Patents

Literature

3313 results about "Plasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics and materials science, plasticity is the ability of a solid material to undergo deformation, a non-reversible change of shape in response to applied forces. For example, a solid piece of metal being bent or pounded into a new shape displays plasticity as permanent changes occur within the material itself. In engineering, the transition from elastic behavior to plastic behavior is called yield.

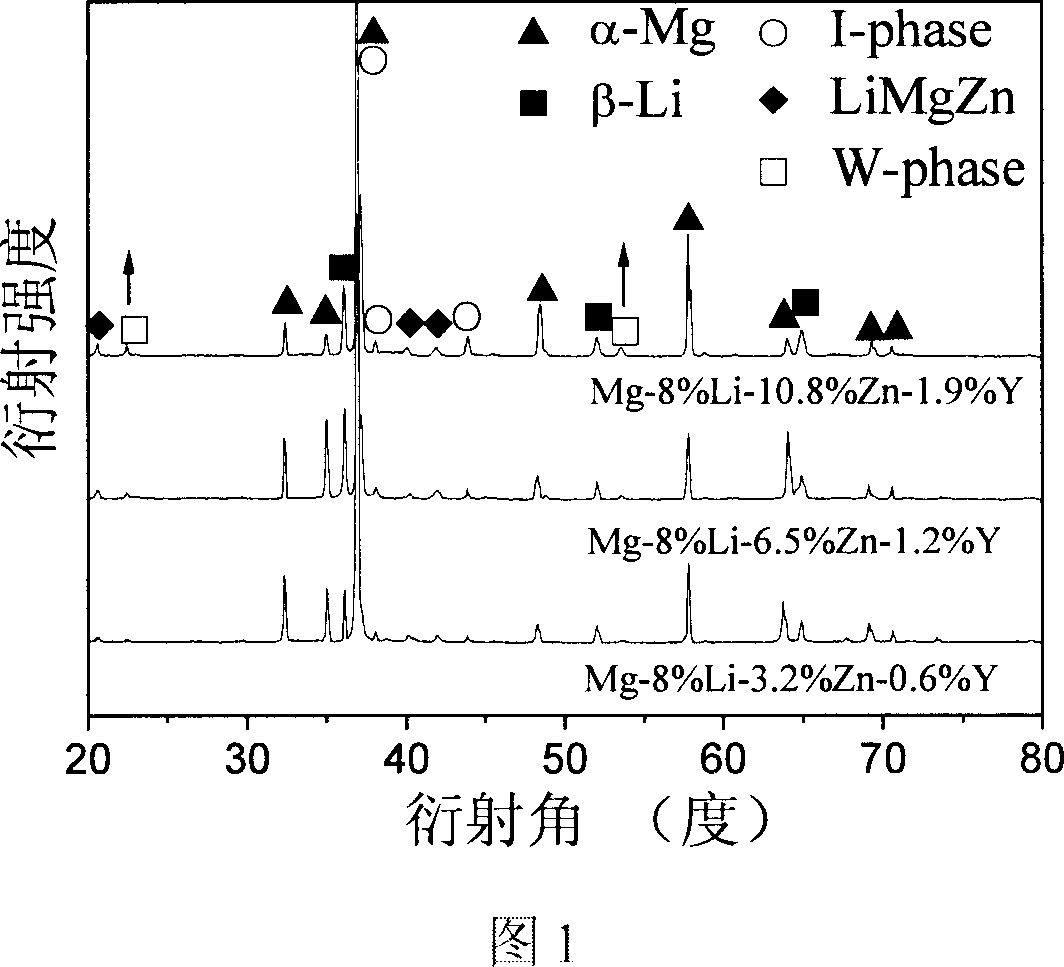

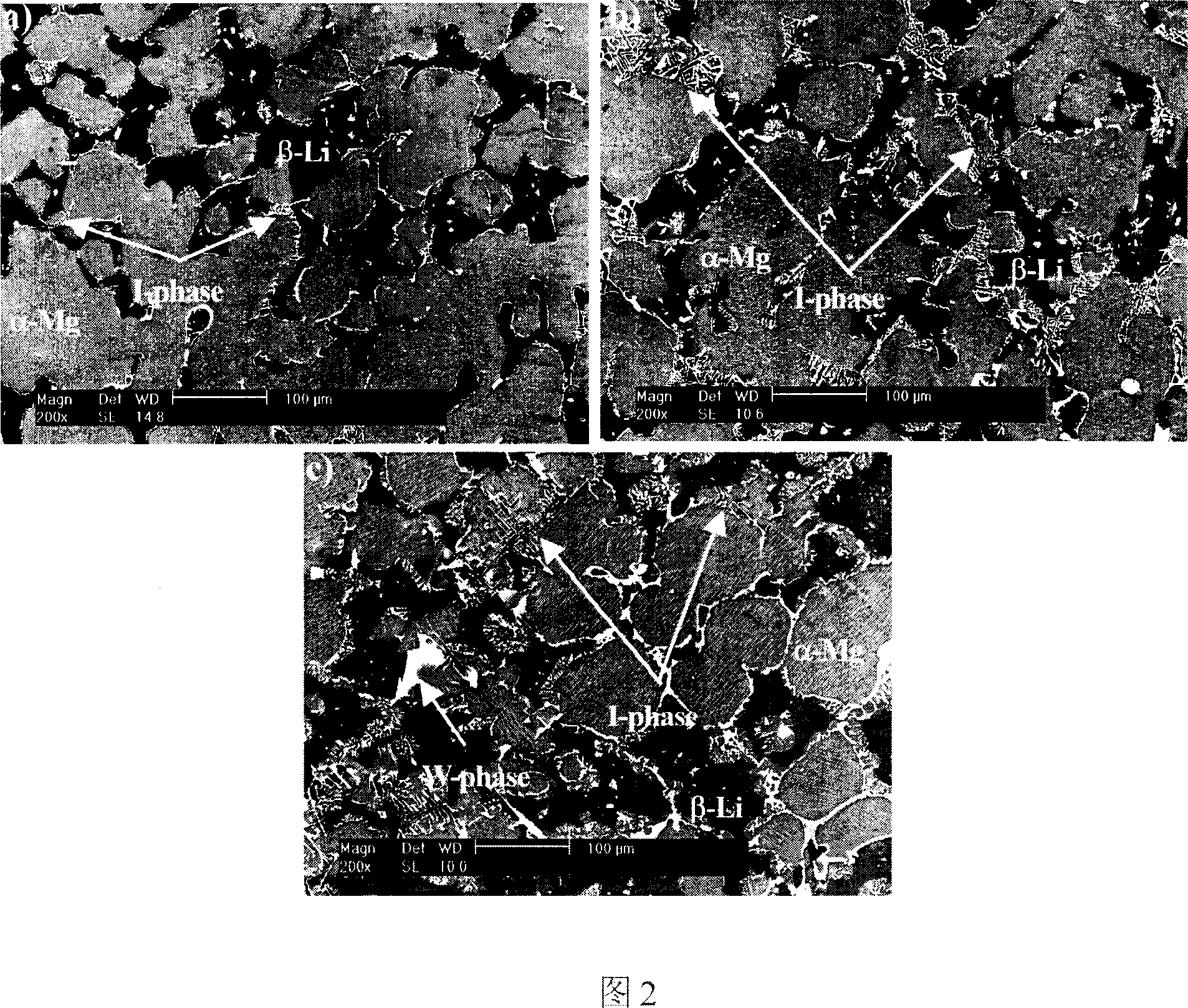

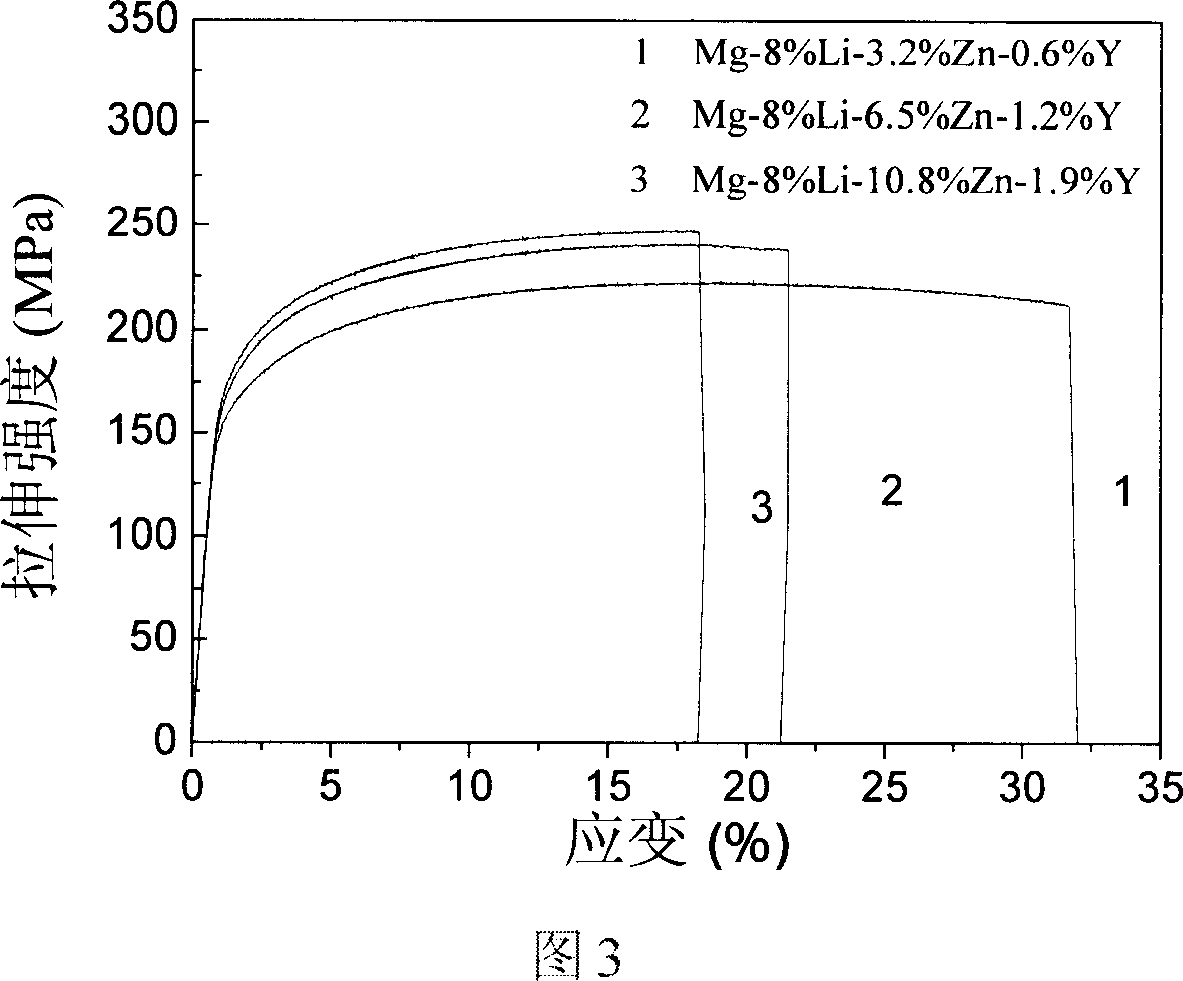

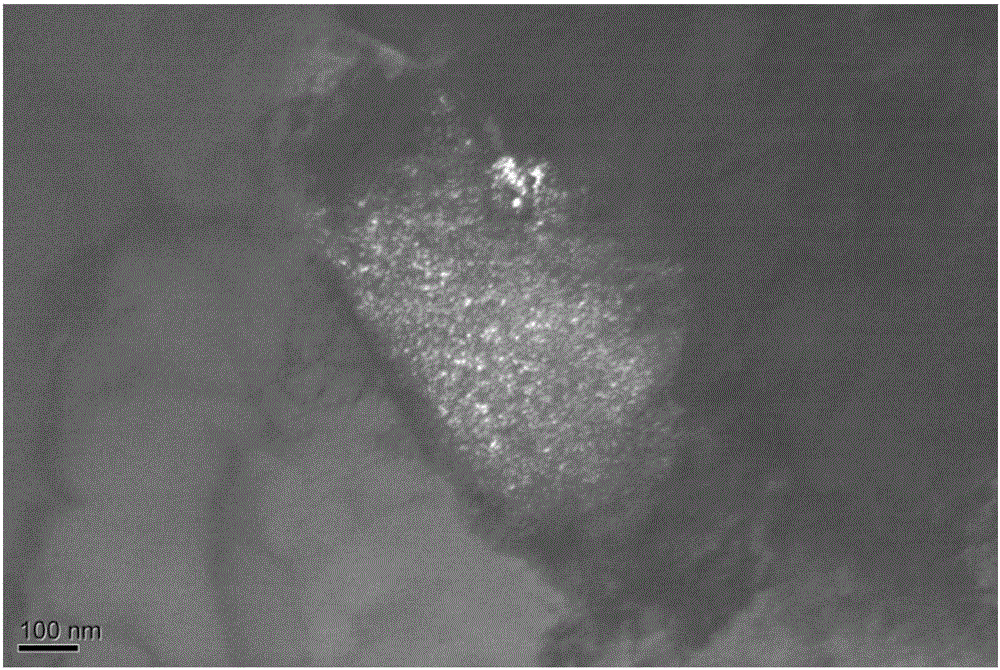

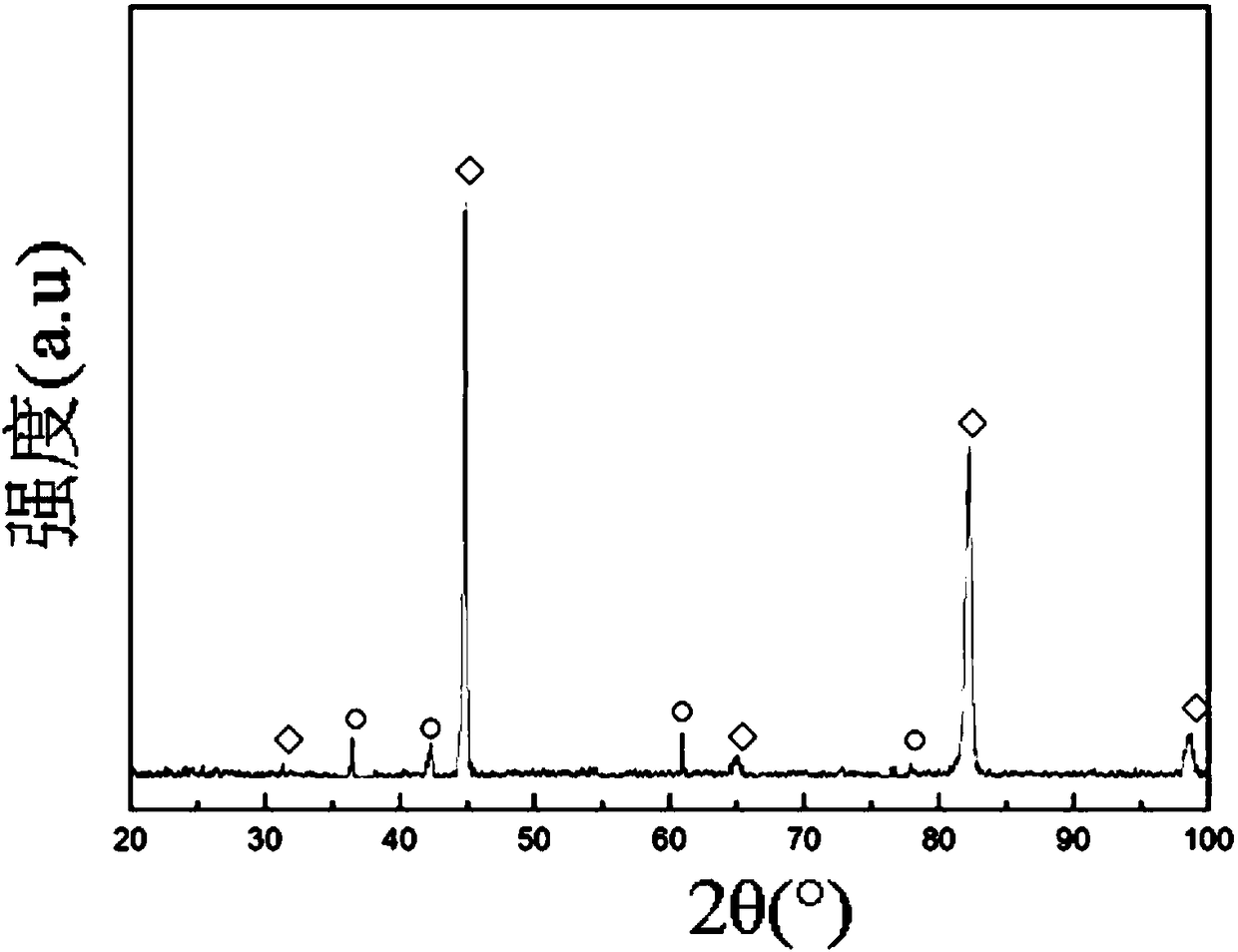

Quasi crystal phase fortified magnesium lithium alloy and its preparation method

The invention relates to Mg-Li alloy with high strength and its preparation techniques. It especially relates to Mg-Li alloy strengthened by quasi-crystalline phase and its preparation techniques, which can solve problems of alloy strengthening. Mg-Li alloy with low density, high strength and good plasticity is prepared by reasonable choosing of alloy elements and introducing quasi-crystalline phase into alloy base. The alloy is two-phase alloys of Mg-Li alloy in alpha-Mg and beta-Li phase areas. Component and content of the alloy are 5.5-11.5% Li, 0.5-15% Zn, 0.1-8% Y, and the allowances are Mg, in which percent is weight proportion. The alloy is made by melting and subsequent processing of hot extrusion and its crafts are simple and convenient to operate. Properties of materials are as follows: tensile strength is sigma b=200-300MPa, yield strength is sigma 0.2=150-260MPa, elongation percentage isdelta=17-65% and density is 1.34-1.83g / cm3.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

