Patents

Literature

86results about How to "Increased deformation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

780MPa-level ultrahigh-strength Fe-Mn-Al-C lightweight cast steel and preparation method thereof

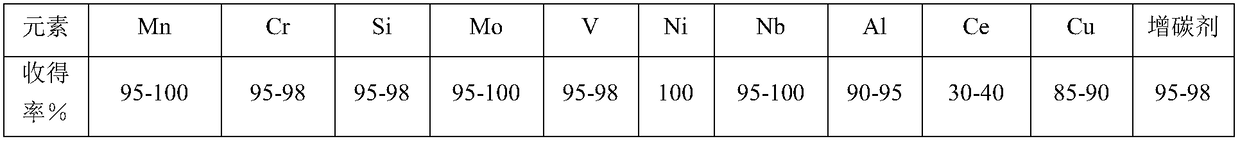

The invention provides 780MPa-level ultrahigh-strength Fe-Mn-Al-C lightweight cast steel and a preparation method thereof. The low-density cast steel comprises, by mass, 0.80-1.30% of C, 15.00-20.00%of Mn, 3.50-8.00% of Al, 0.05-0.25% of Si, 0.5-1.5% of Cr, 0.01-0.06% of Cu, 0.30-0.80% of Mo, 0.05-0.20% of V, 0.01-0.10% of Nb, 0.005-0.025% of Ce, less than or equal to 0.01% of P, less than or equal to 0.01% of S, less than or equal to 0.01% of N, and the balance Fe and unavoidable impurities. Meanwhile, the weight percentage ratio of Mn to Al is no less than 2.5% and no more than 3.0%, and the sum of the weight percentages of Nb and V is no less than 0.10% and no more than 0.20%. The preparation process is simple and free of rolling, and the method can be used for manufacturing automobilestructure castings with complex shapes.

Owner:HEBEI UNIV OF TECH

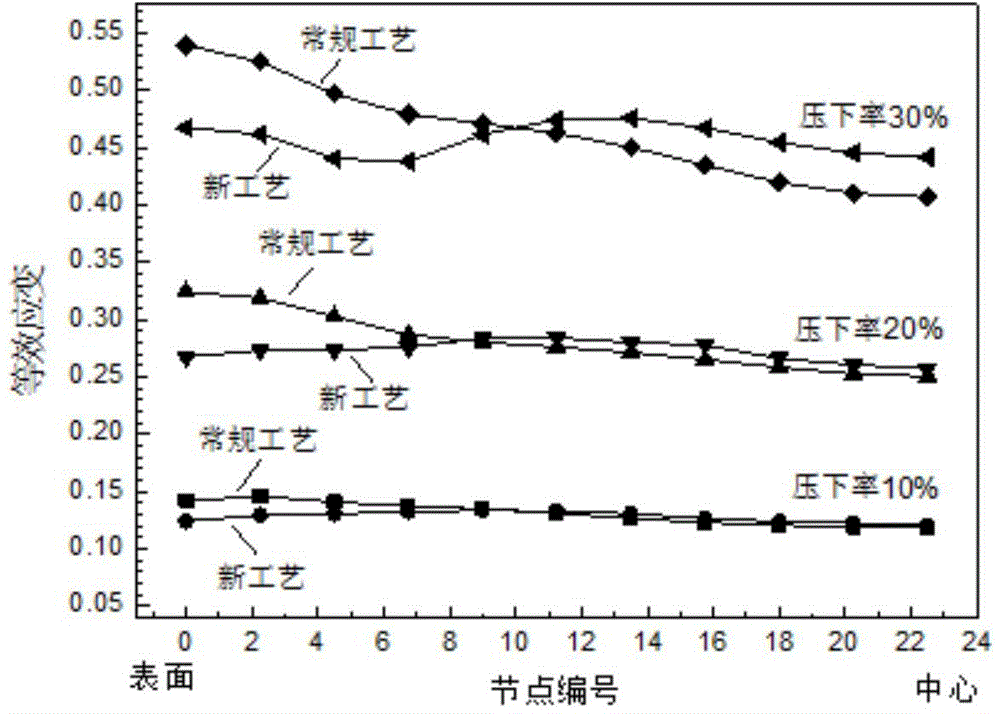

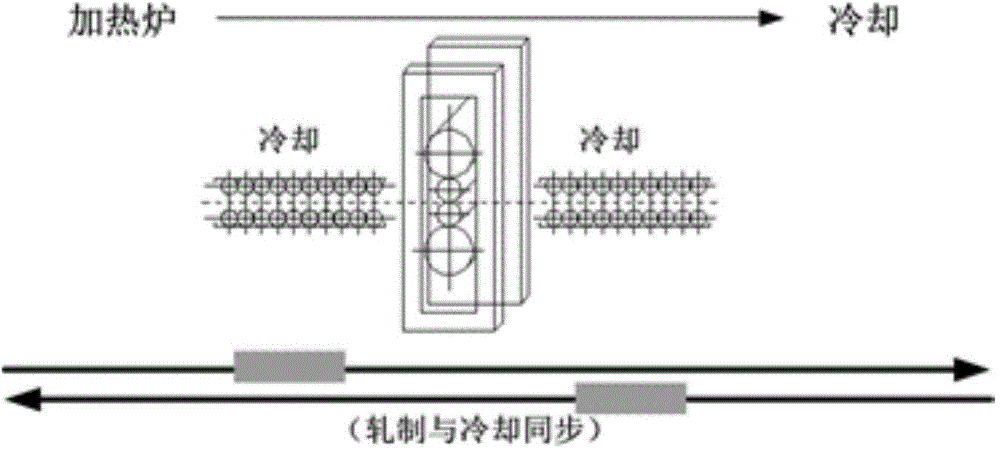

Method for improving deformation and permeability in high-thickness standard steel plate hot rolling process

ActiveCN104525588AEvenly distributedIncreased deformation resistanceWork treatment devicesMetal rolling arrangementsCryogenic hardeningSteel ball

A method for improving deformation and permeability in the high-thickness standard steel plate hot rolling process is characterized in that a uniform fast cooling device is arranged at a position close to the opening of a heavy and medium plate mill or hot strip roughing mill with the length being 5 to 15 meters and the cooling total water being 3,000 to 6,000 cubic meters per hour respectively; before rolling, the cooling device conducts asymmetrical uniform fast cooling to the upper and lower surfaces of a plate blank, a low-temperature hardened layer is formed on the surface of the plate blank, the temperature gradient of a core reaches 2 to 3 DEG C per millimeter, before the cooling returns red, the cooling device can quickly enter the mill to conduct differential temperature rolling, and plate blank core deformation is improved; the cooling device is further combined with asymmetrical rolling, while deepening the plate blank core deformation, the cooling device solves the warping problem caused by the asymmetrical rolling through the asymmetrical cooling of the upper and lower surfaces of the plate blank before rolling. For a steel ball needing two-stage control, the uniform fast cooling device can replace a middle cooling device, shortens or even eliminates the temperature waiting time of swinging steel, and improves the production efficiency.

Owner:NORTHEASTERN UNIV

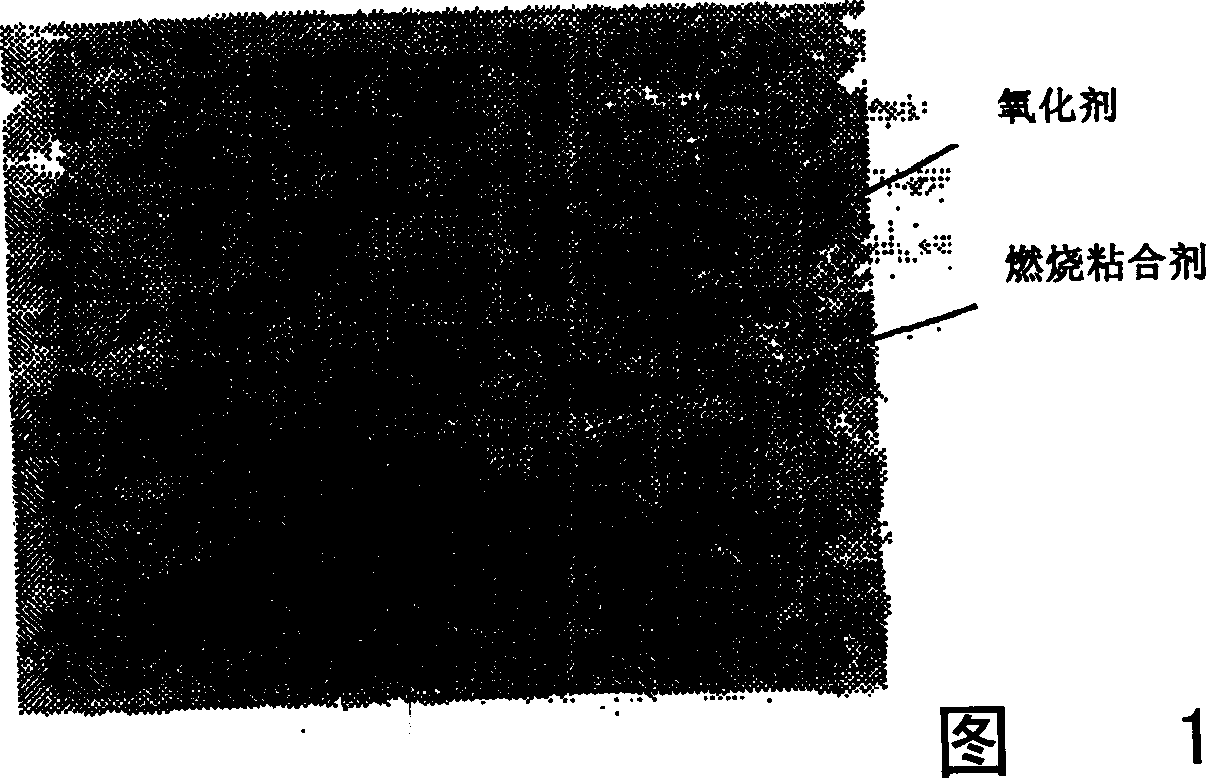

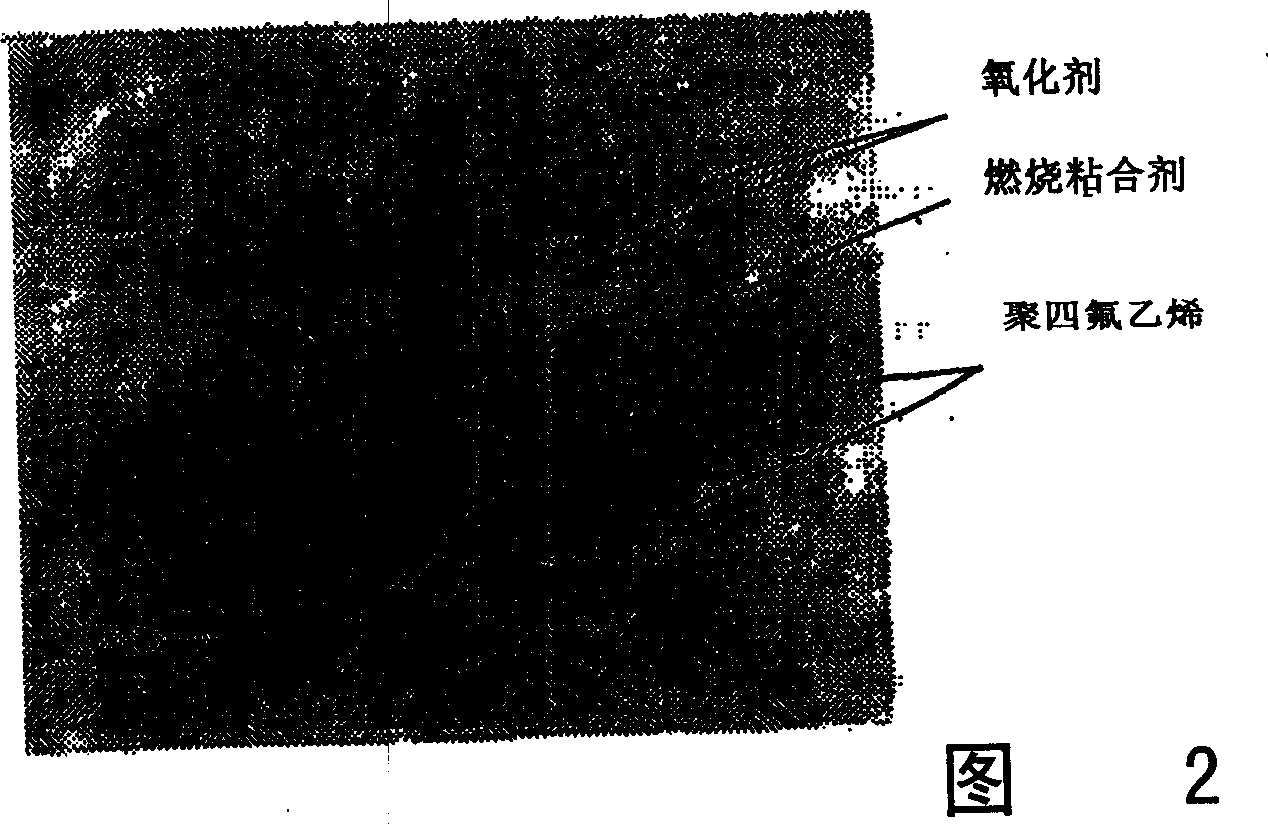

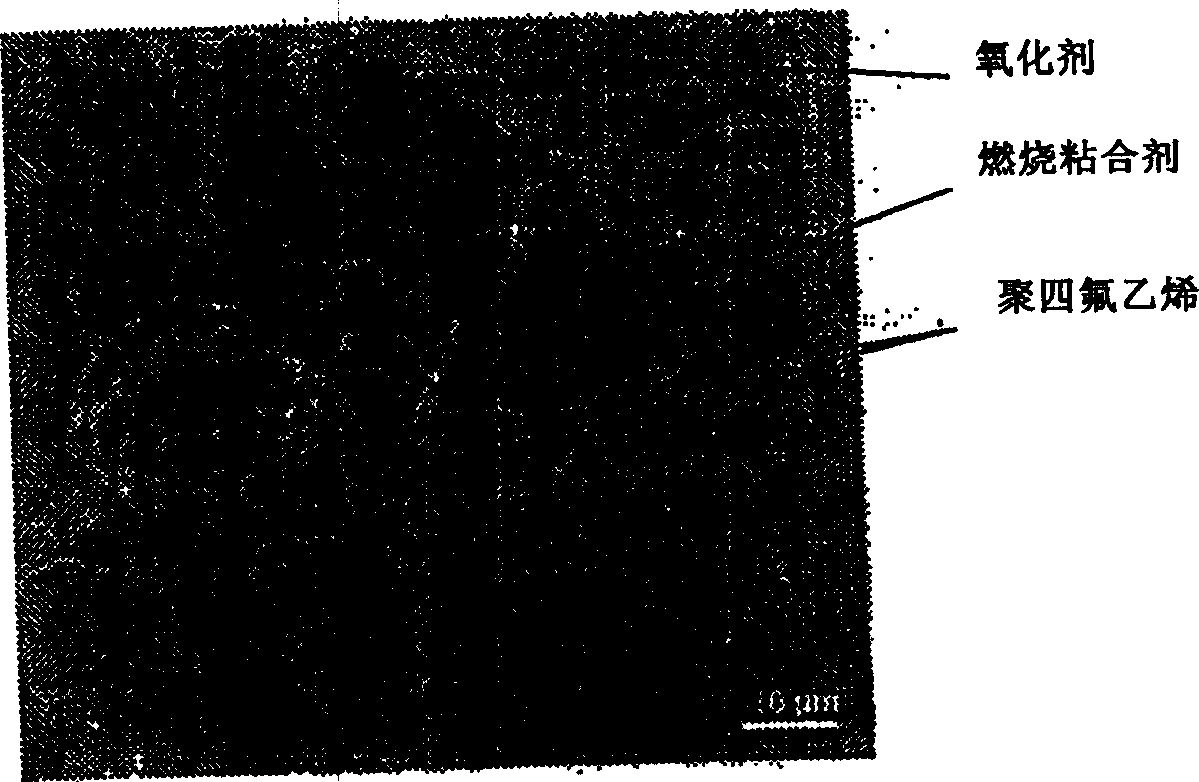

Pyrotechnical aerosol-forming fire-extinguishing composite and method of its prodn

InactiveCN1481266AReduced Toxicity and Explosion HazardReduce riskSmoke/mist generationFire extinguisherPolytetrafluoroethyleneDicarboxylic acid

This invention relates to the field of fire-fighting equipment, specifically to means of fire fighting by a fire-extinguishing aerosol that is formed during burning of pyrotechnical composite and a method of its production. The invention allows to prepare pyrotechnical, aerosol-forming fire-extinguishing composite with good deformation strength characteristics, low fire-extinguishing concentration and regulate burning velocity. The pyrotechnical aerosol-forming fire-extinguishing composite contains an oxidizer, a production process additive and burning binder formed by thermoplastic formaldehyde and phenol polycondensate, plasticized by dicarboxylic acid ester and reinforced by polytetrafluoroethylene. The method of producing the composite consists of mixing of formaldehyde and phenol polycondensate suspension in an organic solvent and polytetrafluoroethylene dispersion in dicarboxylic acid ester, mixing the resulting composition with an oxidizer and a production process additive with subsequent thermomechincal effect. The invention can be used for fire-extinguishing in different structures and devices without harmful effect on human body and living organisms, nature.

