Patents

Literature

82results about How to "Improve product quality level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ageing sweet-white wine and brewing process of ageing sweet-white wine

ActiveCN103911242ABroaden sources of raw materialsEnrich market product typesMicroorganism based processesWine preparationSweet white wineBottle

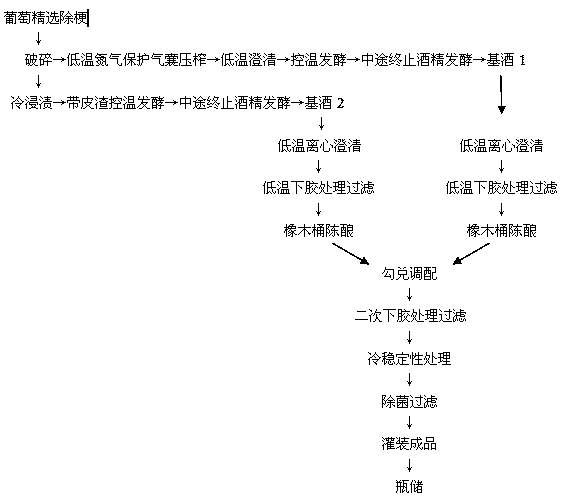

The invention relates to an ageing sweet-white wine and a brewing process of the ageing sweet-white wine, belonging to the technical field of brewing of wines. The physicochemical indexes of the ageing sweet-white wine disclosed by the invention are as follows: the content of reducing sugar is 80-90 g / L; the total acidity is 7.0-8.5 g / L; the alcoholic strength is 10.0-12.0%vol; the content of free sulphur dioxide is 30-45 mg / L; the total content of sulphur dioxide is less than or equal to 250 mg / L; the content of volatile acid is less than or equal to 1.0 g / L. The brewing process of the ageing sweet-white wine disclosed by the invention comprises the following steps of: (1) finely selecting grapes and removing stems; (2) crushing; (3) technically dividing; (4) centrifuging and clarifying at low temperature; (5) fining at low temperature, and filtering; (6) ageing by using an oak barrel; (7) blending and mixing; (8) fining for the second time, and filtering; (9) coldly processing stability; (10) sterilizing and filtering; (11) filling finished goods; (12) storing in a bottle. The ageing sweet-white wine disclosed by the invention is full-bodied in fragrance, graceful, lasting and plump in mouth feel; the brewing process of the ageing sweet-white wine disclosed by the invention is simple, scientific and convenient to operate; the production cost can be effectively reduced; the scale production of high-end sweet-white wines is realized.

Owner:COFCO GREAT WALL WINE YANTAI

Production line device used for similar multistage assembly product code assigning and tracing

ActiveCN104494985AVersatilityLow costPackaging automatic controlSensing by electromagnetic radiationProduction lineAutomatic control

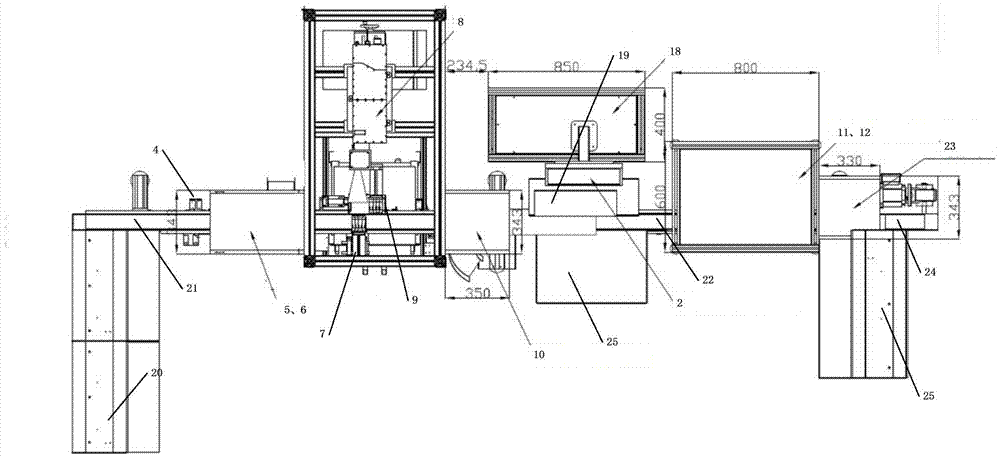

The invention is suitable for the technical field of automatic control, and provides a production line device used for similar multistage assembly product code assigning and tracing. A first bar code reader 5 is used for reading EAN-13 codes of single stage products after separation, a first rejection device 6 is used for rejecting the single stage products with the reading EAN-13 codes, not involved in current work order information, a first obstruction cylinder 7 is used for obstructing the single stage products under a laser coding machine 8, the laser coding machine 8 is used for printing two-dimensional codes on the upward sides of the single stage products, a first pushing cylinder 9 is used for pushing the obstructed single stage products periodically, an interval separation device 10 is used for separating the single stage products moving again at equal intervals according to a setup parameter, a two-dimensional code collector 11 is used for reading the two-dimensional codes of the single stage products, and a second rejection device 12 is used for rejecting the single stage products with the two-dimensional codes which cannot be read successfully. Through operations of an IPC and a PLC device, the parameter setting is finished, so that the production line device can produce special-type or special-stage finished products as required, and has the universality, and the cost is reduced.

Owner:武汉华工赛百数据系统有限公司

Method for producing 4Cr5MoSiV1 mold steel by continuous casting electroslag

The invention belongs to the technical field of steel production methods, and particularly provides a method for producing 4Cr5MoSiV1 mold steel by continuous casting electroslag. The method comprises the following steps that an electric-arc furnace smelts molten steel, a ladle refining furnace refines the molten steel, a vacuum degassing furnace refines the molten steel, continuous casting 235mm x 265mm medium square billet is conducted, electroslag remelting is conducted, heating rolling is conducted, and annealing is conducted. The molten steel component is controlled by, in mass percentage, C: 0.37-0.43%, Mn: 0.30-0.50%, Si: 0.90-1.20%, P: <0.025%, S: 0.010%, Cr: 4.80-5.50%, Mo: 1.20-1.50%, V: 0.90-1.10%, Cu: <0.25%, Ni: <0.25%. The balance is iron and unavoidable impurities. The method for producing 4Cr5MoSiV1 mold steel by continuous casting electroslag uses technology of the continuous casting billet + electroslag remelting + rolling replacing forging to manufacture and produce 4Cr5MoSiV1 mold steel, the comprehensive mechanical properties of the 4Cr5MoSiV1 mold steel are ensured, the production rate of the 4Cr5MoSiV1 mold steel is improved, so that production costs are reduced and production efficiency is increased.

Owner:BENGANG STEEL PLATES

Method for preparing kung-fu black tea

The invention relates to a method for preparing kung-fu black tea. The method includes the nine steps of fresh leaf picking, withering, green making, rolling, temperature control fermenting, drying forming, staged fragrance enhancing, screening tidying and packaging. According to the finished kung-fu black tea prepared with the preparing method, appearance strips are compact and straight, the color and luster is black and oily, the soup color is bright red, tea fragrance is endurable, taste is mellow, internal fragrance is strong, tea soup is bright in color, and the color quality, the fragrance quality and the taste quality of the black tea are comprehensively improved. The quality grade of the product is high, and the increasing taste requirements of consumers can be met.

Owner:务川自治县鑫隆缘茶业有限责任公司

Automatic lamination tray filler for wet silica gel material

ActiveCN102616570AImprove product quality levelAvoid it happening againStacking articlesEngineeringSilica gel

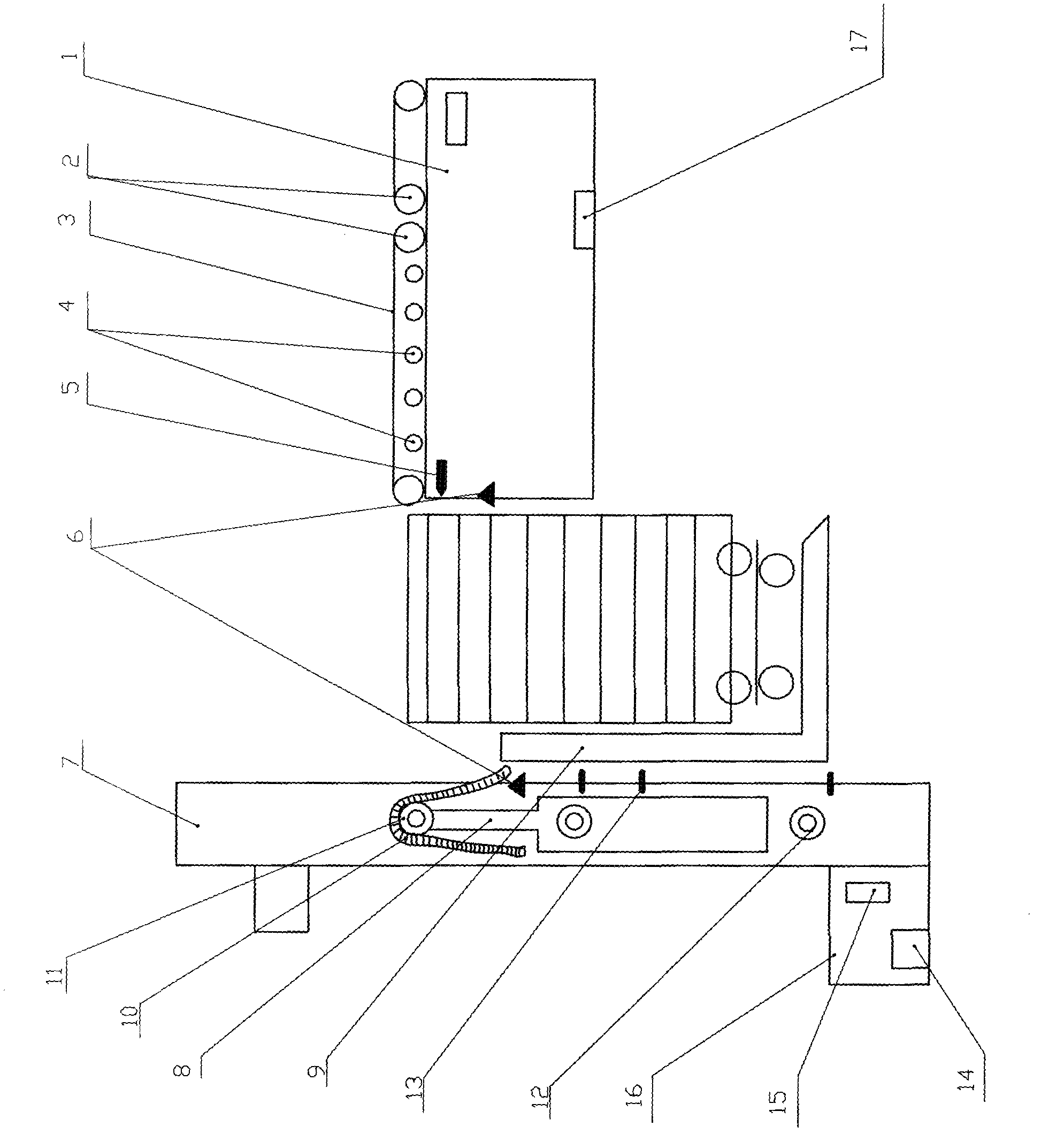

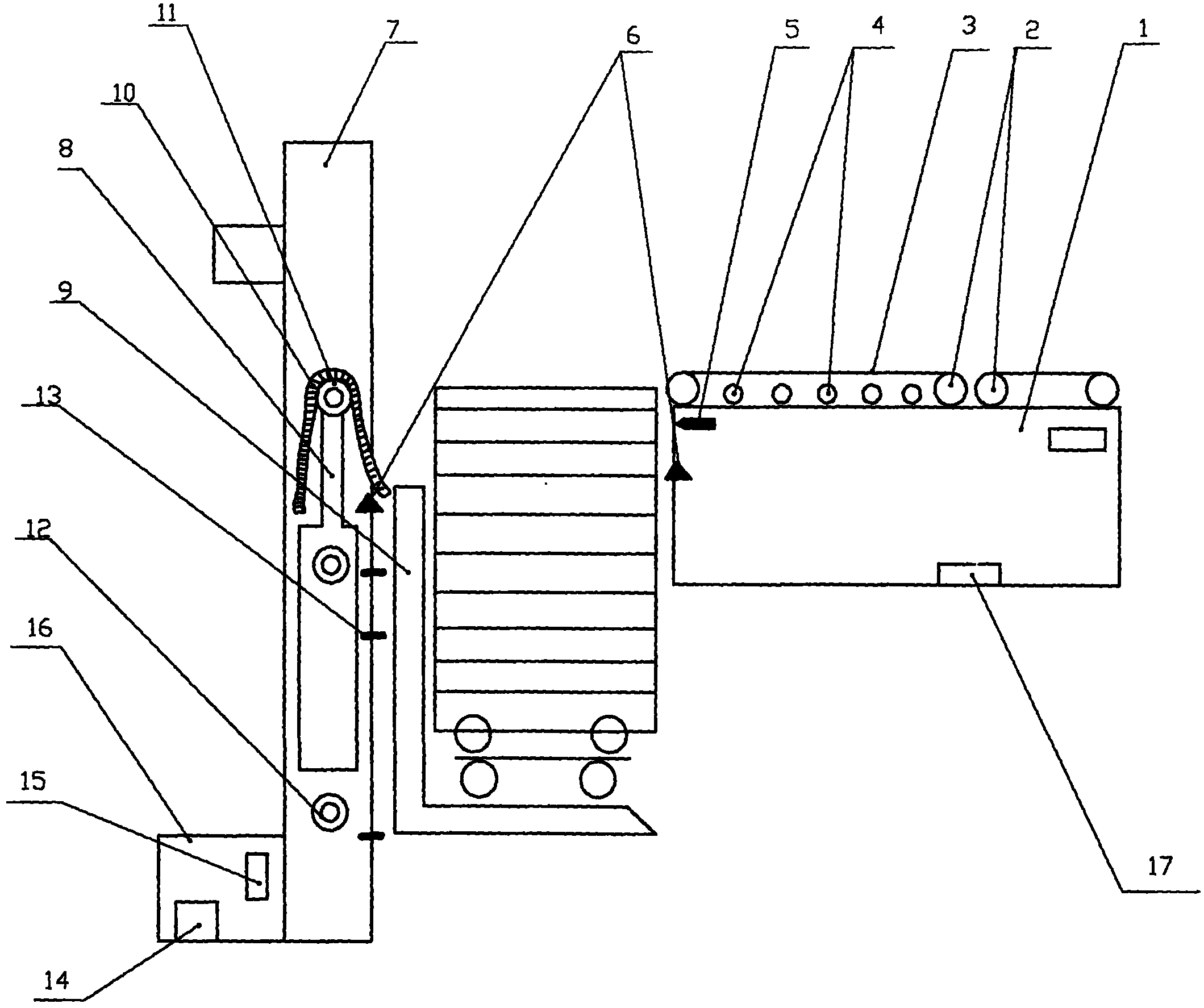

The invention disclose an automatic lamination tray filler for a wet silica gel material, which can relieve the labor loads of workers, prevent silica gel from falling to the ground, improves the quality grade of the silica gel and reduces production cost. The automatic lamination tray filler consists of a belt disc pushing machine system and a loading machine system, wherein the belt disc pushing machine system comprises a belt disc pushing frame and a belt roller; and the loading machine system consists of a loading machine vertical frame, a hydraulic lifting arm, an L-shaped bracket and a hydraulic system device which is arranged on the rear part of the loading machine vertical frame. The automatic lamination tray filler has the advantages that the wet silica gel material is automatically filled on a charging tray frame of a drying cart after a charging tray is pulled to advance through a belt disc pushing machine in the disc charging and drying production process, so that the silica gel can be prevented from falling to the ground, and the quality grade of a silica gel product can be improved. The automatic lamination tray filler is high in loading speed and efficiency, the labor intensity of the workers is reduced, and the production cost is reduced.

Owner:山东辛化硅胶有限公司

Cigarette supplementary lean combined assembling method

ActiveCN101147623AAchieve leanMeet actual needsCigarette manufactureMaterial analysisSystems researchCombinatorial optimization

The present invention relates to an optimized combination method of cigarette auxiliary materials (including cigarette paper, forming paper, joint-wrapping paper and filter rod). Said method includes the following concrete contents: selecting and using orthogonal design to make experiment design, defining test index, defining test factor, selecting and defining horizontal range, making test scheme, test result treatment-range analysis and variance analysis, auxiliary materials combination regulation and optimization.

