Patents

Literature

1822 results about "Triphenylphosphine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

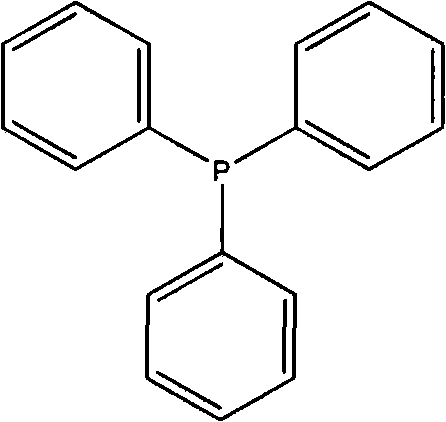

Triphenylphosphine (IUPAC name: triphenylphosphane) is a common organophosphorus compound with the formula P(C₆H₅)₃ - often abbreviated to PPh₃ or Ph₃P. It is widely used in the synthesis of organic and organometallic compounds. PPh₃ exists as relatively air stable, colorless crystals at room temperature. It dissolves in non-polar organic solvents such as benzene and diethyl ether.

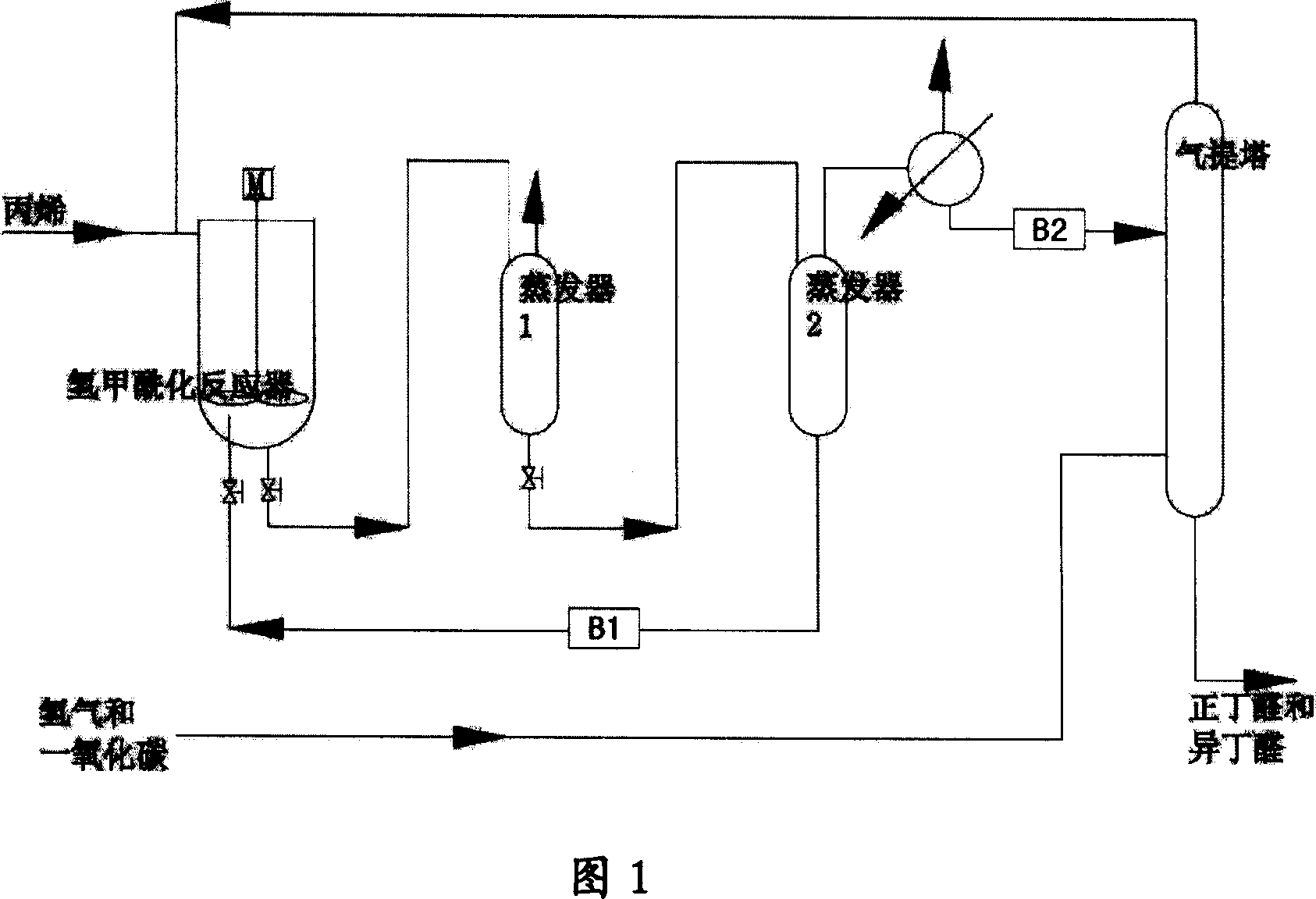

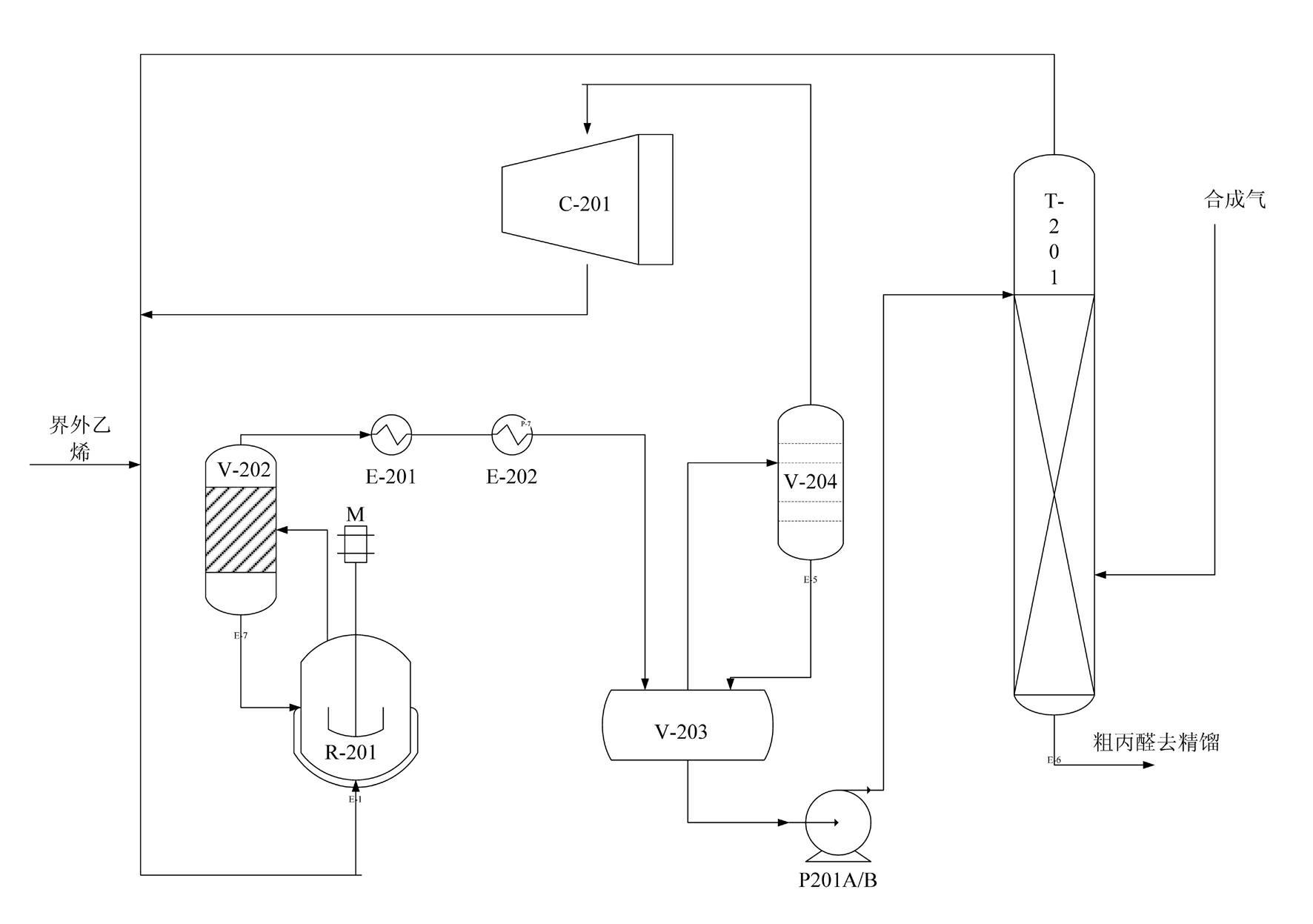

Catalyst system and catalyzing method of propylene hydrogenation and formylation

ActiveCN1986055AReduce dosageImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionFormylation reactionTriphenylphosphine

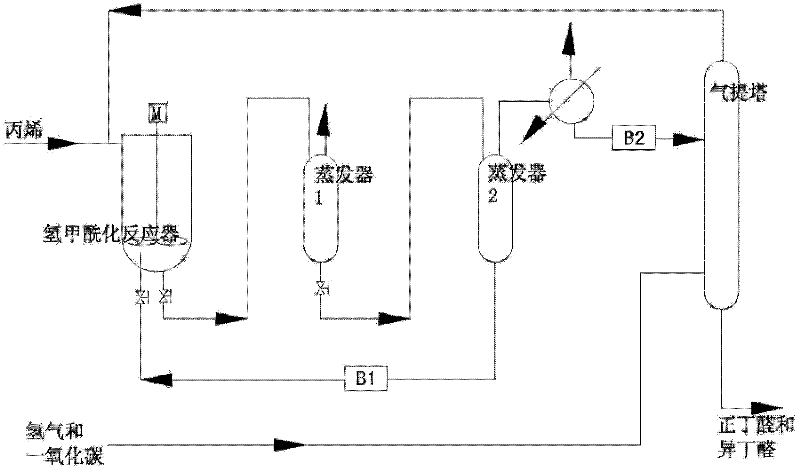

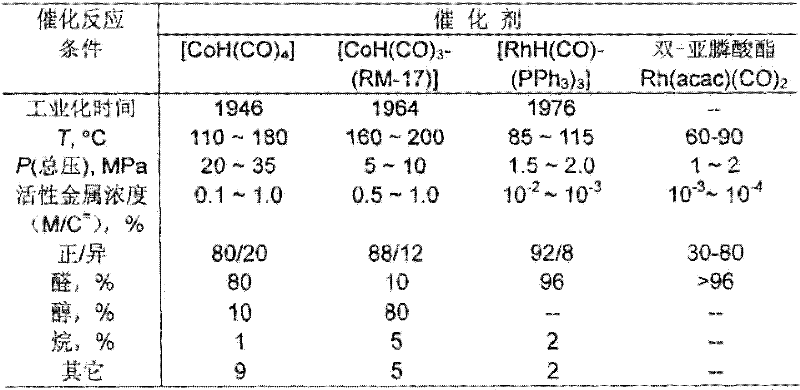

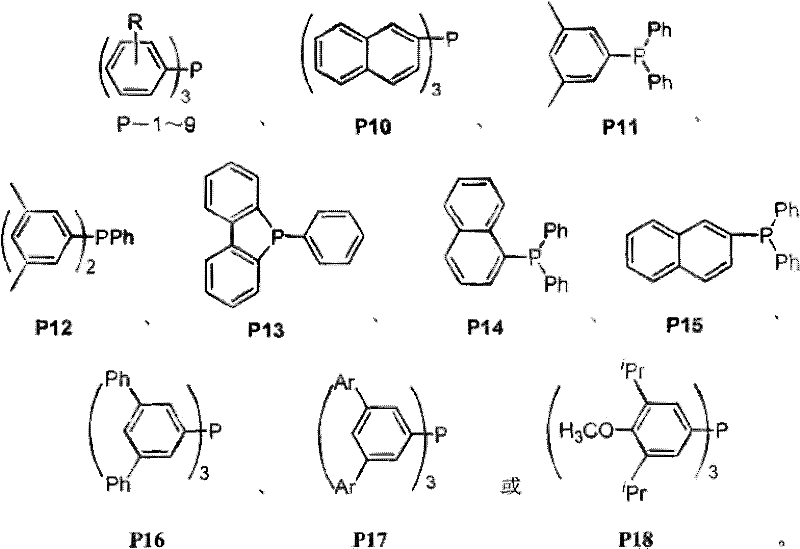

The present invention relates to catalyst system for propylene hydrogenation and formylation and process of catalytically synthesizing butyl aldehyde. The catalyst system is triaryl phosphine-Rh(I) catalyst system with proper additive, such as bisphosphite ester, in proper amount. Compared with similar available catalyst, the catalyst system has obviously higher catalytic acitivity, higher selectivity, higher stability and raised n-butyl aldehyde / isobutyl aldehyde ratio in the catalytically synthesized product.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

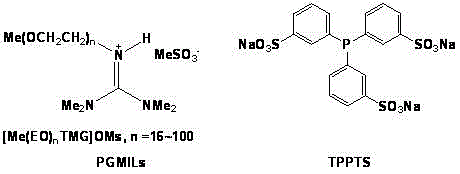

Olefin two-phase hydroformylation method

ActiveCN102617308AEffective fixed loadSeparation and easy handlingOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionTPPTSPolymer science

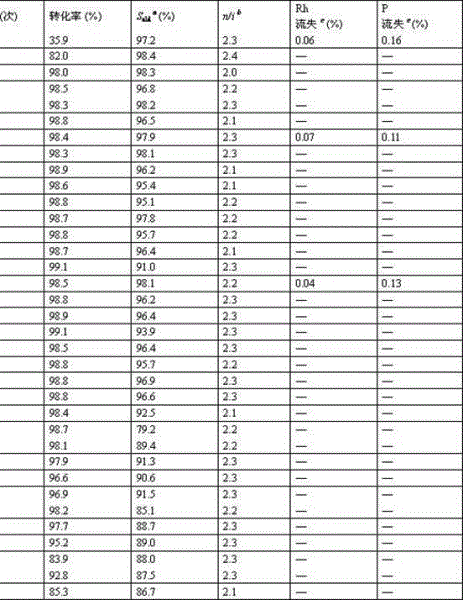

The invention relates to an olefin two-phase hydroformylation method, which consists of three parts: polyether guanidine mesylate ionic liquid (PGMILs) with room temperature solidifiable characteristics, complex catalysts (Rh-TPPTS) formed by RhCl3.3H2O or dicarbonylacetylacetonato rhodium and triphenylphosphine sodium trithionate (TPPTS), and reactants of C6-C14 straight chain 1-olefin, wherein the Rh-TPPTS is dissolved in the PGMILs to form a lower layer catalyst phase, the C6-C14 straight chain 1-olefin or product aldehyde forms an upper layer organic phase, the selectivity of high-carbon aldehyde is 85 to 99 percent, the mol ratio of normal aldehyde to isomerism aldehyde is 2.0 to 2.4, the PGMILs phase containing Rh-TPPTS can be cyclically used for 35 times, the activity and the selectivity are unchanged, the accumulated conversion number (TON) reaches higher than 30000, rhodium flowing to the product phase is 0.04 percent to 0.07 percent, and ultra-long-period catalysis activity and selectivity can be realized.

Owner:山东聚强绿洲生物科技有限公司

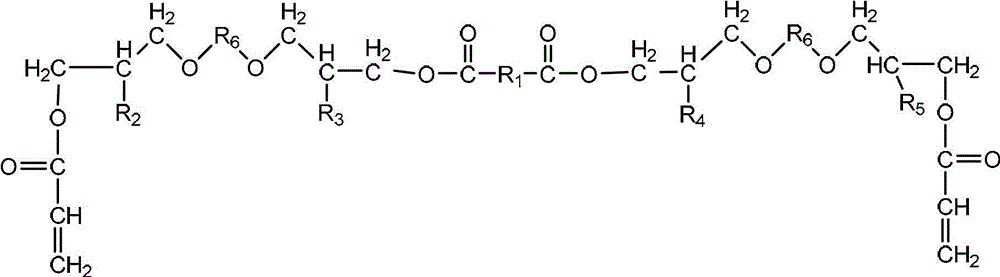

D1369 d radiation curable secondary coating for optical fiber

A new radiation curable Secondary Coating for optical fibers is described and claimed wherein said composition comprises a Secondary Coating Oligomer Blend, which is mixed with a first diluent monomer; a second diluent monomer; optionally, a third diluent monomer; an antioxidant; a first photoinitiator; a second photoinitiator; and optionally a slip additive or a blend of slip additives; wherein said Secondary Coating Oligomer Blend comprises:α) an Omega Oligomer; andβ) an Upsilon Oligomer;wherein said Omega Oligomer is synthesized by the reaction ofα1) a hydroxyl-containing (meth)acrylate;α2) an isocyanate;α3) a polyether polyol; andα4) tripropylene glycol; in the presence ofα5) a polymerization inhibitor; andα6) a catalyst;to yield the Omega Oligomer;wherein said catalyst is selected from the group consisting of dibutyl tin dilaurate; metal carboxylates, including, but not limited to: organobismuth catalysts such as bismuth neodecanoate; zinc neodecanoate; zirconium neodecanoate; zinc 2-ethylhexanoate; sulfonic acids, including but not limited to dodecylbenzene sulfonic acid, methane sulfonic acid; amino or organo-base catalysts, including, but not limited to: 1,2-dimethylimidazole and diazabicyclooctane; triphenyl phosphine; alkoxides of zirconium and titanium, including, but not limited to Zirconium butoxide and Titanium butoxide; and Ionic liquid phosphonium salts; and tetradecyl(trihexyl)phosphonium chloride; andwherein said Upsilon Oligomer is an epoxy diacrylate.