Owner:R AMTECH INT

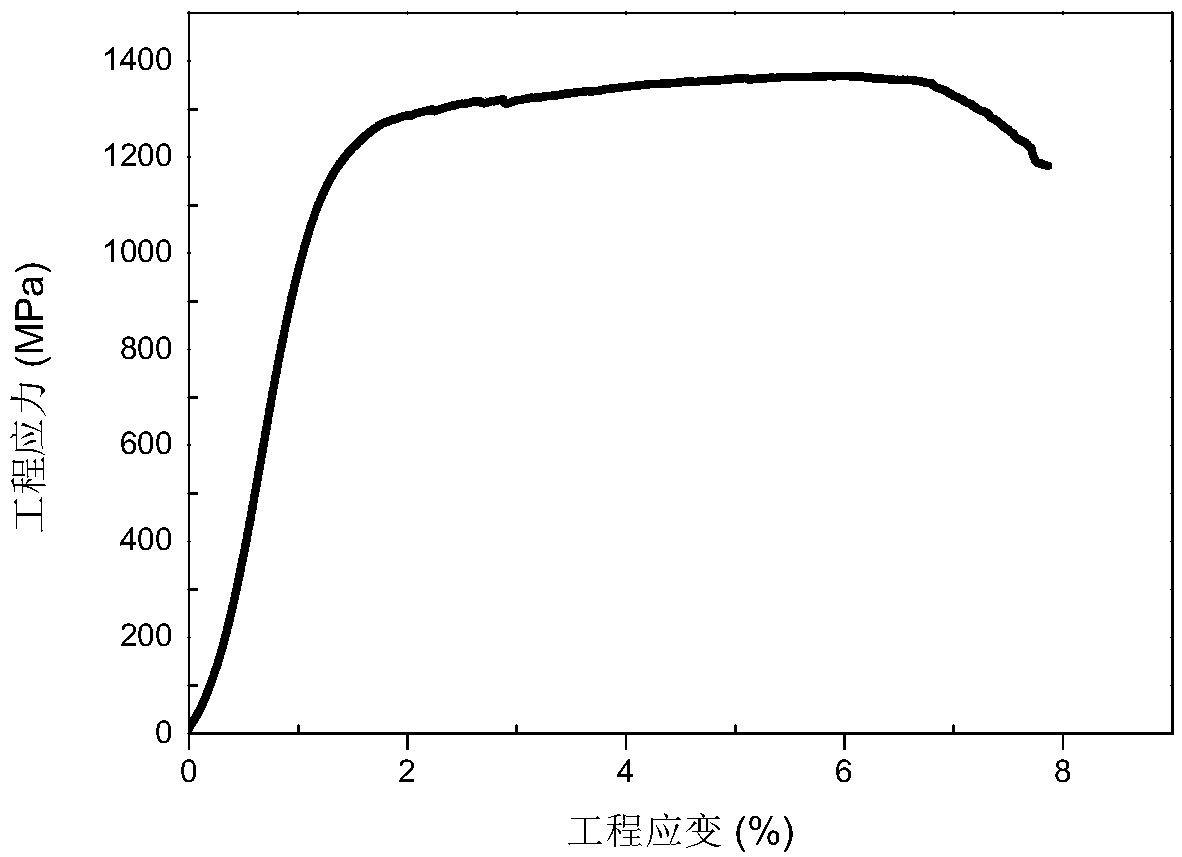

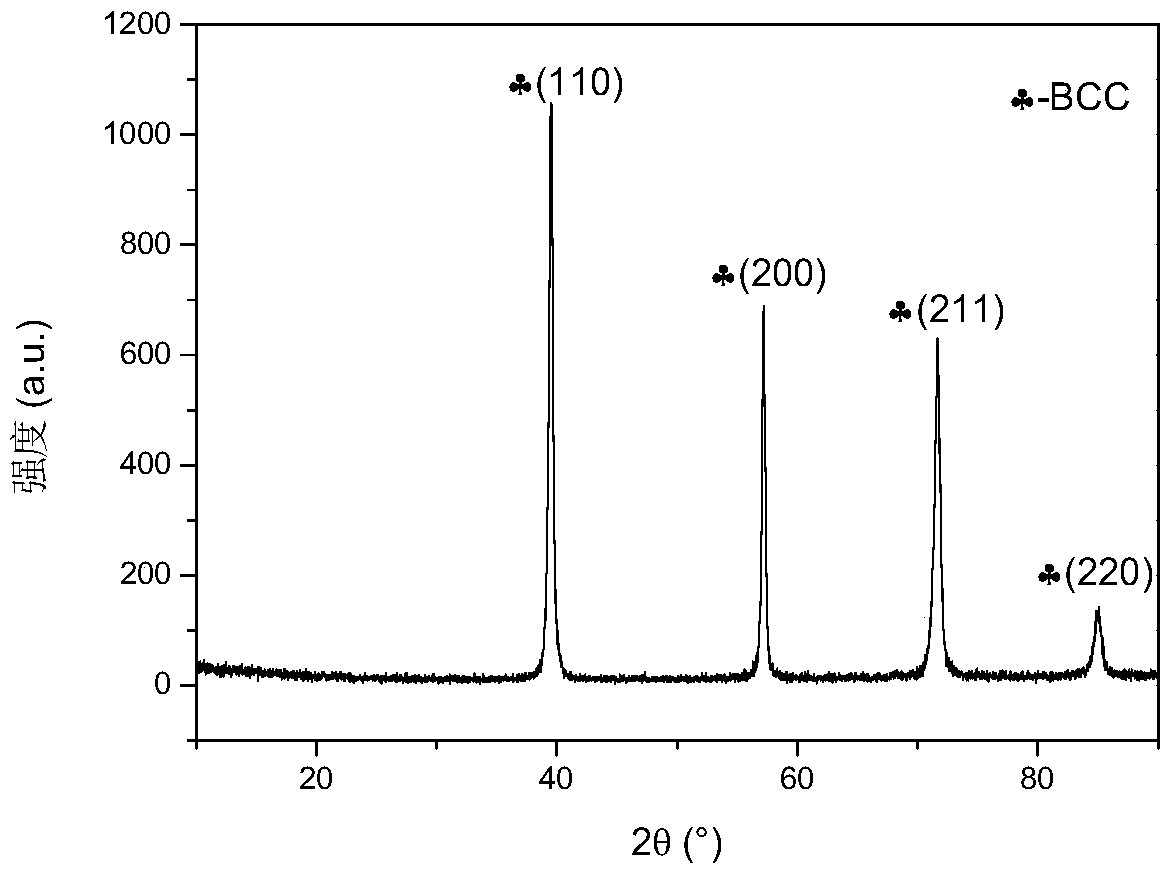

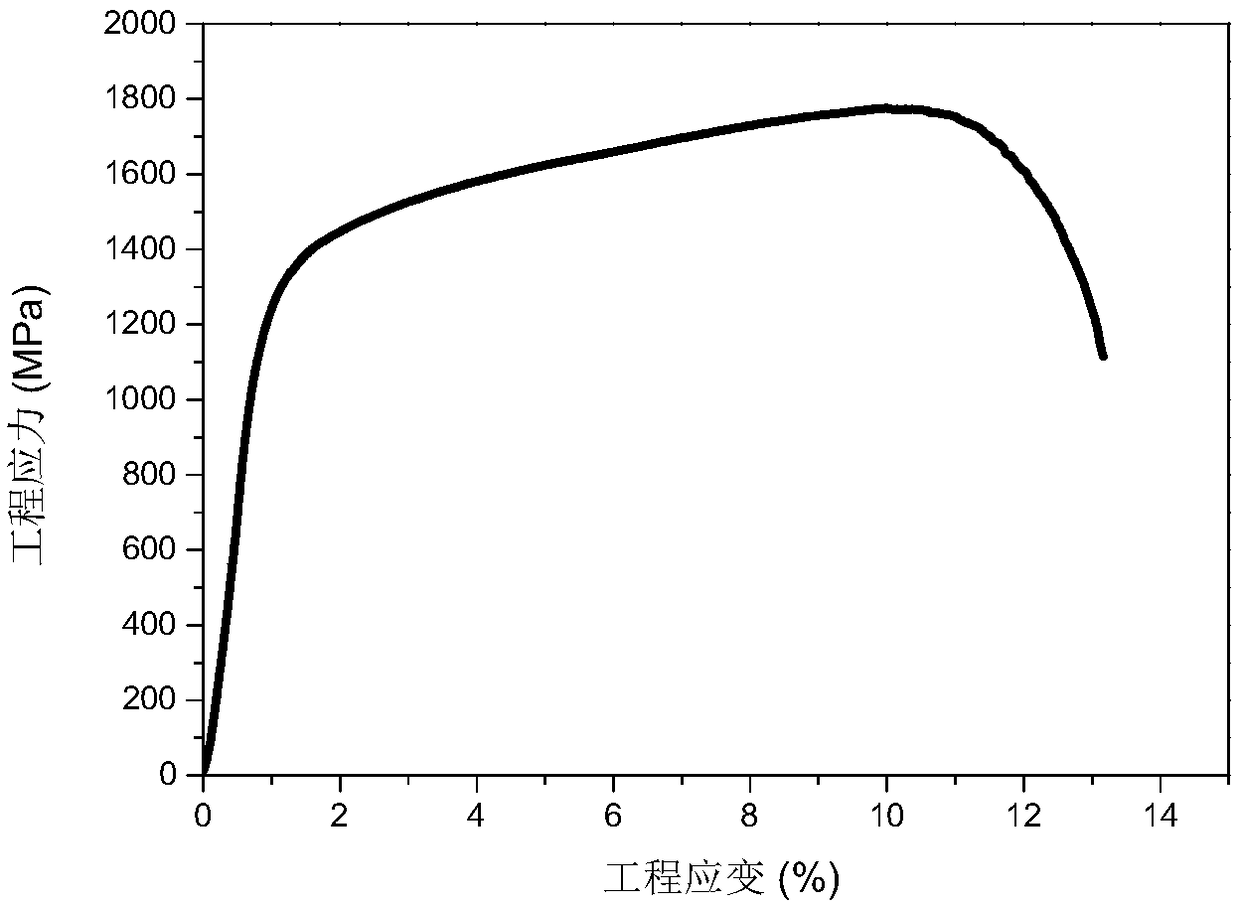

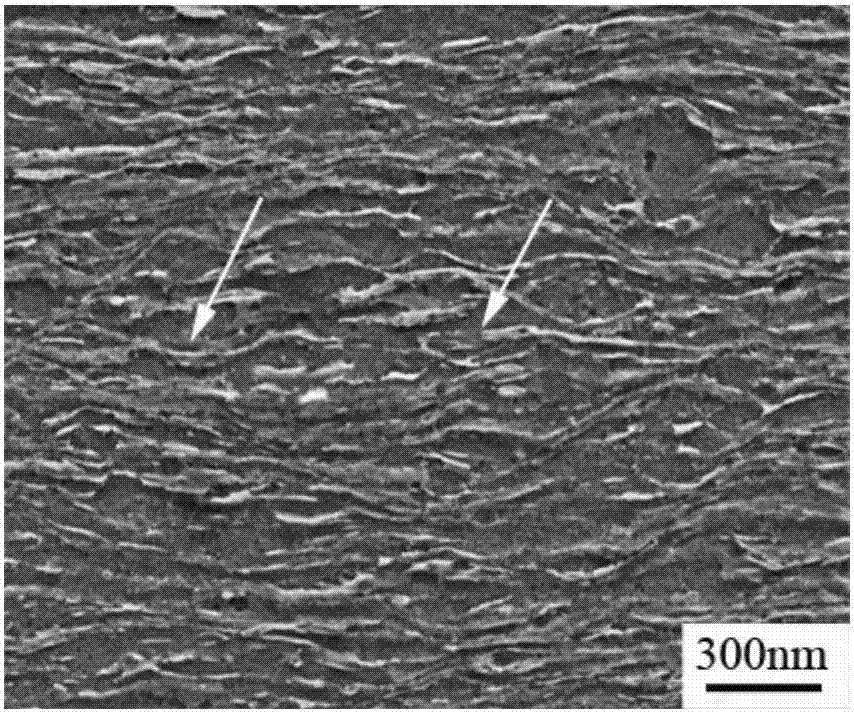

(NbMoTaW)100-xMx series refractory high-entropy alloy and preparation method thereof

ActiveCN109182877AIncreased deformation resistanceImprove solid solution strengthening abilityHigh entropy alloysTemperature resistance

The invention belongs to the field of high-entropy alloy and high temperature resistance alloy, and particularly relates to a (NbMoTaW)100-xMx series refractory high-entropy alloy and a preparation method of the (NbMoTaW)100-xMx series refractory high-entropy alloy. The chemical ingredient of the alloy is (NbMoTaW)100-xMx (0<X<=5%), M is one or two of B, C and O, and the content of each element except for the element M is not smaller than 5% and is not higher than 35%. The preparation method comprises the steps that impurities such as surface scale in needed raw materials are removed, and weighing is carried out according to the atomic ratio; and alloy ingredients are smelted into a cast ingot through vacuum electric arc melting. The high-entropy alloy has the good plasticity at room temperature, meanwhile has the excellent high temperature strength and plasticity, can be used for high temperature structural parts and the like in special working condition environment, and has the wideapplication prospect in the high temperature field.

Owner:UNIV OF SCI & TECH BEIJING

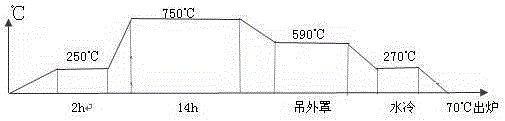

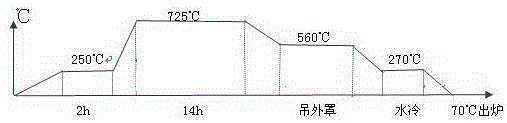

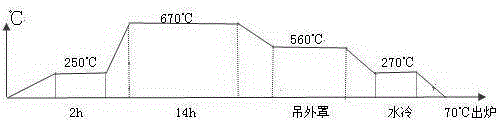

Heat treatment technology of alloy spring cold-rolled steel strip 51CrV4 of automobile clutch diaphragm

ActiveCN105401073AIncreased deformation resistanceAvoid deformationThermal insulationOxidation state

The invention discloses a heat treatment technology of an alloy spring cold-rolled steel strip 51CrV4 of an automobile clutch diaphragm. According to the heat treatment technology, blanks are subjected to cold-rolling deformation for nine times and annealing heat treatment for three times, the temperature of a heating section is controlled, the cooling temperature and speed are controlled, the atmosphere in a heating furnace is heated and subjected to thermal insulation in a non-oxidation state in the cold-rolling and annealing heat treatment processes, and an oxidized grain boundary and a decarburized layer are avoided. With the adoption of the scheme, the production cost is reduced, and the product performance meets the international standard.

Owner:SUZHOU XIANGLOU METAL PROD

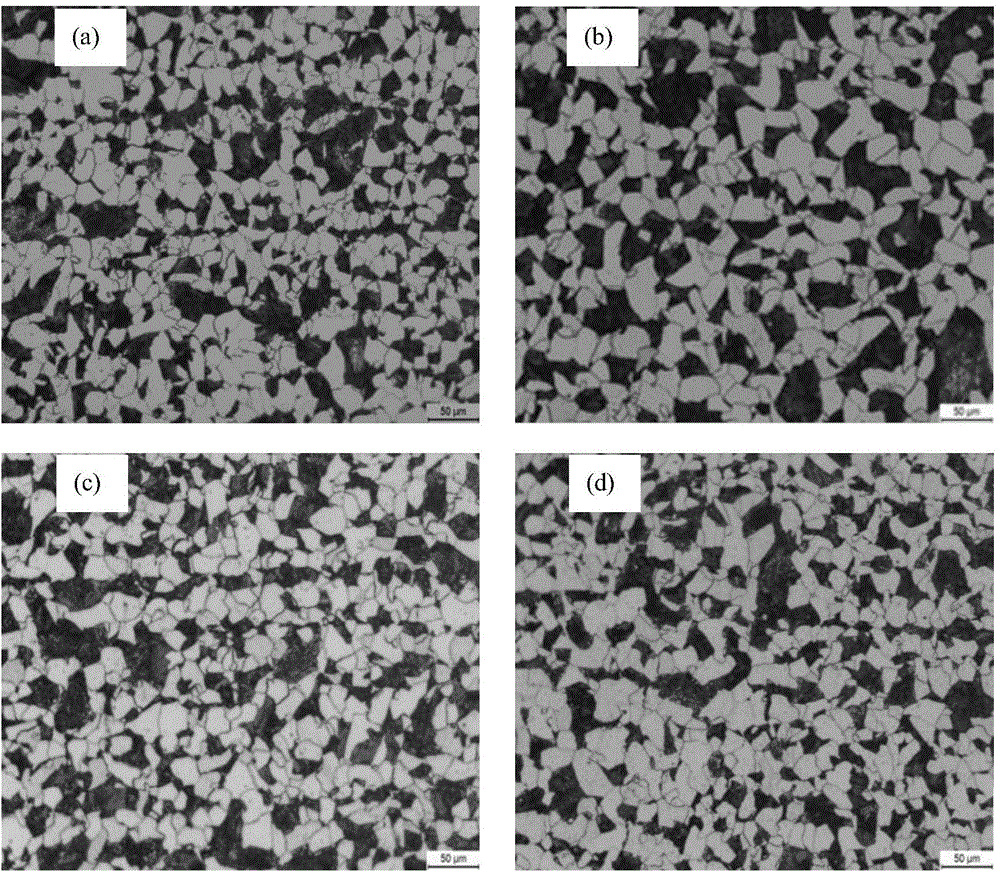

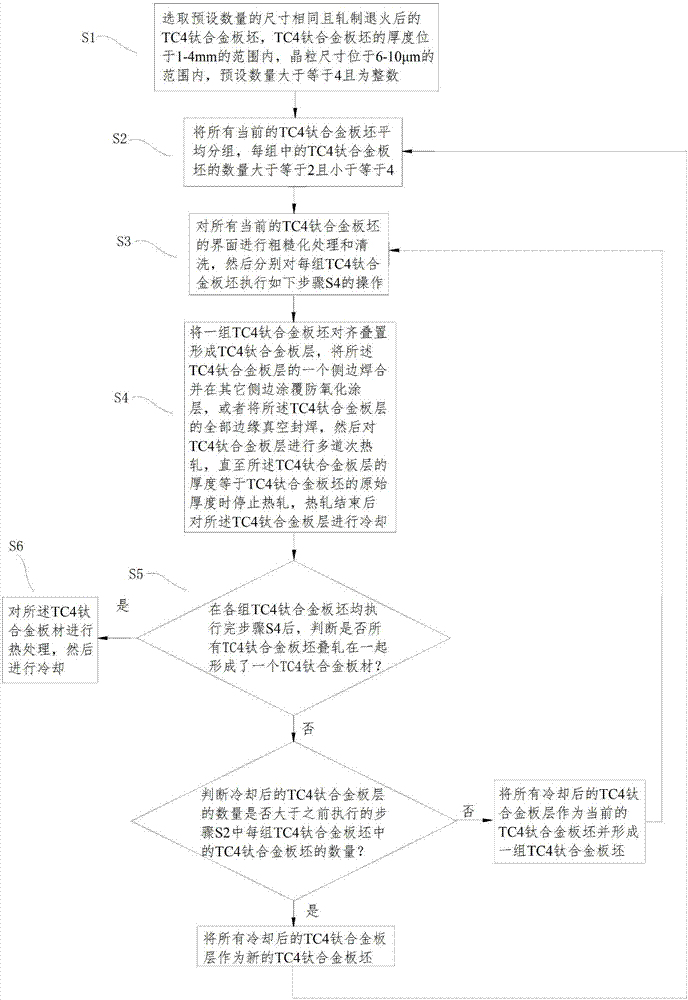

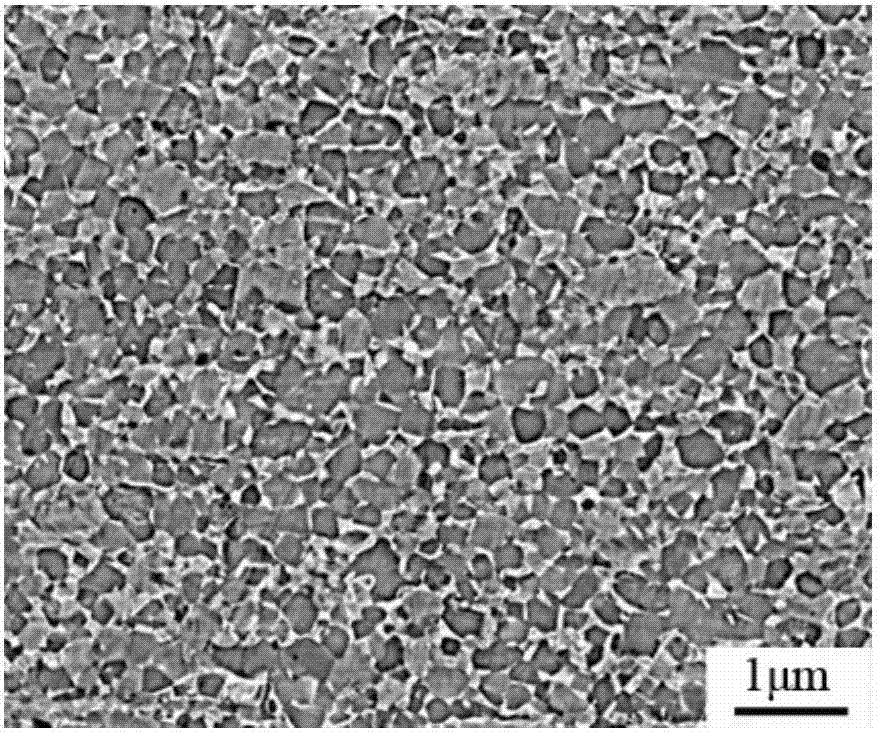

Preparation method of equal-thickness ultrafine grain TC4 titanium alloy plate

InactiveCN107030111AFacilitated DiffusionNo separationWelding/cutting auxillary devicesAuxillary welding devicesTitanium alloyHeat treating

The invention relates to the technical field of metallurgy, in particular to a preparation method of an equal-thickness ultrafine grain TC4 titanium alloy plate. The preparation method comprises the steps that S1, plate blanks obtained after rolling and annealing are taken; S2, the plate blanks are grouped; S3, interfaces of the plate blanks are subjected to roughening treatment and cleaning, and then the following operation of S4 is executed on each group; S4, the plate blanks in each group are stacked into a plate layer, one side edge of each plate layer is welded, the other side edges of each plate layer are coated with anti-oxidation coatings, or all edges of the plate layers are subjected to vacuum seal welding, the hot rolling process is adopted for ply rolling and welding, final hot rolling is carried out till the thickness of the plate layers is equal to the original thickness of the plate blanks, and then air cooling is carried out; S5, if the plate layers need to be grouped again, the plate layers serve as new plate blanks to return to the step S2, and otherwise all the plate layers form a plate blank group to return to the step S3 till all the plate blanks are subjected to ply rolling into the plate; S6, the plate is subjected to heat treatment and then cooled. According to the method, the defects of the insufficient hot rolling deformation and deformation cracking and incomplete welding in the ply rolling process can be overcome, and the equal-thickness ultrafine grain plate can be prepared.