Owner:YUNNAN RES INST OF TOBACCO SCI

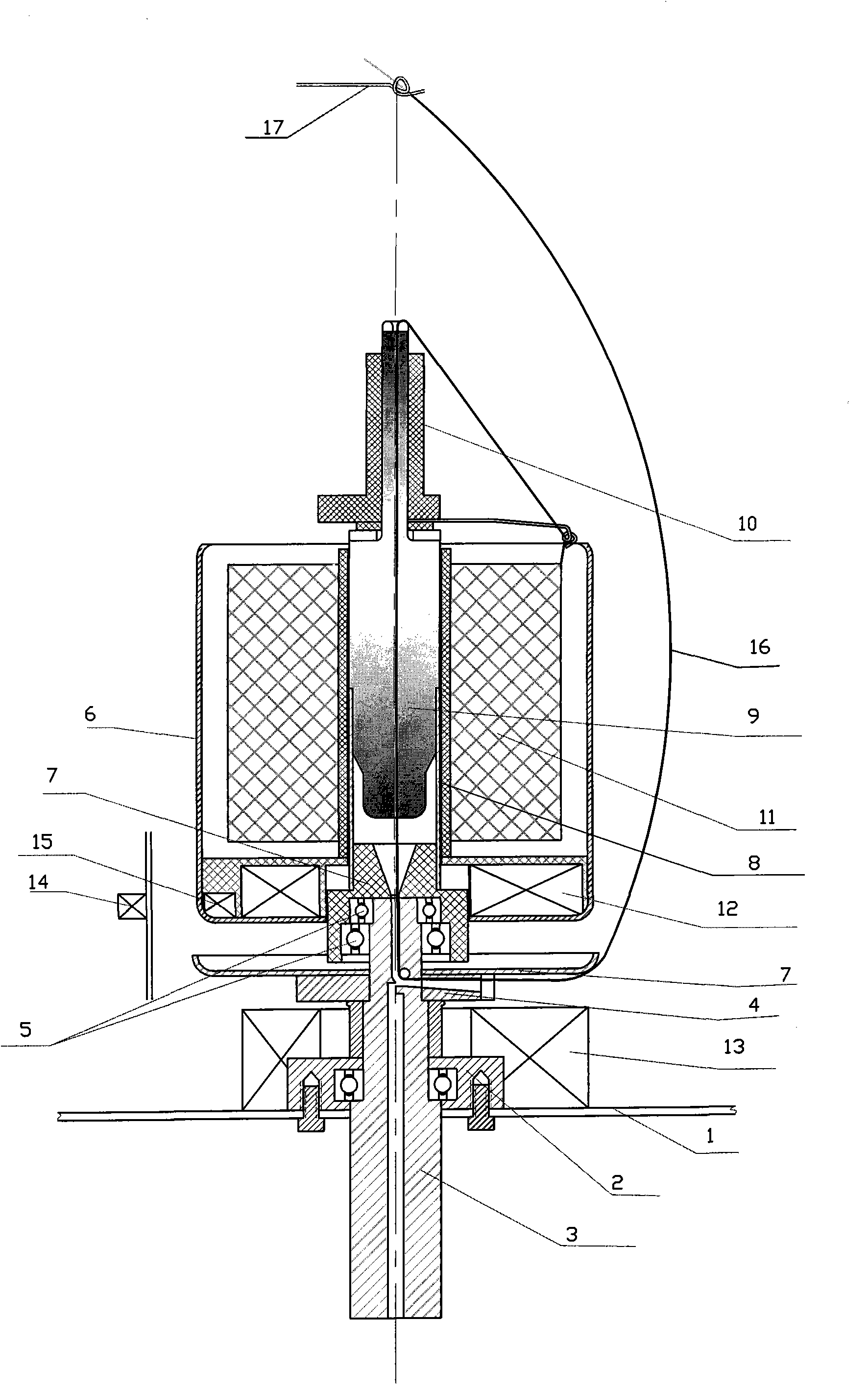

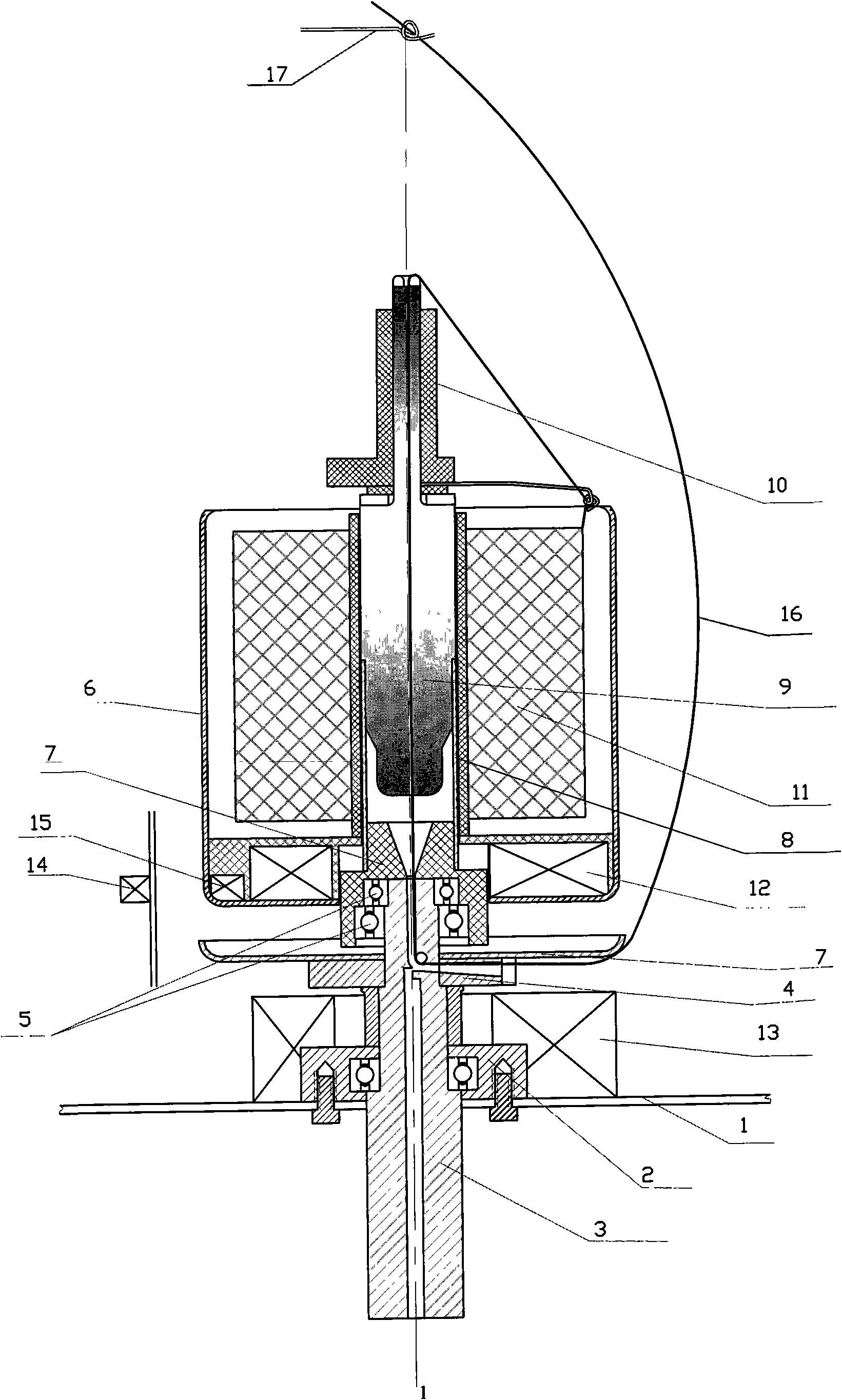

Energy-saving spindle for magnetic suspension two-for-one twister

InactiveCN101831734ADragon belt tension reducedReduce energy consumptionContinuous wound-up machinesRepulsion forceYarn tension

The invention provides an energy-saving spindle for a magnetic suspension two-for-one twister, which not only can be applied to the production of a new-made two-for-one twister, but also can be used for reforming the traditional two-for-one twister. The energy-saving spindle comprises a bottom plate, a bearing pedestal, a spindle blade, a yarn storage disc, a duplex bearing, a sleeve pipe, a hollow pipe, a circular tank shell, a yarn tension device, a flyer, a yarn supply creel and annular permanent magnets. The same poles of the annular permanent magnet installed under the circular tank shell and the annular permanent magnet attracted on the bottom plate (or the bearing pedestal) are opposite each other, so that the circular tank shell and the yarn supply creel float upward by using the polar repulsion principle of magnets; along with the enlargement of the floating distance, the repulsion force is relatively weakened; and when the repulsion force is equal to the total weight of the circular tank shell and the yarn supply creel, the circular tank shell suspends immovably; at the same time, the weight of the circular tank shell and the yarn supply creel presses against the bottom plate, the load on the spindle blade is greatly reduced, thereby achieving the purpose of energy saving and relatively improving the yield and the quality of the product.

Owner:王建伟

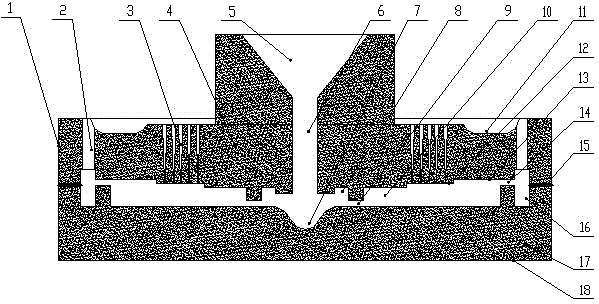

Grinding disc casting, grinding disc casting mold and grinding disc molding process

InactiveCN105057587AImprove product quality levelLow costFoundry mouldsFoundry coresAfter treatmentQuality level

The invention discloses a grinding disc casting which is even in rigidity, good in stability and cutting performance, durable and high in quality and a grinding disc casting mold for manufacturing the grinding disc casting. The mold is reasonable in structural design and good in heat preservation and exhausting performance. The invention further aims to disclose a grinding disc molding process. The product quality level can be greatly improved, after-treatment cost can be reduced, and after-treatment time can be shortened. A grinding disc manufactured through the molding process is good in product quality and high in percent of pass.

Owner:谌征

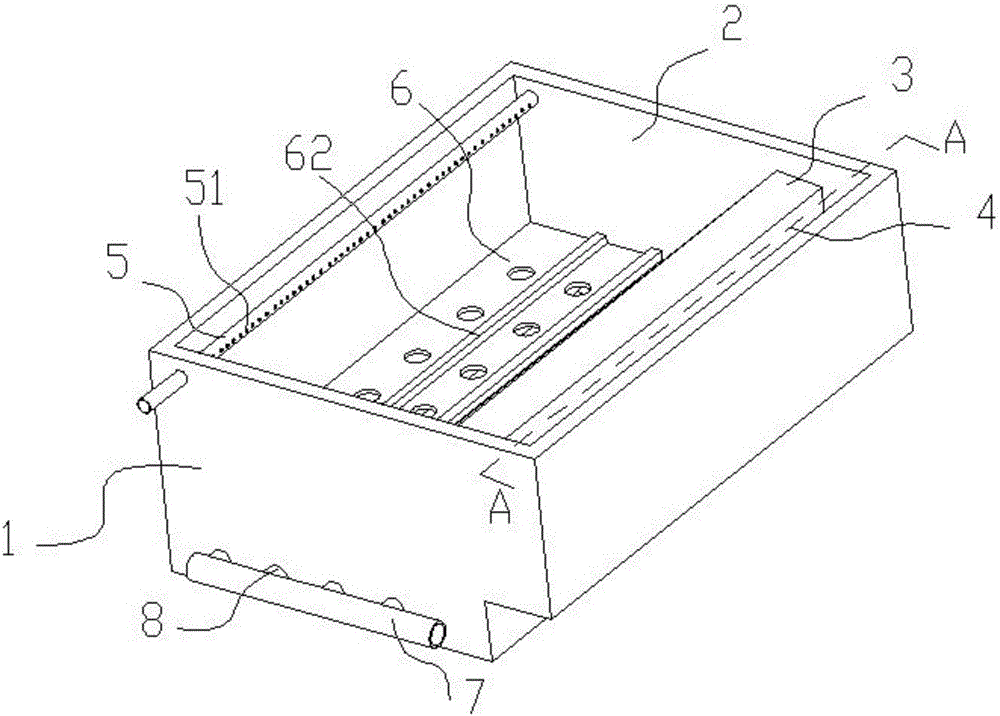

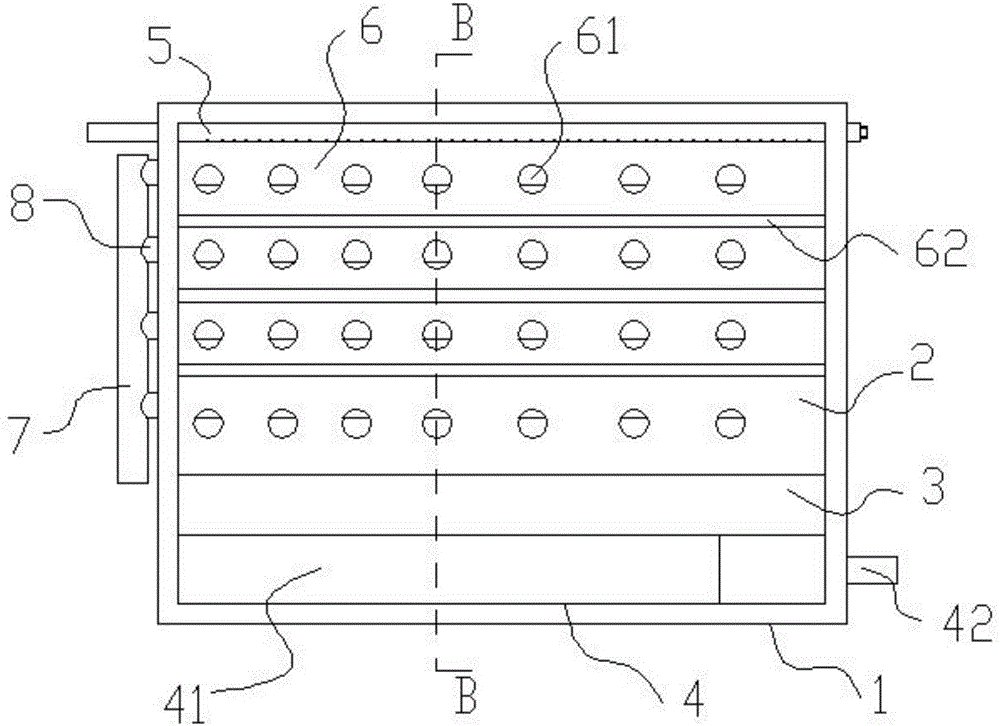

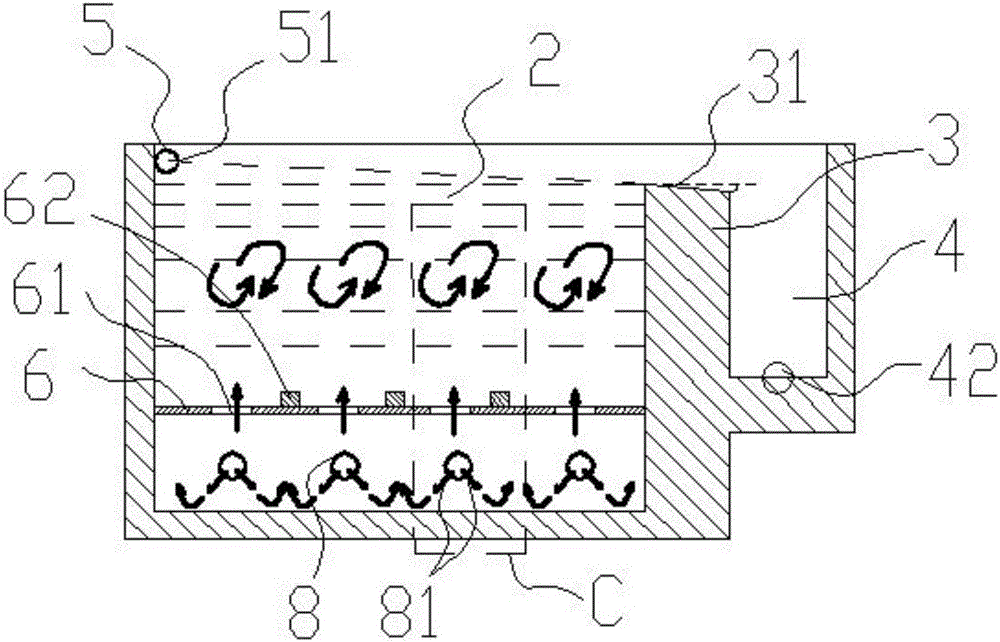

Mica sheet screening and washing device for mica paper production process

ActiveCN106269689AImprove product quality levelImprove protectionSievingScreeningPipe waterPaper production

The invention discloses a mica sheet screening and washing device for a mica paper production process. The mica sheet screening and washing device comprises a screening pond, wherein the screening pond is divided into a washing area and an overflow groove by an overflow baffle; a screening plate and a bottom layer pipe are arranged at a lower end of the washing area; bottom-layer pipe water spraying holes are formed in a side wall of the bottom layer pipe; the bottom layer pipe is connected to tap water through a main water pipe arranged outside the screening pond; a flushing pipe is arranged at one side, which is opposite to the overflow baffle, at the upper end of the washing area; flushing pipe water spraying holes are formed in the side wall of the flushing pipe; the flushing pipe is connected to the tap water after passing through an outer wall of the screening pond. The mica sheet screening and washing device for the mica paper production process, provided by the invention, can be used for washing and filtering dirt and impurities in the mica sheet in a turbulent floatation manner. With the adoption of the mica sheet screening and washing device, the damage on the sheet size of the mica sheet in the mica paper production process is almost zero, so that the mica sheet is convenient to wash and protect. The mica sheet screening and washing device is beneficial to improving the grade of the product quality of mica paper.

Owner:PINGJIANG VPI MICA INSULATING MATERIALS CO LTD

Aseptic production method of hyaluronic acid products

ActiveCN107149688AAvoid degradationImprove product quality levelOrganic active ingredientsAntipyreticCobalt-60Quality level

The invention discloses an aseptic production method of hyaluronic acid products, characterized in that 0.01-0.5% by weight of a preservative is added to a hyaluronic acid product before irradiating under irradiation dosage of 6-10 kGy. By controlling production raw and auxiliary materials, water, environment and packaging materials, adding suitable preservative to the product and performing irradiating with low dosage of cobalt 60, the asepsis standard is met; degradation of high-molecular-weight hyaluronic acid can be prevented, the molecular weight of the hyaluronic can be maintained in a reasonable ratio range, and product quality level is increased.

Owner:NANJING HUAKAI BIOLOGICAL TECH CO LTD

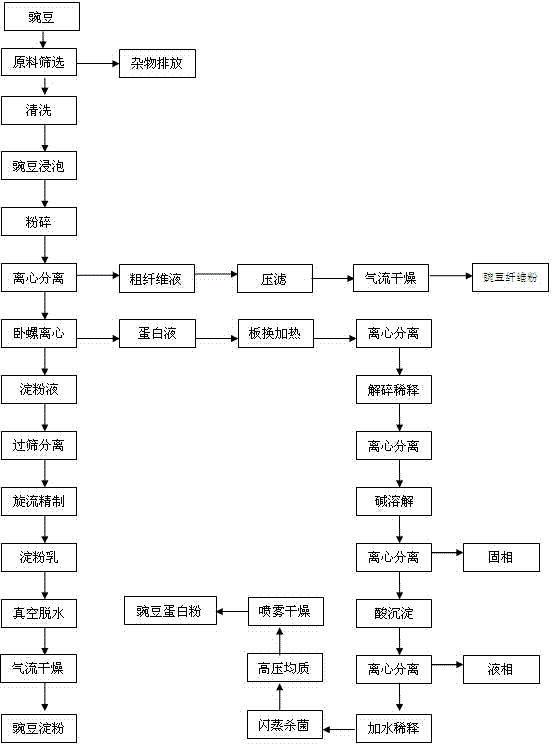

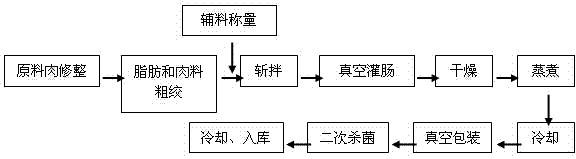

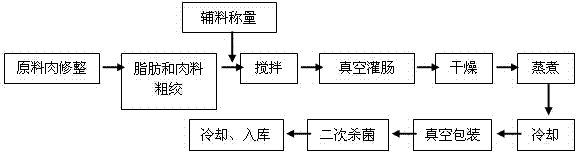

Pea fiber powder as well as application in meat products and production method thereof

InactiveCN104256402ARegulate gut floraRemoval of harmful substancesFood preparationNutritionBoiled ham

The invention discloses a pea fiber powder as well as application in meat products and a production method thereof. The pea fiber powder comprises the following components by weight percent: 70-80 percent of edible fiber, 8-12 percent of pea protein, 8-12 percent of pea starch, 2-10 percent of water and 2-8 percent of ash. The pea fiber powder is added in meat products. A production method of the meat products comprises a method of producing emulsifying smoked and cooked sausages, a method of producing coarse grinding smoked and cooked sausages, a method of producing smoked and cooked hams and a method of producing high-temperature hams, wherein the pea fiber powder is included in all of the methods. The pea fiber powder disclosed in the invention is rich in insoluble dietary fiber, and functions of reducing the product cost, improving the grade of product quality, balancing dietary nutrients and the like are achieved.

