Patents

Literature

453267results about How to "Reduce manufacturing cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

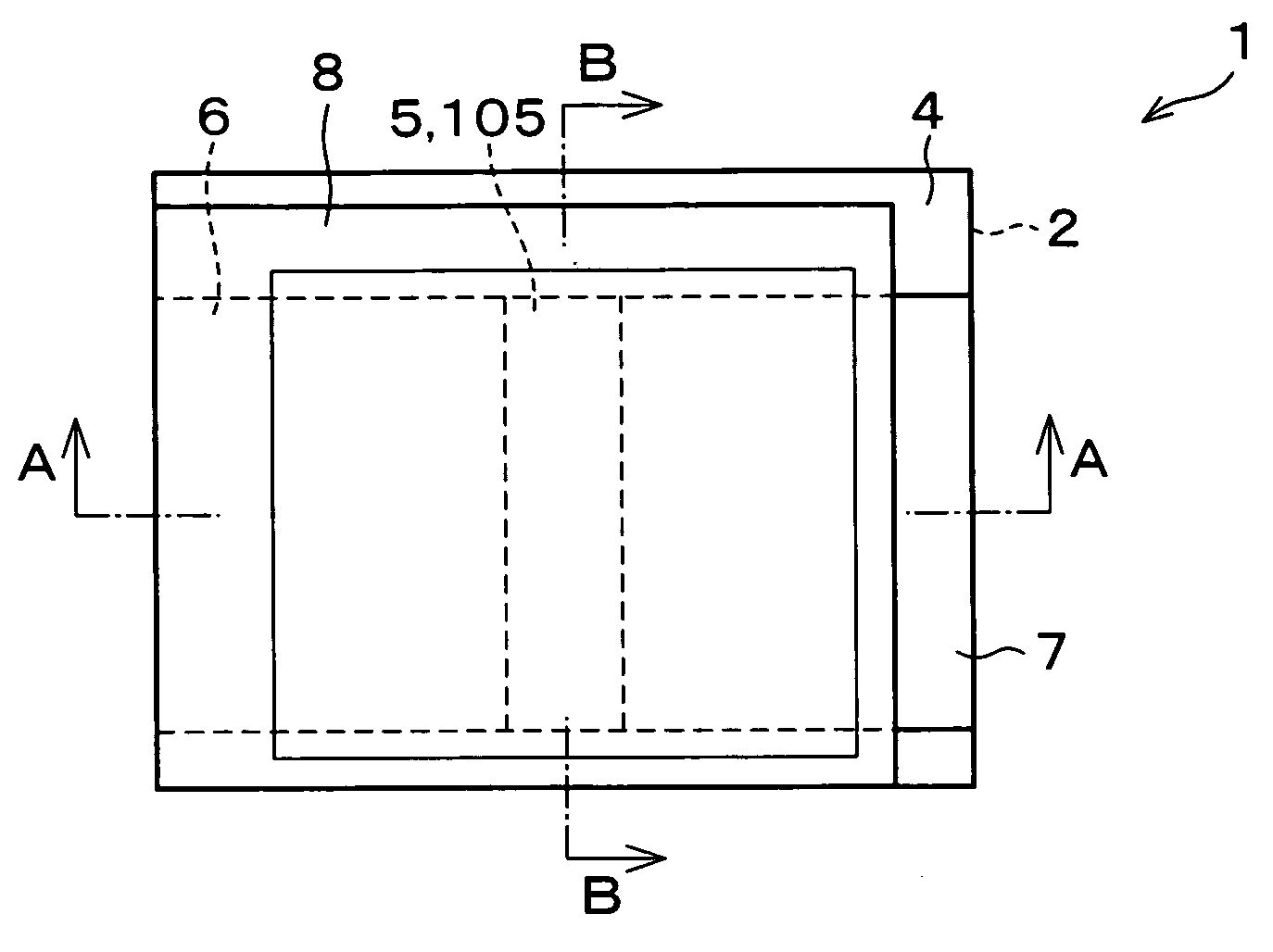

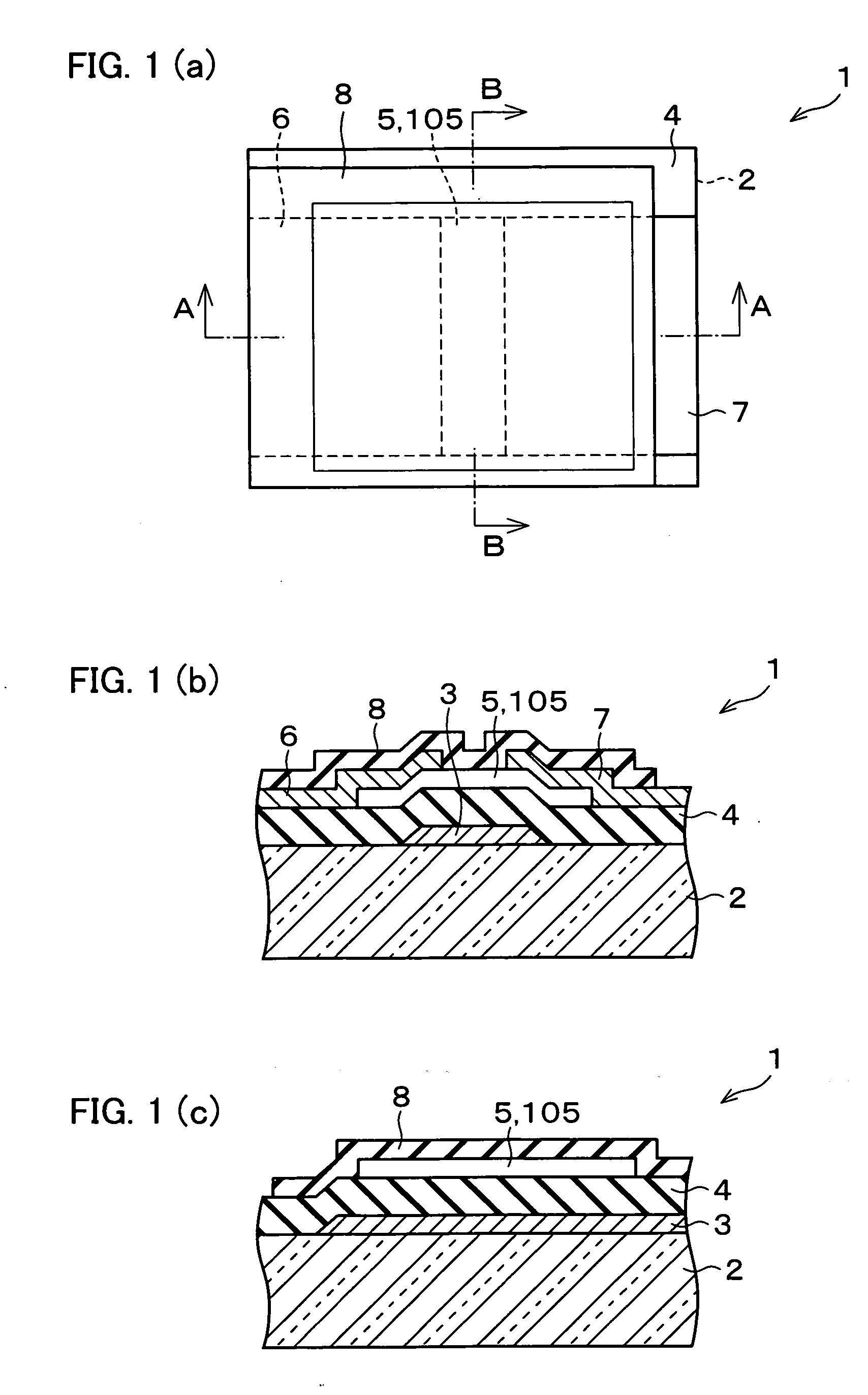

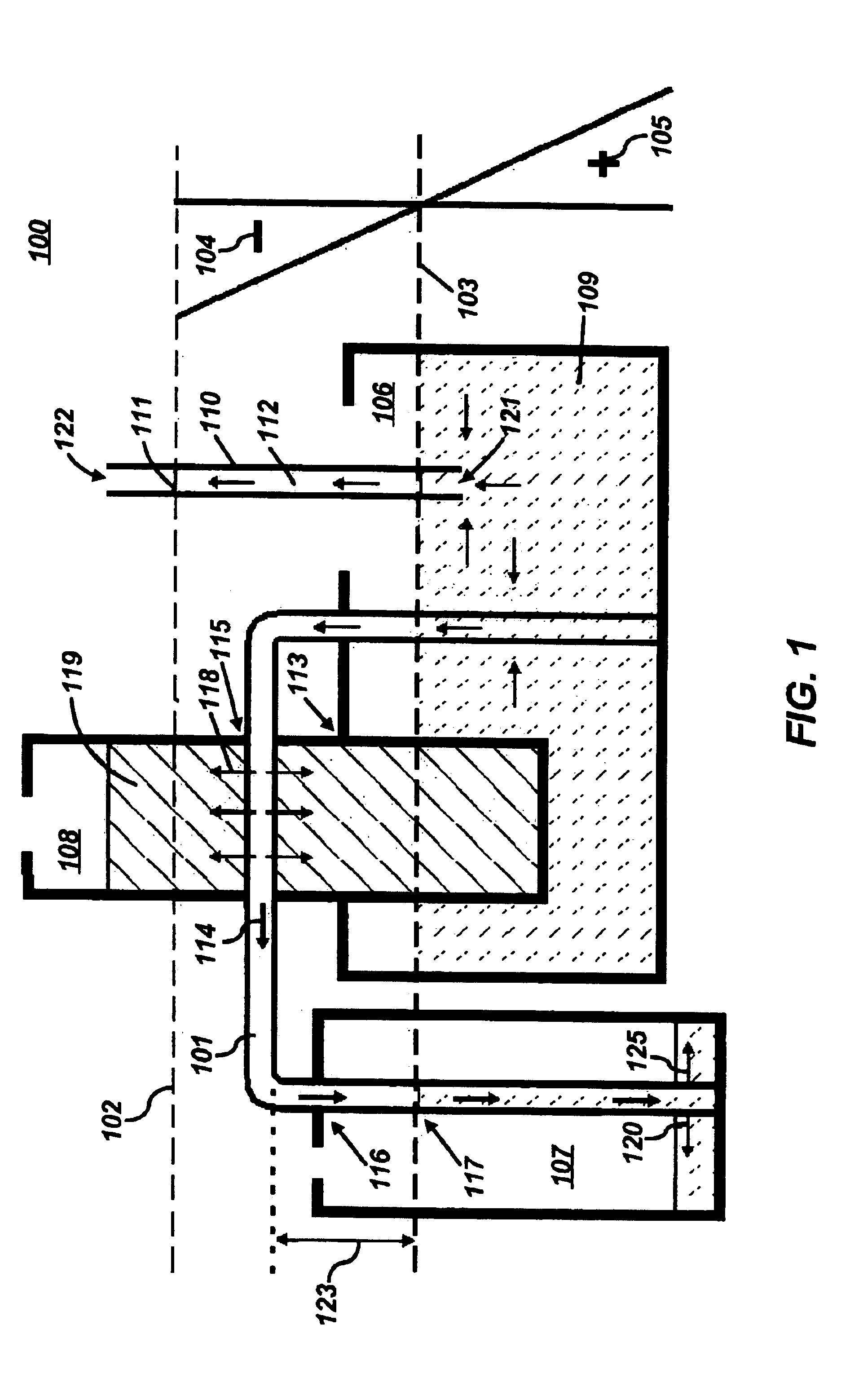

Semiconductor device, manufacturing method, and electronic device

ActiveUS20060244107A1Stabilize element propertyEasy to manufactureTransistorSemiconductor/solid-state device detailsSurface levelIntrinsic resistance

In a thin film transistor (1), a gate insulating layer (4) is formed on a gate electrode (3) formed on an insulating substrate (2). Formed on the gate insulating layer (4) is a semiconductor layer (5). Formed on the semiconductor layer (5) are a source electrode (6) and a drain electrode (7). A protective layer (8) covers them, so that the semiconductor layer (5) is blocked from an atmosphere. The semiconductor layer (5) (active layer) is made of, e.g., a semiconductor containing polycrystalline ZnO to which, e.g., a group V element is added. The protective layer (8) thus formed causes decrease of a surface level of the semiconductor layer (5). This eliminates a depletion layer spreading therewithin. Accordingly, the ZnO becomes an n-type semiconductor indicating an intrinsic resistance, with the result that too many free electrons are generated. However, the added element works on the ZnO as an accepter impurity, so that the free electrons are reduced. This decreases a gate voltage required for removal of the free electrons, so that the threshold voltage of the thin film transistor (1) becomes on the order of 0V. This allows practical use of a semiconductor device which has an active layer made of zinc oxide and which includes an protective layer for blocking the active layer from an atmosphere.

