Patents

Literature

5858results about How to "Prevent collapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor constructions, and methods of forming capacitor devices

InactiveUS20050054159A1Prevent collapsePrevent crashTransistorSolid-state devicesElectrically conductiveEngineering

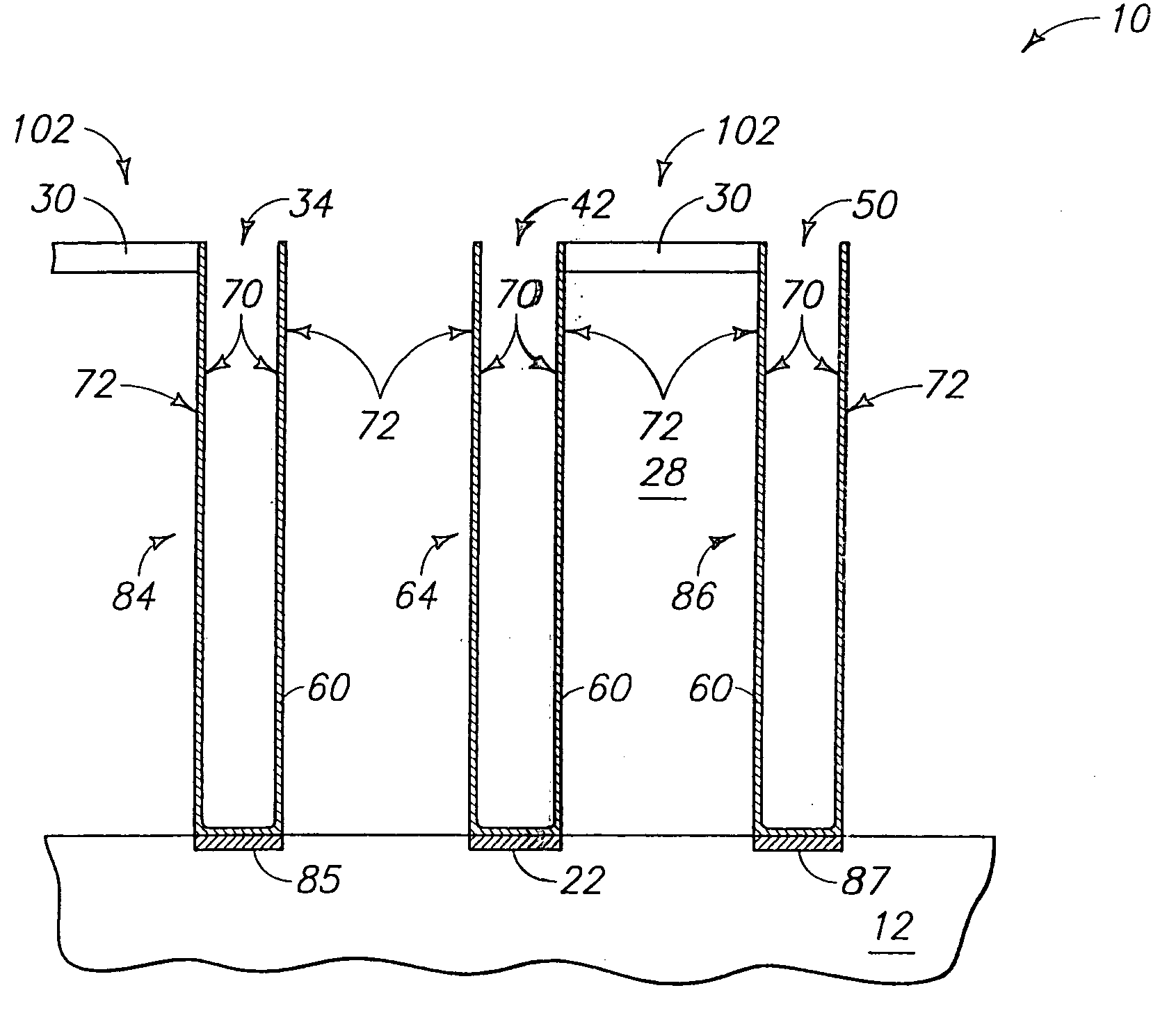

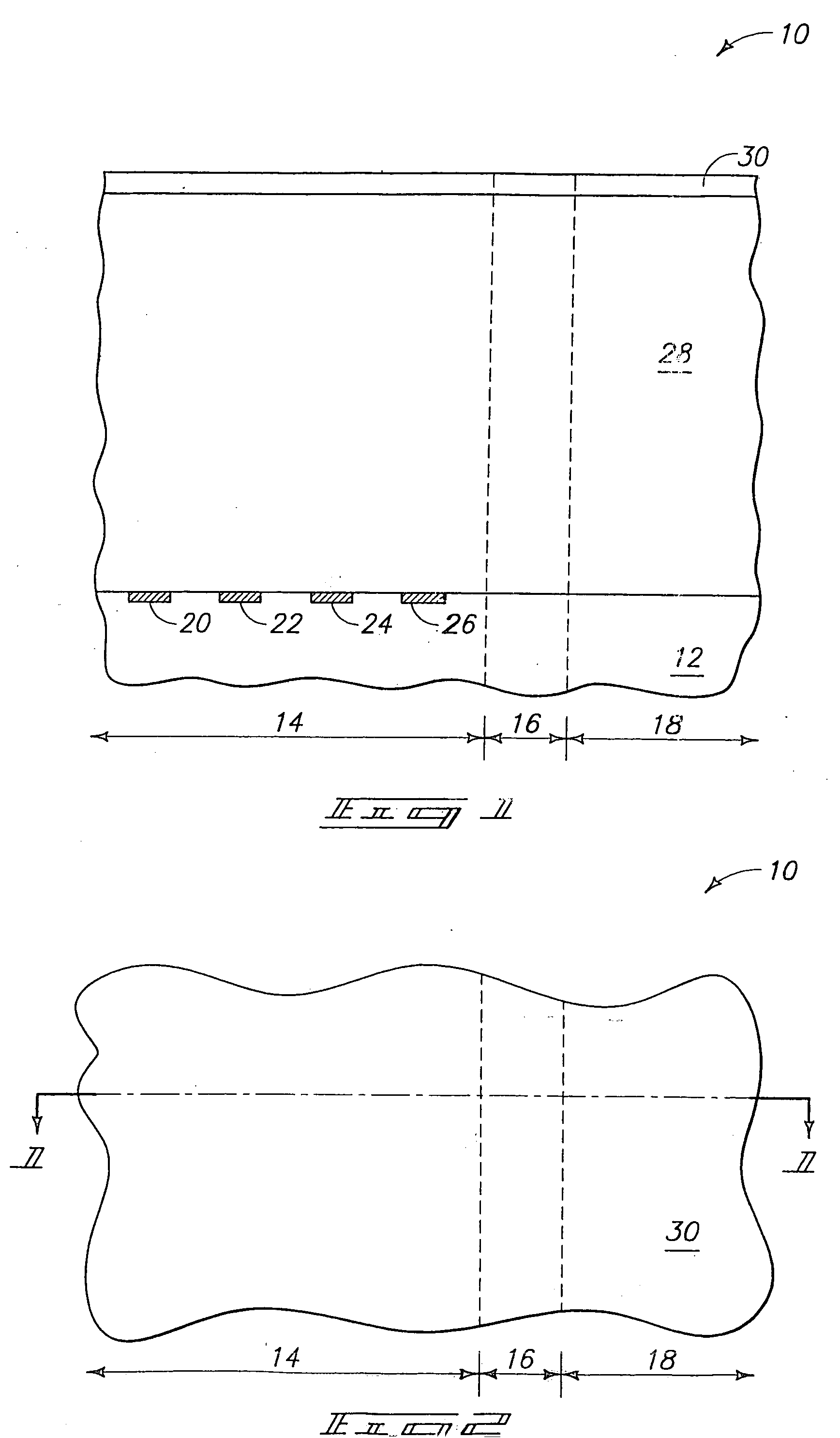

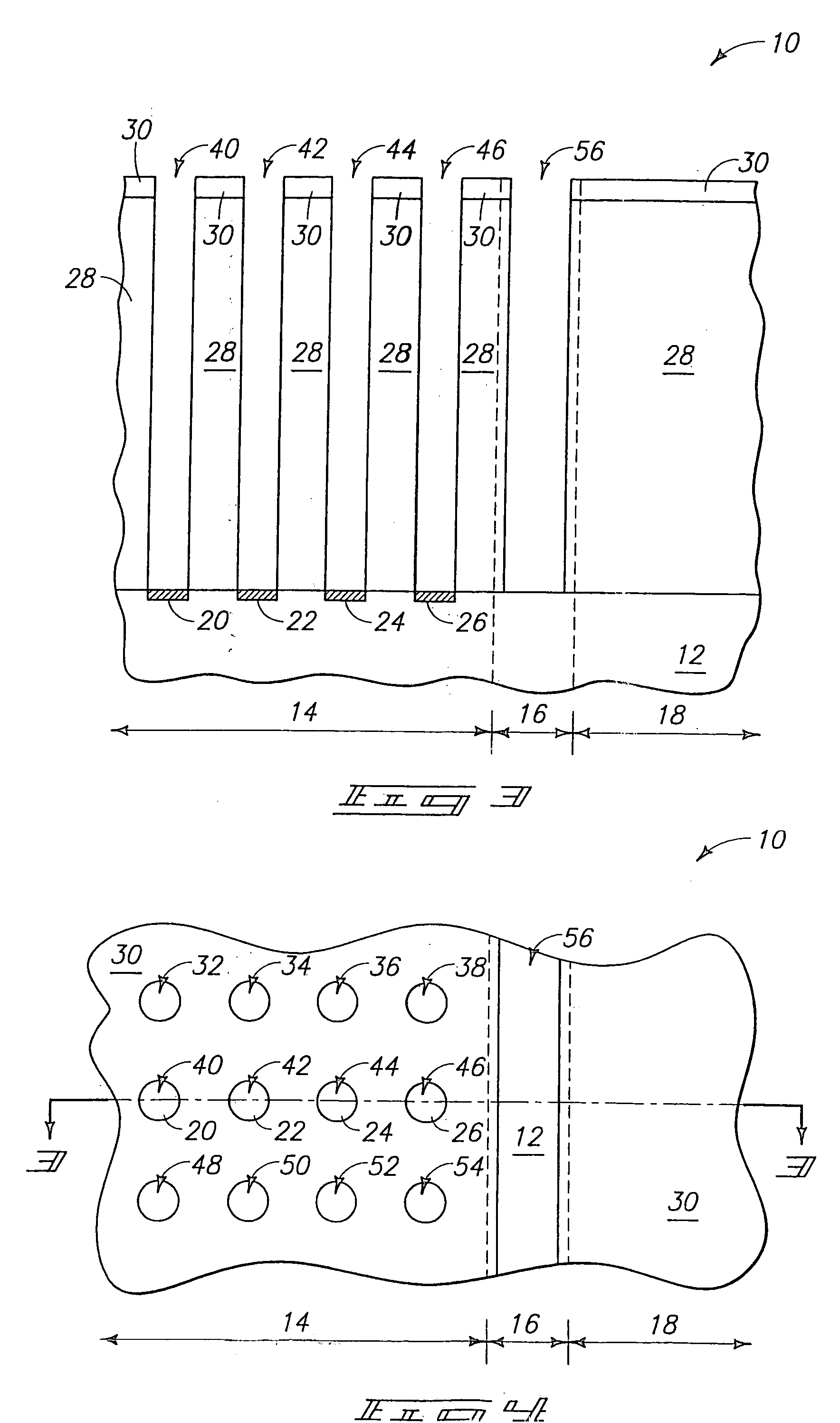

The invention includes semiconductor constructions, and also includes methods of forming pluralities of capacitor devices. An exemplary method of the invention includes forming conductive storage node material within openings in an insulative material to form conductive containers. A retaining structure lattice is formed in physical contact with at least some of the containers, and subsequently the insulative material is removed to expose outer surfaces of the containers. The retaining structure can alleviate toppling or other loss of structural integrity of the container structures. The electrically conductive containers correspond to first capacitor electrodes. After the outer sidewalls of the containers are exposed, dielectric material is formed within the containers and along the exposed outer sidewalls. Subsequently, a second capacitor electrode is formed over the dielectric material. The first and second capacitor electrodes, together with the dielectric material, form a plurality of capacitor devices.

Owner:ROUND ROCK RES LLC

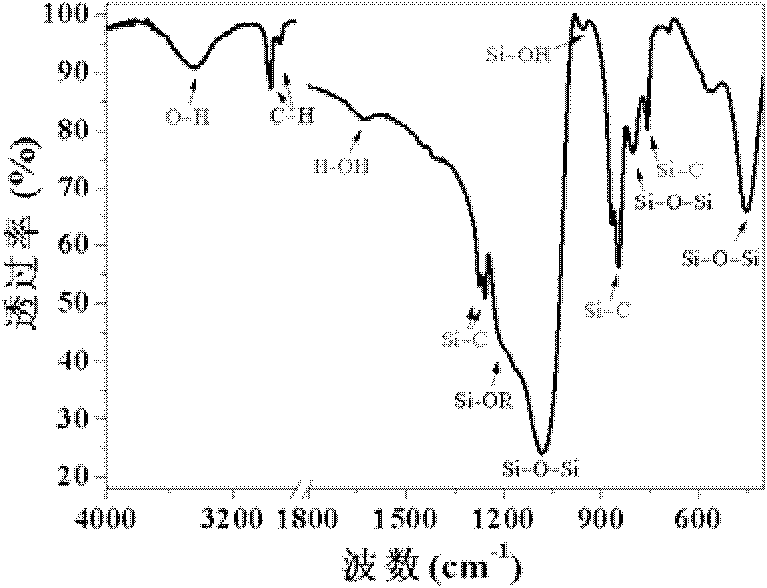

Method for preparing silica aerogel material

The invention discloses a method for preparing a silica aerogel material and relates to the method for preparing the aerogel material, in particular to the method for rapidly preparing a transparent SiO2 aerogel by being based on the sol-gel technology and adopting secondary modification and normal pressure drying. The invention provides the method for preparing the silica aerogel material, and the method has simple technology, short cycle, low cost and good safety and is conductive to large-scale production. Tetraethoxysilane is adopted as a silicon source, methyl trimethoxysilane or methyl triethoxysilane is taken as a modifier of a co-precursor, anhydrous ethanol is taken as a solvent, and hydrochloric acid and ammonia are taken as catalysts. The sol-gel acid-base two-step method is adopted for catalysis, thereby preparing the SiO2 wet gel; and the further modification is carried out on a wet gel sample after aging treatment under certain conditions, and the normal pressure low-temperature drying is finally carried out in air atmosphere, thereby preparing the SiO2 aerogel. The equipment cost during the preparation technology is low, the product has good performances and the reaction process is controllable.

Owner:中科润资科技股份有限公司

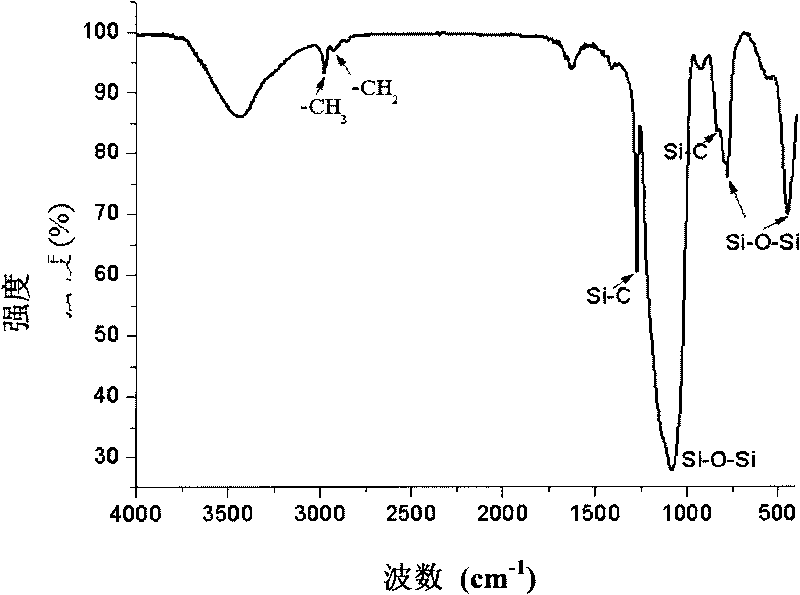

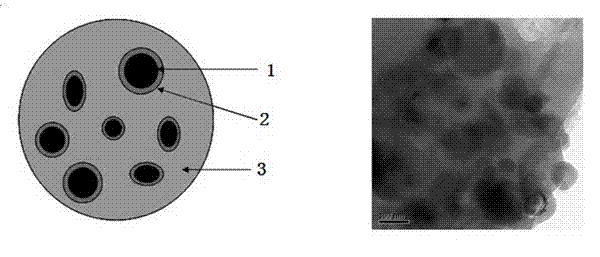

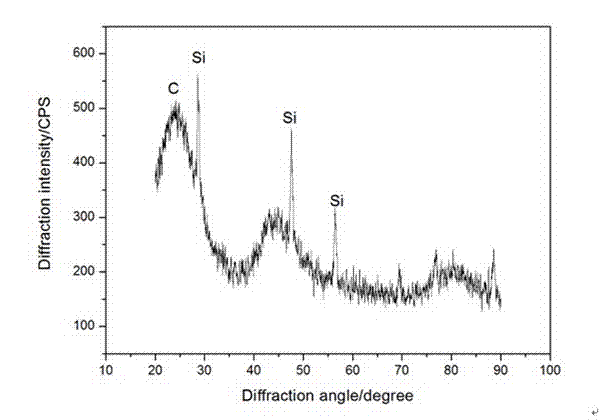

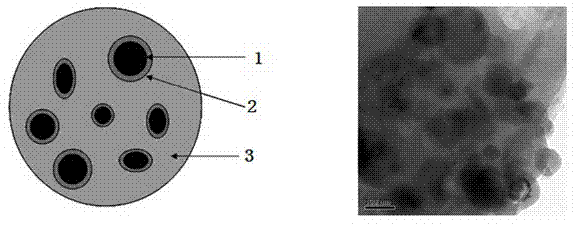

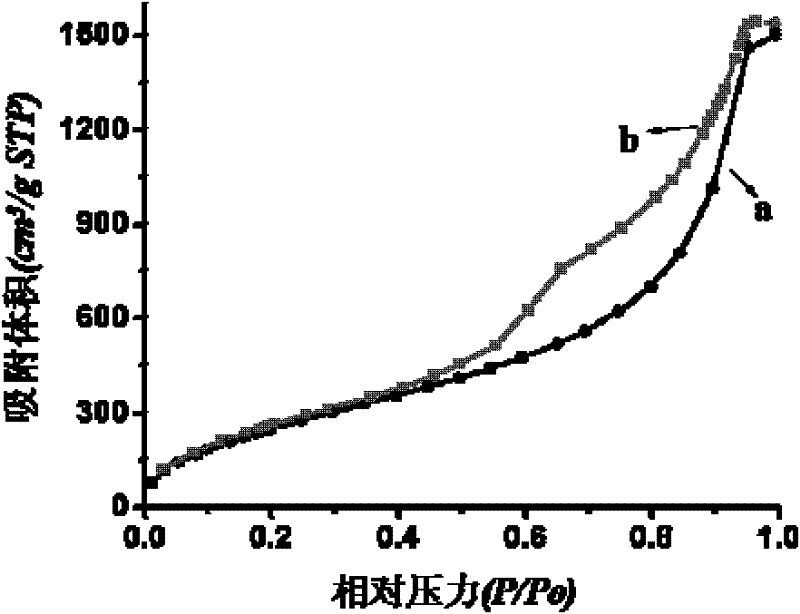

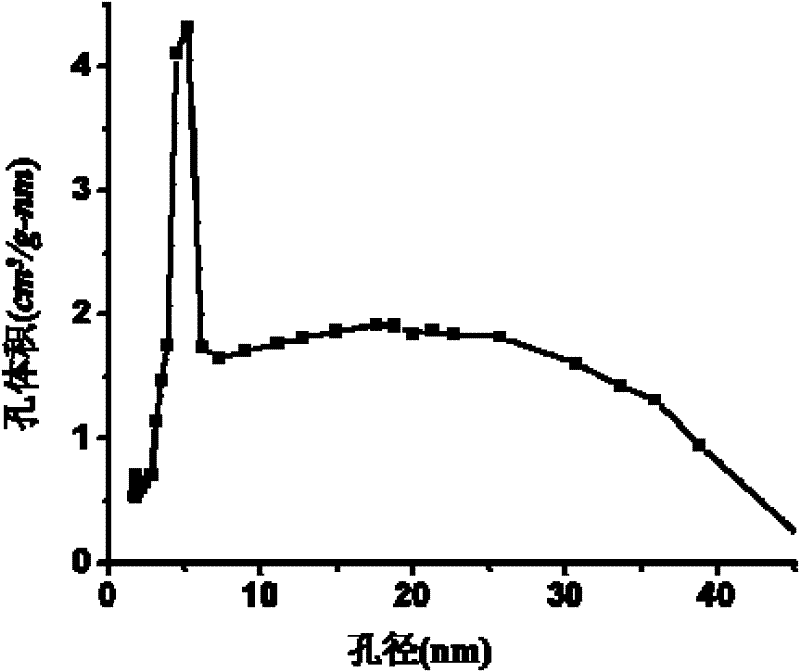

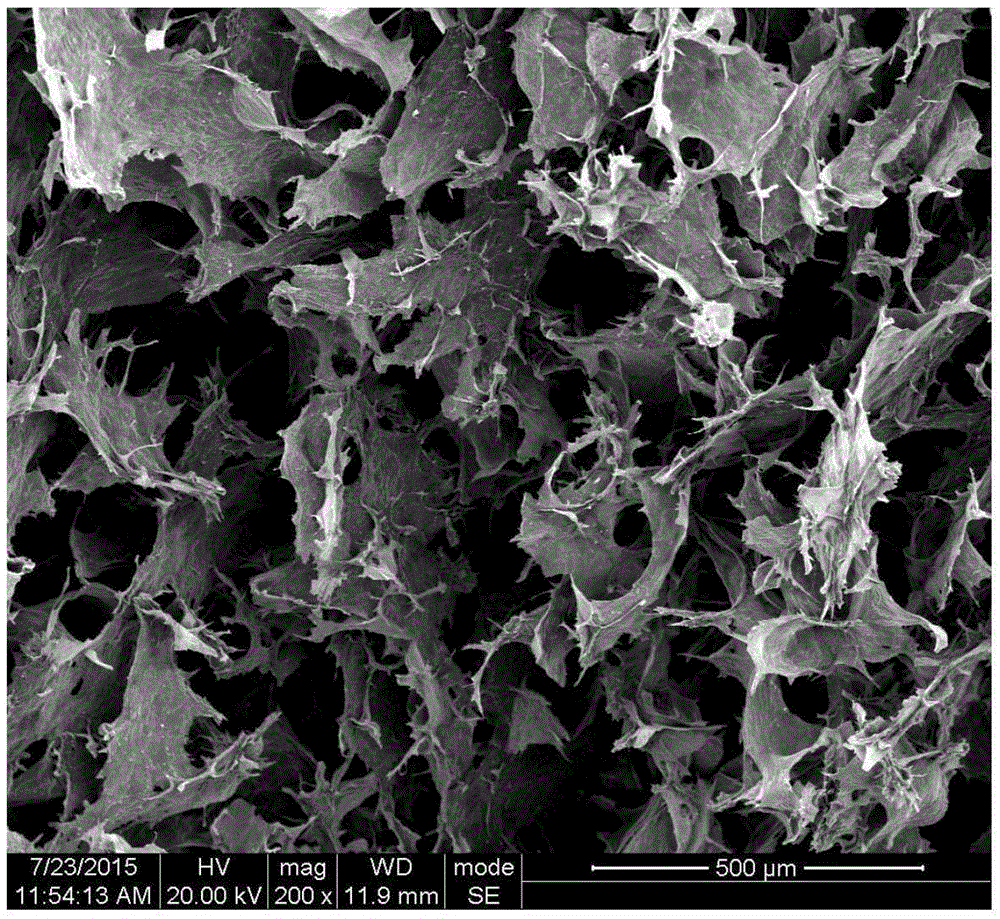

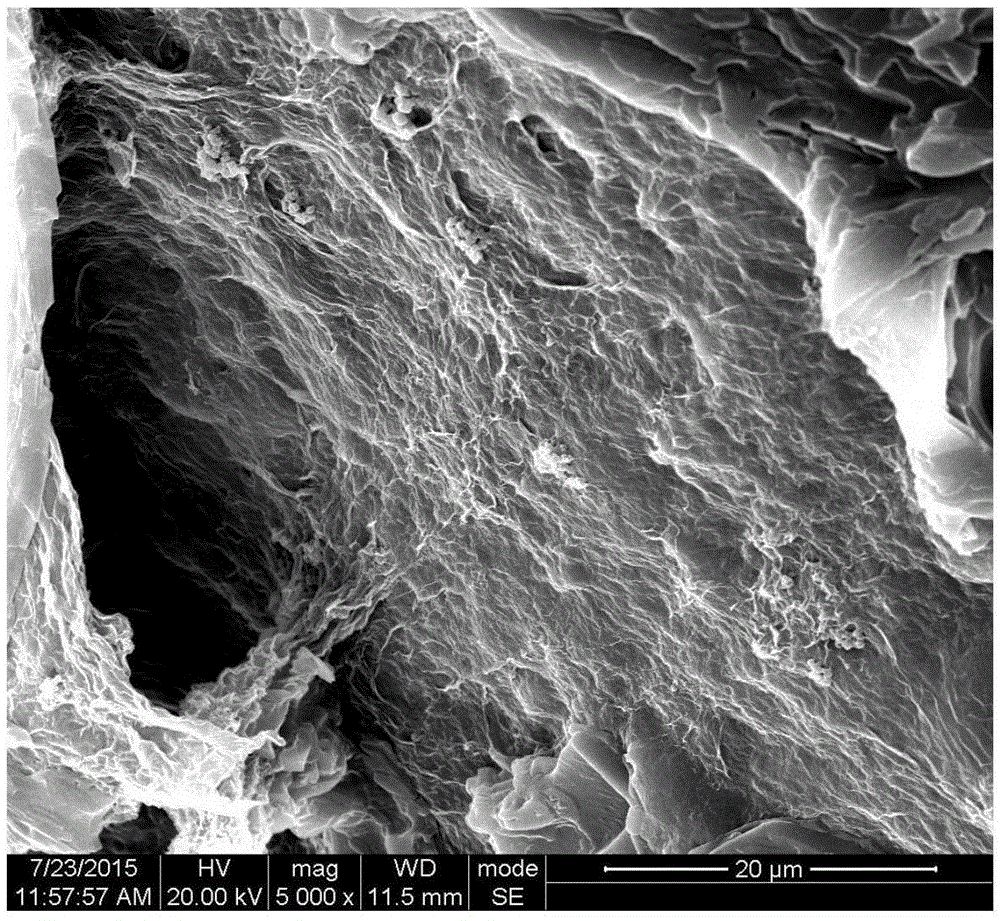

Silicon-carbon composite anode material and preparing method thereof

ActiveCN102509781AHigh specific capacityImprove cycle performanceCell electrodesCarbon compositesPorous carbon

The invention provides a silicon-carbon composite anode material, which comprises a nuclear shell structure and a support substrate, wherein particle size of the silicon-carbon composite anode material is 1-200 micrometers, and porous carbon serving as the support substrate is obtained through decomposition of biomass materials. The invention further provides a preparing method of the silicon-carbon composite anode material, which includes the following steps: 1 reaming the biomass materials in physical activation or chemical activation mode to prepare the porous carbon, or preparing small molecular organics serving as a precursor of the porous carbon in hydrolyzing mode; 2 mixing silica particles and the obtained porous carbon or the precursor of the porous carbon in solution and performing ultrasonic treatment; 3 evaporating the solution mixture to dry so as to obtain solid-state powder; and 4 drying the solid-state powder, and performing thermal treatment, crushing and sieving on the solid-state powder to obtain the silicon-carbon composite anode material. The silicon-carbon composite anode material and the preparing method thereof are simple in process, short in flow path, easy to operate and low in cost, and lithium ion batteries manufactured by the silicon-carbon composite anode material are suitable for various mobile electronic equipment or devices driven by mobile energy.

