Patents

Literature

4595results about How to "Improve dust removal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

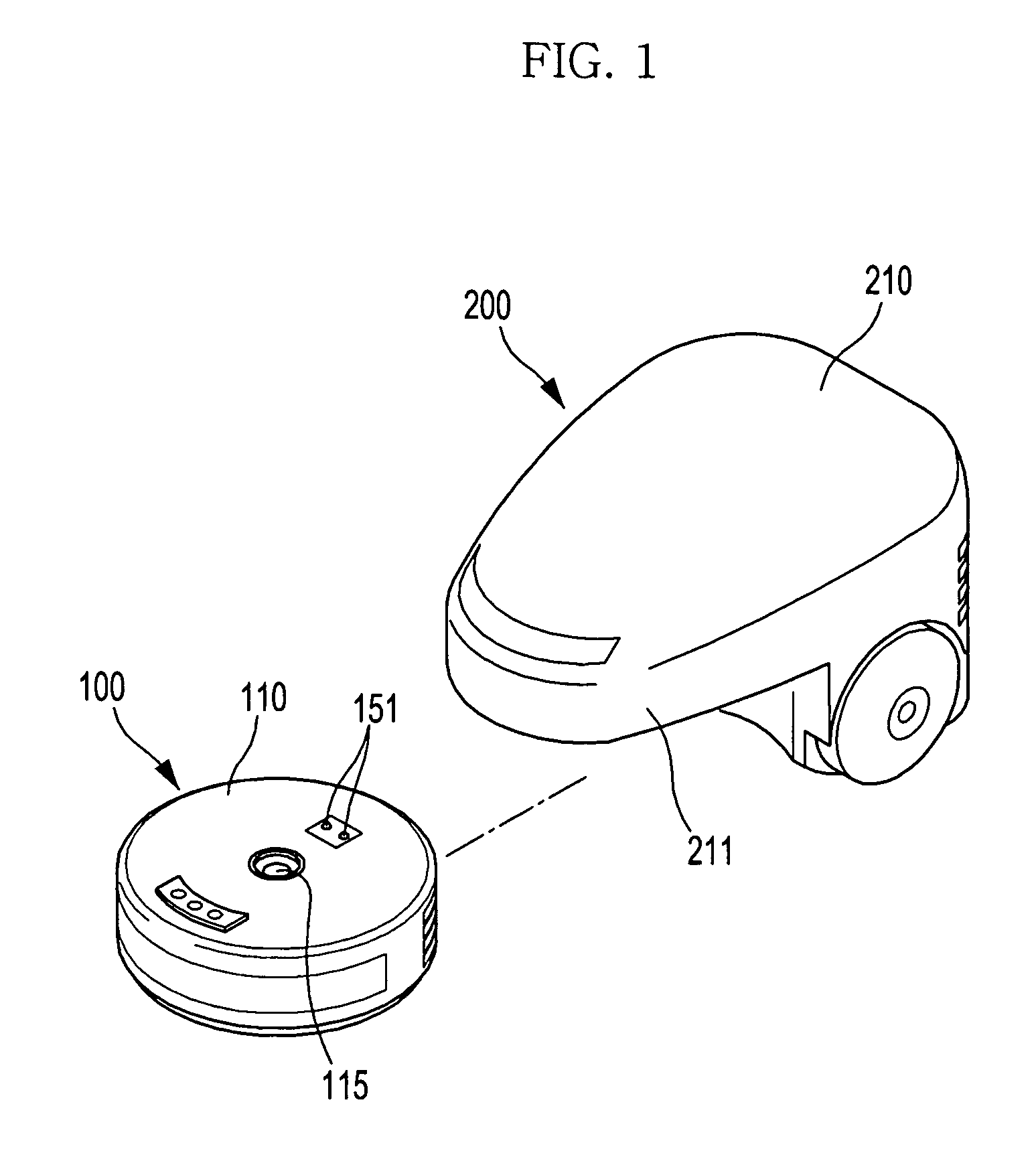

Cleaner system

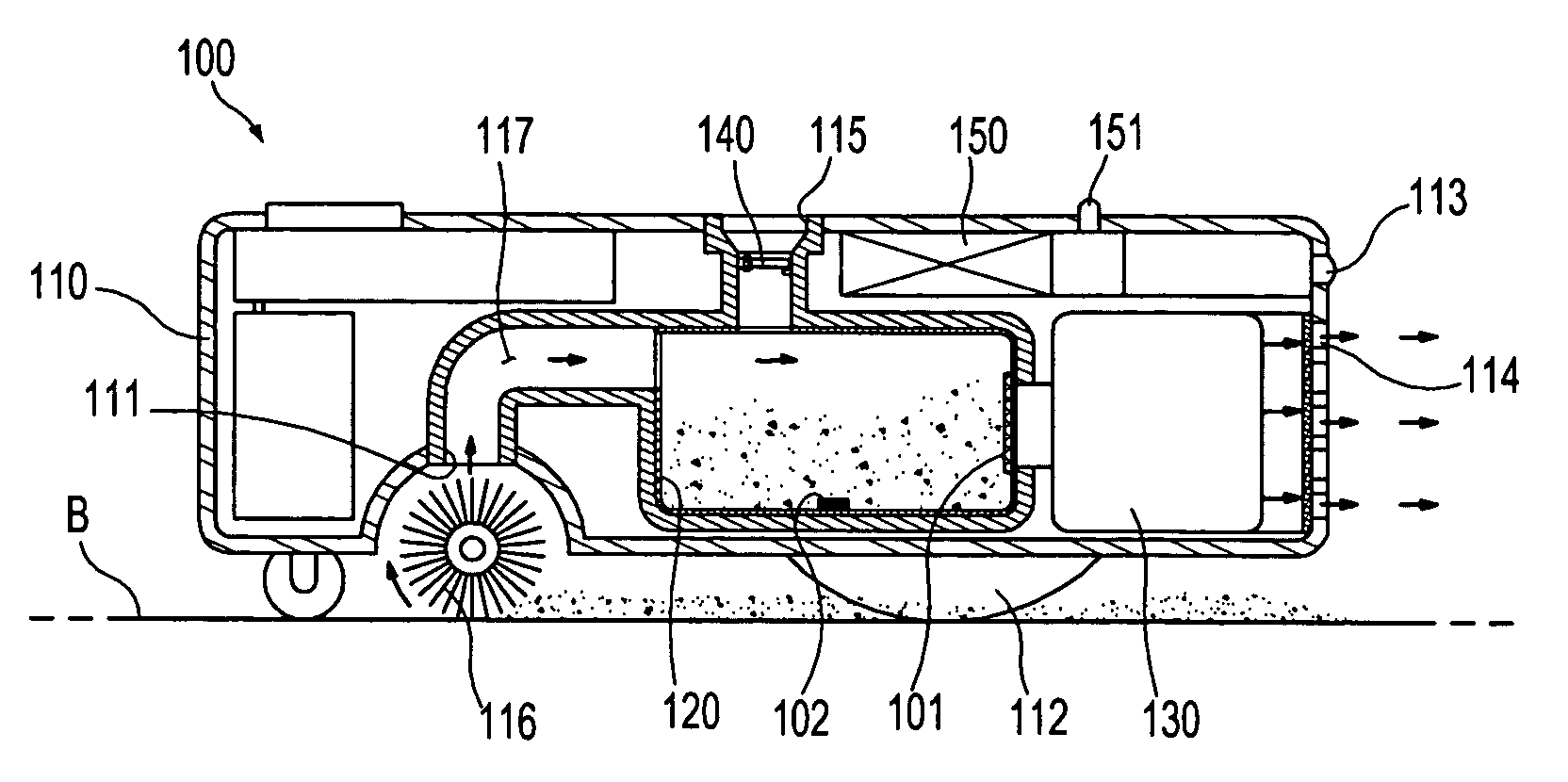

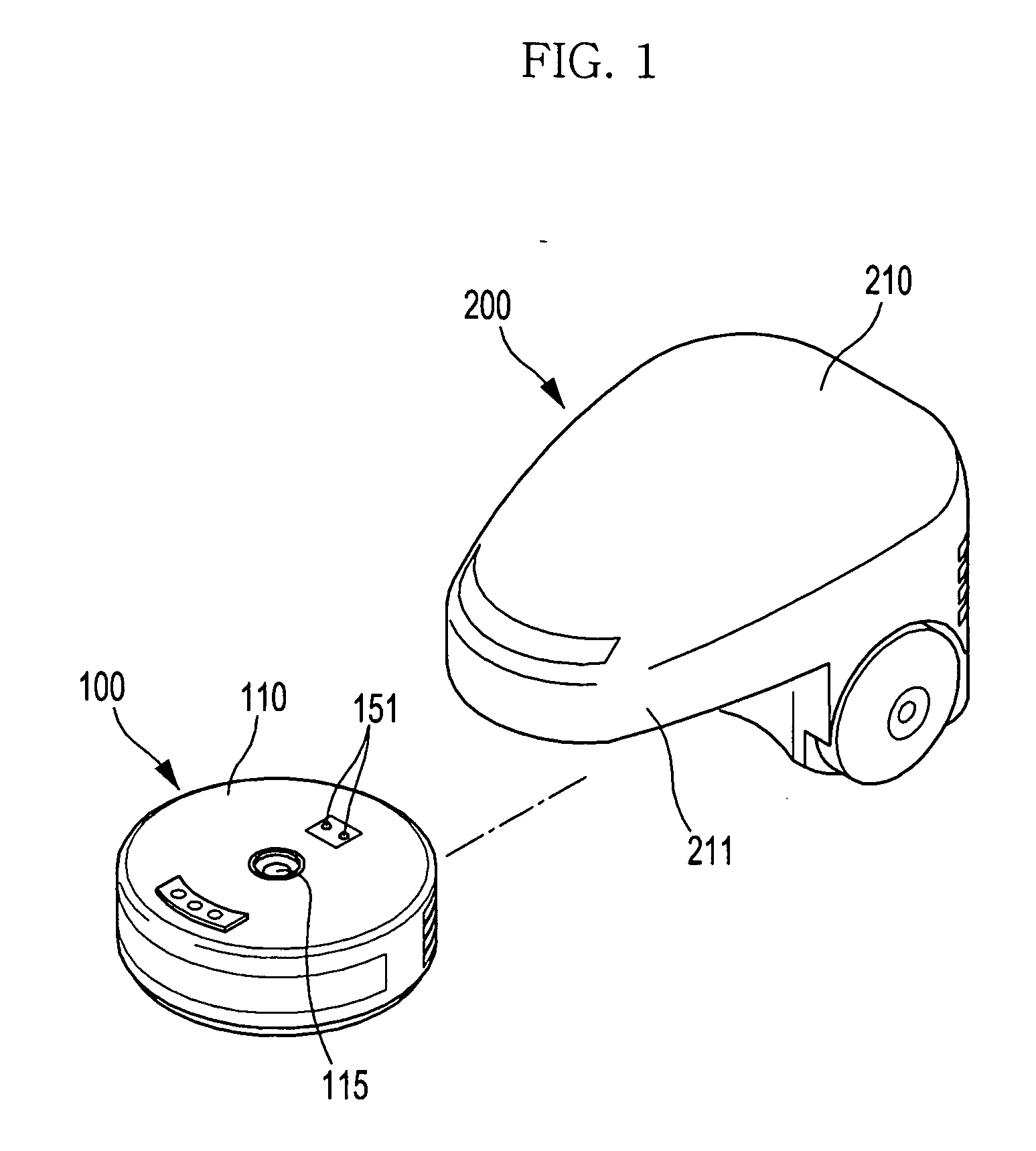

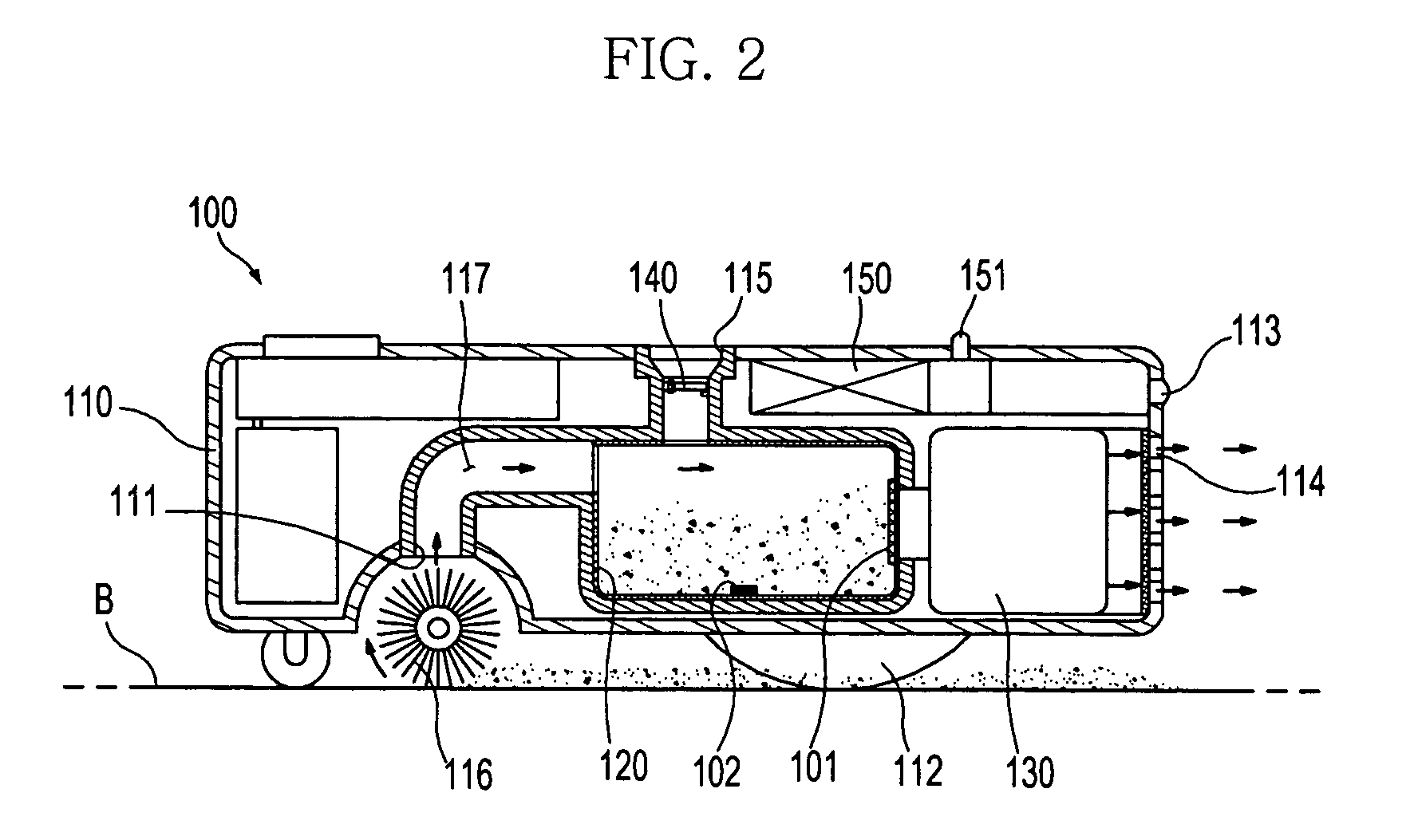

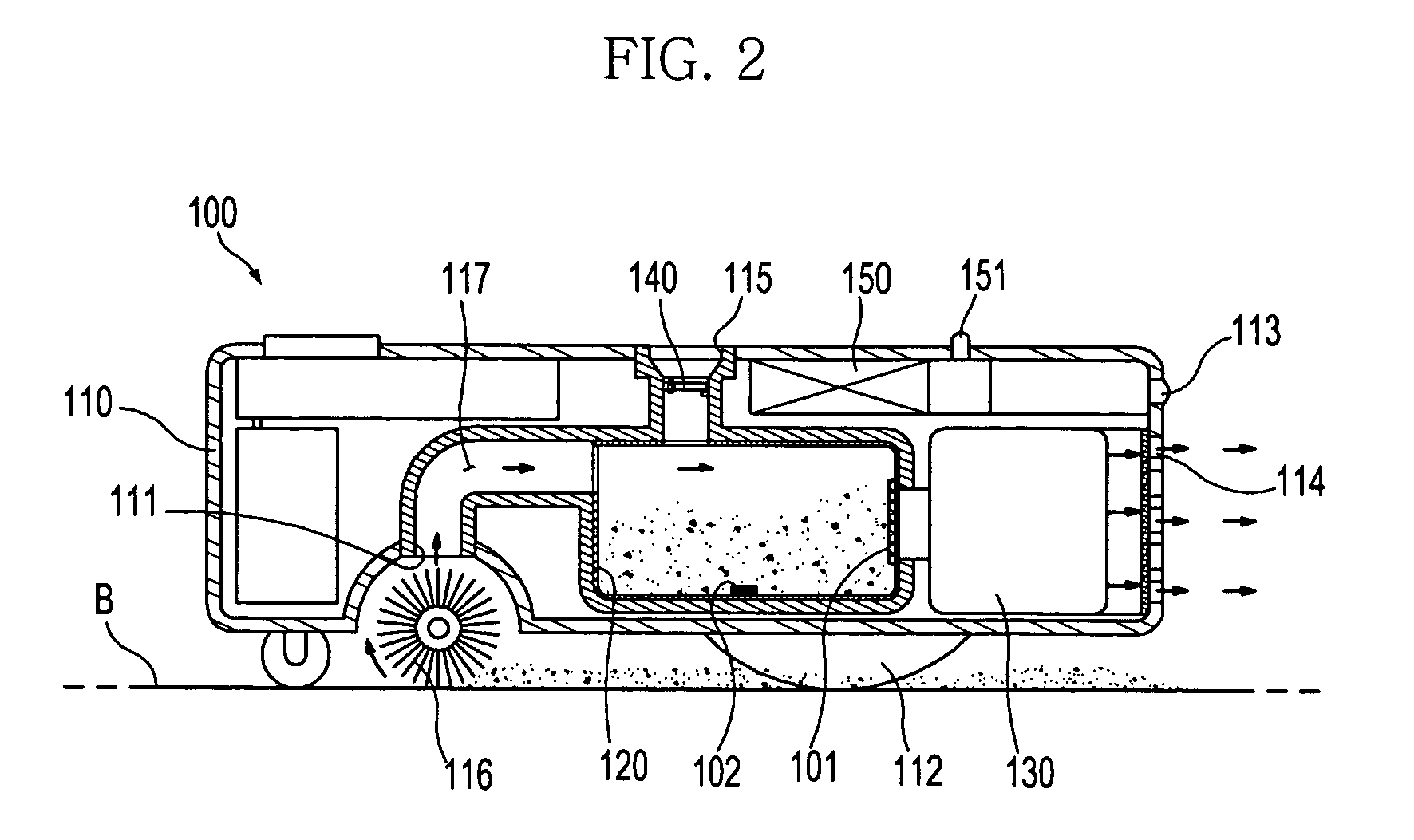

InactiveUS20070157415A1Improved connecting position and structureImprove dust removal effectEngine sealsSuction cleanersDocking stationEngineering

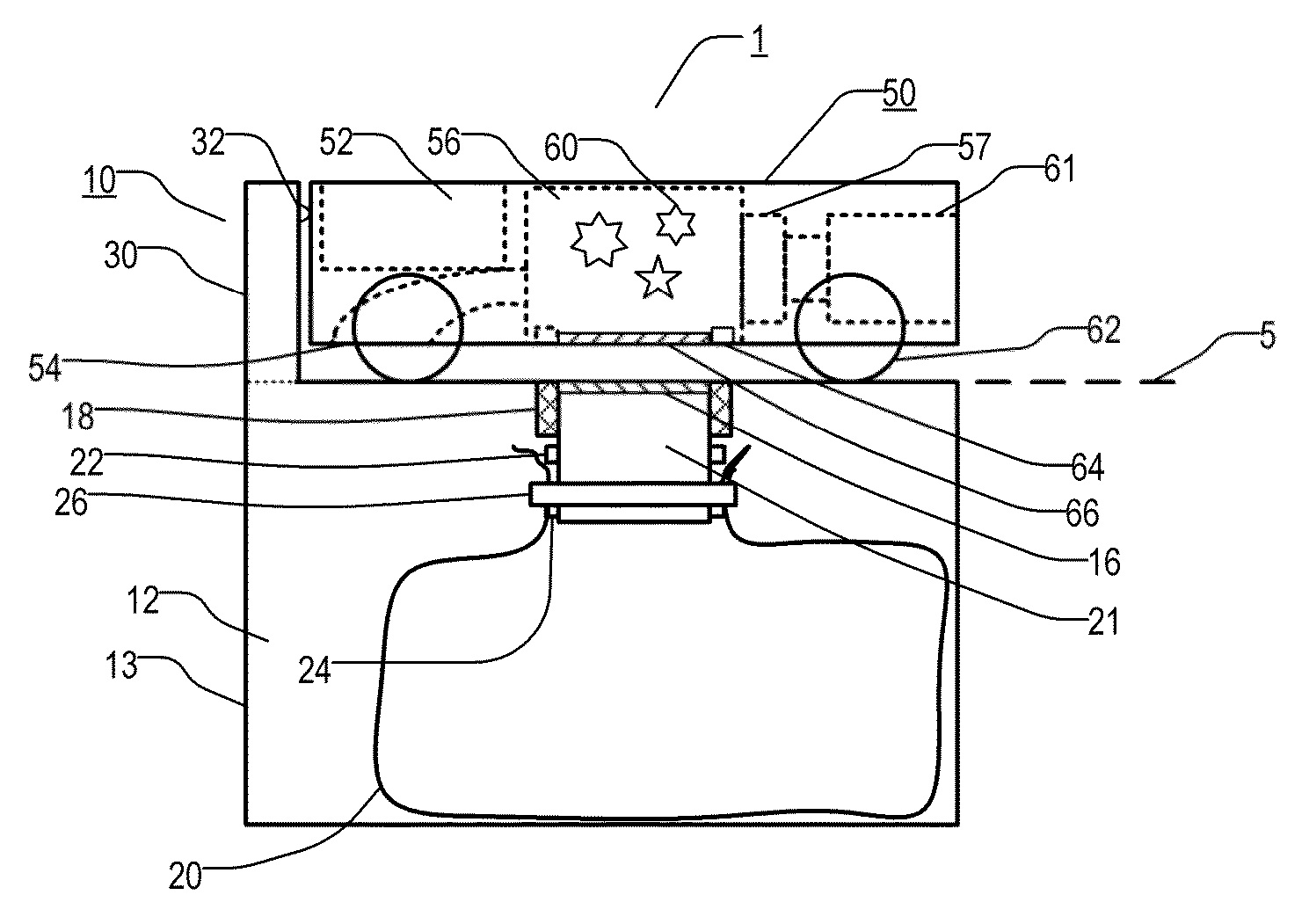

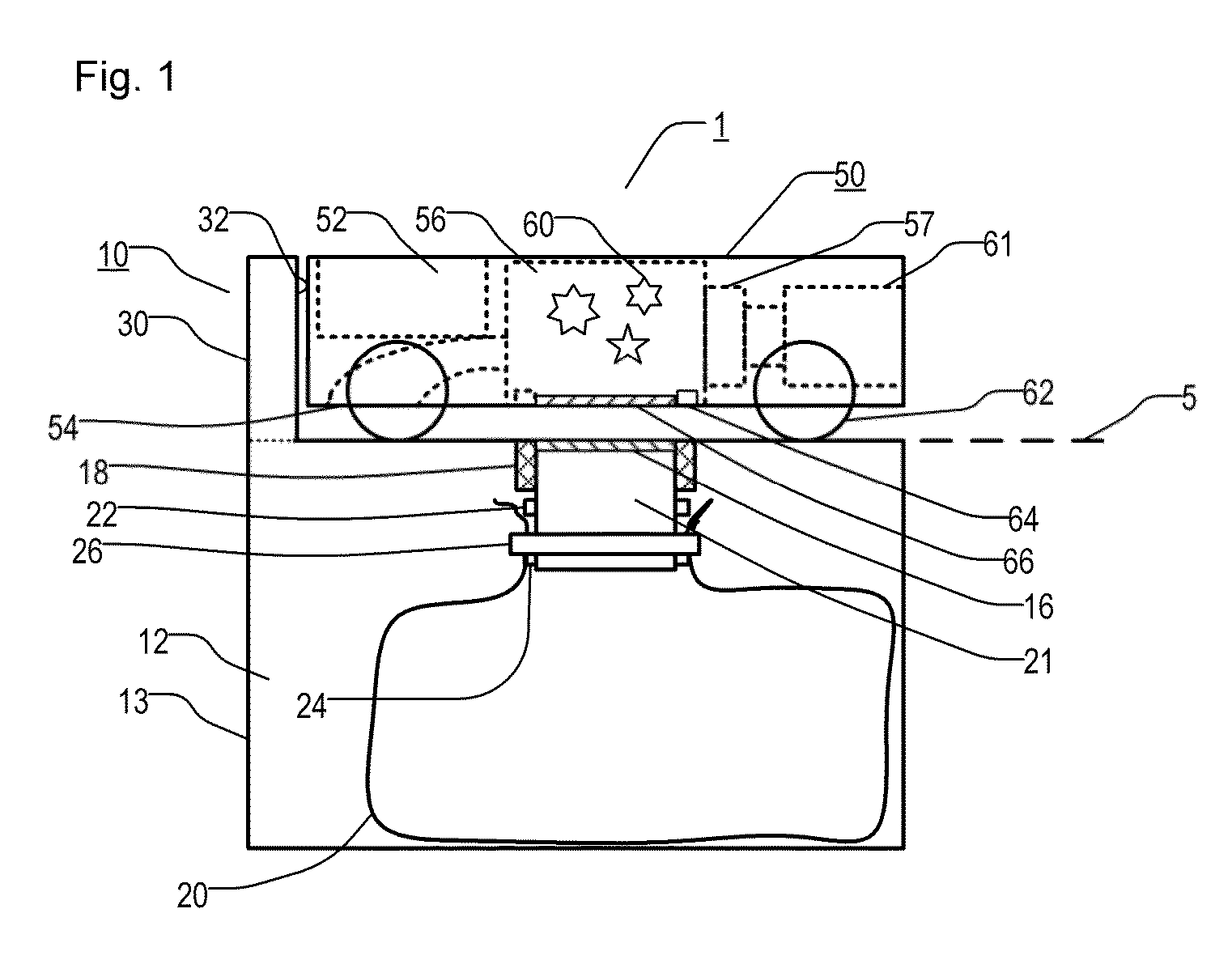

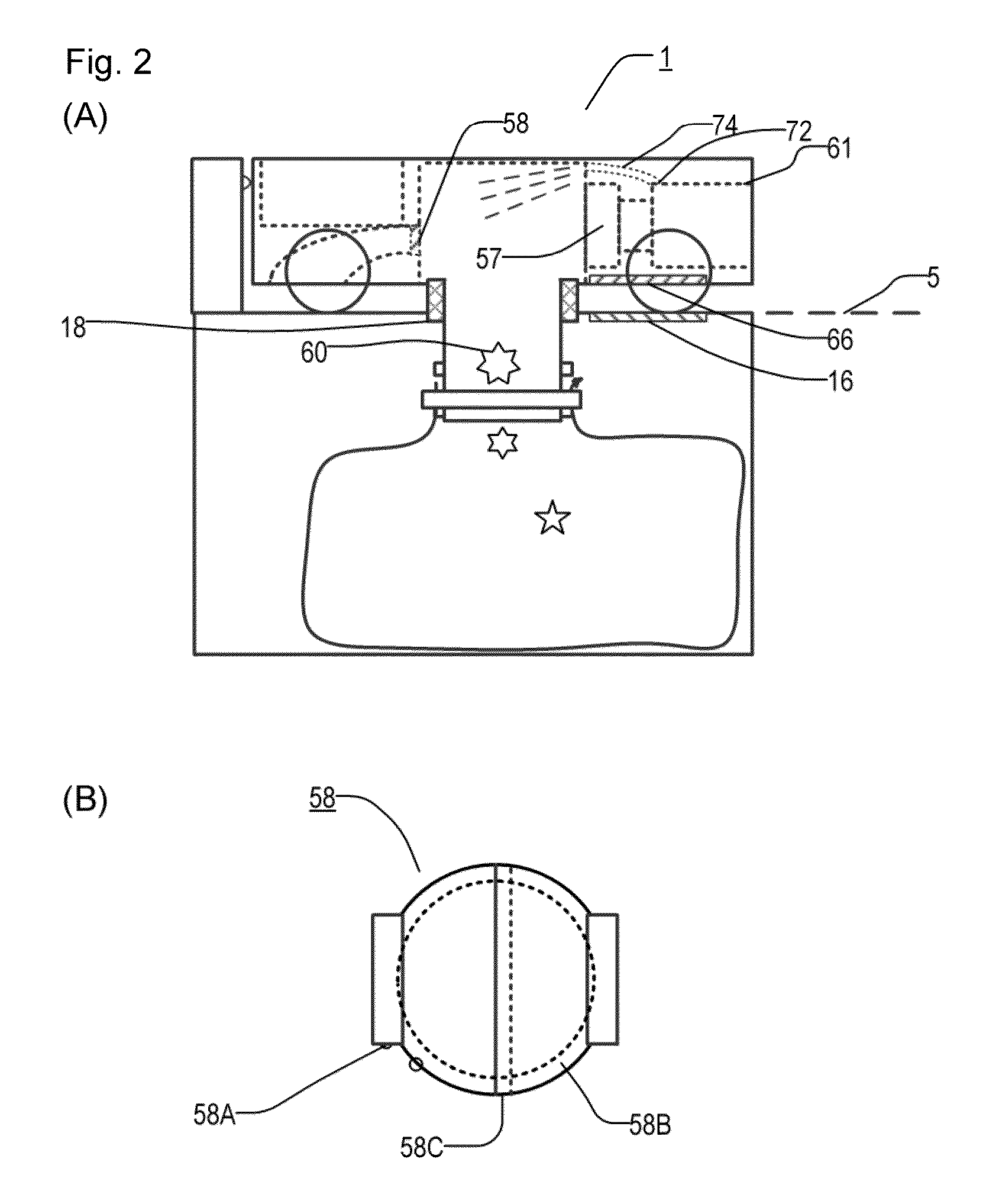

A cleaner system having an improved connecting position and structure between a robot cleaner and a docking station for achieving an improvement in dust removal performance of the docking station. The docking station performs manual cleaning. The robot cleaner has a dust outlet at a top wall of the robot body to discharge the dust collected in the first dust collector into the docking station, and the docking station has a connection port at a position thereof corresponding to the dust outlet to receive the dust discharged from the dust outlet. The robot cleaner or docking station includes a connector to connect the dust outlet to the connection port. The docking station includes a suction part, suction pipe, and suction hole for manual operation. A channel switching member is mounted in the docking station to selectively apply power required to suck dust to the connection port or suction hole.