Owner:SHARP KK +2

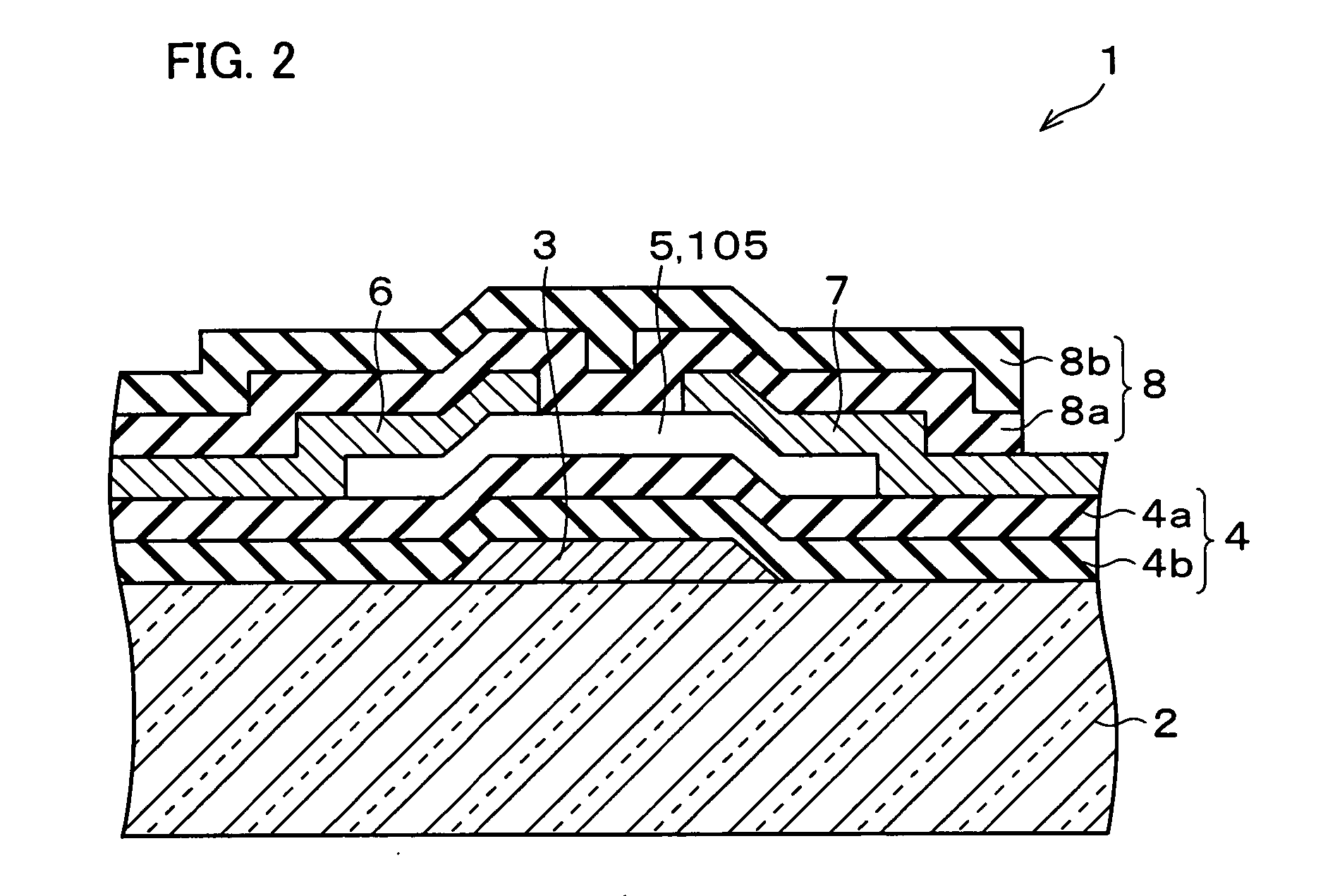

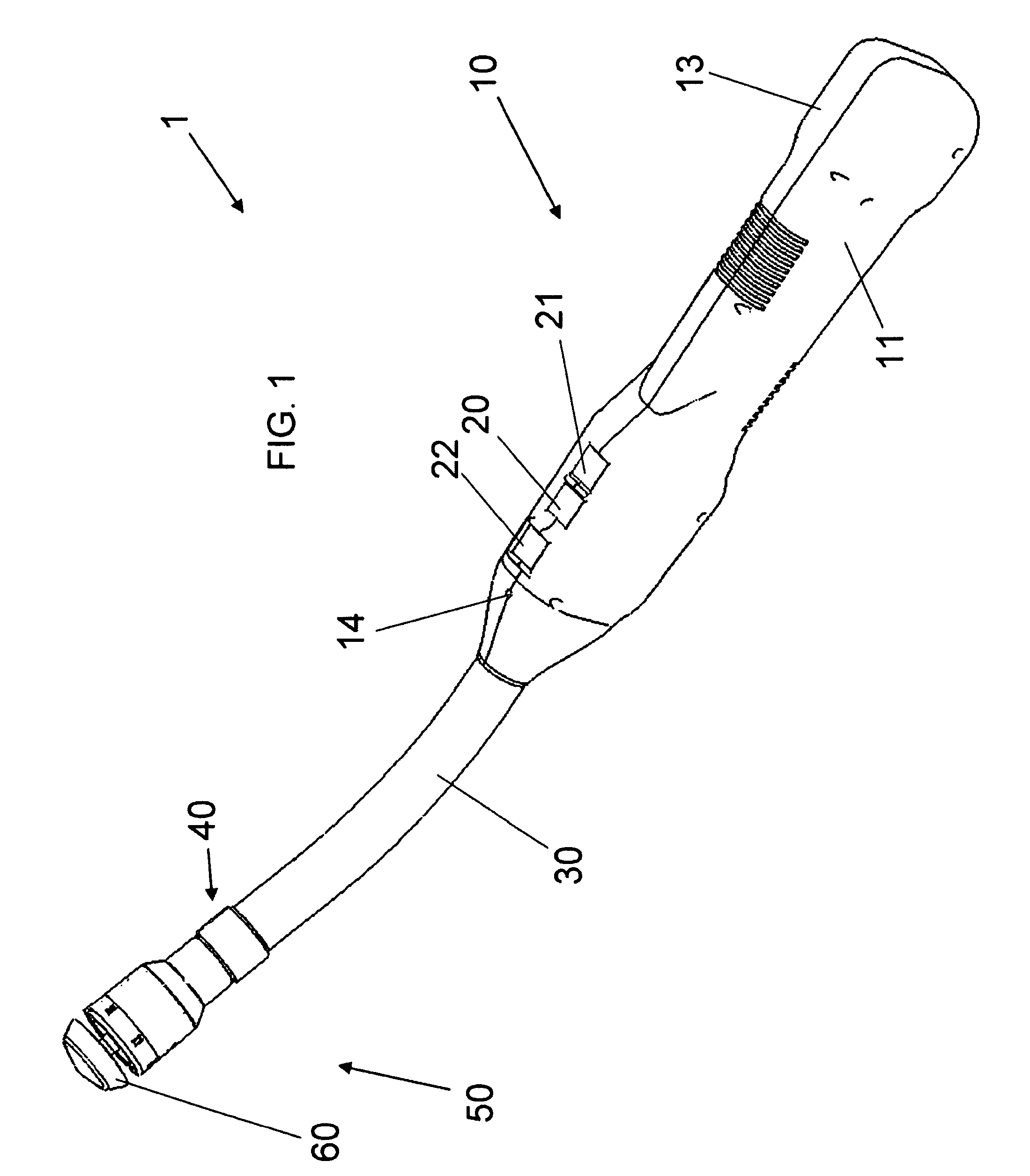

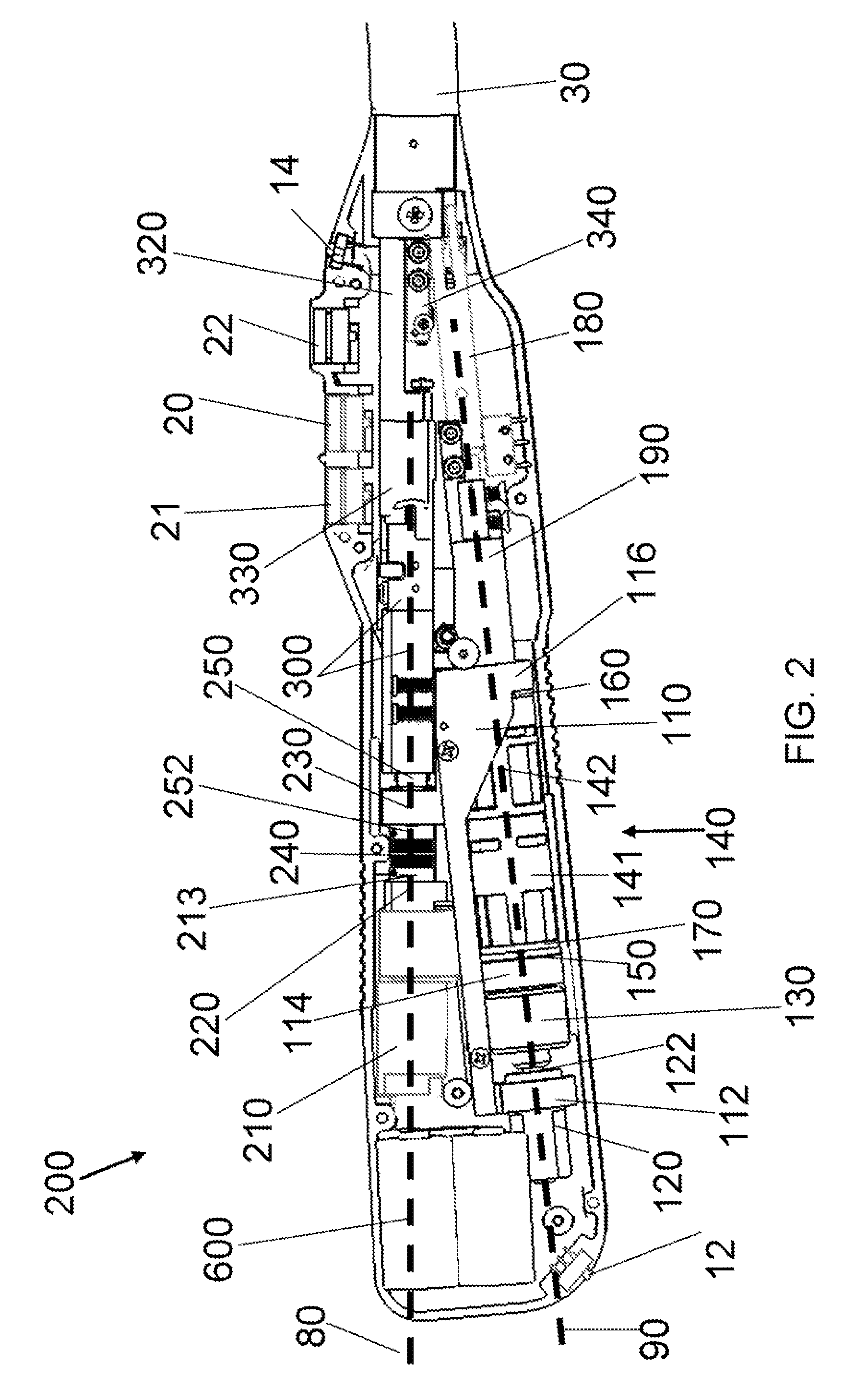

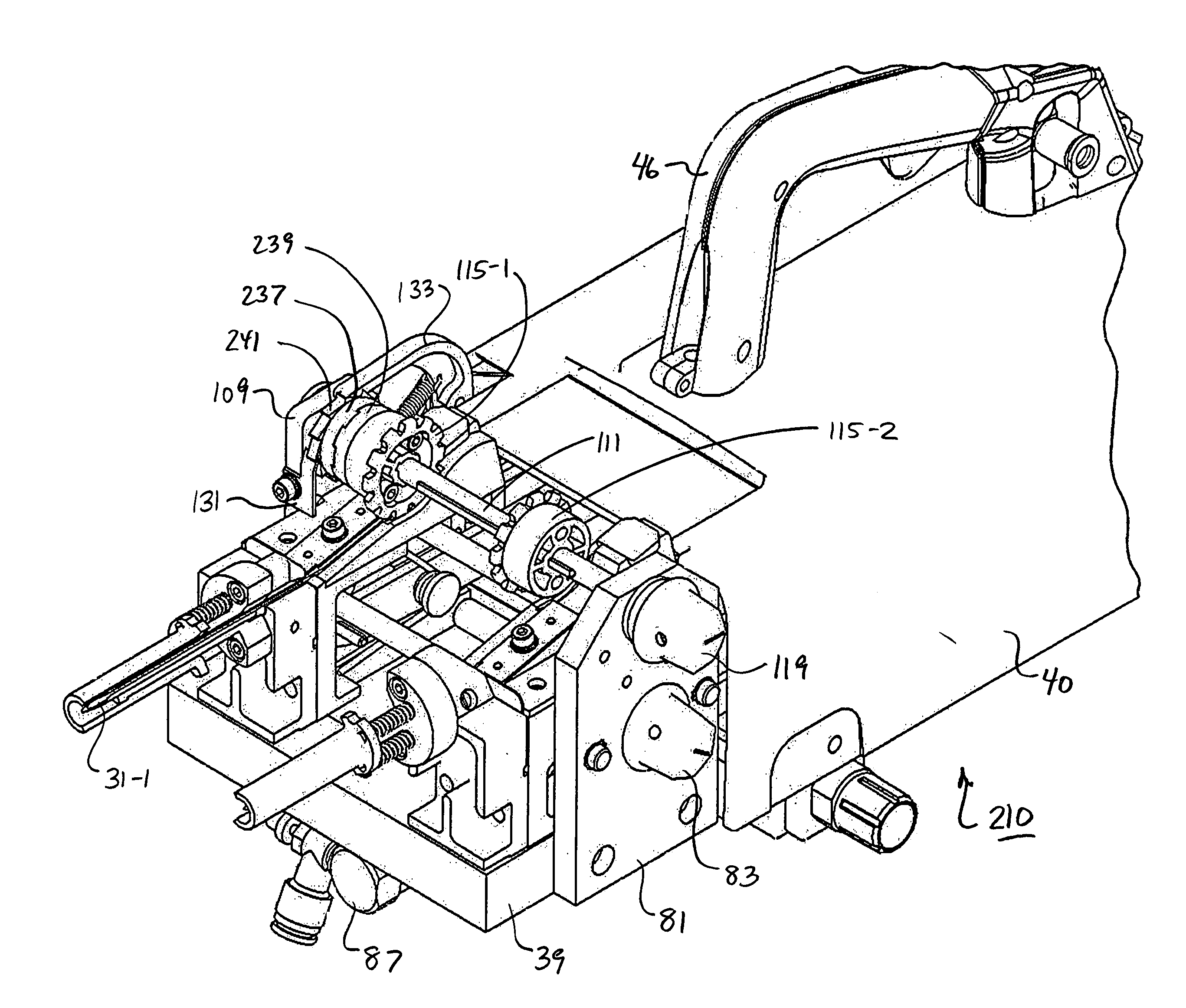

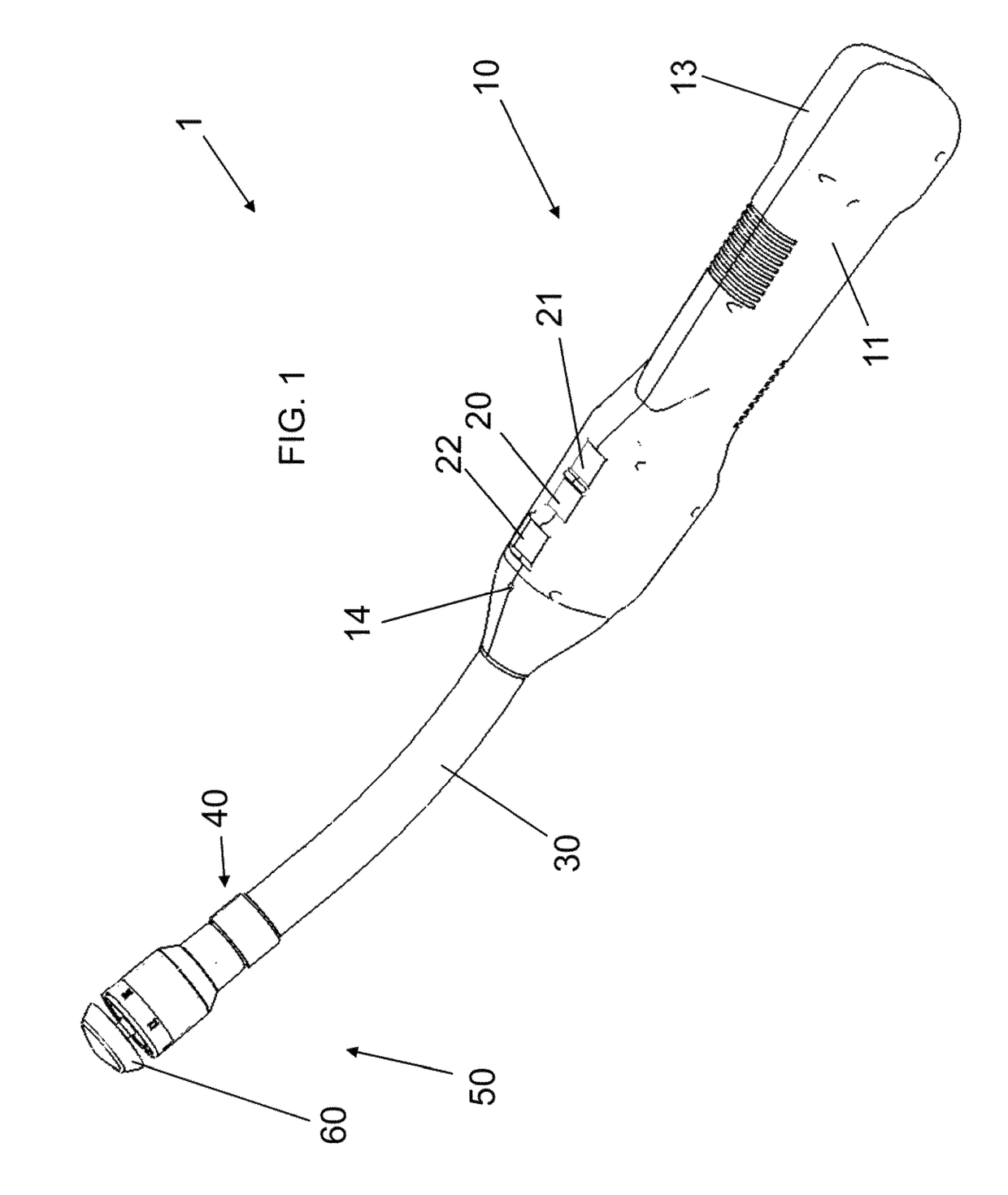

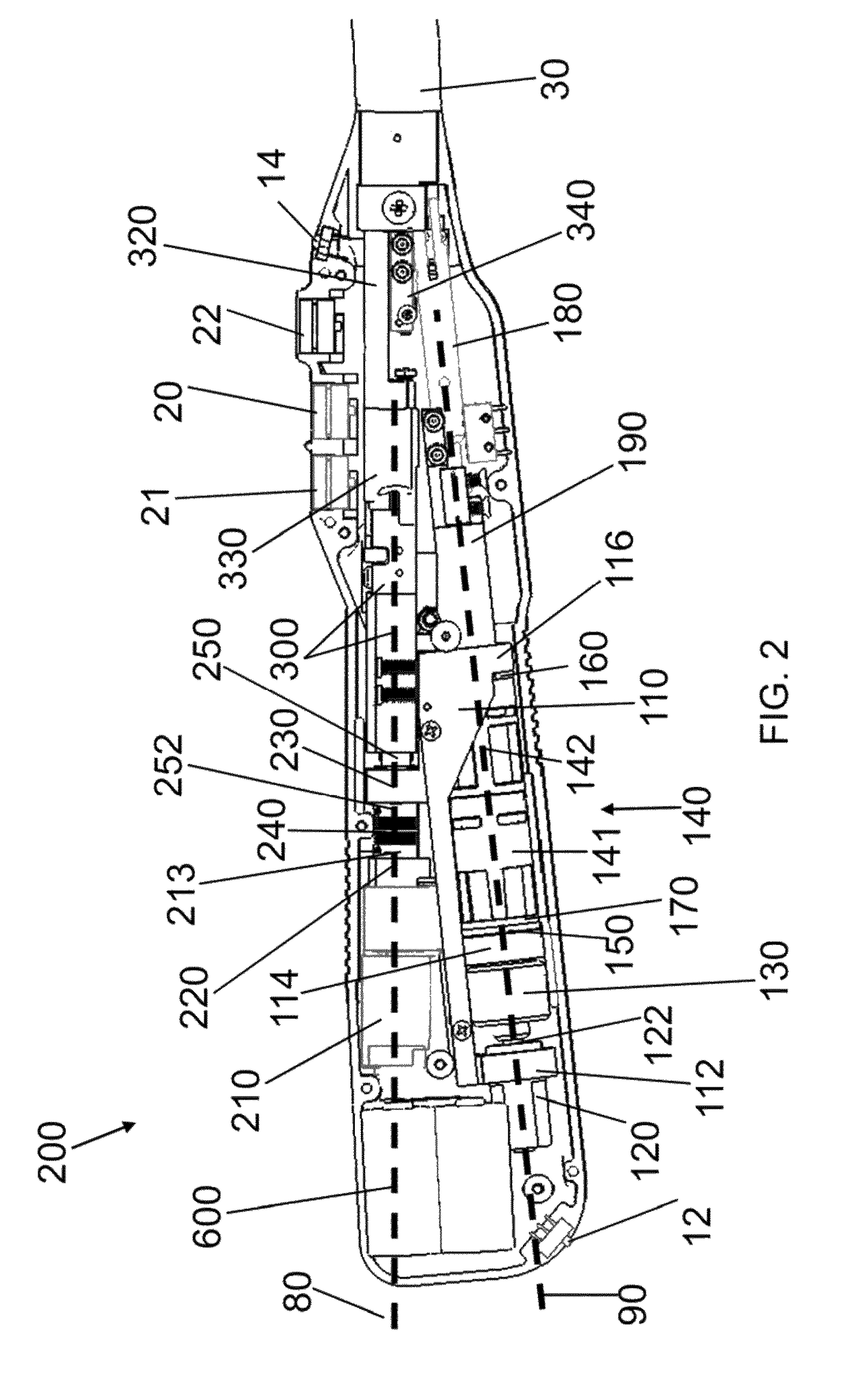

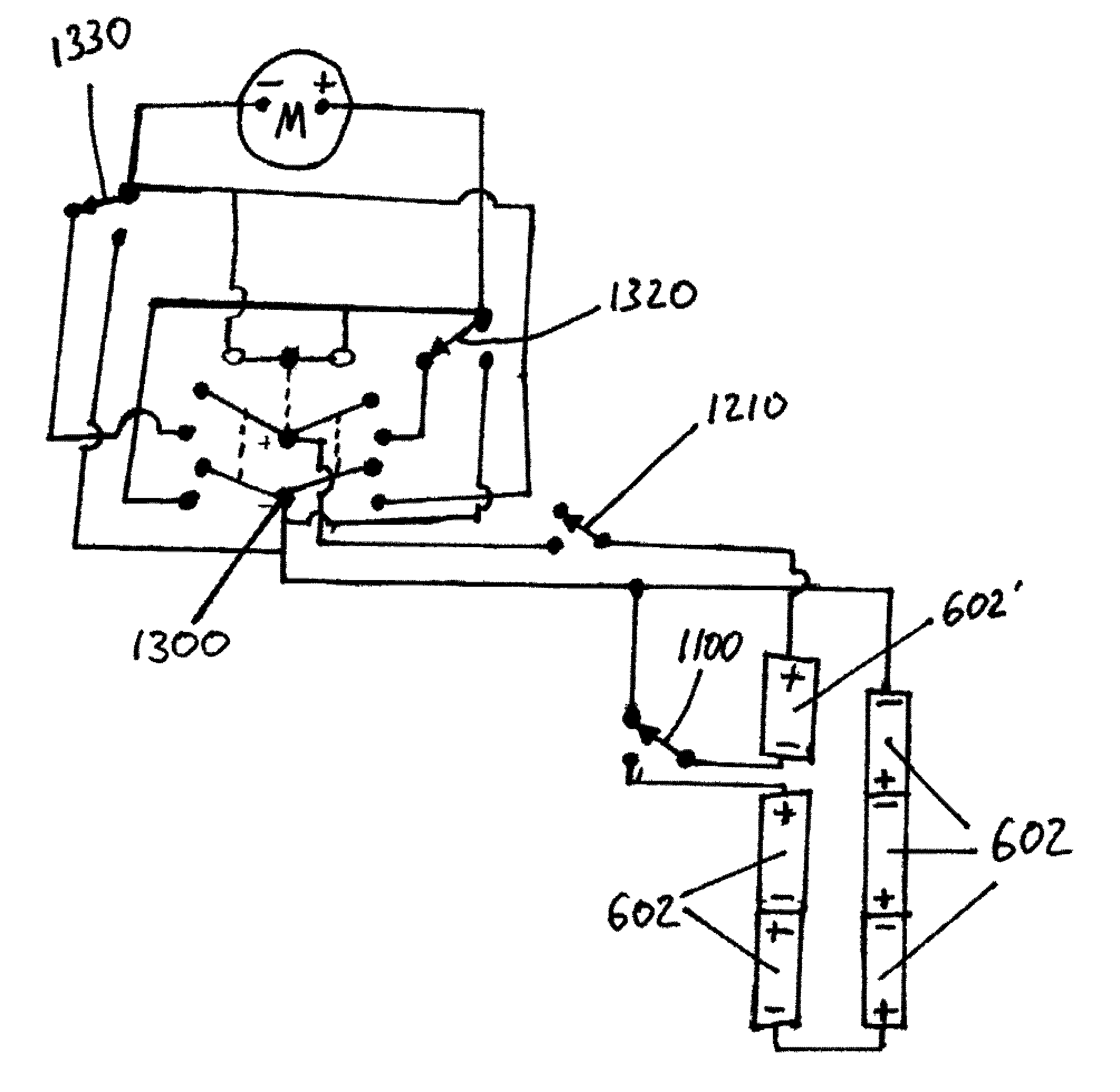

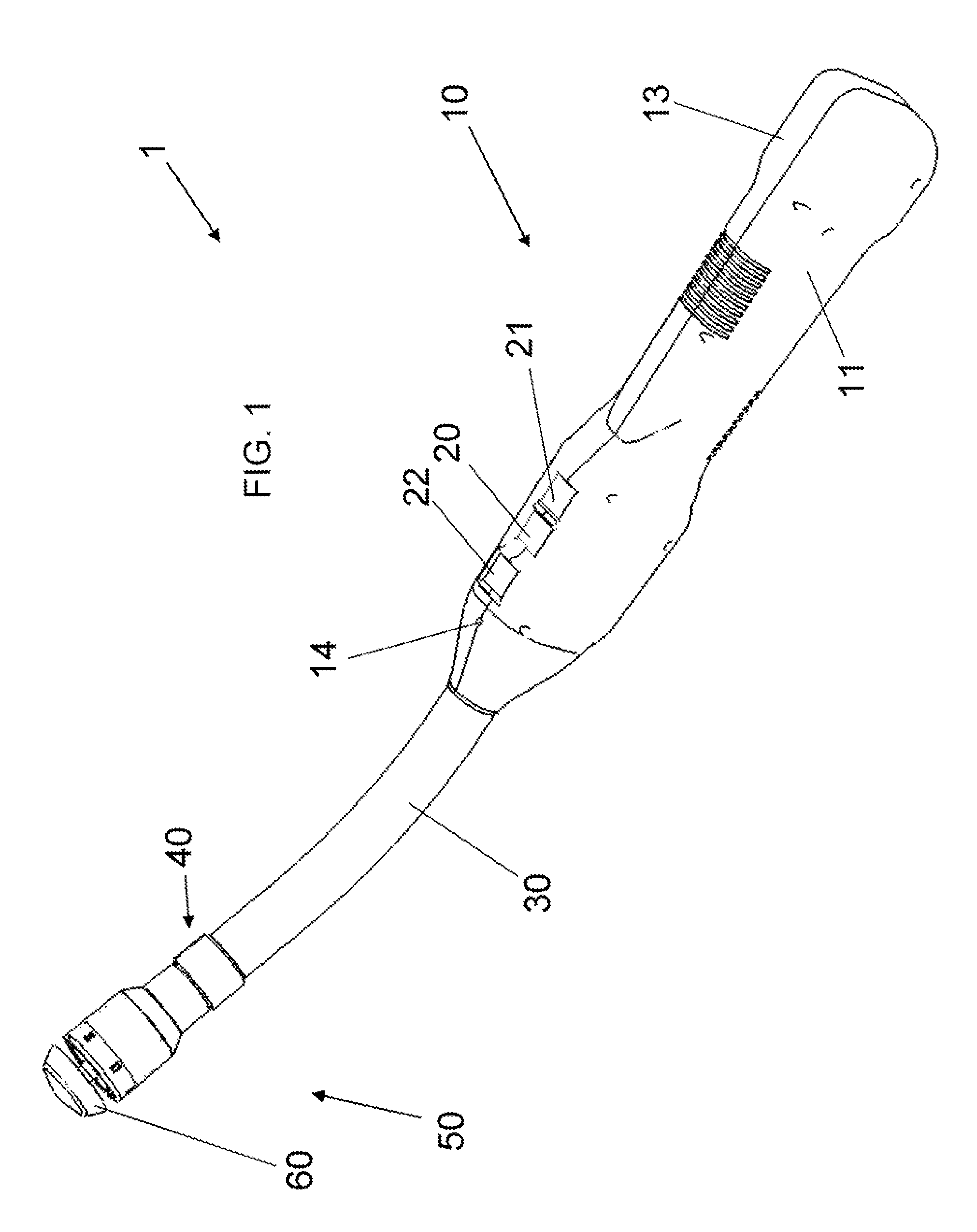

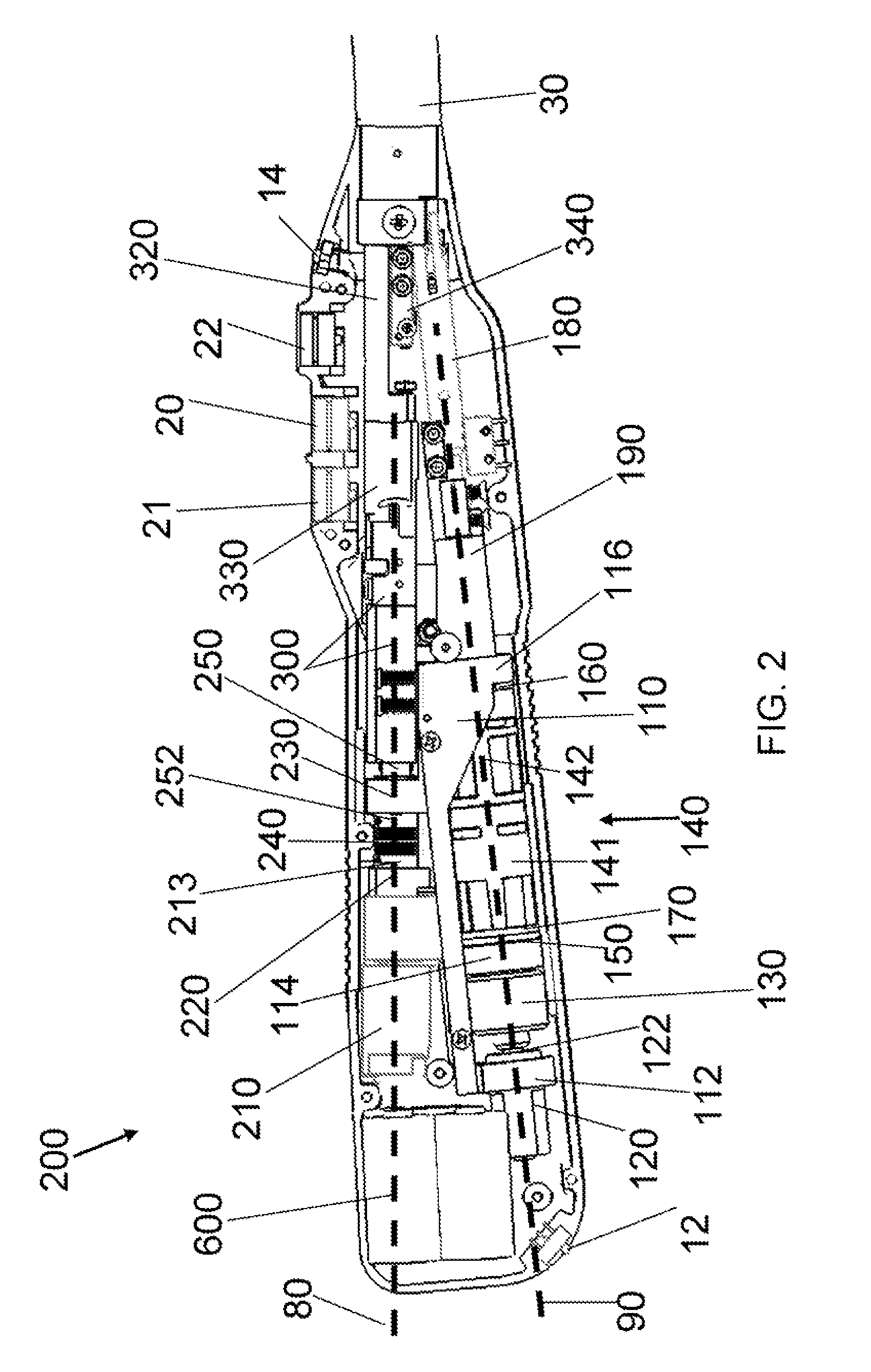

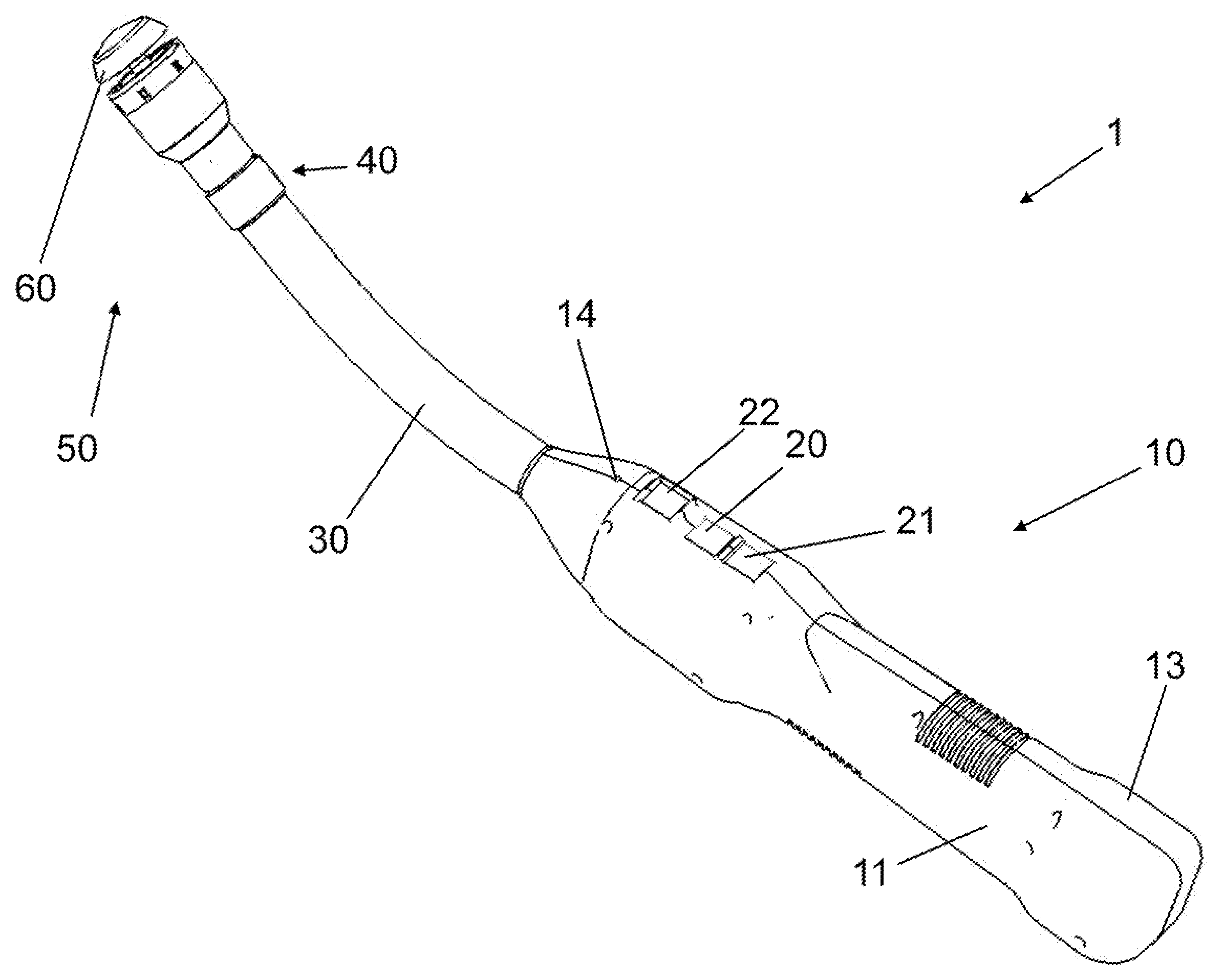

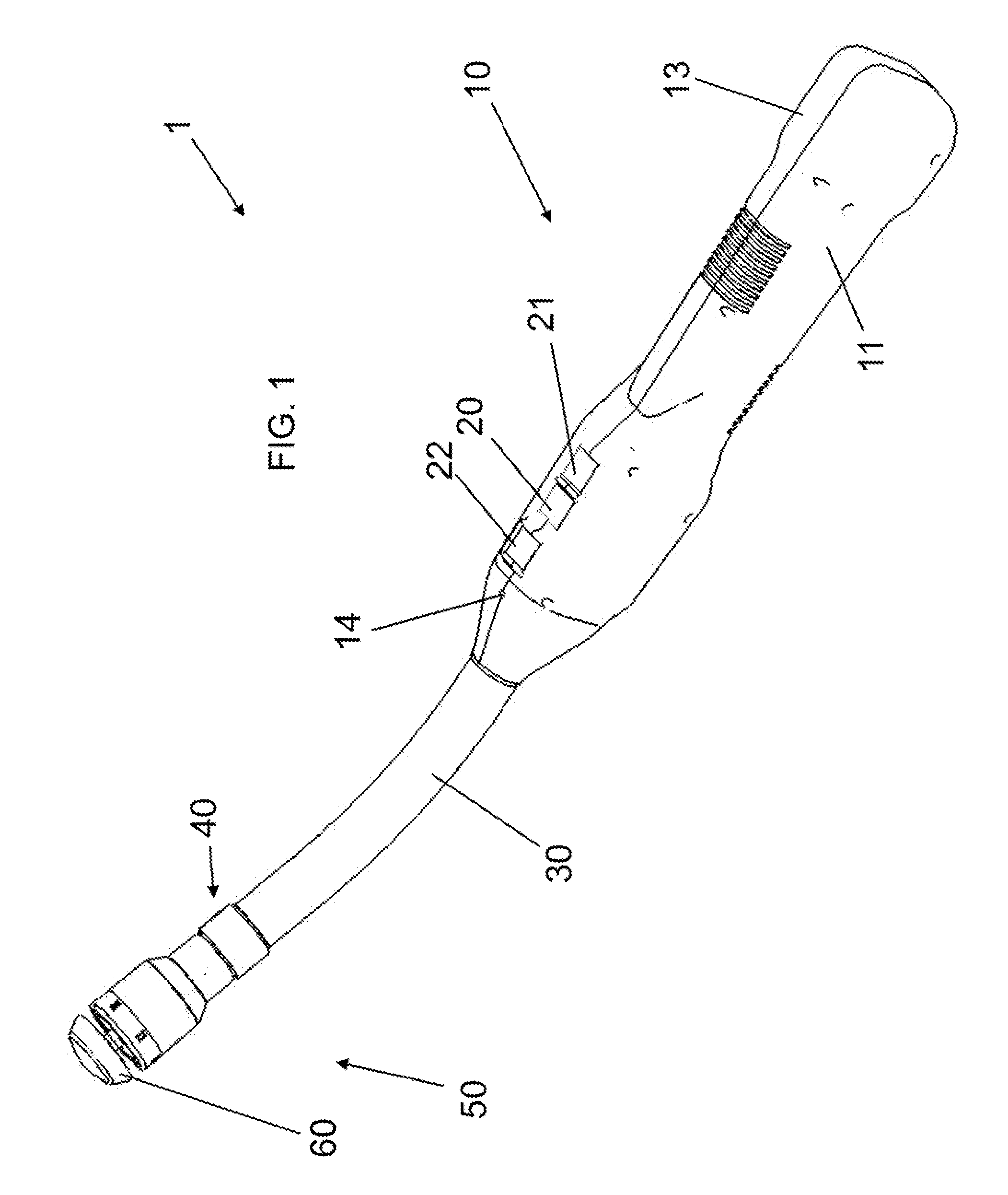

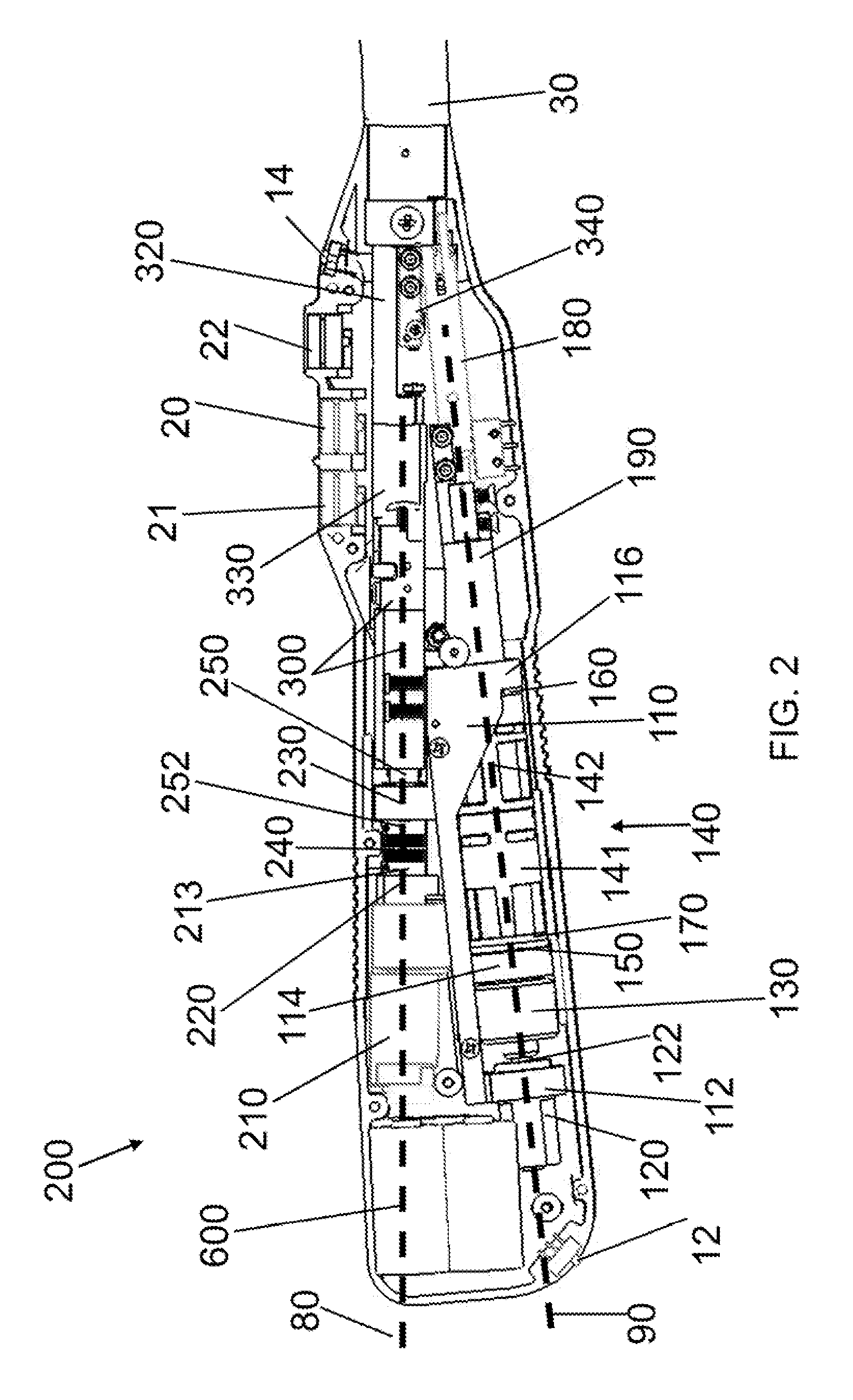

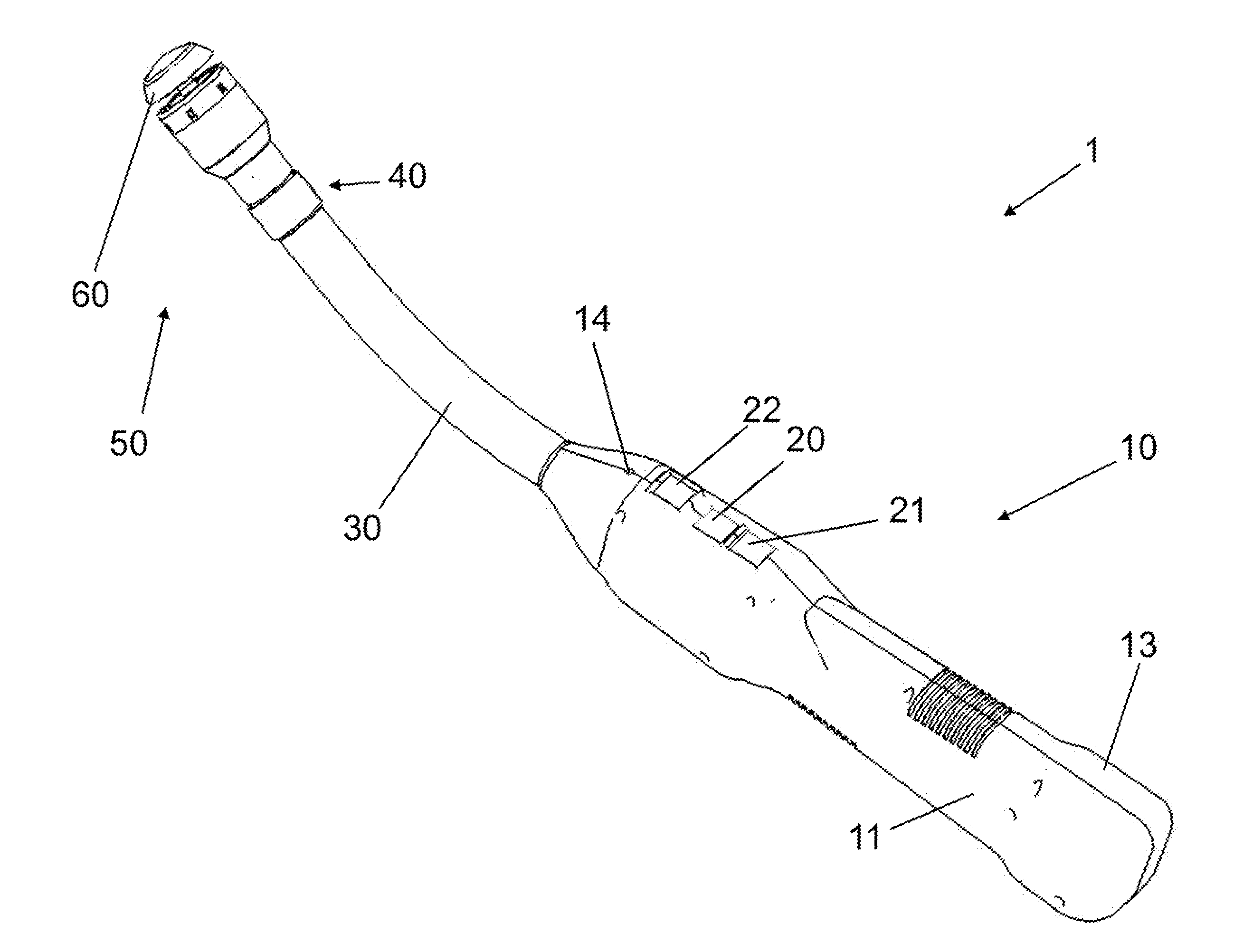

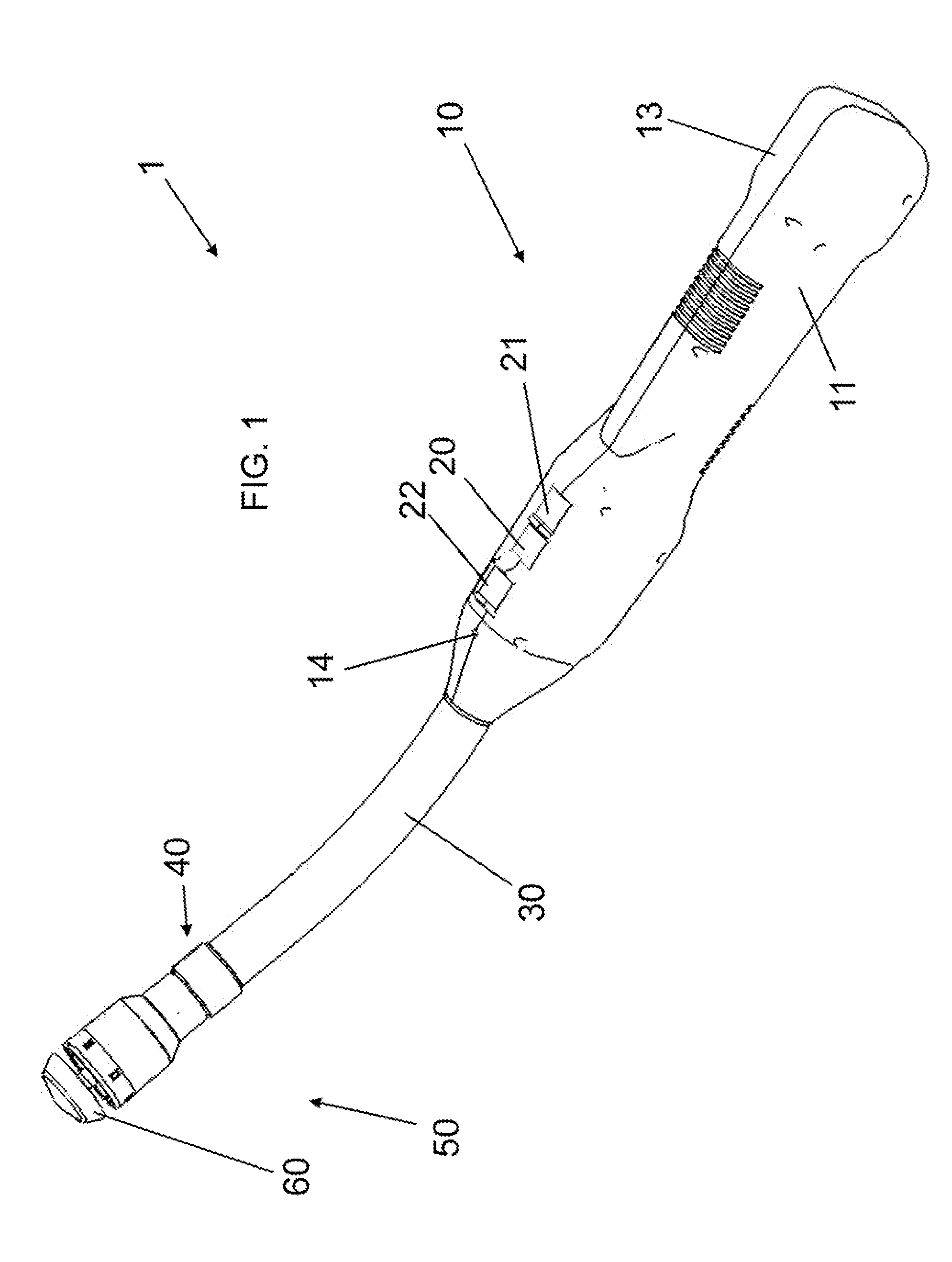

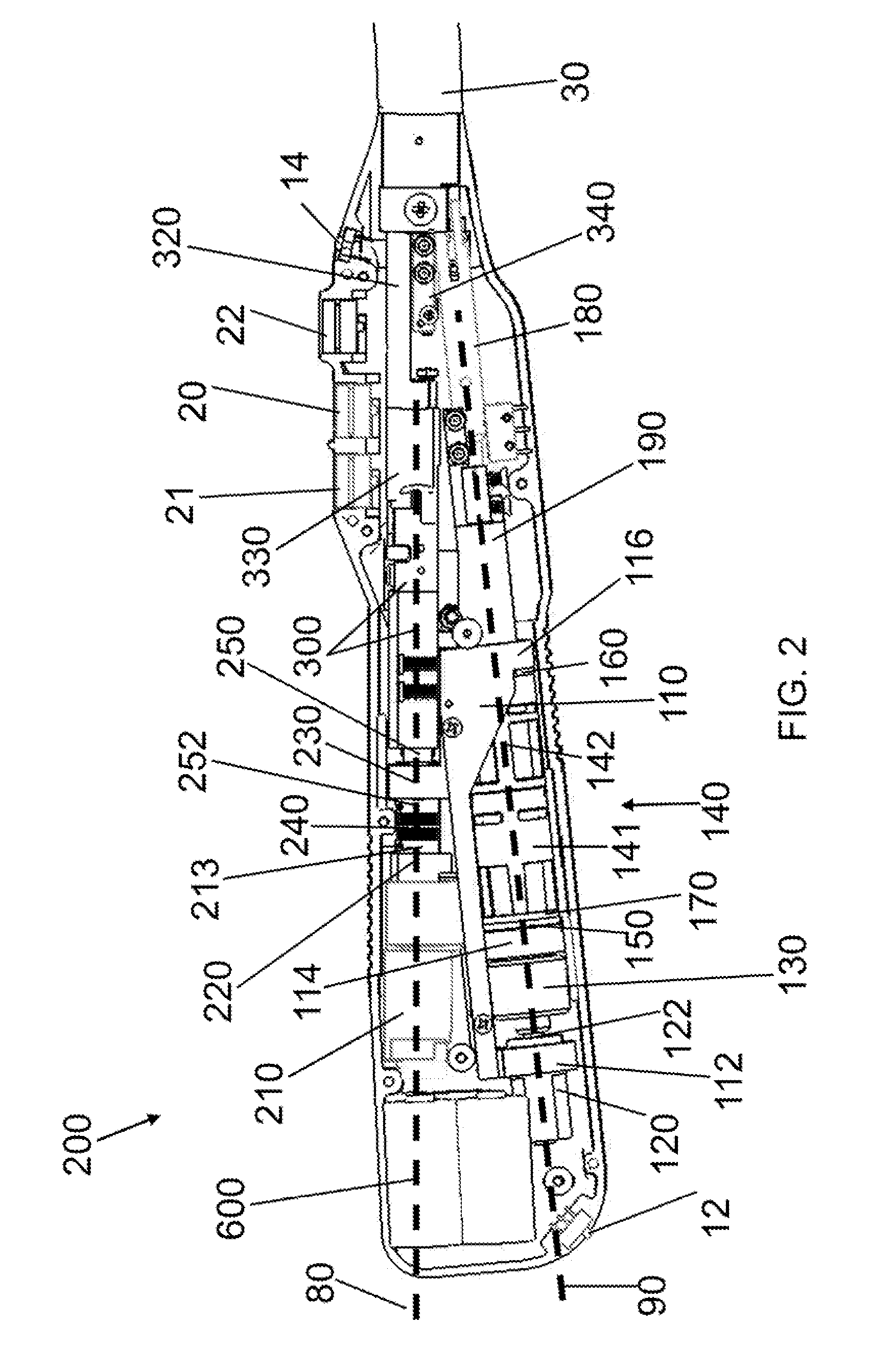

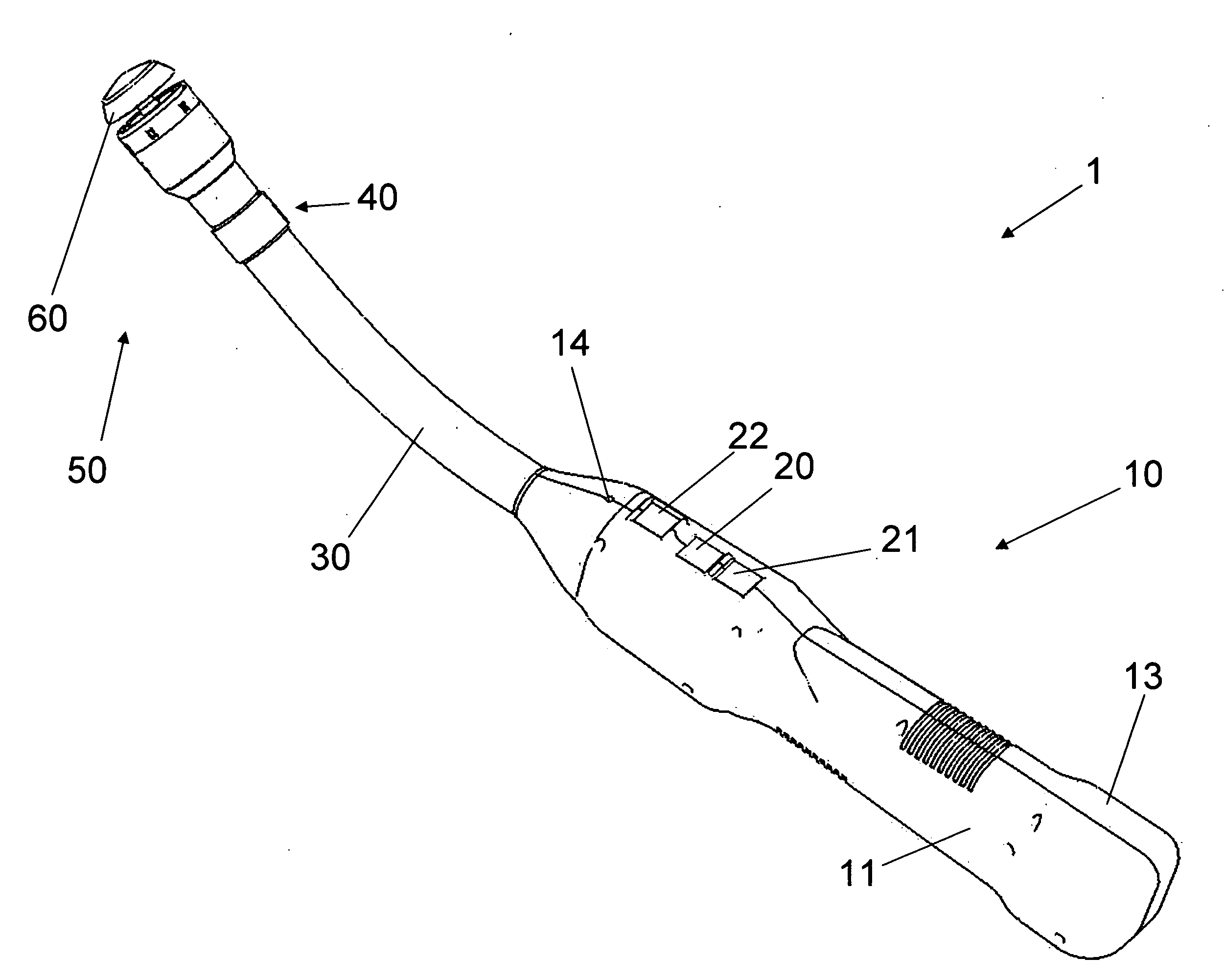

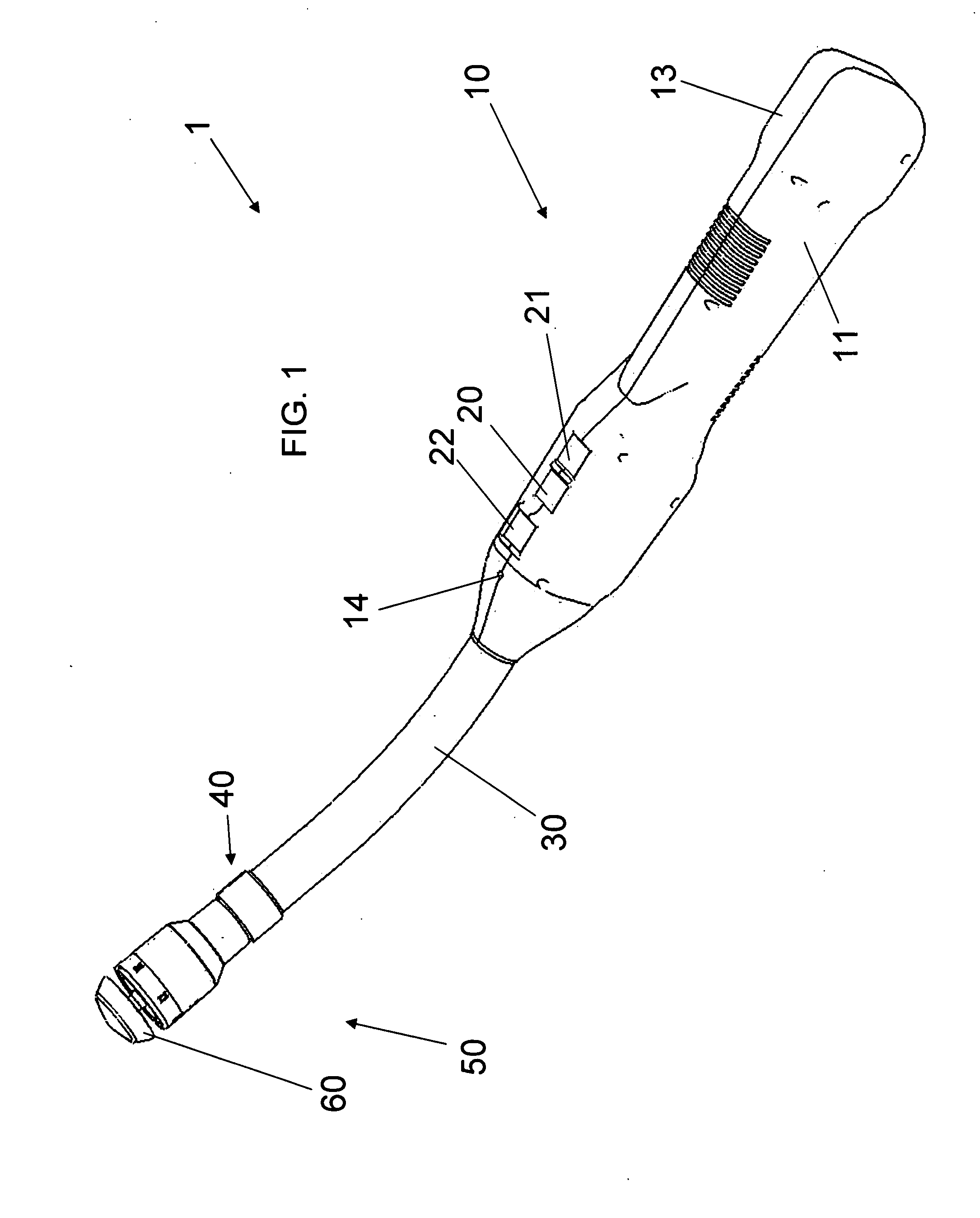

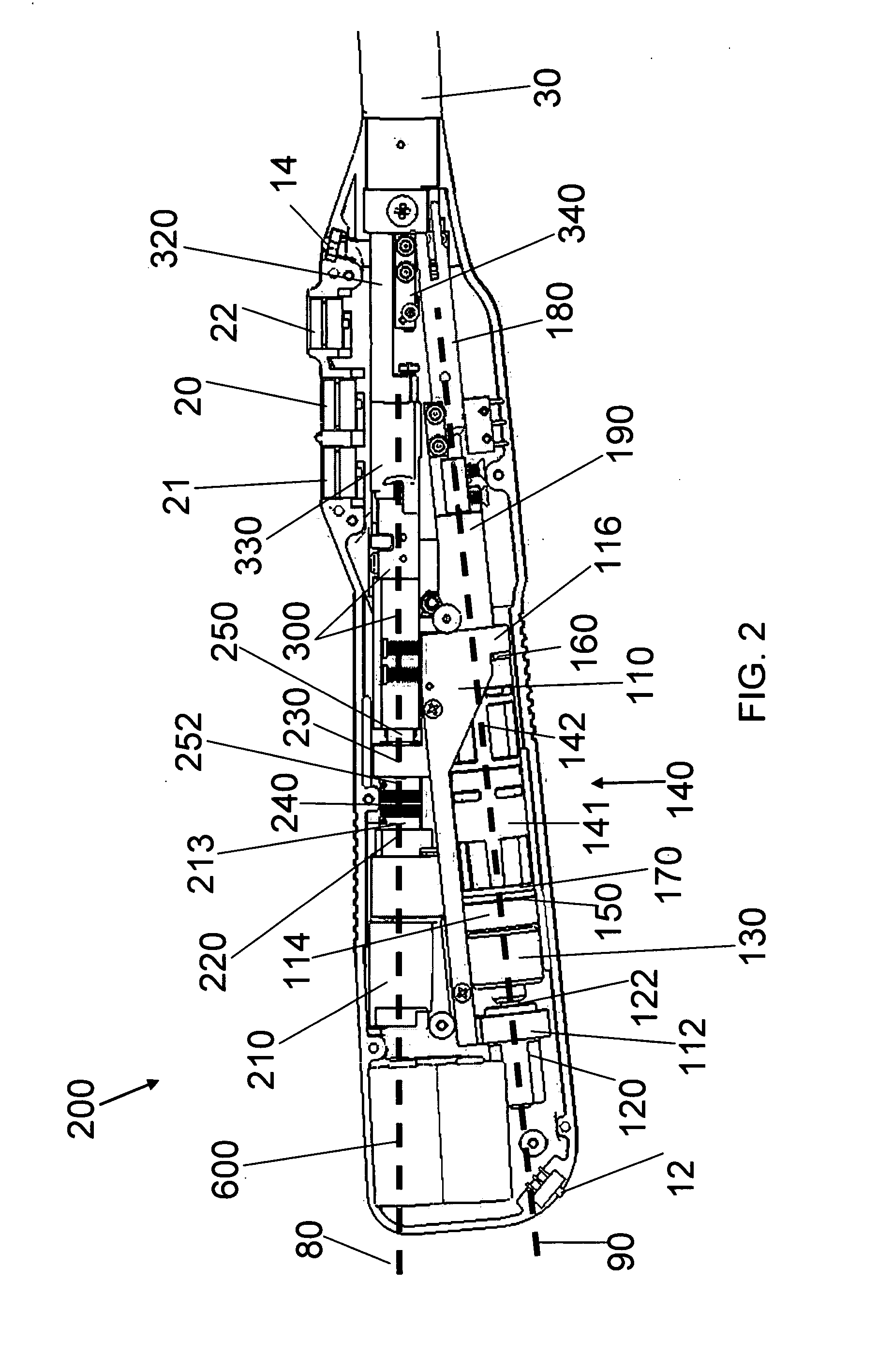

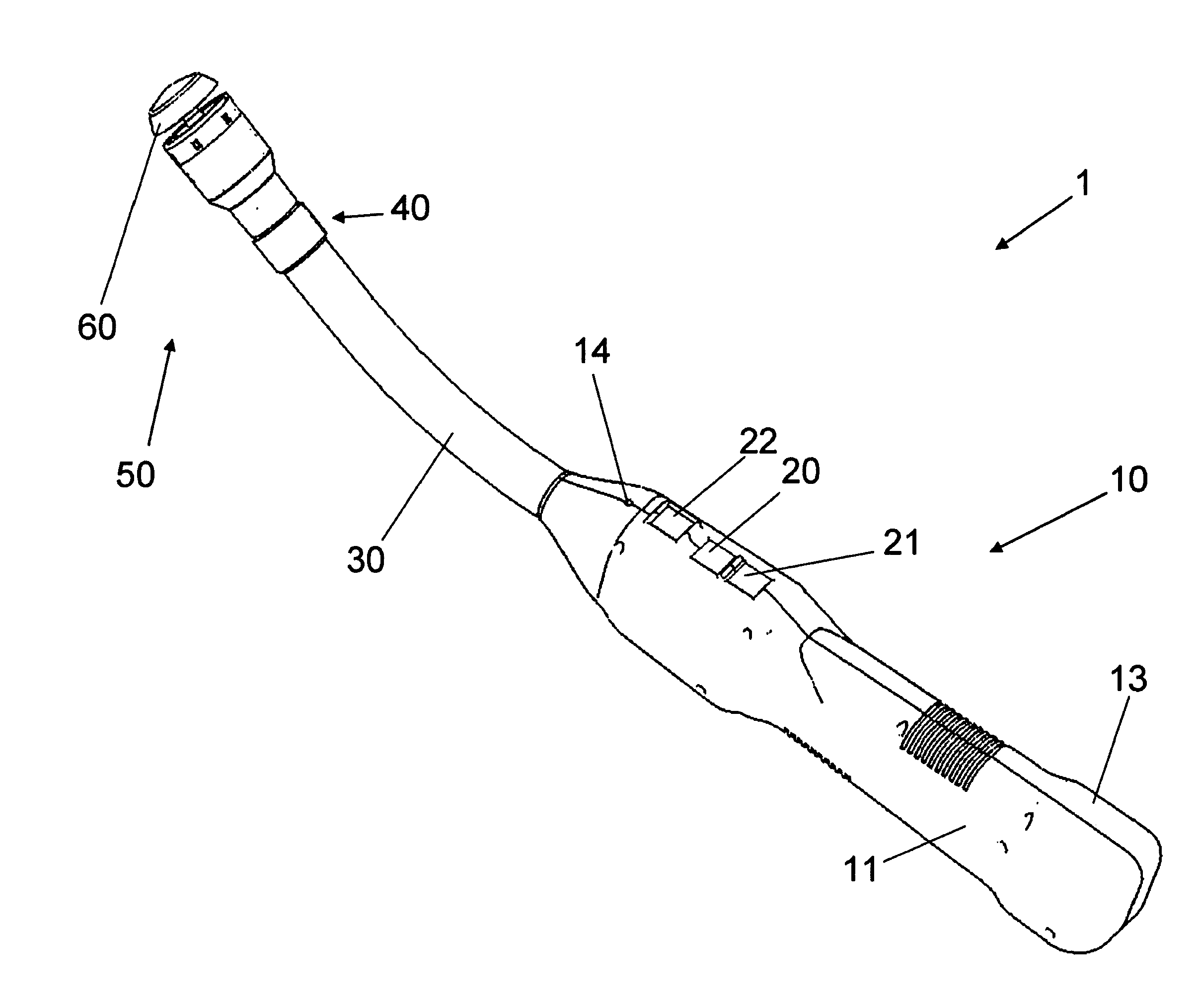

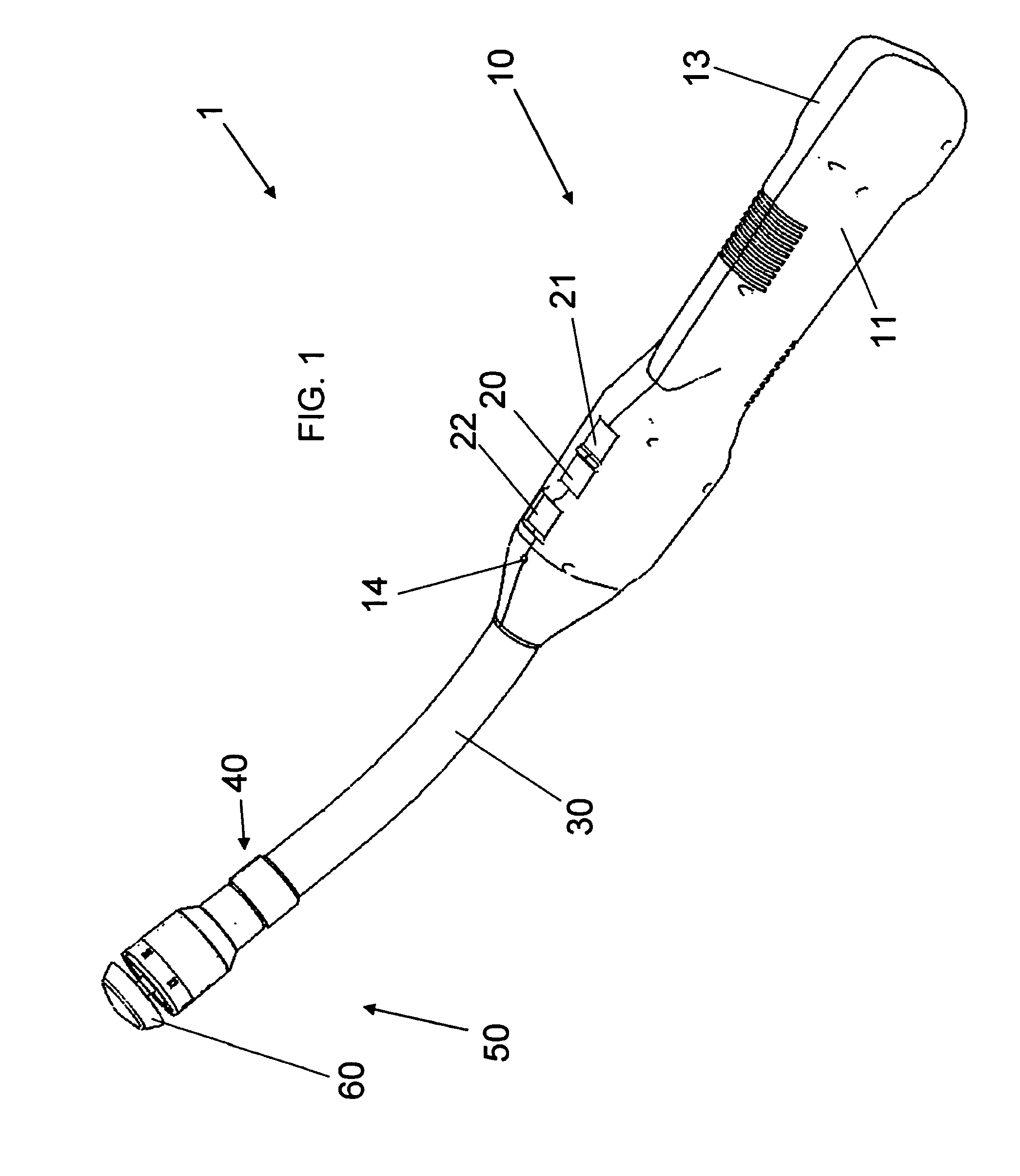

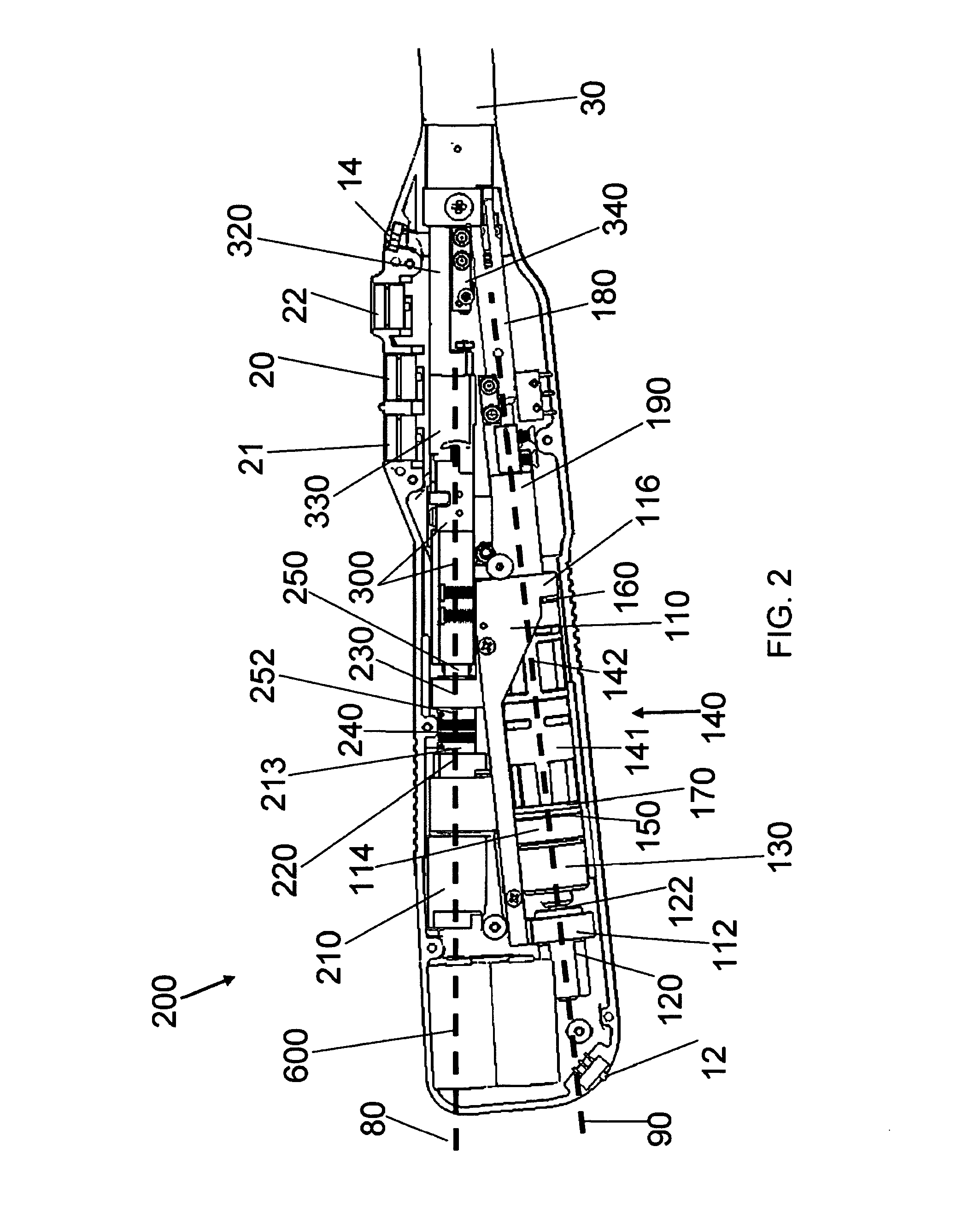

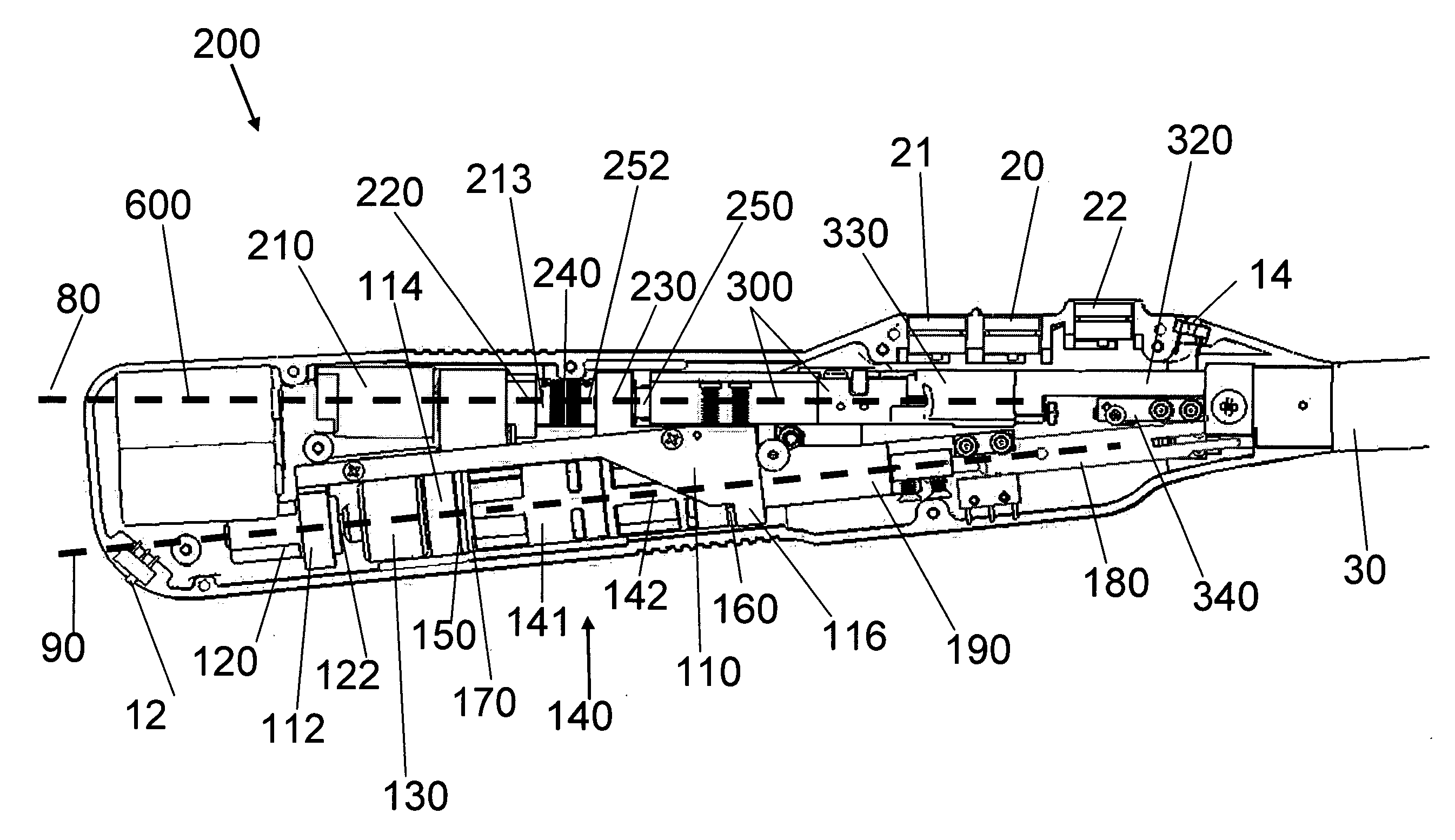

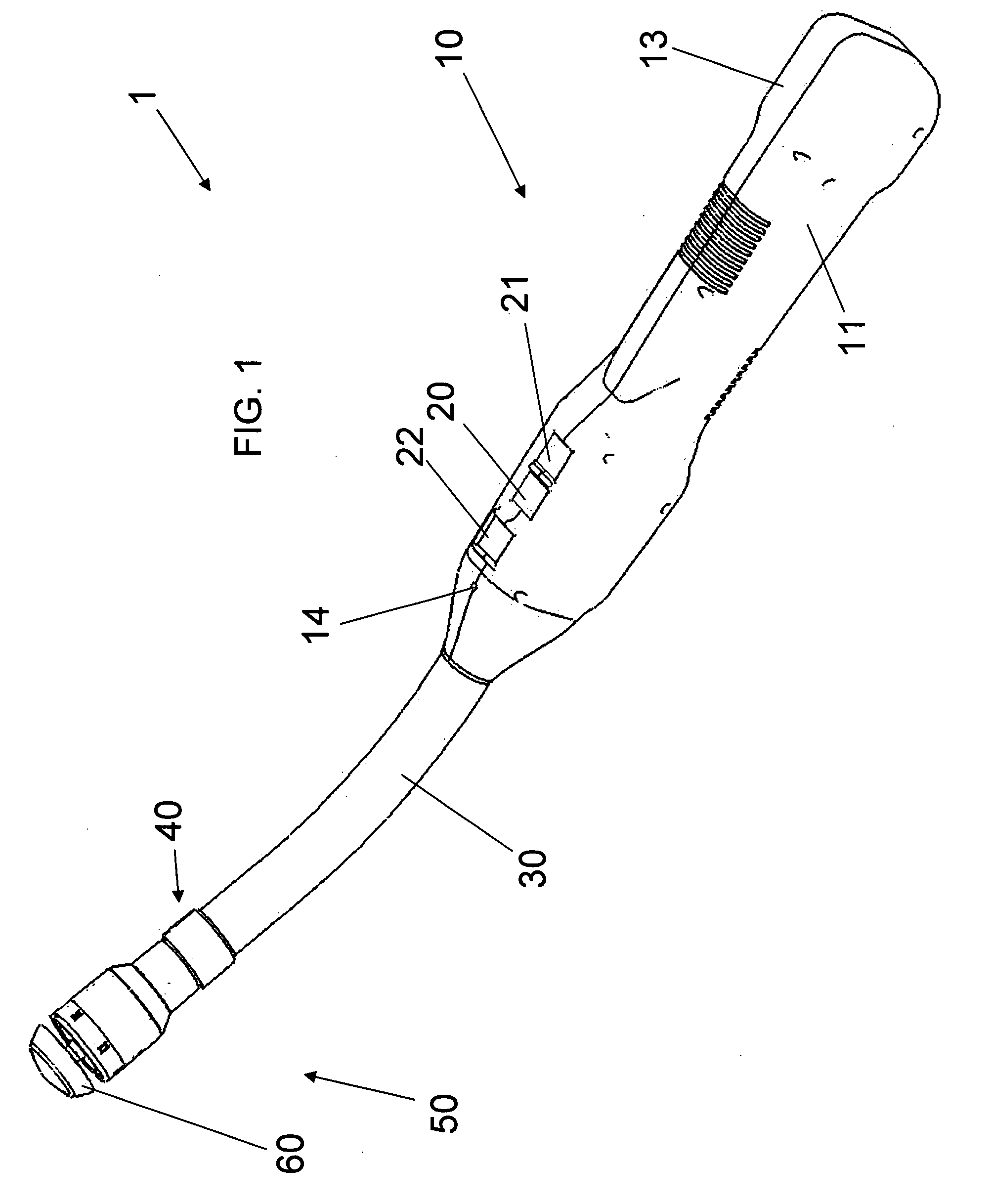

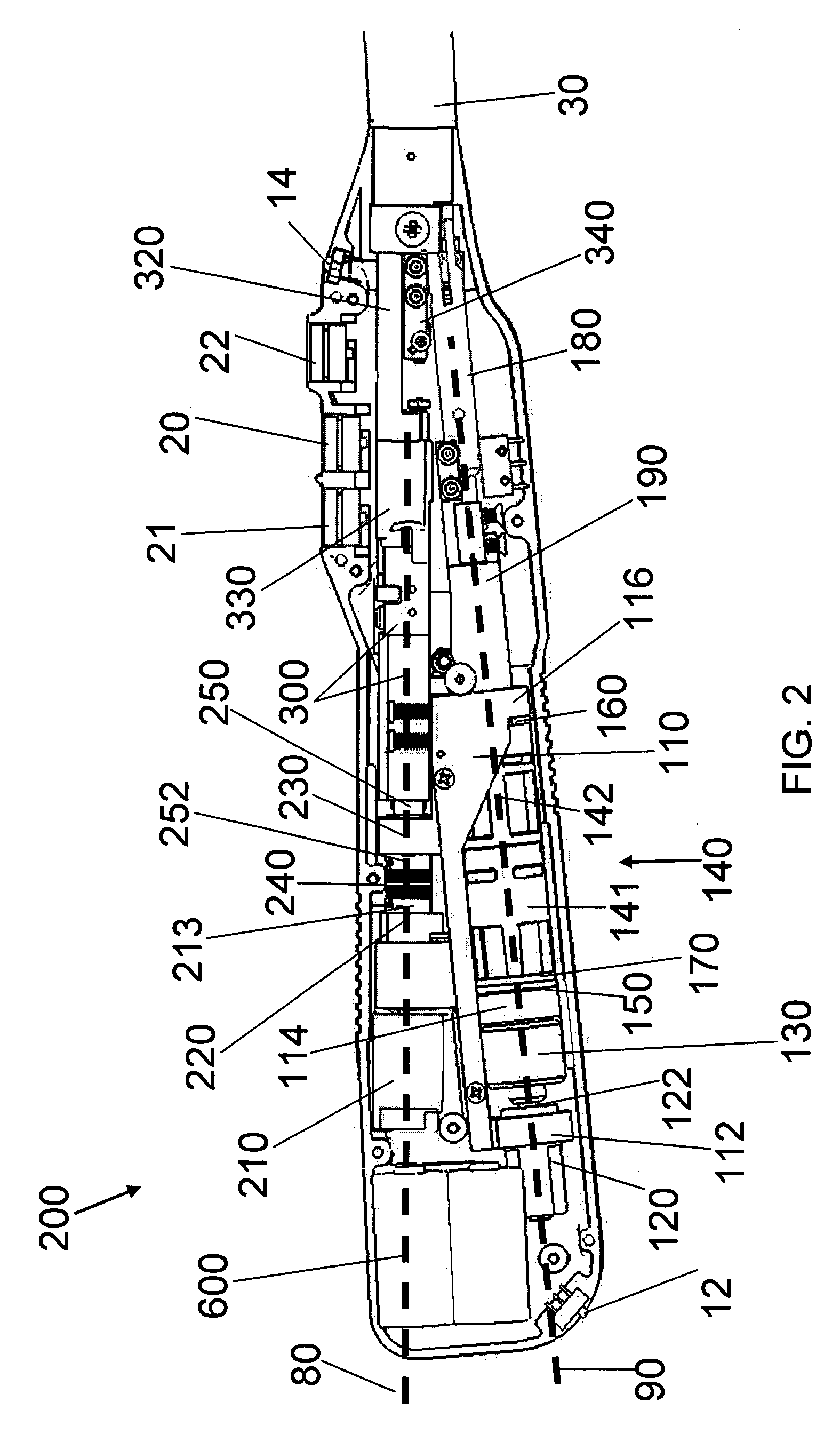

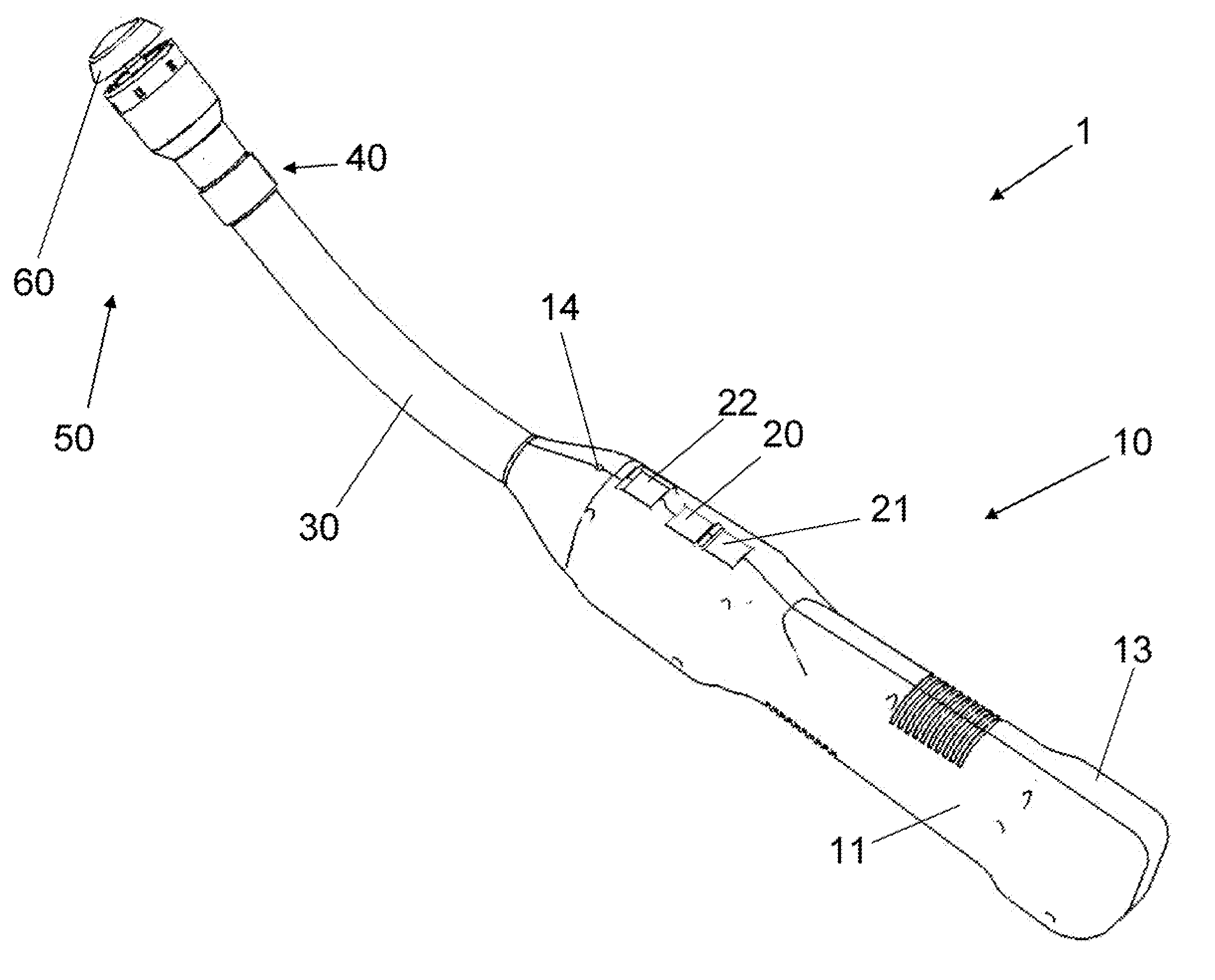

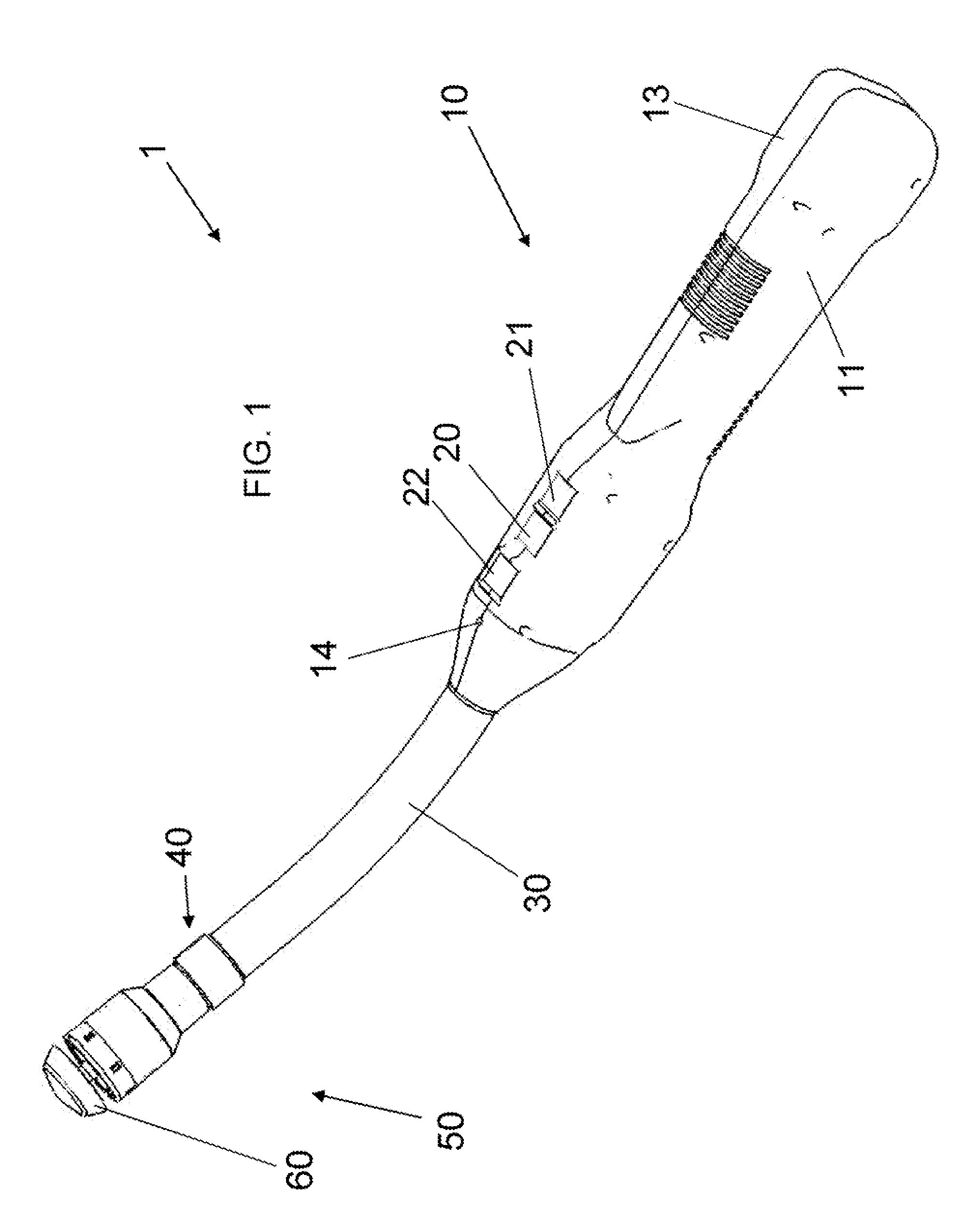

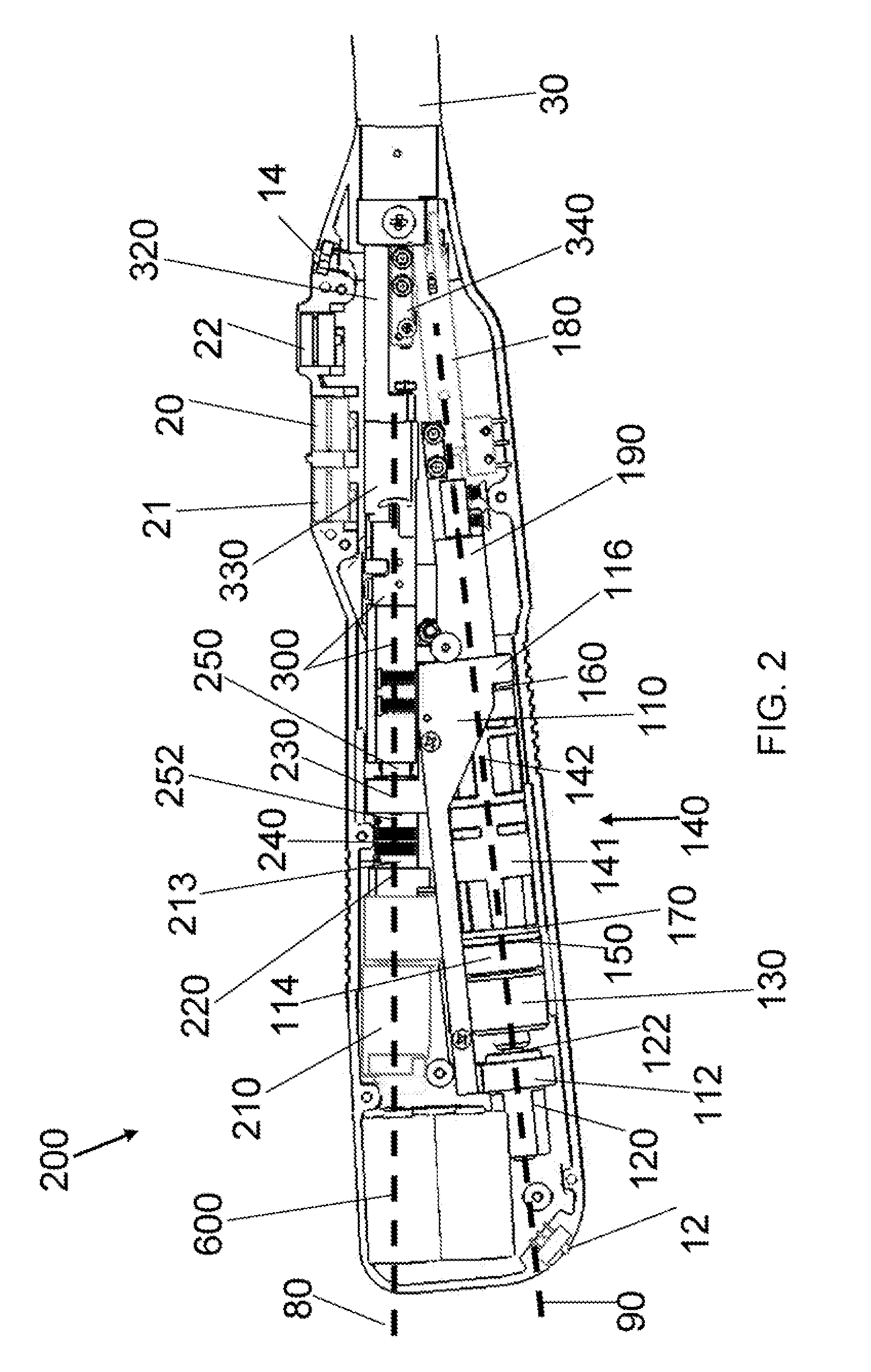

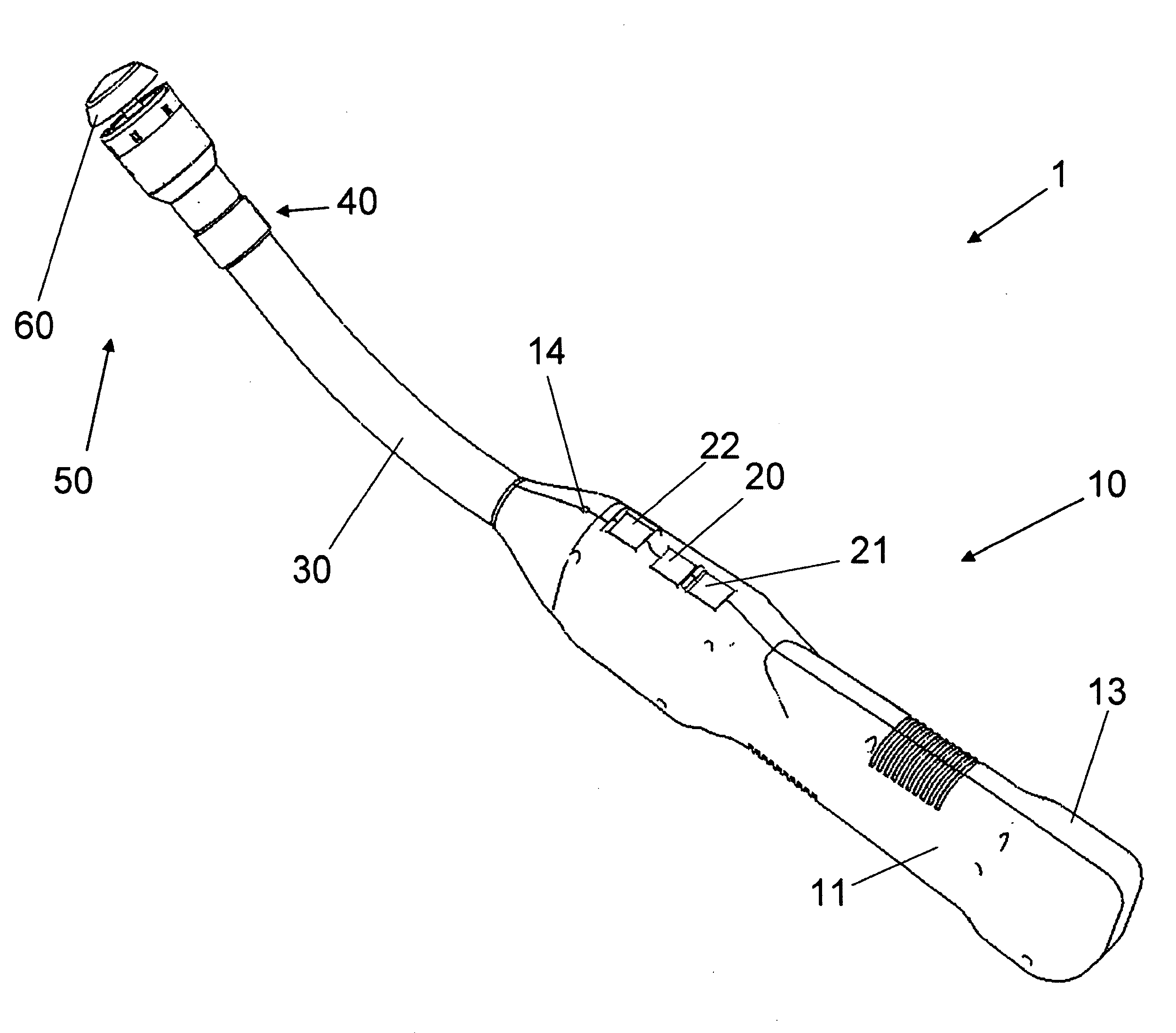

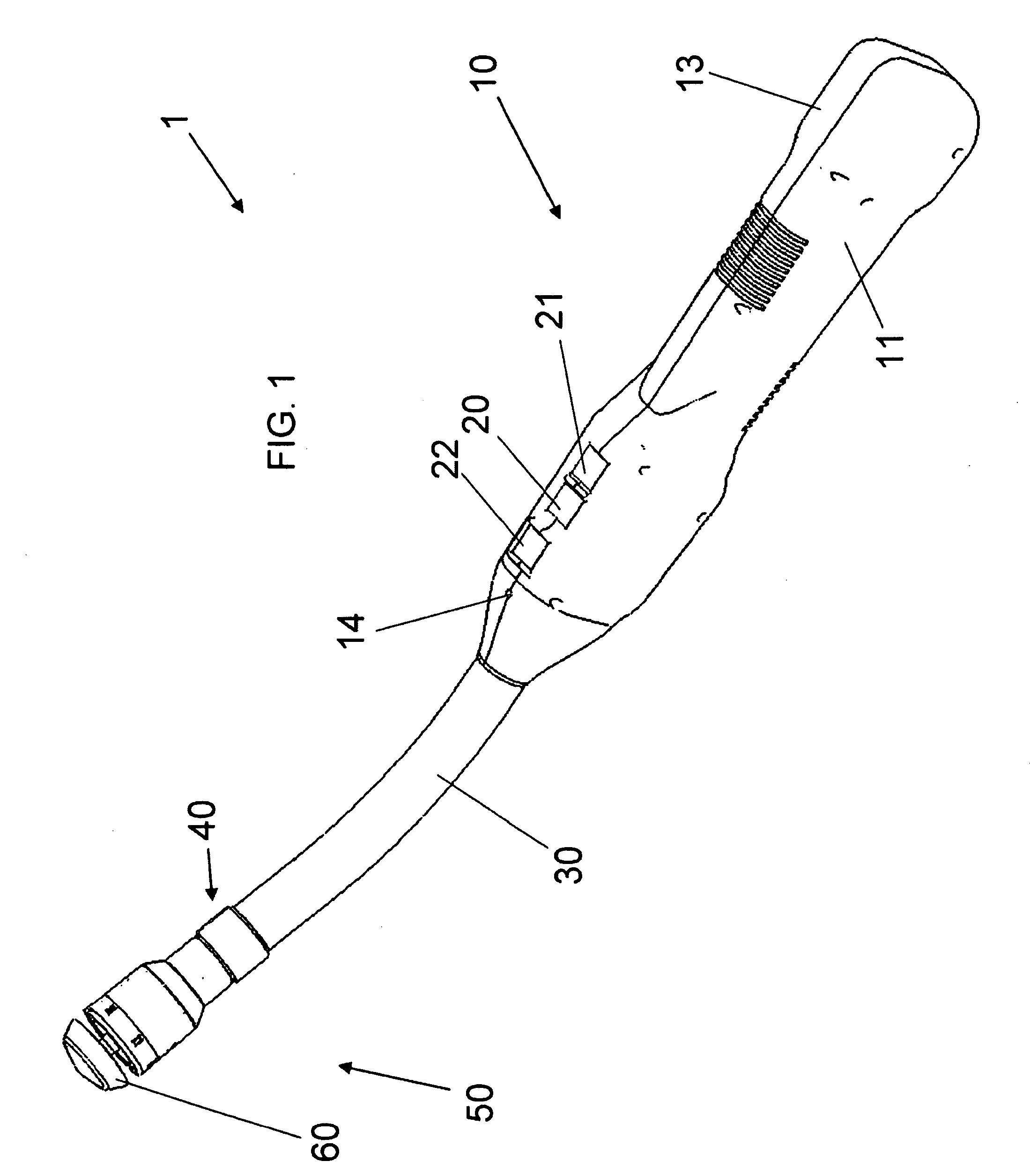

