Patents

Literature

41141results about How to "Less investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

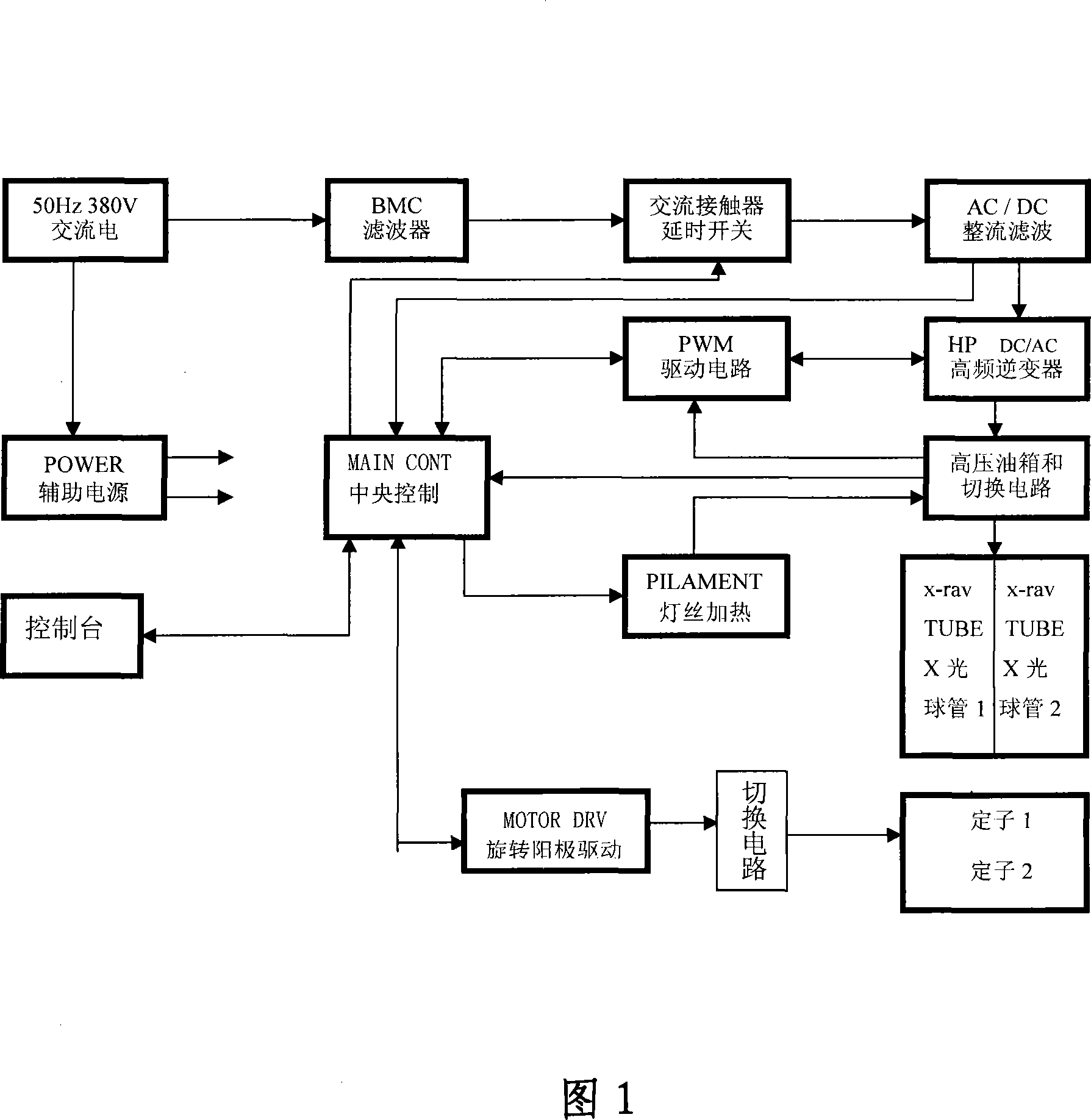

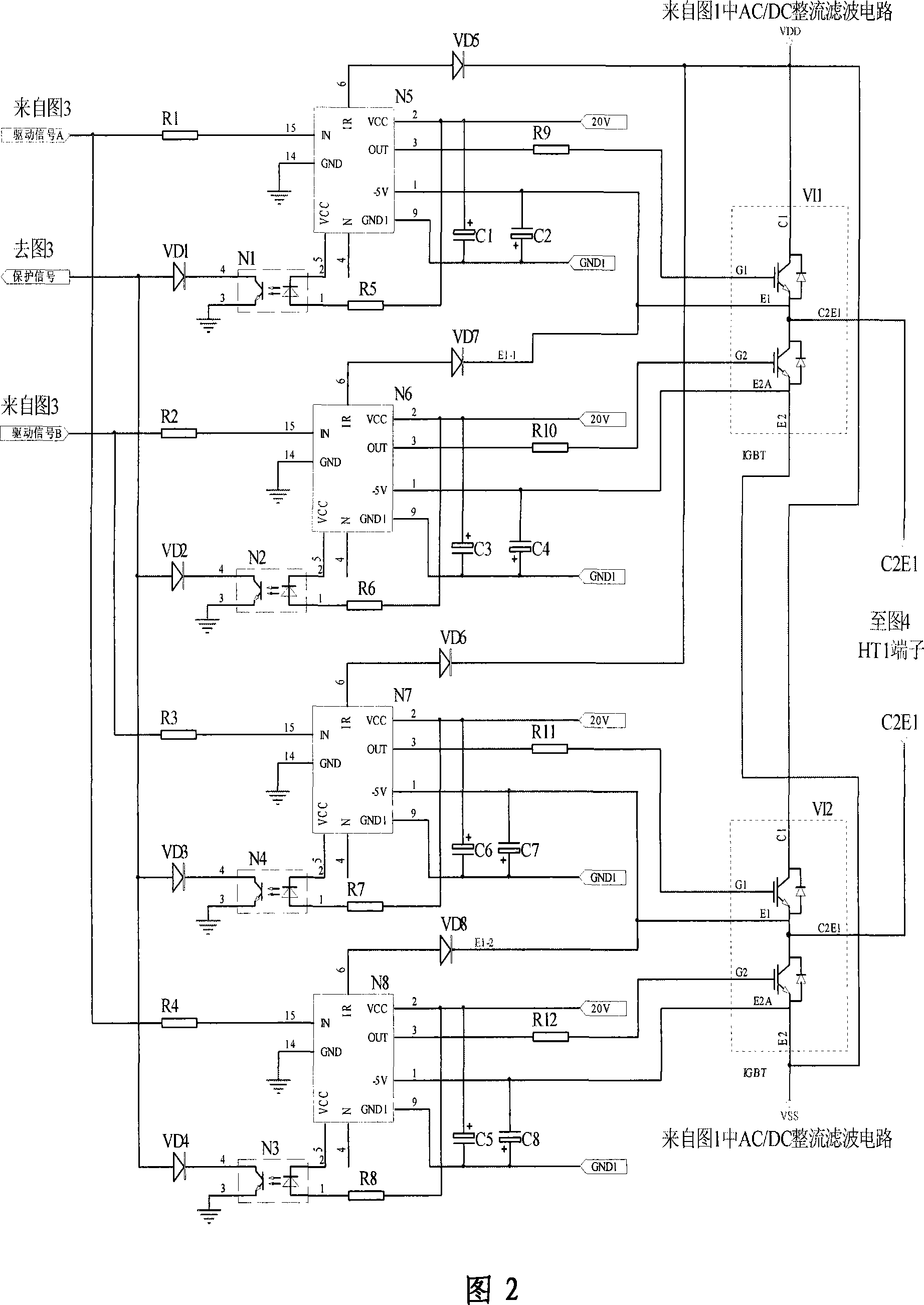

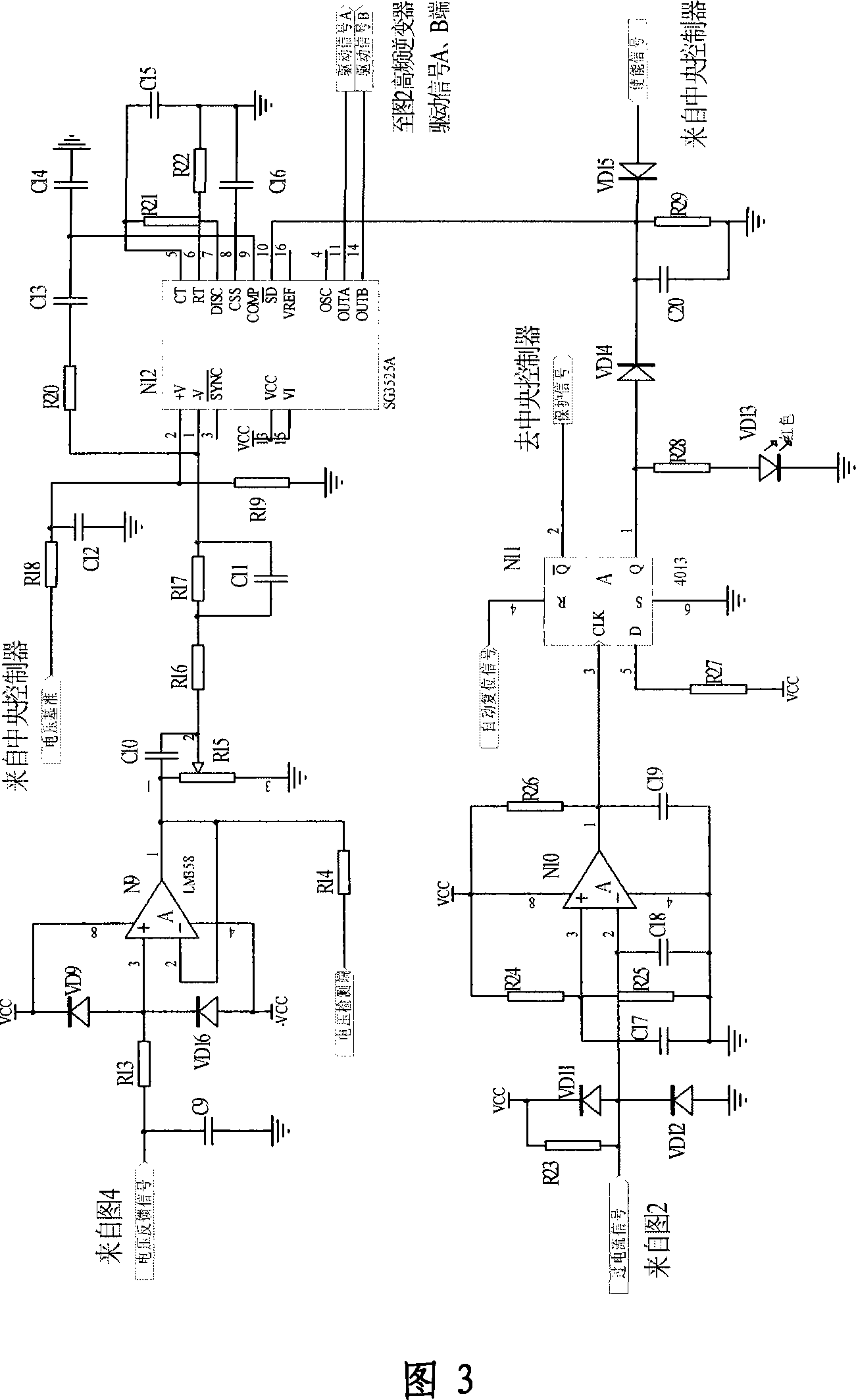

Medical diagnosis X radial high-frequency and high-voltage generator based on dual-bed and dual-tube

ActiveCN101188900ASolve the problem of shift workImprove clarityAc-dc conversionX-ray apparatusX-rayEngineering

The invention discloses a two-bed duplex tube medical diagnosis X-ray high frequency high voltage generator, which comprises a power supply and a central control unit, and also comprises a high frequency inverter circuit, a pulse-width modulation drive circuit and a high voltage commutation circuit. The generator converts the industrial power supply into two way high frequency high voltage, and then obtains positive end DC high voltage and negative end DC high voltage after the rectification and the filter to supply an X-ray pipet for working. Because the frequency is high and the high voltage ripple after the rectification and the filter is minimum, causing the X-ray pipet of a radiographic table and the X-ray pipet of an electric perspective table to work in turn under the condition of arranging only one set of high voltage supply. The equipment investment is saved, and the work of using the X-ray diagnosis for the medical staff is convenient. Being served as the high voltage supply, the invention is also suitable for the safety detection fields such as the industrial fault detection, the civil aviation, the station, the custom, etc., and supplies the stable high quality high voltage for the equipment.

Owner:广西道纪医疗设备有限公司

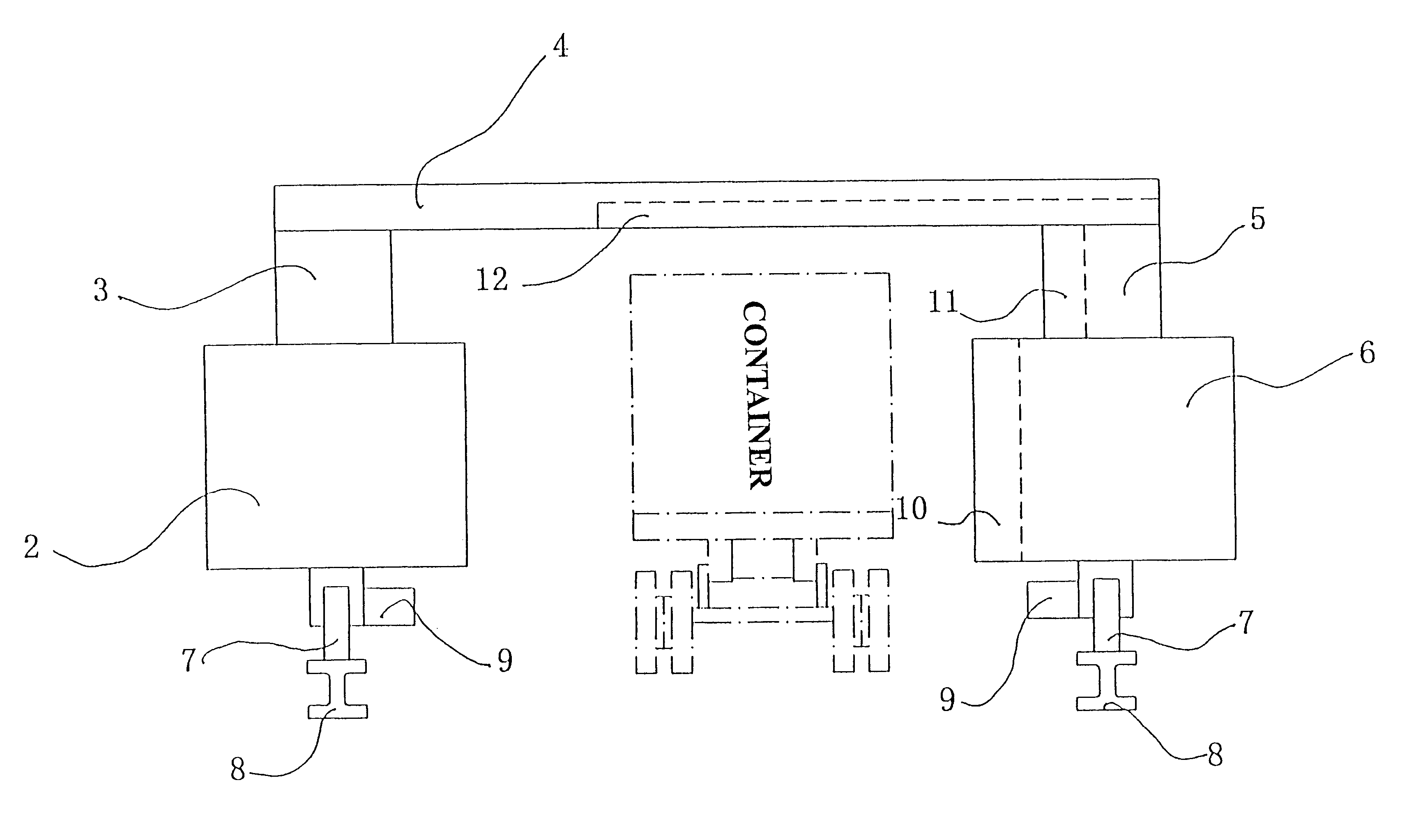

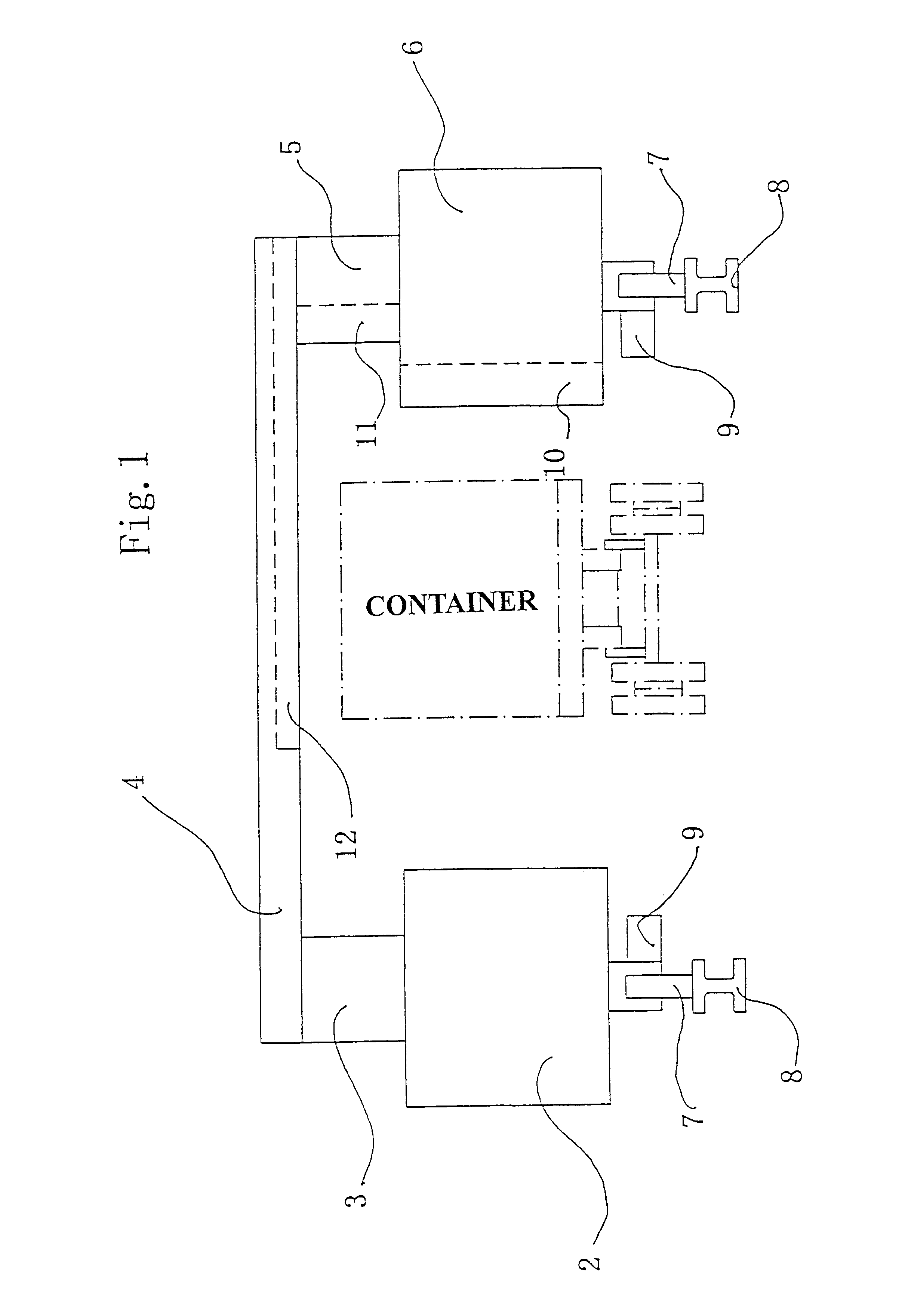

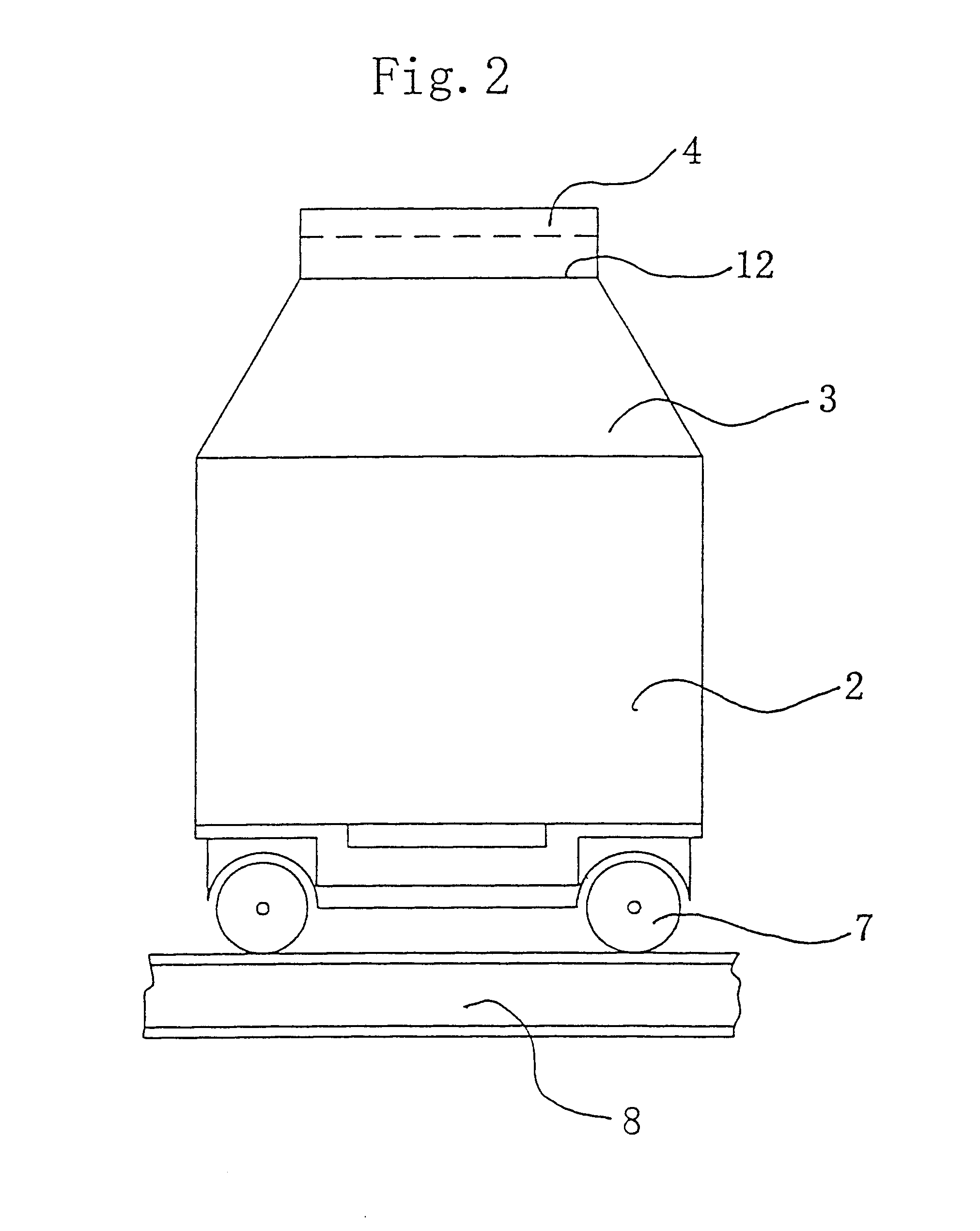

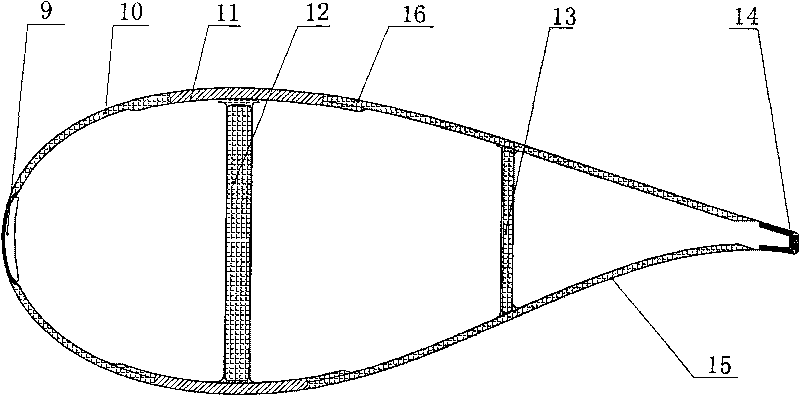

Container inspection apparatus

InactiveUS6563903B2Easy to disassembleEasy to moveUsing wave/particle radiation meansMaterial analysis by transmitting radiationContinuous scanningModular unit

A relocatable container inspection device, which is constituted by modularized units, is used for inspecting a container. The device comprises: a first cabin unit including a radiation source for generating a beam of penetration radiation for penetrating the container to be inspected; a second cabin unit including detectors for detecting the beam of penetration radiation penetrating through the container being inspected and producing corresponding radiographic signals, the second cabin unit and the first cabin unit being arranged oppositely in both sides of an inspection passage; a gantry unit bridging the first cabin unit and the second cabin unit to form a portal-shaped frame adapted for straddling the container being inspected; means for moving the frame relative to the container being inspected along the inspection passage, so that the detectors receive the beam of the penetration radiation generated from the radiation resource and passing through the container being inspected, thereby continuously scanning the container and producing the corresponding radiographic signals, wherein the first cabin unit, the second cabin unit and the gantry unit are all individually made as modular units so as to be quickly and easily assembled and disassembled with each other on the inspection site. In the present invention, all of the modularized units of the container inspection device can be easily assembled and disassembled in the work field, and the dimensions of each modular unit are sized to be suitable for road transports and to be facilitate for the device's movement.

