Patents

Literature

723results about How to "Save production space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

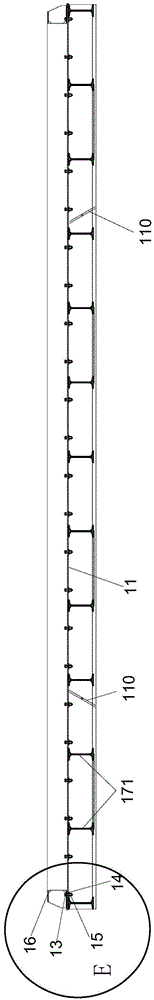

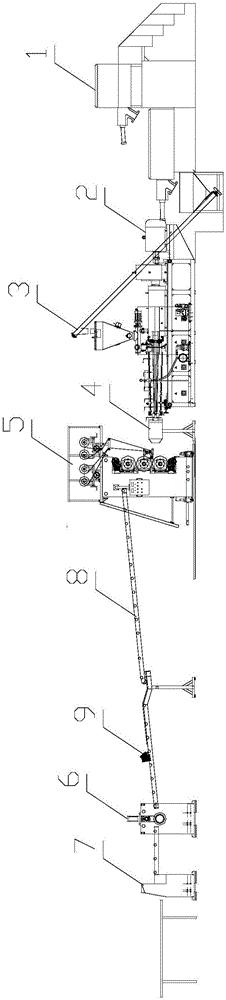

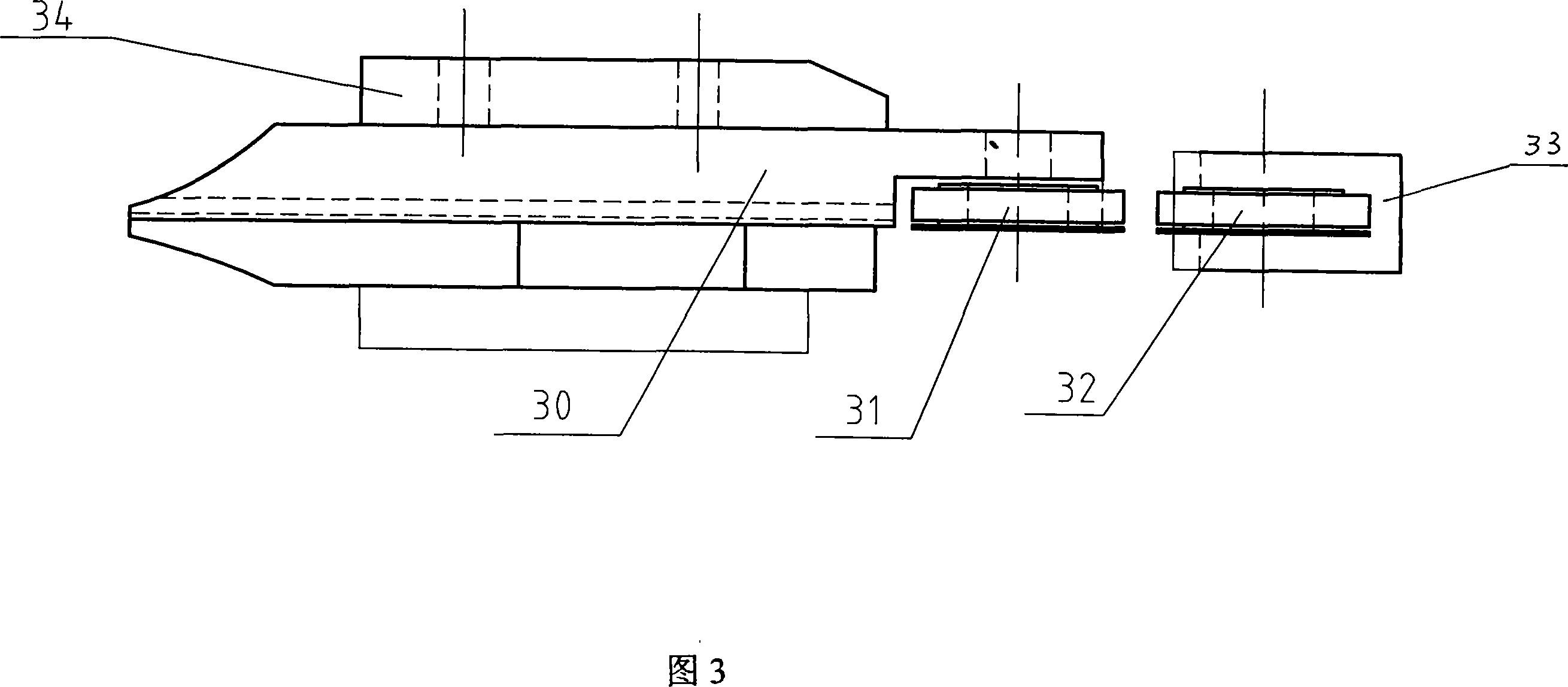

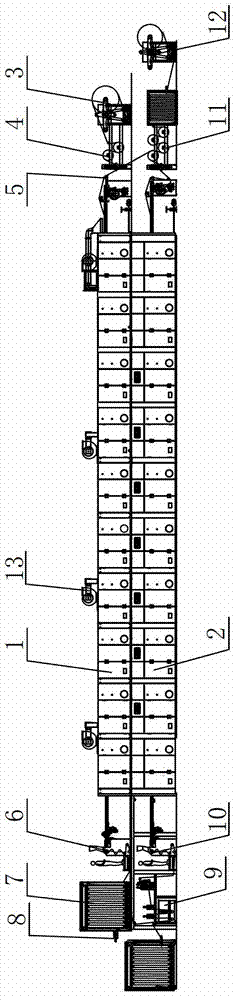

Automatic spraying equipment

InactiveCN102259071AAffect the spraying qualityReduce manual operationsSpraying apparatusPretreated surfacesElectricityControl system

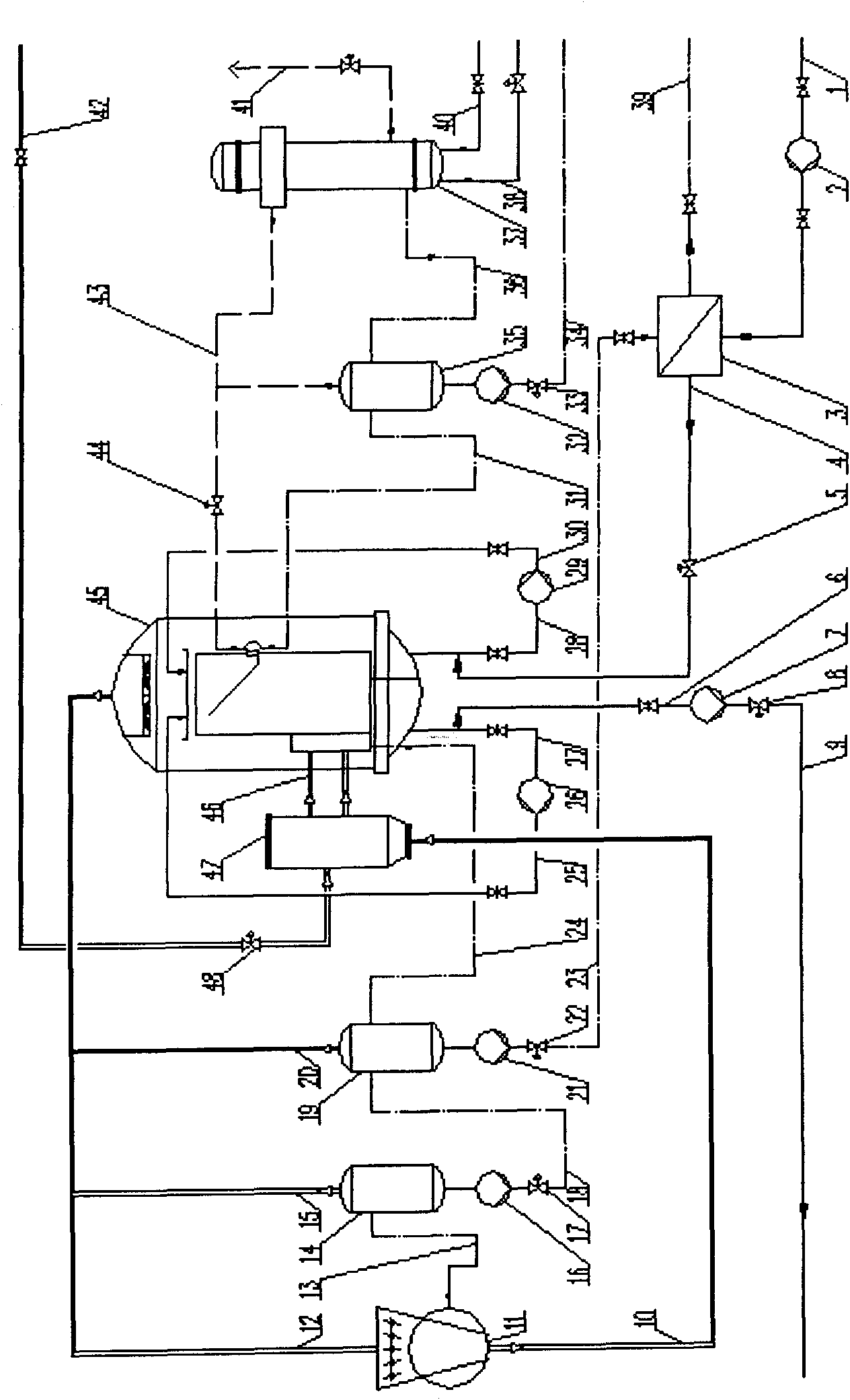

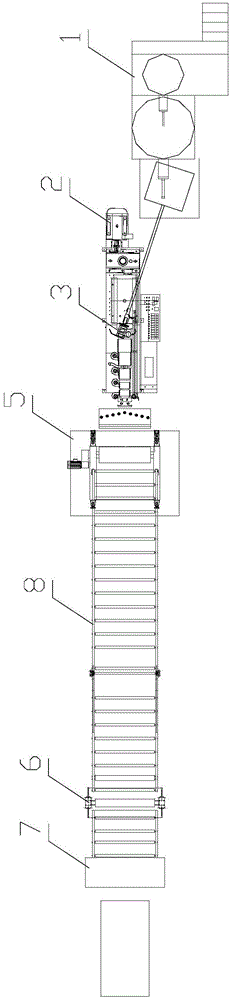

The invention discloses fully-automatic spray coating equipment, which comprises a ground track type conveying chain, a cooling and dedusting device, a spray coating system, an infrared curing furnace, a cooling furnace, an ultraviolet curing furnace, an automatic discharging mechanical arm, an air supply and exhaust system and a control system. The ground track type conveying chain winds along awaist-like line and conducts closed circulating conveying of workpieces; the cooling and dedusting equipment cools and dedusts the workpieces; the spray coating system performs spray coating on the workpieces; the infrared curing furnace performs the infrared curing of the spray-coated workpieces; the cooling furnace is used for cooling the workpieces; the ultraviolet curing furnace is used for ultraviolet curing of the workpieces; the automatic discharging mechanical arm catches and unloads the workpieces; the air supply and exhaust system is arranged above the ground track type conveying chain and is used for supplying air to and exhausting all equipment; and the control system is electrically connected with all components and controls the operation of the components. The high automation degree of the fully-automatic spray coating equipment is high, the spraying effect of the fully-automatic spray coating equipment is desirable, and when the fully-automatic spray coating equipment is used, production space can be saved greatly.

Owner:东莞丰裕电机有限公司

Ultraviolet light cured transfer printing film and preparation method and application thereof

InactiveCN101941339AHigh material strengthGood weather resistanceDecorative surface effectsOrnamental structuresLacquerPrinting ink

The invention belongs to the field of decorative materials, and particularly relates to an ultraviolet light cured transfer printing film and a preparation method and application thereof. The preparation method comprises the following steps of: uniformly coating or printing a mold release agent on a base load film, and performing infrared curing; uniformly coating or printing an ultraviolet light cured printing ink with a patterning function on a mold release agent layer, and performing curing through ultraviolet irradiation; or uniformly coating or printing an ultraviolet cured protective layer coating with anti-scratching and wear-resistant functions on the mold release agent layer first, then uniformly coating or printing the ultraviolet light cured printing ink with the patterning function on the mold release agent layer after the curing through the ultraviolet irradiation, and performing the curing through the ultraviolet irradiation; and uniformly coating or printing an ultraviolet light cured bottom color coating on an ultraviolet light cured printing ink decorative pattern layer, and performing the curing through the ultraviolet irradiation to obtain the ultraviolet light cured transfer printing film which can be used for producing an ultraviolet light cured transfer printing film decorative board. The ultraviolet light cured transfer printing film has high material strength, and has the advantages of high weathering resistance, high environmental protection, rich colors and patterns, full lacquer film, high hardness, scratch resistance, easy cleaning, noninflammability and the like.

Owner:ZHUHAI DONGCHENG UV MATERIALS

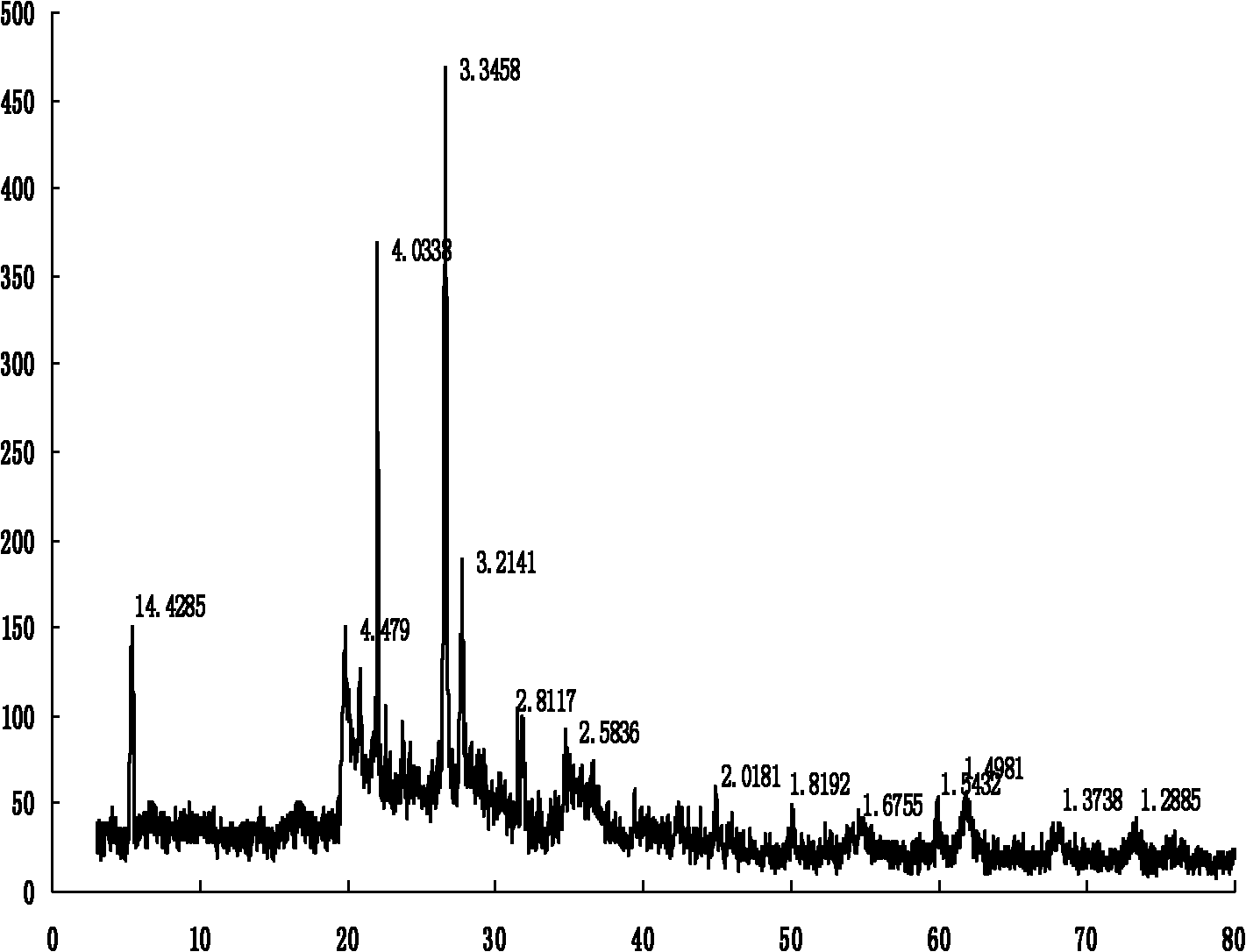

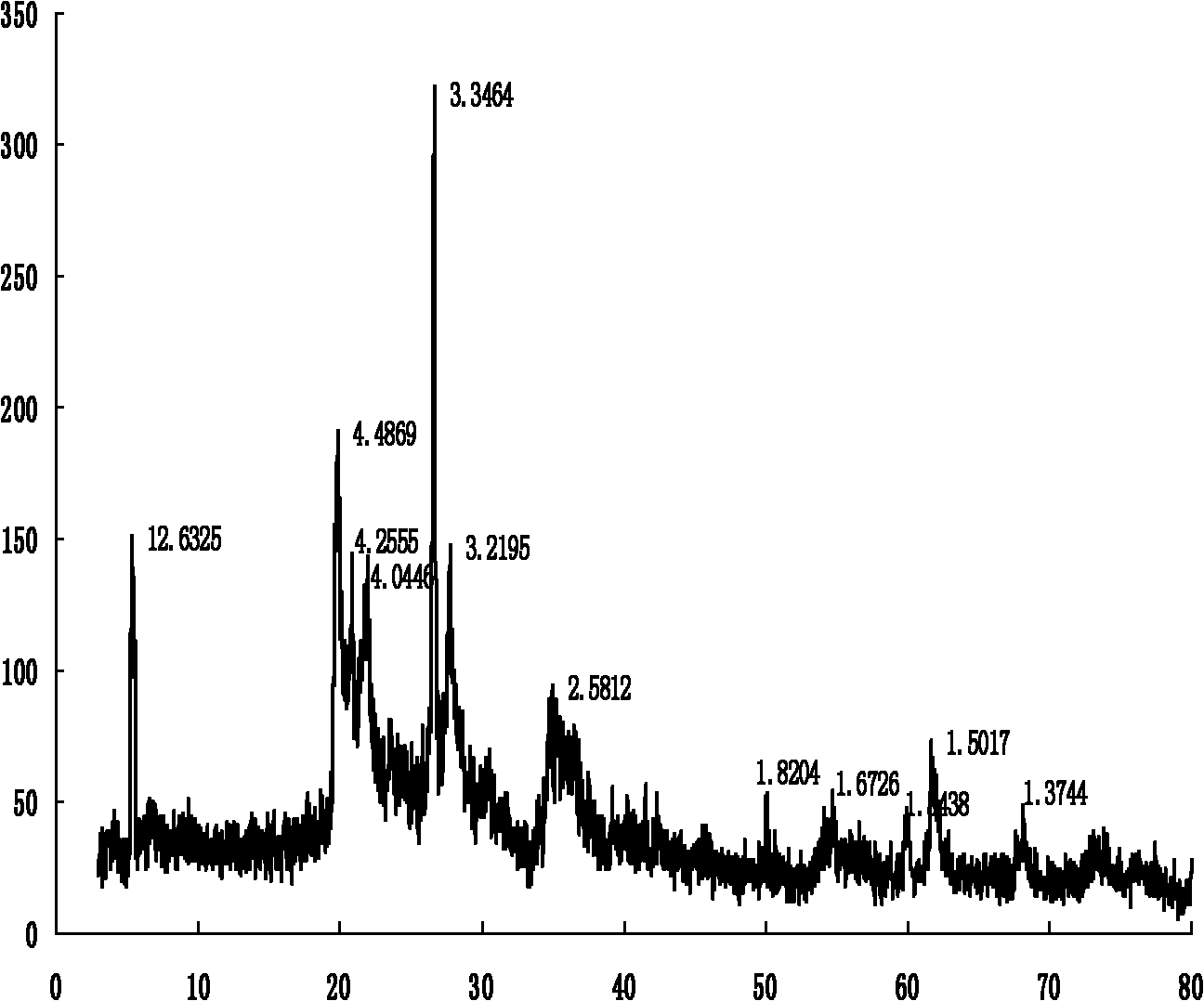

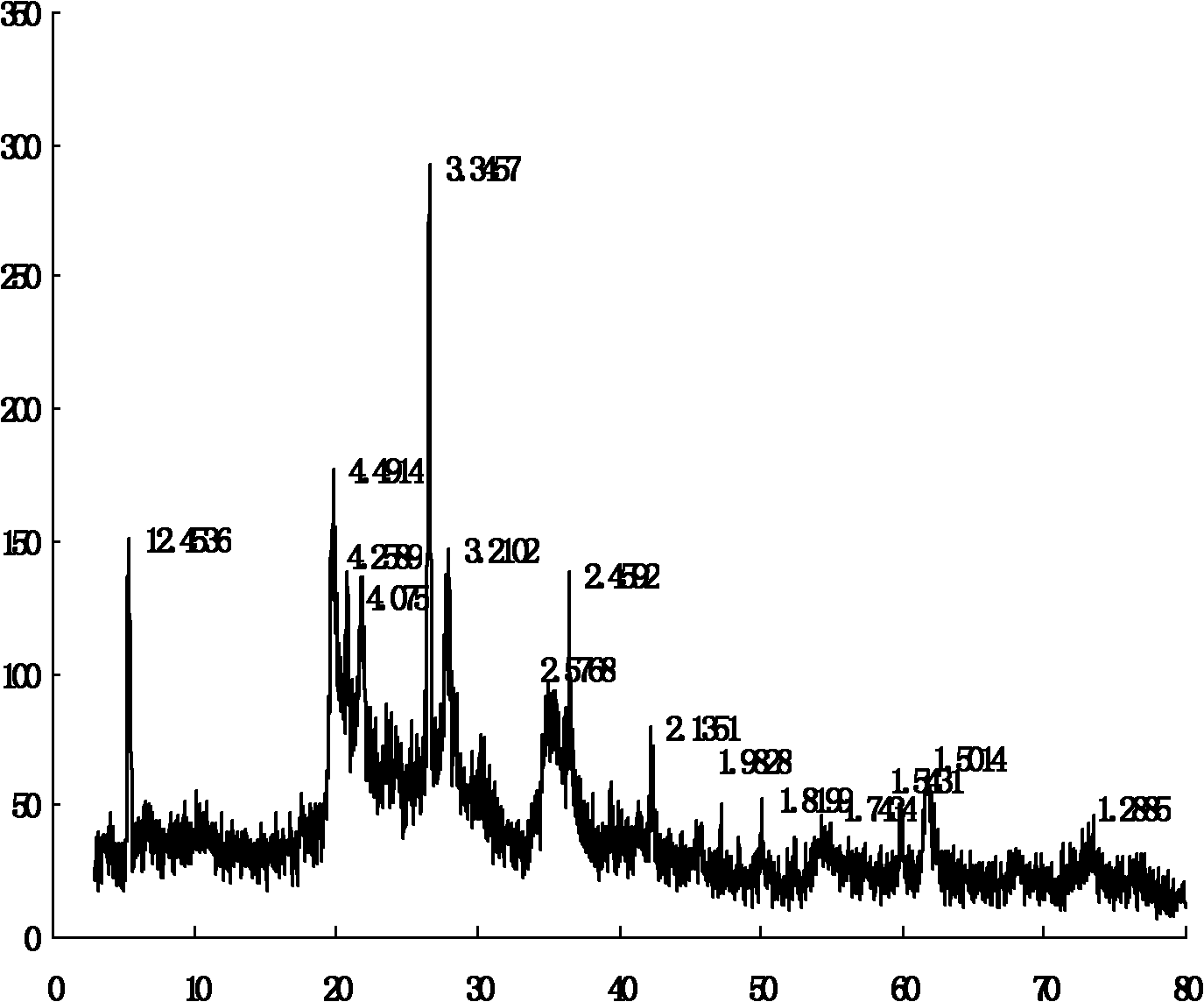

Timber wood hot pressing charing intensification method

ActiveCN101214675AUnlimited thicknessGood dimensional stabilityDrying using combination processesWood compressionCarbonizationVolumetric Mass Density

The present invention discloses a hot-pressing carbonization strengthening method of timbers, which includes drying, planing, hot-pressing carbonization, cooling and other steps. The present invention applies a hot press as a timber-carbonizing device, and the timbers under the state of compression are processed by hot-pressing carbonization. The present invention is characterized in that the investment on carbonization devices is less, the carbonization process is simple, the production is safe, the production efficiency is high, the consumption of heat energy is little, and the production cost is low; moreover, the thickness of the carbonized timbers is not limited, the defects of the timbers, such as deformation, cracking, stiker stain, color difference, knot fall-off, etc., do not occur in the process of production, so the quality of products is high; not only is the size stability and noncorrodibility of the carbonized timbers improved, but also the density and mechanical property of the timbers is increased.