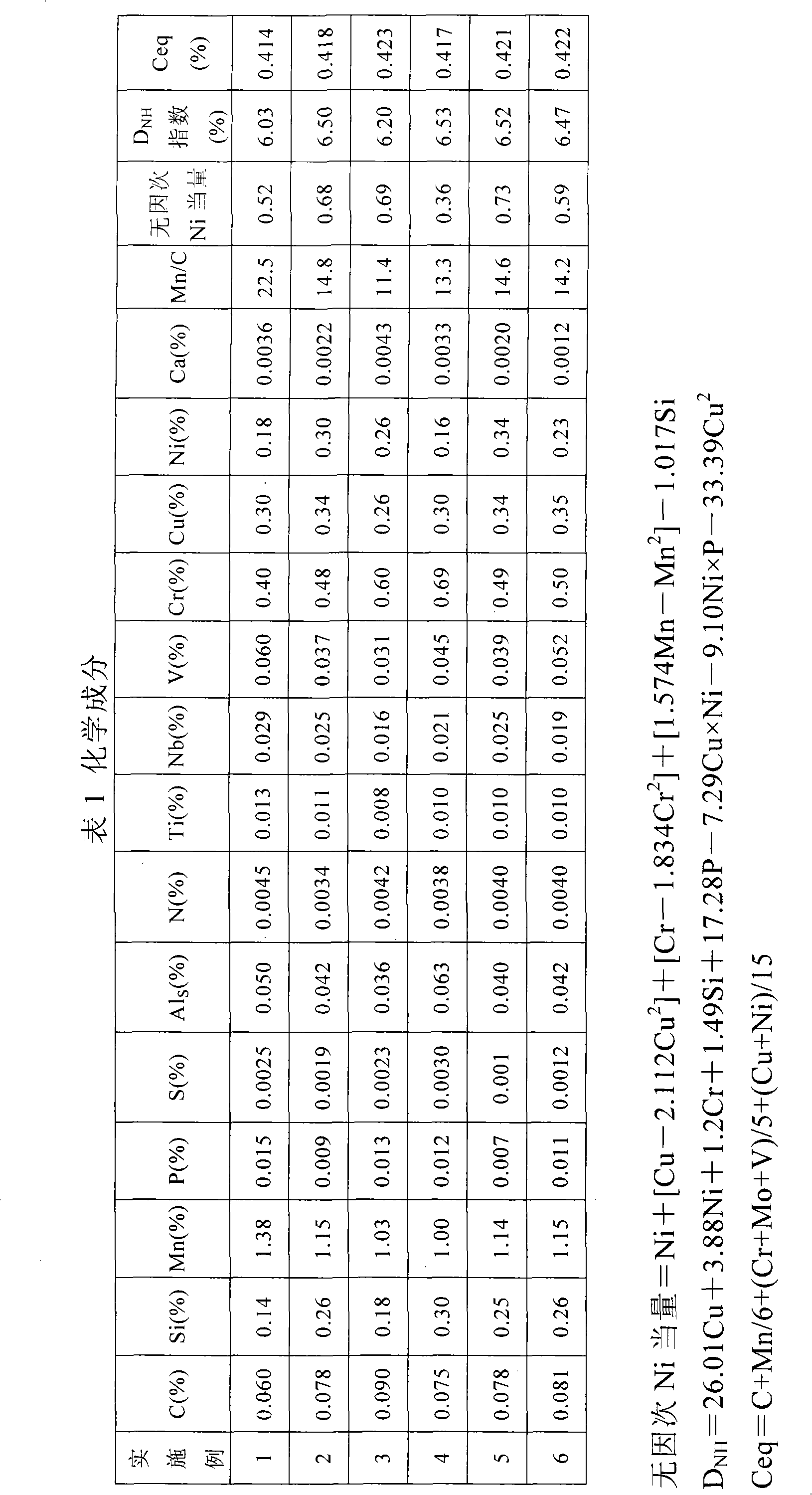

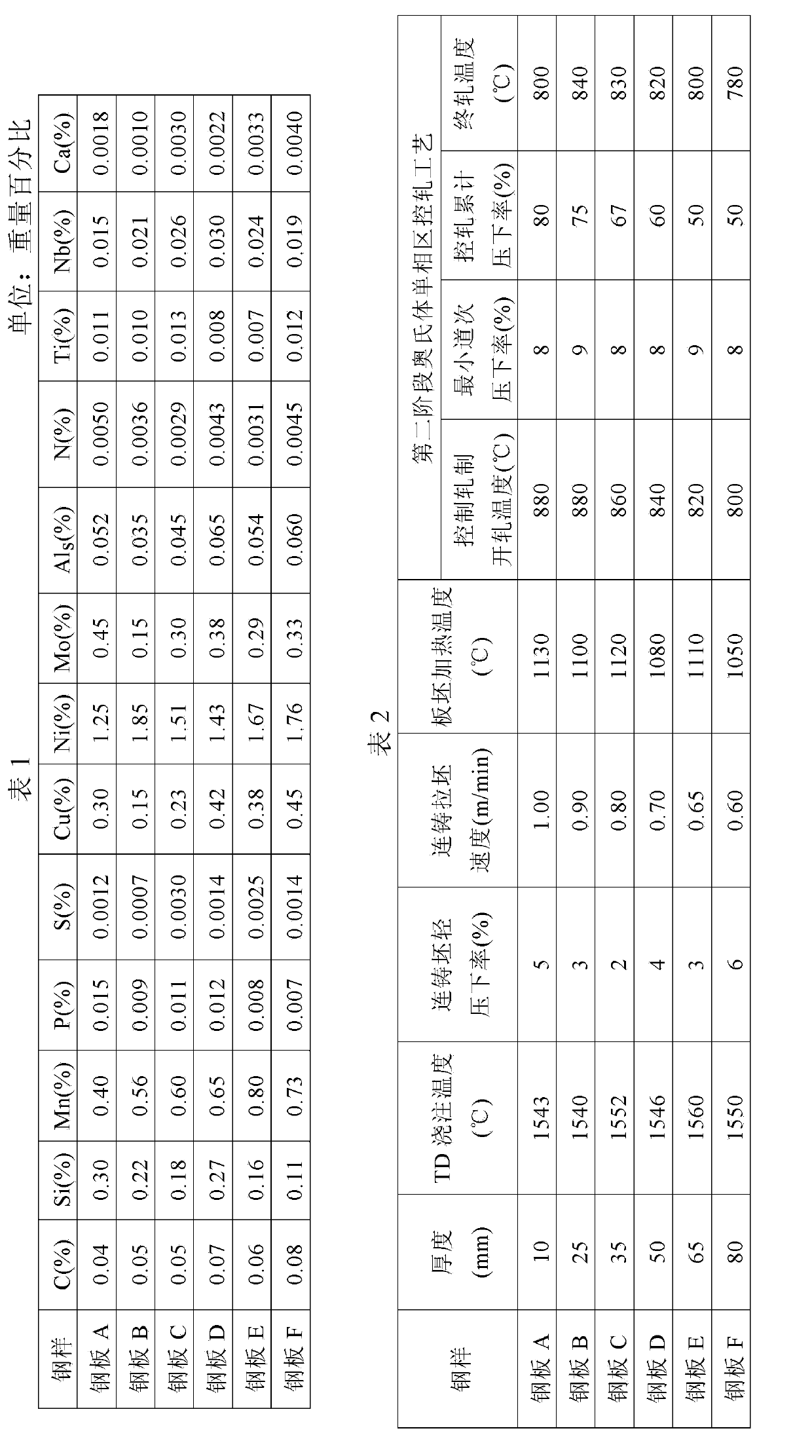

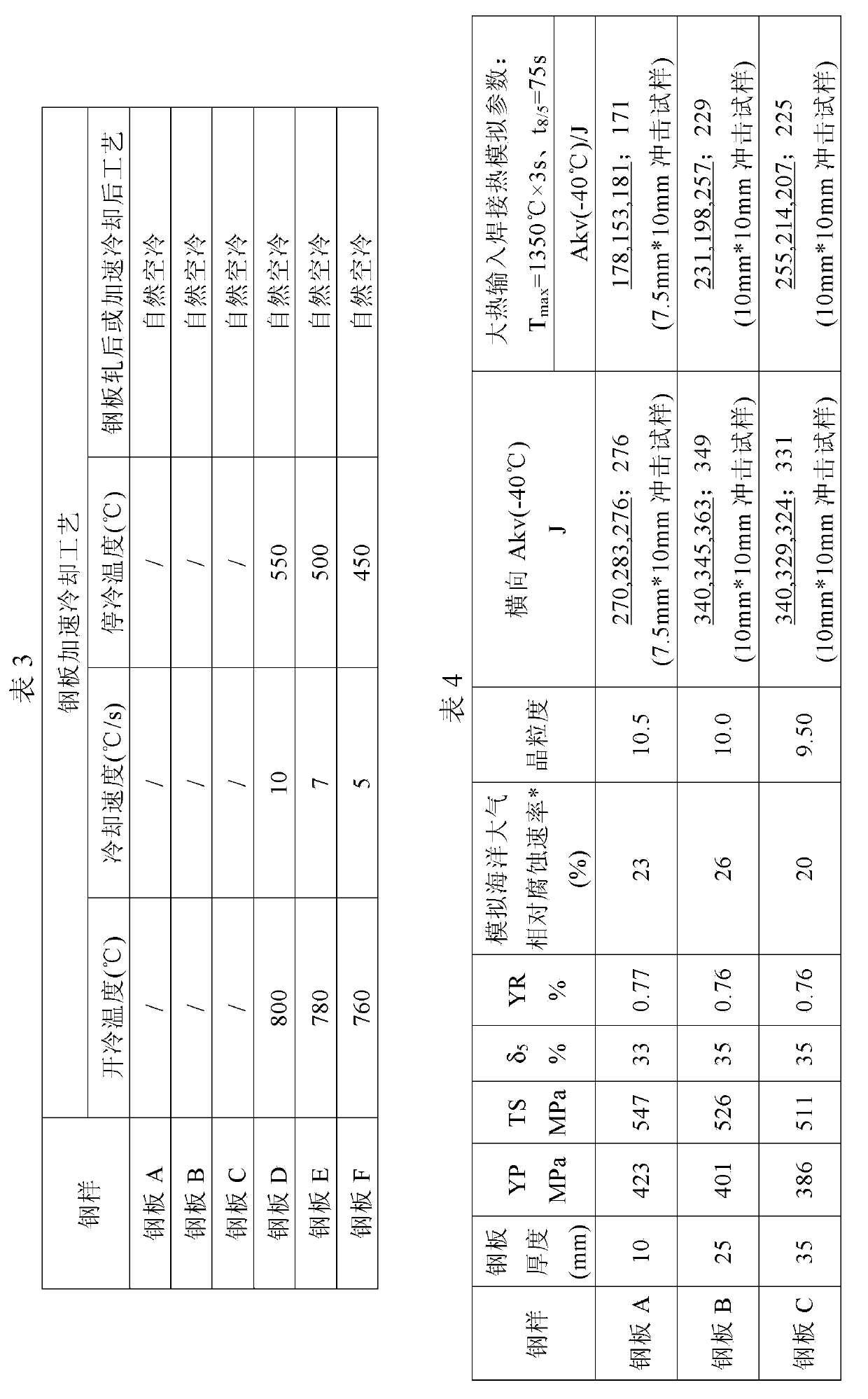

High-performance weather-proof building structural steel and manufacturing method thereof

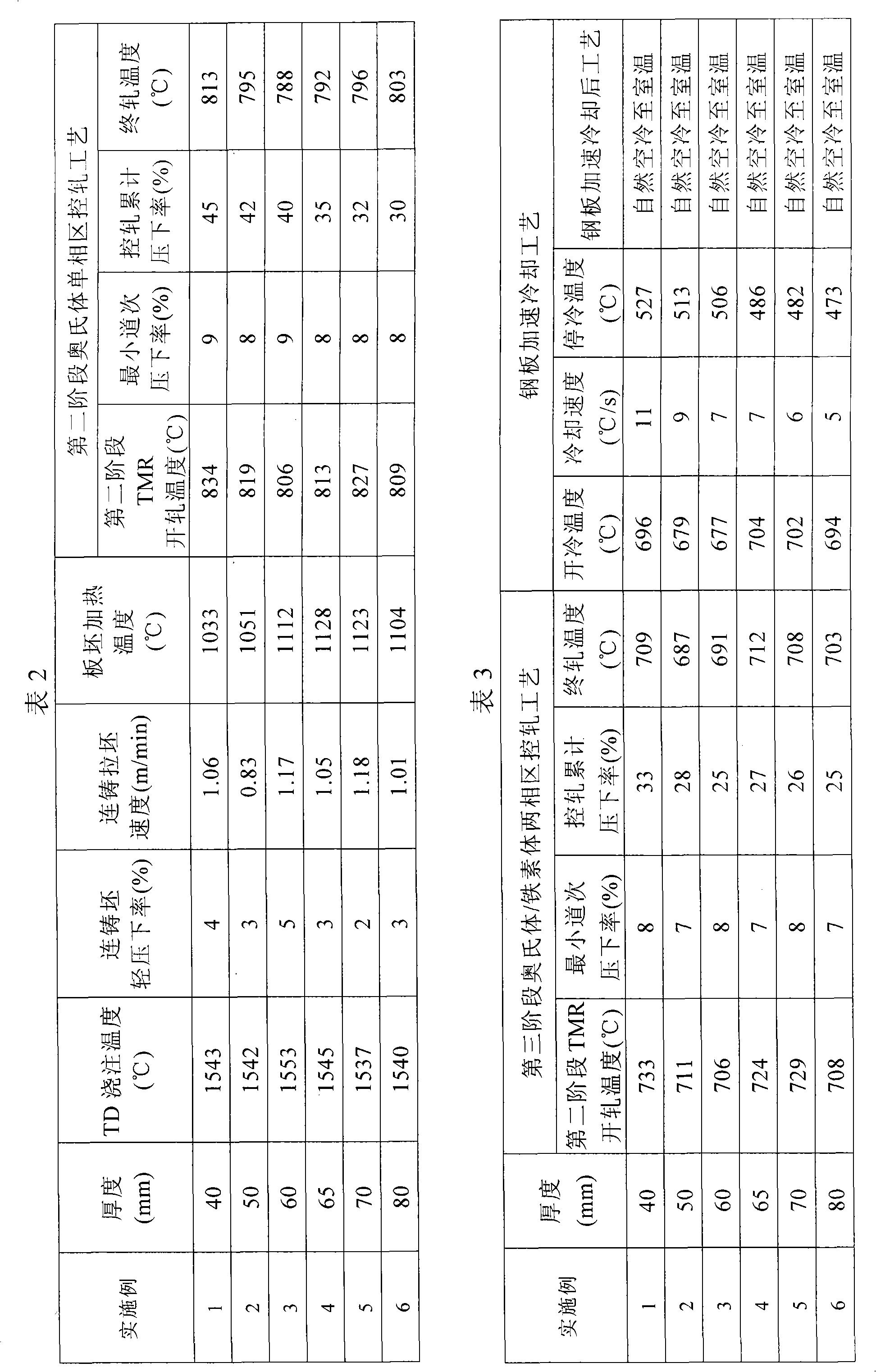

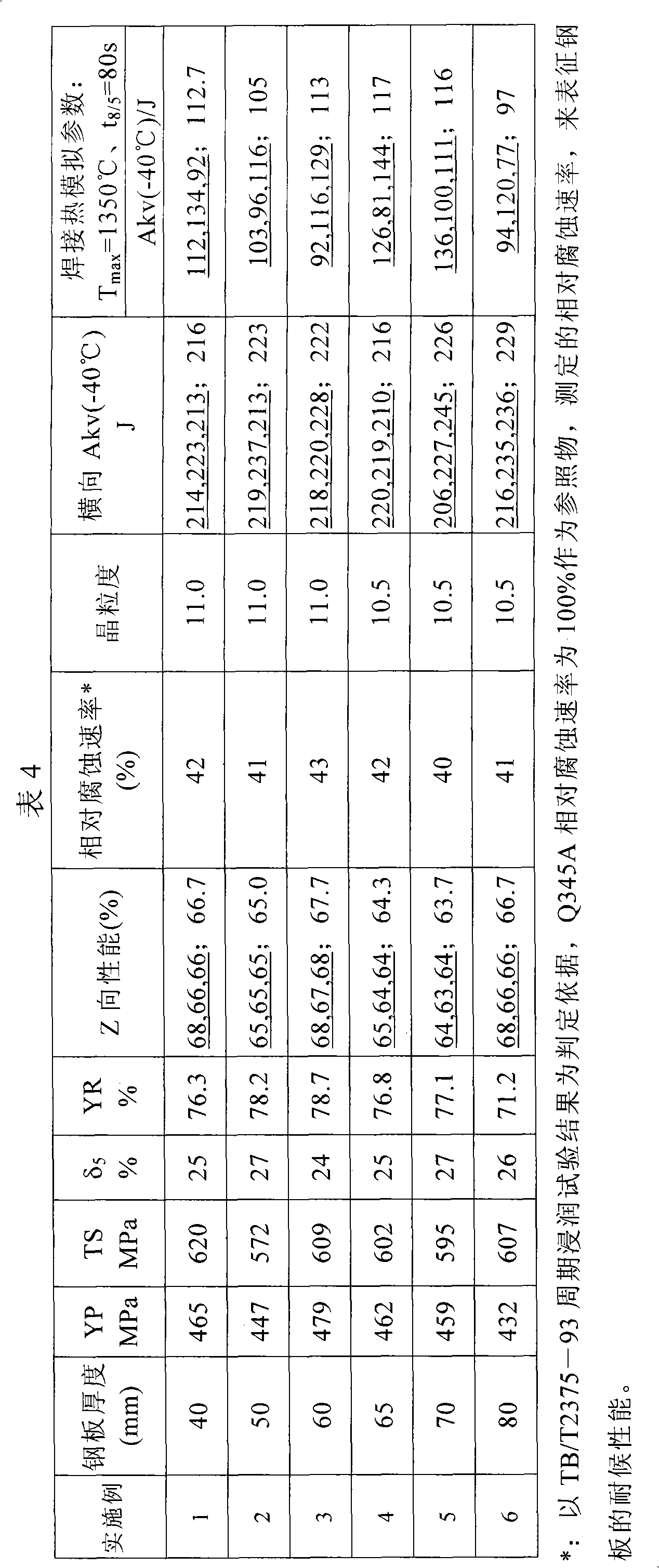

The invention relates to high-performance weather-proof building structural steel and a manufacturing method thereof. The composition system of low C-medium Mn-low N-micro Nb alloying-ultramicro Ti processing low content alloy weather-proof steel is taken as foundation, the acid solution Als content in the steel is increased properly, and the range of the acid solution Als content is controlled; the zero dimension Ni equivalent weight is controlled to be more than or equal to 0.35, the Ceq is less than or equal to 0.425%, and the Mn / C is more than or equal to 10; the weather-proof property index DNH is more than or equal to 6.0%; and the Ca is processed, the Ca / S is controlled within the range of 1.0-3.0, and Ca*S 0.28 is less than or equal to 1.0*10<-3>. By adopting a TMCP technique, a weather-proof steel plate with good toughness, strong plasticity matching, low yield ratio, atmosphere corrosion resistance, excellent weldability and anti-fatigue performance can be obtained, is especially suitable for non-coating high-rise building structure and bridge structure, and can realize stable batch industrialized production with low cost.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

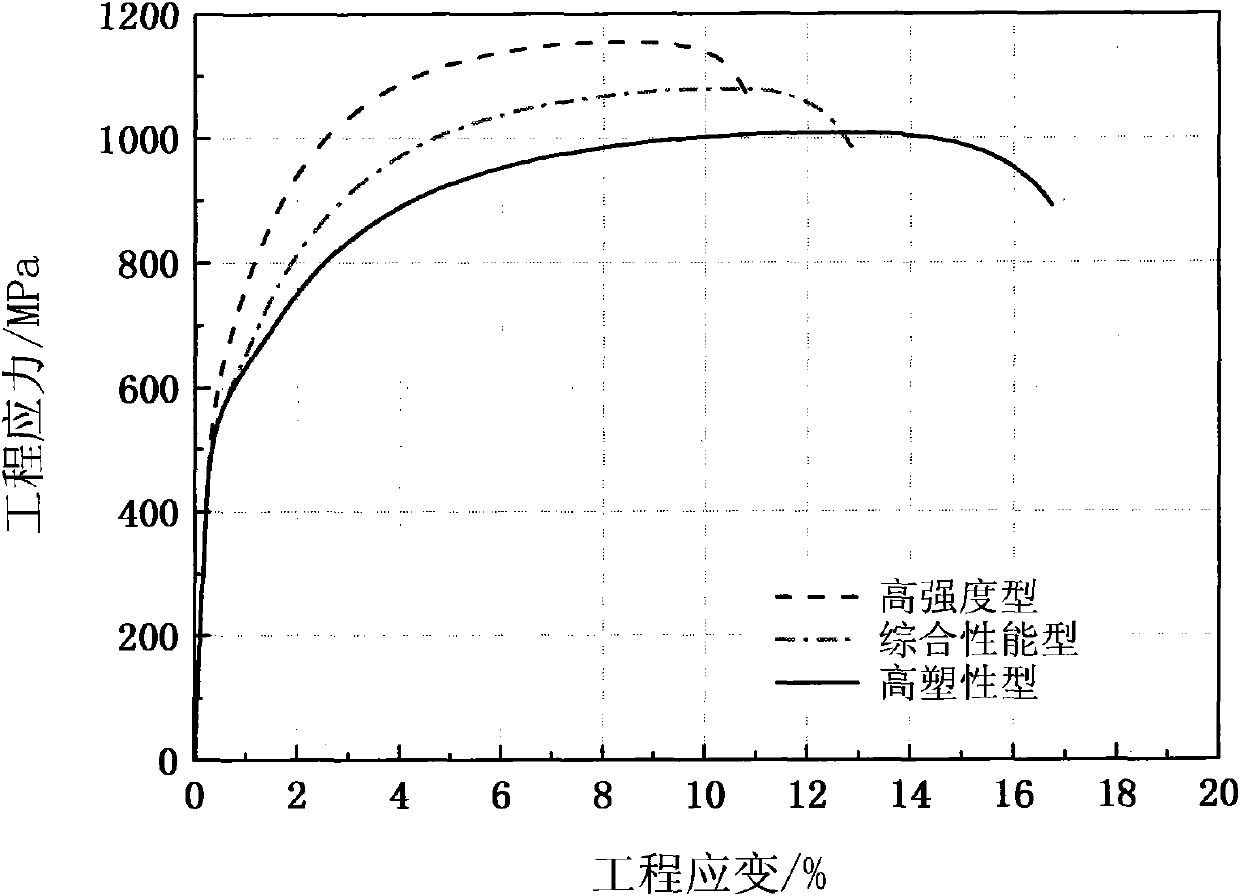

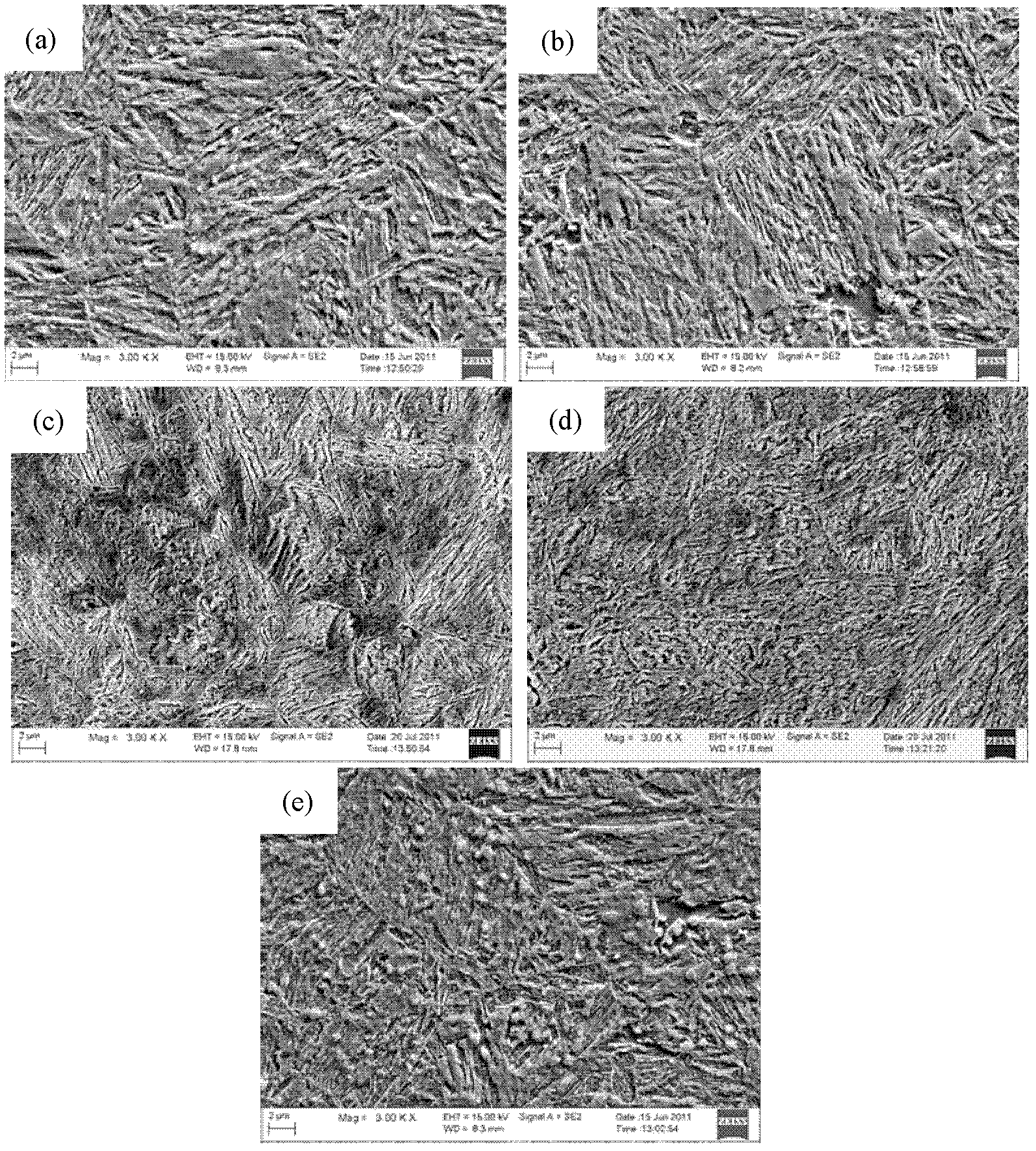

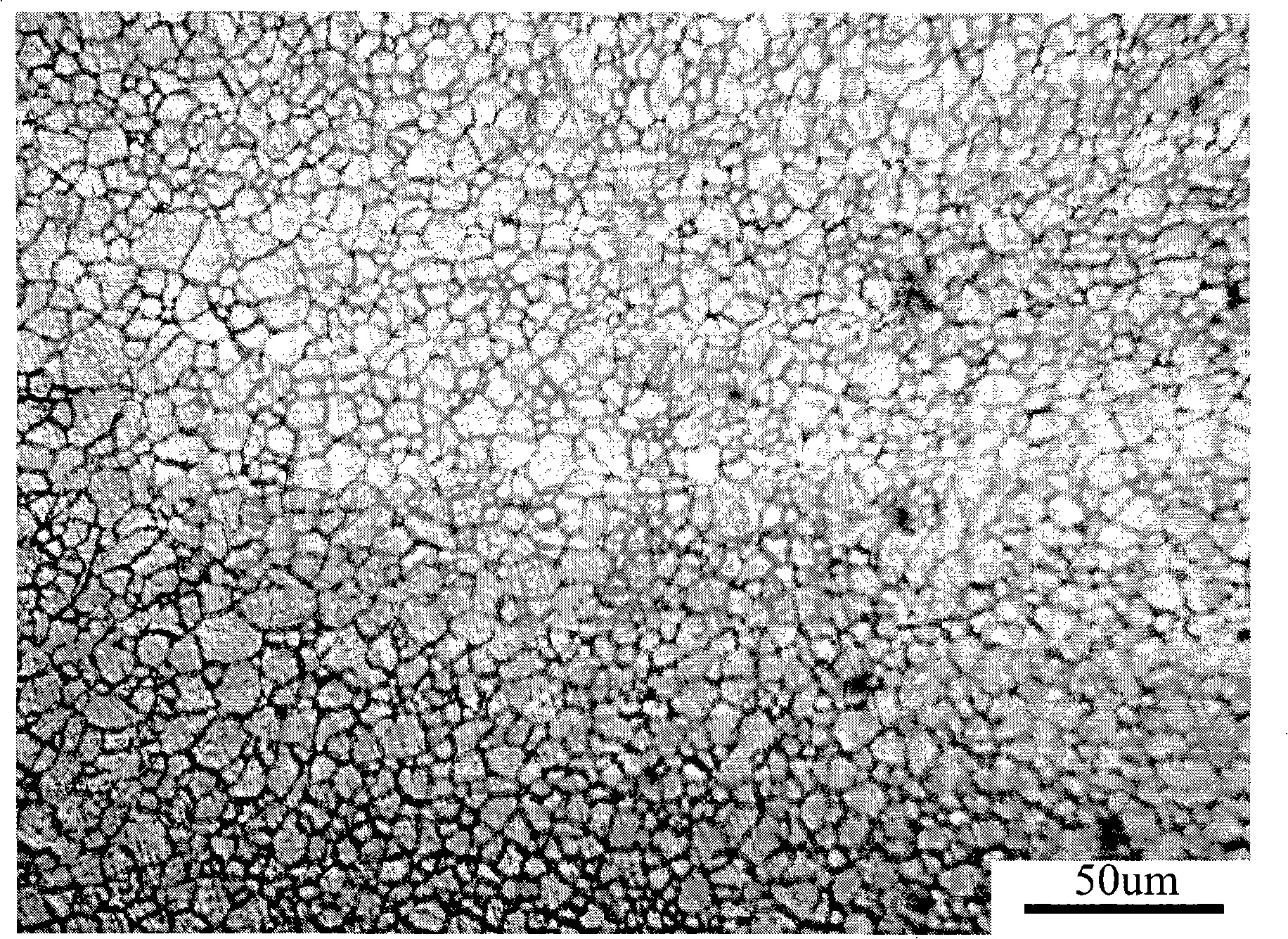

Ti microalloyed ultra-fine grained cold rolling dual-phase steel of 1,000MPa level and preparation method thereof

InactiveCN101768695ALow priceInhibit growthTemperature control deviceFurnace typesChemical compositionMicrometer