Owner:YANTAI SHUANGTA FOOD

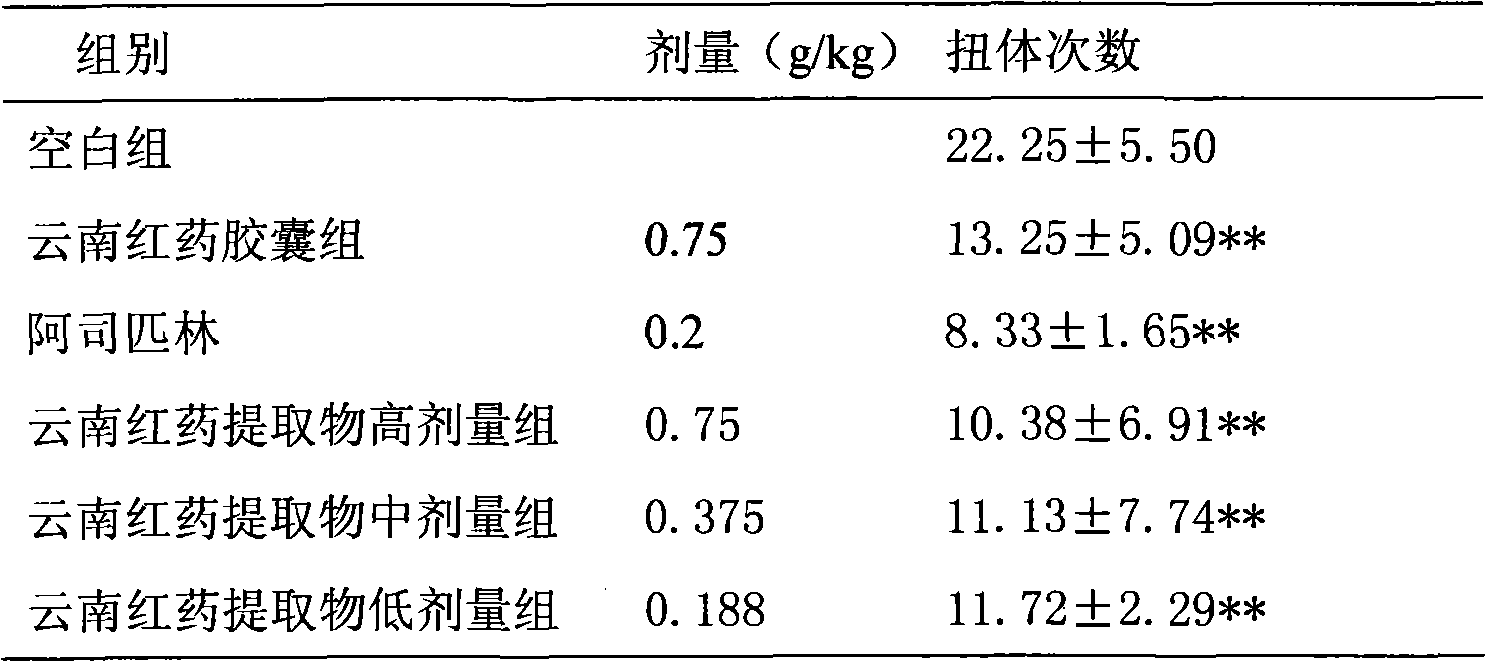

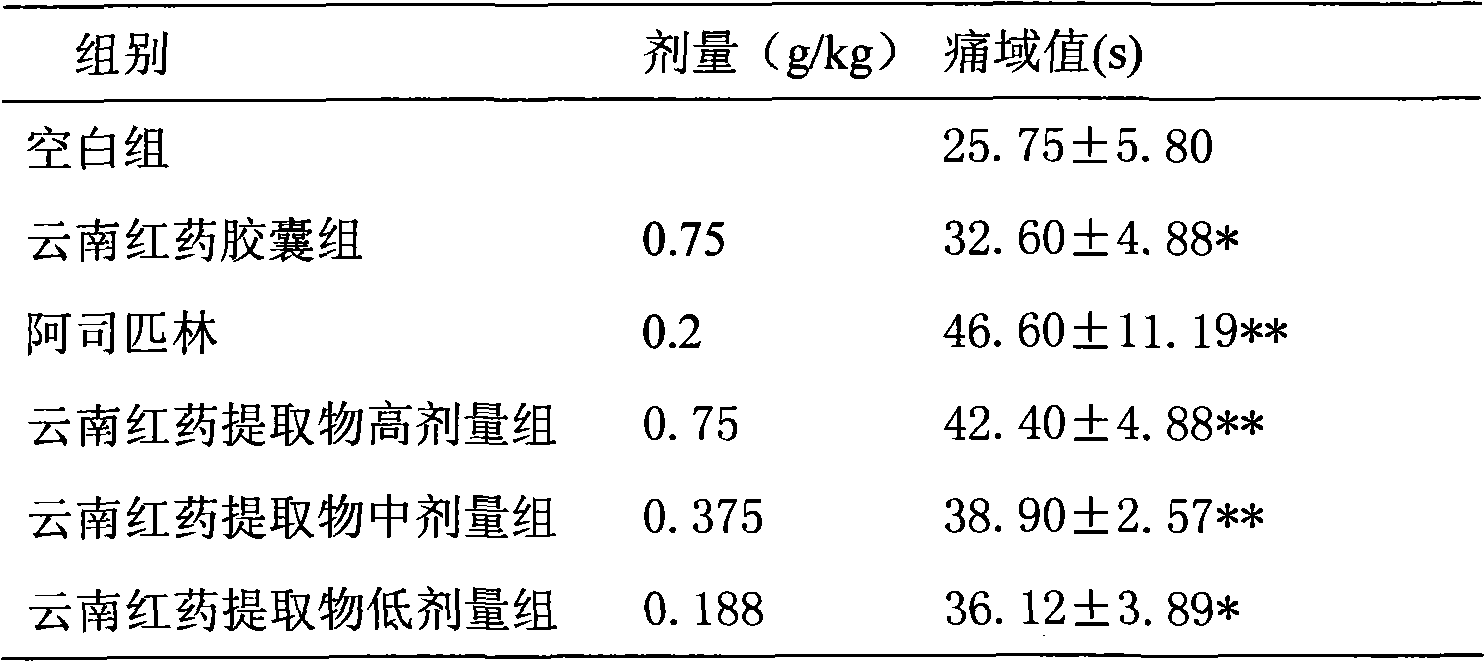

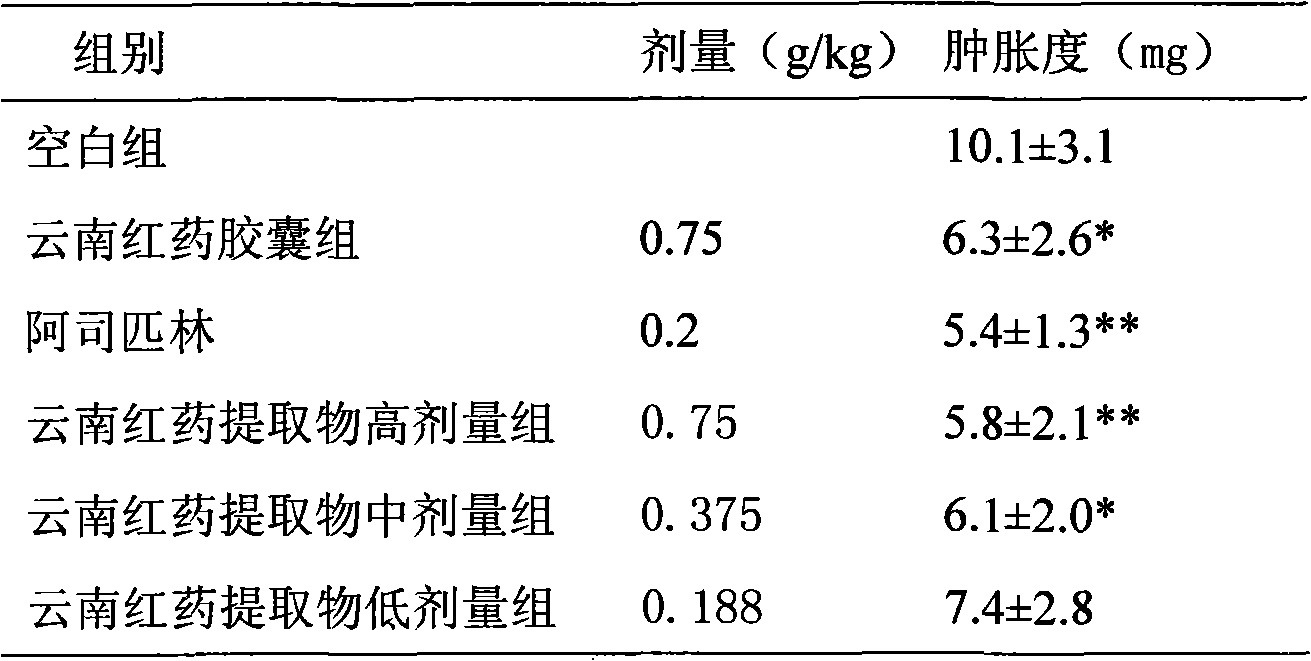

Yunnan hongyao extract and extracting method thereof and application

ActiveCN101279017AFully exert the medicinal effectReduce the number of dosesAntipyreticAnalgesicsBruisePsammosilene

The invention relates to an extract of Yunnan Health Potion (Yuannan Hongyao) and an extracting method and applications thereof. The Yunnan Hongyao comprises raw material components with the following mixing ratio by weight: 50 to 150 parts of root of pseudo-ginseng, 100 to 300 parts of chinese paris rhizome, 20 to 100 parts of dactylicapnos root, 50 to 150 parts of delavay ampelopsis root, 50 to 150 parts of bruiseweed, 60 to 100 parts of hemp, 20 to 100 parts of radix psammosilenes, 10 to 60 parts of acorus gramineus, 50 to 150 parts of scutellaria amonena wight, and 80 to 200 parts of kusnezoff monkshood root, the components are extracted by a certain method to obtain the extract of Yunnan Hongyao which has the functions of hemostasis and analgesis, activating blood and dissolving blood stasis, expelling wind and removing dampness. And the extract of the invention can be used for curing gastric ulcer hemorrhage, bronchiectasis hemoptysis, functional uterine hemorrhage, menorrhagia, fundus hemorrhage, conjunctival hemorrhage, epistaxis, hemorrhoids hemorrhage, soft tissue bruise, rheumatic arthritis, rheumatic pain in waist and lower extremities, etc. and can be made into various formulations.

Owner:YUNNAN PHYTOPHARML

Processing method for making Maofeng tea

InactiveCN105028741AHas a tea-flavored fragranceClear colorPre-extraction tea treatmentHair removalQuality level

The invention relates to a processing method for making Maofeng tea. The processing method for making the Maofeng tea comprises the nine steps of (1) leaf selection, (2) deterioration, (3) rocking, (4) fixation, (5) flattening, (6) hair removal, (7) stir frying, (8) screening and (9) package. Compared with the prior art, rocking and fixation are conducted on tea leaves to control process parameter conditions, so that the Maofeng tea prepared by means of the processing method has the advantages of being delicately fragrant in smell, clear and bright in color and luster, mellow, tasty and refreshing in taste and attractive in appearance, is high in product quality level and can meet the requirement for higher and higher taste of consumers. In addition, the Maofeng tea contains multiple nutrient ingredients and multiple mineral substances required by a human body and has the effects of helping digestion, defending against the cold, recovering from fatigue, strengthening the physique and the like after being drunk for a long period of time.