Owner:广州豪沃仕家具有限公司

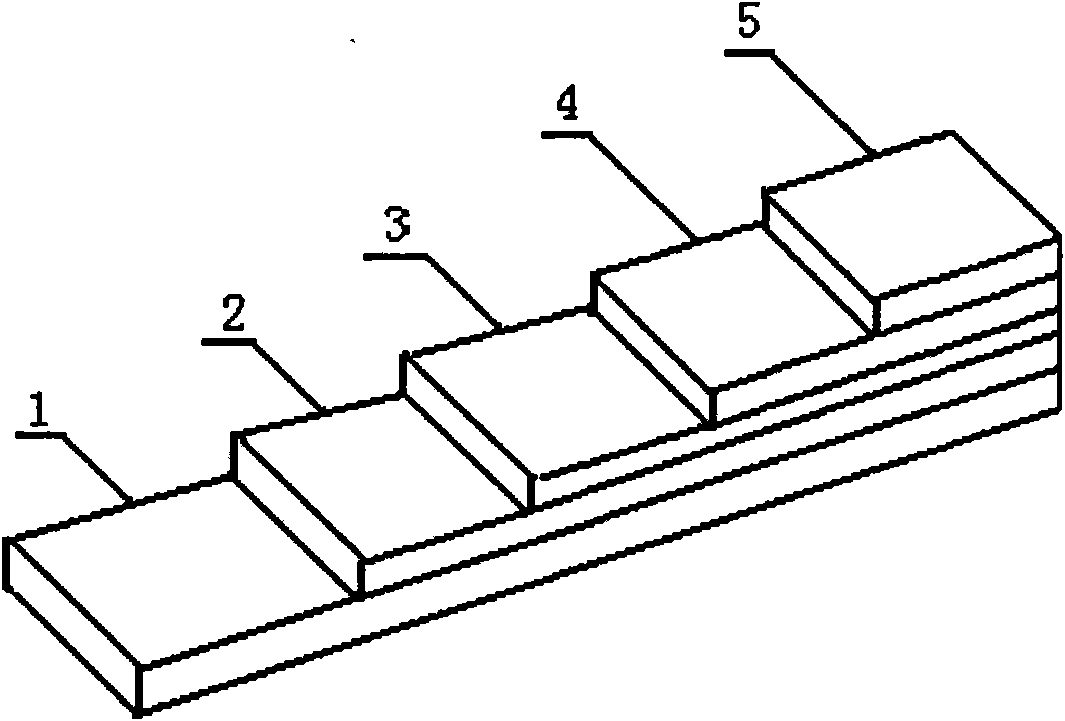

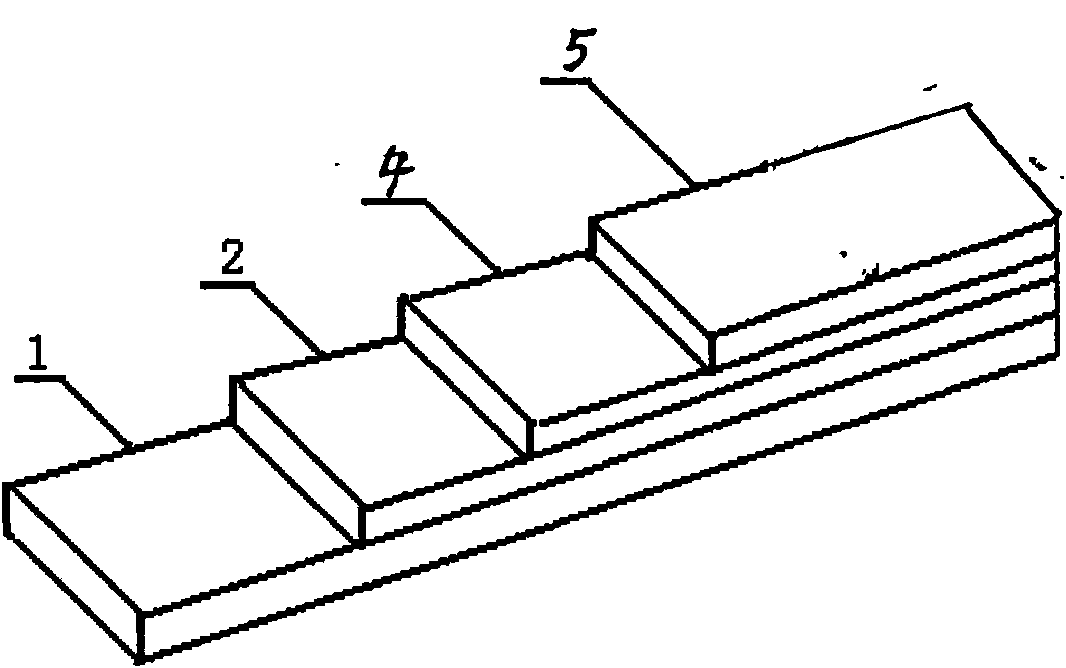

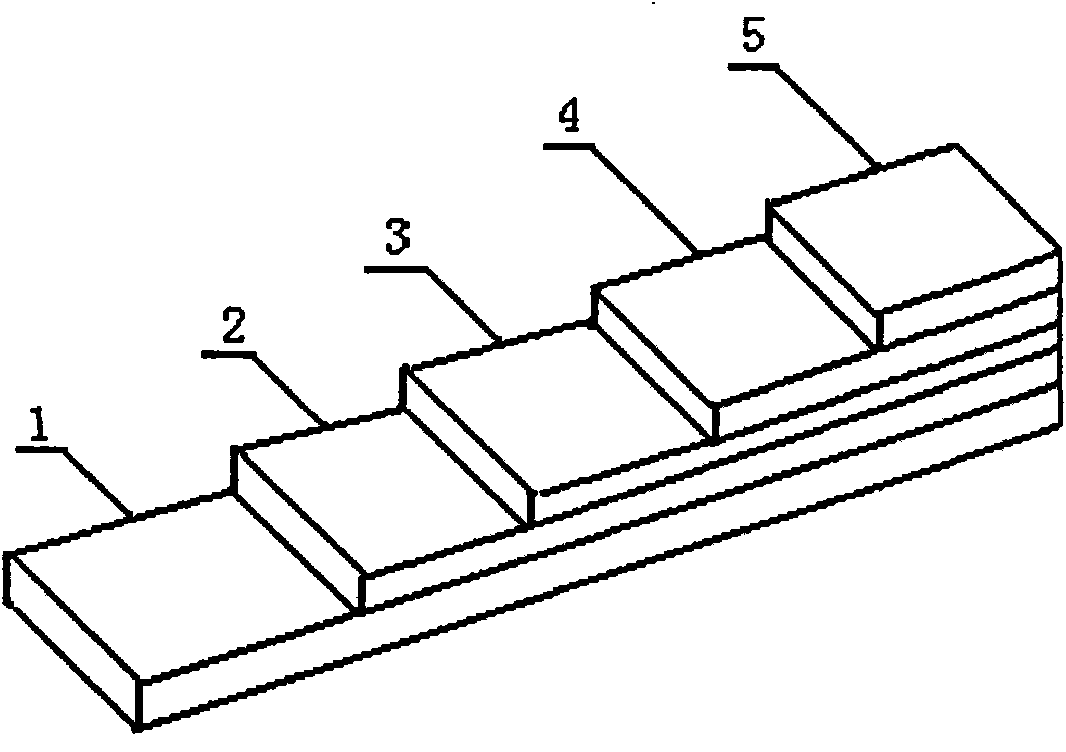

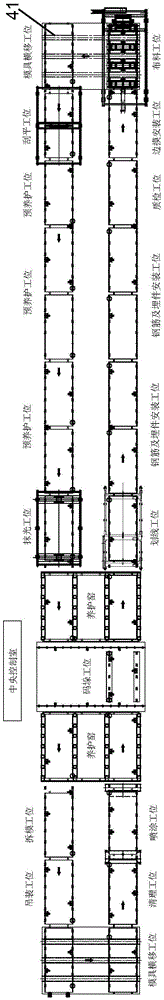

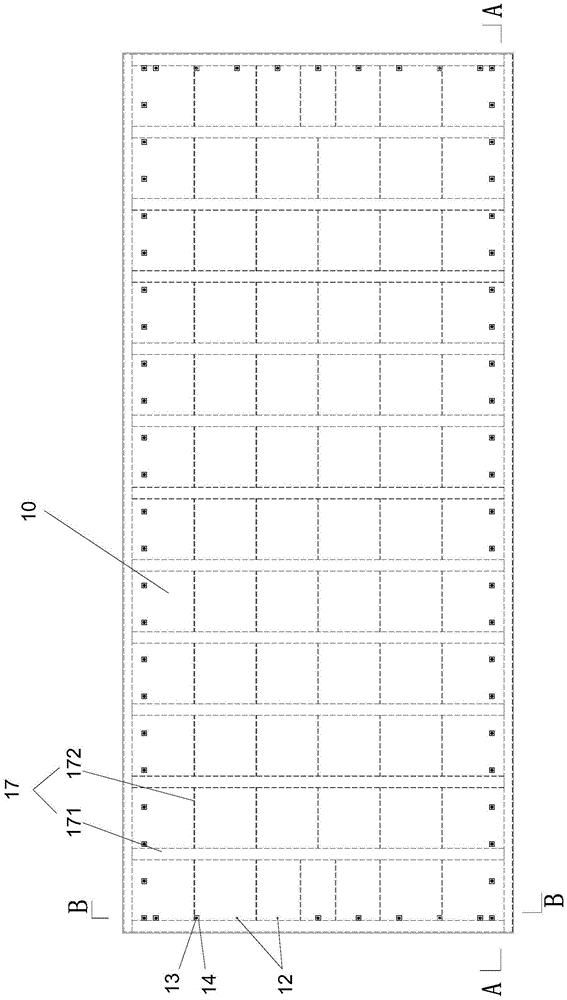

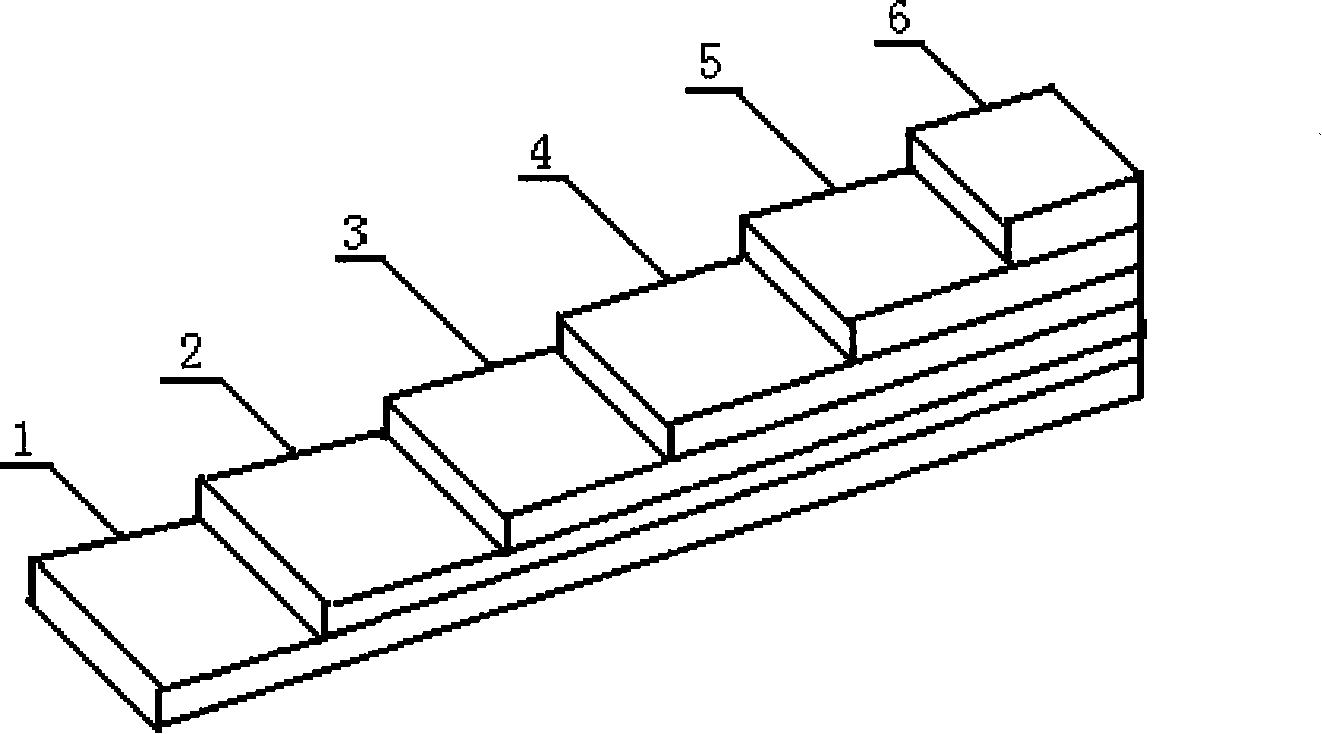

PC component production line

ActiveCN105459258AReduce wasteReduce manufacturing costCeramic shaping plantsFeeding arrangmentsProduction lineMaterial resources

The invention provides a PC component production line. The PC component production line comprises a clearing work station, a spraying work station, a scribing work station, a reinforcing steel bar and embedded part mounting work station, a quality inspection work station, a side die mounting work station, a laying work station, a die transverse movement work station, a leveling work station, a pre-curing work station, a smoothing work station, a curing kiln, a stacking work station, a die removing work station, a lifting work station and the like, which are connected by a conveying rail. A die component moves with the conveying rail in the order of the work stations and is processed by the procedures of all the work stations. Various models and sizes of PC components can be produced and manufactured. The layout of the production line is reasonable. Various PC components can be cyclically produced on one production line, so that various sizes of fixing dies do not need to be manufactured. The waste of material resources is greatly reduced, the production cost is reduced, and the production efficiency is improved.

Owner:HEBEI YUGOU BUILDING MATERIALS CO LTD

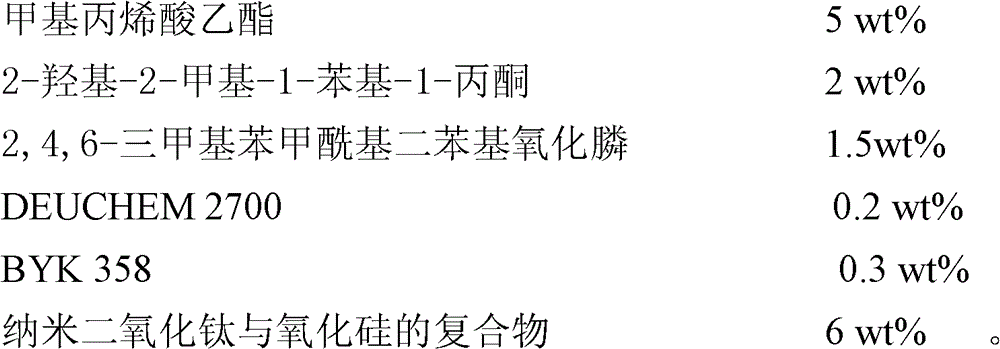

Ultraviolet light-cured self-cleaning coating, and preparation method and application thereof

InactiveCN103059713AWith self-cleaning functionVariety of colorsPolyurea/polyurethane coatingsEpoxy resin coatingsUltraviolet lightsPolymer chemistry

The invention belongs to the field of coatings, and relates to an ultraviolet light-cured self-cleaning coating, and a preparation method and an application thereof. The self-cleaning coating is obtained by mixing 30-80 wt% of a reactive fluorine-containing acrylic ester prepolymer, a acrylic ester prepolymer or a mixture of the above two 10-60 wt% of reactive fluorine-containing acrylic ester monomers, acrylic ester monomers or a mixture of the above two, 2-10 wt% of a photoinitiator, 0-40 wt% of a pigment, 0-30 wt% of an auxiliary agent and 1-30 wt% of a photocatalytic material, based on the total amount of the ultraviolet light-cured self-cleaning coating, grinding and stirring uniformly. The coating is coated on the surface of a substrate. The coated film can produce a photochemical polymerization and is cured under the irradiation of ultraviolet light. The cured film has the advantages of plump film, abundant colors, high hardness, good scratch resistance, good weather resistance and stain resistance, good self-cleaning feature and the like.

Owner:ZHUHAI DONGCHENG UV MATERIALS

Photogravure ink equal to cut ink and its application

This invention relates to a photograghic intaglio printing ink which equals to carving intaglio printing ink. It can be used in photographic intaglio printer, and its outstanding feature is that the price of the printer is cheap, lithographic cost is low, and the post-treatment step of sewage during printing process is unneeded, so the sewage from carving intaglio printing ink printing process is eradicated completely and with no environmental pollution, and the printing ink is no waste and its non-offset performance is very good. It dries quickly, so it shortens the production cycle and saves the production buildings and land. The color of ink of its printing is of distinct hierachical structure and strong stereoscopic feeling. Its printing effect is the same as that of carving intaglio printings. The physicochemical fastness of its printing is superior to that of carving intaglio printings. Its printing cost is low.

Owner:北京万防伪技术有限责任

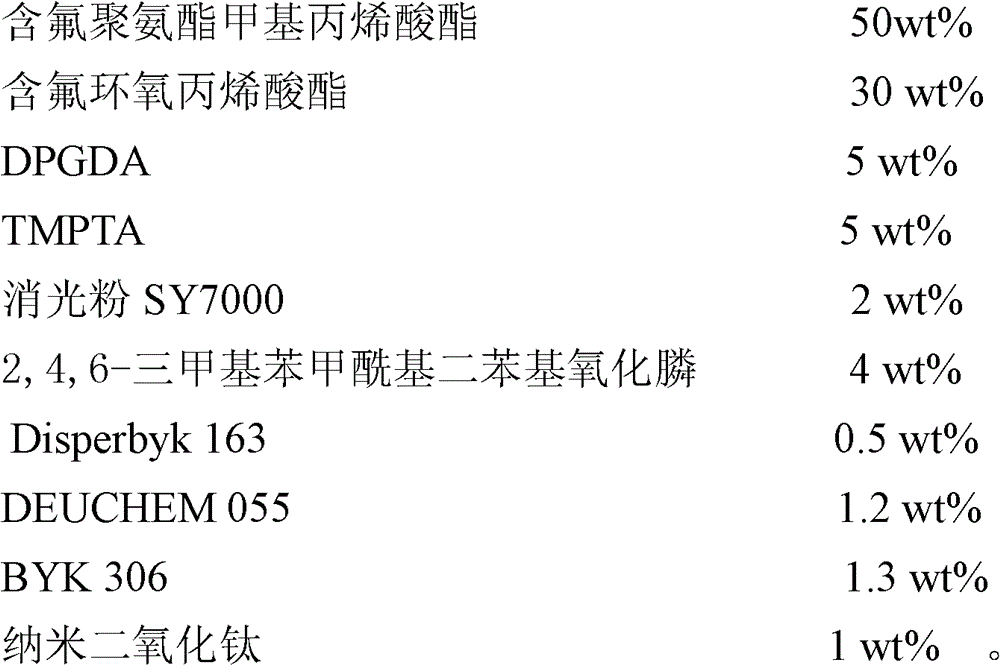

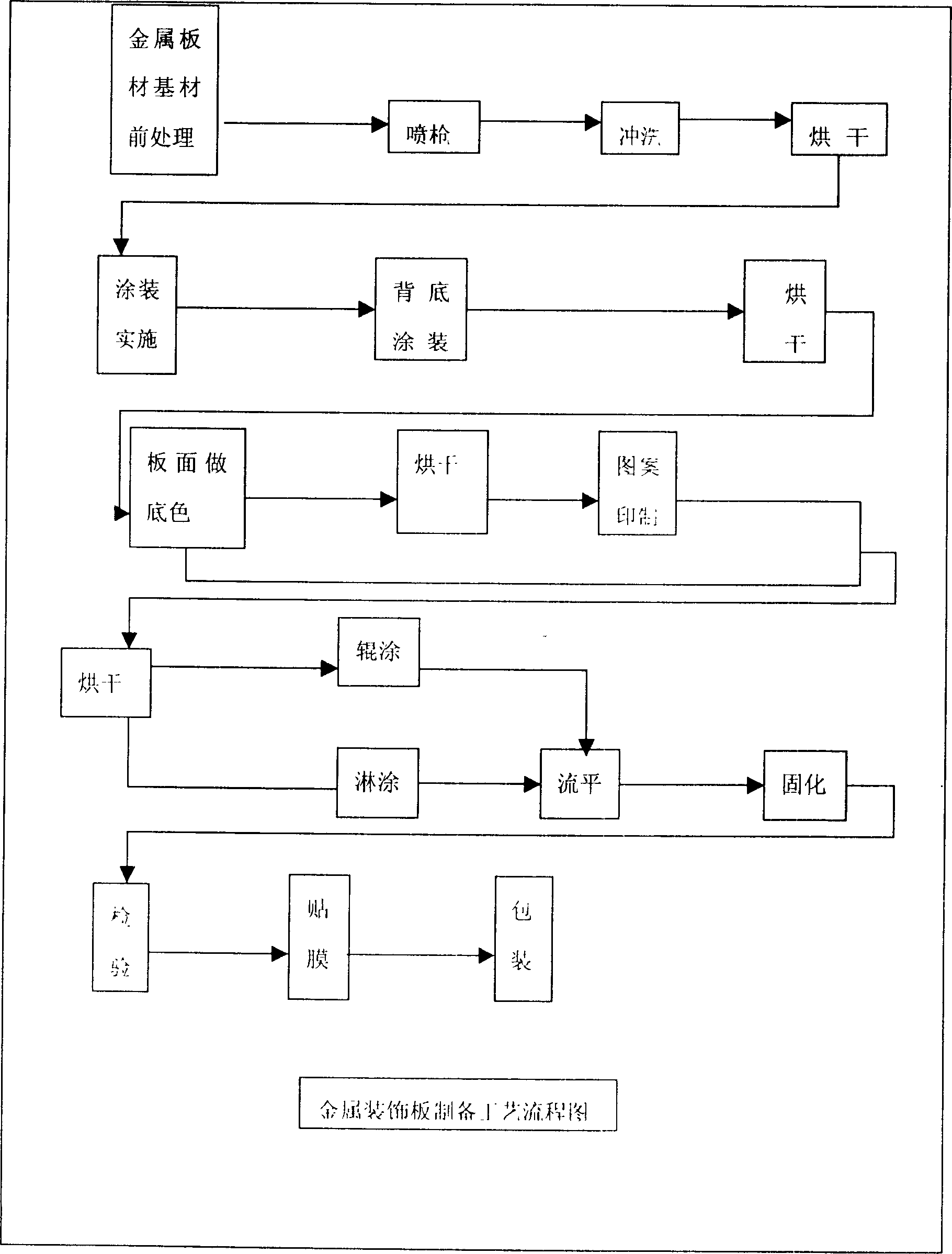

Ultraviolet curing chromatic wall decoration board and preparation method thereof

InactiveCN101158210ASave production spaceIncrease productivityCovering/liningsPretreated surfacesCoated surfacePolypropylene

The invention belongs to the construction material decorative board field, in particular to a UV-curable color wall decorative board produced by coating the surface with UV-curable coatings and a preparation method thereof. A UV-curable putty layer is coated on the surface of the wall decorative board substrate, a UV-curable closed primer layer is coated on the surface of the UV-curable putty layer, a UV-curable color topcoat layer is coated on the surface of the UV-curable closed primer layer, and a polypropylene or polyethylene protective film is coated on the surface of the UV-curable color topcoat layer. A UV-curable white primer layer is positioned between the UV-curable closed primer layer and the UV-curable color topcoat layer. The UV-curable wall decorative board of the invention has the advantages of high timber intensity, good weatherability, good environmental protection ability, rich colors, thick paint film, high rigidity, high scratching resistance, cleaning convenience, and non-inflammability, compared with the existing commonly used wall decorative boards, the invention has better decorative and protective effects.