Owner:SHANGHAI JIAO TONG UNIV

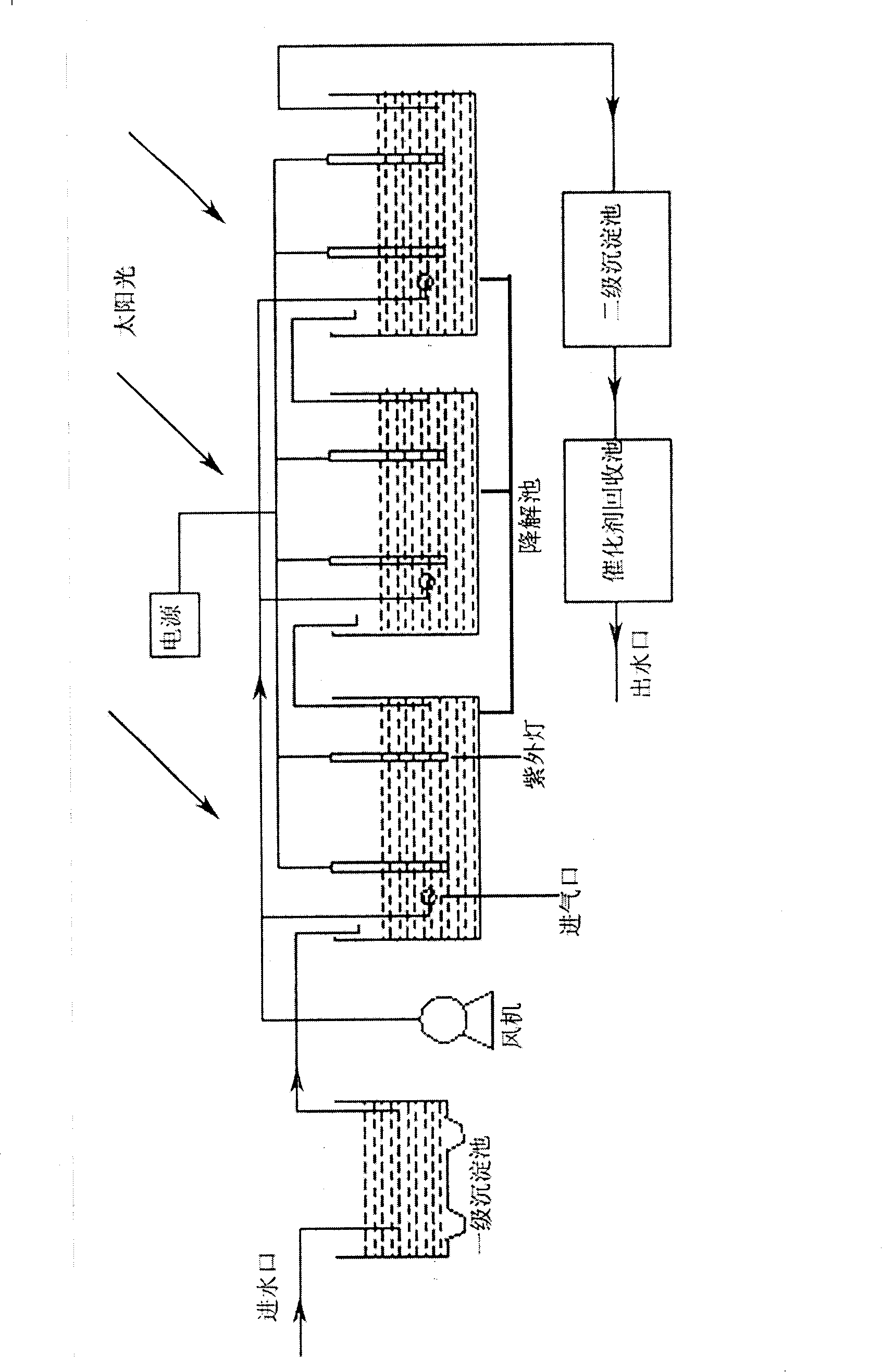

Photocatalysis oxidation treated high concentration organic trade waste

InactiveCN101219371AHigh activityImprove stabilityCatalyst carriersEnergy based wastewater treatmentHigh concentrationEmission standard

The invention relates to a modified loading nano composite photocatalyst which takes titanium dioxide as main part and adopts new reaction technique to degraded the organic industrial wastewater in a water processing system (see attached drawing 1 in Instruction). The main point on preparing the catalyst lies in that titanium dioxide active compounds loaded on different carriers are employed to prepare a loading photocatalyst with grain diameter of 5-40nm; meanwhile, different elements are mixed into the loading photocatalyst to reduce the composition between photoproduciton electron and cavity, which enables the catalyst to move the light absorbing wavelength thereof towards the visible regions, thus effectively improving the degradation rate of organic pollutants as a new environmental-friendly catalyst. As to the new technique of processing the organic industrial wastewater, the invention overcomes the defects that the present photocatalysts are only used for degrading the organic industrial wastewater with low concentration. The catalyst being irradiated respectively or simultaneously under sunbeam and ultraviolet light can decrease COD values of high-concentration organic industrial wastewater from 10000-40000mg / L to less than 100mg / L in short time, thus meeting the national emission standard.

Owner:BEIJING UNIV OF CHEM TECH

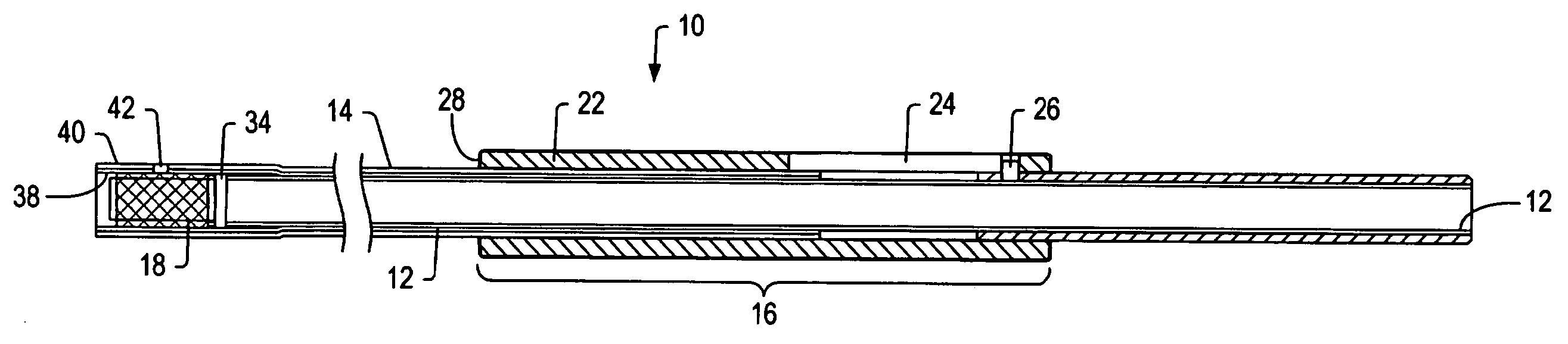

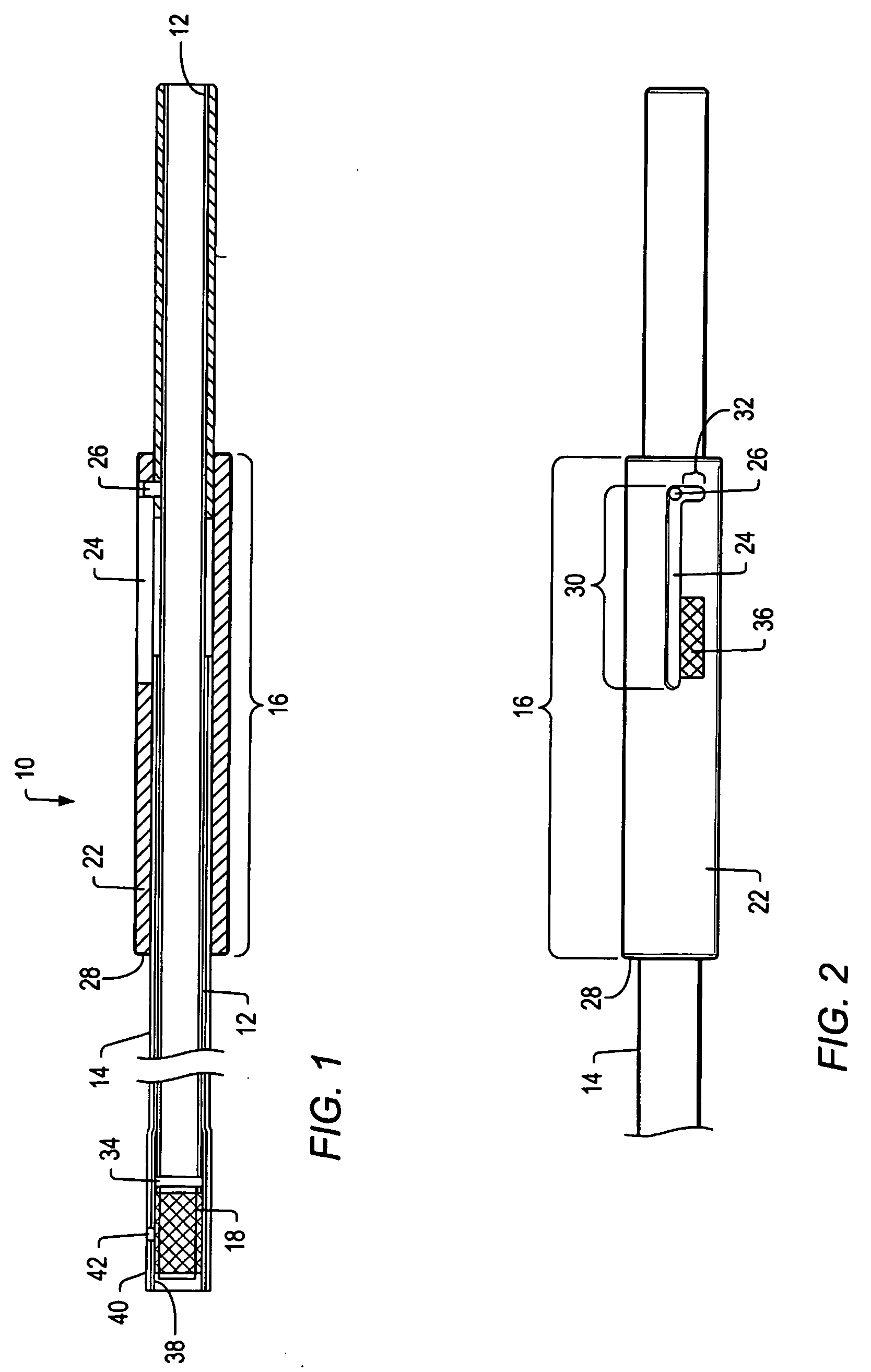

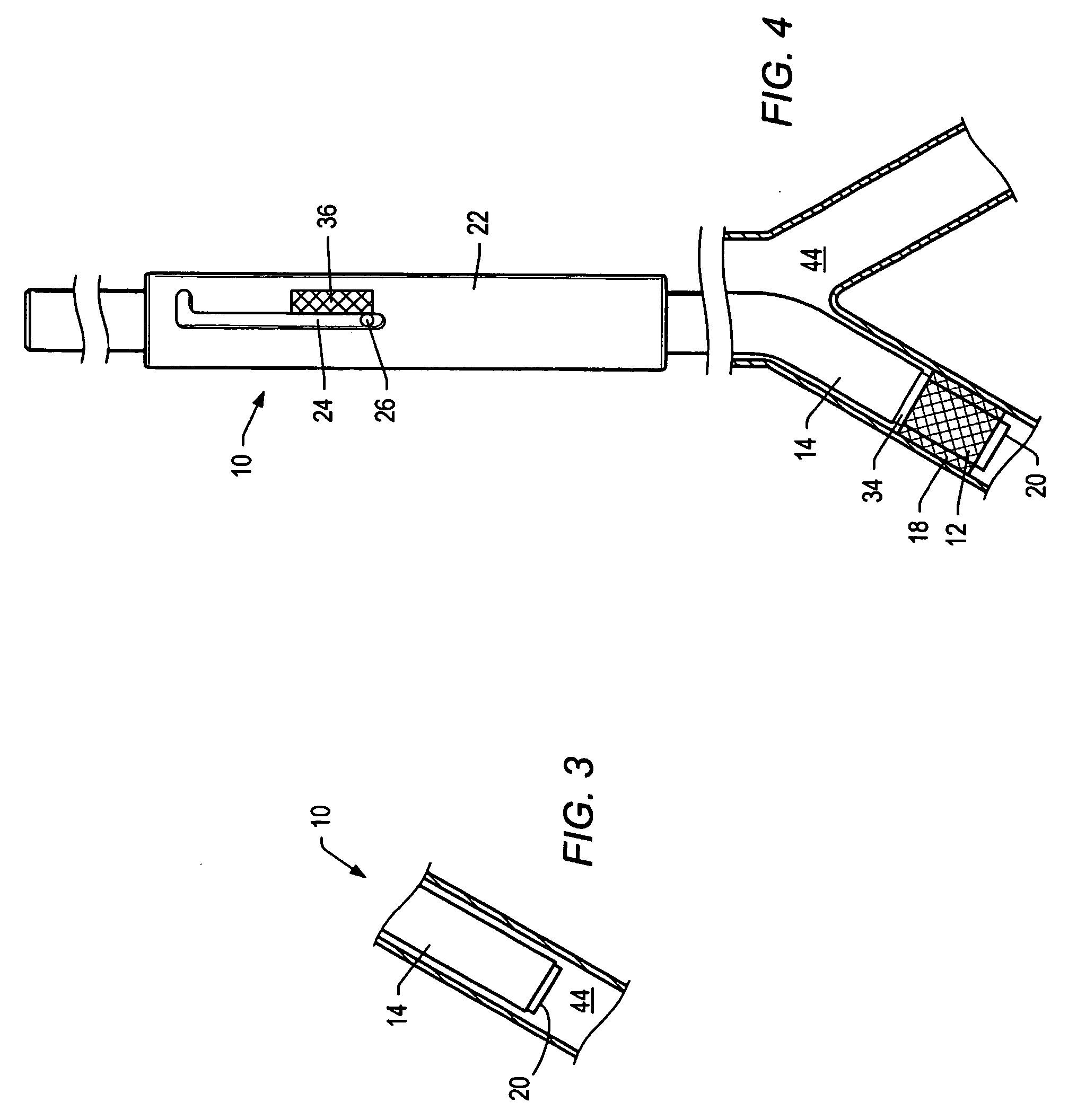

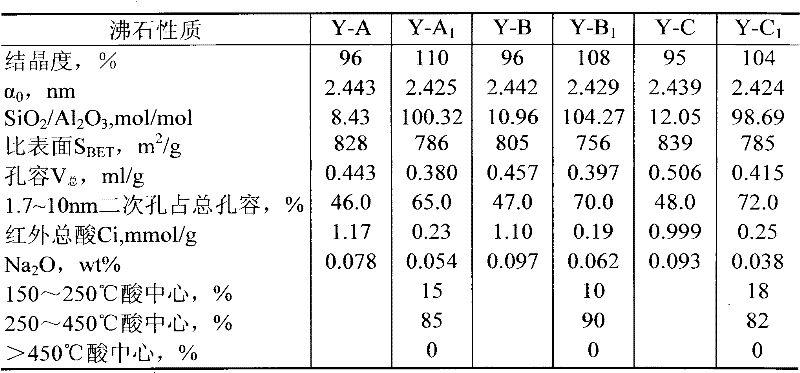

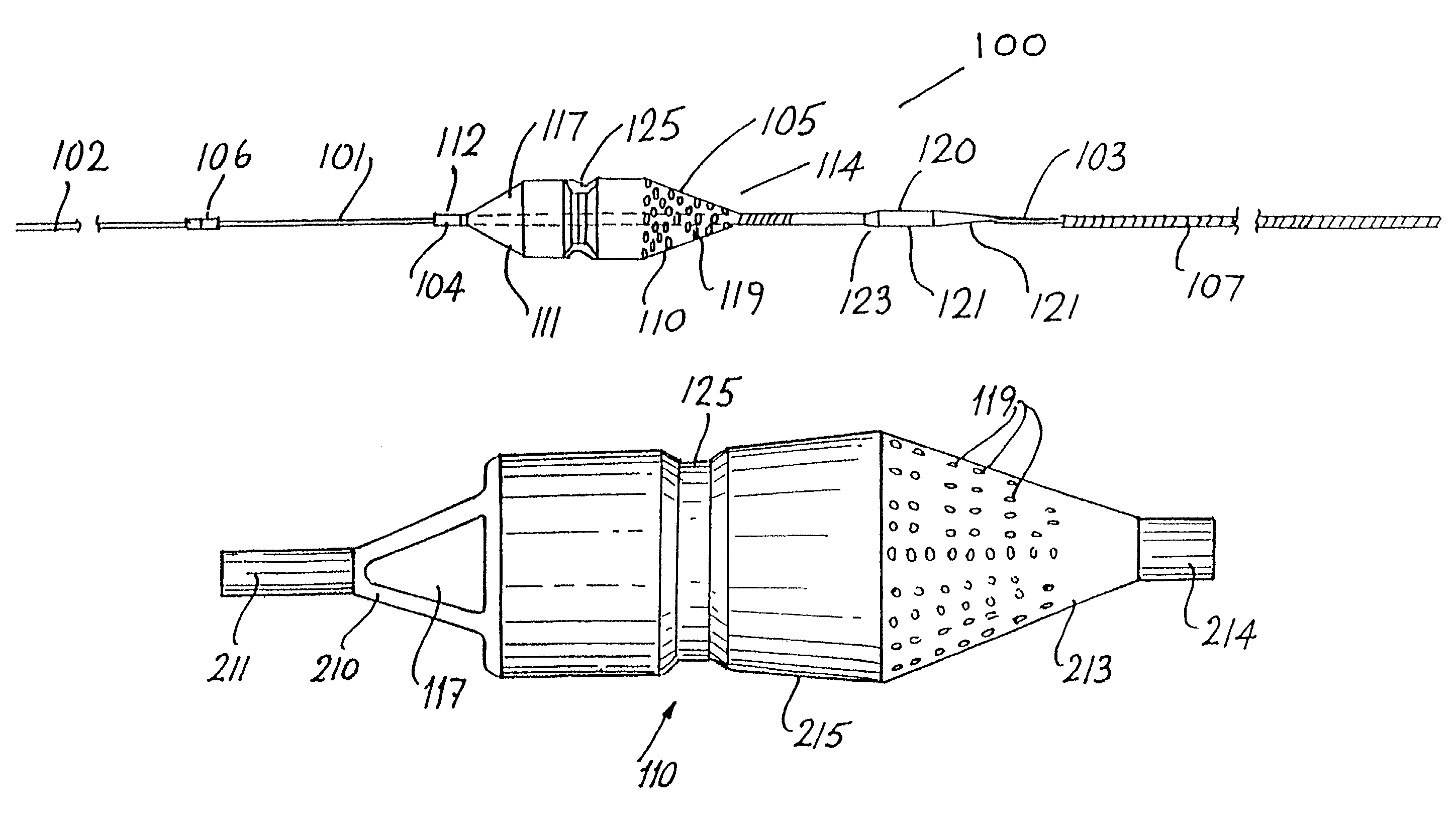

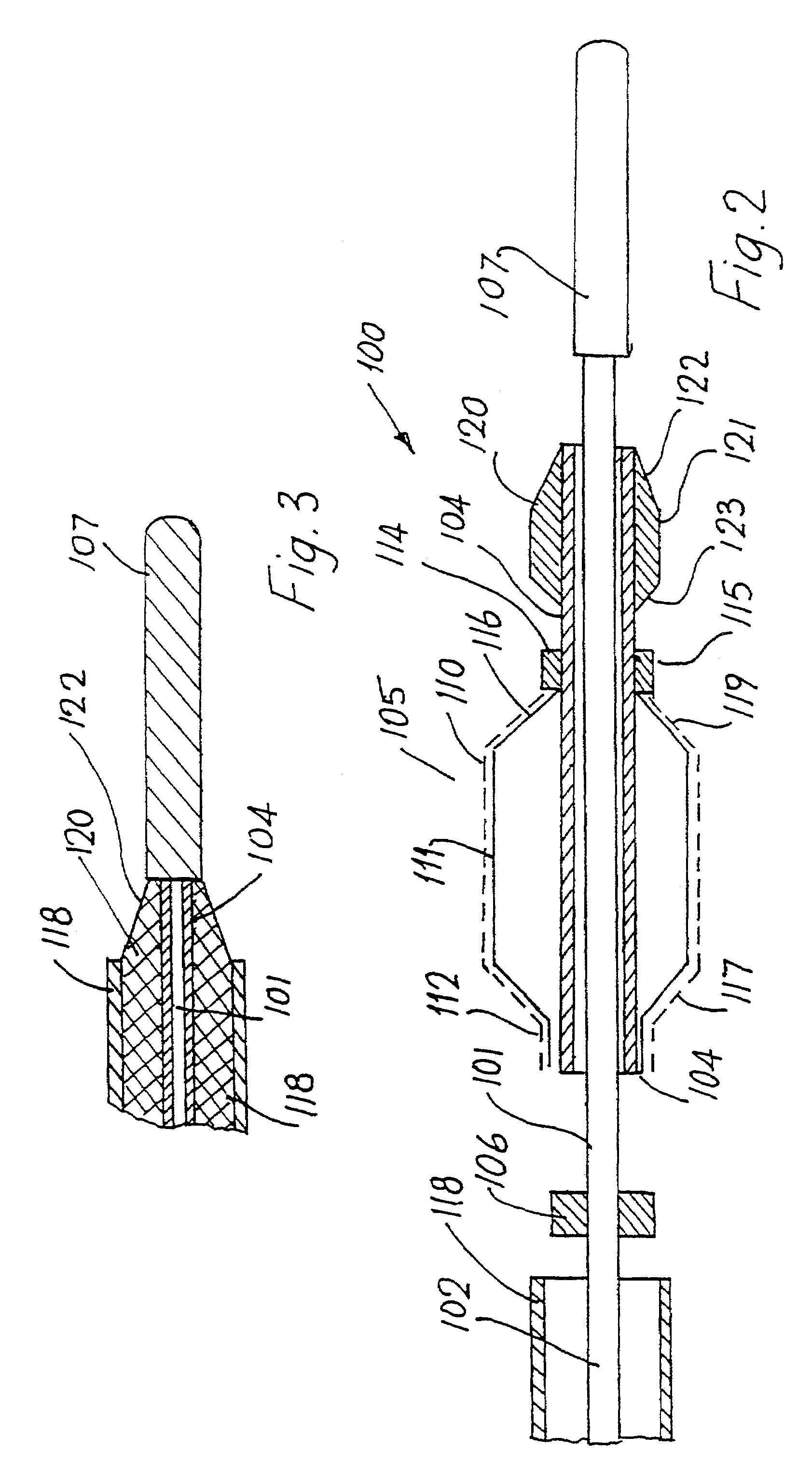

Stent delivery system and method of use

A stent delivery system may be used to position a stent in a body lumen. An endoscope may be positionable in the stent delivery system facilitating direct visual observation during placement of the stent. The stent delivery system may include a first conduit, wherein the endoscope is positionable. A second conduit, wherein the first conduit is positionable, may function to releasably position the stent in the body lumen during use. The stent delivery system may include a lock that functions to inhibit movement of the first conduit relative to the second conduit during use. Retraction of the distal end of the second conduit, relative to the first conduit and the stent, may deploy the stent in a body lumen. Indicia, visibly positioned on the proximal end of the stent delivery system, may function to facilitate determination of an extent of deployment of the stent during use.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

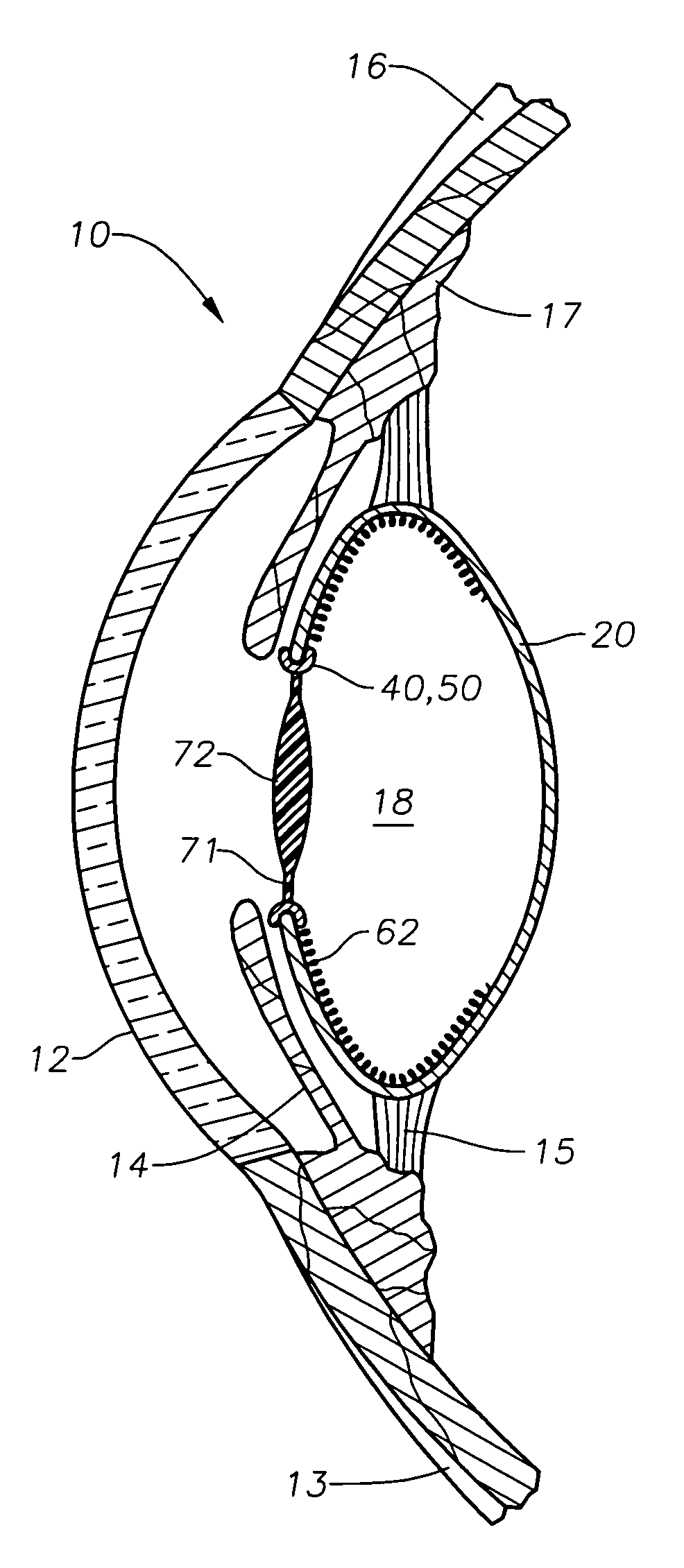

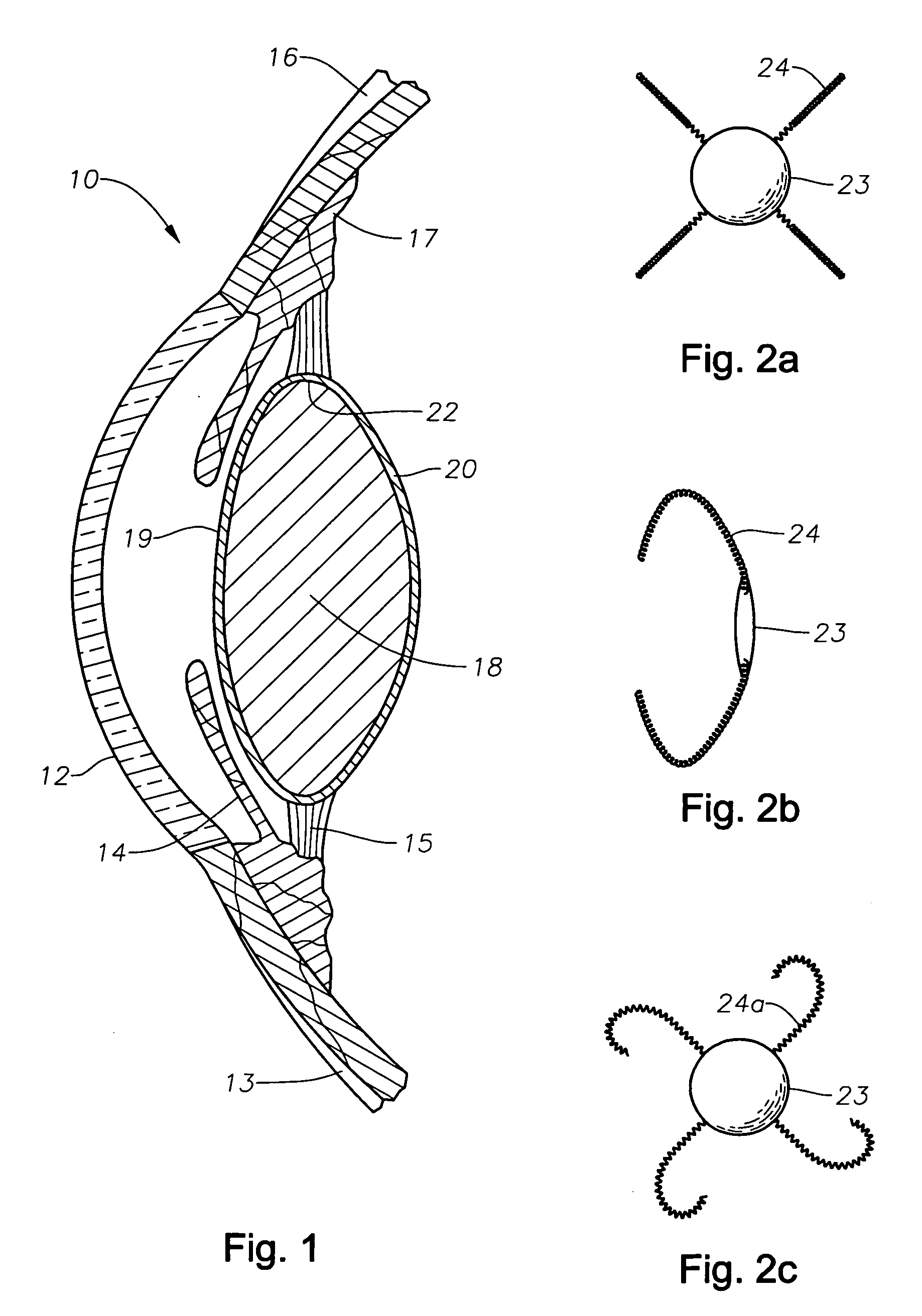

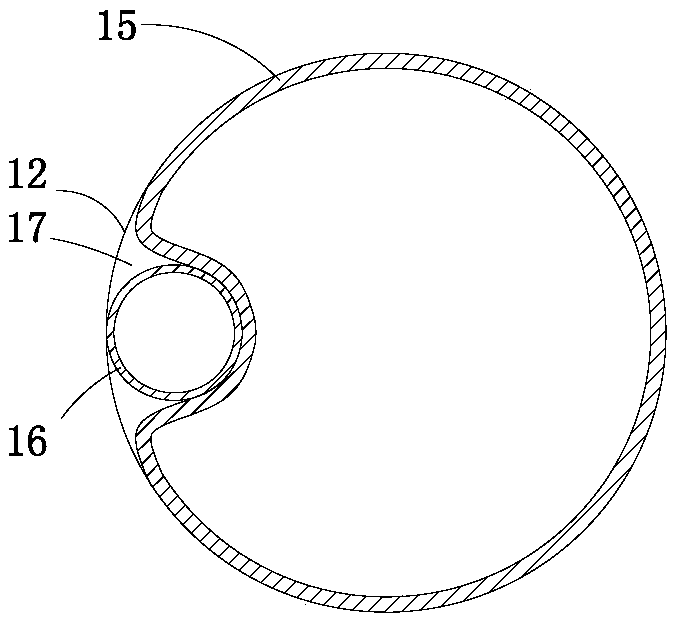

Intracapsular pseudophakic device

Intraocular devices for use in and attached to the natural lens capsule of an eye are provided. The lens capsule may be maintained in a configuration to avoid post-operative changes that are deleterious to vision. Single or dual optic systems are provided, which may be accommodating. Combinations of devices to obtain dual optic systems are disclosed.

