Patents

Literature

3898 results about "Putty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Putty is a material with high plasticity, similar in texture to clay or dough, typically used in domestic construction and repair as a sealant or filler.

Malleable putty and flowable paste with allograft bone having residual calcium for filling bone defects

The invention is directed toward a malleable bone putty and a flowable pastel composition for application to a bone defect site to promote new bone growth at the site which comprises a new bone growth inducing compound of partially demineralized lyophilized allograft bone material having a residual calcium content ranging from 4 to 8% dry weight. The bone powder has a particle size ranging from about 100 to about 800 microns and is mixed in a high molecular weight hydrogel carrier containing a sodium phosphate saline buffer, the hydrogel component of the carrier ranging from about 1.00 to 50% of the composition and having a molecular weight of about at least 700,000 Daltons. The composition has a pH between 6.8-7.4 contains about 25% to about 35% bone powder and can be additionally provided with BMP's.

Owner:MUSCULOSKELETAL TRANSPLANT FOUND INC

Carbon nanotube fiber-reinforced composite structures for EM and lightning strike protection

InactiveUS6986853B2Repaired quickly and efficientlySufficient protectionMaterial nanotechnologyShielding materialsLightning strikeFiber-reinforced composite

A method for repairing fiber-reinforced composite structures while maintaining original EM and lightning protection using carbon nanotubes, fibers, and thermoset resins is disclosed. According to one embodiment of the invention, the method comprises preparing a damaged area for repair; preparing a repair patch for the damaged area, the repair patch comprising nanotubes; applying the repair patch to the damaged area; and curing the repair patch. A repair patch for a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the repair patch includes a binder and nanotubes. A repair resin for repairing a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the repair layer includes a resin and nanotubes. A putty for repairing a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the putty includes a base and electrically conductive carbon nanotubes.

Owner:EIKOS

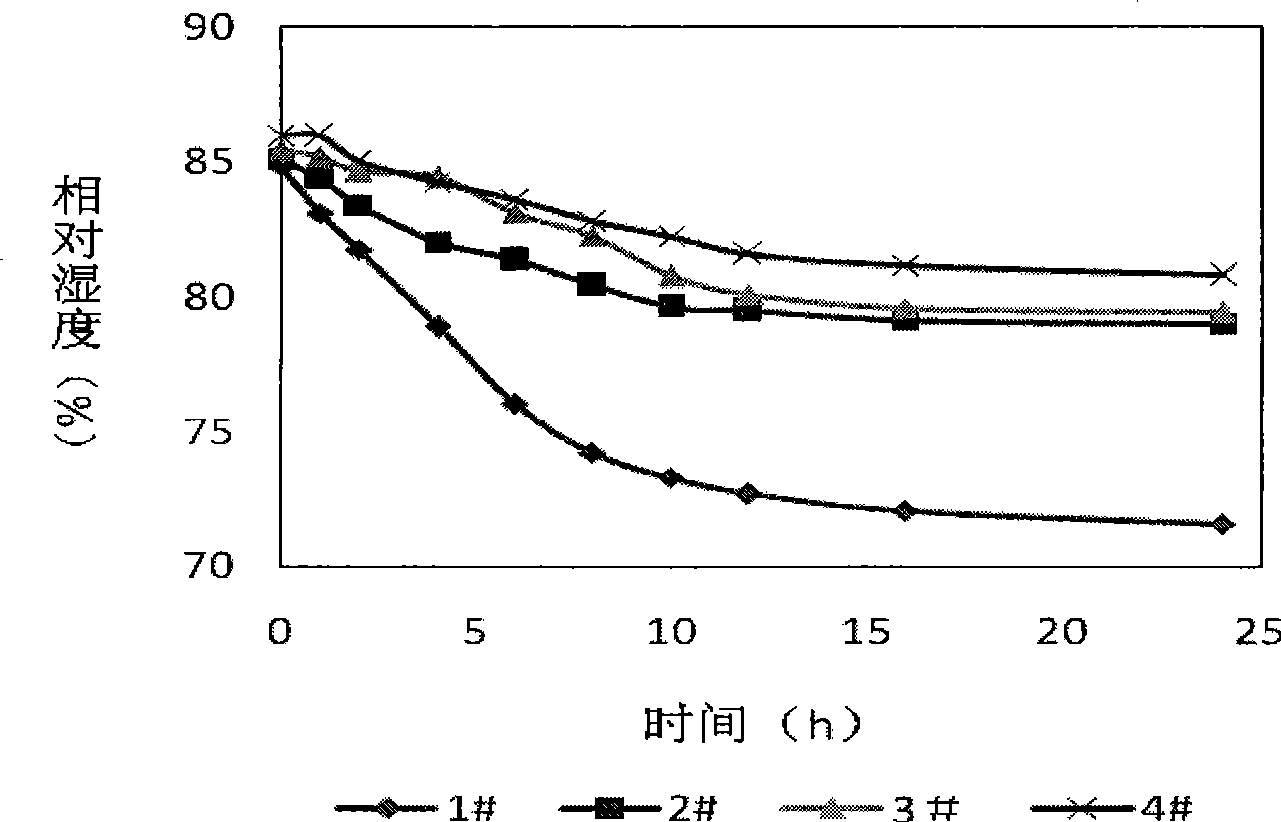

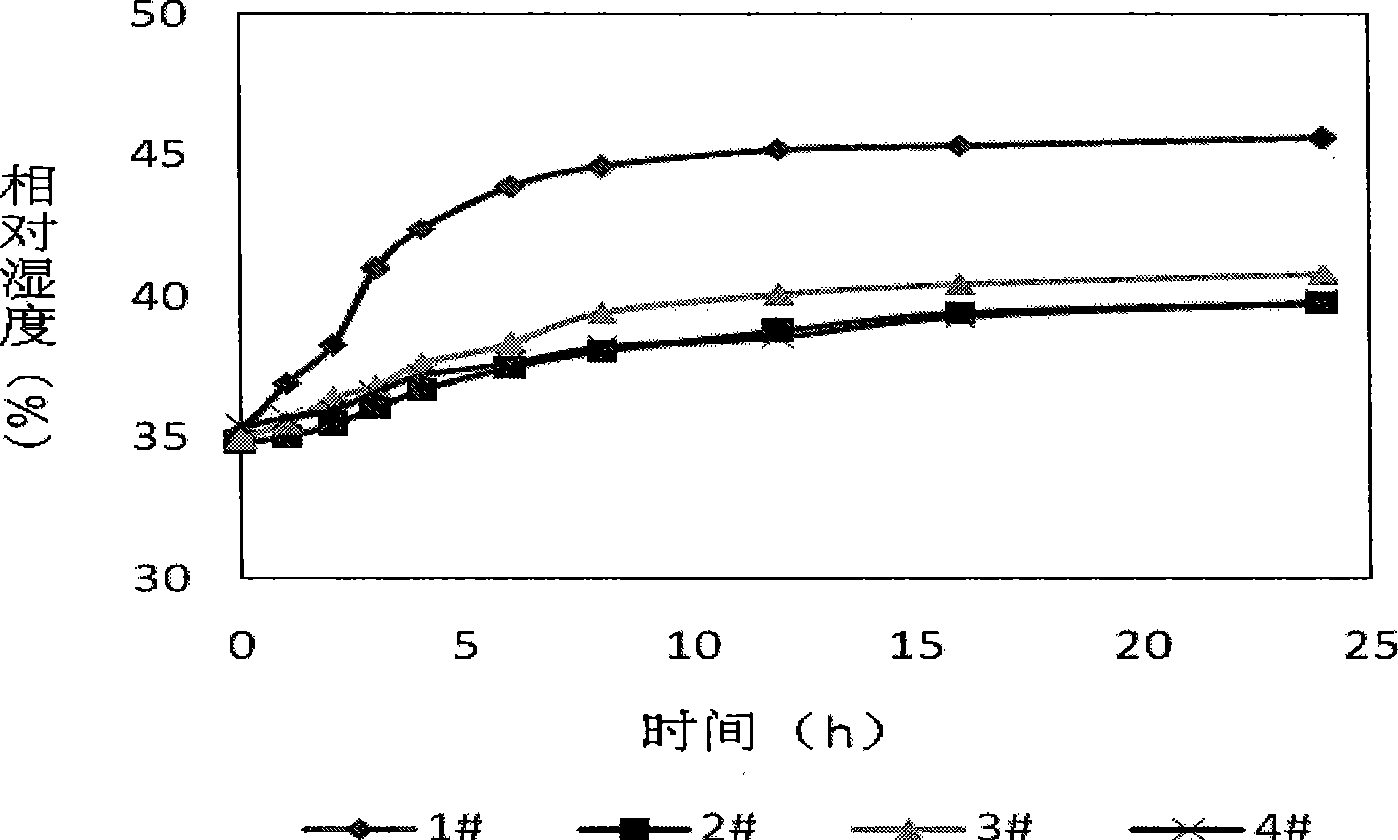

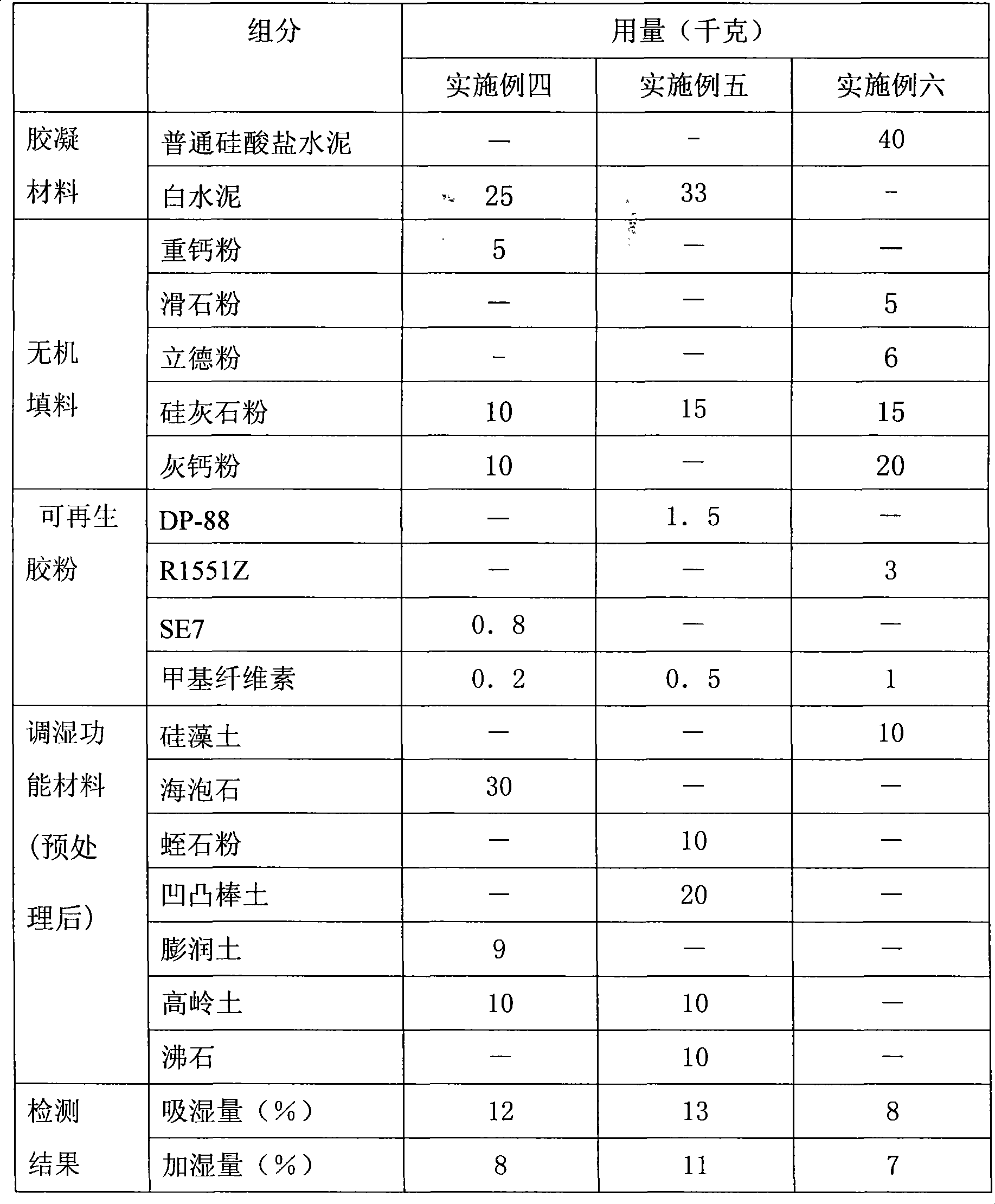

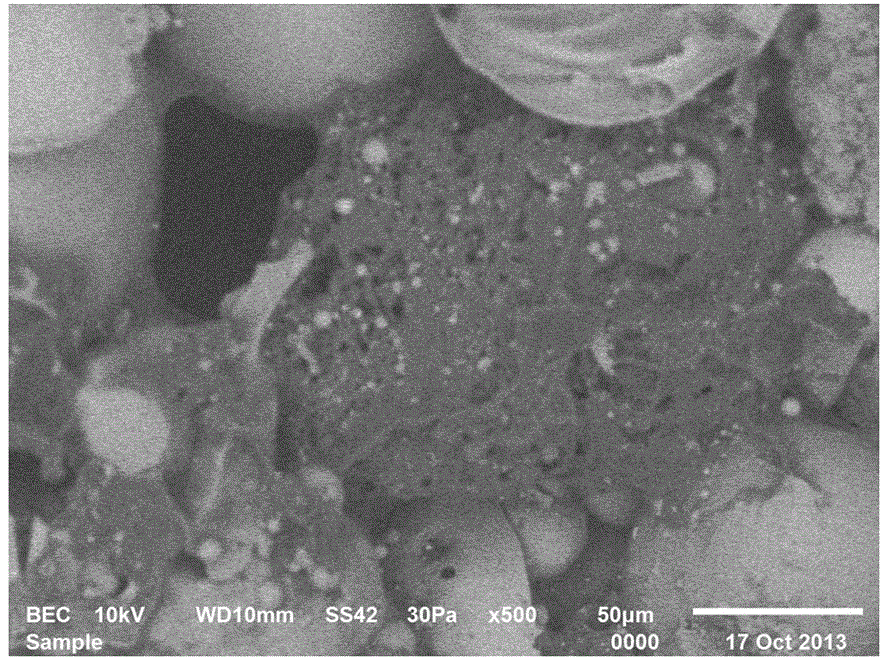

Inorganic putty powder with function of governing humidness

ActiveCN101368014AEffective regulation of relative humidityGood environmental protectionFilling pastesCement coatingsSodium BentoniteMetallurgy

The invention relates to interior wall putty powder with air humidity regulating function, which belongs to the field of building materials. The putty powder is composed of 10 to 50 weight portions of humidity regulating material, 15 to 50 weight portions of inorganic binding material, 15 to 50 weight portions of inorganic filler, and 1 to 5 weight portions of sub divisible rubber powder; the humidity regulating material comprises one type or more than one type of diatomite, sepiolite, attapulgite, vermiculite, zeolite powder, kaolin and bentonite. Because of the environment protection and humidity regulating functions, the multi-pore inorganic mineral material is taken as humidity regulating material and applied in the building interior wall putty powder. With water added in, the putty powder is mixed into lacquer putty and applied on the wall surface, which can effectively regulate the indoor air humidity, so that the indoor air humidity is controlled within the scope which is beneficial to the health of human body; meanwhile, the putty powder has no pollution, no VOC released and can be directly used for decoration.

Owner:CHINA BUILDING MATERIALS ACAD

Carbon nanotube fiber-reinforced composite structures for EM and lightning strike protection

InactiveUS20020180077A1Material nanotechnologyShielding materialsLightning strikeFiber-reinforced composite

A method for repairing fiber-reinforced composite structures while maintaining original EM and lightning protection using carbon nanotubes, fibers, and thermoset resins is disclosed. According to one embodiment of the invention, the method comprises preparing a damaged area for repair; preparing a repair patch for the damaged area, the repair patch comprising nanotubes; applying the repair patch to the damaged area; and curing the repair patch. A repair patch for a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the repair patch includes a binder and nanotubes. A repair resin for repairing a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the repair layer includes a resin and nanotubes. A putty for repairing a composite structure having a conductive layer is disclosed. According to one embodiment of the present invention, the putty includes a base and electrically conductive carbon nanotubes.

Owner:EIKOS

Compositions for repair of defects in tissues, and methods of making the same

ActiveUS20110045044A1Good bone conductionEasy to prepareBiocidePretreated surfacesRepair tissueTissue repair

Tissue repair compositions, particularly bone repair compositions, containing (a) bone fragments and (b) homogenized connective tissue, and methods for making the same are provided. Some of the inventive tissue repair compositions contain a radioprotectant. The compositions can be used in the form of an injectable gel, an injectable paste, a paste, a putty, or a rehydratable freeze-dried form. Kits for using such tissue repair compositions are also provided.

Owner:LIFENET HEALTH

Construction method of anti-plastering putty for concrete structure wall

InactiveCN101363269AThin thickness and small weightLight weightCovering/liningsResource consumptionPutty

The invention discloses a construction method of a wall putty of a plaster-free concrete structure. The construction method comprises the following steps: construction preparation, base course treatment, concave-convex line construction, a first full application of wall putty, flattening, a second full application of wall putty and flattening. The construction method has the advantages of less workload, short construction time, little resource consumption, no hollow drum and crack of the floated coat, no crack at the joint of the primary structure and the secondary structure.

