Patents

Literature

7751 results about "Lacquer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term lacquer is used for a number of hard and potentially shiny finishes applied to materials such as wood. These fall into a number of very different groups. The term lacquer originates from the Sanskrit word lākshā (लाक्षा) representing the number 100,000, which was used for both the lac insect (because of their enormous number) and the scarlet resinous secretion, rich in shellac, that it produces that was used as wood finish in ancient India and neighbouring areas.

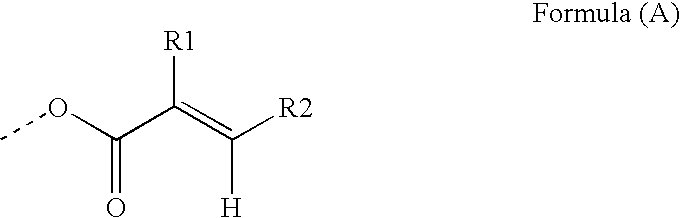

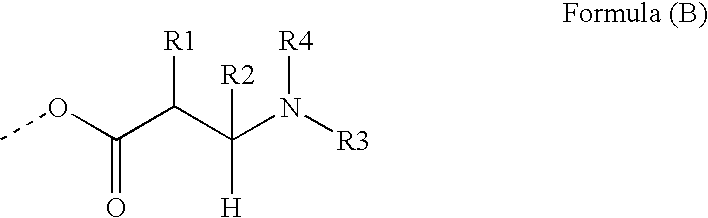

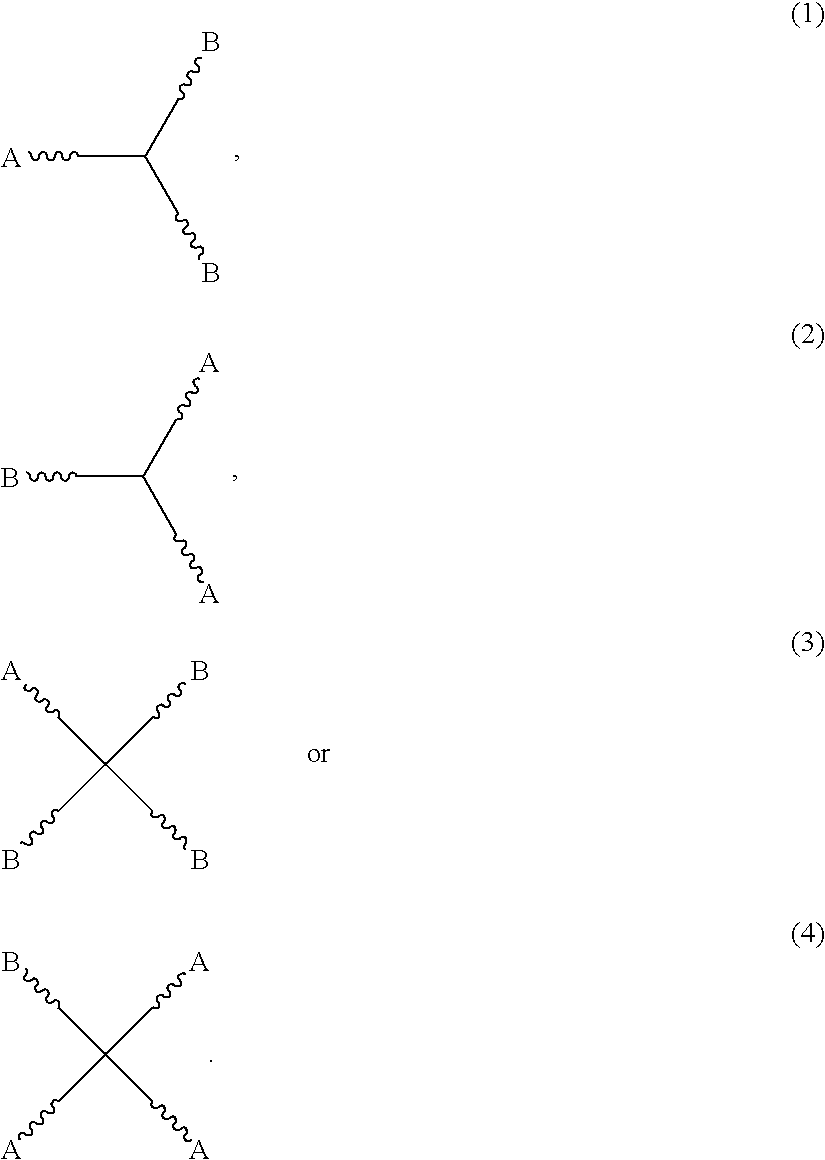

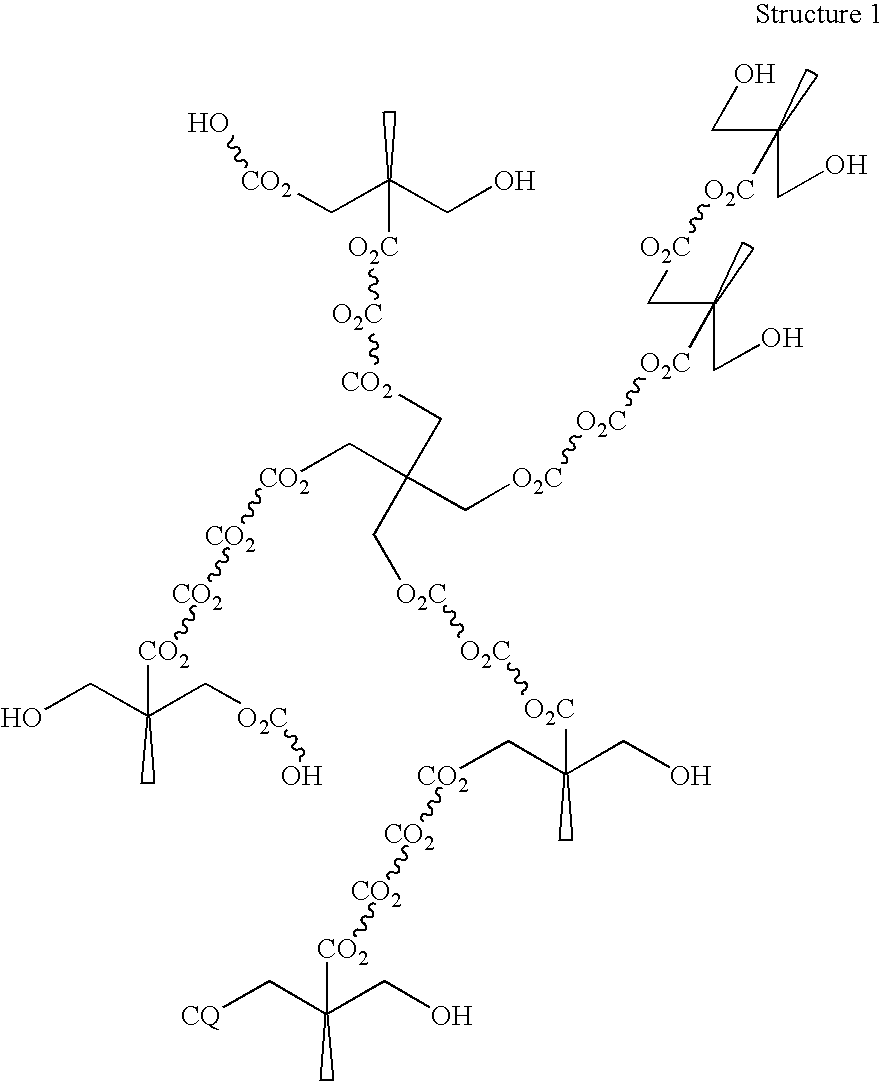

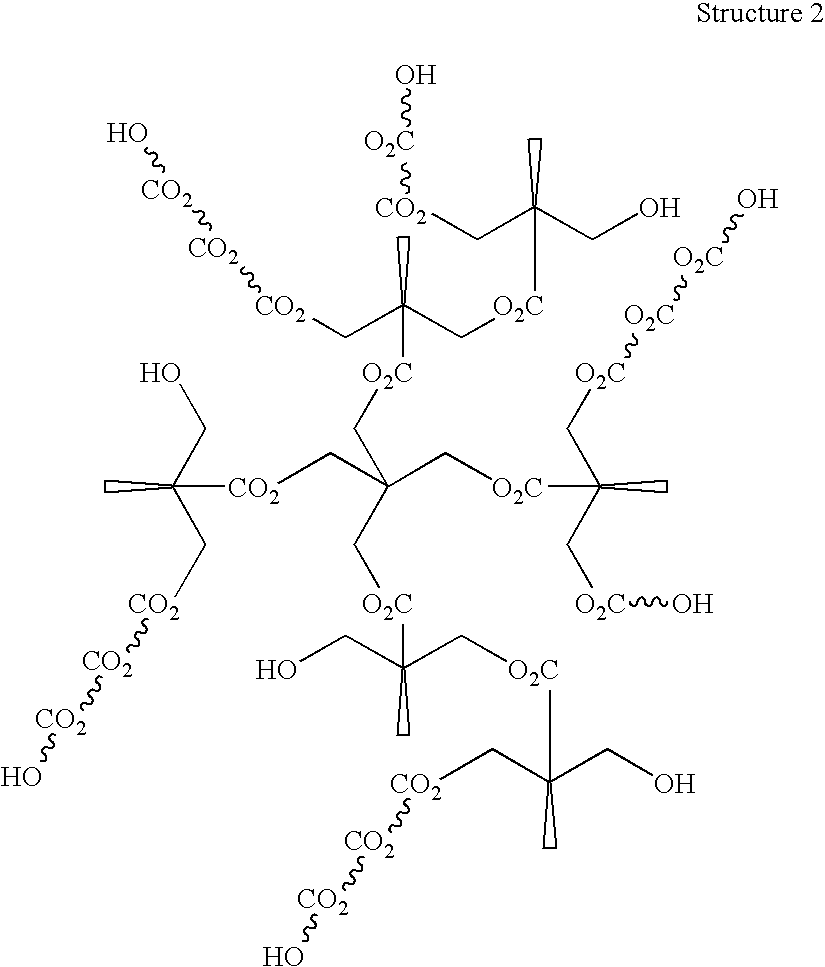

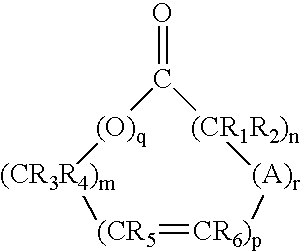

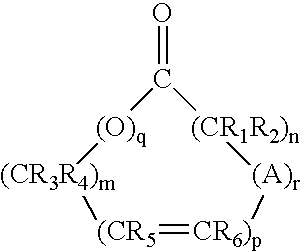

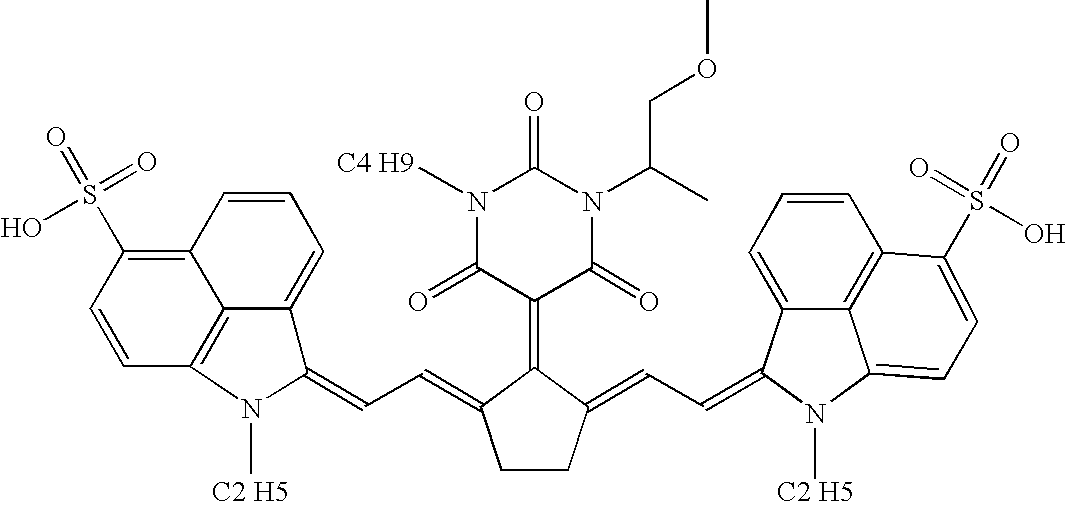

Novel radiation curable compositions

Radiation curable compositions with a polymeric co-initiator are disclosed comprising a dendritic polymer core with at least one co-initiating functional group as an end group. The dendritic polymeric core is preferably a hyperbranched polymer. Industrial applications include varnishes, lacquers and printing inks. The polymeric co-initiator is especially useful in radiation curable inkjet ink.

Owner:AGFA NV

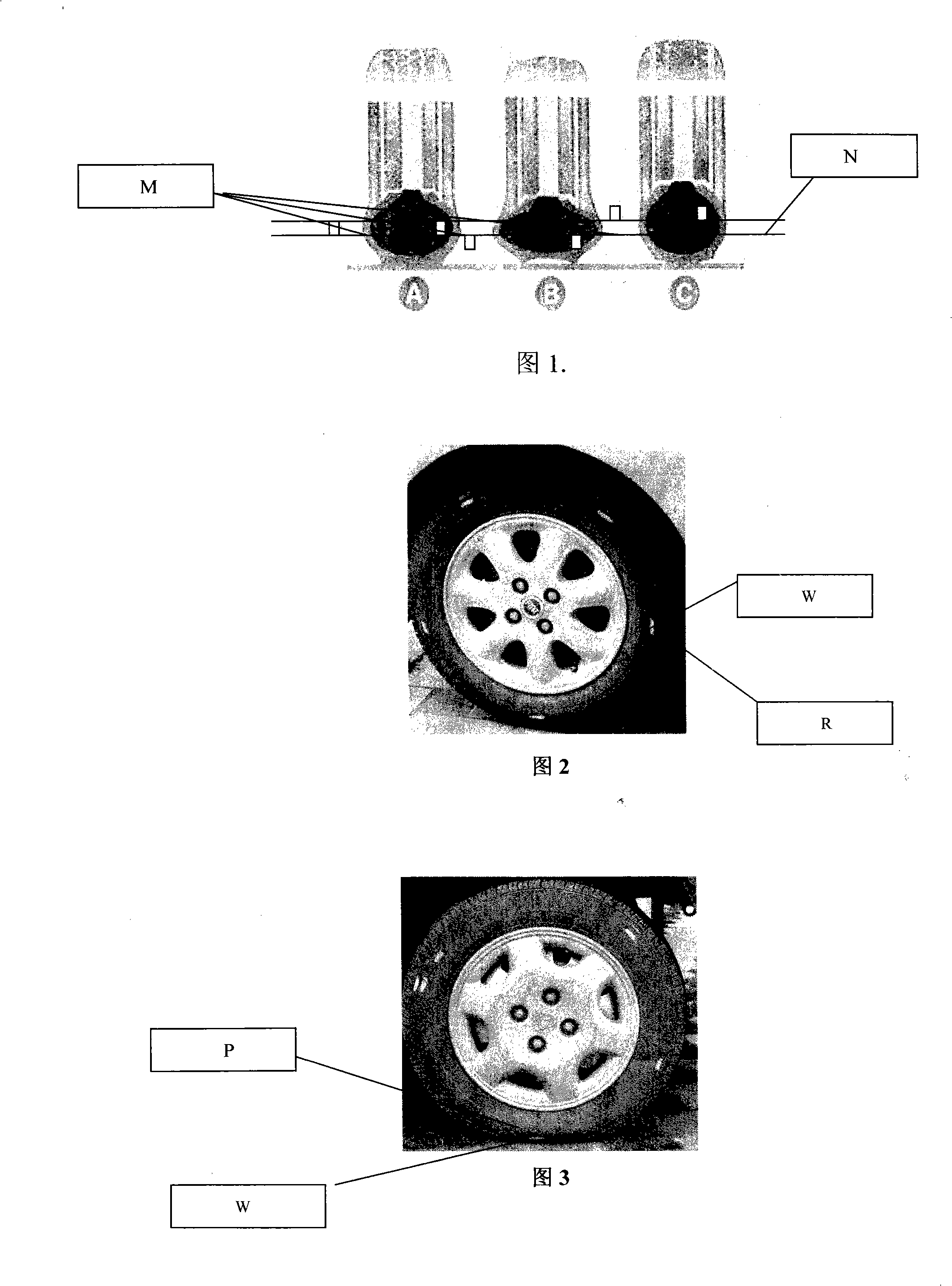

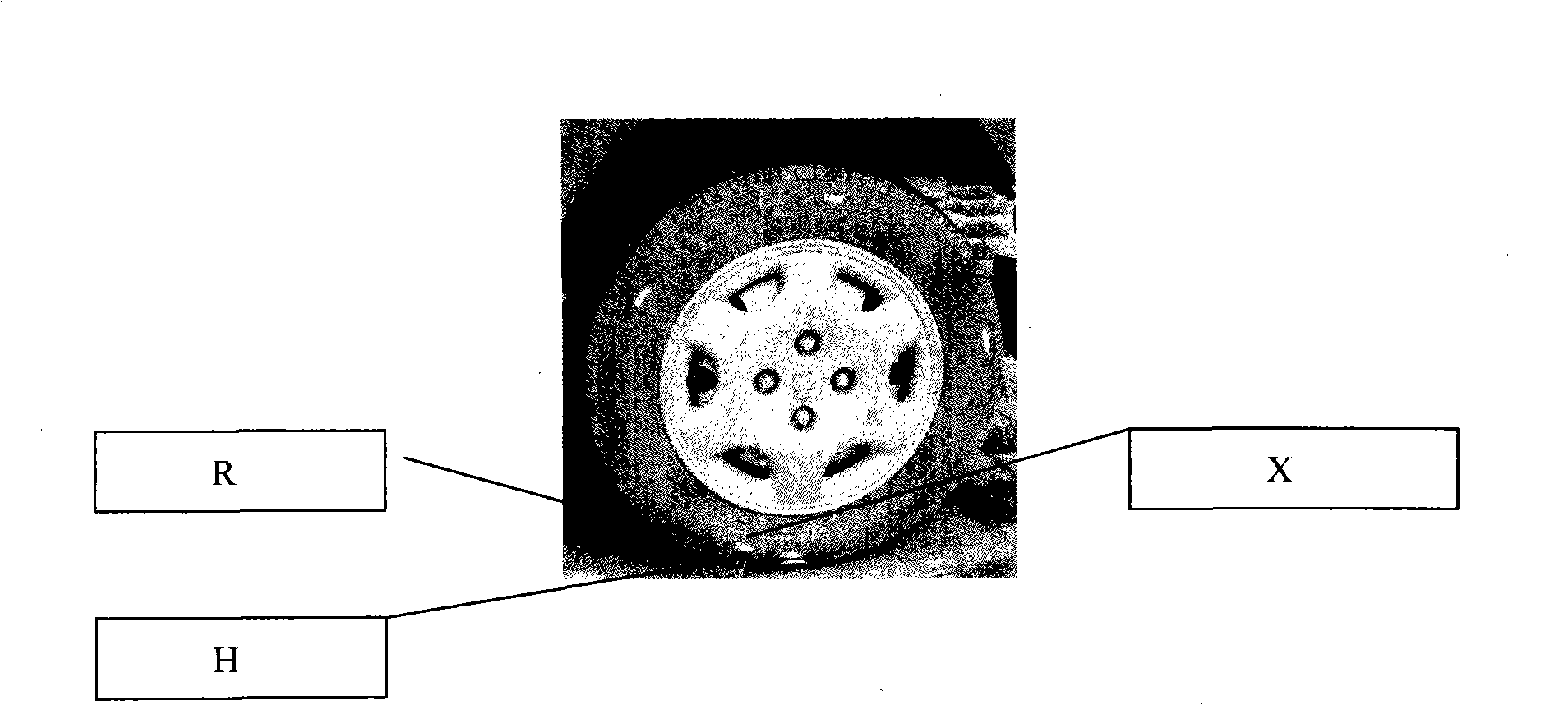

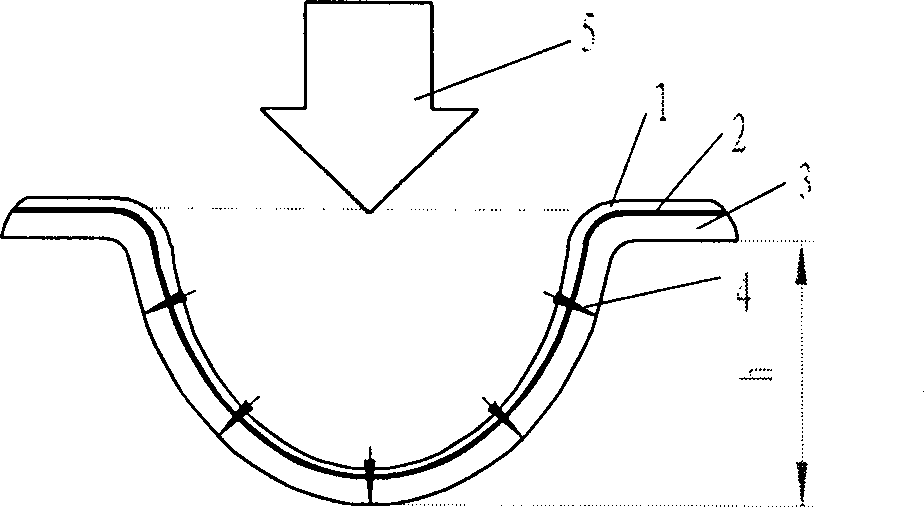

New method of automotive tire pressure detection and safe identification

InactiveCN101337492AImprove safety performanceWith reflective effectTyre measurementsVisibilityLacquer

The invention provides a method for correspondingly marking the most protuberant part of the deformed rubber corresponding to the outer side of an automobile tire with a white fluorescent paint line and coating a red fluorescent paint line in the position which is one second distance below from the white line as a safety mark according to the allowable normal inflation pressure standard range calibrated when the tires of sedans and miniature vehicles leave the factory (for example, the allowable normal inflation pressure standard ranges of a 1.5t FIAT sedan, a 0.6t CHANG'AN STAR miniature minibus and a 1.0t LINGYANG sedan are respectively 2.3 to 2.8 Kg / cm<2>, 2.2 to 2.5Kg / cm<2> and 2.2 to 2.6Kg / cm<2>). When the red fluorescent paint line disappears and the most protuberant part of the deformed rubber on the outer side of the tire is above the white fluorescent paint line, the tire pressure is indicated to be too low, and measures, such as inflation, tire repair, etc., should be carried out. When the most protuberant part is below the white fluorescent paint line and above the red fluorescent paint line, the tire pressure is indicated to be too high, and the measure of deflation should be carried out. The method has the advantages of visibility, rapidness, convenience, safety, practicality and low cost, and is easily accepted by drivers and tire manufacturers, completed at one time in the tire manufacturer and easily generalized and applied.