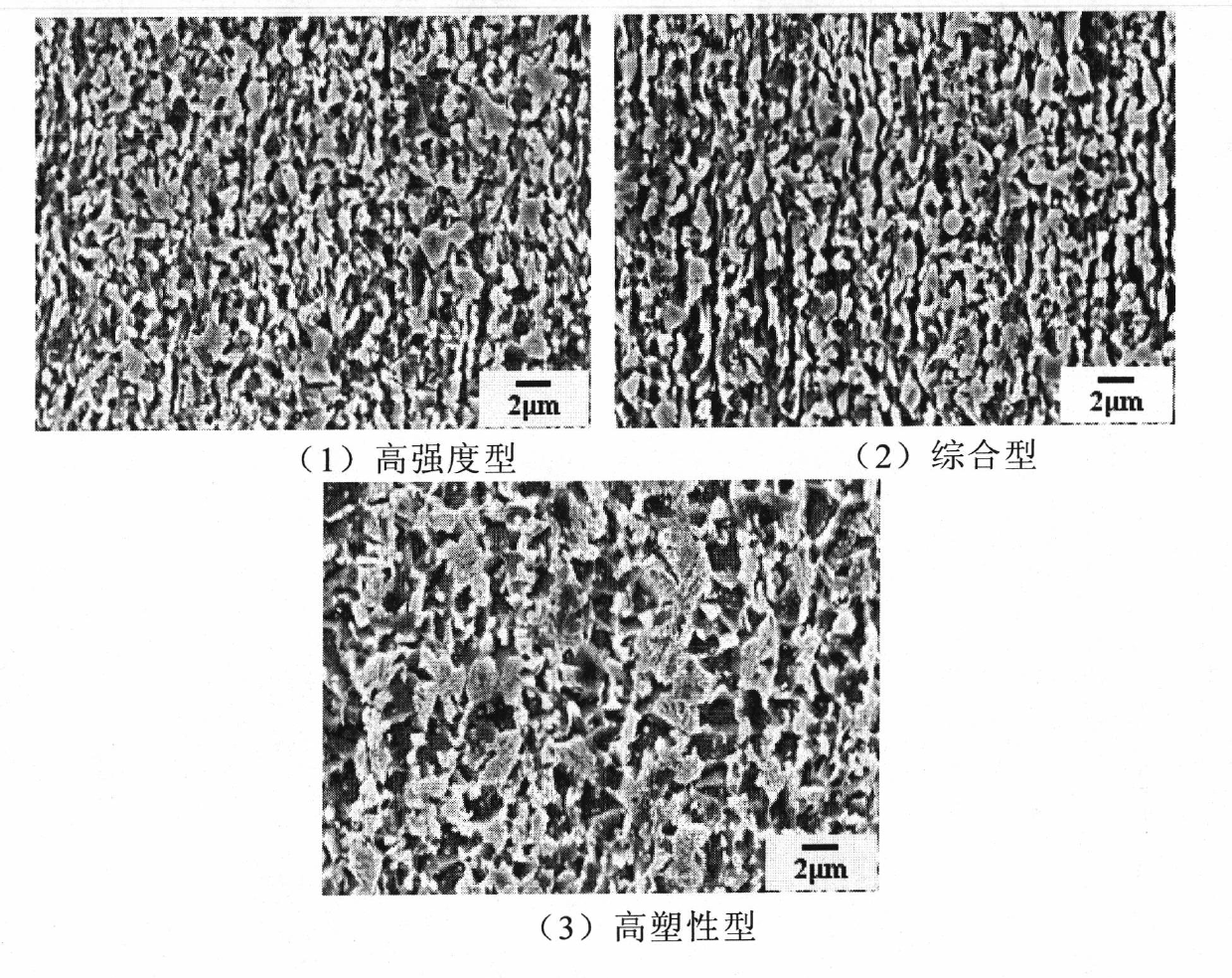

The invention relates to Ti microalloyed ultra-fine grained cold rolling dual-phase steel of a 1,000MPa level and a preparation method thereof, belonging to the technical field of cold rolling ultra-high strength steel for automobiles. The steel comprises the following chemical compositions in percentage by weight: 0.03-0.20 percent of C, 0.20-0.80 percent of Si, 1.2-2.0 percent of Mn, 0.03-0.15 percent of Ti, less than 0.15 percent of S, less than 0.020 percent of P, 0.02-0.15 percent of Als and the balance of Fe. In the invention, C-Si-Mn-Ti is used as a basic alloy system, low-price Ti is adopted, and alloy elements such as Cr, Mo, Nb, V, and the like are not added, thereby reducing the production cost; through a flexible continuous annealing process, the size of a martensite island can be controlled to be 1-2 micrometers or increased to about 5 micrometers under the condition that the quick cooling speed is lower than 50 DEG C / s in continuous annealing so as to obtain the following three different types of dual-phase steel: a high strength type (Rm is 980-1,200MPa, and A50 is 10-13 percent), a high plasticity type (Rm is 980-1,100MPa, and A50 is 14-18 percent) and a synthesizing type (Rm is 980-1,150MPa, and A50 is 12-15 percent); and the yield ratio is 0.47-0.65.

Owner:UNIV OF SCI & TECH BEIJING

Steel for microalloying lorry axle and technique for producing the same

InactiveCN101497968AHigh strengthHigh resistance to crack susceptibilityManufacturing convertersCrack resistanceMetallurgy

The invention discloses microalloyed steel used for an axle of a railway freight car, wherein the microalloyed steel contains the following chemical components by weight: 0.50-0.57 percent of C, 0.17-0.40 percent of Si, 0.60-1.00 percent of Mn, 0.20-0.35 percent of Cr, 0.18-0.40 percent of Ni, 0.08-0.18 percent of Mo, 0.02-0.06 percent of Al, 0.020-0.060 percent of Ti, 0.030-0.10 percent of V, less than or equal to 0.010 percent of S, less than or equal to 0.020 percent of P, less than or equal to 0.005 percent of B, less than or equal to 0. 20 percent of Cu, less than or equal to 0.010 percent of Sb, less than or equal to 0.03 percent of Sn, less than or equal to 0.04 percent of As, less than or equal to 0.0015 percent of [O] and less than or equal to 0.0060 percent of [N], and the rest is Fe. The invention has high strength, good plasticity, good low-temperature impact property and good crack-resistance sensitivity.

Owner:JIANGSU SHAGANG GROUP HUAIGANG SPECIAL STEEL CO LTD

Expanding metal material and bulged tube device for petroleum oil well

ActiveCN1594631AImprove strong plasticitySmooth expansion deformationFluid removalPipe elementsInternal pressureWell drilling

The invention relates to an expanding metal material and expansion tube device for oil well. Expanding metal material consists of :C:0.03-0.5; Si:0-6.0; Mn:0-15; Cr:0-20; Ni:0-20; N:0.02-0.08; P<=0.03; S<=0.03; mixed rare earth:0.1; Ti:0-0.8; Zr:0-1.47; surplus Fe in which carbide gross of TiC and ZrC is 0.1-1.5%. Plasticity K=sigma*delta, amount to 3800MPa%,expansion tube shape memory connector can keep good sealing state after enlarging the diameter, and internal pressure resistance of expansion tube is close to 50Mpa. Warhead piston , centralizer and hydraulic anchor fixing machine all have a simple structure, operate stably, be used easily. The invention has significance in well drilling, well completion and mending well segment, so does other duct mending.

Owner:SHANGHAI GLOBE PETRO EQUIP

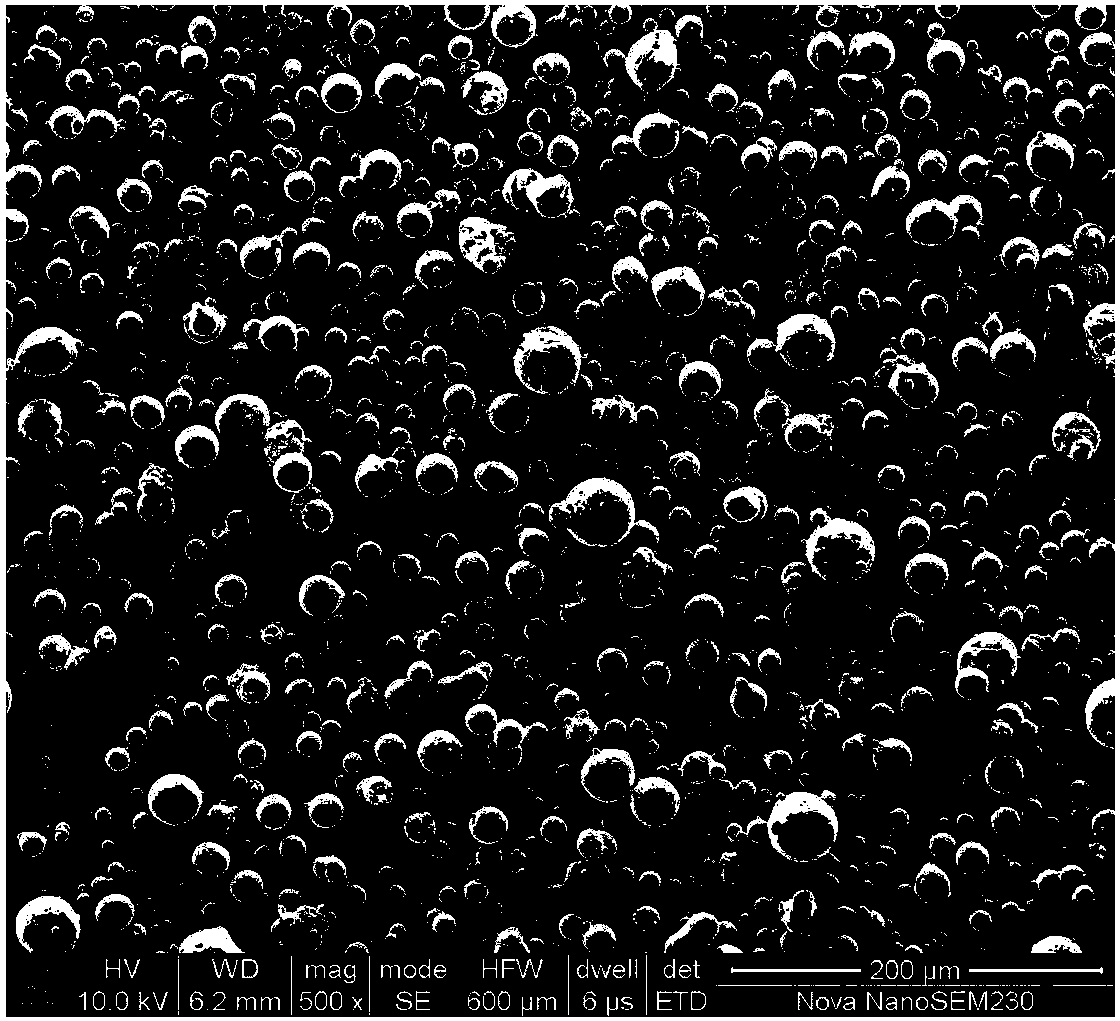

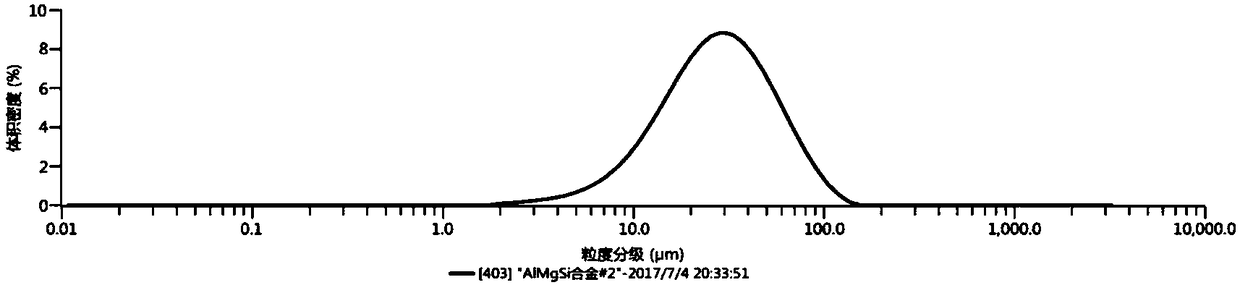

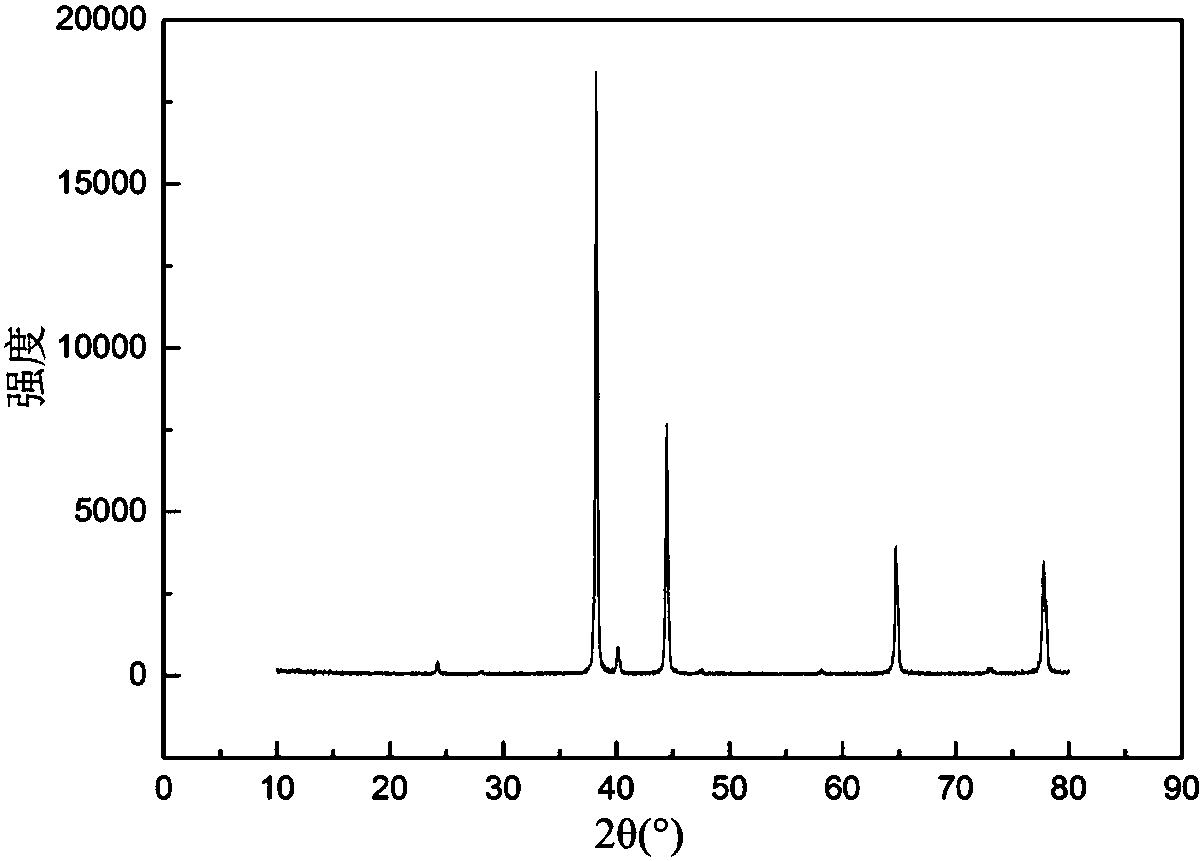

High strength Al-Mg-Sc alloy powder, preparation method thereof, application in 3D printer and 3D printing method of high strength Al-Mg-Sc alloy powder

ActiveCN108465807AHigh strengthImprove plasticityAdditive manufacturing apparatusIncreasing energy efficiencyRare earthHigh intensity

The invention discloses high strength Al-Mg-Sc alloy powder, and a preparation method, application and 3D printing method thereof. The specific combination of the alloy powder has multiple strengthening mechanisms of nanometer precipitation strengthening, fine grain strengthening, solid solution strengthening and the like, and high strength and plasticity are achieved. The rare earth high strengthAl-Mg-Sc alloy powder is subjected to 3D printing, parts are free of cracks, the compactness degree is high, the tensile strength and the elongation percentage are far higher than those of AL-12Si and AlSi10Mg alloys for traditional 3D printing, and the problems that a traditional aluminum alloy is low in 3D printing strength and poor in elongation percentage, and the stretching performance and the elongation percentage cannot be improved at the same time are solved. The tensile strength of the parts formed by printing the high strength Al-Mg-Sc alloy powder can reach 523 MPa or above, and the elongation percentage can exceed 13%.

Owner:CENT SOUTH UNIV +1

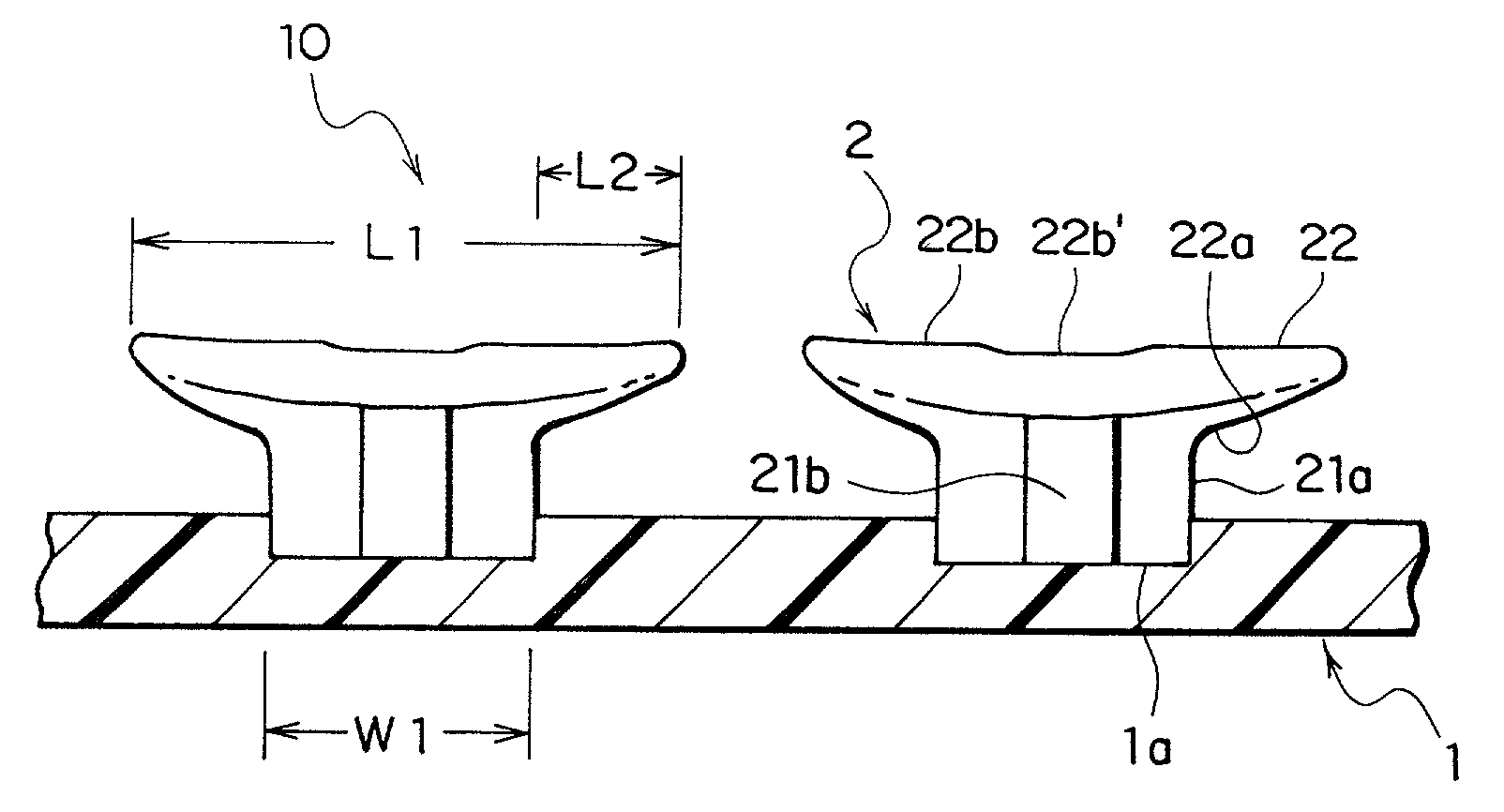

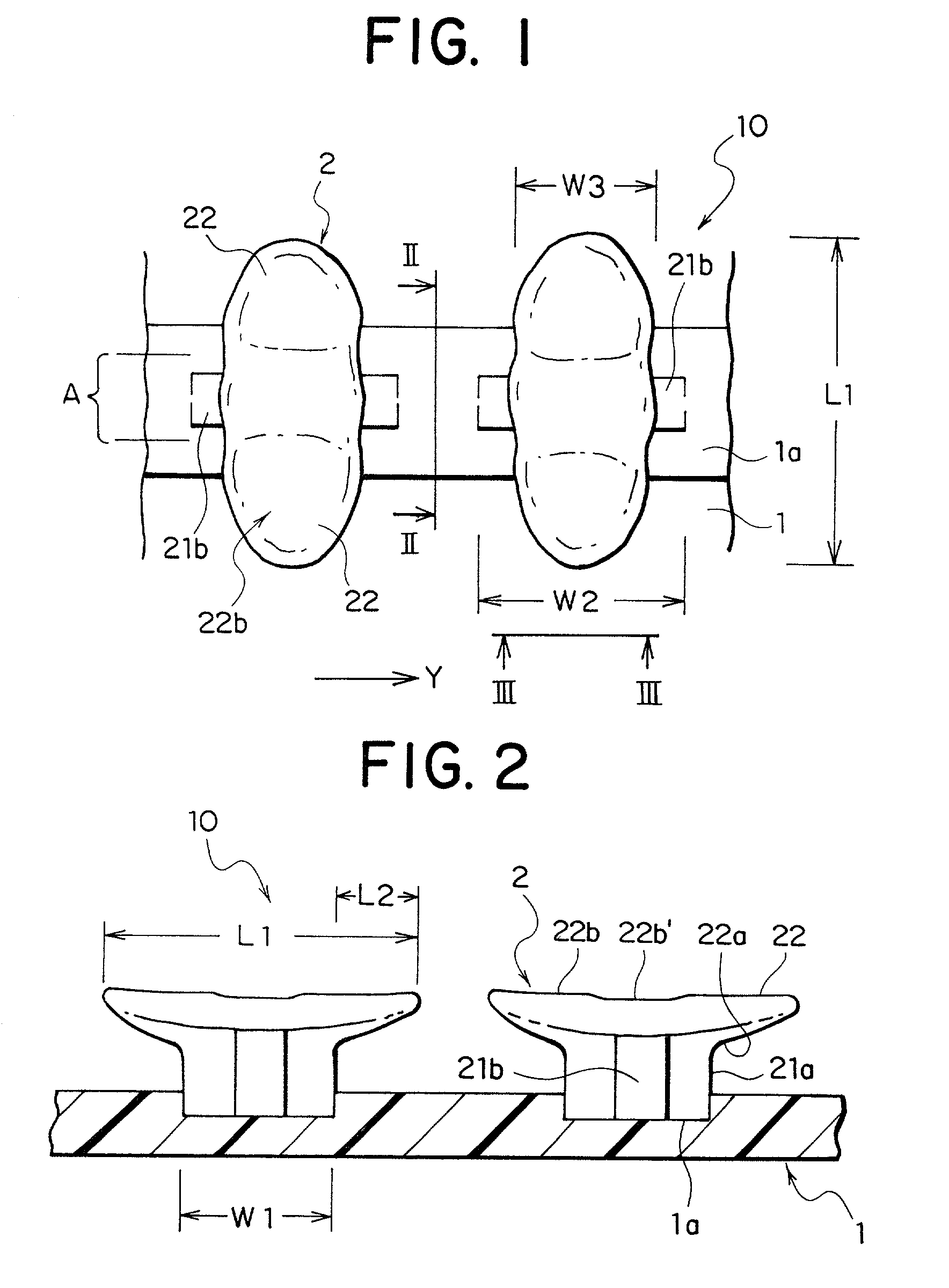

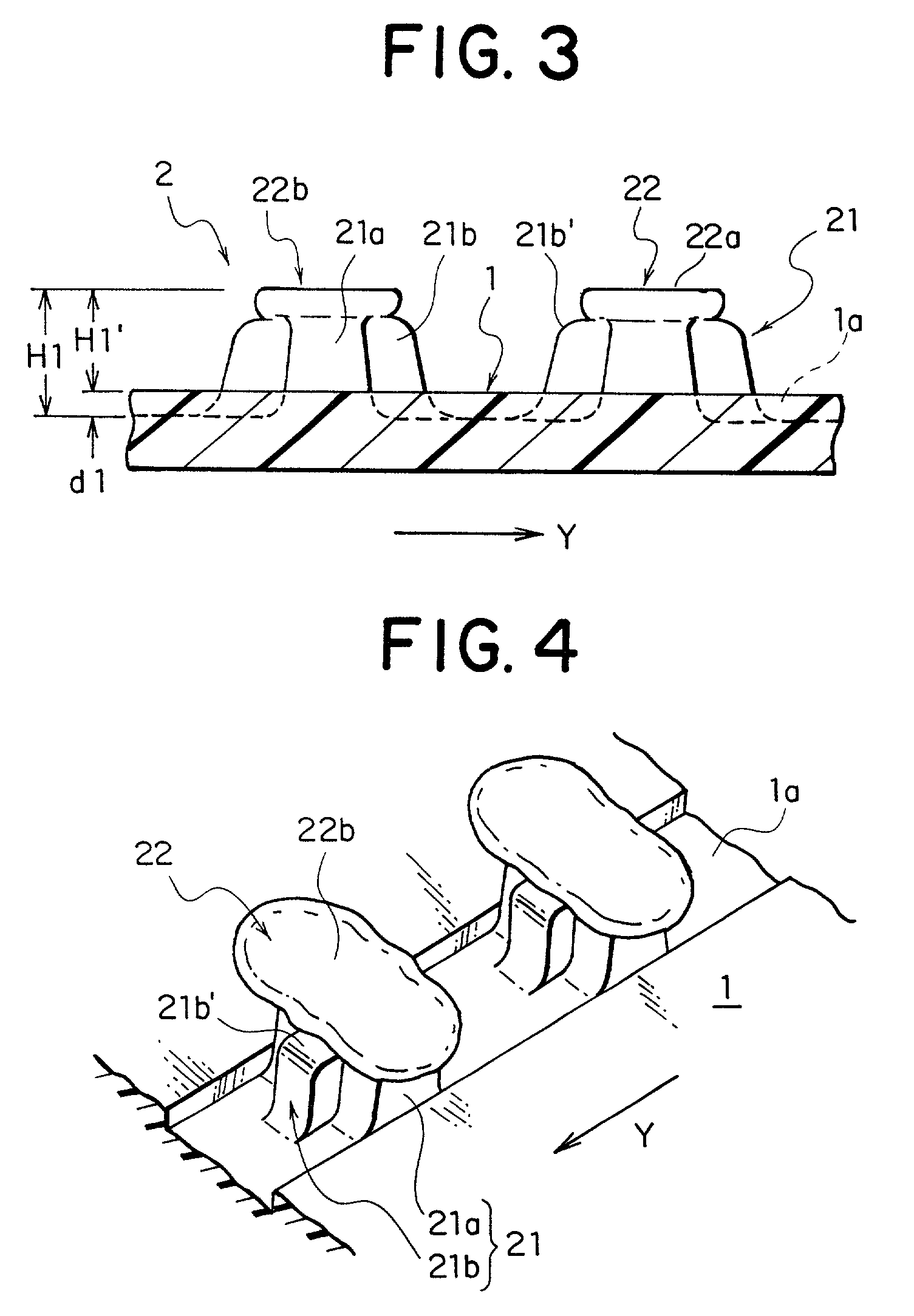

Integral molded surface fastener, and continuous manufacturing method and continuous manufacturing apparatus therefor

InactiveUS20020124359A1Increase participation rateSatisfactory durabilitySnap fastenersLayered productsFiberEngineering

An integral molded surface fastener having minute and peculiar engaging elements, which engage with minute, thickly wooded fiber piles securely while each engaging element secures appropriate engagement strength, shearing strength and separation strength is provided. Further, texture of a surface of the surface fastener is improved and a height of the engaging elements protruded from a surface of a substrate is lower than a conventional type, thereby preventing the engaging elements from being fallen down by a pressing strength. At the same time, a high engaging ratio with a mating pile piece is secured and a durability required for this kind of fastener is satisfied. Preferably, a desired plasticity and tearing strength of the flat substrate are secured. More specifically, a molded surface fastener having minute engaging elements of thermoplastic resin formed together with a substrate by continuous molding is provided, the engaging elements being hook-type engaging elements each comprised of a single column portion having a substantially cross-shaped section provided by intersection of a first column portion and a second column portion and rectangular thin plate-like engaging heads extended in the shape of wings in opposite directions along the width direction of the first column portion intersecting the second column portion around a top end of the column portion, and having substantially the same width dimension as the width dimension of a top end of the second column portion.