Owner:ZHUHAI DONGCHENG UV MATERIALS

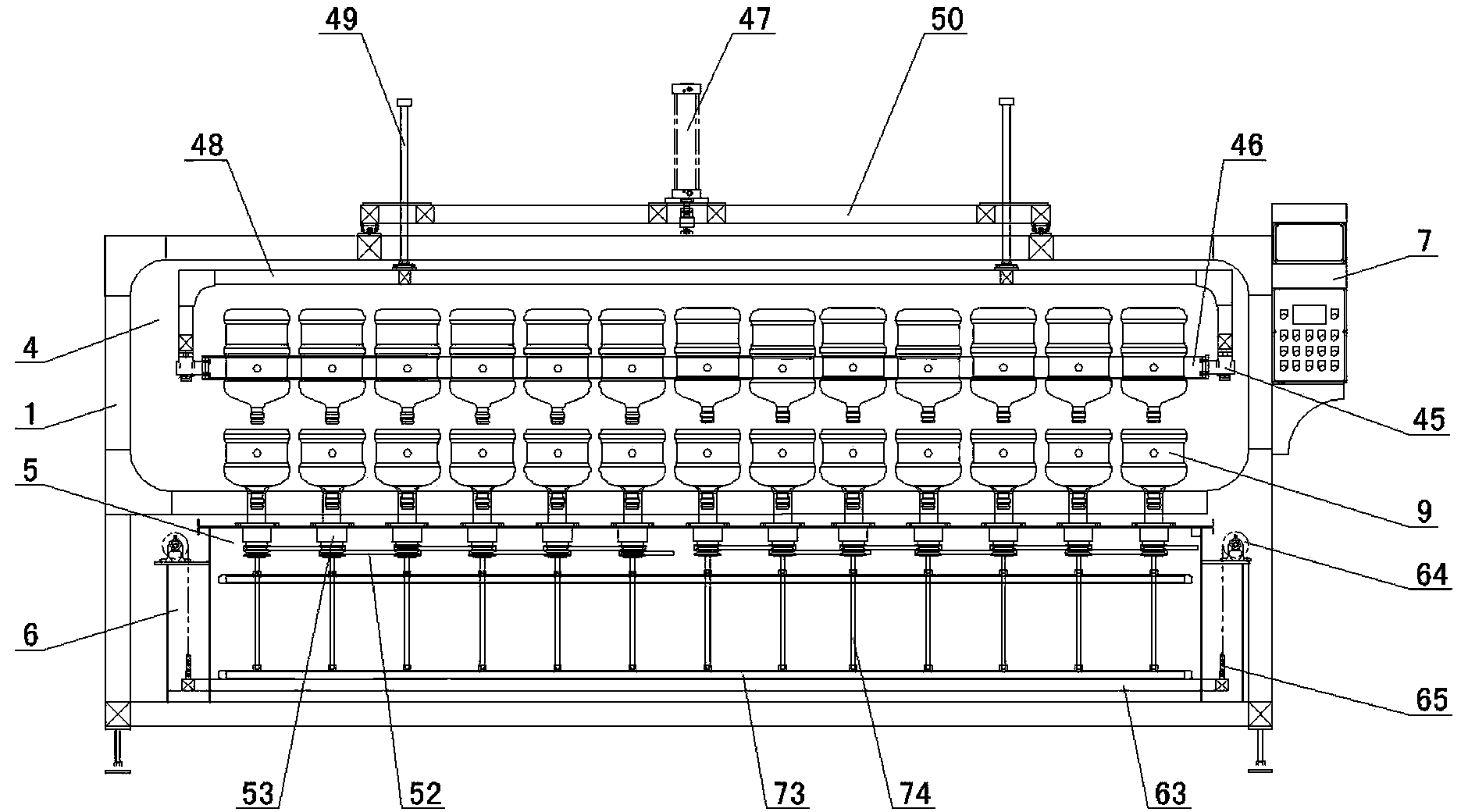

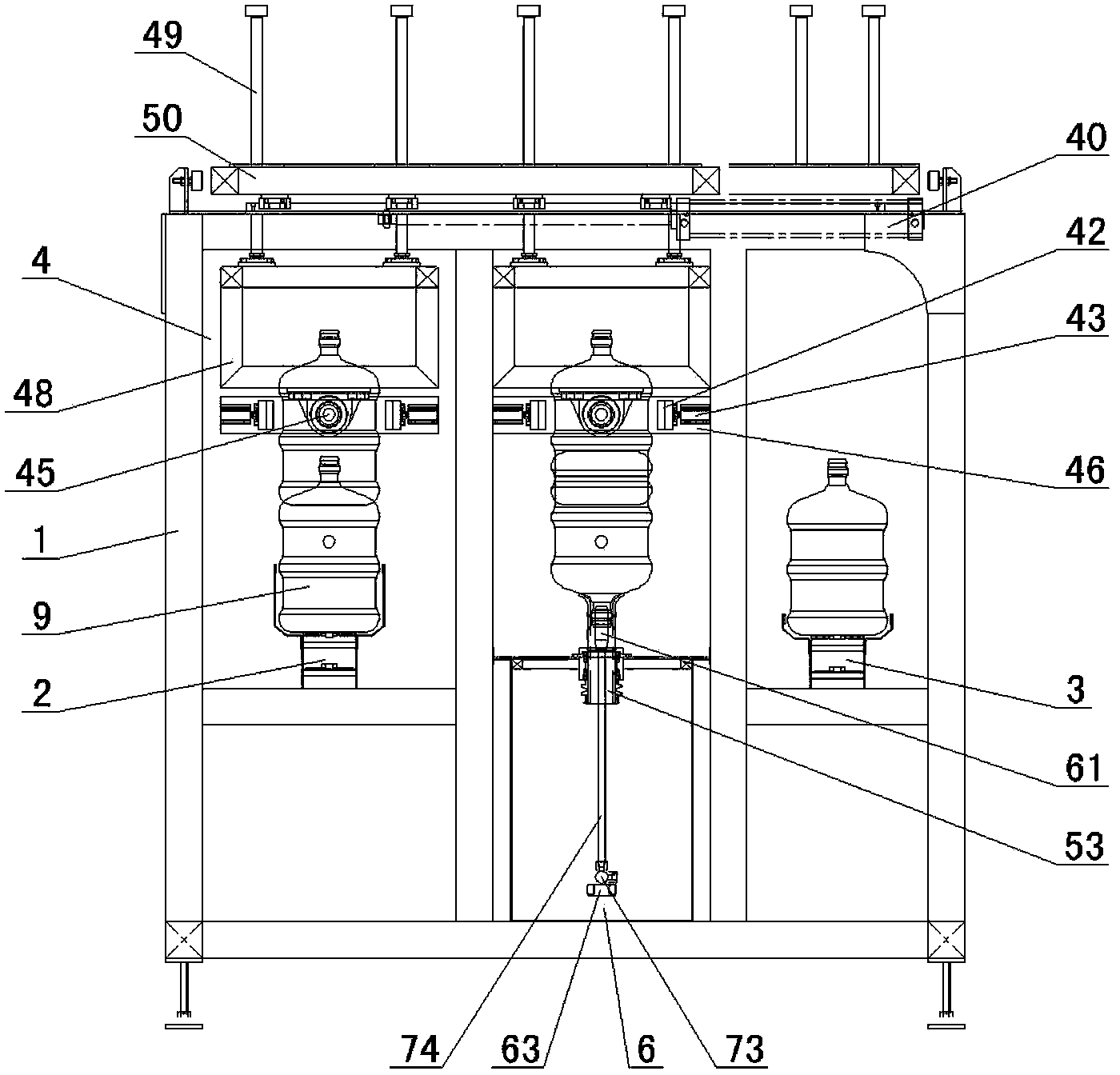

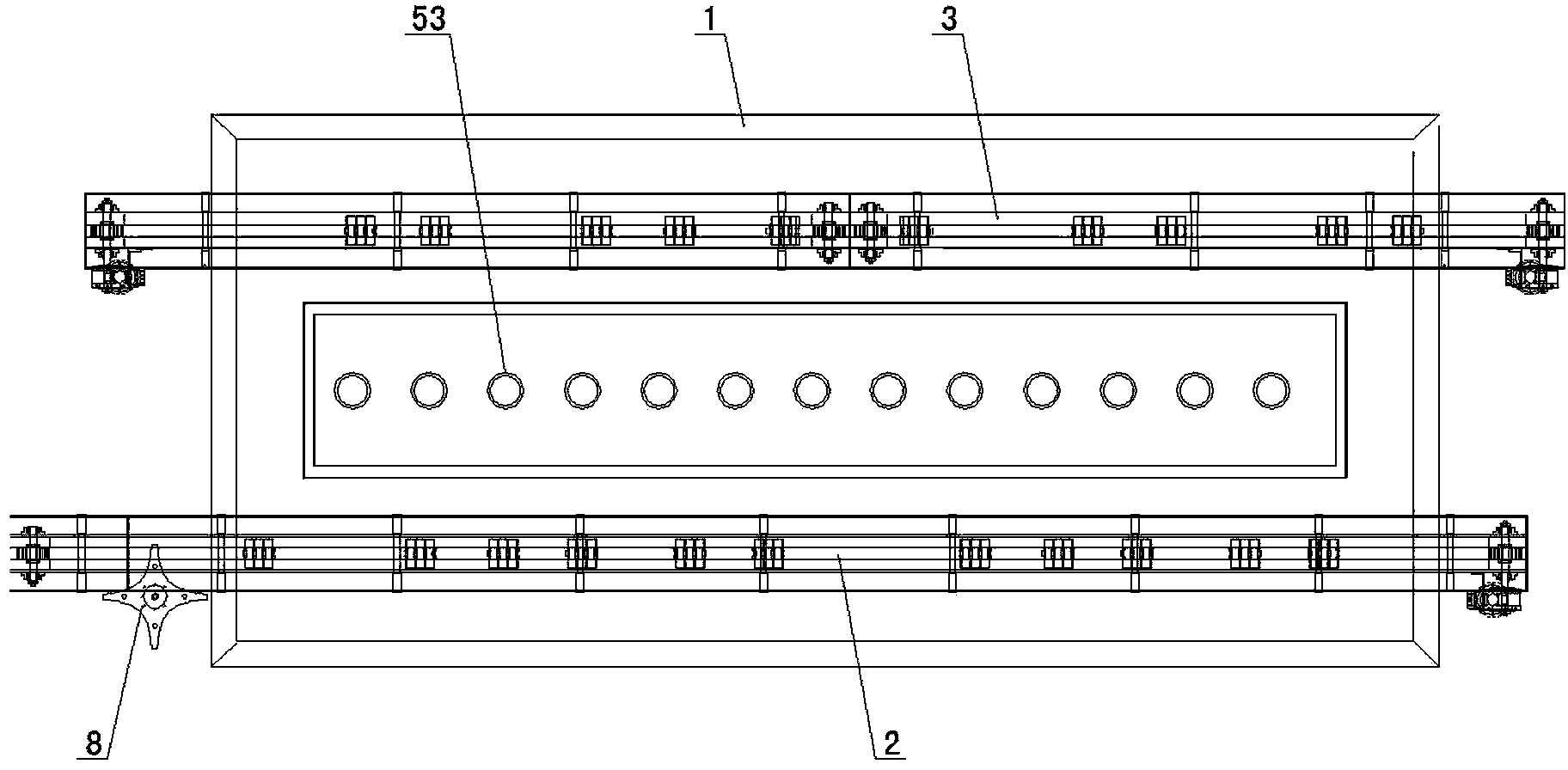

Machine for cleaning inner wall of barrel

ActiveCN103357629AGuaranteed cleaning qualityWork lessHollow article cleaningSpray nozzleEngineering

A machine for cleaning the inner wall of a barrel comprises a machine frame, a barrel inlet conveying chain, a barrel outlet conveying chain, a barrel clamping device, a barrel fixing rotary device, a high-pressure cleaning device and an operation control box, wherein the high-pressure cleaning device comprises a cleaning solution feeding device, a jet head and a pneumatic vertical lifting mechanism; the jet head is communicated with the cleaning solution feeding device through a liquid transport tube; the pneumatic vertical lifting mechanism is mounted on the machine frame and used for driving the jet head to move up and down vertically; at least three nozzles, which form different angles with the horizontal plane, are arranged on the jet head. According to the machine, the inner wall of the barrel of barreled water can be cleaned in an up-down 360 degrees' rotating isopiestic pressure cutting manner, so that each part of the inner wall of the barrel can be cleaned with high-pressure water proportionably, the effect of flushing the inner wall of the barrel completely is achieved effectively, the cleaning quality of the inner wall of the barrel is guaranteed, and the service life of the jet head is prolonged. The machine has the advantages that the structure is reliable; the running is stable; the cleaning efficiency is high; occupied production space is less; the labor cost, manufacture cost and running cost are low.

Owner:广东鼎湖山泉有限公司

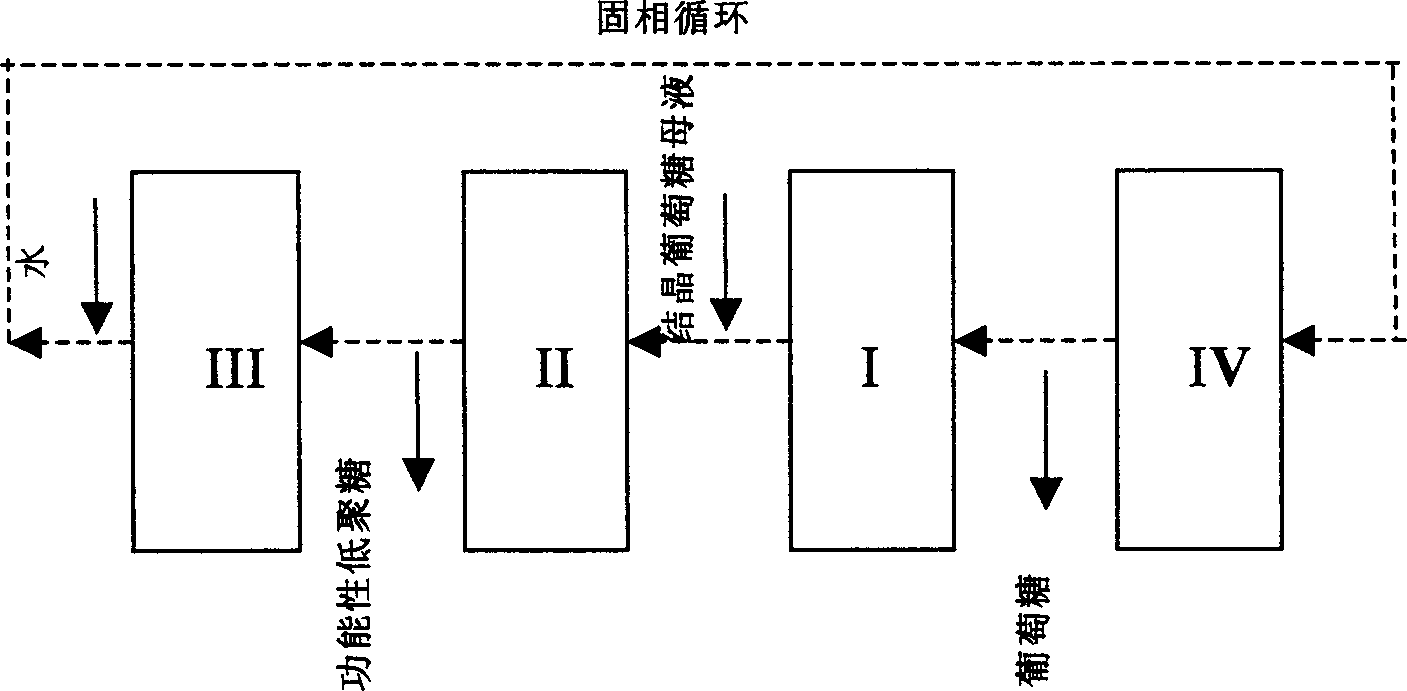

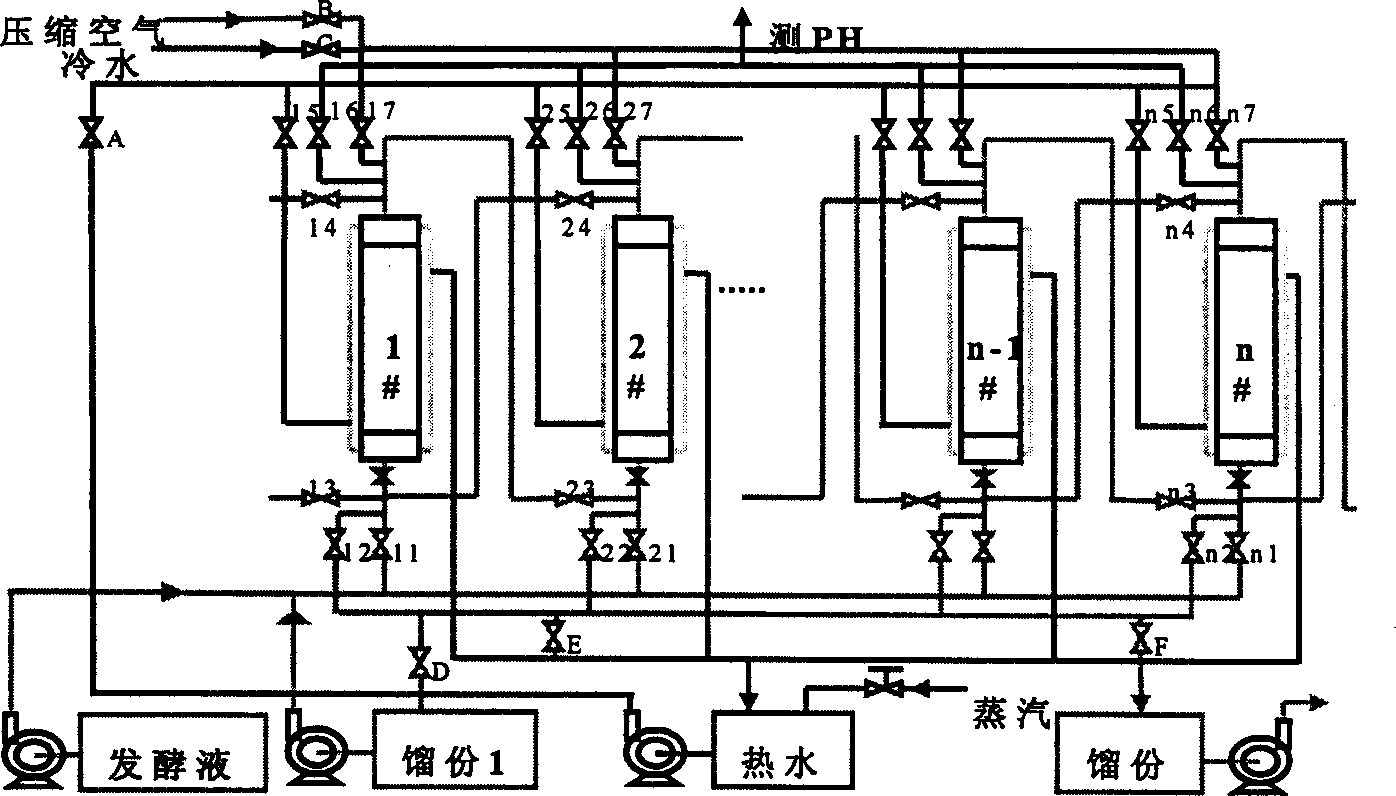

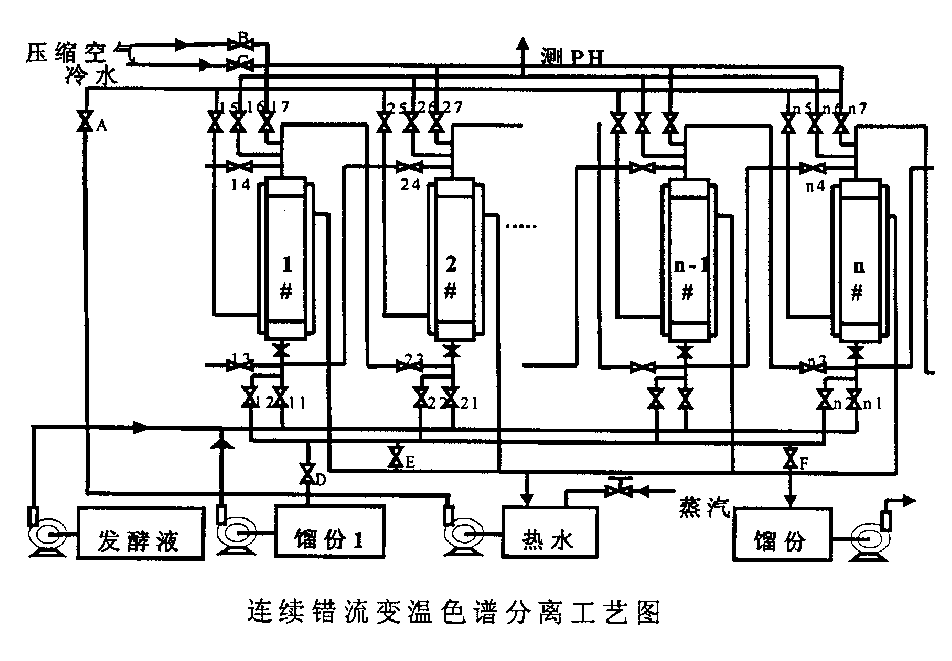

Separation and purification method of trehalose

ActiveCN103450288AHigh purityIncrease profitSugar derivativesDisaccharidesChromatographic separationPurification methods

The invention relates to a separation and purification method of trehalose, which comprises the following steps: (1) carrying out enzymolysis on a trehalase reaction solution prepared by a trehalose synthase conversion process, and filtering to obtain a trehalose crude solution; (2) decolorizing the trehalose crude solution through activated carbon, and filtering to obtain a mixed solution; (3) passing the mixed solution through an ion exchange resin to obtain a glucose-trehalose sugar solution; and (4) concentrating the glucose-trehalose sugar solution, and separating by continuous chromatography with a simulated moving bed to obtain a trehalose solution and a glucose solution. The trehalase reaction solution generated by converting maltose by trehalose synthase is used as the raw material, the maltose which is isomeric with the trehalose is converted by an enzyme process, and impurity glucose, remaining maltose and impurities, such as proteins, pigments, metallic ions and the like, are removed to obtain the high-purity trehalose.

