Patents

Literature

1482 results about "Paper production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paper product with visual signaling upon use

Owner:THE PROCTER & GAMBLE COMPANY

Creping adhesive modifier and methods for producing paper products

ActiveUS8147649B1Prevent adhesive build-upSpeed up the processNatural cellulose pulp/paperMechanical working/deformationAdhesivePaper production

A creping aid system for use on a creping cylinder, for example, a Yankee dryer, comprises a creping adhesive and a creping modifier, the combination comprising polyethylene.

Owner:SOLENIS TECH CAYMAN

Compositions and processes for paper production

ActiveUS20080017337A1Avoid brightness lossIncrease brightnessNatural cellulose pulp/paperSpecial paperPaper productionPapermaking

Oxidative compositions and processes that preserve and enhance the brightness and improve color of pulp or paper when applied during different stages of the papermaking process are identified. The oxidative composition and method maintains and / or enhances brightness, prevents yellowing, and enhances the performance of paper products. Used in combination with optical brighteners and / or chelants the oxidative agents produce a synergistic effect not previously identified in the paper process.

Owner:ECOLAB USA INC

Compositions and processes for paper production

ActiveUS20070062653A1Increase brightnessIncrease resistanceCellulosic pulp after-treatmentNatural cellulose pulp/paperPapermakingPaper production

Compositions and processes that preserve and enhance the brightness and improve color of pulp or paper when applied during different stages of the papermaking process are identified. The composition and method maintains and / or enhances brightness, prevent yellowing, and enhances the performance of paper products. Used in combination with optical brighteners and / or chelants the described agents produce a synergistic effect not previously identified in the paper process.

Owner:ECOLAB USA INC

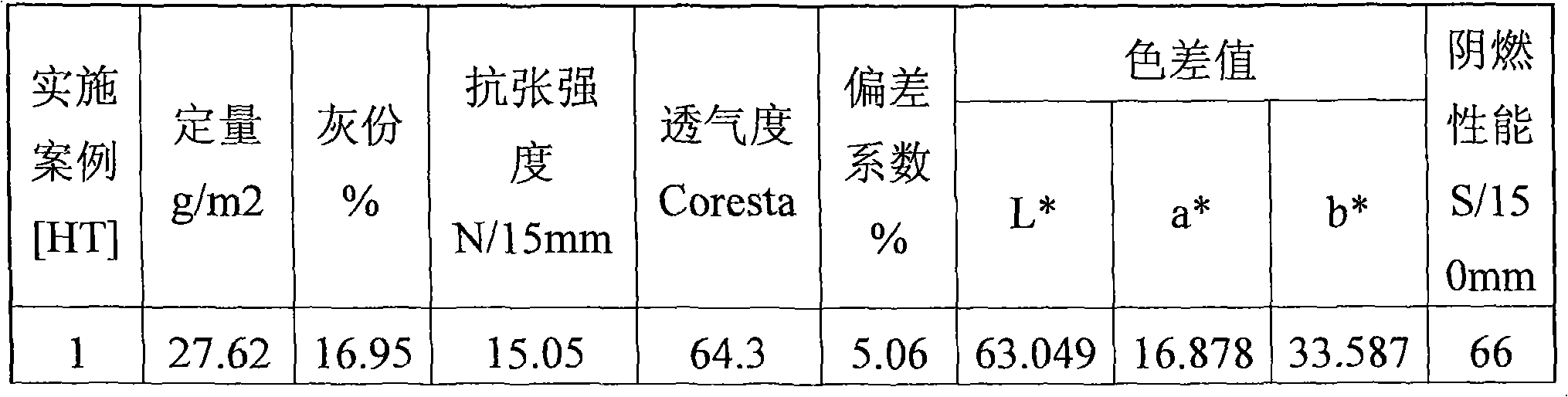

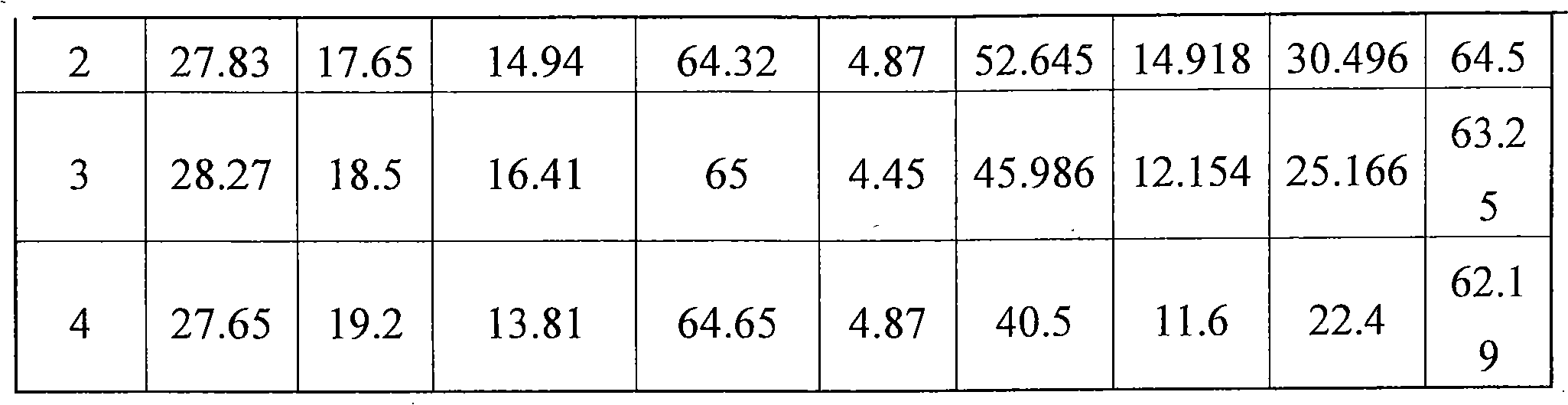

Colorized cigarette paper and preparation method

The invention discloses colorized cigarette paper, which mainly comprises the following components in part by weight: 55 to 70 parts of fiber, 30 to 45 parts of filler, 0.5 to 8 parts of combustion improver and 0.5 to 30 parts of cigarette paste, wherein the cigarette paste comprises the following components in part by weight: 1 to 8 parts of tobacco extract, 0.05 to 4.0 parts of natural extract, 0.001 to 0.05 part of edible pigment and the balance of water. The invention also discloses a preparation method for the colorized cigarette paper, which comprises the following steps of: (1) preparing combustion improver solution; (2) preparing dyeing solution; and (3) respectively adding the combustion improver solution and the dyeing solution prepared in the steps (2) and (3) into the cigarette paper by using a sizing machine for dyeing. The colorized cigarette paper and the preparation method thereof have the advantages that: the color of the cigarette paper is close to the original color of tobacco, so that the colorized cigarette paper has a more natural feel; and the preparation method can be used for production without any change of the production process for the conventional cigarette paper production equipment.

Owner:云南红塔蓝鹰纸业有限公司

Use of alkenyl succinic anhydride compounds derived from symmetrical olefins in internal sizing for paper production

A method of sizing paper for use in applications which require resistance to liquids comprising incorporating in the paper a size composition comprising one or more alkenyl succinic anhydride (ASA) compounds prepared from the reaction of maleic anhydride and one or more substantially symmetrical C20-C28 internal olefins.

Owner:ECOLAB USA INC

Process for the conversion of cellulose acetate waste fibers into a suitable form for paper production and the resultant paper products

InactiveUS20040214702A1Reduce volumeExcessive porosityNon-fibrous pulp additionNatural cellulose pulp/paperFiberAcetic acid

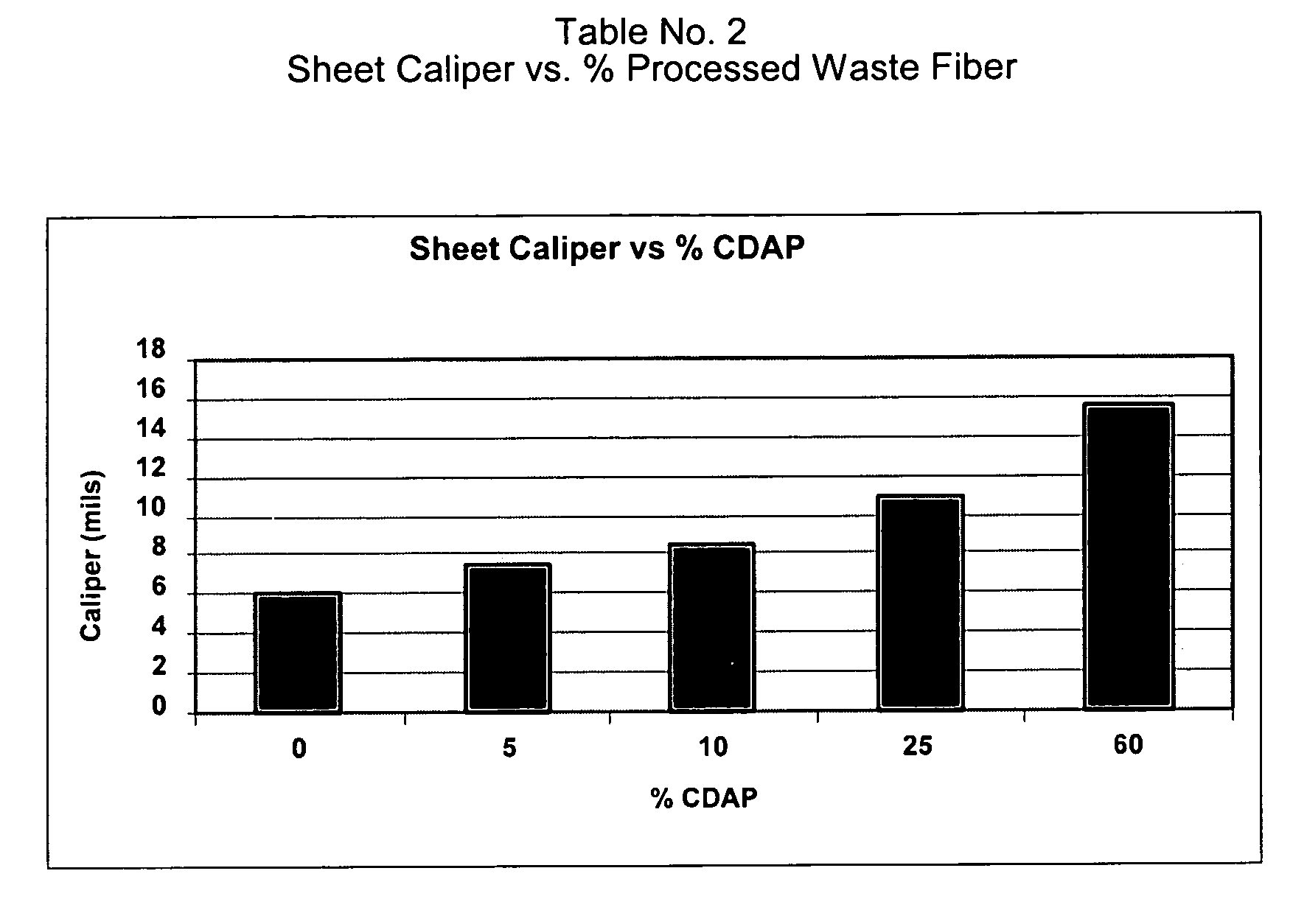

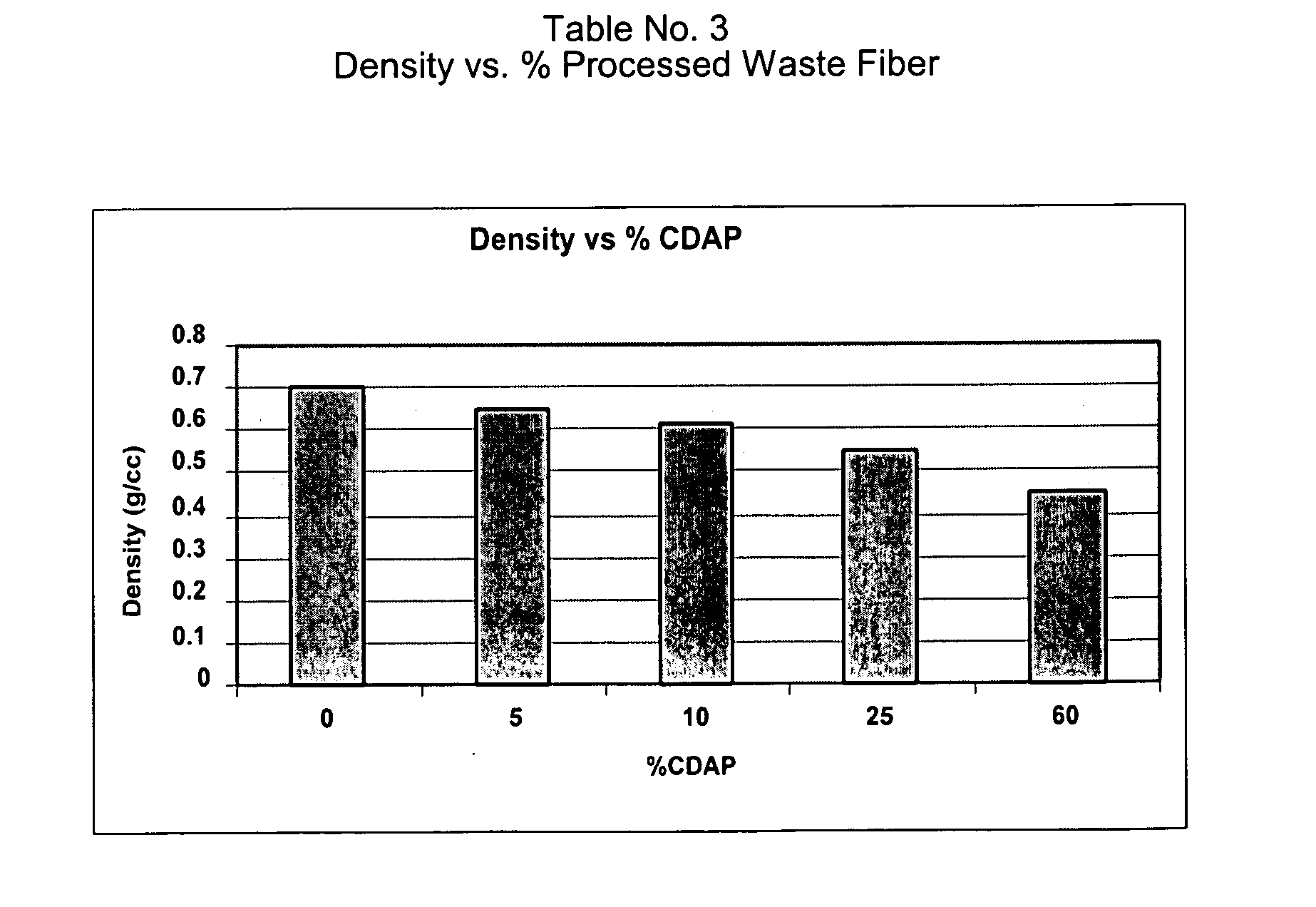

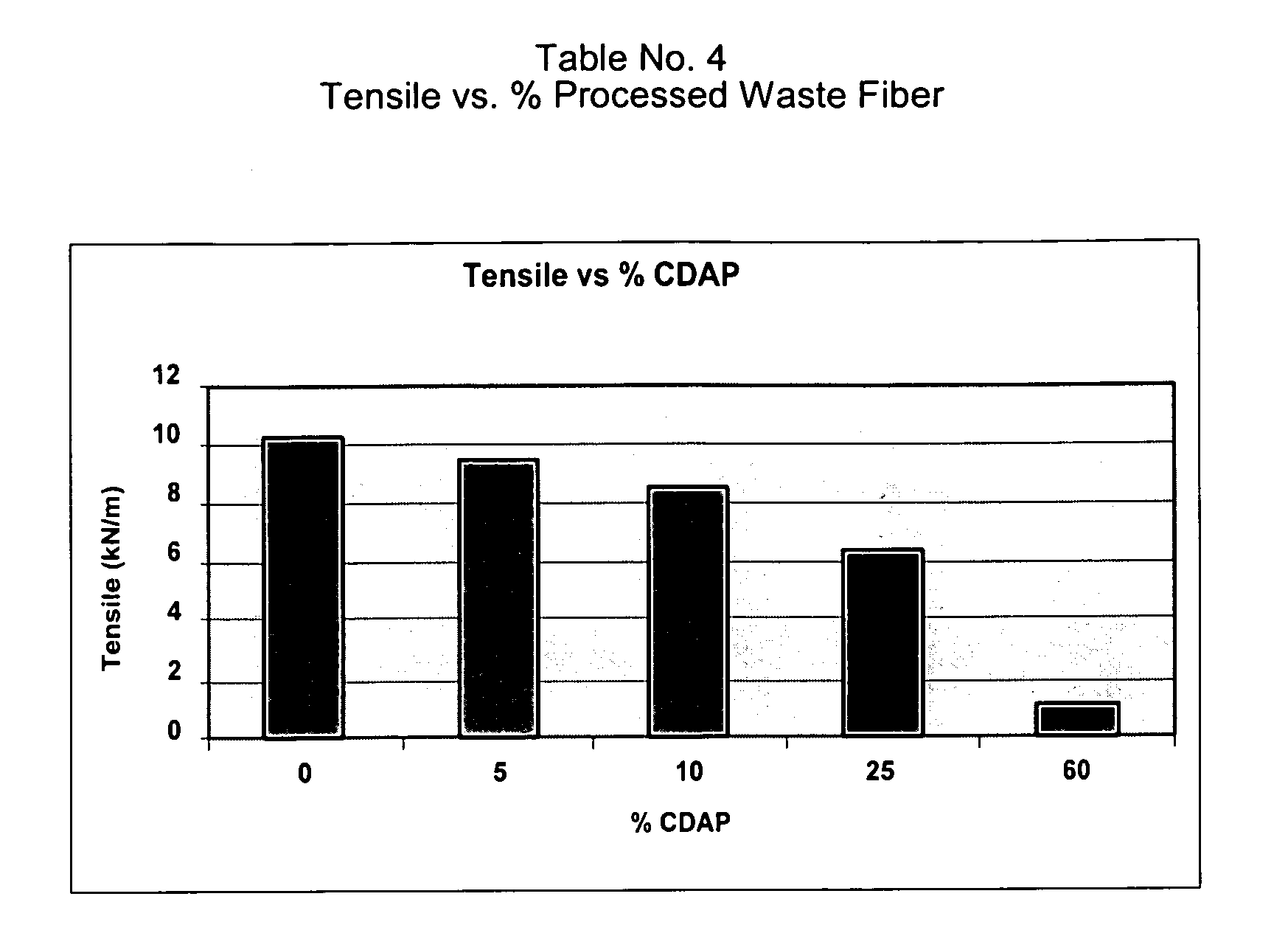

A process for producing artificial fibers without significant fiber surface hydrolysis from waste cellulose acetate continuous filament or filter rods which can then be used in the manufacture of specific paper products. Waste cellulose acetate fibers generated during filament manufacture or cigarette manufacture as off quality production is used for rendering the into a form suitable for specific paper manufacture. Paper products which comprise 1-10% of the subject fiber as part of the pulp furnish is also disclosed.