Owner:SAMSUNG ELECTRONICS CO LTD

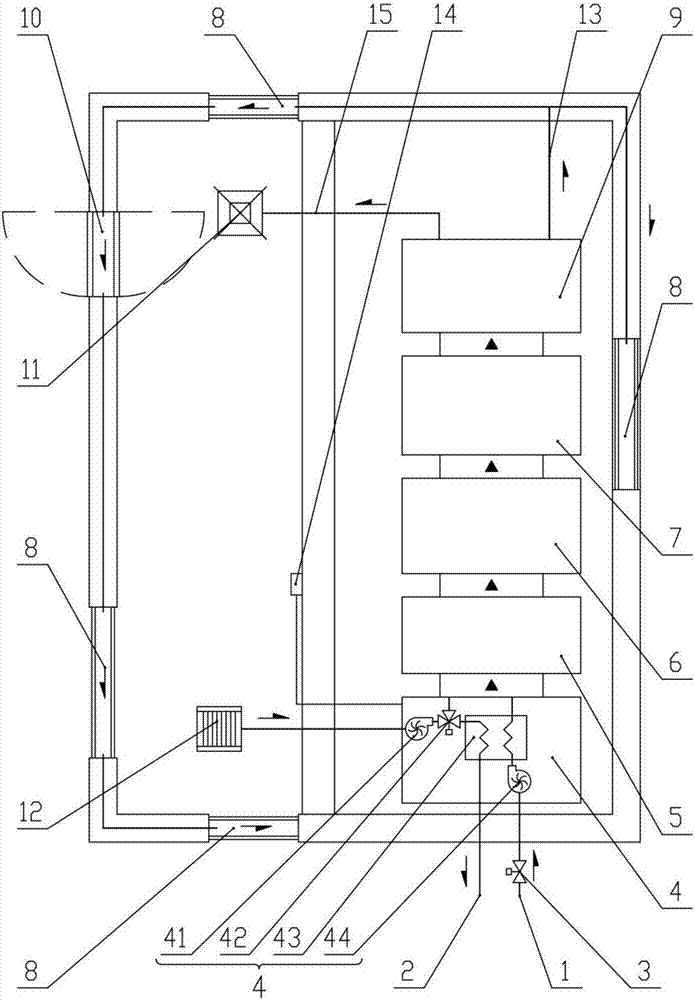

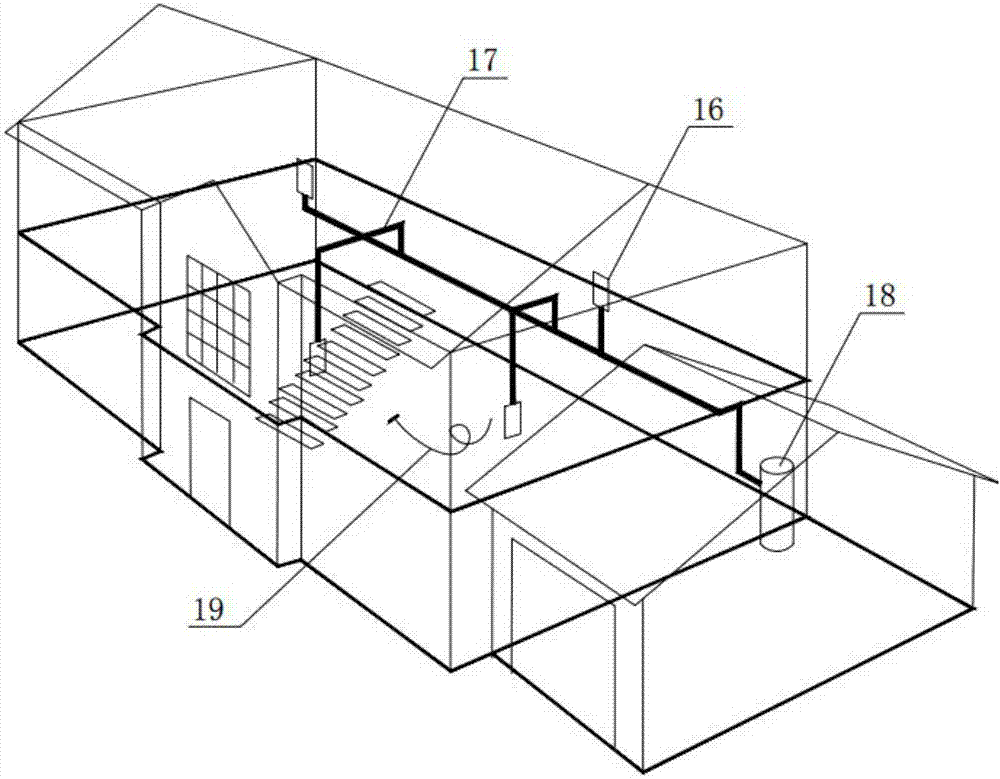

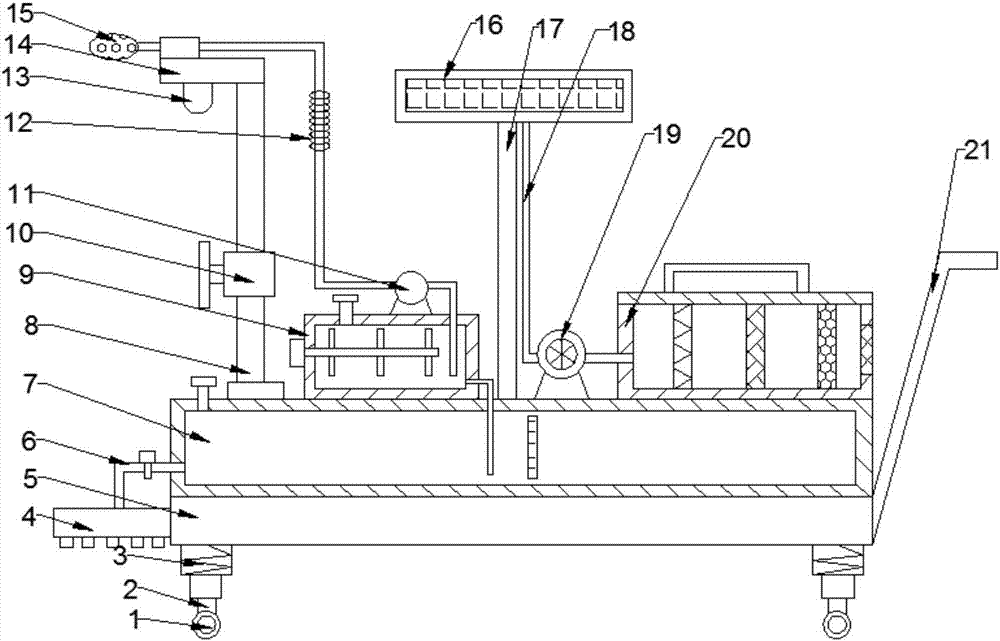

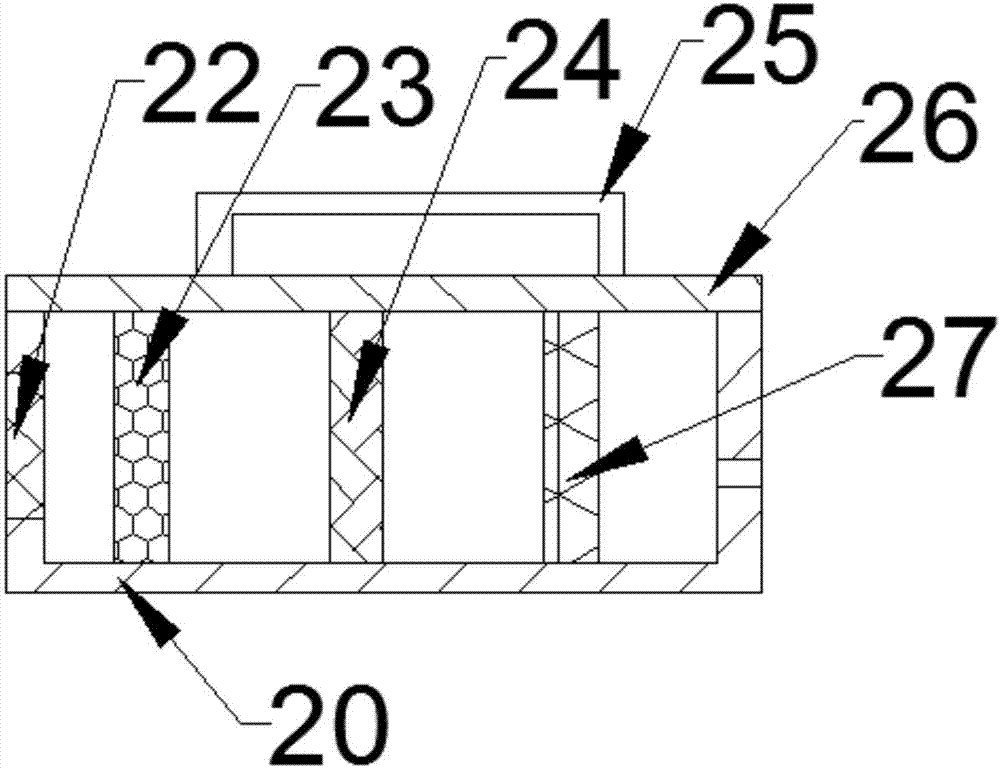

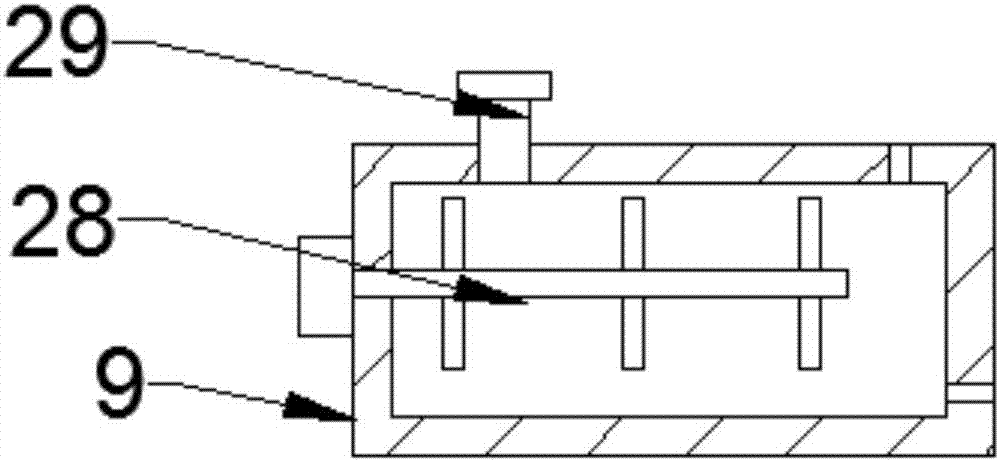

Constant-temperature, constant-humidity and constant-cleanliness silent indoor air system

InactiveCN106895521AAgainst intrusionAvoid damageMechanical apparatusSpace heating and ventilation safety systemsFiltrationFresh air

The invention provides a constant-temperature, constant-humidity and constant-cleanliness silent indoor air system, belongs to the field of indoor intelligent adjustment, and relates to multiple techniques including indoor air pressure control, indoor air purification, an indoor central dedusting system, supercharging and compensation functions for interlayers of double windows and double doors, an outdoor haze isolating system, an indoor air internal-circulation cleaning method, air heat exchange, air heating, refrigeration, dehumidification and the like. According to the constant-temperature, constant-humidity and constant-cleanliness silent indoor air system, the pressure of fresh air is made positive through the interlayers of the double doors and the double windows, the air pressure in the interlayers of the double doors and the double windows is made higher than outdoor air pressure, and outdoor air is prevented from invading indoor air; a small primary-efficiency, medium-efficiency and high-efficiency filtering system is used for filtration, various types of automatic adjustment and control including heating, refrigerating, dehumidifying and the like are conducted on air, pollutant dust generated indoors is removed through the central dedusting system, and the constant-temperature, constant-humidity and constant-cleanliness silent indoor air system is an omnidirectional intelligent air control system.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

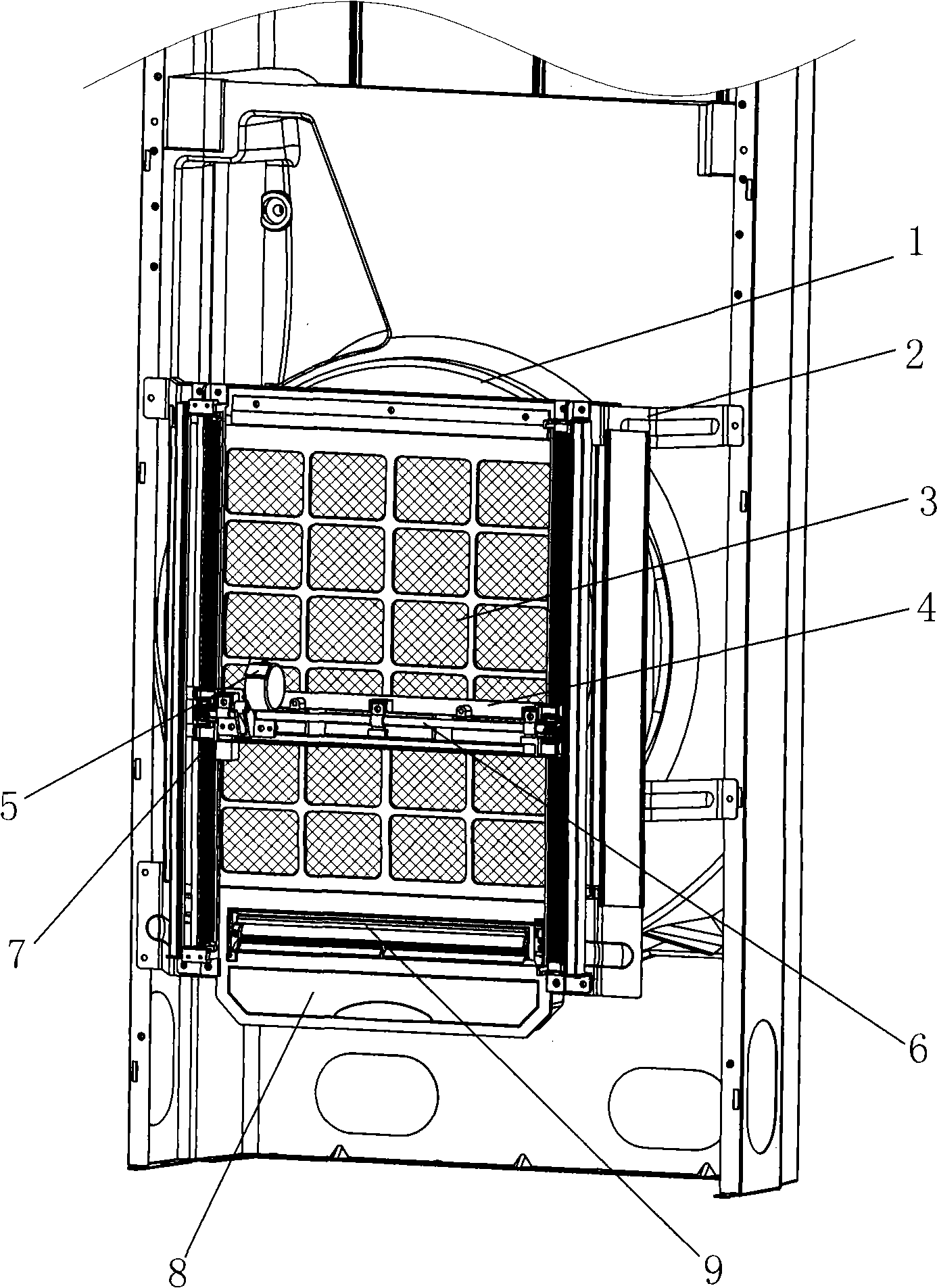

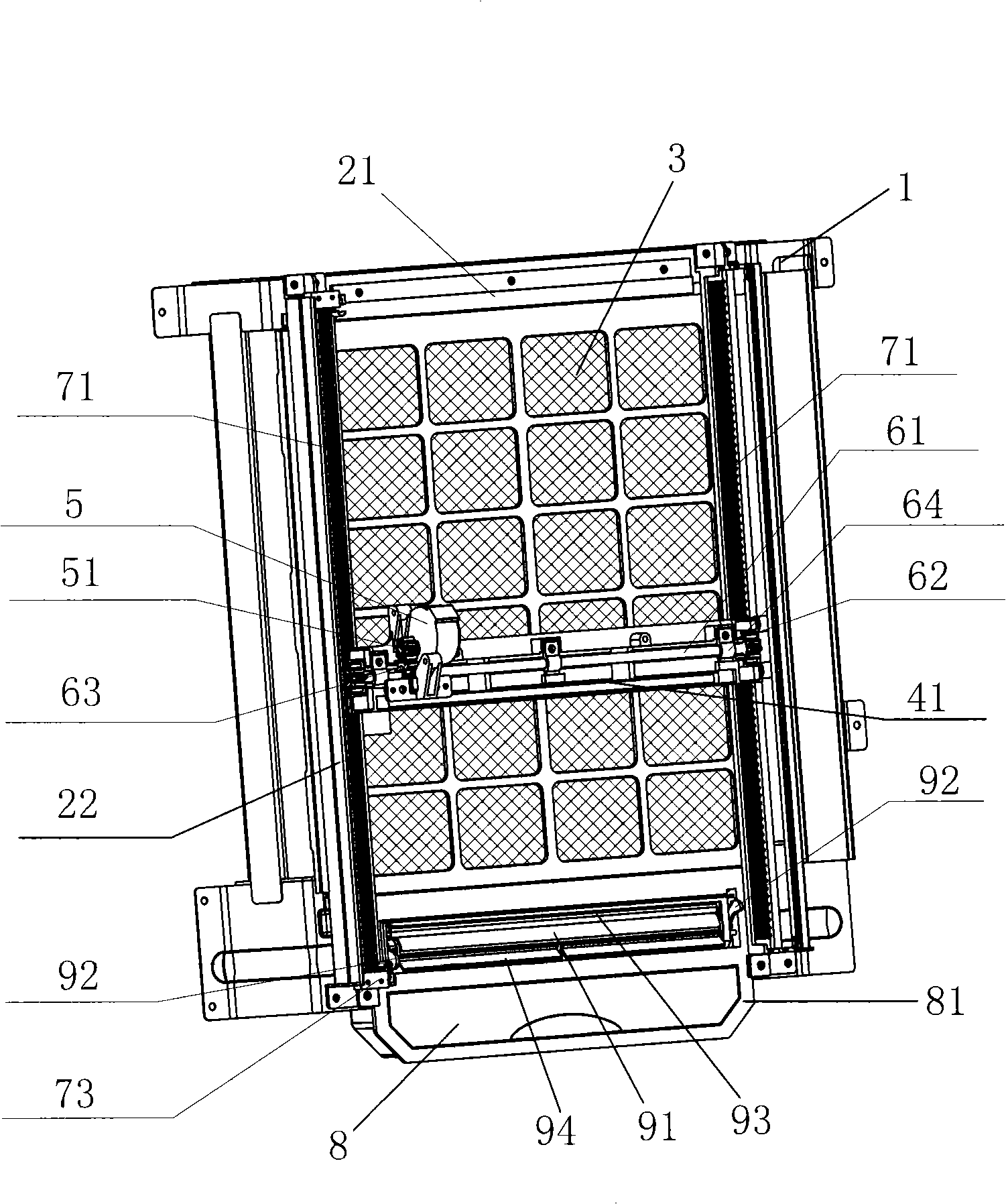

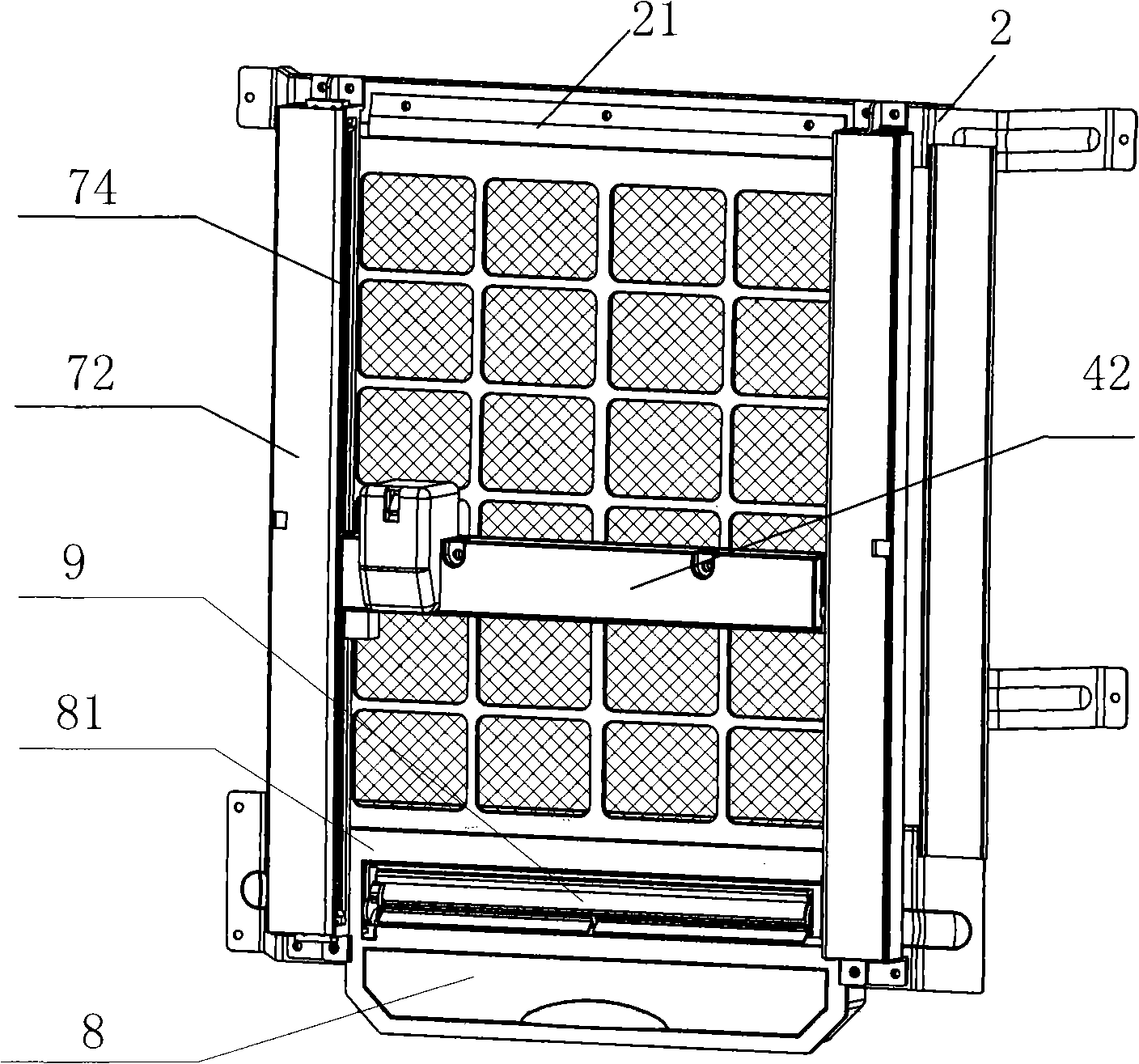

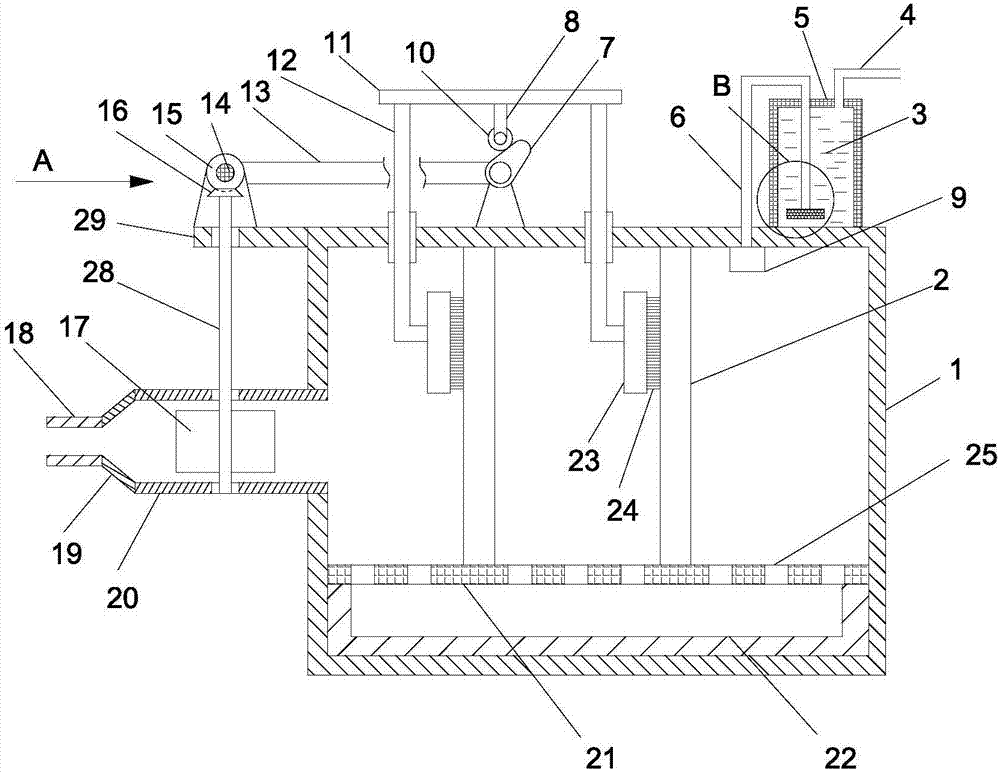

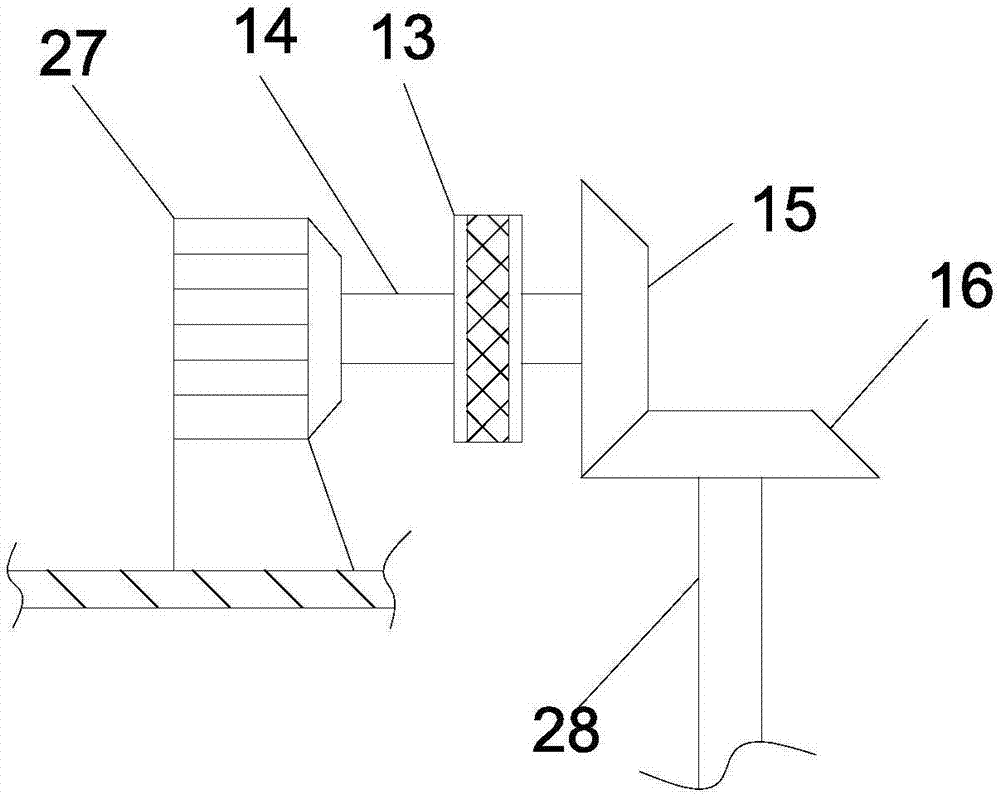

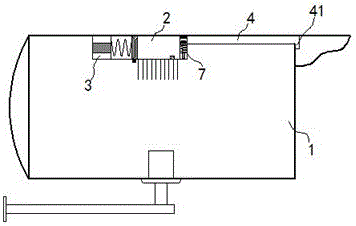

Air conditioner filter screen self-cleaning device

ActiveCN101290151AGuaranteed cleanlinessGuarantee the quality of workMechanical apparatusDispersed particle filtrationDrive motorSelf cleaning

The invention discloses a self-cleaning device for an air conditioner filter screen, which is arranged on filter screen brackets at an air passage spiral casing air inlet of a cabinet air conditioner and is arranged outside the filter screen, an upper bracket and a lower bracket are provided with filter screen guide rails with slots, the filter screen is fixed on the filter screen brackets through the slots of the guide rails, a filter screen cleaning device comprises a cleaning component with a brush, a drive motor fixed on the cleaning component, a driving mechanism connected with the drive motor, a rack set arranged at the left side part and the right side part of the filter screen and a dust box arranged under the filter screen and used for collecting dust; a dust exchange device is arranged between the dust box and the filter screen; the drive motor connected with the driving mechanism drives the cleaning component to slide up and down along the rack set adhering to the filter screen in order to enable the brush to clean dust down; the cleaning component slides down to pass through the dust exchange device and cleans the dust down in the dust exchange device, and then the dust exchange device pours the dust to the dust box. The self-cleaning device for air conditioner filter screen saves time and labor and can be cleaned at any time without disassembling.