Owner:贵州省凤冈县永田露茶业有限公司

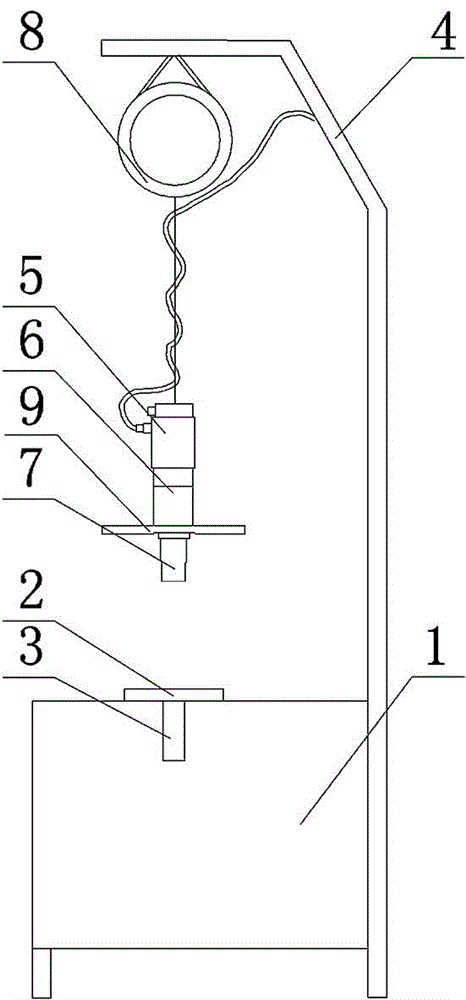

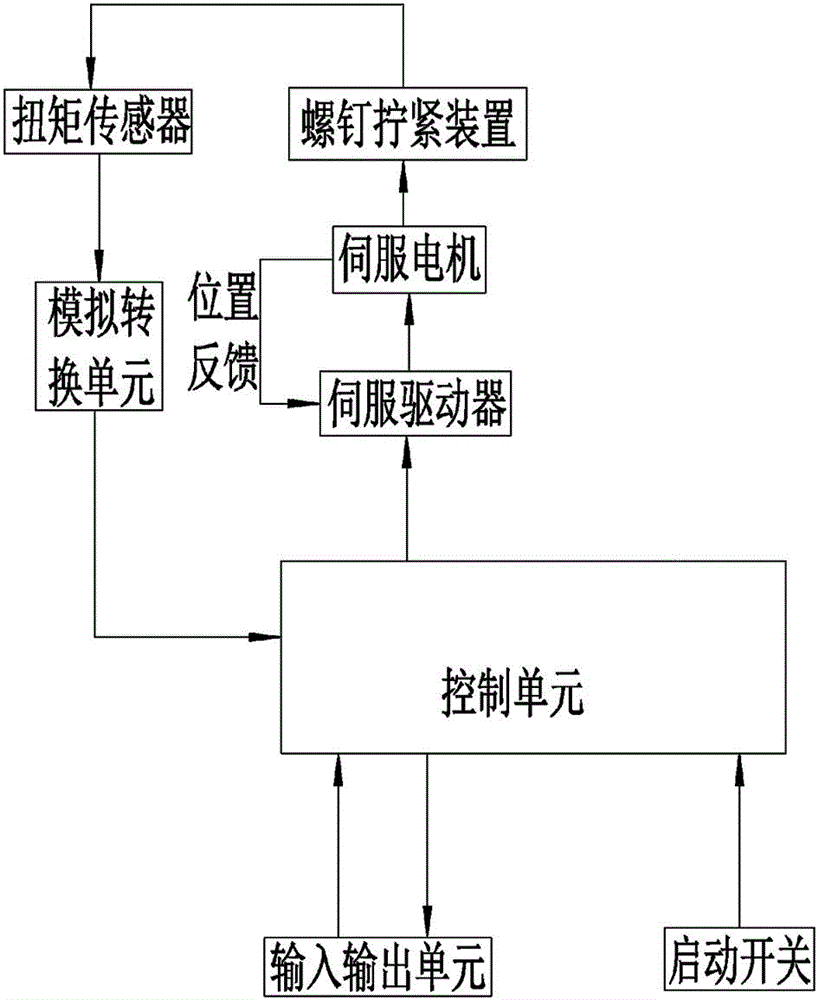

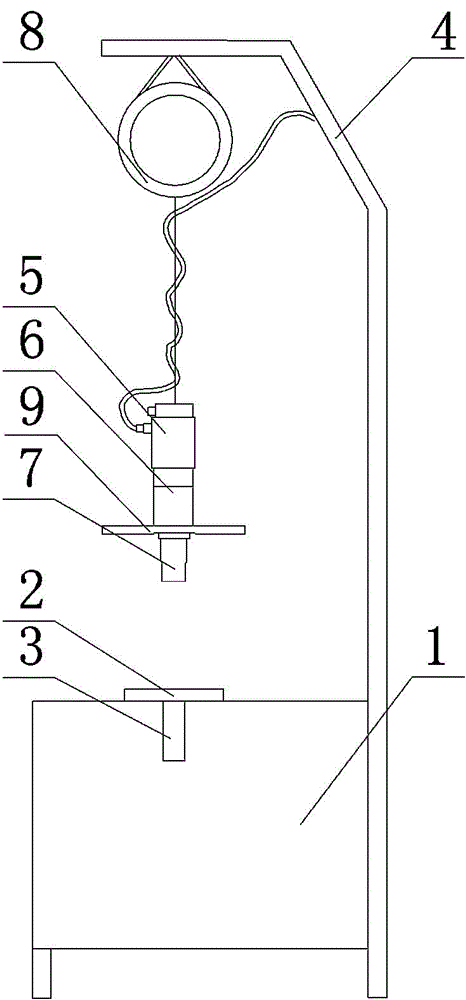

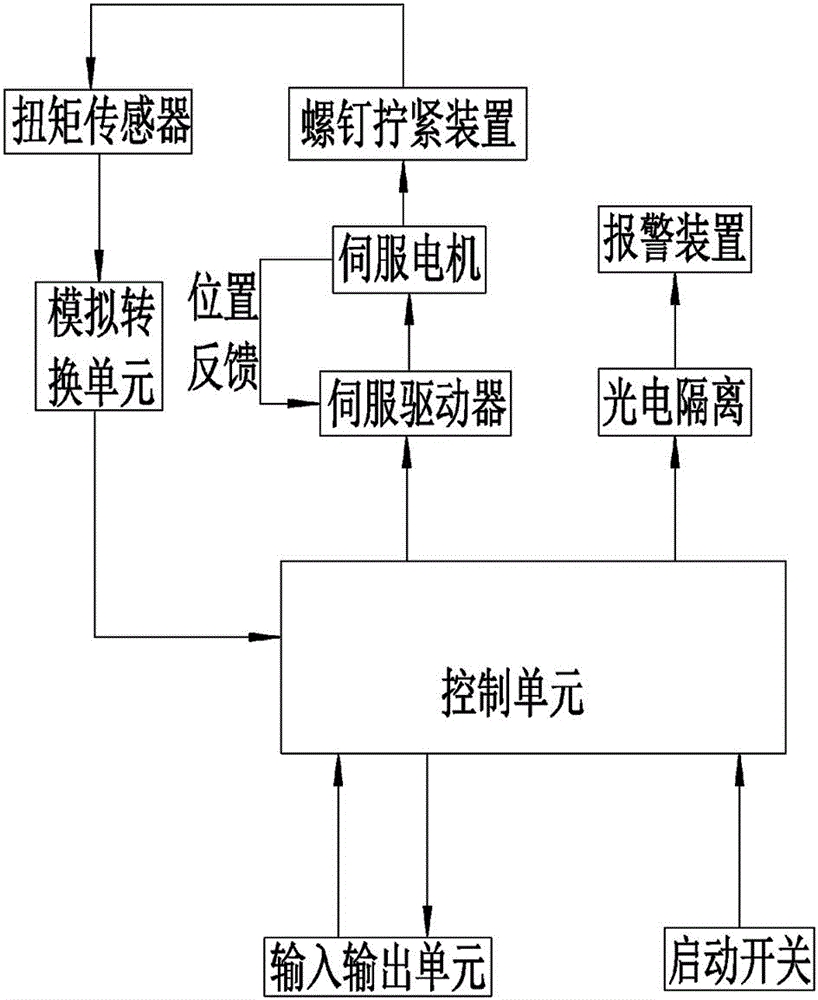

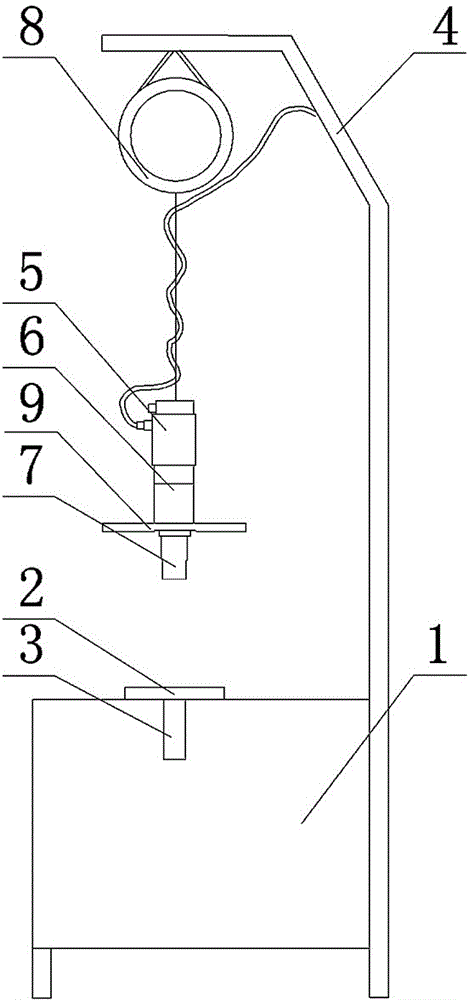

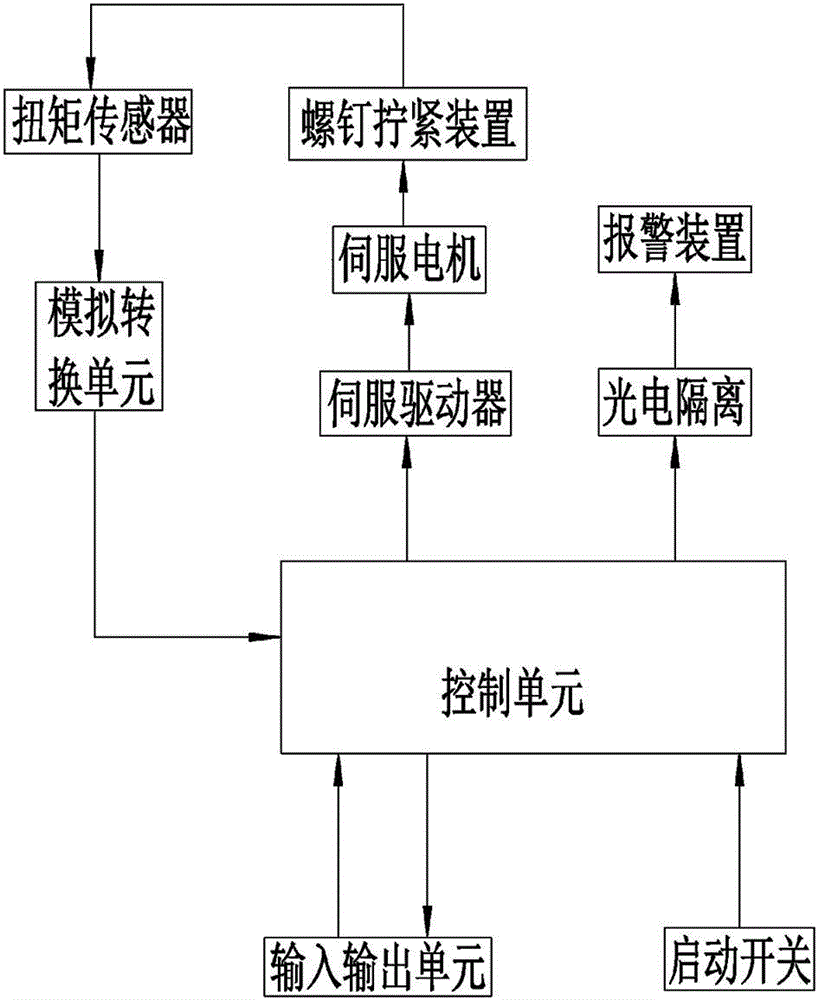

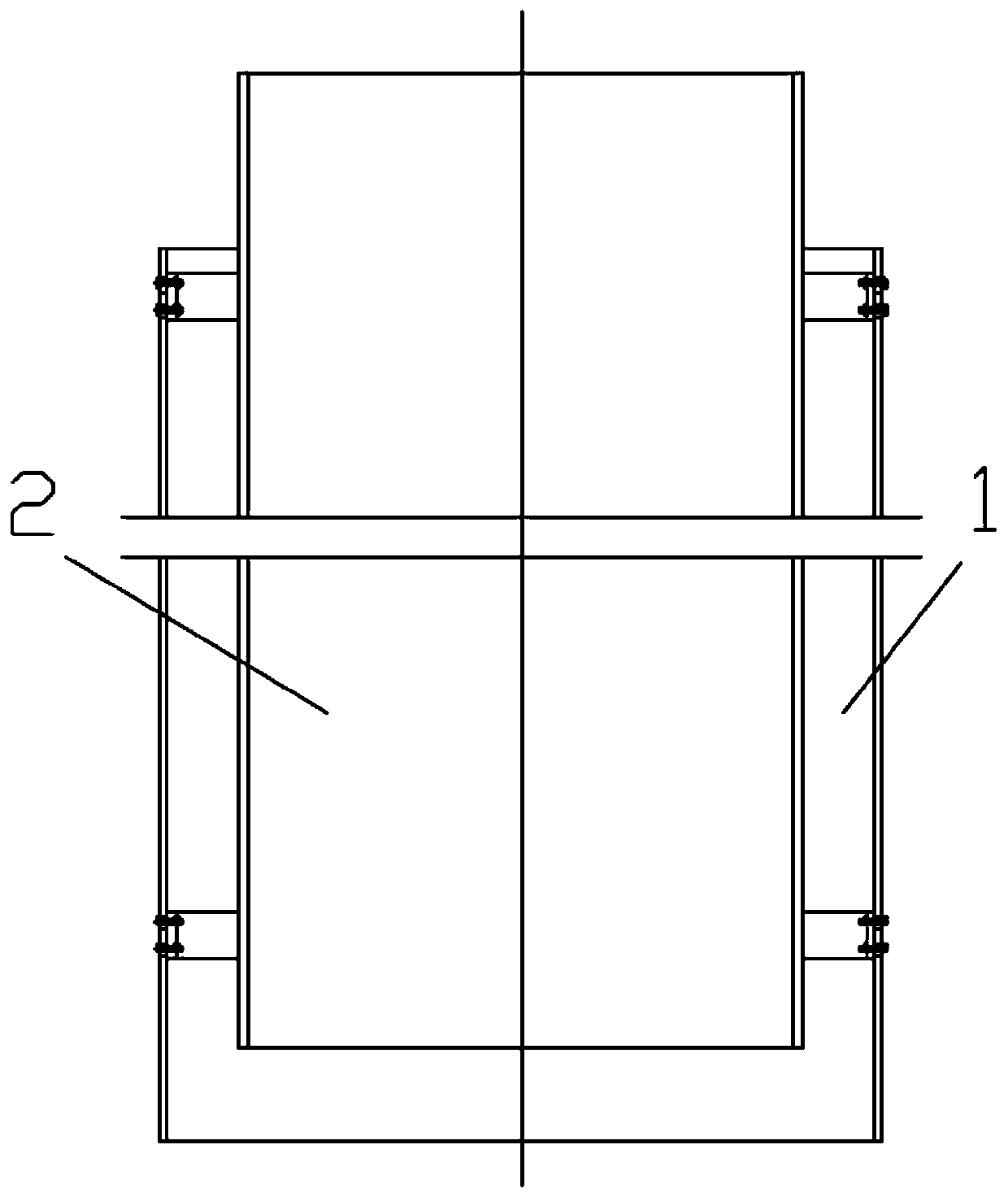

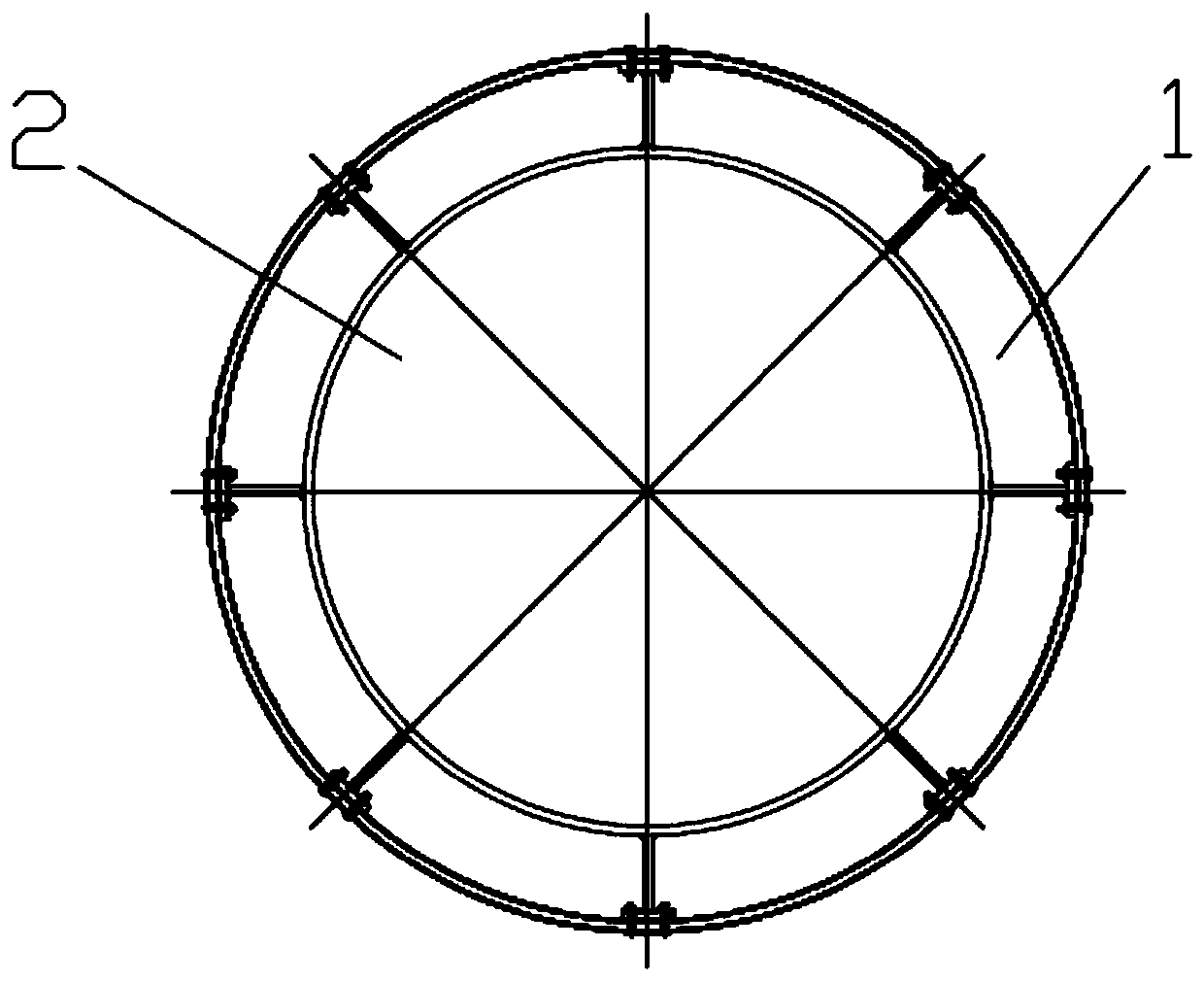

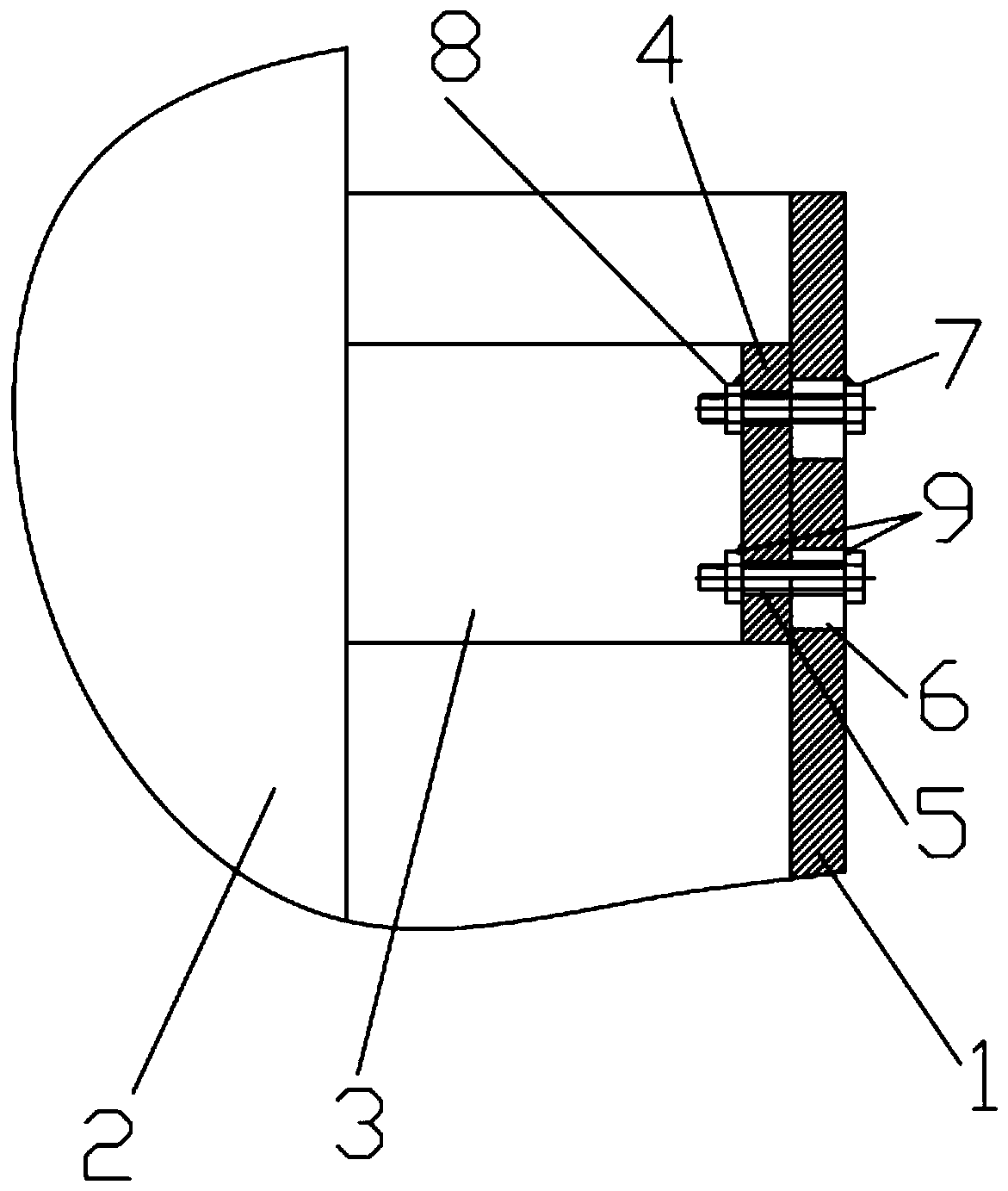

Automatic tightening device with position feedback function

InactiveCN104972294AReduce labor intensityHigh degree of automationMetal working apparatusReduction driveReducer

The invention discloses an automatic tightening device with a position feedback function. The automatic tightening device with the position feedback function comprises a workbench (1), a screw tightening device and a controller. The workbench (1) is provided with a product clamp (2) connected with a torque sensor (3). The screw tightening device comprises a servo motor (5), a speed reducer (6) and a screw sleeve (7). Handles (9) are installed on the two sides of the speed reducer (6). The controller comprises a display unit, a control unit, a digital conversion unit, a servo driver and a starting switch. The automatic tightening device with the position feedback function has the beneficial effects that the degree of automation is high, the labor intensity of workers can be relieved, and working efficiency is improved; accurate and quantitative control over the screw tightening torque is achieved, it can be avoided that screws are not tightened according to the stipulated force value in the manual operation process, and the product quality is improved; the automatic tightening device is suitable for automatically tightening various bolts, the torque can be set as needed, and bolts are installed firmly and reliably.

Owner:CHENGDU LIXIN SCI & TECH

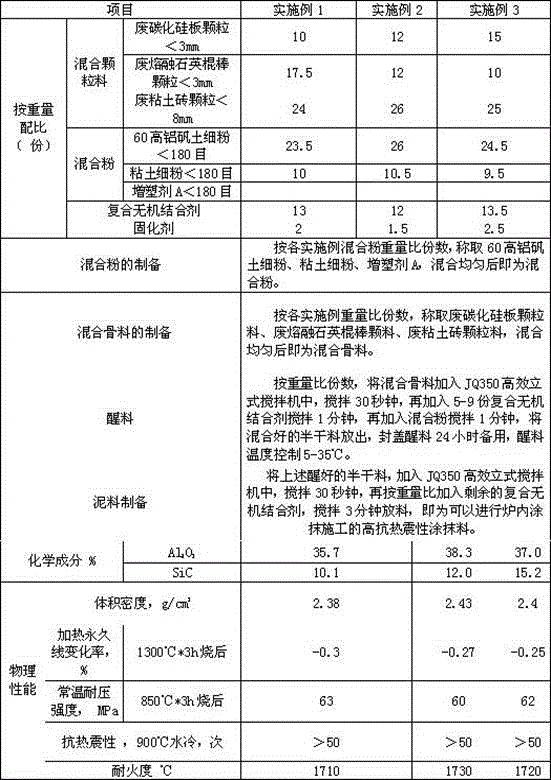

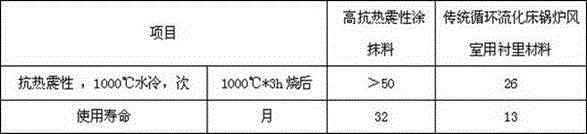

High-thermal-shock-resistance coating for wind chamber of circulating fluidized bed boiler (CFBB) and production process of coating

ActiveCN103951444AImprove thermal shock resistanceExtended service lifeManufacturing technologyThermal shock

The invention discloses a high-thermal-shock-resistance coating for a wind chamber of a circulating fluidized bed boiler (CFBB) and a production process of the coating, belonging to the field of monolithic refractories, and specifically relate to a high-thermal-shock-resistance coating for a wind chamber of a circulating fluidized bed boiler (CFBB) and a preparation method of the coating. The technical scheme for preparing the high-thermal-shock-resistance coating disclosed by the invention is implemented by taking waste silicon carbide plate particles, waste fused silica stick particles and waste clay brick particles as particle materials, taking 60 high-alumina bauxite fine-powder and clay fine-powder are taken as matrix materials, and introducing a composite inorganic binder and a curing agent through the steps of material selection, accurate weighing, material aging, mud material mixing, and the like. Compared with a traditional lining material for a wind chamber of a CFBB, the thermal shock resistance of the high-thermal-shock-resistance coating is significantly increased, and the service life is significantly prolonged.