Owner:STROUD HERBERT D JR +1

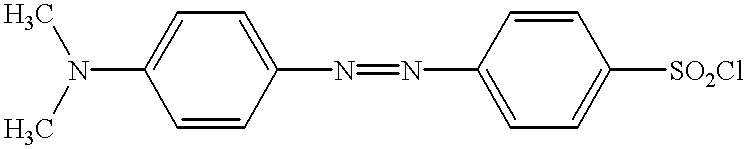

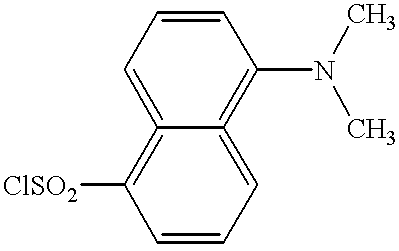

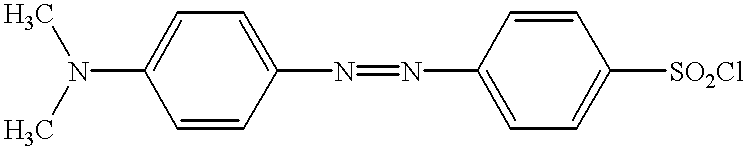

Detectable polymers and methods for detecting polymers in Aqueous systems

InactiveUS6251680B1High molecular weightDecrease in levelAnalysis using chemical indicatorsOrganic detergent compounding agentsThiolPaper production

Polymers having amine-thiol terminal moieties are provided. The amine-thiol terminal moieties are imparted by using amine-thiols as chain transfer agents in aqueous addition polymerizations. The polymers are useful as mineral dispersants, as water-treatment additives for boiler waters, cooling towers, reverse osmosis applications, sugar refining, paper production, geothermal processes and oil wells, and as detergent additives acting as builders, anti-filming agents, dispersants, sequestering agents and encrustation inhibitors.

Owner:ROHM & HAAS CO

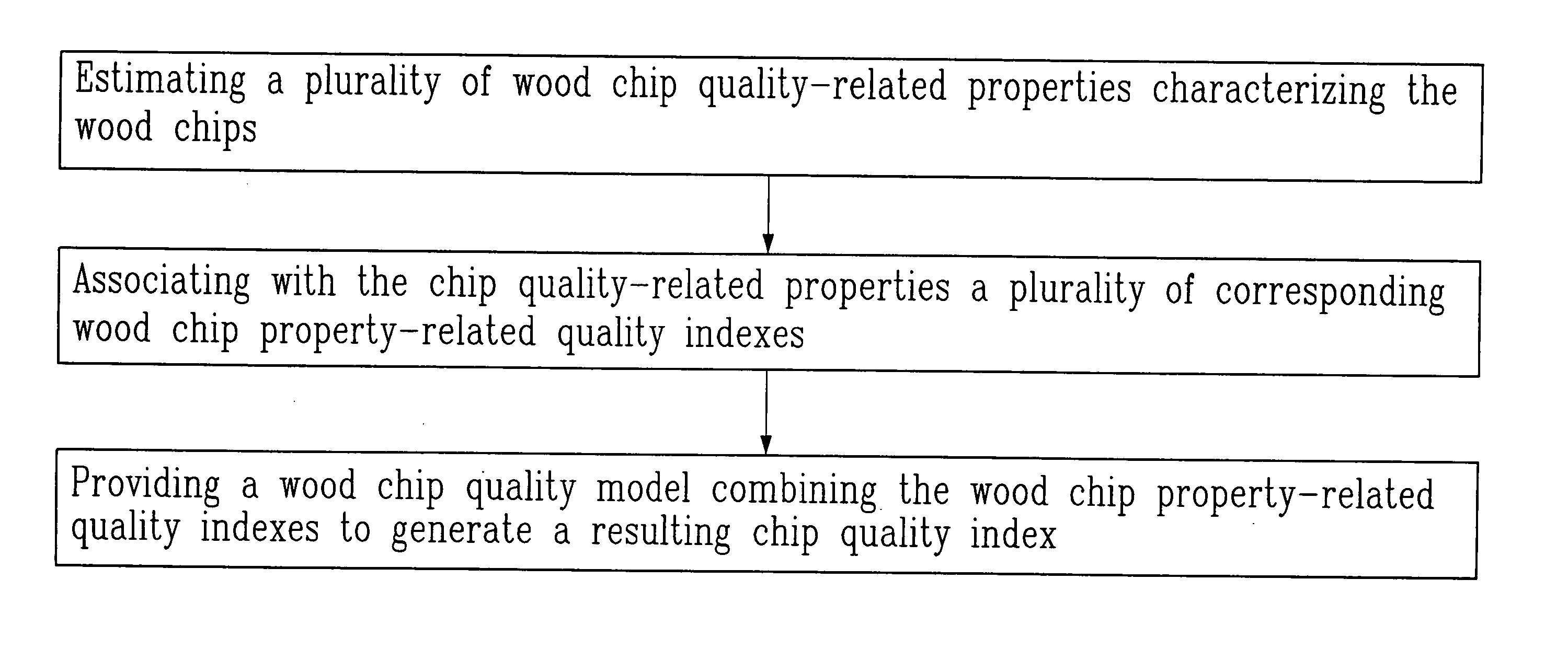

Method for estimating the quality of wood chips

ActiveUS20050027482A1Easy to manageEasy to useOptical radiation measurementDigital data processing detailsPaper productionPulp and paper industry

A method for estimating the quality of wood chips for use in a pulp and paper production process includes estimating a plurality of wood chip quality-related properties characterizing the wood chips, and associating with these properties a plurality of corresponding wood chip property-related quality indexes. A wood chip quality model combining the wood chip property-related quality indexes is used to generate a resulting chip quality index. The properties may include wood species composition, size distribution, impurities content, moisture content and freshness characterizing the wood chips.

Owner:CENT DE RES & DEV IND DU QUEBEC

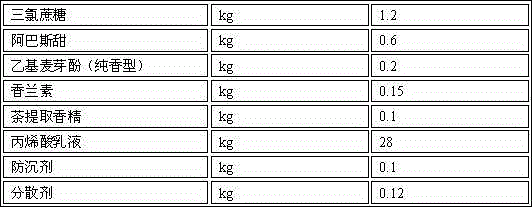

Fragrant and sweet taste cigarette tipping paper production method

ActiveCN104372719AIncrease the fragranceDifferent pumping sensationSpecial paperPaper coatingHot stampingSucrose

The invention relates to a fragrant and sweet taste cigarette tipping paper production method, which specifically comprises: 1, completely mixing alcohol and an acrylic acid emulsion, then sequentially adding chlorosucrose and aspartame, stirring for 10-20 min, then adding an anti-sedimentation agent and a dispersant, stirring for 5-10 min, adding ethyl maltol (pure flavor type), vanillin and tea extraction essence, stirring for 5-10 min to prepare a fragrant and sweet taste ink, and carrying out sealed storage; 2, printing on a gravure printing machine, wherein the printing plate adopts the laser engraving gravure, the ground color ink adopts the inorganic ink, dilution is performed with alcohol, the final color adopts the fragrant and sweet taste ink to coat, and the printing plate with the mesh depth of 35 [mu]m is adopted; 3, the fragrant and sweet taste ink prepared in the step 1 is coated on the surface of tipping paper, and carrying out sealed storage, wherein the printing speed is 100-120 m / min, and the temperature is 80-100 DEG C; and 4, carrying out hot stamping, slitting and perforating on the tipping paper. With the production method, the cigarette tipping paper is endowed with the sweet taste effect, and the fragrance of the cigarette tipping paper is increased.

Owner:QINGDAO JUSTO PACKAGING +1

High voltage resistant electrolytic capacitor paper and preparation method thereof

ActiveCN104988809AHigh strengthSoft touchPlastic/resin/waxes insulatorsPaper coatingElectrolysisPaper production

The invention relates to electrolytic capacitor paper and a preparation method thereof. Raw paper pulp of the electrolytic capacitor paper is composed of insulation wood pulp, cotton pulp and hemp pulp; at least one of the cotton pulp and the hemp pulp is selected, papermaking is conducted on the cotton pump and / or the hemp pump, and raw paper is prepared by the processed cotton pump and / or hemp pump and the insulation wood pump in a composite mode. According to the technical scheme, high voltage resistant electrolytic capacitor paper is obtained through raw paper production and subsequent coating processing, the high voltage resistant electrolytic capacitor paper is better in strength, soft in hand feeling, good in water-absorbing capacity, low in loss value and excellent in voltage-resistance performance, and the voltage-resistance performance can be increased by over 100 V / mm.

Owner:ZHEJIANG KAN SPECIAL PAPER CO LTD +2

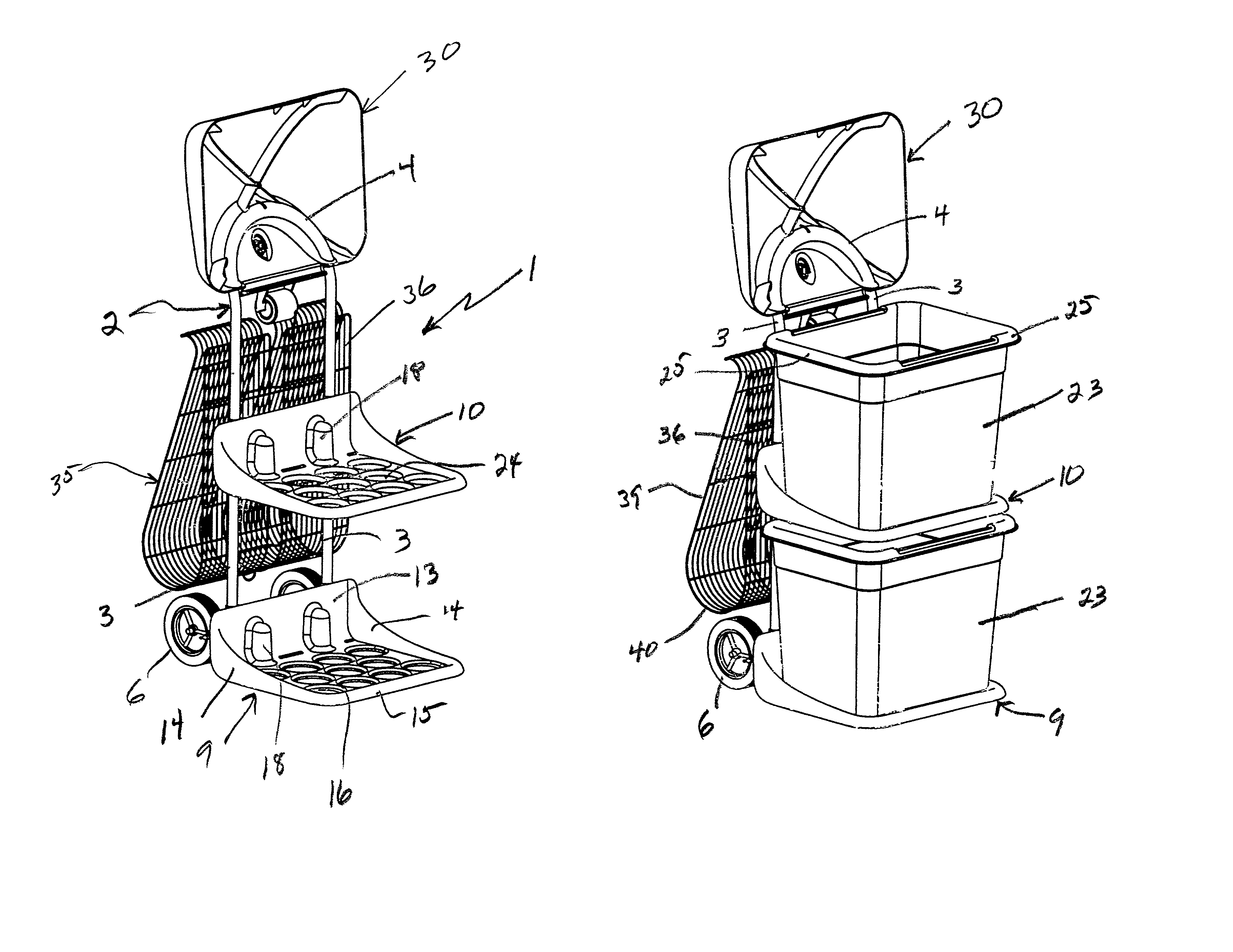

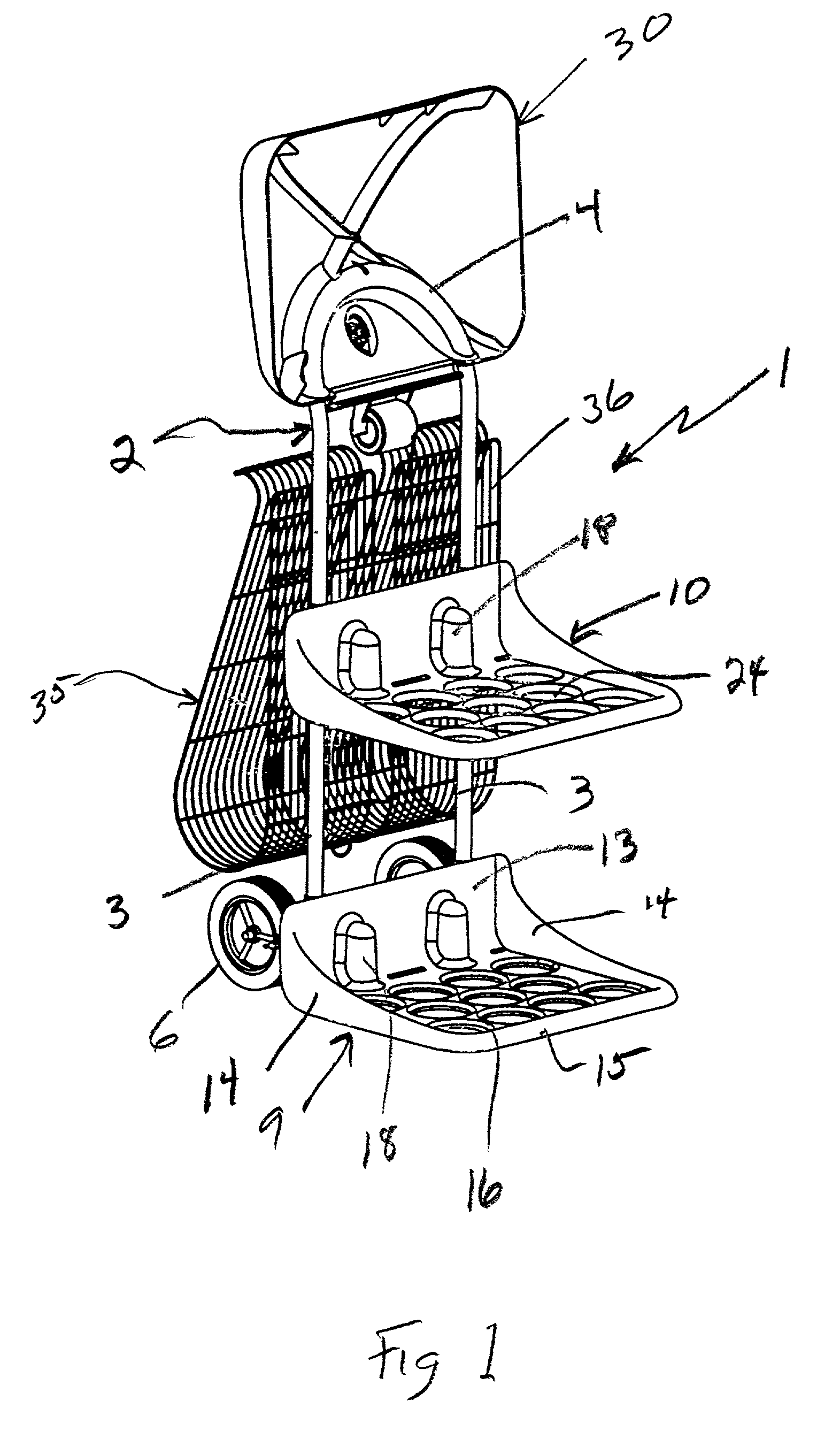

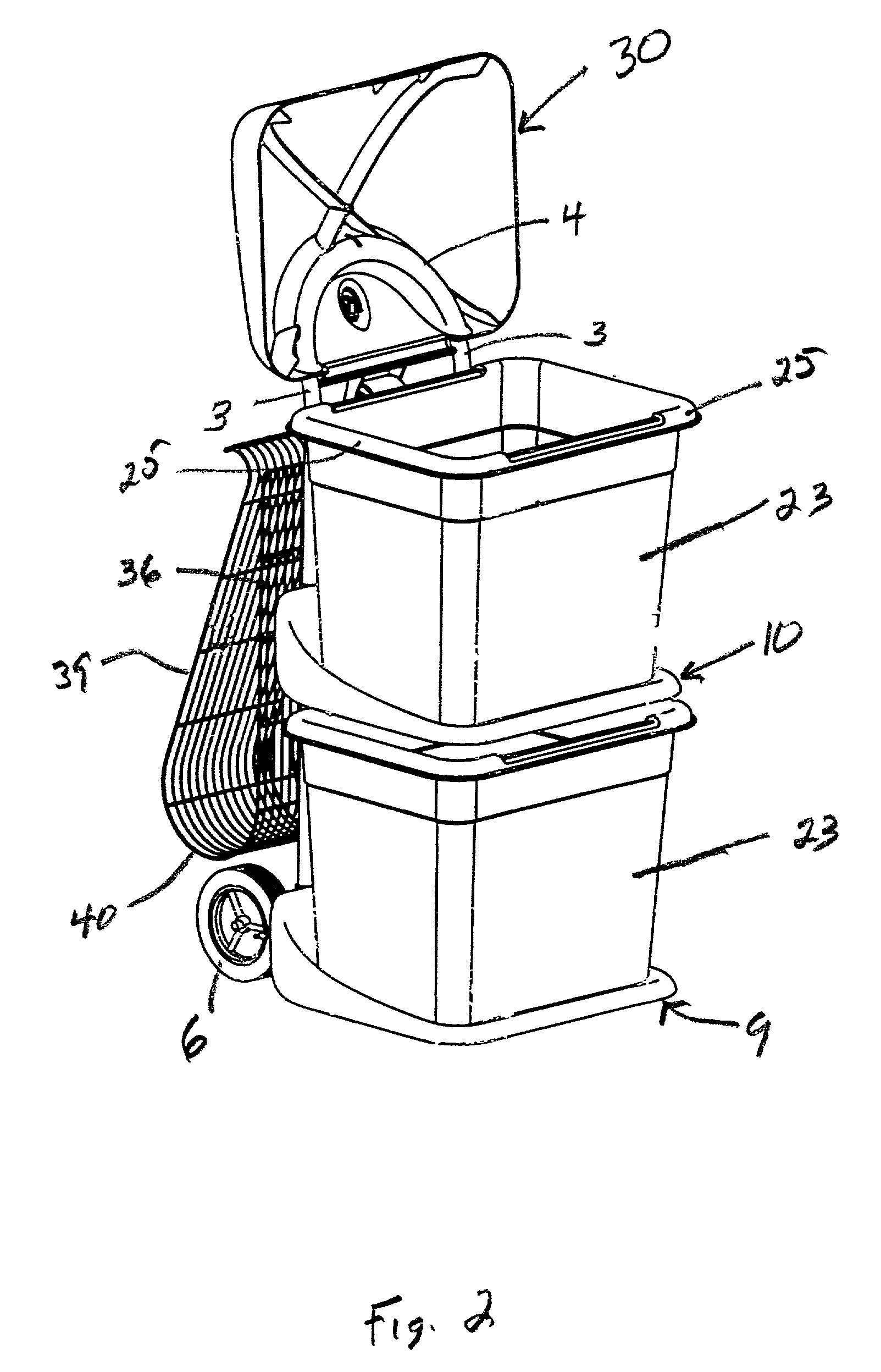

Load dolly

InactiveUS7063339B2Limit opening movementStabilizing lidCarriage/perambulator with single axisWaste collection and transferPaper productionEngineering

A wheeled dolly for storing and transporting a plurality of recycle boxes has an inverted U-shaped tubular frame and a pair of plastic shelves mounted on the frame and extending in a cantilever fashion therefrom. A lid is pivotally mounted on the frame for closing the open top of the top-most box. A metal mesh basket is mounted on the rear of the frame for receiving and storing paper products. A roll of cord is mounted on the lid for discharging a length of cord to tie the paper products into bundles. A cord cutter is mounted on the lid to cut the cord from the roll after it is tied about the paper products.