Owner:HAIER GRP CORP +1

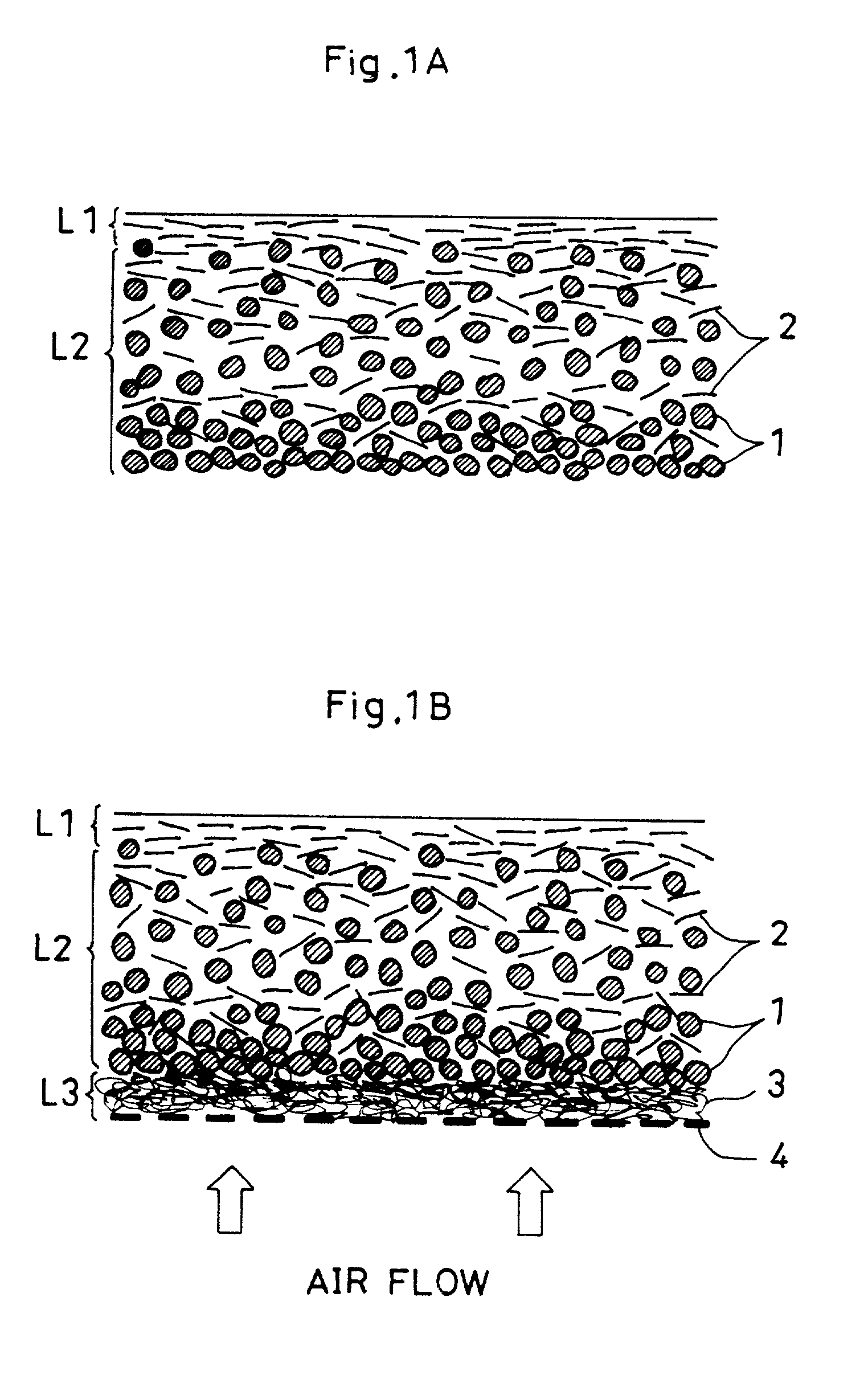

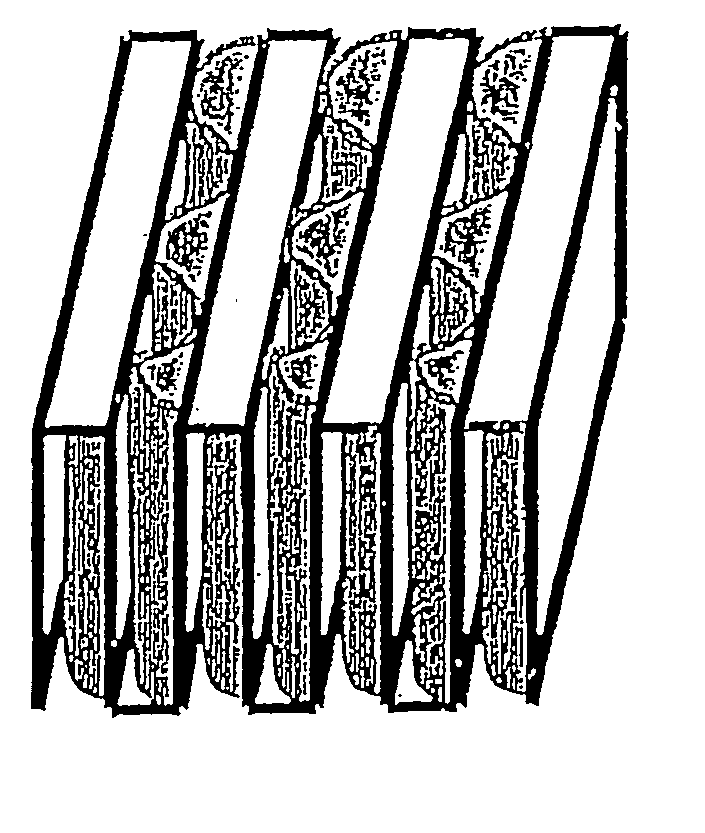

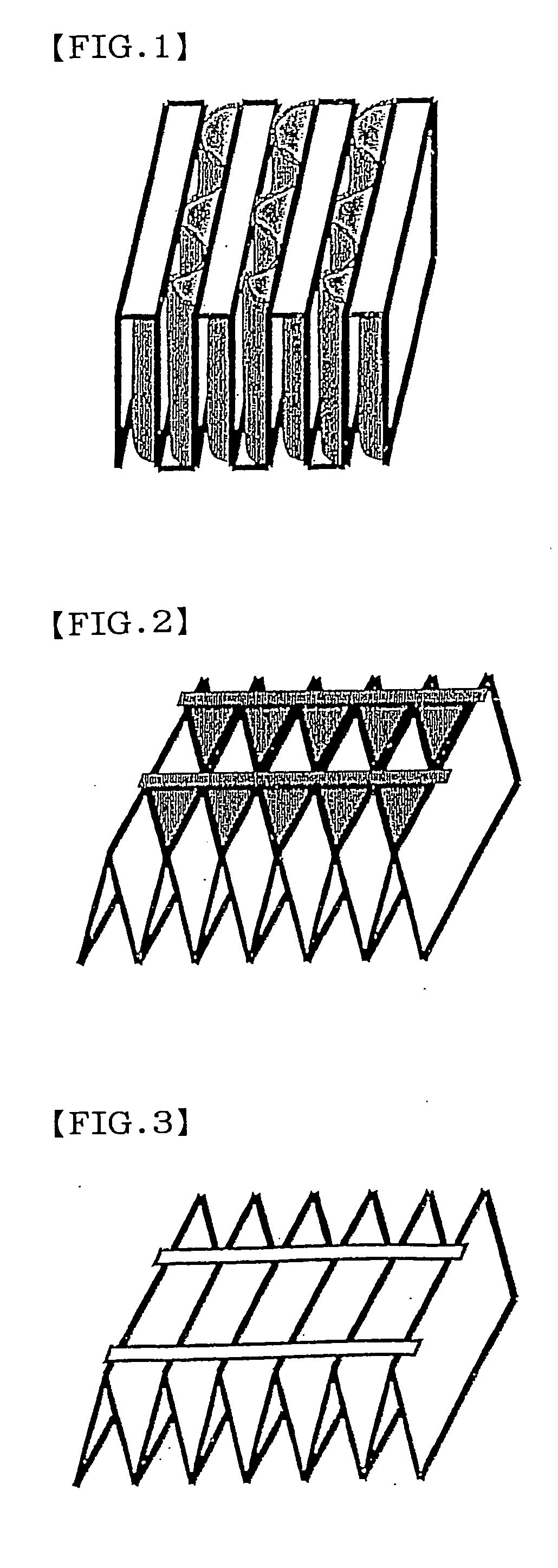

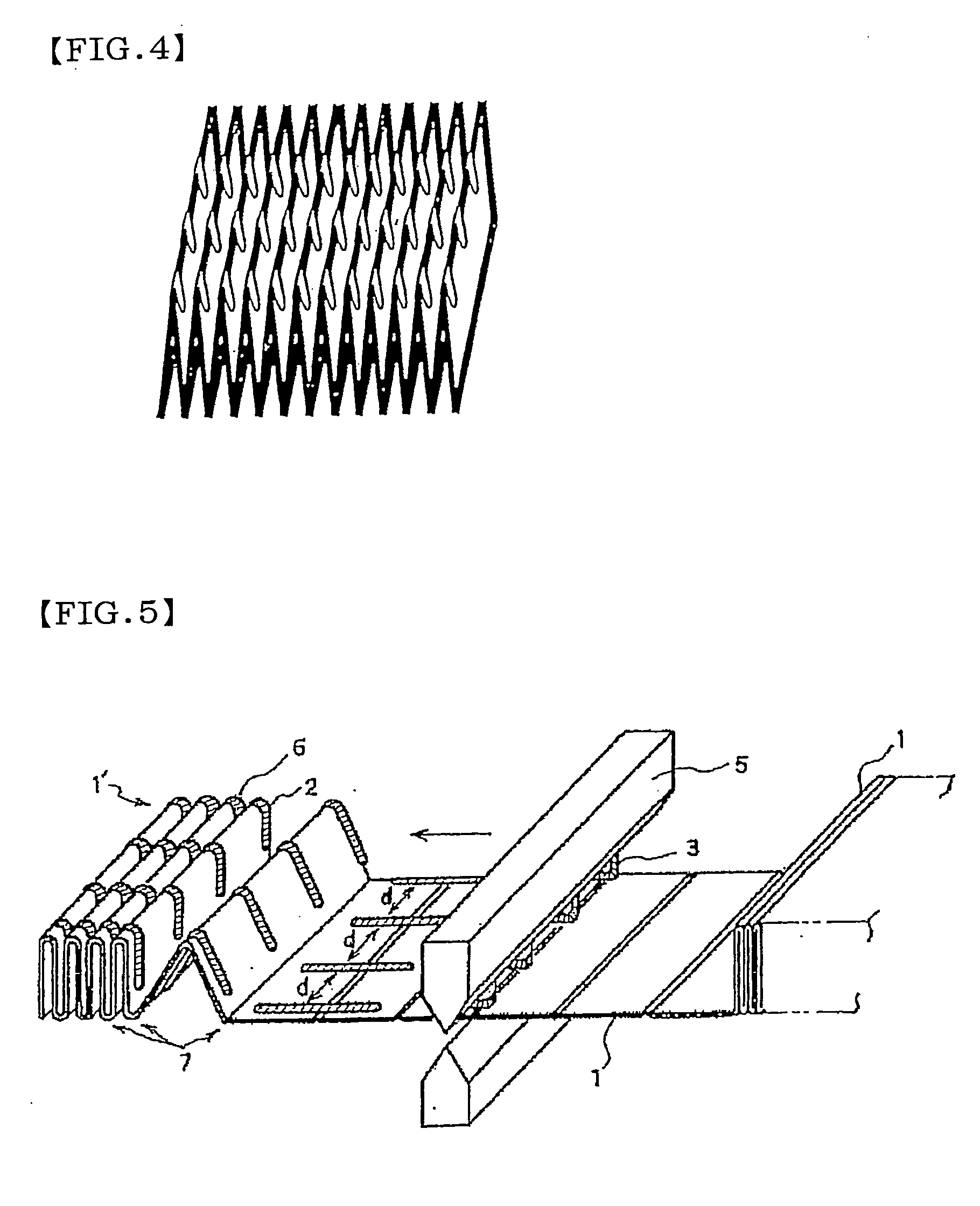

Gas adsorption sheet and air-purifying filter

InactiveUS20030207635A1Improve breathabilityImprove dust removal effectWarp knittingPaper/cardboardFiberSlurry

The gas adsorption sheet of the present invention has a granular activated carbon-containing sheet comprising a granular activated carbon having an average particle diameter of 60 to 600 mum, a supporting fiber for fixing the granular activated carbon in contact with it, and an adhesive fiber which mainly contributes to shape retention. An air-purifying filter of the present invention is obtained by forming the gas adsorption sheet into a shape of pleats or wave. A method for producing a gas adsorption sheet of the present invention comprises a step of forming a granular activated carbon-containing sheet by using an aqueous slurry containing a granular activated carbon, a supporting fiber and a water-swelling adhesive fiber.

Owner:TOYO TOYOBO CO LTD

Cleaner system

InactiveUS7779504B2Improved connecting position and structureImprove dust removal effectEngine sealsSpray nozzlesDocking stationElectric power

Owner:SAMSUNG ELECTRONICS CO LTD

High-effective dust-removing coke quenching tower

ActiveCN101037603AEasy dust removal effectGuaranteed dust removal performanceCoke quenchingSingle stageTower

The invention relates to a highly effective dust removal coke quenching machine, which includes a coke quenching injection pipe, a washing and cooling device, and a dust removal device. The dust removal device, which is disposed single-stage or two-stage, includes a structural framework, a dust removal plate, a dust removal pipe and nozzles, wherein the dust removal plate, which is constituted of a heterotypic baffle sheet folded with a certain angle and a dust removal plate support, is disposed on the structural framework and forms angle of 45-60 DEG with horizontal plane; the dust removal pipe is equably equipped with a plurality of nozzles and is arranged parallel with the dust removal plate. Dust content of stream generated at coke quenching process is greatly reduced by water fog washing, cooling, gravitational settling and purifying of baffle plate type dust removal device, amount of coking powder discharged into air of per ton coke is lower than 50g. Moreover, the baffle plate employs industrial plastic, thereby possessing advantages of corrosion resistance, high strength, aging resistance, good dust removal effect, convenient installation and maintance, and easy cleaning.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

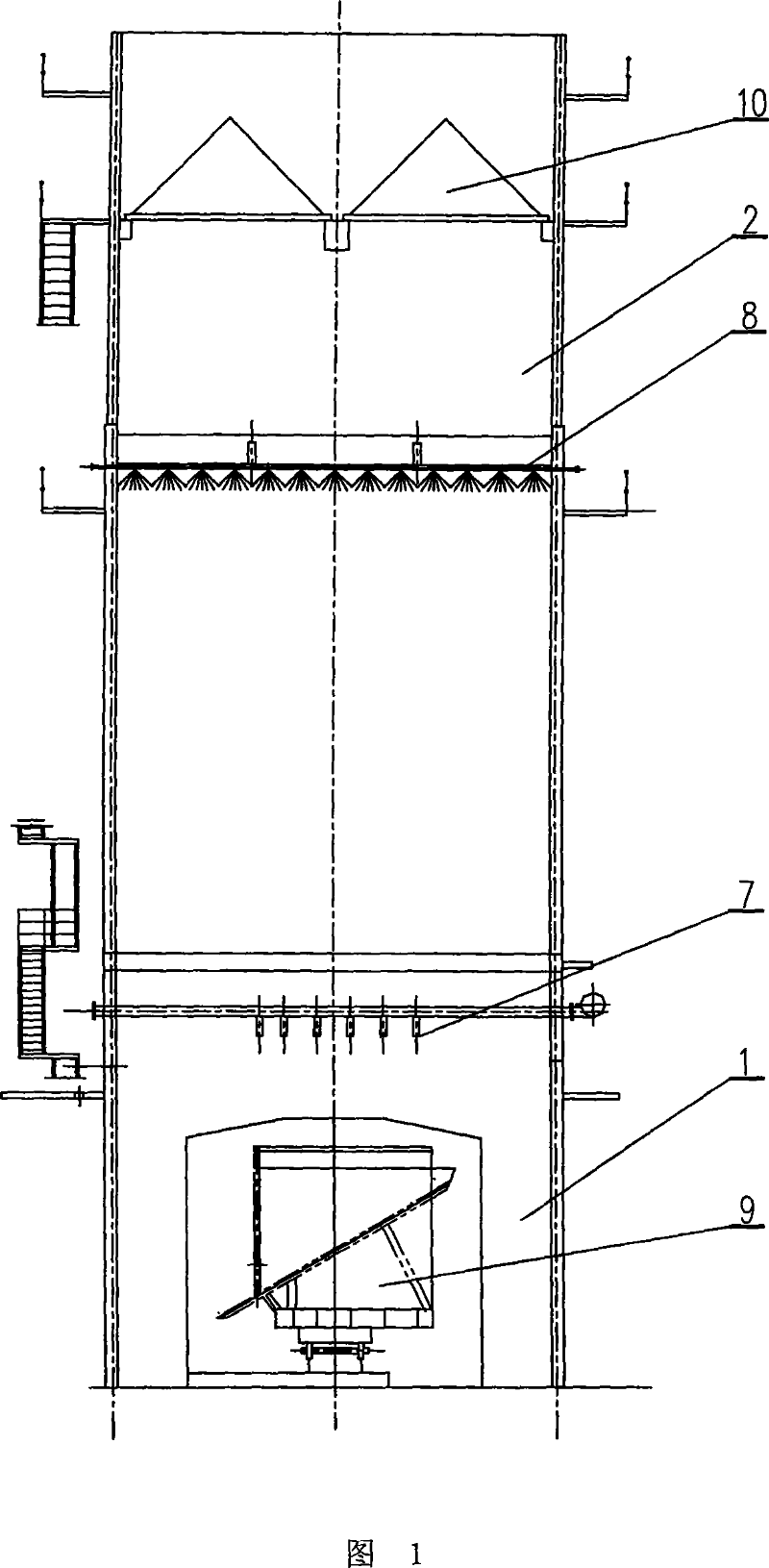

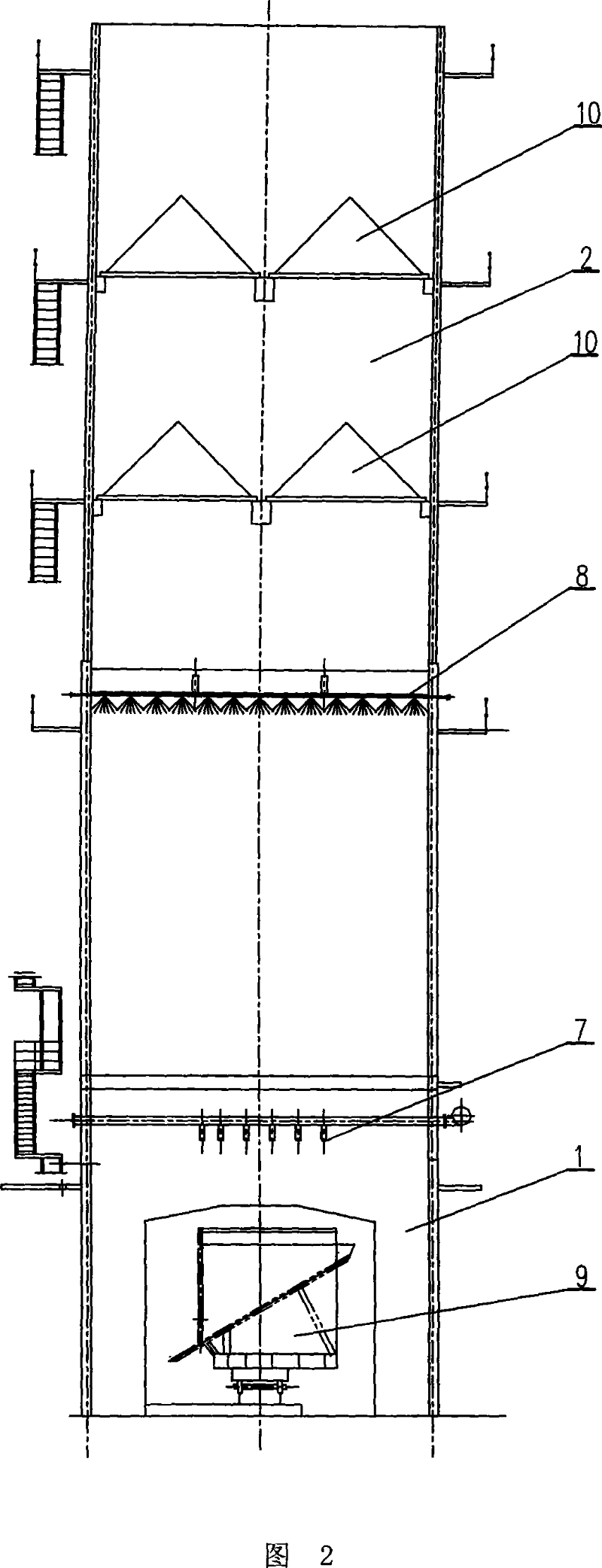

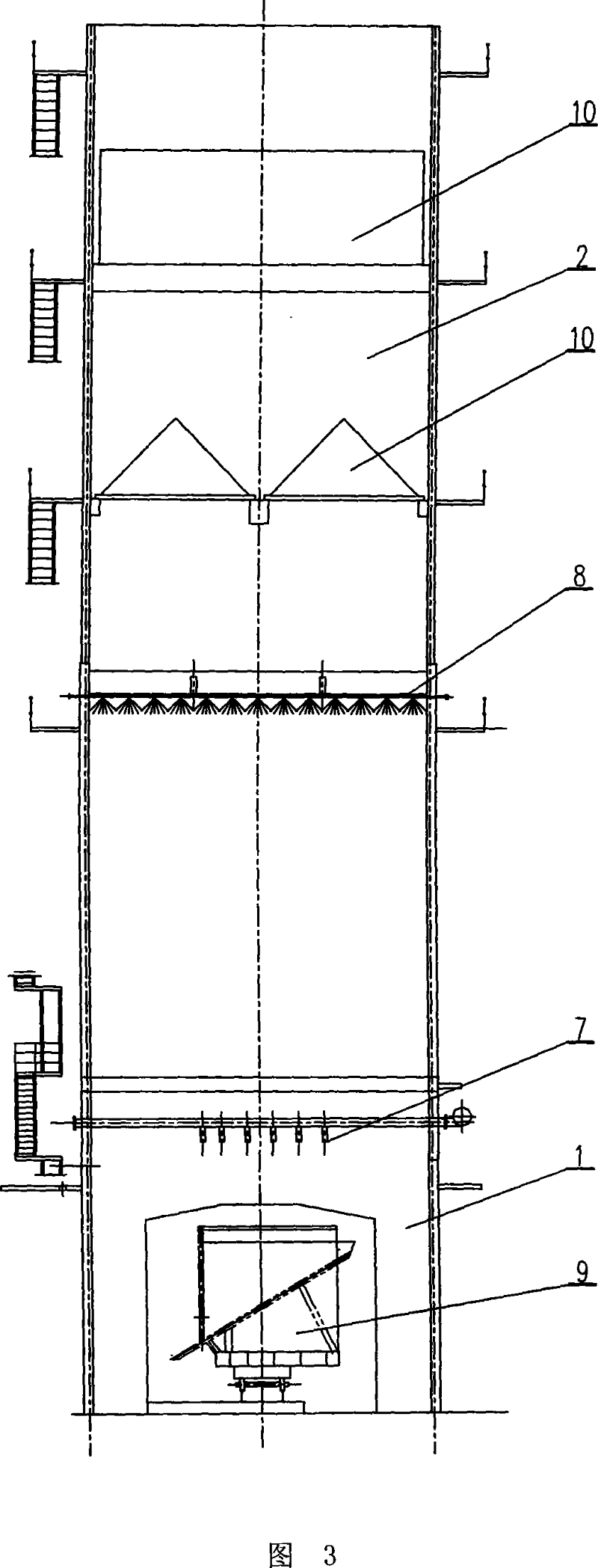

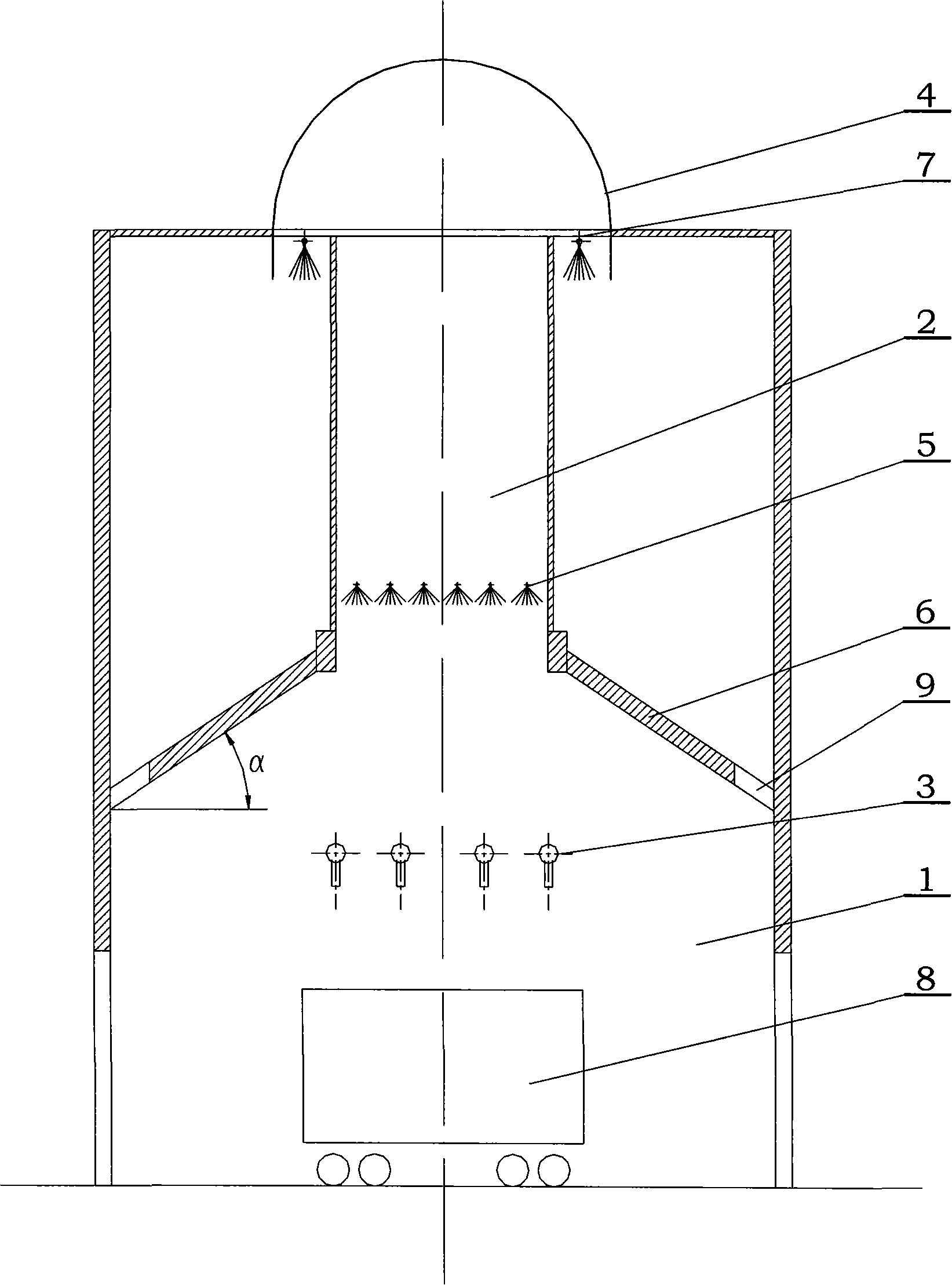

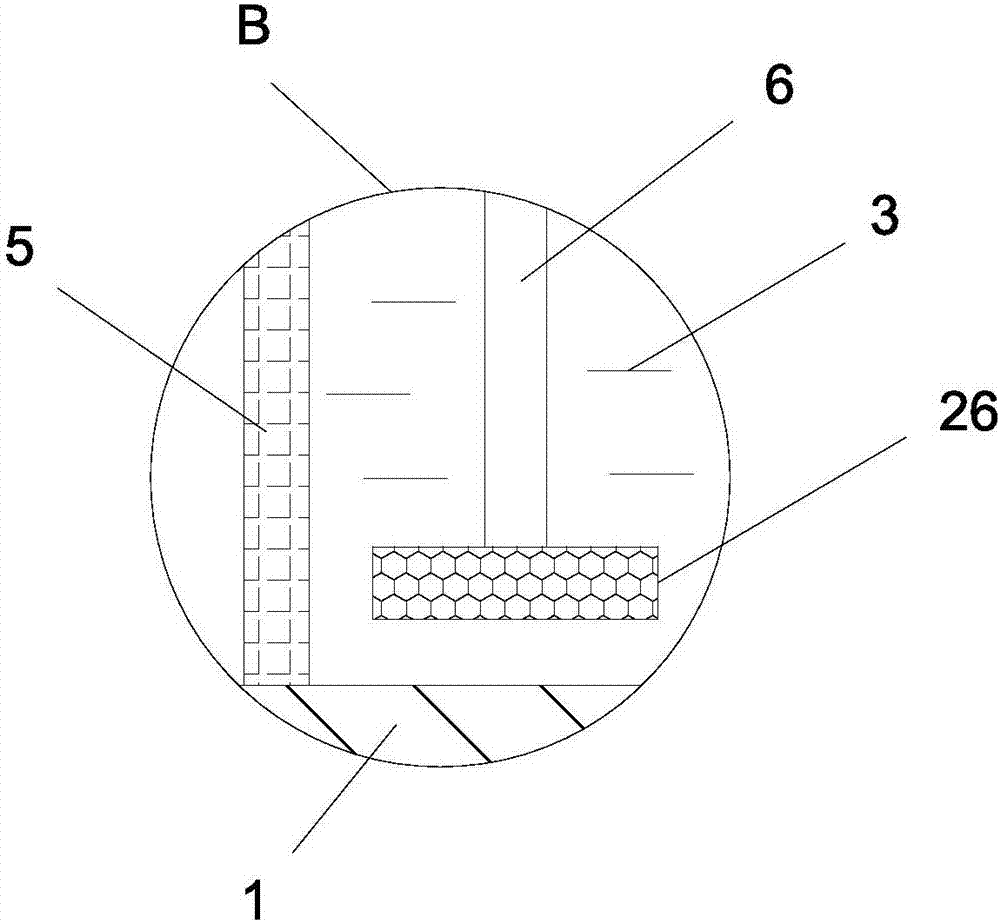

Dome type dust removing coke quenching machine

The invention relates to a dome-like dedusting coke quenching tower, which comprises the following parts: a coke quenching procedure at the bottom and a deduesting procedure at the top, wherein the coke quenching procedure is equipped with a coke quenching injecting pipe; the dedusting procedure is divided into three lattices; the bottom of two side lattices sealed by a tipping plate; the bottom of the tipping plate is equipped with blow-off hole; the included angle alpha of the tipping plate and the horizontal surface is 10-75 degree; the top of the coke quenching injecting pipe and the middle lattice entrance of the dedusting procedure are equipped with a plurality of washing and cooling devices; the top of washing and cooling devices and the top of the coke quenching tower are equipped with dome-like dedusting device which covers the middle lattice and two side lattices of the coke quenching tower dedusting procedure. The invention reduces the dust content after washing the polluting vapor with the water fog, cooling the polluting vapor, settling the polluting vapor gravitively and changing the direction of the gas flowing, which reduces the water consumption.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

