Patents

Literature

880results about How to "Small running resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

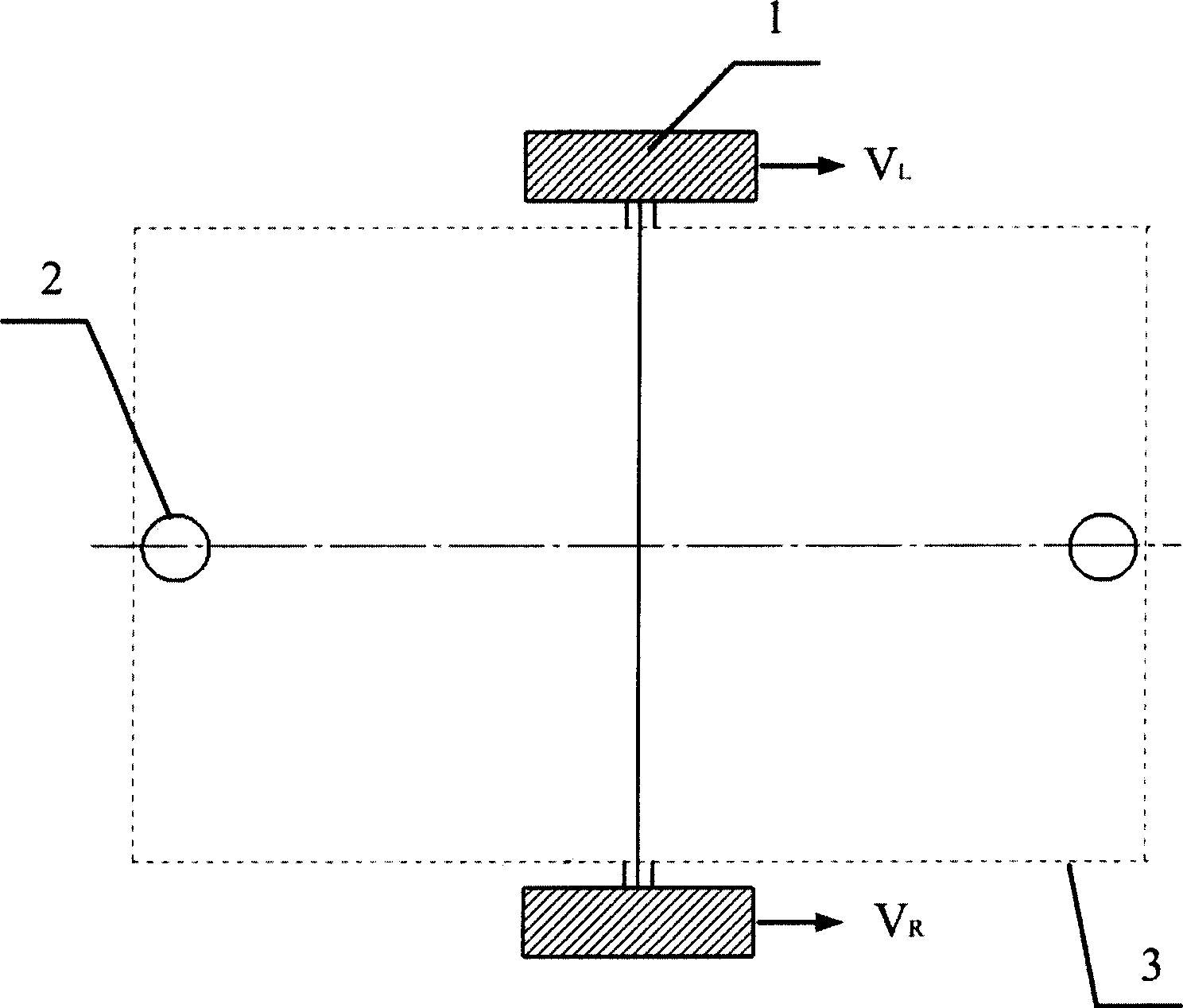

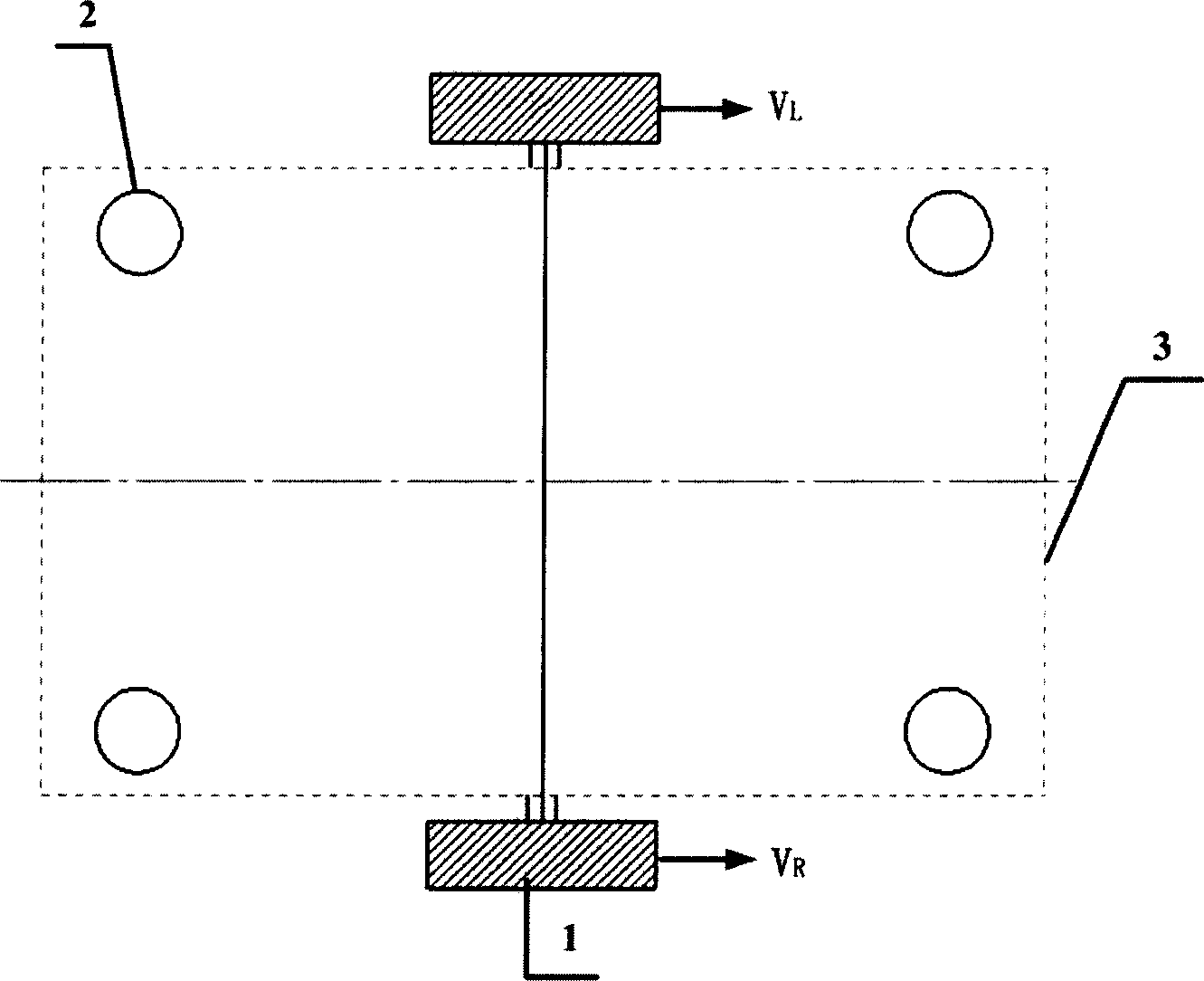

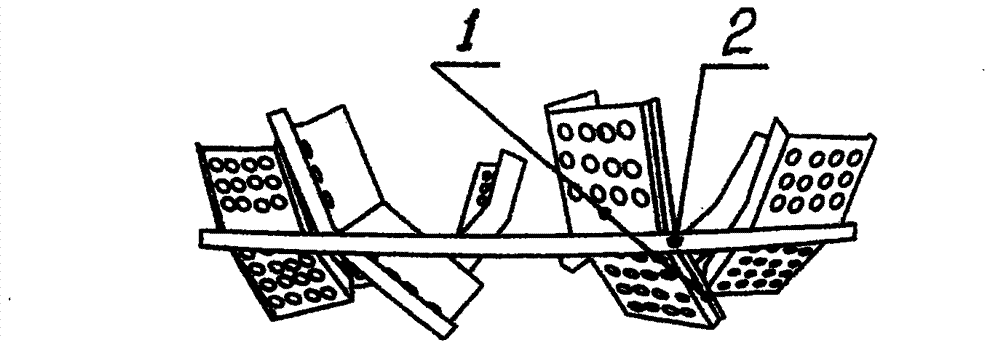

Non-contact magnetically adsorbed wall climbing robot

The present invention is non-contact magnetically adsorbed wall climbing robot, belongs to the field of robot design technology, and aims at providing robot with both high moving flexibility and great loading capacity. The non-contact magnetically adsorbed wall climbing robot includes wheeled moving mechanism and permanent adsorption mechanism. The wheeled moving mechanism includes chassis, driving mechanism and wheels, which are laid symmetrically, driven in differential mode, and turns on wall by means of the speed difference of the wheels. The permanent adsorption mechanism has no contact with the magnetically conducting wall surface, high magnetic energy utilization, and high adsorption capacity. The wall climbing robot has high loading capacity, high motion flexibility, especially high turning flexibility, and excellent application foreground.

Owner:TSINGHUA UNIV

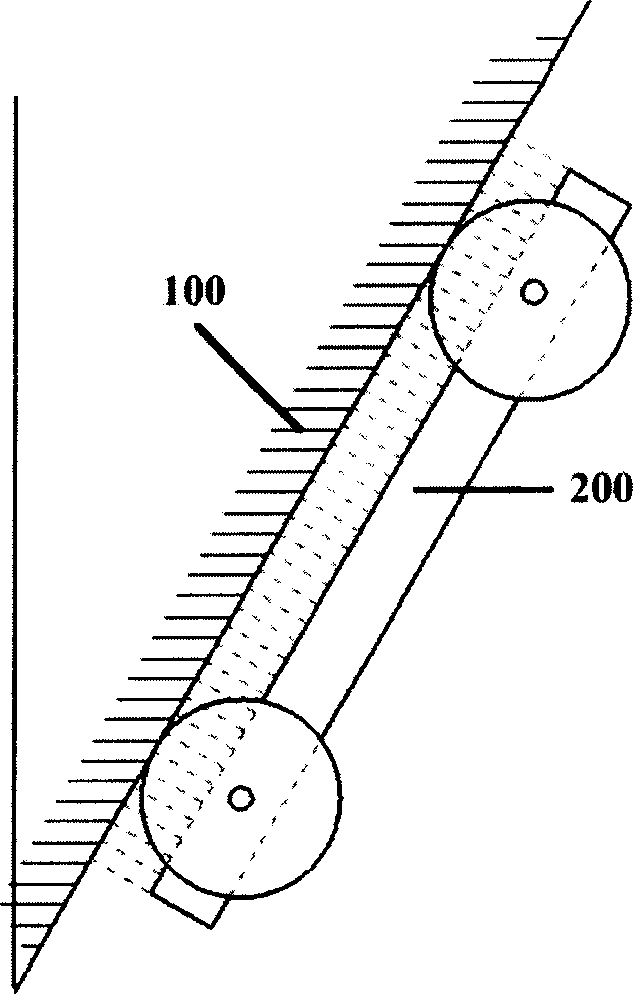

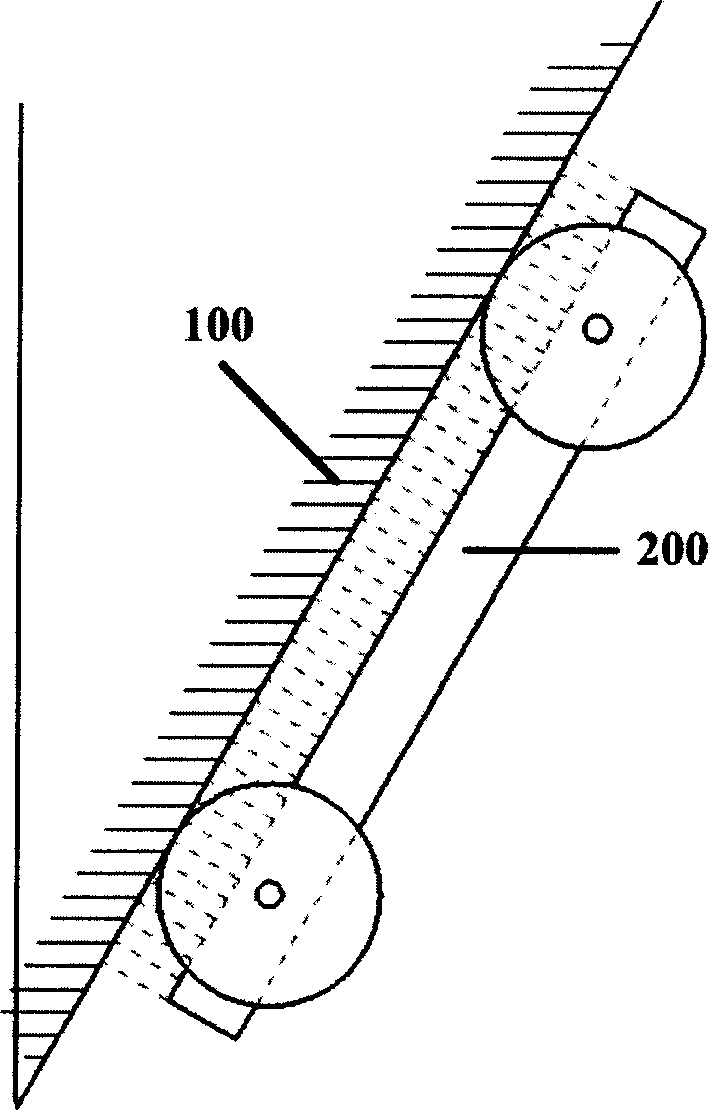

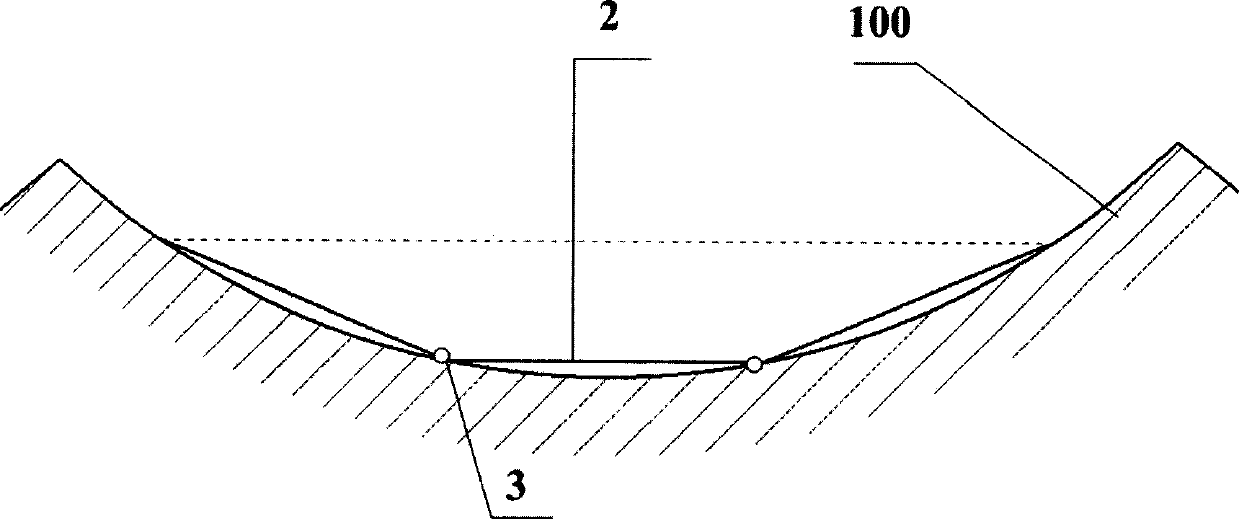

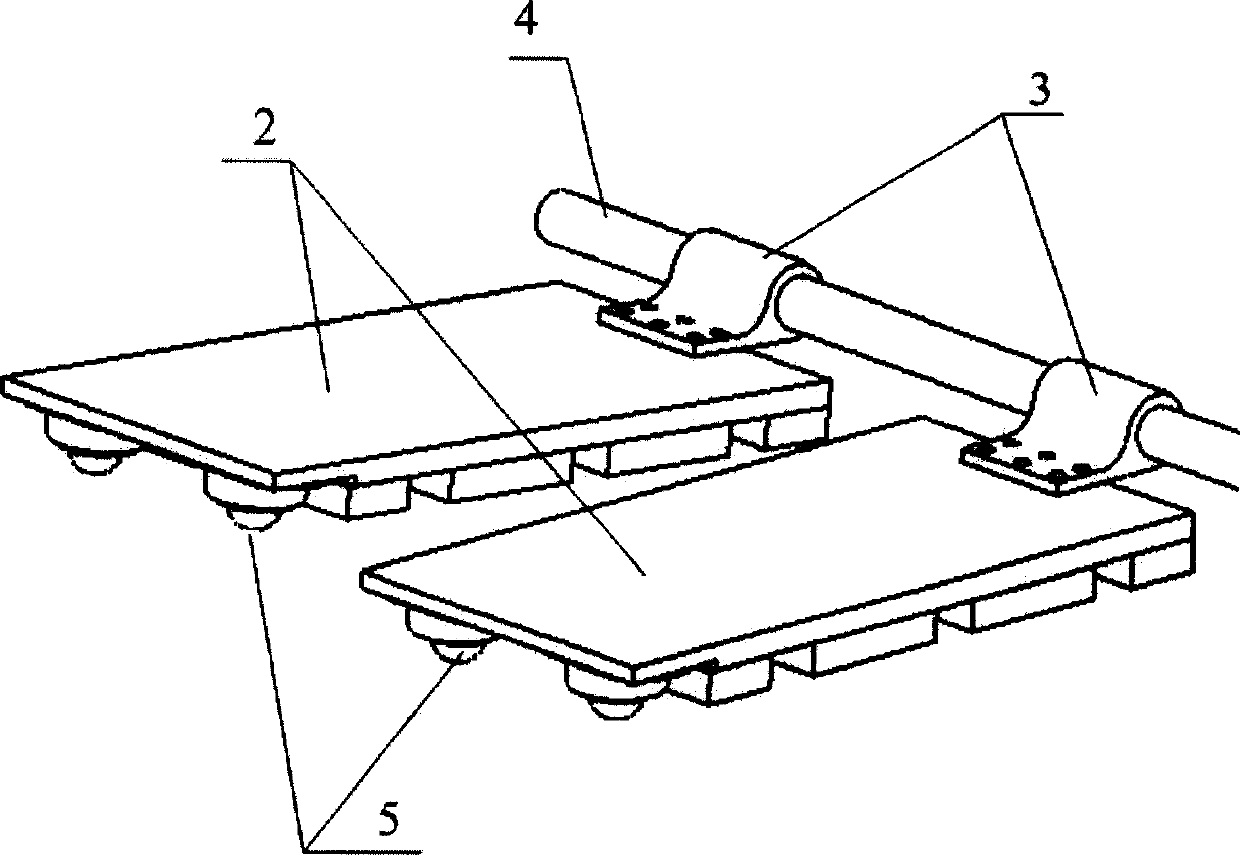

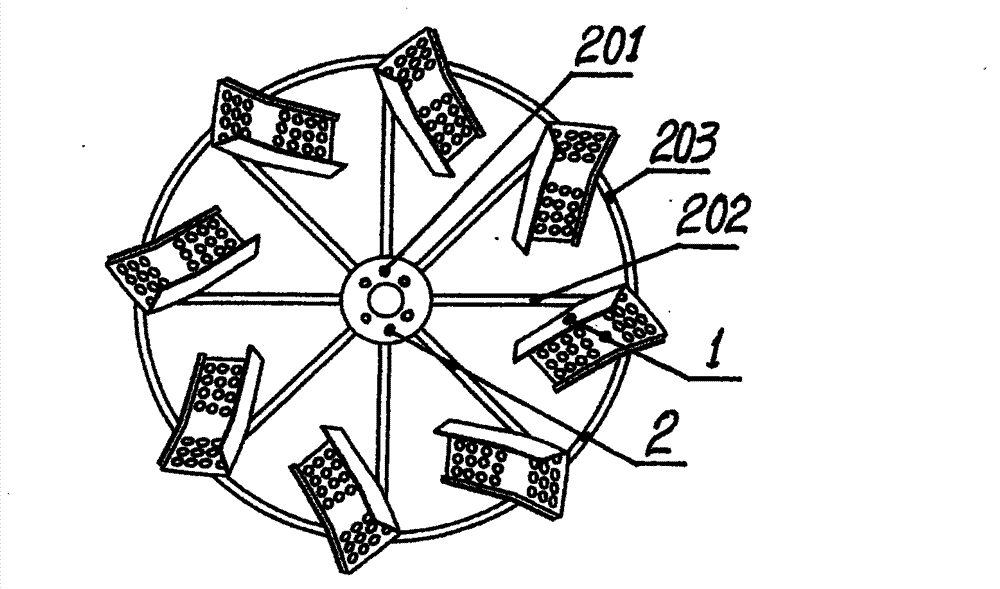

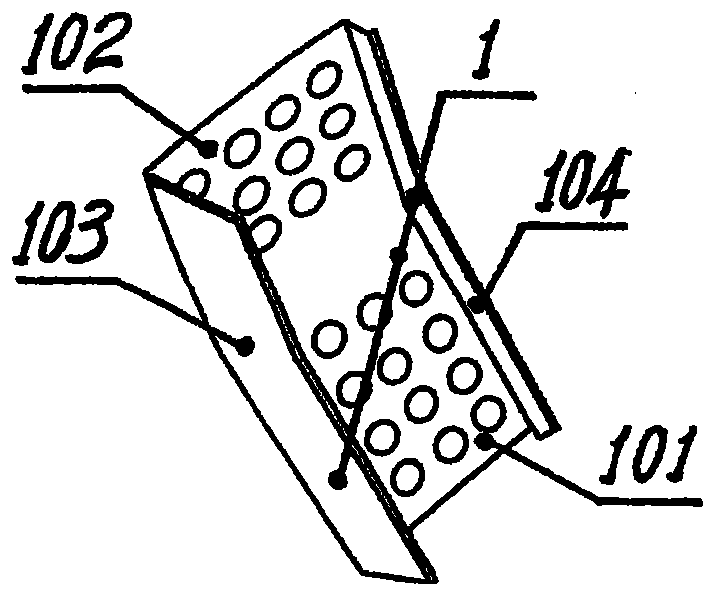

Magnetic adsorption wall climbing robot with curved surface adaptive ability

ActiveCN1736668AWith characteristicsHave made significant progressManipulatorDrive wheelRotational freedom

Disclosed is a magnetic-absorption wall-creeping robot with a self-adaptive capability to curved face, which belongs to the art of robot. Said robot comprises a wheeled shifter and a plural of permanent-magnet absorption devices, the wheeled shifter containing an undercarriage, a drive gear, a traction wheel and an auxiliary balancing wheel; one end of the permanent-magnet absorption device being equipped with the magnetic conduction wall surface by auxiliary balancing wheel, and the other end equipped with the undercarriage or other permanent-magnet absorption device by curved face self-adaptive device with rotational freedom degree of among one to three; the traction wheel being laid out symmetrically and driven by differential drive, and the differential of the traction wheel realizing the deflecting on the magnetic conduction wall surface. The wall-creeping robot having a strong loading power, a flexible motility and a super self-adaptive capability to curved face, has a perfect prospect.

