Patents

Literature

1082results about How to "Mechanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

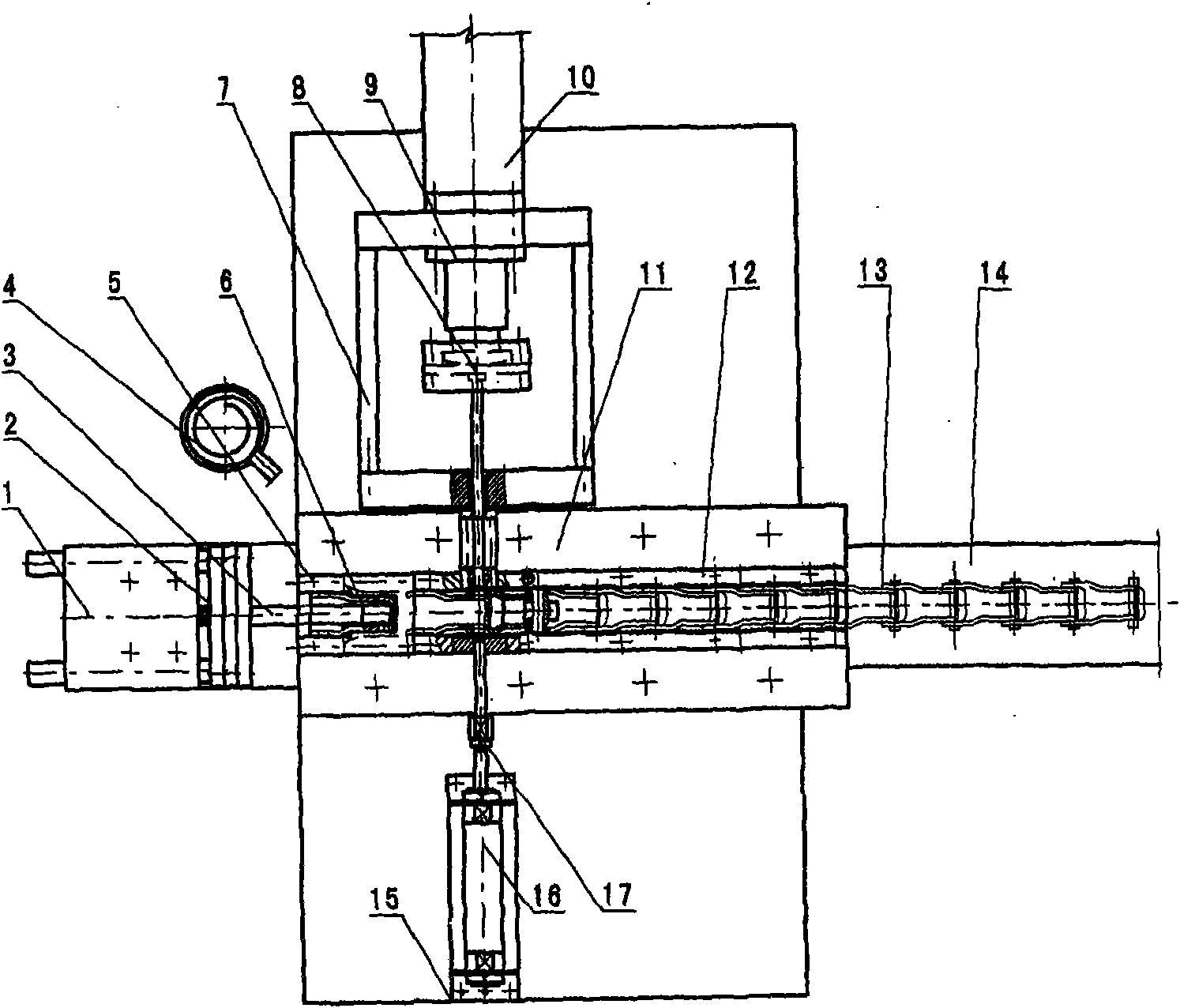

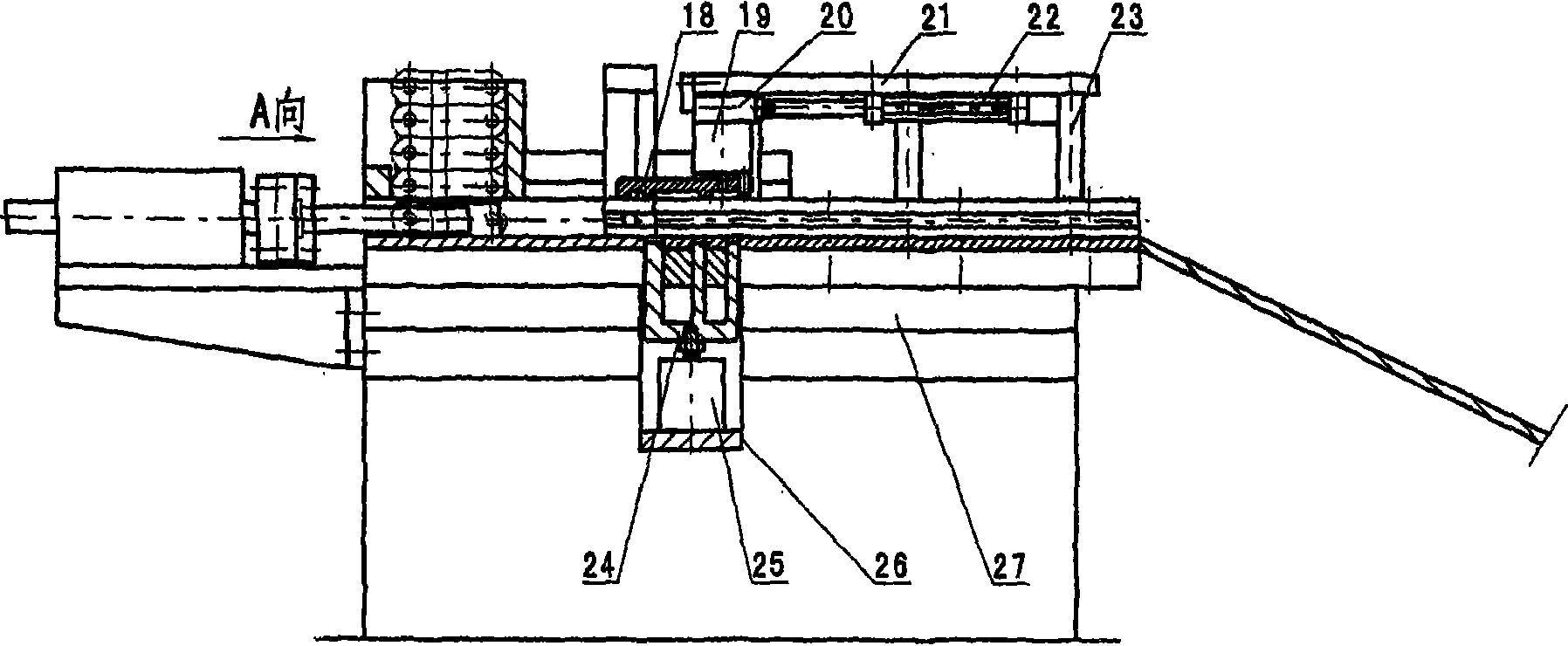

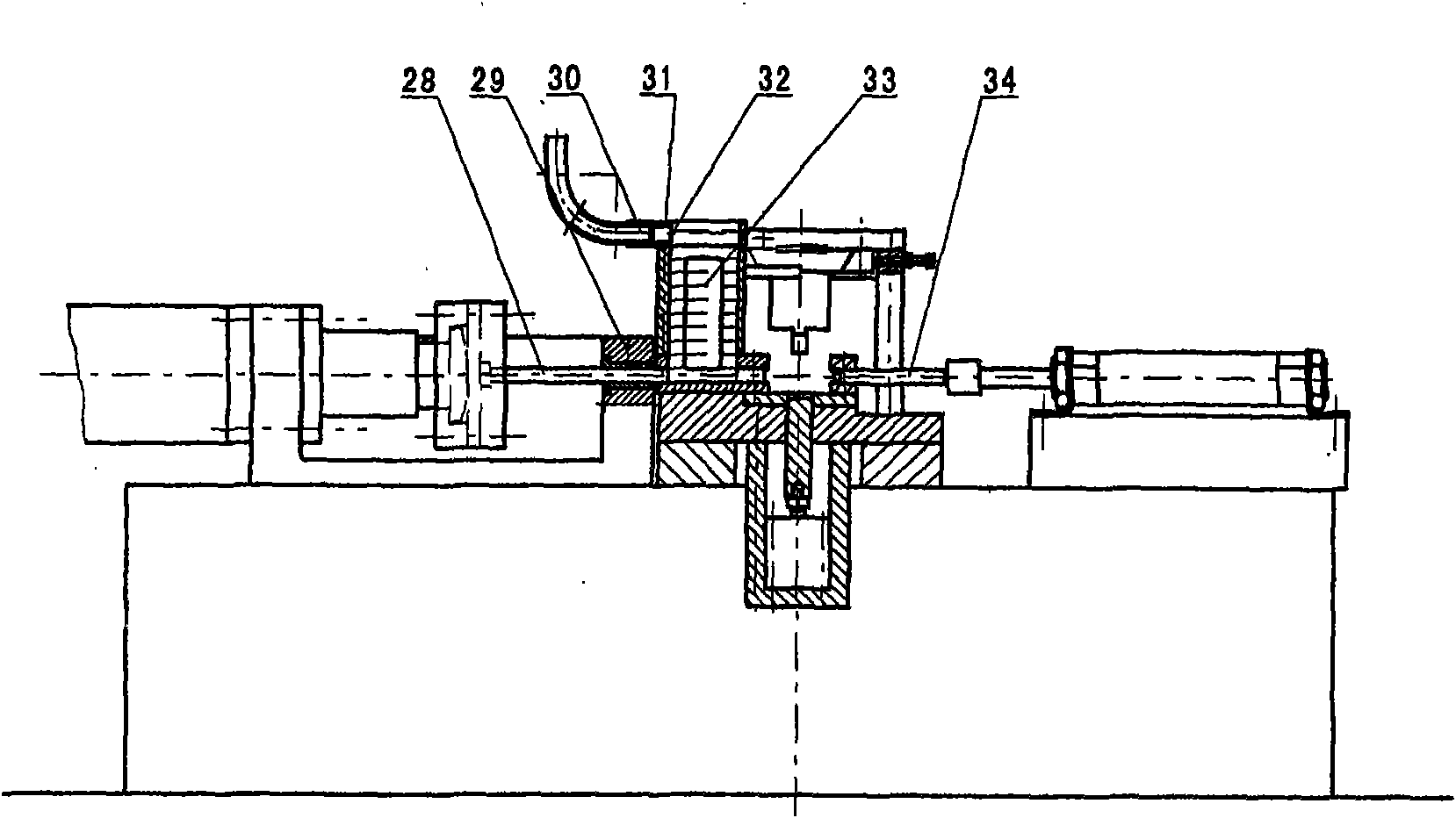

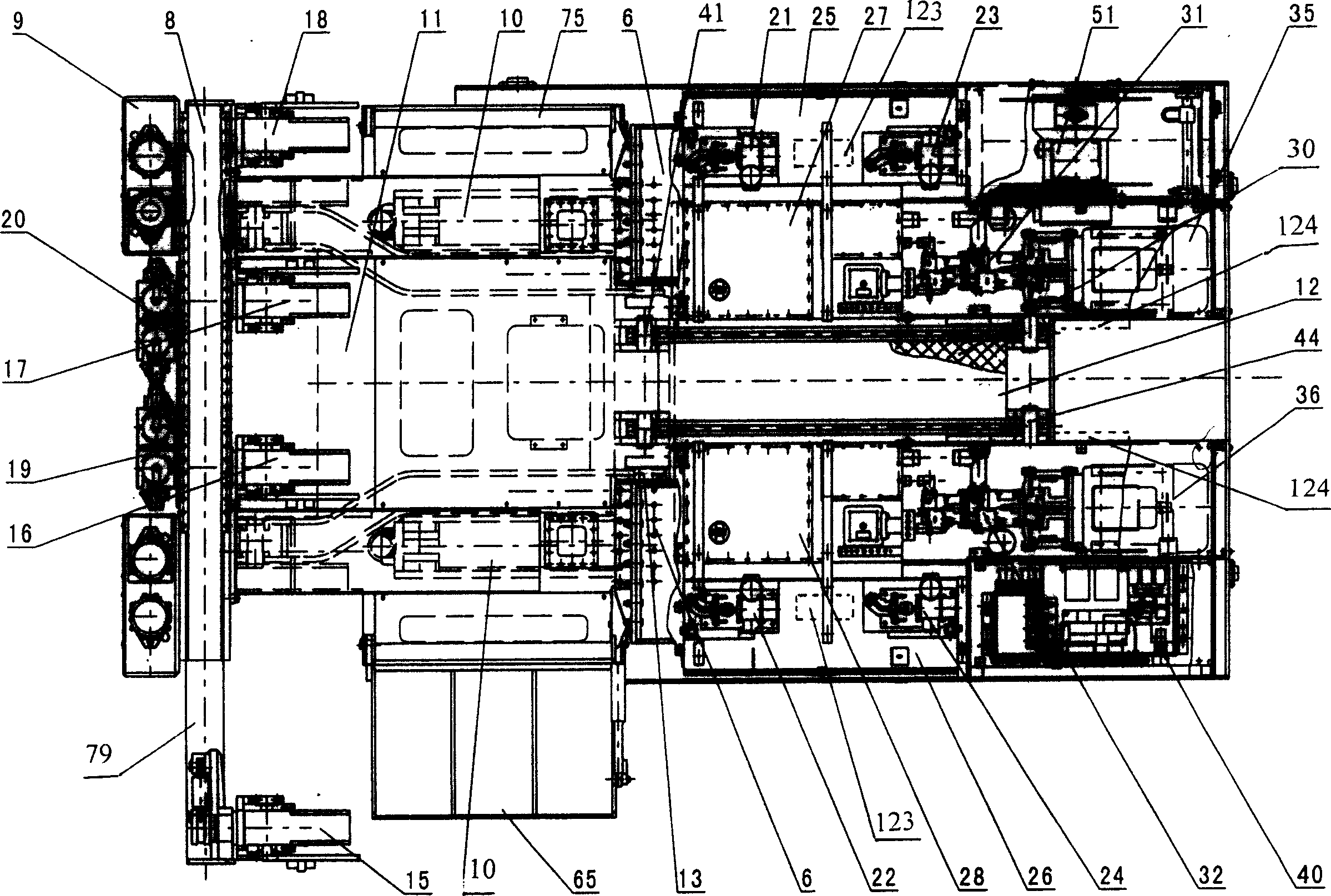

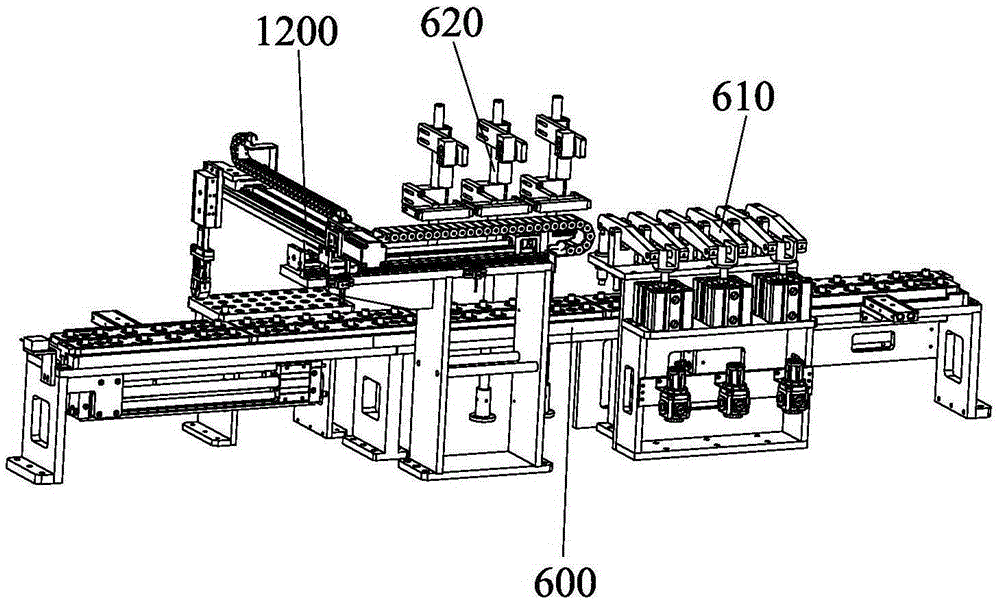

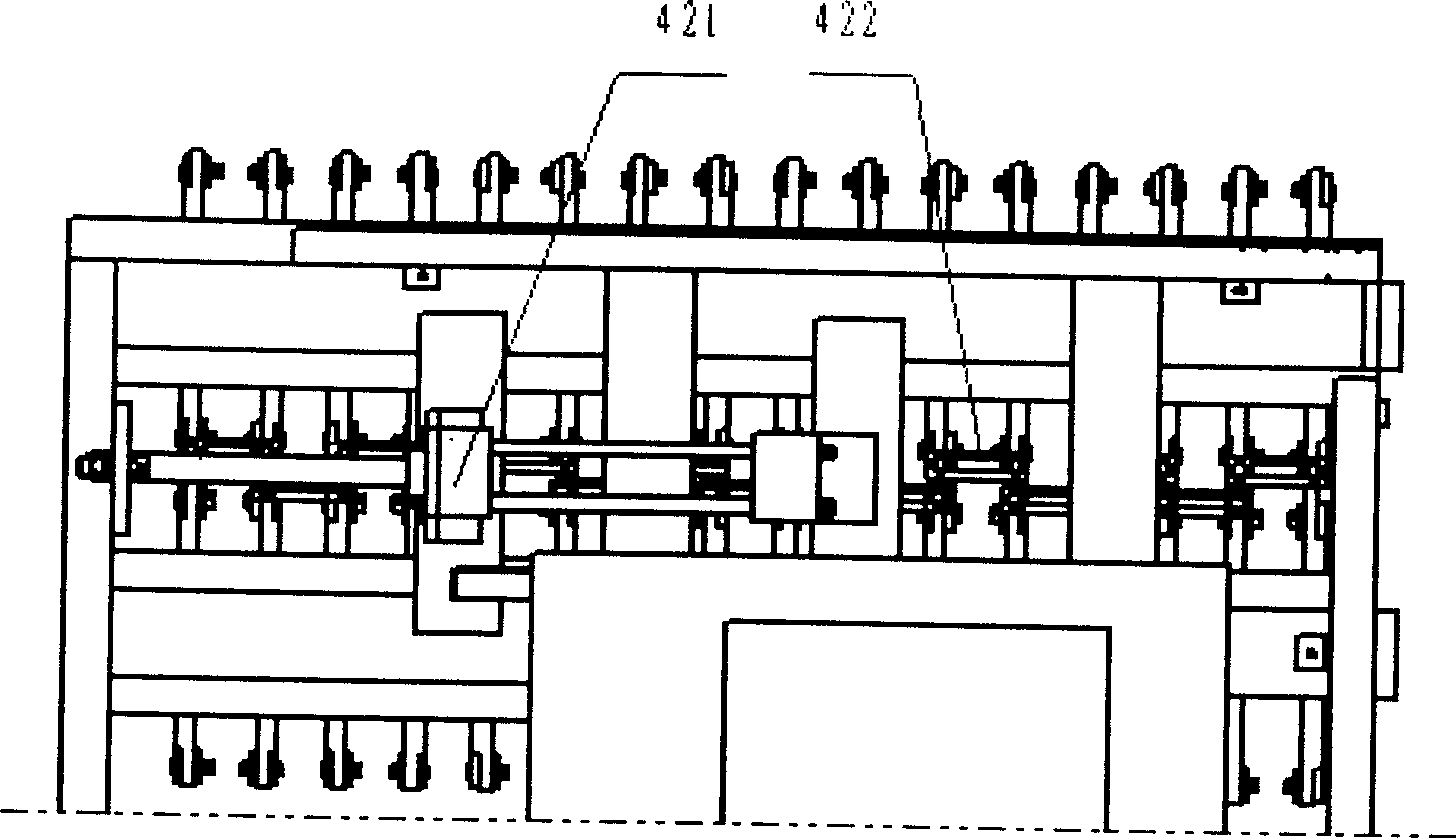

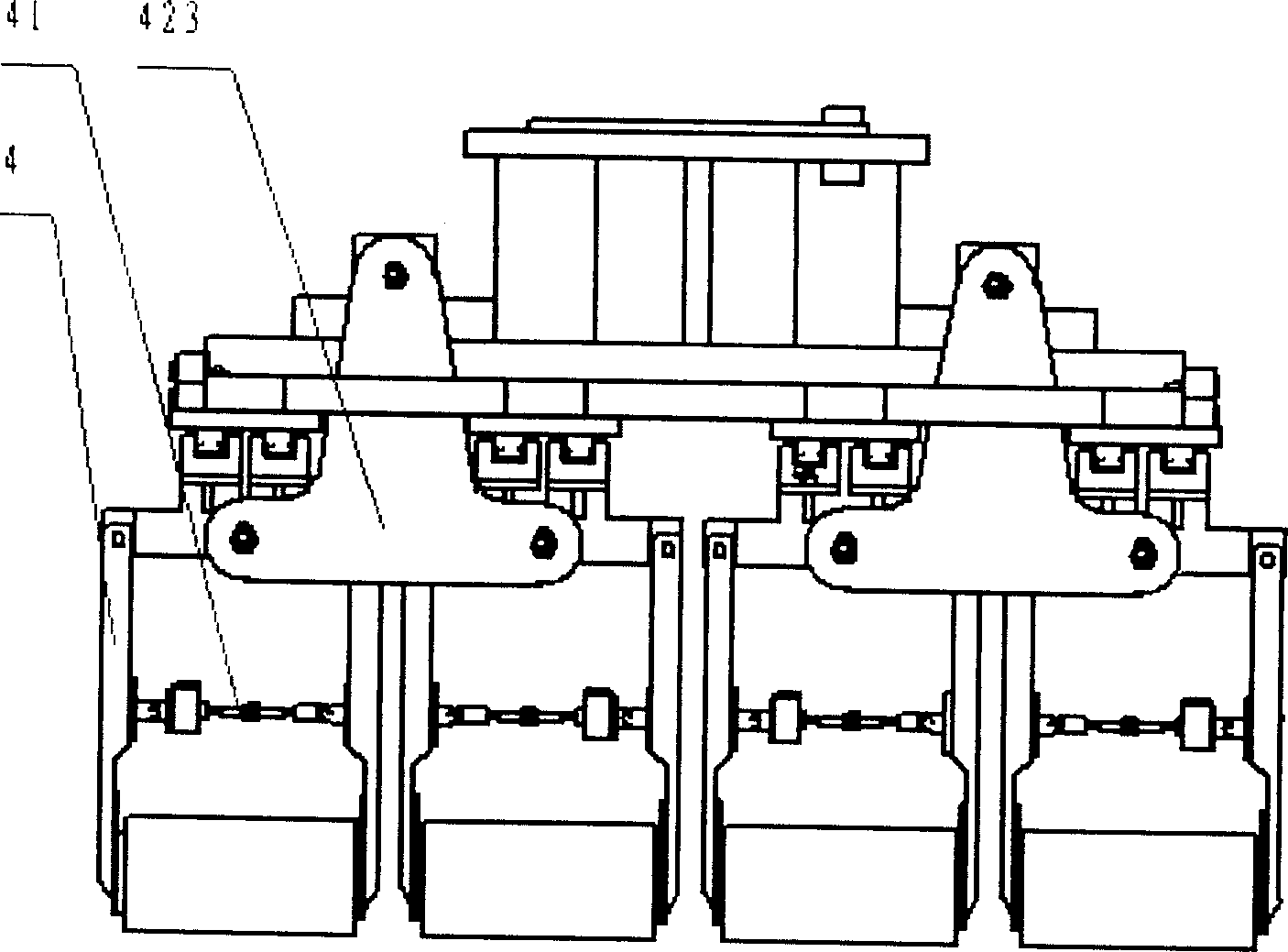

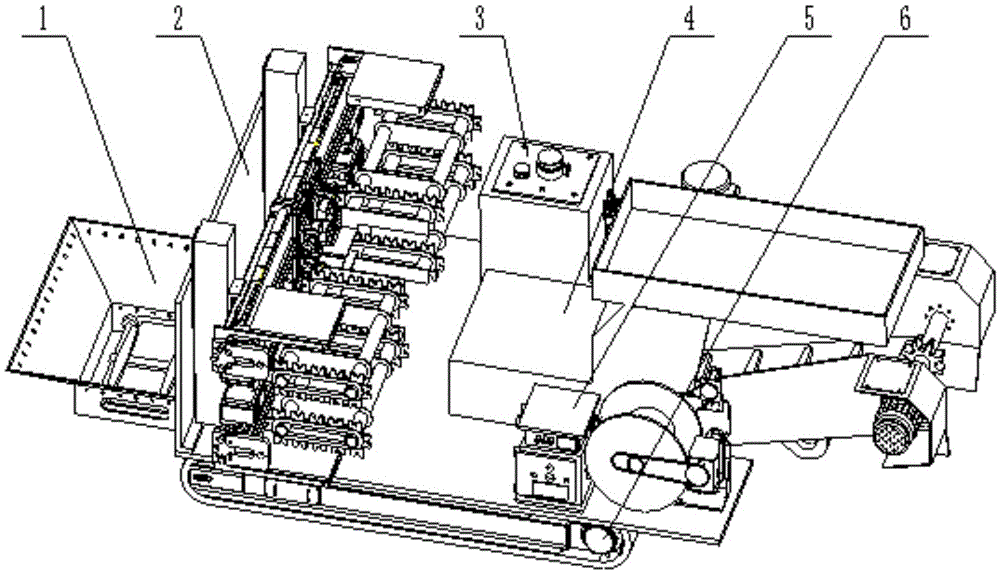

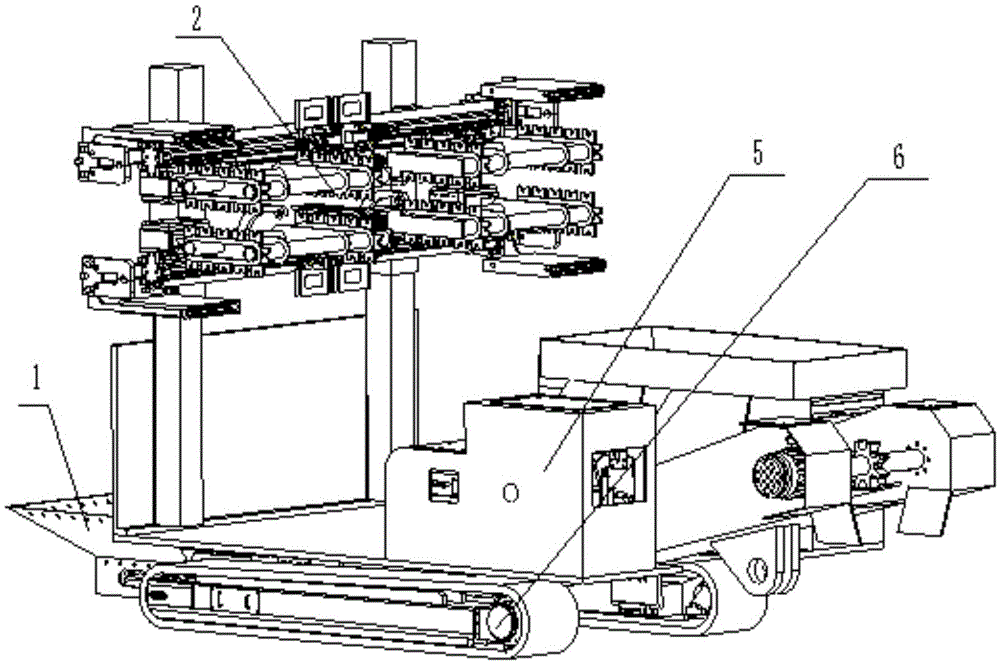

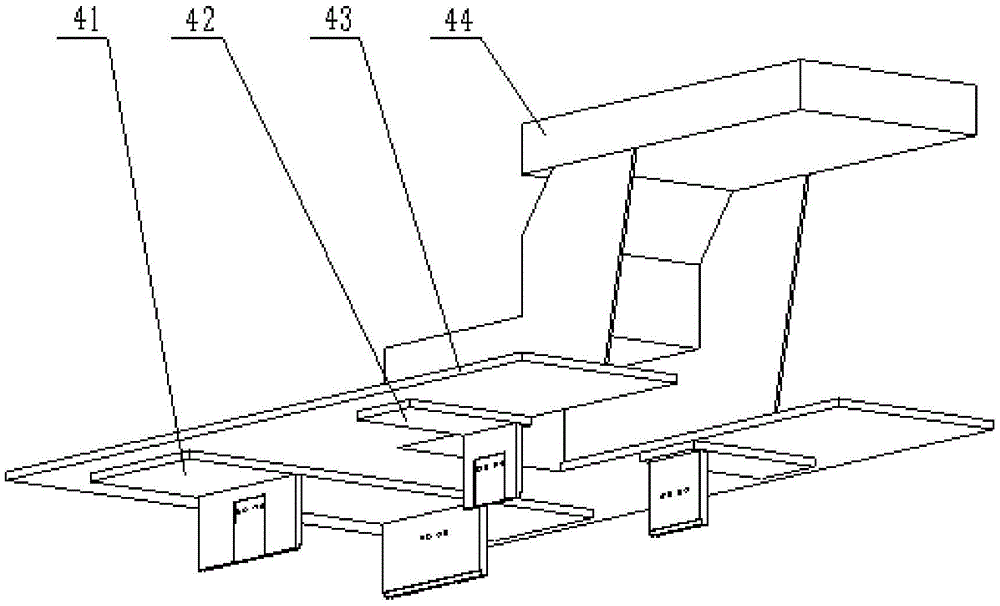

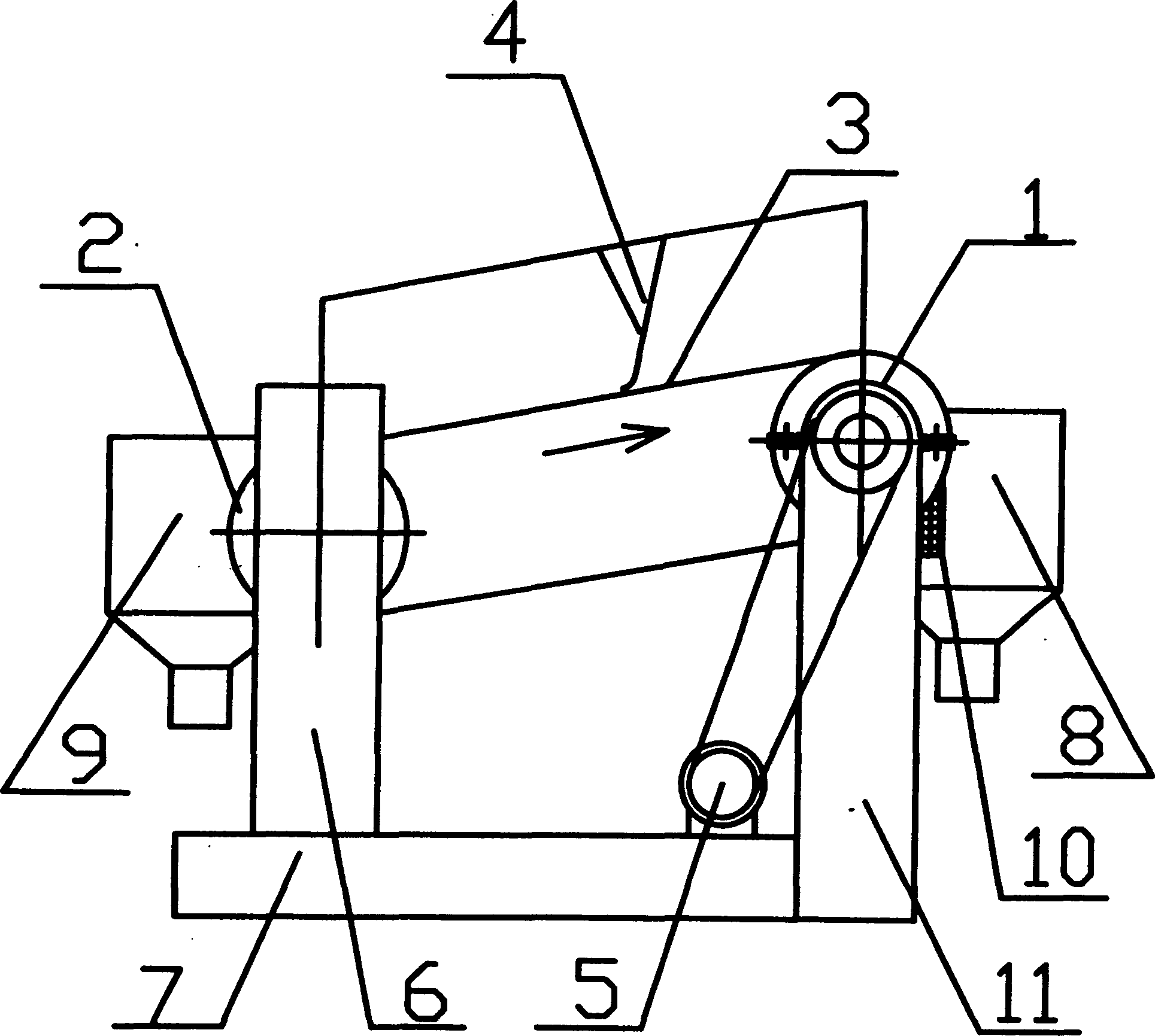

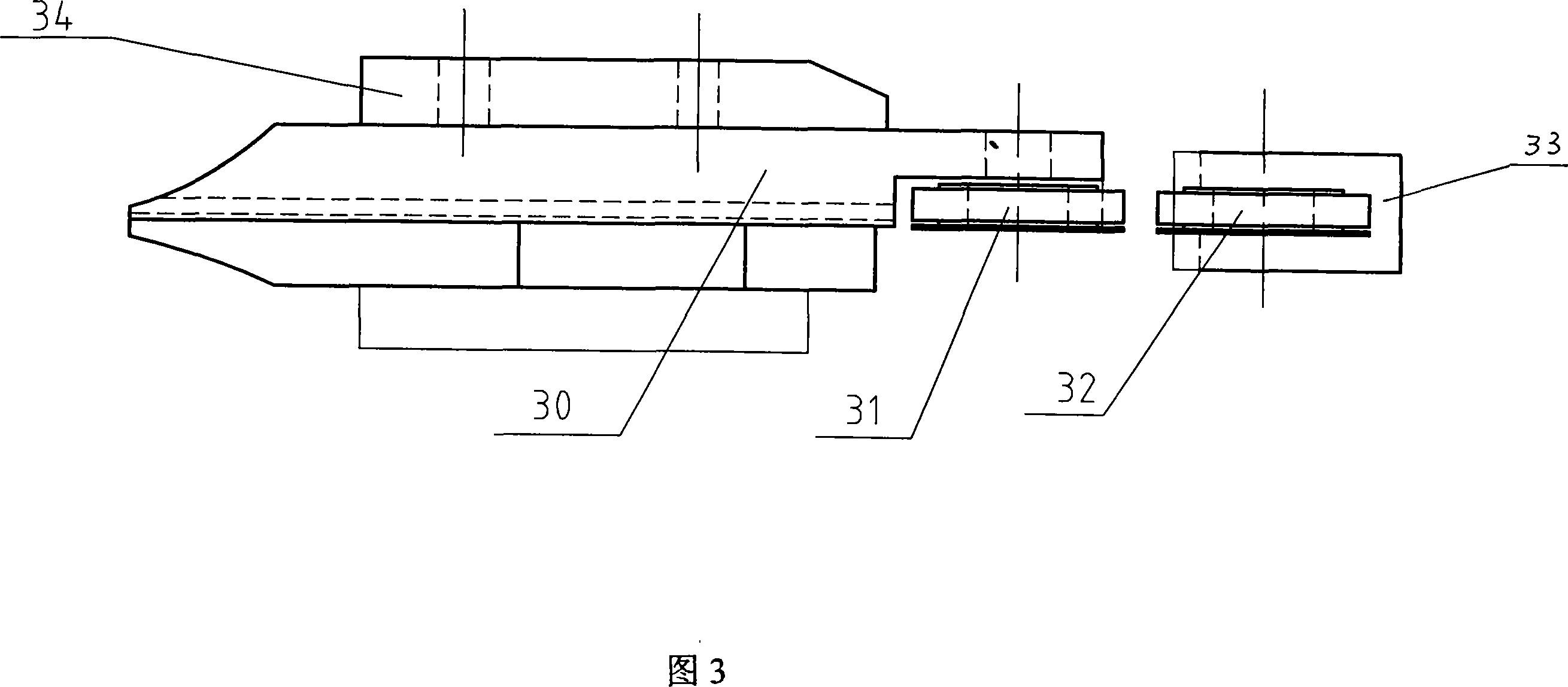

Pintle chain automatic assembly machine

InactiveCN101676049AGood assembly precisionSolve the shortcomings of manual assemblyMetal chainsControl systemEngineering

The invention relates to a pintle chain automatic assembly machine, belonging to the technical field of chain manufacturing machinery. The invention aims to provide a pintle chain automatic assembly machine which is suitable for the assembly production process of pintle chains and has good precision control and high production efficiency. The technical key of the pintle chain automatic assembly machine in that the assembly machine comprises a frame, a link plate feeding mechanism, a link plate positioning mechanism, a pin-penetrating mechanism, a chain element moving mechanism, a PLC automaticcontrol system and a discharging plate, wherein the link plate feeding mechanism comprises a double-cylinder feeding air cylinder (1) and a feeding pole (3) which are arranged in the front of the frame (27) and a link plate-feeding box (5); the link plate positioning mechanism comprises a positioning air cylinder (25) and a positioning block (24) which are arranged below the platen of the frame;the chain pin feeding and pin-penetrating mechanism comprises a pin-pressing air cylinder (10) and a pin-introducing air cylinder (16) which are arranged on the two sides of the parallel track of theplaten of the frame and a vibration pin-distributing disk (4), a pin-sending hose (30) and a pin-collecting box (32) which are arranged on the platen of the frame; the chain element moving mechanism comprises a moving air cylinder (22) and a chain element-pressing air cylinder (19) which are arranged above the platen of the frame; the discharging plate (14)is arranged on the backside of the platenof the frame.