Owner:DSM IP ASSETS BV

A kind of propylene hydroformylation catalytic system and method

InactiveCN102266796AReduce dosageImprove stabilityGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsFormylation reactionTriphenylphosphine

The invention relates to a propylene hydroformylation catalyst system and a method for catalyzing synthesis of butyraldehyde. In the present invention, in the propylene hydroformylation reaction system catalyzed by triarylphosphine-Rh(I), by using appropriate types and quantities of additives, such as bisphosphite, the performance of the Rh(I) / triarylphosphine catalyst can be significantly improved The activity and the positive-iso ratio of butyraldehyde in the product (molar ratio of n-butyraldehyde / isobutyraldehyde>20), and significantly prolong the service life of the bisphosphite ligand, and significantly reduce the amount of triarylphosphine. This type of catalyst system is characterized by higher activity and selectivity than third-generation Rh(I) / triphenylphosphine catalysts and better stability than fourth-generation Rh(I) / bisphosphite catalysts, so The novel catalyst system provided by the present invention can overcome the shortcomings of the third and fourth generation catalysts, reduce the cost of industrialized production of propylene hydroformylation, and provide a new catalyst technology for its industrial application.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

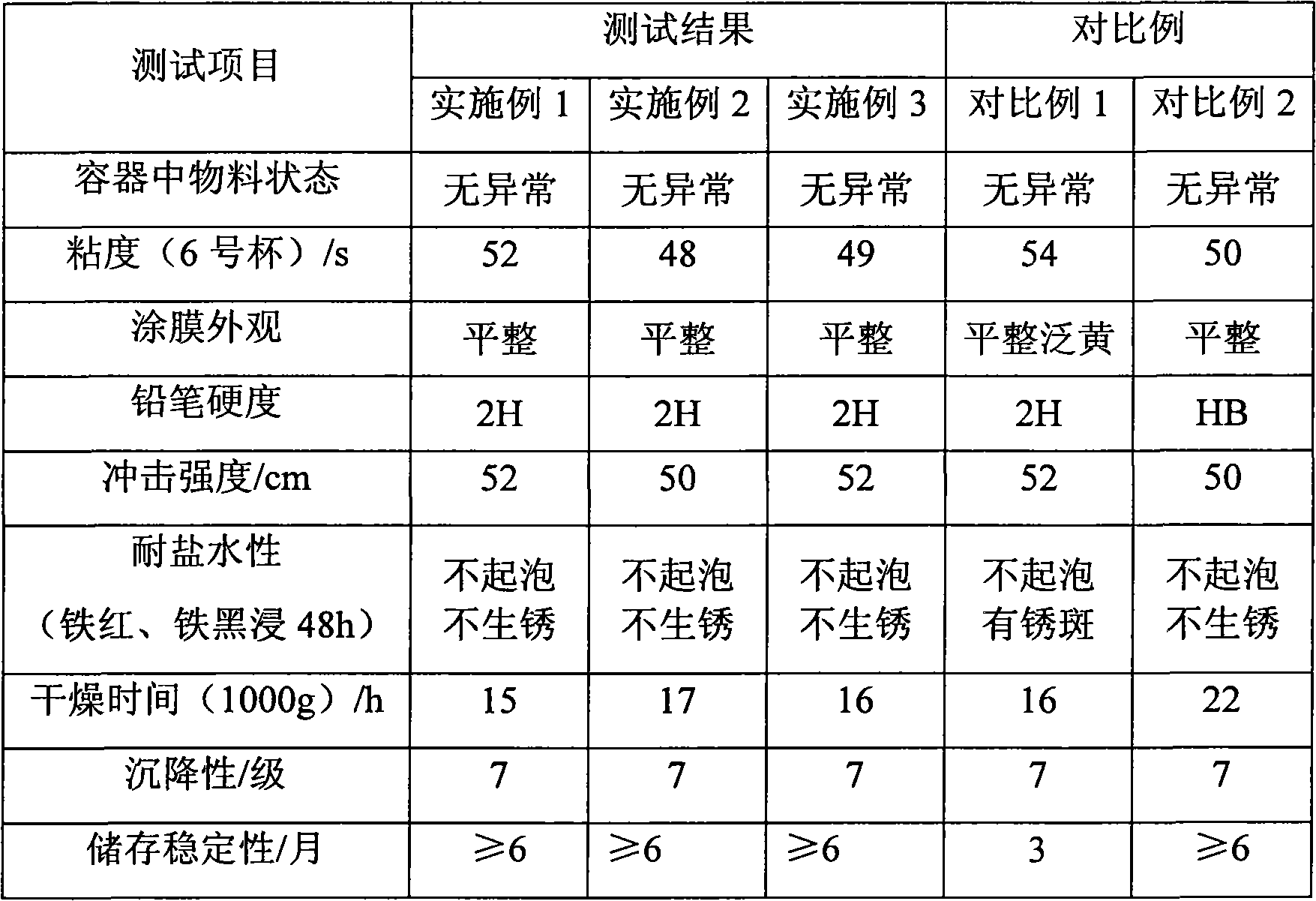

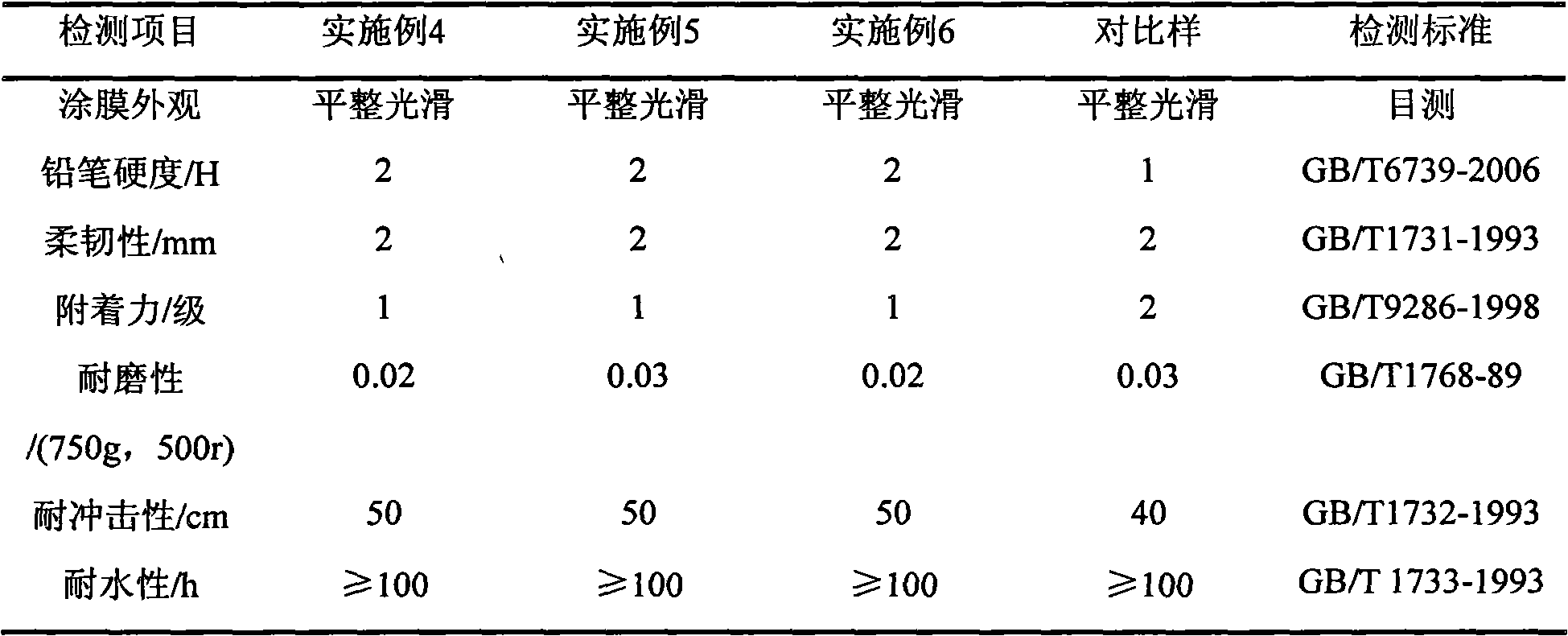

Water-borne epoxy ester modified alkyd resin emulsion and preparation method thereof

InactiveCN101942063AStrong adhesionImprove performanceDyeing processCoatingsEnvironmental resistanceEpoxy

The invention provides water-borne epoxy ester modified alkyd resin emulsion and a preparation method thereof. The method comprises the following steps: allowing unsaturated fatty oil, polyalcohol, epoxy resin and the like to carry out alcoholysis reaction by using triphenylphosphine and an alcoholysis catalyst; adding polyacid for esterification; dropwise adding crylic acid monomers such as methacrylic acid, phenylethylene, butyl acrylate and the like and a silane coupling agent for copolymerization under initiation of benzoyl peroxide; adding amine to the obtained copolymer for neutralizing to form salt; and dispersing with water to obtain the high-performance water-borne epoxy ester modified alkyd resin emulsion. The emulsion maintains self-drying property, flexibility and other excellent properties of alkyd resin, has excellent adhesive property of the epoxy resin as well as excellent adhesion force, excellent physical and mechanical properties and strong water resistance, strong salt fog resistance, strong acid and alkali resistance and other properties; and the emulsion has the advantages of possessing good stability and being nontoxic and harmless, thus meeting the environmental friendly requirement.

Owner:SOUTH CHINA UNIV OF TECH

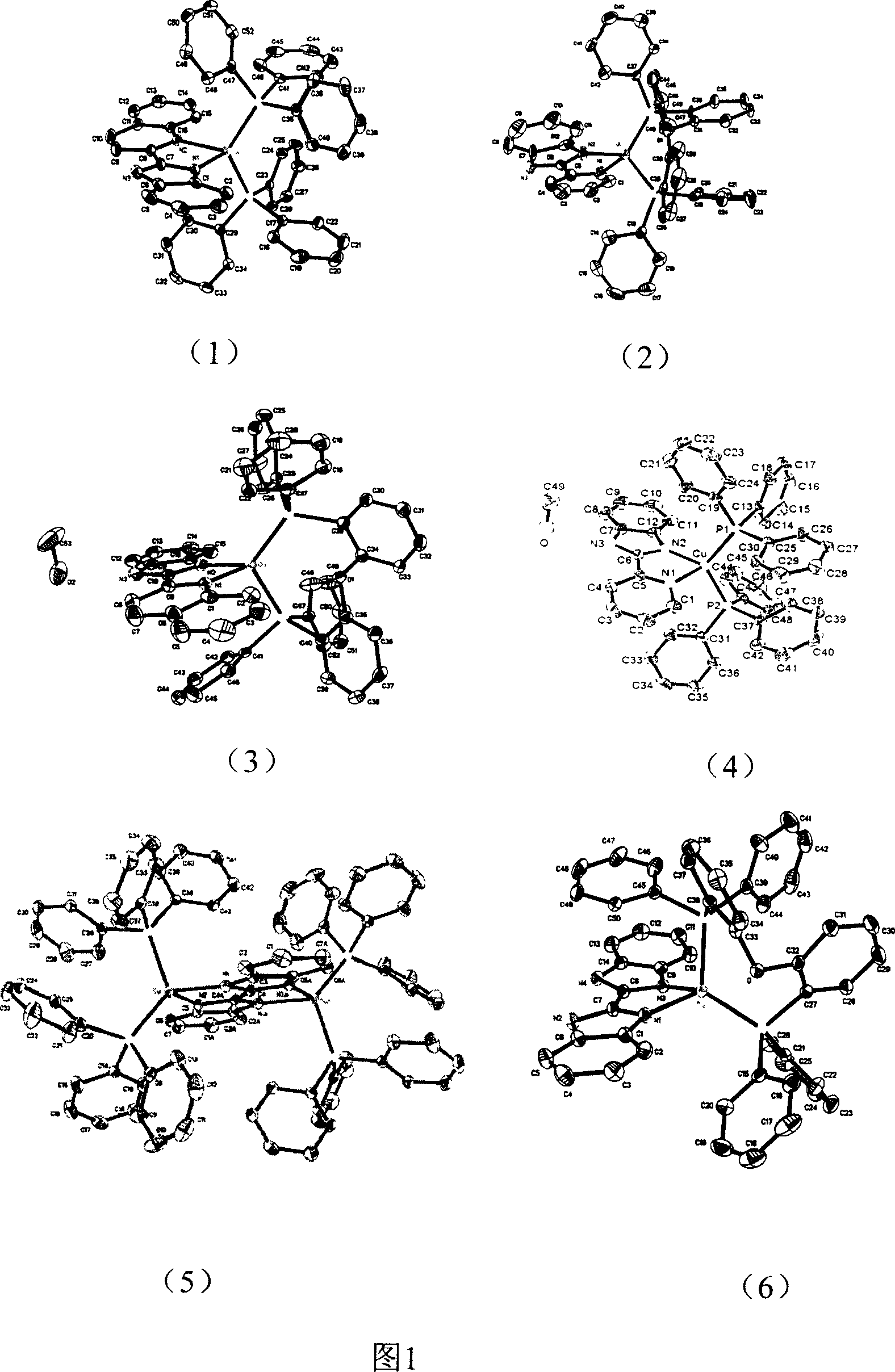

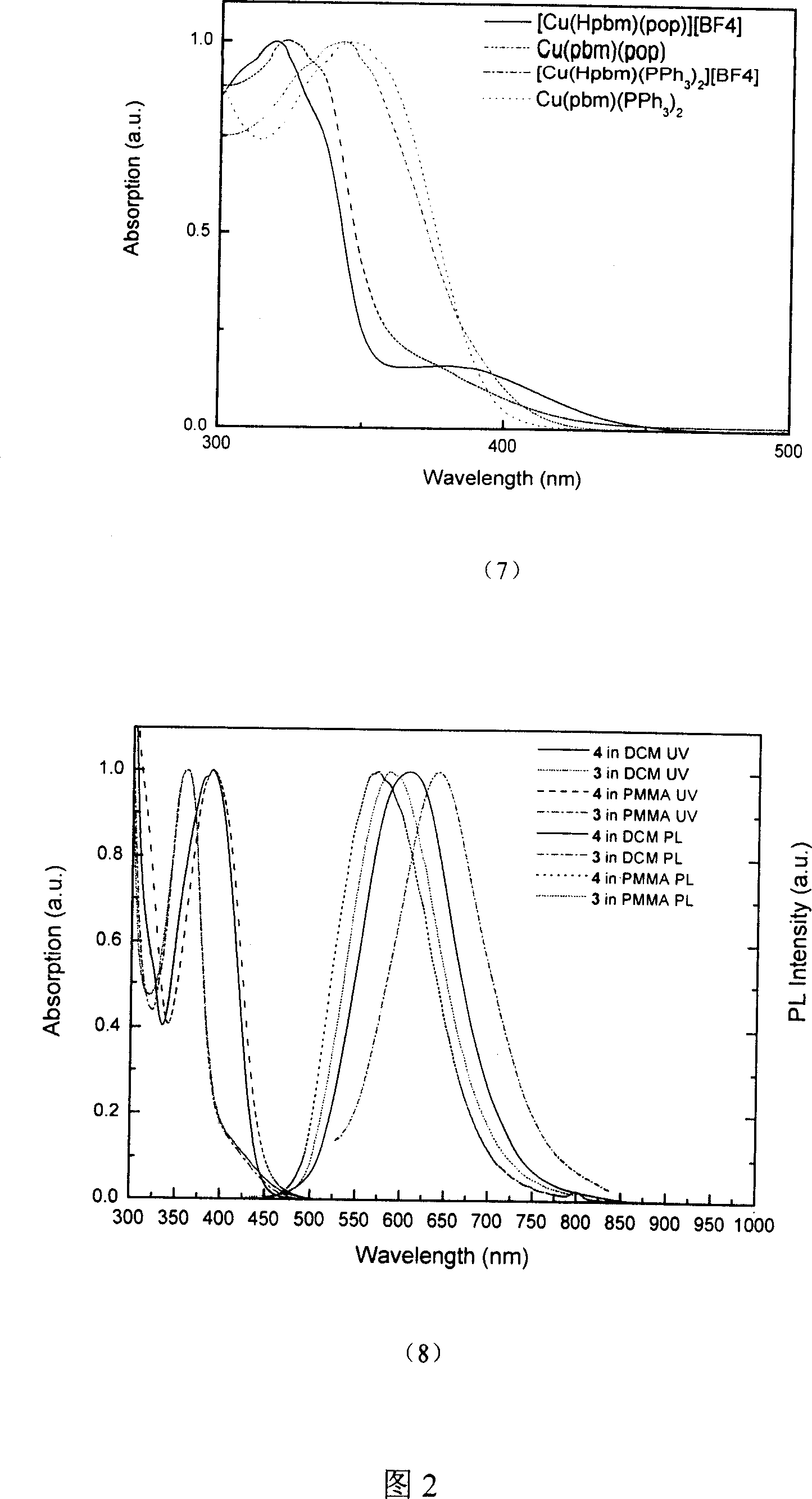

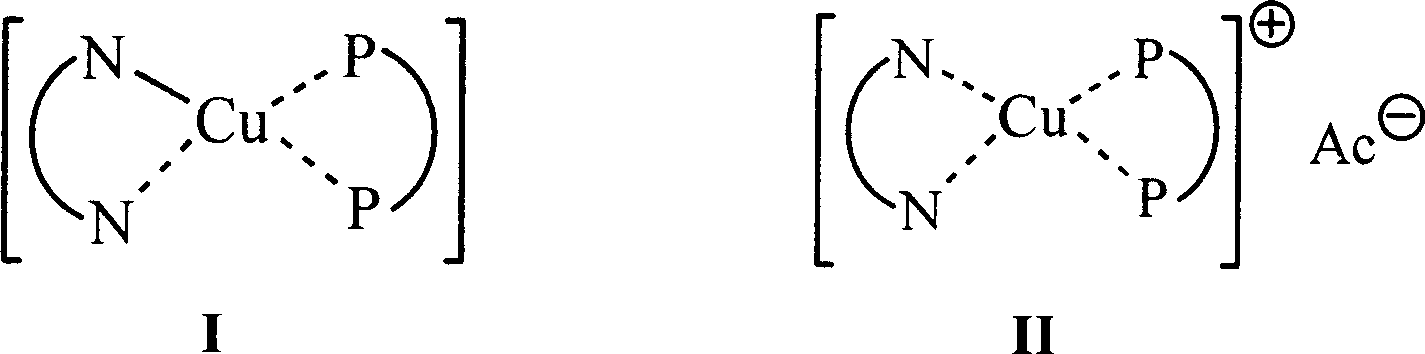

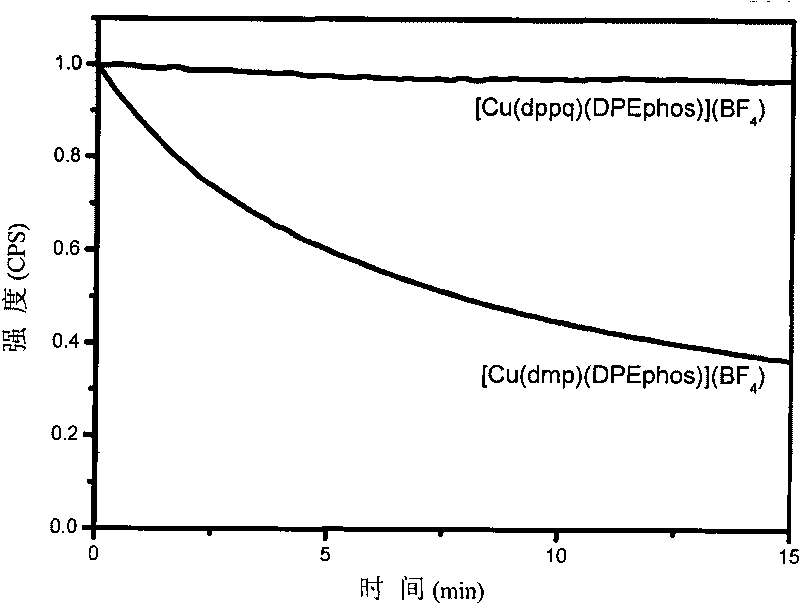

Copper (1) compound with imidazole derivate as compounding body

InactiveCN100999528AEasy to synthesizeEasy to purifyCopper organic compoundsLuminescent compositionsRoom temperatureTriphenylphosphine

The present invention relates to copper complex with imidazole as ligand. Ionic one-valent copper complex is prepared with pyridyl imidazole, pyridyl benzimidazole or quinolyl benzimidazole as the first ligand, triphenyl phosphine or bridged phenyl phosphine as the second ligand and one-valent copper ion. Neutral copper complex may be further obtained under the action of alkali. The ionic copper complex and the neutral copper complex may convert mutually under the action of acid and alkali. This kind of complex possesses strong room temperature phosphorescence emission and may be used as light emitting material.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

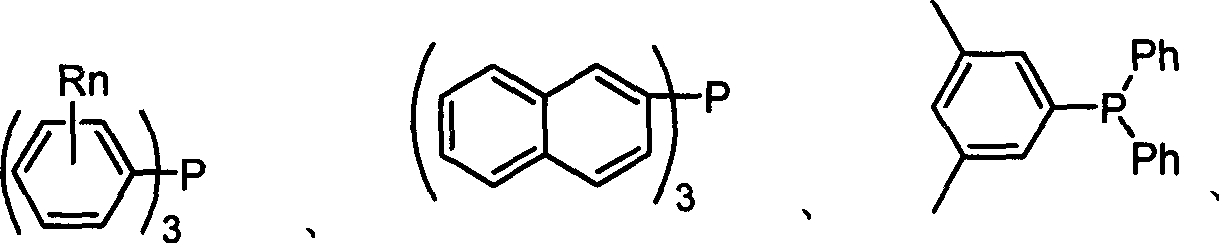

Method for preparing aldehyde through linear chain olefin hydroformylation

InactiveCN102911021AReduce dosageGuaranteed uptimeOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionFormylation reactionDiphosphines

The invention relates to a method for preparing aldehyde through linear chain olefin hydroformylation. According to the method, a continuous reaction mode is used for performing olefin hydroformylation reaction in a homogeneous catalyst system; a catalyst is a composite catalysis system composed of a rhodium complex, a biphenyl backbone or biphenyl backbone diphosphine ligands and triphenylphosphine or triphenyl phosphate monophosphorous ligands; a reaction solvent comprises butyraldehyde, valeraldehyde, toluene or isodecanol; when the catalyst system uses propylene or butene-1 as raw materials under the condition of a low molar ratio of the diphosphine ligands to the rhodium complex, contents of the aldehyde generated by hydroformylation of the propylene and the butene-1 is larger than 97% and 95% respectively; and when the catalyst system uses a mixture of the butene-1 and butene-2 as raw materials, and the content of n-valeraldehyde in hydroformylation reaction products can reach above 85%.