Owner:TSINGHUA UNIV +1

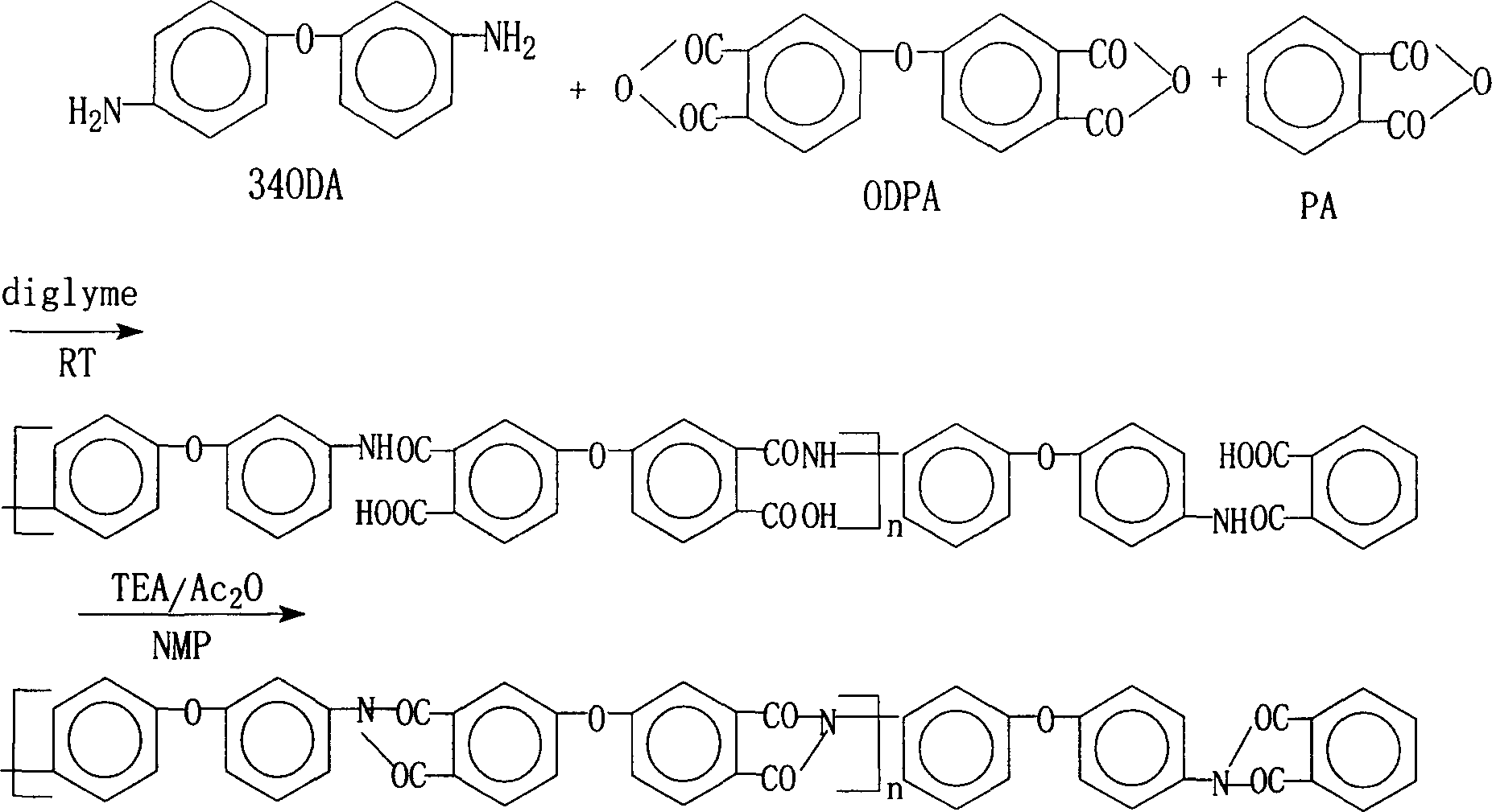

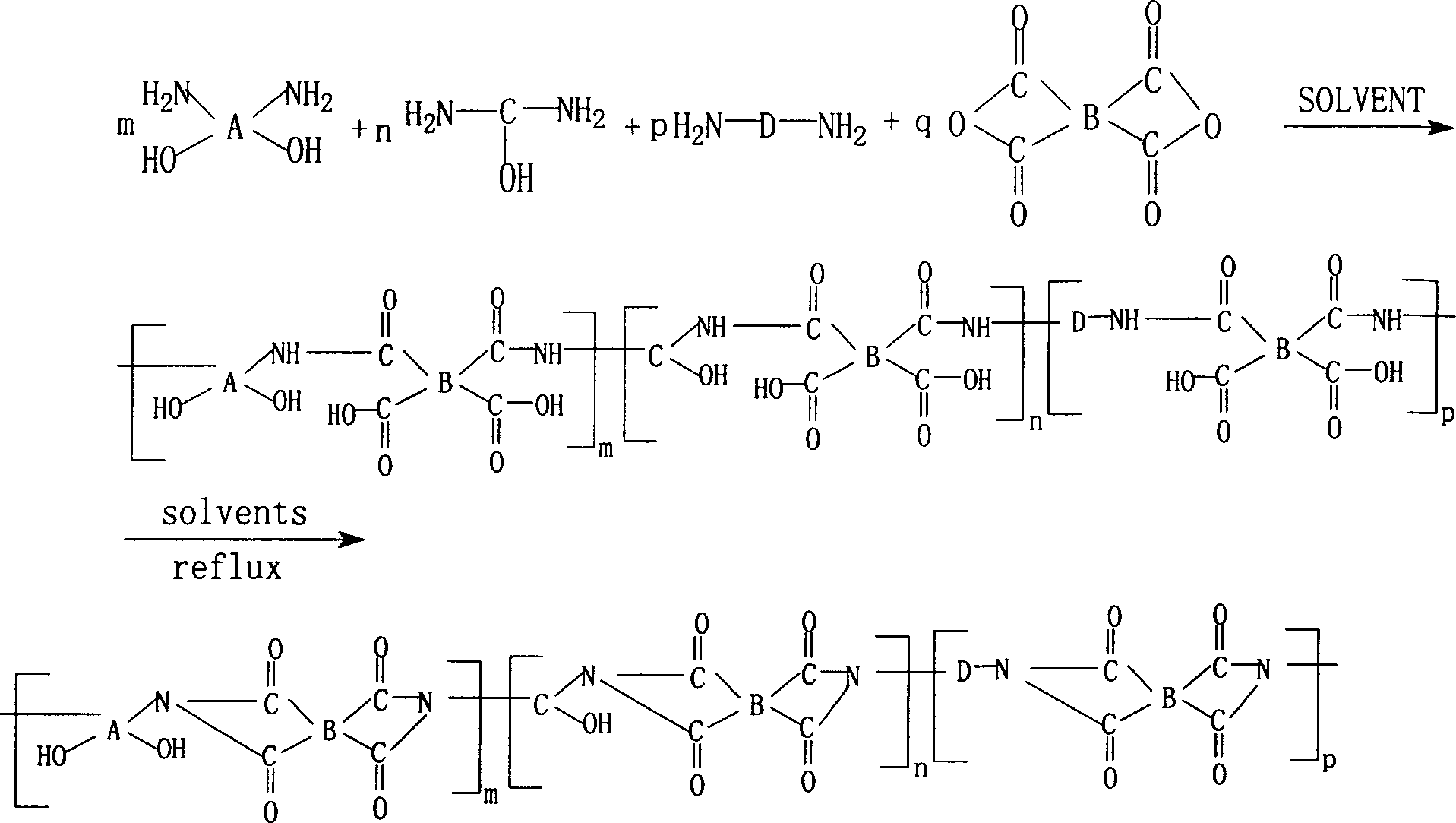

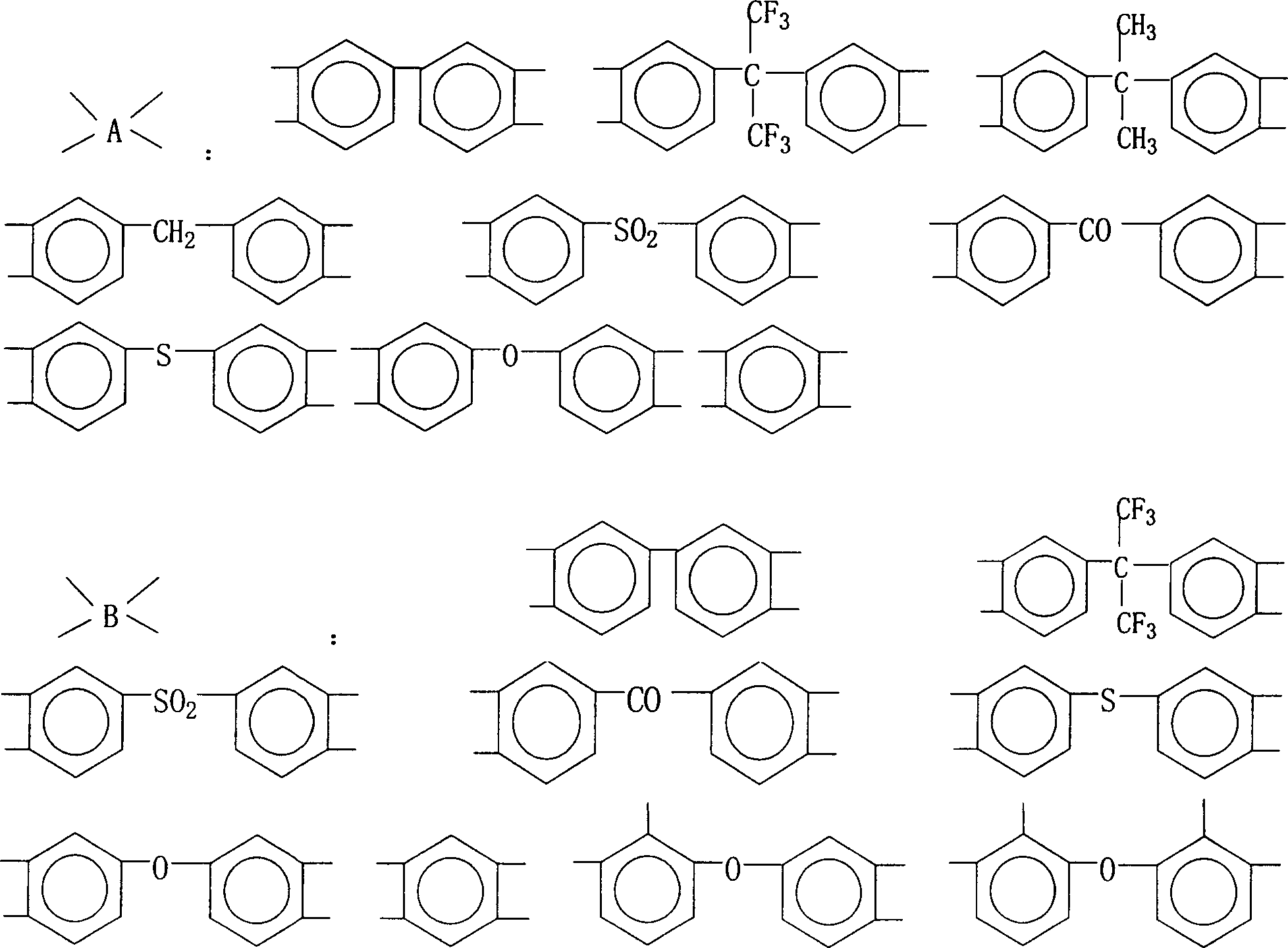

Preparation method of phenolic hydroxyl group containing polyimide powder

The preparation process of phenolic hydroxyl group-containing polyimide powder includes the following steps: 1. reaction of phenolic hydroxyl group-containing aromatic diamine compound or its mixture with other diamine compound and aromatic binary anhydride in the molar ratio of 1 to 1 in strong polar non-protonic organic solvent under protection of nitrogen at 0-30 deg.c for 3-12 hr to obtain transparent ropy polyhydroxy amido acid solution; and 2. adding azeotropic dewatering agent in nitrogen atmosphere and heating to 120-160 deg.c to reflux, azeotropically dewater and imidize for 5-18 hr, cooling to room temperature, washing and vacuum drying to obtain phenolic hydroxyl group-containing polyimide powder. The industrial production process has environment friendship, simple operation, low cost and easy solvent recovery.

Owner:DONGHUA UNIV

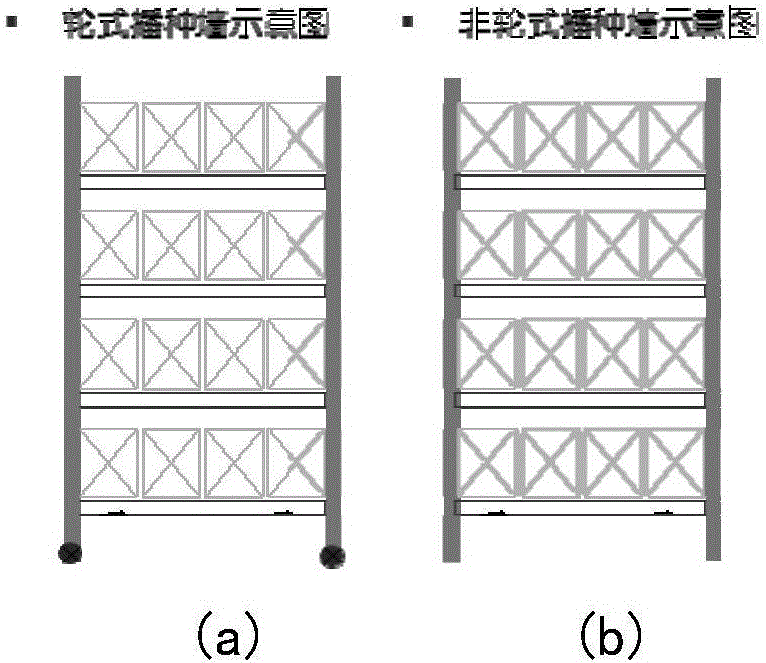

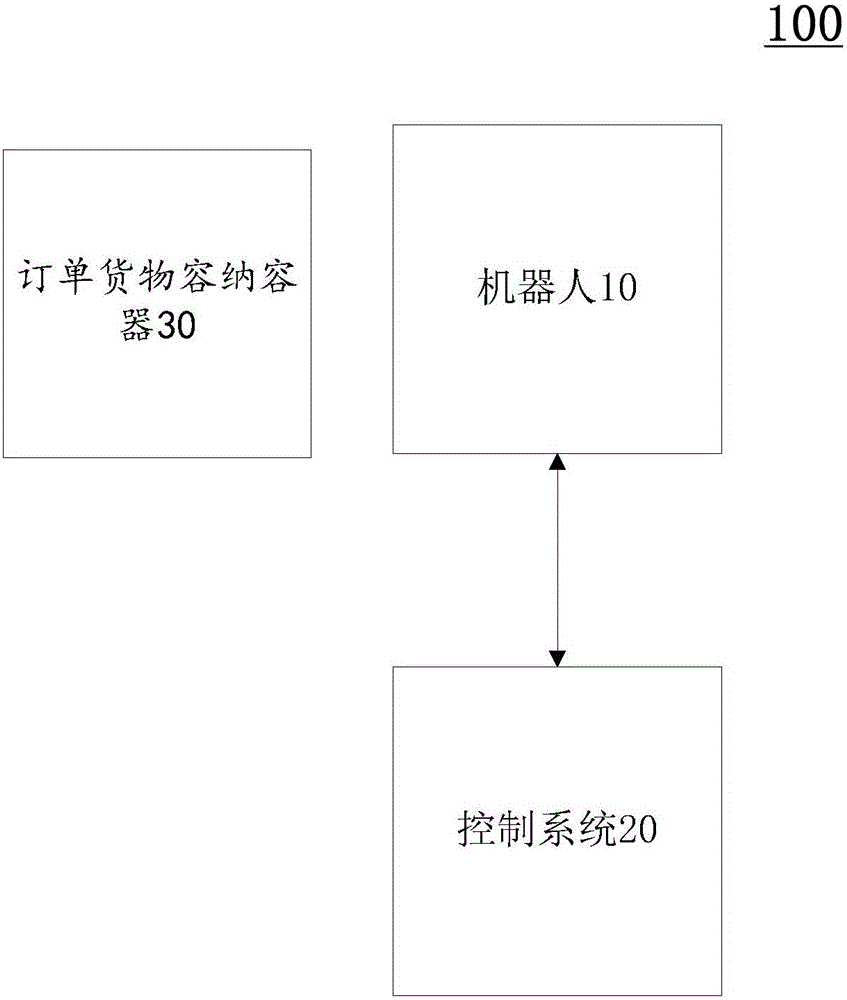

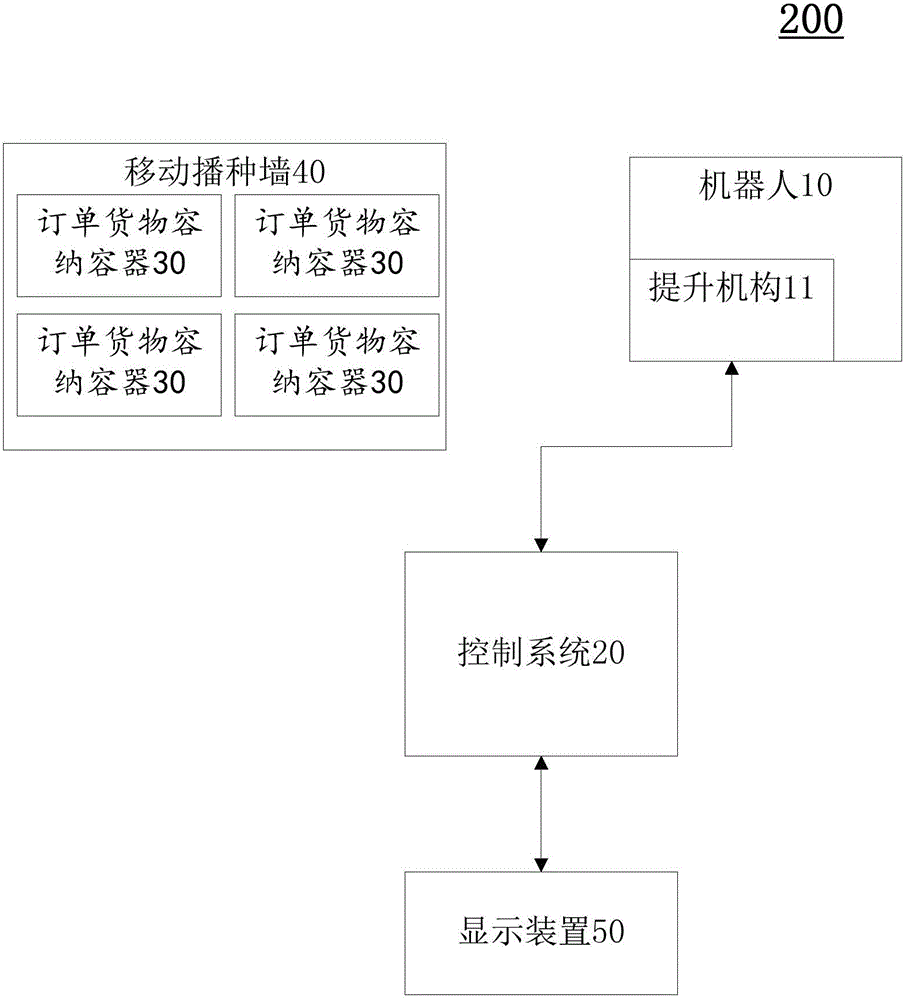

Automatic cargo picking system and automatic cargo picking method

Provided are an automatic cargo picking system and method. The automatic cargo picking system comprises a transfer robot, a control system and multiple ordered cargo containing containers; each ordered cargo containing container is arranged to contain one or more cargoes corresponding to an order; the control system and the transfer robot conduct wireless communication, the automatic cargo picking process comprises the steps that the control system distributes a task order for the transfer robot; the transfer robot obtains empty ordered cargo containing containers, transfers the ordered cargo containing containers to all cargo placing areas where the cargoes corresponding to the order are located to collect the cargoes and transfers the ordered cargo containing containers which complete cargo picking to the designated place. An automatic cargo picking technology is a scheme that the orders are assigned to people, and an original cargo shelf can be used; the cargo-to-people mode can adopt the method of conducting full container and full tray cargo storing on the original cargo shelf, and therefore the problem of frequent shelving is solved; the intelligent transfer robot is utilized for replacing manual transferring, and the labor intensity of picking personnel is reduced.

Owner:BEIJING JIZHIJIA TECH CO LTD

Manufacturing method for carbon fiber antenna surface

The invention relates to a manufacturing method for a carbon fiber antenna surface. The manufacturing method comprises the following steps of 1, prefabricating a die; 2, polishing the die; 3, chemically electroplating the die; 4, measuring the precision, and clearing away impurities; 5, coating a demolding agent; 6, paving carbon fiber cloth on a male die; 7, paving PVC foams on the surface of the male die; 8, paving carbon fiber cloth on the surface of the male die; 9, assembling the male die and a female die, and sealing and fastening the male die and the female die; 10, vacuumizing to enable the vacuum degree in the die to be smaller than -0.096MPa; 11, injecting epoxy resin and a solidifying agent from a material inlet of the female die; 12, sticking a layer of glass paper to the outer surface of a blank after the appearance gets through inspection and is qualified; 13, performing perforation and assembling; and 14, obtaining the carbon fiber antenna surface after the product is qualified through inspection. The carbon fiber antenna surface manufactured by the manufacturing method is smooth, and the precision can reach 0.1R.M.S; and due to normal-temperature solidification, energy is saved, and the cost is lowered.

Owner:XIAN TUOFEI COMPOSITE MATERIAL

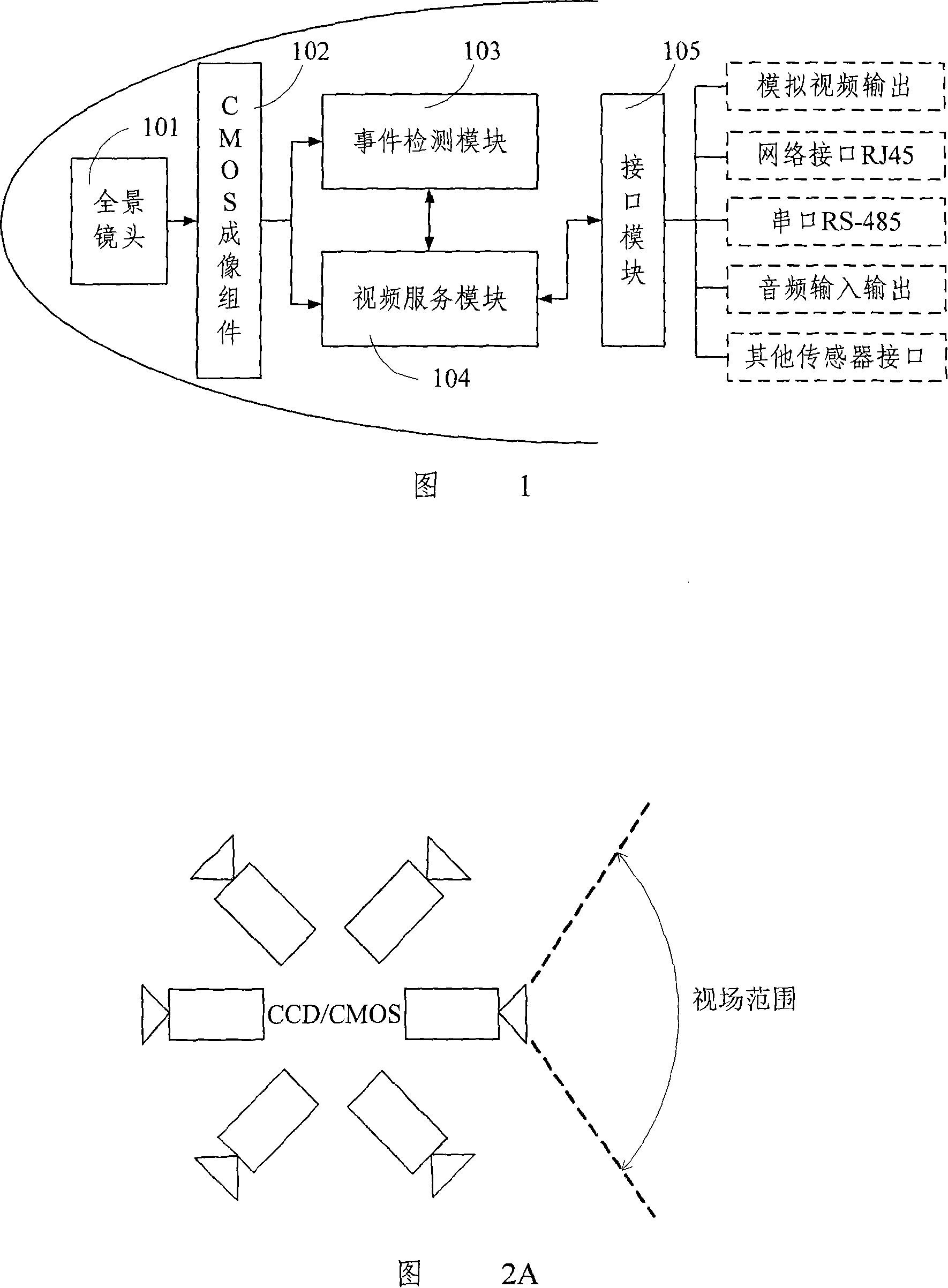

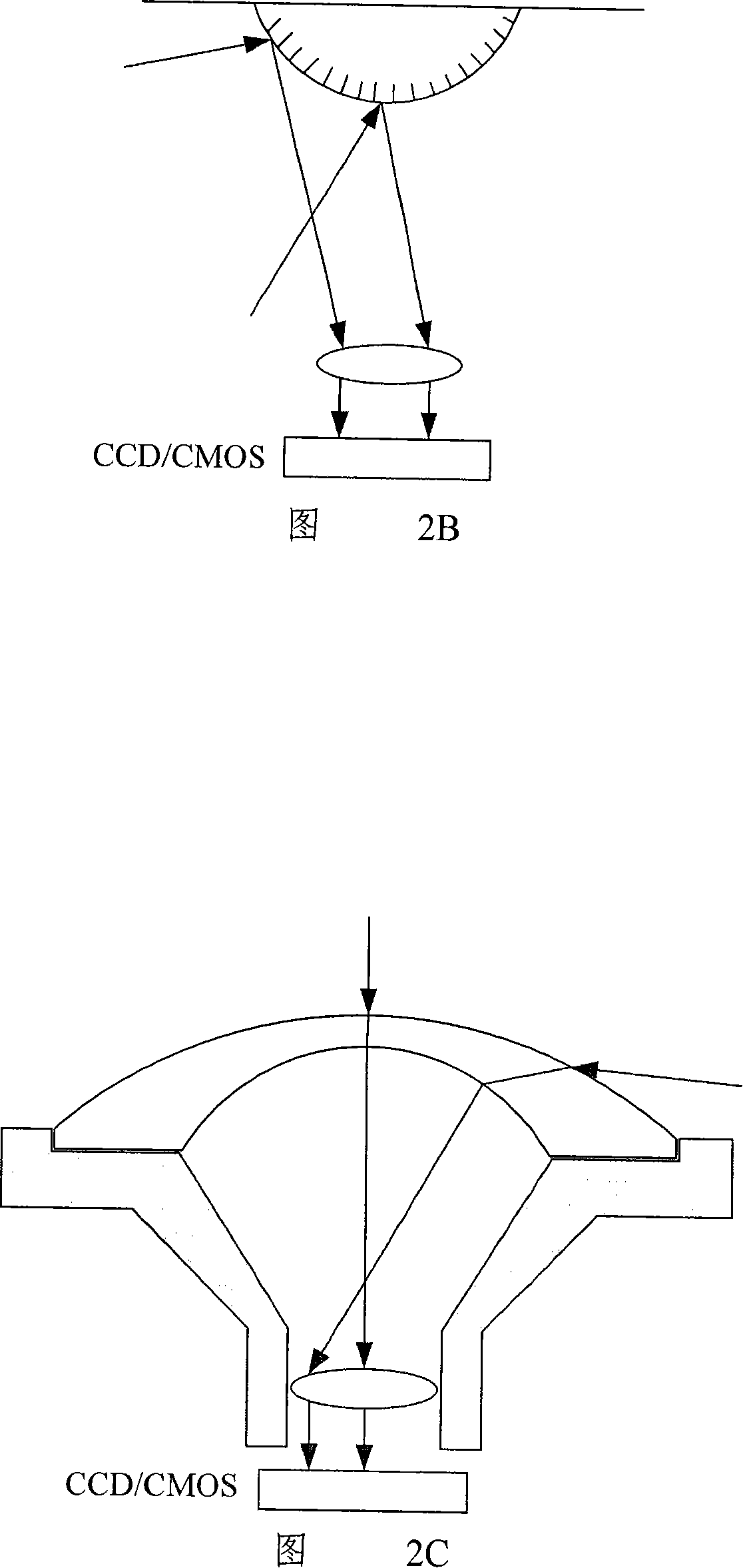

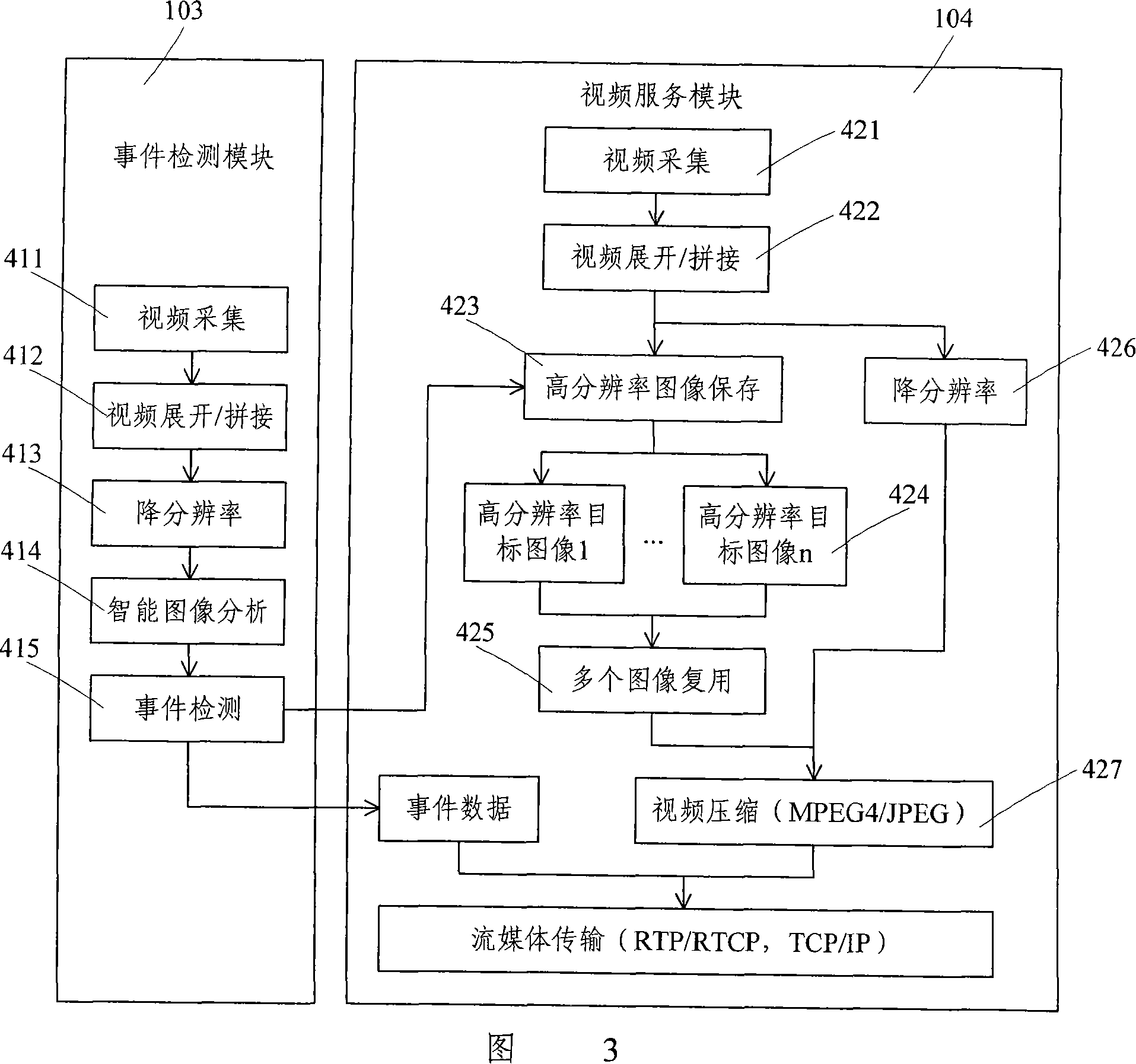

Overall view monitoring method and apparatus

InactiveCN101119482ALess investmentLower requirementImage analysisClosed circuit television systemsCamera lensMonitoring site

The present invention relates to a panorama monitoring method and device, wherein, the panorama camera lens and the imaging component are combined to get the panorama video frequency information of the monitoring scene, and the affair checking module is used for holding intelligent image analyzing for the panorama video frequency information, and according to the obtained intelligent analyzing result to judge whether having the affair to produce in accordance with the advancedly setting alarming condition, and producing affair checking report. The video frequency module is used for using the intelligent analyzing result to realize multi-aim suppositional PTZ following and providing a repeatedly used processing and transmission mechanism for the resolution aiming image, which not only solves the problem of seeing clearly and seeing fully, but also effectively reduces the requirement for the transmission belt width to realize high effective transmission. The interface module is used for applying all the interfaces for the connecting of panorama monitoring device and the outside. According to the proposal of the present invention, the present invention realizes continuously monitoring 360 degrees panorama space without missing out or missing any accident affair, realizing the intelligent monitoring without blind point and dead angle.