Owner:JARKO PAUL R +2

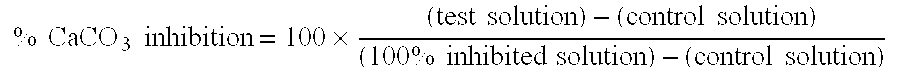

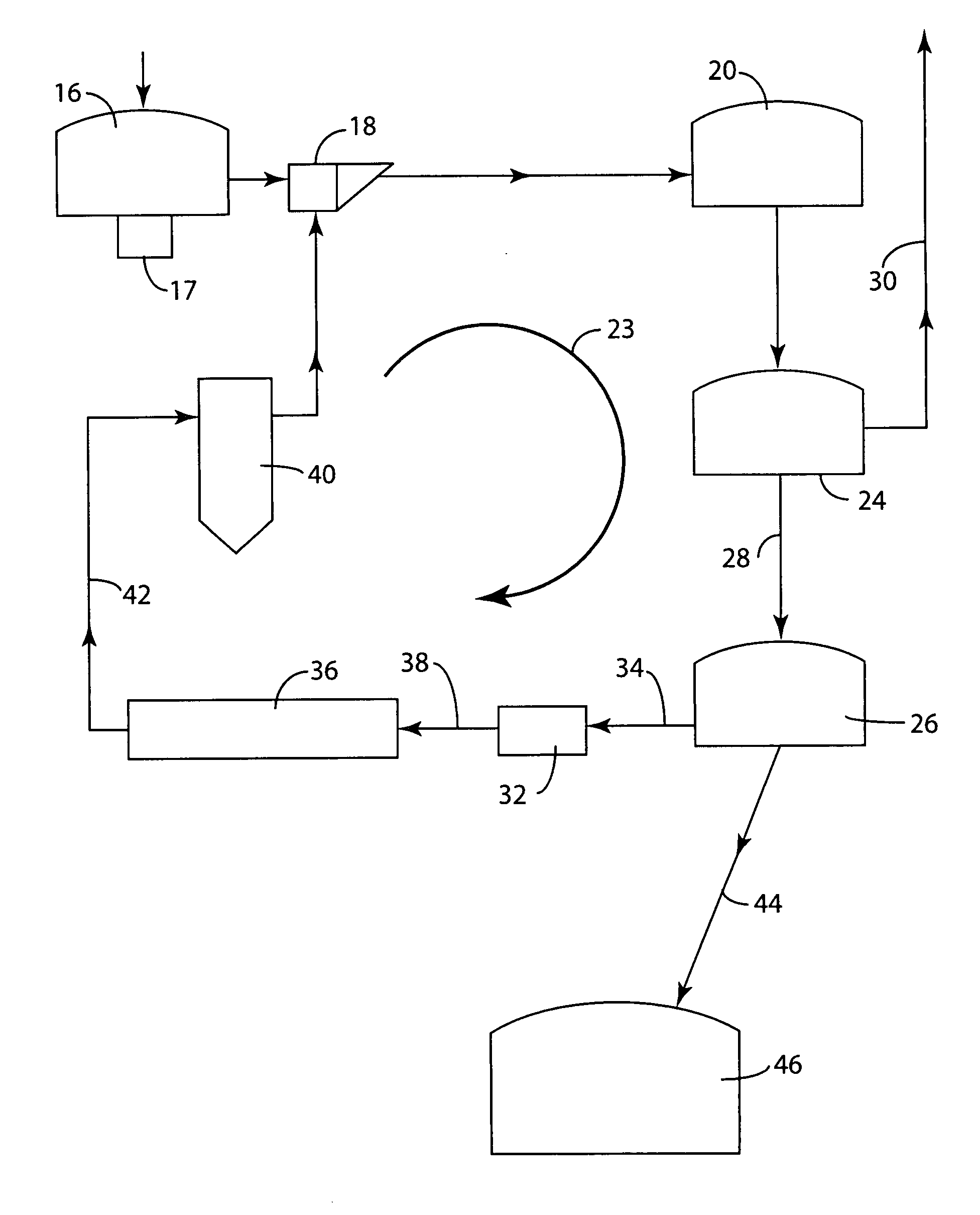

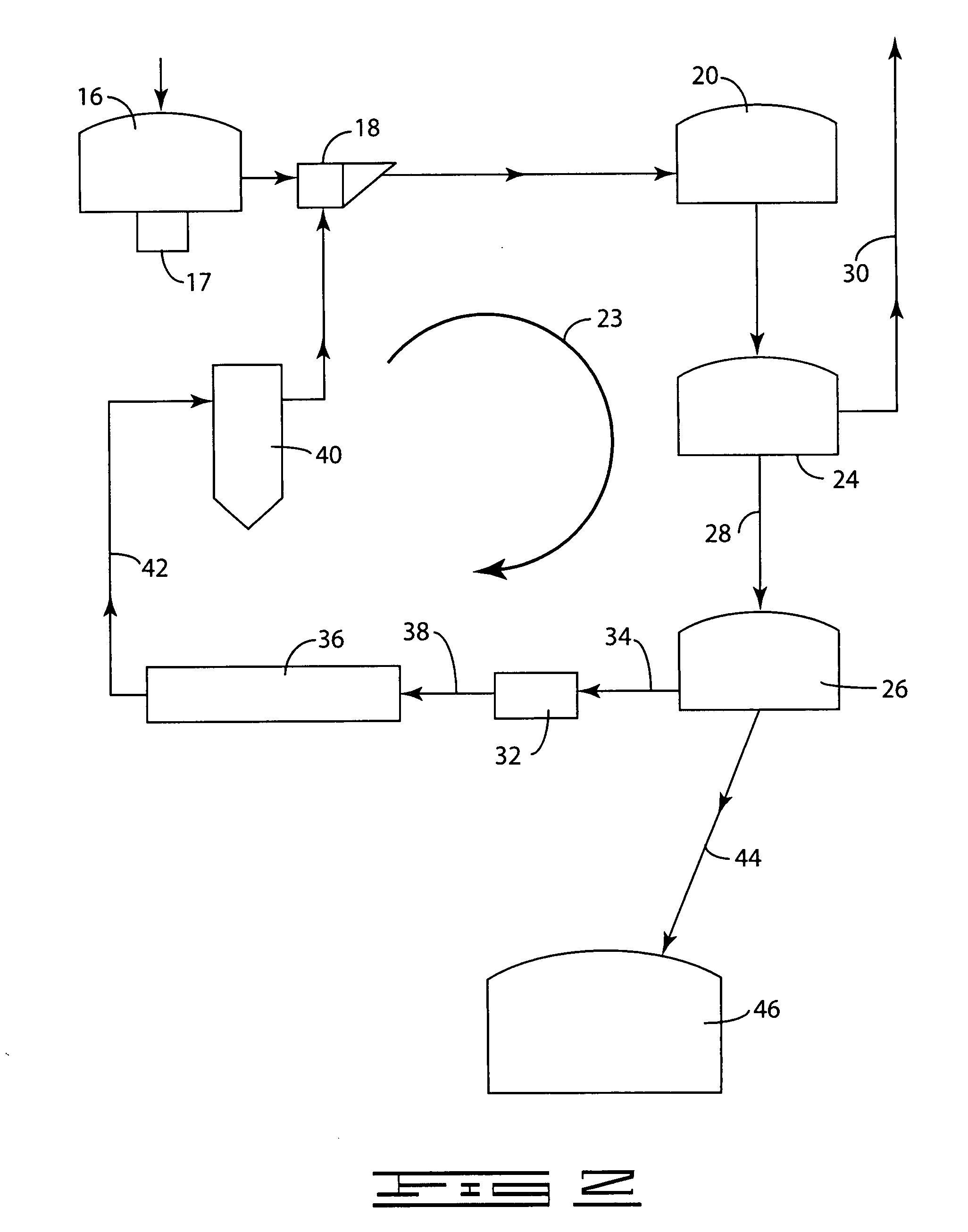

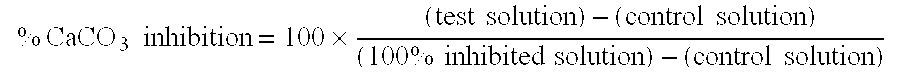

Particulate matter and methods of obtaining same from a kraft waste reclamation

InactiveUS20080219912A1Calcium/strontium/barium carbonatesGas treatmentParticulatesChemical composition

A method for obtaining particulate calcium carbonate having an average particle size less than about 12 microns is provided. The method includes the steps of (1) withdrawing from a pulp mill a mixture containing calcium carbonate; (2) treating the mixture to remove contaminants contained in the mixture to produce a treated mixture containing calcium carbonate and further having a chemical composition and / or purity which substantially inhibits the fusing together of calcium carbonate particulates; (3) recovering from the treated mixture particulate calcium carbonate having an average particle size less than about 12 microns. The calcium carbonate produced has a high surface area to volume ratio and is therefore highly reactive and suitable for numerous applications such as in the treatment of soil, filler paper production, paint production, and contaminant containment in coal stack emission assemblies.