Owner:中建五局第三建设有限公司 +1

Green powdered paint and its prepn

The present invention discloses one kind of green powdered paint and its preparation process. The green powdered paint consists of re-dispersible polymer latex powder 5-20 wt%, white cement 20-40 wt%, calcium carbonate 20-45 wt%, titanium white powder 5-25 wt%, diatomite 2-8 wt%, bentonite 1-2 wt%, cellulose ether 0.2-0.5 wt%, defoaming agent 0.2-0.5 wt% and coloring pigment 0-4 wt%. It is prepared through mixing all the components in a stirrer, and packing. It is used after mixing with water in construction site. It has the combined decoration functions of both putty and emulsion paint and may be used widely for decorating inner and outer wall.

Owner:SOUTH CHINA UNIV OF TECH

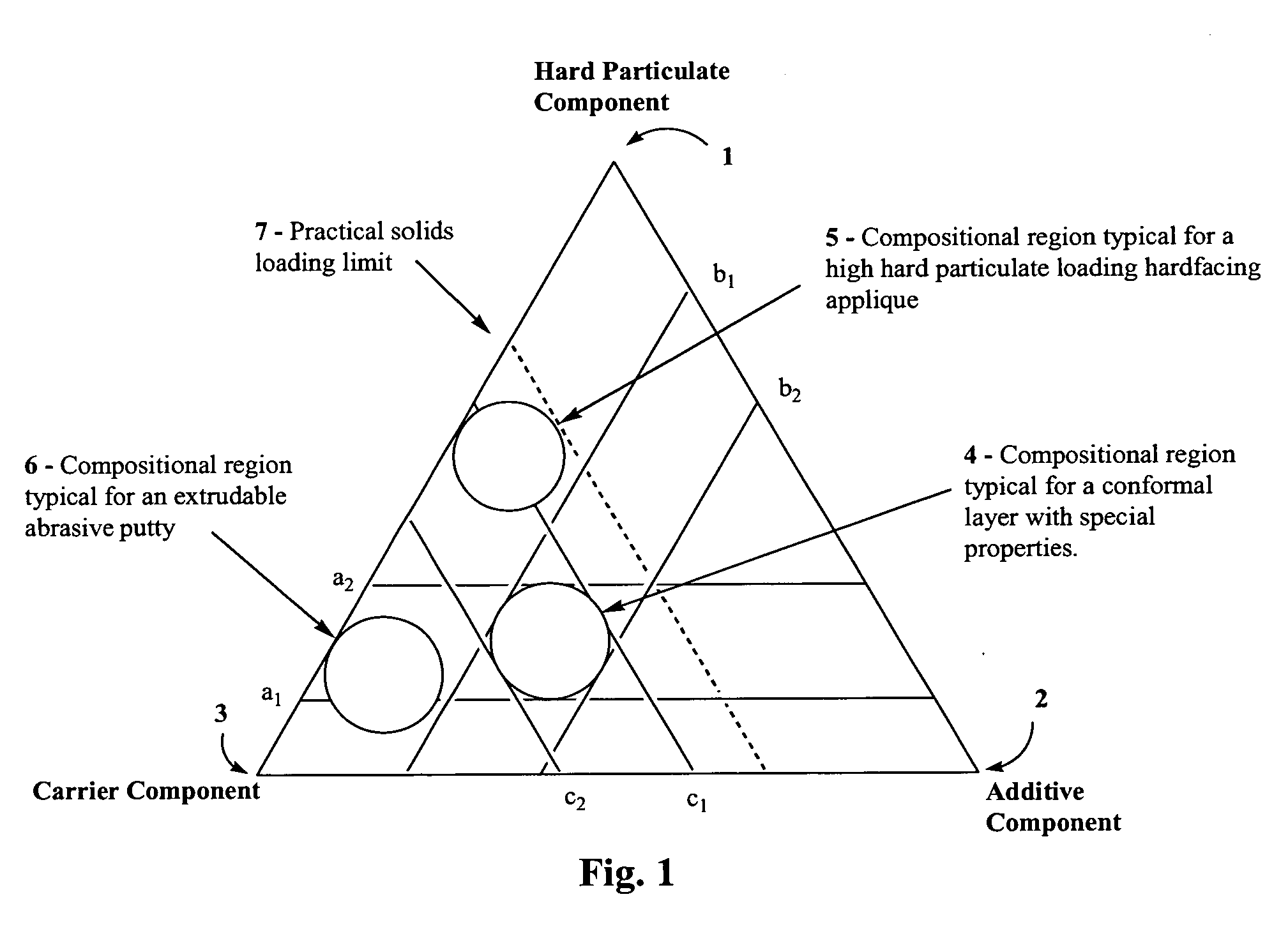

Composite materials and method for making same

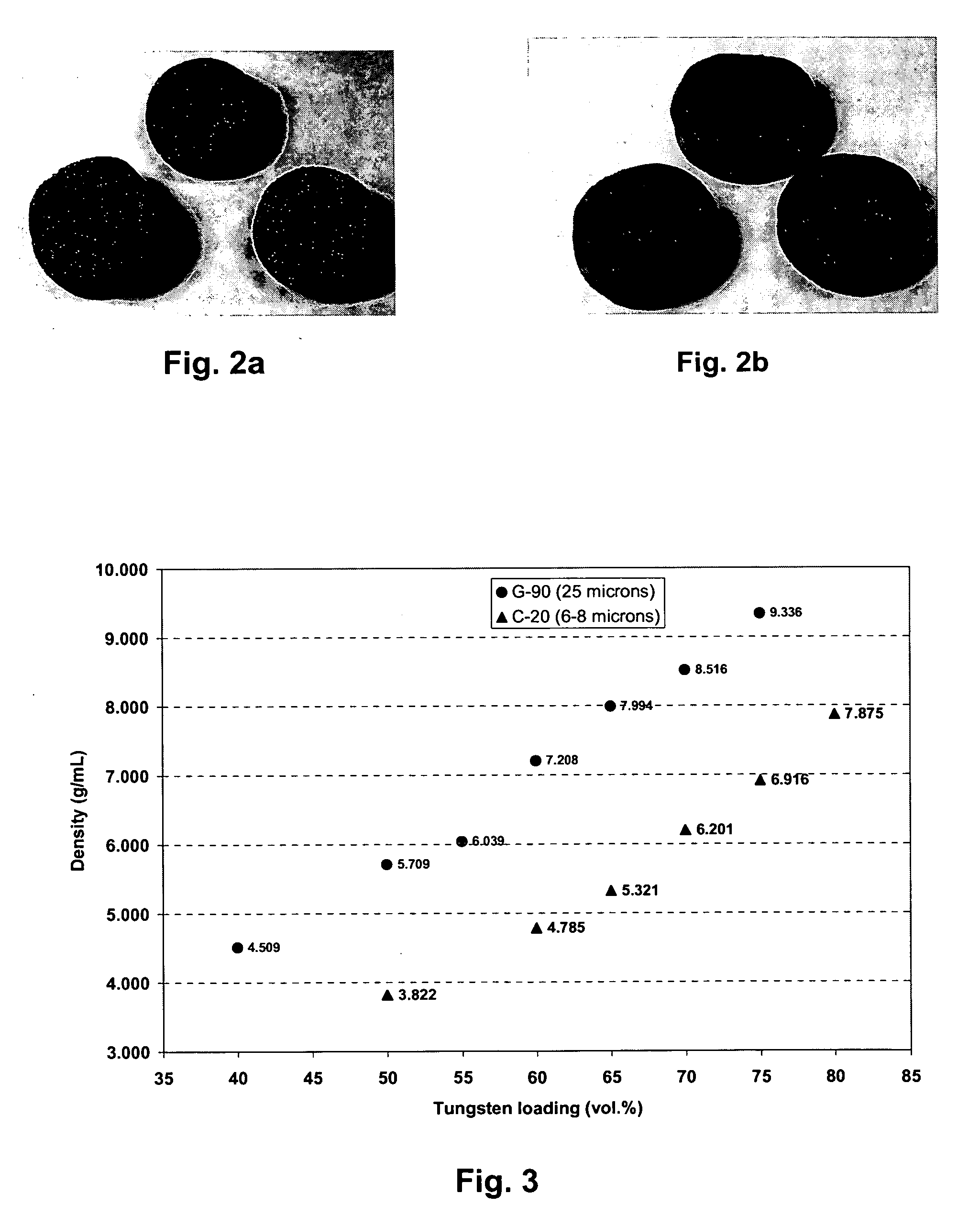

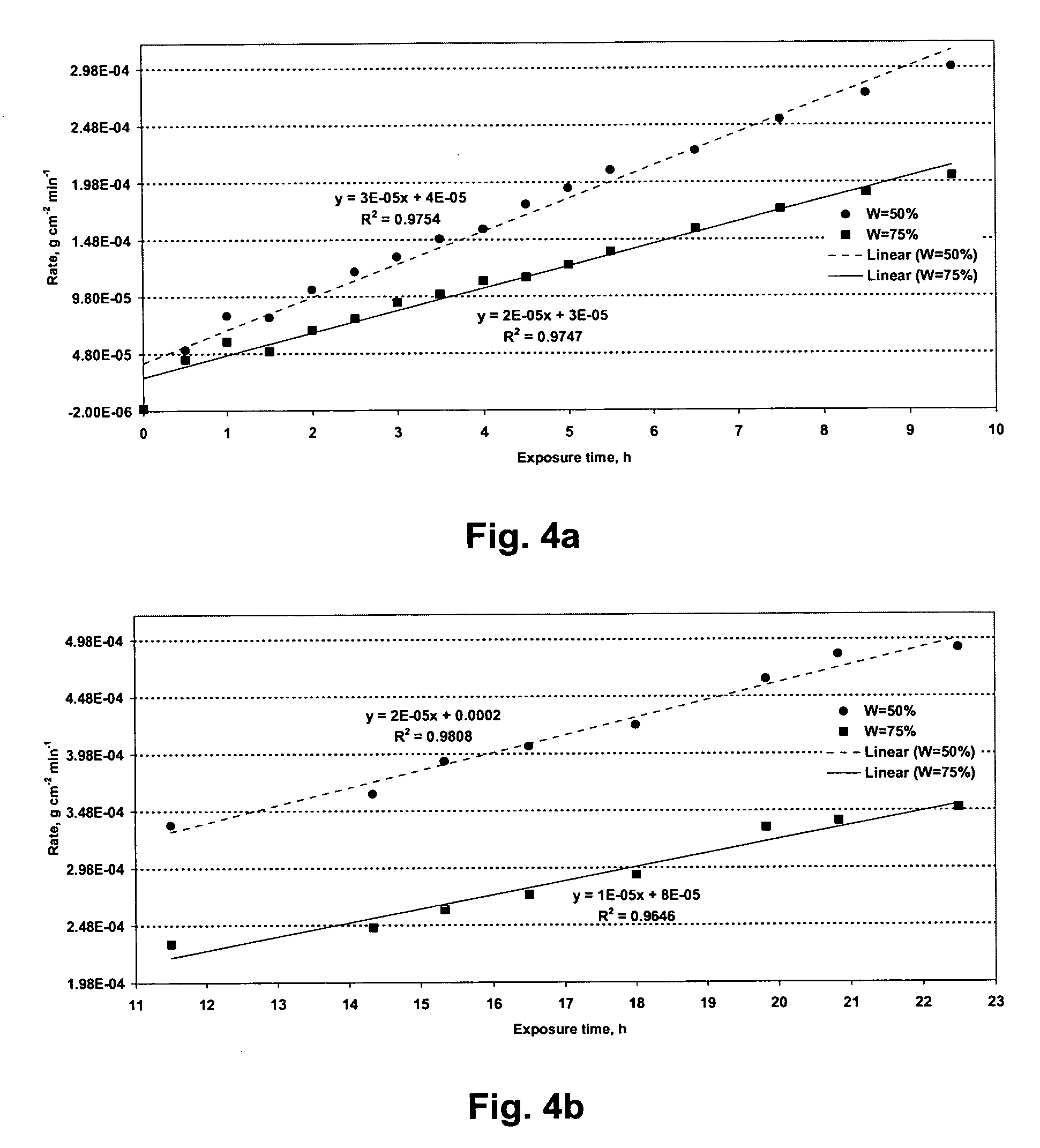

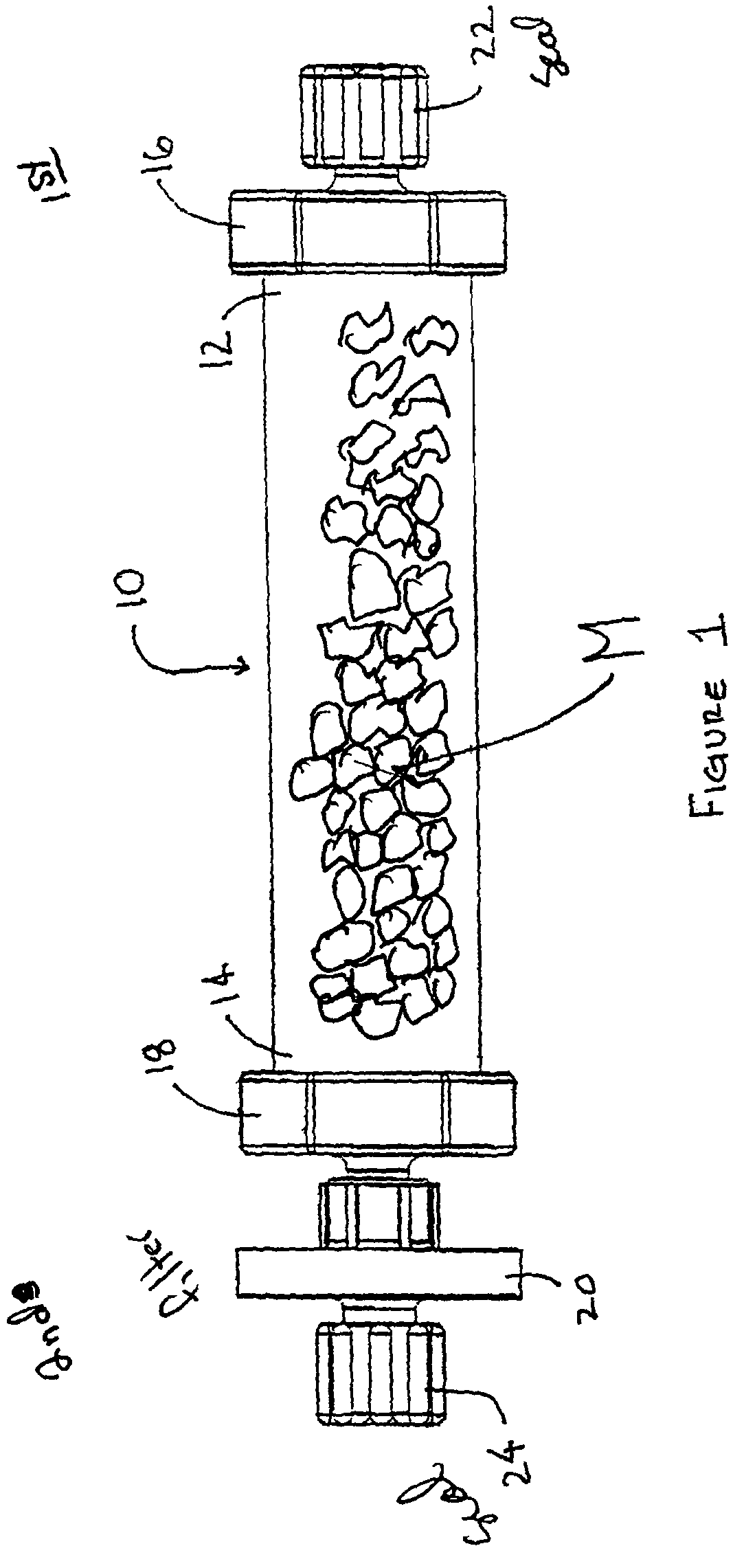

Certain non-limiting embodiments of the present disclosure comprise a family of composite materials targeting specific applications through a materials design approach involving; 1) a hard particulate; 2) a carrier or binder phase; and 3) one or more additives for property enhancement and / or hardness adjustment. According to certain embodiments, the composite material may be one of flexible conformal sheet; a rigid machinable molded preform; and an extrudable putty. Methods of manufacture of the composite materials are also disclosed.