Owner:无锡安科兴业科技有限公司

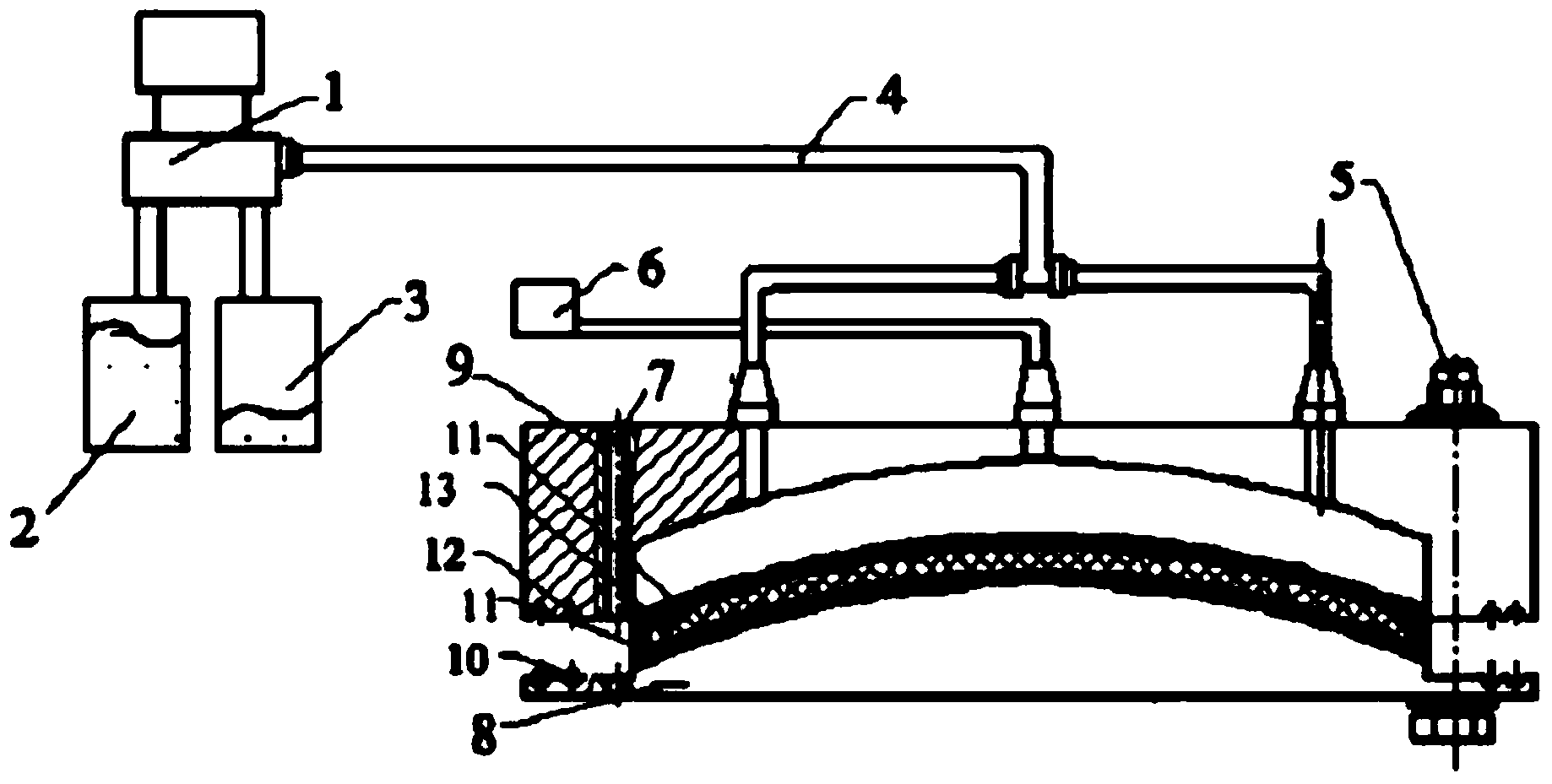

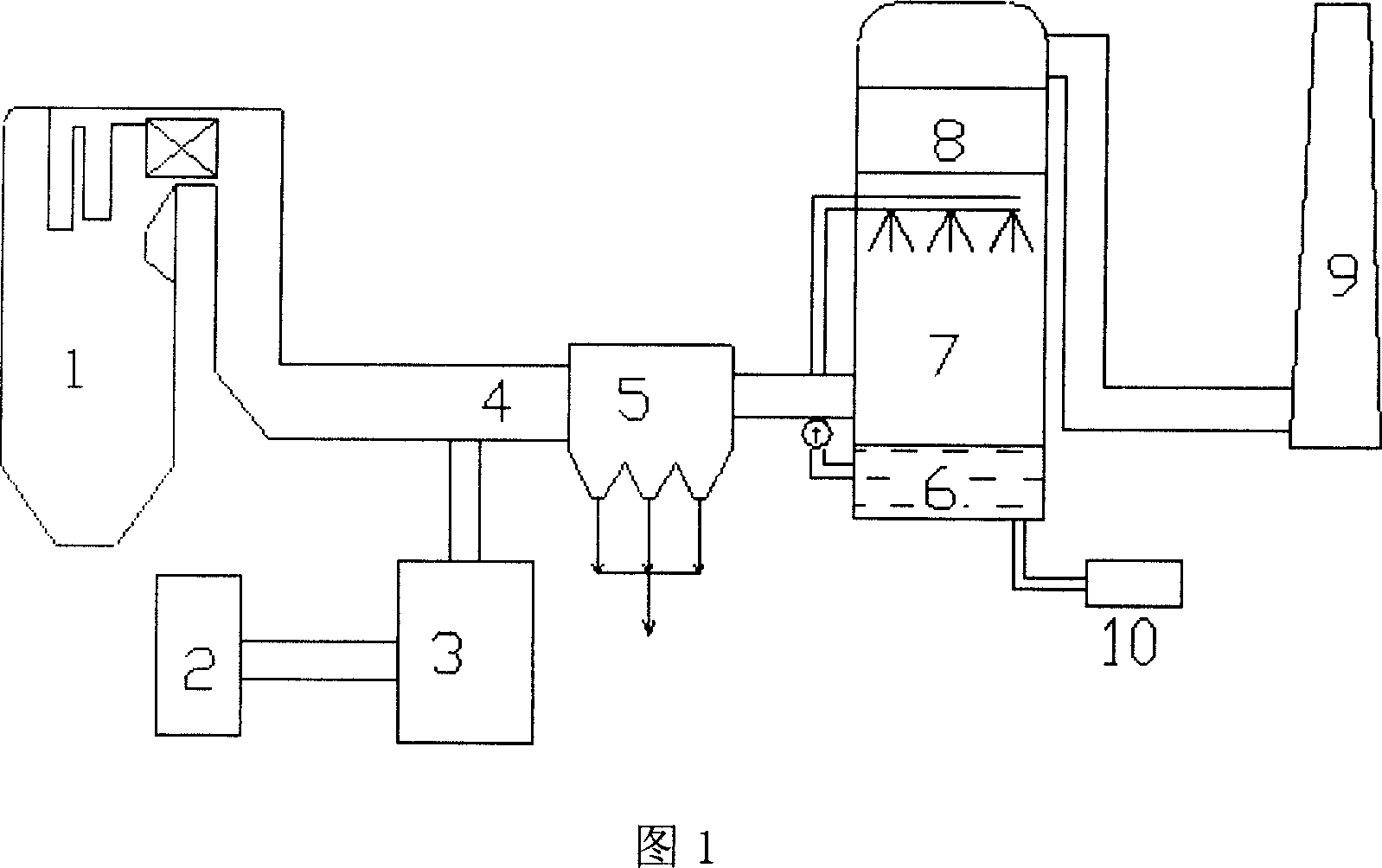

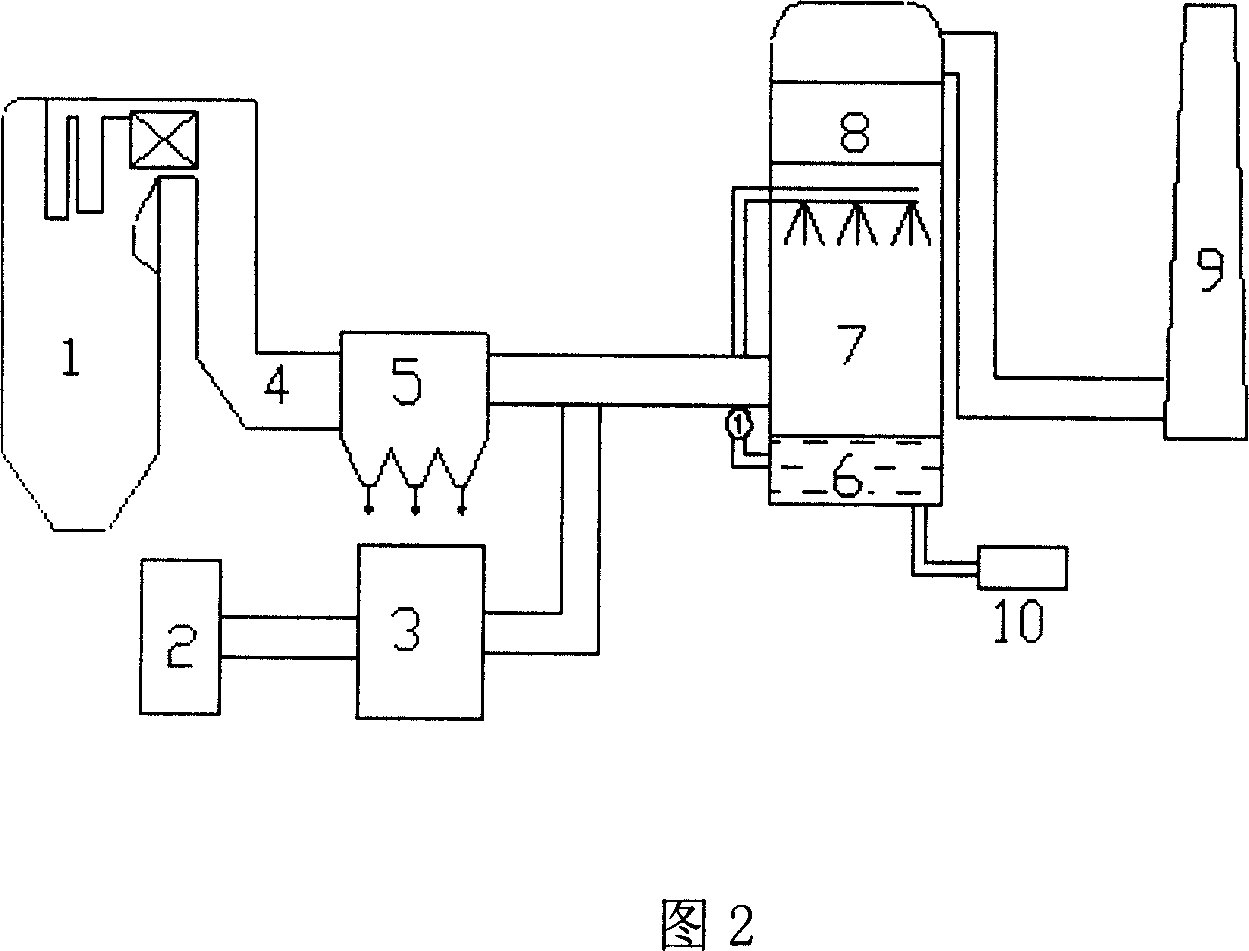

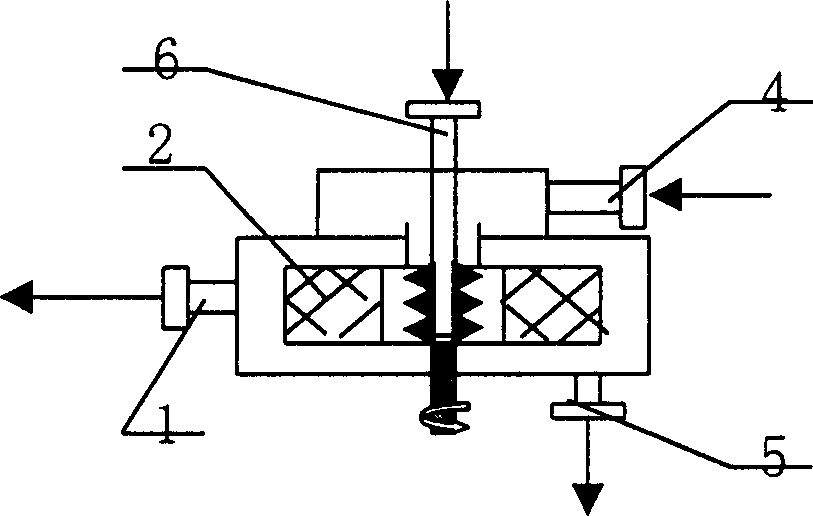

Device and method for coal-burning boiler fume ozone oxidation and simultaneous desulfurization and denitrification

InactiveCN1923341ALess investmentLow running costDispersed particle separationAir quality improvementFlueChemistry

The invention relates to a device for removing several pollutants of boiler smoke. Wherein, it comprises (1), before or after the static deduster 5 of smoke channel 4, ejecting into ozone O3 at low temperature section as 110-150Deg. C, while the ratio between ejected amount and nitrogen oxide is 0.5-1.5, to oxidize the low-level nitrogen oxide insoluble into soluble high-level nitrogen oxide, and the sulfur oxide is transformed into sulfur trioxide, and the reaction time is more then 0.5s; (3), feeding treated smoke into alkali washing tower 7 to wash, and absorbing high-level nitrogen oxide and sulfur oxide.

Owner:ZHEJIANG UNIV +1

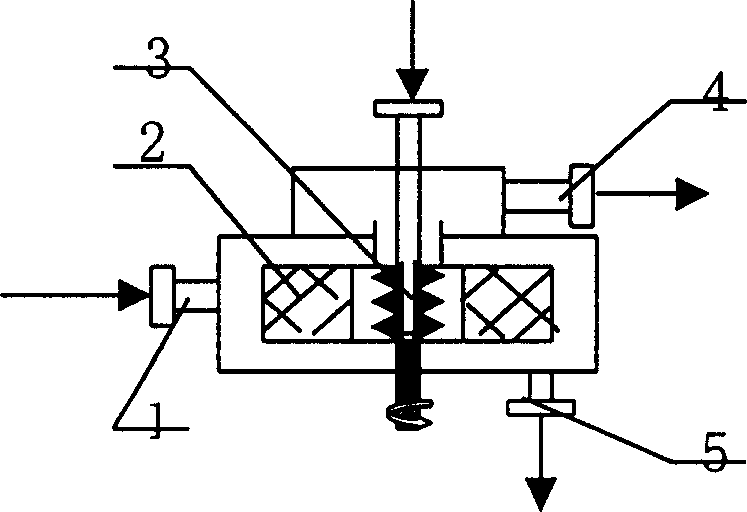

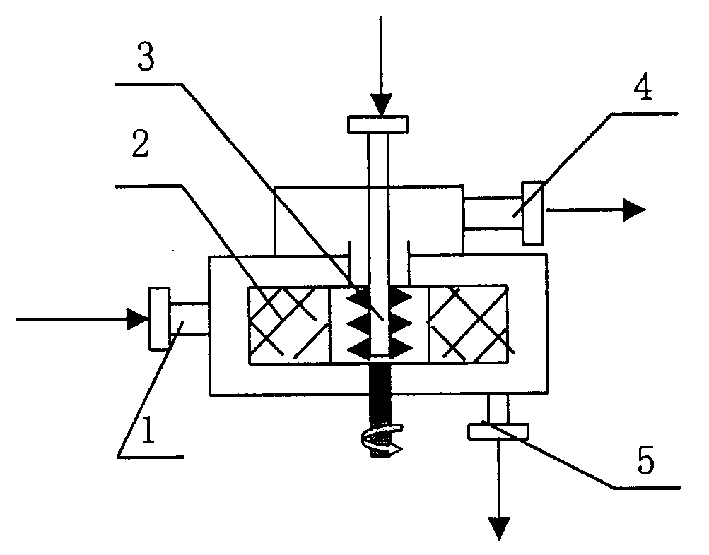

Catalytic reaction method

InactiveCN1507940AReduce dosageIncrease profitChemical/physical/physico-chemical moving reactorsPorous catalystMulti phase

The present invention discloses a catalytic reaction method. Said method can make the catalytic reaction be implemented in the supergravitational field. Said method utilizes the rotary bed supergravitational field equipment as reactor, on the rotor of said rotary bed supergravitational field equipment a porous catalyst layer and / or a porous filler layer are fixed, and the described catalytic reaction is homogeneous reaction or heterogeneous reaction. Said invention cal reduce catalyst consumption, raise utilization rate of catalyst, raise stability of catalyst and can reduce denergy consumption, etc.

Owner:CHINA PETROLEUM & CHEM CORP +2

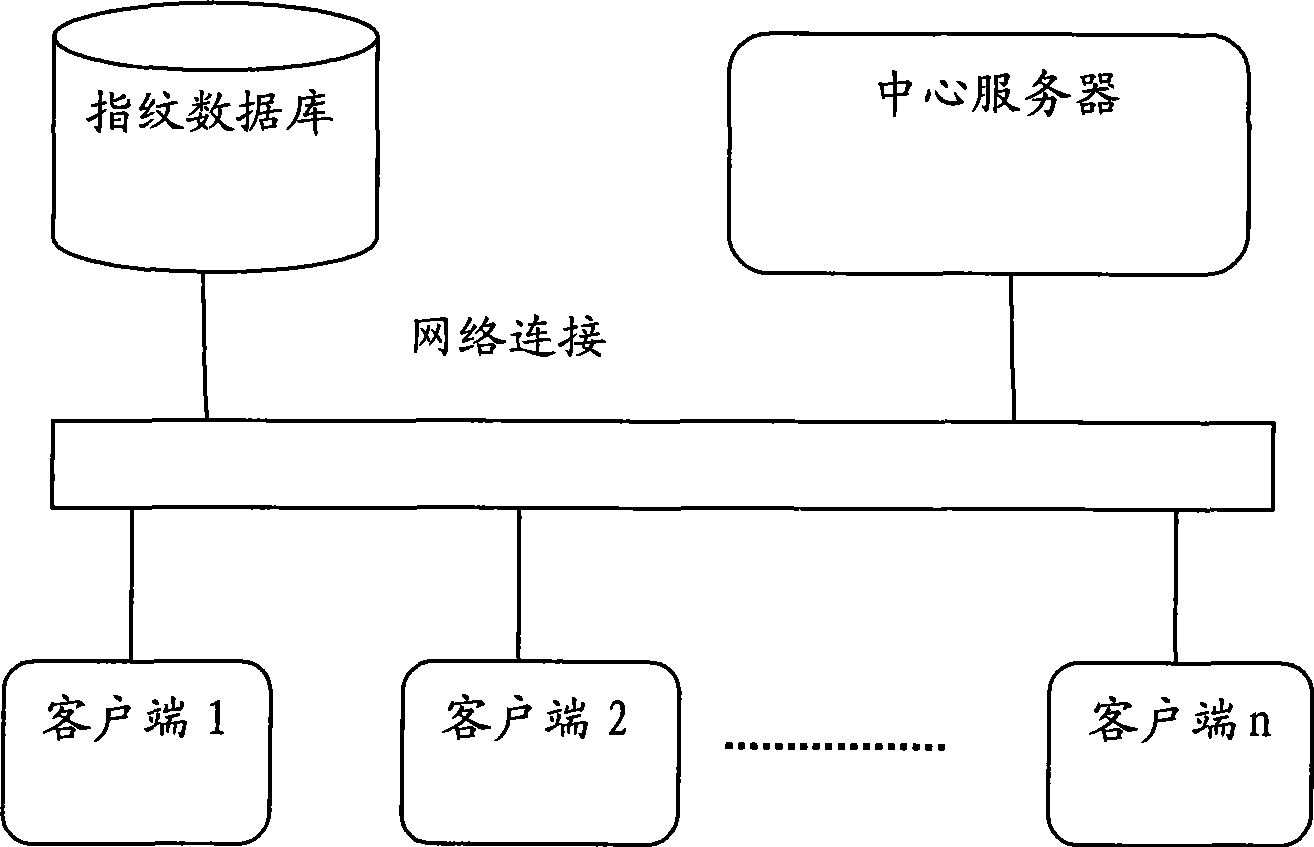

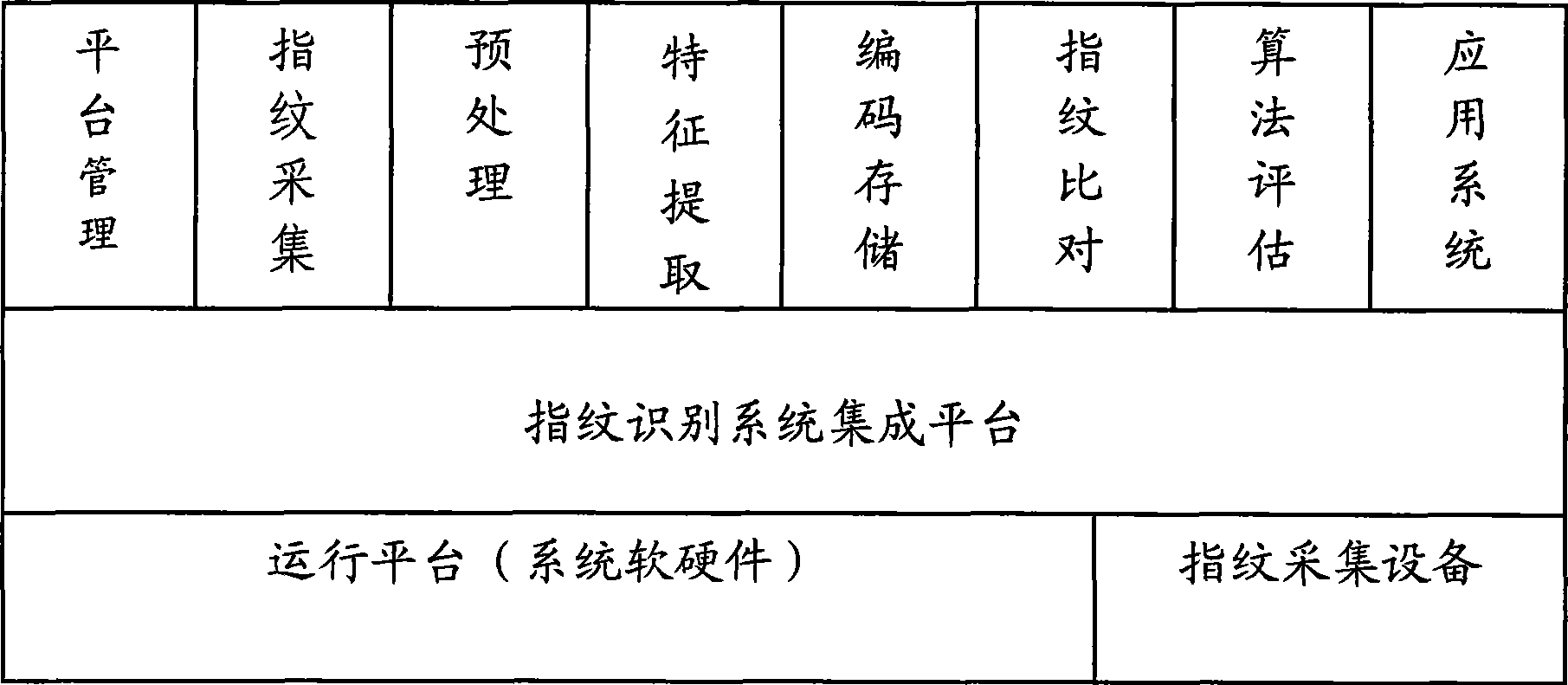

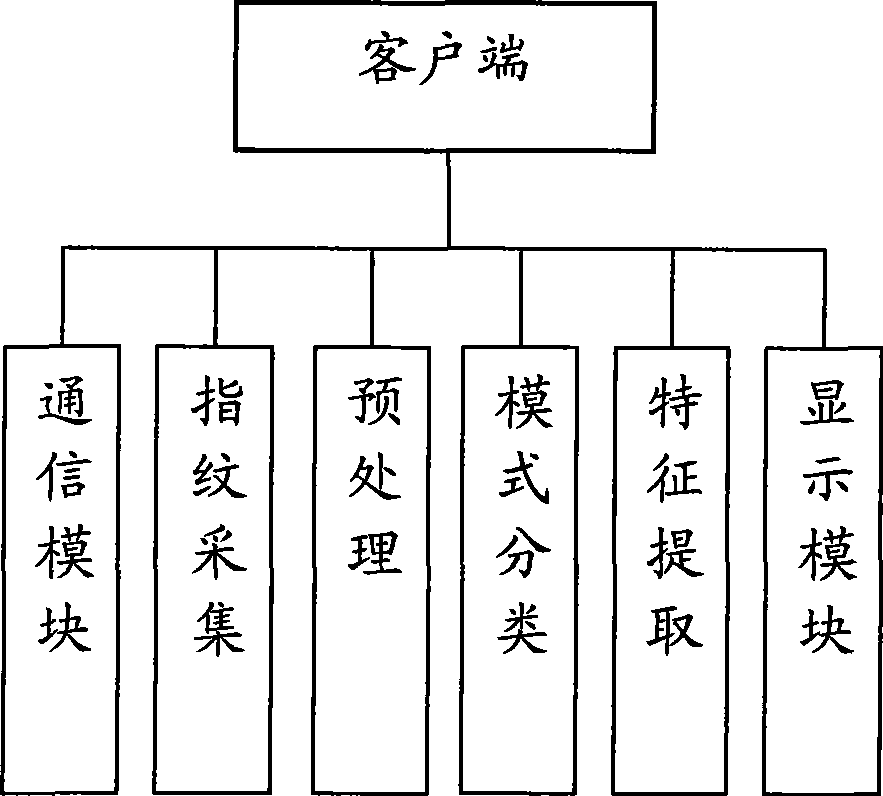

Fingerprint recognition system and control method

InactiveCN101414351AAvoid accessEasy constructionUser identity/authority verificationCharacter and pattern recognitionCapital investmentFingerprint database

The invention discloses a fingerprint identifying system which comprises three large parts of a fingerprint database, a central server and a client terminal; the fingerprint database is mainly used for memorizing the fingerprint characteristic information after digital coding; the central server is mainly responsible for validating the validity of the client terminal, receiving the fingerprint characteristic data, comparing the characteristics and returning the fingerprint identifying result; the client terminal is mainly responsible for collecting the fingerprint, extracting and uploading the fingerprint characteristic data. The system overcomes the defects of the prior art, can provide an online / offline fingerprint identifying system the basic algorithm library of which can be seamlessly expanded and the functions of which can be selected and matched. The fingerprint identifying system can lead a user to obtain the ID identification and authentication services with high quality under the situation of not needing a great amount of capital investment.

