Patents

Literature

58results about How to "High heat and corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ni-based superalloy having high oxidation resistance and gas turbine part

ActiveUS7169241B2High heat and corrosion resistanceImprove the protective effectBlade accessoriesGas turbine plantsRare-earth elementSuperalloy

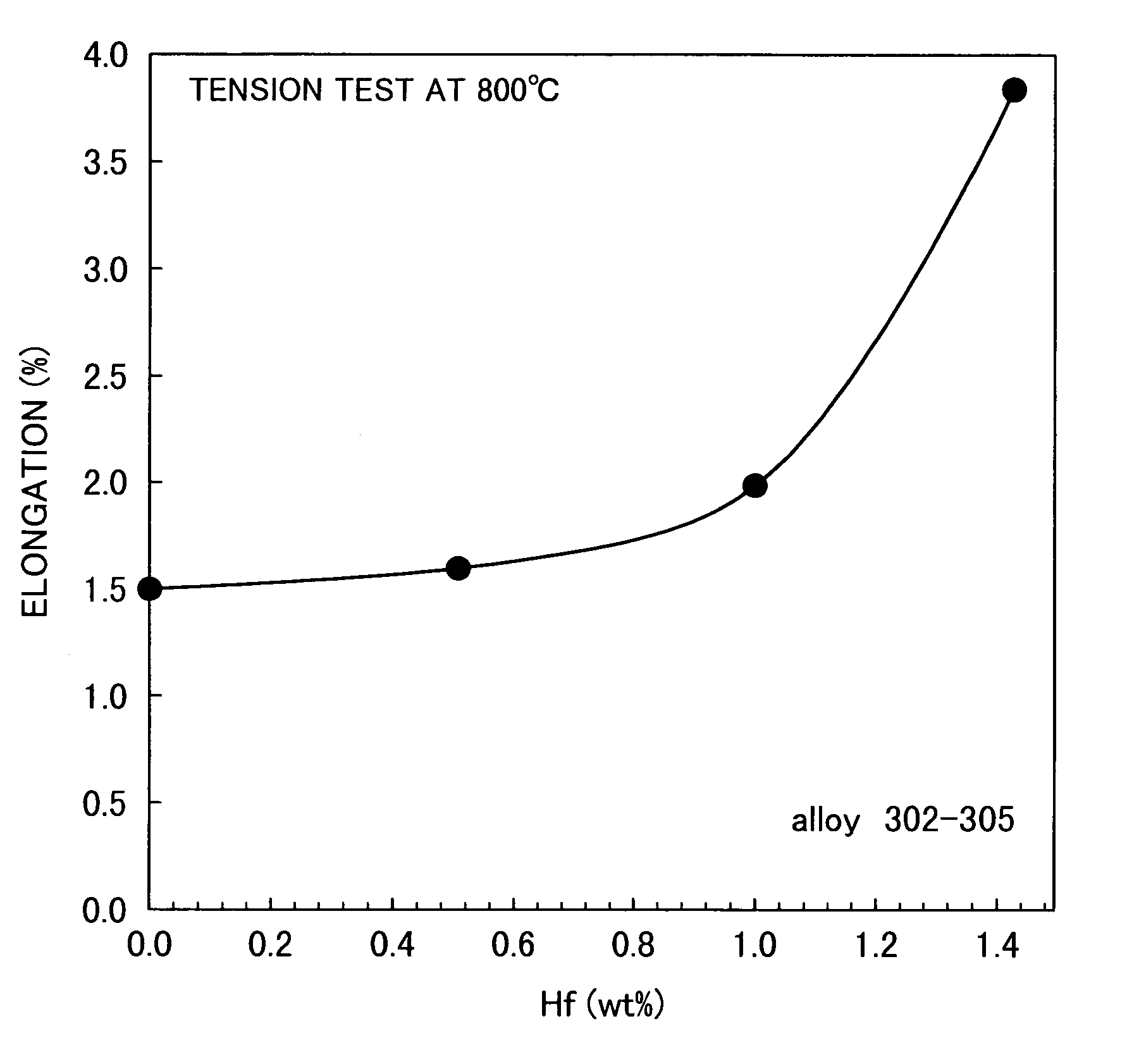

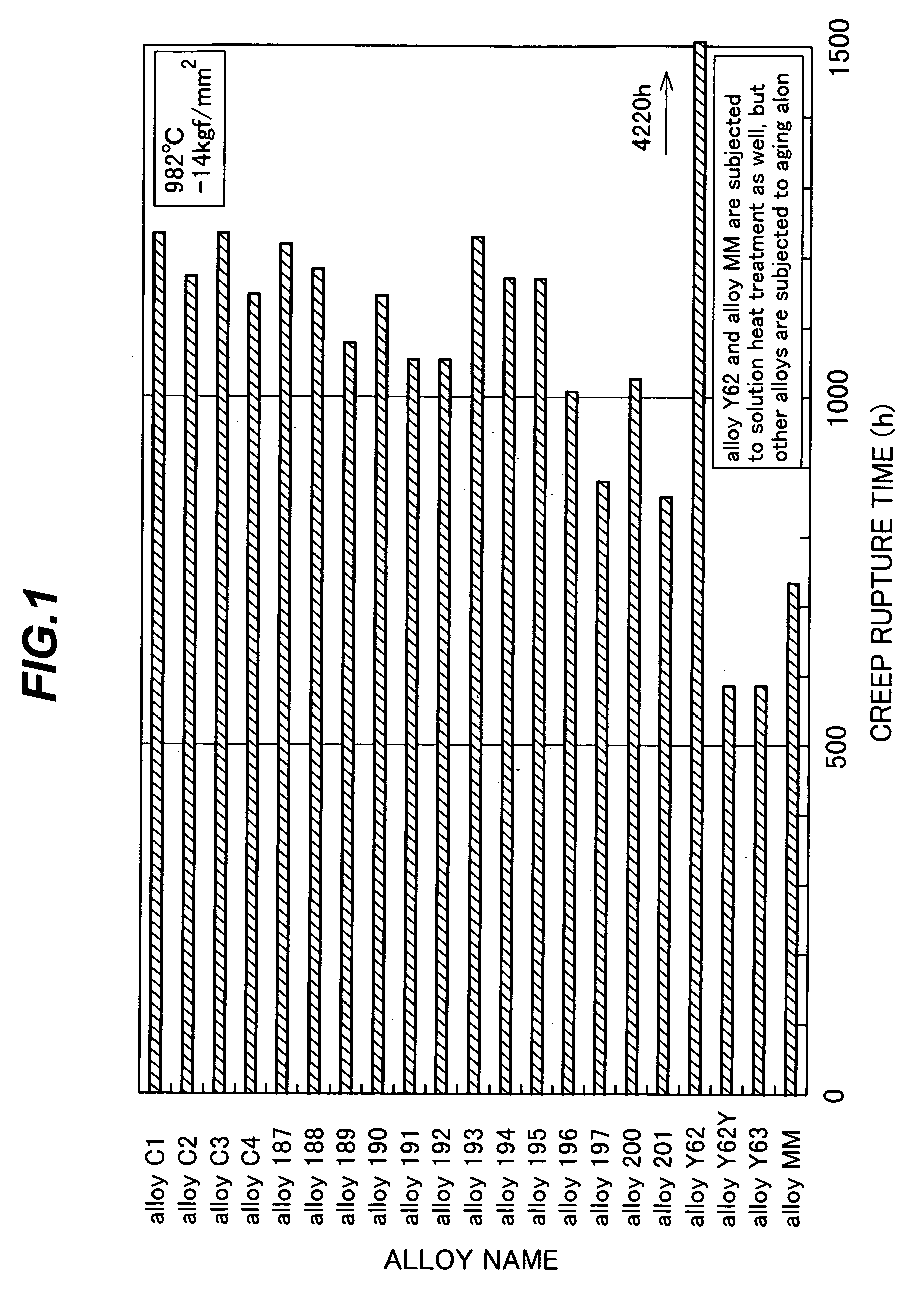

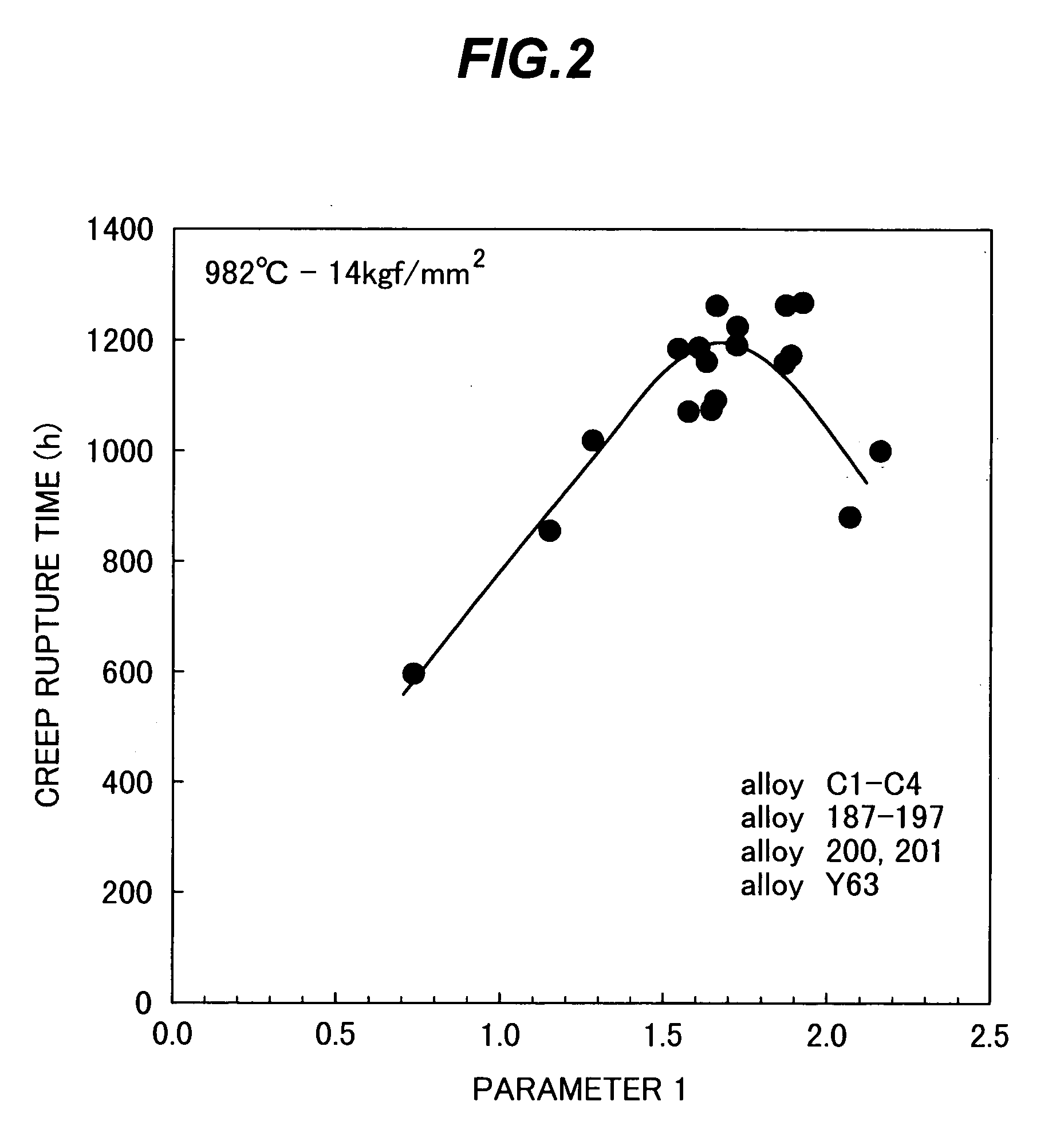

A Ni-based alloy hardened with the γ′ phase, which is able to exhibit not only superior strength at high temperatures, but also excellent hot corrosion resistance and oxidation resistance at high temperatures in spite of containing no Re or reducing the amount of Re. The Ni-based superalloy contains, by weight, C: 0.01 to 0.5%, B: 0.01 to 0.04%, Hf: 0.1 to 2.5%, Co: 0.8 to 15%, Ta: more than 0% but less than 8.5%, Cr: 1.5 to 16%, Mo: more than 0% but less than 1.0%, W: 5 to 14%, Ti: 0.1 to 4.75%, Al: 2.5 to 7%, Nb: more than 0% but less than 4%, V: 0 to less than 1.0%, Zr: 0 to less than 0.1%, Re: 0 to less than 9%, at least one of platinum group elements: 0 to less than 0.5% in total, at least one of rare earth elements: 0 to less than 0.1% in total, and the rest being Ni except for unavoidable impurities.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

A kind of preparation method and application of powder core wire material for nickel-based coating, coating

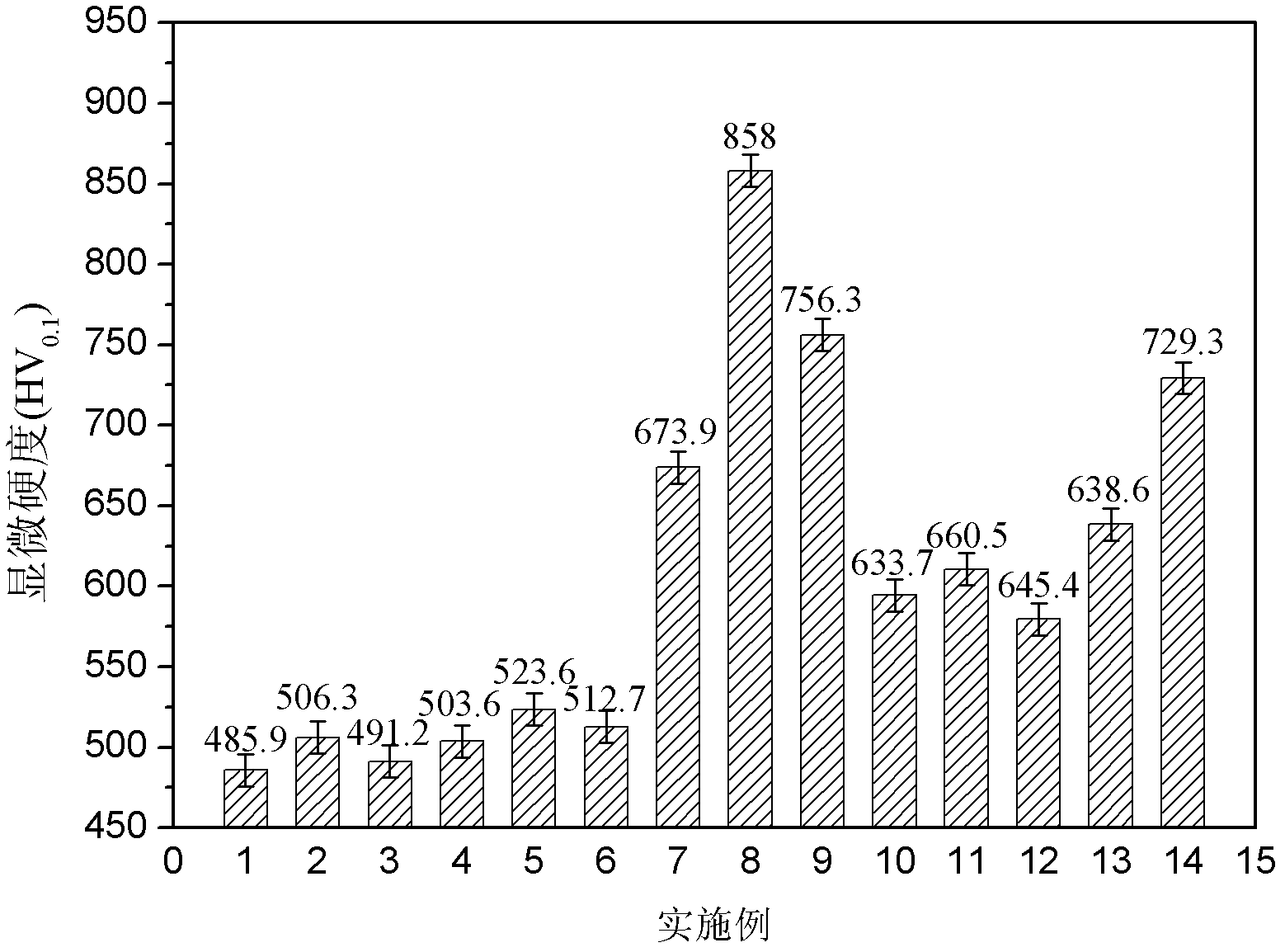

The invention discloses a powder core wire material for preparing a nickel-based coating, a preparation method and application of the coating, and belongs to the field of thermal spraying in material processing engineering. The atomic percentage of the drug core composition is: Cr: 20-35at.%; B: 30-55at.%; C: 2.5-5.5at.%; Ni: balance; the tape used for the powder core wire sheath is Ni-Cr tape ;Powder core wire material filling rate: 32%. When preparing nickel-based coatings containing Cr23C6 ceramic particles reinforced phase by arc spraying, the substrate needs to be pretreated first. Spraying process: voltage 28-34V; current 160-220A; spraying distance 190-210mm; compressed air pressure 0.5-0.6MPa . The invention can obtain a coating with high hardness, good wear resistance and corrosion resistance, and improves the service stability of water-cooled wall tubes and superheater tubes in waste recycling WTE garbage incinerators.