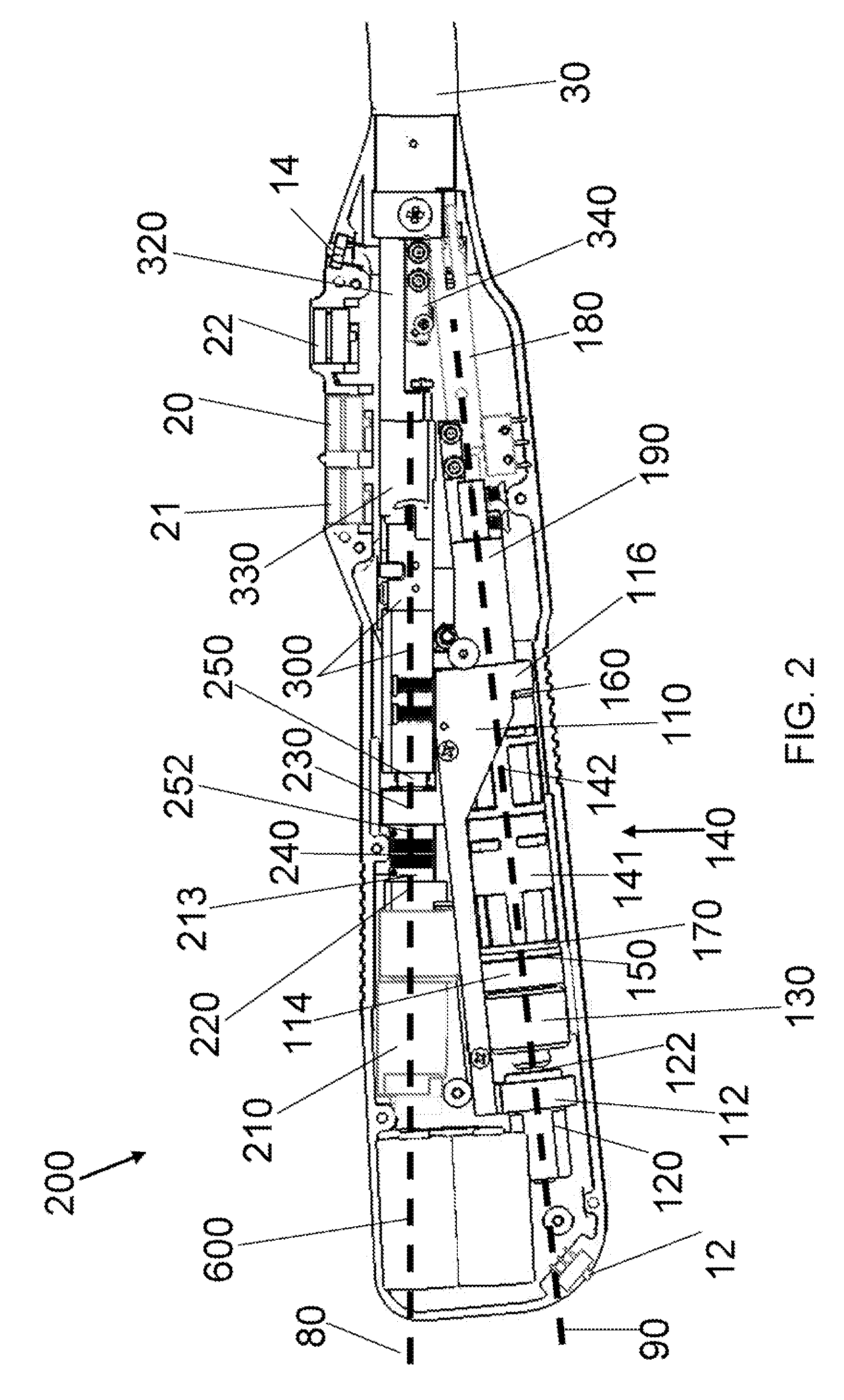

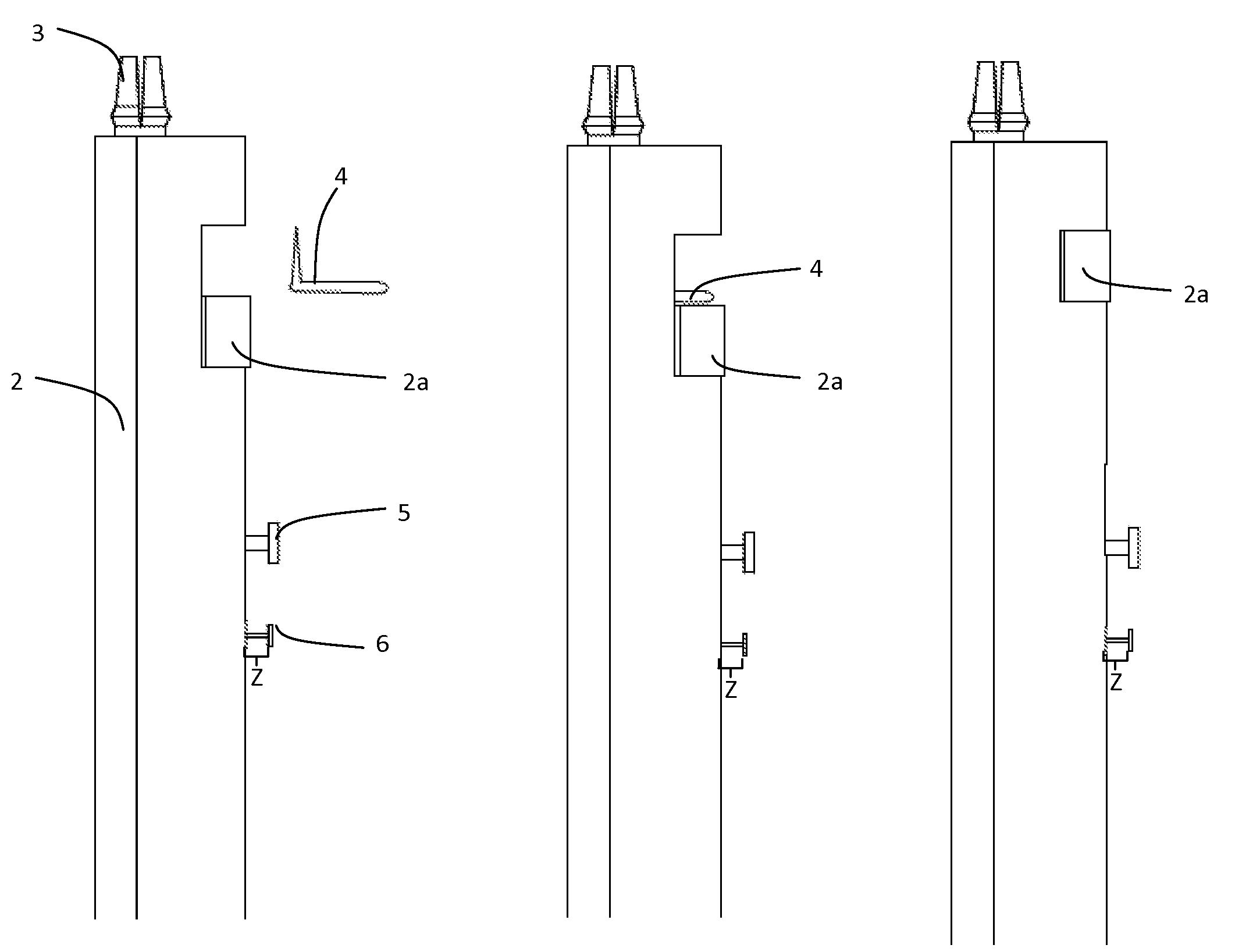

Electrically self-powered surgical instrument with manual release

ActiveUS7959050B2Comfortably fit into a user's handReduce manufacturing difficultySuture equipmentsStapling toolsElectricityEngineering

An electrically operated surgical instrument includes a surgical end effector having an actuation assembly effecting a surgical procedure when actuated and a handle connected to the end effector for actuating the assembly. A part of the assembly moves between start and fully actuated positions. The handle has a self-contained power supply and a drive assembly disposed entirely within the handle. The drive assembly has an electrically powered motor and a controller electrically connected to the power supply and to the motor. The controller selectively operates the motor. A transmission mechanically connects the motor to the moving part and selectively displaces the moving part anywhere between the start and fully extended positions when the motor is operated. A manual release is mechanically coupled to the transmission to selectively interrupt the transmission and, during interruption, displaces the moving part towards the start position independent of motor operation.