Owner:YKK CORP

Low welding crack sensitivity steel plate with yield strength of 690MPa grade and method for producing the same

ActiveCN101418418AReduce C contentLow costTemperature control deviceMetal rolling arrangementsChemical compositionSheet steel

The invention provides a low crack sensitivity steel plate with the yield strength of 690MPa grade and a method for manufacturing the same. The chemical components of the low crack sensitivity steel plate are as follows: 0.03 to 0.06 weight percent of C, 0.05 to 0.40 weight percent of S, 1.30 to 2.00 weight percent of Mn, 0.05 to 0.15 weight percent of Cr, 0.10 to 0.25 weight percent of Mo, 0.03 to 0.08 weight percent of Nb, 0.04 to 0.12 weight percent of V, 0.02 to 0.04 weight percent of Al, 0.004 to 0.030 weight percent of Ti, 0.0010 to 0.0020 weight percent of B, and the balance being Fe and inevitable impurities, wherein the weld crack sensitivity index Pcm is less than or equal to 0.20 percent. The invention adopts a controlled thermo-mechanical rolling and cooling technology to obtain a matrix structure mainly based on a thinned bainite, which is advantageous for improving the steel strength, the plasticity and the toughness of the steel plate. The yield strength of the low weld crack sensitivity steel plate is greater than 690 MPa; the tensile strength is greater than 700 MPa; the Charpy impact energy Akv (20 DEG C below zero) is more than or equal to 150 J; the plate thickness can reach 60 millimeters; and the welding performance is good.

Owner:BAOSHAN IRON & STEEL CO LTD

Hot-rolled high-strength steel plate for electrostatic enamel and method for manufacturing same

ActiveCN101139684ATemperature control deviceHeat treatment process controlHigh resistanceForeign matter

The invention provides a hot-rolled high-strength steel sheet for static enameling and a manufacturing method for the steel sheet. The main components by weight of the steel sheet are: C: 0.02-0.1%, Si<=0.1%, Mn: 0.2-1.5%, P: <=0.035%, S<=0.035%, Al: 0.01-0.1%, N: 0.001-0.01%, Ti: 0.01-0.1 %, Nb: 0.001-0.1%, and the remainder are iron and unavoidable foreign matters. The structure of the steel sheet comprises ferrite and pearlite, an the average particle diameter of the ferrite is not more than 11 micrometer. The manufacturing method of the steel sheet is, rolling twice the continuously cast or steel blanks after heating to 1100-1250 DEG C with total pressure-down amount <=50%, and final rolling temperature >=800 DEG C, then cooling section by section to coiling temperature 550-700 DEG C, and finally leveling the sheet. The hot-rolled high-strength steel sheet is applicable for pressure vessels such as bladders of water heaters, liquid-storing tanks and water buckets, etc. that are manufactured by static enameling process, is of high strength and good plasticity, high resistance to scaling bursting and air tightness.

Owner:BAOSHAN IRON & STEEL CO LTD

Steel plate with thickness of 80mm and low compression ratio for ocean engineering and manufacturing method thereof

ActiveCN102392192ASuitable for productionWide applicabilityTemperature control deviceFurnace typesLaminar coolingCooling temperature

The invention relates to steel for ocean engineering and a manufacturing method thereof, in particular to a steel plate with a thickness of 80mm and a low compression ratio for ocean engineering and a manufacturing method thereof. The steel plate comprises the chemical components with the weight percentages as follows: 0.12 to 0.16 percent of C, 0.20 to 0.40 percent of Si, 1.20 to 1.60 percent ofMn, smaller than or equal to 0.010 percent of P, smaller than or equal to 0.003 percent of S, 0.025 to 0.050 percent of Nb, 0.030 to 0.050 percent of V, 0.010 to 0.020 percent of Ti, smaller than or equal to 0.20 percent of Cr, 0.10 to 0.40 percent of Ni, smaller than or equal to 0.20 percent of Cu, smaller than or equal to 0.08 percent of Mo, 0.0250 to 0.050 percent of Al, smaller than or equal to 20ppm of O, smaller than or equal to 40ppm of N, smaller than or equal to 3ppm of H, and the remaining amount of Fe and inevitable impurities. A controlled rolling and cooling technology is adopted, the heating temperature before rolling is 1180 DEG C to 1250 DEG C, the rough rolling temperature is 1000 to 1100 DEG C, and the finish rolling starting temperature is 850 to 880 DEG C; laminar cooling is conducted after the rolling, the final cooling temperature is 640 to 680 DEG C, and the cooling rate is 5 to 15 DEG C / s; and normalizing treatment is conducted, the normalizing temperature is 890 to 910 DEG C, the heating rate is 1.4min / mm, and the heat preservation time is 50 to 90min. The obtained steel has the characteristics of high strength, good Z-direction lamellar tearing resistant performance, high plasticity, and the like.

Owner:NANJING IRON & STEEL CO LTD

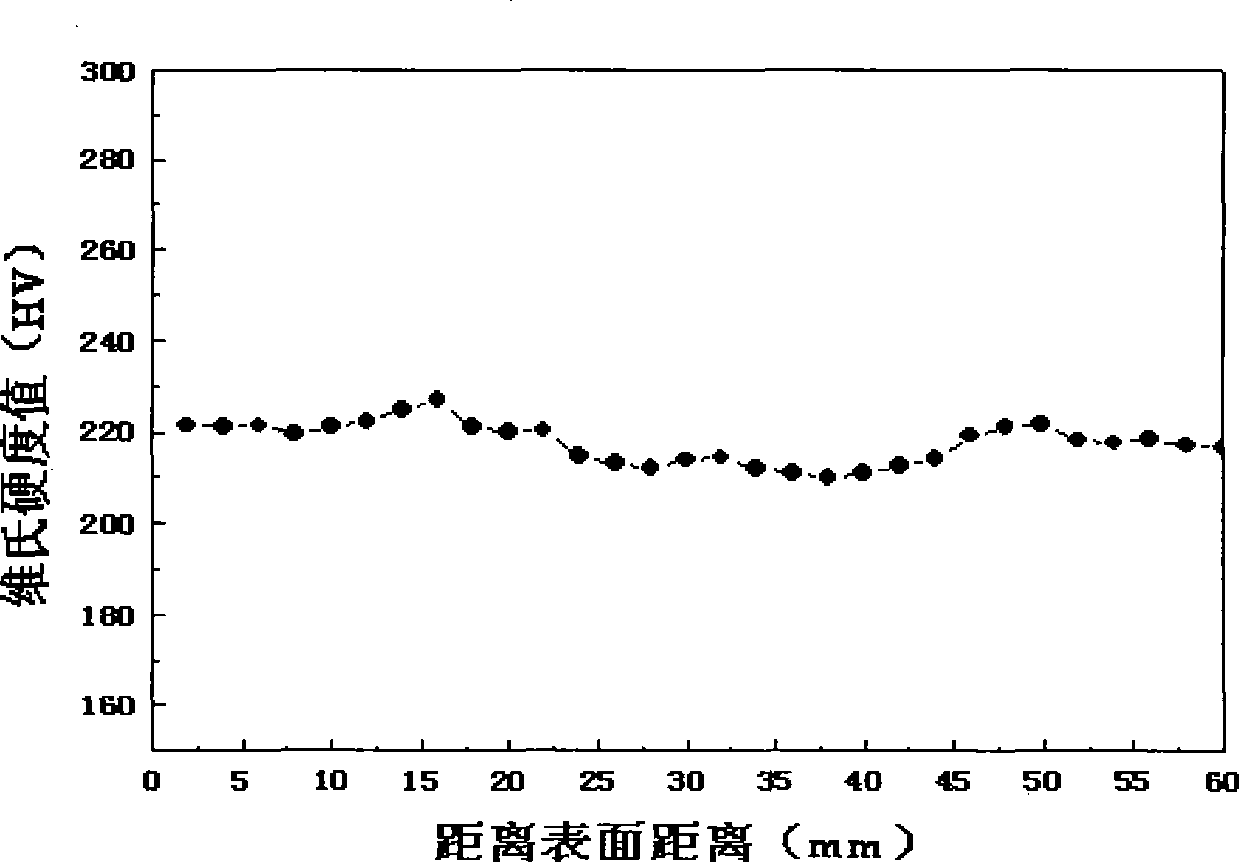

Novel manufacturing process of phi 300 mm-phi 700 mm high-carbon high-chromium cold-working die steel forged round steel

ActiveCN102418042AImprove cleanlinessImprove segregationMetal-working apparatusProcess efficiency improvementCarbideHot working

The invention discloses a manufacturing process of phi 300 mm-phi 700 mm high-carbon high-chromium cold-working die steel forged round steel, and the purpose is to solve the problems of quite severe ununiformity of large-section forging material eutectic carbides and the increase of defects of internal cracks and surface cracks during the forging process caused by segregation deterioration of cast structure carbides of large steel ingots. By using steel-making technical measures such as LF refining, VD degassing, aluminium wire feeding, and the like, the invention improves the molten steel cleanliness, the control of electroslag remelting output power, and the homogenization treatment before forging, and improves the segregation of eutectic carbides and the hot-working plasticity of steel; by controlling the forging heating numbers and various deformation amounts of large high-carbon high-chromium steel ingots, large granular carbides are crushed; the ununiformity of eutectic carbides is improved; crack defects during the forging process are prevented; and the produced high-carbon high-chromium steel large-section forging materials has ununiformity of eutectic carbides of up to grade 4-grade 6; the results of ultrasonic inspection are at good levels of E / e grade, D / d grade.