Owner:BROWN DAVID C

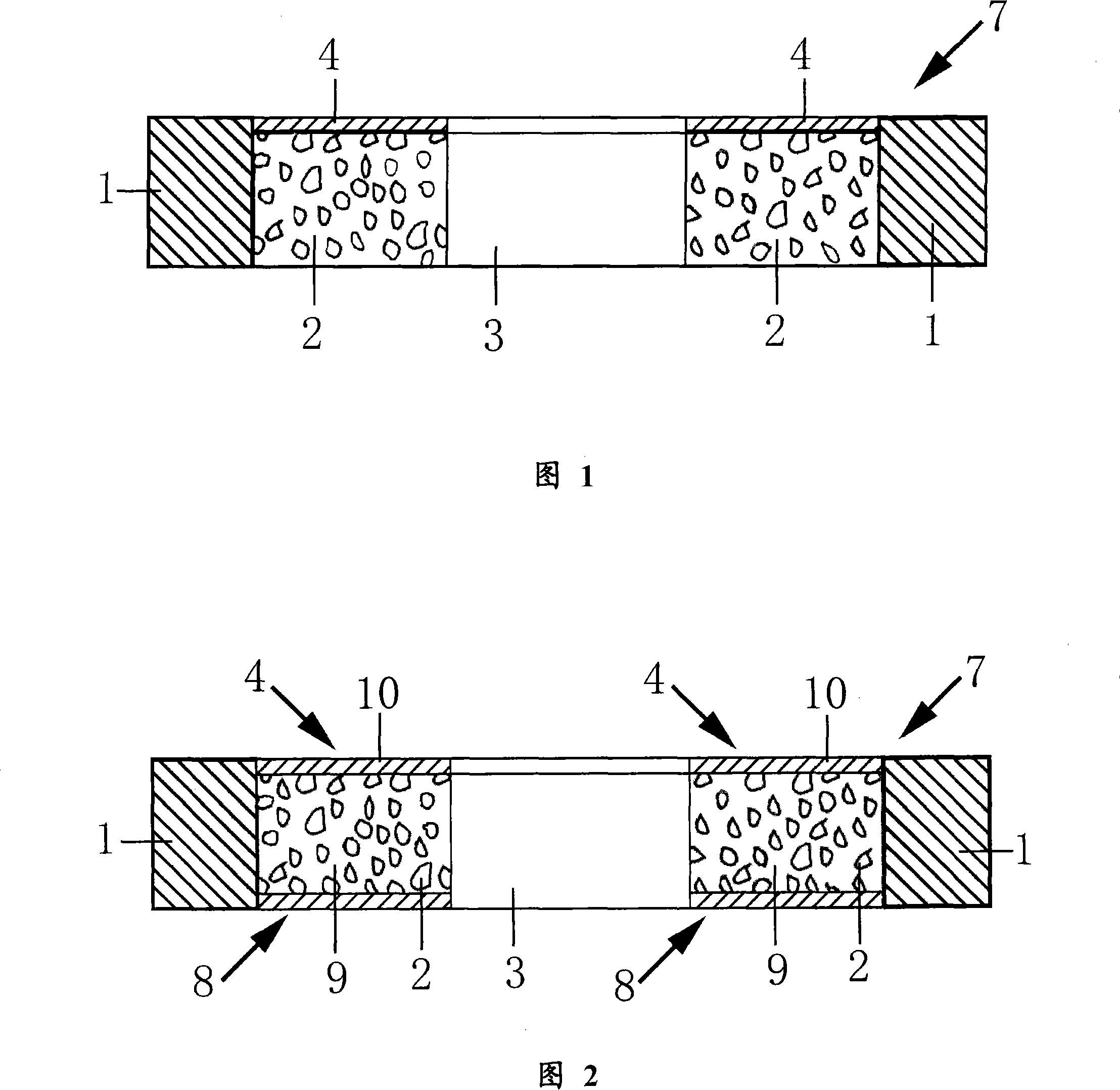

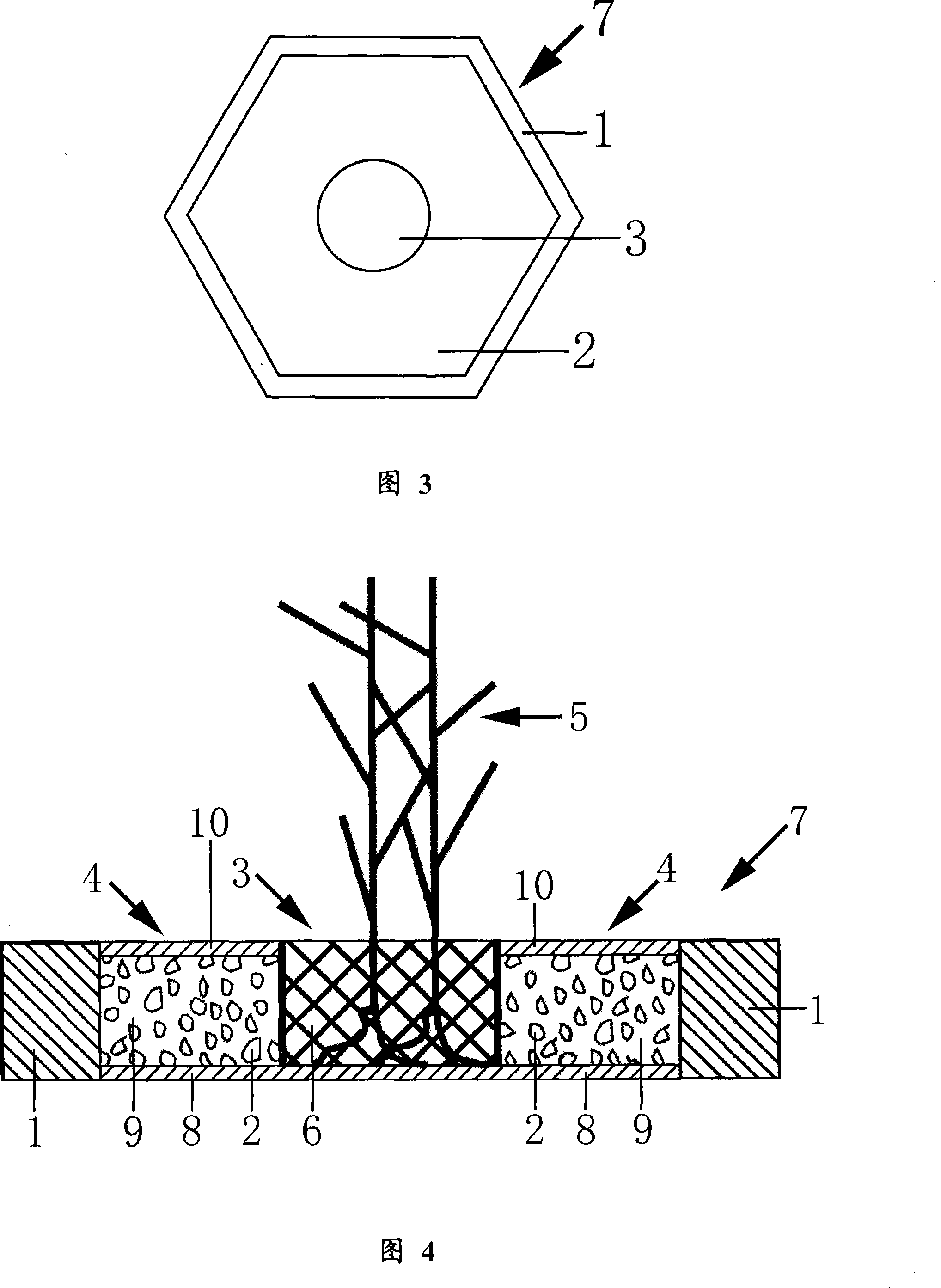

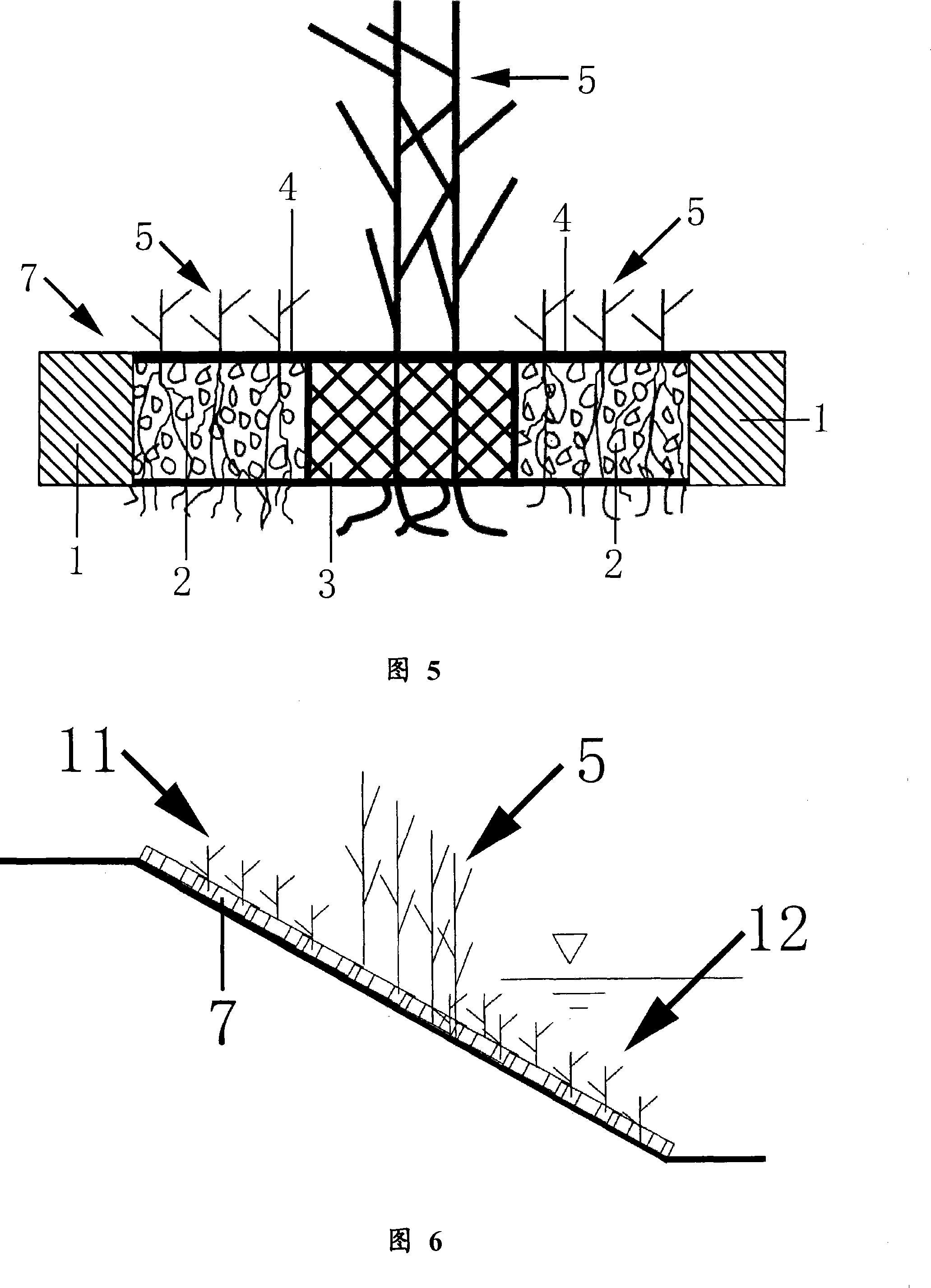

Ecological slope protection vegetation building blocks as well as making method and construction process

InactiveCN101200894APrevent collapseImprove the environmental landscapeSolid waste managementMixing operation control apparatusEngineeringLevee

The present invention relates to a building block of ecological slope protection vegetation, a fabrication method and a construction technique. The building block is composed of a growing bed body, a lath crib, planting troughs, a vegetation layer and a plant, the lath crib wraps the circumference of the growing bed body, the upper plane of the growing bed body is lower than the upper plane of the lath crib and concave, the vegetation layer is formed on the growing bed body, which matches the inner walls of the sectional area of the lath crib to form an integral building block, and more than one planting troughs are arranged on and run through the growing bed body. The design of the present invention is scientific, the structure is reasonable, the restoration of water ecology can reduce the operating cost, environment is improved, ecology is reinstated, harmonious natural beauty is enhanced, and the present invention is suitable for the nidification of small living creatures and the habitation and the survival of aquatic fishes, so that the cutting-off continuity of water and land regions is restored. The present invention is widely applied to channel slope protection, levee slopes, roadsides, airports, parks, public lands, household lawns, sports grounds, etc. The present invention is suitable for cold regions, damp regions, warm and damp intermediate zone, etc.

Owner:TIANJIN WATER RESOURCES RES INST +2

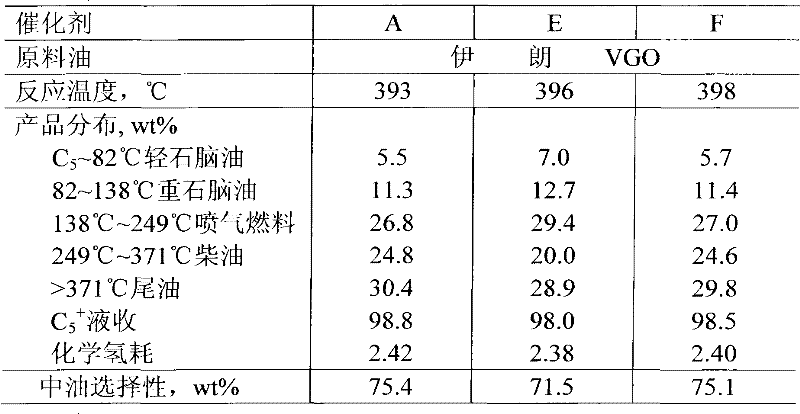

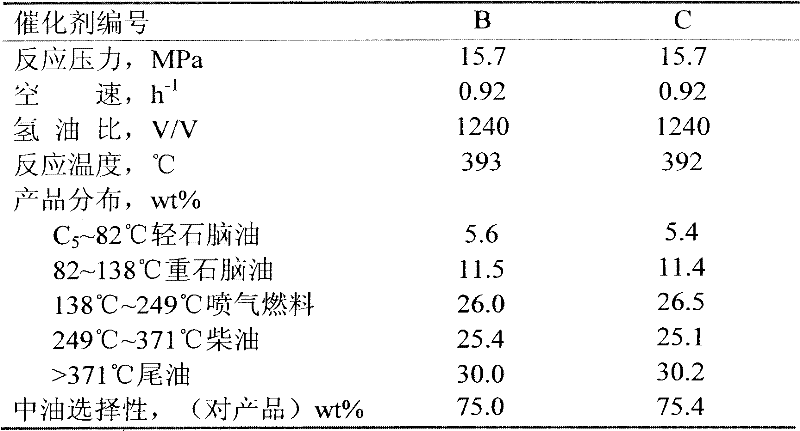

Hydrocracking catalyst with high activity and high-medium oil selectivity and preparation method of hydrocracking catalyst

ActiveCN102441411AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNitrogen

The invention relates to a hydrocracking catalyst with high activity and high-medium oil selectivity. According to the hydrocracking catalyst, amorphous silicon aluminum is used as a carrier, and a specially-modified Y-type molecular sieve is used as acid component, the molecular sieve has high degree of crystallization and low cell parameters, rich secondary holes, large surface area, less uniformly-distributed acid sites, no strong acid center, and most of medium-strength acid centers, and also has strong nitrogen-resisting performance and better damage capacity; and the hydrocracking catalyst using the molecular sieve has high hydrocracking activity and high middle oil selectivity, and stronger nitrogen resisting capacity. The catalyst provided by the invention is used in the process of producing an intermediate distillate product by adopting a heavy hydrocarbon single-section or one-section hydrocracking process, and has better activity and middle oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