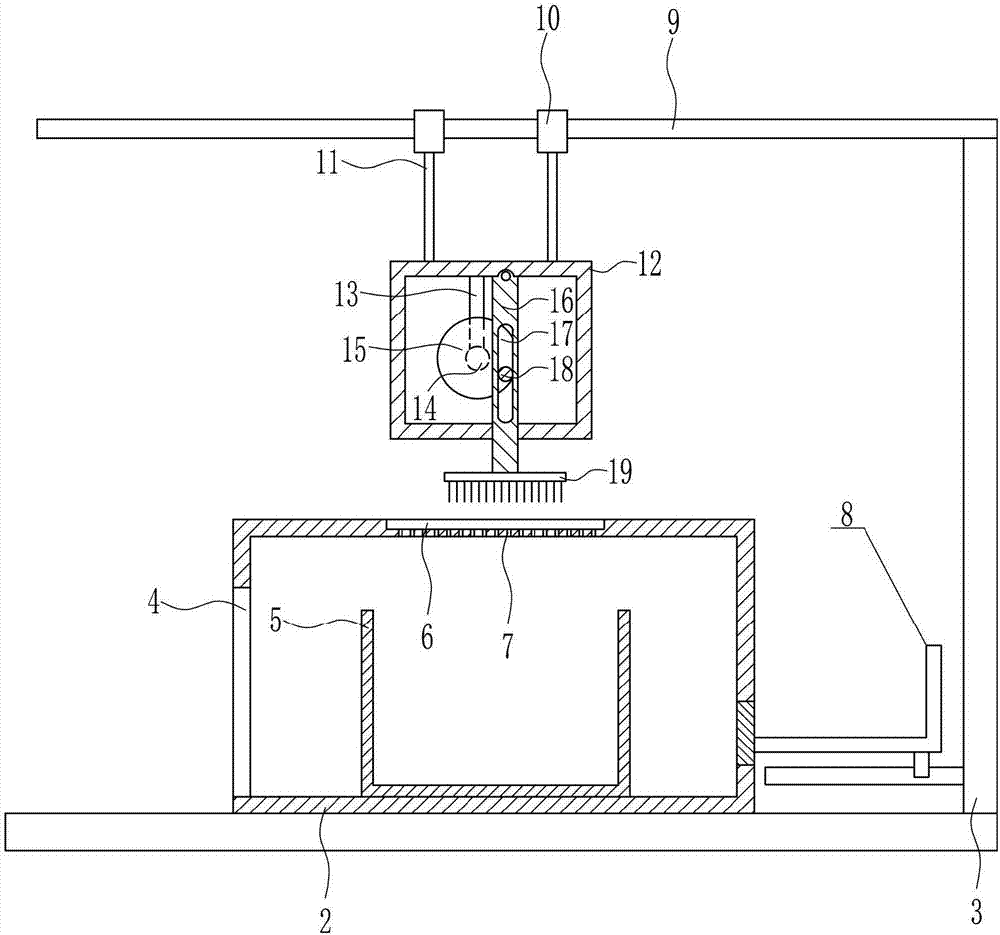

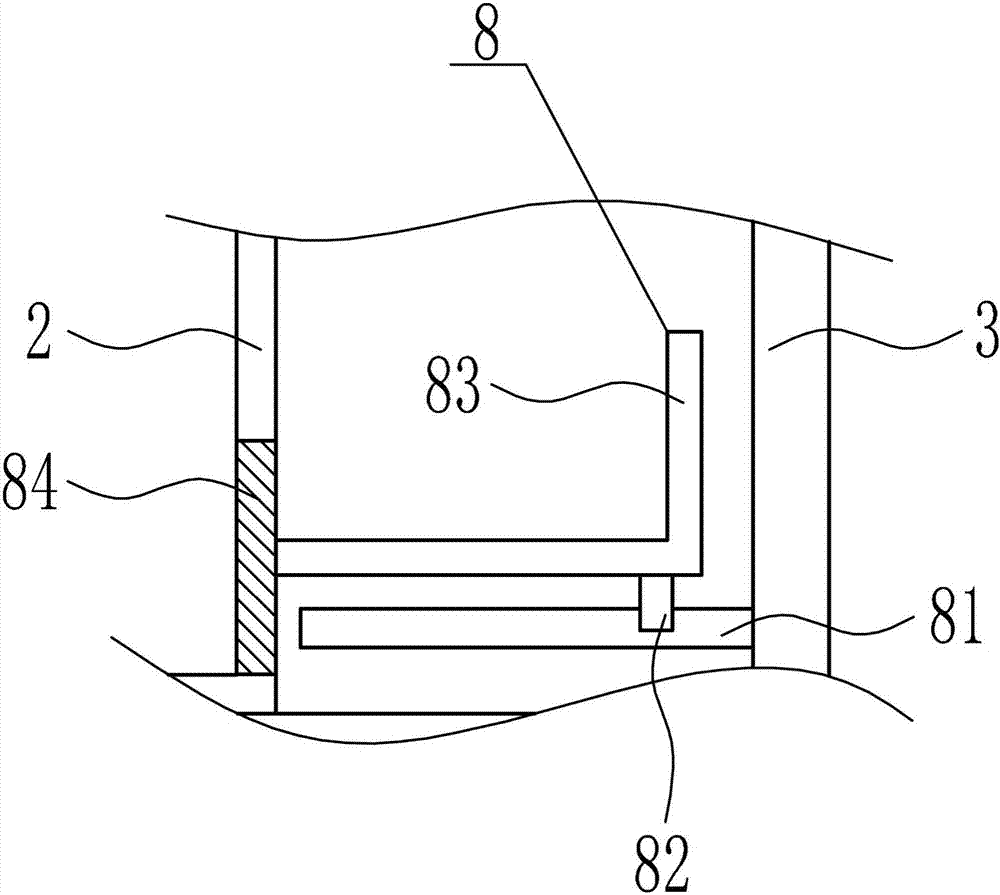

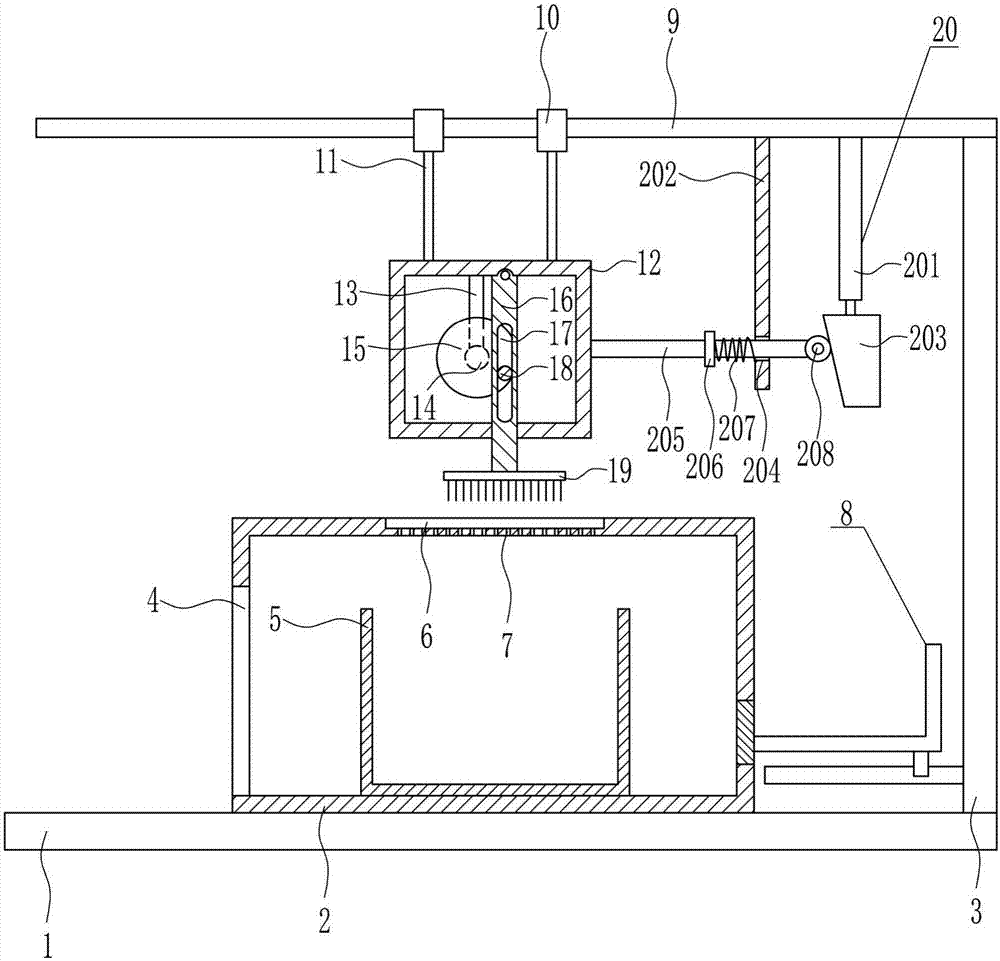

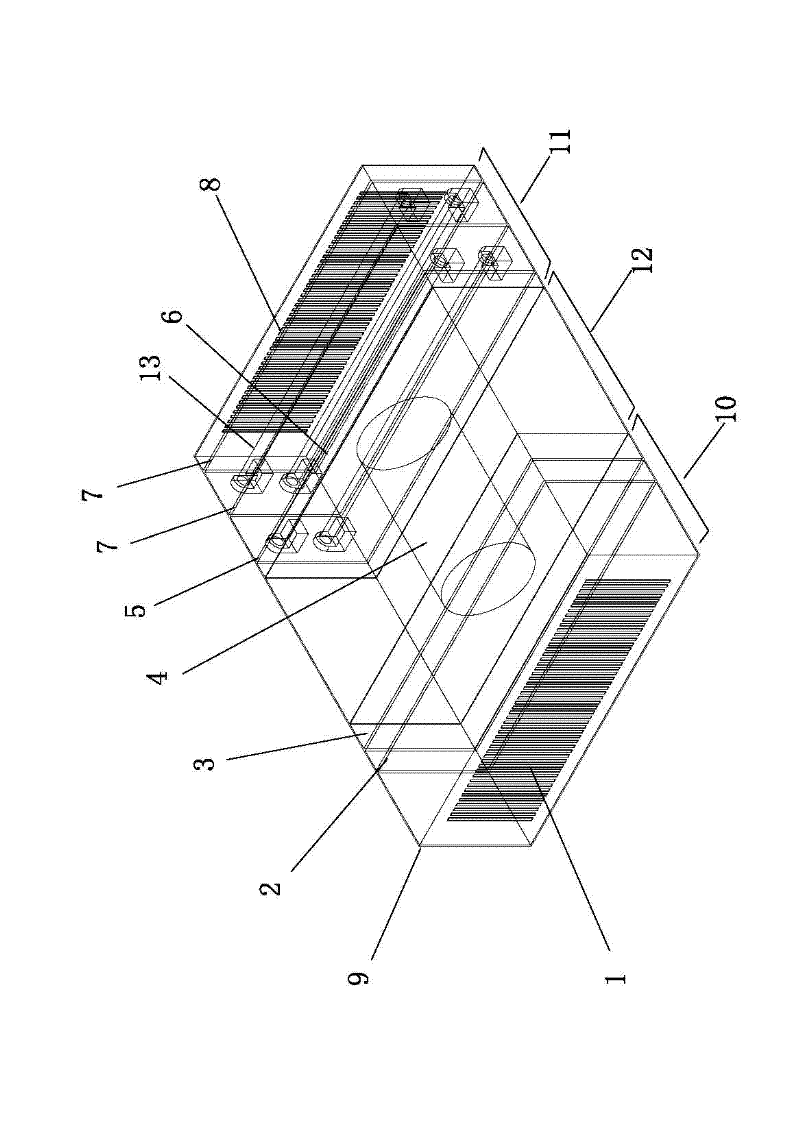

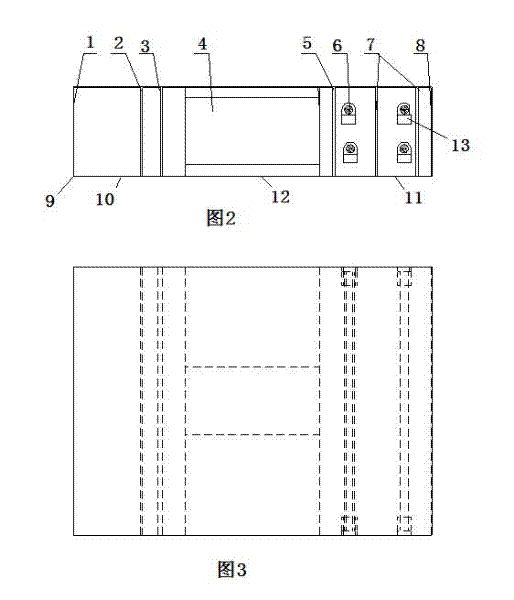

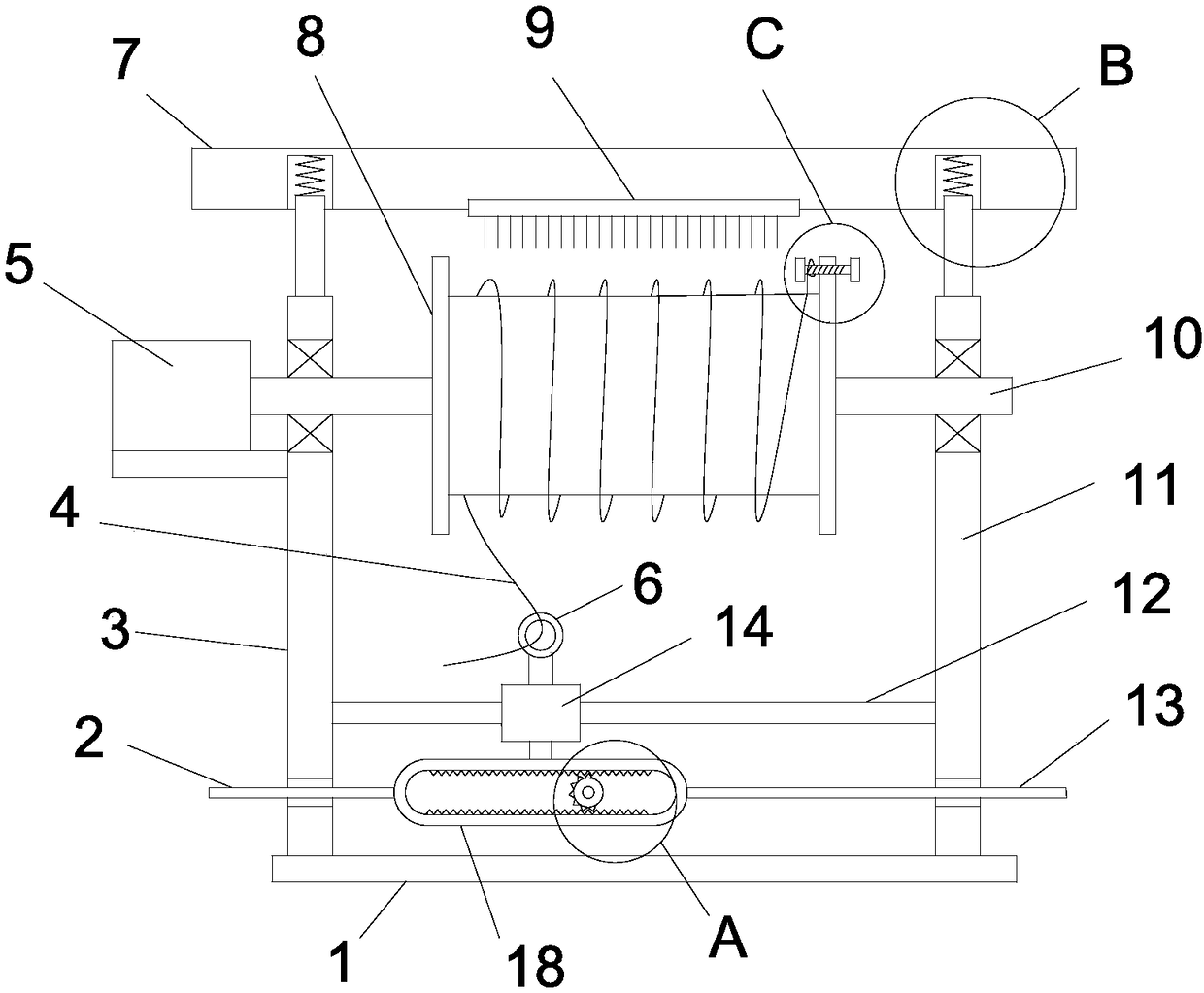

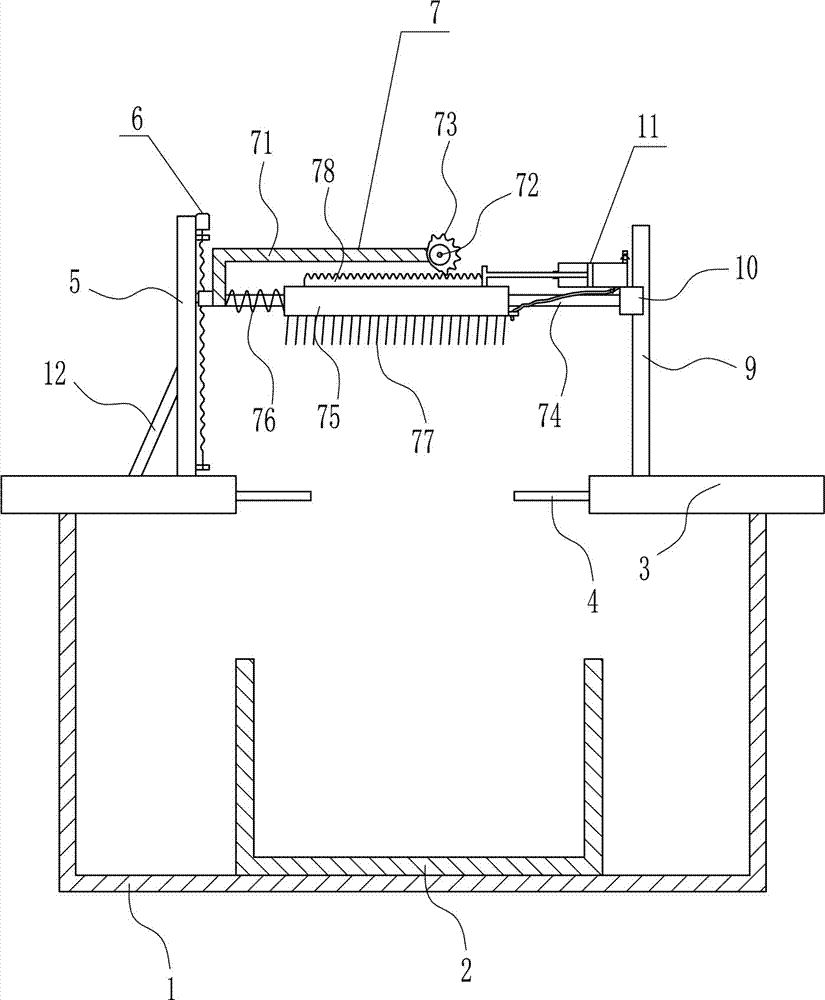

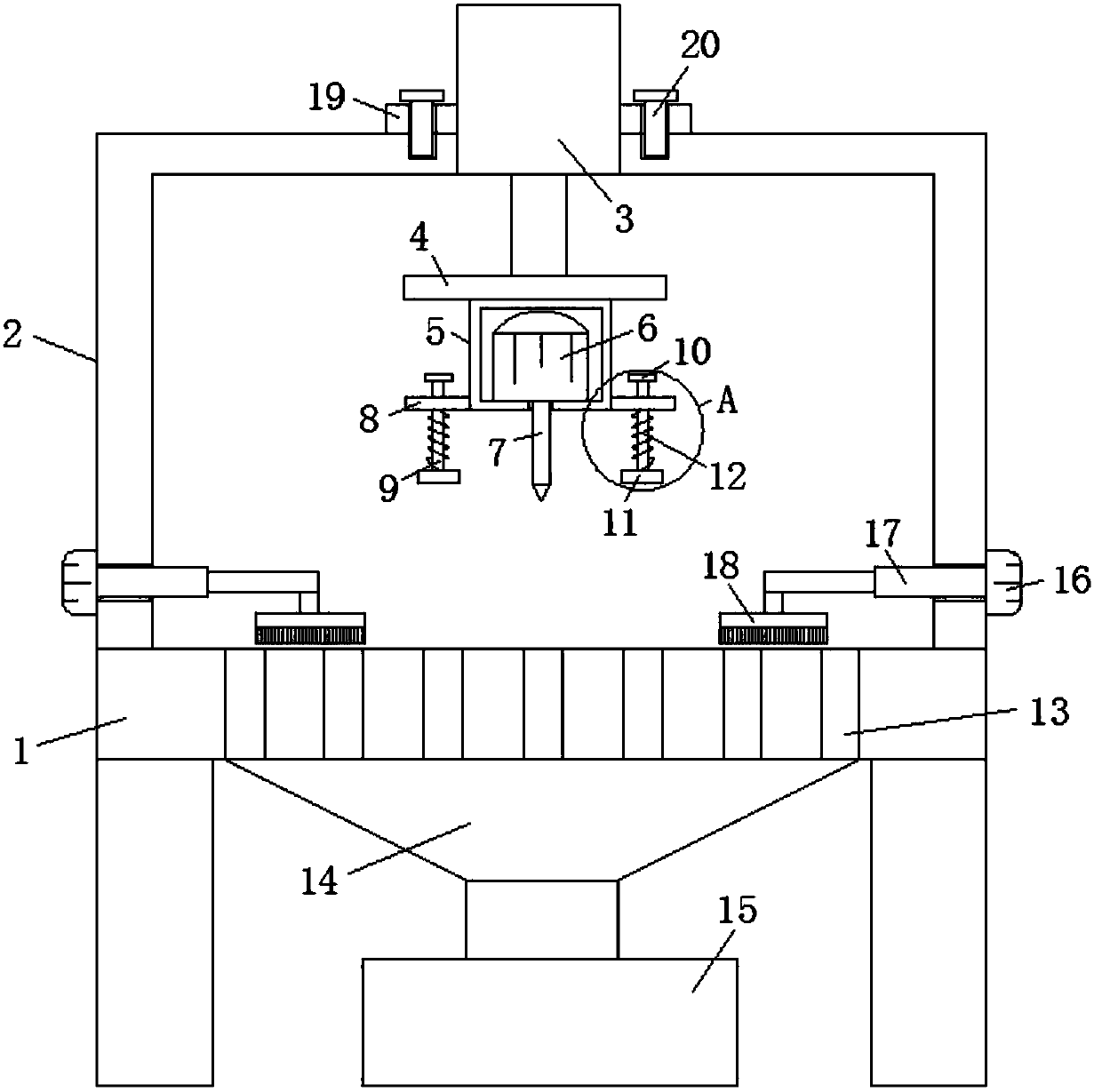

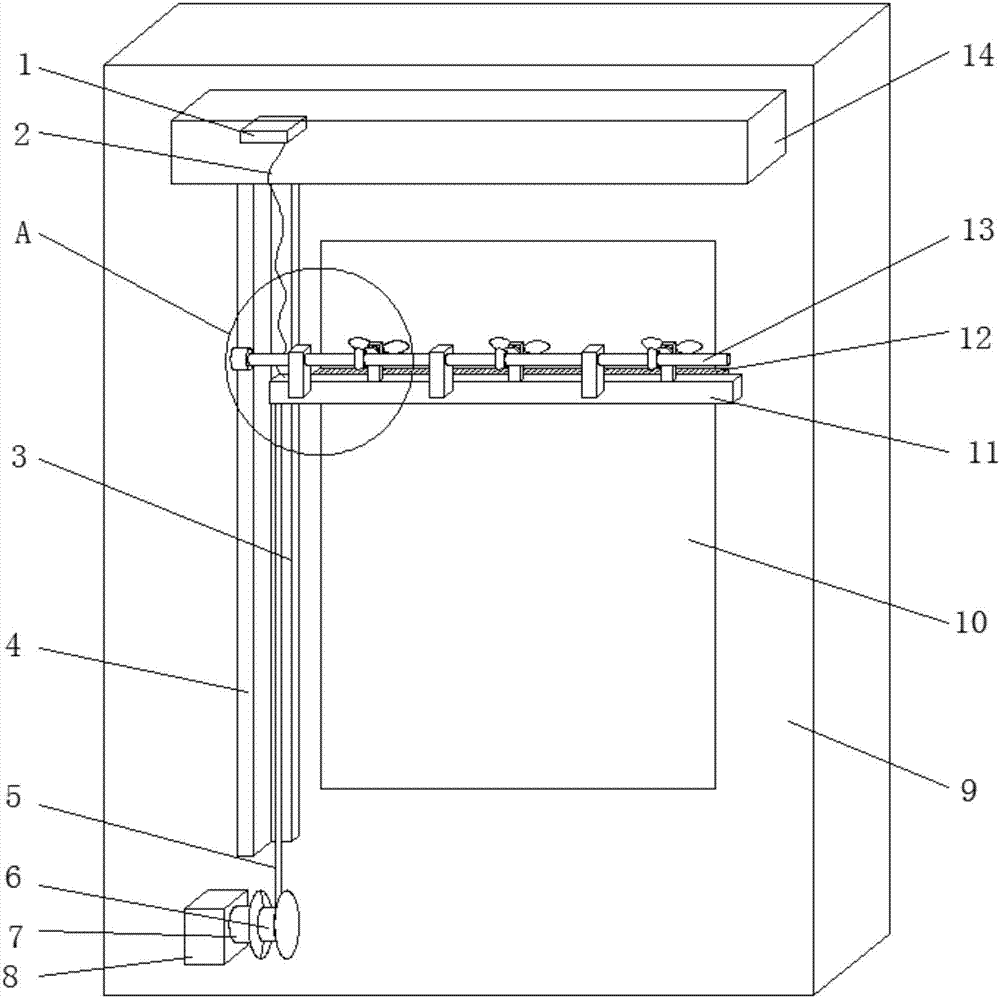

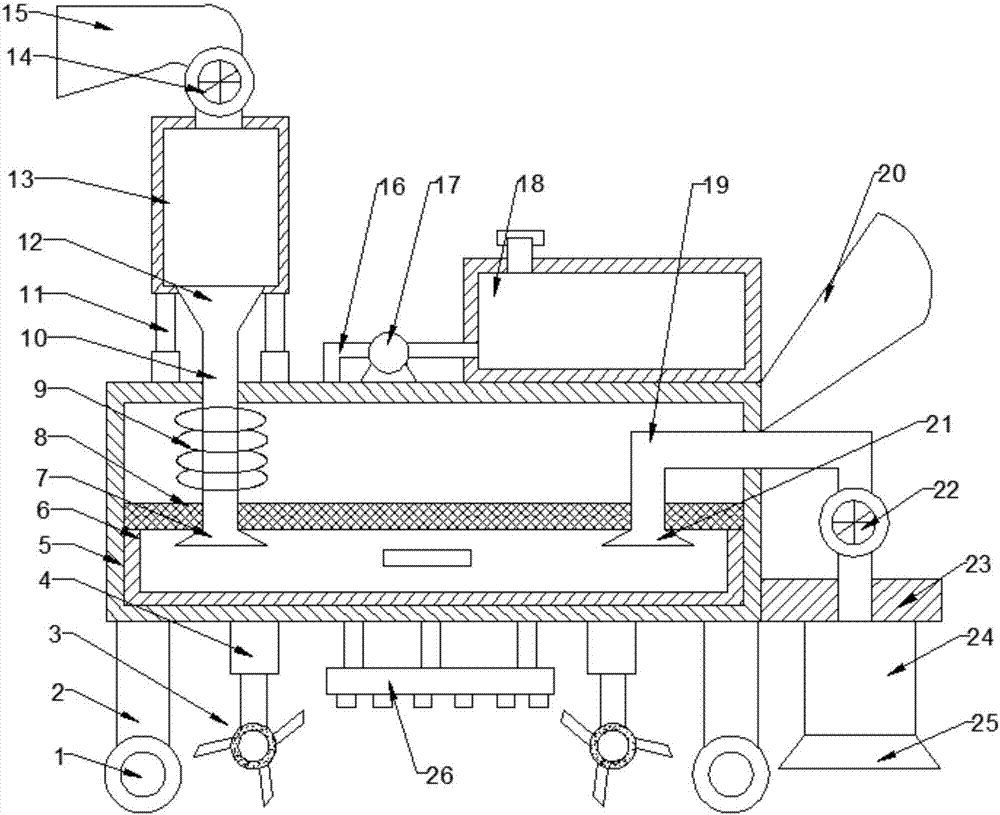

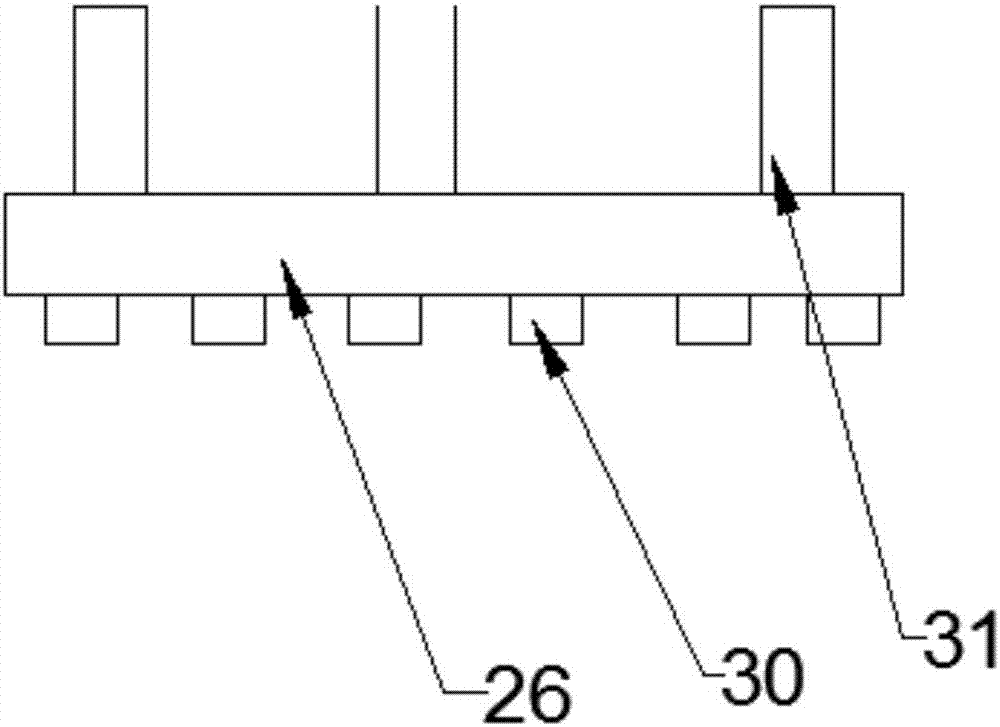

Special PCB circuit board dust removing equipment for electronic scientific and technological development

InactiveCN106944377AImprove dust removal effectEasy to operateCleaning using toolsCleaning using gasesElectrical and Electronics engineering

The invention belongs to the technical field of electronic scientific and technological development, and in particular, relates to special PCB circuit board dust removing equipment for electronic scientific and technological development. The technical problem to be solved by the invention is to provide the special PCB circuit board dust removing equipment for electronic scientific and technological development with good dust removing effect, simple operation and time and labor saving. In order to solve the technical problem, the invention provides the special PCB circuit board dust removing equipment for electronic scientific and technological development. The equipment comprises a baseplate, a box body, a bracket, a collecting frame, a pushing device, a slide rod, a slide sleeve, a first connecting rod, a frame body, a mounting plate, a motor, a turntable, a swing rod and the like; the box body and the bracket are arranged at the top of the baseplate; the box body is positioned on the left side of the bracket; the box body and the bracket are connected with the top of the baseplate through a bolt connecting mode; and an opening is formed in the lower part of the left side of the box body. The equipment removes dust of a PCB circuit board by using swing and left-right movement of a brush; and meanwhile, an air blowing device blows away dust on the PCB circuit board.