Owner:ANHUI HUANGSHAN HENGJIU CHAIN TRANSMISSION CO LTD

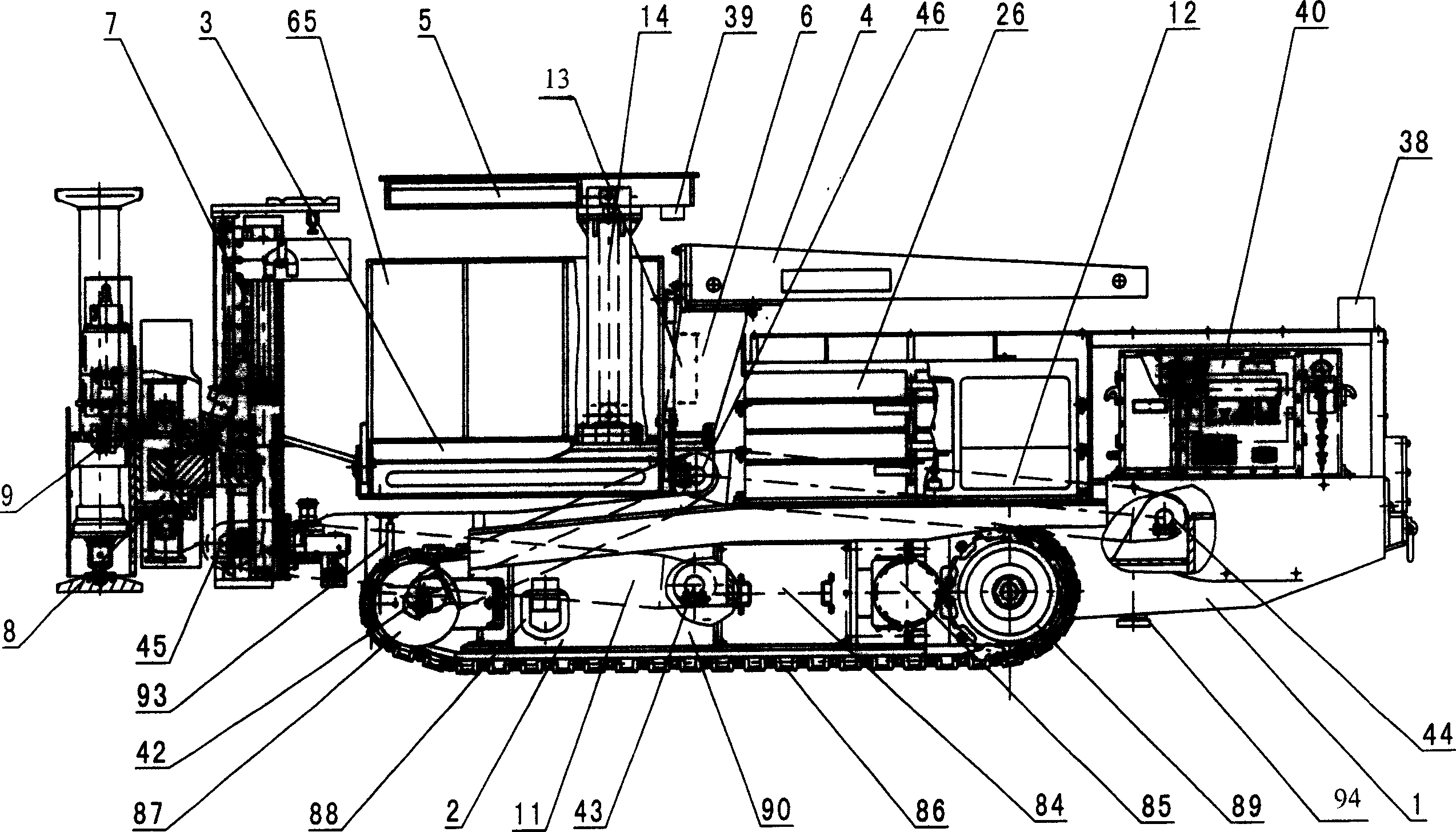

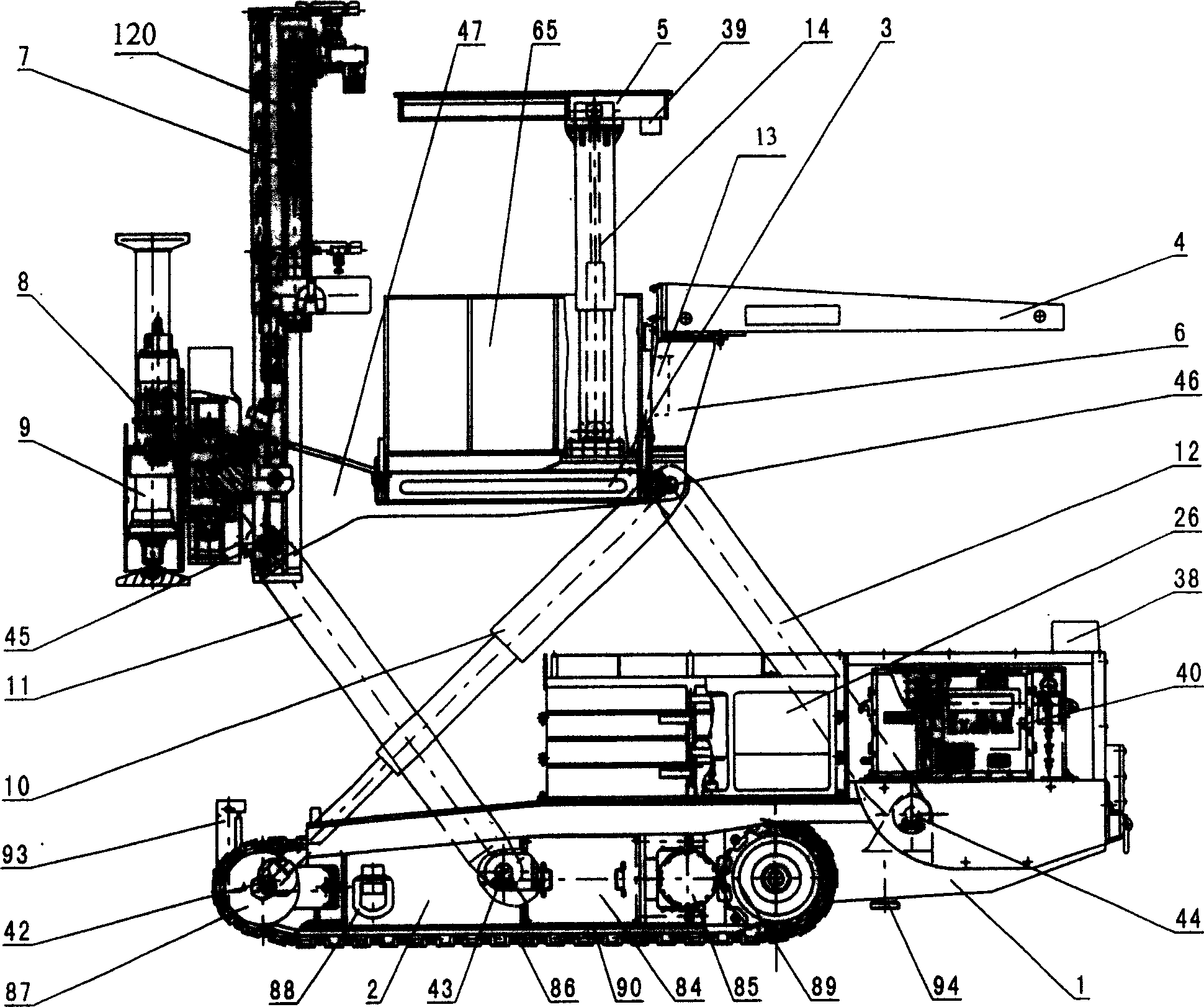

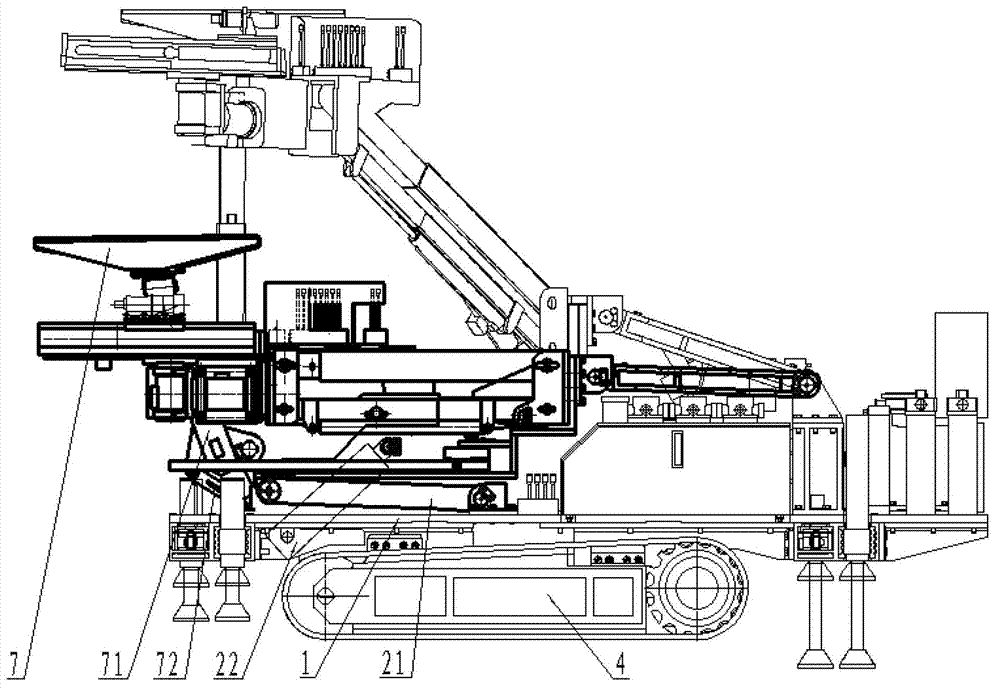

Crawler-type walking rockbolt drilling carriages

ActiveCN1584292AThe mechanical relationship is reasonableMechanizationAnchoring boltsDrilling machines and methodsElectric controlRock bolt

The present invention relates to a crawler running roof-bolting jumbo for coal extraction in the pit. It mainly includes machine seat, working table, running mechanism, lifting mechanism, hydraulic mechanism, dust-removing mechanism, cable-rolling mechanism, drilling cramp component, slideway component, support component and electric control box, said whole machine adopts hydraulic transmission, automatic dust-removing, automatic cable-rolling and crawler running modes, and utilizes the hydraulic oil cylinder to control parallelogram lifting movement and can make moving, lifting and multi-arm roof-bolt drilling works in the excavating tunnel. Said invention is reasonable in structure, large in load-bearing capacity, reliable and high in working efficiency.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP

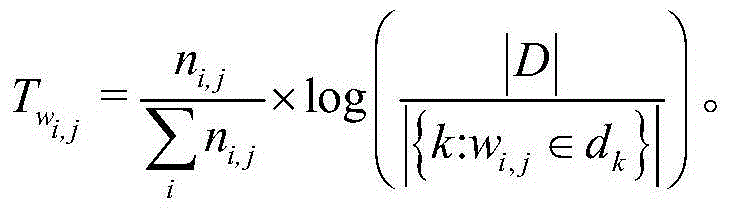

Comment analyzing method and system based on term vector

ActiveCN104573046AFully automatedMechanizationNatural language data processingSpecial data processing applicationsComment typeComment analysis

The invention discloses a comment analyzing method and system based on a term vector and relates to the technical field of emotion analysis, natural language processing and the like. A machine is utilized to analyze the comment, automatic user comment analysis is made by using the machine, and the working efficiency is improved. The method is characterized in that user comments are collected to form a comment corpus, each comment in the comment corpus is converted into the sentence vectors with identical dimension, a plurality of comment types are set, each comment is labeled with the corresponding type according to the labels which are input manually, a classifier is trained with the sentence vectors as the input and the comment type that each sentence vector corresponds to as the output, a new comment is acquired and converted into the sentence vector, and the sentence vector that the new comment corresponds to is input into the classifier to obtain the comment type of the new comment.