Owner:章毅 +2

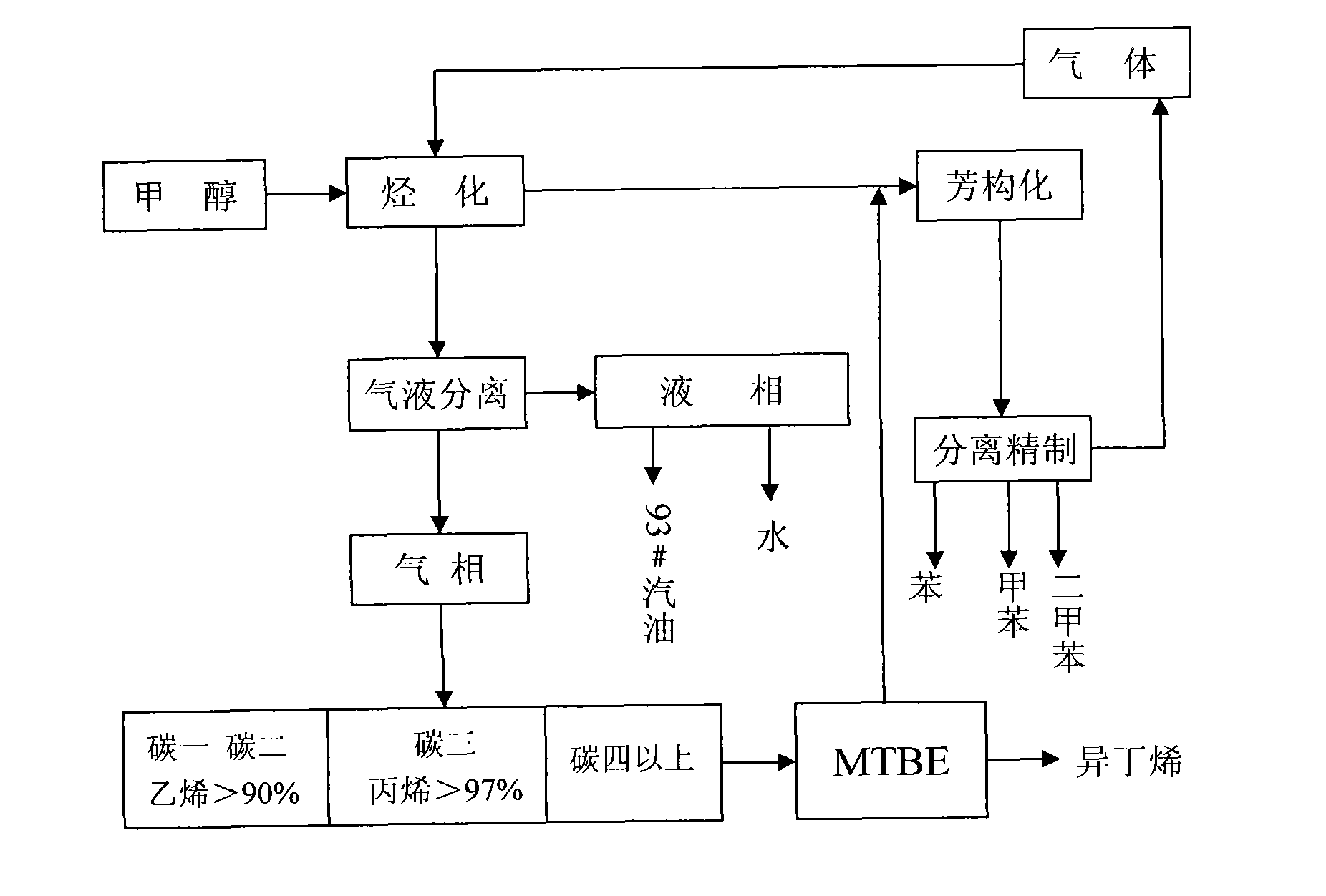

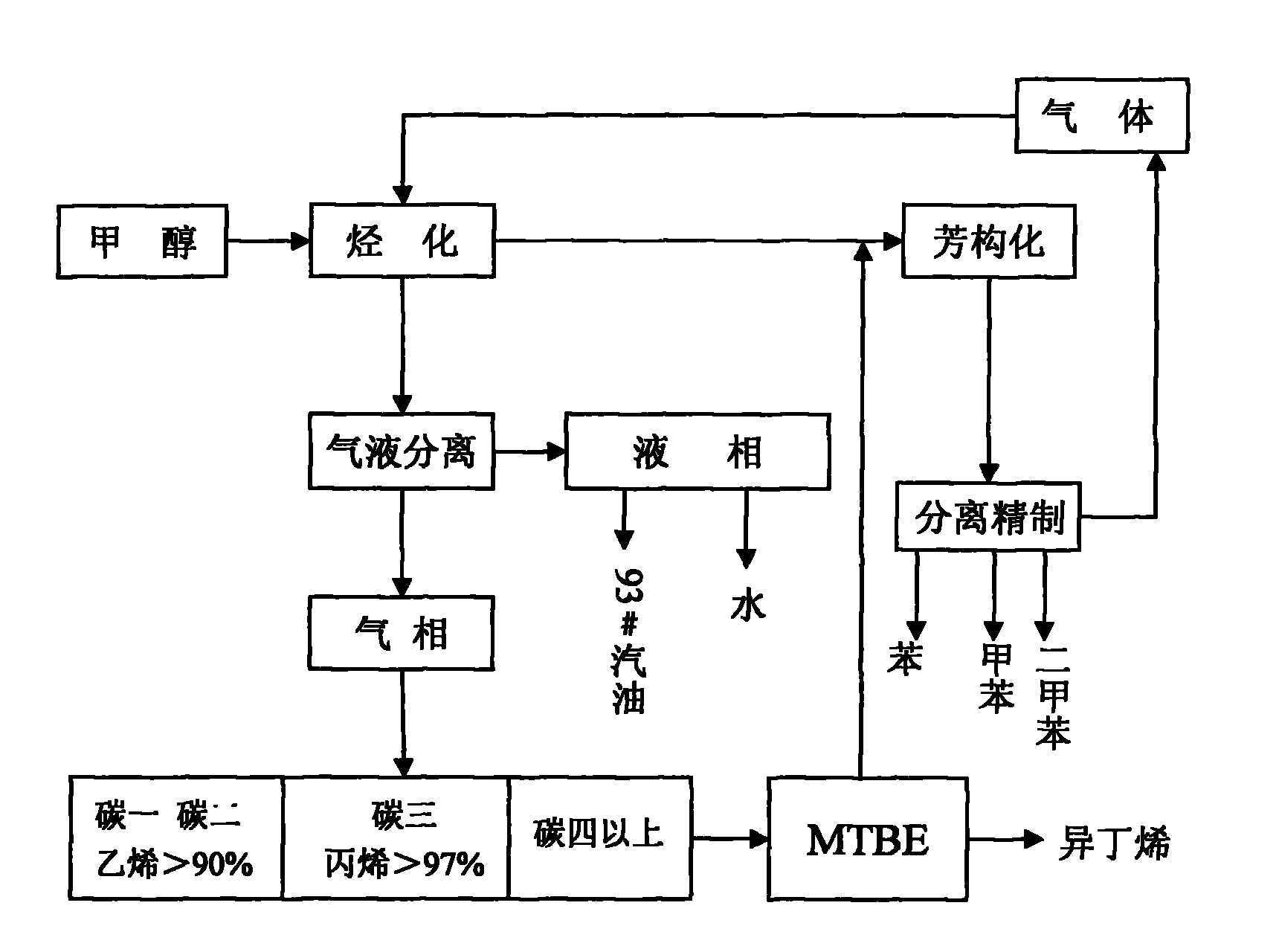

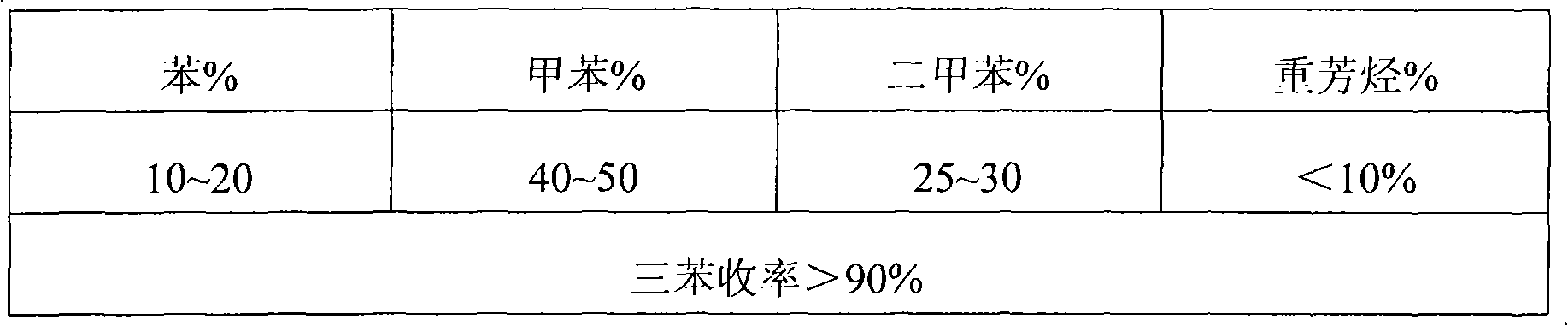

Process for producing low carbon olefin and arene parallel cogeneration gasoline by using methanol as raw material

InactiveCN102146010ALow costReduce energy consumptionHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionEnvironmental resistanceCogeneration

The invention discloses a process for producing low carbon olefin and arene parallel cogeneration gasoline by using methanol as a raw material. In the process, the methanol is used as the raw material and a molecular sieve catalyst is adopted to produce the low carbon olefin and arene parallel cogeneration gasoline by a methanol alkylation reaction and aromatization. In the process, the coal-based methanol is used as the raw material and can replace the conventional petroleum raw material to cogenerate a basis organic chemical raw material, and thus, the dependence degree of the conventional petrochemical industry on the petroleum can be reduced. Meanwhile, the process is also beneficial for reducing the foreign dependence degree of national petroleum, the strategic safety of energy and resources is improved, the production process of the process has low discharge, low pollution and low energy consumption, the requirements on green and environment protection are met, and the process has the advantages of low production cost and strong market competitiveness.

Owner:江苏煤化工程研究设计院有限公司 +2

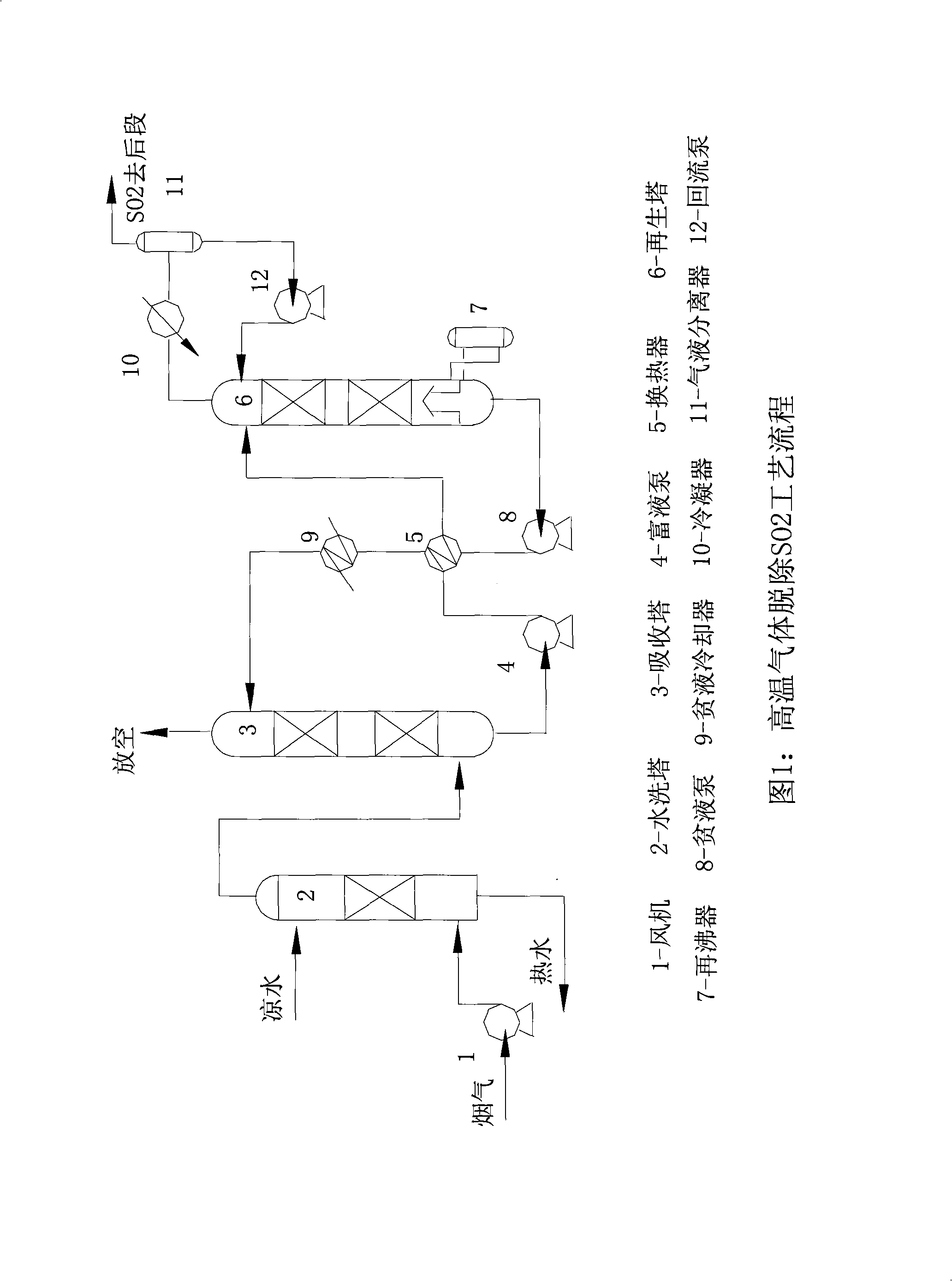

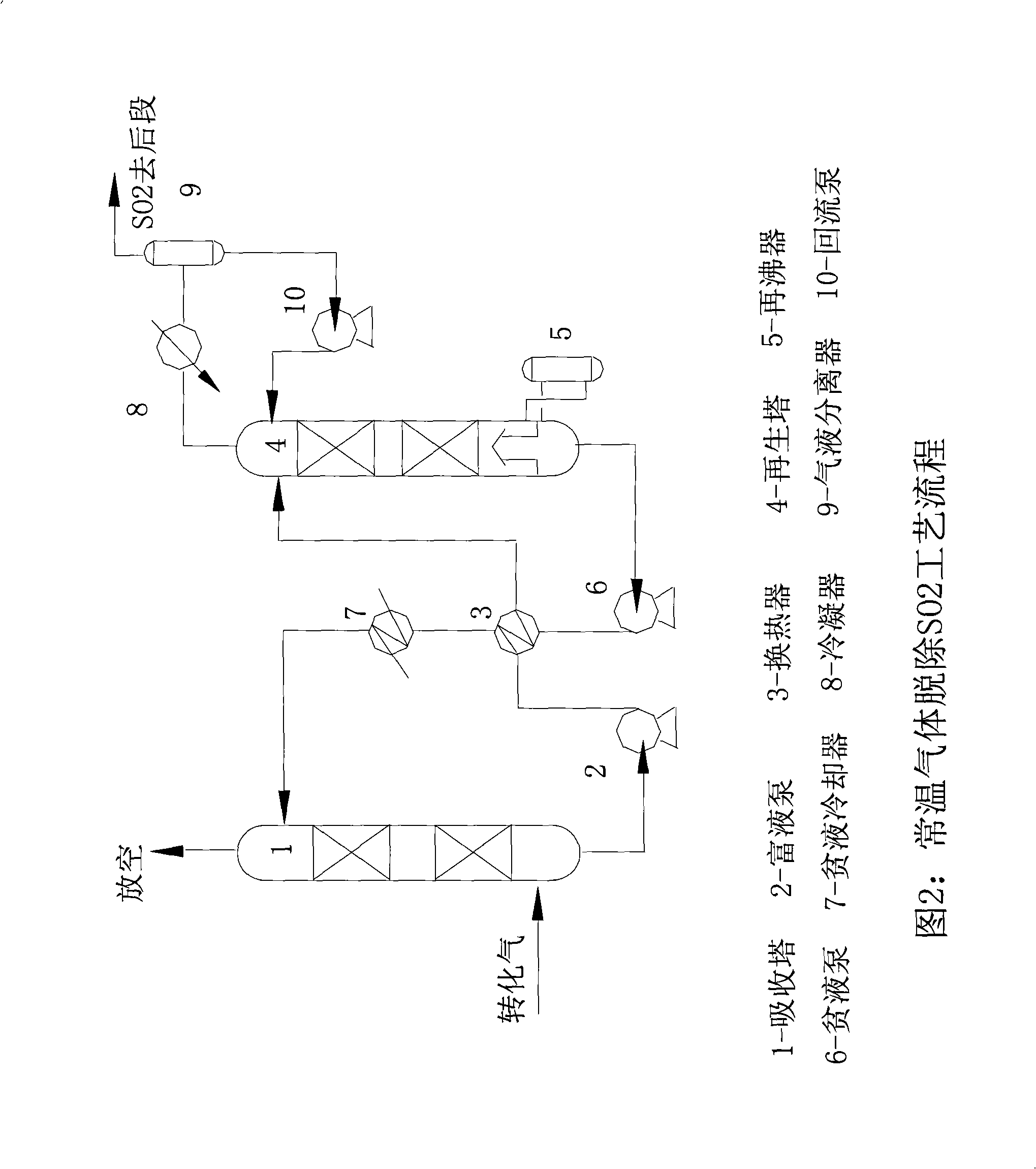

Absorbing agent for removing and recovering sulfur dioxide from gaseous mixture

ActiveCN101274204AReduce operating costsLess investmentSulfur compoundsDispersed particle separationQuinoneAntioxidant

The invention discloses a novel absorbent which can remove SO2 and recover high-consistency SO2 at the same time, aiming at the characteristics of mixed gases such as flue gases of boilers of power plants, metallurgy sintering flue gases, sulfuric acid industrial tail gases, etc. The absorbent provided by the invention has the compositions as follows: (1) the absorbent has substance which contains 2 to 50 percent organic cations and 2 to 50 percent inorganic anions by mass concentration and is used as main component removing the SO2; (2) alkyl alcohol amide with the mass concentration of 0.1 to 3 percent is used as activator for removing the SO2; (3) phenols and quinones with the mass concentration of 0.1 to 0.2 percent are used as antioxidant of the absorbent; (4) metal oxide or inorganic salt with the mass concentration of 0.1 to 0.2 percent is used as corrosion inhibitor of the absorbent; (5) 5 to 95 percent of water is contained. The absorbent absorbs the SO2 gas in the mixed gases under the low temperature of 20 to 80 DEG C, dissolves the SO2 gas under high temperature of 85 to 130 DEG C, and generates the SO2 by-product with the concentration more than 99 percent (dry basis); the absorbent is circularly used.

Owner:HUAXI CHEM INST CHENGDU CITY

A method of manufacturing a carbon fiber antenna surface

The invention relates to a manufacturing method for a carbon fiber antenna surface. The manufacturing method comprises the following steps of 1, prefabricating a die; 2, polishing the die; 3, chemically electroplating the die; 4, measuring the precision, and clearing away impurities; 5, coating a demolding agent; 6, paving carbon fiber cloth on a male die; 7, paving PVC foams on the surface of the male die; 8, paving carbon fiber cloth on the surface of the male die; 9, assembling the male die and a female die, and sealing and fastening the male die and the female die; 10, vacuumizing to enable the vacuum degree in the die to be smaller than -0.096MPa; 11, injecting epoxy resin and a solidifying agent from a material inlet of the female die; 12, sticking a layer of glass paper to the outer surface of a blank after the appearance gets through inspection and is qualified; 13, performing perforation and assembling; and 14, obtaining the carbon fiber antenna surface after the product is qualified through inspection. The carbon fiber antenna surface manufactured by the manufacturing method is smooth, and the precision can reach 0.1R.M.S; and due to normal-temperature solidification, energy is saved, and the cost is lowered.

Owner:XIAN TUOFEI COMPOSITE MATERIAL

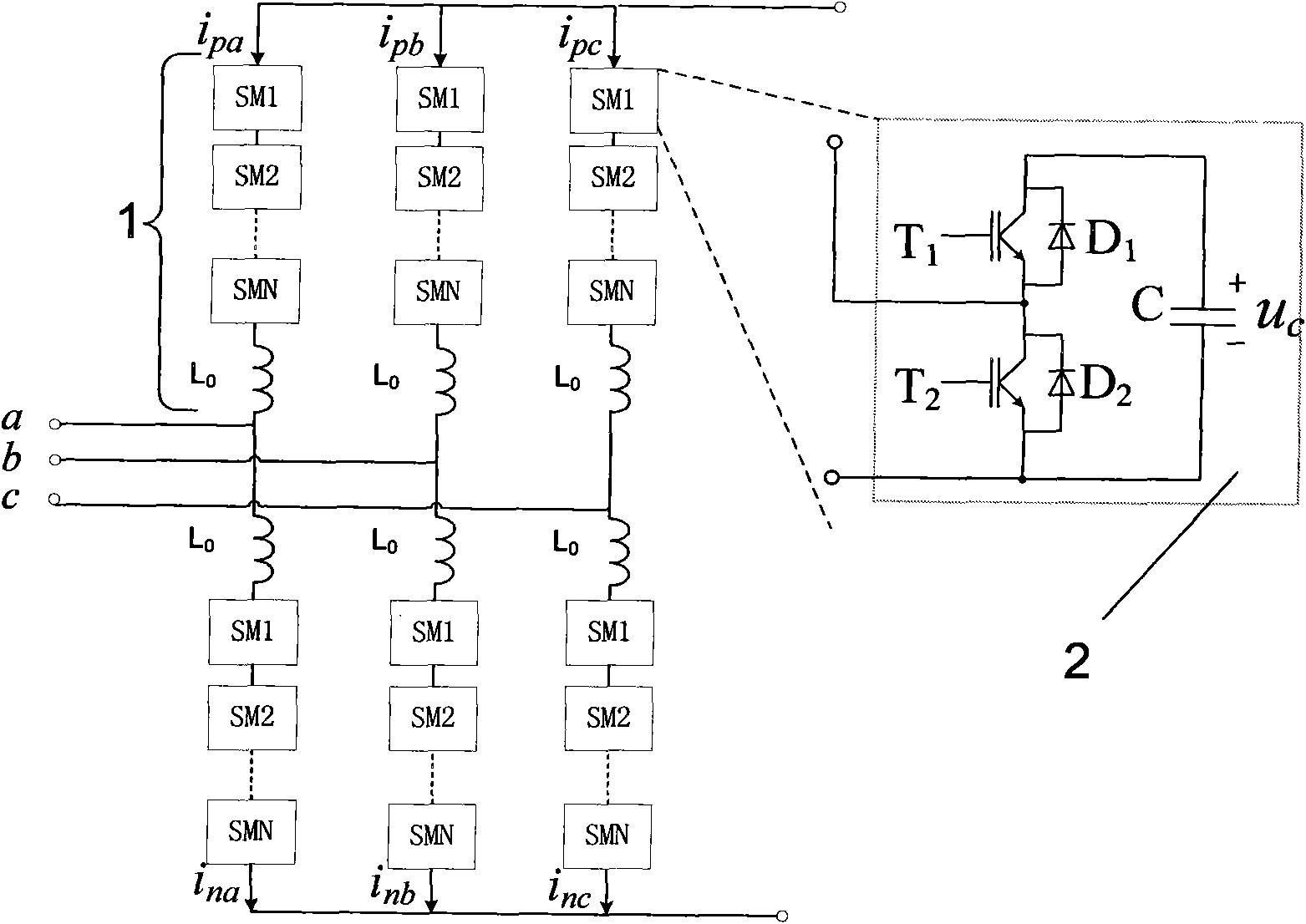

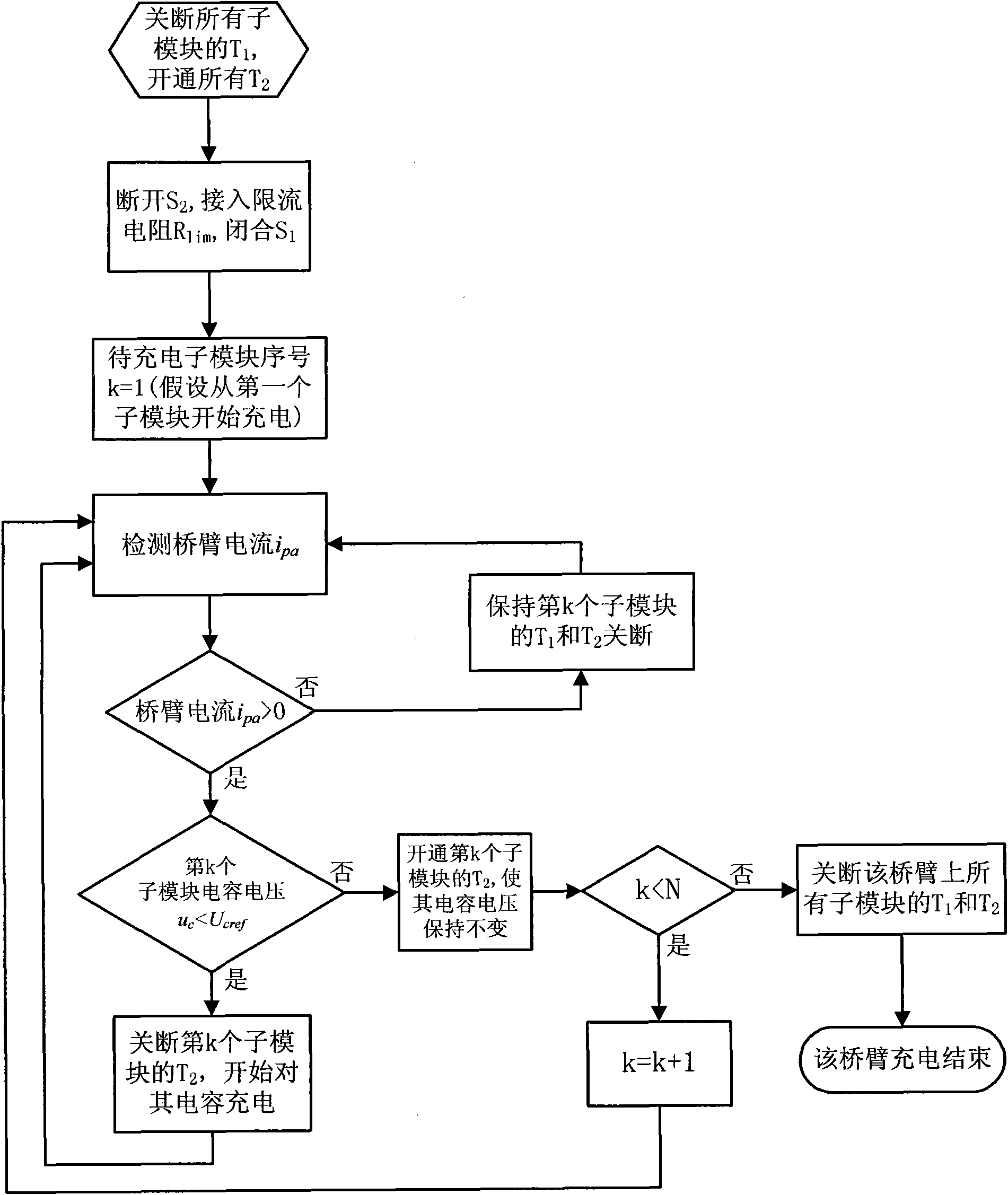

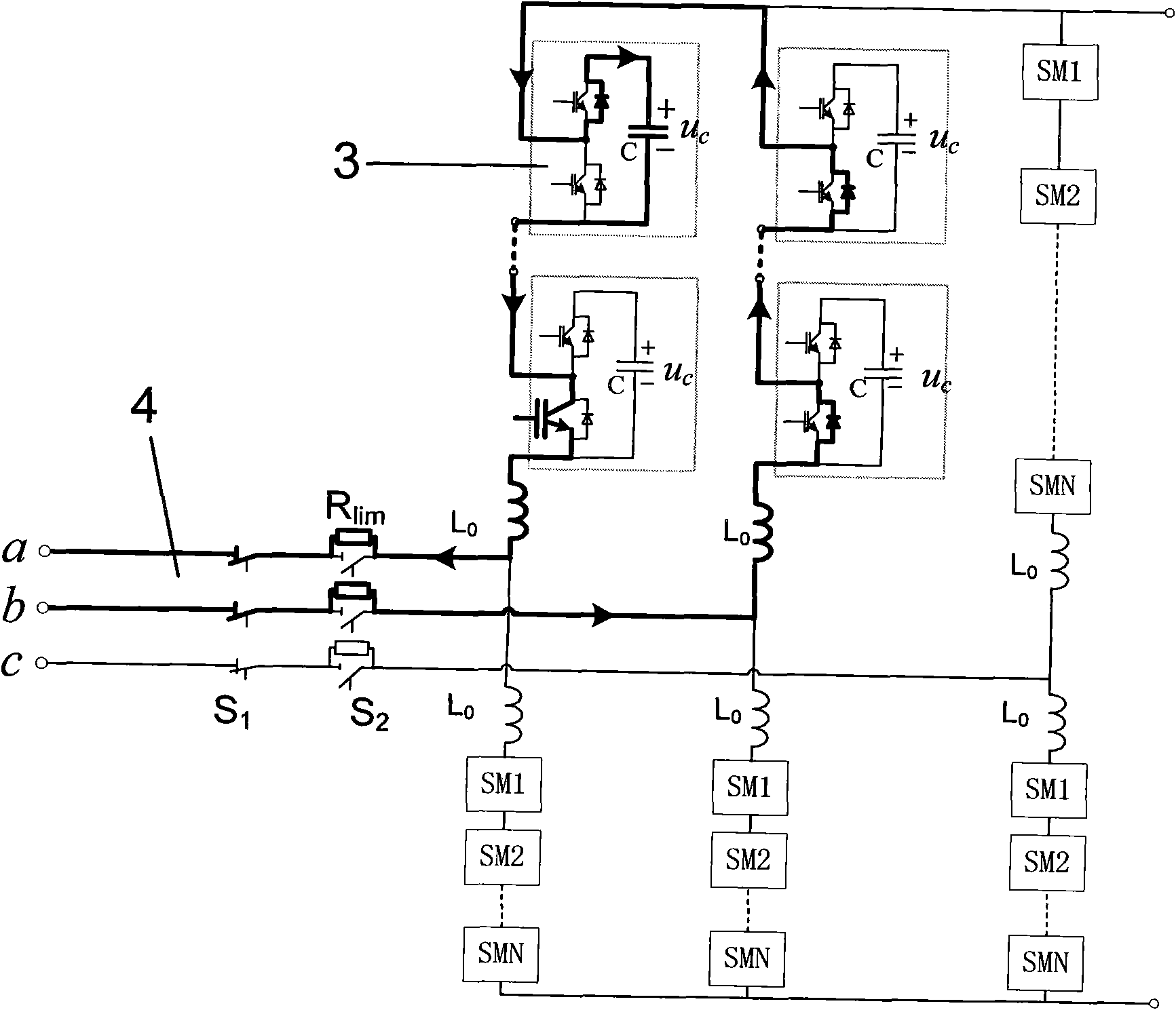

Method for starting three-phase modular multilevel inverter without auxiliary DC power supply

The invention discloses a method for charging and starting a three-phase modular multilevel inverter in a self-excitation way under the condition of no need of an auxiliary DC power supply. In the method, by adopting interphase currents generated by line voltages of an AC system among converter bridge arms, the process of charging capacitors of all the submodules on the bridge arms is completed by controlling switching on and switching off an upper electronic power switch and a lower electronic power switch in the submodules of all the bridge arms when current directions of the bridge arms and capacitor voltages of all the submodules are detected; and all the bridge arms can be simultaneously charged, so that the three-phase modular multilevel inverter can be quickly and normally started in the self-excitation way.

