Mica sheet screening and washing device for mica paper production process

A technology of production process and cleaning device, which is applied in the direction of using liquid cleaning method, sieve, cleaning method and utensils, etc., can solve the problems of unfavorable mica paper production, unfavorable protection of mica flakes, large damage of mica flake diameter, etc. Product quality grade, convenient transportation, small damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be described in detail below with reference to the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

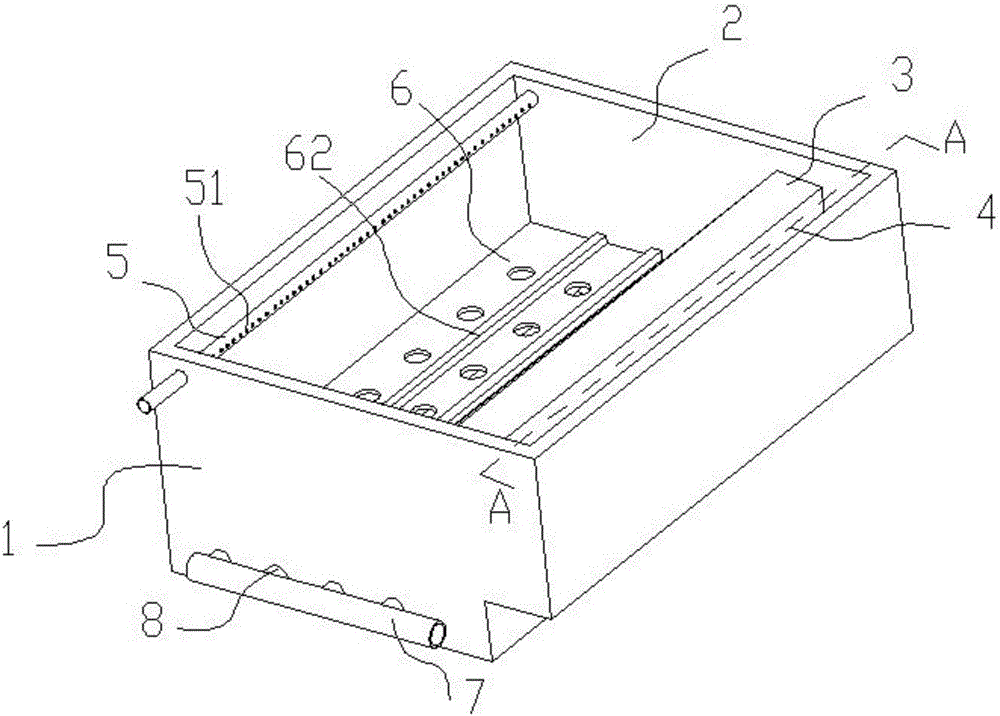

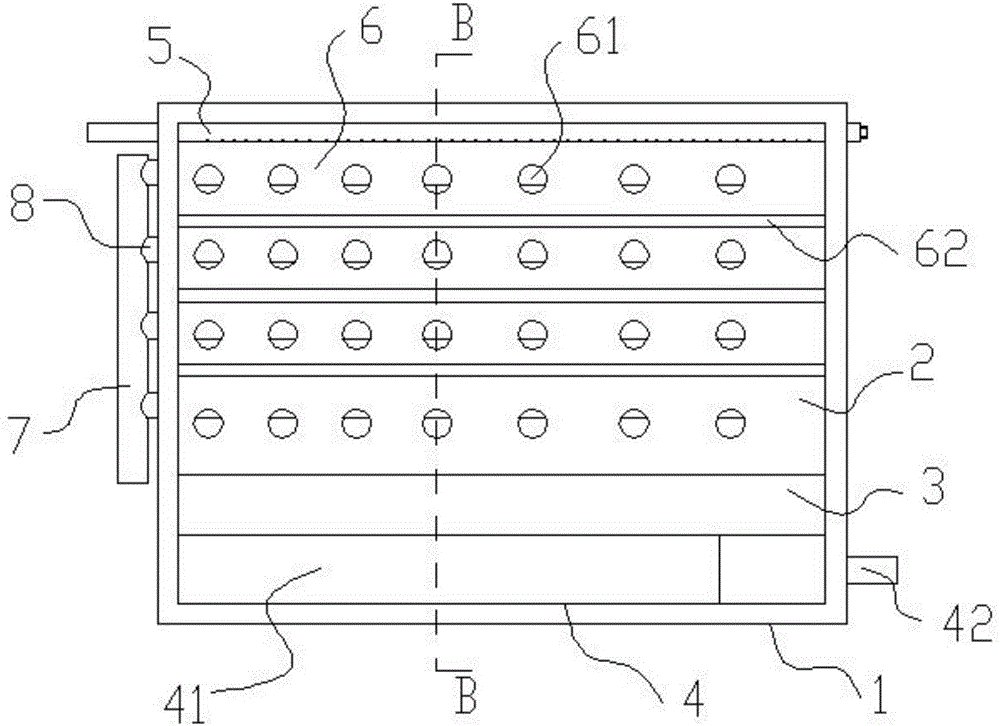

