Patents

Literature

2791 results about "Membrane layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Analyte sensors and methods of manufacturing same

ActiveUS20110027127A1Hot-dipping/immersion processesMaterial analysis by electric/magnetic meansAnalyteEngineering

Analyte sensors and methods of manufacturing same are provided, including analyte sensors comprising multi-axis flexibility. For example, a multi-electrode sensor system 800 comprising two working electrodes and at least one reference / counter electrode is provided. The sensor system 800 comprises first and second elongated bodies E1, E2, each formed of a conductive core or of a core with a conductive layer deposited thereon, insulating layer 810 that separates the conductive layer 820 from the elongated body, a membrane layer deposited on top of the elongated bodies E1, E2, and working electrodes 802′, 802″ formed by removing portions of the conductive layer 820 and the insulating layer 810, thereby exposing electroactive surface of the elongated bodies E1, E2.

Owner:DEXCOM

Analyte sensors and methods of manufacturing same

Analyte sensors and methods of manufacturing same are provided, including analyte sensors comprising multi-axis flexibility. For example, a multi-electrode sensor system 800 comprising two working electrodes and at least one reference / counter electrode is provided. The sensor system 800 comprises first and second elongated bodies E1, E2, each formed of a conductive core or of a core with a conductive layer deposited thereon, insulating layer 810 that separates the conductive layer 820 from the elongated body, a membrane layer deposited on top of the elongated bodies E1, E2, and working electrodes 802′, 802″ formed by removing portions of the conductive layer 820 and the insulating layer 810, thereby exposing electroactive surface of the elongated bodies E1, E2.