Owner:ATI PROPERTIES

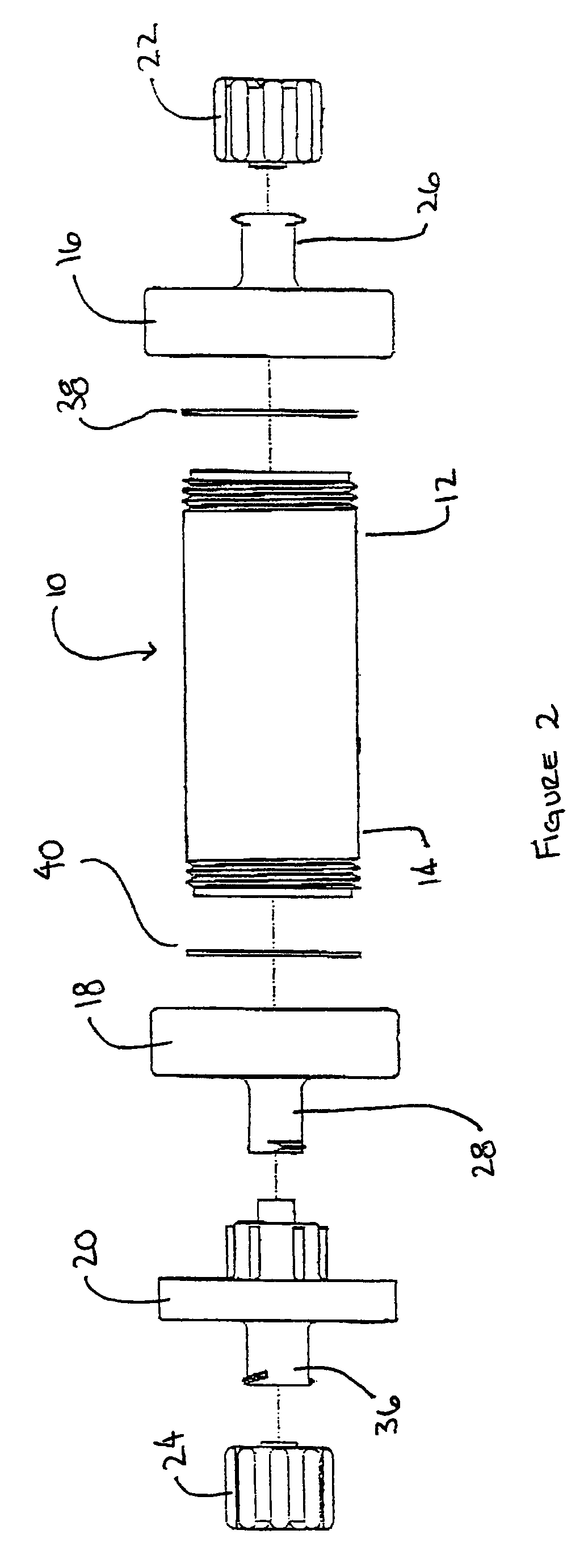

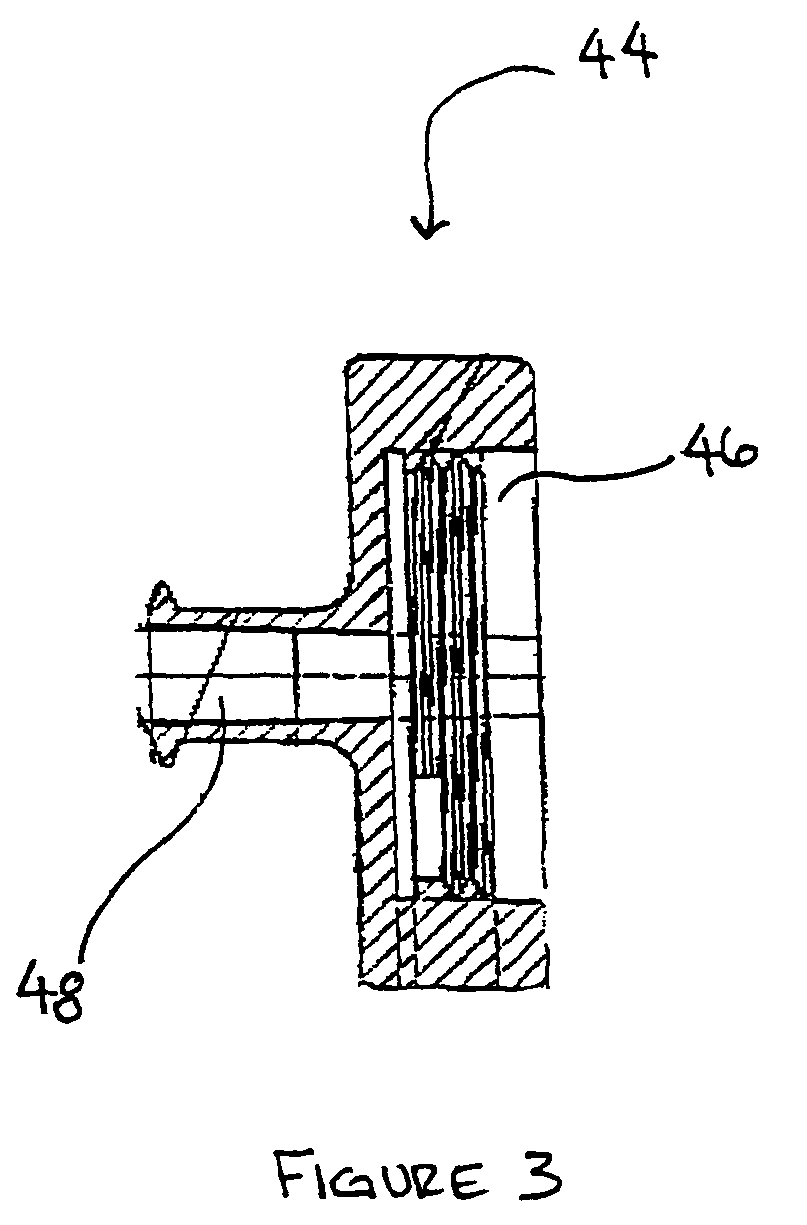

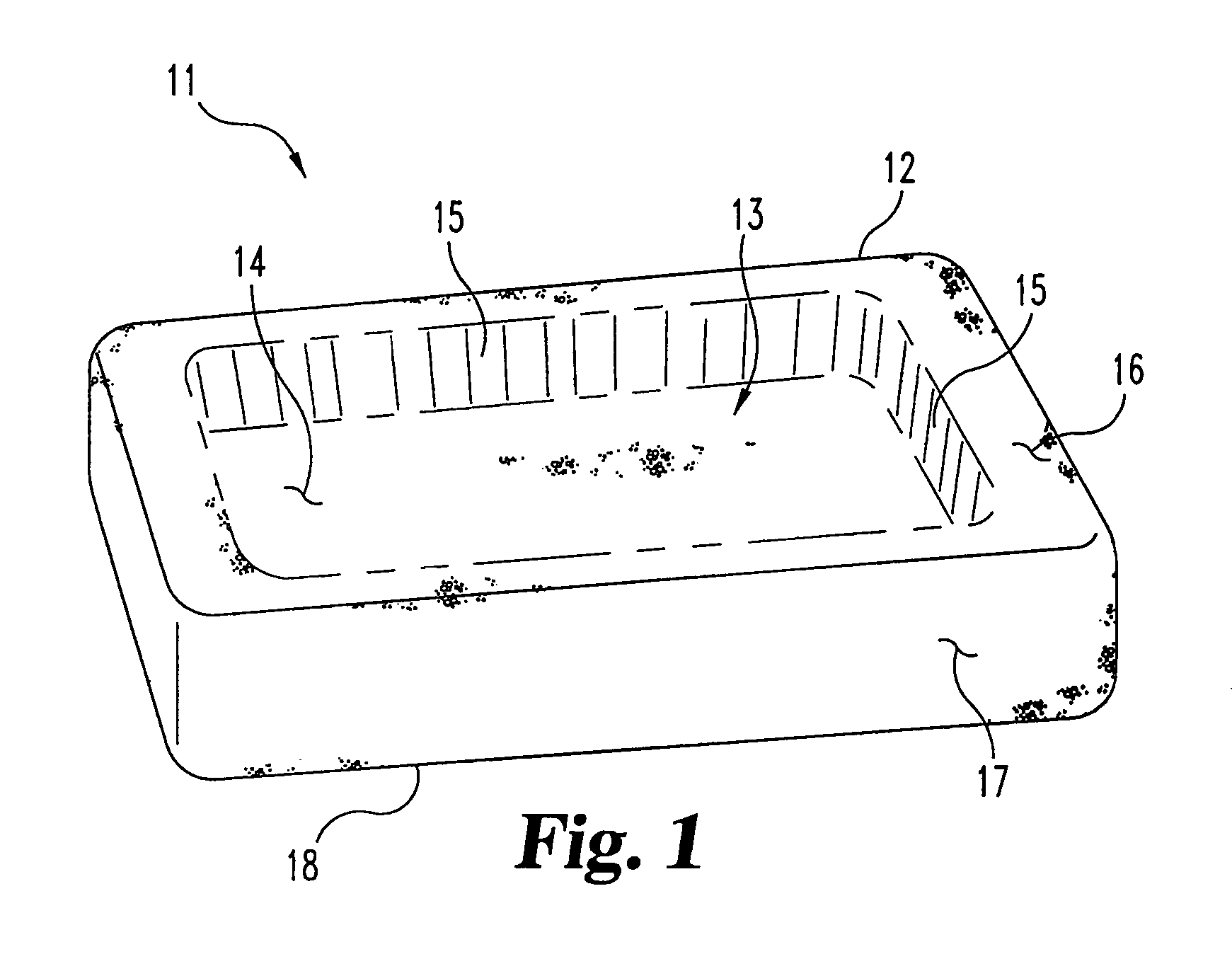

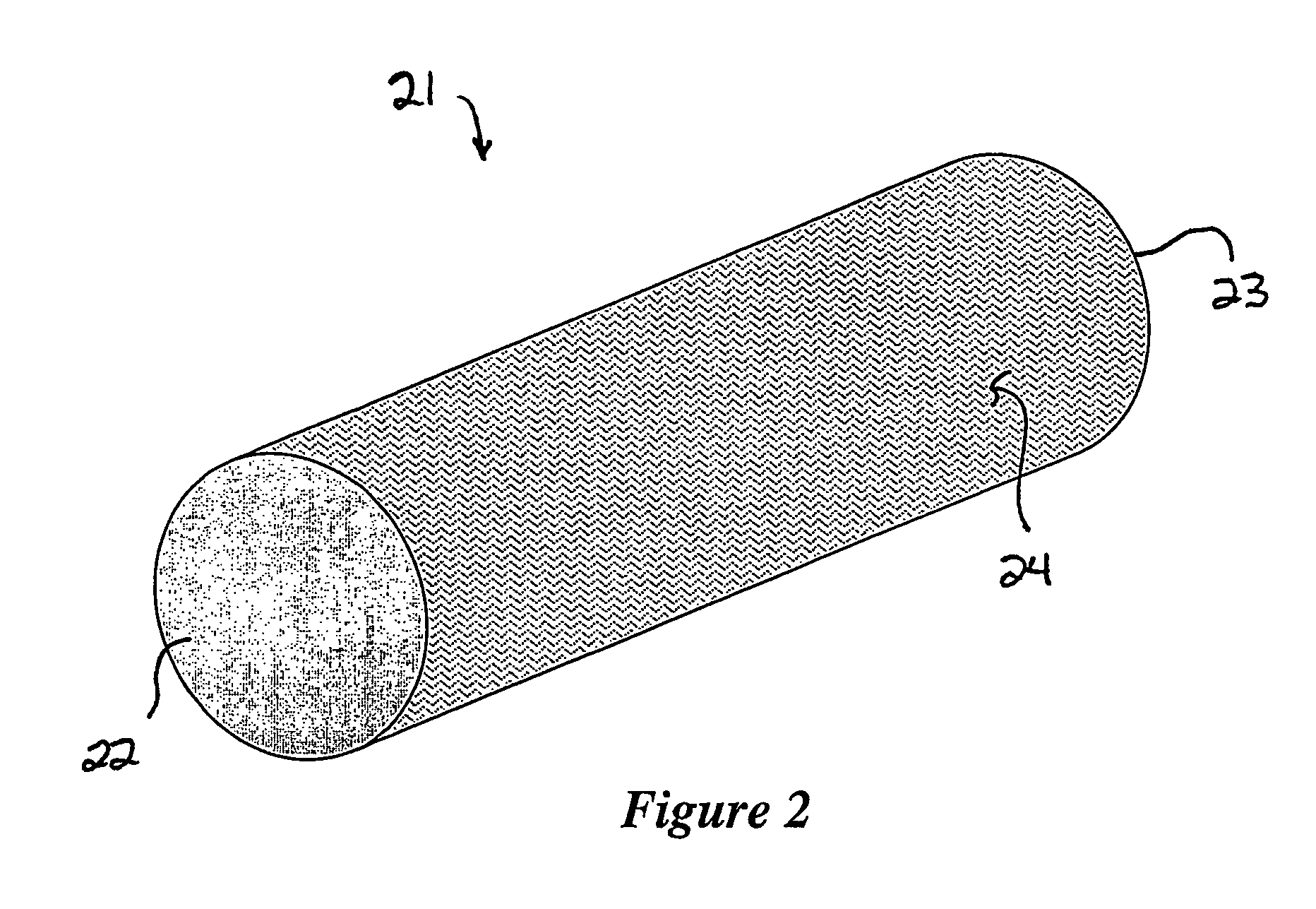

Bone marrow infusion chamber and method

A method and apparatus for preparing a bone graft composite using an infusion chamber. A modular tube having a porous material contained therein and having removable end caps is provided. Bone marrow aspirate or other bone morphogenic protein containing suspensions may be infused into the tube. A filter on one end of the tube prevents the fluid from escaping while permitting air to be expelled from the tube as it is filled with bone marrow aspirate. Once infused into the tube, the bone marrow aspirate is allowed to settle to a putty or paste-like consistency, the putty and material together forming a bone graft composite.

Owner:WRIGHT MEDICAL TECH

Environmental-protection type gypsum-based putty powder for building

InactiveCN1454945AHigh bonding strengthImprove construction efficiencyFilling pastesWater solubleWater holding

The present invention relates to an environment-protecting gypsum base building putty powder, which uses building gupsum as main setting hardening component, and utilizes the composite retarding agent to resolve the problems of that the building gupsum can be quickly set and hardened and single retarding agent can be resulted into large strength loss. Said invention adopts inorganic mineral powder and cellulose ether composition to reduce material cost and improve water-holding property of putty, and adopts water-soluble adhesive powder to raise cohesional strength of building putty, and said environment-protecting type gypsum base building putty powder is a single component solid powder, has no harmful substance, and has good construction property, and said putty surface is fine and smooth.

Owner:CHONGQING UNIV

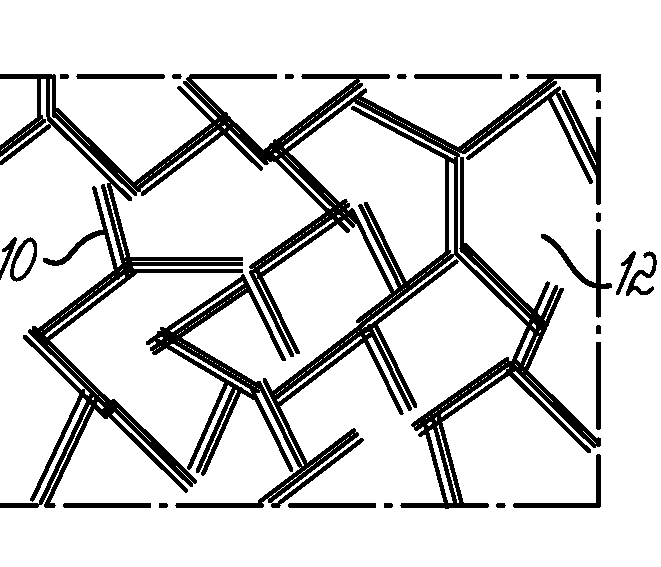

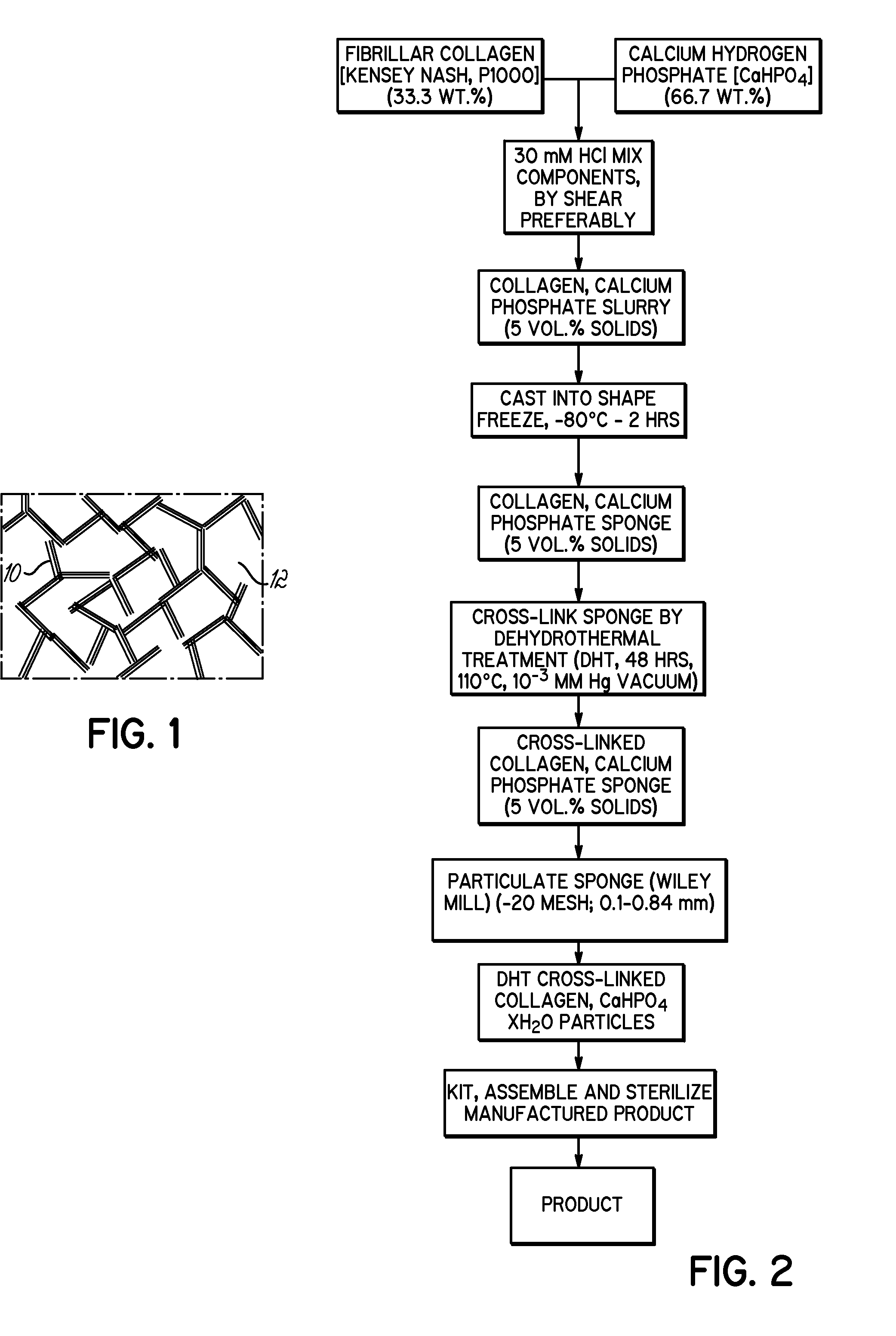

Bone growth particles and osteoinductive composition thereof

InactiveUS20080152687A1Reduce deliveryEnhance in vivo formationPowder deliveryCosmetic preparationsCalcium biphosphateFiber

A biocompatible synthetic bone growth composition comprising a fibrillar collagen component and a calcium phosphate component. The composition is formed into particles, and then formed into a unitary article that may be provided at the site of a skeletal defect. An osteoinductive component may be further added, either before or after forming the unitary article. The composition may be formulated as a paste or putty and facilitates bone growth and / or repair.