Owner:CILAG GMBH INT

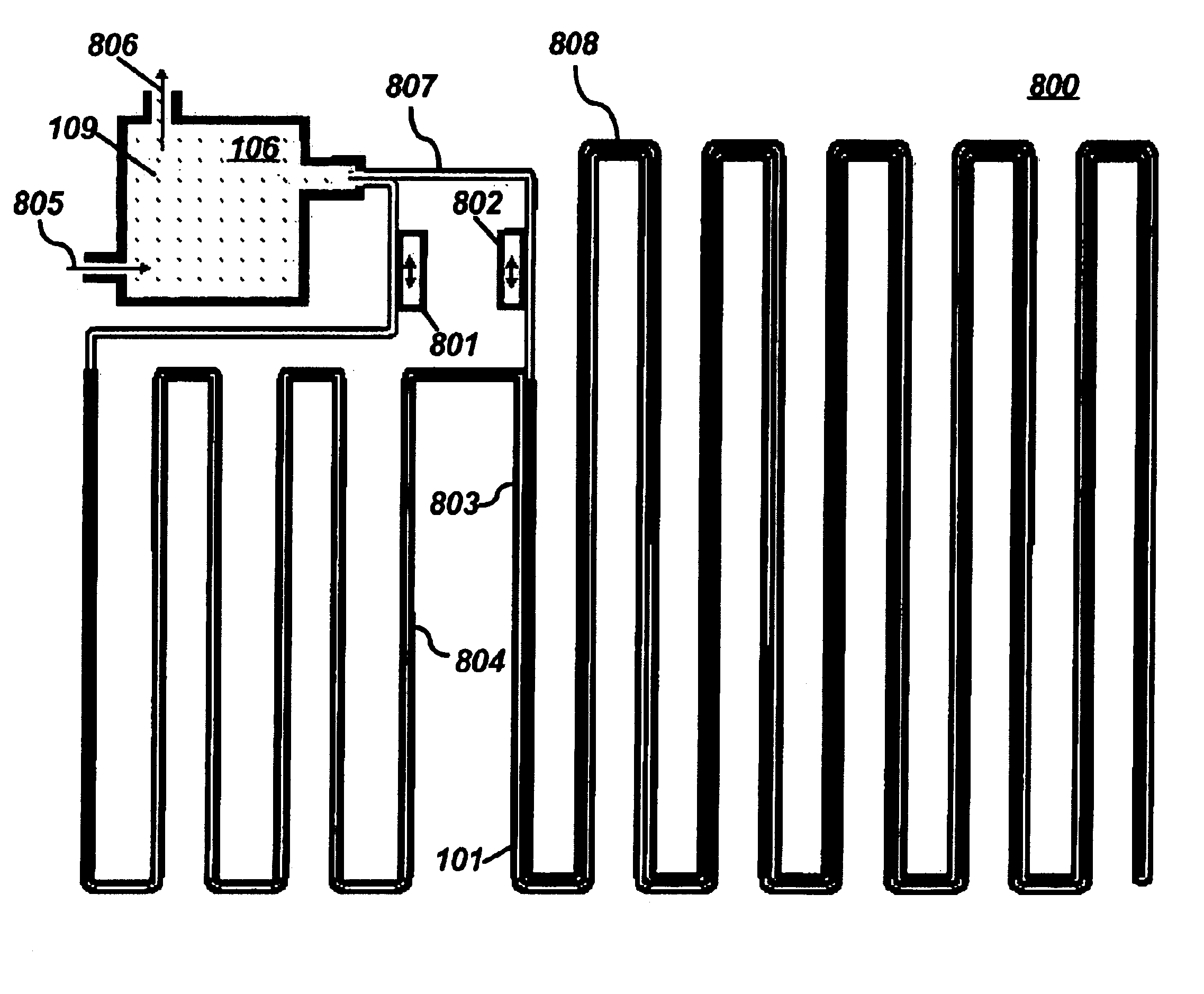

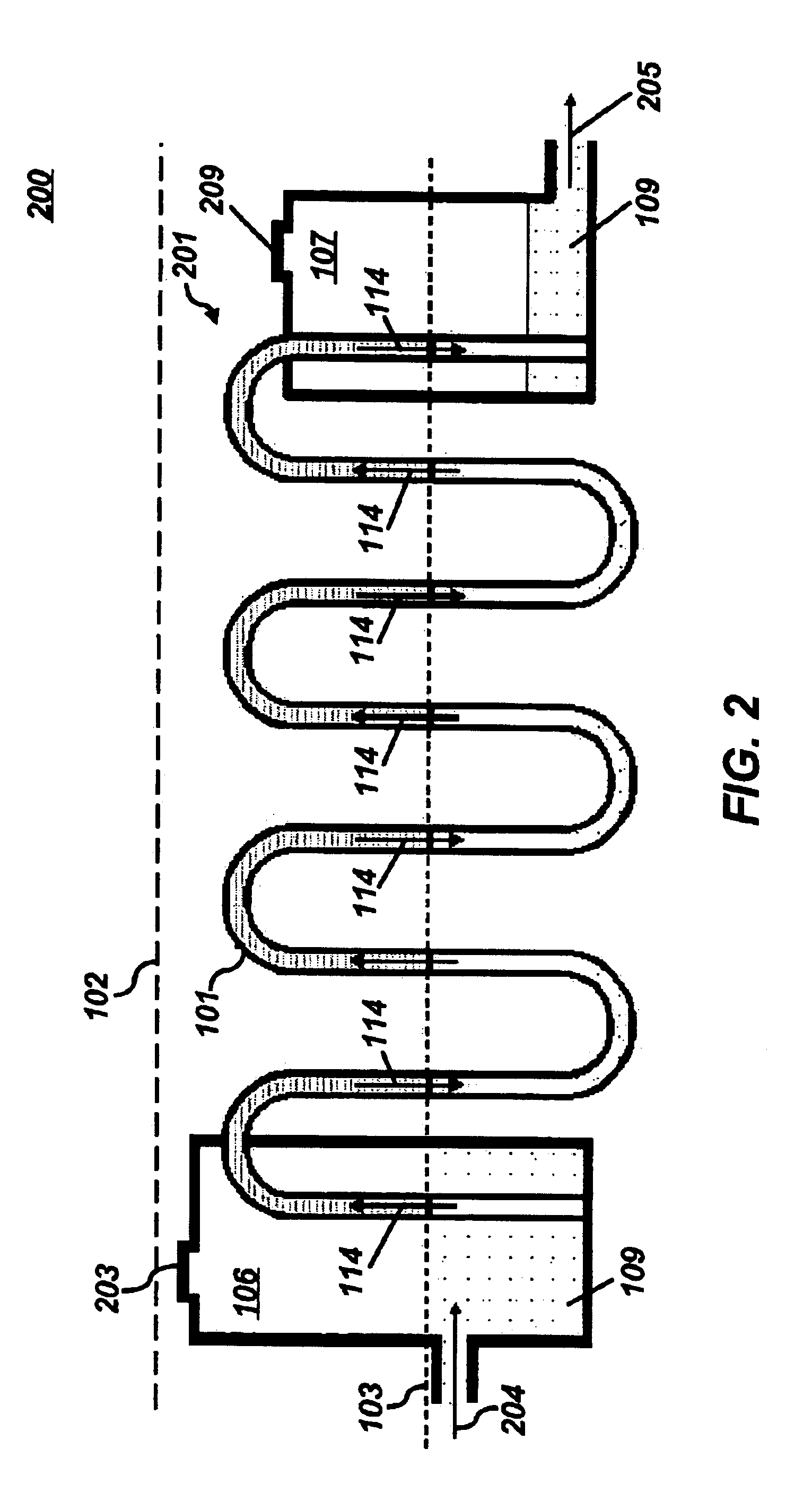

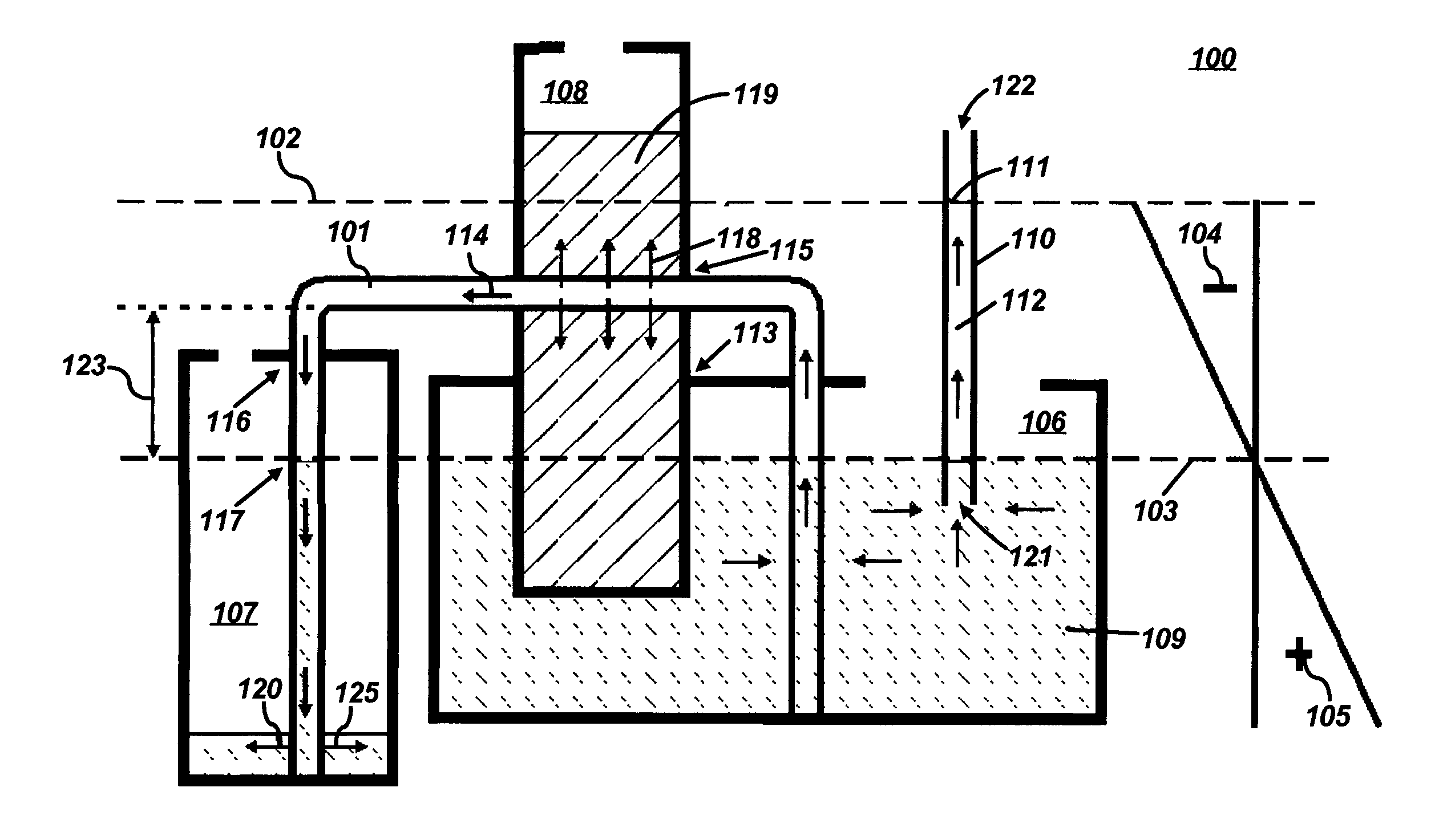

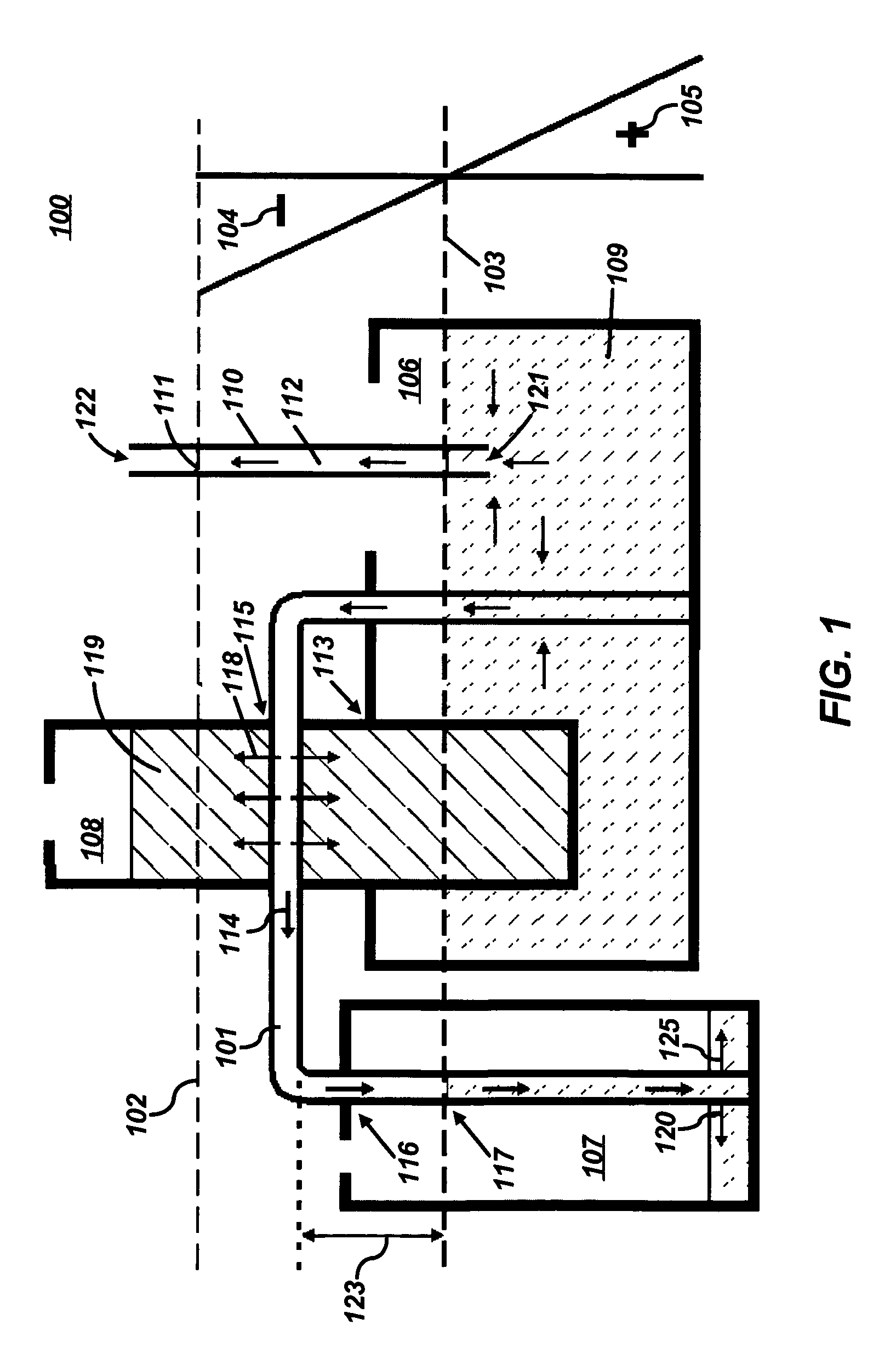

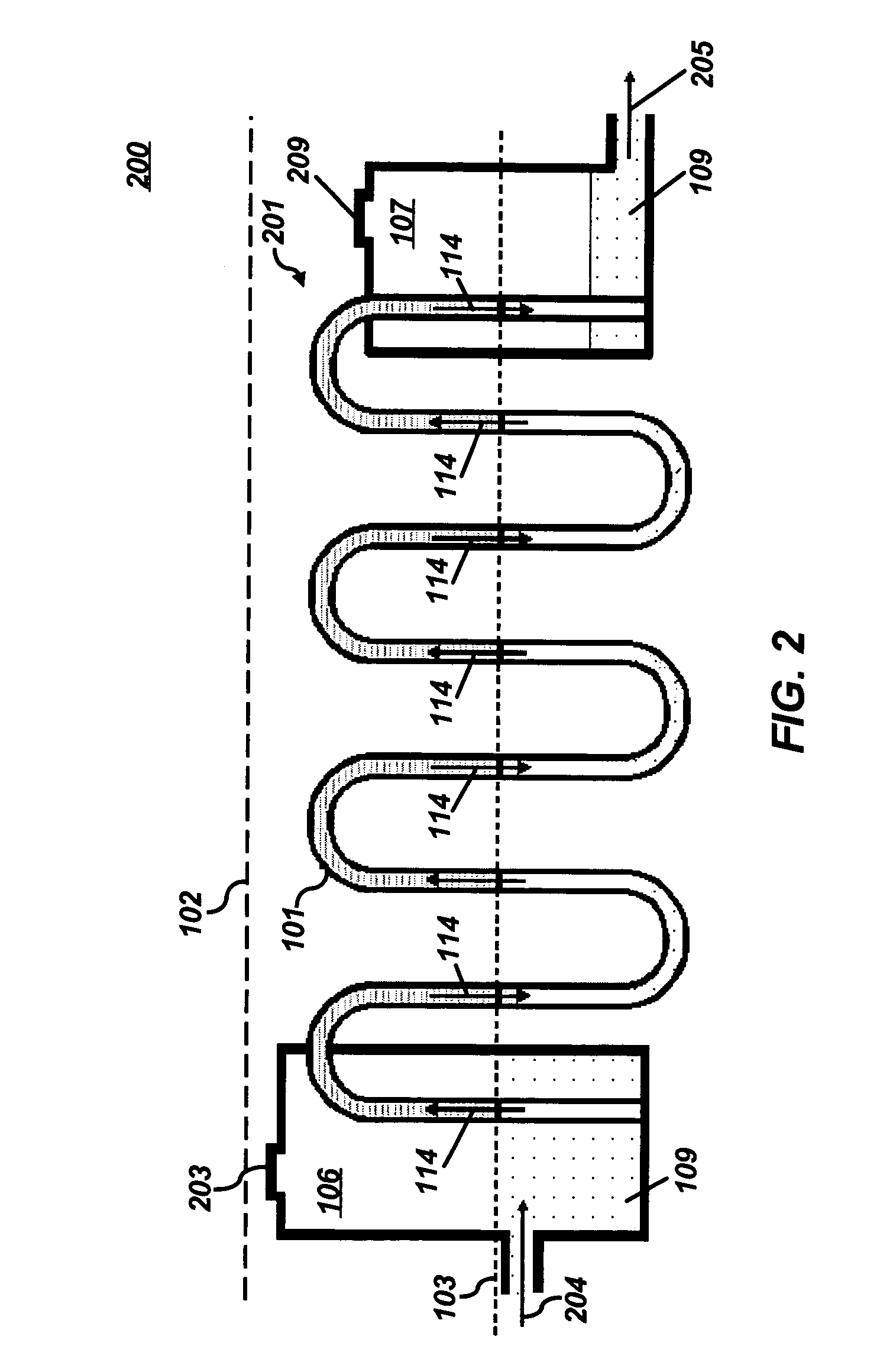

Irrigation and drainage based on hydrodynamic unsaturated fluid flow

InactiveUS6918404B2Improve the level ofHigh porosityPipeline systemsMachines/enginesEnvironmental engineeringPorous microstructure

Irrigation and drainage systems are disclosed, including a saturated zone and at least one pipe in communication with the saturated zone. The pipe(s) can be configured to comprise a tubarc porous microstructure for conducting water from the saturated zone to an unsaturated zone in order to drain the water from the saturated zone. The water can be delivered from the saturated zone to the unsaturated zone through the tubarc porous microstructure, thereby permitting the water to be harnessed for irrigation or drainage through the hydrodynamic movement of the water from one zone of saturation or unsaturation to another.

Owner:TUBARC TECH

Ink refill and recharging system

InactiveUS7066586B2Improve reliabilityPrecise deliveryPipeline systemsPrintingEngineeringPrint-through

Ink refill systems are disclosed. In general, an ink source comprising a saturated zone and a tubarc porous microstructure for conducting ink from the saturated zone to an unsaturated zone are provided. The ink can be delivered from the saturated zone to the unsaturated zone through the tubarc porous microstructure, thereby permitting the ink to be harnessed for ink writing and / or printing through the unsaturated hydrodynamic flow of the ink from one zone of saturation or unsaturation to another.

Owner:TUBARC TECH

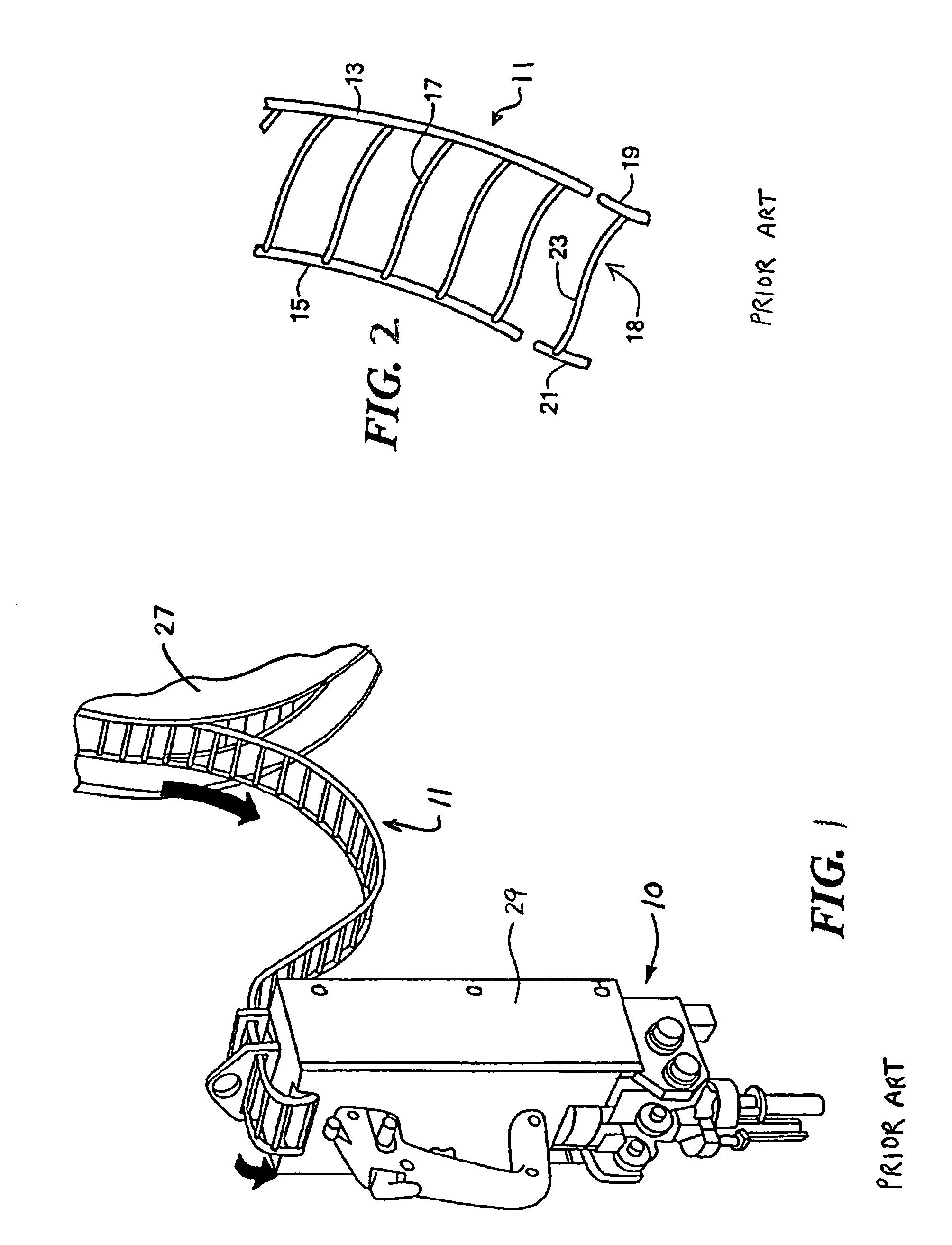

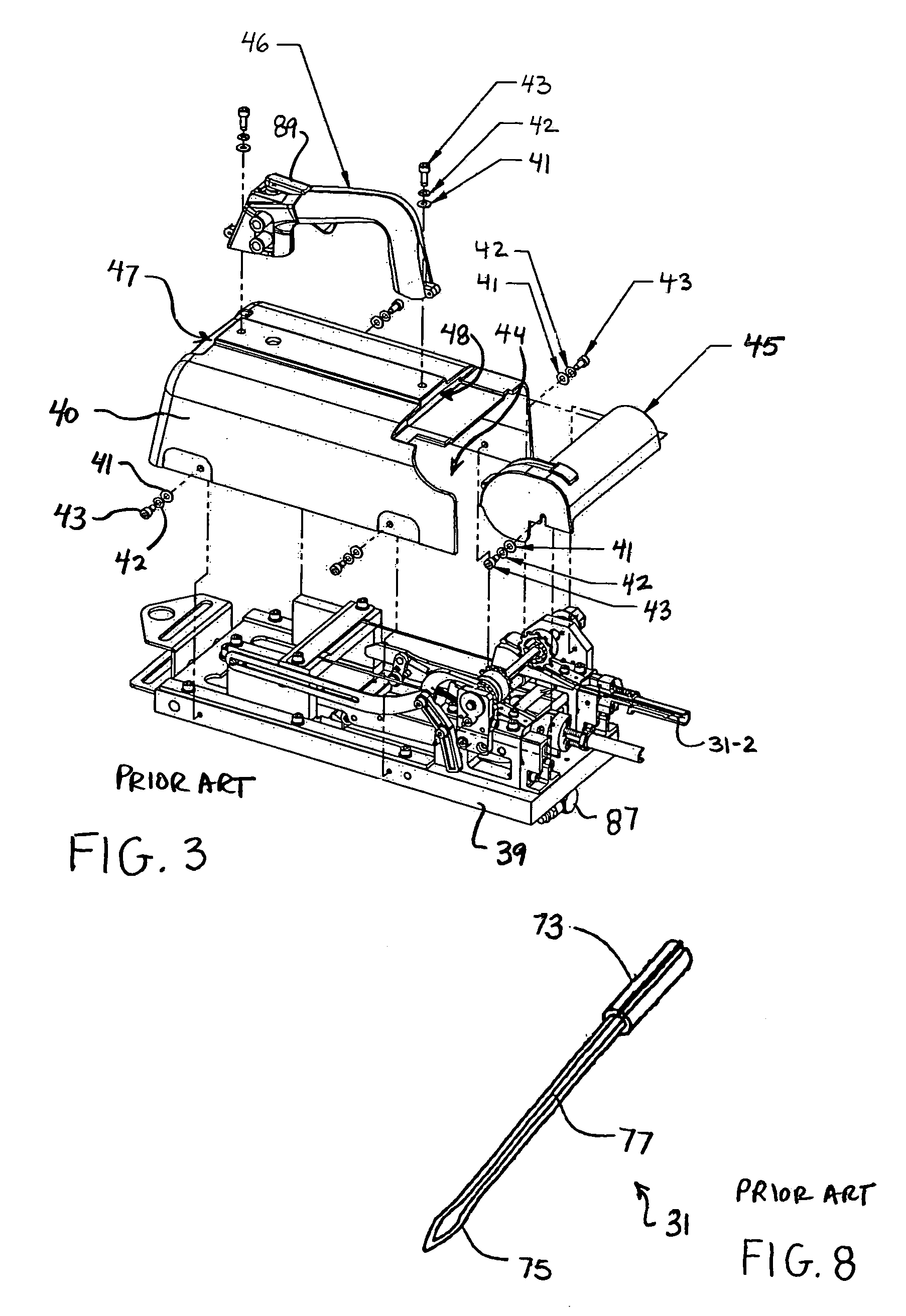

Device for dispensing plastic fasteners

ActiveUS7036680B1Easy to useReduce manufacturing costAffixing tagsCoin-freed apparatus detailsCross-linkEngineering

A device for dispensing an individual plastic fastener from a supply of fastener stock to couple together two or more objects. The supply of fastener stock includes a plurality of equidistantly spaced cross links which are coupled at one end to a continuous side rail. The fastener dispensing device includes a hollowed sharpened needle shaped to define a longitudinal bore and a feed mechanism for advancing the continuous side rail of the fastener stock into direct axial alignment behind the longitudinal bore of the hollowed needle. The feed mechanism includes a rotatably mounted feed shaft, a pair of feed wheels fixedly mounted on the feed shaft, each feed wheel comprising a plurality of sprockets which are sized and shaped to engage the supply of fastener stock, and first and second clutch wheels which are releasably matingly engageable with one another, the first clutch wheel being fixedly mounted on the feed shaft and the second clutch wheel being rotatably mounted on the feed shaft, each of the first and second clutch wheels including a plurality of ratchets. As a feature of the invention, the number of ratchets on each clutch wheel is at most equal to the number of sprockets on each feed wheel.

Owner:AVERY DENNISON CORP

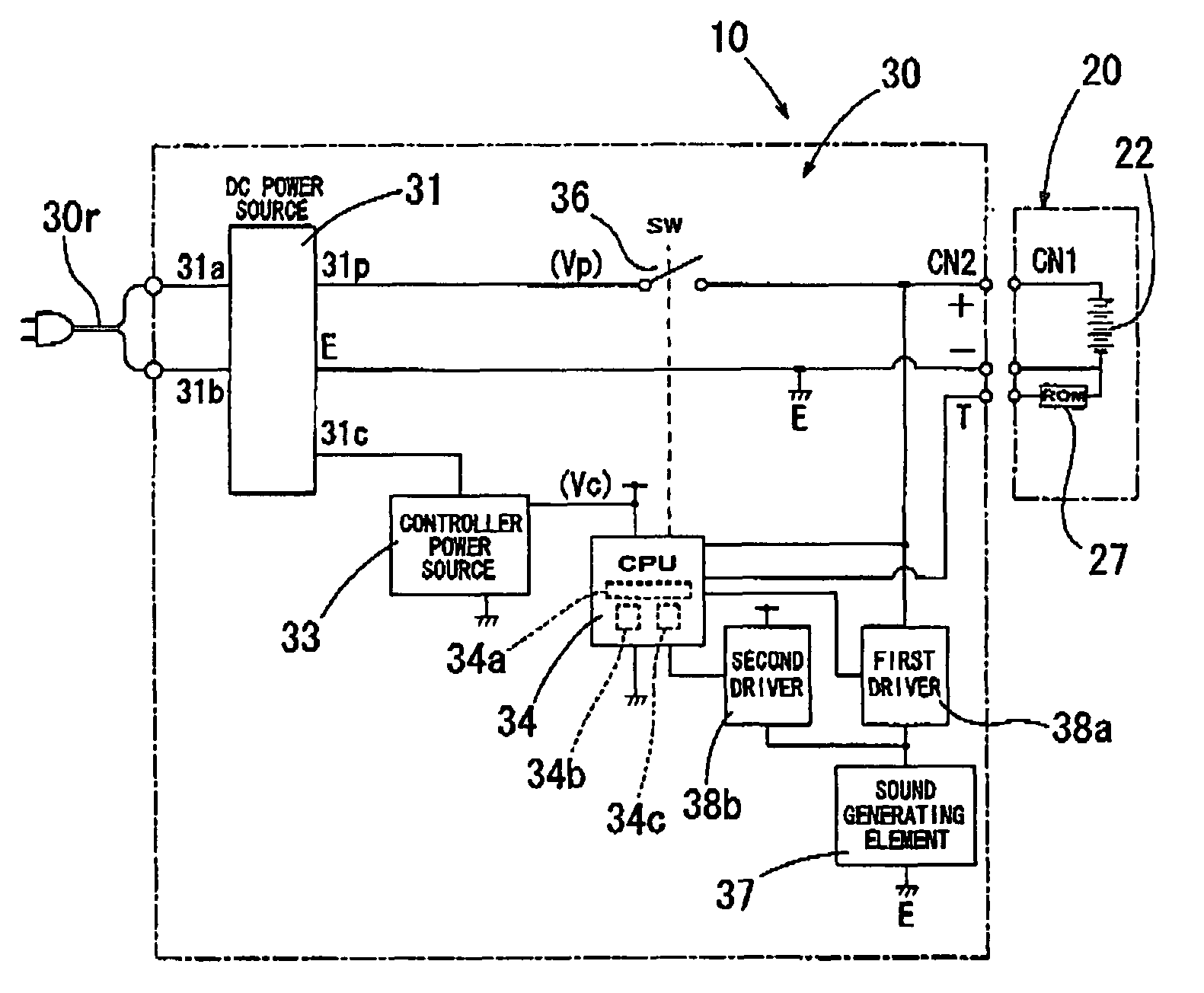

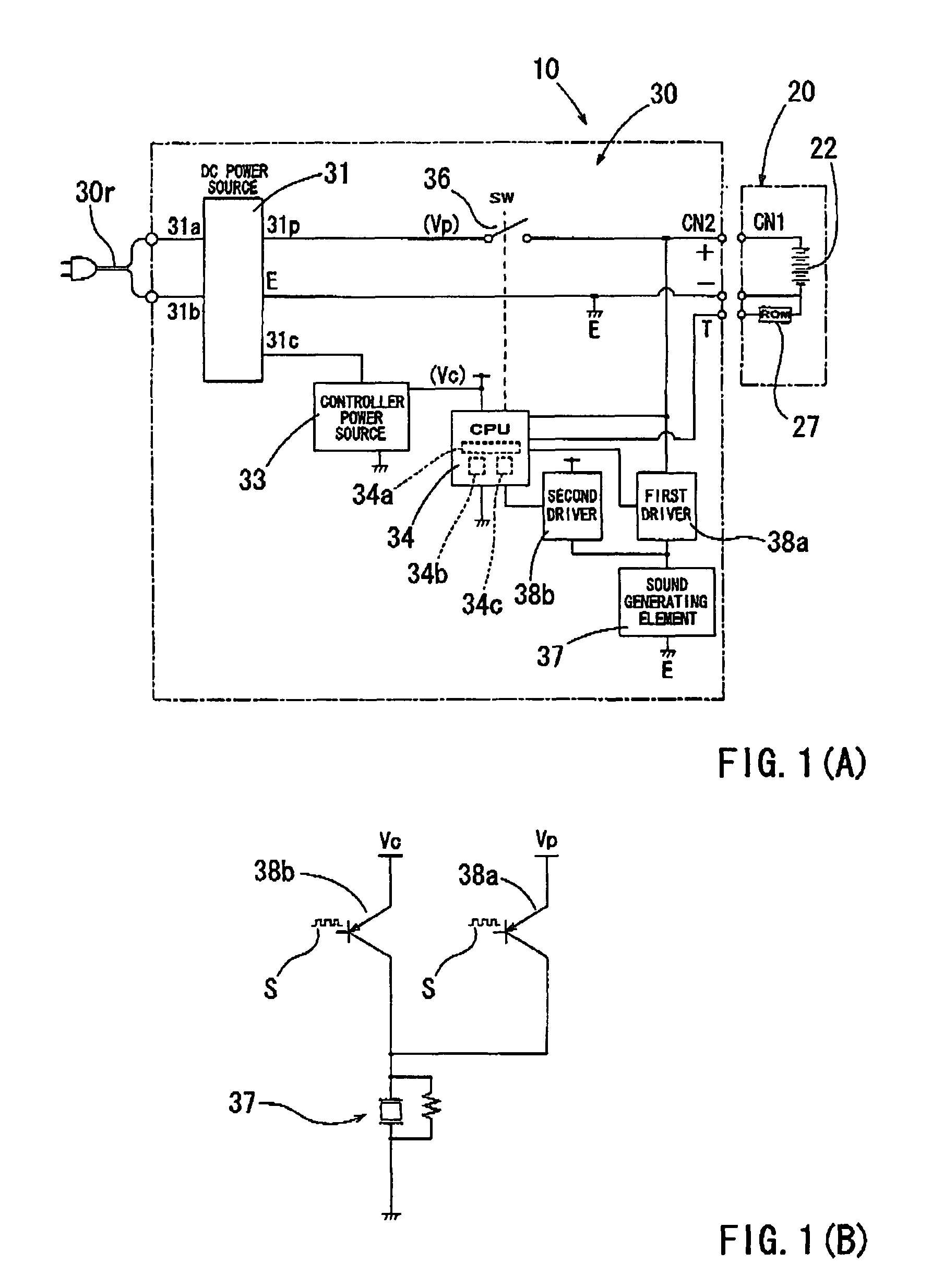

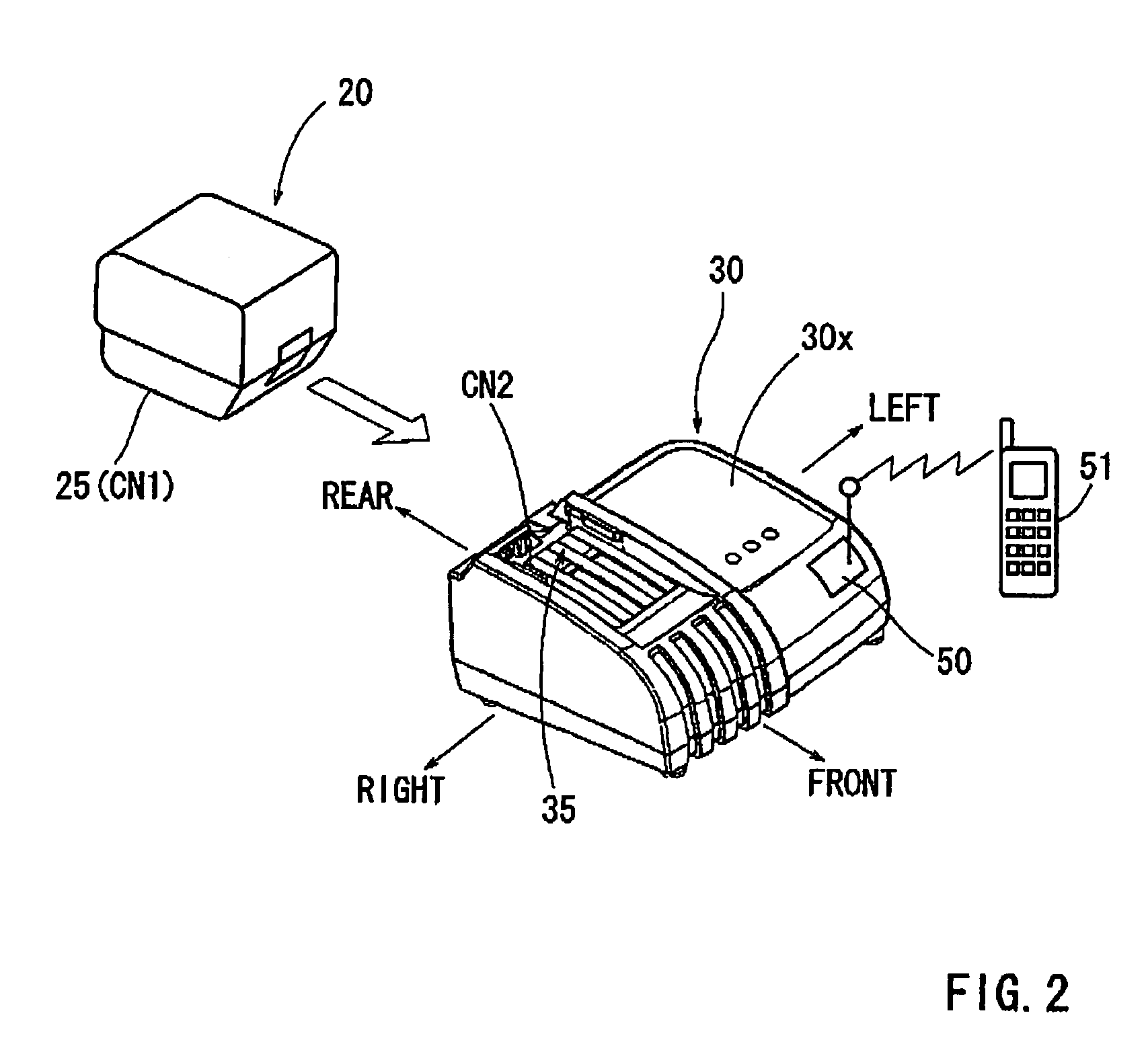

Battery charging systems

ActiveUS7944175B2Reduce manufacturing costImprove performanceCircuit monitoring/indicationDifferent batteries chargingSound productionEngineering

A system for charging a power tool battery includes a charging device capable of charging a battery, a memory device capable of storing data of a plurality of sound patterns, a selecting device capable of selecting a sound pattern data from the plurality of sound patterns, and a sound generating device capable of generating a sound based on the selected sound pattern data when the charging operation of the battery by the charging device has been completed.