Owner:谢子晋

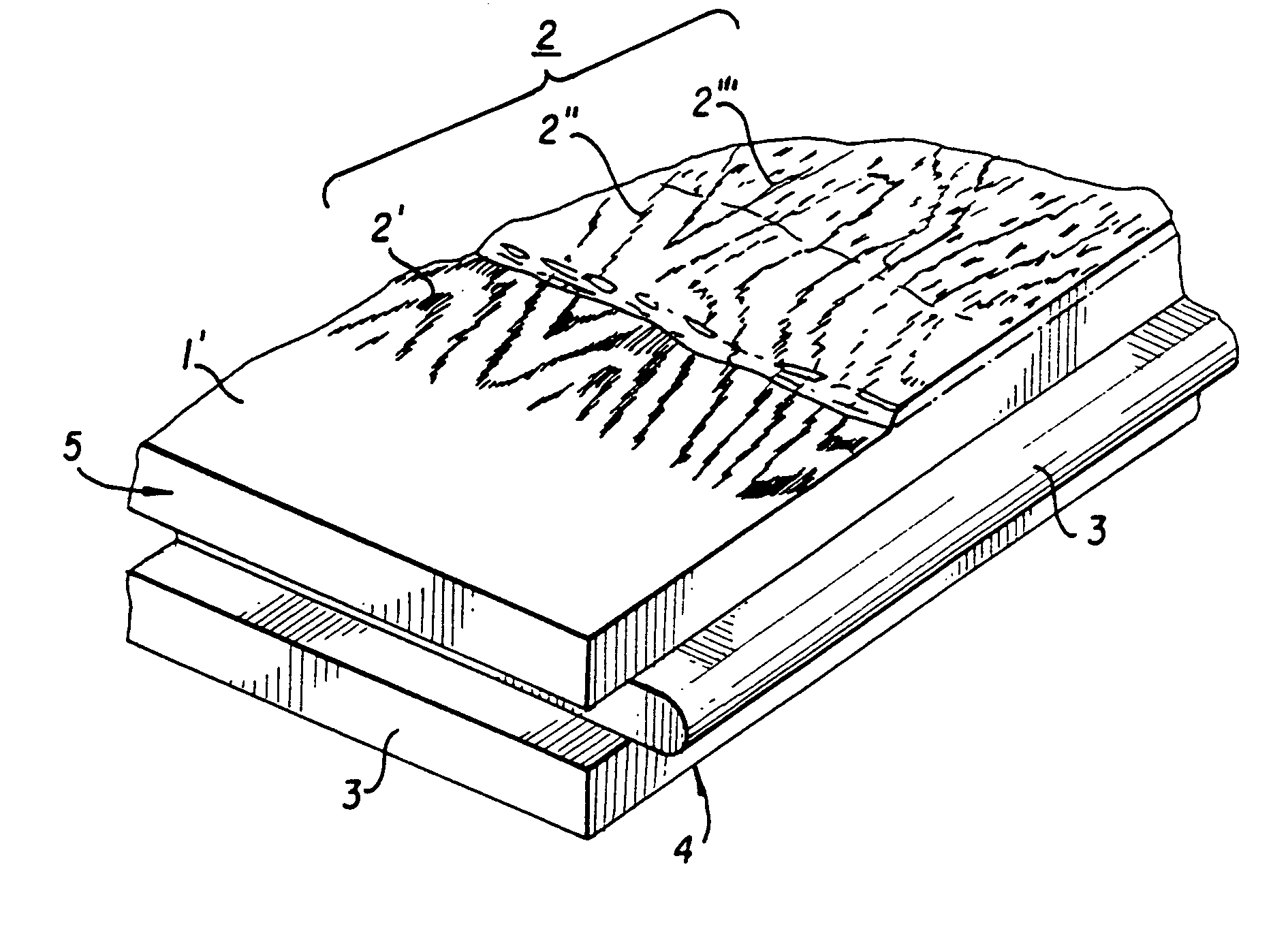

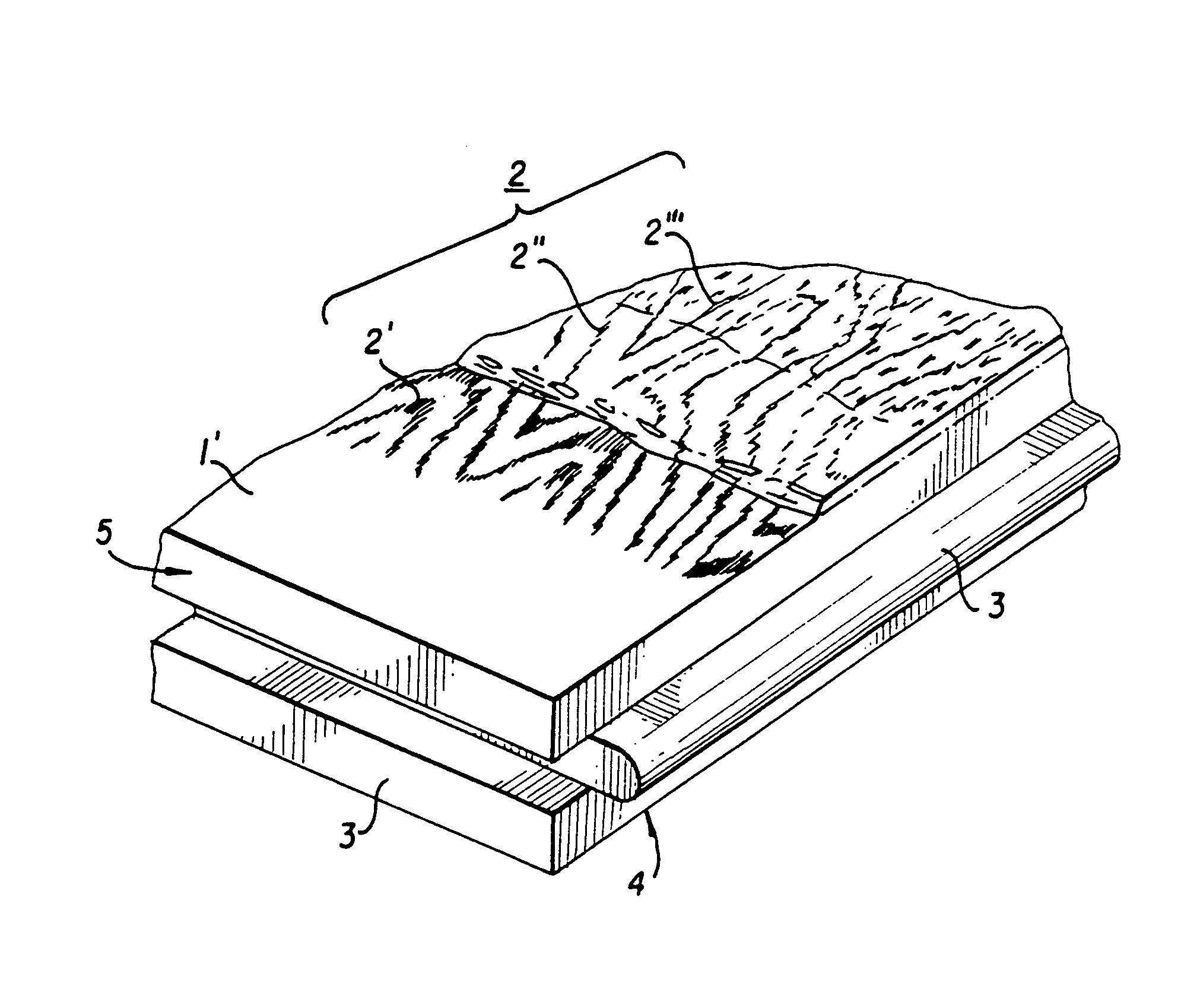

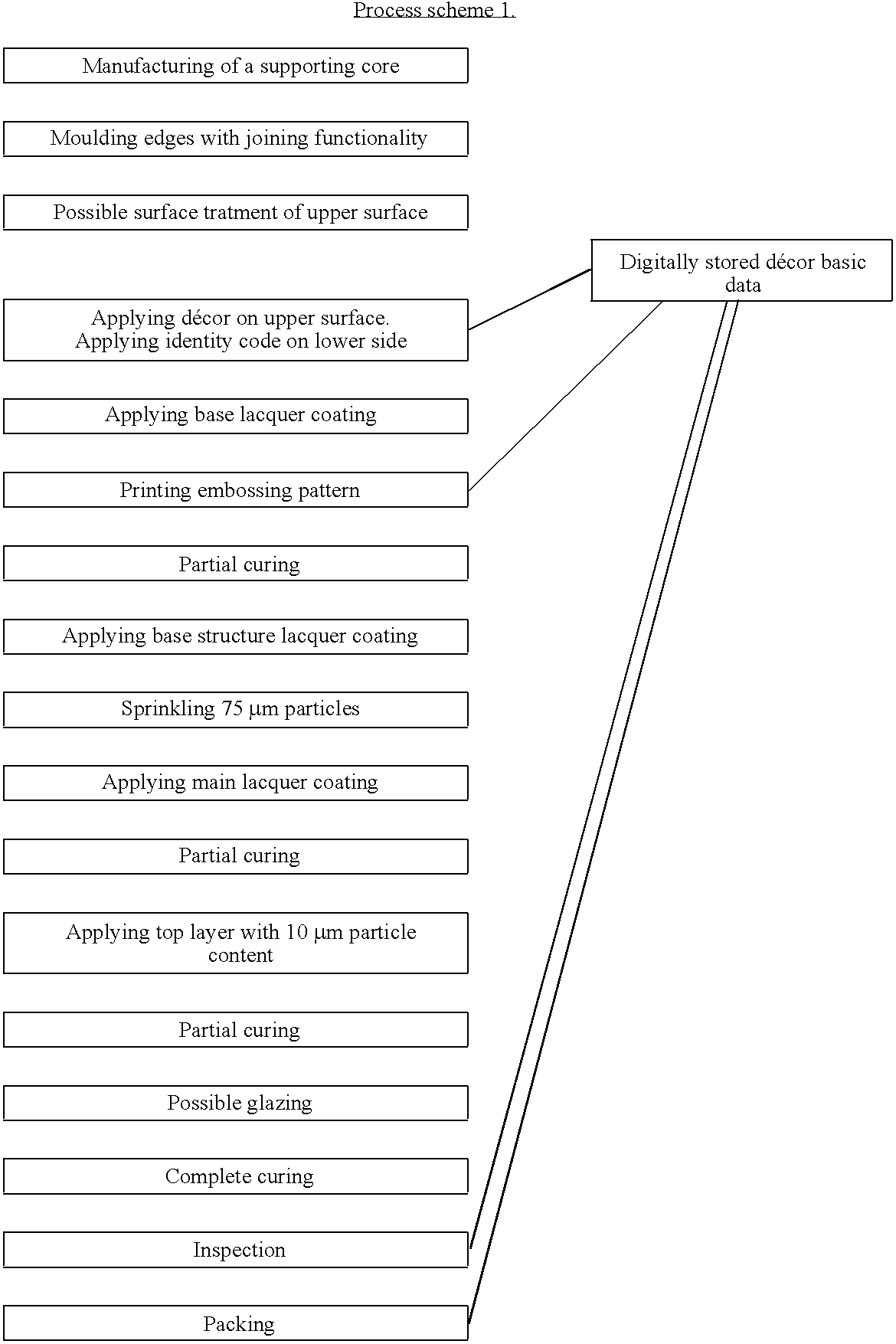

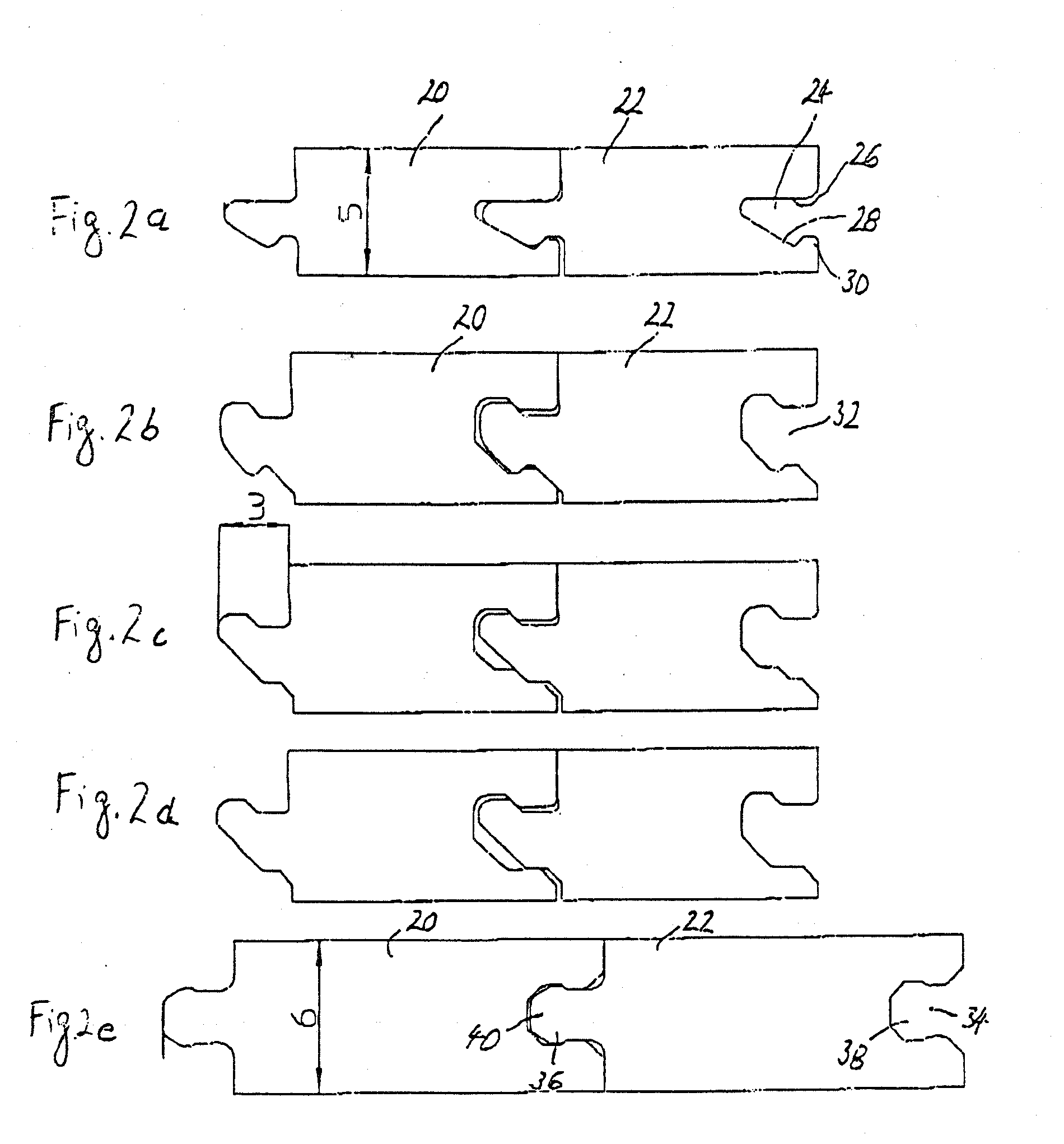

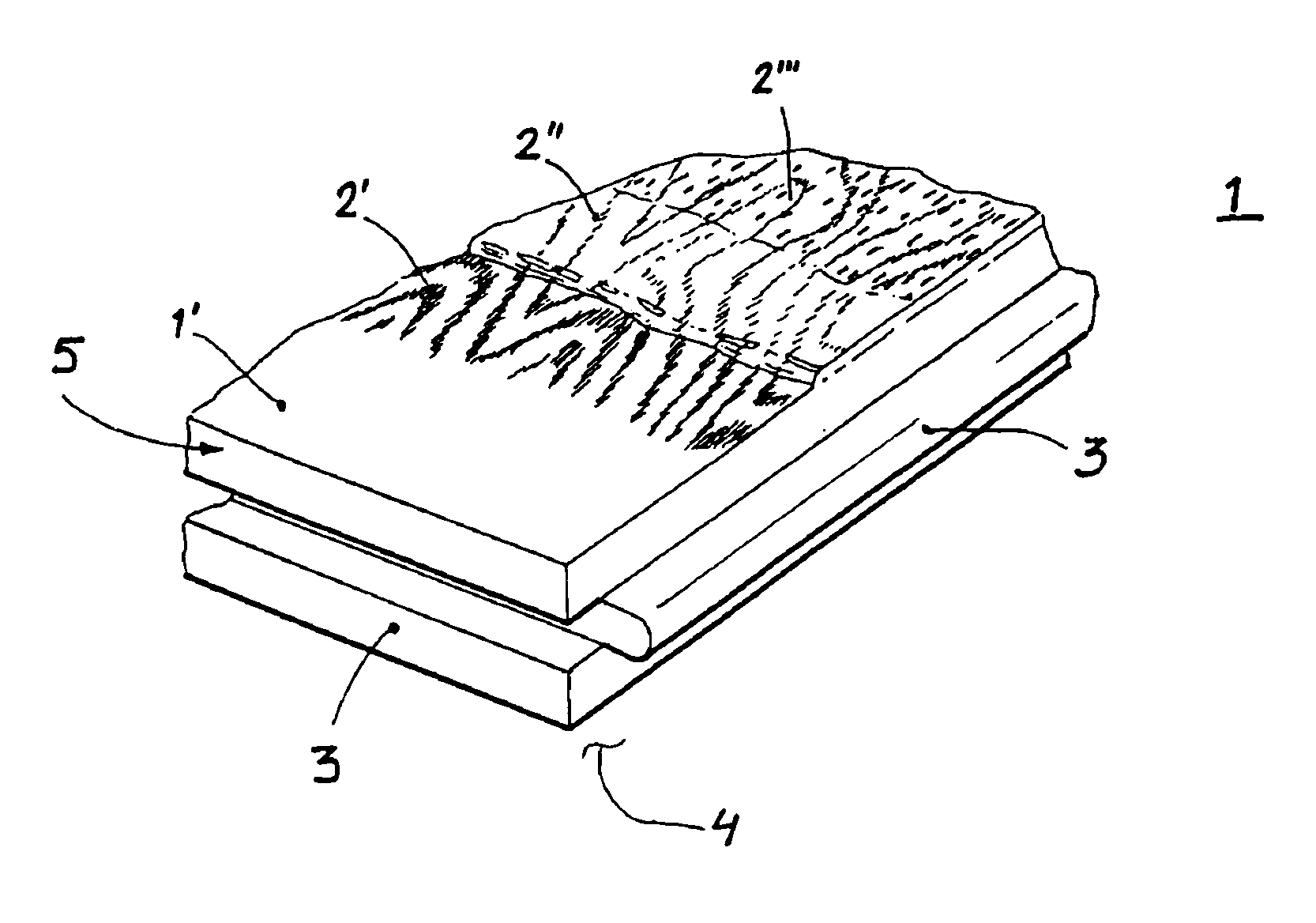

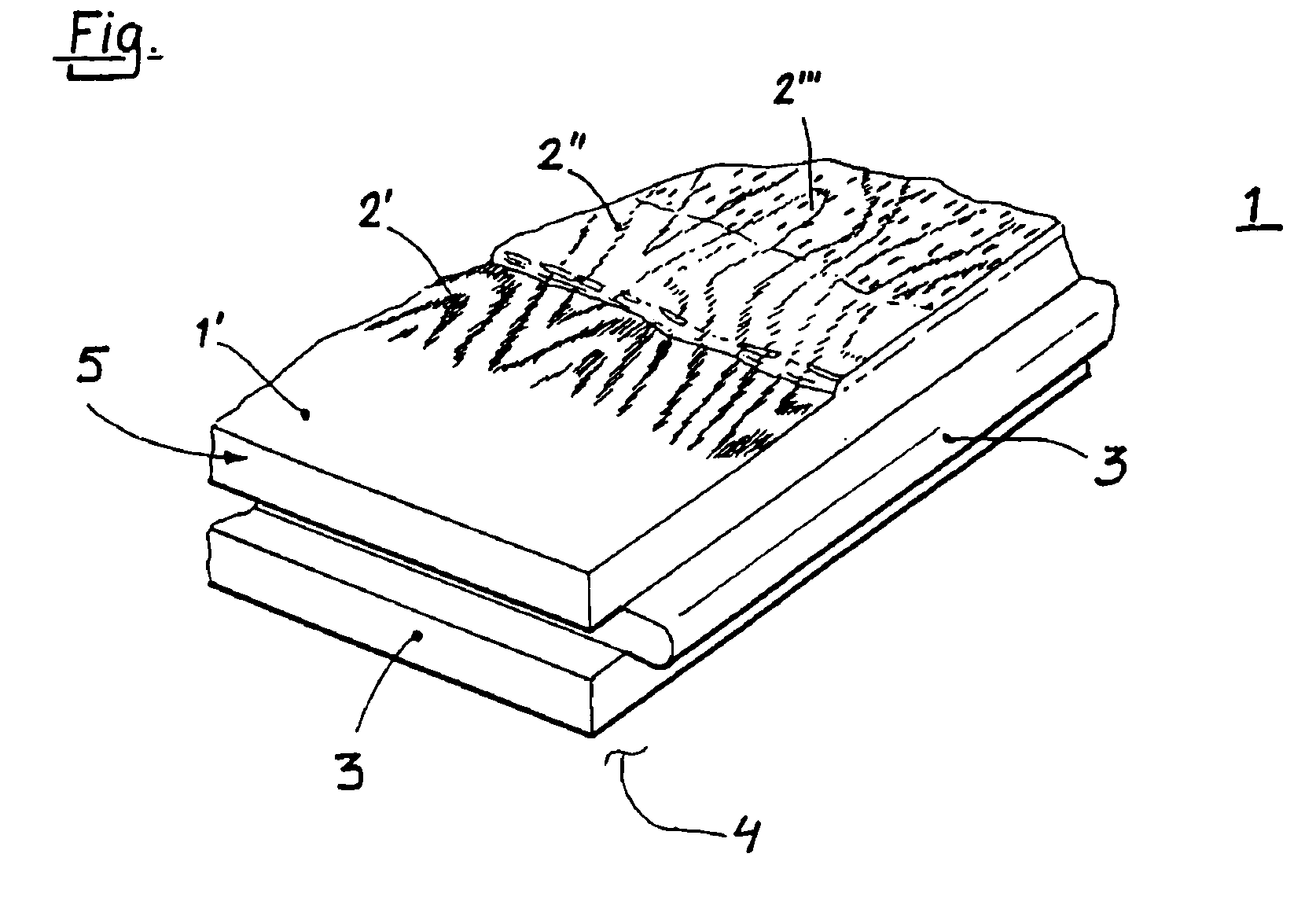

Process for the manufacturing of surface elements with a structured upper surface

InactiveUS6991830B1High resolutionRearrange décorCovering/liningsOrnamental structuresLacquerEngineering

A process for the manufacturing of a decorative surface element, which element comprises a base layer and a decorative upper surface. A wetting repellent lacquer is printed in a predetermined pattern on the decorative upper surface. The wetting repellent lacquer covers only parts of the decorative upper surface. A wear layer of a UV or electron beam curing lacquer is then applied on top of the decorative upper surface which UV or electron beam curing lacquer is repelled from the parts of the surface being covered by the wetting repellent lacquer whereby a surface structure is achieved.

Owner:UNILIN NORDIC AB

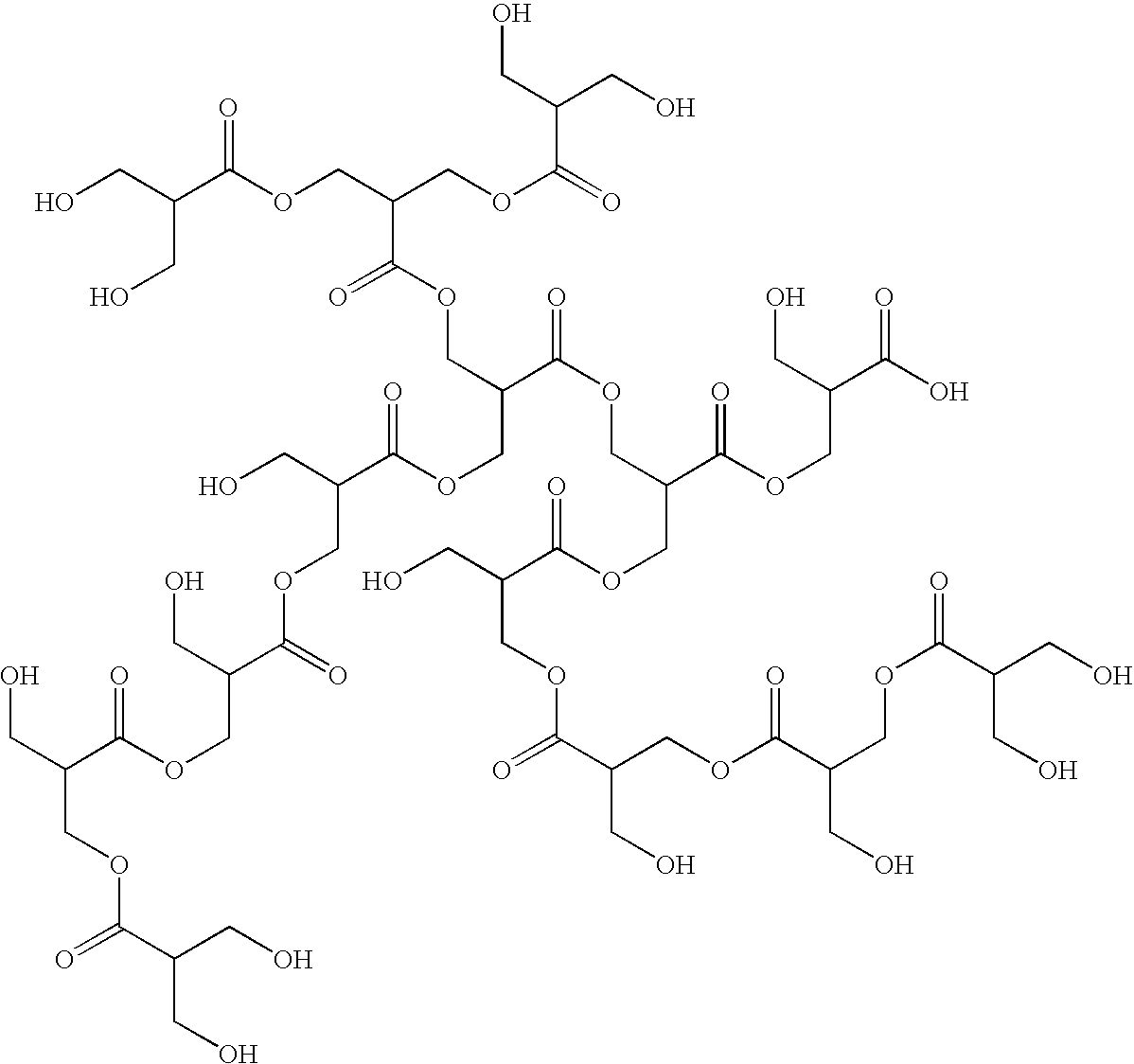

Lacquers containing highly branched copolyester polyol

Owner:AXALTA COATING SYST IP CO LLC

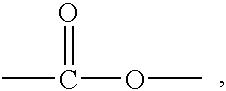

Antifungal nail lacquer and method using same

InactiveUS6224887B1Effective preventionEffective treatmentBiocideCosmetic preparationsAntifungalLacquer

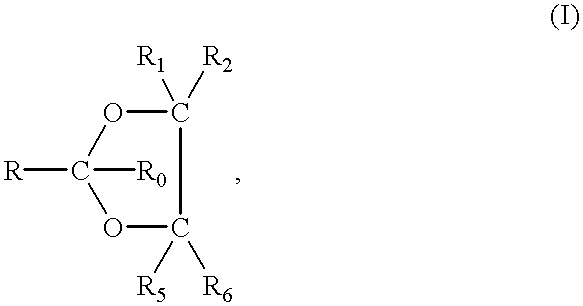

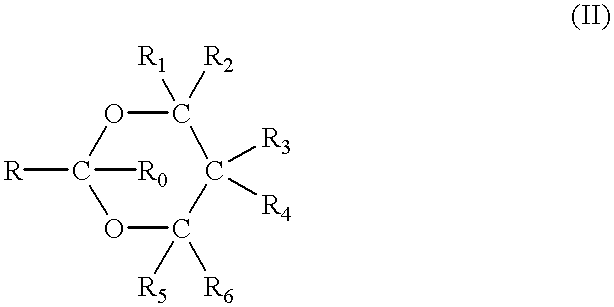

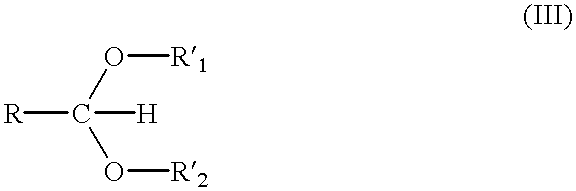

A nail lacquer effective for the treatment or prevention of fungal infections, such as, onychomycosis, includes fungicidally effective amount of ciclopirox, econazole, or other antifungal agent in a clear, stable, film-forming lacquer vehicle which includes a water-insoluble film-forming polymer; 2-n-nonyl-1,3-dioxolane or similar penetration enhancer; and volatile solvent. A plasticizer for the film-forming polymer which is also compatible with the other components may be included although the preferred penetration enhancers may also function as plasticizer. The composition, when applied to the nails provides a hard, clear, water-resistant film containing the antifungal agent. The film is resistant to multiple washings and is effective in the treatment of onychomycosis.