Owner:BEIJING UNIV OF TECH

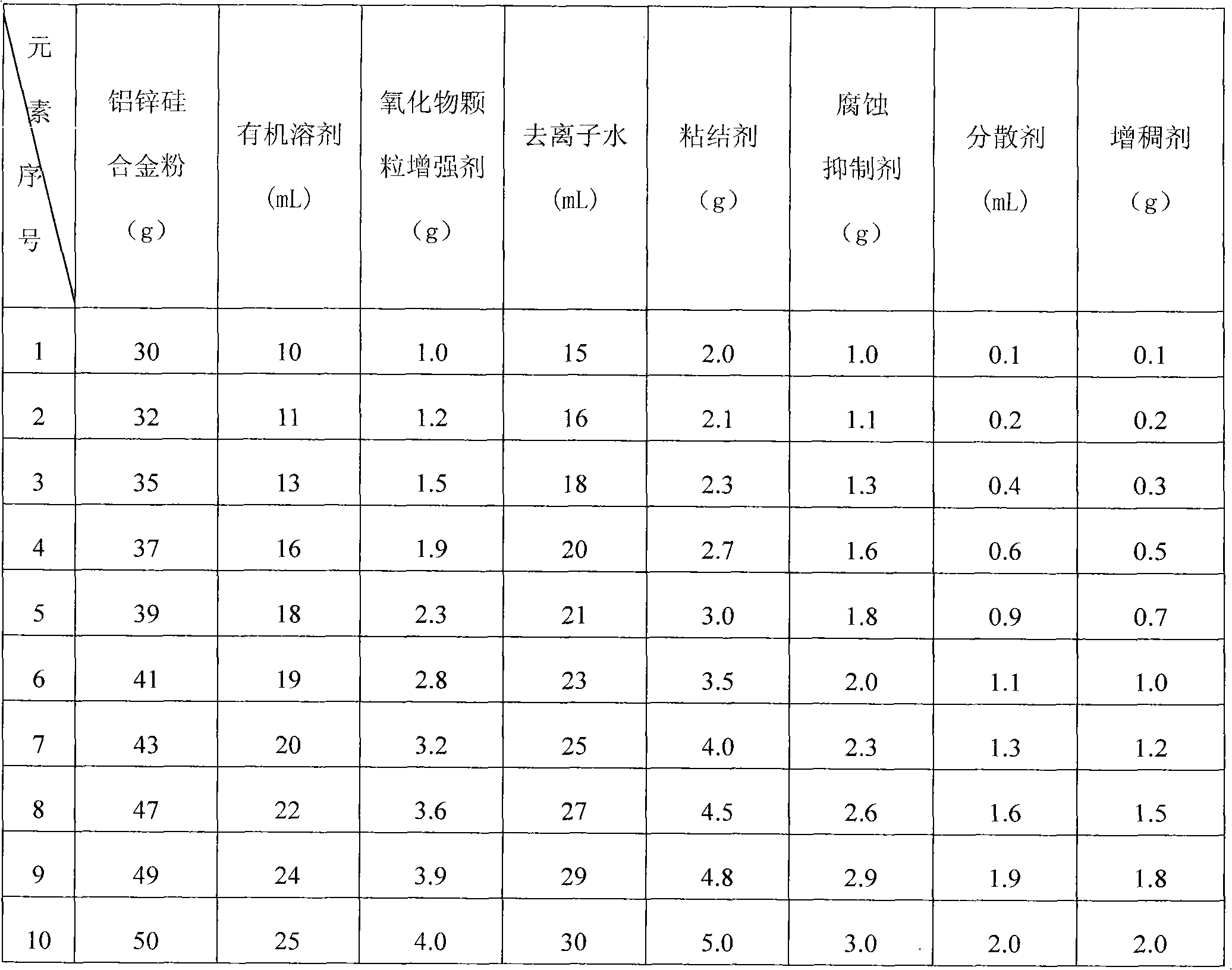

Magnesium-nickel-containing coating for marine climate-resistant preservative treatment

ActiveCN102010624AEnvironmentally friendlySexual stabilityAnti-corrosive paintsOrganic solventAdhesive

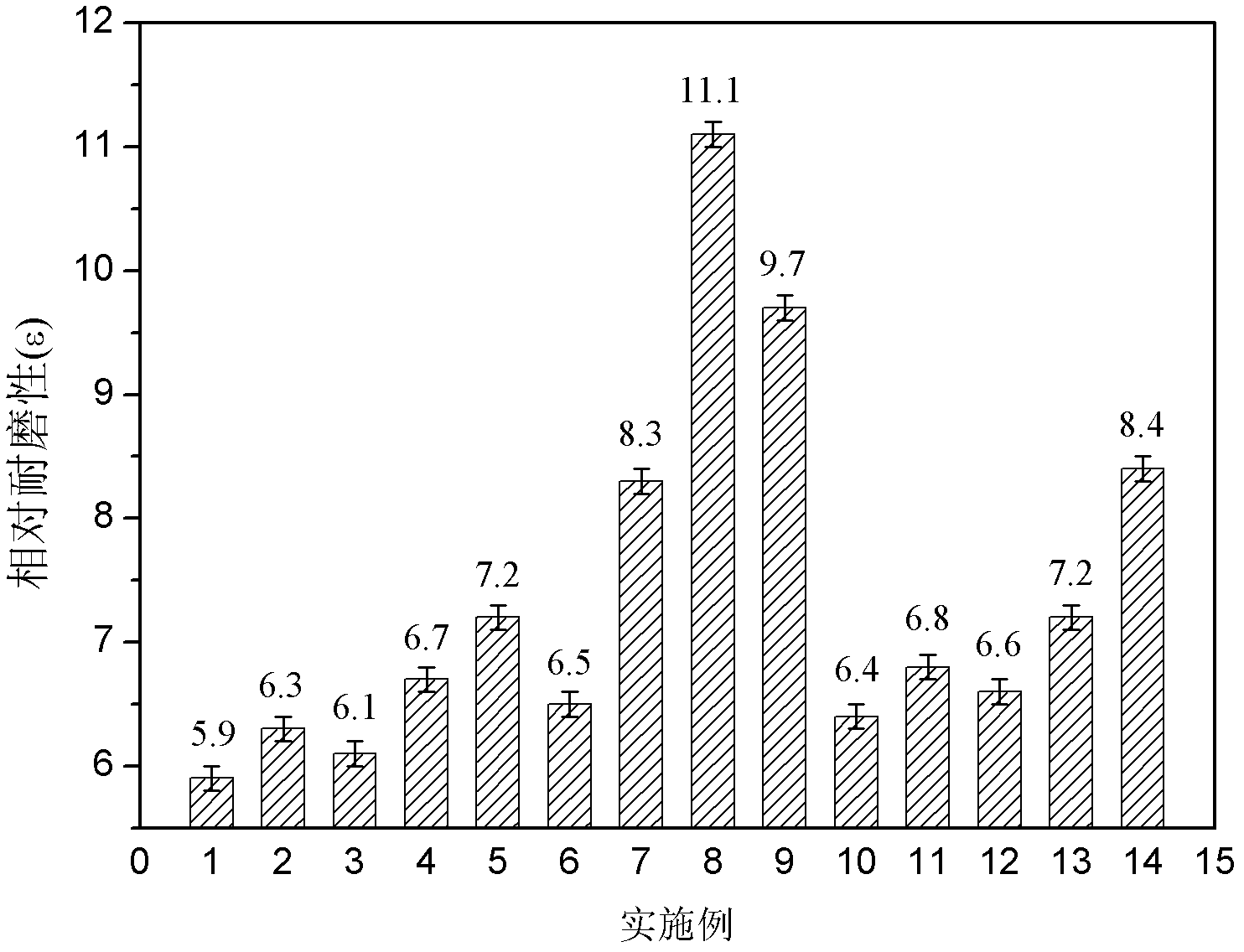

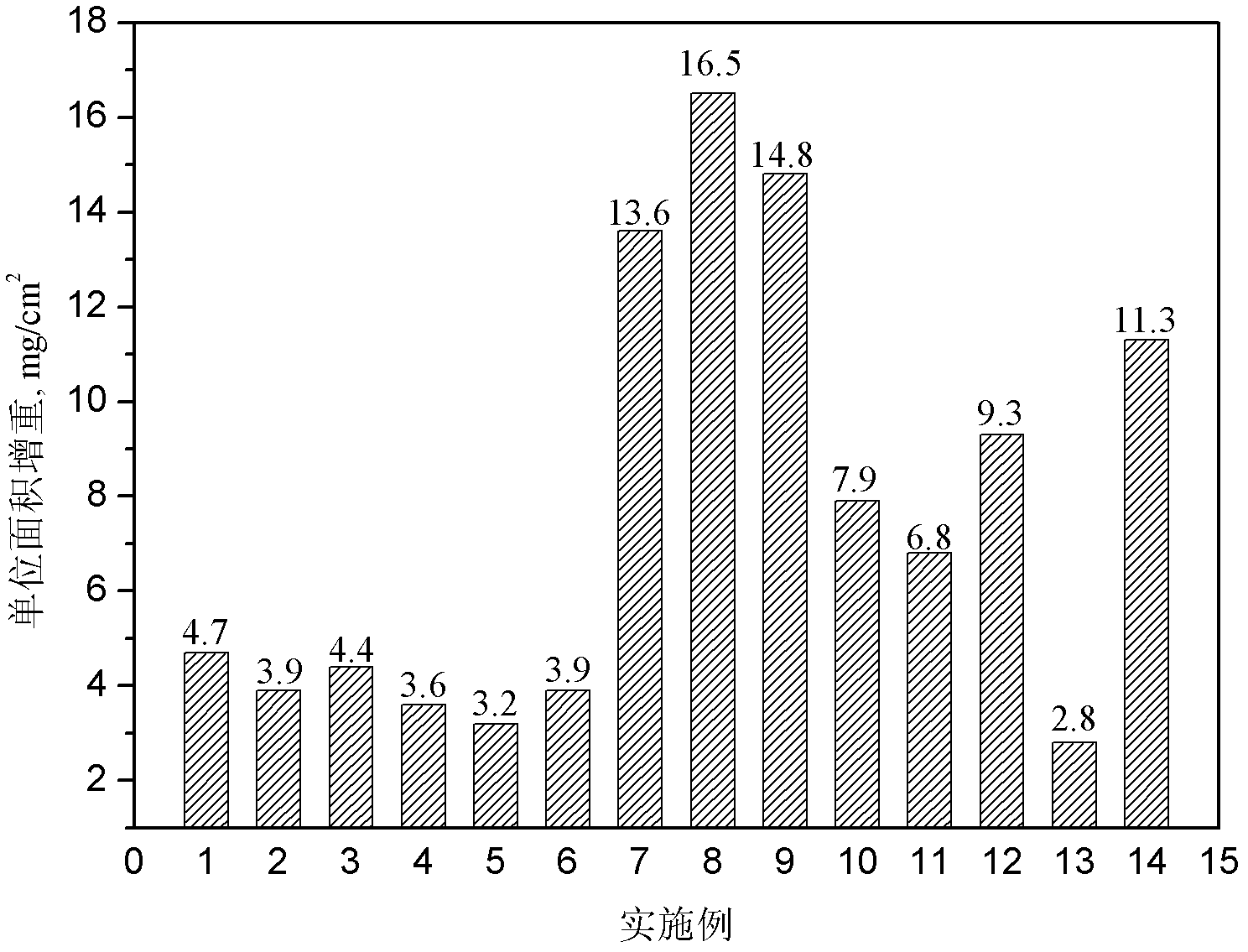

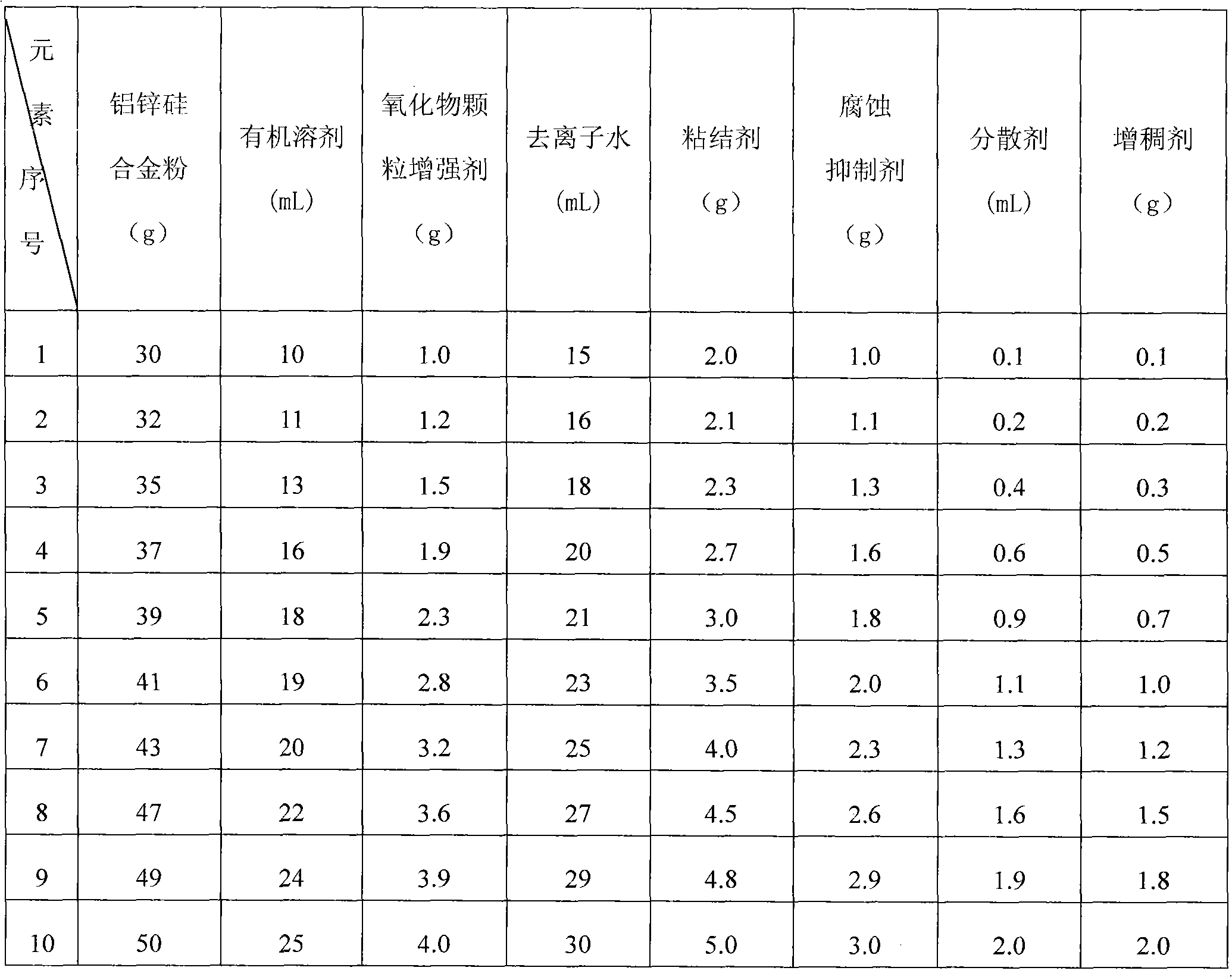

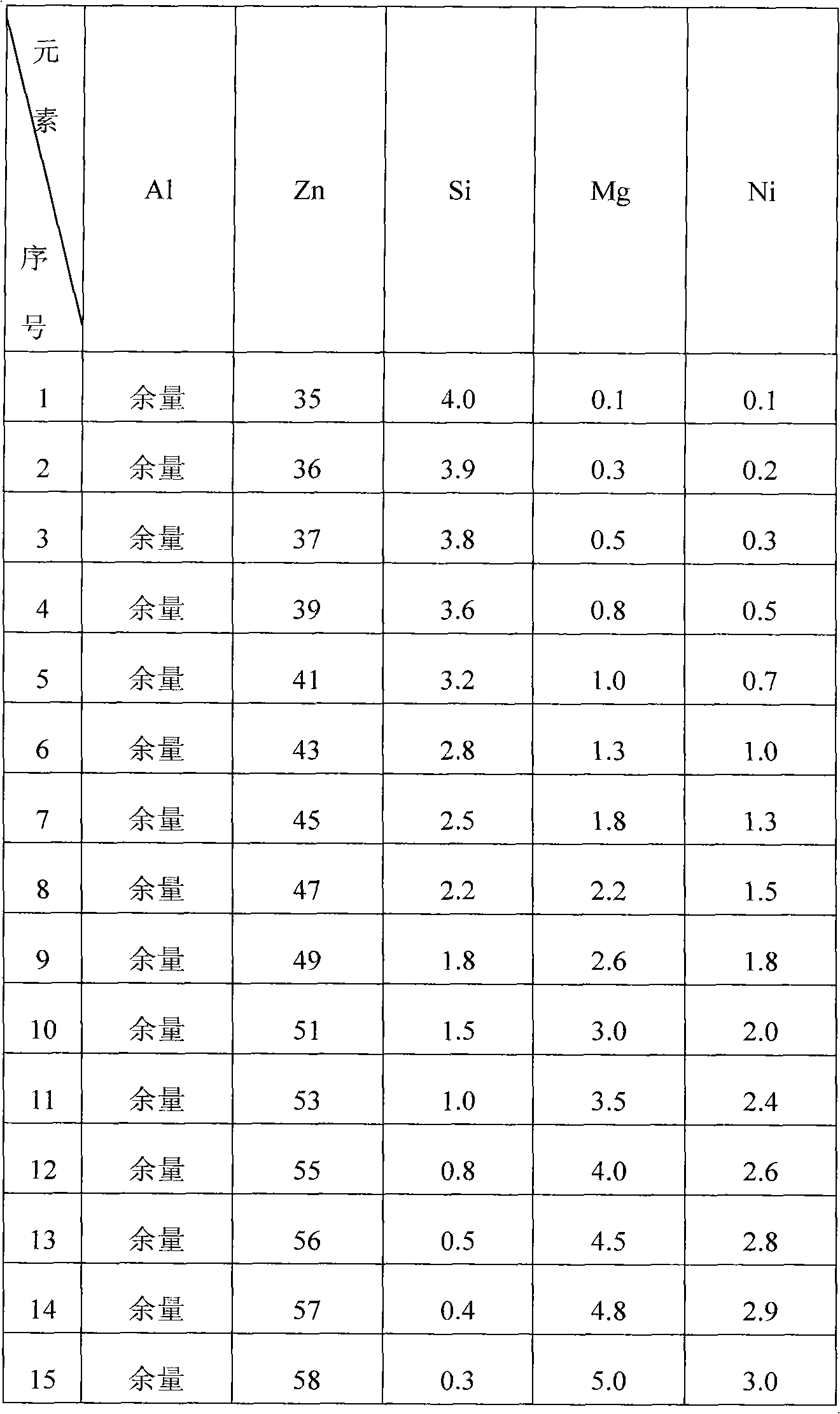

The invention relates to a coating for marine climate-resistant engineering part preservative treatment, which comprises 30.0 to 50.0g of aluminum-zinc-silicone alloy powder, 10.0 to 25.0mL of organic solvent, 1.0 to 4.0g of nano-oxide particle reinforcing agent, 15.0 to 30.0mL of deionized water, 2.0 to 5.0g of adhesive, 1.0 to 3.0g of corrosion inhibitor, 0.1 to 2.0mL of a dispersing agent and 0.1 to 2.0g of thickening agent, wherein the aluminum-zinc-silicone alloy powder consists of aluminum, zinc, silicone, magnesium and nickel.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