Owner:MAKITA CORP

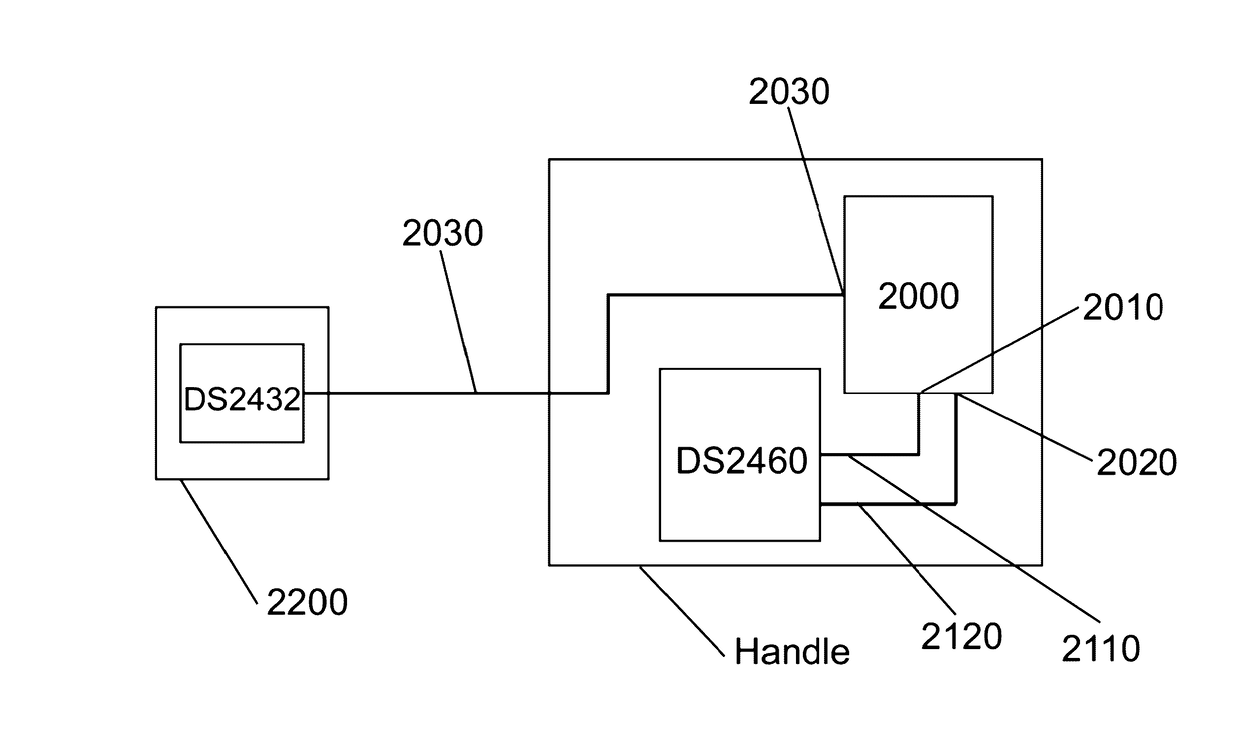

Electrically self-powered surgical instrument with cryptographic identification of interchangeable part

ActiveUS9662116B2Comfortably fit into a user's handReduce manufacturing difficultyDiagnosticsSurgical staplesElectricityActuator

A surgical instrument includes a surgical end effector having a receiving portion for removably receiving therein an interchangeable part. The receiving portion has a communication connection. A handle connected to the end effector actuates the end effector. The handle has a controller electrically connected to the communication connection for authenticating the interchangeable part when placed at the end effector. An interchangeable part is removably connected to the receiving portion and has an encryption device electrically removably connected to the communication connection when placed at the receiving portion. The encryption device authenticates the interchangeable part when queried by the electric controller.

Owner:CILAG GMBH INT

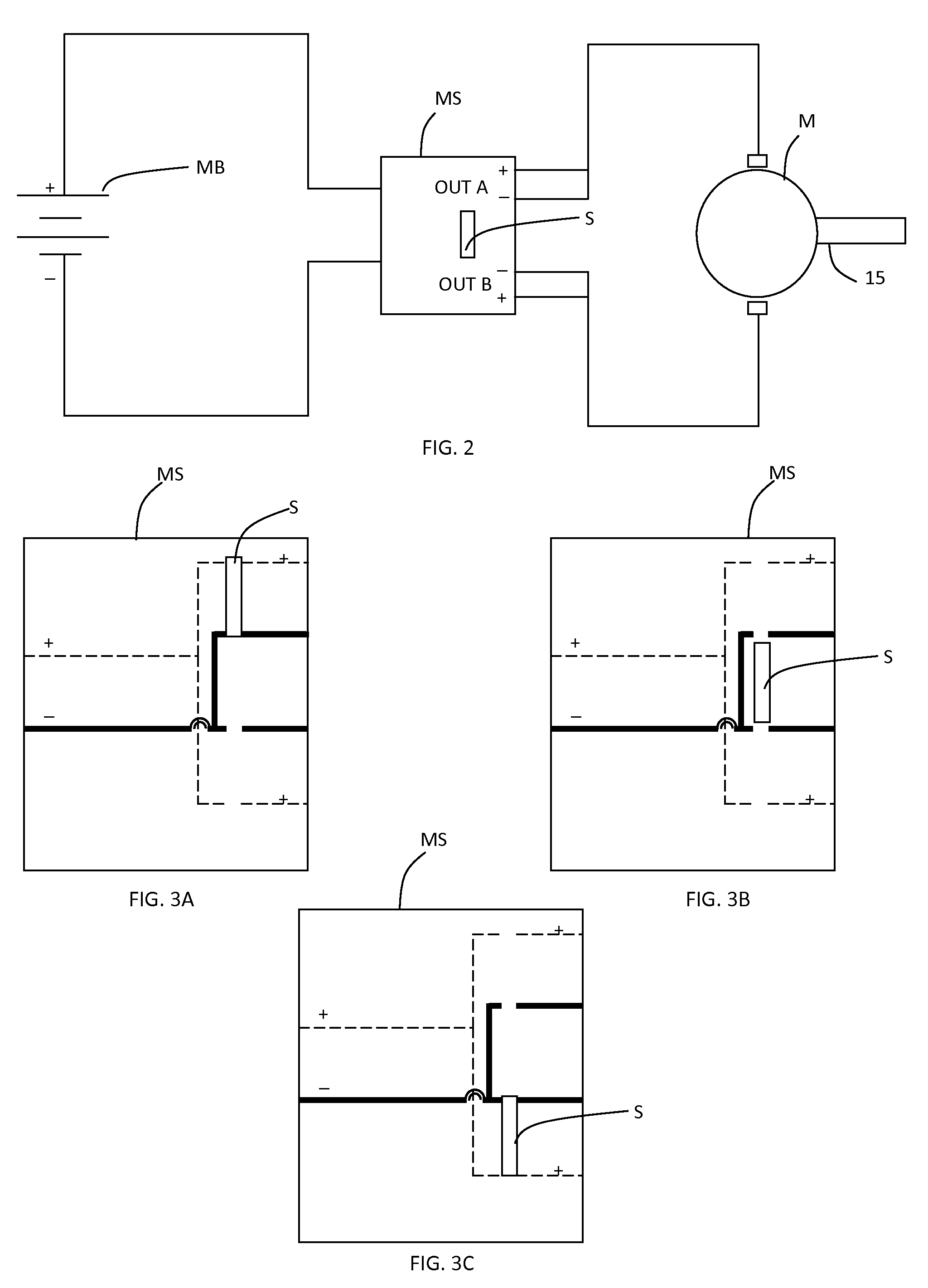

Active braking electrical surgical instrument and method for braking such an instrument

ActiveUS8627993B2Comfortably fit into a user's handReduce manufacturing difficultySuture equipmentsStapling toolsEngineeringActuator

An electrically powered surgical instrument includes a surgical end effector having a surgical procedure effecting actuation assembly. A handle is coupled with the end effector. An electric motor is disposed within a shell of the handle and has power terminals and a drive train actuating the assembly when the motor is supplied with power. A break-before-make power supply switch at the handle selectively controls supply of power to the motor. A post-termination braking circuit electrically short-circuits the power terminals when the switch does not supply power to the motor. A method for post-termination braking of an electrical motor utilizes the permanent magnetic field of the motor to counteract an inertia-induced over-stroke characteristic of the motor, drive train, and / or actuation assembly after powered operation by short-circuiting the still-spinning motor to create an electrically generated magnetic field in opposition to the permanent magnetic field upon ceasing supply of power to the motor.

Owner:ETHICON ENDO SURGERY INC

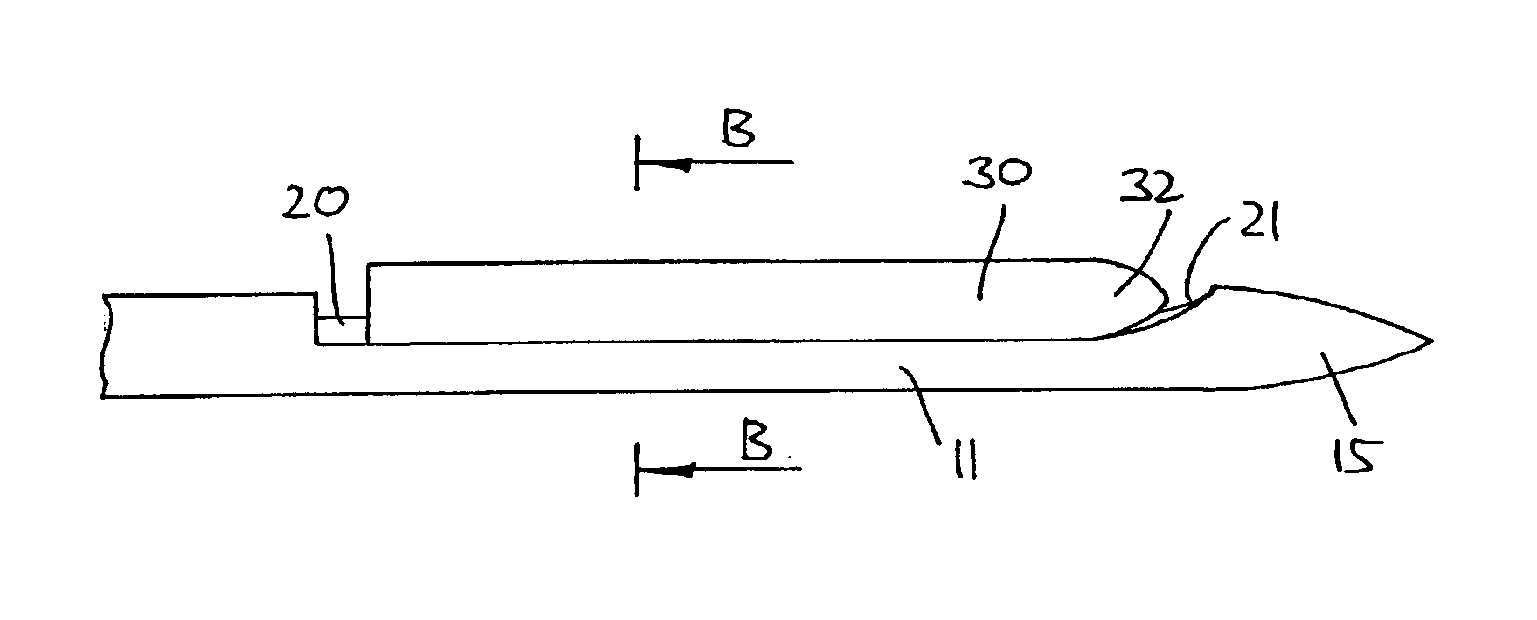

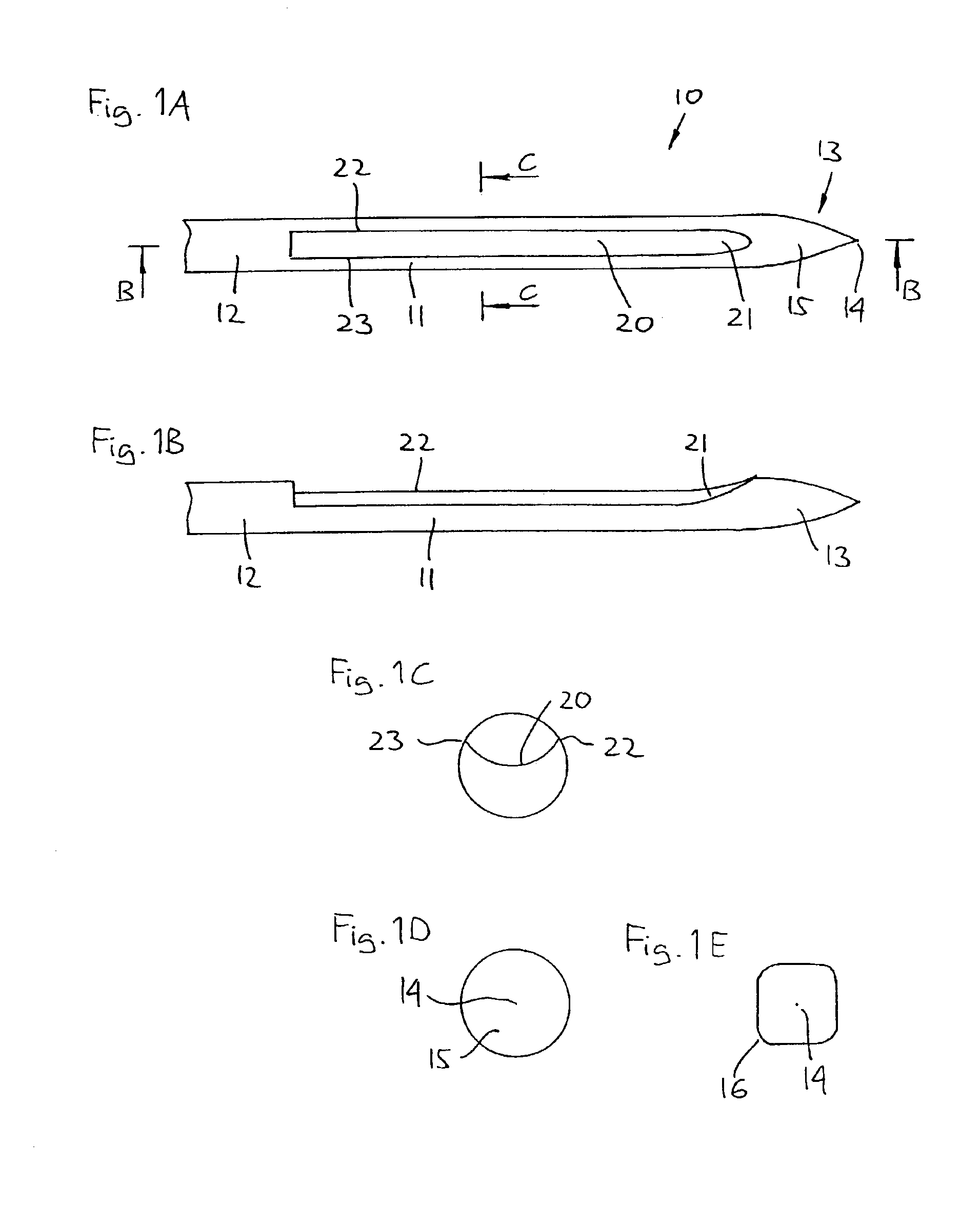

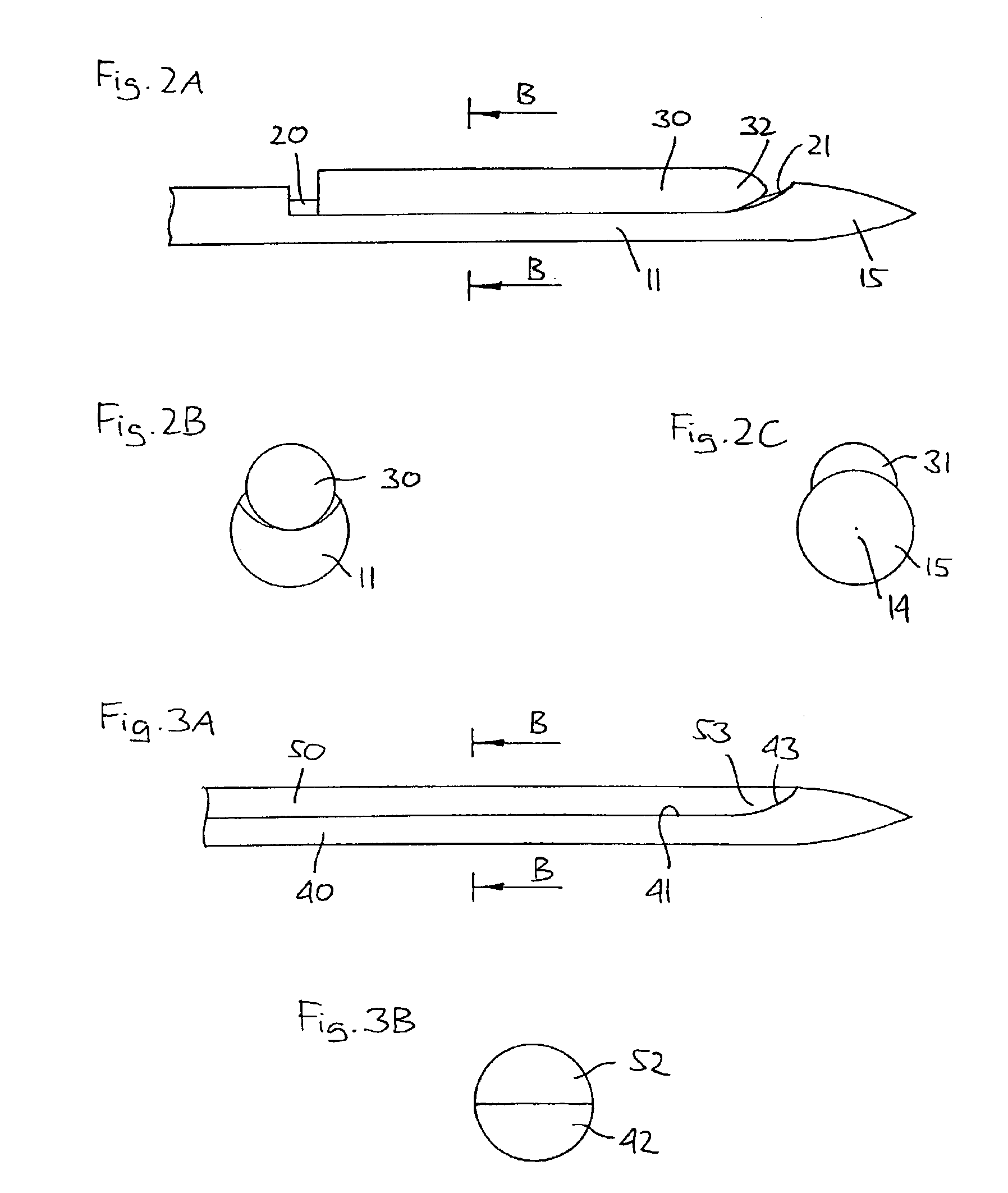

Atraumatic insertion of a subcutaneous device

The invention relates to a concept for placing a subcutaneous device such as a sensor at a selected site within the body of a patient, e.g. to obtain blood glucose readings. In a first aspect, an insertion needle comprises an oblong needle body and a distal end portion, the distal end portion having a pointed distal tip allowing the needle to be introduced subcutaneously and a distally facing generally smooth surface, the body comprising along a portion thereof a longitudinal groove adapted to at least partially accommodate the subcutaneous device. In a second aspect, a combination of an insertion needle and a subcutaneous device form an oblong body portion and a distal end portion formed by either of the members or in combination by the two members, the distal end portion having a pointed distal tip and a distally facing generally smooth surface. By the above configuration, a concept is provided reducing the severity of the body response following transcutaneous placement of a device as well as reducing the pain associated with the insertion.

Owner:NOVO NORDISK AS

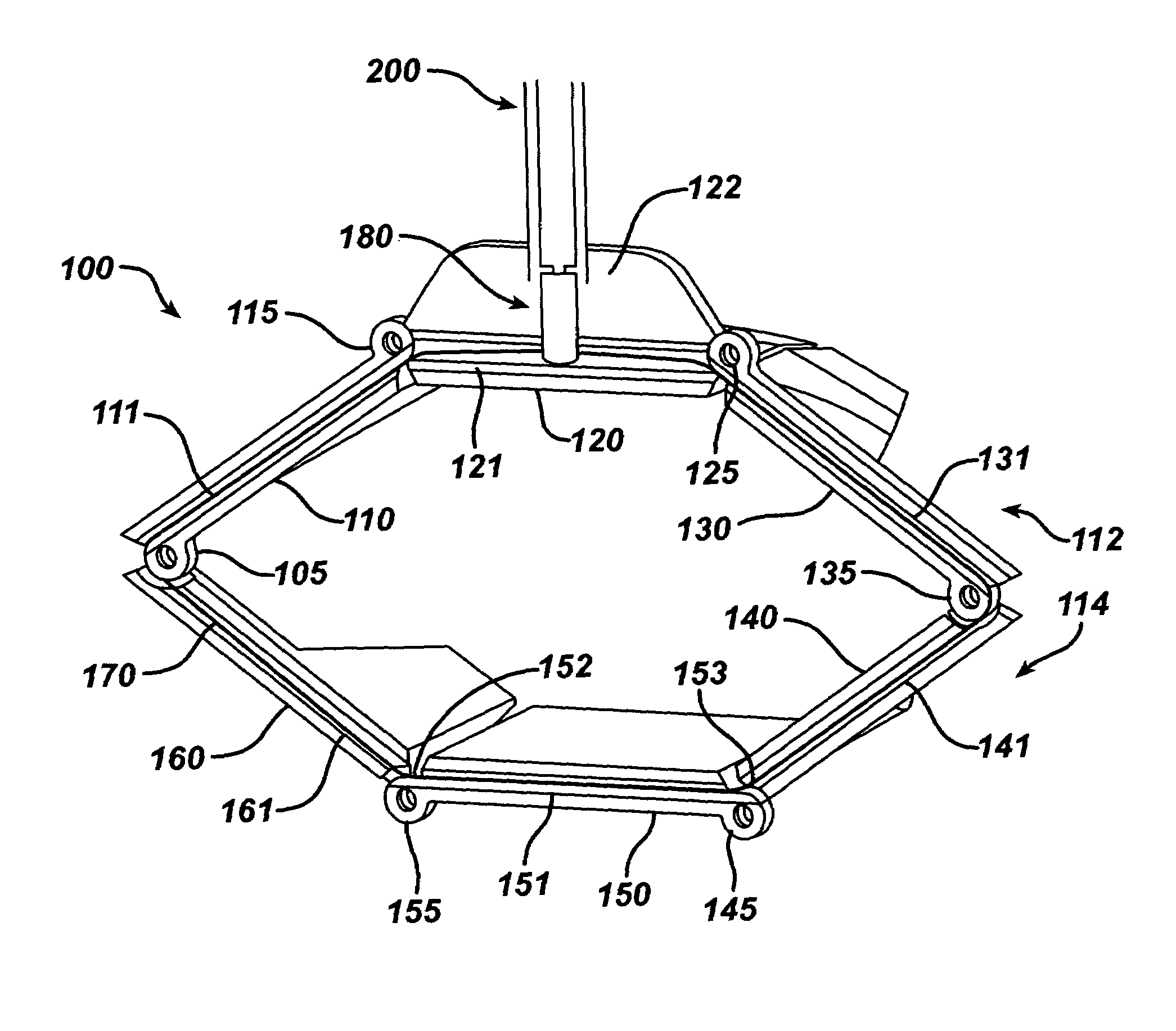

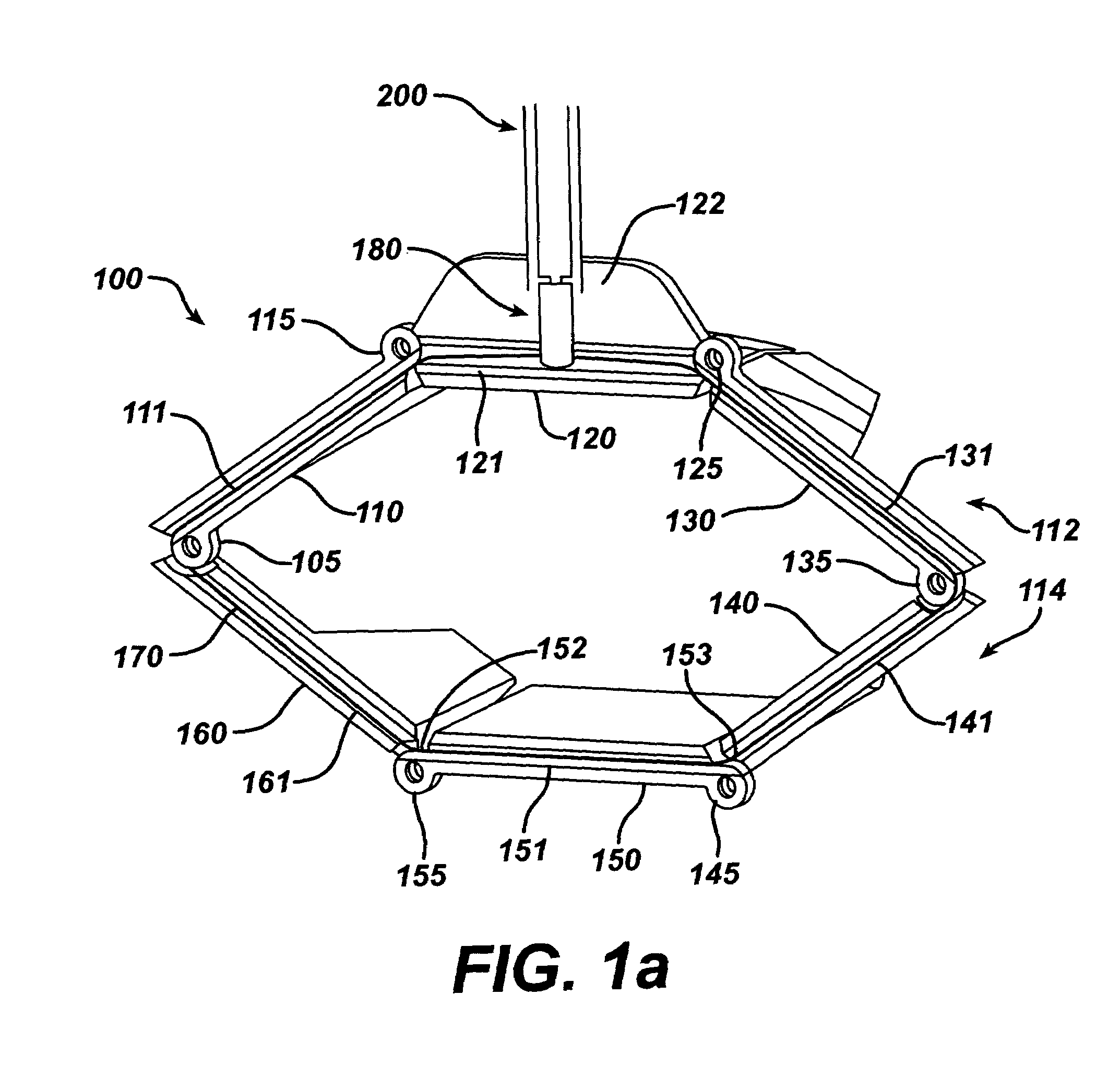

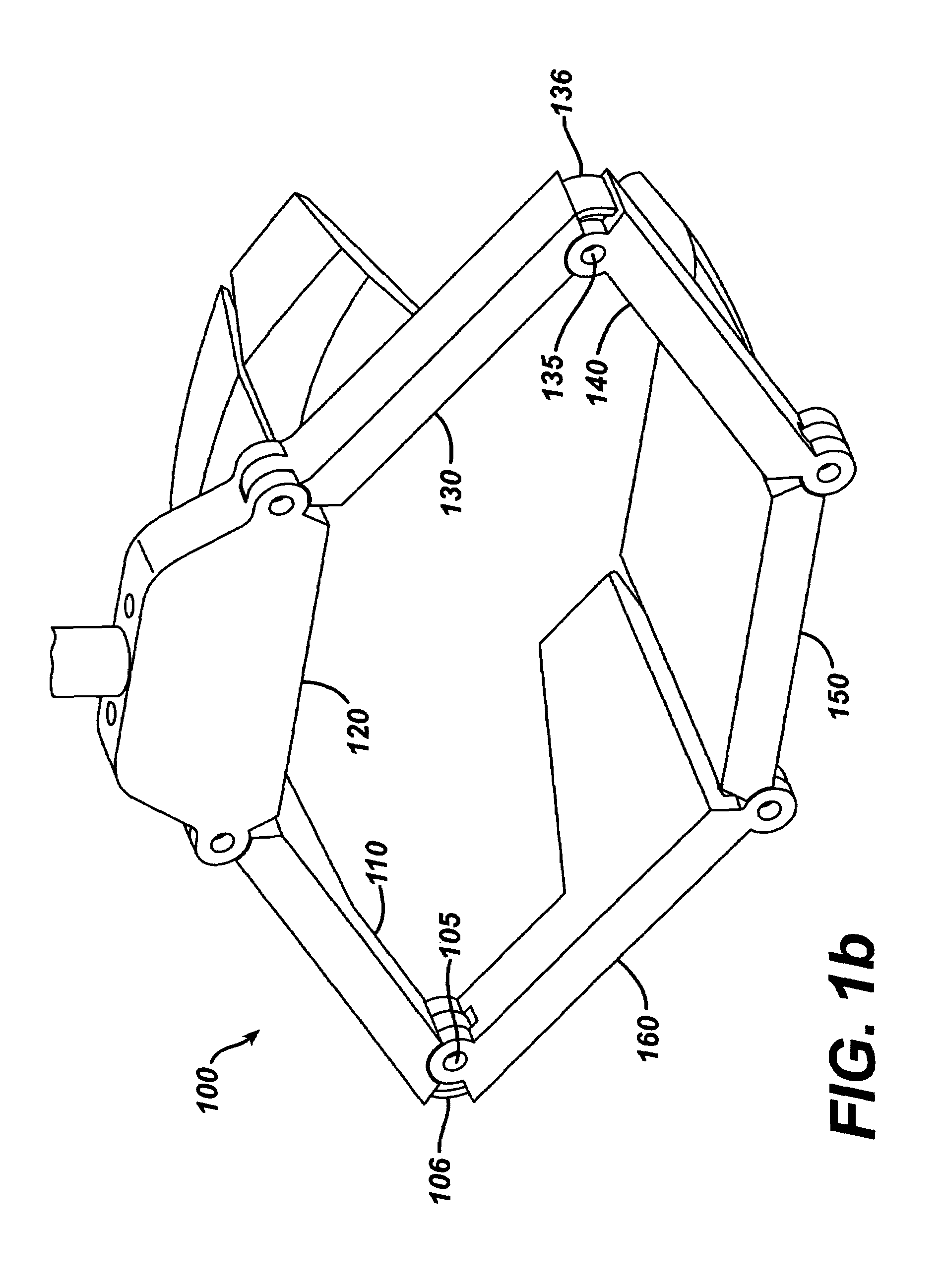

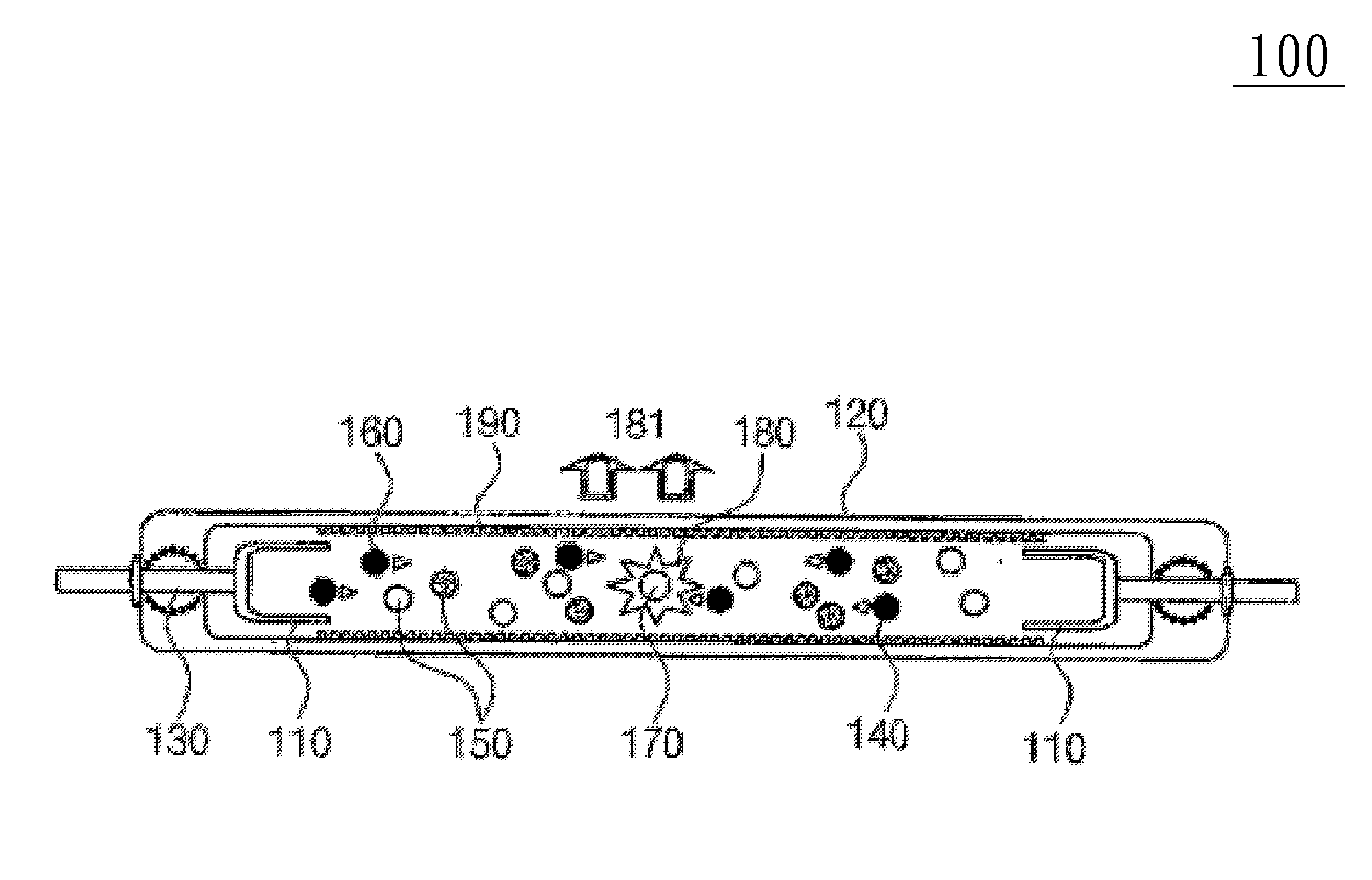

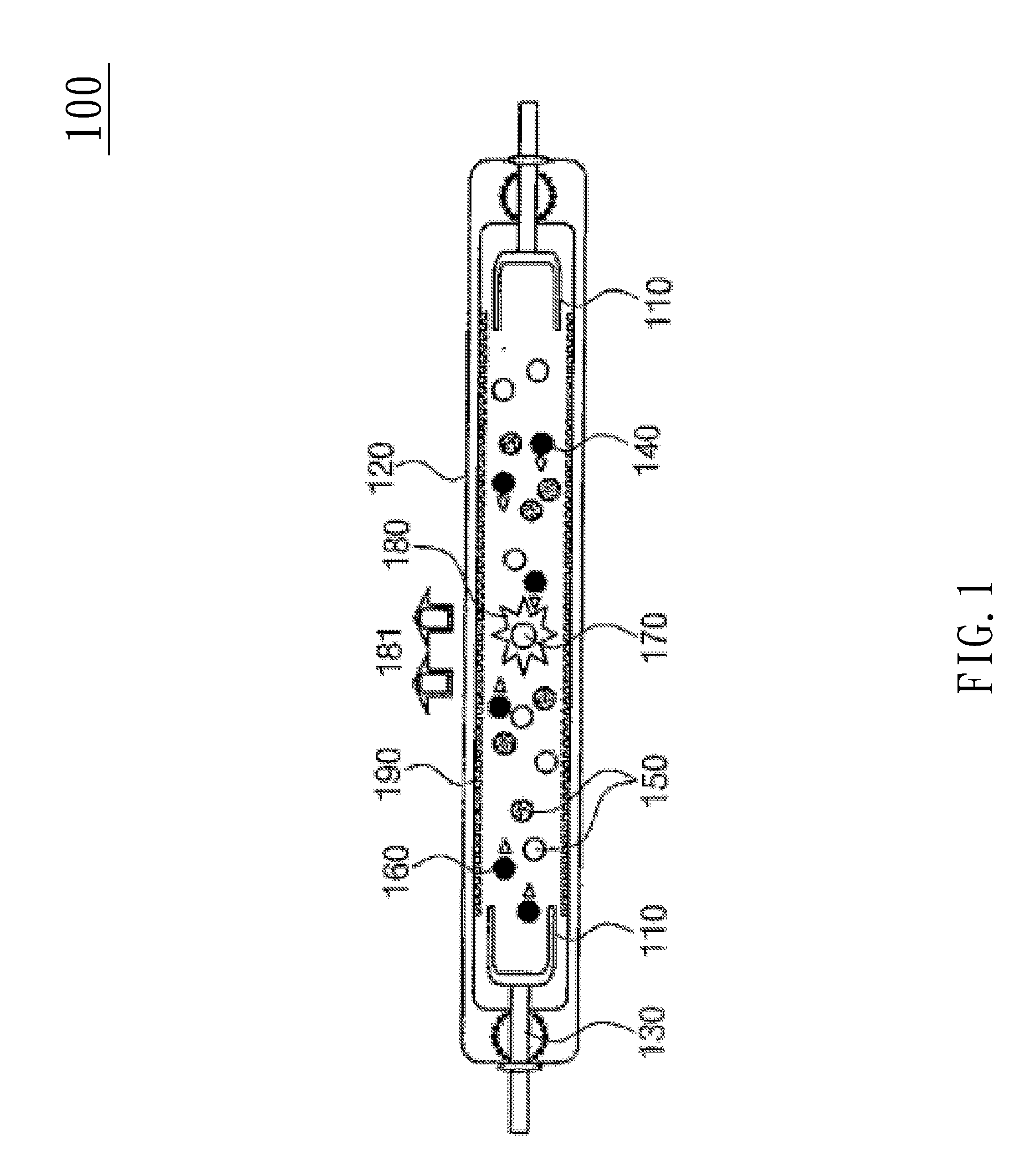

Low profile surgical retractor

A compact, low-profile surgical retractor (100) avoids the need for a bulky frame. The retractor includes retractor blade components (110, 120, 130, 140, 150, 160) joined pivotally. A cable (170) is guided by each retractor blade component. A winding mechanism (180), such as a spool, is carried by one of the retractor blade components (120) for winding up the cable to cause the retractor blade components to transition from a closed position to an open position. The winding mechanism may be actuated by a detachable handle (200). The retractor blade components may be unitary, injection-molded pieces. The retractor blade components may be fixed pivotally, such as by pins, or pivotally joined by living hinges. A less-invasive surgical method is also provided in which the retractor is inserted into the body through an incision.

Owner:EDWARDS LIFESCIENCES LLC

Electrically Self-Powered Surgical Instrument With Cryptographic Identification of Interchangeable Part

ActiveUS20080185419A1Reduce manufacturing difficultyReduce manufacturing costSuture equipmentsStapling toolsElectricityEngineering

A surgical instrument, includes a surgical end effector having a receiving portion for removably receiving therein an interchangeable part. The receiving portion has a communication connection. A handle connected to the end effector actuates the end effector. The handle has a controller electrically connected to the communication connection for authenticating the interchangeable part when placed at the end effector. An interchangeable part is removably connected to the receiving portion and has an encryption device electrically removably connected to the communication connection when placed at the receiving portion. The encryption device authenticates the interchangeable part when queried by the electric controller.

Owner:CILAG GMBH INT

Methods for Cryptographic Identification of Interchangeable Parts for Surgical Instruments

ActiveUS20100230465A1Comfortably fit into a user's handReduce manufacturing difficultySuture equipmentsStapling toolsEngineeringActuator

A method for encrypted authentication of interchangeable parts of a surgical instrument includes providing a surgical end effector at a distal end of a handle of the surgical instrument and electrically connecting an authentication controller within the handle to a receiving portion of the end effector. An interchangeable part is removably placed at the receiving portion. The interchangeable part is authenticated with the authentication controller when the interchangeable part is seated in the end effector.