Owner:QINGDAO SANLI BENNUO CHEM IND +1

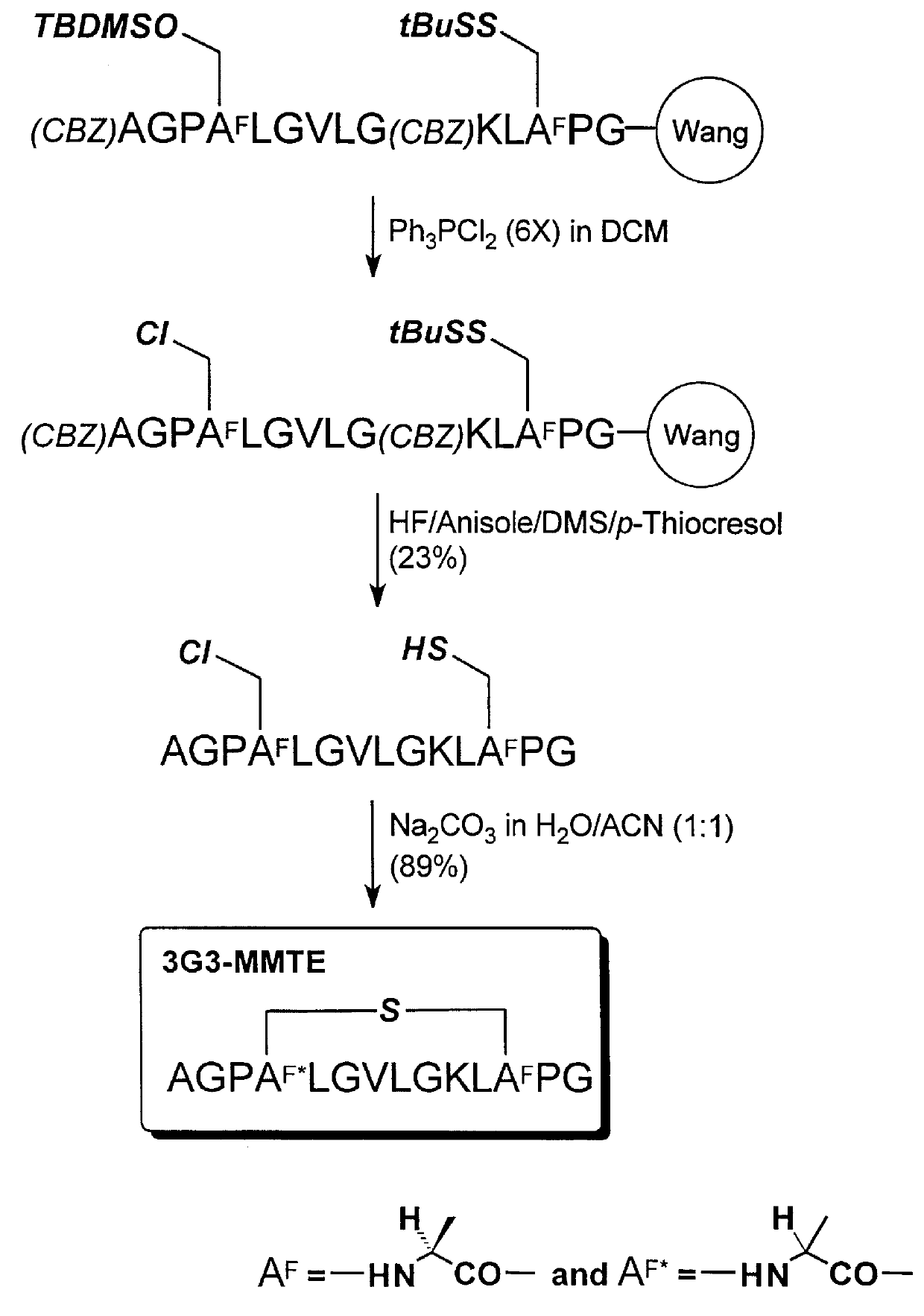

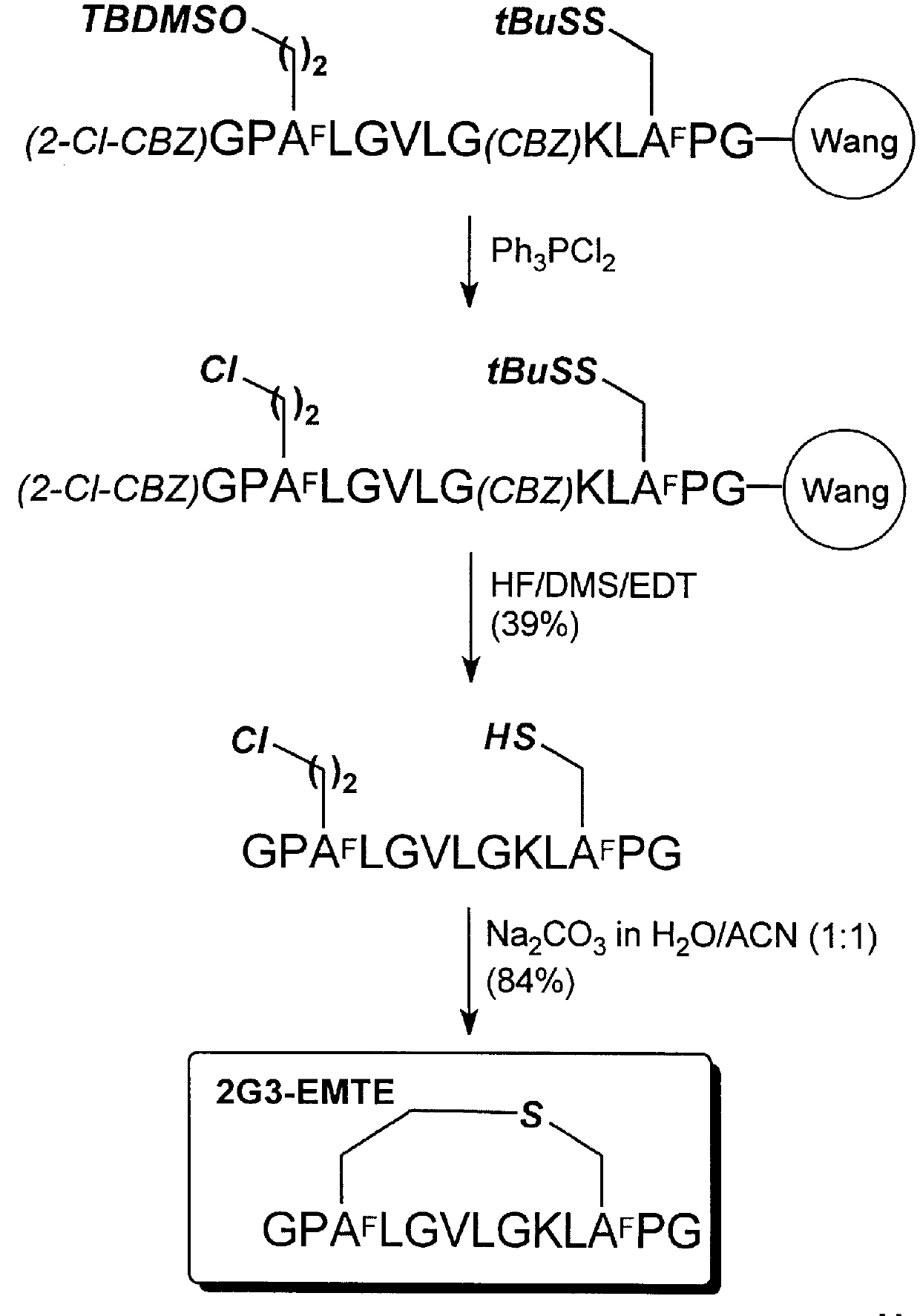

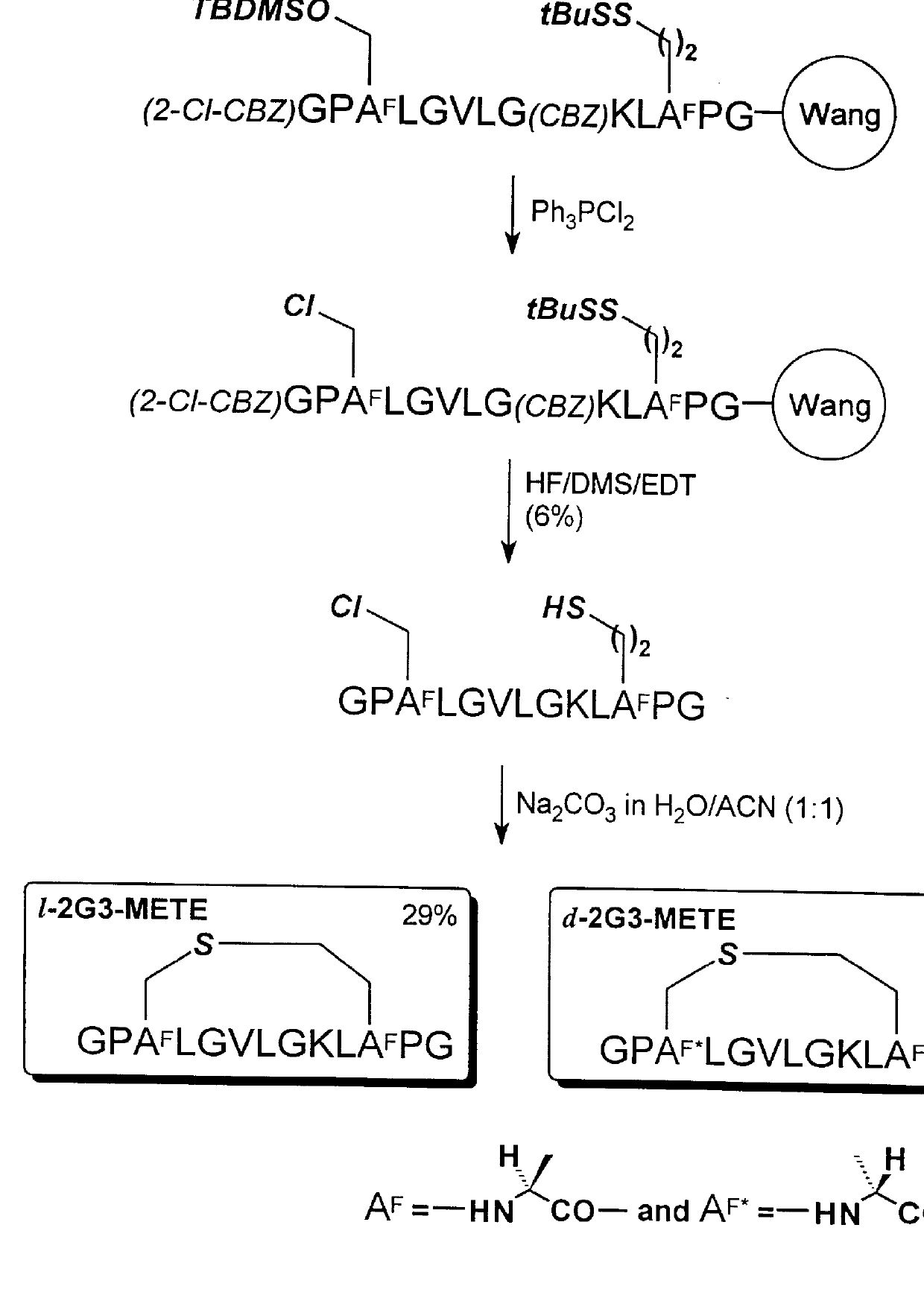

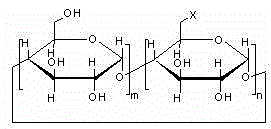

Cyclic polypeptides comprising a thioether linkage and methods for their preparation

This invention relates generally to cyclic polypeptides comprising a thioether linkage and methods for their preparation. More particularly, this invention relates to halogenated polypeptides having at least one haloalanine-like amino acid, and methods for their preparation which involve converting the hydroxyl group (i.e., -OH) of a serine-like amino acid to a halo group (i.e., -X where X is Cl, Br, or I) with the aid of a phosphorus-based halogenation reagent such as a triphenylphosphine dihalide (i.e., (C6H5)3PX2, wherein X is Cl, Br, or I), a triphenylphosphite dihalide (i.e., (C6H5O)3PX2, wherein X is Cl, Br, or I), or a mixture of triphenylphosphine or triphenylphosphite with a halohydrocarbon (i.e., "halo-conversion"). This invention also relates to cyclic polypeptides having at least one polypeptide loop comprising a thioether linkage, and methods for their preparation which employ halogenated polypeptides and which involve intramolecular alkylation of the thiol group of a cysteine-like amino acid by the halo group of a haloalanine-like amino acid under suitable basic conditions to form a thioether linkage (i.e., "cyclization").

Owner:LA JOLLA PHARMA

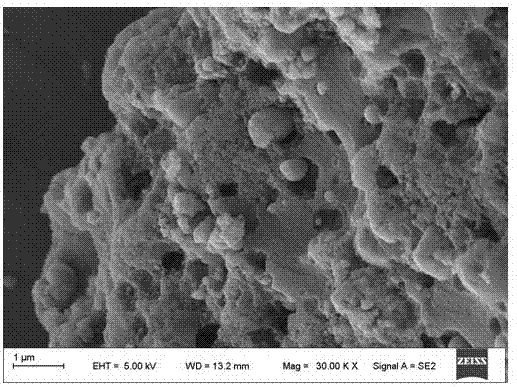

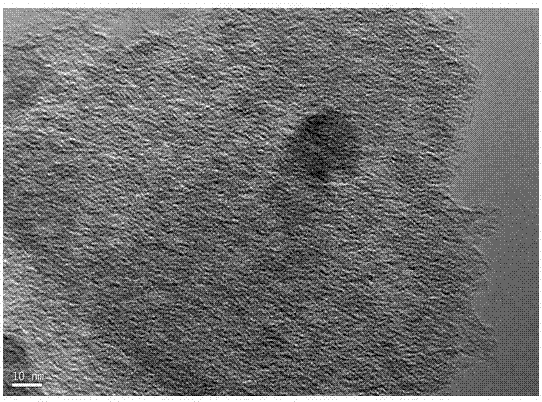

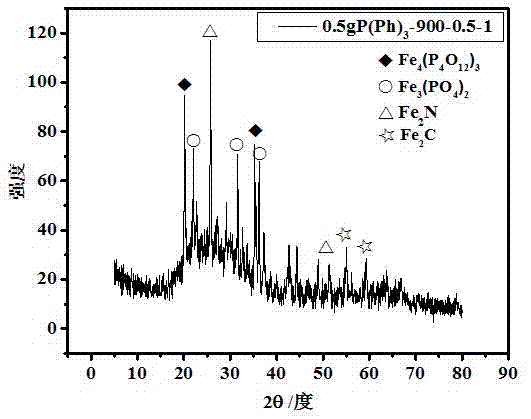

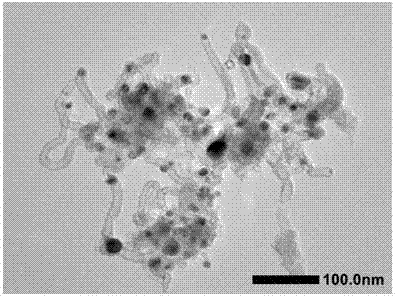

Preparation method of N-P-codoping porous biomass carbon catalyst

ActiveCN106881138ALarge specific surface areaRich microporous structurePhysical/chemical process catalystsCell electrodesMolecular levelNitrogen gas

The invention provides a preparation method of N-P-codoping porous biomass carbon catalyst. Cheap and easy-to-get biomass chitosan is taken as carbon source and nitrogen source (as nitrogen-containing ligand at the same time), organic phosphorus compound triphenylphosphine is taken as phosphorus-containing ligand, the nitrogen-containing ligand and the phosphorus-containing ligand form a coordination compound together with metal ions in metallic salt solution, ZnCl2 is taken as activating agent, the coordination compound is subjected to high-temperature pyrolysis in a nitrogen atmosphere to form holes, and finally diluted hydrochloric acid is used to remove metals for secondary hole formation, so as to prepare the N-P-codoping porous biomass carbon catalyst with rich micropores and a mesopores structure as well as a high specific surface area. The N-P-codoping porous biomass carbon catalyst is comparable to commercial Pt / C (20%) in catalytic performance in an alkaline environment, has good methanol poisoning resistance and stability, and can regulate components and performance of catalyst in molecular level. The N-P-codoping porous biomass carbon catalyst disclosed by the invention is expected to replace cathode oxygen reduction catalyst of the commercial Pt / C, and has a very good industrial application prospect.

Owner:NORTHWEST NORMAL UNIVERSITY

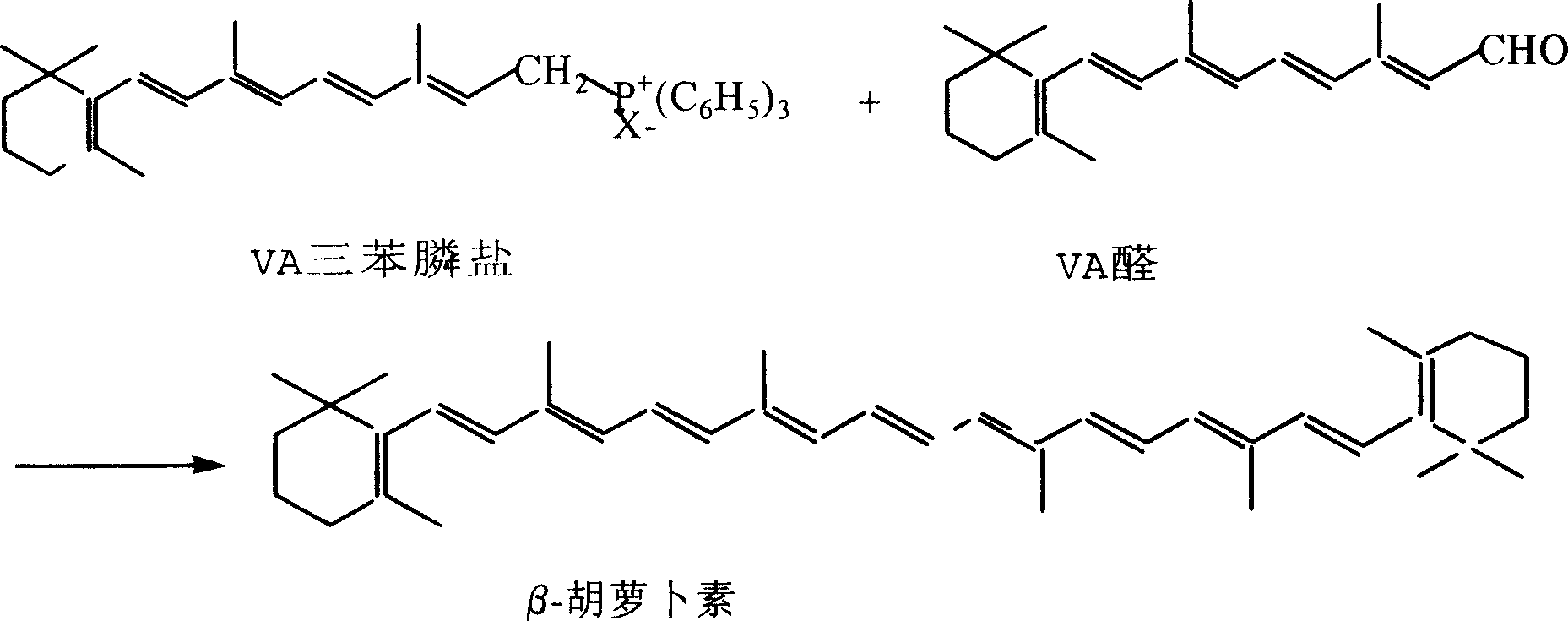

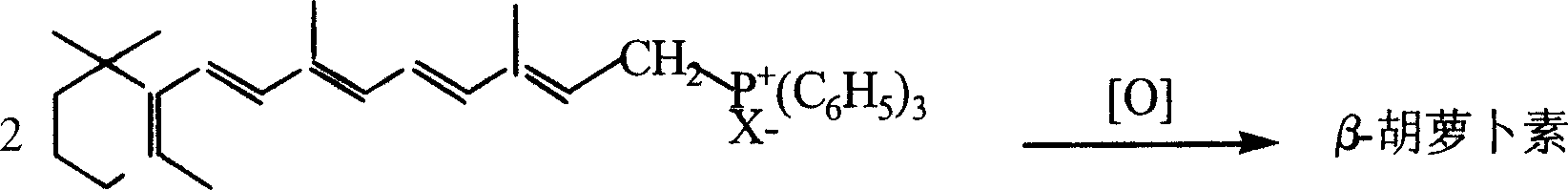

Synthesizing technique for beta-carotene

ActiveCN101081829AAvoid contactReduce the chance of oxidative damageOrganic chemistryBeta-CaroteneOrganic solvent

The present invention discloses new coupling reaction process for preparing beta-carotene. Organic phosphine salt is first prepared through reacting vitamin A derivative and triphenyl phosphine, and then made to produce coupling reaction in the presence of oxidant to obtain beta-carotene. The present invention features that the coupling reaction is completed in a two phase system of water phase and water insoluble organic solvent phase, so that the produced beta-carotene is extracted constantly by the organic solvent phase, decreasing the possibility of oxidizing produced beta-carotene and raising beta-carotene yield.