Owner:NORTHEASTERN UNIV

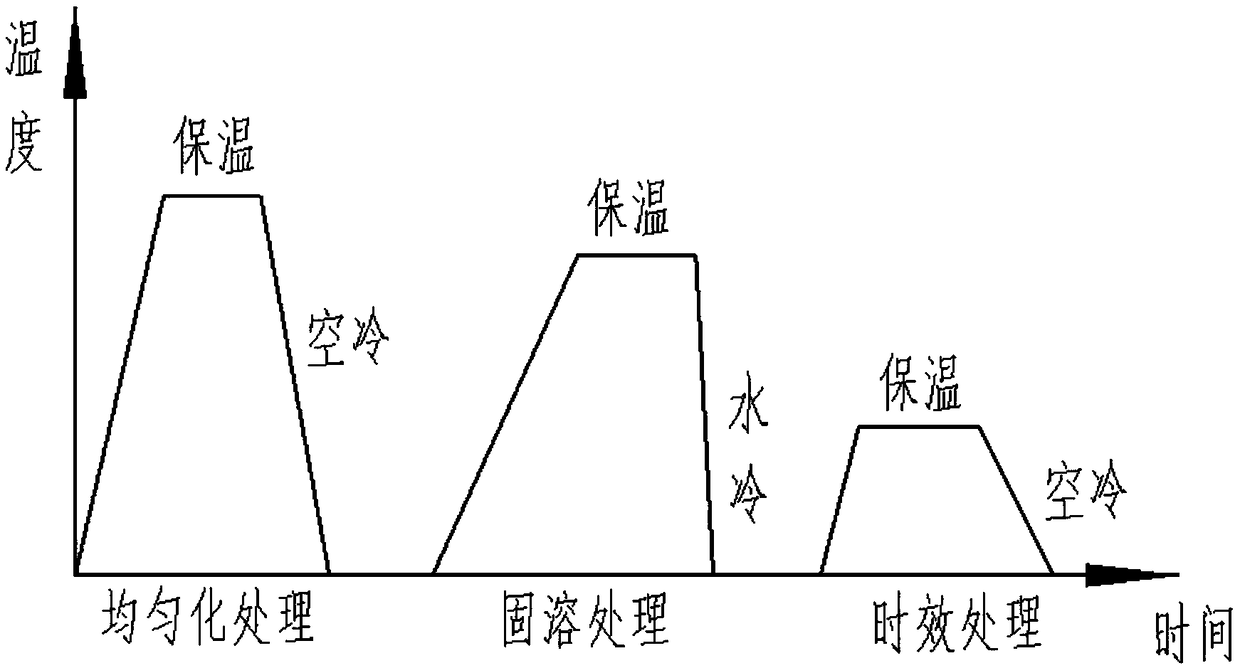

Method for reducing internal residual stress of GH4169 alloy large-size disk forge piece

The invention belongs to the technical field of preparing of a deformation high-temperature alloy GH4169 disk forge piece for an advanced aero-engine, and relates to a method for reducing the internalresidual stress of a GH4169 alloy large-size disk forge piece. The method includes the following steps of preparing a GH4169 alloy pure smelting cast ingot, conducting uniform heat treatment on the GH4169 cast ingot, cogging the cast ingot, preparing a biscuit, conducting compounding and coating, conducting gradient-speed-control constant-temperature die forging, conducting heat treatment on thedisk forge piece, conducting rough machining and conducting stress relief annealing. By means of the prepared low-stress GH4169 alloy disk forge piece, it is ensured that the internal stress of the deformation high-temperature alloy cast ingot is slowly released, the internal metallurgical quality of the alloy ingot is improved, and the disk forge piece can be used for preparing an advanced aero-engine high-pressure compressor disk, a high-pressure turbine disk, a low-pressure turbine disk and other parts.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

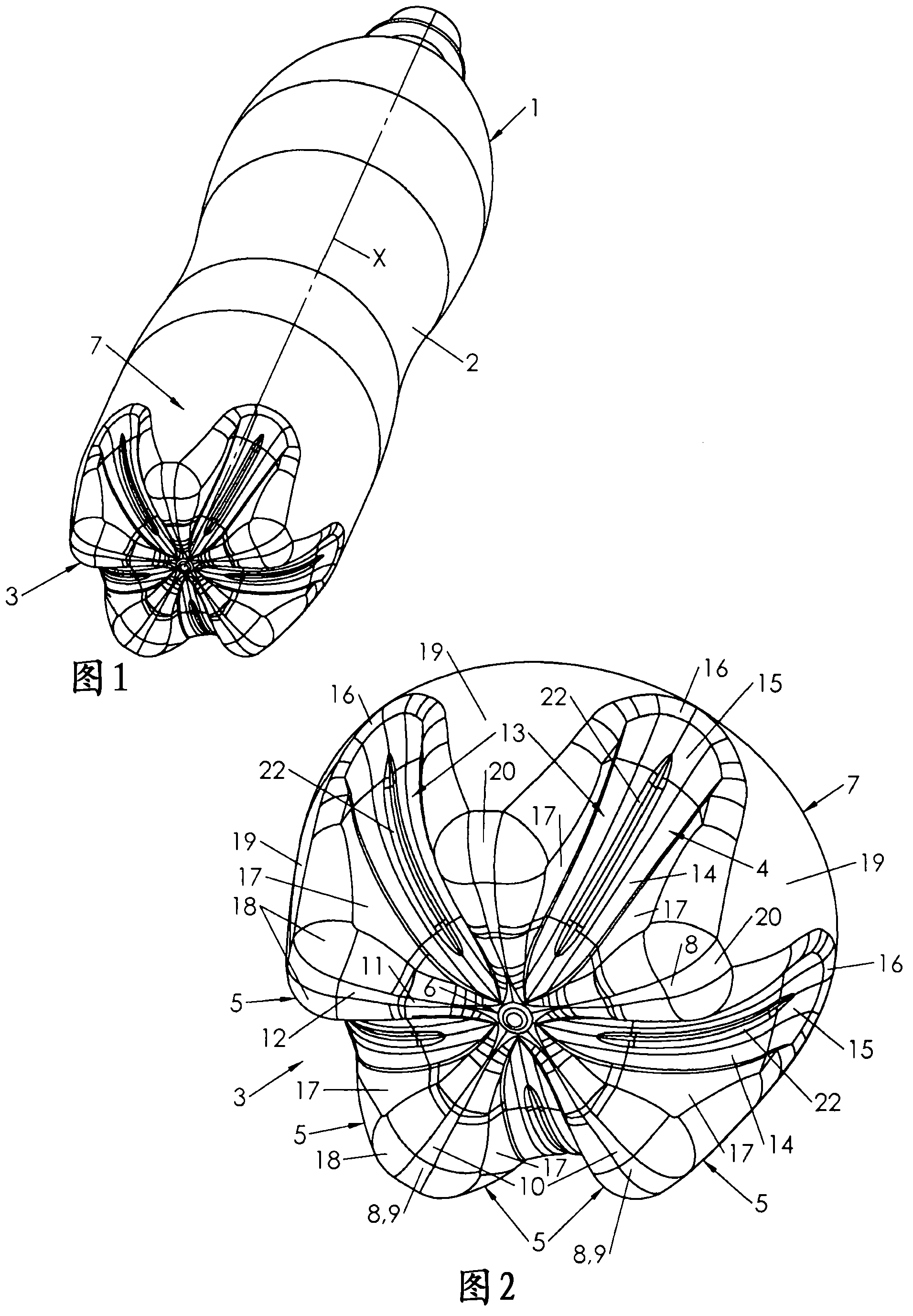

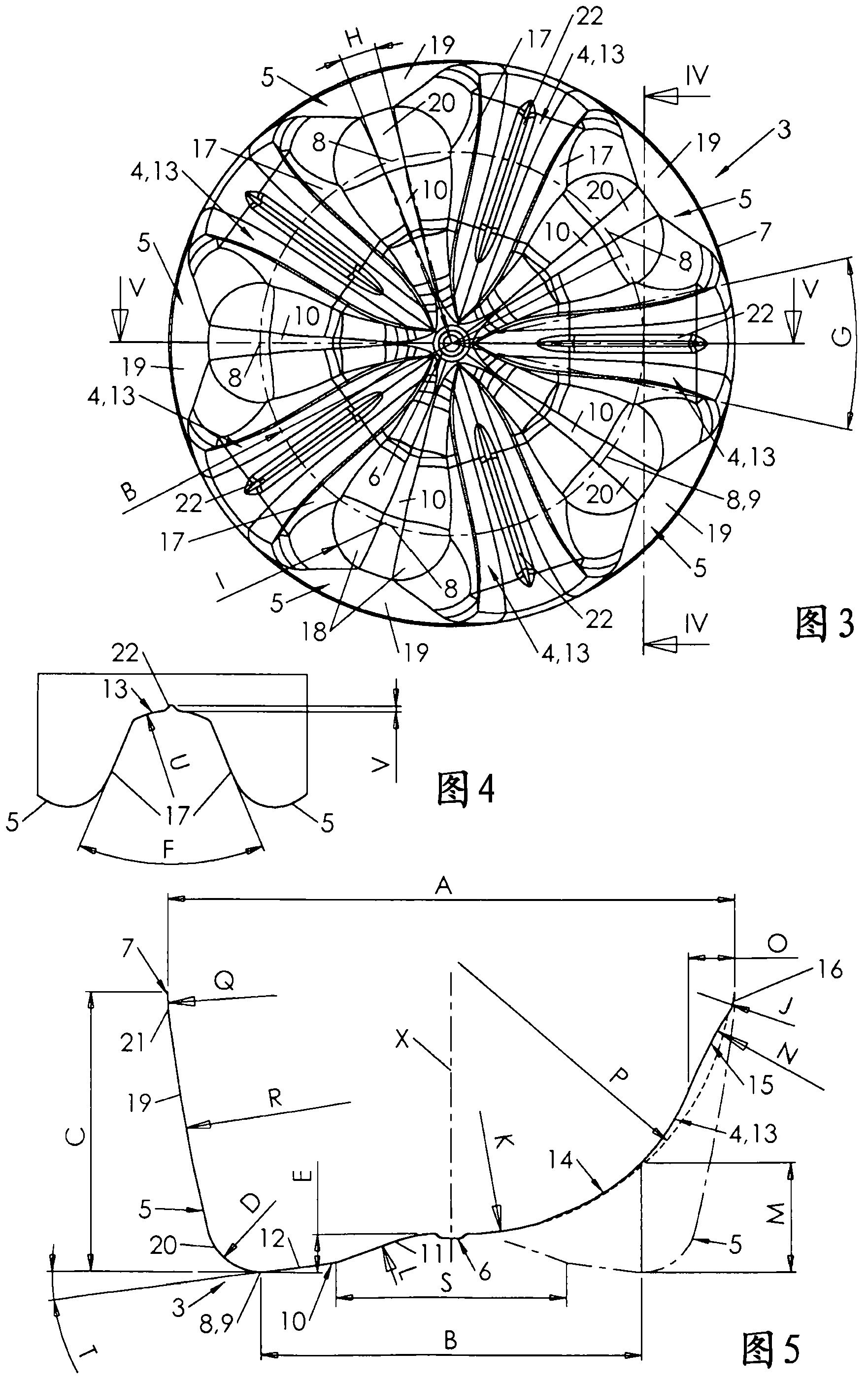

Combined petaloid base of a container

ActiveCN103269953AIncreased deformation resistanceFor long-term storageBottlesSupporting meansEngineeringMechanical engineering

Owner:SIDEL PARTICIPATIONS SAS

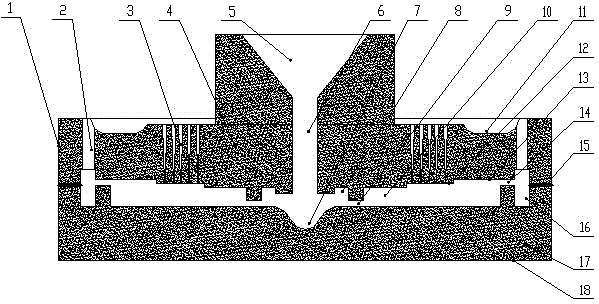

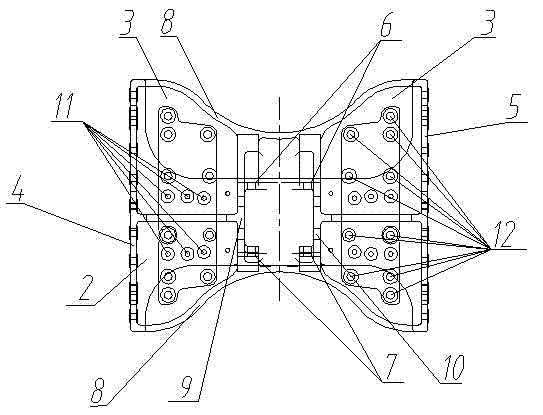

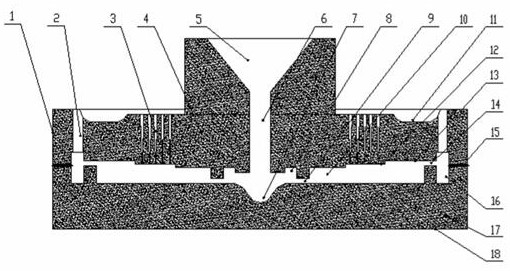

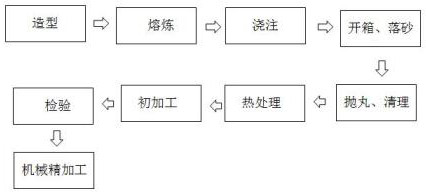

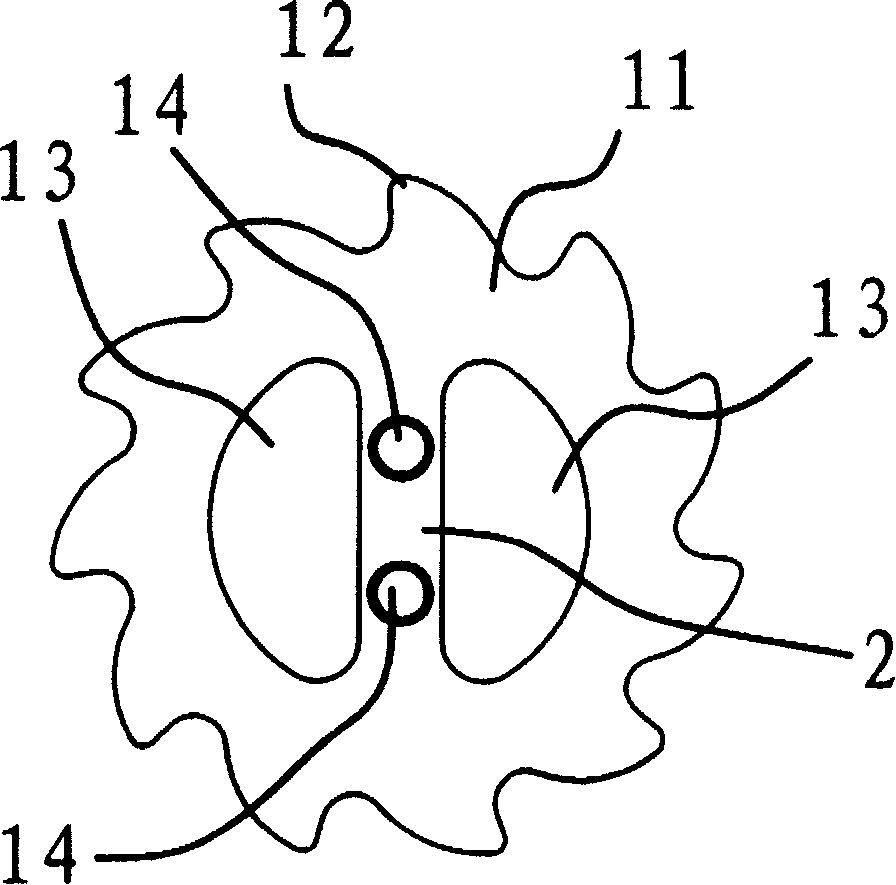

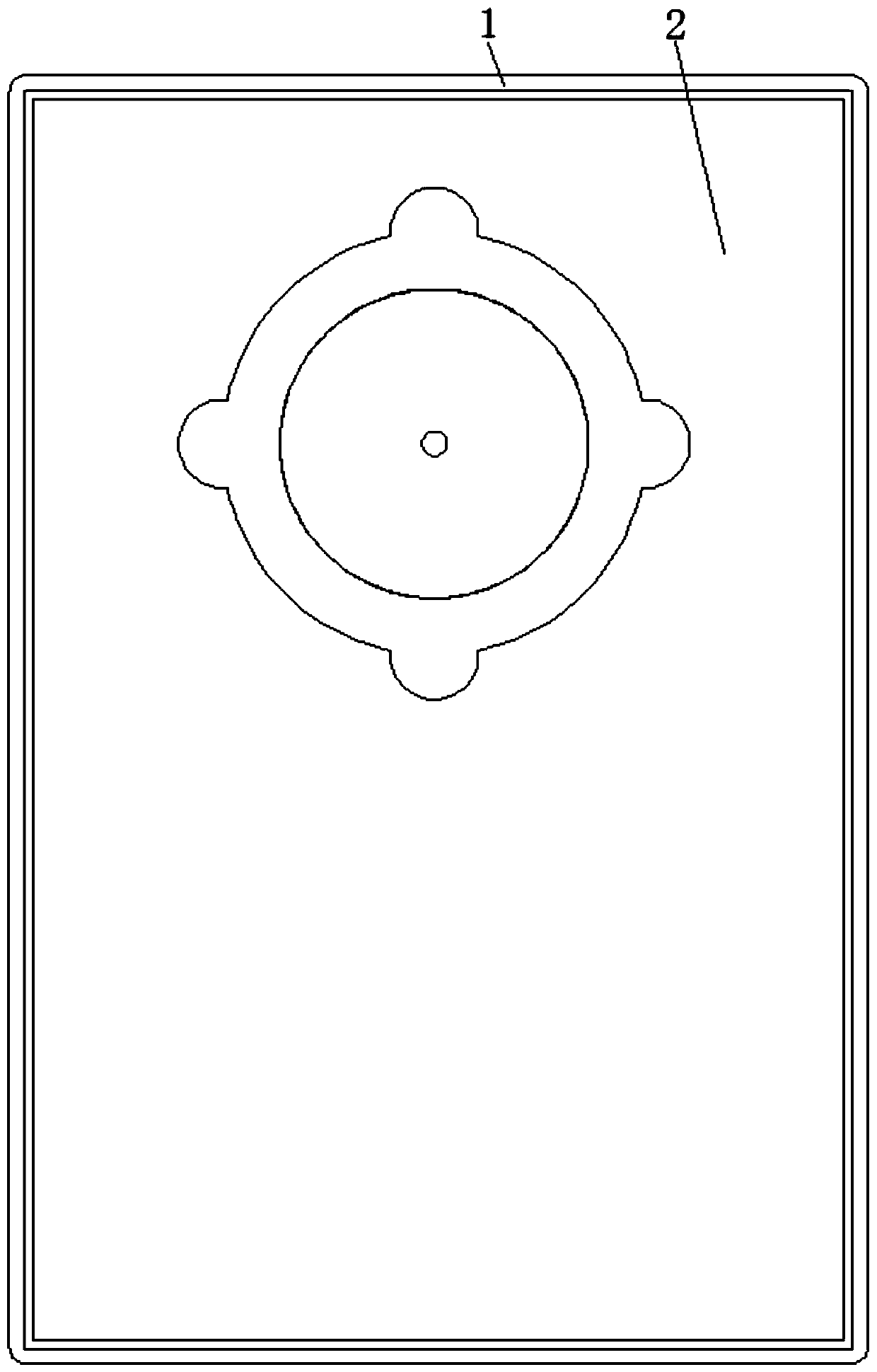

Grinding disc casting, grinding disc casting mold and grinding disc molding process

InactiveCN105057587AImprove product quality levelLow costFoundry mouldsFoundry coresAfter treatmentQuality level

The invention discloses a grinding disc casting which is even in rigidity, good in stability and cutting performance, durable and high in quality and a grinding disc casting mold for manufacturing the grinding disc casting. The mold is reasonable in structural design and good in heat preservation and exhausting performance. The invention further aims to disclose a grinding disc molding process. The product quality level can be greatly improved, after-treatment cost can be reduced, and after-treatment time can be shortened. A grinding disc manufactured through the molding process is good in product quality and high in percent of pass.

