Synthesis method of propionaldehyde by low-pressure carbonyl of ethylene

A technology for oxo synthesis and propionaldehyde, applied in carbon monoxide reaction preparation, organic chemistry and other directions, can solve the problems of cumbersome process operation, large equipment investment, catalyst loss, etc., and achieve the effect of simple separation equipment, reduced equipment investment, and improved conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

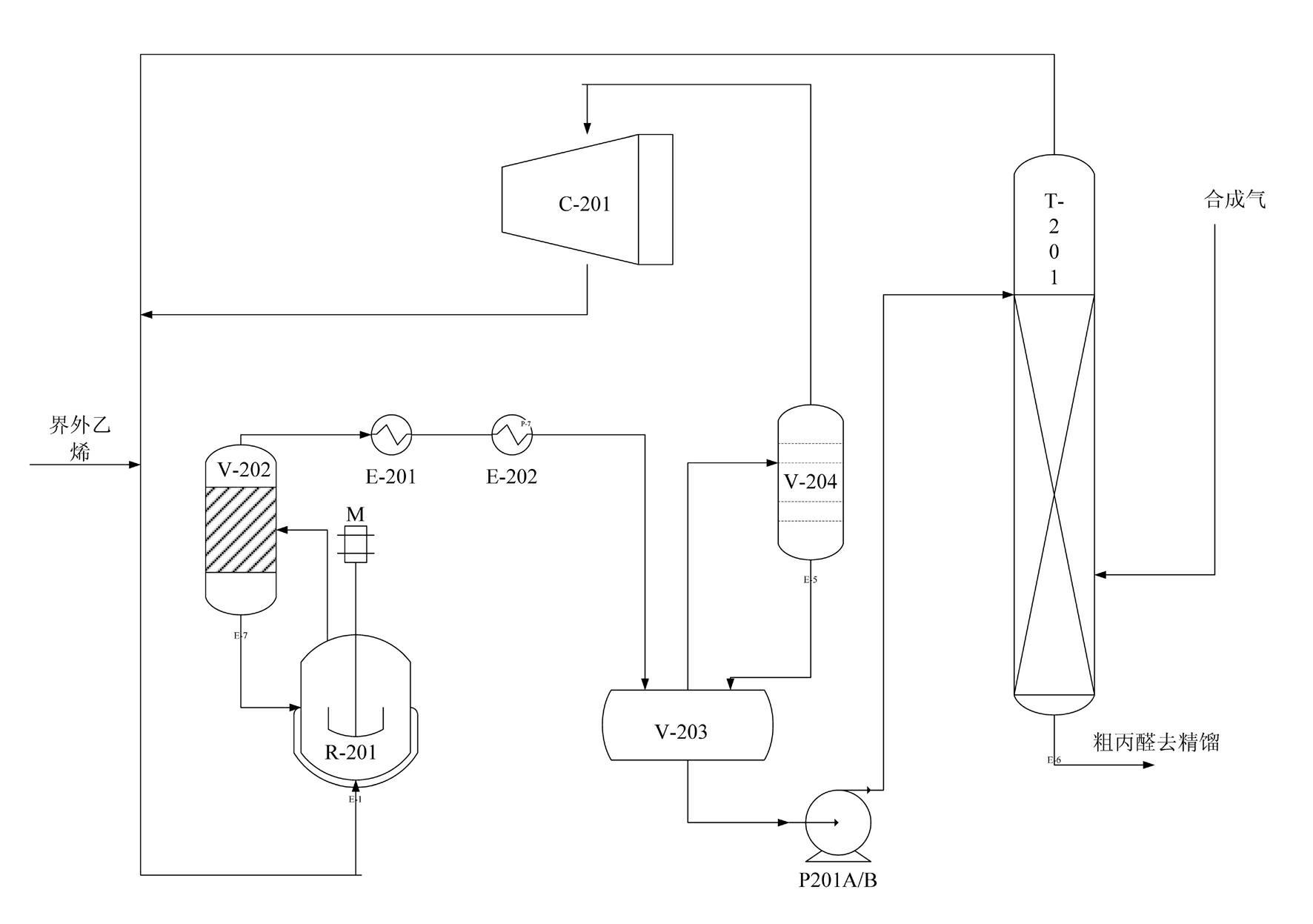

[0035] combine figure 1 The present invention is described in detail:

[0036] After the ethylene in the boundary area is mixed with the raw synthesis gas passing through the stripping tower and the circulating gas from the circulating gas compressor, it enters the carbonylation reactor through the stainless steel injection ring installed at the bottom of the carbonylation reactor R201, and then is stirred to achieve a good Dispersion to improve the mass transfer effect of the gas in the reaction solution, the reaction temperature is 80 ° C, the reaction pressure is 1.5 Mpa, the catalyst is metal rhodium catalyst, the ligand is triphenylphosphine, the solvent is iron-free propionaldehyde, and the catalyst solution is The rhodium concentration was 100 ppm and the triphenylphosphine concentration was 2.0%. This reaction is an exothermic reaction, part of the reaction heat is removed by the coil in the reactor, and the other part of the heat is taken out by the circulating g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com