Owner:ZIMMER ORTHOBIOLOGICS

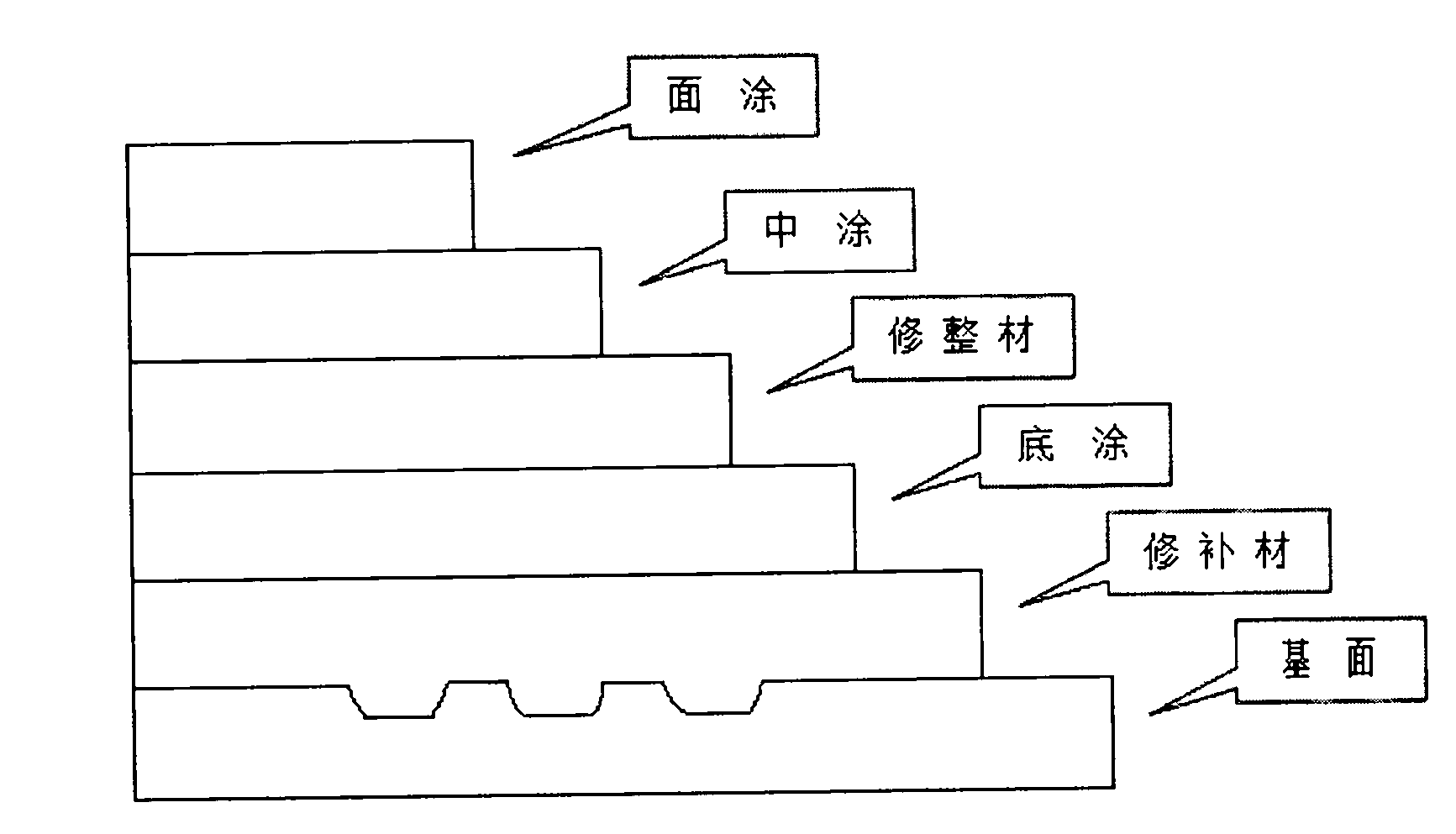

Durability traceless repair method for road and bridge concrete, color difference trimming putty and trimming material

InactiveCN101876162AImprove performanceGood synergyIn situ pavingsFilling pastesAdditive ingredientRepair material

The invention relates to a durability traceless repair method for road and bridge concrete. The method comprises the following steps of: (1) repairing a base surface of the concrete with a surface defect by using a repairing material so as to trim and flatten the base surface, wherein the repairing material comprises polymer fine sand mortar and color difference trimming putty; (2) performing prime coat on the repairing material; (3) preparing a trimming material, wherein the structure and color of the trimming material are similar to those of the concrete, and the trimming material has a high adhesive property; (4) performing floating coat by adopting an organic silicon resin coating; and (5) performing top coat by adopting a coating prepared from a silicon resin accessory ingredient. The formulas of the color difference trimming putty and the trimming material are introduced. The method has the advantages of effectively repairing the surface defect of the concrete structure tracklessly, restoring the strength of the concrete structure and improving waterproof property and durability of the concrete structure.

Owner:上海惠邦特种涂料有限公司

Internal wall putty and production process thereof

The invention belongs to the technical field of building materials, and particularly relates to an internal wall putty which comprises the following components in parts by weight: 150-300 parts of white cement, 500-900 parts of calcium carbonate powder, 10-50 parts of grey desert soil, 1-8 parts of cellulose ether, 7-30 parts of polymer latex powder, 1-10 parts of water repellent, 0.05-3 parts of starch ether and 0.5-7 parts of wood fiber. Compared with the prior art, the internal wall putty has the advantages that 107 glue water or 801 glue water is not used, thus formaldehyde is not contained, the environment is protected; and pregelatinized starch is not used, and the water repellent is added, thus the internal wall putty has the function of preventing water and moisture. In addition, with the white cement and the calcium carbonate powder as the strength basis and the grey desert soil as an auxiliary strength material, the strength of the internal wall putty is ensured; due to the synergistic effect of the cellulose ether and the starch ether, the water-retaining property and the application property of the internal wall putty are ensured; and because the polymer latex powder is added, the flexibility of the internal wall putty and the adhesion of the polymer latex powder and the wall are improved.

Owner:黄明杰

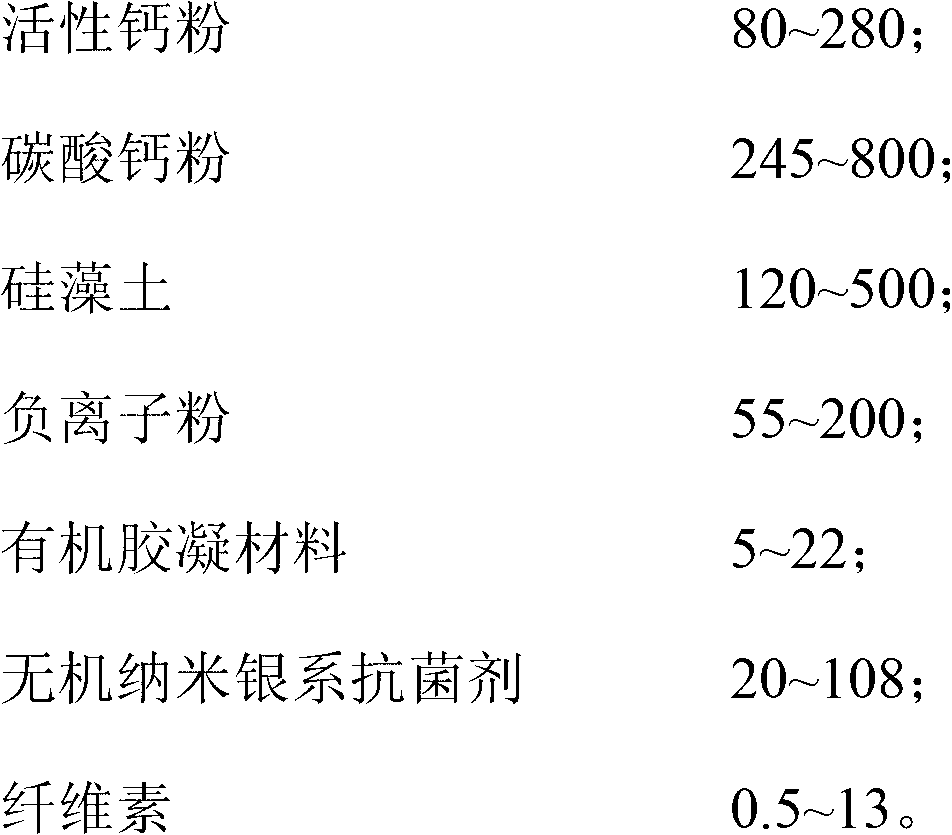

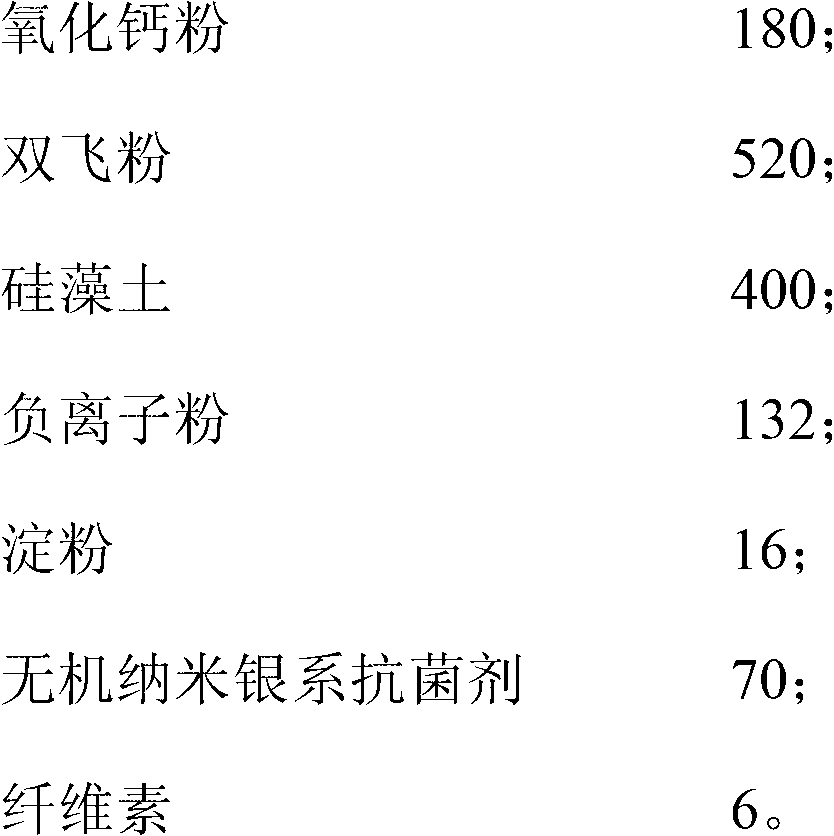

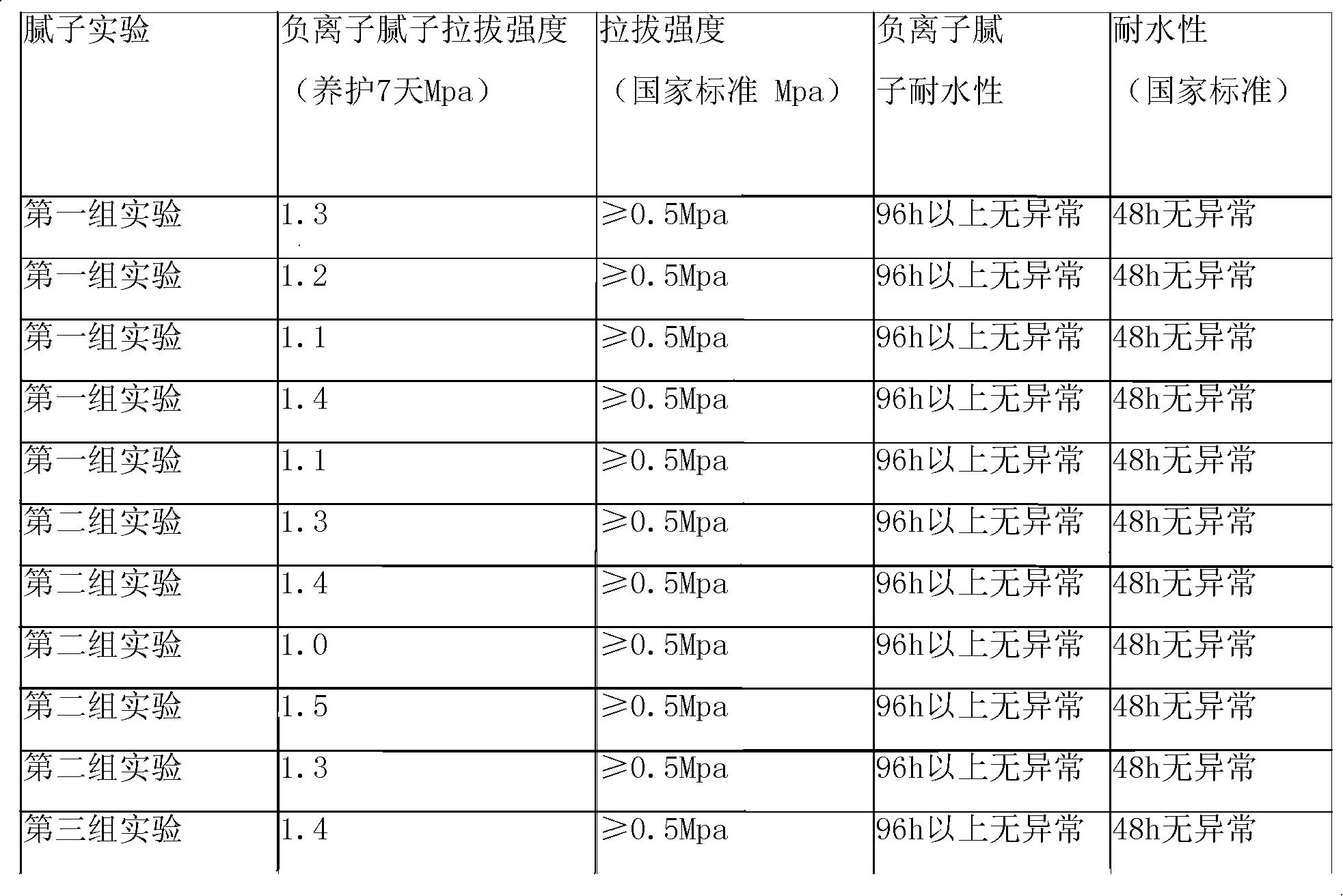

Antibacterial negative ion putty powder

The invention relates to antibacterial negative ion putty powder. The putty powder mainly comprises the following components: active calcium powder, calcium carbonate powder, kieselguhr, negative ion powder, an organic binding material, an inorganic nano-silver germicide and cellulose. The negative ion powder, provided by the invention, comprises the following components: tourmaline powder, cerium oxide, yttrium oxide, neodymium oxide and titanium dioxide. The antibacterial negative ion putty powder, provided by the invention, has an effect of purifying the air, and is mainly manifested in absorbing and neutralizing the positive ions in the air, eliminating toxic and harmful gas such as formaldehyde, ammonium, benzene and the like, which is released in indoor decoration and decoration materials, inhibiting growth of bacterium and mildew, and enhancing antibacterial performance of the putty powder.