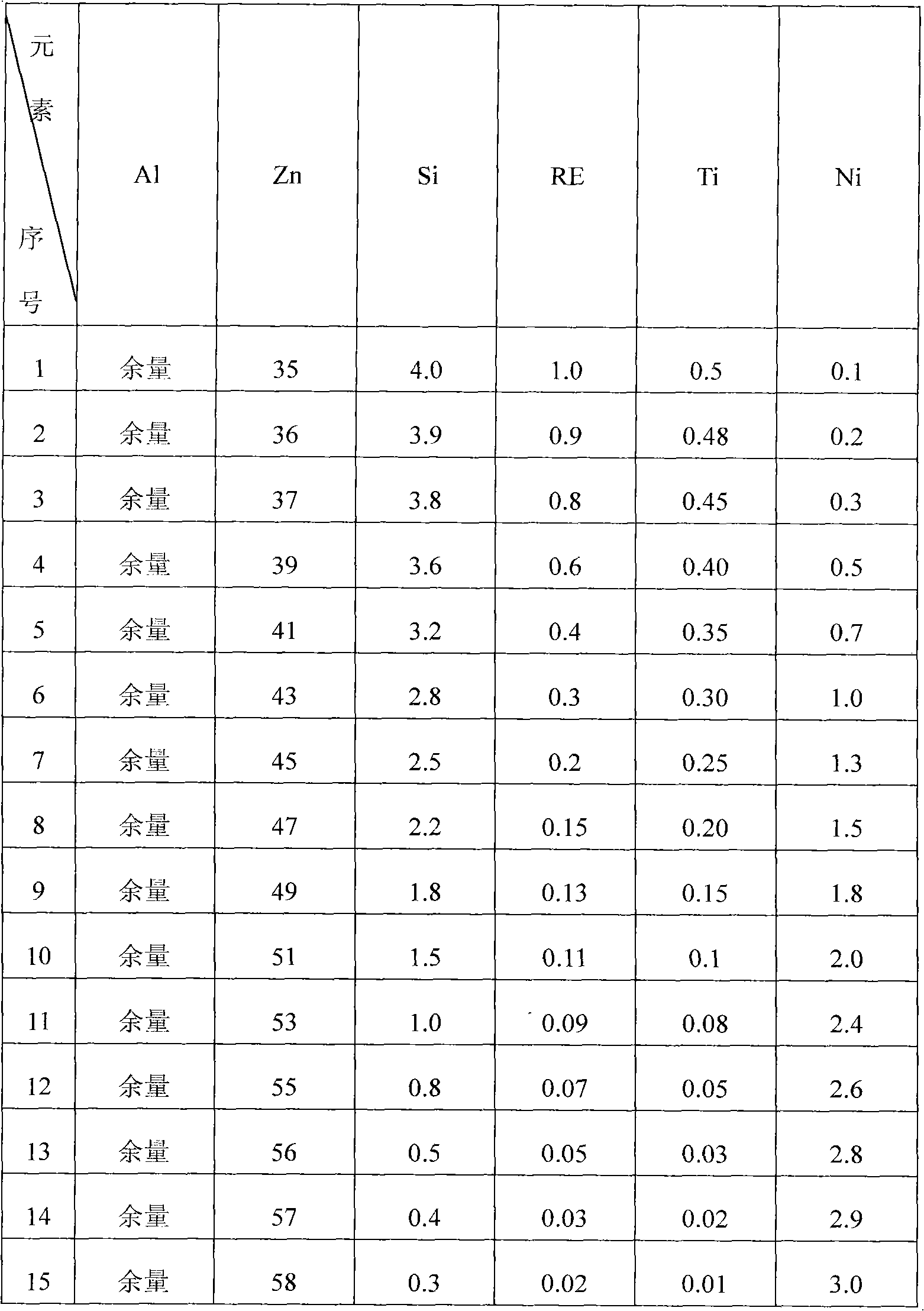

Rare earth-titanium-nickel-containing sea climate resisting paint used for anti-corrosive treatment

ActiveCN102010625AEnvironmentally friendlySexual stabilityAnti-corrosive paintsRheniumOrganic solvent

The invention relates to a sea climate resisting paint used for performing anti-corrosive treatment on engineering parts. The paint comprises the following components: 30.0 to 50.0 grams of aluminum-zinc-silicon alloy powder, 10.0 to 25.0 milliliters of organic solvent, 1.0 to 4.0 grams of nanometer-scale oxide particle reinforcing agent, 15.0 to 30.0 milliliters of deionized water, 2.0 to 5.0 grams of binder, 1.0 to 3.0 grams of corrosion inhibitor, 0.1 to 2.0 milliliters of dispersant and 0.1 to 2.0 grams of thickener, wherein the aluminum-zinc-silicon alloy powder consists of aluminum (Al), zinc (Zn), silicon (Si), rhenium (RE), titanium (Ti) and nickel (Ni).

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

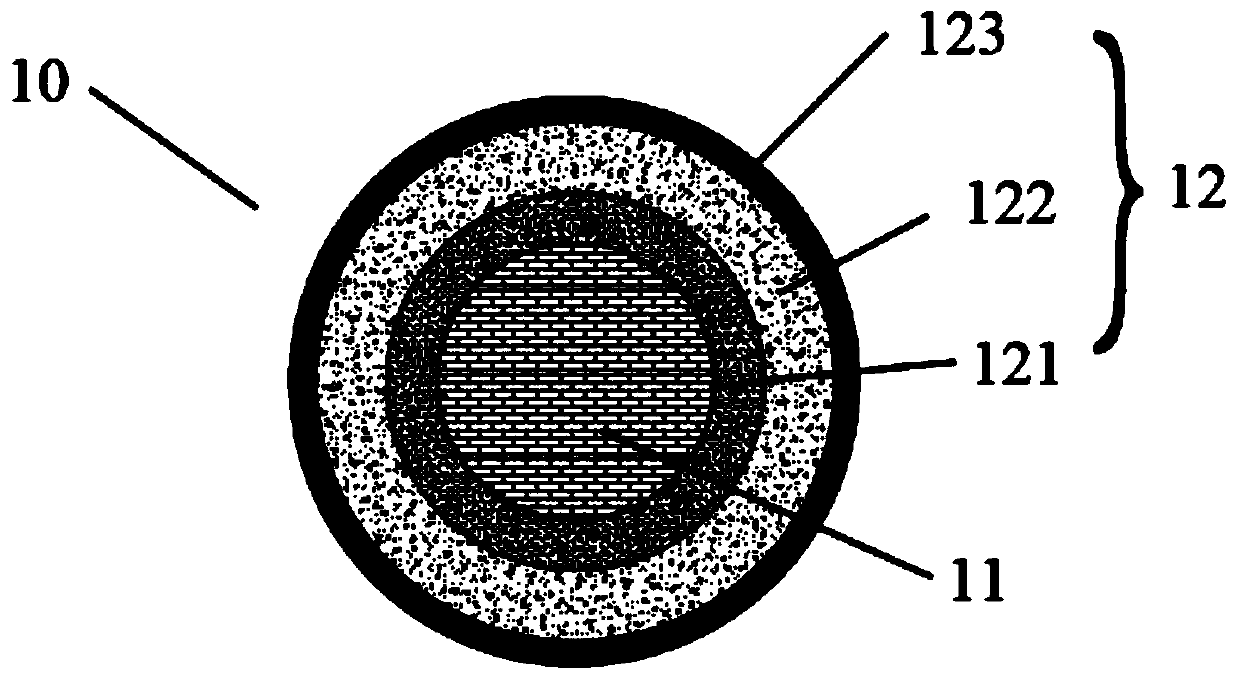

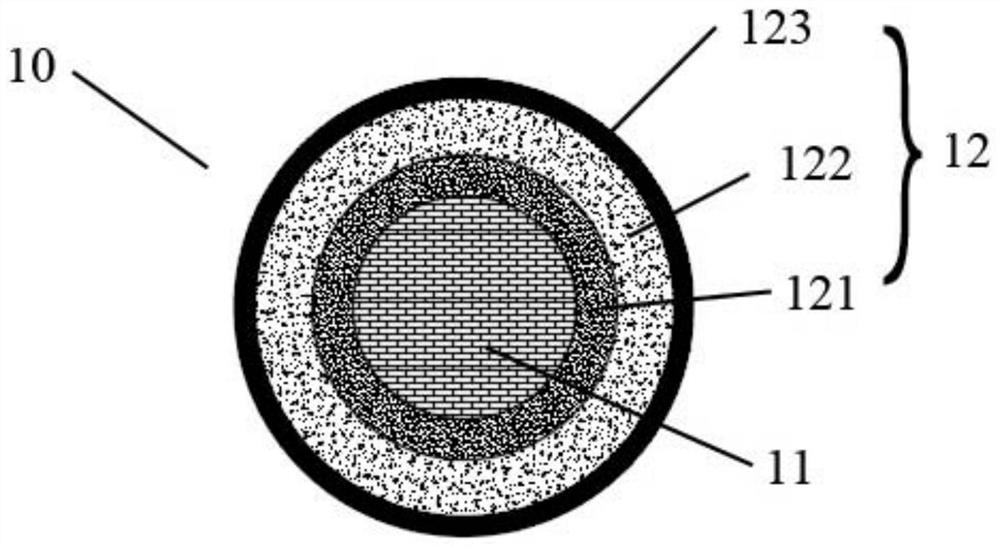

Anti-molten aluminum corrosion coating and preparation method thereof

ActiveCN110195228AHigh temperature wear resistanceAnti-stick to aluminumHot-dipping/immersion processesLiquid surface applicatorsAlloyThermal shock

The invention discloses an anti-molten aluminum corrosion coating. The coating is characterized by comprising at least three sub-coatings, namely the alloy layer arranged on the surface of a substratein a coating mode, a ceramic layer arranged on the surface of the alloy layer in a coating mode and a hole sealing layer arranged on the surface of the ceramic layer in a coating mode. The anti-molten aluminum corrosion coating has high-temperature abrasion resistance, aluminum sticking resistance, molten aluminum corrosion resistance, large bonding strength and excellent thermal shock resistance. Moreover, a preparation method of the anti-molten aluminum corrosion coating is easy to implement, coating materials are easy to obtain, and the production cost is reduced.

Owner:SHANGHAI JUSN SURFACE TECH ENG

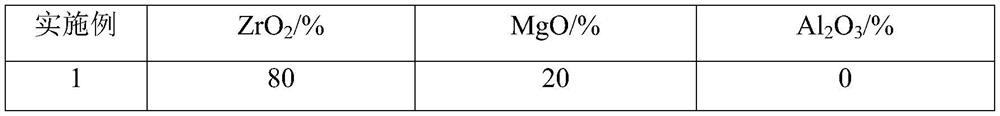

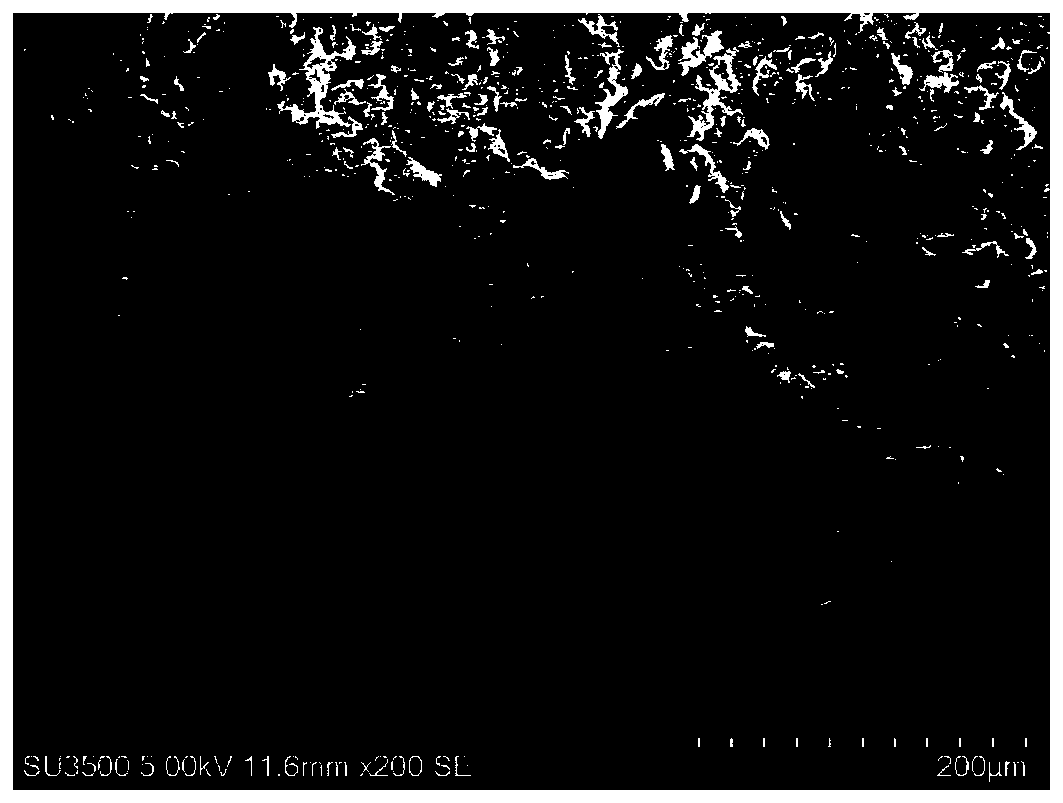

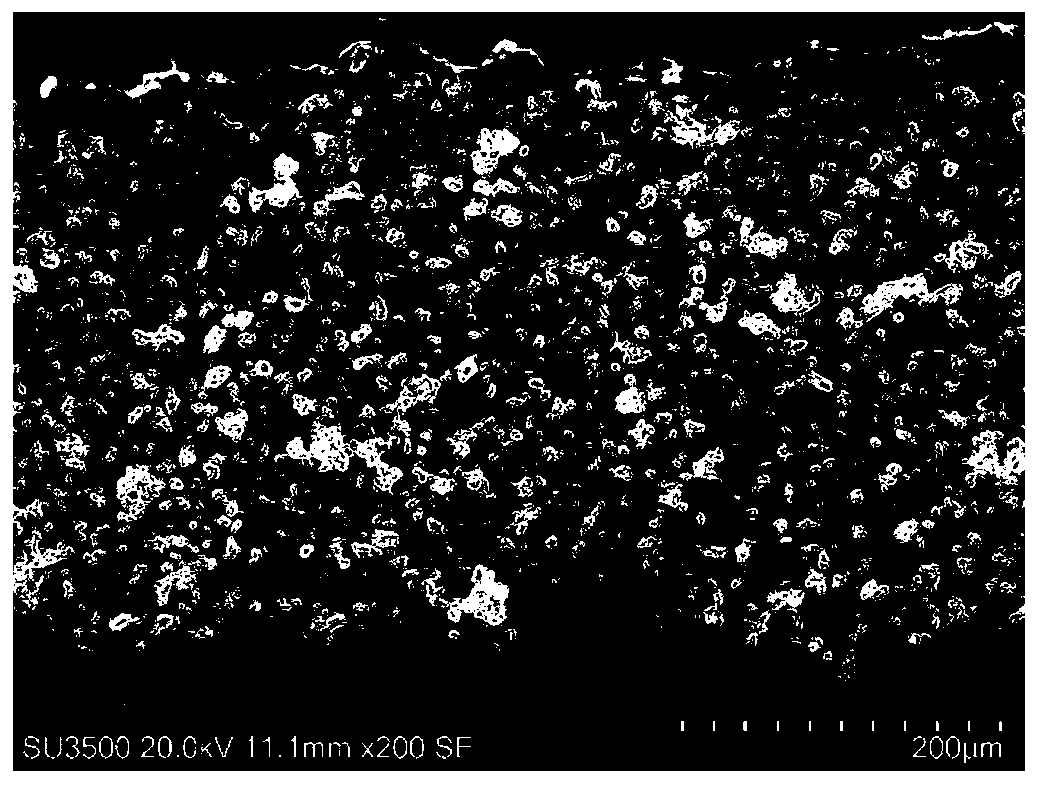

Laser surface treatment method for improving thermal corrosion resistance of thermal barrier coating