Owner:S&S LIME

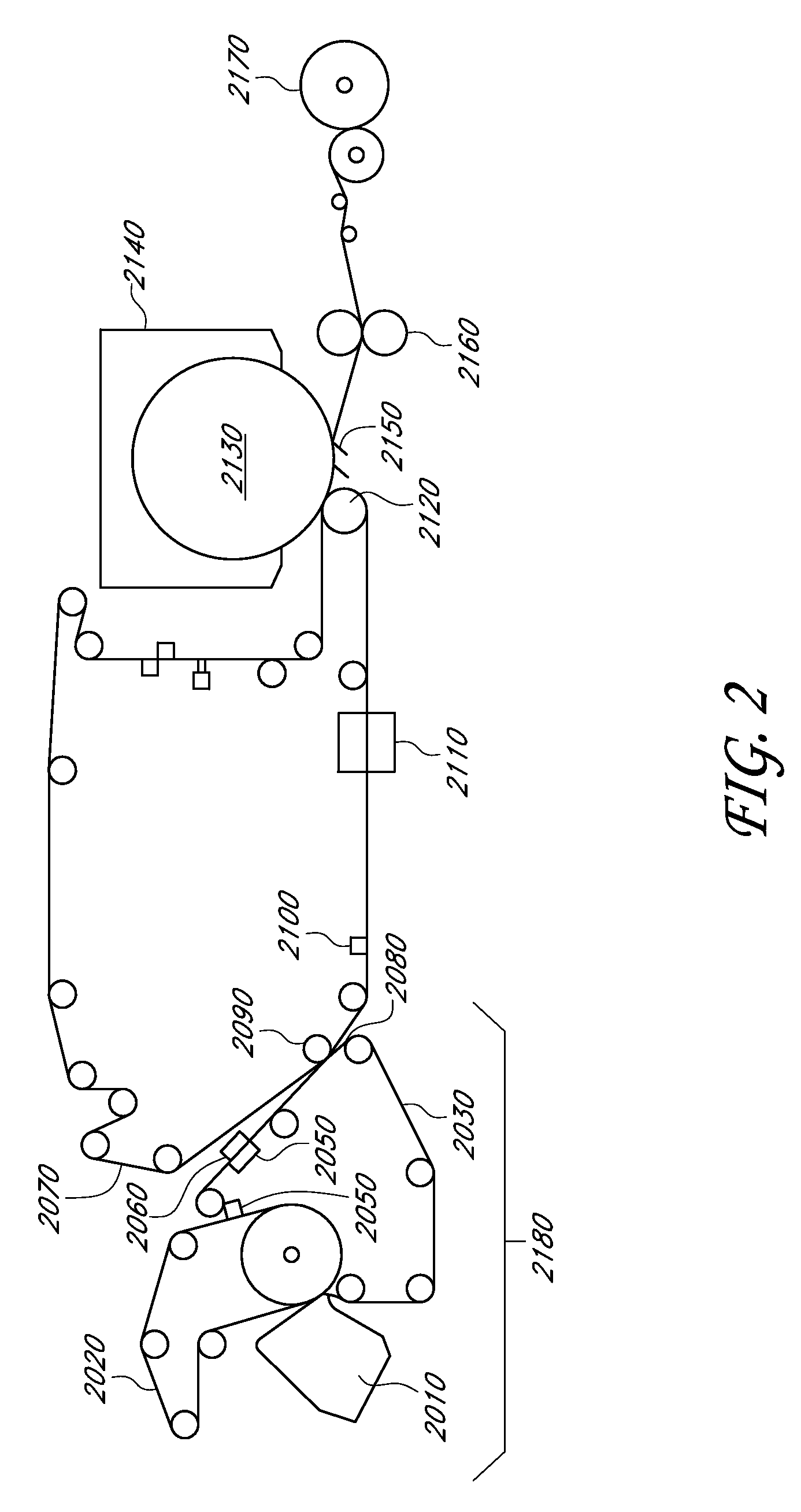

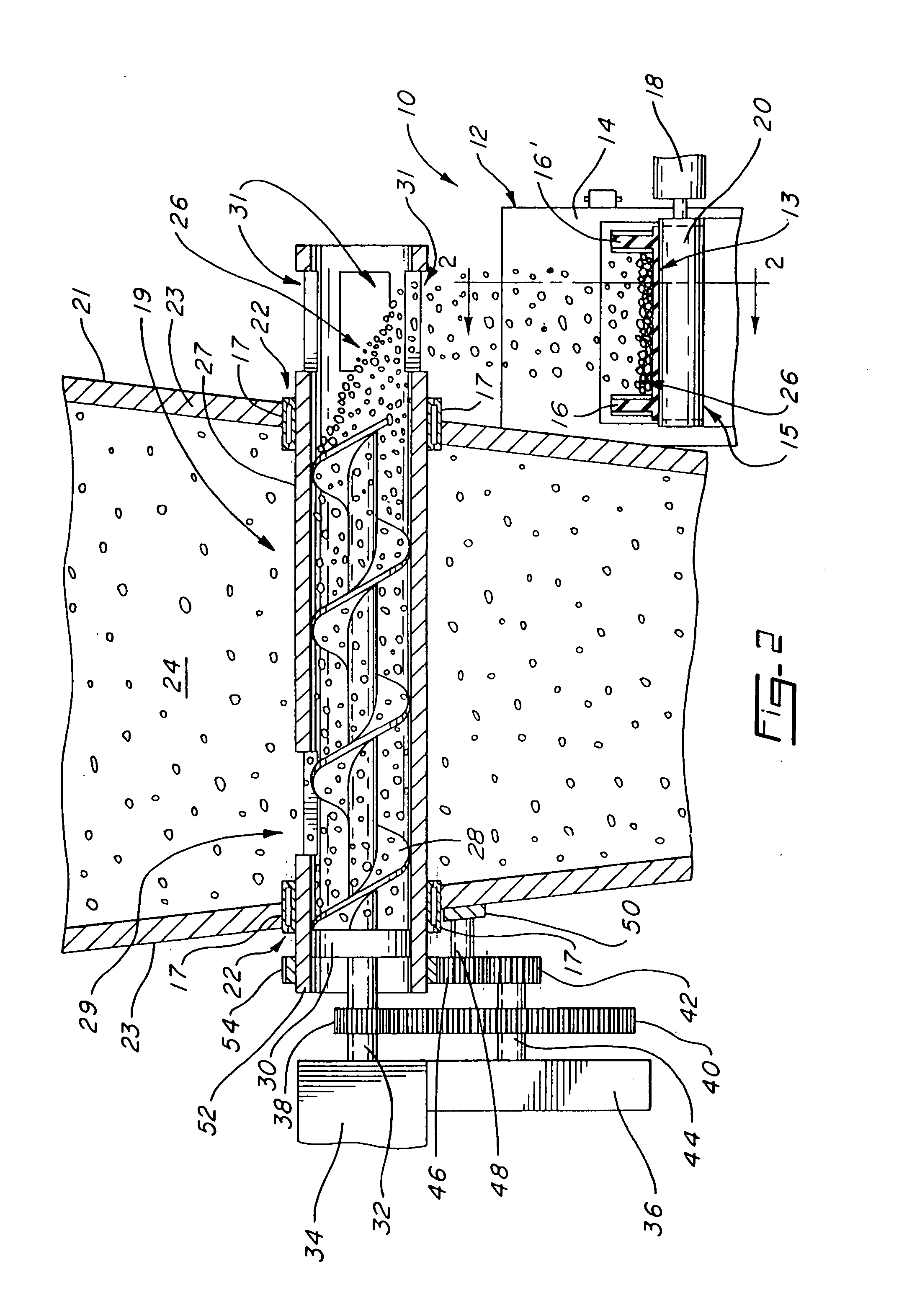

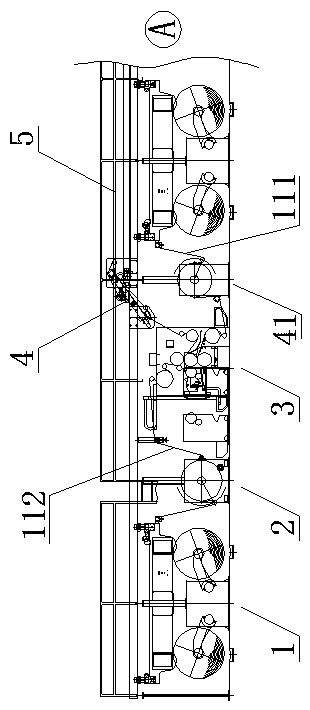

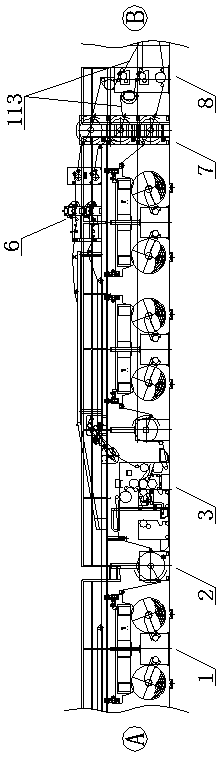

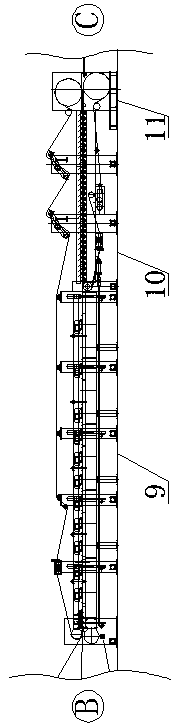

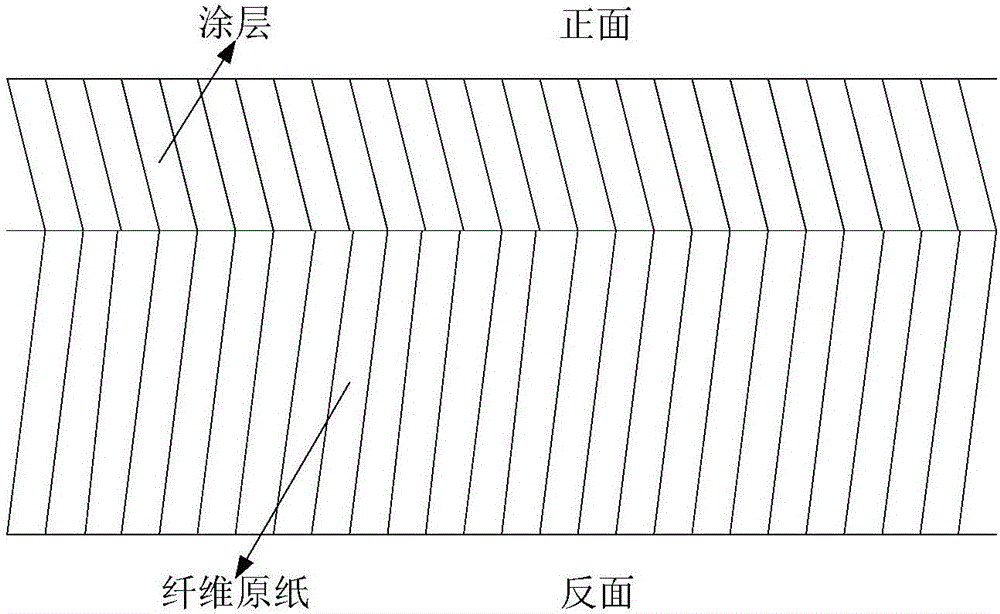

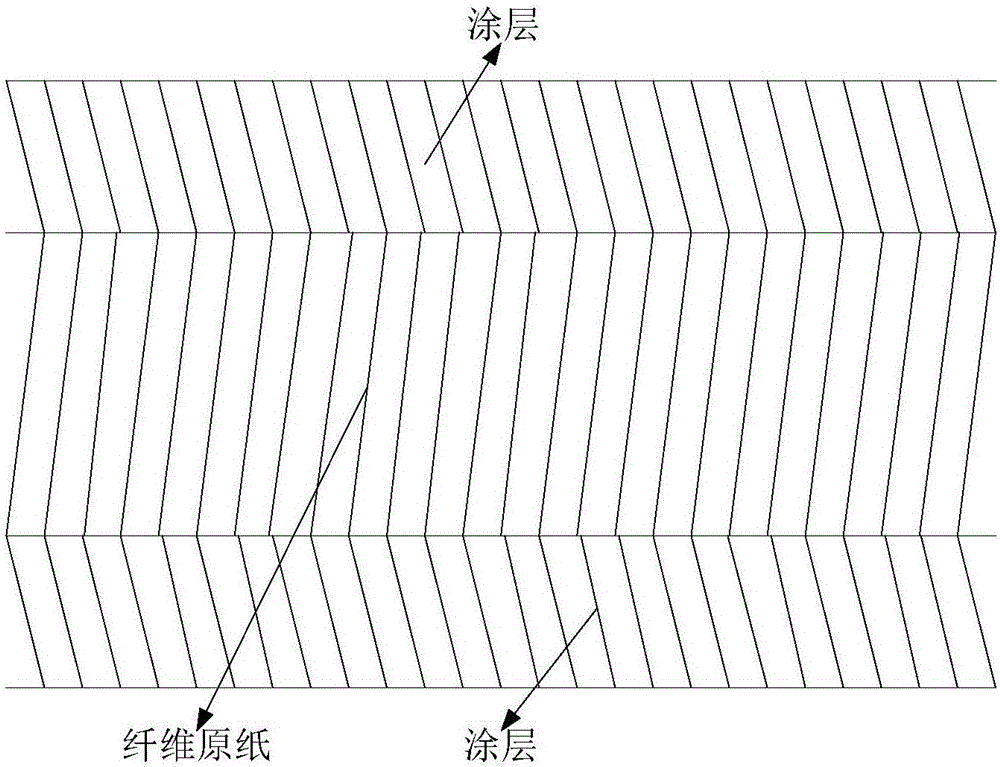

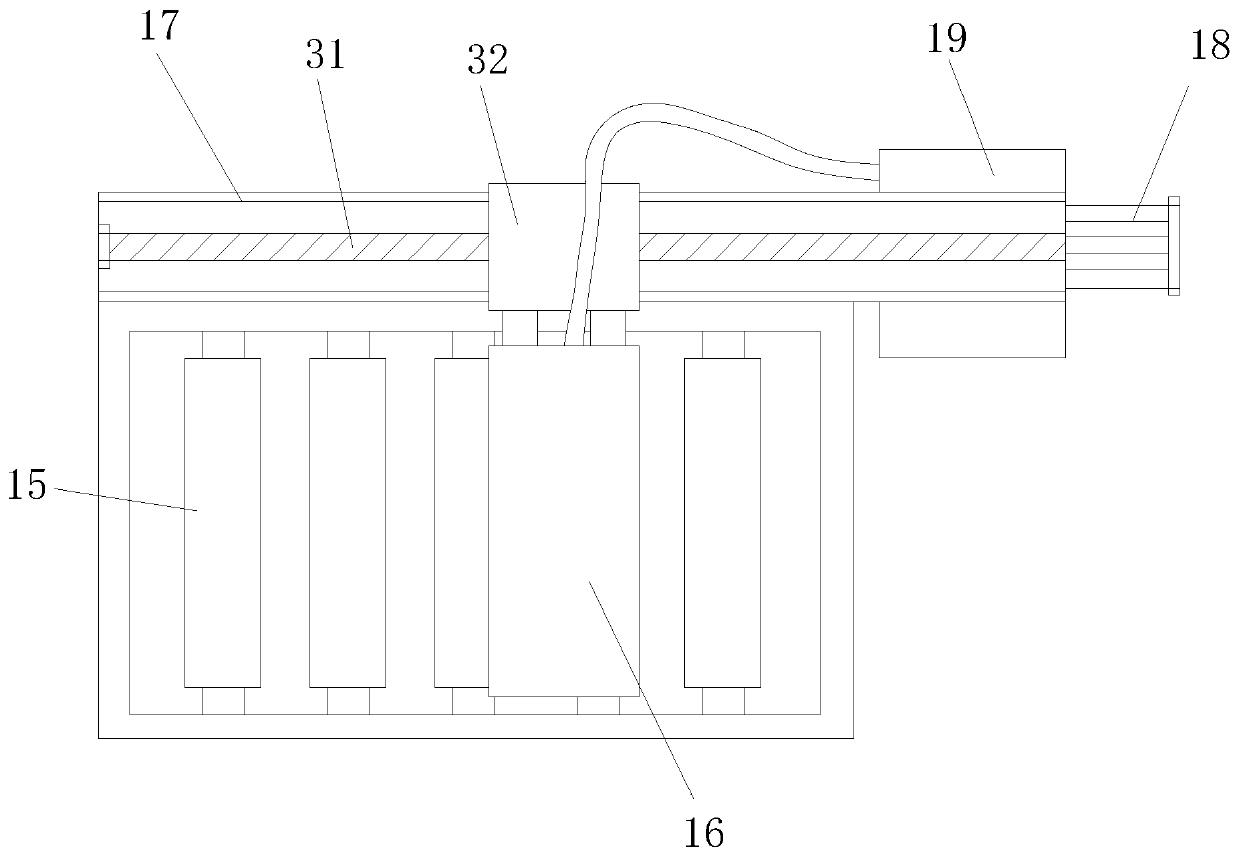

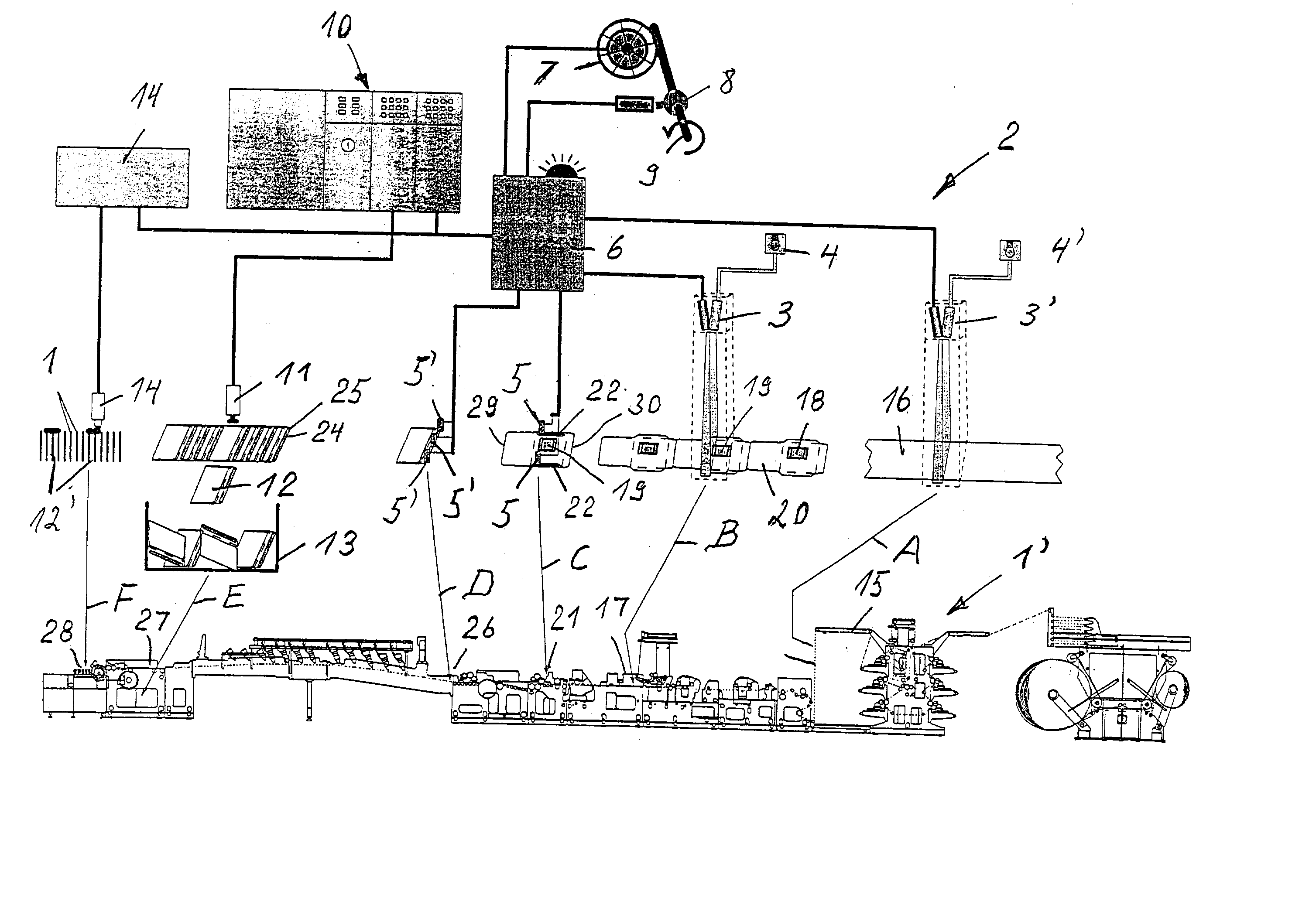

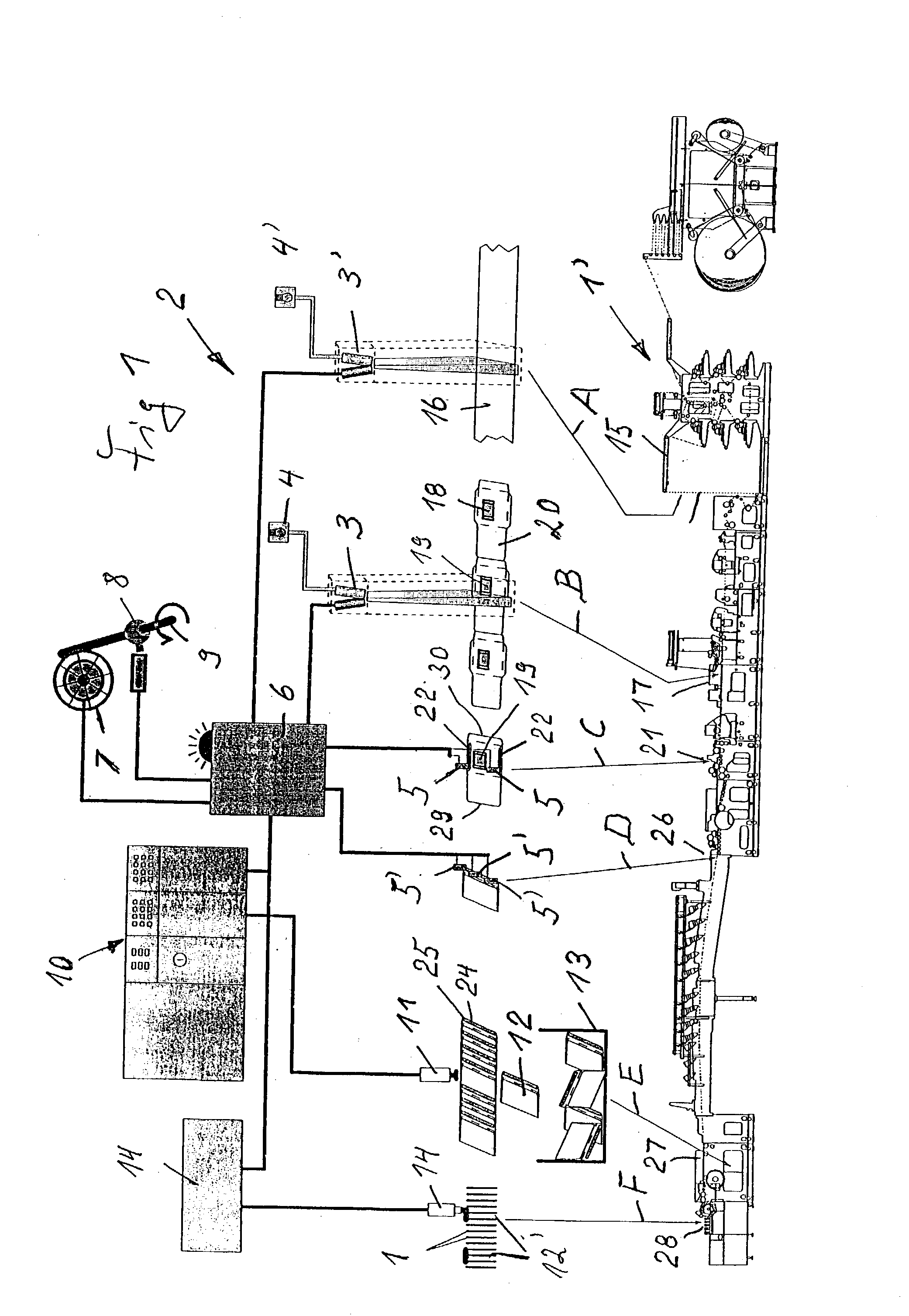

Five-layered corrugated paper production line

ActiveCN109130329AMeet functional needsPrecise position of fixed-point machiningMechanical working/deformationBox making operationsCardboardPaper production

The invention discloses a five-layered corrugated paper production line. The five-layered corrugated paper production line comprises a plurality of body paper racks used for unreeling body paper, facepaper preheating wheels, core paper preheating wheels, a single corrugated paper machine, an upward leading device, a double-layered paper rack, a conveying device, a triple preheating wheel, a pasting machine, a paper board forming machine, a driving device and an N.C. cutting and line pressing edge trimmer, wherein the face paper preheating wheels and the core paper preheating wheels are arranged between every two body paper racks; the single corrugated paper machine is used for roller forming of core paper and further compounding the core paper and face paper into single corrugated paper boards; the upward leading device and the double-layered paper rack are arranged above the single corrugated paper machine; the conveying device is used for conveying the single corrugated paper boards; the triple preheating wheel is used for preheating the single corrugated paper boards and the face paper; the pasting machine is used for pasting the face paper and two layers of the single corrugated paper boards; the paper board forming machine is used for compounding the face paper and the two layers of the single corrugated paper boards into a five-layered corrugated paper board; the drivingdevice is used for conveying the five-layered corrugated paper board; and the N.C. cutting and line pressing edge trimmer is used for shaping the five-layered corrugated paper board. By adoption of the five-layered corrugated paper production line, the corrugated paper board of a five-layered structure can be produced, and fixed-point notching treatment of the five-layered corrugated paper boardcan be conducted; and the automatic detecting and waste discharging functions are further achieved, and the number of discarded products in finished corrugated paper board products is decreased.

Owner:晋江市新达纸箱包装有限公司

High-temperature-resistant non-combustion cigarette paper and preparation method thereof

ActiveCN106480773AMeet high quality requirementsTo achieve the purpose of high temperature resistanceInorganic fibres/flakesWater-repelling agents additionCombustionTar

The invention discloses high-temperature-resistant non-combustion cigarette paper and a preparation method thereof. The preparation method of the high-temperature-resistant non-combustion cigarette paper comprises the following steps: (1) glue application in pulp: a glue application agent is added into the pulp after pulping, and the solid content is controlled to be 1 to 5 percent of the specified quantity of raw paper; (2) surface glue application after papermaking; (3) single-side or two-side coating after glue application, wherein the coating quantity is 5 to 50g / m<2>; fixed quantity before paper sheet coating is 30 to 120g / m<2>. On the basis of the existing cigarette paper production process, the goal of resisting high temperature is achieved through performing glue application and coating treatment on the cigarette paper, so that the cigarette paper can be applied to the heating on non-combustion cigarettes. The high-temperature-resistant non-combustion cigarette paper obtained by the preparation method can be used at 300 to 500 DEG C; in the use process, the cigarette paper hardly generates color change, avoids tar penetration and does not deform; the high-quality requirement of heating non-combustion paper for cigarettes is met.