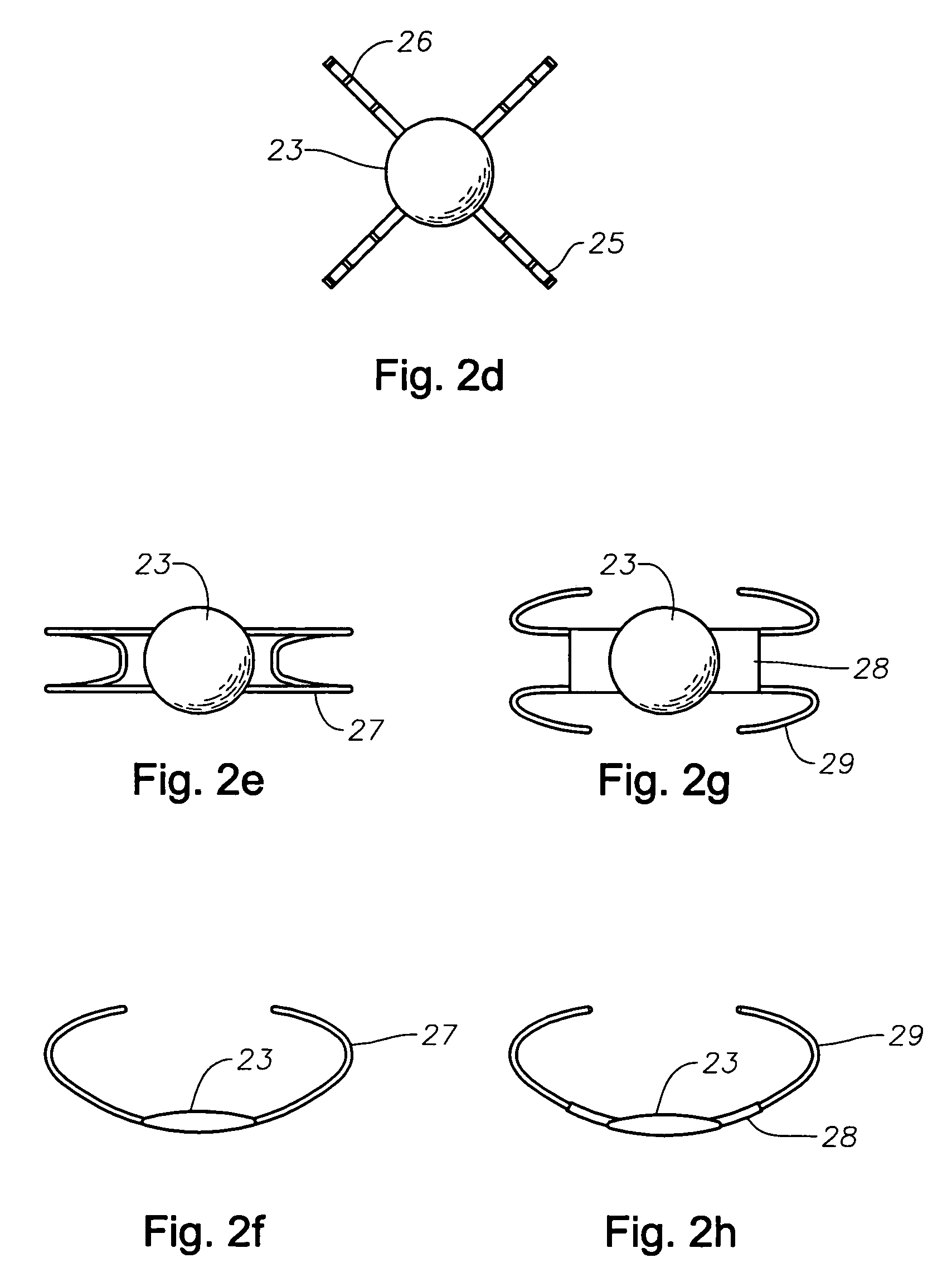

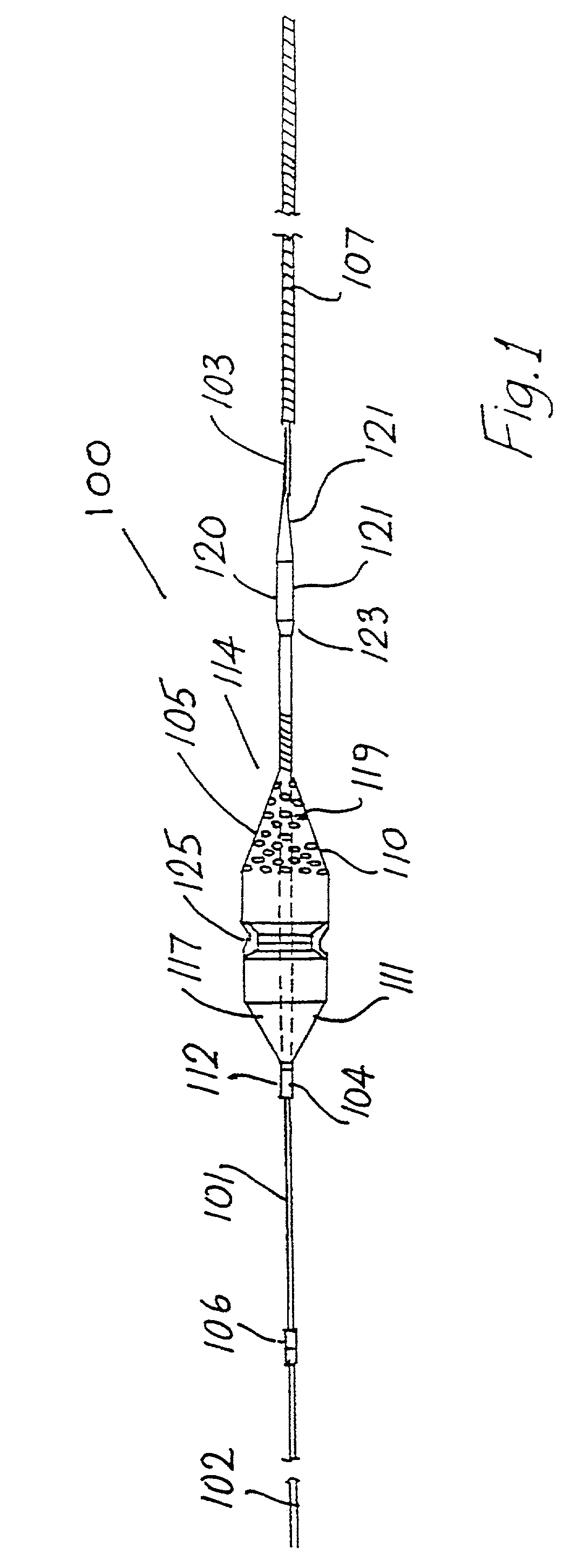

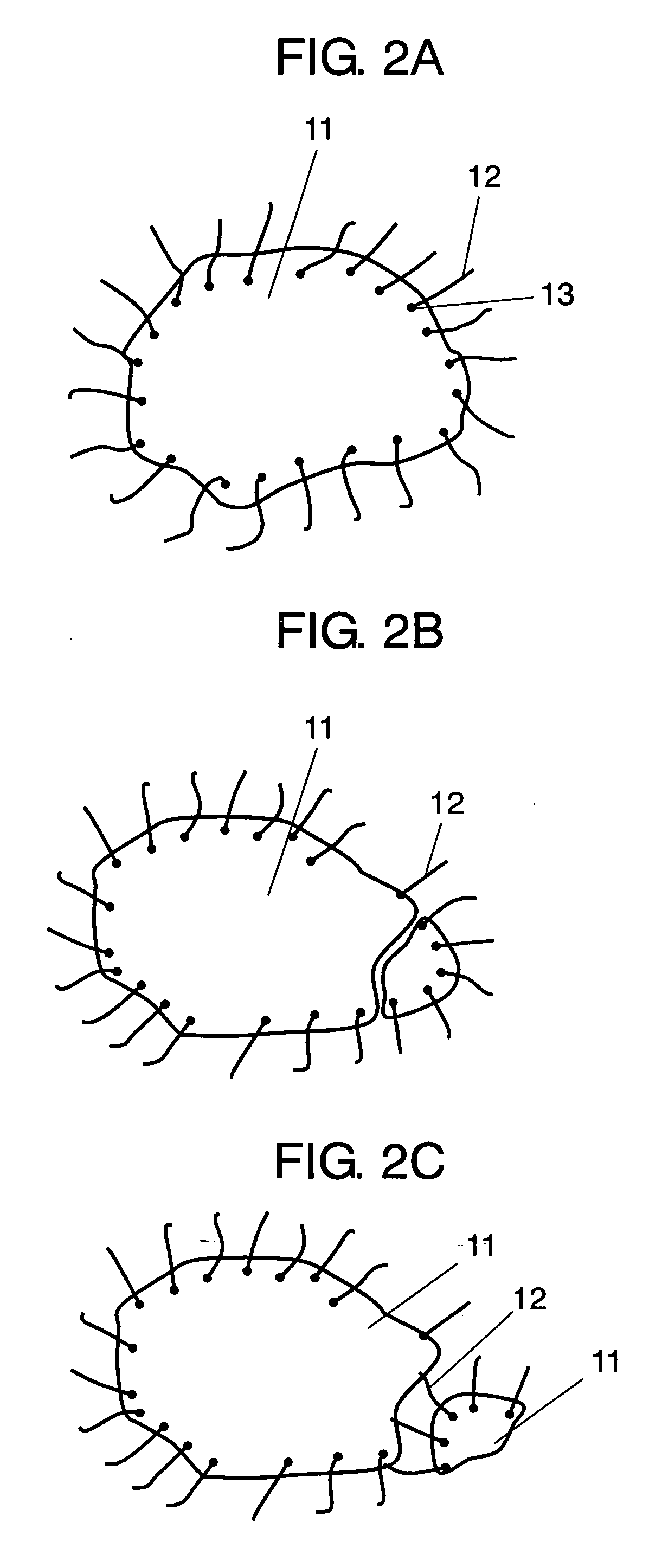

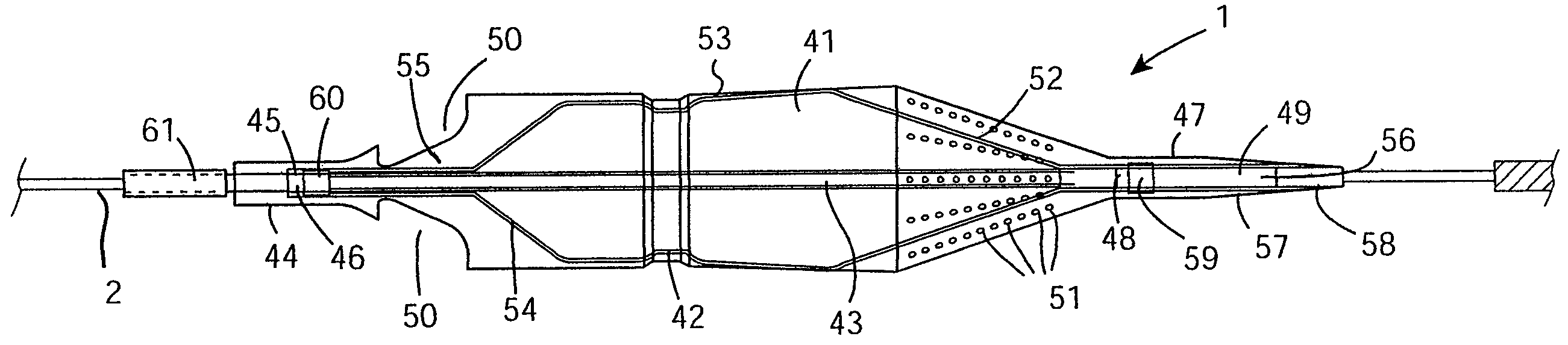

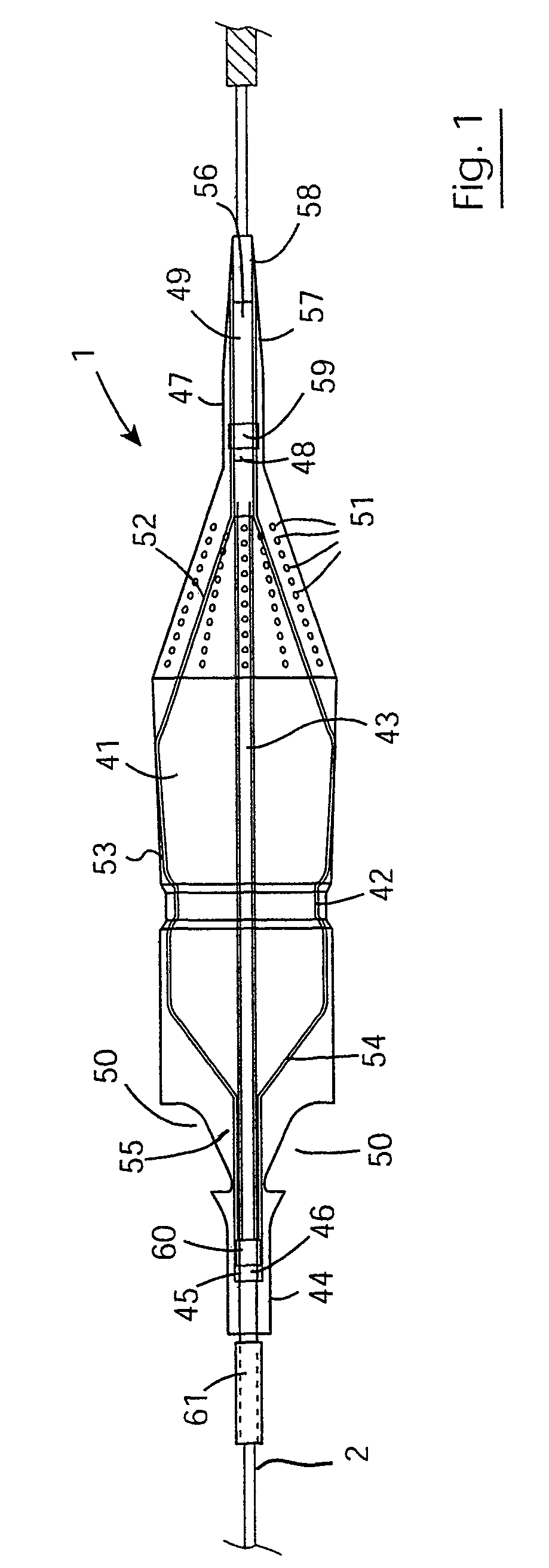

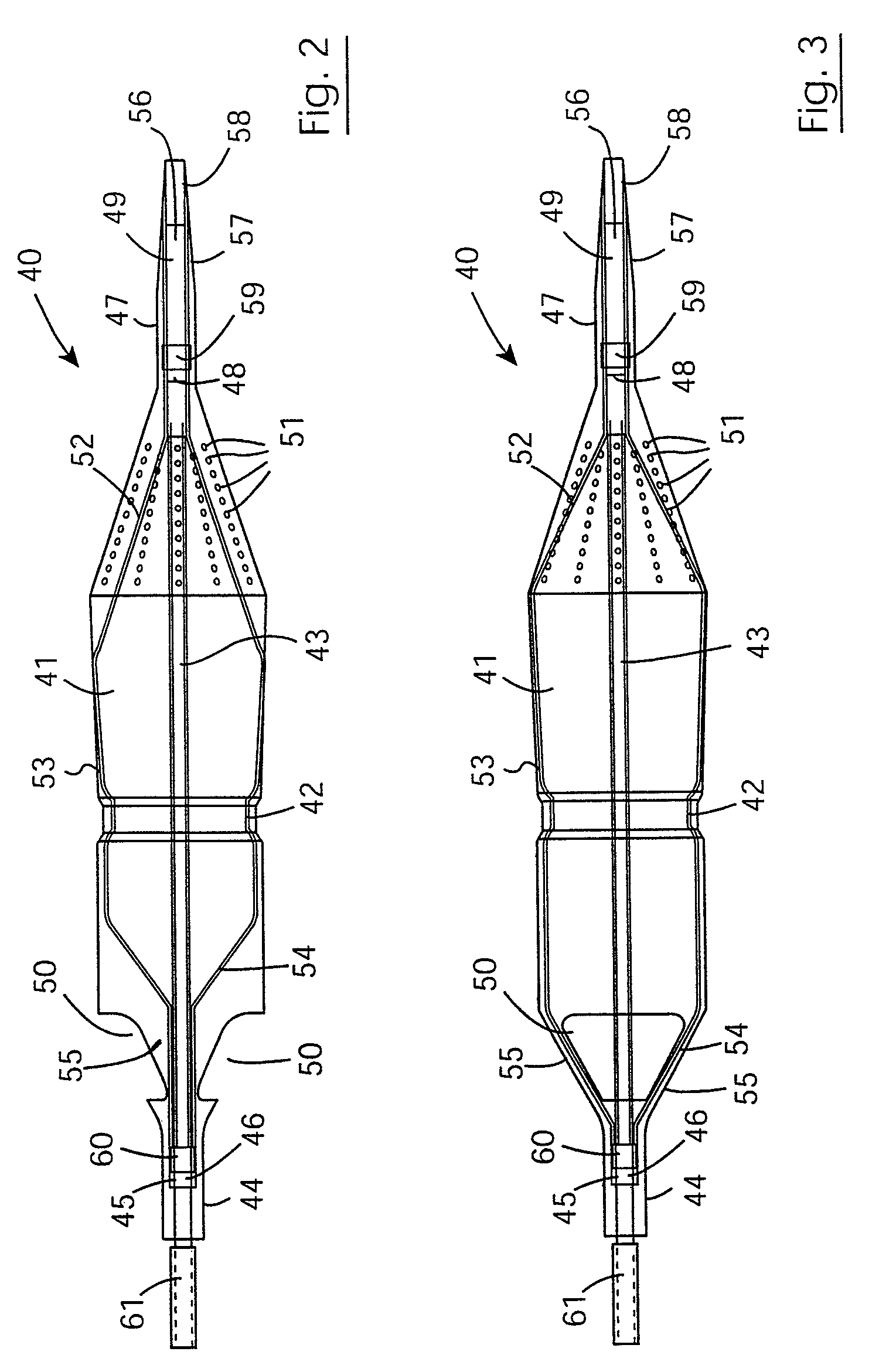

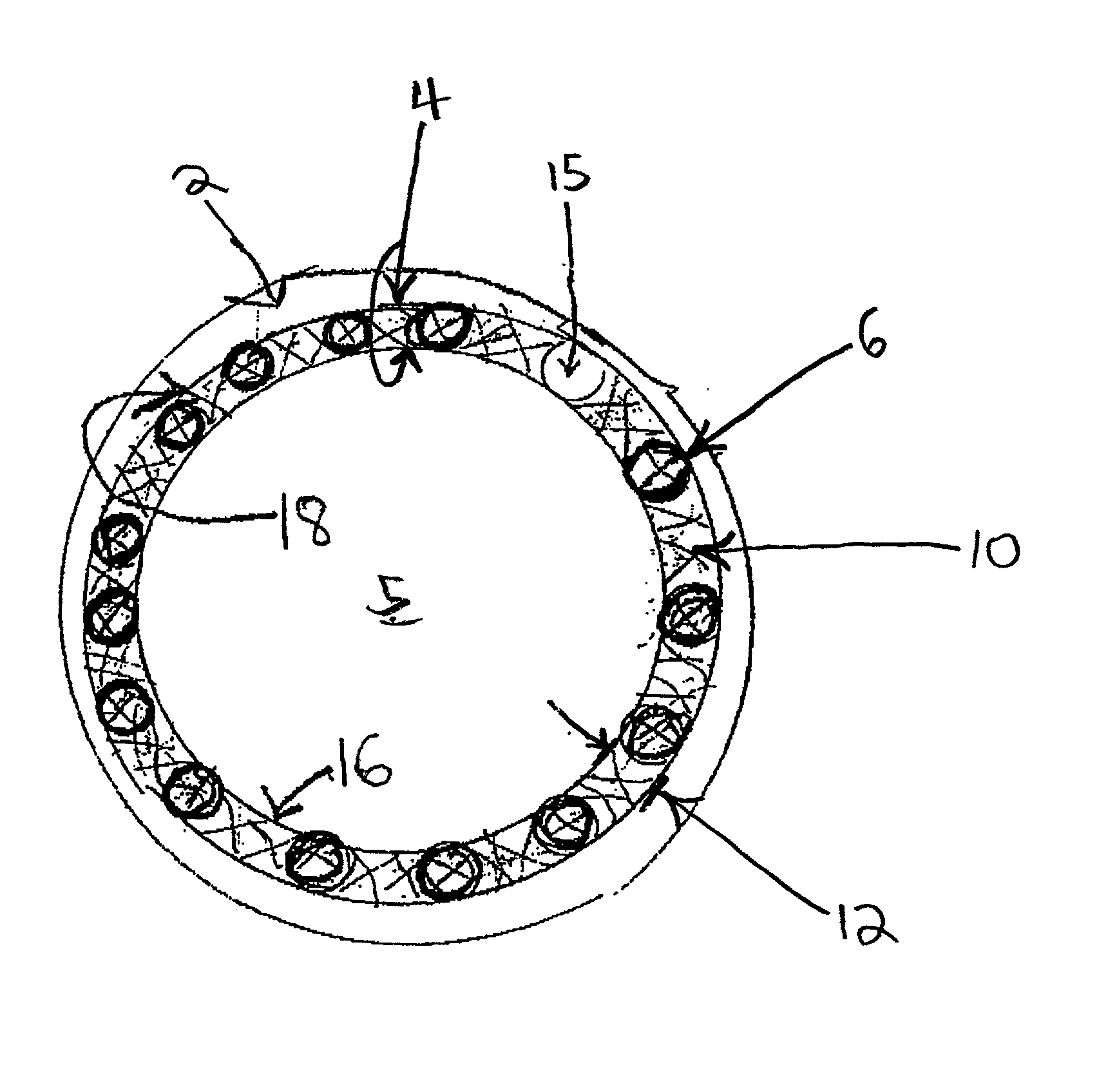

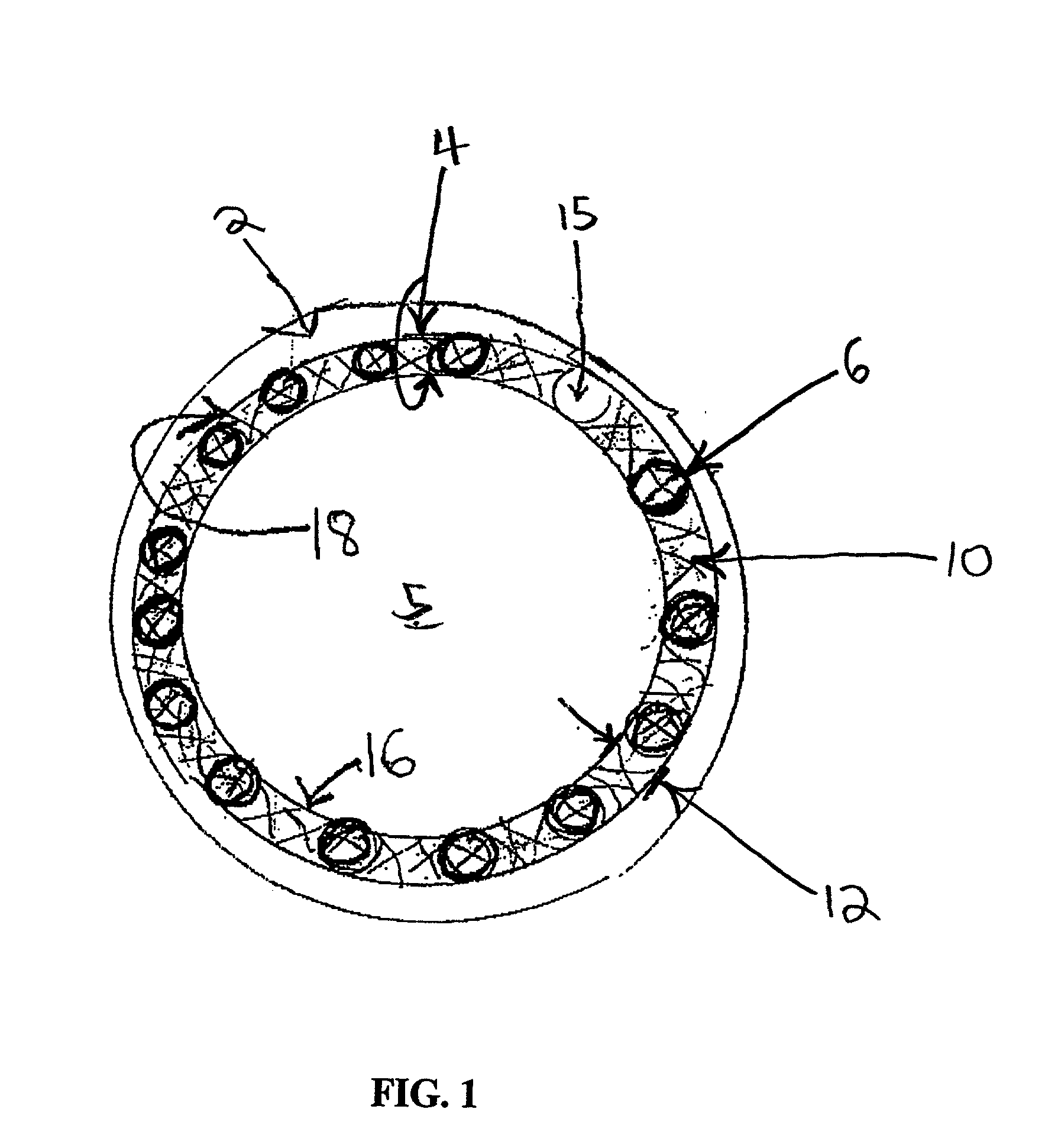

Filter element for embolic protection device

InactiveUS7491215B2Avoid distortionPrevent collapseHaemofiltrationUltrafiltrationEmbolic Protection DevicesDistal portion

A collapsible filter element for a transcatheter embolic protection device comprises a collapsible filter body which is movable between a collapsed stored position for movement through a vascular system and an expanded position for extension across a blood vessel such that blood passing through the blood vessel is delivered through the filter element. A proximal inlet portion of the filter body has one or more inlet openings sized to allow blood and embolic material enter the filter body and a distal outlet portion of the filter body has a plurality of outlet openings sized to allow through-passage of blood, but to retain embolic material within the filter body. The filter body is at least partially of laminate construction comprising a membrane coated with a coating which is biocompatible, the thickness of the coating being from 4% to 40% of the thickness of the membrane. The coating may be of hydrophilic material. To facilitate retrieval of captured embolic material the distal portion and / or an intermediate portion of the filter membrane may be stretchable. The filter body may have regions of varying hardness or stiffness.

Owner:SALVIAC

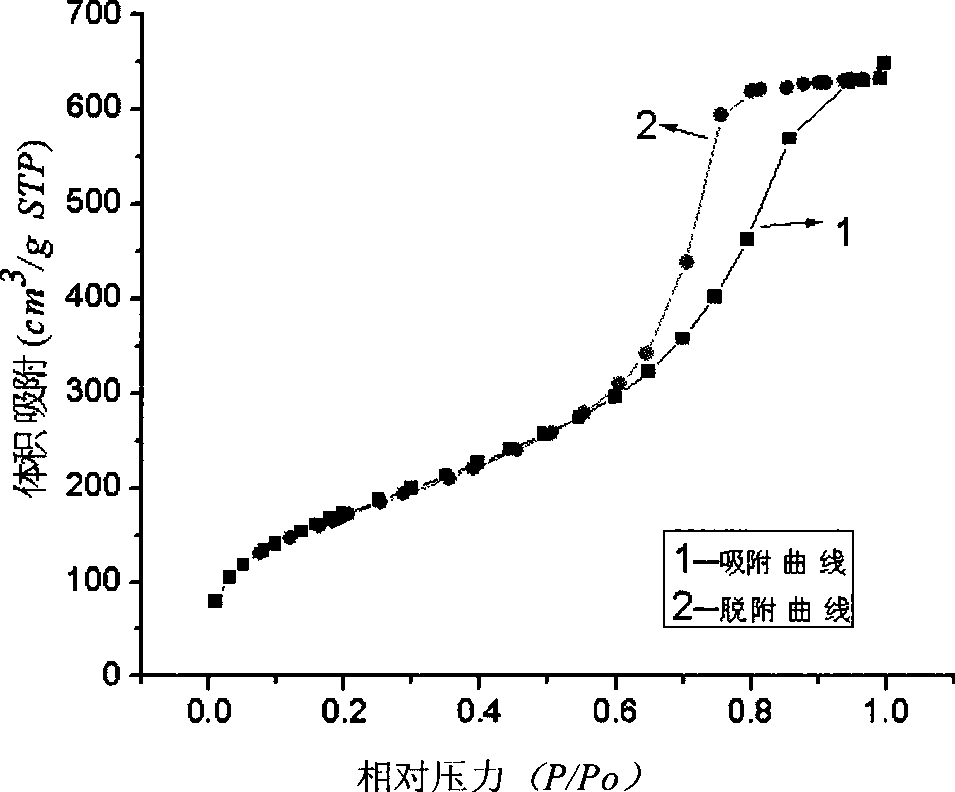

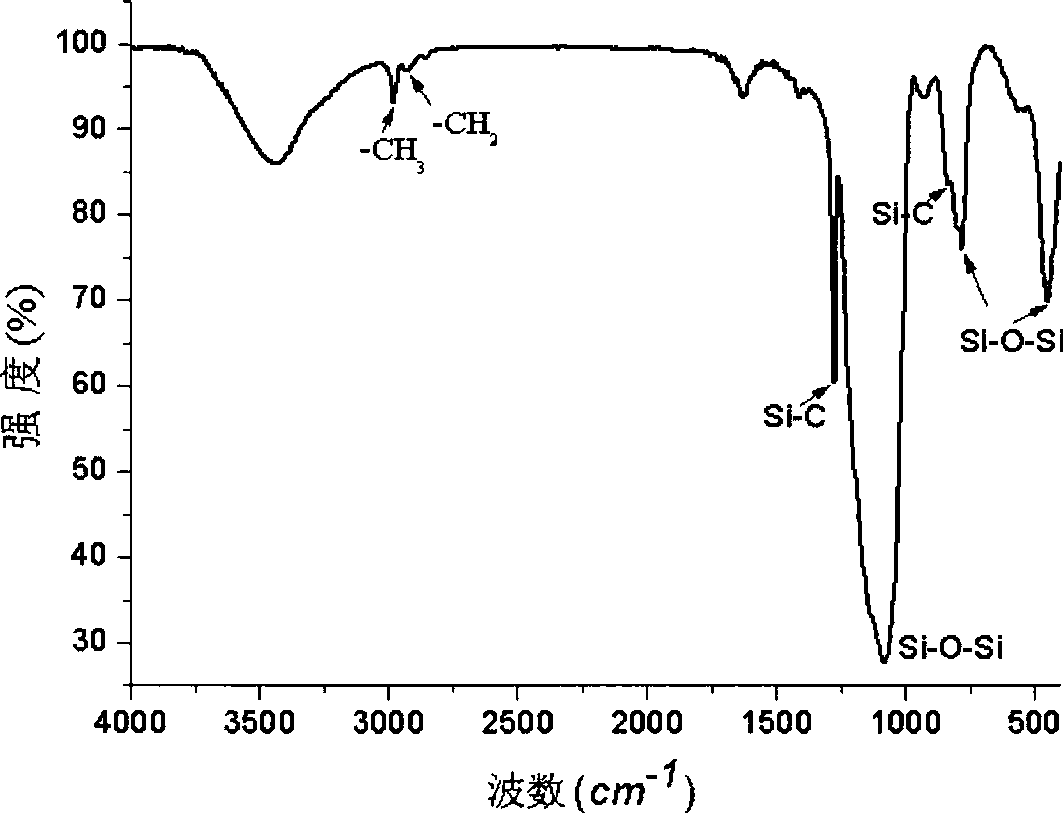

Method for preparing transparent silicon dioxide aerogel by co-precursor normal atmosphere drying

A method for gelating a co-precursor relates to an aerogel. The invention provides a method for preparing transparent silica aerogel by normal pressure drying through a co-precursor method. The method has the advantages of low cost, simple process, short production cycle, controllable reaction course and continuous production. Tetraethyl silicate and absolute ethyl alcohol are put into a container according to a proportion and stirred, and added with methyl triethoxysilane; added with water and stirred; added with hydrochloric acid to regulate the pH of the solution; added with ammonia water to regulate the pH of the system after stirring; the silica sol is kept stand still after stirring to obtain wet gel; the obtained wet gel is put into a normal hexane solution or a normal hexane solution containing the methyl triethoxysilane with volume concentration of 10%-50% for solvent exchange and aging, after being exchanged by the solution containing the methyl triethoxysilane agent, the gel is washed by the normal hexane solution to remove the methyl triethoxysilane remained on the surface of the sample, and the transparent silica aerogel is obtained by drying.

Owner:XIAMEN UNIV

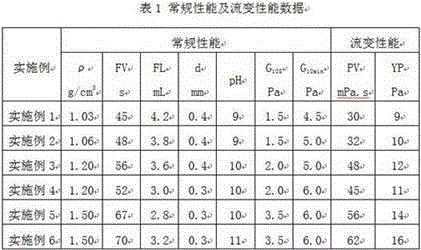

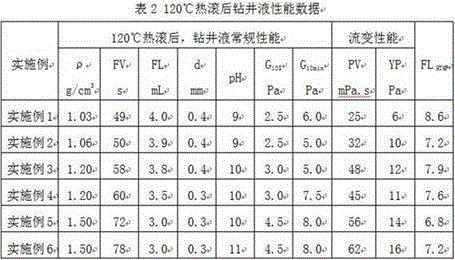

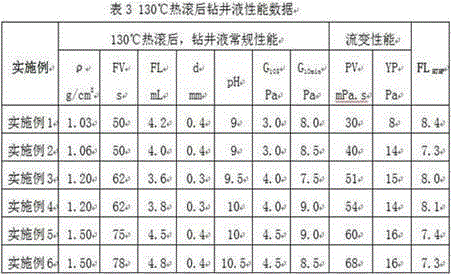

Strong-inhibition anticaving drilling fluid and application thereof

InactiveCN105038737AReduce fluid lossAdjust the flow patternDrilling compositionOrganic chemistryPetroleum engineering

The invention discloses a strong-inhibition anticaving drilling fluid and application thereof. The strong-inhibition anticaving drilling fluid consists of 1000 parts of water, 20 to 60 parts of bentonite for drilling fluid, 5 to 20 parts of sodium carbonate, 5 to 20 parts of alkali, 10 to 20 parts of coating agent, 5 to 20 parts of flow pattern regulator, 5 to 20 parts of shale inhibitor, 10 to 30 parts of borehole stabilizer, 10 to 30 parts of plugging agent, 5 to 30 parts of lubricating agent, 5 to 40 parts of filtrate reducer, 1 to 10 parts of pH regulator, and a proper amount of salts and barite added according to the requirement. The strong-inhibition anticaving drilling fluid has the remarkable characteristics of properties of stabilizing a borehole, protecting an oil layer, improving the drilling speed, and preventing a balled bit and the like from approaching to oil-based drilling fluid.

Owner:北京中科天启油气技术有限公司

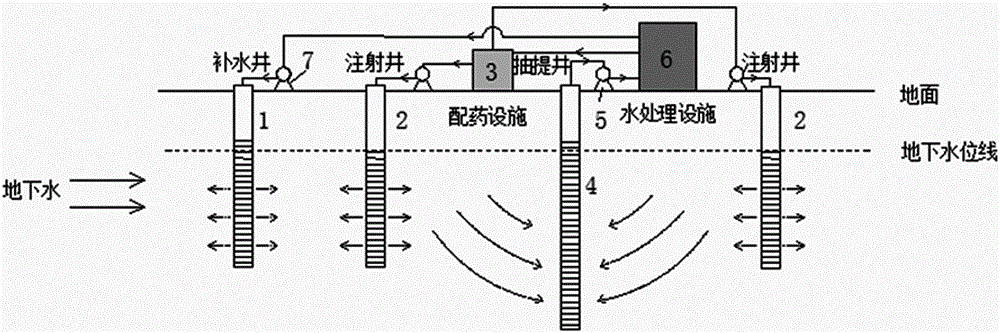

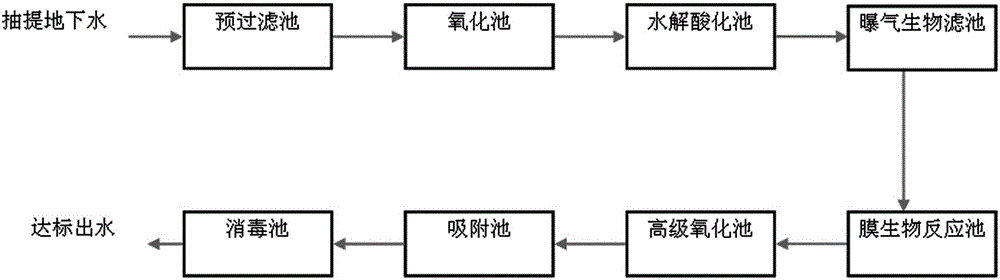

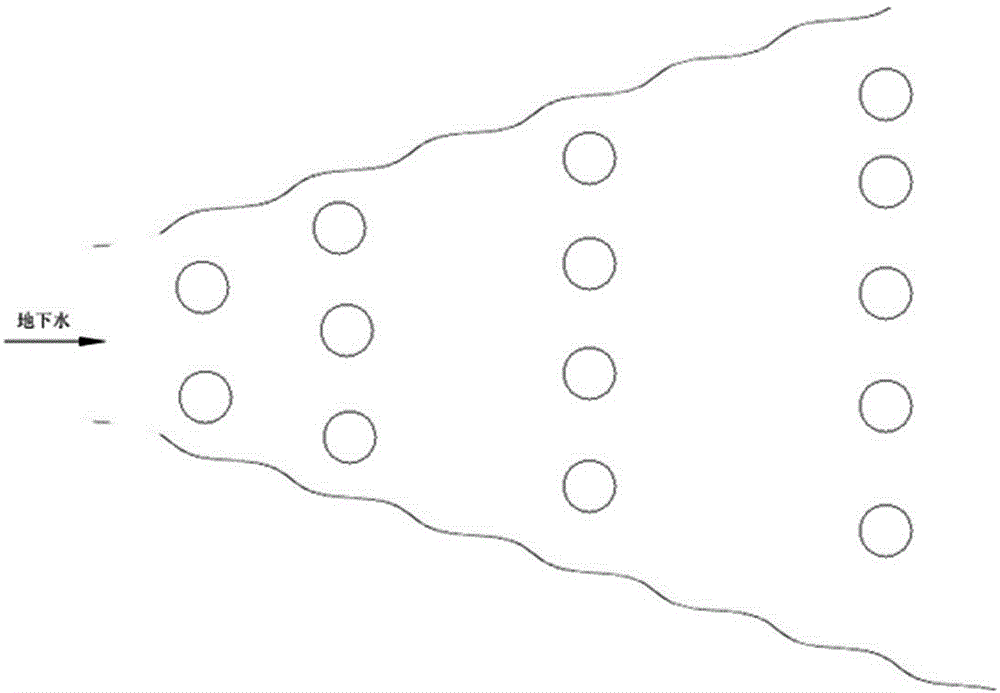

In-situ injection-extraction-water replenishing circulatory disposal system for organic contaminated soil and groundwater and combined remediation method

ActiveCN105032916ASpeed up the flowIncrease the speed of diffusionContaminated soil reclamationMultistage water/sewage treatmentInjection wellWater treatment

The invention discloses an in-situ injection-extraction-water replenishing circulatory disposal system for organic contaminated soil and groundwater and a combined remediation method. The system is consist of an injection well, an extraction well, a water replenishing well, a water treatment facility, a dispensing facility. The method comprises the following steps: extracting a pollution source or groundwater in a seriously polluted area to the ground for processing, then using the processed groundwater as a preparation drug or as replenished water to be directly injected to the underground, and injecting the drug into the underground pollution plume area through the injection well. The system and the method are used for processing the organic contaminated soil and groundwater in situ and have the advantages of being small in disturbance, environmental-friendly, short in remediation cycle and wide in range of application and has no secondary pollution.