Owner:DEXCOM

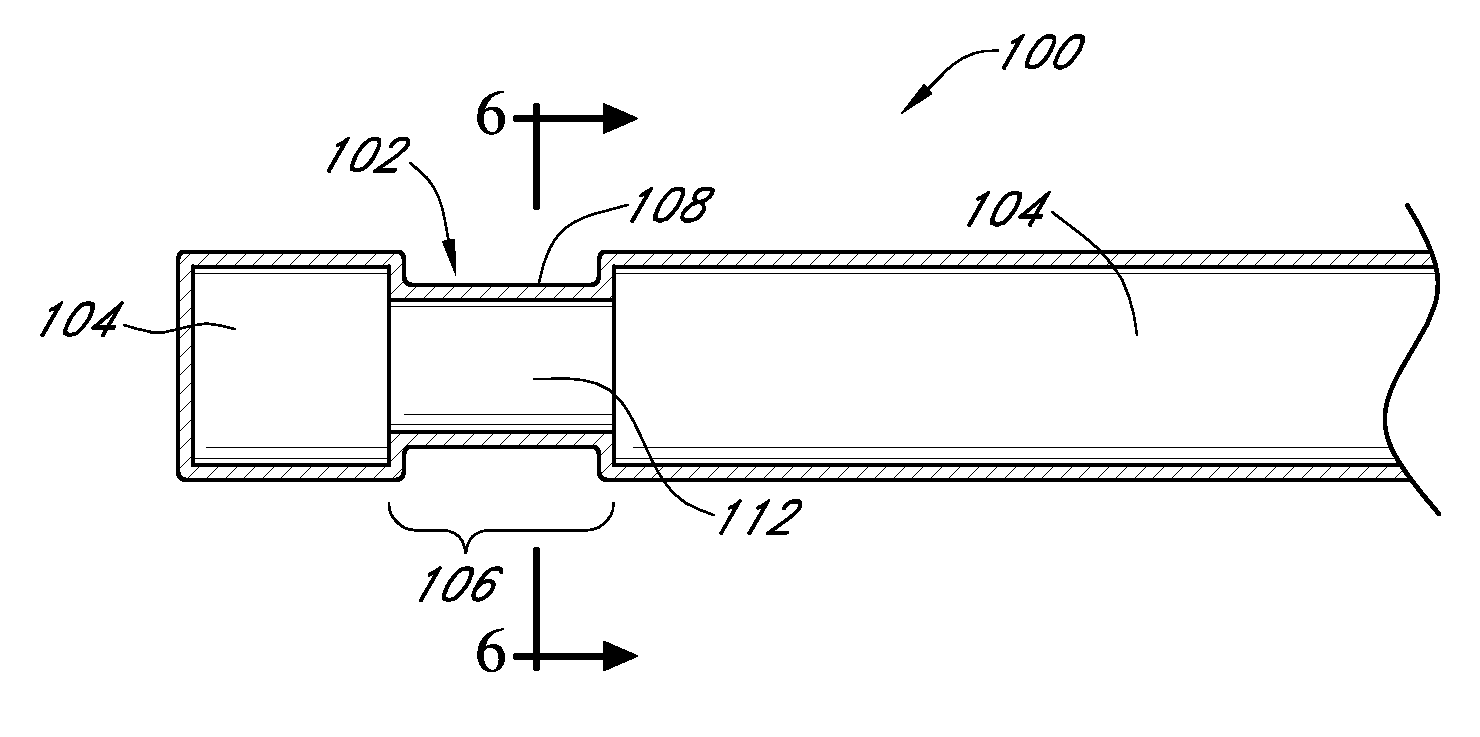

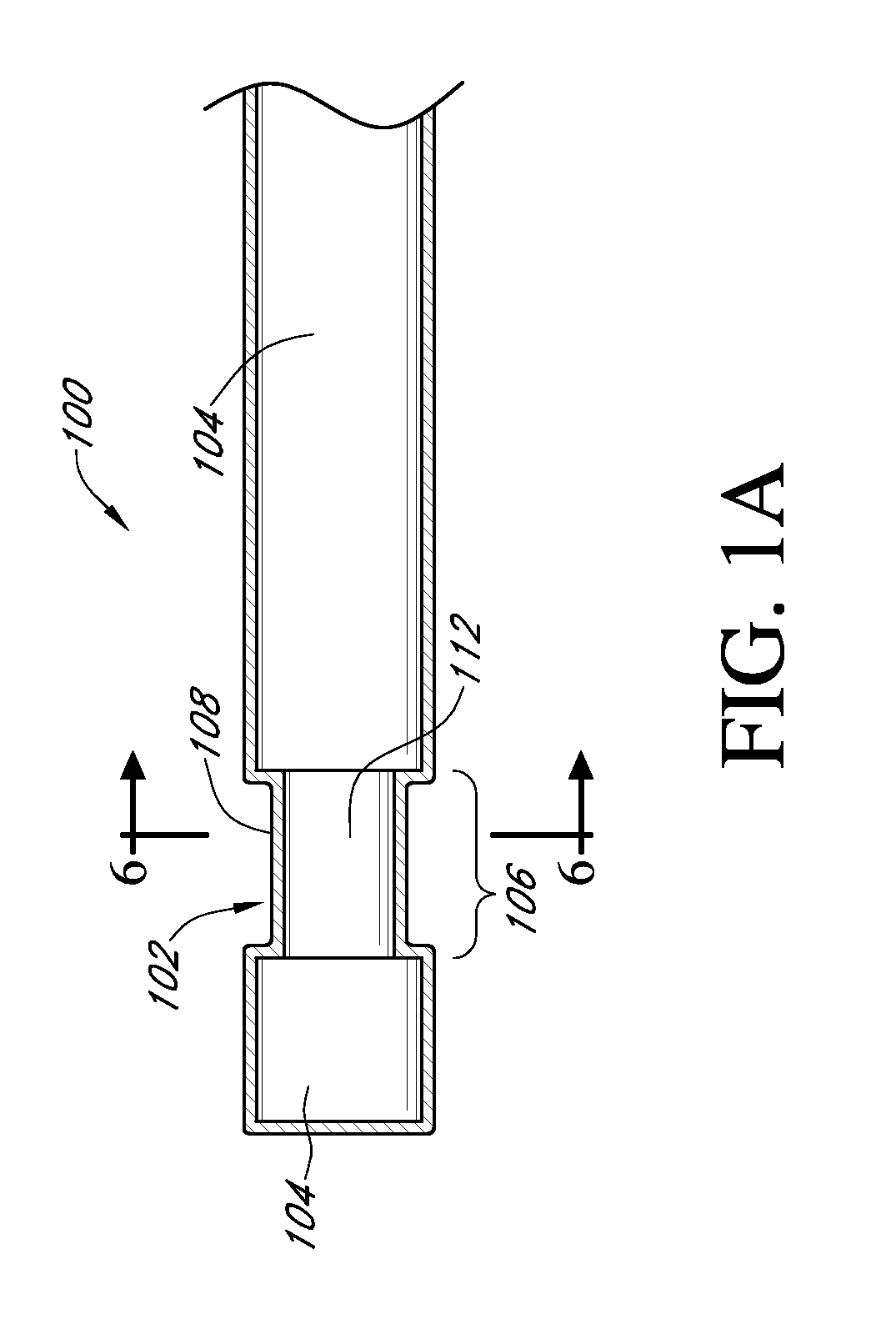

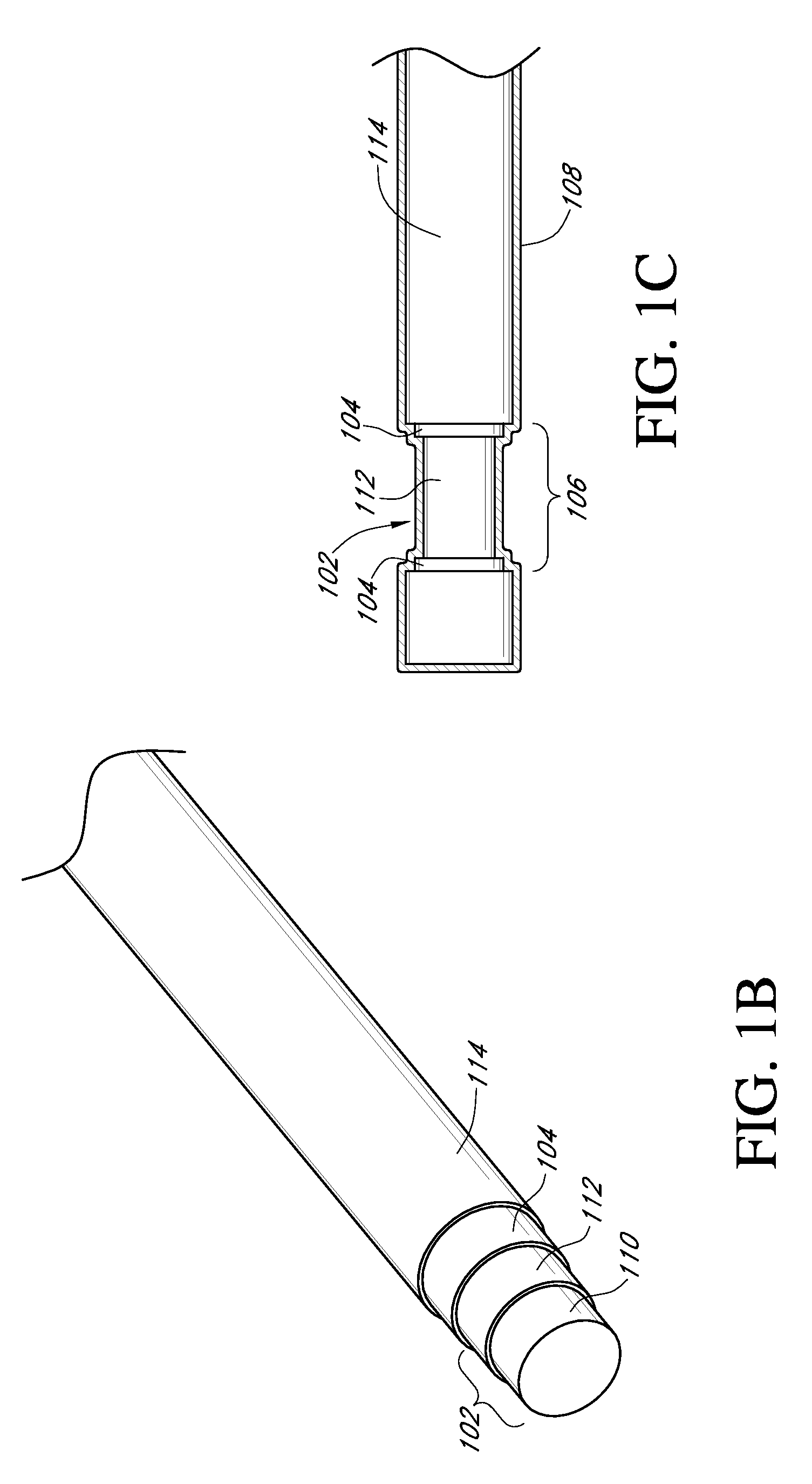

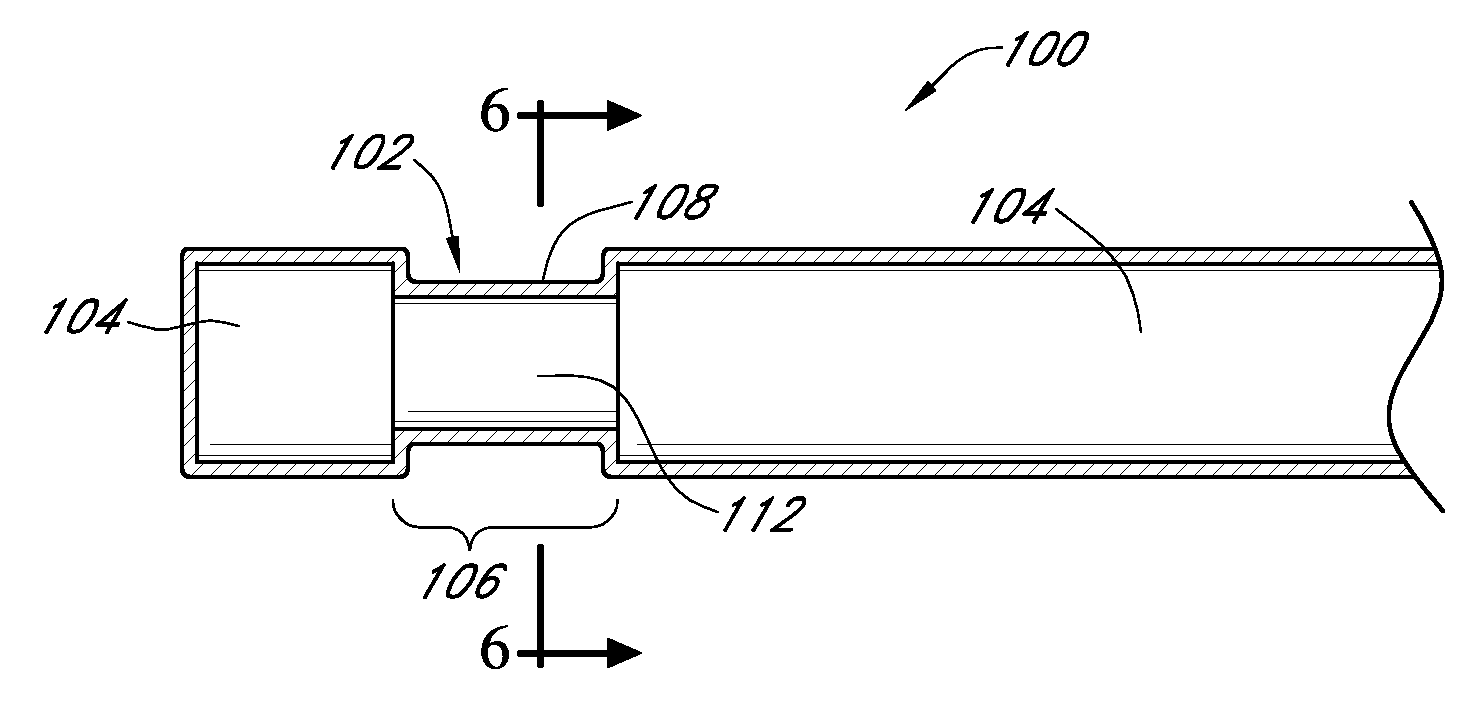

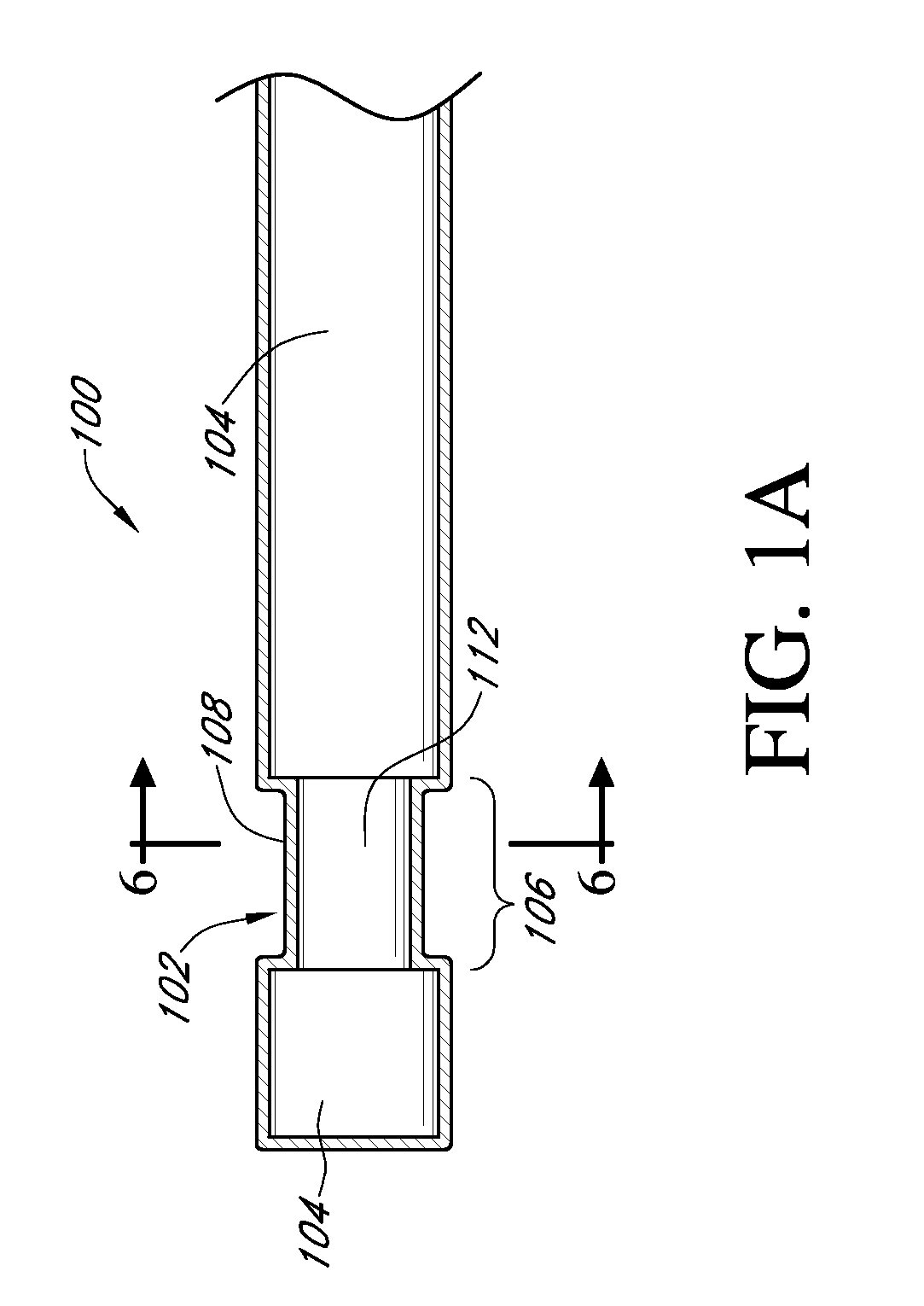

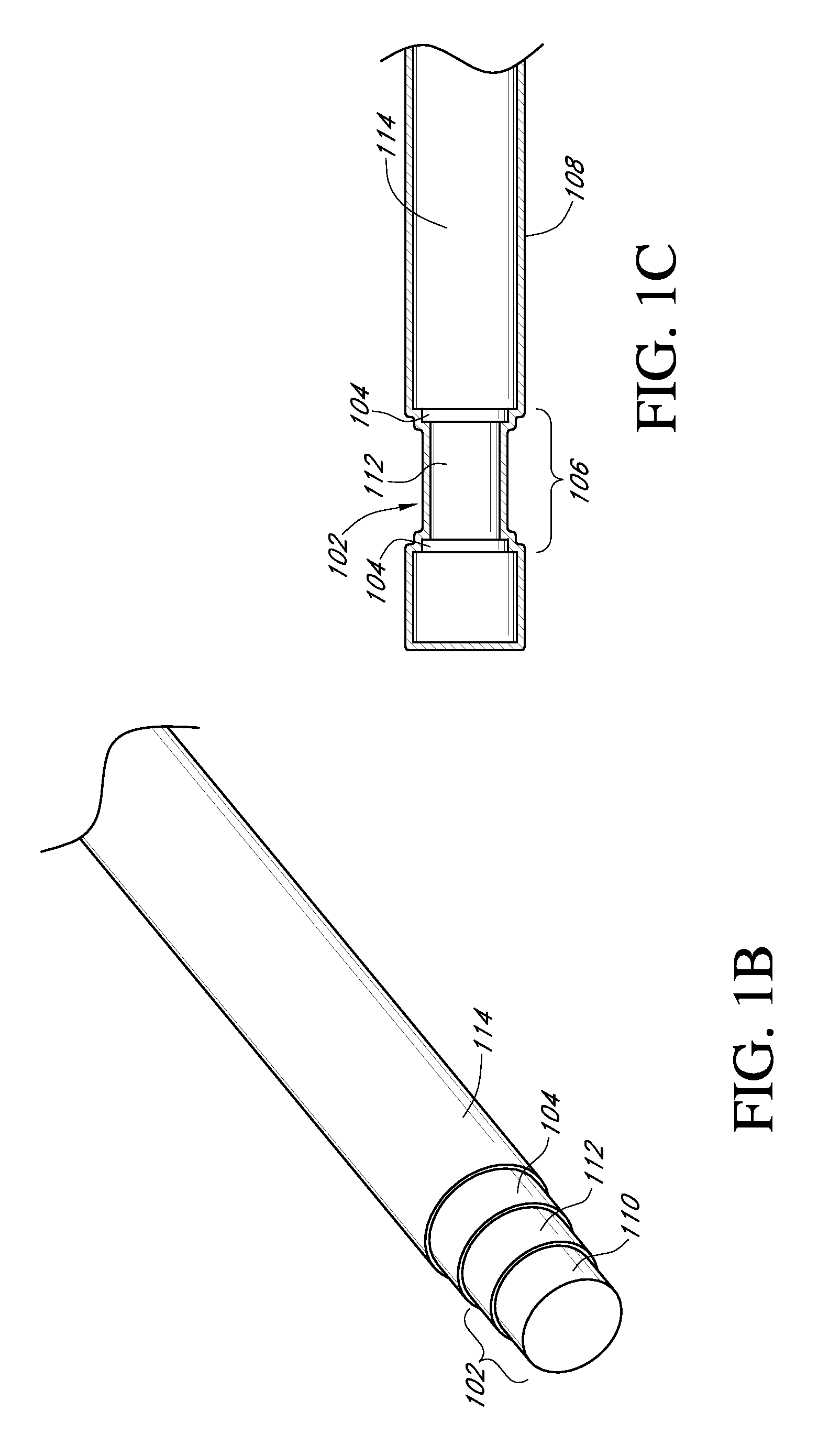

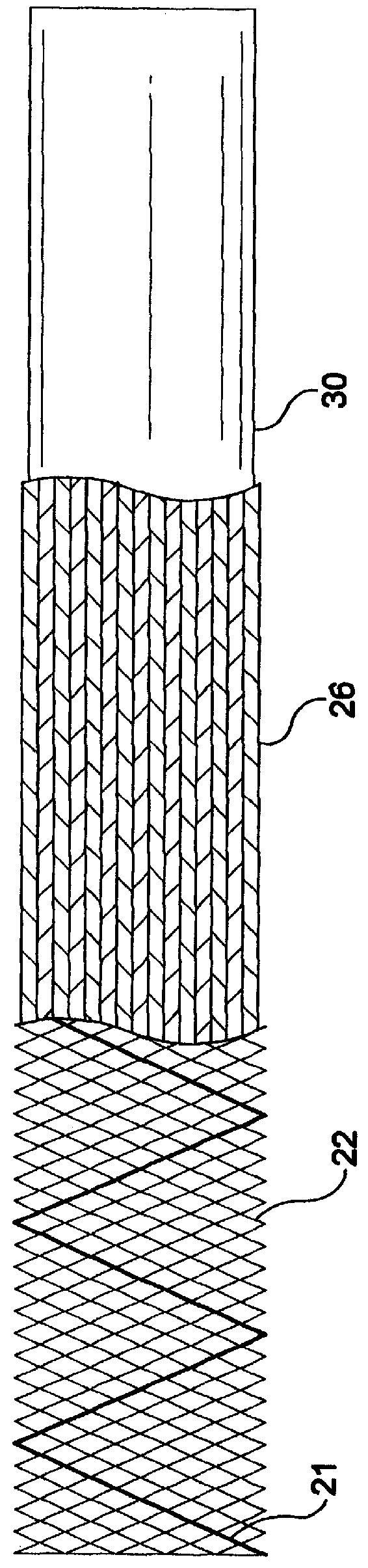

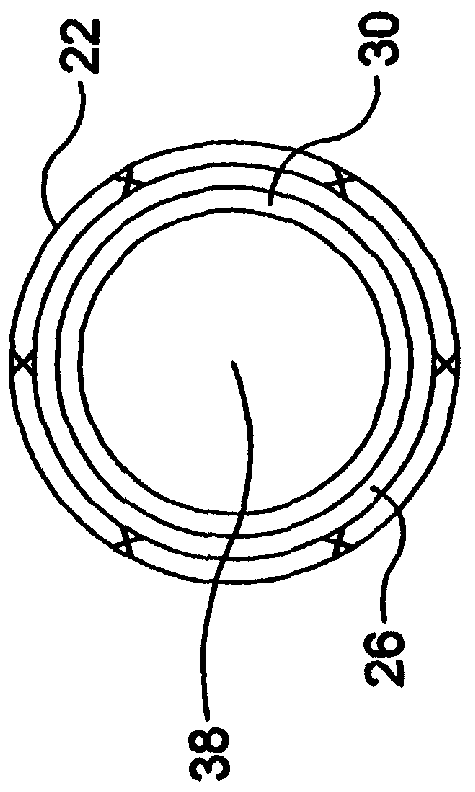

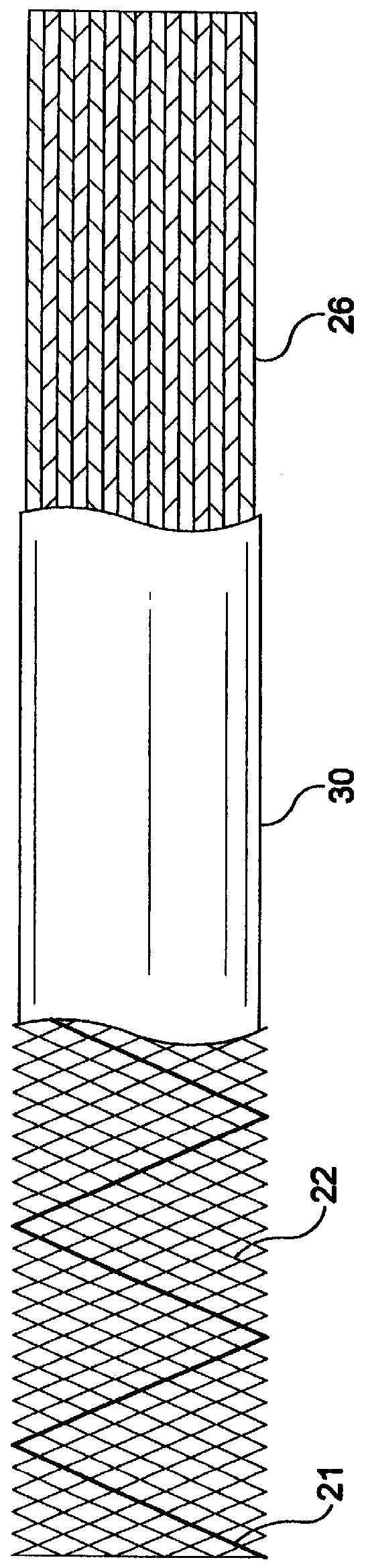

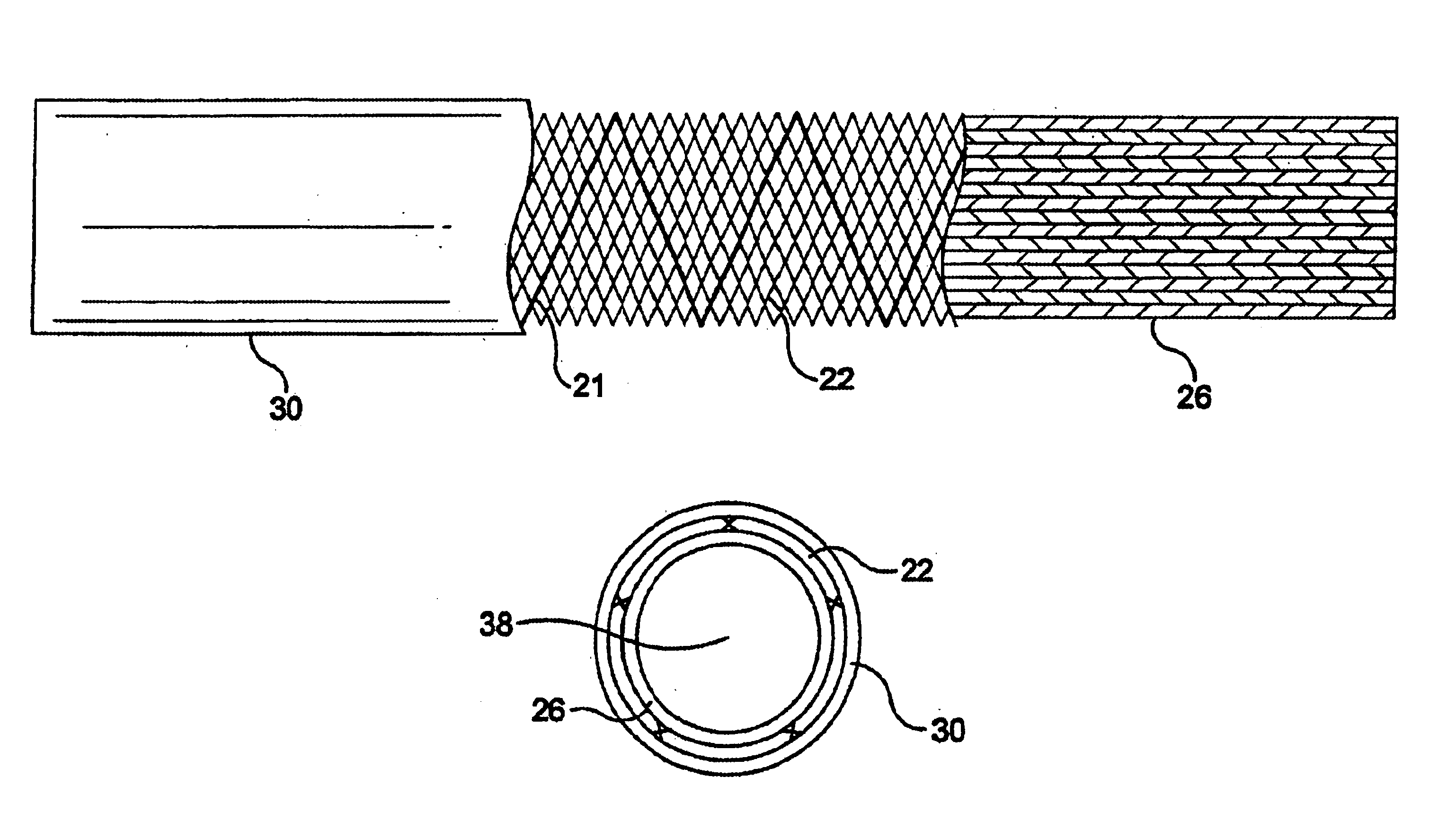

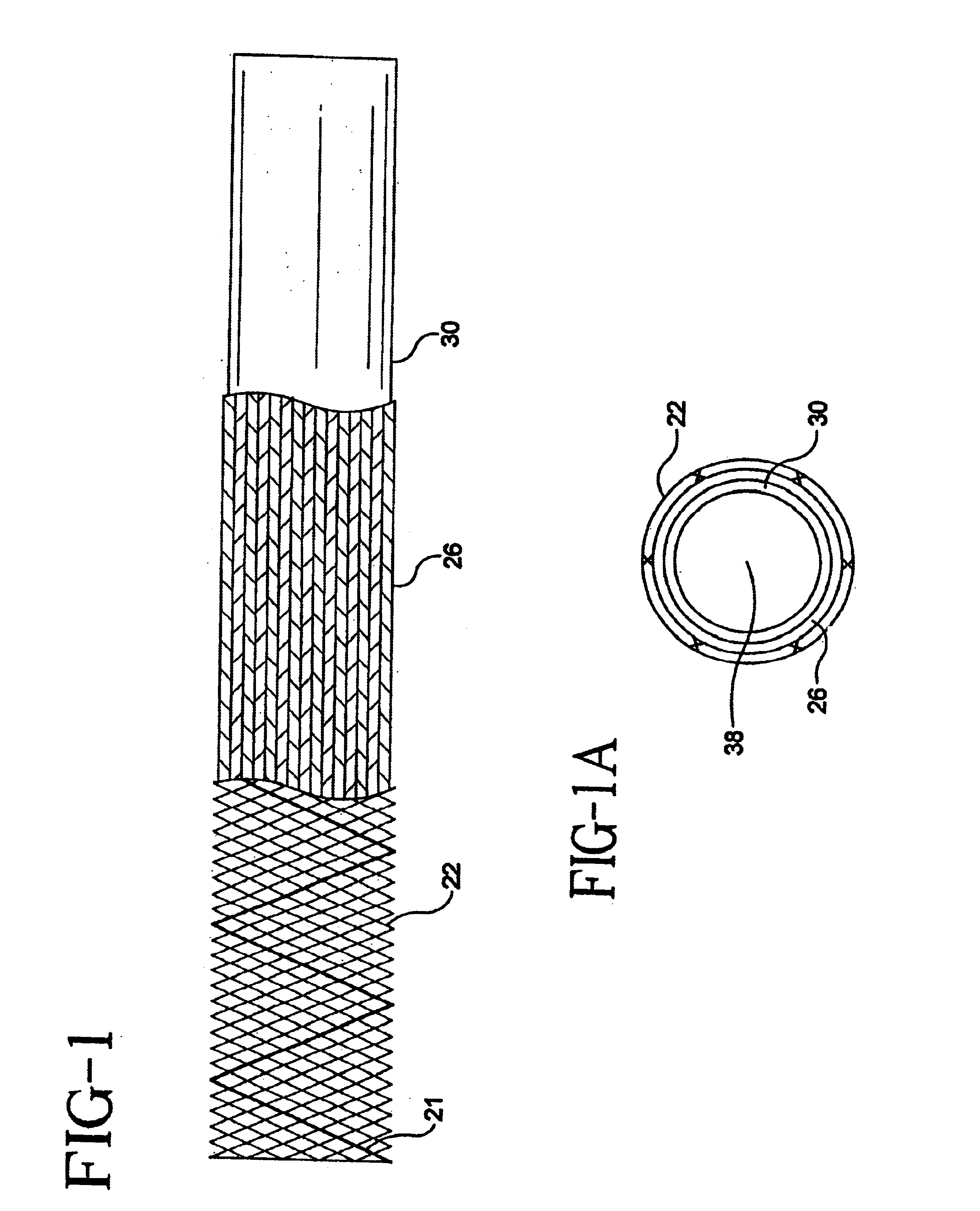

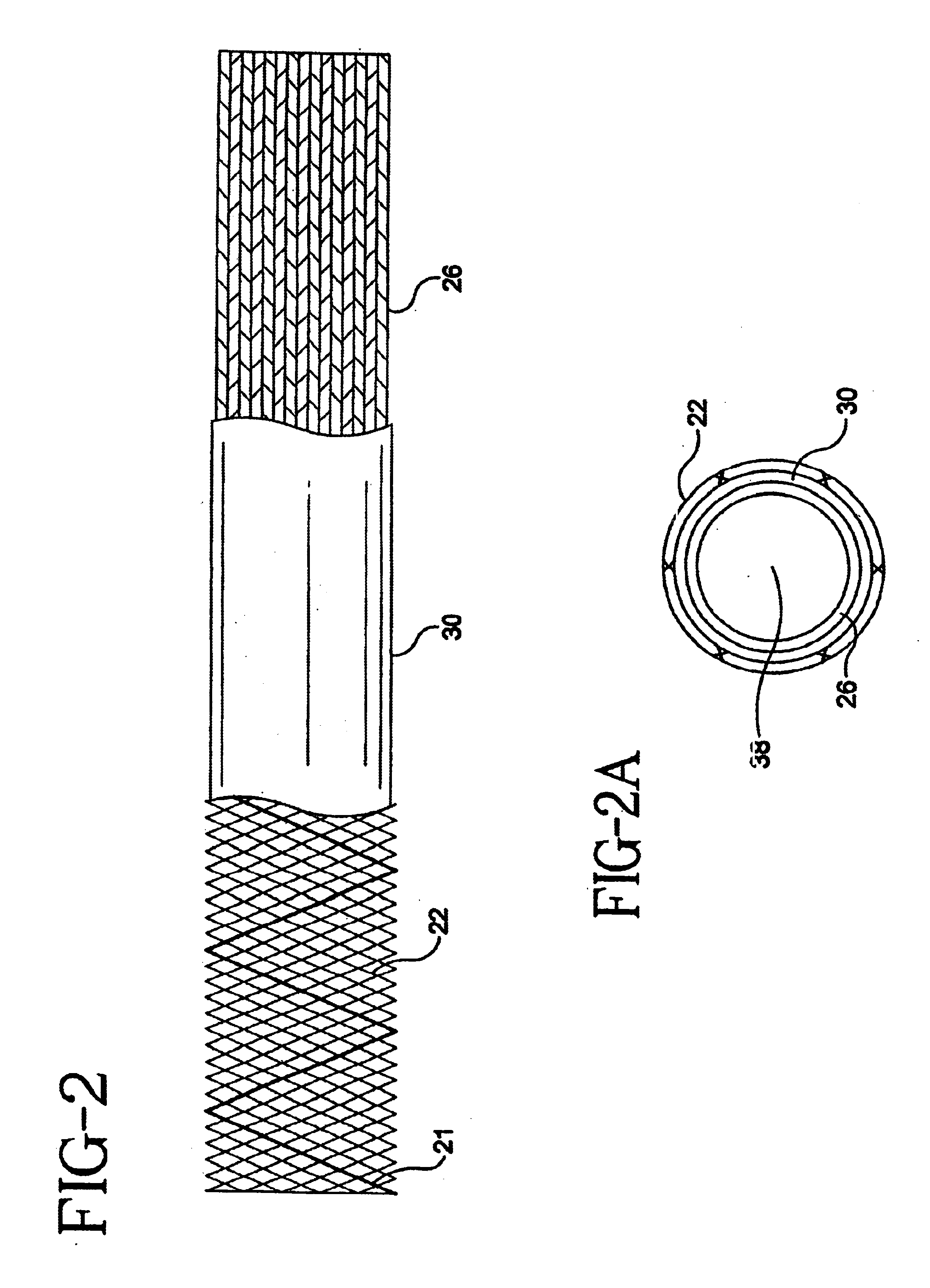

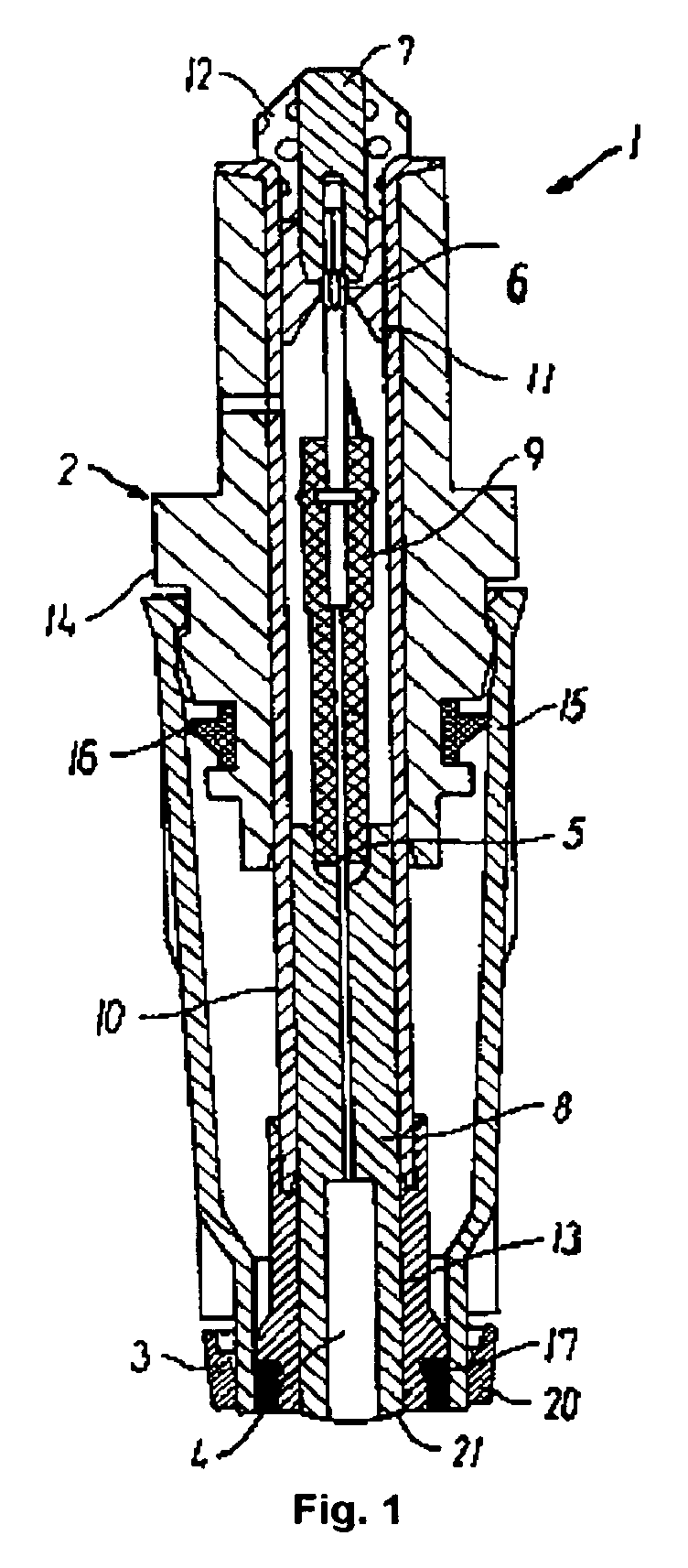

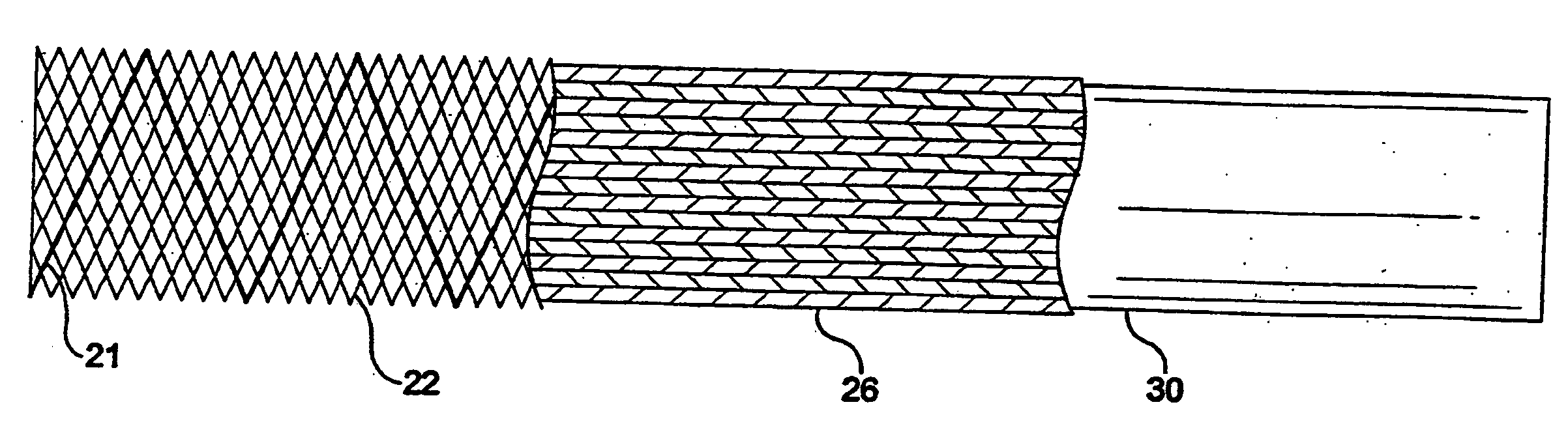

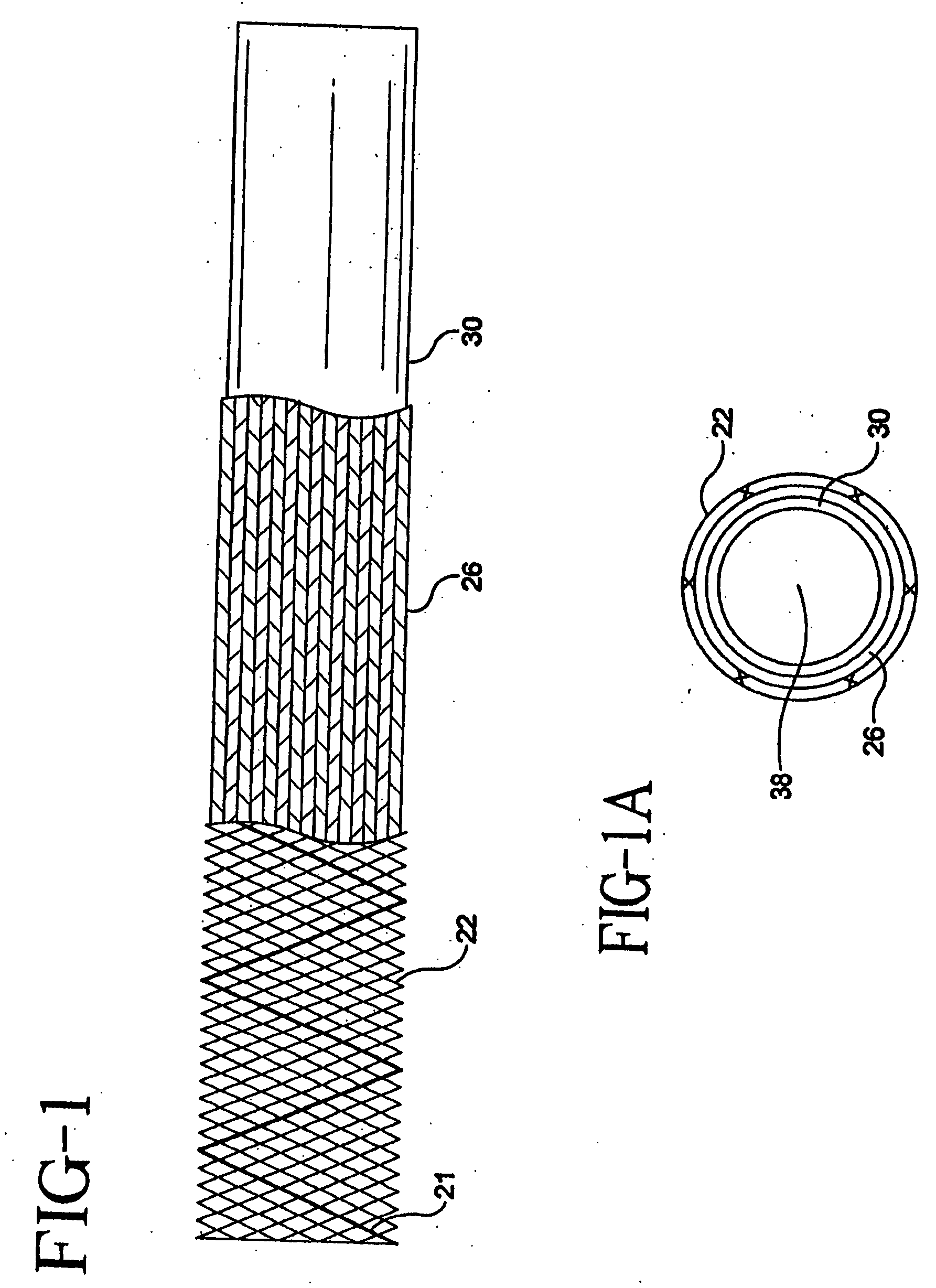

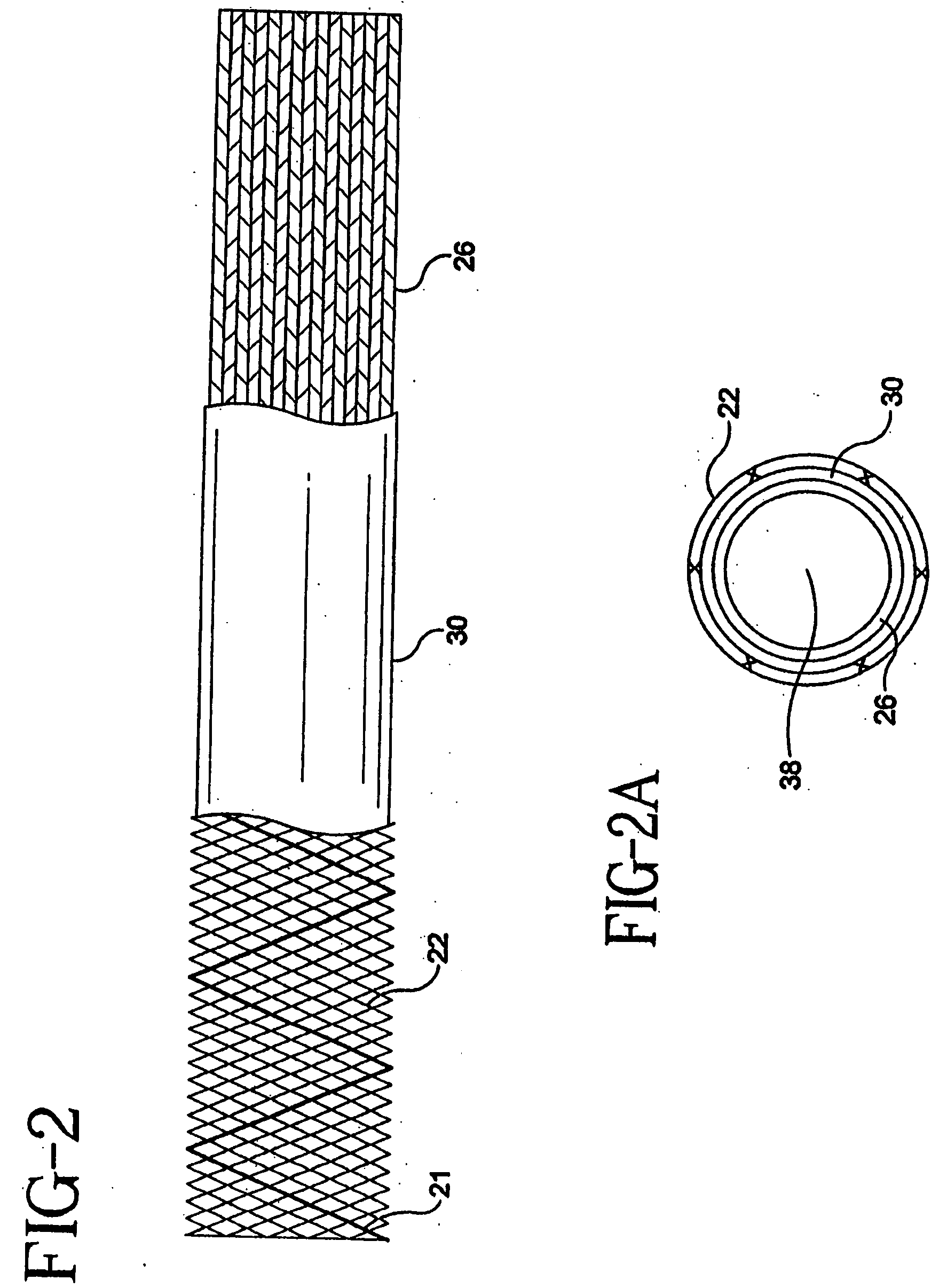

Stent-graft-membrane and method of making the same

A braided self-expandable stent-graft-membrane made of elongated members forming a generally tubular body. A membrane layer and graft layer are disposed on a endoprosthesis such as a stent. The membrane layer is substantially impermeable to fluids. The outermost layer is biocompatible with the body tissue. The innermost layer is biocompatible with the fluid in the passage. An embodiment includes a graft layer disposed on the inside of a stent and a membrane layer disposed on the outside of the stent. The innermost layer is biocompatible with the fluid in the passage. The stent-graft-membrane is used at a treatment site in a body vessel or organ where it is desirous to exclude a first fluid located outside the endoprosthesis from reaching a second fluid located in the lumen. The membrane may be made of silicone or polycarbonate urethane. The graft may be braided, woven, spun or spray-cast PET, PCU, or PU fibers. The layers may include ePTFE or PTFE.