Owner:中烟摩迪(江门)纸业有限公司

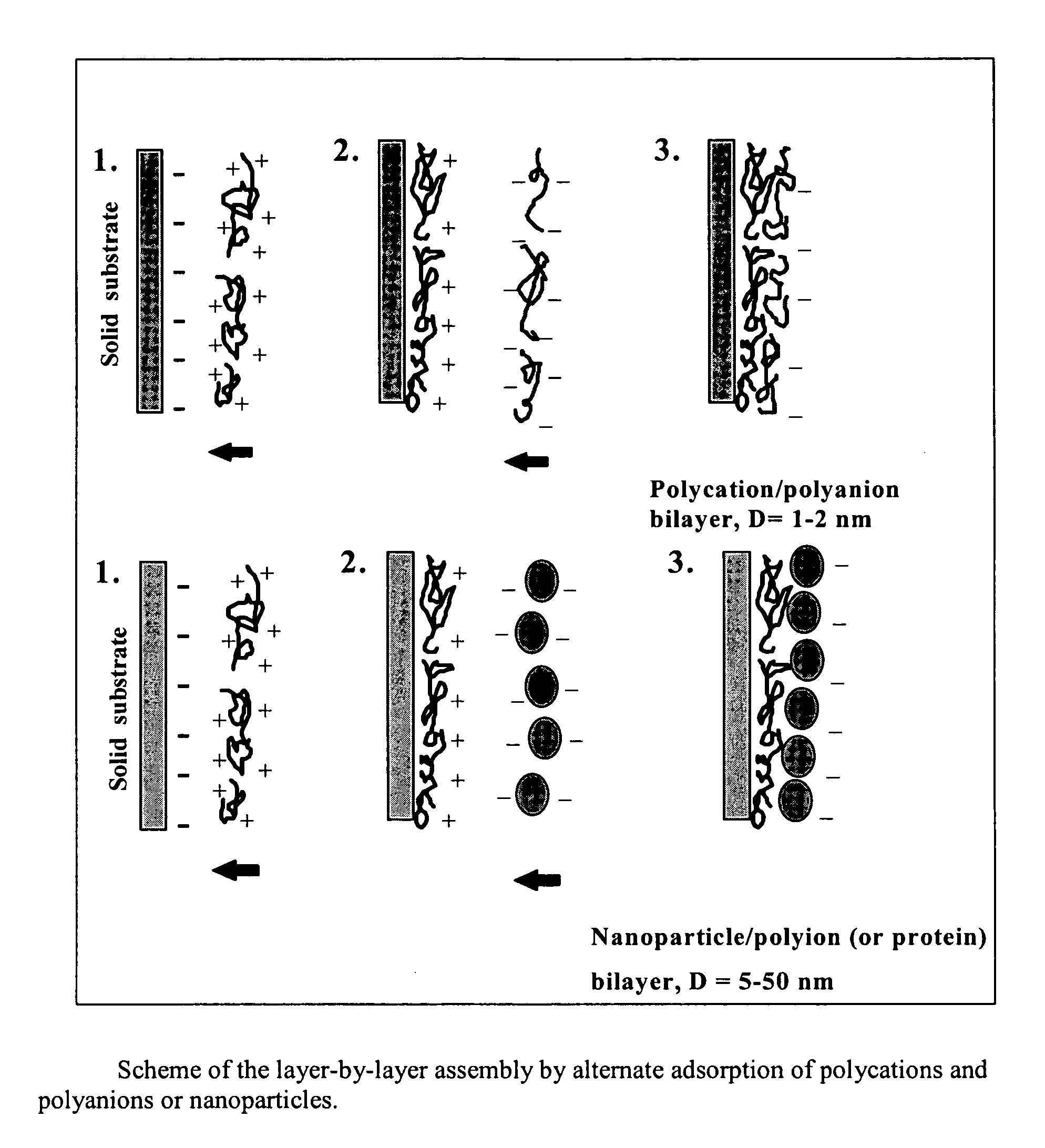

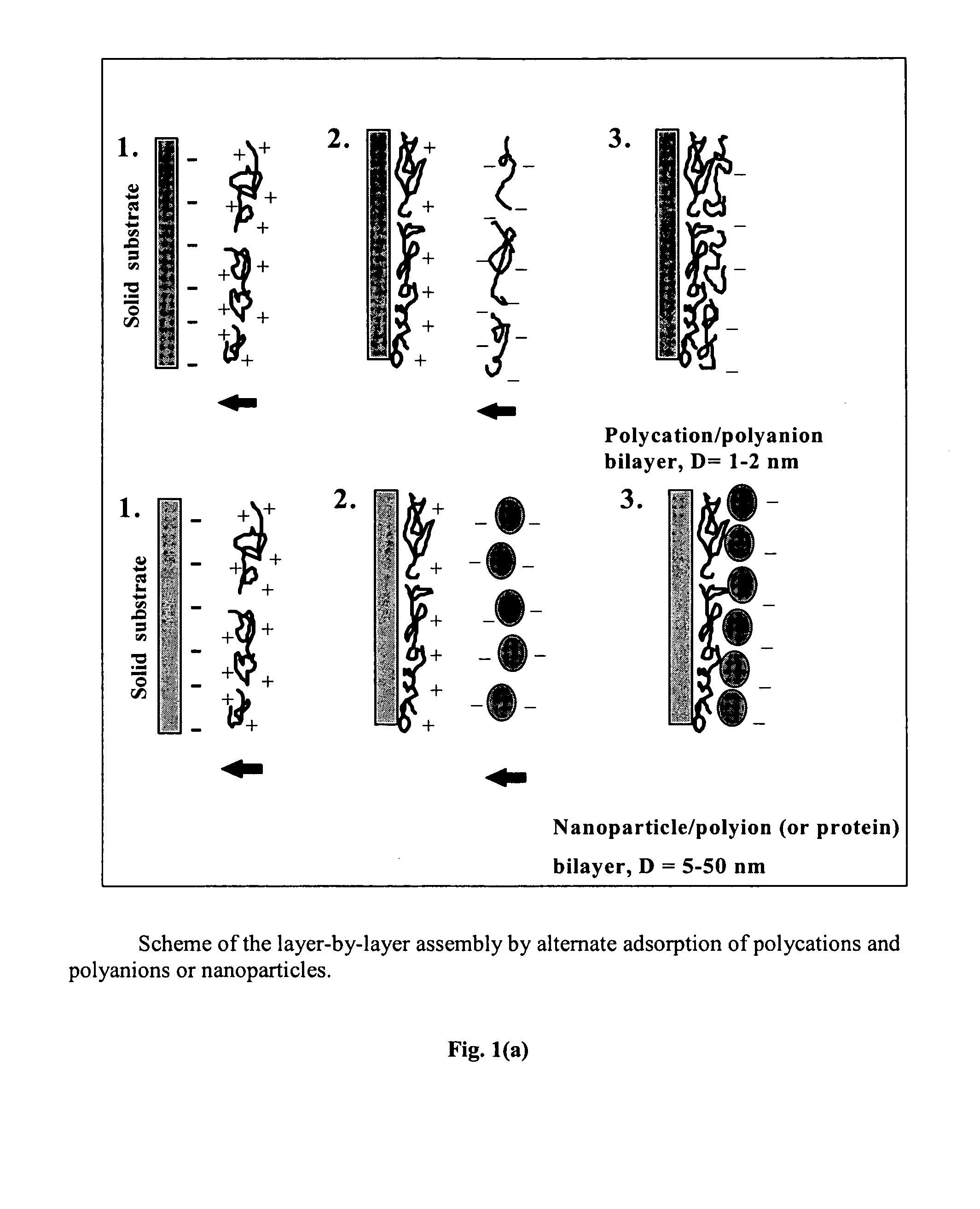

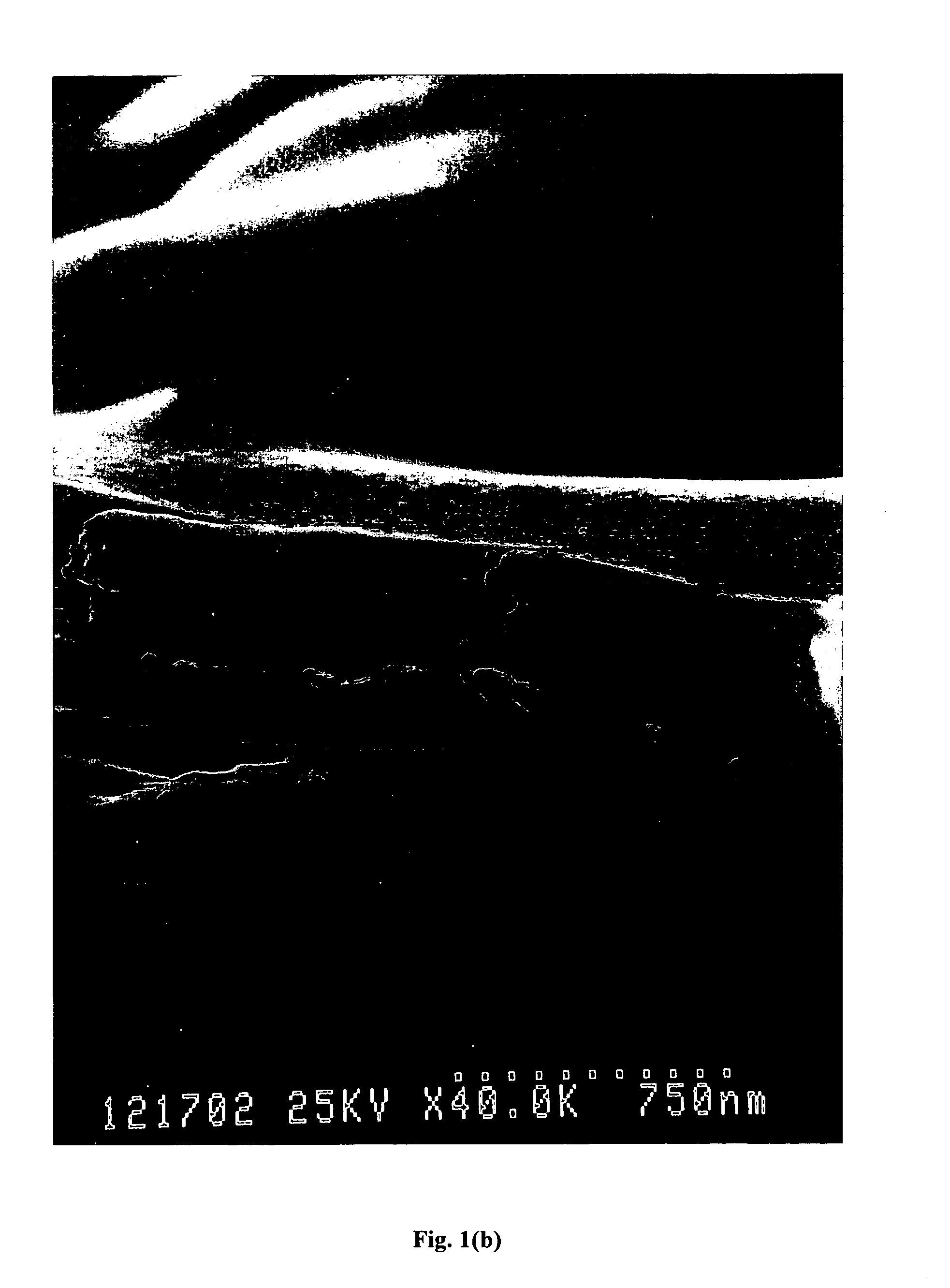

Layer-by-layer nanocoating for paper fabrication

InactiveUS7842162B1Improve performanceEasy to scaleNatural cellulose pulp/paperCoatings with pigmentsPhysical strengthPaper production

A method is provided for manufacturing paper by means of layer-by-layer nanocoating techniques. The method comprises the sequential processing of an aqueous pulp of lignocellulose fibers which is first subjected to nanocoating by alternatively adsorbing onto the fibers multiple consecutively-applied layers of oppositely-charged nanoparticles, polymers and / or proteins thereby making a modified aqueous pulp of multi-layer nanocoated lignocellulose fibers, then draining the water out of the modified pulp to form sheets of multi-layer nanocoated fibers, and drying the formed sheets of multi-layer nanocoated fibers. The resulting dried sheets are then processed to make a finished paper that has superior physical strength and improved surface properties. In a preferred embodiment the starting aqueous pulp of lignocellulose fibers is divided into is separate portions which are separately nanocoated with opposite charges, and then blended to form a complex aggregate pulp of nanocoated fibers before draining and drying it. The method is particularly applicable to the treatment of broken (mill broke) recycled fibers in order to facilitate their usage in paper production.

Owner:LOUISIANA TECH UNIV RES FOUND A DIV OF LOUISIANA TECH UNIV FOUND

Use of alkenyl succinic anhydride compounds derived from symmetrical olefins in internal sizing for paper production

A method of sizing paper for use in applications which require resistance to liquids comprising incorporating in the paper a size composition comprising one or more alkenyl succinic anhydride (ASA) compounds prepared from the reaction of maleic anhydride and one or more substantially symmetrical C20-C28 internal olefins.

Owner:ECOLAB USA INC

Silver-loaded antibacterial paper and preparing method thereof

InactiveCN105780590AFast and good bactericidalFast and good bacteriostasisWater-repelling agents additionReinforcing agents additionPaper productionBleach

The invention discloses silver-loaded antibacterial paper.The silver-loaded antibacterial paper is prepared from a silver-loaded antibacterial agent, a softening agent, a dry strength agent, a wet strength agent, a drying agent, a retention agent, a sizing agent, an antibacterial agent, a dispersing agent and a decolorizer additive.The invention further discloses a preparing method of the silver-loaded antibacterial paper.The method comprises the following steps that pulping, pulp dispersing, pulp milling and pulp beating are carried out, the silver-loaded antibacterial agent is added into the pulp sizing agent, the sizing agent is conveyed, pulp is fed onto a net to be shaped and pressed into paper, pressing is carried out, and dry dehydration and paper forming are carried out.Compared with the prior art, the antibacterial paper and the antibacterial paper production method have the advantages that prebiotics and the antibacterial agent are used in the antibacterial paper in a combined mode, it is ensured that the antibacterial paper has the fast and good sterilization and bacteriostasis effects, can well restrain breeding and growth of microorganisms of the antibacterial paper, the damage to the quality of the antibacterial paper due to breeding of the microorganisms is avoided, and the quality of the antibacterial paper is ensured.