Owner:TSINGHUA UNIV

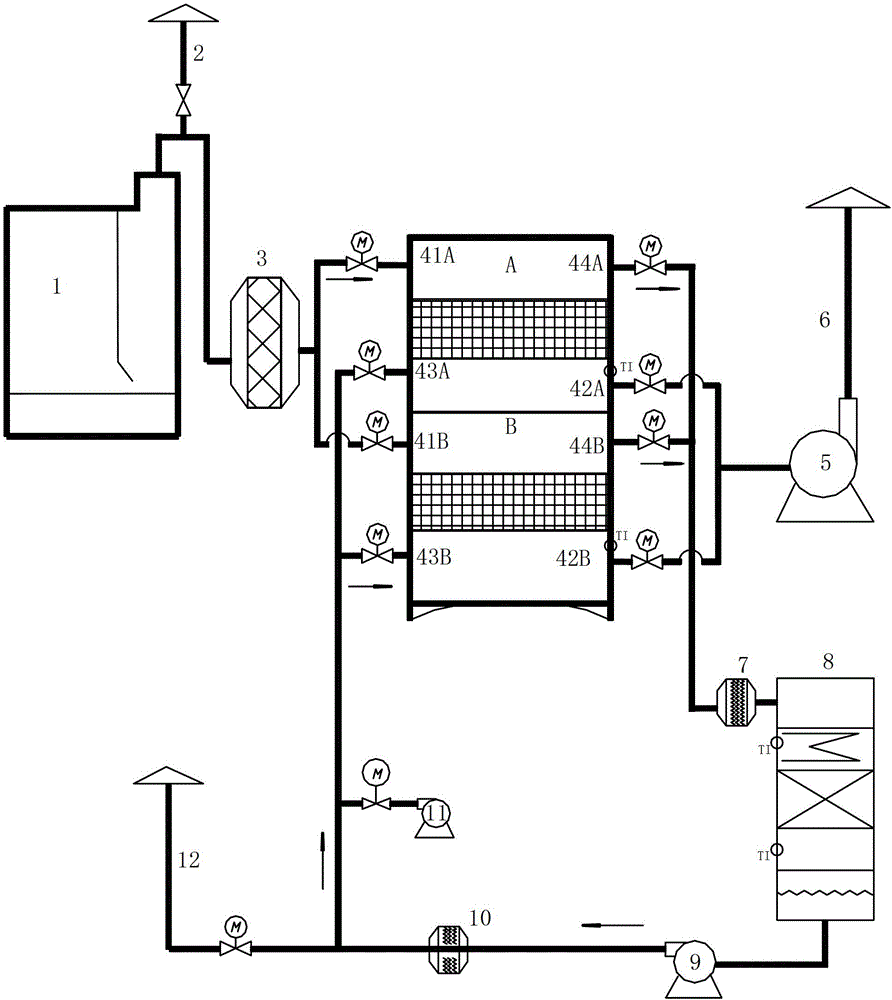

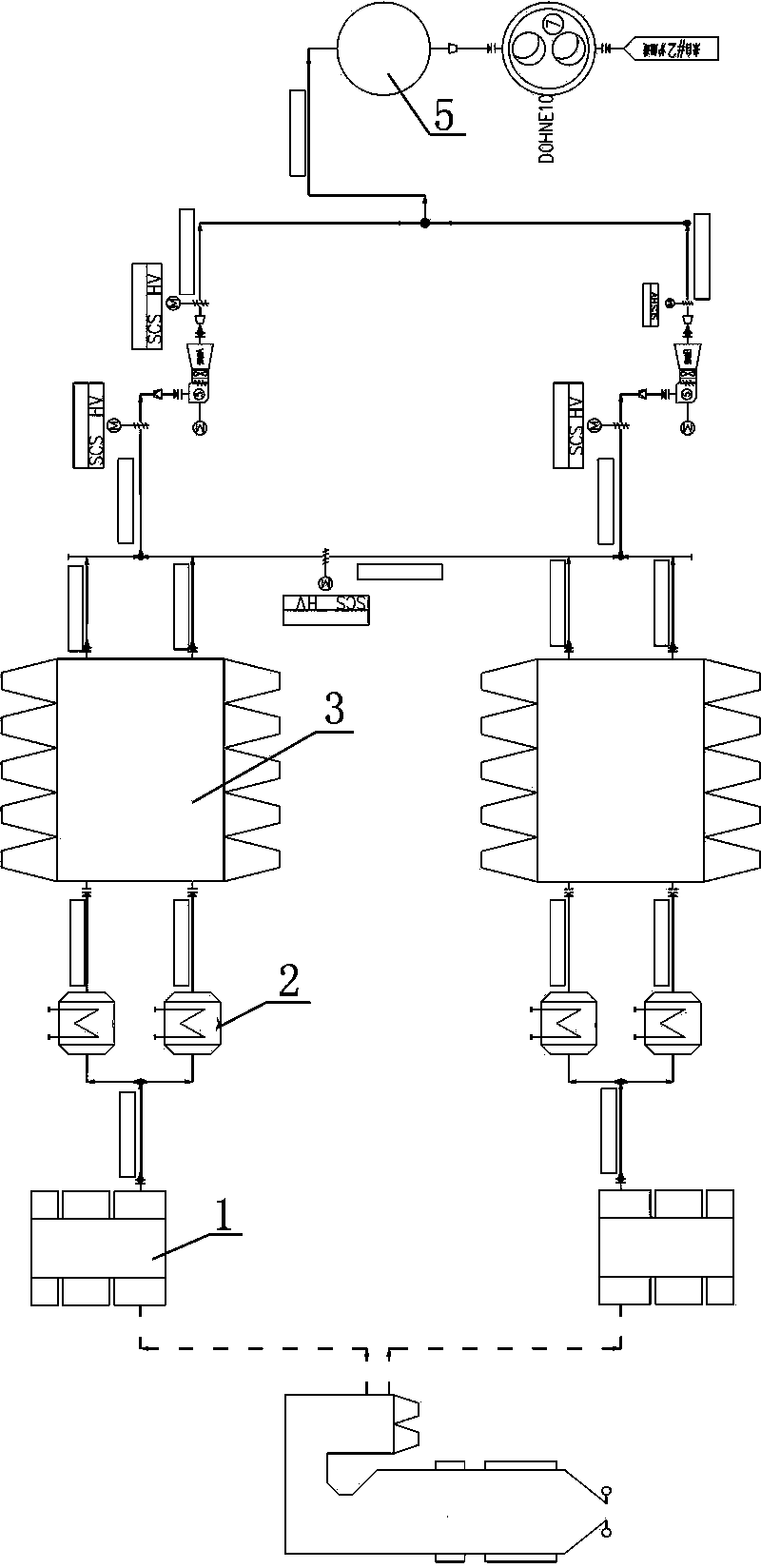

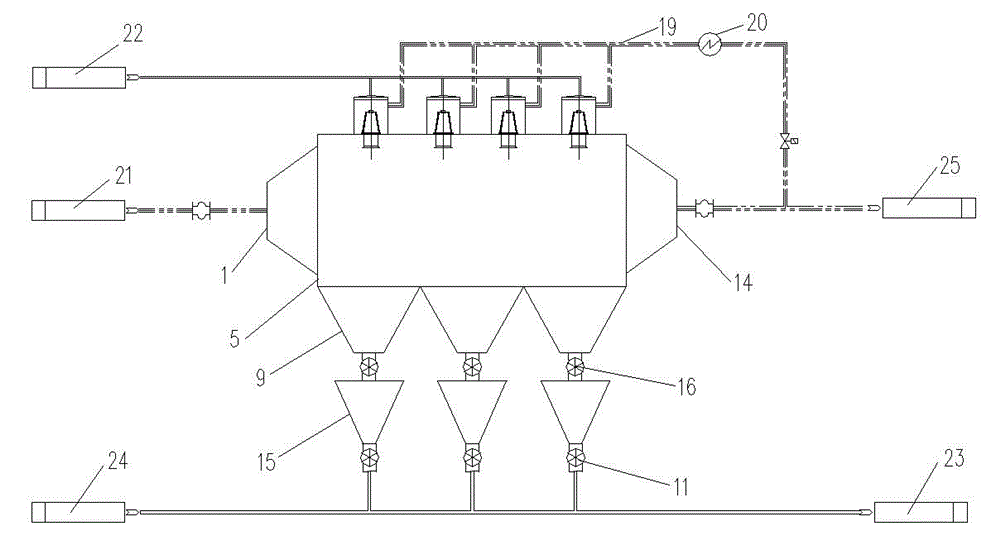

Organic waste gas multifunctional integral processing device

InactiveCN102941000AExtended service lifeLow running costDispersed particle separationIncinerator apparatusActivated carbonProgrammable logic controller

The invention discloses an organic waste gas multifunctional integral processing device, which comprises a programmable logic controller (PLC) control system, a dust filter device, active carbon adsorption beds A and B which are connected in parallel and a catalytic combustion bed. When organic waste gas is adsorbed, the organic waste gas firstly enters into the dust filter device to remove suspended solid; then enters into the active adsorption beds to remove organic substances; finally the purified waste gas is pumped through an adsorption exhaust fan and discharged on standard through an adsorption high-altitude discharge branch. When active carbon is desorbed and regenerated, the hot gas generated by the catalytic combustion bed is pressurized through a desorption fan, and then enters into the active absorption beds to reversely desorb and regenerate the saturated active carbon; the desorbed waste gas enters into the catalytic combustion bed; organics are burned to generate water and carbon dioxide; the hot gas generated at the same time is used for desorbing the active carbon. The processing device is controlled by the PLC, thereby realizing automatic switch between the two absorption beds, so that adsorption and desorption are carried out at the same time. The invention combines two technologies of adsorption and catalytic combustion organically and has complementary advantages.

Owner:TIANJIN UNITED ENVIRONMENTAL ENG DESIGN

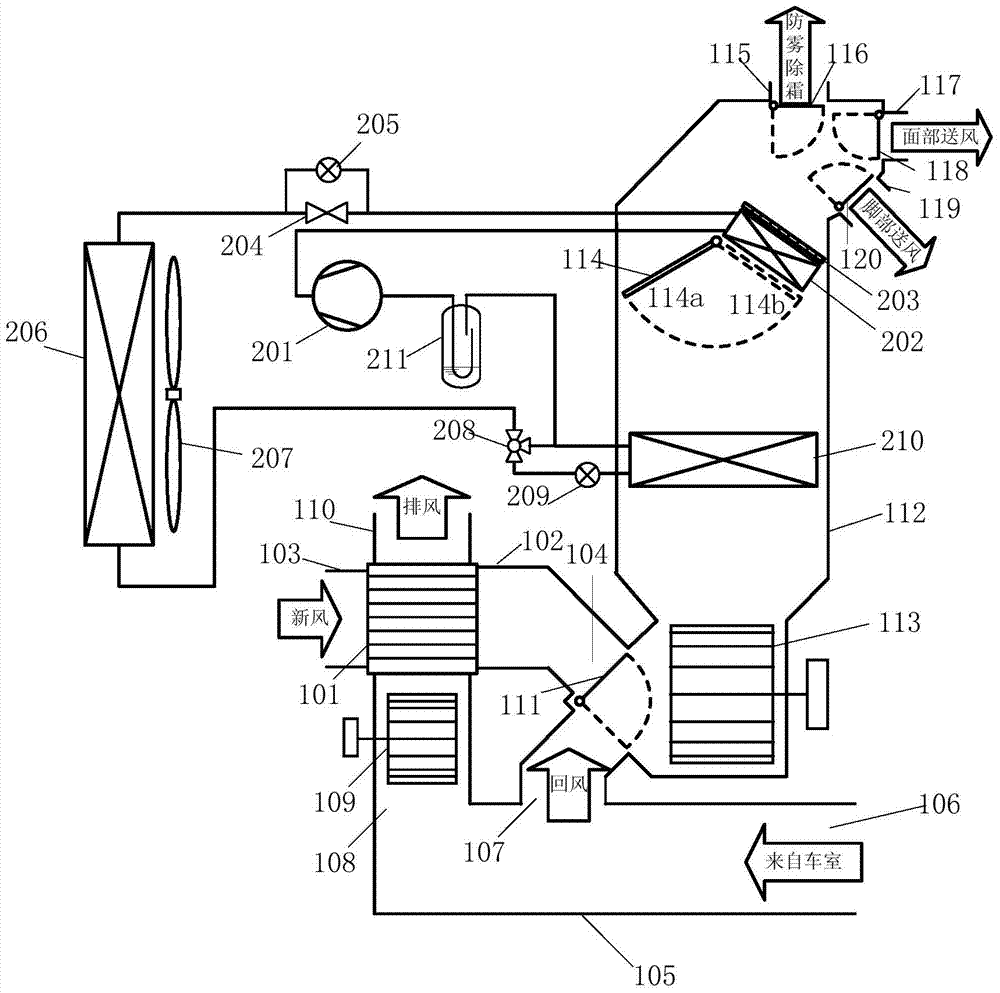

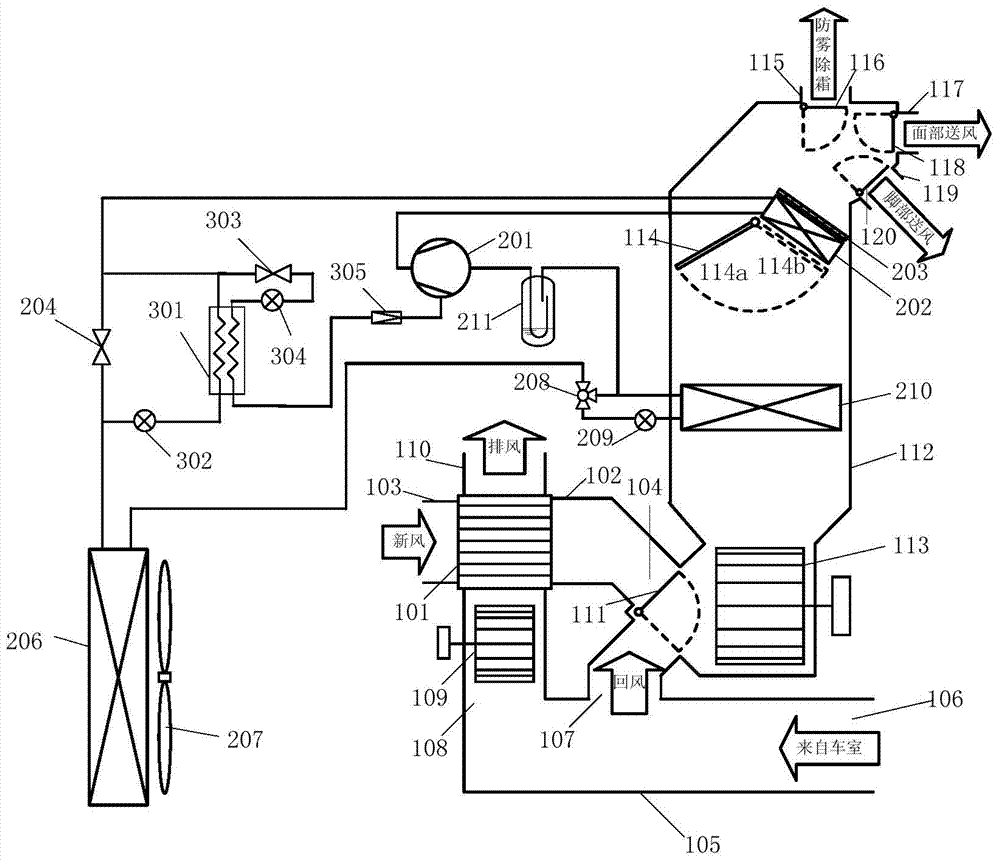

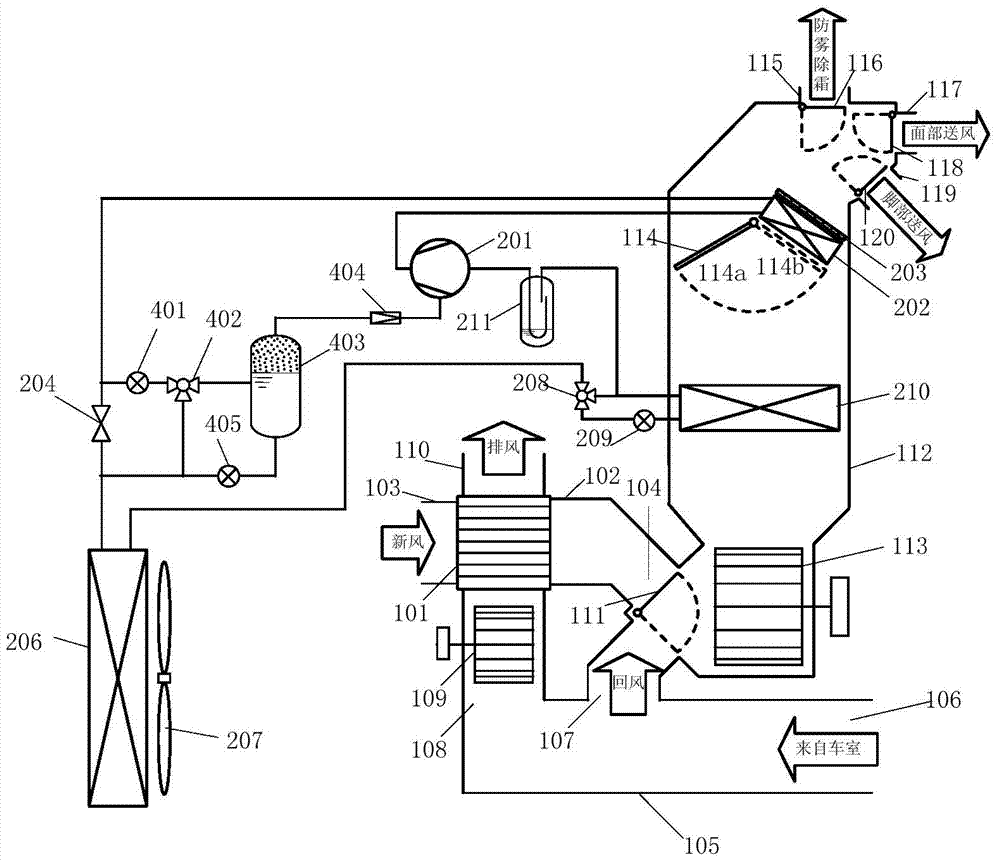

Method for recycling exhaust air heat of electric automobile and heat pump air-conditioning system adopting same

ActiveCN104290561AImprove battery lifeReduce cooling energy consumptionAir-treating devicesHeat recovery systemsAutomobile air conditioningShock resistance

The invention relates to the technical field of automobile air conditioners, in particular to a method for recycling exhaust air heat of an electric automobile and a heat pump air-conditioning system adopting the method. The method for recycling the exhaust air heat of the electric automobile and the heat pump air-conditioning system adopting the method mainly solve the technical problem that in the prior art, due to the fact that a fresh air load is too high in the using process of an air conditioning system of an electric automobile, power consumption of devices is large. By the adoption of the method for recycling the exhaust air heat of the electric automobile, a great amount of heat in exhaust air is recycled, a fresh air load can be lowered to the maximum extent, and therefore compared with the prior art, the power consumption of devices is further reduced. The heat pump air-conditioning system can be switched between a refrigeration mode, a conventional heating mode and a low-temperature heating mode. The heat pump air-conditioning system has the advantages of being high in system efficiency, high in heating performance, low in thermal requirement, high in shock resistance performance, high in system safety and the like under a low-temperature environment.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

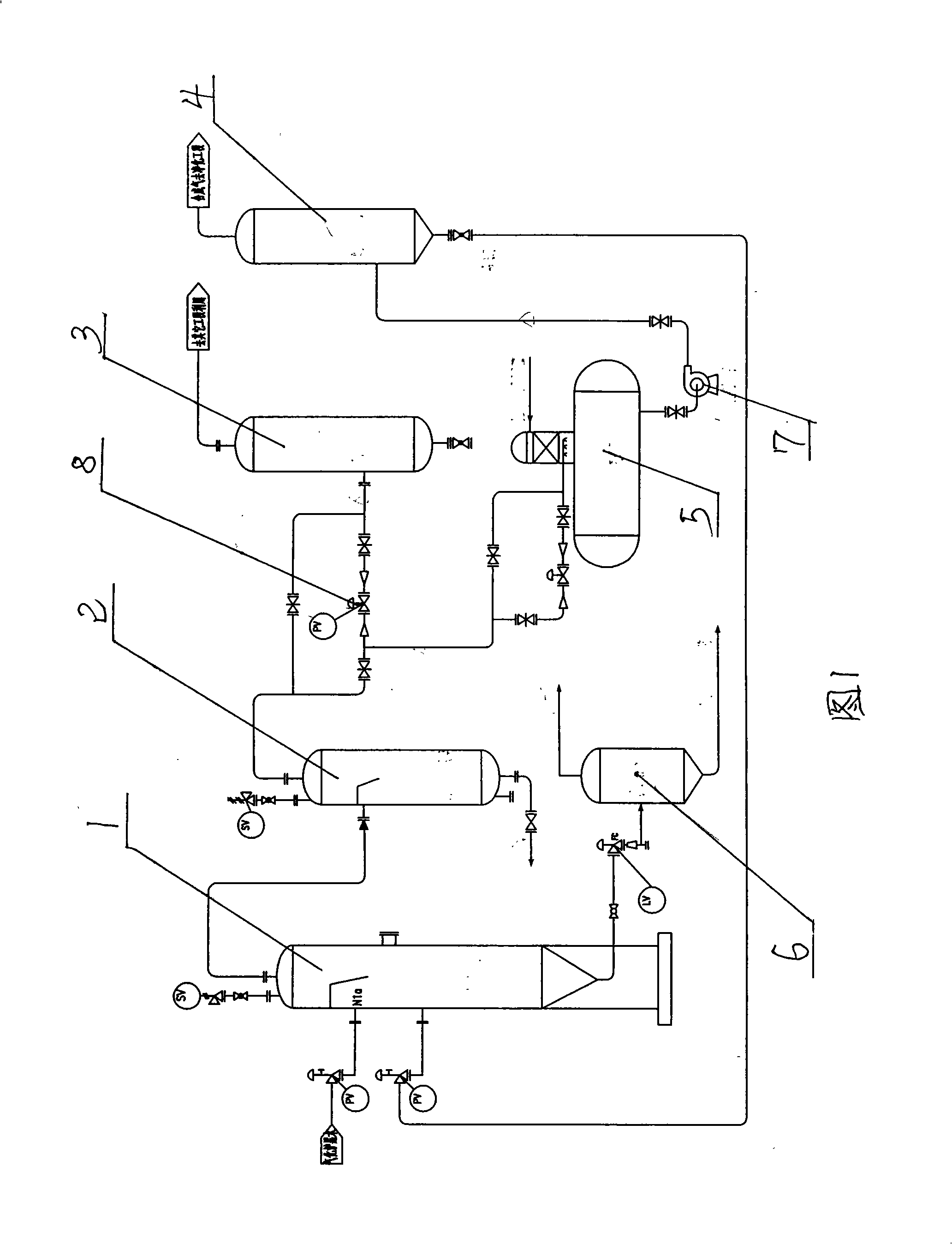

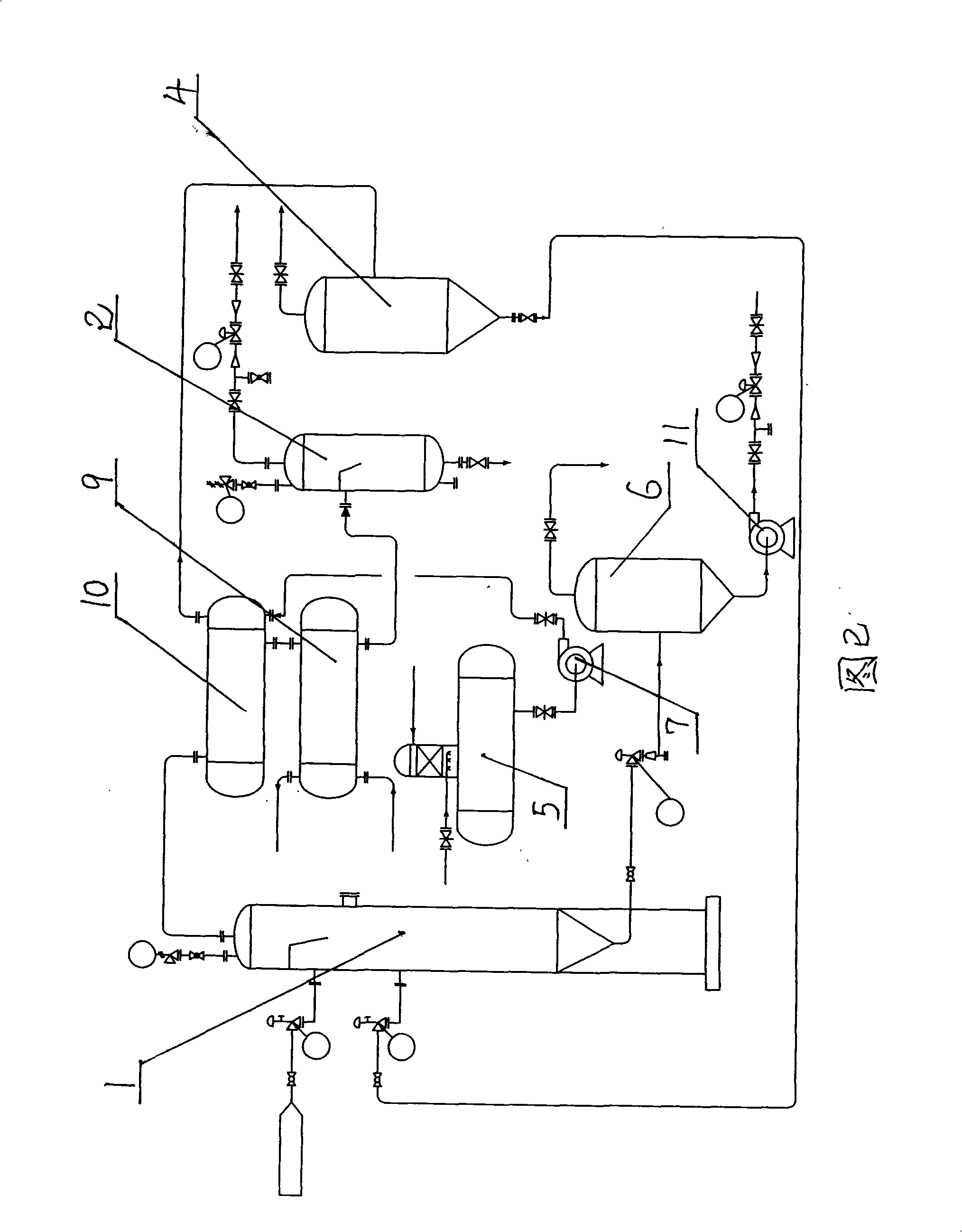

Grey water treatment technology for graded gasification furnace

InactiveCN101306899AImprove transfer efficiencyTake advantage ofMultistage water/sewage treatmentWater/sewage treatment by heatingGas phaseDeaerator

The invention belongs to the ash water processing technology for gasification of coal water slurry in gasified ash water, in particular relating to an ash water processing technique applied in a staged gasification furnace. The technique solves the problems in the prior art of complex structure, energy waste, trivial technological operation and so on. The method comprises the following steps that: black water exhausted from the staged gasification furnace and a syngas scrubber respectively enters into a high-pressure flash tank after decompressed by respective pipes; liquid phase after high-flash flash evaporation in the high-pressure flash tank passes through a pressure-reducing valve and enters into a vacuum flash tank for secondary flash evaporation; the liquid phase after vacuum flash evaporation in the vacuum flash tank enters into a settling tank the position of which is lower than that of the vacuum flash tank for settlement by means of gravity action; gas phase after high-flash flash evaporation in the high-pressure flash tank enters into a separator on the top of the high-flash tank for gas-liquid separation; and one part of separated gas phase enters into a deaerator and directly contacts the ash water for heat exchange, and the other part of the steam enters into a steam buffer tank through a pressure control valve. Compared with the prior flow, the adoption of the flow saves equipment investment by 3 million; and about 10 tons of steam is supplied in normal operation.