Owner:SHANDONG YAOHUA REFRACTORY MATERIAL SCI & TECH CO LTD

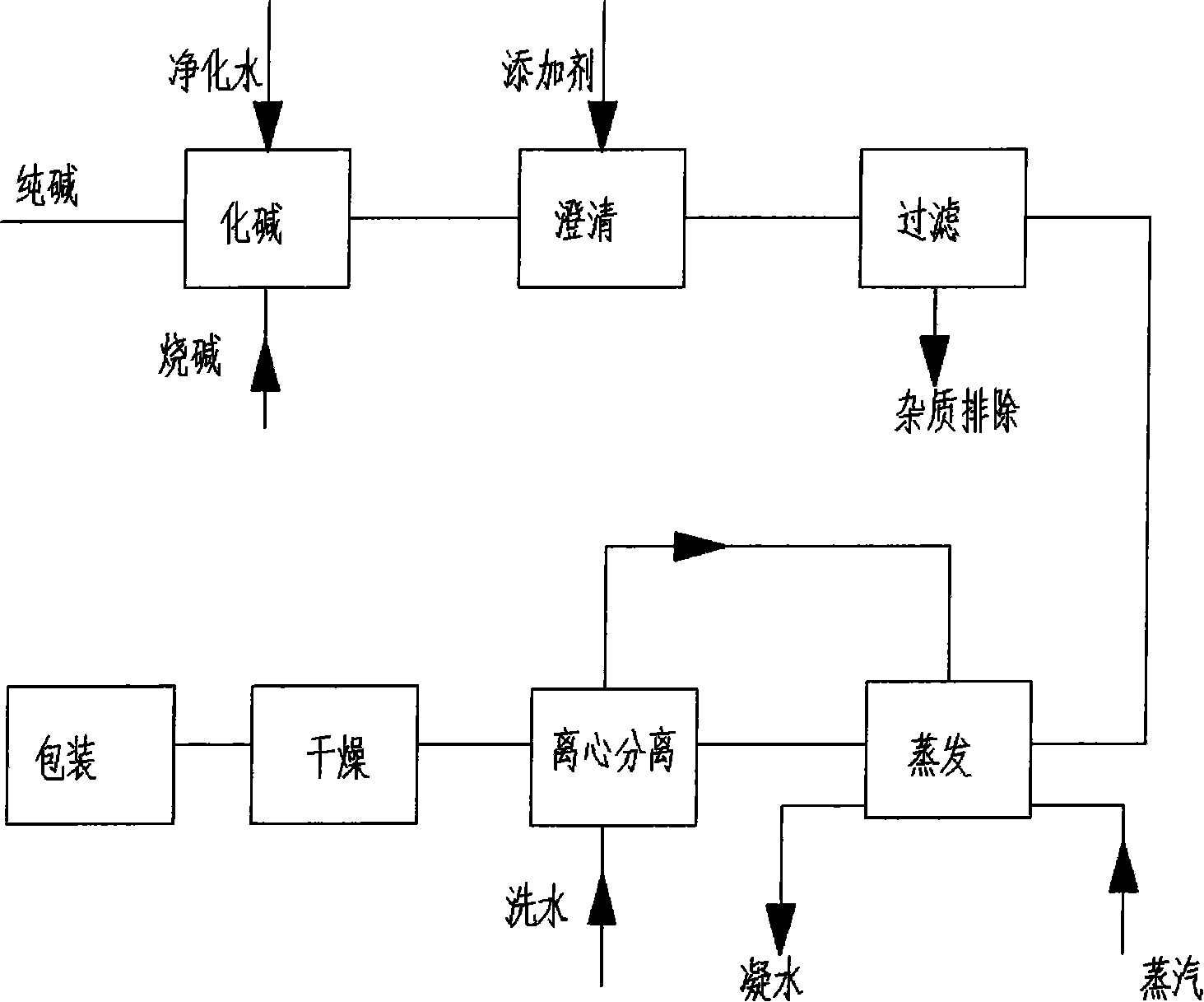

Low-phosphorus low-boron high-pure anhydrous sodium carbonate and preparation method thereof

ActiveCN101148261ASimple processMeet the use requirementsAlkali metal carbonatesAlkali metal sulfites/sulfatesPhosphorus lowPhysical chemistry

The present invention discloses one kind of high purity anhydrous sodium carbonate product with low P and B content and its preparation process. The preparation process includes the following steps: 1. reaction of sodium carbonate, pure water and sodium hydroxide in a reactor; 2. further reaction of the materials in a heat insulating and setting tank; 3. filtering to obtain filtrate; 4. evaporating the filtrate in an evaporator to crystallize; 5. washing the crystallized material in a centrifuge and solid-liquid separating; and 6. drying in a drying bed. The preparation process is simple and the prepared anhydrous sodium carbonate product has high quality and P and B content lower than 5 ppm.

Owner:TIANJIN BOHUA YONGLI CHEM IND

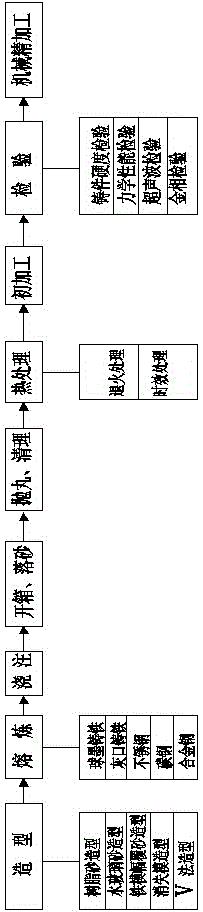

Ultra-large-specification square graphite electrode and preparation method thereof

The invention relates to an ultra-large-specification square graphite electrode. The ultra-large-specification square graphite electrode is prepared from a dry material, green scrap, stearic acid and intermediate-temperature modified asphalt according to the weight ratio of 100: 5: 0.2-0.5: 18.5. The dry material consists of mixed coke large particles, medium particles, powder and graphite scrap. The preparation method comprises the following steps: during preparation, pulverizing and sieving the graphite scrap and petroleum coke to obtain particles with different granularity and powder; mixing the sieved graphite scrap with the petroleum coke according to the ratio to obtain the dry material; and then adding the green scrap in the dry material according to the ratio; and pouring the mixture in a blending system and stirring the mixture; and carrying out mixing and kneading, forming, roasting, graphitizing and machining to obtain the finished product. The quality index and the use performance of the produced ultra-large-specification square graphite electrode reach the national standard. The ultra-large-specification square graphite electrode is accepted by consumers when used, and fills a gap of the field of ultra-large-specification square graphite electrodes.

Owner:山西丹源新材料科技股份有限公司

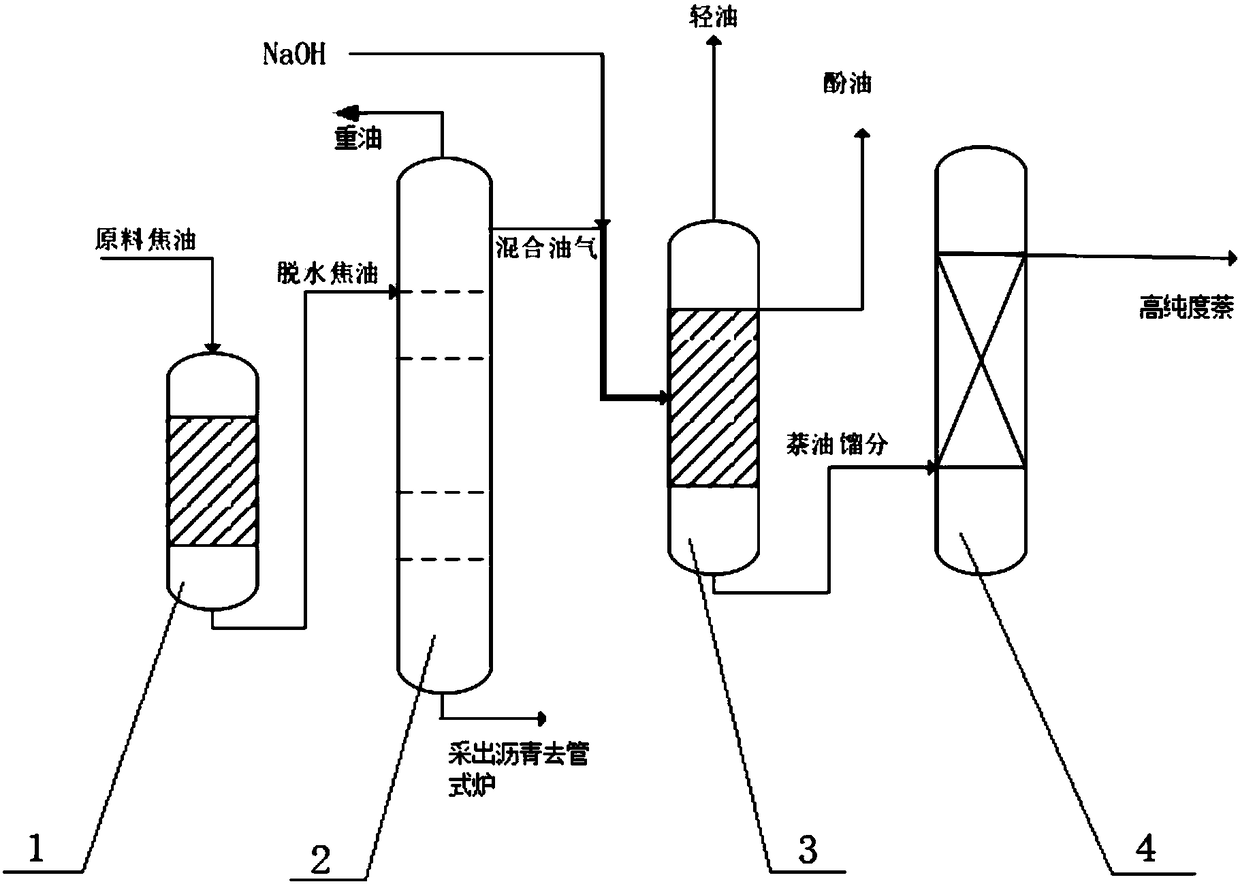

Coal tar deep processing technology for directly extracting industrial naphthalene by adding alkali after normal- and reduced-pressure treatments

The invention discloses a coal tar deep processing technology for directly extracting industrial naphthalene by adding an alkali after normal- and reduced-pressure treatments. In the technology, coaltar is used as a raw material, the alkali is directly added after normal- and reduced-pressure treatments, wherein a preliminary distillation tower and a distillation front tower adopts negative-pressure operation, and other parts adopt normal-pressure operation. The technology is realized by the following process: crude tar is dehydrated by a dehydration tower and then enters the negative-pressure preliminary distillation tower, separation is carried out by the negative-pressure preliminary distillation tower, asphalt is produced at the bottom of the negative-pressure preliminary distillationtower and enters an asphalt process through a tubular furnace, heavy oil is produced at the top of the negative-pressure preliminary distillation tower, preliminary distillation oil gas produced at the top of the negative-pressure preliminary distillation tower enters a distillation front tower, a naphthalene oil fraction is collected at the bottom of the distillation front tower, phenol oil is produced at the top of the distillation front tower, the naphthalene oil fraction collected at the bottom of the distillation front tower enters a naphthalene tower for further separation, and naphthalene oil is produced at the top of the naphthalene tower. The invention has the advantages of good separation ability, low collection temperature of the preliminary distillation fraction, higher quality of the extracted asphalt and the subsequent naphthalene washing oil, and the invention has the advantages of simple process route, energy saving and environmental protection, and high separation ability.

Owner:鞍钢化学科技有限公司

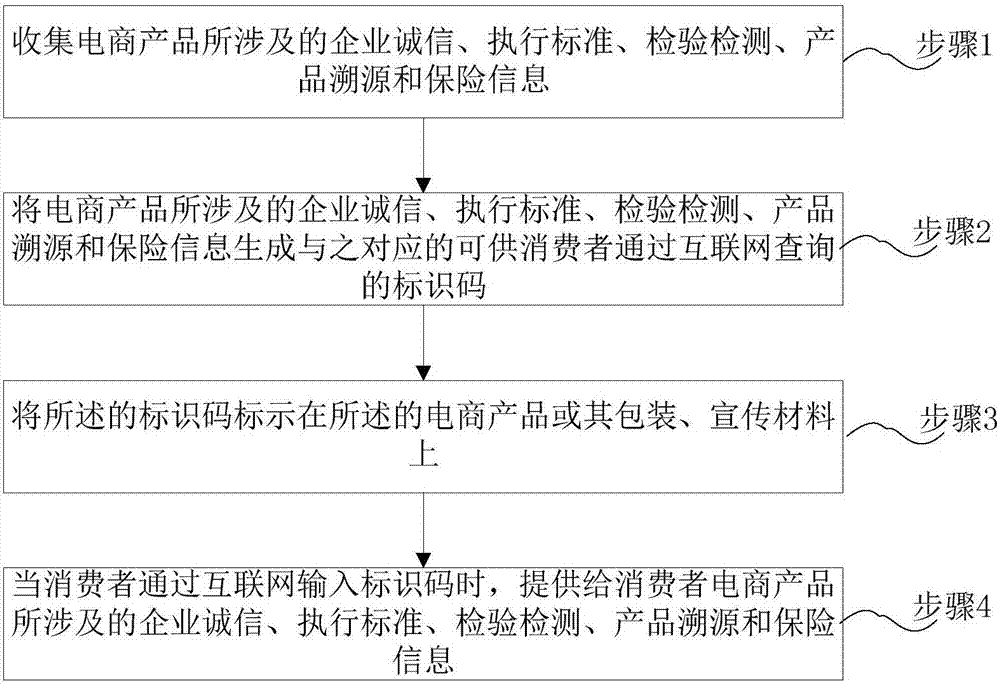

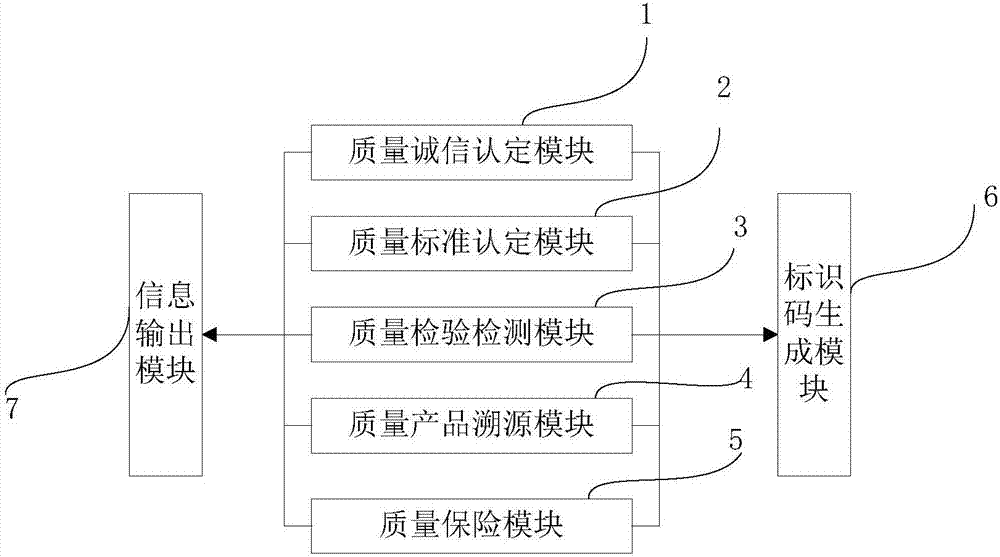

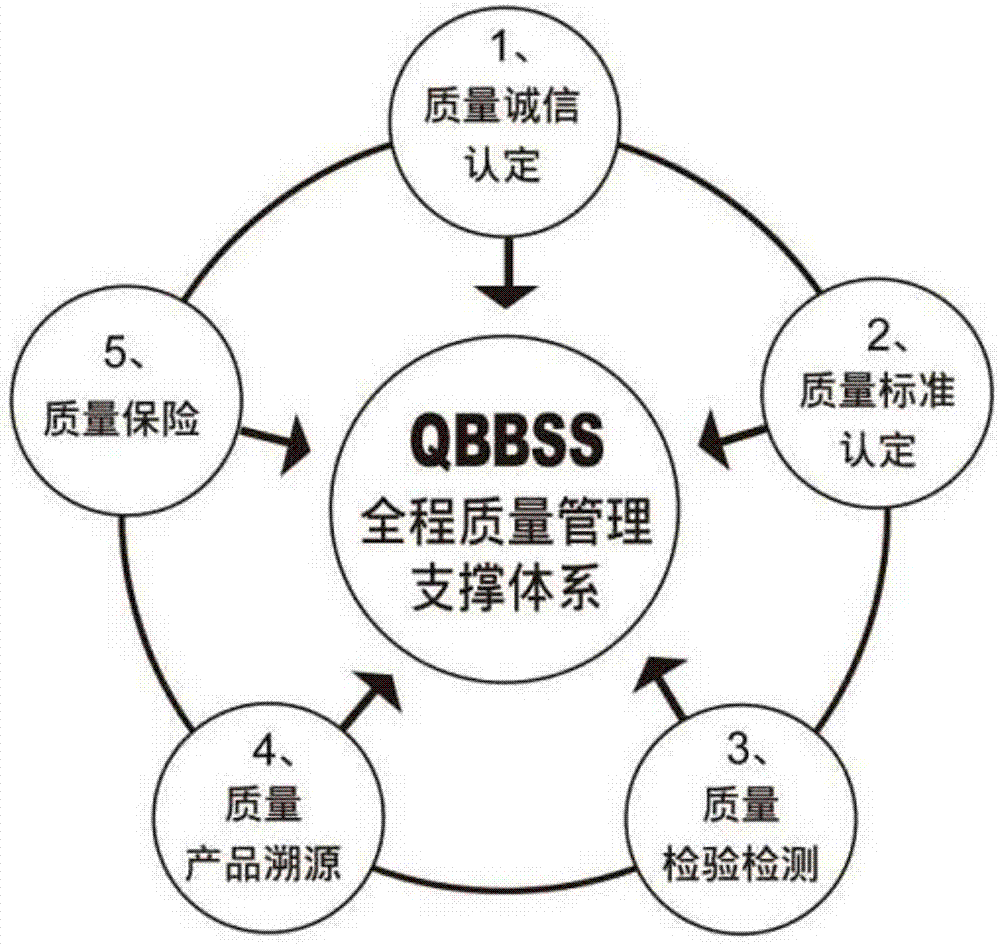

Internet-based e-commerce quality management platform and method

InactiveCN107392626AImprove product quality levelEnsure product quality consistencyBuying/selling/leasing transactionsProcess qualityManagement support systems

The present invention discloses an Internet-based e-commerce quality management method. The method comprises the following steps that: step 1, enterprises credit, executive standards, inspection and testing, product traceability and insurance information which are involved in e-commerce products are collected; step 2, identification codes which are corresponding to the enterprises credit, executive standards, inspection and testing, product traceability and insurance information which are involved in the e-commerce products and can be inquired by consumers through the Internet are generated based on the enterprises credit, executive standards, inspection and testing, product traceability and insurance information which are involved in the e-commerce products; step 3, the identification codes are marked on the e-commerce products or the packages and promotional materials of the e-commerce products; and step 4, when the consumers enter the identification codes through the Internet, the enterprises credit, executive standards, inspection and testing, product traceability and insurance information which are involved in the e-commerce products are provided for the consumers. With the Internet-based e-commerce quality management platform and method of the invention adopted, a five-in-one full-process quality management support system concerning quality credit certification, quality standard certification, quality inspection and testing, quality product traceability and quality assurance can be realized.

Owner:赵茜茜

Nano diatomite treating agent and preparation method thereof

InactiveCN101684614ANo pollution in the processNo harmful chemical elementsFibre treatmentDry-cleaning apparatus for textilesQuality levelSodium metasilicate

The invention relates to a nano diatomite treating agent, comprising 1-5% of nano-silica-base oxide, 15-0% of diatomite, 3-10% of bead alkali, 25-30% of anhydrous sodium metasilicate, 10-25% of sodiumsulfate, 6-8% of sodium dodecylbenzene sulfonate acid, and the balance sodium carbonate. The preparation method comprises the following steps: dispersing the nano-silica-base oxide in a high shear dispersion machine, transferring into a homogenizing stirrer, homogenizing while stirring, adding anhydrous sodium metasilicate and sodium sulfate in turn, adding the bead alkali, the diatomite, the sodium dodecylbenzene sulfonate acid and the sodium carbonate, homogenizing, stirring, and screening to obtain the powder nano diatomite treating agent or pelleting to prepare into graininess. The nano diatomite treating agent has the advantages of being non-toxic, no harmful, no polluted ecological protection green product with no harmful chemical elements, simplifying technological process, being easy to operate, outputting uniform and stable quality, improving production and use environment, no changing of the original equipment of factories, saving energy, reducing comprehensive production cost, prolonging the service life of the equipment and improving quality level of products.