Owner:上海渊泉集币收藏品有限公司

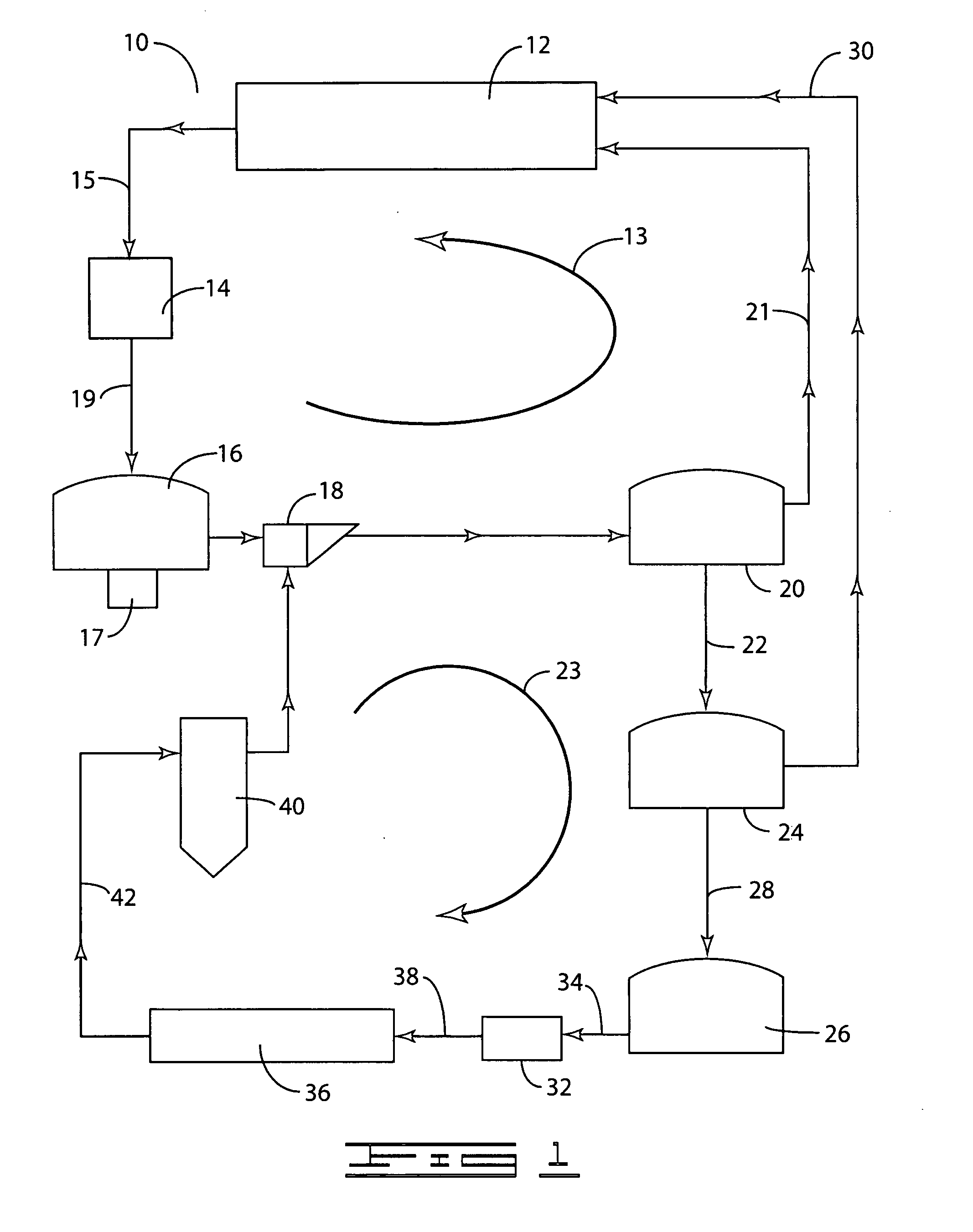

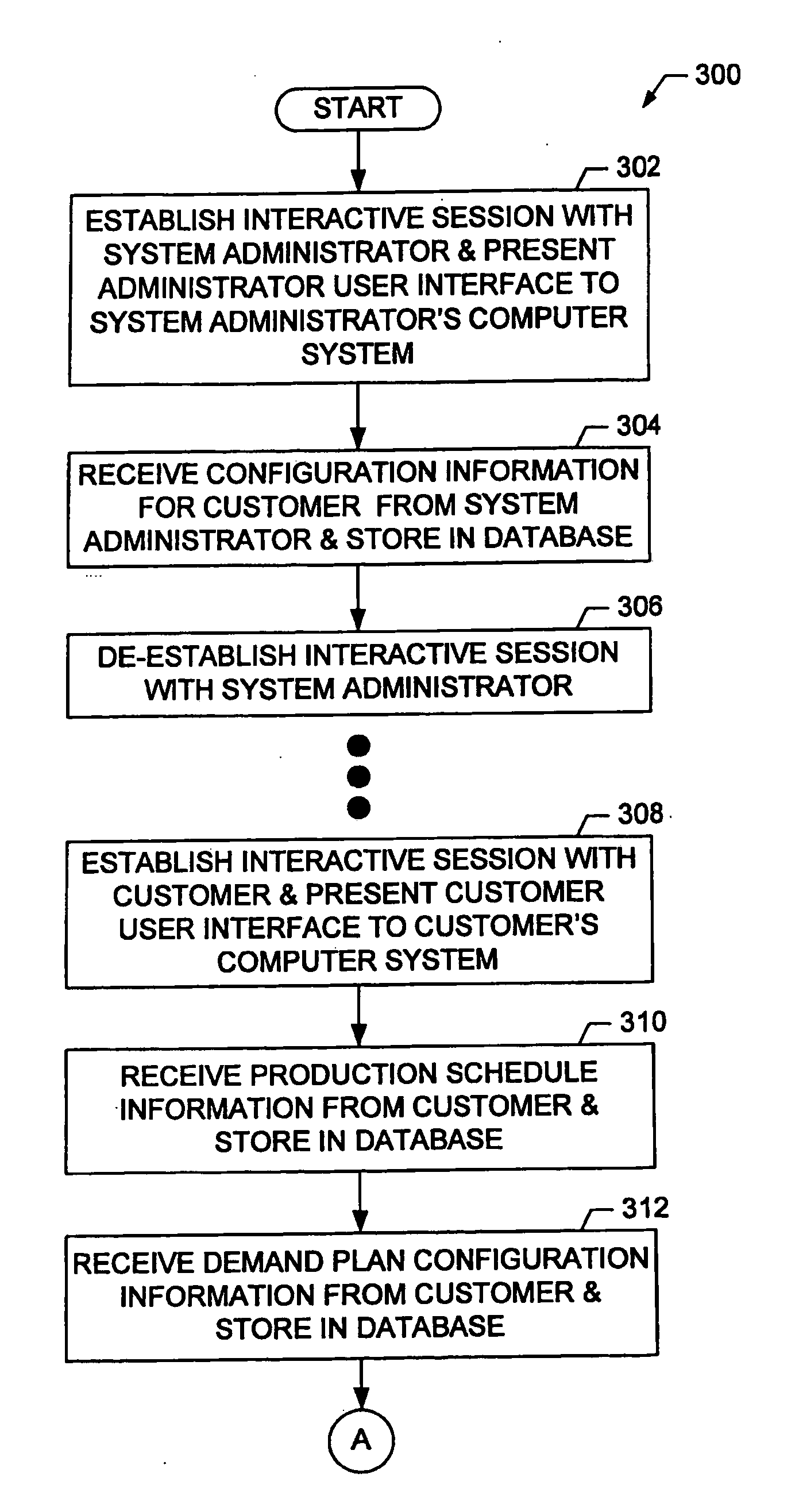

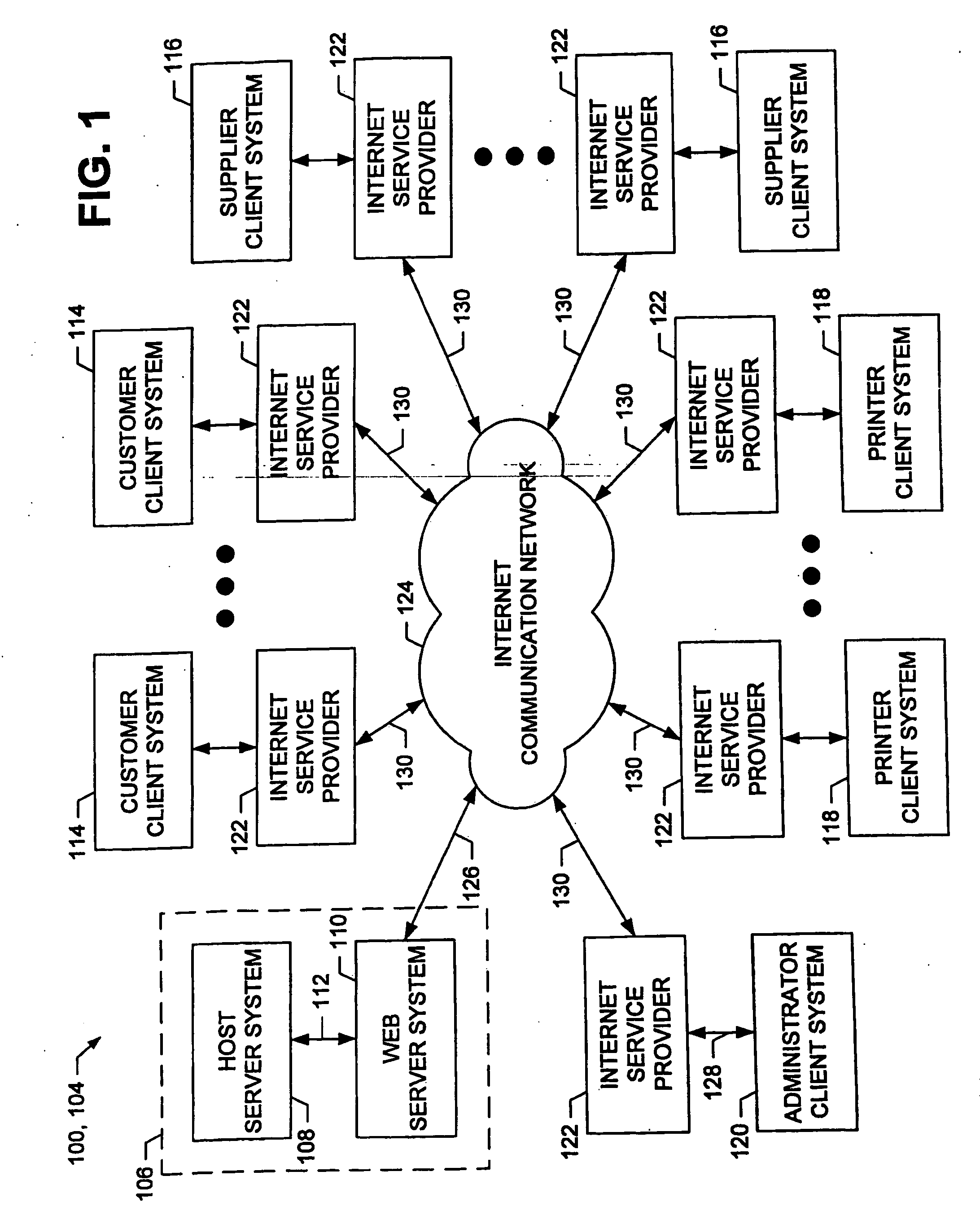

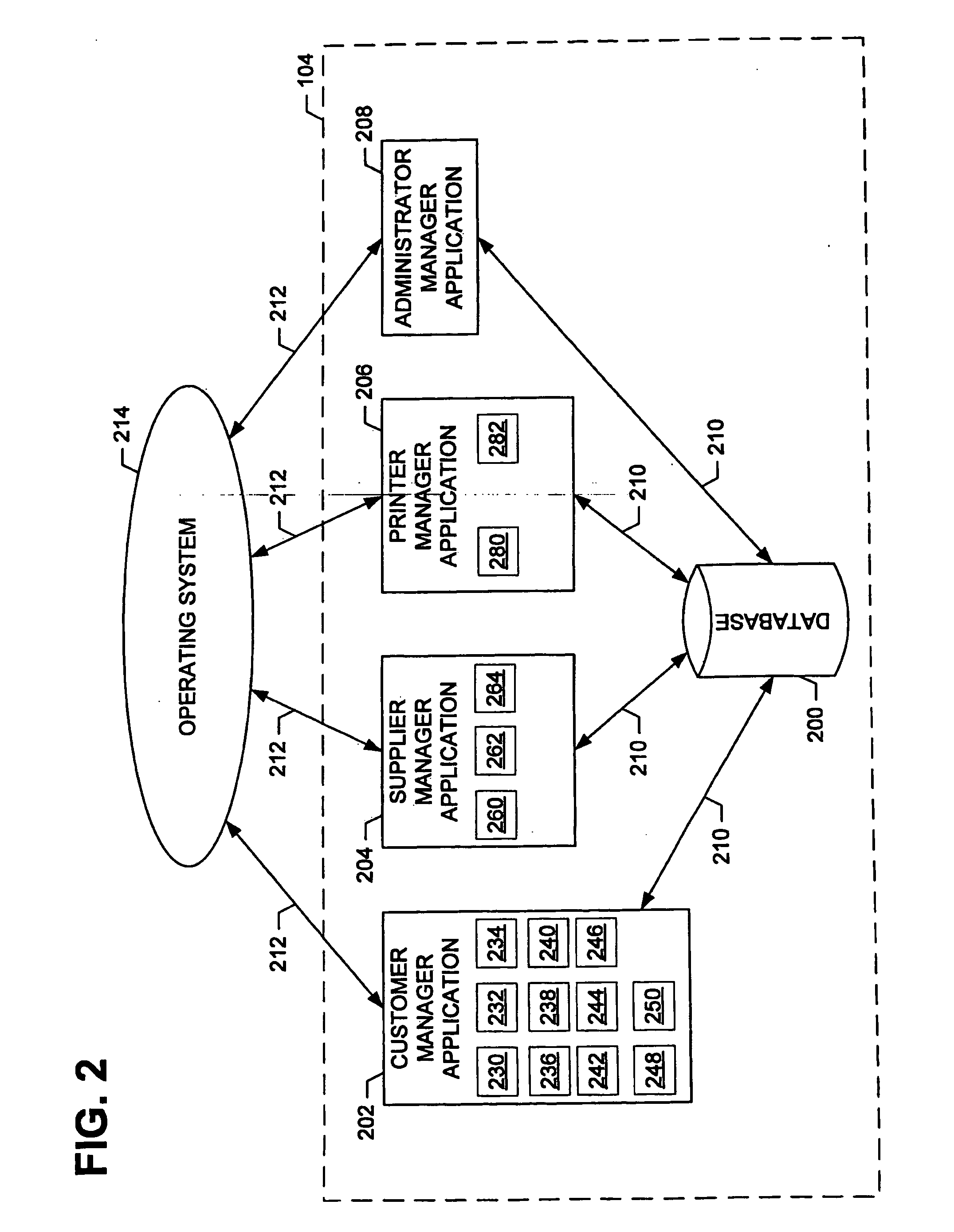

Multi-party, multi-tier system for managing paper purchase and distribution

ActiveUS20070162326A1Effective distributionEfficient productionVolume/mass flow measurementPower supply for data processingPaper productionOrder form

A system, including apparatuses and methods, for paper production and distribution in a communication network environment with multi-party and multi-level production and distribution relationships. The system receives, from one or more communicatively connected paper purchaser computers, parameters representative of the total surface area and physical characteristics of paper products required for printing tasks. The system determines an estimated quantity of the paper products to order based at least in part on the received parameters. Then, the system displays the estimated quantity of the paper to order and communicates orders to production facilities for obtaining such quantity.

Owner:VERSO PAPER HLDG LLC

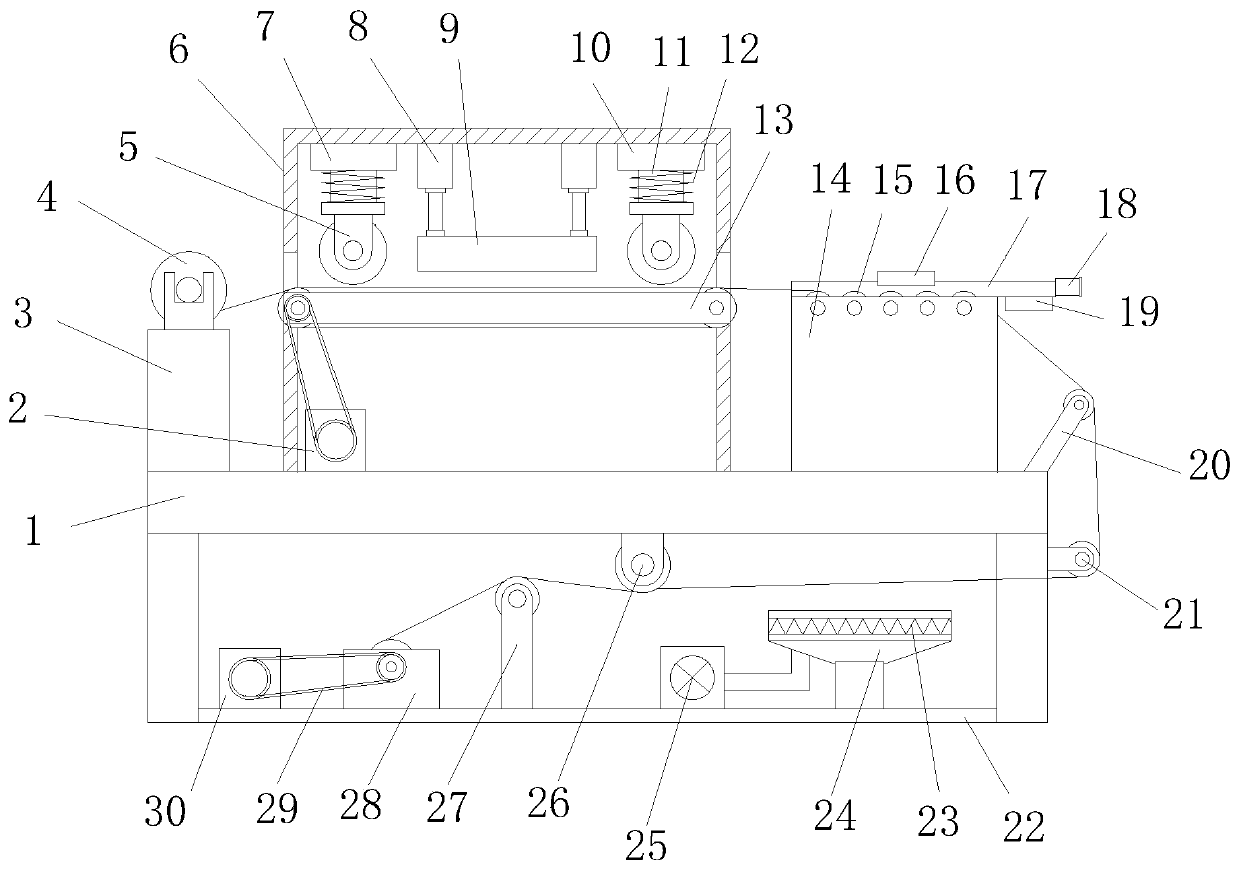

Efficient embossing machine for textile wall paper production

InactiveCN110126451AAvoid damageLow investment costCovering/liningsRotary pressesPaper productionPulp and paper industry

The invention discloses an efficient embossing machine for textile wall paper production. The machine comprises a rack, a uniform pressing device, a stamping device, a drying device and a coiling device, wherein a distributing roller storing rack is fixedly arranged at the upper left end of the rack, and a distributing roller is rotatably mounted at the upper end of the distributing roller storingrack; the uniform pressing device is arranged at the right side of the distributing roller storing rack; the stamping device is arranged at the right side of the uniform pressing device and is fixedly mounted at the upper right side of the rack; a first guide roller is fixedly arranged at the upper right end of the rack; a second guide roller is arranged in the middle of the right side of the rack; a third guide roller is arranged in the middle of the bottom part of the rack; a separating plate is arranged at the inner lower part of the rack; the drying device is arranged at the upper right side of the separating plate; a fourth guide roller is arranged in the middle of the upper part of the separating plate; and the coiling device is arranged at the upper left side of the separating plate. The machine is simple in structure, multifunctional, good in use effect, and high in production efficiency; the product quality is effectively ensured; and the machine is beneficial for popularization.

Owner:苏州前航实业有限公司

Wet strength agent for paper making and preparation thereof

ActiveCN101328696AHigh reactivityImprove bindingReinforcing agents additionFlocculationPaper production

The invention discloses a wet strengthening agent for making paper. The wet strengthening agent is PAE modified by an aliphatic twain-aldehyde compound crosslinking agent. A molecular chain has a three-dimensional net structure. The wet strengthening agent can be preserved for a long time and does not generate bubble or flocculation, etc. The application of the wet strengthening agent in paper production ensures that the paper has good flexibility resistance and wet strengthen. The invention also discloses a method for preparing the wet strengthening agent for making paper.

Owner:CHINA BANKNOTE PRINTING & MINTING

Colorimetric or fluorometric-detectable polymers containing pendant amine groups

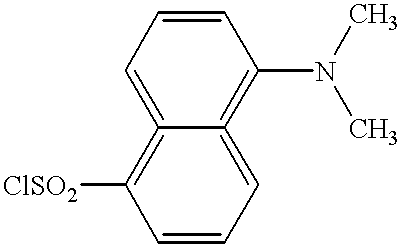

InactiveUS6218491B1Minimize contaminationLow residual monomer contentOrganic detergent compounding agentsScale removal and water softeningThiolFluorescence

Polymers having amine-thiol terminal moieties are provided. The amine-thiol terminal moieties are imparted by using amine-thiols as chain transfer agents in aqueous addition polymerizations.The polymers are useful as mineral dispersants, as water-treatment additives for boiler waters, cooling towers, reverse osmosis applications, sugar refining, paper production, geothermal processes and oil wells, and as detergent additives acting as builders, anti-filming agents, dispersants, sequestering agents and encrustation inhibitors.

Owner:ROHM & HAAS CO

Abrasive disc for papermaking

InactiveCN102517953AImprove wear resistanceIncrease coefficient of frictionOther chemical processesPulp beating/refining methodsPaper productionPapermaking

The invention relates to an abrasive disc for papermaking, which is applied to the beating technology in the paper production process. The abrasive disc for papermaking consists of the following raw materials in parts by weight: 15-50 parts of base material, 15-65 parts of fiber material and 16-65 parts of abrasion-proof material, wherein the particle size of the abrasion-proof material is 50-500 meshes; the base material, the fiber material and the abrasion-proof material have a wetting and splicing effect; and the base material has abrasion resistance and toughness. The abrasive disc provided by the invention has the advantages of reasonable formula design, light weight, low energy consumption, low manufacturing cost, controllable beating quality and stable quality.