Owner:黄思珍

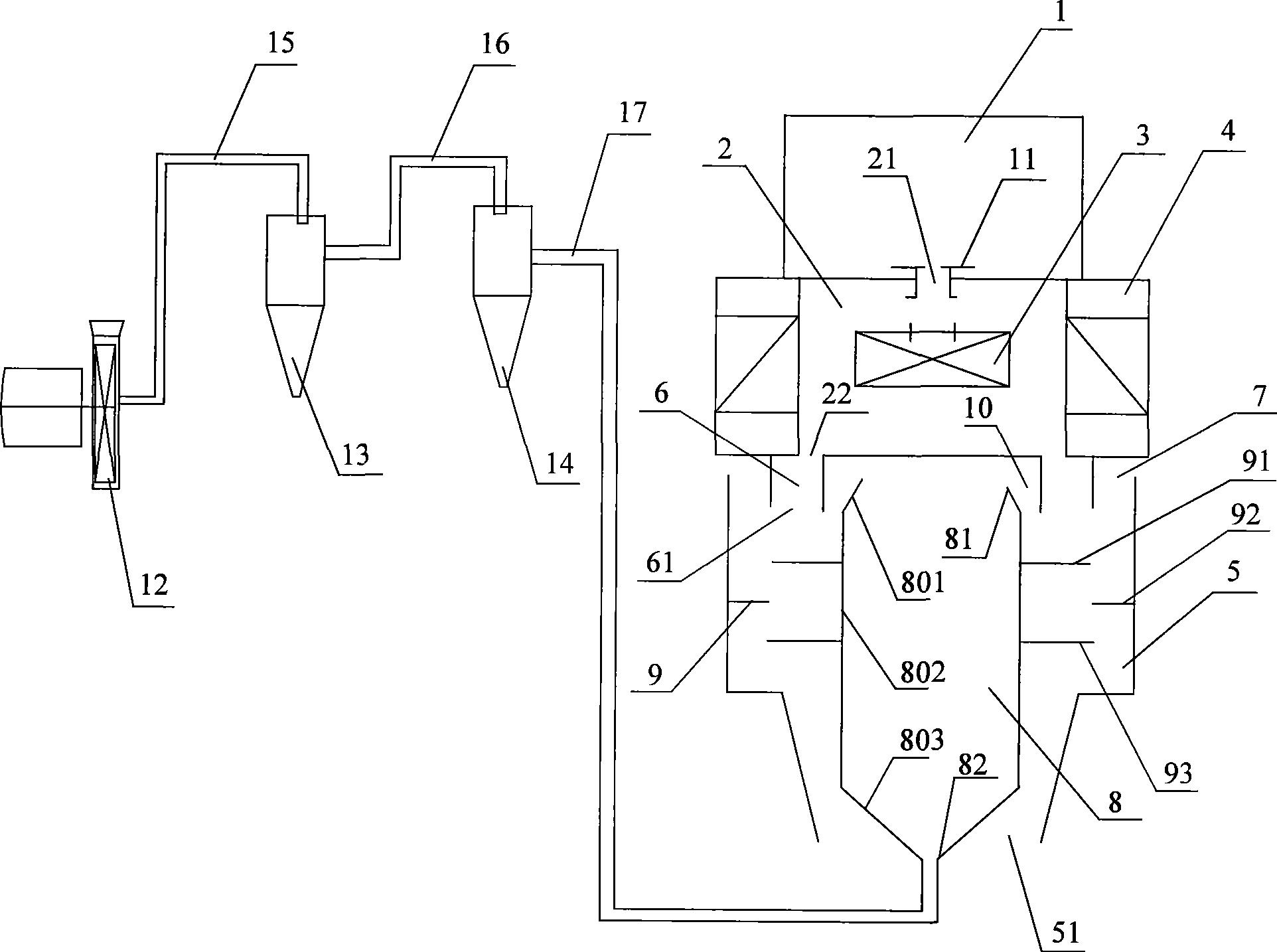

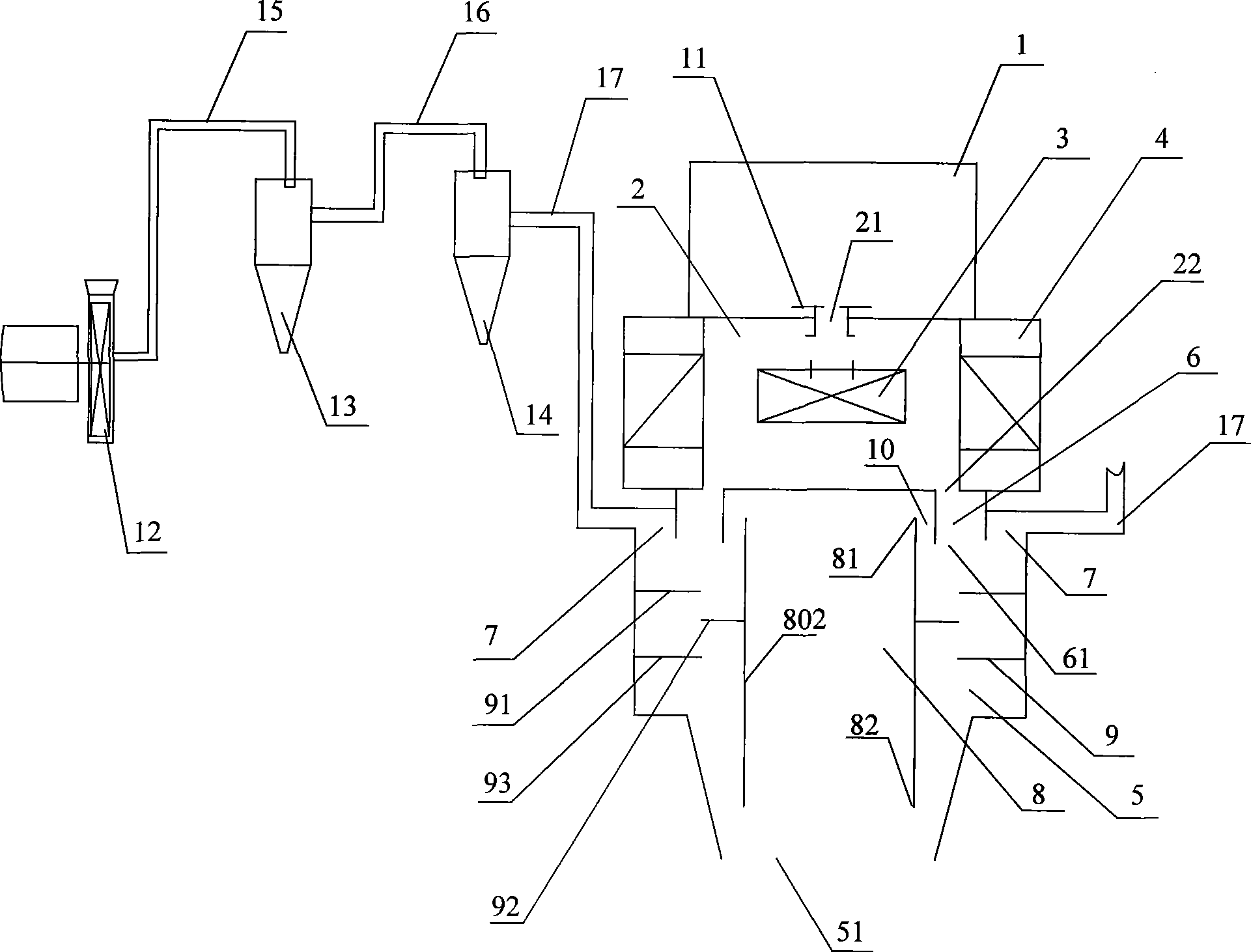

Dry-type sand making method and dry-type sand making machine thereof

The invention discloses a dry sand maker which comprises a hollow crushing cavity (2). A hollow dust removal cavity (5) is arranged under the hollow crushing cavity (2); the upper end of a feeding channel (6) is hermetically connected with a feeding mouth (22) and the lower end (61) thereof is positioned in the dust removal cavity (5) on which an air vent (7) is also arranged; an air duct (8) is arranged in the dust removal cavity (5); the lower end (61) of the feeding channel (6) is staggered with the upper end (81) of the air duct (8) in the horizontal direction; the bottom surface of the dust removal cavity (5) is provided with an outlet (51); a dust absorption component is hermetically connected with the lower end (82) of the air duct (8) or the air vent (7) after passing through the outlet (51). The invention also provides a method for drying sand making simultaneously. By adopting the dry sand maker, the drying sand making can have the advantages of high production efficiency and low environmental pollution.

Owner:吴核明

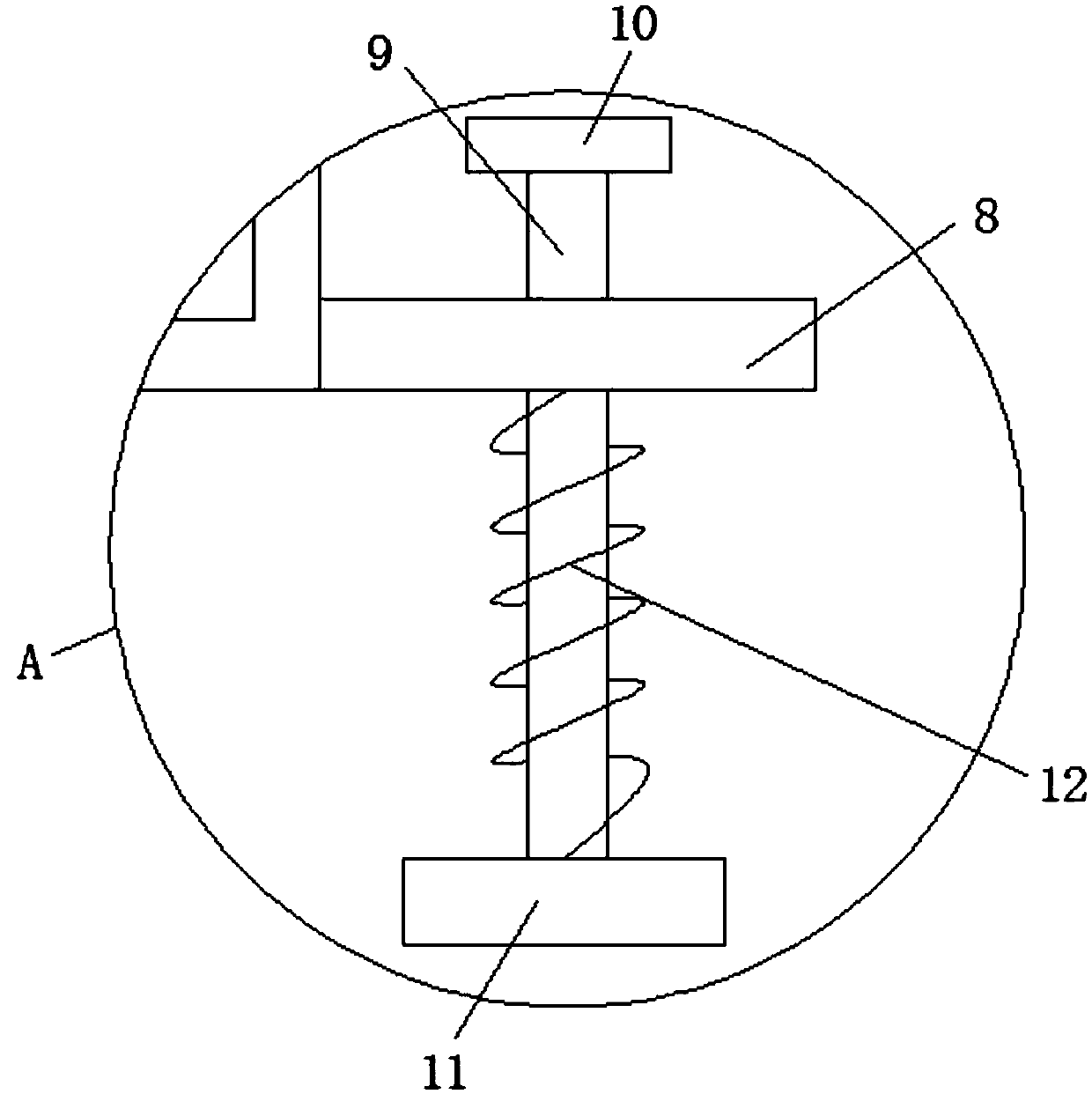

Boiler fuel gas dedusting purifying device

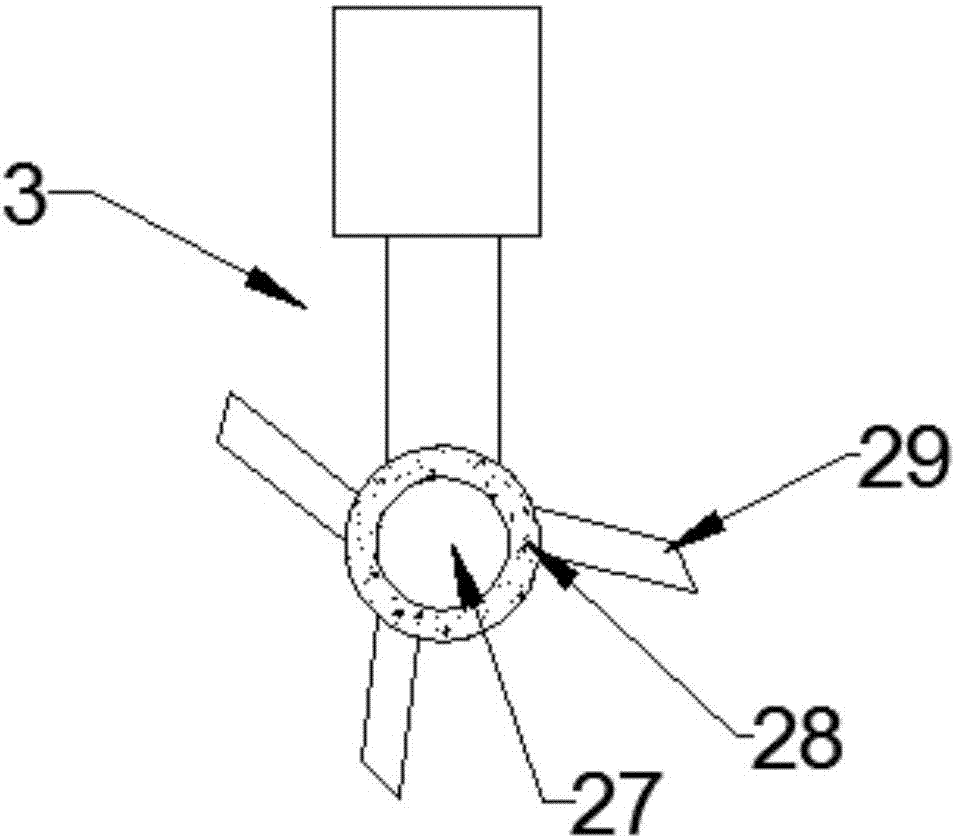

InactiveCN107096361AGood dust removal and filtration effectSpeed up the flowGas treatmentDispersed particle filtrationDrive shaftFlue gas

The invention discloses a boiler fuel gas dedusting purifying device. The boiler fuel gas dedusting purifying device comprises a dedusting chamber; the left side of the dedusting chamber is fixedly provided with an extension board; the extension board is fixedly provided with a driving motor; the driving motor is fixedly provided with a driving shaft; the right end of the driving shaft is fixedly provided with a driving bevel gear; the upper end of a driven shaft is fixedly provided with a driven bevel gear; the driven shaft is fixedly provided with a plurality of blades; the blades are uniformly fixedly arranged on the external surface of the driven shaft along the circumferential direction; two slide bars are arranged on the dedusting chamber; the upper side wall of the dedusting chamber is penetrated by the two slide bars; each of the slide bars is provided with a brushing board; the right side surface of each brushing board is fixedly provided with a hairbrush; the top of the dedusting chamber is provided with a desulphurization tank; one end of a conveyer pipe far from an air pump is provided with an aeration disc; the top of the desulphurization tank is provided with an exhaust pipe. The boiler fuel gas dedusting purifying device is excellent in dedusting filtering effect; flue gas is introduced into the aeration disc for aeration processing, so that sulfides in flue gas are absorbed by a desulfurizer completely, desulphurization effect is excellent; and environment protection emission is realized at last.

Owner:张炳强

Purification treatment device for PM2.5-level dust collecting and carried bacterium killing

InactiveCN102410586AImprove the level of environmental safetySimple structureDispersed particle filtrationLighting and heating apparatusPublic placeEngineering

The invention discloses a purification treatment device for PM2.5-level dust collecting and carried bacterium killing, which is characterized by comprising a box body (9), wherein the box body (9) is provided with a dust air inlet (1) and a purification air outlet (8), the box body (9) is separated into a dust removing unit (10), a power unit (12) and a purification unit (11) through baffle plates, the dust removing unit (10) and the purification unit (11) are provided with a plurality of slots; a more than PM10-level filter net (2), a PM2.5-level filter net (3), an active carbon and nano titanium dioxide modified photocatalyst filter net (5) and a PM2.5-level photocatalyst filter net (7) are inserted into the slots; and the purification unit (11) is also provided with an ultraviolet lamp bank. The purification treatment device has a simple structure, is convenient for manufacture, is beneficial to improvement of environment quality and environment safety level of public places, and has the advantages of good dust removing effect, low cost and convenience for replacement of the filter net.

Owner:江苏瑞丰科技实业有限公司

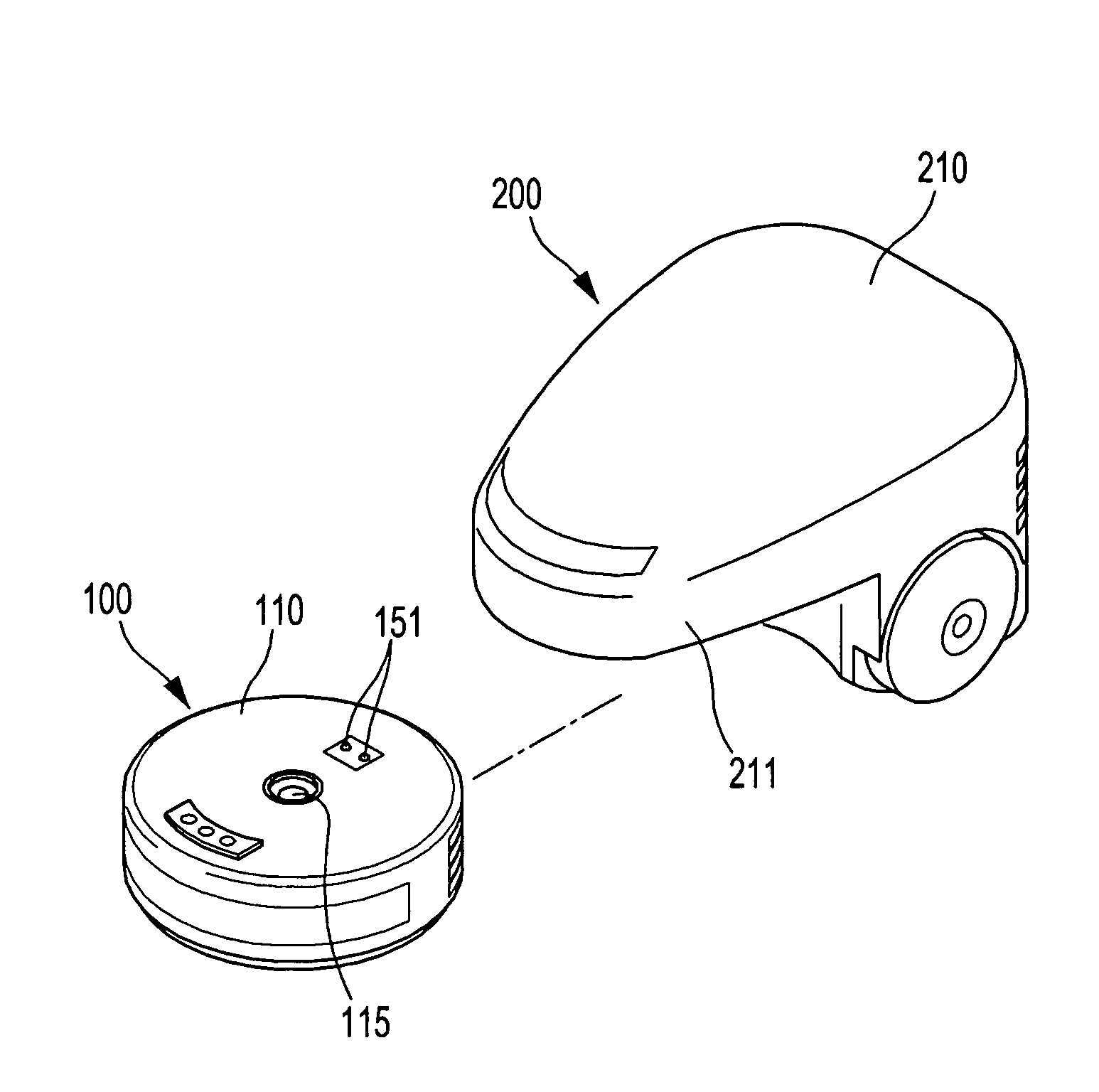

Robot cleaner, dust discharge station, and multi-stage vacuum cleaner

ActiveUS20130031744A1Eliminate needImprove dust removal effectCleaning machinesCleaning equipmentEngineeringVacuum cleaner

An objective of the invention is to eliminate the need of a frequent dust waste by the user and to provide efficient device for wasting the dust that has been collected in the robot cleaner. The invention provides a robot cleaner capable of discharging dust out to a dust discharge station, wherein the robot cleaner is capable of moving autonomously to collect dust, the robot cleaner comprising: a dust container for storing dust; a dust inlet for collecting dust into the dust container; and an opening and closing mechanism of the dust container, provided at a bottom surface of the robot cleaner, for discharging dust collected in the dust container.

Owner:LIFE LABO

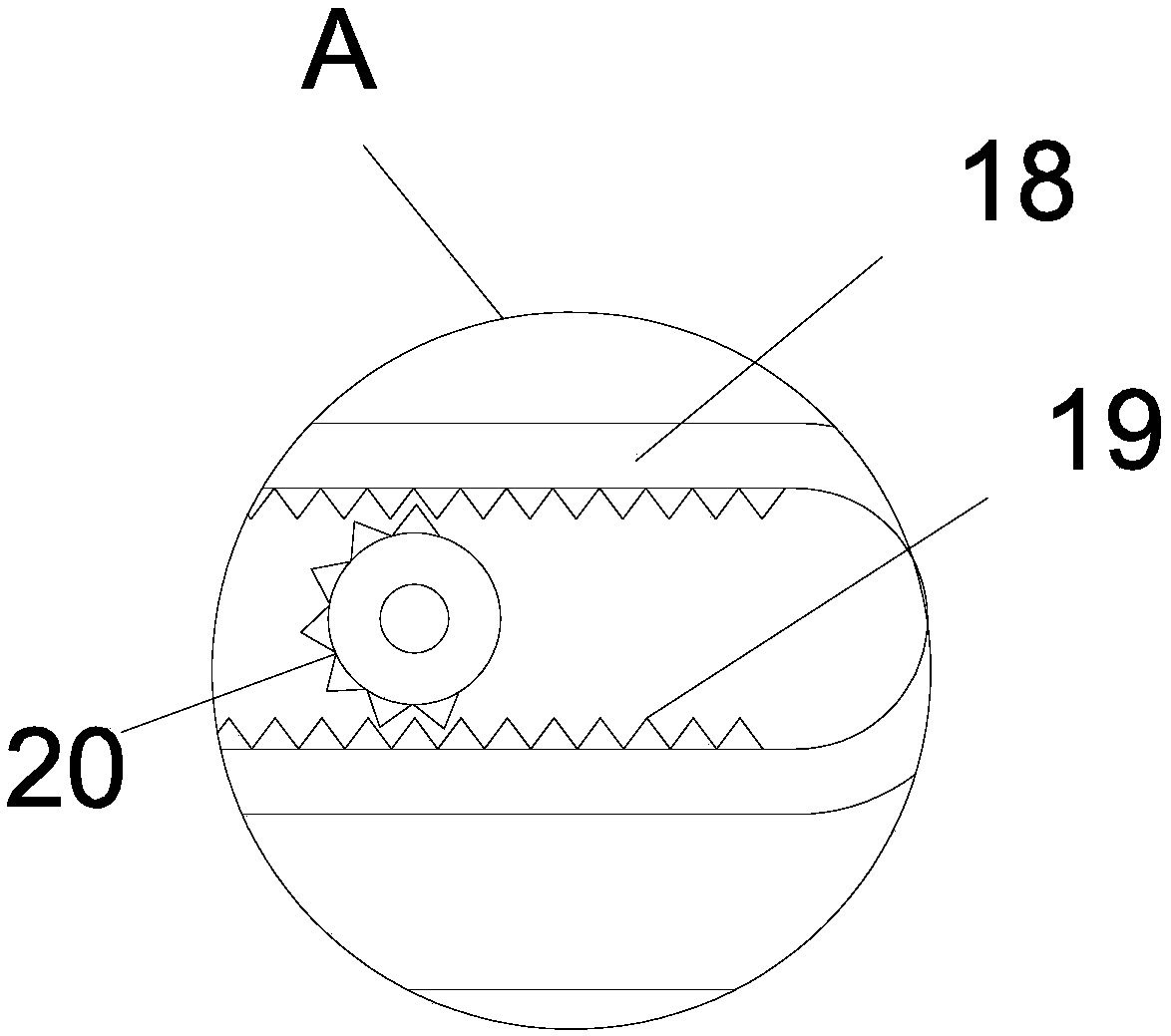

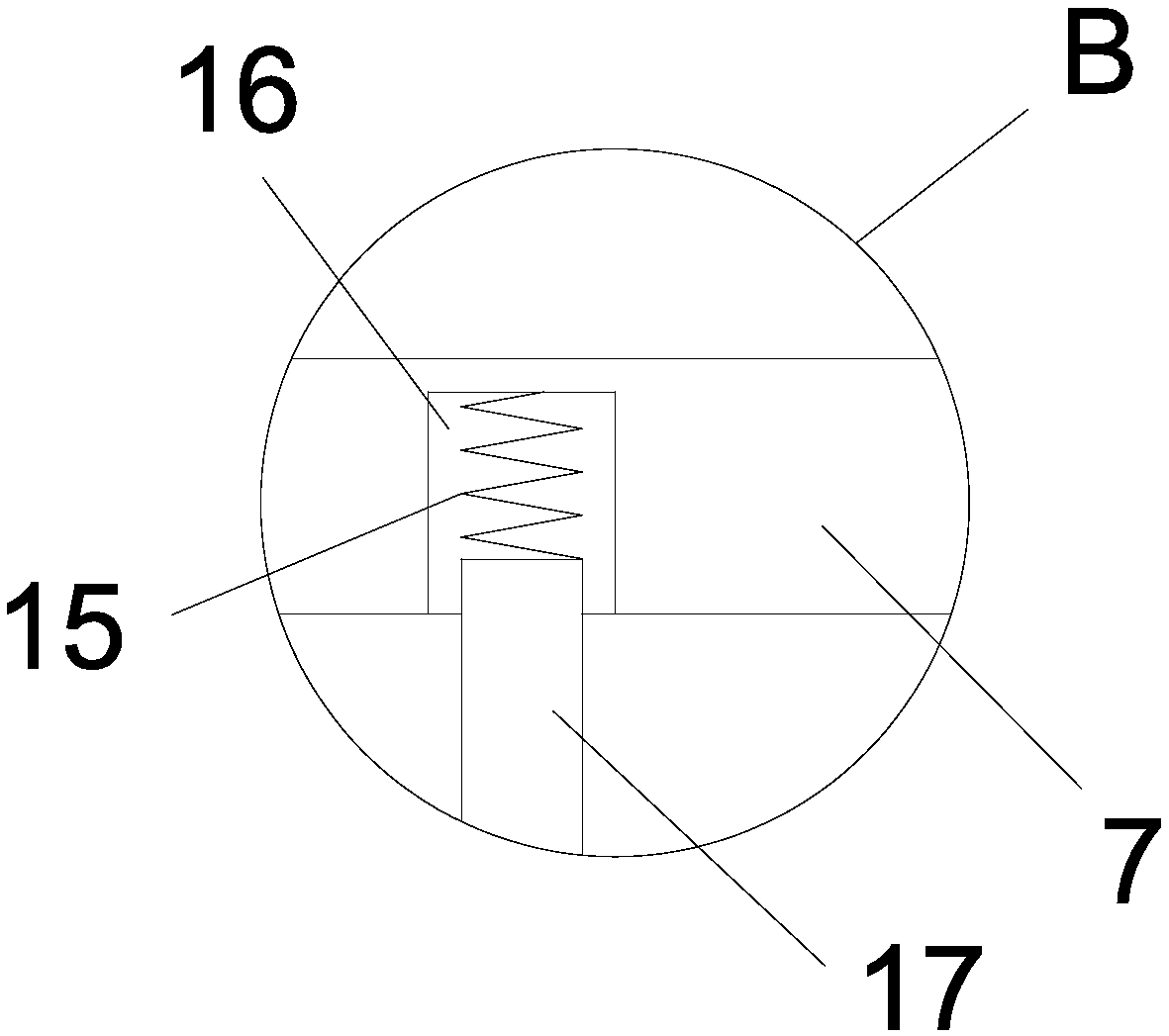

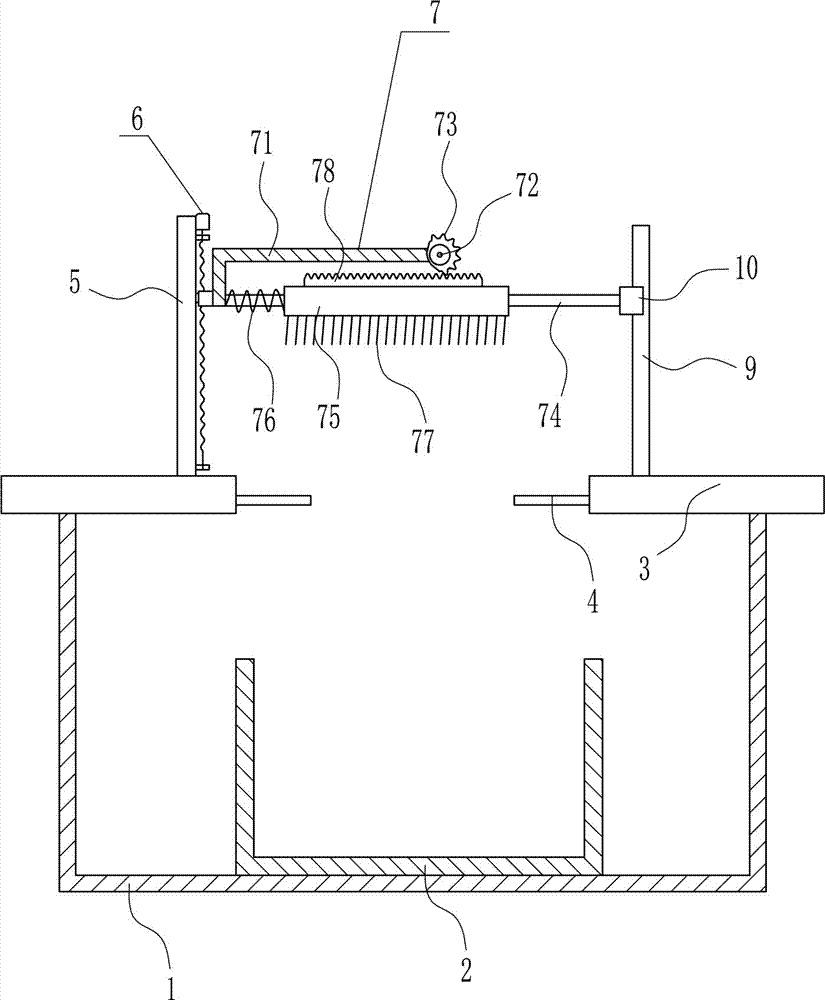

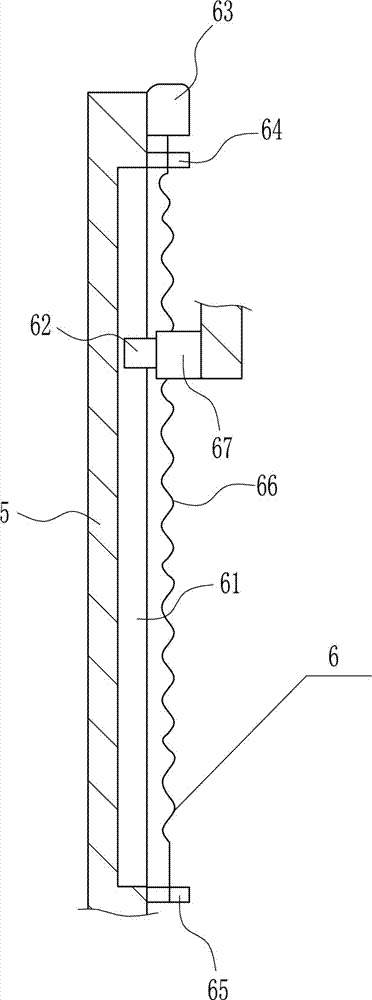

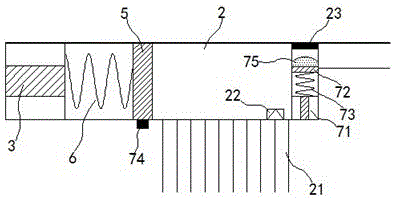

Copper wire winding device with cleaning function

InactiveCN108059032AGood dust removal effectImprove winding qualityFilament handlingCopper wireEngineering