Owner:LIFEPORT SCI

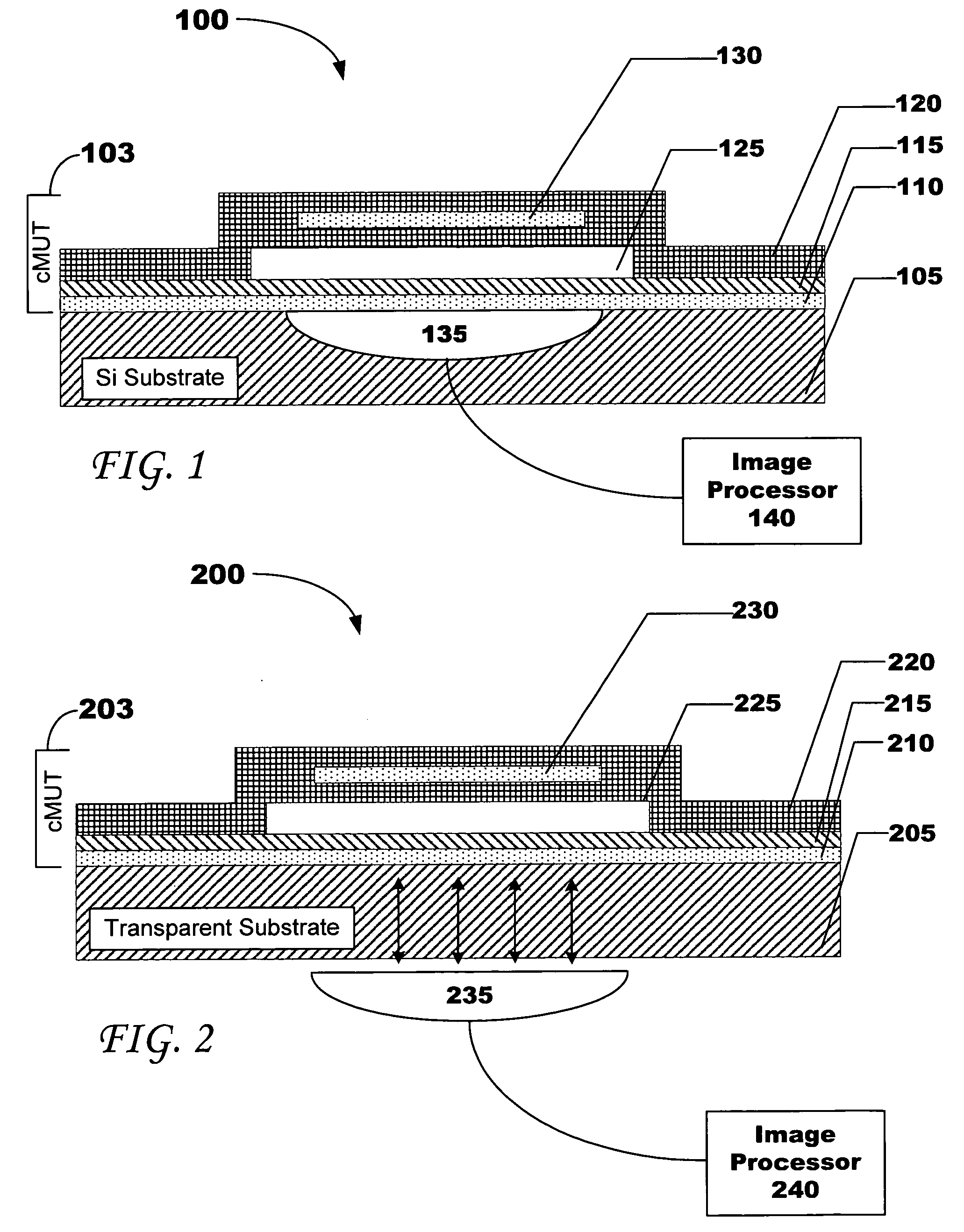

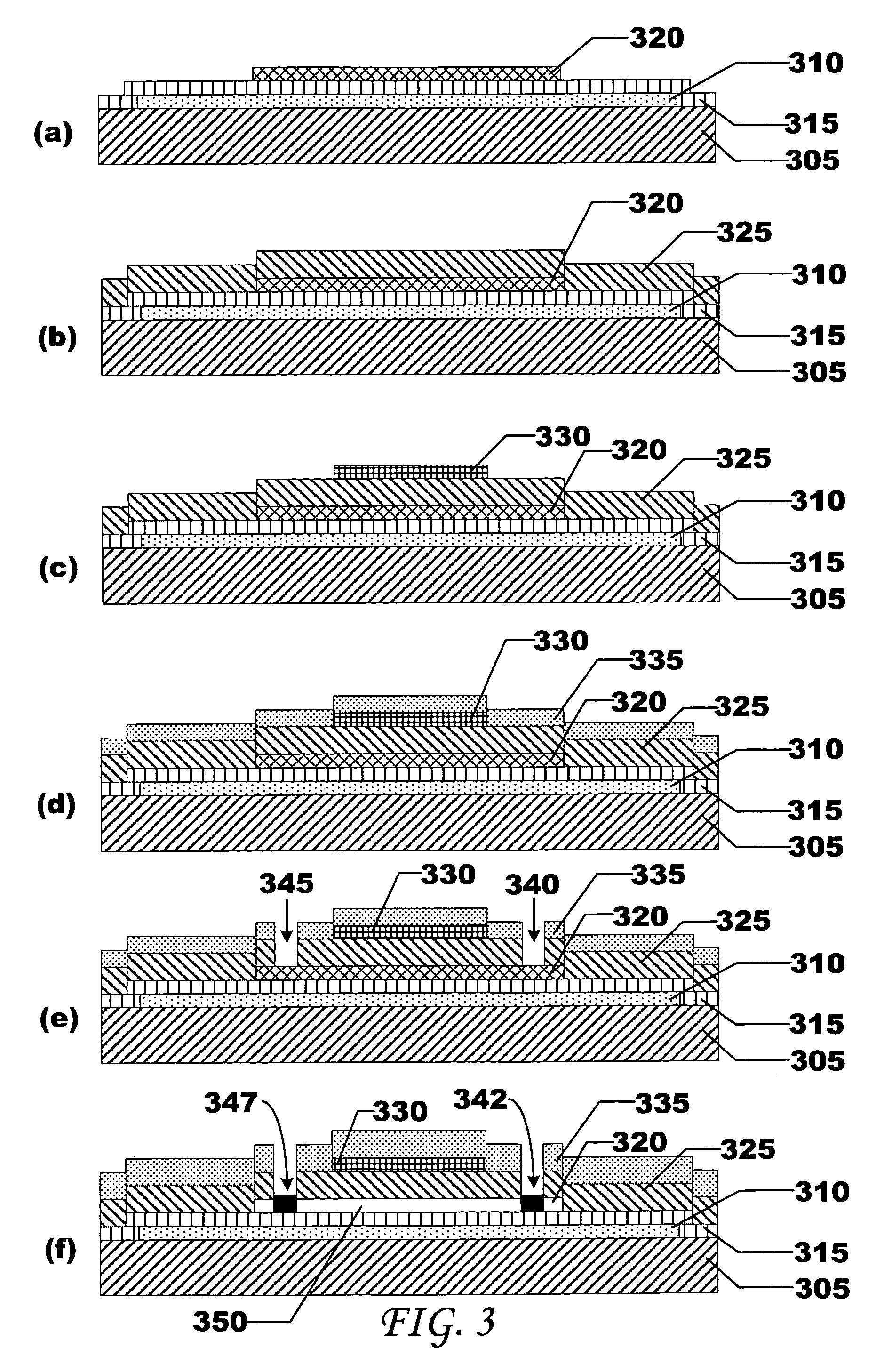

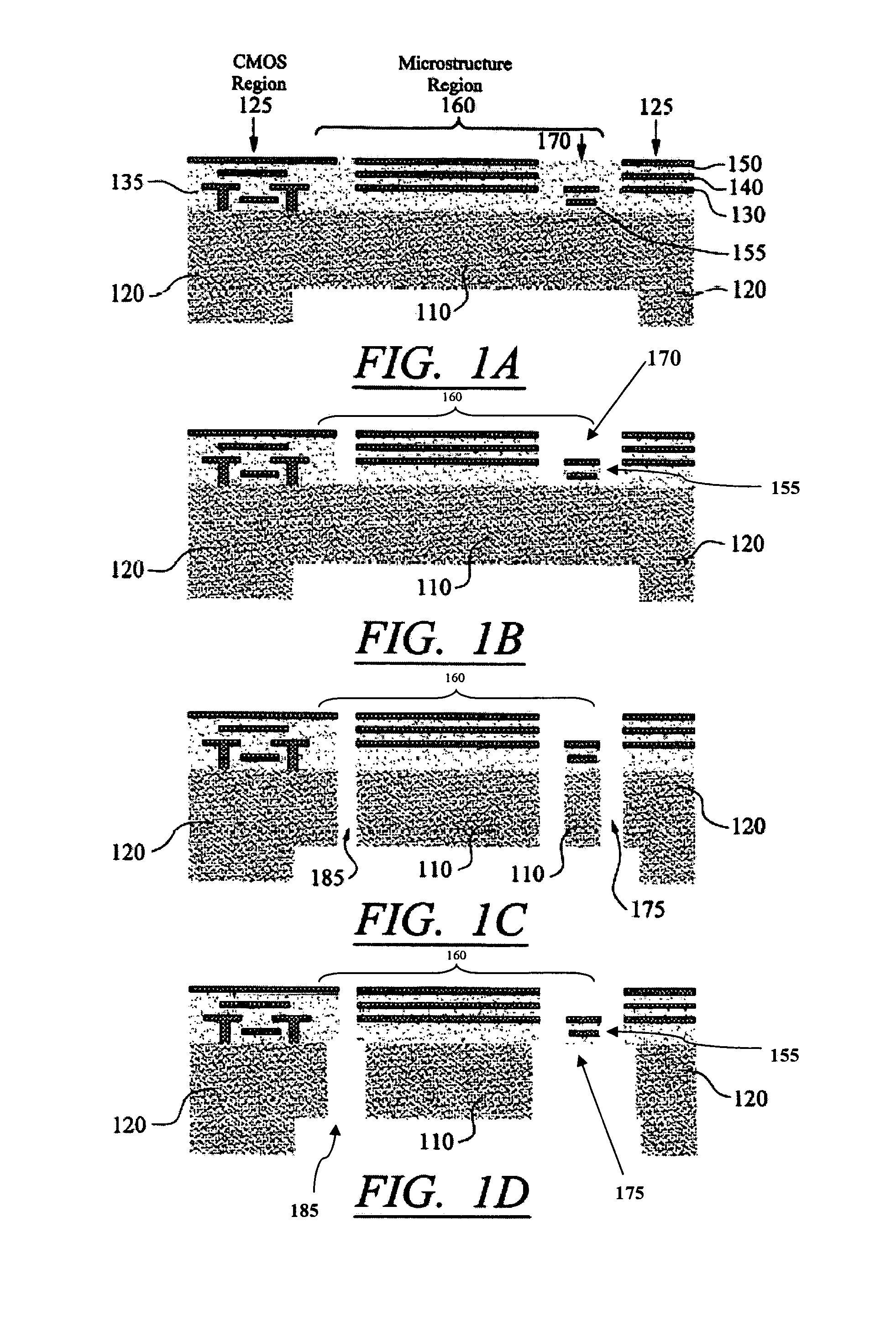

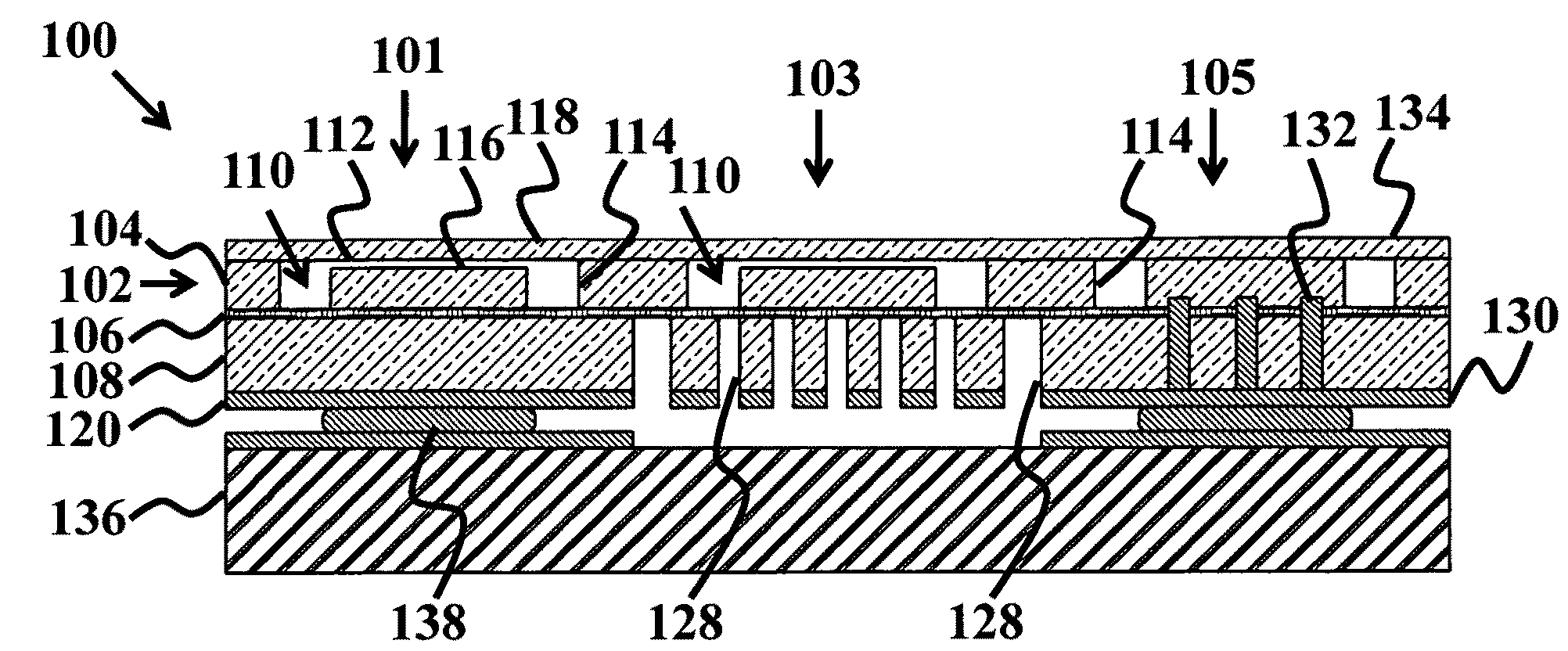

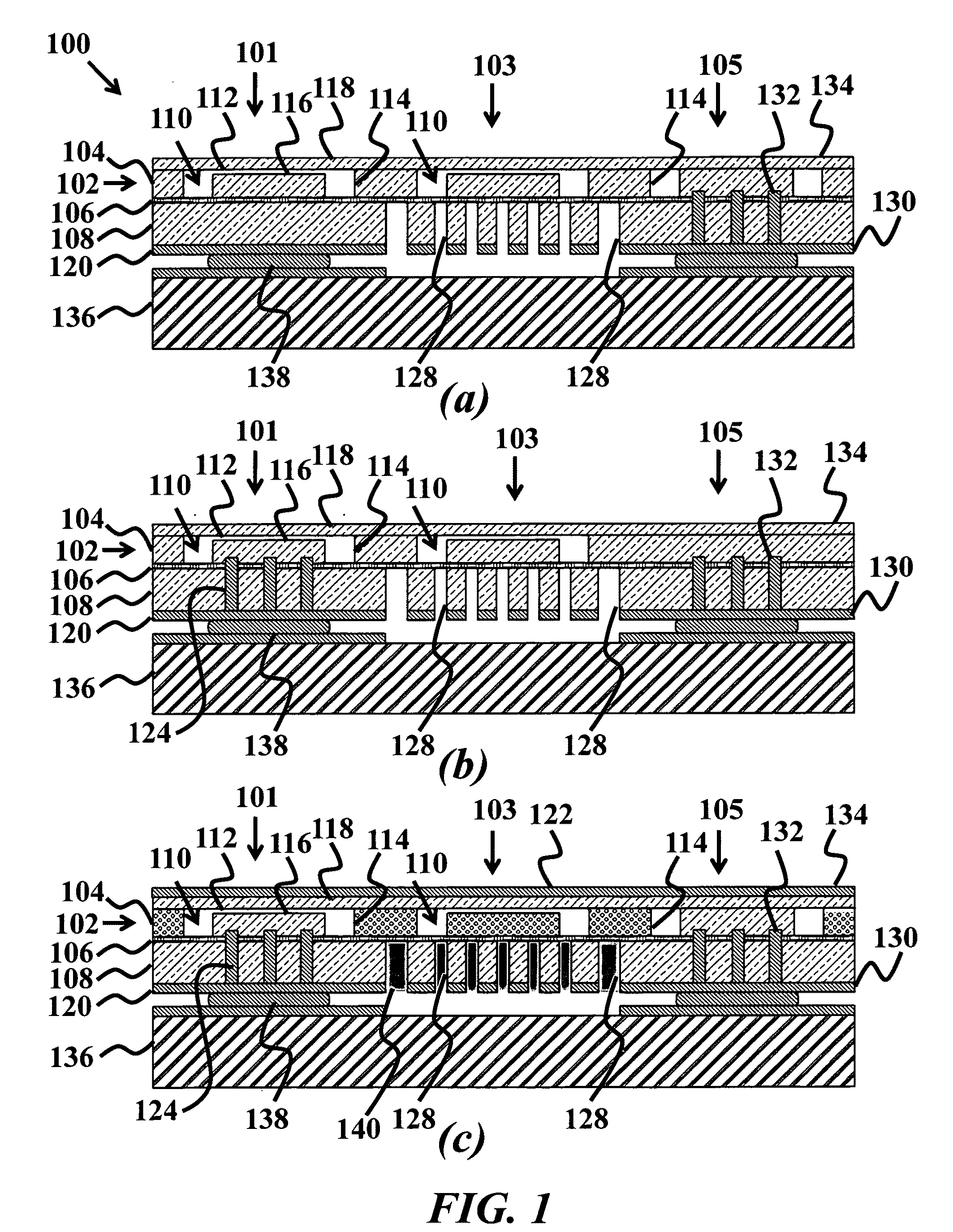

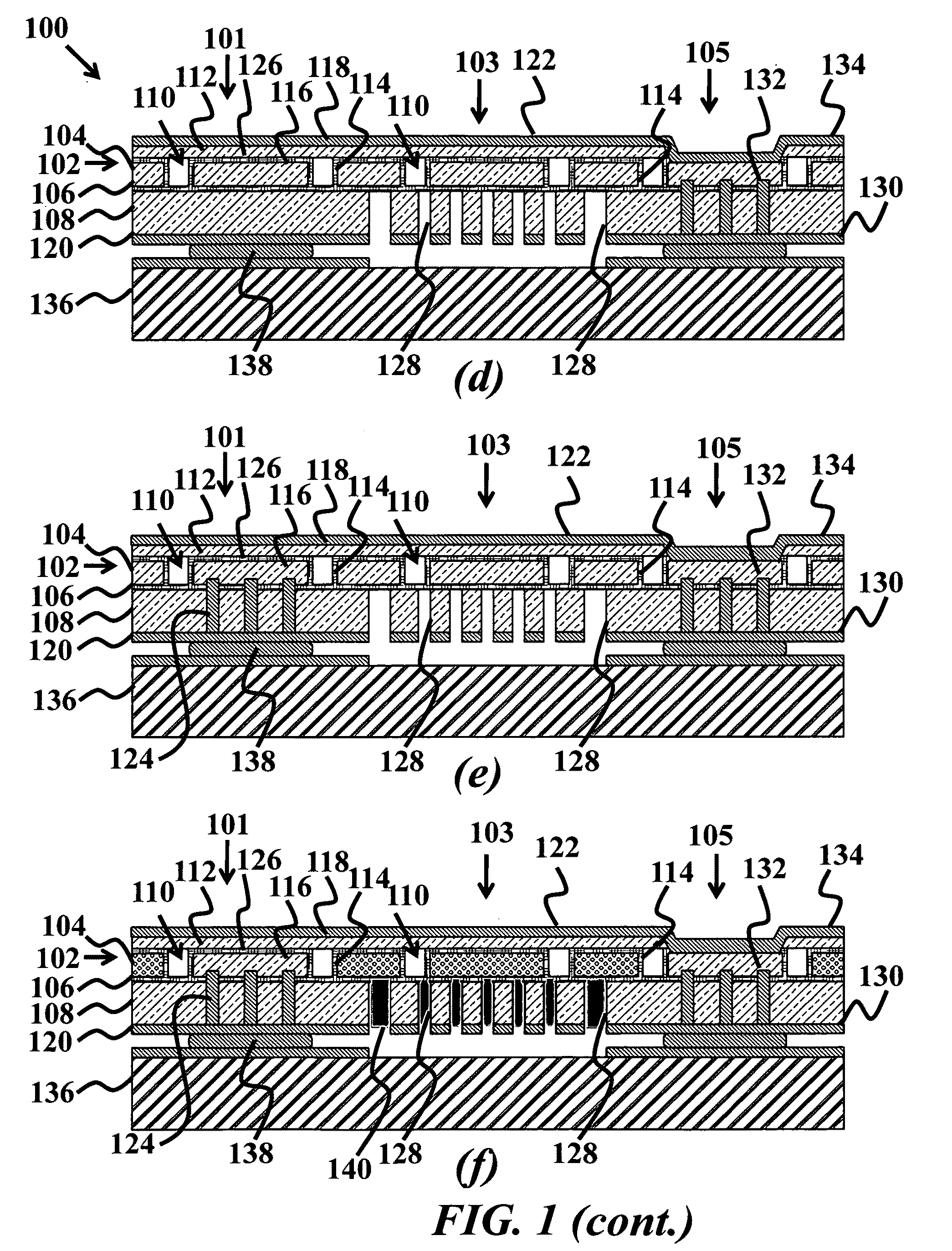

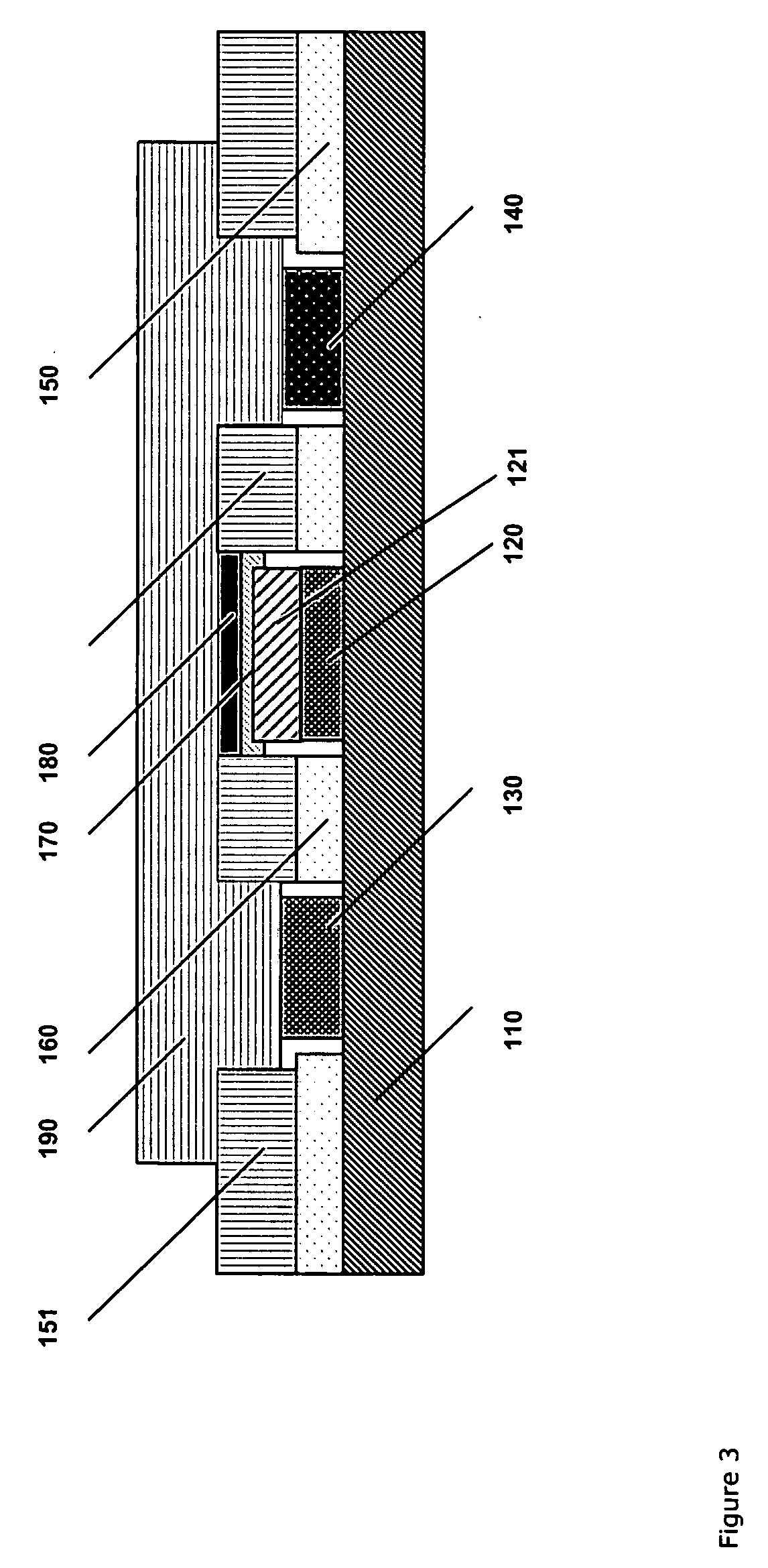

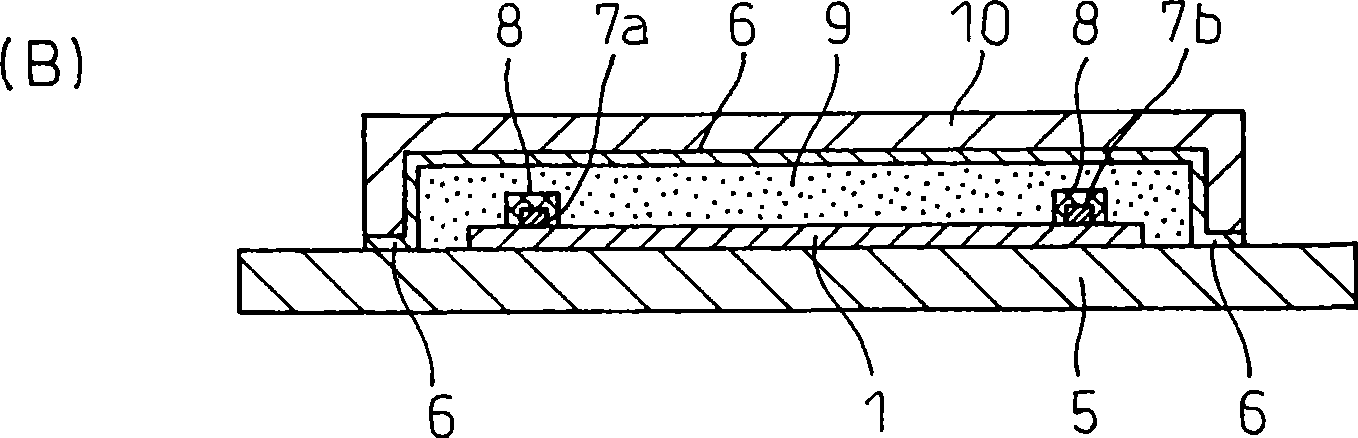

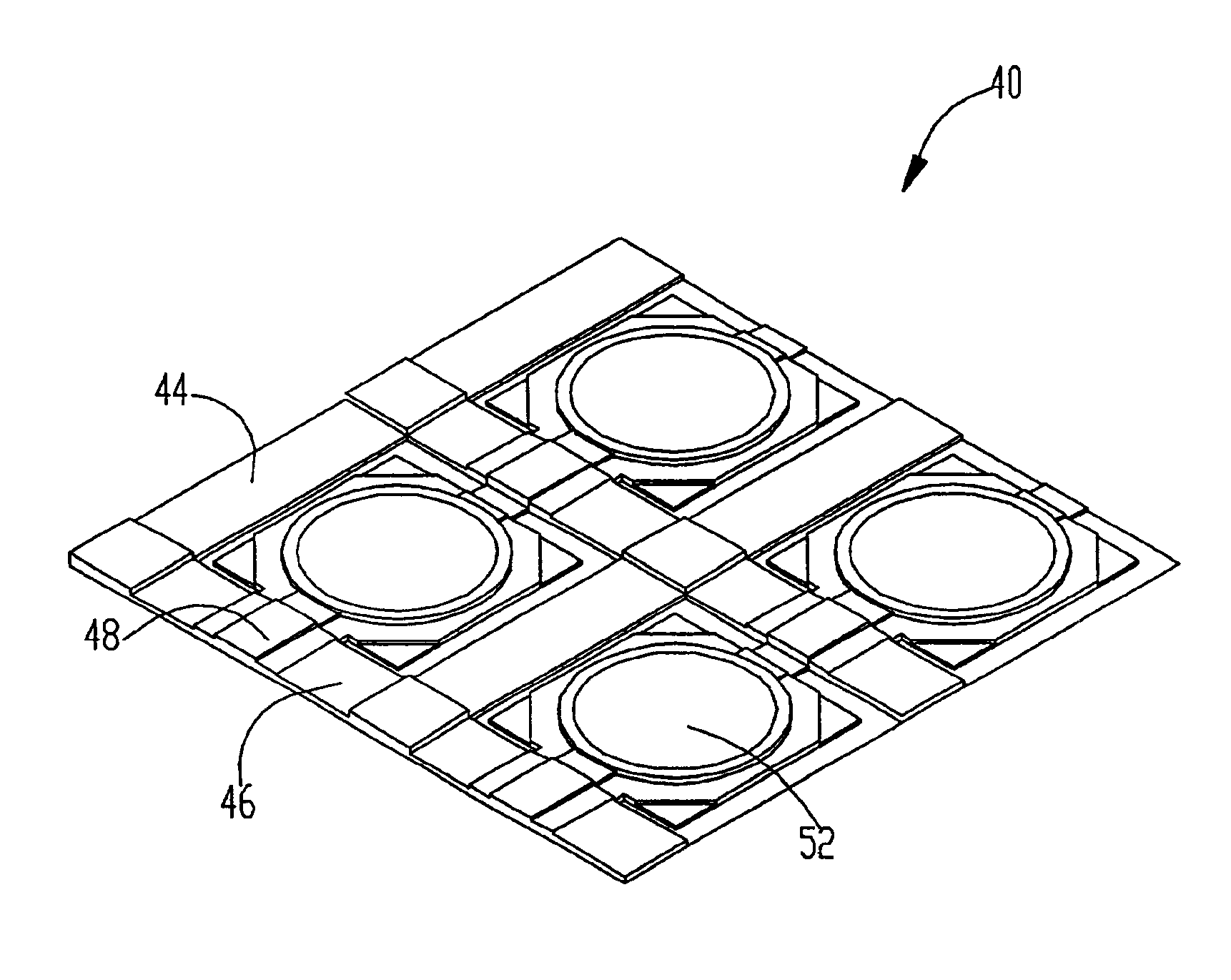

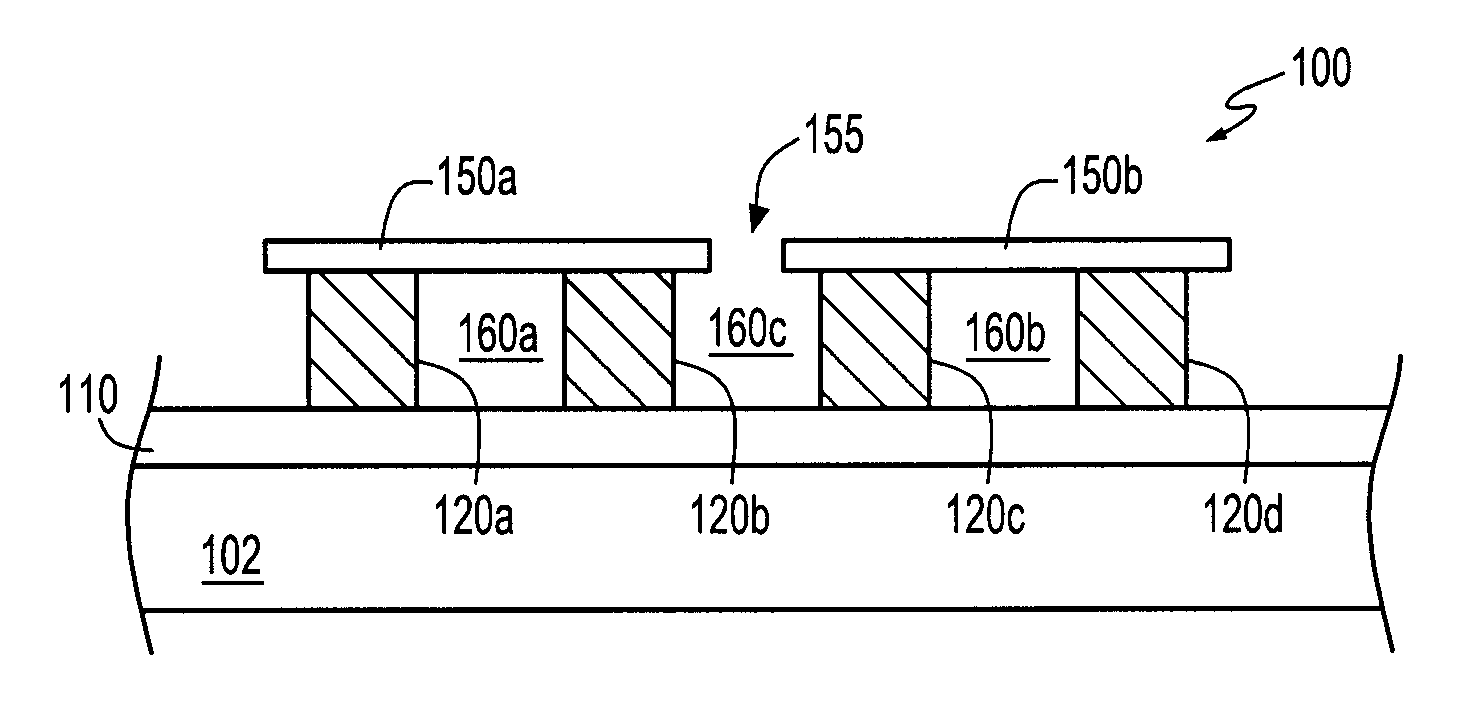

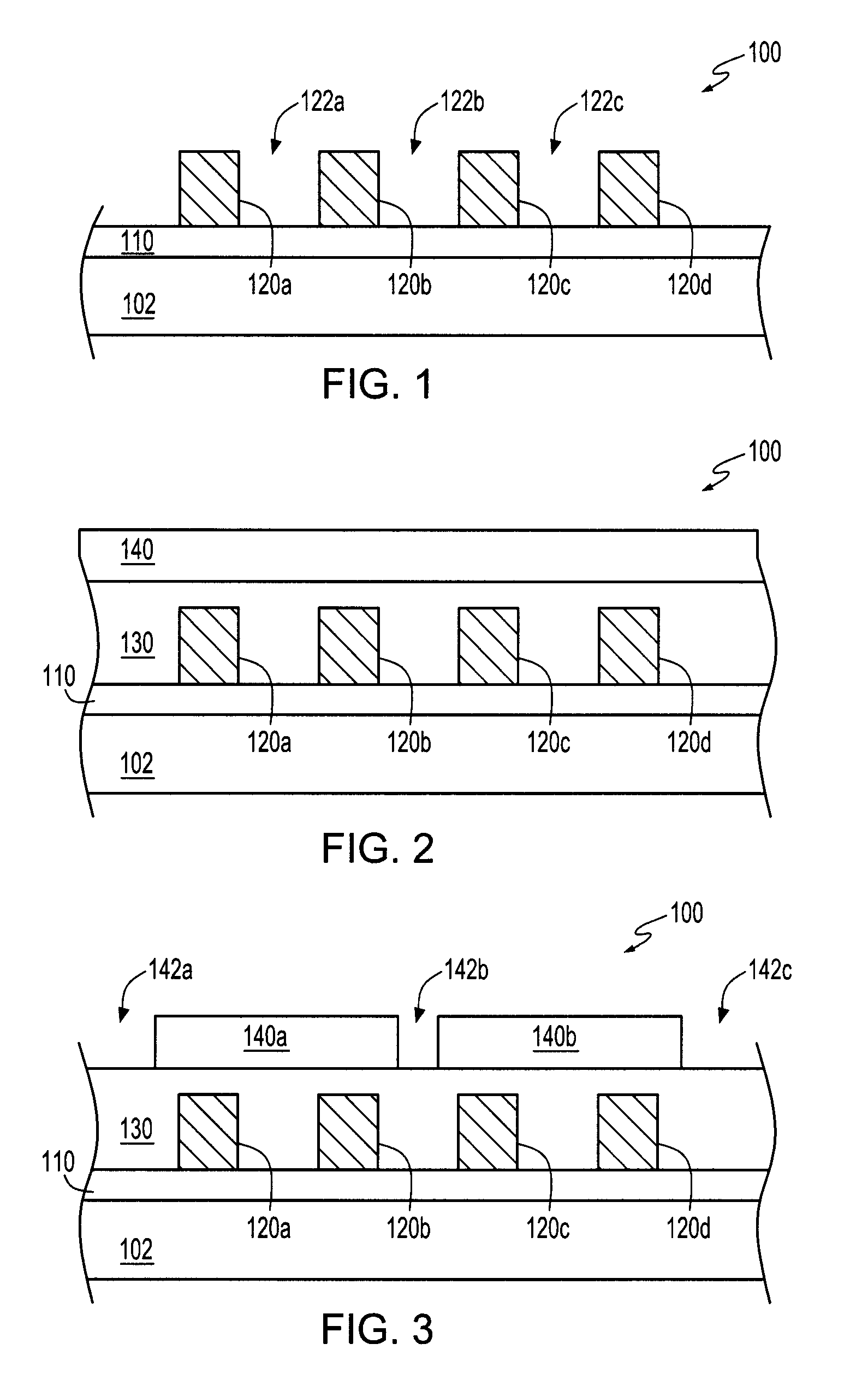

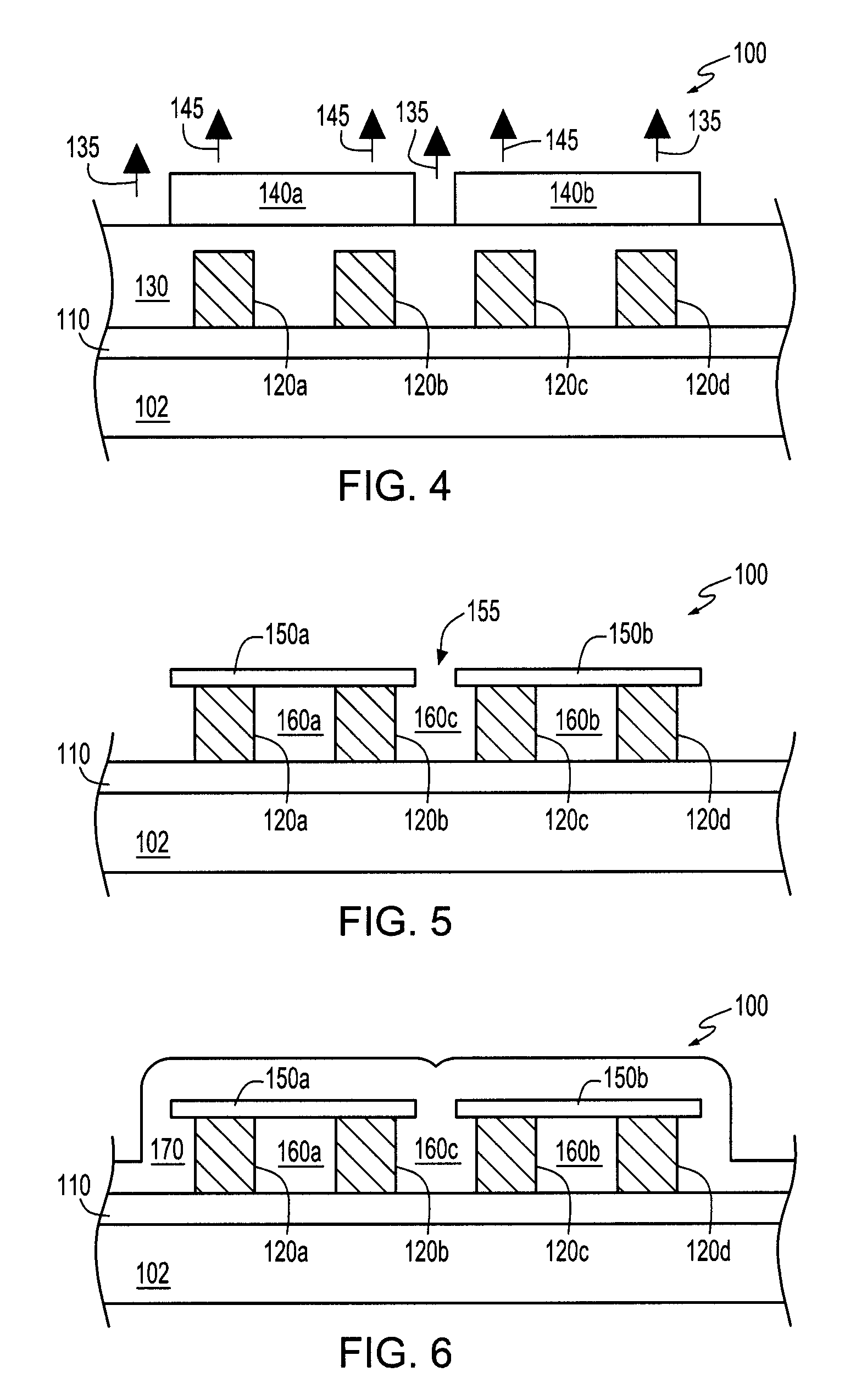

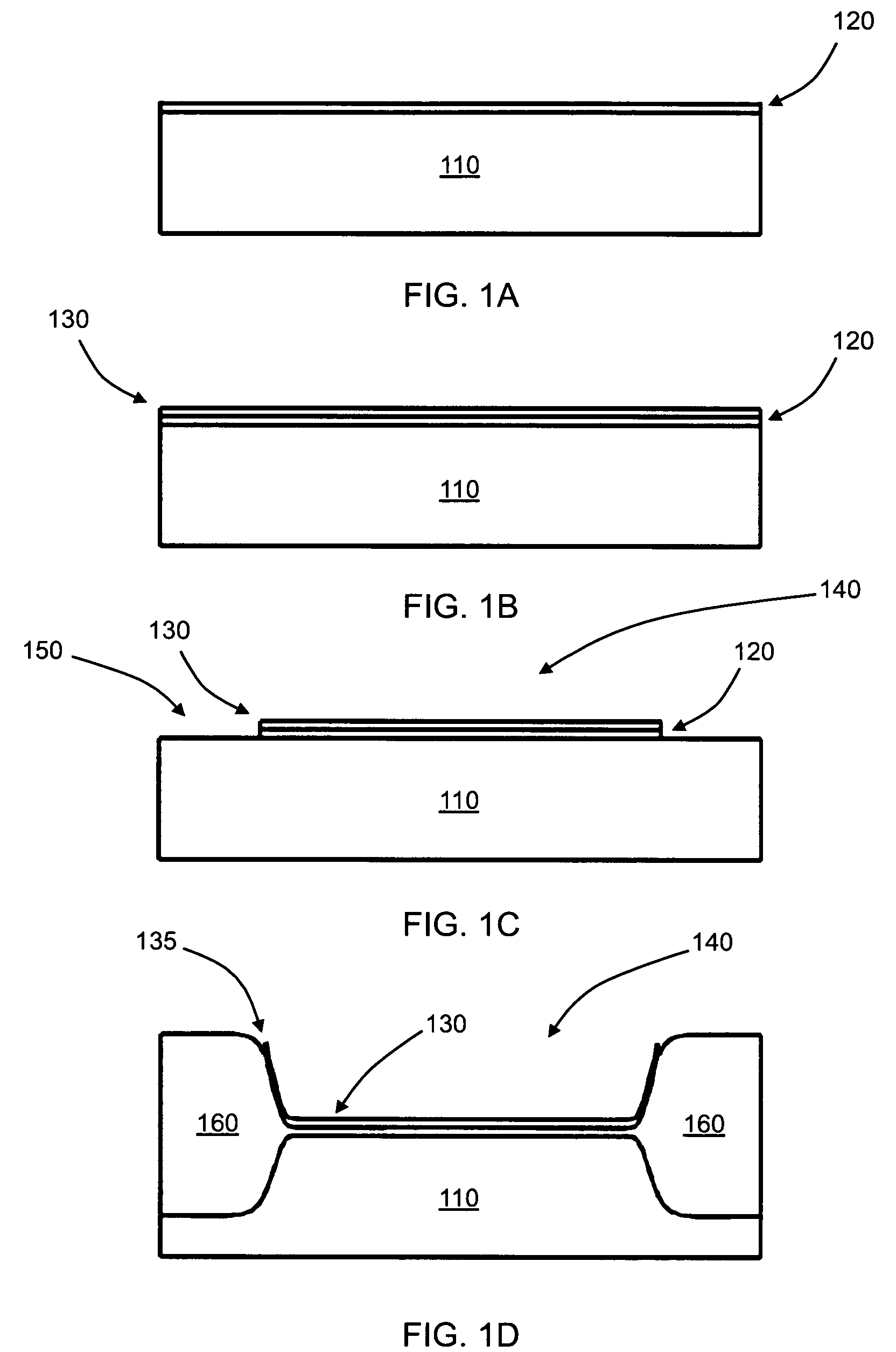

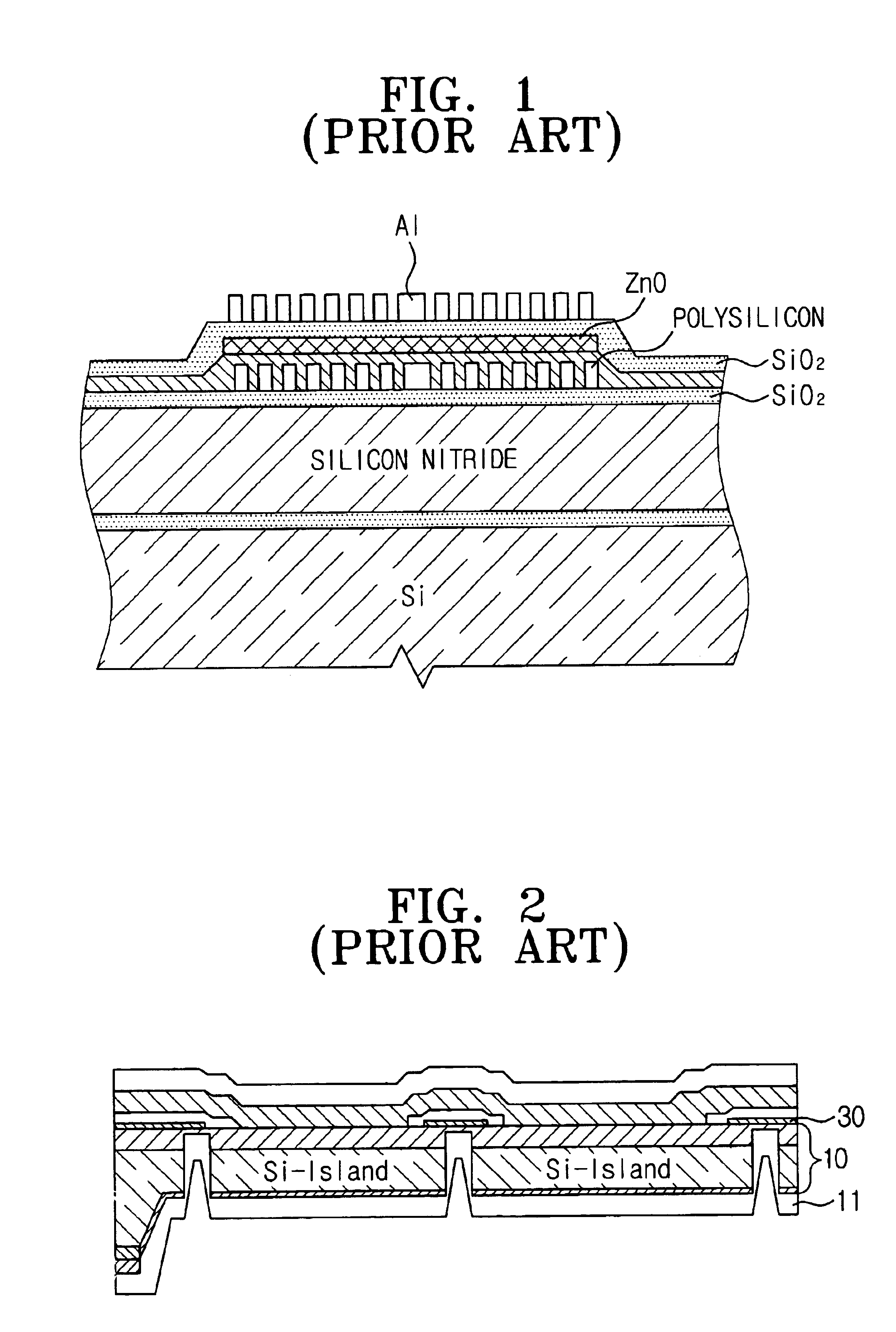

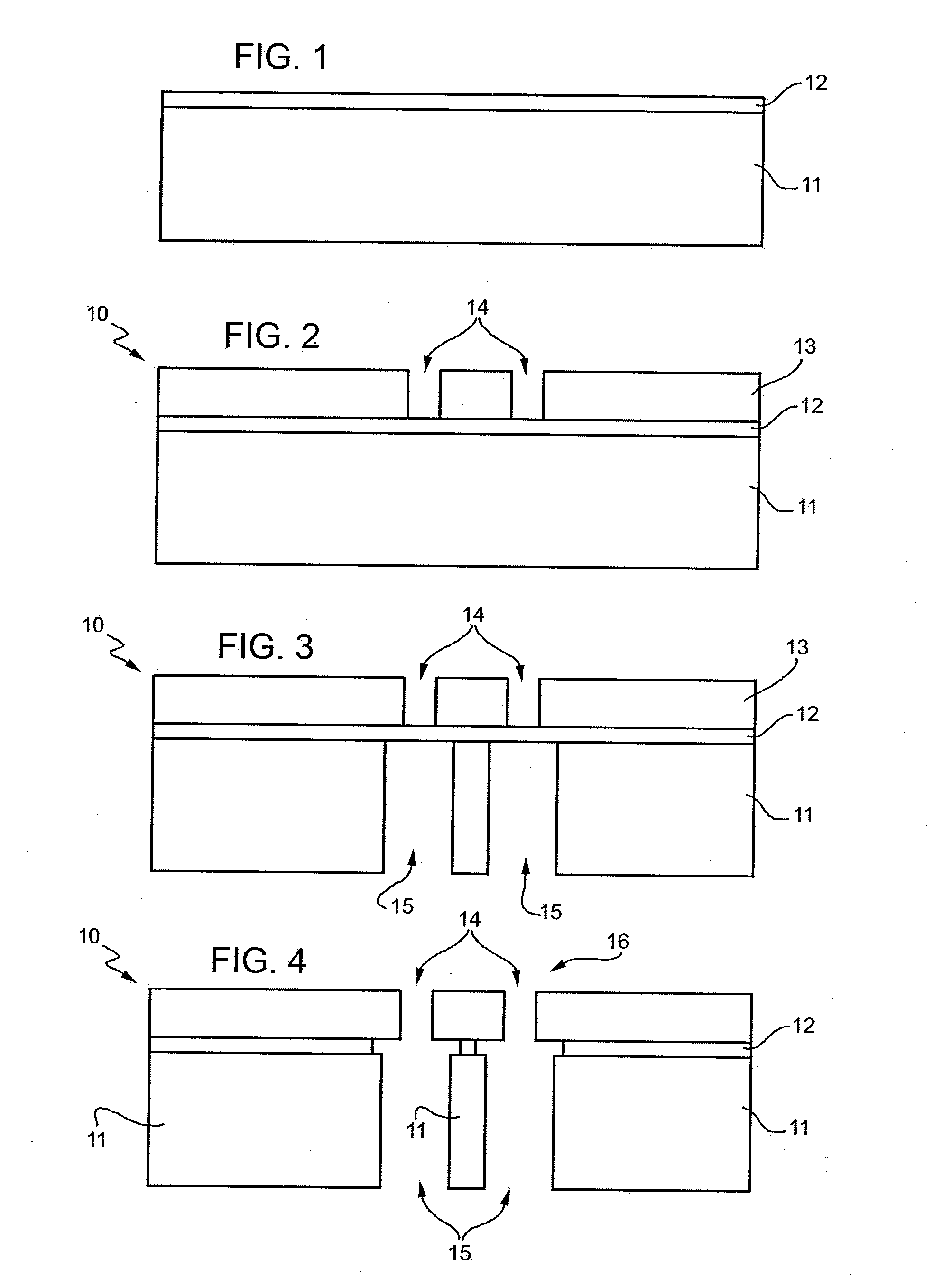

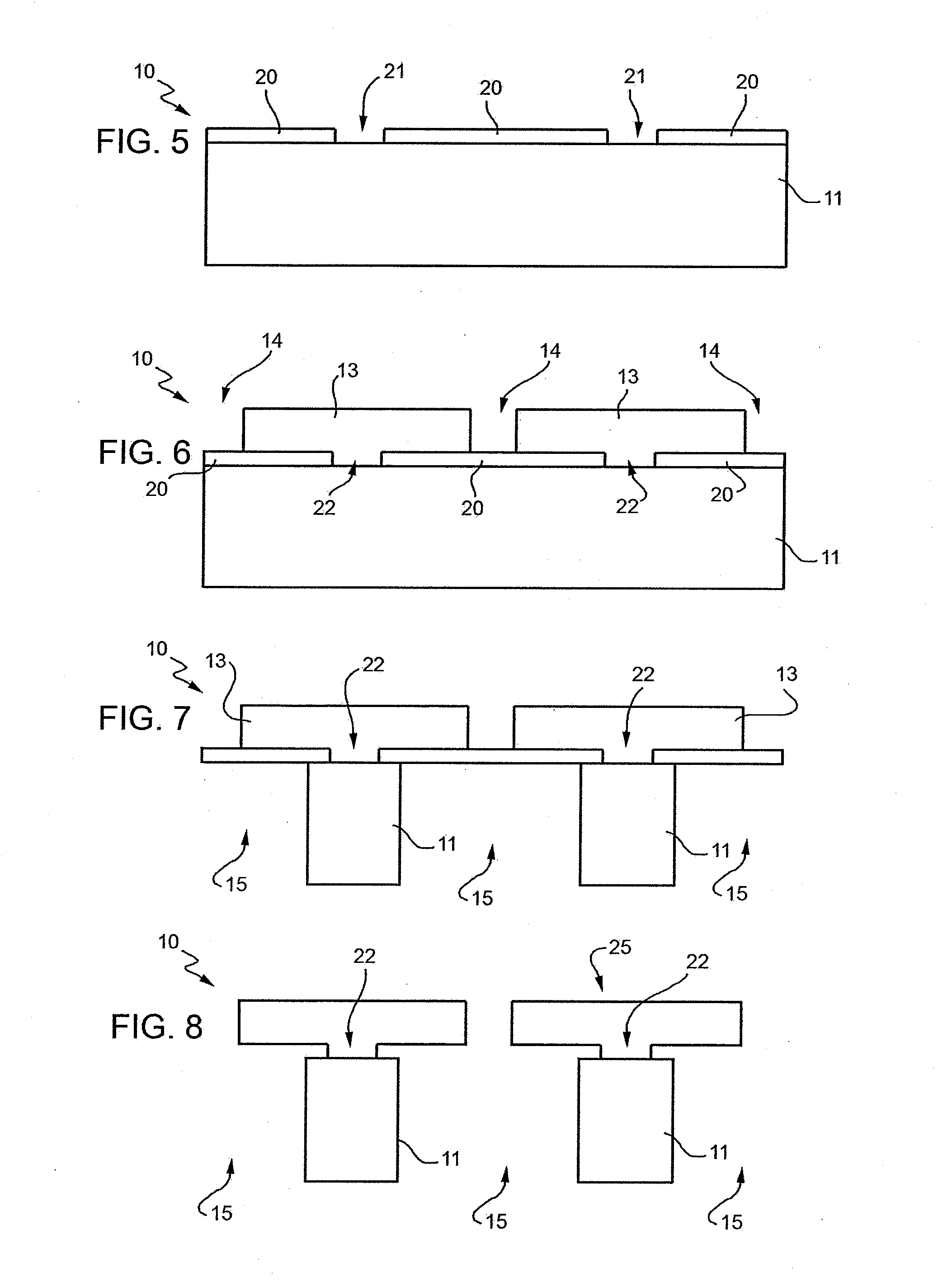

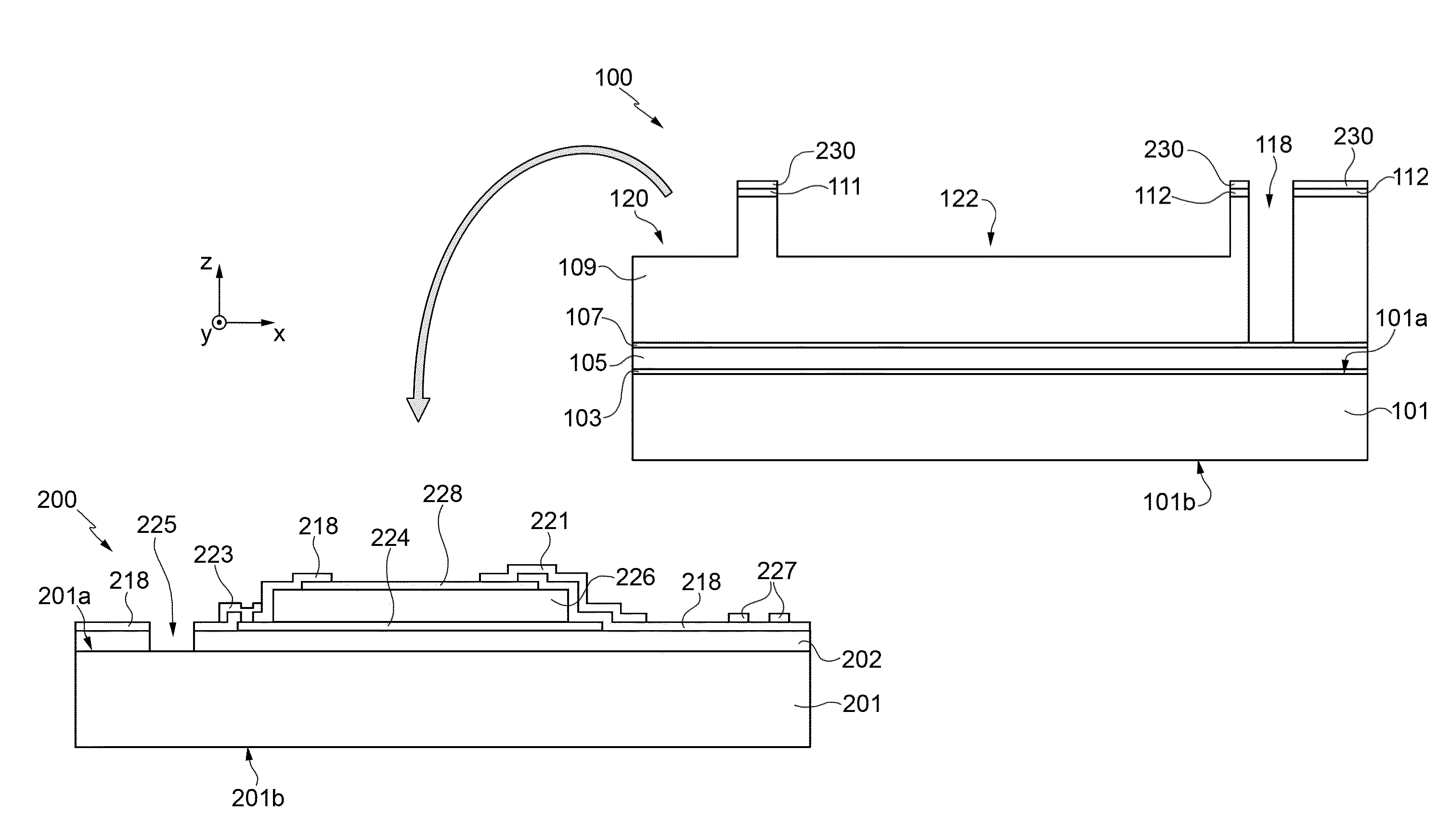

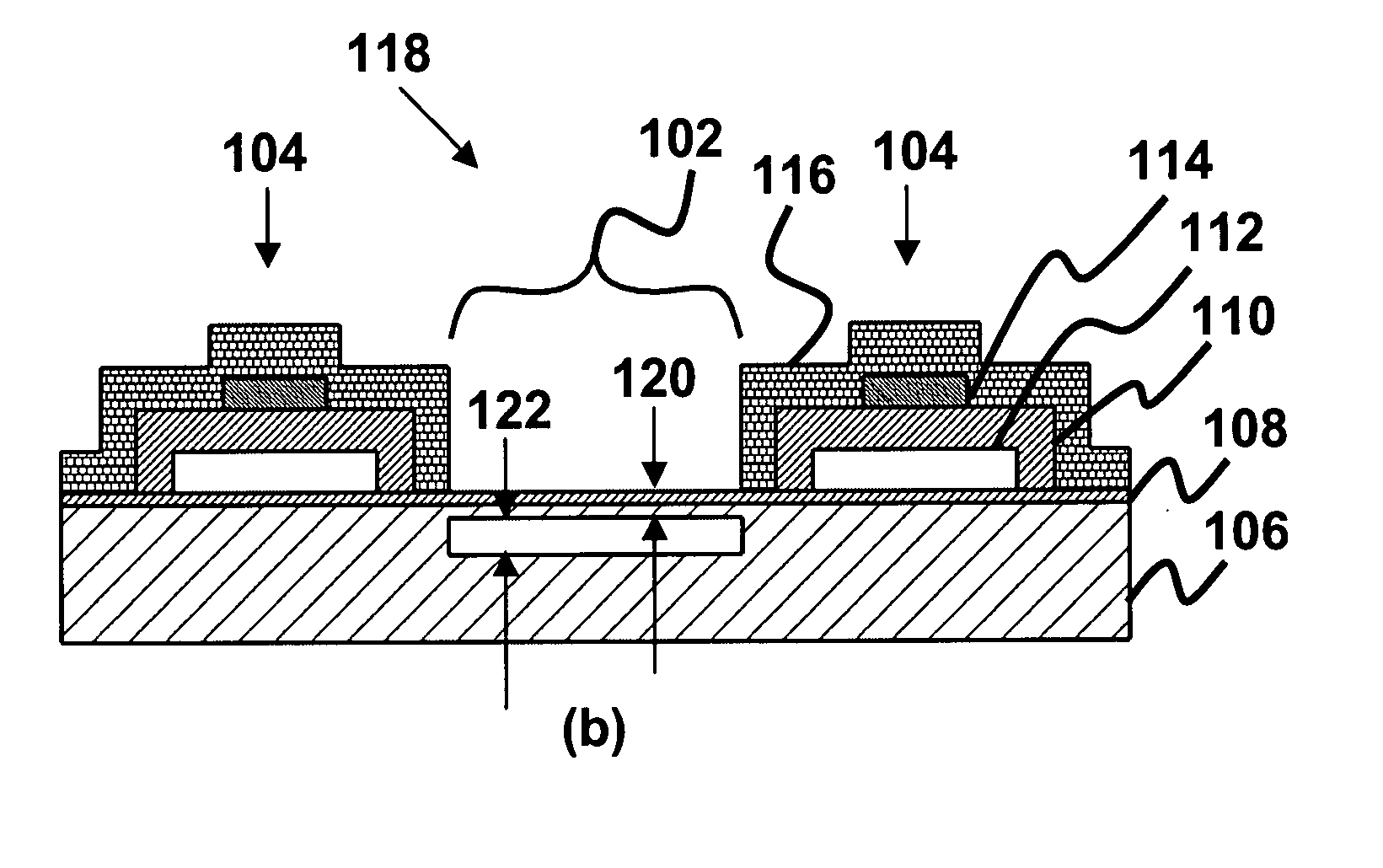

cMUT devices and fabrication methods

InactiveUS20050177045A1Reduce device parasitic capacitanceImprove electrical performanceMaterial analysis using sonic/ultrasonic/infrasonic wavesSurgeryCapacitanceCelsius Degree

Fabrication methods for capacitive-micromachined ultrasound transducers (“cMUT”) and cMUT imaging array systems are provided. cMUT devices fabricated from low process temperatures are also provided. In an exemplary embodiment, a process temperature can be less than approximately 300 degrees Celsius. A cMUT fabrication method generally comprises depositing and patterning materials on a substrate (400). The substrate (400) can be silicon, transparent, other materials. In an exemplary embodiment, multiple metal layers (405, 410, 415) can be deposited and patterned onto the substrate (400); several membrane layers (420, 435, 445) can be deposited over the multiple metal layers (405, 410, 415); and additional metal layers (425, 430) can be disposed within the several membrane layers (420, 435, 445). The second metal layer (410) is preferably resistant to etchants used to etch the third metal layer (415) when forming a cavity (447). Other embodiments are also claimed and described.