Owner:浙江可明生物医药有限公司

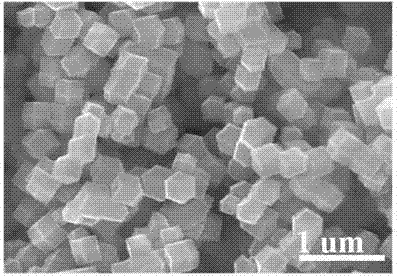

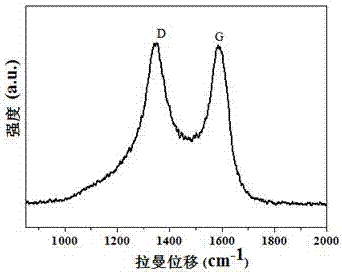

Nitrogen-containing graphitized carbon material adopting double-metal MOFs (metal organic frameworks)

InactiveCN107399729ALarge specific surface areaImprove performanceMaterial nanotechnologyPhysical/chemical process catalystsElectrolysisPorous carbon

The invention provides a nitrogen-containing graphitized carbon material adopting double-metal MOFs (metal organic frameworks). The material is prepared with a method as follows: S1, 2-methylimidazole is dissolved to form a solution A, cobalt salt and zinc salt are mixed to form a solution B, the solution A and the solution B are mixed, left to stand, centrifugalized, washed and dried, and double-metal MOF precursors are obtained; S2, the double-metal MOF precursors formed in S1 are calcined in an inert gas atmosphere, and the calcined double-metal MOF precursors are obtained; S3, the calcined double-metal MOF precursors formed in S2 are mixed with triphenylphosphine or tributyl phosphate in a solution, the mixture is calcined in an inert gas atmosphere, washed and dried, and the nitrogen-containing graphitized carbon material adopting the double-metal MOFs is obtained. The invention provides a highly-graphitized porous carbon material which is high in specific surface area and hierarchically porous, realizes uniform nitrogen doping and contains rich metal-nitrogen structures, the activity of the product in oxygen evolution through water electrolysis is more excellent than that of commercial ruthenium oxide, and the material has great application prospects in energy storage materials.

Owner:SUN YAT SEN UNIV

Acrylic modified epoxy resin emulsion and preparation method thereof

InactiveCN101921373AAvoid stabilityAvoid the adverse effects of later film formationCoatingsEpoxyFatty alcohol

The invention discloses an acrylic modified epoxy resin emulsion and a preparation method thereof. The preparation method comprises the following steps of: mixing epoxy resin, fatty alcohol-polyoxyethylene ether and triphenylphosphine and reacting the mixture at the temperature of between 90 and 110 DEG C for 3 to 5 hours to obtain epoxy resin polyethenoxy ether monoester; controlling the temperature of the obtained epoxy resin polyethenoxy ether monoester within a range from 70 to 90 DEG C; adding sulfamic acid into the epoxy resin polyethenoxy ether monoester, reacting the two materials for 2 to 4 hours, adding aqueous solution of NaOH into the mixture for neutralizing and dispersing, and adjusting the pH to be 7 to 8 after the dispersion to obtain a reactive type anionic and nonionic epoxy resin emulsifier; and polymerizing the emulsifier with epoxy resin and acrylic acid series monomer emulsion to obtain stable environment-friendly acrylic grafted epoxy resin emulsion. The method avoids the influence of the emulsifier on storage stability and later-stage filming of the emulsion; and compared with pure acrylic emulsion, the obtained product has the advantages that the film has more superior wear resistance, adhesion and chemical resistance, and can be applied to metal corrosion-resistant paint, road mark paint, indoor and outdoor floor paint and the like.

Owner:SOUTH CHINA UNIV OF TECH

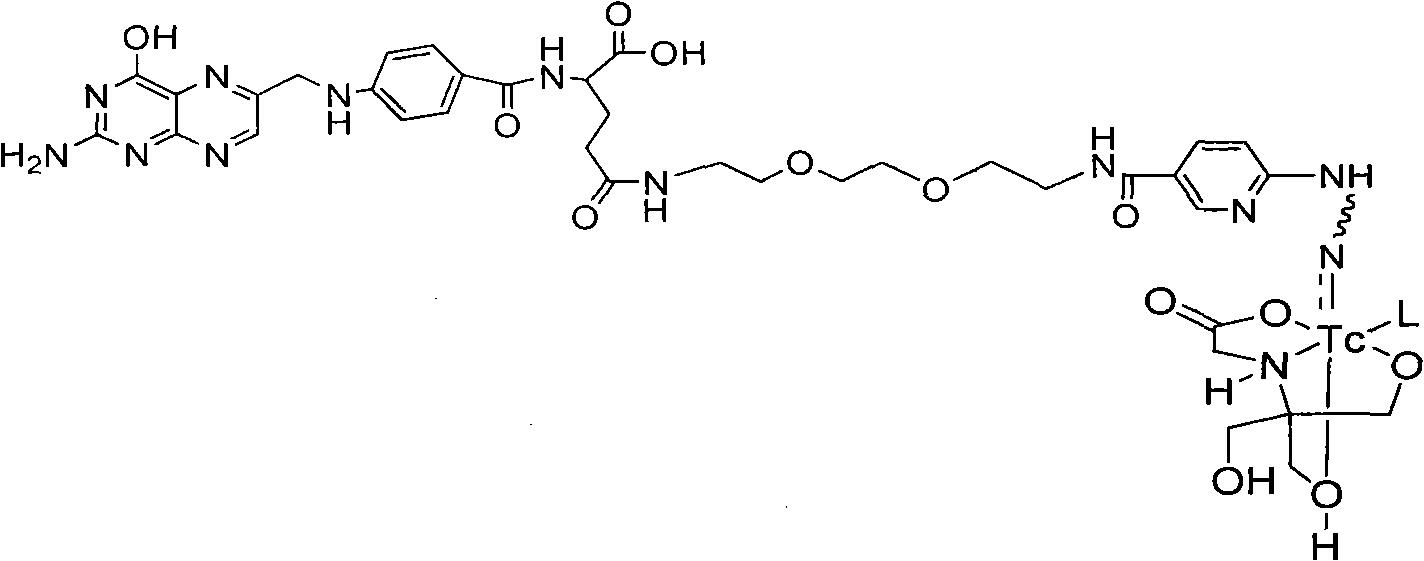

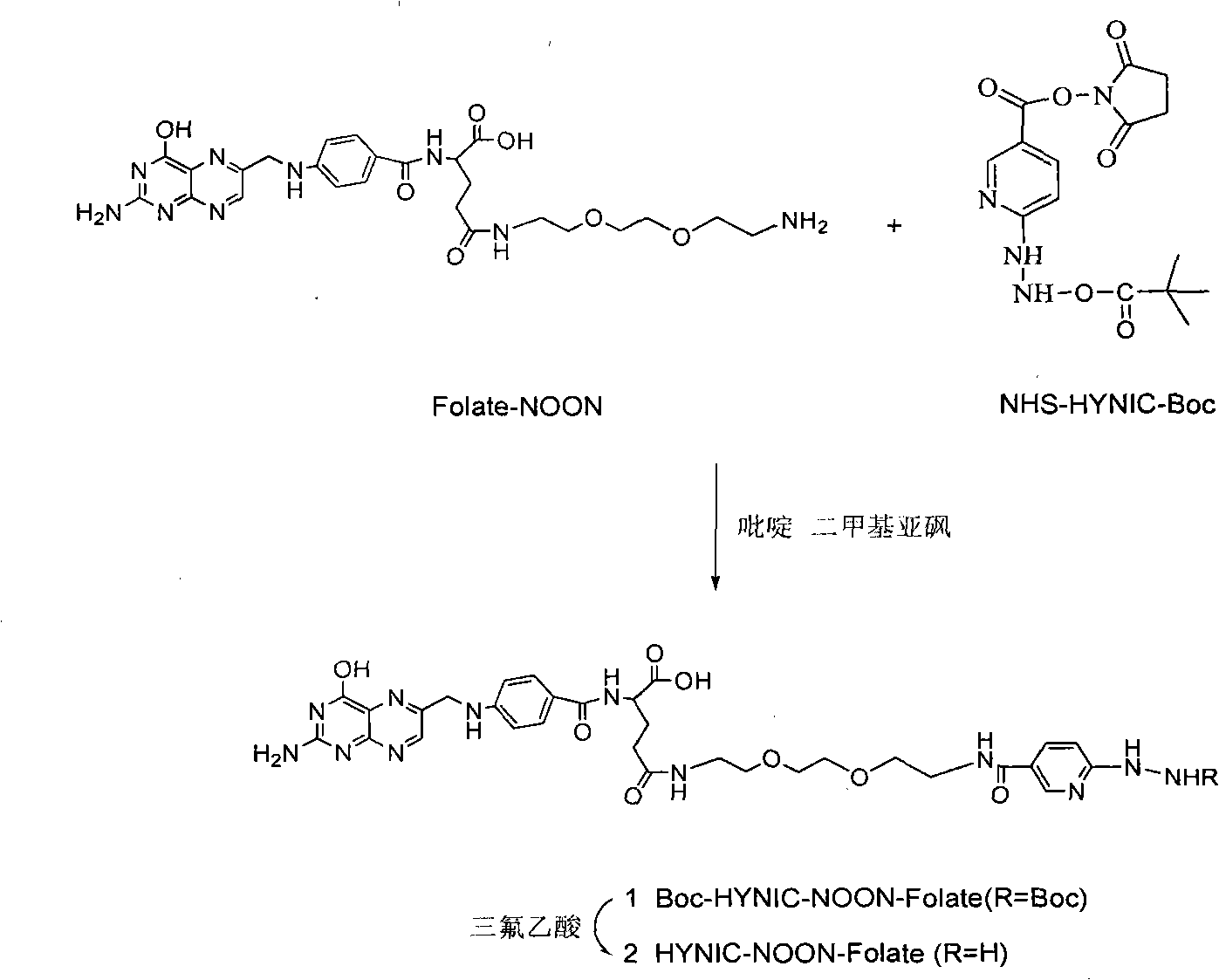

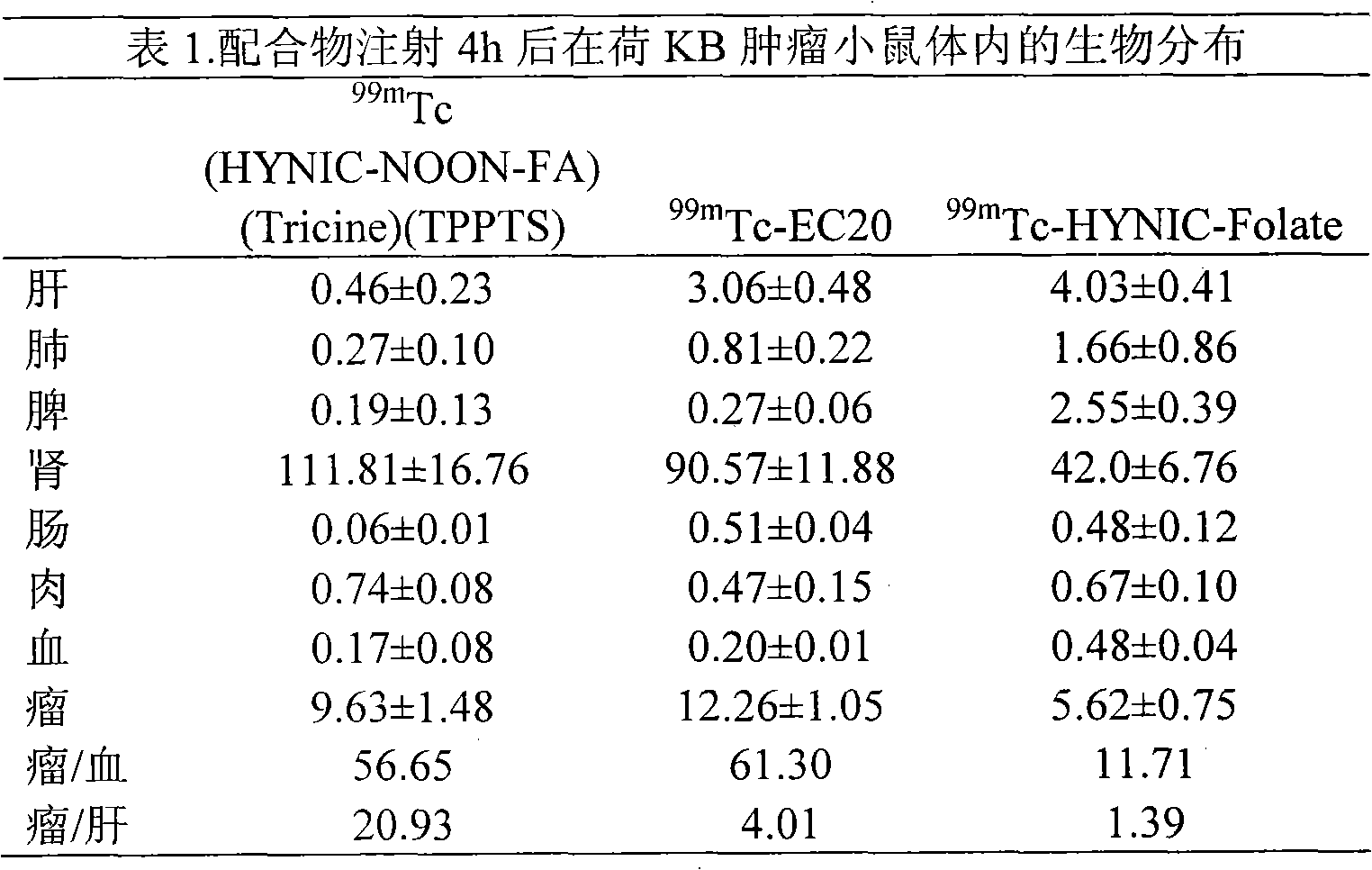

Labeled 99mTc hydrazino-nicotinamide-dioxodecoyl-folic acid coordination compound and preparation method

InactiveCN101863924AImprove performanceRadioactive preparation carriersGroup 7/17 element organic compoundsSodium phosphatesNiacin

The invention discloses a labeled 99mTc hydrazino-nicotinamide-dioxodecoyl-folic acid coordination compound with a general formula of 99mTc(HYNIC-NOON-FA)(Tricine)(L). In the structural formula, L is triphenyl sodium phosphate or triphenyl sodium photrisulfonic acid, wherein 1,8-diamido-3,6-octane dioxide is used as a connecting chain for generating a hydrazino-nicotinamide-3,6-dioxodecoyl-folic acid coupler respectively with folic acid and hydrazino-niacin through amido bonds and coordinating with oxygen atoms and phosphorus atoms in a co-ligand Tricine and an L molecule and 99mTc, and the 99mTc(HYNIC-NOON-FA)(Tricine)(L) coordination compound is obtained through two steps of: (a) synthesizing the hydrazino-nicotinamide-3,6-dioxodecoyl-folic acid coupler used as a ligand; and (b) labeling the 99mTc-hydrazino-nicotinamide-dioxodecoyl-folic acid coordination compound. The coordination compound has the advantages of high radiochemical purity, good stability, high tumor intake, good retention, low non-target organ background and clear tumor SPECT (Single Photon Emission Computed Tomography) development and can be prepared into a novel 99mTc labeled folic acid receptor tumor developer widely applied to the technical field of radioactive pharmaceutical chemistry and nuclear medicine.

Owner:BEIJING NORMAL UNIVERSITY +1

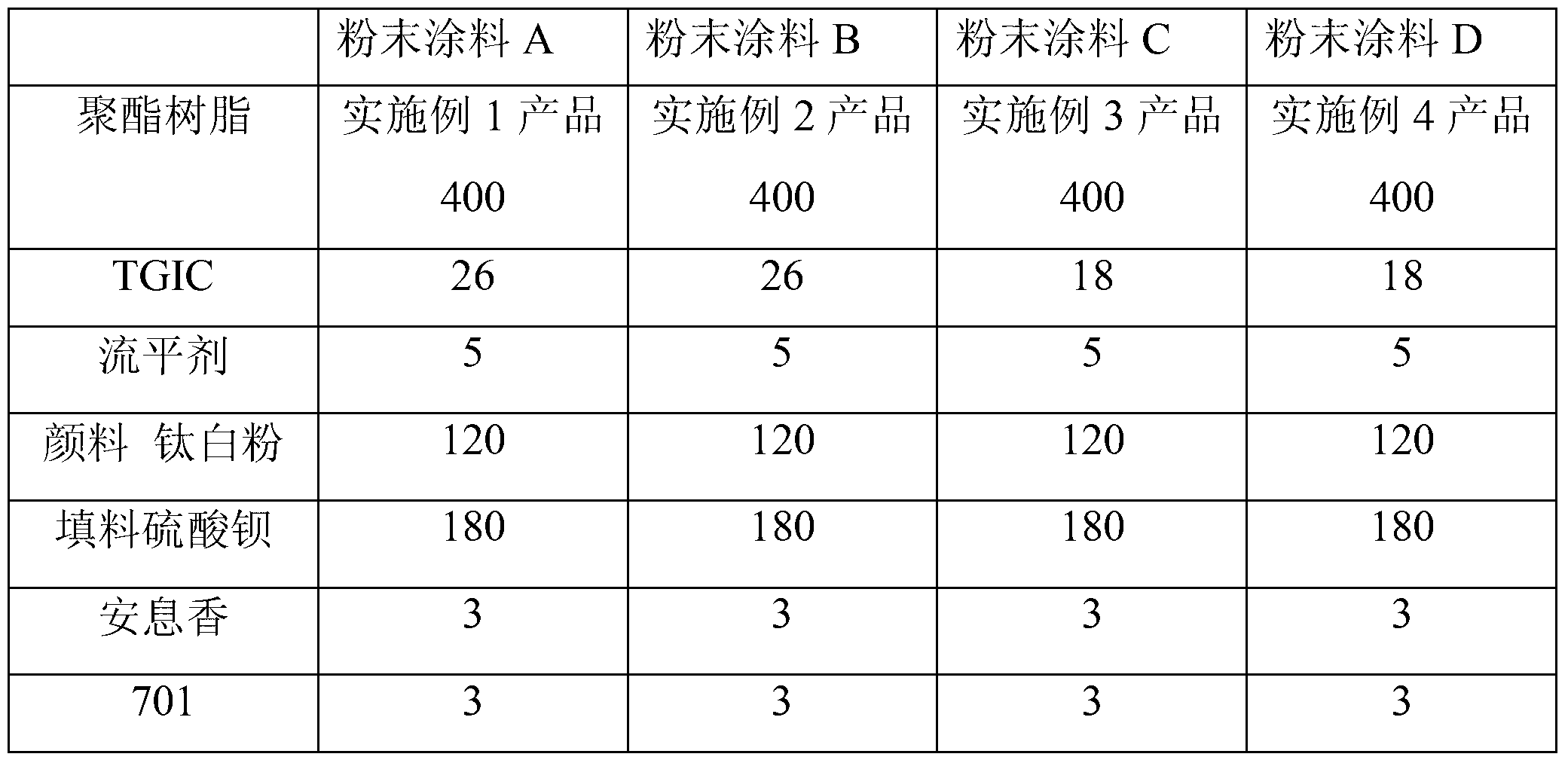

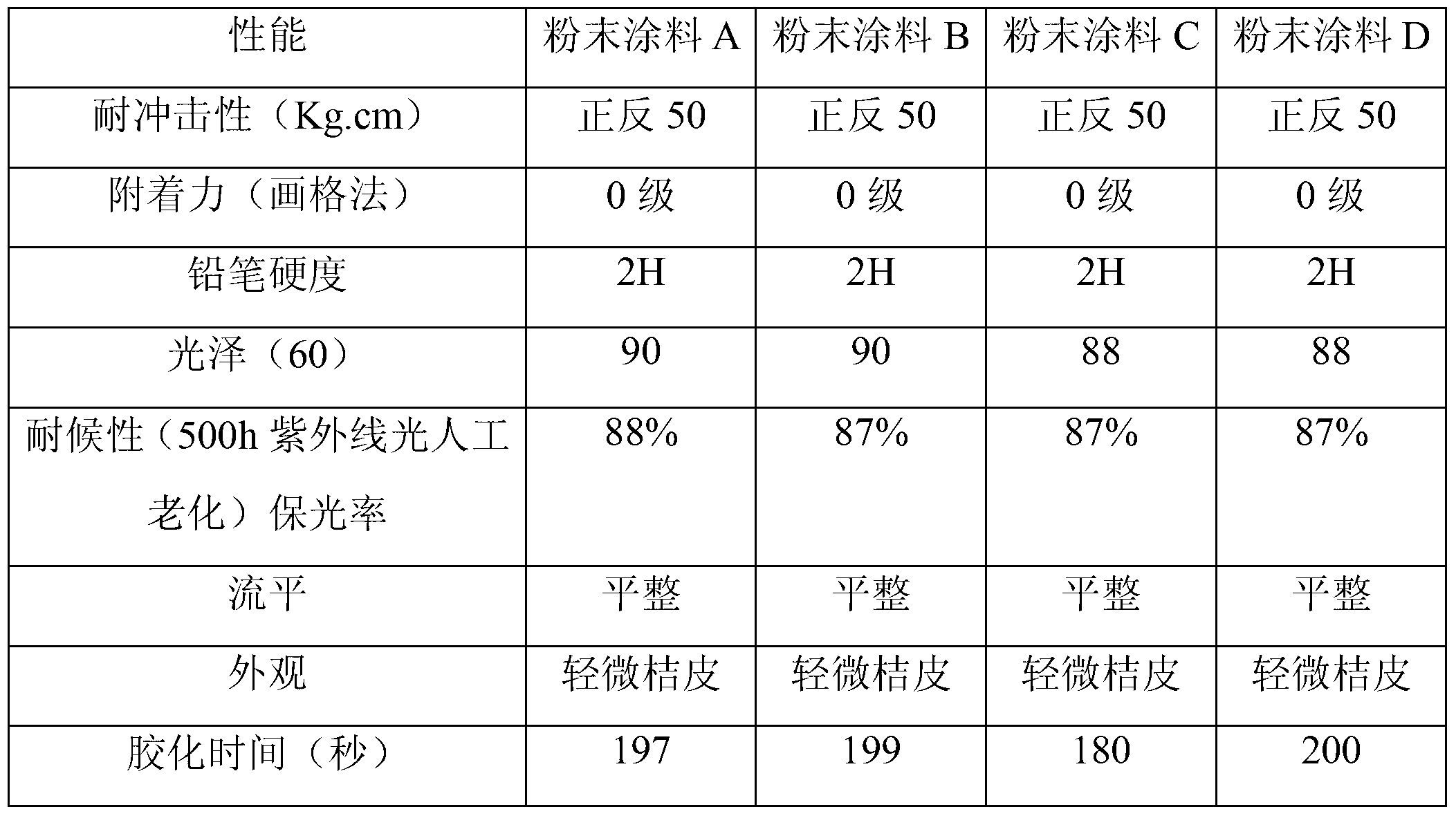

Preparation method of polyester resin used in outdoor weatherable powder paint

InactiveCN103319697AAchieve recyclingReduce productionPowdery paintsPolyester coatingsWaste materialImpurity