Owner:谌征

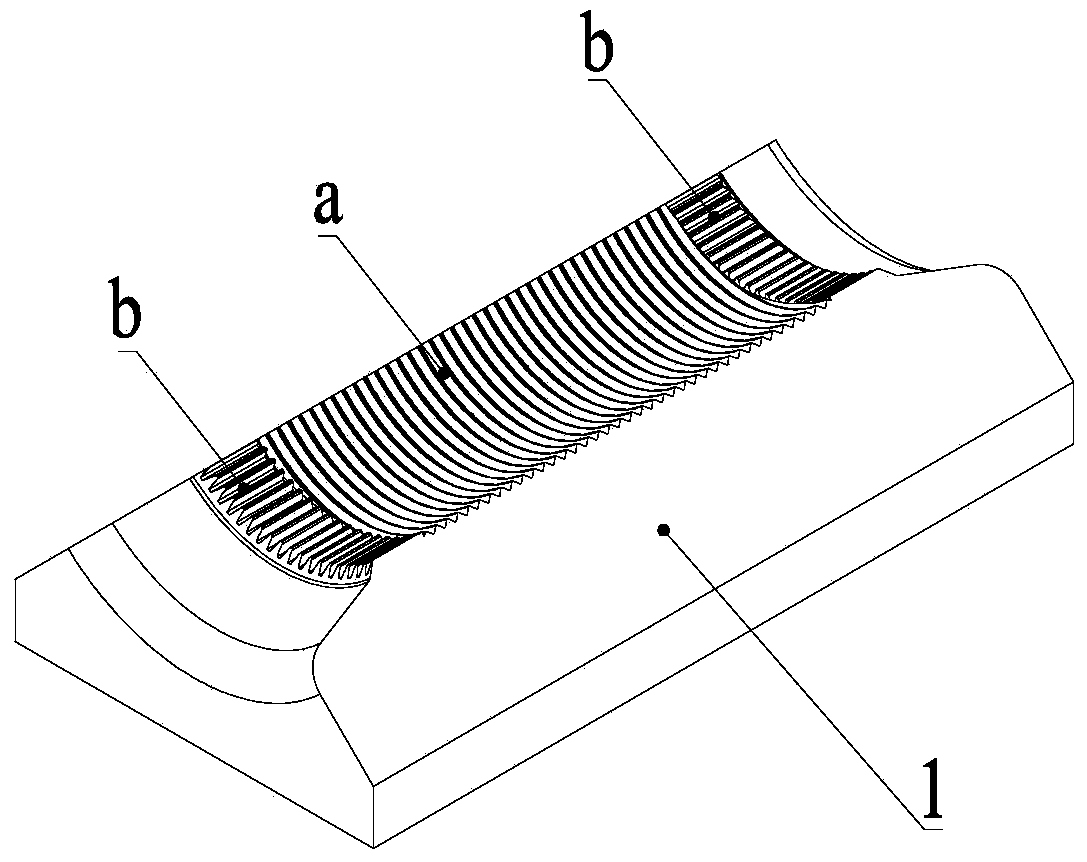

Preparation method of large titanium-cathode roller

InactiveCN101701351AThe size is not easy to controlIncreased deformation resistanceElectrodesHeat-affected zoneSurface layer

The invention relates to a preparation method of a large titanium-cathode roller. The method comprises the following steps of: rolling by adopting a thick titanium plate; after welding, heating a welding line and a welding line heat-affected zone needing heating at 750-980 DEG C for 0.2-2 hours by adopting a medium-frequency induction device; hammering or pressing and rolling the welding line on a rolling mill by a heavy roller to deform a welding line layer with a material deformation degree of 10-20 percent; heating and pressing the welding line heat-affected zone twice to four times; recrystalizing and annealing at 750-850 DEG C for 1-2 hours; and cooling a furnace. The heating and recrystallization of a cathode roller before rolling at a controlled lower heating temperature has great deformation resistance to cause defects and deformation and causes heavy-layer crystal grains only on a surface layer, and the heavy-layer crystal grains can be thinned.

Owner:南京宝泰特种材料股份有限公司

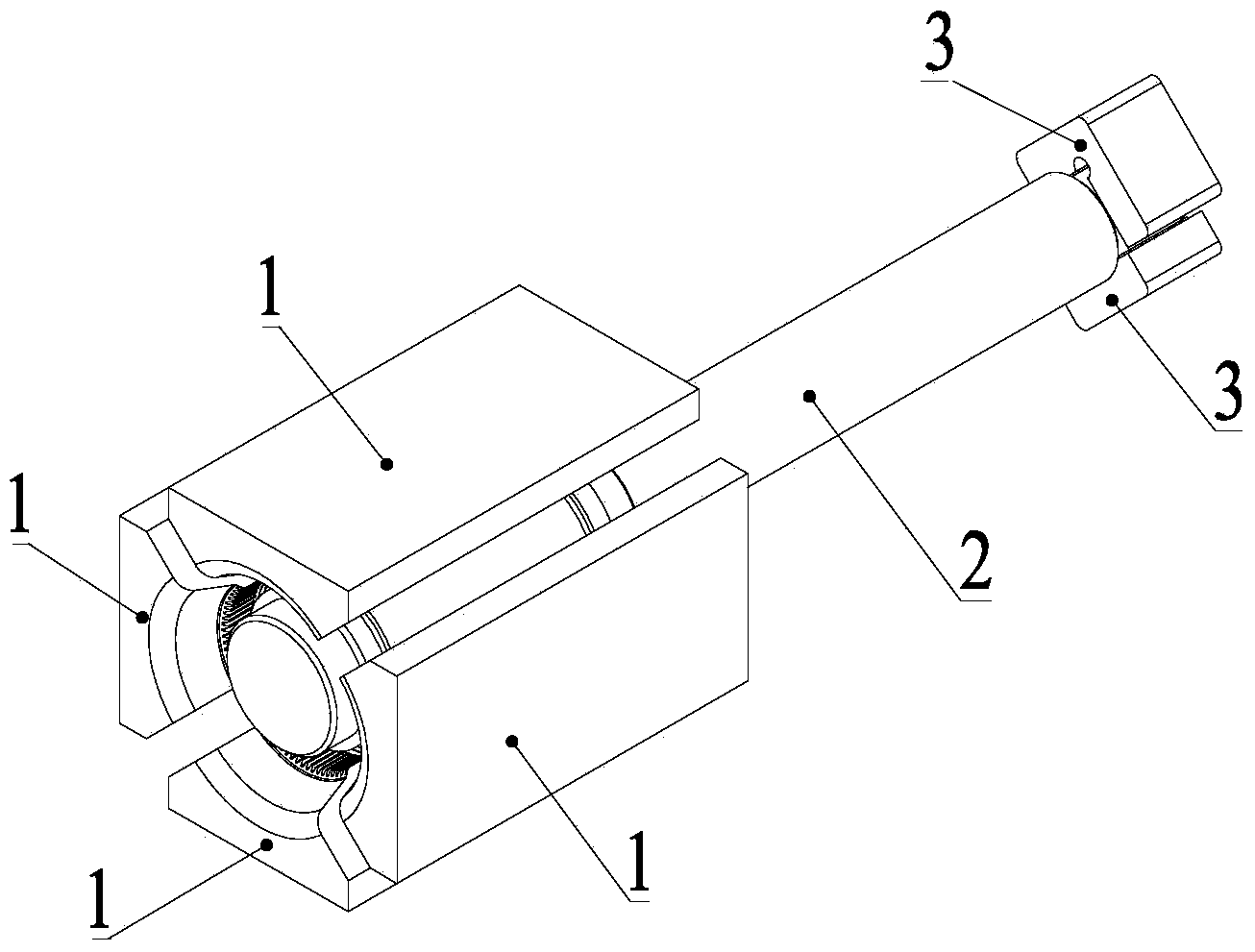

Radial forging method for forming short lead screw of inverted planetary roller screw pair

ActiveCN104001851AIncreased deformation resistanceHigh hardnessForging/hammering/pressing machinesEngine componentsOne passRoller screw

The invention provides a radial forging method for forming a short lead screw of an inverted planetary roller screw pair. The radial forging method for forming the short lead screw of the inverted planetary roller screw pair includes the steps that a radial forging die is provided with a thread form segment and a gear form segment simultaneously; a workpiece is rotated, the radial forging die conducts blow forging and then is lifted up, and the mentioned steps are continuously repeated until radial forging forming of the short lead screw with the specified radial forging amount is completed; forming and manufacturing of the short lead screw is completed through one pass or multiple passes; plastic forming of threads and gears of the short lead screw are completed simultaneously, a thread segment and a spline segment of the formed and manufactured short lead screw are integrated. The forming and manufacturing time is short, the part reliability is high, and the mechanical strength is high; through the method, large-diameter thread and gear coaxial parts with similar features can also be formed; the method is combined with a medium-high-frequency induction heating method, the parts made of materials with large deformation resistance, high hardness and hard deformation can be formed.

Owner:XI AN JIAOTONG UNIV

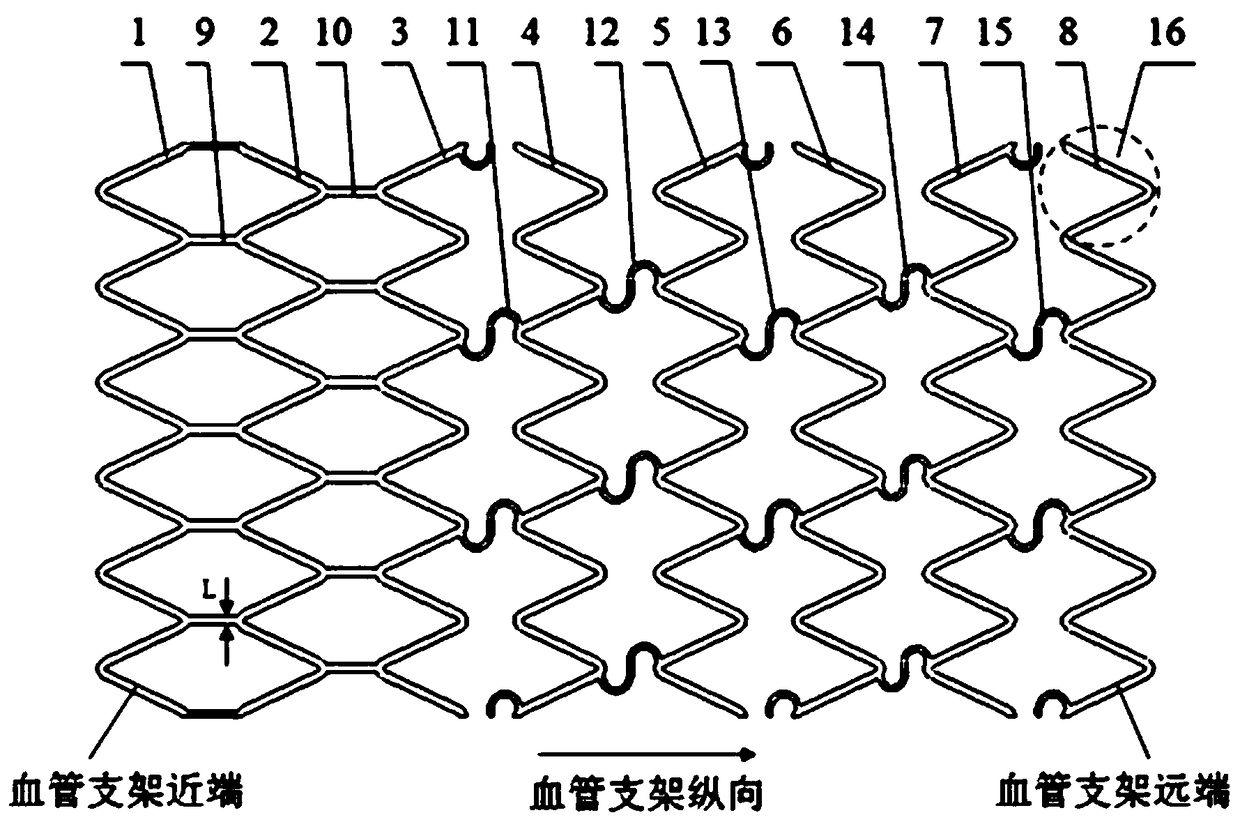

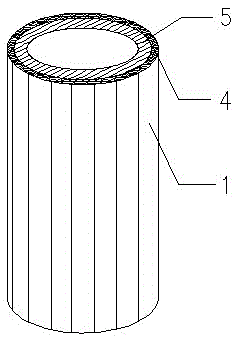

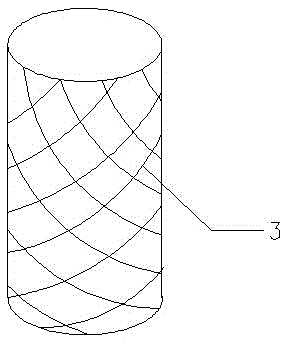

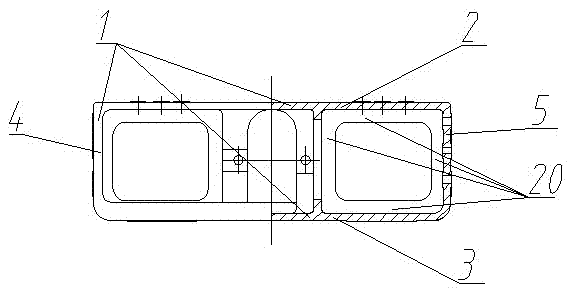

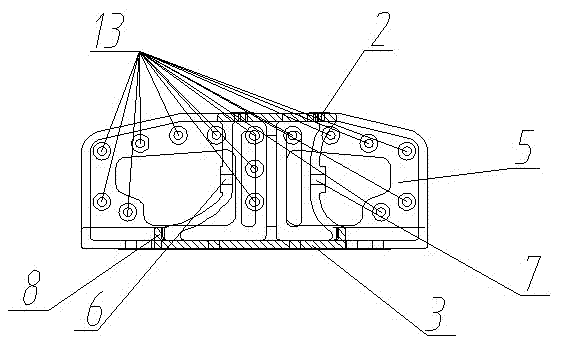

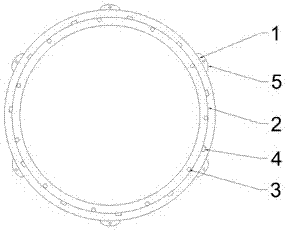

A vascular stent with anti-longitudinal deformation

InactiveCN105167881BIncreased deformation resistanceImprove flexibilityStentsBlood vesselsInsertion stentPercent Diameter Stenosis

The present invention provides a vascular stent with anti-longitudinal deformation. The vascular stent includes several groups of annular supports and connecting ribs connected between every adjacent two groups of the annular supports; the vascular stent is nearly The adjacent annular supports at the end are connected by straight-line connecting ribs, and the middle and distal ends of the vascular stent are connected by S-shaped connecting ribs, taking into account the longitudinal strength and flexibility of the vascular stent in the longitudinal direction; at the same time, Increase the number of circumferential linear connecting ribs at the proximal end of the vascular stent, further enhance the longitudinal strength of the proximal end of the vascular stent, and ensure the overall flexibility and transportability of the vascular stent so that it can reach the vascular lesion smoothly Moreover, the width of the straight-line connecting ribs at the proximal end of the vascular stent is increased to further ensure that the proximal end of the vascular stent has sufficient longitudinal strength, and at the same time increases its contact area with the plaque, which can reduce the In-stent restenosis.

Owner:JIANGSU UNIV

Novel MPP power cable sheath pipe

InactiveCN106243495AImprove stabilityHighly corrosivePlastic/resin/waxes insulatorsInsulated cablesAntioxidantEngineering

The invention discloses a novel MPP power cable sheath pipe, which consists of the following raw materials by weight: 8-12 parts of polypropylene, 3-7 parts of polyethylene, 15-25 parts of active calcium carbonate, 1-10 parts of glass fiber, 0-1 part of a coupling agent, 0.1-0.5 part of an antioxidant, and 0.3-1 part of a lubricant. The MPP power cable sheath pipe provided by the invention has strong chemical stability and corrosion resistance, good mechanical properties, and high compressive strength, and can play a very good protective role to the cable. Pipe connection can adopt a variety of ways so as to maximumly facilitate on-site construction, and the cable threading protection sheath pipe has excellent comprehensive performance, and can reach good protection and anti-ageing effect on cable. The MPP power cable sheath pipe has anti-deformation strength increased by 30%, welding joint tensile strength increased by 70%, and a non-excavation drag corner up to 60%.