Owner:FUSHUN SPECIAL STEEL SHARES

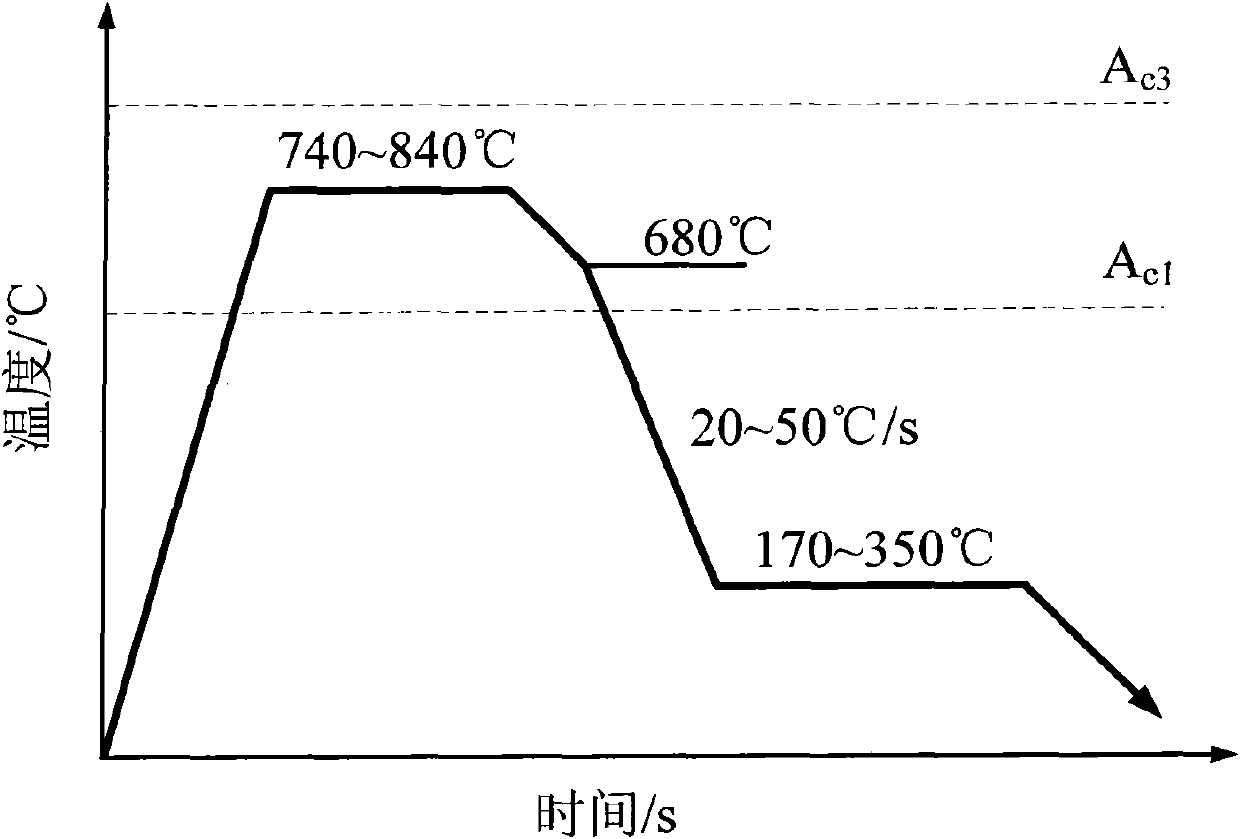

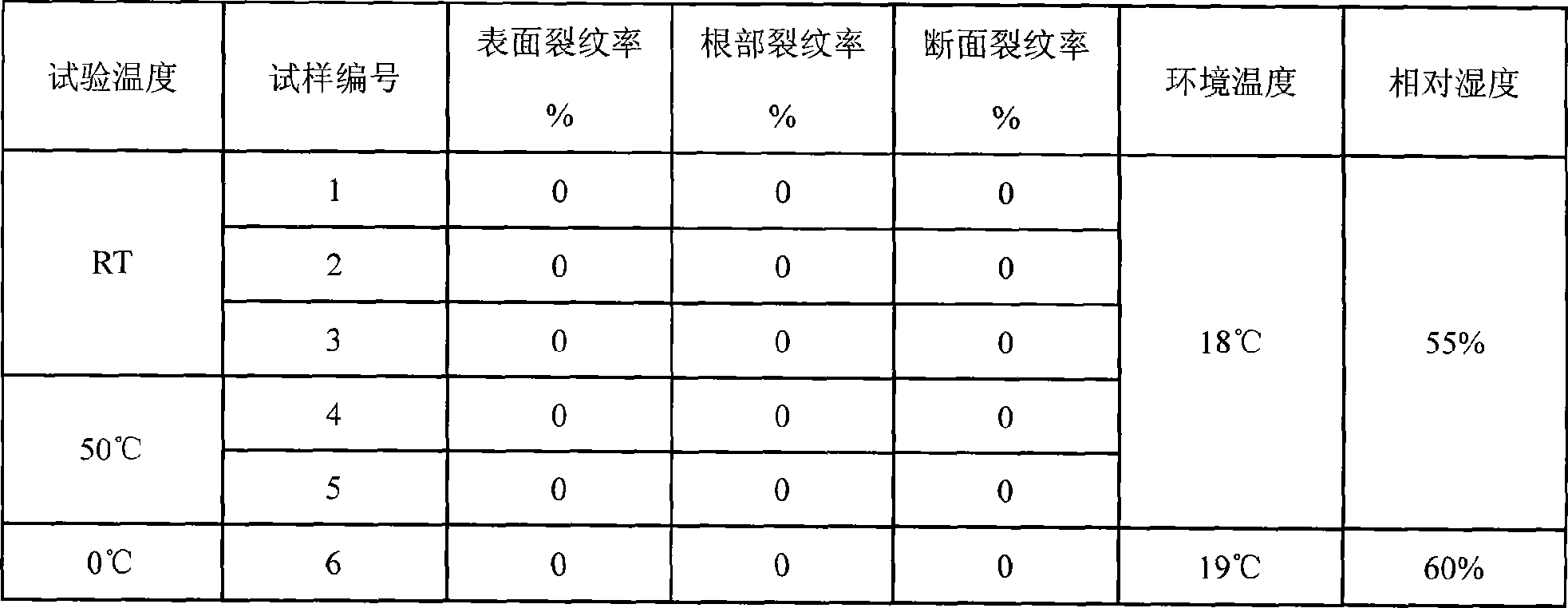

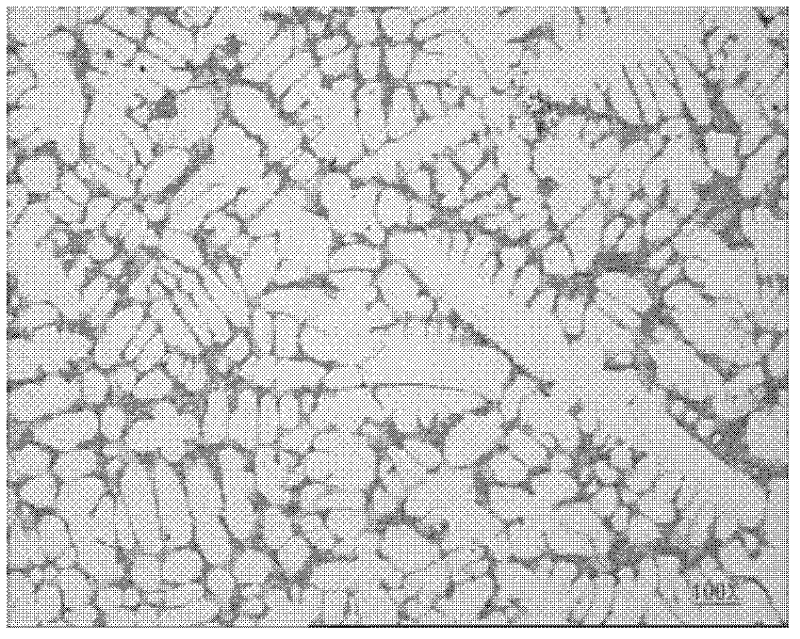

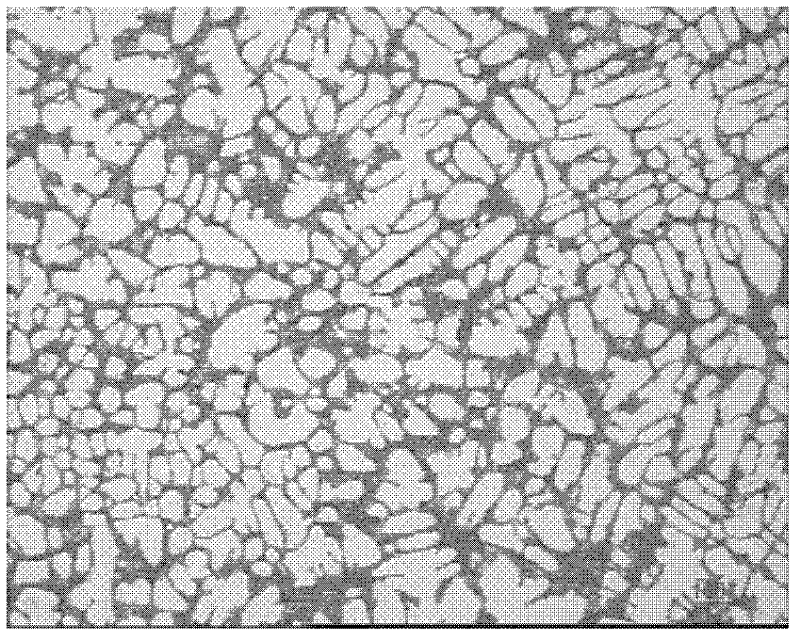

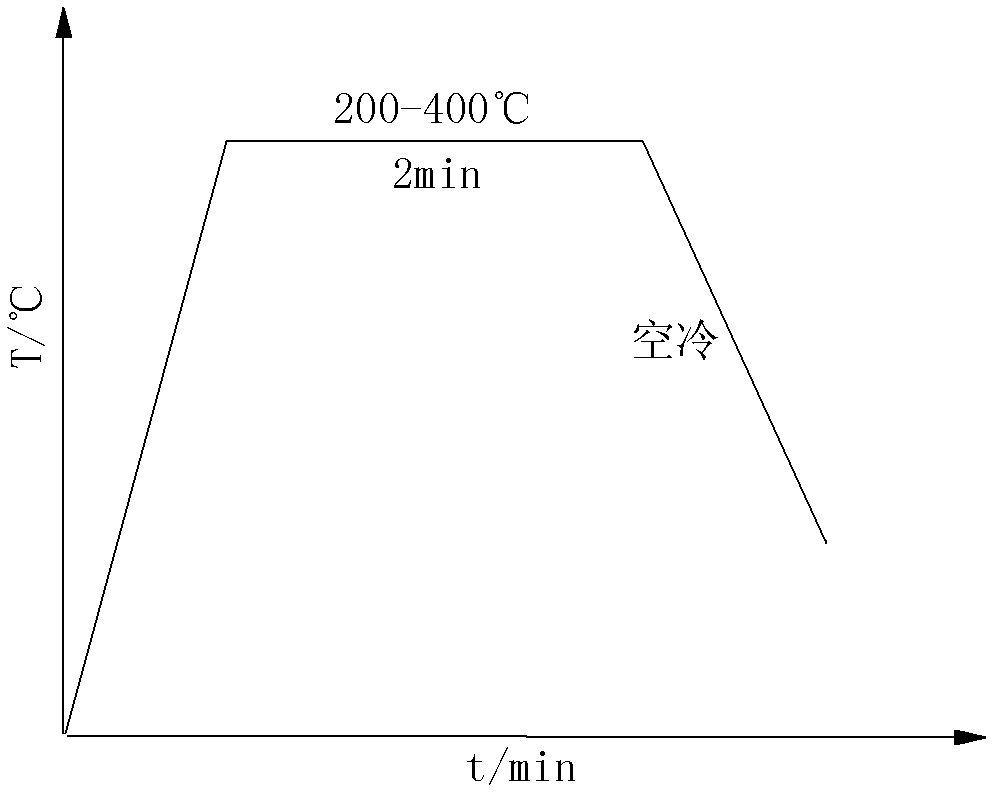

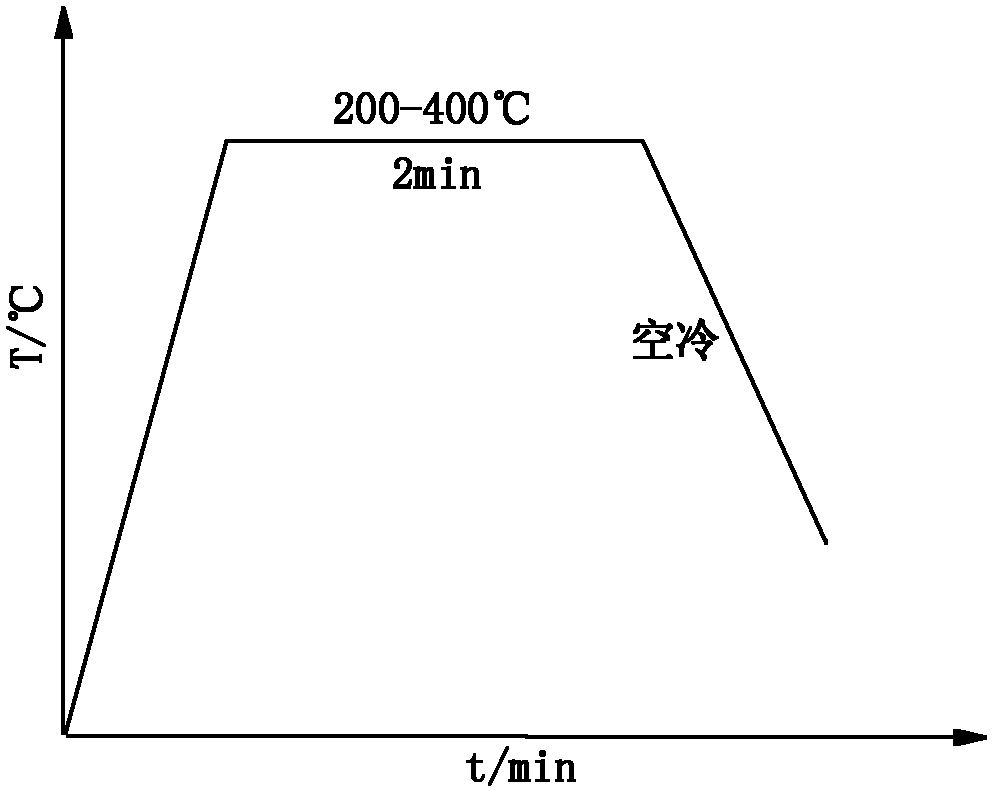

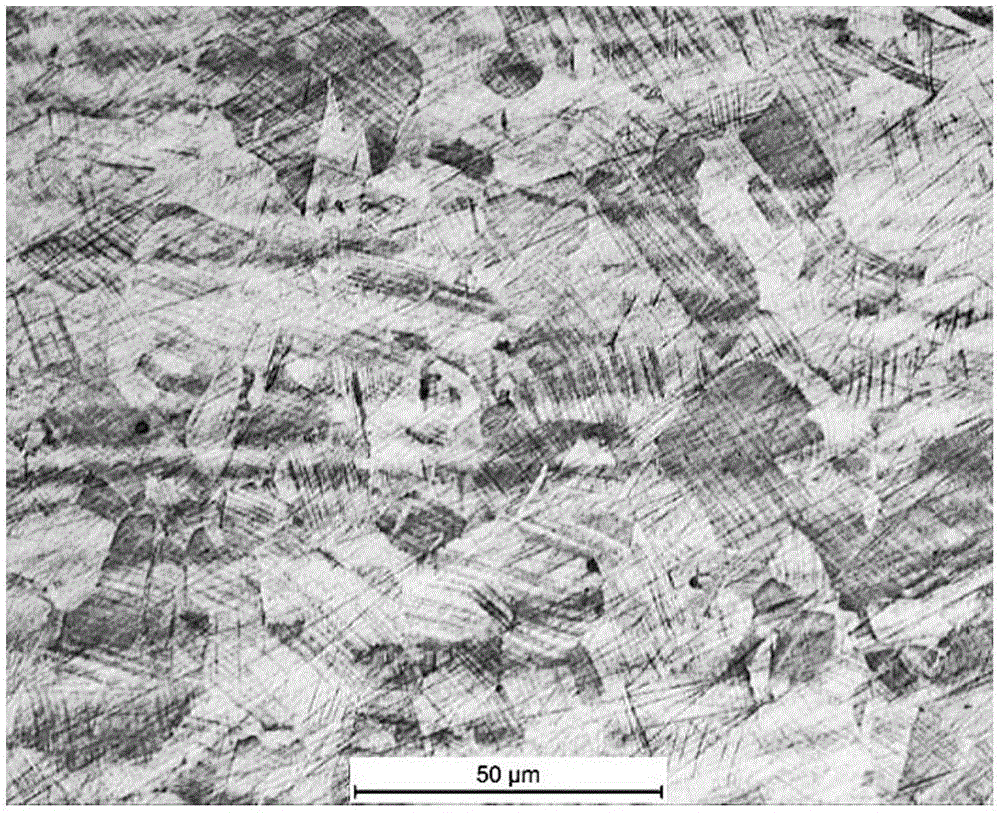

A heat treatment method for high-strength and toughness hot-formed steel sheets for automobiles

The invention provides a heat treatment method for high-strength and toughness hot-formed steel plates for automobiles, which belongs to the technical field of high-strength steels for automobiles, and aims to solve the problems of high strength but poor plasticity of steel plates for hot-formation at present. Technical measures to solve the problem: the mass percentage of the components is: C: 0.2~0.4%, Si: 0.1-0.5%, Mn: 1.0~2.0%, Cr: 0.1~0.5%, B: 0.001-0.005%, Ti : 0.01~0.05%, Al: 0.01-0.1%, P: <0.02%, S: <0.01%, N: <0.01%, and the balance is iron and unavoidable impurities. In the range of ~500℃, tempering treatment is carried out for 1-5min. The invention has the advantages that after the tempering treatment, the plasticity of the hot-formed steel is significantly improved while the strength is slightly reduced, and the toughness of the steel plate after hot stamping is improved.

Owner:UNIV OF SCI & TECH BEIJING

Aluminum alloy used for preparing high-strength high-plasticity aluminum matrix composite material and aluminum matrix composite material

The invention discloses an aluminum alloy used for preparing a high-strength high-plasticity aluminum matrix composite material and the aluminum matrix composite material, and belongs to the field of metal matrix composite materials and aluminum alloys. The aluminum alloy comprises chemical components including, by weight percent, 0.3%-0.7% of Si, 0.7%-1.4% of Mg, 0.6%-1.2% of Cu and the balance Al. Ceramic particles such as SiC, Al2O3, B4C, TiC and TiB2 and nanocarbon such as carbon nano tubes and graphene are added into the aluminum alloy to serve as a wild phase, the yield strength of the prepared composite material is obviously improved, and the composite material can reach the level of 2000 series aluminum alloy matrix composite material with the same wild phase content. Meanwhile, the aluminum matrix composite material has the good plasticity, and cold deformation machining can be carried out without cracking. Meanwhile, the natural aging negative effect (parking effect) of the prepared composite material is weak, and the strength of the composite material obtained through manual aging after natural aging can reach the strength value obtained through direct manual aging after quenching.

Owner:中科复材(滨州)新材料有限公司

High-strength rebar and manufacturing process thereof

InactiveCN101275197AImprove the strength of steel barsStable mechanical propertiesTemperature control deviceProcess efficiency improvementChemical IngredientsRebar

A high intensity deformed steel bar and a manufacturing procedure thereof are disclosed, belonging to the field of steel metallurgy and suitable for the deformed steel bar with 12mm to 40mm production standard. The high intensity deformed steel bar of the invention comprises the ingredients: C: 0.12-0.25%; Si; 0.12-0.80%; Mn: 0.30-1.55%, P: 0.01-0.035%, S: 0.01-0.040%, equivalent weight of carbon: 0.19-0.51% the rests are Fe. The procedure flow of the invention comprises the steps of: squaring billet, heating, roughly and intermediately rolling, precisely rolling, performing QTB water penetration, placing on a cooling bed (cooling naturally), scaling, checking and putting into storage. The invention has the advantage that: chemical ingredients are designed diversely according to the diverse production standards of the deformed steel bar, the after-rolling remaining heat treatment procedure is used to keep the steel bar in a good plasticity and toughness.

Owner:TIANJIN IRON & STEEL GRP

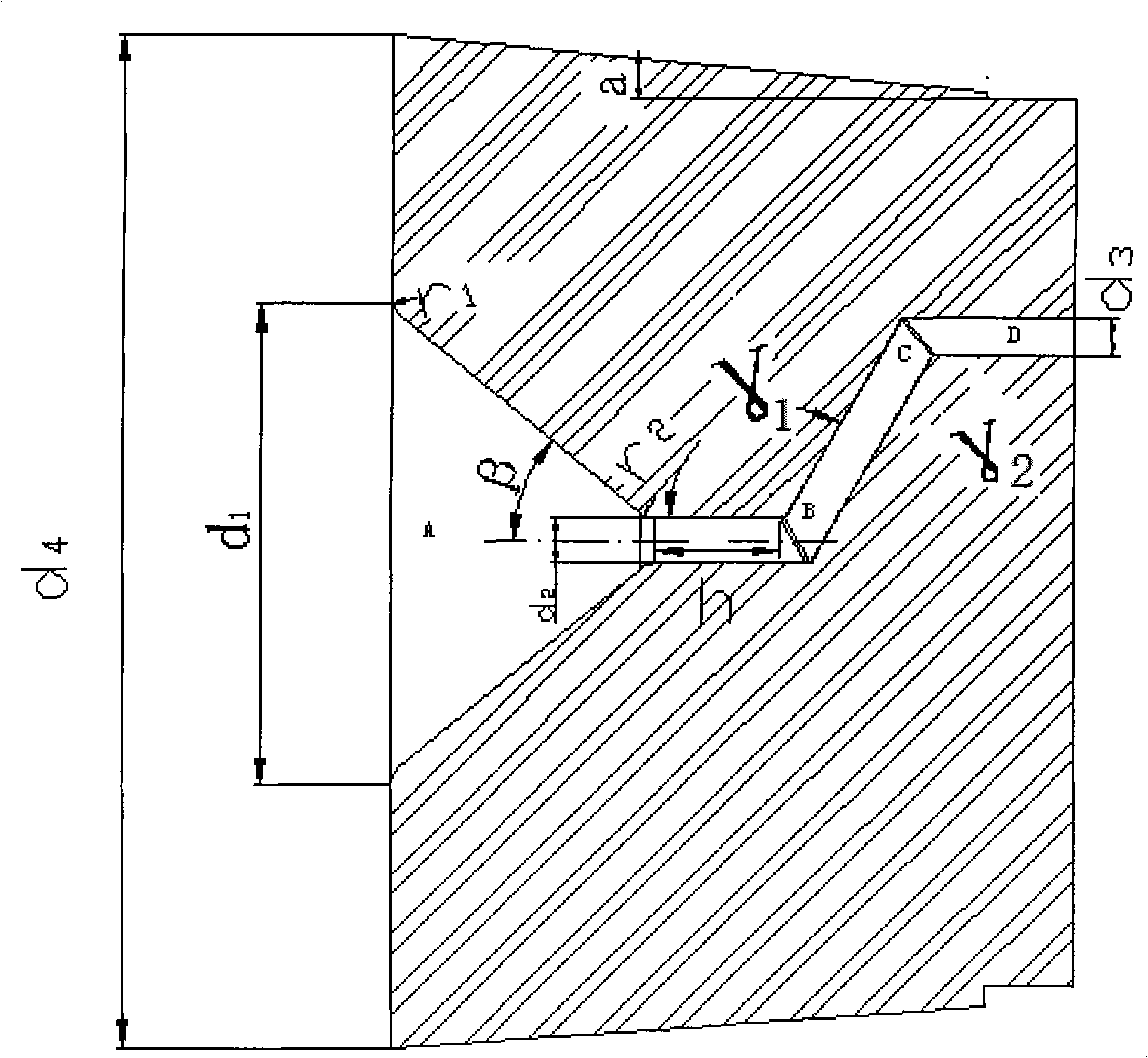

Method for preparing magnesium alloy section bar by continuous corner shearing and squeezing shaping and mold

InactiveCN101406906AImprove material plasticityImprove plasticityExtrusion diesExtrusion control devicesGrain structureHigh strain

The invention relates to a method for preparing a magnesium alloy section through continuous angle rotation shearing, extrusion and shaping and a mould. The method comprises the following steps: (1) a magnesium alloy blank material is subjected to homogenization treatment; (2) a mould of an extrusion mould with a plurality of angle rotation and molding is preheated; and the inside of a mould passage is evenly coated with lube; (3) an extrusion cylinder is heated to a temperature of between 175 and 325 DEG C; and (4) the homogenized blank material is heated to a temperature of between 200 and 350 DEG C; the extrusion ratio of the extrusion mould is between 4 and 100; and the magnesium alloy blank material is subjected to unidirectional extrusion at an extrusion speed of between 3 and 6 m / min so that the magnesium alloy blank material is subjected to compression and extrusion with high extrusion ratio and equal passage extrusion with a plurality of angle rotation. The magnesium alloy material prepared through the method has an ultrafine crystal grain structure, has the advantages of substantially improving the plasticity, low temperature superplasticity and high strain speed of the magnesium alloy material and has high yield stress.

Owner:CHONGQING UNIV

Economical ultralow-temperature steel and preparation method thereof

The invention relates to economical ultralow-temperature steel. The economical ultralow-temperature steel is prepared from, by mass percent, 0.3%-0.6% of C, 20%-28% of Mn, 0.1%-0.5% of Si, 2.5%-5.5% of Cr, 0.3%-0.8% of Cu, 0.01%-0.10% of N, 0.01%-0.05% of Al, not larger than 0.03% of P, not larger than 0.01% of S and the balance Fe and inevitable impurity elements. According to the economical ultralow-temperature steel, an austenitic structure is obtained through the heating process, the rolling process and the cooling process, and the usage temperature can reach -196 DEG C. Compared with 9Ni steel, the plasticity of the economical ultralow-temperature steel is remarkably improved; and compared with austenitic stainless steel, strength is remarkably improved, and the alloy cost is greatly reduced.

Owner:NANJING IRON & STEEL CO LTD

60-steel hot rolling coil rod with high strength and high plasticity and production method thereof

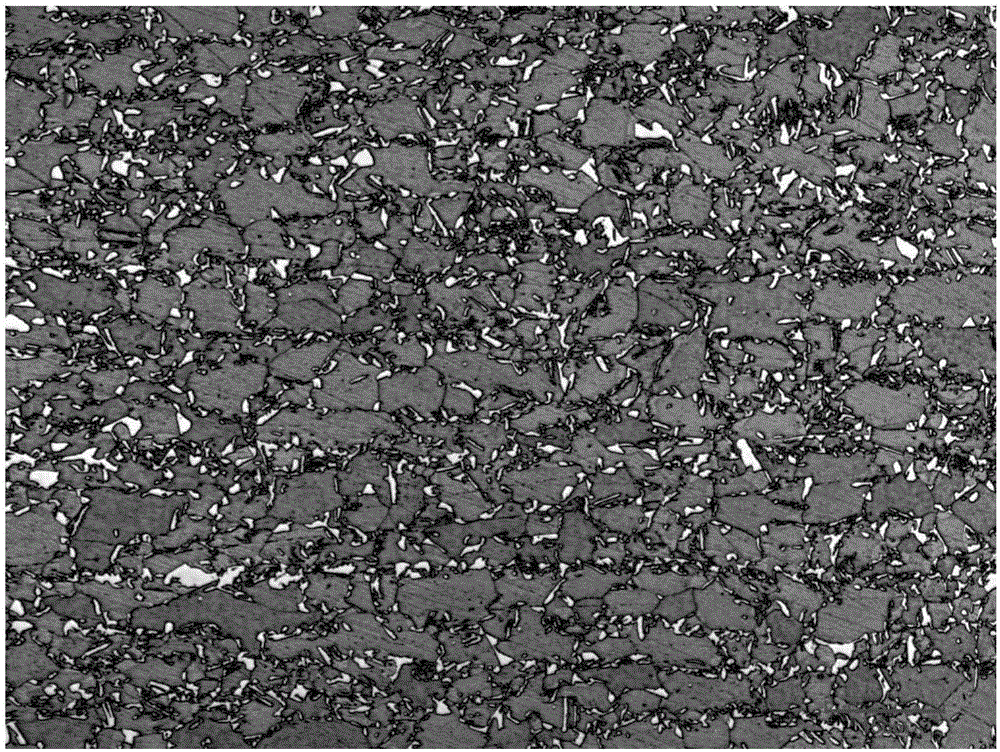

ActiveCN104213033ACompact configurationReasonable configurationTemperature control deviceWork treatment devicesChemical substancePlasticity

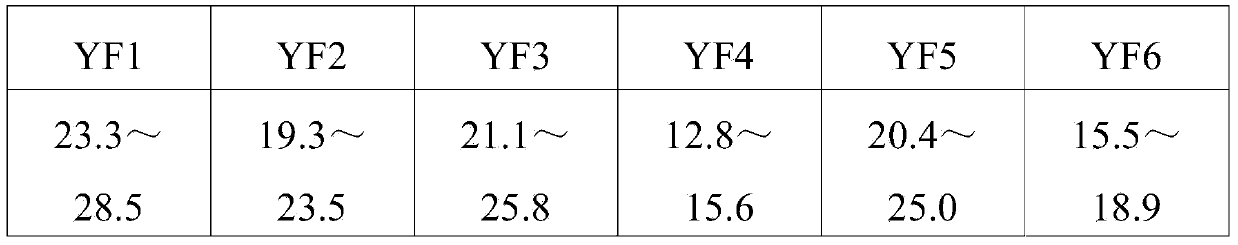

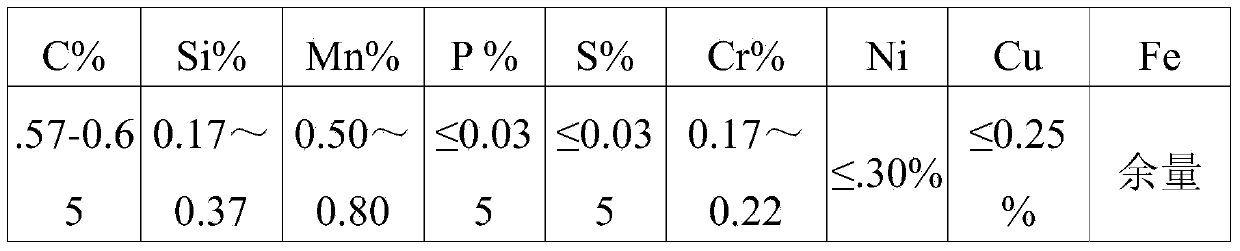

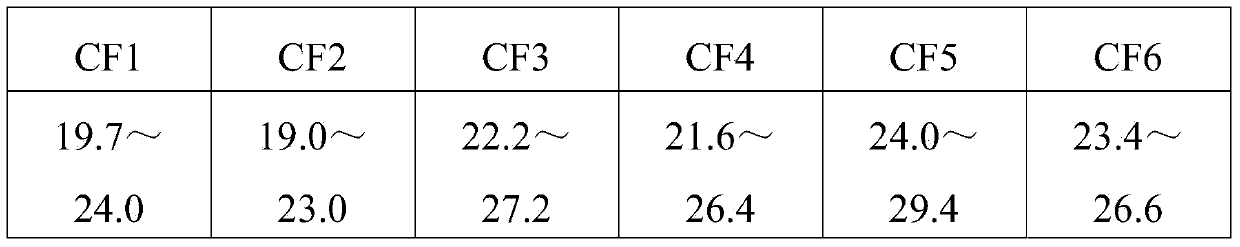

A 60-steel hot rolling coil rod with high strength and high plasticity and production method thereof belong to the hot rolling coil rod and production method thereof. The coil rod consists of the following chemical substances by weight percentage (%): 0.57-0.65 % of C, 0.17-0.37 % of Si, 0.50-0.80 % of Mn, 0.16-0.25 % of Cr, <= 0.35 % of P, <= 0.035 % of S, <= 0.30 % of Ni, <= 0.25 % of Cu, and the balance of Fe. The hot rolling coil rod with Phi 6.5 mm has a tensile strength of 990-1060 Mpa, a reduction of area of 50-60 % and a Sorbit rate of 85-90 %. The coil rod and the production method thereof have advantages that the process equipment and parameter setting are reasonable, the long-standing problem is solved, the product quality is improved, the deep processing of the coil rod is easy, a thinner steel wire product is easily drawn, the load that the steel strand processed with the steel wire can bear is substantially increased, the reduction of area of the steel wire is improved, the intermediate thermal treatment process is omitted and the energy is saved.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Plasticity-enhanced cold-rolled hot-dip galvanized dual-phase steel and production method thereof

The invention discloses plasticity-enhanced cold-rolled hot-dip galvanized dual-phase steel and a production method thereof. The dual-phase steel comprises the chemical components of, by weight, 0.12-0.18% of C, 0.3-0.6% of Si, 1.3-2.3% of Mn, 0-0.01% of P, 0-0.01% of S, 0.4-0.9% of Al, and the balance Fe and inevitable impurities. The technical problems of how to reduce the alloy or process cost and improve the galvanized surface quality on the basis of meeting the intensity requirement are solved, and the technical effects of reducing the alloy cost and improving the galvanized surface quality are achieved.

Owner:SHOUGANG CORPORATION

Base-containing high-entropy alloy composite and preparation method thereof

ActiveCN108504890AGood comprehensive mechanical propertiesBroad application prospectsHigh entropy alloysLimit strain

The invention discloses a base-containing high-entropy alloy composite and a preparation method thereof, and relates to a high-entropy alloy and a preparation method. The base-containing high-entropyalloy composite and the preparation method aim at solving the problems that the mechanical strength and the plasticity of an existing high-entropy alloy can not be improved, and the fragility is high.The base-containing high-entropy alloy composite is formed by preparing the following components of, by mass percentage, 1-20% of reinforced phase and 80-99% of base-containing high-entropy alloy matrix. The preparation method comprises the following steps that one, a raw base-containing high-entropy alloy composite is weighed; and two, the raw base-containing high-entropy alloy composite weighedin the Step one is smelted by an electric arc smelting method or an induction smelting method, and a base-containing high-entropy alloy is obtained. The yield strength of the prepared base-containinghigh-entropy alloy composite is 1200-2100 Mpa, the breaking strength is 2300-4000 MPa, and the limiting strain epsilon p (%) is 20-50%. The base-containing high-entropy alloy composite can be obtained.