Owner:CILAG GMBH INT

Liquid crystal display device

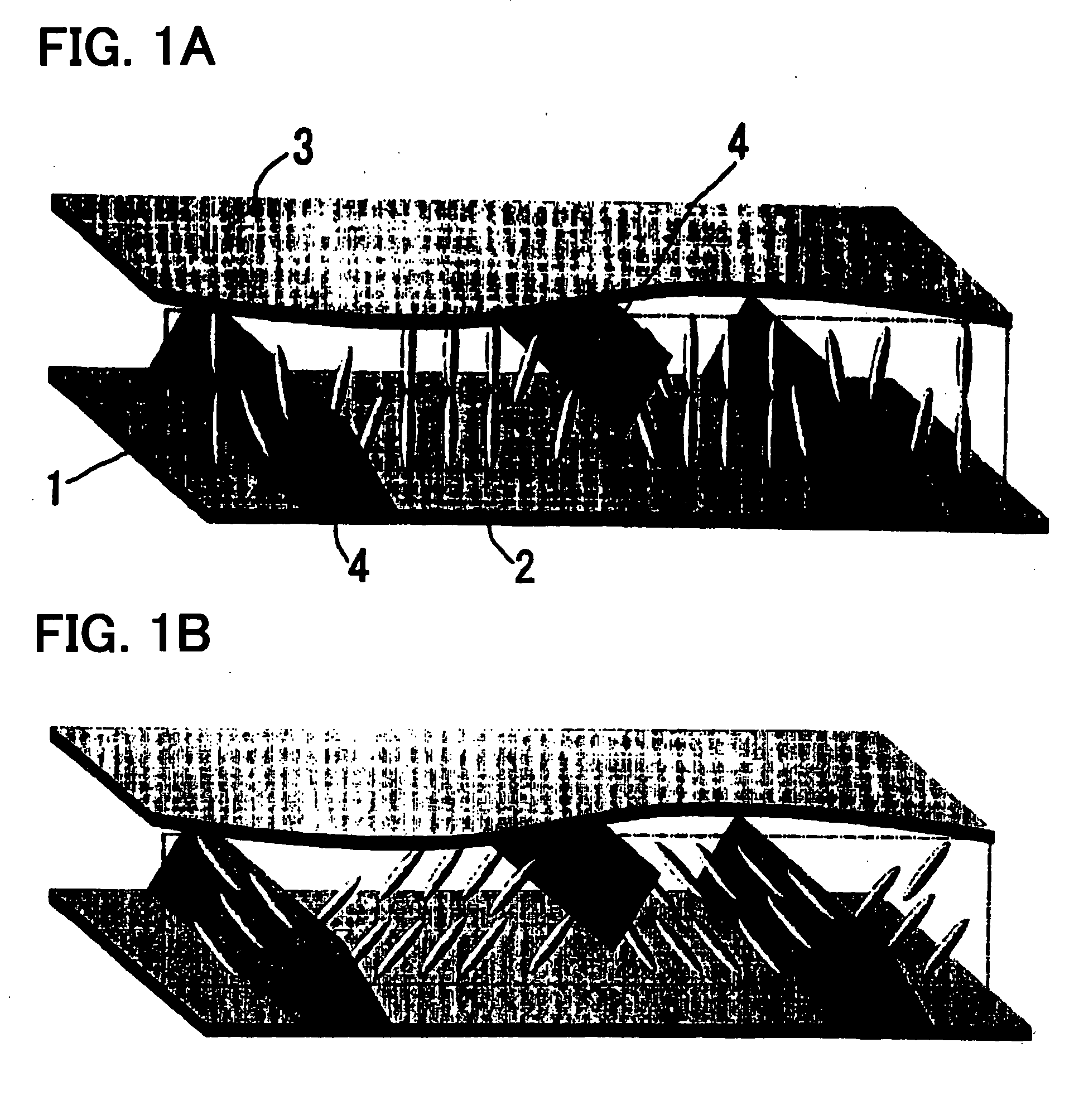

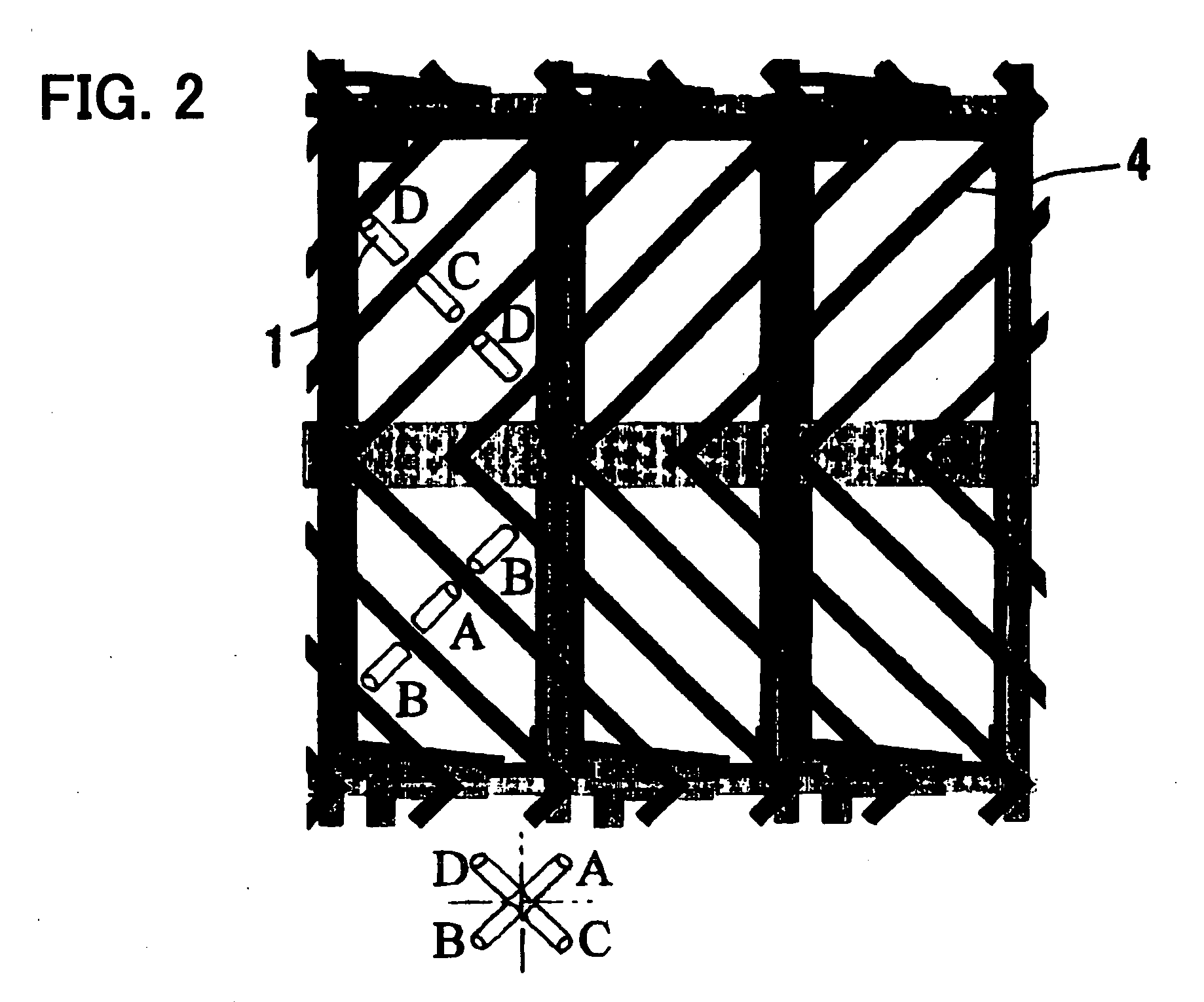

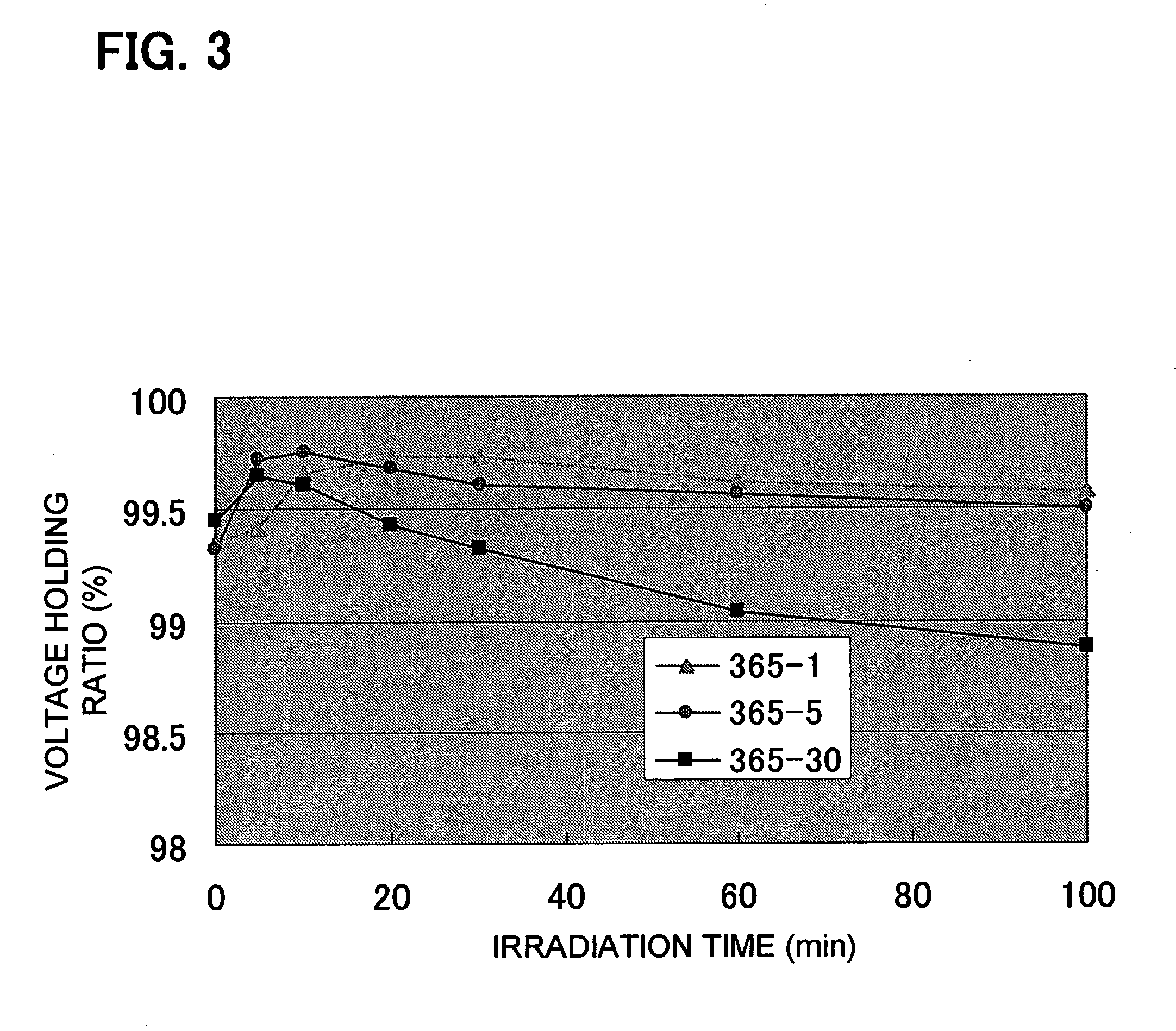

InactiveUS20060066793A1Low costImprove production yieldLiquid crystal compositionsNon-linear opticsChemistryCompound (substance)

A high-performance liquid crystal display device is provided that can be manufactured at a low cost and a high production yield. In this liquid crystal display device, a liquid crystal composition comprising liquid crystal molecules and a polymerizable compound that can be polymerized by ultraviolet rays or by a combination of ultraviolet rays and heat is disposed between a pair of substrates; the polymerizable compound is polymerized, forming a liquid crystal layer, by an operation including irradiation of ultraviolet rays that do not contain wavelength components of not higher than 313 nm; and uneven portions are installed on the liquid crystal layer contacting surface, or a slit pattern is installed in an electrode, or uneven portions are installed on the liquid crystal layer contacting surface, and a slit pattern is installed in the electrode.

Owner:SHARP KK

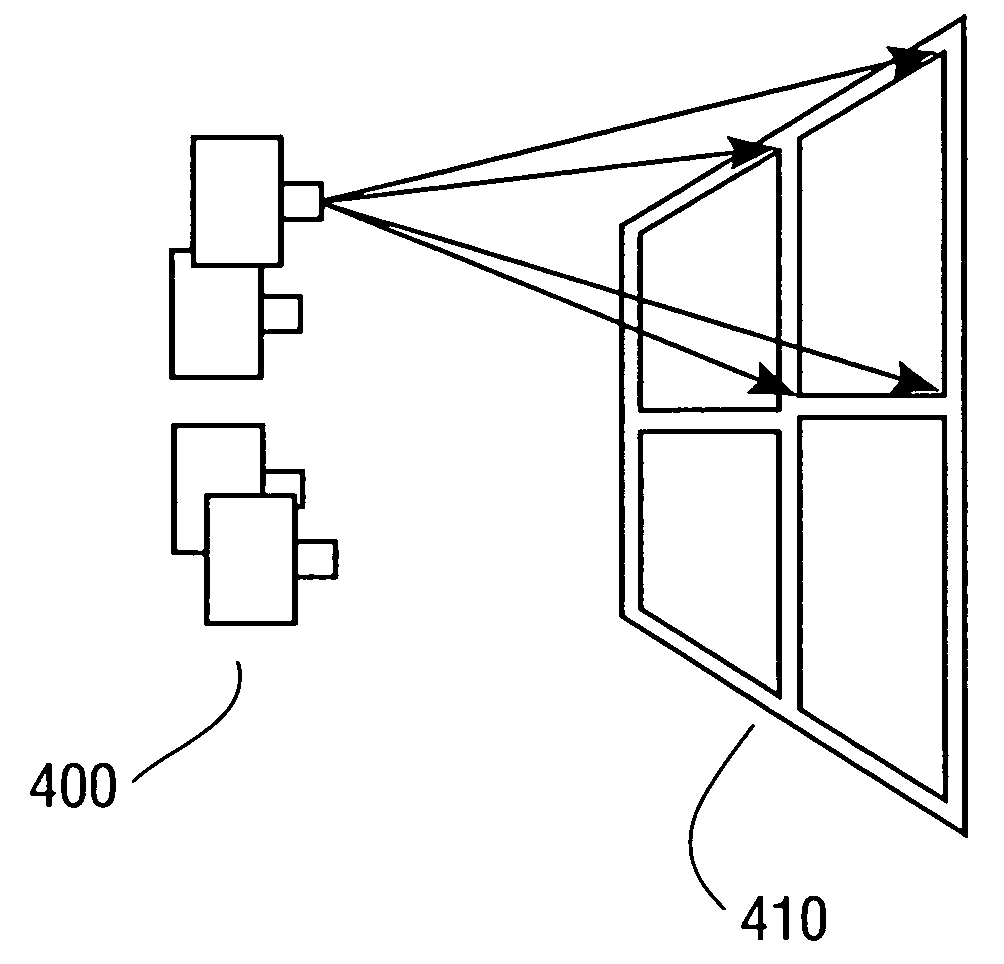

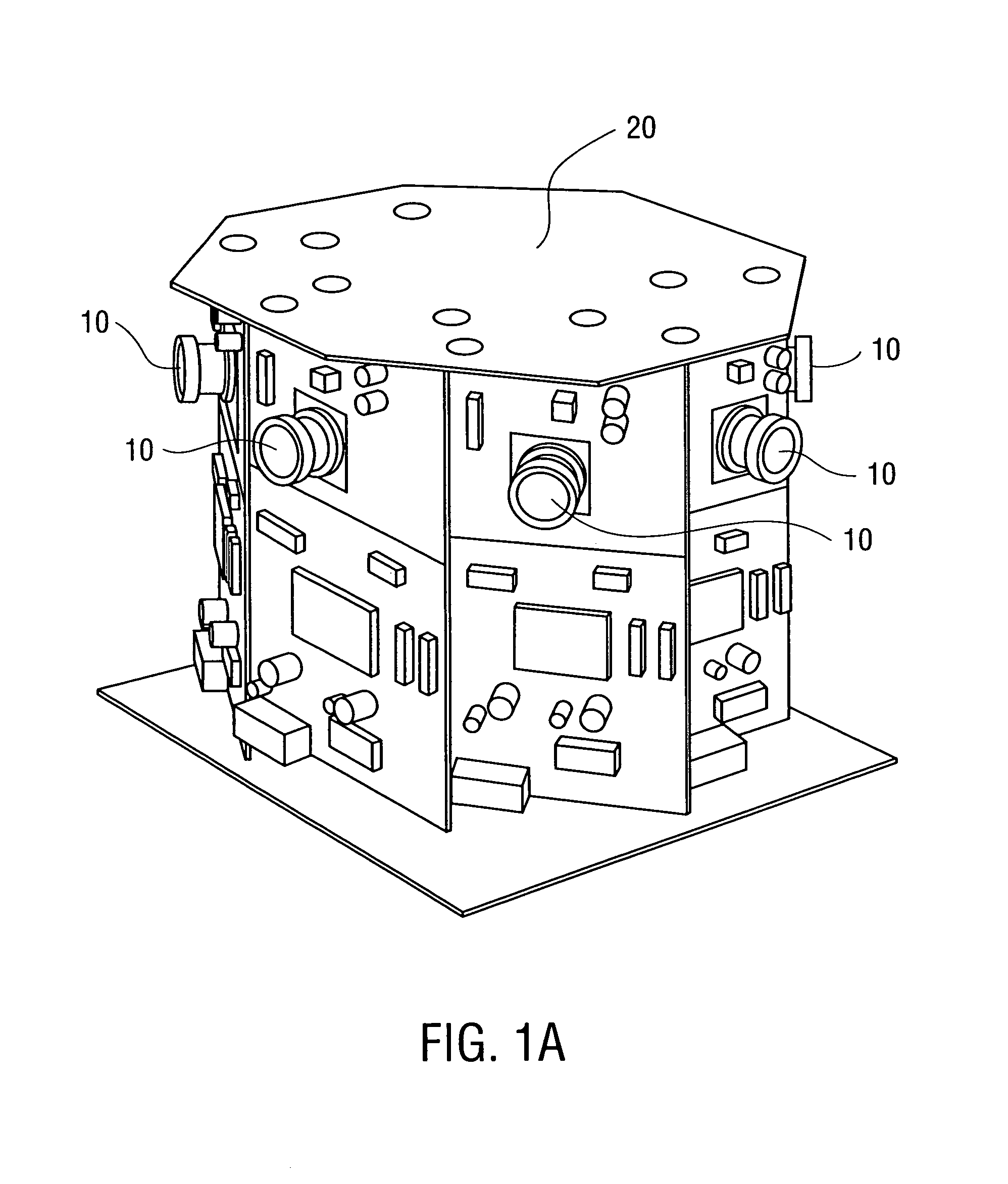

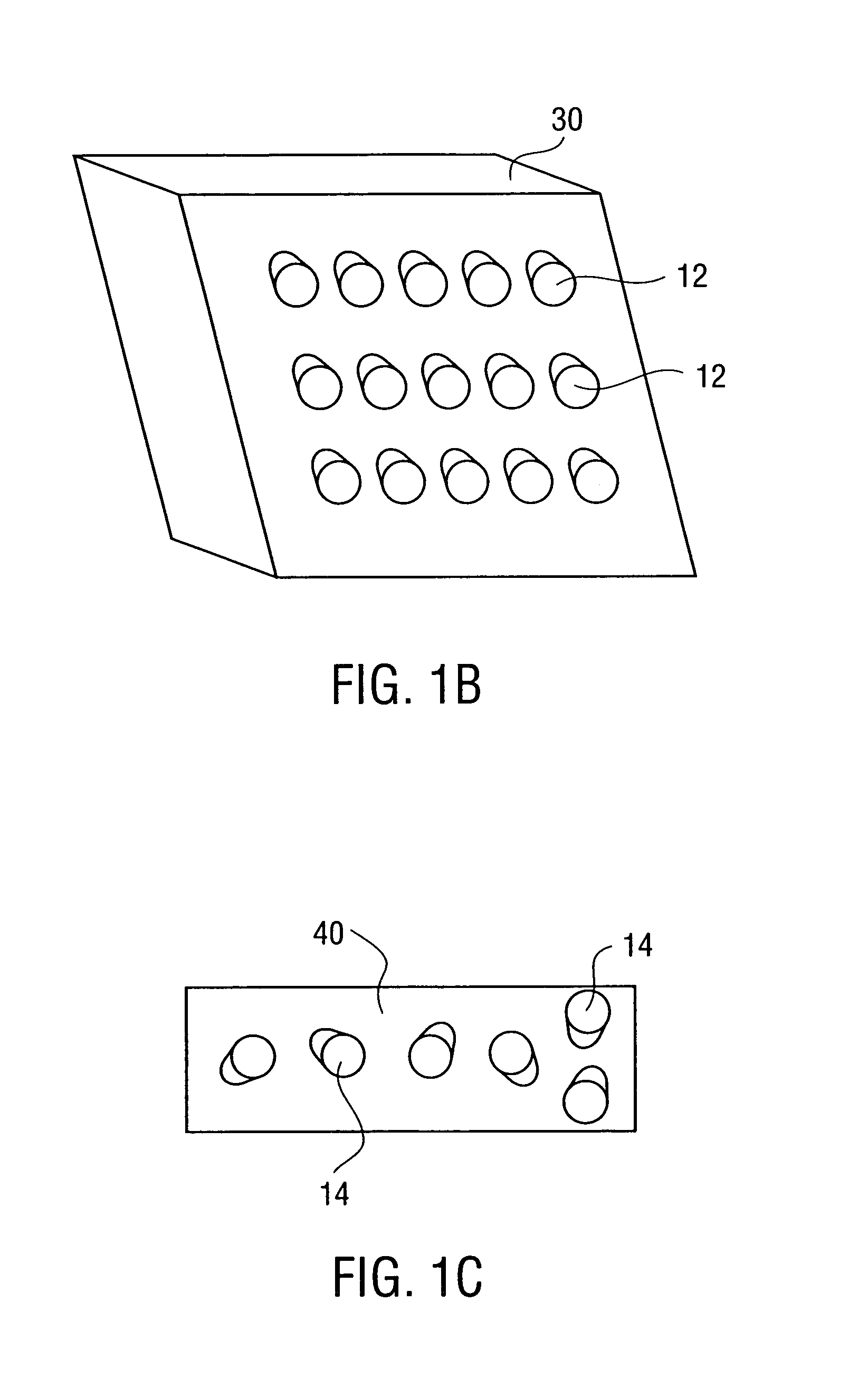

Automatic video system using multiple cameras

InactiveUS7015954B1Reduce manufacturing costCombine accuratelyImage enhancementTelevision system detailsDynamic equationCombined use

A camera array captures plural component images which are combined into a single scene from which “panning” and “zooming” within the scene are performed. In one embodiment, each camera of the array is a fixed digital camera. The images from each camera are warped and blended such that the combined image is seamless with respect to each of the component images. Warping of the digital images is performed via pre-calculated non-dynamic equations that are calculated based on a registration of the camera array. The process of registering each camera in the arrays is performed either manually, by selecting corresponding points or sets of points in two or more images, or automatically, by presenting a source object (laser light source, for example) into a scene being captured by the camera array and registering positions of the source object as it appears in each of the images. The warping equations are calculated based on the registration data and each scene captured by the camera array is warped and combined using the same equations determined therefrom. A scene captured by the camera array is zoomed, or selectively steered to an area of interest. This zooming- or steering, being done in the digital domain is performed nearly instantaneously when compared to cameras with mechanical zoom and steering functions.

Owner:FUJIFILM BUSINESS INNOVATION CORP

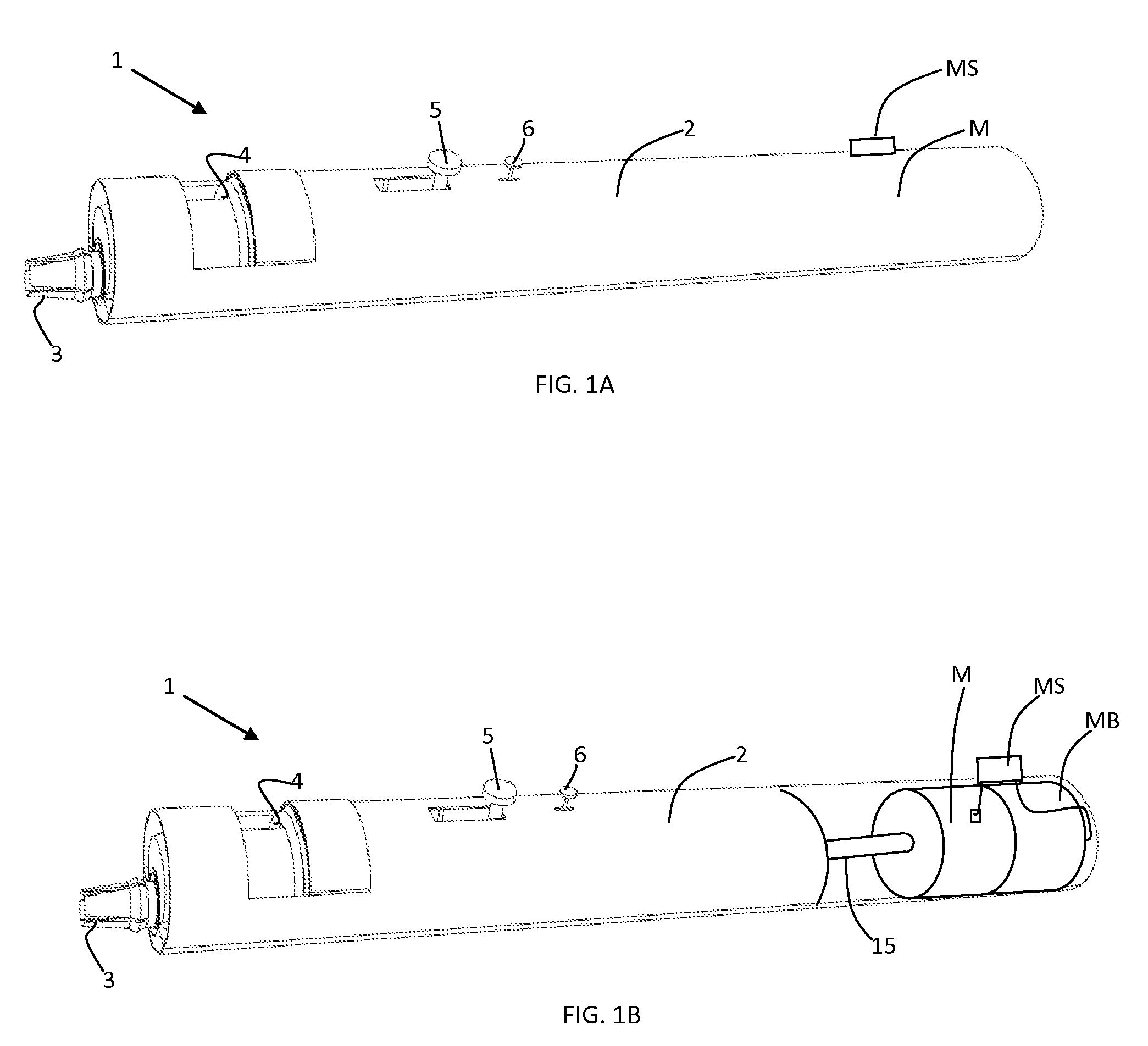

Electric surgical instrument with optimized power supply and drive

ActiveUS20070270784A1Comfortably fit into a user's handReduce manufacturing difficultySuture equipmentsStapling toolsAverage currentActuator

A surgical instrument includes a surgical end effector having at least one actuation assembly to effect a surgical procedure when actuated, an electric motor operationally connected to the end effector to operate the at least one actuation assembly, and a power supply electrically connected to the motor and selectively powering the motor to actuate the actuation assembly. The power supply has a battery cell with a critical current rate and, when activated to power the motor and actuate the actuation assembly, operates the cell at a super-critical current rate or at an average current rate above the critical current rate. The power supply selectively powers the motor to actuate the assembly less than 16 times during a clinical life of at least one of the end effector, the motor, and the power supply. When actuated, the assembly operates only between 0.5 seconds and 16 seconds in duration.

Owner:CILAG GMBH INT

Method for Operating an Electrical Surgical Instrument with Optimal Tissue Compression

ActiveUS20080245841A1Comfortably fit into a user's handReduce manufacturing difficultySuture equipmentsStapling toolsElectricityEngineering

A method for effecting a tissue-compressing surgery at a user-selected compression force provides an electrical switch having switching states changed solely by mechanical movements. The switch is mechanically coupled with an adjustable biasing device retaining the switch in one state until a force greater than the bias device is imparted to the switch. The switch is in line with a tissue-compressing device to place a proportional amount of compression force on the switch as imparted upon the tissue. The biasing device is set to a desired state-changing tissue compression force so that the switch changes its state when the force on the switch is at least the desired force. Tissue compresses until a force imparted on the switch at least equals the desired state-changing tissue compression force and, at such time, the switching state changes and, thereafter, a surgical procedure is carried out on the compressed tissue.

Owner:CILAG GMBH INT

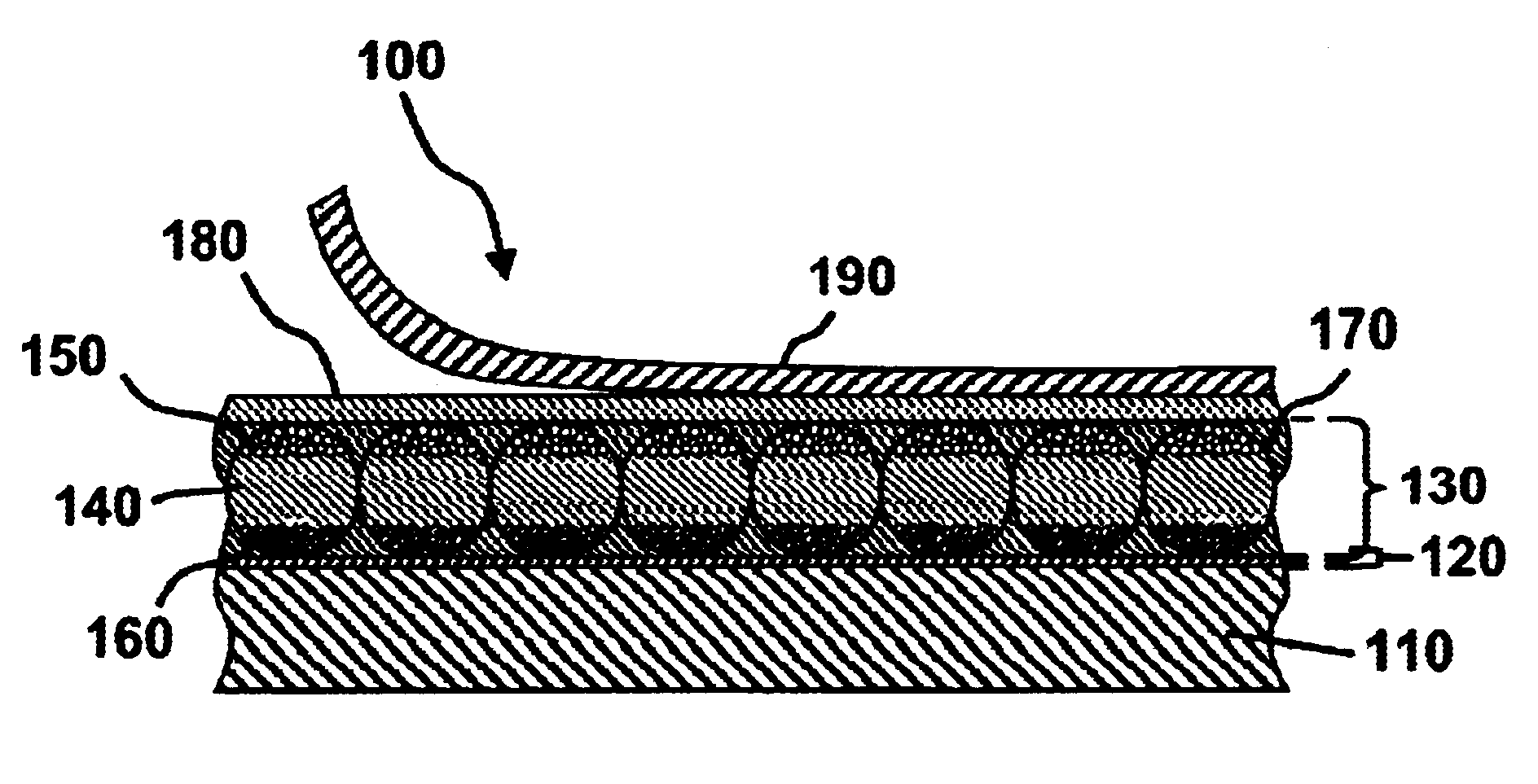

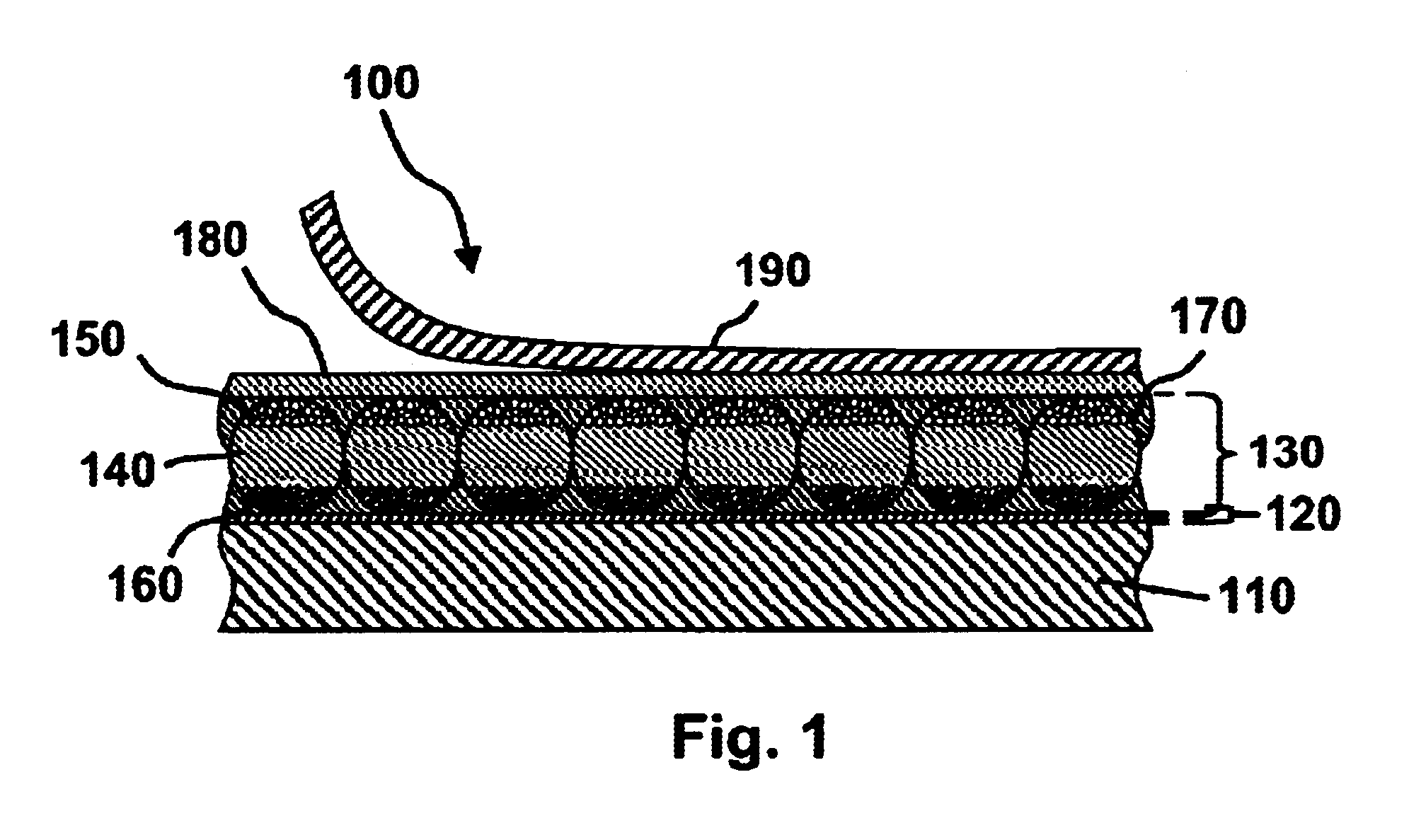

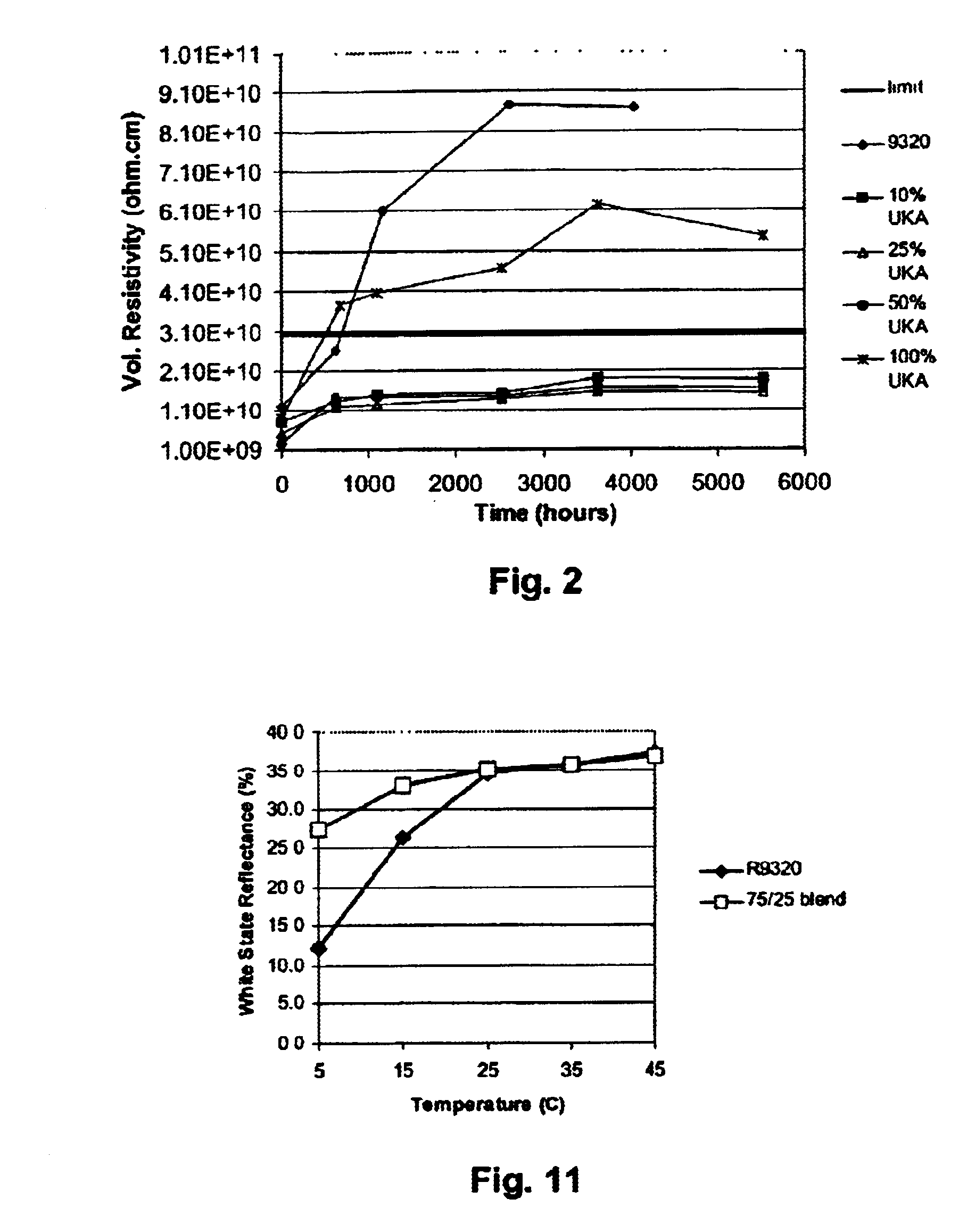

Electro-optic display and lamination adhesive

InactiveUS6831769B2Reduce adverse effectsGood optical performanceLamination ancillary operationsPolyureas/polyurethane adhesivesAdhesiveElectrophoresis

An electro-optic display comprises first and second substrates and a lamination adhesive layer and a layer of a solid electro-optic material disposed between the first and second substrates, the lamination adhesive layer having a volume resistivity, measured at 10° C., which does not change by a factor of more than about 3 after being held at 25° C. and 45 percent relative humidity for 1000 hours. The electro-optic material is preferably an encapsulated electrophoretic material. Other desirable characteristics of lamination adhesives for use in electro-optic displays are also described.