The invention discloses a copper wire winding device with a cleaning function. The copper wire winding device comprises a bottom plate. A left vertical plate and a right vertical plate are verticallyand fixedly arranged on the bottom plate. The upper end of each of the left vertical plate and the right vertical plate is vertically and fixedly provided with a vertical shaft. A pressing plate is horizontally arranged above the left vertical plate and the right vertical plate. The outer surface of a driving shaft is sleeved with and fixedly provided with a winding roller. A horizontal rod is horizontally and fixedly arranged between the left vertical plate and the right vertical plate. A sliding sleeve is fixedly provided with a limiting ring, and a copper wire penetrates the limiting ring.Straight racks are horizontally and fixedly arranged on the upper inner side wall and the lower inner side wall of a concentric-square-shaped frame. The copper wire is wound through the winding roller, the sliding sleeve is driven by the concentric-square-shaped frame to reciprocate left and right along the horizontal rod, accordingly, the limiting ring is used for driving the copper wire to reciprocate left and right, the copper wire is prevented from being excessively centralized at one position of the winding roller, and the copper wire is evenly wound around the winding roller; and a brushand the copper wire relatively rotate in the copper wire winding process, a very good dust removing effect is achieved, and the winding quality is improved.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

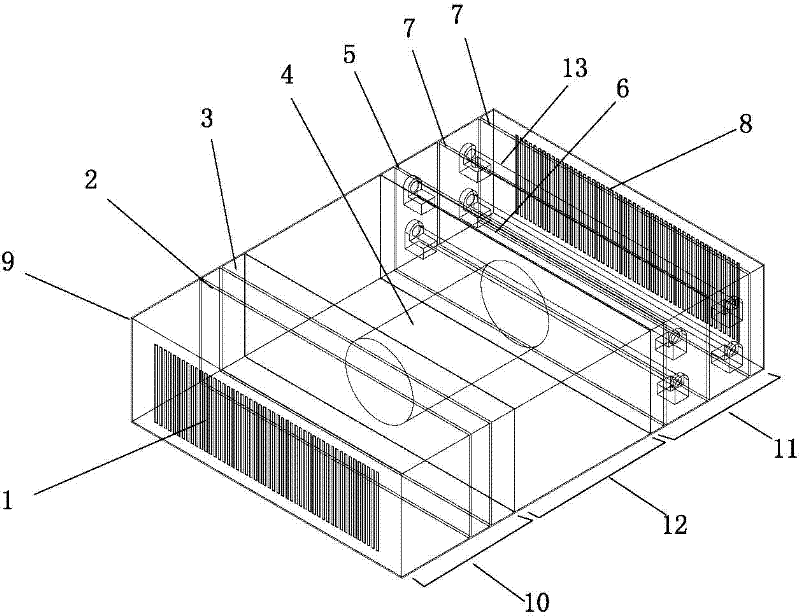

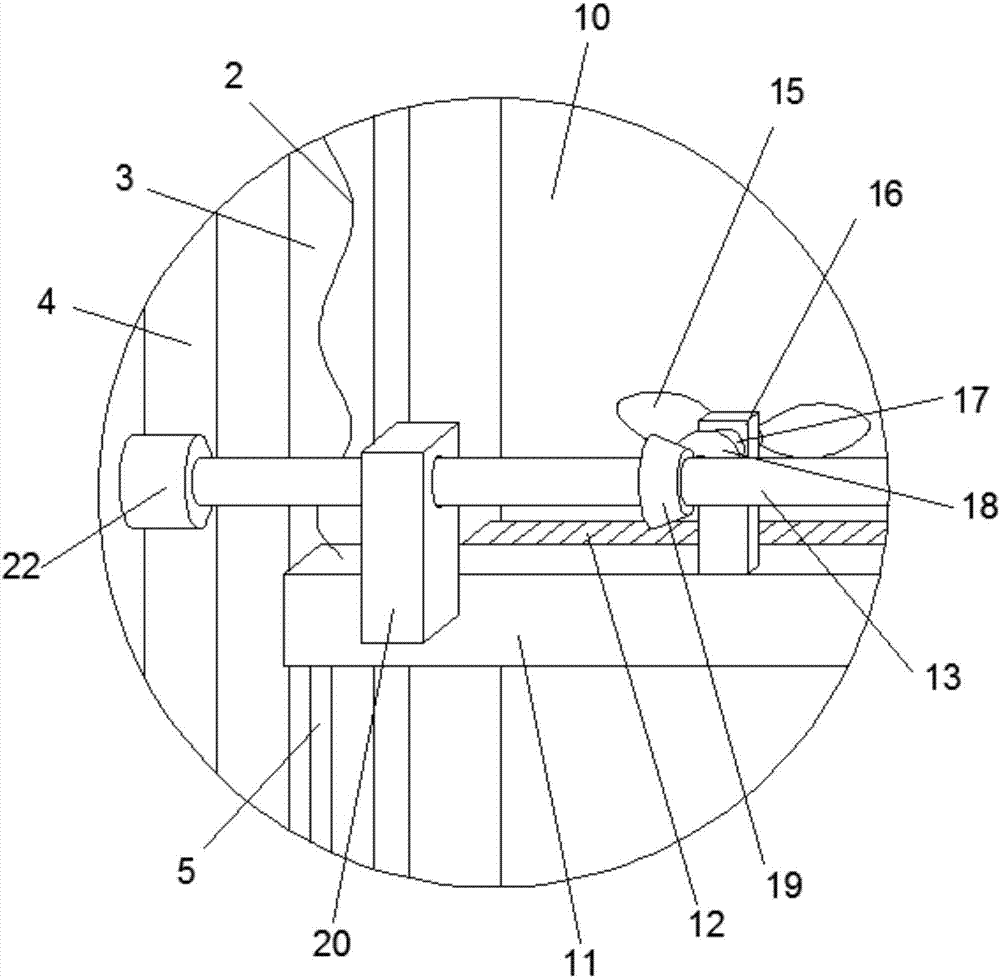

High-efficiency dust removal device for circuit board

InactiveCN106944376AImprove dust removalImprove dust removal effectCleaning using toolsCleaning using gasesEngineeringBolt connection

The invention relates to a dust removal device for a circuit board, particularly to a high-efficiency dust removal device for the circuit board. The invention technically aims to provide a high-efficiency dust removal device for the circuit board, with the advantages of time and labor saving, high dust removal speed and capability of collecting falling dust in the dust removal process but without influence on surrounding environment. According to the above technical scheme, the invention provides a high-efficiency dust removal device for the circuit boards, comprising a frame, a collection box, fixed blocks, a holding plate, etc.; the collection box is installed in the middle of the inner bottom of the frame through bolted connection, and the fixed blocks are symmetrically installed at the left and right sides of the frame top through bolted connection. In the invention, the circuit board can be cleaned through moving a brush right and left; at the same time, air is ejected from an air outlet pipe to blow dust on the circuit board to speed up dust removal of the circuit board.

Owner:刘养青

Automatic dust removal heat dissipation monitoring camera

InactiveCN106101497AExtended service lifeImprove work performanceTelevision system detailsColor television detailsSurveillance cameraGuide tube

The invention relates to an automatic dust removal heat dissipation monitoring camera. The automatic dust removal heat dissipation monitoring camera comprises a shell and a lens. A heat absorption cavity is fixed in the shell. An electromagnet element is mounted at the bottom of the heat absorption cavity. An air jet hole is arranged at the top of the heat absorption cavity. An air guide tube communicates with the air jet hole. The air outlet end of the air guide tube stretches out of the shell and is close to the lens. A piston plate made of a ferromagnetic material is mounted in the heat absorption cavity in a sliding mode. The piston plate and the electromagnet element are connected through a pressure spring. A unidirectional air inlet tube is mounted on a side wall of the heat absorption cavity. The unidirectional air inlet tube is close to the top of the heat absorption cavity. A normally closed pressure valve is mounted at the air jet hole. The normally closed pressure valve is close to a pressure sensitive switch. The pressure sensitive switch is connected with the circuit of the electromagnet element in series. The monitoring camera is simple in structure and convenient to maintain, and the service life is effectively prolonged.

Owner:苏州亿泰信息科技有限公司

Wrought fiber sheet and filter unit

InactiveUS20050172812A1Improve stabilityHigh molecular weightDispersed particle filtrationElectrostatic separationAir cleaningElectret

A wrought fiber sheet or air cleaning filter unit that exhibits high performance and is biodegradable so as to enable reducing load upon environment. The wrought fiber sheet is produced by coupling biodegradable fiber sheets having electret properties by means of a configuration reinforcing member of a biodegradable material. Further, the frame for accommodating the wrought fiber sheet is also constituted of a biodegradable member so as to obtain an air cleaning filter unit that exerts biodegradability as a whole.

Owner:TOYO TOYOBO CO LTD

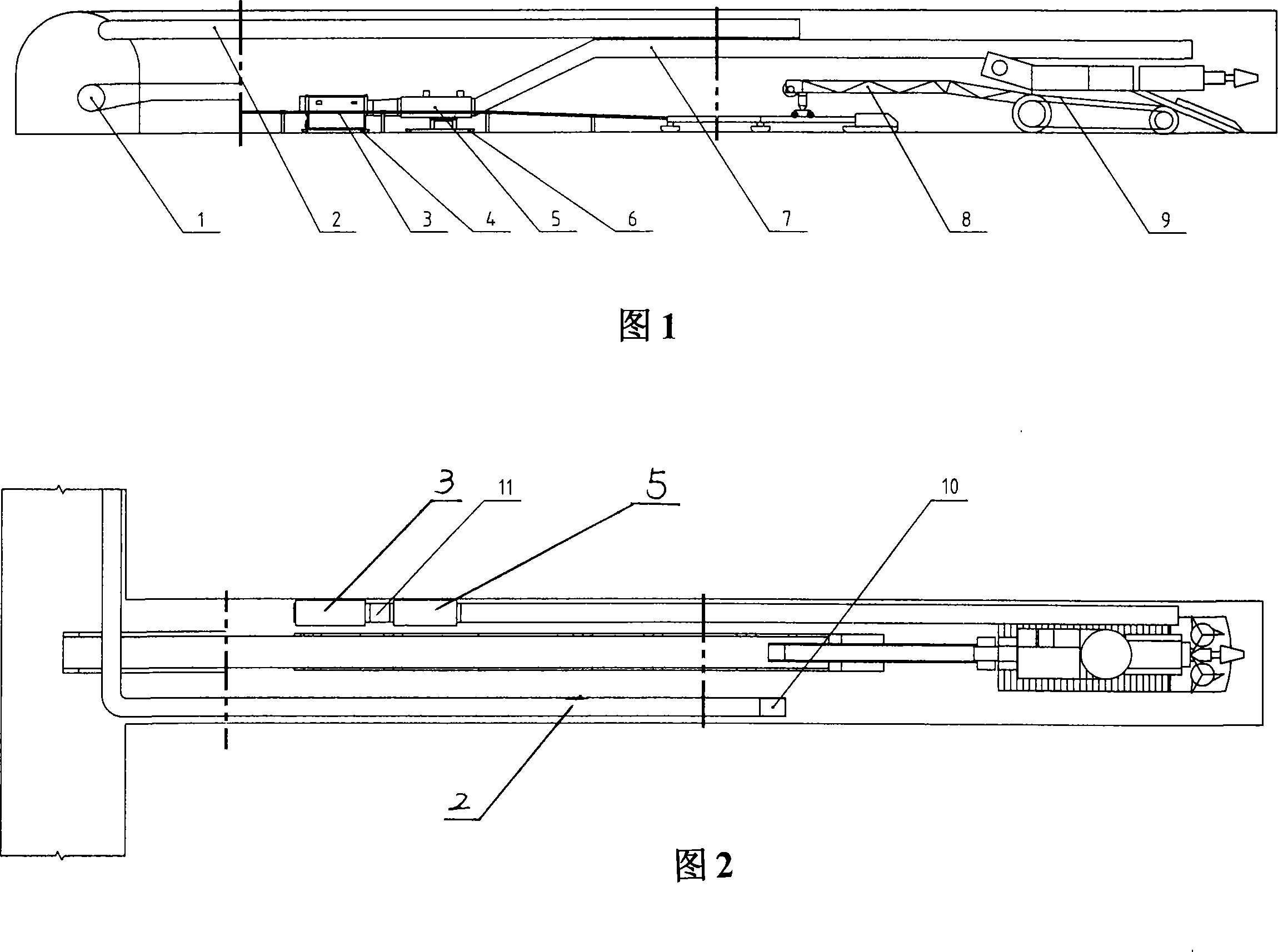

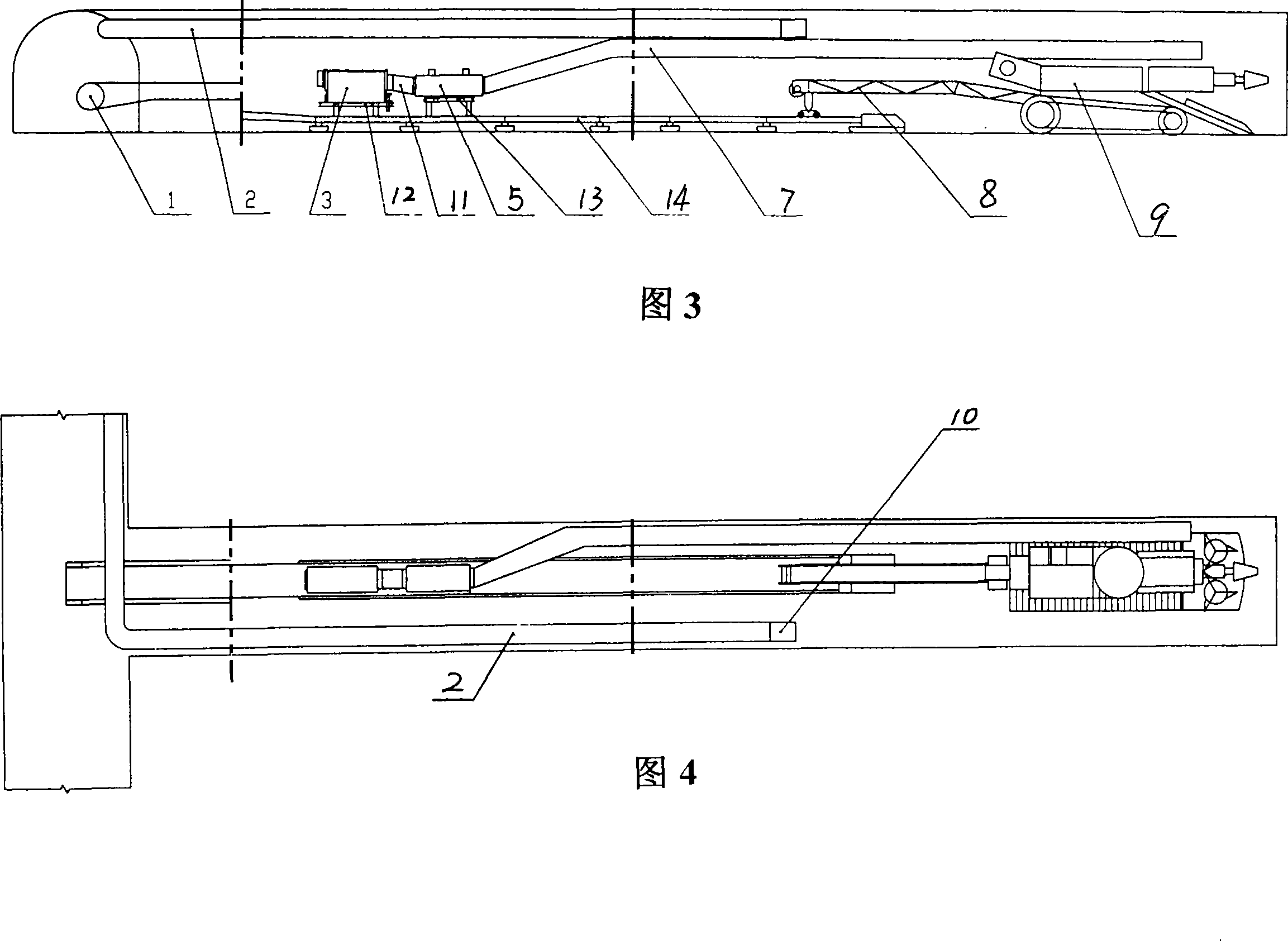

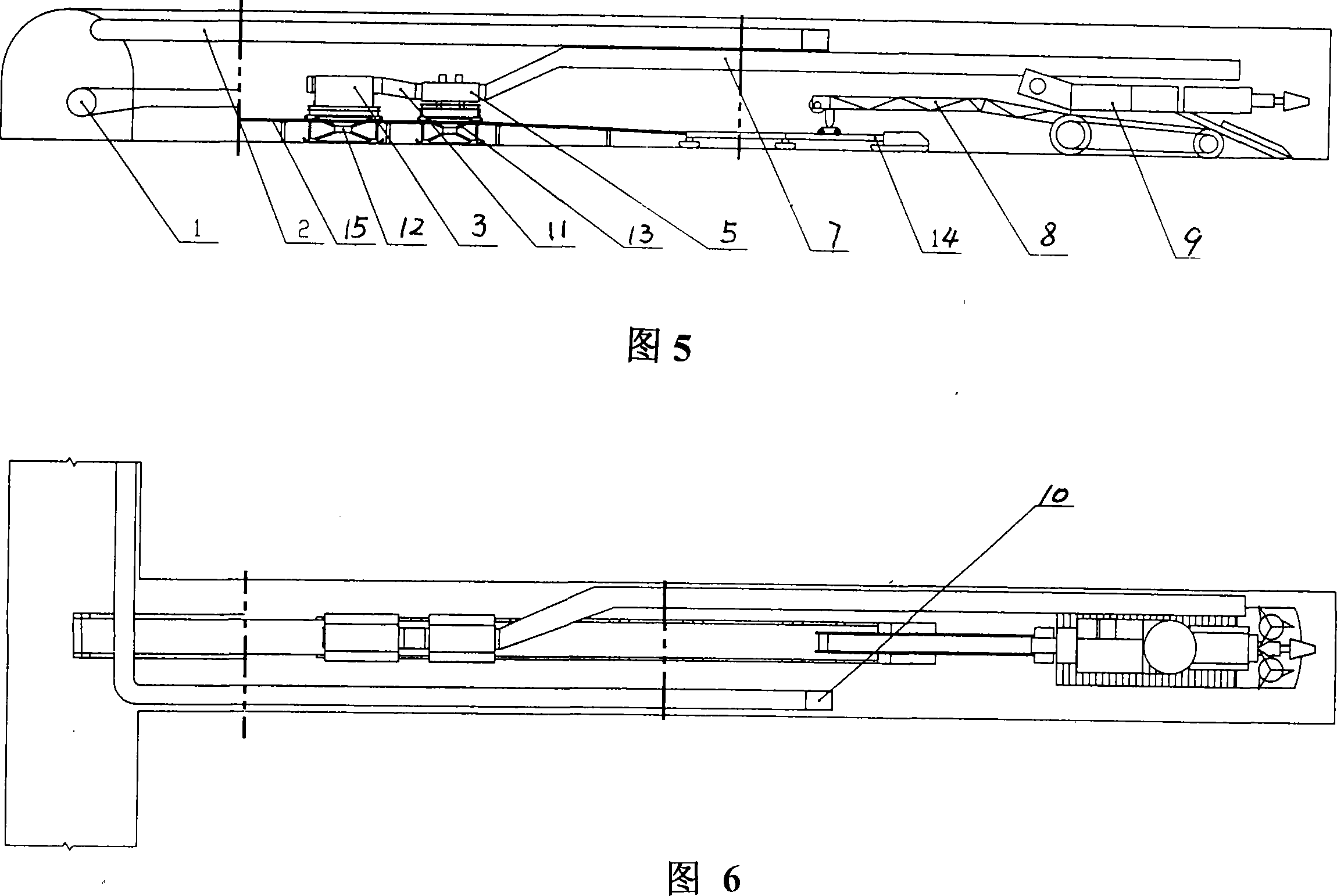

Digging laneway aerating and dust removing system arrangement method

InactiveCN101169041ADisadvantages of reducing open rateSolve the problem of poor ventilation and dust removal effectDust removalFire preventionCycloneHooping

The invention provides an arrangement method of a ventilating and dust-removing system for the excavation tunnel, and includes a boring machine, a belt feeding machine, a belt transshipment device, a dust-removing device, and a ventilating device. The boring machine is connected with the belt transshipment. The transshipment device is set on the belt feeding machine, and the negative pressure wind cylinder of the ventilating device is hung on the tunnel and connected with a fan in a hooping method. Two positive pressure wind cylinders are arranged on the ventilating device, one positive pressure wind cylinder is connected with a fan and a dust catcher in the hooping method; the other positive pressure wind cylinder is connected with a cyclone in the hooping method and is hung on the tunnel. The dust catcher of the dust-removing device is set up on a dust catcher supporting device. The dust-removing device is arranged on a position 20 to 40 meters behind the boring machine, and the negative pressure wind cylinder is connected at a position 3 to 5 meters apart from and opposing the drivage face, fresh air is pressed in by the positive pressure wind cylinder, and the outlet is 15 to 35 apart from and opposing the drivage face. The ventilation arrangement of the method is rational and safe, the movement is convenient, the operation is simple, the dust removing effect is good, the water consumption is low, and the cost is low.

Owner:TANGSHAN KAILUAN GUANGHUI EQUIP MFGCO

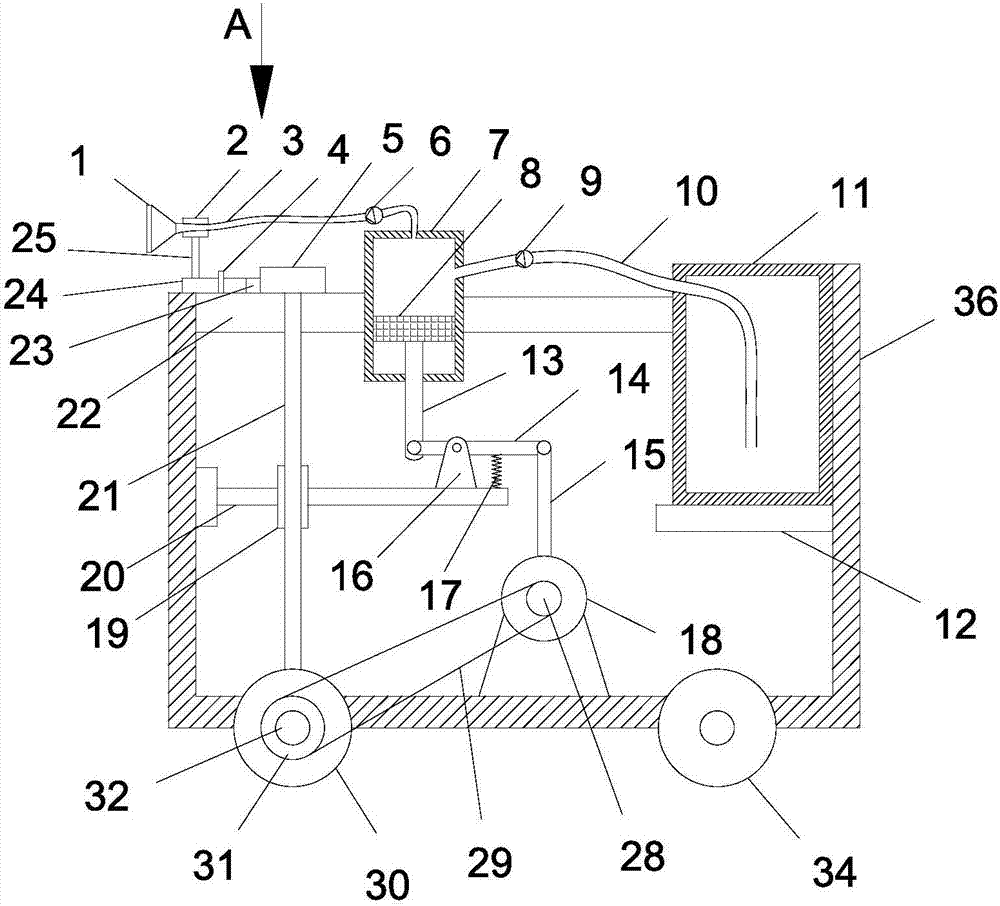

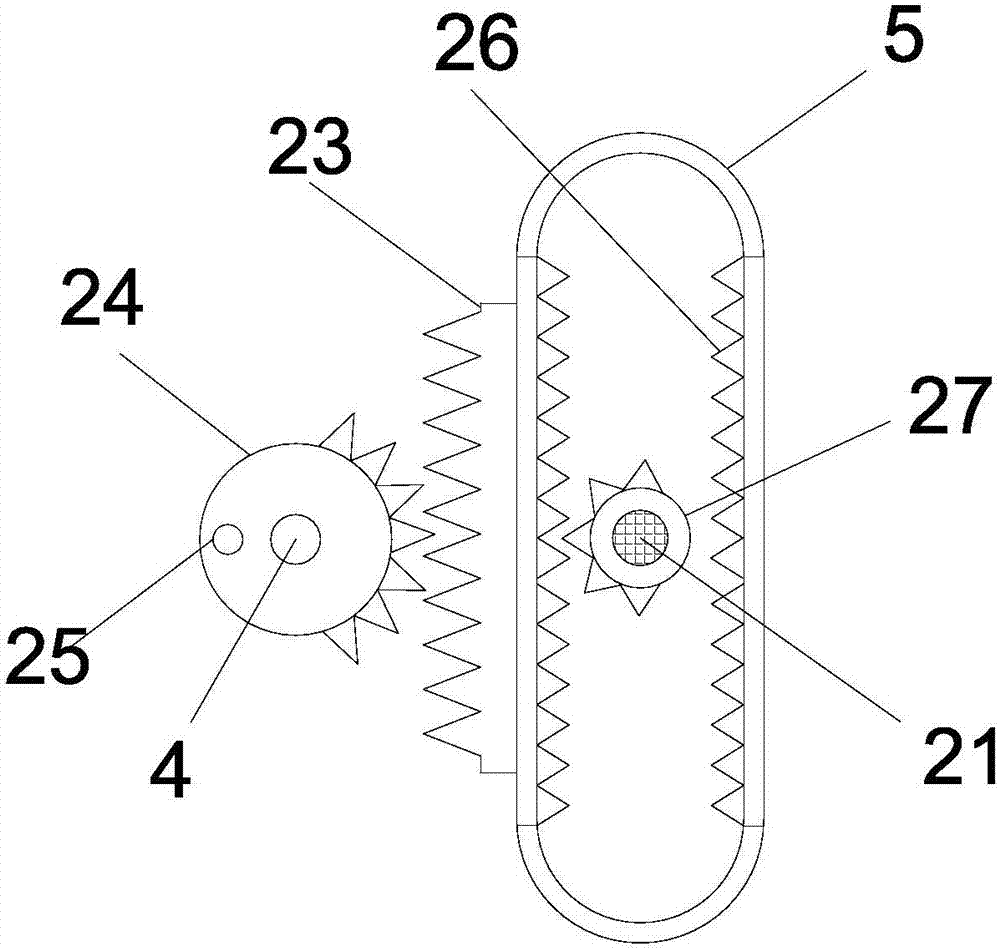

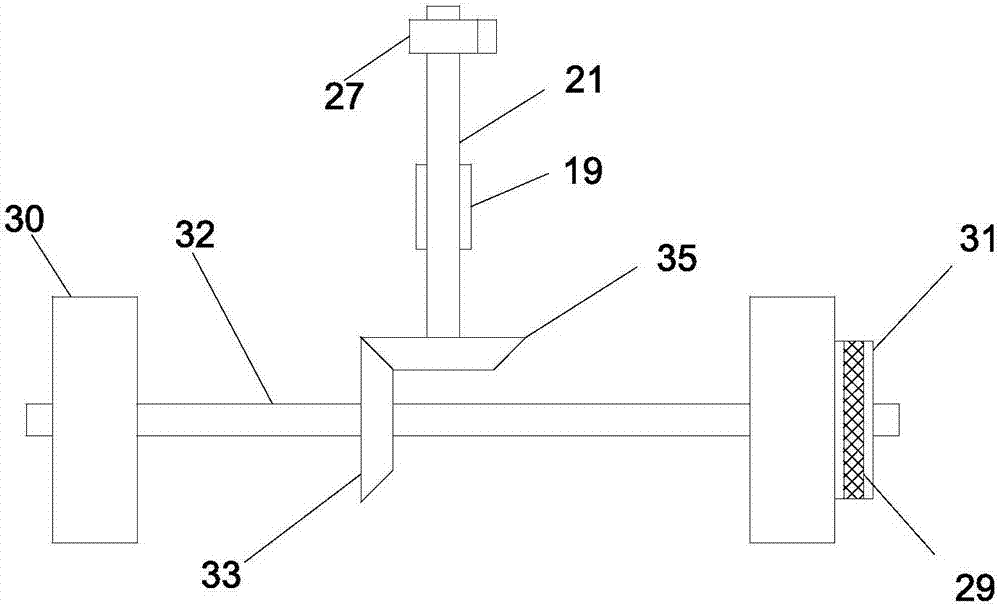

Auto-oscillation sprinkler for building construction

InactiveCN107130555AAchieve horizontal swingLarge range of dust suppressionRoad cleaningDrive shaftArchitectural engineering

The invention discloses an auto-oscillation sprinkler for building construction. The auto-oscillation sprinkler comprises a car body, wherein a front road wheel and a back road wheel are arranged at the bottom of the car body in a rotating manner; a driving chain wheel is in transmission connection with a driven chain wheel through a transmission chain belt; a hinged support seat is fixedly arranged on a fixed plate and is hinged with a lever; the lever is provided with a connecting rod; the upper end of the connecting rod is hinged with the right end of the lever; the lower end of the connecting rod is hinged with the edge of a runner; a piston head is arranged in a water collecting sleeve in a sliding manner; a piston rod is fixedly arranged on the lower side surface of the piston head; a second incomplete gear is coaxially and fixedly arranged at the upper end of a longitudinal drive shaft, is located in a square frame and is meshed with an inner rack; one end, far away from a sprinkler head, of a water outlet hose is tightly connected with the water collecting sleeve; a water tank is filled with clean water; and a suction hose communicates between the water tank and the water collecting sleeve. The auto-oscillation sprinkler is capable of watering the areas in front of the car body and on the left and right of the car body in the advancing process, and is wider in dust fall range and better in dust removal effect.

