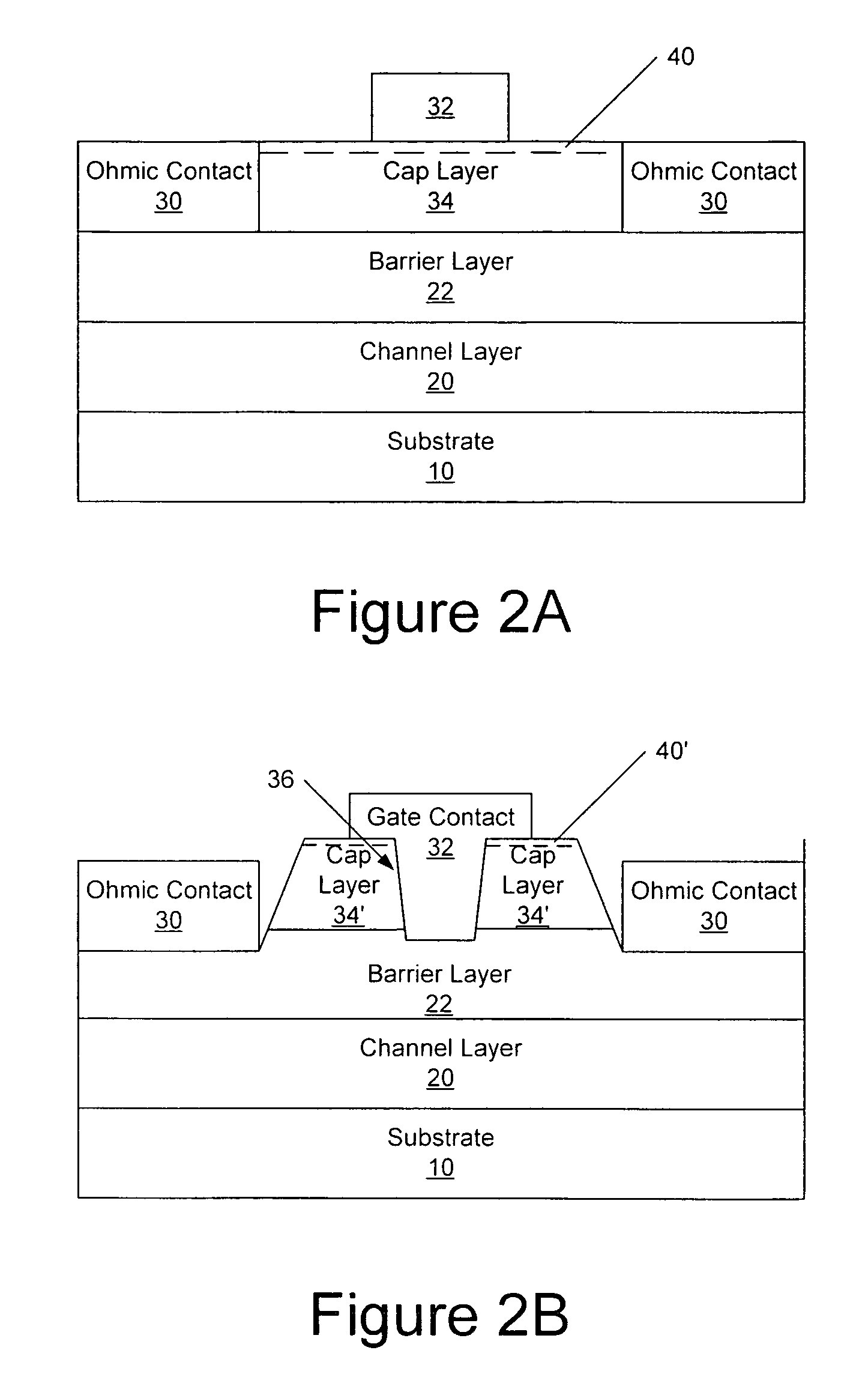

Cap layers and/or passivation layers for nitride-based transistors, transistor structures and methods of fabricating same

ActiveUS20060108606A1Increase concentrationSemiconductor/solid-state device detailsSolid-state devicesOhmic contactHigh electron