Owner:ZHEJIANG UNIV

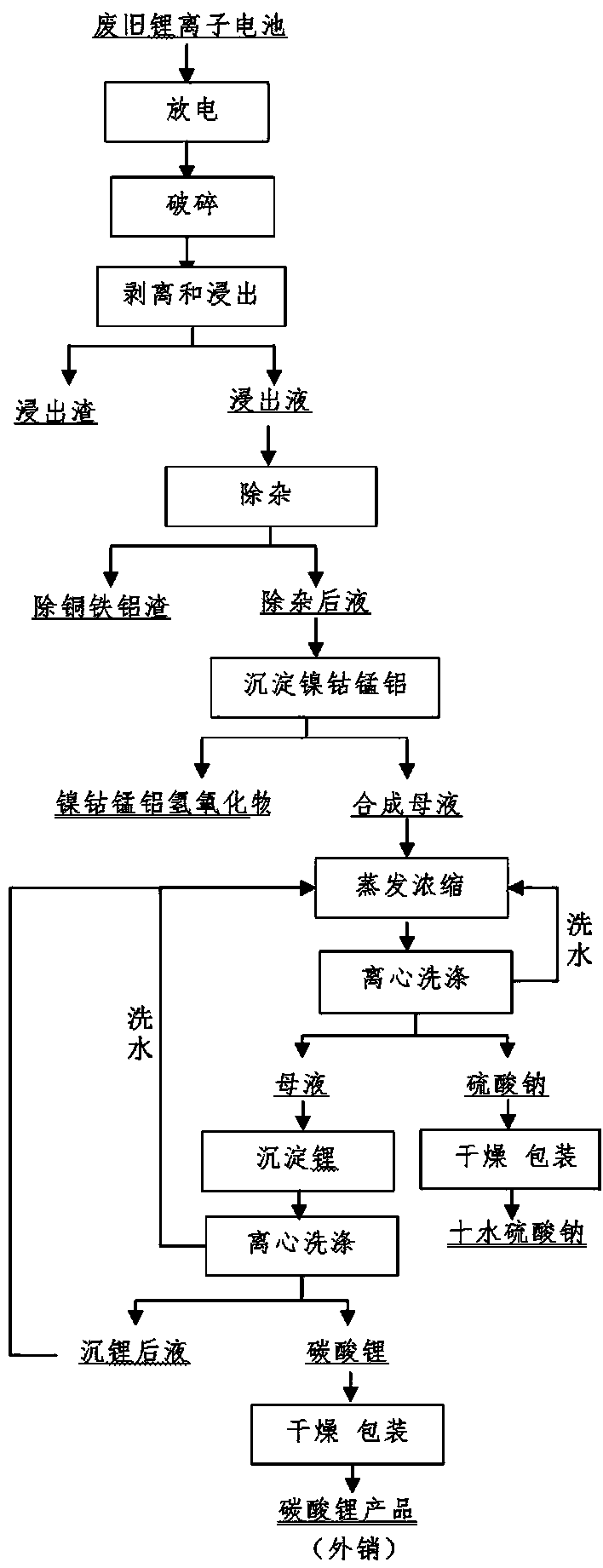

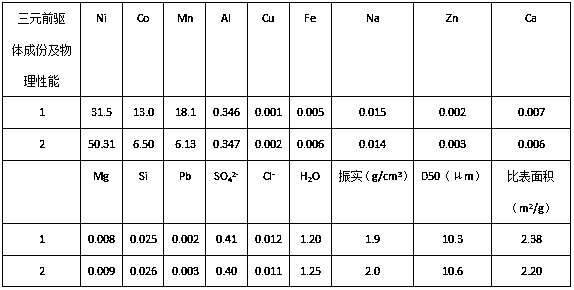

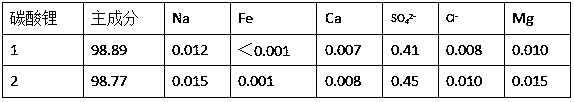

Recycling method for valuable metal from waste nickel-cobalt-manganese lithium ion battery

InactiveCN107653378AReduce lossesLess investmentWaste accumulators reclaimingProcess efficiency improvementSlagManganese

The invention relates to a method for recycling valuable metal from a waste nickel-cobalt-manganese lithium ion battery. The method comprises the following steps of: dismounting, discharging and crushing the battery, soaking crushed waste nickel-cobalt-manganese lithium ions into sulfuric acid with certain concentration, adding a reducing agent to strip positive and negative pole pieces, and leaching valuable metals of nickel, cobalt, manganese and lithium; and replacing leach liquor with iron powder to remove copper, carrying out hydrolyzing to remove iron and aluminum, and dosing an impurity-removed solution to synthesize an aluminum coated nickel, cobalt and manganese ternary positive electrode material precursor, evaporating and concentrating the synthesized solution, adding carbonateor introducing carbon dioxide to recycle lithium. According to the method disclosed by the invention, stripping and leaching are synchronously completed, chemical precipitation is performed to removecopper, iron and aluminum, slag amount is small, slag filter performances are good, and the impurity-removed solution is used for synthesizing the aluminum coated nickel, cobalt and manganese ternaryprecursor, so that the recovery rate of valuable metal is increased; and the recovery rate for nickel, cobalt and manganese is 96% or higher in the whole process, the total recovery rate of lithium is90% or higher, the technological process is short, operation is simple, equipment is less, and the cost is low.

Owner:JINCHUAN GROUP LIMITED +1

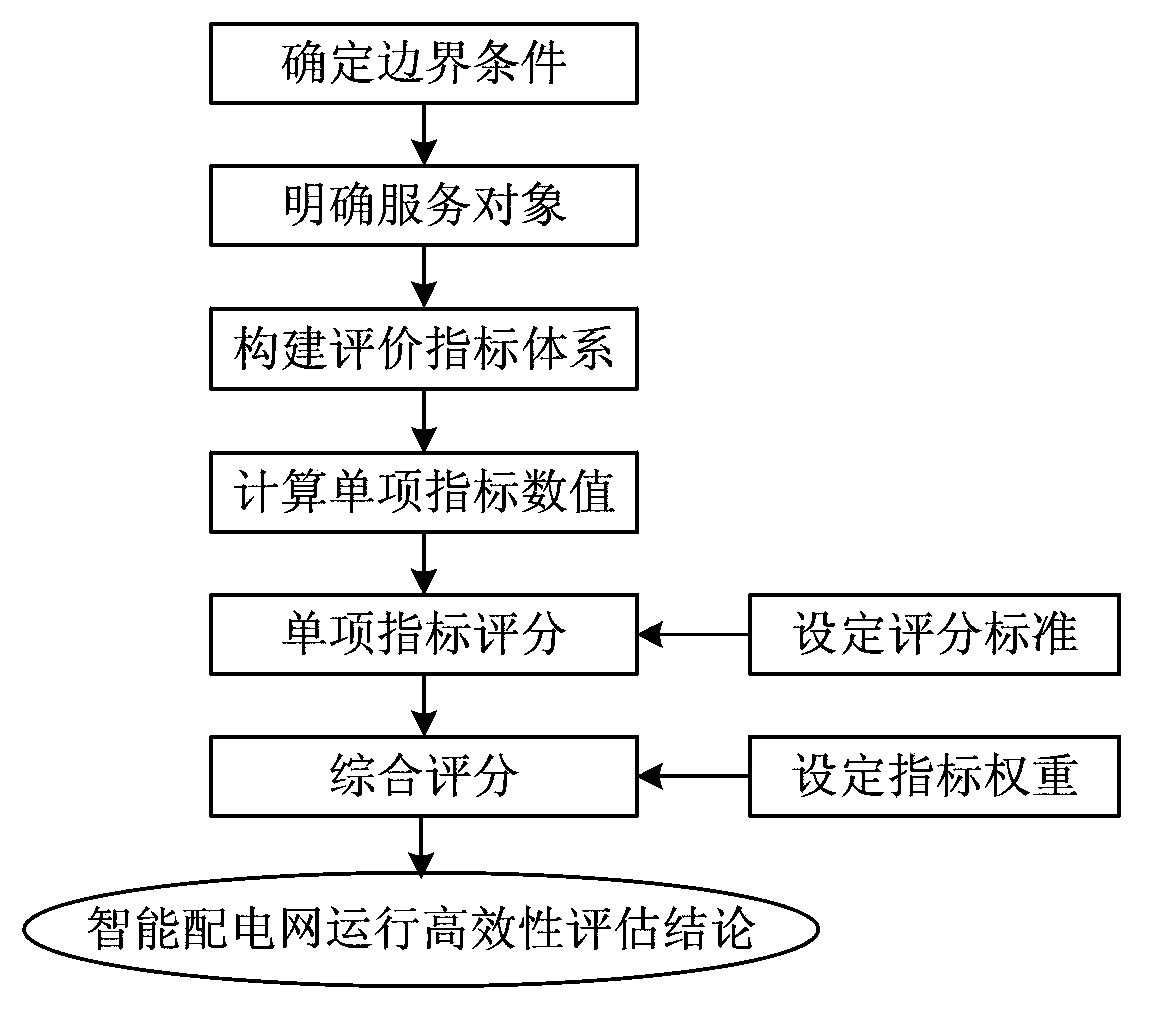

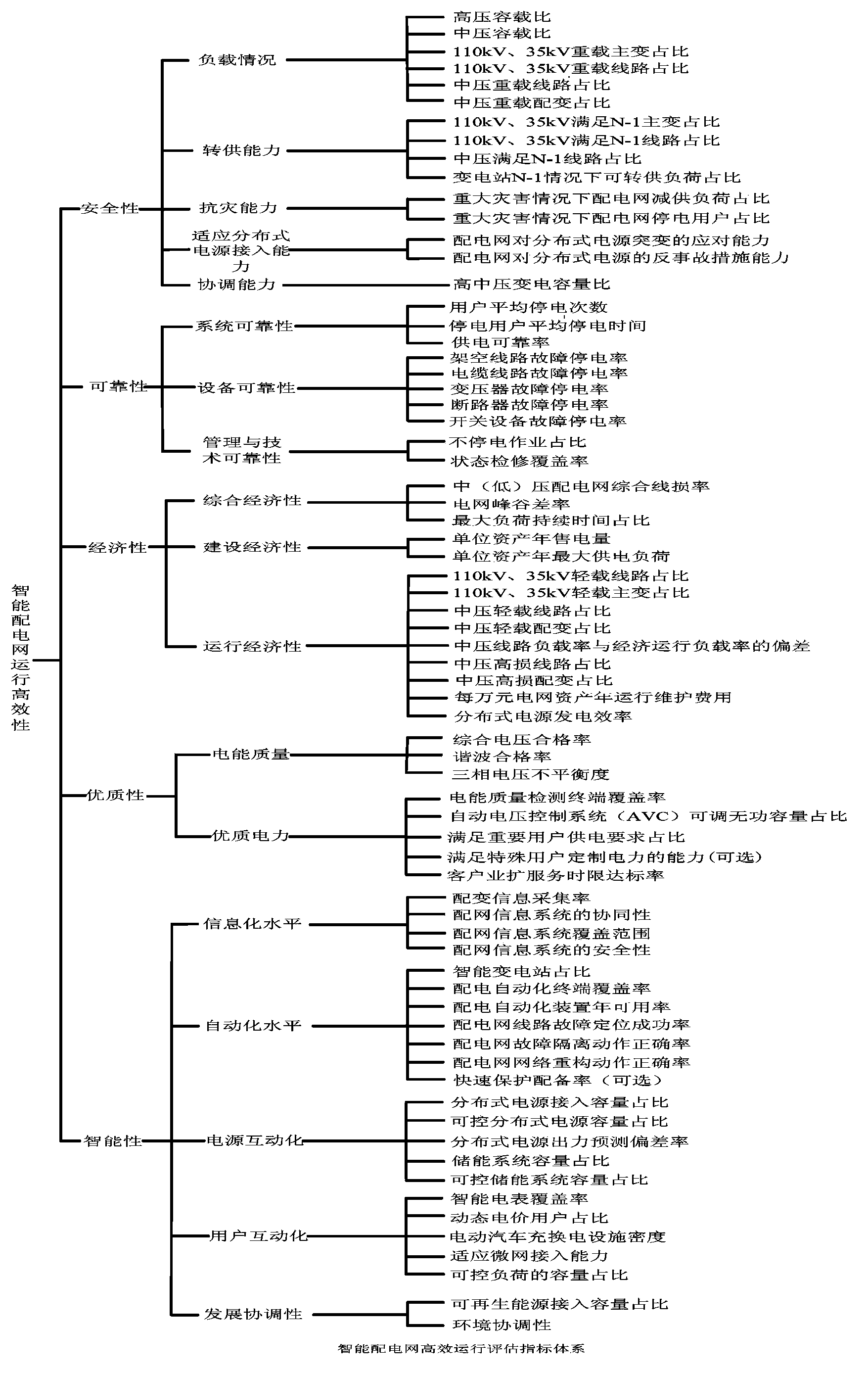

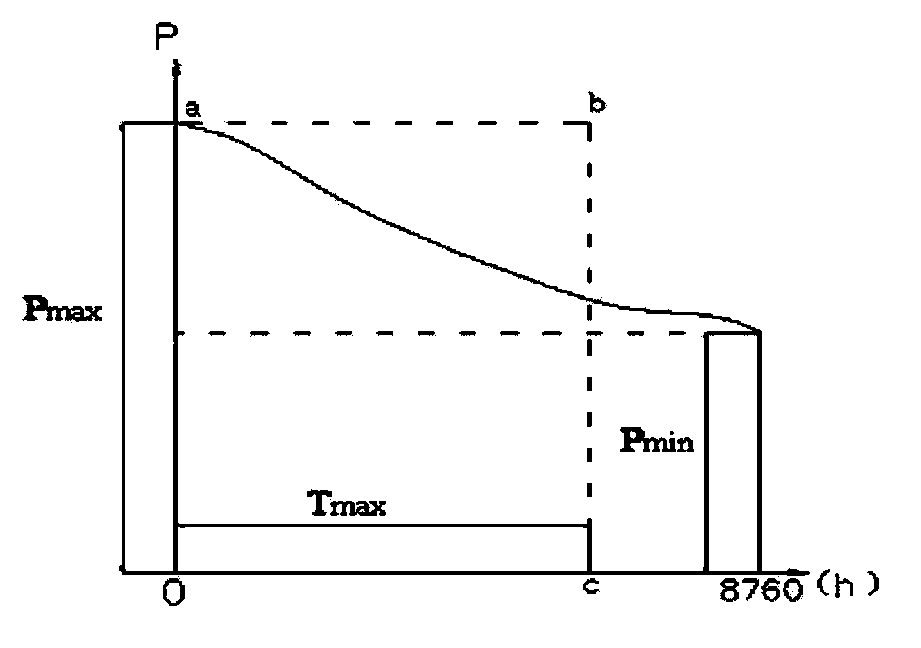

Assessment method of efficient operation of intelligent power distribution network

InactiveCN103903058AHigh utility valueLess investmentForecastingSystems intergating technologiesSafety indexPower grid

The invention relates to an assessment method of efficient operation of an intelligent power distribution network. The assessment method comprises the steps of: (1) determining boundary conditions; (2) determining service objects; (3) building an assessment index system which includes a power distribution network safety index, a power distribution network reliability index, a power distribution network economical efficiency index, a power distribution network high operation quality index and a power distribution network intelligence index; (4) determining assessment index numerical values of single items; (5) scoring for single items of assessment indexes; (6) performing comprehensive scoring of the assessment index system; and (7) judging whether efficient operation of the power distribution network is achieved according to a comprehensive score of the assessment index system in Step (6). The assessment method for efficient operation of the intelligent power distribution network in the invention has a relatively wide range of application, can comprehensively assess the operating state of the intelligent power distribution network, and an assessment result provides an importance basis for decision-making work of power grid dispatching, planning and operation management personnel.

Owner:CHINA ELECTRIC POWER RES INST +2

Manufacturing method for crystallized fruit

The invention relates to a manufacturing method for crystallized fruit, which comprises the following steps: (1) preparing the following raw materials by weight percent: 20-67.7% of fruit embryos, 32.05-53.0% of sugar crops, 0.1-5% of filling materials, 0-5% of medicinal and food homologous traditional Chinese medicines, 0.05-10% of seasoning spices, 0.1-2.0% of preservatives and 0-5% of pigments; (2) pre-treating the raw materials by preparing liquid sugar, filling material liquid, traditional Chinese medicine extracts and preservative solution; (3) soaking: adding the liquid sugar material,the seasoning spices, the pigments, the liquid sugar, the filling material liquid and the traditional Chinese medicine extracts into a soaking cylinder and mixing uniformly to form the mixed materialliquid, adding the fruit embryos into the soaking cylinder, increasing the temperature of the mixed material liquid to 50-60 DEG C and keeping the temperature for 10-15 hours; (4) leaching and drying; and (5) drying to obtain the crystallized fruit. The manufacturing method for crystallized fruit is easily performed, the full utilization of fruit resource is realized, and the manufactured crystallized fruit is full of nutrition and tastes fresh and cool.

Owner:汕头市天悦轻工技术科技有限公司 +3

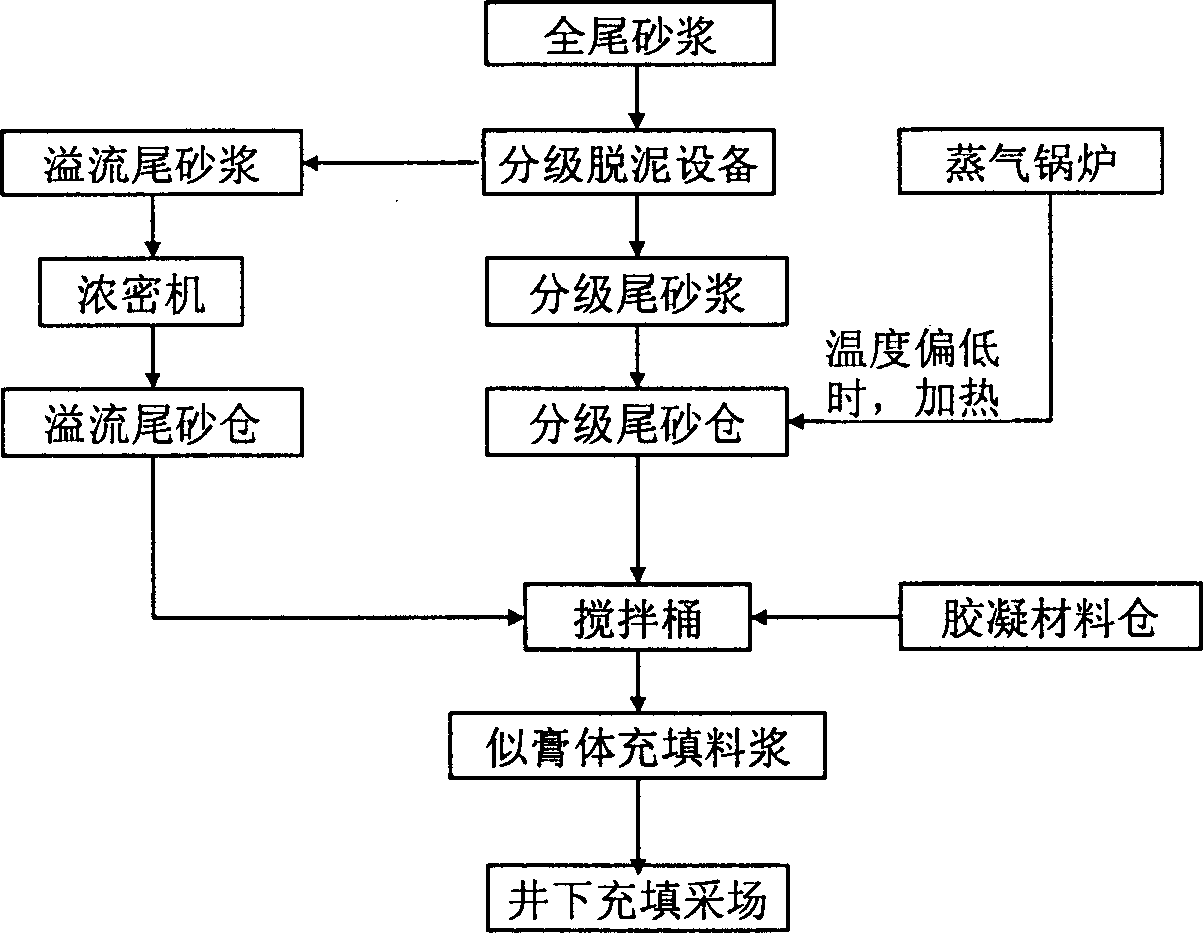

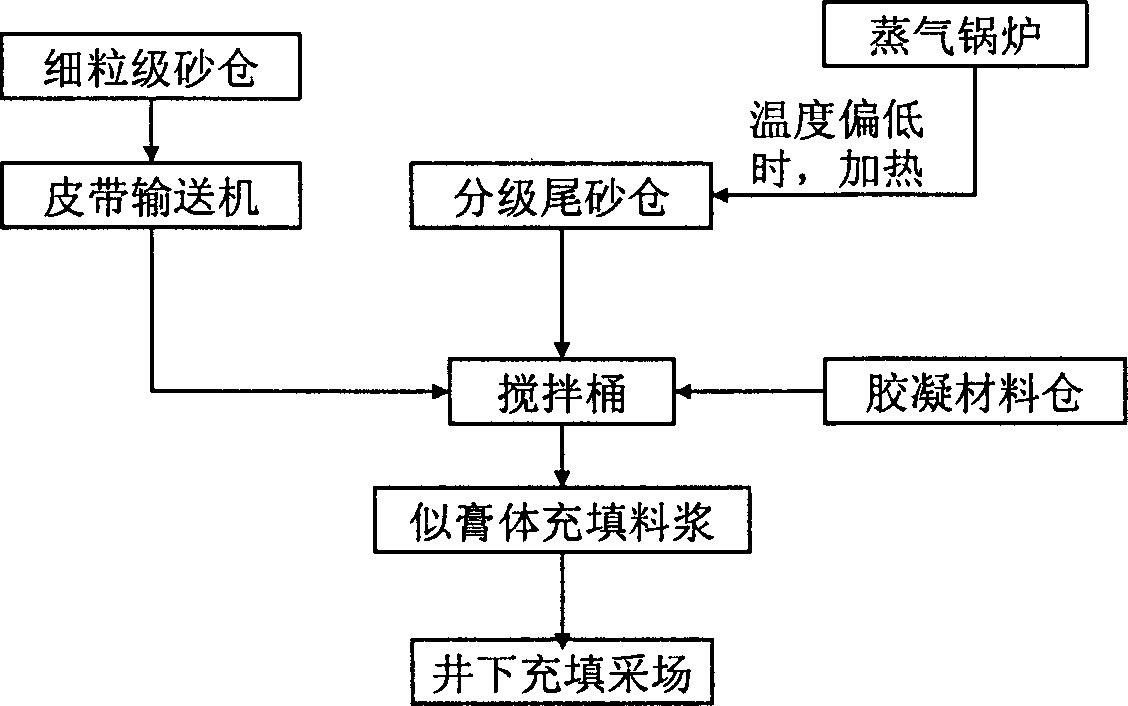

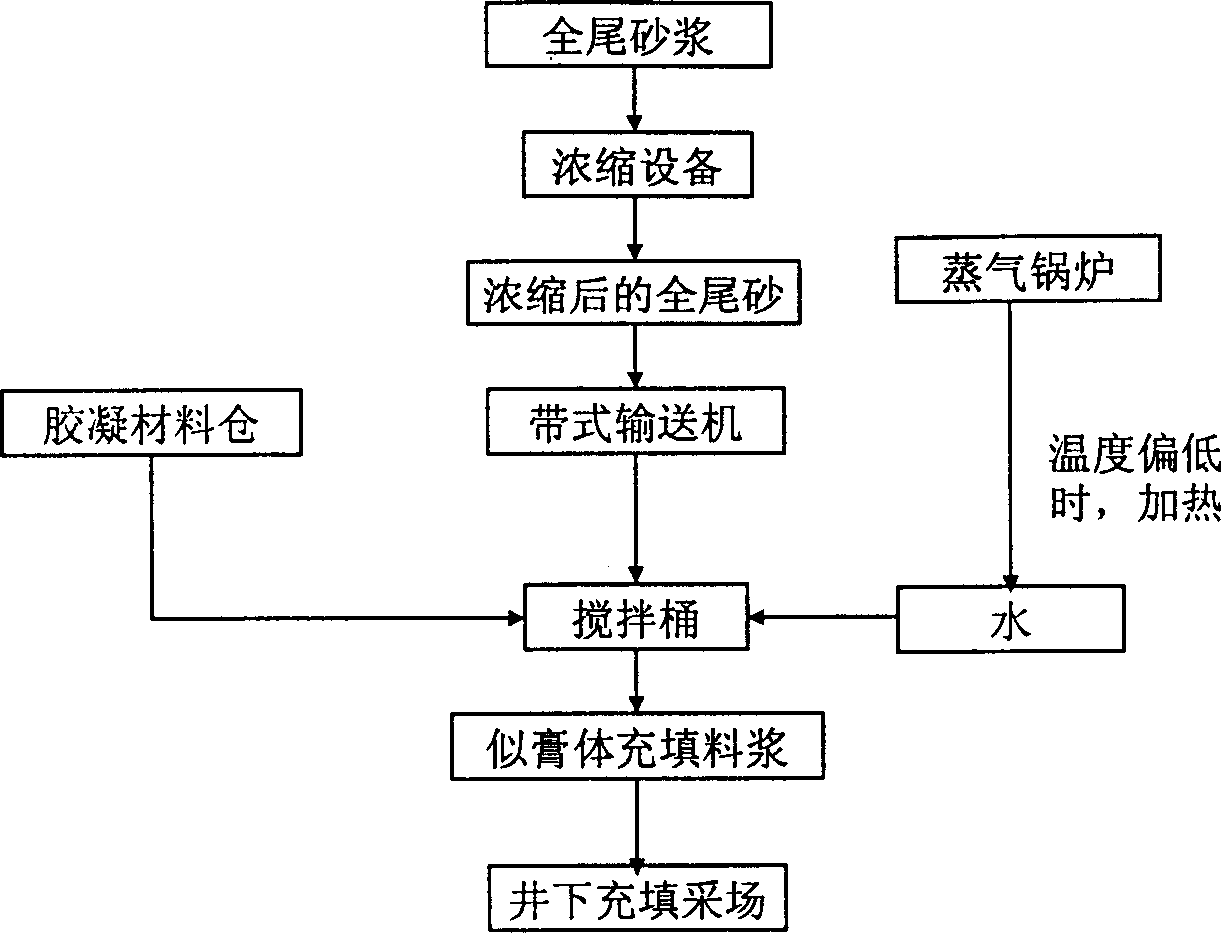

Cementing materials for filling, slurry and preparing and filling processes

InactiveCN1424275AReduce manufacturing costLess investmentSolid waste managementMaterial fill-upSlurrySulfur containing