Owner:GEORGIA TECH RES CORP

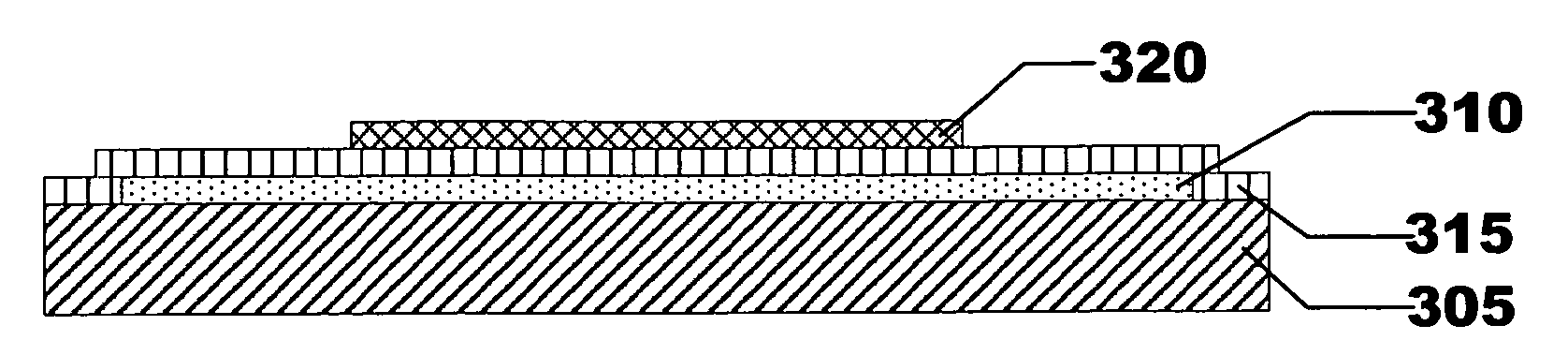

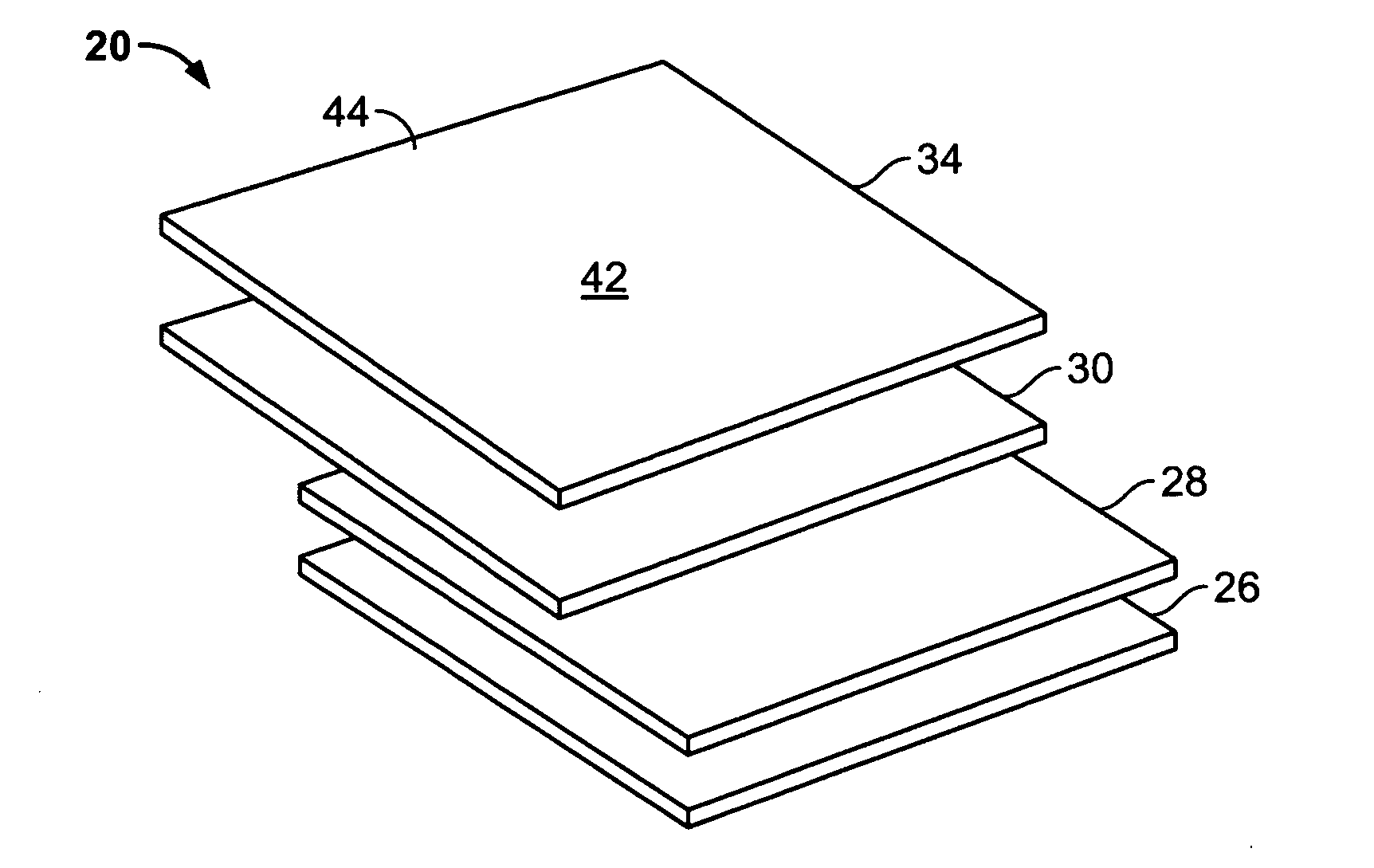

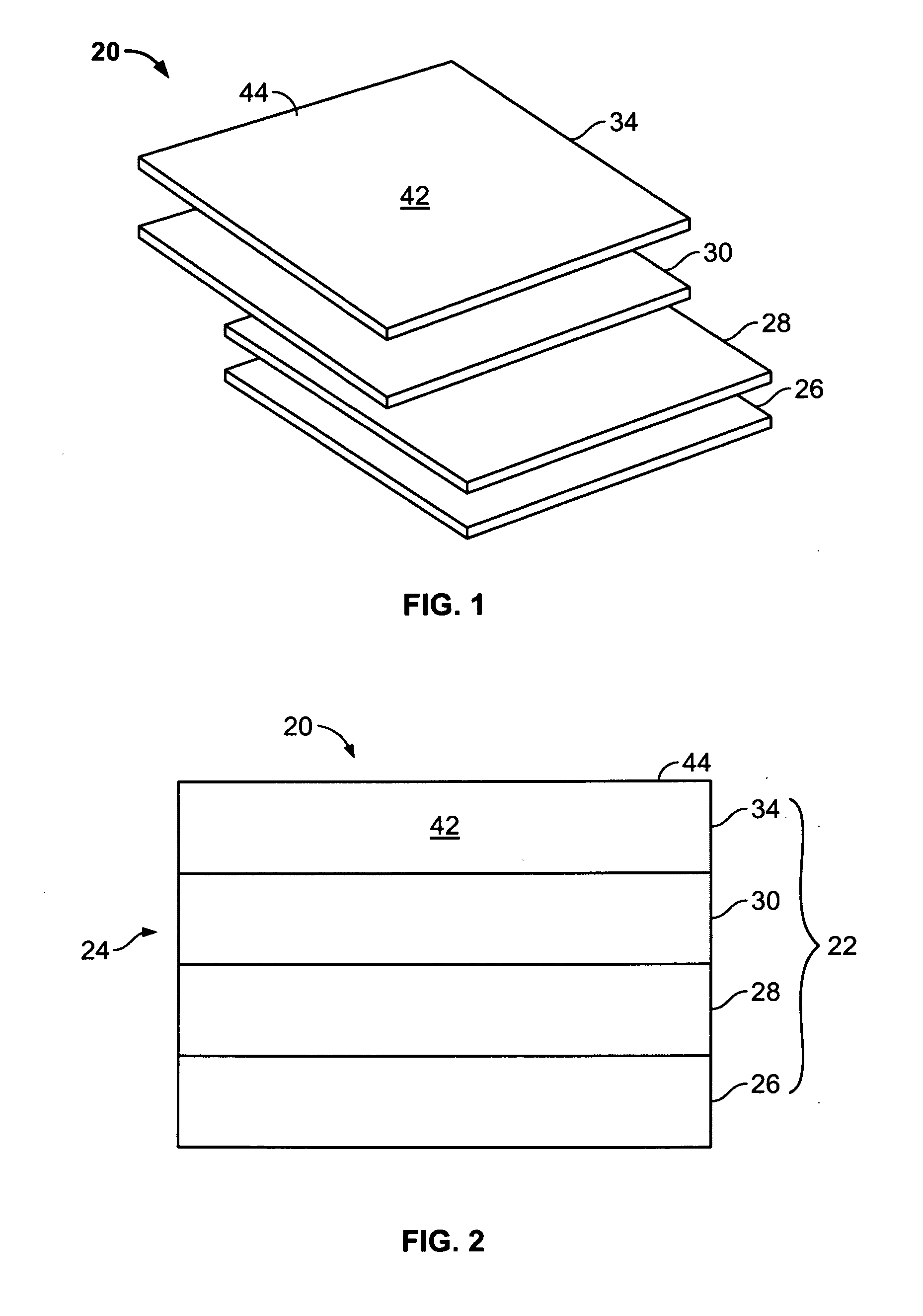

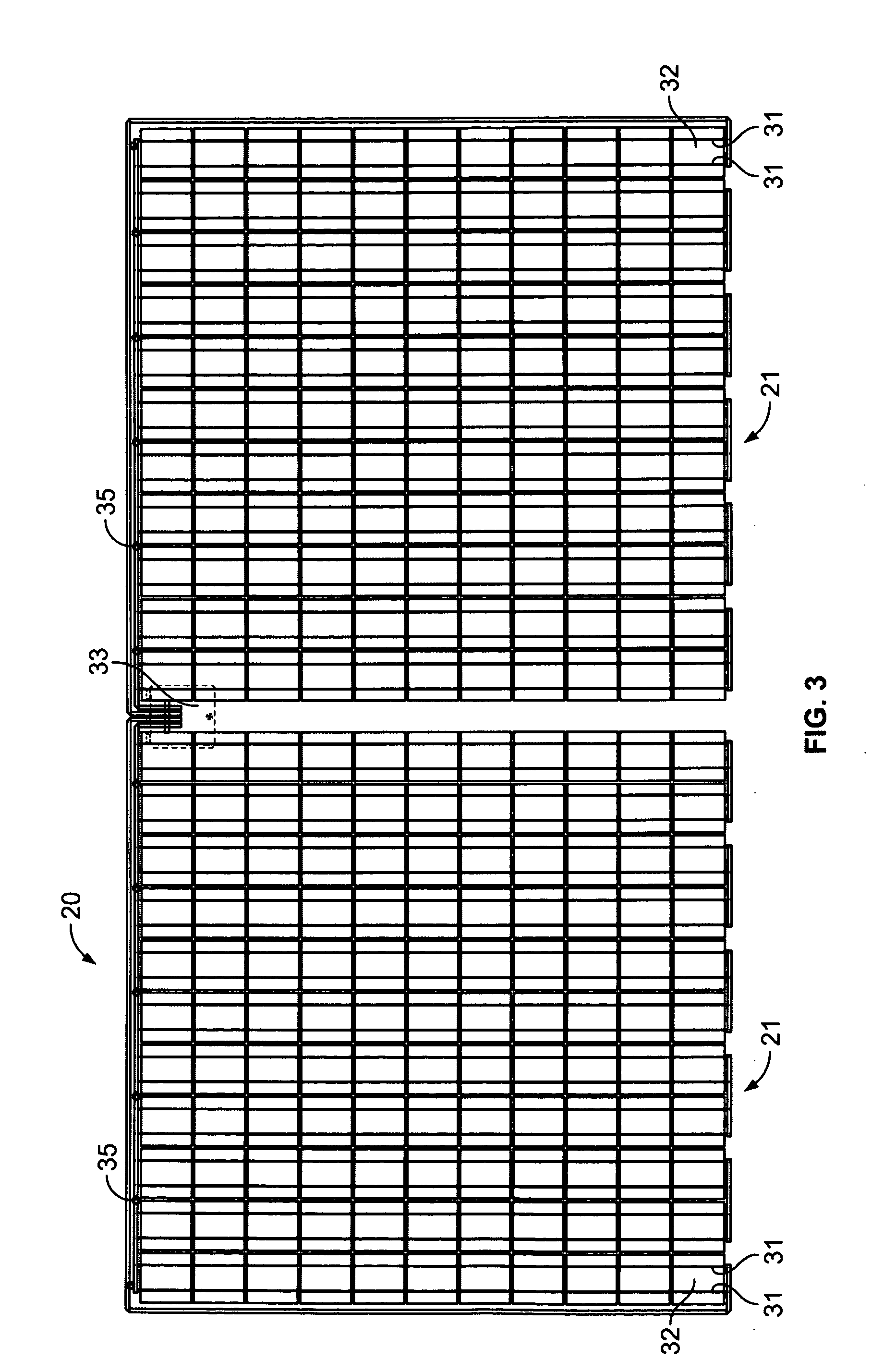

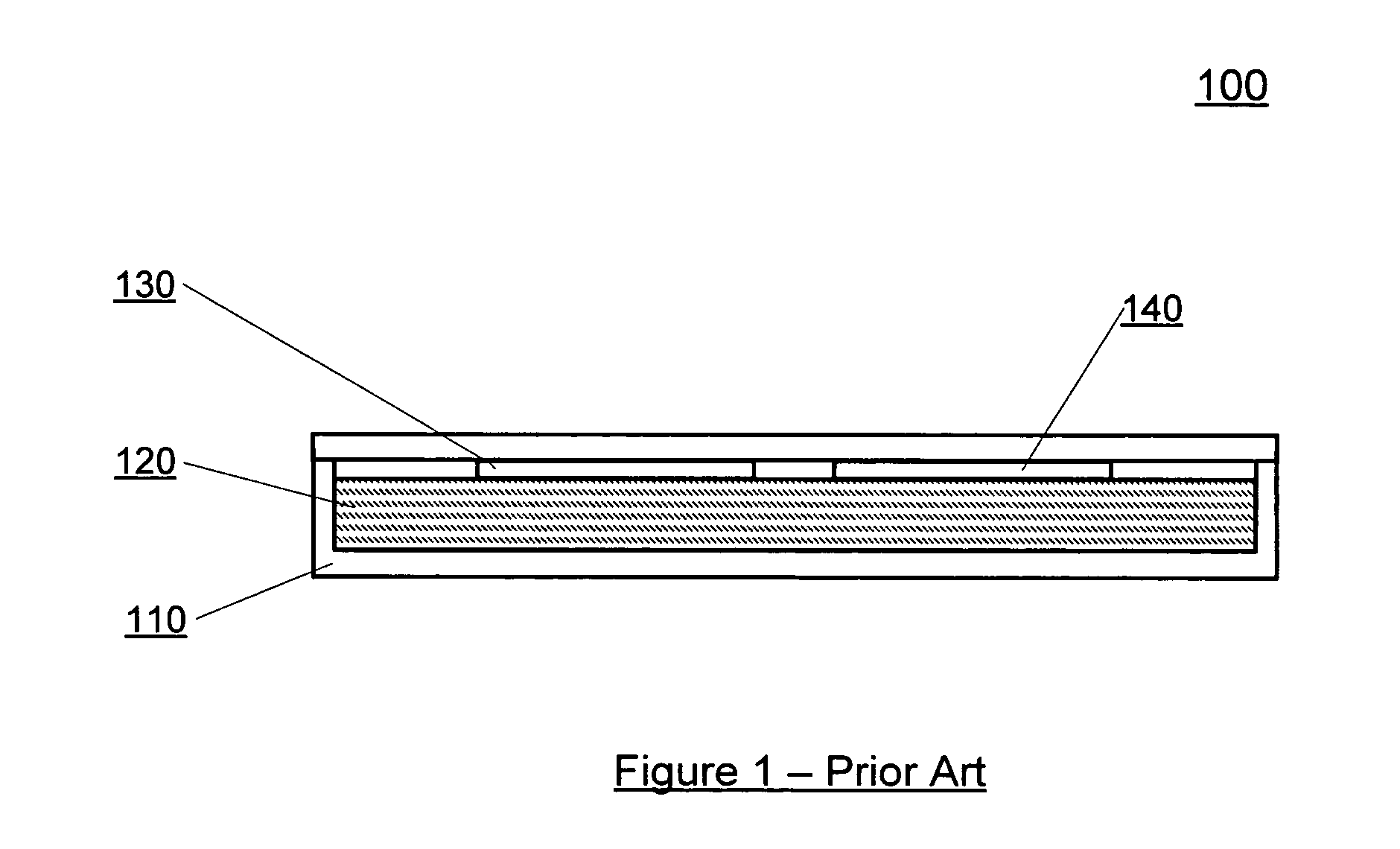

Photovoltaic system and method of making same

The present invention relates to a photovoltaic system and methods of making same. The photovoltaic system has a plurality of layers attached to each other to form a unitary structure. More specifically, the photovoltaic system includes: a base, flexible membrane layer; a photovoltaic layer having at least one photovoltaic cell associated therewith; a semi-rigid layer for supporting the photovoltaic layer and imparting rigidity thereto; and a top, transparent, protective layer for protecting the base, flexible membrane layer, the semi-rigid layer and the photovoltaic layer from exposure to the environment. The photovoltaic layer and the semi-rigid layer are disposed between the base, flexible membrane layer and the top, protective layer. Additional layers of adhesive may be disposed between the various layers to facilitate bonding thereof.

Owner:OPEN ENERGY CORP

Stent-graft-membrane and method of making the same

A braided self-expandable stent-graft-membrane made of elongated members forming a generally tubular body. A membrane layer and graft layer are disposed on a endoprosthesis such as a stent. The membrane layer is substantially impermeable to fluids. The outermost layer is biocompatible with the body tissue. The innermost layer is biocompatible with the fluid in the passage. An embodiment includes a graft layer disposed on the inside of a stent and a membrane layer disposed on the outside of the stent. The innermost layer is biocompatible with the fluid in the passage. The stent-graft-membrane is used at a treatment site in a body vessel or organ where it is desirous to exclude a first fluid located outside the endoprosthesis from reaching a second fluid located in the lumen. The membrane may be made of silicone or polycarbonate urethane. The graft may be braided, woven, spun or spray-cast PET, PCU, or PU fibers. The layers may include ePTFE or PTFE.

Owner:LIFEPORT SCI

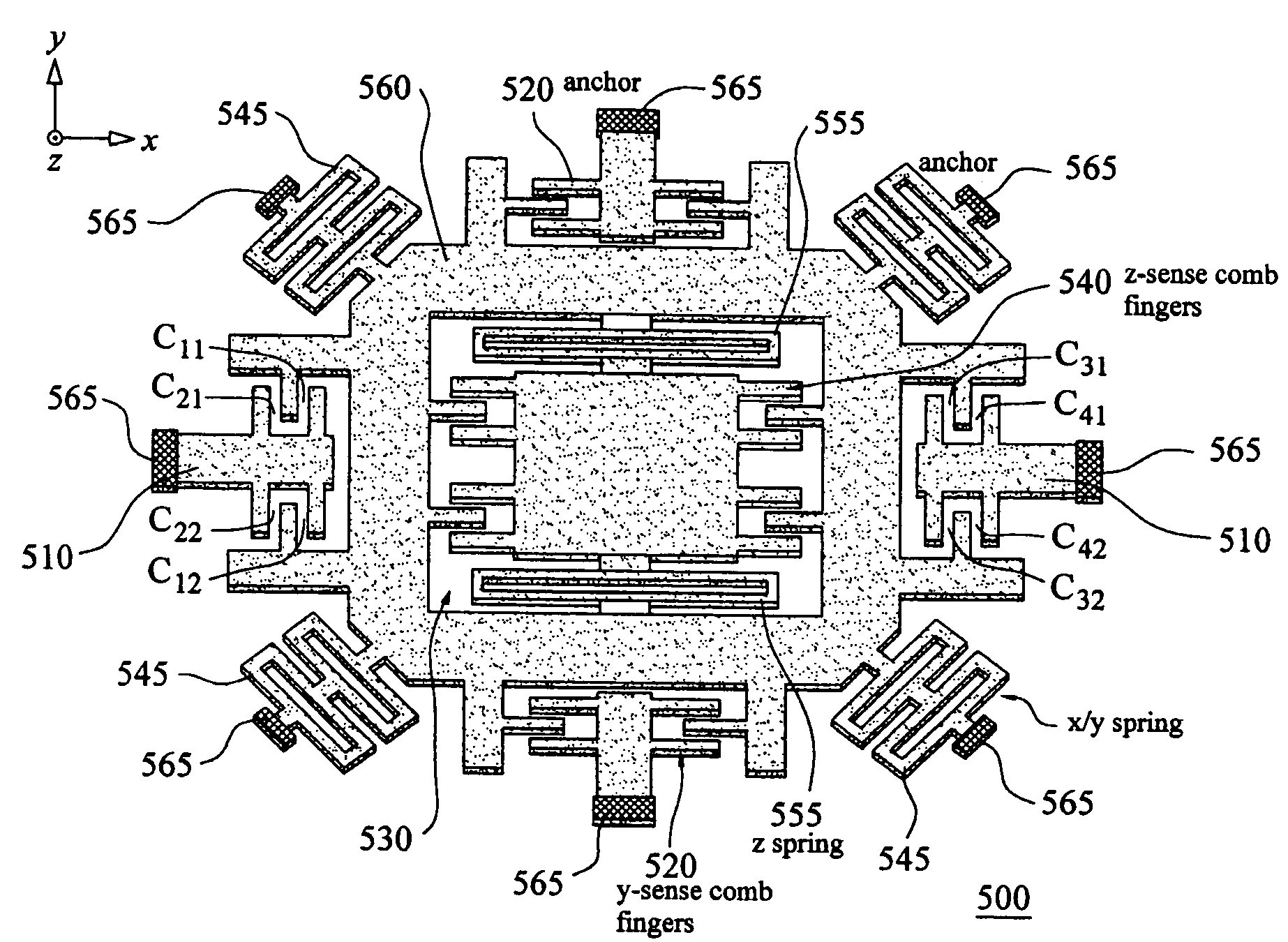

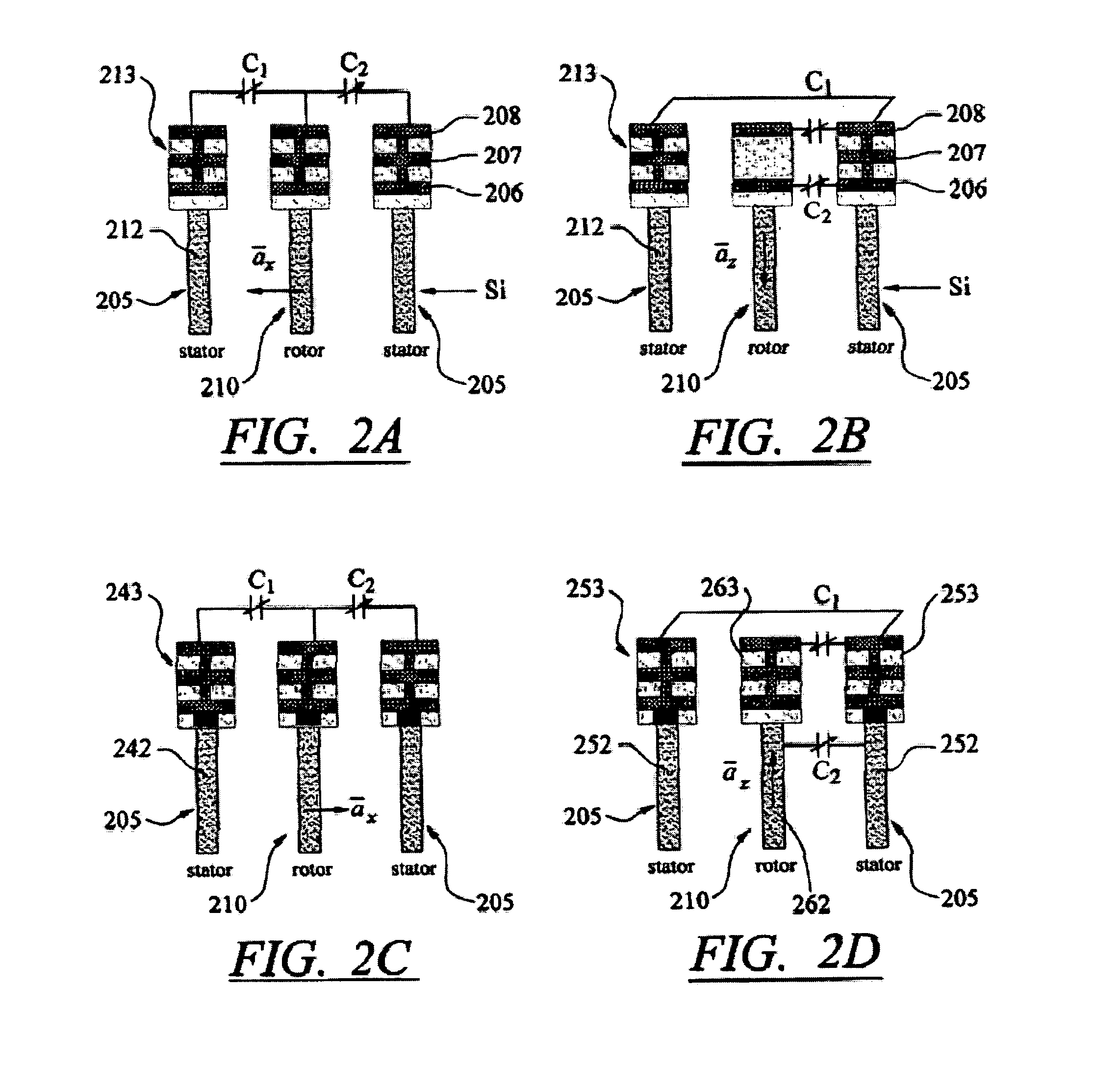

Integrated monolithic tri-axial micromachined accelerometer

InactiveUS7258012B2Acceleration measurement using interia forcesImpedence networksAccelerometerSingle crystal substrate

A monolithic integrated 3-axis accelerometer chip includes a single crystal substrate, the substrate including at least one single crystal membrane layer portion. A single sensor microstructure made from the single crystal membrane senses acceleration in each of the three orthogonal directions. At least one electronic circuit can also be disposed on the chip, such as a circuit for driving, detecting, controlling and signal processing.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Direct wafer bonded 2-D CUMT array

ActiveUS20090122651A1Ultrasonic/sonic/infrasonic diagnosticsMechanical vibrations separationCapacitanceCapacitive micromachined ultrasonic transducers

A capacitive micromachined ultrasonic transducer (CMUT) array connected to a separate electronic unit is provided. The CMUT array includes at least two active elements, a ground element at the array end, and a non-active element having isolation trenches disposed between the active and ground elements. The active element includes a doped first silicon layer, a doped second silicon layer, and a first insulating layer disposed there between. A cavity is in the first silicon layer having a cross section that includes vertical portions disposed at each end of a horizontal portion, and the vertical portion spans from the first insulating layer through the first silicon layer such that a portion of the first silicon layer is isolated by the first insulating layer and the cavity. A membrane layer on the first silicon layer spans the cavity. A bottom electrode is disposed on the bottom of the second silicon layer.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Enzyme sensor with a cover membrane layer covered by a hydrophilic polymer

ActiveUS20060275857A1Bioreactor/fermenter combinationsBiological substance pretreatmentsHydrophilic polymersAnalyte

The present disclosure relates to an improved enzyme sensor comprising a cover membrane layer of a porous polymeric material, the outer surface and pore mouths of at least one face of the porous polymeric material being covered by a hydrophilic polymer. The sensor is useful determining the presence or amount of biologicial analytes, e.g., glucose, lactate, creatine, creatinine, etc.

Owner:RADIOMETER AS

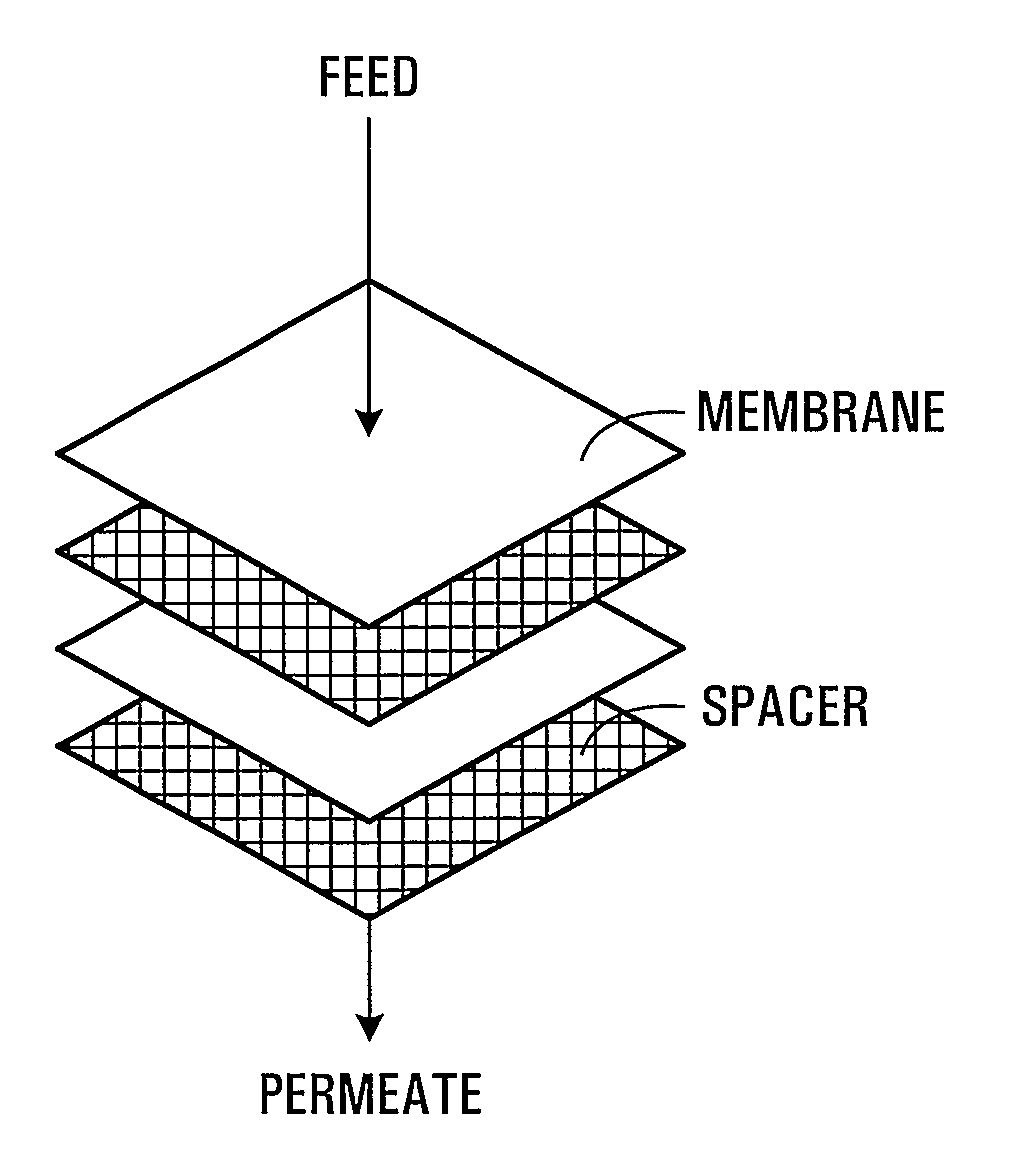

Membrane Stacks

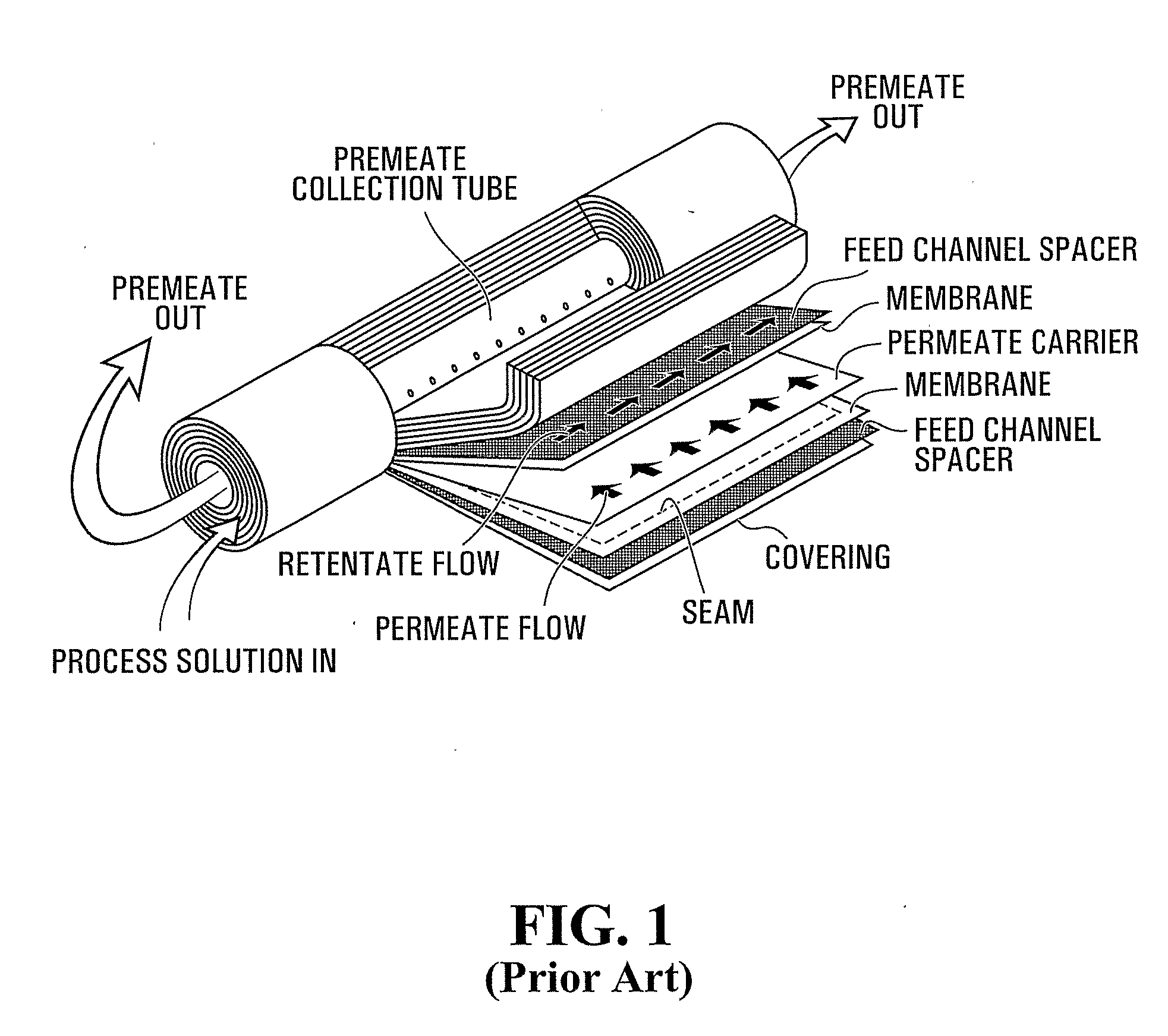

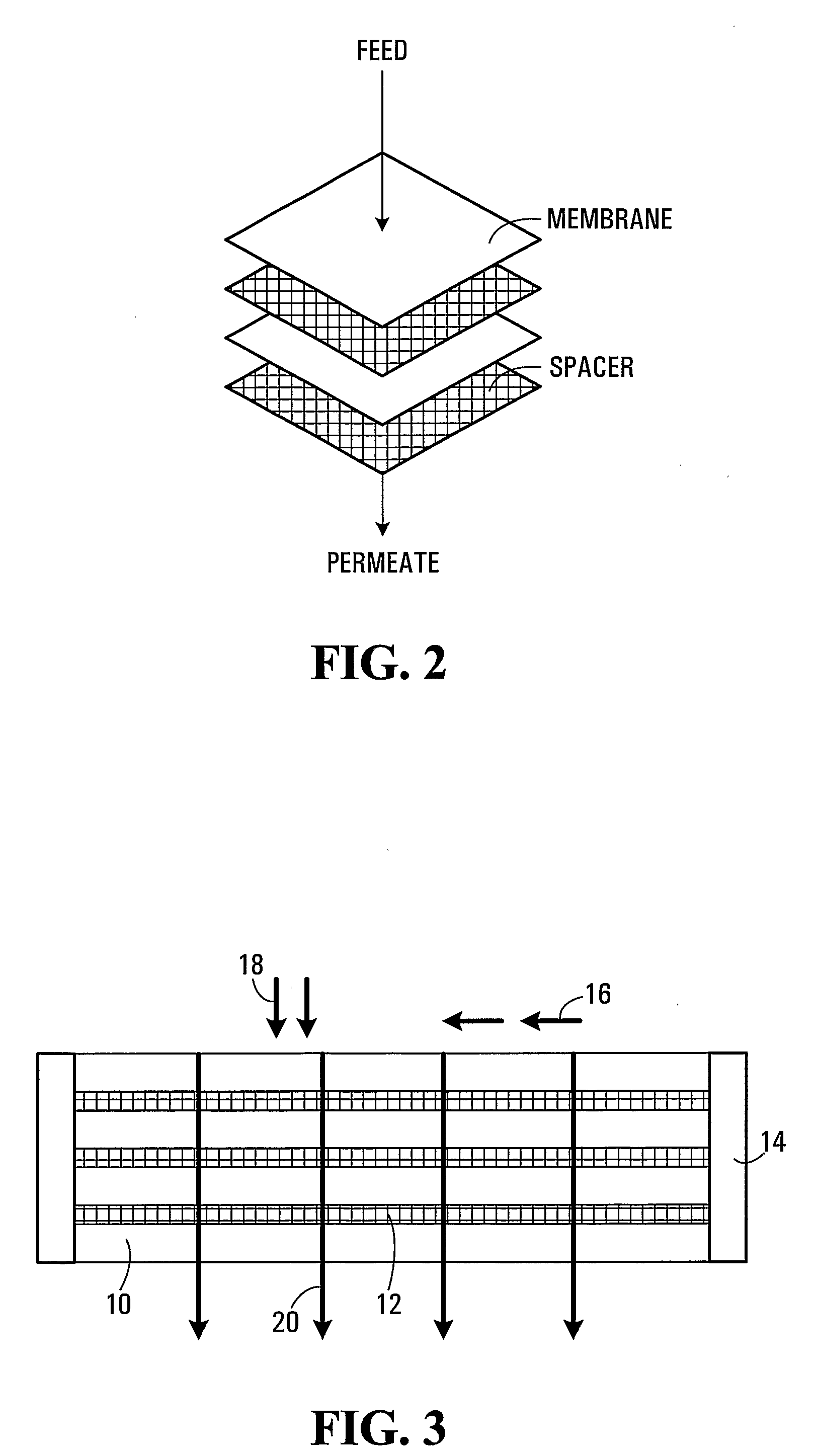

ActiveUS20080017578A1Improve throughputEasy to separateMembranesGeneral water supply conservationMembrane configurationMolecular physics

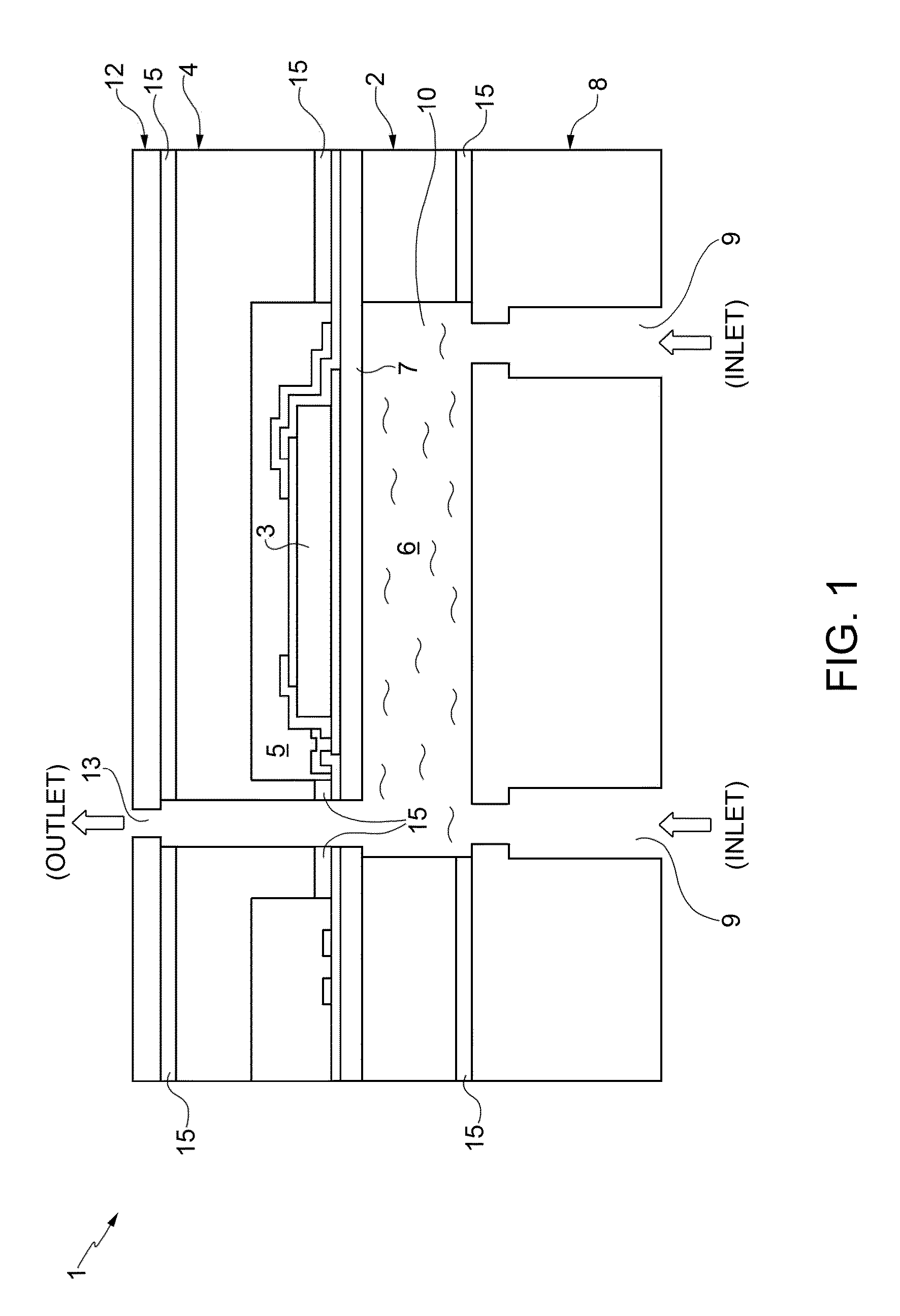

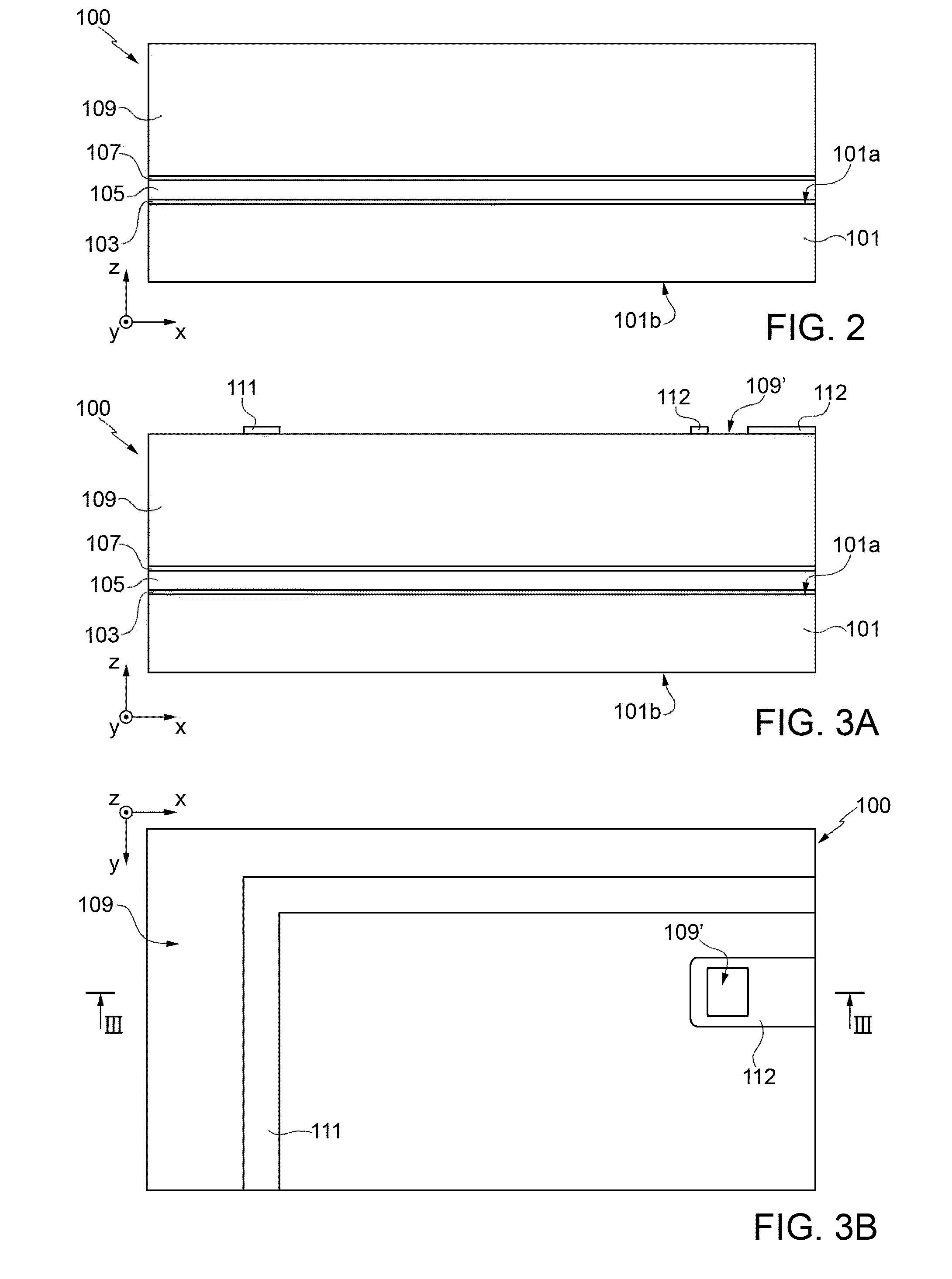

The present application discloses a membrane stack comprising a first and second membrane layers, and a spacer layer disposed between said first and second membrane layers, said membrane stack configured such that fluid passes through said membrane stack in a direction substantially perpendicular to the plane of said membrane layers and said spacer layer. The application also discloses a module comprising a membrane as described above, said module having a fluid flow path that is substantially perpendicular to the plane of the major surface of the membrane and spacer layers in said membrane stack.

Owner:MERCK MILLIPORE LTD

Stent-graft-membrane and method of making the same

A braided self-expandable stent-graft-membrane made of elongated members forming a generally tubular body. A membrane layer and graft layer are disposed on a endoprosthesis such as a stent. The membrane layer is substantially impermeable to fluids. The outermost layer is biocompatible with the body tissue. The innermost layer is biocompatible with the fluid in the passage. An embodiment includes a graft layer disposed on the inside of a stent and a membrane layer disposed on the outside of the stent. The innermost layer is biocompatible with the fluid in the passage. The stent-graft-membrane is used at a treatment site in a body vessel or organ where it is desirous to exclude a first fluid located outside the endoprosthesis from reaching a second fluid located in the lumen. The membrane may be made of silicone or polycarbonate urethane. The graft may be braided, woven, spun or spray-cast PET, PCU, or PU fibers. The layers may include ePTFE or PTFE.