Owner:MACROCHEM CORP

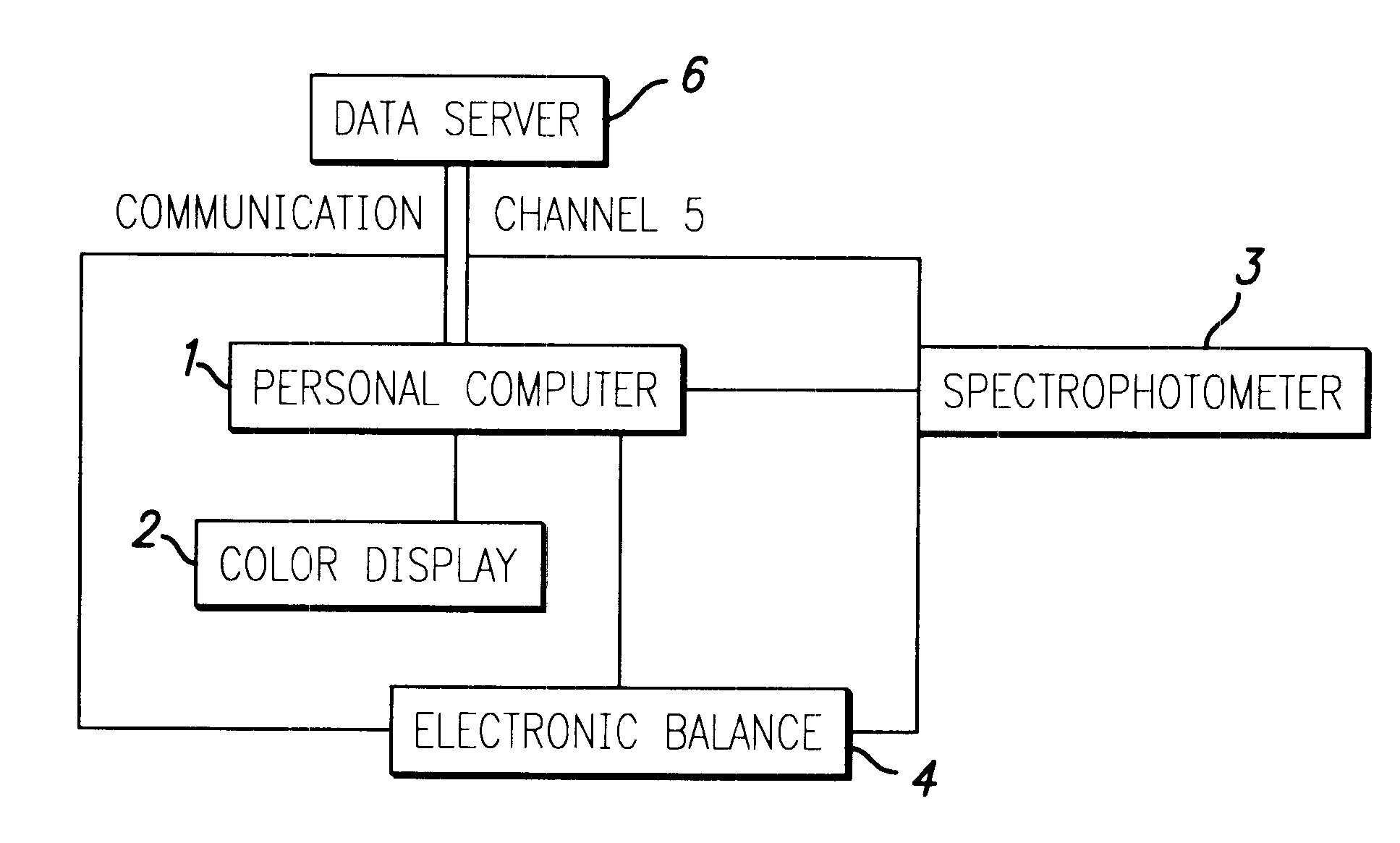

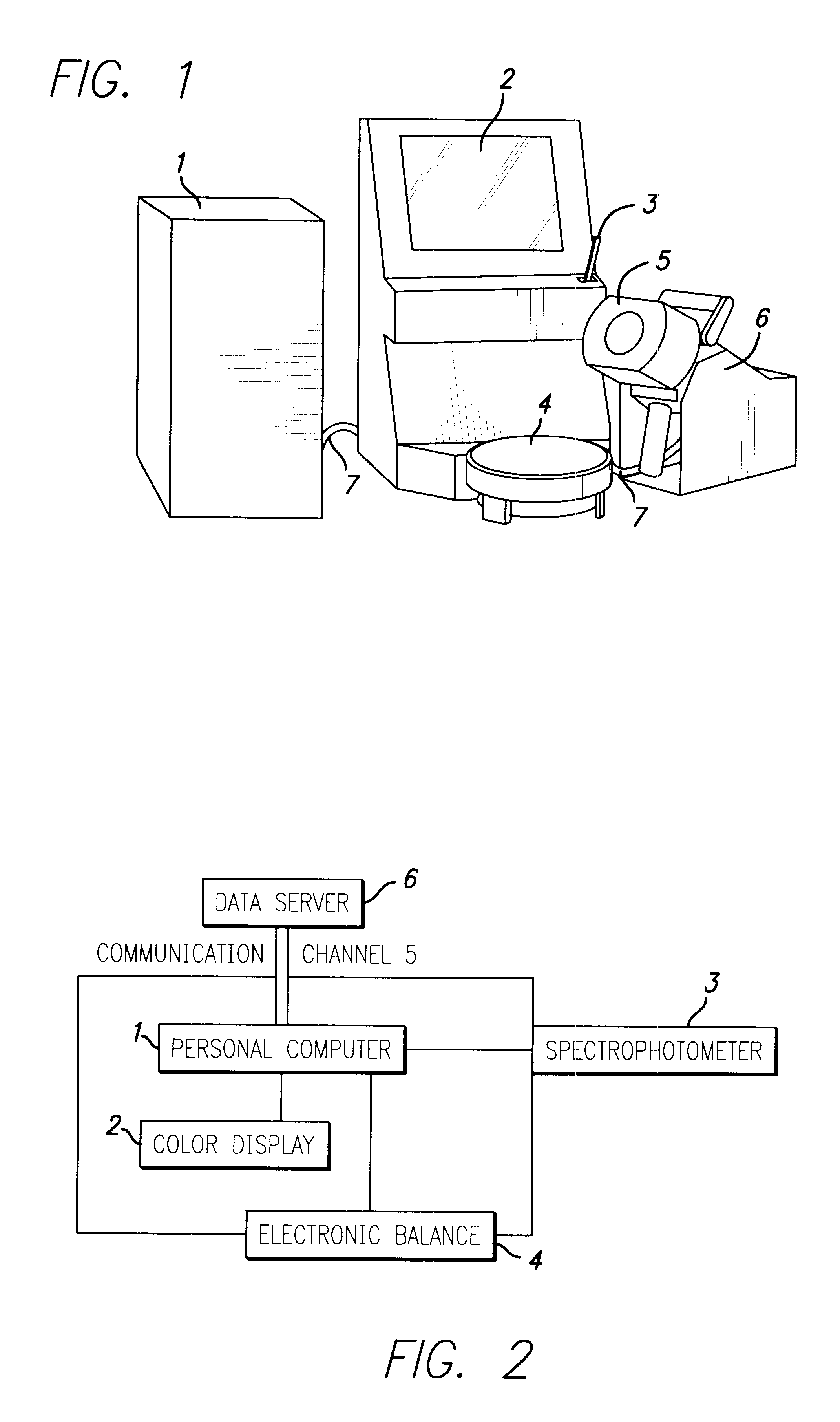

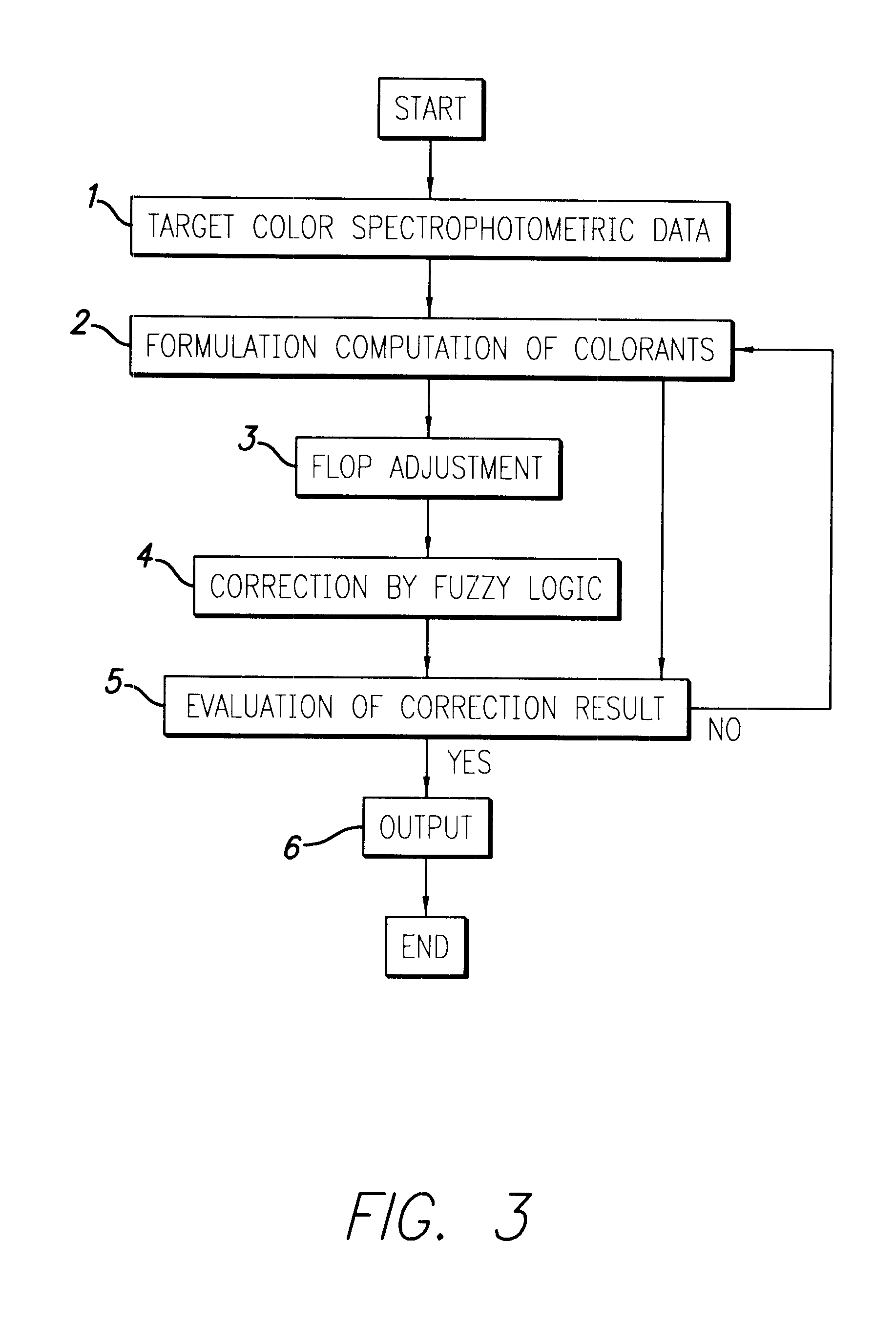

Color matching apparatus for automotive repair paints

This invention provides a color matching apparatus for automotive repair paints with which the color matching of a repair paint to an existing paint, whether containing or not containing a metallic or pearlescent pigment, can be performed with high precision in a reduced number of steps even by the novice. The apparatus of the invention comprises a computer, a color data file and a database reference system.

Owner:NIPPON PAINT CO LTD +1

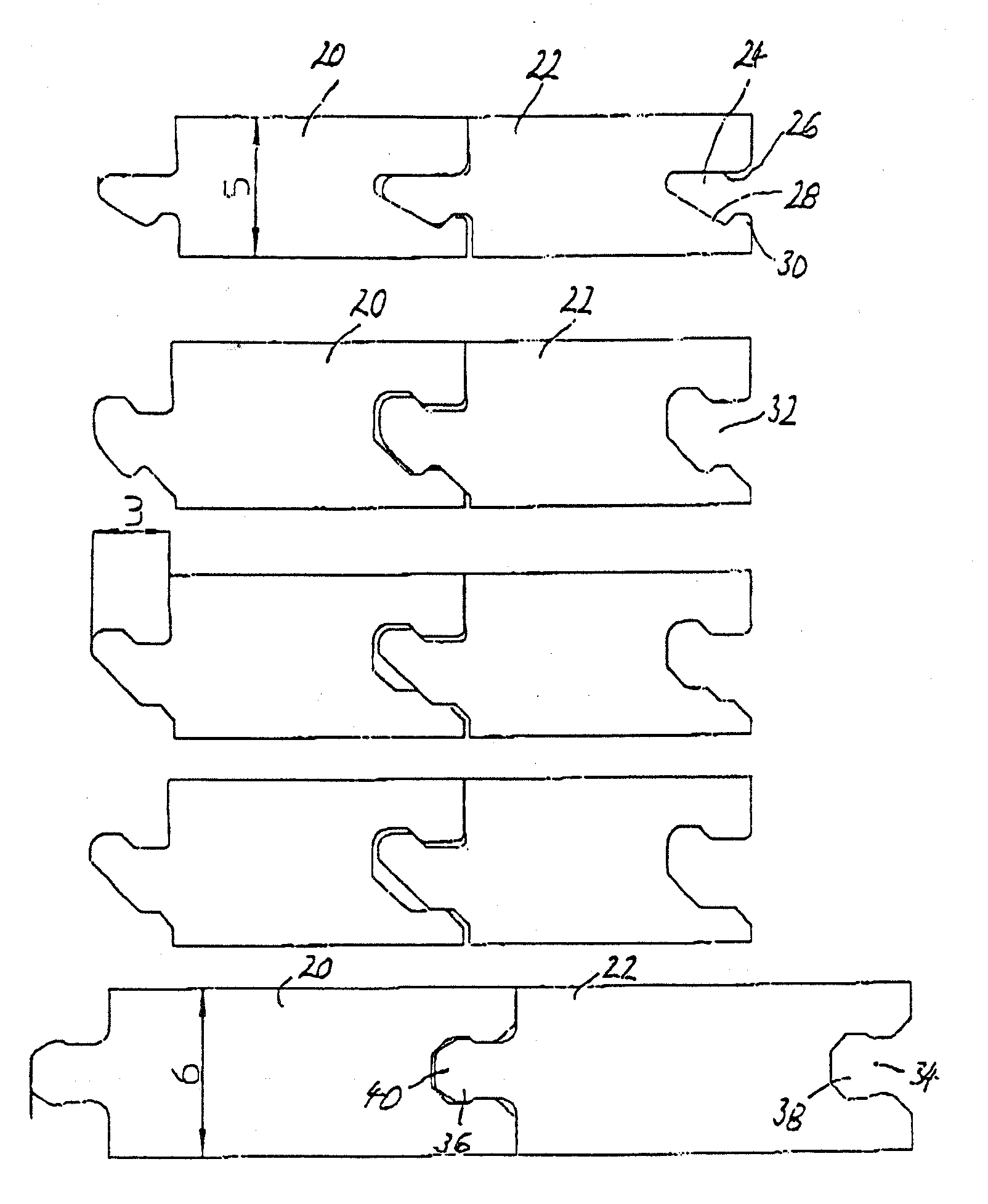

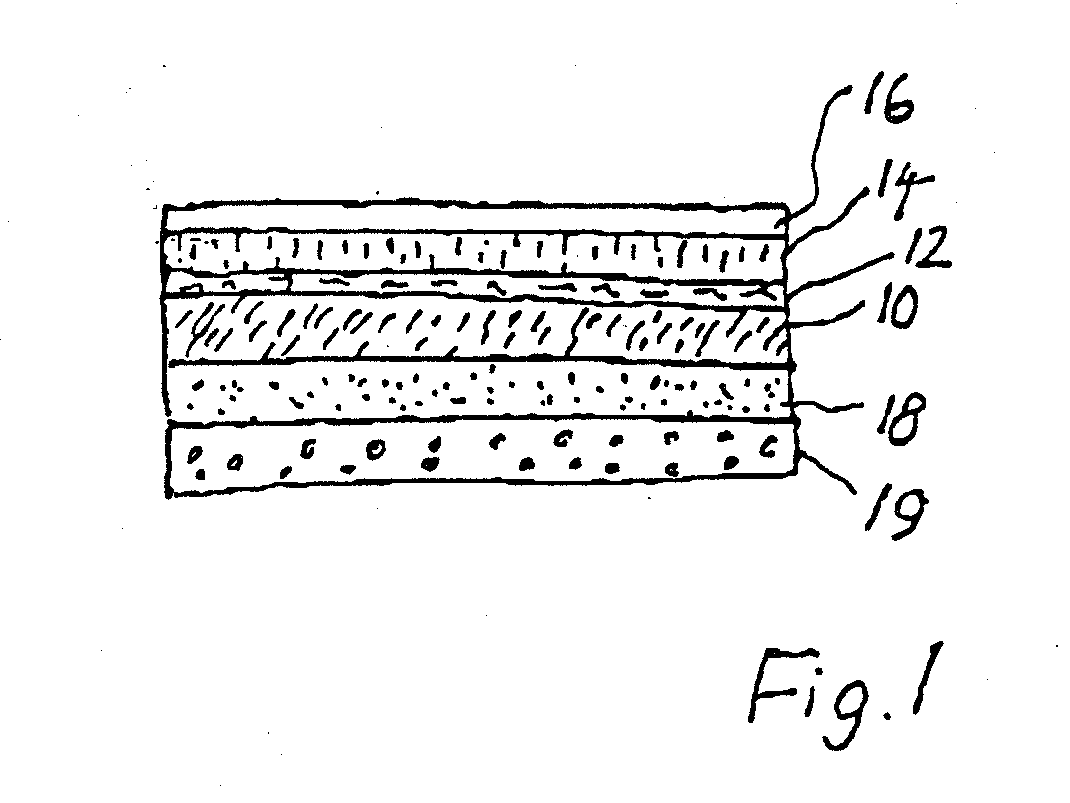

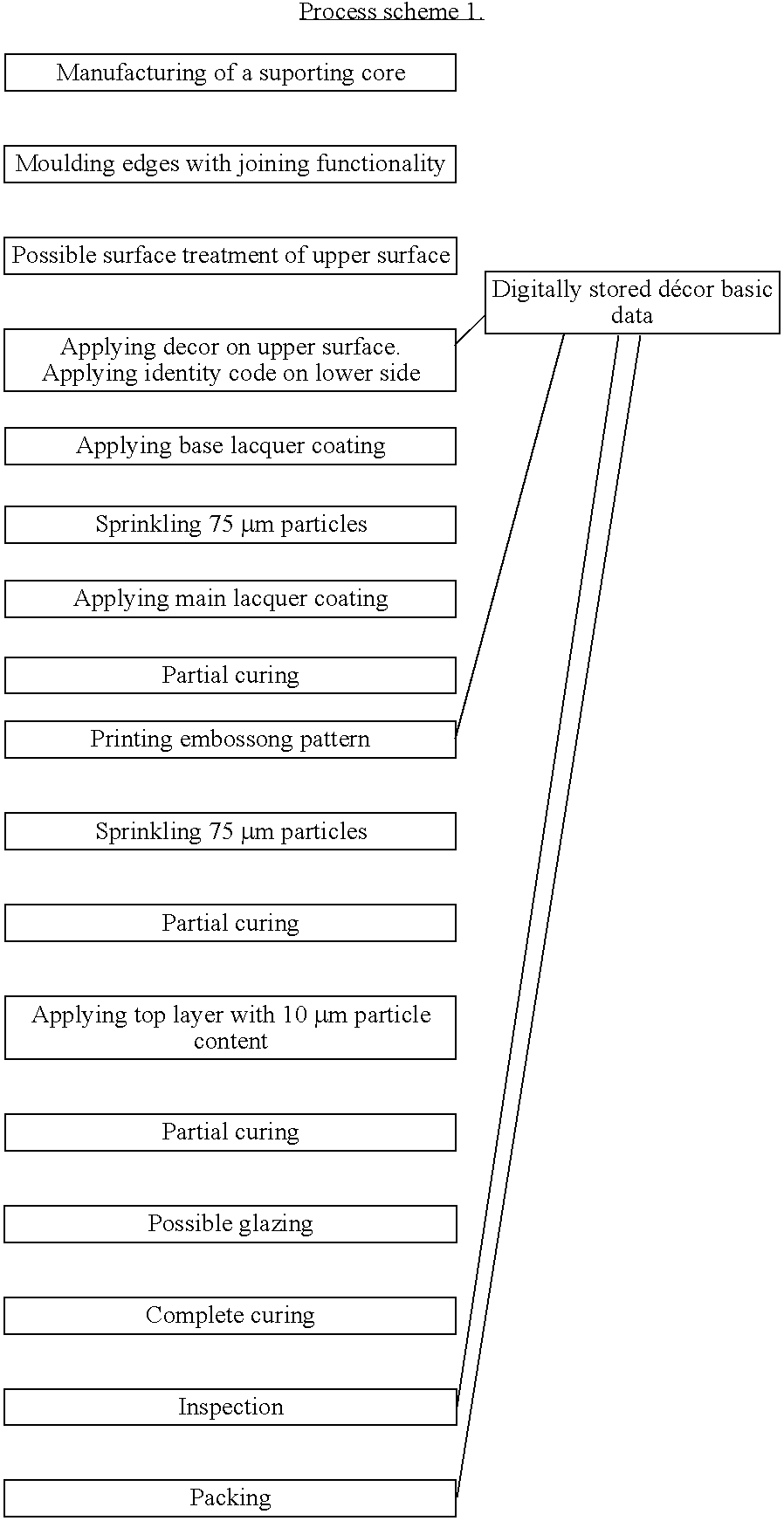

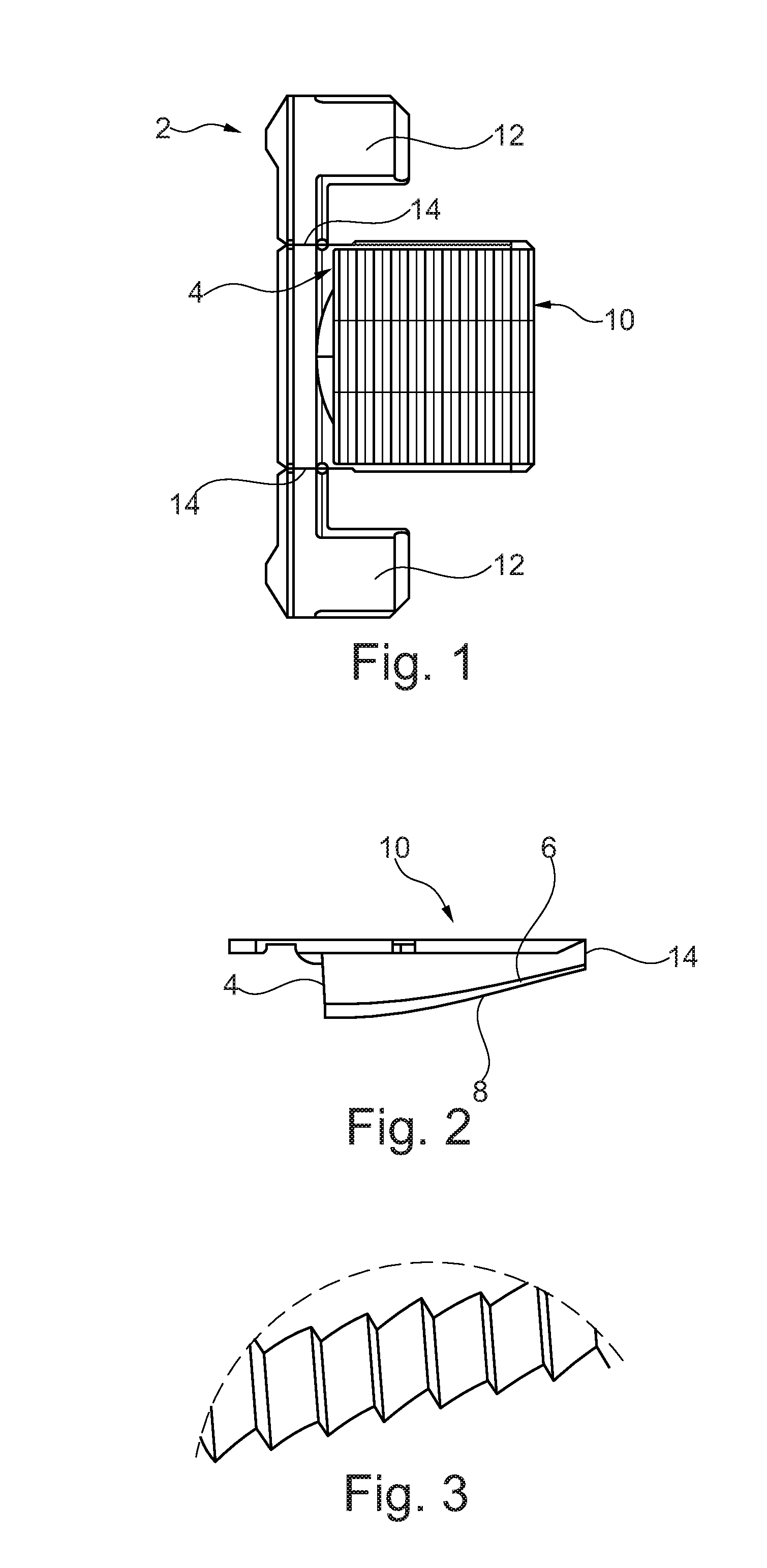

Floor Panel

ActiveUS20110296780A1Improve noise characteristicsThe process is simple and fastConstruction materialLamination ancillary operationsLacquerEngineering