Owner:TIANCHANG JULONG TRAVEL PAINT

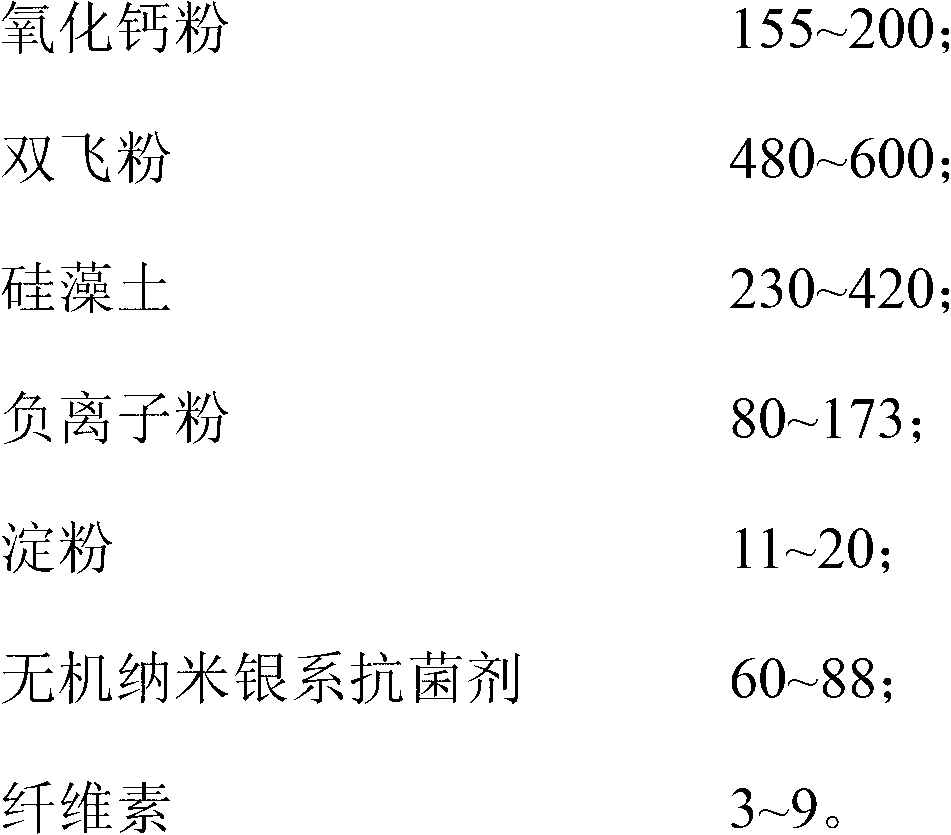

Architectural interior anion waterproof putty powder and preparation method thereof

InactiveCN101225261AHigh removal rateImprove water resistanceFilling pastesLight energyWater resistant

The invention relates to a building interior anionic water resistant putty powder. The weight ratios of the components are 100 to 300 portions active calcium powder, 200 to 700 portions calcium carbonate powder, 50 to 200 portions anion powder, 1 to 10 portions cementing material and 1 to 5 portions cellulose; wherein, the anion powder is the mixed powder of ultrafine tourmaline powder and physical adsorption materials, the fineness of the ultrafine tourmaline powder is more than 2.6 Mum and the purity of the ultrafine tourmaline powder is more than 95 percent, the physical adsorption material is diatomite or modified active carbon and the weight of the physical adsorption material is 20 to 35 percent the total weight of the anion powder. The building interior anionic water resistant putty powder has the advantages that: the preparation method does not need the excitation of light energy sources and has not the danger of over standard radioactivity, so the removal ratios of formaldehyde and toluene is increased greatly, the putty powder plays the role of eliminating pollution and purifying air, meanwhile, the water resistant performance of the putty powder are enhanced.

Owner:莱恩斯建材(北京)有限公司

Fluoropolymer organic lining anticorrosive material for chimney, flue and other pipelines and containers and construction method thereof

ActiveCN101891993AImprove temperature resistanceImprove acid resistanceBio-packagingLarge containersVulcanizationAdhesive

The invention provides an anticorrosive material for a chimney, a flue and other containers and pipelines and an anticorrosive construction process. The construction method of the anticorrosive material comprises the following steps: using crude rubber with higher fluorine content as a raw material, then adding curing agent, stabilizer, special stuffing and other components, and mixing to form precuring gross rubber; dissolving the rubber by using low-molecular weight esters and ketones as the solvent to form a putty type rubber paste; and finally, adding special additives, uniformly mixing, coating to the inner walls of a chimney, a flue and a chemical container, and curing into the polymerized fluororubber organic lining under the room-temperature condition. The material can be independently used as the anticorrosive material, and can also be used for protecting common foam glass bricks (ceramic bricks) and adhesive for anticorrosive purpose in the domestic chimney (flue) at present. The invention well solves the technical problems of fluororubber room-temperature curing and difficult anticorrosive construction, can be used in a high-temperature environment of more than 230 DEG C, and can endure high-concentration sulfuric acid, nitric acid, hydrochloric acid, phosphoric acid, hydrofluoric acid, corresponding salts and a mixture thereof. The anticorrosive lining material is economically affordable, has extremely high comprehensive anticorrosive properties such as temperature resistance, acid resistance and the like, and is applicable to the anticorrosive treatment of a cured chimney.

Owner:重庆大众防腐股份有限公司

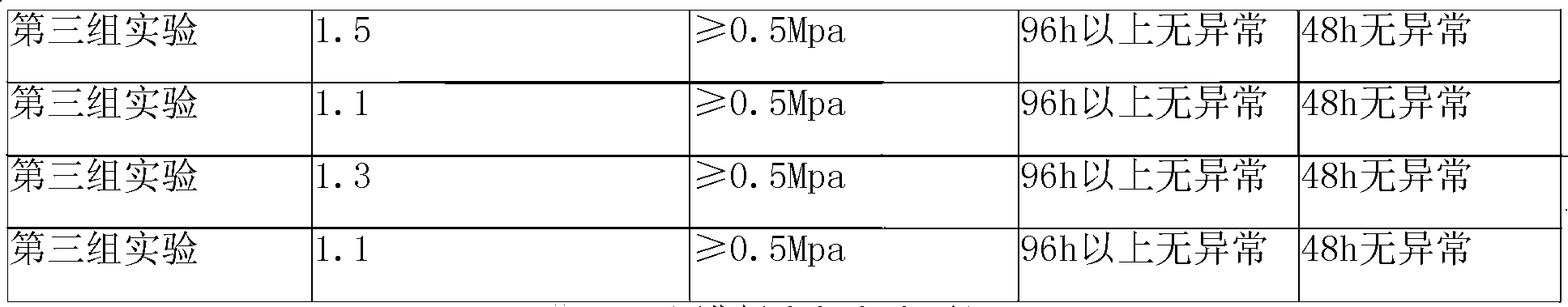

Cohesive osteogenic putty and materials therefor

Described is an implantable medical material comprising a malleable, cohesive, shape-retaining putty including mineral particles, insoluble collagen fibers and soluble collagen. The medical material can be used in conjunction with biologically active factors such as osteogenic proteins to treat bone or other tissue defects in patients.

Owner:WARSAW ORTHOPEDIC INC

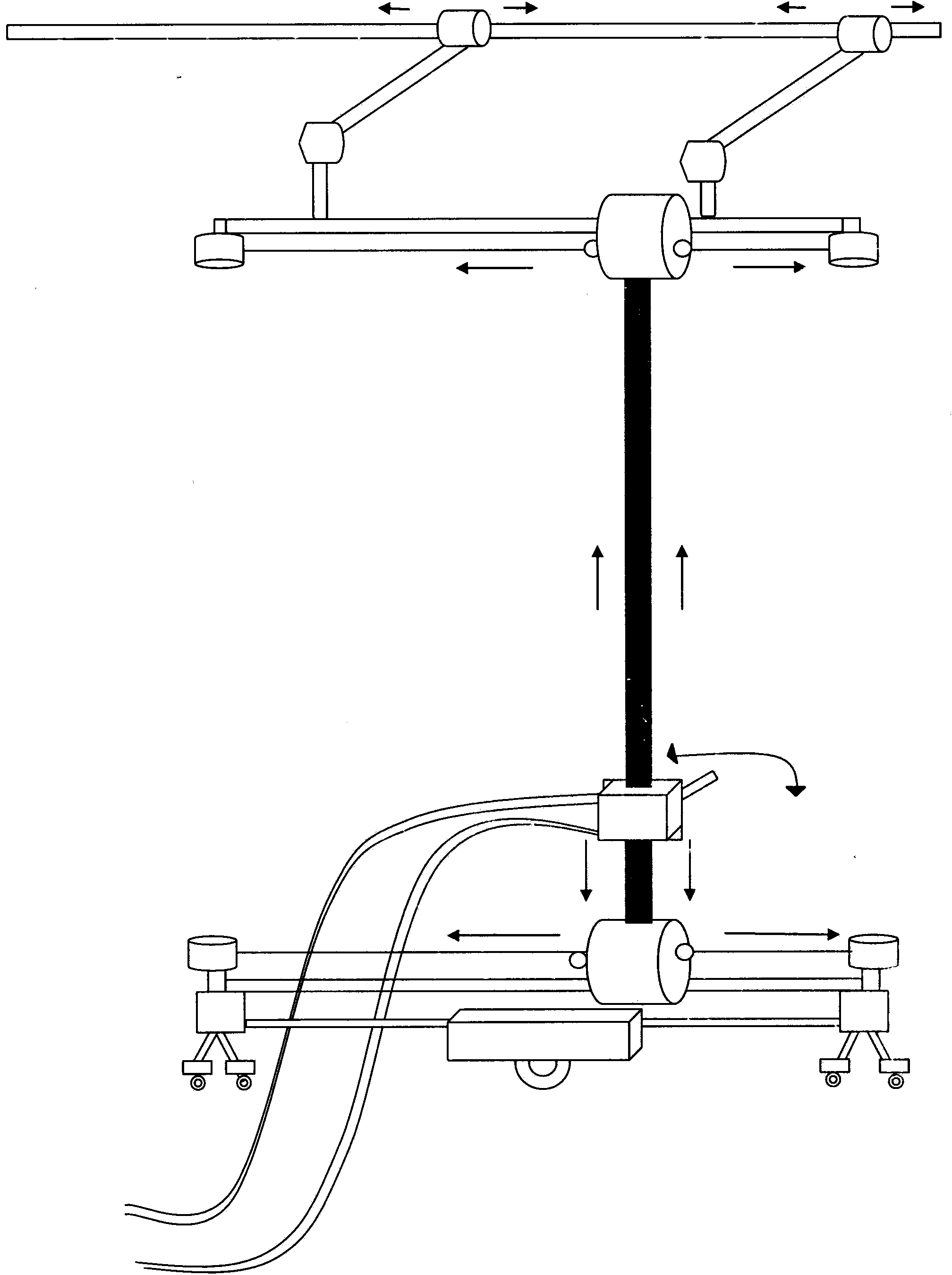

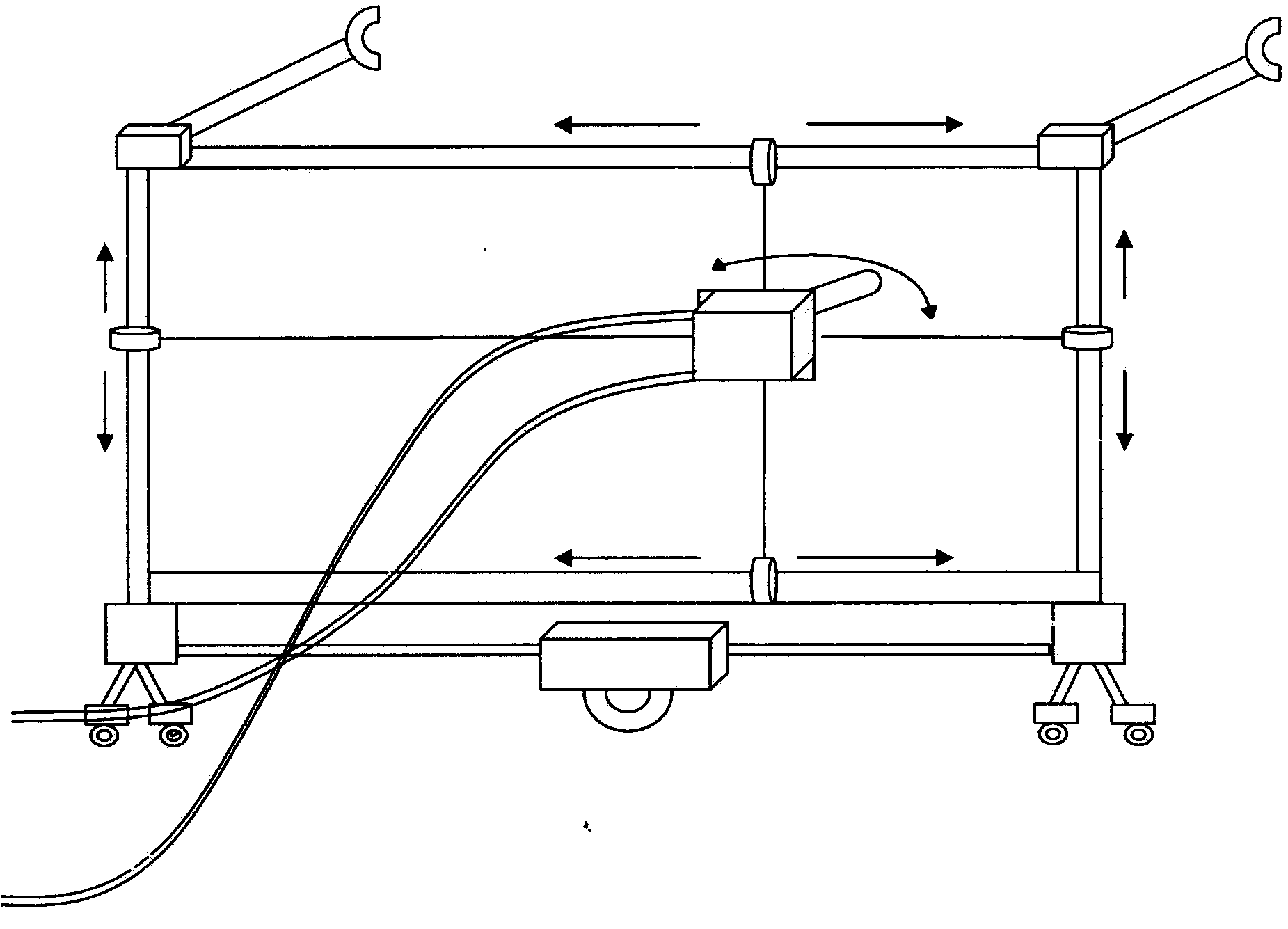

Surface spraying and rendering robot for building

InactiveCN104343230AImprove construction efficiencyApply evenlyBuilding constructionsGraphicsAngular velocity

The invention provides a surface spraying and rendering robot for a building. The robot can be used for automatically spraying and rendering cement mortar, lime mortar, putty mortar and other materials, and can also be used for spraying embossed graphics. The robot is of two structures according to the height of a wall body of the building. The robot is characterized in that a spraying and rendering head is fixed through a transverse and longitudinal moving device and used for accurately moving and spraying and rendering in the transverse and longitudinal directions; the spraying and rendering head is equipped with a camera device; the self-cleaning function is brought, so that the camera shooting picture cannot be influenced by the spraying of mortar, and a worker can remotely monitor the spraying and rendering effect; the spraying thickness is controlled through the swinging angular velocity and moving rate of the spraying head; a spraying and rendering device is equipped with a touch part and a distance sensor which enables uniform coating and rendering, and the efficiency and reliability are higher than manual operation. According to the robot, a plurality of spraying heads or rendering knives can be arranged and switched by program control; different building materials can be loaded; the colorful embossed graphics can be sprayed based on the computer picture; the working scope and route of the robot can be set by the computer program, and the learning can be performed automatically through the teaching program.