A gelatining material similar to cream for filling underground working surface is preapred from the Ca-contained non-crystal and microcrystal material, alkali and / or sulfur contained exciting material, active material, aggregate and regulator. A filling slurry is prepared from said gelatining material, filling aggregate, fine particles, regulator and water through heating to at least 18 deg.C and proportional mixing.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

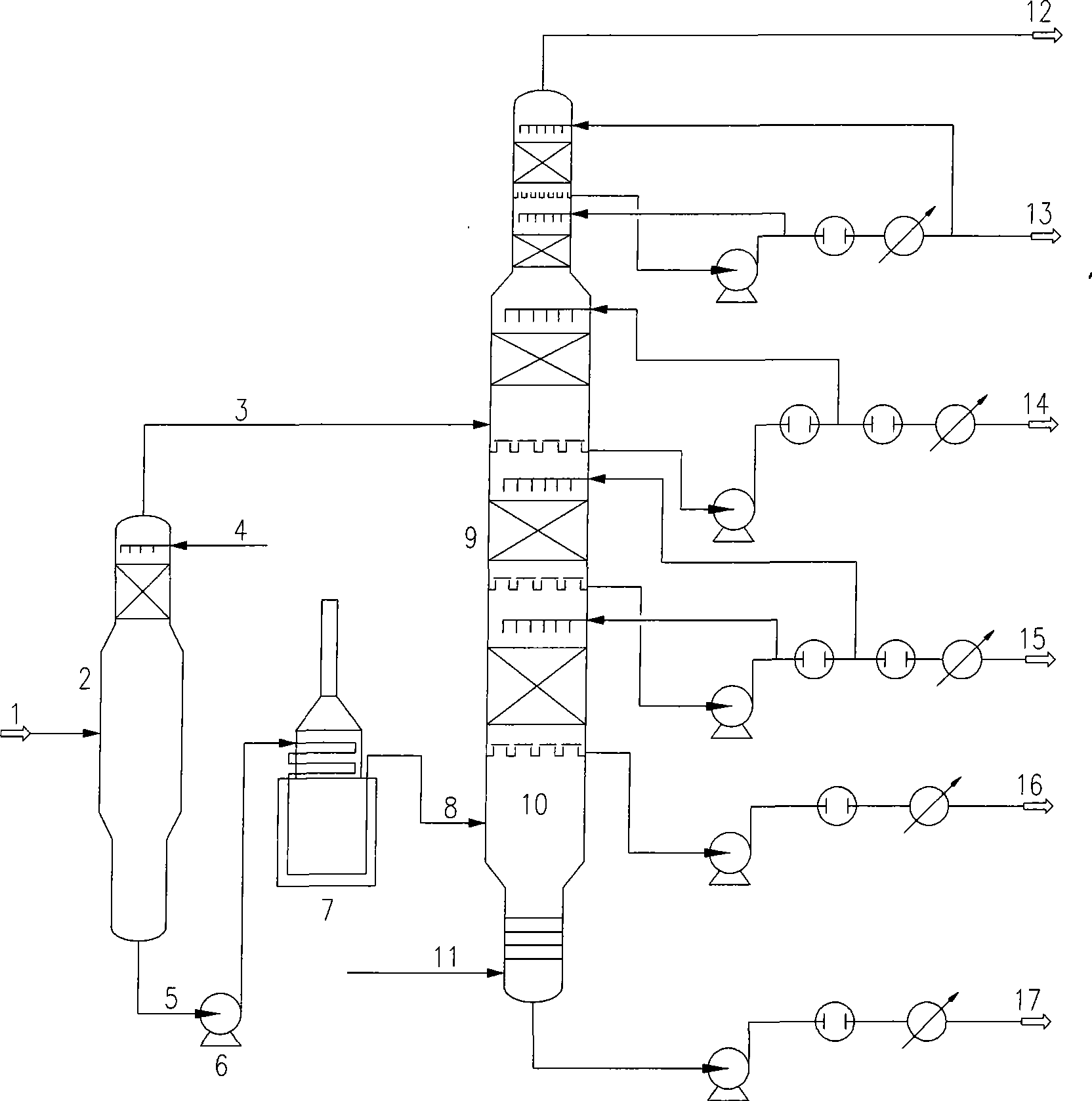

Atmospheric vacuum distillation method and apparatus with vacuum flash vaporizer

InactiveCN101376068AReduce the amount of feedEasy to handleVacuum distillation separationVacuum distillationVaporizationPulp and paper industry

The invention relates to an atmospheric and vacuum distillation device with a vacuum flash tower and a method thereof. The atmospheric and vacuum distillation device with a vacuum flash tower is characterized in that the vacuum flash tower arranged in front of a vacuum furnace is connected with the vacuum furnace and a vacuum tower through a pump and a pipeline. Constant bottom oil (1) is introduced into the vacuum flash tower (2)at first, and the operation pressure at the top part of the vacuum flash tower is higher than the operation pressure at the top part of the vacuum tower (9) by10 to 200mmHg; Flash cap gas (3) is introduced into the upper part or the lower part of an outlet for a side product which is similar to Flash cap gas fraction; flash bottom oil (5) is introduced into the vacuum furnace (7) through a flash bottom oil pump (6); when the flash bottom oil is heated to 350 to 430 degrees, air-liquid mixing vacuum tower feed material is obtained through partial vaporization and is introduced into a flash evaporation segment (10) of the vacuum tower through a transfer line (8); and products with different fractions are drawn from the side of the vacuum tower and vacuum residue is drawn from the bottom of the vacuum tower. Through adding the vacuum flash tower to improve the working process of the atmospheric and vacuum distillation device, the invention achieves the advantages of increasing treatment capacity, increasing vacuum distillation yield, and reducing energy consumption.

Owner:TIANJIN UNIV +2

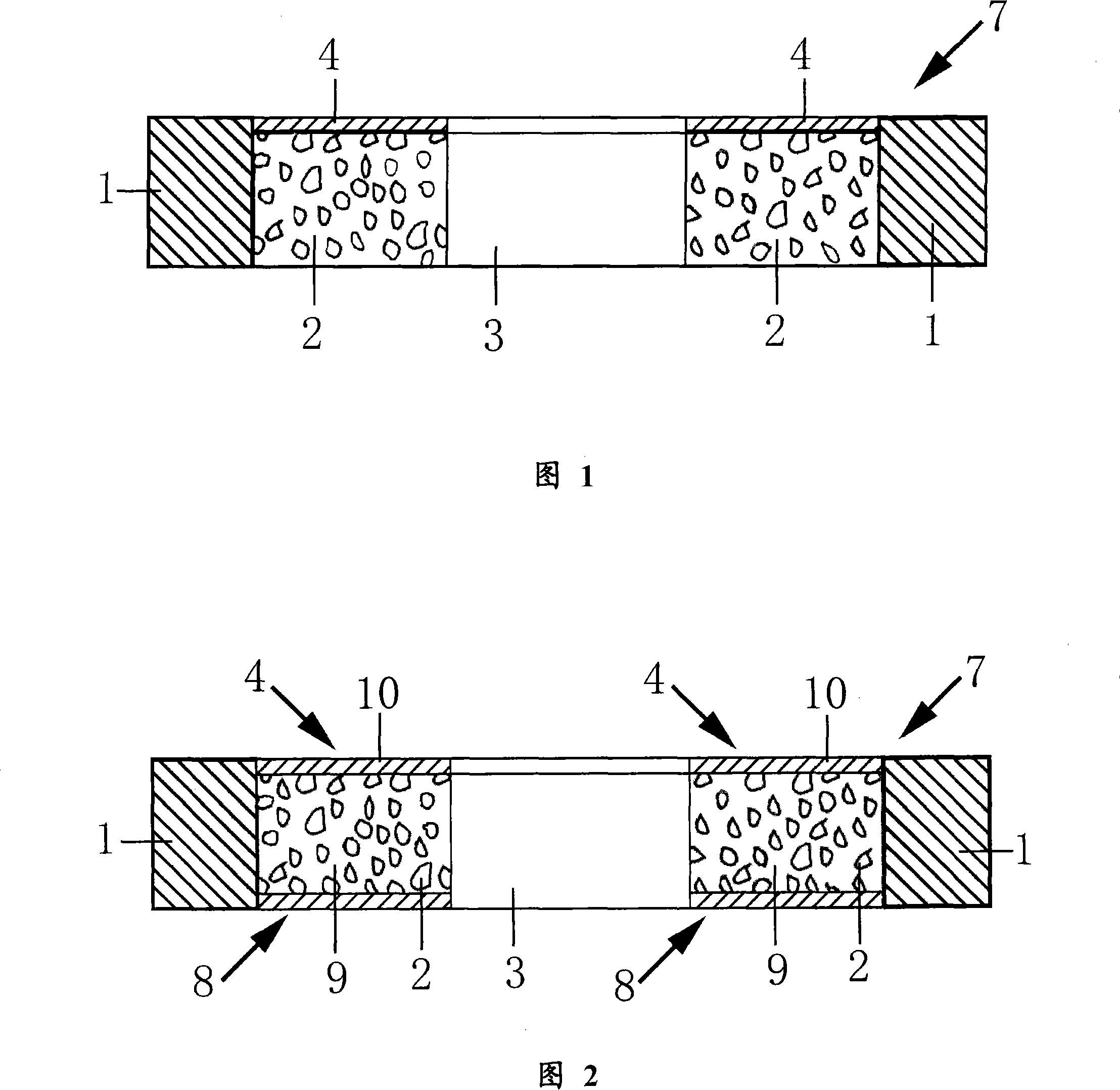

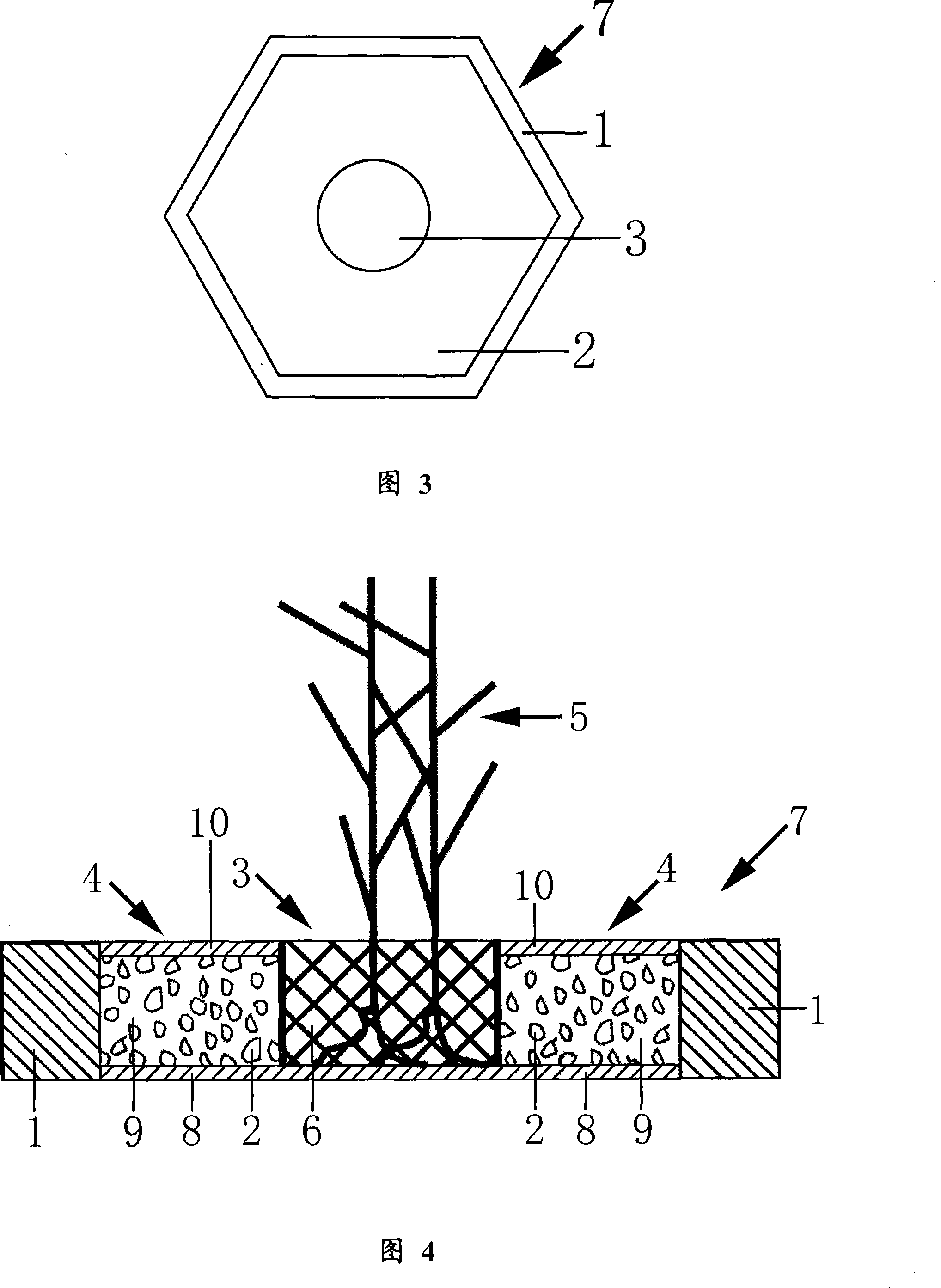

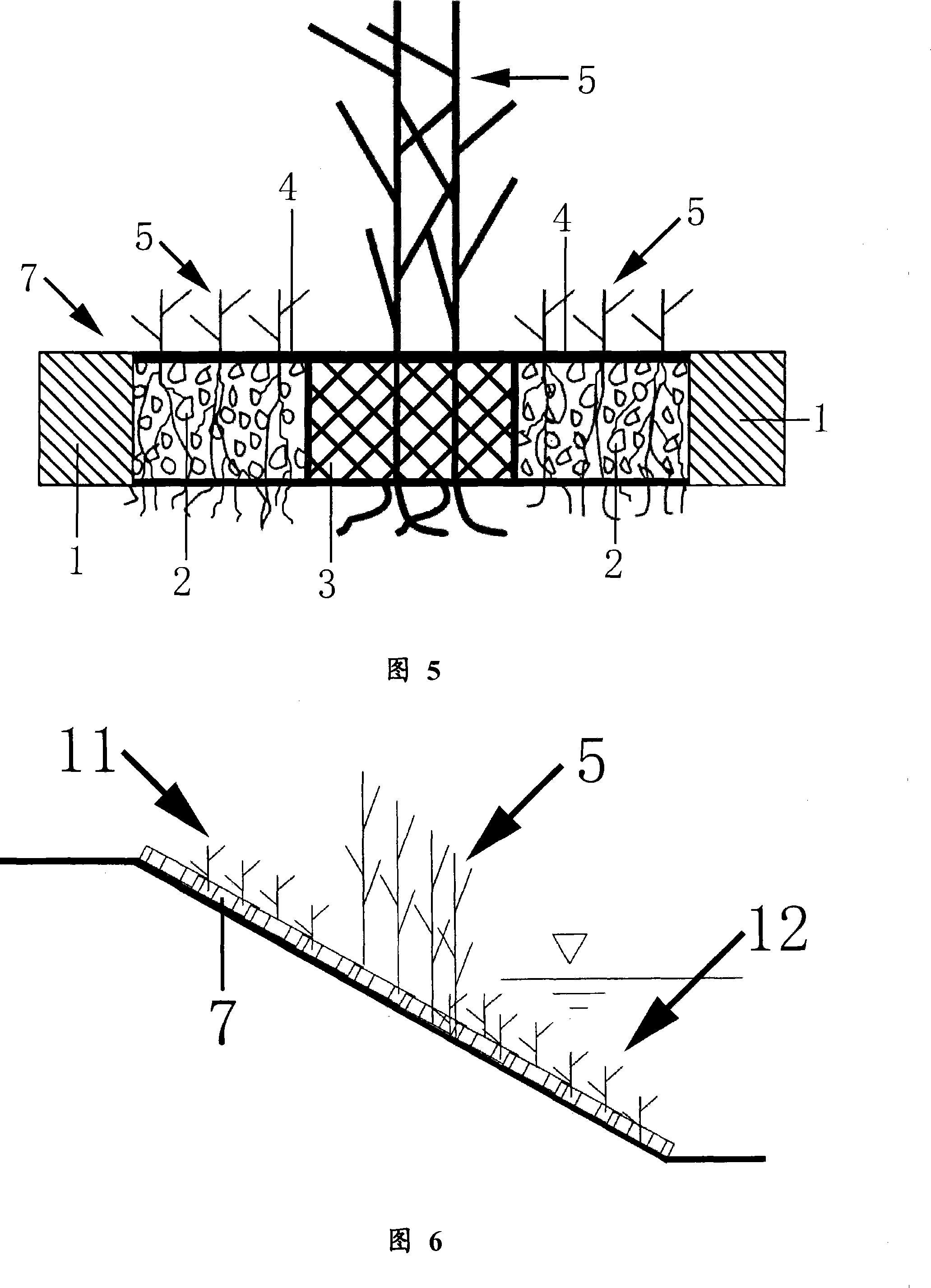

Ecological slope protection vegetation building blocks as well as making method and construction process

InactiveCN101200894APrevent collapseImprove the environmental landscapeSolid waste managementMixing operation control apparatusEngineeringLevee

The present invention relates to a building block of ecological slope protection vegetation, a fabrication method and a construction technique. The building block is composed of a growing bed body, a lath crib, planting troughs, a vegetation layer and a plant, the lath crib wraps the circumference of the growing bed body, the upper plane of the growing bed body is lower than the upper plane of the lath crib and concave, the vegetation layer is formed on the growing bed body, which matches the inner walls of the sectional area of the lath crib to form an integral building block, and more than one planting troughs are arranged on and run through the growing bed body. The design of the present invention is scientific, the structure is reasonable, the restoration of water ecology can reduce the operating cost, environment is improved, ecology is reinstated, harmonious natural beauty is enhanced, and the present invention is suitable for the nidification of small living creatures and the habitation and the survival of aquatic fishes, so that the cutting-off continuity of water and land regions is restored. The present invention is widely applied to channel slope protection, levee slopes, roadsides, airports, parks, public lands, household lawns, sports grounds, etc. The present invention is suitable for cold regions, damp regions, warm and damp intermediate zone, etc.

Owner:TIANJIN WATER RESOURCES RES INST +2

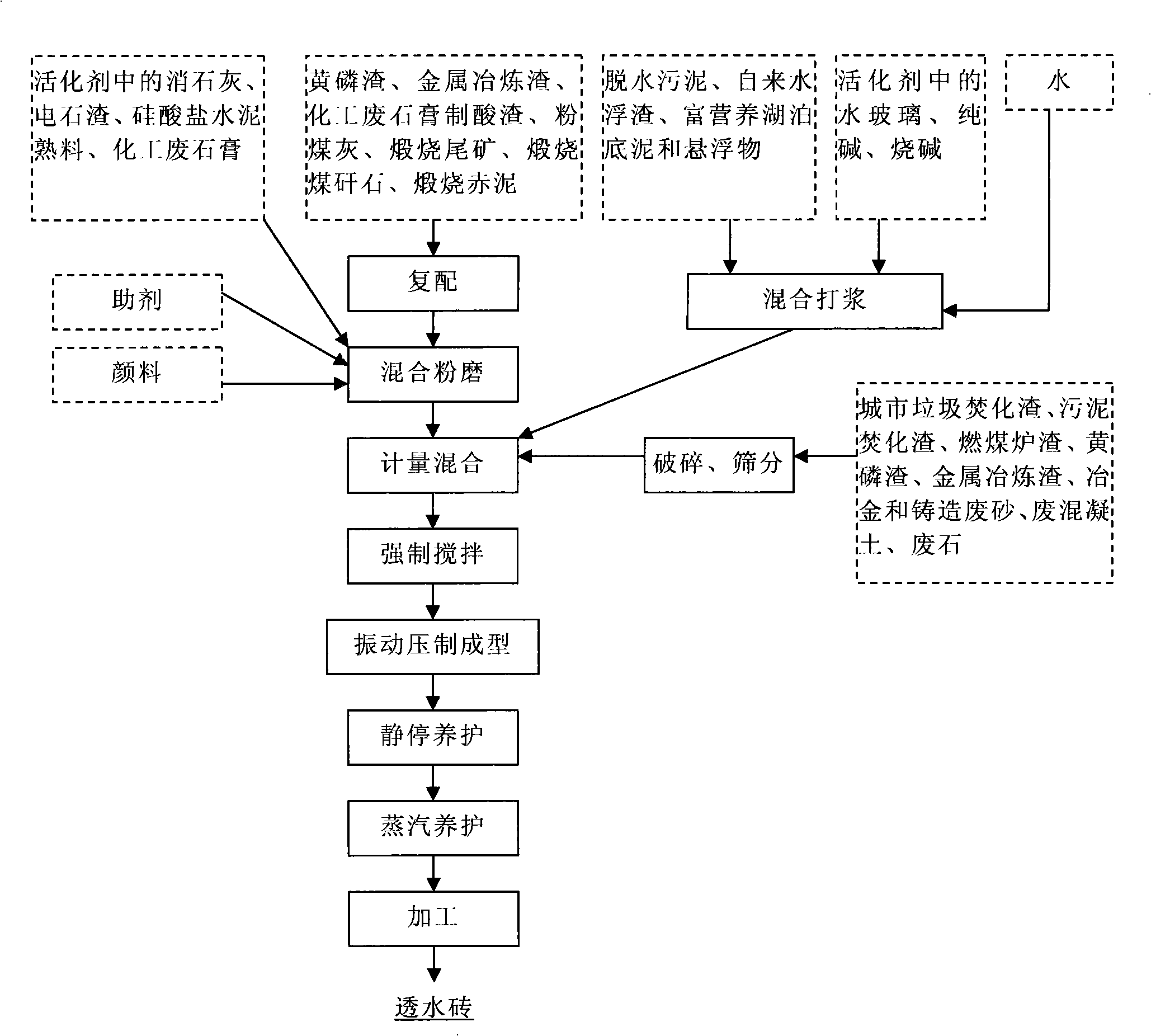

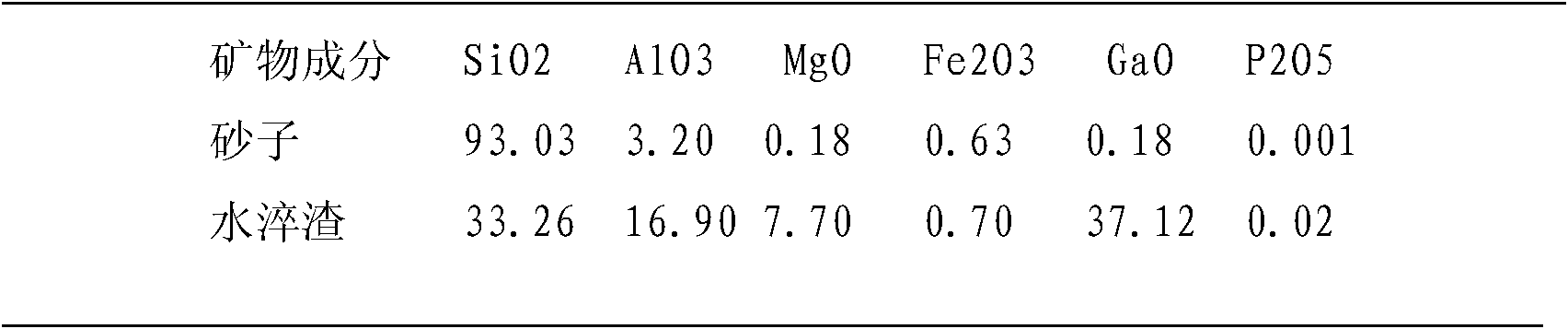

Low-temperature ceramic permeable bricks and production method thereof

InactiveCN101289310ASolve pollutionLow costCeramic materials productionClaywaresNatural resourceState of art

The invention relates to a low temperature ceramics non-watertight brick made of solid waste slag and a manufacture method thereof, belonging to the technical field of building materials. The mixture ratio by weight of the components of the low temperature ceramics non-watertight brick is that waste slag gelled material to waste slag skeletal material to porogenic agent to activating agent to addition agent to paint to water is equal to 100:200-800:0.1-40:13-50:0.2-3.0:0.1-7.0:1-20. After the process, mixture, vibrating forming and maintenance process for the raw materials, the raw materials are prepared into the low temperature ceramics non-watertight brick with a filled pore by taking the low temperature ceramics mineral as the matrix phase and taking the inorganic waste slag particle as the wild phase. Compared with the prior art, the low temperature ceramics non-watertight brick has the advantages of high strength, good permeability of water, high salvage value, simple process, low cost, environment protection and natural resources reservation, etc. which can be widely applied to the laying of urban highways.

Owner:KUNMING UNIV OF SCI & TECH

Investment precision casting technology for producing automobile I-shaped front axle

InactiveCN101147954ALess investmentReduce manufacturing costFoundry mouldsFoundry coresSteelmakingWax

The present invention relates to a fusible pattern precision casting process for producing automobile H-shaped front axle. Said casting process includes the following steps; (1), preparing wax pattern; (2), applying coating material onto the wax pattern surface for several times, spreading sand and making the coating material hardened pattern shell be primarily formed, removing wax and forming pattern shell; (3), firing pattern shell; (4), pouring the molten steel into the pattern shell, before steel-smelting having to make analysis of charge mixture ratio, in the course of smelting steel having to make on-the-spot sample analysis and furnace rear analysis, adding required additive and deoxidant so as to make the molten steel be reached to the defined chemical components requirement; (5), removing pattern shell from obtained automobile H-shaped front axle casting, cleaning sand and cutting spure; (6), grinding, finishing and checking casting; (7), making quenching and tempering, heat treatment; (8), making correction and shot blasting treatment; and (9), making metalworking treatment.

Owner:NANPING AUTO FORGING & STAMPING FACTORY

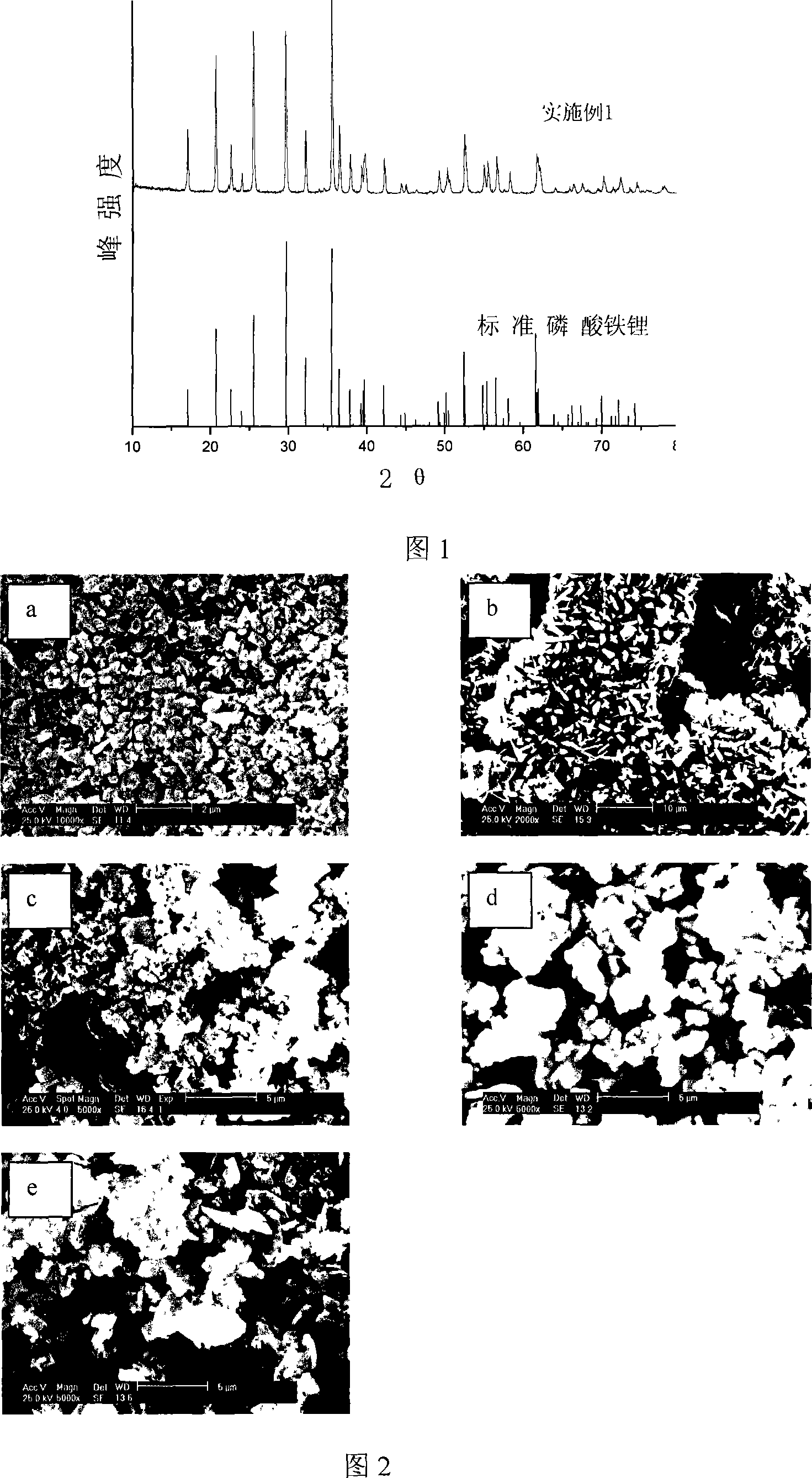

Hydrothermal synthesis method for lithium ion-cell anode material of ferric phosphate lithium

InactiveCN101117216AImprove electrochemical performanceShorten the diffusion pathCell electrodesPhosphorus compoundsExhaust valveDead volume

The invention discloses a hydrothermal synthesis method of lithium-ion battery anode material of lithium iron phosphate, relating two kinds of metal phosphate. The steps are as follows: lithium source and phosphorus source are dissolved in water or mixed with water, and added into the reaction autoclave, the quaternary cationic surfactants and the alkylphenols polyoxyethylene ethers nonionic surfactant is also added into the reaction autoclave, the air in the dead volume of the autoclave inside is purged by the inert gas, the autoclave is sealed and heated to 40-50 DEG C with stirring, a feed valve and an exhaust valve are opened, pure ferrous salting liquid is added into the autoclave, and then the autoclave is sealed for the reaction of the material at 140 to 180 DEG C for 30 to 480 minutes; the mixture ratio of the invention is set as follows: the molar ratio of Li, Fe and P is 3.0-3.15:1:1.0-1.15, and then the resultant is filtered, washed, dried and carbon-coated, thus the lithium iron phosphate is obtained. The lithium iron phosphate which is produced by the invention has the advantages that: the electrochemical performance is excellent, the particle size distribution of which the D50 is between 1.5 um to 2 um is even, the phase purity is above 99 percent and the electronic conductivity of the material is improved.