Owner:吴佳雯

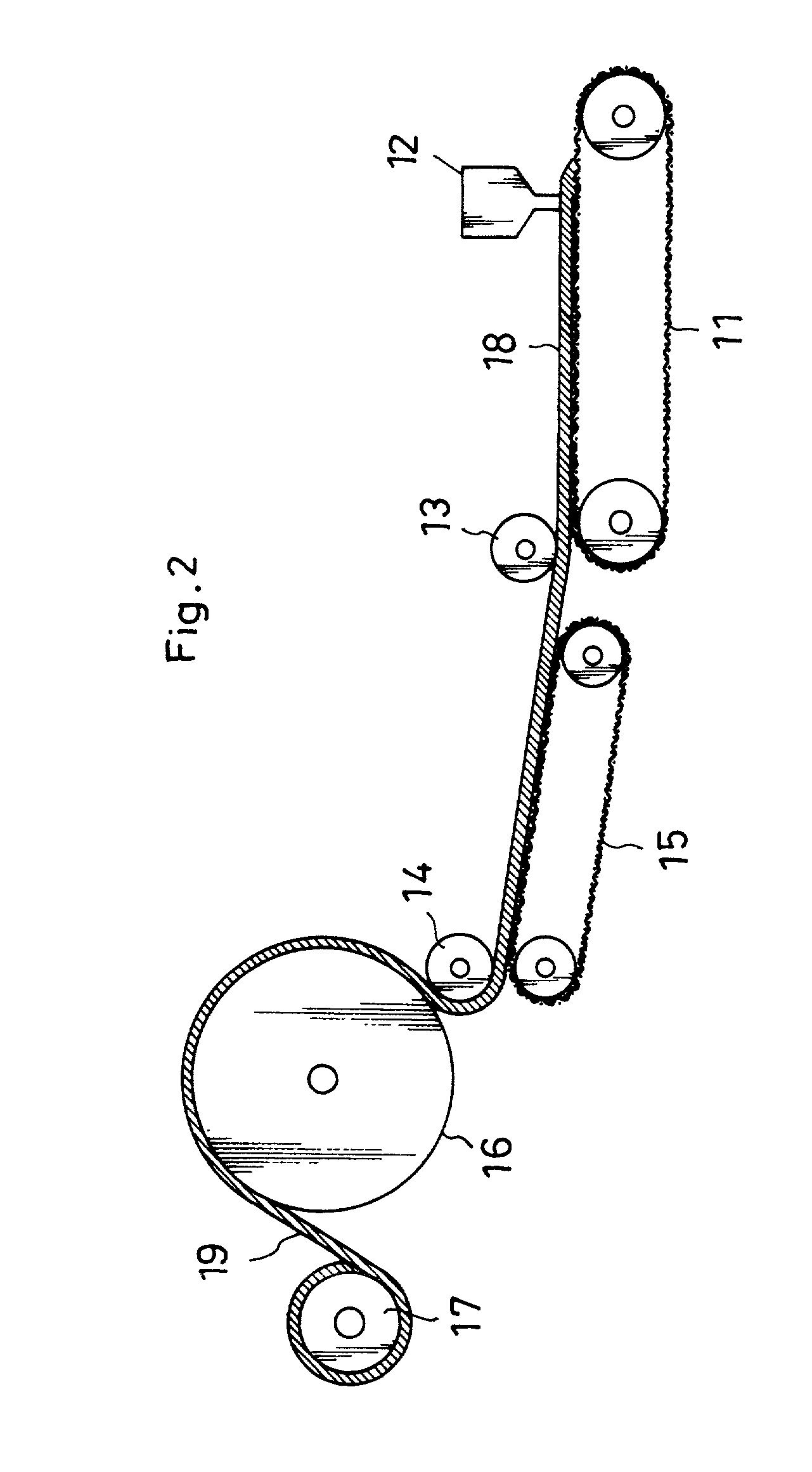

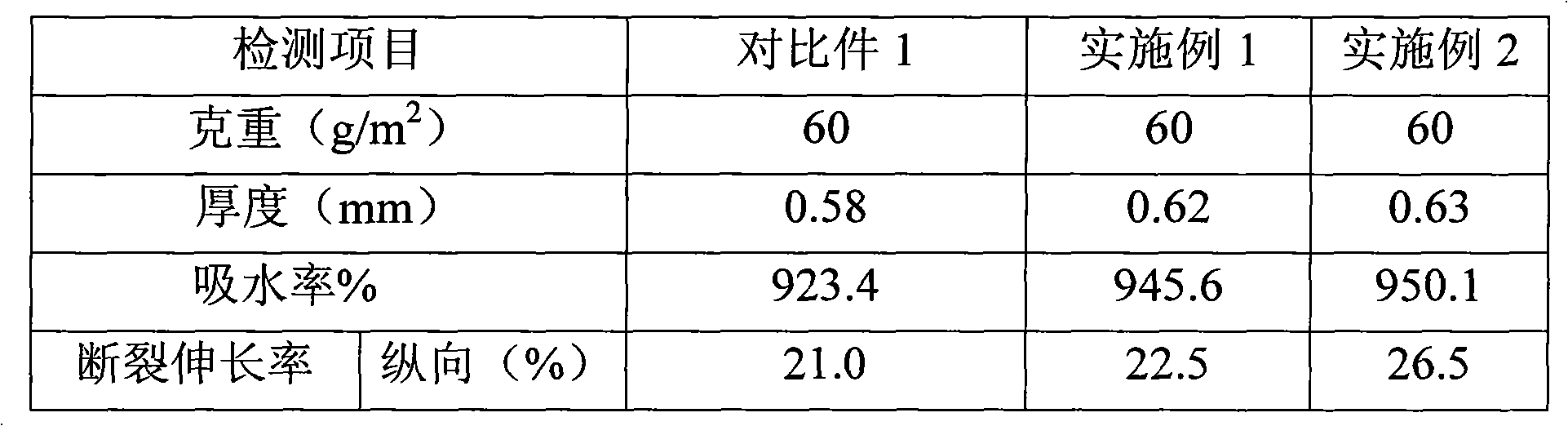

Degradable composite spunlaced nonwovens and manufacturing method thereof

ActiveCN101619520ASoft and thickImprove water absorptionSynthetic resin layered productsNon-woven fabricsFiberMaterials science

The invention discloses degradable composite spunlaced nonwovens with thick and soft feel, fine water absorptivity and good dedusting effect and a manufacturing method thereof. For the degradable composite spunlaced nonwovens, spunlaced processing is carried out on the an upper layer, an intermediate layer and a lower layer by an unwinding method in a on-line or off-line manner, the upper layer is a degradable fiber carded web, the intermediate layer is wood pulp fiber air laying and the lower layer is polylactic acid nonwovens. The manufacturing method comprises the following steps of wood pulp fiber airlaying, degradable fiber opening picking, carded web, spunlacing and baking, which respectively controls an airlaying conveying fan, a forming suction fan, recycling suction fan efficiency, an opening picking gauge, carded main cylinder speed, chest cylinder speed and up-down random roller speed, pressure of each water stabs head of spunlacing, baking suction machine, circulation fan, exhaust fan efficiency, baking temperature and the like.

Owner:大连瑞源非织造布有限公司

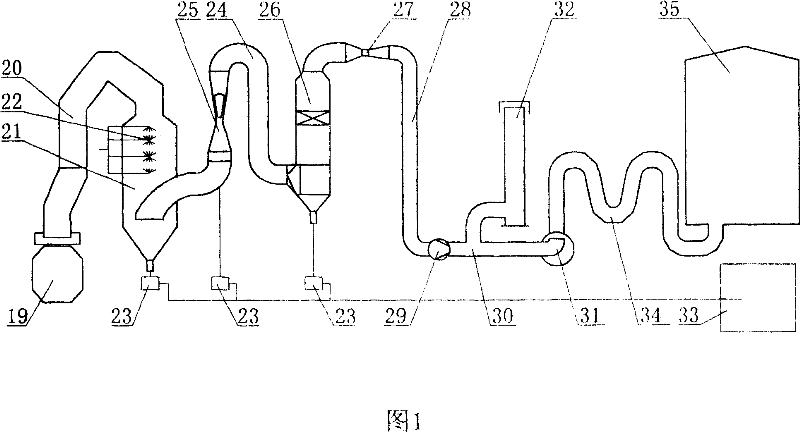

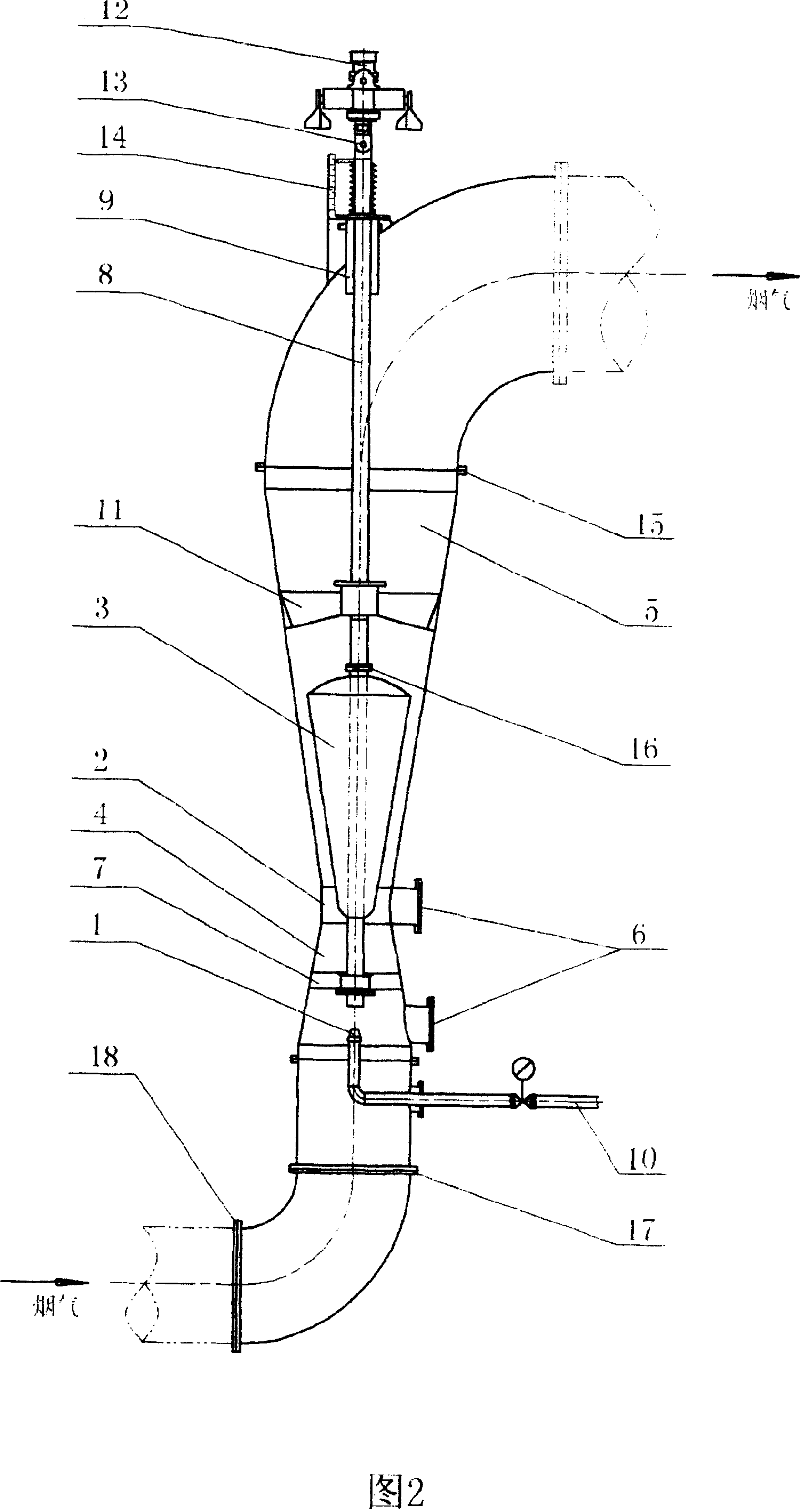

Device for purifying air by eliminating smoke and dust and the technique thereof

ActiveCN101036847AImprove purification effectImprove dust removal effectCombination devicesLighting and heating apparatusFlue gasTranspiration

A flue gas purifying collector and process method thereof are provided. The flue gas purifying collector comprises a transpiration cooling flue, a water seal, a flue, a ring-seal Venturi tube, a dehydrator, a flowmeter, pipelines, a main air blower, a three-way valve, a rotary water seal, an irradiation flue pipe, a water treatment device, a U-shape water seal, a gas cabinet, etc, characterized in that the transpiration cooling flue is connected with a cooling washing tower with a nozzle arranged inside the cooling washing tower, the flue gas outlet on the lower part of the collector is connected to the flue gas inlet on the lower part of the ring-seal Venturi tube, the flue gas outlet of the ring-seal Venturi tube is connected to the dehydrator, and on the throat opening of the ring-seal Venturi tube and below the heavy iron are arranged a water supply pipe and a nozzle, and a heavy iron inversed cone is arrange inside the throat opening. An up-running type flue gas flowing manner and water supply below the heavy iron are employed in the process provided in the invention, redundant mechanical water can be directly reclaimed without passing through the throat opening of the ring-seal Venturi tube, water is atomized thoroughly and agglomerates with dust on the throat opening of the ring-seal Venturi tube, thereby improving dust purifying and dust collecting effect, facilitating the adjustment of the heavy iron, and preventing dust agglomeration below the heavy iron and dust deposit on the throat opening of the ring-seal Venturi tube.

Owner:北京中冶设备研究设计总院有限公司

Hardware fitting machining perforating device with automatic dust removal function

InactiveCN107695780AKeep Countertops CleanGood countertop cleanlinessMaintainance and safety accessoriesBoring/drilling machinesComputer hardwareDust control

The invention discloses a hardware fitting machining perforating device with an automatic dust removal function. The hardware fitting machining perforating device comprises a working table, a box shell is fixedly connected to the upper end of the working table, an air cylinder is arranged at the center of the upper end of the box shell, a fixing plate is fixedly connected to the lower end of the air cylinder through a piston rod, a motor shell is fixedly connected to the bottom of the fixing plate, a hole drilling motor is installed inside the motor shell, a drill bit is fixedly connected to an output shaft of the hole drilling motor, a plurality of chip spaces are evenly formed in the inner wall of the table face of the working table, a dust cage is communicated with the bottoms of the chip spaces, and the lower end of the dust cage is connected with a dust collector through a guide pipe. The hardware fitting machining perforating device is simple in structure and easy to operate, chippings generated by perforating can be collected, meanwhile, the cleaning effect is better, and the table face cleanliness of the working table is kept.

Owner:泰州亚东链条有限公司

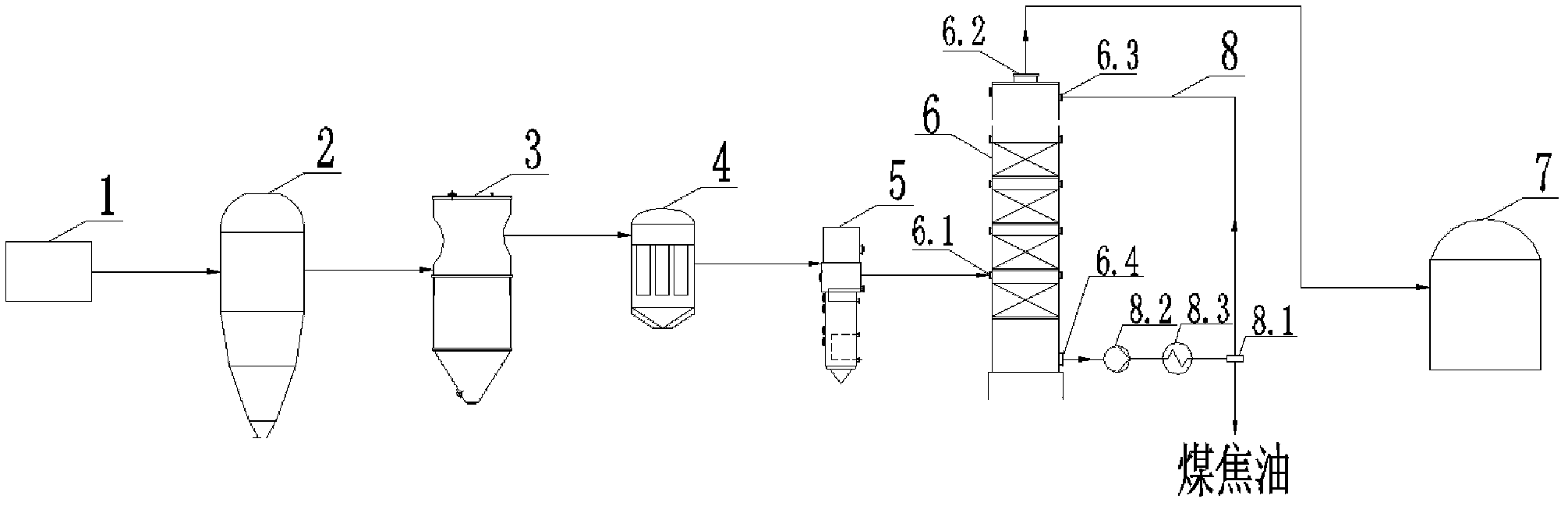

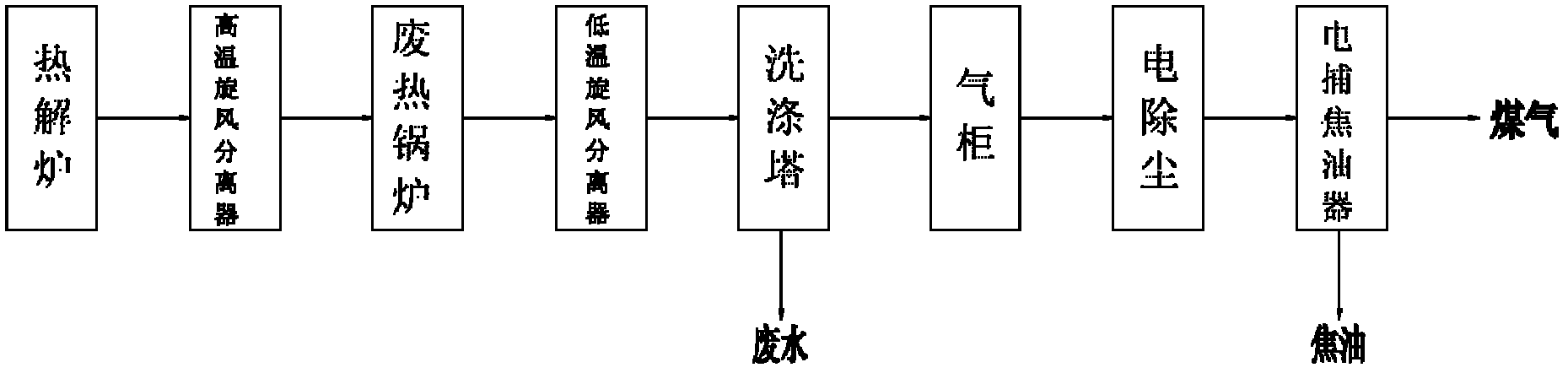

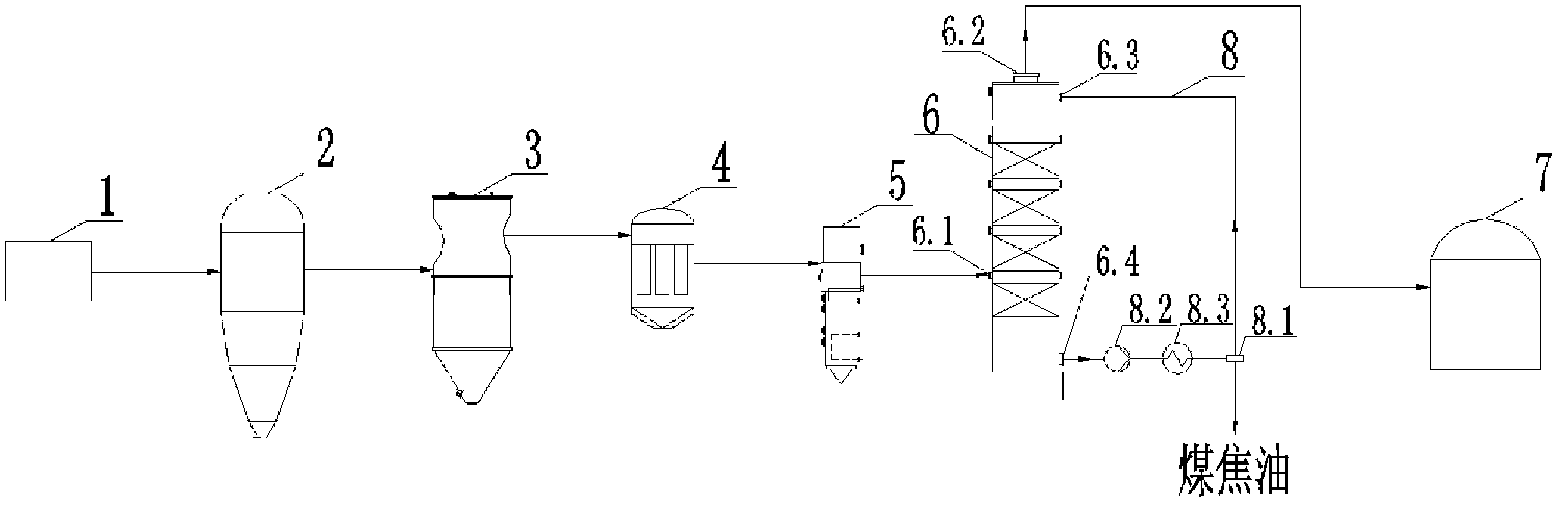

Gas purification process and system

InactiveCN102492490AReduce moisture contentImprove qualityCoke ovensEnergy inputCycloneProcess engineering

The invention relates to a gas purification process and a system, which solve the problem that the existing gas purification process is complex in process, large in waste water amount, high in production cost, poor in dedusting effect and low in coal tar quality. The technical scheme is that raw material coal is predried in a dryer and then sent to a high temperature pyrolysis furnace for pyrolysis, untreated gas containing ash and coal tar and produced through pyrolysis is sent to a high temperature cyclone separator to remove ash in large particles, dedusting of the untreated gas after removing the ash in large particles is further carried out through a high temperature filter, gas is carried out waste heat recovery through a waste heat boiler after dedusting, the gas which exchanges heat to the temperature of 300-350 DEG C enters a chilling tower and is contacted with coal tar oil at the temperature of 40-80 DEG C in an adverse current mode so as to conduct washing and cooling, the coal tar contained in the gas enters the coal tar oil and is discharged from a tower bottom, the gas is washed and cooled to 40-100 DEG C at the tower top to obtain clean gas, and the clean gas is sent to a gas cabinet. The gas purification process and the device are simple, free of waste discharge, good in gas dedusting effect, high in byproduct coal tar quality and low in production cost.

Owner:WUHUAN ENG

Dual type building dust removal device

The invention provides a dual type building dust removal device, and belongs to the technical field of buildings. A water spraying plate is arranged at the left end of a bottom plate; an atomizing nozzle is arranged on the upper surface of a bracket; a dust collecting plate is fixedly arranged on the upper surface of a water tank through a supporting frame; a cover plate is arranged on the upper surface of a dust filtering box, and a filter screen plate is fixedly arranged on the left side of the lower surface of the cover plate; a sponge screen plate is arranged in the middle of the lower surface of the cover plate, and an activated carbon adsorption net layer is arranged on the right side of the lower surface of the cover plate; a stirring device is arranged in an inner cavity of a dust removal agent box. The right end of a water pump is connected with the dust removal agent box through a water outlet pipe, the left end of the water pump is connected with the atomizing nozzle through a water outlet pipe, so that the dust removal device has the function of spraying liquid chemical to adsorb dust in air; the right end of a suction pump is connected with the dust filtering box through a dust suction pipe, so that the dust removal device has the function of adsorbing dust impurities in the air. The dust removal device has the advantages of being simple in structure, high in practicability and good in dust removal effect.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

Dust preventing agent and preparation method thereof

InactiveCN101037589AEasy to solvePlay the role of purifying the airOther chemical processesMethacrylatePersulfate

The invention discloses a dust preventing agent, which includes components of water or deionized water, acrylic acid, methacrylate, acrylamide and initiator, wherein proportion of each component is: 90-120 quotient of water or deionized water; 7-12 quotient of acrylic acid or 2-4 quotient of methyl methacrylate, ethyl methacrylate or propyl methacrylate; 2-4 quotient of acrylamide; 0.05-0.1 quotient of persulfate initiator; 0.03-0.05 quotient of crosslinking agent and 5-10 quotient of neutralizer which are also added. The dust preventing agent is thick liquid and is used after diluting, when being sprayed, the dust preventing agent can adsorb dust in air and combine with granule on ground surface to form film structure, and the dust preventing agent also possesses water-absorbing quality and water-retention property to prevent dust flying and clean air.

Owner:NANJING UNIV

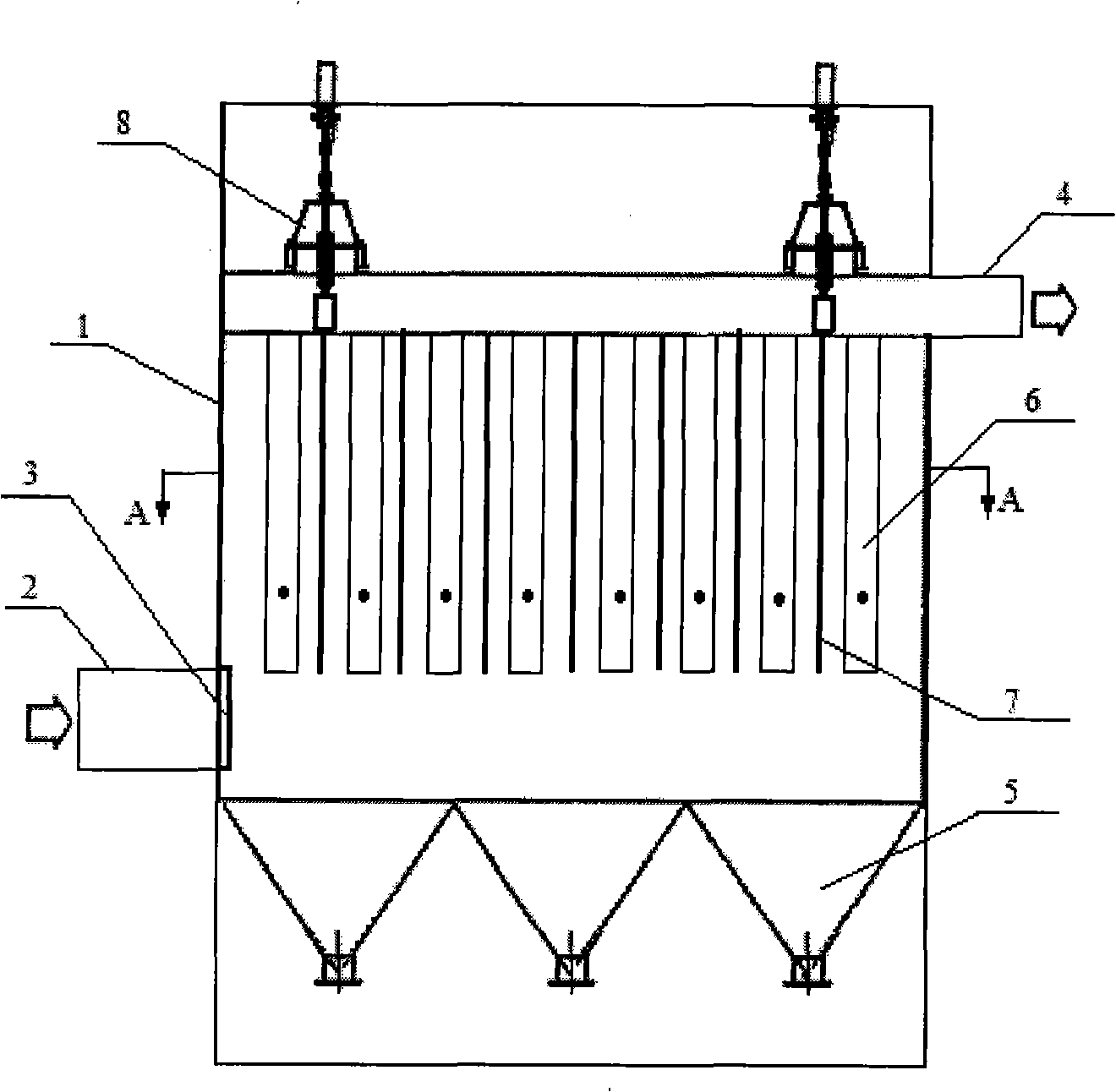

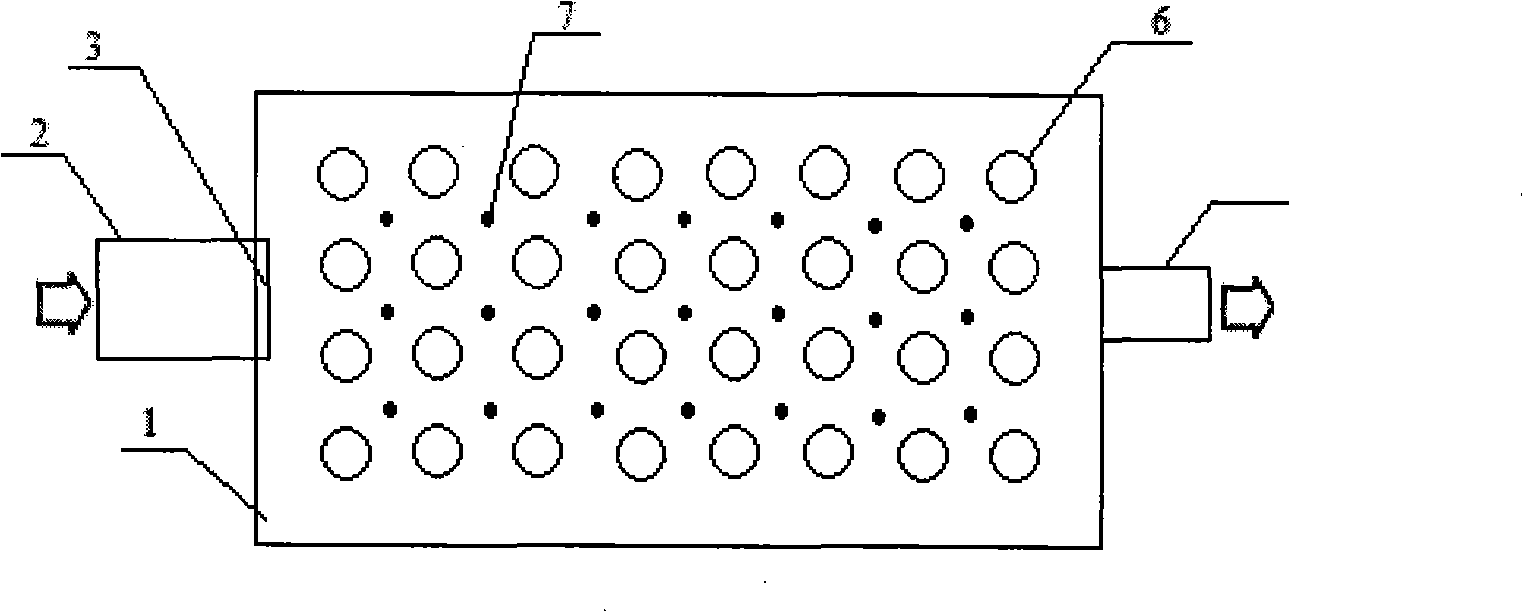

Bag type dust arrest pole electric dust-collecting device

InactiveCN101274305AEfficient removalSmall running resistanceCombination devicesElectrostatic separationElectricityHigh pressure