Owner:山西丰喜肥业(集团)股份有限公司临猗分公司

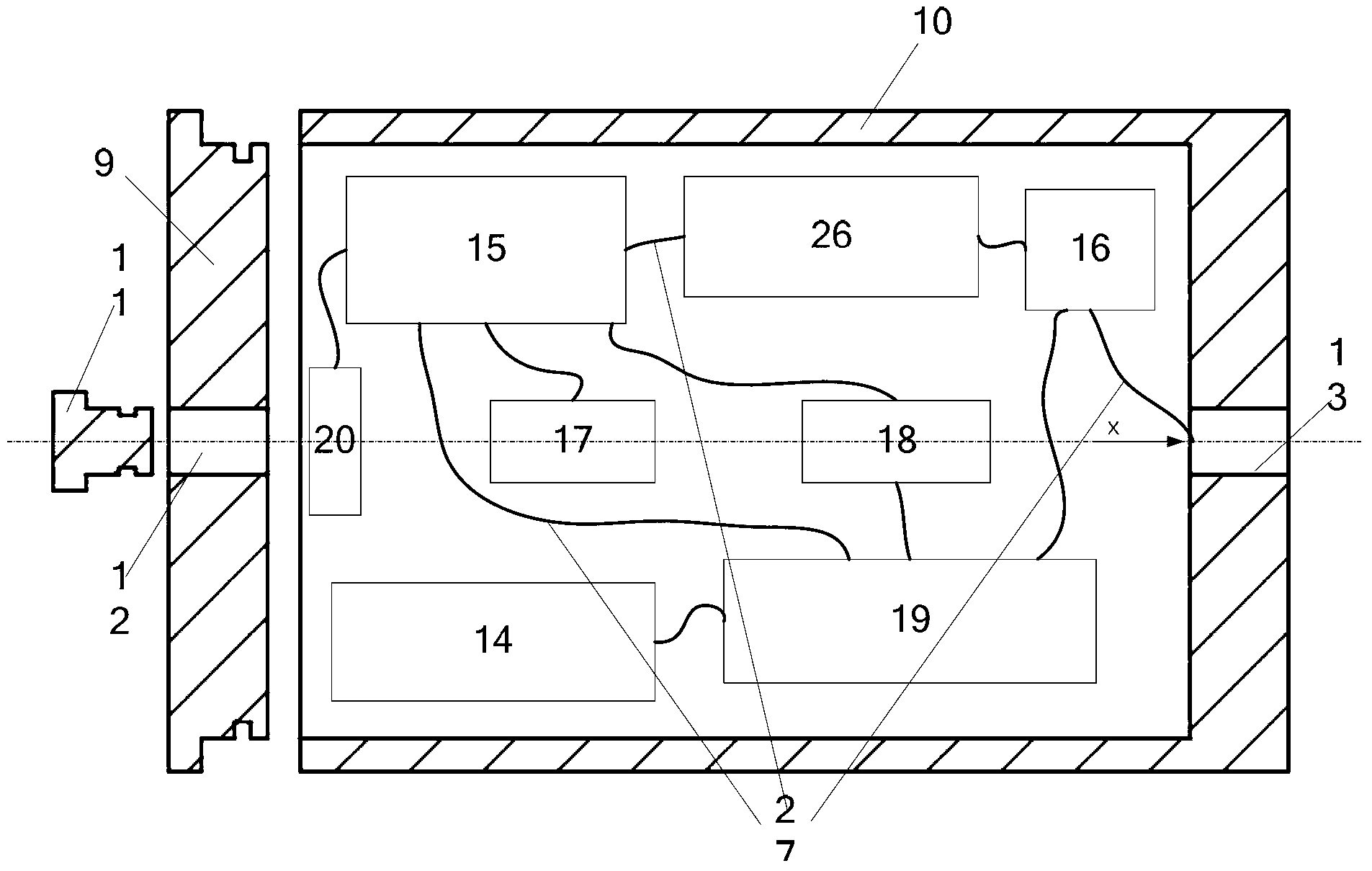

Inner detection system for submarine pipelines and detection method thereof

The invention discloses an inner detection system for submarine pipelines and a detection method thereof. The inner detection system comprises an electronic sealed cabin arranged in a supporting frame. The supporting frame is provided with a supporting roller array, an odometer wheel, a pressure sensor, a temperature sensor and a sound sensor, wherein the supporting roller array, the odometer wheel, the pressure sensor, the temperature sensor and the sound sensor are distributed in an annular mode. The detection method includes: the inner detection system is connected to an upper computer to download signals collected by the sensors, and filtering and noise reduction processing is performed on the signals; traveling mileage of the inner detection system and included angles of the axis of the inner detection system and a local geomagnetic field and local gravitational acceleration are calculated at any time t, and a direction vector of the axis of the inner detection system is obtained through the included angles; the position of the inner detection system at any time is obtained; and whether leakage exists is judged through comparison of processed sound signals, pressure signals and temperature signals, and leakage rate is estimated. The inner detection system for submarine pipelines and the detection method of the inner detection system achieve detection of little leakage, improve detection accuracy, reduce detection difficulty and cost, and shorten detection period.

Owner:TIANJIN UNIV

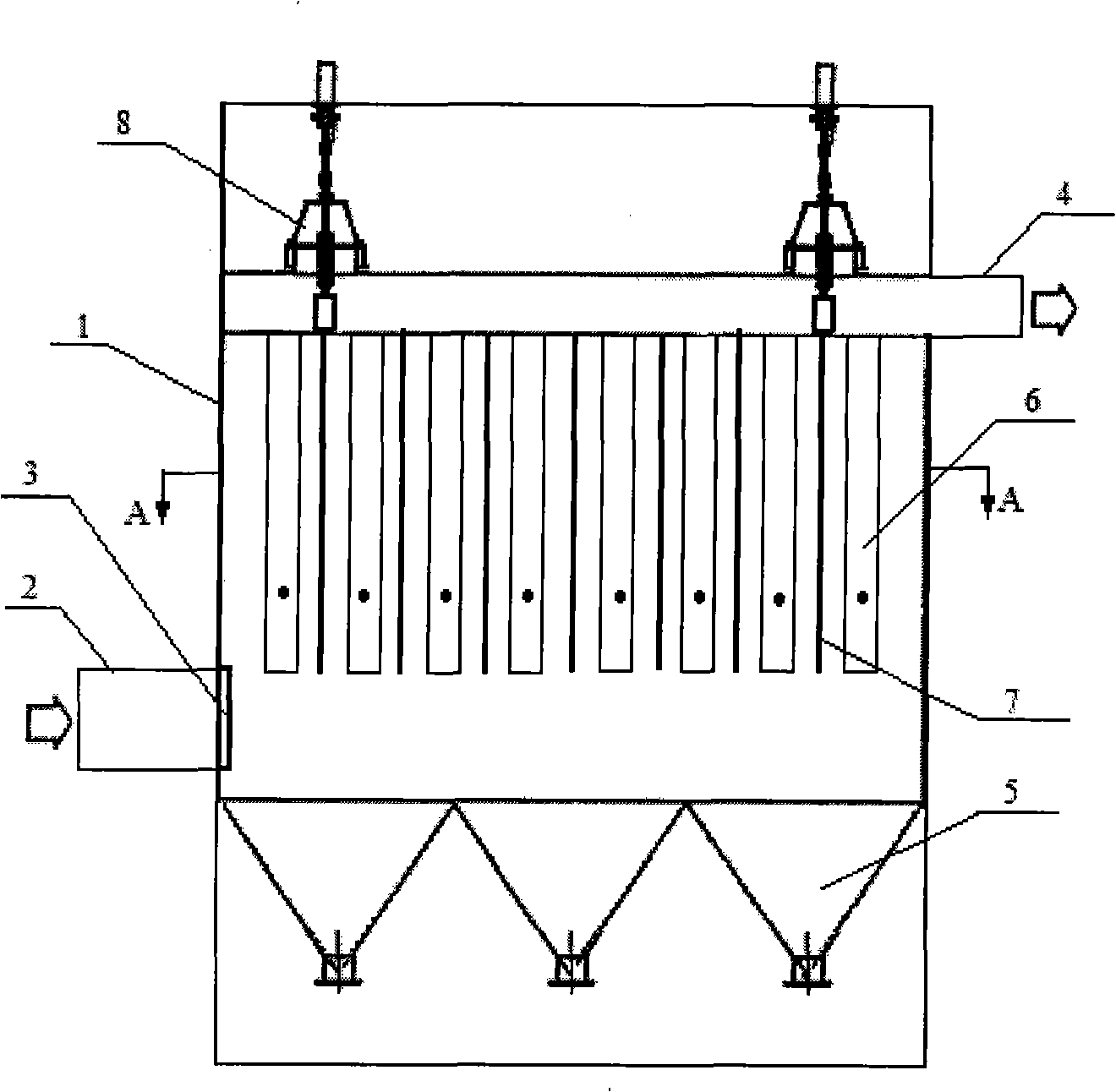

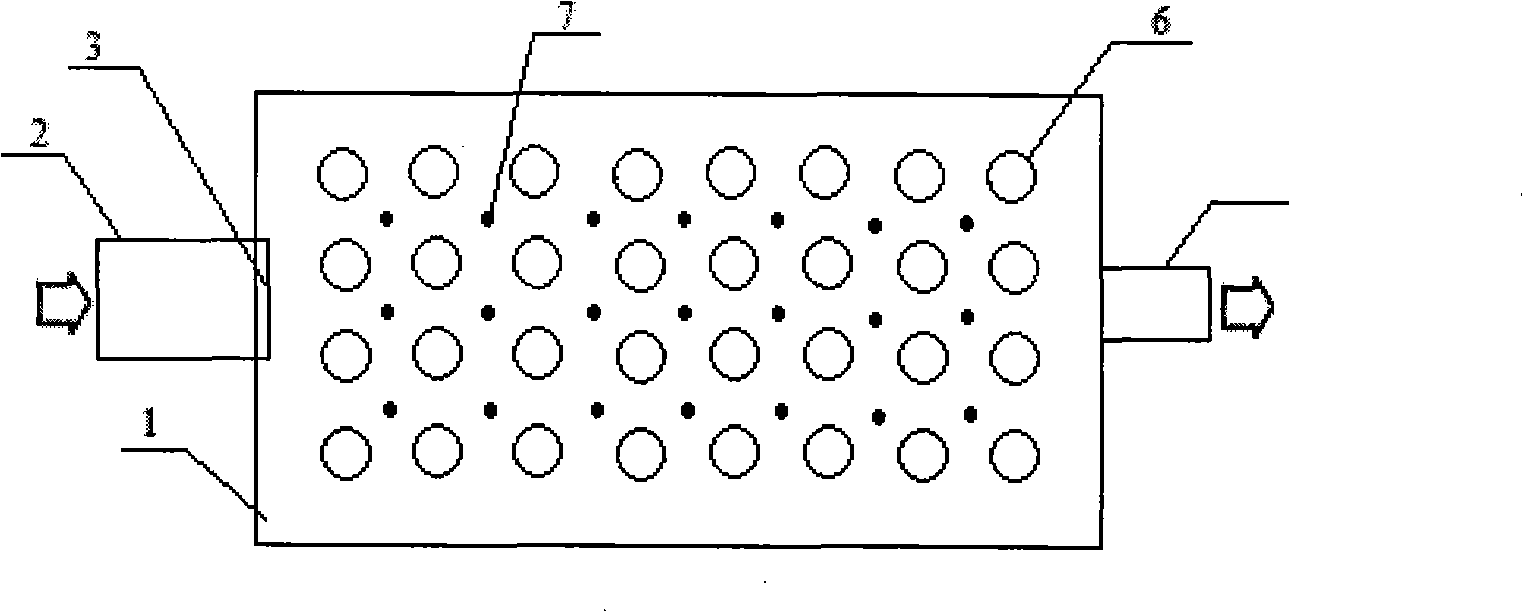

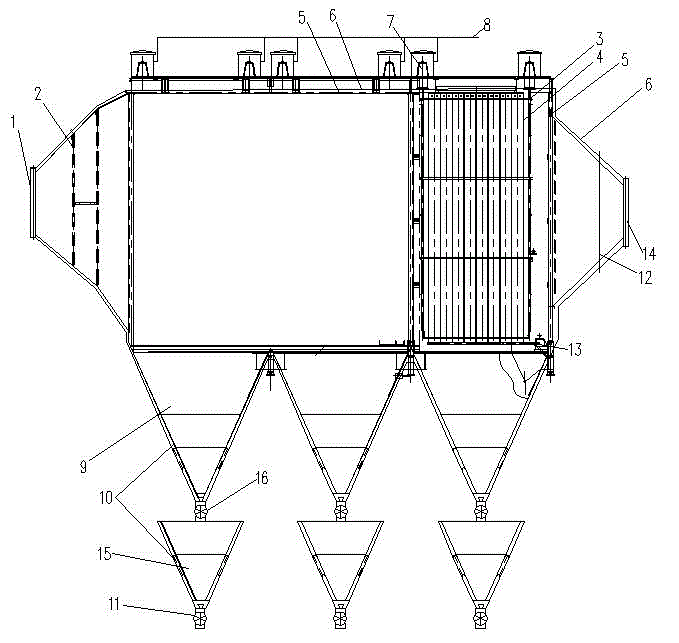

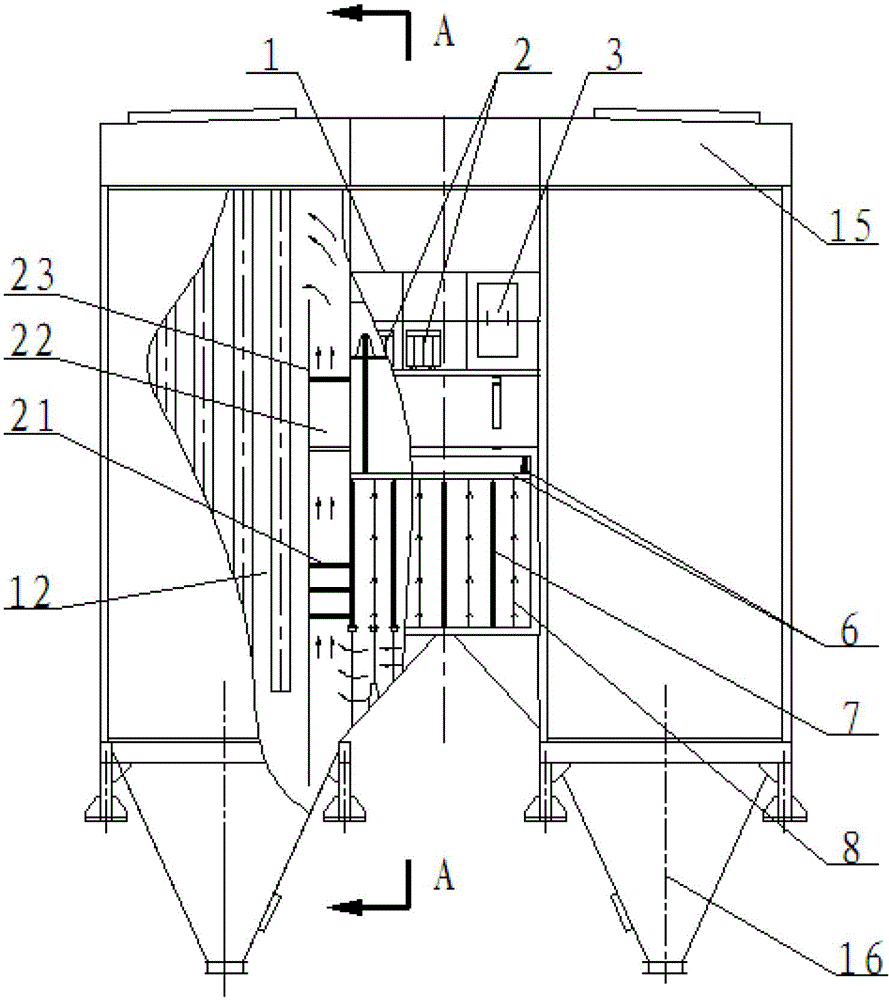

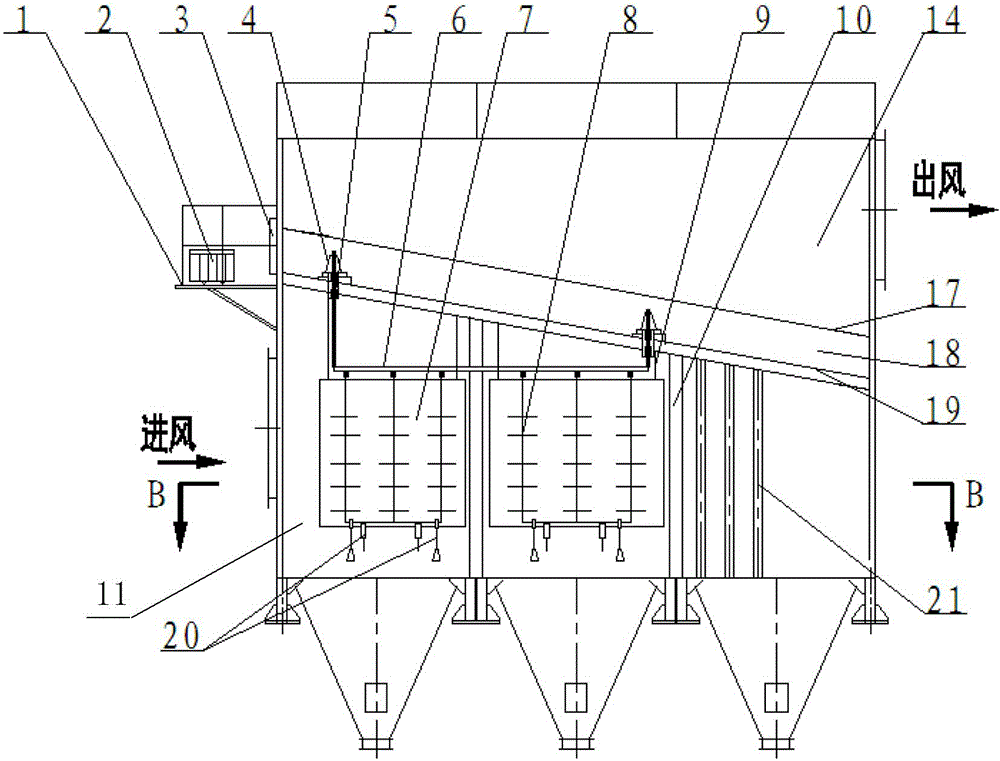

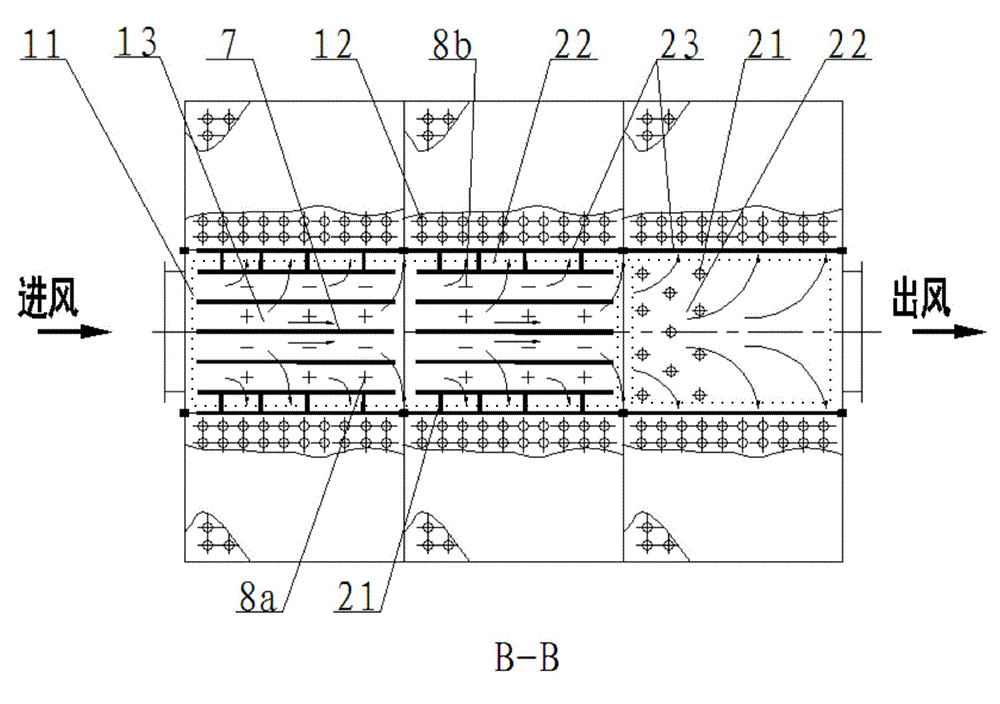

Bag type dust arrest pole electric dust-collecting device

InactiveCN101274305AEfficient removalSmall running resistanceCombination devicesElectrostatic separationElectricityHigh pressure

The invention discloses a polar electricity dust removing device with bagged dust collection, which comprises a dust remover shell, a smoke gas inlet, a uniform air board, a smoke gas outlet, dust buckets, filtering bags, electrode wires and a high-voltage insulating compartment, wherein, a plurality of rows of cloth bags are evenly arranged at interval inside the shell, and the high-voltage electrode wires are arranged at the circle center of a concentric circle of every four cloth bags and connected with a power source through the high-voltage insulating compartment arranged at the top of a dust remover; the uniform air board is arranged under a plurality of rows of filtering bags at the lateral wall of the dust remover shell close to the smoke gas inlet, multiple levels of dust buckets are arranged under the multiple rows of filtering bags, and the smoke gas outlet is arranged above the multiple rows of filtering bags at the lateral wall of the dust remover shell. The polar electricity dust removing device with bagged dust collection has the advantages of simple and unique structure, superior technical performance, smaller resistance, effective overcoming of the reverse corona phenomenon and good dust removing effect, etc. The polar electricity dust removing device with bagged dust collection improves the integral dust removing efficiency under the agglomeration action of electrostatic fields and the interception action of the cloth bags, effectively protects the filtering bags from being burned out by discharge sparks by adopting protective cage structure, and reduces device cost by substituting the steel polar plates with the filtering bags.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