Owner:中节能大地(杭州)环境修复有限公司

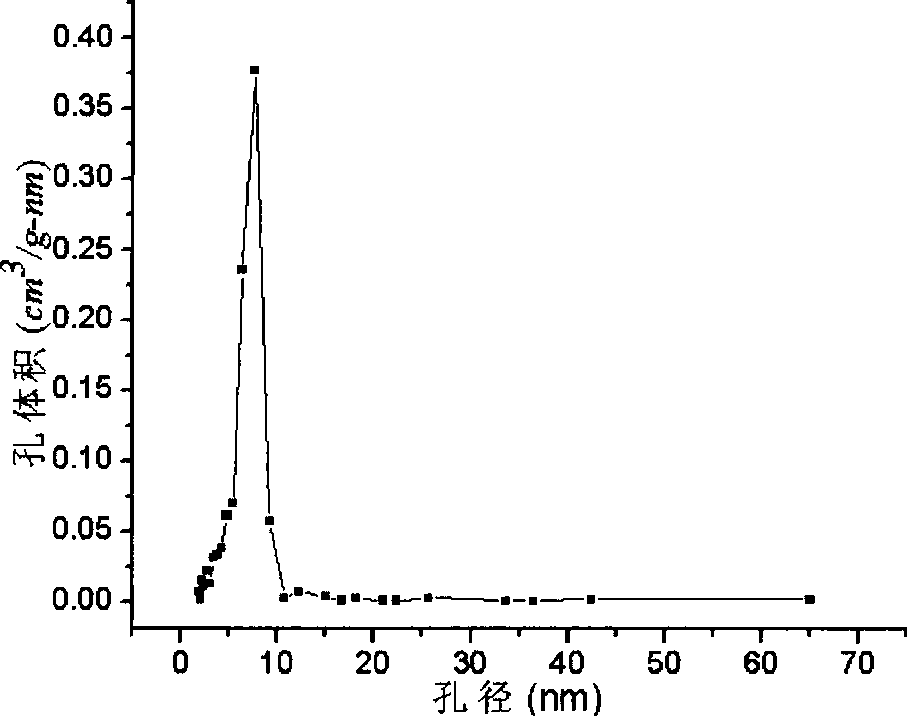

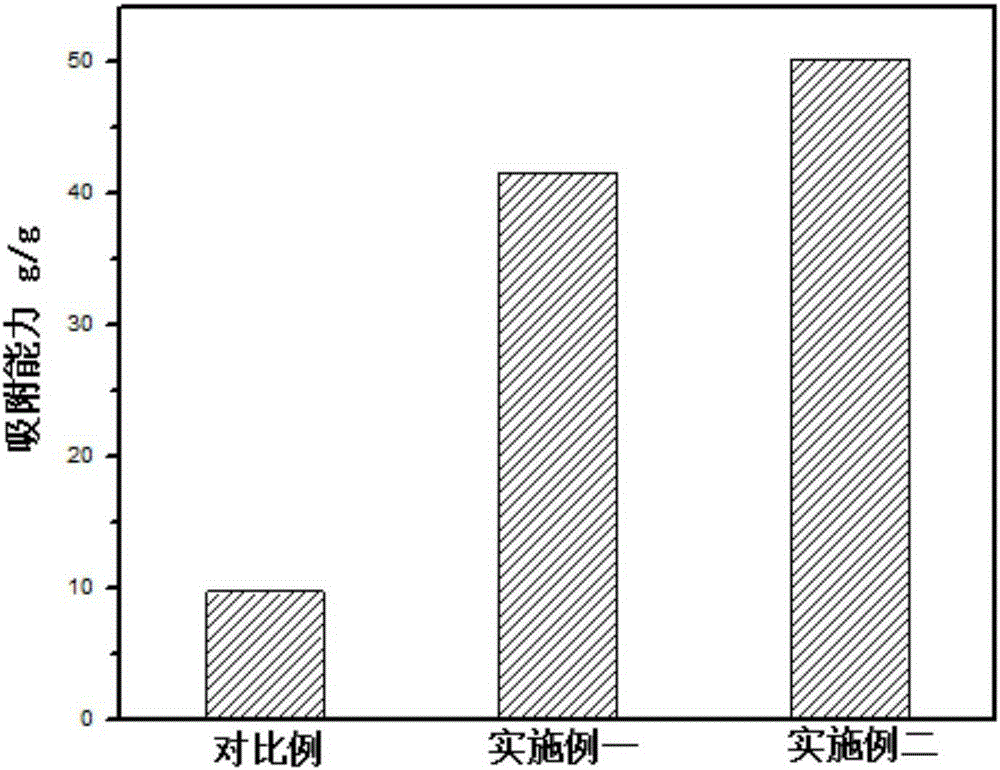

Method for preparing foam material reinforced silica aerogel composite material

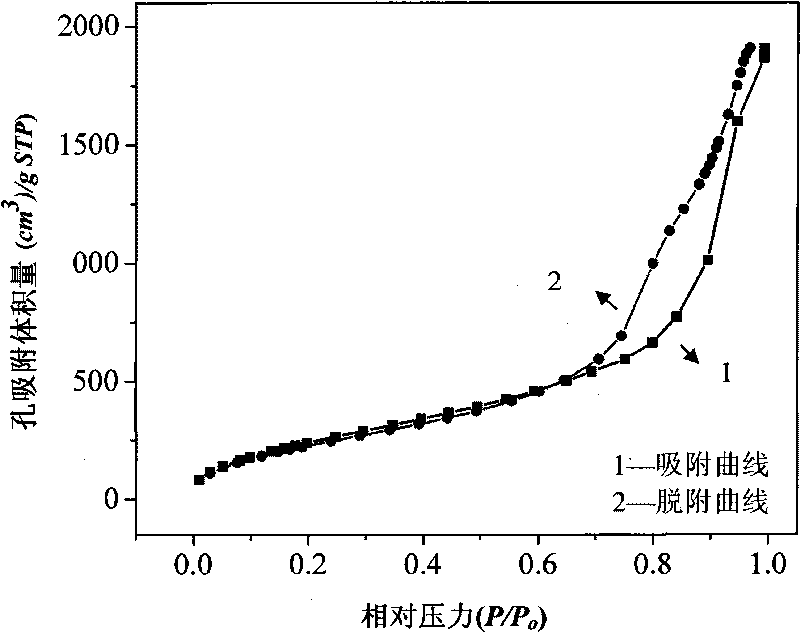

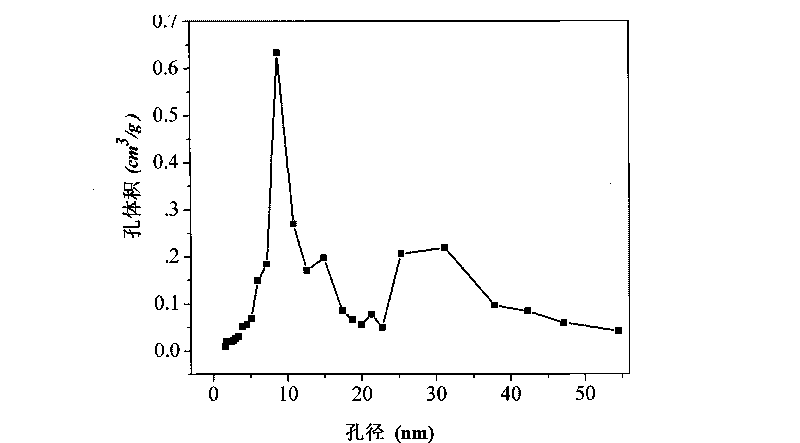

The invention discloses a method for preparing a foam material reinforced silica aerogel composite material and relates to silica aerogel. The method comprises the following steps of: preparing silica plural gel and aging the silica plural gel, modifying and drying. Through test, porosity is 80 t o 95 percent, density is 0.15 to 0.5g / cm<3>, the Brunauer-Emmett-Teller (BET) specific surface area is 600 to 1,100m<2> / g, and a water contact angle is 130 to 160 degrees; the foam material reinforced silica aerogel composite material is super hydrophobic; aerogel pore size distribution is relativelycentralized and the pore size of the aerogel is 2 to 50nm; and coefficient of heat conductivity is 0.01 to 0.035 W / (m.K), compression strength is 0.3 to 2Mpa (2 percent deformation), and elastic modulus is 1 to 5 Mpa. Meanwhile, the foam material reinforced silica aerogel composite material has good heat insulation performance, and adsorption performance, environment-friendliness and the other excellent performance. The method is simple, is short in a cycle, low in cost, and high in safety, and contributes to large-scale production; and by the method, excellent performance of the aerogel can be kept and the mechanical property of aerogel can be improved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

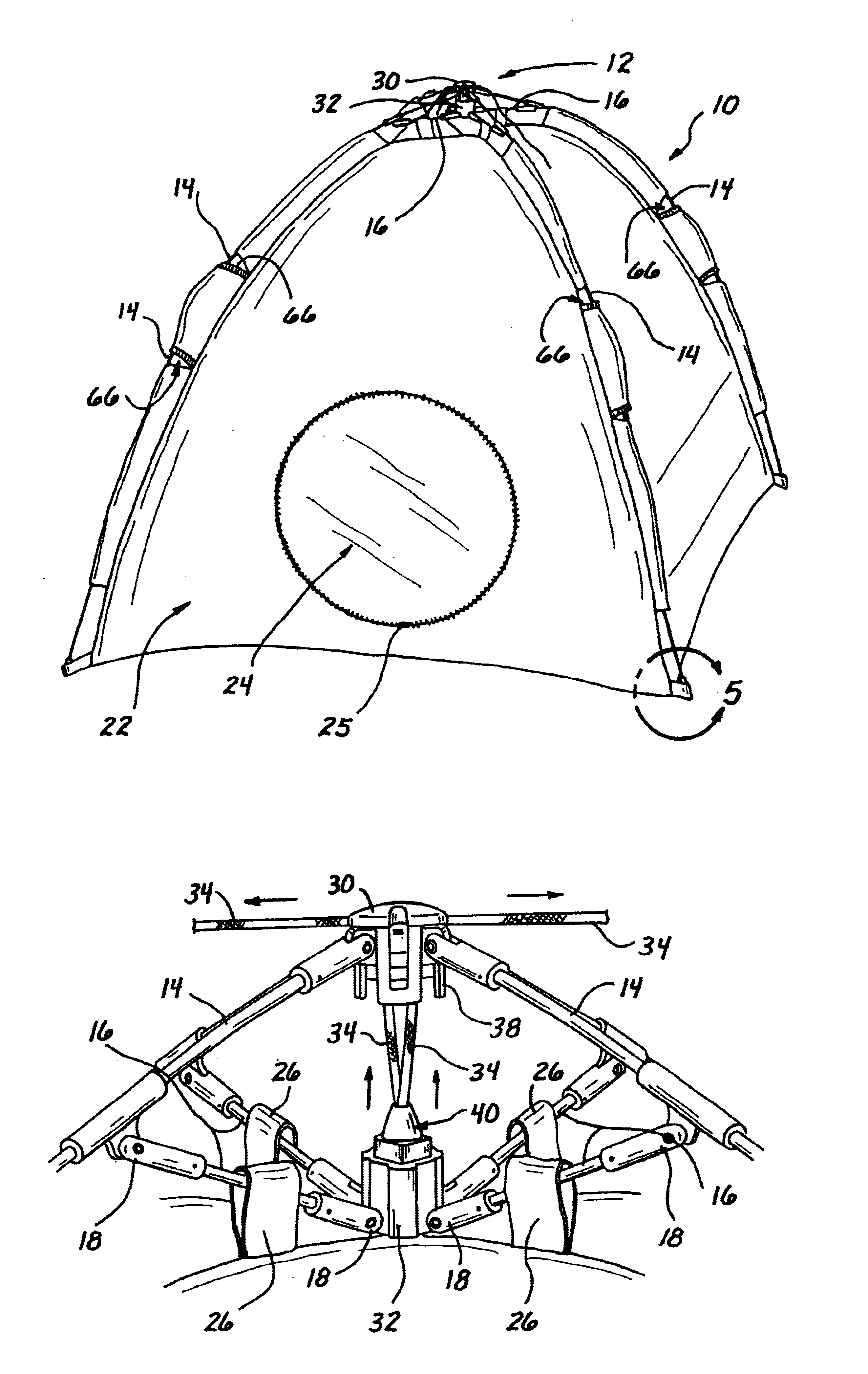

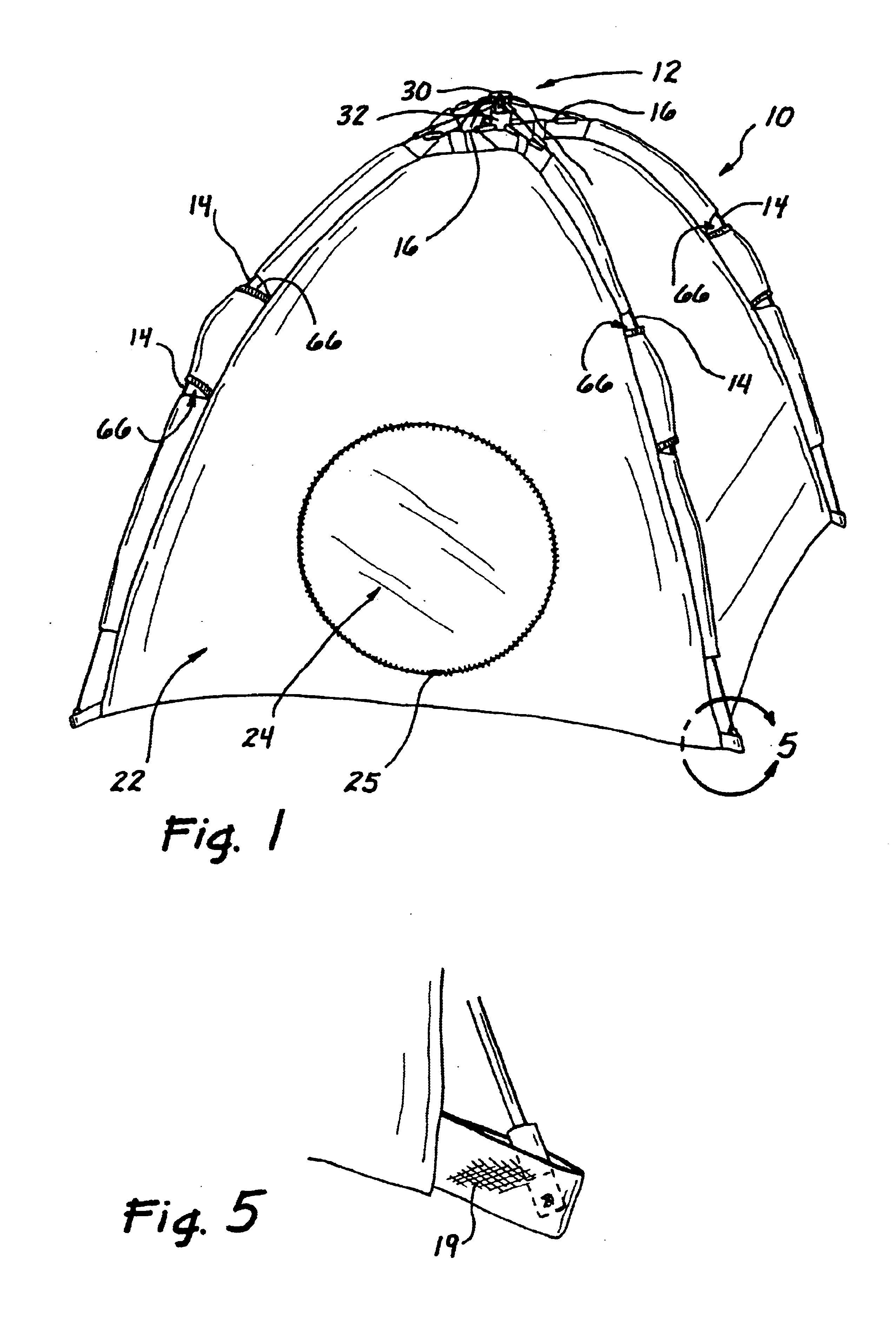

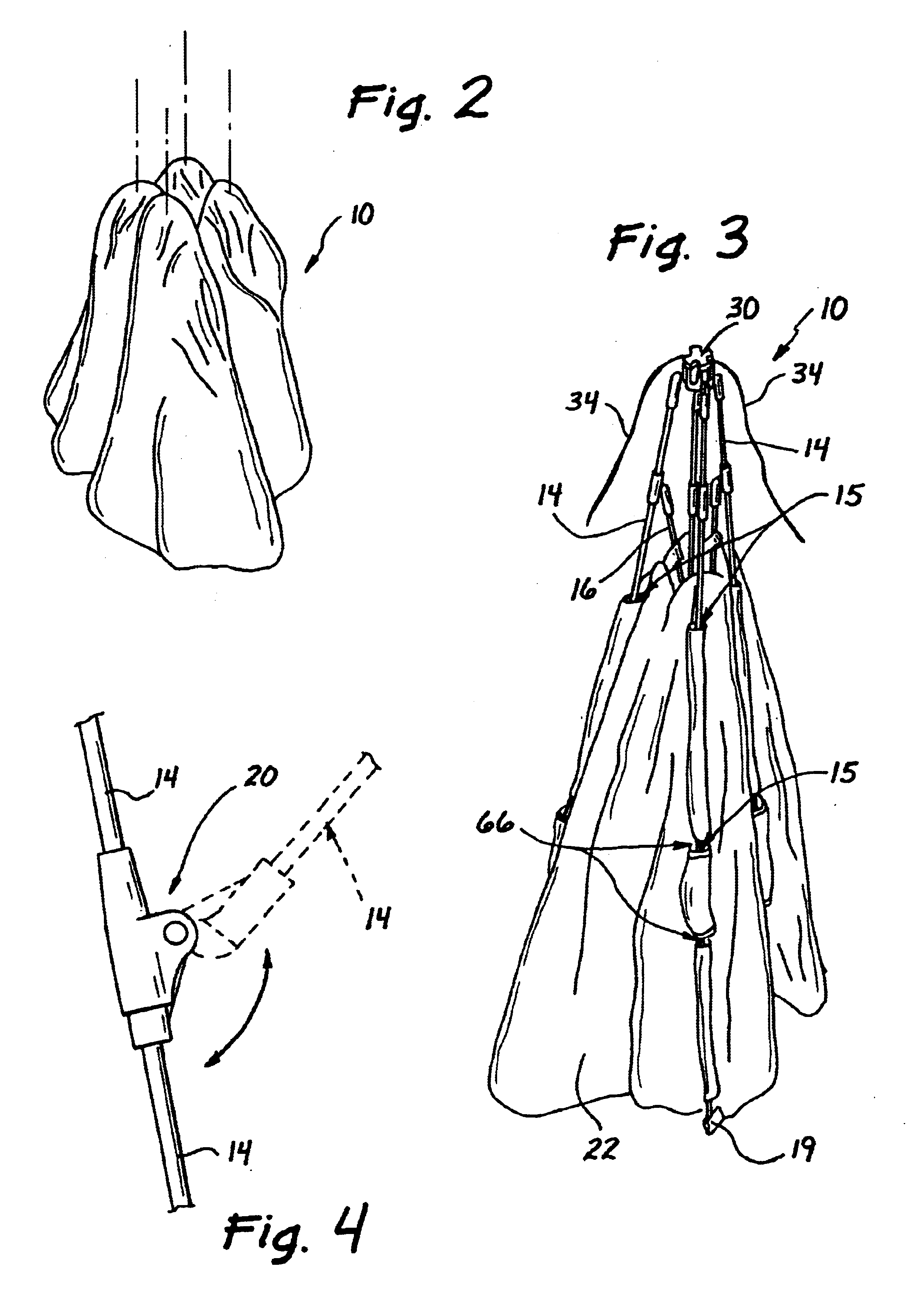

Easily constructable and collapsible portable tents

A collapsible structure comprising a collapsible support structure having a flexible covering disposed thereon. The support structure comprises a plurality of pole members that emanate from an upper assembly. The upper assembly has first and second hub members that, when brought into abutting contact with each other, cause the structure to assume a fully constructed configuration but when separated from each other allow the structure to become collapsed. In many embodiments, the structure can be converted from its constructed configuration to its collapsed configuration substantially with the use of a single hand. In some embodiments, 2 or more of the collapsible structures may be joined together to form a multi-unit structure. These collapsible structures may include decorative markings on the flexible cover, especially in embodiments intended for use by or entertainment of children.

Owner:WINPLUS

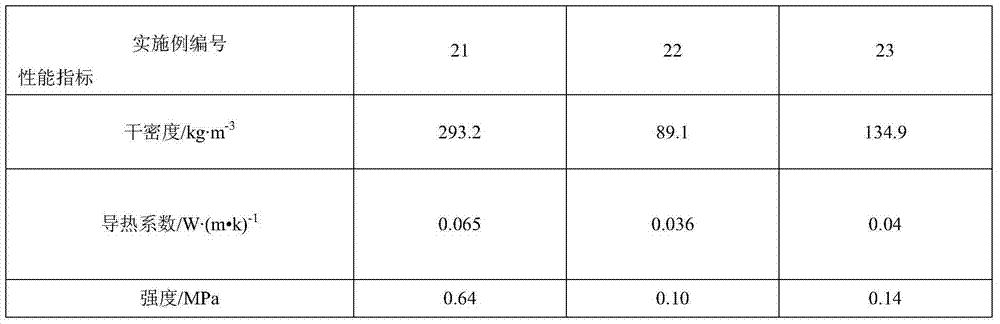

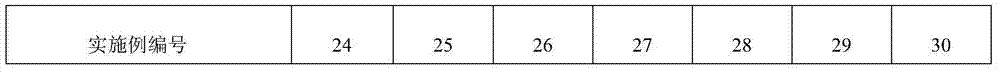

General purpose Portland cement based ultra-light physical foamed concrete

ActiveCN104774033AReduce raw material usageReduce resource consumptionCeramicwareCushionPortland cement

The invention discloses general purpose Portland cement based ultra-light physical foamed concrete which is characterized by being prepared by mixing, forming and maintaining the following components in percentage by weight: 20-70% of general purpose Portland cement, 0-40% of a type A admixture or / and 0-40% of a type B admixture, 0.5-4% of a type C additive, 0.3-2% of a foaming agent, 0-1% of a water reducing agent, 0-4% of fibers and 25-60% of water. The general purpose Portland cement based ultra-light physical foamed concrete disclosed by the invention has the characteristics of ultra-low dry density, low thermal conductivity, relatively high strength, wide raw material source, low cost, simple preparation process, easy maintenance process selection and the like, is suitable to serve as an earthquake-proof and energy-absorbing material, a lightweight cushion course and a catalyst carrier material in a thermal insulation project, a floor heating project and a back filling project, and is particularly suitable for a building exterior wall external thermal insulation system, a roof thermal insulation system, a composite thermal insulation wall body and a buffer energy absorbing system.

Owner:SOUTHWEAT UNIV OF SCI & TECH

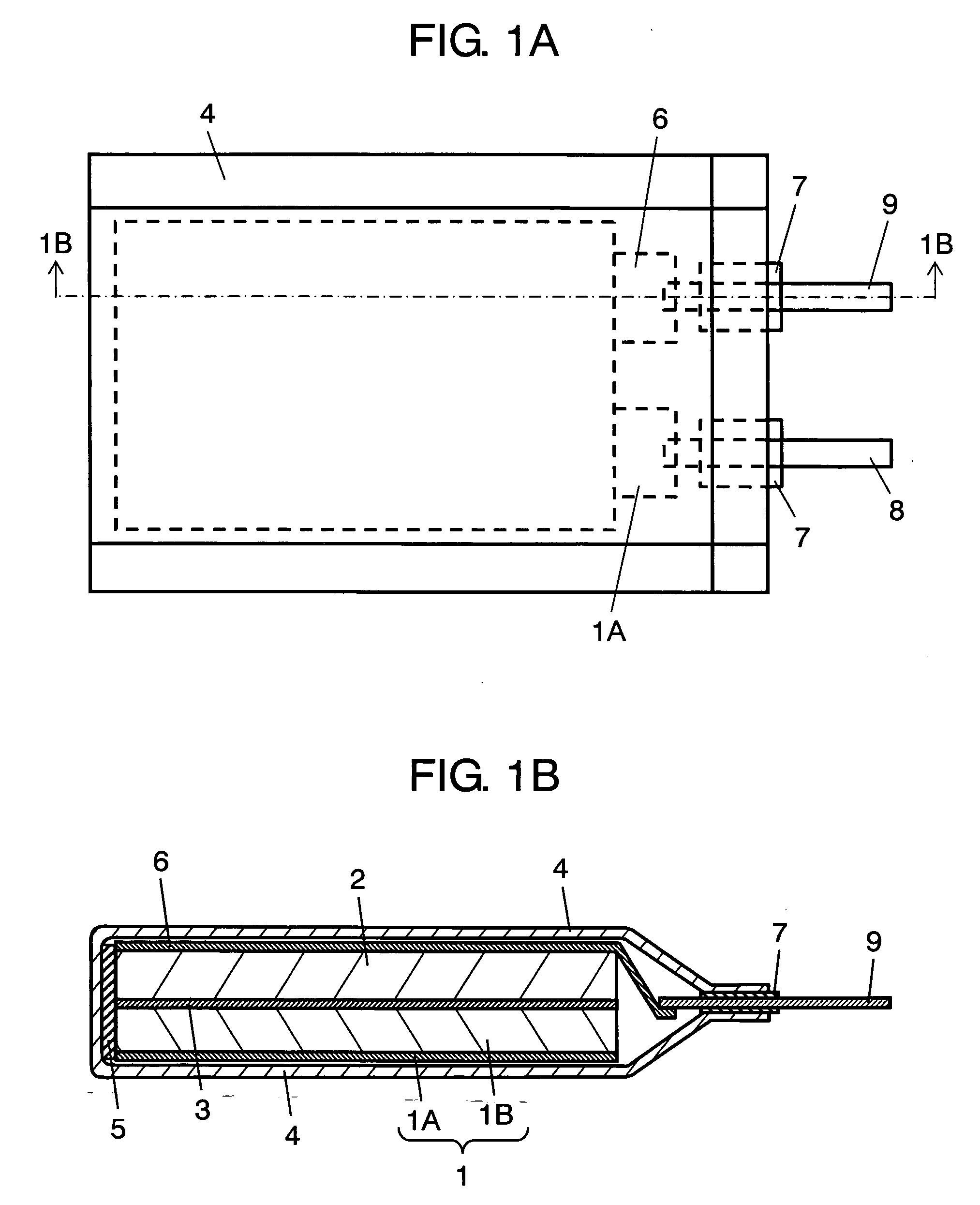

Negative electrode for non-aqueous electrolyte secondary batteries, non-aqueous electrolyte secondary battery having the electrode, and method for producing negative electrode for non-aqueous electrolyte secondary batteries

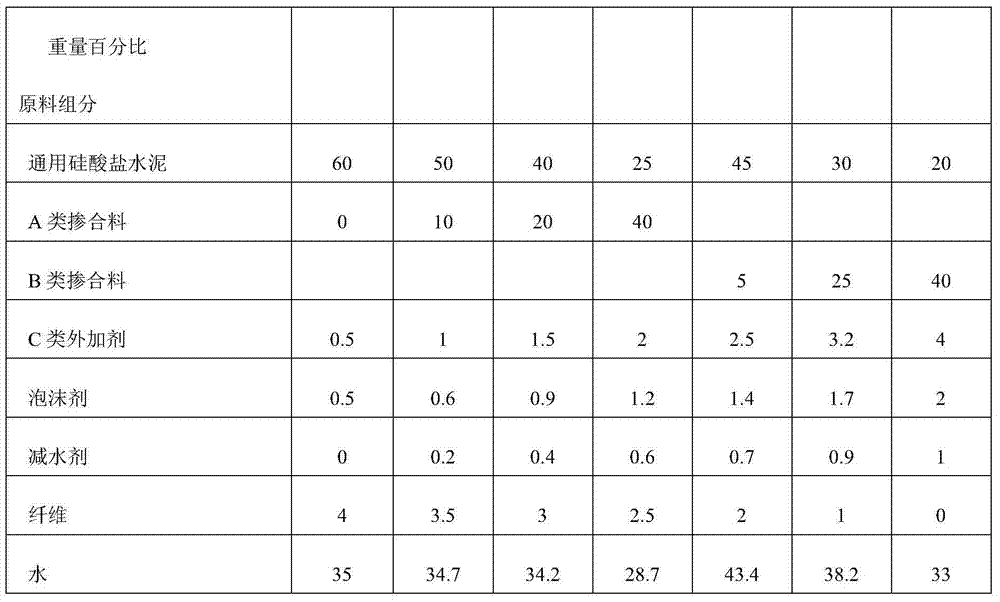

InactiveUS20070111102A1Excellent cycle characteristicsPrevent collapseMaterial nanotechnologyFinal product manufactureFiberManganese

A negative electrode for non-aqueous electrolyte secondary batteries has a mixture layer including a composite negative electrode active material which is composed of active material cores capable of charging and discharging at least lithium ions; carbon nanofibers; and catalyst elements. The carbon nanofibers are attached to the surfaces of the active material cores. The catalyst elements are at least one selected from the group consisting of copper, iron, cobalt, nickel, molybdenum, and manganese, and promote the growth of the carbon nanofibers. The active material cores have the carbon nanofibers therebetween.

Owner:PANASONIC CORP

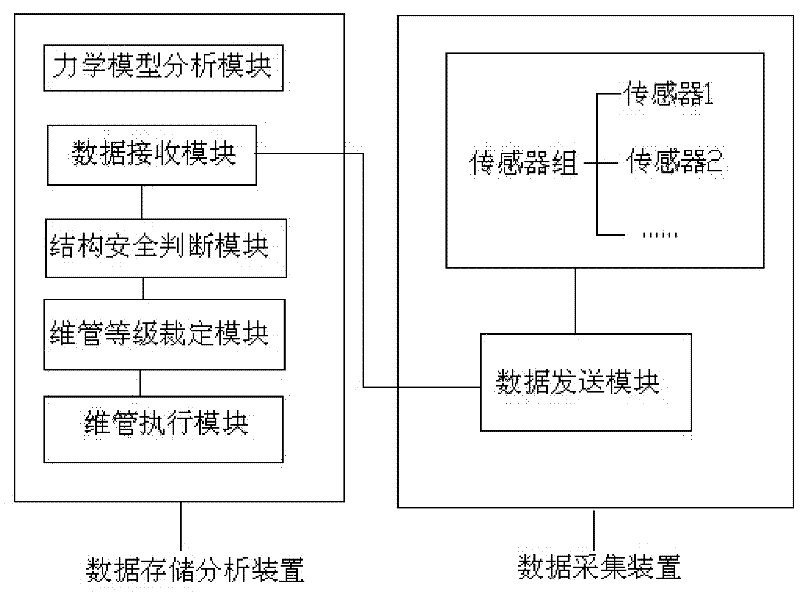

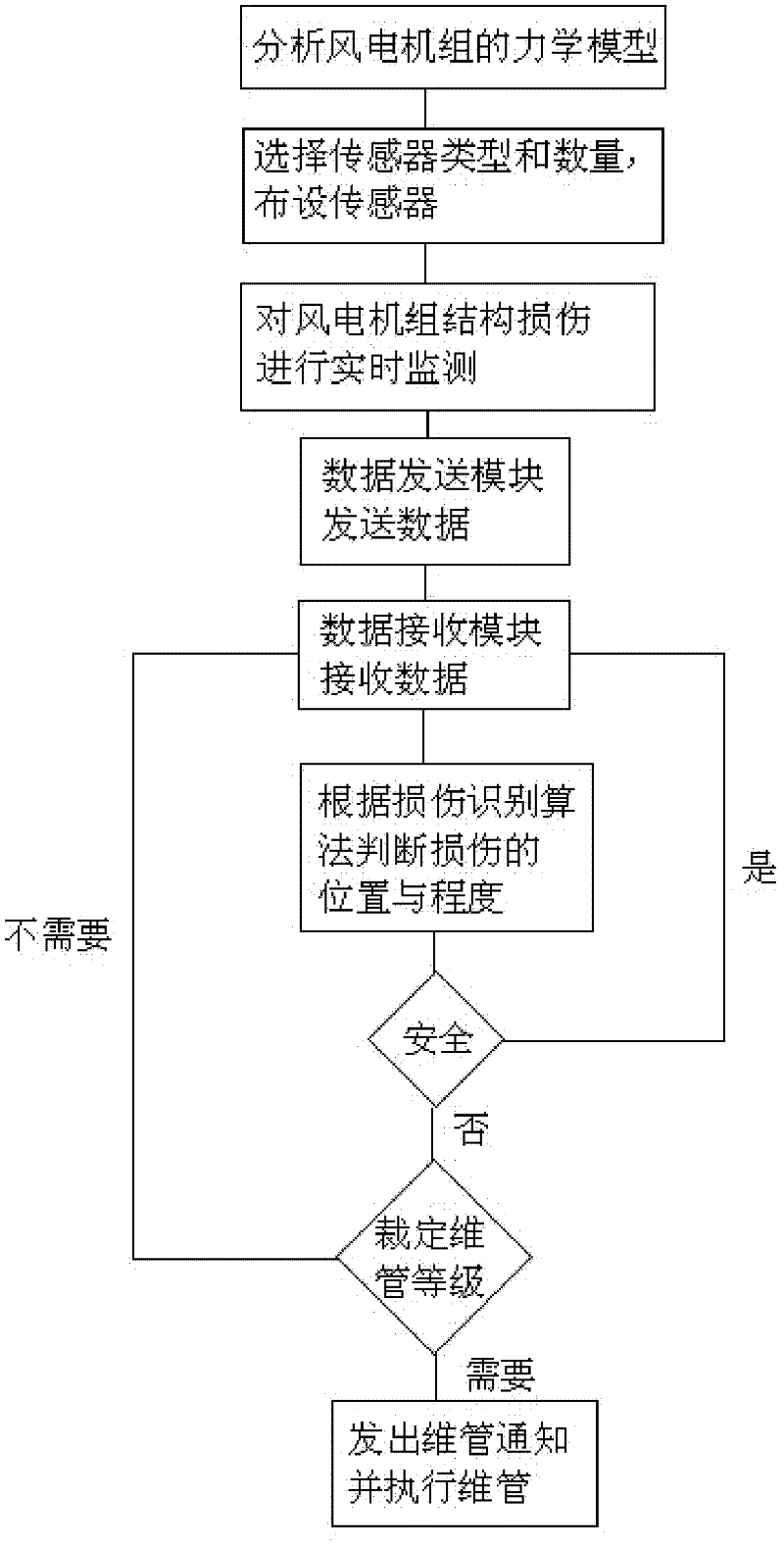

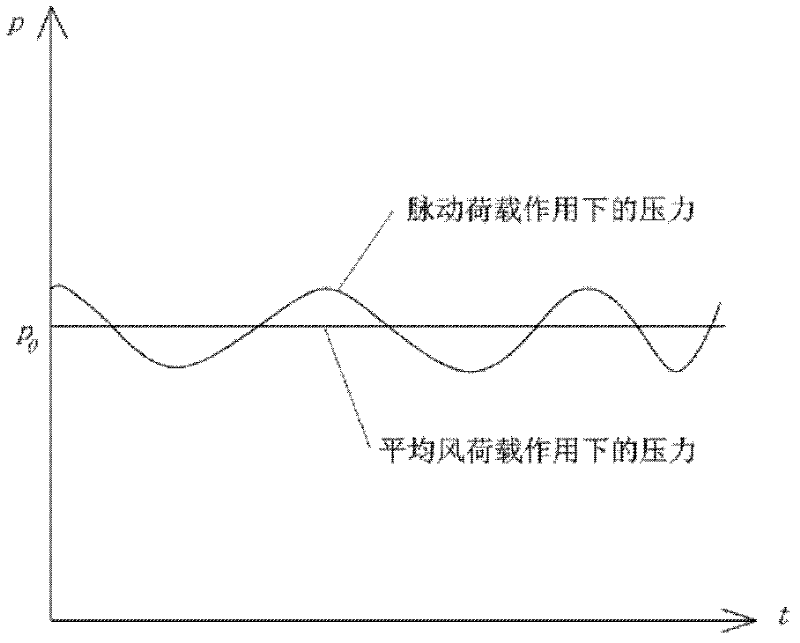

Health monitoring system and method for wind generator system structure

InactiveCN102330645AAssess securityImprove operational efficiencyWind energy generationWind motor componentsElectricityMechanical models

The invention discloses a health monitoring system and method for a wind generator system structure. The system provided by the invention comprises a data storage analytical device and a data collecting device, wherein the data storage analytical device and the data collecting device are communicated through a wireless signal, the data storage analytical device comprises a mechanical model analytical module, a data receiving module, a structure safety judging module, a vascular grade judging module and a vascular execution module; the data collecting device comprises a sensor group and a data transmitting module, and the sensor group is connected with the data transmission module through a wire cable; and the system judges whether the structure is damaged or not through a certain detection means and a method, the locating and evaluation of the damage are carried out to avoid the damage, thereby realizing the damage detection of a wind power generation infrastructure and health monitoring of a discriminating structure. Meanwhile, the invention also aims to provide a health monitoring method for the wind generator system structure.