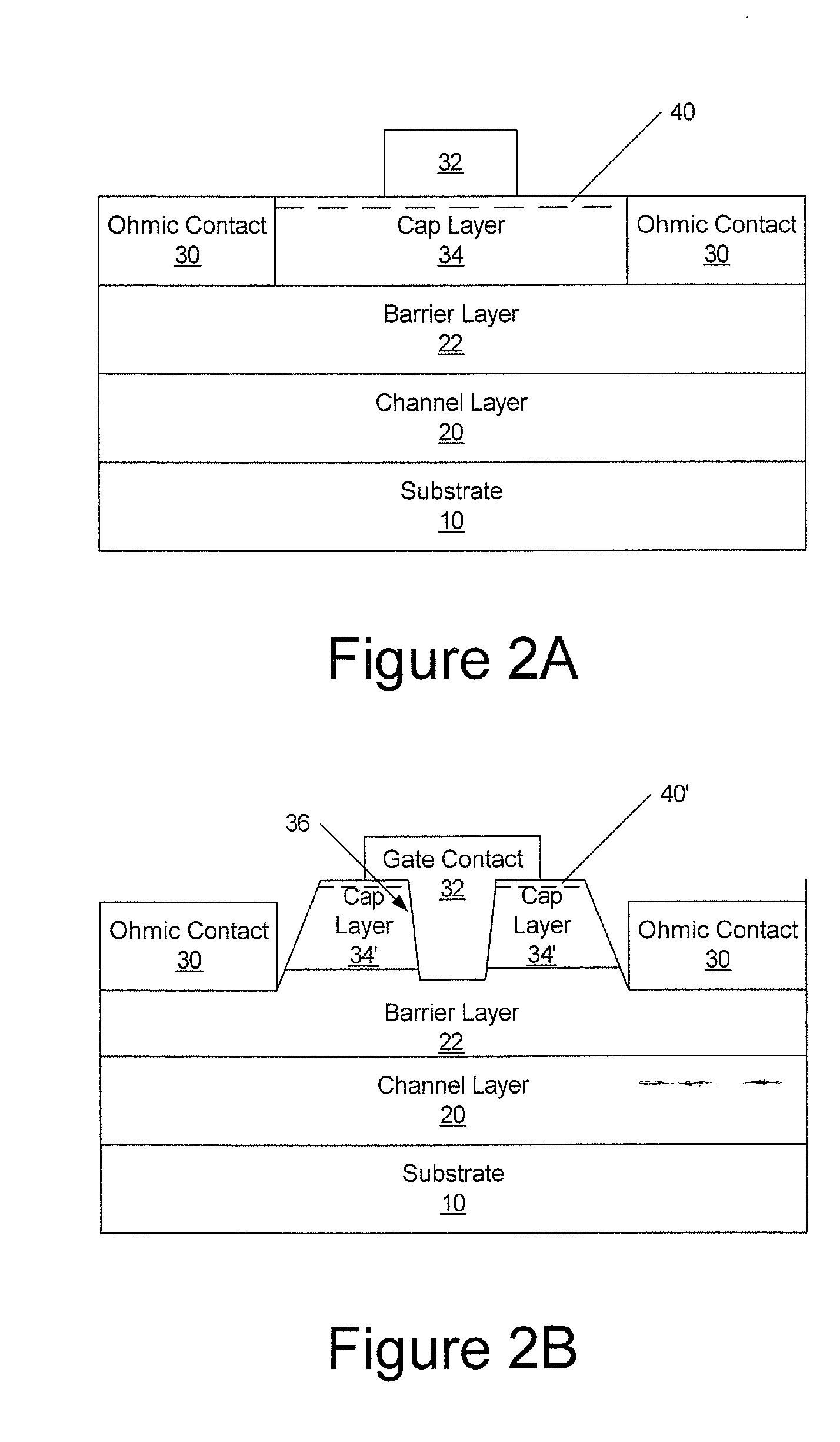

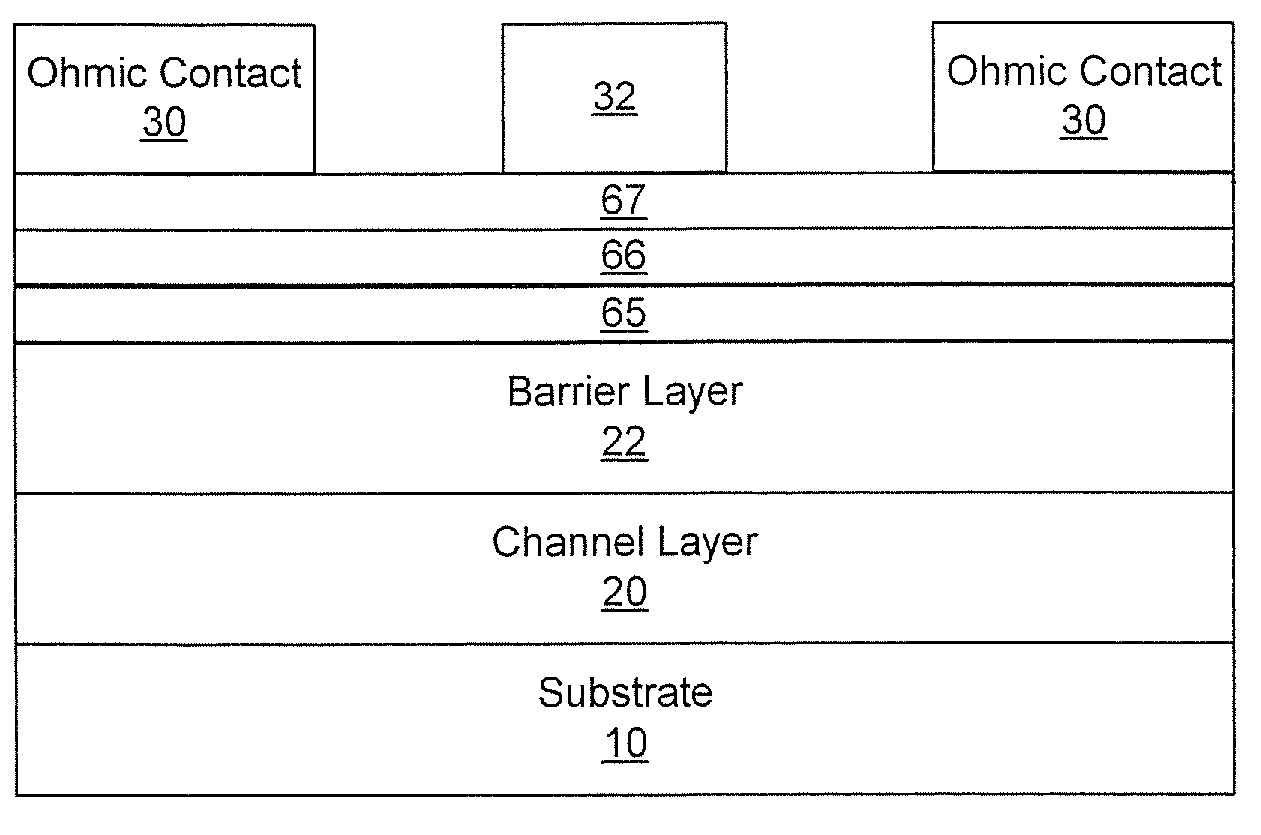

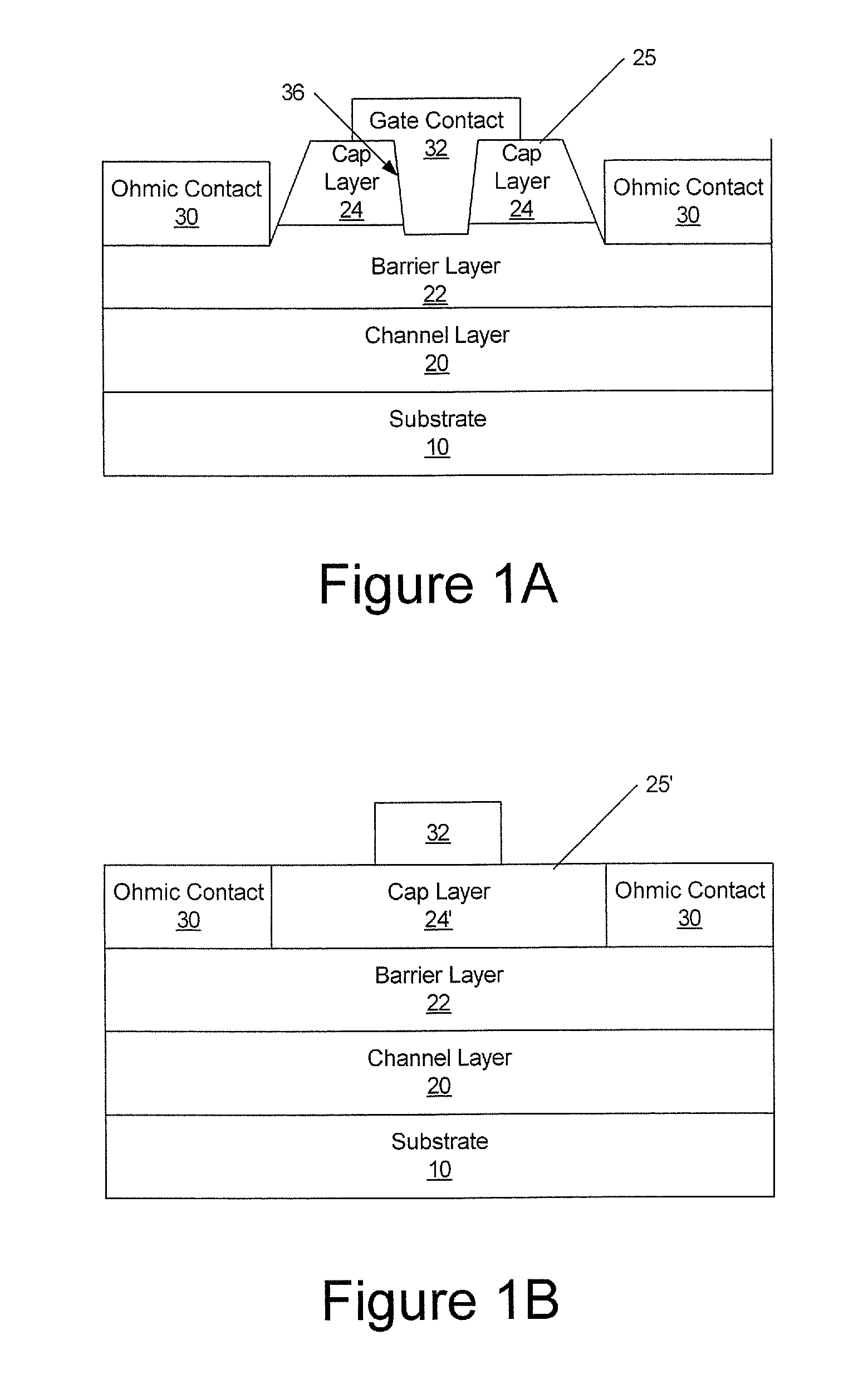

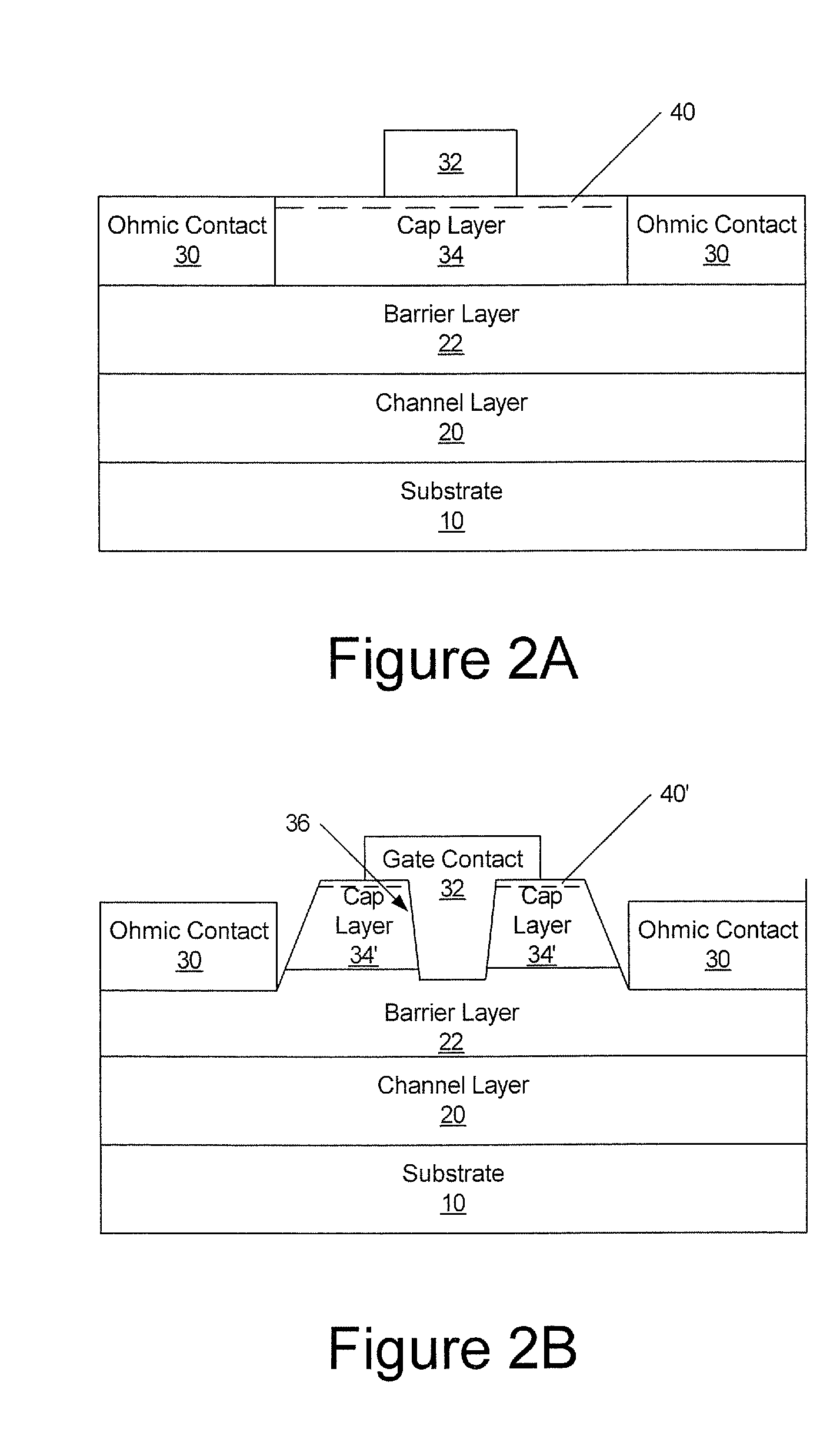

High electron mobility transistors are provided that include a non-uniform aluminum concentration AlGaN based cap layer having a high aluminum concentration adjacent a surface of the cap layer that is remote from the barrier layer on which the cap layer is provided. High electron mobility transistors are provided that include a cap layer having a doped region adjacent a surface of the cap layer that is remote from the barrier layer on which the cap layer is provided. Graphitic BN passivation structures for wide bandgap semiconductor devices are provided. SiC passivation structures for Group III-nitride semiconductor devices are provided. Oxygen anneals of passivation structures are also provided. Ohmic contacts without a recess are also provided.

Owner:CREE INC

Cap Layers Including Aluminum Nitride for Nitride-Based Transistors and Methods of Fabricating Same

ActiveUS20070164315A1Increase concentrationSemiconductor/solid-state device detailsSolid-state devicesOhmic contactGraphite

High electron mobility transistors are provided that include a non-uniform aluminum concentration AlGaN based cap layer having a high aluminum concentration adjacent a surface of the cap layer that is remote from the barrier layer on which the cap layer is provided. High electron mobility transistors are provided that include a cap layer having a doped region adjacent a surface of the cap layer that is remote from the barrier layer on which the cap layer is provided. Graphitic BN passivation structures for wide bandgap semiconductor devices are provided. SiC passivation structures for Group III-nitride semiconductor devices are provided. Oxygen anneals of passivation structures are also provided. Ohmic contacts without a recess are also provided.

Owner:CREE INC

Cap layers including aluminum nitride for nitride-based transistors

ActiveUS7709859B2Semiconductor/solid-state device detailsSolid-state devicesOhmic contactHigh electron

High electron mobility transistors are provided that include a non-uniform aluminum concentration AlGaN based cap layer having a high aluminum concentration adjacent a surface of the cap layer that is remote from the barrier layer on which the cap layer is provided. High electron mobility transistors are provided that include a cap layer having a doped region adjacent a surface of the cap layer that is remote from the barrier layer on which the cap layer is provided. Graphitic BN passivation structures for wide bandgap semiconductor devices are provided. SiC passivation structures for Group III-nitride semiconductor devices are provided. Oxygen anneals of passivation structures are also provided. Ohmic contacts without a recess are also provided.

Owner:CREE INC

Transistors having buried n-type and p-type regions beneath the source region

High electron mobility transistors are provided that include a non-uniform aluminum concentration AlGaN based cap layer having a high aluminum concentration adjacent a surface of the cap layer that is remote from the barrier layer on which the cap layer is provided. High electron mobility transistors are provided that include a cap layer having a doped region adjacent a surface of the cap layer that is remote from the barrier layer on which the cap layer is provided. Graphitic BN passivation structures for wide bandgap semiconductor devices are provided. SiC passivation structures for Group III-nitride semiconductor devices are provided. Oxygen anneals of passivation structures are also provided. Ohmic contacts without a recess are also provided.

Owner:CREE INC

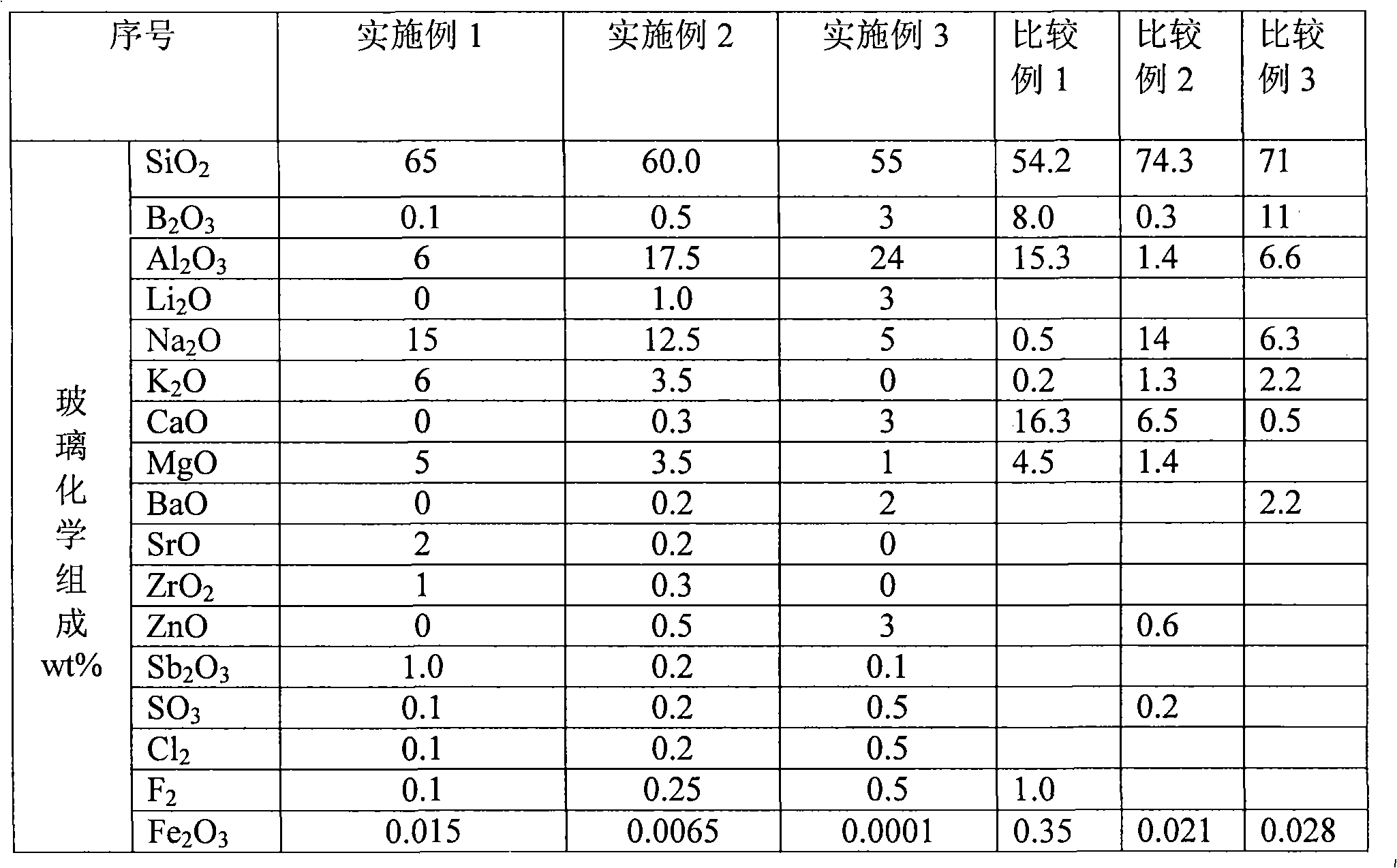

High strength aluminosilicate glass and chemically toughening process thereof

ActiveCN101337770AMeet the screen saver functionProtective functionGlass tempering apparatusAlkali freeShock resistance

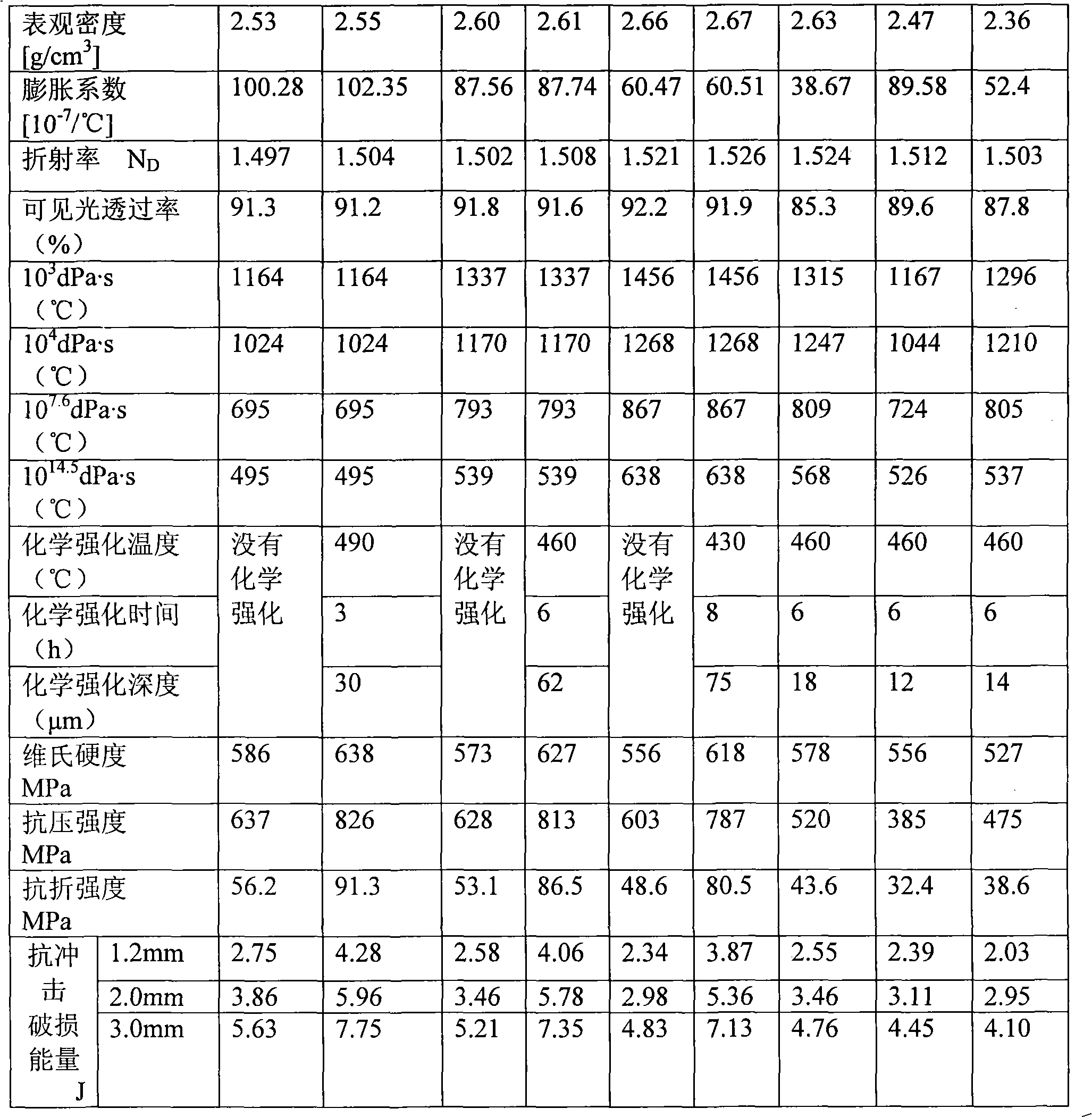

The invention relates to a high-strength aluminate silicate glass and a chemical toughening method thereof, and belongs to the silicate glass field. The glass comprises the following chemical components (weight percent): 55 to 65 weight percent of SiO2, 0.1 to 3 weight percent of B2O3, 6 to 24 weight percent of Al2O3, 3 to 9 weight percent of MgO plus CaO plus BaO plus SrO, 0 to 1 weight percent of ZrO2, 0 to 2 weight percent of ZnO, 0.1 to 0.5 weight percent of Cl2, 0.1 to 1.0 weight percent of Sb2O3, 0.1 to 0.5 weight percent of SO3 and 0.1 to 0.5 weight percent of F2, and belongs to a aluminate silicate glass system. The high-strength aluminate silicate glass is prepared through a known plate glass production method, and then is subjected to the strengthening treatment by adopting the chemical toughening method. The glass has high permeability of visible light, and relatively common soda lime glass, neutral medicine glass and alkali-free high-aluminum glass have good shock resistance property, high scratch resistance property and high durability. The high-strength aluminate silicate glass is applied to the screen surface protection of plasma display products and liquid crystal display products, the protection of touch screens, the screen protection of automated teller machines, and the screen protection of other electronic products (Mobile phones, PDAs and media machines, etc.), thereby effectively preventing the impact and the scratch damage to the glass surface of display products. The high-strength aluminate silicate glass contains no harmful elements.