ActiveCN108220953AHigh heat and corrosion resistanceReduced surface corrosionMolten spray coatingCoated surfaceHigh energy

The invention discloses a laser surface treatment method for improving the thermal corrosion resistance of a thermal barrier coating, belonging to the technical field of treatment of thermal barrier coatings. The method comprises the following steps: S1, ultrasonically cleaning the surface of the thermal barrier coating, and adjusting the spot shape of a laser to a rectangular shape; S2, adjustingthe laser in the step S1 to emit low energy density laser, and carrying out self-preheating scanning on the thermal barrier coating treated in the step S1; S3, adjusting the laser in the step S1 to emit high energy density laser, and carrying out re-melting scanning on the thermal barrier coating treated in the step S2; S4, adjusting the laser in the step S1 to emit medium energy density laser, and performing a slow-cooling scanning on the thermal barrier coating treated in the step S3; S5, naturally cooling the thermal barrier coating treated in the step S4 to room temperature, and then using compressed air to remove impurities on the surface of the coating cooled to room temperature. After the coating is treated by using the method, the coating is smooth and dense, the thermal corrosionof corrosive salt is inhibited, and the service life of the coating is prolonged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

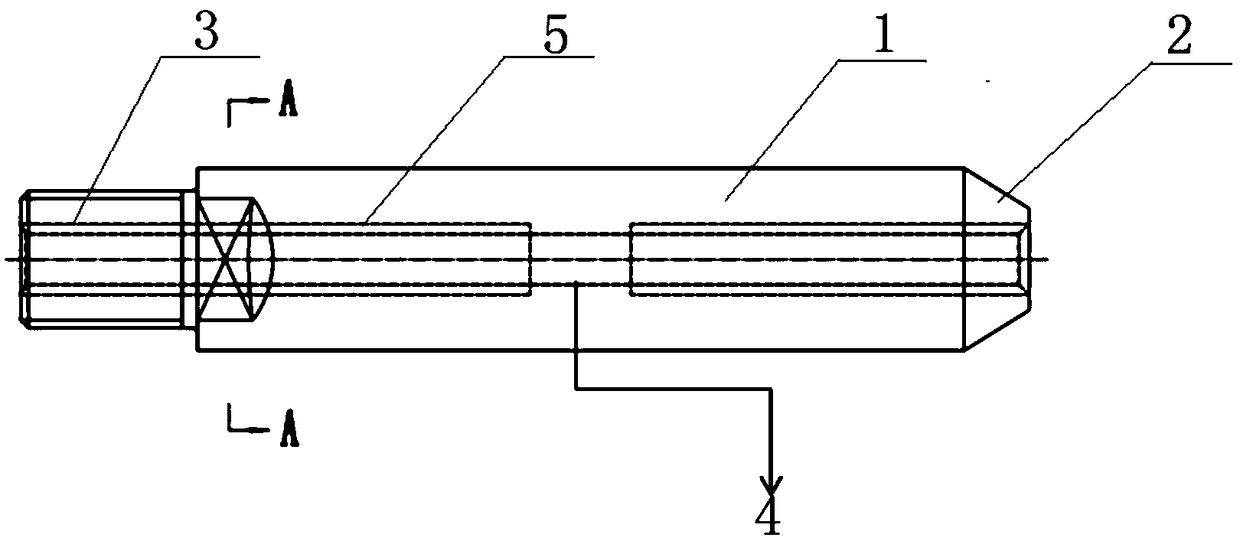

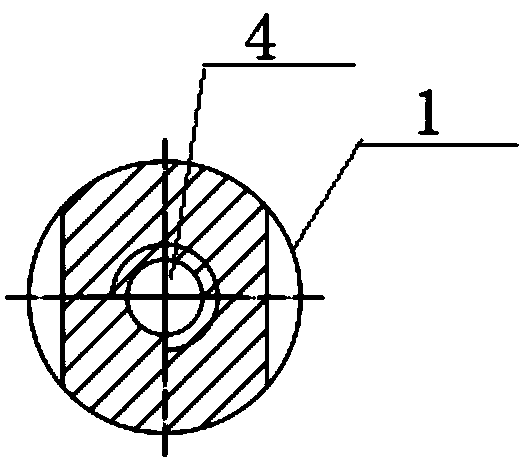

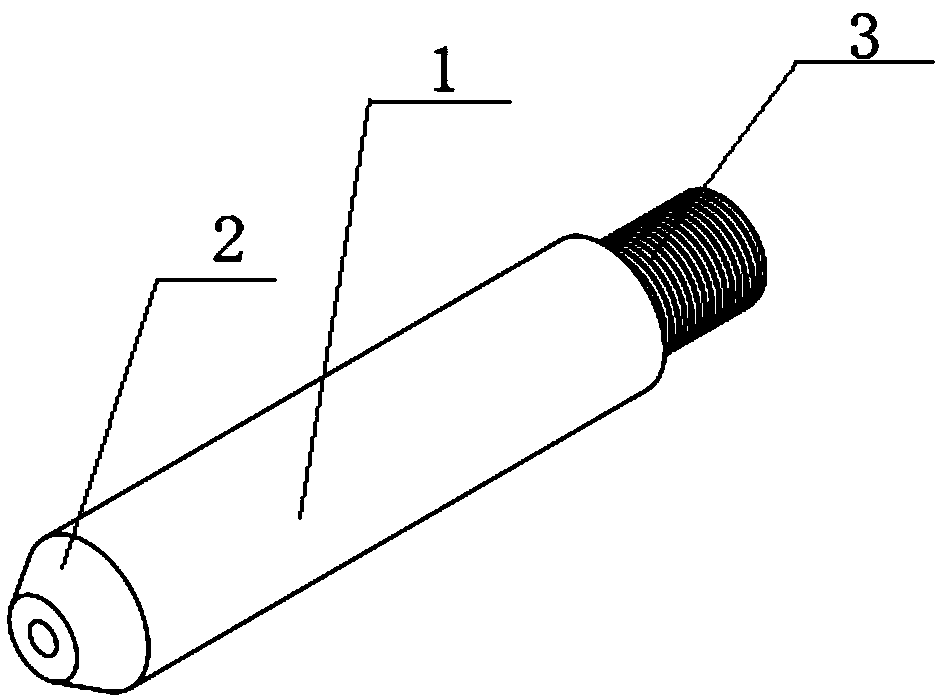

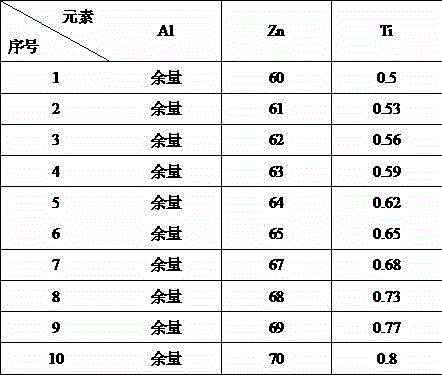

High-temperature alloy core rod applied to planetary rolling mill for rolling copper and copper and preparation method of high-temperature alloy core rod

ActiveCN109402424AGood high temperature fatigue performanceLess copper stickingFoundry mouldsSolid state diffusion coatingSuperalloyMechanical property

The invention relates to a high-temperature alloy core rod applied to planetary rolling mill for rolling copper and copper and a preparation method of the high-temperature alloy core rod, and belongsto the technical field of metal machining. The high-temperature alloy core rod comprises 11.50-14.00% of Cr, 3.80-5.2% of Mo, 5.50-6.50% of Al, 0.50-1.00% of Ti, 1.80-2.80% of Nb and Ta, 0.005-0.020%of B, 0.08-0.20% of C, 0.050-0.20% of Zr, 0-0.50% of Si, 0-0.50% of Mn, 0-0.015% of P, 0-0.015% of S, 0-2.50% of Fe and the balance Ni. In the preparation process, a mother alloy cast ingot is prepared through vacuum induction smelting, vacuum induction remelting is carried out, a high-temperature alloy core rod blank is prepared through investment casting, the blank is subjected to hot isostaticpressure treatment and subsequent heat treatment, then the blank is polished and subjected to finish machining, and finally the core rod is subjected to surface aluminizing treatment to improve the surface hardness and corrosion resistance at high temperature. The high-temperature alloy core rod prepared through the preparation method has relatively high comprehensive mechanical property, long infatigue life and high in high-temperature strength, the service life of a die is obviously prolonged, the preparation process is simple, and the process is short.