Owner:HEBEI LITAO BATTERY MATERIAL

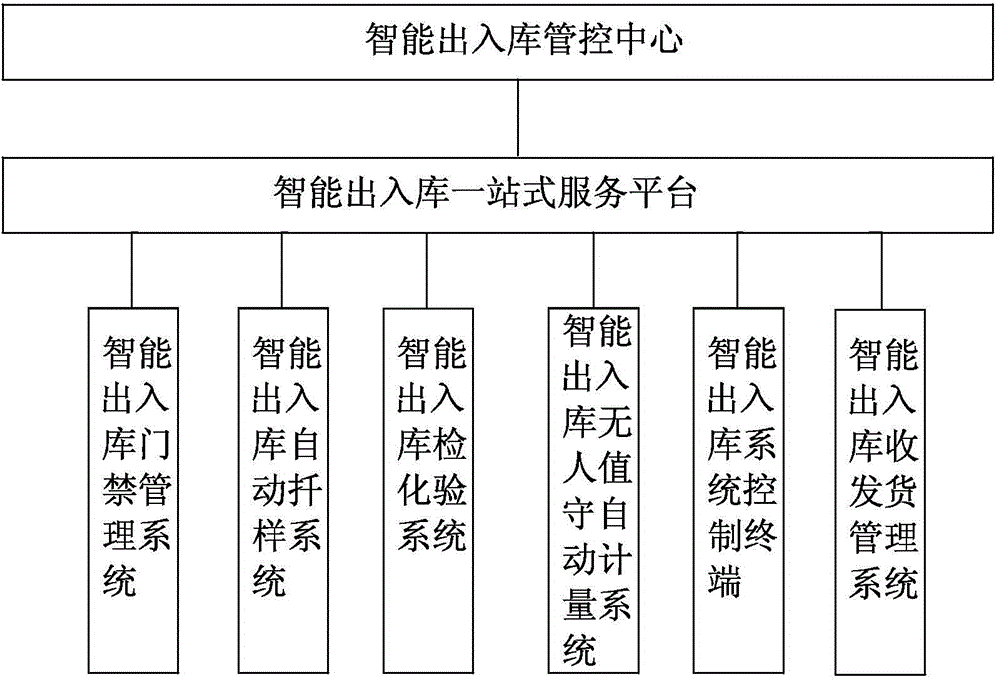

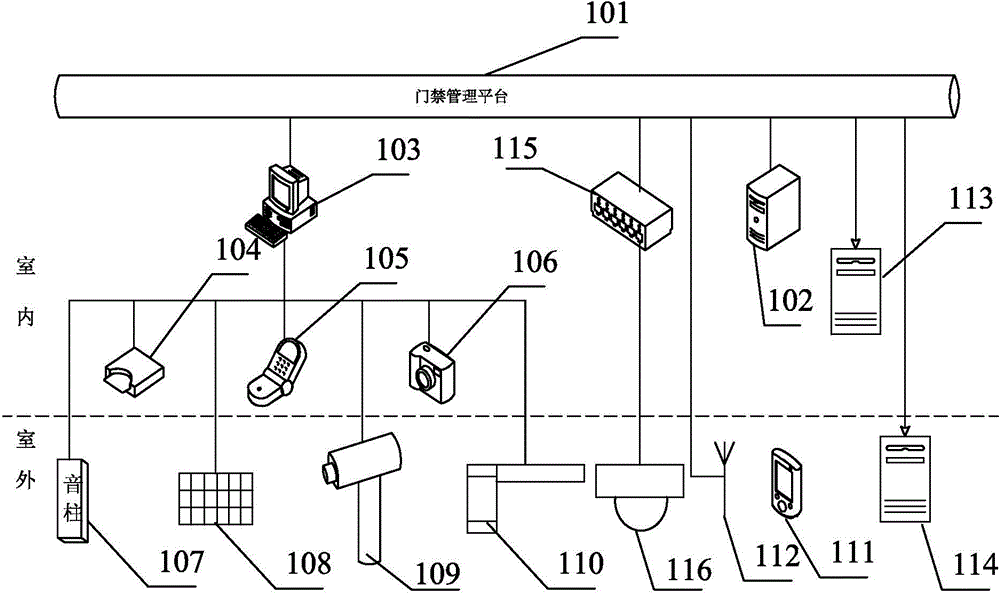

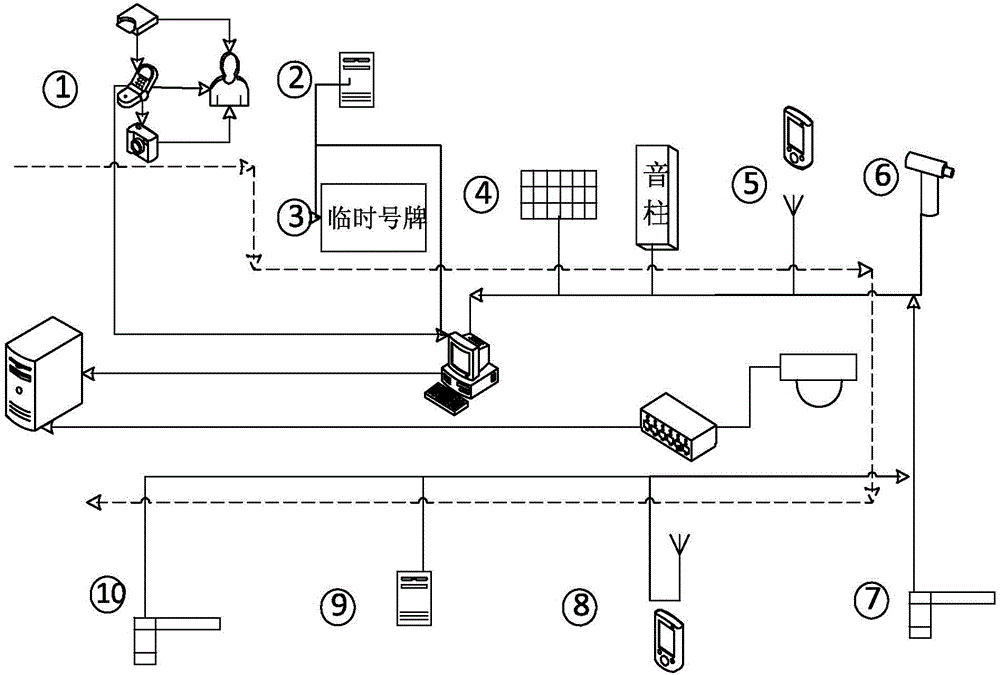

Intelligent depot output-input system of digital grain depot

ActiveCN103559605ASimplify business processesRealize paperless managementIndividual entry/exit registersLogisticsIntelligent managementComputer science

The invention discloses an intelligent depot output-input system of a digital grain depot. The intelligent depot output-input system of the digital gain depot comprises an intelligent depot output-input access control system, an intelligent depot output-input automatic sampling system, an intelligent depot output-input examination assay system, an intelligent depot output-input unattended operation automatic metering system, an intelligent depot output-input system control terminal, an intelligent depot output-input goods receiving-sending management system, an intelligent depot output-input system one-stop service platform and an intelligent depot output-input system control center. The intelligent depot output-input access control system, the intelligent depot output-input automatic sampling system, the intelligent depot output-input examination assay system, the intelligent depot output-input unattended operation automatic metering system, the intelligent depot output-input system control terminal, the intelligent depot output-input goods receiving-sending management system and the intelligent depot output-input system control center are connected with the intelligent depot output-input system one-stop service platform. According to the intelligent depot output-input system of the digital grain depot, a computer, the RFID internet of things technology, the communication technology and the information technology are converged together, networking, automation and intelligent management of the depot output and input are achieved, and labor participation is reduced.

Owner:JINAN JINZHONG ELECTRONICS SCALE +1

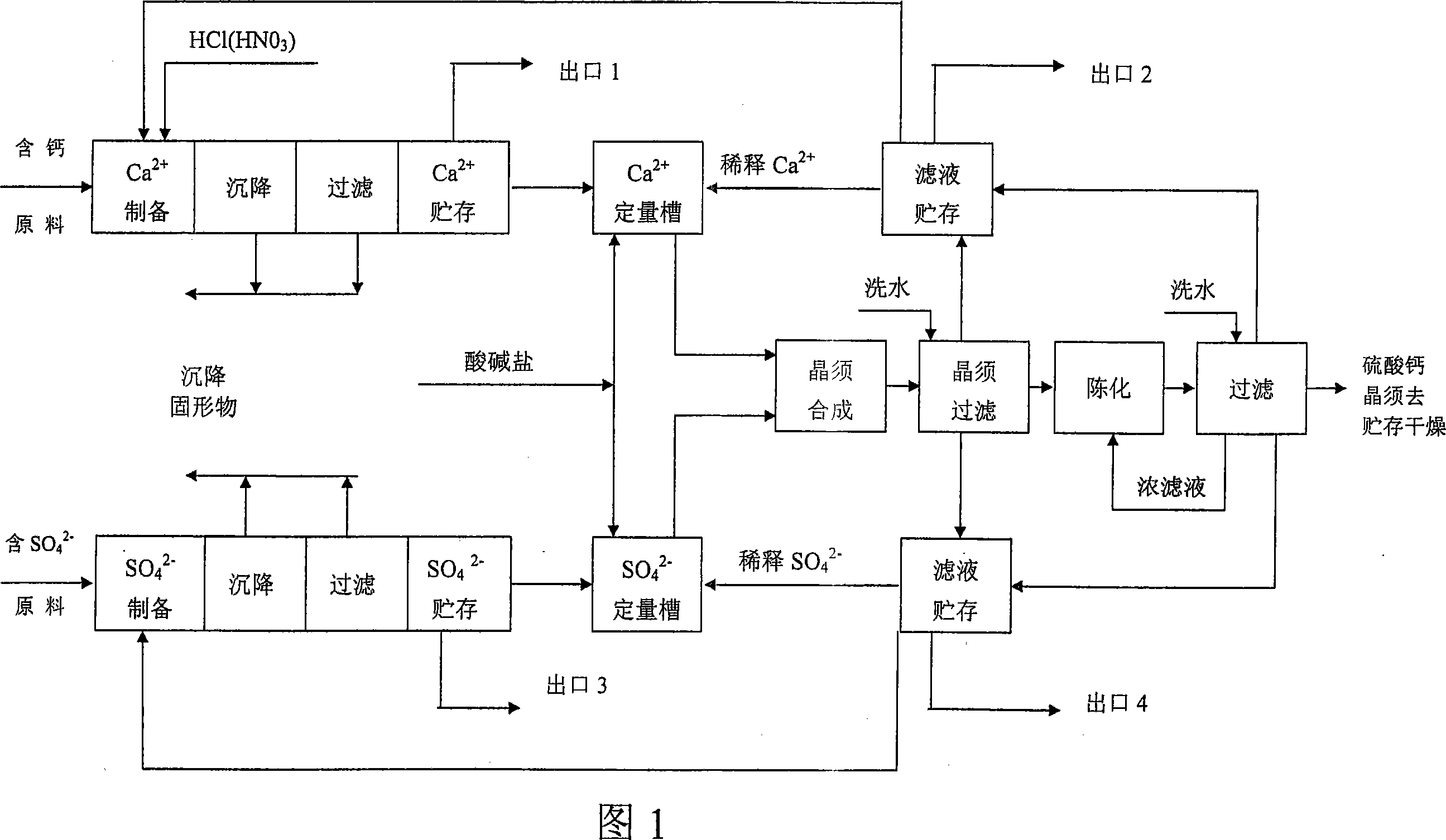

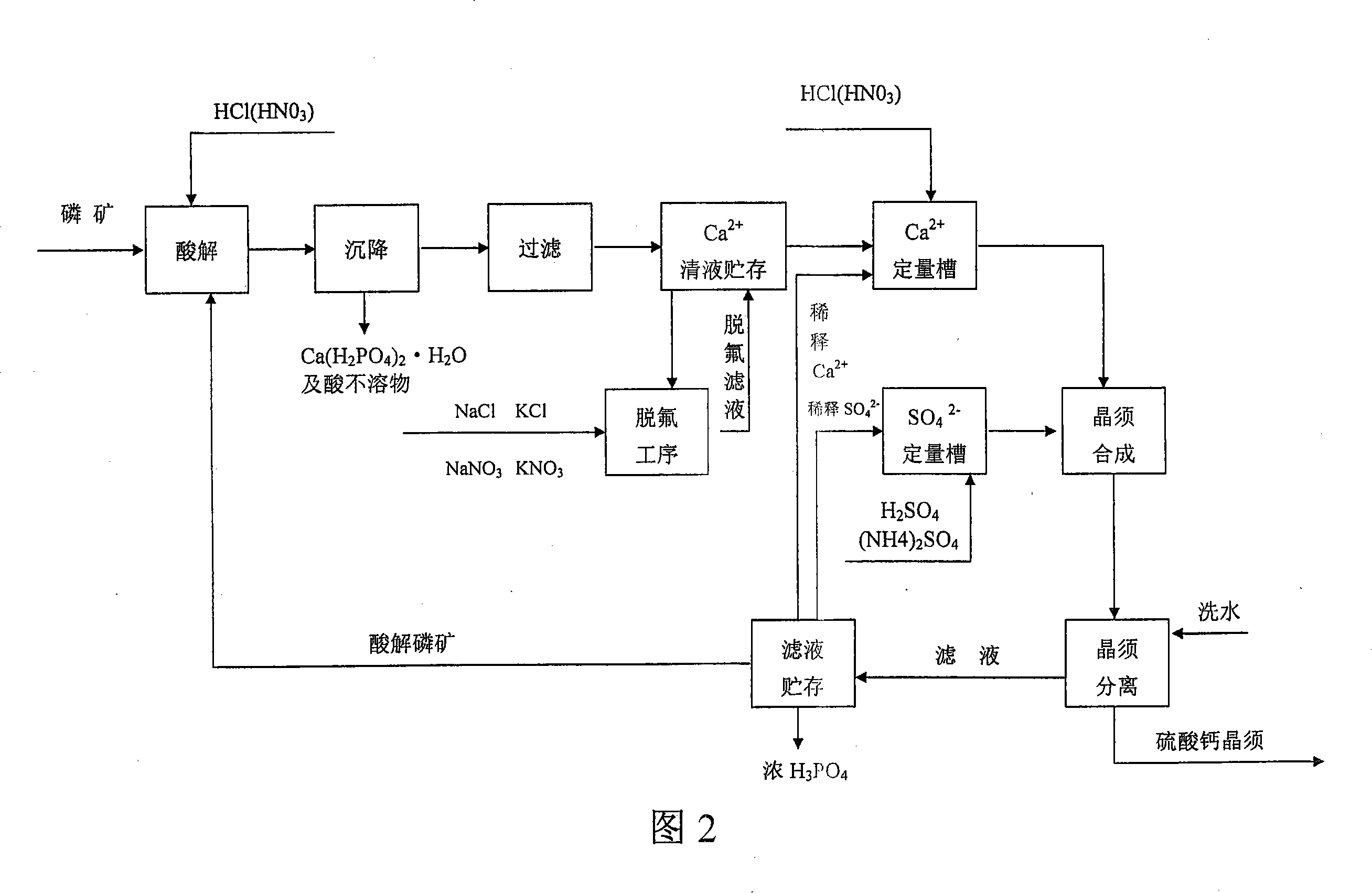

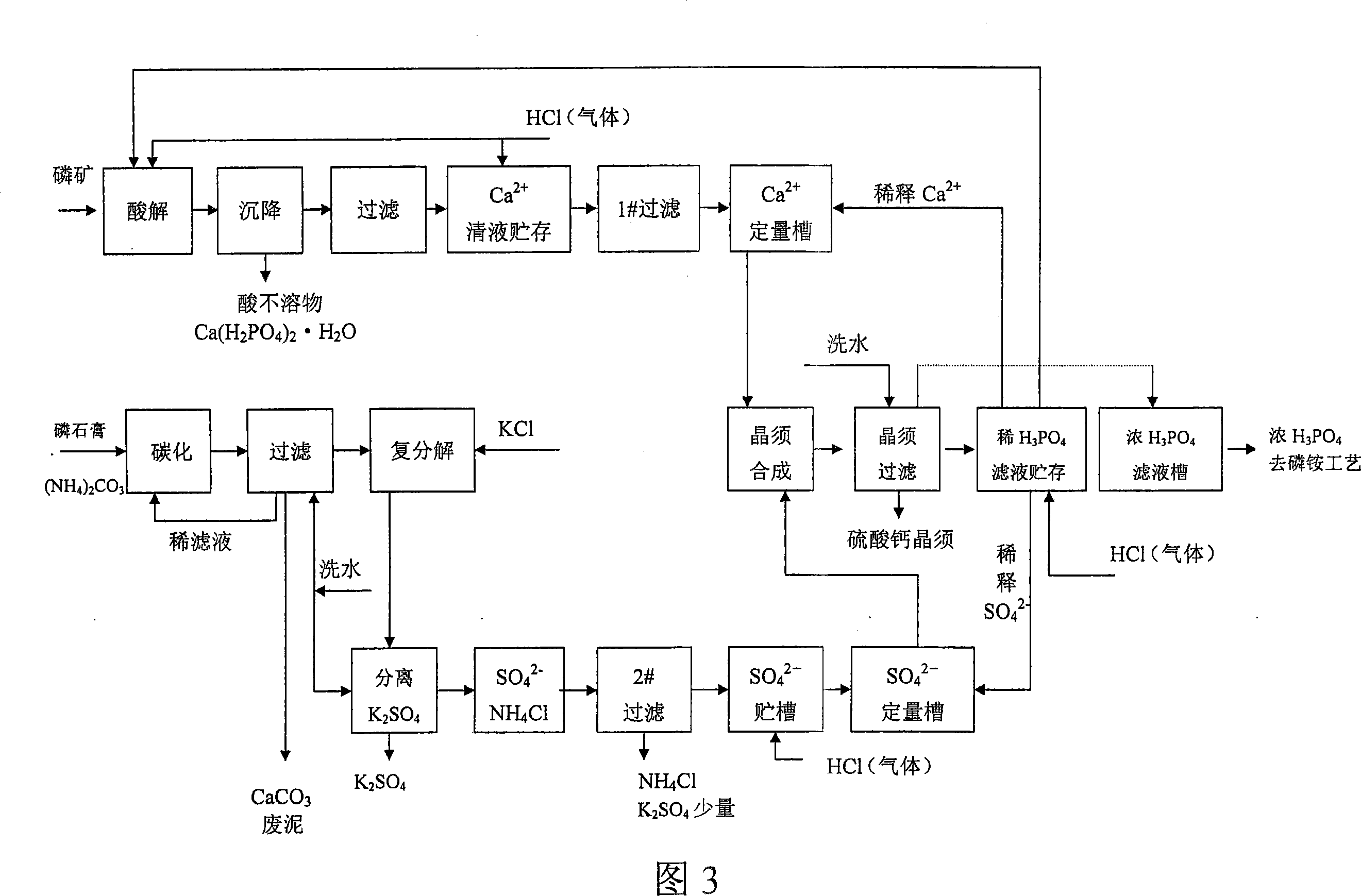

Mass production method for calcium sulfate whisker

ActiveCN101168852ALarge amount of preparationImprove environmental benefitsPolycrystalline material growthFrom normal temperature solutionsSulfateSludge

The invention discloses a new method for large-scale production of calcium sulfate whiskers, which is characterized in that a large number of cheap water-soluble Ca2+ and water-soluble SO42- ions are used at a certain pH, salt-containing impurities and whisker control agents and a certain synthesis Calcium sulfate whiskers were synthesized under conditions such as , aging, and temperature. The invention has the advantages of simple process, low investment, low cost and excellent products. It can be co-produced with various existing processes containing Ca2+ and SO42-, can eliminate the waste water and waste residue pollution of these processes, and can greatly improve these co-production processes. economic benefits.

Owner:武善东 +1

Ultraviolet light cured transfer printing film and preparation method and application thereof

InactiveCN101941339AHigh material strengthGood weather resistanceDecorative surface effectsOrnamental structuresLacquerPrinting ink

The invention belongs to the field of decorative materials, and particularly relates to an ultraviolet light cured transfer printing film and a preparation method and application thereof. The preparation method comprises the following steps of: uniformly coating or printing a mold release agent on a base load film, and performing infrared curing; uniformly coating or printing an ultraviolet light cured printing ink with a patterning function on a mold release agent layer, and performing curing through ultraviolet irradiation; or uniformly coating or printing an ultraviolet cured protective layer coating with anti-scratching and wear-resistant functions on the mold release agent layer first, then uniformly coating or printing the ultraviolet light cured printing ink with the patterning function on the mold release agent layer after the curing through the ultraviolet irradiation, and performing the curing through the ultraviolet irradiation; and uniformly coating or printing an ultraviolet light cured bottom color coating on an ultraviolet light cured printing ink decorative pattern layer, and performing the curing through the ultraviolet irradiation to obtain the ultraviolet light cured transfer printing film which can be used for producing an ultraviolet light cured transfer printing film decorative board. The ultraviolet light cured transfer printing film has high material strength, and has the advantages of high weathering resistance, high environmental protection, rich colors and patterns, full lacquer film, high hardness, scratch resistance, easy cleaning, noninflammability and the like.

Owner:ZHUHAI DONGCHENG UV MATERIALS

Method for treatment and in-situ ecological restoration of black and stink riverway by using microorganism

InactiveCN102050523AReduce organic matterGood governanceWater resource protectionBiological water/sewage treatmentMicroorganismWater treatment system

The invention discloses a method for treatment and in-situ ecological restoration of a black and stink riverway by using microorganism. The invention is characterized in that target strains with pertinence are selected from sewage and then matched and combined with the existing strains to form compound microbial agents; and the sewage in the riverway is treated by using the matched compound microbial agents. In the invention, according to the specific pollution conditions of the riverway, the selected strains which are grown in the sewage are used to treat the sewage in the riverway, and the strains are matched and combined with the existing strains aiming at the pollution conditions of the water body in the riverway, so that the strains can exert synergistic effects in a microorganism sewage treatment system, thereby rapidly forming superior floras so as to decompose, absorb and transfer pollutants in the riverway and then achieving the optimum treatment efficiency. In the invention, the microorganism is firstly used to treat the water body, and then the water body is treated through the self-cleaning capability of the water body, thereby reaching the purpose of curing the exterior and the inherence and not generating secondary pollution. The method has the characteristics of safety, high efficiency, low cost, small investment and the like, and is simple to operate.

Owner:赵亚勋 +3

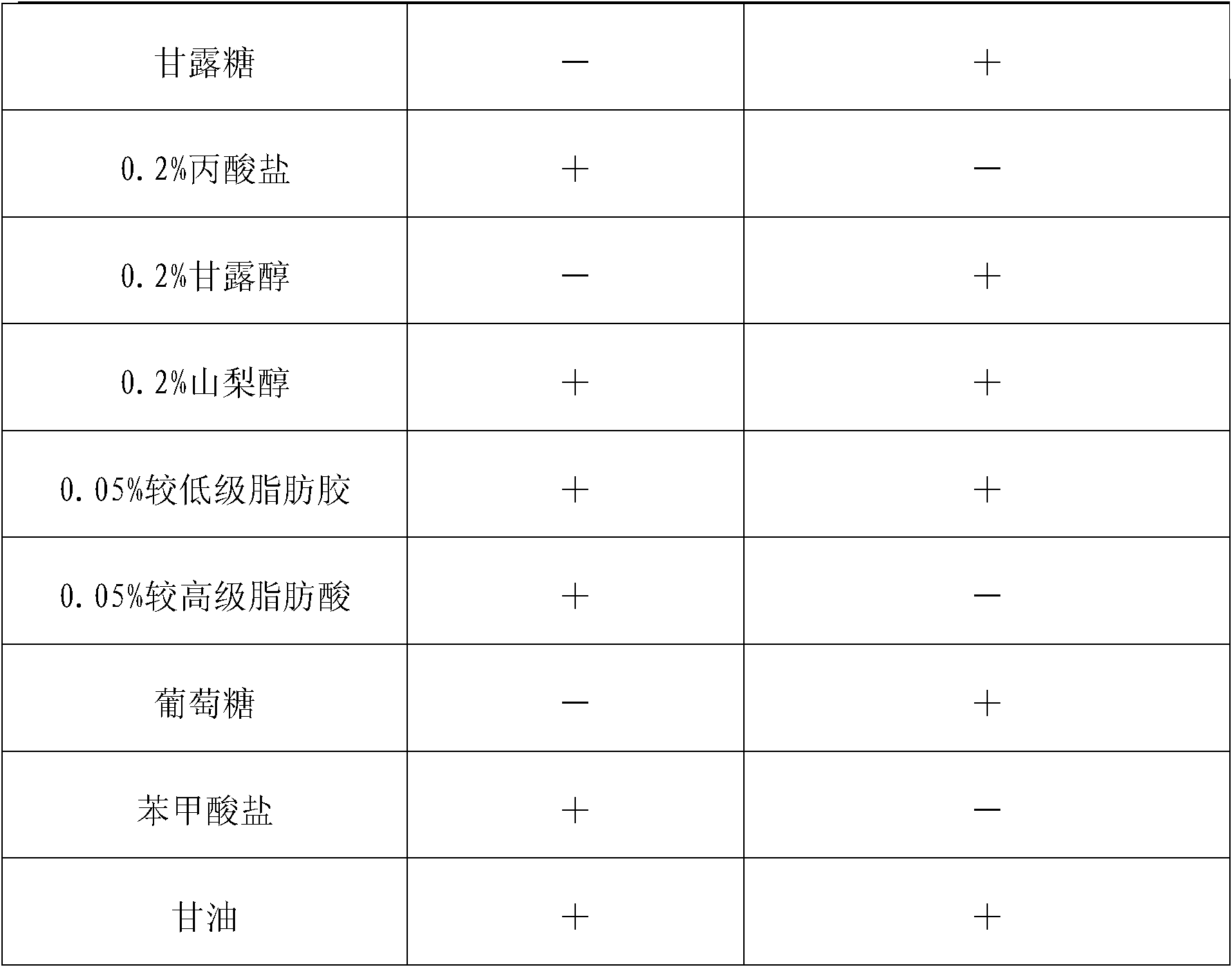

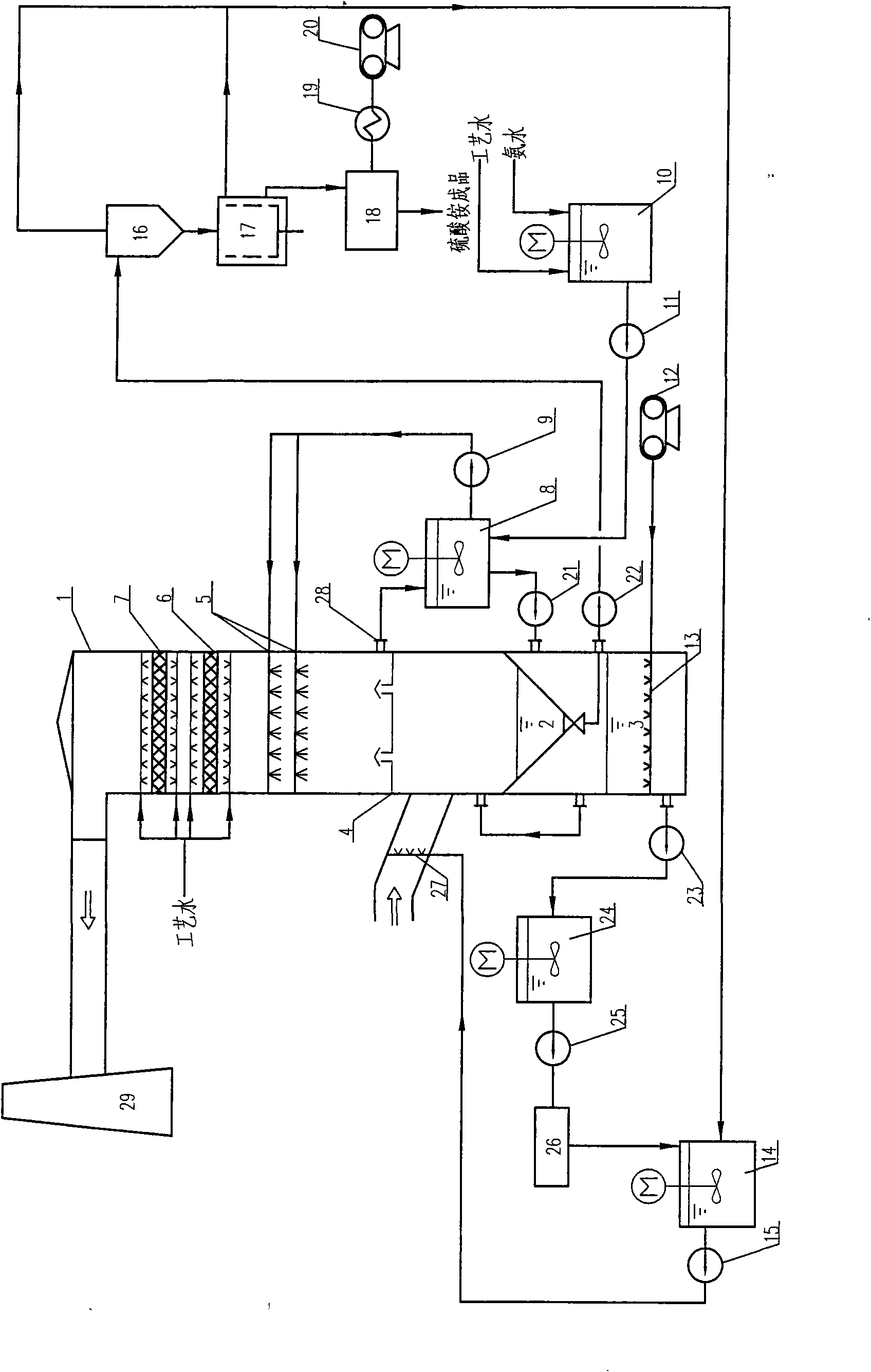

Energy-saving and high-quality ammonia desulphurization process for ammonia sulfate recovery

InactiveCN101579602ALow recycling comprehensive operating costConsiderable "positive benefit"Dispersed particle separationThermal energySulfate

The invention belongs to flue gas desulphurization technology of the environmental protection field. To solve the problems of large energy consumption, lower product quality and large investment in recovering ammonia sulfate by an ammonia desulphurization technique, the invention provides an energy-saving and high-quality ammonia desulphurization process for ammonia sulfate recovery. The process adopts ammonia water as a desulfurizer, ammonium sulfite is produced after the ammonia water and flue gas are decarbolized completely, and ammonia sulfate is produced after the ammonium sulfite is forcibly oxidized in a tower; impurities in the ammonia sulfate solution is removed by filtering, the filtrate is contacted with high-temperature flue gas in a desulfurizing tower for heat exchange, and when flue gas is cooled, the ammonia sulfate solution is heated and saturated; and then after crystallization of the saturated ammonia sulfate solution for a period of time, high-quality ammonia sulfate is produced after centrifugal drying. By adopting the technical proposal of the invention, not only thermal energy of an ammonia sulfate product which is produced by drying process can be greatly saved, high-quality ammonia sulfate fertilizer can be recovered, occupation area can be reduced and investment can be save, but also flue gas emission can meet the standard, without resulting in secondary pollution such as waste water and the like.