Owner:安庆市悦发管业有限公司

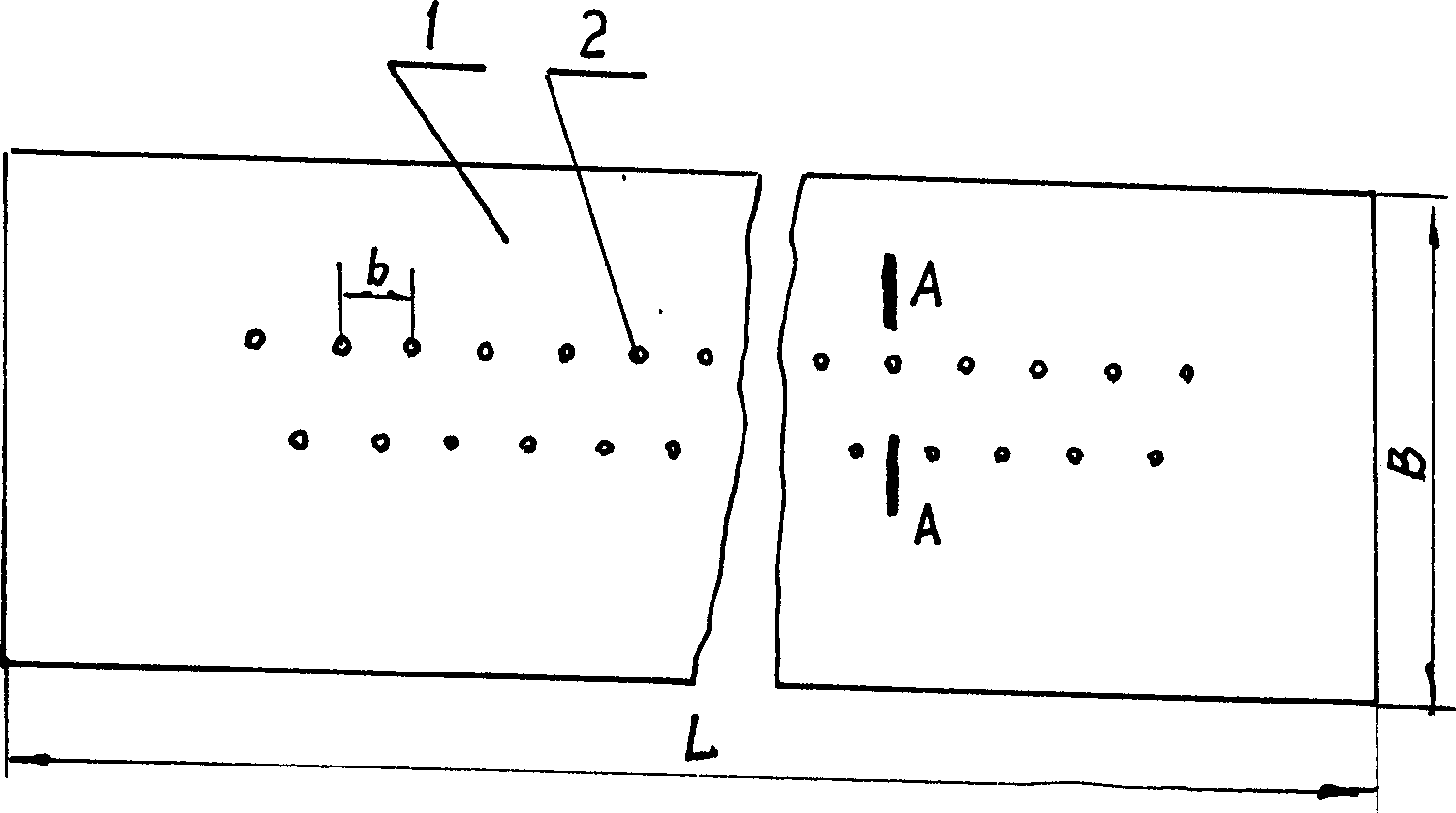

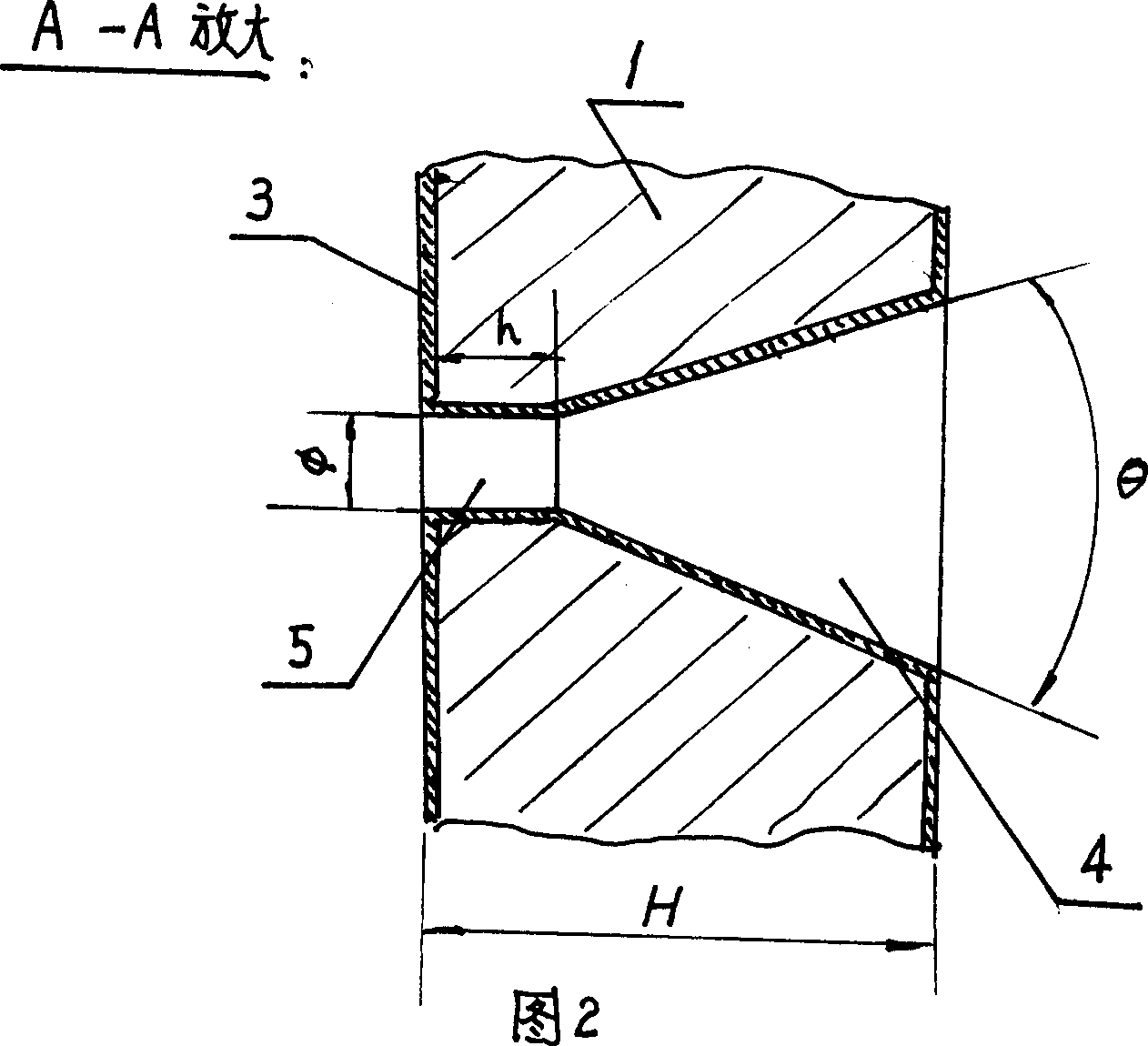

Hydraulic needle plate and its manufacture process

InactiveCN1468996AIncreased deformation resistanceGreatly slow down its water spray small deformation resistanceNeedling machinesManufacturing cost reductionHardness

The present invention is hydraulic needle plate and its manufacture process. The hydraulic needle plate is manufactured with bronze and through machining and ageing treatment, or with pure titanium and through machining and surface nitridation treatment. The hydraulic needle plate has high surface hardness, long service life, good machining performance and low manufacture cost.

Owner:金学民

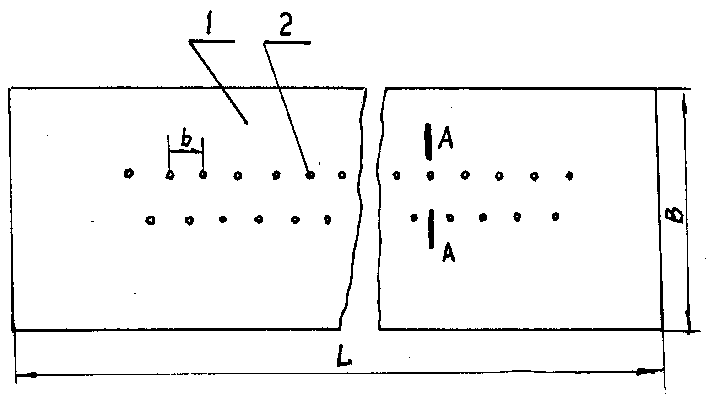

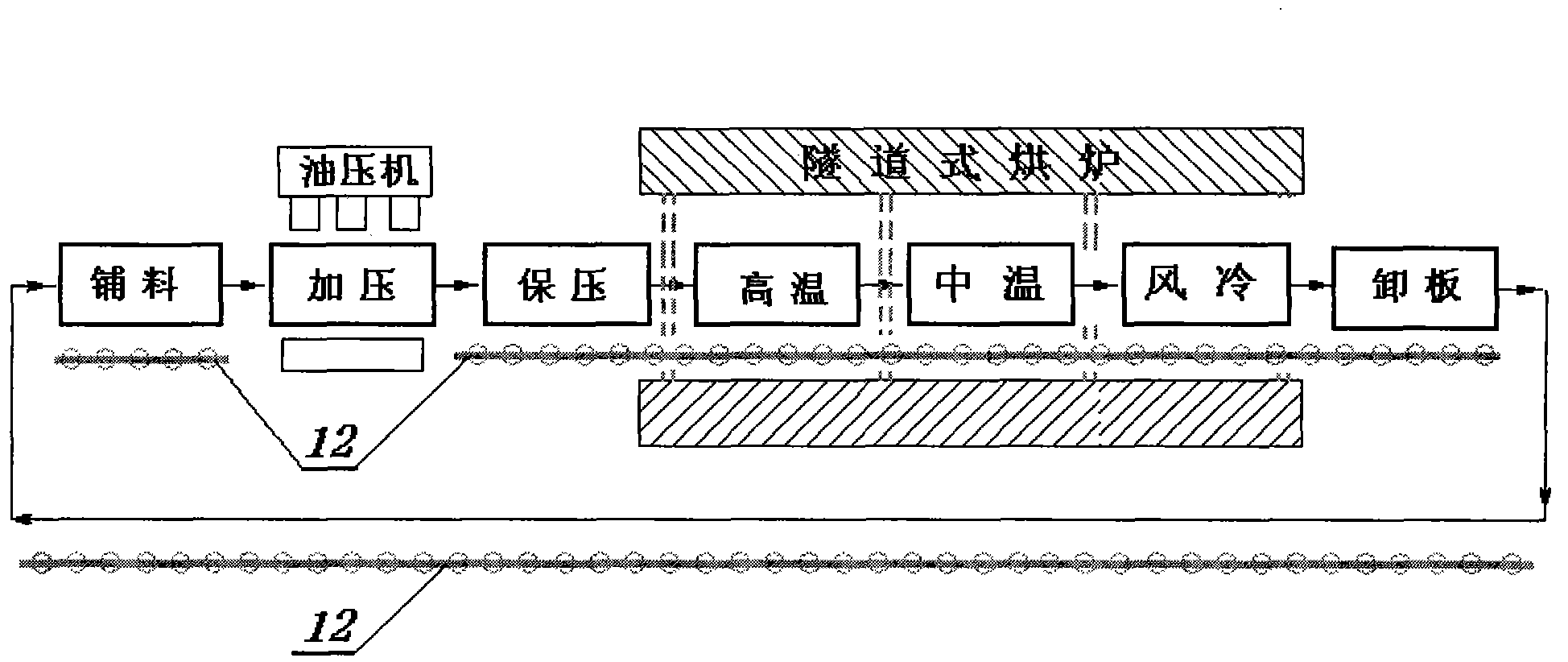

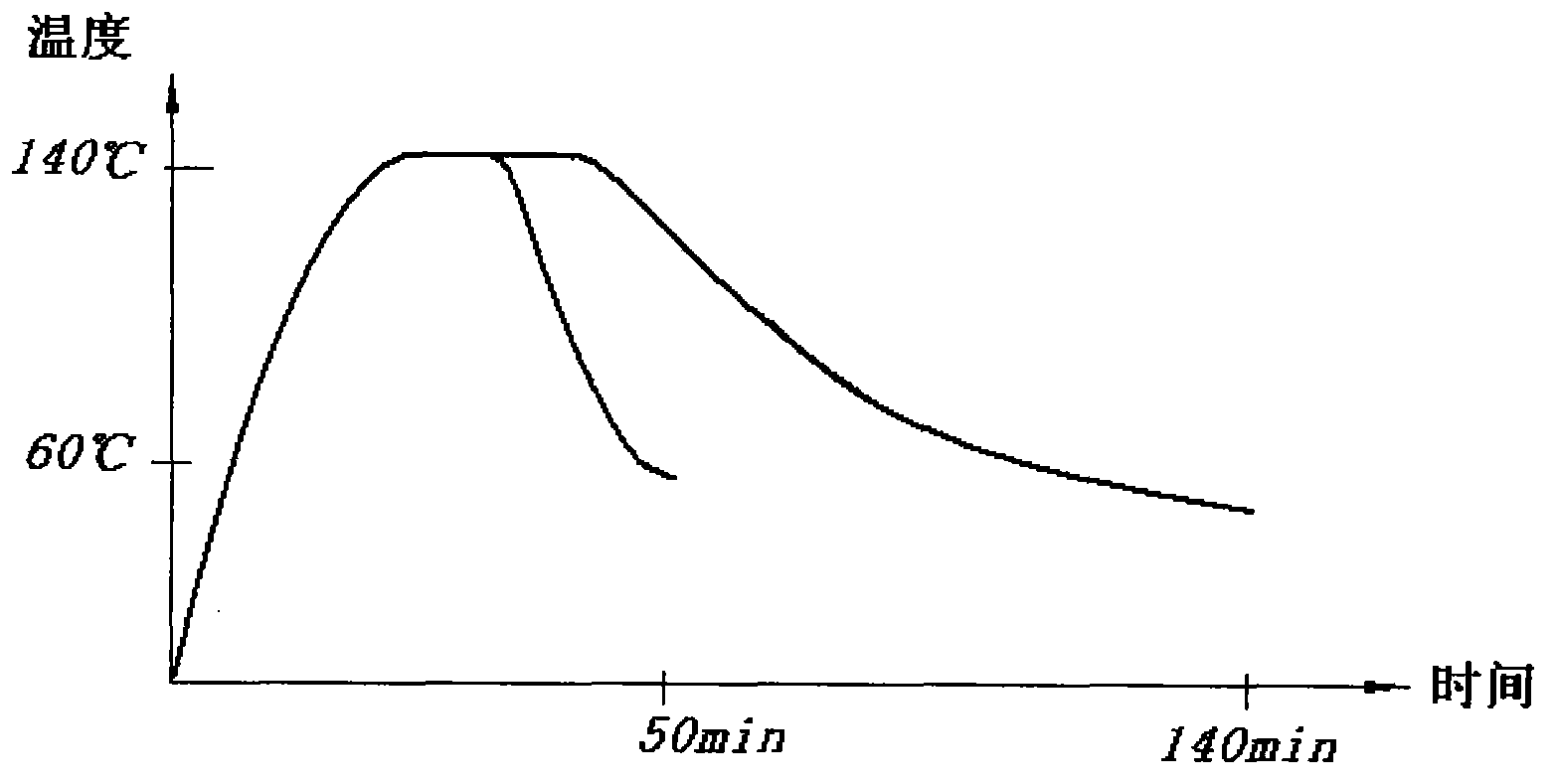

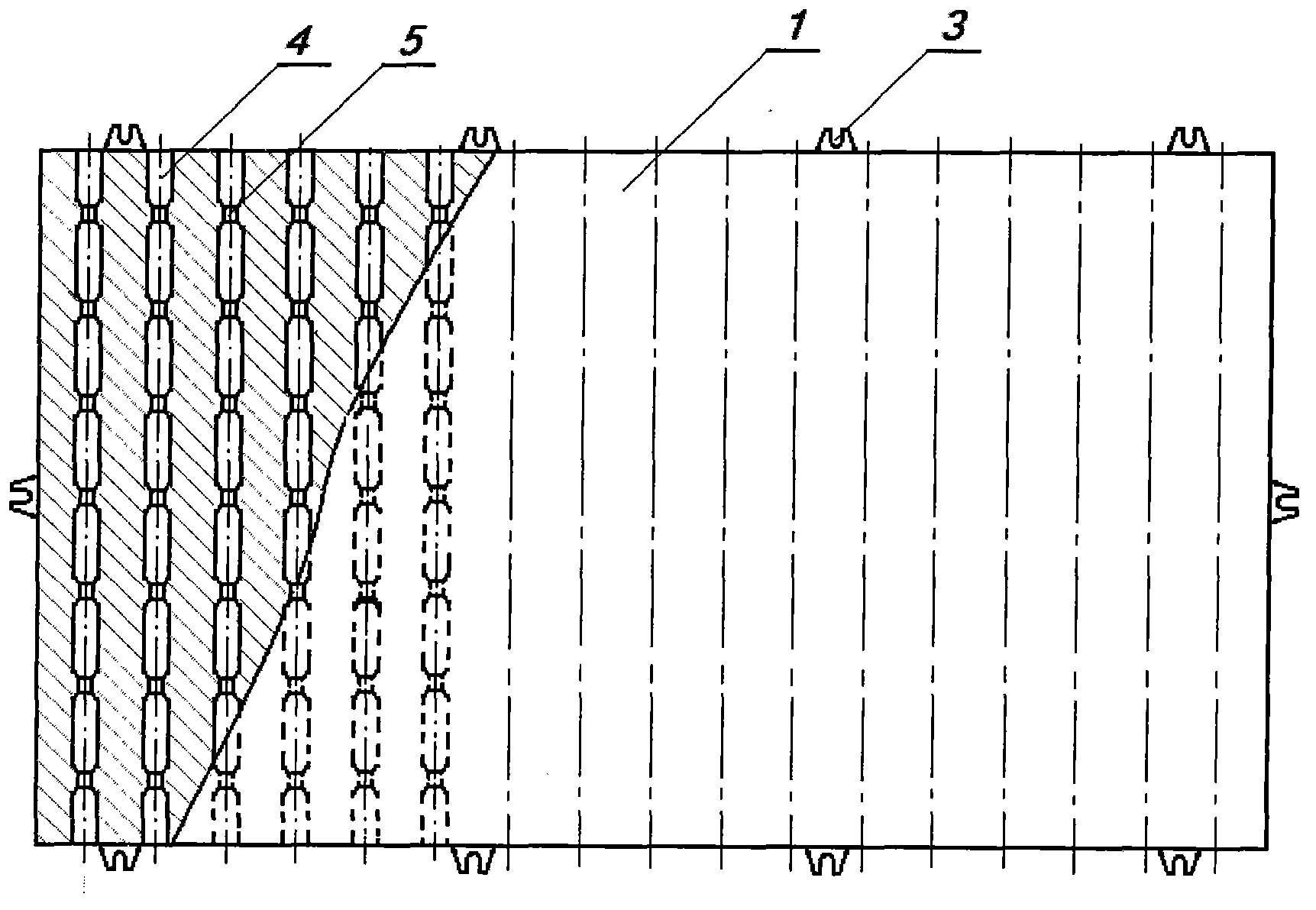

Phenolic resin bamboo plywood manufacturing process

InactiveCN102837349AIncreased deformation resistanceUniform and rapid pressure moldingWood working apparatusFlat articlesDecompositionPhenol formaldehyde resin

The invention provides a novel and continuous phenolic resin bamboo plywood manufacturing process; the preliminary bamboo decomposition and processing as well as unit desugaring and drying and phenolic resin glue application stages are the same with those of a bamboo plywood production process of the prior art, while the pressurization, the formation, the curing, the heating and the pressure maintenance of bamboo plywood materials are carried out on different equipment, wherein the pressurization of the bamboo plywood materials is carried out on a press on which no heat source needs to be fed in; meanwhile, a special clamp is adopted to maintain the pressure; the formation and the curing of the bamboo plywood materials are carried out in a tunnel-type baker; and a roller conveying device continuously conveys the bamboo plywood during a pressure maintenance process, so that the technical practice in the hot pressing and formation and curing stages in the bamboo plywood production is changed with less investment.

