L-shaped full-closed environment-friendly hot galvanizing production equipment and method

A production process and closed technology, applied in hot dip plating process, metal material coating process, coating and other directions, can solve the problem of zinc oxide sticking to the filter bag, etc., achieve automatic pickling, not easy to corrode, solve the problem Effects of pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

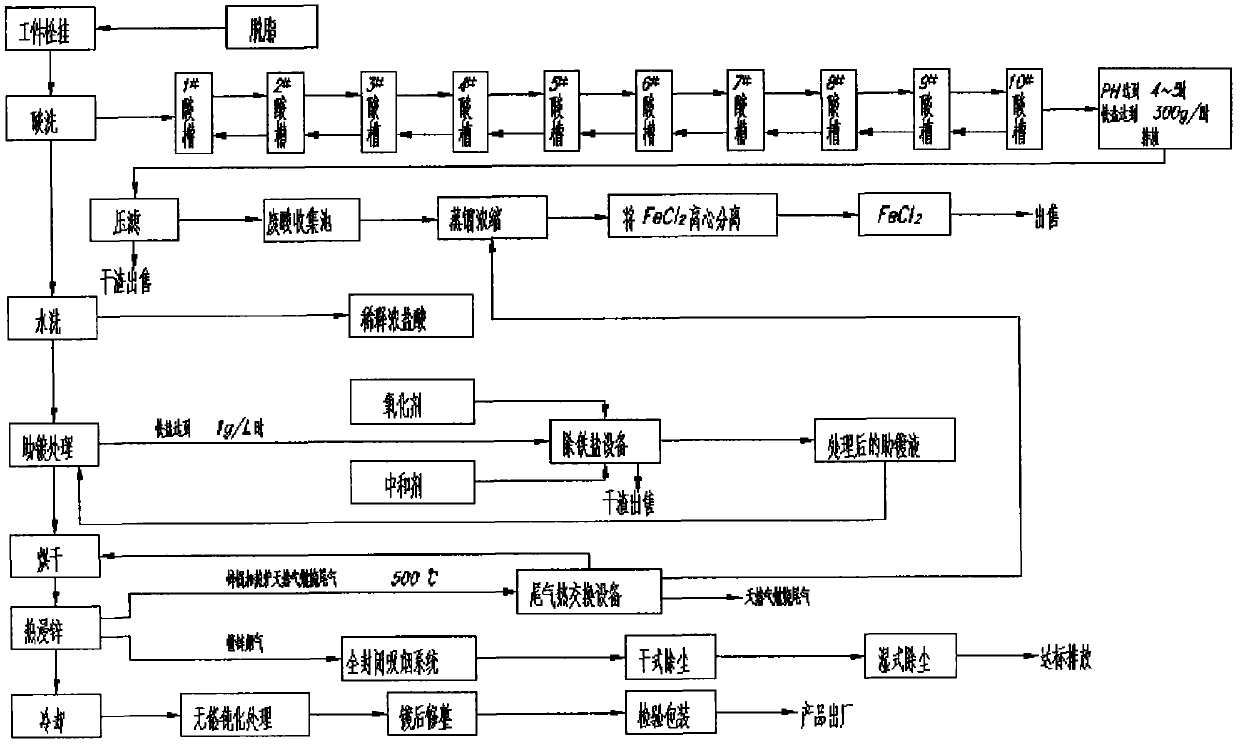

Method used

Image

Examples

Embodiment Construction

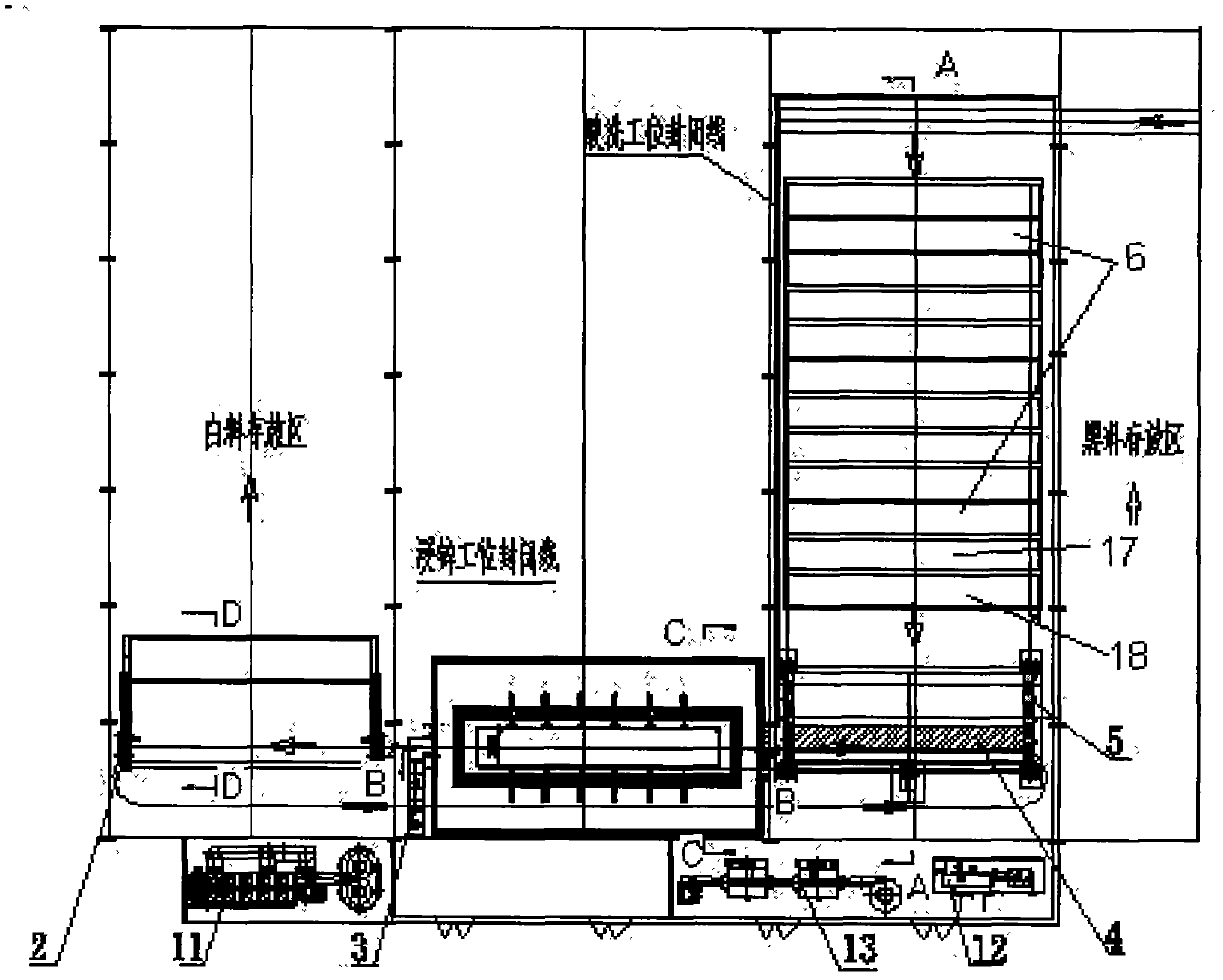

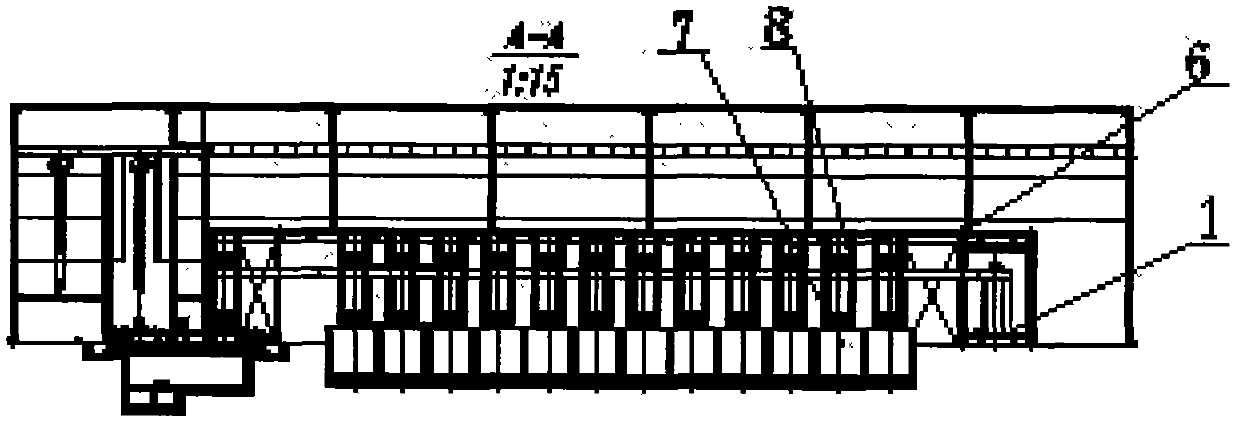

[0042] The present invention will be further described below in conjunction with accompanying drawing:

[0043] Explanation of the symbols in the figure: self-propelled feeding ground rail car 1, cooling translational rail car 2, waste heat utilization system of galvanizing furnace 3, hot air drying system 4, chain conveying equipment 5, anti-collision pickling tank 6, fully enclosed Acid mist collection system 7, pickling workpiece automatic conveying system 8, fully enclosed galvanizing tank flue gas recovery system 9, galvanizing ring rail crane 10, galvanized flue gas dry dust collector-swirl plate wet combined flue gas purification equipment 11. Iron and salt purification equipment for plating flux 12. Secondary water curtain acid mist purification equipment 13. Cooling water tank 14. Hot-dip galvanizing tank 15. Feed door between galvanized closed rooms 16. Rinse tank 17. Plating aid tank 18.

[0044] see Figure 1-7 As shown, the L-shaped fully enclosed environmentall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com