Owner:朱国荣

Bobbin paper production technology

ActiveCN104278594AAvoid pollutionSave resourcesWaste product additionSpecial paperHigh concentrationBobbin

The invention discloses a bobbin paper production technology which comprises the following steps: (1) papermaking reclaimed pulp undergoes high-concentration degritting and disk milling and then is placed into a coarse pulp tank; (2) waste paper is crushed by a pulper, and crushed paper pulp undergoes high-concentration degritting and then is placed into the coarse pulp tank; (3) coarse pulp in the coarse pulp tank is separated by a defibrator; (4) medium-concentration degritting is carried out; (5) fine screening and concentration are carried out; (6) the pulp is placed into a concentration tank; (7) the pulp undergoes disk mill and then is placed into a finished product tank; (8) the pulp is delivered to a machine chest, and paper mill sludge is added into the machine chest; (9) drifting is carried out through a drifting system, and a water repellent agent is added; (10) the raw material is conveyed to a net part of a paper machine, a dry strength agent is added into the net part, and starch is sprayed; (11) the raw material is processed by a press part of the paper machine; (12) the raw material is processed by a drying part of the paper machine; and (13) finished paper is reeled. According to the invention, reclaimed pulp and paper mill sludge which are generated during the papermaking process are fully utilized for production of bobbin paper. Thus, resources are saved; cost is reduced; and environmental pollution is also avoided.

Owner:ZHEJIANG RONGSHENG PAPER IND HLDG

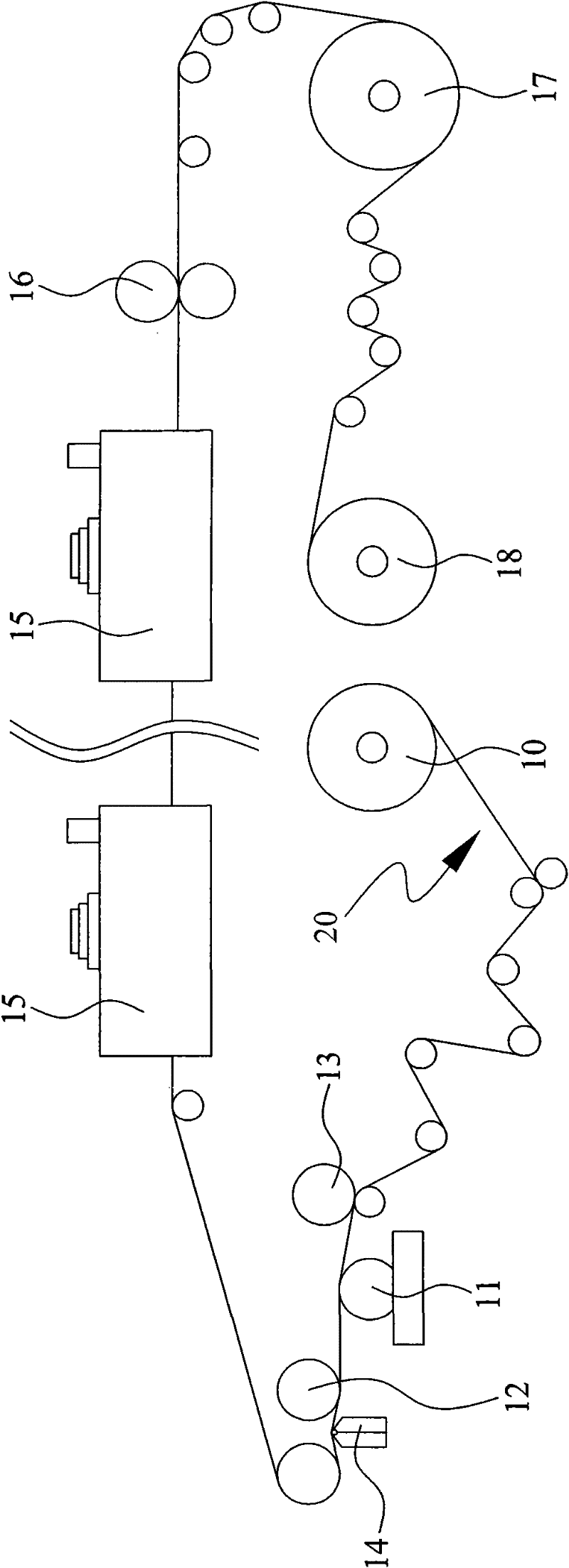

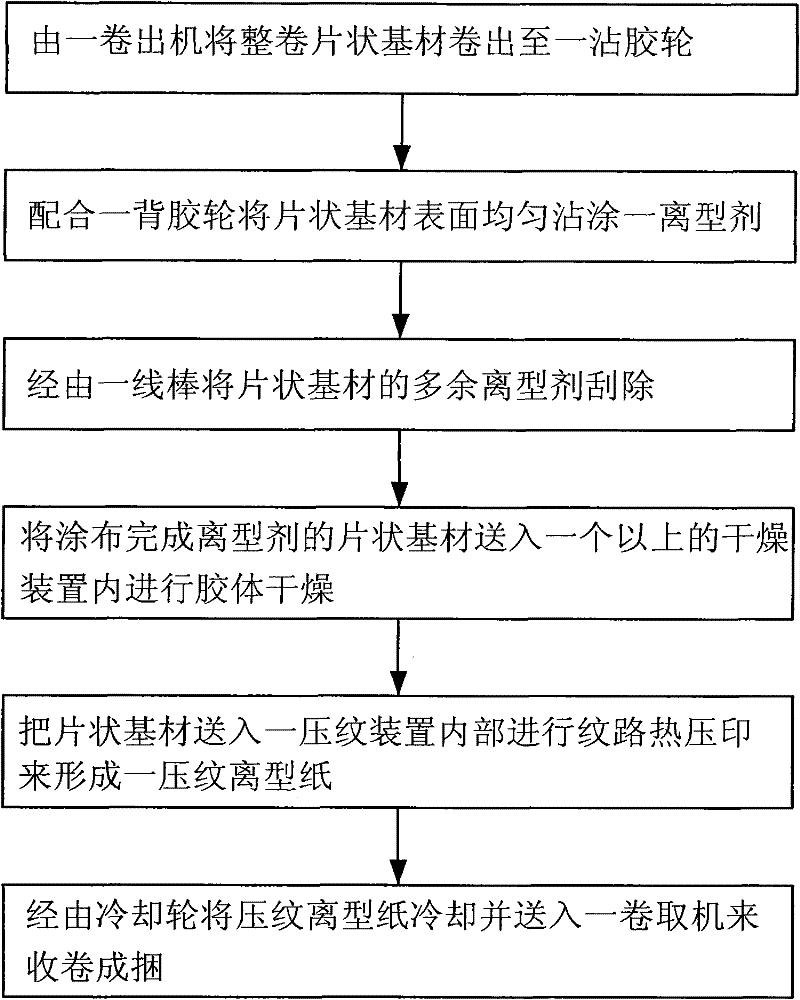

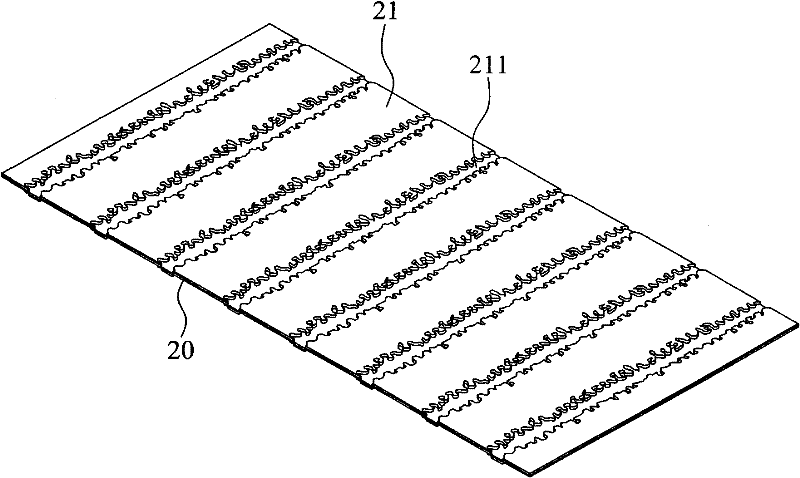

Manufacturing method and structure of embossed release paper

InactiveCN102296487AShorten production timeReduce manufacturing costSpecial paperPaper/cardboardHot stampingPaper production

The invention relates to a method for manufacturing embossed release paper and its structure. The unwinding machine rolls out the entire roll of sheet-shaped substrate to a rubber-coating wheel, and cooperates with the pressing wheel to evenly coat the surface of the sheet-shaped substrate with a release agent. The excess release agent is then scraped off by a wire bar, and the sheet substrate coated with the release agent is sent to the drying device for colloid drying, and then the sheet substrate is sent to the embossing device for texture heat embossing To form the embossed release paper, and finally the embossed release paper is cooled by the cooling wheel and sent to the coiler to be wound into bundles. The embossed release paper has a sheet substrate, and a first release agent layer is arranged on the surface of the sheet substrate, and the first release agent layer has an embossed texture. The invention produces embossed patterns on the release paper through a single multiple processing, which improves the traditional need for additional secondary processing to emboss the pattern after the release paper is coated with a release agent and rolled into a bundle, so as to reduce the release Paper production time and cost.

Owner:许辉雄

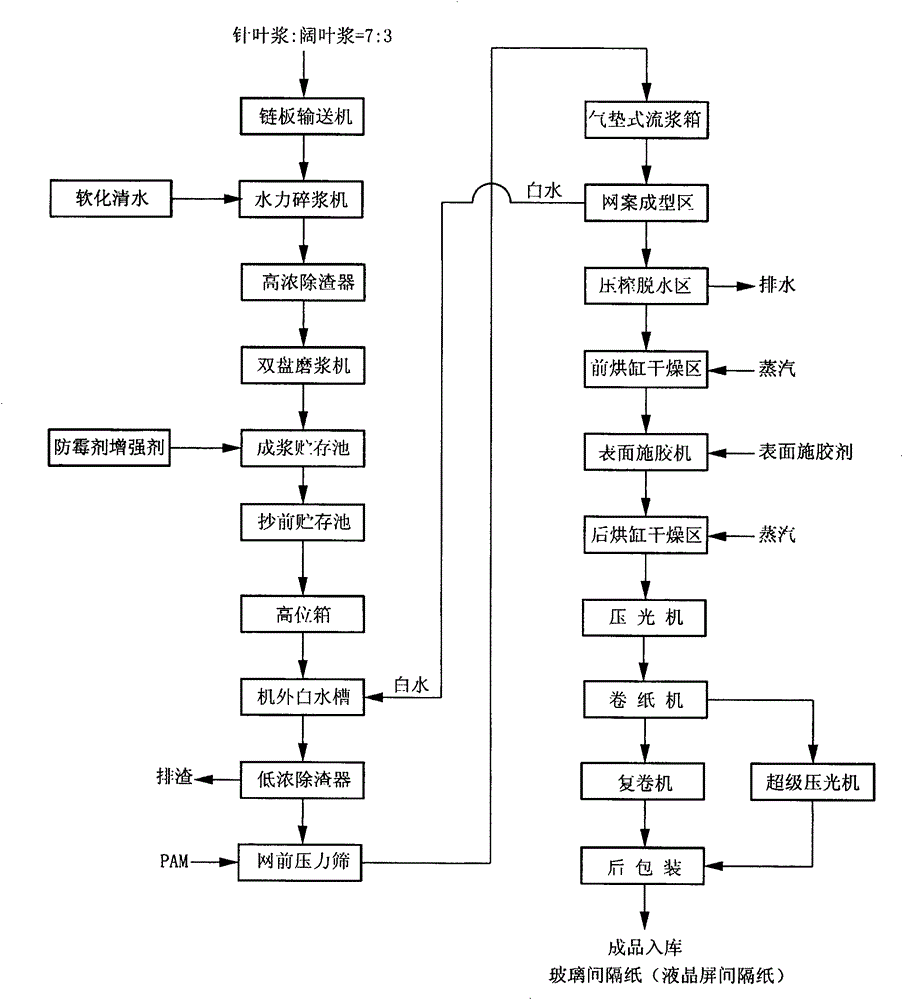

Glass backing paper production process

InactiveCN103603232AIncrease productivityImprove drynessFlexible coversWrappersPaper productionHigh stiffness

The invention relates to a glass backing paper production process. The papermaking speed is 250m / min to 350m / min, the production efficiency is high, an air-cushion pulp box and a ceramic dehydrating chopping board are adopted in a papermaking forming area, pulp is uniform to distribute, and the quality is stable; a primary vacuum pre-pressing, four-roller three-pressure-interval composite pressing, vacuum adsorption and moving and glazing pressing are adopted in a pressing and dehydrating area, the dryness of paper entering a drying cylinder is increased, and the loose thickness of the paper is not damaged; a drying part adopts five groups of drying cylinders, namely totally 36 drying cylinders with the diameter of 1500mm, a closing gearbox, a closed steam cover, a paper guiding rope, a surface glue application machine, a glaze pressing machine, a paper coiling machine, a re-coiling machine, a super glazing pressing machine and the like, so that the smoothness of a product is improved, picking and powder can be prevented from dropping, and the high stiffness requirement can be met.

Owner:苏州惠通新型材料科技有限公司

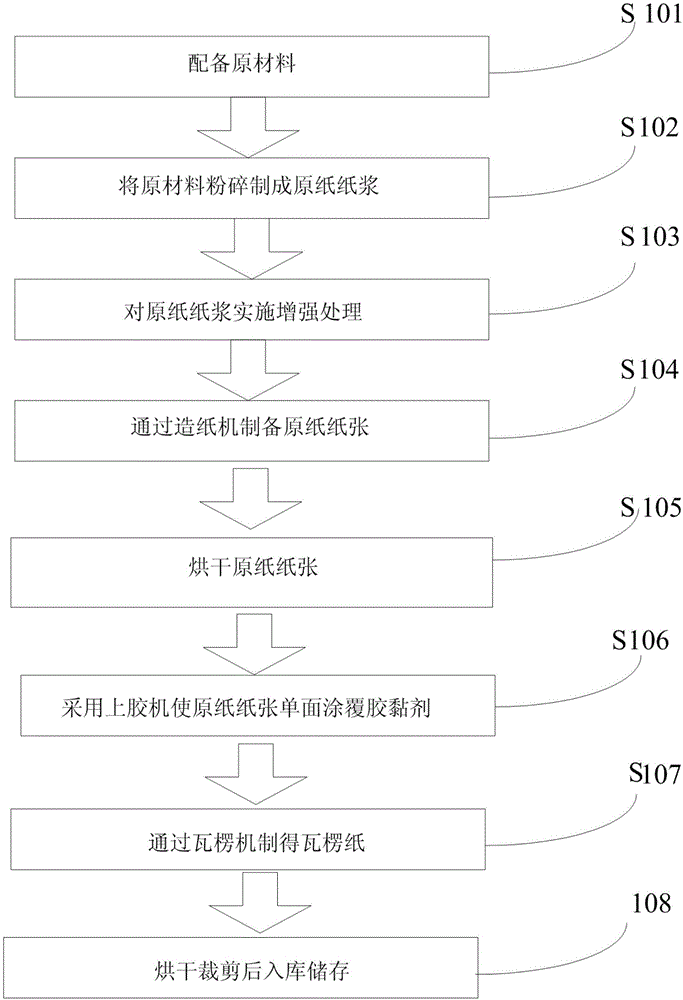

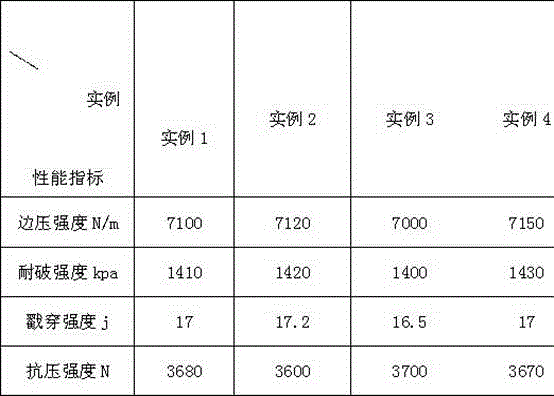

High-strength corrugated-paper production process

InactiveCN106351056AHigh strengthExtended service lifeWater-repelling agents additionReinforcing agents additionWear resistantPaper production

The invention provides a high-strength corrugated-paper production process. The high-strength corrugated-paper production process includes the steps: preparing raw materials and smashing the same to produce into paper pulp via grinding, and subjecting the paper pulp to purification treatment of sieving and deslagging; performing hardening treatment on the paper pulp subjected to the purification treatment; producing the paper pulp subjected to the hardening treatment into an original paper base; subjecting the original paper base to coating with a wear-resistant agent through a coating machine; drying and shaping to form the product to be put in storage. The corrugated paper produced with the corrugated-paper production process is high in strength, long in service life, satisfied to use requirement, reasonable in technology design, low in material consumption, low in production cost and wide in application to the technical field of corrugated boxes.

Owner:浙江兴舟纸业有限公司

Method and apparatus for detecting product defects during the production of mailing products, hygiene products, or folded paper products

InactiveUS20030110739A1Secure and reliable productionEnvelopes/bags making machineryBag making operationsProduction linePaper production

To detect product defects during the production of mailing products, hygiene products or folded paper products, optical imaging sensors or capacitive sensors monitor at least one characteristic parameter or feature of the products successively moving through the production machine, to detect an actual value of each characteristic parameter or feature of each product. The detected actual value is compared with a stored nominal value for the respective characteristic parameter or feature. The result of the comparison is used to initiate or control a further measure, such as ejecting a defective product from the production line, marking a defective product so that it can be visually recognized and manually removed from the production line, or initiating corrective measures to correct the cause of the defect. The characteristic parameters or features relate to the dimensions, the position, and / or the form of the product or parts of the product.