Owner:郑西涛

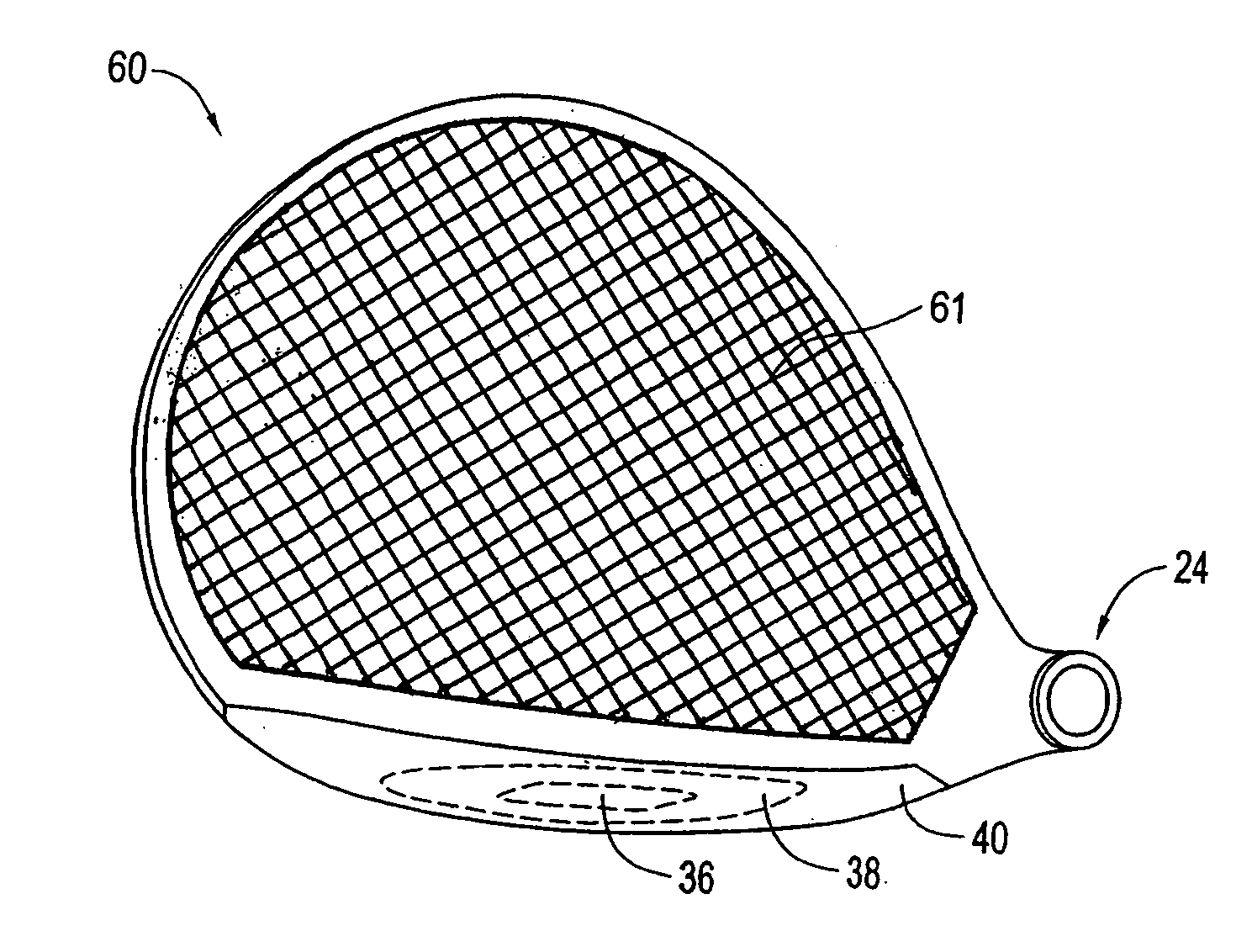

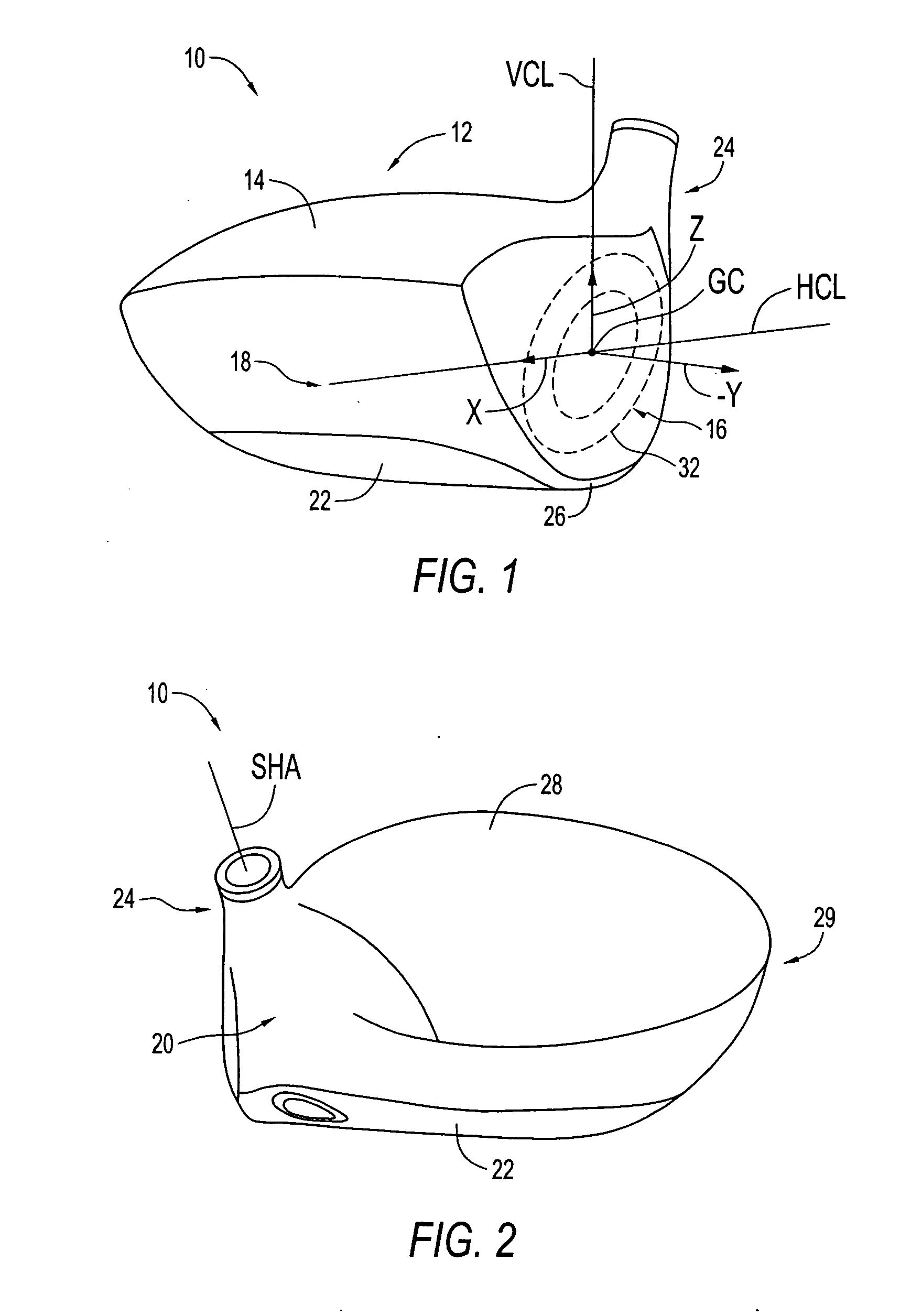

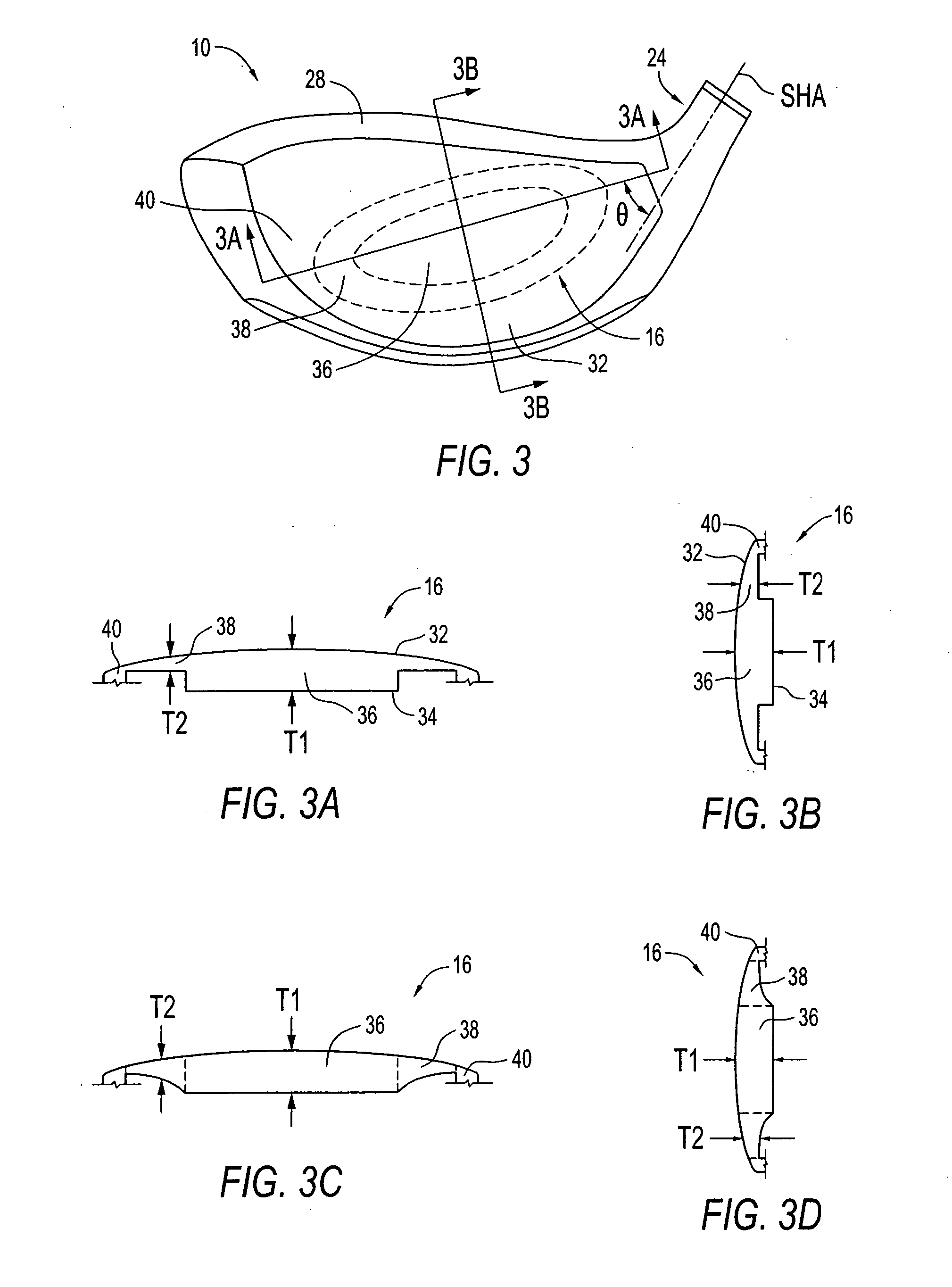

Composite metal wood club

InactiveUS20060293118A1Increased bending stiffnessIncrease elasticityAnalysing solids using sonic/ultrasonic/infrasonic wavesGolf clubsSurface layerHigh density

A metal wood golf club head adapted for attachment to a shaft, comprising of a body portion and a crown portion, each portion constructed of a different density material. Combining a high-density material in the body portion, with a low-density material in the crown portion, creates an ultra-low center of gravity relative to the geometric face center, resulting in higher launch angles and spin rate ratios. The material for the crown portion is preferably a composite. The crown portion comprises an inner surface layer of a vibration dampening material. The transverse surfaces of the crown and body portions creating a gap that is filled with a shock absorption material such as putty or a rubber based structural adhesive.

Owner:ACUSHNET CO

External wall flexible waterproof putty powder and preparation method thereof

The invention relates to external wall flexible waterproof putty powder and a preparation method thereof. The flexible waterproof putty powder consists of the following components according to weight percentage: 22% of cement, 20.5% of heavy calcium carbonate, 15% of quartz powder, 8% of diatomite, 8% of talcum powder, 5% of kaolin, 5% of ash calcium, 3% of ethylene oxide, 2% of a retarder, 0.3% of HPMC, 3% of latex powder, 2% of wollastonite powder, 2% of a catalyst, 0.4% of a dehydrating agent, 0.5% of wood fiber, 0.3% of starch ether and 3% of other fillers, wherein the particle size of the heavy calcium carbonate powder is controlled as follows: d97 is smaller than 10 microns, d50 is 1.5 microns, the whiteness is greater than 95%, and the CaCO3 content is greater than or equal to 98%; the quartz powder with 1-3 microns accounts for 57%, 5-8 microns for 22%, 9-15 microns for 13%, and 15-18 microns for 8%; the diatomite is 260-300 mesh; for kaolin, d97 is about 15 microns, d50 is about 2 microns, and the whiteness is greater than 92%; the retarder includes 72% of a citric acid retarder and 28% of a sodium polyphosphate retarder; the length-diameter ratio of wollastonite powder is greater than 10; HPMC adopts hydroxypropyl methyl cellulose with the viscosity of 100,000. The external wall flexible waterproof putty powder has the characteristics of being white, fine and smooth, good in construction workability, high in strength, good in water resistance and anti-cracking.