Owner:JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

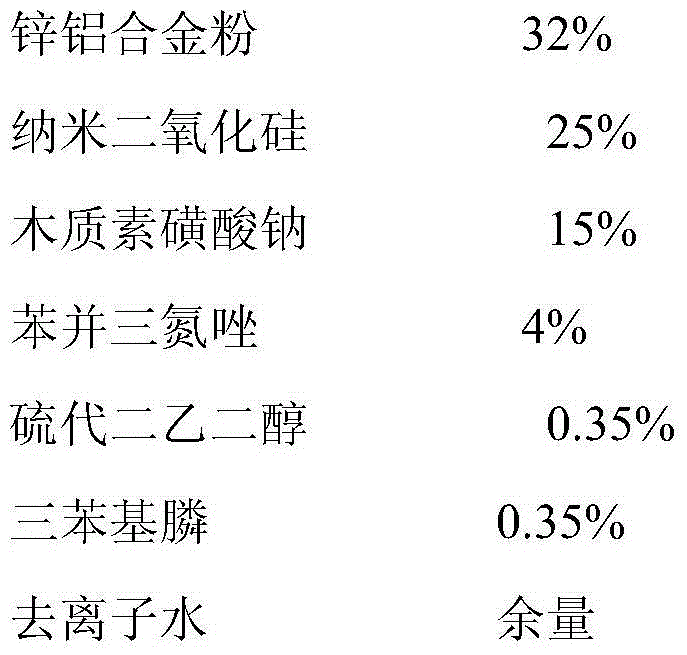

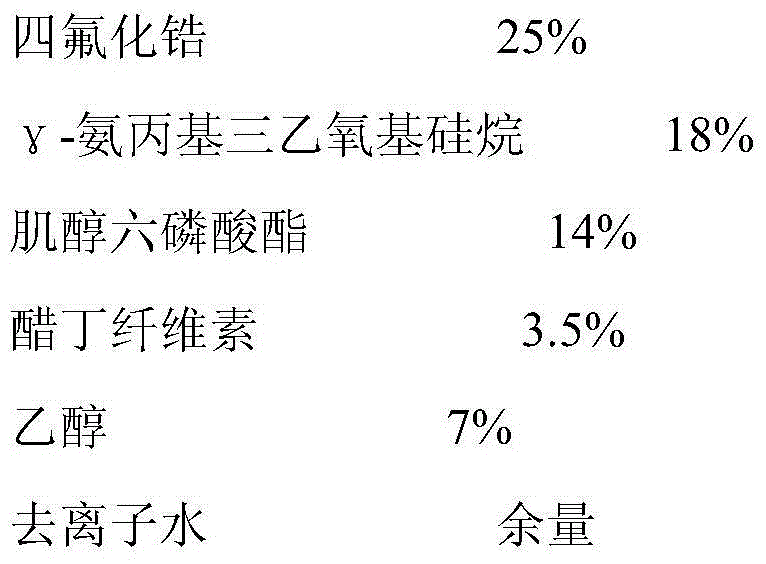

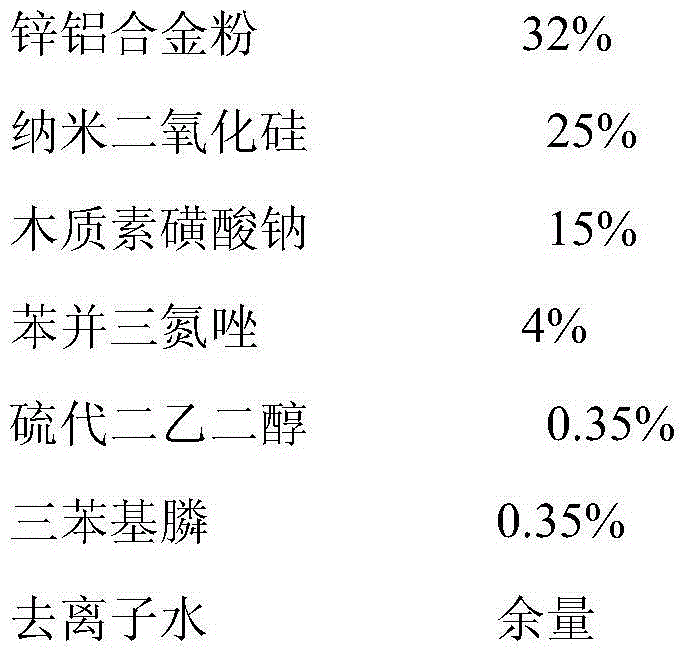

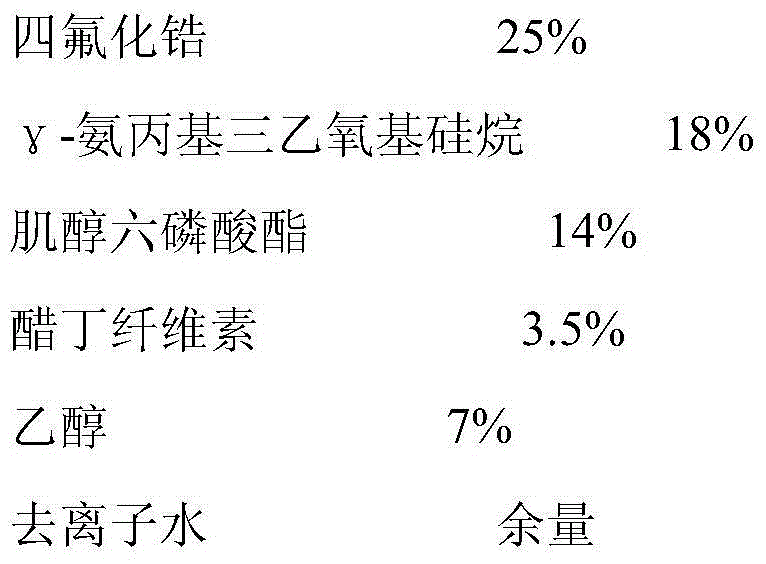

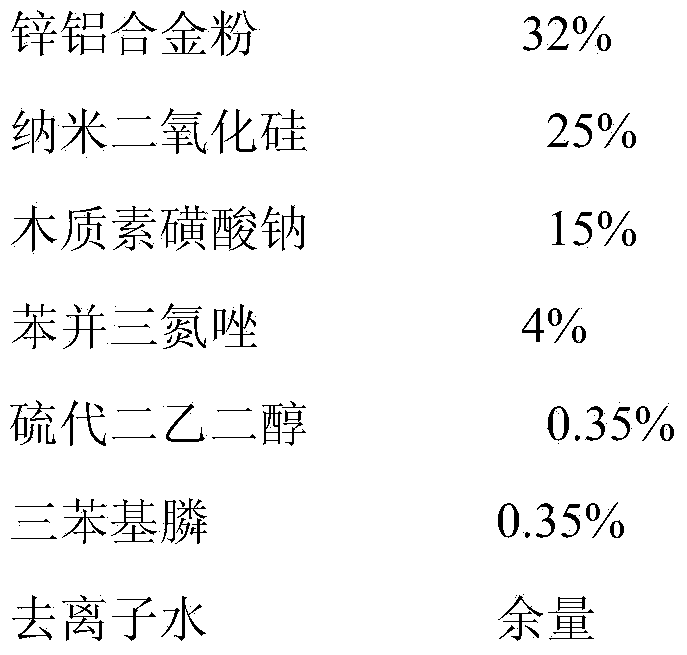

Titanium-containing chromium-free zinc-aluminum coating anti-corrosive paint

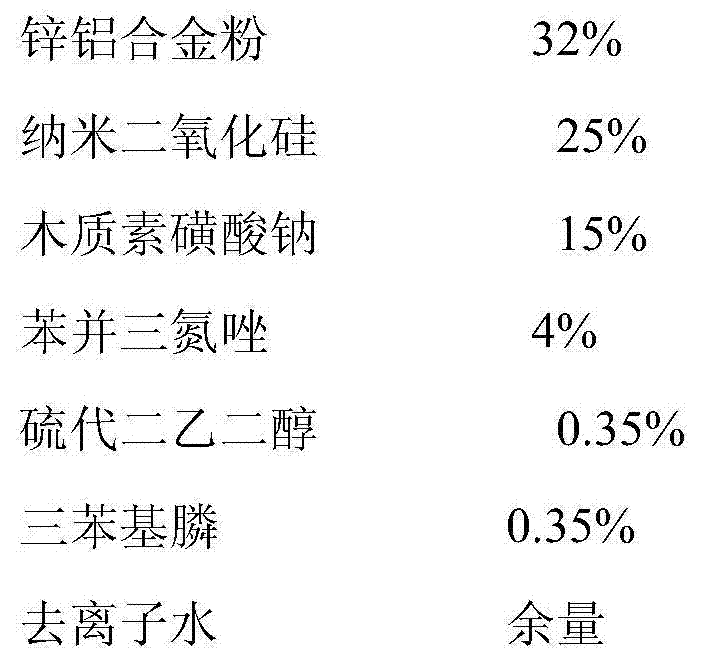

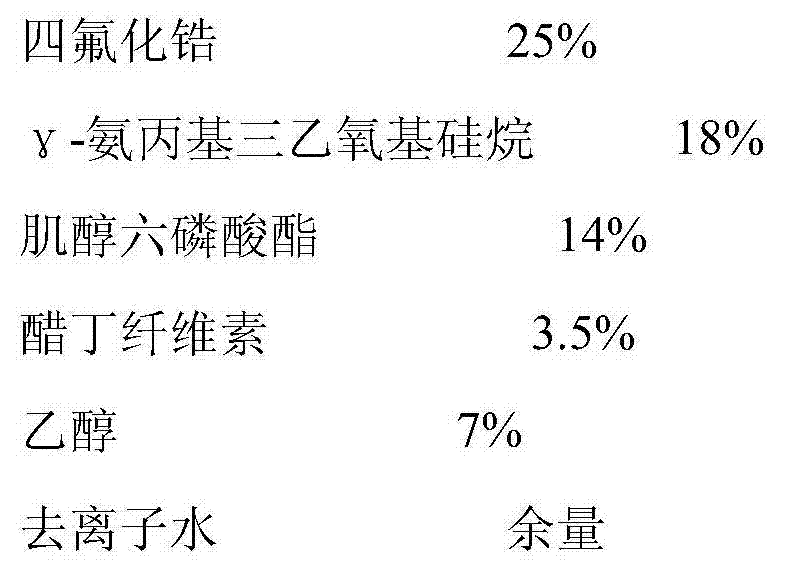

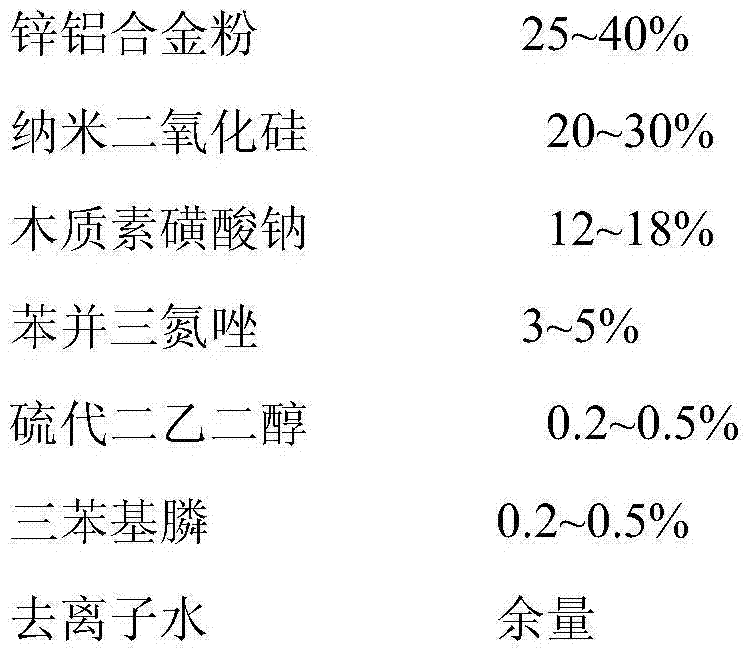

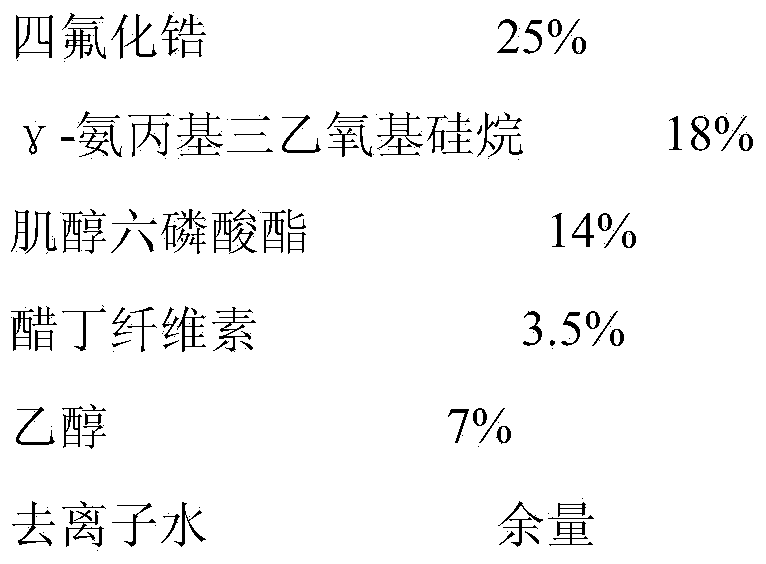

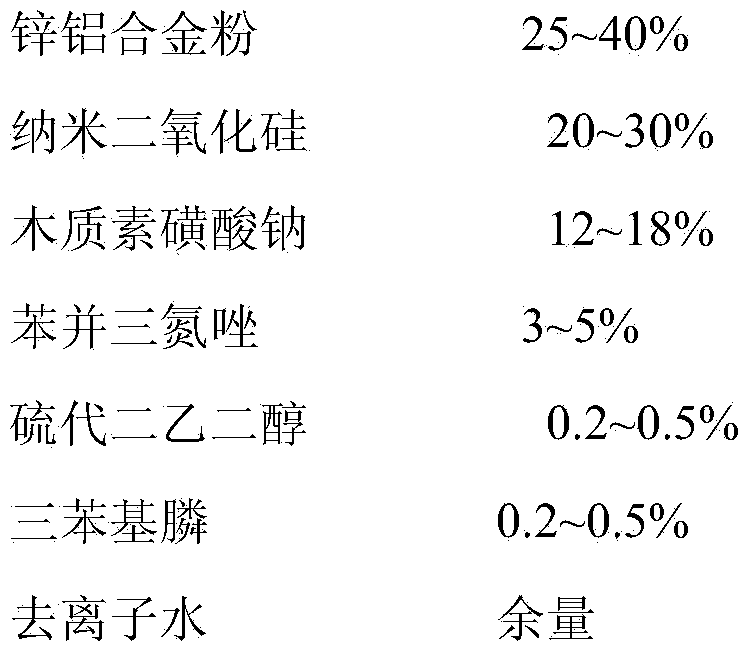

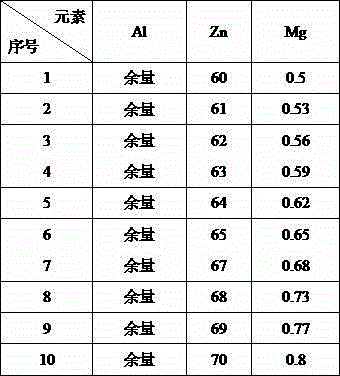

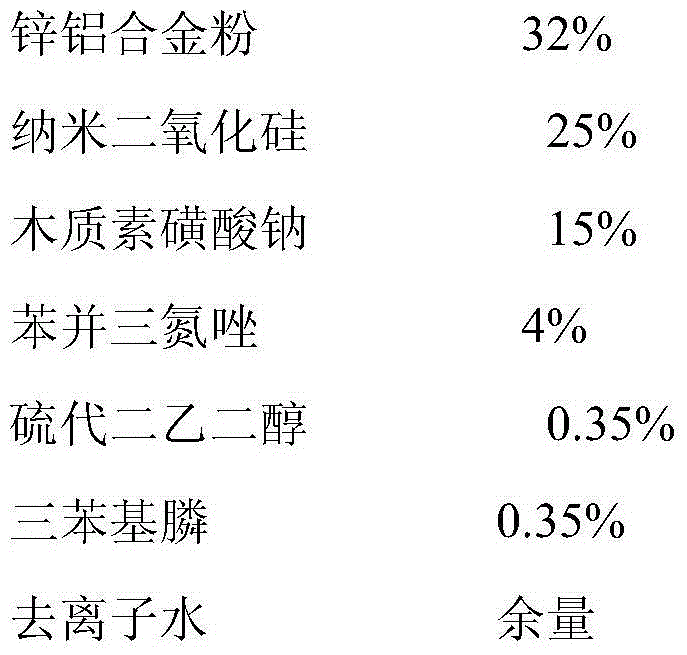

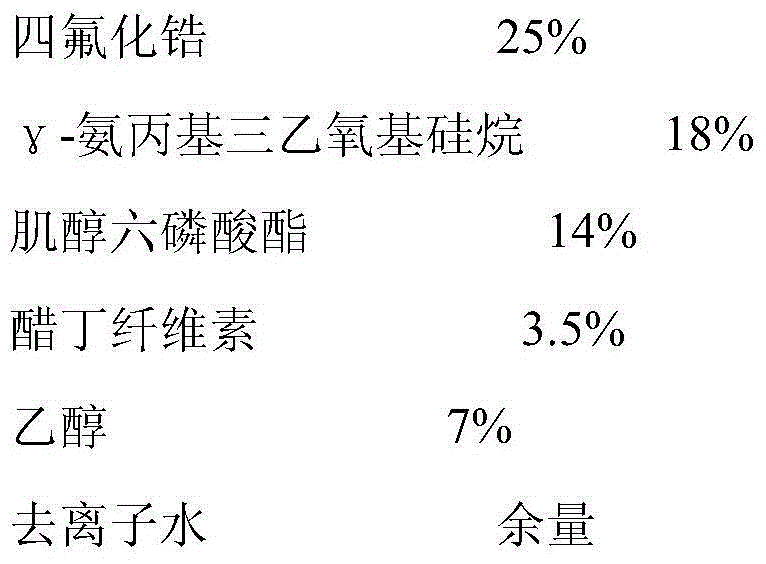

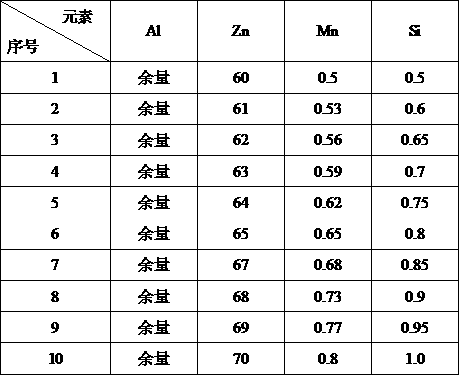

InactiveCN103044990BExcellent curing temperatureLow curing temperatureAnti-corrosive paintsChromium freeInositol hexaphosphate