Owner:SUZHOU SHINWU OPTRONICS TECH

Al-Zn-Mg-Si alloy for hot dipping steel

InactiveCN101457320AAvoid gatheringDeterioration of surface propertiesHot-dipping/immersion processesRare earthZinc alloys

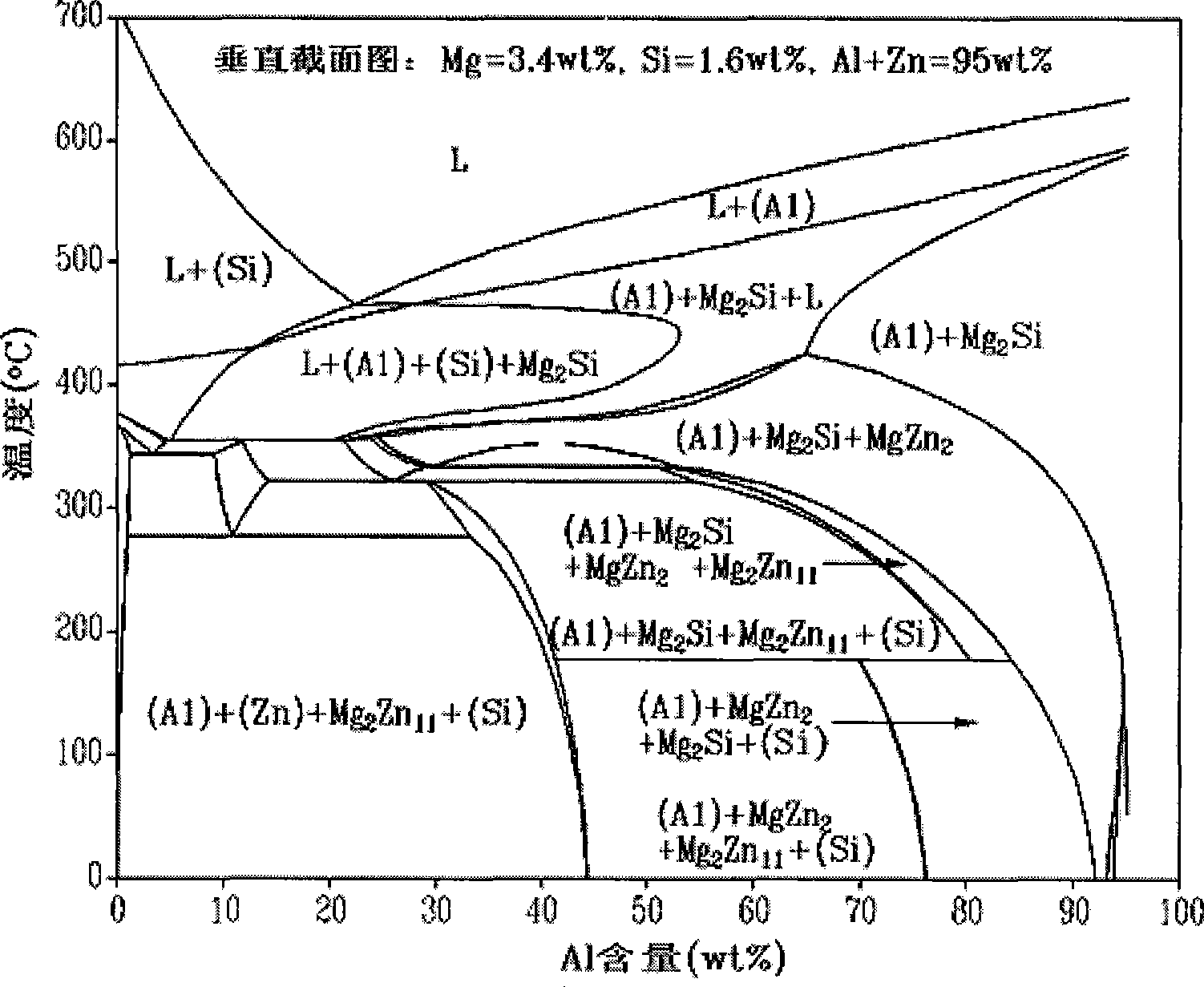

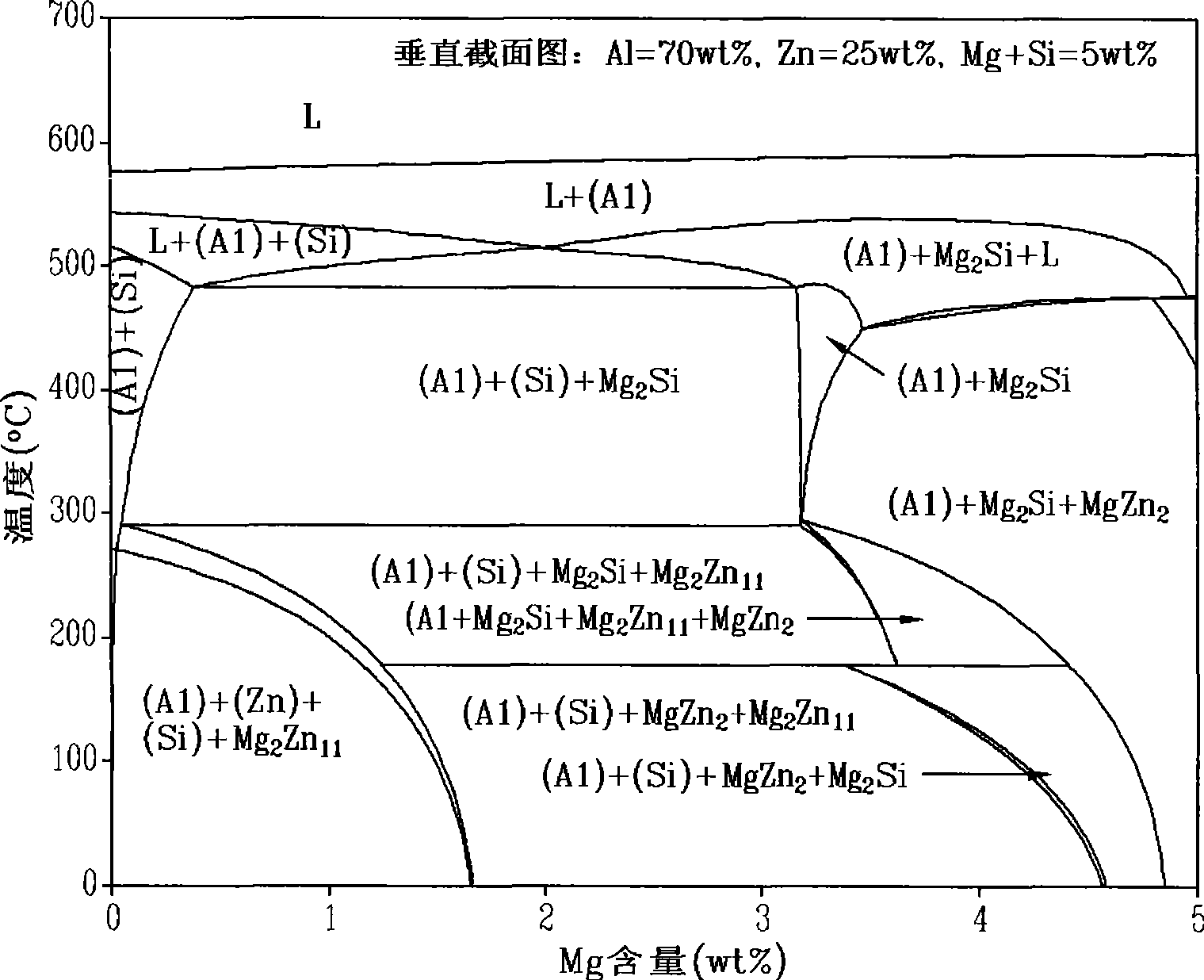

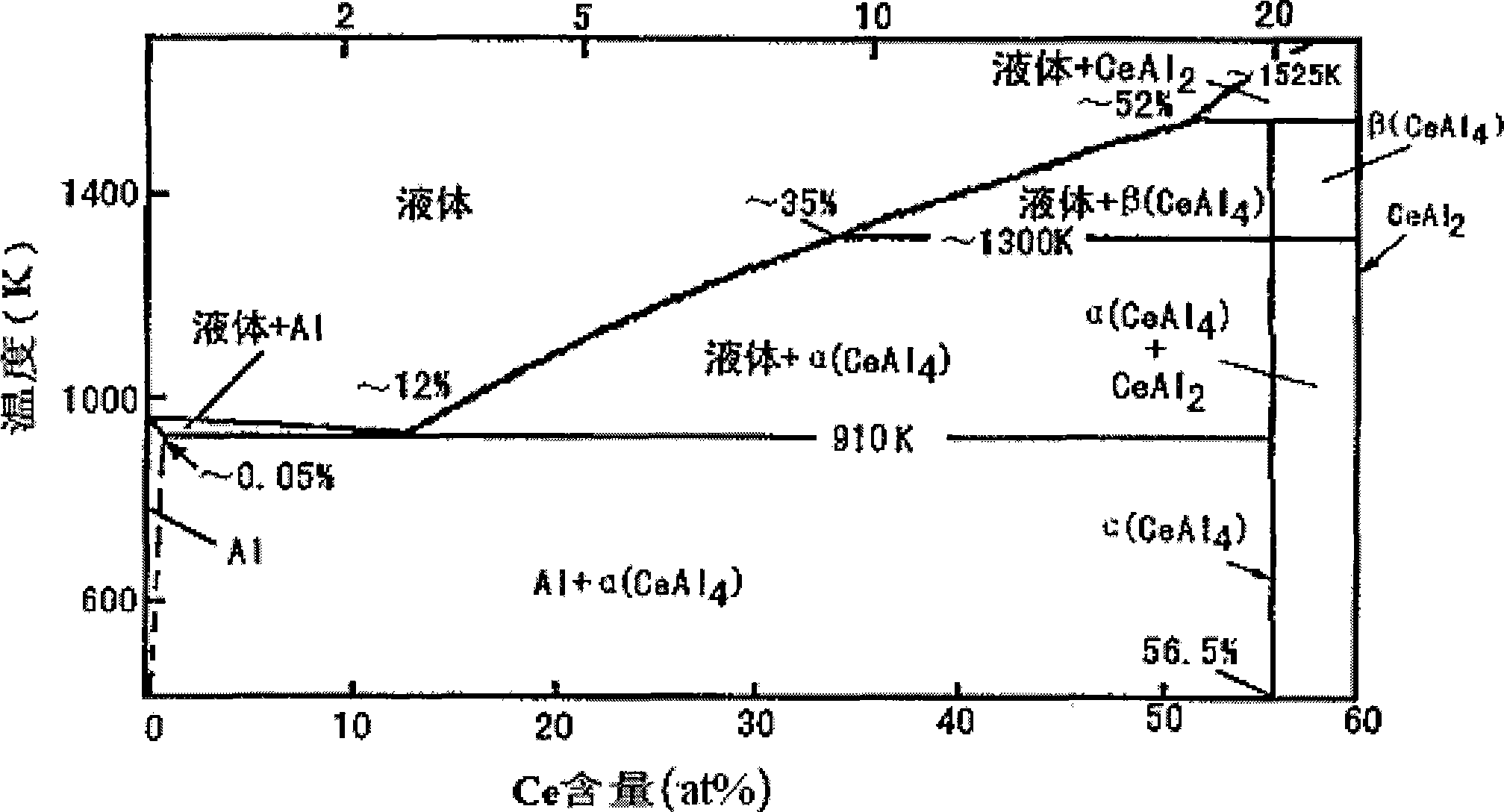

The invention provides a rare earth-containing Al-Zn-Mg-Si alloy with high aluminum content for hot-dipping steel products, comprising the following compositions by weight percent as follows; Al: 50-75%, Mg: 1-5%, Si: 0.5-2.5%, the addition of 0.002-0.1% of Ti, 0.001-0.045% of B and 0.05-1% of rare earth (La or Ce), and the balance of Zn and unavoidable impurities. The invention utilizes corrosion resistance of Mg2Si and grain-refining effect of the rare earth, the Ti and the Bi elements to improve quality of plating solution and obtain a high aluminum content aluminum-zinc alloy cladding with ,a bright and smooth surface and great corrosion resistance property. In addition, the content of aluminum in the alloy is up to 50-75%, thereby lowering production cost.

Owner:SHANGHAI UNIV

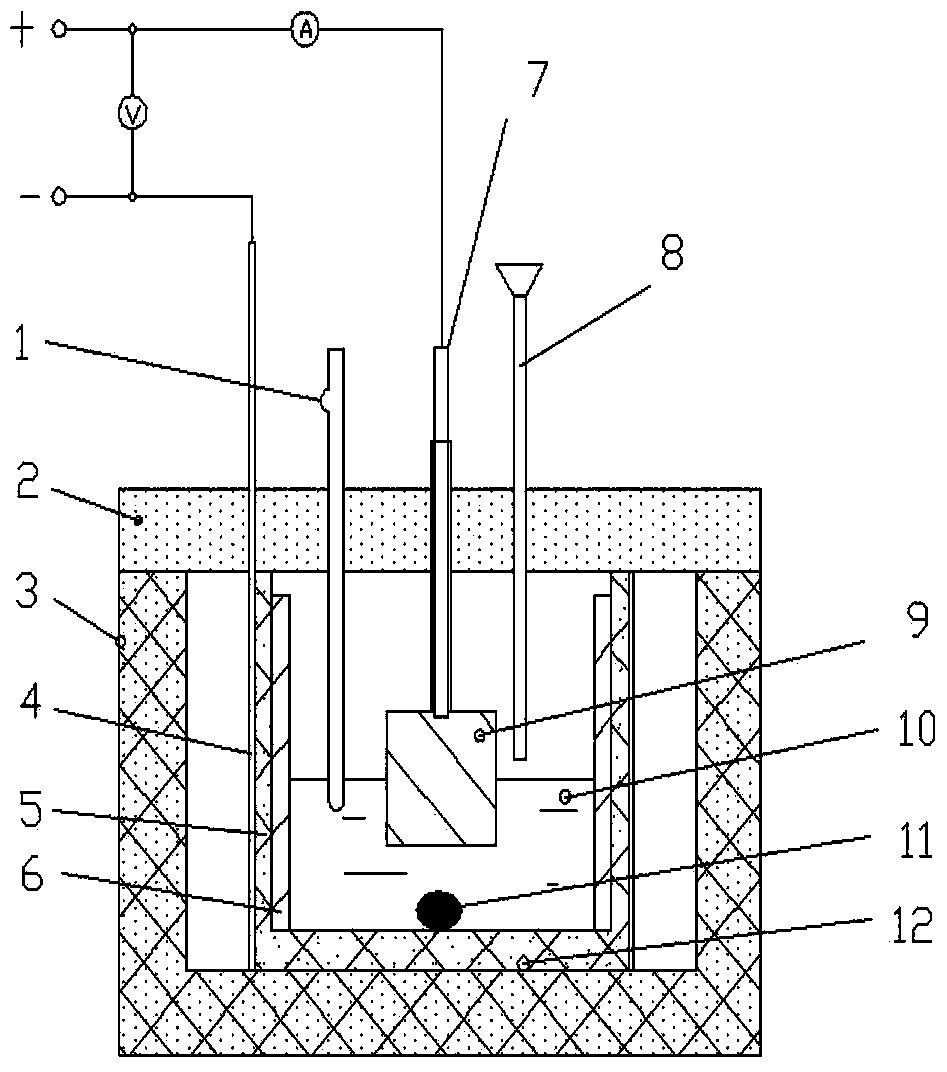

Aluminum electrolysis inert anode

InactiveCN103757661AAvoid consumptionWith energy saving and emission reductionElectrolysisHigh entropy alloys

The invention provides an aluminum electrolysis inert anode of which the material is a high-entropy alloy. The high-entropy alloy contains 5-10 alloy elements of which the mole ratio can be identical or different; and the atomic percent of each main element is 5-35%. The high-entropy alloy inert anode has the characteristics of favorable high-temperature oxidation resistance, high aluminum electrolysis salt corrosion resistance, high electric conductivity and the like. The high-entropy alloy prepared by the smelting method has the advantages of simple technique and low cost, and is easy for connection. When being used for aluminum electrolysis, the high-entropy alloy can avoid the consumption of the carbon anode and the emission of the CO2 gas, and has the advantages of energy saving and emission reduction.

Owner:FUJIAN UNIV OF TECH

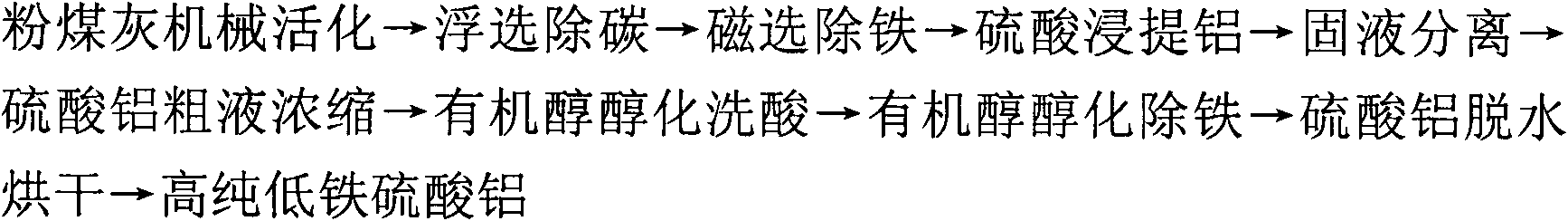

Technological method for producing high-purity low-iron aluminum sulfate by using coal ash and comprehensively utilizing coal ash

InactiveCN102101689AEasy industrial iron removalLow costPigmenting treatmentSolid waste disposalBiological activationCoal

The invention discloses a technological method for producing high-purity low-iron aluminum sulfate by using coal ash and comprehensively utilizing the coal ash, comprising the following steps of: carrying out mechanical activation, flotation decarburization, magnetic separation for deferrization, aluminum extraction with sulfuric acid, solid-liquid separation, concentration of aluminum sulfate crude liquor, organic alcohol alcoholization for acid rinse, organic alcohol alcoholization for deferrization and aluminum sulfate dewatering and drying on the coal ash to obtain the high-purity low-iron aluminum sulfate with low Fe content. The invention solves the problems on impurity removal and purification of the aluminum sulfate in the recycling process of the coal ash, simplifies the process flow, reduces the energy consumption, solves the technical problem of overlarge accumulation of secondary residue quantity, achieves high extraction ratio of aluminum contained in the coal ash, and realizes the recycling of organic alcohol and sulfuric acid and the comprehensive utilization of side products including unburnt black, magnetic iron powder, iron-containing aluminum sulfate crystals, high-silicon-dust active mineral blending materials or novel silicon-magnesium cement, and the like. The technological method has the advantages of simple process, short flow, easiness for control of a production process, high aluminum extraction ratio, low impurity content of products and stable quality.