Owner:杭州正博新型建筑材料有限公司

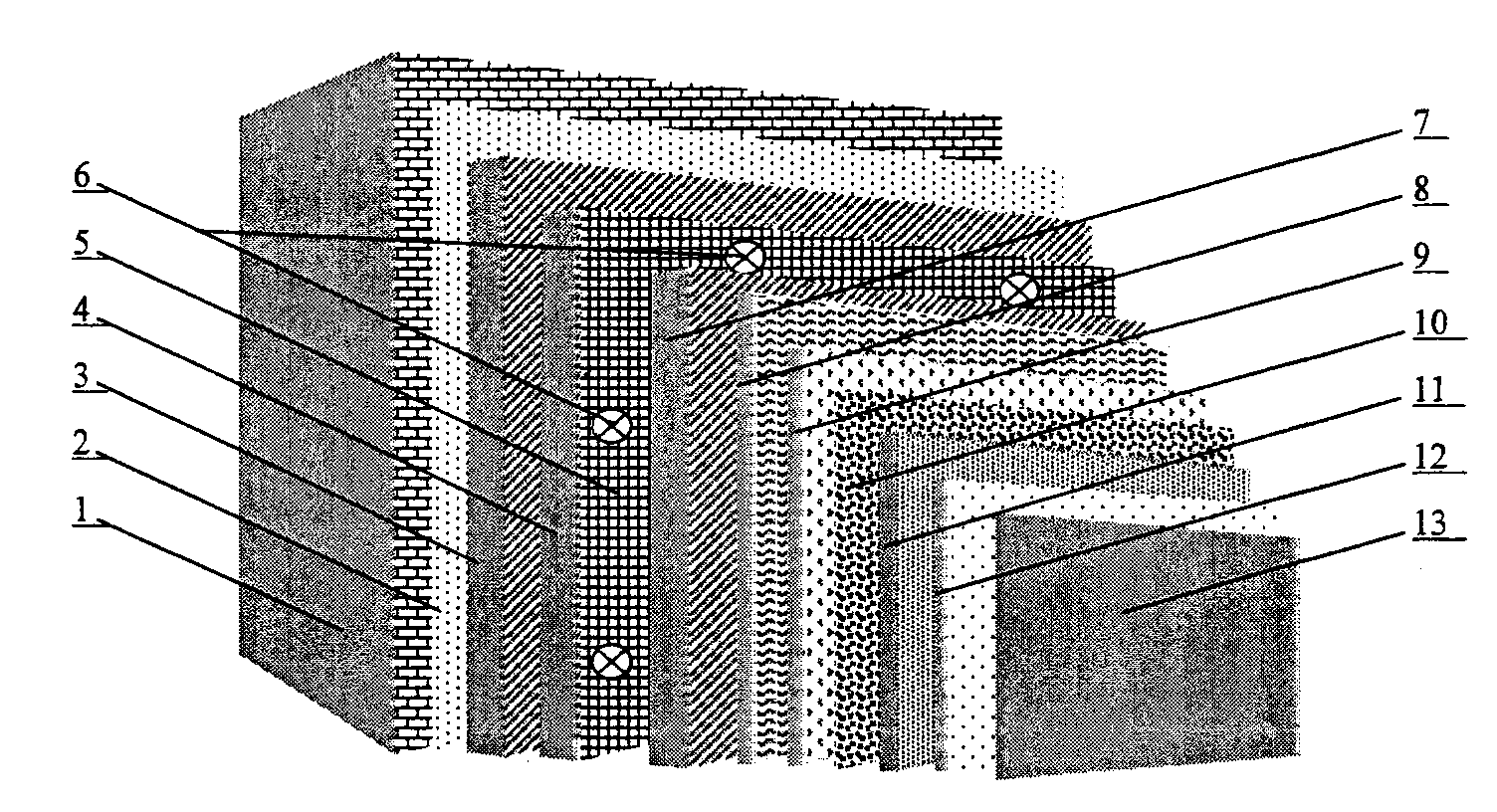

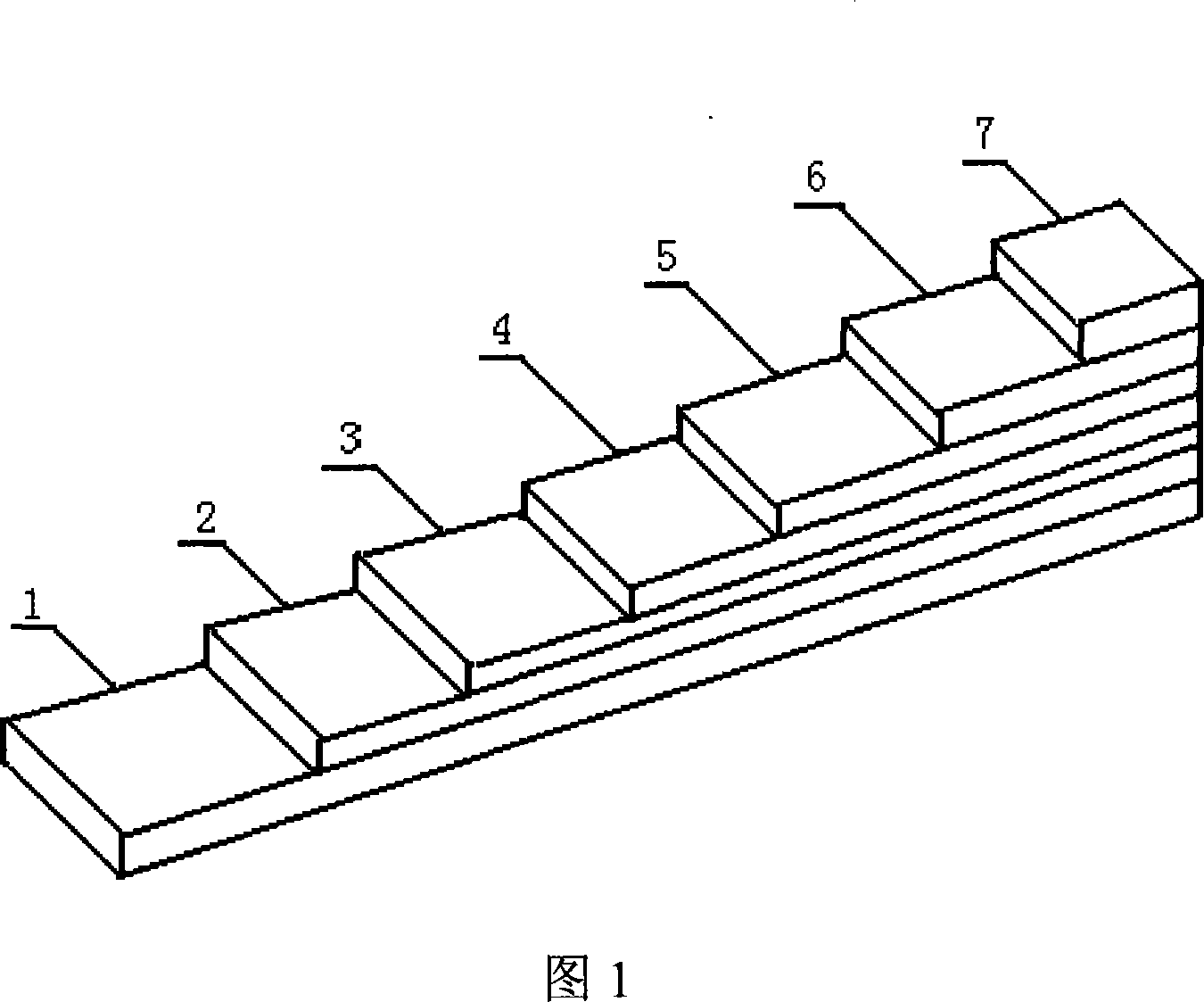

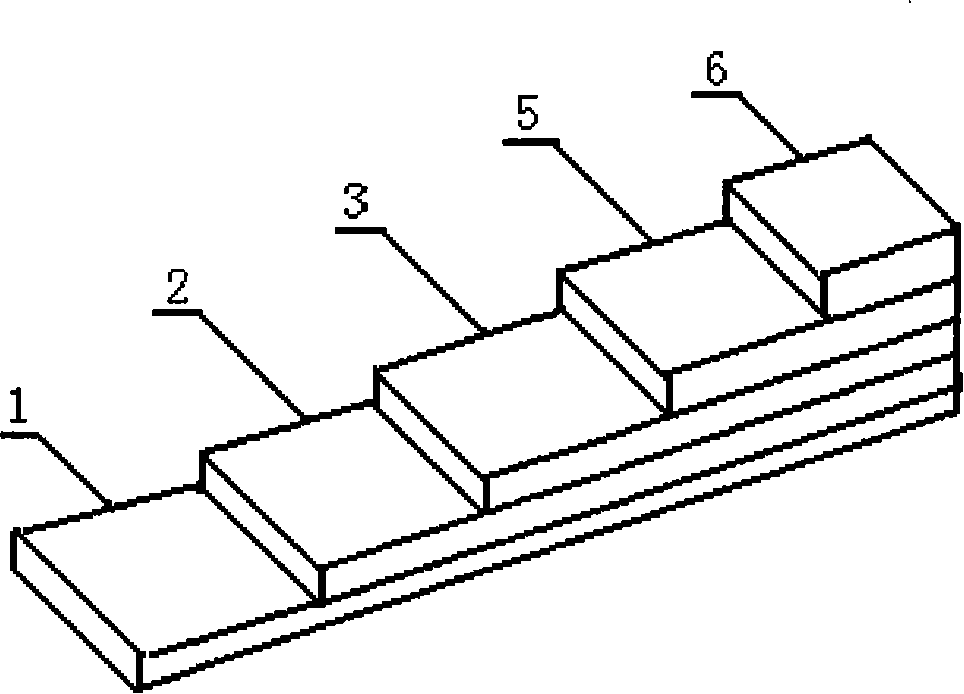

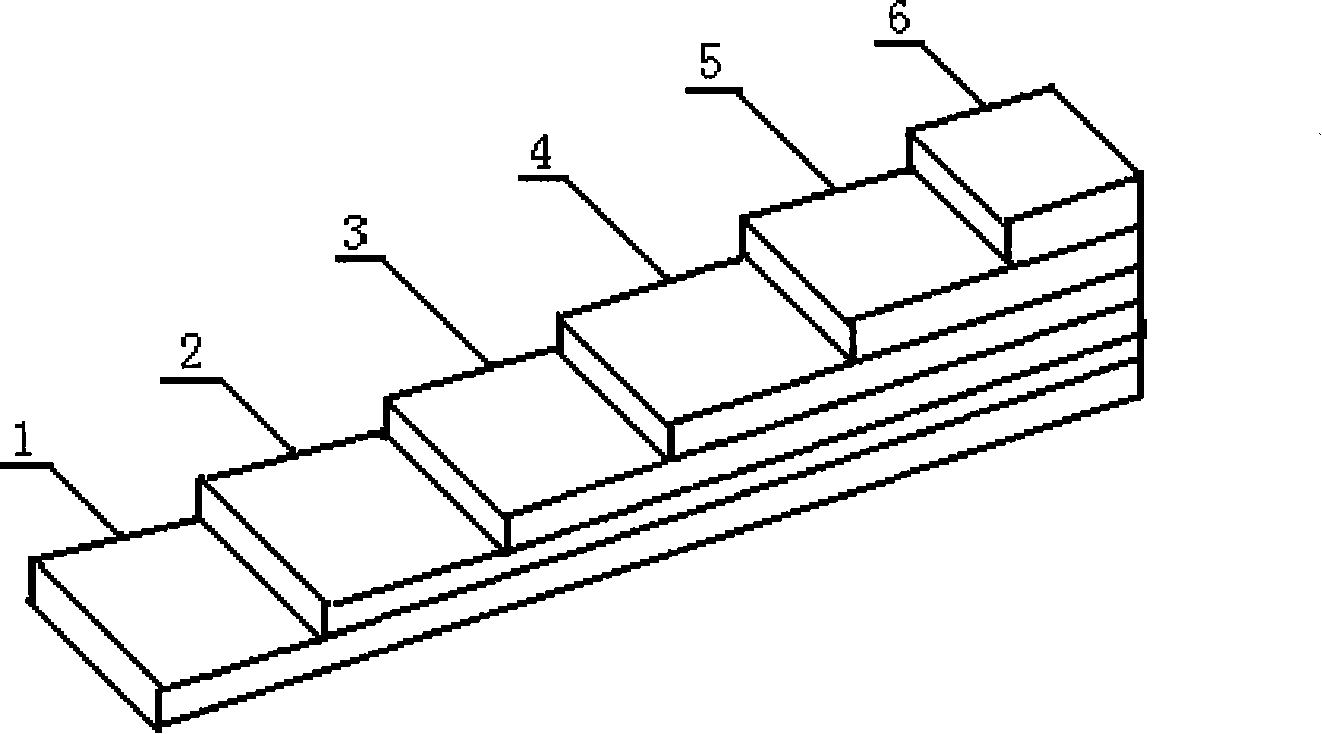

Method for retreading old porcelain brick wall by paint

InactiveCN101586401AAvoid crackingImprove water resistanceCovering/liningsBuilding repairsGlass fiberBrick

The invention relates to a method for retreading the old porcelain brick wall by the paint, a retreading decorative layer composed of a interface binder layer (2), a first polymer cracking-resistant putty layer (3), a second polymer cracking-resistant putty layer (4), a glass fiber girding cloth (5), a third polymer cracking-resistant putty layer (7), a double-component flexible putty layer (9), a smooth surface putty layer (9), a seal coat layer (10), a middle coating layer (11), a flexible silicone-acrylate latex paint layer (12) and a fluoric-carbon coating varnish layer (13) is formed on the old wall surface porcelain brick of the old wall (1), an anchor nail (6) passes through the glass fiber gridding cloth (5), the second polymer cracking-resistant putty layer (4) and the first polymer cracking-resistant putty layer (3) and is embedded in the old wall (1) for the mechanical reinforcement, all layers above are dried and solidified and are integrated with the old wall (1) firmly to complete the retread of the old wall surface. The construction cost and the labor strength are low, the old porcelain brick on the wall surface can not fall off, the decorative is high.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Ultraviolet (UV) digital jet printing manufacturing method of plate-type components of floor boards and furniture

The invention relates to an ultraviolet (UV) digital jet printing manufacturing method of plate-type components of floor boards and furniture, which comprises the following process steps of 1 manufacturing digital jet printing pattern decoration picture; 2 preparing a base material; 3 coating aqueous back cover putty; 4 digitally printing a UV decoration layer in a jetting mode; 5 coating a UV primer layer; and 6 coating UV finish. The manufacturing method has the advantages of (1) directly printing on the surfaces of plate-type base materials of a density board, a multi-layer plywood, a laminated wood, a common board, a wood model and the like; (2) using electromagnetic radiation of ultraviolet light to enable UV printing ink jetted from a sprayer to be rapidly solidified on the plate-type base materials; (3) reducing scrappage of material pieces, effectively improving work efficiency and reducing cost; and (4) being free of volatile odor and environment-friendly in production processes due to the fact that the UV printing ink is solidified in a short time. In addition, during UV digital jet printing manufacture of the plate-type components of the floor boards and the furniture, production quantity can be flexibly set according to requirements, material categories, colors and pictures can be changed at random, one-piece cost and effect same regardless of the batch size.

Owner:南京雷励数码科技有限公司

Thermal insulation putty for internal walls and application method thereof

The invention discloses a thermal insulation putty for internal walls, which is characterized in that the raw material at least contains the following components: component 1: 1 part by mass of solution containing polyhydroxy high-molecular compounds on the basis of polyhydroxy high-molecular compounds; component 2: 0.1-1 part of isocyanate foaming crosslinking agent; component 3: 10-20 parts of thermal insulation filler; component 4: 0.5-2 parts of silica sol; and component 5: 0.1-2 parts of inorganic powder material. The total water content in the solution containing polyhydroxy high-molecular compounds and silica sol is 8-16 parts. The method comprises the following steps: uniformly mixing the components to form a paste; plastering the paste on the surface of the internal wall of a building by a plastering construction technique, wherein the plastering thickness is 3-20 millimeters; forming distributed bubbles in the plastering layer, and crosslinking and hardening the component 1 to form the thermal insulation putty layer. The thermal insulation putty for internal walls have low volume weight and low thermal conductivity; and the foamed high polymer material is used as an adhesive and has the phase-change energy storage effect, thereby enhancing the thermal insulation property of the putty.

Owner:FUKE TECH (SUZHOU) CO LTD

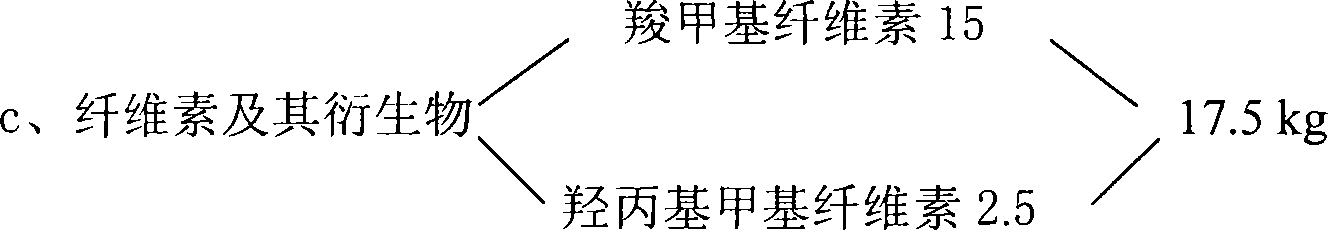

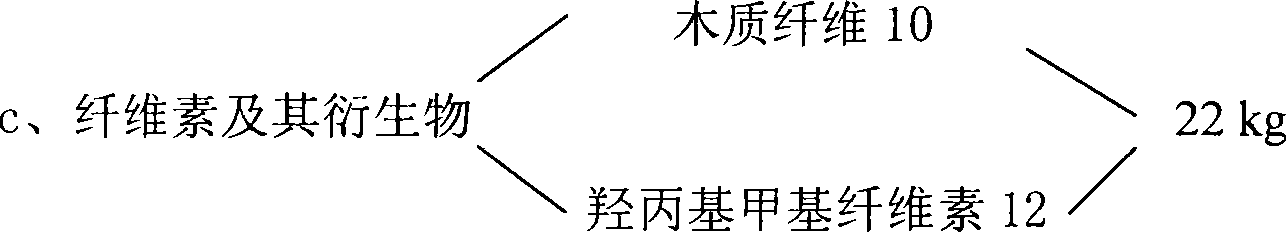

Water soluble adhesive

InactiveCN101058701AGood adhesionStrong adhesionNon-macromolecular adhesive additivesStarch adhesivesCellulosePolymer science

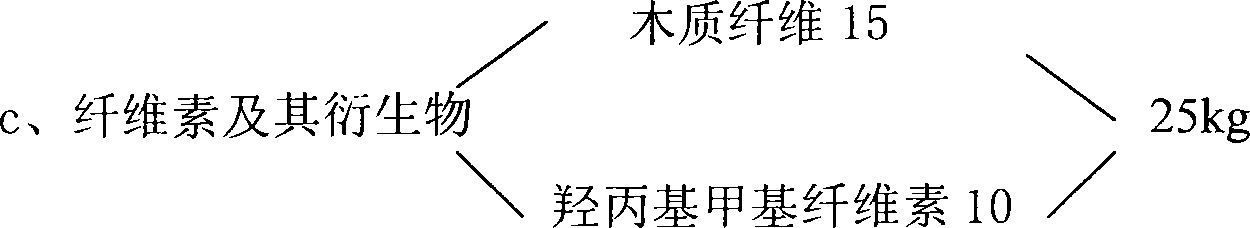

The invention discloses a water-soluble adhesive, which comprises the following parts: 30-65% pregelatinized starch, 10-20% 2488 polyvinyl alcohol, 13-37% cellulose and its derivant, 0-20% redispersion emulsion powder, 0. 15-0. 5% thickener and 0. 3-0. 8% high-activity zinc oxide, wherein each component is stirred evenly under the drying condition to form the product; the grain size of pregelatinized starch is 20-40 or 80-100 order, which can be allocated into gel powder to form common glue with 6% water after stirring 30min or interior-exterior wall putty powder adhesive after blending diflying powder or cement with weight at 0. 2: 10 directly.

Owner:陈峰磊

Ultraviolet light curing overlay film decorative board for wall and method for making same

InactiveCN101235672AHigh strengthGood weather resistanceCovering/liningsDecorative surface effectsCoated surfaceLacquer

The invention belongs to the building material decorative plate field, in particular to an ultraviolet light solidified tectorial member wall decorative plate which is produced through coating ultraviolet light solidifying pigment on the surface and a preparation process which comprises coating a layer of ultraviolet light solidified penetrating agent on the surface of a wall decorative plate basal body surface, coating a layer of ultraviolet light solidified putty on the surface of the coating of ultraviolet light solidified penetrating agent, coating a layer of ultraviolet light solidified sizing varnish primer on the surface of the coating of ultraviolet light solidified putty, hotly stamping a layer of heat transfer film on the surface of the coating of ultraviolet light solidified sizing varnish primer, coating a layer of ultraviolet light solidified protecting varnish, and adhering a polypropylene or polyethylene protection film on the surface of the coating of ultraviolet light solidified protecting varnish. The ultraviolet light solidified tectorial member wall decorative plate has the advantages of strong plate strength, excellent weatherability and environment-friendly, rich color and patterns, full lacquer film, high hardness, scratch resistance, easy cleaning and non flame, and has more excellent decorative effect and protective effect than a common universe wall decorative plate.