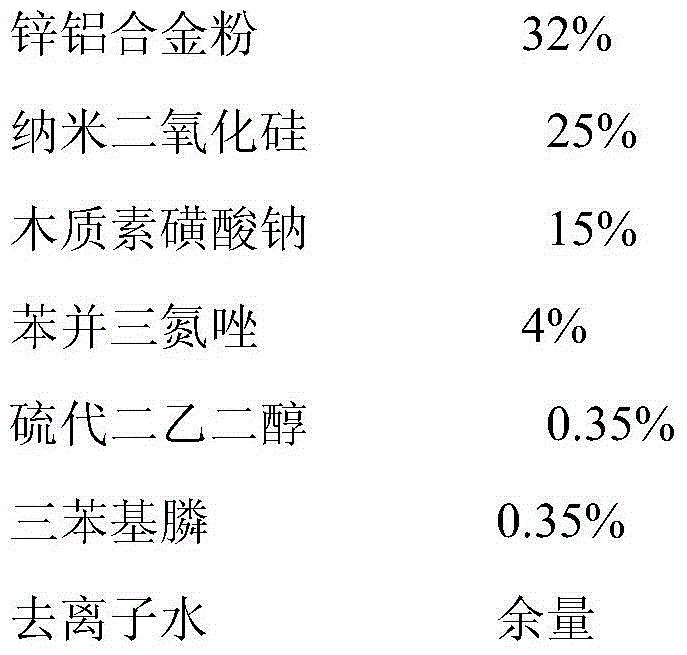

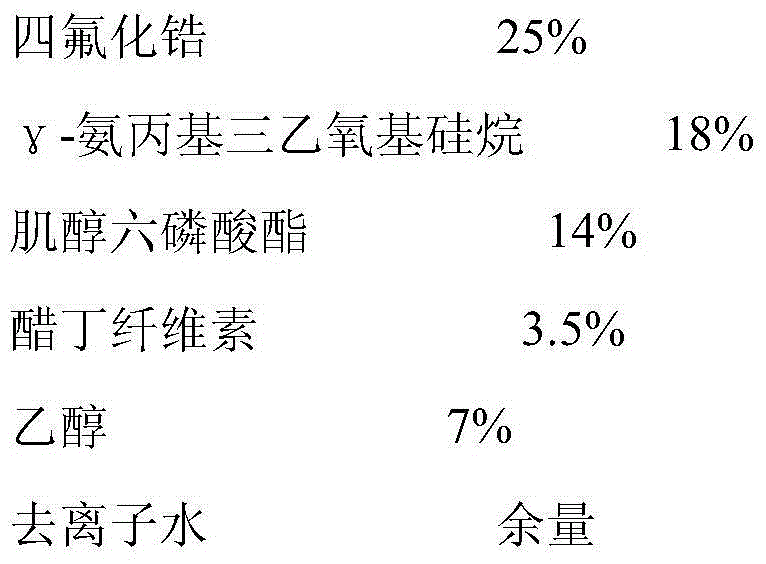

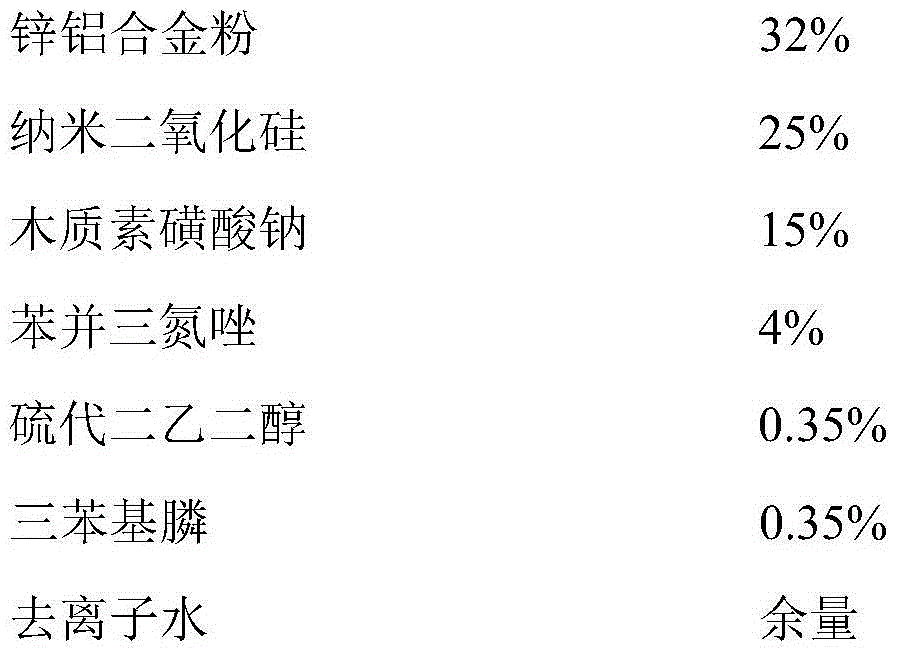

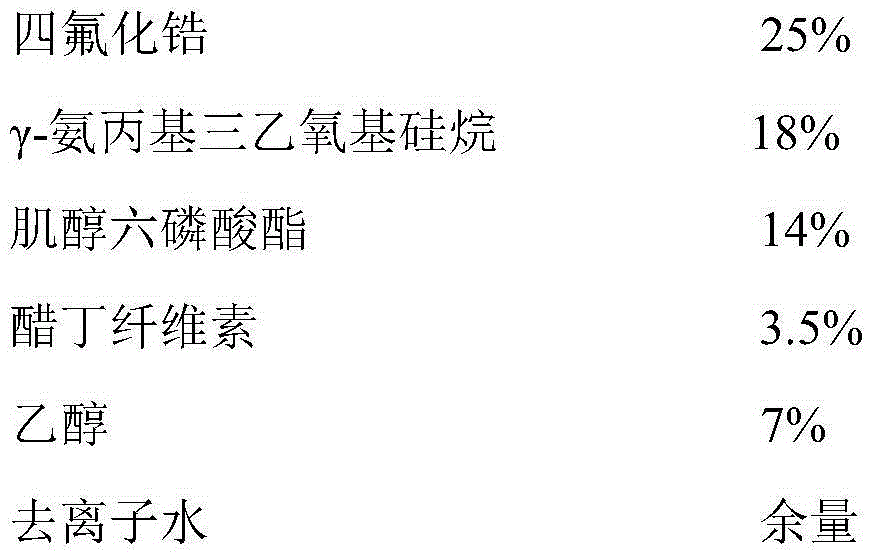

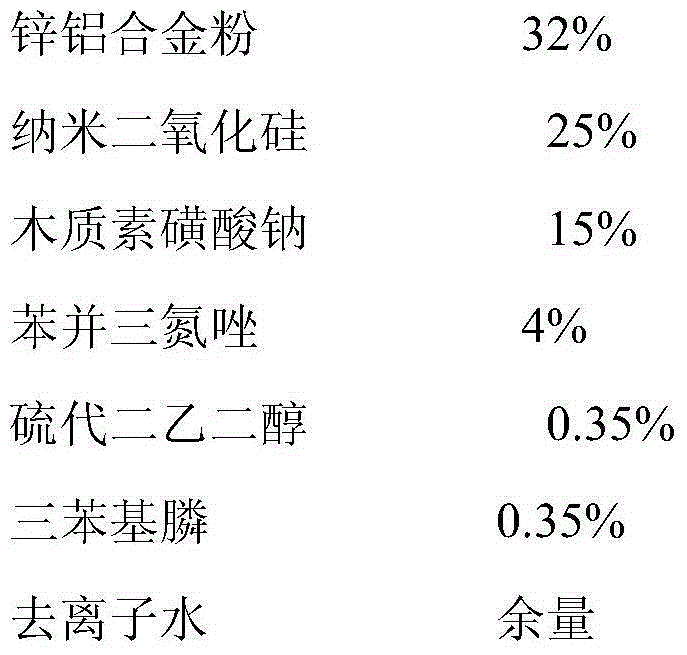

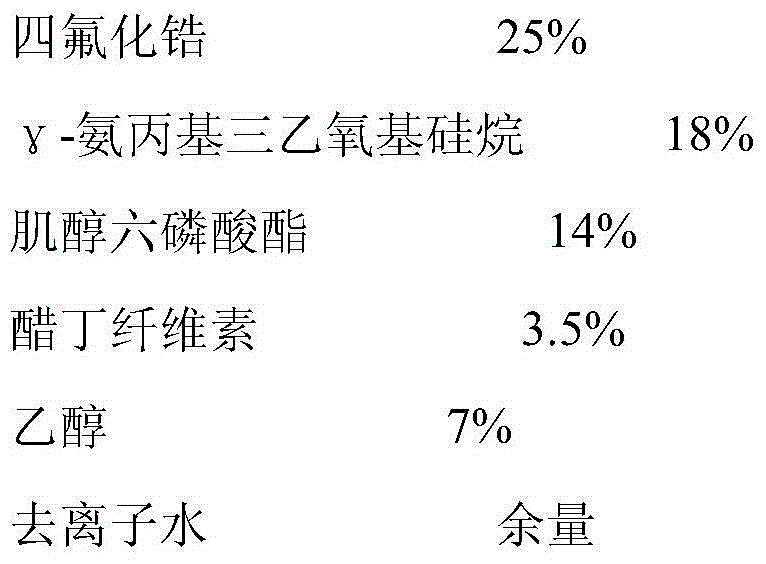

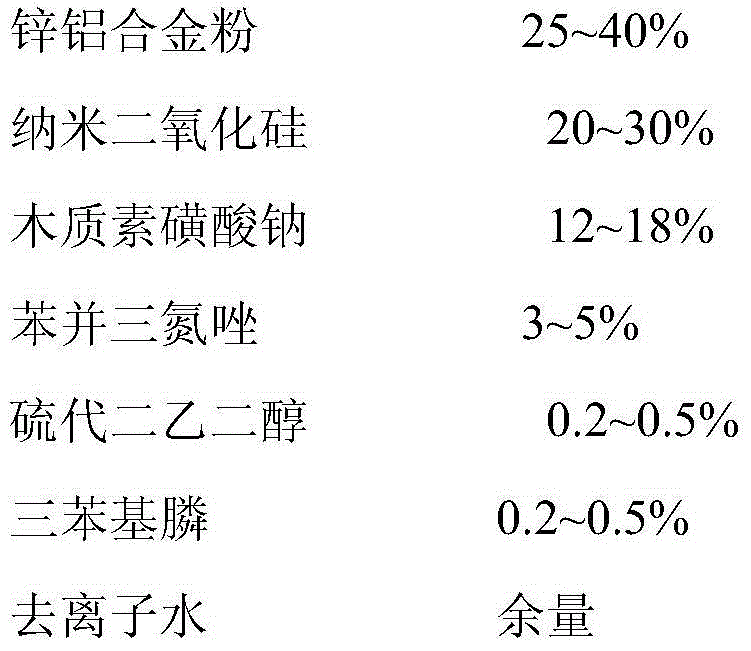

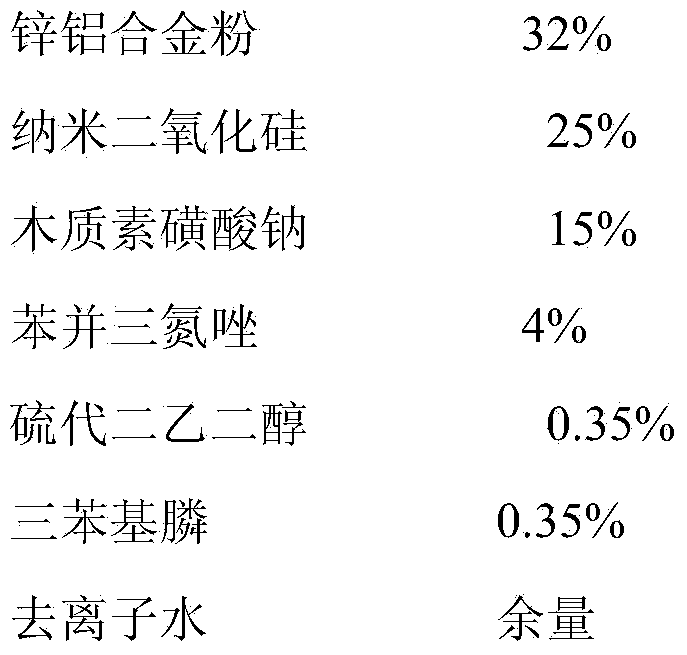

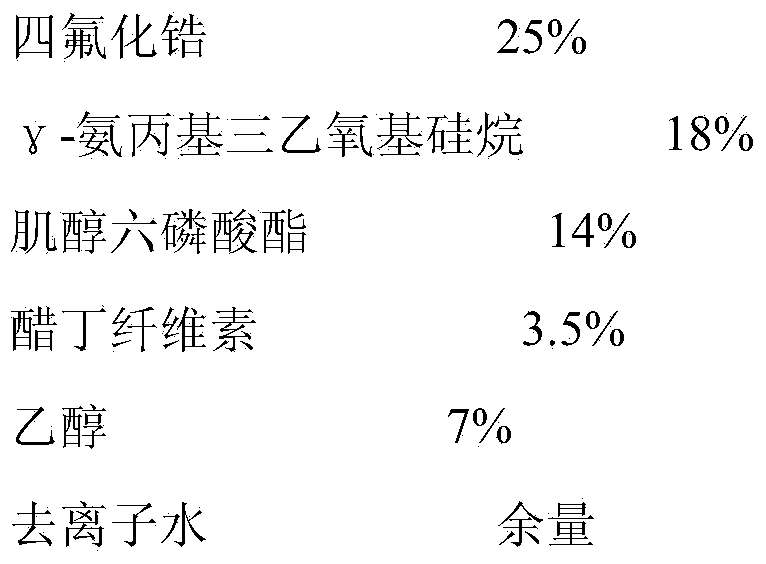

The invention discloses titanium-containing chromium-free zinc-aluminum coating anti-corrosive paint which comprises an A component and a B component at a mass ratio of 3:1, wherein the A component comprises the following raw materials: allumen powder, nano-silica, sodium lignosulphonate, benzotriazole, sulpho-diethylene glycol, triphenylphosphine and deionized water; the B component comprises the following raw materials: zirconium tetrafluoride, gamma-aminopropyl triethoxy silane, inositol hexaphosphate, cellulose acetate-butyrate, ethanol and deionized water; and the allumen powder comprises Zn, Al and Ti. The paint has the characteristics of no toxicity, harmlessness, no pollution, low-temperature immediate processing, easiness in operation, extensive raw material sources, low price, cleaner production and the like.

Owner:RUGAO CITY LEHENG CHEM COMPANY

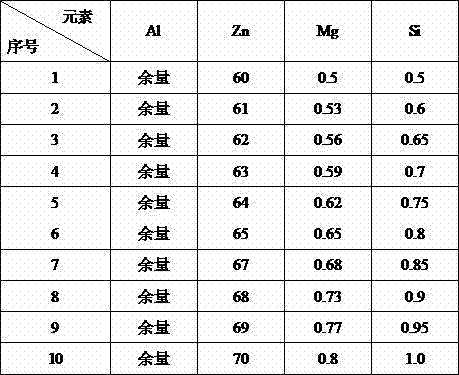

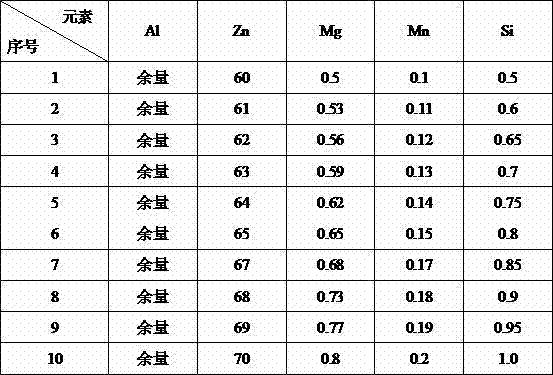

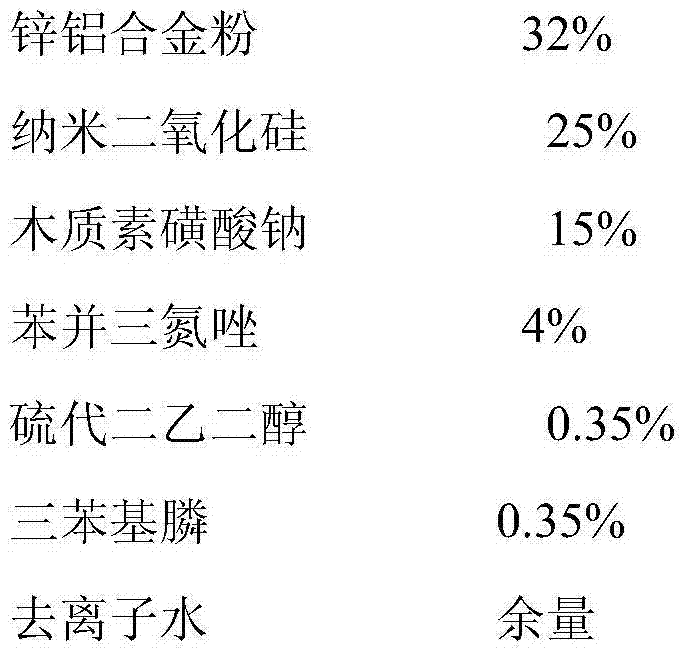

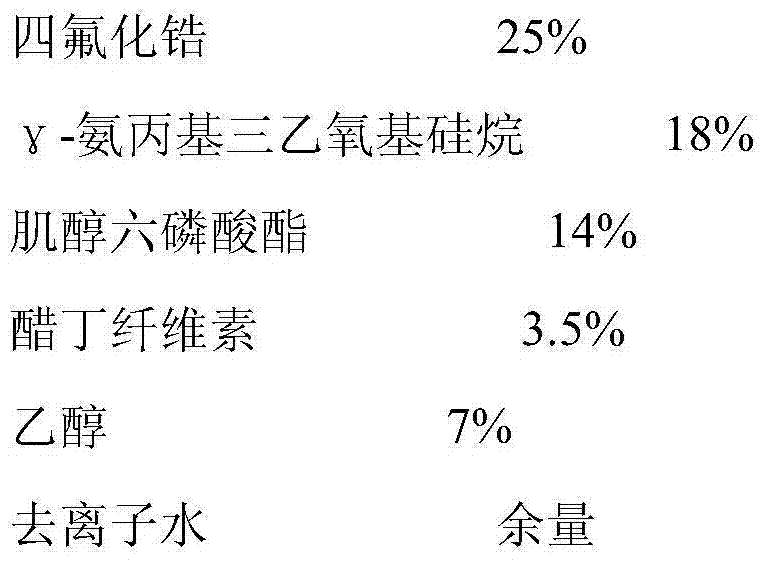

Magnesium-silicon-containing chromium-free zinc-aluminum coating anti-corrosive paint

InactiveCN103044988AExcellent curing temperatureLow curing temperatureAnti-corrosive paintsChromium freeSilanes

The invention discloses magnesium-silicon-containing chromium-free zinc-aluminum coating anti-corrosive paint which comprises an A component and a B component at a mass ratio of 3:1, wherein the A component comprises the following raw materials: allumen powder, nano-silica, sodium lignosulphonate, benzotriazole, sulpho-diethylene glycol, triphenylphosphine and deionized water; the B component comprises the following raw materials: zirconium tetrafluoride, gamma-aminopropyl triethoxy silane, inositol hexaphosphate, cellulose acetate-butyrate, ethanol and deionized water; and the allumen powder comprises Zn, Al, Mg and Si. The paint has the characteristics of no toxicity, harmlessness, no pollution, low-temperature immediate processing, easiness in operation, extensive raw material sources, low price, cleaner production and the like.

Owner:广西南宁维一防腐科技有限公司

High-temperature alloy for electronic firework push rod as well as preparation process and application of high-temperature alloy

ActiveCN114293067AReduce contentAdd solid solution strengthening elementsFurnace typesCasting cleaning apparatusHeat stabilitySuperalloy

Owner:上海康晟航材科技股份有限公司

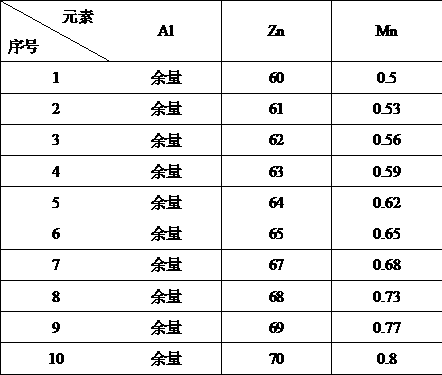

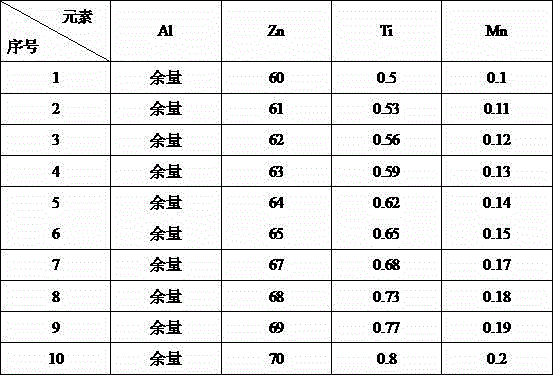

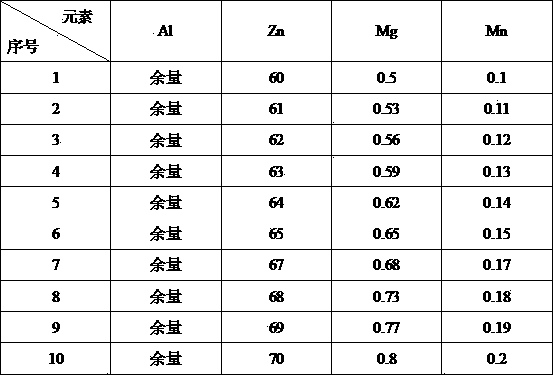

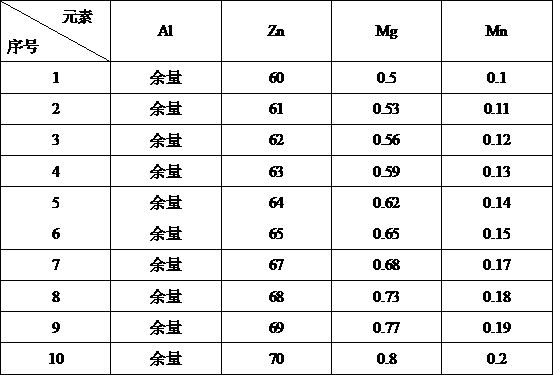

Manganese containing anticorrosion paint with chromium-free zinc aluminium coating

InactiveCN103275527AExcellent curing temperatureLow curing temperatureAnti-corrosive paintsChromium freeManganese

The invention discloses a manganese containing anticorrosion paint with chromium-free zinc aluminium coating, and the A and B two-component are composed according to 3:1 mass ratio, wherein, A component comprises the following raw materials: zinc aluminium alloy powder, nanometer silica, sodium lignosulfonate, benzotriazol, sulfo diethylene glycol, triphenyl phosphine and deionized water; B component comprises the following raw materials: zirconium tetrafluoride, gamma-amino propyl triethoxysilane, inositol hexaphosphate, cellulose acetate butyrate, ethanol and deionized water. The zinc aluminium alloy powder is composed of Zn, Al, Ti and Mn. The product has the characteristics of nontoxicity, innocuity, no pollution, low temperature rapid treatment, simple operation, wide raw material source, low price, cleaning production, etc.