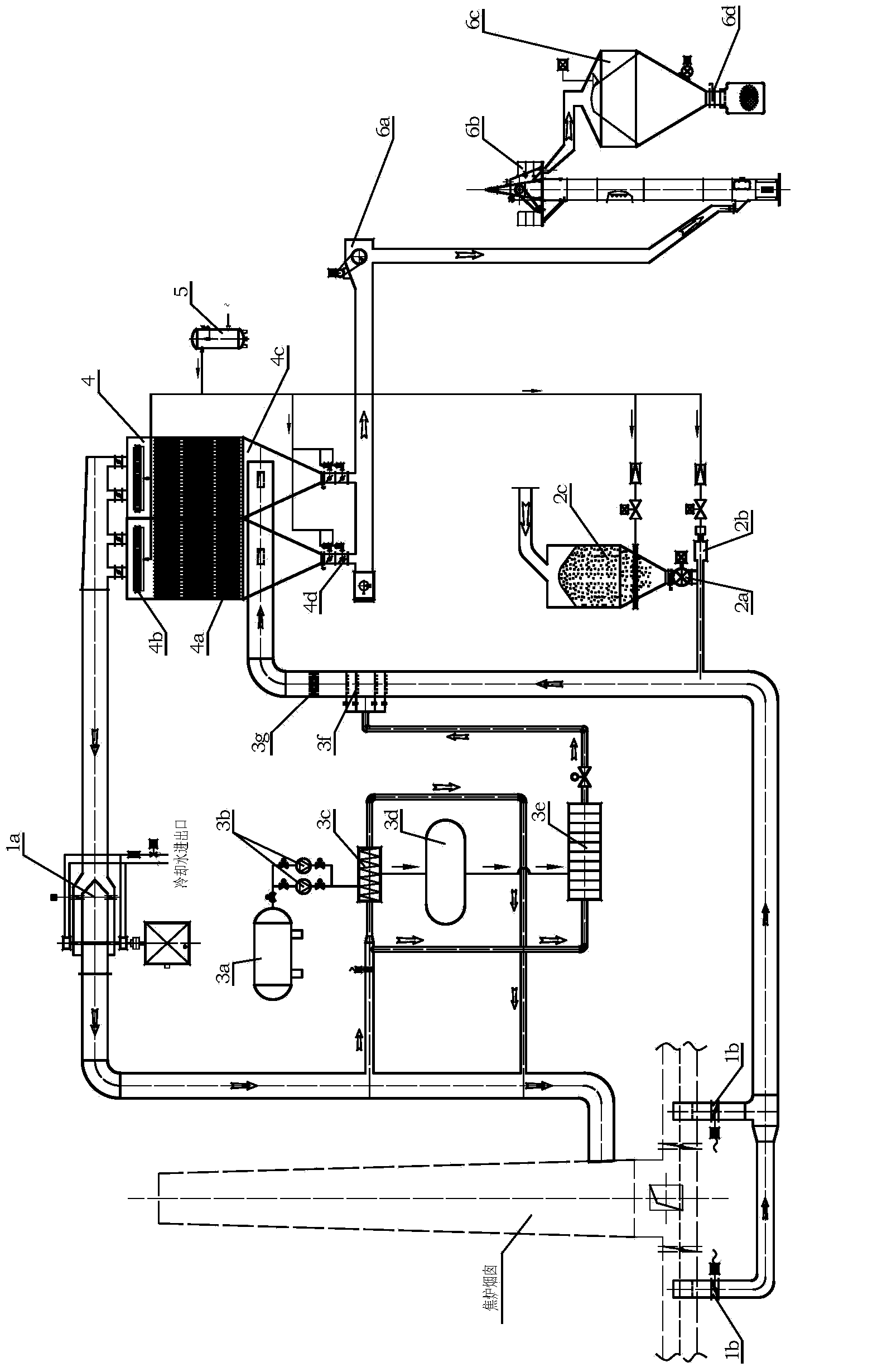

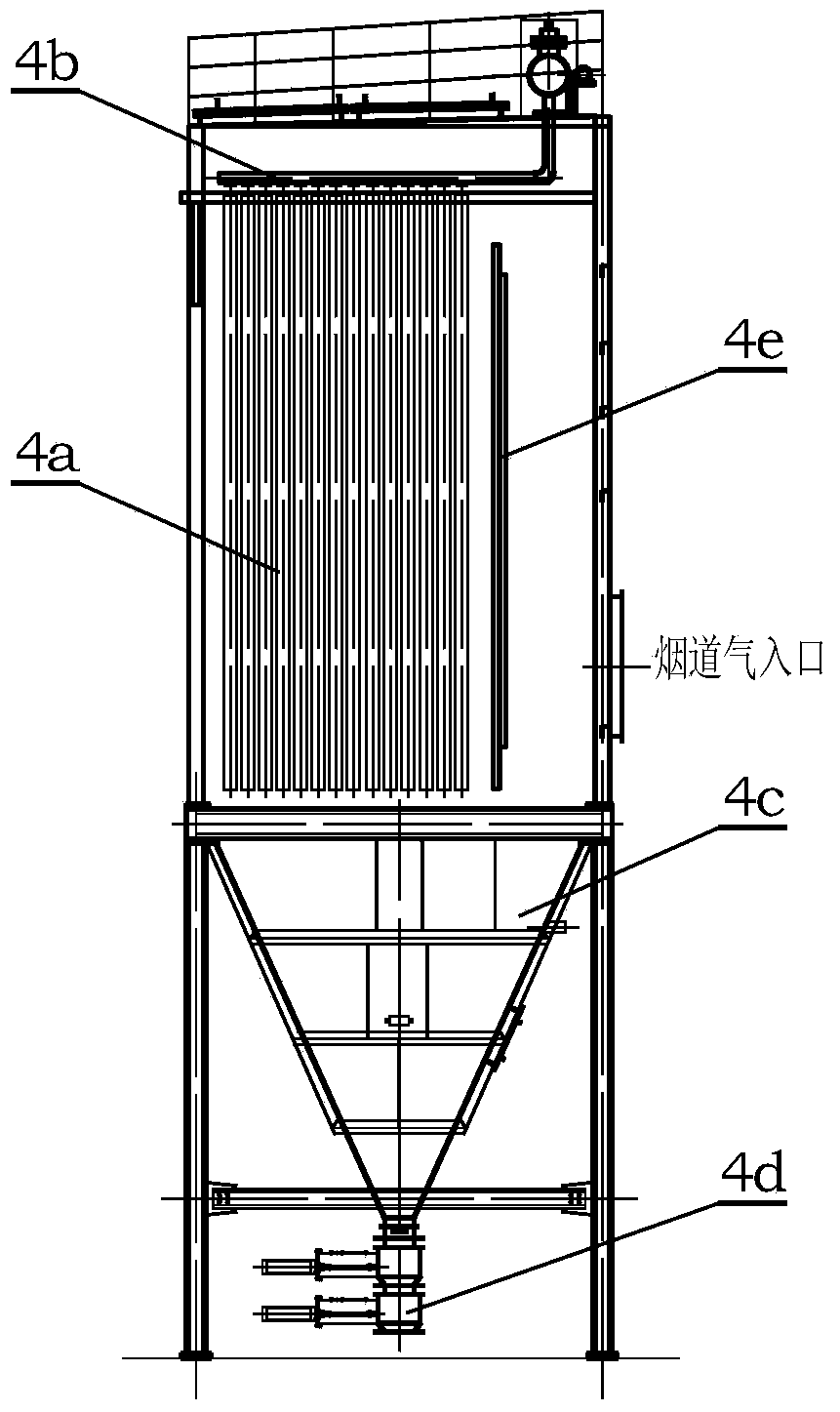

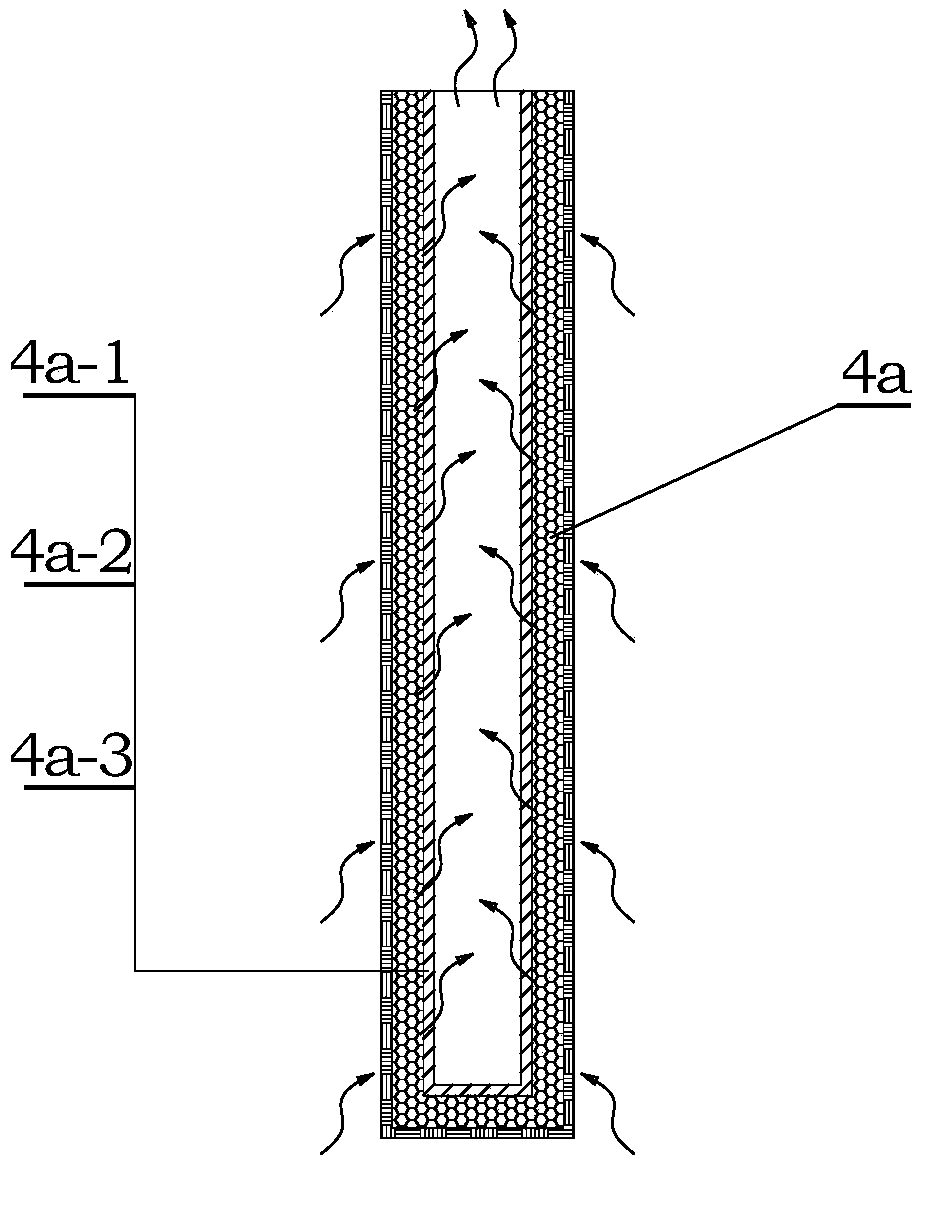

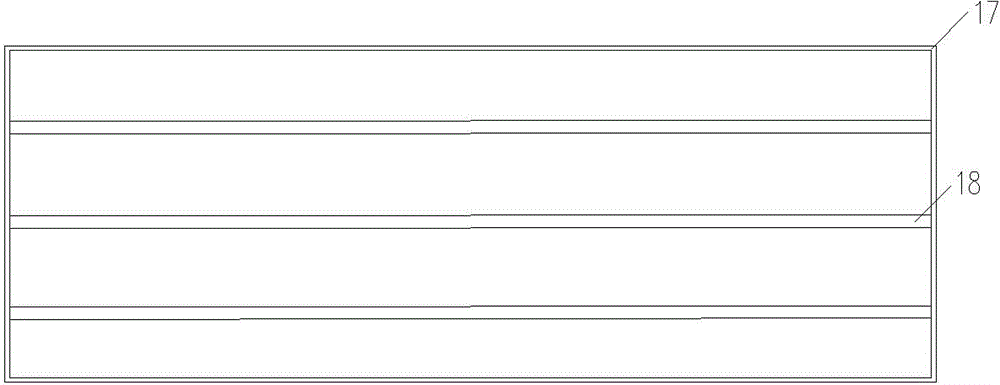

Integrated low-temperature flue gas desulfurization, denitration and ammonia removal process

ActiveCN103816780AImprove dust filtration efficiencyImprove efficiencyDispersed particle separationEvaporationEmission standard

The invention relates to an integrated low-temperature flue gas desulfurization, denitration and ammonia removal process suitable for the desulphurization and the denitration of coke oven flue waste gas of which flue gas temperature is greater than 180 DEG C and the content of SO2 is less than 150 mg / Nm3. According to the process, dry desulphurization is performed before denitration according to a fluidized principle, ammonia gas produced by evaporating residual ammonia water at an ammonia evaporation workshop section in a coking plant is used as a reducing agent, a cloth bag combining with an ammonia removal catalyst composite structure is used as a dust removing and denitration manner, and during efficient desulphurization and denitration, an escape amount of ammonia is controlled to be lower than a national emission standard value. Compared with the prior art, the process has the benefits that 1), the integrated desulphurization, denitration and ammonia removal efficiency is high; 2) the denitration manner is unique, and the structural form of equipment is advanced; 3) ash removal is simple; 4) the energy is saved, and the operating cost and the once investment are reduced; 5) residual ammonia water in a coal gas purification process is fully recycled; 6) the residual heat is fully recycled.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

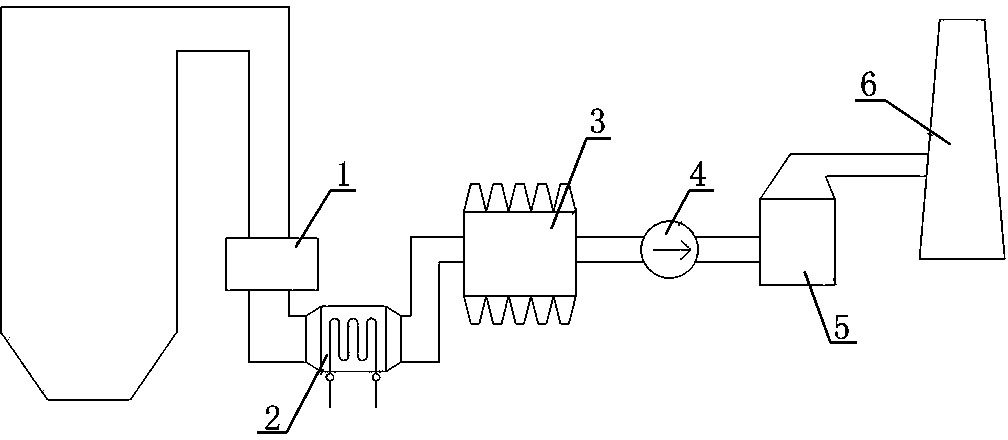

Low temperature electric precipitation system in fuel electric plant

InactiveCN103363536AImprove the dust collection rateMeet the requirements of emission standardsLighting and heating apparatusAir preheaterEnvironmental resistance

A low temperature electric precipitation system in a fuel electric plant comprises at least one air preheater, at least one electric precipitator and connecting pipes for connecting the air preheater and the electric precipitator together, a flue-gas heat exchanger for lowering the flue-gas temperature entering the electric precipitator to enable the flue-gas temperature to reach or be lower than flue-gas dew point at the temperature of 90 DEG C is arranged between the air preheater outlet and the electric precipitator inlet; the electric precipitator is communicated with a desulfuration absorption tower through an induced-draft fan; a chimney is connected with the rear part of the desulfuration absorption tower. The flue-gas heat exchanger adopts a backward flow heat exchange type; a vertical pipe heat exchange flow passage or a horizontal pipe heat exchange flow passage is arranged at the inner part of the flue-gas heat exchanger; the system has the characteristics that the project equipment investment is reduced; the auxiliary power ratio is lowered; the energy is saved; the consumption is reduced; the heat economy of the unit can be improved; the latest environment-friendly emission standard can be satisfied.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST +1

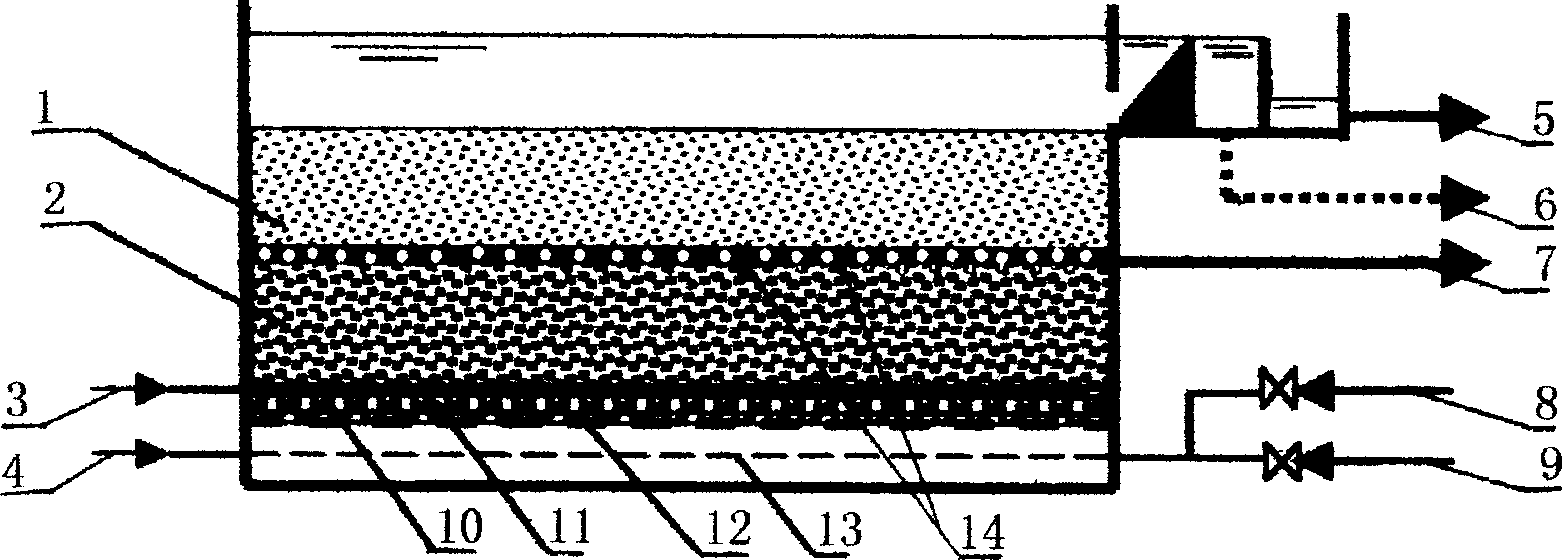

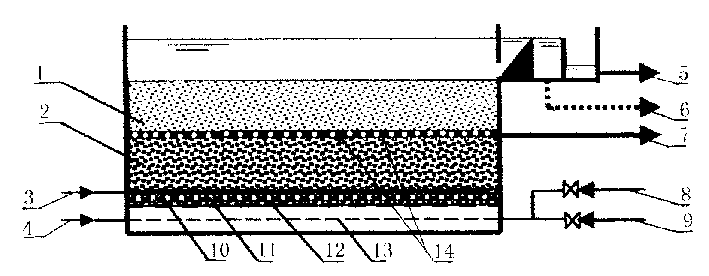

Double-layer filter material biological aeration filter pond

InactiveCN1401592ASmall running resistanceReduce backwash water consumptionTreatment using aerobic processesSustainable biological treatmentGranularitySludge

An aerating biologic filter pool with dual layers of filter material for treating sewage is characterized by that two filter materials with different granularities are used, middle discharge tubes with water holes are arranged between two filter layers, and air and water are alternatively used for flushing. Its advantages are both decarbonating and nitrifying functions, high effect, simple system and low cost.

Owner:TSINGHUA UNIV +1

Method and apparatus for converting rotary motion into reciprocating impact motion

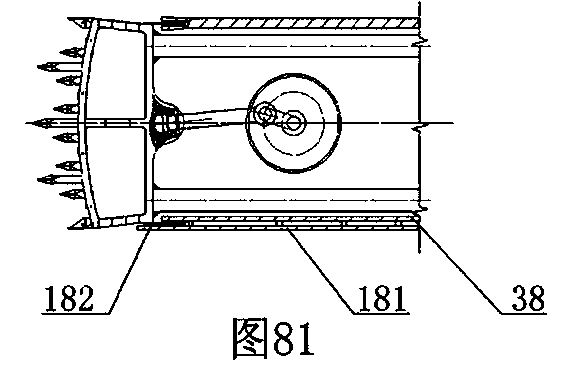

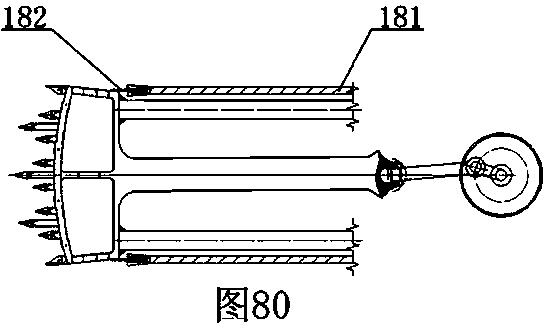

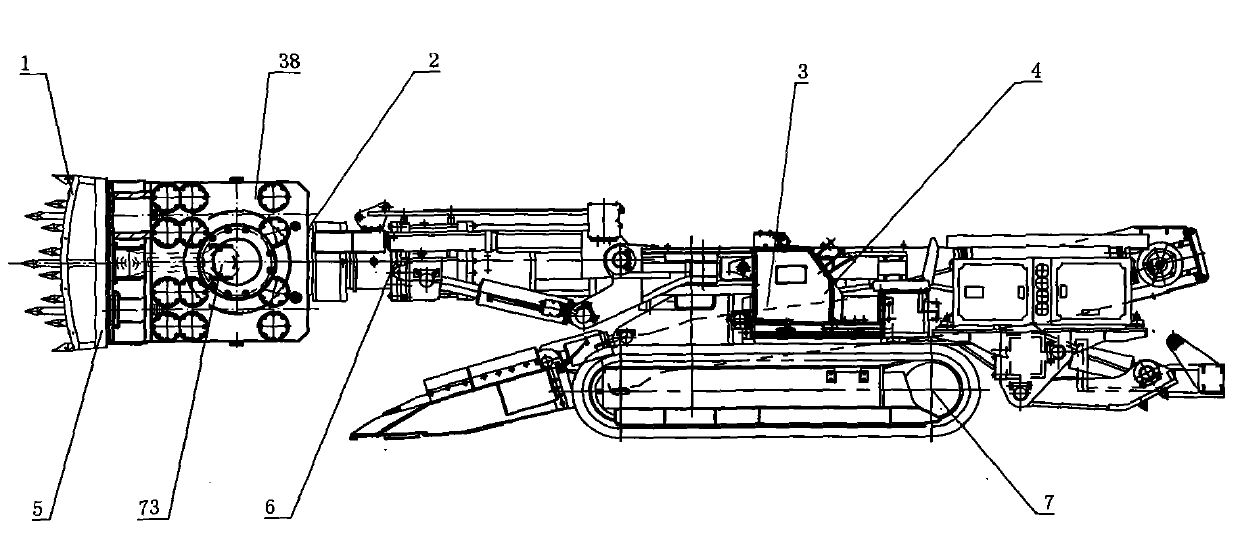

ActiveCN103498673APass smoothlySmooth nestingDriving meansPercussion drillingDrive shaftReciprocating motion

A method and device for converting rotary motion to reciprocating percussion motion. The device comprises a machine body (4), a travel portion (7), and a reciprocating percussion portion (5). The reciprocating percussion portion (5) comprises a percussion drive mechanism (2), a rocker arm (6), and a percussion head (1). The percussion drive mechanism (2) comprises a percussion power source member (11), a transmission component, and a crankshaft (10). The percussion power source member (11) comprises a motor, and the motor comprises a power output shaft (14). The transmission component comprises a power gear (13) and a transmission gear (12). The power gear (13) is mounted on the power output shaft (14). The transmission gear (12) drives the crankshaft (10). The transmission component comprises a transmission shaft. The power output shaft (14) is perpendicular to the rocker arm (6), and is parallel to the transmission shaft and the crankshaft (10) so that the transmission gear (12) drives the crankshaft (10) to convert rotary motion to reciprocating motion; or the power output shaft (14) is parallel to the rocker arm (6), the crankshaft (10) is driven to convert rotary motion to reciprocating motion after the power direction is changed by a power bevel gear and a transmission bevel gear. The crankshaft (10) drives the percussion head (1) to perform reciprocating percussion. The travel portion (7) drives the machine body to travel. The machine body (4) drives the reciprocating percussion portion (5) to move and work continuously. The device applies to the mining field or mechanical engineering field, and has advantages such as strong structural strength and a small amount of maintenance.

Owner:刘素华

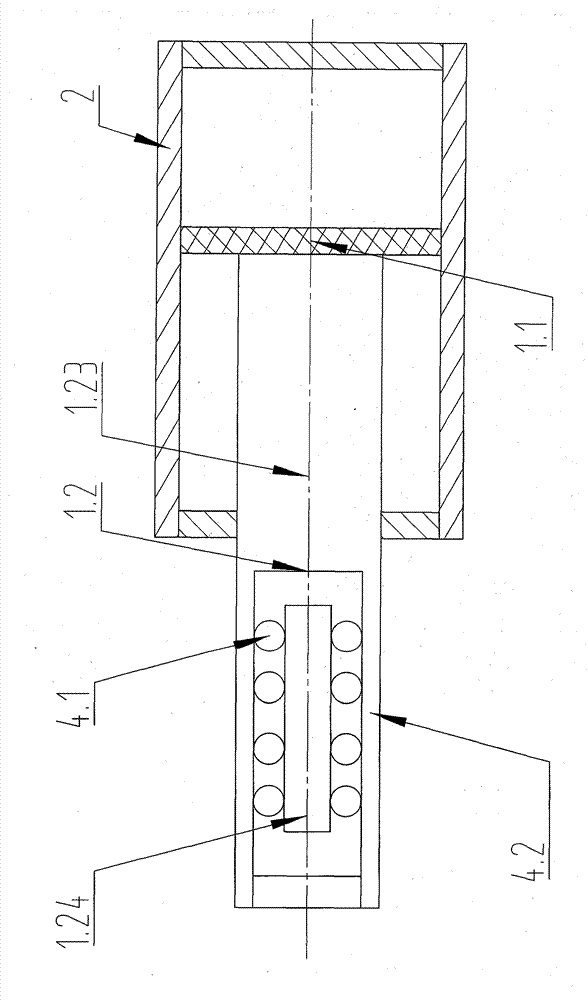

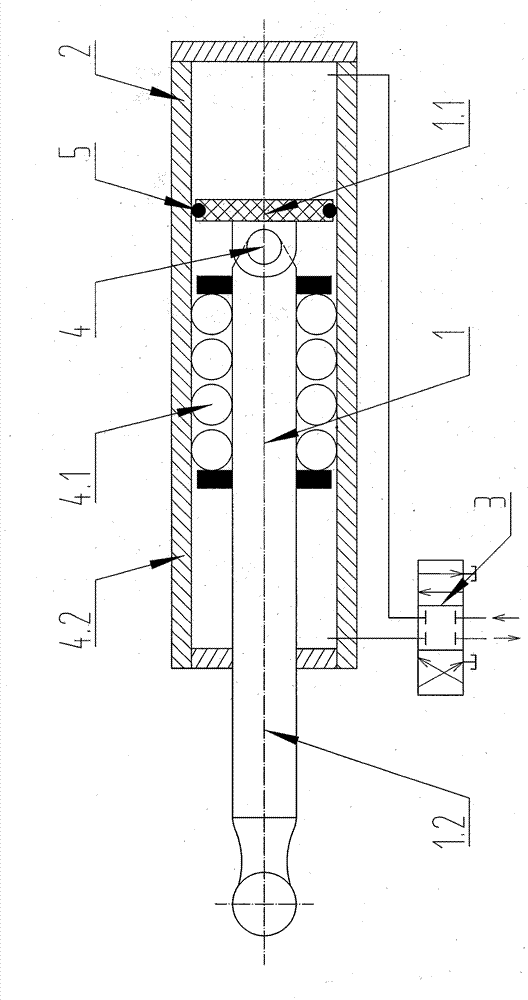

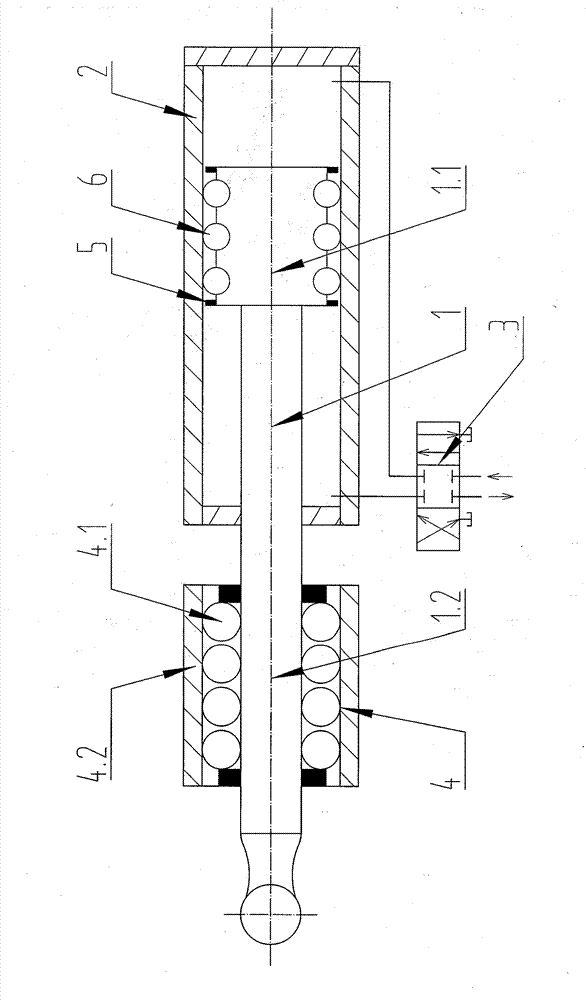

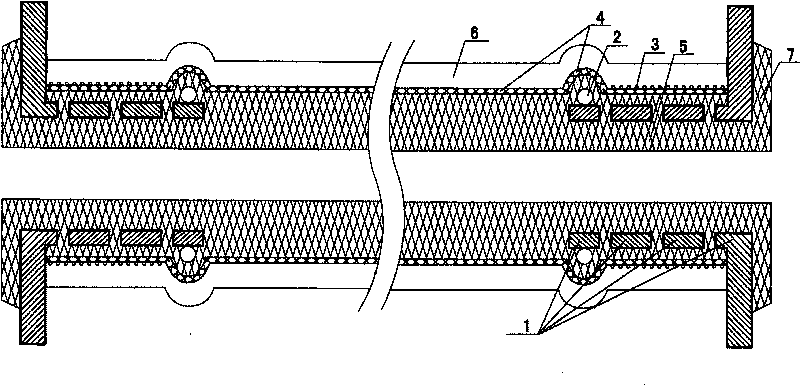

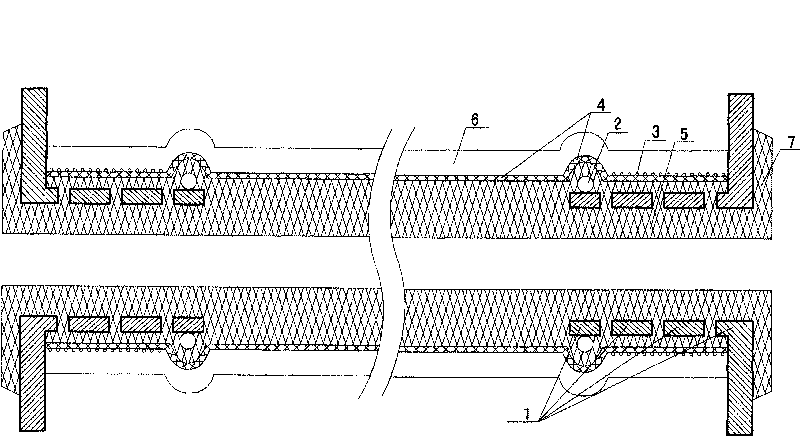

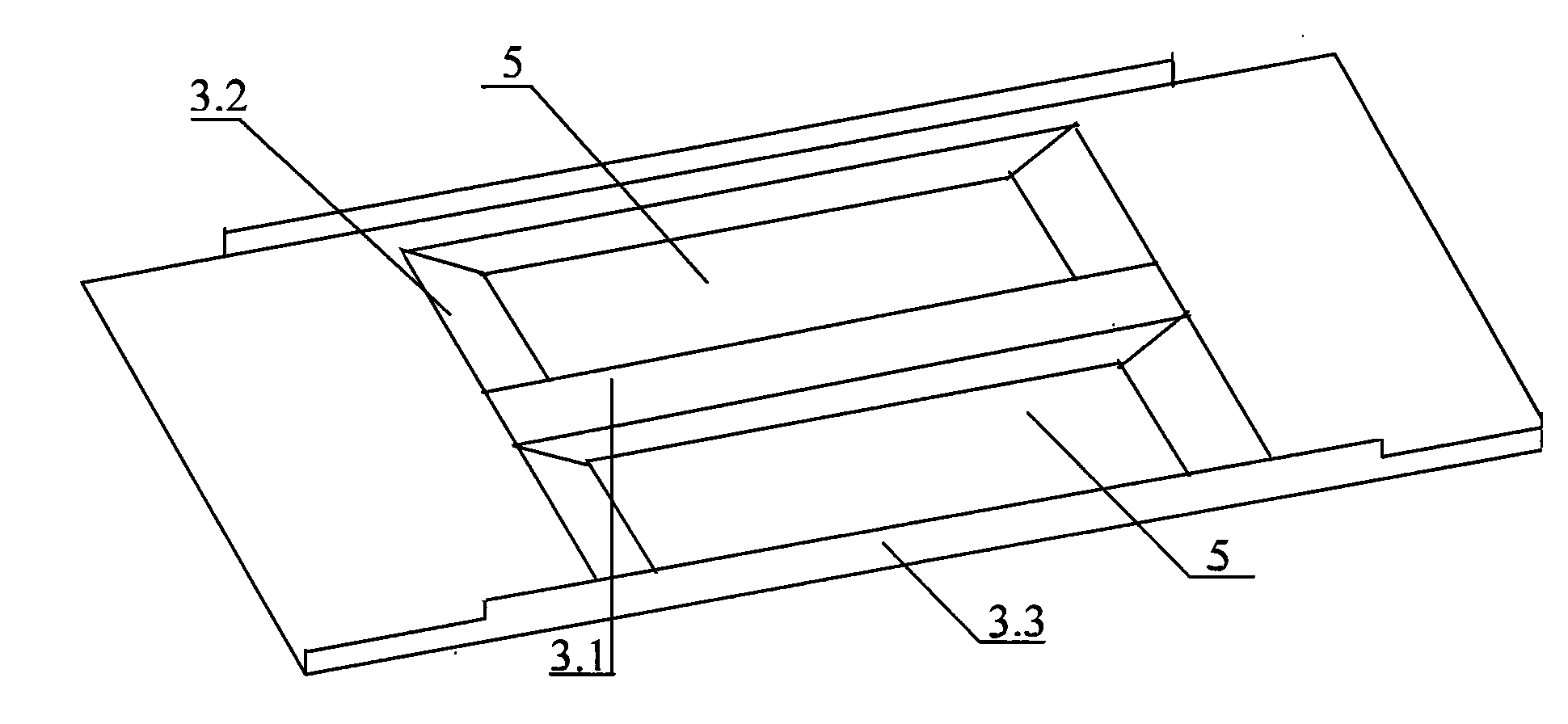

Method for utilizing rolling friction to centralize piston rod to do reciprocating motion and actuating device for utilizing rolling friction to centralize piston rod to do reciprocating motion through implementing method

