Method for manufacturing wave shaped spring

A wave spring and manufacturing method technology, applied in the field of spring manufacturing and wave spring manufacturing, can solve the problems of the wave crest and wave trough not corresponding to the wave trough, the phenomenon of insufficient tightness and looseness, low production efficiency, etc. Produce effects with a small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] A manufacturing method of a wave spring, characterized in that the CNC spring coiling machine equipment is refitted into winding multi-layer wave spring equipment for production, and the method is as follows:

[0031] The first step: equipment modification

[0032] Retrofit the CNC coil spring machine equipment to coil multi-layer wave spring equipment;

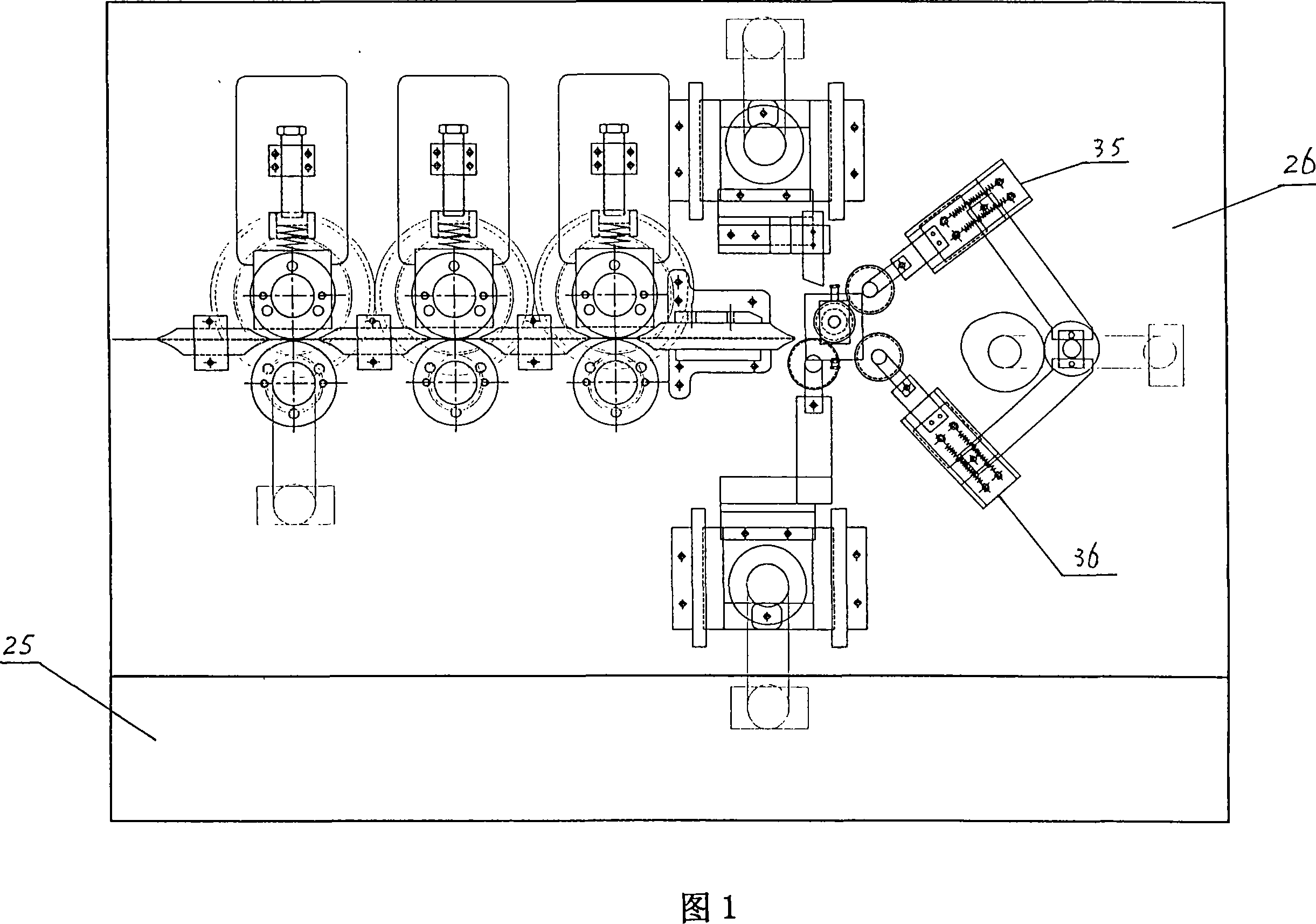

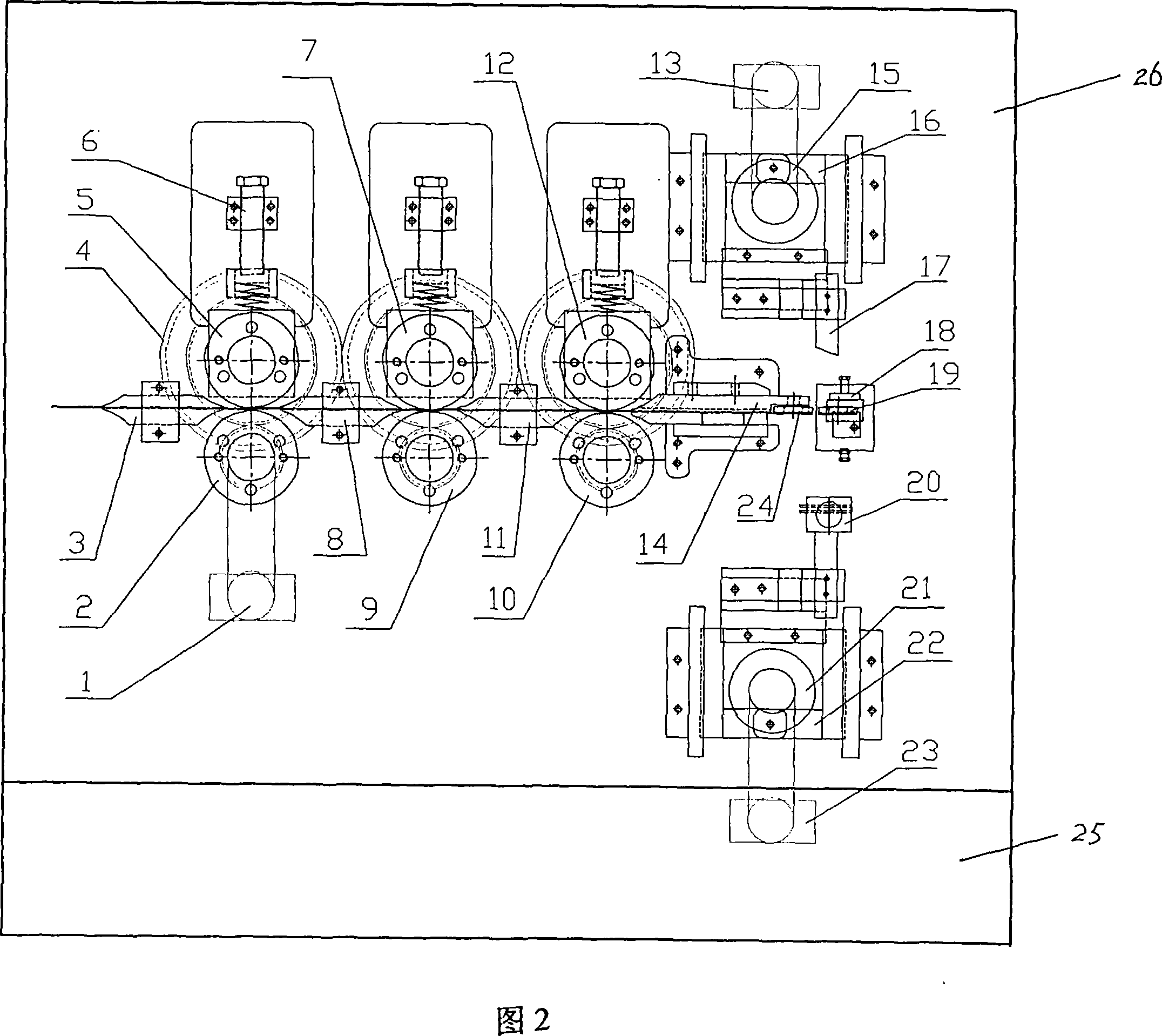

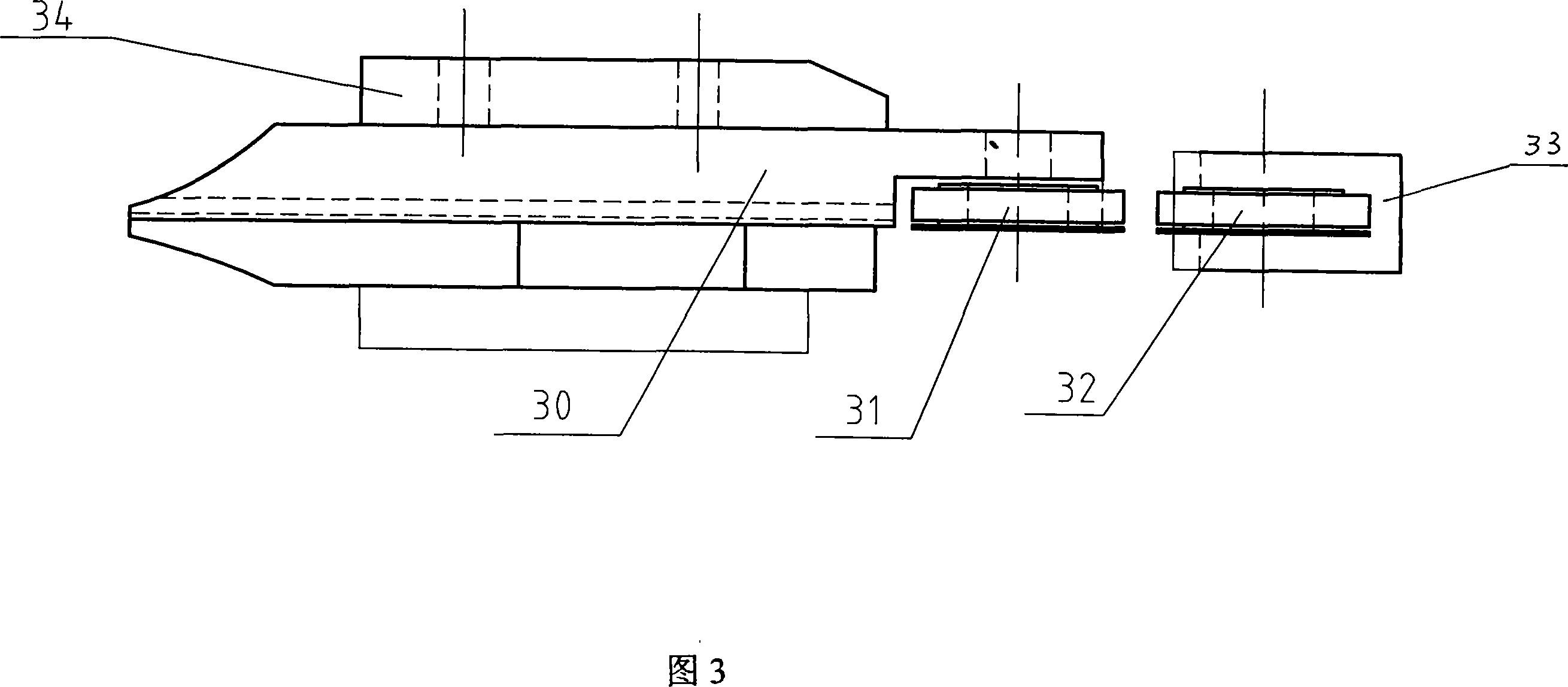

[0033] As shown in Figure 1, it is a schematic diagram of the equipment structure of the CNC spring coiling machine. The CNC spring coiling machine was originally a five-axis linkage CNC machine with five servo motors driving the X-axis, Y-axis, Z-axis, A-axis, and B-axis. The device consists of servo motors 1, 13, 23, rollers 2, 5, 7, 9, 10, 12, guide plates 3, 8, 11, gears 4, adjusting screw 6, outlet guide plates 14, rotating wheels 15, 21, Turning wheel mechanism 16,22, cutter 17, guide wheel mechanism 18, guide wheel 19, probe device 20, guide wheel 24, power source 25, equipment frame 26, X axis mechanism 36 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com