Owner:ZHUCHENG DONGXIAO BIOTECH

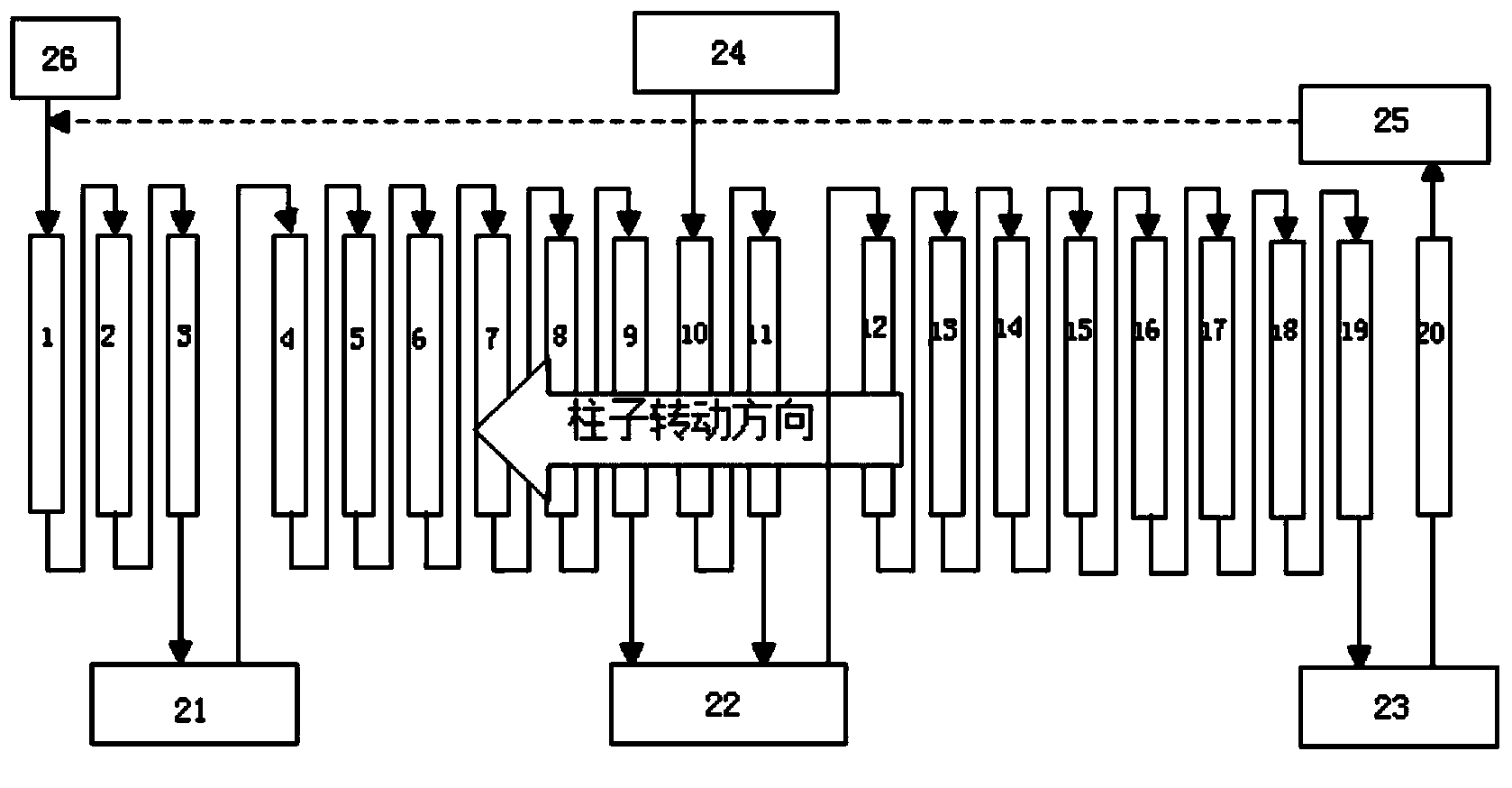

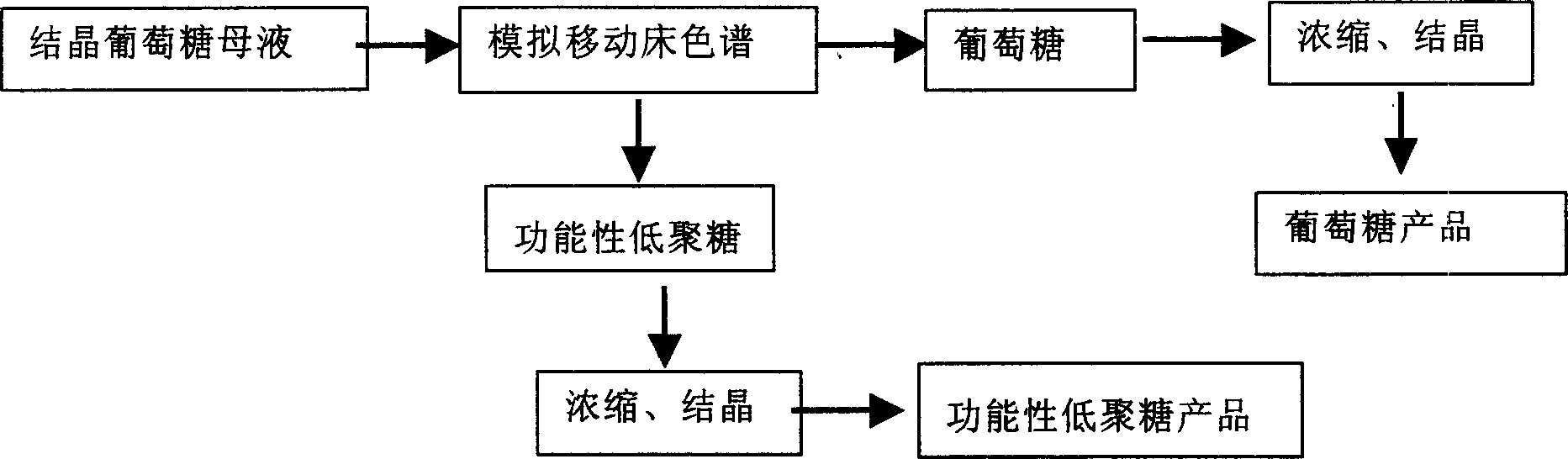

Method for extracting high purity glucose and functional oligose from crystalline glucose mother liquid

InactiveCN1715423AGood adsorption and separation performanceIncrease profitGlucose productionSimulated moving bedD-Glucose

The present invention provides a method of extracting high purity glucose and functional oligose form crystalline glucose mother liquid, and relates to the preparation technology of high purity glucose and functional oligose. By means of synthesizing special resin and analog mobile bed technology, the present invention separates and prepares high purity glucose and functional oligose form crystalline glucose mother liquid. The specific process is that crystalline glucose mother liquid is made to pass through chromatographic analog mobile bed system to separate glucose from functional oligose completely with water as elutent and at the operation temperature of 35-95 deg c to obtain the component with rich glucose and the component with rich functional oligose.

Owner:JIANGNAN UNIV

Preparation method for capsicum thick broad-bean sauce

InactiveCN104207106ARealize large-scale productionClean thoroughlyFood preparationGlass fiberCapsicum annuum

A preparation method for capsicum thick broad-bean sauce employs the following steps: step 1, preparing cleaned fresh capsicum accounting for 70% by weight of raw materials; step 2, crushing fresh capsicum obtained in the step 1 for usage; step 3, mixing crushed capsicum obtained in the step 2 with broad bean accounting for 30%, pumping the mixture into a food-grade glass-fiber-reinforced-plastic fermentation tank by a pump and stirring uniformly; step 4, after uniform stirring is performed, controlling the temperature to be 28-38 DEG C, and performing fermentation, when the temperature is relatively low, conveying steam through a stainless steel pipe twinning round the tank body for keeping warm, guaranteeing the fermentation temperature, stirring once every 3-5 days during fermentation, stirring for 20 min in each stirring process, and fermenting for 5 months, so as to obtain a finished product; and step 5, opening a discharging port at the bottom of the tank and discharging the fermented finished product capsicum thick broad-bean sauce, performing product detection and packaging and warehousing. The preparation method realizes scalization, intensification and cleansing, and helps to save production field, reduce labor cost, shorten fermentation period and improve production efficiency.

Owner:遵义市名城酿造厂

Biological compound fertilizer and production process thereof

InactiveCN101555173ASolve watering and irrigation problemsLow input costBio-organic fraction processingWaste based fuelContinuous croppingChemical reaction

The invention relates to a biological compound fertilizer and a production process thereof, which relates to the field of agricultural fertilizers and the production thereof. The prior biological bacterial fertilizer has the problems of not comprehensive enough nutrition, poorer water retention and drought-resistant degree and lower survival rate of biological bacteria. The invention provides a prescription that the biological compound fertilizer contains liquid-fertilizer sustained release agent with micropores, compound biological fertilizer, high-efficient organic matters, inorganic N P, K and micro elements in the lack of soil; and the production process adopts a method of roller- extrusion cold prilling and has no drying and air-cooling procedures and no any chemical actions. The invention has the advantages of more comprehensive nutrition, water retention, drought and continuous cropping resistance, the improvement of the survival rate and the reproduction rate of biological bacteria and balanced crop growth.

Owner:NANYANG BOLIDA FERTILIZER

Circulation evaporator

InactiveCN101811743ANon-deterministicLower evaporation temperatureWater/sewage treatment by heatingPapermakingSewage

The invention discloses an evaporator for performing innocent treatment on sewage in industries of papermaking and the like. In an existing device, a secondary steam pipe is connected to an inlet of a compressor; an outlet of the compressor is connected with a steam inlet of a steady head tank; the other steam inlet pipe of the steady head tank is connected with a fresh steam pipe of a boiler; a steam outlet of the steady head tank is connected with a falling-film evaporator which is at least provided with one circulating pipe connected with a circulating pump; an outlet of a stripper plant of the falling-film evaporator is communicated with a non-condensable air pipe and a heavily-polluted condensate water outlet pipe which is communicated with a water inlet of a heavily-polluted condensate water tank; a water outlet of the heavily-polluted condensate water tank is communicated with a heavily-polluted condensate water delivery pipe; and a condensation water outlet pipe of a condenser is communicated with the water inlet of the heavily-polluted condensate water tank.

Owner:兰州节能环保工程有限责任公司 +1

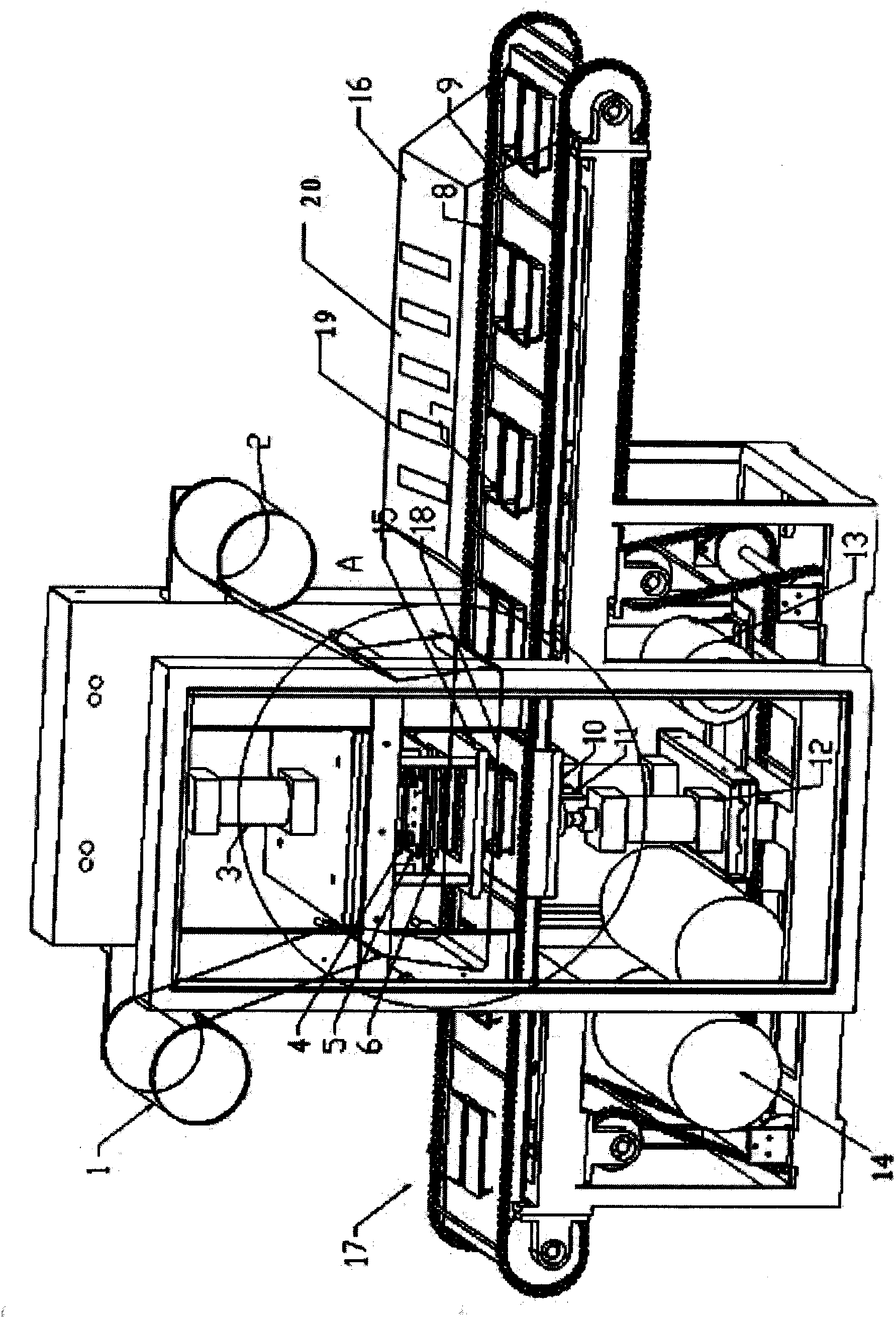

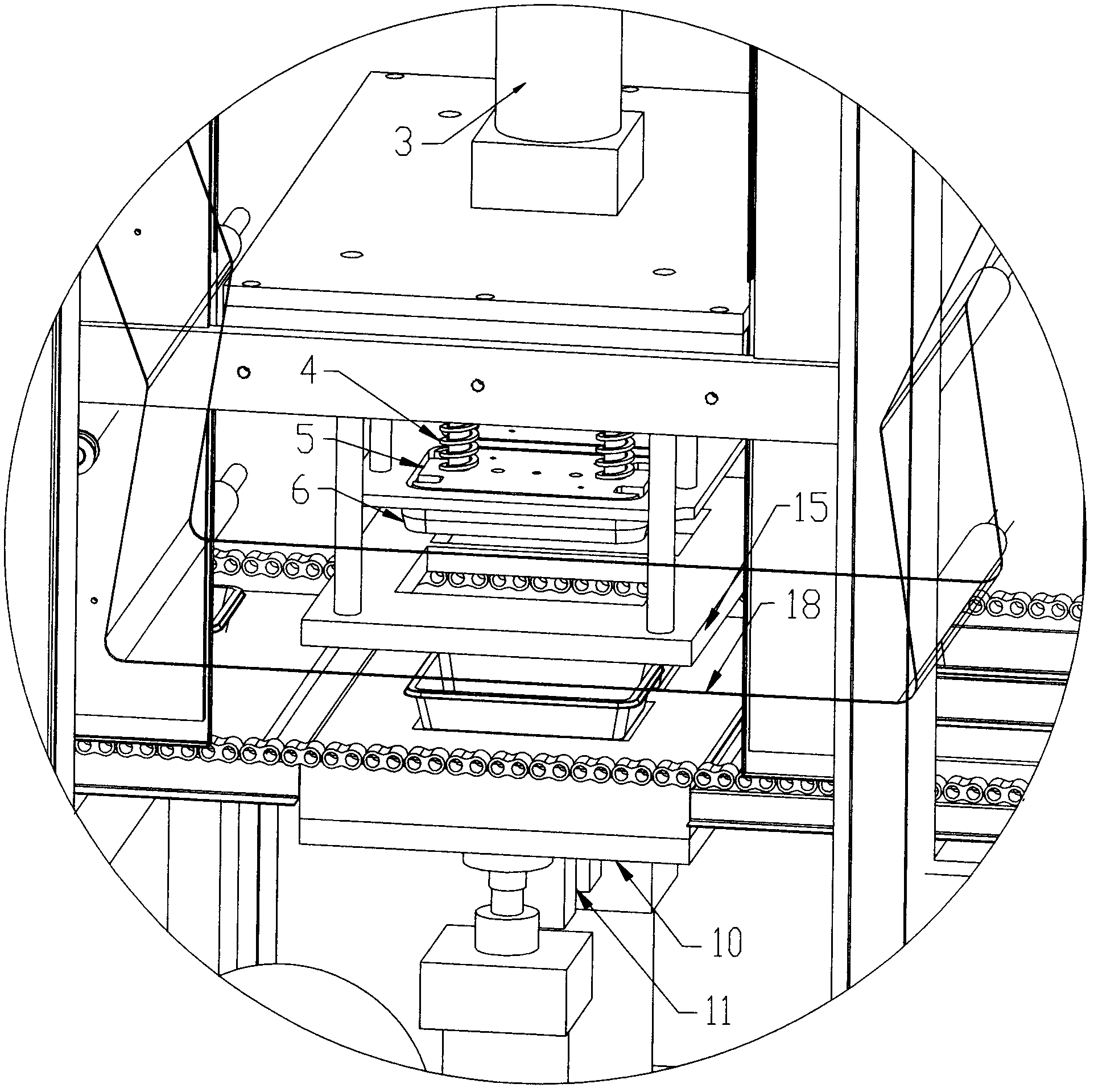

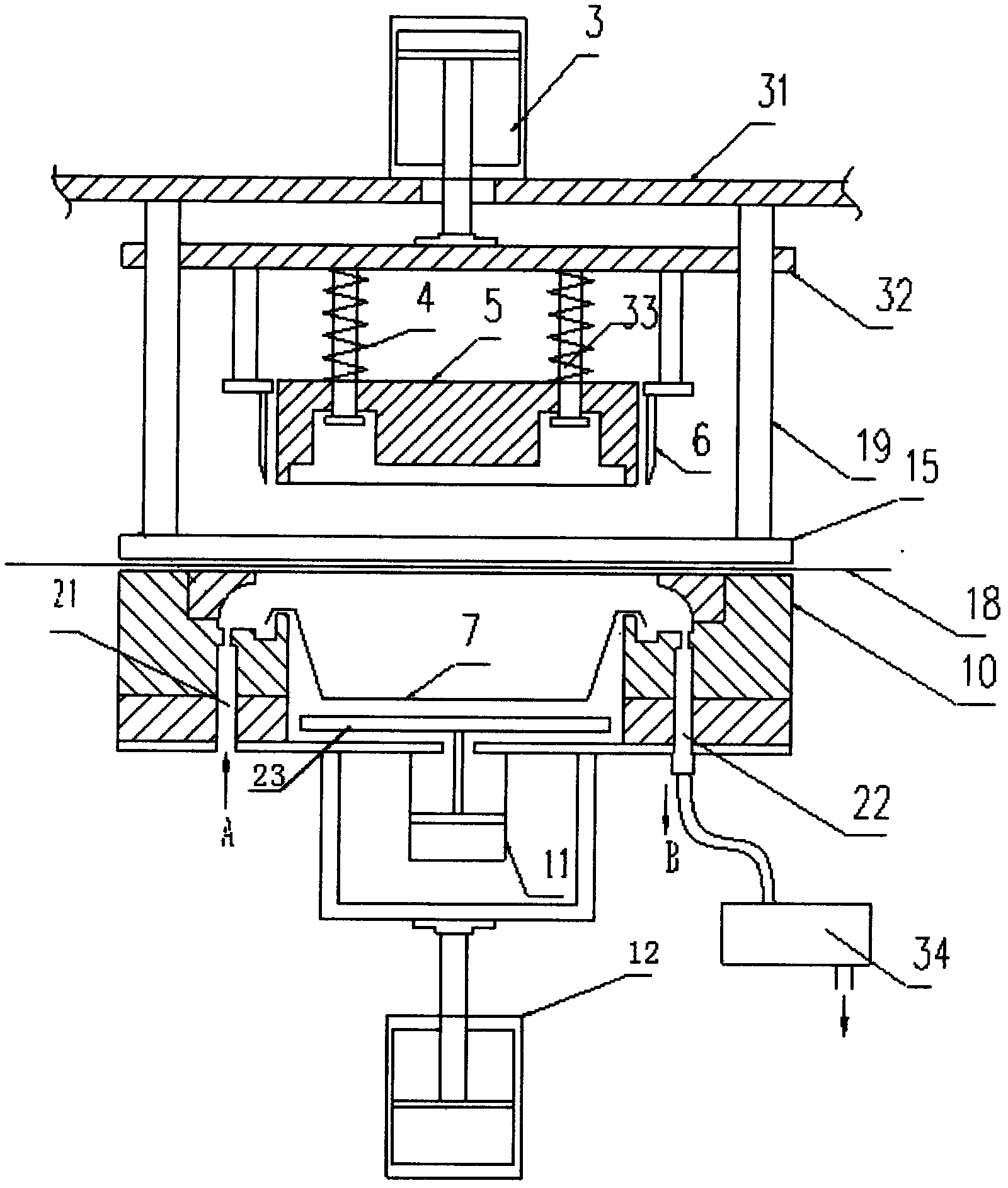

Pulse sterilization continuous box type modified atmosphere packaging machine

InactiveCN103419960ASimple structureCompact structurePackage sterilisationPackaging by pressurising/gasifyingControl systemEngineering

The invention discloses a pulse sterilization continuous box type modified atmosphere packaging machine. The modified atmosphere packaging machine comprises a transmission system, a packaging system and a film sealing system and further comprises a control system, wherein the transmission system, the packaging system and the film sealing system are installed on a rack, a sterilization system is installed at the front end of the transmission system, and the packaging system comprises a film sealing device, a gas replacement device, a hot-sealing device and a cutting device. With the method, the modified atmosphere packaging machine is simple in structure, capable of performing continuous sterilization and continuous and automatic modified atmosphere packaging on products through a small number of work stations, high in packaging speed and capable of achieving the high gas replacement rate and the high gas mixing accuracy.

Owner:沈滢

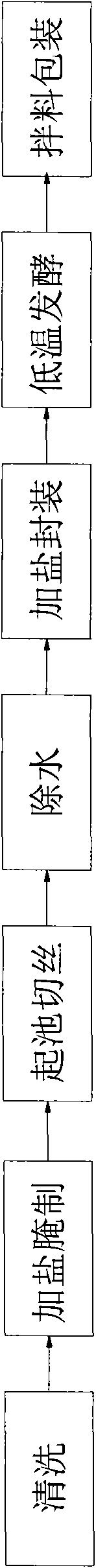

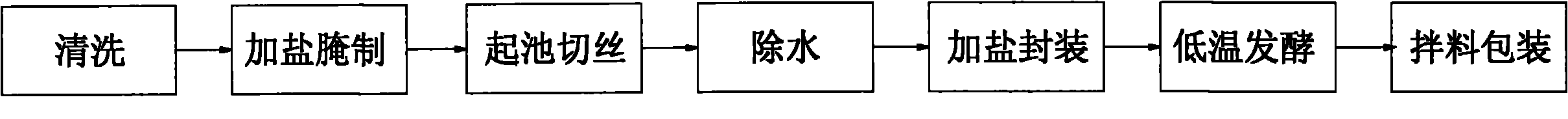

Mustard tuber production process

InactiveCN101849660AEmission reductionEtain organic matterFood preparationOrganic matterPlant Tubers

The invention belongs to the technical field of mustard tuber production processes, and in particular relates to a mustard tuber pickling process. The mustard tuber pickling process of the invention comprises the following steps of washing, adding salt and pickling, taking the mustard tuber out of a tank and shredding the pickled mustard tuber, removing water, adding the salt and encapsulating, fermenting at a low temperature, washing for desalting, removing the water, mixing condiments, packaging and the like. By using the mustard tuber pickling process, complicated working procedures in the conventional production process are changed; and the process procedures are simplified obviously. In the mustard tuber pickling process, a low-salt low-temperature pickling and fermenting process is adopted and only a small amount of water is used for washing and desalting simply in production, so sewage discharge volume is very small, environment is protected, organic matters and fragrant matters in a mustard tuber raw material are preserved maximally and the quality of the mustard tuber is improved at the same time.