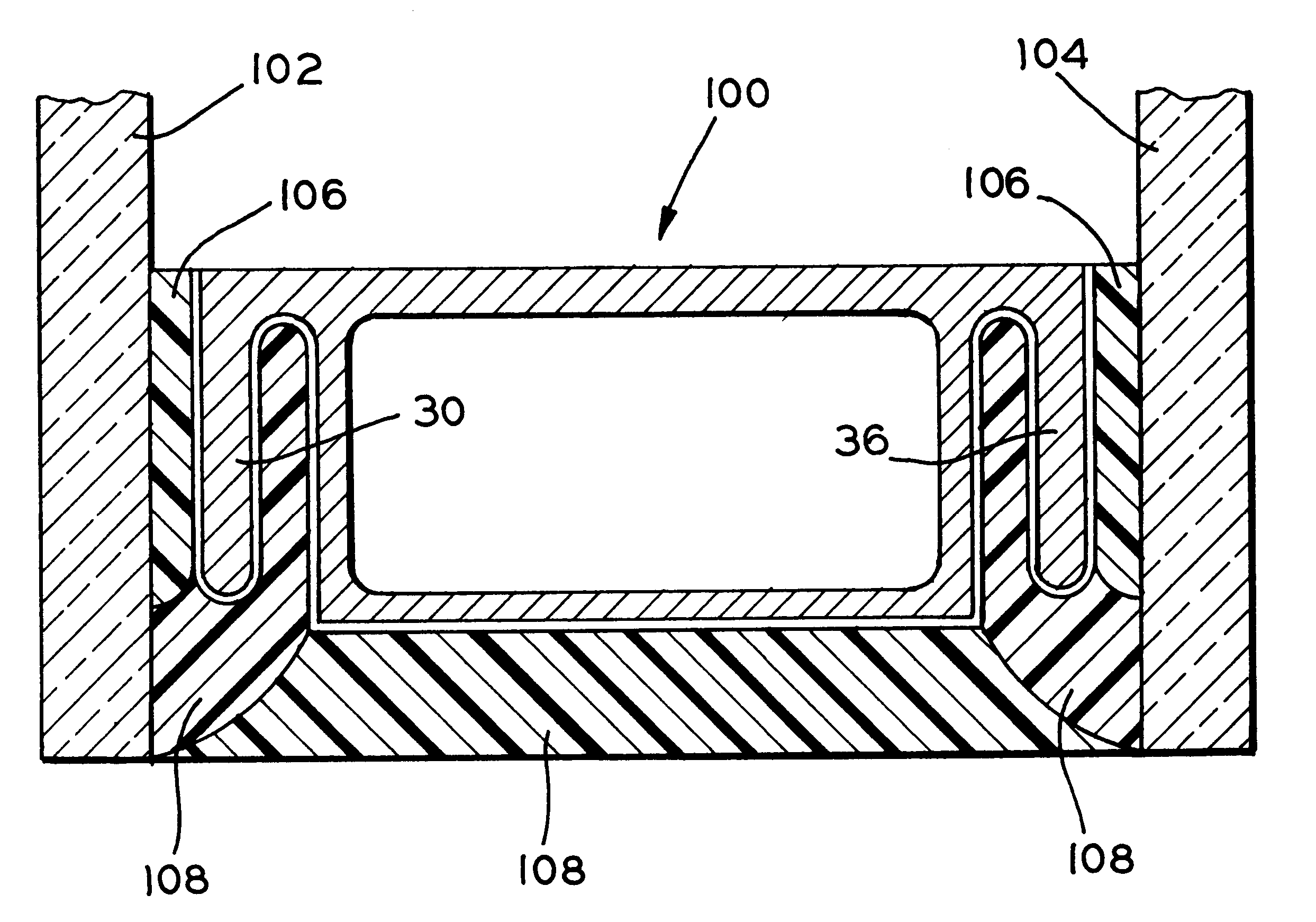

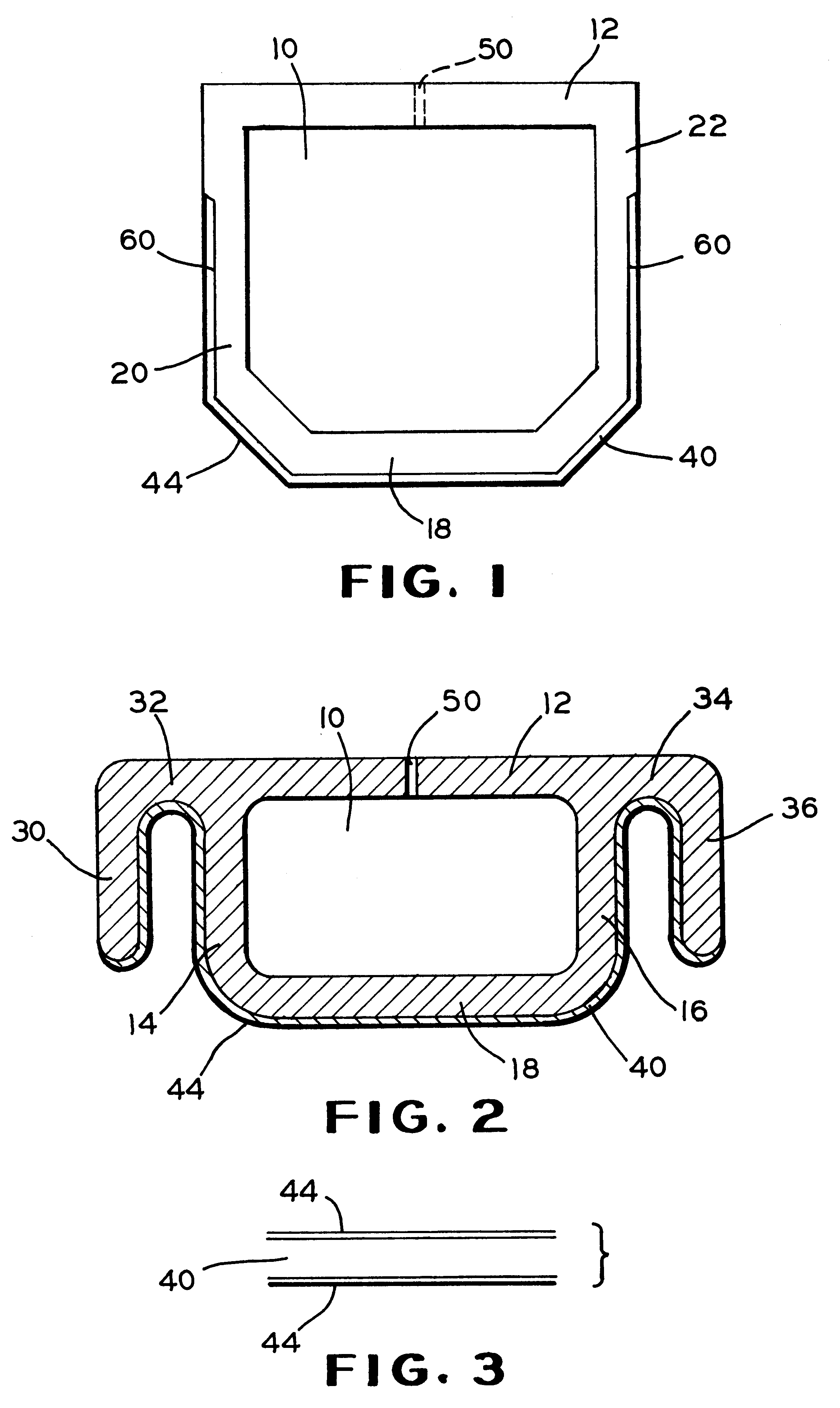

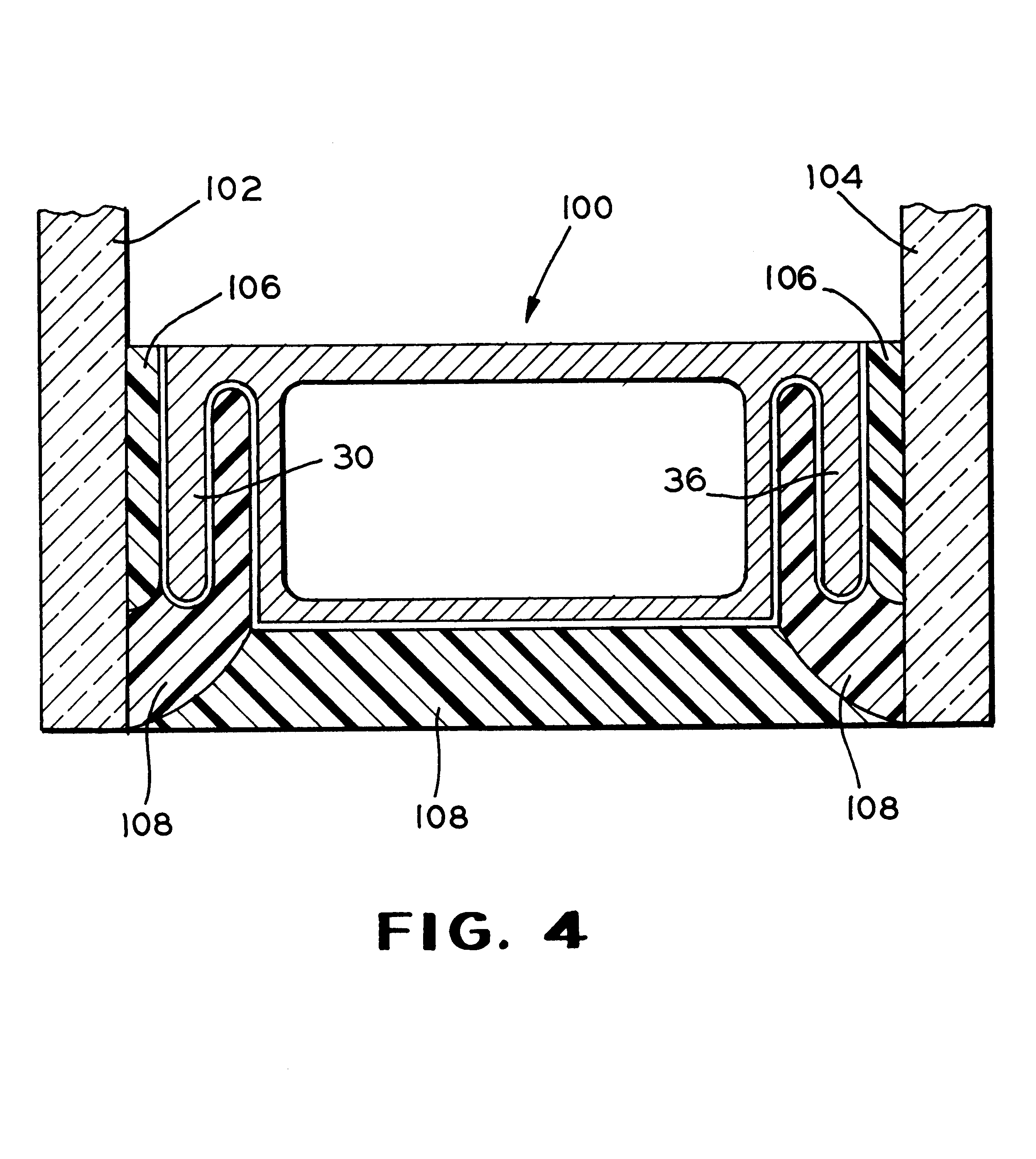

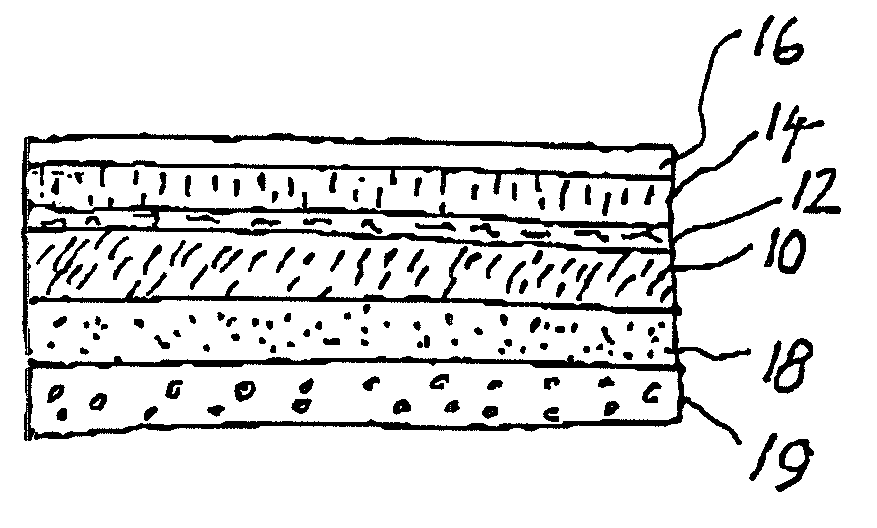

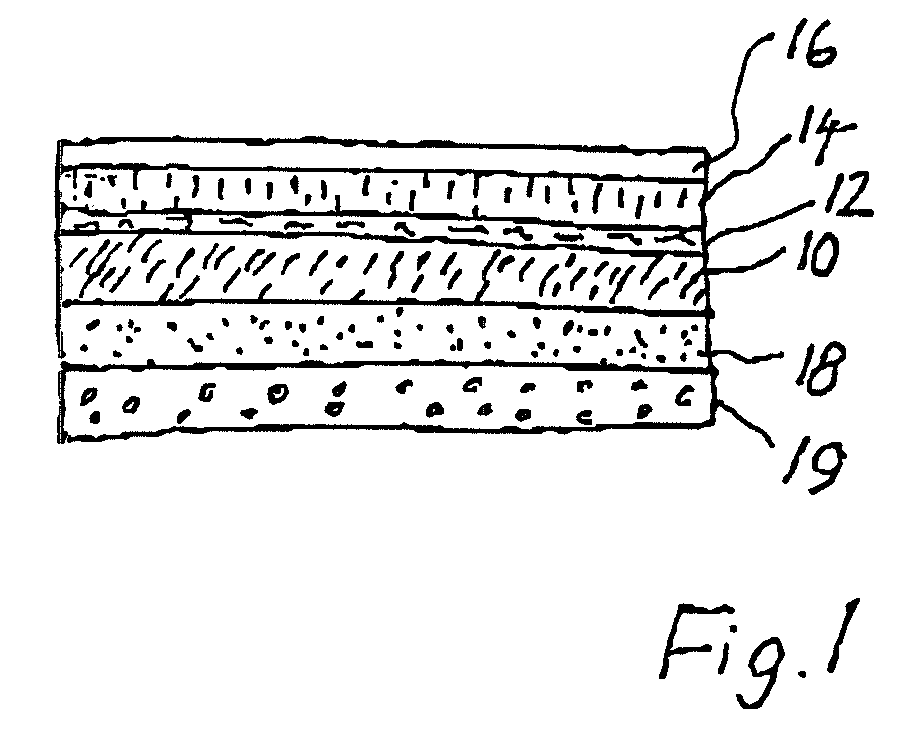

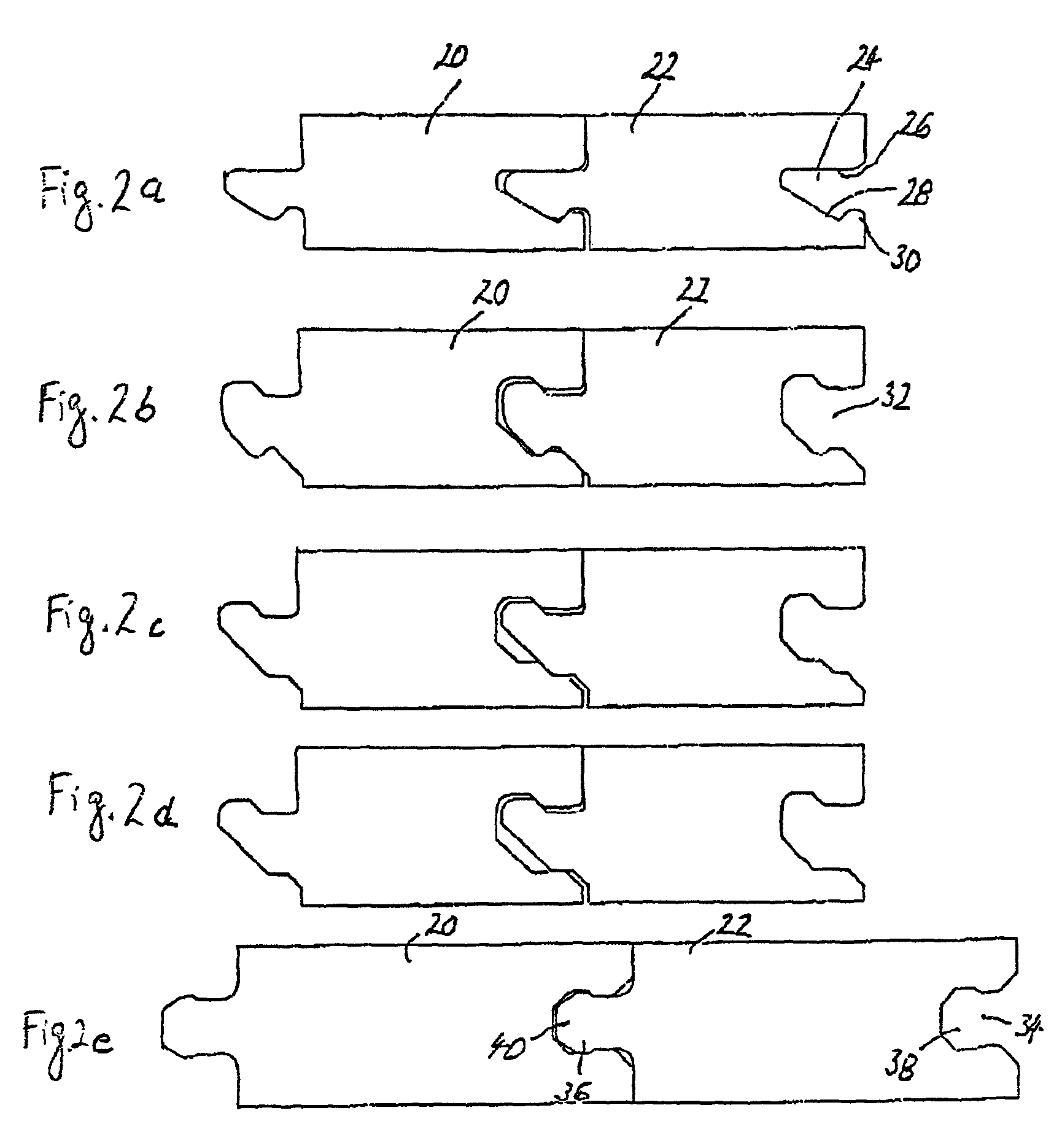

A floor panel in the form of a multilayer, rectangular laminate with a soft core (10) of plastic, a décor film (12) on the upper side of the core (10), a transparent finishing layer (14) and a transparent lacquer layer (16) applied on the finishing layer (16), as well as a back-pull layer (18) on the back of the core (10), with a lockable tongue and groove connection at least at two mutually opposite edges of the panel (20, 22).