Owner:E INK CORPORATION

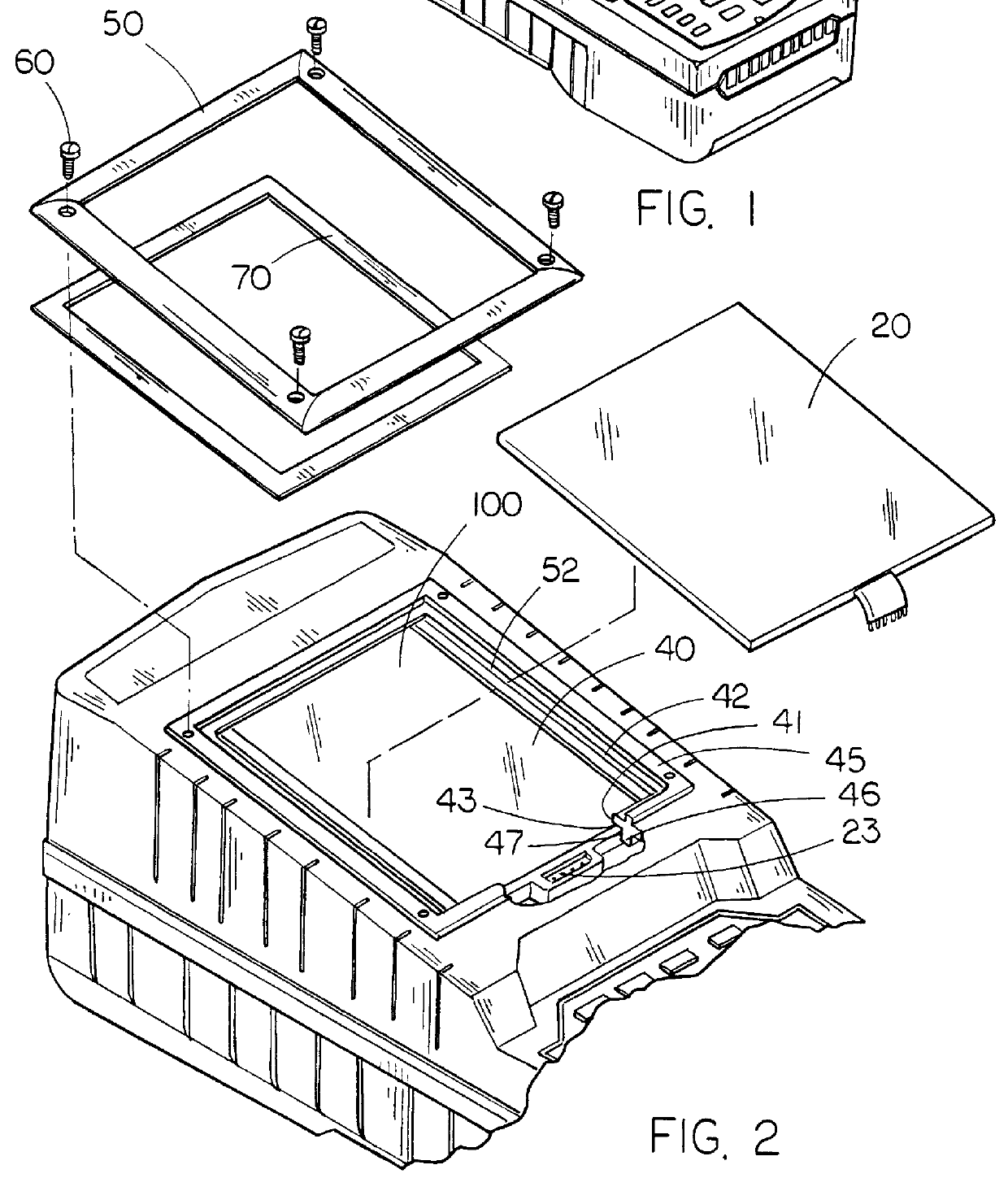

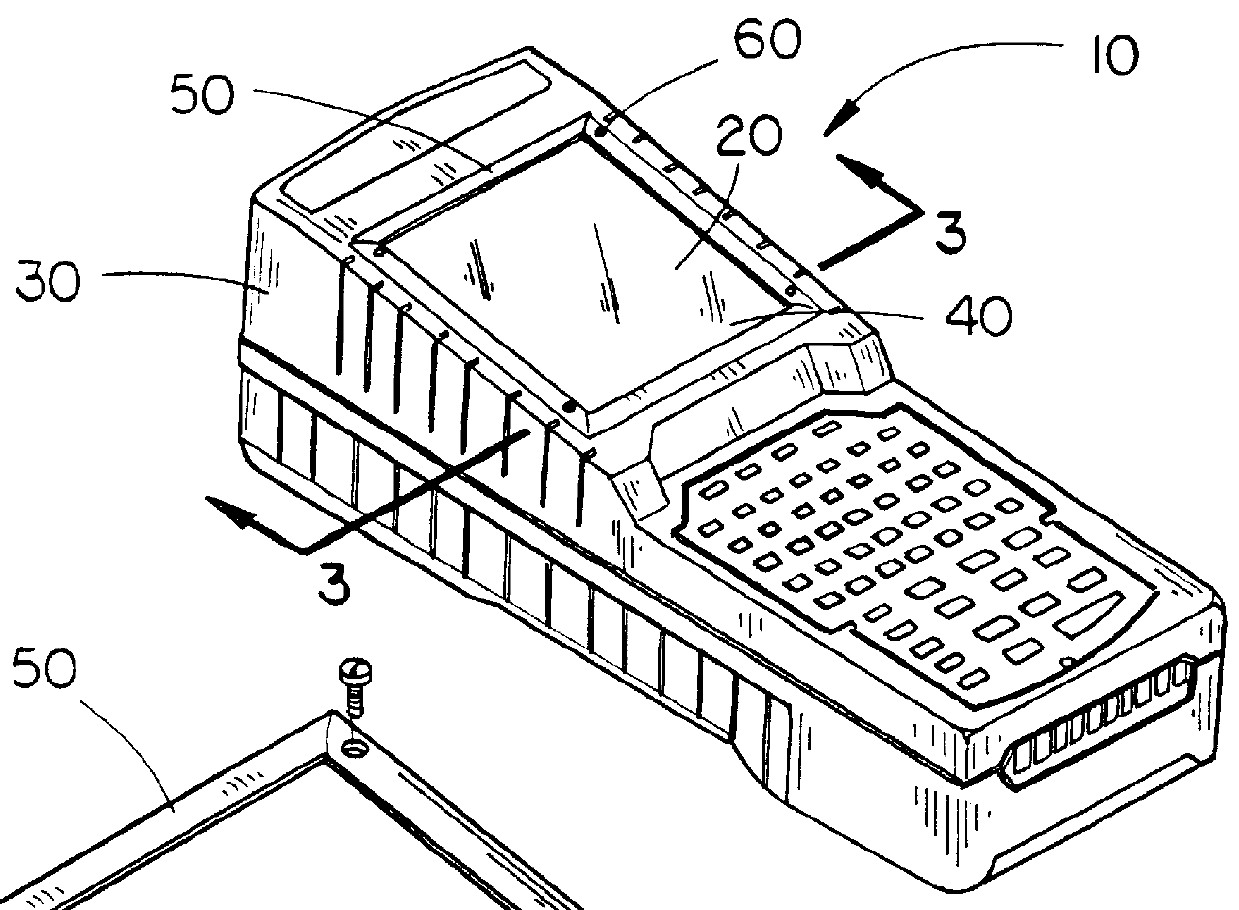

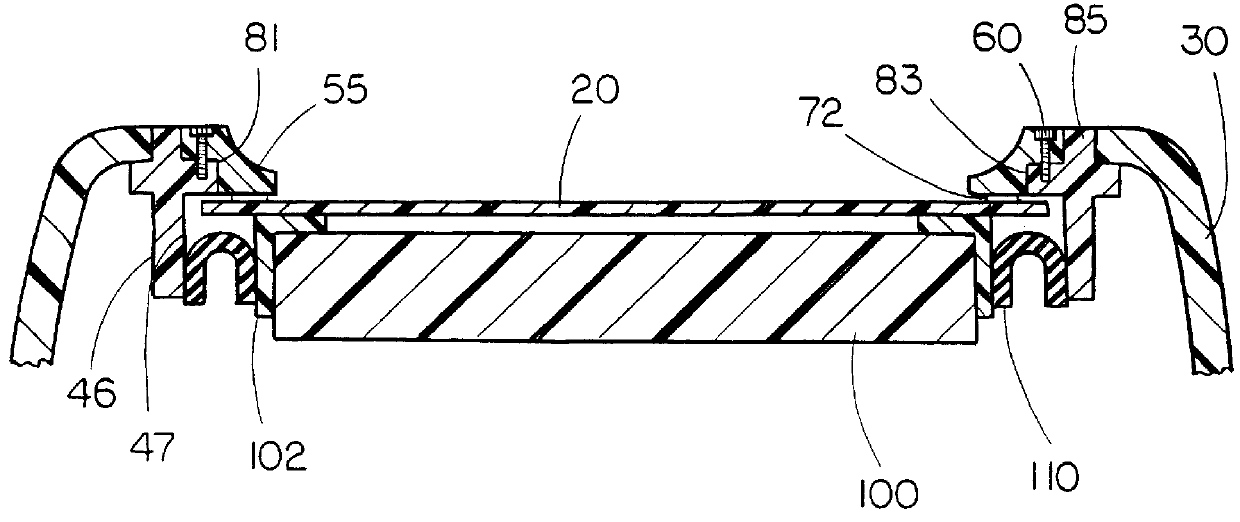

Hand-held portable data terminal having removably interchangeable, washable, user-replaceable components with liquid-impervious seal

InactiveUS6031524AFast replacementCorrection can not be performedInput/output for user-computer interactionDigital data processing detailsElectricityPortable data terminal

The present invention includes a user-replaceable components assembly which permits rapid and intuitively obvious replacement of components in devices such as portable electronic devices. An environmental seal is provided around the components to protect the inner circuitry of the electronic device. Shock-resistant mounting of a display panel beneath the keypad and accommodation for the electrical connection between the keypad and the portable electronic device's inner circuitry are also provided. An environmental seal is provided around a touch sensitive panel to protect the inner circuitry of the electronic device. Shock-resistant mounting of a display panel beneath a touch sensitive panel and accommodation for the electrical connection between the touch sensitive panel and the inner circuitry of an electronic device are further provided.

Owner:INTERMEC IP

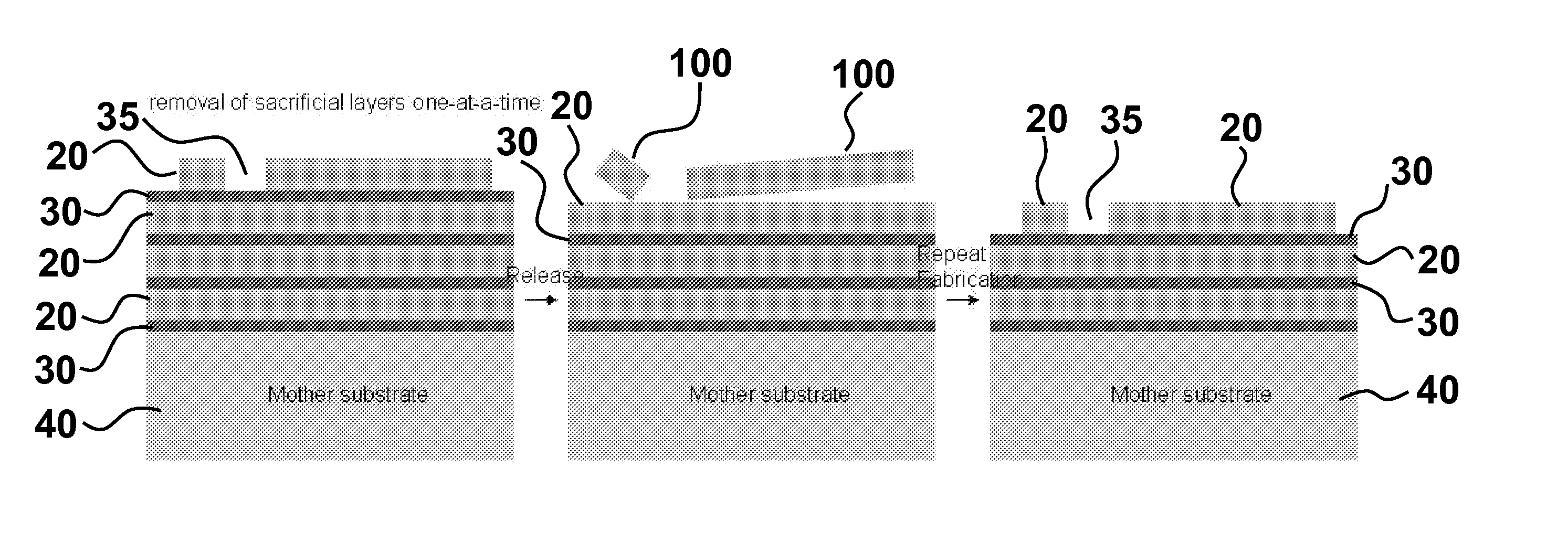

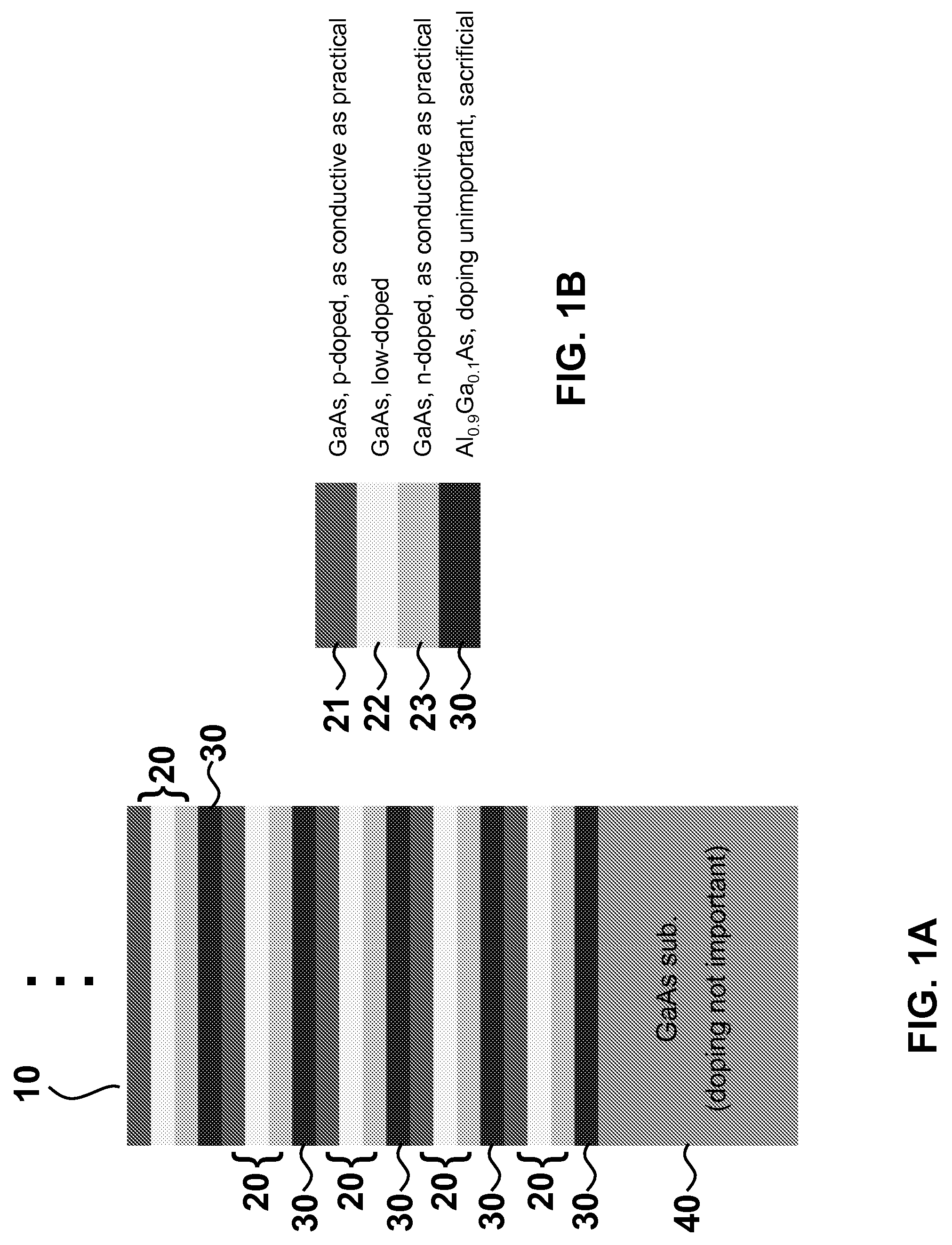

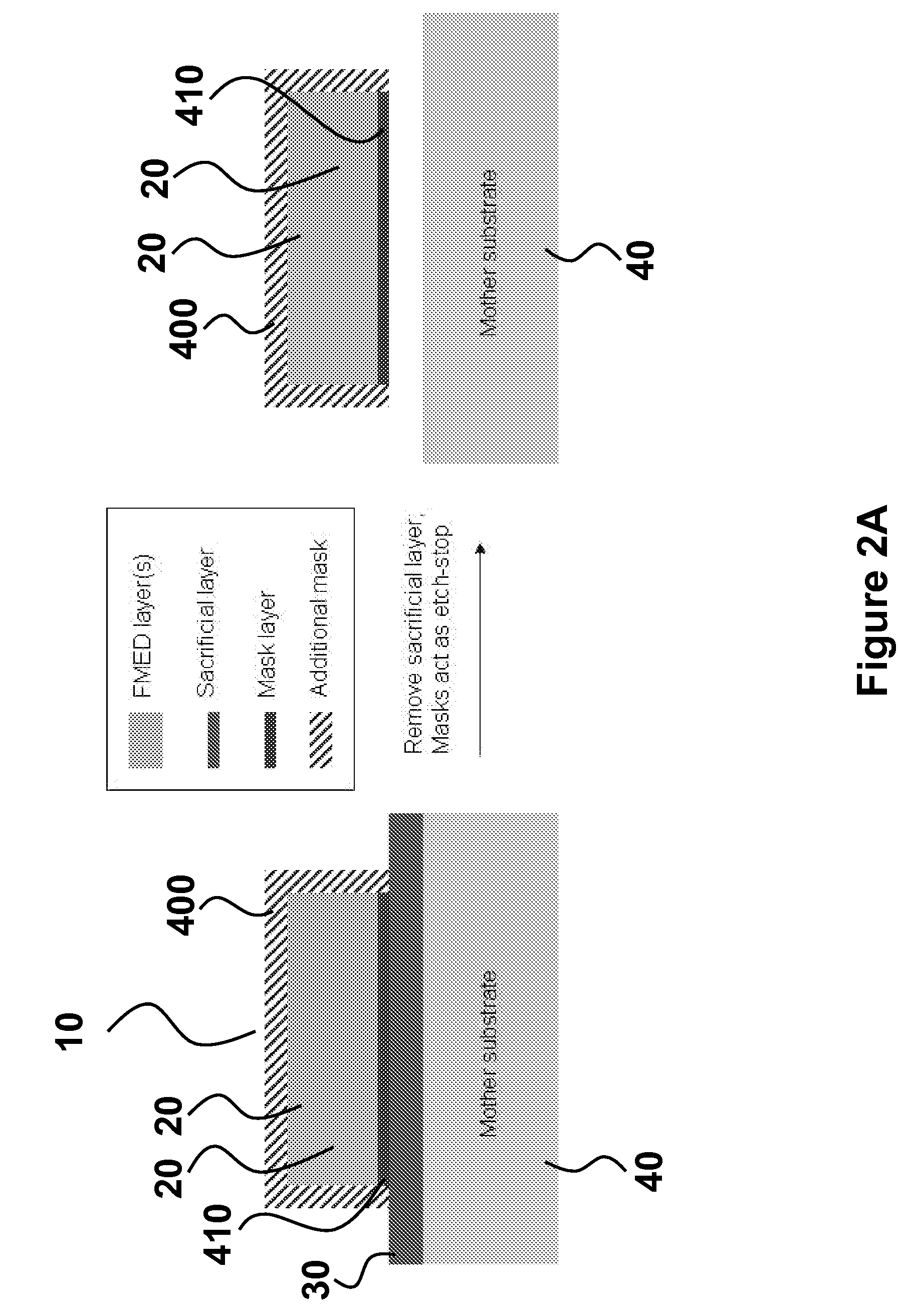

Release strategies for making transferable semiconductor structures, devices and device components

ActiveUS20080108171A1Low cost structureLow costFinal product manufactureNanoinformaticsSemiconductor structureDevice Subassembly

Provided are methods for making a device or device component by providing a multilayer structure having a plurality of functional layers and a plurality of release layers and releasing the functional layers from the multilayer structure by separating one or more of the release layers to generate a plurality of transferable structures. The transferable structures are printed onto a device substrate or device component supported by a device substrate. The methods and systems provide means for making high-quality and low-cost photovoltaic devices, transferable semiconductor structures, (opto-)electronic devices and device components.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Electrical surgical instrument with optimized power supply and drive

ActiveUS20070270884A1Comfortably fit into a user's handReduce manufacturing difficultySuture equipmentsStapling toolsActuatorOperating time

A surgical instrument includes an end effector having an actuator effecting a surgical procedure when actuated, an electric motor operating the actuator, and a power supply actuating the actuator when power is supplied to the motor. The power supply has a battery cell with a given rated power for an operating period of over 15 seconds and for a total aggregate operating time of over 300 seconds. The motor and power supply are configured to utilize the battery cell at a power greater than the given rated power. The motor characteristics are selected to utilize the battery cell for periods of operation of less than 16 seconds and for a total aggregate operating time of less than 300 seconds. A one-handed handle contains all of the power supply, at least part of an anvil control assembly, and at least part of an electrically-powered stapler / cutter control assembly.

Owner:CILAG GMBH INTERNATIONAL

Active braking electrical surgical iinstrument and method for braking such an instrument

ActiveUS20100096431A1Comfortably fit into a user's handReduce manufacturing difficultySuture equipmentsStapling toolsSurgical instrumentInstrumentation

An electrically powered surgical instrument includes a surgical end effector having a surgical procedure effecting actuation assembly. A handle is coupled with the end effector. An electric motor is disposed within a shell of the handle and has power terminals and a drive train actuating the assembly when the motor is supplied with power. A break-before-make power supply switch at the handle selectively controls supply of power to the motor. A post-termination braking circuit electrically short-circuits the power terminals when the switch does not supply power to the motor. A method for post-termination braking of an electrical motor utilizes the permanent magnetic field of the motor to counteract an inertia-induced over-stroke characteristic of the motor, drive train, and / or actuation assembly after powered operation by short-circuiting the still-spinning motor to create an electrically generated magnetic field in opposition to the permanent magnetic field upon ceasing supply of power to the motor.

Owner:ETHICON ENDO SURGERY INC

Electrically Self-Powered Surgical Instrument With Manual Release

ActiveUS20090057369A1Comfortably fit into a user's handReduce manufacturing difficultySuture equipmentsStapling toolsElectricityEngineering

An electrically operated surgical instrument includes a surgical end effector having an actuation assembly effecting a surgical procedure when actuated and a handle connected to the end effector for actuating the assembly. A part of the assembly moves between start and fully actuated positions. The handle has a self-contained power supply and a drive assembly disposed entirely within the handle. The drive assembly has an electrically powered motor and a controller electrically connected to the power supply and to the motor. The controller selectively operates the motor. A transmission mechanically connects the motor to the moving part and selectively displaces the moving part anywhere between the start and fully extended positions when the motor is operated. A manual release is mechanically coupled to the transmission to selectively interrupt the transmission and, during interruption, displaces the moving part towards the start position independent of motor operation.

Owner:CILAG GMBH INT

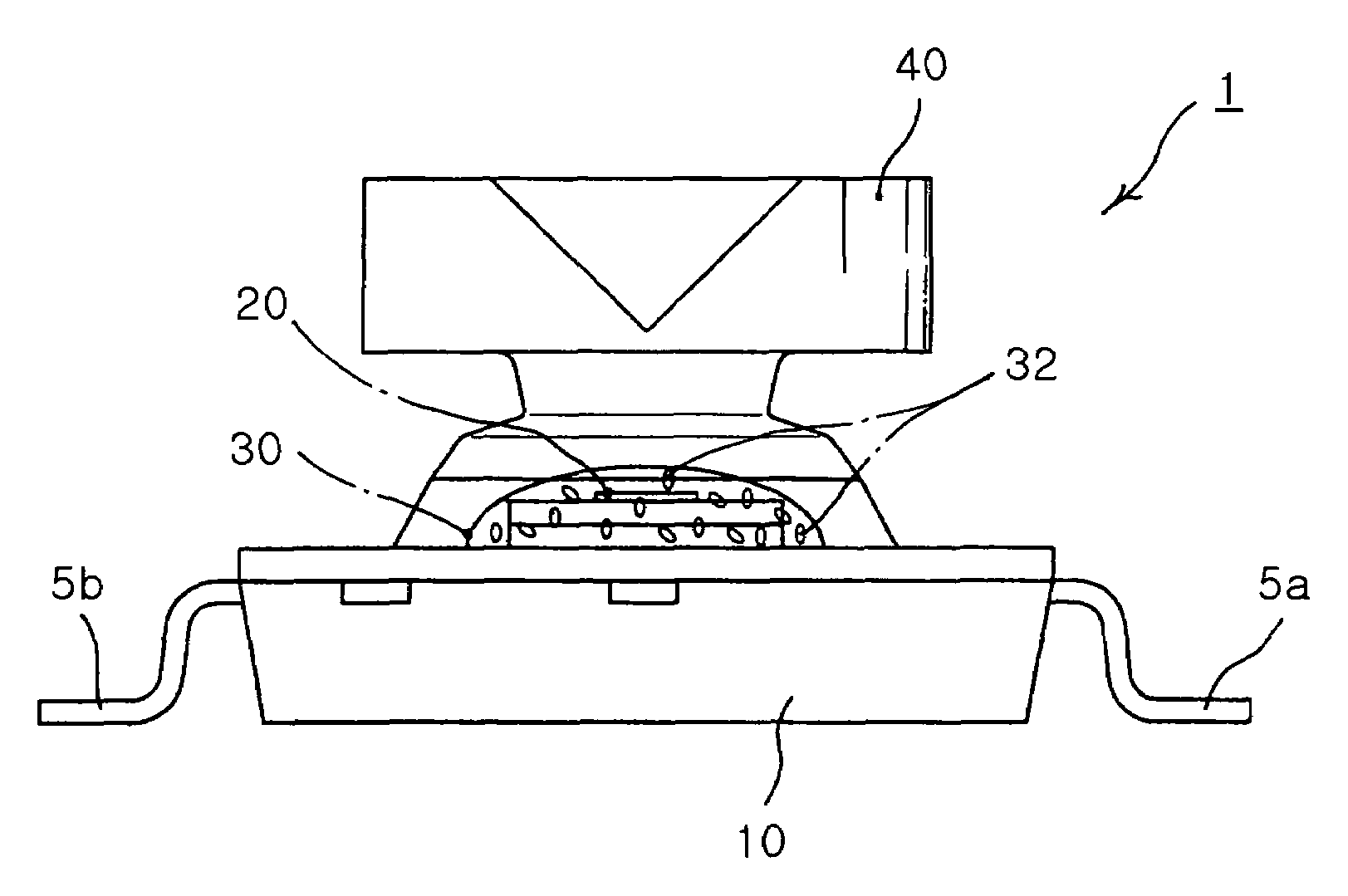

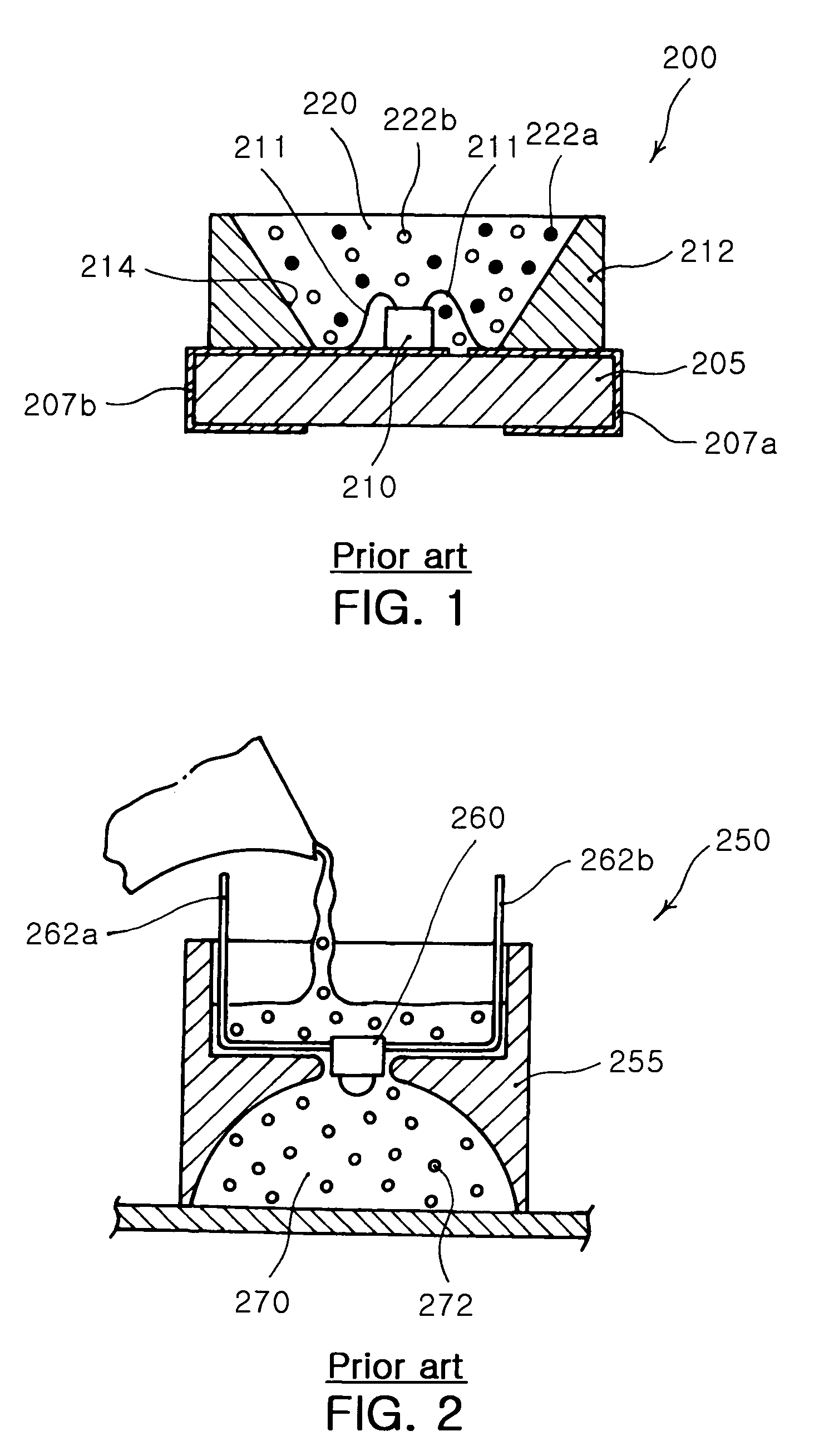

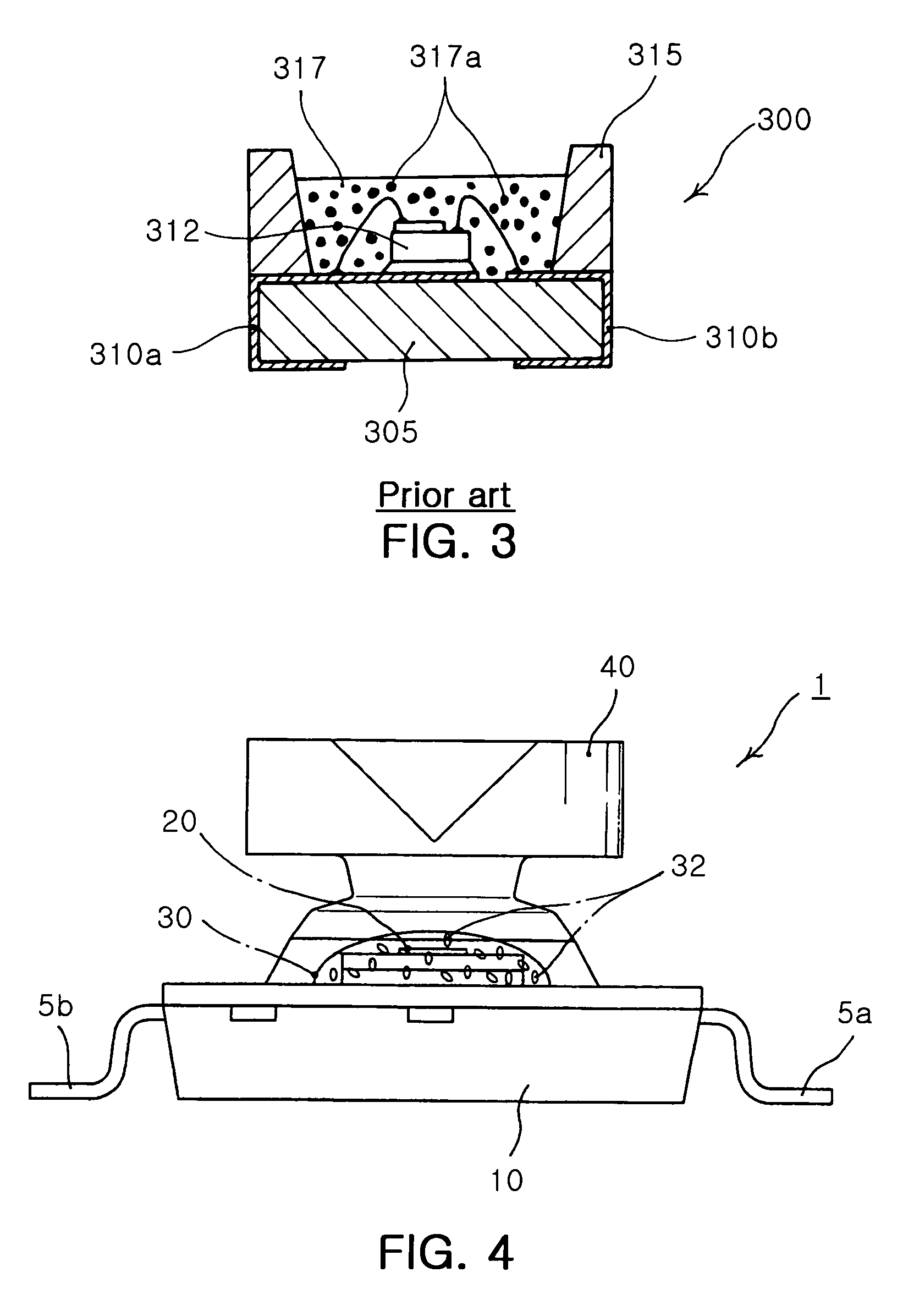

Light emitting diode package with diffuser and method of manufacturing the same

ActiveUS7501656B2Reduce thicknessIncrease freedomSolid-state devicesSemiconductor devicesEngineeringSealant

The invention relates to an LED package for facilitating color mixing using a diffuser and a manufacturing method of the same. The LED package includes a substrate with an electrode formed thereon, and an LED chip mounted on the substrate. The LED package also includes an encapsulant applied around the light emitting diode chip, containing a diffuser. The LED package further includes a lens part disposed on the light emitting diode chip and the encapsulant to radiate light in a wide angle. The LED package allows light from the light emitting diode chip to be emitted out of the package without distortion. The invention allows light to exit through the encapsulant containing the diffuser and the lens part, achieving uniform diffusion and emission of light from the LED chip, thereby increasing a radiating angle and obtaining a uniform light source.

Owner:SAMSUNG ELECTRONICS CO LTD

Biopsy and sutureless device

InactiveUS8540646B2Speed up the processEliminate needVaccination/ovulation diagnosticsExcision instrumentsTissue sampleSurgical department

A dermal punch device for automatically extracting a sample of tissue of a predetermined size and shape from a body comprising a retractable cutter and a sutureless biopsy closure mechanism that includes a wound closure fastener member adapted to be disposed over a biopsy region after the performance of the biopsy, wherein wound closure fastener member is applied without the need of several instruments to seal the wound. The wound closure fastener member is dispensed by a sutureless biopsy closure dispenser located at the same distal end of the biopsy punch device surrounding the biopsy punch cutter assembly avoiding the need of separates instruments, reducing the wound closing steps and surgical procedure time.

Owner:MENDEZ COLL JOSE ARTURO

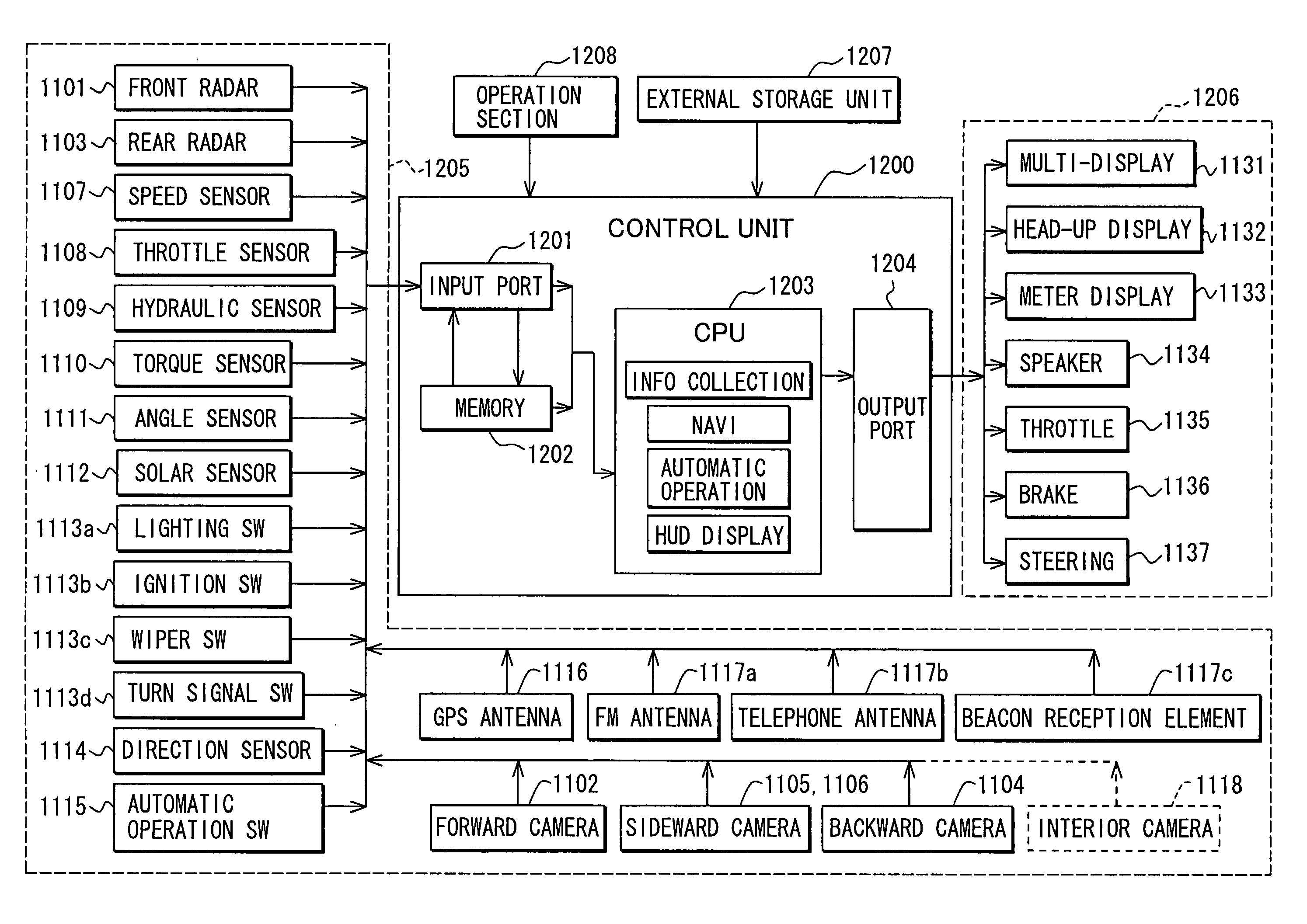

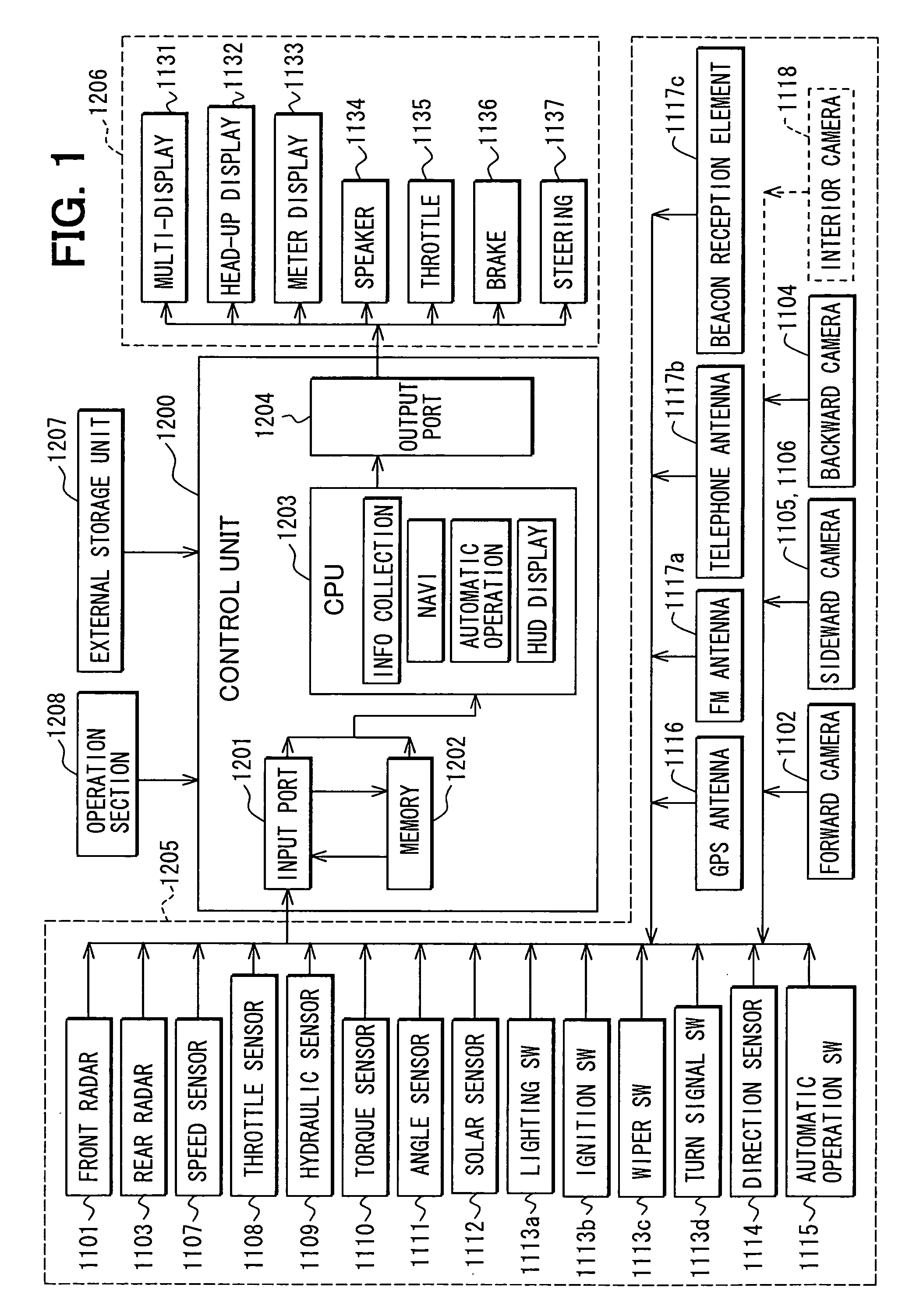

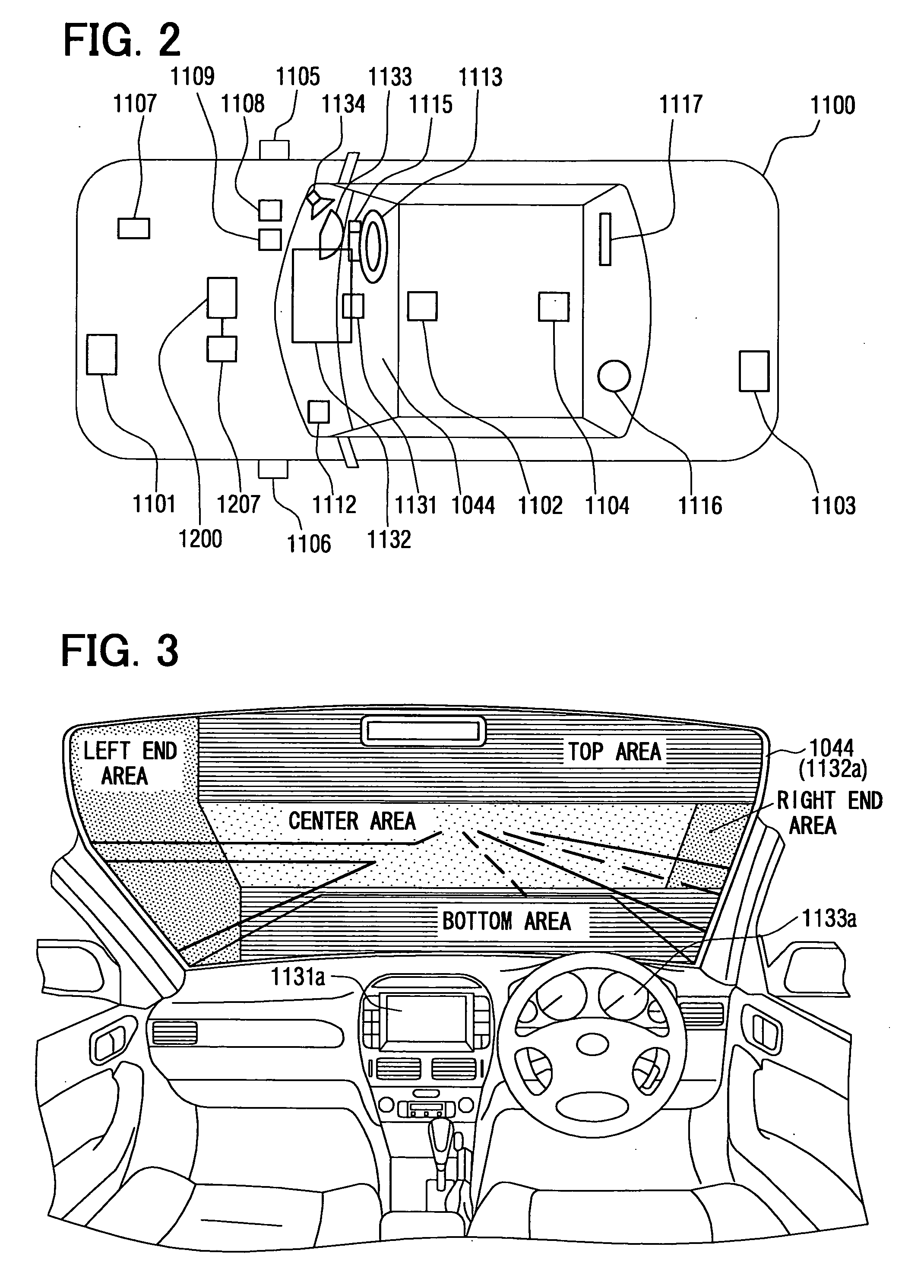

Vehicle information display system

ActiveUS20050154505A1Easy to understandMuch information without hindering a driver's visual fieldInstruments for road network navigationRoad vehicles traffic controlHead-up displayInformation display systems

A vehicle information display system includes a head-up display for reflecting an image on a windshield of a vehicle and displaying the image so that a driver recognizes the image as a virtual image. Information is collected for being displayed by the head-up display. A circumstance of the vehicle, a circumstance of surrounding of the vehicle, or a circumstance of the driver is detected. The collected information is classified in accordance with a detection result. Then, display contents of the head-up display are controlled in accordance with a classification result.