Owner:张海燕 +1

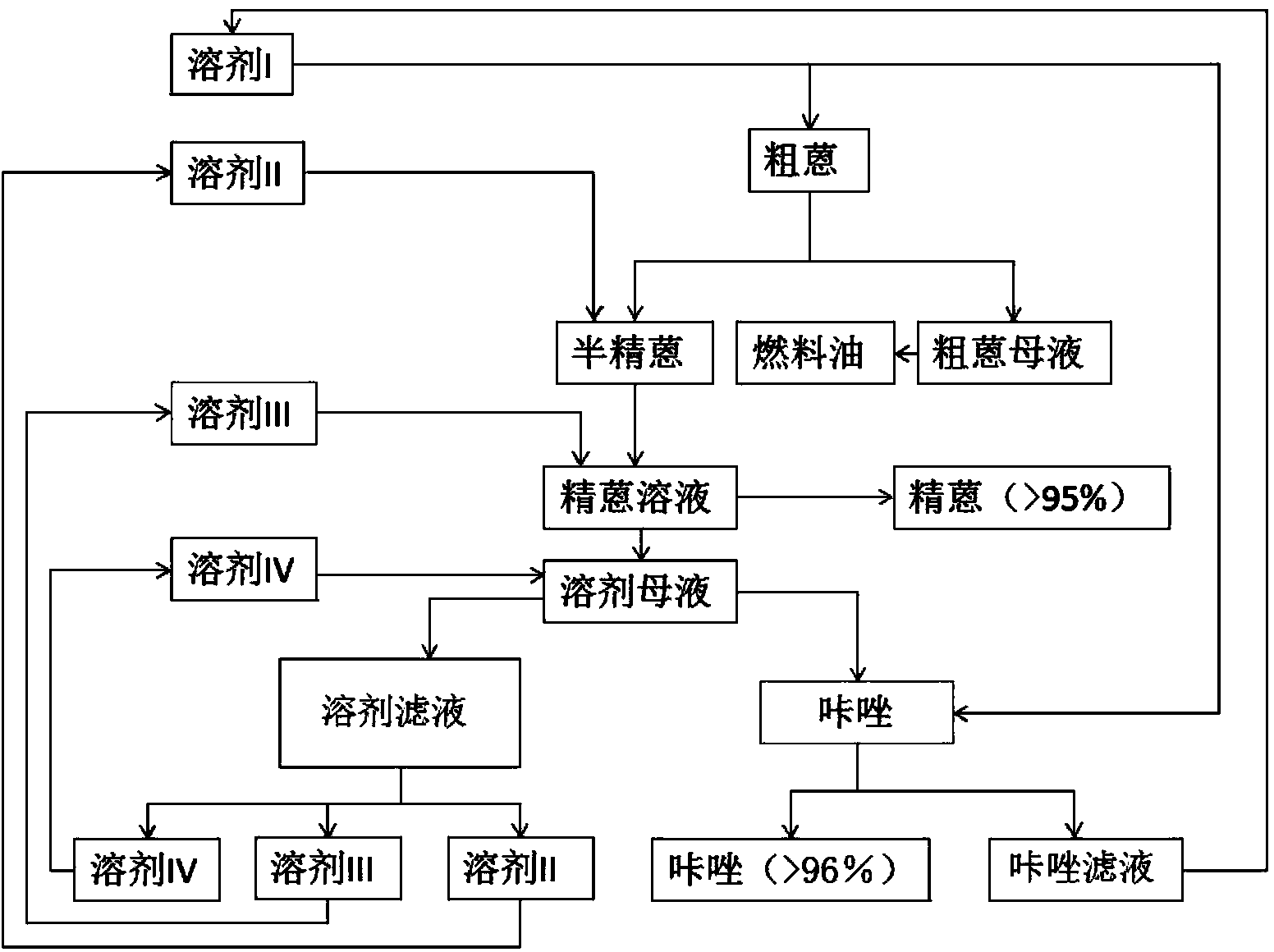

Refined anthracene and carbazole purification method

InactiveCN103880732AImprove product quality levelHigh purityHydrocarbonsCrystallisation purification/separationAnthracenePurification methods

The invention relates to a refined anthracene and carbazole purification method. The purification method comprises the following steps: crystallizing and separating crude anthracene in a solvent I by adopting a solvent extraction and crystallization process, wherein crystal substances are semi-refined anthracene and the solution is a crude anthracene mother liquid; dissolving the semi-refined anthracene in a solvent II, ending heating and dropwise adding a solvent III for precipitation, separating the crystal substances to obtain the refined anthracene of which the concentration is higher than 95%; adding a solvent IV into the filtrate for crystallization to obtain the carbazole and solvent filtrate, separating the solvent filtrate to obtain the solvents II, III and IV which are recyclable, dissolving the carbazole into the solvent I for recrystallization, and separating final carbazole solids to obtain the carbazole of which the concentration is higher than 96%, wherein the crude anthracene mother solution and the carbazole filtrate can be used for replacing the solvent I for the crystallization of the semi-refined anthracene so as to realize recycling, and after saturation, the crude anthracene mother liquid and the carbazole filtrate can be used as fuel oil. The method is simple to operate, high in separation efficiency and free of generation of wastes during the whole reaction process.

Owner:SHANGHAI YUGAO ENVIRONMENTAL TECH CO LTD

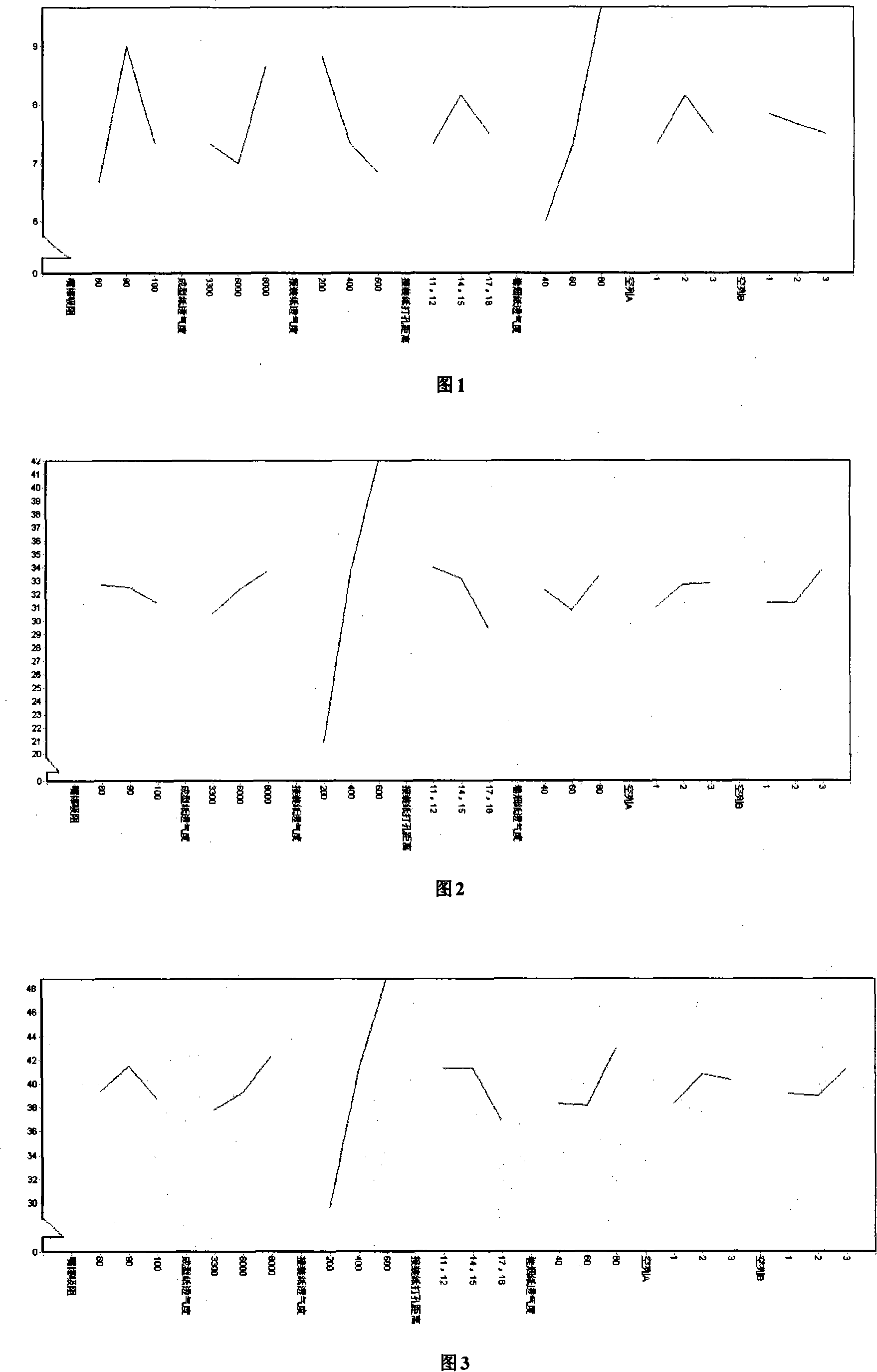

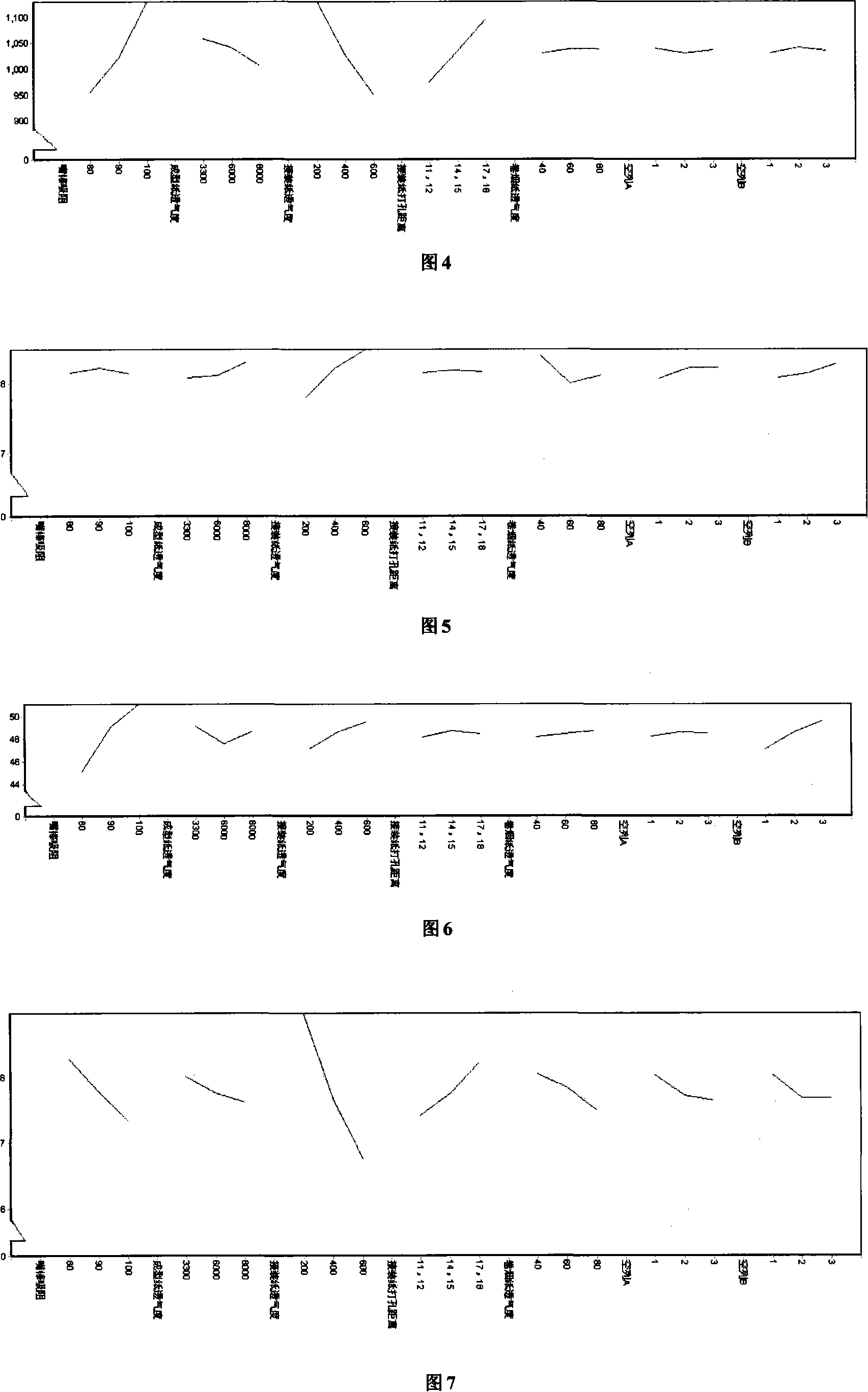

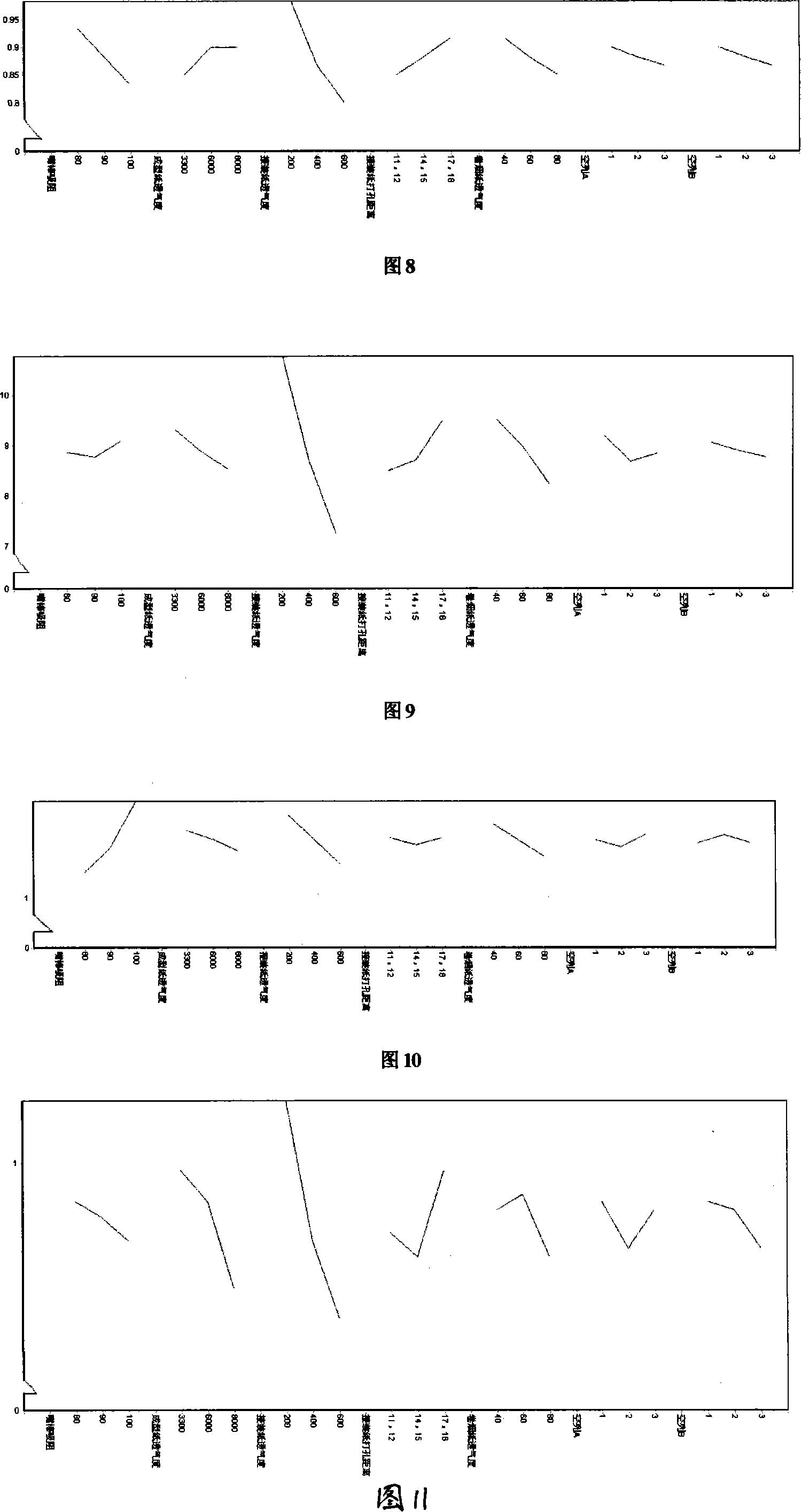

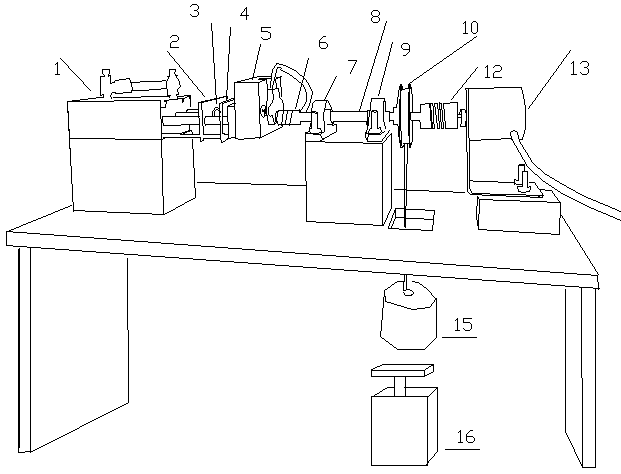

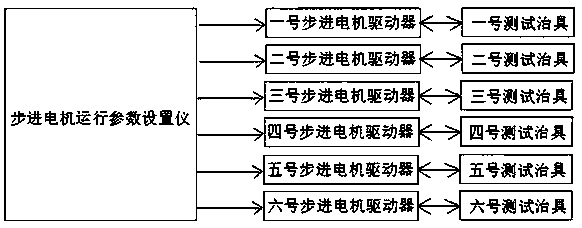

Stepping motor comprehensive performance test system

PendingCN110596589AImprove product quality levelReduce manufacturing costDynamo-electric machine testingMotor testingProximity sensor

The invention discloses a stepping motor comprehensive performance test system. The test system is composed of three parts including one stepping motor operating parameter setting instrument, six stepping motor drivers of the same specifications, six groups of motor test fixtures of the same specifications; the test system can simultaneously test steering, moment of force, angles, current and insulating and voltage resistance performance of six stepping motors. Each group of the fixtures in the six groups of motor test fixtures is composed of a three-rod air cylinder 1, two spring clip plates2 and 4, a No.1 spring 3, two ejector rods (mounted between a motor base and the spring clip plate), the motor base 5, a No.1 coupler 6, a No.2 spring, a connection shaft 8, two bearing pedestals 7 and 9, a scale pan 10, a weight 15, a No.2 coupler 12, an angle sensor 13, a base plate, a cushion block, a weight pushing air cylinder 16 and a proximity sensor.