Owner:HARBIN INST OF TECH

High plasticity, high tenacity and ultra-high tensile steel, and manufacturing method thereof

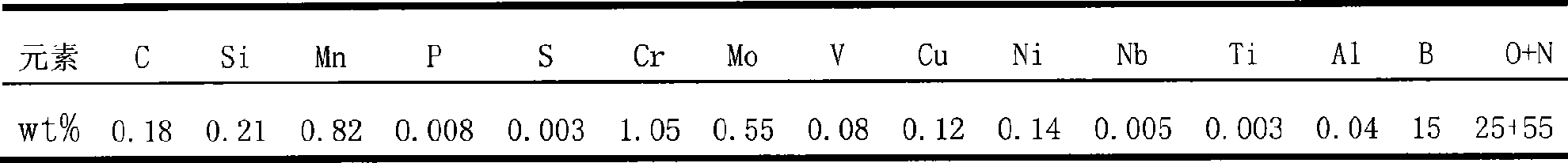

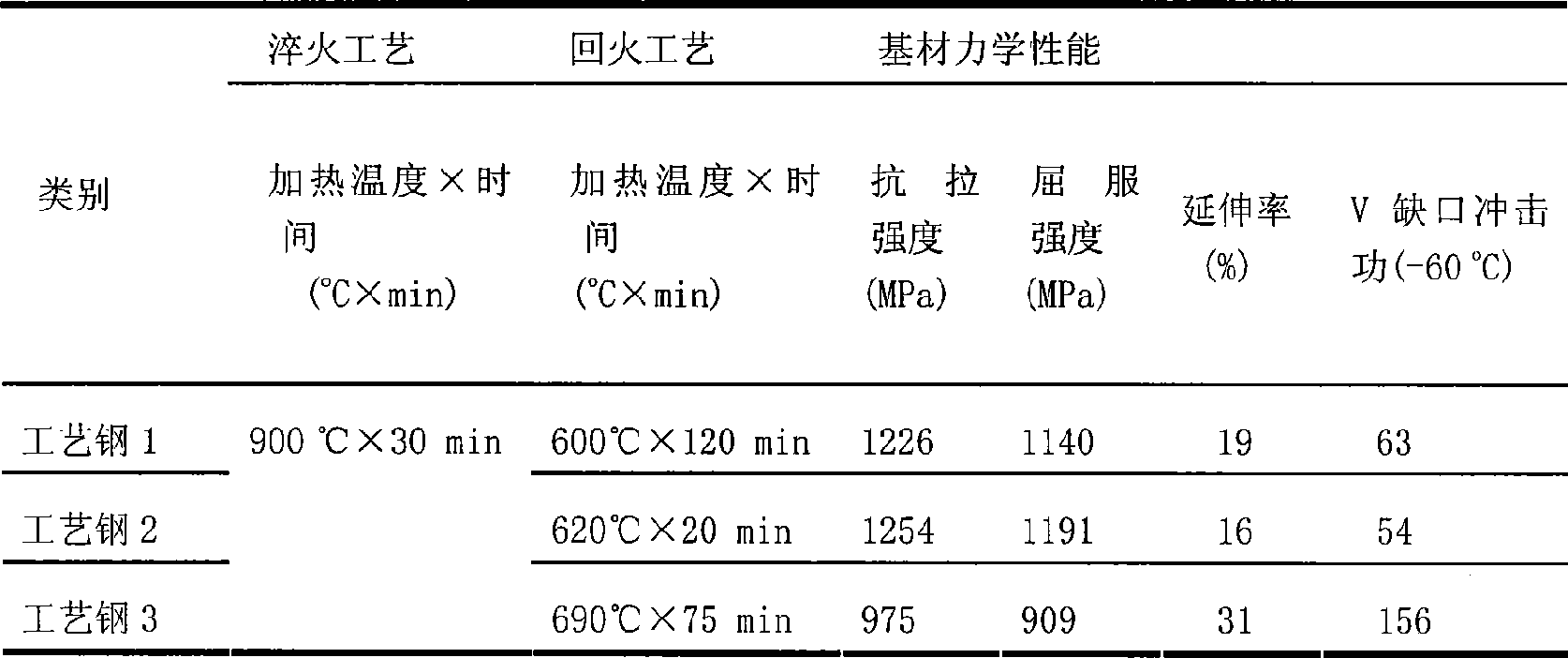

InactiveCN101481779ATemperature control deviceProcess efficiency improvementQuenchingHeat processing

The invention discloses a steel with high plasticity, high toughness and high strength and a manufacturing method thereof. The chemical compositions of the steel are as follows in terms of weigh percentage: 0.15 to 0.30 of C, 0.20 to 1.40 of Mn, 0.10 to 0.50 of Si, less than or equal to 0.015 of P, less than or equal to 0.012 of S, less than or equal to 0.20 of Ni, 0.40 to 1.50 of Cr, 0.25 to 1.35 of Mo, 0 to 0.10 of V, less than or equal to 0.2 of Cu, 0.01 to 0.05 of Al, 0.0005 to 0.0020 of B, less than or equal to 0.010 of (O+N) and the balance of Fe and impurities. The manufacturing method comprises the following steps: smelting according to the formula, continuous casting into a blank, hot rolling into plates or tubes, quenching at the temperature of 875 to 930 DEG C and holding the temperature for 25 to 40 minutes, tempering at the temperature of 625 to 675 DEG C for 30 to 90 minutes, then air cooling, and quenching and tempering heat treatment. The steel has yield strength of more than or equal to 1000MPa, tensile strength of more than or equal to 1100MPa, zero-degree-centigrade charpy impact work of more than or equal to 100J, specific elongation of 20 to 30 percent and is applicable to manufacture important structures of engineering machinery, high buildings and oil well pipes, and the like.

Owner:YANSHAN UNIV

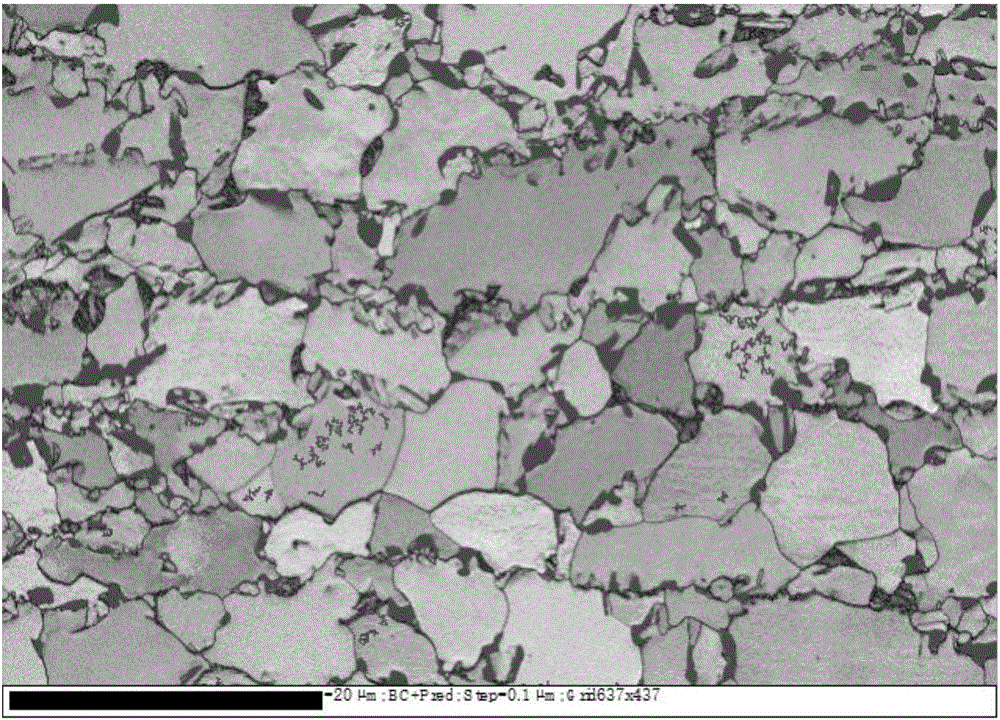

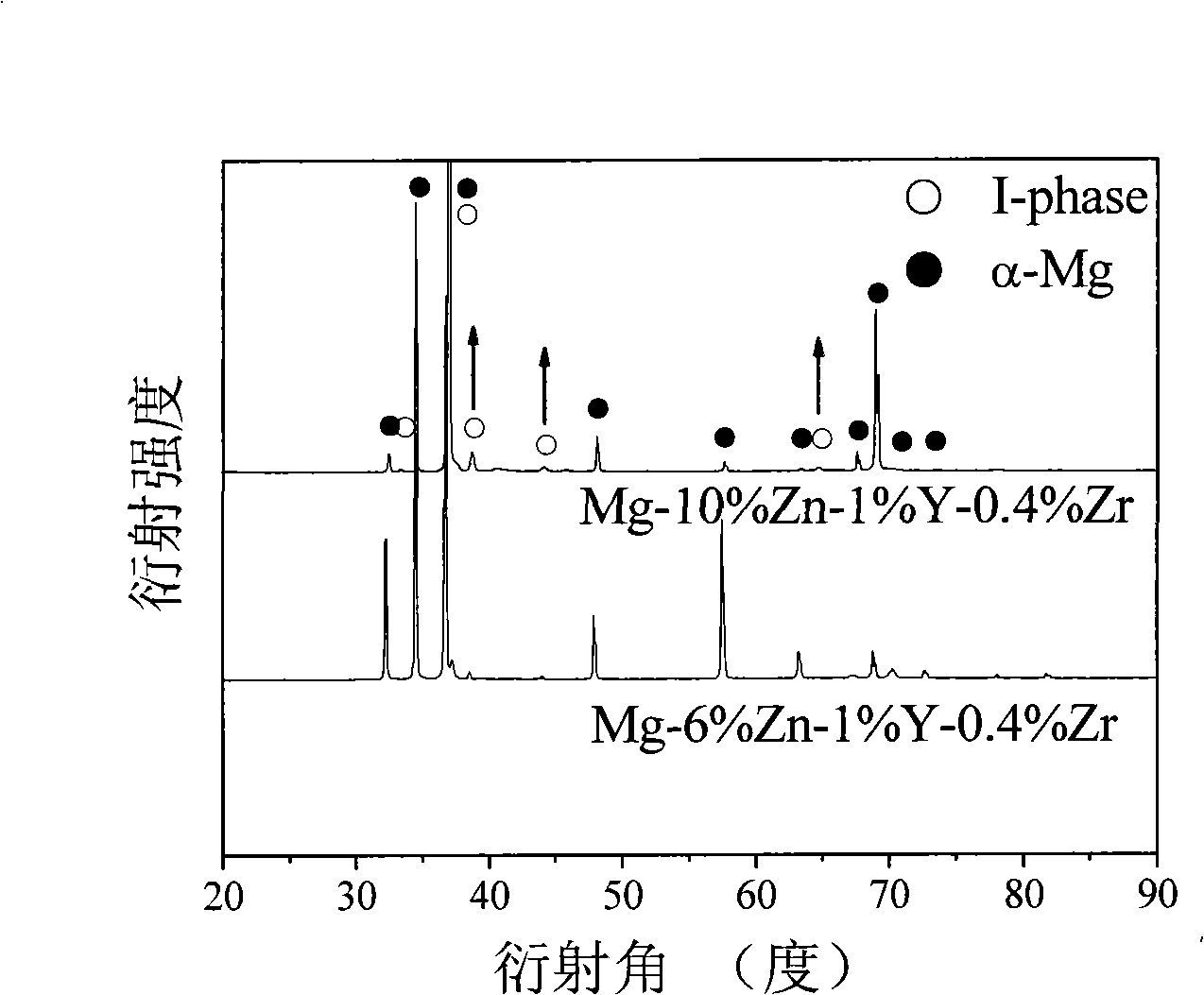

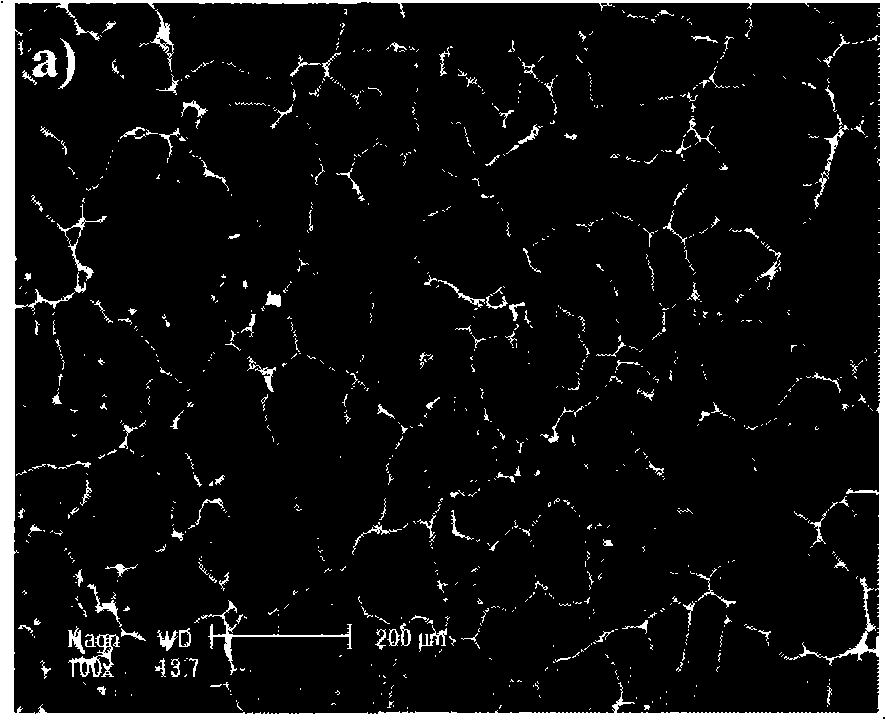

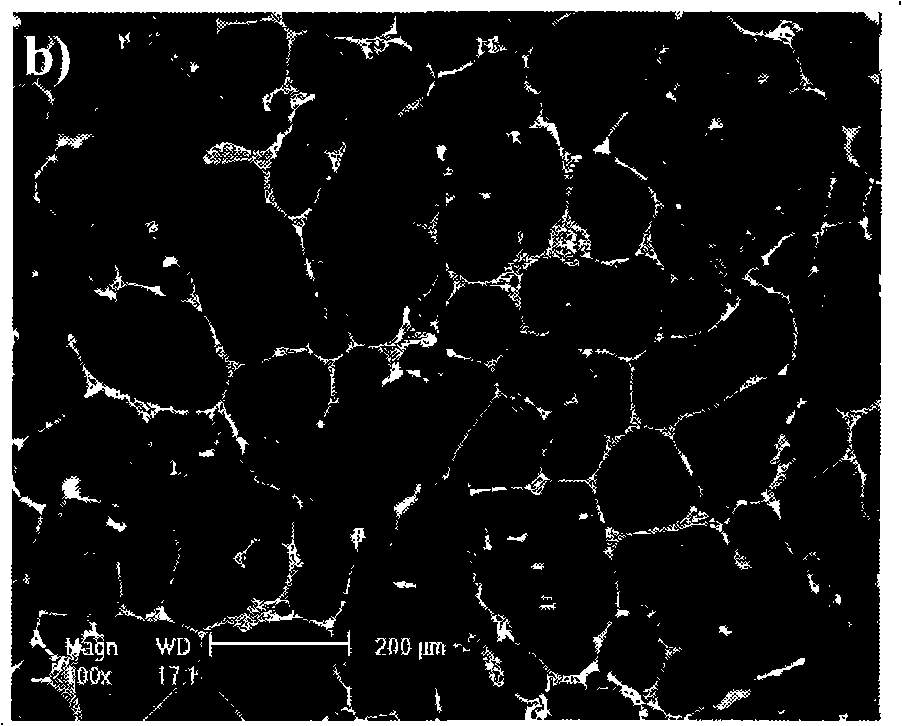

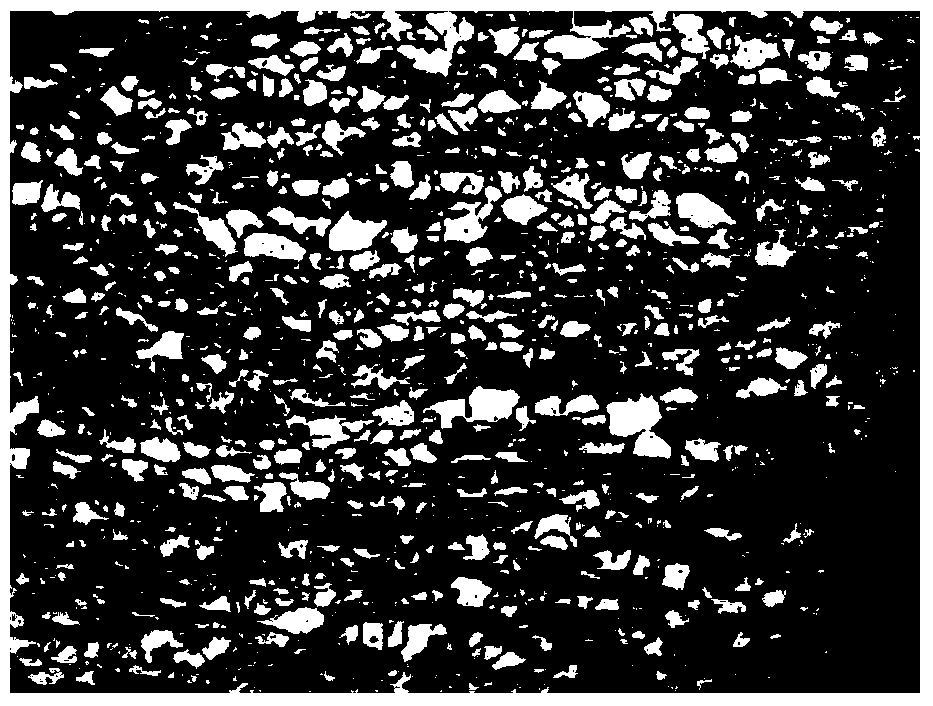

Y reinforced Mg-Zn-Y-Zr system magnesium alloy with effective utilization of rare earth element and production method

The invention relates to a lanthanon Y which is utilized to strengthen magnesium alloy effectively and a preparation technology thereof, in particular to a quasicrystal phase which is utilized to strengthen Mg-Zn-Y-Zr magnesium alloy and a preparation method thereof, and the problems such as magnesium alloy strengthening, etc. are solved. On the premise of definite Y contents, the volume percentage of the quasicrystal phase which is led into a magnesium alloy matrix to reach the maximum through reasonably choosing the rate between Zn and Y in the alloy (the rate between Zn and Y ranges from 6 to 15), so as to prepare the Mg-Zn-Y-Zr magnesium alloy with low density, high strength and better plasticity. The magnesium alloy material has the components and the contents thereof as follows: the content of zinc (Zn) ranges from 5 to 30 percent; the content of yttrium (Y) ranges from 0.5 to 5 percent; the content of zirconium (Zr) ranges from 0.3 to 0.8 percent, and the others are magnesium (Mg); all the percentage are weight percentage. The magnesium alloy material are processed through alloy melting and subsequent hot extrusion processing and deformed into products, and the operation of the processing technology is simple and convenient. The tensile strength of the material satisfies that Sigma (b) ranges from 290 to 360MPa, the yield stress delta0.2 ranges from 175 to 260MPa, the unit extension Delta ranges from 10 to 18 percent, and the density is 1.84 to 2.73g / cm<3>.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

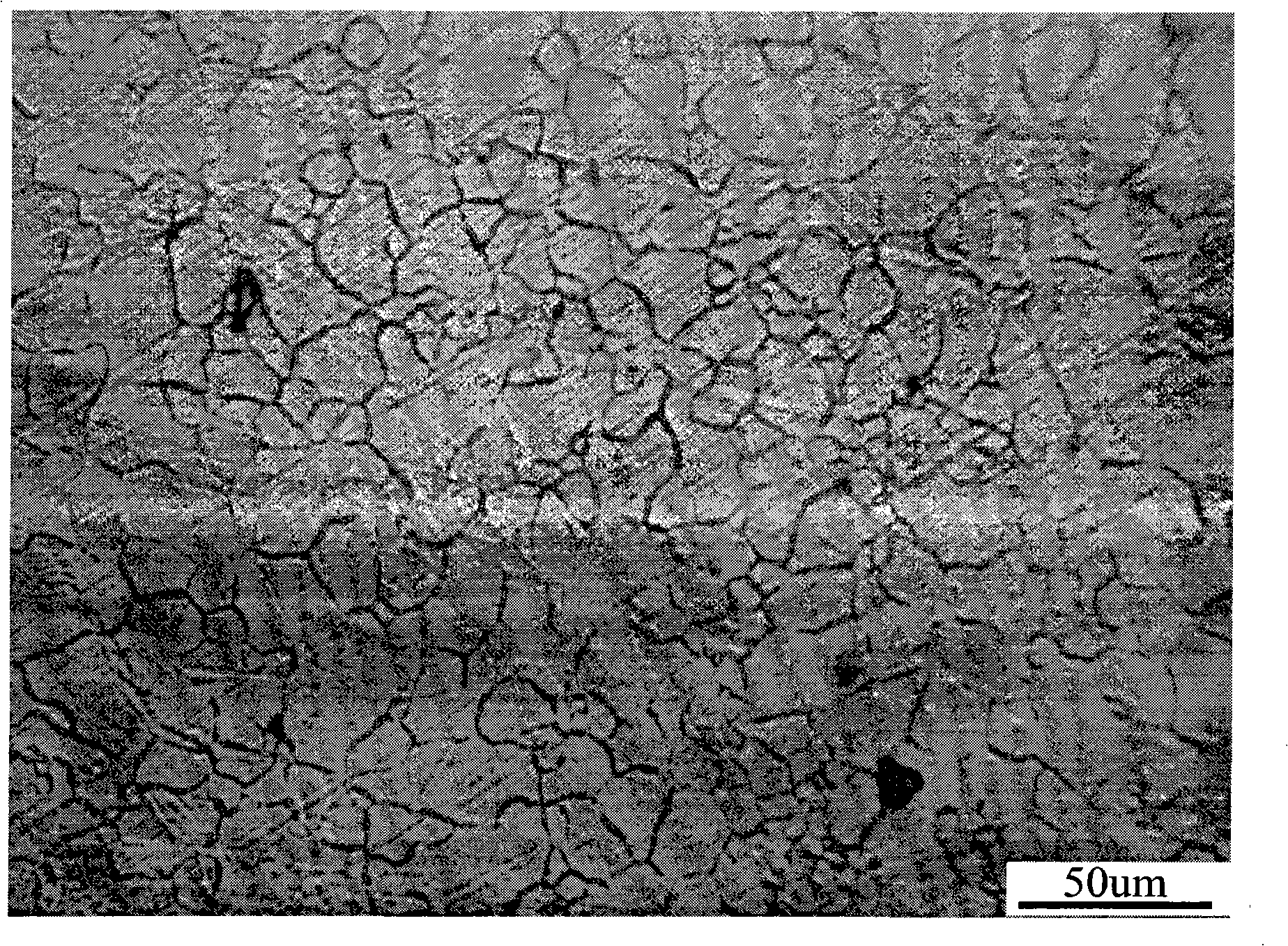

High-boron low-carbon abrasion resistant cast steel and heat treatment method thereof

InactiveCN101260501ARich sourcesReduce manufacturing costProcess efficiency improvementElectric furnaceChemical compositionRoom temperature

The invention relates to high-boron low-carbon wearproof cast steel and a heat treatment method thereof, which belongs to the steel material technical field. The cast steel comprises the following chemical compositions in percentage by weight (wt percent): 0.15 to 0.30 percent of C, 1.5 to 2.5 percent of B, 2.6 to 3.0 percent of Si, 1.4 to 1.8 percent of Cr, 0.5 to 0.8 percent of Mn, 0.05 to 0.12 percent of Ce, 0.03 to 0.15 percent of V, 0.03 to 0.15 percent of Ti, less than 0.05 percent of P, less than 0.05 percent of S, the balance being Fe, the content of v and Ti is more than 0.01 and less than 0.25. In the invention, a casting is kept between 880 DEG C and 920 DEG C for 1h to 3h, treated by isothermal quench in an isothermal salt bath furnace with the temperature between 250 DEG C and 300 DEG C, is kept for 2h to 4h and later cooled in the air to room temperature, thereby obtaining the high-boron low-carbon wearproof cast steel. Compared with the prior art, the cast steel and the technology of the invention have the advantages of good plasticity and toughness, high wear resistance , low cost, etc.

Owner:BEIJING UNIV OF TECH

High-performance marine climate resistant steel plate and manufacturing method thereof

The invention relates to a high-performance marine climate resistant steel plate and a manufacturing method thereof. The high-performance marine climate resistant steel plate comprises the following components in percentage by weight: 0.040-0.080 percent of C, less than or equal to 0.30 percent of Si, 0.40-0.80 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.003 percent of S, 0.15-0.45 percent of Cu, 1.25-1.85 percent of Ni, 0.15-0.45 percent of Mo, 0.007-0.013 percent of Ti, 0.015-0.030 percent of Nb, 0.035-0.065 percent of Als, less than or equal to 0.0050 percent of N, 0.001-0.004 percent of Ca and the balance of Fe and inevitable impurities. According to the high-performance marine climate resistant steel plate and the manufacturing method thereof, a low-alloy weathering resistant steel system adopting ultralow C-low Mn-high Als-low N-(Cu and high Ni) alloying-Nb microalloying-ultramicro Ti treatment is used for controlling sea atmosphere corrosion resistant parameter Eta to be greater than or equal to 1.36, (%Ni)*(%Mo) to be greater than or equal to 0.27, Ceq to be less than or equal to 0.42 percent, Ca treatment and Ca / S to be 1.0-3.0 and Ca*S0.28 to be less than or equal to 1.0*10<-3>; the sea atmosphere corrosion resistant steel plate with excellent toughness, strong plasticity matching, low yield ratio, sea atmosphere corrosion resistant property and fatigue resistance is obtained by adopting TMCP, and the sea atmosphere corrosion resistant steel plate can be welded at high heat input.