Owner:I4F LICENSING NV +2

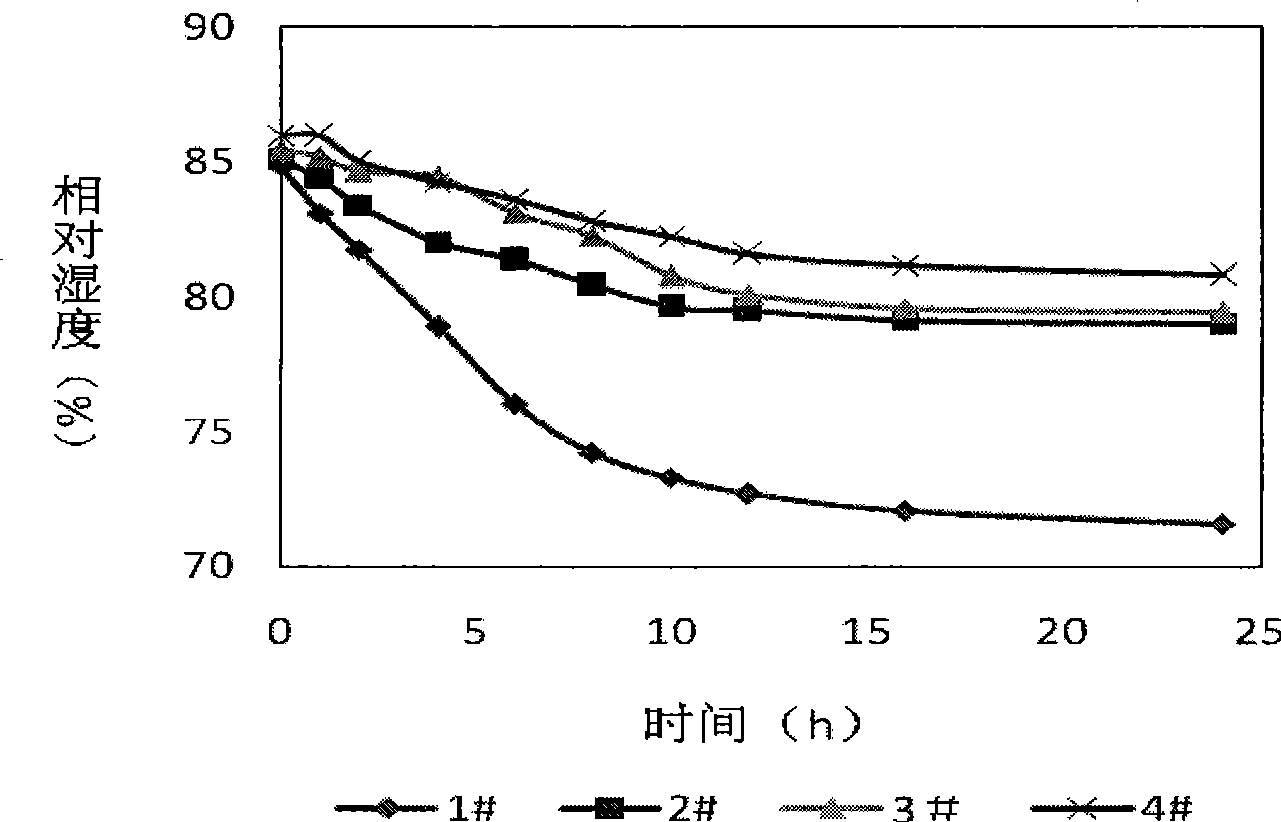

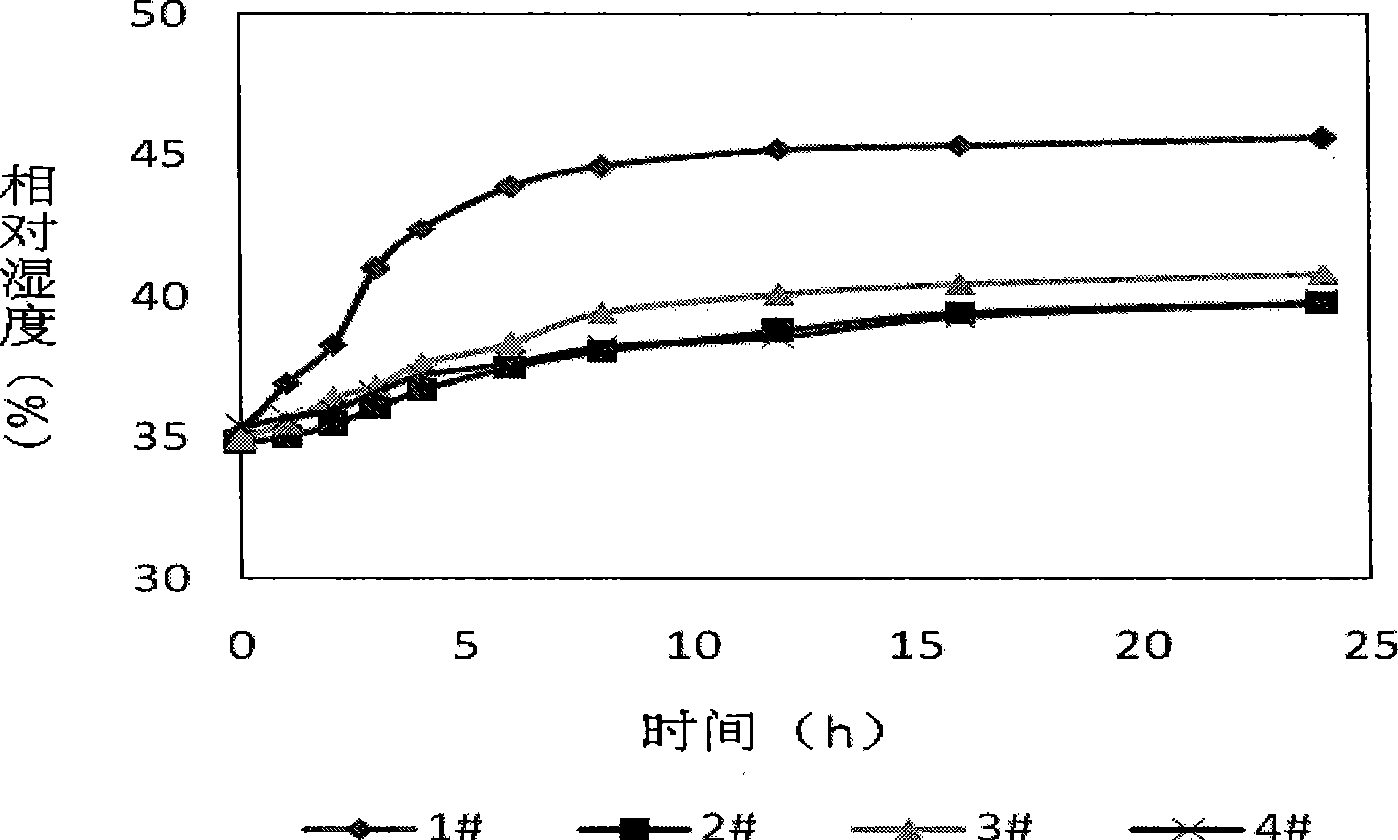

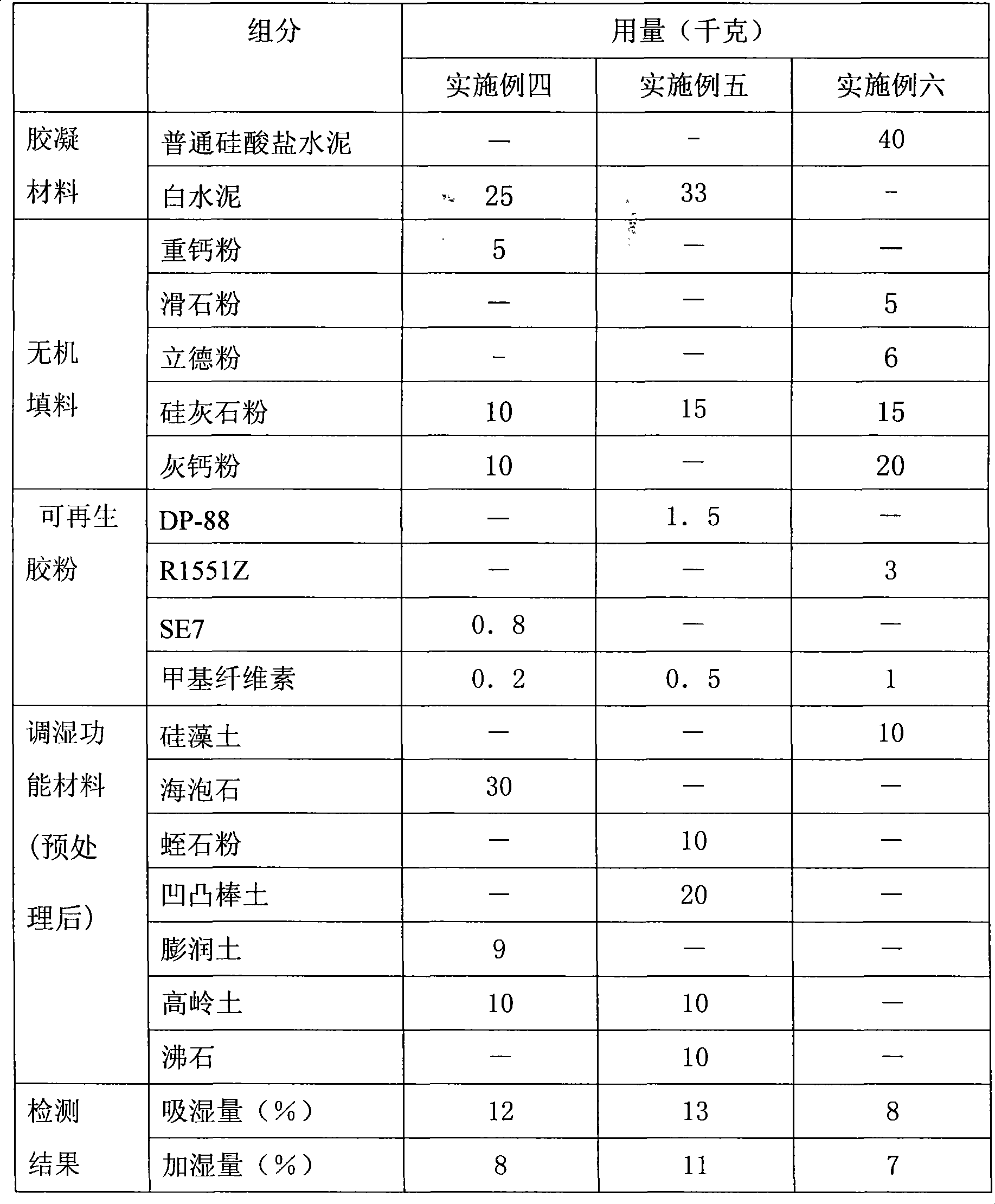

Inorganic putty powder with function of governing humidness

ActiveCN101368014AEffective regulation of relative humidityGood environmental protectionFilling pastesCement coatingsSodium BentoniteMetallurgy

The invention relates to interior wall putty powder with air humidity regulating function, which belongs to the field of building materials. The putty powder is composed of 10 to 50 weight portions of humidity regulating material, 15 to 50 weight portions of inorganic binding material, 15 to 50 weight portions of inorganic filler, and 1 to 5 weight portions of sub divisible rubber powder; the humidity regulating material comprises one type or more than one type of diatomite, sepiolite, attapulgite, vermiculite, zeolite powder, kaolin and bentonite. Because of the environment protection and humidity regulating functions, the multi-pore inorganic mineral material is taken as humidity regulating material and applied in the building interior wall putty powder. With water added in, the putty powder is mixed into lacquer putty and applied on the wall surface, which can effectively regulate the indoor air humidity, so that the indoor air humidity is controlled within the scope which is beneficial to the health of human body; meanwhile, the putty powder has no pollution, no VOC released and can be directly used for decoration.

Owner:CHINA BUILDING MATERIALS ACAD

Spacing profile for double-glazing unit

A spacing profile for a spacing frame, which is to be fitted in the edge area of a double-glazing unit, forming an interspace, with a profile body of a material possessing low thermal conductivity and with a diffusion-impermeable metal foil which is bonded to the profile body so as to establish a material fit, is characterized in that the metal foil is, at least on the surface facing away from the profile body, provided with a corrosion preventing coating which comprises a colored lacquer coating and / or a layer of chromium or of a chromium alloy, wherein the corrosion preventing coating comprises a thickness which is lower by at least a factor of 2.5, preferably by at least a factor of 10 and further preferred by at least a factor of 20, as compared to the thickness of the metal foil.

Owner:PILKINGTON DEUTLAND

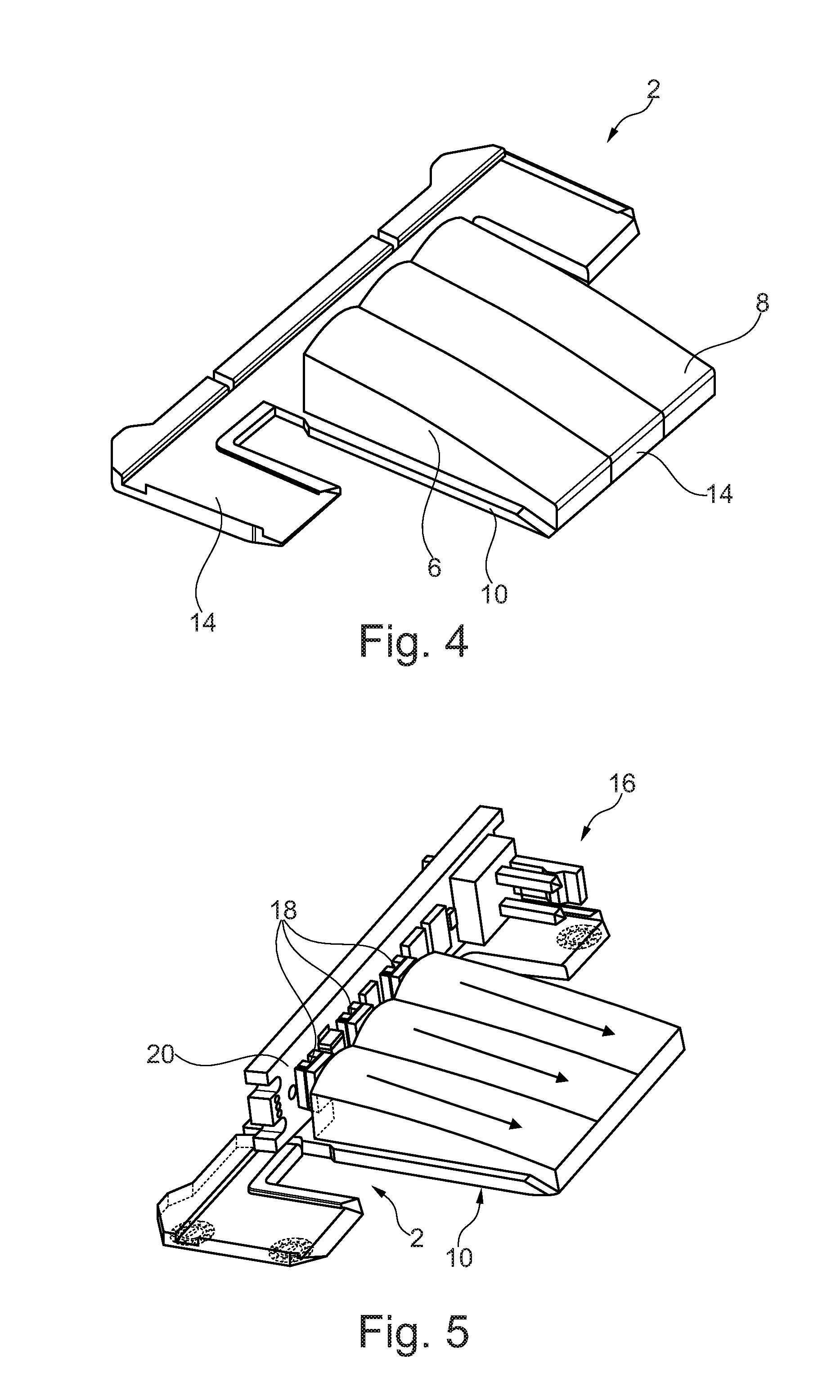

Floor panel

ActiveUS8071193B2Improve noise characteristicsThe process is simple and fastCeilingsWallsLacquerEngineering

The invention relates to a floor panel in the form of a multilayer, rectangular laminate with a soft core (10) of plastic, a décor film (12) on the upper side of the core (10), a transparent finishing layer (14) and a transparent lacquer layer (16) applied on the finishing layer (16), as well as a back-pull layer (18) on the back of the core (10), with a lockable tongue and groove connection at least at two mutually opposite edges of the panel (20, 22).

Owner:I4F LICENSING NV +2

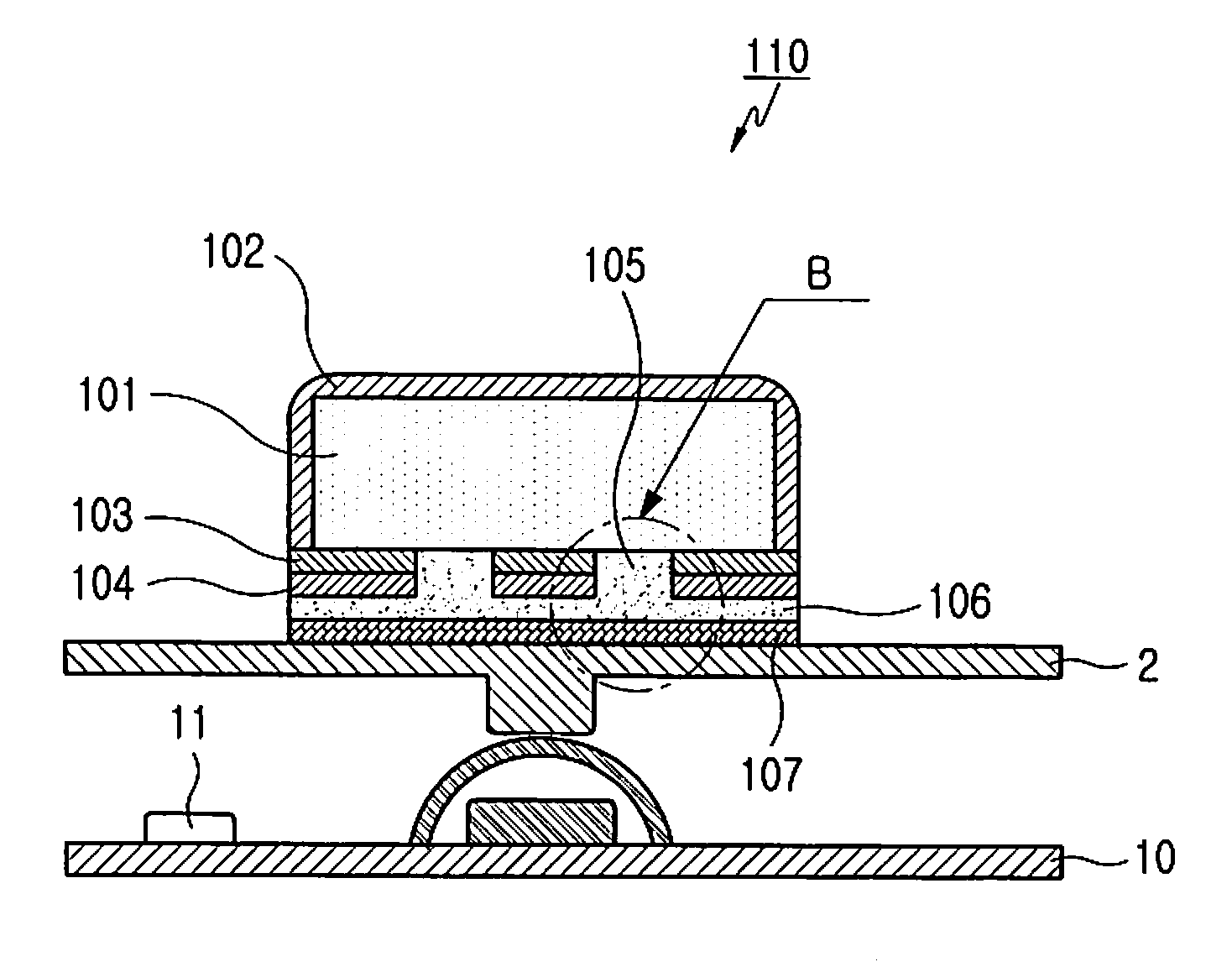

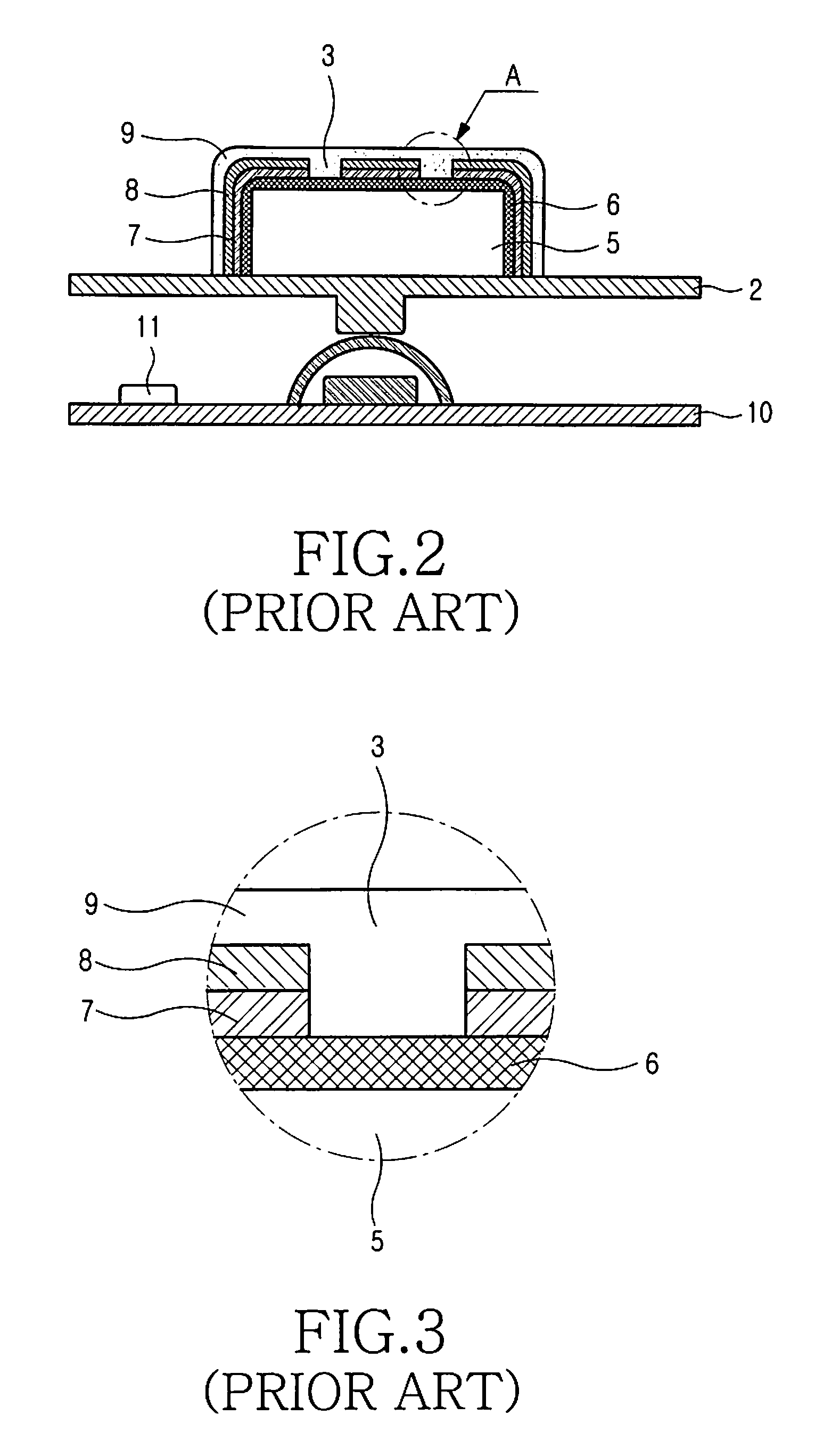

Manufacturing method of keypad for mobile phone and keypad manufactured thereby

ActiveUS7414213B2Increase resistanceHigh hardnessInput/output for user-computer interactionEmergency actuatorsLaser processingLacquer

Disclosed is a manufacturing method of a keypad for a mobile phone and the keypad manufactured thereby, in which a vacuum deposition layer and a cellophane paper are attached to a lower surface of a key in the keypad. The keypad for a mobile phone includes a plurality of keys, each key includes a key body of a transparent resin material and a high-hardness transparent coating layer coated onto a surface of the key body in order to increase hardness, and each key comprises a key background color paint layer for color presentation, coated onto a lower surface of the key body; an opaque paint layer coated onto a lower surface of the key background color paint layer; a transparent marking portion formed by performing a laser processing according to a shape of a numeral, a character, or a symbol with respect to the lower surface of the key body so as to remove the color paint layer and the opaque paint layer; a metallic vacuum deposition layer formed on the lower surface of the key body and a lower surface of the opaque paint layer; and a transparent color-printed layer or a cellophane paper attached to a lower surface of the metallic vacuum deposition layer so as to present various colors.

Owner:ROVI GUIDES INC

Antifungal nail lacquer and method using same

A nail lacquer for the treatment or prevention of fungal infections, such as, onychomycosis, includes fungicidally effective amount of ciclopirox, econazole, or other antifungal agent in a compatible film-forming lacquer vehicle which includes a water-insoluble film-forming polymer; pentadecalactone, or similar cyclic lactone compound or derivative thereof, and volatile solvent. The pentadecalactone functions as a plasticizer for the film-forming polymer and as a penetration enhancer for the antifungal agent. The composition, when applied to the nails provides a hard, clear, water-resistant film containing the antifungal agent. The compositions are used for the treatment of onychomycosis.

Owner:CPEX PHARMACEUTICALS INC

Process for the manufacturing of surface elements with a structured top surface

A process for the manufacturing of a decorative surface element, which element comprises a base layer and a decorative upper surface. A radiation curing lacquer is printed in a predetermined pattern as an uppermost layer on the decorative upper surface. The radiation curing lacquer covers only parts of the decorative upper surface whereby the lacquer is exposed to radiation whereby it cures. A surface structure is hereby achieved.

Owner:UNILIN NORDIC AB

Light Guiding Device

ActiveUS20160209000A1Reduce gapEvenly distributedCladded optical fibreLight guides detailsMobile vehicleLacquer

A light guiding device for an illumination device, especially for a motor vehicle or an indicator device in a rearview device of a motor vehicle includes a light coupling side for incoupling light from a light source, a reflection side having a reflection layer; and a light outcoupling side, which is disposed generally opposite the reflection side. A clearance between the reflection side and the light outcoupling side generally decreases as the distance from the light incoupling side increases. The reflection side having the reflection layer is configured so that light arriving from the light incoupling side is deflected to the light outcoupling side. The reflection layer may be a paint or lacquer layer that is imprinted or evaporation-coated on the reflection side.

Owner:SMR PATENTS S A R L

Highly wearable vacuum coating ultraviolet curing coatings

ActiveCN101157808AImprove adhesionImproved RCA wear performancePolyurea/polyurethane coatingsWear resistantLacquer

The invention relates to the electronic application-coating field, in particular to uv-curing coating with high wearing resistance and vacuum coating. The compositions and contents of the invention are: 10 wt percent to 30 wt percent of difunctional group polyurethane acrylate, 10 wt percent to 40 wt percent of high functional group polyurethane acrylate, 5 wt percent to 20 wt percent of high functional group acrylate monomer, 0 wt percent to 15 wt percent of monofunctional group acrylate monomer, 1 wt percent to 10 wt percent of acid adhesive promoter, 1 wt percent to 6 wt percent of photoinitiator, 0 wt percent to 5 wt percent of nano wearing resistance materials, 0.1 wt percent to 2 wt percent of additive and 10 wt percent to 50 wt percent of solvent. The invention is designed for providing surface protection for vacuum coating parts of electric products such as mobile phone, MP3, and digital camera, etc., and is characterized by good surface effect, good performances of ultrawear-resistance, high temperature and humidity resistance, anti-cold thermal cycling and anti-yellowing, etc., wherein, RCA wear can be up to more than 1500 times, which can effectively improve the service life of electric products. The invention effectively enhances the adhesion and wearing resistant performance of the uv-curing and vacuum coating dope, solves the matching problem of the bottom and surface lacquer of the uv-curing and vacuum coating dope, and has broad university.