Owner:CHONGQING FULING ZHACAI GROUP

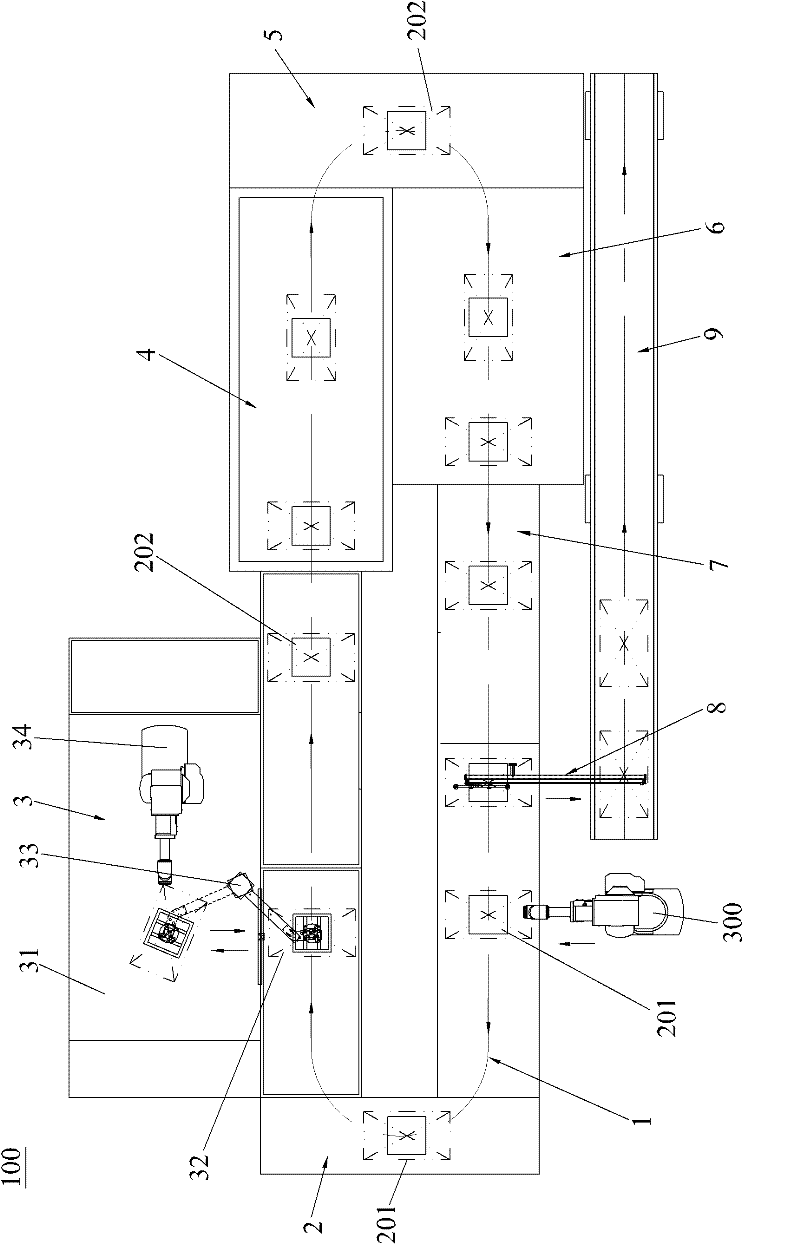

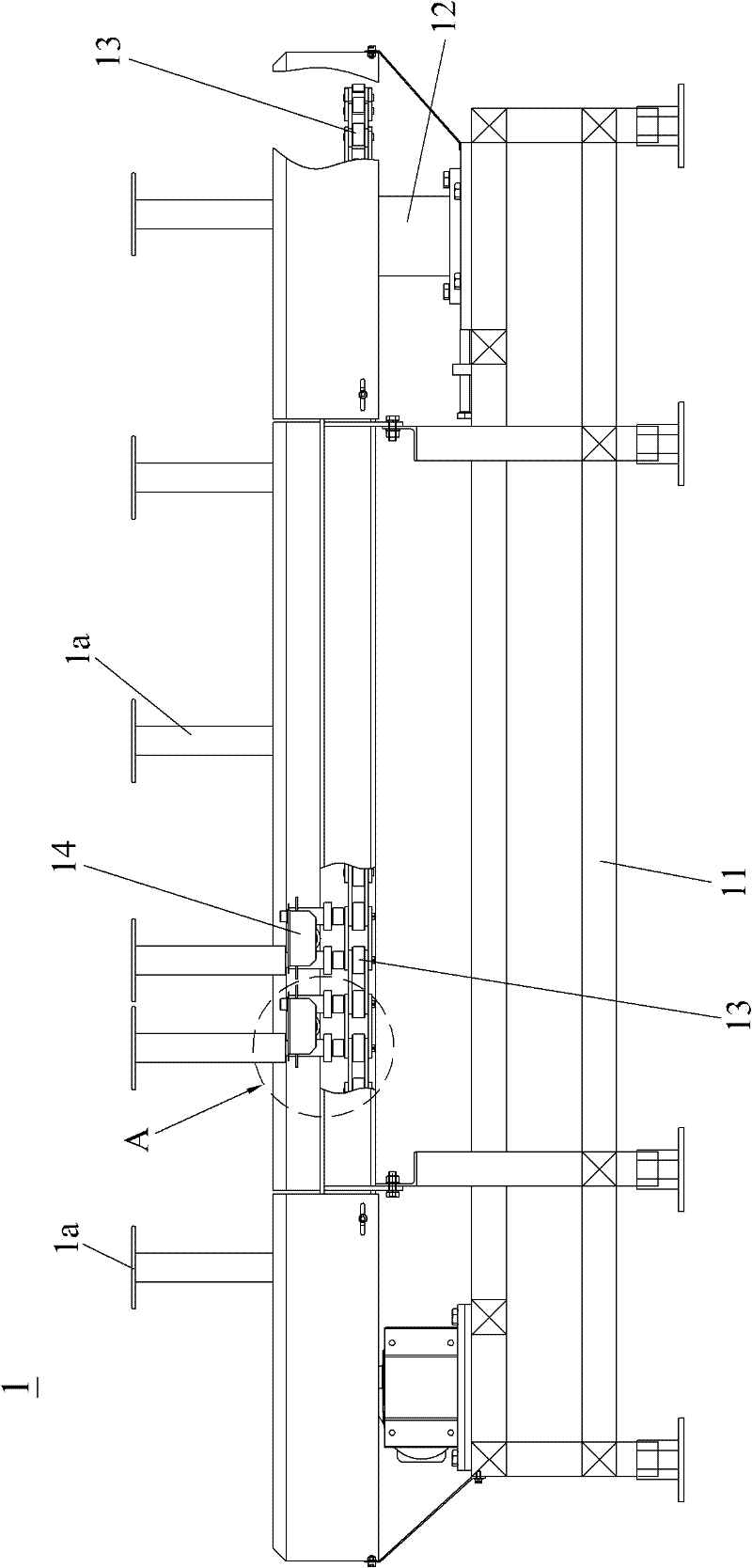

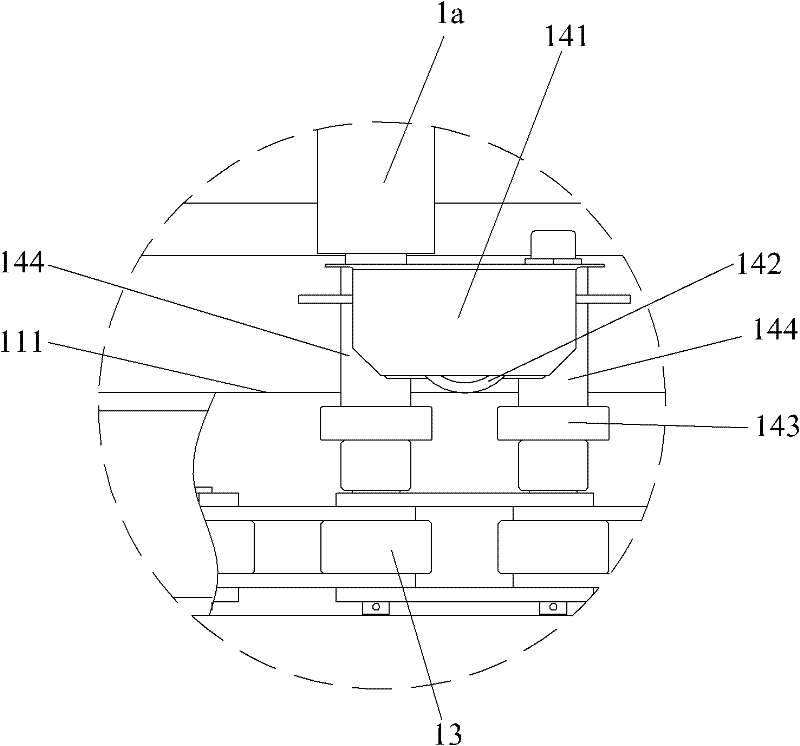

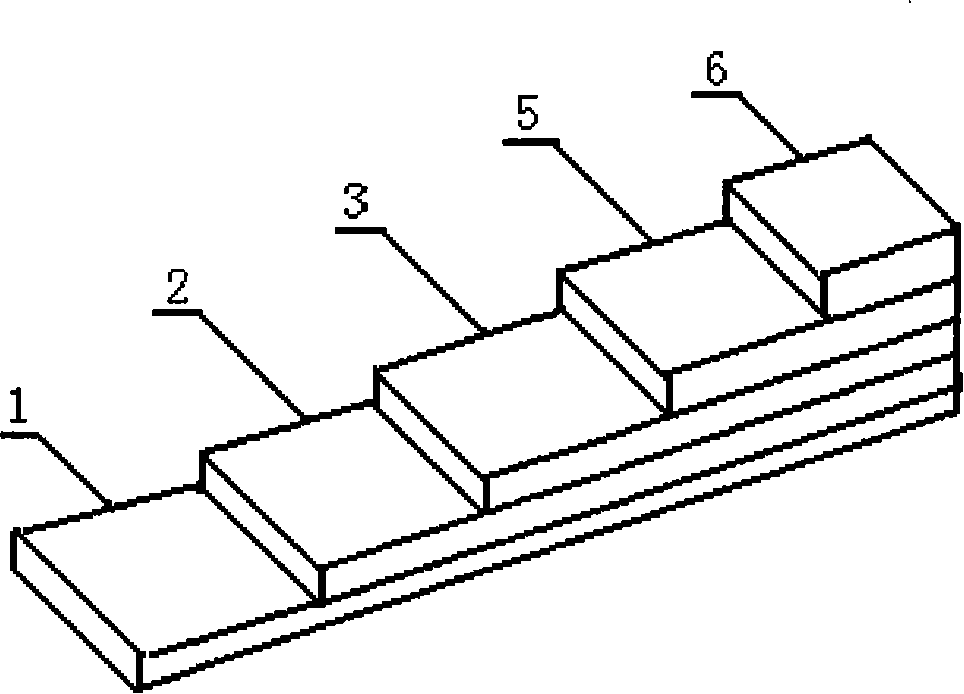

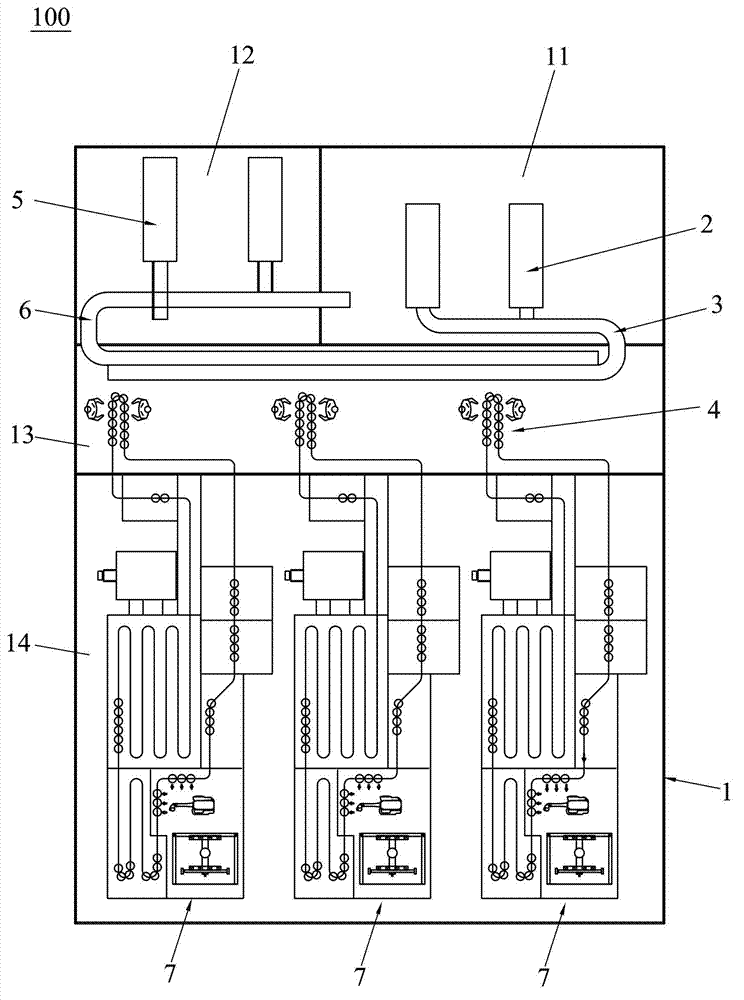

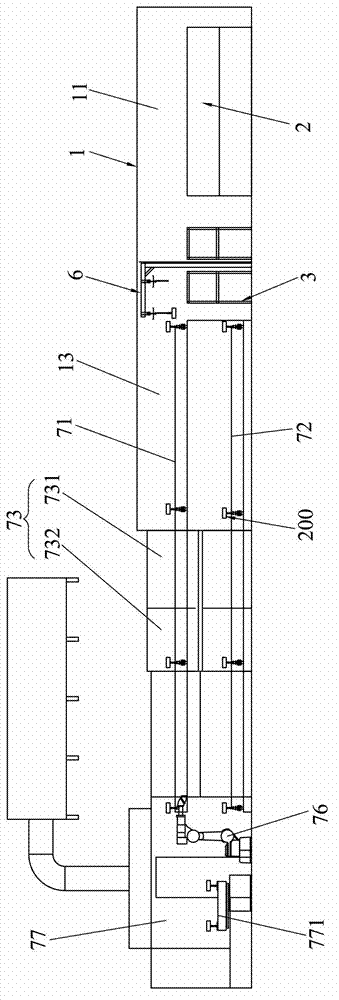

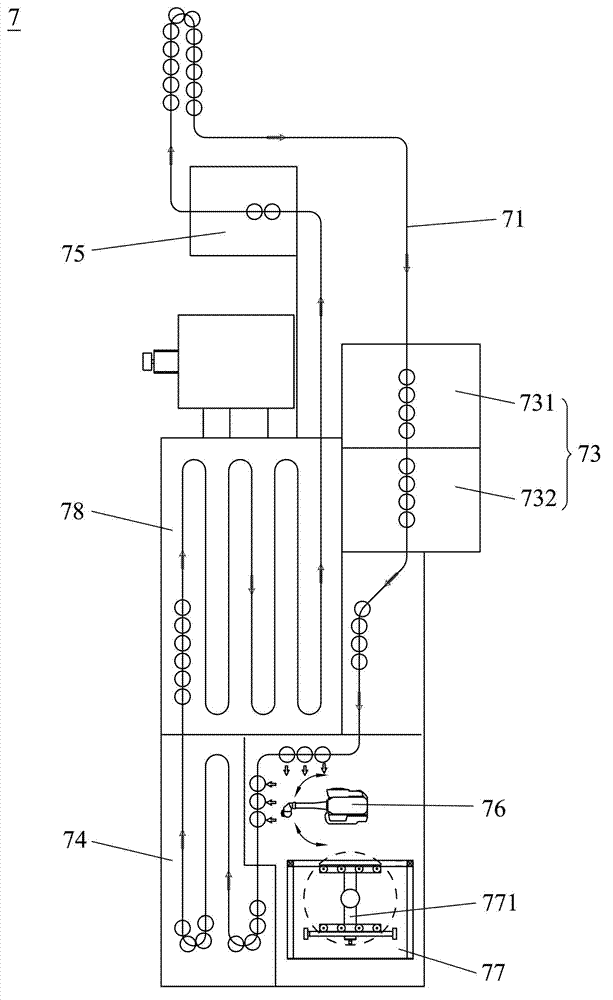

Spraying production line

InactiveCN102847630AQuick color change paintingReduce in quantitySpraying apparatusPretreated surfacesProduction lineEngineering

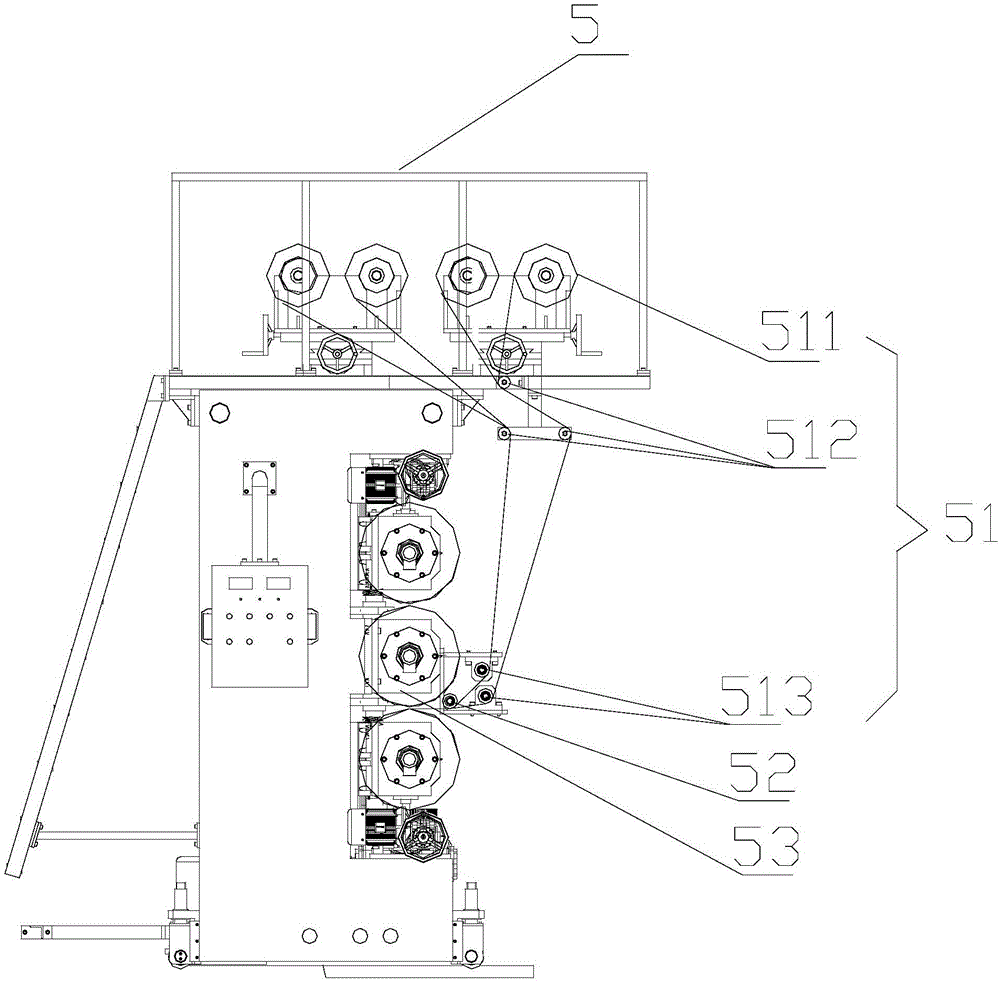

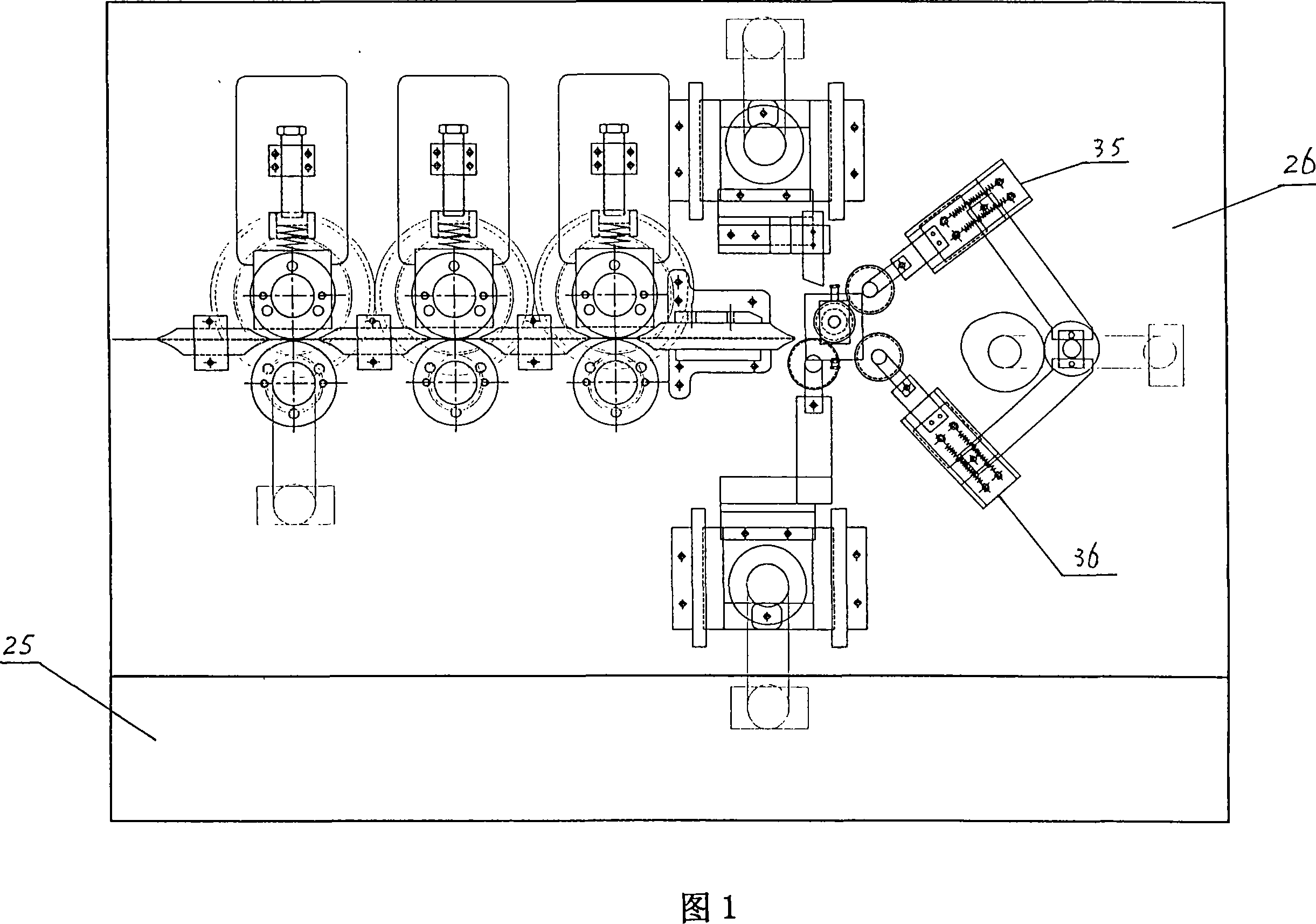

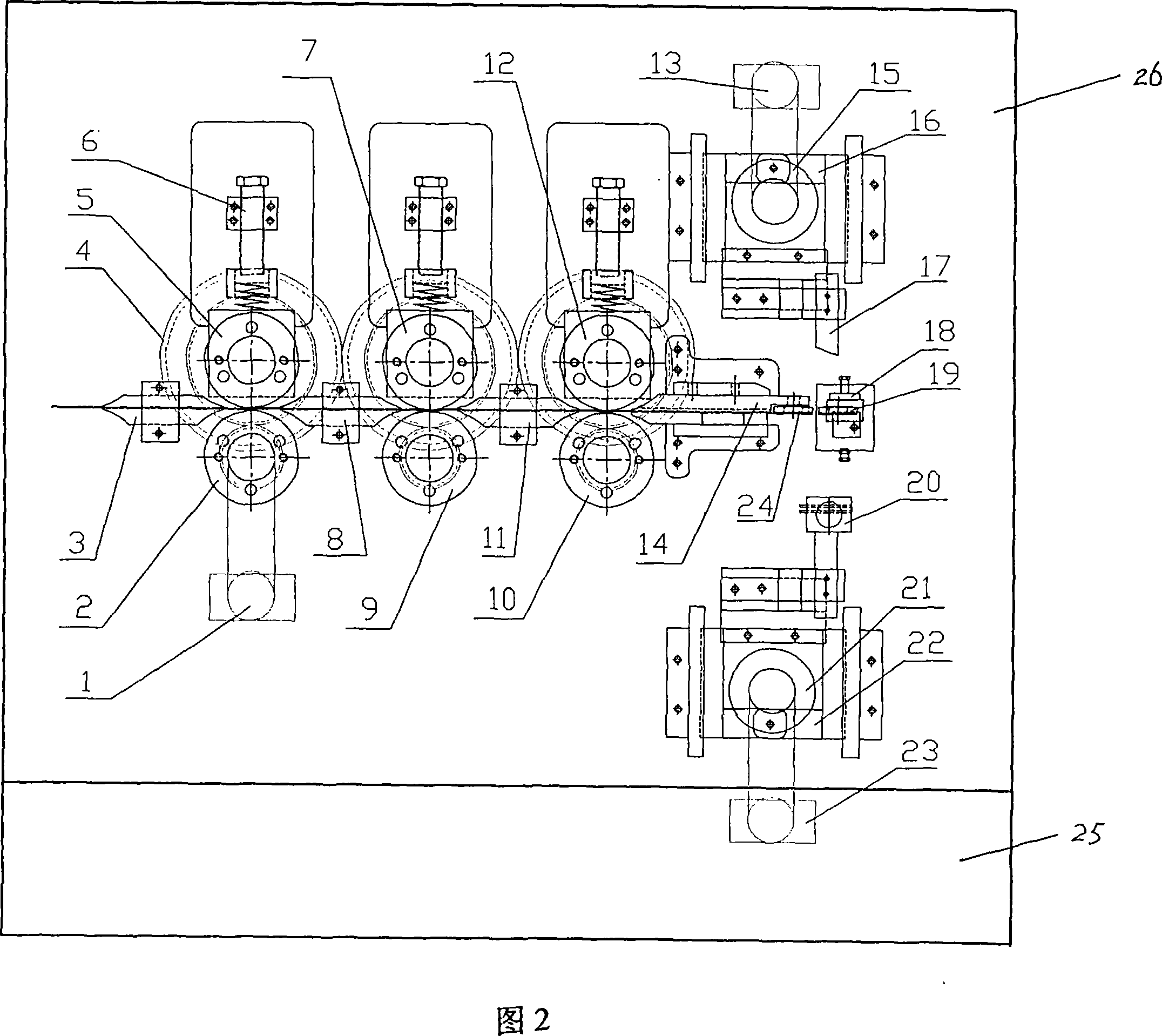

The invention discloses a spraying production line, which is applicable to conducting spraying on a workpiece clamped on a workpiece holder and comprises at least one spraying line. The spraying line comprises at least two circulation conveying chains, a dust removing chamber, a leveling chamber, a baking oven, as well as a manipulator and a spraying room that are used by the first and second circulation conveying chains together; the circulation conveying chains are arranged vertically; the workpiece holder enters the dust removing chamber, the spraying chamber, the leveling room and the baking oven in the conveying direction sequentially; the manipulator can seize or place the workpiece holder on the circulation conveying chains and the spraying room; the spraying room is provided with a color changing system and at least two spray guns; and the color changing system controls the spray guns to conduct color changing and spraying on the conveyed workpiece in turns. The spraying production line has the advantages that color changing and spraying are quick; the area occupied by equipment is reduced; the equipment utilization rate is increased; and the production efficiency is improved.