Owner:内蒙古昶泰资源循环再生利用科技开发有限责任公司 +2

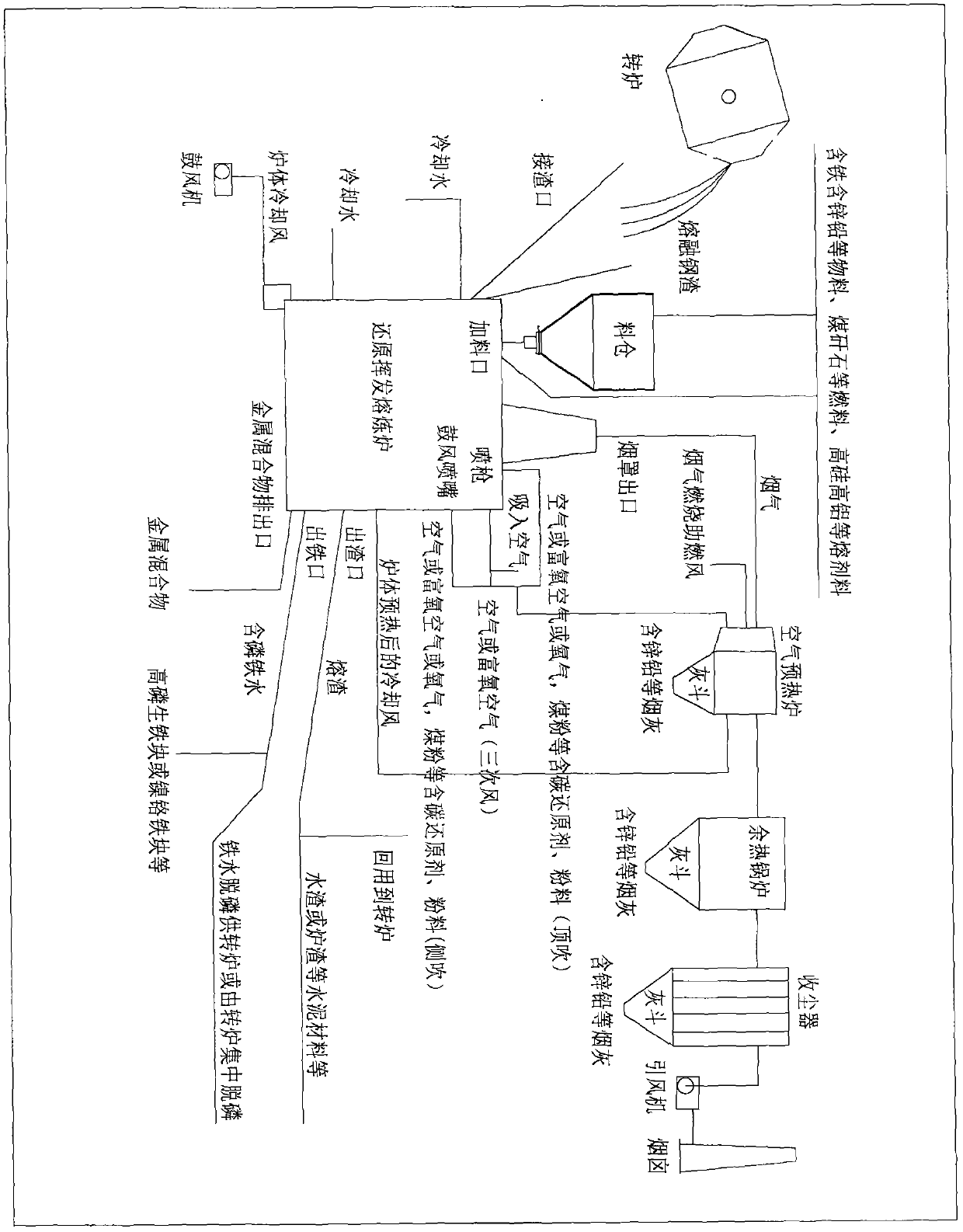

Cooperative processing and recycling method for material containing iron and/or zinc, lead, copper and tin, and the like and molten steel slag

PendingCN108676942AReduce outputEfficient recyclingRecycling and recovery technologiesProcess efficiency improvementMolten slagMaterials science

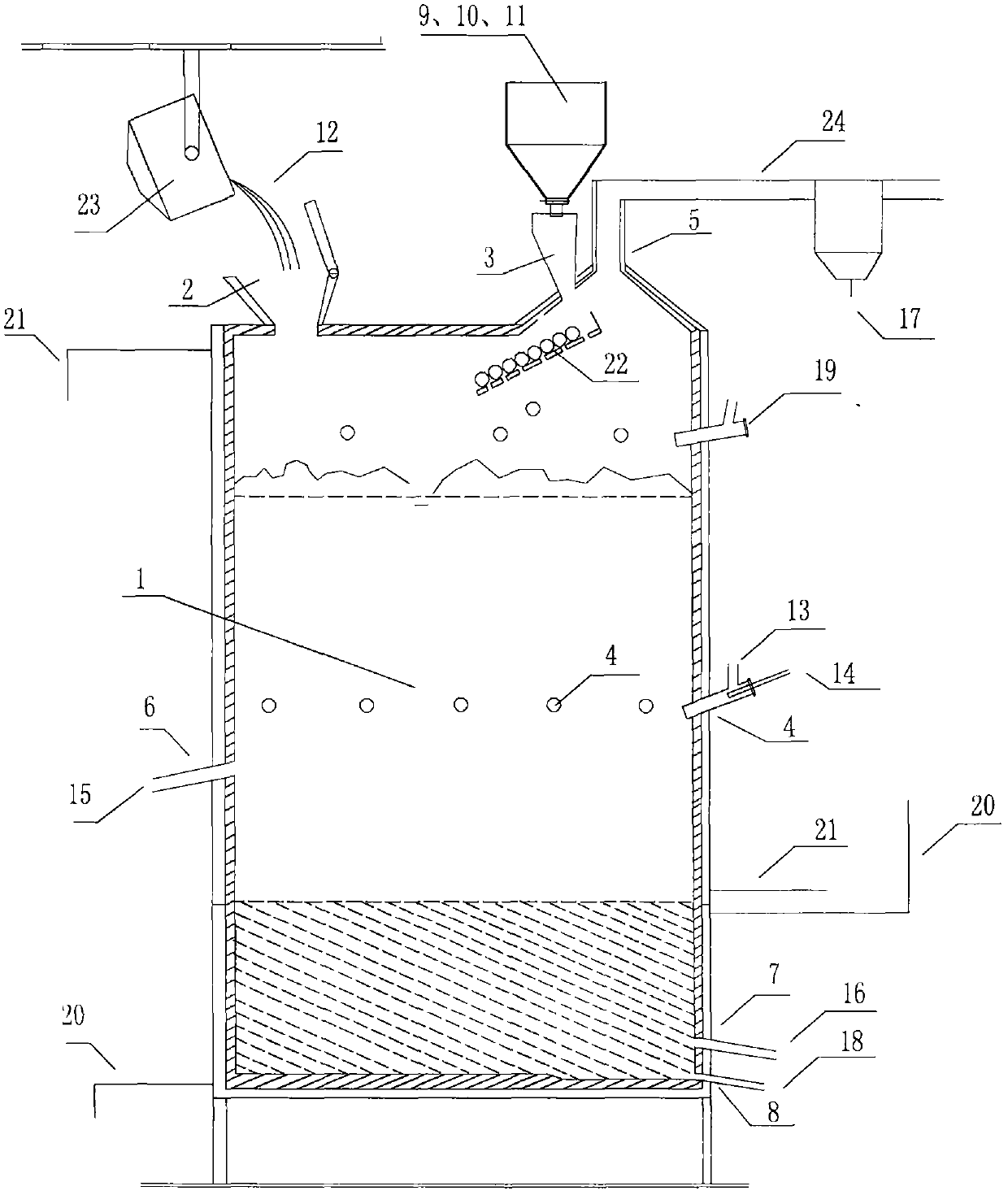

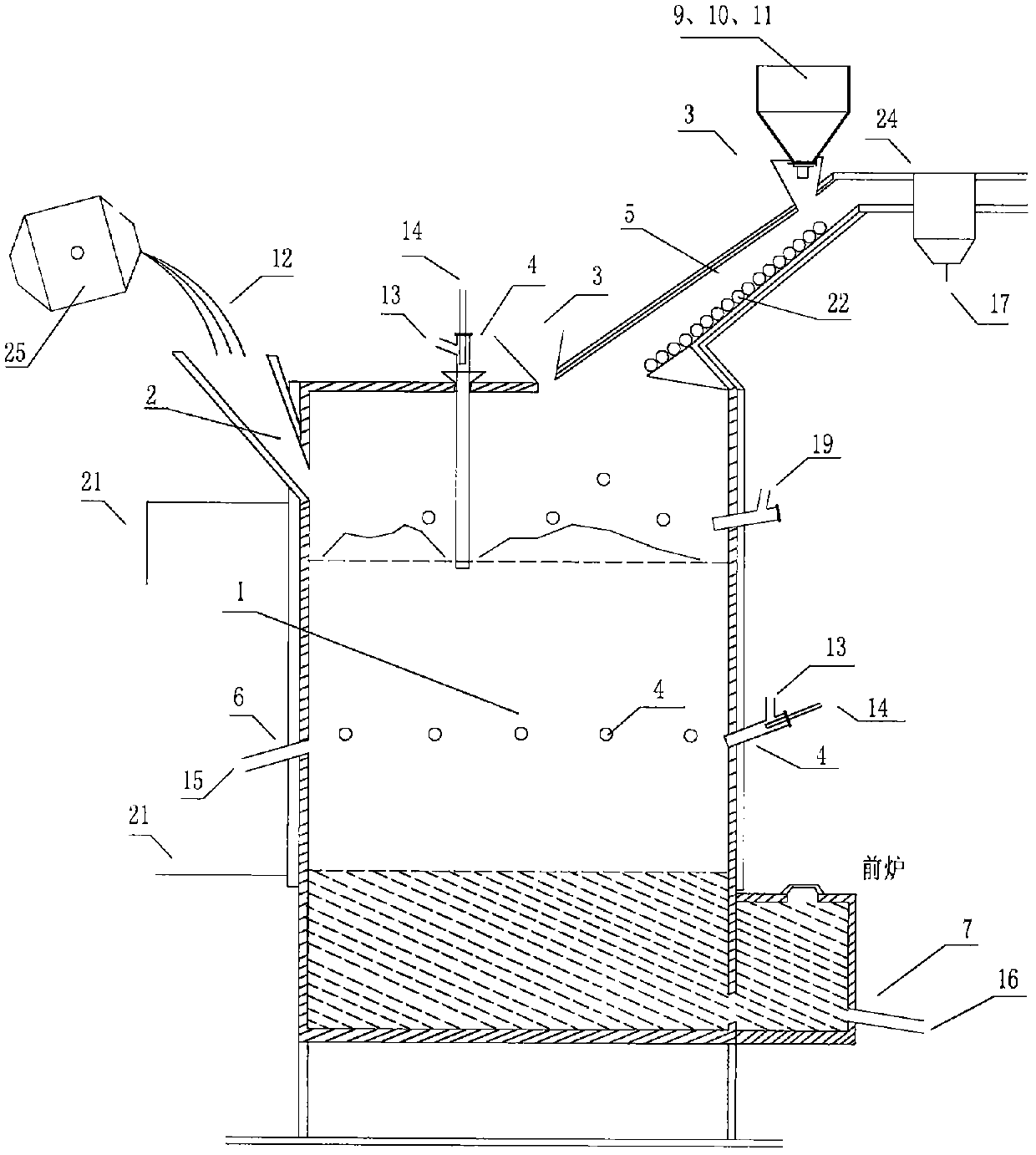

The invention discloses a process method for cooperatively and continuously processing waste containing iron and / or zinc, lead, copper and tin, and the like and molten steel slag on line, separating and recycling metal such as iron, zinc, lead, copper and tin as well as molten slag. The cooperative processing and recycling method is characterized in that pellets prepared from waste containing iron, zinc, lead, copper, tin and the like, particles, a blocky material containing iron, zinc, lead, copper, tin and the like and high-temperature molten steel slag are added into a reducing, volatilizing and smelting furnace, molten iron, which is obtained by air-blowing, adding of fuels such as coal gangues and flux such as high silicon and high aluminum, high-temperature reducing and volatilizingtreatment, is discharged from an iron outlet of the reducing, volatilizing and smelting furnace; volatilized substances such as zinc and lead and smoke gas are sucked into a dust collector for being collected and utilized; enriched metal such as gold, silver, copper, tin and lead is discharged from a discharge hole in the bottommost part of the reducing, volatilizing and smelting furnace for beingrecycled; and molten slag is discharged through a slag outlet, water slag and the like or the molten slag is returned into a converter for being recycled. Waste containing iron, zinc, lead, copper, tin and the like, molten steel slag and coal gangue waste slag and the like are cooperatively and continuously treated to separate and recycle useful metal, so that remarkable energy-saving environment-friendly social benefits and economic benefits are achieved.

Owner:湖南建鑫冶金科技有限公司

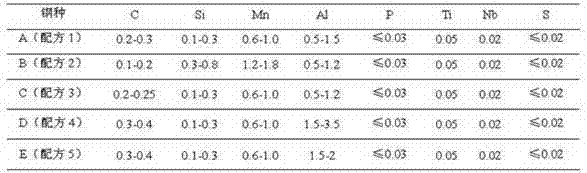

Continuous casting protection slag for high-alumina steel and manufacture method thereof

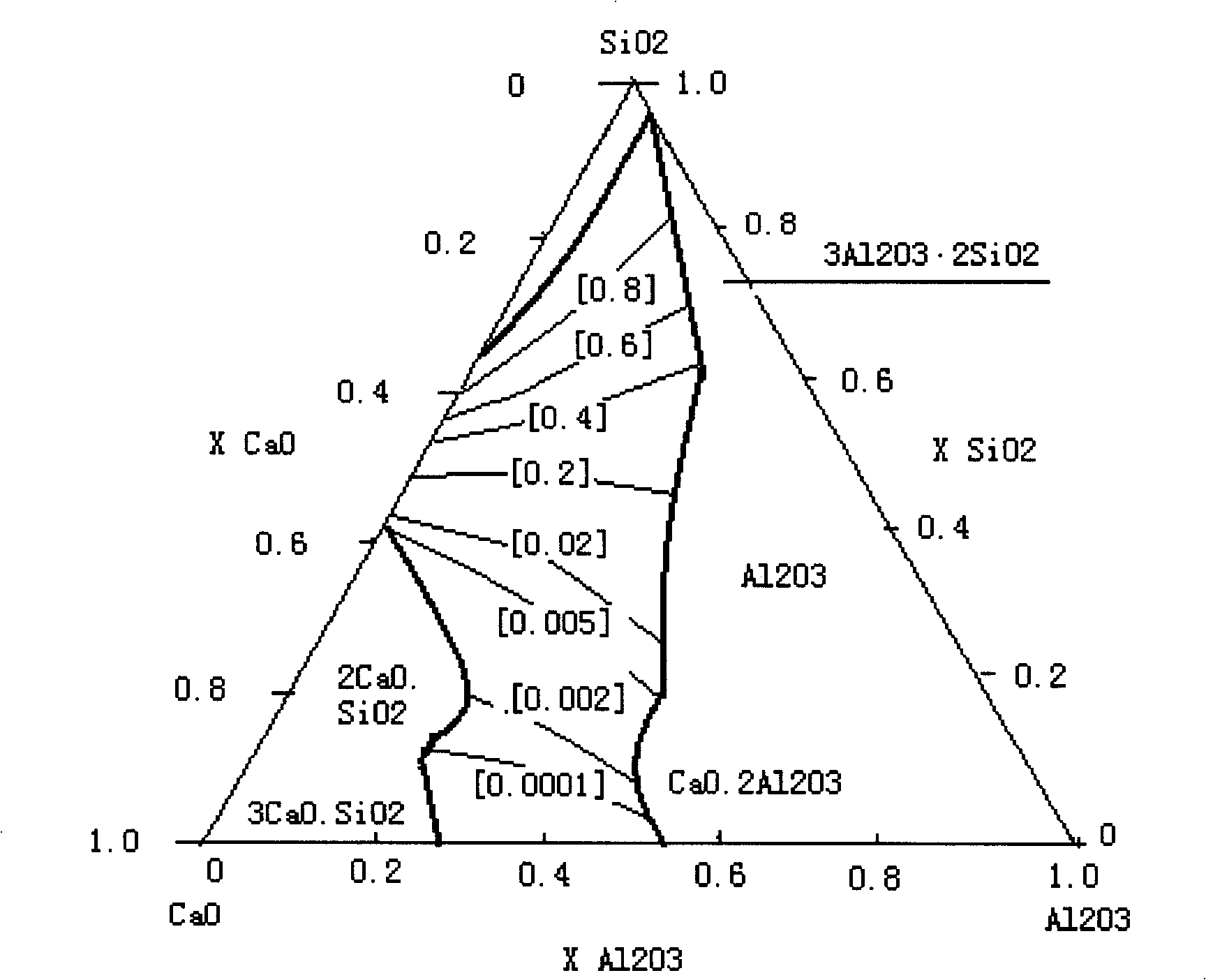

InactiveCN101332497ASolving Continuous Casting ProblemsInhibit denaturation of slagChemical compositionSlag