Owner:章五明

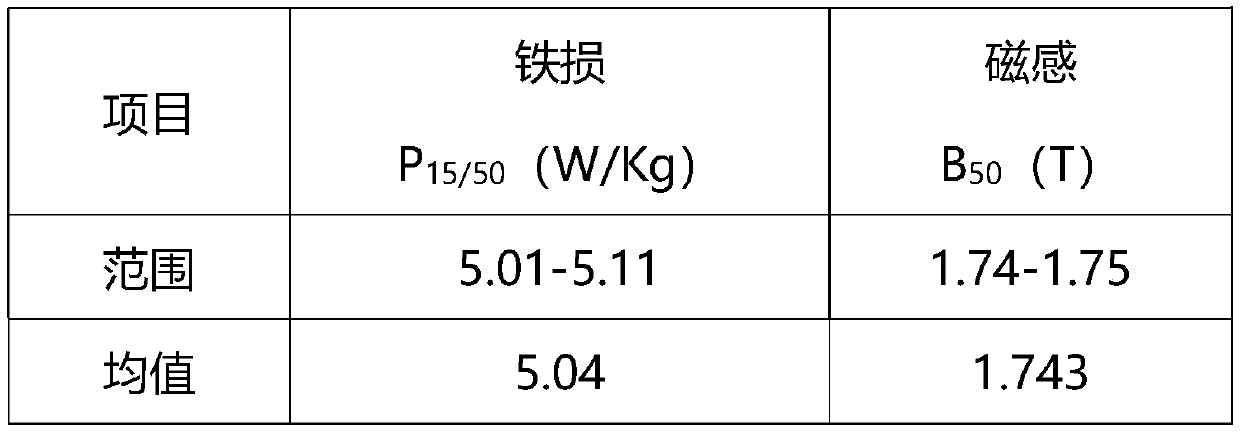

Method for optimizing electromagnetic performance of non-oriented silicon steel, and non-oriented silicon steel

InactiveCN111270123AIncreasing the continuous annealing temperatureImprove electromagnetic performanceContinuous annealingHeating furnace

The invention particularly provides a production method for optimizing an electromagnetic performance of non-oriented silicon steel. The production method for optimizing the electromagnetic performance of the non-oriented silicon steel comprises the following steps of (1) smelting according to setting components, wherein the non-oriented silicon steel is prepared from the chemical components in percentage by mass: less than or equal to 0.005 percent of C, 0.50 to 0.80 percent of Si, 0.10 to 0.30 percent of Mn, 0.02 to 0.05 percent of P, 0.20 to 0.30 percent of Als, less than or equal to 0.004percent of S, less than or equal to 0.003 percent of O, less than or equal to 0.003 percent of N, less than or equal to 0.004 percent of Nb, less than or equal to 0.004 percent of V, less than or equal to 0.004 percent of Ti, less than or equal to 0.005 percent of Cr, and the balance Fe and inevitable impurities; and casting into a casting blank with the thickness ranging from 70 to 85mm; (2) heating in a roller way type heating furnace, wherein the heating temperature is less than or equal to 1080 DEG C, the initial rolling temperature ranges from 1020 DEG C to 1060 DEG C, and the finish rolling temperature ranges from 850 to 880 DEG C; and (3) acid pickling a hot-rolled coiled plate through an acid pickling unit, rolling the coiled plate for 5 passes at a time through a CVC6-roller single stand cold rolling mill until the thickness is 0.5mm; continuously annealing for 1.5 to 5min; and finally coating an insulating film.

Owner:BENGANG STEEL PLATES

Torque-fixed screw fastening apparatus for detecting screw slippage state

InactiveCN104977114AReduce labor intensityHigh degree of automationMeasurement of torque/twisting force while tighteningProgramme control in sequence/logic controllersReduction driveUltimate tensile strength

The invention discloses a torque-fixed screw fastening apparatus for detecting screw slippage state. The torque-fixed screw fastening apparatus comprises a workbench (1), a screw fastening apparatus and a controller, wherein the workbench (1) is provided with a product clamp(2), which is connected with a torque sensor (3), the screw fastening device comprises a servo motor (5), a decelerator(6) and a screw sleeve (7), handles (9) are installed on the two sides of the decelerator(6), and the controller comprises a display unit, a control unit, a simulated conversion unit, a servo driver and a starting switch. The torque-fixed screw fastening apparatus is high in automation level, lowers labor intensity and improves work efficiency. Accurately quantitative control of screw tightening torque is realized, incapability of following the predetermined force value during manual tightening of a screw can be prevented, and the product quality is improved. The torque-fixed screw fastening apparatus is applicable to automatic tightening of various bolts, torques can be set according to requirement and bolts can be installed firmly and reliably.

Owner:CHENGDU LIXIN SCI & TECH

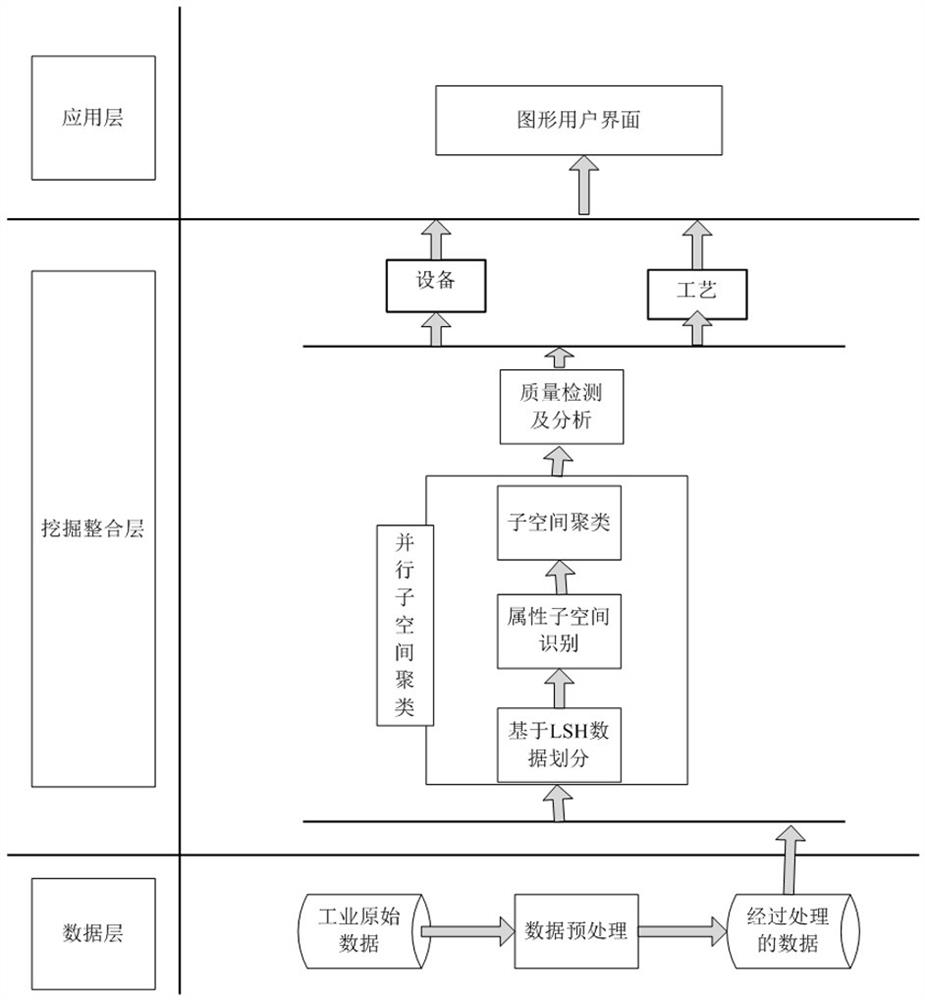

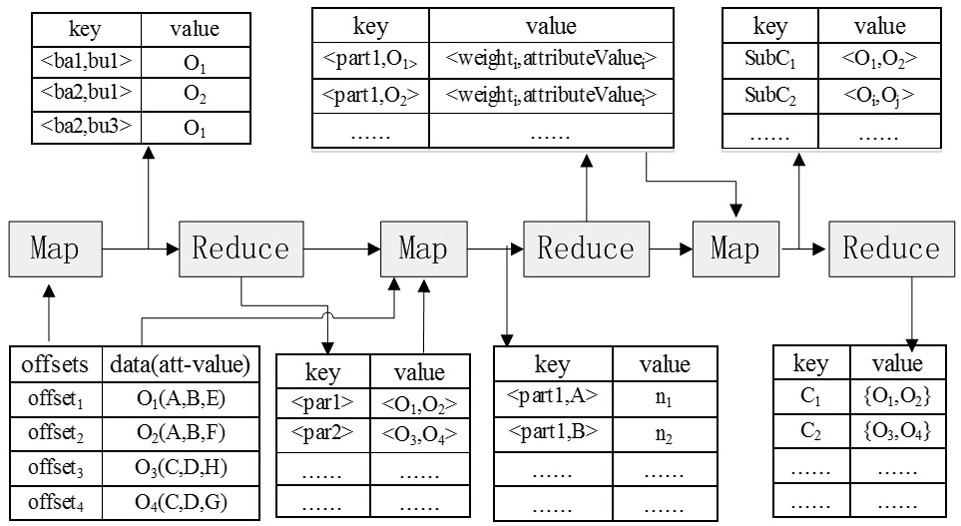

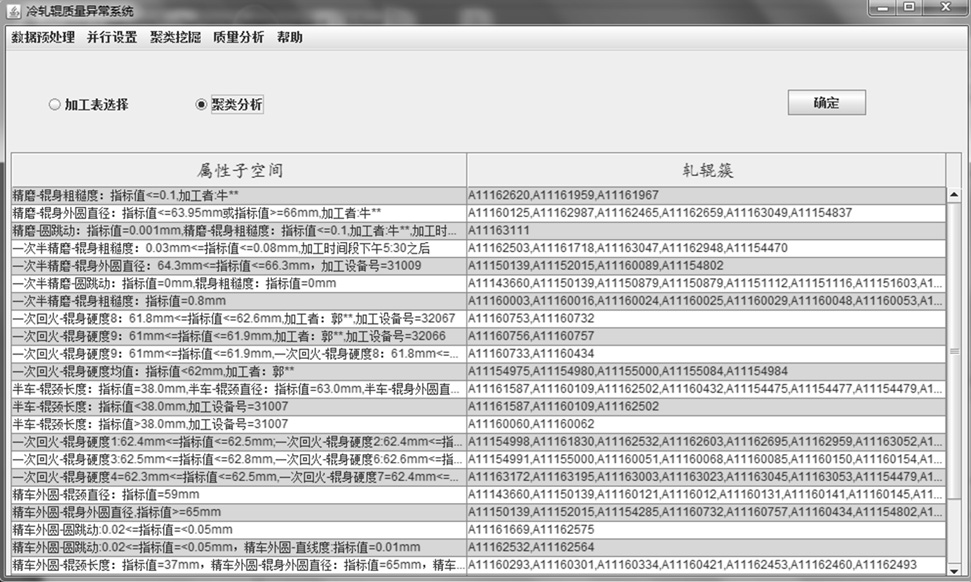

Mechanical product quality analysis method based on subspace clustering

PendingCN112434923AImprove product quality levelCharacter and pattern recognitionResourcesDistributed File SystemData node

The invention discloses a mechanical product quality analysis method based on subspace clustering, and belongs to the technical field of mechanical product quality analysis. The technical problem to be solved is to provide a mechanical product quality analysis method based on subspace clustering. According to the technical scheme, the method comprises the following steps: in a Hadoop cluster, uploading processed process data to an HDFS (Hadoop Distributed File System) of Hadoop for storage according to the change of data volume; specifically, in a Hadoop cluster, executing three jobs in sequence: dividing similar process data into the same data block by adopting an LSH-based data division method, and projecting the similar process data to the same data node; identifying attribute subspacesof data on each data node; achieving a parallel subspace clustering process, generating a final clustering result from the sub-clusters obtained in the local clustering stage, and discovering a common recessive problem which influences the product quality and is hidden in a cluster set according to the clustering result. The method is applied to mechanical product quality analysis.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

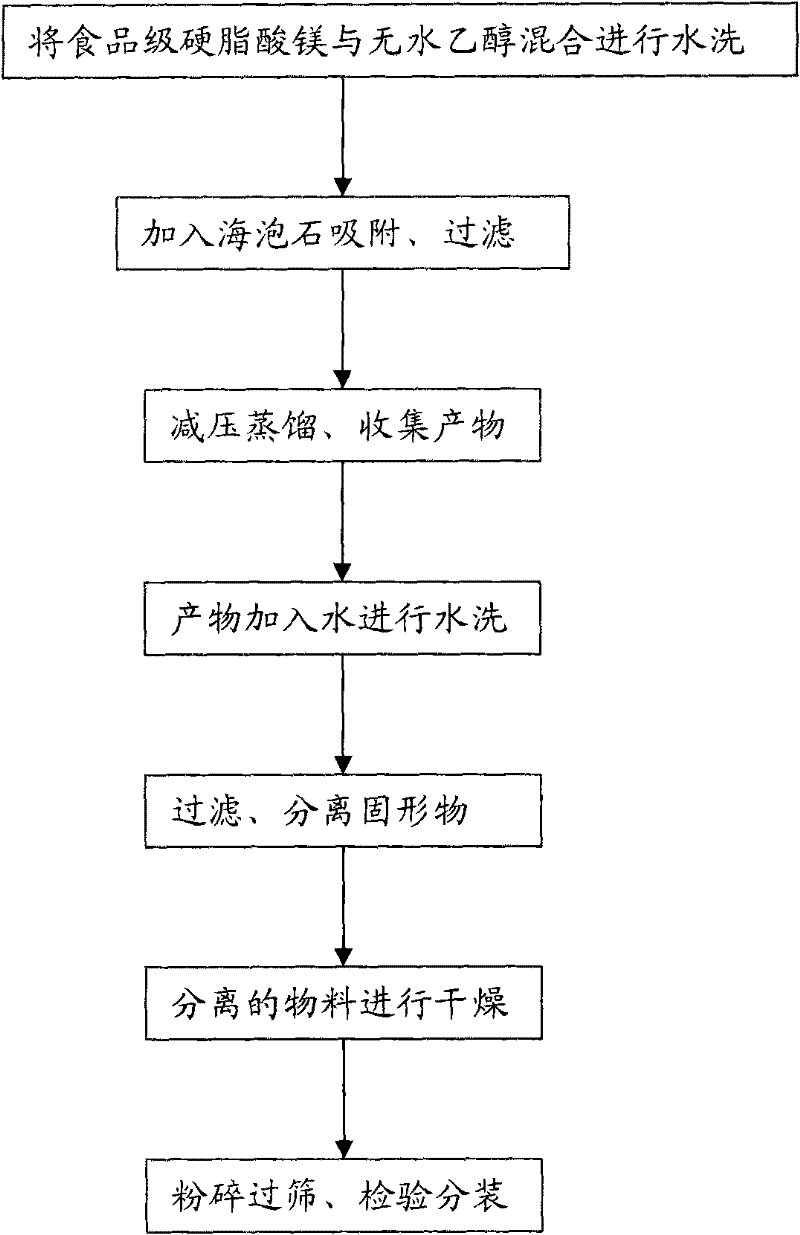

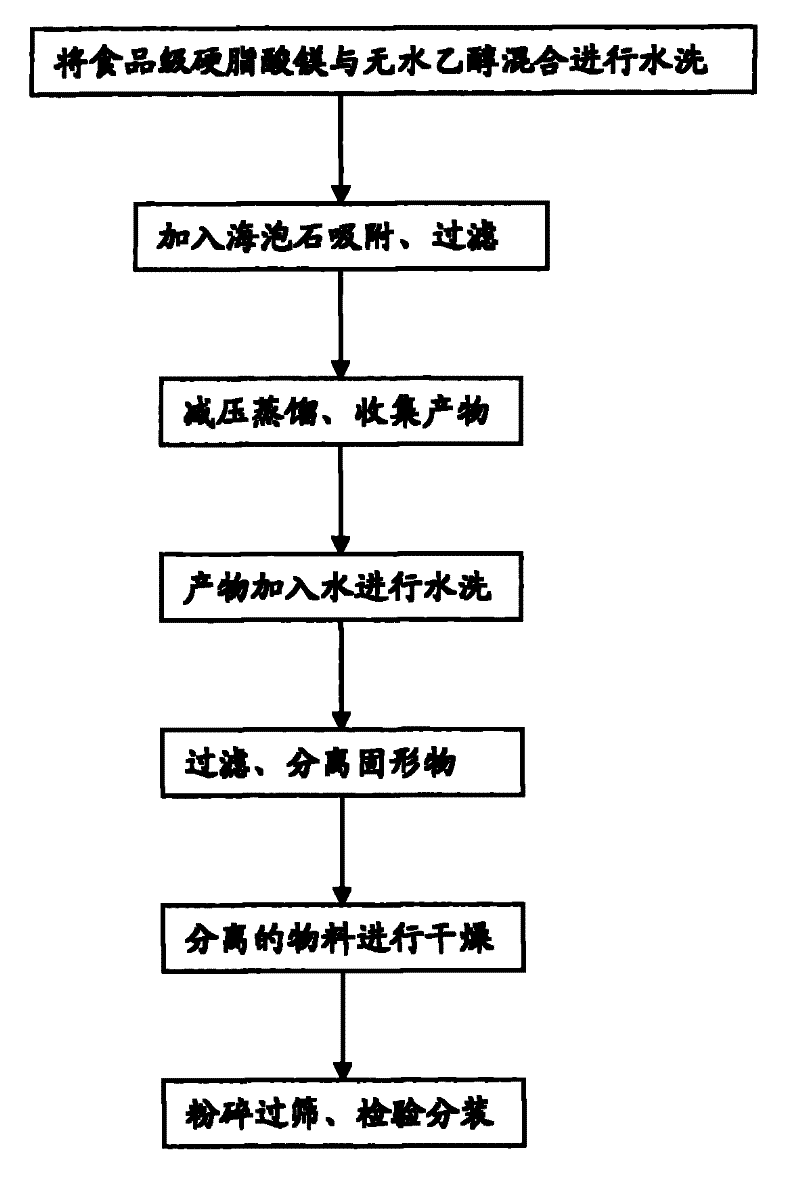

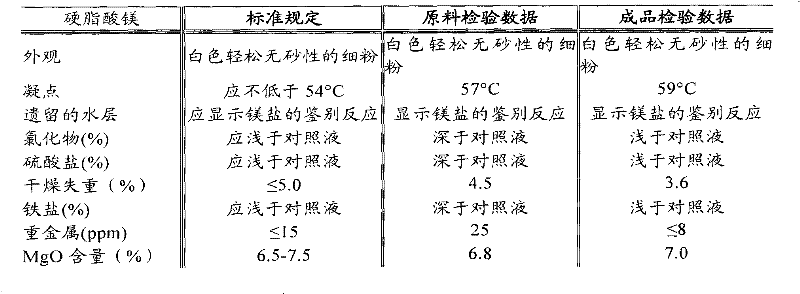

Medicinal-grade magnesium stearate and refining process thereof

ActiveCN101747175ASimple preparation processLow costCarboxylic compound separation/purificationAlcoholMagnesium stearate

The invention provides a medicinal-grade magnesium stearate and a refining process thereof. The process comprises the following steps: (a) adding a food-grade magnesium stearate in a dissolving tank and then adding absolute ethyl alcohol, stirring for 15 to 30 minutes at the speed of 100 to 150 rpm under the temperature of 50 to 70 DEG C, wherein the mixing proportion of the magnesium stearates and the absolute ethyl alcohol is 1 to 10 (g / ml); (b) adding 10 to 20 g / ml sepiolite absorbents modified by iron to the obtained solution for oscillation and absorption for 2 to 3 h and then filtering;(c) distilling the filtrate at reduced pressure under the temperature of 60 to 70 DEG C to recover ethyl alcohol, thereby collecting a product; (d) adding the product in the dissolving tank and adding purified water, stirring for 15 to 30 minutes at the speed of 100 to 150 rpm under the temperature of 70 to 90 DEG C, wherein the mixing proportion of the magnesium stearates and the purified water is 1 to 8 (g / ml); (e) filtering, drying, sieving, testing and split charging to obtain the product.