Owner:吴建华

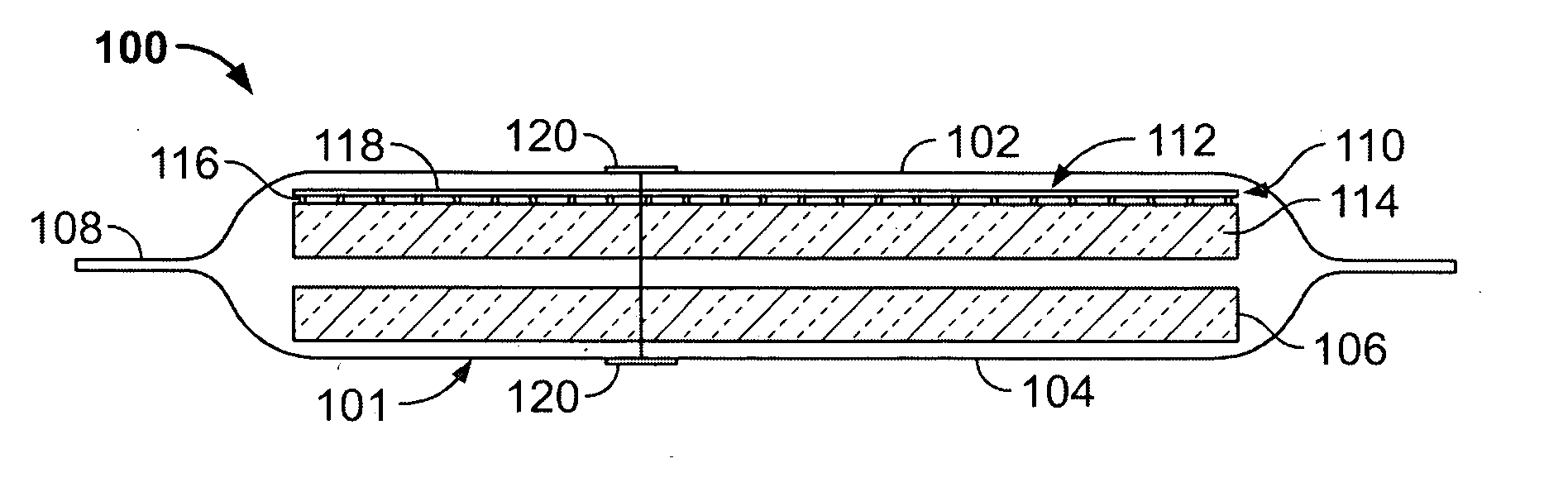

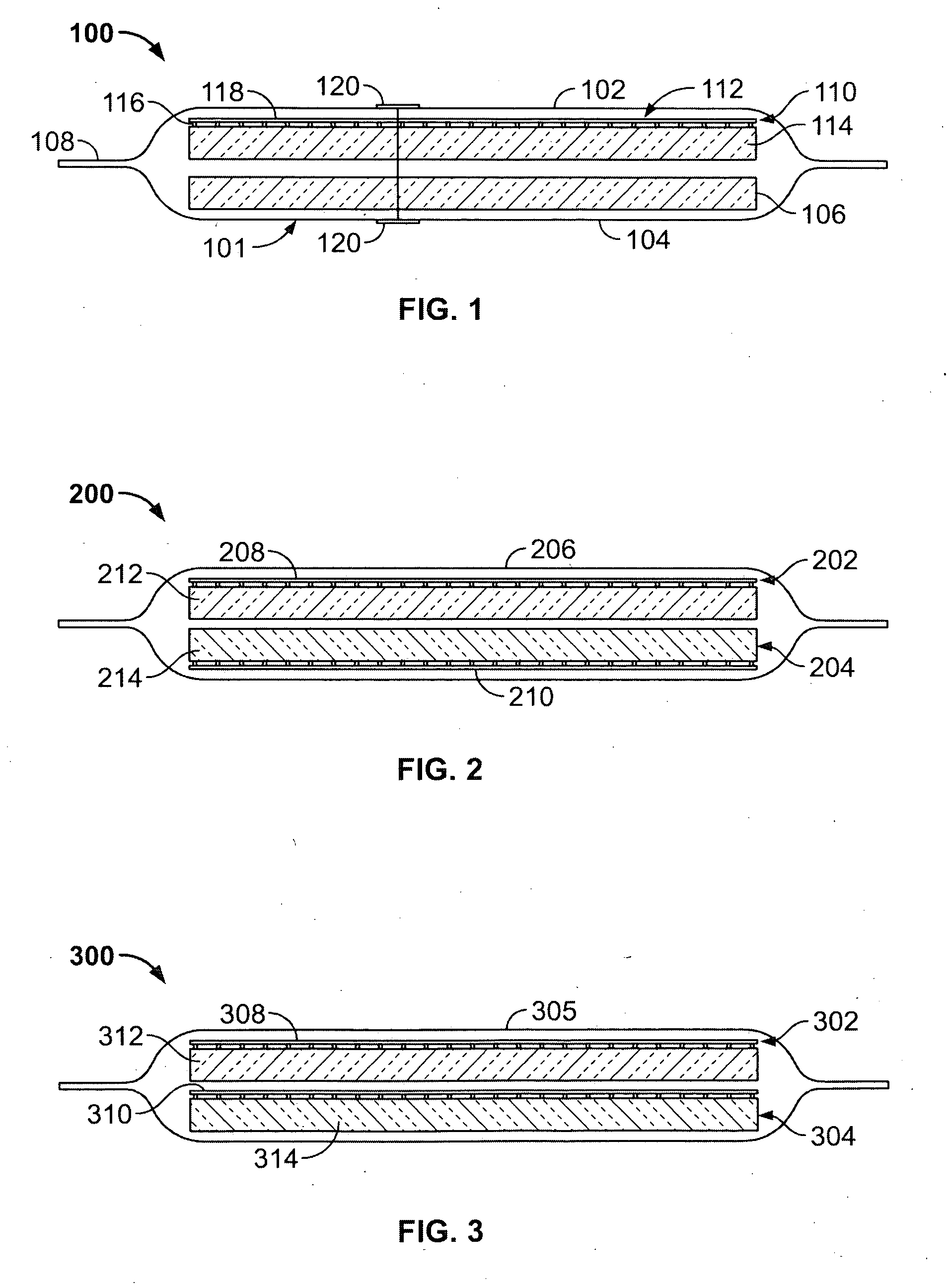

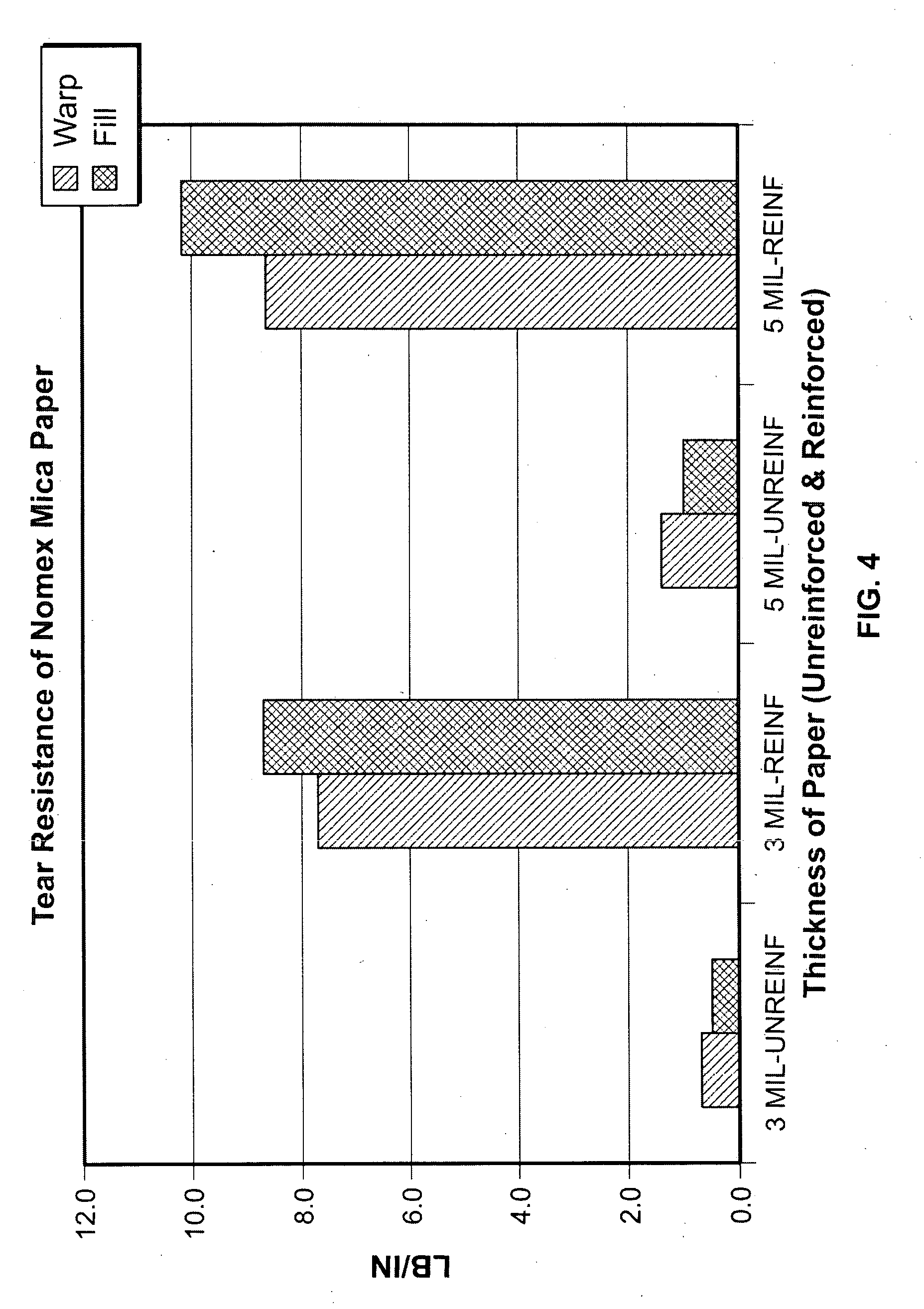

Light weight fire-blocking insulation blanket with improved durability and handleability

InactiveUS20060046598A1Light weightPrevent collapseSynthetic resin layered productsPaper/cardboard layered productsEngineeringHigh intensity

A lightweight insulation blanket for aircraft insulation or the like includes a lofted fibrous batting laminated to a relatively tough or high-tensile sheet of thin material, which provides improved handleability and durability to the batting. The high-tensile sheet may be a flexible fire-blocking sheet or non-woven fabric of refractory materials, which may be reinforced by a scrim. The batting and laminated fire-blocking sheet may be encased in a protective covering.

Owner:ORCON CORP

Medical device

A collapsible filter element (40) for a transcatheter embolic protection device (1). The filter element (40) comprises a collapsible filter body (41) which is movable between a collapsed stored position for movement through a vascular system and an expanded position for extension across a blood vessel such that blood passing through the blood vessel is delivered through the filter element (40). A proximal inlet portion of the filter body (41) has two inlet openings (50) sized to allow blood and embolic material enter the filter body (41), and a distal outlet portion of the filter body (41) has a plurality of small outlet openings (51) to allow through-passage of blood, but to retain embolic material within the filter body (41). The filter body (41) is of an oriented polymeric material.

Owner:SALVIAC

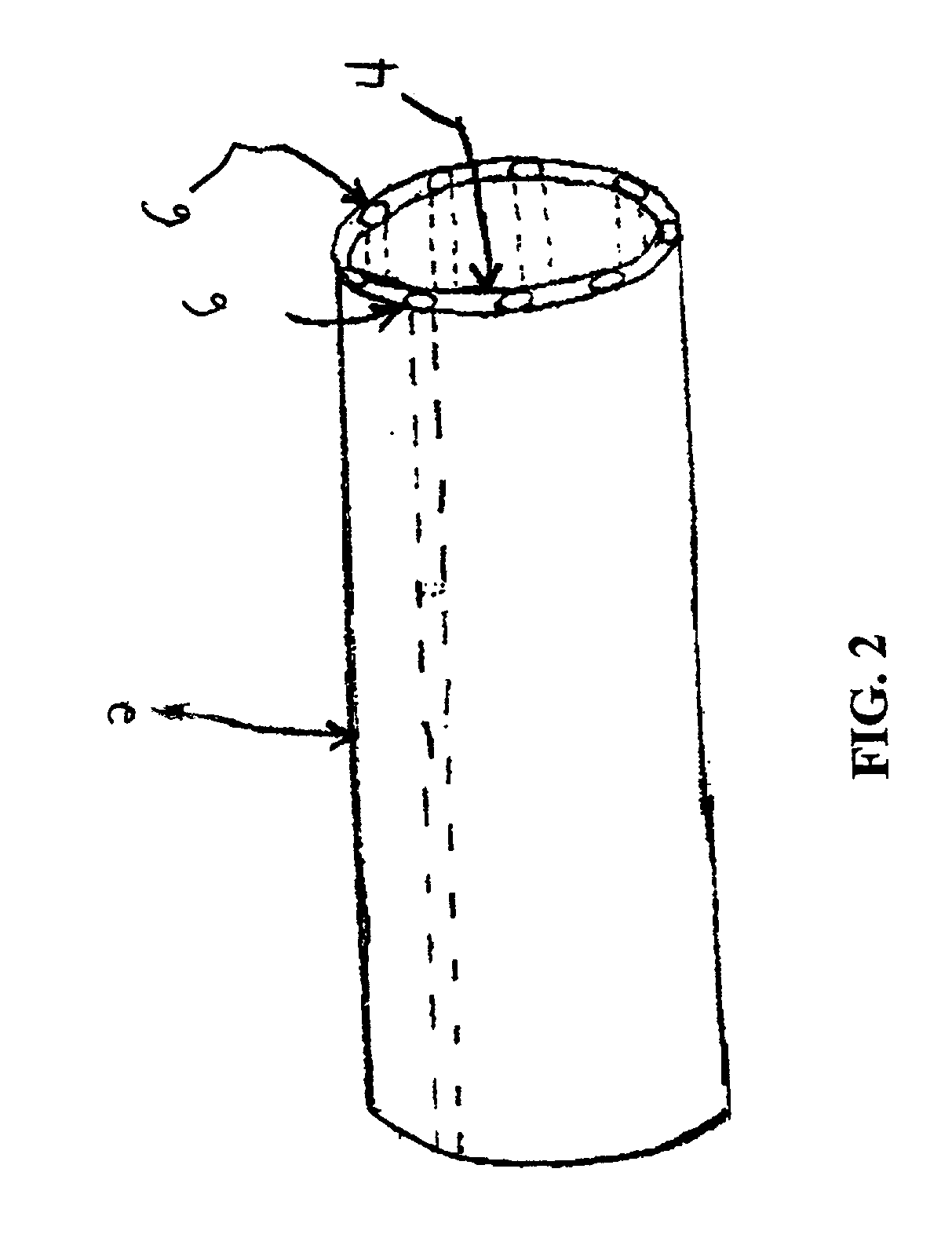

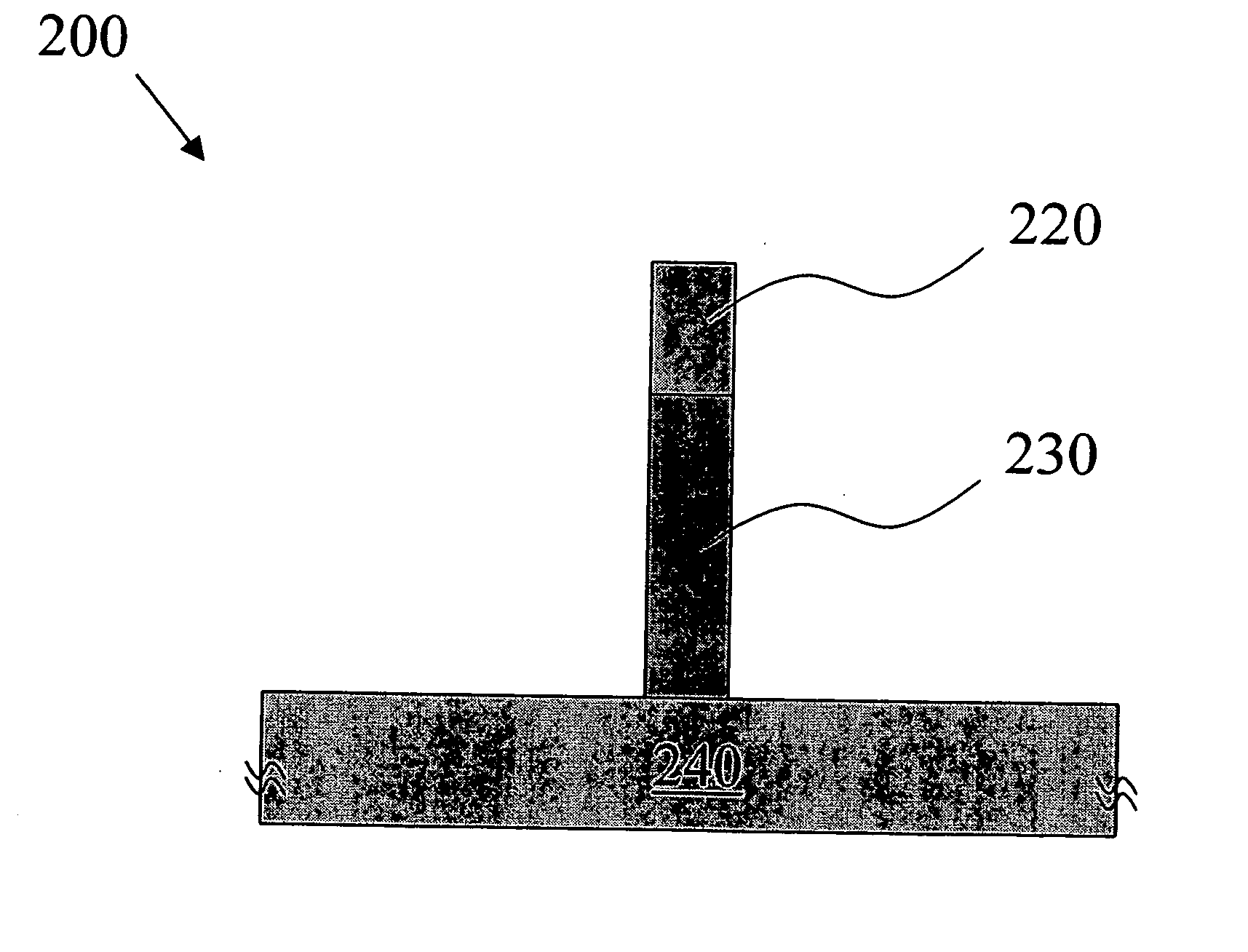

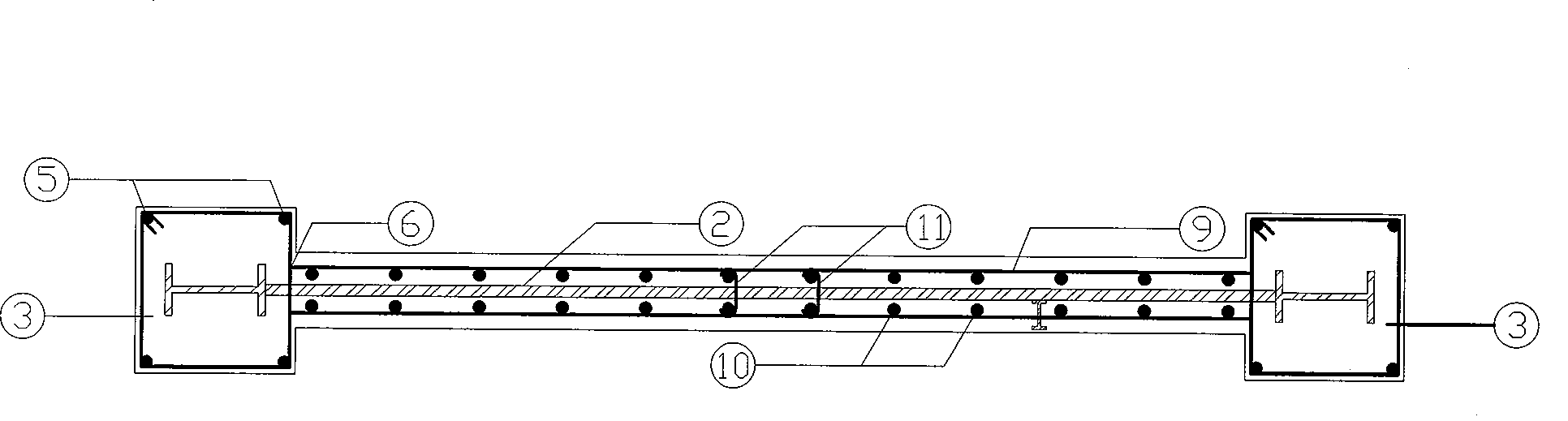

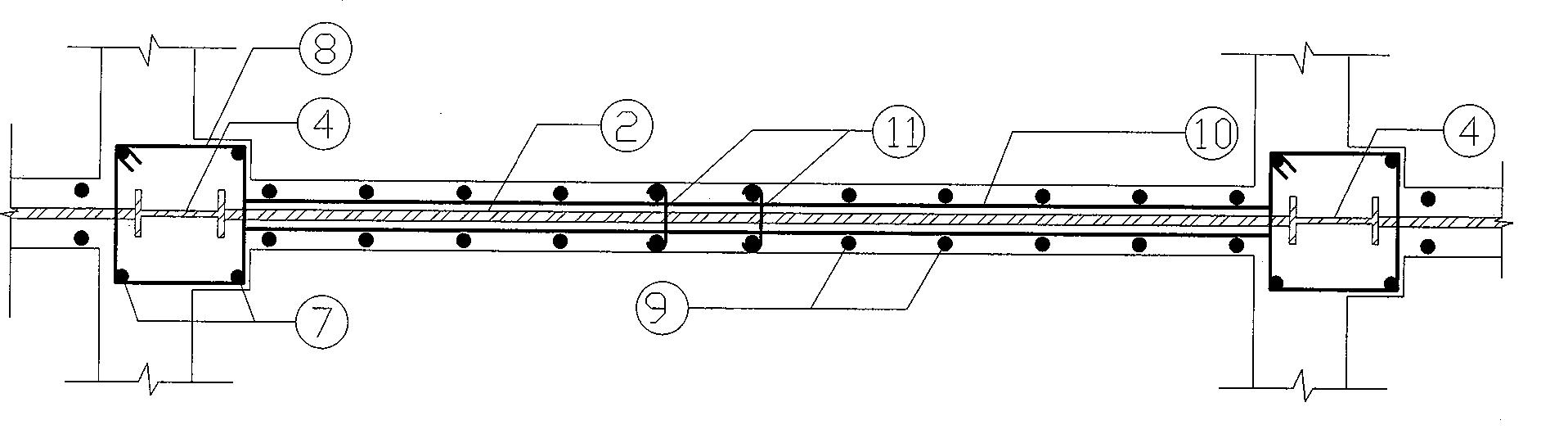

Method and apparatus for lining a conduit

InactiveUS20020033554A1Facilitates inspection and installation and servicingReduce or eliminate "slLaminationTyresFiberSlurry

Method and apparatus for installing a liner material into a host conduit such as, e.g., a sewer pipe, hydrocarbon pipeline, gas line, water line, industrial chemical pipe, or a saltwater line. The liner material may include a compression liner and / or a preliner that is attached to the inner wall of the host conduit to repair or reinforce the host conduit or separate the host conduit from materials transported within the new liner formed from the liner material. Curable resin, slurry, or cement can be placed between the liner material and the host conduit to affix the liner material into place. Before and during curing, a fluid such as air or water can be used to inflate the compression liner outwardly toward the host conduit. Spacers positioned between at least a portion of the liner material and the host conduit may be used to (i) calibrate the thickness of the liner material and curable material that is cured to form the new liner, and (ii) form communication channels adapted to house devices such as wire, cable, fiber optic cable, telephone lines, power lines, etc. The spacers and channels can be selectively inflatable to various sizes to allow calibration of the liner thickness and to form communication channels having a selected width or height. Additionally, the liner material may be formed into a one-piece, tubular lining member having an inflatable enclosure defined between an inner and an outer layer of the lining member. The enclosure can be selectively inflated to (i) calibrate the resulting thickness of the cured liner material, and (ii) form communication channels running along the length of the host conduit.