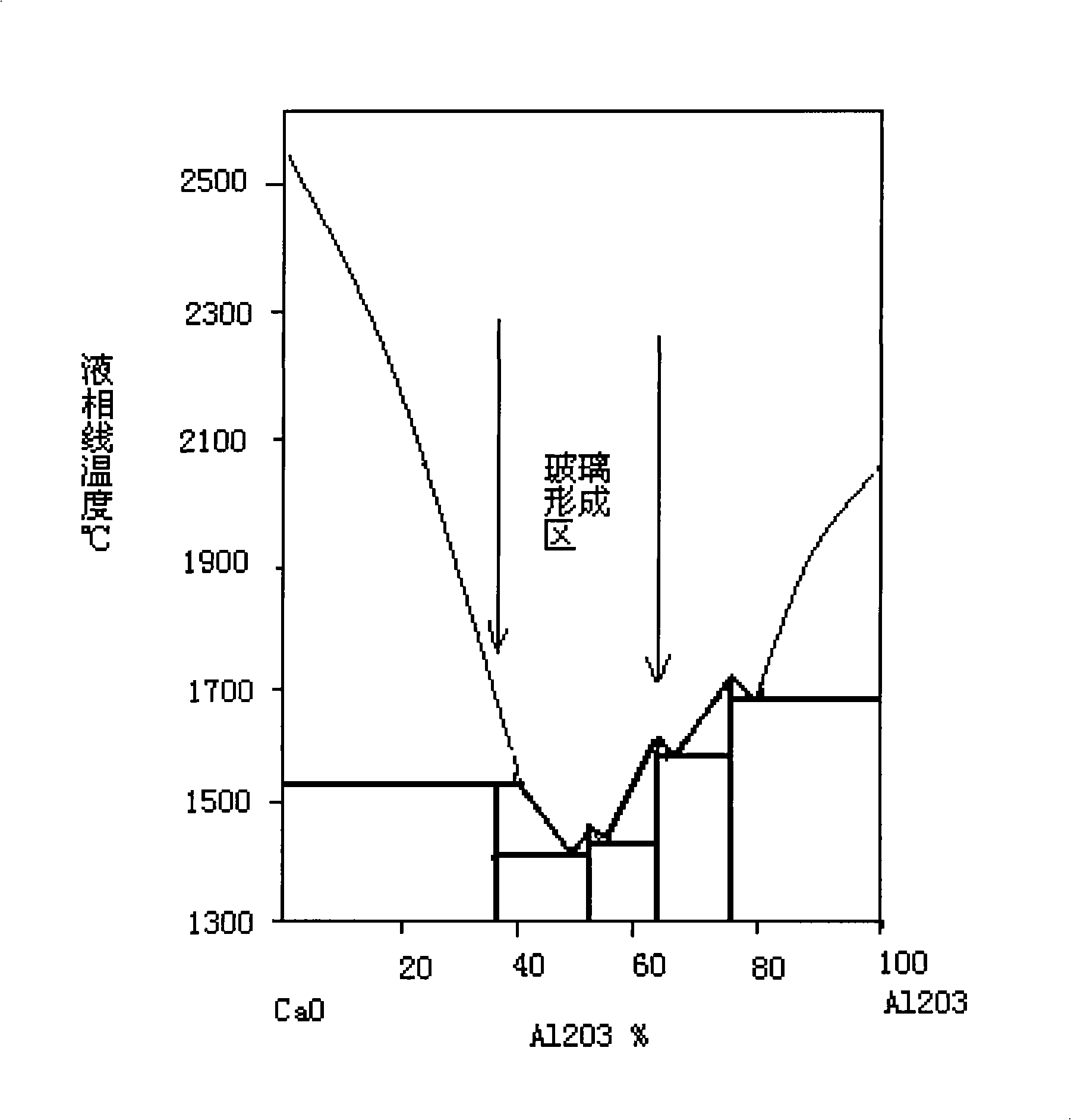

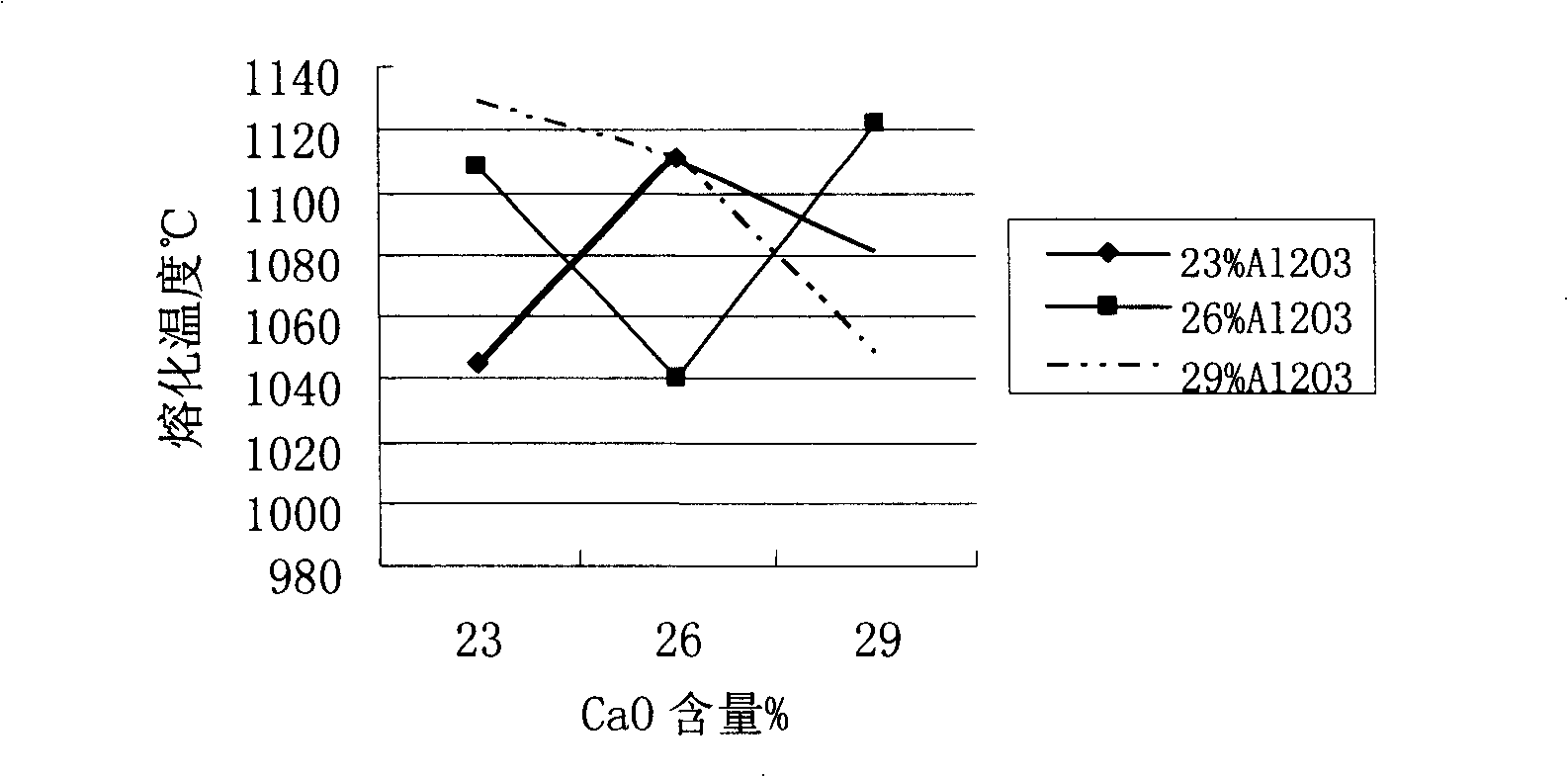

The invention relates to a steel-making auxiliary material and a production method thereof, in particular to a continuous casting powder for high-aluminum steel and a production method thereof. The invention is mainly technically characterized in that the casting powder raw material is prepared by using the following chemical components with the percentage: CaO+Al2O3 accounts for 50%-60%, and the ratio of CaO to Al2O3 is 0.7-1.3, SrO accounts for 4-10%, BaO accounts for 2-5%, MgO accounts for 1-3%, fluxing agent is composed of Na2O which accounts for 10-16%, Li2O accounting for 2-5%, F accounting for 6-12%, and SiO2 which is kept less than or equal to 2%. The casting powder is produced by the steps of melting, water quenching, drying and crushing and by adding a carbon material. The continuous casting powder can inhibit the oxidized strong reducing elements from entering the slag to cause the slag denaturation; and can ensure smooth continuous casting production of steel products containing high aluminum, Ti and rare earths, and good surface quality of casting blank.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for high-efficiency separation and comprehensive utilization of iron, aluminum and sodium in high-iron red mud

ActiveCN102851425AWon't breakReasonable useCombustible gas chemical modificationProcess efficiency improvementRed mudSlag

The invention provides a method for high-efficiency separation and comprehensive utilization of iron, aluminum and sodium in high-iron red mud. The method comprises the following steps of adding iron ore concentrate and coke powder into high-iron red mud as a raw material, pressing the mixture into red mud pellets, drying, pre-heating, directly reducing metallic oxides of iron and sodium by a rotary hearth furnace, feeding the reduced metalized pellets into an iron bath-type oxy-coal smelting reduction furnace, carrying out high-temperature melting separation, using separated iron for steel-making, recovering alumina from the modified high-aluminum slag, recovering the metallic oxide of sodium from smoke dust carried by exhaust gas, improving quality of mixed gas produced by the iron bath-type oxy-coal smelting reduction furnace, and feeding back the treated mixed gas to the rotary hearth furnace for use. The method provided by the invention can effectively realize high efficiency recovery and large-scale industrial comprehensive utilization of a red mud resource.

Owner:NORTHEASTERN UNIV

Crystallizer casting powder for high-aluminum steel continuous casting

The invention relates to a crystallizer casting powder for high-aluminum steel continuous casting. The casting powder comprises the following elementary components in percentage by weight: not less than15% but not more than 40% of CaO, not less than 3% but not more than 15% of SiO2, not less than 10% but not more than 20% of Al2O3, not more than 3% of MgO, not more than 3% of Fe2O3, not less than6% but not more than 15% of F, not more than 1.5% of Na2O, not less than 3% but not more than 10% of Li2O, not less than 5% but not more than 20% of BaO, not more than 5% of SrO, not more than 5% o B2O3, not less than 2% but not more than 15% of C, and the balance of impurities. The preparation method of the casting powder comprises the following steps of: calculating and weighing the required raw materials according to ratio ranges of the elementary components, mixing and uniformly smelting the mixture in an ore heating furnace, cooling, crushing, adding required carbon materials, carrying out fine grinding, and finally drying and granulating in a spray granule drying tower. The casting powder has the capability of reducing the reactivity of slag steel so that the performance deterioration of the casting powder caused by the reaction of the slag steel can be slowed, the interfacial tension of the slag steel is improved so as to prevent slag entrainment, excellent casting blank lubricating and heat-transfer controlling characters are ensured, the capability of absorbing Al2O3 inclusions is improved, and a high-aluminum steel casting blank which has excellent surface quality and high quality can be cast.

Owner:CHONGQING UNIV

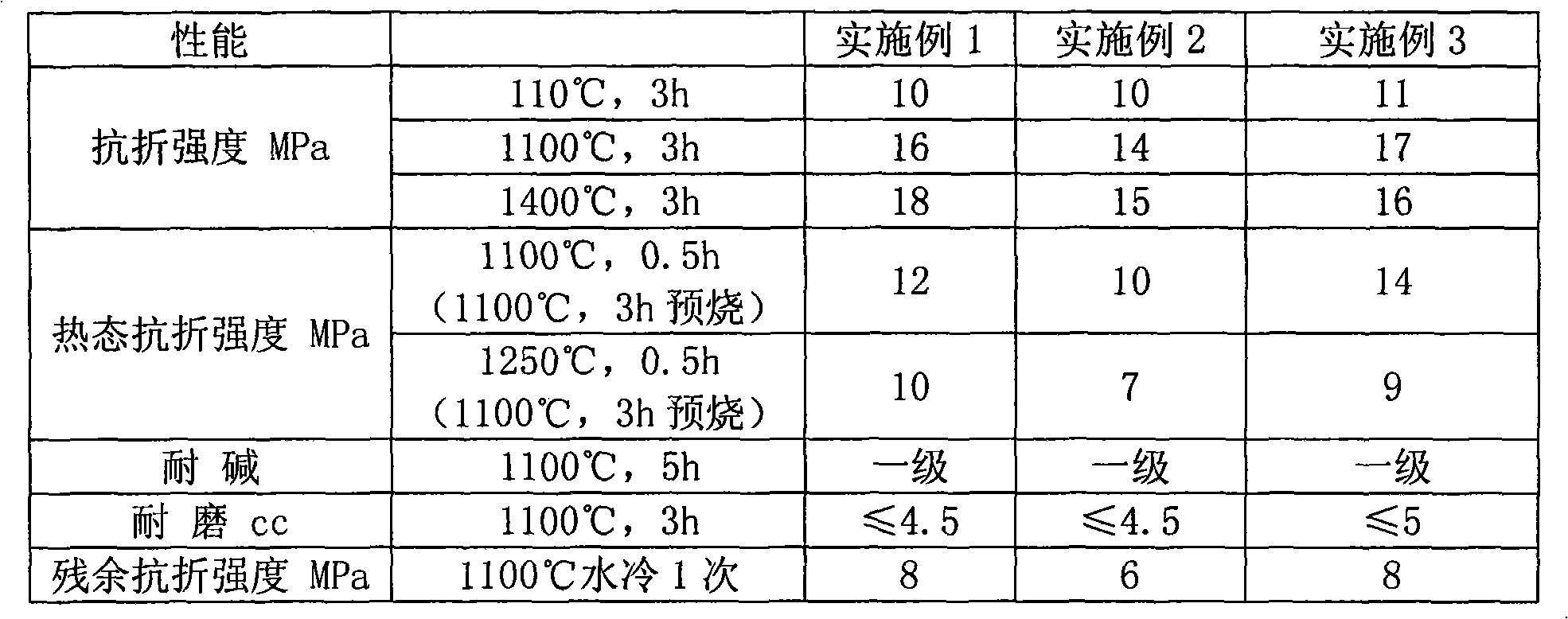

Wear and corrosion resistant castable prepared from bauxite-based homogenous material and preparation method thereof

ActiveCN101885617AUniform structureSmall fluctuations in water addition during constructionPliabilityCement kiln

The invention discloses wear corrosion resistant castable prepared from a bauxite-based homogenous material and a preparation method thereof, which belong to the technical field of castable refractory. In the invention, by using the characteristics of the bauxite-based homogenous material, such as homogeneous chemical components and structure, stable performance, mulite main crystal phase, small linear change, high high-temperature strength and certain flexibility due to mutual insertion of micro crystals and the like, the shortcomings of low middle-temperature strength and poor wear resistance and alkali corrosion resistance of the conventional high-aluminum bauxite castable are overcome, and the problems of low middle-temperature strength, poor wear resistance and poor alkali, chloride and sulphur corrosion resistance of the conventional high-aluminum and corundum castable are effectively solved. The wear and corrosion resistant castable with high middle-temperature performance is prepared. The wear corrosion resistant castable and the preparation method thereof have the advantages of small fluctuation of water adding amount in construction, stable usability, reduction rate of partial corrosion, prolonged service life and wide application to a kiln hood, a grate cooler, a tertiary air duct and a decomposing furnace of a dry process cement kiln and relative parts of other ceramic and petrified thermo-technical kilns and the like.