InactiveCN103291683AReduce twistReduce friction lossFluid-pressure actuatorsReciprocating motionPressure.drive

The invention belongs to the field of machinery, and relates to a hydraulic drive, gas drive or solid flowing pressure drive device and equipment, particularly to a method for utilizing rolling friction to centralize a piston rod to do reciprocating motion and an actuating device for utilizing rolling friction to centralize the piston rod to do reciprocating motion through implementing the method. The actuating device comprises a piston rod, a cylinder body, a controlling piece and a centralizer, wherein the piston rod comprises a piston and a cylinder rod; the centralizer comprises a guiding rolling element and a guiding rolling element supporting piece; the guiding rolling element is arranged between the guiding rolling element supporting piece and the cylinder rod; the controlling piece controls flow of liquid, gas or solid; the piston drives the cylinder rod to do reciprocating motion; and the guiding rolling element fits the guiding rolling element supporting piece and the cylinder rod to rotate and centralizes the motion direction of the cylinder rod through the rolling friction.

Owner:刘素华

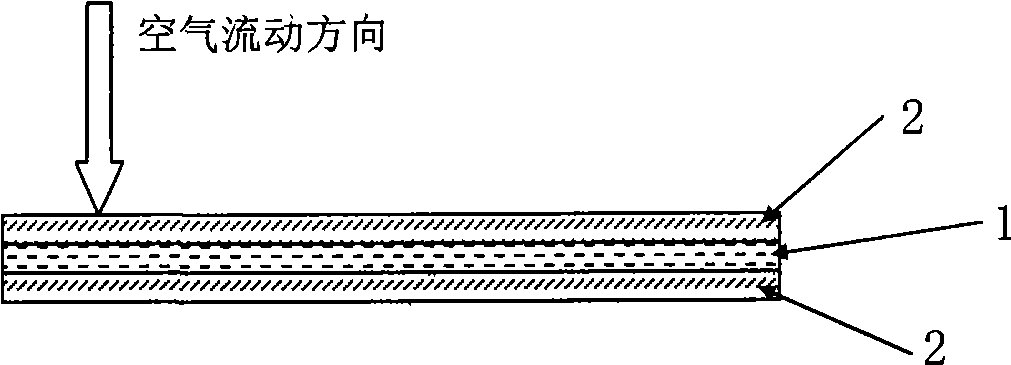

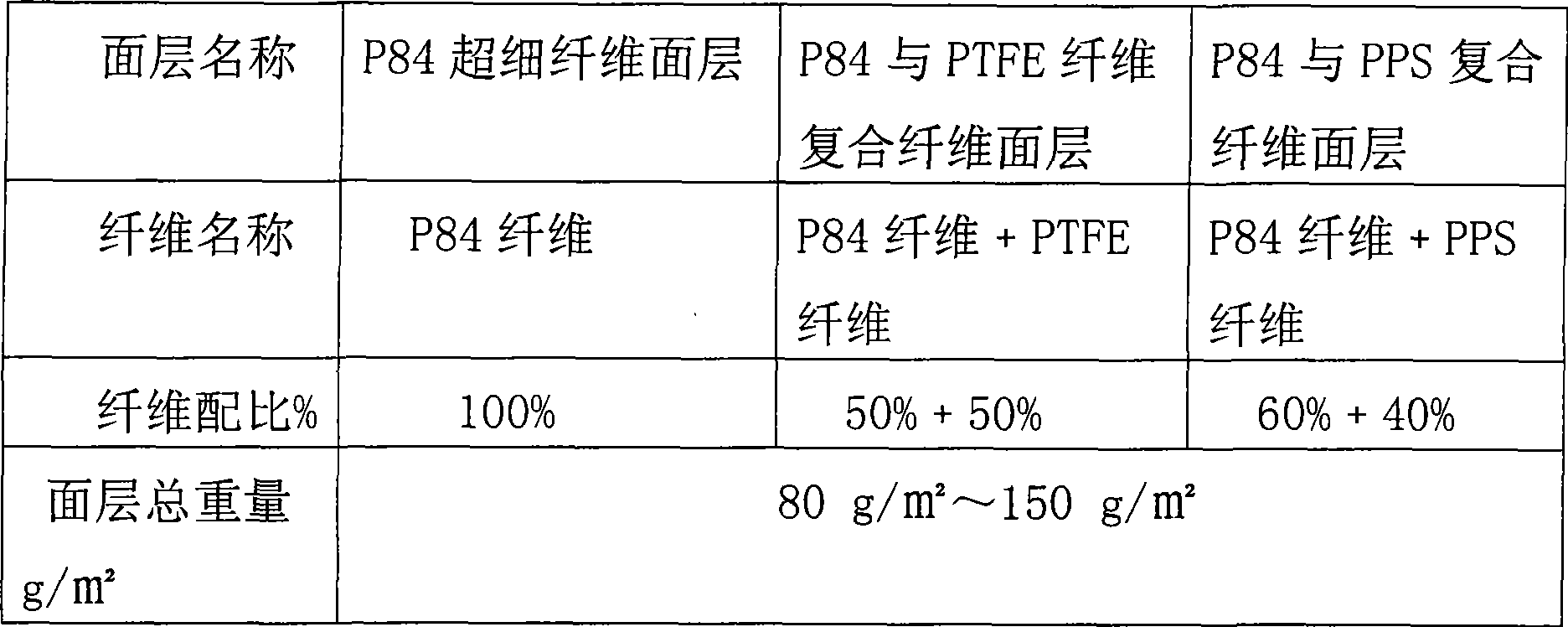

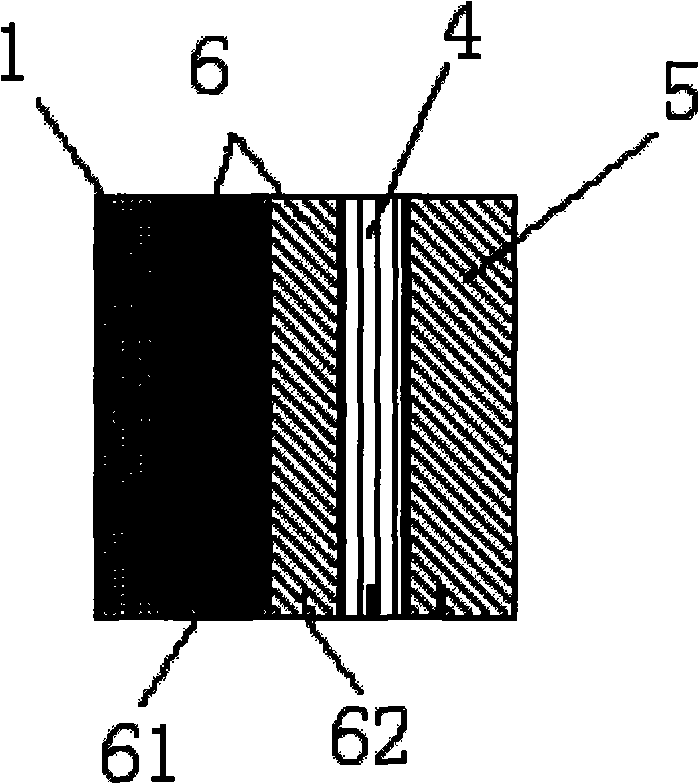

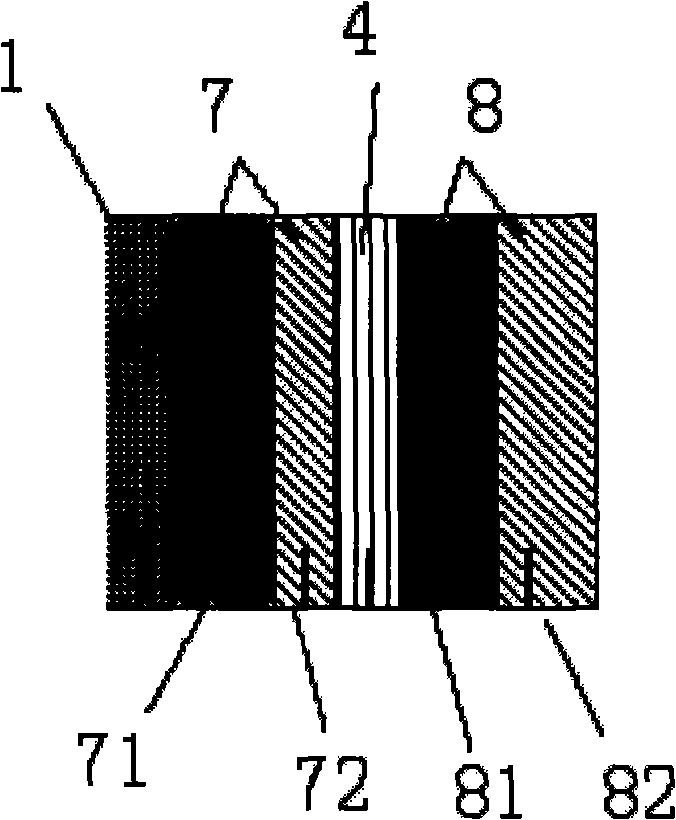

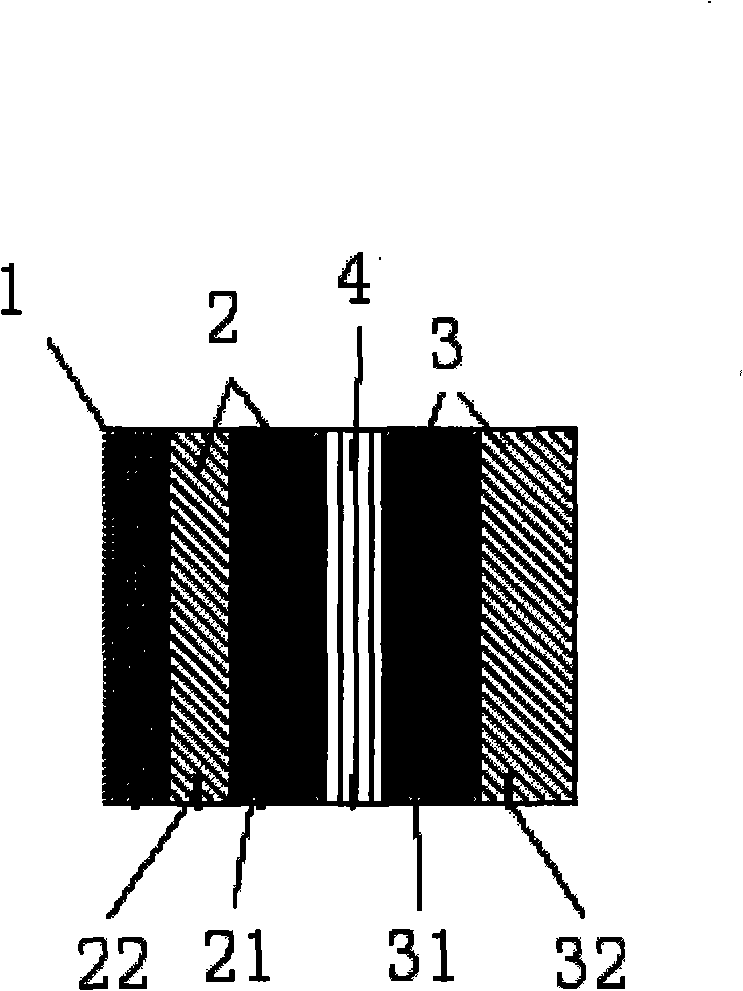

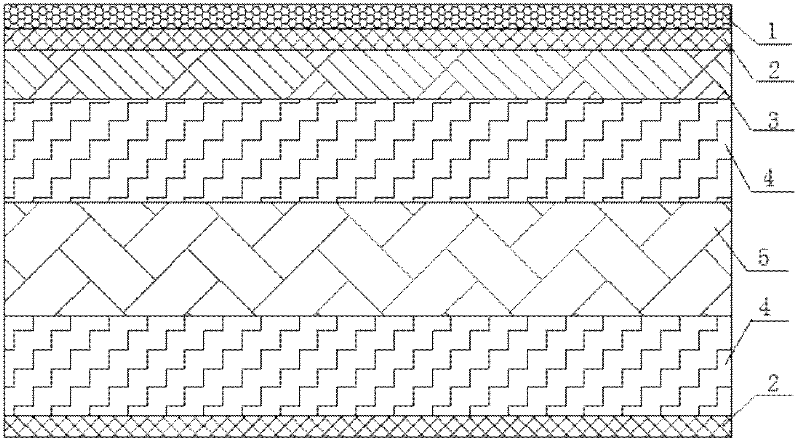

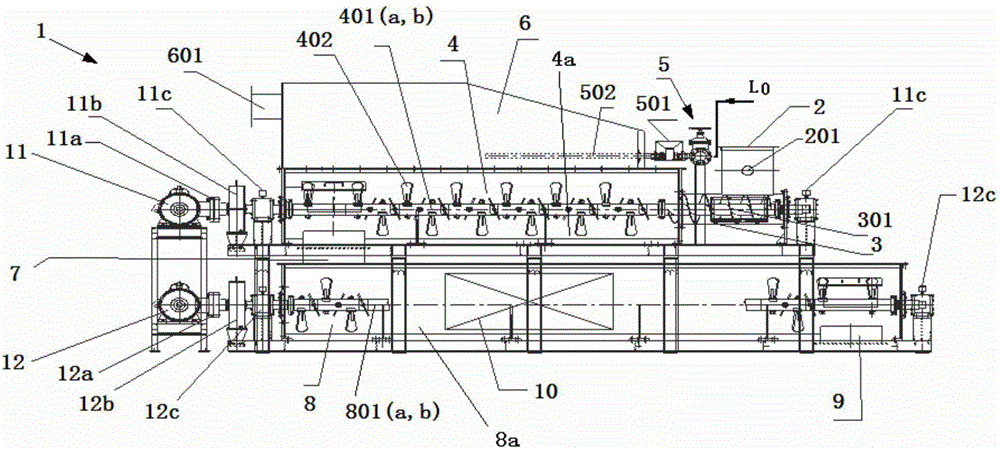

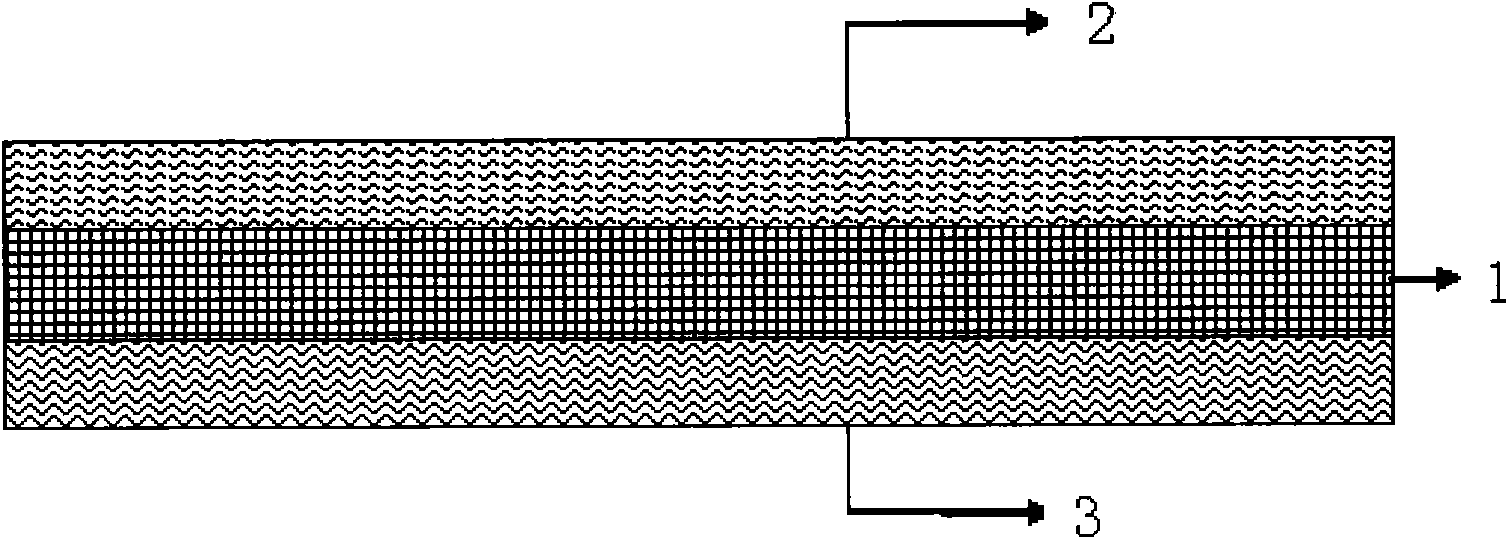

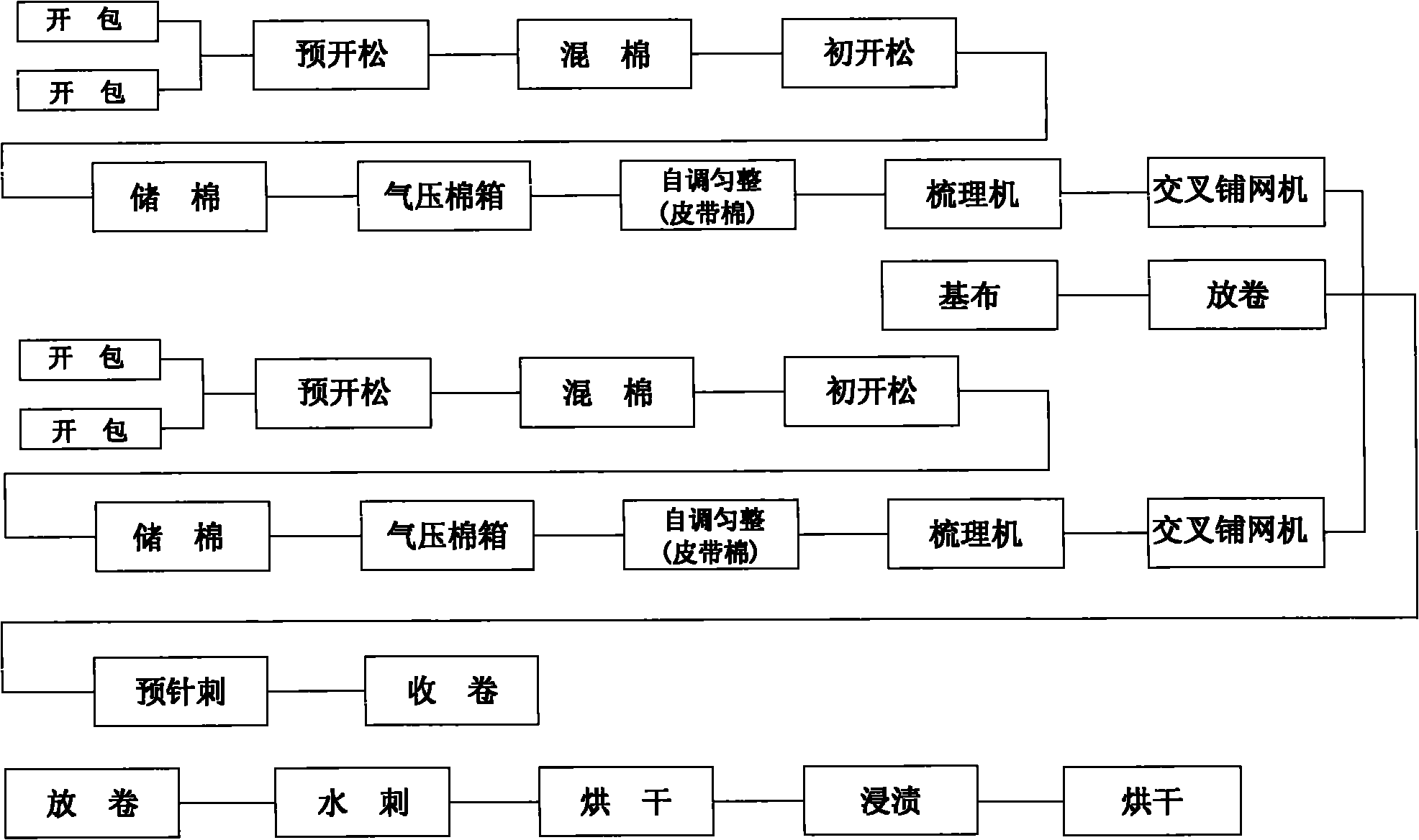

Non-woven filter felt combining air-laid web with pinprick reinforcement and production method

ActiveCN101530698AHigh temperature resistantAnti-acid and alkali corrosionLayered productsFiltration separationSurface layerPunching

The invention provides a non-woven filter felt combining air-laid web with pinprick reinforcement, wherein, the non-woven filter felt has a layered structure, the intermediate layer is high-tenacity and low-elongation type base cloth, and the upper surface and the lower surface of the high-tenacity and low-elongation type base cloth are symmetrically glued with a fiber surface layer or an extra fine fiber surface layer. The production method essentially comprises the technology of producing the surface layer air-laid web: producing the base cloth; producing the needled-punched felt; impregnating; calendering; coating; preliminary drying; solidifying in a way of curing; trimming; winding; and finishing a product. The invention has the advantage that the technology combining the air-laid web with the pinprick reinforcement is used for producing the non-woven filter felt, thereby combining the respective advantage of the two technologies, improving the service life of filter materials, and having high filtration efficiency, high physical and mechanical properties, as well as low cost. Compared with the normal method for filtrating materials with needle punching, the invention can obviously improve the wearing resistance, the fold-resistance capability and the tensile strength, and can bear hyperfiltration load, wherein, the filtering rate can reach more than 1.0 m / min, and the running resistance is low.