Owner:HEAGY RICHARD T +3

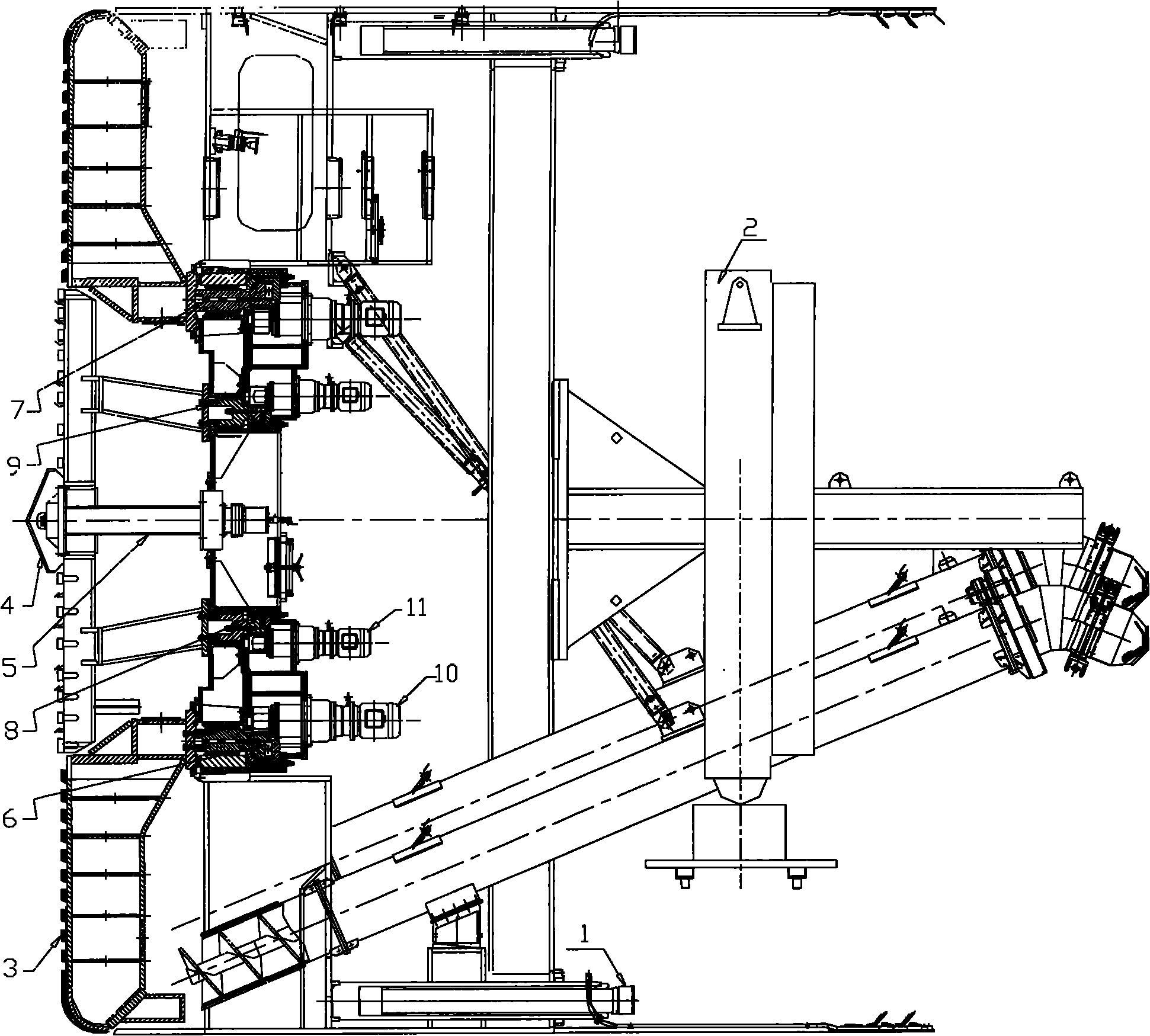

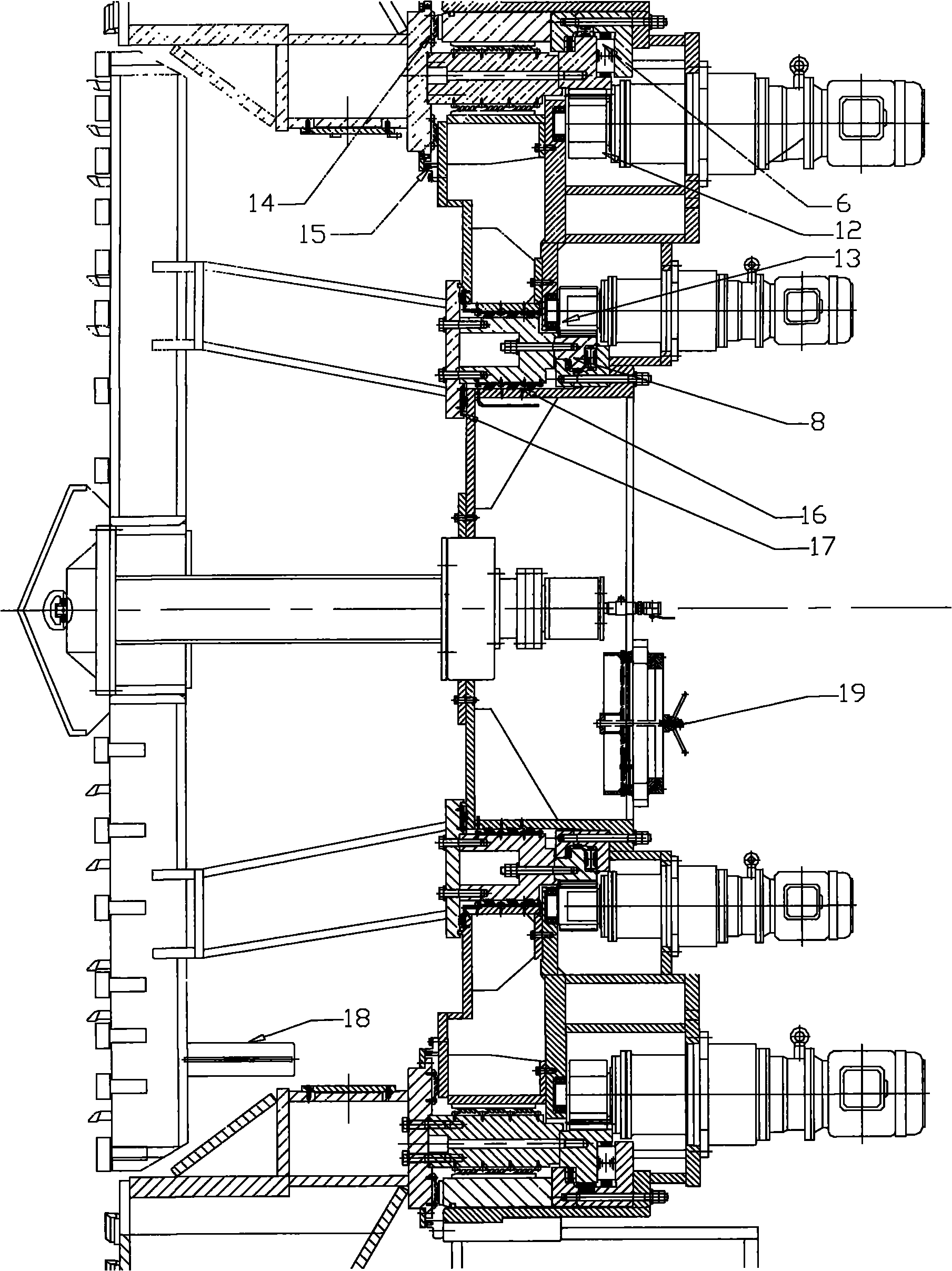

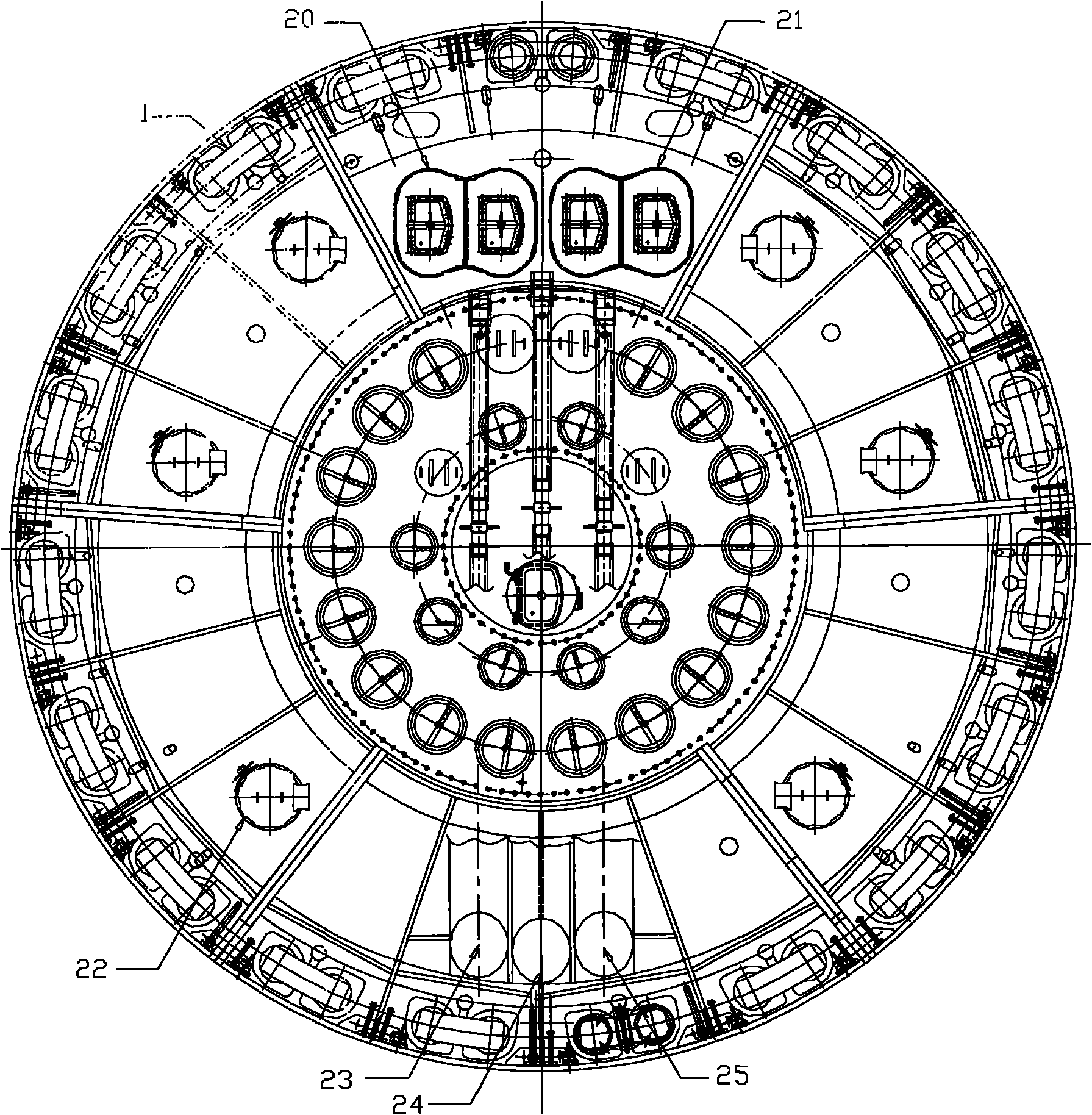

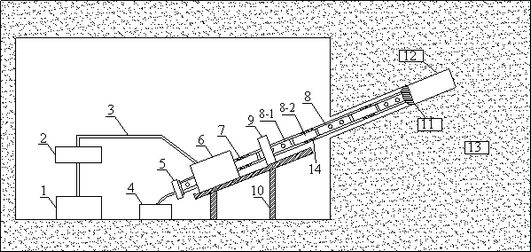

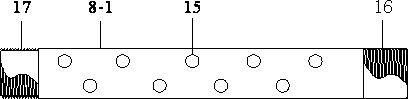

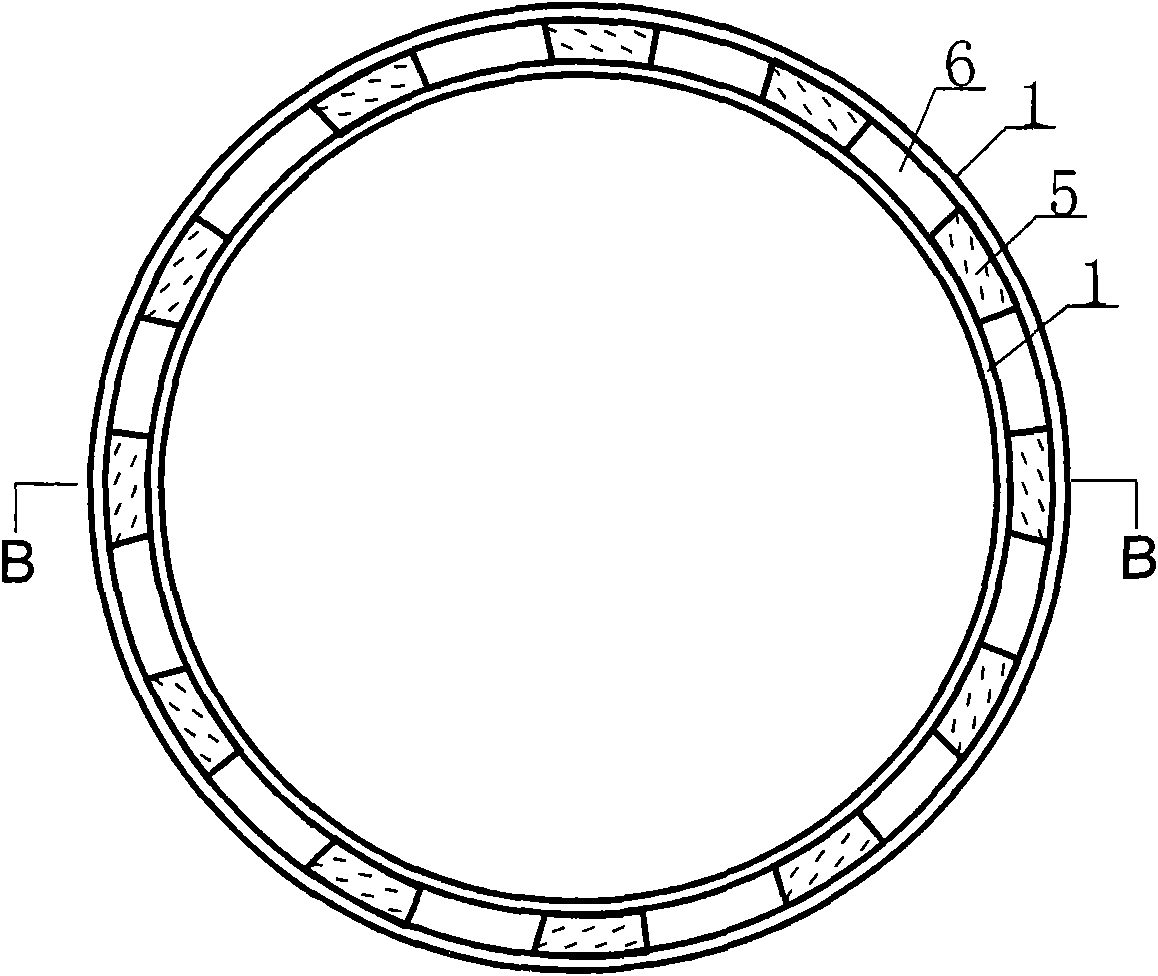

Large-diameter earth pressure balance shield machine

InactiveCN101798928AReduce wear rateChange the situation of uneven damageTunnelsControl theoryEarth pressure balance

The invention relates to a large-diameter earth pressure balance shield machine. The machine comprises a cutterhead, a cutterhead drive part, a propulsion oil cylinder, an erector, spiral conveyors and a frame; the cutterhead is a double-cutterhead which comprises a peripheral large cutterhead and an independent central cutterhead; the cutterhead drive part comprises two driving mechanisms which drive the peripheral large cutterhead and the independent central cutterhead respectively; and the peripheral large cutterhead and the independent central cutterhead rotate independently and bidirectionally. Compared with the prior art, the shield machine adopts the double-cutterhead design, greatly optimizes a cutting speed of the cutterhead on a soil body, further improves a propulsion speed of the shield, optimizes the disturbance effect of the cutterhead on the soil body, and prevents the rolling of a shield machine body; different opening rates are designed on the cutterhead and are suitable for different situations of a central part and a peripheral part when a tunnel is advanced; and three spiral conveyors discharge soil, effectively control the posture of the shield, and prevent the deviation of a tunnel axis.

Owner:SHANGHAI LIXING ENG TECH DEV

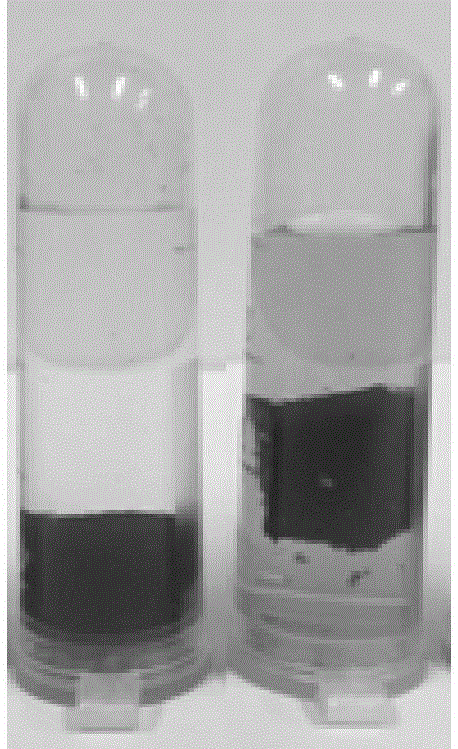

Preparation method for oxidized graphene-poly-dopamine composite aerogel

InactiveCN105254916AIntegrity guaranteedGuaranteed stabilityOther chemical processesAlkali metal oxides/hydroxidesPorosityFreeze-drying

The invention provides a preparation method for oxidized graphene-poly-dopamine composite aerogel. The preparation method comprises the following steps that 1, 0.15-0.7 g of dopamine powder is dissolved in 10-18 ml of distilled water, the dopamine aqueous solutions are mixed with 50-60 ml of oxidized graphene aqueous solutions with the concentration of 5-6 mg / ml, and stirring is performed to obtain oxidized graphene-dopamine mixed solutions; 2, 3-9 ml of tris aminomethane buffer solutions with the concentration of 0.1-0.12 mol / L are dropwise added into the mixed solutions while stirring is performed, stirring is continuously performed for 2-2.5 h, and standing is performed to enable the dopamine to be fully polymerized to obtain oxidized graphene-poly-dopamine composite aquogel; 3, after being placed in an environment with the temperature ranging from minus 20 DEG C to minus 10 DEG C to be frozen for 24-30 h, the composite aquogel is processed through freeze drying, and then the oxidized graphene-poly-dopamine composite aerogel is obtained. The method is simple in technology, and the prepared composite aerogel has the advantages of being high in porosity, excellent in adsorptivity, high in strength and the like.

Owner:SOUTHWEST JIAOTONG UNIV

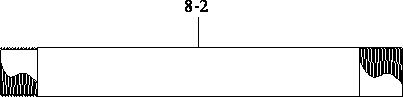

Gas extraction and drilling cooperative drilling and protecting integrated system for soft coal seams and process

ActiveCN102587828AOvercome the problem of frictional resistanceReduce displacementDrilling rodsGas removalHydraulic pumpAir compressor

A gas extraction and drilling cooperative drilling and protecting integrated system for soft coal seams and process belong to soft coal seam cooperative drilling and protecting systems and process. The gas extraction and drilling cooperative drilling and protecting integrated system mainly consists of a control table, a hydraulic pump station, an air compressor, a feeding device, a drill stem, a hole protecting tube, a drill bit and the like. The hole protecting tube is located in the drill stem, and the hole protecting tube and the drill stem are synchronously connected and drill cooperatively. The depth of a drilled hole is equal to the length of the hole protecting tube. Finally, the hole protecting tube penetrates through the drill bit, and the drill stem is withdrawn while the hole protecting tube is remained in the hole to realize functions of supporting a hole wall and extracting gas. The system and the process are convenient in operation, the hole protecting tube and the drill stem realize cooperative drilling and protecting, the hole protecting tube is easy to be remained in the drilled hole, problems that the hole collapses and the hole protecting tube is difficult to be fed to the drilled hole can be resolved, the hole protecting depth is high, the hole wall can be supported more effectively, deformation and collapse are prevented, accordingly high gas extraction concentration and flow of the soft coal seams are guaranteed, and the gas extraction and drilling cooperative drilling and protecting integrated system for soft coal seams and the process are particularly applicable to quite soft coal seams with the value of the firmness factor f smaller than 0,3.

Owner:CHINA UNIV OF MINING & TECH

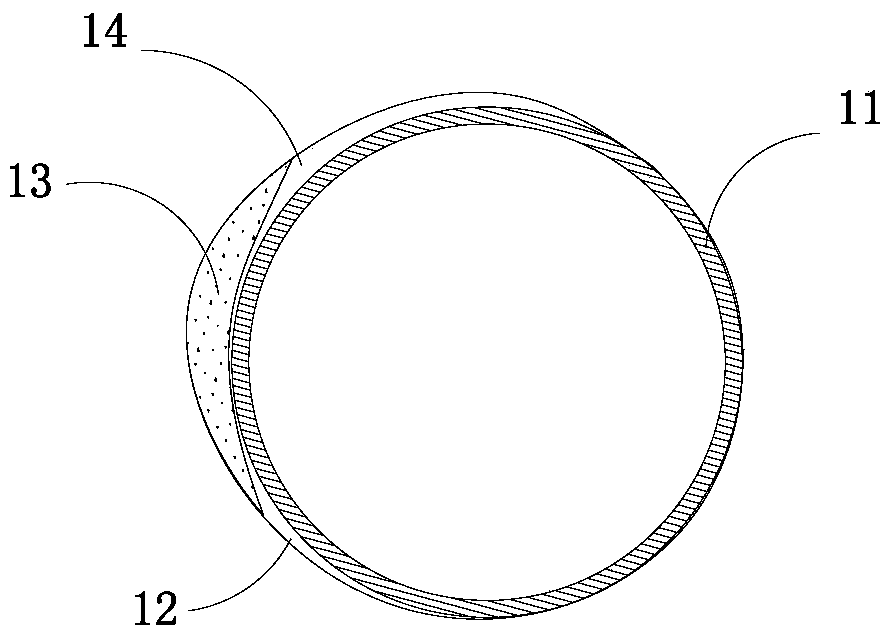

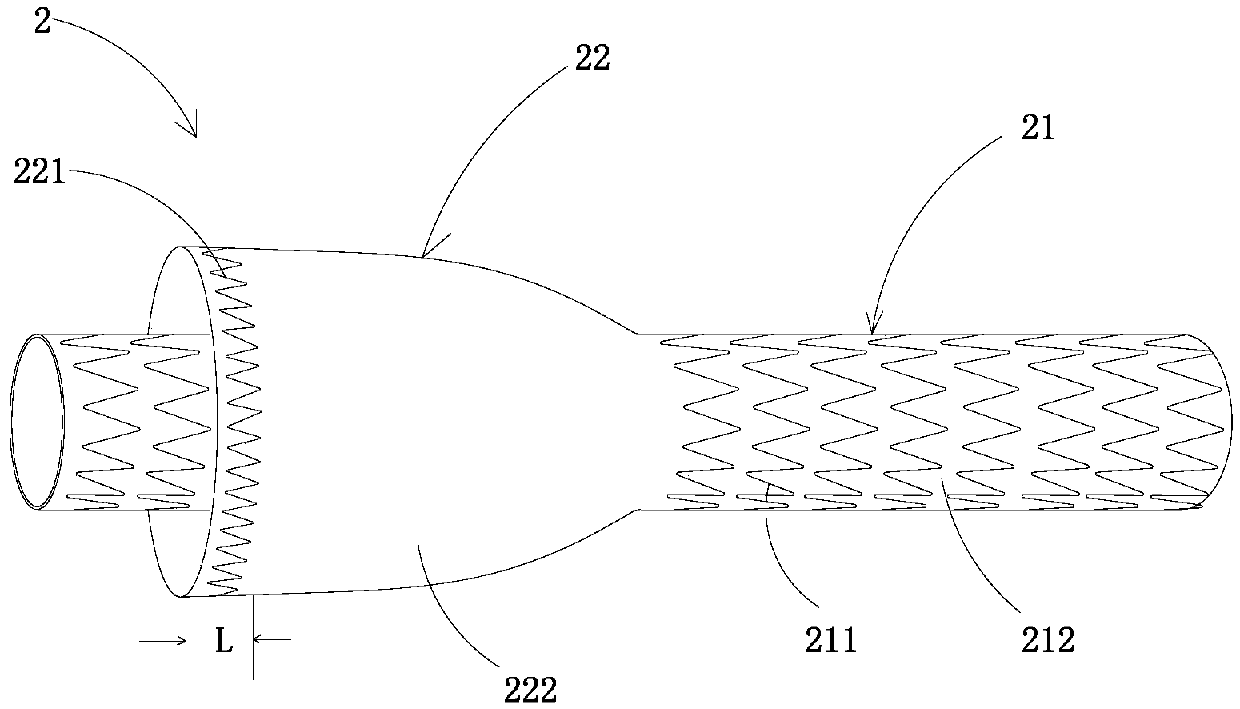

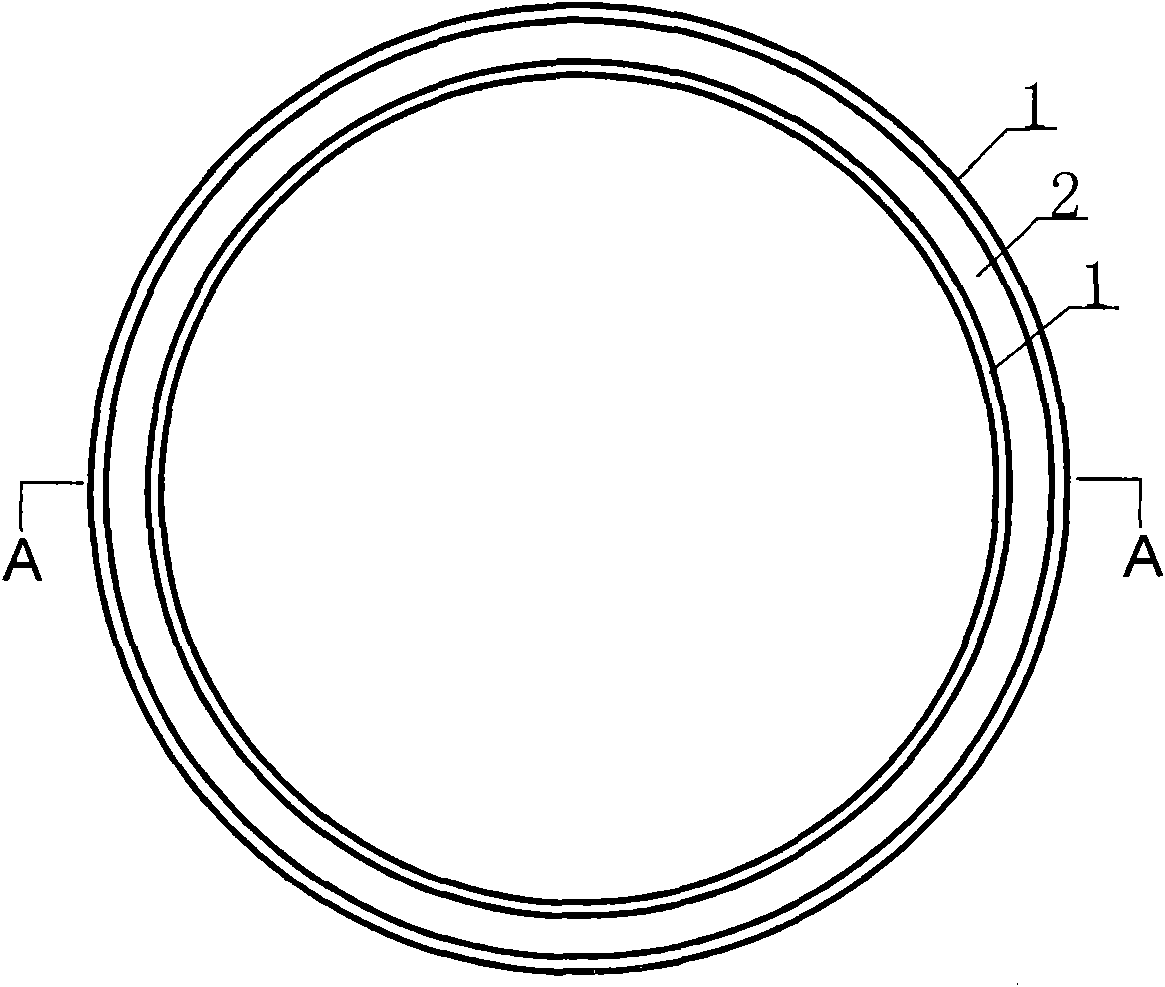

Pipe cavity bracket

The invention discloses a pipe cavity bracket. The pipe cavity bracket comprises a first pipe body and a second pipe body which sleeves the first pipe body, wherein at least one end of the second pipe body is in sealed connection with the outer surface of the first pipe body; in a radial supporting section of the pipe cavity bracket, the first pipe body comprises at least one first radial supporting structure which is arrayed along the peripheral direction of the first pipe body; the second pipe body comprises at least one second radial supporting structure which is arrayed along the peripheral direction of the second pipe body and a covering membrane covering the second radial supporting structure; a radial deformation capability of the second radial supporting structure is greater than that of the first radial supporting structure. After the pipe cavity bracket is planted, a semi-sealed gap can be formed between the first pipe body and the second pipe body or between the second pipe body and a pipe cavity wall; blood flowing into the gap can be used as a filling material to block an I type inner leakage channel, so that the blood is prevented from flowing into tumors or an interlayer. Under the impact of the blood, the first pipe body and the second pipe body both can keep a radial supporting shape and the end faces of near ends of the first pipe body and the second pipe body are not deformed, so that the blood flowing into the pipe cavity is prevented from being blocked.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

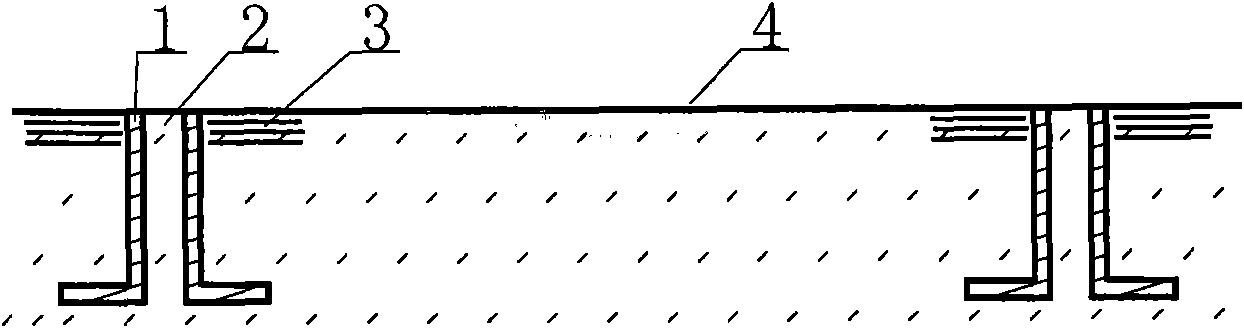

Method for connecting slotted sections in underground construction of diaphragm wall

The invention discloses a method for connecting slotted sections in underground construction of diaphragm wall of 'deep wall, large thickness and needing rock-socketed' applied to large acale bridges and construction foundation pit excavation. The method comprises the following steps: establishing a guide wall and a construction platform; constructing I phase slotted section of the diaphragm wall; constructing of a slotted eye of II phase slotted section of the diaphragm and jagged section surface of the I phase slotted section; forming an underground diaphragm wall; cleaning and brushing the wall of the II phase slotted section repeatedly up and down by a special steel brush carried by a hydraulic grab, until the steel brush does not have obvious spare, deposit on the bottom of the eye does not increase; releasing a reinforcing cage and casting concrete so as to complete the connection of I phase slotted section and II phase slotted section after the II phase slotted section is completed; forming a complete diaphragm wall after connection. After the method is adopted, the progress of the construction of the underground diaphragm wall is greatly improved; construction cost is saved; construction problems, such as concrete circumferential motion prevention, water seepage in seam and the like can be completely solved by the jagged connection section so as to improve construction quality and safety reliability.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