The invention discloses a preparation method of polyester resin used in outdoor weatherable powder paint. The method comprises the steps that: (1) washed, impurity-removed, and crushed PET raw material is subjected to a trans-esterification reaction with dihydric alcohol with a boiling point higher than that of ethylene glycol under the existence of a trans-esterification catalyst; after the trans-esterification reaction is finished, polyol, polyacid / anhydride, and a stabilizer are added; an esterification reaction is carried out under the effect of an esterification catalyst; isophthalic acid and a curing accelerator triphenylphosphine are added, and a stirring reaction is carried out, such that the polyester resin used in outdoor weatherable powder paint is obtained. The polyester resin has the characteristics of outdoor weatherability, baking resistance, salt spray resistance, and the like of a powder paint synthesized and produced by using weatherable polyester resin, and has good gloss, impact resistance, and excellent leveling performance. The pollutions to the environment caused by polyester waste material and esterification water produced in purified terephthalic acid synthesis are reduced. Therefore, the technical scheme provided by the invention is environment-friendly.

Owner:江苏宝田新材料股份有限公司

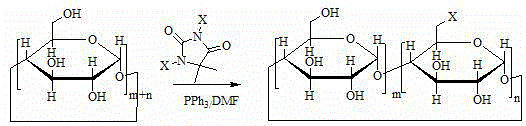

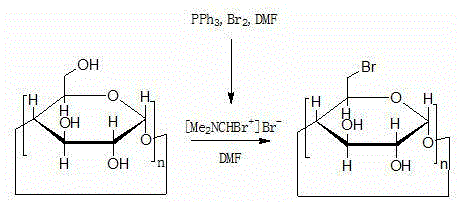

Method for preparing 6-deoxy-6-haloalkyl cyclodextrin

The invention discloses a method for preparing 6-deoxy-6-haloalkyl cyclodextrin. The method comprises the following specific steps: in a N, N-dimethylformamide solvent, firstly reacting 1,3-dihalo-5, 5-dimethylhydantoin and triphenylphosphine to form a salt and substituting with cyclodextrin to form halide. The method has the advantages and beneficial effects that compared to the existing preparation method, the reaction quality is significantly improved, the content of a product can be not less than 95% and the product yield can reach 80%; and 1,3-dihalo-5, 5-dimethylhydantoin used in the reaction is cheap and easily available and is stable in property and the 6-deoxy-6-haloalkyl cyclodextrin is conductive to industrial production.

Owner:CHINA OTSUKA PHARM CO LTD

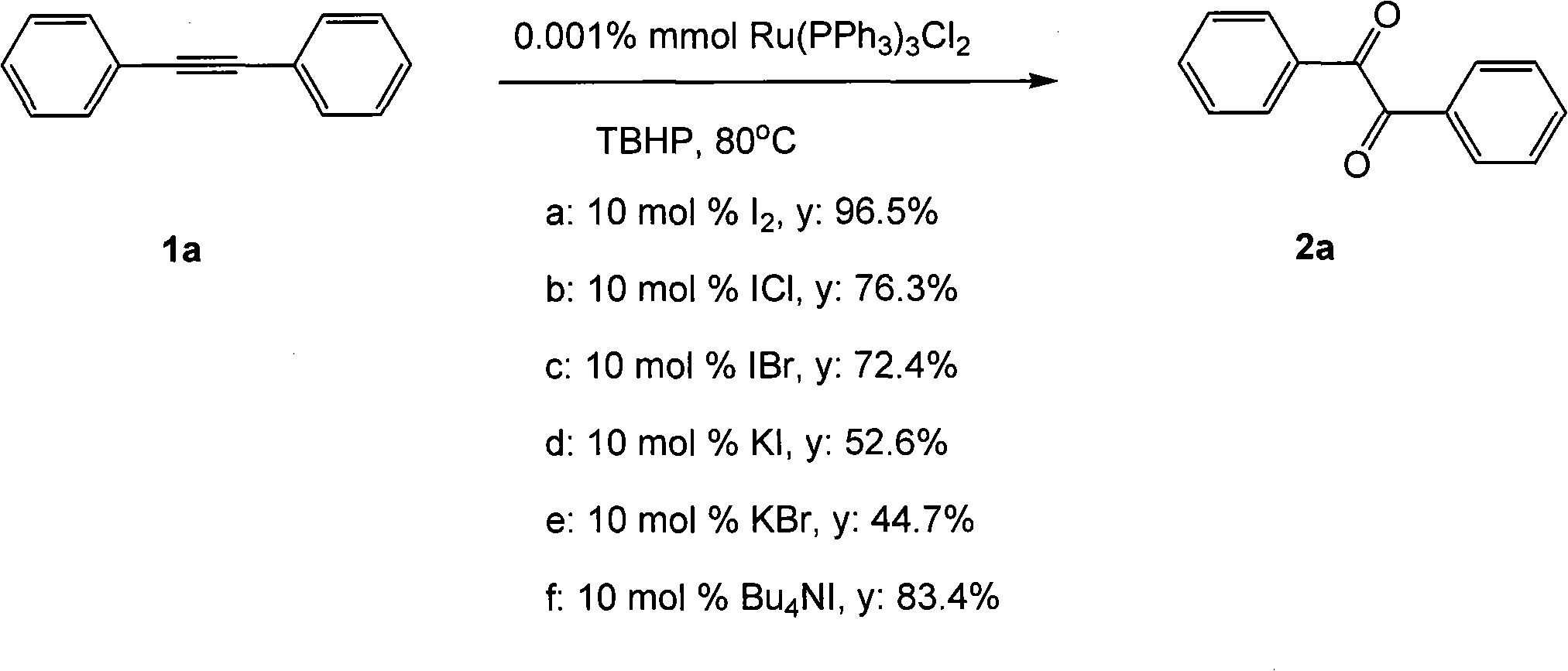

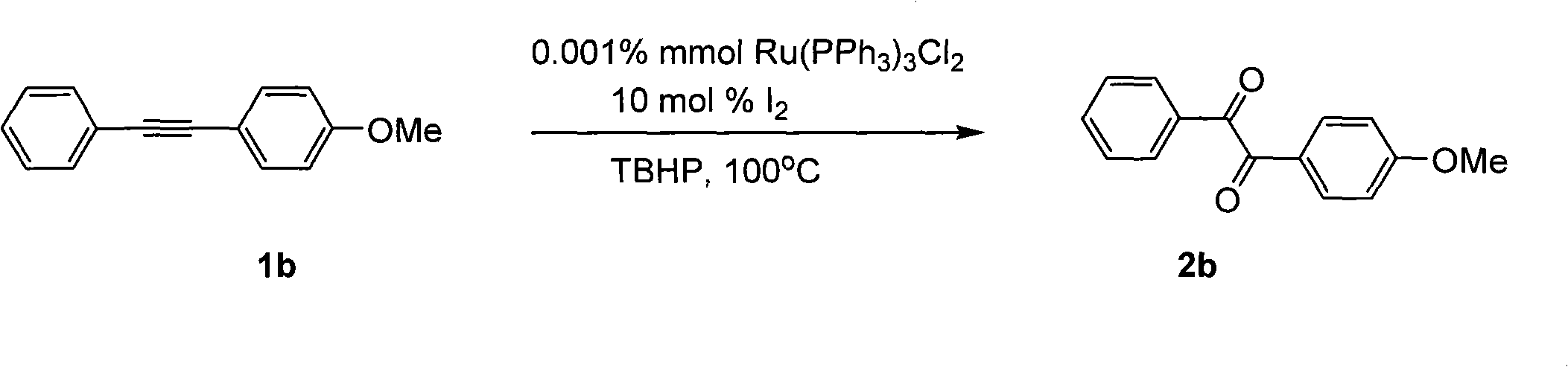

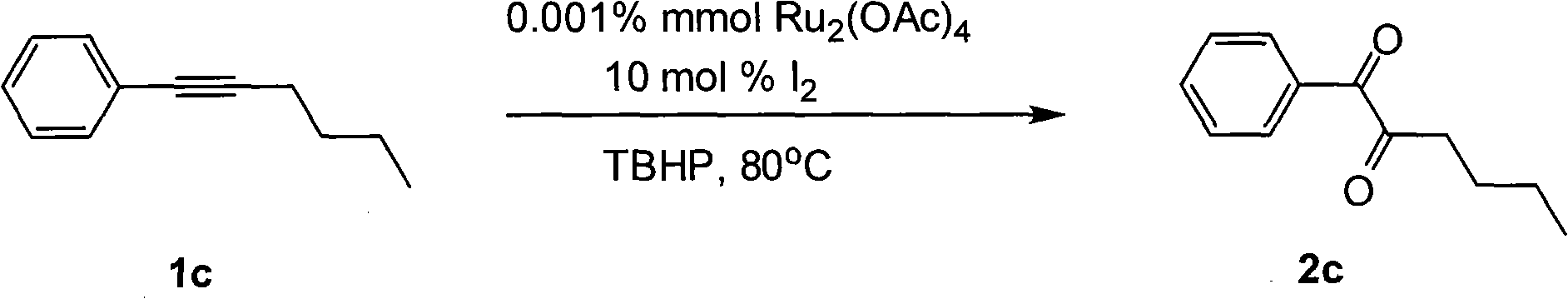

Method for preparing 1, 2-diketone by catalyzing and oxidizing alkynes

InactiveCN101624322AMild reaction conditionsMeet the requirementsCarboxylic acid nitrile preparationOrganic compound preparationCatalytic oxidationKetone

The invention belongs to the field of catalysis and oxidization, and particularly discloses a method for preparing 1, 2-diketone by catalyzing and oxidizing alkynes. The method comprises the following steps: taking alkynes R1-C-C-R2 (acetylenic link exists between C and C) as a reaction substrate, taking one of TBHP, m-chloroperoxybenzoic acid and p-benzoquinone as a oxidant, taking one of dichloro (p-cymene) ruthenium (II) dimer, tri (triphenylphosphine) ruthenous chloride, ruthenium acetate, ruthenium dichlorophenyl (II) dimer, ruthenium trichloride, BINAP ruthenous chloride, dodecacarbonyltriruthenium and tricarbonyldichlororuthenium (II) dimer as a catalyst, taking one of iodine, iodine chloride, iodine bromide, potassium iodide, tetrabutyl ammonium iodide and potassium bromide as a cocatalyst, and taking 1, 4-dioxane as a solvent to react under 40 DEG C to 100 DEG C for 4 to 24 h to prepare the 1, 2-diketone. The method is economic, environmental-friendly and mild.

Owner:SUZHOU UNIV

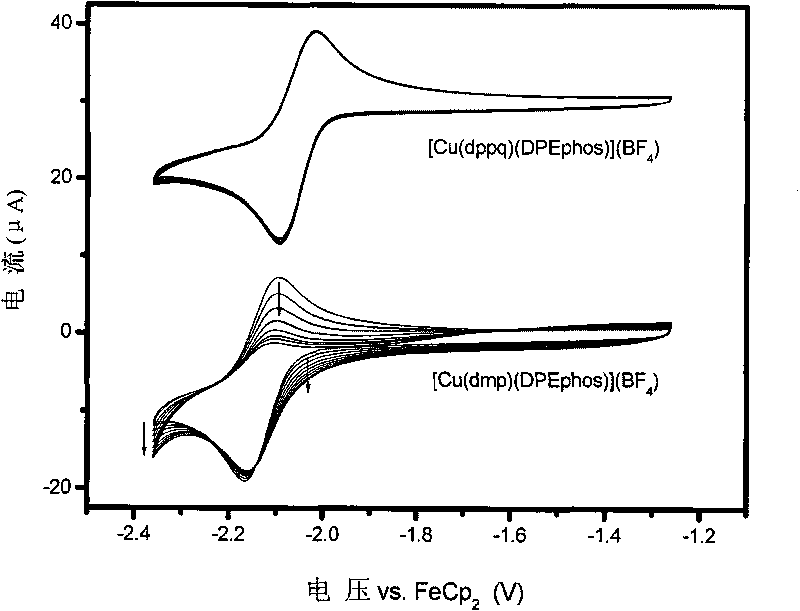

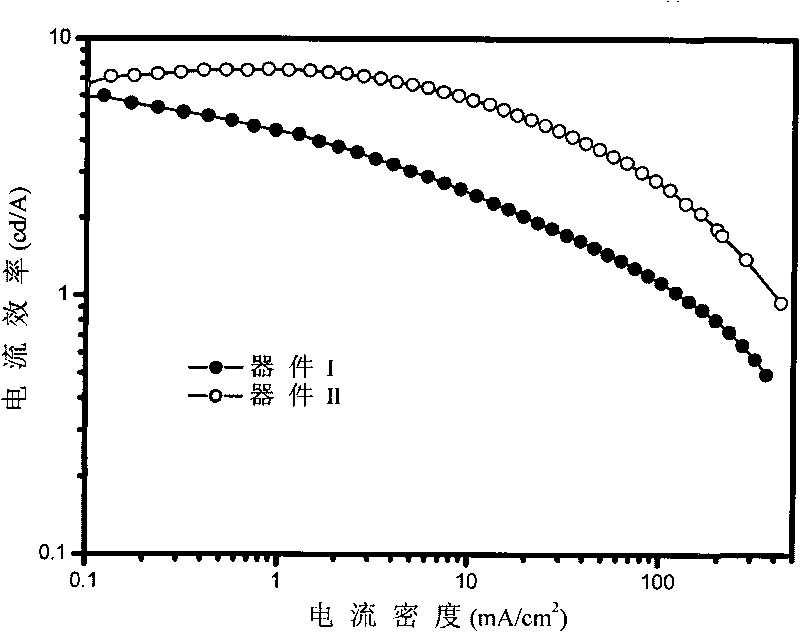

Cooper (I) phosphorescent complexes using 8-phosphinoquinoline derivative as ligand and application thereof

The invention relates to a synthesis method of a cooper (I) phosphorescent complexes using a 8-phosphinoquinoline derivative as a ligand and application thereof in an organic electroluminescence device. The cooper (I) complexes has an asymmetric bidentate N^P type ligand, and compared with the traditional cooper (I) phosphorescent complexes using a diimine / triphenylphosphine mixed ligand, the invention has better photochemical and electrochemical stability, which ensures that the invention becomes an ideal material for preparing the organic electroluminescence device.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Supported catalyst for preparing aldehyde by olefin hydroformylation

InactiveCN1736602AIncreased space-time yieldSimple compositionOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionMolecular sieveTetrafluoroborate

Disclosed is a supported catalyst mainly containing sulfonated triphenylphosphine- rhodium complex and is used for preparing aldehyde by hydroformylation of olefin, and relates to an ionic liquid catalyst. It contains solid oxide, sulfonated triphenylphosphine- rhodium complex, sulfonated triphenylphosphine ligand and ionic liquid. The solid oxide is one from hole molecular sieve, SiO2, TiO2, gamma- Al2O3; sulfonated triphenylphosphine- rhodium complex is single-sulfonated triphenylphosphine- rhodium complex, di- sulfonated triphenylphosphine- rhodium complex and tri- sulfonated triphenylphosphine- rhodium complex; and the ionic liquid is 1, 1, 3, 3, - tetramethyl guanidine lactate, 1- butyl- 3- methyl imidazolium tetrafluorborate and 1- butyl- 3- methyl imidazolium hexafluorophosphate. By mass ratio, the solid oxide is among 50%- 90%, the ionic liquid 8%- 49%, and rhodium 0.05%- 2%, and by molecular ratio phosphine to rhodium is 3- 200.