Owner:SHANGHAI BG INDAL FABRIC

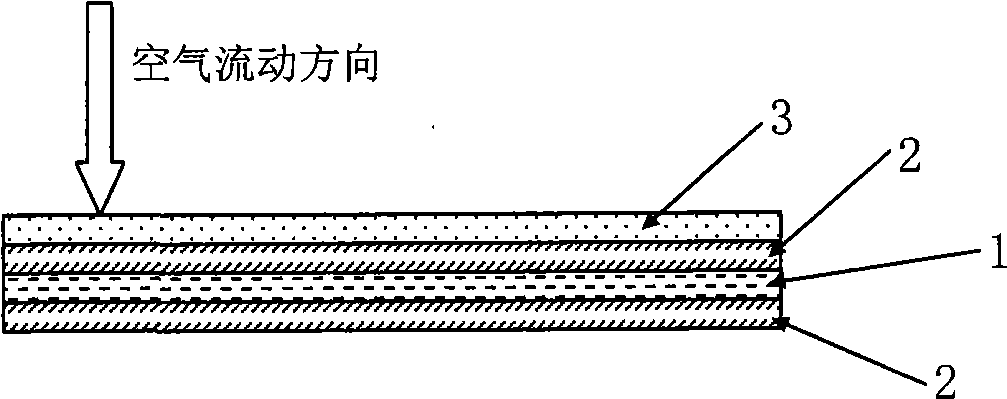

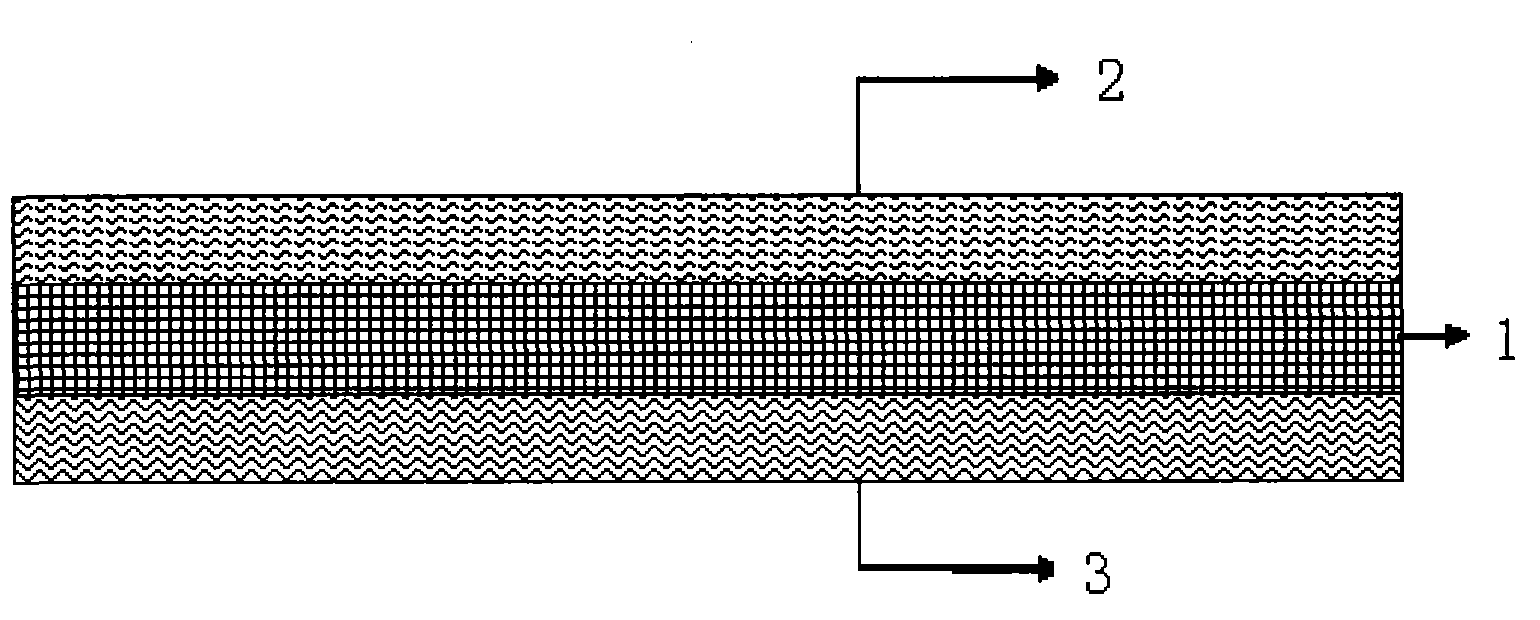

Dual-effect filter material for removing dust and decomposing dioxin and preparation method thereof

InactiveCN101306280AAvoid easy cloggingExtended service lifeLayered productsDispersed particle separationFiberDual effect

The invention relates to a dual-purpose filter material of dust removal and dioxin decomposition and a preparation method thereof, the filter material comprises a dust-facing surface, a supporting catalyst layer, a basic cloth layer and a supporting layer, the dust-facing surface is arranged on one side of the supporting catalyst layer; one surface of the basic cloth layer is arranged on the other side of the supporting catalyst layer, and the other surface of the basic cloth layer is arranged on the supporting layer; and the supporting catalyst layer is constituted by overlapping and covering a catalyst layer on a catalyst supporting layer. The preparation method has the steps of using the air flow of a polytetrafluoroethylene fiber containing a dioxin decomposition catalyst to form a net, taking the polytetrafluoroethylene fiber as the dust-facing surface, carrying out layer-overlapping of a plurality of structures, and using acupuncture, post-treatment and other techniques for processing. The process of the invention has simple and easy operation, low processing cost and small damage on the fiber, thereby being widely applicable to the dust removal and the dioxin decomposition of high-temperature tail gas.

Owner:NANJING JIHUA 3521 SPECIAL EQUIP +1

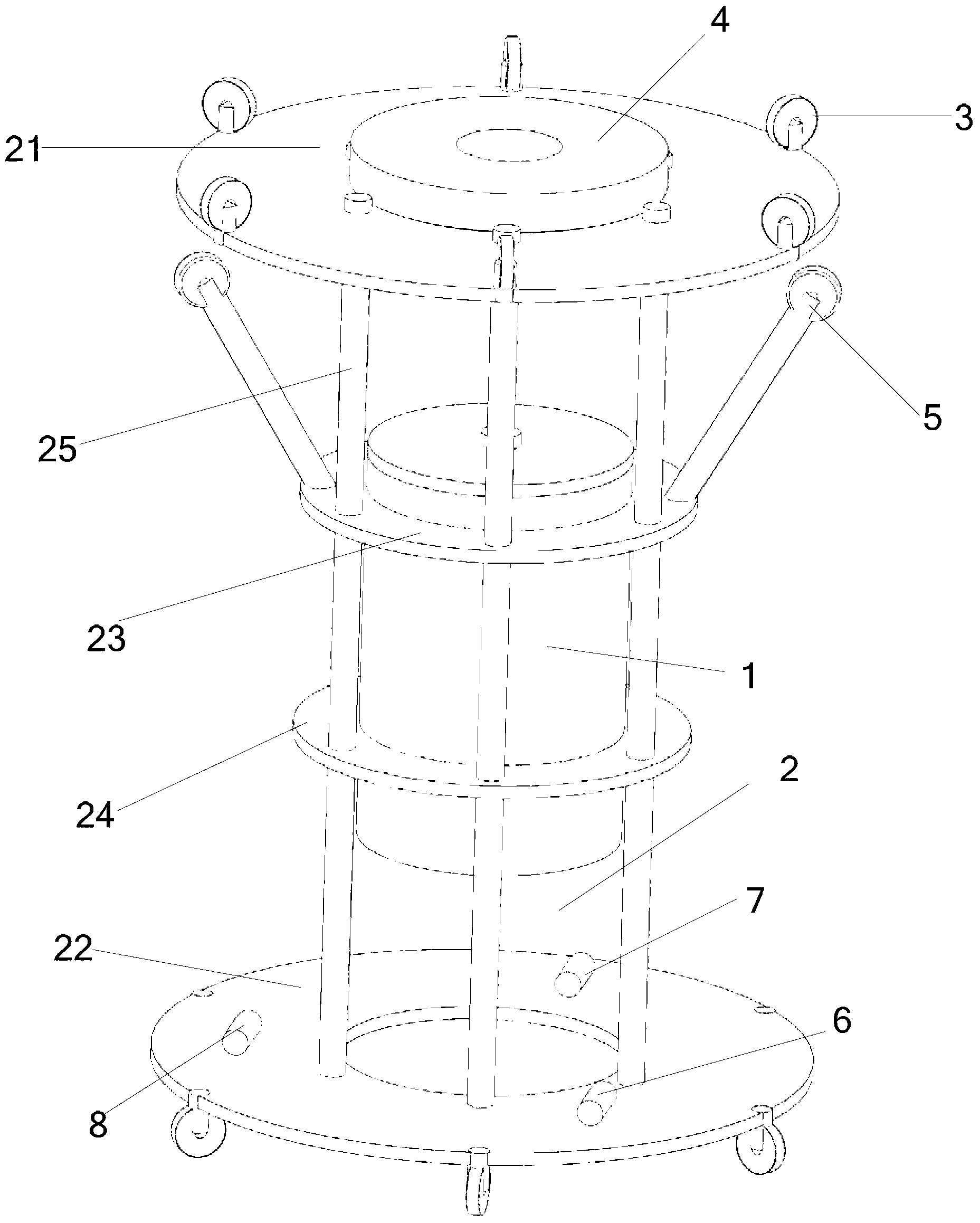

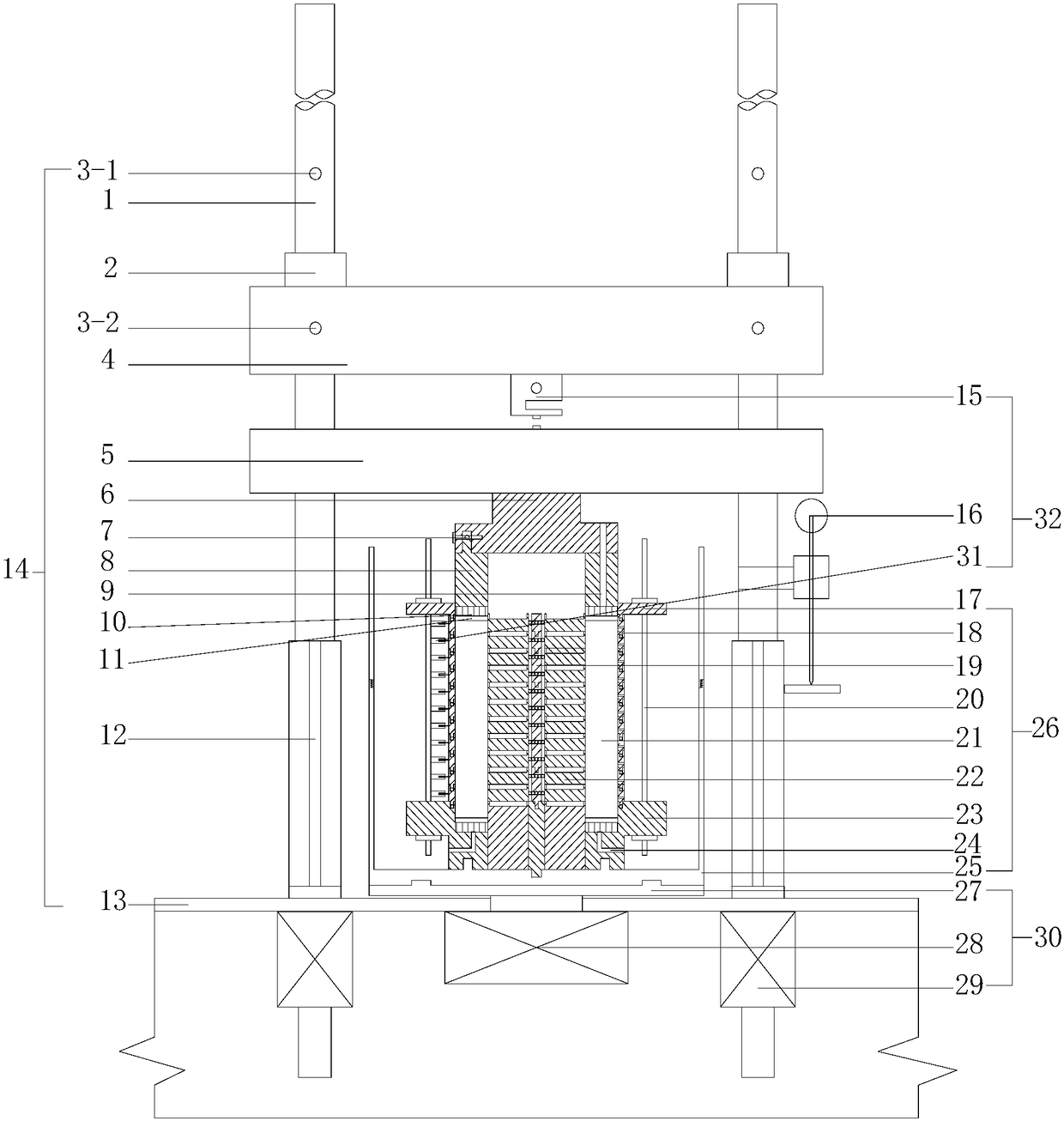

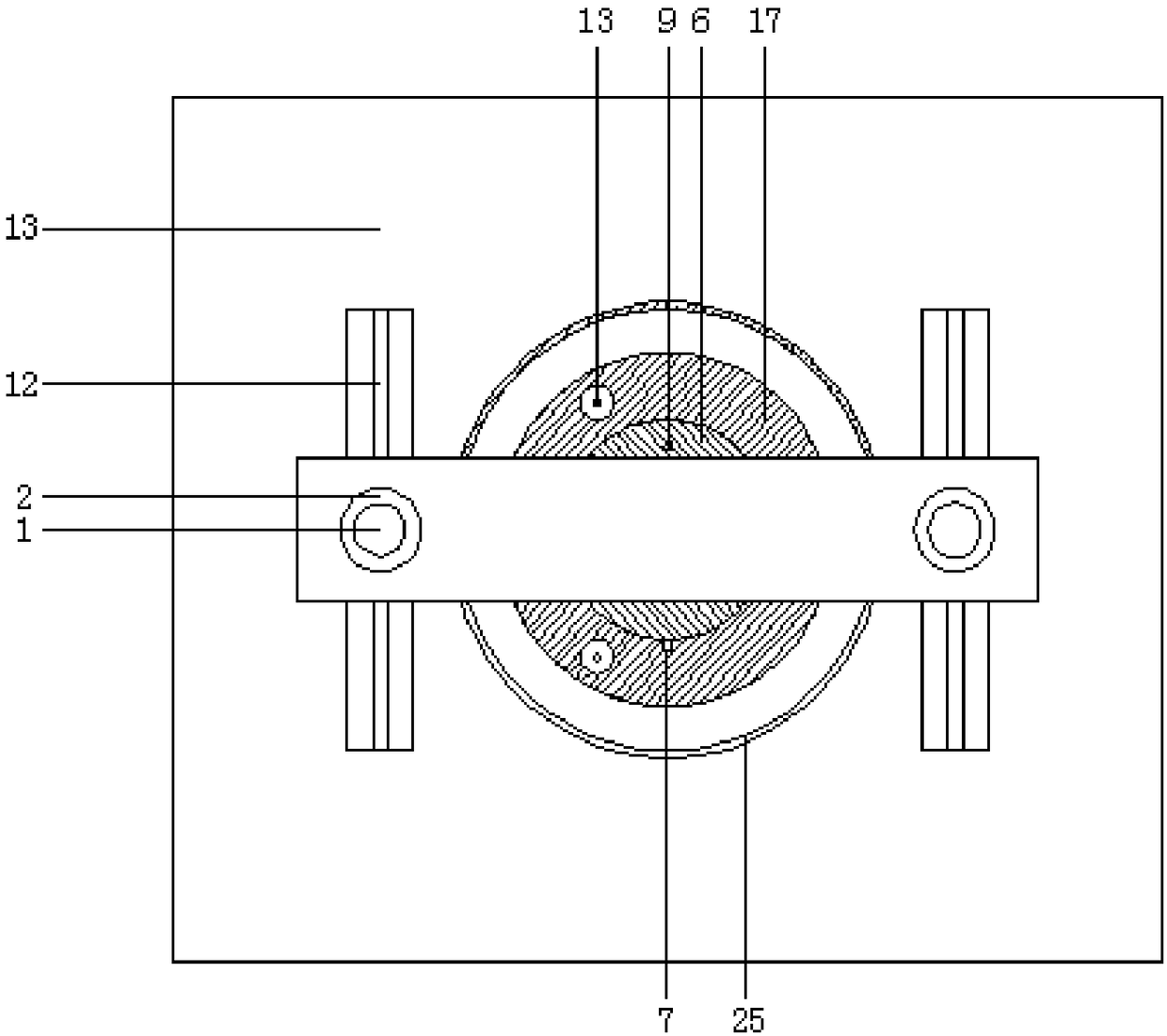

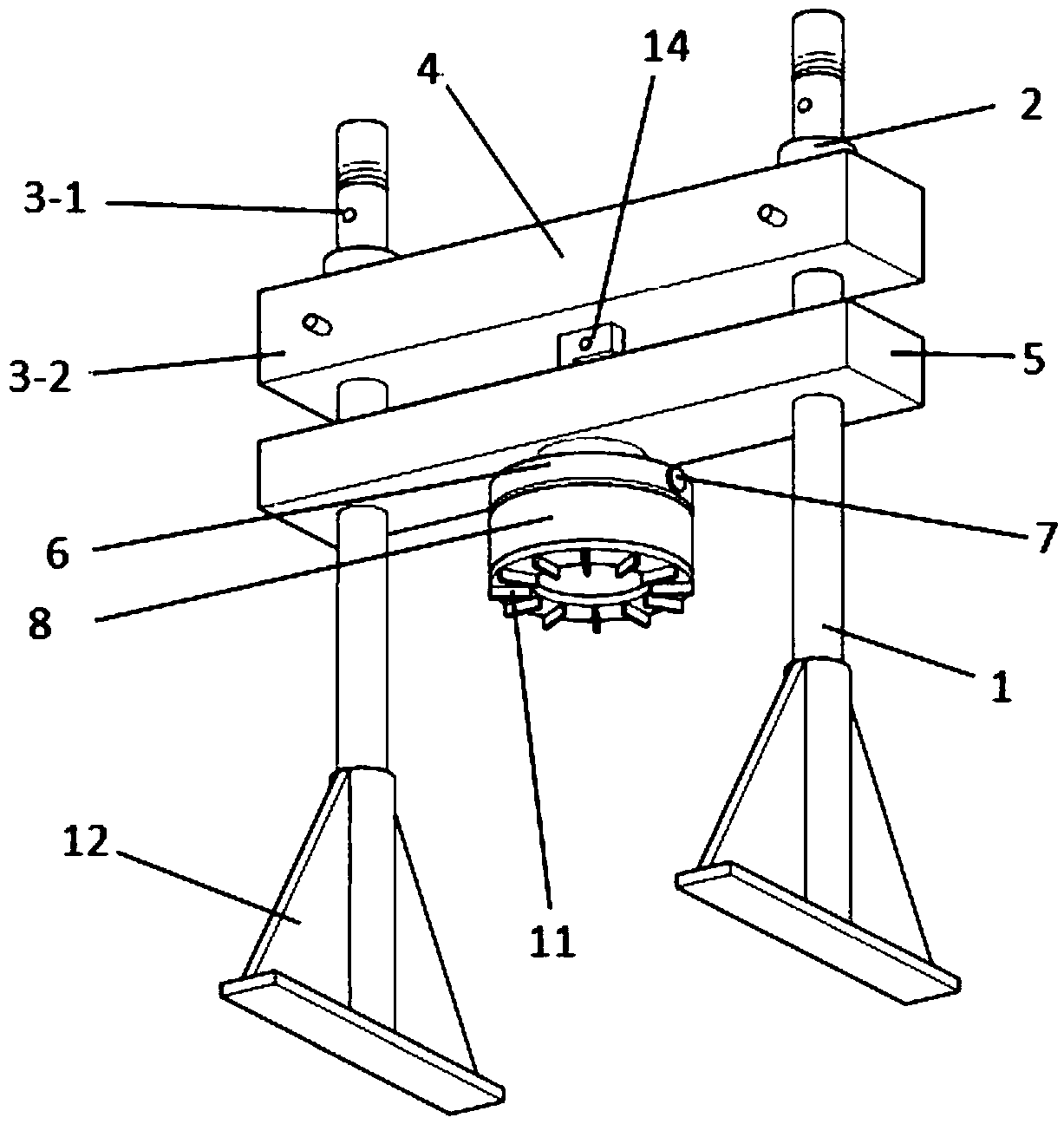

Overlaying-ring ring shear apparatus as well as overlaying ring shear test

PendingCN108225945AAutomate operationThe test process is simple and simpleMaterial strength using steady shearing forcesSoft layerTest sample

The invention belongs to the field of geotechnical test and deformation simulation, and particularly relates to an overlaying-ring ring shear apparatus and an overlaying ring shear test for continuouslarge-displacement shear deformation characteristic research of soil and complicated structural soil deformation simulation. The overlaying-ring ring shear apparatus comprises a vertical pressurizingmechanism, a twisting mechanism, a vertical assisting pressure applying mechanism and an overlaying ring shear box mechanism; the overlaying ring shear box mechanism is arranged on the twisting mechanism and can be driven by the twisting mechanism to rotate; the vertical pressurizing mechanism can apply vertical pressure to the overlaying ring shear box mechanism by virtue of the vertical assisting pressure applying mechanism; the limitless deformation ring-shaped shear of different geotechnical test samples of different heights can be performed, and the test sample is enabled to have certainfreedom and continuity in the deformation process; and the overlaying-ring ring shear apparatus can also be used for researching a deformation law of different material contact surfaces, simulating long-distance deformation of the complicated structural soil landslide as well as searching soft layers.

Owner:FUJIAN GEOLOGICAL ENG SURVEY INST

Nano shell powder ecological functional flatly painted coating

The invention relates to environmental protection paint, in particular to nano shell powder ecological functional flatly painted coating. The coating is prepared from shell powder (calcined), ash-calcium, kaolin, heavy calcium carbonate, hydrated magnesium silicate, titanium dioxide, vinyl acetate, hydroxyethyl cellulose, polyving akohol, polydimethylsiloxane, a water reducer and a defoamer. The coating solves the problem that indoor ornament or decoration paint is not environment-friendly. The coating has the characteristics that the coating is antifungal, purifies the air, prevents mildew, adopts a spiral pore structure, is 3.0mm in press coating thickness and high in glossiness, does not has obvious color aberration, is resistant to shock, abrasion, water, high and low temperature weather and aging, and ensures that the service life of a product reaches more than 20 years.

Owner:通化市星赛尔生物科技有限公司

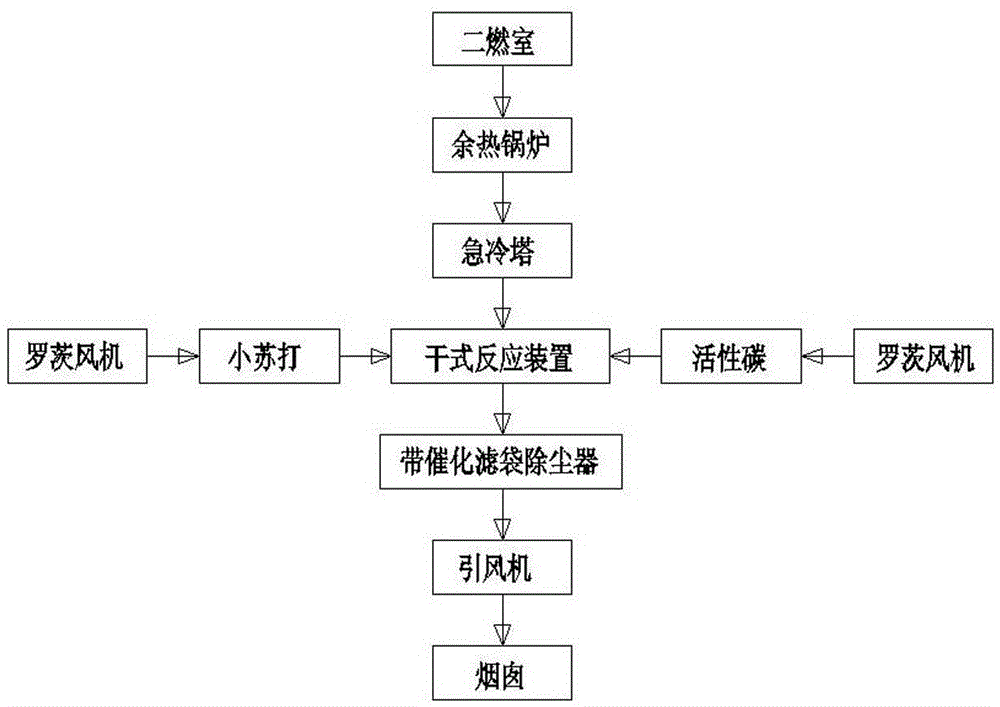

Ultra-clean treatment method for incinerated tail gas

InactiveCN105627335ALow powerSmall running resistanceDispersed particle separationCombustion technology mitigationCombustion chamberAtmospheric air

The invention discloses an ultra-clean treatment method for incinerated tail gas. The ultra-clean treatment method is characterized by sequentially comprising the steps that the tail gas continues to be combusted through a secondary combustion chamber; heat recovery is conducted on the tail gas through a waste heat boiler; the tail gas is cooled through a quench tower; baking soda powder and active carbon powder are sprayed into the tail gas exhausted out of the quench tower, and the tail gas, the baking soda powder and the active carbon powder are mixed and fed into a dust remover provided with a catalytic filtering bag to remove heavy metal and dioxin in the tail gas; and the qualified tail gas with the acid gas being removed is exhausted into the atmosphere through an induced draft fan and a chimney. The ultra-clean processing method is simple in technique. By treating and incinerating the tail gas through the method, spraying, washing and smoke reheating are not needed, the effect for removing the dioxin in the tail gas is good, fire disasters can be avoided, and the operation cost is reduced; and in addition, secondary pollution such as sewage is avoided. The ultra-clean processing method is suitable for treating the tail gas exhausted from household refuse and hazardous waste combustion furnaces.

Owner:JIANGSU QUANNENG ELECTROMECHANICAL EQUIP ENG LTD BY SHARE LTD

Wear-resistant rubber polyurethane compound hose

InactiveCN101694253AIncrease elasticityReduce wearFlanged jointsFlexible pipesWear resistantFlanging

A wear-resistant rubber polyurethane compound hose is characterized by comprising a bearing layer (4), a wear-resistant layer (5) and a protective layer (6). The inner wall of a pipeline is formed by the wear-resistant layer (5), the bearing layer (4) is arranged on the outer wall of the wear-resistant layer (5), the protective layer (6) is disposed on the outer layer of the bearing layer (4); the wear-resistant layer (5) is an elastic pipe body formed by pouring polyurethane materials inside a die, and is arranged to be an integral structure with a flange steel ring (1) via a pouring hole on the flange steel ring (1). A circular sealing flanging (7) is disposed outwards on the wear-resistant layer (5) along a flange disk, the bearing layer (4) is formed by weaving more than one layer of cord threads in a cross-intertwining arrangement outside the tube body of the wear-resistant layer (5), and one layer of steel wires is wound on the outer side of a reinforced steel ring (2) at the position of the flange steel ring (1) once every 2-4 layers of cord threads are wound. The wear-resistant rubber polyurethane compound hose has the advantages of fine wear resistant property, scale prevention, low running resistance, fine water resistant property, fine aging resistant property, fine combination and long service life.