Owner:浙江晨峰模板有限公司

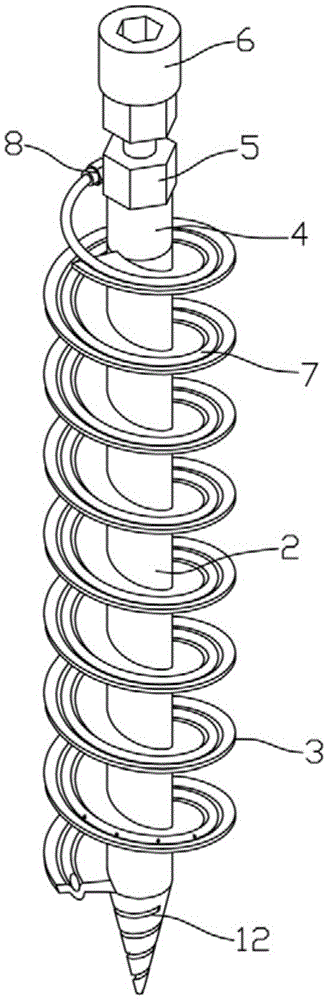

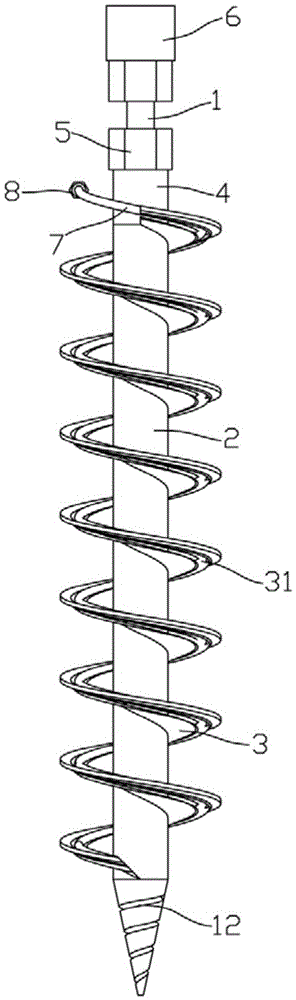

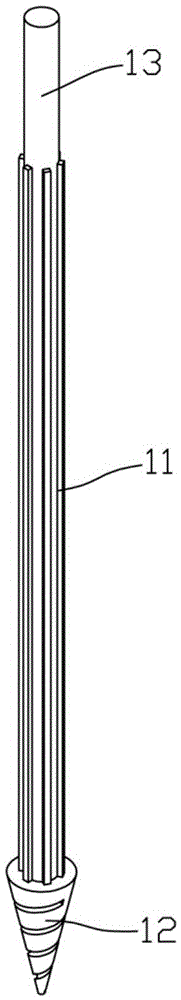

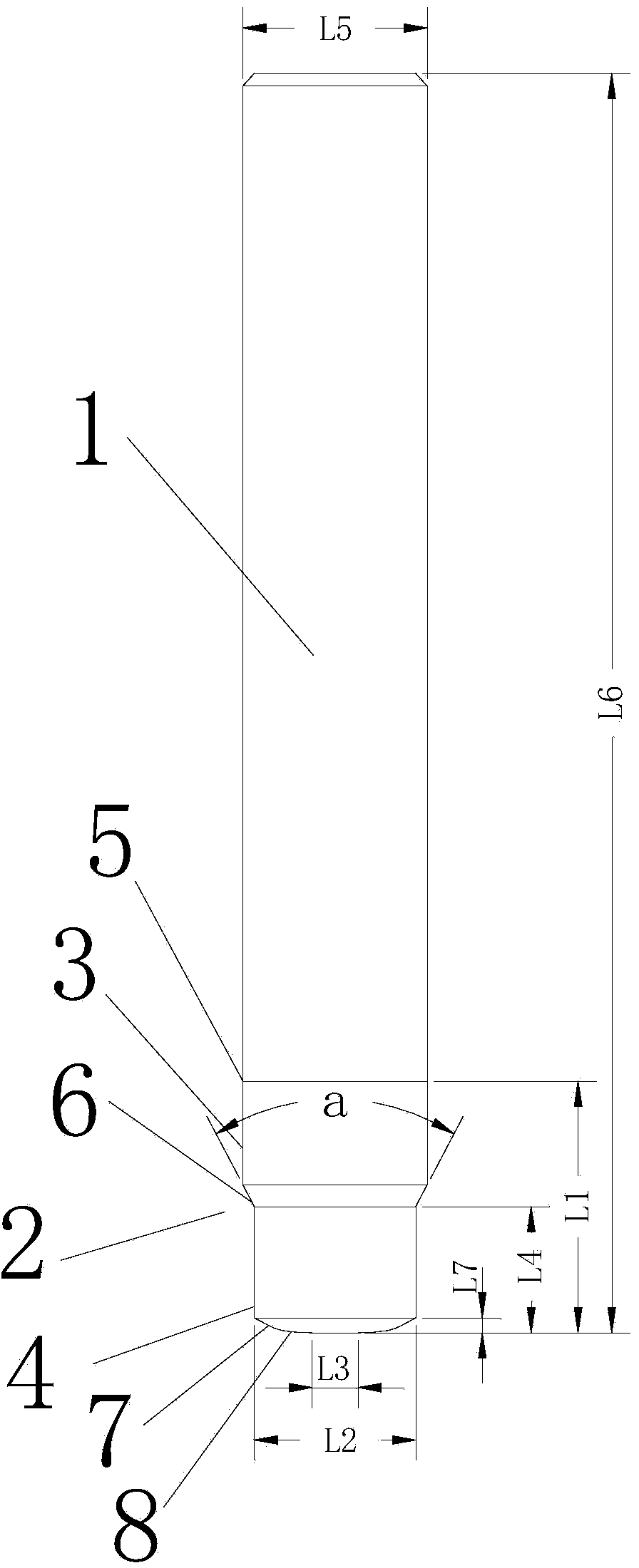

Structure-optimized drill rod on spiral drilling machine

ActiveCN105484681AHigh strengthIncreased deformation resistanceDrilling rodsFlushingSpiral bladeEngineering

The invention discloses a structure-optimized drill rod on a spiral drilling machine. A rod body of the drill rod is composed of a spline shaft, a drill bit and a double-screw bolt. The drill bit and the double-screw bolt are formed at the upper end and the lower end of the spline shaft respectively. A spline sleeve is inserted into the spline shaft. A spiral blade is fixedly welded to the outer wall of the spline sleeve. A rib groove for extending a spiral line of the spiral blade is formed in the spiral blade. A spiral water conveying pipe is welded into the rib groove of the spiral blade. A water pipe joint is fixedly connected to the upper end of the water conveying pipe. A spiral guide round rod is fixedly welded to the lower end of the water conveying pipe and fixedly welded into the rib groove in the lower end of the spiral blade. Inclined guide angles are formed at the bottom end of the guide round rod and the bottom end of the spiral blade. A plurality of water outlet holes are formed in the wall of the lower end of the water conveying pipe. The spiral blade of an existing spiral drilling machine is modified, the rib groove is additionally formed to enhance strength of the spiral blade, the spiral blade is provided with an output pipe, the output pipe can be used when the spiral drilling machine sprays water, and abrasion to the spiral blade can be reduced.

Owner:XUZHOU SHENGHE WOOD

Alloy component of low-cobalt high-temperature alloy supercharging turbine and preparation method of low-cobalt high-temperature alloy supercharging turbine

ActiveCN109022923AReduce usageElement mass fraction decreasedFoundry mouldsFoundry coresChemical compositionMo element

The invention discloses an alloy component of a low-cobalt high-temperature alloy supercharging turbine. The chemical composition of the alloy comprises the following chemical elements by mass percentage: 0.08-0.16% of C, 12.00-15.00% of Cr, 5.00-7.00% of Mo, 1.00-3.00% of Co, 5.00-5.70% of Al, 1.20-1.70% of Ti, 2.00-2.50% of Ta, 6.00-8.00% of W, 0.01-0.2% of B and the balance Ni. The compositionof Cr, Mo, W in the alloy is controlled as following: the specific value between the sum of the mass fraction of the W element and the Mo element to the mass fraction of the Cr element is less than 1.0. The invention further discloses a preparation method of the low-cobalt high-temperature alloy supercharging turbine, and belongs to the technical field of automotives. By means of the alloy component, the strategic scarce resources Co are saved greatly, and meanwhile, the obtained supercharging turbine is not prone to hot-cracking.

Owner:JIANGYIN UNI POL +1

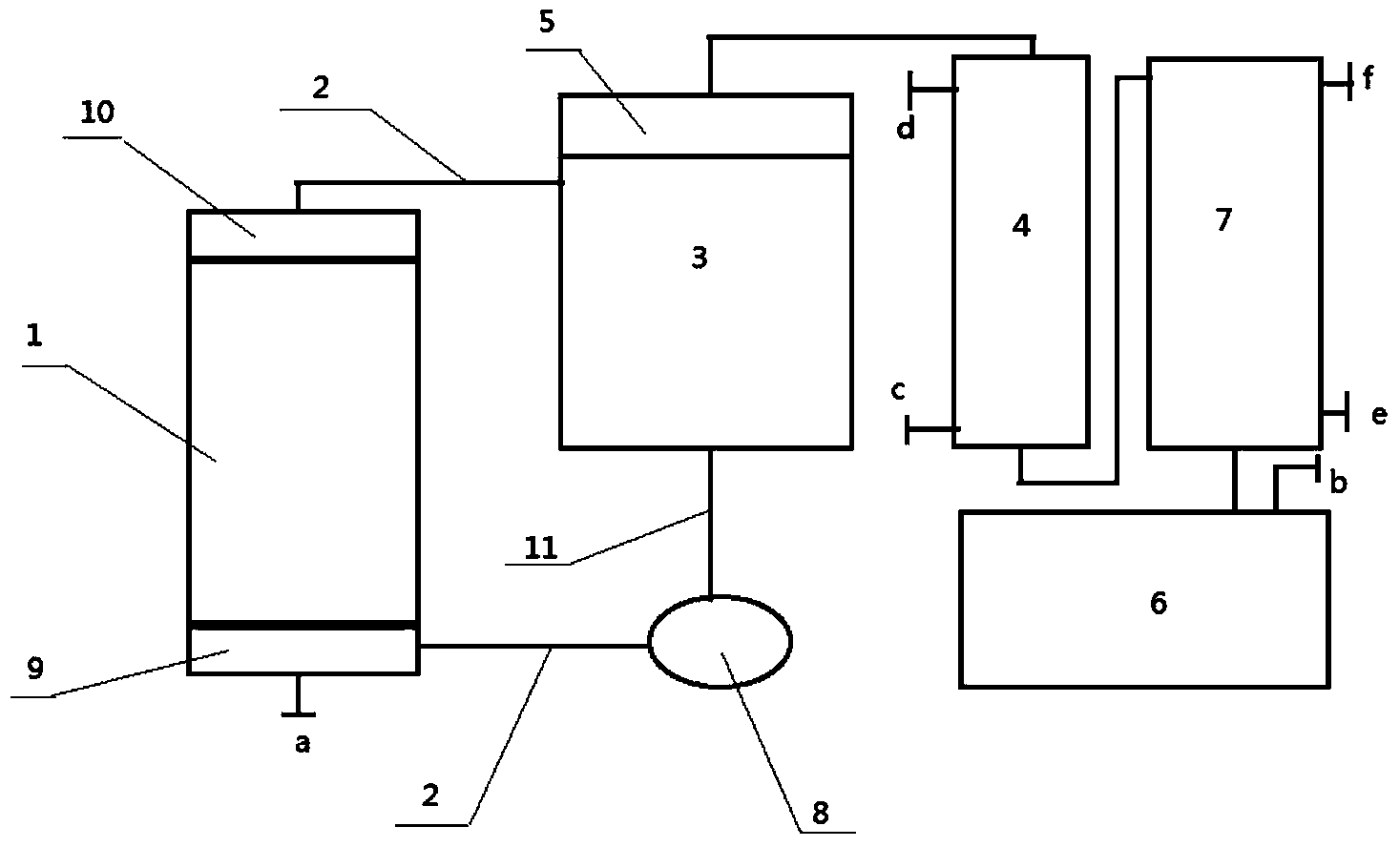

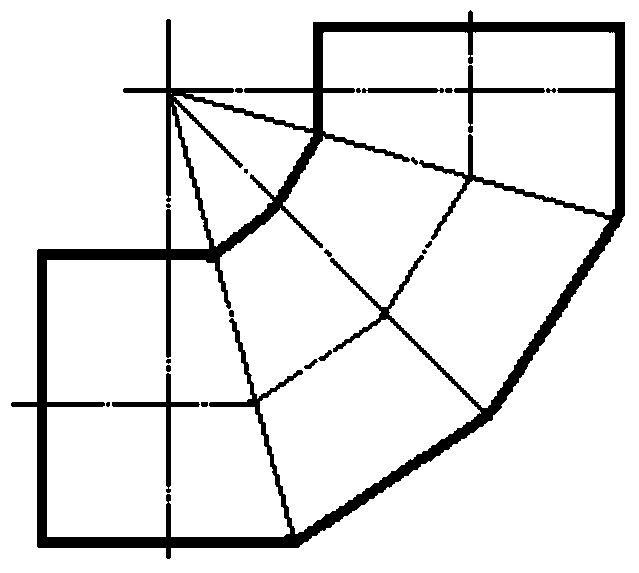

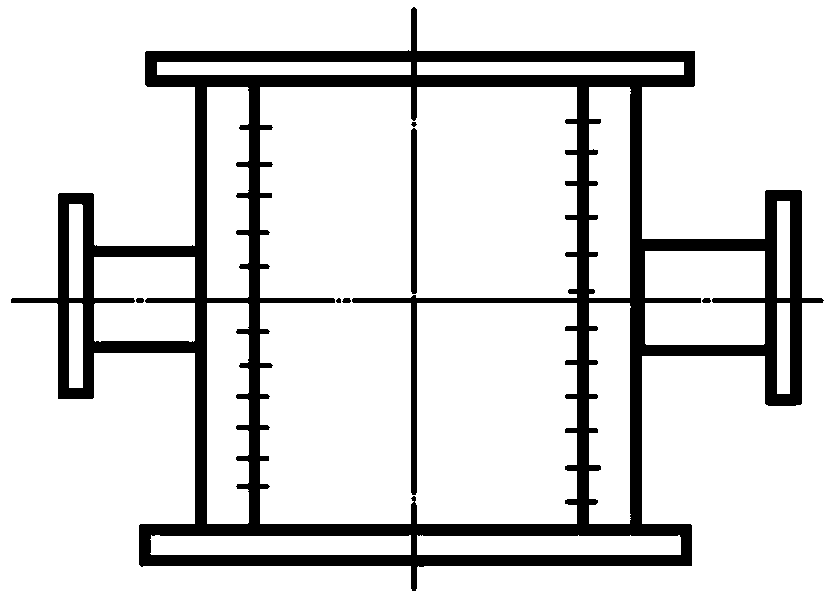

Online tons-level traditional Chinese medicine anti-wall-hanging evaporation and concentration device and operating method thereof

The invention provides an online tons-level traditional Chinese medicine anti-wall-hanging evaporation and concentration device and an operating method thereof. A gas-liquid-solid three-phase natural circulation fluidized bed evaporation and concentration device in an industrial production scale in which the heating area of a heater is 18.9 m<2> and the evaporative power is 1100-1400 kg / h is determined. The inventions and innovations of a screen type discharging device, a 90-degree multi-section short-radius elbow connecting pipe and a demister on the upper part of a separation chamber are designed. At present, the production operation result of the industrial scale device of about 100-ton extracting solutions of Menopause Ease and other over ten traditional Chinese medicines proves that compared with a traditional two-phase flow evaporation concentrator with the heating area of 18 m<2> in a factory and an operating method thereof, the device and the method under approximate operation conditions have the advantages that the total heat transfer coefficient and evaporation intensity are improved, a wall hanging phenomenon of the two-phase flow evaporation concentrator is avoided, the wall hanging phenomenon existing in a traditional Chinese medicine extracting solution evaporation concentrator is eliminated, and high-efficiency continuous and stable operation is realized.

Owner:TIANJIN UNIV

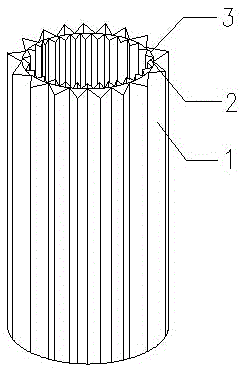

Filter element of gas filter

InactiveCN105545554AIncreased deformation resistanceDoes not affect filteringMachines/enginesLiquid fuel feedersFuel filterPulp and paper industry

The invention discloses a filter element of a gas filter. The filter element comprises outer-layer filter paper, a plastic supporting net and inner-layer filter paper. The outer-layer filter paper and the inner-layer filter paper are hollow cylindrical bodies formed through longitudinal folding. The plastic supporting net is clamped between the outer-layer filter paper and the inner-layer filter paper. The upper portion and the lower portion of the filter element are fixed in a fused mode through resin adhesive tape and a non-woven fabric gasket. Compared with the prior art, the filter element has the following advantages that a double-layer filter paper structure is adopted, the plastic supporting net is additionally arranged between the outer-layer filter paper and the inner-layer filter paper, the deformation-resistant strength of the filter element is enhanced, and meanwhile the connection problem between the outer-layer filter paper and the inner-layer filter paper is solved; due to the fact that meshes of the plastic supporting net are large, filtering of gas dirt cannot be affected, the two ends of the filter element are fixed in the fused mode through the resin adhesive tape and the non-woven fabric gasket, the structure is simple, machining is convenient, the step of welding the filter element with an outer end cover is avoided, and efficient filtering, simple manufacturing, environment friendliness and reduction of manufacturing cost are achieved.

Owner:BENGBU CITY MINGWEI FILTER CO LTD

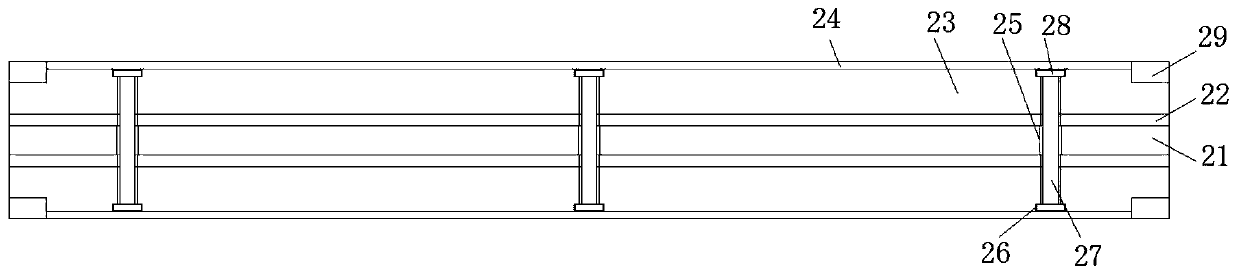

Fifth cast beam of frame of heavy truck

InactiveCN102530080AExtended service lifeReasonable structureUnderstructuresVehicle frameArchitectural engineering

The invention provides a fifth cast beam of a frame of a heavy truck, belonging to the heavy truck. The fifth cast beam is characterized by mainly consisting of a beam body, a front push rod support and a rear push rod support, wherein the front push rod support and the rear push rod support are arranged in an inner chamber of the beam body, the beam body is shaped as a box provided with a cavity, and mainly consists of a top plate, a bottom plate, a left side plate and a right side plate which are cast into a whole, the left side plate and the right side plate are vertical panels which are arranged symmetrically, front lightening holes and rear lightening holes are formed on surfaces of the left side plate and the right side plate, the top plate is biased forwards relative to the bottom plate, the bottom plate is an symmetrically arranged butterfly plate, symmetric arc-shaped recesses are formed on a front edge and a rear edge of the top plate, turnup reinforcing rib plates are arranged at the front edge and the rear edge of the bottom plate, the front push rod support and the rear push rod support are symmetrically arranged in a rectangular space at the middle part of the beam body, and are cast into a whole, side plate mounting holes are arranged on the left side plate and the right side plate respectively, riveting through holes are respectively formed on the top plate in a bilaterally symmetrical manner, and bolt connecting holes are formed on the bottom plate respectively in a bilaterally symmetrical manner. The fifth cast beam provided by the invention has the advantages of high torsion resistance, high deformation resistance and long service life.