Owner:XIAMEN UNIV

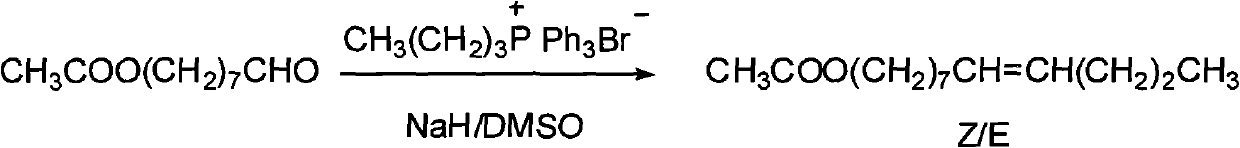

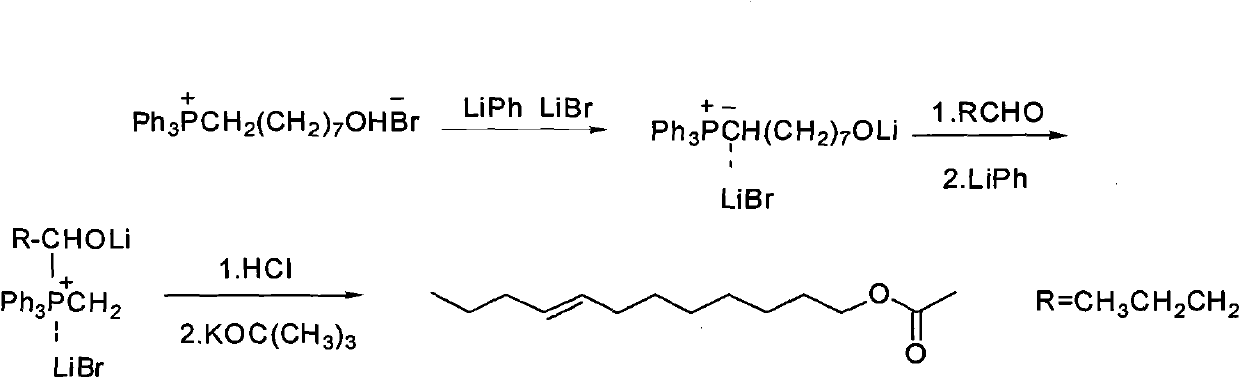

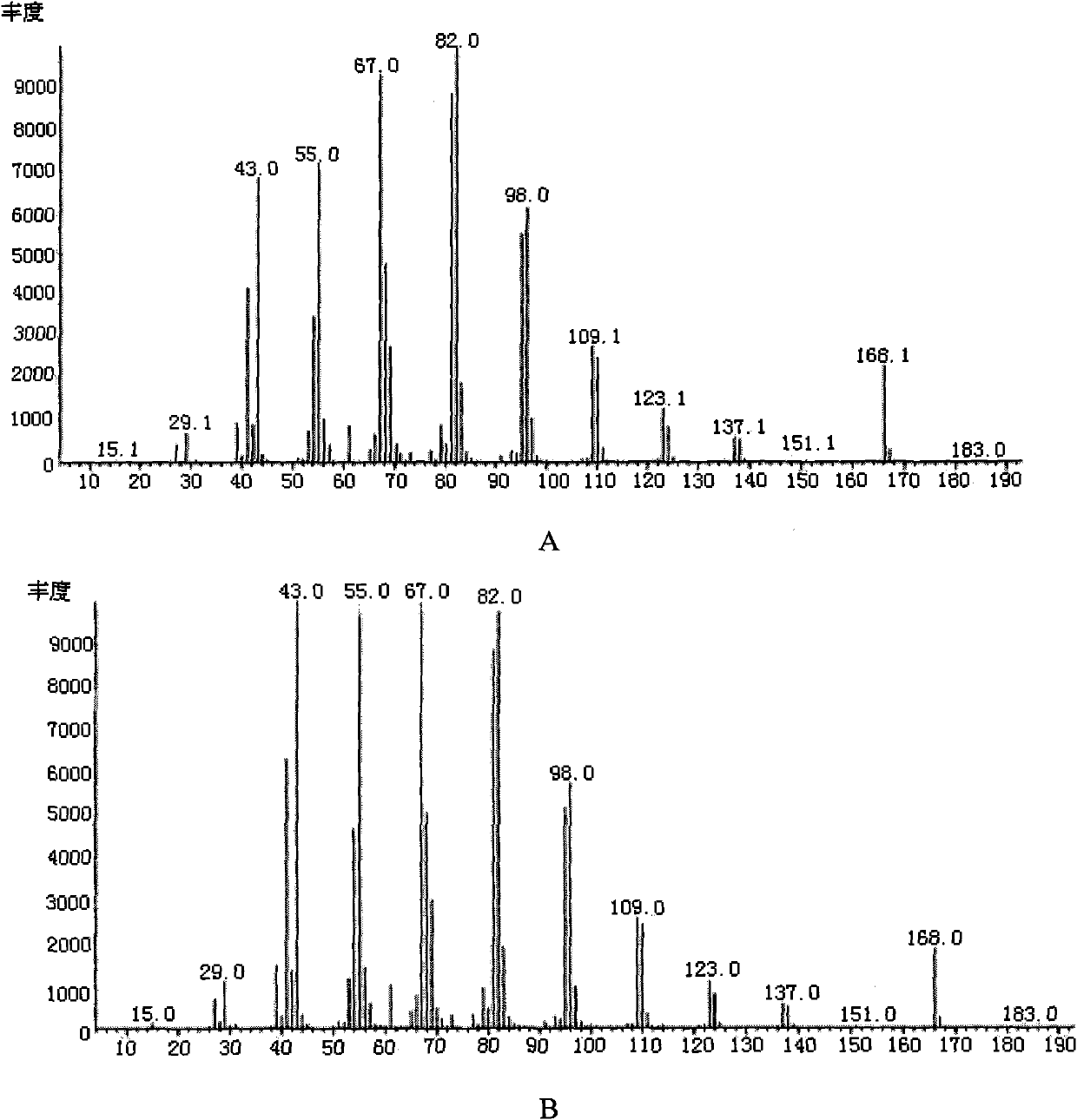

Synthesizing method of oriental fruit moth sex pheromone 8(Z/E)-dodecylene-1-alcohol acetate

InactiveCN101906034AGood choiceHigh yieldOrganic compound preparationCarboxylic acid esters preparationChemical synthesisAlcohol

The invention relates to the field of chemical synthesis of inset sex pheromone, in particular to a synthesizing method of oriental fruit moth sex pheromone 8(Z / E)-dodecylene-1-alcohol acetate. The method comprises the following steps of: reacting 8-hydroxy octyl triphenylphosphine salt with strong base to generate corresponding sodium alcoholate salt; continuously reacting the sodium alcoholate salt with the strong base to generate ylide reagent; performing Witting reaction on the ylide reagent with n-butanal under the action of mixed solvent of large-polar solvent and small-polar solvent to obtain the important midbody 8(Z / E)-dodecylene-1-alcohol of inset sex pheromone, and then acetylizing to obtain the 8(Z / E)-dodecylene-1-alcohol acetate. The synthesizing method has easily obtained materials, simple operation, common-use solvent, good selectivity and high activity for inducing inset sex pheromone, and the proportion of Z / E-8-dodecylene-1-alcohol acetate is as high as 95:5. The invention is suitable for large-scale industrial production.

Owner:PHEROBIO TECHNOLOGY CO LTD +1

Method for synthesizing acetylacetonatodicarbonyl rhodium

InactiveCN102093432AHigh yieldShorten the distillation processGroup 8/9/10/18 element organic compoundsInorganic saltsOrganic solvent

The invention discloses a method for synthesizing acetylacetonatodicarbonyl rhodium, which comprises the following steps: (1) mixing rhodium trichloride hydrate and N,N-dimethyl formamide, heating the mixture to 120 and 150 DEG C in a protective atmosphere of nitrogen, adding diacetone after rhodium trichloride hydrate dissolves completely, heating till the refluxing reaction is accomplished completely, standing reaction solution at room temperature, cooling, adding aqueous solution of an inorganic salt or inorganic alkali or mixed aqueous solution of the inorganic salt and the inorganic alkali, precipitating, and performing the post treatment of precipitate to obtain acetylacetonatodicarbonyl rhodium; and (2) dissolving the acetylacetonatodicarbonyl rhodium prepared by the step (1) in an organic solvent, adding triphenylphosphine, starting reaction, and obtaining acetylacetonatodicarbonyl rhodium after no air bubbles escape. The method improves the step yield and single-pass total yield of product, adopts a relatively environmentally-friendly solvent, reduces production cost and has obvious economic and environmental advantages.

Owner:杭州凯大催化金属材料股份有限公司

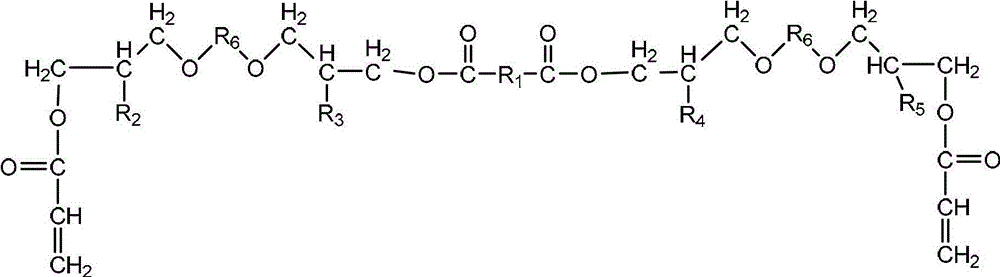

Multifunctional urethane acrylate oligomer as well as synthesis method and application thereof

ActiveCN102911338AImprove brittlenessImprove toughnessPolyurea/polyurethane coatingsSynthesis methodsReaction temperature

The invention discloses a multifunctional urethane acrylate oligomer as well as a synthesis method and application thereof. The synthesis method comprises the following steps: synthesizing a modified glycidyl ether by adding a diglycidyl ether, a dibasic acid and a catalyst which is the triphenylphosphine into a reactor and subjecting the materials to reaction at 120-150 DEG C for 2.5-3.5 hours; synthesizing a semi-adduct by dropwise adding acrylic hydroxy ester and dibutyltin dilaurate into diisocyanate, and keeping the reaction temperature at 40-50 DEG C until the concentration of the isocyanate group is 48-52% of the initial concentration; and synthesizing a hydroxyl-group containing multifunctional urethane acrylate. In the process of synthesizing, by using the difference of raw materials and controlling the proportion of monomers for reaction, the soft and hard segments are introduced into the molecule structure so that the toughness is increased, and the brittleness of the coating film is improved. The hydroxyl groups are provided in the molecular structure design, which is helpful to the improvement of the adhesion of the coating film on the substrate in the later period.

Owner:CHANGXING PHOTOELECTRIC MATERIAL +1

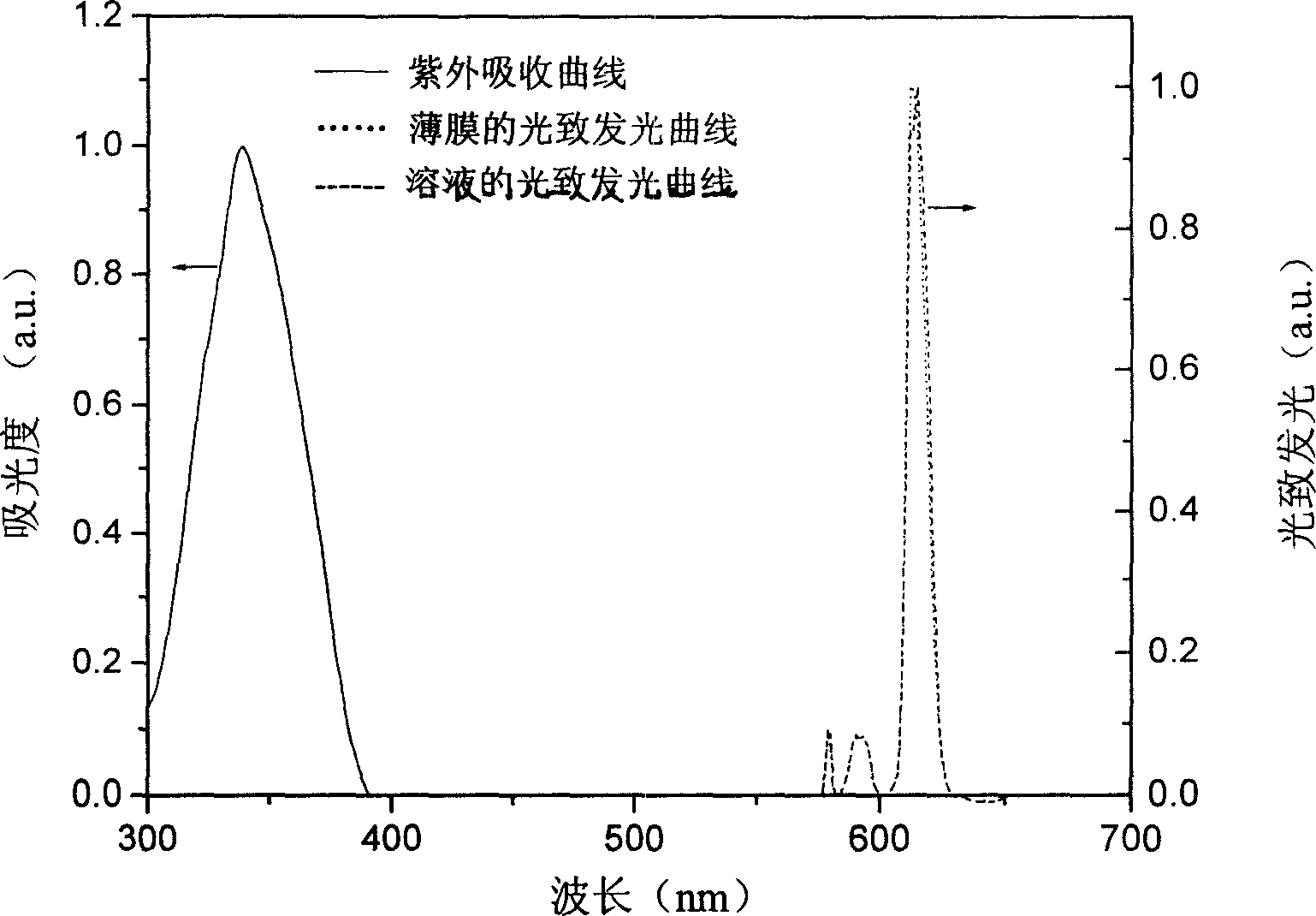

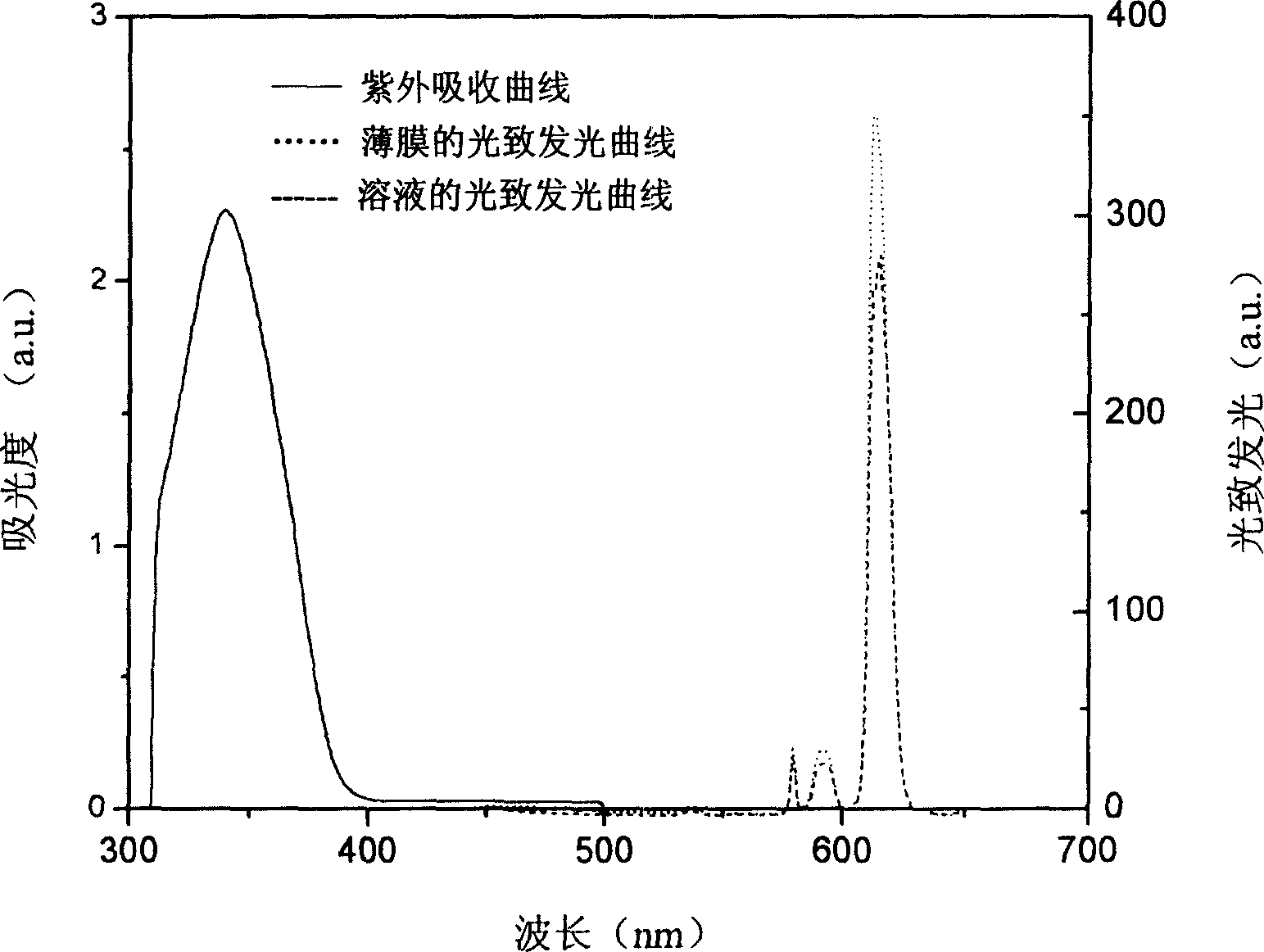

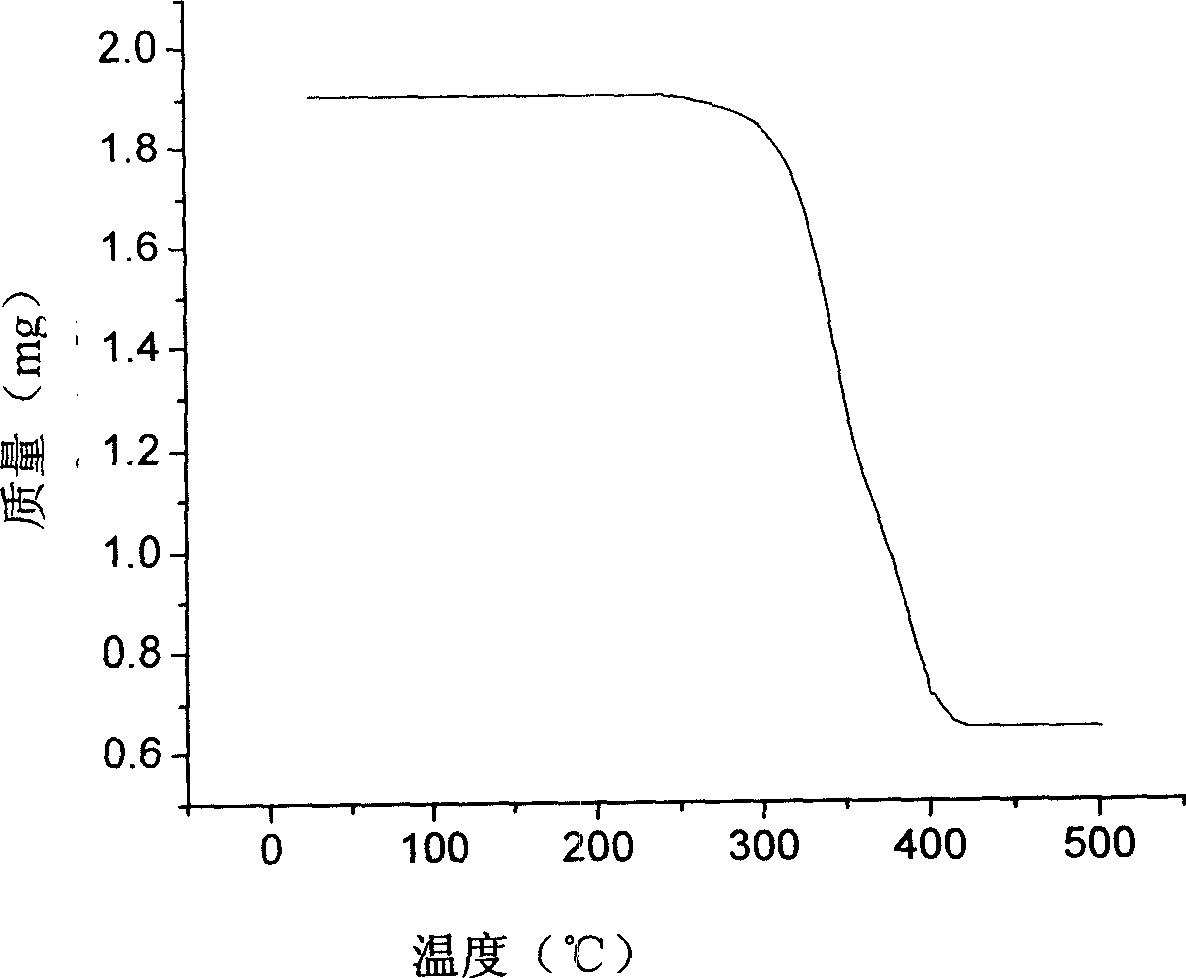

Rare earth complexes chelated by aromatic base substituted diphosphine dioxide and its synthesizing process

InactiveCN1687080AElectrical apparatusGroup 5/15 element organic compoundsHigh current densityRare earth

The present invention relates to a kind of high-performance photoelectric function rare earth complex material and its preparation method. Said invention uses substituted diphosphine dioxide containing aromatic group as ligand, and utilizes complexation reaction to synthesize a series of high-effective rare earth photoelectric function complexes, and prepares doped red electroluminescent device containing above-mentioned rare earth photoelectric function material, said electroluminescent device can obtan satisfactory result in the luminance, current density and efficiency under the high current density.