Owner:CHENDU PINGUO TECH

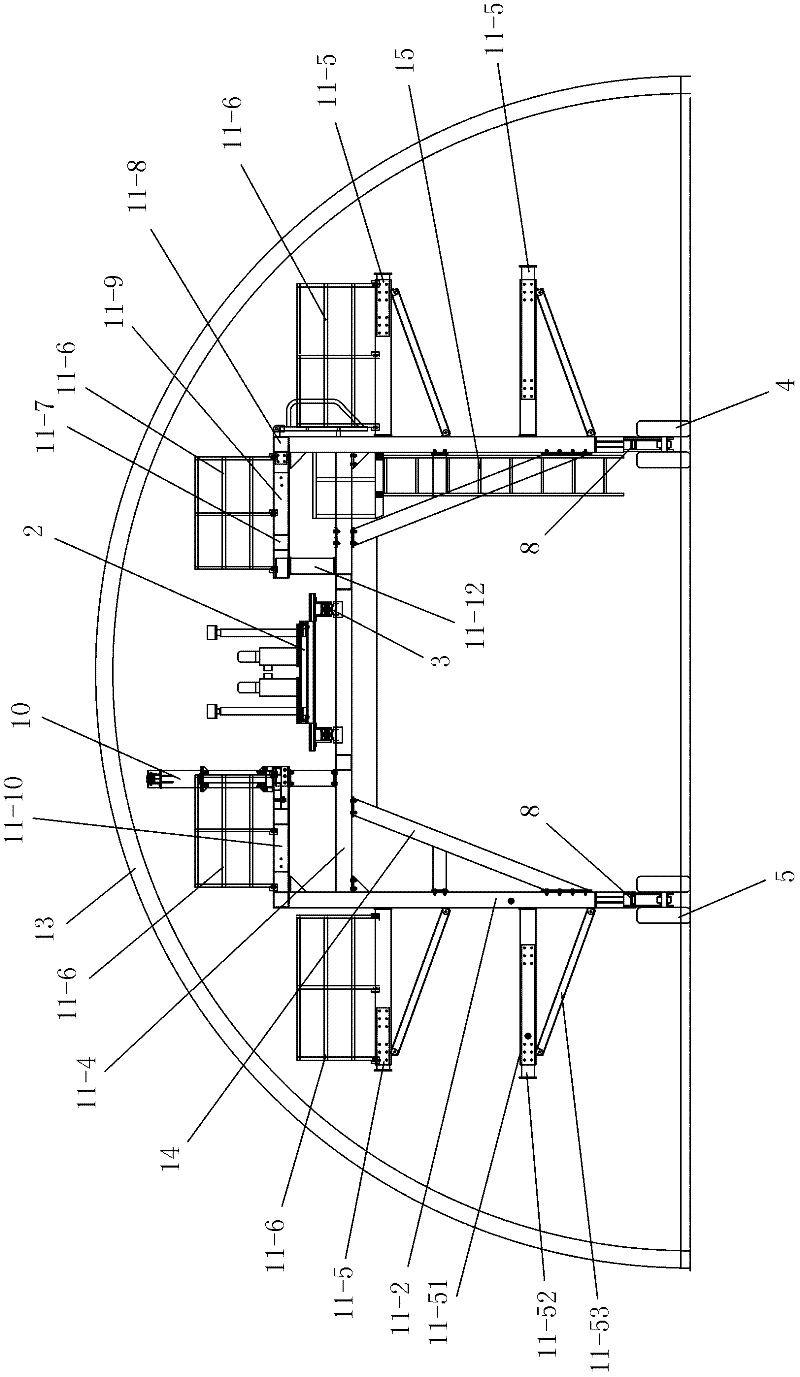

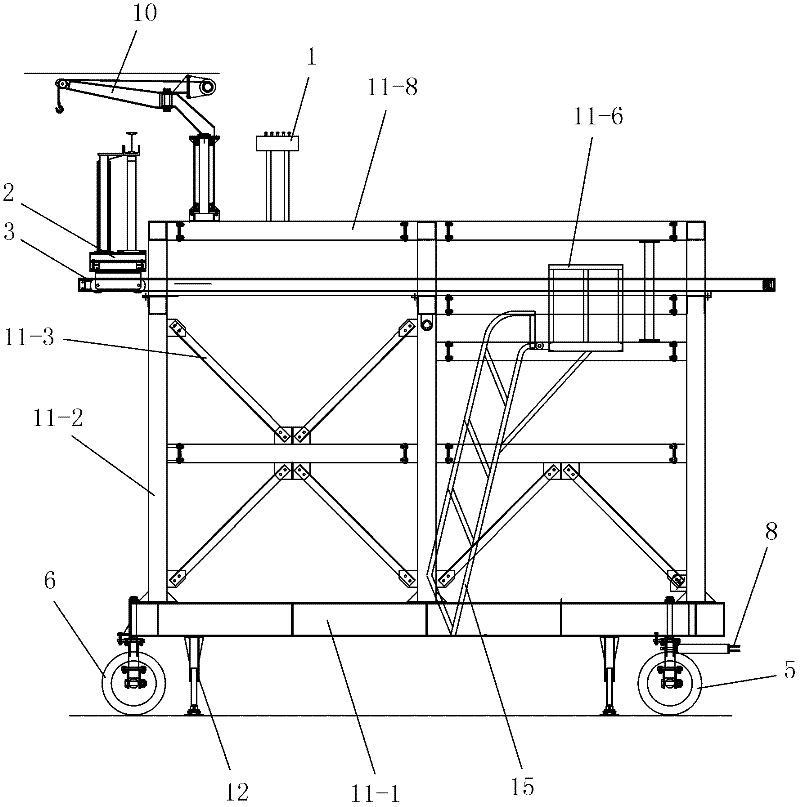

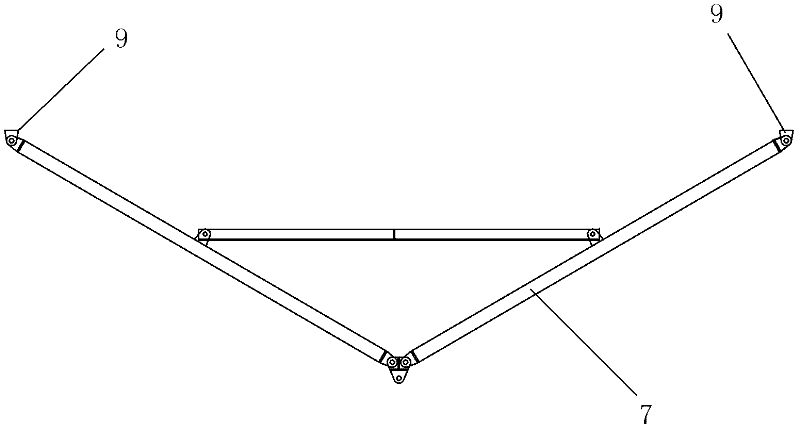

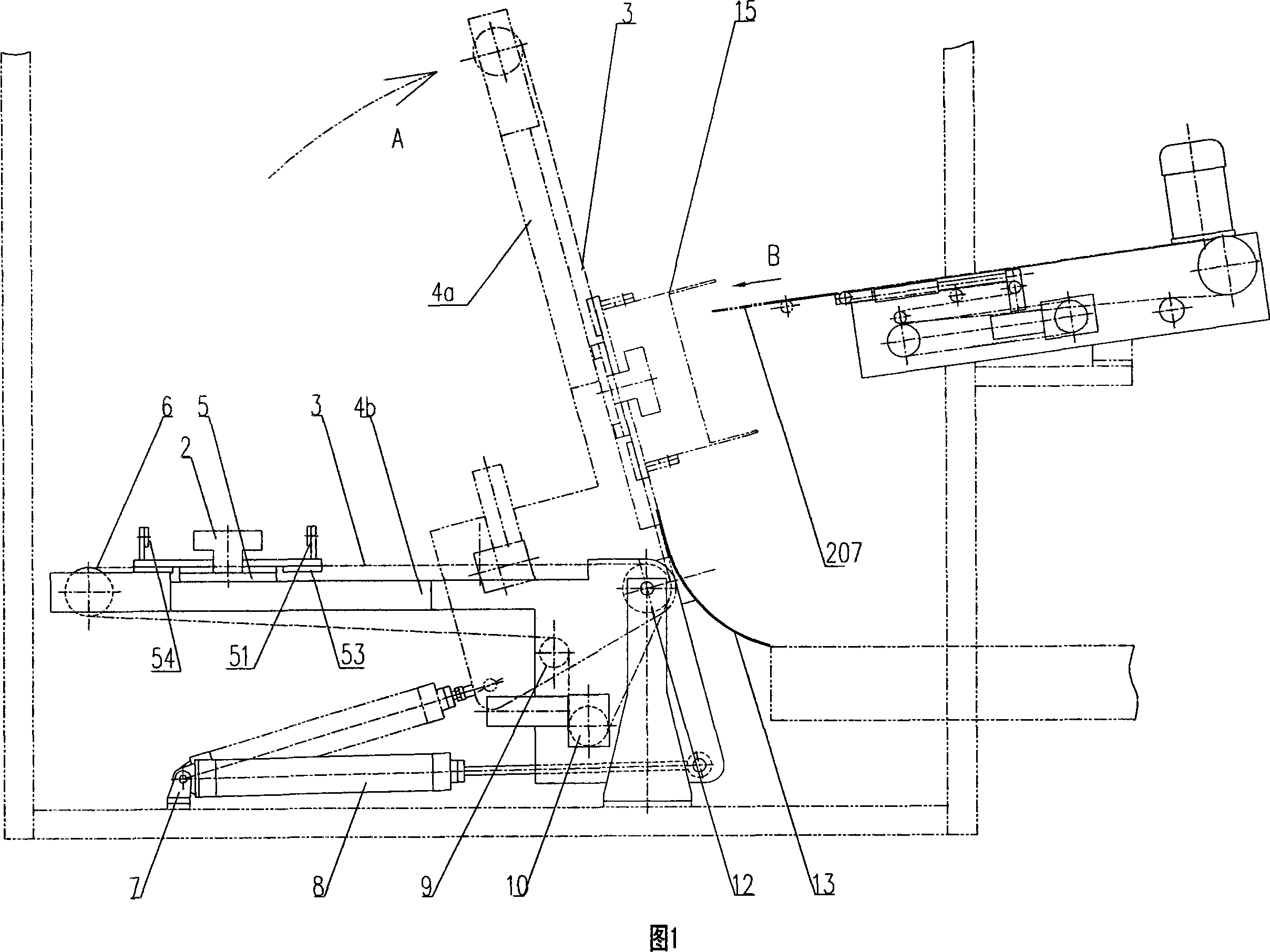

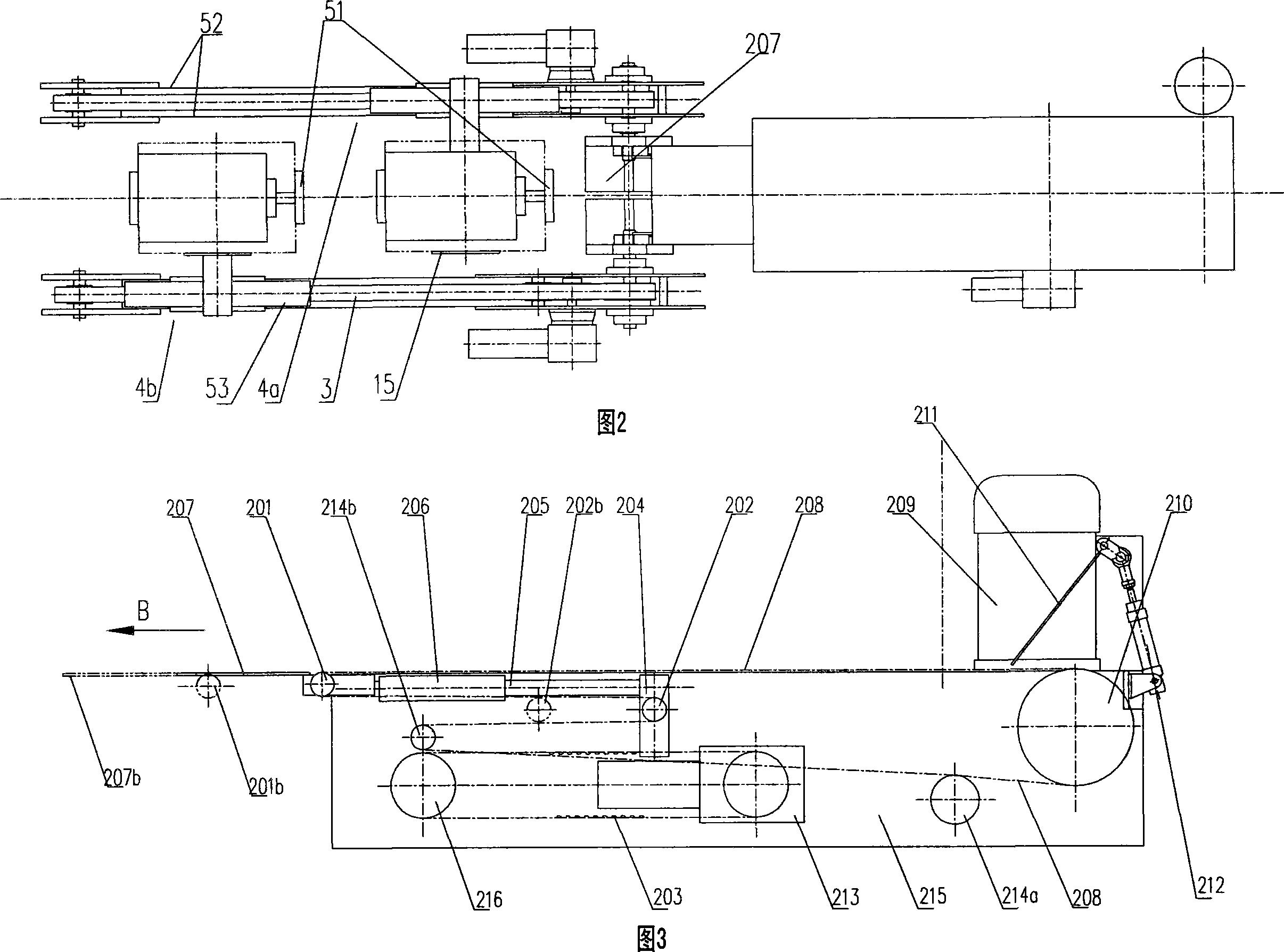

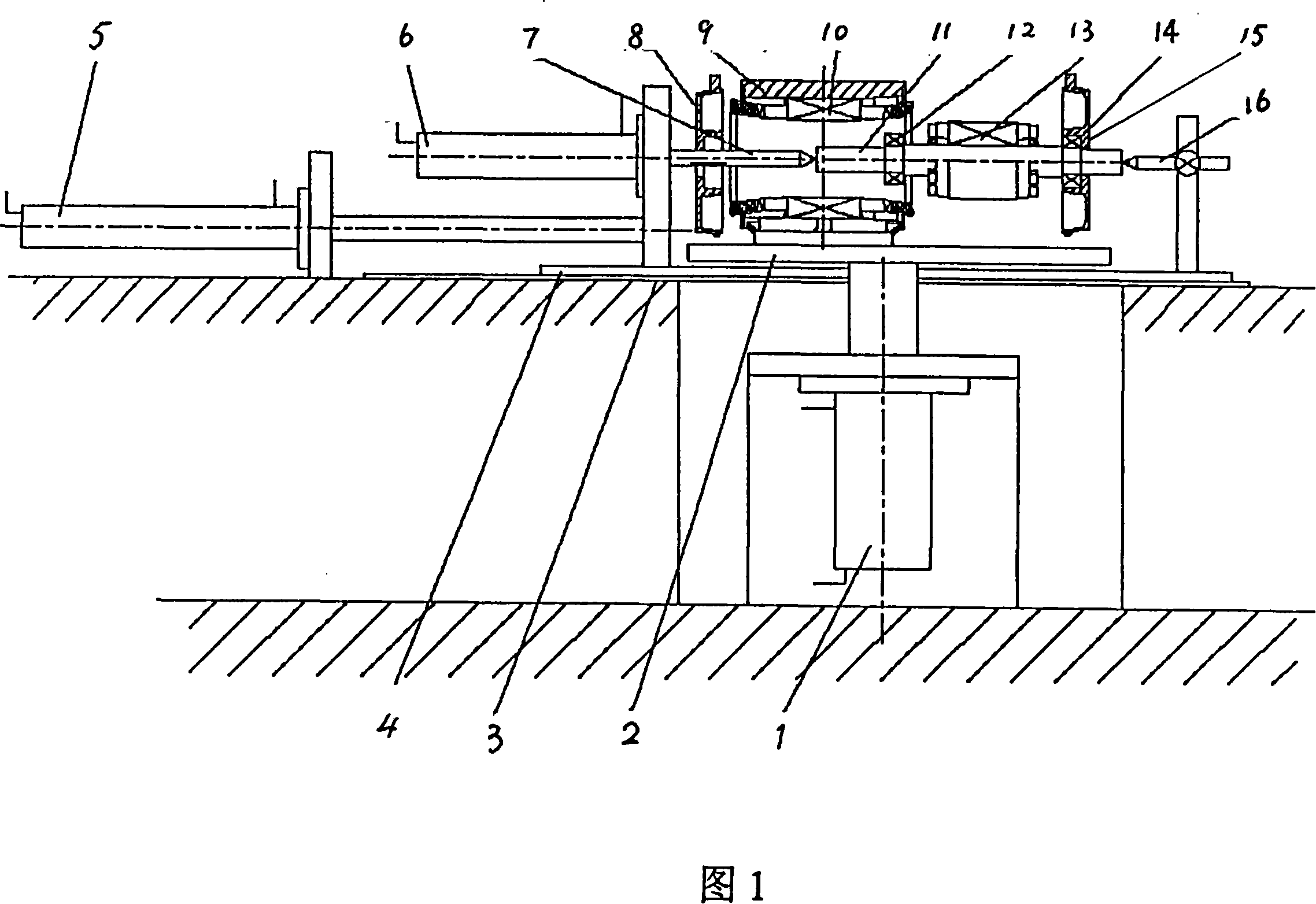

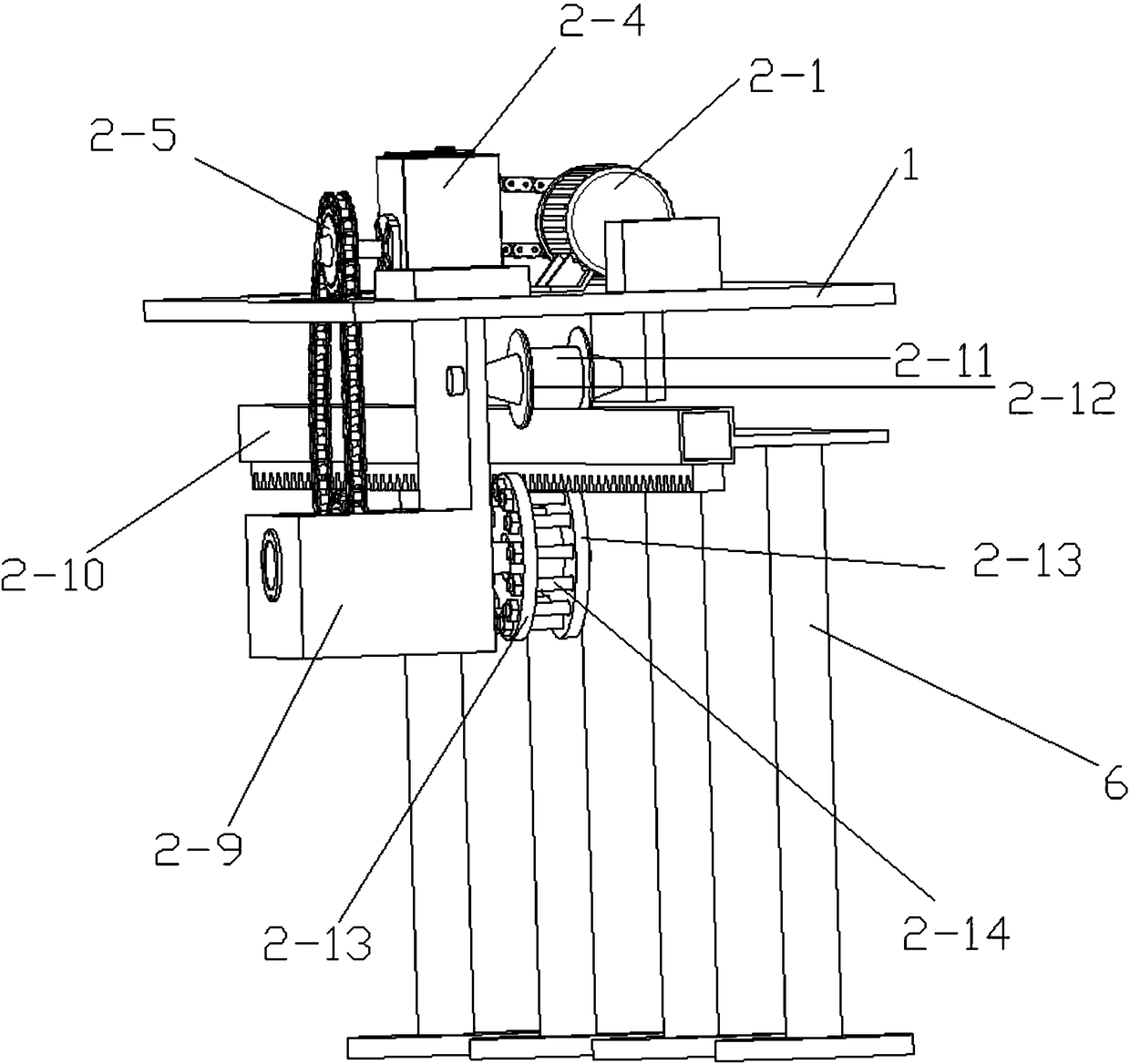

Tunnel arch installation vehicle

ActiveCN102287209ASimple structureReasonable designUnderground chambersTunnel liningWork performanceEngineering

The invention discloses a tunnel arch center installation operation vehicle. The tunnel arch center installation operation vehicle comprises a machine frame, a travelling mechanism, a traction mechanism, an arch center lifting device for lifting tunnel arch centers which are arranged on the rear part of the machine frame and are needed to be installed one by one, and an arch center transferring mechanism for transferring the arch centers which are lifted by the arch center lifting device one by one through alignment and adjustment; the arch center transferring mechanism comprises a translating trolley which can move forward and backward on the upper part of the machine frame, a lifting mechanism for stably lifting the tunnel arch centers, and a left and right movement mechanism for driving the lifting mechanism to synchronously move left and right; and the translating trolley, the left and right movement mechanism, and the lifting mechanism align and adjust the tunnel arch centers front and back, right and left and up and down respectively. The tunnel arch center installation operation vehicle has a reasonable design, is convenient to assemble, and easy and convenient to operate, safe and reliable in working performance, and good in a using effect, and can solve the problems of large working difficulty in movement and accurate positioning of steel arch centers after lifting during the installation of the conventional steel arch centers, low installation efficiency, large labor intensity and the like.

Owner:CHINA RAILWAY FIRST GRP CO LTD

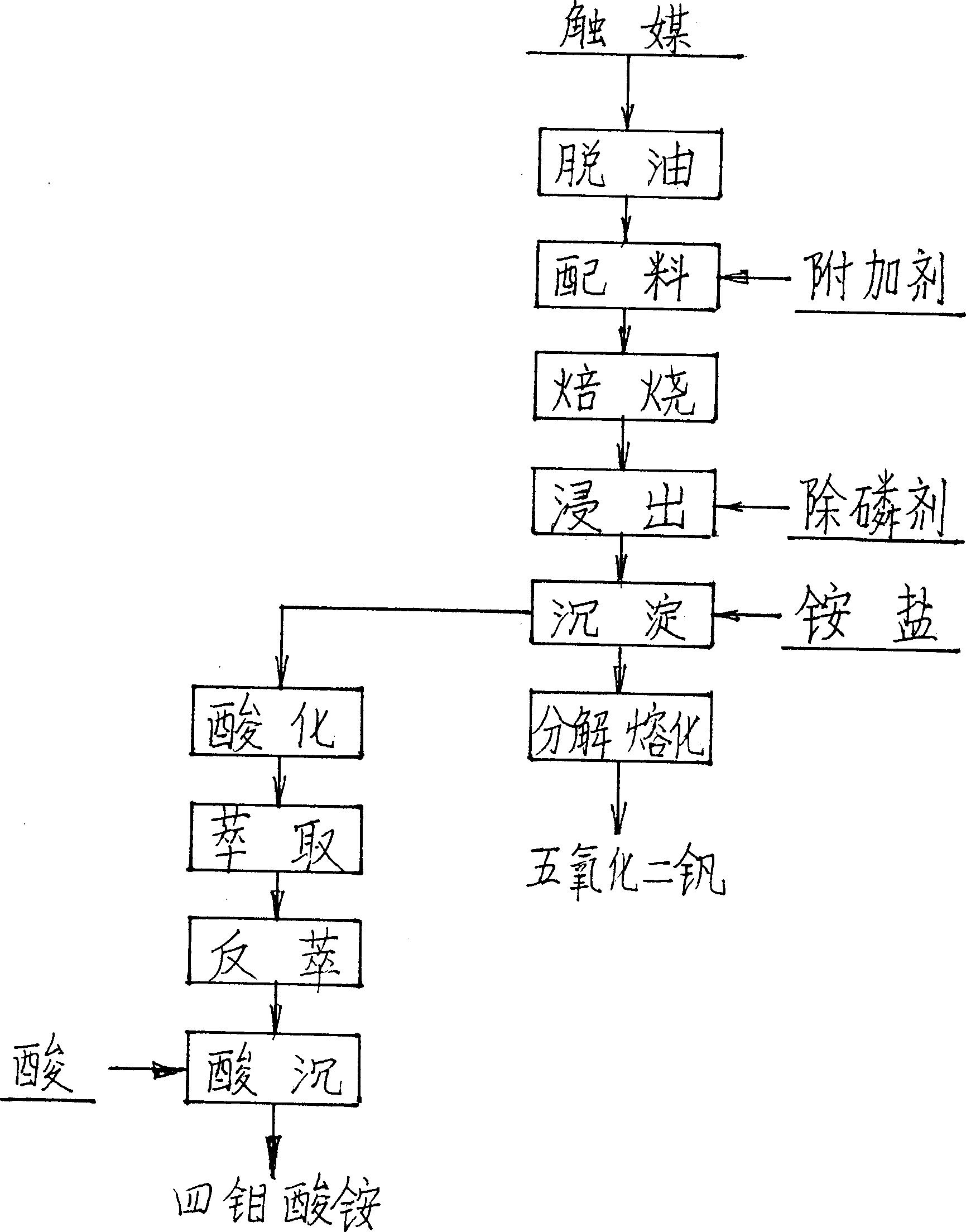

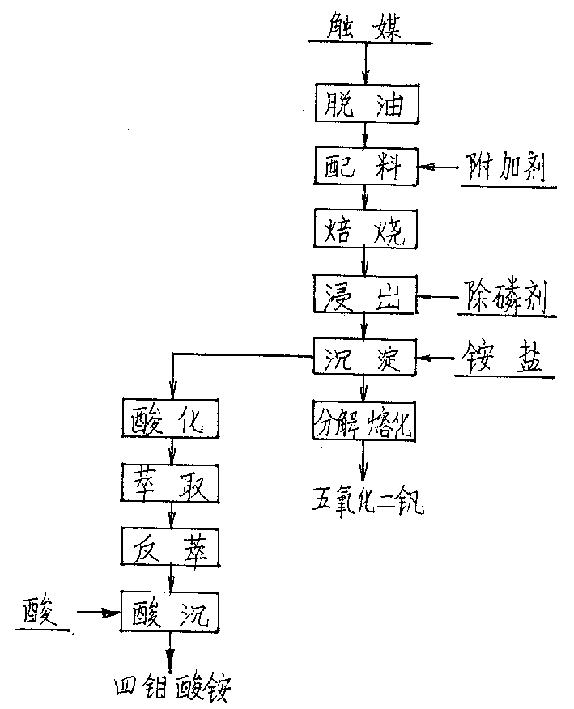

Wet process of extracting vanadium and/or molybdenum from waste catalyst

InactiveCN1453379ALess investmentReduce consumptionProcess efficiency improvementMagnesium saltAmmonium metavanadate

The present invention is wet process of extracting vanadium and / or molybdenum form waste petrochemical catalyst alumina carrier containing V, Mo and other elements. The wet process includes high-temperature deoiling the catalyst in natural granularity, mixing with sodium carbonate, high-temperature oxidation and roasting in a kiln or furnace to obtain water soluble sodium vanadate and sodium molybdate; countercurrent water soaking of the chamotte to obtain solution containing V and Mo in certain concentration, adding calcium salt and magnesium salt to eliminate P and other impurities, addingammonium salt solution into the clear solution to obtain ammonium metavanadate, decomposing and melting ammonium metavanadate to obtain V2O5 product; adding acid to the supernatant and organic phase extraction of Mo, ammonia water reverse extraction to obtain ammonium molybdate, and adding acid to precipitate ammonium tetramolybdate or molybdate product.