Owner:湖北三雷德化工有限公司

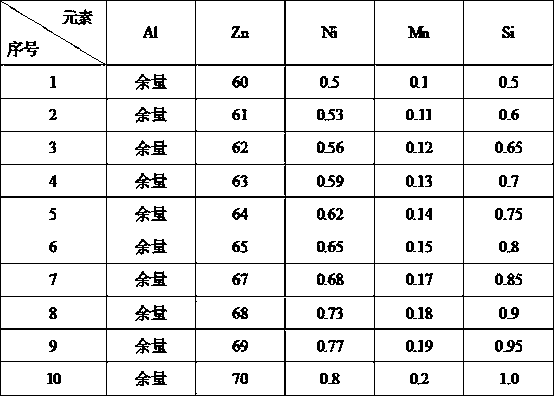

Nickel-manganese-silicon containing anticorrosion paint with chromium-free zinc aluminium coating

ActiveCN103275526AExcellent curing temperatureLow curing temperatureAnti-corrosive paintsChromium freeManganese

The invention discloses a nickel-manganese-silicon containing anticorrosion paint with chromium-free zinc aluminium coating, and the A and B two-component are composed according to 3:1 mass ratio, wherein, A component comprises the following raw materials: zinc aluminium alloy powder, nanometer silica, sodium lignosulfonate, benzotriazol, sulfo diethylene glycol, triphenyl phosphine and deionized water; B component comprises the following raw materials: zirconium tetrafluoride, gamma-amino propyl triethoxysilane, inositol hexaphosphate, cellulose acetate butyrate, ethanol and deionized water. The zinc aluminium alloy powder is composed of Zn, Al, Ni, Si and Mn. The product has the characteristics of nontoxicity, innocuity, no pollution, low temperature rapid treatment, simple operation, wide raw material source, low price, cleaning production, etc.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Nickel-based superalloy wear surface size repairing method

PendingCN114686798ASmall difference in coefficient of thermal expansionExtended service lifeMolten spray coatingAbrasive blastingSuperalloy

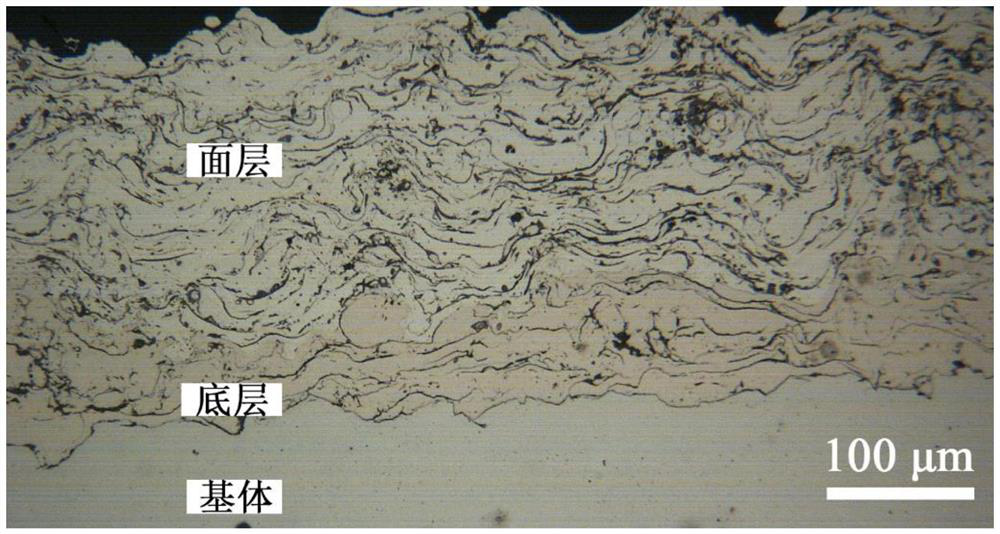

The invention discloses a method for repairing the size of a nickel-based superalloy wear surface, relates to the field of aero-engine maintenance, and aims to repair the size of a wear surface of a part made of a nickel-based superalloy material. According to the technical scheme, the nickel-based high-temperature alloy abrasion surface size repairing method comprises the steps that S1, repairing pretreatment is conducted, specifically, the abrasion surface of a part is cleaned, shielding protection before sand blasting is conducted on the portion outside a repairing area, and then sand blasting coarsening is conducted on the repairing area; s2, NiAl powder is subjected to plasma spraying on the repaired area, and a bonding bottom layer is formed; s3, CoCrNiW powder is subjected to plasma spraying on the bonding bottom layer, and a working face layer is formed; and S4, the repaired area is machined, so that the thickness and the surface roughness of the coating meet the technological requirements. The method is used for carrying out size repair on the worn surface of the part made of the nickel-based superalloy material, for example, the method is used for carrying out size repair on the end face of a shell of an outer cover of a gas turbine of an aero-engine.

Owner:PLA NO 5719 FACTORY

A chrome-free zinc-aluminum coating anticorrosion coating containing titanium-manganese

ActiveCN103275528BExcellent curing temperatureLow curing temperatureAnti-corrosive paintsChromium freeManganese

The invention discloses a titanium-manganese containing anticorrosion paint with chromium-free zinc aluminium coating, and the A and B two-component are composed according to 3:1 mass ratio, wherein, A component comprises the following raw materials: zinc aluminium alloy powder, nanometer silica, sodium lignosulfonate, benzotriazol, sulfo diethylene glycol, triphenyl phosphine and deionized water; B component comprises the following raw materials: zirconium tetrafluoride, gamma-amino propyl triethoxysilane, inositol hexaphosphate, cellulose acetate butyrate, ethanol and deionized water. The zinc aluminium alloy powder is composed of Zn, Al, Ti and Mn. The product has the characteristics of nontoxicity, innocuity, no pollution, low temperature rapid treatment, simple operation, wide raw material source, low price, cleaning production, etc.

Owner:QIDONG QINGQING VEGETABLE & FRUIT RURAL LAND STOCK PROFESSIONAL COOP

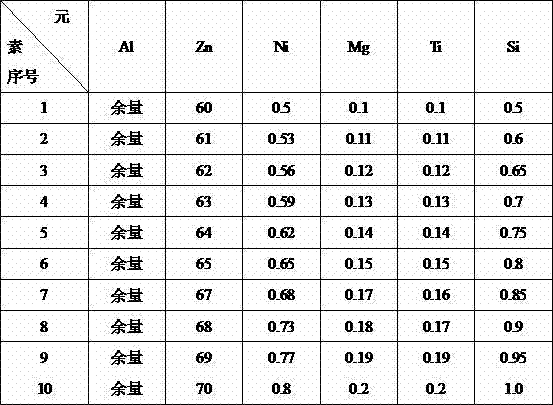

Nickel-magnesium-titanium-silicon-containing chromium-free zinc-aluminum coating anti-corrosive paint

InactiveCN103044993AExcellent curing temperatureLow curing temperatureAnti-corrosive paintsChromium freeSilanes

The invention discloses nickel-magnesium-titanium-silicon-containing chromium-free zinc-aluminum coating anti-corrosive paint which comprises an A component and a B component at a mass ratio of 3:1, wherein the A component comprises the following raw materials: allumen powder, nano-silica, sodium lignosulphonate, benzotriazole, sulpho-diethylene glycol, triphenylphosphine and deionized water; the B component comprises the following raw materials: zirconium tetrafluoride, gamma-aminopropyl triethoxy silane, inositol hexaphosphate, cellulose acetate-butyrate, ethanol and deionized water; and the allumen powder comprises Zn, Al, Ti, Ni, Mg and Si. The paint has the characteristics of no toxicity, harmlessness, no pollution, low-temperature immediate processing, easiness in operation, extensive raw material sources, low price, cleaner production and the like.

Owner:重庆海塑南邦铝业有限公司

Anti-melting aluminum corrosion coating and preparation method thereof

ActiveCN110195228BHigh temperature wear resistanceAccelerated corrosionHot-dipping/immersion processesLiquid surface applicatorsAlloyAluminum corrosion

Owner:SHANGHAI JUSN SURFACE TECH ENG

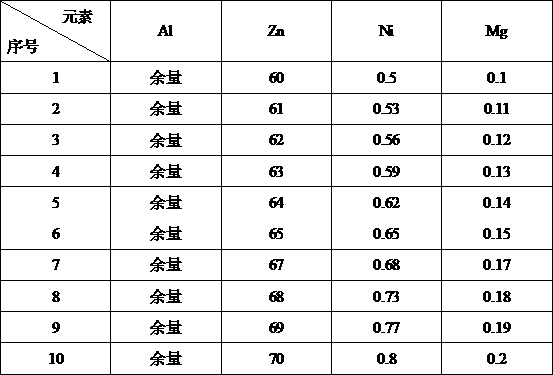

Nickel-magnesium-containing chromium-free zinc aluminum coating corrosion-resistant coating

ActiveCN103059614AExcellent curing temperatureLow curing temperatureAnti-corrosive paintsChromium freeAlloy

The invention discloses nickel-magnesium-containing chromium-free zinc aluminum coating corrosion-resistant coating. The nickel-magnesium-containing chromium-free zinc aluminum coating corrosion-resistant coating consists of a component A and a component B, wherein the mass ratio of the component A to the component B is 3:1; the component A comprises the following raw materials: zinc aluminum alloy powder, nano-silicon dioxide, sodium lignosulphonate, benzotriazole, sulfo-diethylene glycol, triphenylphosphine and deionized water; the component B comprises the following raw materials: zirconium tetrafluoride, gamma-aminopropyl triethoxysilane, inositol hexaphosphate, cellulose acetate-butyrate, ethanol and deionized water; and the zinc aluminum alloy powder comprising Zn, Al, Ni and Mg. The product has the characteristics of no toxicity, no harm, no pollution, low-temperature quick treatment, simplicity in operation, wide sources of raw materials, low price, clean production and the like.

Owner:TONGXIANG TONGDE ELECTRIC POWER FITTING

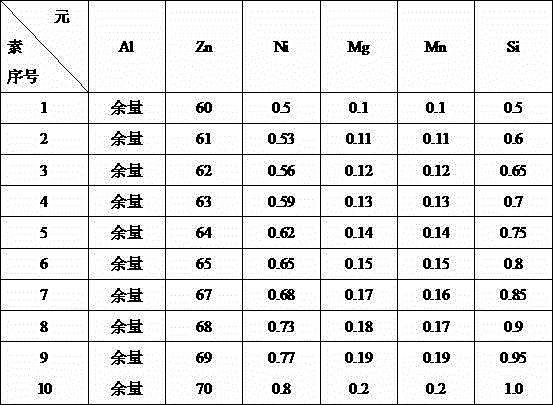

Chrome-free zinc-aluminum coating anticorrosive paint comprising nickel-magnesium-manganese-silicon

InactiveCN103232735BExcellent curing temperatureLow curing temperatureAnti-corrosive paintsCellulose acetateManganese

The invention discloses a chrome-free zinc-aluminum coating anticorrosive paint comprising nickel-magnesium-manganese-silicon. The paint is composed of a component A and a component B with a mass ratio of 3:1. The component A comprises the raw materials of zinc-aluminum alloy powder, nano-silica, lignin sodium sulfonate, benzotriazole, thio diethylene glycol, triphenylphosphine, and deionized water. The component B comprises zirconium tetrafluoride, gamma-aminopropyl triethoxysilane, inositol hexaphosphate, butyl cellulose acetate, ethanol, and deionized water. The zinc-aluminum alloy powder is composed of Zn, Al, Ni, Mg, Mn and Si. The product provided by the invention has the advantages of no toxicity, no harm, no pollution, low-temperature fast processing, simple operation, wide raw material source, low cost, clean production, and the like.

Owner:HUNAN QIANXIN PIPE IND

Magnesium-manganese-silicon-containing chromium-free zinc-aluminum coating anti-corrosive paint

ActiveCN103044994BExcellent curing temperatureLow curing temperatureAnti-corrosive paintsChromium freeManganese

The invention discloses magnesium-manganese-silicon-containing chromium-free zinc-aluminum coating anti-corrosive paint which comprises an A component and a B component at a mass ratio of 3:1, wherein the A component comprises the following raw materials: allumen powder, nano-silica, sodium lignosulphonate, benzotriazole, sulpho-diethylene glycol, triphenylphosphine and deionized water; the B component comprises the following raw materials: zirconium tetrafluoride, gamma-aminopropyl triethoxy silane, inositol hexaphosphate, cellulose acetate-butyrate, ethanol and deionized water; and the allumen powder comprises Zn, Al, Mg, Mn and Si. The paint has the characteristics of no toxicity, harmlessness, no pollution, low-temperature immediate processing, easiness in operation, extensive raw material sources, low price, cleaner production and the like.

Owner:山东涂客环保科技有限公司

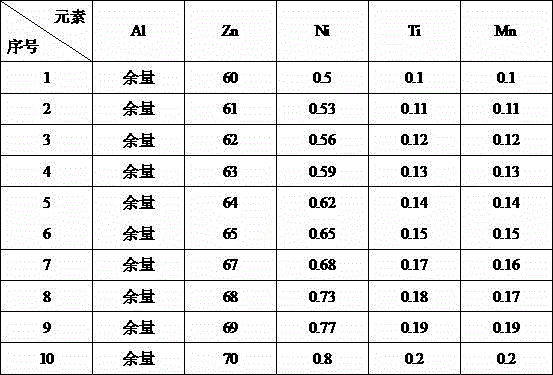

Chrome-free zinc-aluminum coating anticorrosive paint comprising nickel-titanium-manganese

ActiveCN103232737BExcellent curing temperatureLow curing temperatureAnti-corrosive paintsCellulose acetateManganese

The invention discloses a chrome-free zinc-aluminum coating anticorrosive paint comprising nickel-titanium-manganese. The paint is composed of a component A and a component B with a mass ratio of 3:1. The component A comprises the raw materials of zinc-aluminum alloy powder, nano-silica, lignin sodium sulfonate, benzotriazole, thio diethylene glycol, triphenylphosphine, and deionized water. The component B comprises zirconium tetrafluoride, gamma-aminopropyl triethoxysilane, inositol hexaphosphate, butyl cellulose acetate, ethanol, and deionized water. The zinc-aluminum alloy powder is composed of Zn, Al, Ti, Ni and Mn. The product provided by the invention has the advantages of no toxicity, no harm, no pollution, low-temperature fast processing, simple operation, wide raw material source, low cost, clean production, and the like.

Owner:FOSHAN HAIHUA SURFACE TREATMENT TECH CO LTD

Nickel-magnesium-titanium-manganese-containing chromium-free zinc aluminum coating corrosion-resistant coating

InactiveCN103059616BExcellent curing temperatureLow curing temperatureAnti-corrosive paintsChromium freeManganese

The invention discloses nickel-magnesium-titanium-manganese-containing chromium-free zinc aluminum coating corrosion-resistant coating. The nickel-magnesium-titanium-manganese-containing chromium-free zinc aluminum coating corrosion-resistant coating consists of a component A and a component B, wherein the mass ratio of the component A to the component B is 3:1; the component A comprises the following raw materials: zinc aluminum alloy powder, nano-silicon dioxide, sodium lignosulphonate, benzotriazole, sulfo-diethylene glycol, triphenylphosphine and deionized water; the component B comprises the following raw materials: zirconium tetrafluoride, gamma-aminopropyl triethoxysilane, inositol hexaphosphate, cellulose acetate-butyrate, ethanol and deionized water; and the zinc aluminum alloy powder consists of Zn, Al, Ni and Mg. The product has the characteristics of no toxicity, no harm, no pollution, low-temperature quick treatment, simplicity in operation, wide sources of raw materials, low price, clean production and the like.

Owner:江苏卫斯包装有限公司

Chrome-free zinc-aluminum coating anticorrosive paint comprising magnesium-manganese

ActiveCN103232734BExcellent curing temperatureLow curing temperatureAnti-corrosive paintsCellulose acetateManganese

The invention discloses a chrome-free zinc-aluminum coating anticorrosive paint comprising magnesium-manganese. The paint is composed of a component A and a component B with a mass ratio of 3:1. The component A comprises the raw materials of zinc-aluminum alloy powder, nano-silica, lignin sodium sulfonate, benzotriazole, thio diethylene glycol, triphenylphosphine, and deionized water. The component B comprises zirconium tetrafluoride, gamma-aminopropyl triethoxysilane, inositol hexaphosphate, butyl cellulose acetate, ethanol, and deionized water. The zinc-aluminum alloy powder is composed of Zn, Al, Mg, and Mn. The product provided by the invention has the advantages of no toxicity, no harm, no pollution, low-temperature fast processing, simple operation, wide raw material source, low cost, clean production, and the like.