Owner:YANGQUAN JINYU TONGDA HIGH TEMPERATURE MATERIALS +1

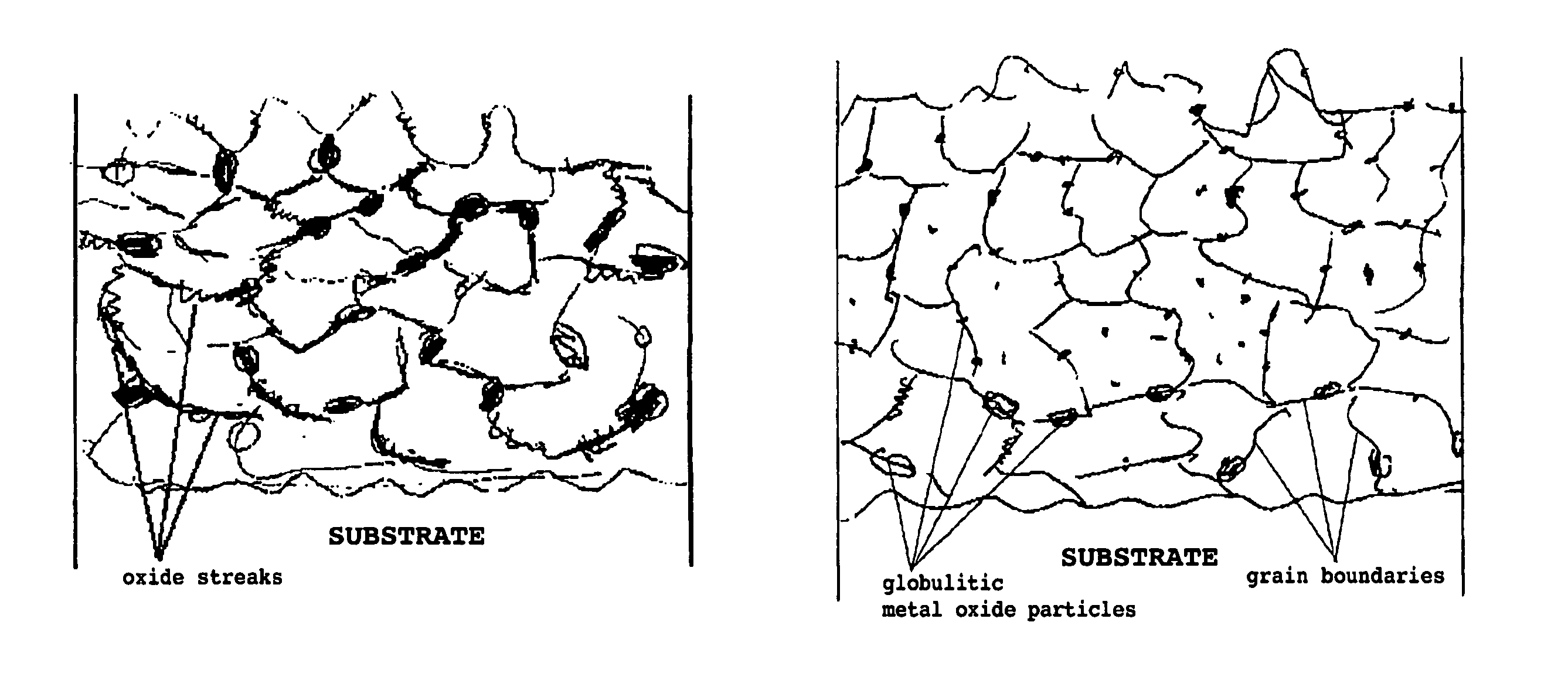

Protective coating for application to a substrate and method for manufacturing a protective coating

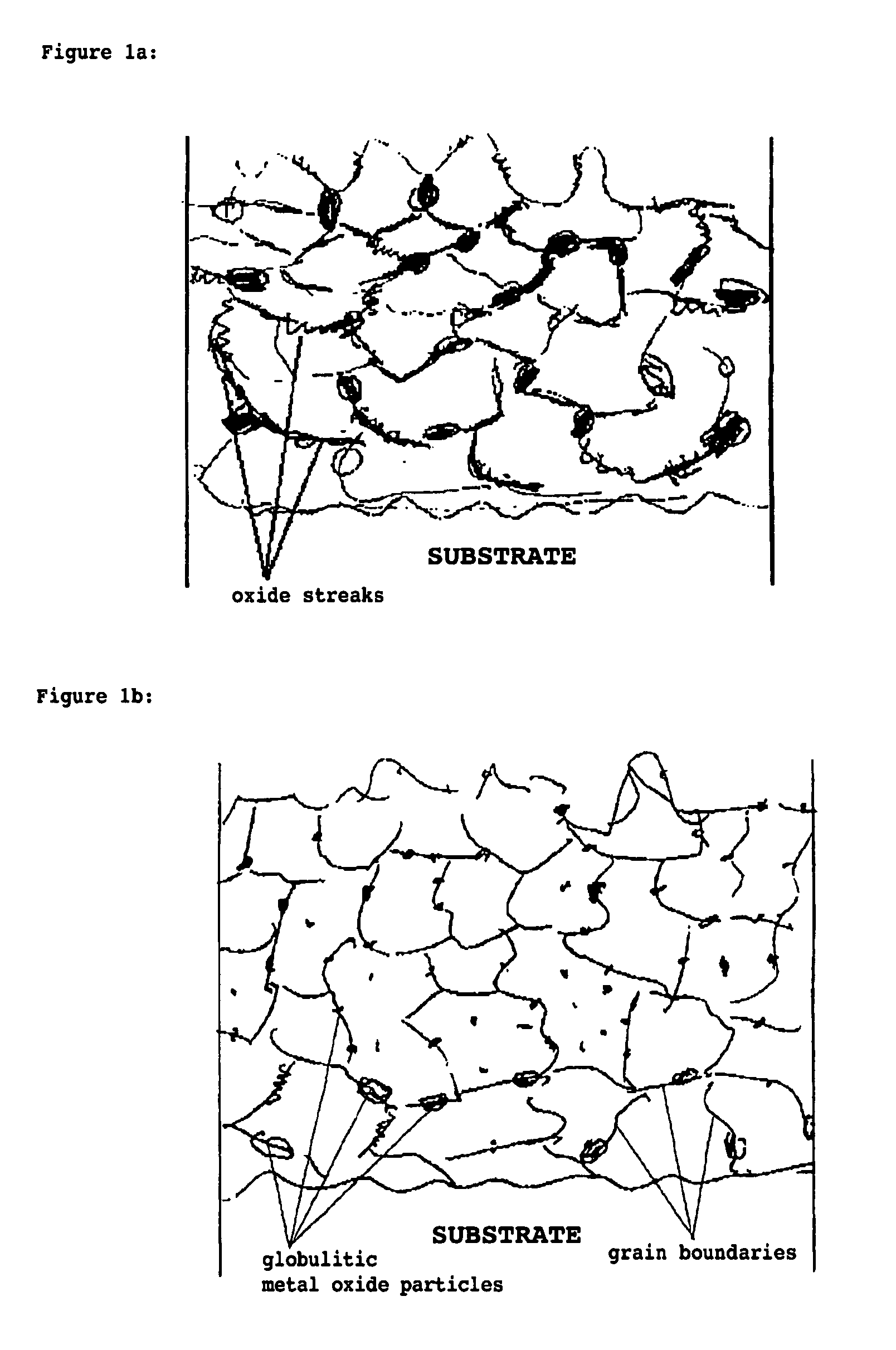

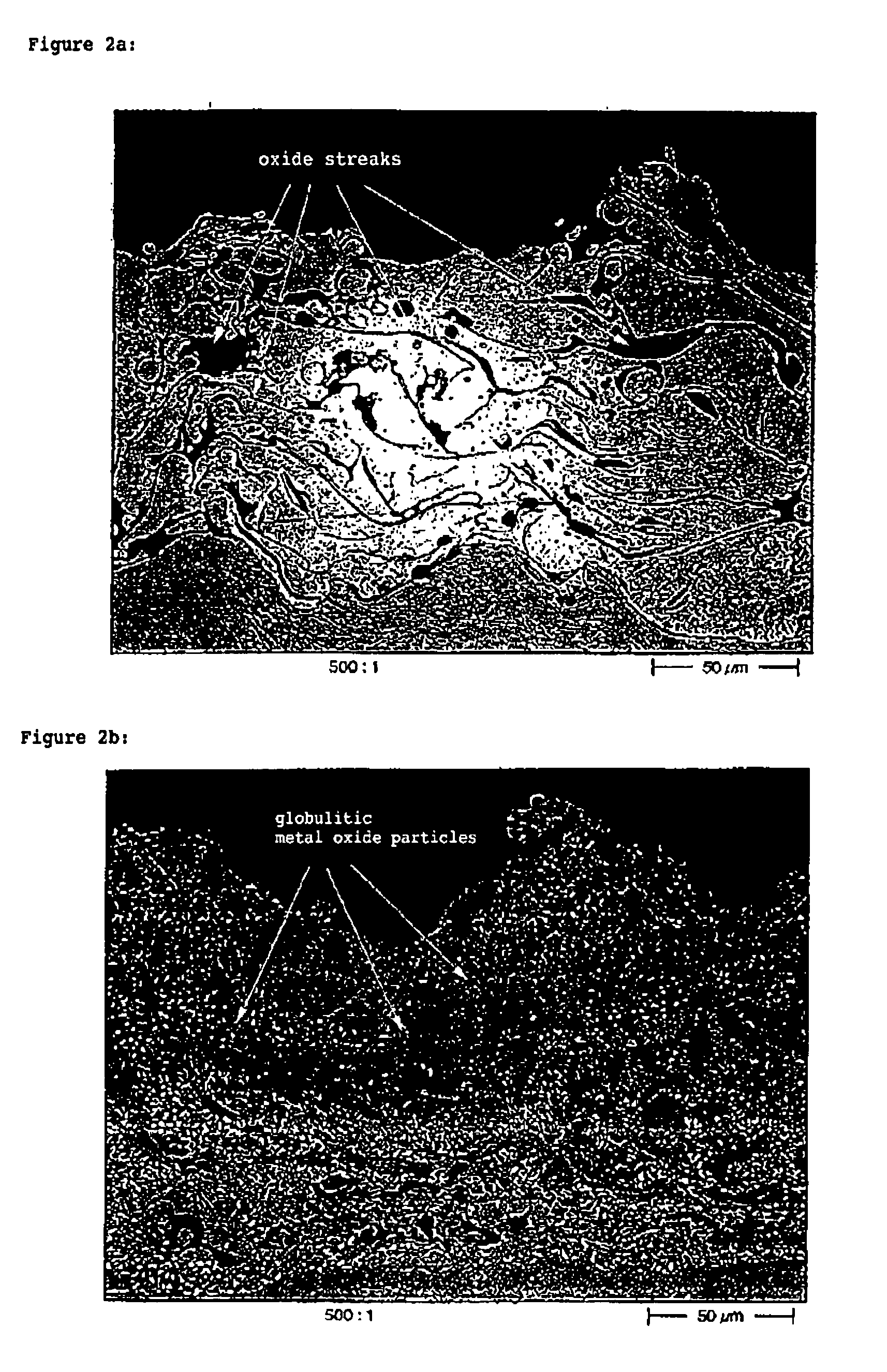

InactiveUS20060292390A1High heat and corrosion resistanceCost-effective manufacturingMolten spray coatingPretreated surfacesMetallic materialsSpray coating

A refractory, oxidation-resistant, and corrosion-resistant protective coating for application to a substrate, in particular for application to parts of turbines or aircraft propulsion engines, is described, including a spray coating made of a thermally sprayed, primarily metallic material, the coating being at least partially subjected to a thermochemical aluminum (Cr, Si) deposition process having a specifically high aluminum deposition activity after the application of the protective coating to the substrate, in such a way that the protective coating has alloy gradients of Al (Cr, Si) which increase from the substrate surface to the coating surface and isolated globulitic metal oxide particles. Furthermore, a method for manufacturing this protective coating and its use are described.

Owner:MTU AERO ENGINES GMBH

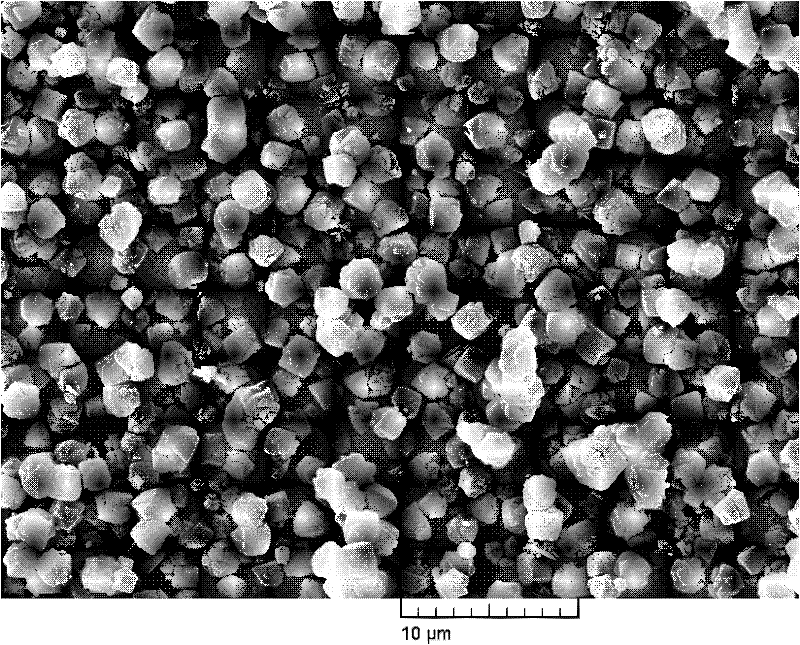

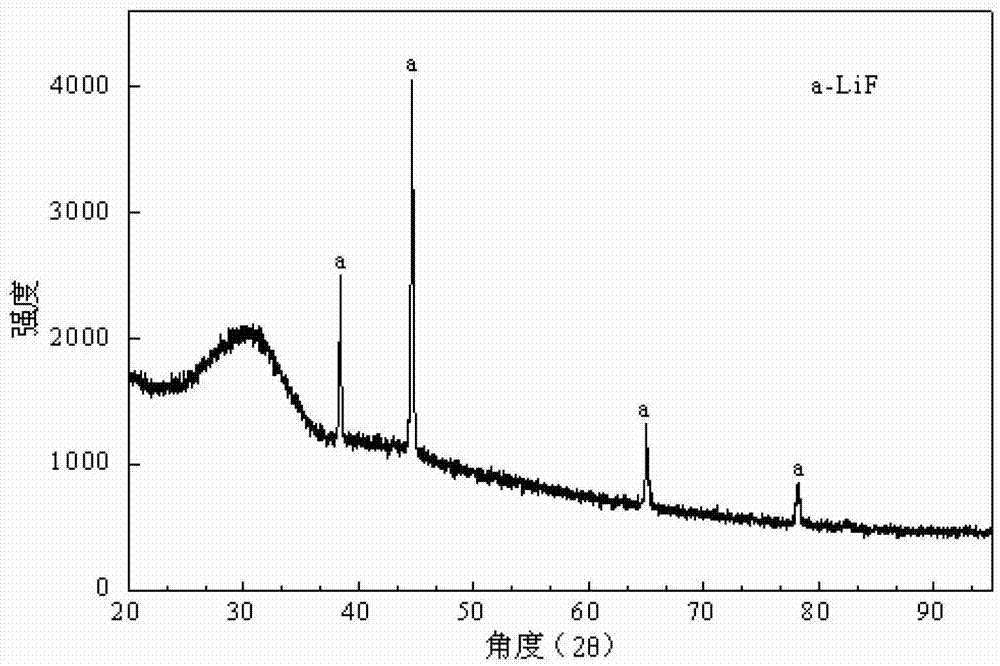

Method for preparing NaY molecular sieve with high aluminum-silicon ratio

ActiveCN102198950AShorten crystallization timeHigh ratio of silicon to aluminumFaujasite aluminosilicate zeoliteMolecular sieveSodium aluminate

The invention relates to a method for preparing a NaY molecular sieve with a high aluminum-silicon ratio, which comprises the following steps of: mixing a silicon source, an aluminum source and deionized water, uniformly mixing two guide agents in different molar ratios, water glass, acidic aluminum salt and sodium aluminate solution in a molar ratio of gel materials to prepare two gels, and crystallizing respectively, wherein the molar ratio of the gel materials is (1.0-6.5)Na2O:Al2O3:(5.0-18)SiO2:(100-280)H2O, and Al2O3 in the guide agents accounts for 0.01 to 15 percent of the total weightof Al2O3; uniformly mixing the two gels in a mass ratio of 1:(0.1-10) to prepare a mixed gel; and crystallizing the prepared mixed gel at the temperature of between 80 and 120 DEG C for 2 to 50 hoursto prepare the NaY molecular sieve. Compared with the prior art, the method has the advantages that: the NaY molecular sieve with the high aluminum-silicon ratio can be prepared in shorter time underthe condition of the same feeding molar ratio.