Owner:CITIC JINZHOU METAL

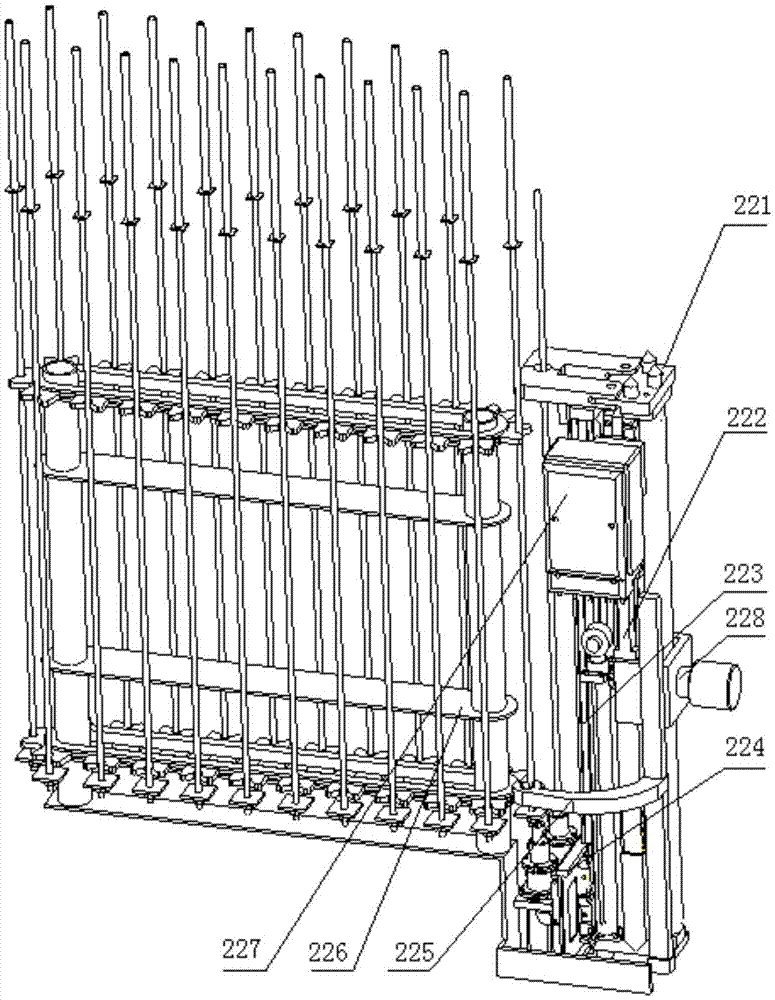

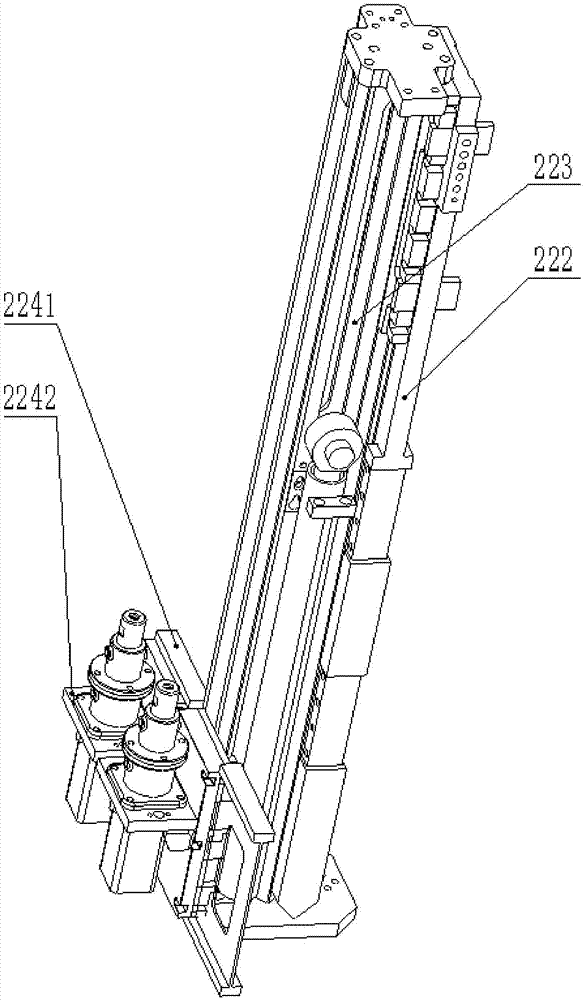

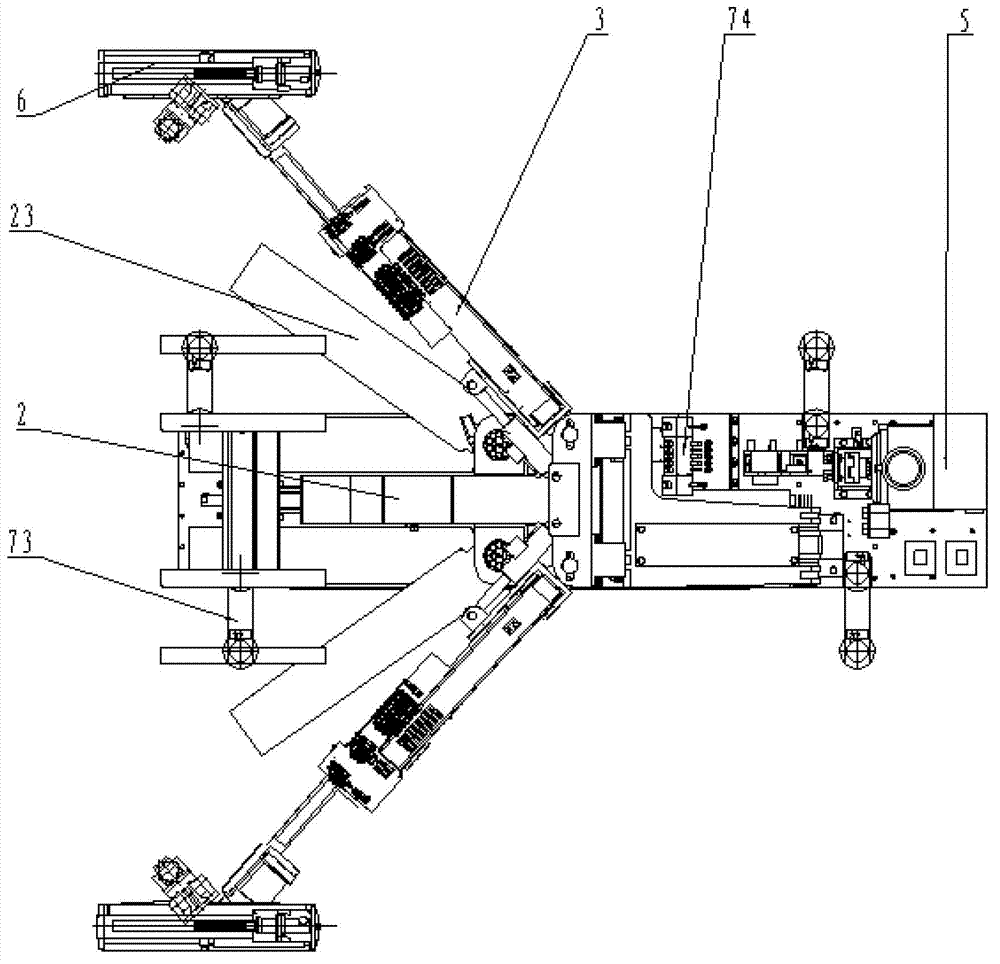

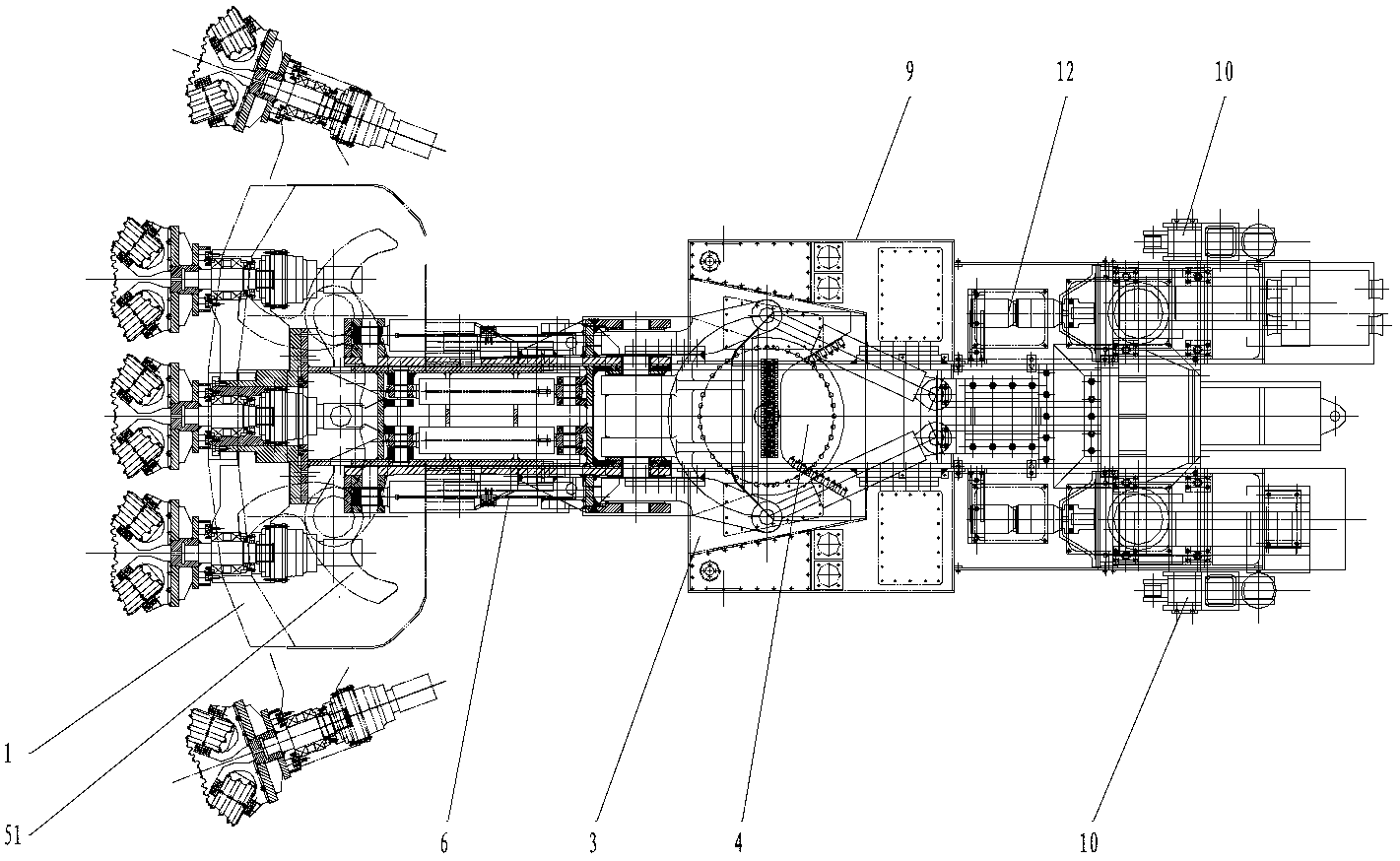

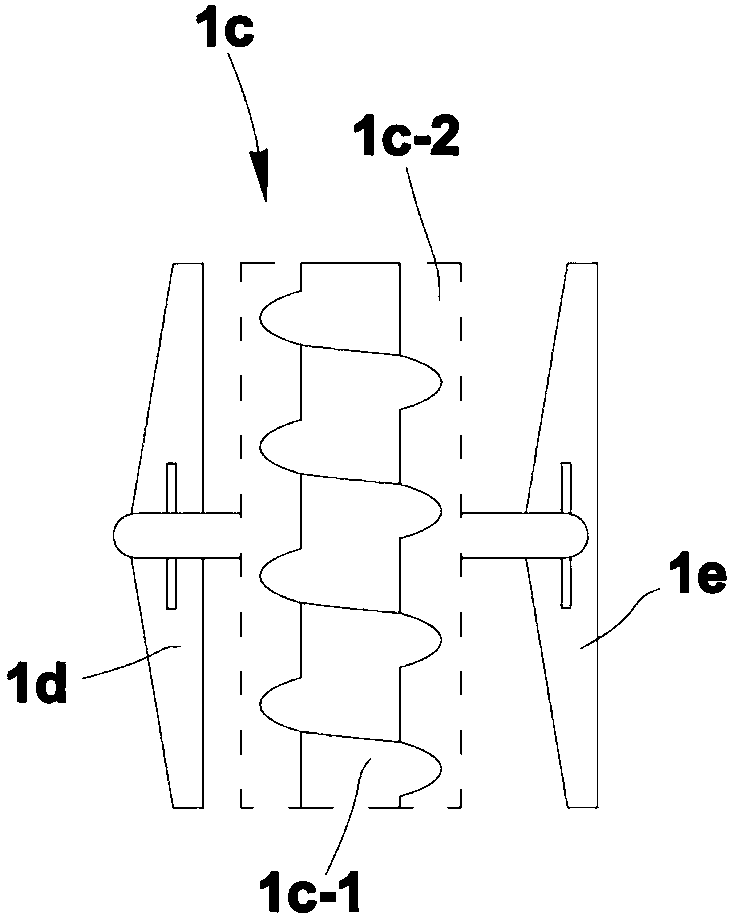

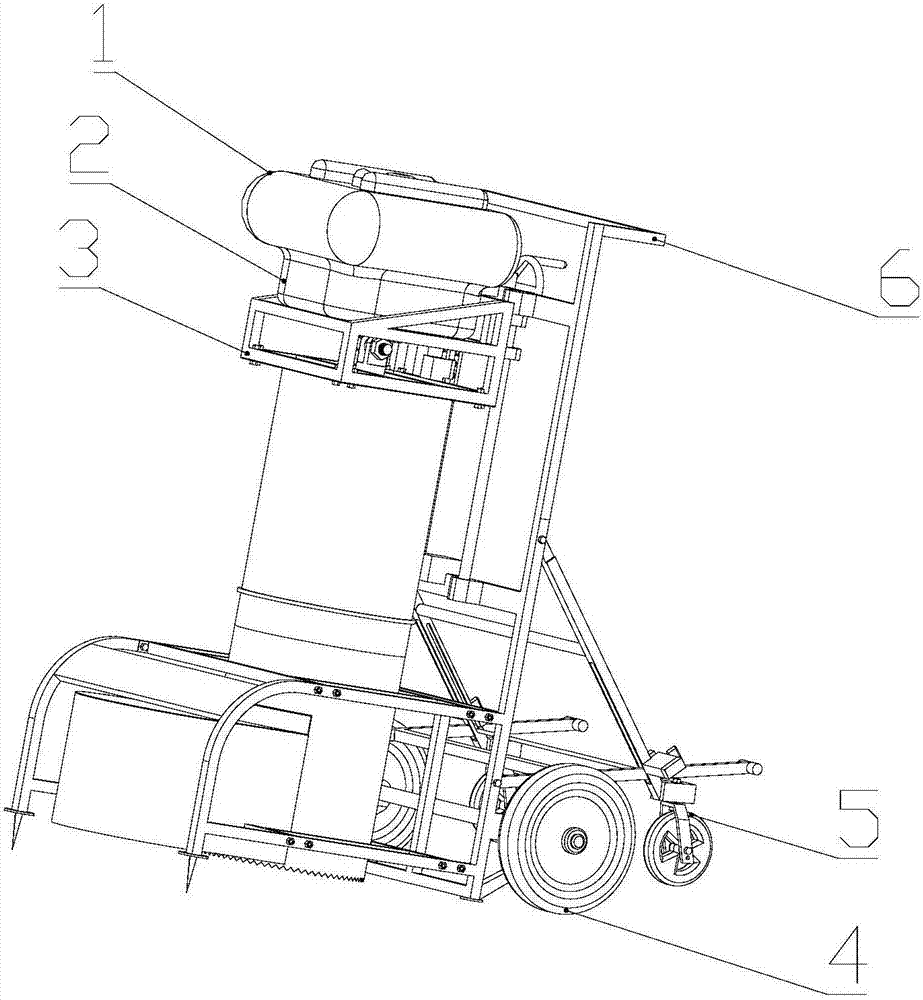

Anchor rod jacking drilling machine and anchor rod jacking drilling carriage with same

ActiveCN105443037AImprove locking abilityMechanizationDerricks/mastsAnchoring boltsUltimate tensile strengthTransferring (function)

The invention discloses an anchor rod jacking mechanism which comprises a fixing mechanism, a supporting mechanism, a sliding block and a drill box mechanism. The fixing mechanism comprises a base, a stand plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the stand plate. The supporting mechanism and the sliding block are in sliding connection with the opposite side faces of the stand plate through the guide blocks respectively. One end of the supporting mechanism and one end of the slide block are connected with base through telescopic oil cylinders. The drill box mechanism comprises a bottom frame and two independent drill box sliding seats. The bottom frame is connected with the base, and the drill box sliding seats can horizontally move along the bottom frame. When the drill box sliding seats move to the sliding block, the drill box sliding seats can be connected with the other guide rail face of the sliding block and slide along the sliding block. The invention further discloses an anchor rod jacking drilling carriage with a drilling machine. The anchor rod jacking drilling carriage comprises a four-wall anchor rod jacking drilling carriage body and a six-arm anchor rod jacking drilling carriage body. The drilling machine in the anchor rod jacking drilling carriage can work at the same time. Fast supporting operation on a top plate can be achieved, the structure is compact, and multiple functions are achieved. The anchor rod jacking mechanism and the anchor rod jacking drilling carriage operate in cooperation with heading equipment to complete the supporting and transferring function synchronously, operating personnel are greatly reduced, the labor intensity is lowered, and the supporting efficiency and safety are improved.

Owner:蒲长晏

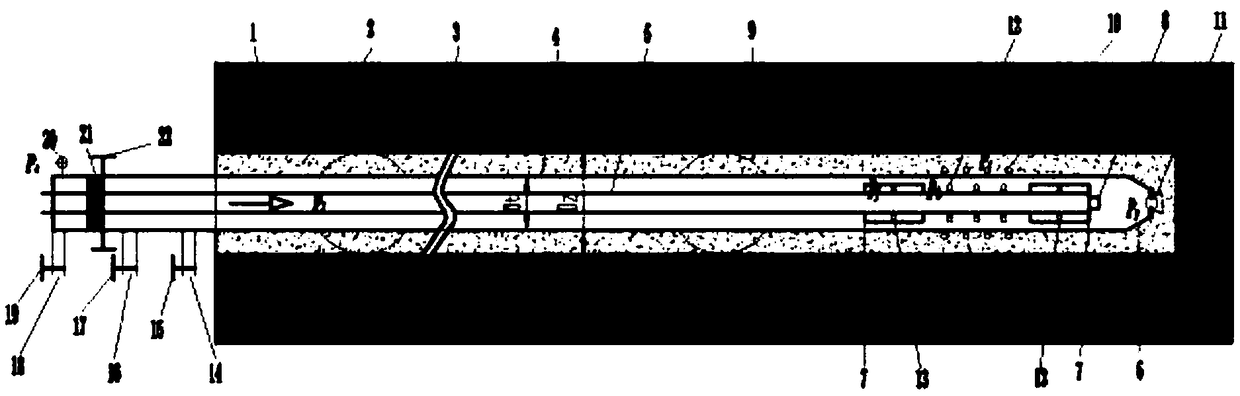

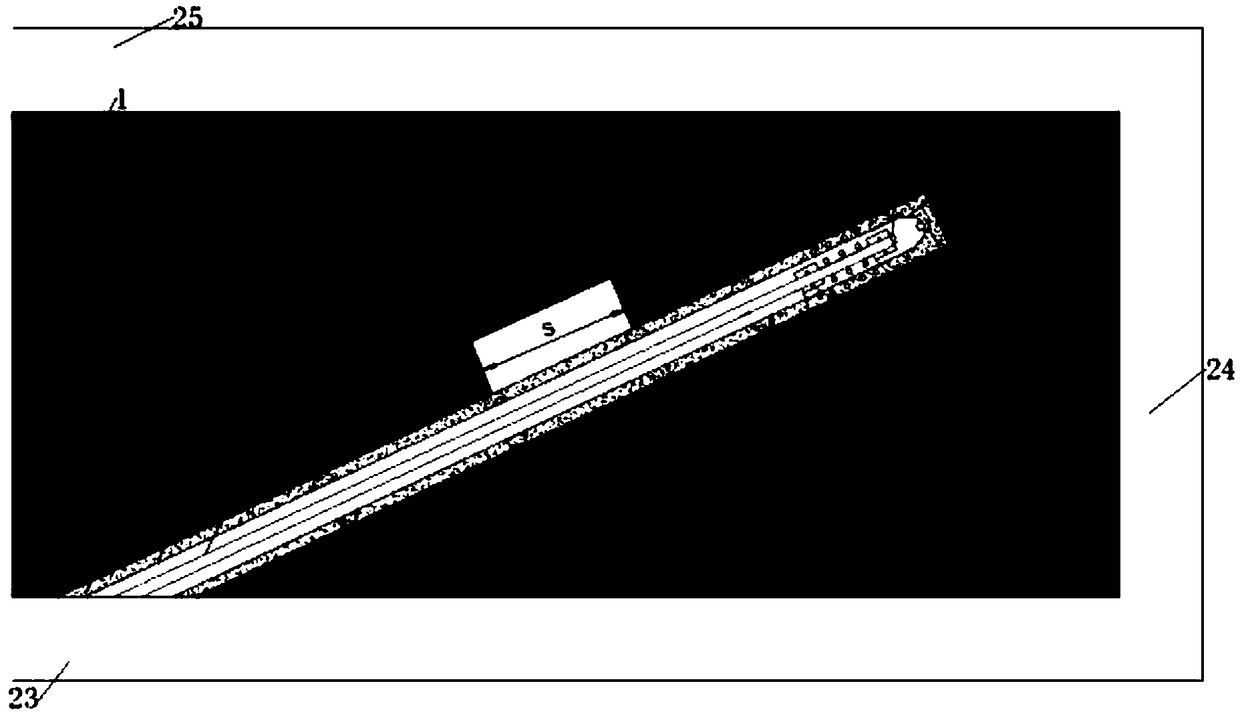

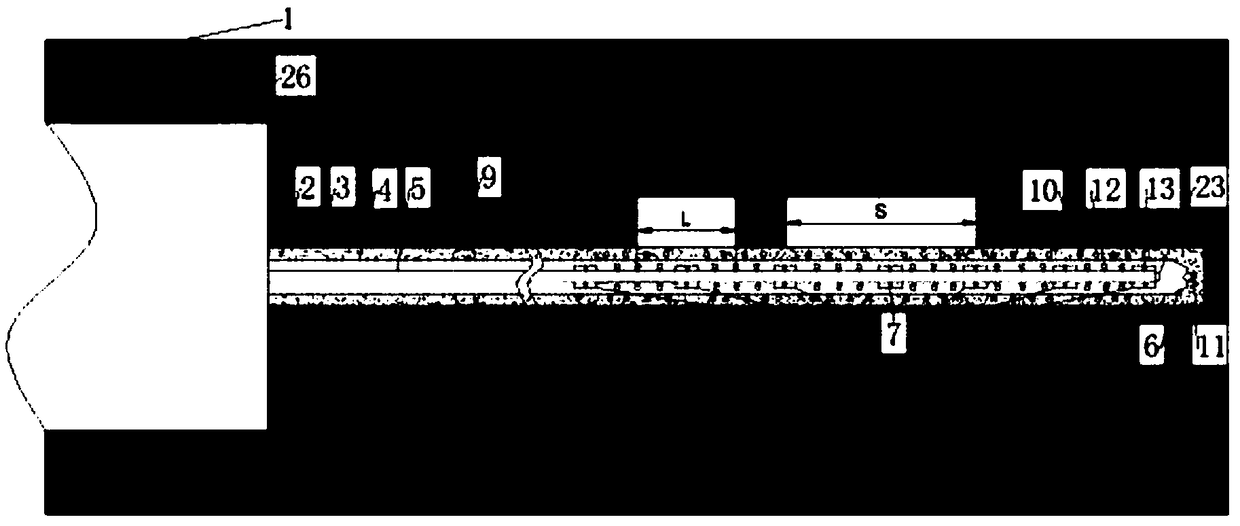

Coal mine underground coal seam long drill hole staged fracturing permeability increase and gas extraction method

ActiveCN108643877AIncrease the scope of fracturing anti-reflectionEfficient extractionFluid removalGas removalUnderground tunnelCement paste

The invention discloses a coal mine underground coal seam long drill hole staged fracturing permeability increase and gas extraction method. The coal mine underground coal seam long drill hole stagedfracturing permeability increase and gas extraction method comprises the steps that a long drill hole with the length more than 100m are drilled into a coal seam using a underground tunnel drilling machine for a coal mine or a kilometer drilling machine; a rigid casing with an one-way valve is lowered into to protect the hole directly using the underground tunnel drilling machine or the kilometerdrilling machine, and casing centralizers are installed at regular intervals; after the casing is lowered, preset volumetric cement paste is injected into an annular space between the outer wall of the casing and a drill hole wall to carry out blocking and sealing; a rigid fracturing pipe with two or multiple packers is lowered into the casing to carry out coal seam staged fracturing step by stepor multistage staged fracturing; and the fracturing pipe and the packers are removed after staged fracturing permeability increase, the casing of coal seam long drill hole opening is accessed with a gas extraction pipeline after drainage finishes to carry out efficient extraction of gas. The engineering amount of a tunnel and hole-drilling can be greatly reduced, the coal seam gas extraction efficiency is improved, and the coal mine underground gas treatment cost is reduced.

Owner:CHINA UNIV OF MINING & TECH

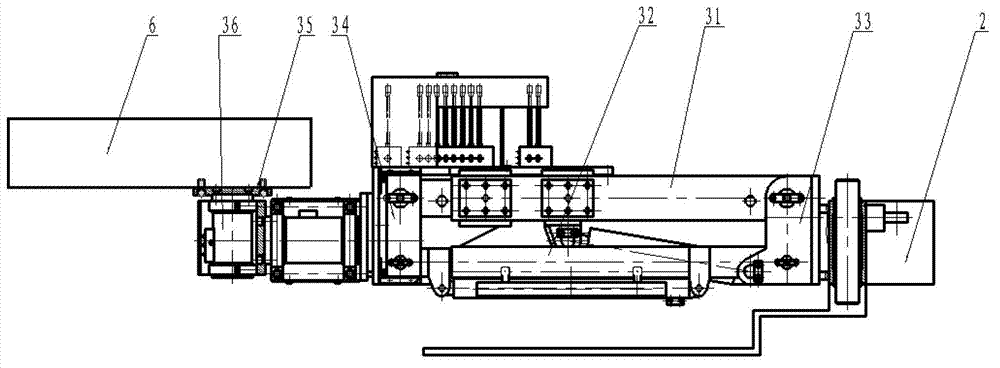

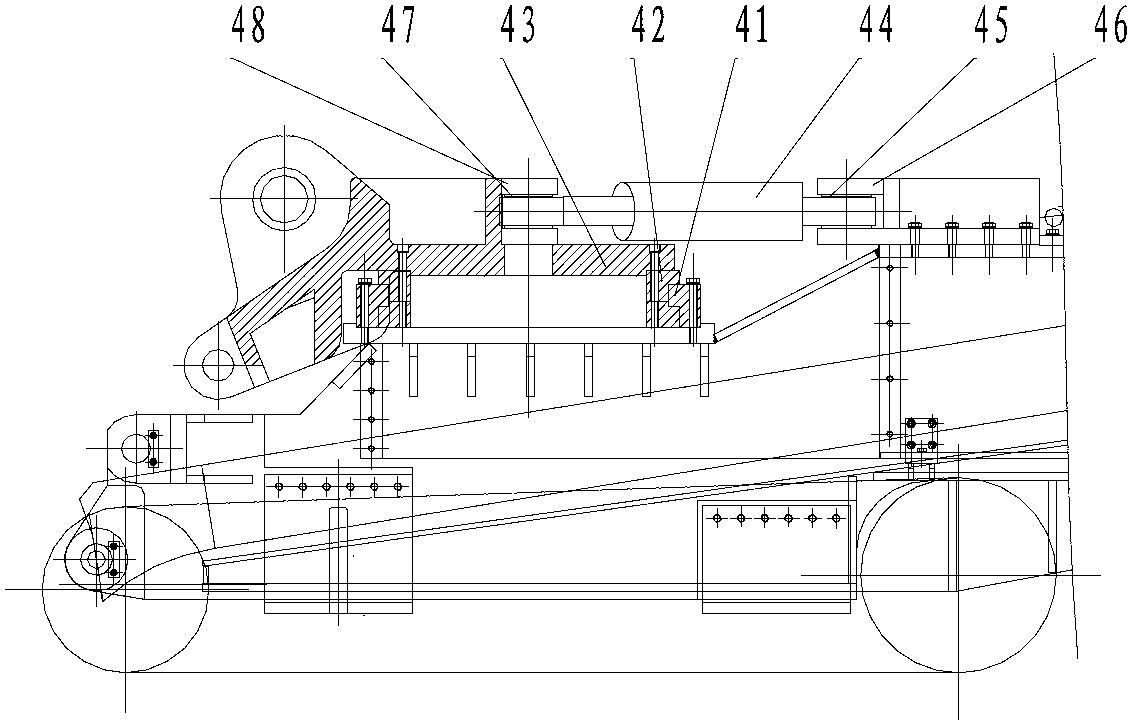

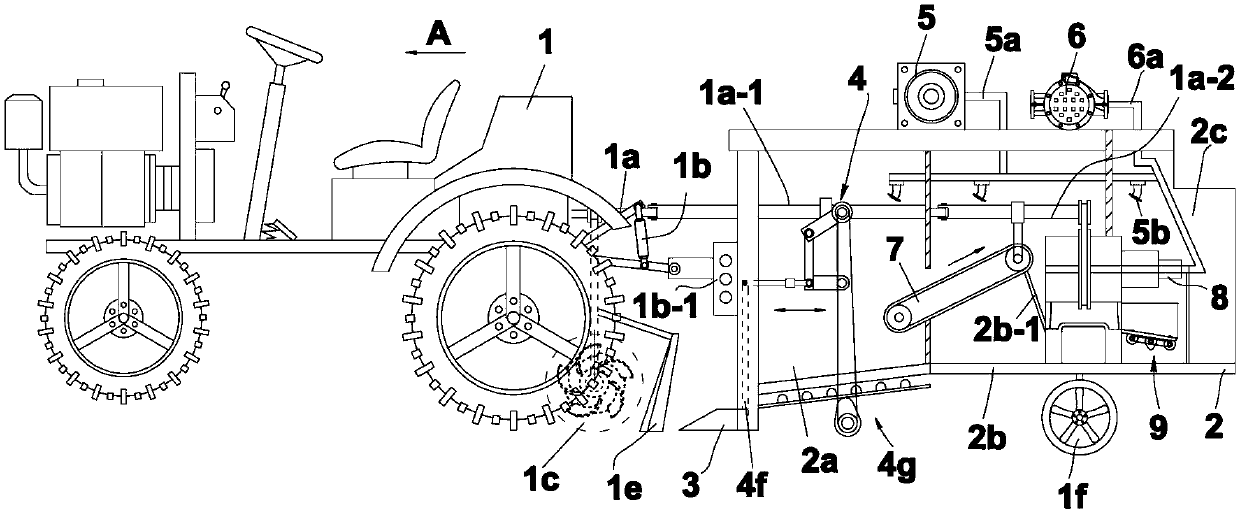

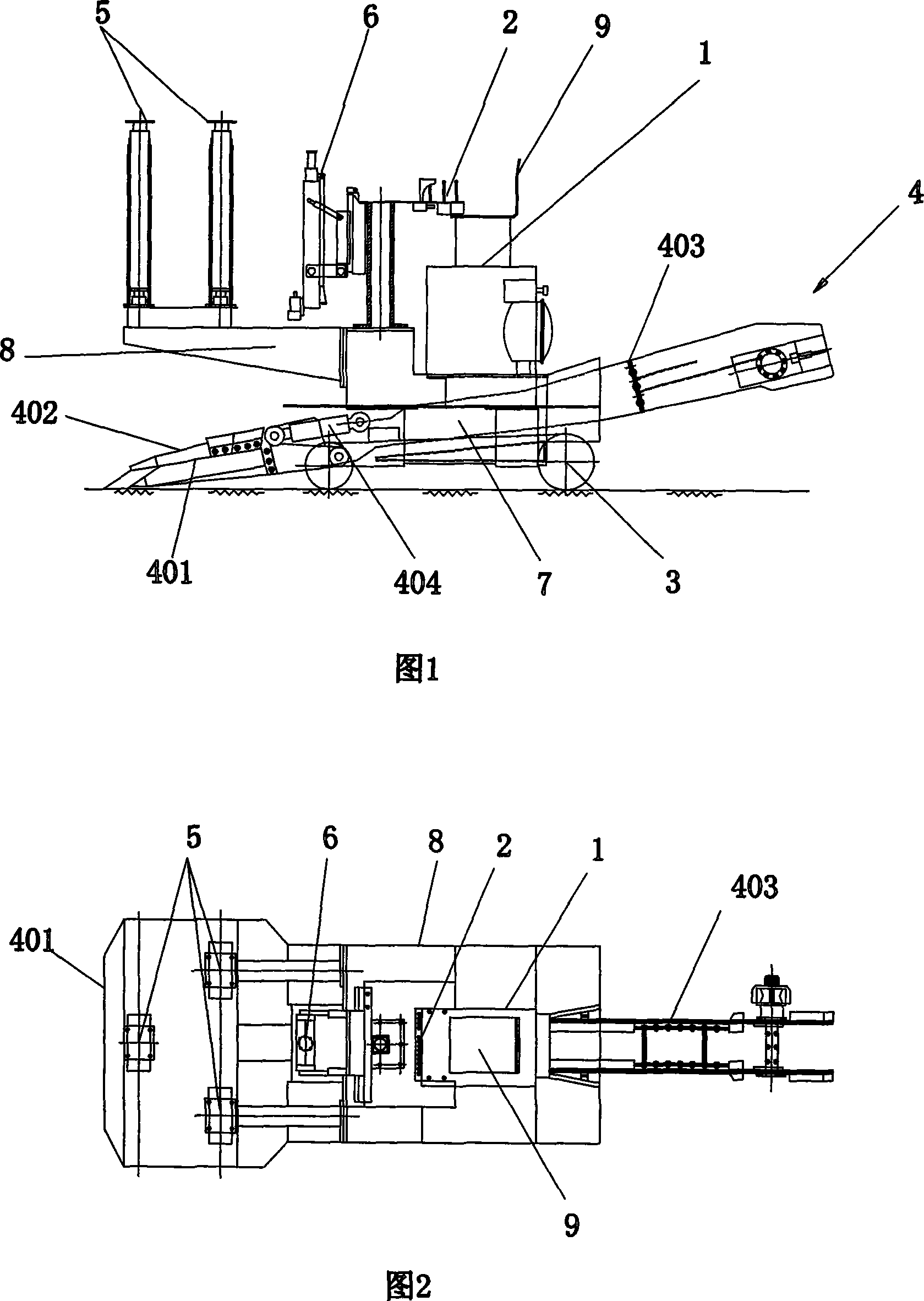

Narrow-machine-body full-hydraulic bolt and anchor cable drill carriage for coal mine tunnel