Owner:HUNAN SOKAN NEW MATERIAL

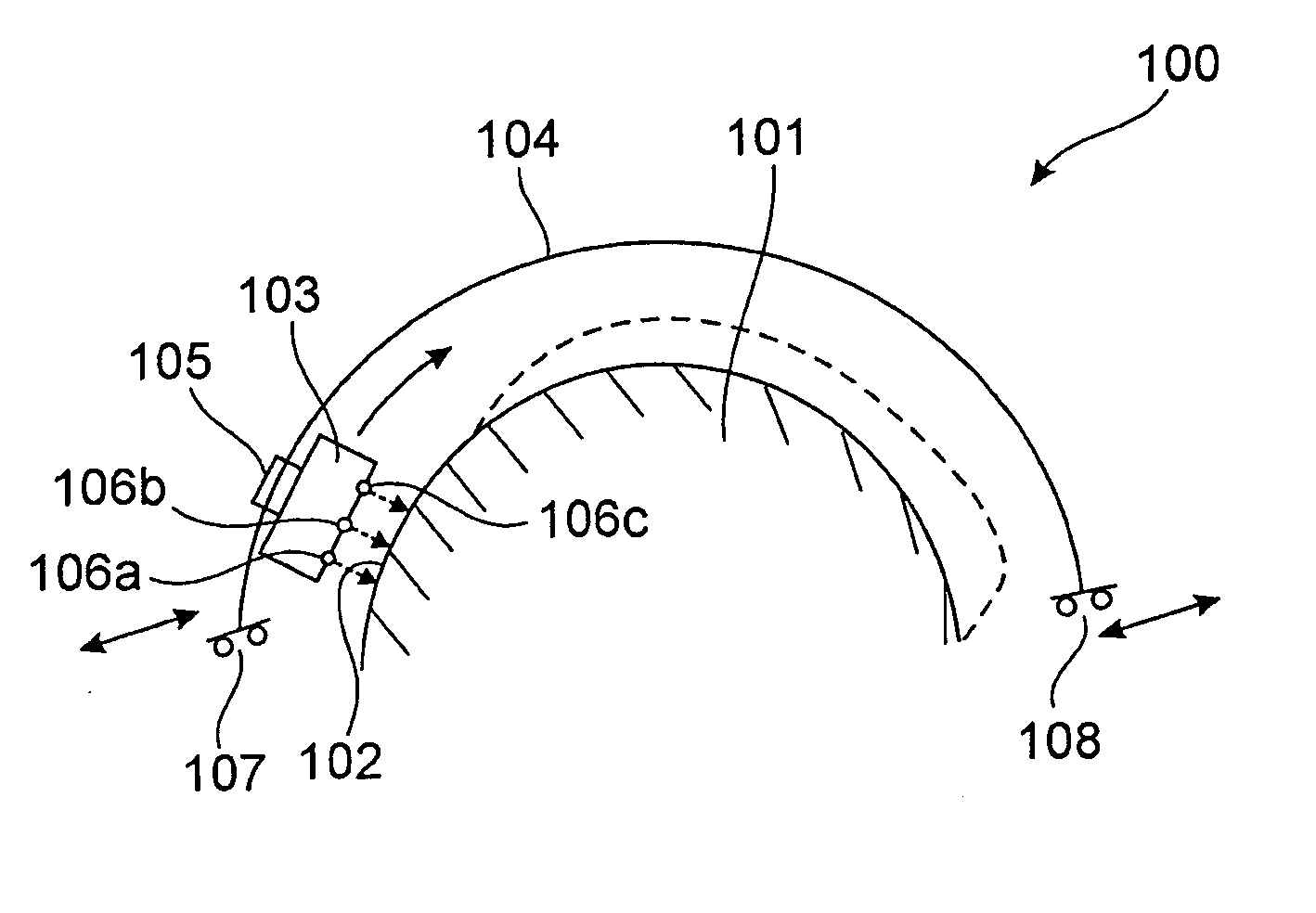

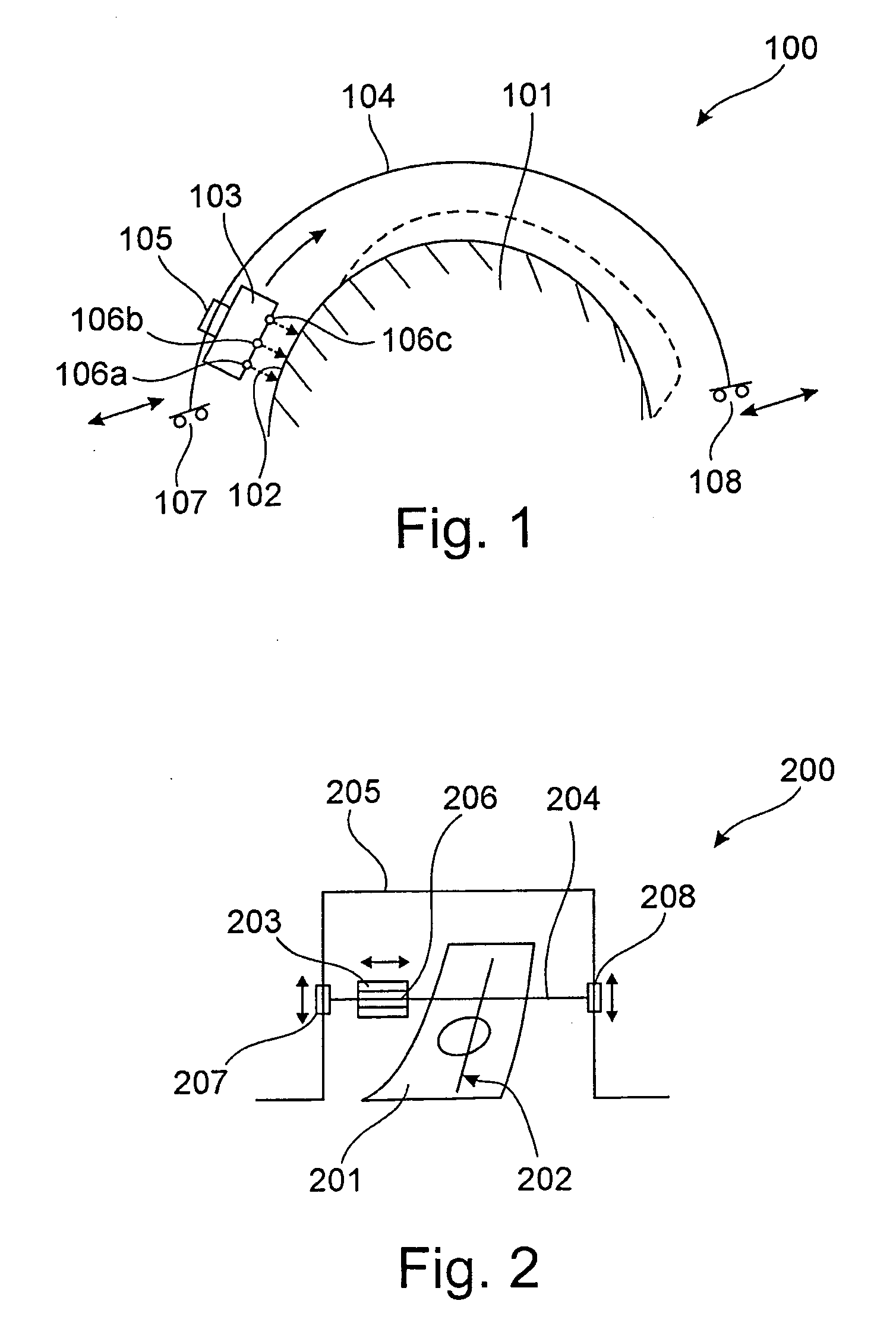

Painting device, painting arrangement, method for painting a curved surface of an object, and use of an inkjet device for painting an aircraft

Owner:AIRBUS OPERATIONS GMBH

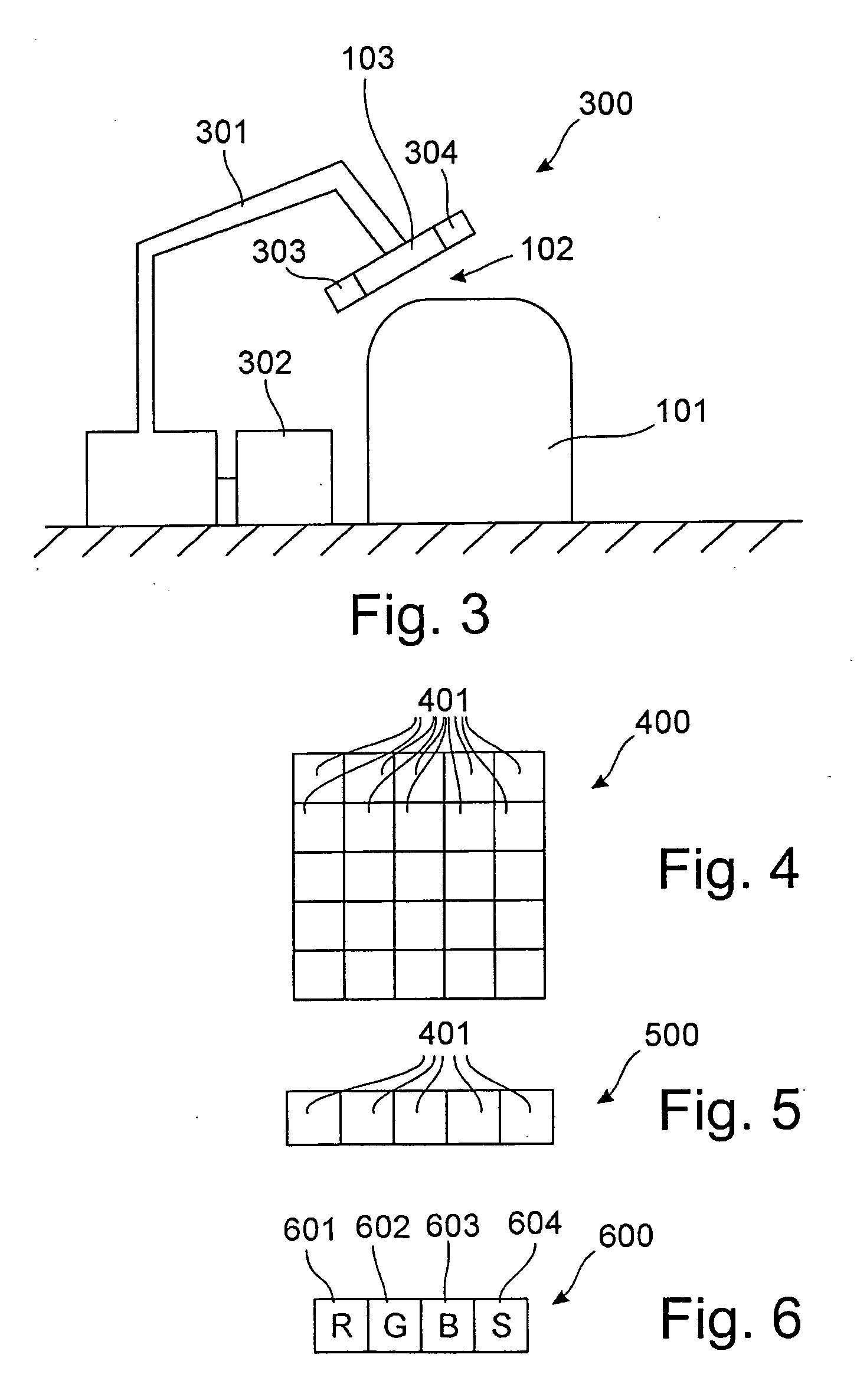

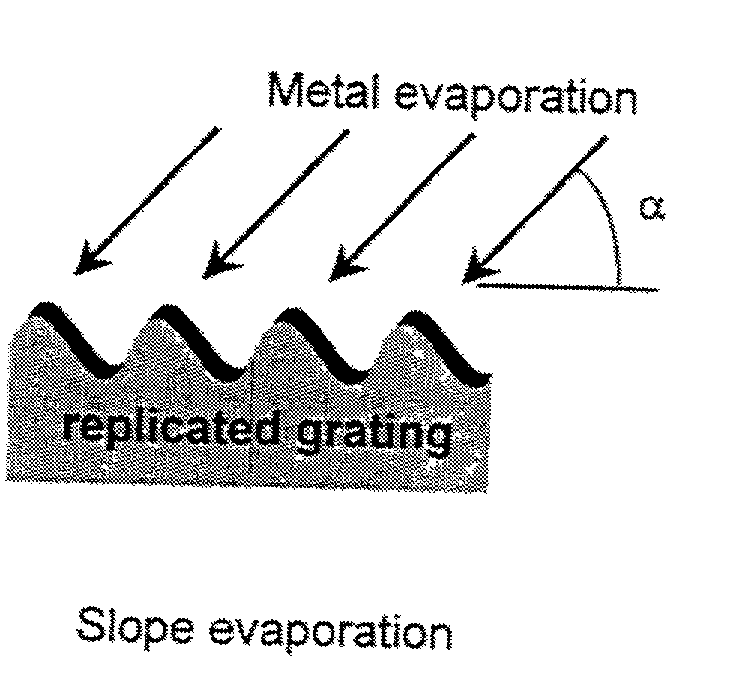

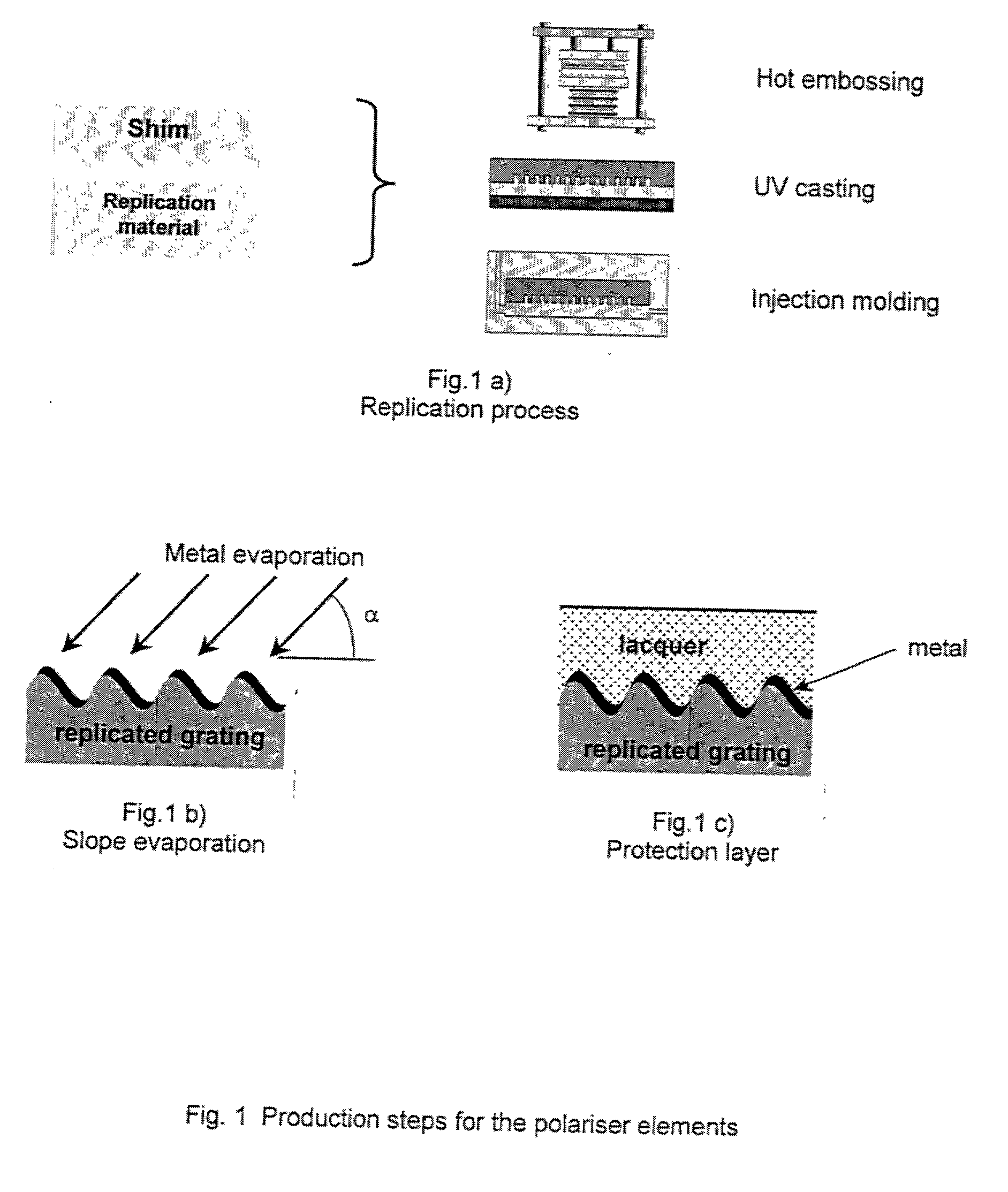

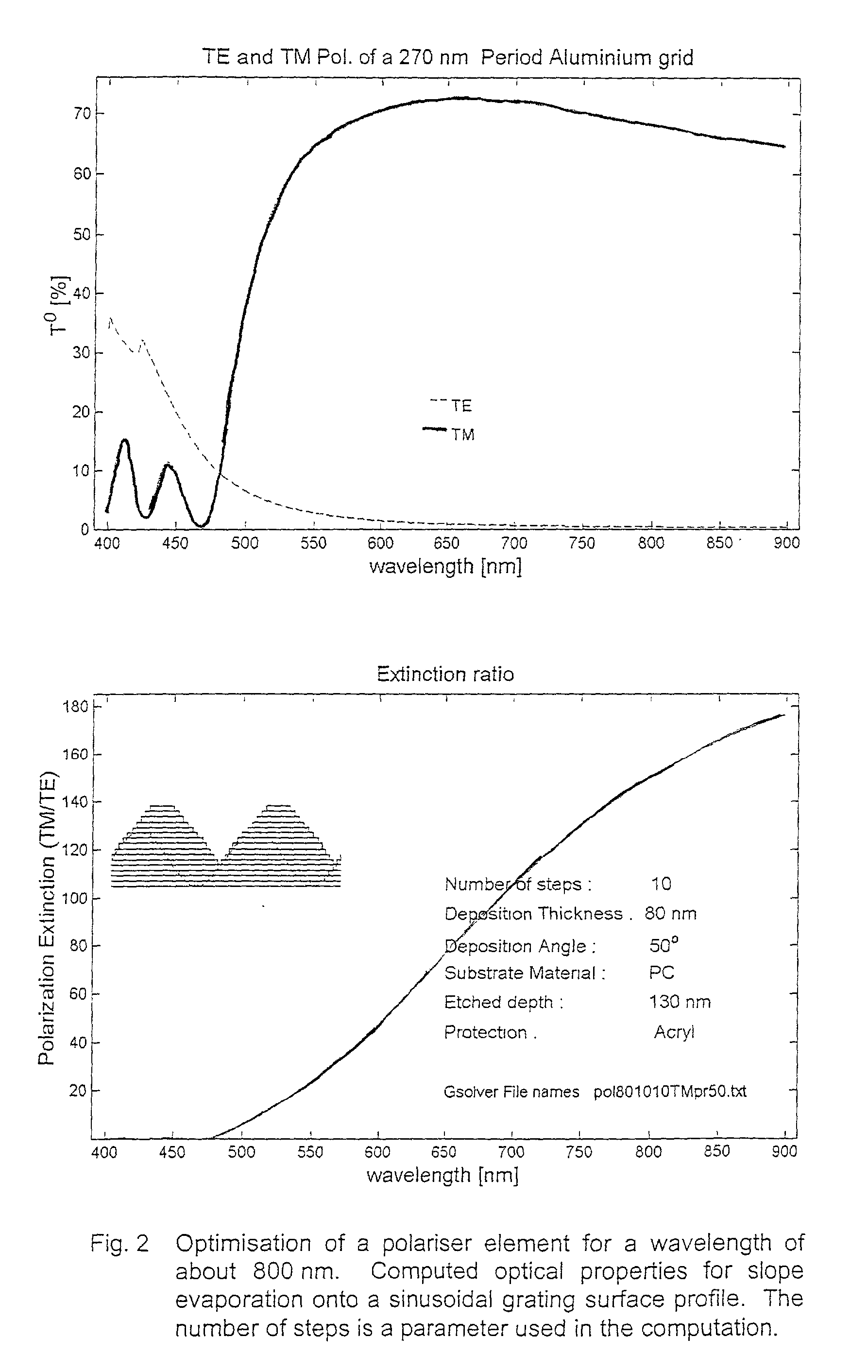

Polarisers and mass-production method and apparatus for polarisers

InactiveUS20020191286A1Low cost productionHigh hardnessPolarising elementsOptical articlesGratingLacquer

A method of mass producing polarizes comprises designing by rigorous diffraction theory an optimized grating profile, replicating the profile in a polymer or other substrate, and slope evaporating a metal onto the substrate. The angle of slope evaporation, the metal, and the thickness of the metal are optimized for a given wavelength using rigorous diffraction theory. The polarizer may be coated with a protective coating, such as an acrylic based lacquer or Magnesium Fluoride (MgF2). The optical effect of the coating is also taken into account in the design using rigorous diffraction theory.

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

Infrared reflective wall paint

ActiveUS7157112B2Reduce energy consumptionReduce absorptionLiquid surface applicatorsElectrostatic spraying apparatusInfraredLacquer

Owner:TEXTURED COATINGS OF AMERICA

General water-based quick-drying anti-rust paint and preparation method thereof

InactiveCN102993810AAdvanced Technology FormulaAdvanced DesignRosin coatingsAnti-corrosive paintsWater basedLacquer

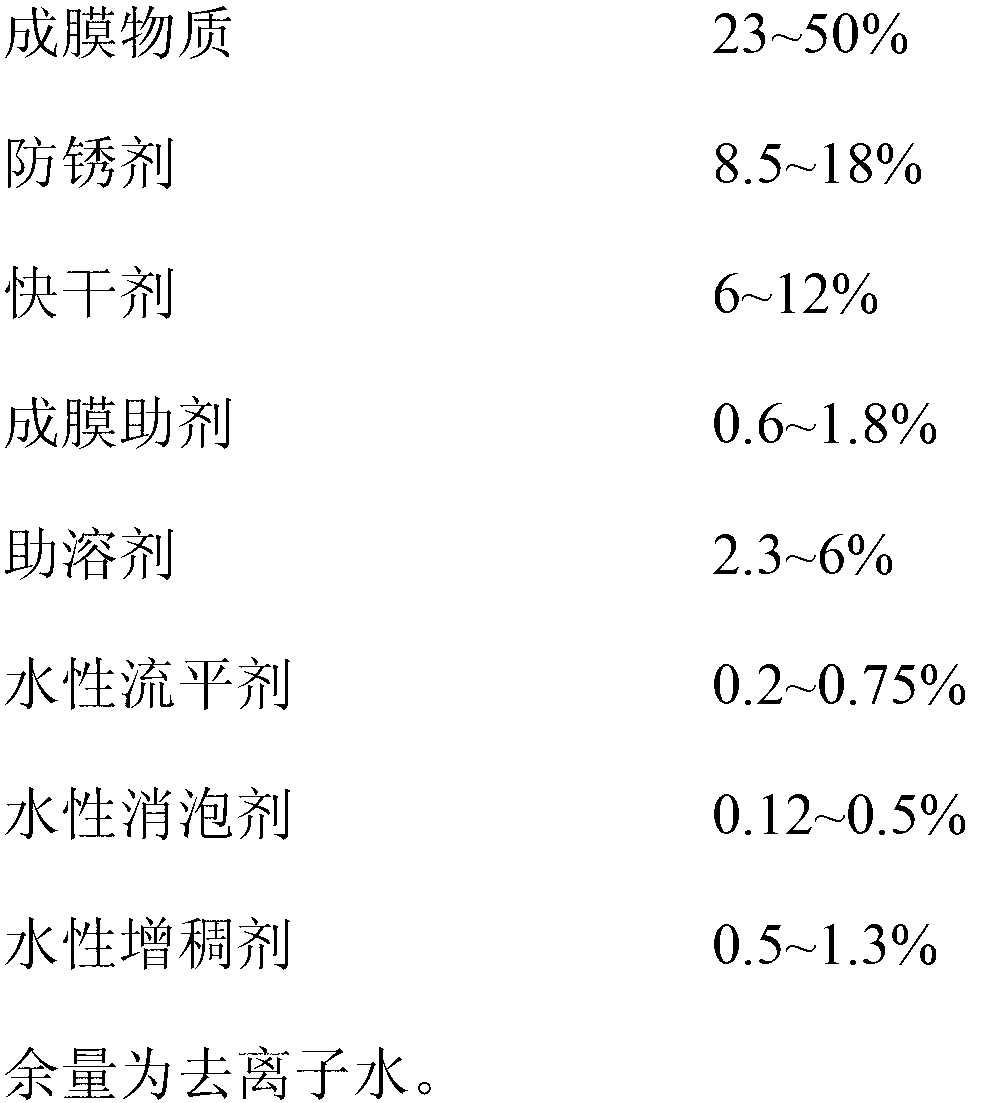

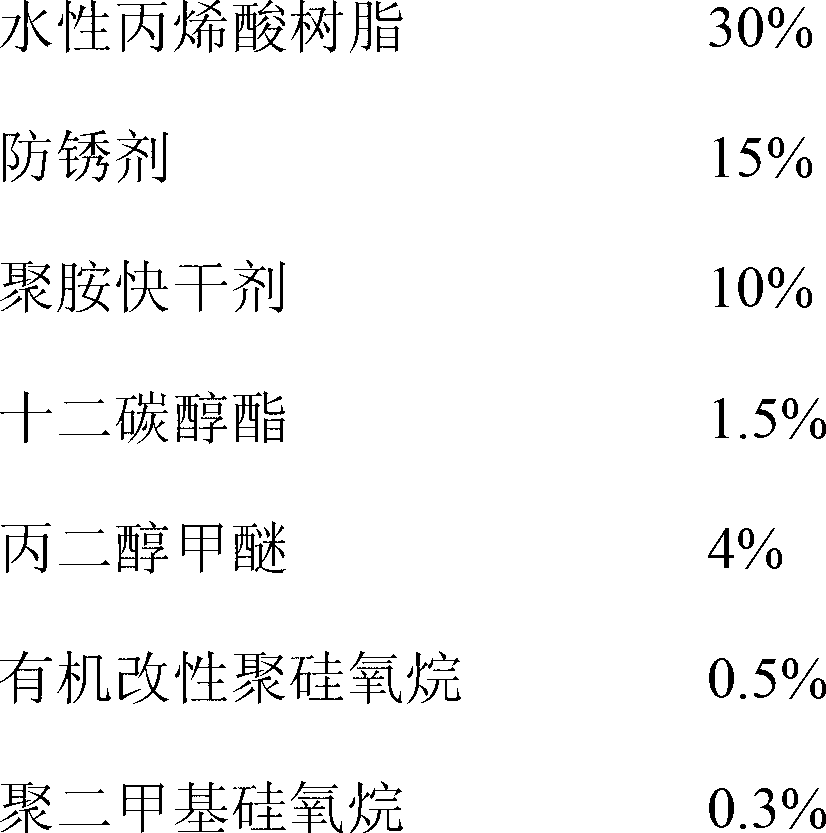

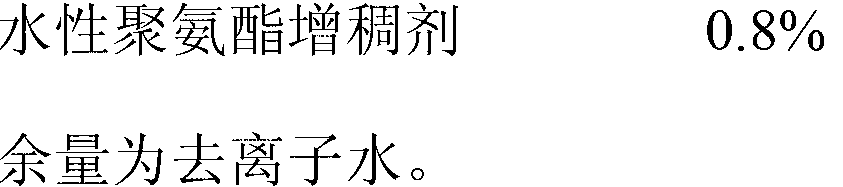

The invention relates to a general water-based quick-drying anti-rust paint and a preparation method thereof. The general water-based quick-drying anti-rust paint comprises the following components in percentage by weight: 18%-55% of film-forming substance, 6%-22% of anti-rust agent and the balance of water. The preparation method comprises the following steps of: firstly pre-dispersing the components except the anti-rust agent according to the formula ratio; then adding the anti-rust agent according to the formula ratio; and re-dispersing to obtain the general water-based quick-drying anti-rust paint. The general water-based quick-drying anti-rust paint disclosed by the invention is safe and nontoxic, contains no lead, chromium or other hazard pigments and derivatives, can not burn or explode, is suitable for safe production, has the advantages of plump paint film, excellent decoration and protection, excellent adhesive force and adjustable glossiness, and is simpler in production process compared with an oil paint.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

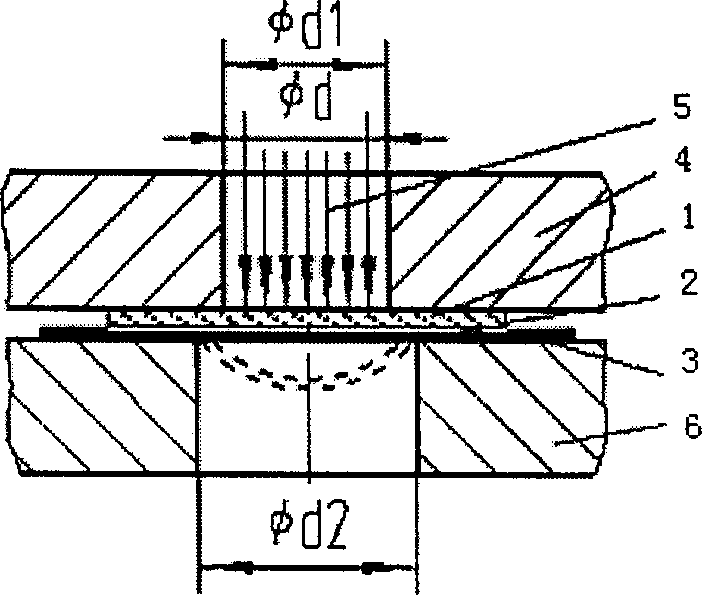

Flexible lamina for laser impact treatment

InactiveCN1404954AConvenient laser shock treatmentIncrease peak pressureLaser beam welding apparatusSilicone GelsLacquer

The present invention is applicable to utilization of laser impact wave technique to modify material surface or make cold-plasticity forming of metal plate material. Said invention adopts two groups of GN-521 organic silicone gel solutions with different components and additive, and mixes them according to a certain formula, after said mixture is solidified, a transparent constraining layer for laser is formed, and an energy-absorbing layer of 86-1 type black paint can be sprayed on the constraining layer to form the sticking film integrating energy-absorbing layer and constraining layer into one body and possessing a certain flexibility.