Owner:PETROCHINA CO LTD +1

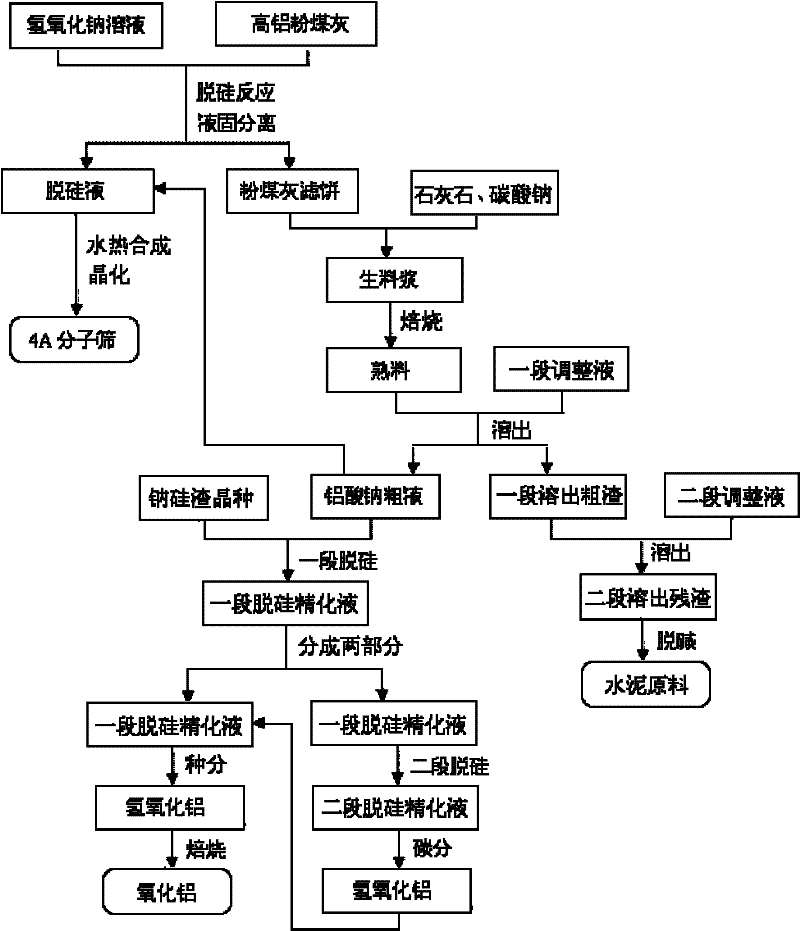

Method for production of alumina, joint product of cement and joint product of 4A zeolite molecular sieve with high aluminum fly ash

InactiveCN102225778AReduce dosageReduce trafficAluminium oxides/hydroxidesDecompositionAluminium hydroxide

The invention provides a method for production of alumina, a joint product of cement and a joint product of 4A zeolite molecular sieve with high aluminum fly ash. The production of alumina with high aluminum fly ash comprises the steps of: pre-desilication, raw slurry preparation, clinker calcination, clinker leaching, first and second stage deep desilication, carbon dioxide decomposition, seed precipitation, aluminum hydroxide calcination, thus obtaining alumina. Part of the sodium aluminate crude liquor generated from pre-desilication can be used to synthesize a 4A zeolite molecular sieve with desilication liquor, and residues from clinker leaching can be used for cement production after desilication. Characterized by simple process, low energy consumption, low cost and high utilization rate of raw material, the method of the invention is suitable for industrial application.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

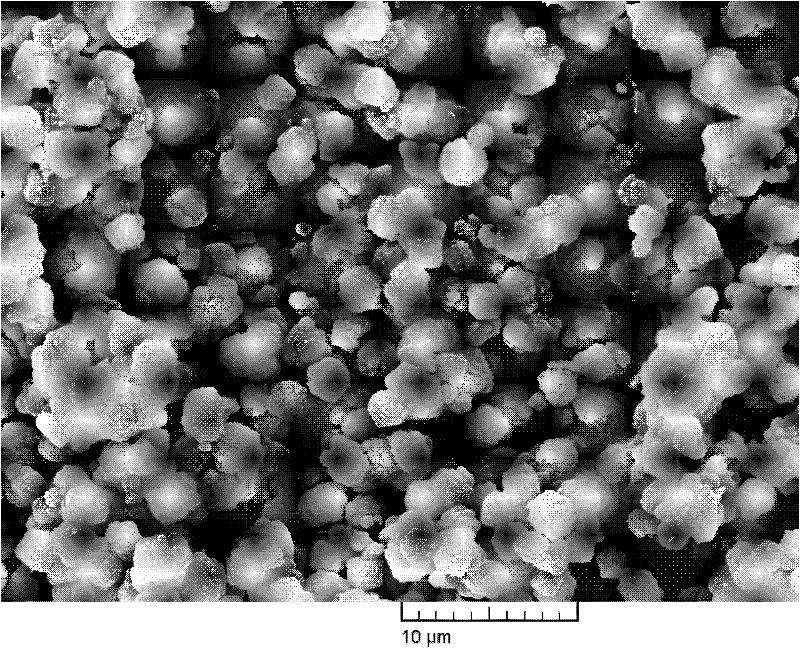

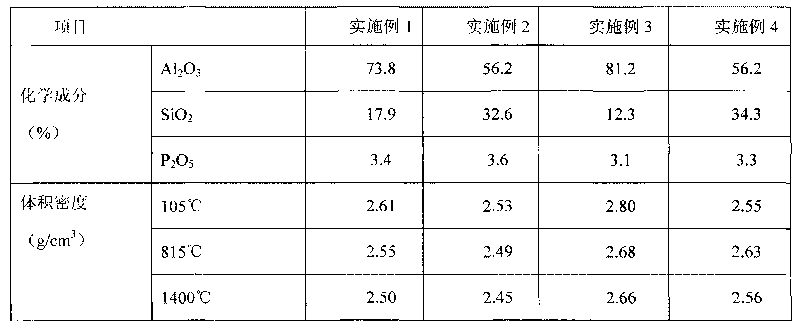

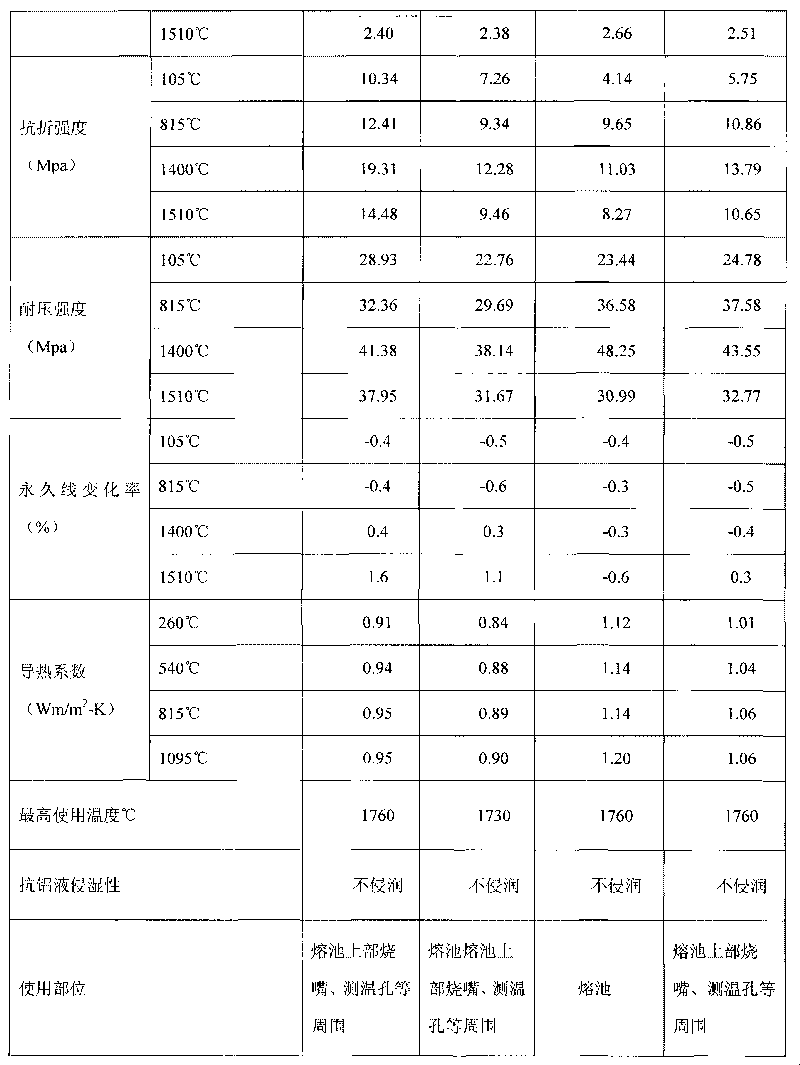

Aluminium liquid infiltration-resistant high-aluminum plastic material and preparation method

ActiveCN101734935AAvoid enteringImprove anti-aluminum wetting agentSodium BentonitePlastic materials

The invention discloses an aluminium liquid infiltration-resistant high-aluminum plastic material and a preparation method, and the high-aluminum plastic material comprises the following raw materials by mass percent: 50-60wt% of high-aluminum granule of which the grain size is 5-0.088mm after pickling, 15-30wt% of high-aluminum fine powder of which the grain size is less than 0.088mm after pickling, 3-8% of fraxinus mandshurica clay, 3-9% of sodium bentonite, 2-11% of active alpha-alumina micro powder, 3-5% of silica powder, 1-6% of anti-aluminium liquid wetting agent formed by compounding BaSO4 and Na3AlF6, phosphoric acid with the concentration of 75% and oxalate, wherein the high-aluminium granule and the high-aluminium fine powder are respectively one of alumina, fused brown corundum, fused white alumina, dense fused corundum, tabular alumina and mullite with the content of Al2O3 being greater than 70%. The high-aluminum plastic material in the invention has the advantages of aluminium liquid infiltration resistance, long retention period and convenient construction.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Method for preparing silicon dioxide and aluminum oxide from coal ash

ActiveCN101993084AMild desilication reactionWeak corrosiveSilicaSolid waste disposalFoam concreteHigh pressure

Owner:CHINACOAL PINGSHUO GRP

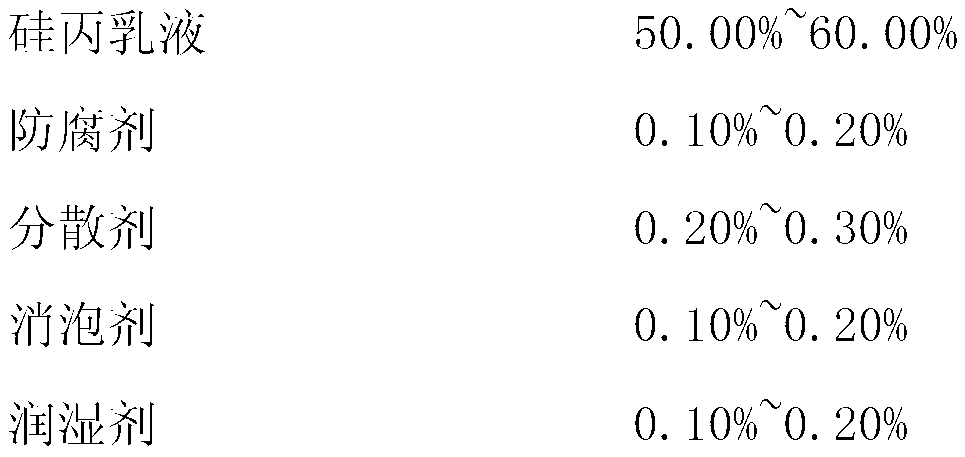

Flame-retardant waterproof material and preparation method thereof

ActiveCN103232208AFast constructionImprove waterproof performanceHeat proofingFire proofingInsulation systemFire retardant

The invention discloses a flame-retardant waterproof material which can be used in an exterior wall outer insulation system. The material comprises two components which are respectively a liquid material and a powder material. The liquid material comprises the components of: silicone acrylic emulsion, a preservative, a dispersing agent, a defoaming agent, a wetting agent, and water. The powder material comprises the components of: common Portland cement, high-aluminum cement, quartz sand, cellulose ether, a water-reducing agent, and a flame retardant. The material is used in an exterior wall outer insulation system, and solves problems of high flammability and fire-prone property of an organic insulation plate of a current exterior wall outer insulation system during construction and after application. Also, the product has good flexibility and water resistance, such that a problem of reduced insulation effect after the exterior wall cracks and water is let in is solved.

Owner:XUZHOU WONIUSHAN NEW WATERPROOF MATERIALS +1

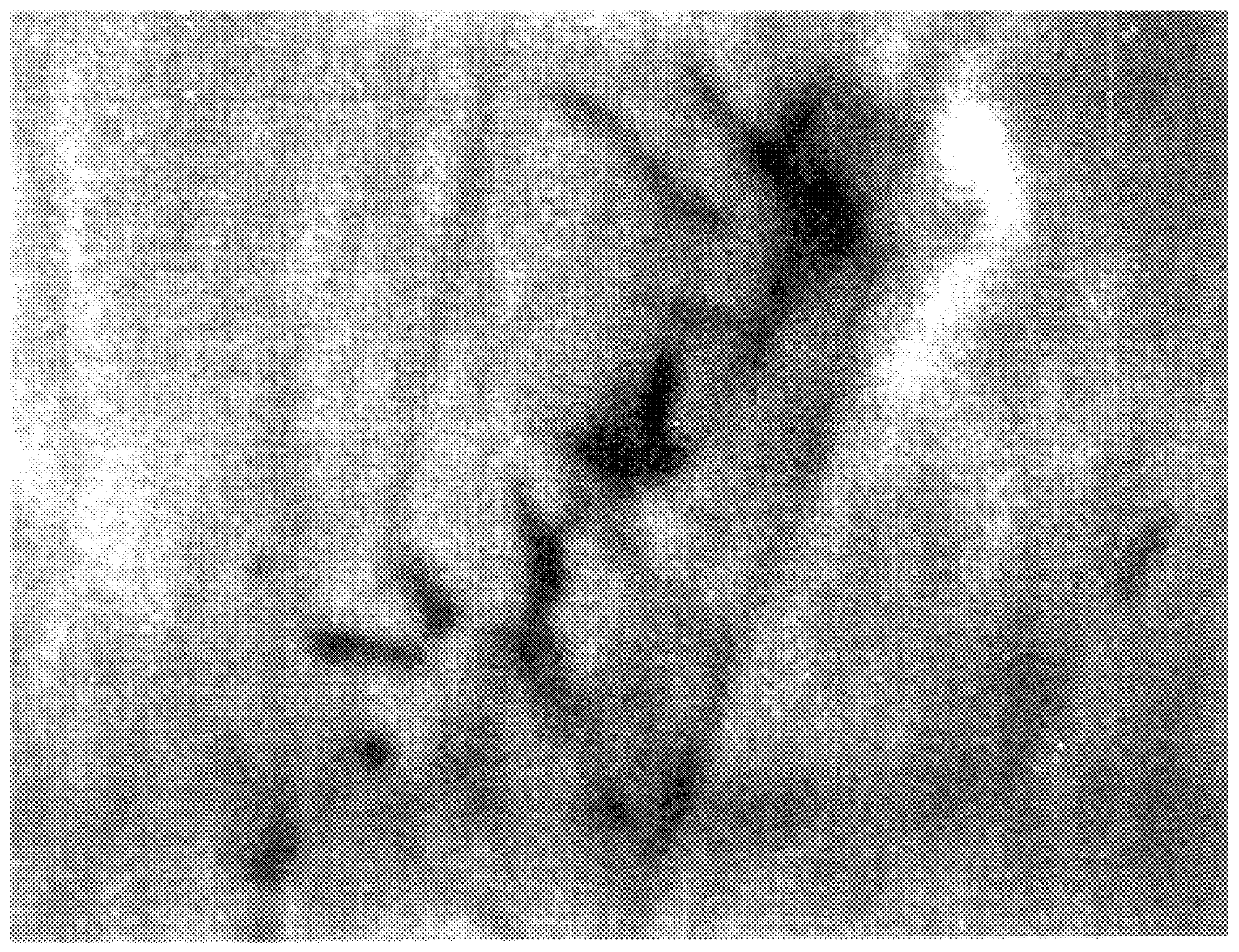

Process for manufacturing a foil of ferritic stainless steel having a high aluminum content, aluminum-containing ferritic stainless steel, and catalyst support useful for a motor-vehicle exhaust

InactiveUS6086689AHot-dipping/immersion processesDispersed particle separationRare-earth elementHydrogen atmosphere

Process for manufacturing a foil of ferritic stainless steel having a high aluminum content, which can be used in particular for a catalyst support in a motor-vehicle exhaust, wherein a ferritic stainless steel sheet of the following composition: 0.005%<carbon<0.060% 10%<chromium<23% 0.1%<aluminum<3% 0.003%<nitrogen<0.030% 0.1%<manganese<2% 0.1%<silicon<2% rare-earth elements in a proportion of between 0.03% and 0.15%, is subjected to: plating between two sheets of aluminum in order to obtain a laminate, rolling the laminate to a thickness of 0.03-0.25 mm to form a foil, static diffusion annealing the foil in a hydrogen atmosphere, and finish rolling greater than 20%.