Owner:东莞丰裕电机有限公司

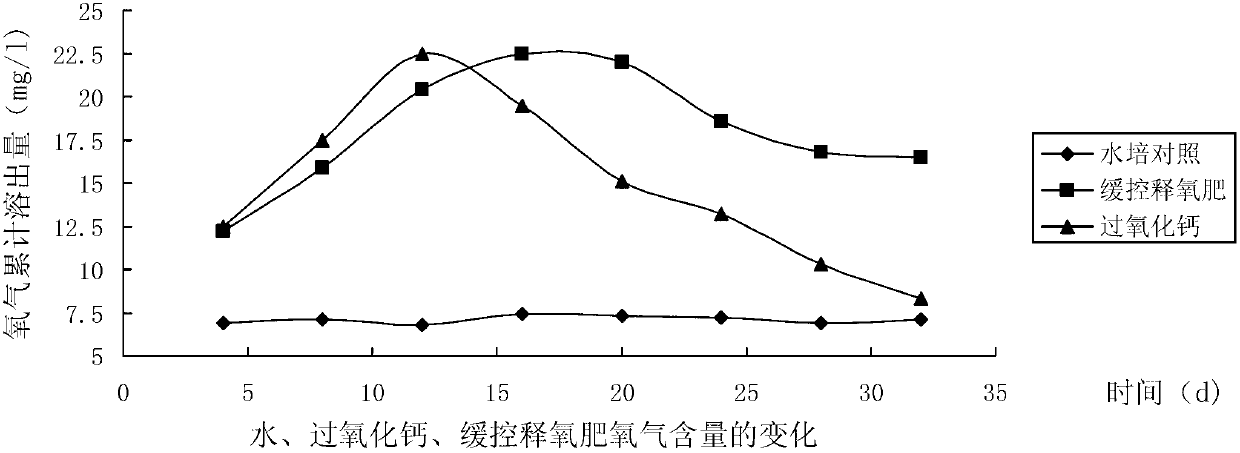

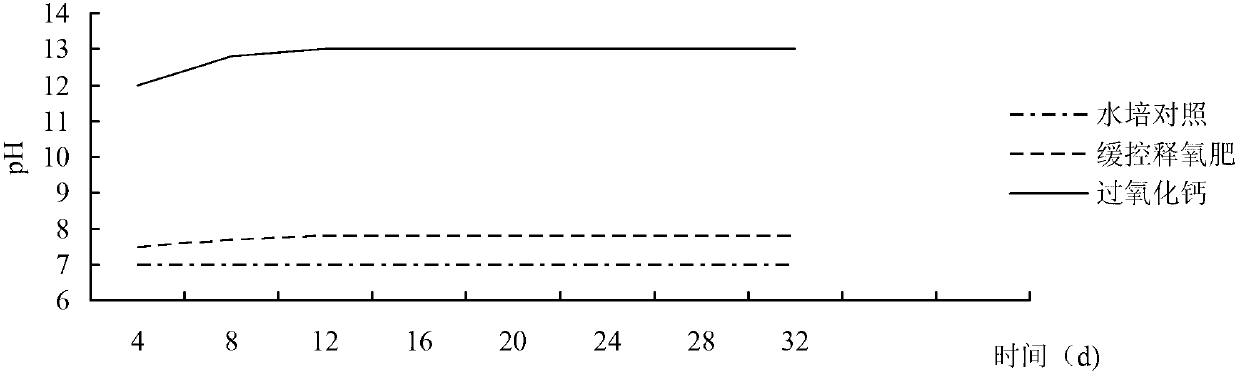

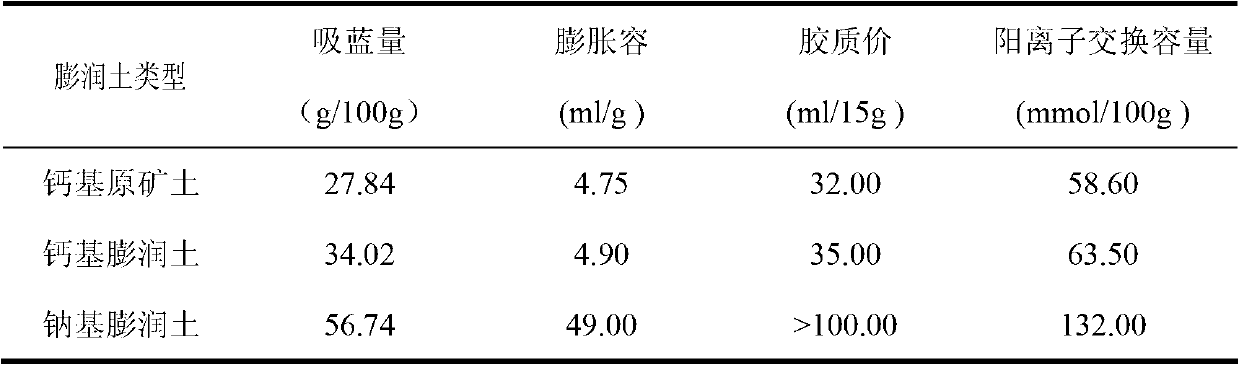

Sustained oxygen release fertilizer and preparation method thereof

InactiveCN102924176AMaintain physiological metabolismMaintain normal growth and developmentFertilizer mixturesPolyvinyl alcoholSuperoxide

The invention discloses a sustained oxygen release fertilizer which adopts a mixture comprising calcium superoxide, sodium bentonite and polyvinyl formal. The mass ratio of sodium bentonite to calcium superoxide is 12 to 5, and the mass of the polyvinyl formal is 15 percent of the gross mass of the sustained oxygen release. The sustained oxygen release fertilizer discusses the oxygen release feature and the pH value variation in the condition of aqueous medium. Experimental results show that compared with applying calcium superoxide powder only, the sustained oxygen release fertilizer has the characteristics that the fertilizer effect period is long, the applying method is simple, the production technology is simple, the source of material selected is wide, the material is environmentally friendly, and the sustained oxygen release fertilizer can be widely applied.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

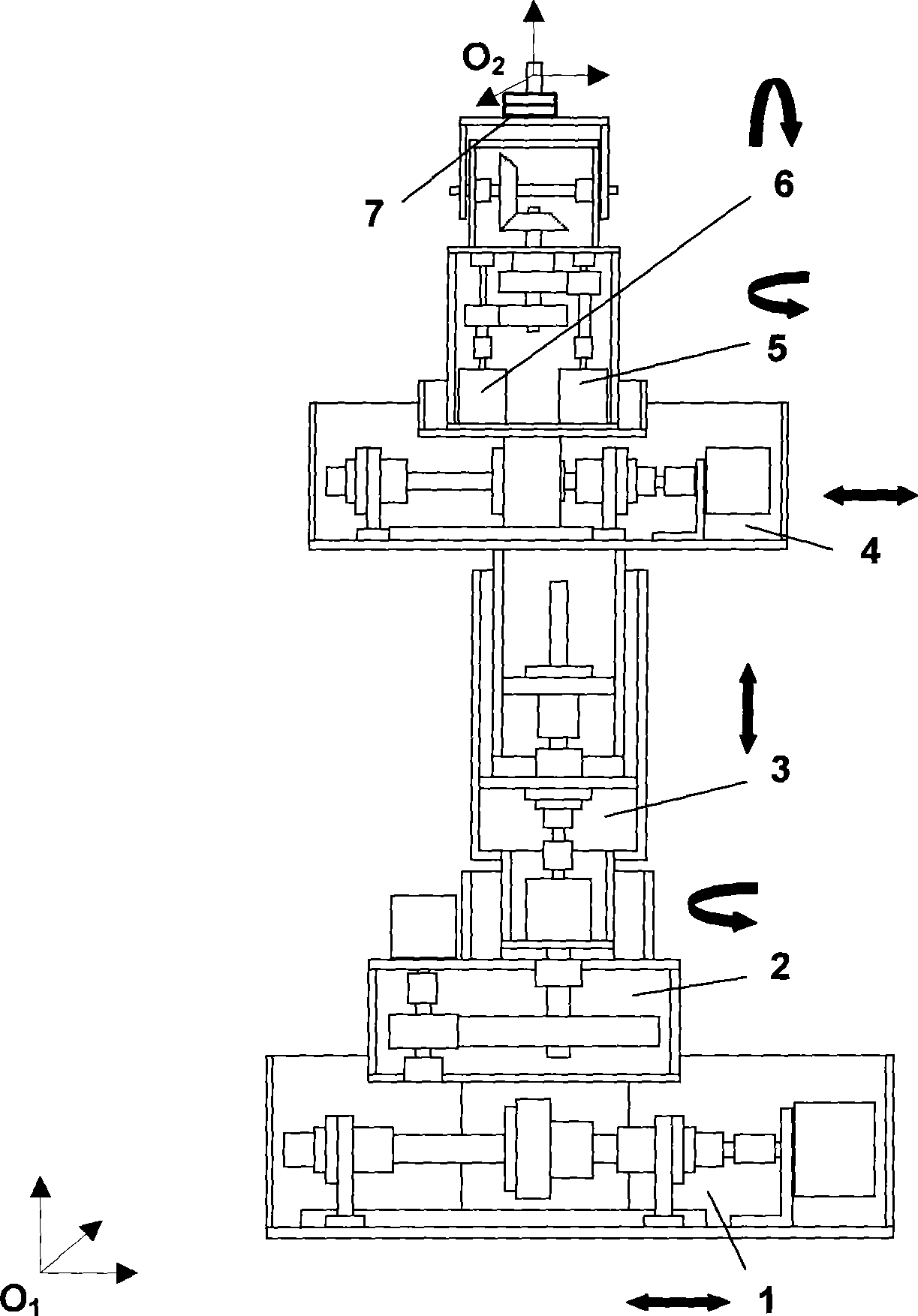

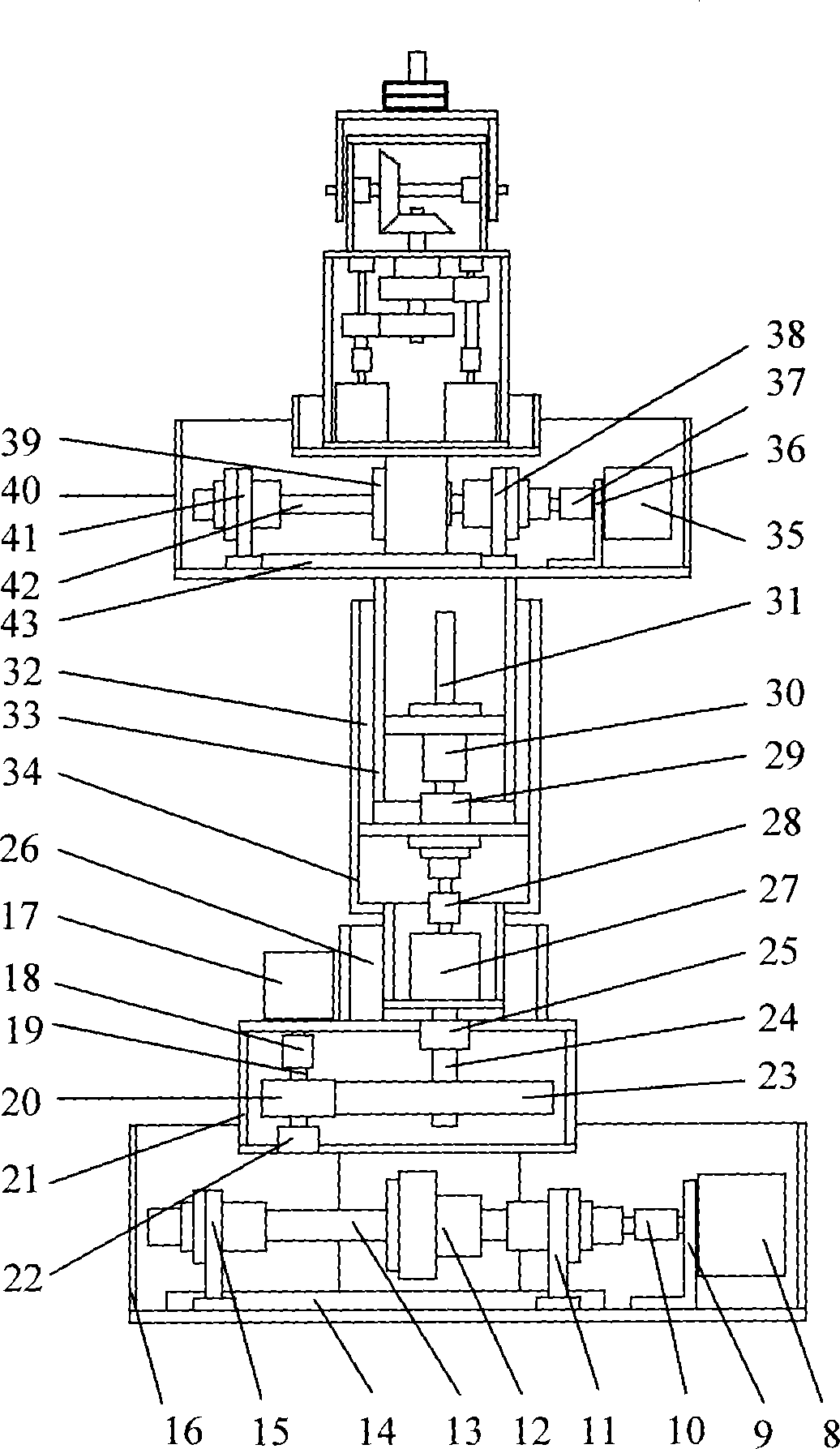

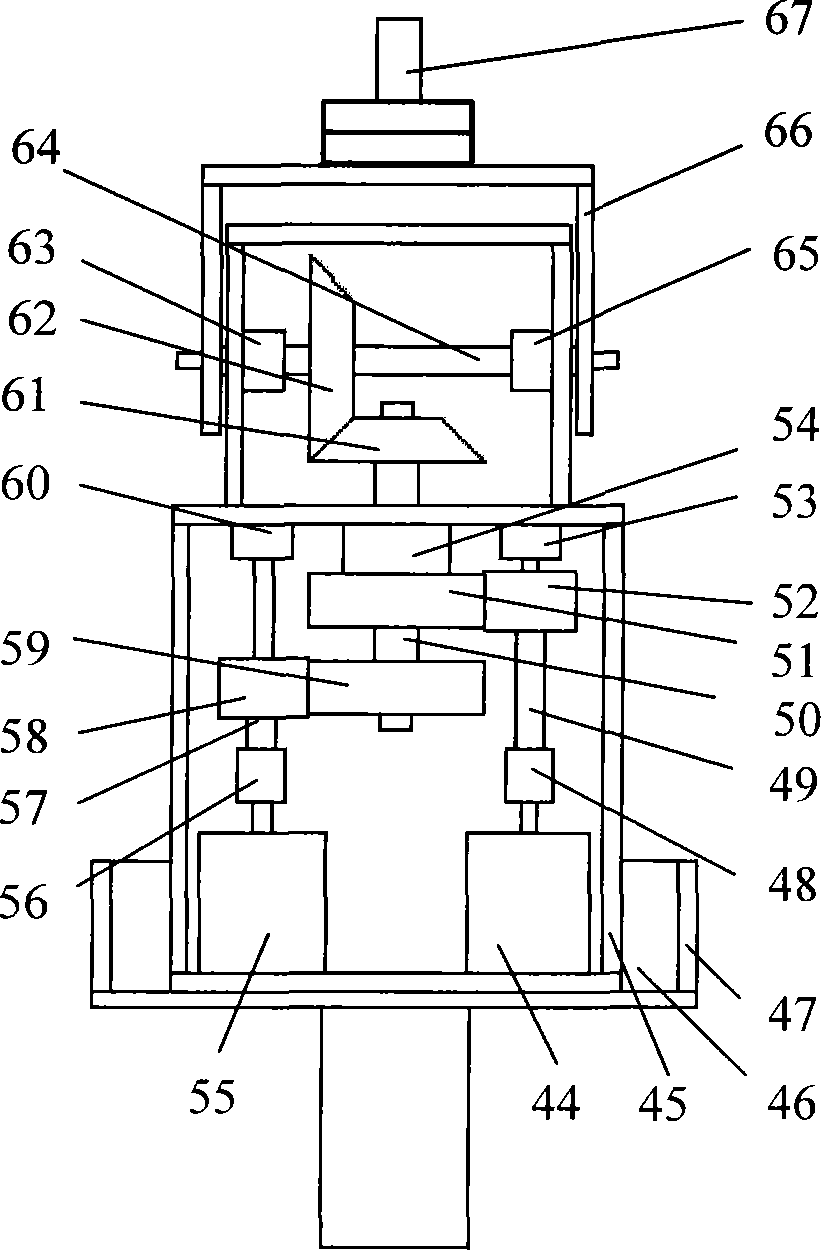

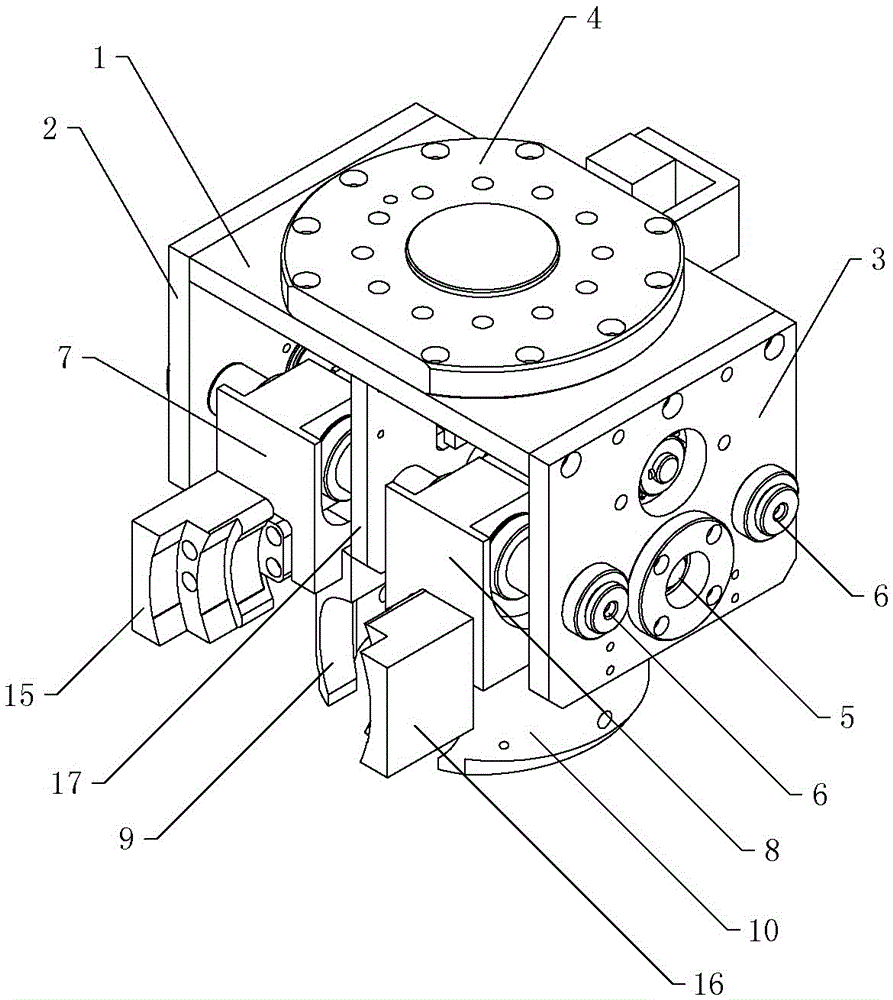

Flexible locating cramping apparatus controlled by servo

InactiveCN101249597ARapid positioningEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMultiple degrees of freedom

The invention relates to a flexible positioning fixture controlled by a servo. The whole fixture, from the bottom to the top, comprises a first horizontal direction moving servo control mechanism, a first rotation direction servo control mechanism, a vertical direction movement servo control mechanism, a second horizontal direction moving servo control mechanism, a second rotation direction servo control mechanism, a third rotation direction servo control mechanism and a positioning pin mechanism. The positioning pin mechanism is an actuating mechanism of the entire mechanism and plays a positioning role on the assembly of workpieces. The position precision of the positioning pin mechanism is achieved by the servo control mechanisms in the moving directions and rotating directions. The positioning fixture realizes multiple-degree-of-freedom adjustment, meets the characteristic requirement of the flexible fixture produced by a variety of similar vehicle models, has the capability of quickly, accurately and automatically adjusting the three-dimensional position and posture of the positioning pin according to the variation of the positioning positions of different products, and realizes the space positioning of different positioning modes.