Owner:BAOSHAN IRON & STEEL CO LTD

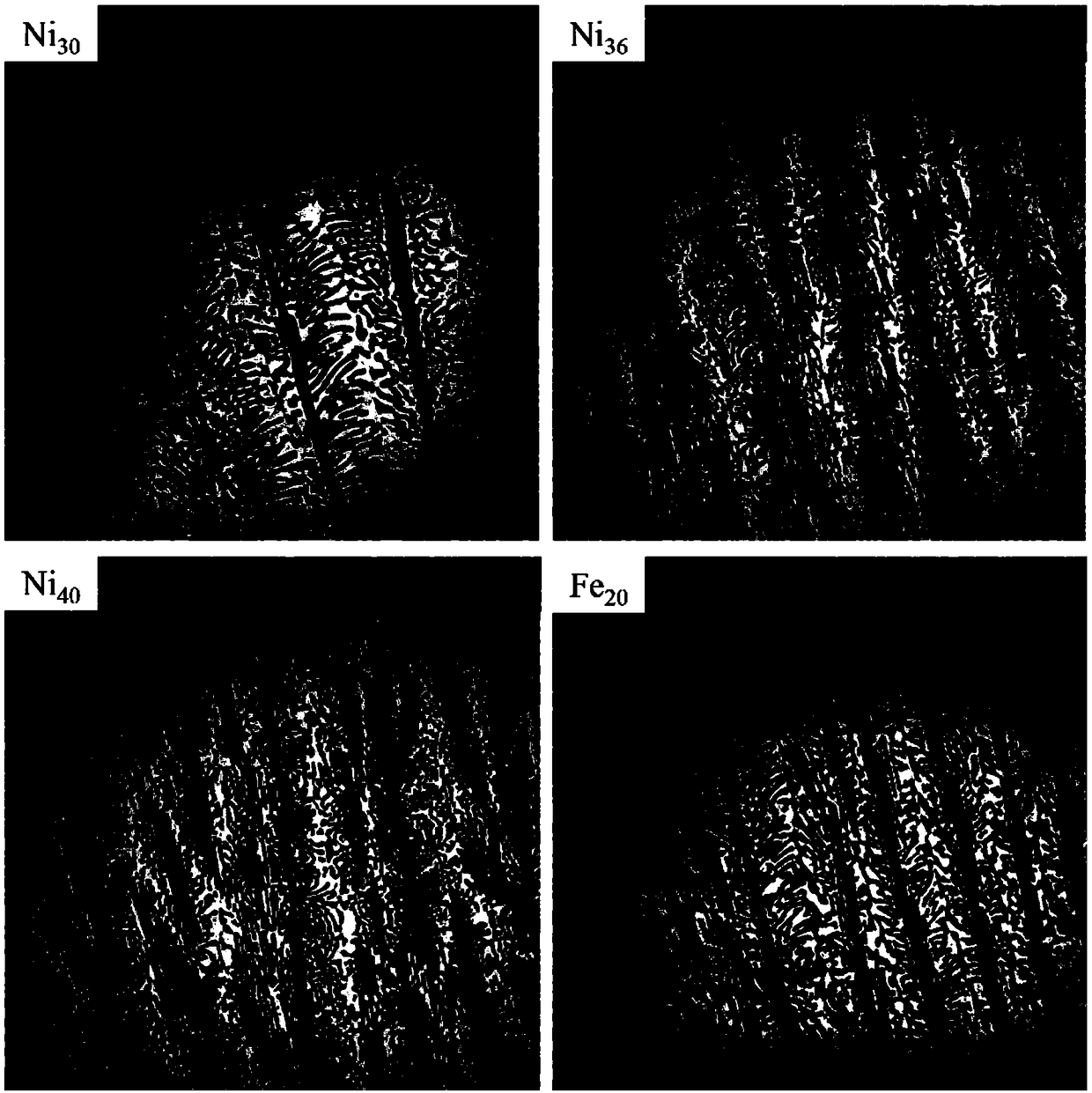

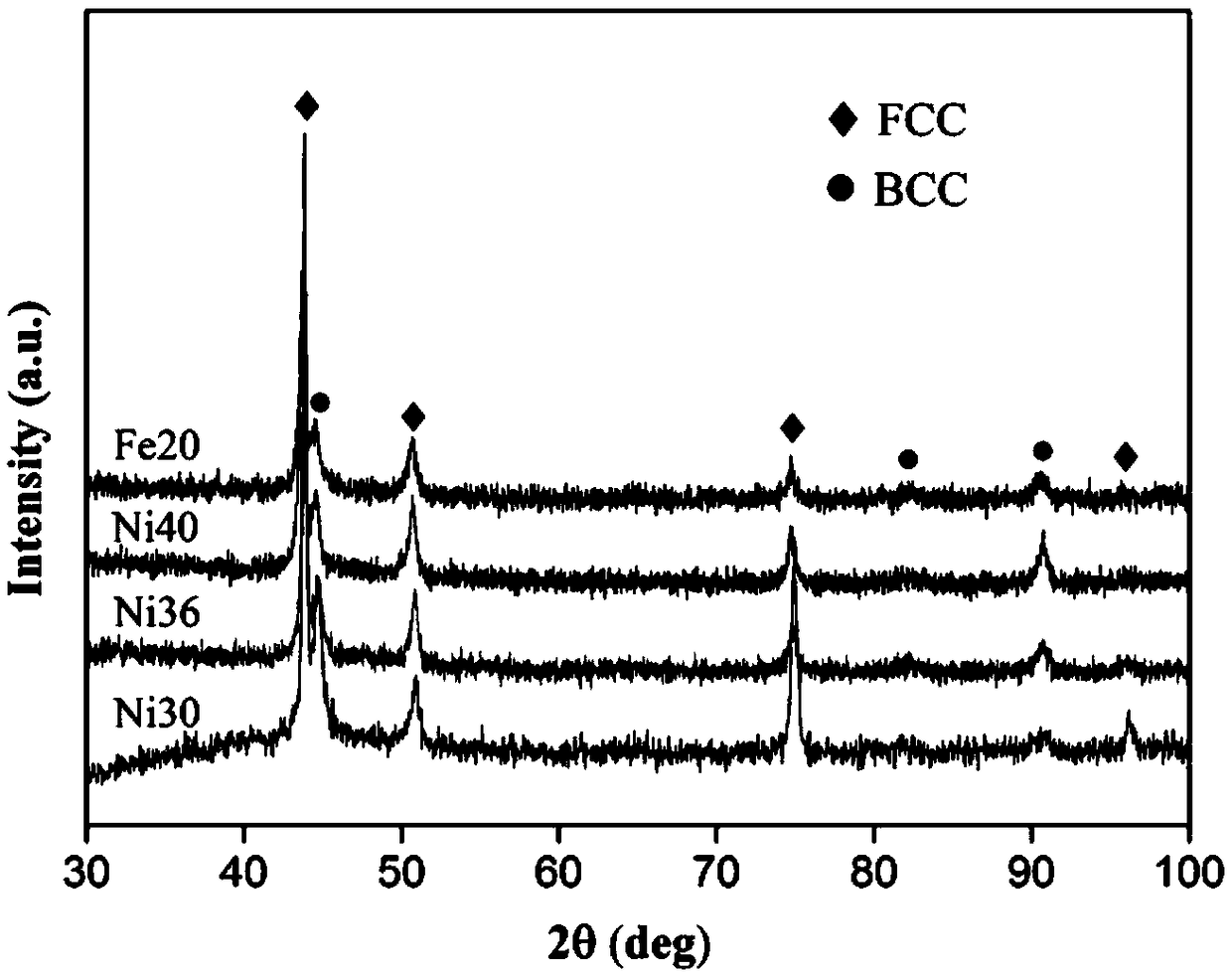

High-strength and high-plasticity eutectic high-entropy alloy and preparation method thereof

The invention discloses a high-strength and high-plasticity eutectic high-entropy alloy and a preparation method thereof. The high-strength and high-plasticity eutectic high-entropy alloy is preparedfrom the major elements of Ni, Co, Fe, Cr, Al and the trace elements X; the alloy composition is NiaCobFecCrdAleXf, wherein a, b, c, d, e and f represent the molar percentages of the corresponding elements, a+b is greater than or equal to 58 and less than or equal to 62, a is greater than or equal to b, c+d is greater than or equal to 18 and less than or equal to 22, c is greater than or equal tod, e is greater than or equal to 17 and less than or equal to 19, and f is less than or equal to 5.3; and the trace elements X comprise the following elements of W, Nb, Mo, B and C. The preparation method for the eutectic high-entropy alloy comprises the following steps that firstly, the alloying elements of the Ni, the Co, the Fe, the Cr, the Al and the X are descaled and cleaned and are weighedand mixed according to a certain molar ratio, a mother alloy is smelted, and finally suction casting is carried out so as to obtain the eutectic high-entropy alloy. The alloy combines the face-centered cubic phase and the body-centered cubic phase and has the advantages of being high in strength and high in plasticity, the elements such as the Al, the Cr and the W are beneficial to the improvementof the oxidation resistance, the corrosion resistance and the high-temperature stability of the alloy, and the comprehensive performance of the alloy is quite excellent.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

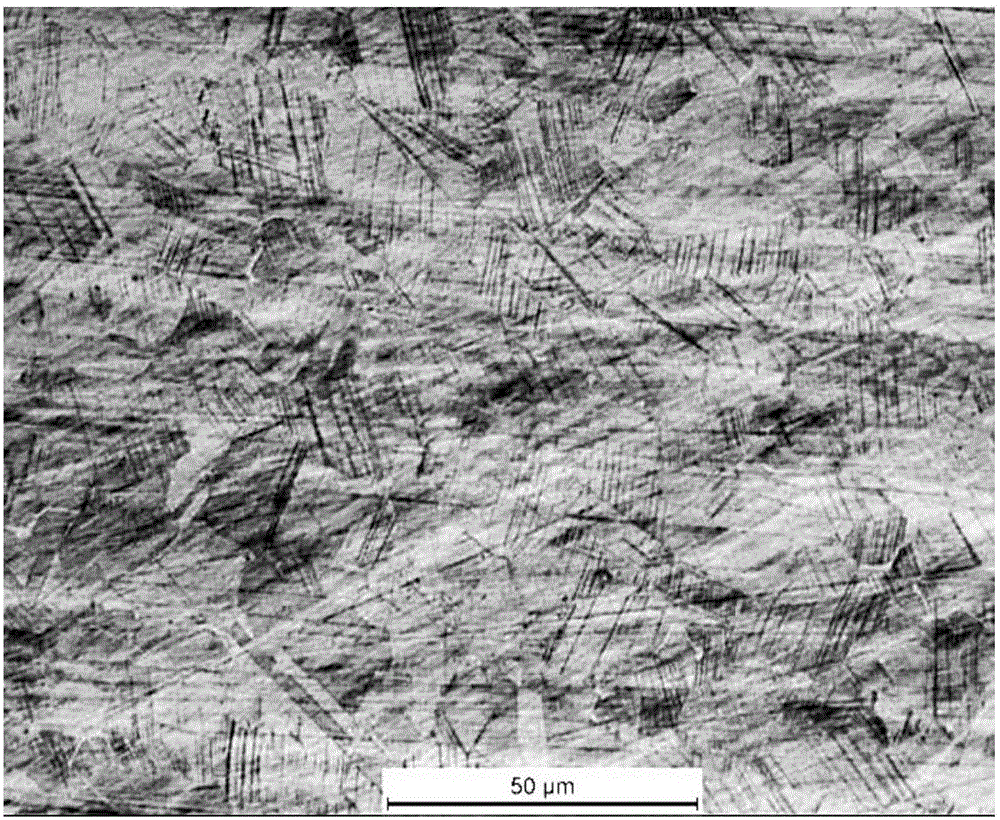

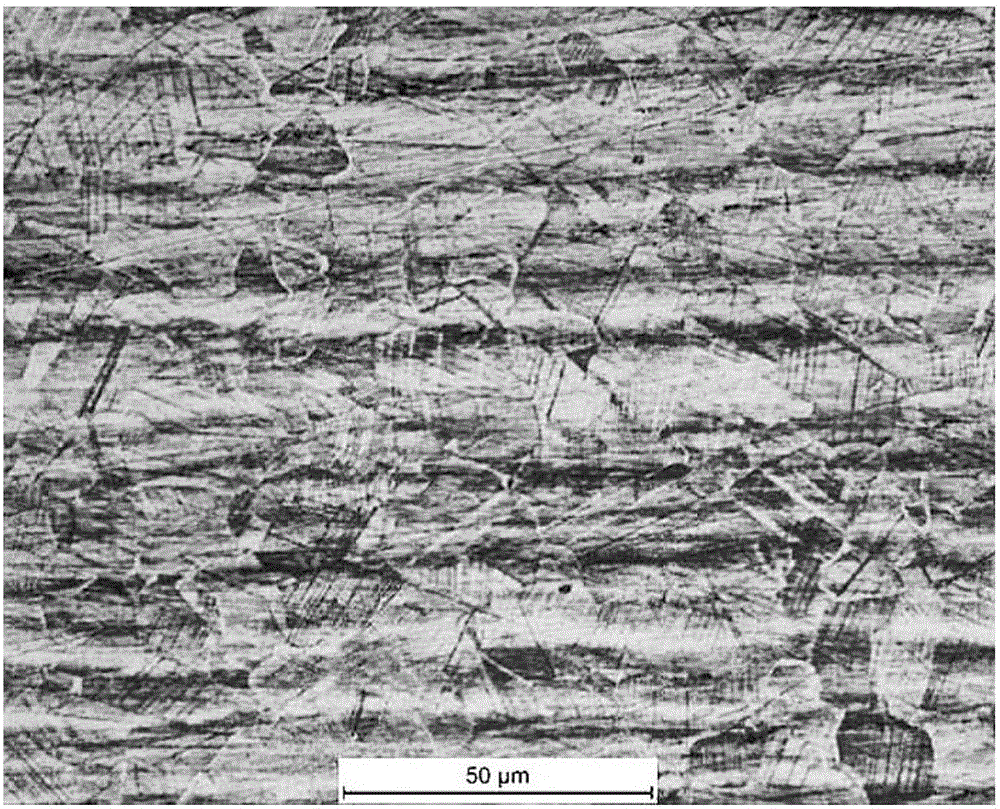

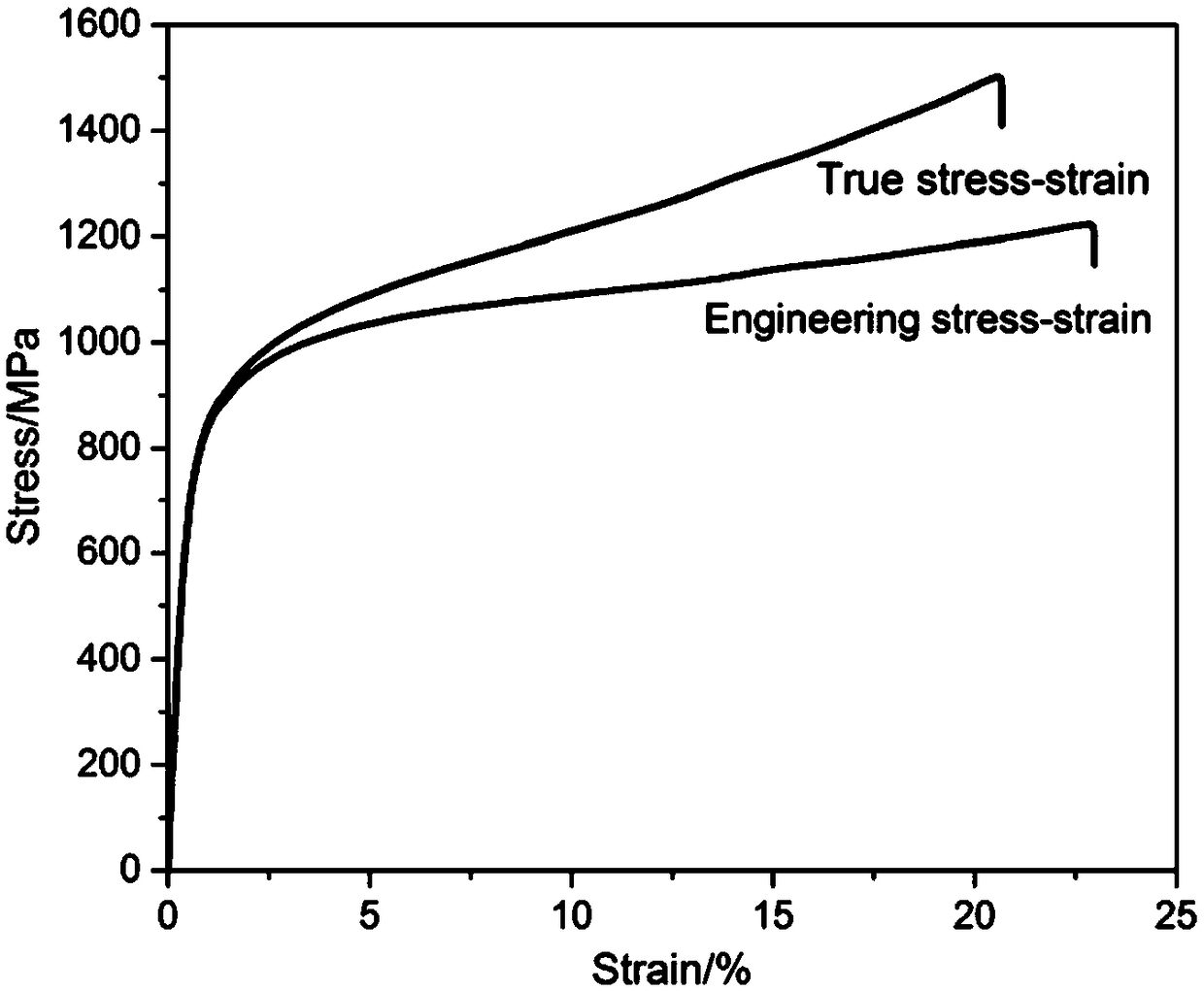

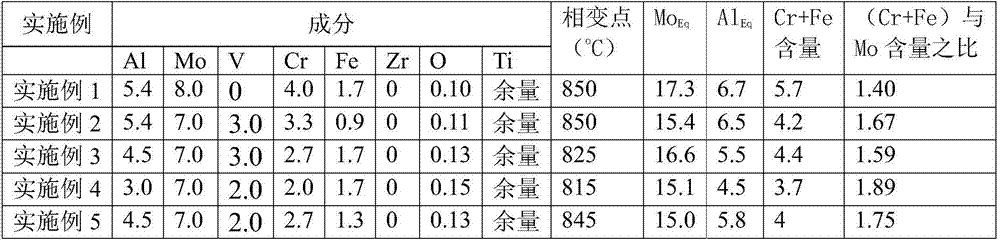

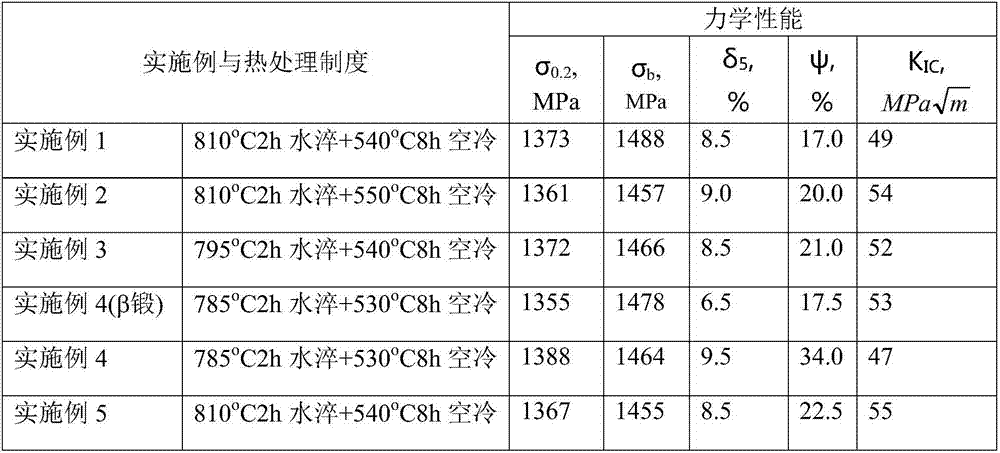

Titanium alloy with high strength, high plasticity and good fracture toughness and preparing technology of titanium alloy

InactiveCN107217173AImprove mechanical propertiesHigh molybdenum equivalentRoom temperatureTitanium alloy

The invention discloses a titanium alloy with high strength, high plasticity and good fracture toughness and a preparing technology of the titanium alloy and belongs to the technical field of the material science. The titanium alloy includes, by weight percent, 2.5%-6.0% of Al, 6.5%-8.5% of Mo, 0%-3.0% of V, 1.5%-4.5% of Cr, 0.7%-2.0% of Fe, 0%-2.5% of Zr, 0.05%-0.2% of O and the balance Ti and inevitable impurities. The titanium alloy with the component feature is subjected to proper deformation and heat treatment, and therefore the titanium alloy with the tensile strength being 1450 MPa or above, the ductility being not smaller than 5% and the fracture toughness being not smaller than the value (please see the value in the specification) can be obtained, good toughness performance is achieved, and the titanium alloy is suitable for being applied to structural parts which work under the room temperature and have the requirements for high strength and good fracture toughness.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Aluminum alloy and casting method thereof, and method for extruding profile

The invention belongs to the technical field of aluminum alloys, and particularly relates to an aluminum alloy, a method for casting a cast ingot from the aluminum alloy, and a method for extruding a profile from the cast ingot. The invention aims to provide an aluminum alloy which has high strength and favorable processability. The high-strength aluminum alloy provided by the invention comprises the following components in percentage by weight: 0.5-1.5% of Mg, 0.25-1.2% of Si, 0.6-1.2% of Cu, 0.1-0.8% of Mn, 0.01-0.2% of Cr, 0.01-0.15% of Ti and the balance of Al. The yield strength of the hollow profile of the alloy in the T6 state (after completing aging treatment) is up to 350 MPa, the tensile strength is up to 400 MPa, and the plasticity is higher than 10%; and the hollow profile has favorable welding performance and fatigue resistance.