Owner:UGINE SA

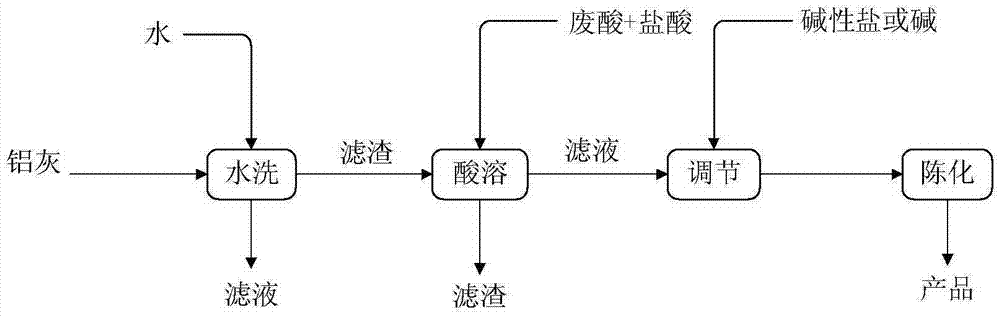

Method for producing aluminum polychlorid water purifying agent from waste hydrochloric acid and aluminum ash

InactiveCN106892444AQuick buildGuaranteed stabilityAluminium chloridesWater/sewage treatment by flocculation/precipitationLiquid productResource utilization

The invention relates to a method for producing an aluminum polychlorid water purifying agent from waste hydrochloric acid and aluminum ash. The method comprises the following steps: carrying out dissolving reaction on the solid waste aluminum ash produced in an aluminum electrolysis process and waste hydrochloric acid produced in a resource utilization process of high-aluminum coal ash, so as to obtain an aluminum-containing solution; adding alkaline salt or alkali into the aluminum-containing solution, and carrying out polymerization reaction, so as to obtain a primary product; and ageing the primary product, so as to obtain an aluminum polychlorid liquid product. By utilizing the method, the problems of solid waste pollution and wastewater emission can be solved, and the aluminum polychlorid product meeting the index requirements of national standard (GB15892-2009) can be prepared; and the method has good economic and social values.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

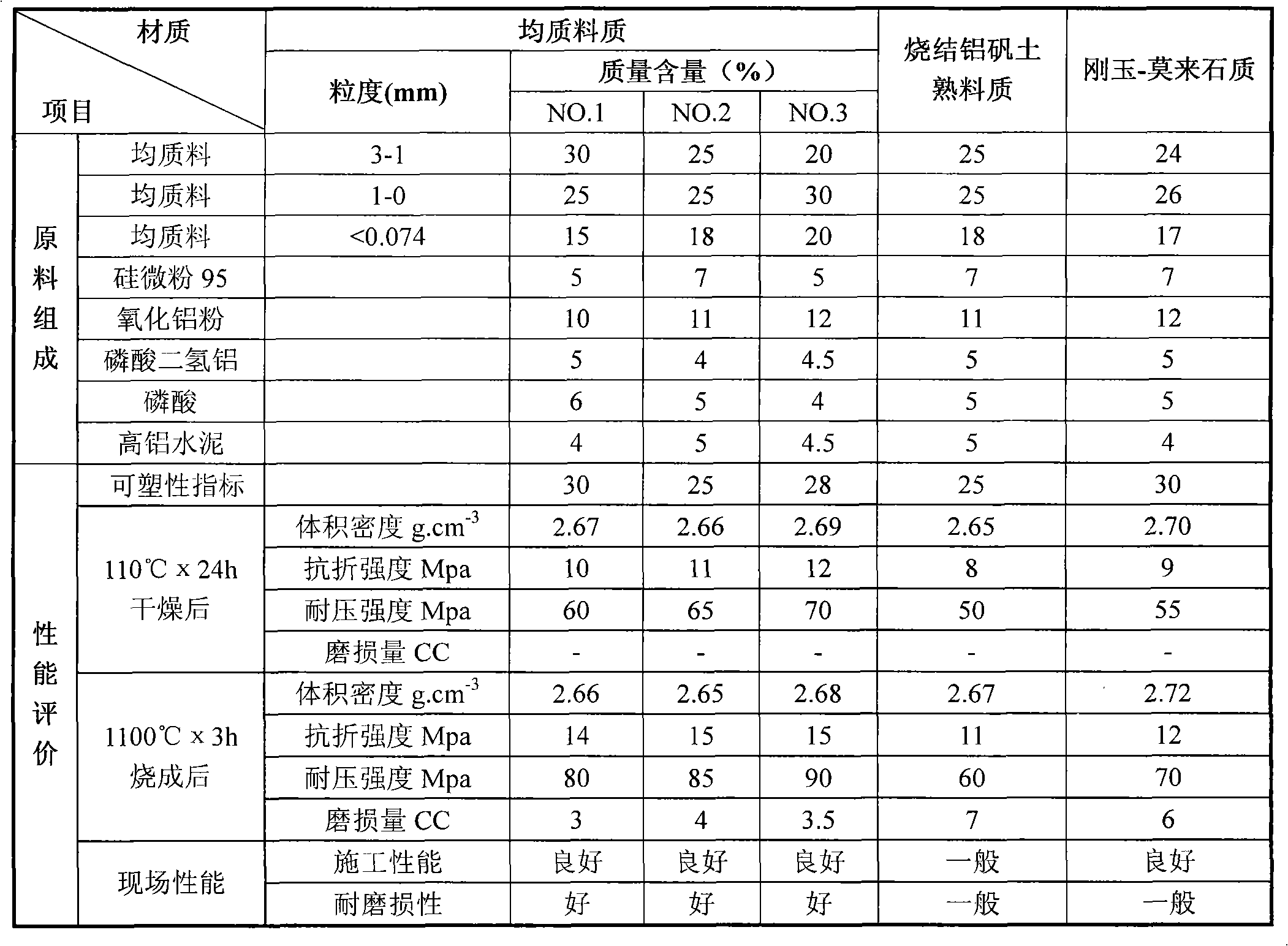

Homogeneous material-containing corundum-mullite high-strength abrasion-resisting plastic

The invention discloses a homogeneous material-containing corundum-mullite high-strength abrasion-resisting plastic, belonging to the field of high-temperature abrasion-resisting fireproofing material, comprising high-aluminum homogeneous material, alumina fine powder, silica fine powder, clay, phosphoric acid, aluminum dihydrogen phosphate solution, pure calcium aluminate cement and the like as raw materials, wherein the homogeneous material is as follows: the content of Al2O3 is 70-90% and the volume density is 2.9-3.5g.cm<-3>. Synthetic homogeneous material with low water-absorption, low porosity and high homogeneity is used for substituting the traditional natural raw material of sintered alumina clinker with high-absorption, high porosity and low homogeneity or composite raw material system of corundum and mullite to produce homogeneous corundum-mullite high-strength abrasion-resisting plastic. Distinguished from the castable, the plastic can be directly utilized in the construction method of smearing and ramming without supporting a module. The material of the invention is good in workability, high in strength, good in abrasive resistance and optimal in on-site usage effect, which is in favour of prolonging service life of furnace lining and improving utilization efficiency of the high-temperature furnace.

Owner:TONGDA REFRACTORY TECH CO LTD

Method for producing alumina by using high sulphur bauxite

ActiveCN101456572AImprove energy efficiencyPromote dissolutionAluminium oxides/hydroxidesFluidized bedSulfur

The invention relates to a method for producing alumina by utilization of high-aluminum alumyte, which belongs to the technical field of metallurgy. The method comprises: firstly, grinding alumyte ores, and adopting a fluidized bed to perform roasting and desulfurization pretreatment; secondly, treating obtained roasted ores by a Bayer process, and obtaining Al2O3 products after stripping, crystal seed decomposition and calcining treatment; and thirdly, introducing roasted tail gas generated by roasting into red mud under the stirring condition, and absorbing SO2 in the tail gas. The method has low stripping temperature, can effectively remove sulfur element in the ores, has great significance in developing and using the ores for alumina industrial production practice, uses the red mud during industrial production of alumina as an absorbent of the low concentration SO2 tail gas during roasting, and realizes dealkalization and modification treatment and comprehensive utilization of the red mud.

Owner:NORTHEASTERN UNIV

Waterproof and anti-corrosion repair mortar for polymer cement-based concrete structure

The invention relates to a waterproof and anti-corrosion repair mortar for a polymer cement-based concrete structure, in particular to a cement concrete repair material for a cement concrete structure, which is used for carrying out bonding reinforcement and repair on defects of municipal roads, municipal services, bridges and water conservancy projects (dams and gates). The waterproof and anti-corrosion repair mortar is prepared by mixed materials and water, and the mixed materials comprise the following components in parts by weight: 20-30 parts of portland cement, 0.01-0.05 part of high-performance water-reducing agent, 1-5 parts of high-aluminum cement, 15-30 parts of quartz sand, 25-60 parts of gravel and 1-3 parts of acrylic adhesive powder, 1-3 parts of fiber material, while the using amount of water accounts for 5-14% of the total parts of the mixed materials. Due to the adoption of the technical scheme, the waterproof and anti-corrosion repair mortar has the characteristics of good pressure resistance, high flexural strength, high bonding strength, good durability, convenient and fast construction, fast setting and early strength shrinkage control, and can greatly shorten the repair time and quickly resume the traffic in particular to roads.

Owner:卢建华

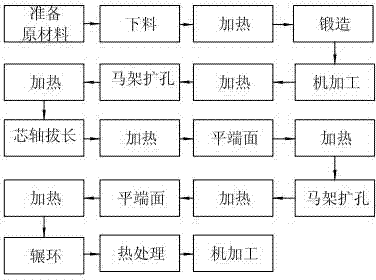

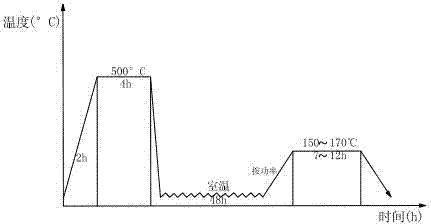

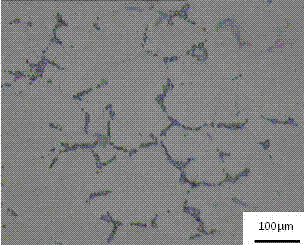

Processing technique of high aluminum alloy cylinder

The invention relates to a processing technique of a high aluminum alloy cylinder. The processing technique includes the following technical processes: preparing raw materials->baiting->heating ->forging->machining->heating->expanding holes of a mandrel supporter->drawing out a mandrel ->heating->flattening an end face->heating->expanding holes of the mandrel supporter->heating ->flattening an end face->heating->rolling ring->thermal treatment ->machining. Through hot die forging and optimized heat treatment method, the defective percentage of the high cylinder after shaping is obviously reduced, the anisotropism of the high aluminum alloy cylinder is obviously decreased, and cost of processing and reshaping in post period is saved, and the material utilization rate is greatly improved; particularly, the aluminum alloy ductility is effectively expanded; the high cylinder is mainly used for aviation and other fields; the work piece after processing by the technique can perfectly realize the lightweight goal of an aerospace craft.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

Environment friendly low-gas-content aluminum alloy ingot and production method thereof

The invention discloses an environment friendly low-gas-content aluminum alloy ingot which comprises the following components in percentage by weight: 1.6-3.3 percent of Cu, 9.8-11.8 percent of Si, 0-0.29 percent of Mg, 0-0.08 percent of Zn, 0-0.8 percent of Fe, 0-0.48 percent of Mn, 0-0.48 percent of Ni, 0-0.1 percent of Ti, 0-0.1 percent of Pb, 0-0.2 percent of Sn, 0-0.25 percent of other trace elements and the balance of aluminum. Meanwhile, the invention also discloses a production method of the environment friendly low-gas-content aluminum alloy ingot. The environment friendly low-gas-content aluminum alloy ingot has the advantages of low gas and dreg content, high aluminum liquid cleanness and good mechanical and machining properties. The production method has the advantages of low production cost and high efficiency and effectively solves the pollution problem of the secondary aluminum industry.

Owner:YE CHIU METAL RECYCLINGCHINALTD

Aluminum-plastic composite packing separating agent and method of separating and reclaiming the same

The invention discloses a release agent of aluminum composite packing and the recovery method thereof. Said aluminum composite packing release agent is composed of sulfuric acid or phosphoric acid with a concentration of 5-20% and oxidizer. It applies as following steps: soaking the aluminum composite packing material in the sulfuric acid or phosphoric acid with a concentration of 5-20% at 40-80 DEG C, 0.1-0.5% cationic surfactant or only in the release agent containing sulfuric acid or phosphoric acid with a concentration of 5-20%, stirring uniformly; feeding oxidizer, stirring; aluminium layer and plastic layer being automatically peeled off after soaking for 1-20 minutes; washing the packing material with water twice or three times, removing the surface residual release agent; releasing the aluminum foil and plastic layer. The invention can separate the aluminum composite packing quickly and has a high aluminum coefficient of recovery, meanwhile provides a good working environment to the operator.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-Al2O3 content high-aluminum steel continuous casting slag powder

The invention belongs to the technical field of treating molten metal by using protection powder, and relates to high-Al2O3 content high-aluminum steel continuous casting slag powder, in particular to high-aluminum steel slab continuous casting slag powder of which Al content in steel is more than 1.5 percent. The slag powder comprises the following chemical components in percentage by mass: 5 to 20 percent of CaO, 5 to 20 percent of BaO, 20 to 50 percent of Al2O3, 2 to 15 percent of B2O3, less than or equal to 7 percent of SiO2, and 6 to 13 percent of CaF2, 6 to 13 percent of Na2O, 1 to 4 percent of LiO2, 2 to 6 percent of MnO, and 3 to 10 percent of C which are used as fluxing agents. The slag powder is good in glassy form, reaction between aluminum in steel and SiO2 in slag can be greatly reduced, and the substantial increasing of the Al2O3 content in slag can be inhibited, so the stability of the components and the performance of the slag powder in the casting process can be guaranteed.

Owner:ZHONG NAT ENG & RES CENT

Water-based paint for iron casting through lost foam casting die

InactiveCN102921880AHigh temperature strengthSuitable for high temperature breathabilityFoundry mouldsFoundry coresSODIUM METAPHOSPHATECellulose

The invention discloses a water-based paint for an iron casting through a lost foam casting die. The paint comprises refractory aggregate, binders, a suspending agent, additives and a dispersing agent, wherein the refractory aggregate comprises high aluminum powder, zircon powder and pyrophyllite; the binders comprise silica sol or white emulsion, polyvinyl acetate emulsion, bentonite and sodium hexametaphosphate; the suspending agent comprises sodium carboxymethylcellulose; the additives comprise Tween, octanol, sodium carbonate, cryolite and iron oxide powder; and the dispersing agent is water. According to the paint, suitable ingredients are chosen, the content is adjusted, a suitable mixing process is adopted, and therefore performances such as normal temperature and high-temperature strength, suitable high-temperature permeability and good leveling property, suspension property and painting performance of a coating can be satisfied completely. The paint is suitable for gray iron castings with different trademarks and enables the expendable casting die to be stripped with the iron casting easily, particularly for stripping in flakiness of a sintered coating during cleaning, and the possibilities for diverse defect generation on the surface of the iron casting are reduced; and simultaneously, pollution of coating components to the environment is reduced greatly due to the selection of phosphate assistant.

Owner:XUZHOU PENGJU SNAPDRAGON ARTS & CRAFTS

Plastic-aluminum separating agent and plastic-aluminum separating method

The present invention relates to aluminum-plastic separating agent and aluminum-plastic separating process, and belongs to the field of composite aluminum-plastic material recovering technology. The aluminum-plastic separating agent consists of formic acid and dichloromethane as the main components as non-ionic surfactant. The aluminum-plastic separating process with the aluminum-plastic separating agent includes the steps of crushing and washing composite aluminum-plastic material, compounding aluminum-plastic separating agent liquid, soaking, taking out, centrifugally separating, washing and drying. The present invention has high aluminum-plastic separating efficiency, less environmental pollution and low cost, and is suitable for industrial recovery of waste composite aluminum-plastic material.

Owner:曹光军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com