Owner:JIANGSU UNIV

Method of producing an information carrier

InactiveUS20080136160A1Obvious advantagesOther printing matterDuplicating/marking methodsLacquerEngineering

Methods for producing an information carrier comprising the steps of: (1) providing an information carrier precursor comprising: a rigid sheet or support; a receiving layer configuration comprising at least one constituent layer; and a layer or element capable of a human-readable or machine-readable change upon absorbing UV, visible or IR radiation, wherein at least one layer of the receiving layer configuration is opaque, porous, has the capability of being rendered substantially transparent upon penetration by a lacquer provided at the outermost surface of the receiving layer configuration and comprises at least one pigment and at least one binder; (2) realizing a temporary transparentization pattern by applying a vaporizable liquid pattern-wise or integrally to the receiving layer configuration; (3) writing with a light source a first pattern in the layer or element capable of human readable or machine-readable change; and in any order evaporating the vaporizable liquid; applying a second pattern to the outermost layer of the receiving layer configuration; and realizing a permanent transparentization pattern by applying a lacquer pattern-wise or integrally to the receiving layer configuration; with the proviso that the lacquer is applied after the vaporizable liquid has been evaporated, thereby producing an information carrier.

Owner:AGFA GEVAERT AG

Low loose density sheet-like silver powder preparation method

The invention relates to a method for preparation of low apparent density sheet silver powder, which comprises five steps: choosing materials, ball grinding, one- time surface modified, drying, and secondary surface modified. With the silver powder of silver content more than 99.95% and granularity among 0.1- 1um as the material, by wet ball grinding with the existence of mill medium, mill auxiliary agent and liquid lubricant, one- time chemical modification treatment, and one- time dry ball grinding modification treatment, the low apparent density sheet silver powder is prepared. The time of wet ball grinding being among 2- 8h that is 1 / 5 of the time of mechanical ball grinding and the apparent density being only 1 / 2 of that of mechanical ball grinding, with the invented, it solves the problem of deposition and agglomeration in conductive paint; and with twice surface modified treatment, coating two- layer protective film, the first layer being dispersion film and the second being directional floating film, the dispersibility and flotation property of the silver powder are improved, and the silver powder is the required material of producing electromagnetic shielding paint and conductive paint. Every index of the silver powder can satisfy the requirement of conductive paint and shielding pain.

Owner:KUNMING HENDERA SCI & TECH

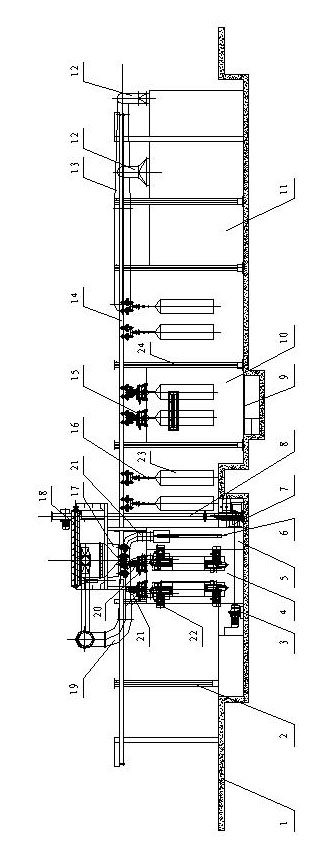

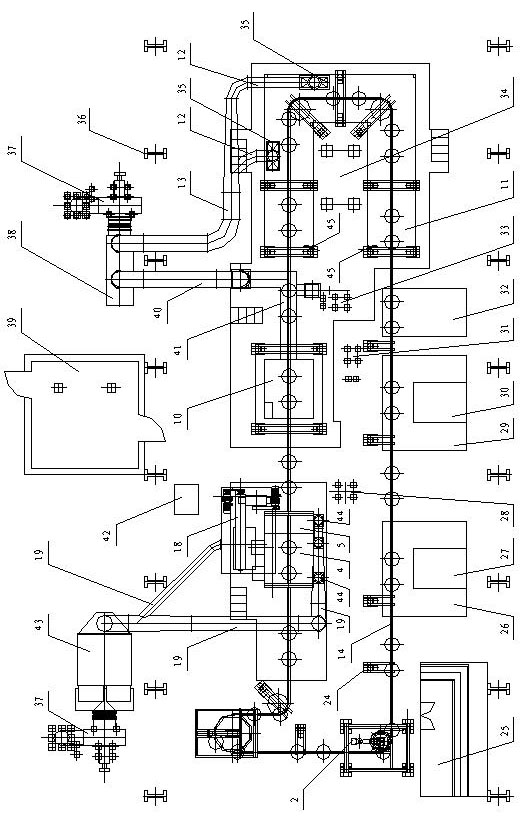

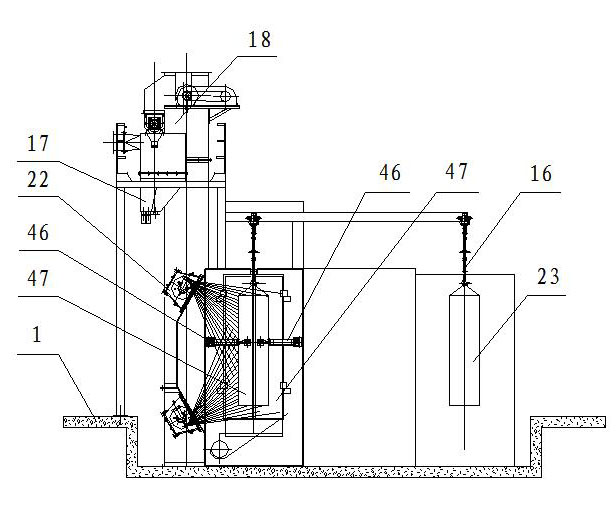

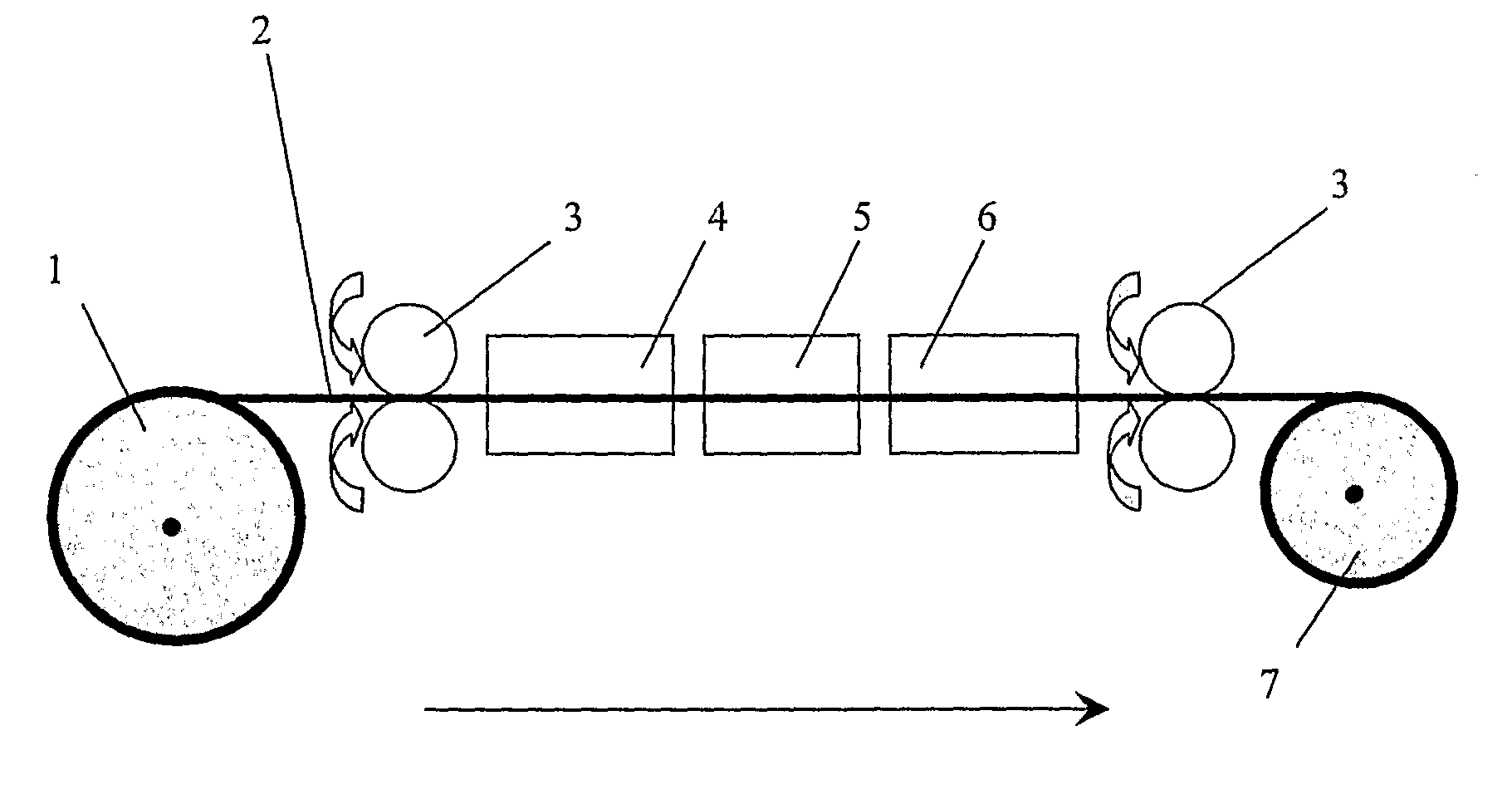

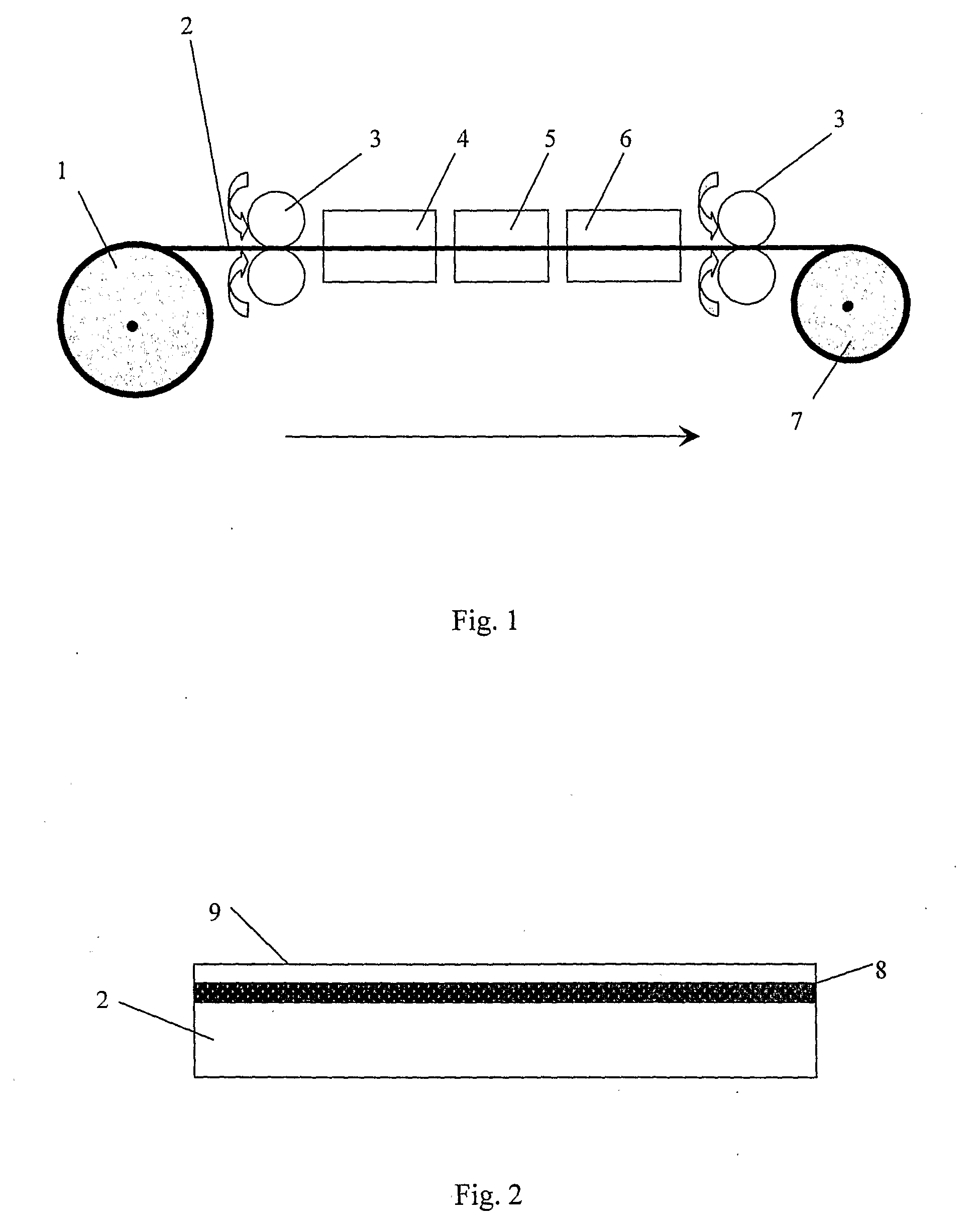

Hydraulic cylinder surface shot blasting, paint spraying and drying system and shot blasting, paint spraying and drying process thereof

InactiveCN101972726AIncrease productivityImprove cleanlinessSpraying apparatusPretreated surfacesHydraulic cylinderLacquer

The invention relates to a hydraulic cylinder surface shot blasting, paint spraying and drying system and a shot blasting, paint spraying and drying process thereof, and the hydraulic cylinder surface shot blasting, paint spraying and drying system consists of a hanging chain conveying system, a shot blasting working position, a paint spraying working position, a drying working position, an overhauling working position, an unloading working position, a loading working position, a paint mixing room, an air compressor and an operating room. The shot blasting, paint spraying and drying process comprises the following process steps: loading of a piece, shot blasting, derusting and cleaning (10-15min), automatic paint spraying (3-5min), paint refinishing, leveling (5min), drying at 60-80 DEG C (30min), natural cooling and unloading of the piece. The hydraulic cylinder surface shot blasting, paint spraying and drying system has the advantages of high degree of mechanical and electrical automation, small occupied area, good safety performance, and high production efficiency, is not affected by weather and can ensure the cleanliness, the temperature, the illumination and the safety and sanitation standard required by the paint spraying environment; and the shot blasting, paint spraying and drying process is simple, safe, time-saving, environment-friendly and high in working efficiency and can obtain the good appearance quality of a paint film.

Owner:中煤邯郸煤矿机械有限责任公司

Coated Metal Product, Method to Produce It and Use of the Method

InactiveUS20090181262A1High quality finishResistant to damageDecorative surface effectsPretreated surfacesLacquerMetallic substrate

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Nano antibacterial water woodenware paint and preparing method thereof

InactiveCN101016431AGood yellowing resistanceGood sealingLiquid surface applicatorsAntifouling/underwater paintsWater basedEmulsion

The invention discloses a preparing method of single component nanometer antibiotic water-based woodware paint, which is characterized by the following: the three diverse water-based polyurethane resin emulsion, water-based acrylic acid modified polyurethane resin emulsion and nanometer water-based acrylic resin emulsion are mixed with diverse ratio as film forming matter; it drops the cost of this product and possesses merits of low VOC value, blocking resistance, fish tail tolerant, pollution tolerant, yellowed tolerant and good blocking; the organic swelled ground prefabricated sol is the carrier of compositing type inorganic antibacterial agent, it incorporates multiple inorganic nanometer composition. This invention is easy to process, which can resolve craft problems of sedimentation, discoloration and birdnesting.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

Sand-in-water colorful imitation stone paint

InactiveCN104312351AHigh transparencyHigh viscosityAntifouling/underwater paintsPaints with biocidesElastomerCrack resistance

The invention discloses sand-in-water colorful imitation stone paint. The invention provides sand-in-water colorful imitation stone paint which has a thick coating, high bonding strength, good water resistance, ageing resistance and good storage stability and is a technical progress in the paint industry. The paint is prepared by preparing a crosslinking agent, a dispersing agent, cellulose, a defoaming agent, bactericide, a pH (potential of hydrogen) regulator, a thickening agent, an antifreezing agent, a film formation assistant, a setting agent, titanium dioxide, colored sand and emulsion into a protection glue solution, base paint and a continuous phase and mixing the protection glue solution, the base paint and the continuous phase uniformly. In the paint, the crosslinking agent is an elastomer and nano gel with high grade of transparency, high viscosity and high thixotropy; after the colored sand is added to the paint, colored particle hardness of the paint is adjustable; the paint is suitable for various colors and patterns; and the paint has the advantages of good storage stability, no color bleeding, high possibility of granulation, good water resistance, lasting weatherability, crack resistance high stone imitation degree, simple construction, low cost and workhour saving.