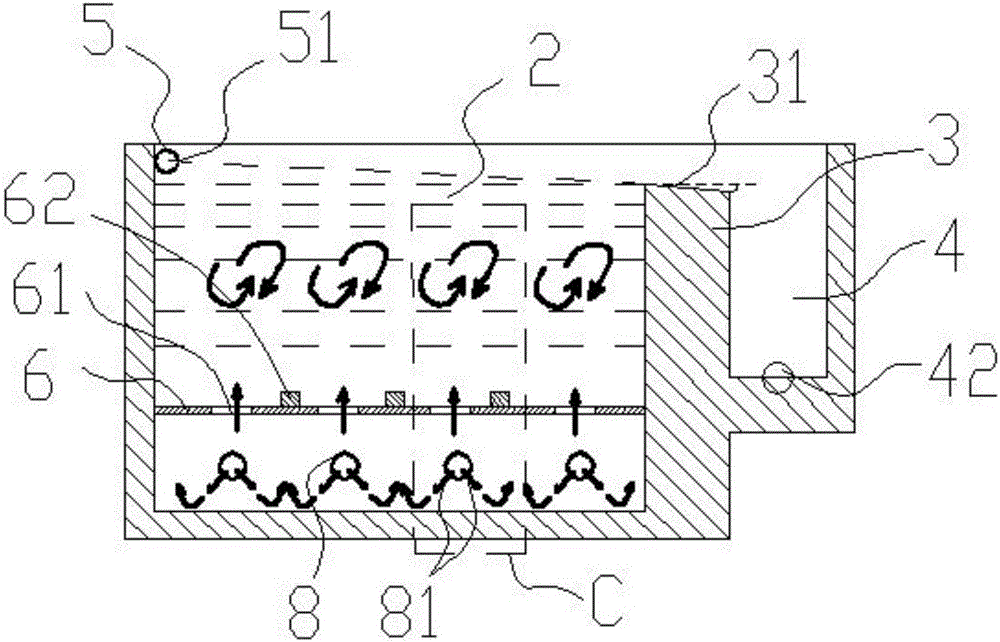

[0033] like Figure 1-Figure 3 As shown, the specific structure of the present invention is: a mica sheet screening and cleaning device used in the production process of mica paper, which comprises a screening pool 1, and the screening pool 1 is divided into a cleaning area 2 and an overflow baffle 3 by an overflow baffle. Flow tank 4, and the top of overflow baffle 3 is lower than the peripheral height of screening pool 1; a sieve plate 6 is arranged at the lower end of the cleaning area 2, and a bottom pipe 8 is provided below the sieve plate 6, and the side wall of the bottom pipe 8 is provided with Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com