Owner:柳州远翅塑料有限公司

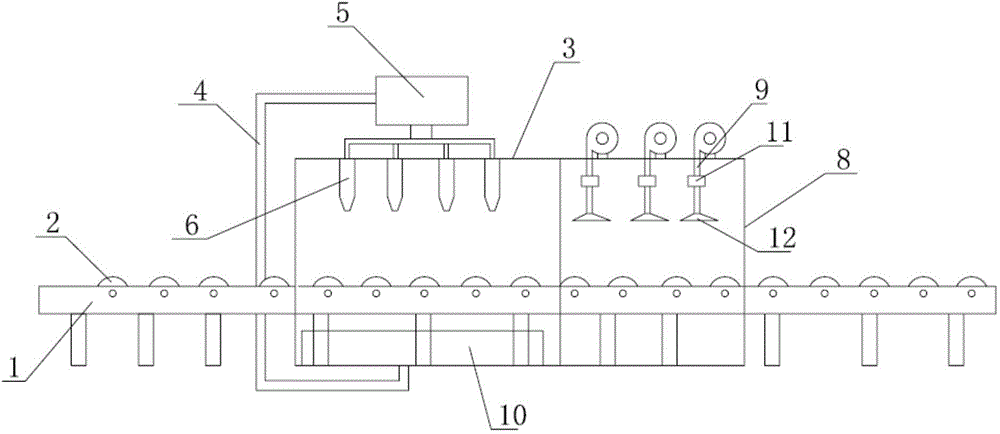

Surface automatic spray painting and drying device in steel structure

InactiveCN105689181AIncrease profitFast curingLiquid surface applicatorsSpraying apparatusEngineeringSpray painting

The invention relates to a surface automatic spray painting and drying device in a steel structure. The surface automatic spray painting and drying device in the steel structure comprises a conveying platform, a spray painting tank and a surface drying tank, wherein roller shafts are uniformly distributed on the conveying platform; the conveying platform transversely penetrates through lower parts of the spray painting tank and the surface drying tank sequentially; a plurality of paint spraying heads arranged towards the conveying platform are uniformly installed at the top part of the spray painting tank; a plurality of blowing sprinklers arranged downwards are uniformly formed in the top end in the surface drying tank vertically; a paint collection tank is installed at the bottom of the spray painting tank; and a heater is installed at the middle part of each blowing sprinkler. The surface automatic spray painting and drying device in the steel structure adopts an automatic spray painting device, is high in paint utilization ratio, prevents waste, accelerates the curing speed of paint through a heating blowing manner, improves the production efficiency and saves the production space.

Owner:宁波科恩达钢结构有限公司

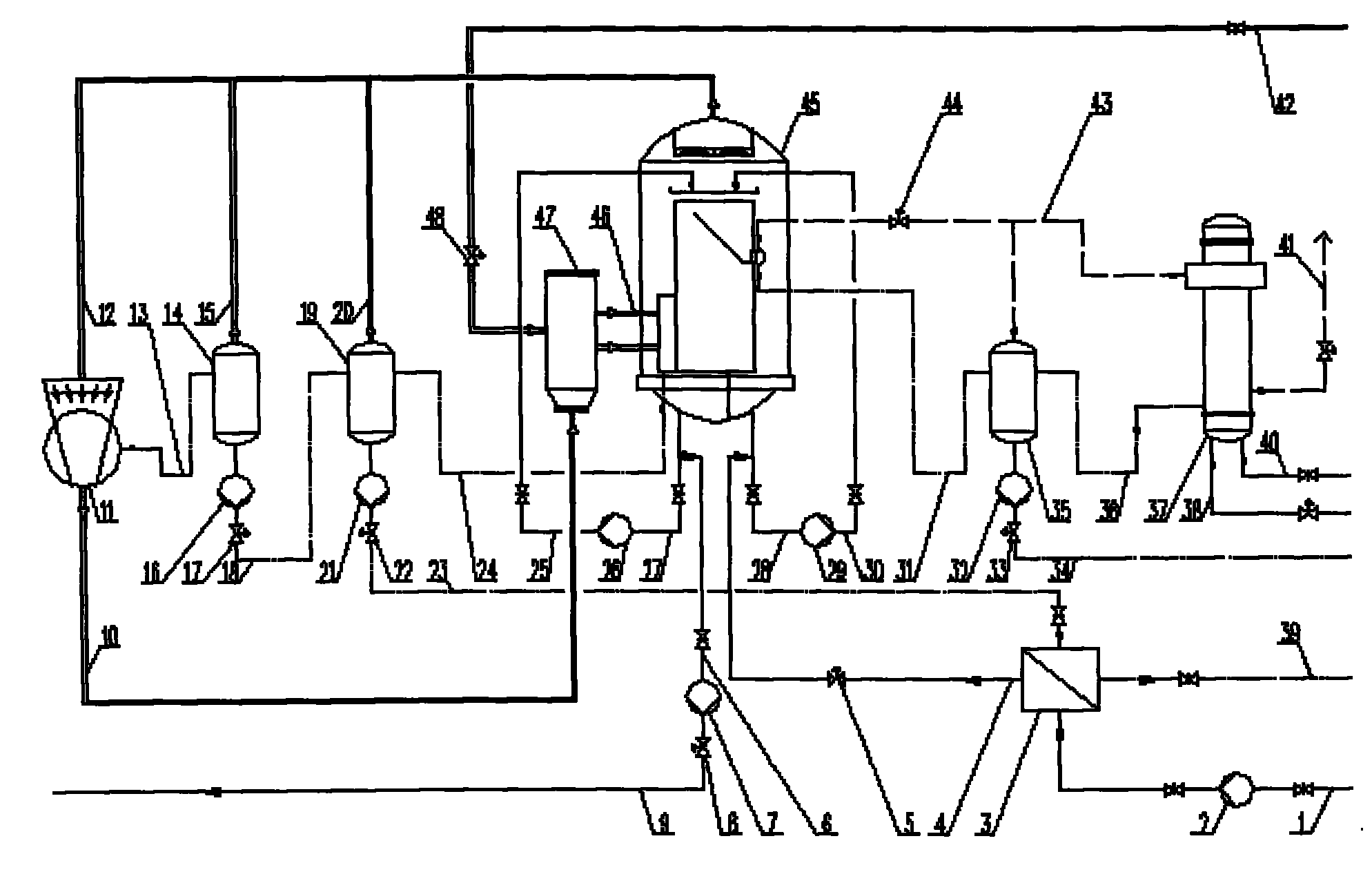

Clean productive process for extracting citric acid from citric acid fermentation liquid

InactiveCN1358707ARealize cleaner productionHigh yieldCarboxylic compound separation/purificationOrganic acidOrganic solvent

The present invention relates to a clean production process for extracting citric acid from citric acid fermented liuqor, includes the following steps: synthesizing weak-acid strong-base amphoteric resin specially used for adsorbing and separating citric acid, adopting fixed bed with said resin and using continuous cross-current temperature-changing chromatographic adsorption technique to make separation and purification from the fermented liquor so as to obtain clean and pure citric acid product. Under the condition of low temp. the fermented liquor is passed through the resin bed, the citric acid can be adsorbed, and then the hot water can be used, and passed through the saturated resin bed, so the citric acid can be desorbed. It uses heat difference as power for elution, so it does not used acid, does not use alkali and orgnaic solvent chemical product.

Owner:俞铮 +1

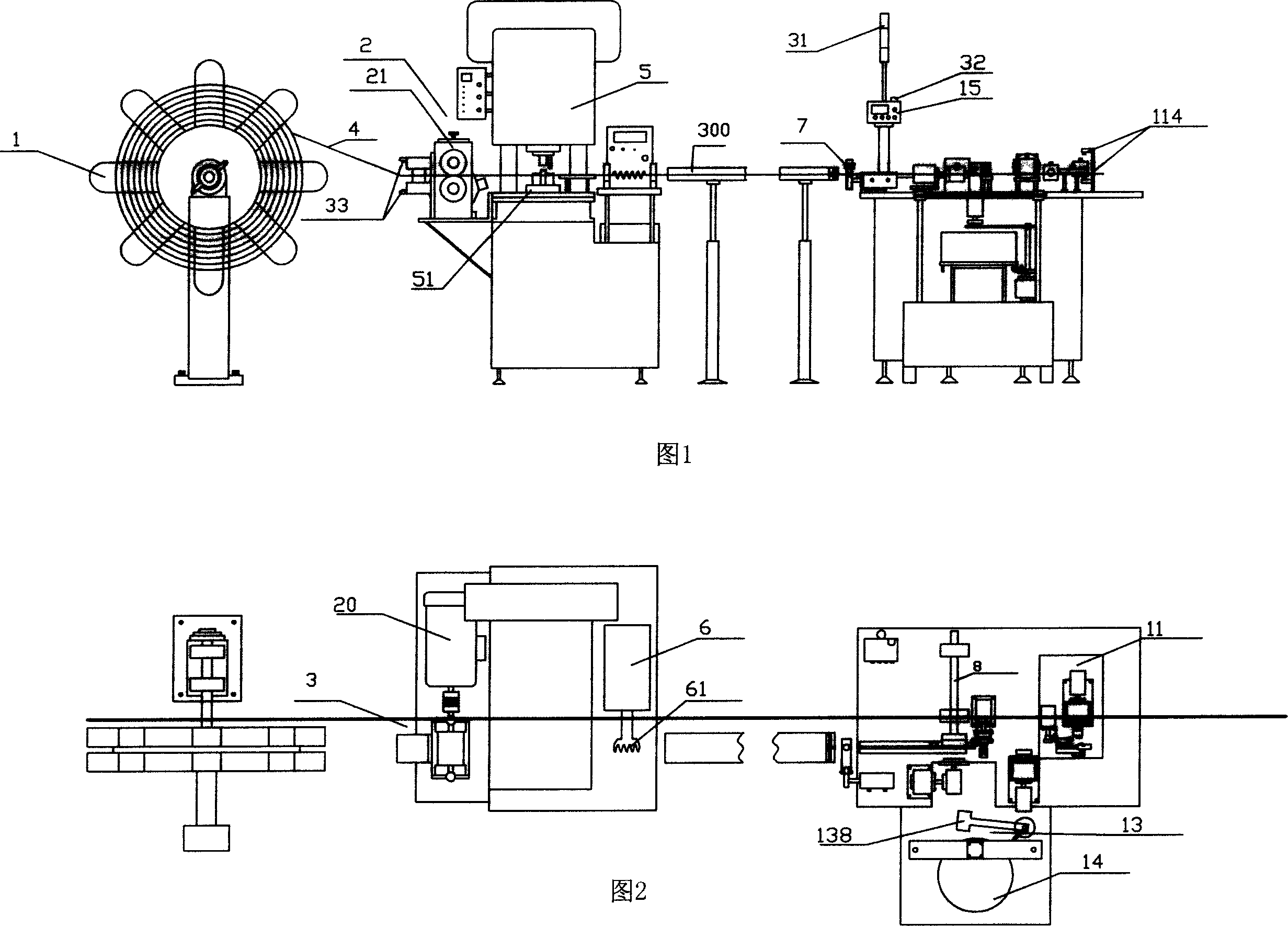

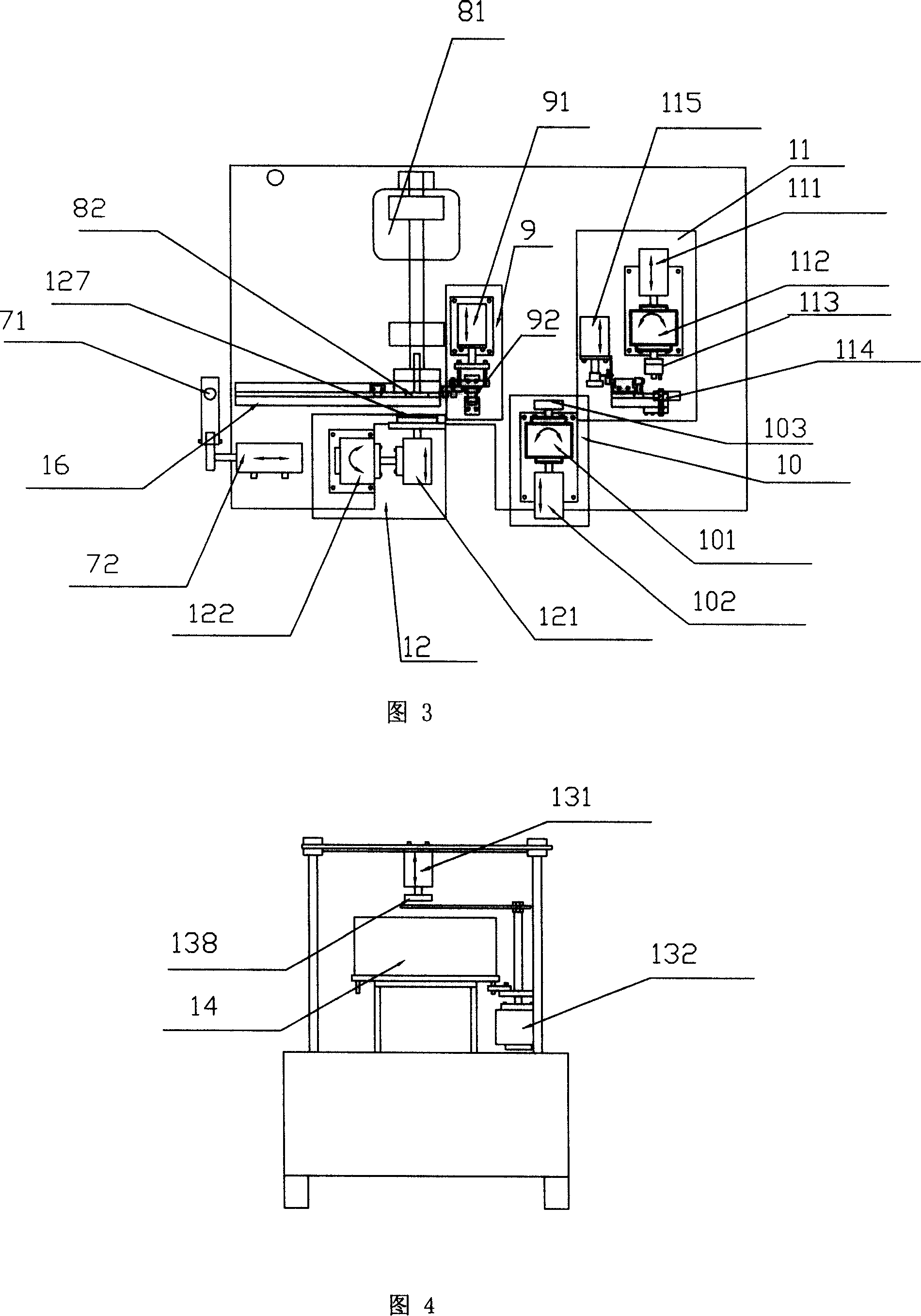

Automatic scroll spring forming apparatus

ActiveCN101020291ARealize automated productionIncrease productivityMetal-working feeding devicesOther manufacturing equipments/toolsProduction linePunch press

The automatic scroll spring forming apparatus includes a disc type feeder frame, a material failure optoelectronic controller, a length determining feeder, a punch with die, a high frequency annealer, an electromagnetic sucking head, a crimper, a former, a hook feeding device, a hook bender, an unloading device, an acceptor, a collector and controlling system. Under the control of the controlling system, the present invention completes the whole process including material feeding, cutting, high frequency annealing, bending hook, feeding hook, curling, unloading and collecting. The present invention has the advantages of integrated production line, low production cost, high product precision, etc.

Owner:宁波韵升弹性元件有限公司

Bentonite binder and preparation method thereof

InactiveCN102070153AReduce usageImprove bindingFoundry mouldsFoundry coresSodium BentoniteHexamethylenetetramine

The invention relates to a bentonite binder and a preparation method thereof, belonging to the processing field of bentonite, and aiming at providing a bentonite binder with a better sodiumizing modification effect and a preparation method of the bentonite binder. The preparation method of the bentonite binder comprises the following steps: using bentonite ore as raw material, adding a sodiumizing agent accounting for 2-5wt% of bentonite ore and an accelerator accounting for 0.35-1.2wt% of bentonite ore, wherein the accelerator is at least one of ammonium oxalate, sodium polyacrylate, hexamethylenetetramine and tripolycyanamide; evenly mixing and carrying out sodiumizing modification, drying, smashing to obtain the bentonite binder. In the preparation method, required equipment is simple and is convenient for maintenance, the production efficiency is high, and energy-saving effect is obvious, and the bentonite binder is suitable for continuous production. The bentonite binder of the invention has higher water absorption rate and is a bentonite binder with high adhesive property; and the bonding force of the iron ore concentrate is greatly increased after the bentonite binder is used in the iron ore pelletizing metallurgy industry, thus improving the pelletizing rate of the iron ore concentrate.

Owner:PANZHIHUA UNIV

One-time machining molding mechanism for PVC sheet floor

InactiveCN105172155AShorten the production cycleEasy to operateFlat articlesEngineeringProduct processing

The invention relates to the field of machinery, in particular to a one-time machining molding mechanism for a PVC sheet floor. According to the product machining sequence, a material mixing machine, an extrusion machine, a feeding machine, a die, a laminating and calendaring machine, a traction machine and a plate shearing machine are sequentially connected end to end. The laminating and calendaring machine and the traction machine are connected through a supporting frame. The supporting frame is provided with an edge cutting device. The laminating and calendaring machine is provided with two sets of roll shafts. One set of the roller shafts is used for conveying wearproof films, and the other set of the roller shafts is used for conveying texture films. According to the one-time machining molding mechanism for the PVC sheet floor, anti-slip wearproof finished products can be manufactured at a time, and the production cycle of the products is shortened by over one time.

Owner:南京赛旺科技发展有限公司

Method for manufacturing wave shaped spring

InactiveCN101058143AMechanizationCompact structureFurnace typesHeat treatment process controlWave shapeEngineering

The invention relates to the manufacturing of a wave shape spring that modifies the CNC spring roller into several-layer spring equipment for production, for the benefit of improving productivity, quality, feature, dimension, cosmetic for mass production.

Owner:上海核工碟形弹簧制造有限公司

Core-board with new structure and its production process

InactiveCN1346734AHigh yieldImprove production siteWood veneer joiningWood layered productsEngineeringUltimate tensile strength

A core-board with novel structure features that its both surface plys and core ply are all the single board with the thickness of more than 4 mn. Its production method includes using the rotating cutter to cut timber for obtaining single board with more than 4 mm of thickness, drying for 1-4 days, gluing their together to obtain three-ply board, abrading both surfaces, and gluing veneer. Its advantages are high utilization rate of timber (80-90%), saving electric energy by 60% or more, simple method, and high performance and quality of product.

Owner:滕恩荣

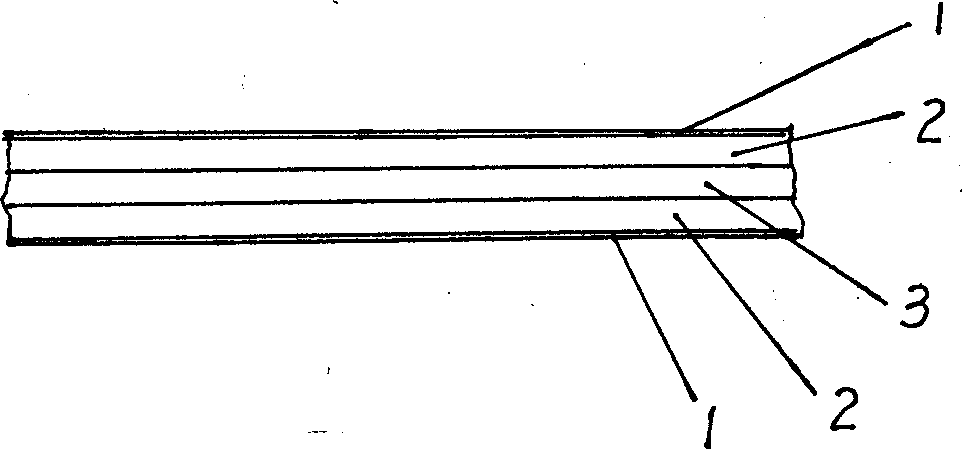

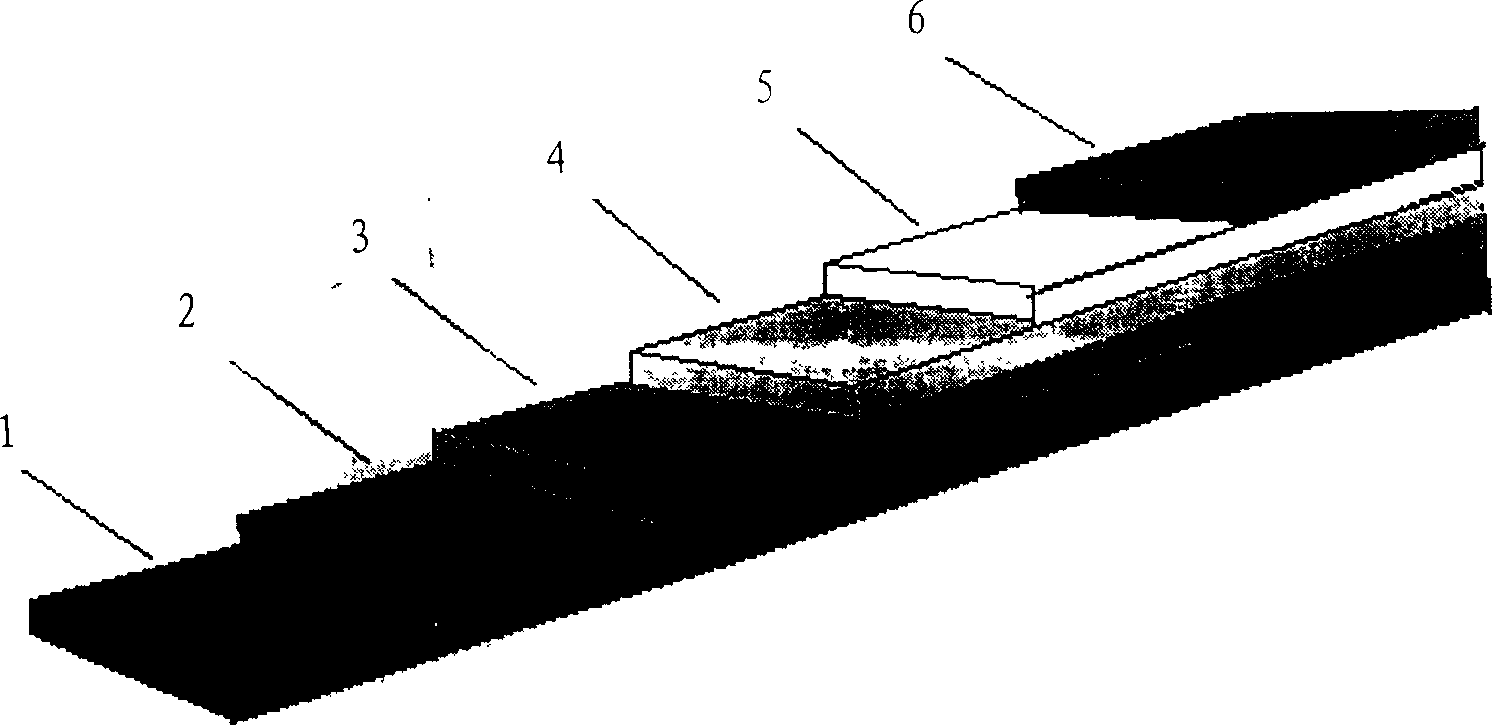

Metal material decorative board and its preparing method

InactiveCN1532049AScratch resistantAging resistantConstruction materialSpecial ornamental structuresTectorial membraneMetallic materials

The present invention relates to metal plate for building, electric appliance casing, etc. and is especially decorative metal material board and its production process. The decorative board is composite structure comprising the first layer of metal base material, the second monochromic layer, the third decorative pattern layer, the fourth protecting layer of light cured resin and the fifth layer of protecting film. Owing to the protecting layer of light cured resin formed through spraying or roller painting, the decorative metal board is beautiful and possesses stereo feeling. The decorative metal board may be produced in required size to avoid waste, the production process has low cost, high efficiency, low power consumption and no environmental pollution.

