Process for manufacturing an integrated membrane of nozzles in MEMS technology for a spray device and spray device using such membrane

a manufacturing process and spray device technology, applied in metal-working devices, microelectromechanical systems, coatings, etc., can solve the problems of not enabling a high reproducibility of nozzles and a particularly complex manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

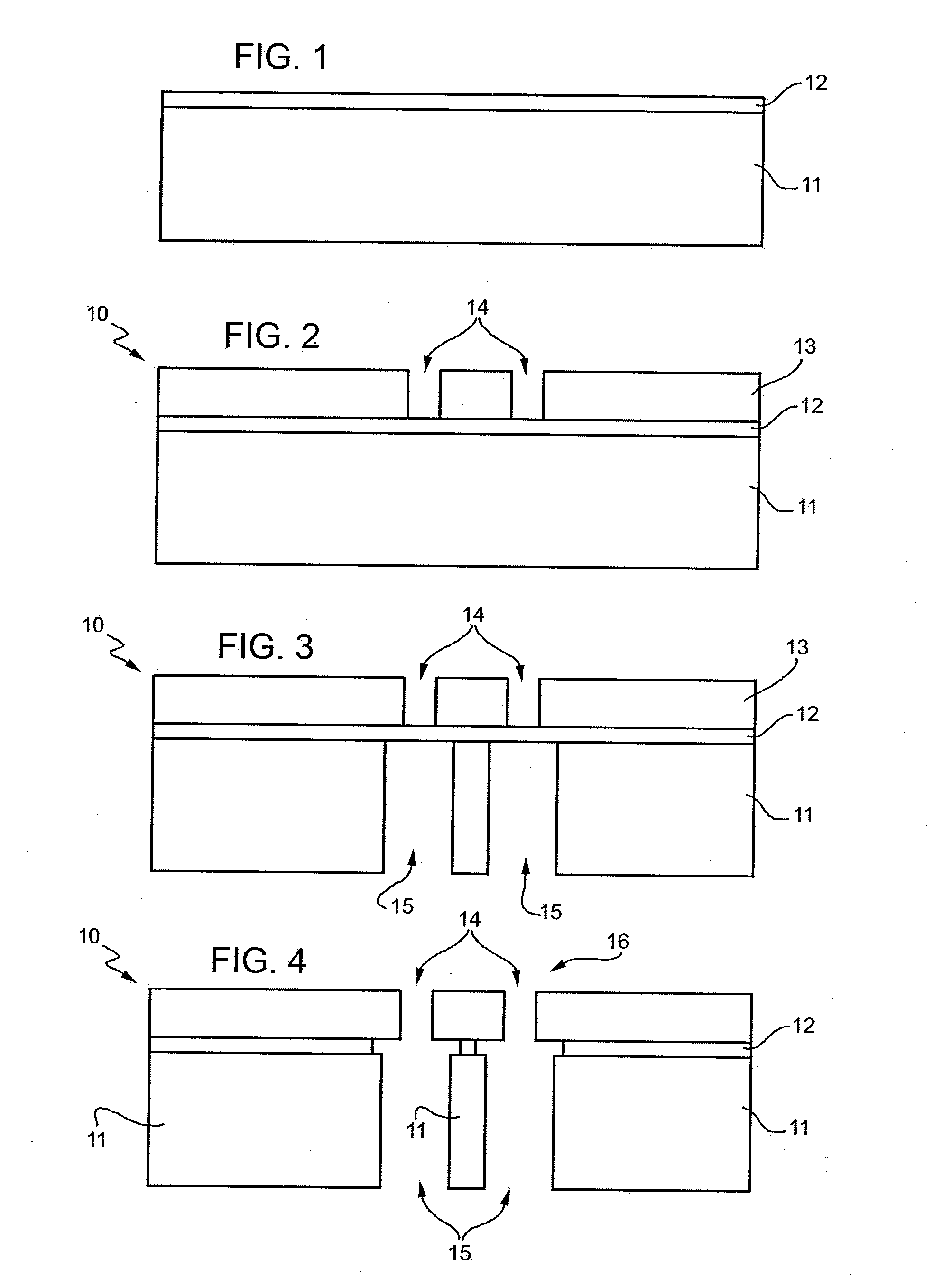

[0019]As is shown in FIG. 1, according to one embodiment of the present disclosure, a wafer 10 is provided, comprising a substrate 11 made, for example, of silicon of an N type having a thickness of between 400 μm and 725 μm, preferably 400 μm. A sacrificial layer 12 is then laid, made, for example, of silicon oxide, which has a thickness of between 0.6 μm and 1.5 μm, preferably 0.8 μm.

[0020]Next (FIG. 2), grown on the wafer 10 is a membrane layer 13, preferably made of non-doped polysilicon. Alternatively, the membrane layer 13 may be made of deposited material, compatible with silicon processing technology (e.g., deposited polysilicon). Providing a membrane layer 13 made of grown or deposited material (thus differing from the substrate in either material and / or crystalline structure) has the advantage that the choice of the material to be used may be tuned according to the particular application of the membrane layer 13. In fact, by varying the material of the membrane layer 13, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com