Owner:SNTO TECH GRP

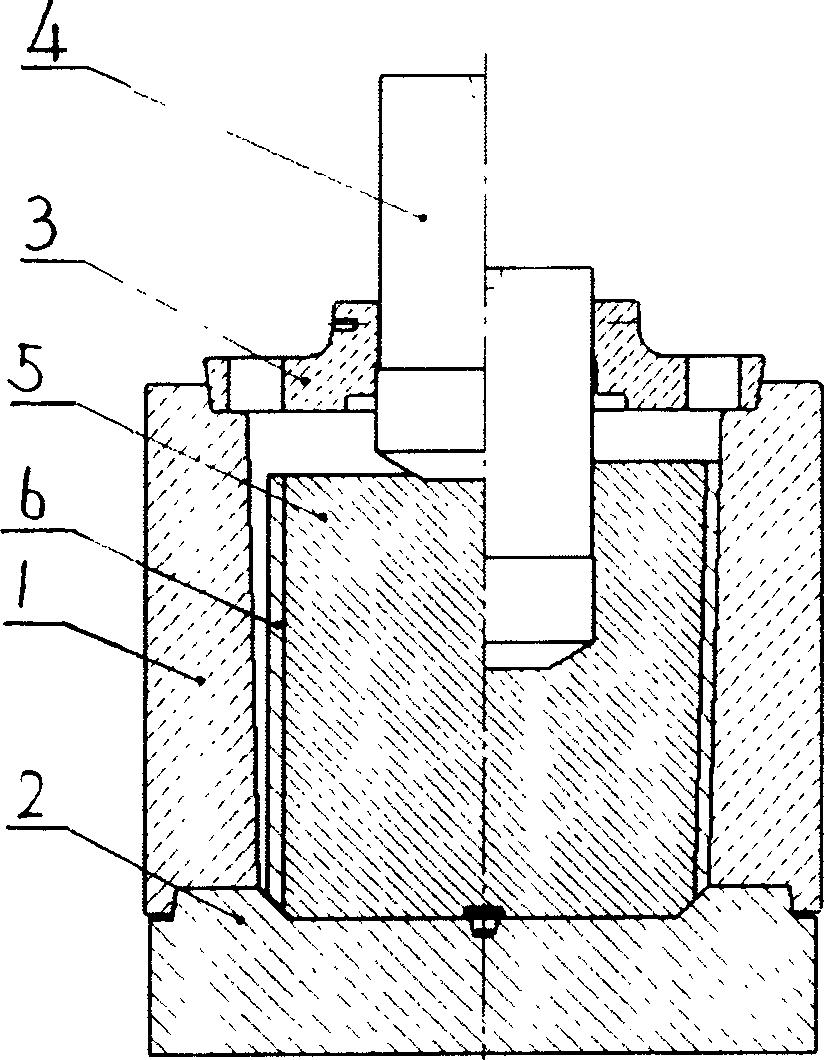

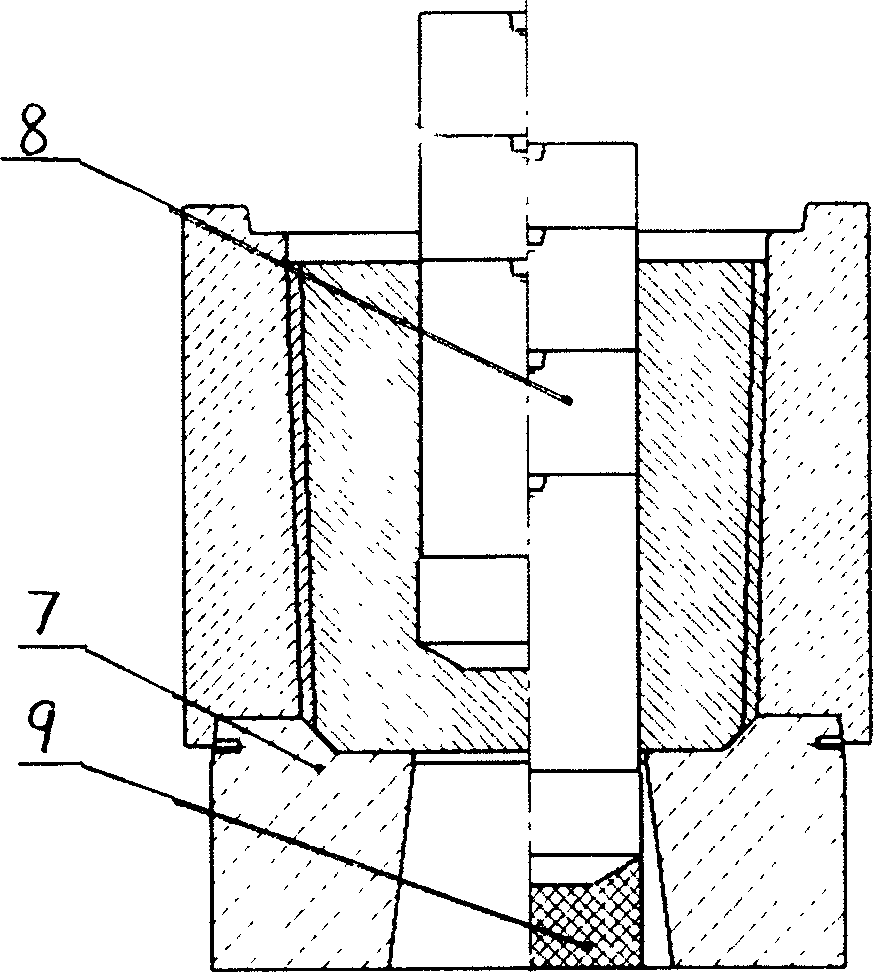

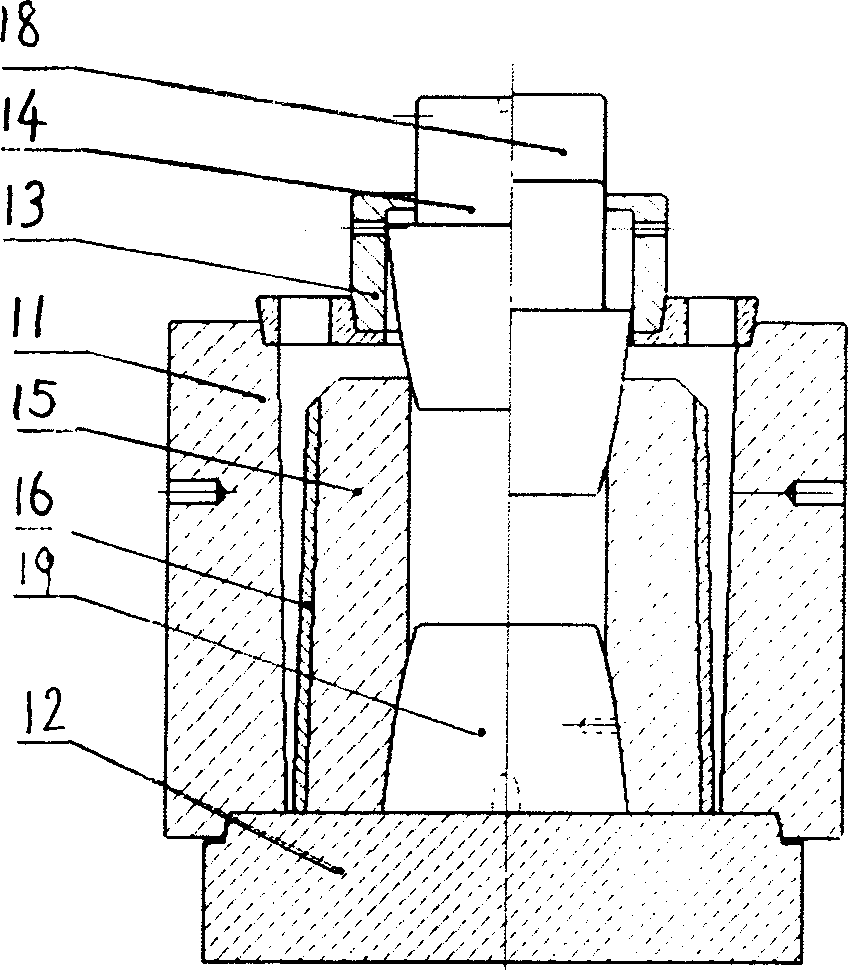

Method for producing circular cog hot forged from generator protective ring and mould

InactiveCN1736630AImprove stress statusAvoid cracksForging/hammering/pressing machinesHollow articlesCrystalliteLubrication

The invention discloses a method and the die for preparation of a hot forging ring billet of the guard ring of generator, and relates to a forging technique and the device of guard ring part of generator. The prior hot forging technique is flat-die forging, easily to produce crack in the process. The invention using confined shaping in die instead of flat-die forging, it improves the state of stress and prevents the crack effectively. With the symmetry of sphere plunger axis in the process of fan boring, the crystal particles are fine and uniform, which provides a perfect condition for cold strain intensification. With the jacket shaping of billet, it can improve lubrication and decrease friction, and can keep the temperature of the hot billet effectively, improving the plasticity and decreasing the shaping pressure. The invention solves the three problems that the crack is easy to produce, the structure property is not uniform, and the shaping pressure is large; compared with the prior technique, the invention has a projecting progress and a distinctive effect.

Owner:DEYANG WANXIN POWER STATION PROD DEV

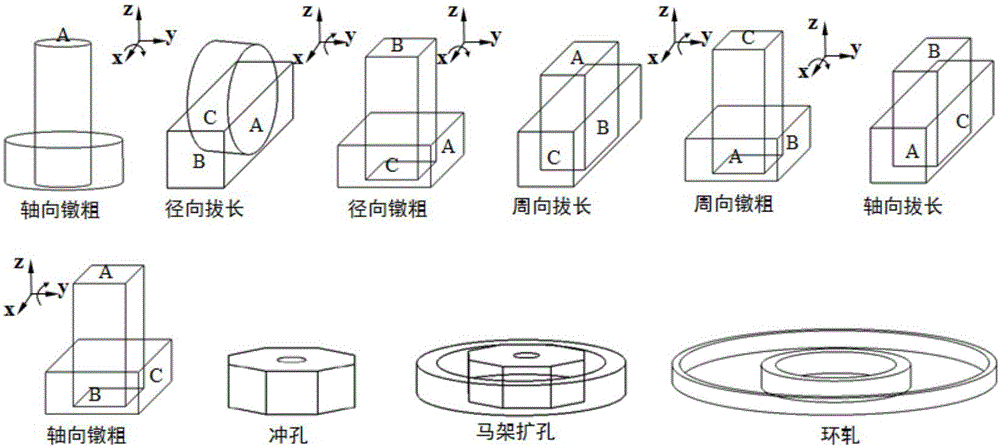

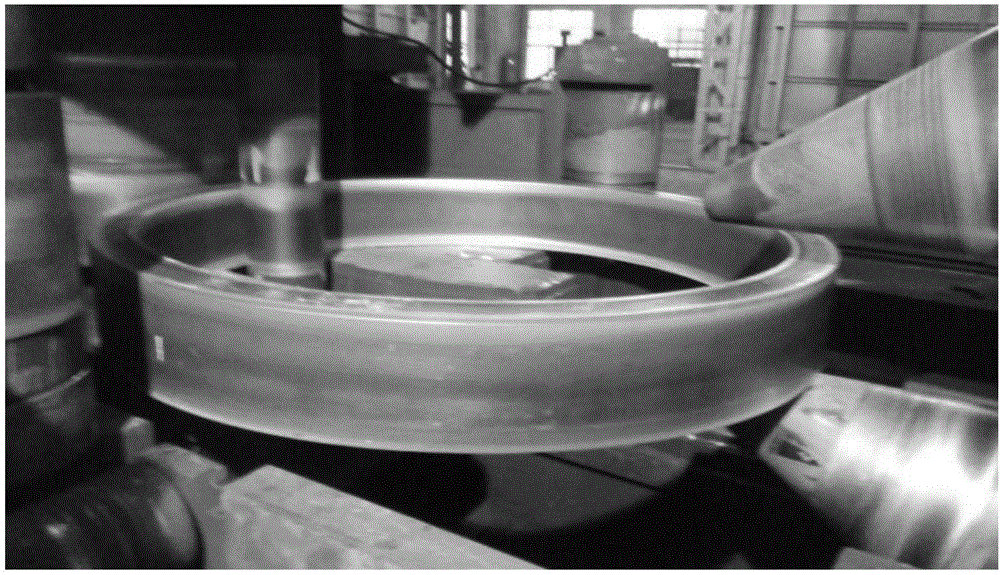

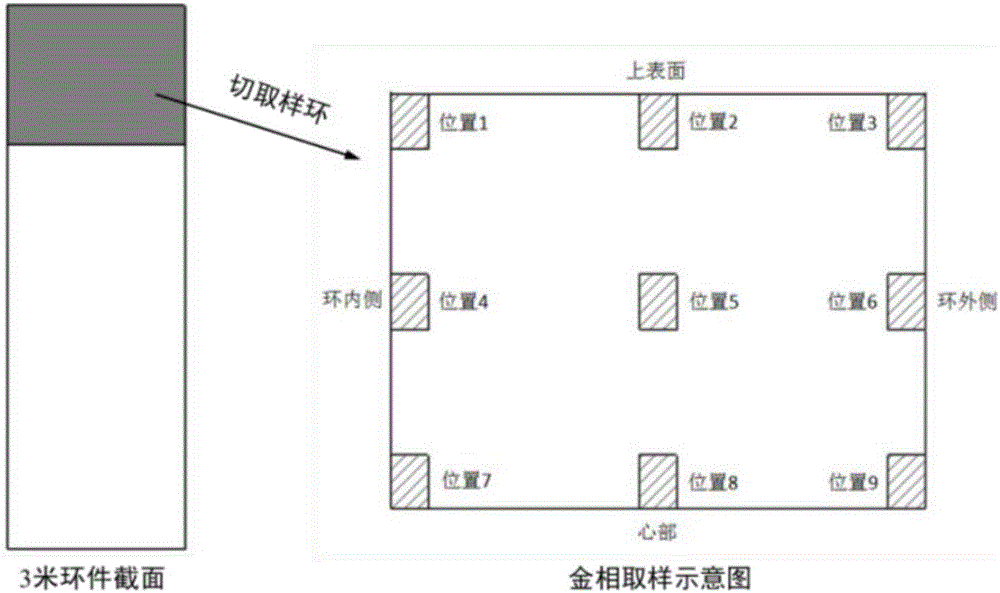

Process method for improving comprehensive mechanical property of 2219 aluminum alloy ring piece

The invention relates to the technical field of metal material deformation heat treatment processes and discloses a process method for improving the comprehensive mechanical property of a 2219 aluminum alloy ring piece so that coarse residual crystalline phases of the large-size 2219 aluminum alloy ring piece can be fully crushed and crystalline grains can be refined and equiaxed, thus, the strength and the plasticity of the 2219 aluminum alloy ring piece are improved at the same time, and the anisotropy is decreased. The process method comprises the steps of multi-directional forging, punching, mandrel supporter broaching, piecewise rolling and heat treatment. In the multi-directional forging step, the heating temperature of a blank is 500 DEG C-520 DEG C, and the final forging temperature is higher than or equal to 380 DEG C. Piecewise rolling comprises the steps that in the first stage, the ring blank is heated to 420 DEG C-460 DEG C and subjected to hot rolling on a ring rolling machine, and the hot rolling deformation quantity is 30%-40%; and in the second stage, the ring piece subjected to hot rolling is air-cooled to 240 DEG C-280 DEG C and is continuously subjected to medium and low temperature rolling on the ring rolling machine, and the deformation quantity is 15%-25%.

Owner:湖南中创空天新材料股份有限公司

Preparation method of particle-reinforced magnesium-based composite material

The invention relates to a preparation method of a particle-reinforced magnesium-based composite material and aims at solving the problem that the particle-reinforced magnesium-based composite material prepared by an existing method is low in strength and poor in plasticity, particles are unevenly dispersed in magnesium alloy and the preparation time is long. The preparation method comprises the following steps of 1 preparing a magnesium alloy semi-solid melt; 2 preparing a particle-magnesium alloy melt; 3 enabling the particle-magnesium alloy melt to be solidified and formed. The preparation method has the advantages that the tensile strength and yield strength of the obtained particle-reinforced magnesium-based composite material are improved by 50%-150%, the highest elongation rate reaches to 8%; the particles are evenly dispersed in the magnesium alloy, the pore defect in the magnesium-based composite material is overcome; the process is simple, the preparation time is shortened by 15%-30%. The particle-reinforced magnesium-based composite material can be obtained by using the preparation method.

Owner:严格集团股份有限公司

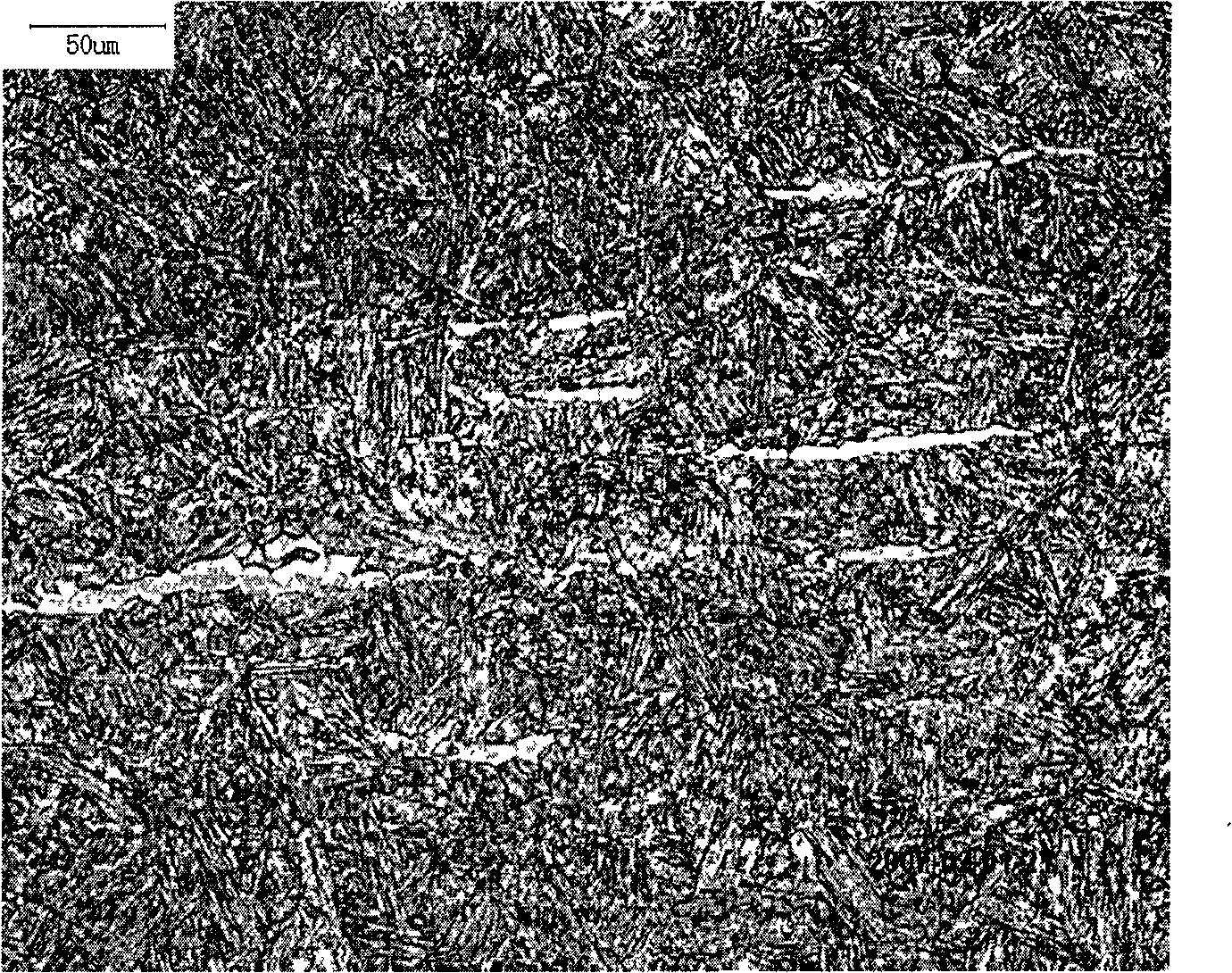

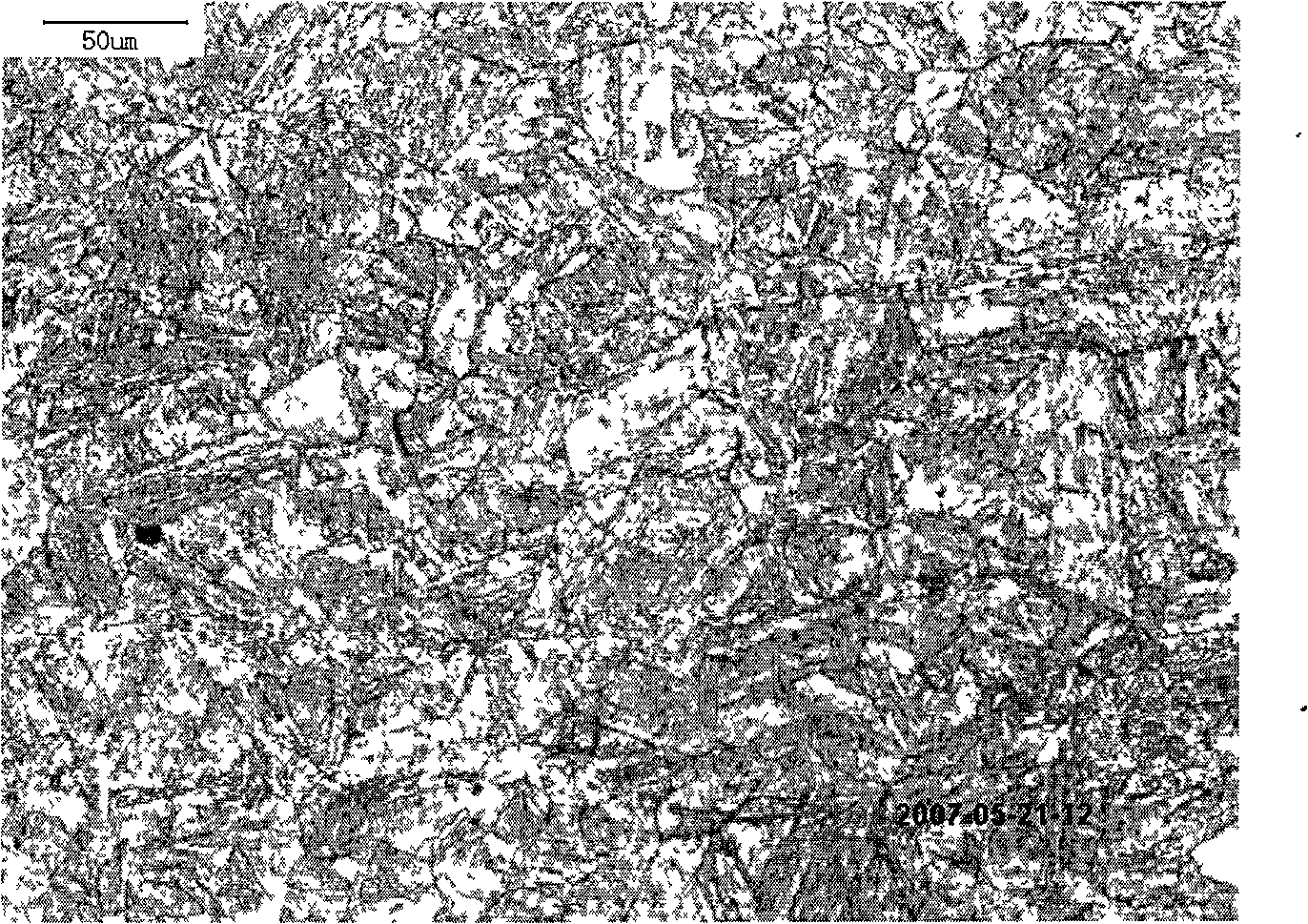

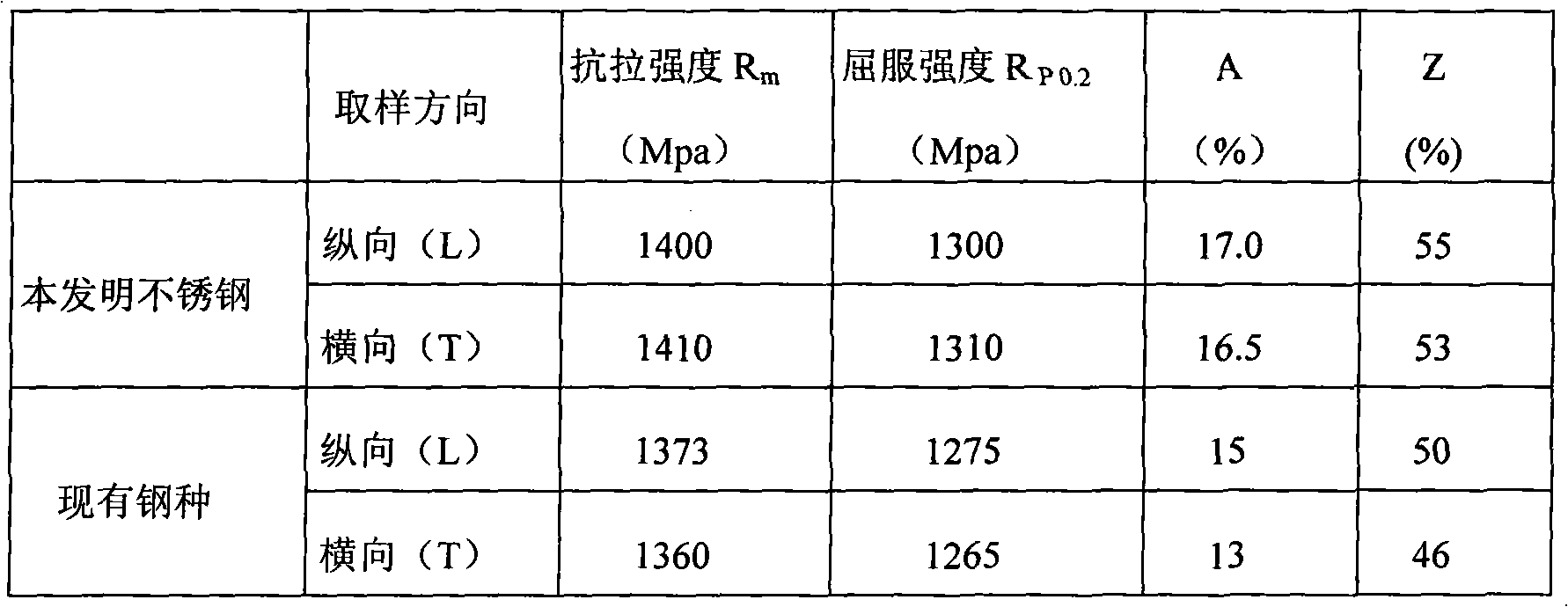

Martensite precipitation hardening stainless steel for structural member and manufacturing method thereof

The invention provides a martensite precipitation hardening stainless steel for structural member and a manufacturing method thereof. The martensite precipitation hardening stainless steel comprises the following chemical components in percentage by weight: less than or equal to 0.05 percent of C, 13.50 to 15.50 percent of Cr, 2.5 to 4.0 percent of Cu, 3.0 to 5.0 percent of Ni, 0.15 to 0.40 percent of Nb and Ta, 0.010 to 0.040 percent of N, 0.050 to 0.15 percent of V, less than or equal to 0.80 percent of Si, less than or equal to 1.00 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, and the balance of Fe and inevitable impurities. The stainless steel is smelted by combining an electric furnace, AOD refining and vacuum self-consuming technology, so the stainless steel has the characteristics of high strength, good plasticity, good corrosion resistance and the like, and can meet the requirements of high-strength components such as high-pressure values, oil drill, efficient heavy-duty machinery and the like on material performance.

Owner:宝武特种冶金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com