InactiveCN102900362AMechanizationIncrease the level of mechanized supportAnchoring boltsCutting machinesEngineeringRock bolt

The invention relates to a narrow-machine-body full-hydraulic bolt and anchor cable drill carriage for a coal mine tunnel. The narrow-machine-body full-hydraulic bolt and anchor cable drill carriage comprises a machine body part, a lifting platform, a drill boom mechanism, crawler-type walking mechanisms and an electric cabinet, wherein the lifting platform is arranged at the machine body part through a foldable connecting rod and a lifting oil cylinder; the drill boom mechanism is arranged on the lifting platform through a feeding mechanism; the crawler-type walking mechanisms are arranged on two sides of the machine body part; and the electric cabinet is used for controlling the lifting oil cylinder and the crawler-type walking mechanisms. According to the narrow-machine-body full-hydraulic bolt and anchor cable drill carriage disclosed by the invention, the support of an anchor rod is completely mechanized, the support efficiency and the support quality of the bolt and anchor cable are greatly improved, the standardization degree is improved, the better stabilizing action is realized and the reliable use of the drill carriage and the safe operation of operators are fully ensured.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

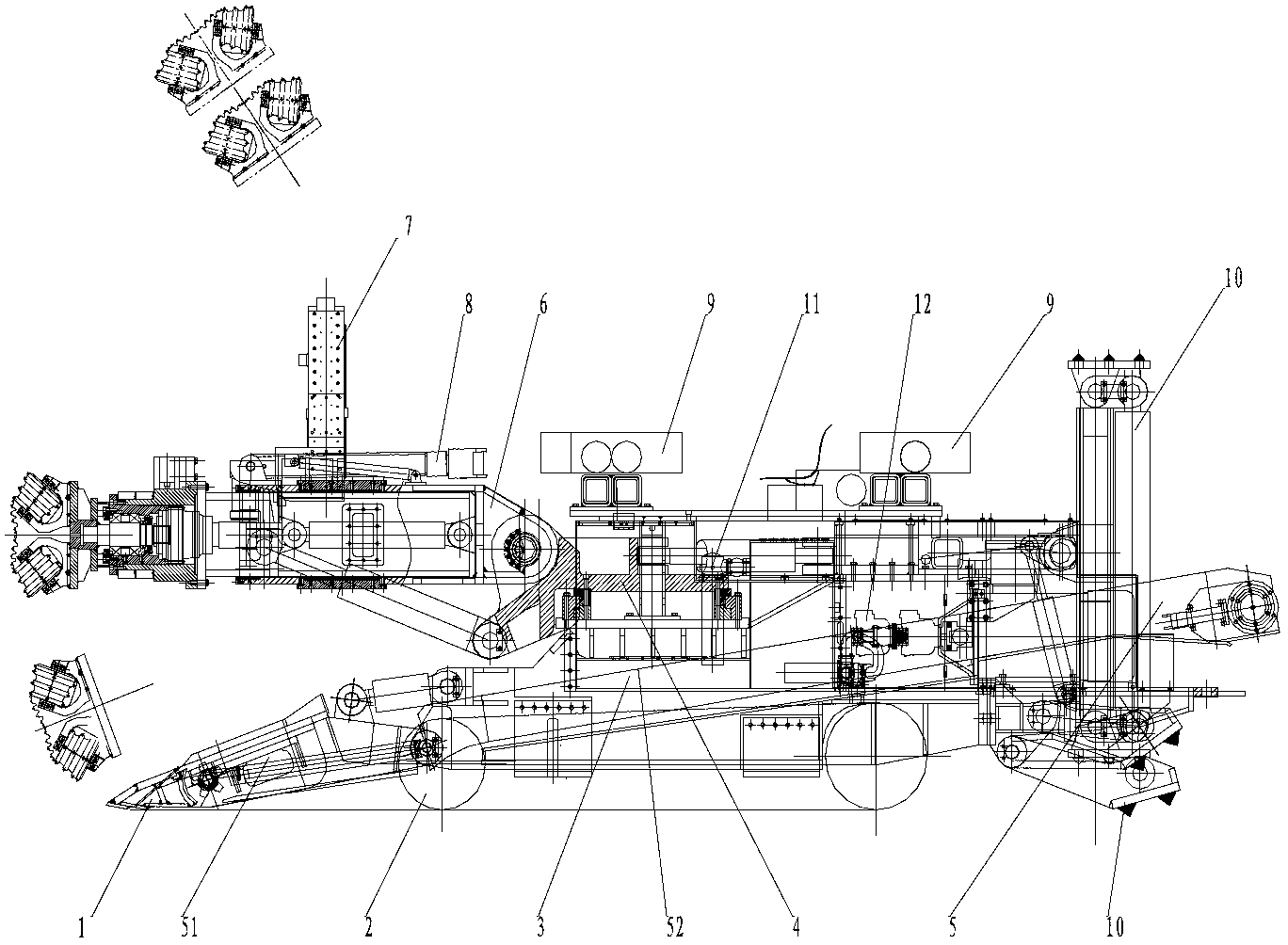

Comprehensive mechanization stone drift heading machine set

InactiveCN102704927AGuarantee the construction qualityReduce labor intensityMine roof supportsDriving meansControl systemEngineering

The invention relates to a comprehensive mechanization stone drift heading machine set, which comprises a shovel plate part, a caterpillar band travelling part, a rack, a belt conveying part, a flexible cutting part, a hydraulic drilling rig device, an advance support device, a hydraulic control system and an electric control system. The comprehensive mechanization stone drift heading machine set is characterized by also comprising a rotation part, two side supporting devices and top and bottom plate supporting devices. The comprehensive mechanization stone drift heading machine set disclosed by the invention is improved and perfected to enable the structure design to be more reasonable and compact, and the performances, such as working efficiency, stability, reliability, and safety of the set, are improved. Comprehensive mechanization construction equipment is provided for mine underground stone drift heading, and is especially adaptive to the underground stone drift mechanization operation and construction of various big, medium and small mines.

Owner:马晓山

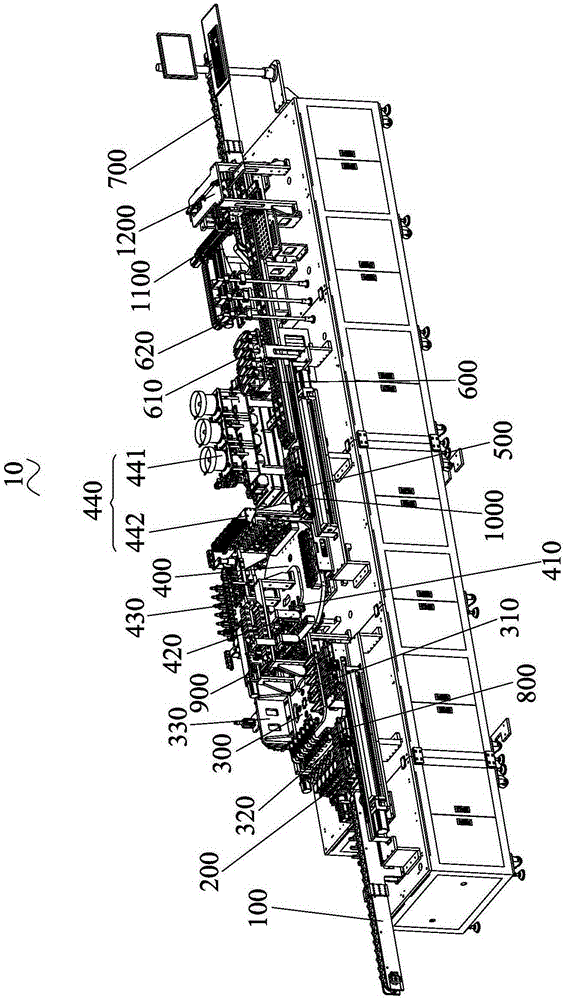

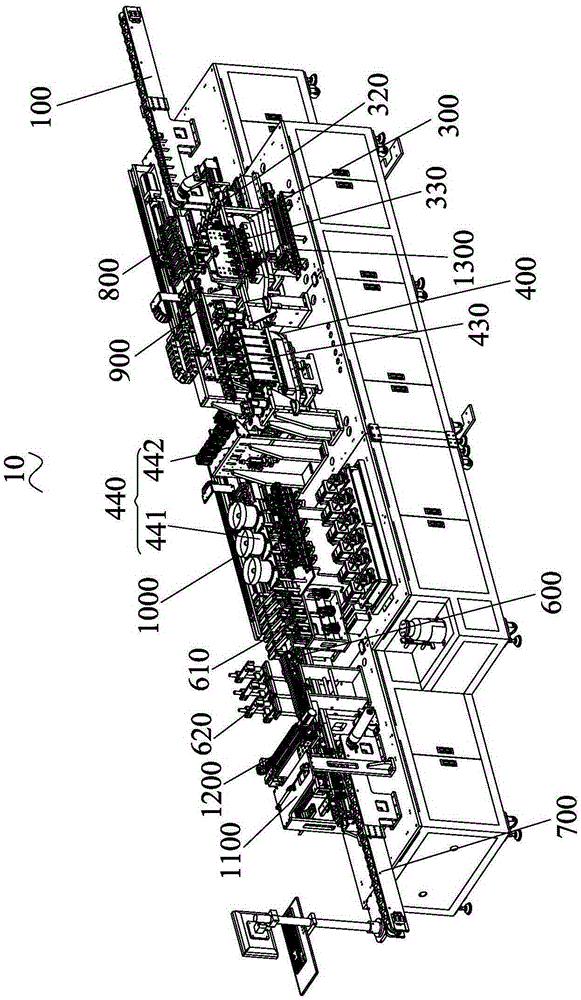

Battery filling machine

ActiveCN105355833AMechanizationRealize automated productionCell component detailsManipulatorAssembly line

The invention discloses a battery filling machine, which comprises a feeding assembly line, a front weighing device, a first rotating plate, a second rotating plate, a rear weighing device, a main assembly line, a blanking assembly line, a feeding manipulator, a transfer manipulator, a material shifting manipulator, a lower good product manipulator and a lower defective product manipulator, wherein the feeding manipulator is connected among the feeding assembly line, a front weighing station and the first rotating plate; the transfer manipulator is connected between the first rotating plate and the second rotating plate; the material shifting manipulator is connected among the second rotating plate, a rear weighing station and the main assembly line; the lower good product manipulator is connected between the main assembly line and the feeding assembly line; a front battery in-place detection device, a filling hole correction device and a front filing hole detection device are arranged on the first rotating plate in a surrounding manner; a rear battery in-place detection device, a rear filing hole detection device, a battery filling device and a prepressing nail device are arranged on the second rotating plate in the surrounding manner; and an all-rivet device and a rivet detection device are sequentially arranged on the main assembly line. Through coordination of the components, feeding, filling, riveting and blanking are carried out on a battery, so that mechanical and automatic production is achieved.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

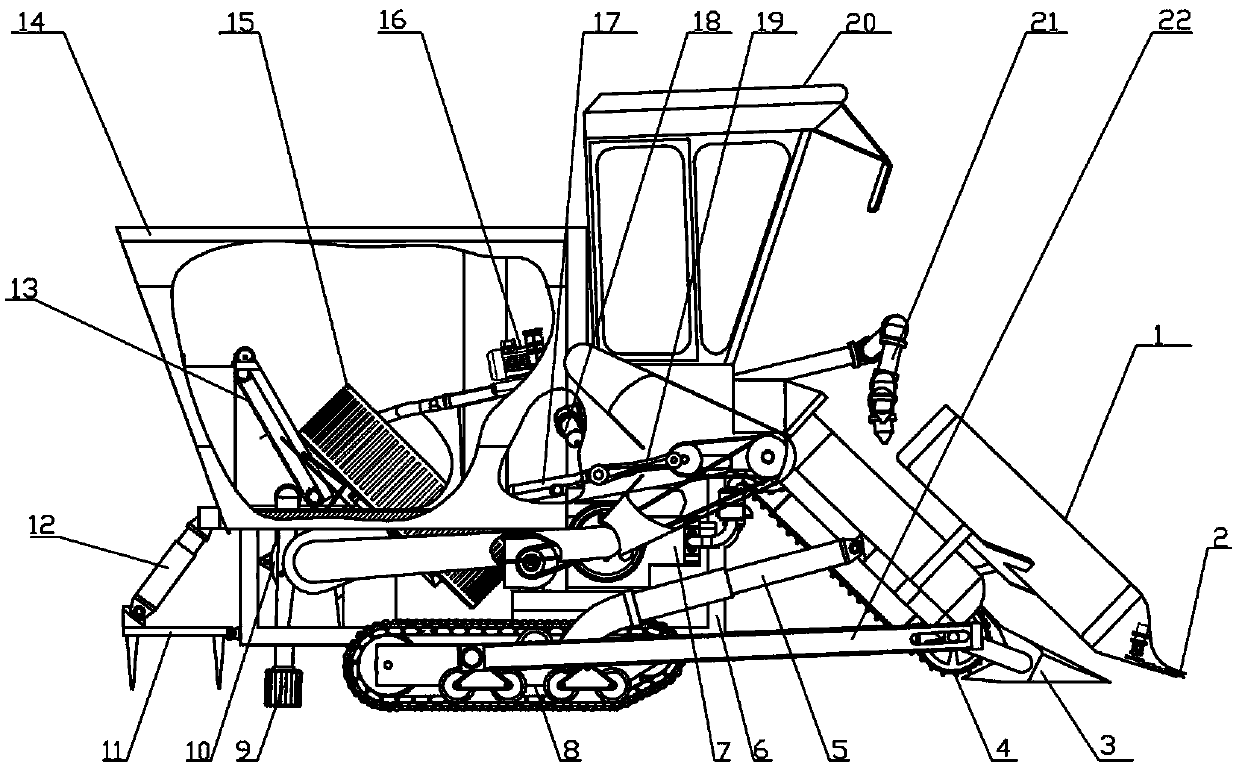

Associative type water chestnut harvesting machine

InactiveCN103749069AMechanizationEasy to storeDigger harvestersWater ChestnutsAgricultural engineering

The invention relates to an associative type water chestnut harvesting machine which comprises a hydraulic type caterpillar band chassis. A cab, a compartment, a diesel engine power mechanism, an excavation conveying device, a vibrating screen, a slush pump washing device, a rotary cage high-pressure air pump air drying device and a field leveling harrow are installed on the caterpillar band chassis through a rack. According to the associative type water chestnut harvesting machine, residual water chestnut straws and weeds in the field can be eliminated, water chestnuts can be excavated out from soil, meanwhile, the soil and water on the water chestnuts are completely removed, and the bumpy field after excavation is recovered to be in an original level state. According to the associative type water chestnut harvesting machine, the water chestnut harvesting mechanization is achieved, and the water chestnut harvesting quality and the water chestnut harvesting working efficiency can be greatly improved.

Owner:东北大学秦皇岛分校

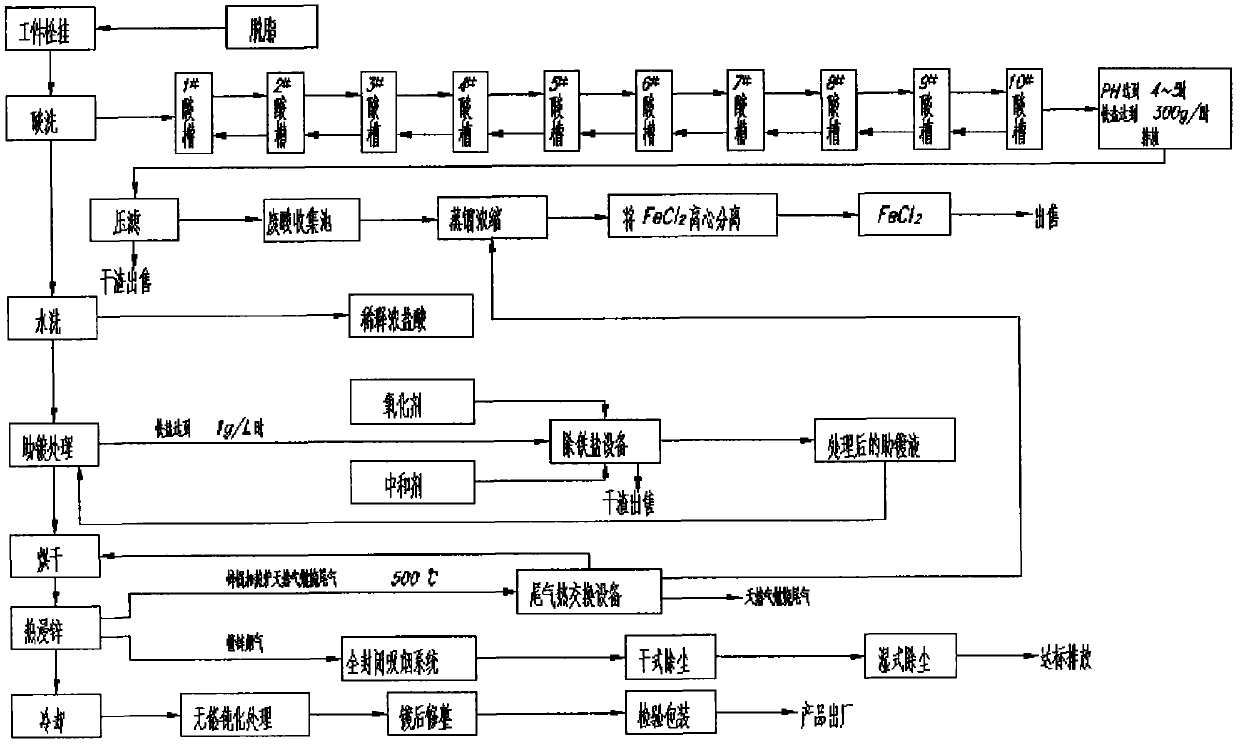

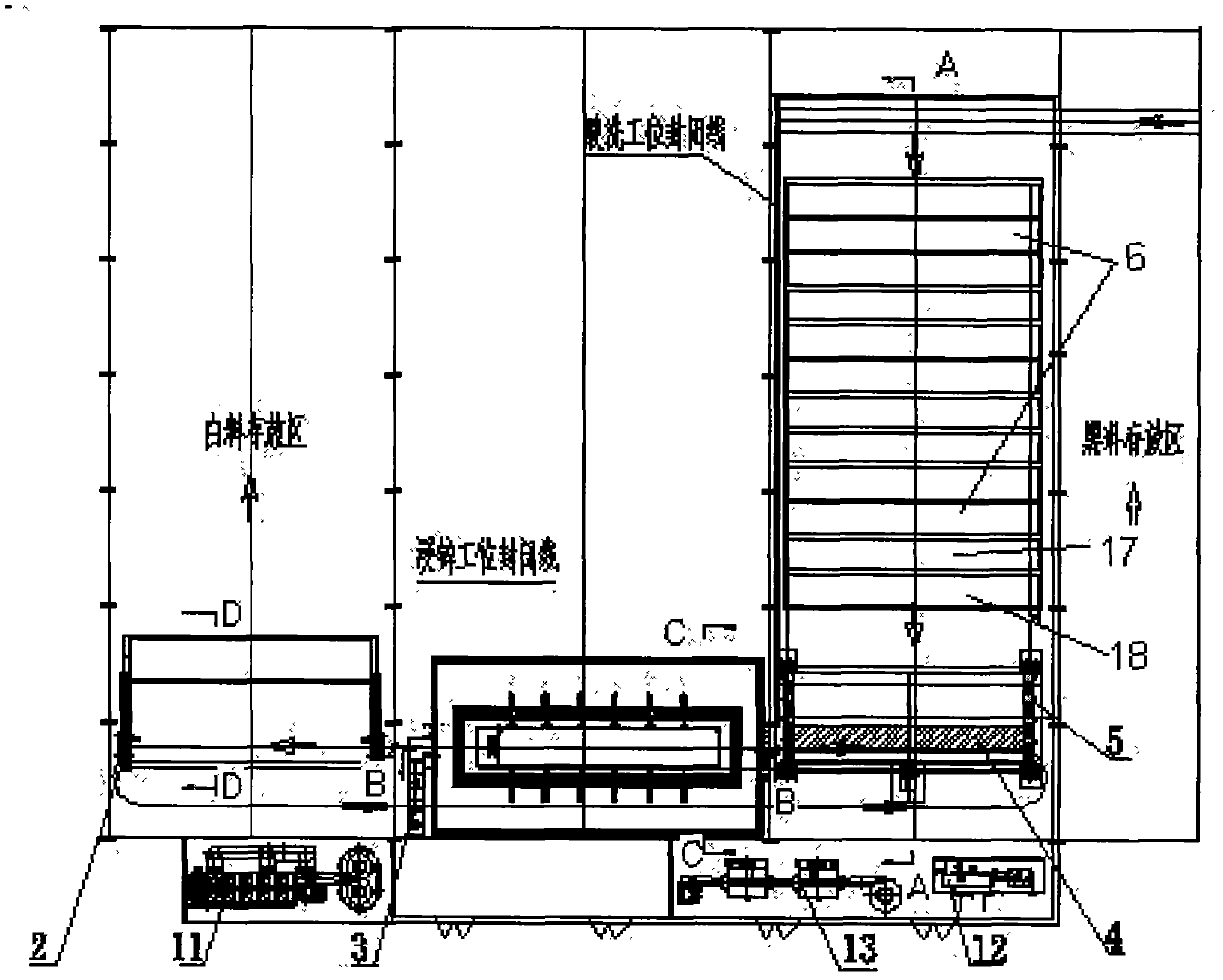

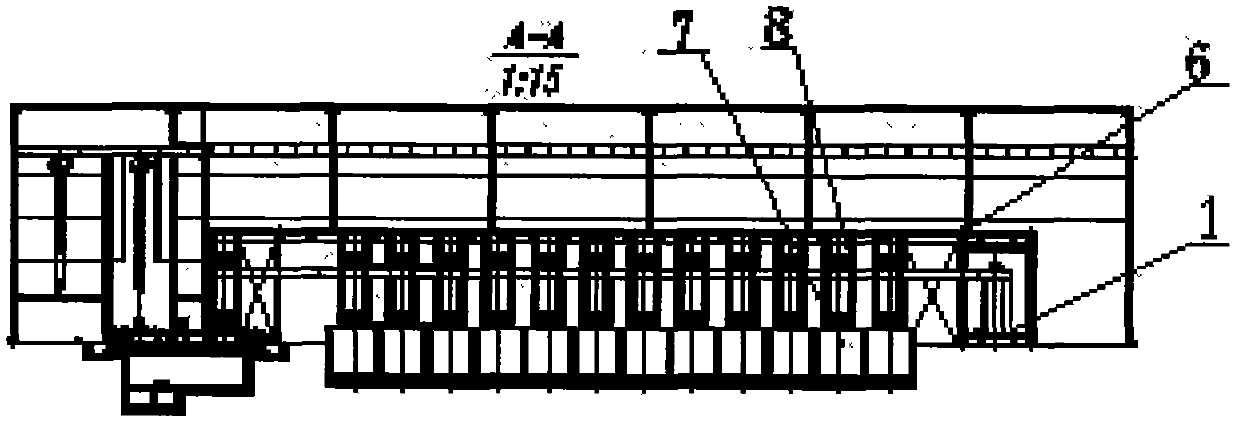

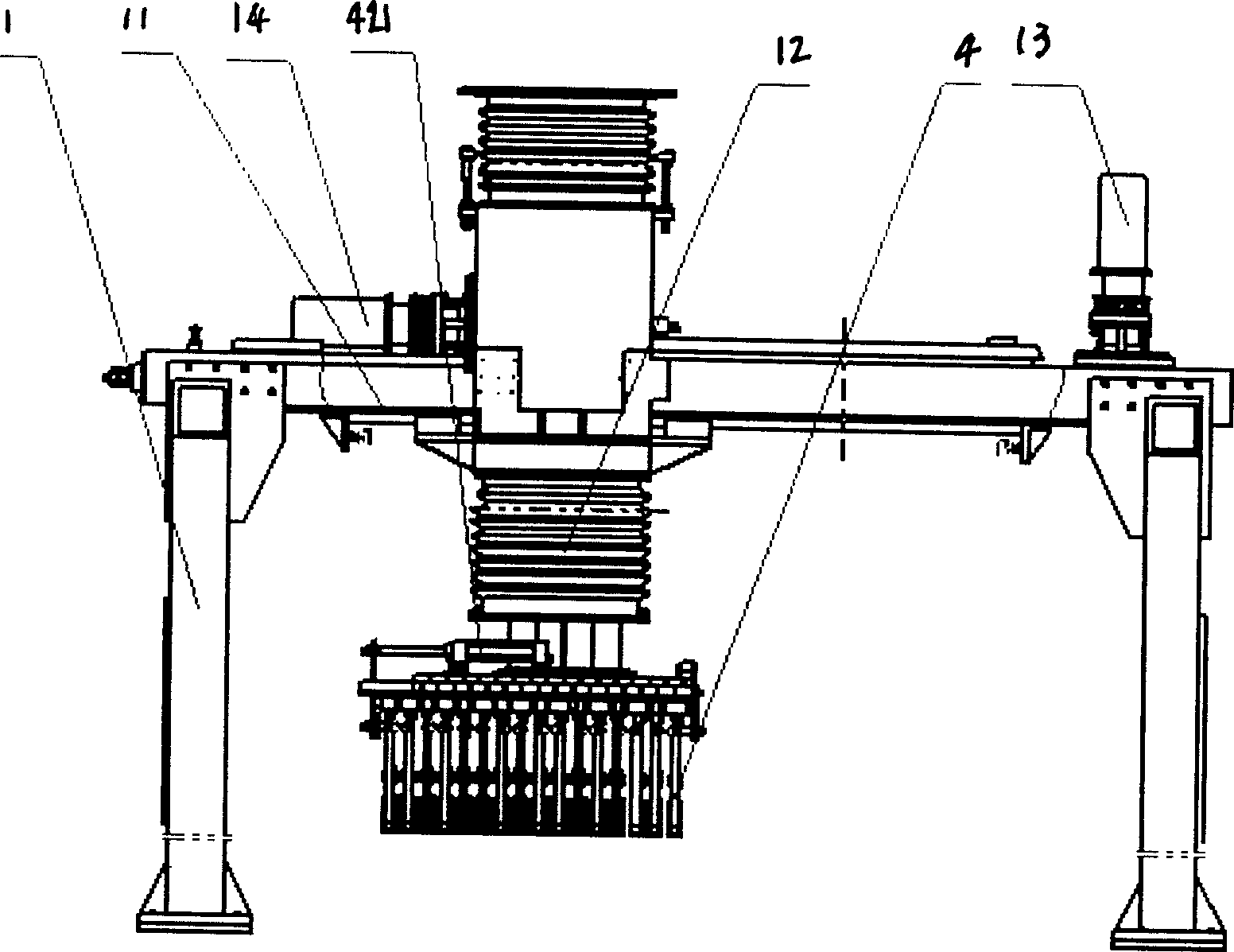

L-shaped full-closed environment-friendly hot galvanizing production equipment and method

InactiveCN102400075ADiffusion space is smallConvenient smokingHot-dipping/immersion processesAcid washingProcess engineering

The invention discloses an L-shaped full-closed environment-friendly hot galvanizing production method. The method is characterized in that: acid washing step-by-step automatic operation is implemented by adopting a mechanical hydraulic transmission manner, namely an acid washing workpiece automatic conveying system horizontally or vertically lifts to automatically convey workpieces to be galvanized to specified anti-collision acid washing tanks for acid washing and dust removing treatment step by step according to the multi-tank acid washing technological requirements, and the whole acid washing process is sequentially, progressively and automatically finished according to the technological requirements. The L-shaped full-closed environment-friendly hot galvanizing production method is pollution-free, environment-friendly, low in energy consumption, mechanical and automatic, and has the characteristics of full closure and integration of reclamation and treatment; and by the method, acid washing automation is realized, the labor intensity is furthest lightened, the production efficiency is improved, and the problem of pollution is solved.