Owner:DENSO CORP

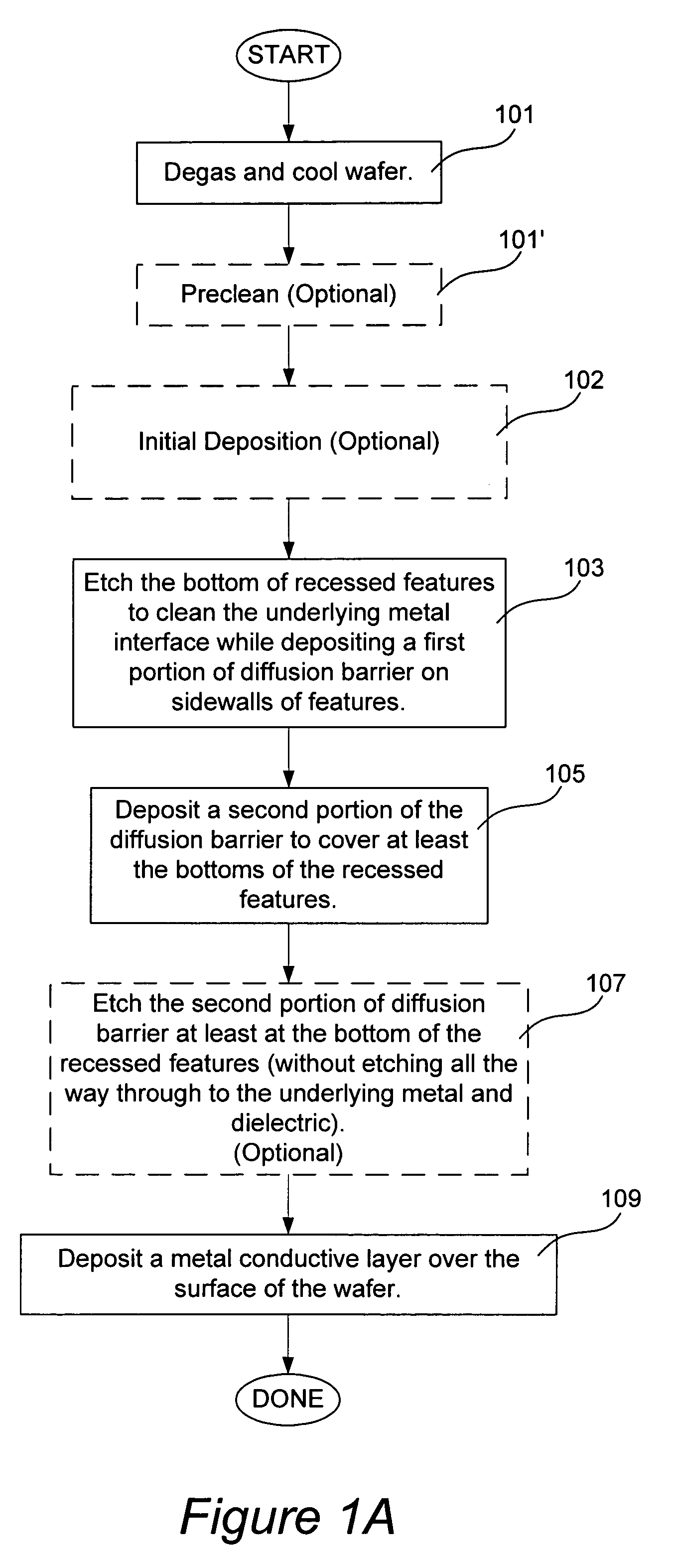

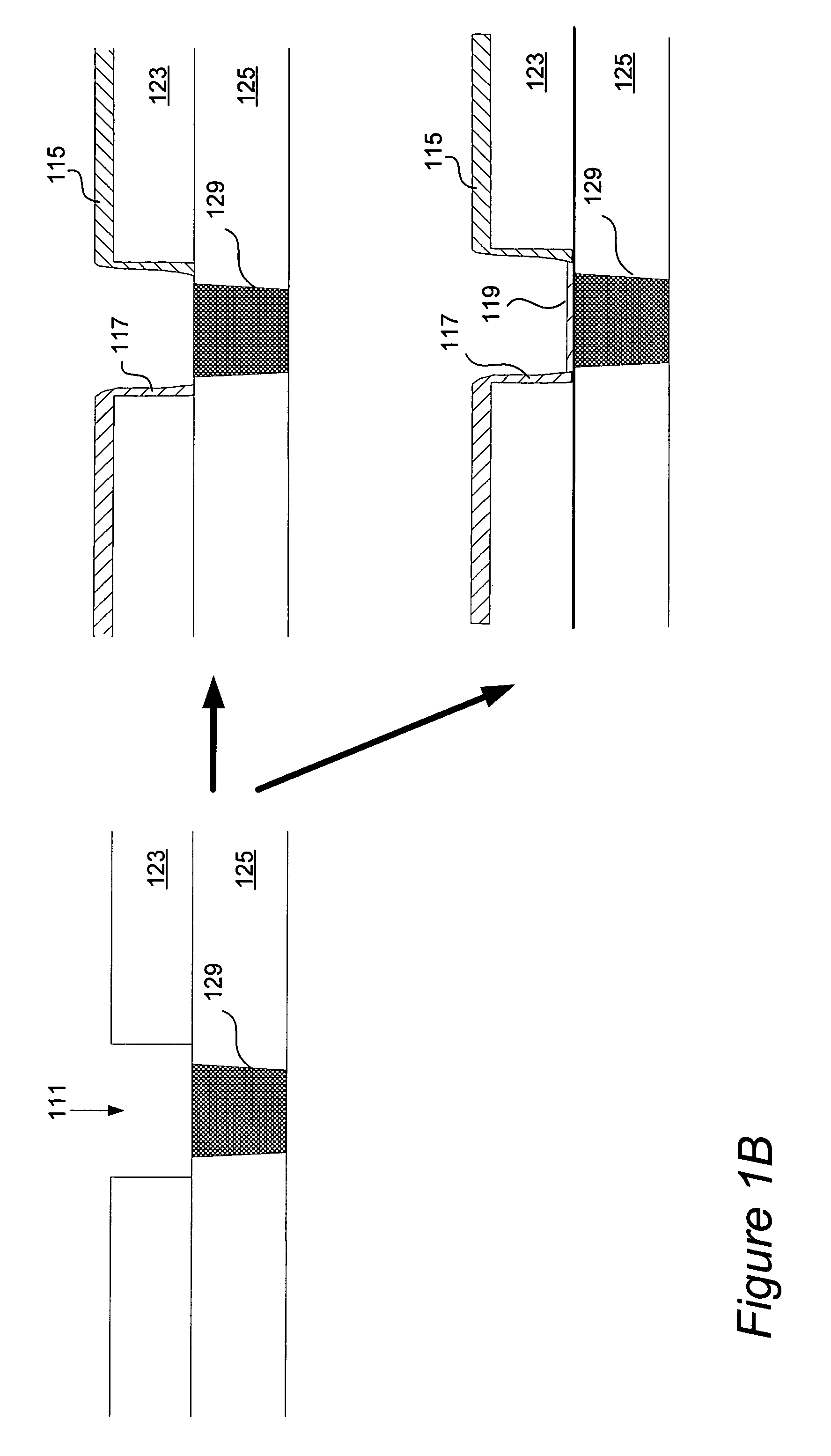

Barrier first method for single damascene trench applications

InactiveUS7186648B1Increase throughputHigh throughputSemiconductor/solid-state device manufacturingMetal interconnectEtching

Methods for forming a diffusion barrier on low aspect features of an integrated circuit include at least three operations. The first operation deposits a barrier material and simultaneously etches a portion of an underlying metal at the bottoms of recessed features of the integrated circuit. The second operation deposits barrier material to provide some minimal coverage over the bottoms of the recessed features. The third operation deposits a metal conductive layer. Controlled etching is used to selectively remove barrier material from the bottom of the recessed features, either completely or partially, thus reducing the resistance of subsequently formed metal interconnects.

Owner:NOVELLUS SYSTEMS

Attapulgite argil powder with air purifying function

ActiveCN102173743BImprove adhesionImprove plasticityDispersed particle separationDeodrantsFiberHazardous substance

The invention discloses an attapulgite argil powder with an air purifying function. The technical scheme is as follows: the attapulgite argil powder with an air purifying function is prepared from high-viscosity attapulgite clay, an attapulgite constant-humidity conditioner, a natural mineral adsorbing / filtering agent, Cacumen Biotae, aluminum silicate fiber and polyacrylamide. The attapulgite argil powder is prepared by the following steps: pulverizing the materials, soaking and aging to obtain a wet mixture, extruding the wet mixture into a strip, airing the strip, pulverizing to obtain powder, and packaging to obtain the finished product. The attapulgite argil powder has favorable cohesive property, plasticity, thixotropy, fire resistance and thermal stability; the pottery prepared from the attapulgite argil powder with an air purifying function contains a great deal of micropores and activated carbon, thus, has the characteristics of low shrinkage, no cracking or deformation and favorable adsorbability, and can effectively adsorb formaldehyde, ammonia, benzene and other harmful substances in the air, thereby protecting the environment and improving good health of people. The invention is suitable for producing pottery artware with an air purifying function.

Owner:江苏世澳非金属应用科技有限公司

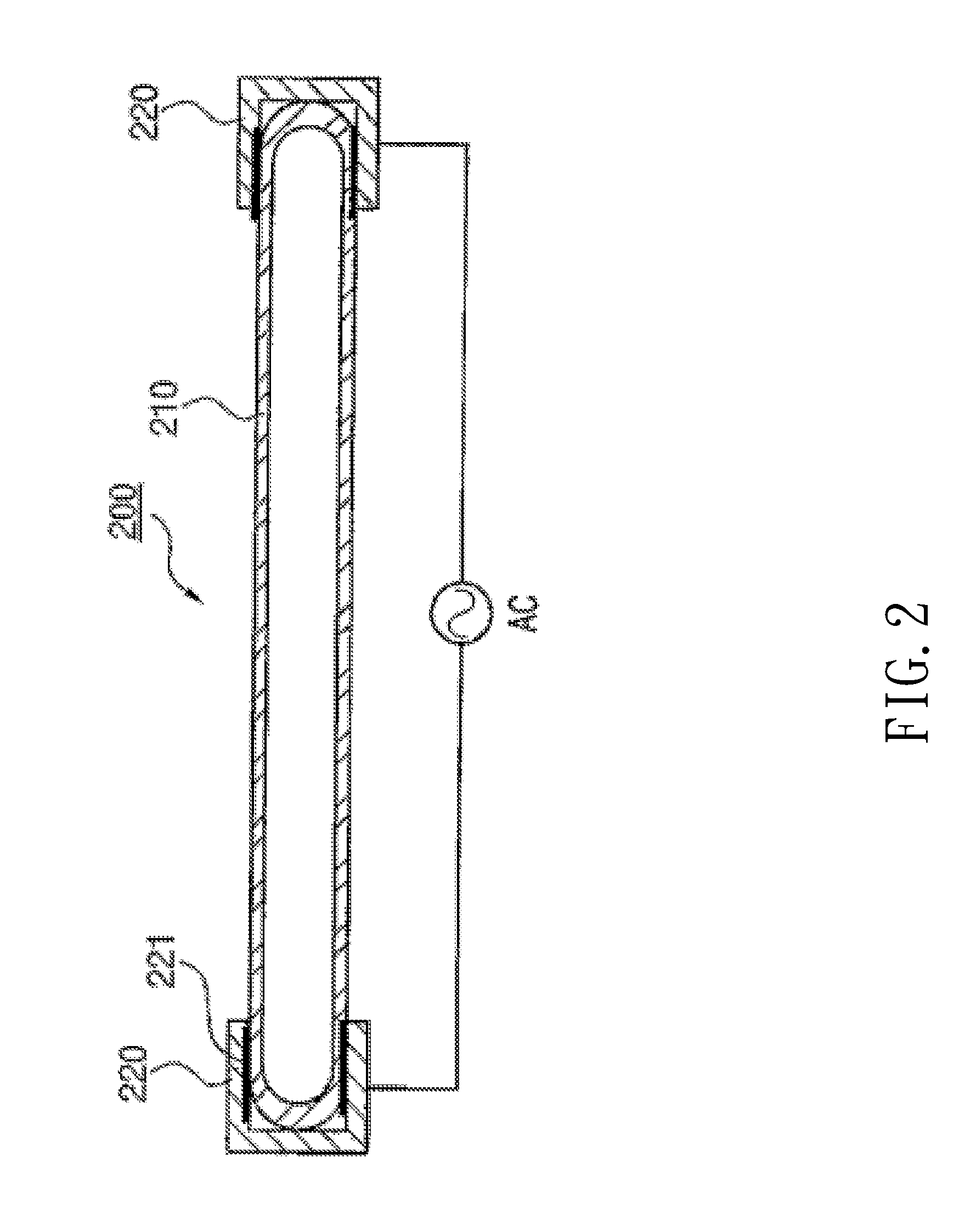

Ceramic-glass composite electrode and fluorescent lamp having the same

InactiveUS20120212121A1Low costSimple structureDischarge tube luminescnet screensLamp detailsGlass compositesAdhesive

The present invention provides a ceramic-glass composite electrode and a fluorescent lamp having the same. The ceramic-glass composite electrode according to the present invention is a ceramic-glass composite, which is disposed at the ends of a glass tube of the fluorescent lamp. A stopper is disposed at the end of the glass tube for pushing against the ceramic-glass composite electrode and limiting the position of the ceramic-glass composite electrode slipped on the glass tube. Thereby, flowing of adhesives into the glass tube is avoided when the adhesives are used for gluing the glass tube and the ceramic-glass composite electrode, and hence extending the lifetime of the fluorescent lamp.

Owner:SANTOMA

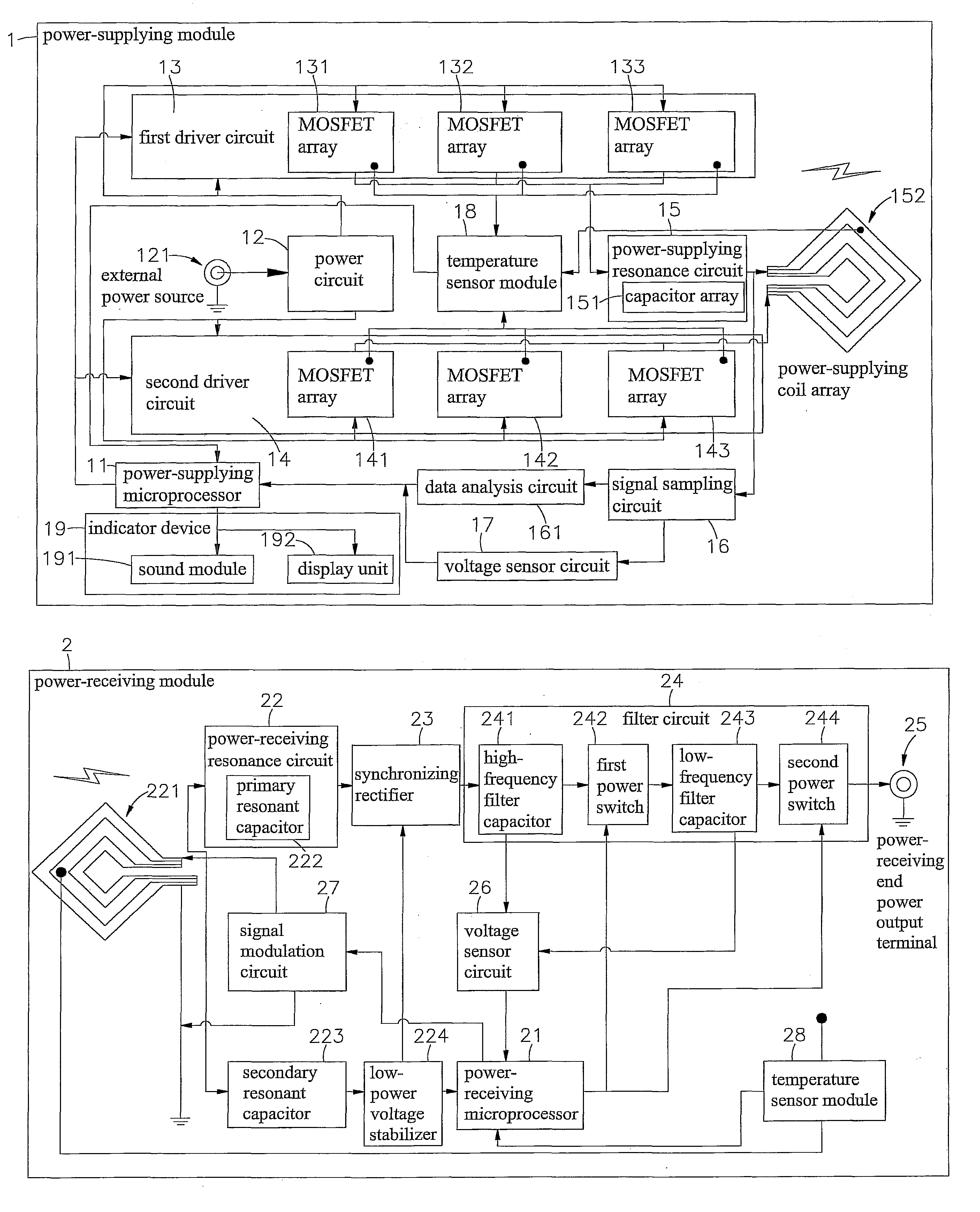

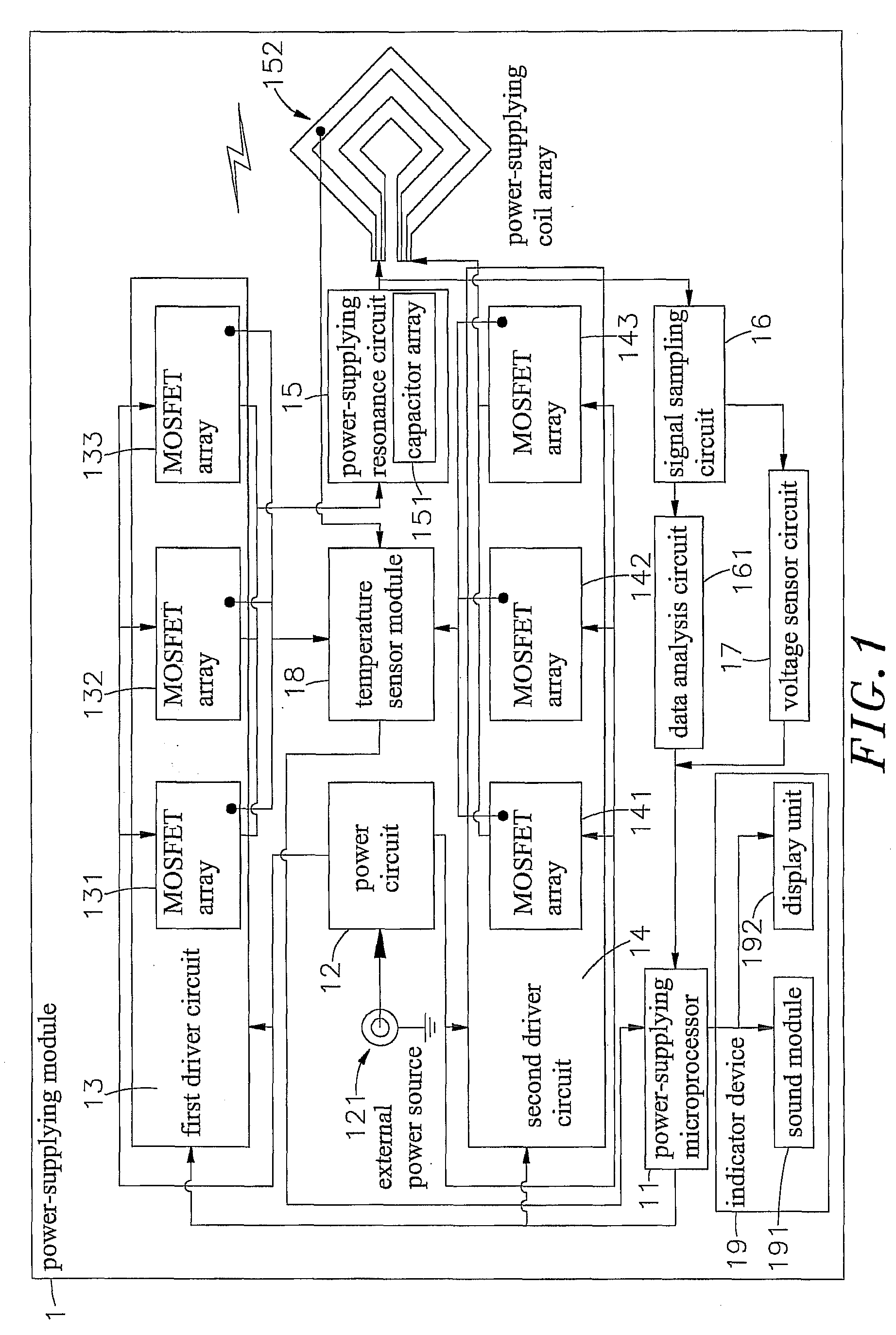

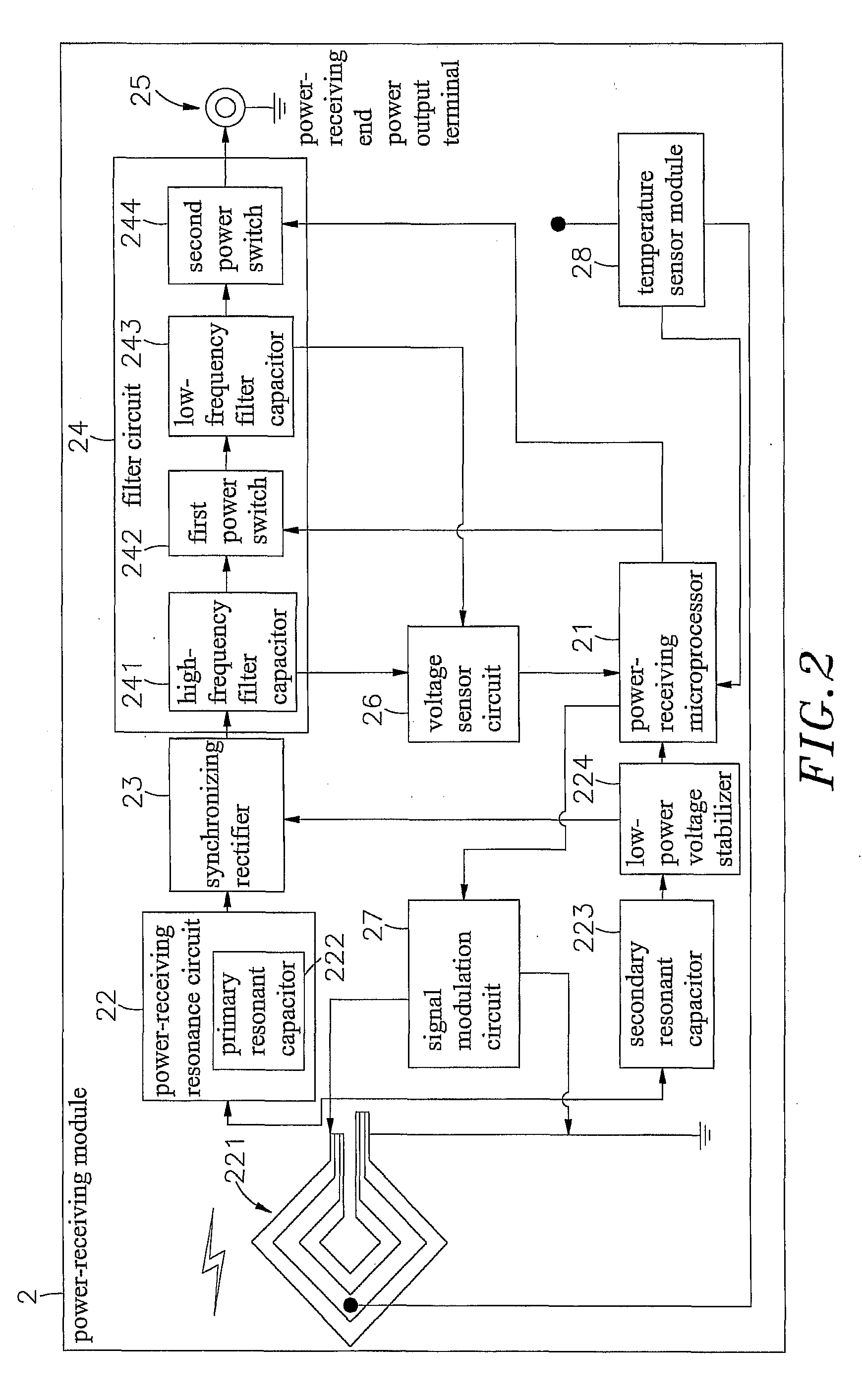

Power transmission method of high-power wireless induction power supply system

ActiveUS20110291489A1Improve transmission efficiencyReduce manufacturing costMechanical power/torque controlElectromagnetic wave systemElectric power transmissionFrequency modulation

A power transmission method used in a high-power wireless induction power supply system consisting of a power-supplying module and a power-receiving module is disclosed. The power-supplying module regulates its output energy by means of frequency modulation and driving power adjustment, enabling the energy to be received by the power-receiving module and transmitted through a power-receiving coil array and a primary resonant capacitor and a secondary resonant capacitor of power-receiving resonance circuit, a synchronizing rectifier, a low-power voltage stabilizer, a high-frequency filter capacitor, a first power switch, a low-frequency filter capacitor and a second power switch of a filter circuit for output to an external apparatus.

Owner:FU TONG TECH

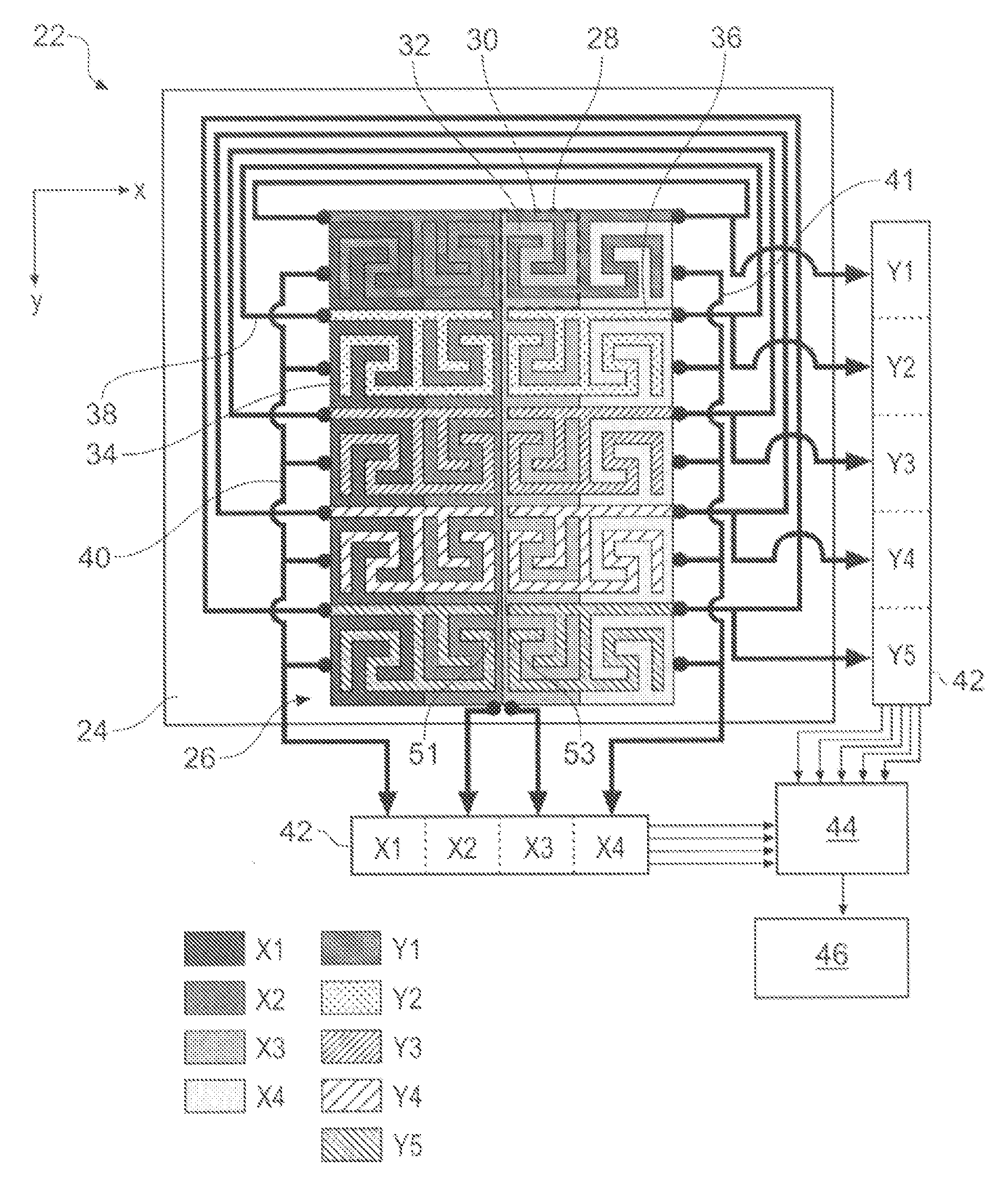

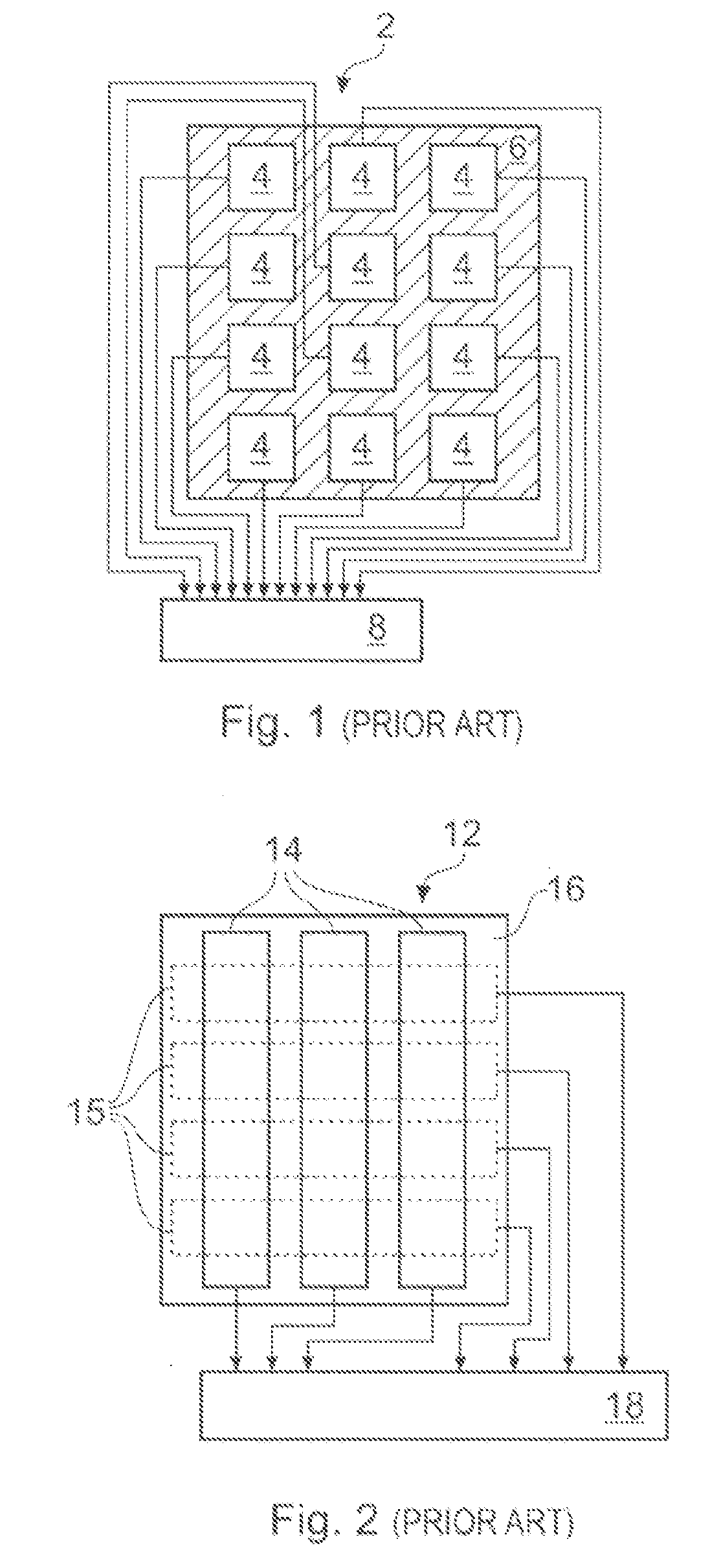

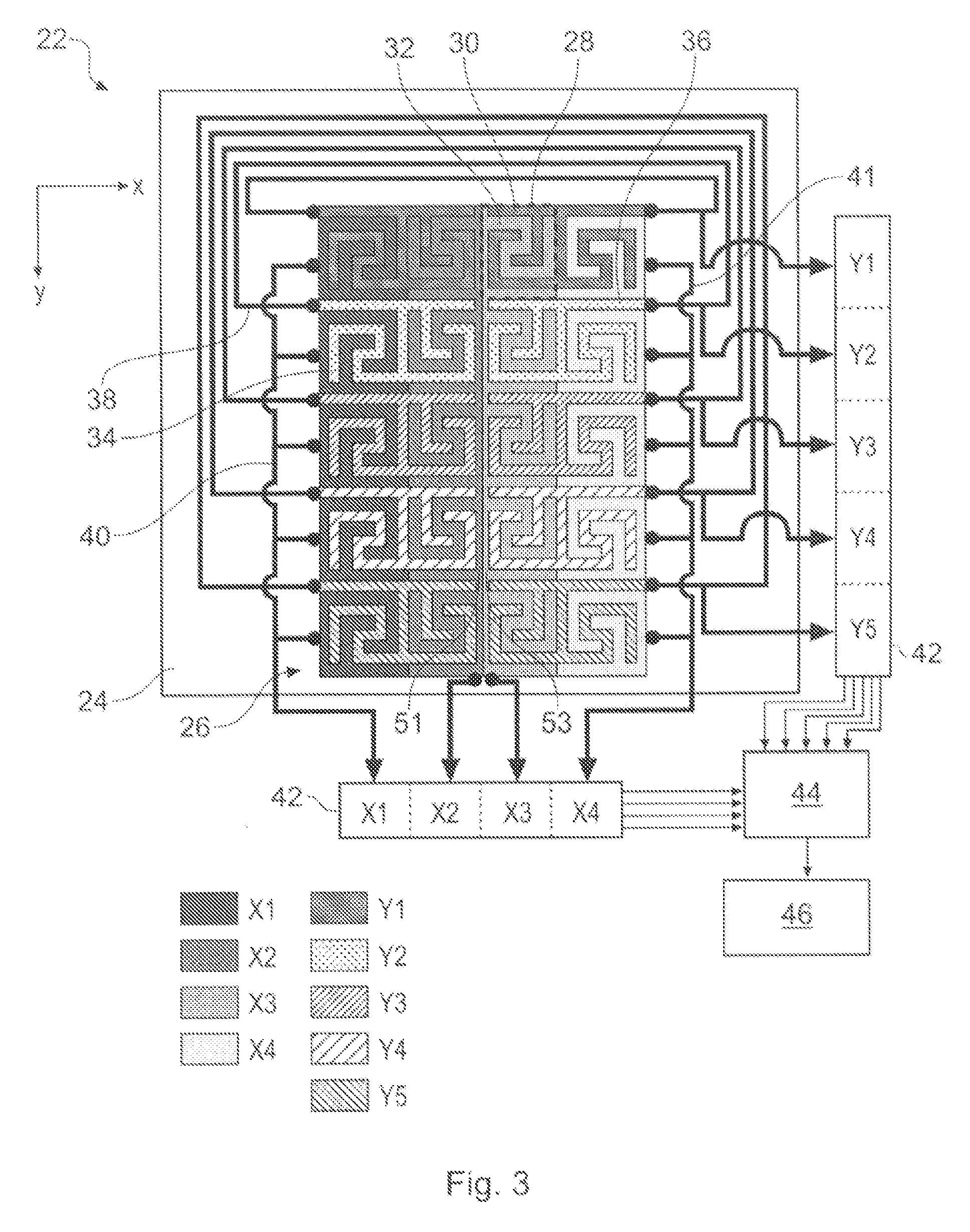

Two-Dimensional Position Sensor

ActiveUS20070008299A1Reduce manufacturing costEliminate needSolid-state devicesElectronic switchingCapacitanceElectrical connection

A capacitive position sensor for determining the position of an object along first and second directions is described. The sensor comprises a substrate having an arrangement of electrodes mounted on a single surface thereof. The electrodes are arranged so as to define an array of sensing cells arranged in columns and rows to form a sensing area. Each of the sensing cell including a column sensing electrode and a row sensing electrode with the column sensing electrodes of sensing cells in the same column being electrically coupled together and the row sensing electrodes of sensing cells in the same row also being electrically coupled together. Row sensing electrodes of sensing cells at opposing ends of at least one of the rows are connected together by an electrical connection made outside of the sensing area so that there is no requirement for electrical connections to cross within the sensing area, thus providing a capacitive position sensor having a sensing area with electrodes on only one side of a substrate.

Owner:NEODRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com