Owner:ZHUHAI DONGCHENG UV MATERIALS

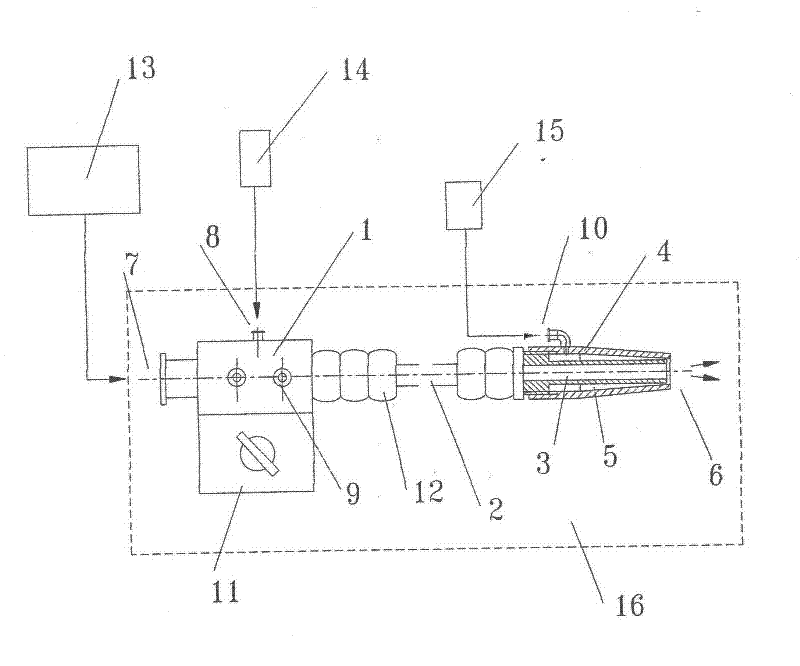

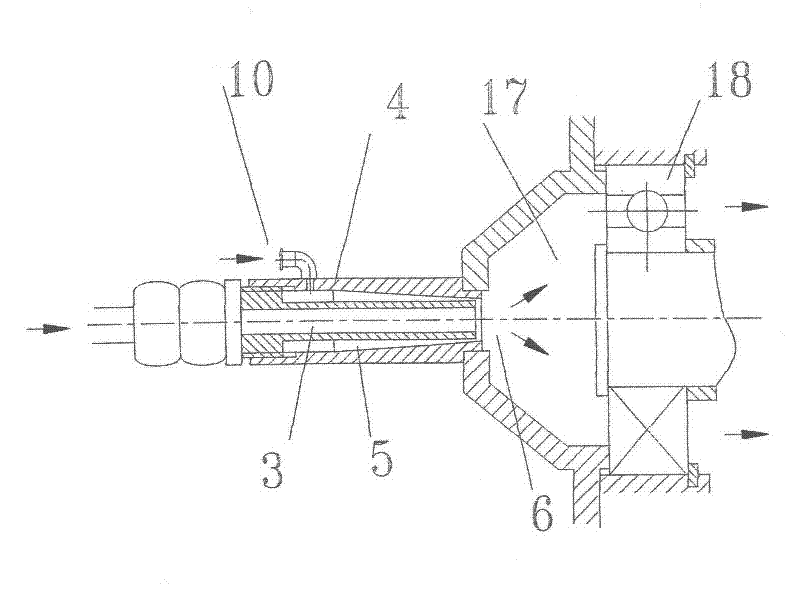

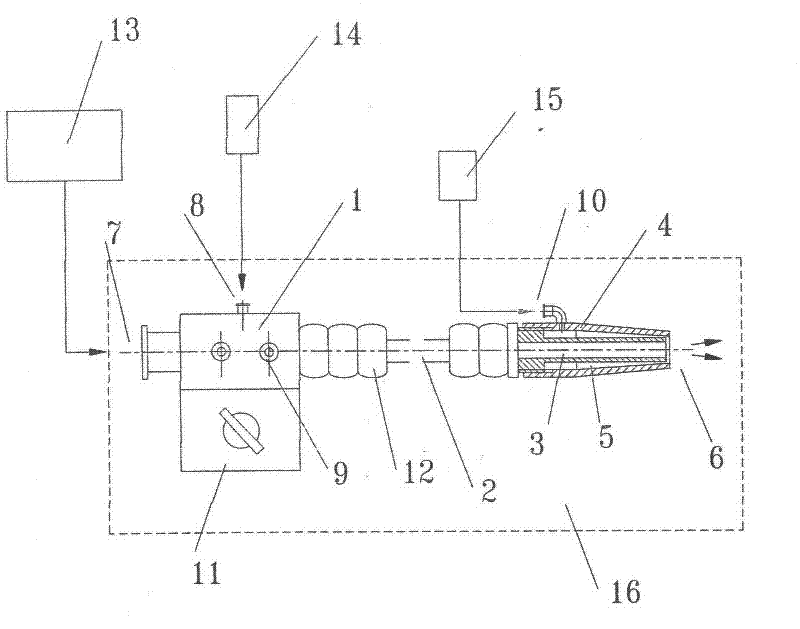

System for mixed flow spraying, cooling and lubricating

InactiveCN102430956ASimple structureReduce usageMaintainance and safety accessoriesWater basedMixed flow

The invention relates to a system for mixed flow spraying, cooling and lubricating, which is related to the technology for the cooling and lubricating of machine tools and mechanical transmission mechanisms and mainly related to the method for the cooling and lubricating of the heating areas of a cutting heating point, a bearing and other transmission mechanisms by using normal-temperature or low-temperature gas, a proper amount of oil-based cooling and lubricating medium and a proper amount of water-based cooling and lubricating medium in a mixed flow spraying mode. The system is characterized in that a mixed flow sprayer can obtain normal-temperature or low-temperature gas, a proper amount of oil-based cooling and lubricating medium and a proper amount of water-based cooling and lubricating medium from a device for supplying gas, a device for supplying a proper amount of oil and a device for supplying a proper amount of water, and all the fluid can be sprayed and atomized to the heating areas together through a shared spraying nozzle. The system can also adopt a set of device for supplying gas and a plurality of mixed flow sprayers to cool and lubricate the heating areas on all parts of equipment at the same time in different modes such as the single gas spraying mode, the single oil mist spraying mode, the single water mist spraying mode and the mixed gas, oil and water flow spraying and atomizing mode to achieve the purposes of strengthening cooling and lubricating efficiency, reducing temperature rise, reducing cooling and lubricating liquid usage amount, preventing pollution, simplifying equipment structure, realizing multiple function of one system and saving the production site.

Owner:张昌义 +1

Double-layer hot-air stenter machine

ActiveCN103205870ASave production spaceIncrease productivityHeating/cooling textile fabricsStretchingEngineeringNonwoven fabric

The invention discloses a double-layer hot-air stenter machine which is adaptable to oiling, tentering, drying and sizing of thick microfiber nonwoven fabrics and is adaptable to tentering, drying and sizing of knitted, woven or non-woven fabrics. The double-layer hot-air stenter machine comprises an upper drying chamber and a lower drying chamber. Fabric feeding rails are arranged inside the upper drying chamber and the lower drying chamber respectively. A fabric feeding frame is arranged at a fabric feeding end of the upper drying chamber, and a transmission roller and a transmission headstock are arranged on the inner side of the fabric feeding frame. An upper overfeed, an upper fabric storing frame and a towing padder are arranged at a fabric discharging end of the upper drying chamber sequentially. An upper oil groove and a lower overfeed unit are arranged at a fabric feeding end of the lower drying machine, and a drying cylinder assembly and a lower fabric storing frame are arranged at a fabric discharging end of the lower drying chamber sequentially. A dehumidifying device is arranged at the top of the upper drying chamber. Double-layer structure is adopted in the drying chambers of the double-layer hot-air stenter machine, precious production space is saved, and meanwhile, working efficiency is high, and energy is saved.

Owner:无锡市康达印染设备制造有限公司

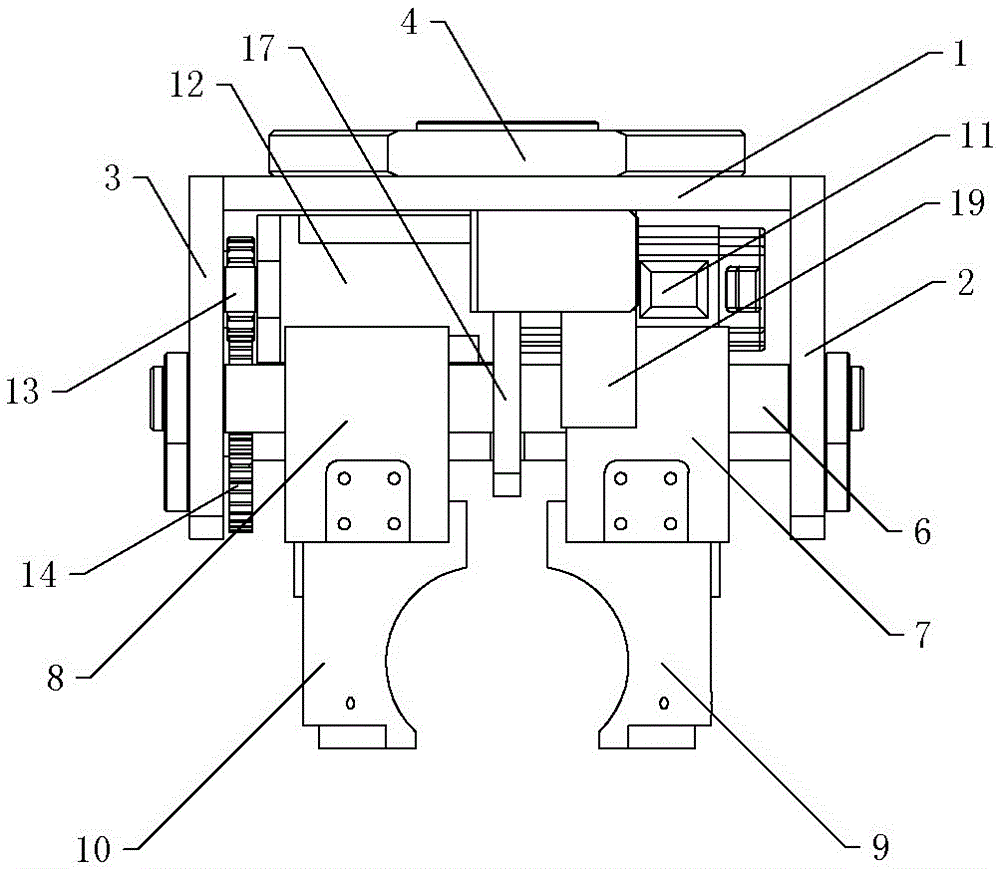

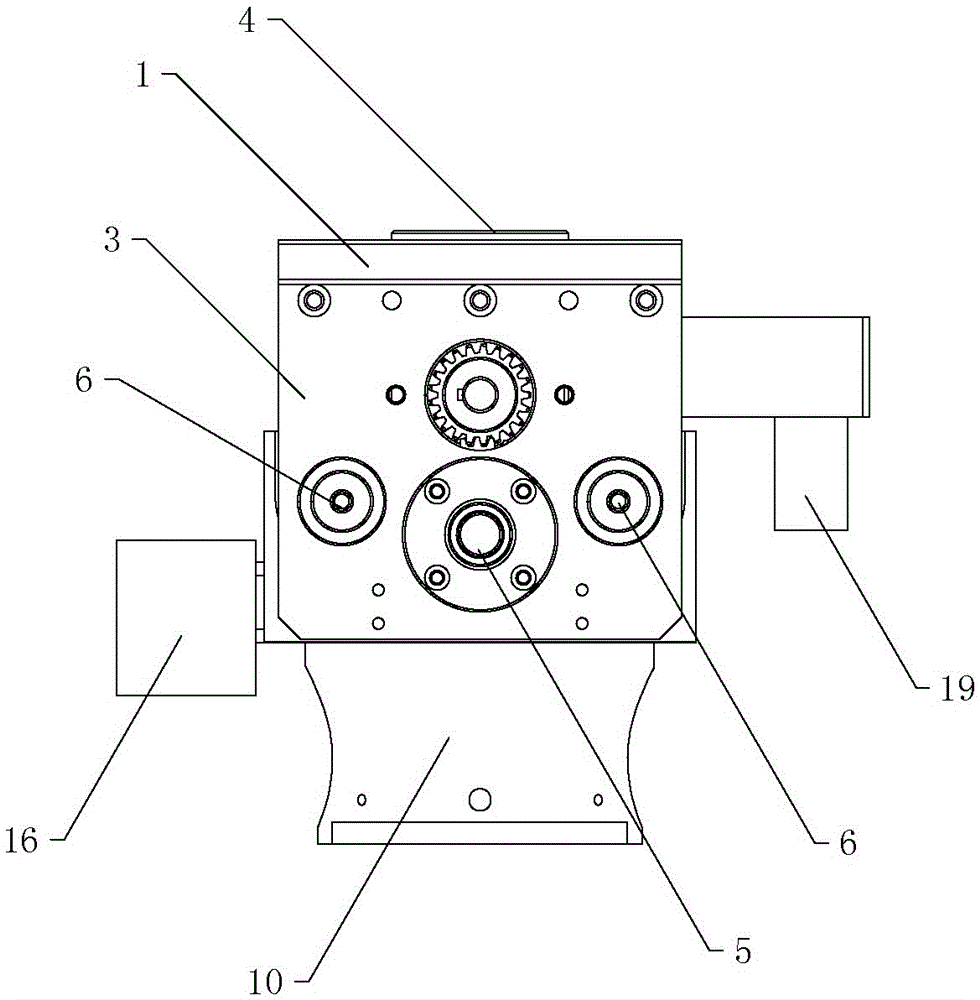

Multifunctional intelligent clamping jaw and joint robot

InactiveCN105690417AReduce volumeSave production spaceProgramme-controlled manipulatorGripping headsElectric machineryDrive motor

The invention discloses a multifunctional intelligent clamping jaw and a joint robot. The multifunctional intelligent clamping jaw comprises a bracket, a drive motor, a transmission device and a clamping block, wherein an upper fixed plate, a first side plate and a second side plate are arranged on the bracket; the transmission device is provided with a lead screw, a first lead screw nut, a second lead screw nut, a first guide post slide block, a second guide post slide block and guide posts; the lead screw is provided with reverse threads which are separately arranged at axial two sides of the lead screw; the first lead screw nut and the second lead screw nut are separately in transmission screw joint with the lead through the reverse threads at the two sides of the lead screw; the first guide post slide block and the second guide post slide block are separately arranged at the axial two sides of each guide post in a sleeved manner; the clamping block is provided with a first clamping block and a second clamping block which are matched with each other; the output shaft of the drive motor is in driving connection to the lead screw; and the first clamping block and the second clamping block get close to each other or get far away from each other in the axial direction of the lead screw. The joint robot comprises a machine body and an arm, and further comprises the multifunctional intelligent clamping jaw. The multifunctional intelligent clamping jaw has the characteristics of high production efficiency, low production cost, good adaptation, and a compact and simple structure.

Owner:GUANGZHOU JIANENG AUTOMATION EQUIP CO LTD

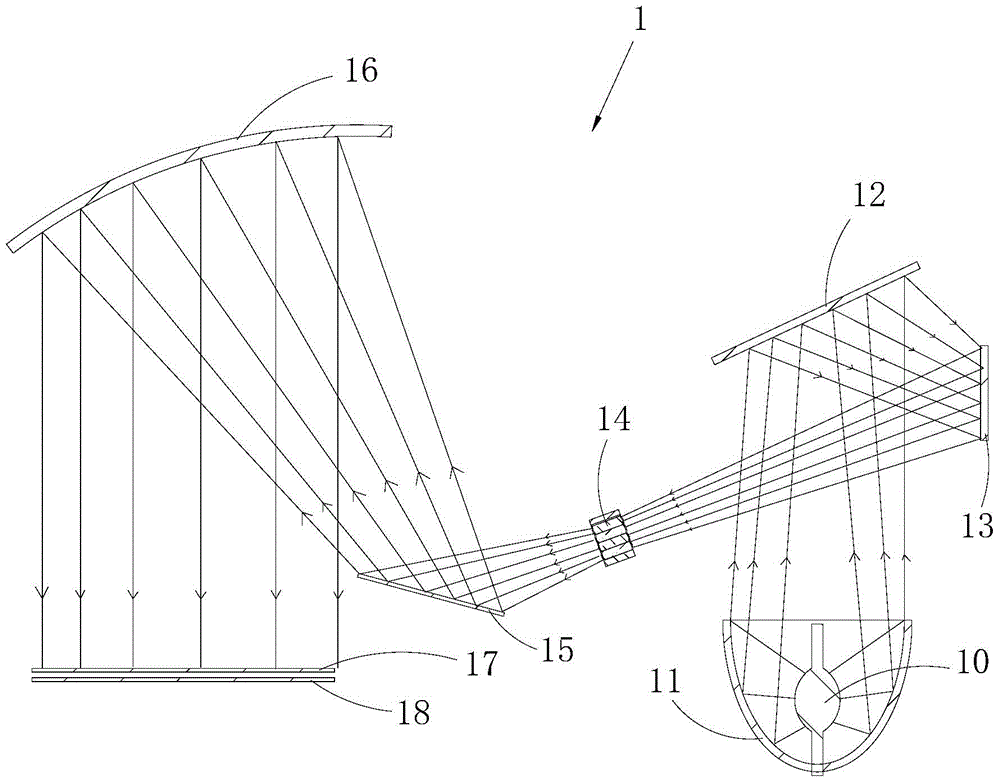

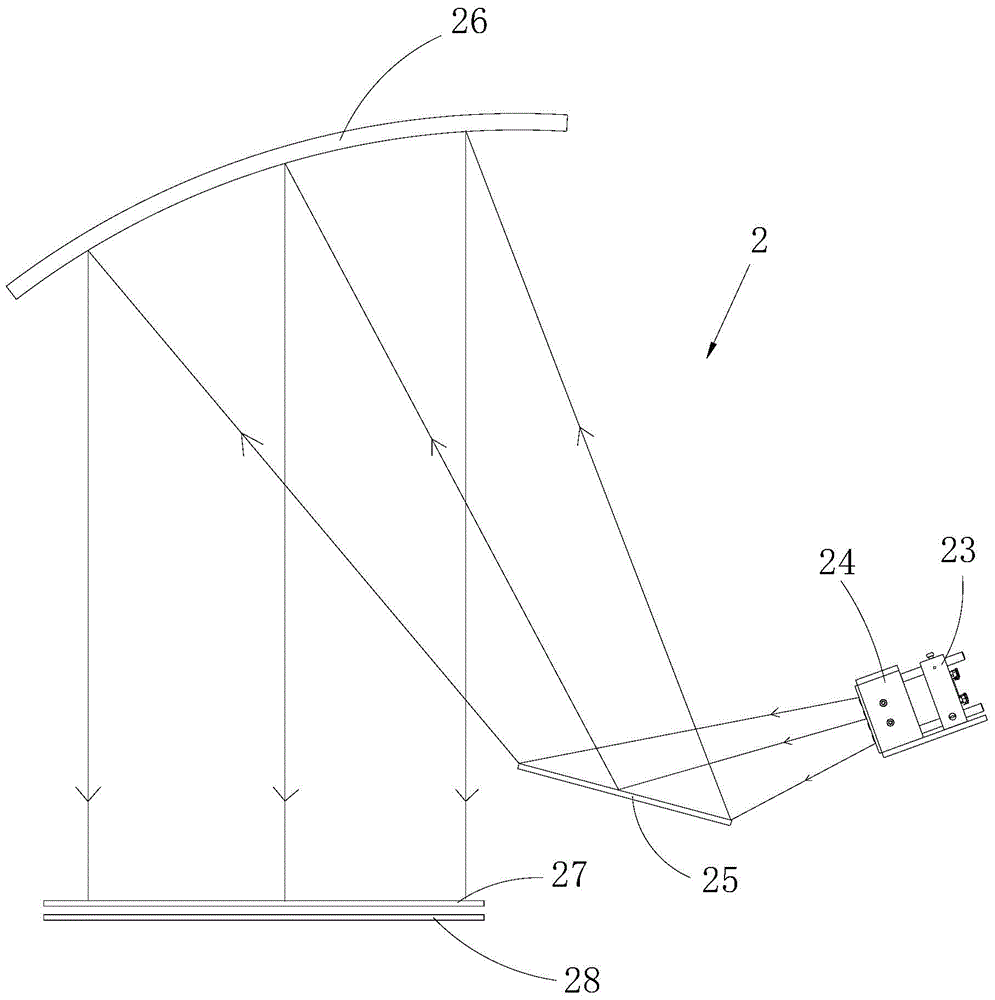

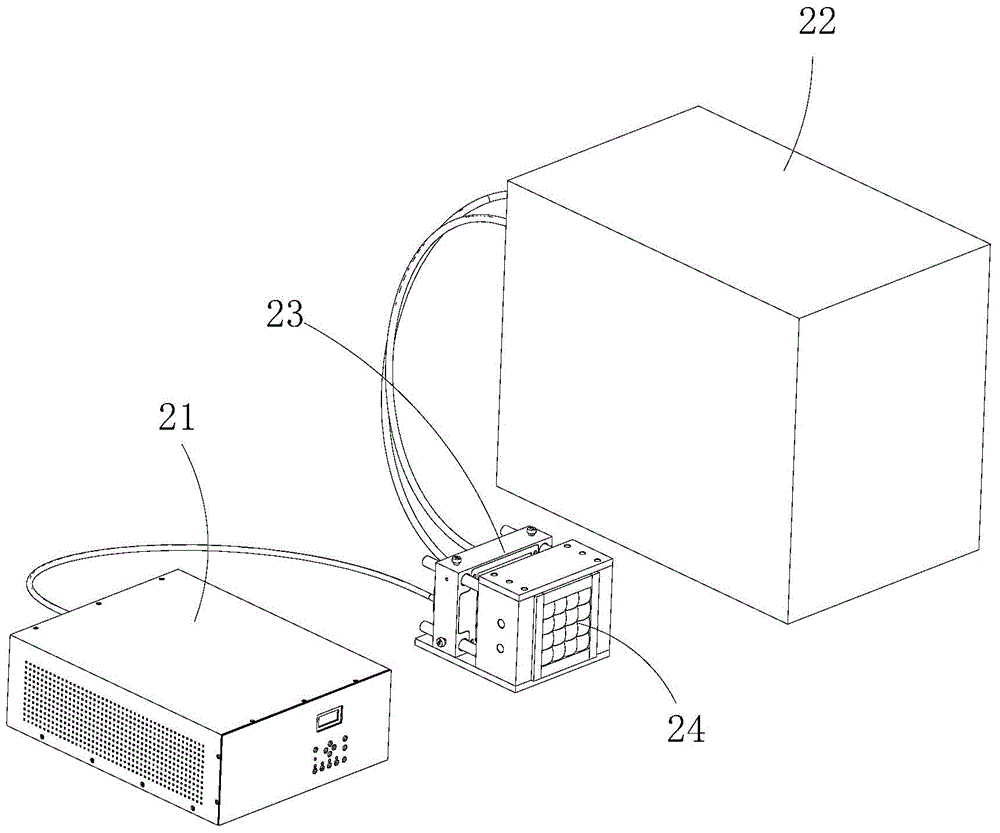

UV LED light source structure and parallel light exposure machine

ActiveCN105301910AIncrease heatIncrease power consumptionPhotomechanical exposure apparatusMicrolithography exposure apparatusLeast costPlane mirror

The invention relates to the technical field of exposure machines, and discloses a UV LED light source structure and a parallel light exposure machine. The UV LED light source structure comprises a UV LED lamp head, a fly eye lens module, a plane mirror and a spherical mirror, wherein the UV LED lamp head, the fly eye lens module, the plane mirror and the spherical mirror are sequentially arranged along a light path direction of the UV LED light source structure; a UV LED lamp bead is arranged in a UV LED; the UV LED lamp head and the fly eye lens module are adjacently arranged in parallel; the UV LED lamp head is adjacently connected with the fly eye lens module in parallel through an adjusting mechanism capable of adjusting the distance between the UV LED lamp head and the fly eye lens module; the UV LED lamp bead is arranged in front of the fly eye lens module; and parallel light for exposure is formed by the fly eye lens module, the plane mirror and the spherical mirror. The UV LED light source structure is applied to an existing parallel light exposure machine; equipment does not need to be upgraded by a customer and does not need to be transformed on a large scale; the low-temperature, energy-saving, environment-friendly and safe exposure machine employing the UV LED light source structure can be obtained with the least cost; the production delay is avoided; and the cost is greatly reduced.

Owner:张河生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com