Owner:梁宝忠

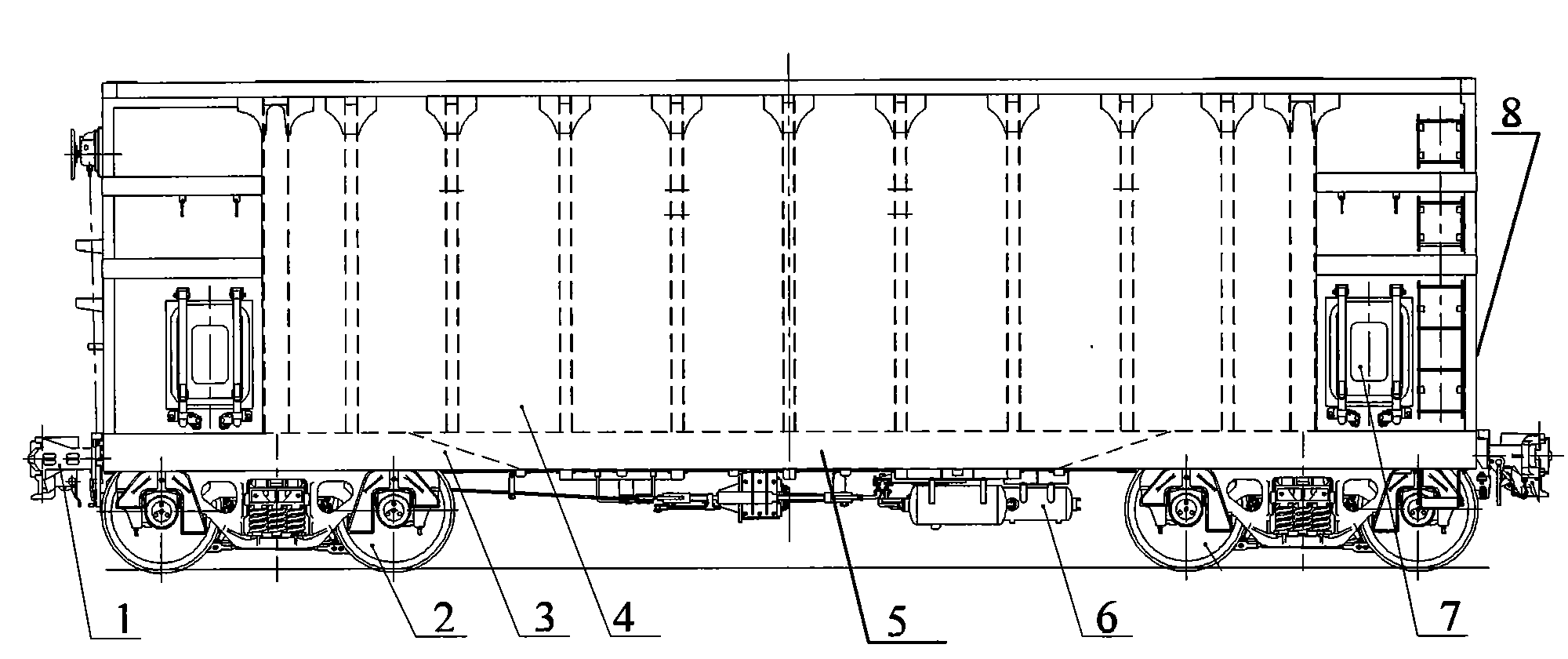

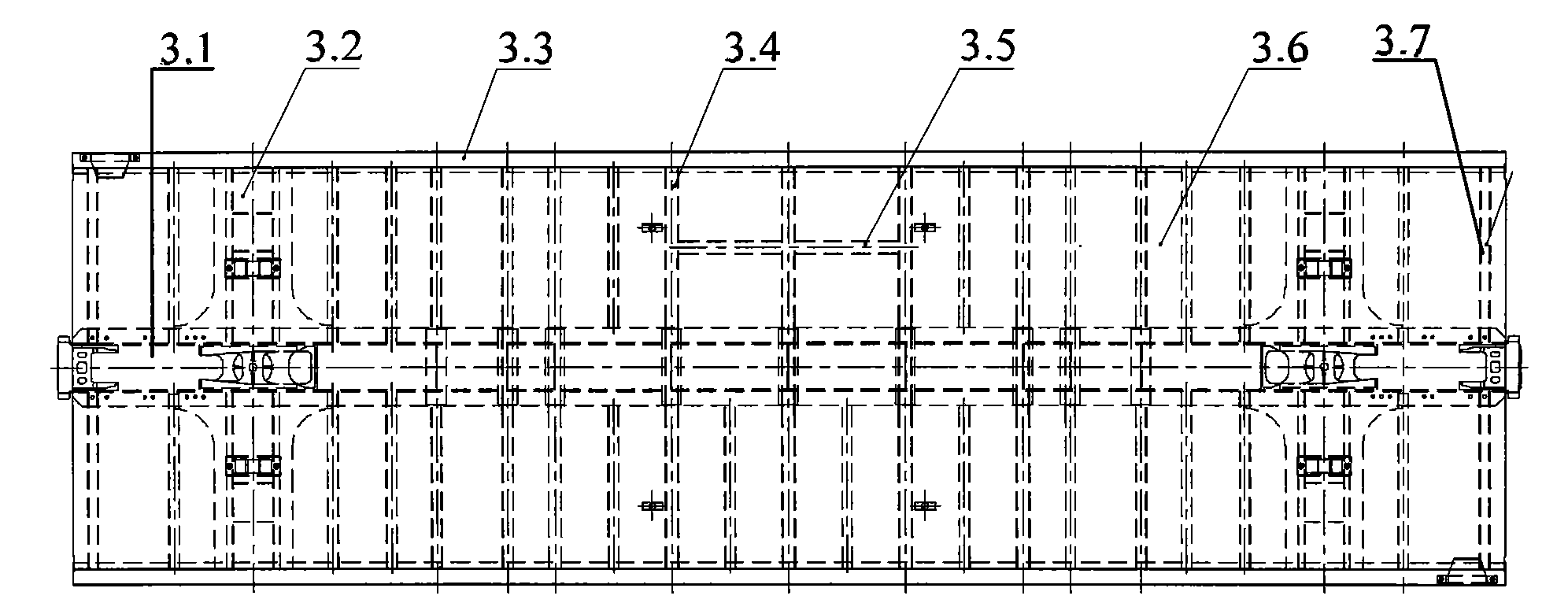

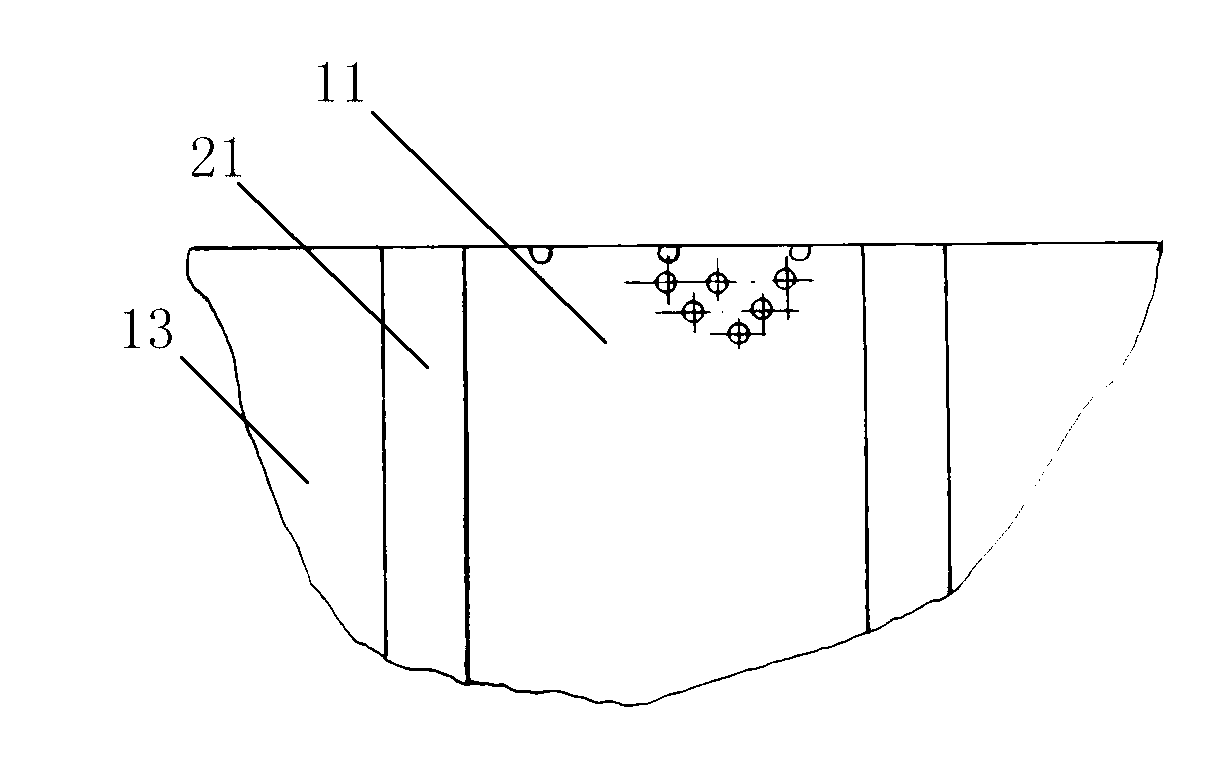

Special gondola vehicle with a shallow concave bottom for coal transportation

ActiveCN101585364ALower center of gravityEasy maintenance and repairRailway transportAxle-box lubricationBogieEngineering

A special gondola vehicle with a shallow concave bottom for coal transportation belongs to the transportation facilities, in particular to a railway truck gondola vehicle. The gondola vehicle comprises a vehicle body, a vehicle coupler buffer device, a braking device and a bogie. The vehicle body comprises a chassis, a side wall and an end wall. The key technique is that the chassis comprises a centre sill, a sleeper beam, a lower side beam and an end beam, two downwards concave shallow concave bottoms are arranged between the two sides of the centre sill and between the lower side beam and the sleeper beam in the middle of the side wall, the depths of the shallow concave bottoms are aligned with the lower plane of the centre sill, the side wall comprises a side wall board and a side post, the two ends of the side wall are end door panels which are inwards concave with respect to the side wall board to form stages, so as to form the end door plate with a concave structure. The invention not only effectively increases the vehicle body volume, but also decreases vehicle height of center of gravity, and improves vehicle riding quality.

Owner:CRRC MEISHAN

High-temperature electrostatic precipitation system

ActiveCN104001622AGood rapping acceleration distributionImprove cleanlinessExternal electric electrostatic seperatorElectric supply techniquesParticulatesThermal insulation

The invention relates to a high-temperature electrostatic precipitation system. The high-temperature electrostatic precipitation system comprises a gas inlet, a deduster housing, a gas outlet and a layered ash bucket. Left and right ends of the deduster housing are respectively connected to the gas inlet and the gas outlet. The lower end of the deduster housing is connected to the layered ash bucket. An anode plate and a cathode rod are arranged in the deduster housing. A sealing housing is arranged around the deduster housing. A cavity is formed between the sealing housing and the deduster housing. Alumina porcelain is used for insulation between the cathode rod and the deduster housing. The alumina porcelain is connected to a hot air purging device. The bottom of the anode plate is provided with a mechanical vibration device. The periphery of the layered ash bucket is provided with a thermal insulation device. The layered ash bucket comprises an upper ash bucket and a lower ash bucket. The upper ash bucket is connected to the deduster housing. One end of the lower ash bucket is connected to the upper ash bucket by a cindervalve and the other end of the lower ash bucket is connected to an ash bucket pneumatic conveying device. The high-temperature electrostatic precipitation system can guarantee that the electric deduster effectively gathers fine particles in cracking gas at a high temperature of 300-800 DEG C and realizes equipment operation resistance less than 600Pa.

Owner:ZHEJIANG UNIV

PTFE (polytetrafluoroethylene) composite filtering material and its manufacturing method

ActiveCN102357321AHigh tensile strengthAccelerated corrosionSynthetic resin layered productsGlass/slag layered productsGlass fiberSurface layer

The invention provides a PTFE composite filtering material with good comprehensive performances and low cost, as well as its manufacturing method. From a dust contact face, the PTFE composite filtering material of the invention comprises in order: a PTFE microporous membrane layer, a PTFE dipping treatment layer, a PTFE superfine surface layer, a glass fiber layer, a sewing thread base cloth layer, a glass fiber and a PTFE dipping treatment layer. The PTFE composite filtering material provided in the invention has extremely high tensile strength and corrosion resistance, good filtering performance, low operation resistance, low production cost and long service life, and is suitable for dust filtration in complicated working conditions like high operation temperature, strong corrosion, great dust content, high filtration accuracy requirement, thus being a novel filtering material of high cost performance.

Owner:昆山万瑞达工业纺织品有限公司

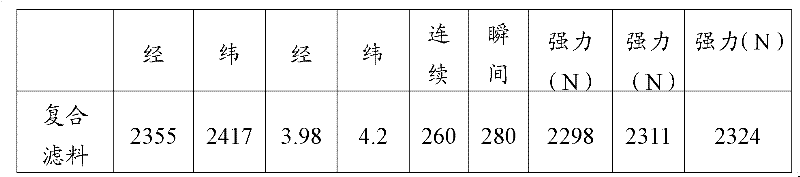

Two-phase flow jet-type boosting heat exchanger

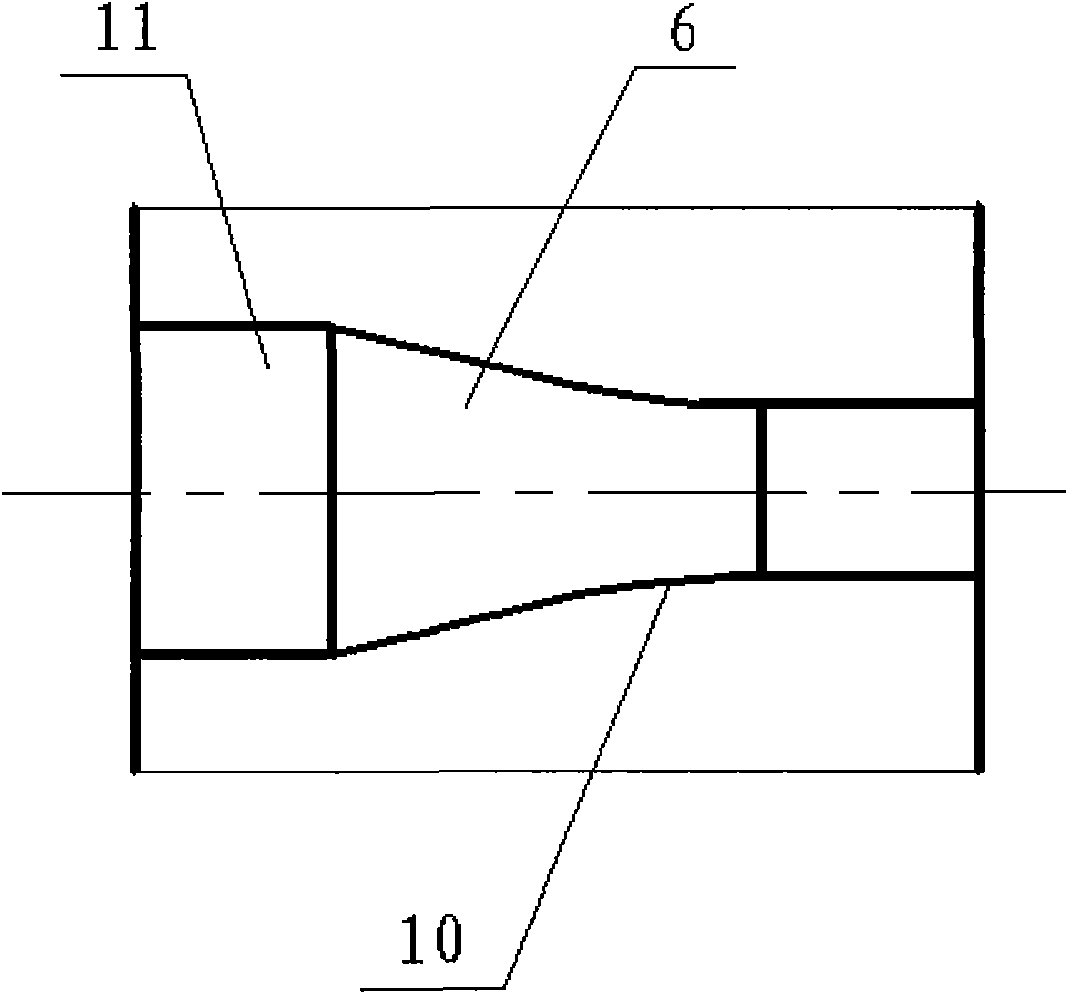

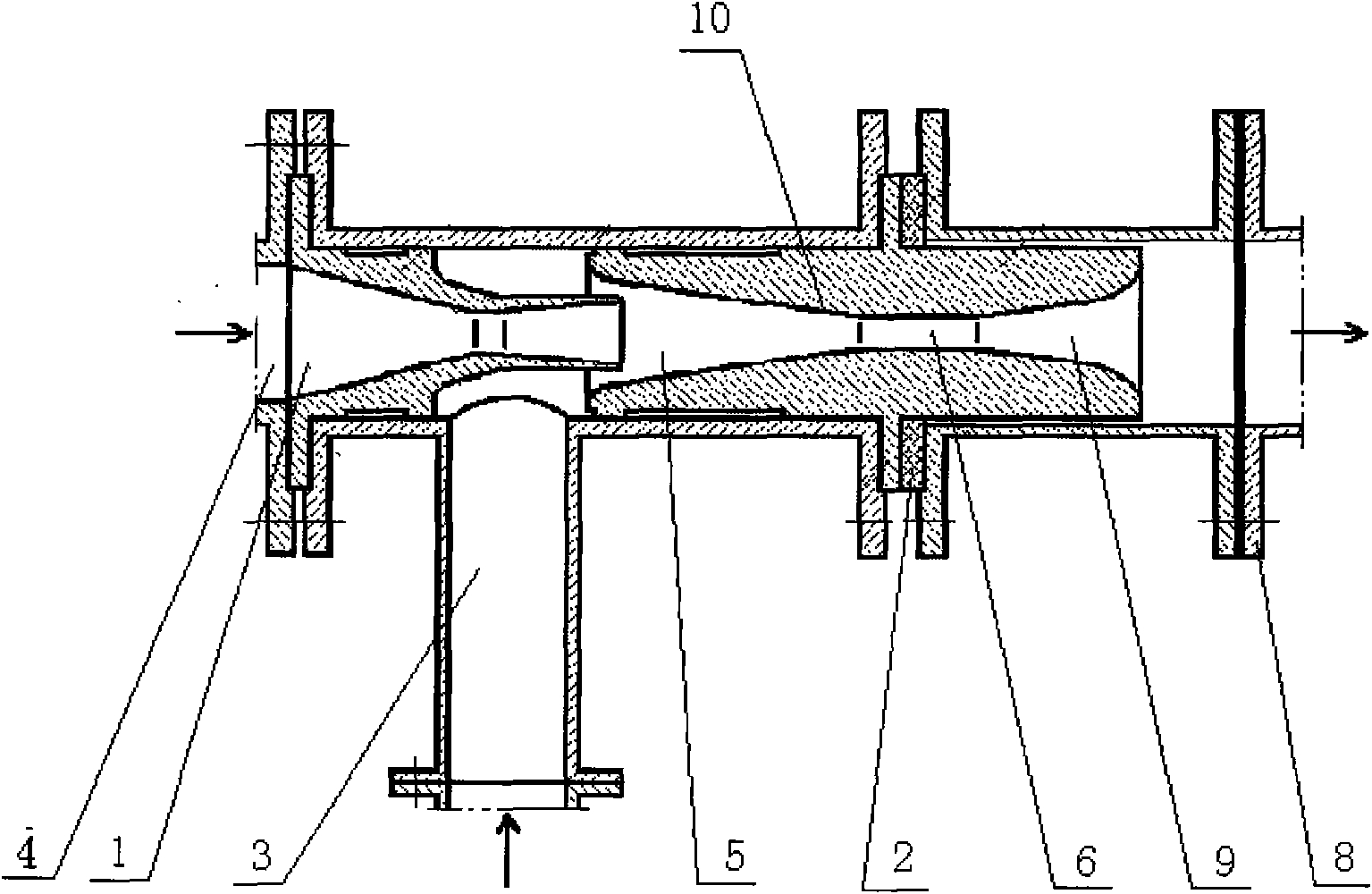

InactiveCN101936309AReduce in quantitySimple structureJet pumpsMachines/enginesSteam pressurePore water pressure

The invention discloses a two-phase flow jet-type boosting heat exchanger. The cavity of a pressurizing mixing chamber is designed into a reducing structure so that a steam pressure drives a water pressure or the water pressure drives the steam pressure, namely, steam enters from a center and water enters from circumference or water enters from the center and the steam enters from the circumference. The working principles are injection and pumping, namely, a high-pressure fluid generates an injection fluid by a nozzle, the pressure is decreased at the outlet of the nozzle to pump a low-pressure fluid around, and the high-pressure fluid and the low-pressure fluid are mixed in the reducing structure of the mixing chamber. When the injection fluid is the steam, a Laval nozzle is adopted, and when the injection fluid is water, a reducing nozzle is adopted, so that the two-phase flow jet-type boosting heat exchanger can be suitable to be used for the occasion with relatively higher inlet steam pressure and relatively lower inlet water pressure and the occasion with relatively lower inlet steam pressure and relatively higher inlet water pressure. When in use, the heat exchanger has obvious pressurization and instantaneous heating effects, thereby saving electric energy and heat energy and decreasing use cost.

Owner:LUOYANG BLUE SEA INDAL

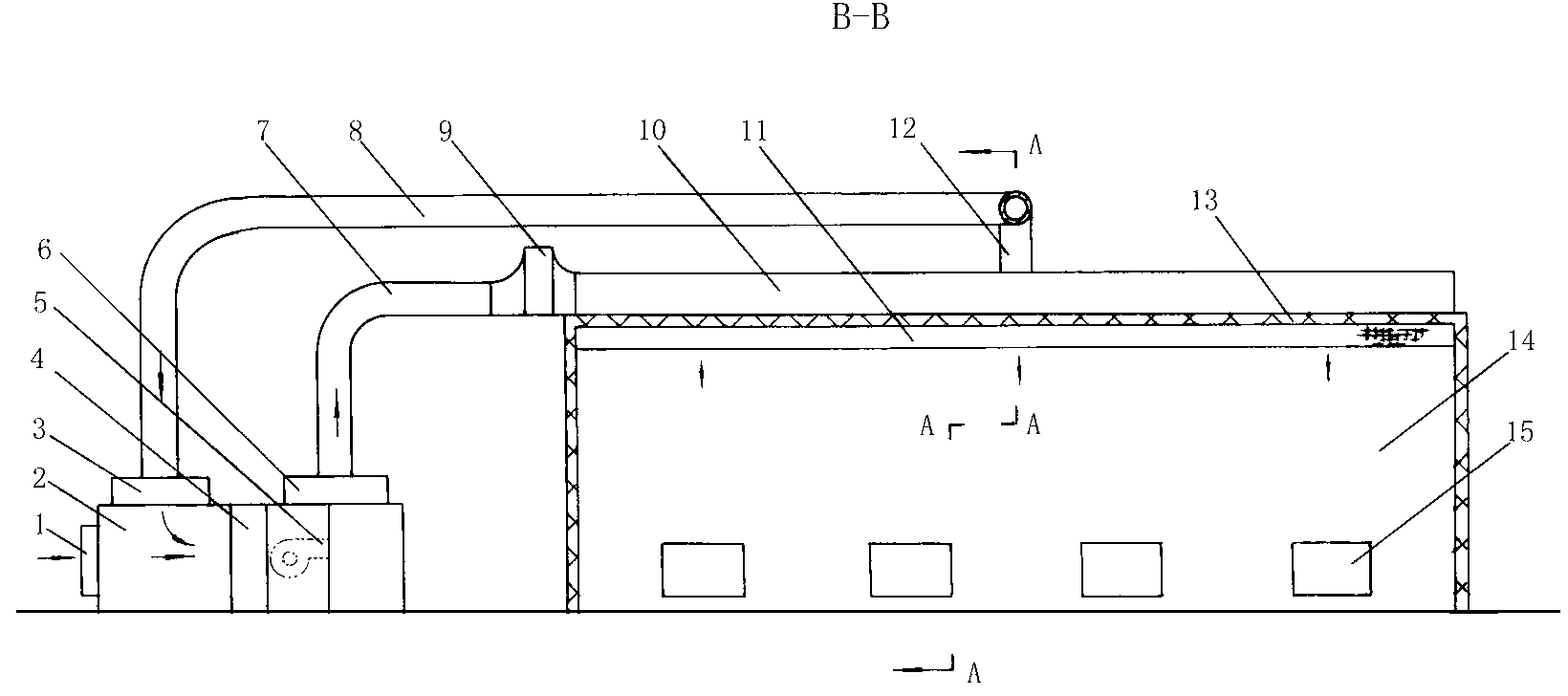

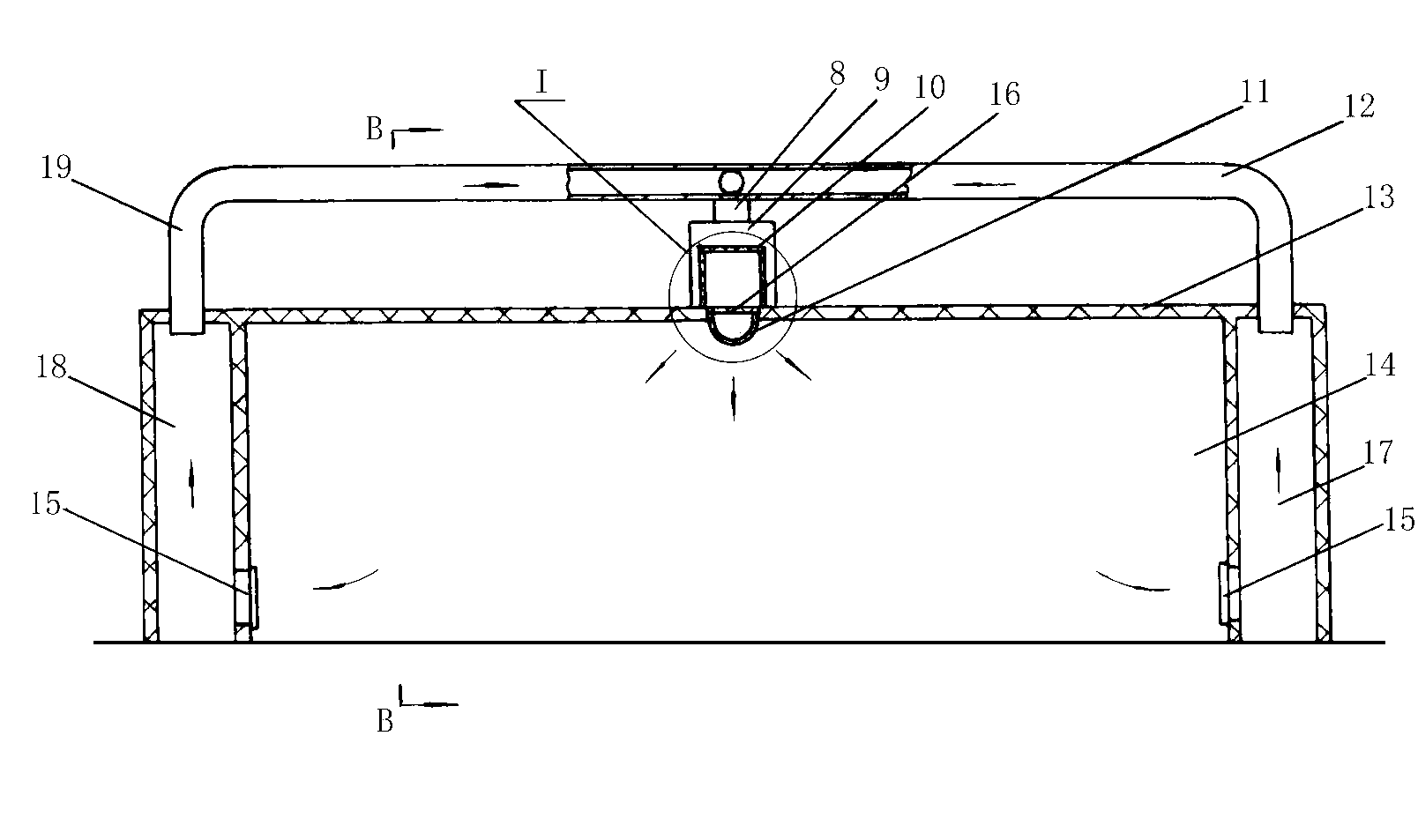

Low steady-speed radial flow clean room air-conditioning air supply and return system

ActiveCN103322657ASmall running resistanceSlow down the spreadDucting arrangementsLighting and heating apparatusSuspended particlesFresh air

The invention relates to a low steady-speed radial flow clean room air-conditioning air supply and return system which comprises a radial flow air supply channel device, a wall-mounted air return channel device, an air-conditioning outlet static pressure box, an air-conditioning air return port static pressure box and an air-conditioning fresh air port filtering device, the radial flow air supply channel device comprises a clean room roof, a static pressure box type air supply channel, a pressure equalizing partition plate, an arc-shaped radial flow cover, a damping layer and a high efficiency filter bank, and the wall-mounted air return channel device comprises a sandwich wall type air return duct and a filtering device mounted at an air return port of the lower end of the sandwich wall type air return duct. The air supply and return system has the advantages that the operation resistance of the air supply and return system is reduced, the diffusion speed of harmful suspended particles in a clean room is the lowest, fewer high efficiency filter banks are used, the clean room is low in construction investment, energy-saving in operation and convenient to maintain, the air cleanliness class of the clean room is improved by more than 30% as compared with that of a mixed airflow clean room, clean time can be shortened by more than 40%, and airflow in the clean room is reasonably distributed.