Owner:TONGXIANG TONGDE ELECTRIC POWER FITTING

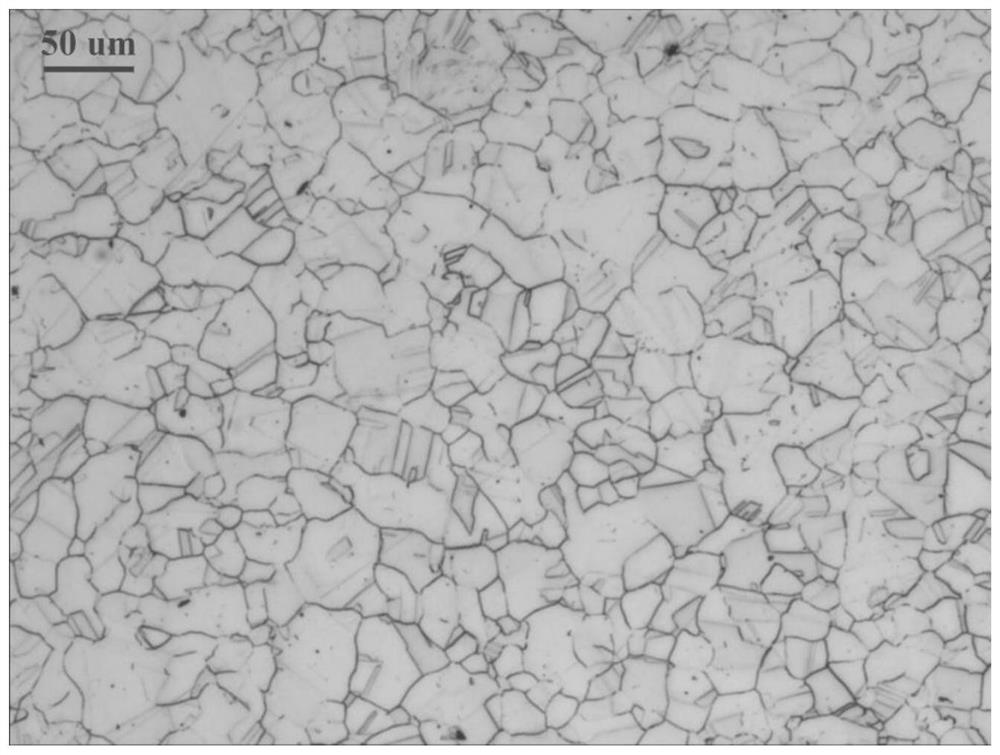

A kind of pre-hardened plastic mold steel plate and tmcp production method thereof

ActiveCN107557694BMeet the use requirementsHigh heat and corrosion resistanceChemical compositionSheet steel

The invention discloses a precuring plastic mold steel plate and a TMCP production method thereof. The steel plate comprises the chemical components of, by mass, 0.40-0.46% of C, 0.80-1.10% of Mn, 0.80-1.10% of Si, less than or equal to 0.015% of S, less than or equal to 0.020% of P, 0.80-1.10% of Cr, less than or equal to 0.25% of Mo, 0.015-0.040% of Al, and the balance iron and unavoidable impurities. The production method comprises a rolling procedure and a cooling procedure. The Mo content is lower than 0.25%, valuable alloy elements such as Ni, Nb, Ti and V are not added, so that the production cost is effectively lowered. The even hardness between 28-34 HRC can be obtained by controlling the cooling and re-reddening temperature after rolling and no tempering heat treatment is conducted, and the precuring plastic mold steel plate and the TMCP production method thereof have the characteristics of being simple in production technology, reasonable in chemical component design, and good in product property.

Owner:TANGSHAN IRON & STEEL GROUP +1

Chrome-free zinc-aluminum coating anticorrosive paint comprising magnesium-manganese

ActiveCN103232734AExcellent curing temperatureLow curing temperatureAnti-corrosive paintsCellulose acetateManganese

The invention discloses a chrome-free zinc-aluminum coating anticorrosive paint comprising magnesium-manganese. The paint is composed of a component A and a component B with a mass ratio of 3:1. The component A comprises the raw materials of zinc-aluminum alloy powder, nano-silica, lignin sodium sulfonate, benzotriazole, thio diethylene glycol, triphenylphosphine, and deionized water. The component B comprises zirconium tetrafluoride, gamma-aminopropyl triethoxysilane, inositol hexaphosphate, butyl cellulose acetate, ethanol, and deionized water. The zinc-aluminum alloy powder is composed of Zn, Al, Mg, and Mn. The product provided by the invention has the advantages of no toxicity, no harm, no pollution, low-temperature fast processing, simple operation, wide raw material source, low cost, clean production, and the like.

Owner:TONGXIANG TONGDE ELECTRIC POWER FITTING

Magnesium-titanium-manganese-containing non-chrome zinc-aluminum coating anticorrosive paint

InactiveCN103087562BExcellent curing temperatureLow curing temperatureAnti-corrosive paintsManganeseAlloy

Owner:ZHONGSHAN YINSAISHITE ELECTRONICS TECH CO LTD

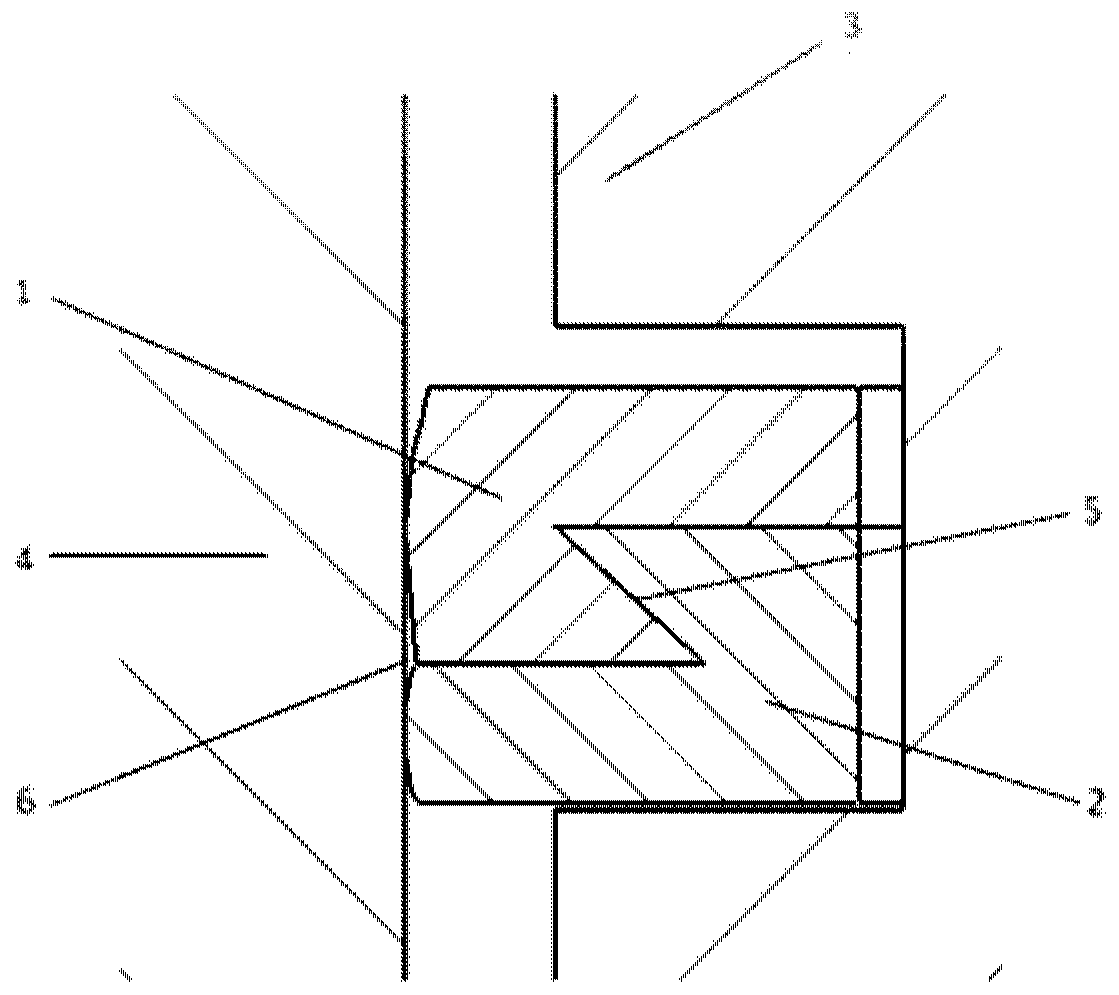

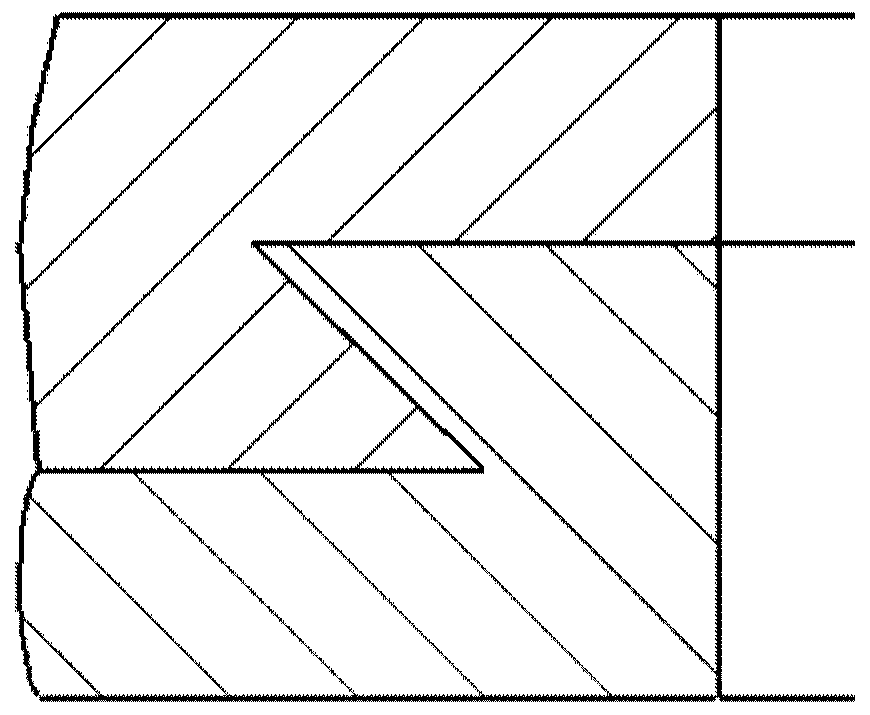

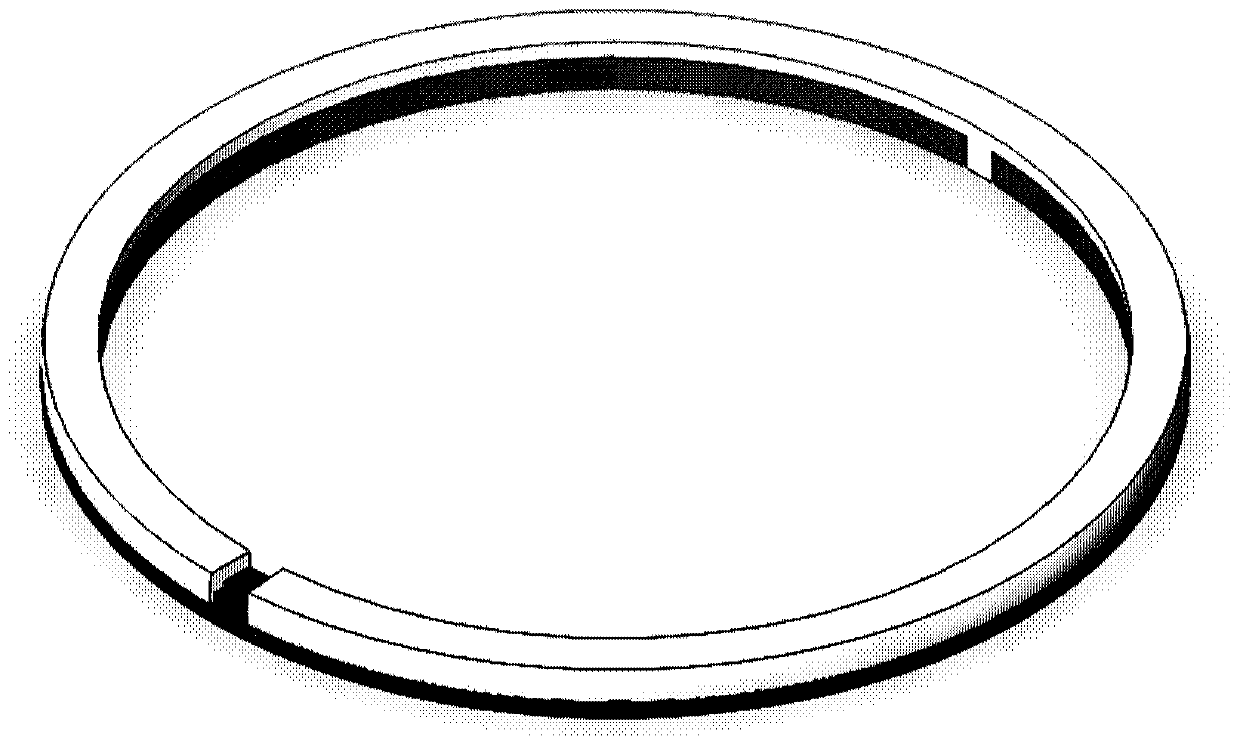

Ablation-resistant bimetal combined piston ring, internal combustion engine and sealing method

PendingCN110185795AImprove sealing effect and lifeHigh heat and corrosion resistancePiston ringsEngineeringExternal combustion engine

The invention discloses a bimetal combined piston ring, an internal combustion engine adopting same and a piston sealing method. Specifically, the bimetal combined piston ring comprises a metal firstpiston ring and a metal second piston ring; the cross section of a main body of the first piston ring is stepped; the stepped surface is positioned on the inner circumferential side of the first piston ring; the inner circumferential surface of the lower section of a step is a conical surface inclined inwards towards the vertical surface of the step by 15-75 DEG; the cross section of a main body of the second piston ring is stepped; the stepped surface is positioned on the outer circumferential side of the second piston ring; and the outer circumferential surface of an upper section of the step is an outer inclined conical surface complementary to the cone angle of the inner inclined conical surface of the first piston ring. By applying the piston ring, the dynamic property of the internalcombustion engine can be improved, and meanwhile, the wear rate of the piston ring is reduced, so that the service life of the ring is prolonged.

Owner:TIANJIN UNIV

Nickel-magnesium-containing chromium-free zinc aluminum coating corrosion-resistant coating

ActiveCN103059614BExcellent curing temperatureLow curing temperatureAnti-corrosive paintsChromium freeAlloy

The invention discloses nickel-magnesium-containing chromium-free zinc aluminum coating corrosion-resistant coating. The nickel-magnesium-containing chromium-free zinc aluminum coating corrosion-resistant coating consists of a component A and a component B, wherein the mass ratio of the component A to the component B is 3:1; the component A comprises the following raw materials: zinc aluminum alloy powder, nano-silicon dioxide, sodium lignosulphonate, benzotriazole, sulfo-diethylene glycol, triphenylphosphine and deionized water; the component B comprises the following raw materials: zirconium tetrafluoride, gamma-aminopropyl triethoxysilane, inositol hexaphosphate, cellulose acetate-butyrate, ethanol and deionized water; and the zinc aluminum alloy powder comprising Zn, Al, Ni and Mg. The product has the characteristics of no toxicity, no harm, no pollution, low-temperature quick treatment, simplicity in operation, wide sources of raw materials, low price, clean production and the like.

Owner:TONGXIANG TONGDE ELECTRIC POWER FITTING

Magnesium-containing chromium-free zinc-aluminum coating anti-corrosive paint

InactiveCN103044982BExcellent curing temperatureLow curing temperatureAnti-corrosive paintsChromium freeSilanes

The invention discloses magnesium-containing chromium-free zinc-aluminum coating anti-corrosive paint which comprises an A component and a B component at a mass ratio of 3:1, wherein the A component comprises the following raw materials: allumen powder, nano-silica, sodium lignosulphonate, benzotriazole, sulpho-diethylene glycol, triphenylphosphine and deionized water; the B component comprises the following raw materials: zirconium tetrafluoride, gamma-aminopropyl triethoxy silane, inositol hexaphosphate, cellulose acetate-butyrate, ethanol and deionized water; and the allumen powder comprises Zn, Al and Mg. The paint has the characteristics of no toxicity, harmlessness, no pollution, low-temperature immediate processing, easiness in operation, extensive raw material sources, low price, cleaner production and the like.

Owner:广州致辉精化股份有限公司

Chromium-free zinc-aluminum coating anticorrosion material comprising manganese-silicon

ActiveCN103232736AExcellent curing temperatureLow curing temperatureAnti-corrosive paintsChromium freeCellulose acetate

The invention discloses a chromium-free zinc-aluminum coating anticorrosion material comprising manganese-silicon. The material is composed of a component A and a component B according to a mass ratio of 3:1. The component A comprises zinc-aluminum alloy powder, nano-silica, sodium lignosulfonate, benzotriazole, thio diethylene glycol, triphenylphosphine, and deionized water. The component B comprises zirconium tetrafluoride, gamma-aminopropyl triethoxysilane, inositol hexaphosphate, butyl cellulose acetate, ethanol, and deionized water. The zinc-aluminum alloy powder is composed of Zn, Al, Mn and Si. The material provided by the invention has the advantages of no toxicity, no harm, no pollution, low-temperature fast processing, simple operation, wide raw material source, low cost, clean production, and the like.

Owner:苏州盛泽科技创业园发展有限公司

A Laser Surface Treatment Method for Improving Thermal Corrosion Resistance of Thermal Barrier Coatings

ActiveCN108220953BHigh heat and corrosion resistanceReduced surface corrosionMolten spray coatingHigh energyVolumetric Mass Density

The invention discloses a laser surface treatment method for improving the thermal corrosion resistance of a thermal barrier coating, belonging to the technical field of treatment of thermal barrier coatings. The method comprises the following steps: S1, ultrasonically cleaning the surface of the thermal barrier coating, and adjusting the spot shape of a laser to a rectangular shape; S2, adjustingthe laser in the step S1 to emit low energy density laser, and carrying out self-preheating scanning on the thermal barrier coating treated in the step S1; S3, adjusting the laser in the step S1 to emit high energy density laser, and carrying out re-melting scanning on the thermal barrier coating treated in the step S2; S4, adjusting the laser in the step S1 to emit medium energy density laser, and performing a slow-cooling scanning on the thermal barrier coating treated in the step S3; S5, naturally cooling the thermal barrier coating treated in the step S4 to room temperature, and then using compressed air to remove impurities on the surface of the coating cooled to room temperature. After the coating is treated by using the method, the coating is smooth and dense, the thermal corrosionof corrosive salt is inhibited, and the service life of the coating is prolonged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com