Owner:LIFEPORT SCI

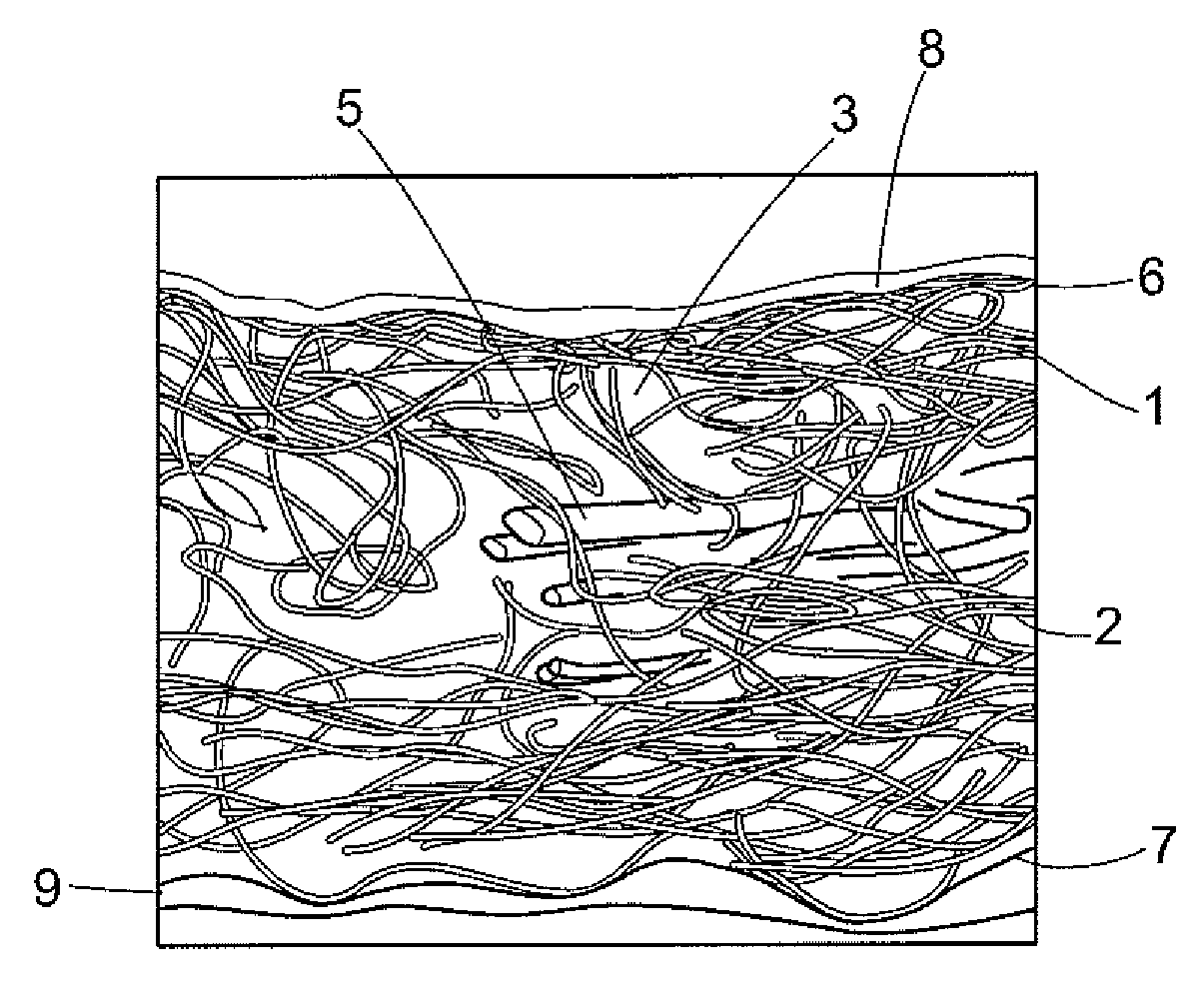

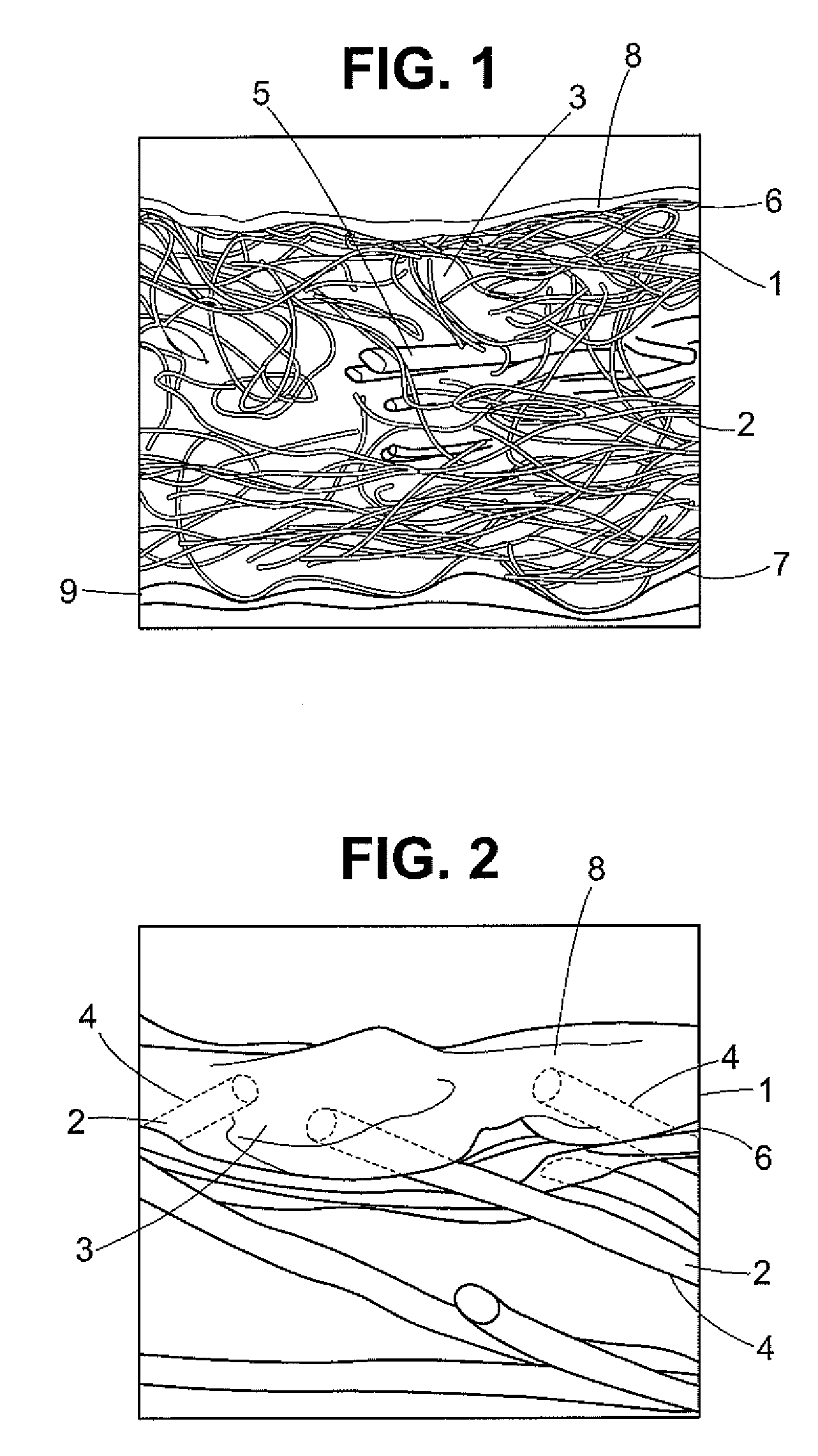

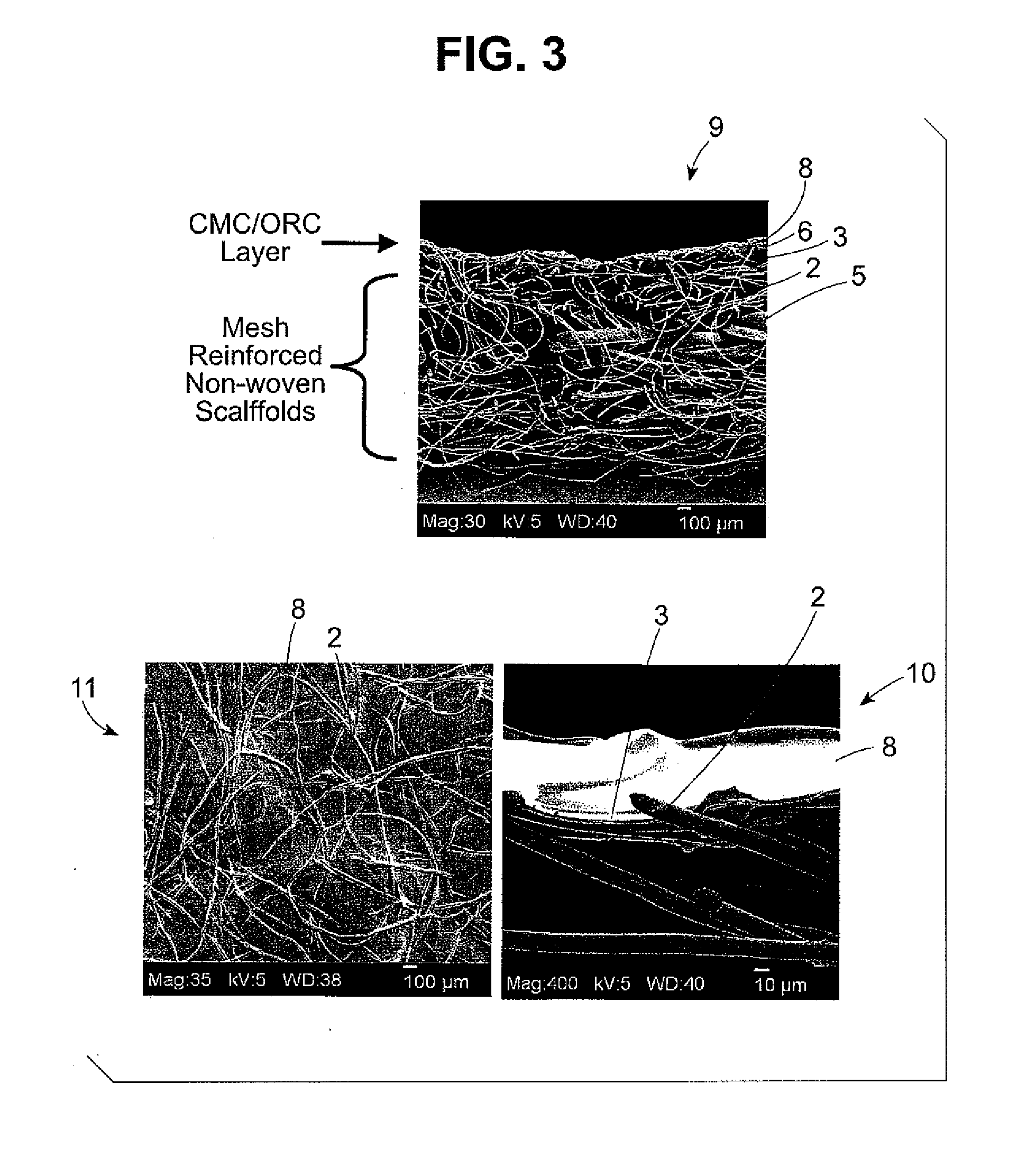

Coated Tissue Engineering Scaffold

The invention concerns scaffolds comprising a coating on at least one surface that partially penetrates into the void spaces of the scaffold. The invention further concerns scaffolds comprising a partially penetrated anti-adhesion absorbable membrane layer.

Owner:ETHICON INC

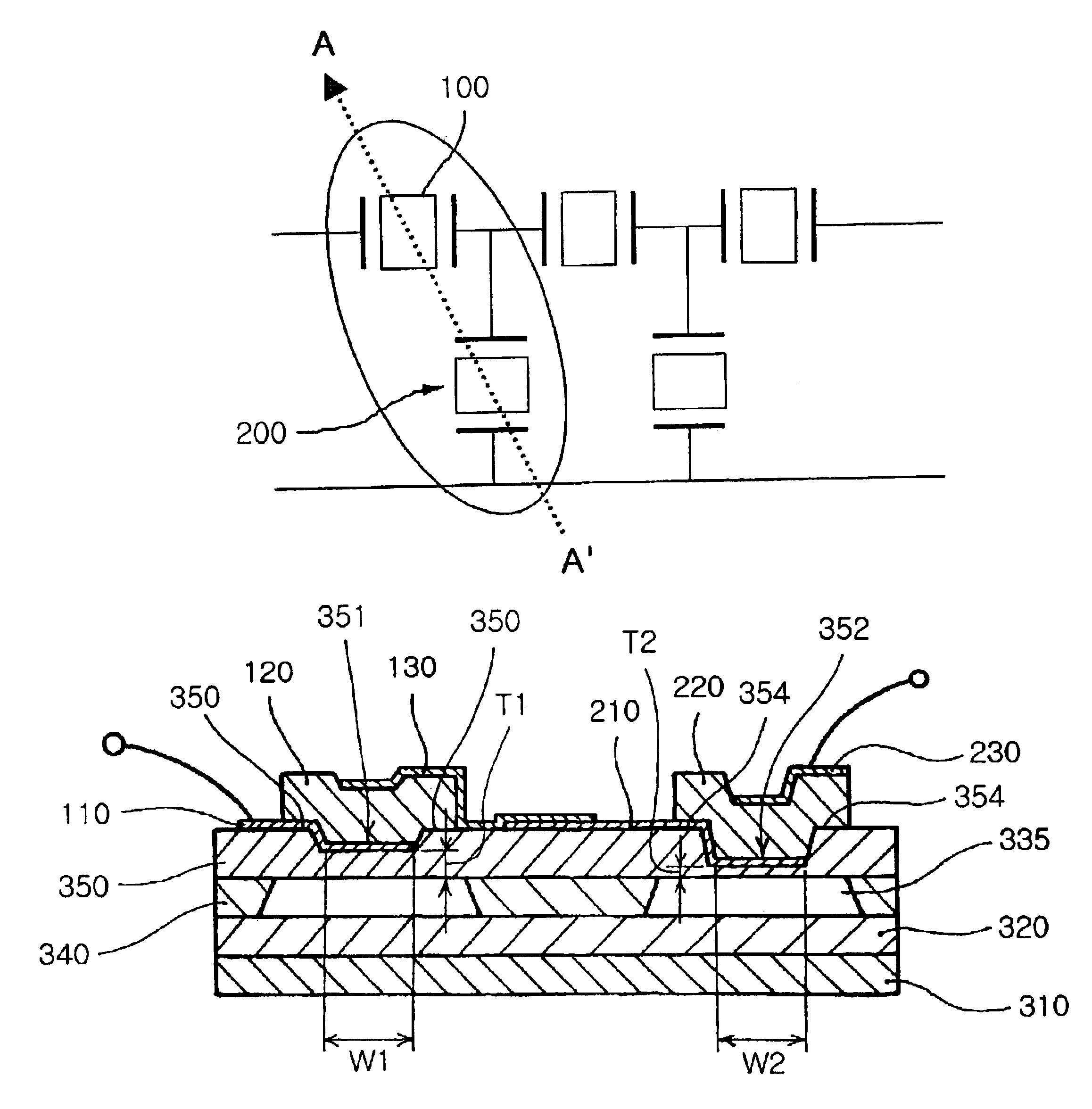

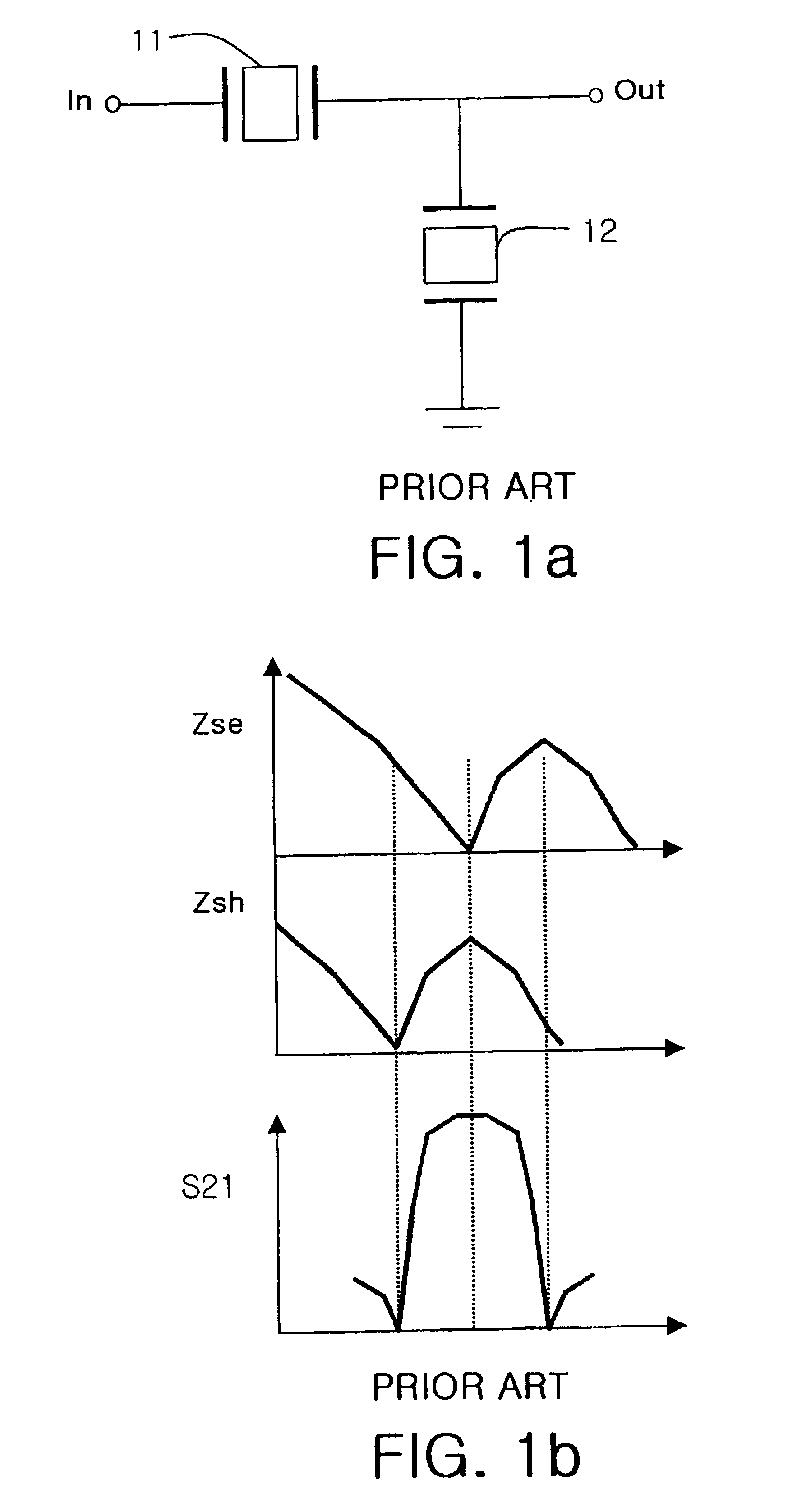

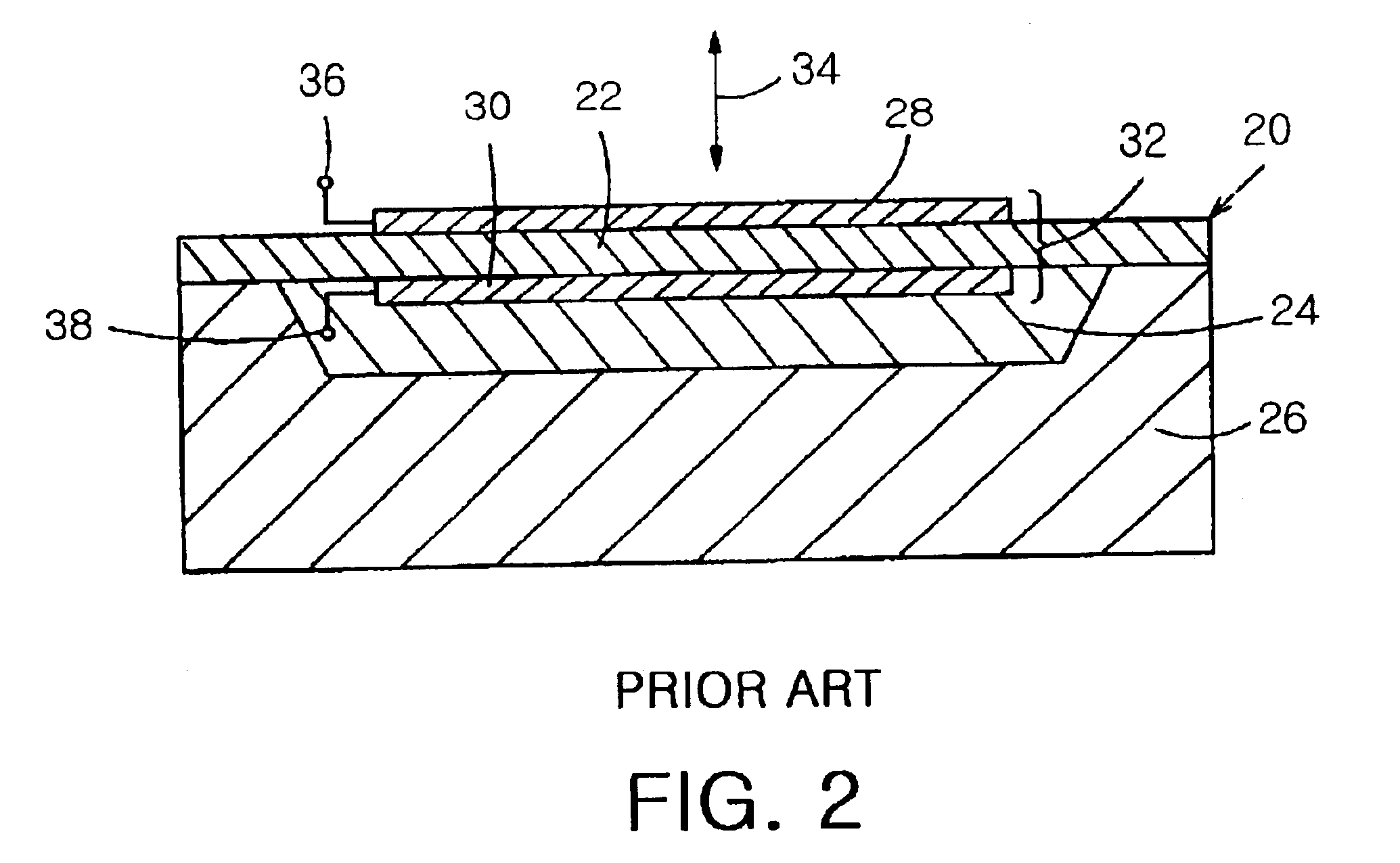

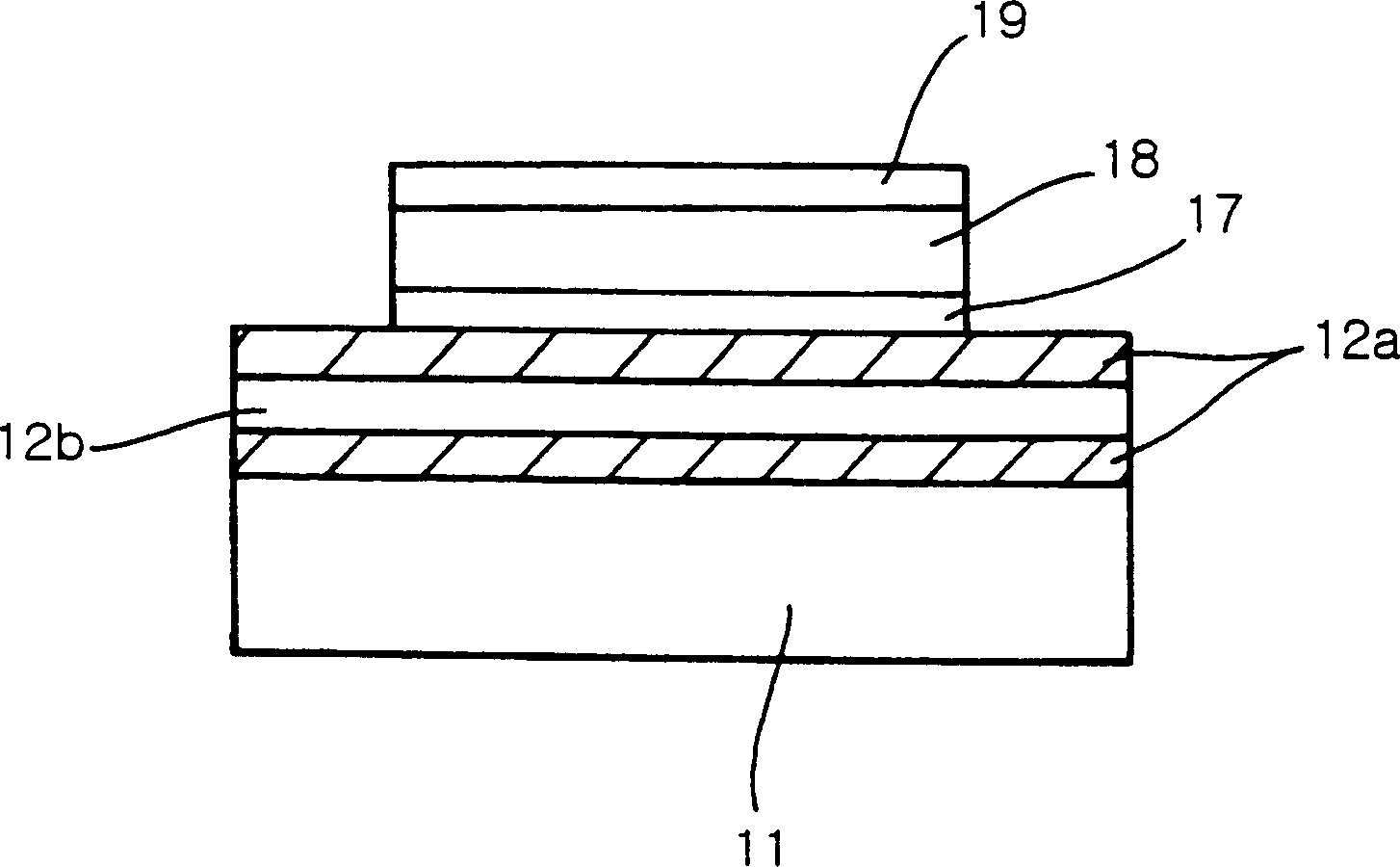

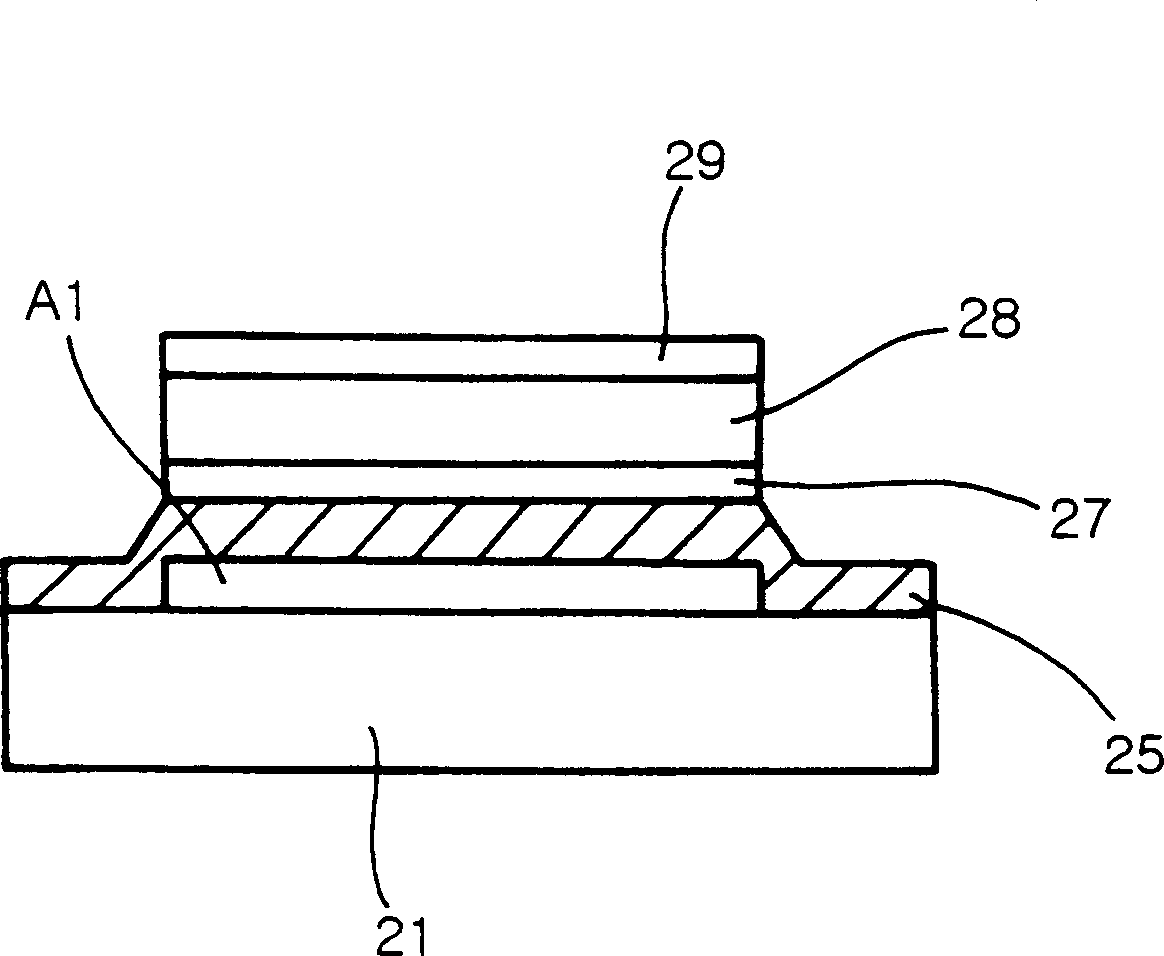

Film bulk acoustic resonator (FBAR) device

InactiveUS6842089B2Stable structureImprove featuresPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksThin-film bulk acoustic resonatorAcoustics

Disclosed are a film bulk acoustic resonator (FBAR) device and a method for fabricating the film bulk acoustic resonator (FBAR) device. The film bulk acoustic resonator (FBAR) device comprises a membrane layer having a plurality of active regions and provides different resonant frequencies by providing different thicknesses of the active regions of series resonators and shunt resonators, and by controlling the thicknesses, respectively. A plurality of the film bulk acoustic resonator (FBAR) devices having different resonant frequencies are manufactured on a substrate, thereby simultaneously manufacturing a transmission filter and a reception filter on the same substrate. Further, the film bulk acoustic resonator (FBAR) device has a stable structure and excellent characteristics.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

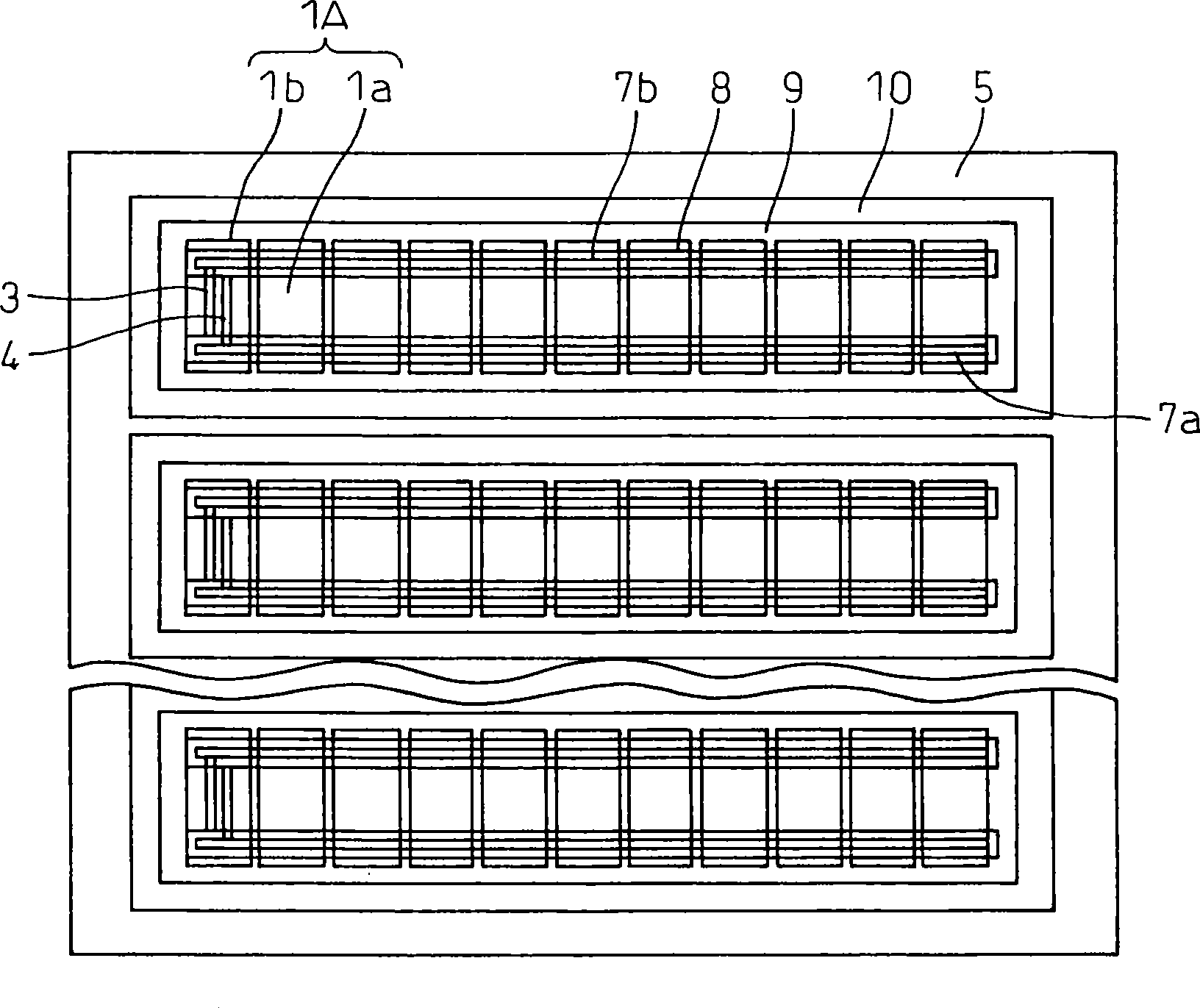

Flexible film-like solar cell composite layer

InactiveCN101465386APrevent moisture absorptionFully flexiblePhotovoltaicsPhotovoltaic energy generationEngineeringMoisture absorption

The invention provides a flexibility water proof membrane solar cell compound layer body capable of preventing a conductive section moisture absorption and power output from reducing, wherein a solar cell layer (1) is jointed on a flexibility water proof support membrane material (5), a flexibility adhesive resin layer (9) and a flexibility surface protective membrane layer (10) are covered on the solar cell layer in turn, and further extend outward, thereby jointing on the support membrane material (5). The solar cell layer is sealed. An anode and a cathode conductive sections in the solar cell layer are covered directly by a conductive section damp course or indirectly by the resin layer (9), and a crosslinking resin layer (6) formed between the resin layer (9) and the membrane layer (10) according to demands.