Owner:ZHUHAI DONGCHENG UV MATERIALS

Ultraviolet curing chromatic wall decoration board and preparation method thereof

InactiveCN101158210ASave production spaceIncrease productivityCovering/liningsPretreated surfacesCoated surfacePolypropylene

The invention belongs to the construction material decorative board field, in particular to a UV-curable color wall decorative board produced by coating the surface with UV-curable coatings and a preparation method thereof. A UV-curable putty layer is coated on the surface of the wall decorative board substrate, a UV-curable closed primer layer is coated on the surface of the UV-curable putty layer, a UV-curable color topcoat layer is coated on the surface of the UV-curable closed primer layer, and a polypropylene or polyethylene protective film is coated on the surface of the UV-curable color topcoat layer. A UV-curable white primer layer is positioned between the UV-curable closed primer layer and the UV-curable color topcoat layer. The UV-curable wall decorative board of the invention has the advantages of high timber intensity, good weatherability, good environmental protection ability, rich colors, thick paint film, high rigidity, high scratching resistance, cleaning convenience, and non-inflammability, compared with the existing commonly used wall decorative boards, the invention has better decorative and protective effects.

Owner:ZHUHAI DONGCHENG UV MATERIALS

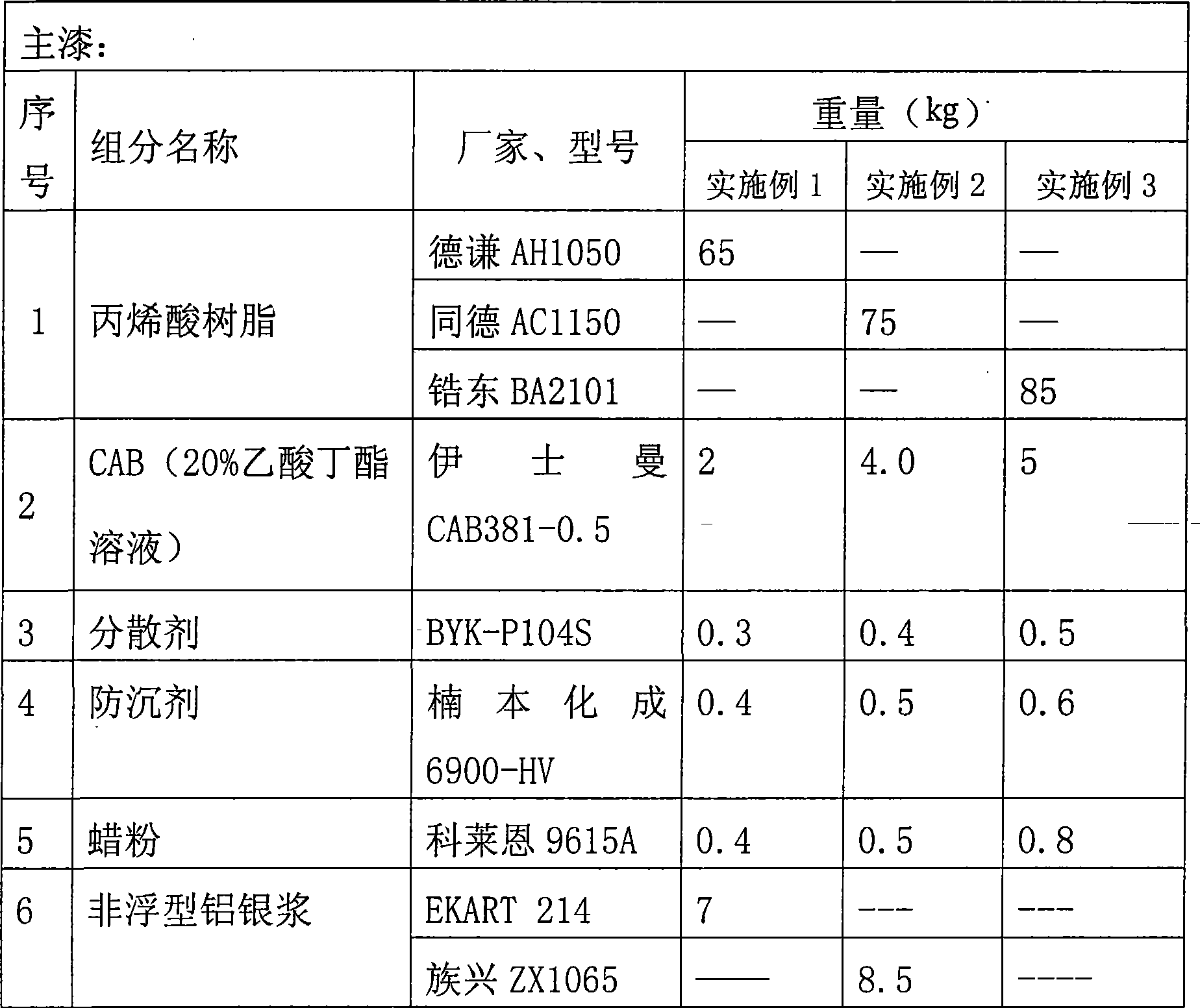

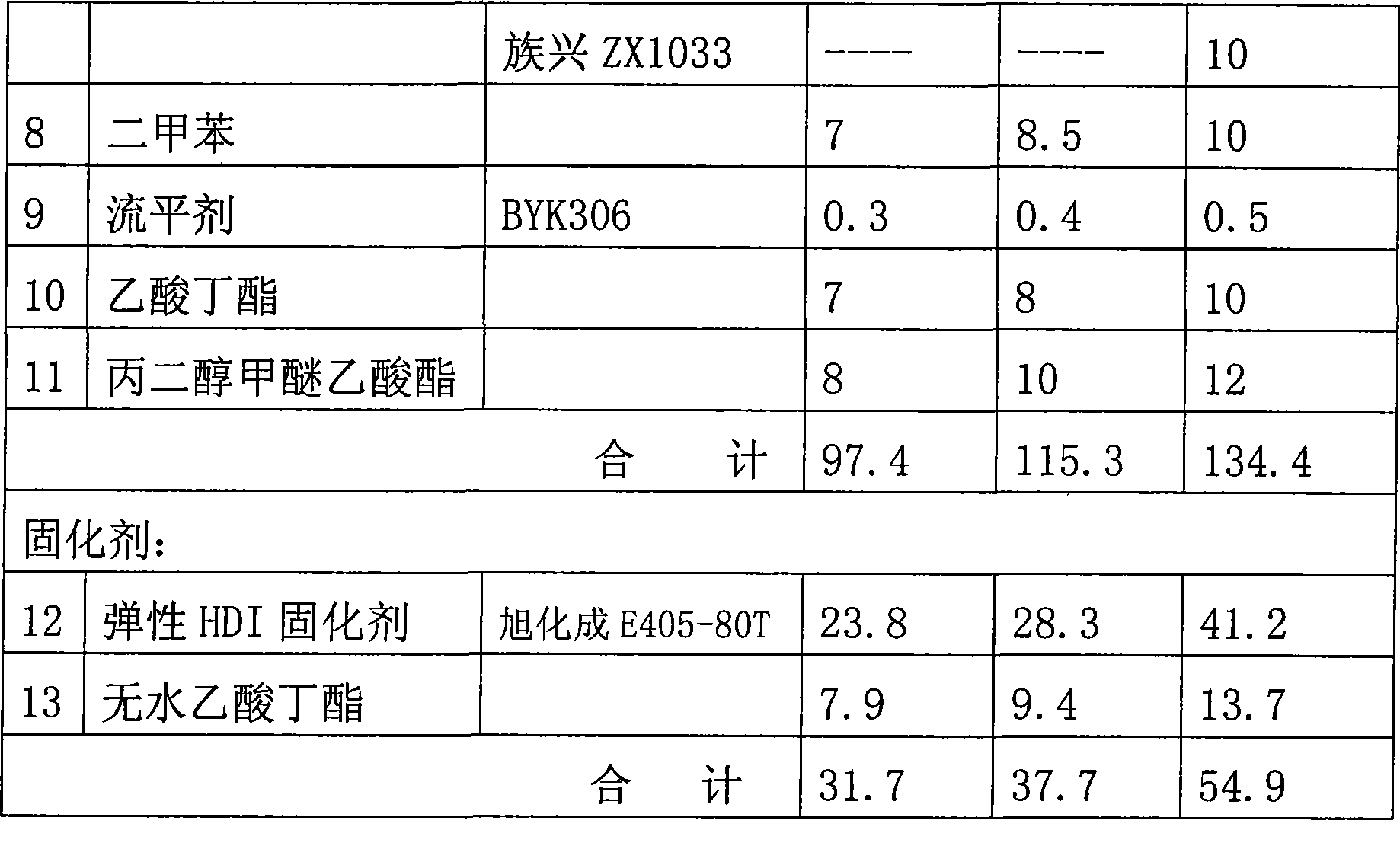

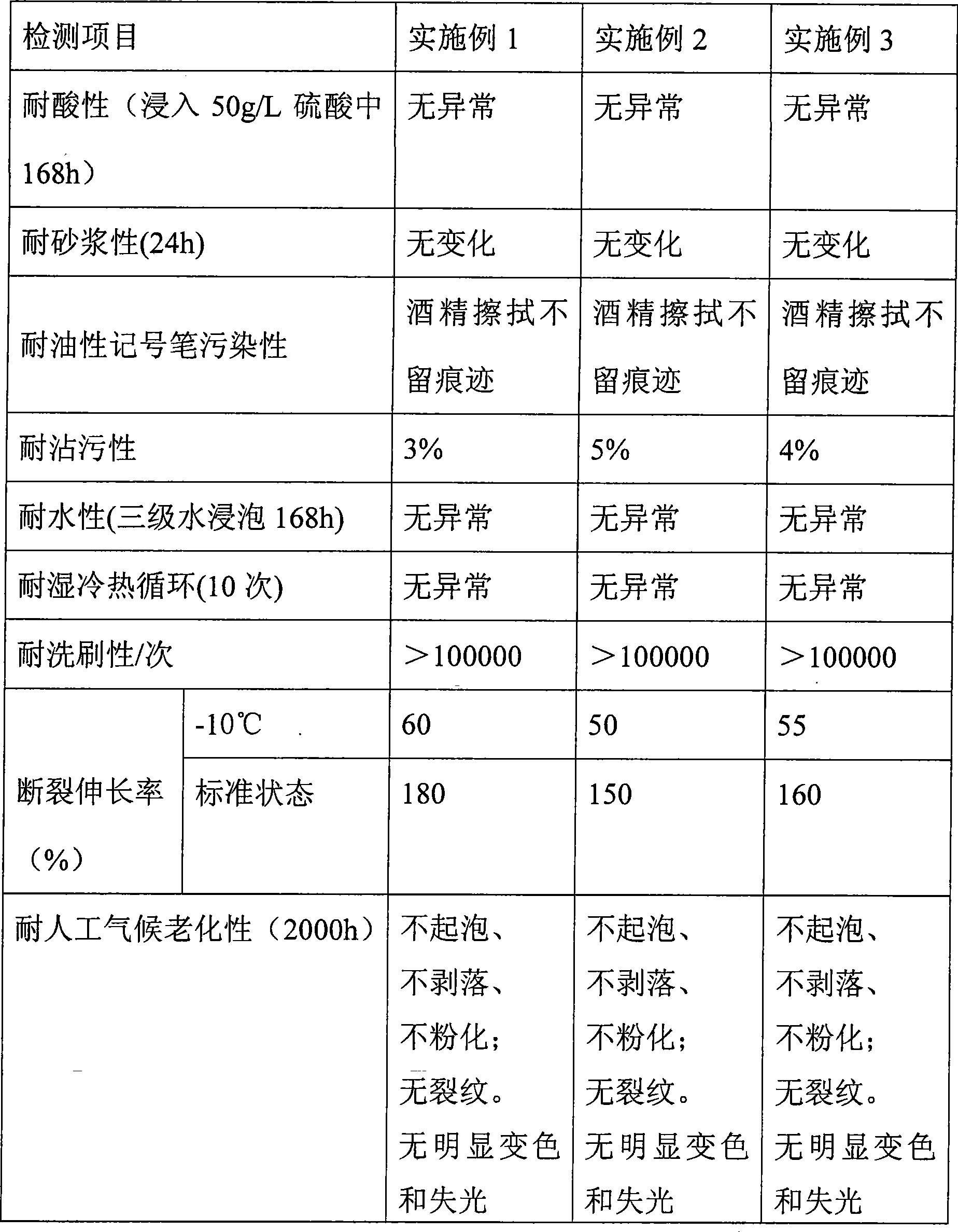

Elastic polyurethane silver paint and preparation method and use method thereof

ActiveCN101386771AGood room temperatureIncrease elasticityLiquid surface applicatorsPolyurea/polyurethane coatingsWaxWeather resistance

The invention discloses elastic polyurethane silver paint. Main paint of the elastic polyurethane silver paint is prepared from compositions according to the following weight proportion: 65 to 85 percent of a hydroxy acrylic acid resin, 2 to 5 percent of 20 percent CAB381-0.5, 0.3 to 0.5 percent of a dispersant, 0.4 to 0.6 percent of an anti-settling agent, 0.3 to 0.5 percent of a flatting agent, 0.4 to 0.8 percent of wax powder, 7 to 10 percent of non-leafing aluminum paste, 7 to 10 percent of dimethylbenzene, and 15 to 22 percent of mixed solvent; a curing agent of the elastic polyurethane silver paint is formed by mixing compositions according to the following weight percent: 75 percent of elastic HDI curing agent, and 25 percent of absolute butyl acetate; and the weight proportion of the main paint to the curing agent is calculated based on a hydroxyl value of acrylic acid resin and the NCO content of the curing agent, and OH / NCO is equal to 1 to (1.05-1.15). The elastic polyurethane silver paint has excellent weather resistance, stain resistance, scrubbing resistance and decoration property, is a coating variety with excellent performance which is second only to fluorocarbon paint, also has good elasticity at normal temperature and low temperature, can resist fine cracks, can prevent cracks on the surface of a coating caused by the fine cracks of a putty layer, and can also be used as finish for a complete anti-cracking aluminum-imitation plate coating system that flexible putty is matched with an elastic primer and an elastic middle coating.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

External thermal insulation system with low-thermal-conductivity and high-strength mortar

InactiveCN102912866ASimple construction processRandom shapeCovering/liningsClimate change adaptationEpoxyFiberglass mesh

The invention discloses an external thermal insulation system with low-thermal-conductivity and high-strength mortar. The external thermal insulation system comprises interface mortar, heat insulation mortar, anti-crack plastering mortar, alkali-resistant fiberglass mesh, flexible waterproof putty and modified epoxy resin. The system adopts onsite plastering type cavity-free external thermal insulation procedures, and a face layer adopts a flexible gradient material matching system. The system has the advantages of high wind pressure resistance, weather resistance, integral crack resistance, fire rating, impact resistance, thermal storage capacity, air permeability and dimensional stability, small contraction, excellent heat insulation performance and the like. Further, the external thermal insulation system is simple in construction process, can be moulded optionally, and is especially applicable to buildings rich in building elevation and available for direct construction on base layers poor in evenness.

Owner:池州市崇源节能建筑材料有限公司

Pasty heat-insulating elastic putty

The invention discloses pasty heat-insulating elastic putty. The preparation method of the pasty heat-insulating elastic putty comprises the following steps of taking elastic emulsion as film-forming material, silicon-aluminum base ceramic hollow microspheres as heat-insulating filler, shape-stabilized phase change material as energy storage and temperature adjustment filler, and triple superphosphate and French chalk as mineral filler with the cooperation of auxiliary agents and water, firstly, preparing sepiolite shape-stabilized phase change material, secondly, mixing and stirring the elastic emulsion, dispersing agent, antifoaming agent, anti-mildew agent, ethylene glycol, dissolved hydroxypropylmethylcellulose solution, wood fiber, the triple superphosphate, the French chalk and the ceramic hollow microspheres to form an uniform pasty body, thus preparing the pasty heat-insulating elastic putty. In the invention, the putty coating can shade crack of a protective layer, prevent a decorative coating film from cracking, strengthen the heat-insulating effect and improve the energy saving efficiency, and has high percentage elongation at rupture, heat storage and temperature adjustment and control effect, remarkable heat-insulating and cooling effects, excellent physicochemical property and wide market prospect.

Owner:BEIJING COATINGS

Epoxide resin based piezoelectric composite damping material and method for preparing the same

The invention introduces an epoxy resin-based piezoelectric and composite damping material and a preparation method thereof, which comprises the following materials by weight portion: 100 portions of epoxy resin, 30 portions to 220 portions of piezoelectric ceramic powder, 0.5 portion to 5 portions of graphitized carbon black and 30 portions to 120 portions of curing agent. After being mixed, dispersed and added with the curing agent to be evenly blended and then poured, cured and shaped, the piezoelectric and composite material can be polarized in an HVDC oil-bath electric field and has good damping property (tan Delta is not less than 0.3) in a wide-temperature range (10 to 100 DEG C) and can also be applied in projects as free damping material as well as in an intelligent vibration and noise reduction system. In addition, the piezoelectric and composite material can be made into damping paint, putty, slurry and potting adhesive and poured into various section materials to be used in vibration and noise reduction projects in the fields such as vehicles, industrial machinery, civil construction, household appliances, precision instruments, military equipment, etc.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com