Owner:FUDAN UNIV

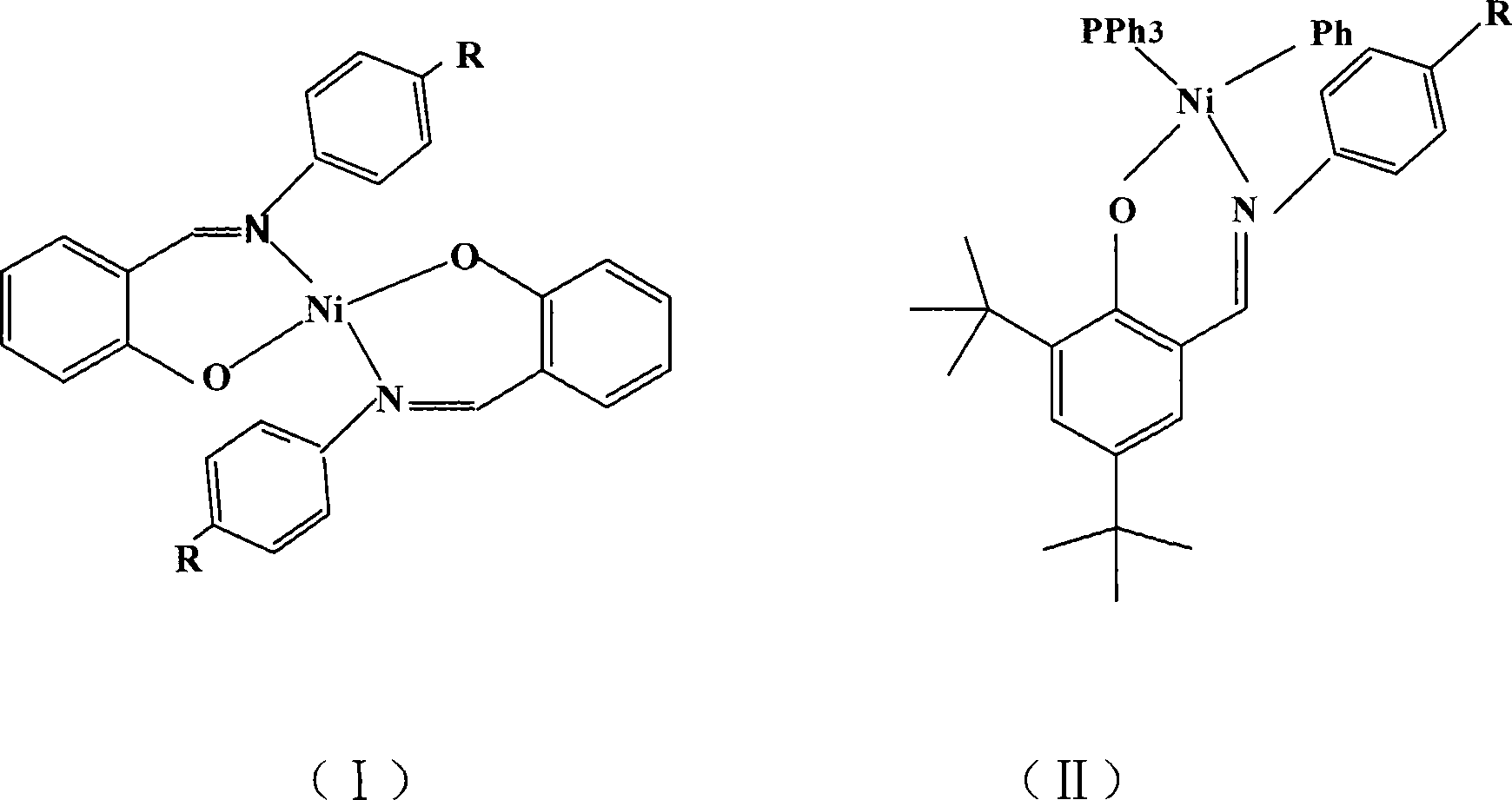

Preparation method of cyclolefin copolymer

The present invention discloses process of preparing cycloolefine copolymer. The present invention synthesizes norbornene copolymer material with different monomer contents through polymerization of styrene or methyl methacrylate and norbornene in different monomer material ratios at proper temperature and in the presence of catalyst system comprising salicylal imine-Ni compound, polyaluminoxane and triphenyl phosphine.

Owner:SUN YAT SEN UNIV

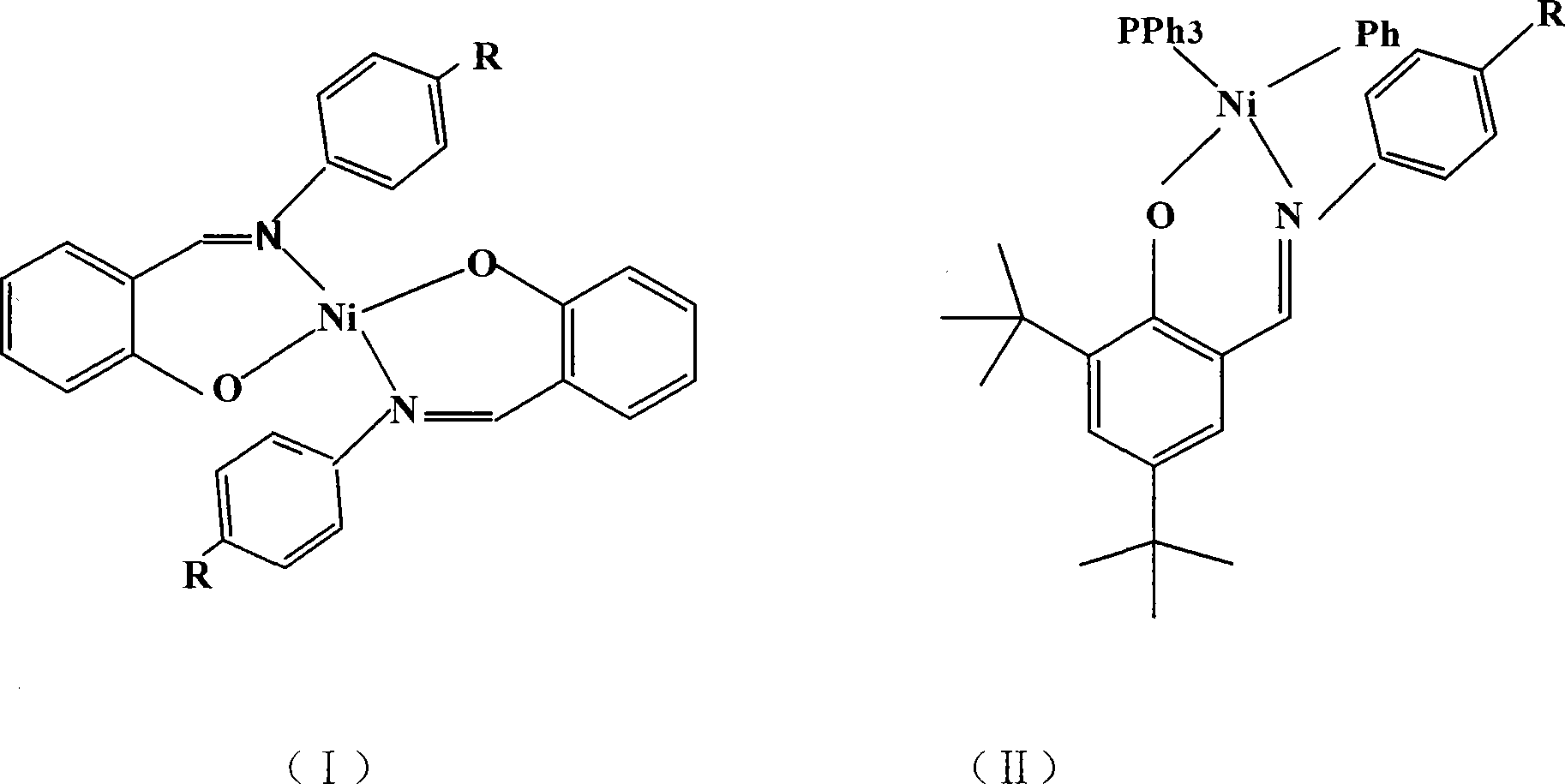

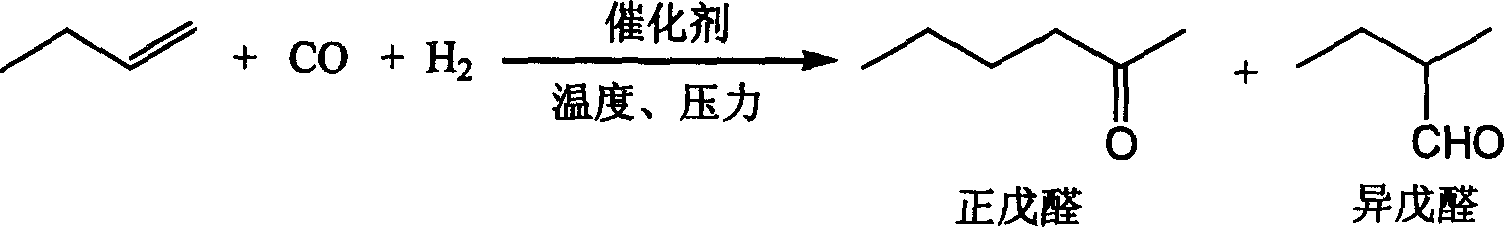

Preparing-1-pentanal from mixed solvent ion liquid of tetrafluorborate methyl buty I imidazole salt/water

InactiveCN1562932AGood choiceIncrease reaction ratePreparation by carbon monoxide reactionSolventIonic liquid

Prepn. of 1-valeric aldehyde by hydro-formylation of 1-butylene, carbon monoxid and hydrogen, catalyzed by rhodium trichloride and sodium m-triphenylphosphine trisulfonate, in mixed water solution of [Bmin] BF4. Then, the product is obtd. by gravitational settling and liquid separation. This method has advantages of: high yield, high selectivity, good prodn. environment and simple producing process. The product can be used as intermediate of perfumery, 1-pentoric acid and other fine chemicals.

Owner:EAST CHINA NORMAL UNIV

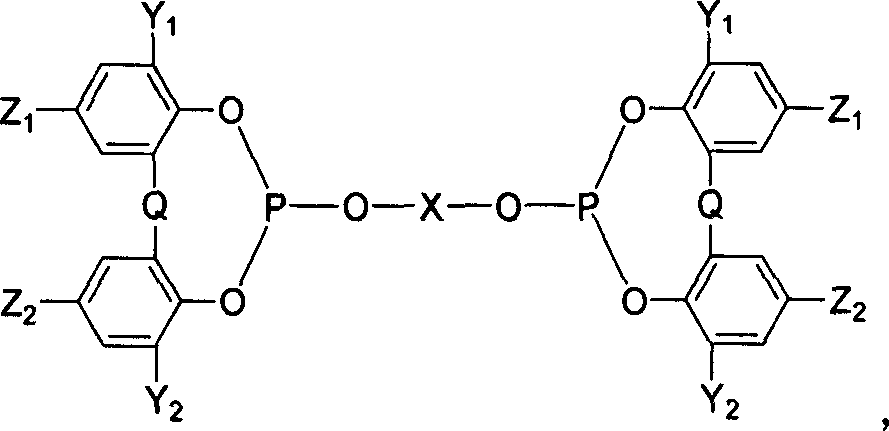

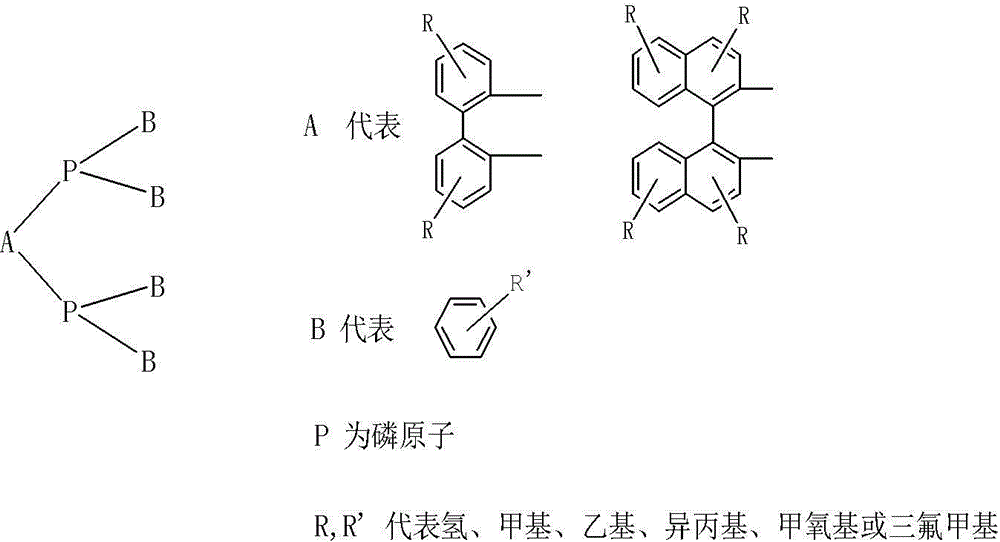

Phosphorus-containing catalyst composition and hydroformylation process using the same

ActiveCN101801528ALow selectivityHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsTriphenylphosphinePhosphine oxide

The present invention relates to a catalyst composition that includes a triphenylphosphine ligand, a monodentate phosphine ligand, a monodentate phosphine oxide ligand, and a transition metal catalyst, and a hydroformylation process using the same. In the hydroformylation process using the catalyst composition according to the present invention, the high catalytic activity can be obtained, and the selectivity (N / I selectivity) in respects to normal- or iso-aldehyde can be desirably controlled.

Owner:LG CHEM LTD

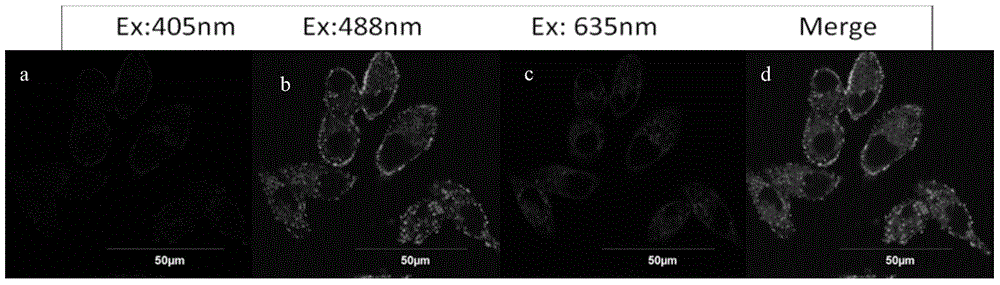

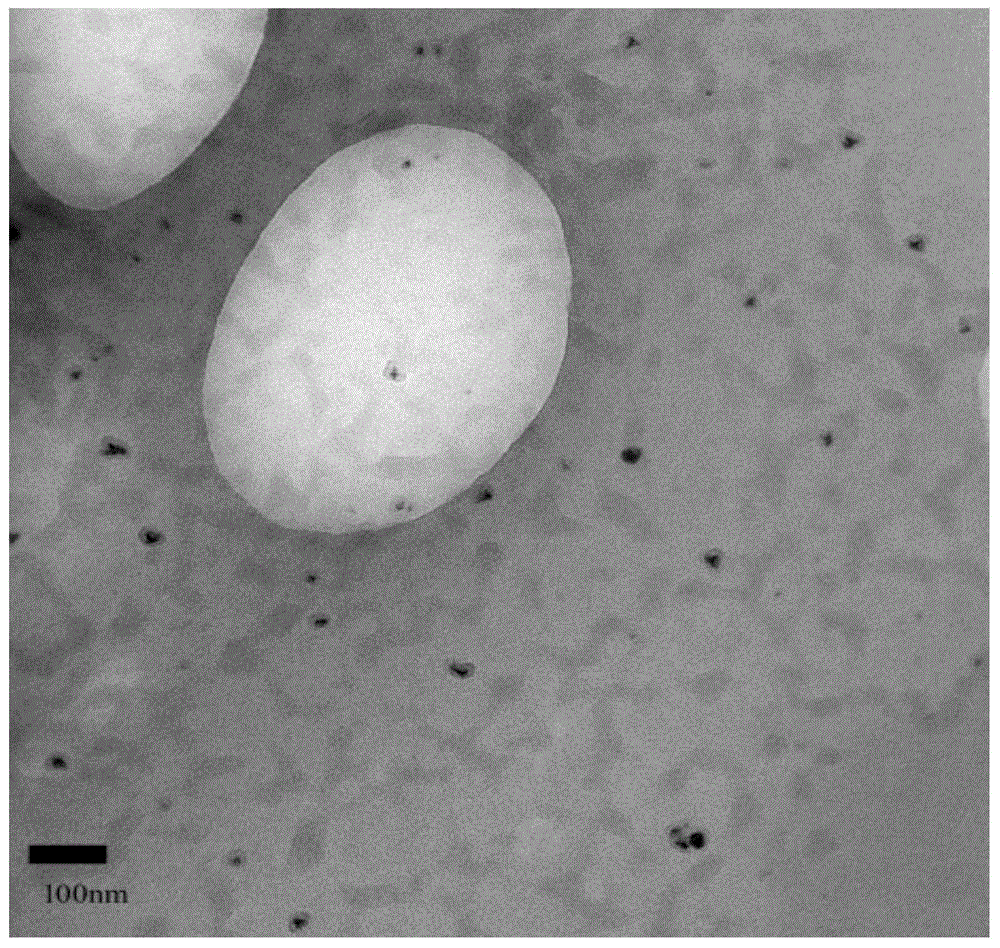

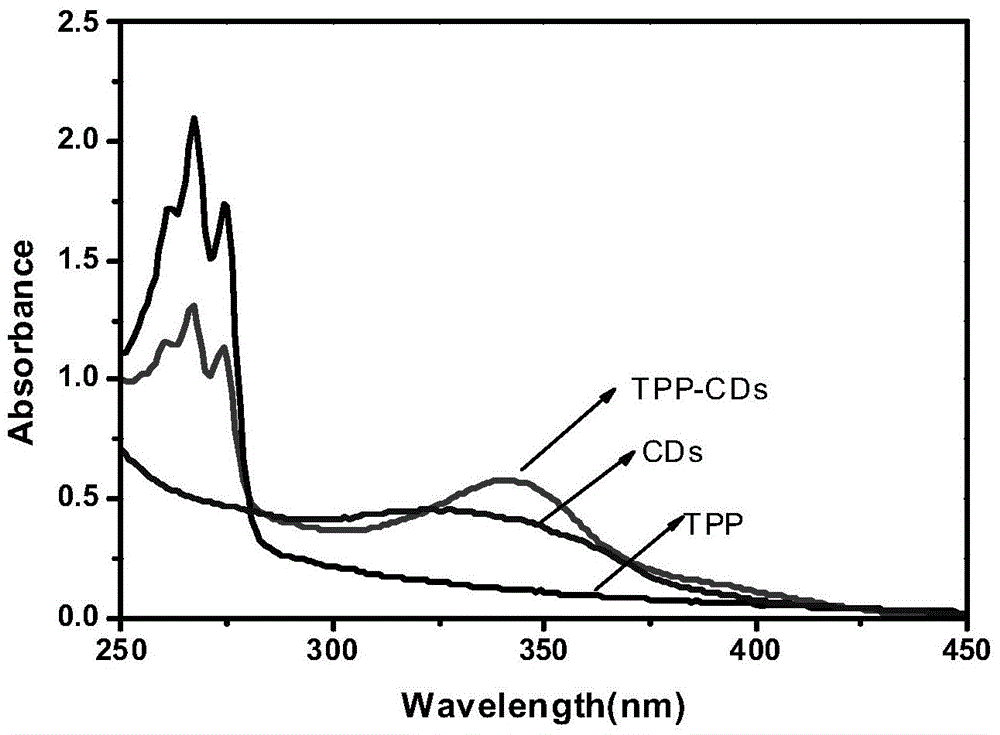

A carbon-base fluorescence probe for a targeting living cell mitochondrion and preparation thereof

InactiveCN104694116AEasy to prepareNo separate steps requiredFluorescence/phosphorescenceLuminescent compositionsSolubilityMitophagy

Preparation of a novel living cell mitochondrion probe based on carbon dots (CDs) is disclosed. A product TPP-CDs is prepared by synthesizing the CDs surfaces of which are provided with amino by adopting citric acid and urea as raw materials through a hydrothermal method, grafting with a triphenylphosphine (TPP) small molecule the tail end of which is provided with carboxyl through an amidation reaction, and separating and purifying by utilization of an aqueous membrane and a glucan G-25 gel column. The mitochondrion probe is simple in preparation method and capable of large-scale production, has good water solubility, good light stability and wide excitation and emission spectrum ranges, and breaks the current situation that mitochondrion probes at present generally are poor in water solubility and liable to fluorescence quenching. In addition, the mitochondrion probe is low in cell toxicity and biological-friendly, and can be successfully used for mitochondrion imaging of living cells.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