Owner:TAKASHIMA & CO LTD +1

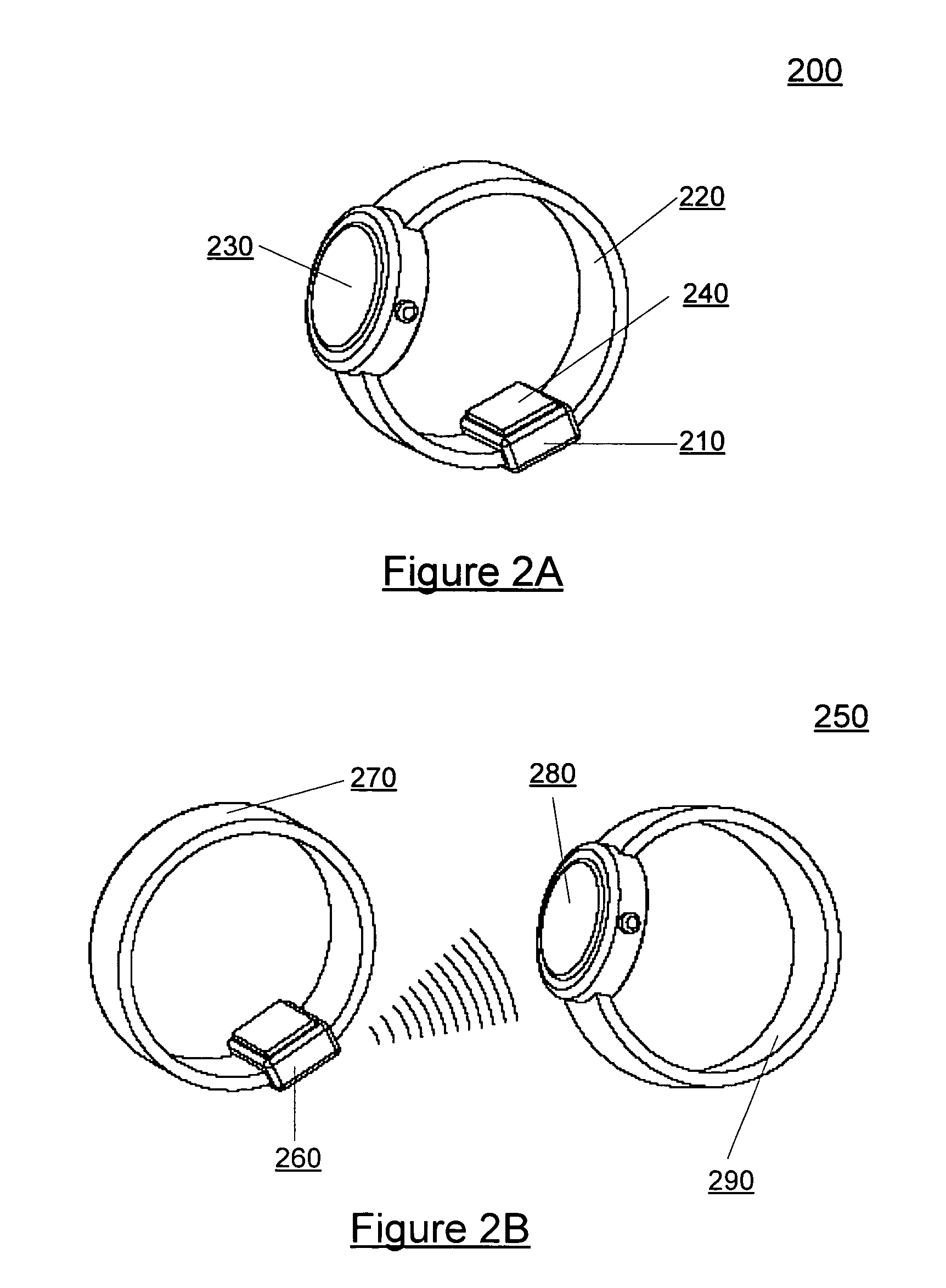

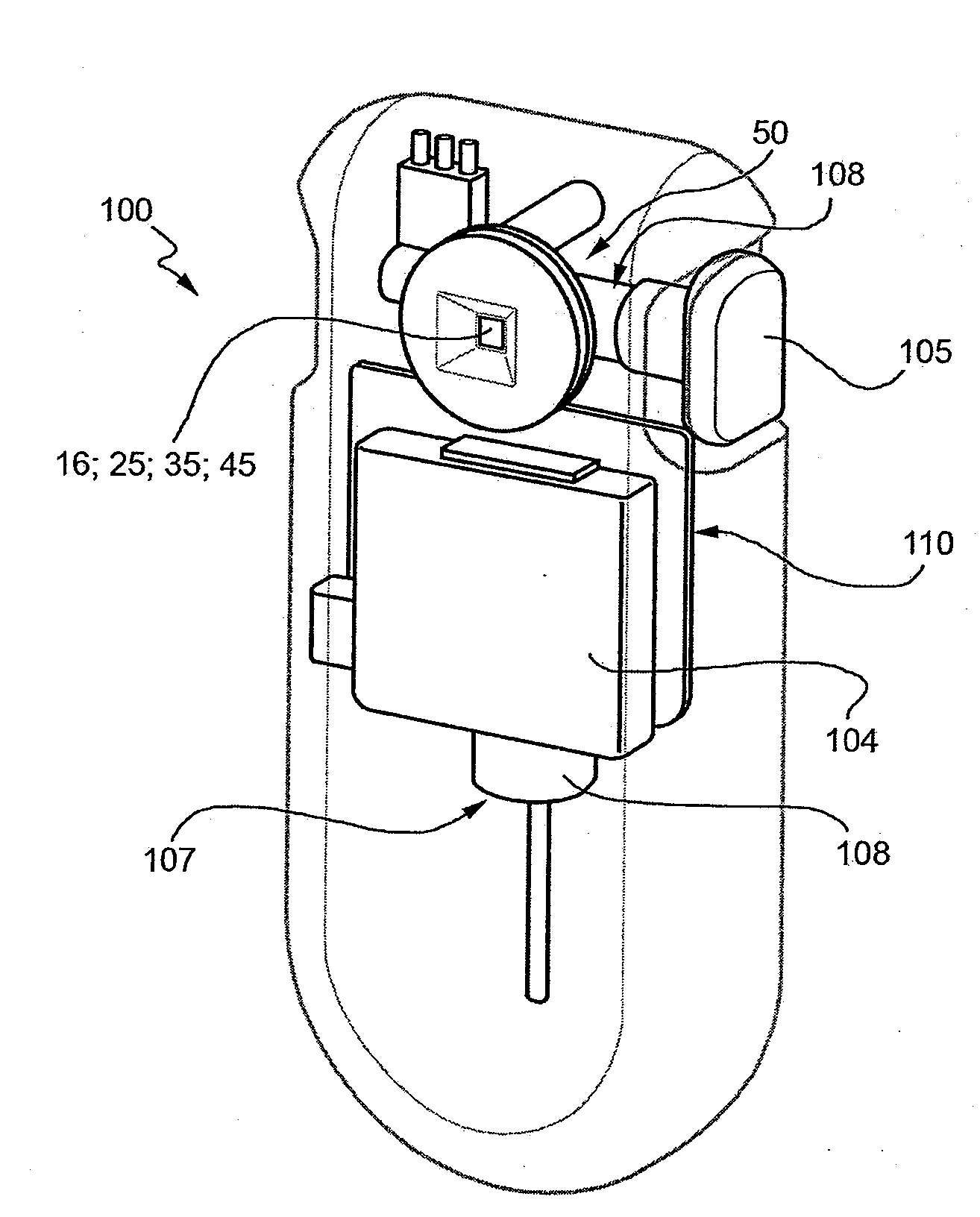

Ultrasonic monitor for measuring blood flow and pulse rates

InactiveUS7798970B2Small footprintReduced Power RequirementsBlood flow measurement devicesHeart/pulse rate measurement devicesPulse rateTransducer

Owner:SALUTRON

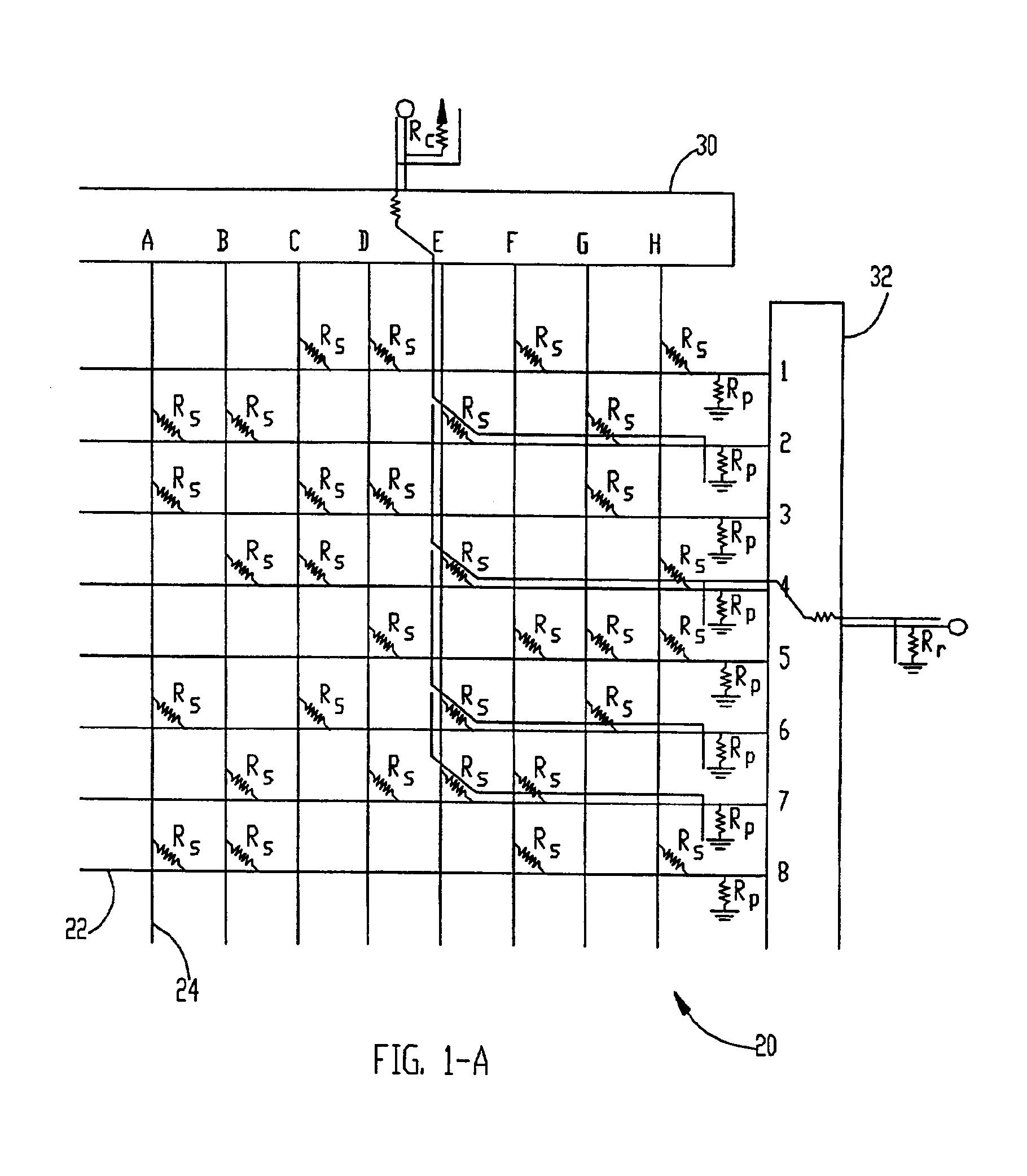

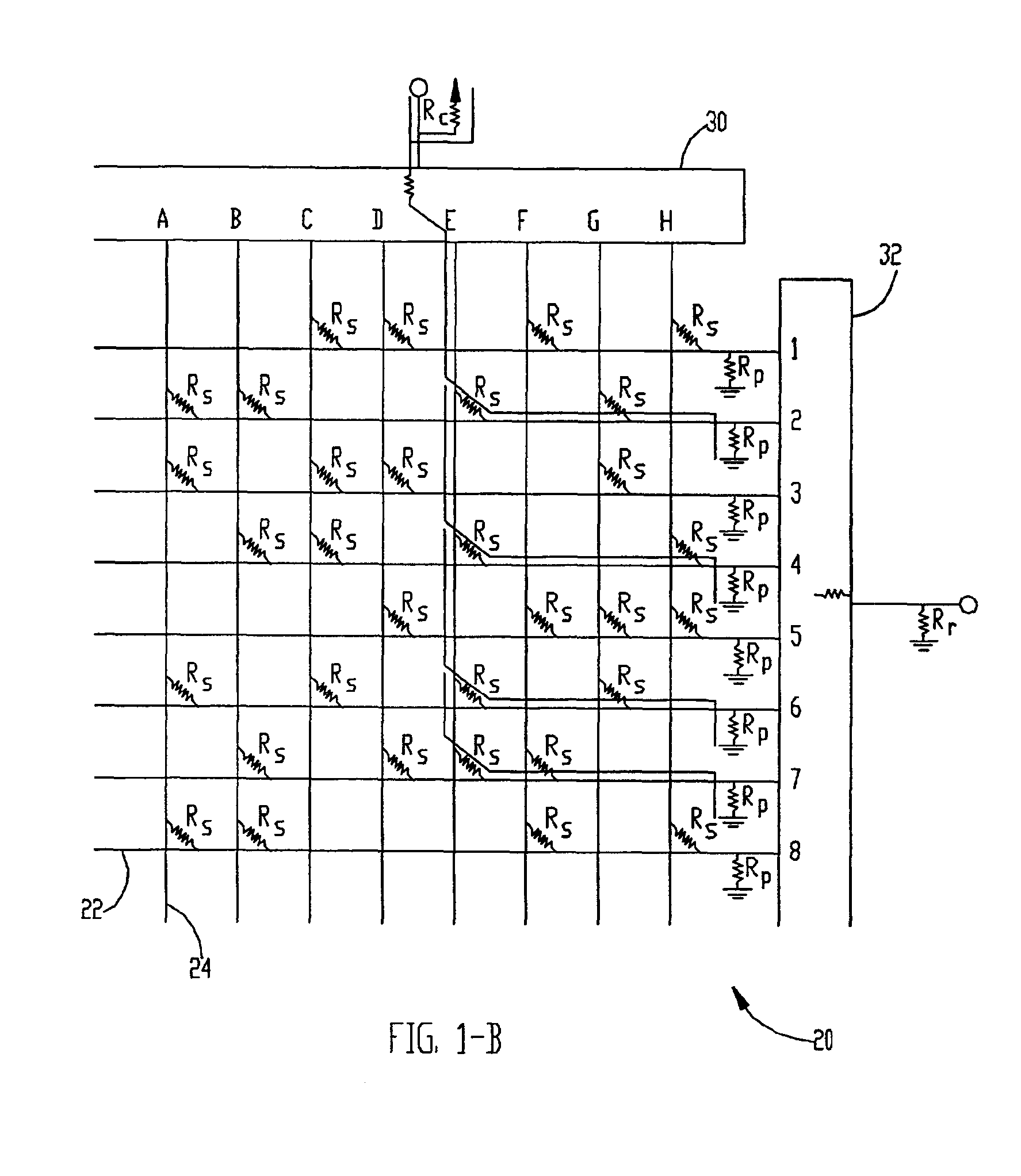

Fingerprint sensors using membrane switch arrays

InactiveUS6889565B2Electrostatic/electro-adhesion relaysResistance/reactance/impedenceMembrane switchEngineering

A sensor for identifying fingerprints or other skin textures includes an array of cells each including a membrane switch. Each switch includes a fixed lower electrode disposed on a chip substrate, and a flexible membrane disposed over the lower electrode and capable of flexing downward to establish electrical contact between the lower electrode and an upper electrode. The upper electrode can form the membrane itself or a layer of the membrane, or can be attached to other membrane layers. Switches situated underneath skin ridges change state (e.g. are closed) by the applied pressure, while switches underneath skin valleys remain in their quiescent state (e.g. open). Adjacent switch chambers are connected by fluid tunnels which allow the passage of air between the chambers. Each chamber is substantially closed to the exterior of the sensor, such that particles from the environment cannot contaminate the switch contact surface defined between the switch electrodes. The cells are preferably not hermetically sealed, such that the pressure within the chamber interiors can stay equal to the external (atmospheric) pressure in varying environmental conditions. The membrane design of the cells according to the preferred embodiment allows improved sensor robustness, enhanced resistance to impact forces, decreased vulnerability to particle contamination, and reduced inter-cell crosstalk.

Owner:LENOVO PC INT

Air gap interconnect structure and method of manufacture

A dual layer of polymeric material is deposited with a base layer and top layer resist onto an integrated circuit structure with topography. The base layer planarizes the surface and fills in the native topography. The base layer decomposes almost completely when exposed to an oxidizing environment. The top layer contains a high composition of oxidizing elements and is photosensitive. (i.e., the layer can be patterned by exposing normal lithographic techniques.) The patterning allows the creation of escape paths for the decomposition products of the underlying base layer. This structure is decomposed in an oxidizing ambient (or plasma) leaving behind a thin carbon-containing membrane. This membrane layer blocks deposition of future layers, creating air gaps in the structure.

Owner:IBM CORP

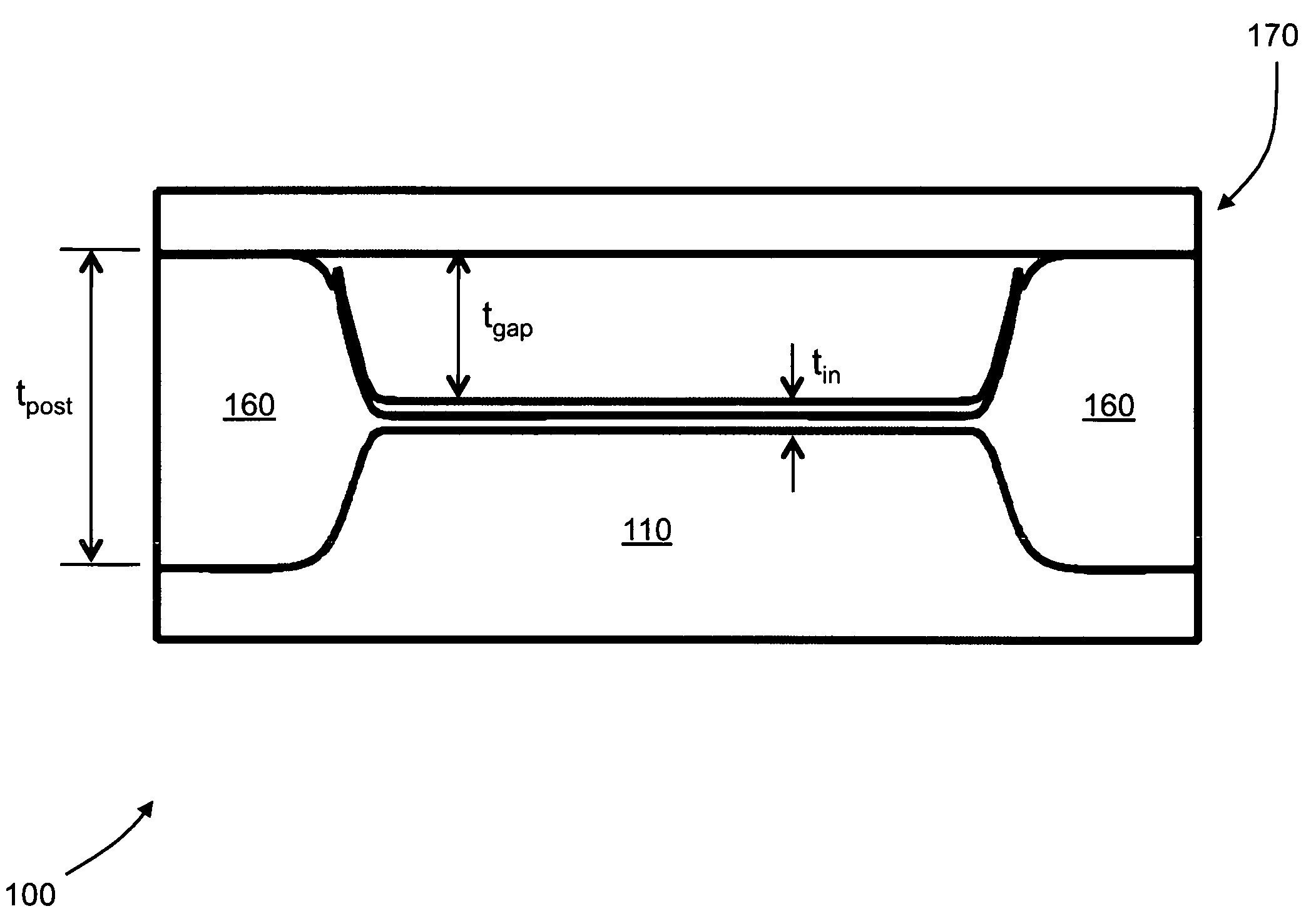

Fabrication of capacitive micromachined ultrasonic transducers by local oxidation

ActiveUS7745248B2Reduce parasitic capacitanceImprove breakdown voltageSemiconductor/solid-state device manufacturingMechanical vibrations separationCapacitanceCapacitive micromachined ultrasonic transducers

The current invention provides methods of fabricating a capacitive micromachined ultrasonic transducer (CMUT) that includes oxidizing a substrate to form an oxide layer on a surface of the substrate having an oxidation-enabling material, depositing and patterning an oxidation-blocking layer to form a post region and a cavity region on the substrate surface and remove the oxidation-blocking layer and oxide layer at the post region. The invention further includes thermally oxidizing the substrate to grow one or more oxide posts from the post region, where the post defines the vertical critical dimension of the device, and bonding a membrane layer onto the post to form a membrane of the device. A maximum allowed second oxidation thickness t2 can be determined, that is partially based on a desired step height and a device size, and a first oxidation thickness t1 can be determined that is partially based on the determined thickness t2.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

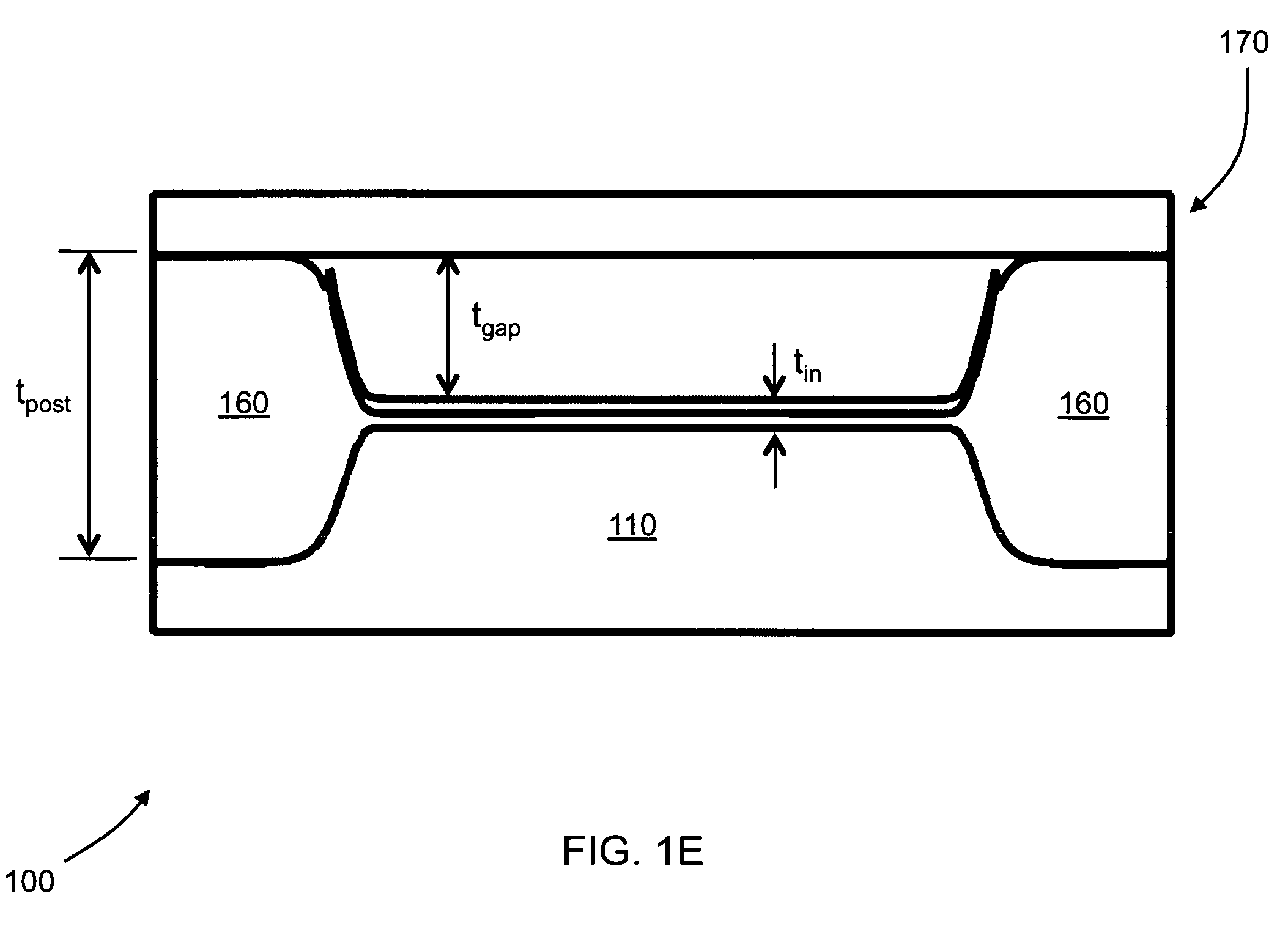

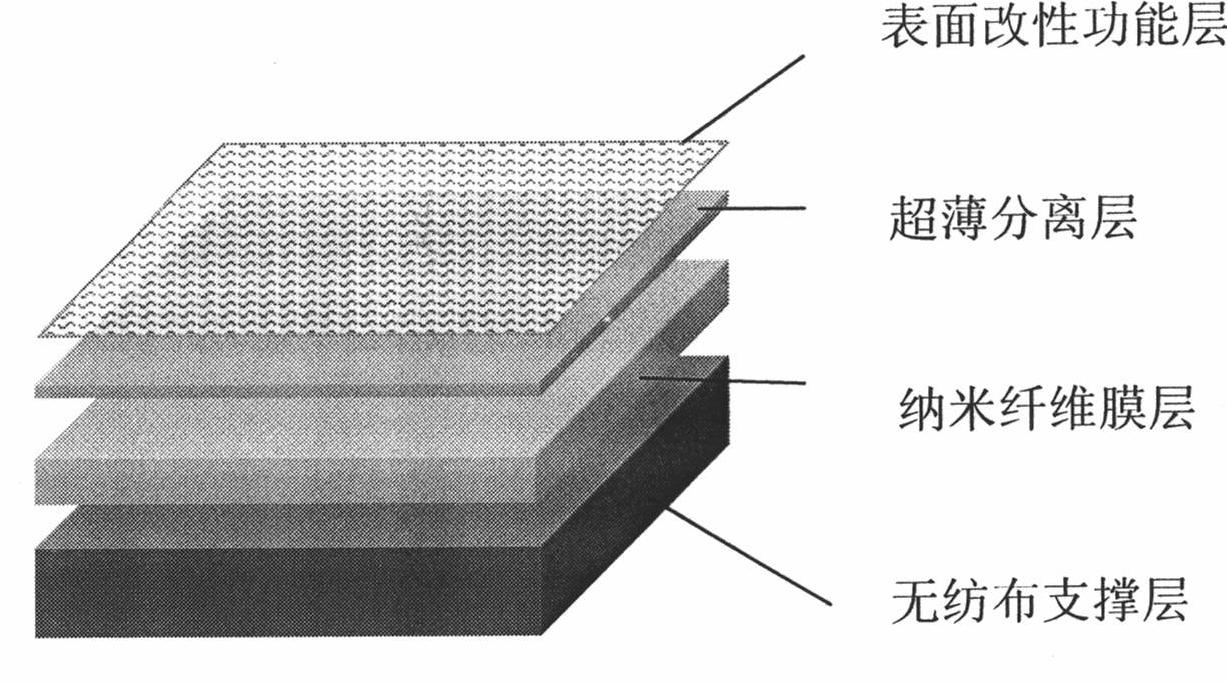

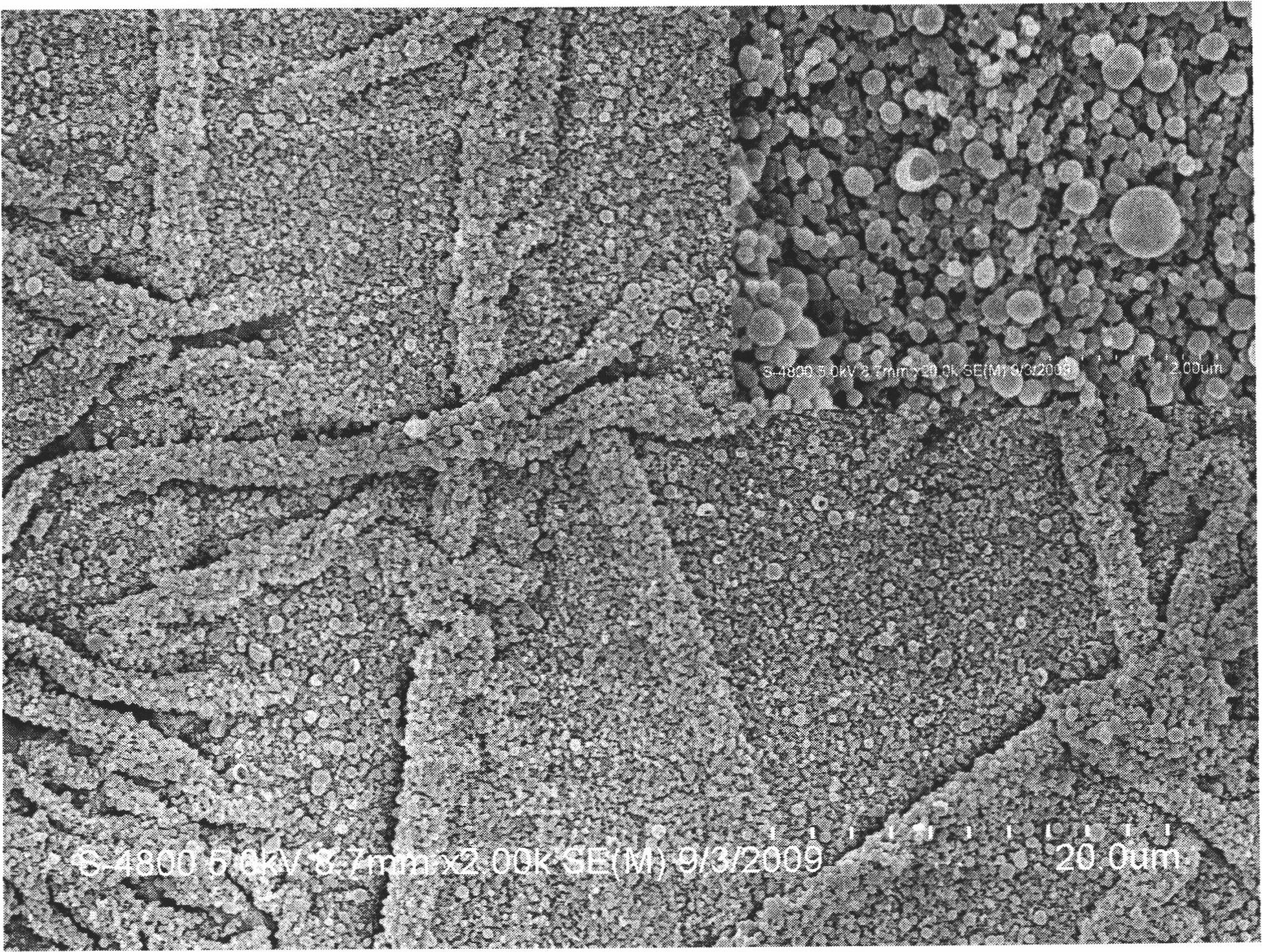

Hyperfiltration membrane or nanofiltration membrane with multi-layered composite structure and preparation method thereof

InactiveCN102139187AIncrease water fluxHigh retention rateSemi-permeable membranesEnvironmental resistanceHydrophilic polymers

The invention relates to a hyperfiltration membrane or nanofiltration membrane with a multi-layered composite structure and a preparation method thereof. The hyperfiltration membrane or nanofiltration membrane is a polymer electrostatic spinning nanofiber membrane layer characterized in strong chemical resistance prepared through an electrostatic spinning method, a hydrophilic polymer ultra-thin separation layer obtained through interfacial polymerization, and a functional group surface modification functional layer formed through the grafting reaction of reactant gases on the surfaces of hydrophilic polymers, or a long-chain polymer surface modification functional layer formed through the grafting reaction of the reaction gases on the surfaces of the hydrophilic polymers, or a functionalgroup-containing long-chain polymer surface modification functional layer through the grafting reaction of the reaction gases with the functional groups on the surfaces of the hydrophilic polymers. The hyperfiltration membrane or nanofiltration membrane with the multi-layered composite structure has the advantages of high water flux, high cutting rate and stable chemical performances. The filtration membrane can be used for the production of domestic water, drinking water or water in special conditions, and is suitable for the medical field, food field, environmental protection field and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