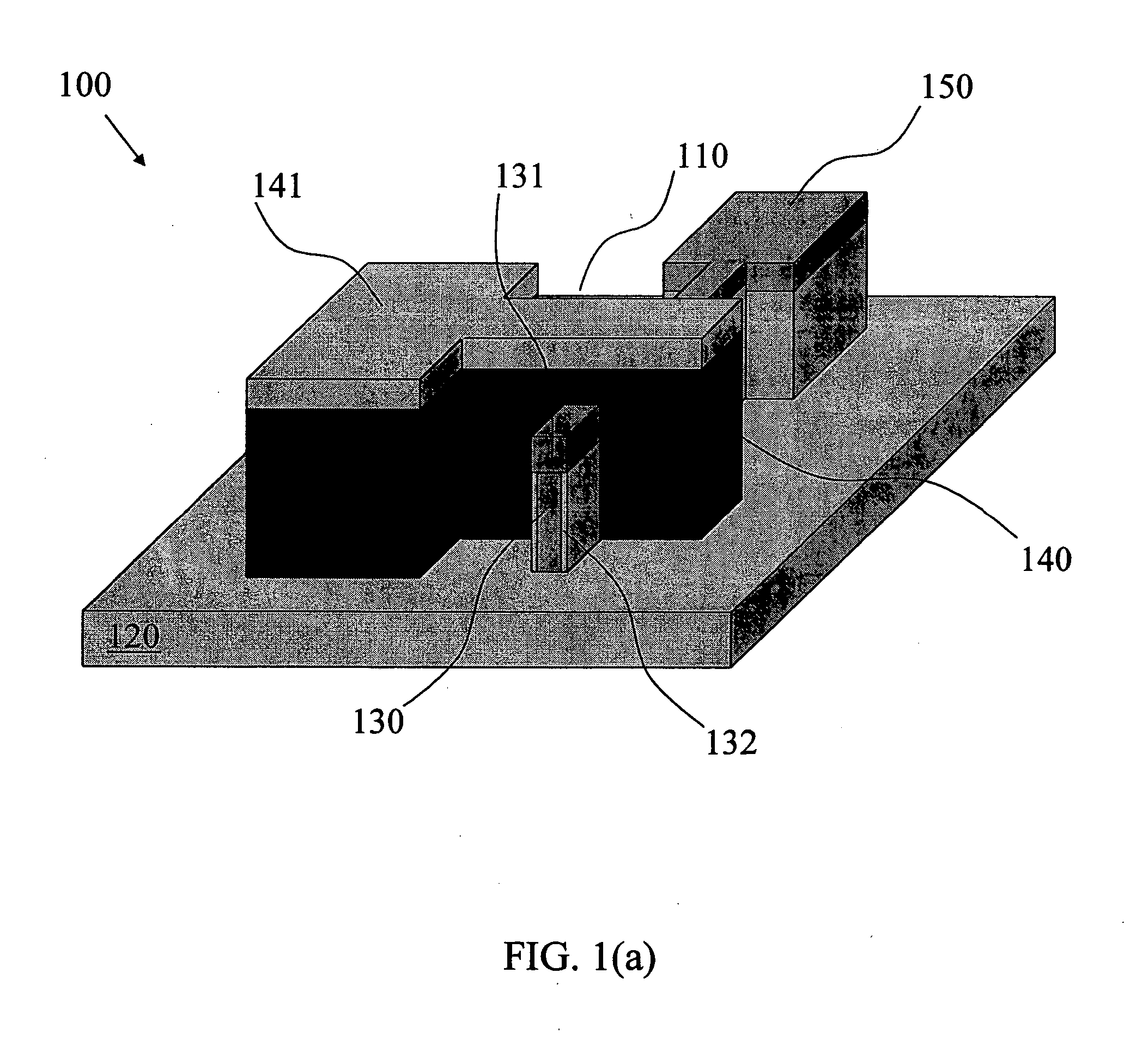

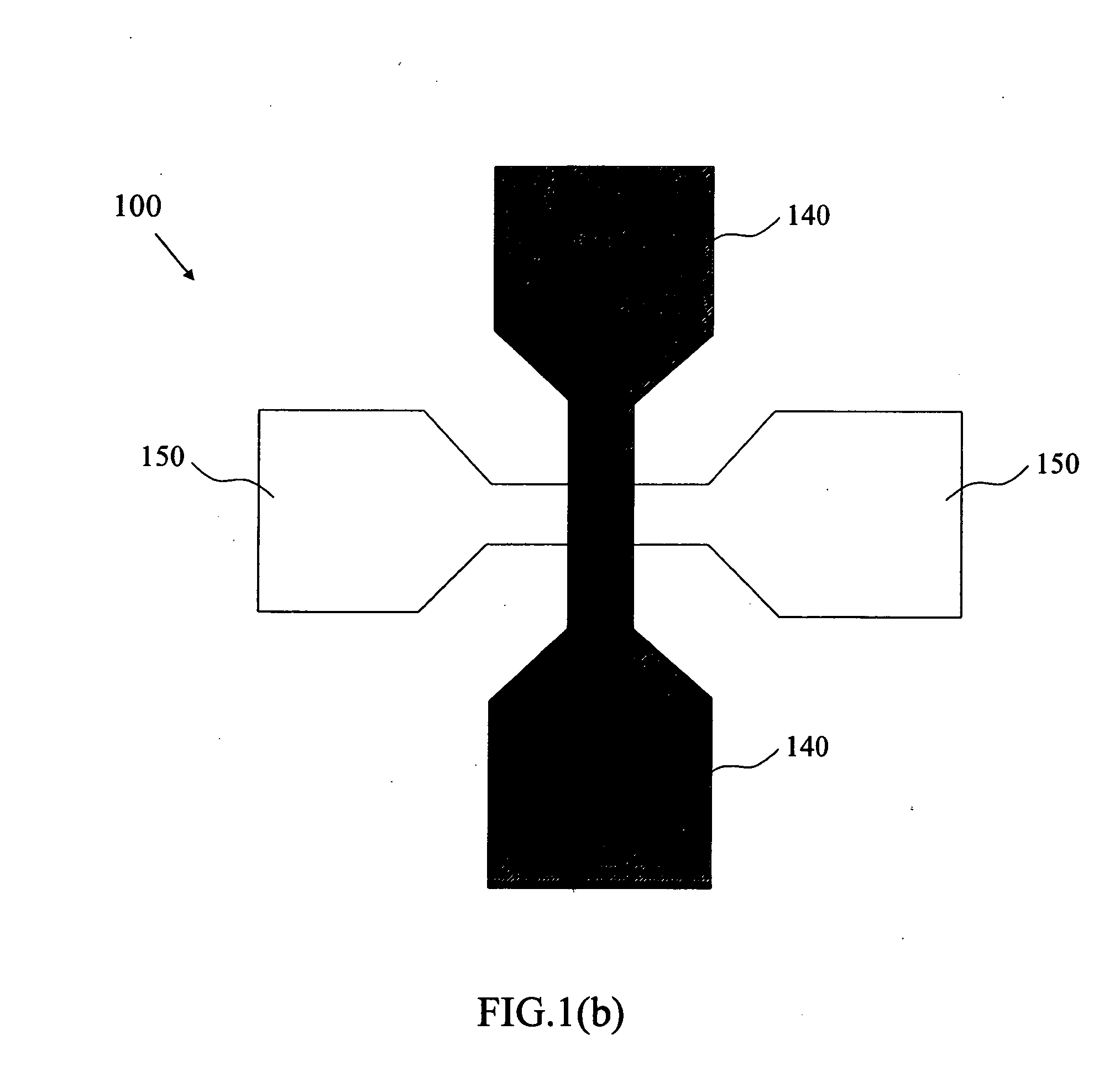

Method for patterning fins and gates in a FinFET device using trimmed hard-mask capped with imaging layer

InactiveUS20060177977A1Prevent collapsePreventing hard-mask-shape irregularizationSemiconductor/solid-state device manufacturingSemiconductor devicesEtching selectivityAspect ratio

A capped trimming hard-mask patterning process to form ultra-thin structures can include depositing a hard-mask layer over a layer of patterning material, depositing an imaging layer over the hard-mask layer, patterning the imaging layer and the hard-mask layer, selectively trim etching the hard-mask layer to form a pattern hard mask, and removing the portions of the patterning layer using the pattern hard mask formed from the trimmed hard-mask. Thus, the use of thin imaging layer, that has high etch selectivity to the hard-mask layer, allows the use of trim etch techniques without a risk of hard-mask erosion or the aspect ratio pattern collapse. That, in turn, allows for the formation of the ultra-thin pattern with widths less than the widths of the pattern of the imaging layer.

Owner:THE HONG KONG UNIV OF SCI & TECH

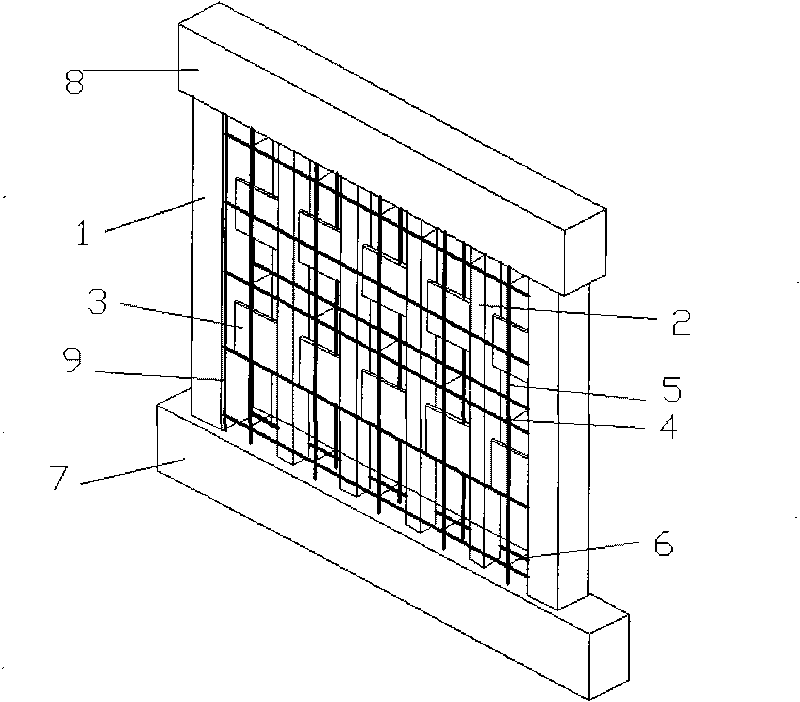

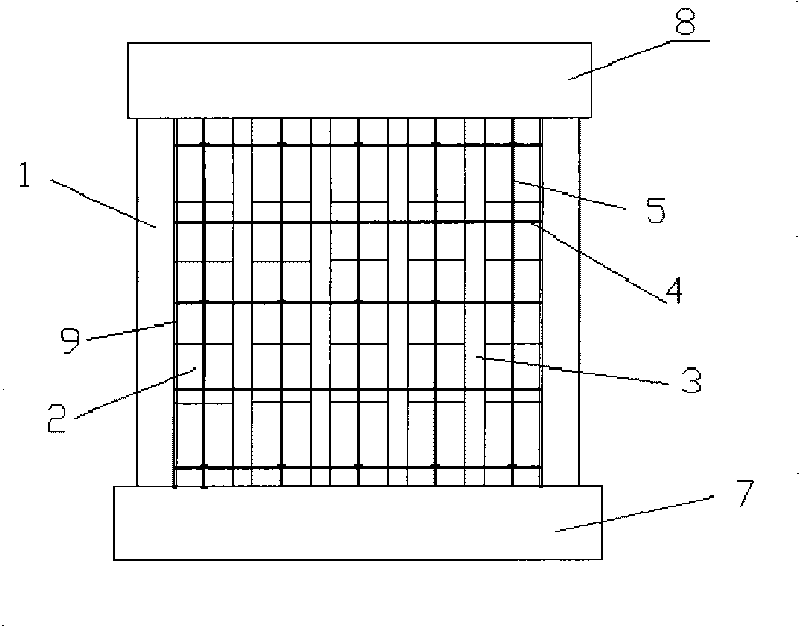

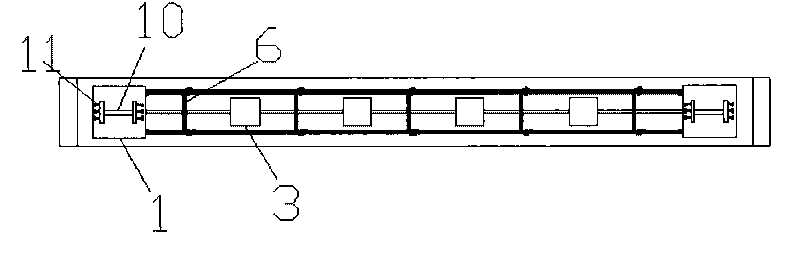

Shear wall with inbuilt continuous-row steel tube concrete core column and soft steel energy consumption bond and manufacturing method thereof

InactiveCN101761154ASuppression of out-of-plane instability problemsImprove vertical bearing capacityWallsBuilding material handlingRebarUltimate tensile strength

The invention discloses a shear wall with an inbuilt continuous-row steel tube concrete core column and a soft steel energy consumption bond and a manufacturing method thereof, belonging to the field of steel tube concrete combined shear wall. The shear wall comprises a combined steel tube concrete frame and a shear wall body, wherein the shear wall body comprises a steel tube concrete core column and a soft steel energy consumption bond, and the left end and the right end of the steel plate energy consumption bond are fixedly connected with the core column and the steel tube concrete frame; two sides of the continuous-row core column are provided with longitudinal and transverse mat reinforcements, and reinforcements on two sides are connected by binding rebars; soft steel energy consumption short steel plates the strength of which is smaller than that of the steel plate are arranged between the core columns and between the core column and a frame column, thus greatly improving the ductility and the flexural rigidity of the shear wall; meanwhile, because the short steel plate is equivalent to a connecting beam, the effect of invisible 'strong column and week beam' can be realized; and the soft steel energy consumption bond, the concrete wall body, the frame column and the core column jointly form three defensive lines of a lateral force resisting system. The invention adopts the steel tube concrete core column and the soft steel energy consumption bond as the lateral force resisting system, improves the vertical rigidity and the bearing capacity of the shear wall, has the advantages of convenient construction and shortened construction period and is more economical.

Owner:BEIJING UNIV OF TECH

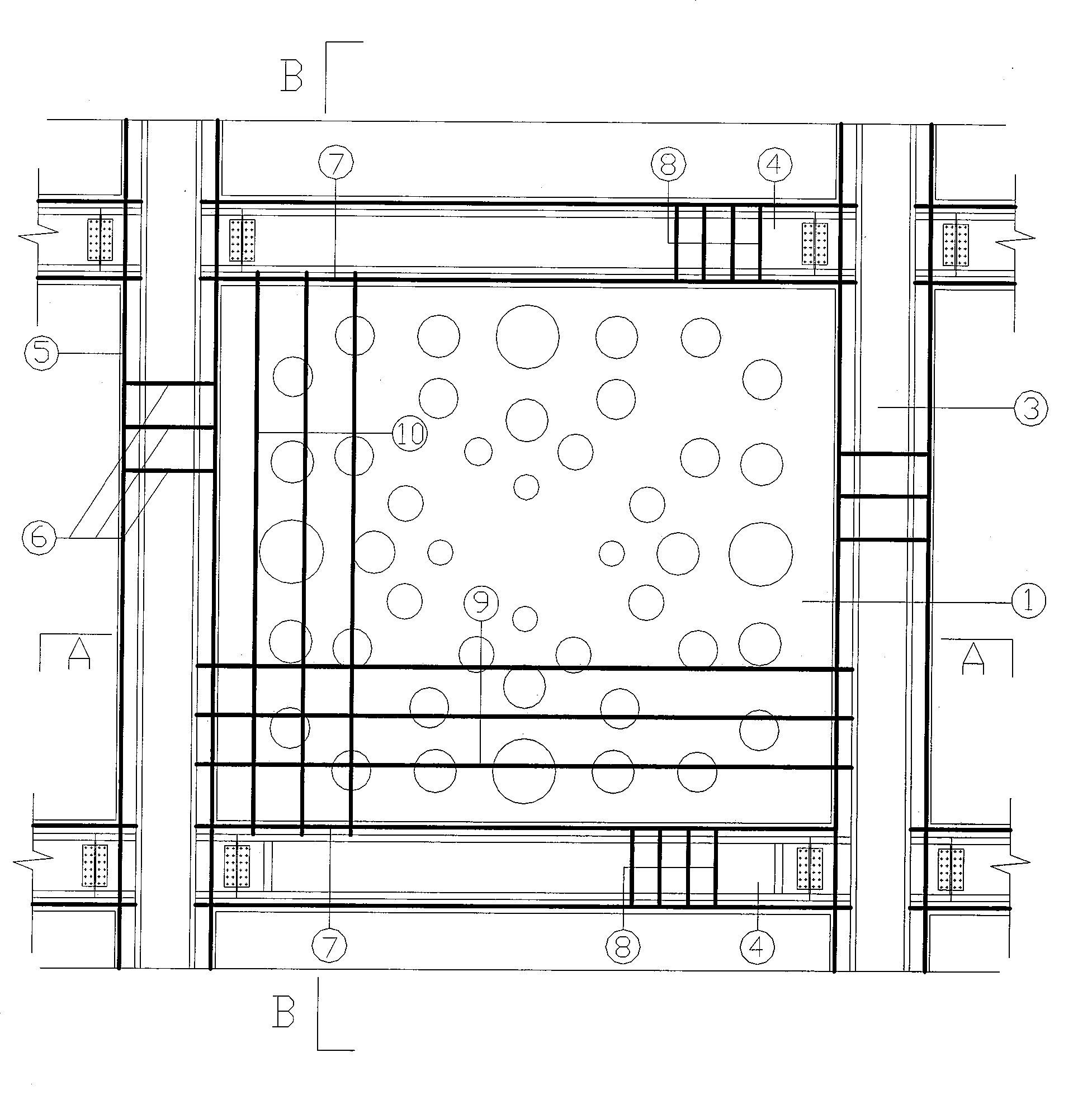

Section steel concrete- punched steel plate-concrete combined shear wall and method for producing the same

InactiveCN101457560AIncreased shear capacityIncrease the usable areaWallsShock proofingRebarSteel plates

The invention relates to a shear wall, in particular to a profile steel concrete-punching steel plate-concrete combined shear wall and a manufacturing method thereof. The shear wall is limited by a profile steel concrete column and formed by a steel plate combination structure which is covered with concrete outside and provided with holes; the shear wall is provided with the steel plate, and then two sides of the steel plate are configured with a reinforcing mesh formed by reinforcing steel bars which are distributed transversely and longitudinally, and a drawknot rib that passes through the holes is used for connecting the reinforcing meshes at the two sides of the steel plate together; finally, the concrete is poured. The profile steel concrete-punching steel plate-concrete combined shear wall can improve the carrying capacity, reduce the attenuation speed of rigidity and carrying capacity, lead the later period shakeproof performance of the wall to be relative stable, and weakens the damage caused by cutting and gliding at the bottom.

Owner:BEIJING UNIV OF TECH

Preparation method of graphene oxide/silicon dioxide hybrid aerogel

A preparation method of graphene oxide / silicon dioxide hybrid aerogel comprises the following steps: A, adding 0.05-0.1 mol of a precursor into 9-18 ml of distilled water and dropwise adding a hydrolyst with its concentration of 0.2-0.6 mol / L into the precursor aqueous solution, wherein molar ratio of the hydrolyst to the precursor is 1:20-1:100; stirring at 20-30 DEG C for 5-8 h; adjusting pH value to 6-7 and stirring for 5-45 min so as to obtain a dispersion containing silicon dioxide microspheres; B, adding water to dilute the silicon dioxide microsphere dispersion by 5-50 times, carrying out iso-volume mixing on the diluted silicon dioxide microsphere dispersion and a graphene oxide dispersion with its concentration being 0.6-2 mg / ml, stirring for 10-30 min, carrying out ultrasonic treatment for 10-30 min so as to obtain graphene oxide / silicon dioxide hybrid aerogel; and C, freezing the hybrid aerogel under liquid nitrogen for 5-10 min, freeze-drying and dewatering to obtain the graphene oxide / silicon dioxide hybrid aerogel. The method is environmentally friendly, and the technology is simple. The prepared hybrid aerogel has advantages of complete gel network structure, high porosity, good adsorptivity, high strength, low density and the like.

Owner:SOUTHWEST JIAOTONG UNIV

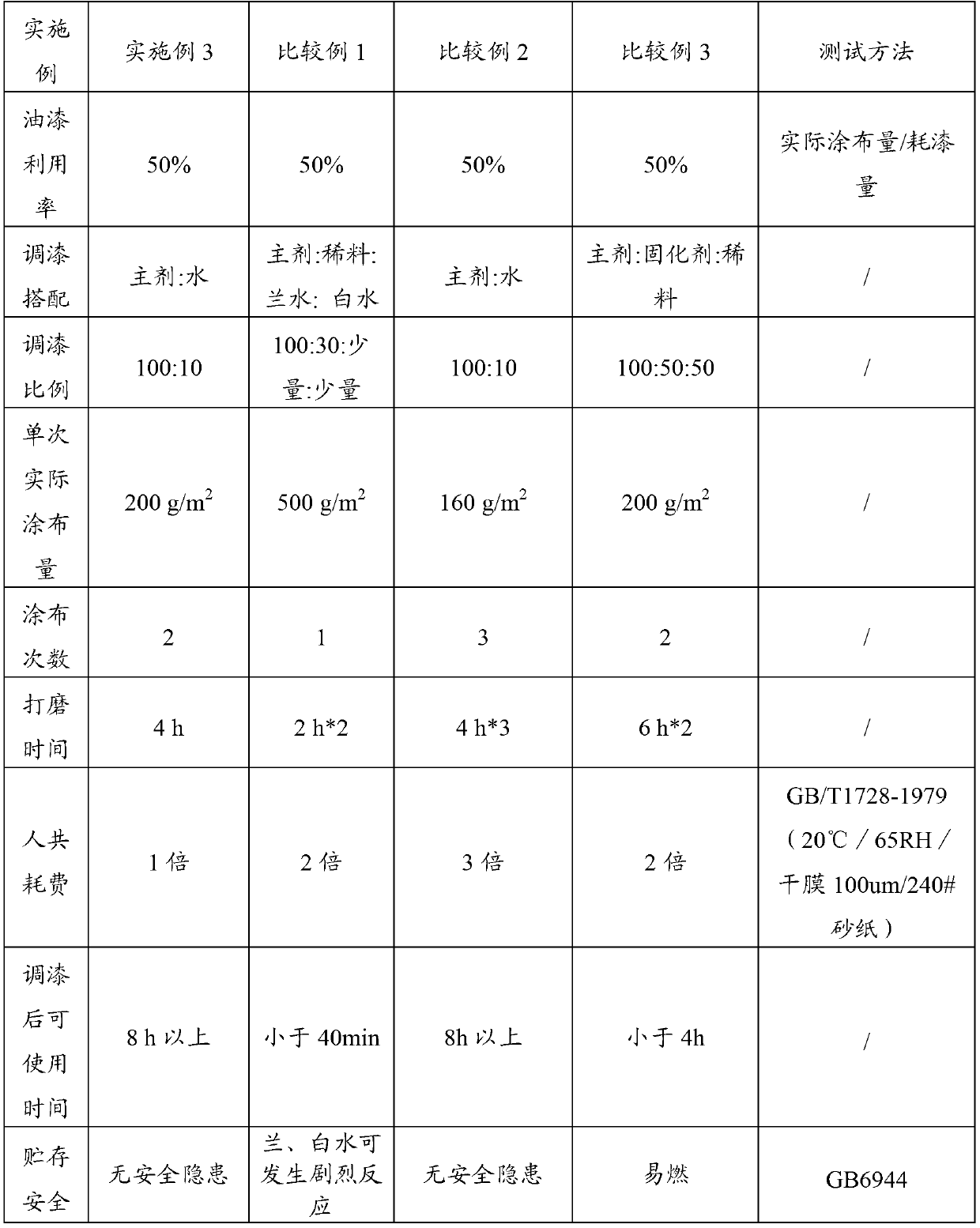

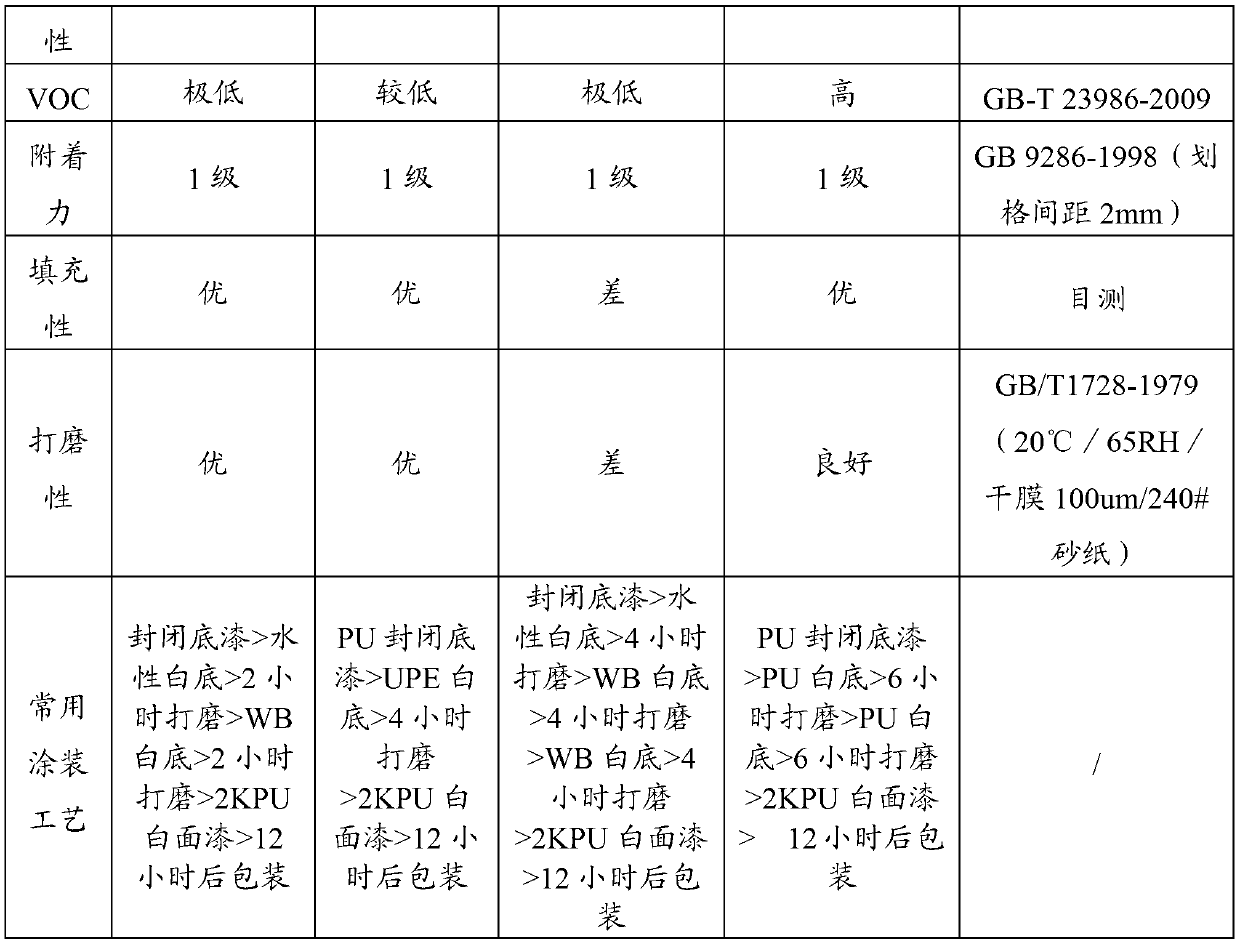

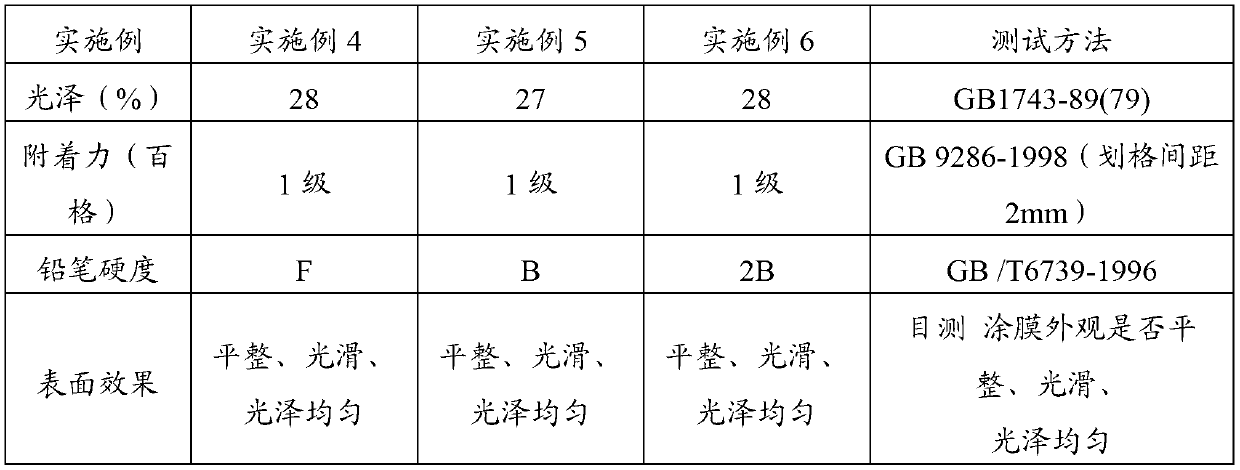

Water-based wood white primer as well as preparation method and use method thereof

ActiveCN103131284AHigh hardnessImprove adhesionAntifouling/underwater paintsPaints with biocidesWater basedLacquer

The invention relates to a water-based wood white primer as well as a preparation method and a use method thereof. The water-based wood white primer provided by the invention comprises the following components by weight: 15-35wt% of water-based resin, 0.2-0.6wt% of a defoaming agent, 0.5-1.5wt% of a wetting dispersant, 5-15wt% of titanium dioxide, 5-20wt% of talcum powder, 15-40wt% of coarse whiting, 0.2-0.8wt% of a thickening agent, 2-7wt% of a film-forming auxiliary agent, 0.1-0.4wt% of a substrate wetting agent, 0.1-0.4wt% of biocide mildewcide and 2-10wt% of water. The water-based wood white primer provided by the invention can be used together with solvent-based finishing paint, does not generate adverse film-painting defects, such as lifting, collapse and foaming adhesion, and has very low volatile content of VOC (Volatile Organic Compounds) and high value of environmental protection.

Owner:紫荆花制漆(成都)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com