Owner:张志红

Stacker

The present invention relates to stacking apparatus, such as brick, etc. and is especially one stacker comprising frame, controller and driving mechanism. Structurally, the stacker has one elevating pedestal on the straight line tracks and with two moving directions, one horizontal motor fixed on the frame for the horizontal motion of the elevating pedestal, one vertical motor fixed over the elevating pedestal for the vertical motion of the elevating pedestal, and several pairs of manipulators with clamping mechanism installed below the elevating pedestal. The stacker is used in stacking adobes in high efficiency.

Owner:FUJIAN HAIYUAN AUTOMATIC EQUIP CO LTD

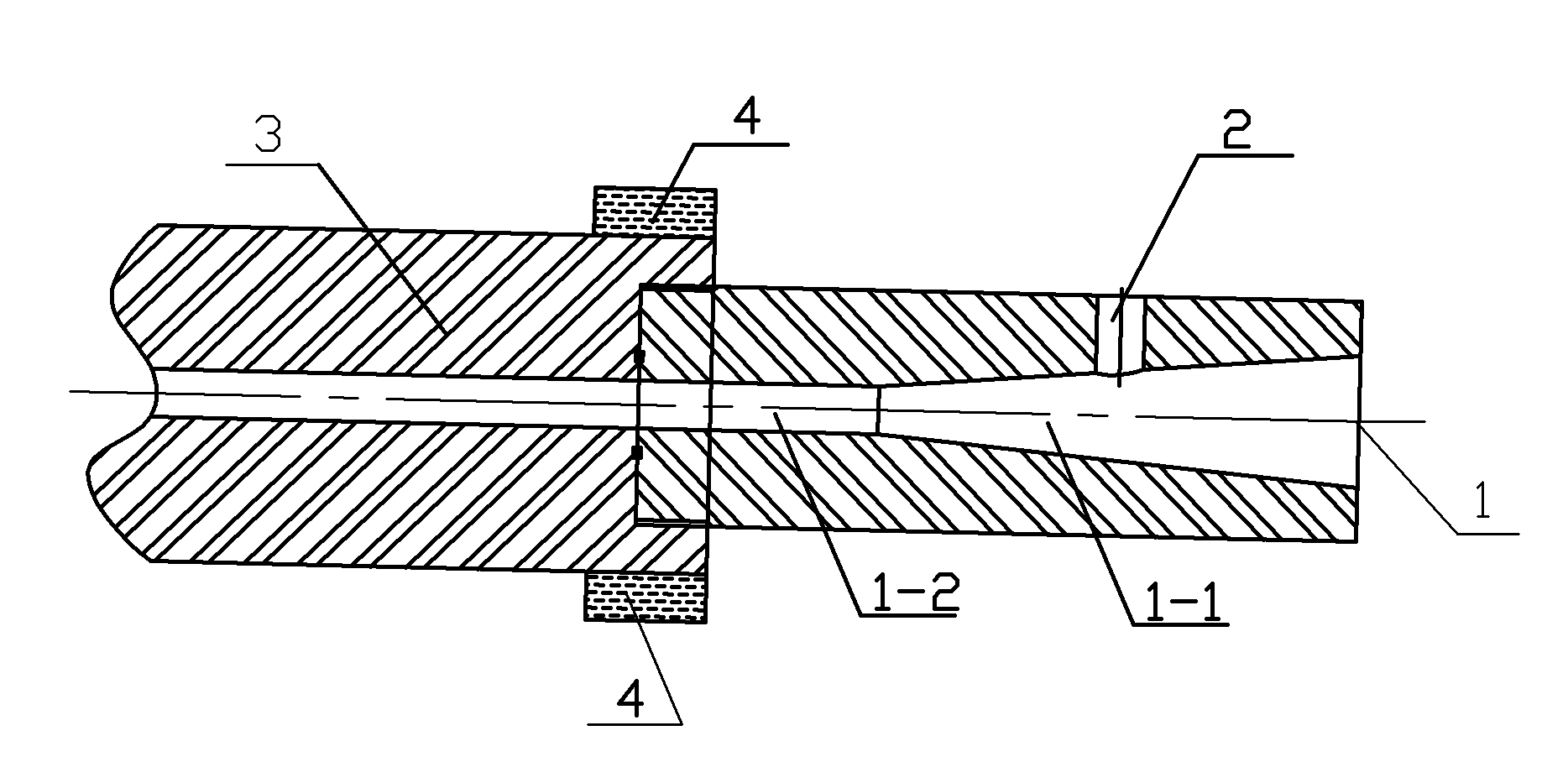

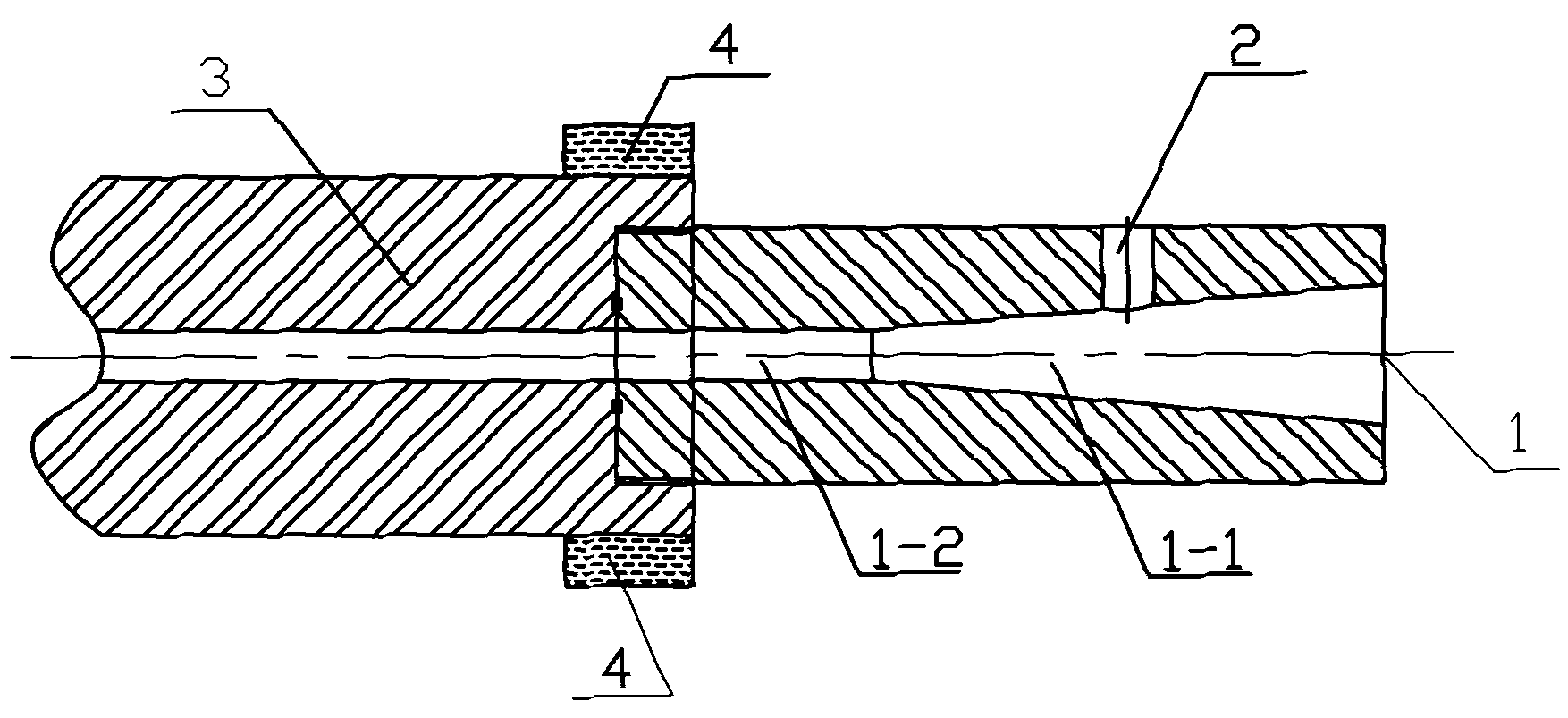

Injection die for injection and pull-extrusion process and method for preparing resin matrix composite by using same

The invention discloses an injection die for an injection and pull-extrusion process and a method for preparing a resin matrix composite by using the same, relating to an injection die and a method for preparing a resin matrix composite by using the same. Through the invention, the problem that the existing injection dies for the injection and pull-extrusion process are complicated in structure is solved. The injection die is provided with a die cavity and a glue injection hole, wherein the die cavity consists of a round table-shaped die cavity and a cylindrical die cavity; and the glue injection hole is located on the die wall of the round table-shaped die cavity. The method comprises the steps of: injecting a resin matrix into the round table-shaped die cavity through the glue injectionhole; causing continuous fibers to enter the die cavity of the injection die from a large-diameter end of the round table-shaped die cavity of the injection die under the traction of a traction device and then enter a die cavity of a pull-extrusion molding die through the cylindrical die cavity; and carrying out sizing and curing. The die cavity of the injection die is conical in front part and flat in rear part, the fibers of a solvent impregnated resin are stressed by a small-diameter end of the round table-shaped die cavity and the die wall of the cylindrical die cavity and then air bubbles are discharged, therefore, the void ratio of the composite is reduced and the mechanical property is improved. The injection die is simplified and the application range of the injection and pull-extrusion process is enlarged.

Owner:HARBIN FRP INST

Sweet potato saccharified potato paste and method for processing instant product series thereof

ActiveCN101347219AGuaranteed Physical PropertiesMechanizationFood preparationReady to eatAlpha-amylase

The invention discloses a processing method of a saccharified mashed sweet potato and series mashed sweet potato ready-to-eat products, and belongs to the technical field of food processing. The method comprises the steps as follows: (1) pretreatment of sweet potatoes of raw material; (2) preparation of the saccharified mashed potatoes: prepared mashed potato and high-temperature-resistant alpha-amylase are evenly mixed with the proportion of 100kg:5-50ml and stewed for 10-30min at the temperature of 90-100 DEG C, and then are rapidly heated to 105 DEG C to inactivate enzyme, thus obtaining the saccharified mashed potatoes; (3) preparation of the series saccharified mashed sweet potato ready-to-eat products. The processing method adopts the high-temperature-resistant alpha-amylase and is complemented with a two-step heating process to saccharify partial starch in the mashed sweet potato, and the method provides the saccharified mashed sweet potato with naturally saccharified flavor and taste and prolongs the processing period. The processing method overcomes great amount loss in natural saccharification in long term storage in the conventional process as well as reduces production cost. The processing method can be popularized in food processing enterprises.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

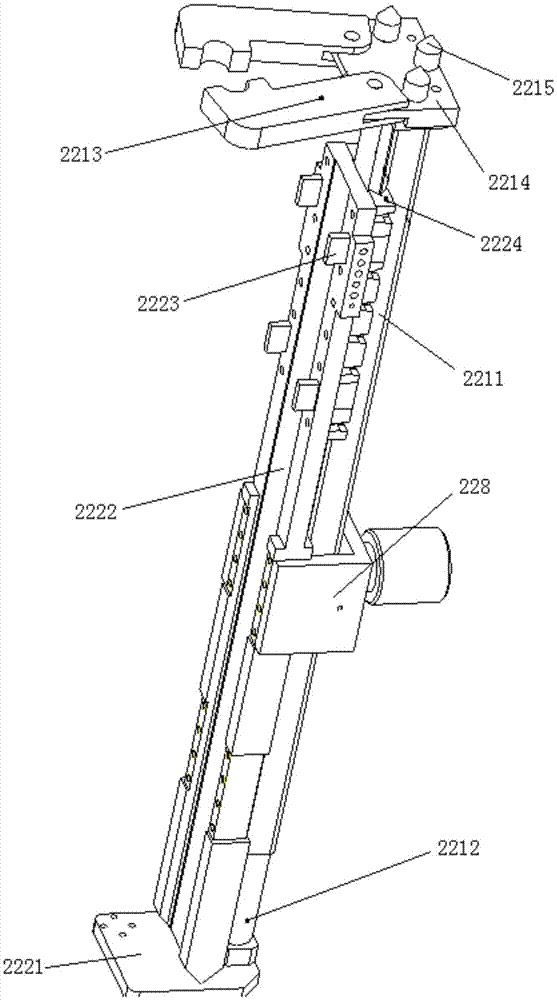

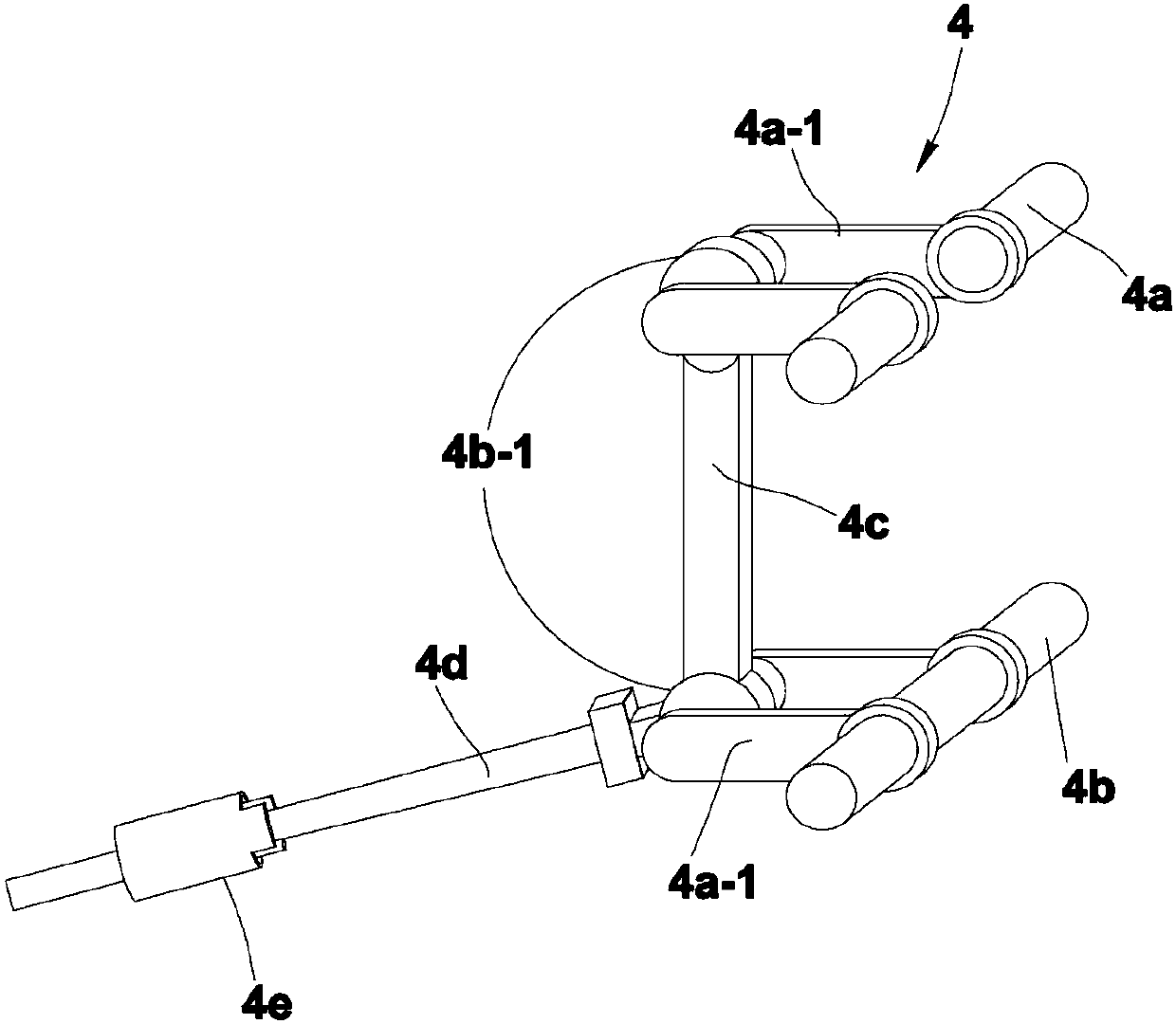

Side bolt drilling machine and side bolt drilling carriage with same

ActiveCN105626108ALarge storage capacityMeet construction needsDerricks/mastsAnchoring boltsEngineeringRock bolt

The invention discloses a side bolt drilling machine which comprises a fixing mechanism, a supporting mechanism, a sliding rack, a drilling box mechanism and a cartridge conveying box. The fixing mechanism comprises a base, a vertical plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the vertical plate. The supporting mechanism and the sliding rack are in sliding connection with the opposite side faces of the vertical plate respectively through the guide blocks, and one end of the supporting mechanism and one end of the sliding rack are connected with the base through a telescopic oil cylinder. The drilling box mechanism comprises a bottom rack and two independent drilling box sliding seats. The bottom rack is fixedly connected with the base, the drilling box sliding seats can horizontally move along the bottom rack, and when the drilling box sliding seats move to the sliding rack, the drilling box sliding seats can be connected with the other guide rail face of the sliding rack and slide along the sliding rack. The cartridge conveying box is used for completing the automatic cartridge feeding procedure of the drilling machine. The invention further discloses a side bolt drilling carriage with the drilling machine. By means of automatic cartridge feeding and automatic anchor bolt mounting, mechanization and automation of anchor bolt supporting work are achieved, the construction needs of a plurality of rows of side bolts can be met, and the side bolt drilling carriage works in cooperation with heading equipment to synchronously complete side bolt supporting and transferring functions.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

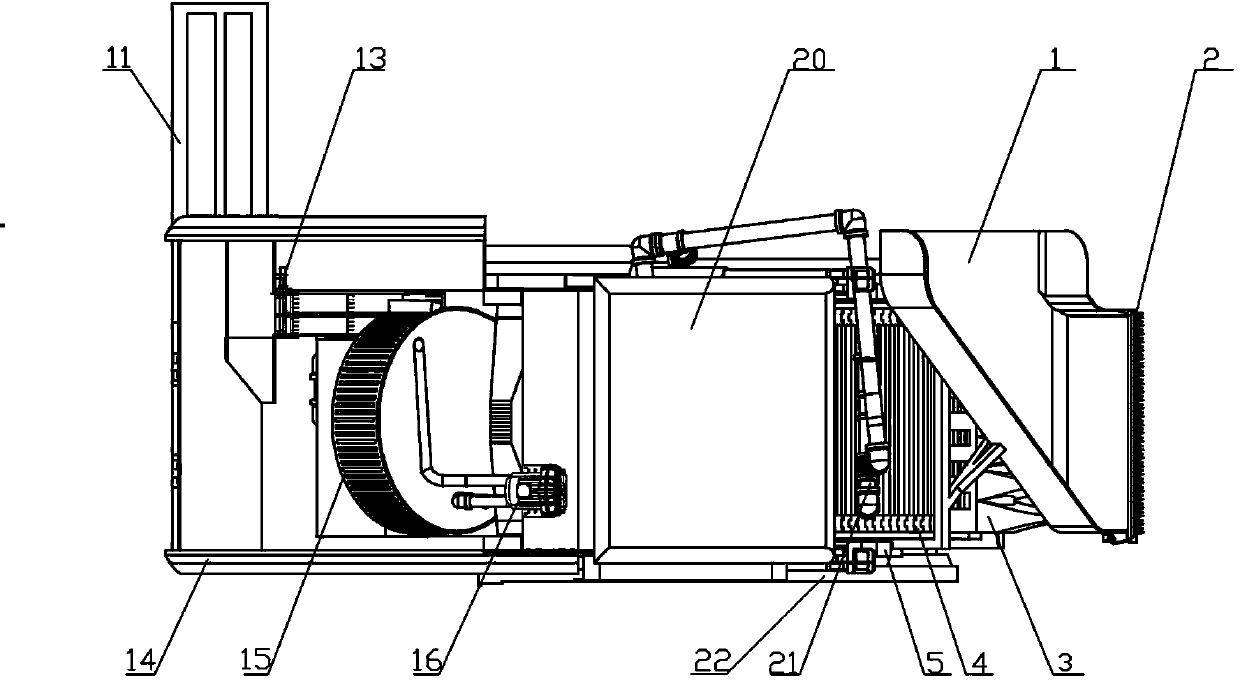

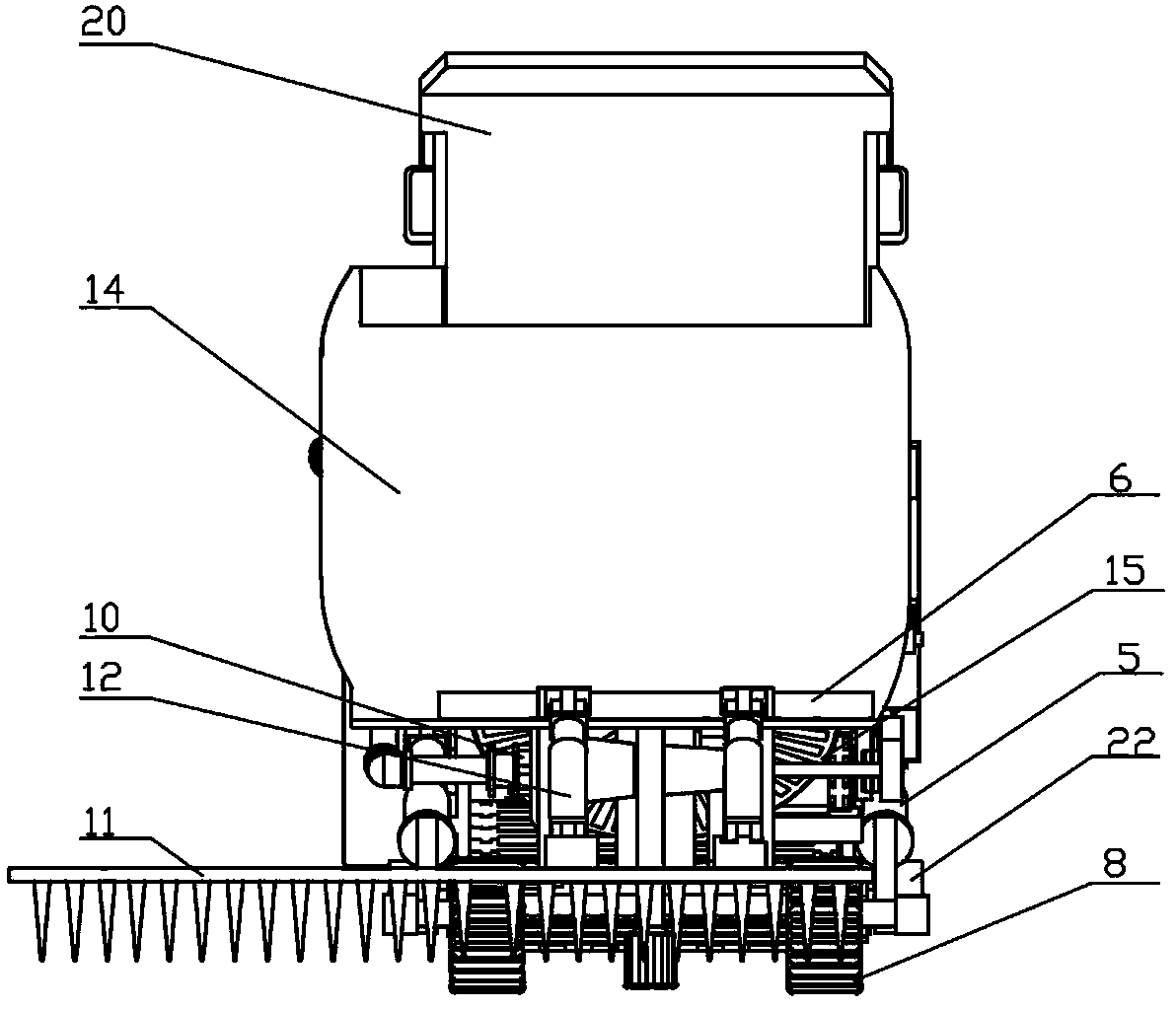

Integrated harvester of water chestnut

The invention relates to the technical field of agricultural machinery, in particular to an integrated harvester of water chestnuts. The integrated harvester of the water chestnuts is characterized inthat the integrated harvester of the water chestnuts comprises a walking machine and a frame; the walking machine is connected with a hydraulic suspension system which is connected with an engine ofthe same; the hydraulic suspension system comprises a transmission case and a hydraulic cylinder; a spindle I is fixed on a smashing mechanism behind the walking machine in drive connection; a shovelboard is arranged at the entrance of a front chamber and in active fit with the front chamber; a push plate vibration mechanism is installed in the front chamber; a mud pump and a high pressure air pump are mounted on the frame and powered by a generator configured by the engine; a water and gas mixing cleaning mechanism is installed in a transport warehouse; a compensatory cleaning mechanism is arranged just below the water and gas mixing cleaning mechanism; a water outlet of the mud pump is connected with a water pipe; a pluarlity of nozzles are mounted on the water pipe; an air outlet of the high pressure air pump is connected with an appendix. The integrated harvester of the water chestnuts has the advantages of being clean after five times of cleaning during work process of the wholemachine, greatly reducing damage during harvesting, improving harvesting efficiency and reducing farmers' harvesting costs.