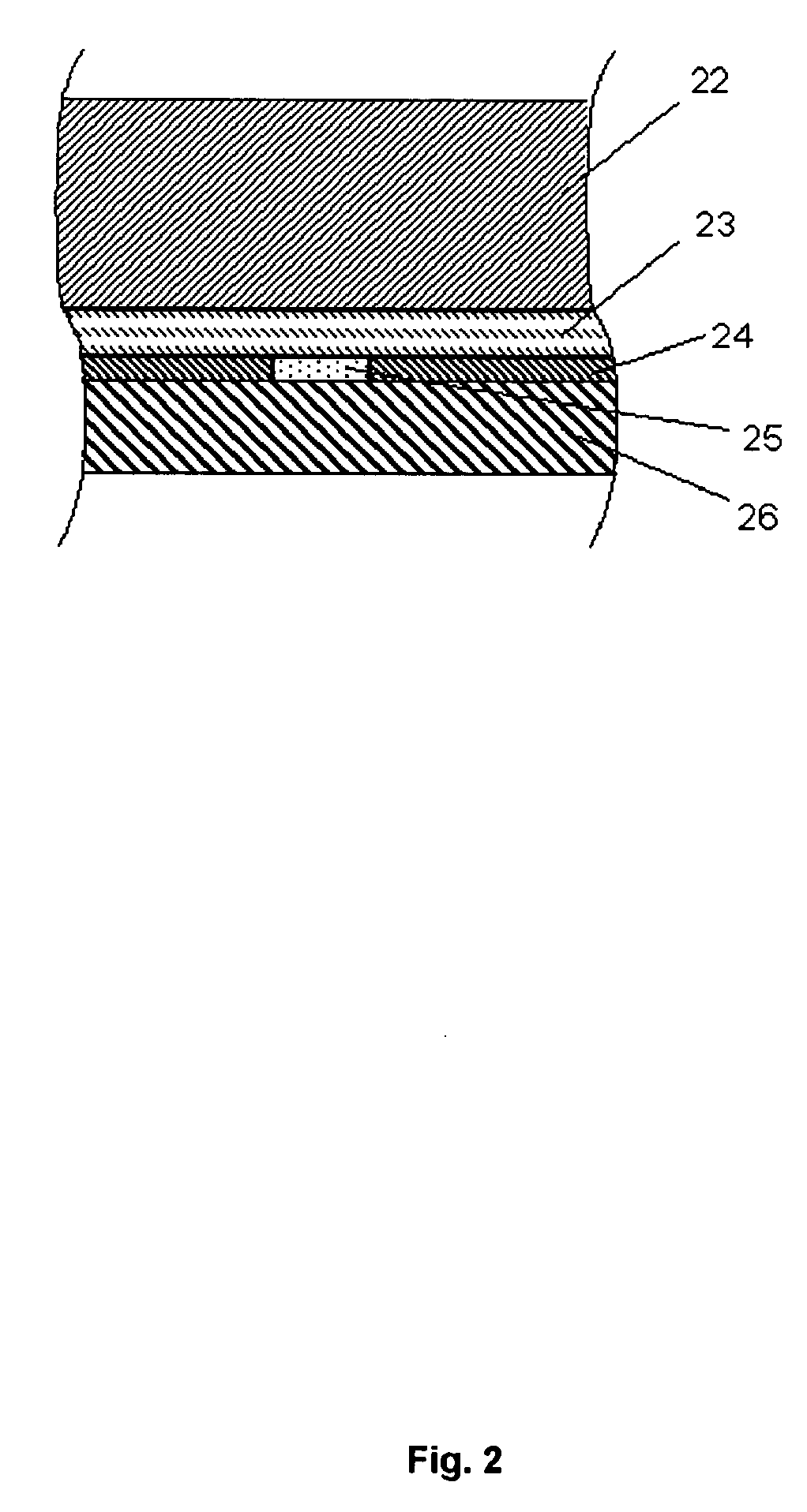

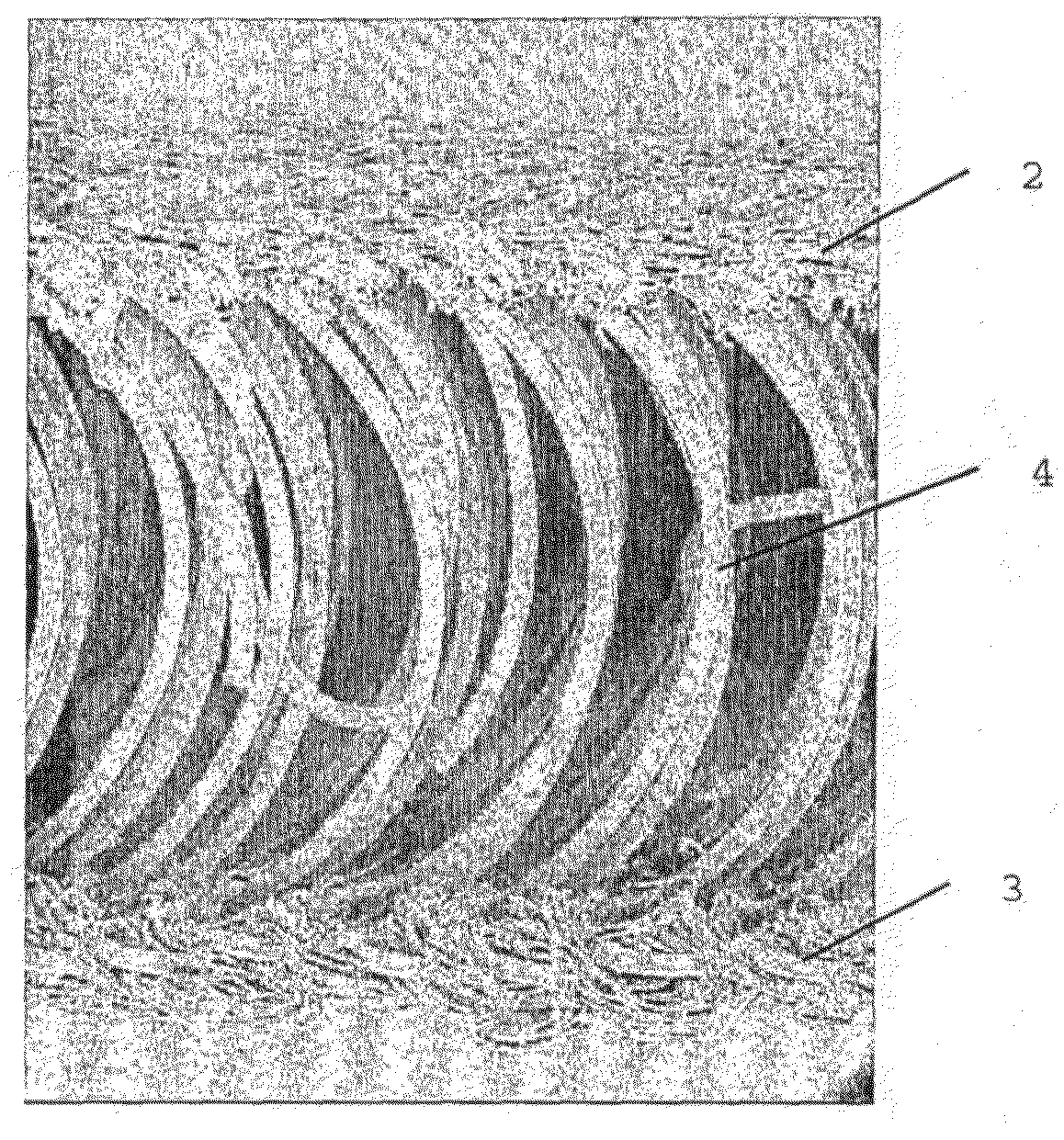

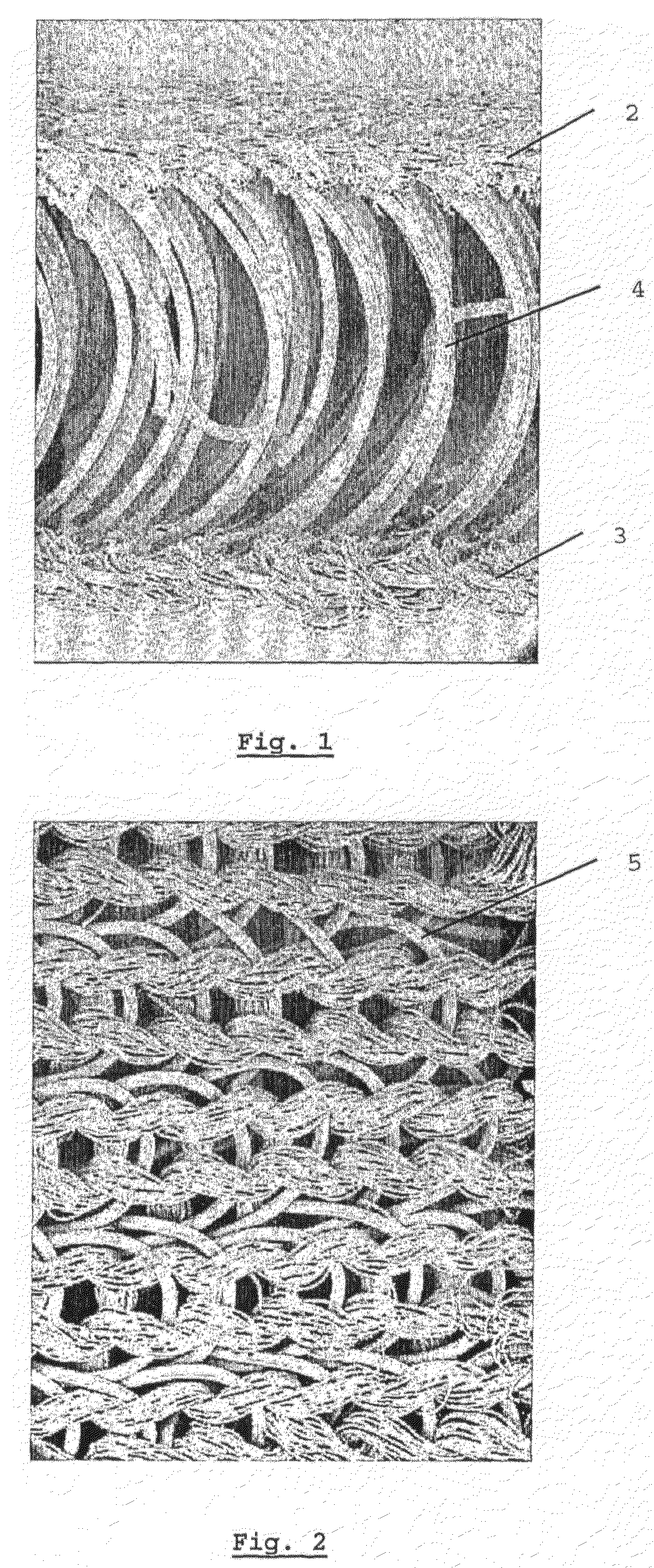

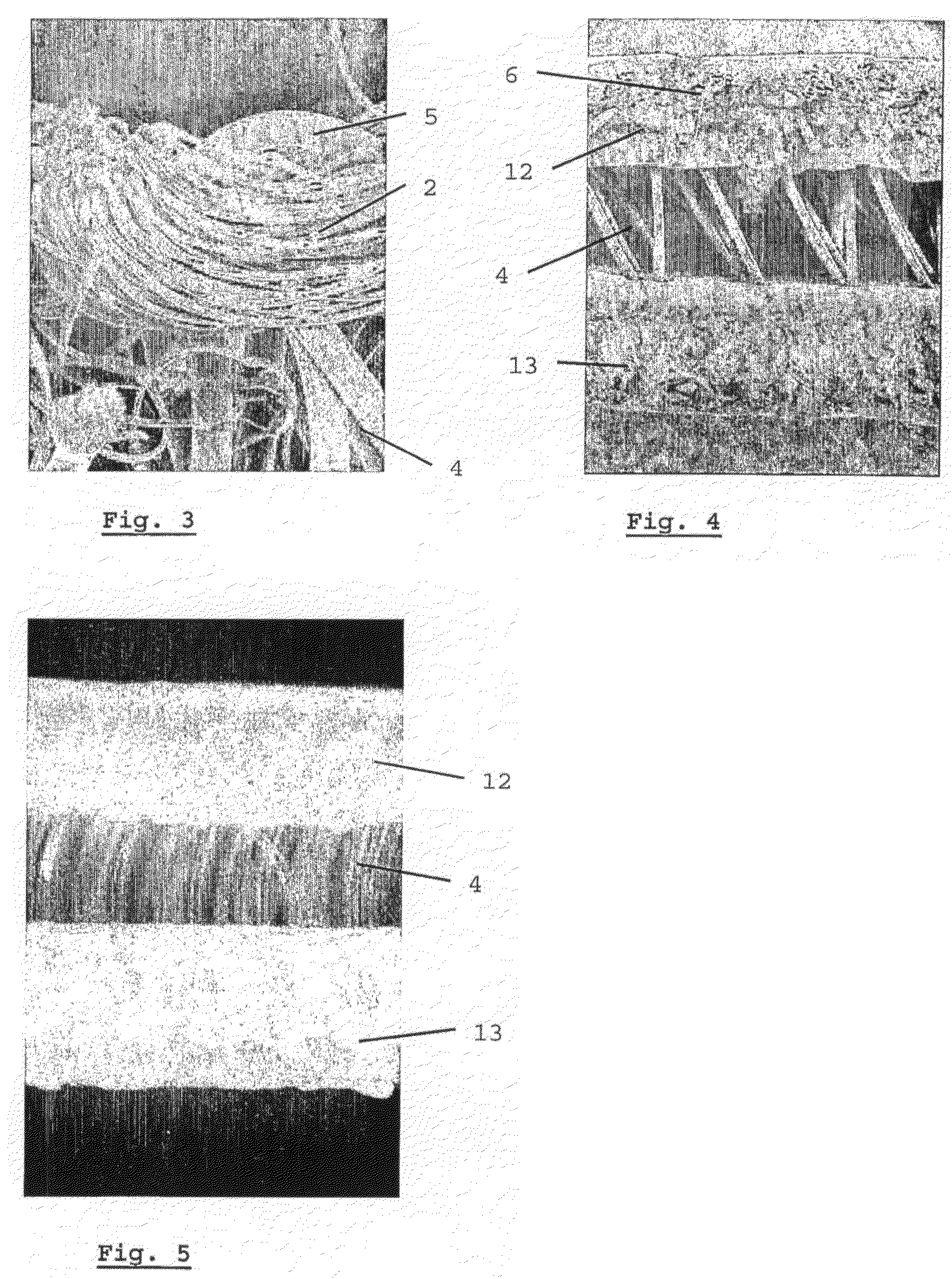

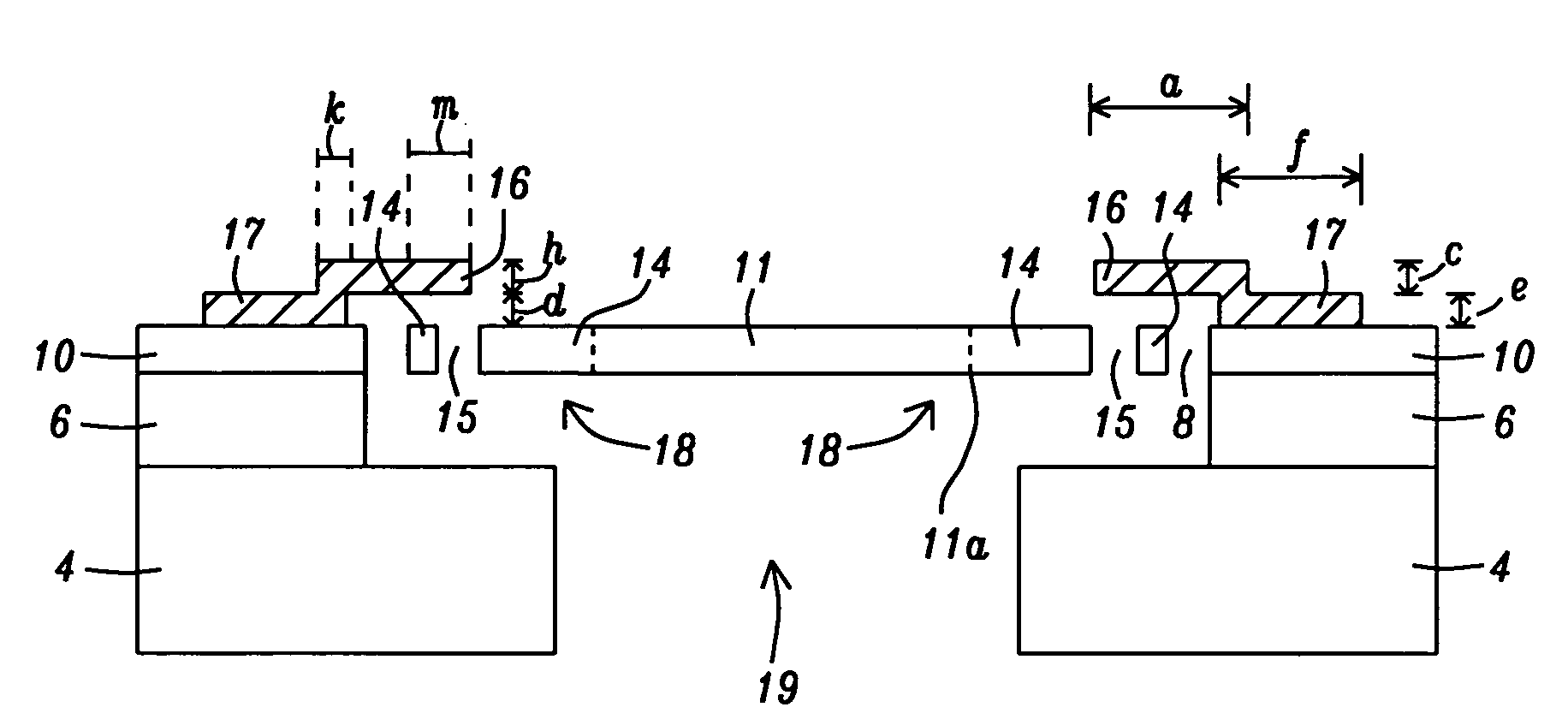

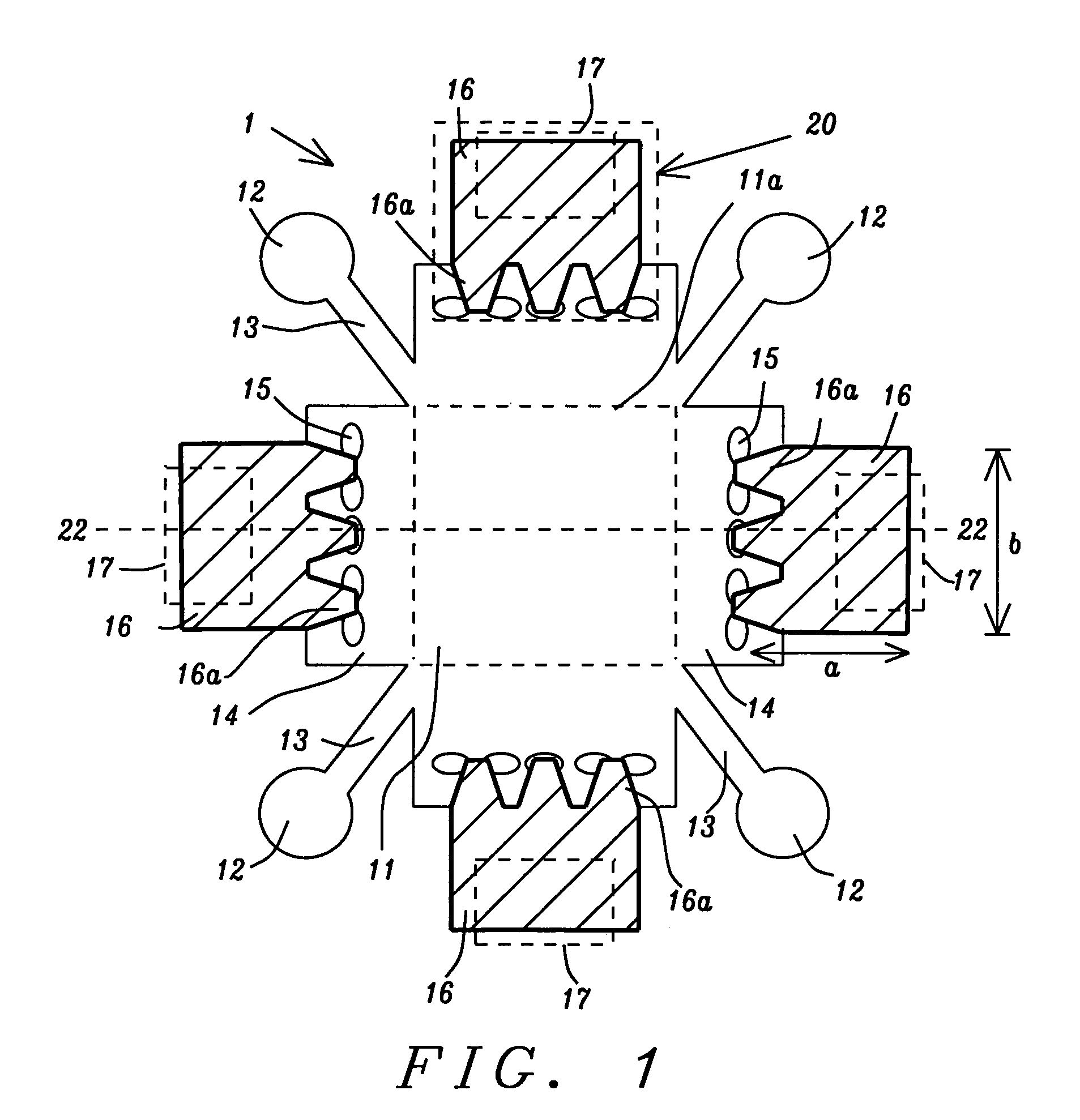

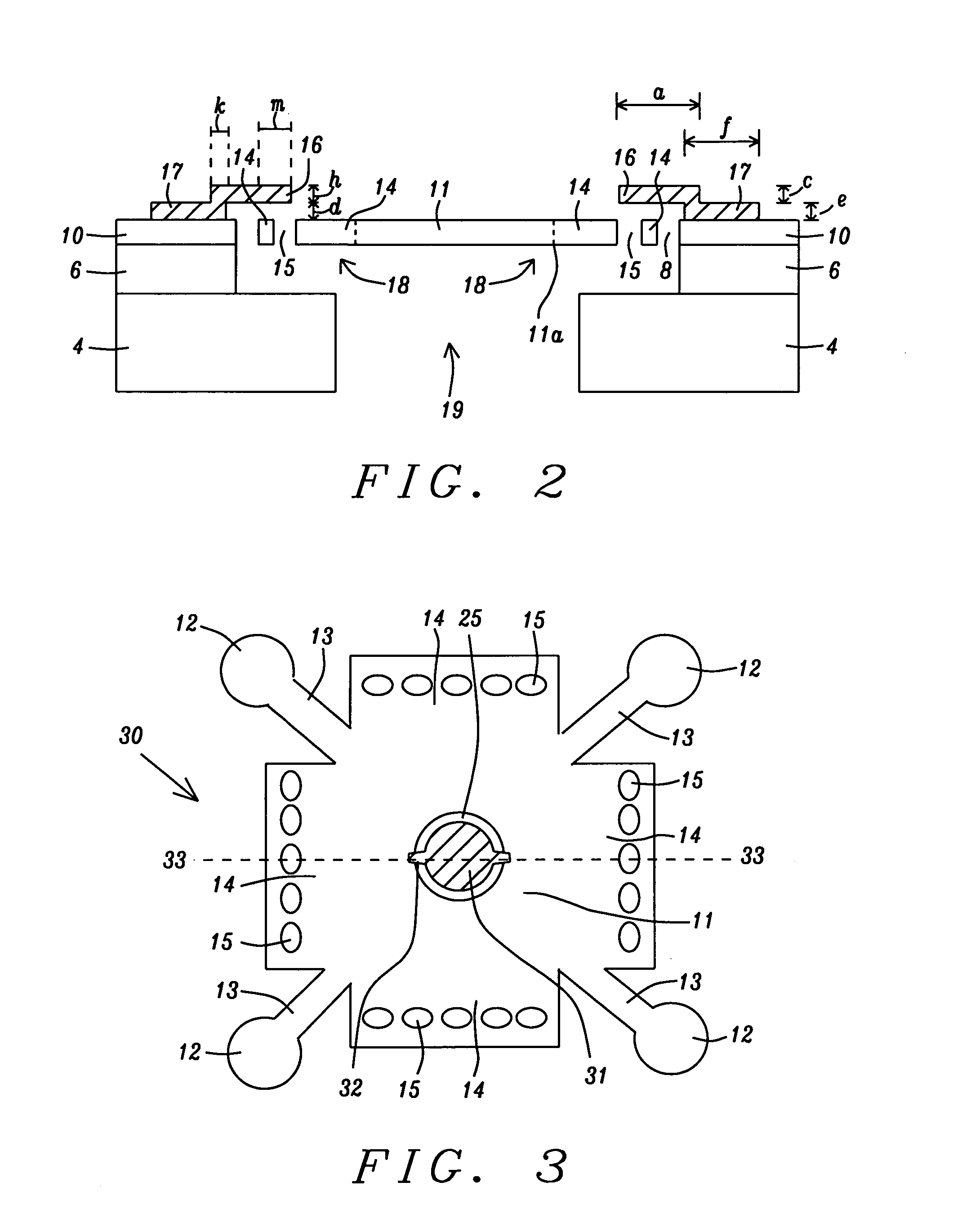

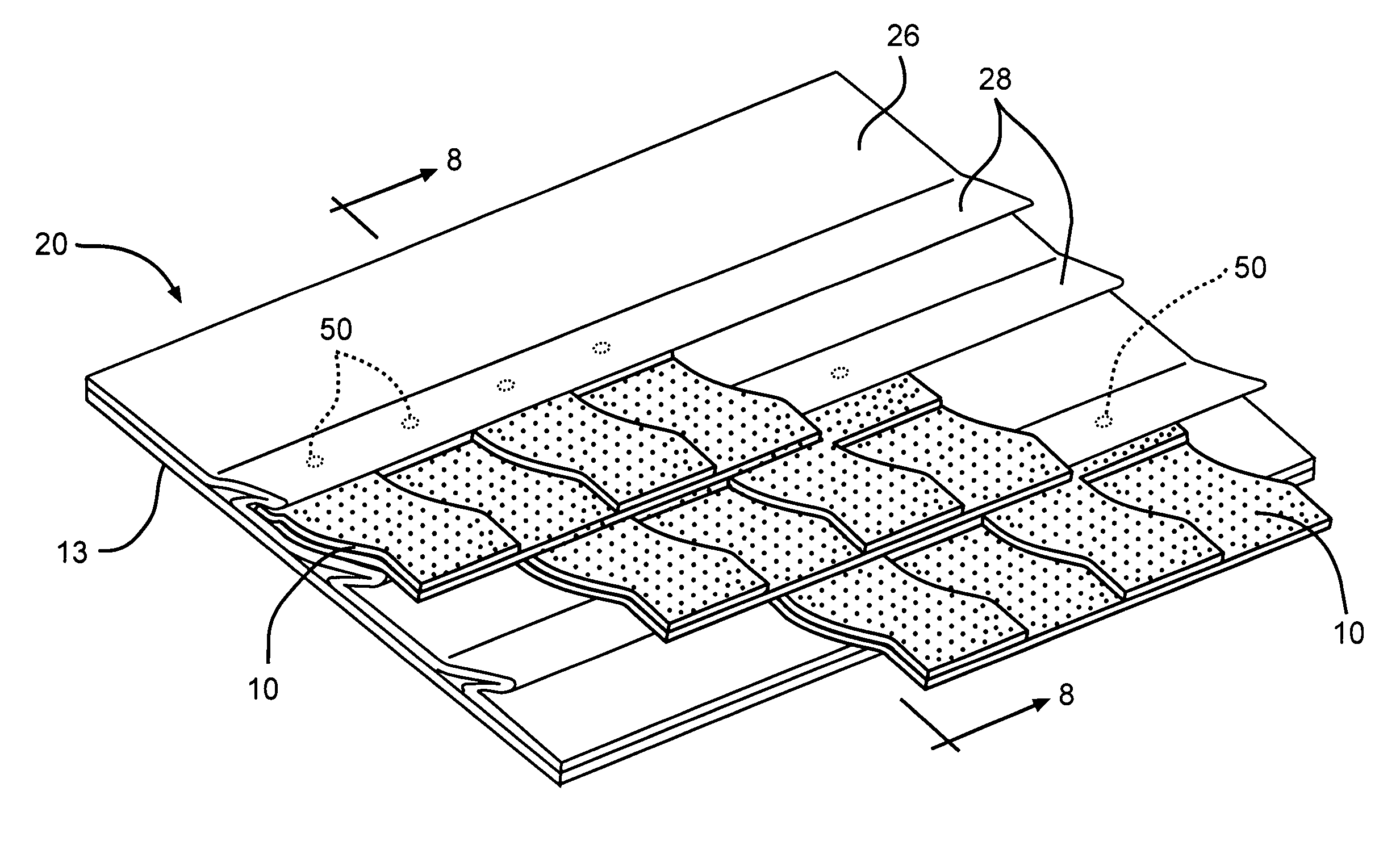

Integrated permeate channel membrane

A membrane has a permeate channel including a 3D spacer fabric having an upper and a lower fabric surface (2,3) spaced apart by monofilament thread (4) at a predefined distance, the permeate channel being interposed between two membrane layers (12, 13), wherein the membrane layers are linked at a multitude of points with the upper and lower fabric surfaces to form an integral structure with a high bonding strength suitable for backflush operations. A method provides an integrated permeate channel membrane, including the steps of: —Providing a 3D spacer fabric having an upper and lower surface fabric (2,3) spaced apart by monofilament thread (4) at a predefined distance; and—Applying a membrane layer to both the upper and the lower surface fabric.

Owner:BLUE FOOT MEMBRANES NV

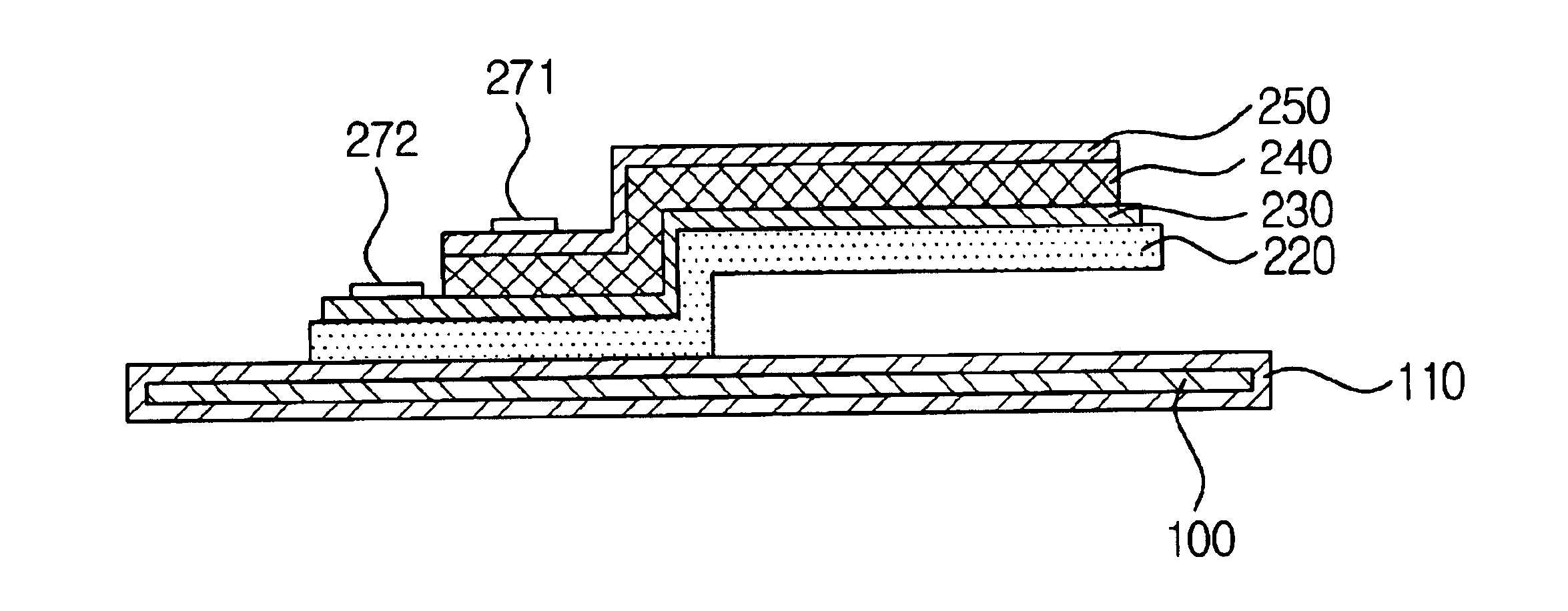

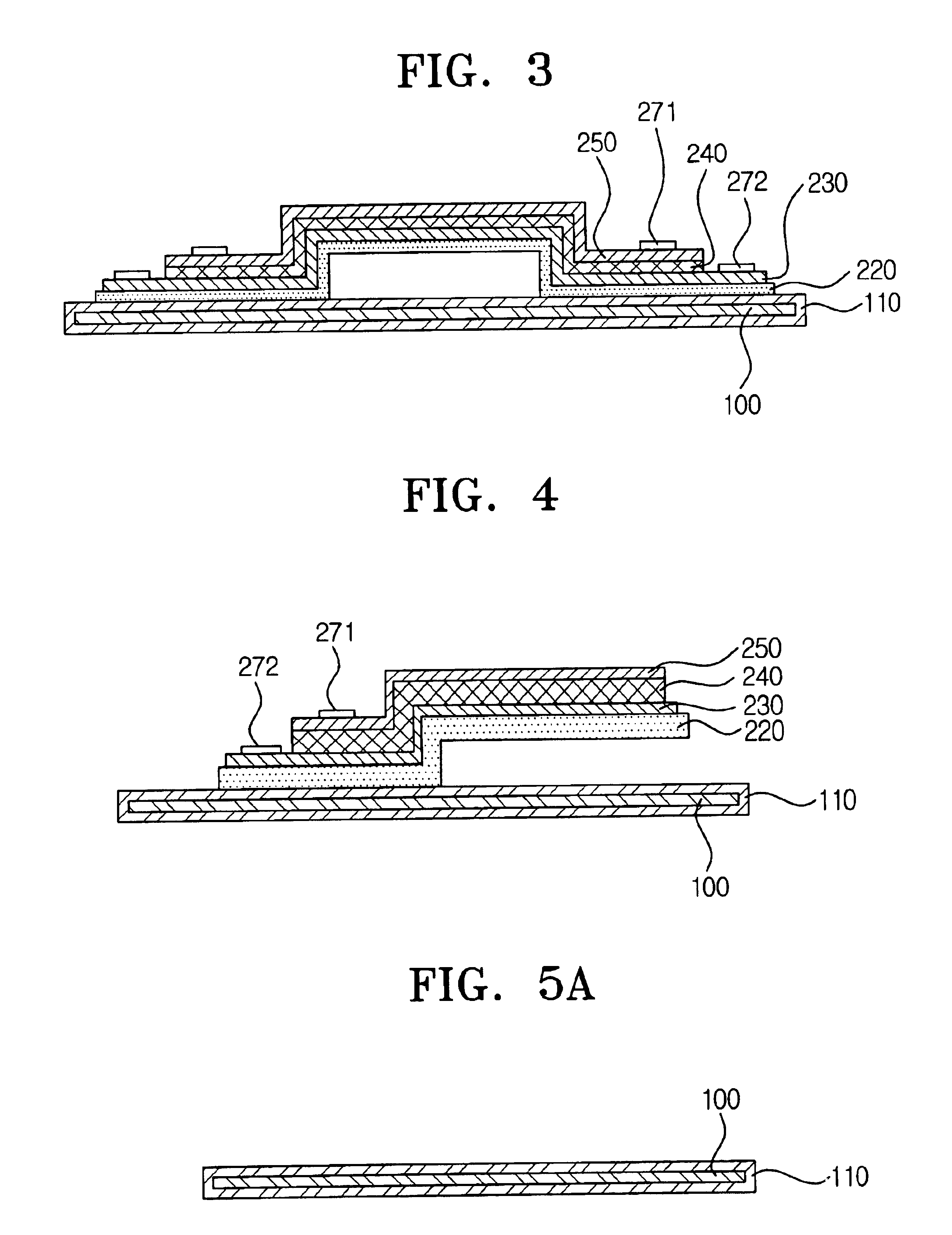

Flexible MEMS transducer and manufacturing method thereof, and flexible MEMS wireless microphone

InactiveUS6967362B2Increase depositionPiezoelectric/electrostrictive microphonesPiezoelectric/electrostrictive device manufacture/assemblyWireless microphoneTransducer

A flexible wireless MEMS microphone includes a substrate of a flexible polymeric material, a flexible MEMS transducer structure formed on the substrate by PECVD, an antenna printed on the substrate for communicating with an outside source, a wire and interface circuit embedded in the substrate to electrically connect the flexible MEMS transducer and the antenna, a flexible battery layer electrically connected to the substrate for supplying power to the MEMS transducer, and a flexible bluetooth module layer electrically connected to the battery layer. The flexible MEMS transducer includes a flexible substrate, a membrane layer deposited on the substrate, a lower electrode layer formed on the membrane layer, an active layer formed by depositing a piezopolymer on the lower electrode layer, an upper electrode layer formed on the active layer, and a first and a second connecting pad electrically connected to the lower and upper electrode layers, respectively.

Owner:SAMSUNG ELECTRONICS CO LTD

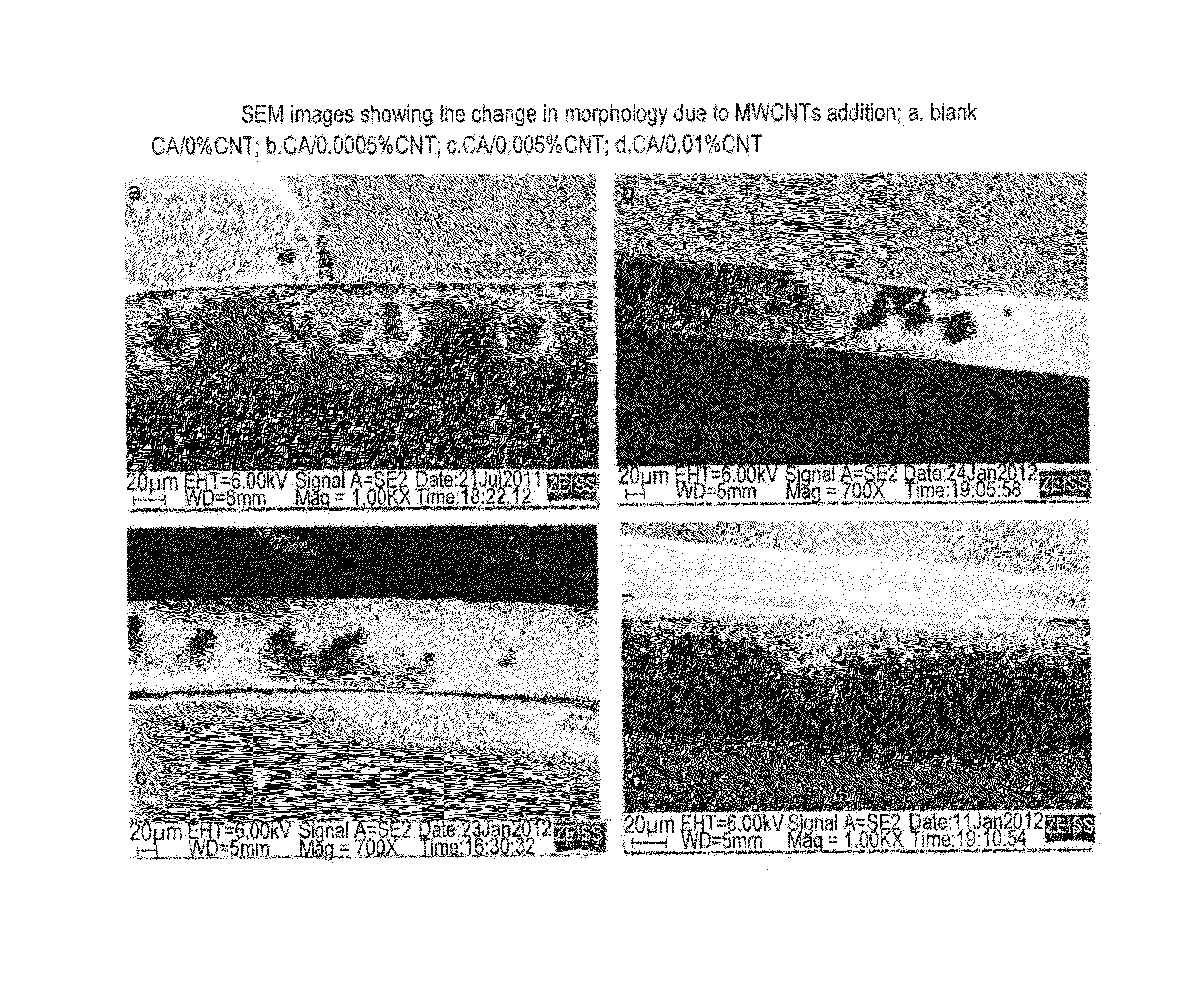

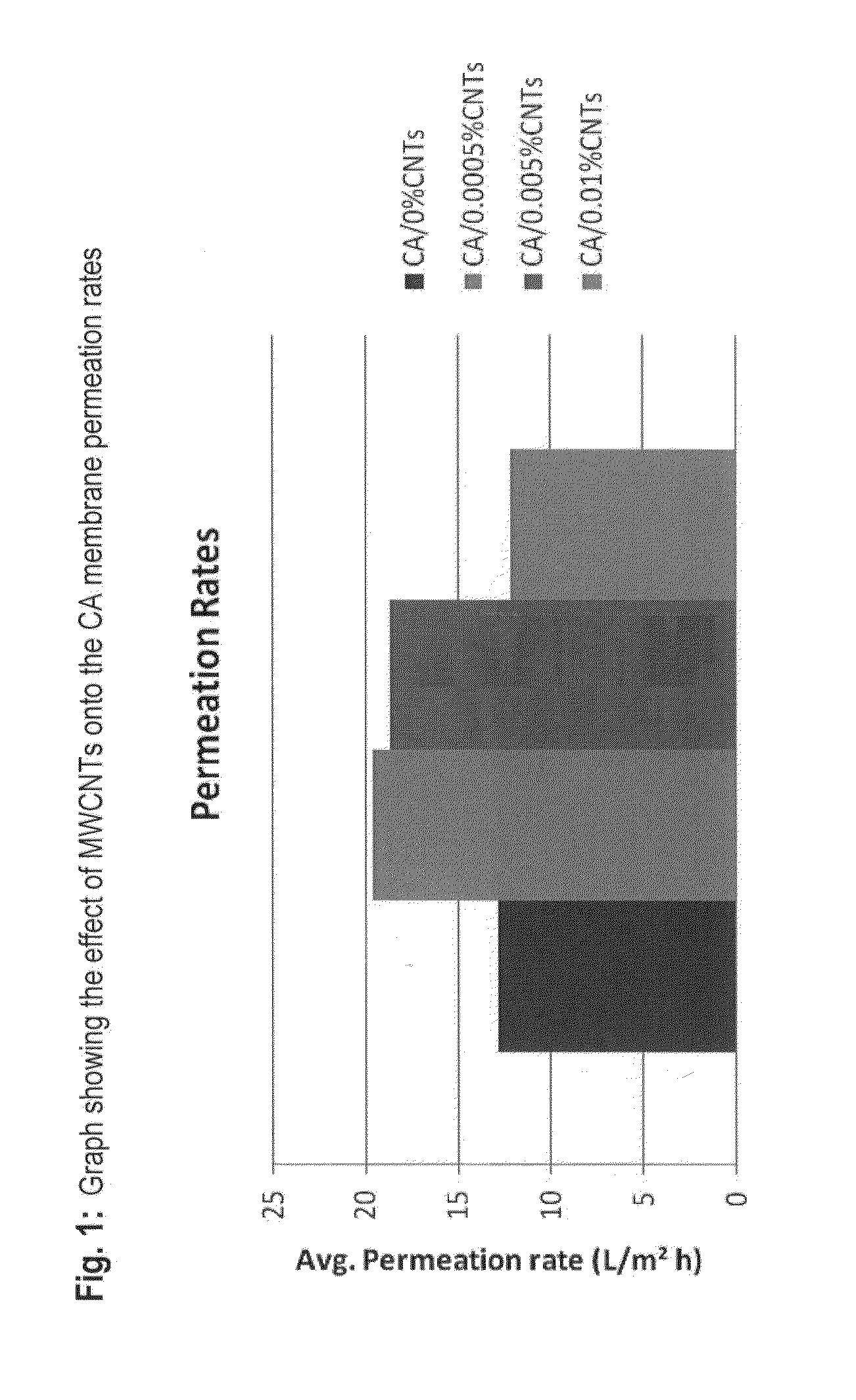

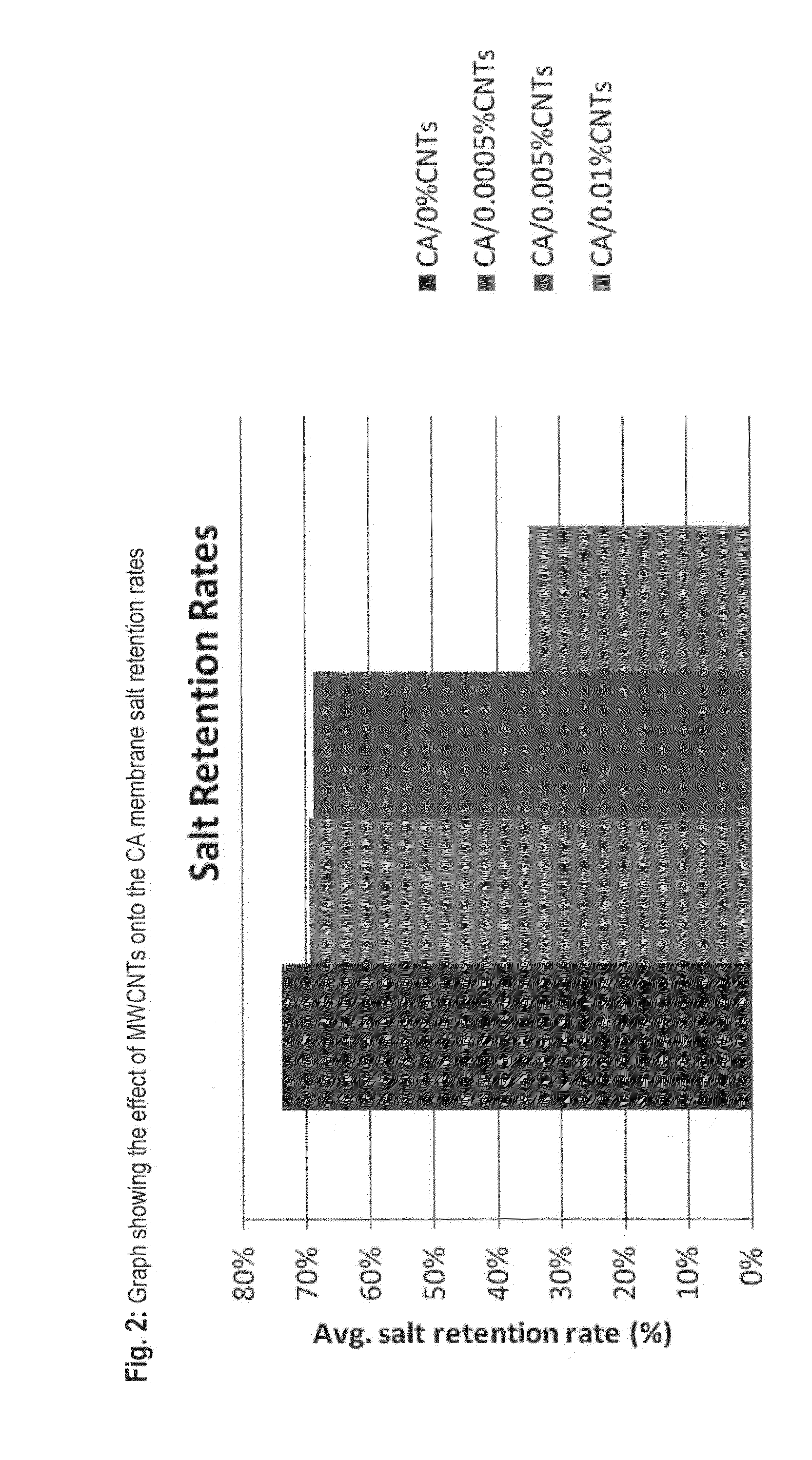

Polymer-carbon nanotube nanocomposite porous membranes

This invention relates to an asymmetric composite membrane containing a polymeric matrix and carbon nanotubes within a single membrane layer, where the carbon nanotubes are randomly oriented within the polymeric matrix and the composite membrane is formed by phase inversion. This invention also relates to a method for producing the composite membrane which includes: coating a surface with a film of a polymer solution containing a polymeric matrix and carbon nanotubes dissolved in at least one solvent; immersing the coated surface in a non-solvent to affect solvent / non-solvent demixing resulting in phase inversion to form a carbon nanotube-containing membrane; and optionally, removing the carbon nanotube-containing membrane from the surface. The invention also relates to a desalination method using the composite membrane.

Owner:AMERICAN UNIV OF CAIRO AUC

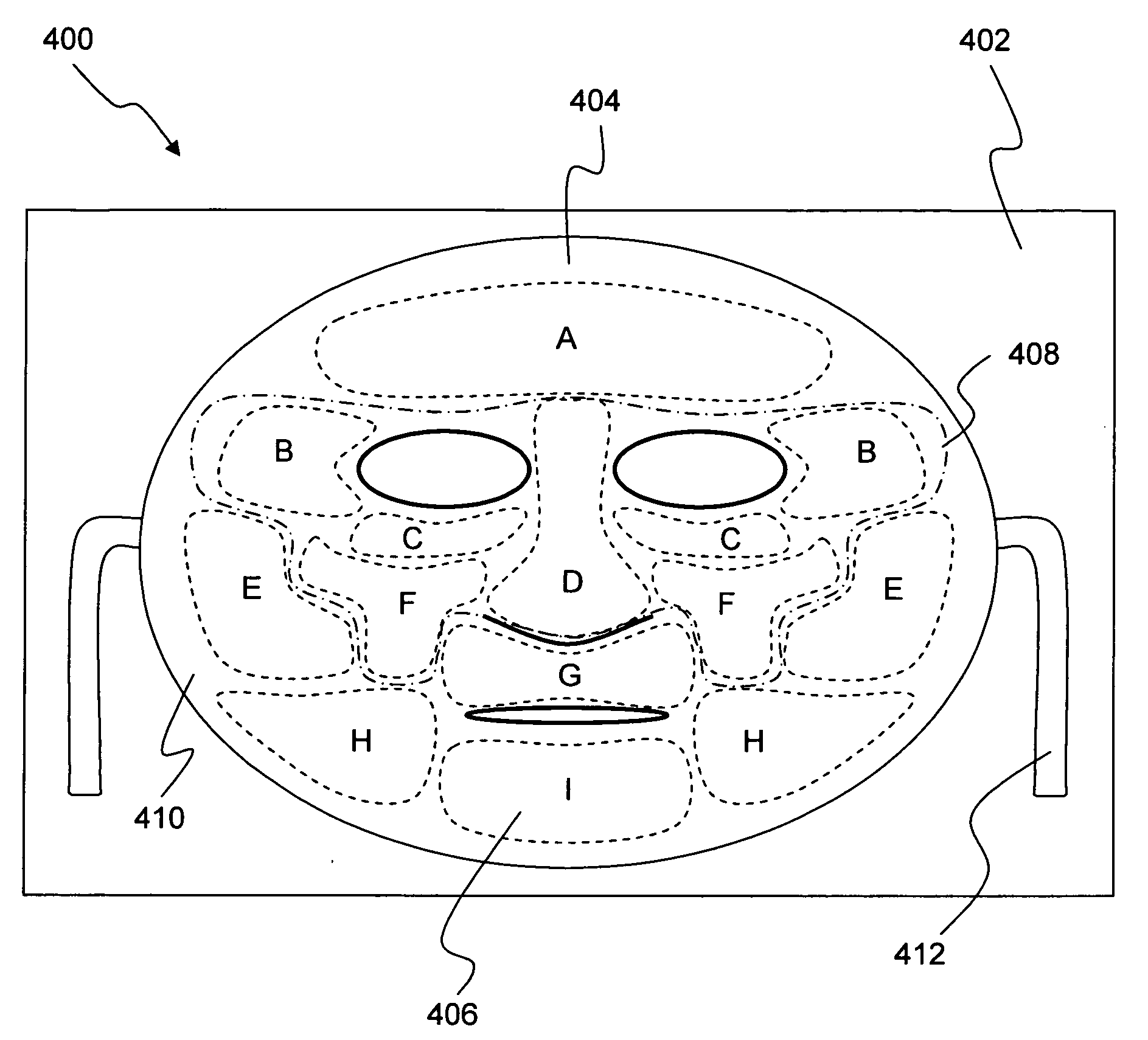

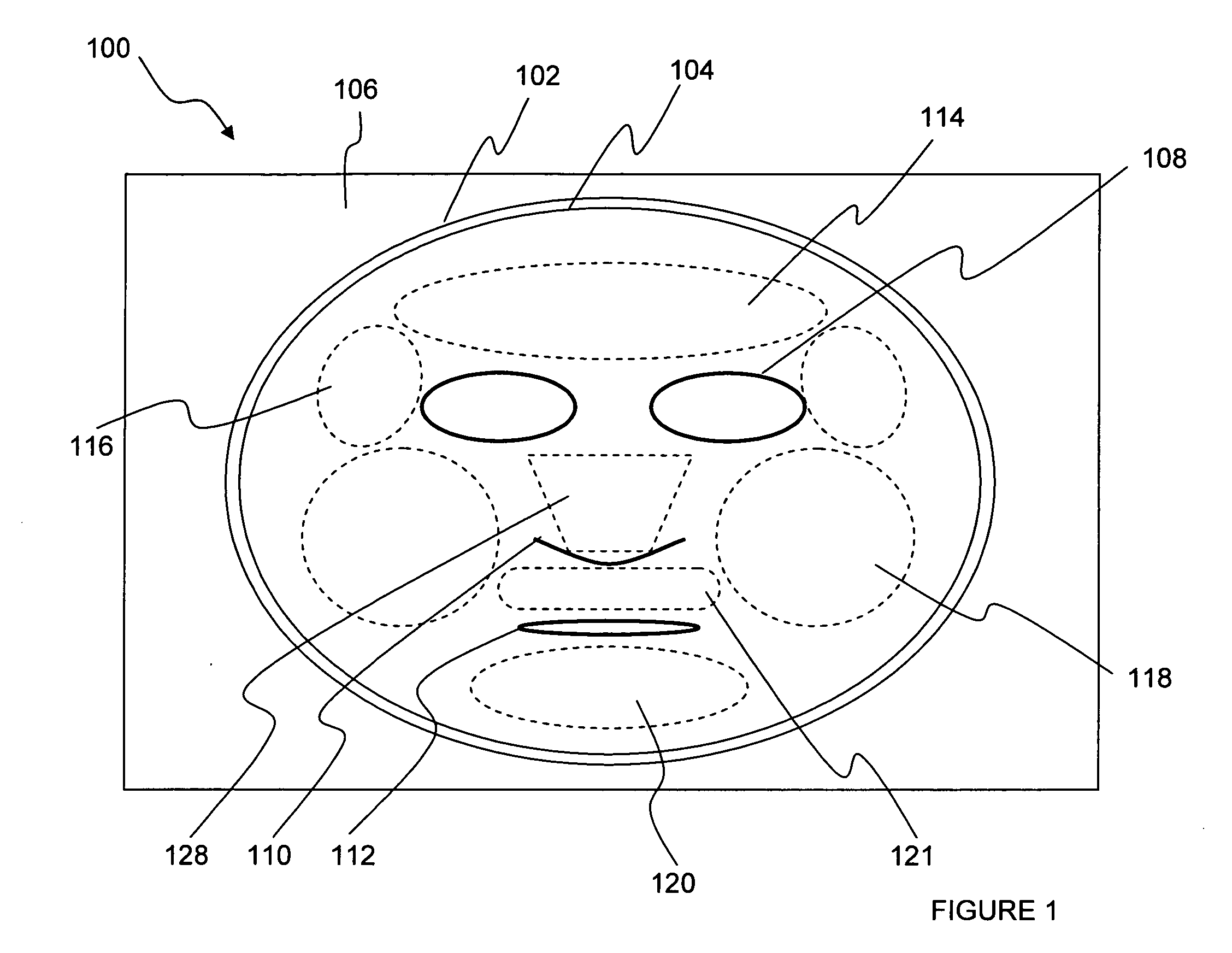

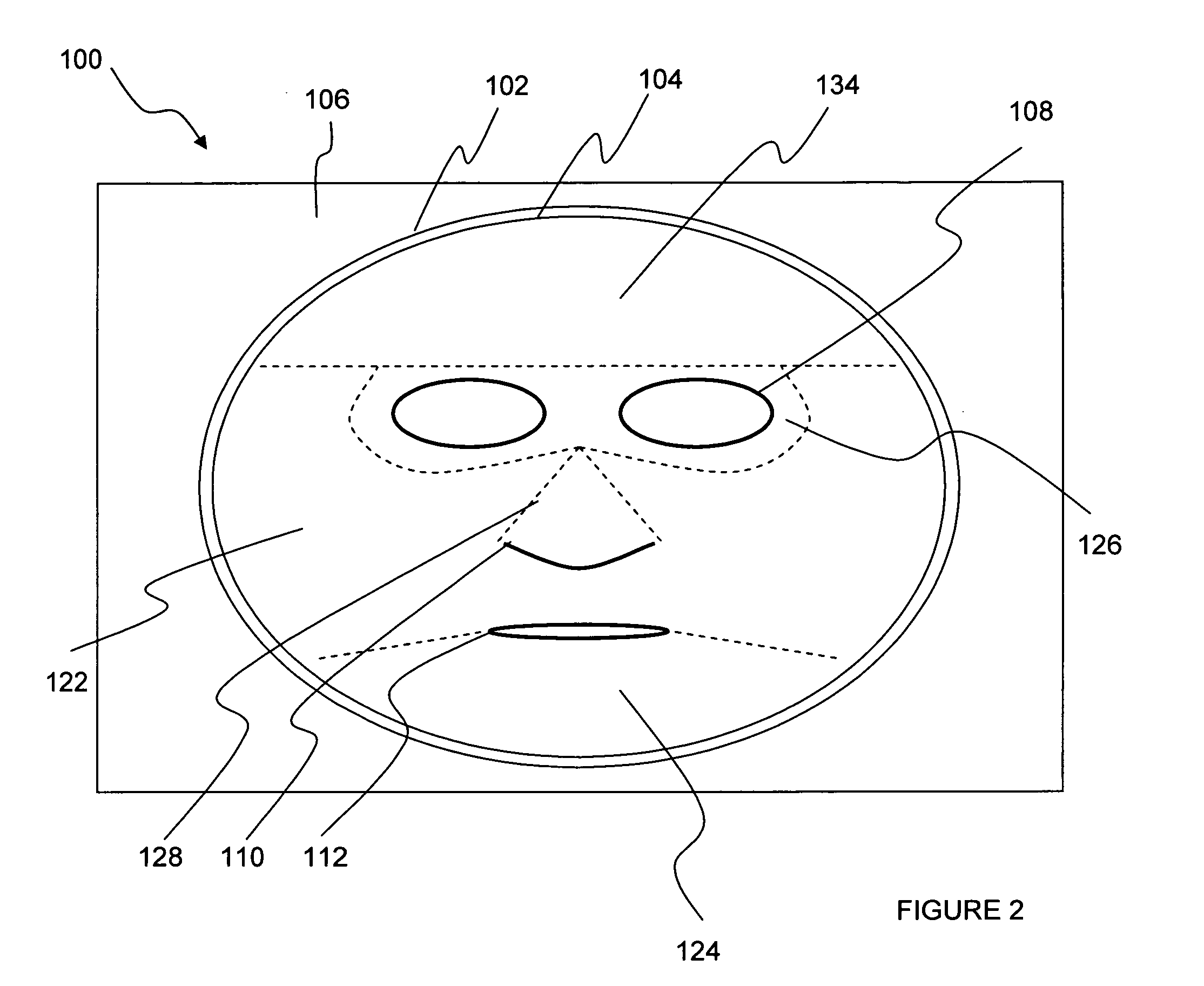

Temperature controlled facial mask with area-specific treatments

A temperature controlled cosmetic treatment facial mask with area-specific treatments of the present invention includes a substantially planar mask body which is formed with cut-outs for a person's eyes, nose, and mouth. The mask may include a number of large and small area treatment zones in combination with asymmetrical treatment zones suitable for treatment of specific and localized skin conditions. The treatments zones are coated with skin treatments, such as compounds, lotions, gels, and the like as are known in the facial treatment, cosmetics, spa and medical industry. The mask may include a self-heating or cooling substrate to provide temperature control to the face mask and each mask may include heating areas, cooling areas, or both. A system is also provided that includes an imaging device that feeds its output to a central computer system having an image analyzer, CPU, memory and Look Up Table, and face map for determining specific treatment requirements for the particular patient. An output from the central computer system is provided to a treatment deposition device which deposits various treatments onto an intermediate membrane layer to generate a custom temperature controlled facial mask with area-specific treatments for that particular patient.