Owner:ANHUI HUALING AUTOMOBILE

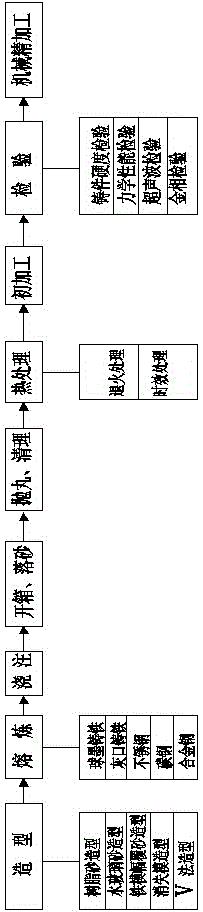

Forging technology of high-strength TC4 titanium alloy column part

ActiveCN109731942AImprove deformation resistanceIncreased deformation resistanceHigh intensityThermal treatment

The invention provides a forging technology of a high-strength TC4 titanium alloy column part. The forging technology comprises the specific steps of material feeding, blank turning, heating before forging, tool and die preheating, first time of upsetting, drawing, second time of upsetting, thermal treatment and quality inspection. According to the forging technology, because of the transformationprocess of upsetting, drawing and upsetting, the deformation in the forging process is increased, and the forging process route is reasonable. According to the forging technology, during the processof drawing, because the section of a blank bar is set to be a hexagon, or heptagon or octagon, no over protruding edges are formed in corners, the temperature gradient between different positions on the surface of the blank bar is decreased, deformation is more uniform when load is applied, and the surface quality of a forge piece is better. According to the forging technology of the high-strengthTC4 titanium alloy column part, in the process of the second time of upsetting, both the hammer drop speed and hammer drop force are larger than those of the first time of upsetting; before the second time of upsetting, the temperature of the blank bar is low, at this time, large axial deformation ranging from 30% to 50% is applied to the blank, a long-strip shaped alpha phase can be promoted tobe broken, and the shape characteristics of a Widmannstatten structure is effectively changed.

Owner:天津航天长征技术装备有限公司

Grinding disc, model for casting grinding disc and casting process of grinding disc

InactiveCN113042684AUniform hardnessCool evenlyFoundry mouldsGrinding devicesMaterials scienceIndustrial engineering

The invention discloses a grinding disc, a model for casting the grinding disc, a casting process of the grinding disc, and optimization design and innovation of the casting process of the grinding disc. According to the casting process of the grinding disc, the product quality and the product qualification rate can be improved, a scientific heat treatment technology is designed according to the technical quality requirement of grinding, the molecular structure is improved, and therefore the grinding disc is good in stability, the product quality is stable in the using and producing process, the work efficiency is improved, and the service life is prolonged.

Owner:扬州振光机械有限公司

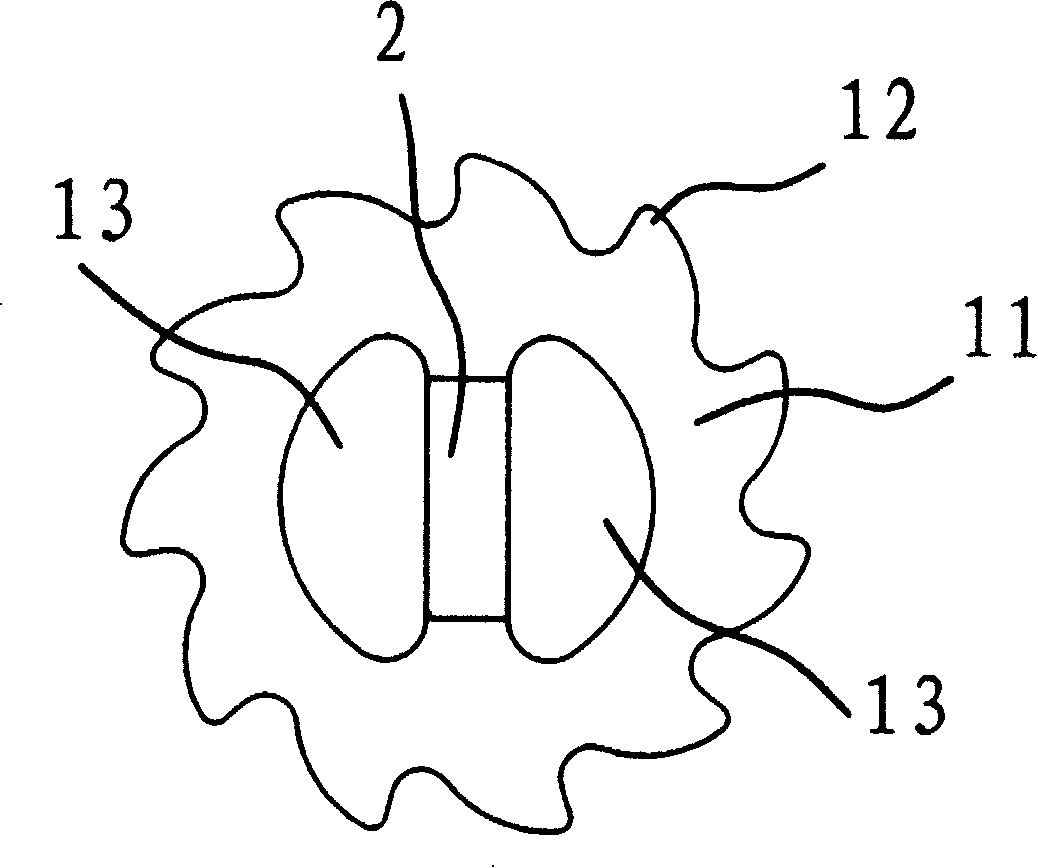

Ratchet wheel of binding device

ActiveCN100400238CHigh mechanical strengthImprove convenienceLoad securingWire toolsEngineeringUltimate tensile strength

Ratchet wheel for binding device belongs to mechanical technique field and solves problem for weak mechanical intensity of reel in existing device. It comprises wheel body with ratchet around body outside and two axis holes in body for reel passing; there is supporting bar between holes fixed on and bumped toward wheel body; when assembling ratchet wheel, make the supporting bar toward inside to shorten their distance and then increase reel mechanical intensity. It just needs to change ratchet wheel shape to achieve purpose; meantime, increases cost little; however, it improves blinding device performance marked, safe and reliable, and has high use value.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

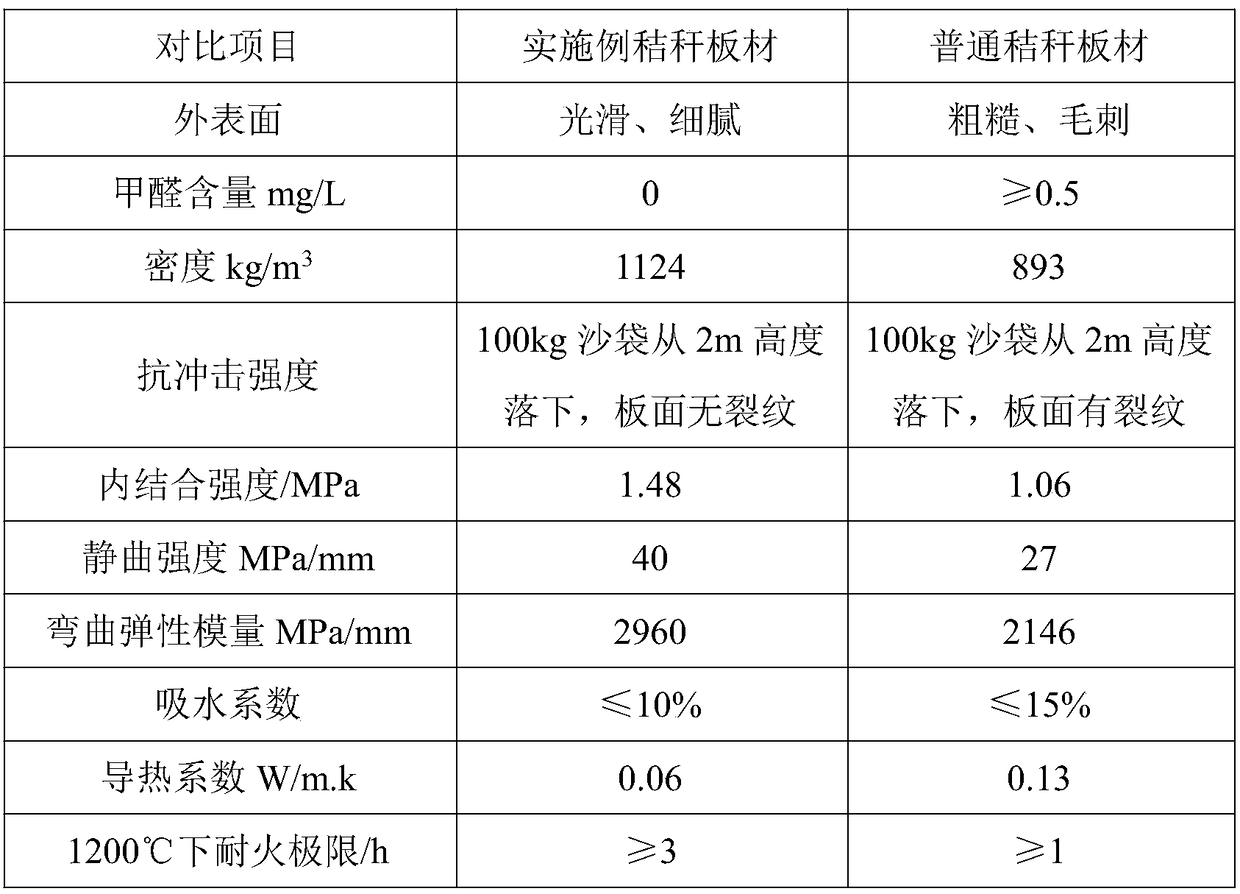

Environment-friendly flame-retardant straw plate and preparation method thereof

InactiveCN109318340AReduce incinerationHigh strengthWood working apparatusFlat articlesEnvironmental resistanceCellulose

The invention discloses an environment-friendly flame-retardant straw plate. The environment-friendly flame-retardant straw plate is prepared from crop straw, bamboo charcoal fibers, glutinous rice flour, an aluminic acid ester coupling agent, polyanionic cellulose, diatomite, a magnesium hydroxide flame retardant, silica fume and deionized water. The straw plate has the high strength, the flame retardant property is good, various properties all meet the corresponding requirements, green and environmental protection are achieved, zero formaldehyde emission is achieved, the oxidation resistanceis high, the mass is low, the high additional value of the crop straw is increased, straw burning and tree cutting are reduced while the production cost is reduced, and the market application prospect is very wide.

Owner:安徽科纳家居饰材有限公司

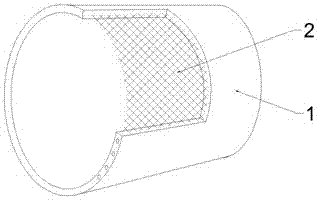

Large-diameter anti-cracking PE pipe

PendingCN107191691AAvoid crackingIncreased deformation resistanceRigid pipesPipe protection against damage/wearDeformation effectEngineering

The invention provides a large-diameter anti-cracking PE pipe. The large-diameter anti-cracking PE pipe comprises a pipe body, wherein the pipe body is made of polyethylene materials, a barrel-shaped reinforcing layer is arranged in the middle of the pipe wall of the pipe body, the reinforcing layer is formed in a way that a metal net is rolled, six to eight inner reinforcing strips which are made of steel wires of which the diameter is 3 to 5 mm are arranged on the inner side of the reinforcing layer and are uniformly distributed along the length direction of a pipeline, outer reinforcing strips which are made and formed by bamboo strips or steel bands are arranged on the outer side of the reinforcing layer, concave-convex surface reinforcing ribs are arranged on the surface of the pipe body, and steel wires of which the diameter is 2 mm are arranged in the surface reinforcing ribs. By adopting the scheme, the large-diameter anti-cracking PE pipe has the advantages of reasonable structure and good anti-cracking and anti-deformation effects and is especially suitable for large-diameter pipelines above 0.8 meter.

Owner:长兴佳能高分子材料有限公司

Three-edge tungsten steel forming tool

InactiveCN104368860ASimple structureReduce volumeMilling cuttersWorkpiecesMachined surfaceEngineering

The invention belongs to the field of cutting tools and in particular relates to a three-edge tungsten steel forming tool. A groove is formed in the joint of a tool neck and a knife handle, and a chamfer is formed at the joint of the tool neck and a tool bit; three cutting edges are arranged on the cutting end surface of the end part of the tool bit; openings of the three cutting edges pass through the center, and the cutting edges are smooth; the chamfer is 60 degrees; the length of a cutting part is 10mm; the diameter of the tool bit is 7mm; the diameter of the front end of the tool bit is 2mm; the length of the tool bit is 5mm; the distance from the cutting end surface to the end part of the tool bit is 0.59mm; and the tool bit is made of tungsten steel. The three-edge tungsten steel forming tool is high in milling speed on a small workpiece, and according to the three-edge tungsten steel forming tool, the machined surface is smooth, and the machining precision is improved.

Owner:常州市文每机械配件厂

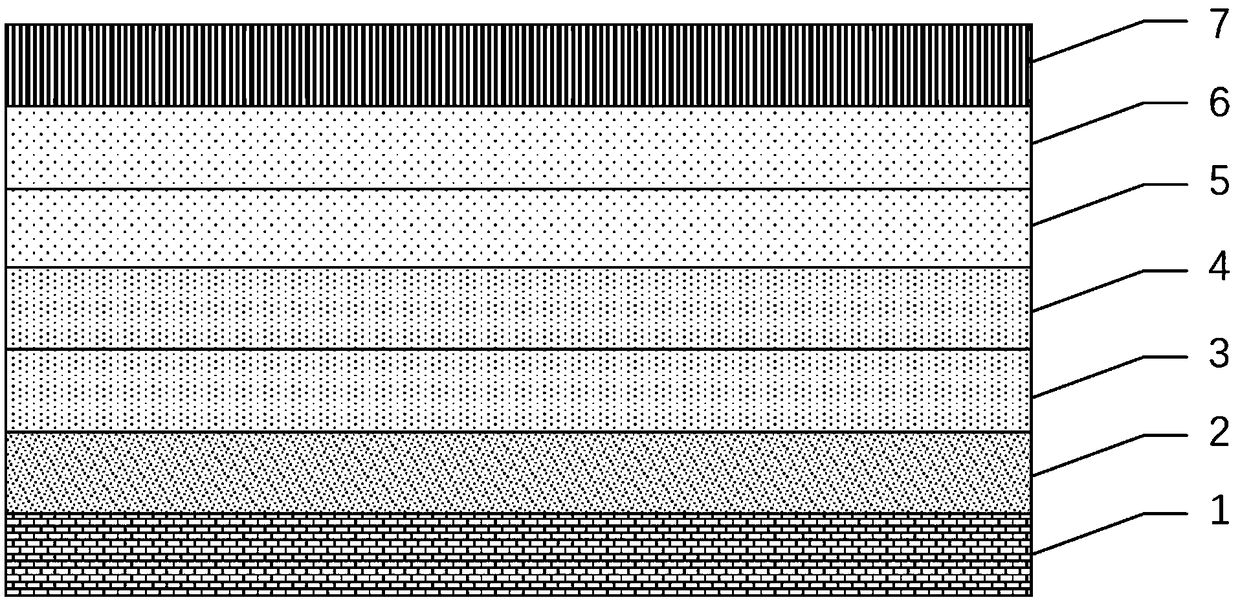

Anti-deformation flame retardant solid door and preparation method thereof

InactiveCN110219557ANon-flammableIncreased deformation resistanceFireproof doorsWood veneer joiningSolid woodPulp and paper industry

The invention relates to the related technical field of wooden doors, and discloses an anti-deformation flame retardant solid door and a preparation method thereof. The anti-deformation flame retardant solid door comprises a fixed outer frame, and a door body is fixedly clamped to the inner side of the fixed outer frame. The door body comprises a high-strength fiberboard, asbestos layers are bonded to the upper surface and the lower surface of the high-strength fiberboard, decorative boards are bonded to the surfaces, away from the high-strength fiberboard, of the two asbestos layers, and theside surfaces, away from the corresponding asbestos layers, of the two decorative boards are coated with flame retardant layers. Through holes communicating mutually are formed in the high-strength fiberboard, the asbestos layers and the decorative boards, embedded grooves communicating with the through holes are formed in the two decorative boards, reinforcing rods are arranged on the inner sidesof the through holes in a penetrating mode and extend to the inner sides of the corresponding embedded grooves, and external threads are arranged at the two ends of the reinforcing rods. According tothe anti-deformation flame retardant solid door and the preparation method thereof, the integral anti-deformation strength of the door body is effectively enhanced by using a high-strength limiting board, the integral using strength is effectively increased, and the comprehensive using performance of the anti-deformation flame retardant solid door is effectively improved.