Owner:惠安县德虹数控设备有限公司

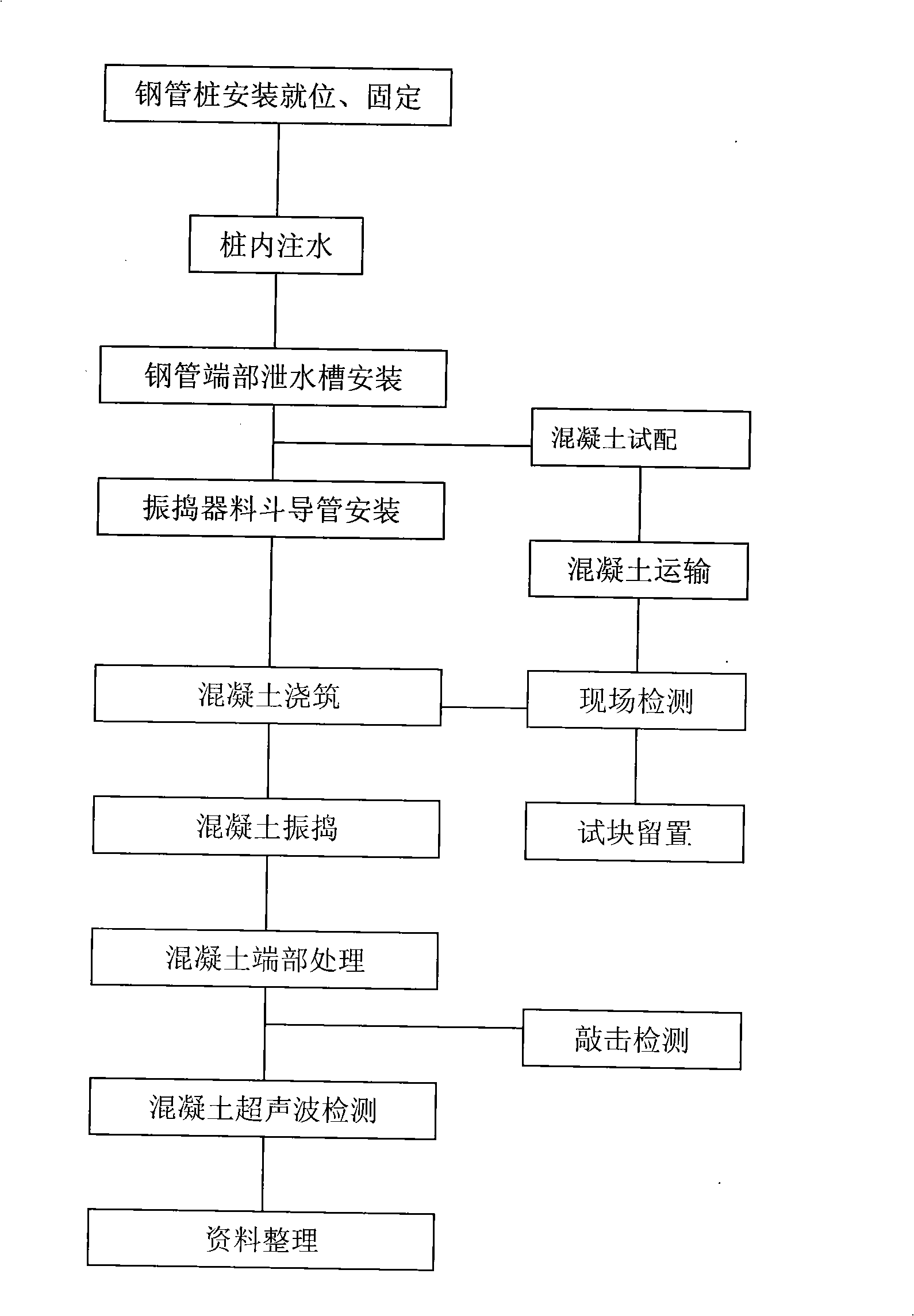

Construction method of steel pipe concrete column

InactiveCN101319550AImprove compactnessReduce air bubblesStrutsCeramic shaping apparatusSteel tubeAir bubble

The invention relates to the building field. The invention relates to a construction method for a concrete filled steel tubular column, comprising the following steps that: a tube is filled with water at first, and then a tremie is put down to the bottom of a pile; concrete is poured into the steel tube by a hopper through the tremie, and a vibrating tamper which is attached to the outerwall of the tube performs concrete vibrating when placing is performed simultaneously; primary concrete placing is performed until the height is 3 to 5 meters on the upper side of a nozzle of the tremie, and the tremie is lifted and guaranteed that the embedding depth of the tremie in concrete is not less than 2 meters; secondary concrete placing is performed, and the vibrating tamper which is attached to the outside of the tube on the bottom layer is started; lifting and placing are repeated, and the concrete is placed to the top of the column; and laitance is removed. The construction method solves the problem of the separation phenomenon caused by overhigh concrete placing height, increases the compactness of the concrete, reduces the number of air bubbles, has small shrinkage clearance between the concrete and the steel tube, can well give play to the function of stress, is convenient in construction, is mechanized, and is simple and convenient in operation. Moreover, the quality can be guaranteed; the equipment is saved by 30 percent; the stability is strong; and 50 percent of raw steel materials and 35 percent of the concrete are saved when the steel tube and the concrete are under same stress, thereby the production cost is effectively reduced.

Owner:DALIAN SANCHUAN CONSTR GROUP

Explosion coal-falling, coal-loading, coal-conveying and anchor-rod supporting mechanism integration operation method and apparatus

InactiveCN101025086AIncrease the speed of excavationExcavation section is largeUnderground miningSurface miningResource recoveryEngineering

The invention provides a blast-winning, coal loading, coal conveying and anchor rod-timbering mechanical integrated operating method and device. And the device mainly comprises: hydraulic system, hydraulic control table, track walking part, coal loading and conveying part, timbering part, and hydraulic anchor rod machine, and the method uses integrated device, scraper conveyor and gate coal conveyor; and its drivage circulating speed is 1m to 1.5 m, blast-winning and after the fumes have settled, making the integrated device enter into the operating site, and after completing coal loading and conveying, making anchor rod timbering; after completing the anchor rod timbering operation, making the integrated device exit the operating site and over 20 meters distant from the operating site, and then making drilling and blasting operation. And it improves explosion level of blast winning and resources recovery, and reduces operators.

Owner:闫振东

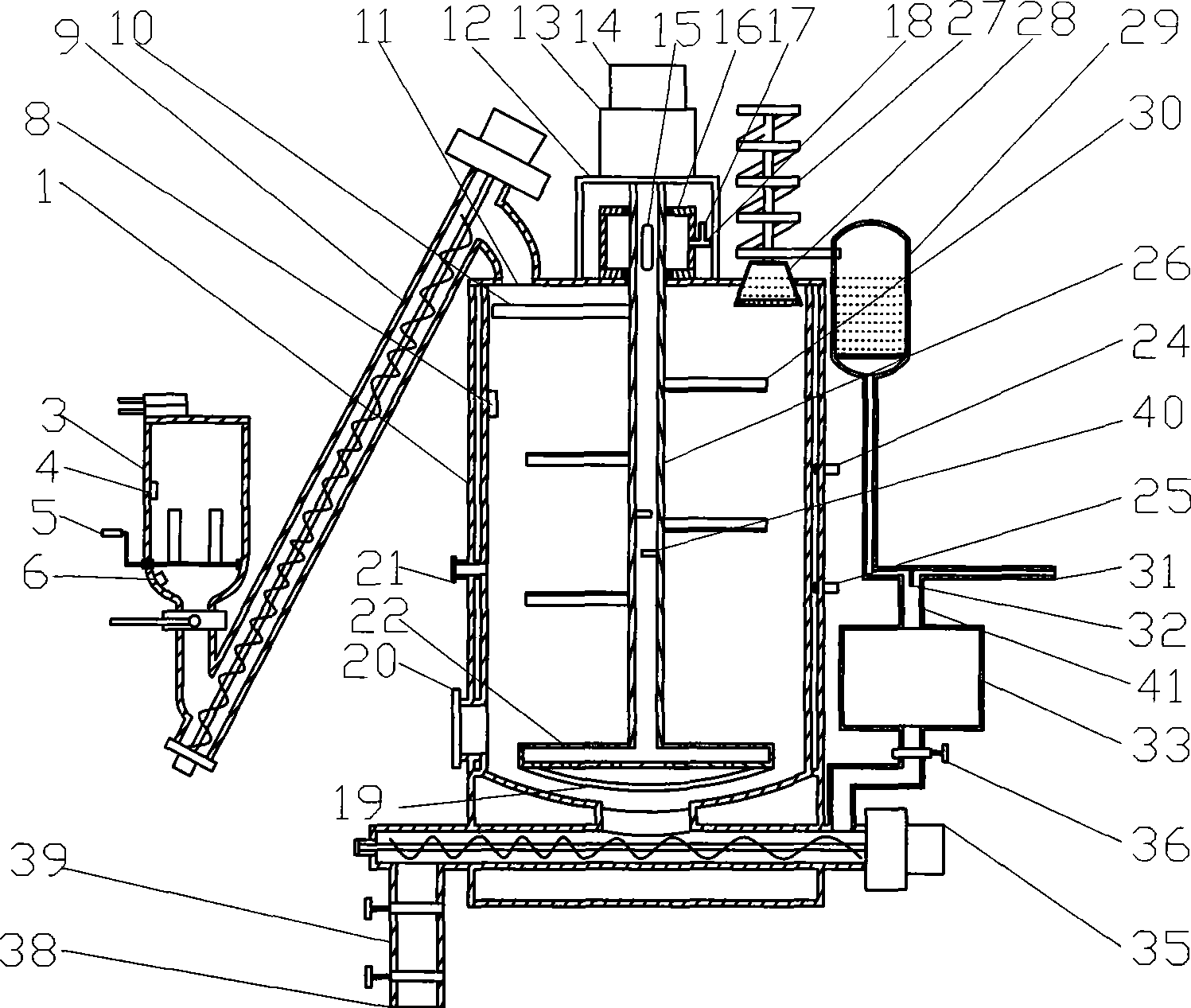

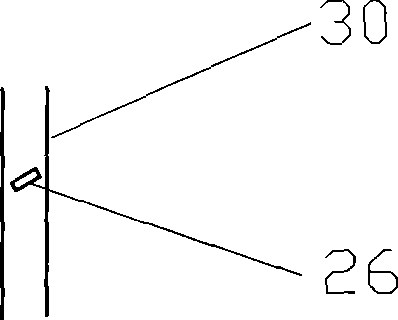

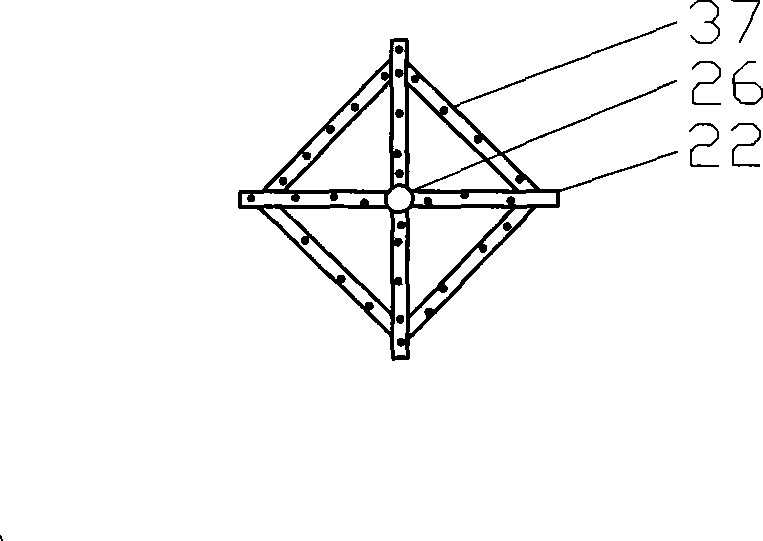

Biomass gasification furnace

InactiveCN101481630AIncrease contentAdjustable temperatureCombined combustion mitigationCombustible gas productionCombustionWater vapor

The invention relates to a biomass gasification furnace which comprises a furnace body, a feed inlet opened on the top of the furnace body, a filter embedded on the top of the furnace body, a fire observation hole and a lighting-up hole which are arranged on the side wall of the furnace body, a radiator connected with the filter, a purifier connected with the radiator, an exhaust pipe connected with the purifier, an ash hole communicated with the bottom of the furnace body, a mixer shaft arranged inside the furnace body, stirring teeth arranged on the mixer shaft, a mixer shaft motor arranged outside the furnace body, a feeding storage hopper that is connected at the front end of the feed inlet and can control the inlet and outlet materials, and a ash discharge hopper that is used for communicating the ash hole and the bottom of the furnace body and can control the inlet and outlet ash. The invention has the advantages that the biomass gasification furnace can continuously supply gas when the material is added and the ash is discharged, the gas dust in the furnace is not discharged outside, the position of a gasification layer in the furnace is unchangeable, water vapor can be used for combustion-supporting, etc.

Owner:蒋启富

Dry direct seeding cultivation method for rice

ActiveCN103477928AConserve waterSave on electricity billsFertilising methodsRice cultivationHectarePhosphate

The invention relates to the field of rice cultivation methods and discloses a dry direct seeding cultivation method for rice. The dry direct seeding cultivation method for the rice comprises mechanically melting snow and dispersing moisture of the soil compulsively in old rice fields and preparing the soil by pulverizing through a rice field soil pulverizer in a high speed before seeding; deep applying 360 kg of prolonged and controlled release NPK (Nitrogen Phosphorus Potassium) compound fertilizer which is rich in microelement and has the effective dose of 50 %, 75 kg of diammonium phosphate or monoammonium phosphate and 18 kg of granular biological bacterial fertilizer to side positions 6 to 10 cm lower of rice seeds per hectare in one time and applying no fertilizer for the whole growth period; starting irrigating rice seedling at the rice period with four leaves and one center and manually replenishing water in the three water requirement critical period; weeding chemically; preventing and treating pest and disease damage; controlling rice blast. The dry direct seeding cultivation method for the rice has the advantages of solving the problems that the amount of labor used is large and the water is wasted during the rice cultivation process, increasing yield by 10 to 15 percent compared with water direct seeding, increasing yield by 5 to 10 percent compared with rice transplanting, being water saving, labor saving and mechanical in tilling, enabling tillering generation to be early and tillering number to be large, being good in soil permeability and enabling rice root system to be flourish.

Owner:付吉新

Rotation type separation facility for sieving round wood from powder

InactiveCN1872431AResolve discontinuitiesThe operation process is simpleGradingDrive motorLeather belt

A rotary separator for screening spherical particles is composed of drive roller, driven roller, conveying belt, feeding hopper, drive motor for driving said drive roller via belt, height-regulating slide block mechanism for regulating the distance between drive roller and driven roller, tensional slide block mechanism for regulating the tension of conveying belt, spherical particles collecting bucket, aspherical particles collecting bucket, cleaning brush, and base.

Owner:UNIV OF SCI & TECH BEIJING

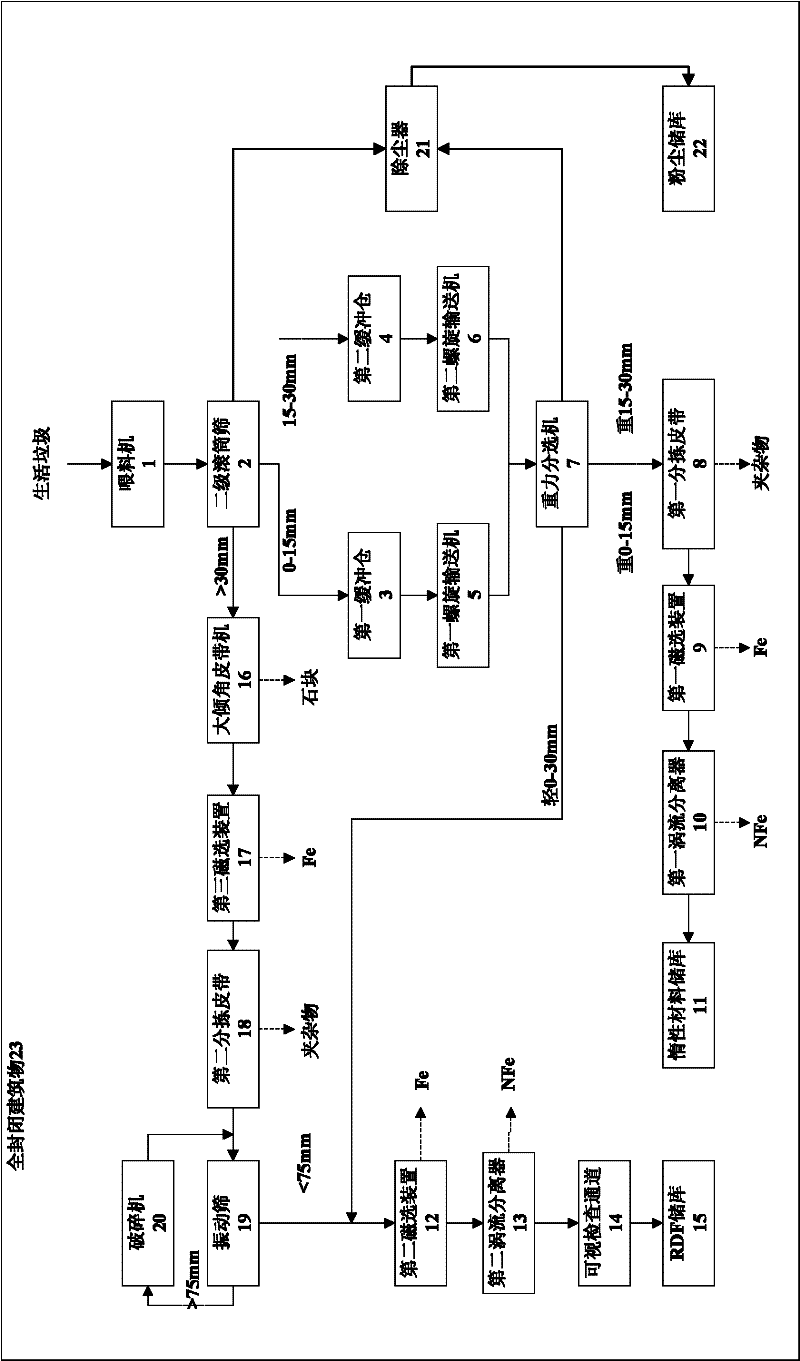

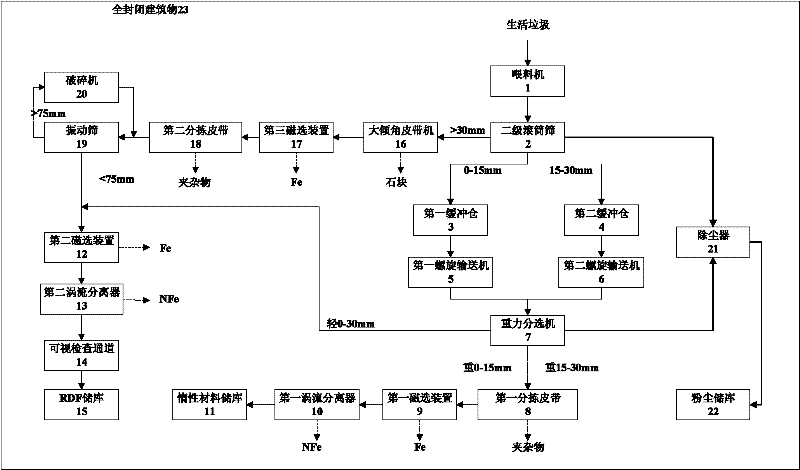

Municipal waste separation system

ActiveCN102189094AEfficient separationImprove working environmentSolid waste disposalSolid separationHazardous substanceEngineering

The invention relates to a municipal waste separation system. The municipal waste separation system is characterized by comprising a feeding machine, a secondary rotary screen, a first buffer bin, a second buffer bin, a first spiral conveyer, a second spiral conveyer, a gravity separator, a first sorting belt, a second sorting belt, a first magnetic separation device, a second magnetic separationdevice, a third magnetic separation device, a first vortex separation device, a second vortex separation device, an inert material storage hall, a resource description framework (RDF) storage hall, alarge-inclination-angle belt machine, a vibrating screen and a crushing machine. The separation system has high sorting efficiency, and can effectively separate combustible substances, insert components, ferrous metal / non-ferrous metal, and harmful substances in the pre-crushed and dried municipal waste to facilitate subsequent comprehensive utilization. The separation process is totally closed,remote operation and control is performed by using a computer, waste is not required to be directly contacted, the working environment of workers is improved, mechanization and automation are realized, and efficiency is improved.

Owner:华新环境工程有限公司

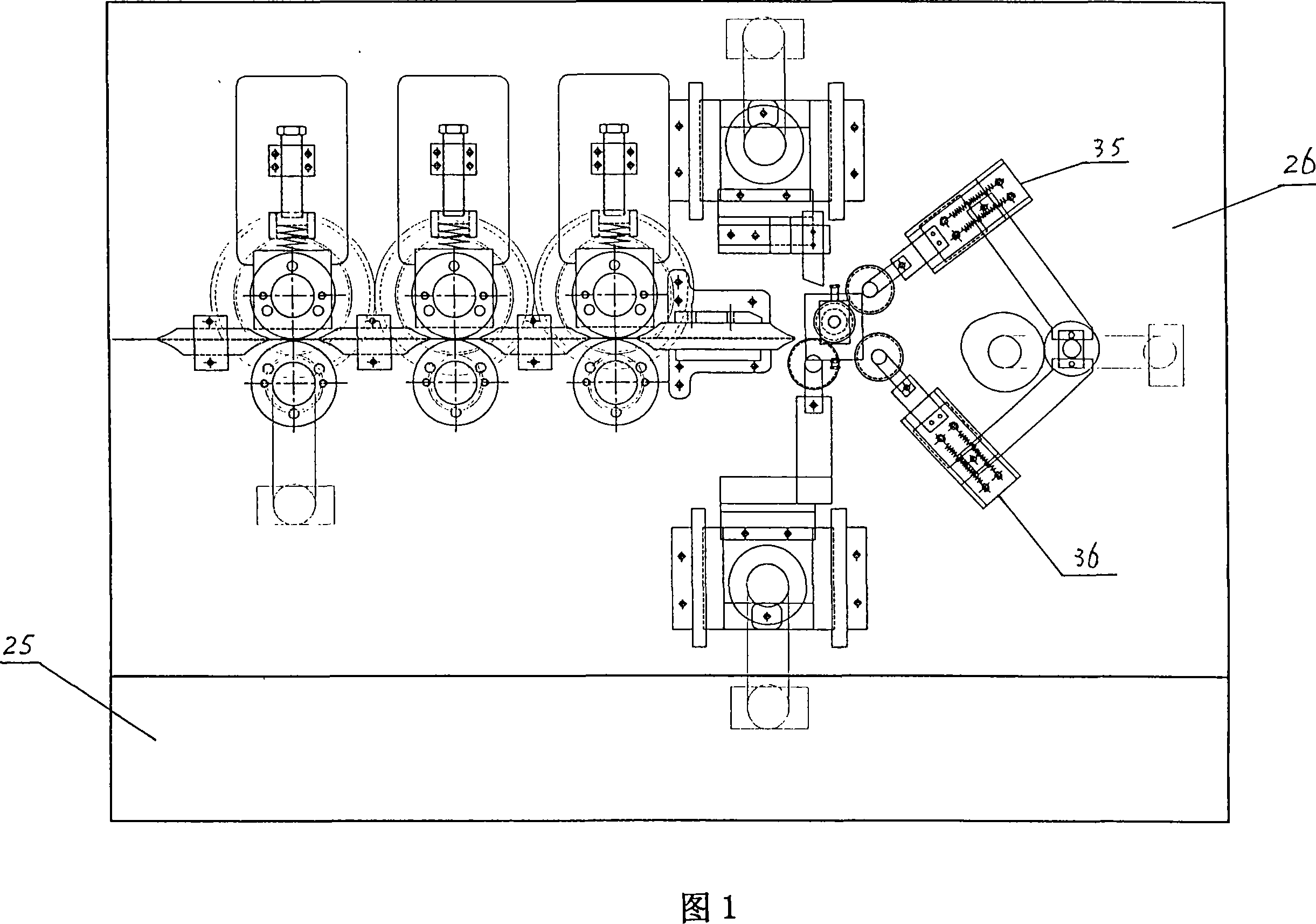

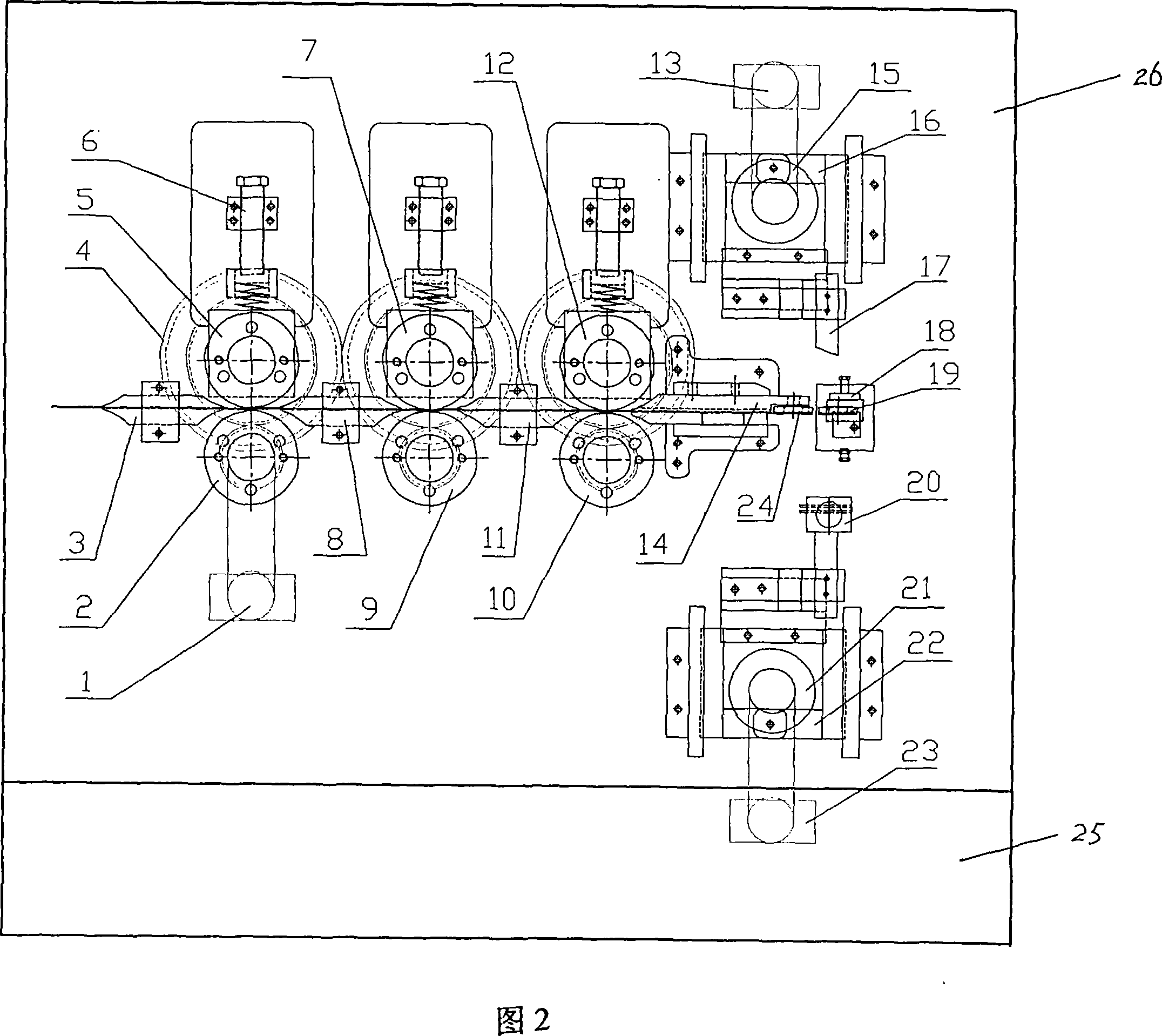

Method for manufacturing wave shaped spring

InactiveCN101058143AMechanizationCompact structureFurnace typesHeat treatment process controlWave shapeEngineering

The invention relates to the manufacturing of a wave shape spring that modifies the CNC spring roller into several-layer spring equipment for production, for the benefit of improving productivity, quality, feature, dimension, cosmetic for mass production.