Owner:广西启利新材料科技股份有限公司

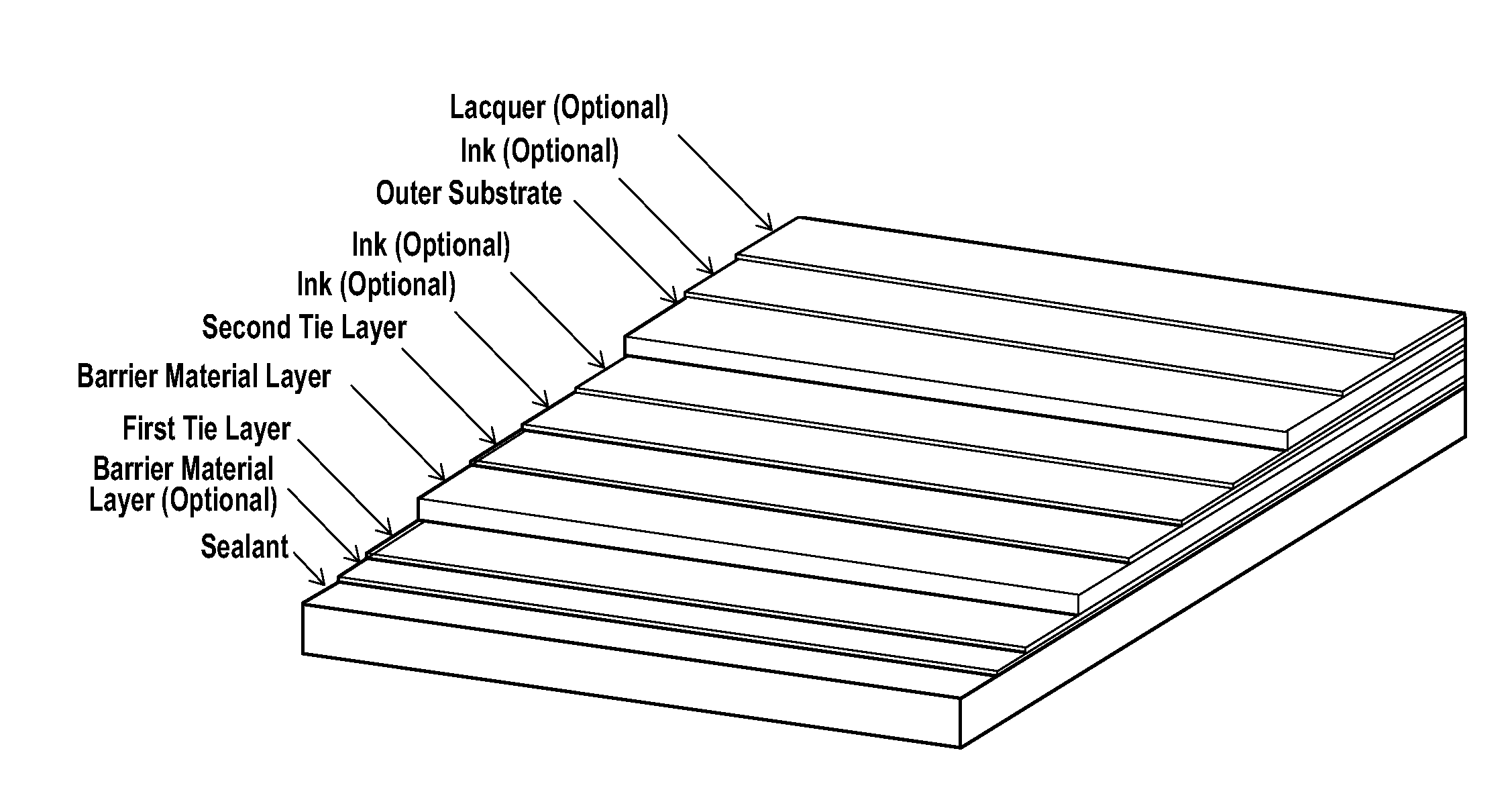

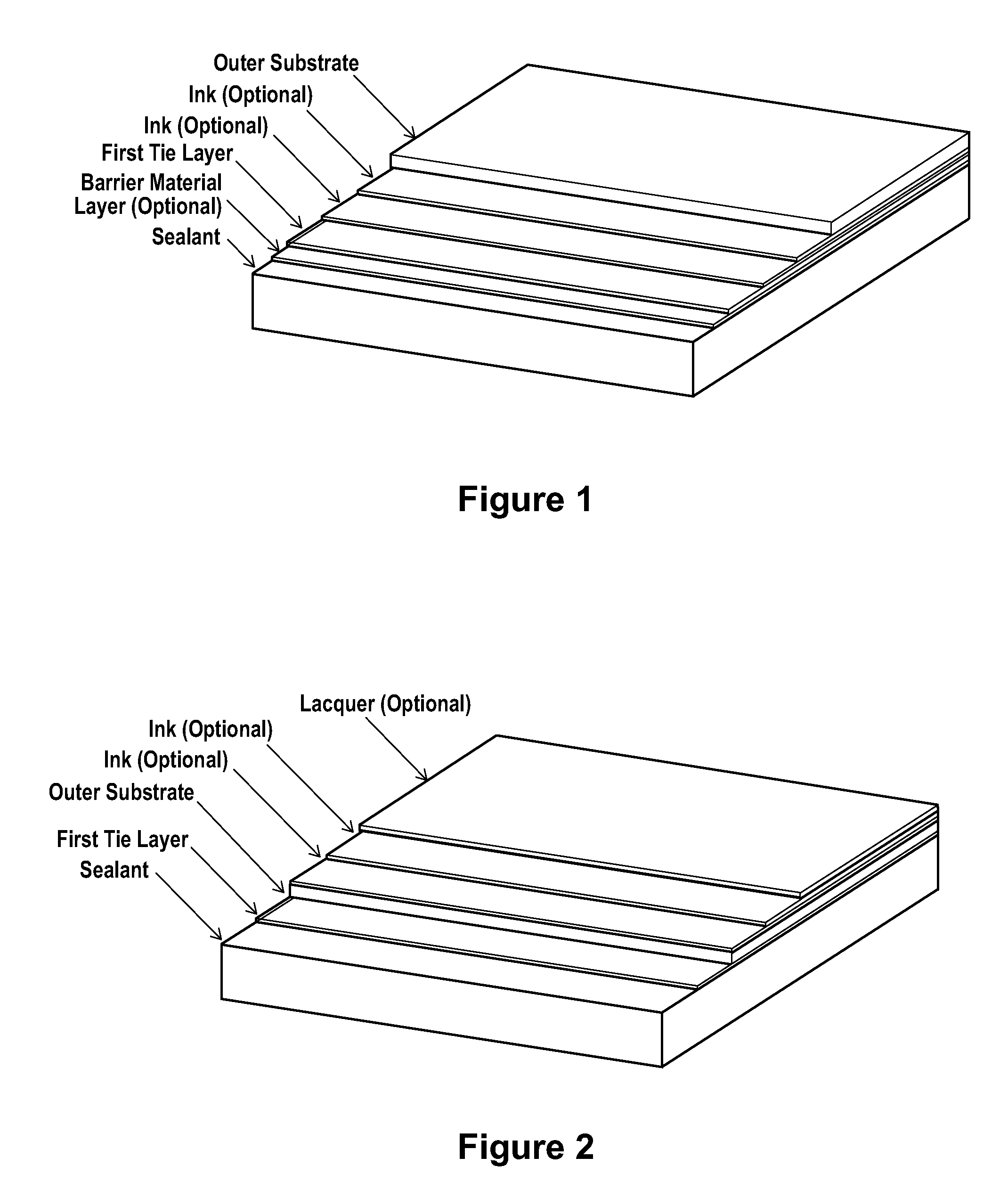

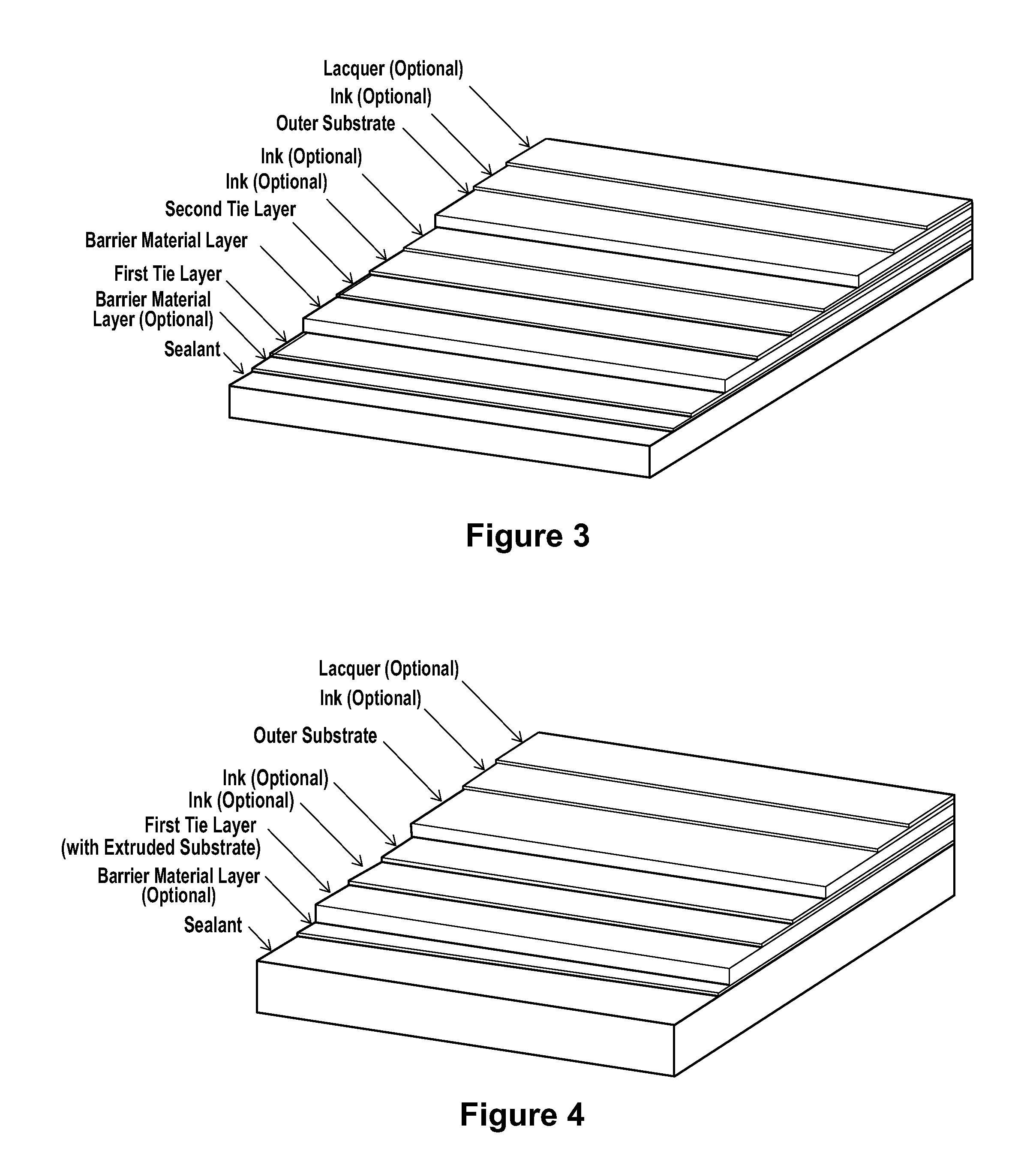

Flexible barrier packaging derived from renewable resources

Disclosed herein are flexible barrier packages composed of materials that are substantially free of virgin, petroleum-based compounds. The flexible barrier packages contain a sealant that has a biobased content of at least about 85%. The sealant is laminated to an outer substrate that has a biobased content of at least about 95% via a tie layer that can further include an extruded substrate. The extruded substrate has a biobased content of at least about 85%. Ink optionally can be deposited on either side of the outer substrate, and the exterior surface of the outer substrate can further include a lacquer. A barrier material layer can be deposited or laminated between the first tie layer and the outer substrate. The flexible barrier packages of the invention are useful for enclosing a consumer product, such as, for example, food, drink, wipes, shampoo, conditioner, skin lotion, shave lotion, liquid soap, bar soap, toothpaste, and detergent.

Owner:THE PROCTER & GAMBLE COMPANY

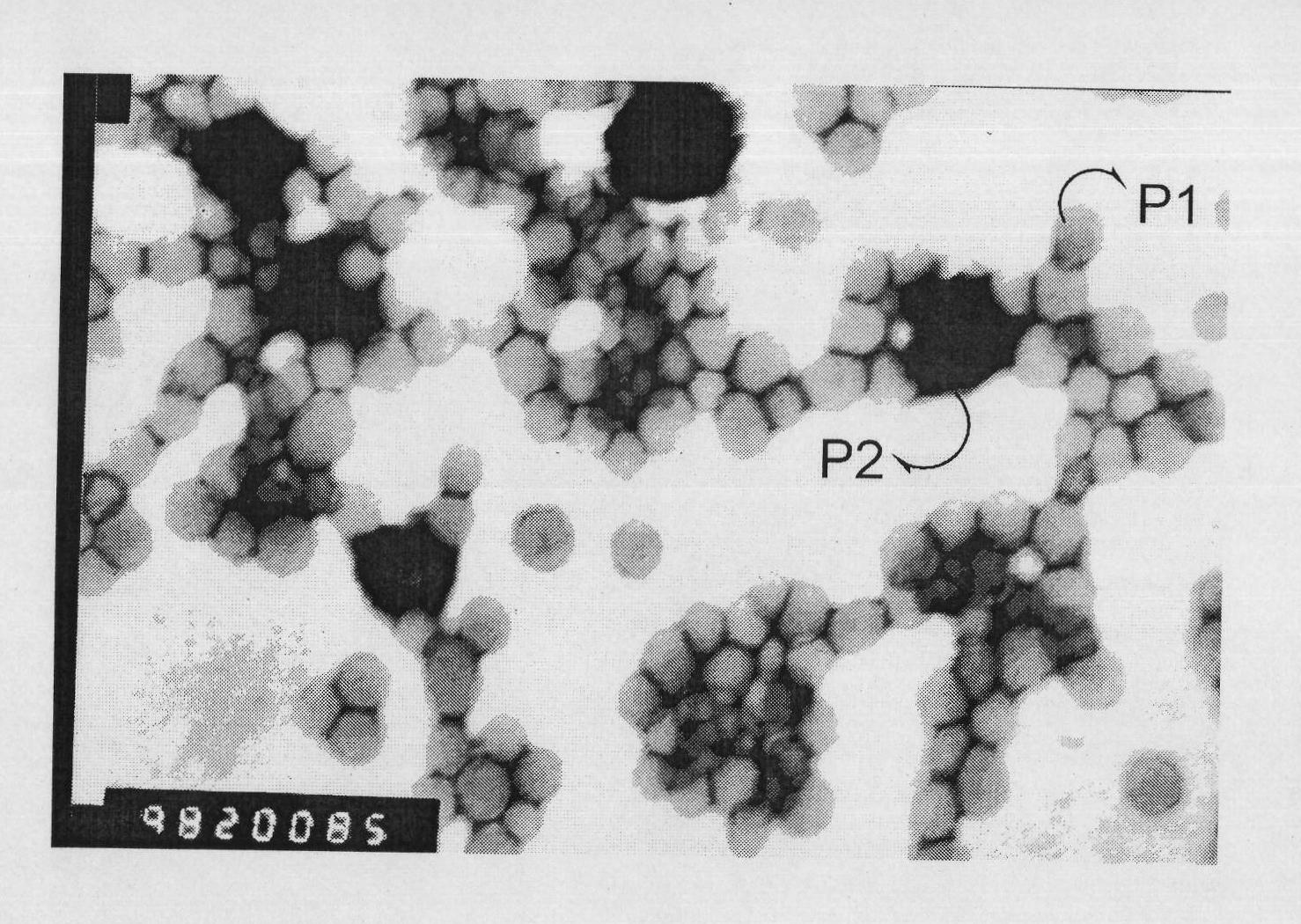

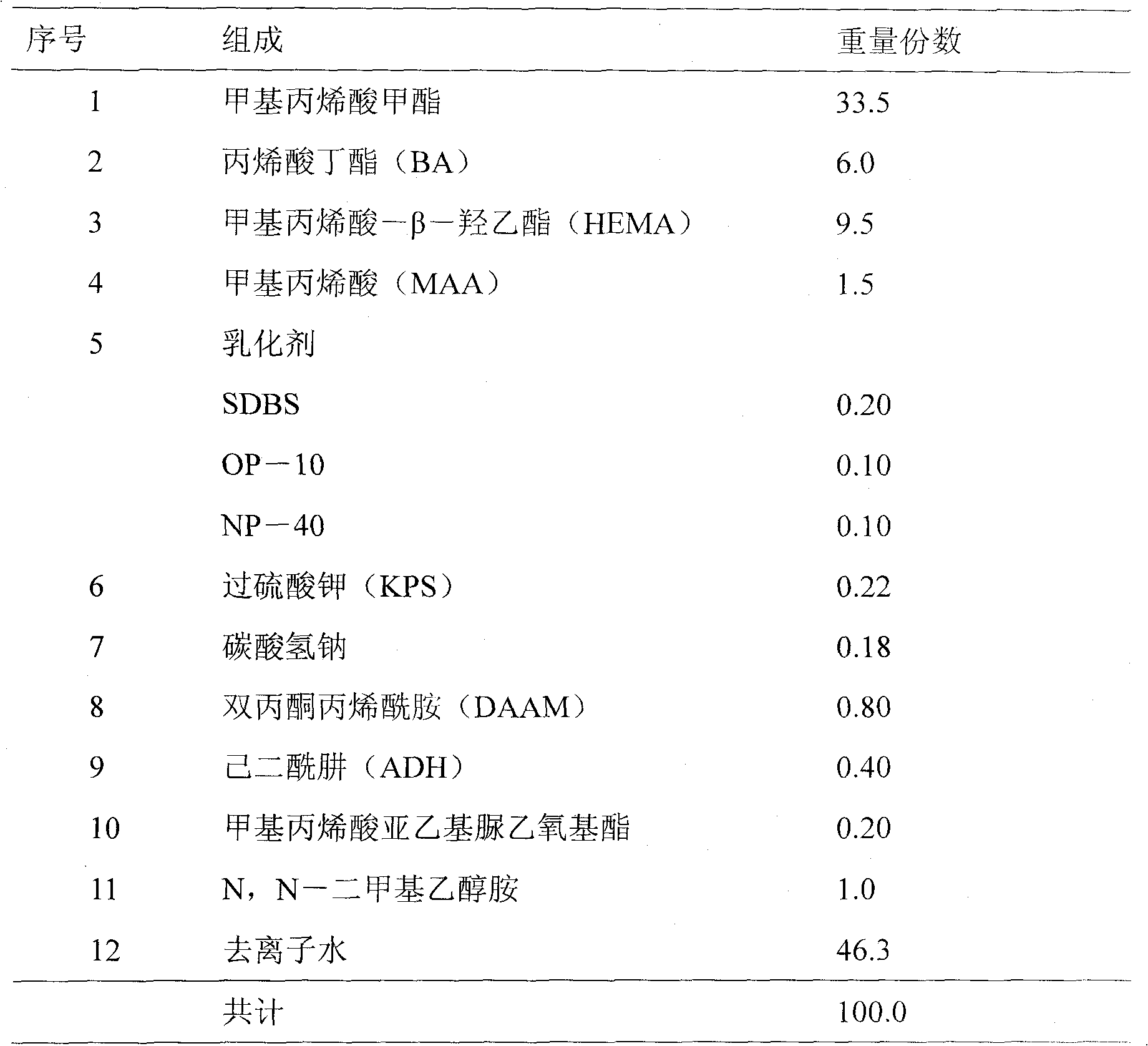

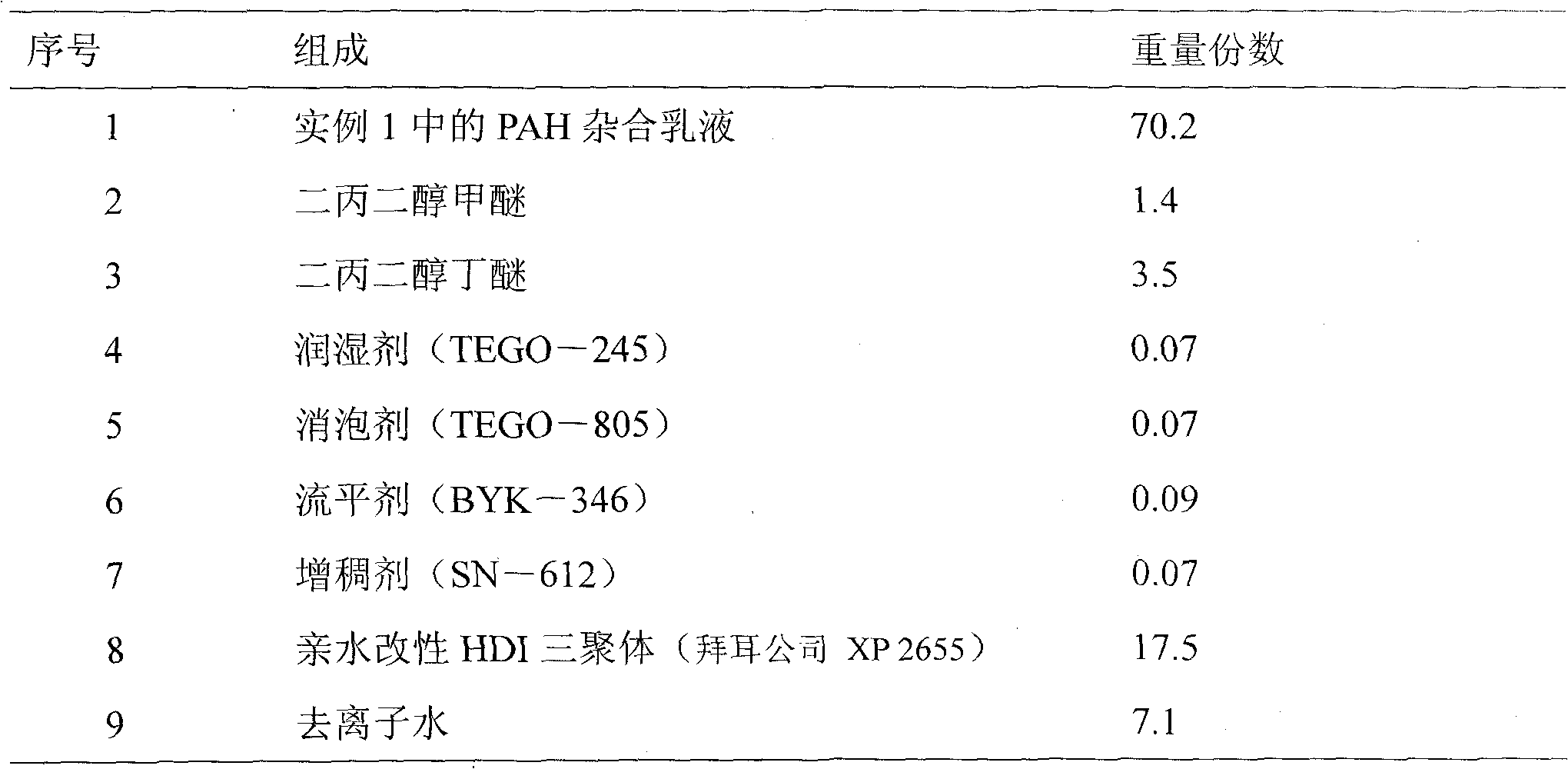

Preparation method and application of acrylate heterozygotic emulsion

ActiveCN101787098ASmall particle sizeWide particle size distributionPolyurea/polyurethane coatingsPolymer scienceLacquer

The invention discloses a preparation method and an application of an acrylate heterozygotic emulsion. In the invention, the acrylate heterozygotic emulsion is synthesized by adopting a seed emulsion polymerization process and combining a process of instantly neutralizing and segmentally adding polar monomers. The acrylate heterozygotic emulsion comprises macroparticles consisting of polymers P2 rich in hydroxyl groups on a surface layer and microparticles consisting of polymers P1 rich in carboxylate on the surface layer. Compared with a conventional hydroxy acrylate emulsion, the acrylate heterozygotic emulsion has smaller mean grain size and wider grain size distribution on emulsion particles. The acrylate heterozygotic emulsion can be adopted to prepare aqueous bi-component polyurethane wood coatings, and a coating layer of the coating has excellent property of resisting water and solvents, high crosslinking density and hardness, good mechanical property, scratching resistance and wear resistance. The acrylate heterozygotic emulsion has compact coating structure, high glossiness and better combination property, and not only can be applied to high-grade wood coatings, but also can be applied to automotive refinish paint, metallic anti-corrosion paint, other industrial protective paint, and the like.

Owner:SOUTH CHINA UNIV OF TECH

Ultraviolet light curing nano antibacterial woodenware paint and preparation method thereof

InactiveCN1927971AEase of industrial productionNo harmAntifouling/underwater paintsPaints with biocidesLacquerUltraviolet lights

The present invention discloses one kind of ultraviolet ray cured nanometer antibiotic woodenware lacquer and its preparation process. The ultraviolet ray cured nanometer antibiotic woodenware lacquer includes epoxy acrylate, polyurethane acrylate, diluent, nanometer inorganic antiseptic, nanometer inorganic stuffing and photoinitiator. The preparation process includes adding nanometer inorganic antiseptic and nanometer inorganic stuffing into the diluent, stirring to disperse homogeneously, adding epoxy acrylate, polyurethane acrylate and photoinitiator and mixing homogeneously. The woodenware lacquer with nanometer inorganic antiseptic can inhibit the growth and propagation of bacteria and microbes to produce long term antibiotic effect.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

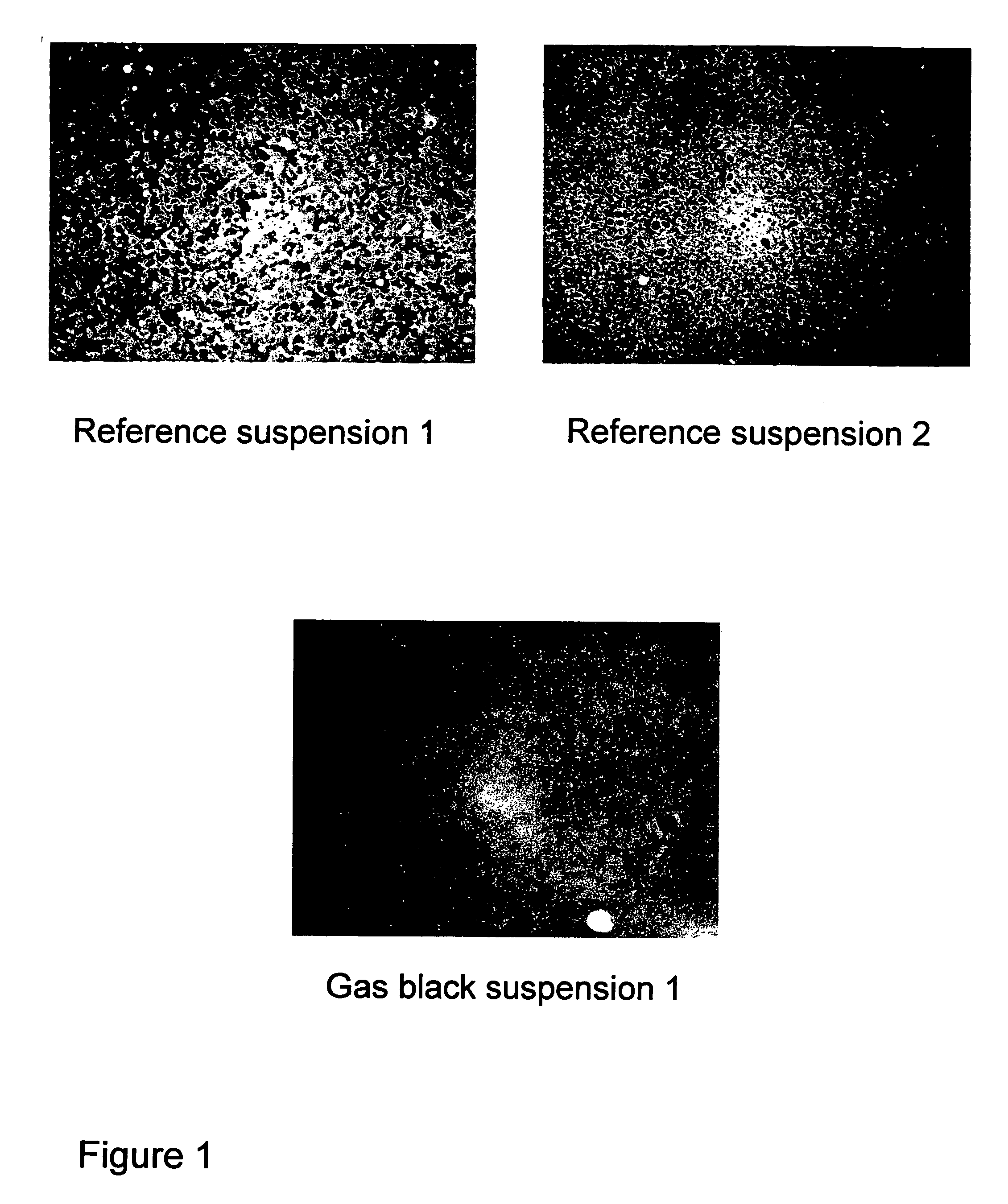

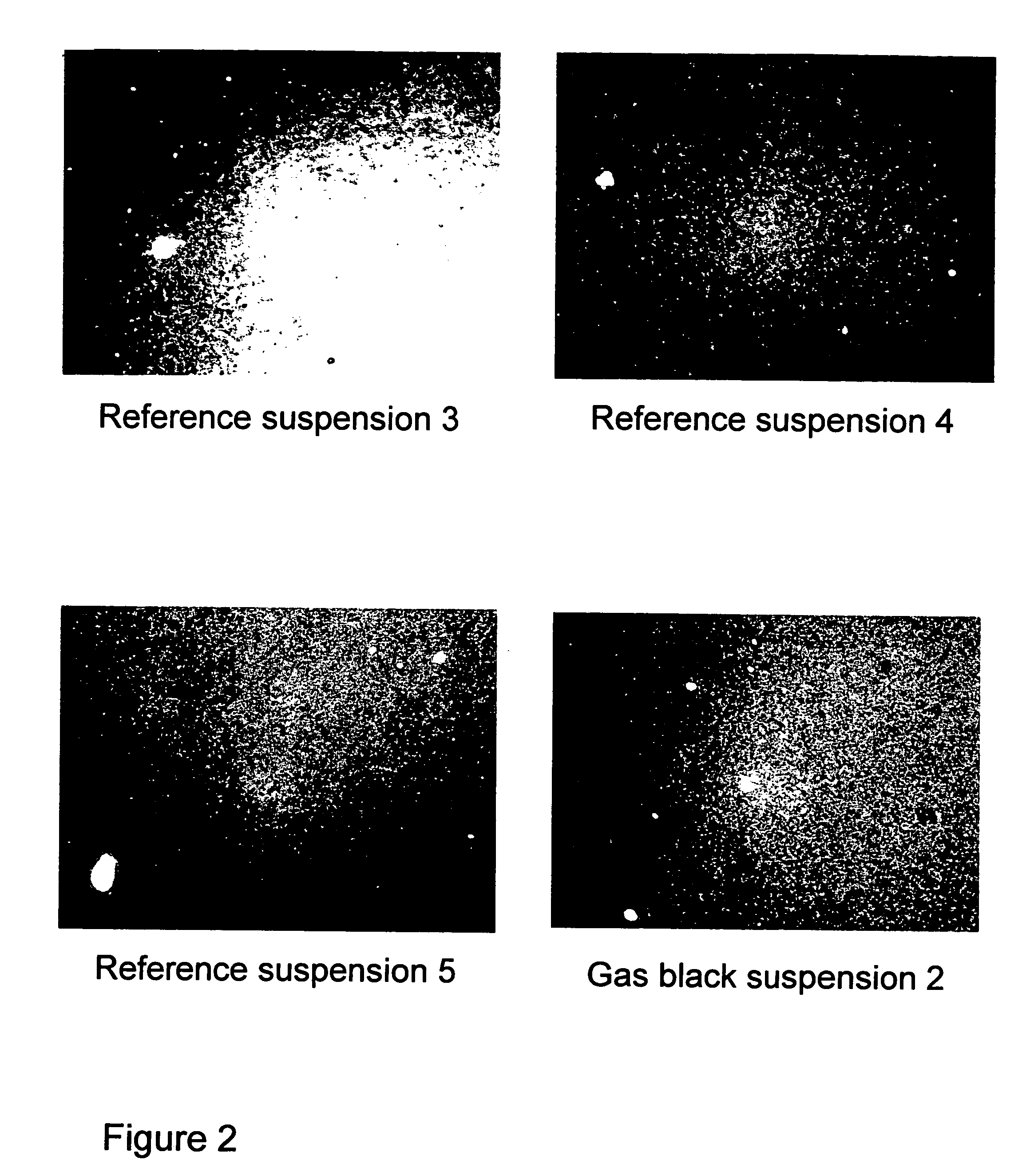

Aqueous, colloidal, freeze-resistant and storage-stable gas black suspension

InactiveUS20040087707A1Low viscosityImprove suspension stabilityDuplicating/marking methodsSpecial tyresZeta potentialLacquer

Aqueous, colloidal, freeze-resistant and storage-stable gas black suspension are disclosed containing 2-30 wt. % gas black, 0-40 wt. % carbon black, a dispersion-supporting additive, a biocide and water and having a zeta potential of less than -10 mV, a surface tension of greater than 50 mN / m and an average particle size of less than 200 nm. The aqueous, colloidal, freeze-resistant and storage-stable gas black suspension is produced by dispersing the gas black and the carbon black in water together with the dispersion-supporting additive and biocide. Inks, ink-jet inks, lacquers and printing inks can be made from these suspensions.

Owner:EVONIK DEGUSSA GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com