Owner:ZHEJIANG PANJIA DOOR IND CO LTD

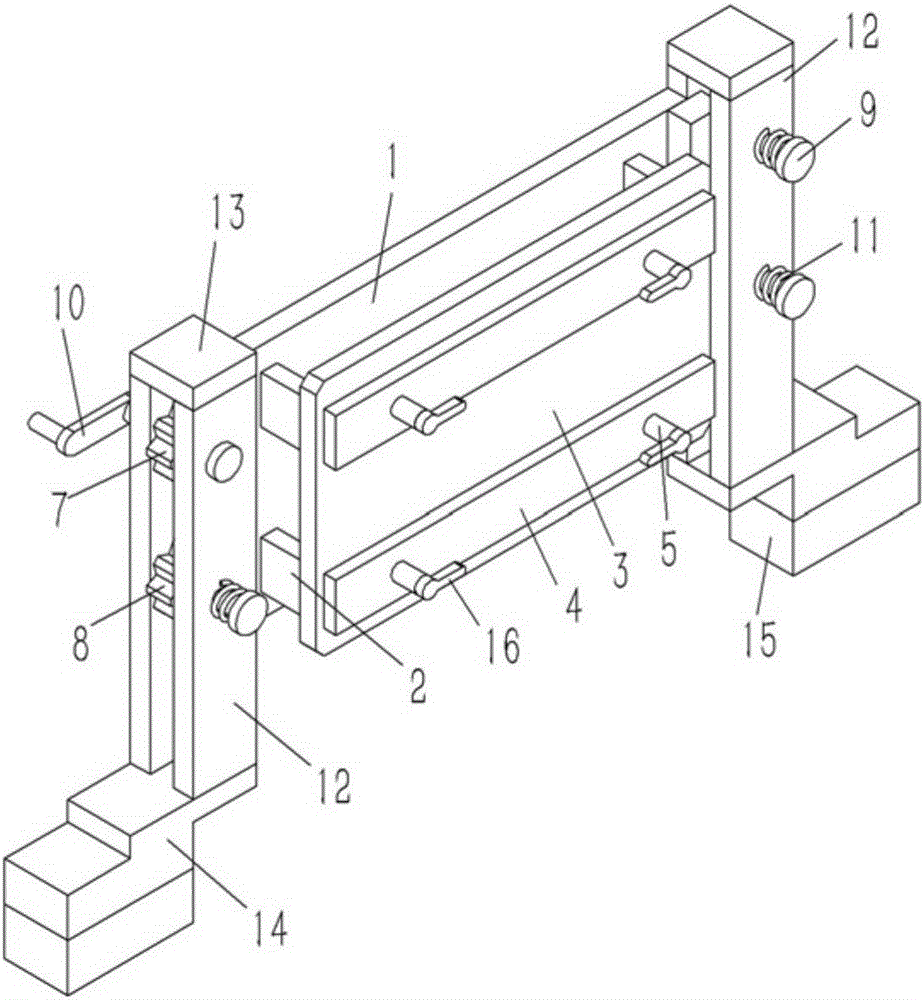

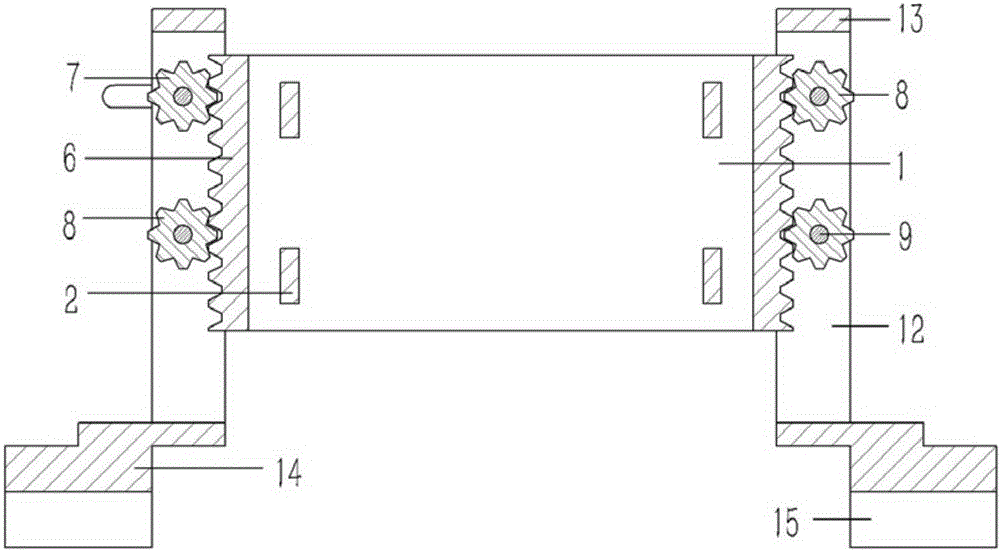

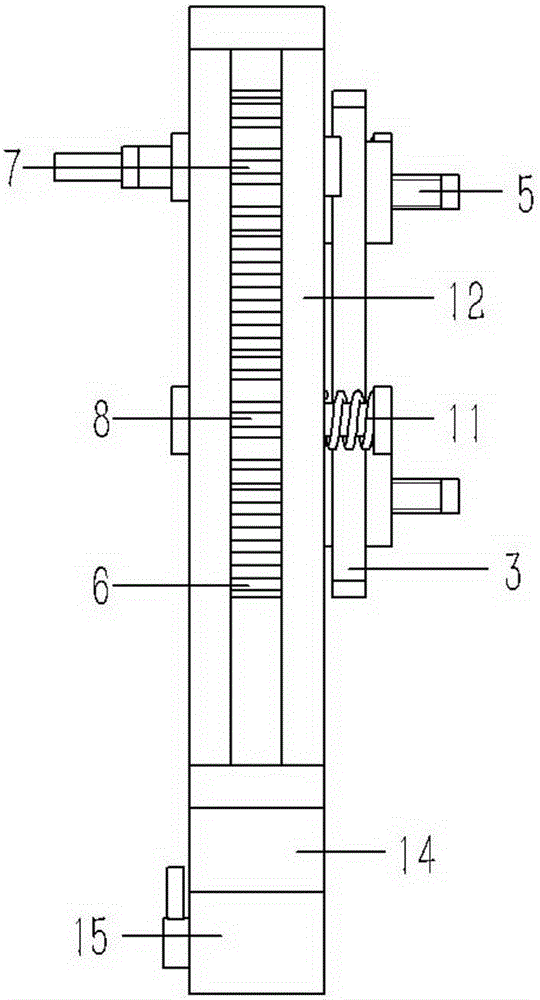

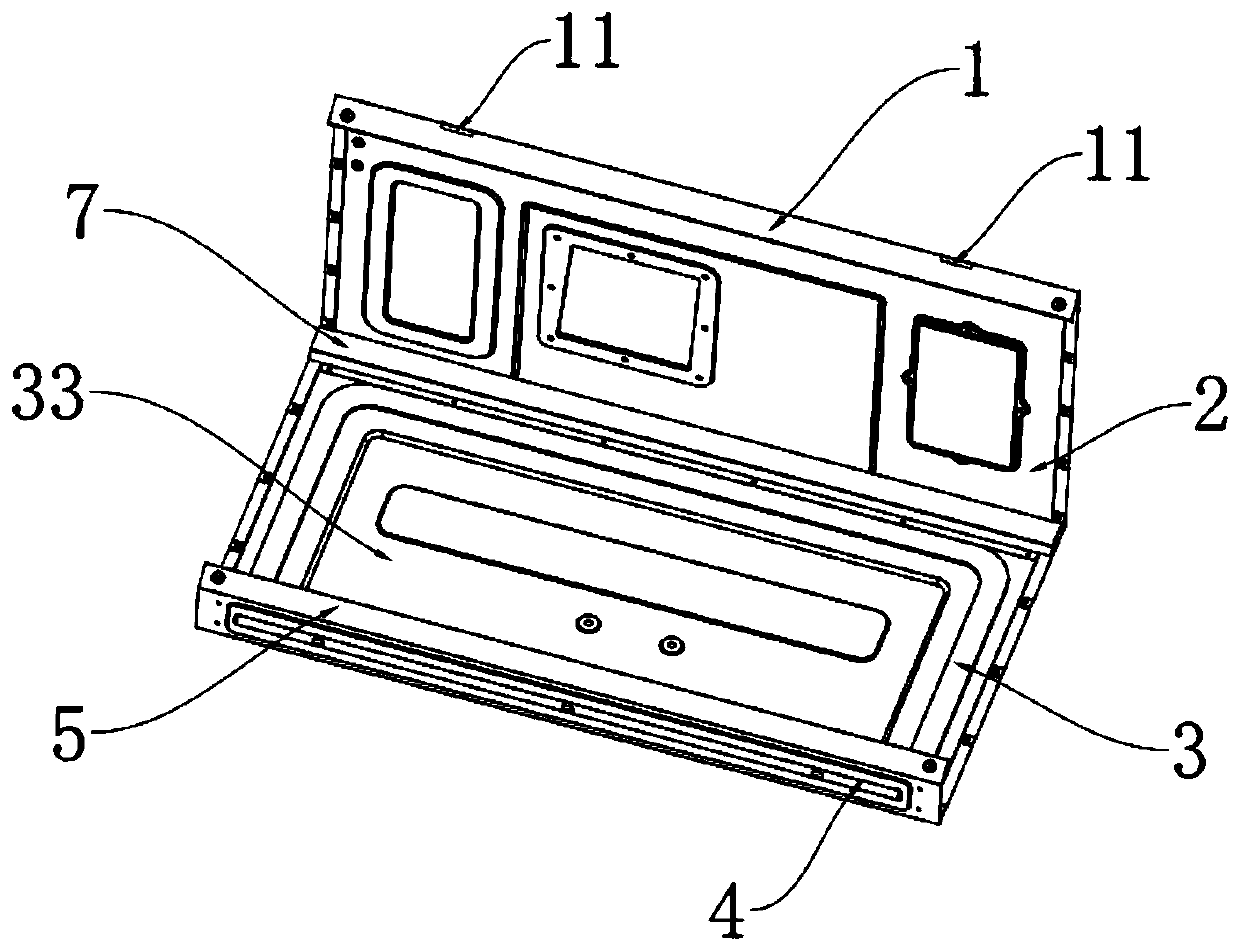

Auxiliary jig for polishing of side of light guide plate

ActiveCN106272063AEasy to operateImprove securityPolishing machinesGrinding work supportsLight guideEngineering

The invention discloses an auxiliary jig for polishing of side of a light guide plate. The jig comprises a rear clamping plate, a plurality of insertion plates are fixed to the two sides of the front end face of the rear clamping plate, the front ends of the insertion plates penetrate through a front clamping plate to be fixed to a positioning plate, and a plurality of fastening bolts are connected with the positioning plate through threads; the two side edges of the rear clamping plates are fixedly provided with vertical racks, the rack on one side of the rear clamping plate is meshed with a driving gear and a driven gear, the rack on the other side of the rear clamping plate is meshed with a driven gear, the driven gears and the driving gear are fixed to hinge shafts in an inserted and sleeved mode, the two ends of each hinge shaft are hinged to side plates respectively, the upper ends of the side plates are fixed to connection blocks, the lower ends of the side plates are fixed to connection bases, and the bottom ends of the connection bases are fixedly connected with magnet suction cups; one end of the portion, on the driving gear, of the corresponding hinge shaft is fixedly connected with a rocker. The jig is simple in structure, assists a manual polishing light guide plate in use, brings convenience to manual polishing, and can effectively improve polishing safety.

Owner:东莞新涛有机玻璃有限公司

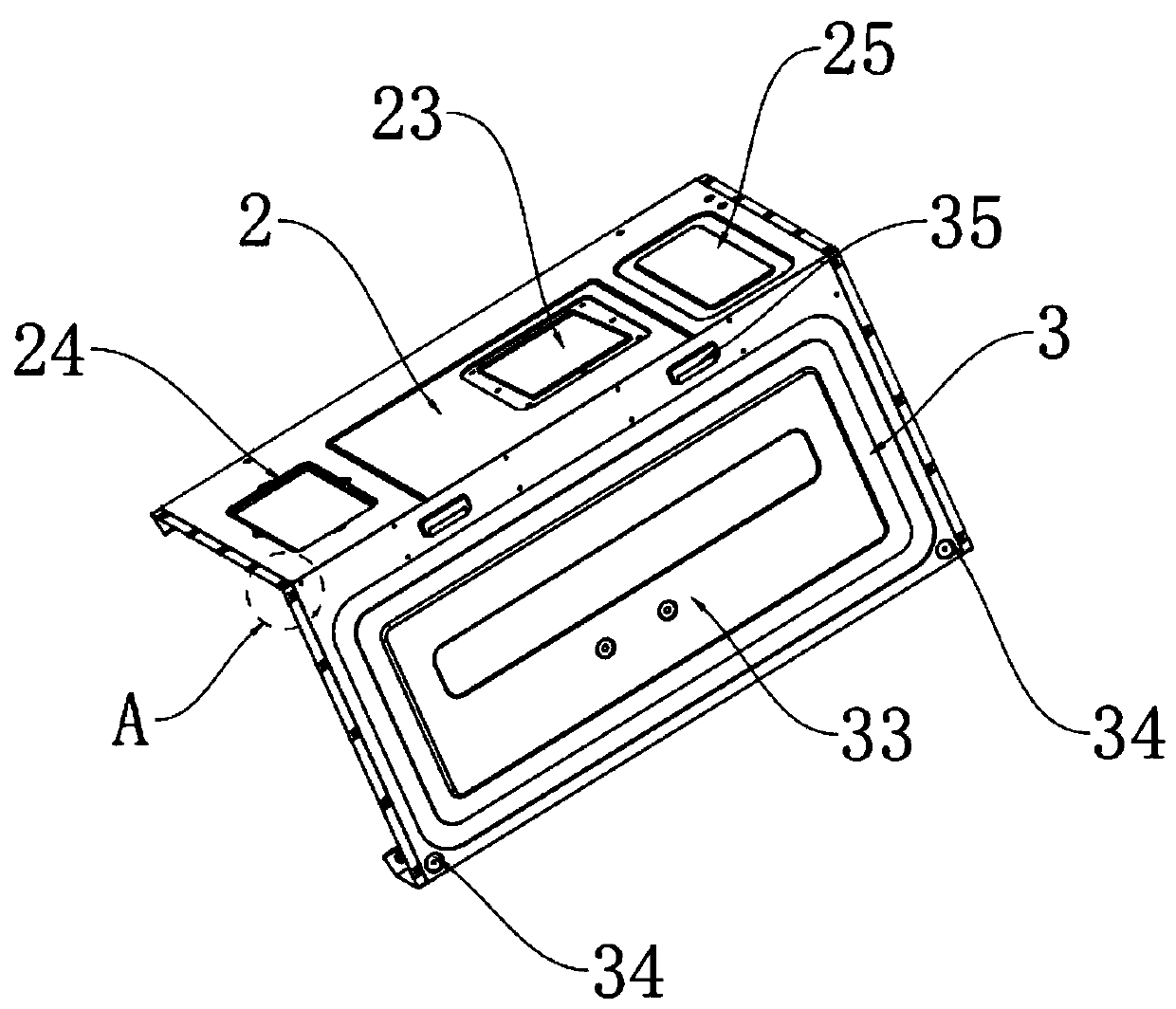

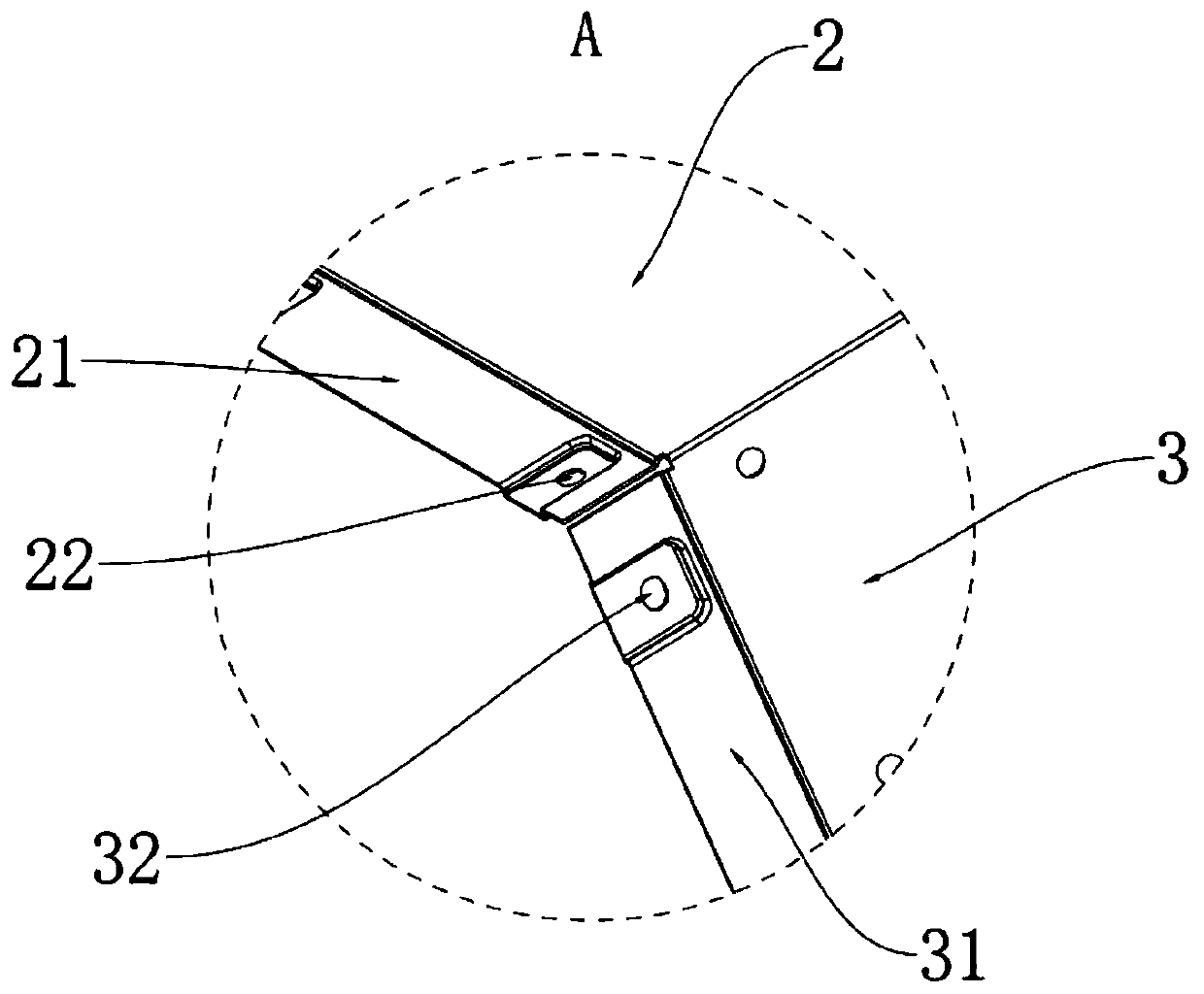

Top plate and back plate integrated structure and side draught range hood

PendingCN110081490ASimple processEasy to processDomestic stoves or rangesLighting and heating apparatusManufactured materialAgricultural engineering

The invention provides a top plate and back plate integrated structure and a side draught range hood. The top plate and back plate integrated structure comprises a top folding edge, a top plate, a back plate, a bottom plate and an oil baffle plate which are integrally formed in sequence, the front end of the top plate is connected with the top folding edge, the rear end of the top plate is connected with the upper end of the back plate, the rear end of the bottom plate is connected with the lower end of the back plate, the front end of the bottom plate is connected with the lower end of the oil baffle plate, and the side draught range hood comprises the top plate and back plate integrated structure. According to the top plate and back plate integrated structure, the top folding edge, the top plate, the back plate, the bottom plate and the oil baffle plate are arranged to be a structure which is integrally formed, so that structures for assembling and connecting the top folding edge, the top plate, the back plate, the bottom plate and the oil baffle plate are omitted, then integrally manufactured materials are saved, and the overall attractiveness is also improved; and the integralforming process is simple, the processing is convenient, and screw driving or welding does not need to be carried out among the top folding edge, the top plate, the back plate, the bottom plate and the oil baffle plate during subsequent assembling, so that the assembly efficiency is improved.

Owner:宁波奥克斯厨电制造有限公司 +1

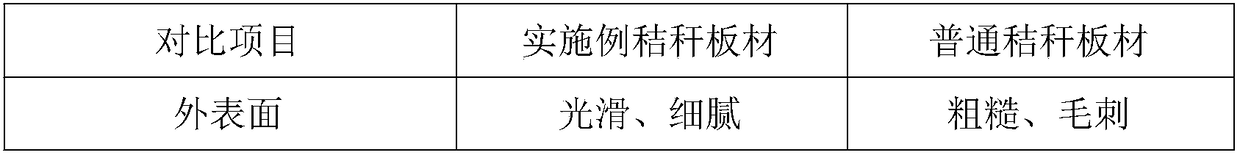

Mildewproof, mothproof and bacteriostatic straw plate and preparation method thereof

InactiveCN109291204AHigh densityHigh bonding strengthWood working apparatusDomestic articlesSurface layerUltimate tensile strength

The invention discloses a preparation method of a mildewproof, mothproof and bacteriostatic straw plate. The preparation method comprises the following steps: smashing crop straws into particles, soaking the particles in sodium hydroxide solution and sulfuric acid solution to obtain straw fibers, mixing the straw fibers with rosemary powder, bamboo charcoal fiber, expanded vermiculite and kieselguhr separately to obtain a surface layer mixture, mixing the straw fibers with coconut carbon fiber and green bean starch to obtain a core layer mixture, paving the surface layer mixture into a die according to the odd number layer principle, paving the core layer mixture into the die according to the even number principle, and carrying out drying, thermo-compression formation, cooling, demoulding,maintaining, edge cutting and packaging to obtain a finished product. The mildewproof, mothproof and bacteriostatic straw plate is non-toxic, tasteless, formaldehyde-free, and environmental-friendly,has higher strength, is high in fireproof performance and humidity resistance, is light in weight, facilitates transportation and construction installation and can enhance memory and refresh throughrosemary. Various performance of the mildewproof, mothproof and bacteriostatic straw plate meets corresponding requirements. Furniture made of the mildewproof, mothproof and bacteriostatic straw platecan effectively prevent mildew, acarid, resist bacteria and can automatically adjust the indoor humidity.

Owner:安徽科纳家居饰材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com