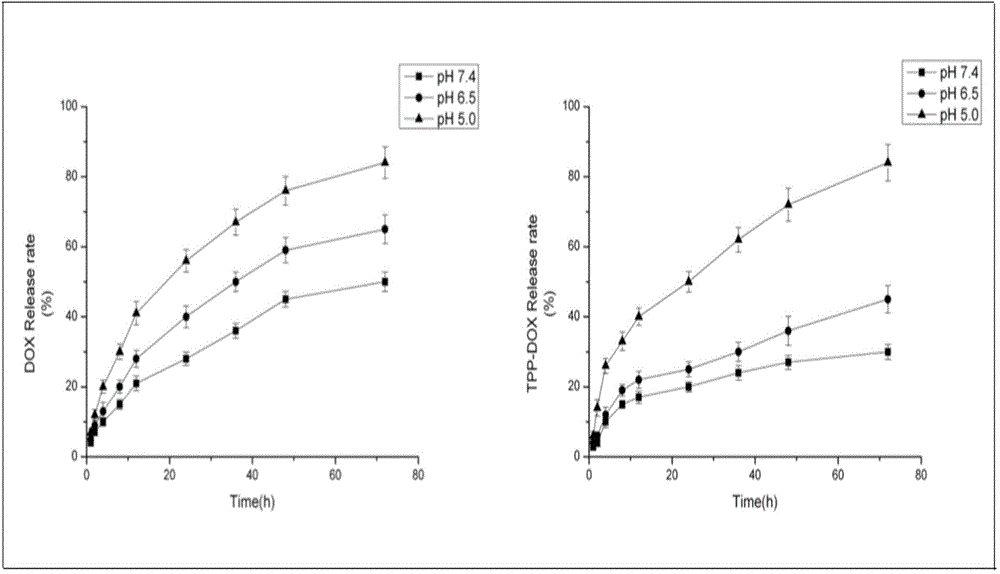

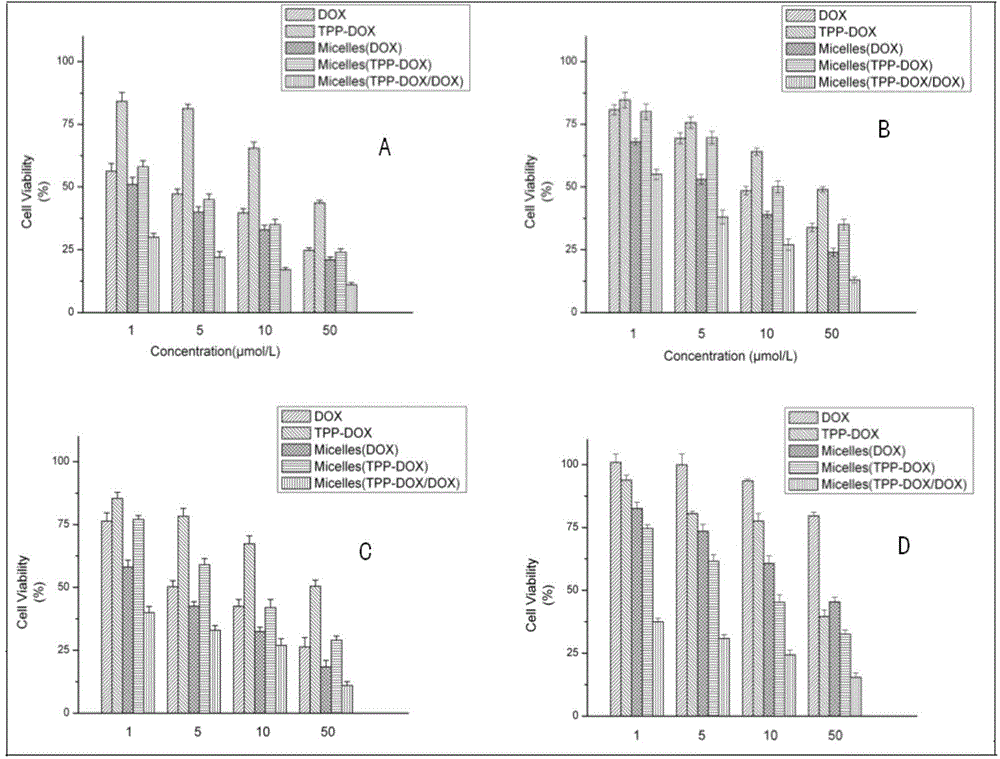

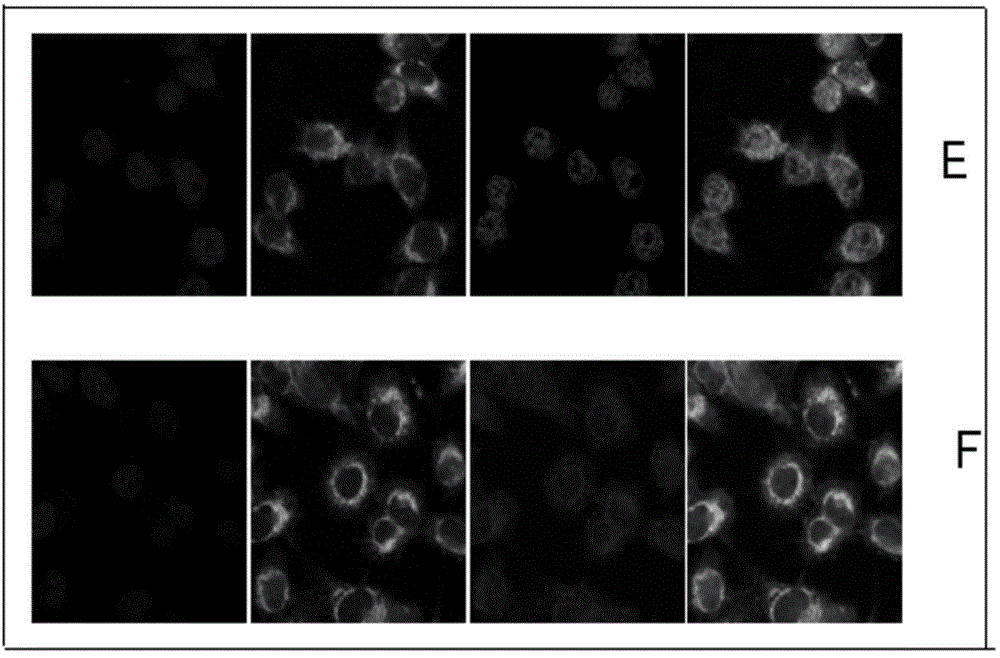

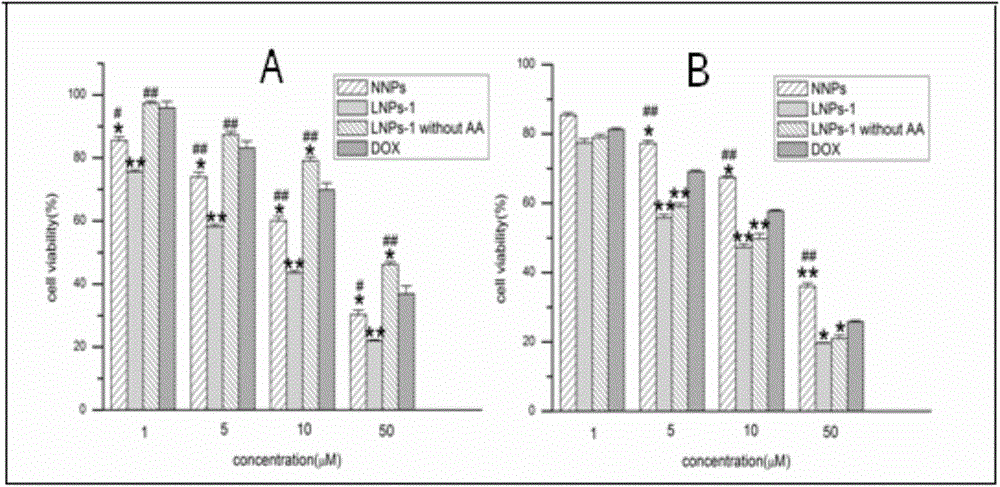

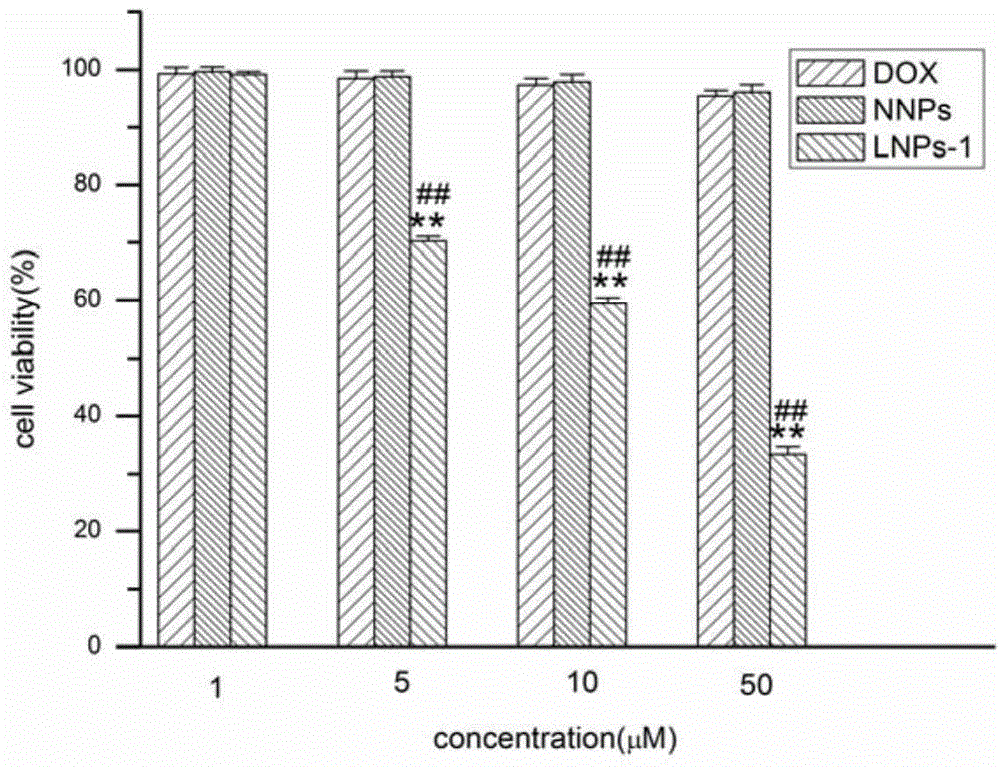

Mitochondria-targeting micelle drug delivery system capable of reversing drug resistance of tumor

InactiveCN104523723AIncrease the effective concentrationReduce distributionOrganic active ingredientsPharmaceutical non-active ingredientsPolyethylene glycolMitophagy

The invention provides a mitochondria-targeting micelle drug delivery system capable of reversing drug resistance of tumor. The drug delivery system is a polymer micelle which is obtained through self assembly of a block copolymer folic acid-polyethylene glycol-polyaspartic acid, also a mitochondria-targeting doxorubicin-triphenylphosphine compound (TPP-DOX) is synthesized, and doxorubicin and doxorubicin-triphenylphosphine (DOX / TPP-DOX) are together wrapped in the polymer micelle, so that the drug delivery micelle is obtained. The drug delivery system is capable of giving play to active targeting effect and possesses acid-sensitive characteristic, is capable of simultaneously releasing doxorubicin in mitochondria and nucleus in a positioning way after entering a tumor cell, helps to enhance antitumor activity and reverse the drug resistance of tumor, and provides a new strategy for the dilemma that chemotherapeutics drugs easily generate drug resistance.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Method for removing catalyst from unsaturated copolymer hydrogenated solution

The present ivnention provides a method for removing rhodium and / or ruthenium catalyst from unsaturated copolymer homogeneous hydrogenated solution, and is characterized by that it makes the peroxide, aqueous solution of extraction agent and hydrogenated solution of the unsaturated copolymer produce reaction together to extract the rhodium and / or ruthenium catalyst into the aqueous solution, and separate them from copolymer solution. In the butadiene-acrylonitrile copolymer hydrogenated solution in which the rhodium organic coordination compound is used as catalyst the one-step removing rate of rhodium can be up to above 98.8%, and in the butadiene-acrylonitrile copolymer hydrogenated solution using rhodium and ruthenium bimetal organic coordination compound as catalyst the one-step removing rates of rhodium and ruthenium can be respectively up to 99.9% and 98.3%.

Owner:NANTEX IND

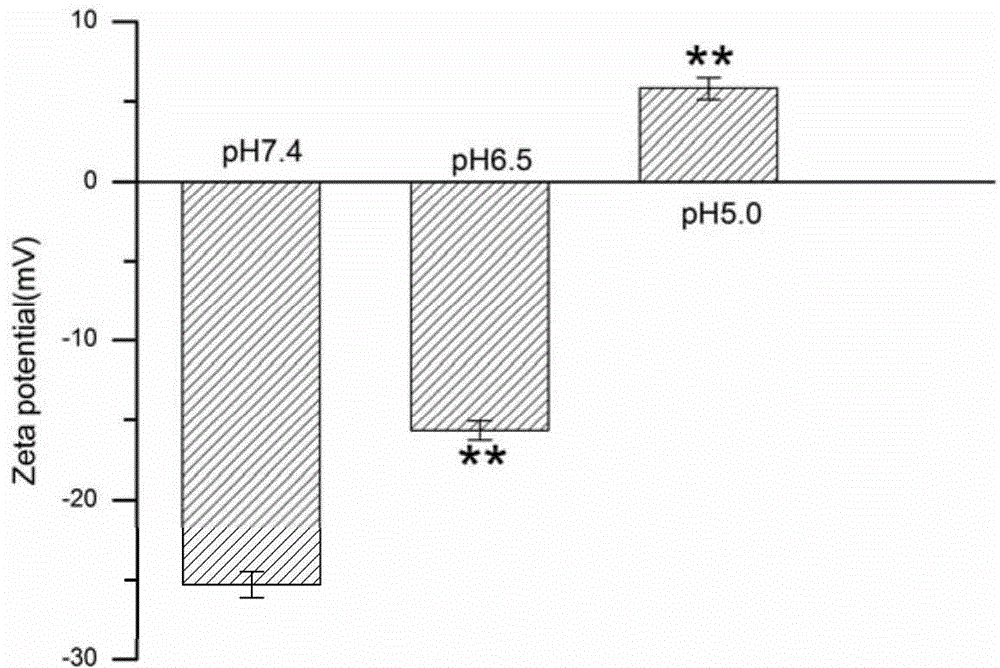

Tumor active-targeting nano drug delivery system capable of reversing drug-resistance

InactiveCN104398493APossesses active targeting propertiesIncrease intakeOrganic active ingredientsAntiinfectivesCholesterolPolyethylene glycol

The invention provides a tumor active-targeting nano drug delivery system capable of reversing drug-resistance. The drug delivery system is polylactic-co-glycolic acid (PLGA) nanoparticles mixed with lipid, and the nanoparticle core is PLGA. Drug-loaded nanoparticles are prepared as follows: inserting AA-polyethylene glycol-cholesterol linkers and triphenylphosphine-cholesterol linkers in the surface of PLGA; encapsulating DOX into the PLGA nanoparticles mixed with lipid to obtain the drug-loaded nanoparticles. The drug delivery system has the acid sensitivity, which enables the drug delivery system to proactively recognize tumor cells and position and release DOX into the mitochondria and cell nuclei of tumor cells, thereby enhancing the anti-tumor activity, reversing the drug-resistance of the tumor and providing a new strategy for improving the efficacy of DOX.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

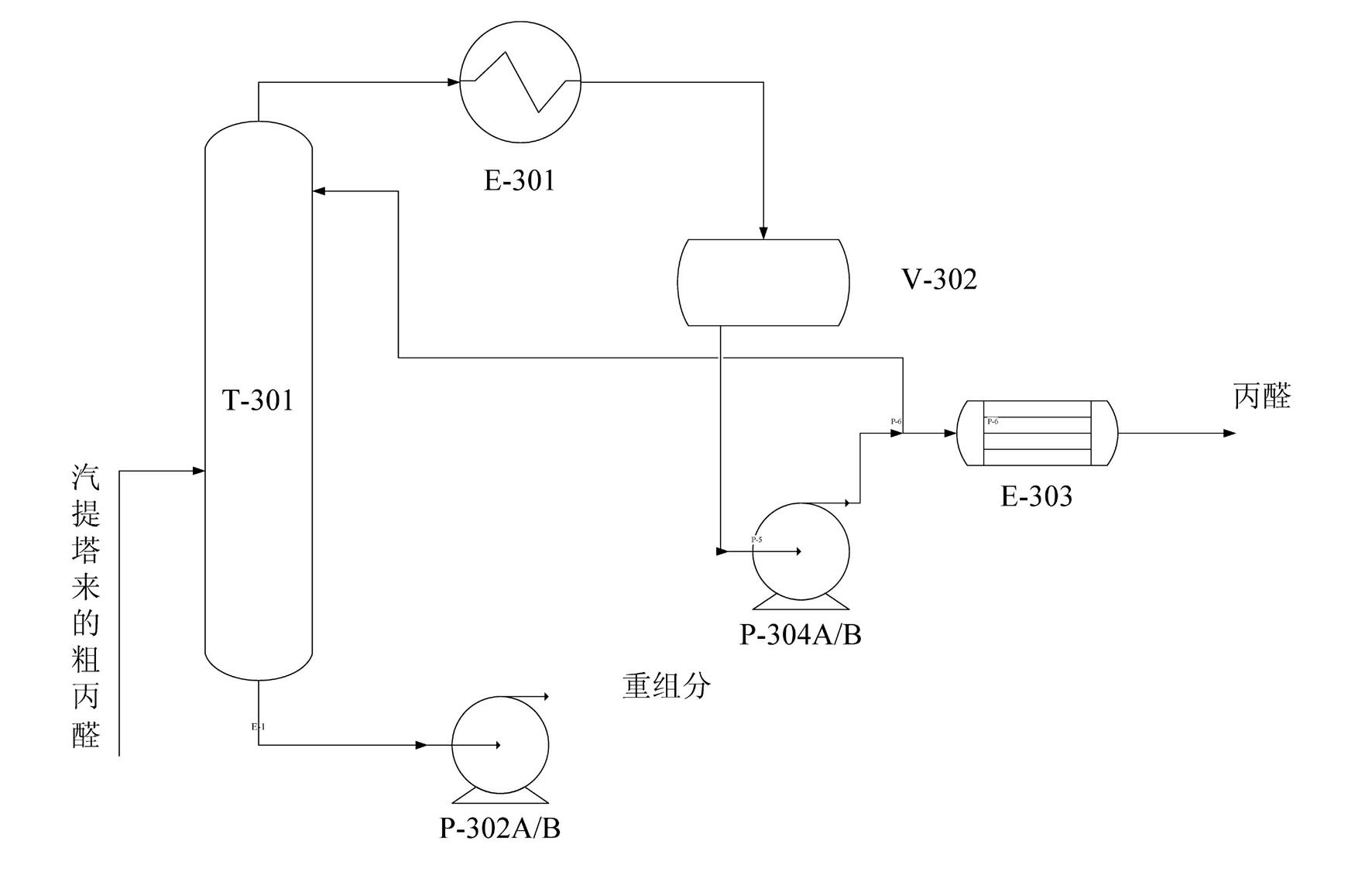

Synthesis method of propionaldehyde by low-pressure carbonyl of ethylene

ActiveCN102115433AReduce consumptionLess investmentPreparation by carbon monoxide reactionPhosphoniumFormylation reaction

The invention provides a synthesis method of propionaldehyde by low-pressure carbonyl of ethylene, belonging to a preparation method of saturated compound which contains -CHO group and is connected with a noncyclic carbon atom. The synthesis method comprises the steps of: taking ethylene, carbon monoxide and hydrogen as raw materials, adopting a rhodium / phosphonium complex catalyst system, and synthesizing the propionaldehyde by ethylene hydrogen formylation reaction. The synthesis method is characterized by comprising a synthesis operating unit and a rectification operating unit, wherein thesynthesis operating unit comprises a compressor, a synthesis reactor, a coarse propionaldehyde collecting tank and a gas stripping column; an entrainment separator is respectively arranged above the synthesis reactor and the coarse propionaldehyde collecting tank; and an iron-free propionaldehyde solution catalyst system of metal rhodium catalyst and ligand triphenylphosphine is used, the rhodiumconcentration in the catalyst solution is 80ppm-150ppm, and the weight percentage concentration of the triphenylphosphine is 1.5%-3%. The synthesis method of the propionaldehyde by the low-pressure carbonyl of the ethylene is simple in equipment, less in investment, simple in technological operation, and small in catalyst consumption. Counting as the ethylene, the raw material conversion rate is more than or equal to 90%, and the propionaldehyde product content is more than or equal to 99.5%.

Owner:南京诺奥新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com