Owner:上海核工碟形弹簧制造有限公司

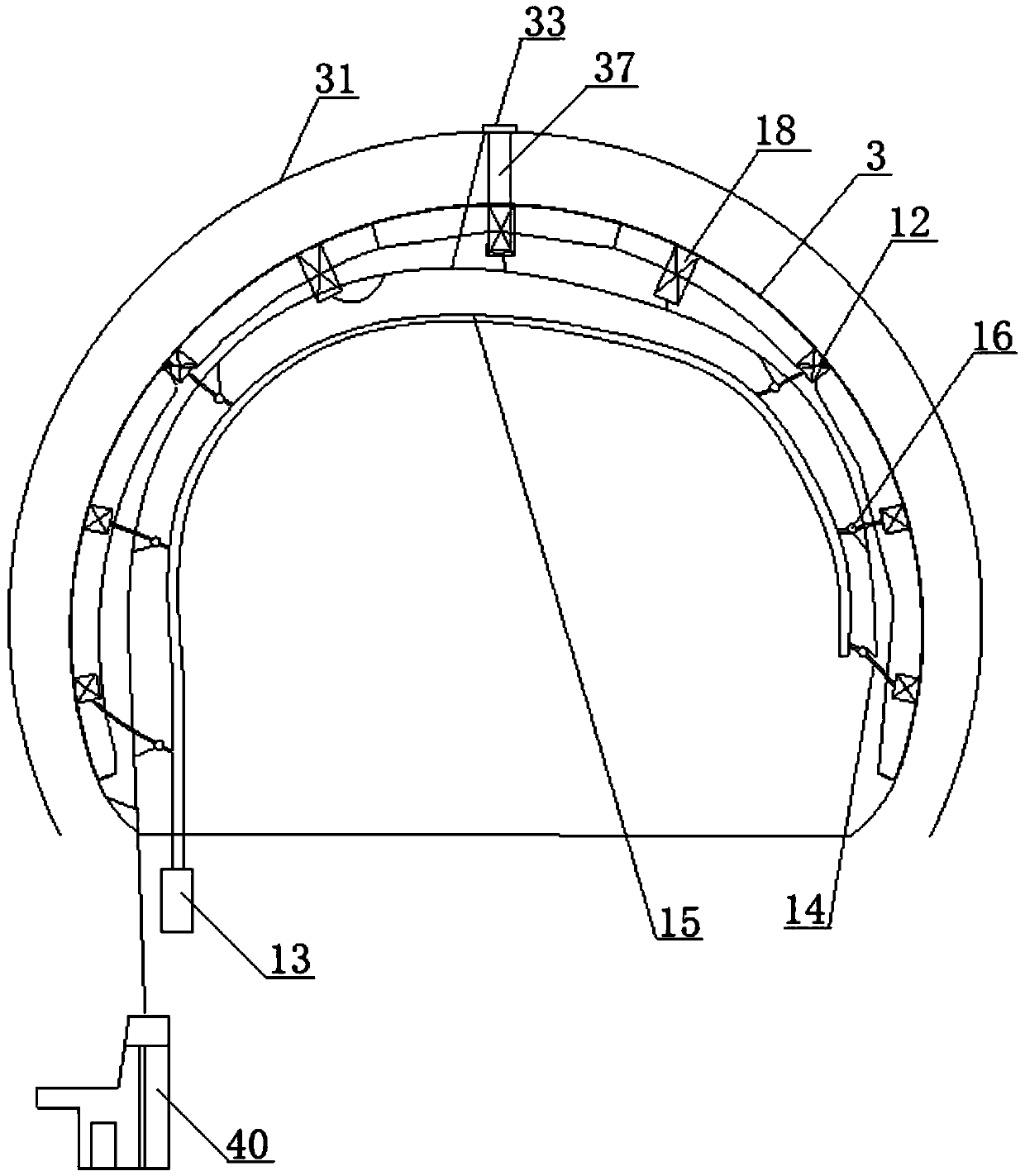

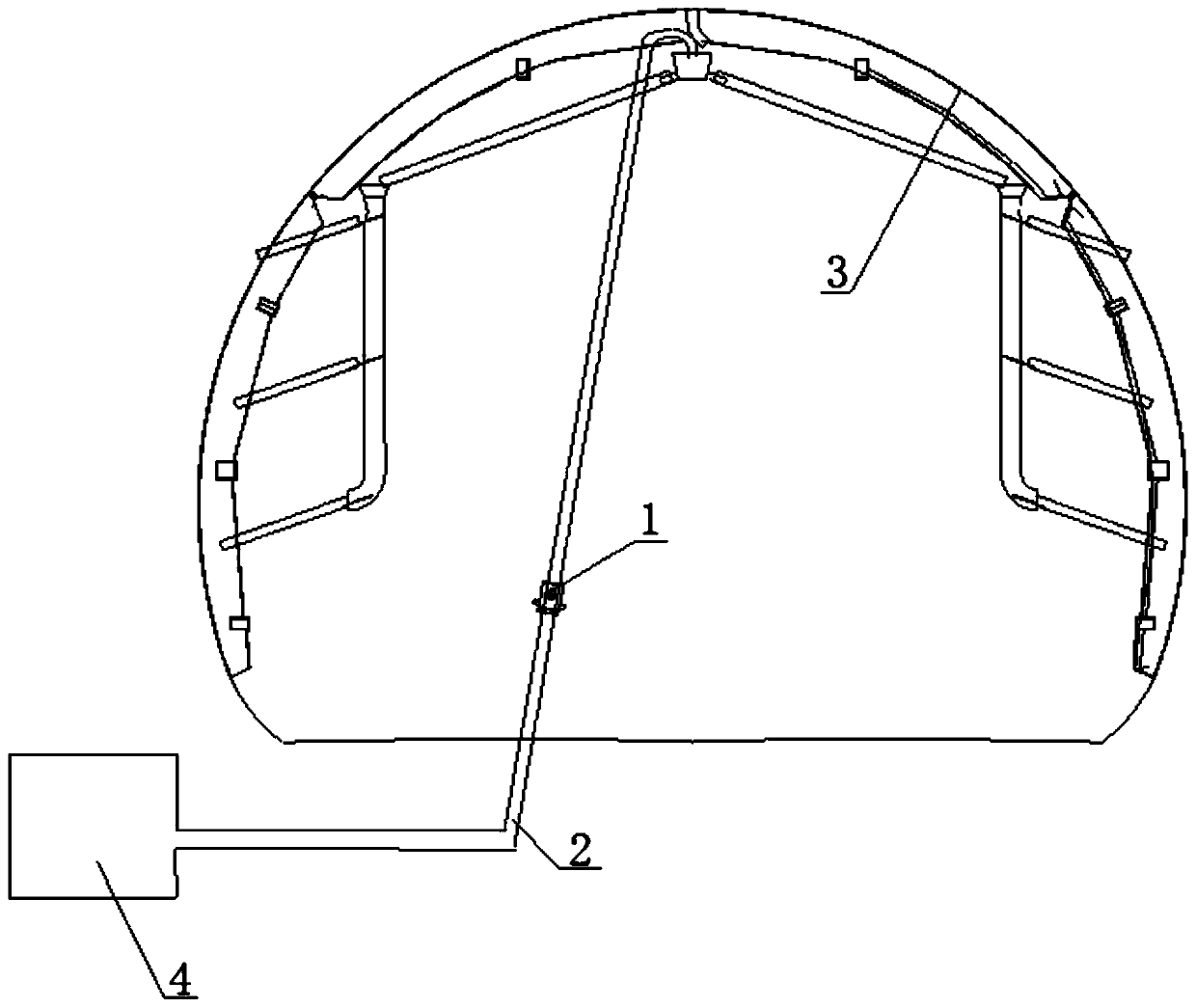

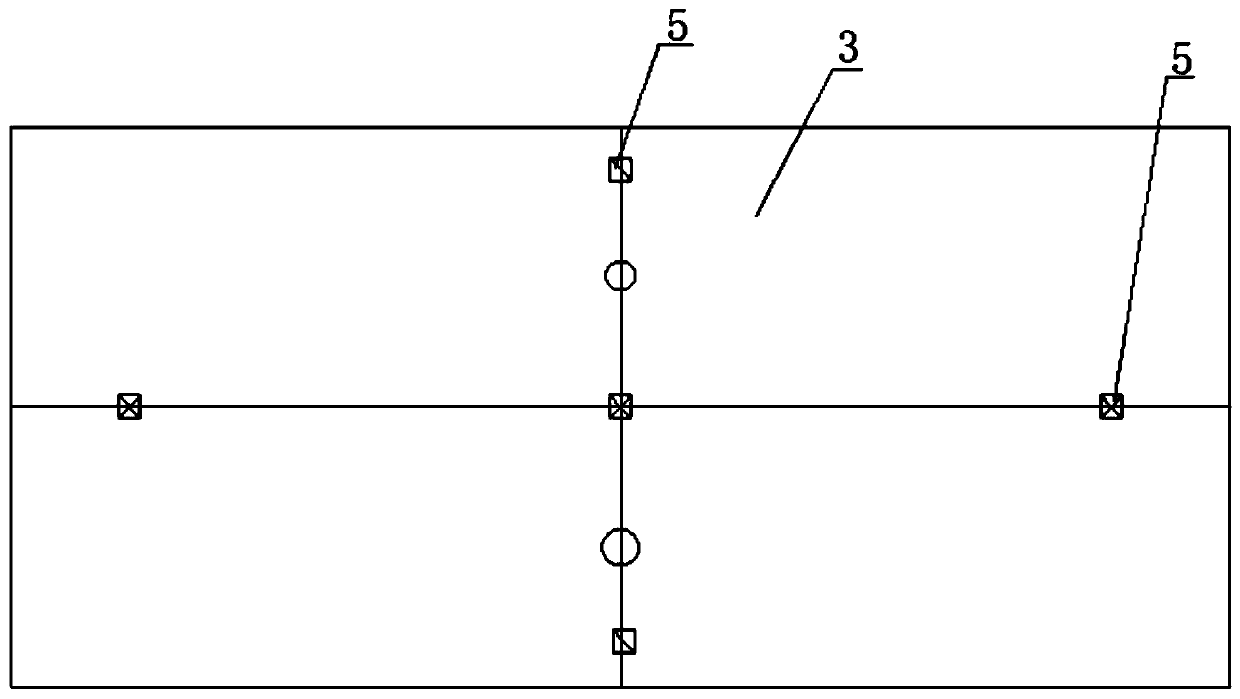

Construction method of tunnel two-lining concrete pouring system

ActiveCN109826649AWon't crackQuality assuranceUnderground chambersApparatus for force/torque/work measurementPressure senseEngineering

The invention relates to a construction method of a tunnel two-lining concrete pouring system, which comprises the following steps of: carrying out full-coverage scanning on a primary cross section byusing a three-dimensional laser scanner, calculating an estimated pouring two-liner concrete square quantity, and transmitting the estimated pouring two-liner concrete square quantity to an electriccabinet (40); installing a strip-shaped pressure sensing gasket (33) and a transparent pipe (30); installing a pressure sensing chip (9), a pressure sensing piece (32) and a temperature sensor (5); arranging a high-frequency pneumatic vibrator (12) and an automatic insertion type vibrator (18), and installing a flow sensor (1); stopping jacking when the pressure sensing value of the pressure sensing chip (9) is greater than the pressure resistance value of the upper plate two-lining concrete, installing a comprehensive pipe (3); pressing air, monitoring the square quantity of the concrete; carrying out pneumatic vibrating; carrying out insertion vibrating; judging that the concrete is full, and finishing pouring the concrete. The automation of the pouring of the two-lining concrete is achieved.

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY 11 BUREAU GRP +1

Soft bag packing device

ActiveCN101100224AReduce manufacturing costMechanizationPackaging automatic controlIndividual articlesEngineeringMechanical soft

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

Technology device for magnetic permanent electromotor stator/rotor installation

InactiveCN101123382AMechanizationImprove efficiencyManufacturing dynamo-electric machinesPush and pullHydraulic cylinder

The invention relates to a technological equipment used for assembling of rotors and stators of permanent magnetic motors, which comprises three relatively independent hydraulic systems ( hydraulic cylinders) and auxilliary tools and fixtures, a rack and a trolley. The hydraulic systems ( hydraulic cylinders) are arranged on left side of the technological equipment. The auxilliary tools and fixtures are arranged on the right side of the technological equipment. The rack and the trolley are arranged under the auxilliary tools and fixtures. The hydraulic systems are a lifting hydraulic cylinder, a clamping hydraulic cylinder, a push-and-pull hydraulic cylinder which are relatively independent systems. The height of an operating platform can be adjusted through adjustment of a platform hydraulic system to adapt to the heights of centers of stators of different frame numbers. A thimble of a shaft having a rotor (a front and rear bearing, a rear end cover) is provided with a clamp so that the thimble is clamped. The work trolly is pushed and pulled so that the rotor inserts or pushes a stator in. The auxilliary tools and fixtures comprise a front thimble and a rear thimble and so on. The technological equipment achieves mechanization by replacing human beings to assemble the stators and rotors of the permanent magnetic motors; the efficiency is high; and the utility model works safely and reliably.

Owner:SHANGHAI ELECTRICAL APP RES INST GRP +1

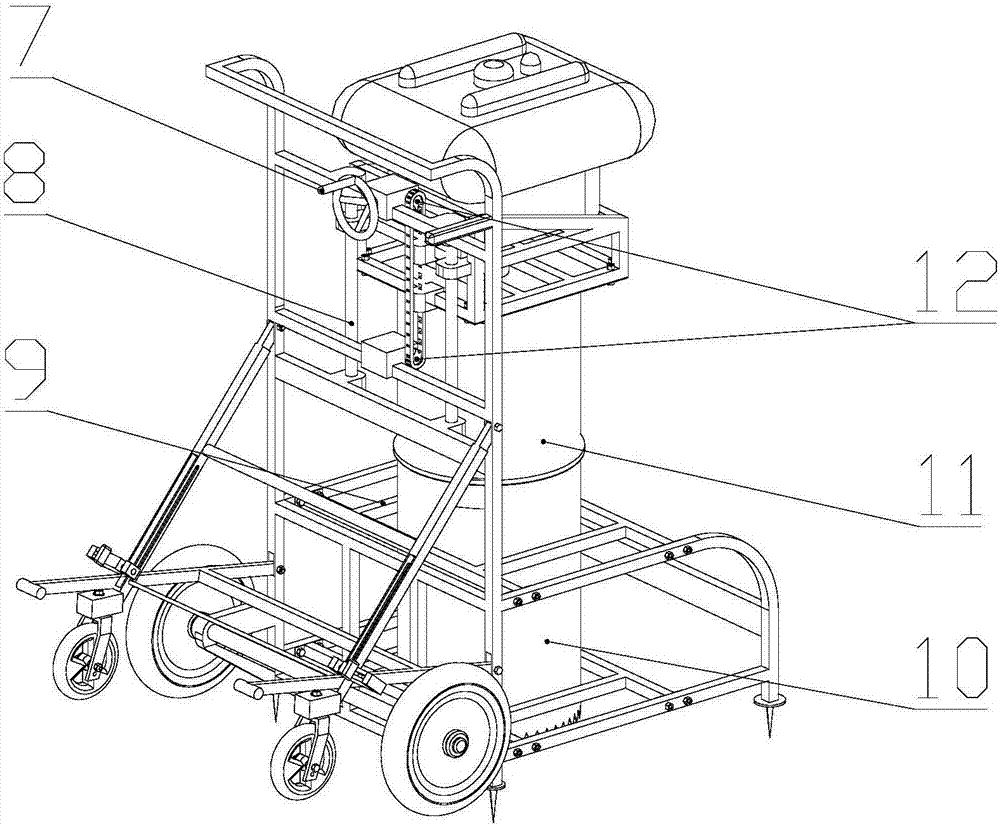

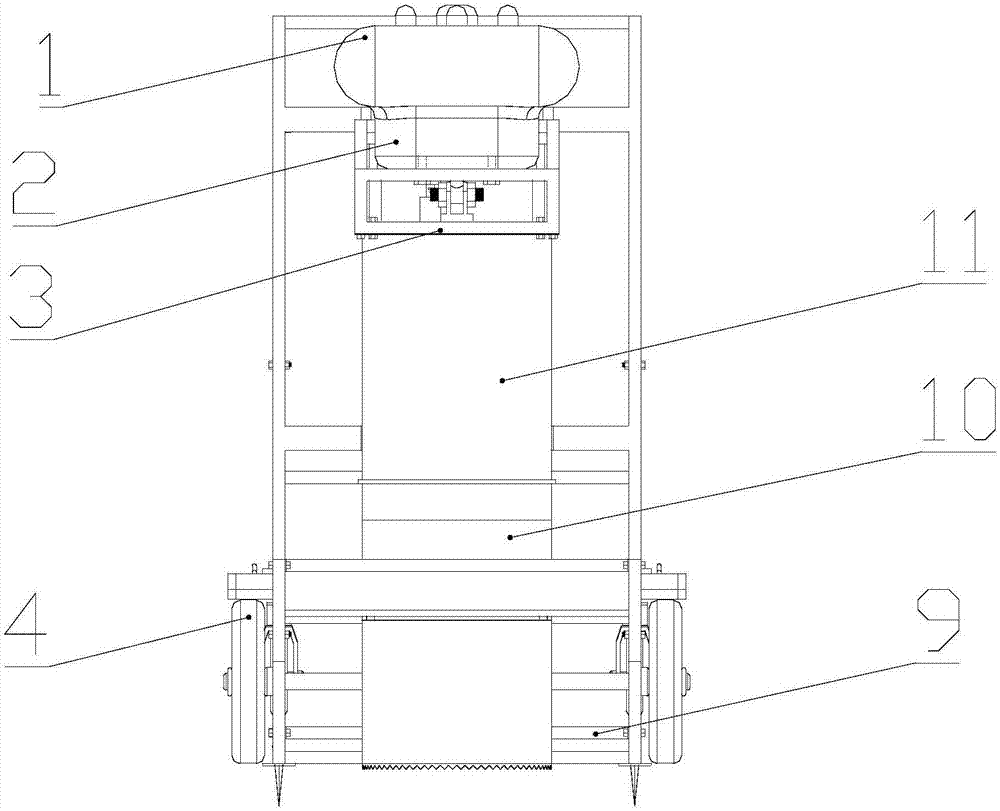

Integrated machine for in-situ hole digging, material mixing and backfilling and working method thereof

ActiveCN106888629AMechanizationReasonable structural designPlantingFertiliser distributersReduction driveCompound structure

The invention relates to an integrated machine for in-situ hole digging, material mixing and backfilling and a working method of the integrated machine for the in-situ hole digging, material mixing and backfilling. The integrated machine comprises a power system, a drill bit lifting device, a walking device and an operation device; the power system comprises an engine and a reducer; the drill bit lifting device comprises lifting hand wheel, a lifting reducer, a linear guide rail, a lifting frame, a chain wheel and a chain; the walking device comprises a supporting rear wheel and a supporting front wheel; the operation device comprises a drill bit, a sleeve rack, an upper sleeve, a lower sleeve, a discharge port baffle plate and a discharge pipeline; the invention puts forward an integrated design of in-situ hole digging, material mixing and backfilling for fruit tree planting to realize mechanized fruit tree planting process, the integrated machine for the in-situ hole digging, material mixing and backfilling is reasonable in structural design, low in cost, convenient to operate and use, high in efficiency of hole digging, material mixing and backfilling, and low in labor intensity. A hole digging and material mixing composite structure of the single-blade double-diameter drill bit and a lifting material mixing cavity is innovated, and performs hole digging and material mixing simultaneously, and further is high in efficiency and mixing uniformity of fertilizer, microorganisms and soil.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Processing method of tippy tea

The invention discloses a processing method of tippy tea, which comprises the following steps: selecting medium and small-sized leaves of which the length is 1.7cm-3.2cm, wherein each medium and small-sized leaf comprises one single bud or one bud and one leaf; spreading and greening the leaves, removing water, and conveying and quickly cooling the water-removing leaves simultaneously; naturally regaining the moisture of the leaves in the conveying process, and automatically putting the moisture-regaining leaves into a twisting machine through a conveying and lifting machine; twisting, conveying and lifting the leaves: twisting the leaves until the twisted leaves are basically in strip shapes, have verdant leaf color, soft strips and slight fragrance and are sticky; mechanically conveying the leaves uniformly; preliminarily baking the leaves, and conveying and quickly cooling the preliminarily baked leaves simultaneously; spreading and airing the leaves from bottom to top in a blowing way on a spreading and airing platform; and forming, thinning and drying the leaves. The invention realizes the purpose of mechanically, continuously and cleanly processing the tippy tea, and simultaneously improves the quality and the yield of the processed products.

Owner:都匀供销茶叶有限责任公司

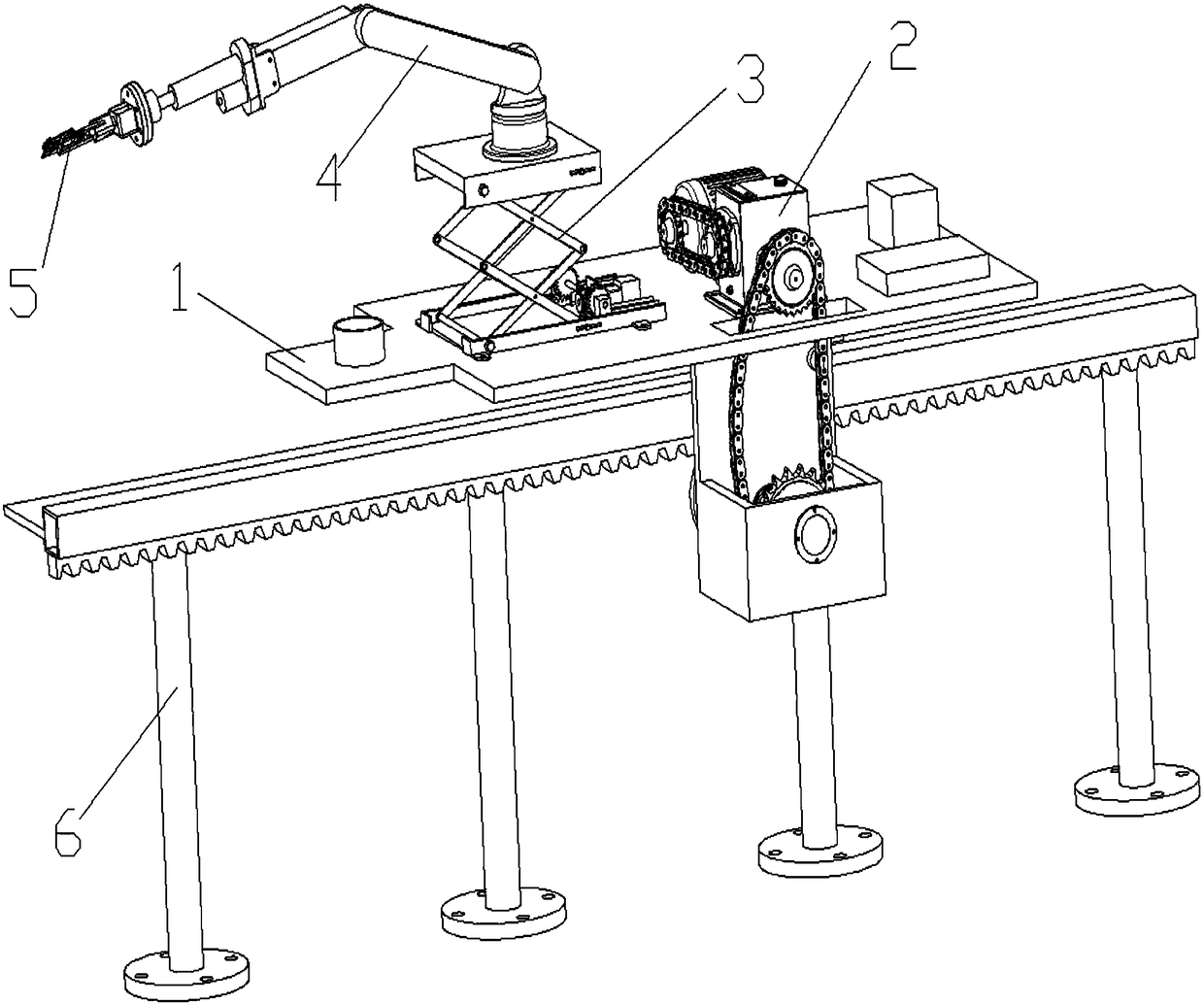

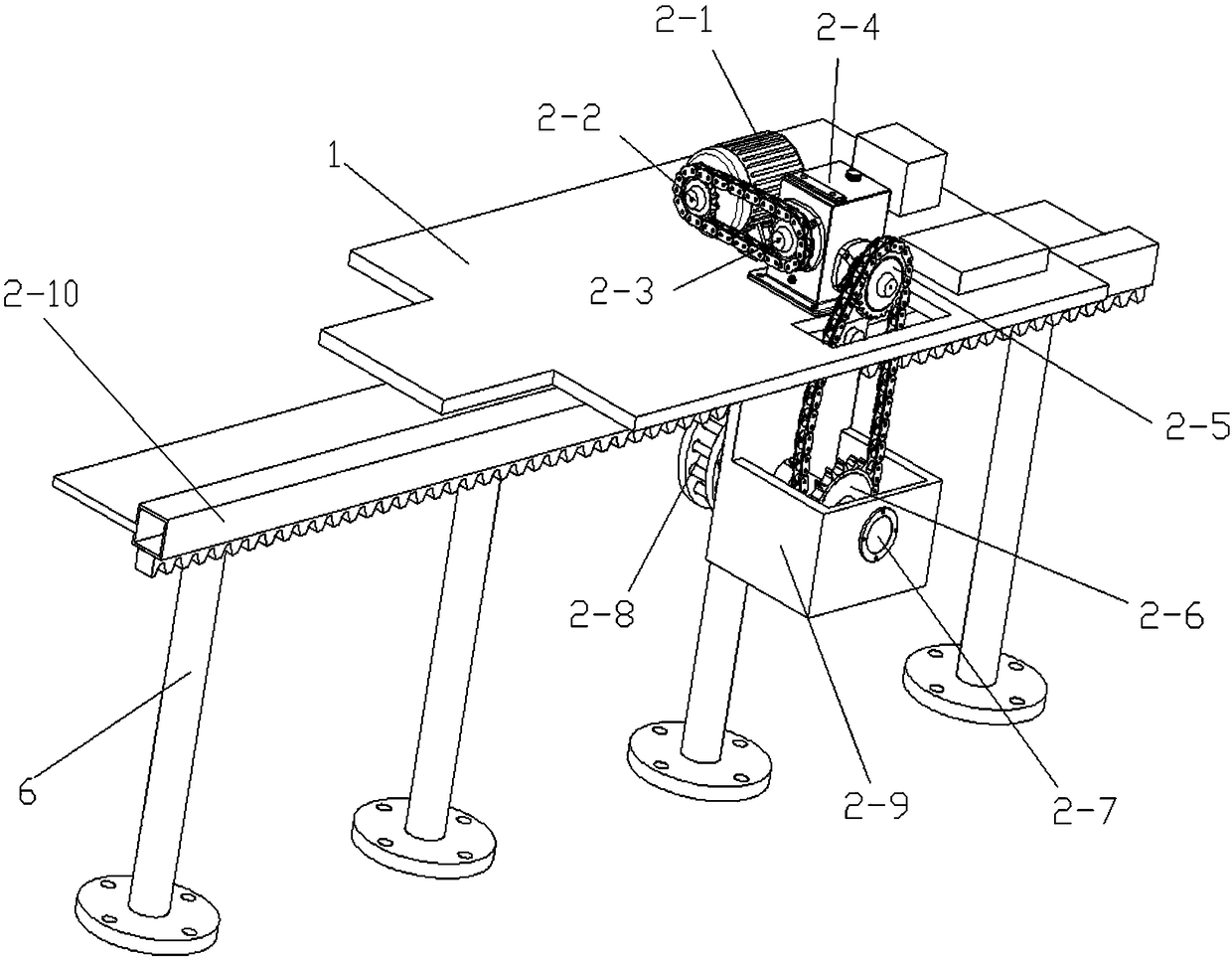

Rail-mounted tea picking robot for hilly and mountain areas

PendingCN108555921AMechanizationImprove stabilityManipulatorPicking devicesMountainous terrainAgricultural engineering

The invention relates to a rail-mounted tea picking robot for hilly and mountain areas and belongs to the technical field of agricultural picking machinery. The rail-mounted tea picking robot for thehilly and mountain areas comprises a platform, a driving device, a lifting device installed on the platform, a mechanical arm installed on the lifting device, and a picking hand installed on the output end of the mechanical arm. The robot is used in the hilly and mountain areas, the driving device drives the whole platform to move along a rack rail in the hilly and mountain areas, the lifting device drives the whole mechanical arm to ascend or descend, and thus the height of the picking hand is increased or decreased to adapt to the heights of different tea; and then a first rotating motor candrive the whole mechanical arm and the picking hand to rotate in the vertical direction, the mechanical arm can expand the picking range of the picking hand, a second electric pushing rod works, stems of the tea are shorn off, and the tea is clamped through a clamp and then placed in a proper place. The rail-mounted tea picking robot can be used for picking the tea in the hilly and mountain areas.

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com