The invention discloses a polar electricity dust removing device with bagged dust collection, which comprises a dust remover shell, a smoke gas inlet, a uniform air board, a smoke gas outlet, dust buckets, filtering bags, electrode wires and a high-voltage insulating compartment, wherein, a plurality of rows of cloth bags are evenly arranged at interval inside the shell, and the high-voltage electrode wires are arranged at the circle center of a concentric circle of every four cloth bags and connected with a power source through the high-voltage insulating compartment arranged at the top of a dust remover; the uniform air board is arranged under a plurality of rows of filtering bags at the lateral wall of the dust remover shell close to the smoke gas inlet, multiple levels of dust buckets are arranged under the multiple rows of filtering bags, and the smoke gas outlet is arranged above the multiple rows of filtering bags at the lateral wall of the dust remover shell. The polar electricity dust removing device with bagged dust collection has the advantages of simple and unique structure, superior technical performance, smaller resistance, effective overcoming of the reverse corona phenomenon and good dust removing effect, etc. The polar electricity dust removing device with bagged dust collection improves the integral dust removing efficiency under the agglomeration action of electrostatic fields and the interception action of the cloth bags, effectively protects the filtering bags from being burned out by discharge sparks by adopting protective cage structure, and reduces device cost by substituting the steel polar plates with the filtering bags.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

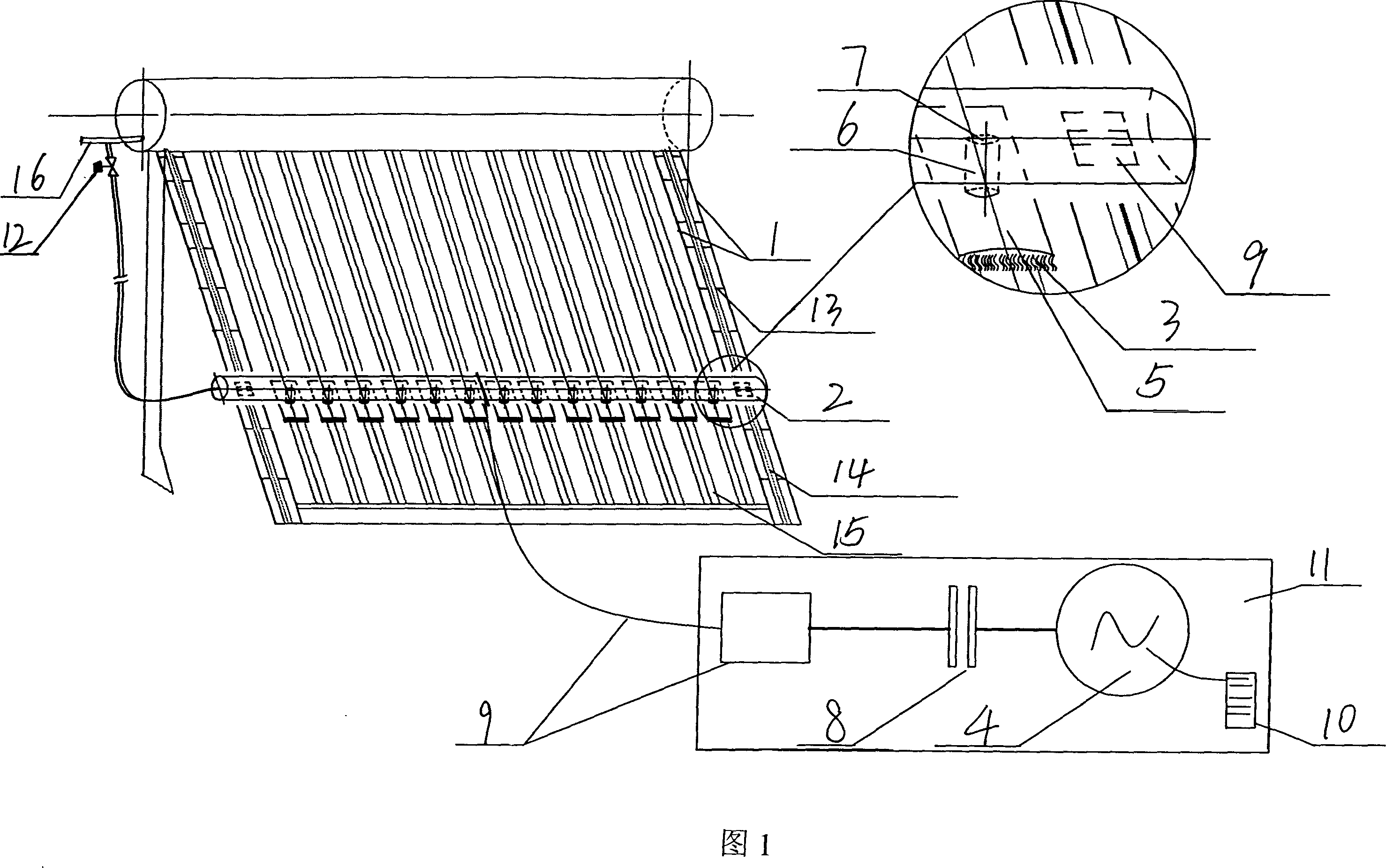

Solar vacuum tube heat-collector superficial dust automatic cleaning device

InactiveCN1970175ASolve the heatEasy to cleanSolar heating energySolar heat devicesCollector deviceEngineering

The automatic cleaning device for the accumulated dust on the surface of the solar vacuum tube heat accumulator comprises the track on the heat accumulator along its surface, sliding bar moving up and down on the said surface along the track, with soft wiping block on the slide bar connecting with the solar vacuum tube, and drive moving device moving up and down along the solar heat accumulator surface driven by the electric motor reacting with the said surface on the slide bar with good solution for the heating issue due to accumulated dust on the vacuum tube surface, with simple structure, safe, reliable and good dust eliminating effect.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Easily-cleaned outdoor display screen

InactiveCN107134217AImprove the display effectEfficient removalCleaning using toolsCleaning using gasesGear driveEngineering

The invention discloses an easily-cleaned outdoor display screen, belonging to the field of display screens. The easily-cleaned outdoor display screen comprises a screen body; the screen body is connected to a base, a sliding rod is fixedly connected with the base, and a support rod is connected with the sliding rod in a sliding way; a dust cleaning brush is fixedly connected to the bottom side of the support rod, and props against the screen body; the sliding rod is fixedly connected with a rack. When more dust exists on the display screen, a drive motor drives a winding wheel to wind a pull wire so as to pull the support rod, and the dust is cleaned by the cleaning brush arranged at the bottom side of the support rod; furthermore, a gear drives a first rotating shaft to rotate under the action of the rack, so that the first rotating shaft drives a second rotating shaft to rotate by means of a bevel gear, and the second rotating shaft drives a blower fan to rotate; therefore, the blower fan blows away the dust while the cleaning brush cleans the dust, so that the dust on the screen body of the display screen is effectively removed, and the display screen further achieves a good display effect.

Owner:HEFEI HUIKE PRECISION DIE CO LTD

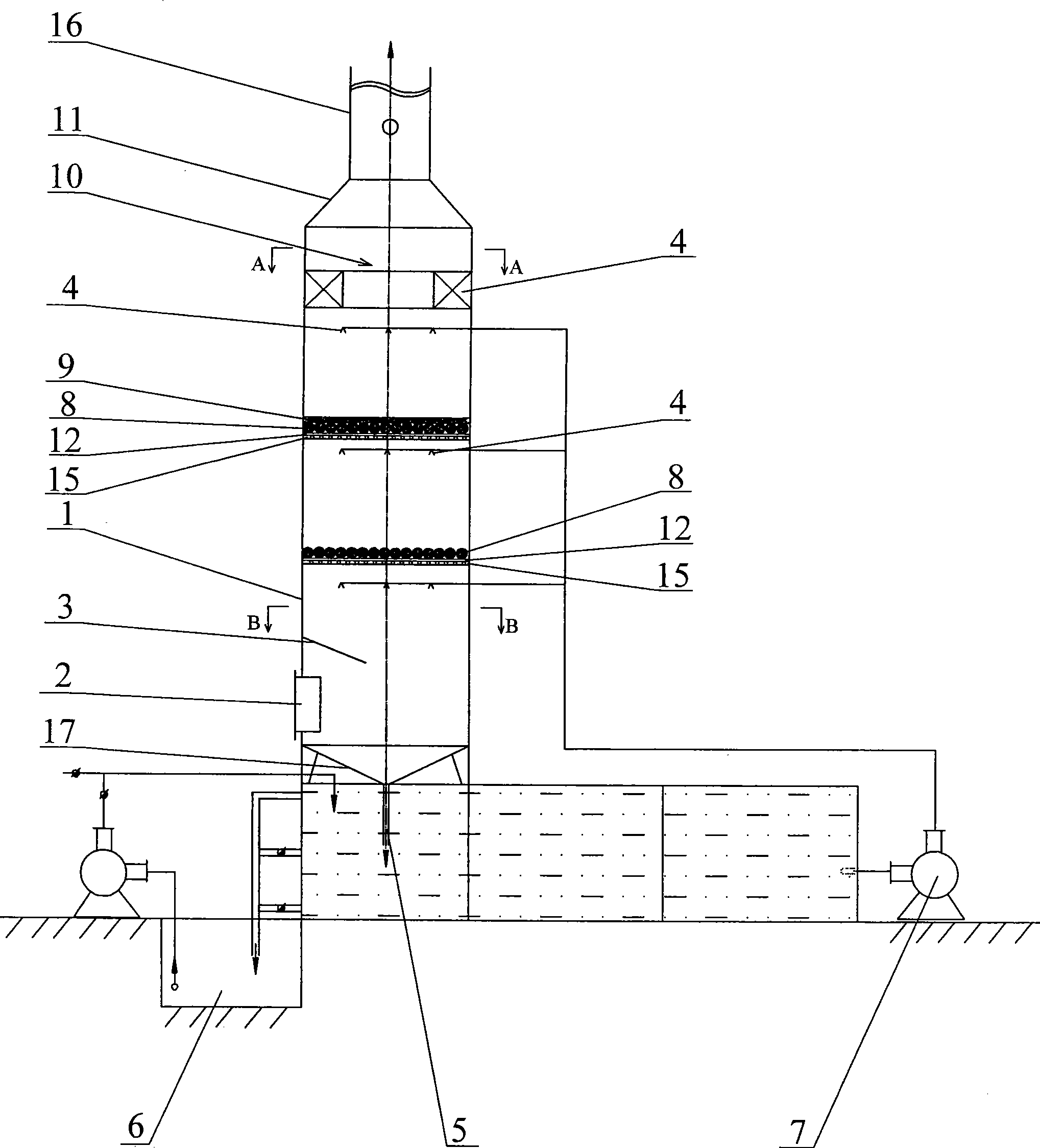

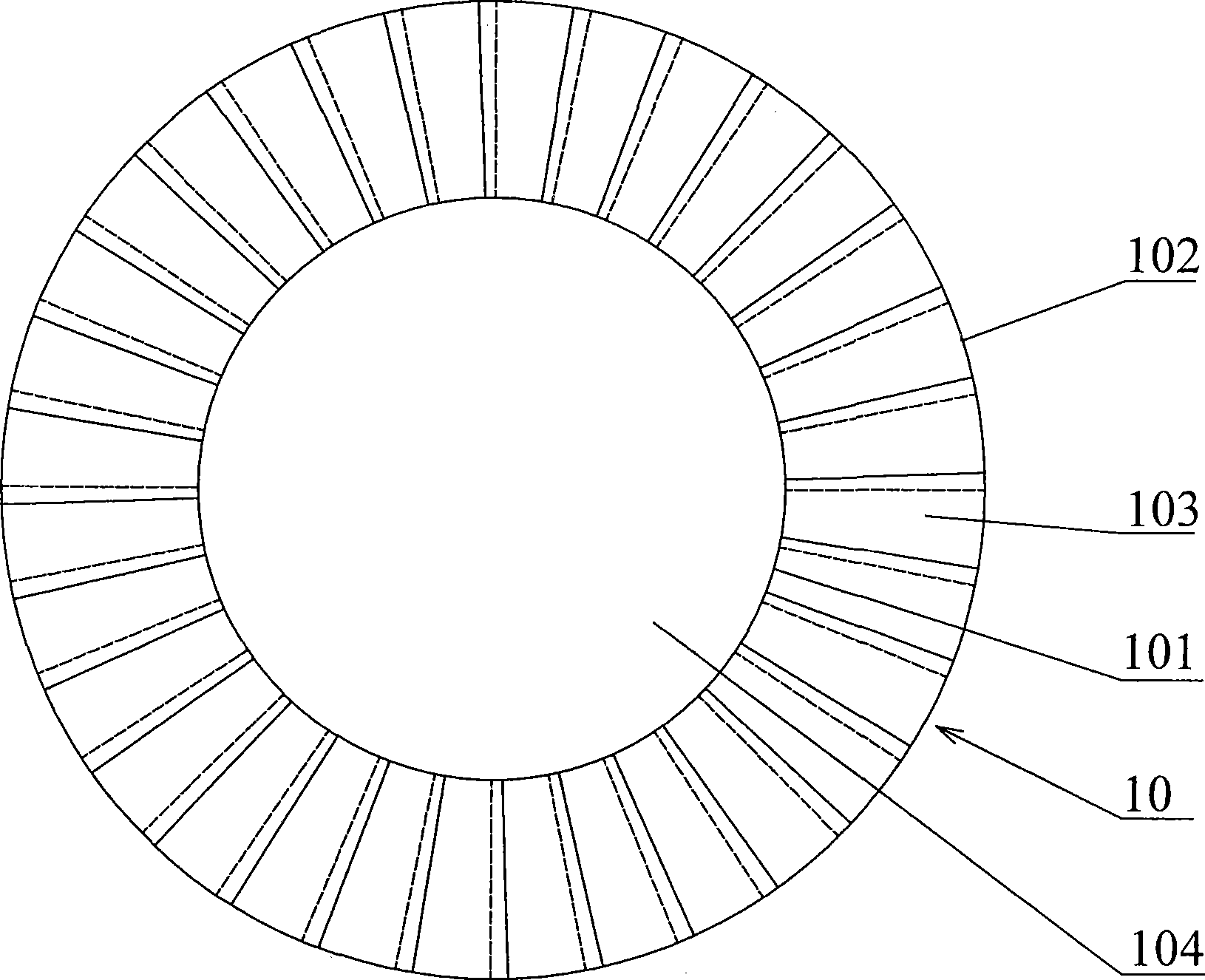

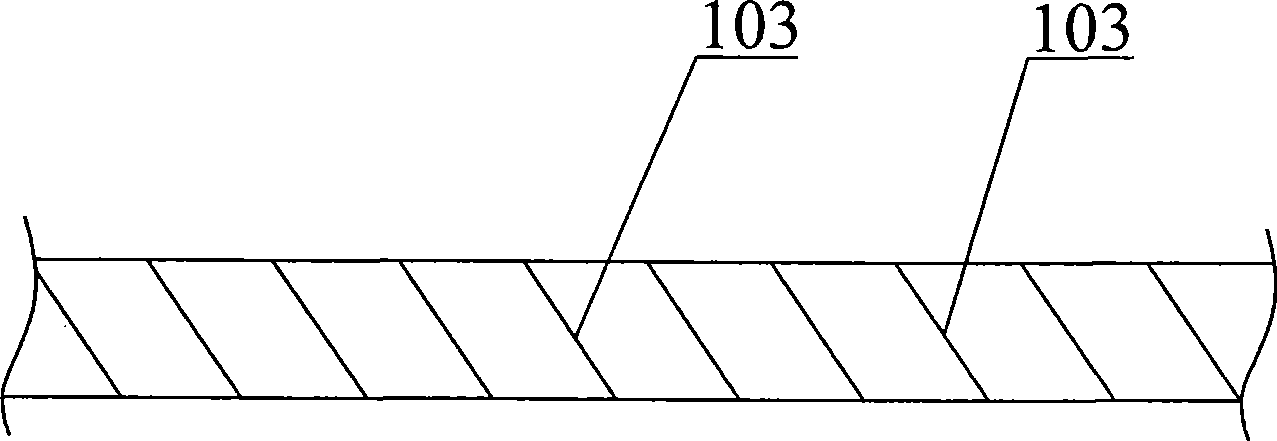

Spraying and dust-removing system

InactiveCN101502733AImprove dust removal effectWon't clogUsing liquid separation agentWater storage tankTower

The invention relates to a spray dedusting system, a dedusting tower is erected on a circulating deposition tank, an opening is opened at the top of the dedusting tower, the dedusting tower is connected with a smoke pipe, the inner wall of the dedusting tower corresponding to the upper part of the exit end of the smoke pipe is provided with a water baffle, the dedusting tower above the water baffle is internally provided with a plurality of spray heads, the bottom end of the dedusting tower corresponding to the lower of the exit end of the smoke pipe is provided with a water sealing device inserted in the circulating deposition tank, the spray heads are connected with the water outlets of a spray pump by pipelines, the water inlets of the spray pump are arranged in the circulating deposition tank, a quality regulating water storage tank is arranged beside the circulating deposition tank, a quality regulating mild base block layer is paved on the bottom of the quality regulating water storage tank, a non-water tight gland layer is paved on the quality regulating mild base block layer, a water supply device used for supplying water to the quality regulating water storage tank from the circulating deposition tank is arranged between the circulating deposition tank and the quality regulating water storage tank, and a water supplementing device for supplementing water to the circulating deposition tank from the quality regulating water storage tank is arranged between the circulating deposition tank and the quality regulating water storage tank.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

Dust removing and falling device for construction sites

InactiveCN107983724AEasy height adjustmentEasy to remove dustCombination devicesRoad cleaningArchitectural engineeringWater spray

The invention provides a dust removing and falling device for construction sites, and belongs to the technical field of construction dust removal. The dust removing and falling device comprises a dustremoving and collecting device, and a water spraying and dust falling device; a feed cylinder is fixedly arranged at the upper end of a hydraulic extension rod; a spring extension pipe is arranged ona connecting pipe; a collecting container is arranged at the bottom of an inner cavity of a collecting box; a cleaning device is arranged below the extension rod; a dust sucking cylinder is arrangedat the lower end of a fixed plate; the lower side of the left side of a water tank is connected with a water pump through a water outlet pipe; and the left end of the water pump is connected with a water spraying plate through a water outlet pipe. As the feed cylinder is fixedly arranged at the upper end of the hydraulic extension rod, the device achieves a function of conveniently adjusting the height of the feed cylinder to conveniently remove dust in the construction sites; the water spraying plate is arranged below the collecting box through a support rod to achieve functions of water spraying and dust falling; and the device has the characteristics of simple structure, high practicability and good dust removing and falling effects.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

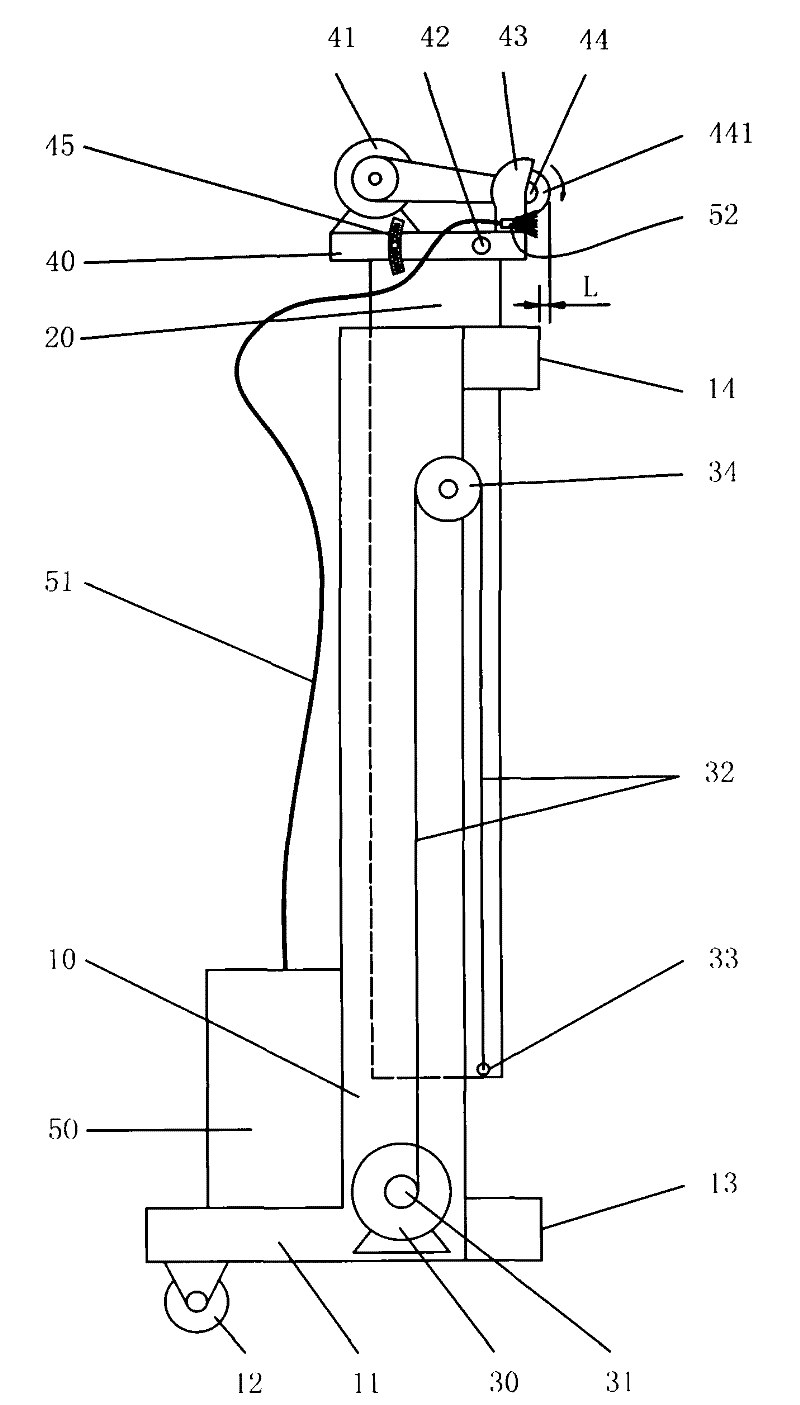

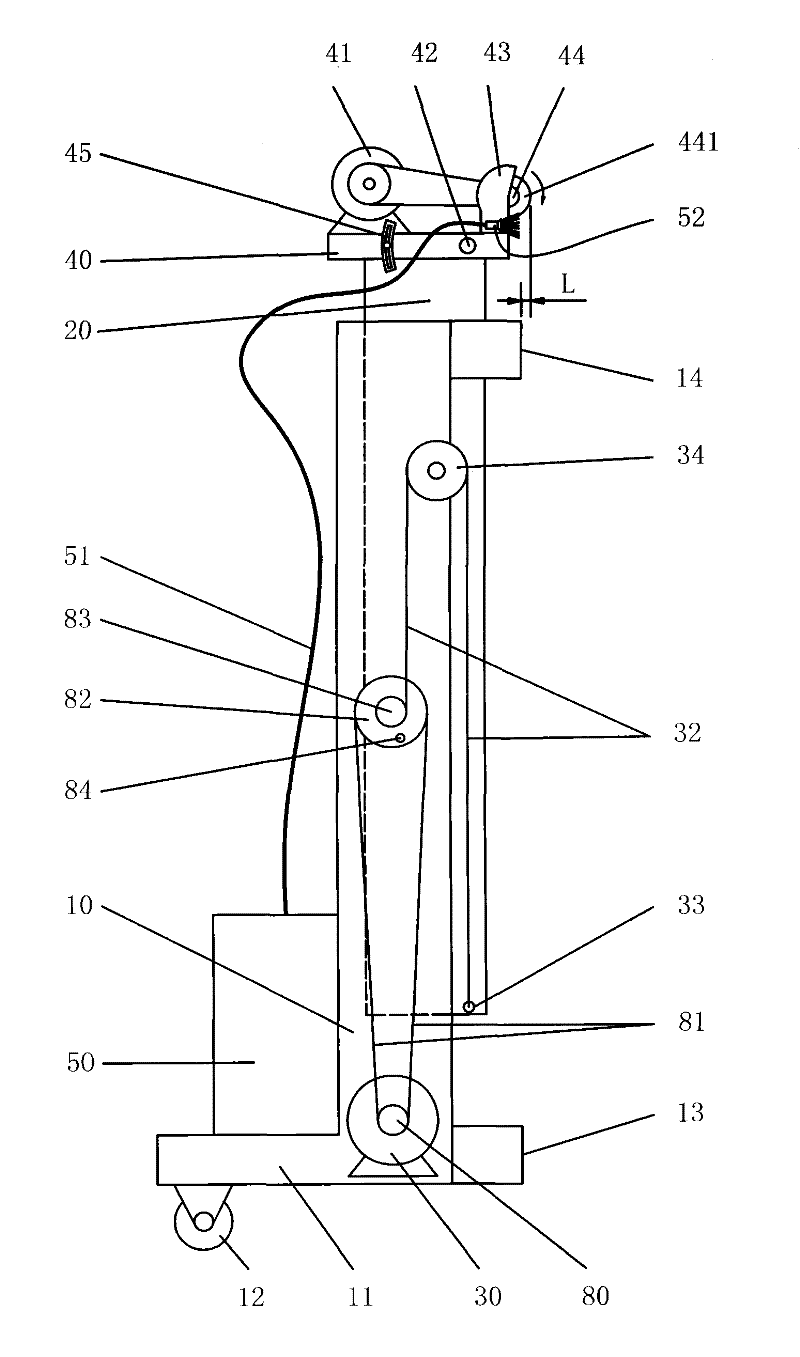

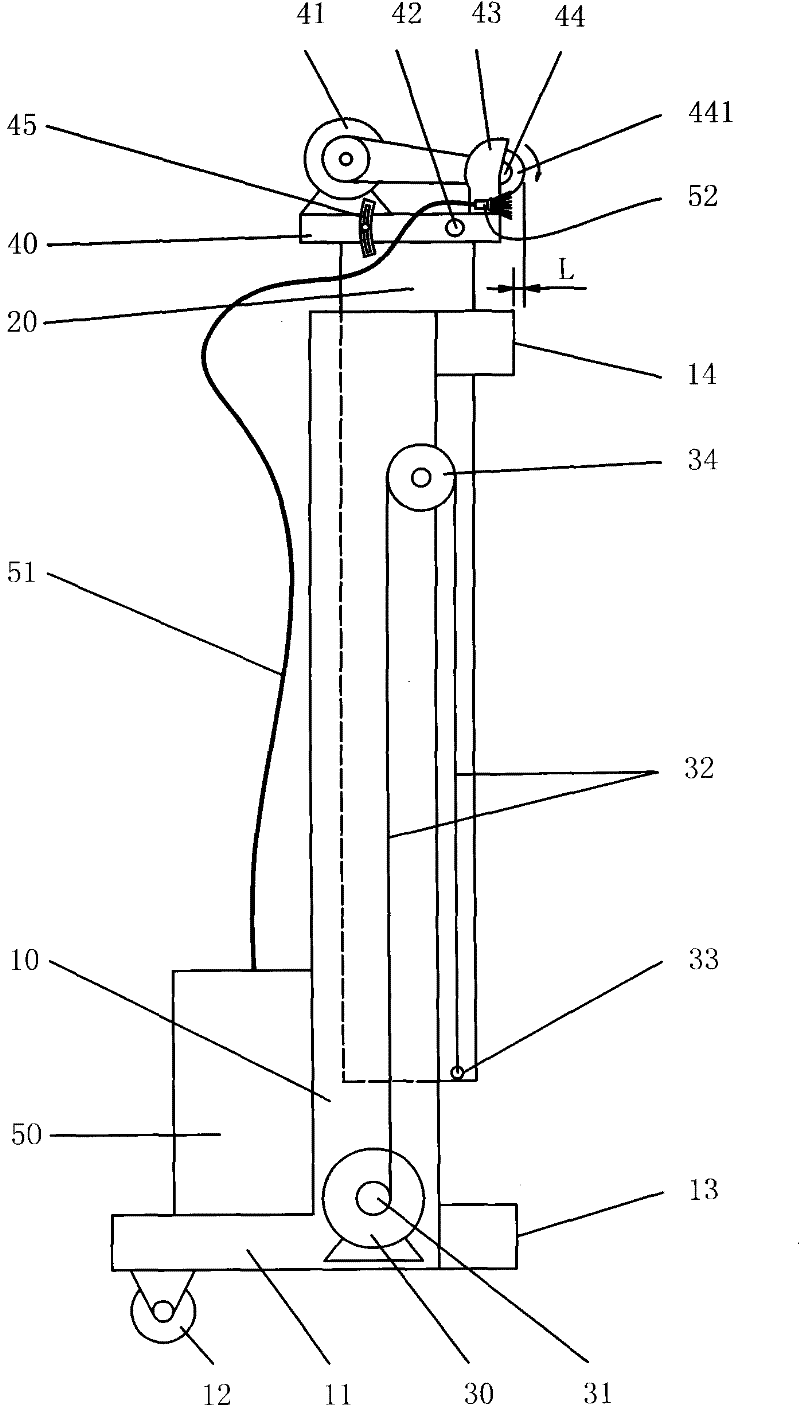

Retractable dust-free wall grooving machine

InactiveCN102174853ASimple construction processIncrease productivityBuilding constructionsSpray nozzleCircular saw

The invention belongs to the technical field of wall grooving machines, and relates to a retractable dust-free wall grooving machine. A base is provided with a slide rail and an atomization dedusting mechanism; a sliding rod which moves along the slide rail and a sliding rod lifting mechanism are arranged on the slide rail; both the upper part and the lower part of the front side face of the slide rail are provided with a limited block; a grooving operation part is hinged on the upper part of the sliding rod; in the grooving operation part, a motor is arranged on a mounting frame, more than two circular saw blades are arranged on a rotating shaft driven by the motor, a safety hood is arranged on the rear part of the circular saw blade, and a spray nozzle which is connected with the atomization dedusting mechanism by a guide pipe is arranged on the lower side of the safety hood; and in the sliding rod lifting mechanism, a steel cable unreeling and reeling barrel is arranged on a motor shaft which is arranged on the base, one end of a steel cable is fixed on the steel cable unreeling and reeling barrel, and the other end of the steel cable passes through a pulley arranged on the upper part of the slide rail and is fixed at the lower end of the sliding rod. The machine has a simple structure, a good dedusting effect, low labor intensity, high efficiency, low production cost and adjustable grooving depth and is suitable for grooving a wall.

Owner:李茂铁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com