Owner:FOREVER YOUNG INT

Process for manufacturing an integrated membrane of nozzles in MEMS technology for a spray device and spray device using such membrane

A process for manufacturing a membrane of nozzles of a spray device, comprising the steps of laying a substrate, forming a membrane layer on the substrate, forming a plurality of nozzles in the membrane layer, forming a plurality of supply channels in the substrate, each supply channel being substantially aligned in a vertical direction to a respective nozzle of the plurality of nozzles and in direct communication with the respective nozzle.

Owner:STMICROELECTRONICS SRL

Silicon microphone with impact proof structure

ActiveUS20080031476A1Avoid breakingPiezoelectric/electrostrictive microphonesTransducer detailsDielectric layerMechanical engineering

Improved impact proof capability of a silicon microphone sensing element is achieved with a stopper element that limits the maximum vibration of moveable parts. The stopper has a lower anchor portion and upper finger portion that is elevated a certain distance above the diaphragm and overhangs the outer edges of the perforated plates. The stopper is formed on a stack consisting of a lower substrate, a middle dielectric layer, and an upper membrane layer. There is a back hole in the substrate and an air gap in the dielectric layer to allow sound to impinge on the diaphragm. The number of fingers and composition of the stopper is variable. Optionally, the stopper has a center support design and is formed on a center anchor within an opening in the diaphragm. An upper finger region overhangs the diaphragm near the center opening and thereby prevents breakage due to large vibrations

Owner:SHANDONG GETTOP ACOUSTIC

Method for manufacturing a fluid ejection device and fluid ejection device

A method for manufacturing a fluid ejection device, comprising the steps of: providing a first semiconductor body having a membrane layer and a piezoelectric actuator which extends over the membrane layer; forming a cavity underneath the membrane layer to form a suspended membrane; providing a second semiconductor body; making, in the second semiconductor body, an inlet through hole configured to form a supply channel of the fluid ejection device; providing a third semiconductor body; forming a recess in the third semiconductor body; forming an outlet channel through the third semiconductor body to form an ejection nozzle of the fluid ejection device; coupling the first semiconductor body with the third semiconductor body and the first semiconductor body with the second semiconductor body in such a way that the piezoelectric actuator is completely housed in the first recess, and the second recess forms an internal chamber of the fluid ejection device.

Owner:STMICROELECTRONICS INT NV

Flexible display device and manufacturing method of the same

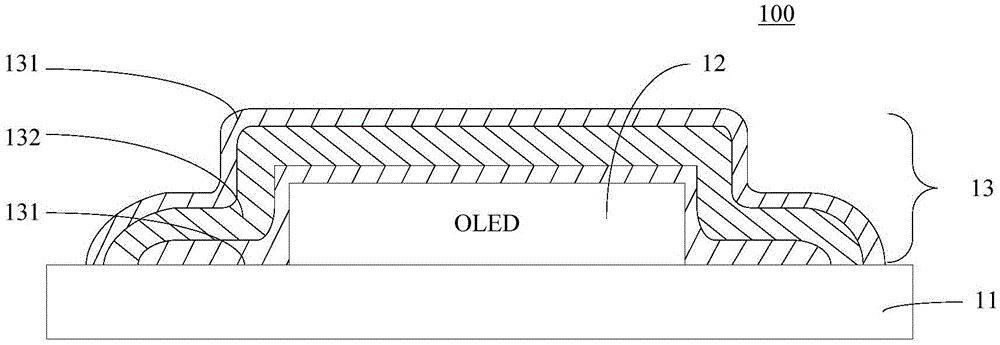

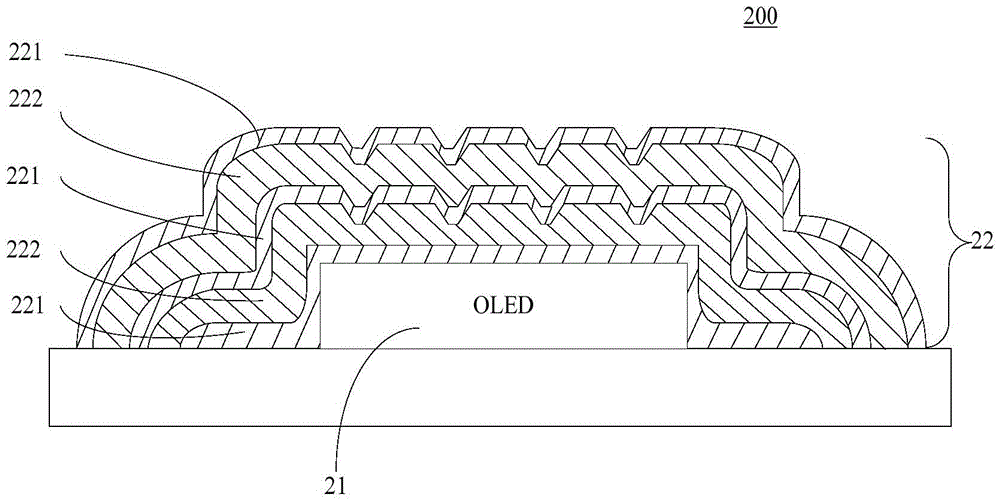

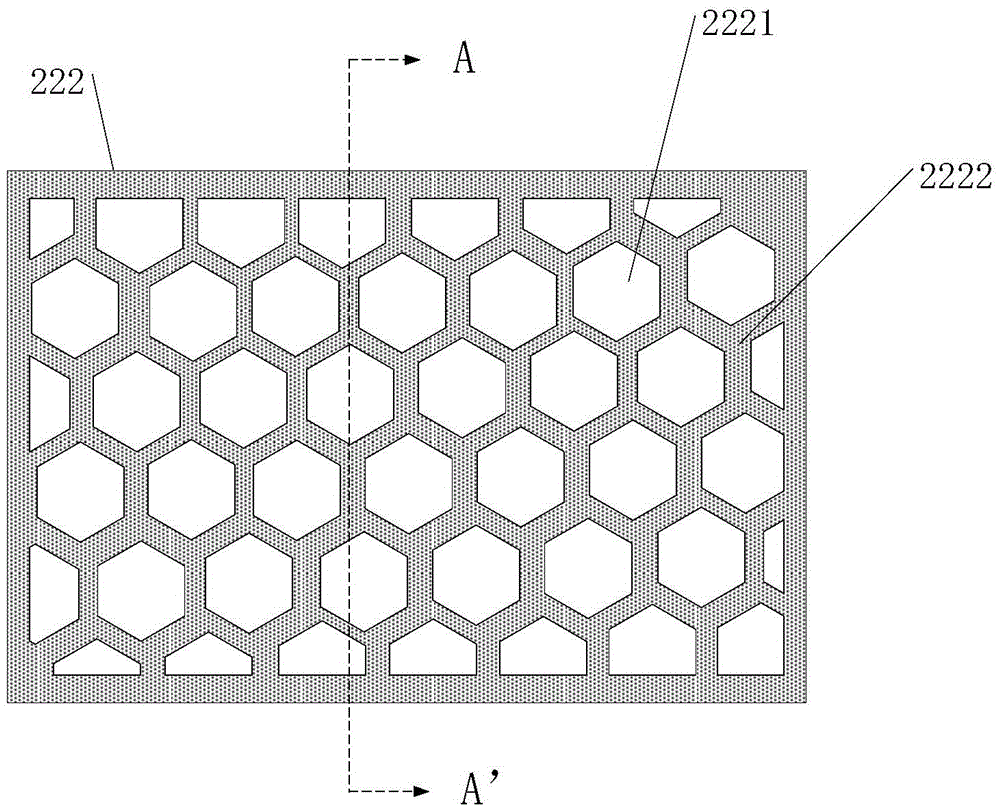

InactiveCN105552246AInhibition of fractureCrack suppressionSolid-state devicesSemiconductor/solid-state device manufacturingStress concentrationOxygen

The invention discloses a flexible display device and a manufacturing method of the same. A specific embodiment of the flexible display device includes a luminescent device and a packaging layer used for packaging the luminescent device, the packaging layer includes at least one organic membrane layer and at least one inorganic membrane layer which are superposed, wherein the organic membrane layer includes a plurality of pattern units and non-pattern units used for separating the plurality of the pattern units, the thickness of the pattern units and that of the non-pattern units are not the same, and the inorganic membrane layers cover the pattern units and the non-pattern units. According to the flexible display device provided by the invention, the organic membrane layers are divided into the pattern units and the non-pattern units, and the thickness of the pattern units and that of the non-pattern units are different, thereby enabling the inorganic membrane layers uniformly covering the organic membrane layers to become uneven. Thus water steam and oxygen can be prevented from immerging into the luminescent device, and cracks of the inorganic membrane layers generated due to stress concentration can also be prevented.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

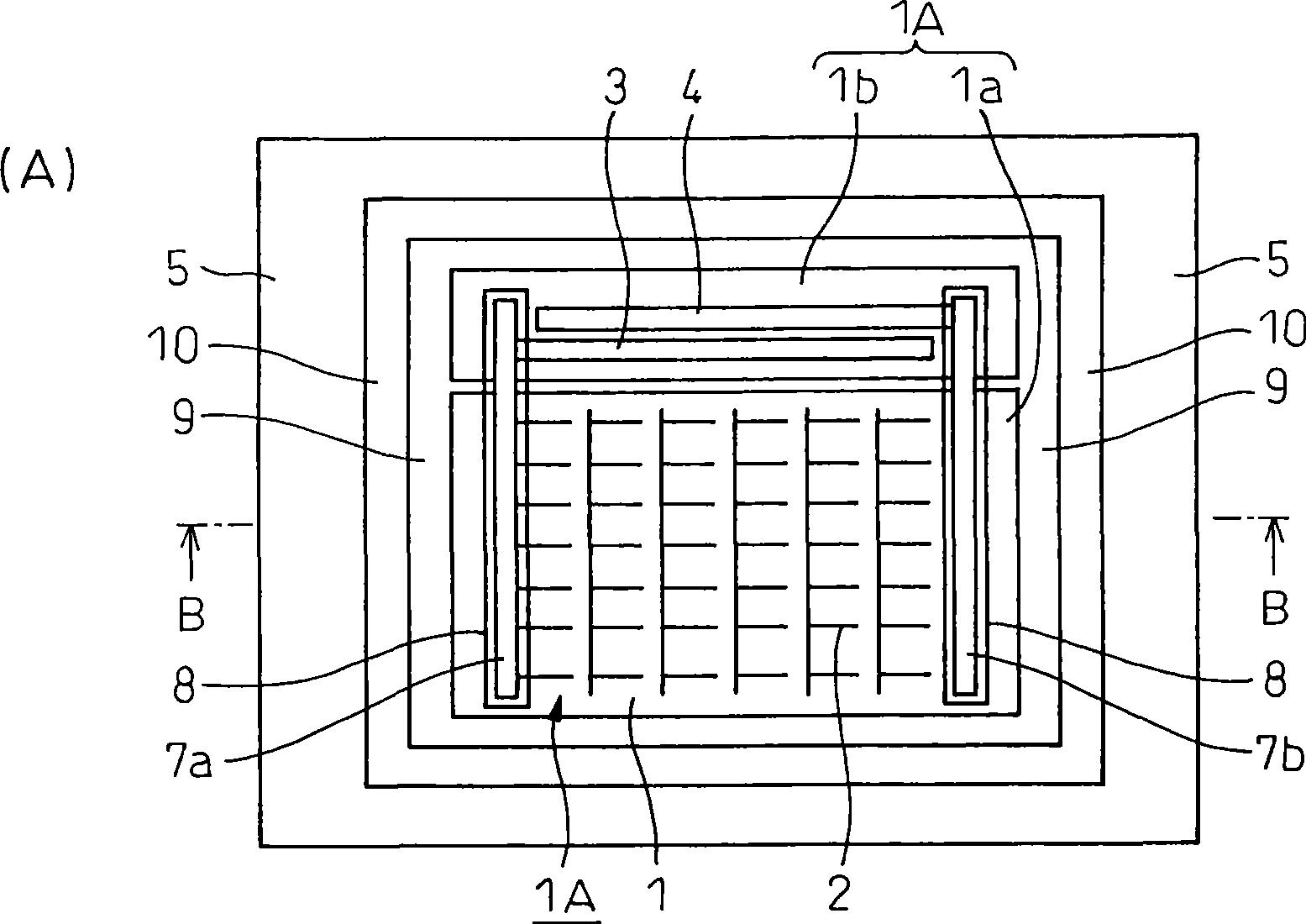

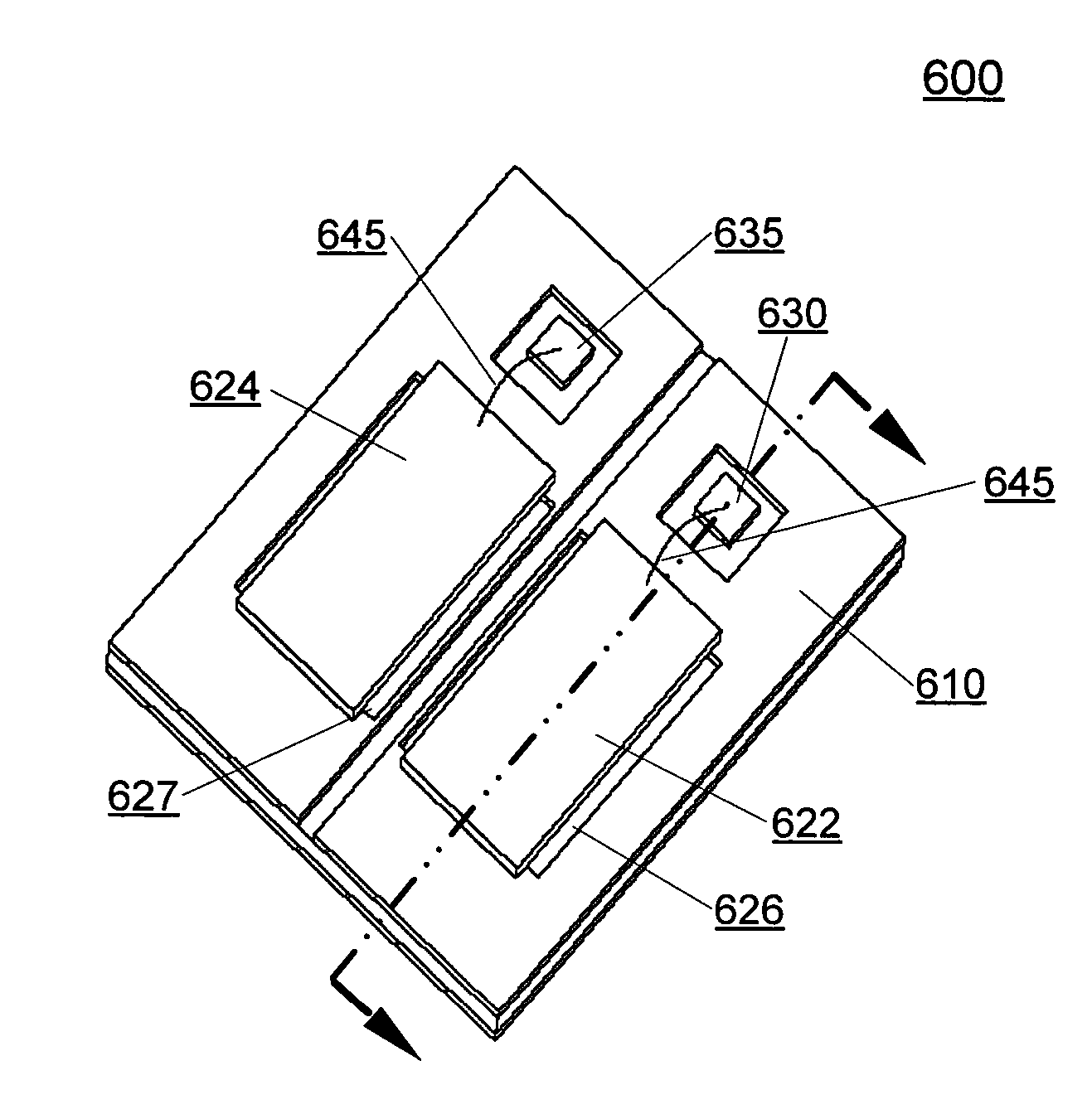

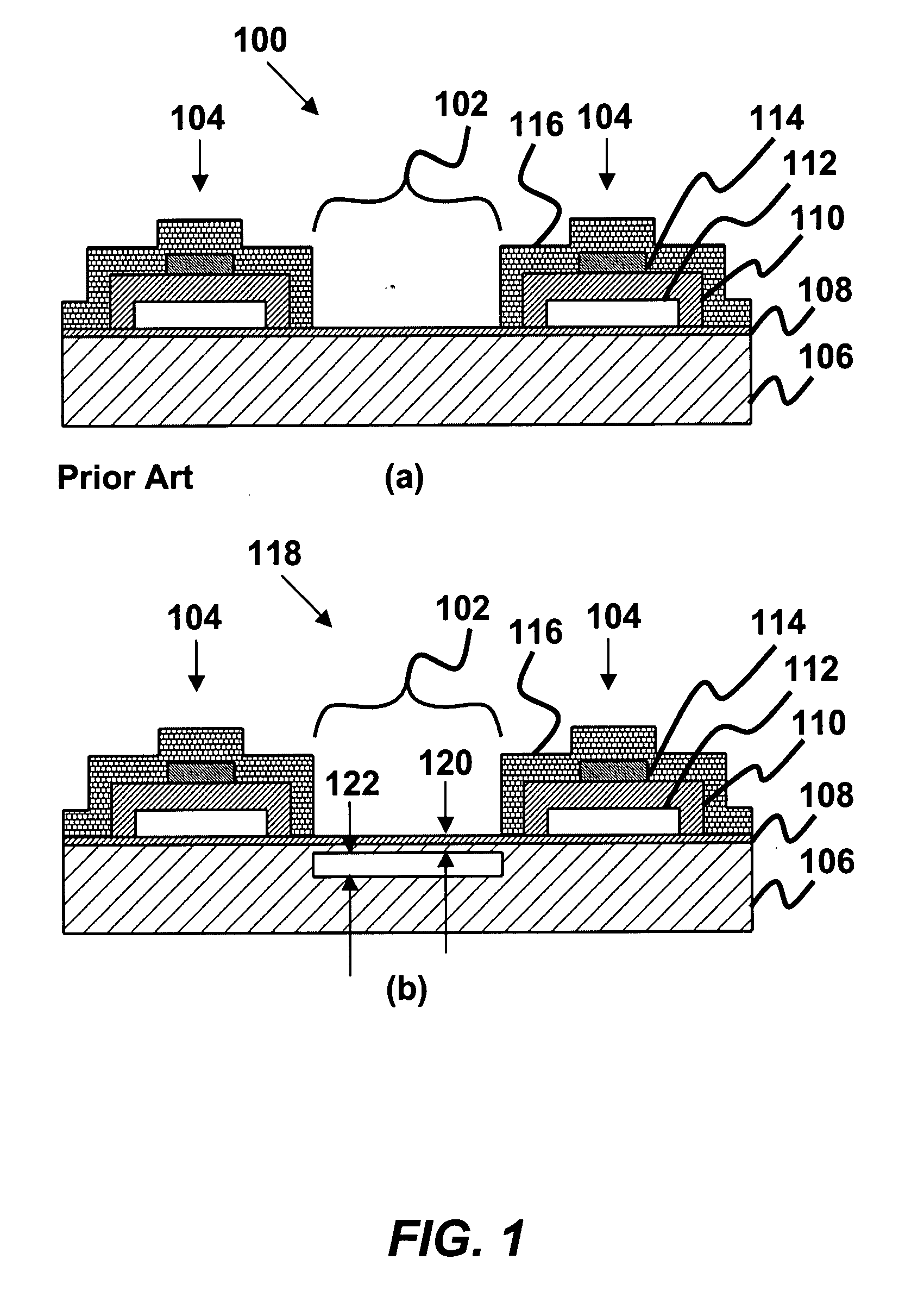

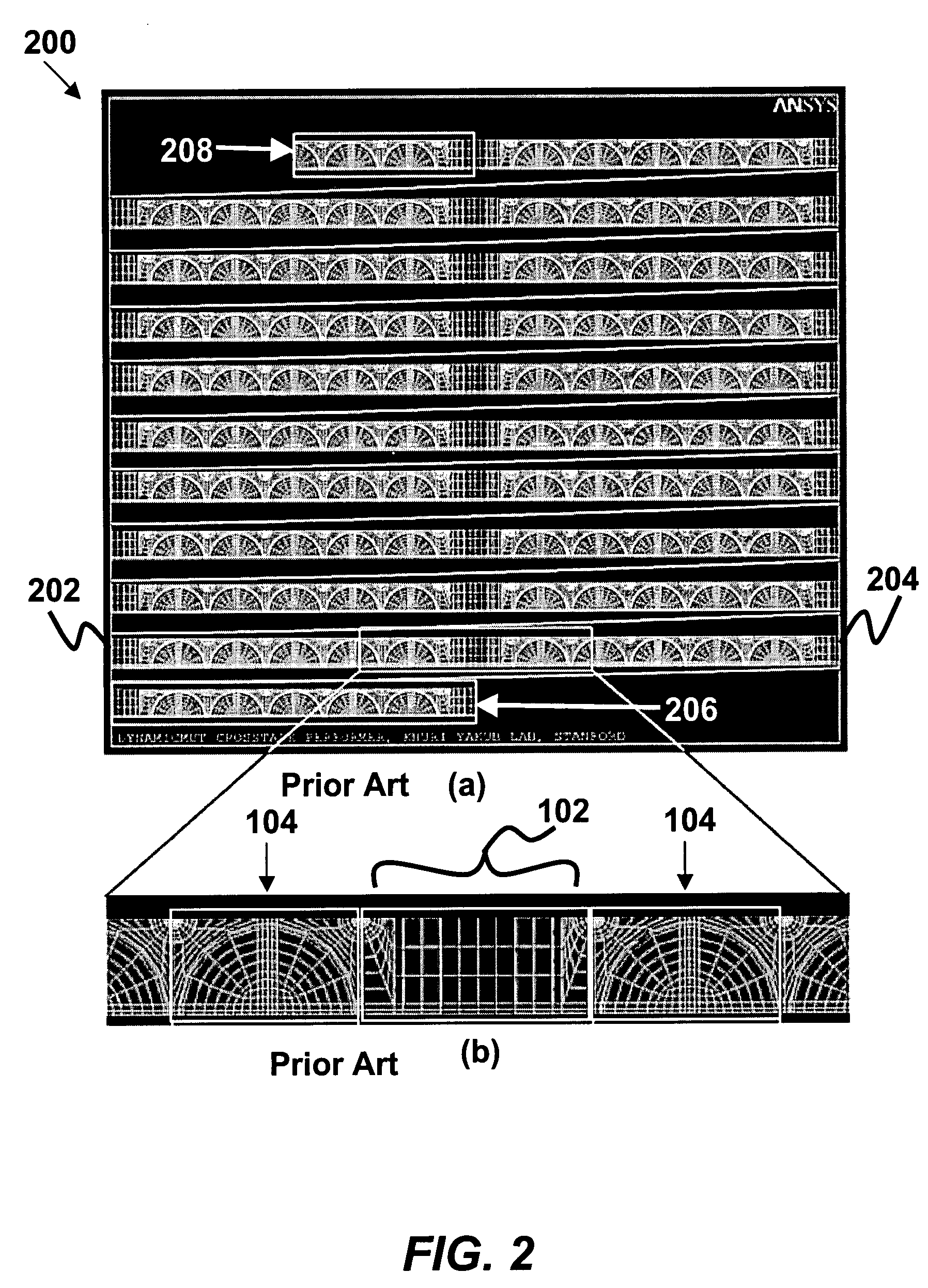

Acoustic crosstalk reduction for capacitive micromachined ultrasonic transducers in immersion

ActiveUS20080259725A1Reduce capacityReduce crosstalkPiezoelectric/electrostriction/magnetostriction machinesMechanical vibrations separationCapacitanceInsulation layer

A reduced crosstalk capacitive micromachined ultrasonic transducer (CMUT) array is provided. The CMUT array has at least two CMUT array elements deposited on a substrate, at least one CMUT cell in the array element, a separation region between adjacent CMUT array elements, and a membrane formed in the separation region. The membrane reduces crosstalk between adjacent array elements, where the crosstalk is a dispersive guided mode of an ultrasonic signal from the CMUT propagating in a fluid-solid interface of the CMUT array. Each cell has an insulation layer deposited to the substrate. A cell membrane layer is deposited to the insulation layer, where the cell membrane layer has a vacuum gap therein. The cells further have an electrode layer deposited to a portion of the membrane layer, and a passivation layer deposited to the electrode layer, the cell membrane layer and to the insulation layer.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

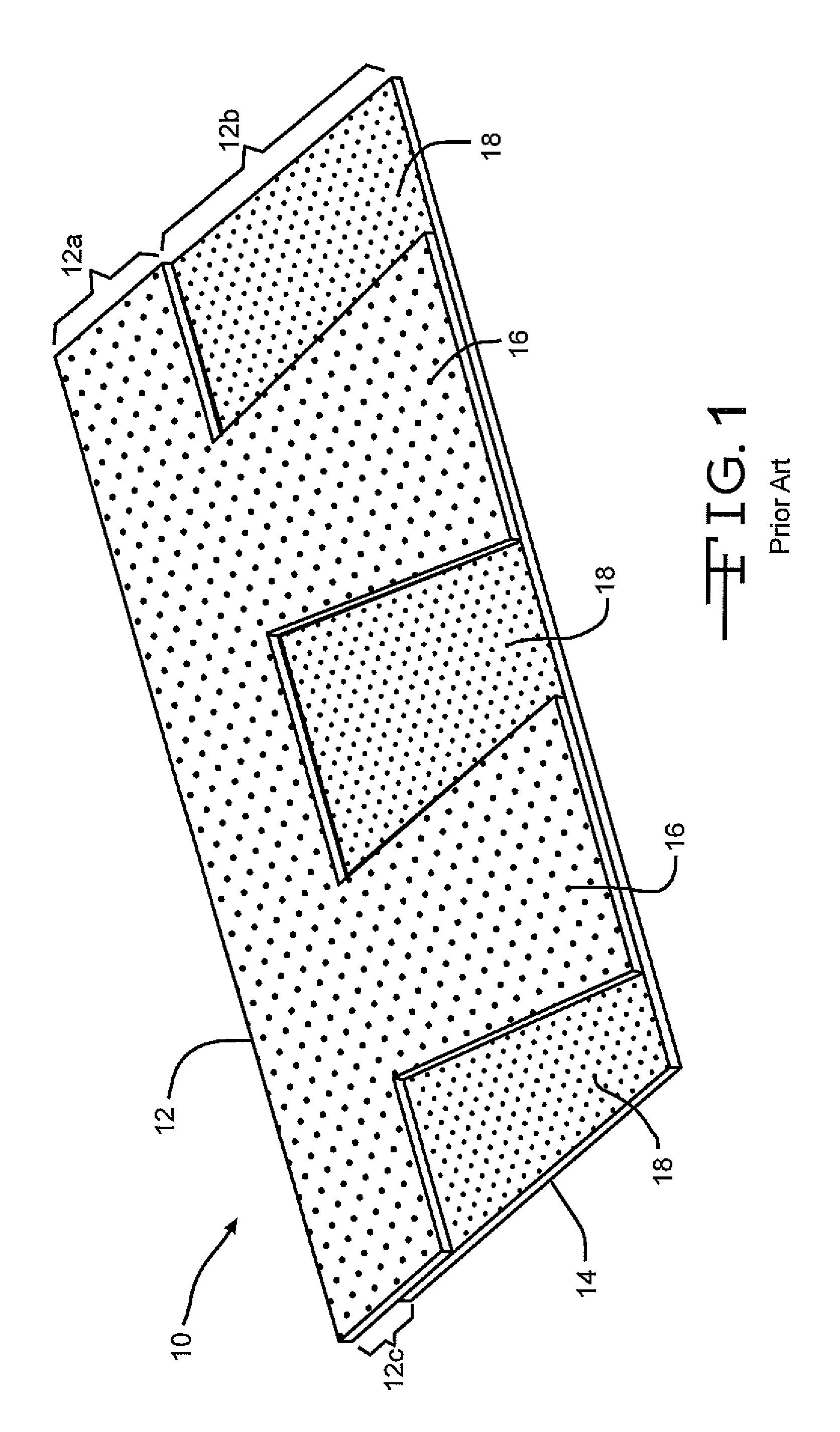

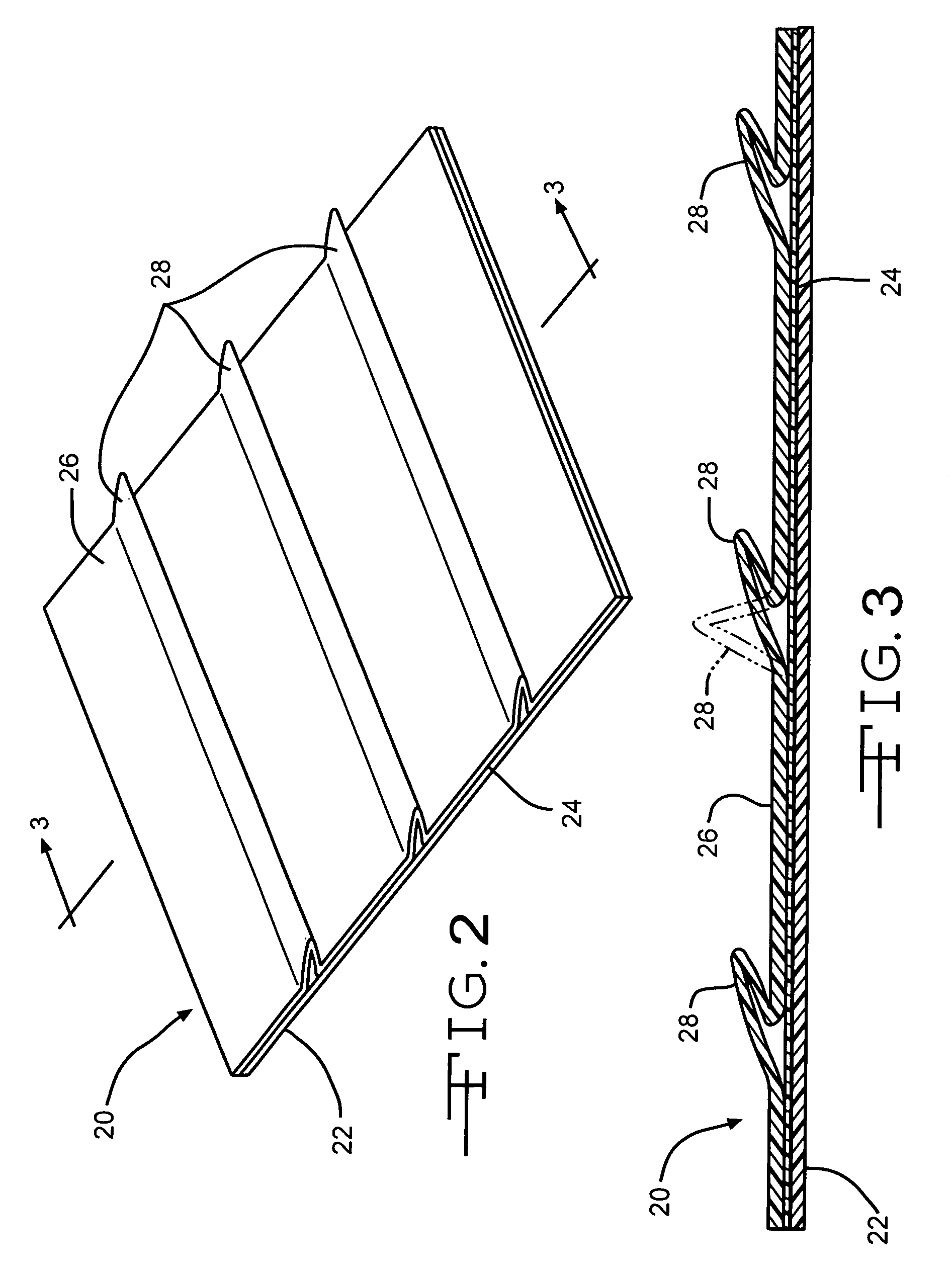

Pleated roofing membrane and roofing shingle system

This invention relates to an underlayment for use under a plurality of courses of roofing shingles. The underlayment includes a water impermeable membrane layer containing at least one flap extending horizontally across the membrane layer. The flap is movable between a flat position and a raised position. In the raised position, an upper edge of a roofing shingle can be positioned under the flap. The upper edge of the roofing shingle can then be subsequently overlapped by the flap when the flap is moved into the flat position. The flap can then subsequently be overlapped by another course of roofing shingles.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

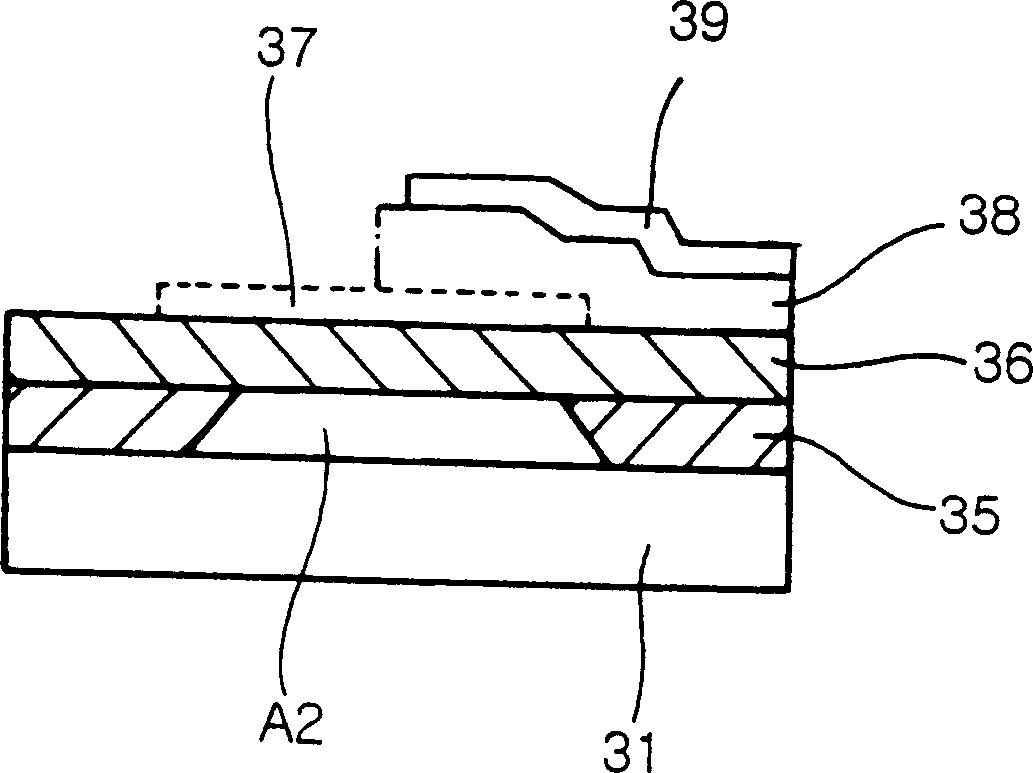

Film bulk acoustic resonator and method of forming the same

InactiveCN1450719ALow insertion lossPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksThin-film bulk acoustic resonatorStructural Problem

A film bulk acoustic resonator (FBAR) includes an insulation layer on a substrate to prevent a signal from being transmitted to a substrate. The FBAR includes a portion of a membrane layer corresponding to an activation area to adjust a resonance frequency band and improve a transmission gain of the resonance frequency band, the portion of the membrane layer being partially etched to have a thickness less than the other portion of the membrane layer. A method of forming the FBAR includes forming an sacrificing layer made of polysilicon, forming an air gap using a dry etching process, and forming a via hole. The method prevents structural problems occurred in a conventional air gap forming process and provides locations and the number of the via holes to be controlled.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com