Owner:SHIJIAZHUANG AOXIANG MEDICAL ENG

Frame type high efficiency impeller of impeller aerator

The invention relates to the machinery technical field and provides a frame type high efficiency impeller of an impeller aerator. A key technology that a circular ring frame is combined with angle set shovel-shaped or spoon-shaped blades with holes is adopted; angles which are formed between lower water shifting plates and upper water guiding plates are 90 to 160 degrees; the inner sides of the lower water shifting plates and the upper water guiding plates are provided with inner water guiding plates and the outer sides of the lower water shifting plates and the upper water guiding plates are provided with outer water guiding plates in a perpendicular mode to form the blades; the inner ends of radiation supports are fixed connected with a shaft disk and the outer ends of the radiation supports are fixedly connected with a circular ring to form a transmission connection plate; the plane which is formed by being close to the fixed joint of the outer ends of the radiation supports and the circular ring is fixedly connected with the lower water shifting plates to form 30 to 90 degrees of angles; meanwhile the radiation supports are fixedly connected with the inner water guiding plates to form 20 to 90 degrees of angles or angles in 90 to 135 degrees outward; shaft holes of the shaft disk are fixedly connected with power shafts. The frame type high efficiency impeller of the impeller aerator is used for performing aeration on a fish pond and is simple and reasonable in structure, long in service life, stable and reliable in effect, small in power, easy to manufacture and low in cost.

Owner:梁家明

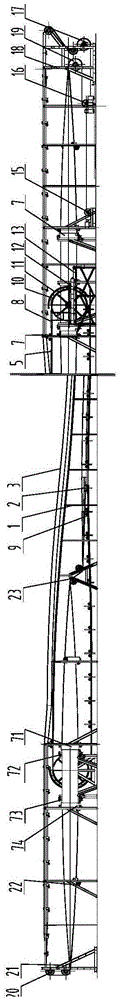

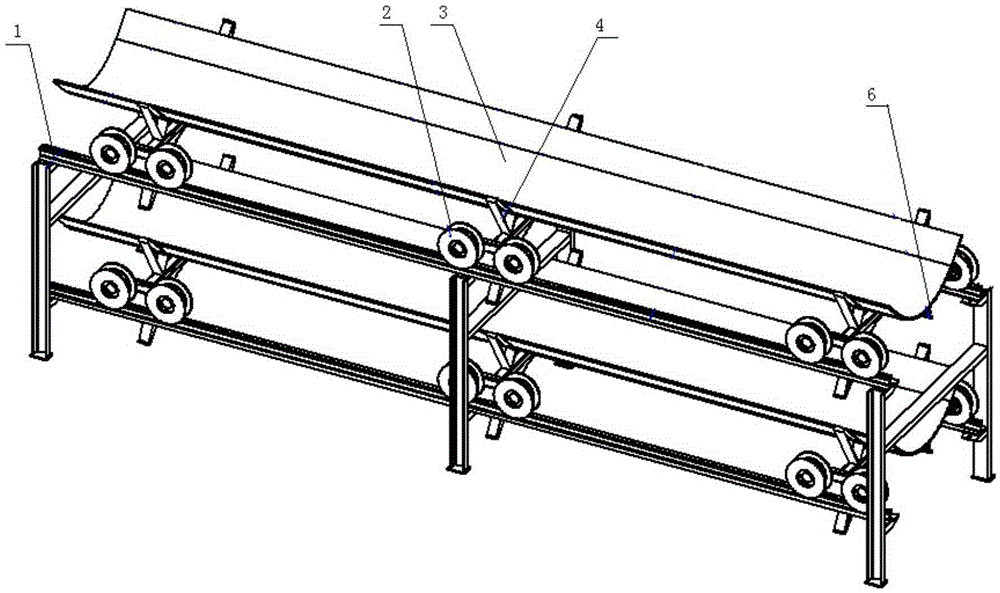

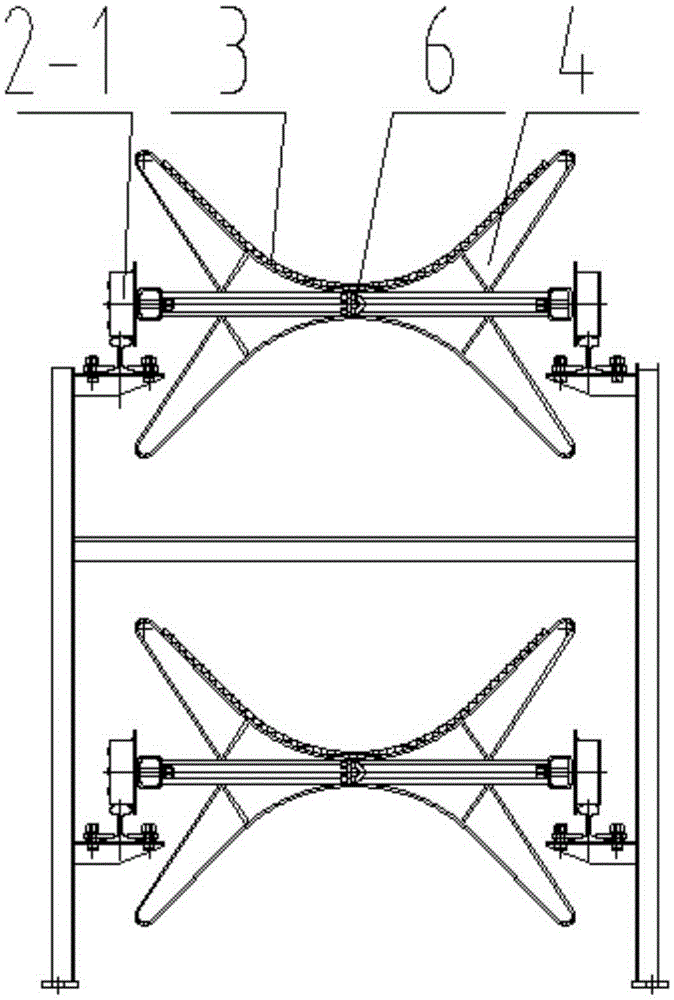

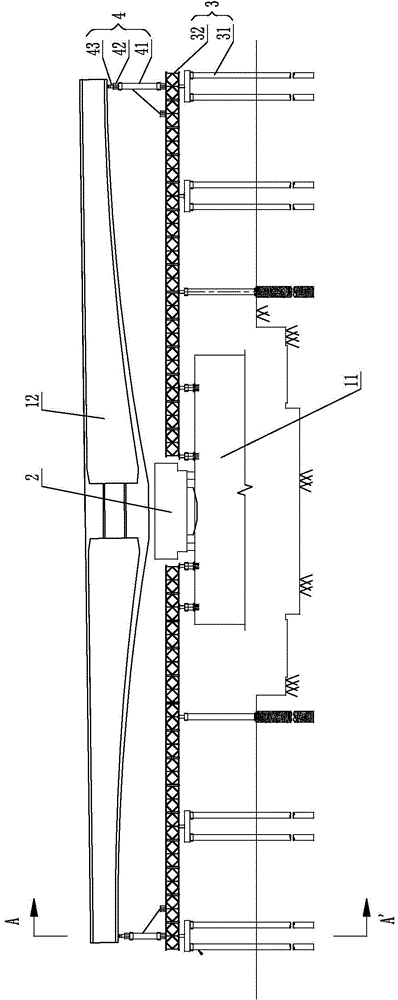

Rail type belt conveyor

The invention relates to a rail type belt conveyor. The rail type belt conveyor comprises a support, a machine head frame, a machine tail frame, an upper guide rail, a lower guide rail, a towing trolley, a rubber belt, a steel wire rope, closed-loop systems, a driving roller, an elevating supporting roller set, a redirection frame and a triangular frame. The elevating supporting roller set is mounted at the position, close to the machine head frame, of the support, the redirection frame is mounted on the machine tail frame, a redirection drum is arranged on the machine head frame, and a tensioning vehicle is arranged at the position, close to one side of the redirection drum, of the support; and the triangular frame is arranged at the position, between the two closed-loop systems, of the support, and the rubber belt is wound around the elevating supporting roller set, the redirection drum, the tensioning vehicle, a supporting roller on the redirection frame and a supporting roller on the triangular frame. The rail type belt conveyor has the beneficial effects that a traditional rubber belt machine structure is removed, a supporting belt trolley is used for replacing a part of a common supporting roller, the cost and the mounting cost are reduced, and revolutionary innovation is brought to bulk conveying.

Owner:LIBO HEAVY MACHINE TECH

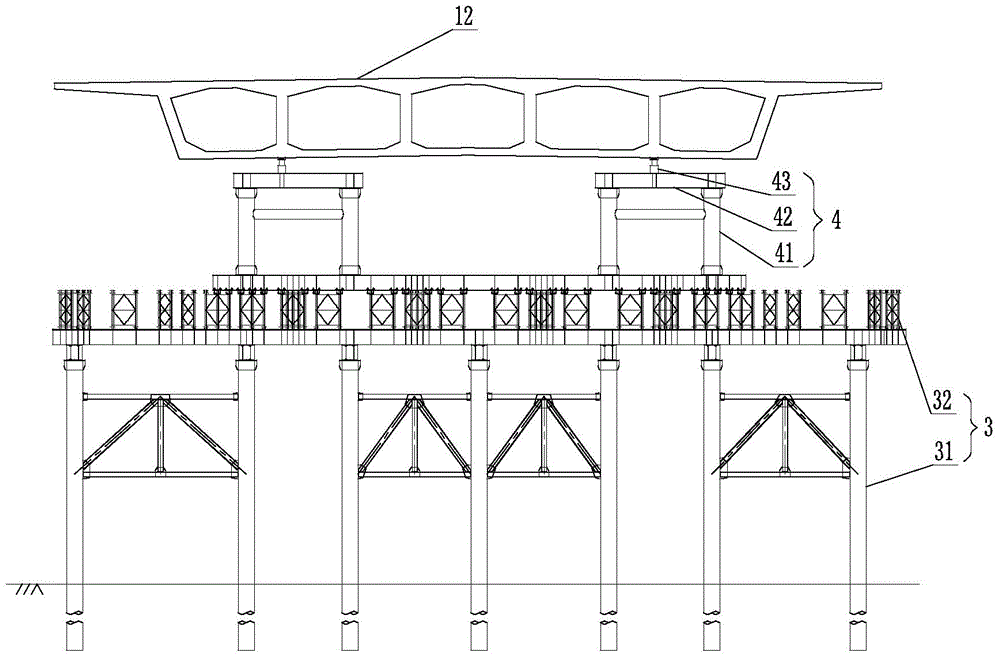

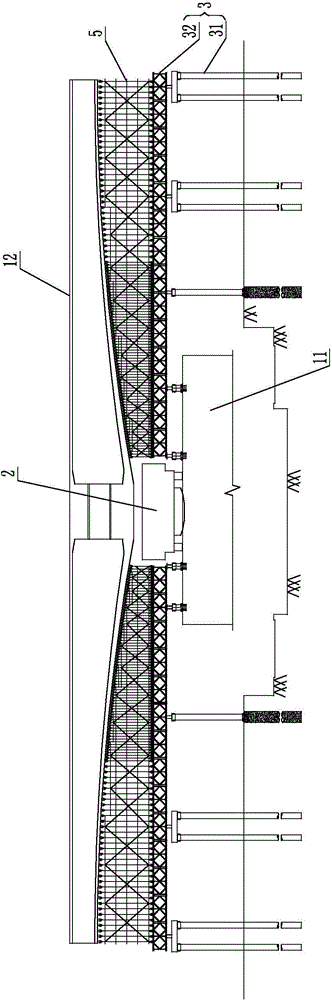

Balance weighing structure and balance weighing method for horizontal rotating construction of box girder bridge

ActiveCN104452603ASmall running resistanceAvoid damageBridge erection/assemblyBox girderBalance test

The invention relates to the technical field of bridge construction, in particular to a balance weighing structure and a balance weighing method for horizontal rotating construction of a box girder bridge. A rotation plate is arranged on the top of a pier and in the center of the bottom of a girder, each truss is arranged below the girder along the length direction of the girder, one end of each truss is fixed onto the top of the pier, and the other end of each truss is erected on the ground through a vertical column; each group of auxiliary weighing systems is positioned between the end, in the length direction, of the girder and the truss at the same end. The method includes: arranging a lower support and an upper support on two sides of the pier, and casting the girder in situ on the rotation plate and the two groups of upper supports; demounting part of the upper supports, and arranging the auxiliary weighing systems between the end of the girder and the lower supports at the same end; performing balance test, and balancing to enable a center of gravity of the girder to be coincided with the center of the rotation plate; rotating the rotation plate to complete construction. The balance weighing structure and the balance weighing method for horizontal rotating construction of the box girder bridge have the advantages that a T structure is adjusted to a balanced state, directly jacking on the rotation plate is avoided, and the bridge is protected from damages owing to low jacking force.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +1

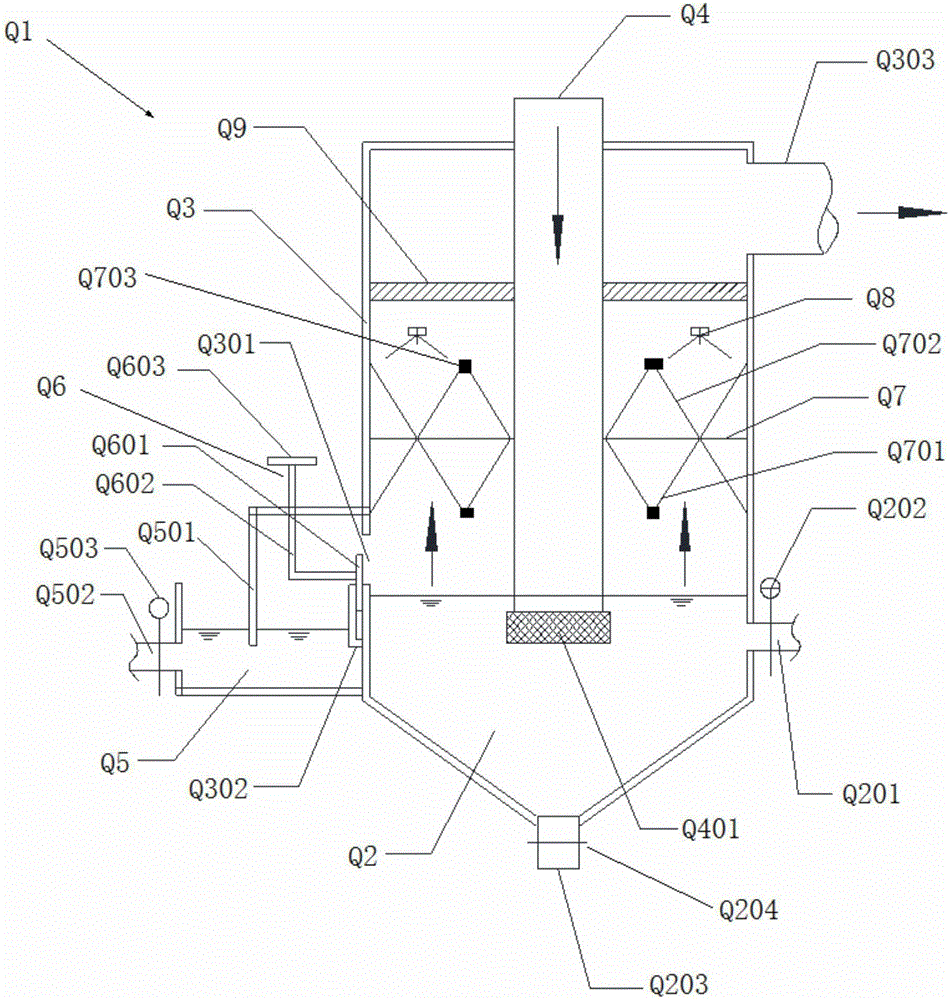

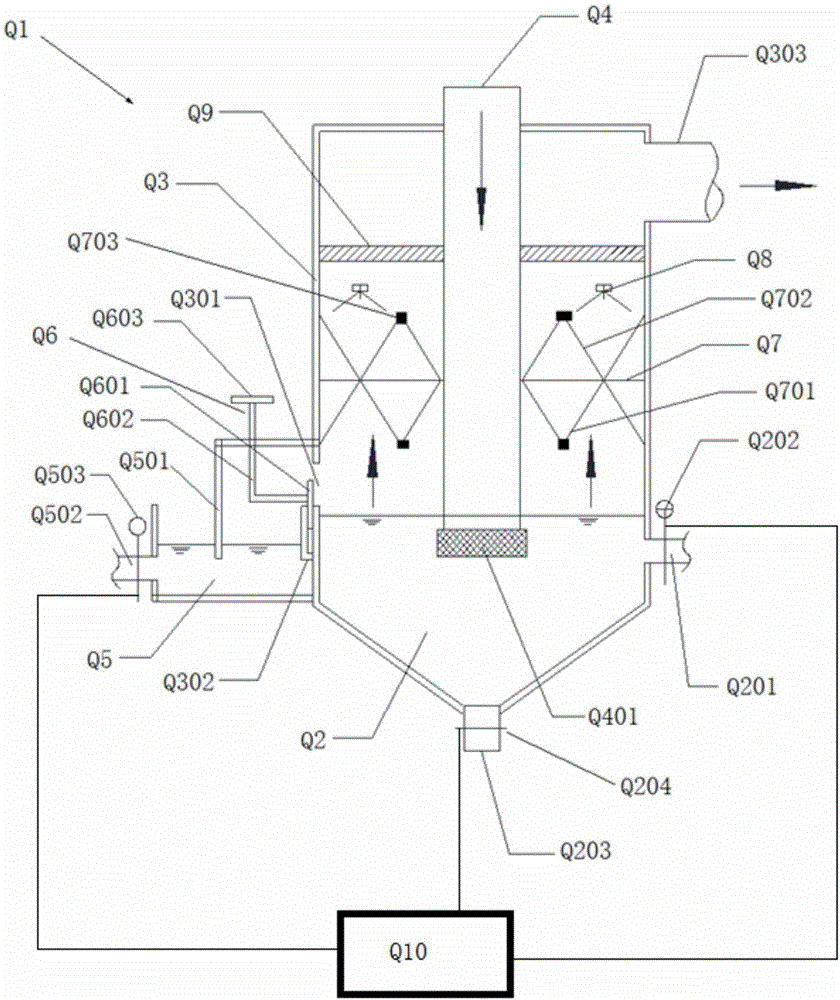

Water bath deduster, dedusting method and quicklime slaking and dedusting device

ActiveCN105833627ATargeted captureImprove dust removal efficiencyCombination devicesUsing liquid separation agentWater bathsEngineering

The invention provides a water bath deduster (Q1) which comprises a dedusting pool (Q2), a duduster shell (Q3) positioned below the dedusting pool (Q2) and a dedusting pipeline (Q4). One end of the dedusting pipeline (Q4) is externally connected with a dedusting port of a lime slaker while the other end of the same penetrates the deduster shell (Q3) from top to bottom and extends into the dedusting pool (Q2) below the deduster shell (Q3), a below-liquid pipeline nozzle (Q401) is arranged at the end, extending into the dedusting pool (Q2), of the dedusting pipeline (Q4), and the tail end of the below-liquid pipeline nozzle (Q401) is of a netty structure or a porous structure. The invention provides the efficient quicklime slaking water bath deduster and a quicklime slaking dedusting sewage treatment method and aims to solve the problem of poor quicklime slaking dedusting effect, the problem of environment pollution caused by a lot of dust and smoke generated during quicklime slaking, the problem of environment pollution caused by lime slaking dedusting sewage and the problem of how to recycle dedusting sewage.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

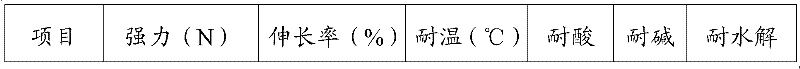

Specific composite filter material for coal-fired power plant electric bag integration project

InactiveCN101804273AImprove Oxygen LimitationStrong chemical resistanceCombination devicesLayered productsCompound (substance)Engineering

The invention discloses a specific composite filter material for a coal-fired power plant electric bag integration project; the composite filter material comprises base cloth, a dust facing surface and a bottom layer; the dust facing surface is arranged on the upper surface of the base cloth; the bottom layer is arranged on the lower surface of the base cloth; the dust facing surface is mixedly blended from PTFE fibers and PPS fibers, wherein the weight proportion of the PTFE fibers is 30 to 70 percent; the base cloth is interwoven from 100 percent PTFE long filaments in the longitudinal and latitude directions; and the bottom layer is mixedly blended from the PTFE fibers and the PPS fibers, wherein the weight proportion of the PTFE fibers is 30 to 70 percent. The fibers tangle through an acupuncture and spunlace composite process to form a plain blanket which is soaked into chemical solvent, so as to further improve the corrosion resistance and chemical performance resistance. The specific composite filter material for the coal-fired power plant electric bag integration project has smooth surface, improves the dust removing capability, reduces the operation resistance of equipment, prolongs the service life, can ensure the use for 35000h in the electric bag integration project, and is applicable to the coal-fired power plant electric bag integration project.

Owner:NANJING JIHUA 3521 SPECIAL EQUIP

Pre-charging electrocoagulation bag type dust remover

The invention relates to a pre-charging electrocoagulation bag type dust remover. A dual- pole charging device is arranged in an air inlet flue (11) and comprises a group of earth poles (7) arranged at intervals and positive and negative discharging poles (8), so that dual-pole charging regions (13) with positive and negative alternate electric fields are formed. A mixed coagulation region (22) is arranged in the tail space of the air inlet flue (11) and the buffering space of a filtering cabin, so that the coagulation efficacy of PM2.5 subparticles is observably improved. Coagulated large particles rapidly enter a filter bag filtering cabin (12) along with air currents, so that dust-air separation is performed by the filter bag. The dust remover disclosed by the invention utilizes a dual-pole charging electrocoagulation mechanism, and oversized PM2.5 subparticles are regularly arrayed on the surface of the filter bag and loosely stacked, so that the oversized PM2.5 subparticles are very liable to trap and remove. The dust remover has the significant characteristics of good coagulation effect on the subparticles, high trapping efficiency on the PM2.5 and the like, and is particularly suitable for reforming and improving a bag type dust remover adopting a traditional structure. The dust remover is economical, practical, convenient and high-efficiency.

Owner:ENELCO ENVIRONMENTAL TECH ANHUI

Welding aluminum alloy sheet for railway motor train set with two hundred kilometers per hour and manufacturing method

ActiveCN101457319AMeet the use requirementsImprove applicabilityThick plateUltimate tensile strength

The invention discloses a weldable aluminum alloy plate for a railway motor train unit with the speed of 200km per hour and a manufacturing method and relates to an aluminum alloy plate and the manufacturing method thereof. The invention aims at solving the problems of heavy car body and high cost caused by the use of stainless steel plates in the railway motor train unit with the speed of 200km per hour currently. The plate comprises the following compositions by weight percent: 0.30% of Si, 0.35% of Fe, 0.20% of Cu, 0.20-0.70% of Mn, 1.00-2.00% of Mg, 0.30% of Cr, 4.00-5.00% of Zn, 0.20% of Ti, 0.25% of Zr, 0.10% of V and the balance of Al. The method comprises the following steps: setting the solid-melting treatment temperature between 468 and 472 DEG C; pre-stretching a thick plate for 60 to 90 minutes, and cold quenching in the water with the temperature below 34 DEG C. The plate has a tensile strength not smaller than 315N / mm<2>, a disproportionate extension strength not smaller than 195N / mm<2>, a simple process and a high qualified rate of products.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com