Owner:山西晋丰节能环保工程设计有限公司

Technological process for producing super-thick plate

InactiveCN101439348AQuality improvementLow costTemperature control deviceElectron beam welding apparatusElectro-slag remeltingVacuum chamber

The invention relates to a process for producing an ultra-thick plate and belongs to the field of rolling and producing an ultra-thick steel plate in the metallurgical industry. The invention mainly overcome the defect of producing the ultra-thick steel plate by a traditional model casting manufacturing blank and an electro-slag remelting manufacturing blank. The method comprises the following steps: cutting and fixing lengths of the blanks, mechanically conditioning the blanks (eliminating, leveling and cleaning a single-surface oxide layer of a casting blank with a milling machine, a planer or a shot blast); clamping an assembly (relatively superposing the cleaning surfaces of the two blanks after processing, placing the two blanks oppositely and clamping the blanks); mounting the blanks in a vacuum chamber of an electronic beam welding machine for purpose of vacuuming; sewing the assembly on the electronic beam welding seal edge, heating the assembly in a furnace and rolling the assembly through temperature control; and then producing the ultra-thick steel plate. Compared with the traditional electro-slag remelting production process, the process has the advantages of high production efficiency, reduced electric power consumption, less investment of production devices and low production cost. Compared with the traditional die casting production process, the process solves the problem of segregation and looseness of a large-scale die casting ingot center part; the finished product ratio is high; and the finished product ratio of blank assembly is over 90 %.

Owner:SHANDONG IRON & STEEL CO LTD

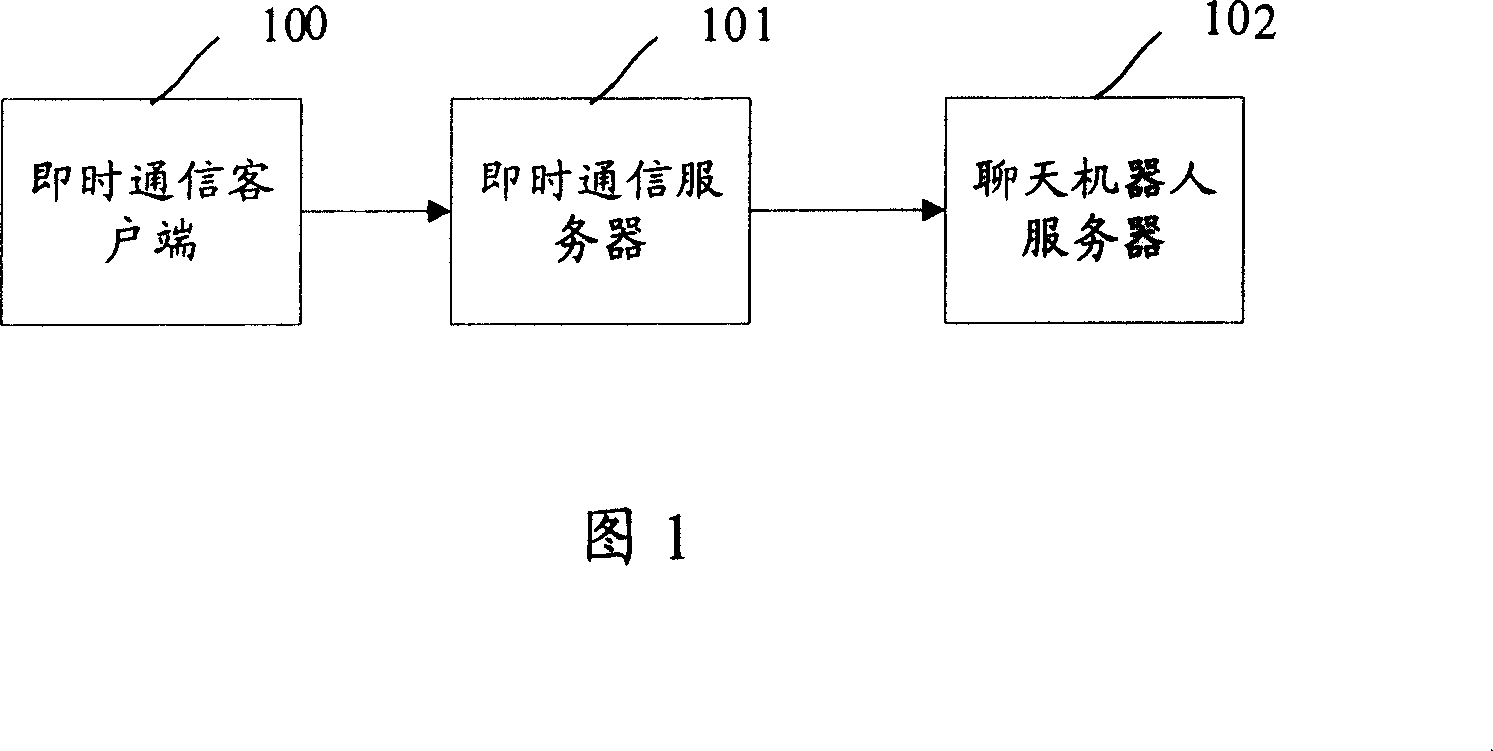

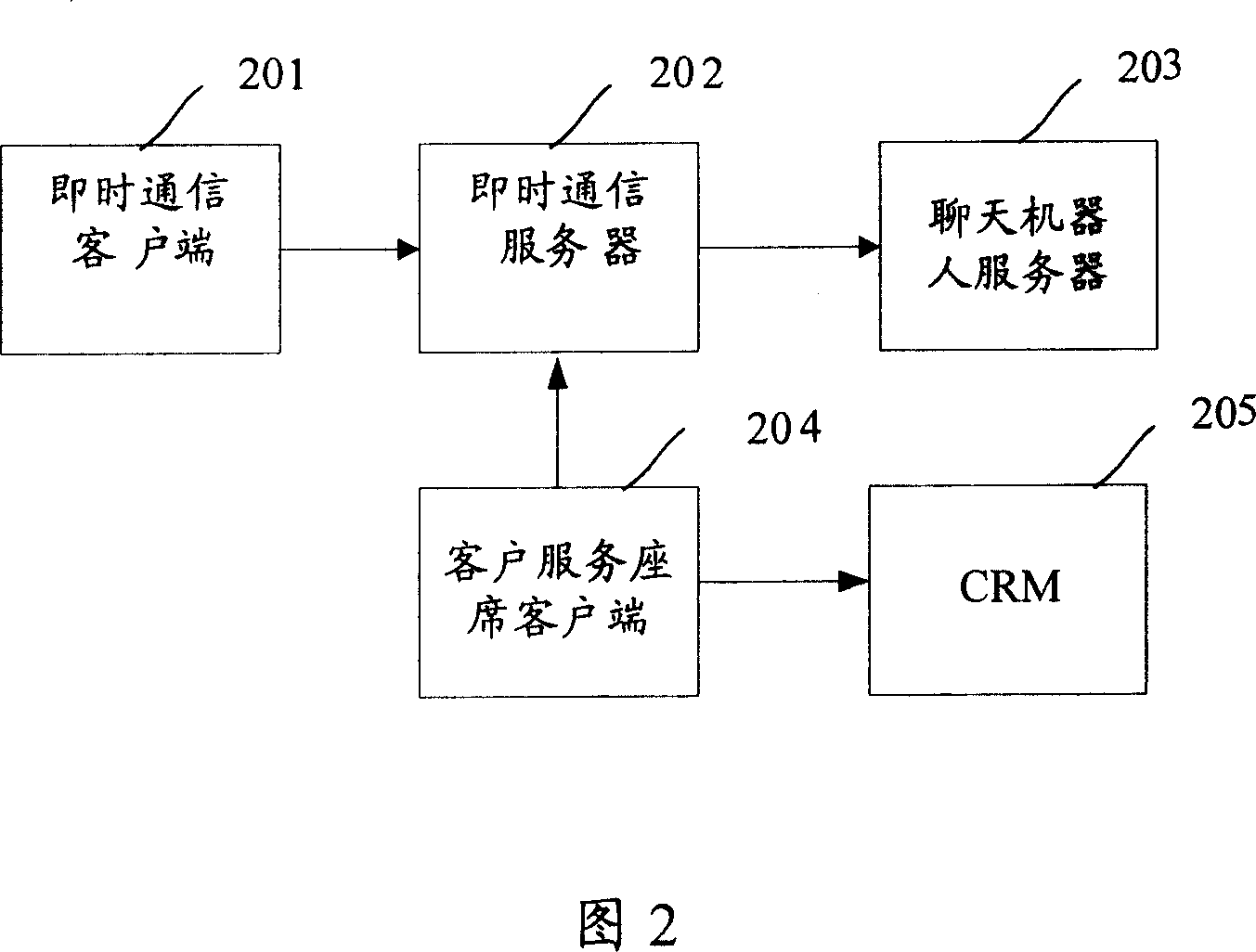

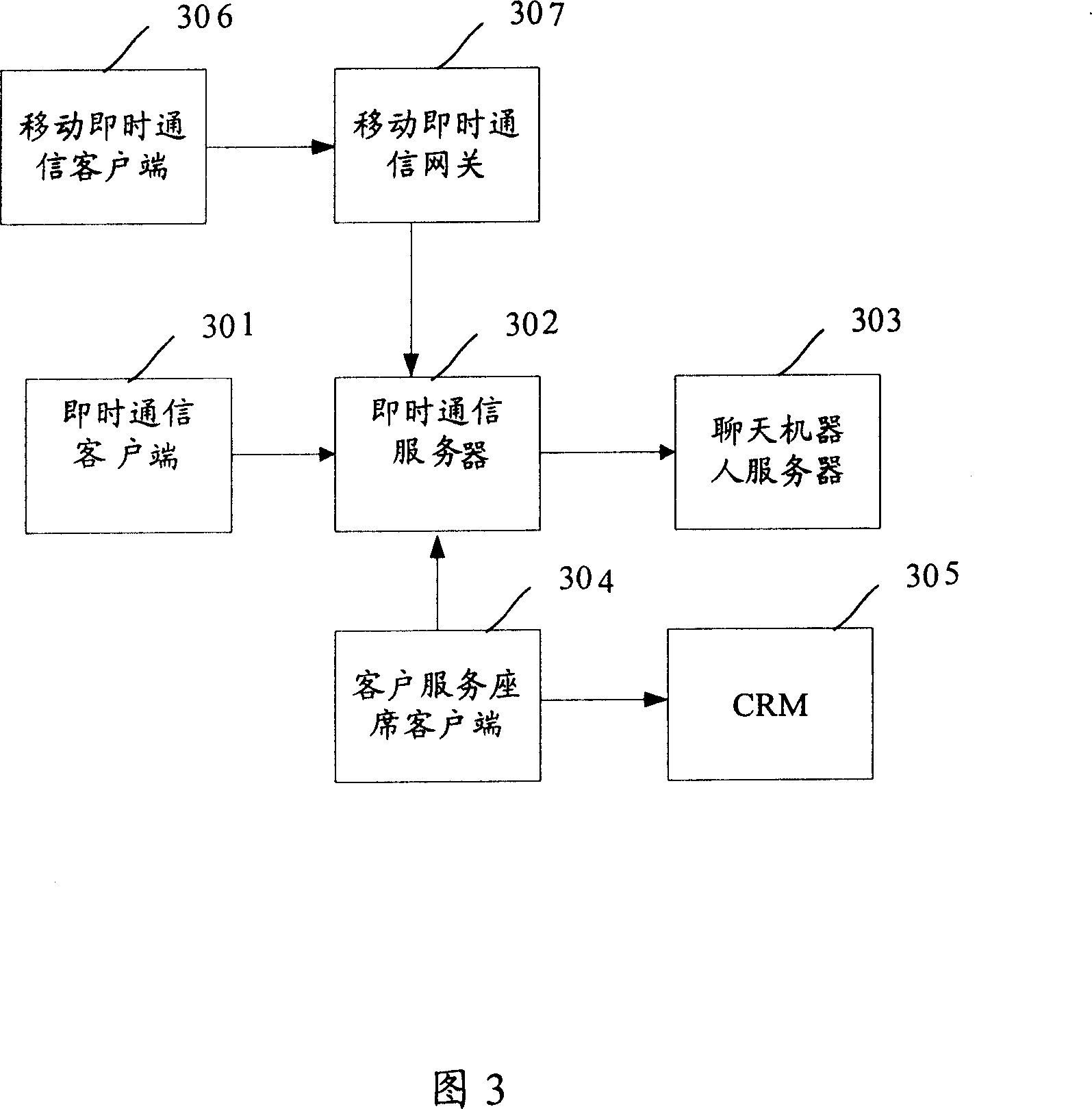

Method and system for realizing automatic reply

ActiveCN101076184ALess investmentReduce or even eliminate human involvementAutomatic call-answering/message-recording/conversation-recordingRadio/inductive link selection arrangementsClient-sideCommunications server

The system comprises: an instant communication server used for establishing the connection between the instant communication client side and the robot chat server; an instant communication client side used for sending the session message to the robot chat server via the instant communication connection; a robot chat server used for receiving the session message sent from the instant communication client side, finding the answer, and sending the answering message to the communication client side. The Invention also reveals a method thereof.

Owner:TENCENT TECH (SHENZHEN) CO LTD

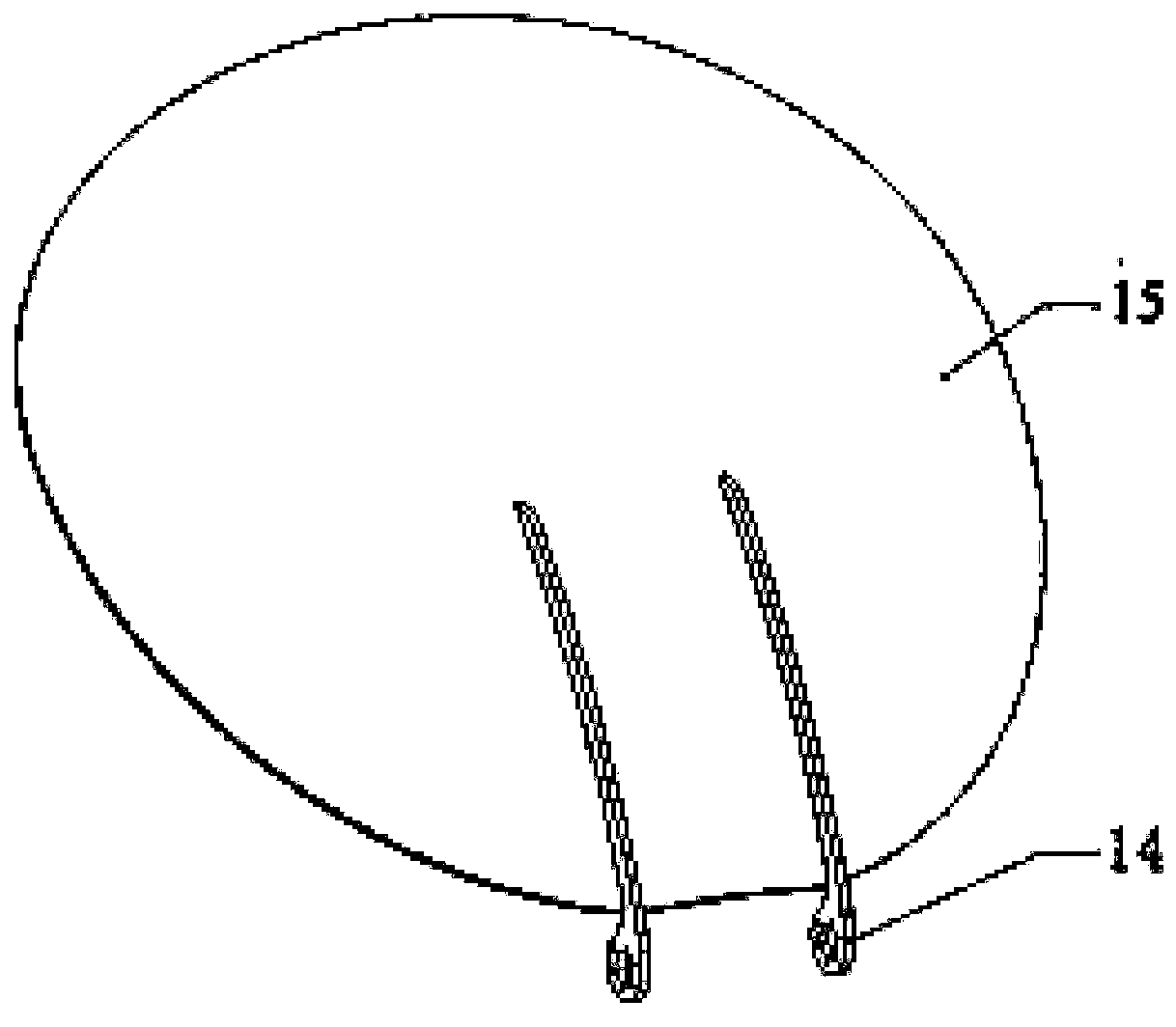

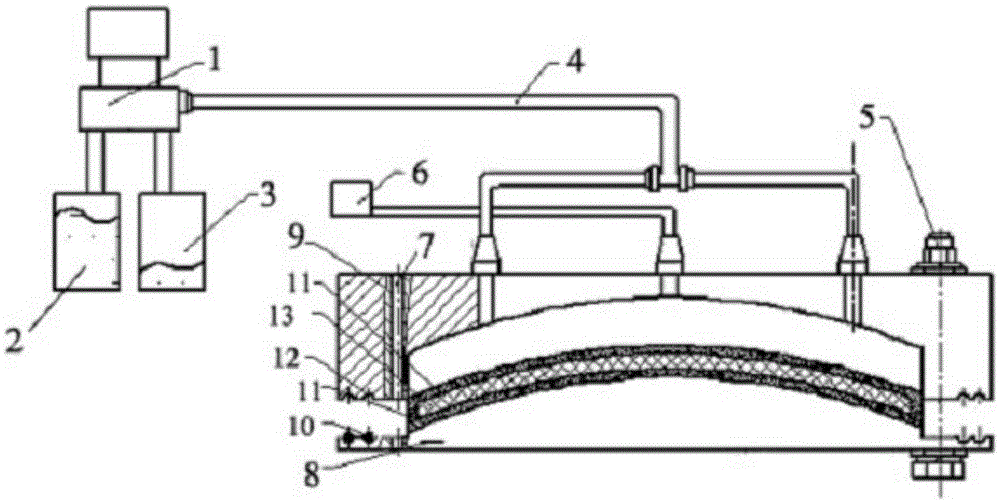

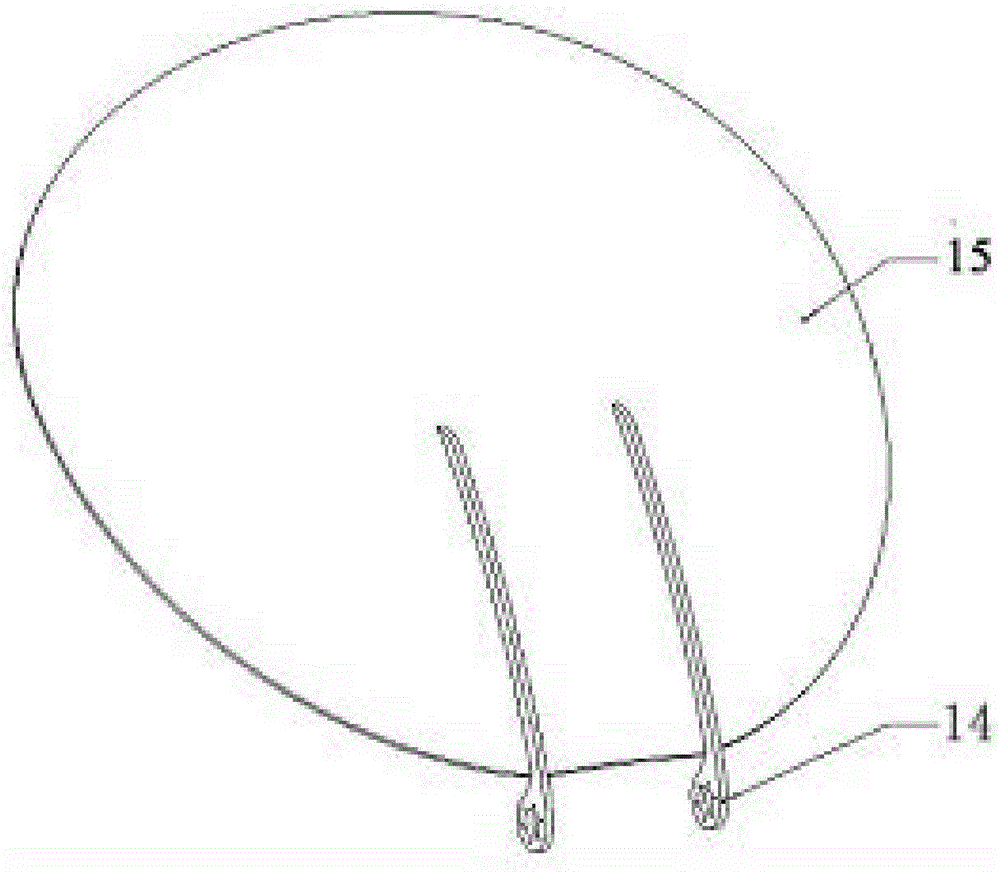

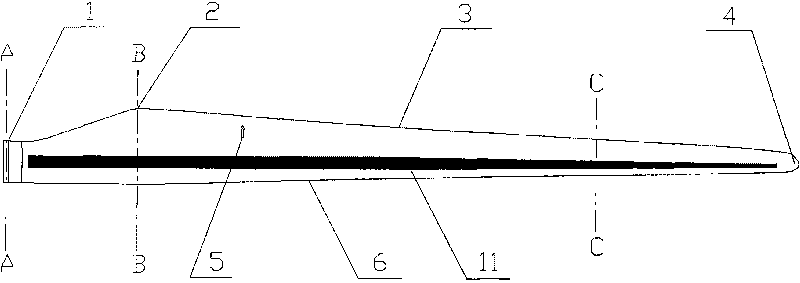

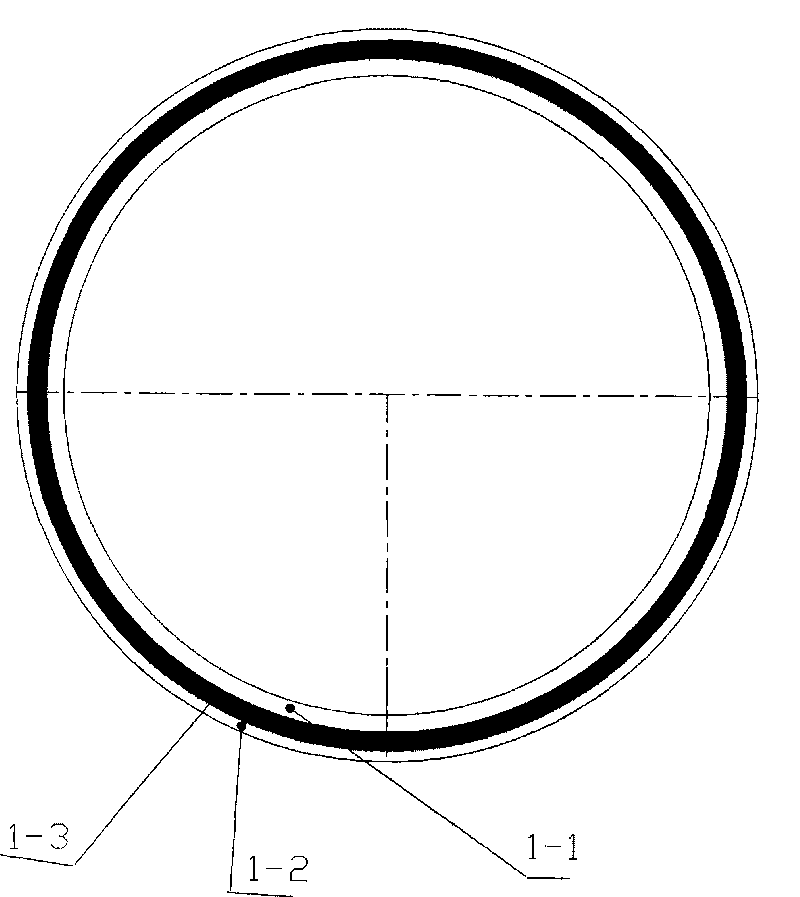

Wind turbine blade for large-scale wind generating set, and molding method thereof

ActiveCN101749194AReduce manufacturing costLess investmentFinal product manufactureMachines/enginesElectricityTurbine blade

The invention discloses a wind turbine blade for a large-scale wind generating set (wind-power blade for short). The wind-power blade has a thin shell structure and is combined by adhering two pieces of semi-shells; crossbeams which are extended from a blade root to a blade tip are respectively arranged in the two shells of the blade; a main shear web is adhered between the two crossbeams so as to form an I-shaped structure; a trailing edge shear web which is parallel to the main shear web is arranged on the side, between the two shells, close to the trailing edge; and the upper end and the lower end of the trailing edge shear web are respectively connected with the two shells. The invention also discloses a molding method for the wind turbine blade, which comprises the step of performing one-time molding on the crossbeams, a blade root enhancement layer and a shell by the technology of vacuum perfusion (RIM). Due to the adoption of the solution of the one-time molding technology, the quality defect caused by post molding of a composite material is avoided, the structural strength of a manufactured wind-power blade is improved and the service life of the manufactured wind-power blade is prolonged, and production efficiency is remarkably improved and production cost is reduced.

Owner:CHONGQING GENERAL IND (GRP) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com