Owner:HUNAN ER KANG PHARMA

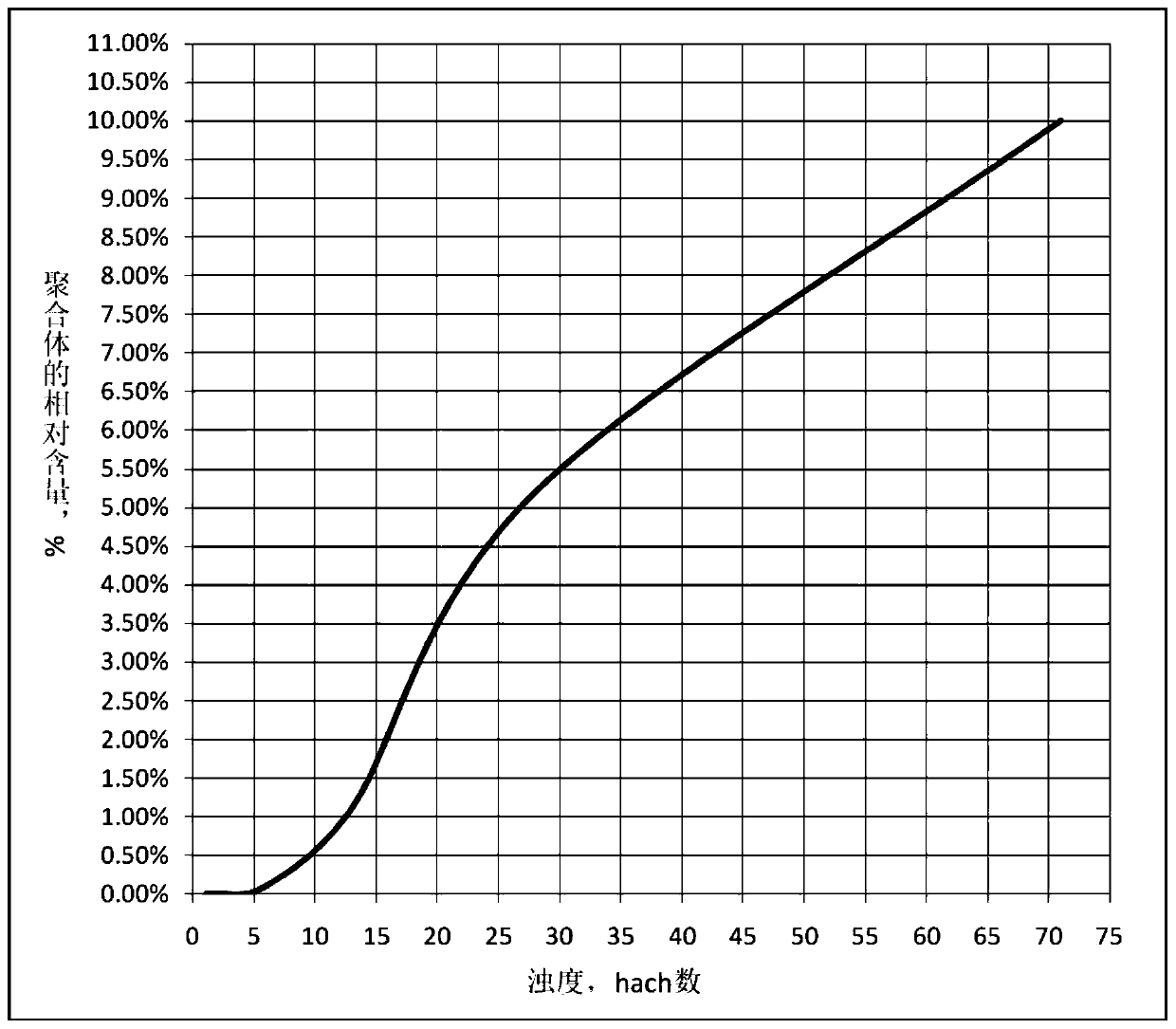

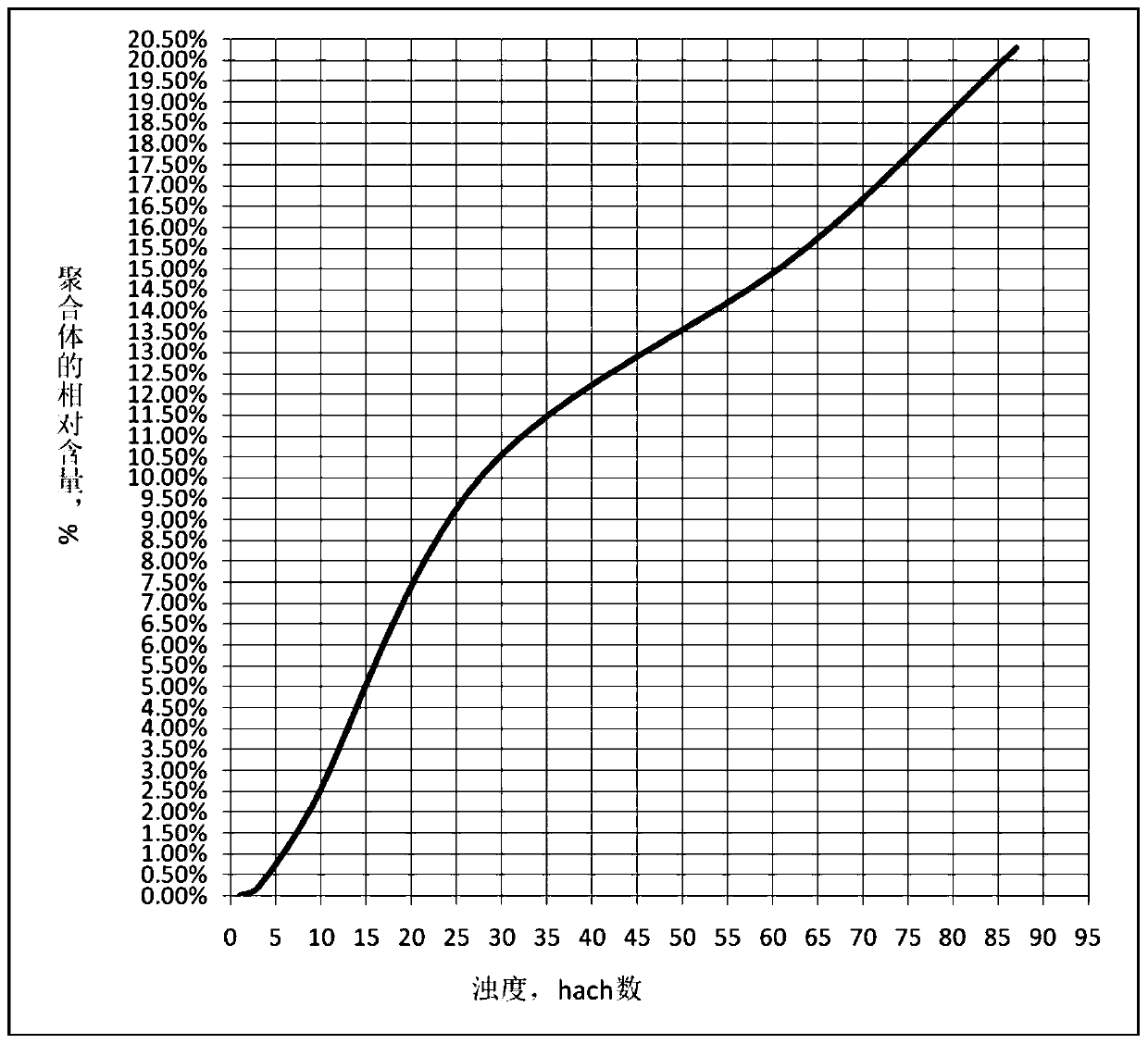

Method for evaluating relative content of silane coupling agent polymer

ActiveCN110927196AAvoid elevated levelsAvoid the problem of large turbidity valuesWater resource assessmentAnalysis using nuclear magnetic resonanceAqueous solutionMaterials science

The invention provides a method for evaluating the relative content of a silane coupling agent polymer. The method comprises the following steps: a) testing a silane coupling agent by using a nuclearmagnetic resonance silicon spectrum method to obtain the relative content of the silane coupling agent polymer; b) preparing a silane coupling agent into ethanol or an aqueous solution, and testing byusing a turbidity meter to obtain a turbidity value X1; c) establishing a 'turbidity-polymer relative content' standard curve by taking the turbidity value as an X axis and taking the silane couplingagent polymer relative content value as a Y axis; d) preparing a to-be-tested sample into ethanol or an aqueous solution, and testing to obtain a turbidity value X2 of the to-be-tested sample; and e)corresponding the turbidity value X2 of the to-be-tested sample to the X-axis data on the standard curve, and finding out the Y-axis value corresponding to the point, namely the value of the relativecontent of the polymer of the to-be-tested sample. According to the method, the relative content of the polymer in the sample can be relatively accurately measured by establishing a standard curve ofturbidity numerical value-relative content numerical value of the polymer.

Owner:南京曙光新材料有限公司

High-safety assembling tool based on torque feedback

InactiveCN105014366AReduce labor intensityHigh degree of automationMetal working apparatusReduction driveUltimate tensile strength

The invention discloses a high-safety assembling tool based on torque feedback. The high-safety assembling tool comprises a workbench (1), a screw screwing apparatus and a controller, wherein the workbench (1) is provided with a product clamp (2), the product clamp (2) is connected with a torque sensor (3), the screw screwing apparatus comprises a servo motor (5), a decelerator (6) and a screw sleeve (7), and the two sides of the decelerator (6) are provided with a handle (9); and the controller comprises a display unit, a control unit, a simulation conversion unit, a servo driver and a starting switch. According to the invention, the high-safety assembling tool has the following advantages: the automation degree is high, the labor intensity of workers can be mitigated, and the work efficiency is improved; accurate quantified control of screwing torque through screws is realized, the problem that the screw cannot be screwed according to a specified force value during manual operation can be prevented, and the product quality is improved; and the tool is suitable for automatic screwing of various bolts, the torque can be set according to requirements, and the bolts are firmly and reliably installed.

Owner:CHENGDU LIXIN SCI & TECH

Connecting structure for rising cylinder and descending cylinder of gasification furnace and manufacturing method

ActiveCN110172364AOptimal Design StructureSimple preparation techniqueGranular/pulverulent flues gasificationManufacturing technologyEngineering

The invention provides a connecting structure for a rising cylinder and a descending cylinder of a gasification furnace and a manufacturing method and relates to the technical field of designing and manufacturing of the rising cylinder and the descending cylinder of the gasification furnace. The connecting structure for the rising cylinder and the descending cylinder of the gasification furnace aims at solving the problems of unreasonable hole structure, high manufacturing difficulty, poor machining and manufacturing quality and low production efficiency of the rising cylinder and the descending cylinder of the gasification furnace. The gasification furnace comprises the rising cylinder, the descending cylinder and 6-12 T-shaped supporting components which are arranged at the upper and lower ends of the rising cylinder; the T-shaped supporting components consist of distance plates and connecting plates; multiple circular holes are formed in the rising cylinder; multiple waist-shaped holes are formed in the connecting plates; the number of the circular holes is the same as that of the waist-shaped holes; the axes of the corresponding circular holes coincide with the corresponding waist-shaped holes; and through hexagon bolts and hexagon nuts, the rising cylinder is connected with the connecting plates through bolts. The invention provides the connecting structure for the risingcylinder and the descending cylinder of the gasification furnace and the manufacturing method.

Owner:HARBIN BOILER

Immediate throat cool buccal dripping pill and detection method thereof

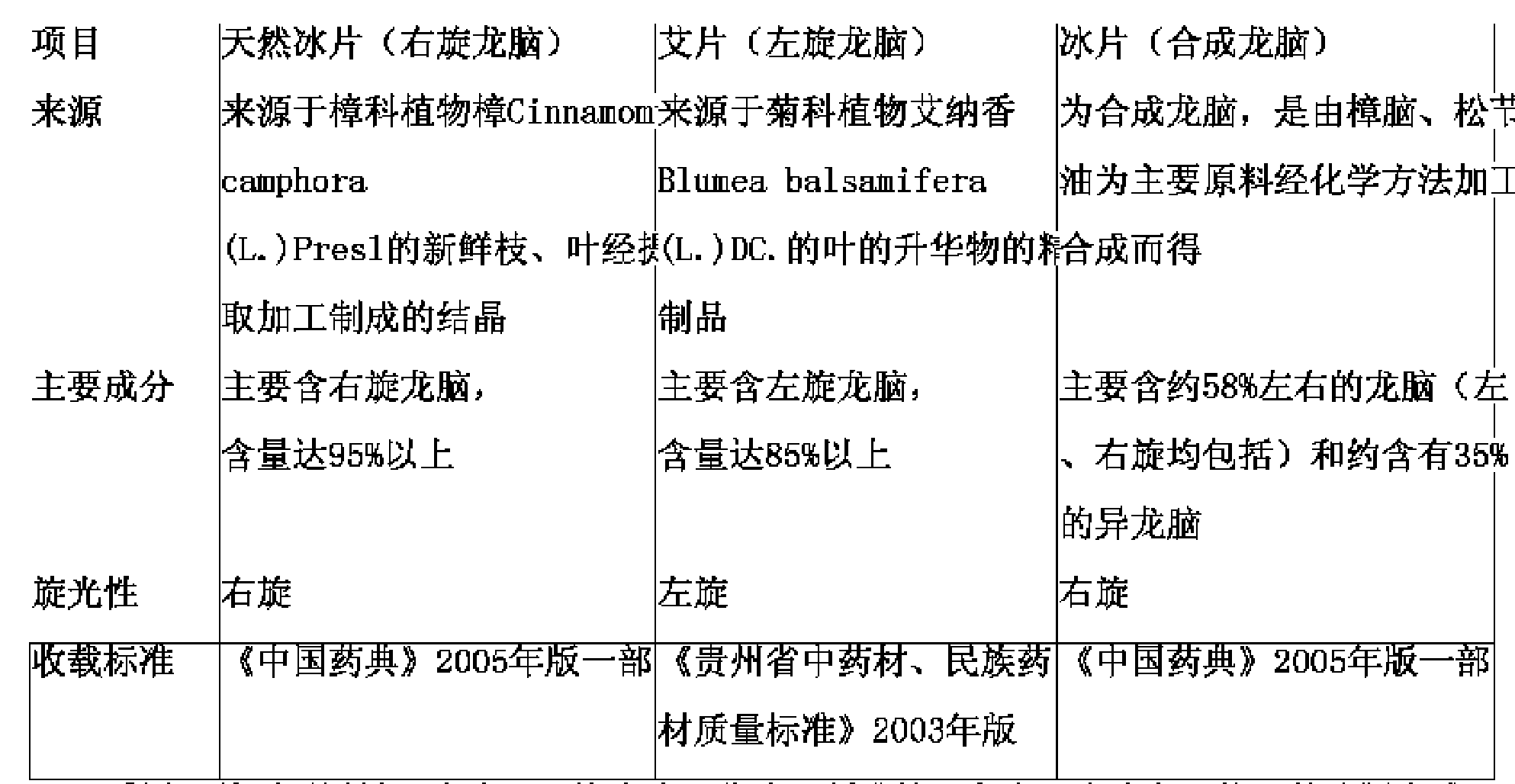

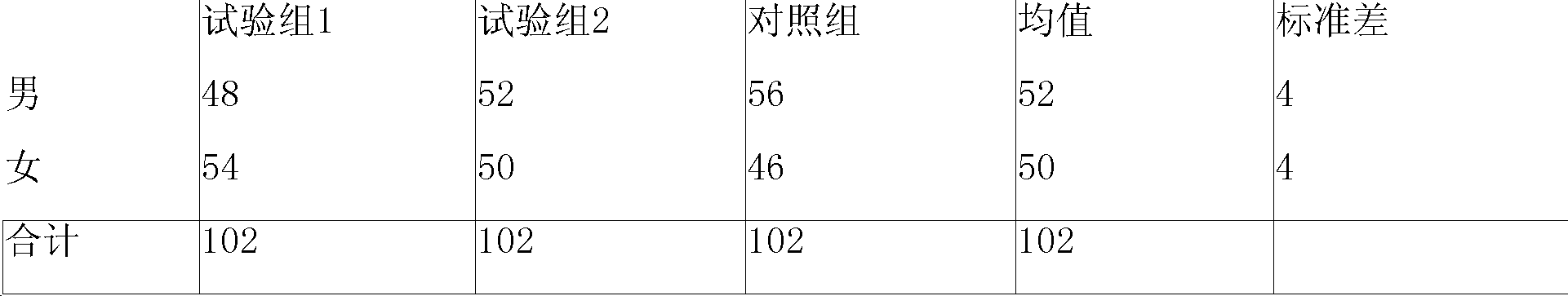

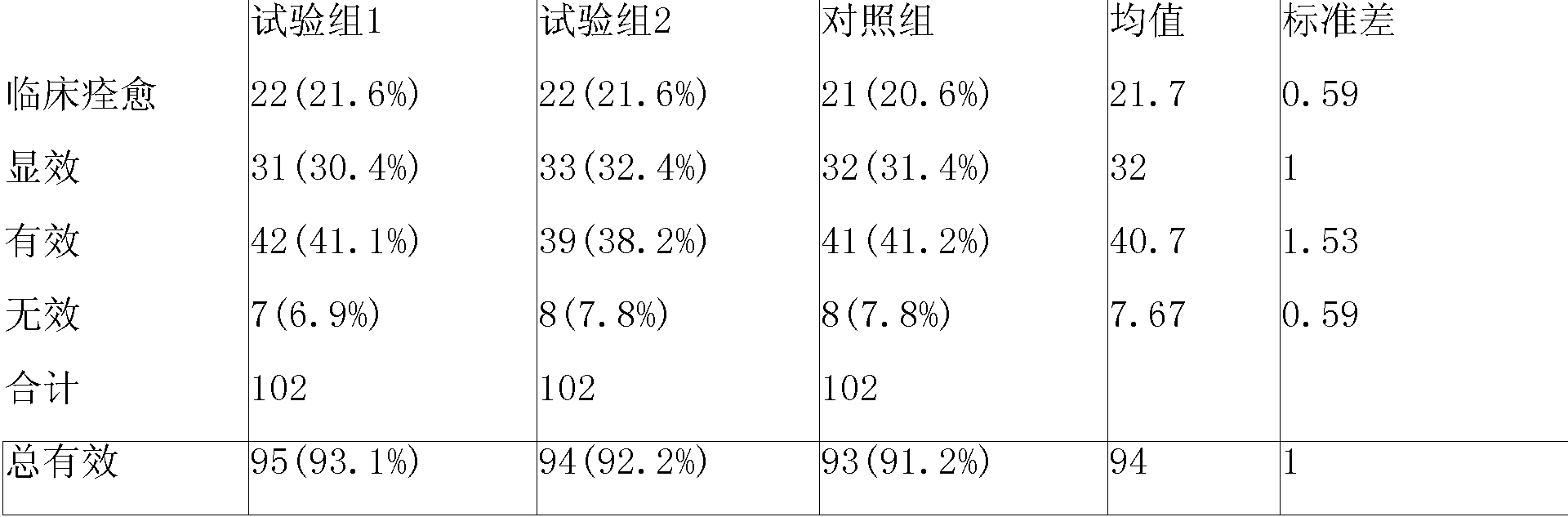

InactiveCN101518567ASignificant effectLow toxicityHydroxy compound active ingredientsComponent separationDiseaseSide effect

The invention discloses an immediate through cool buccal dripping pill for treating laryngeal disease and a detection method thereof. The immediate through cool buccal dripping pill is prepared by the following components by weight: 2.5 portions of natural borneol, 1.25 portions of blumea oil, 1.5 portions of dementholised peppermint oil, 0.75 portion of menthol, 1.5 portions of mono-ammonium glycyrrhizinate and 17.5 portions of polyethyleneglycol 6000. Compared with the prior art, the invention adopts the natural borneol to replace moxa pieces or synthesized borneol to prepare the buccal dripping pill for treating laryngeal disease; the obtained dripping pill has obvious curative effect, little toxicity and little side effect; the natural borneol has high content of effective components and is beneficial to producing; and the quality of the immediate through cool buccal dripping pill is improved. In addition, the detection method provided by the invention refers to method of detecting the optical activity of finished product and detecting the content of dextrorotation camphol in the finished product by adopting chiral capillary gas chromatography and has strong specificity, high precision, good stability and accurate measuring result, thereby effectively preventing various adulteration behaviors and effectively ensuring the quality and the curative effect of the buccal dripping pill for treating laryngeal disease.

Owner:贵州黄果树立爽药业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com