Owner:WINKLER DUNNEBIER GMBH

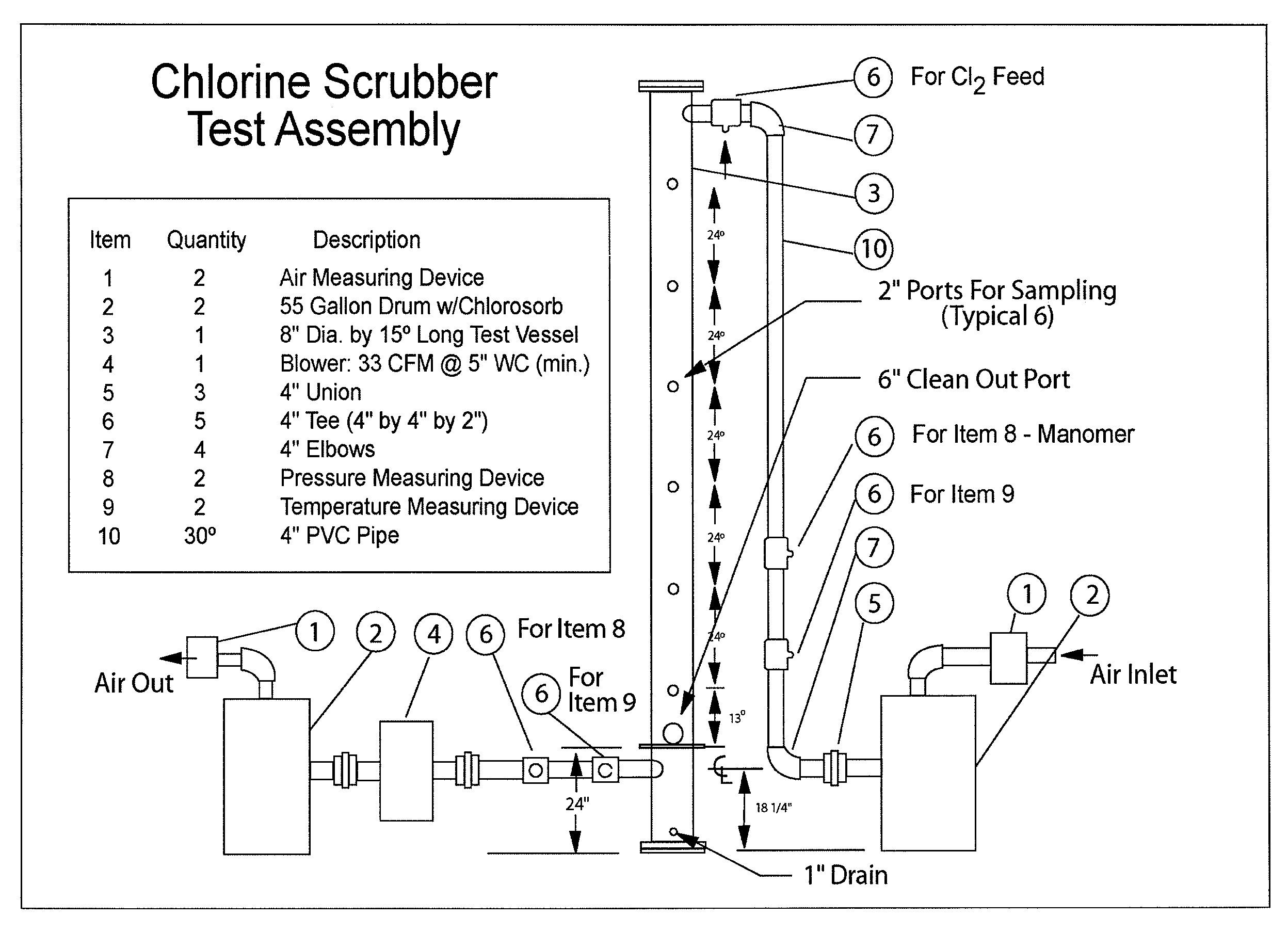

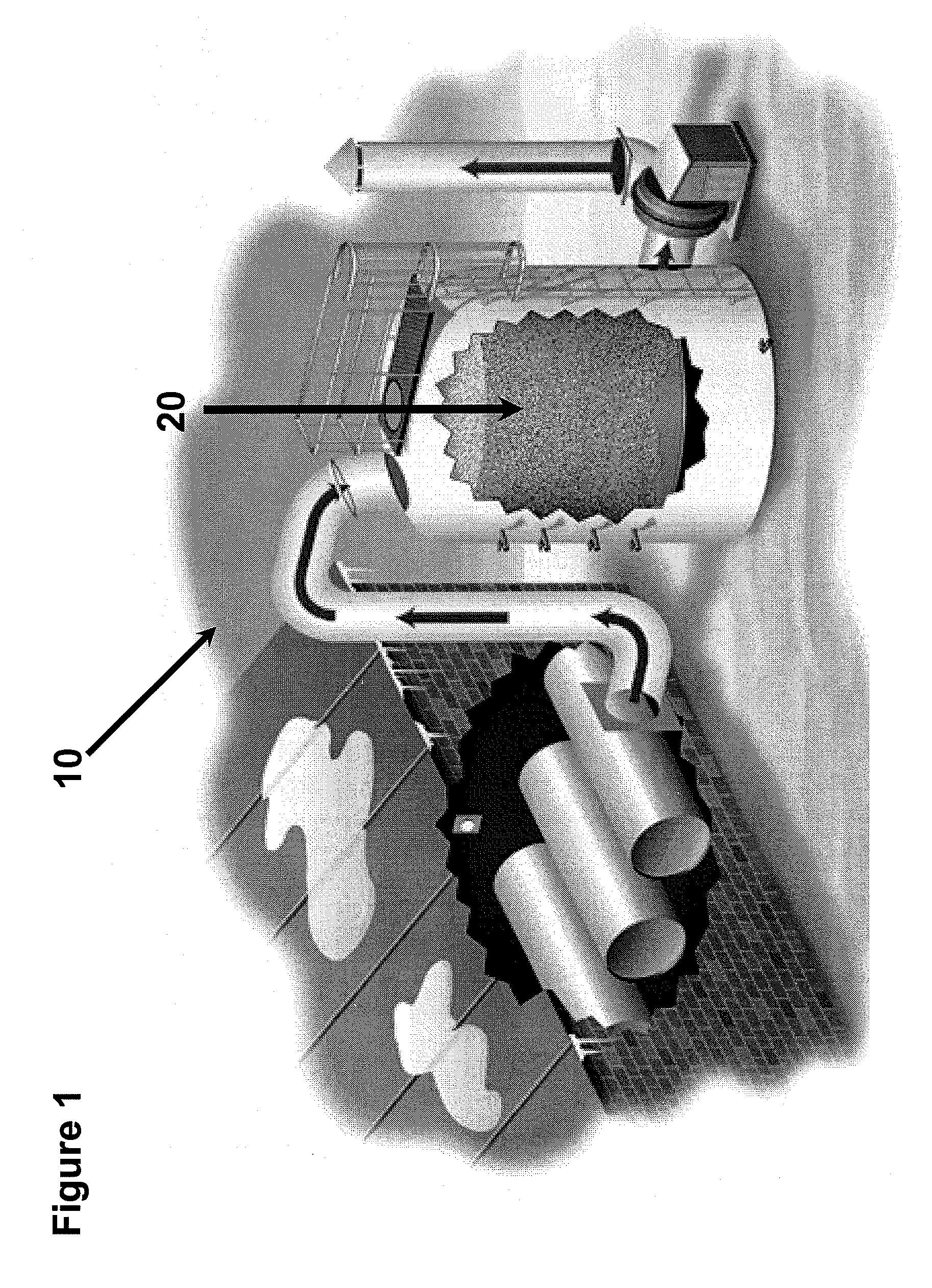

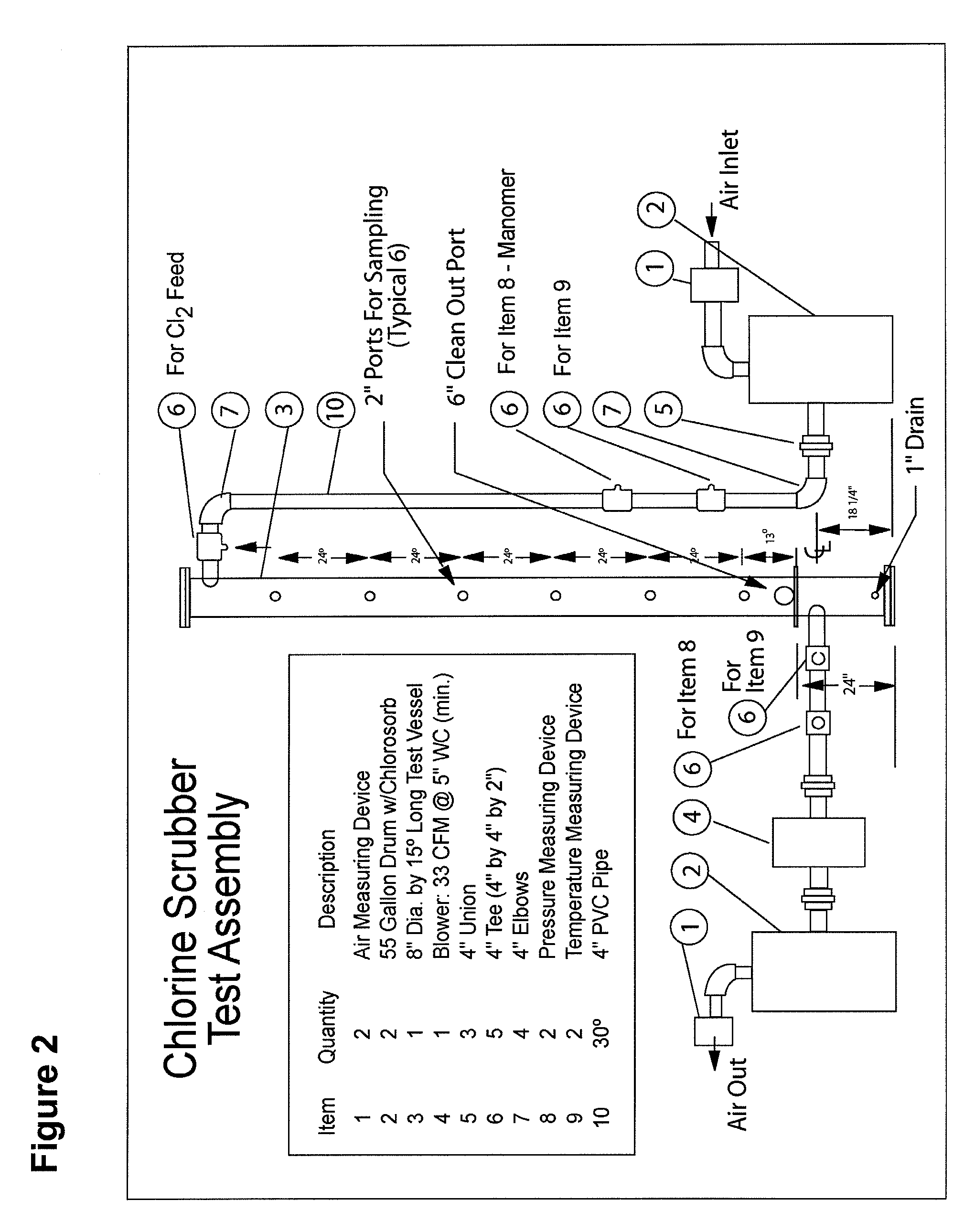

Dry-Scrubbing Media Compositions and Methods of Production and Use

ActiveUS20080127822A1Increase capacityImprove efficiencyCombination devicesNitrogen compoundsPotassium carbonatePetroleum

Dry-scrubbing media compositions, methods of preparing same, and methods of use are provided. The compositions contain activated alumina and potassium carbonate. Optionally, activated carbon and other impregnates, such as sulfates of group 1A metals, are included in the compositions. The compositions exhibit improved efficiency and capacity for the removal of compounds such as chlorine or sulfur dioxide from an air-stream. The compositions are particularly useful for reducing or preventing the release of toxic gaseous compounds from the areas such as petroleum storage areas, refineries, drinking water systems, sewage treatment facilities, swimming pools, hospital morgues, animal rooms, and pulp and paper production sites.

Owner:PURAFIL

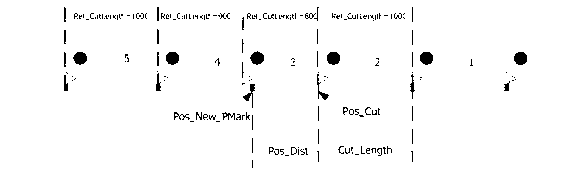

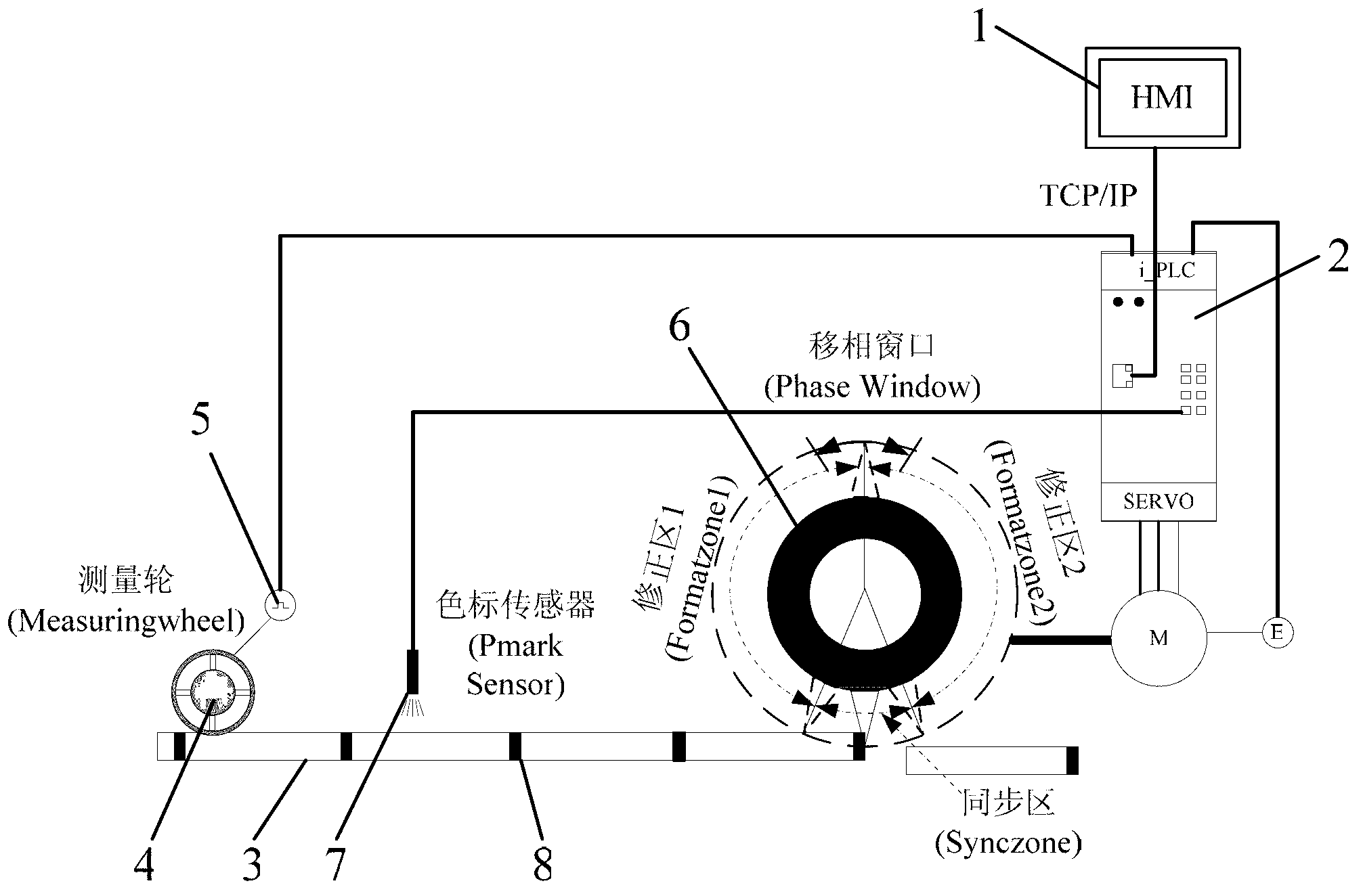

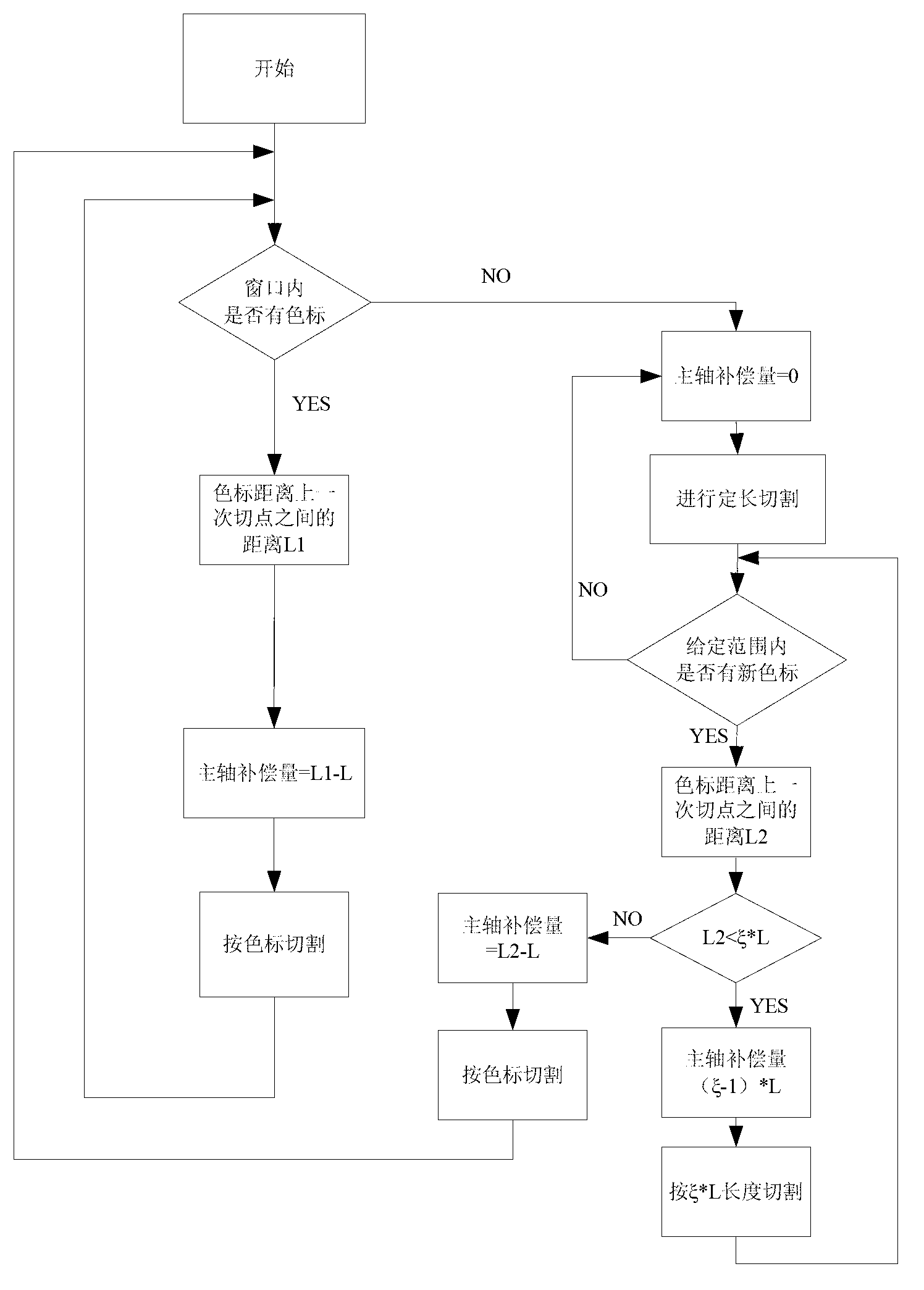

Color mark shearing method implemented by transverse cutting machine

InactiveCN103286812AAvoid wastingSolve the problem of missing labels in printingMetal working apparatusPaper productionEngineering

The invention relates to a color mark shearing method implemented by a transverse cutting machine, and belongs to the field of movement control. The color mark shearing method includes implementing a color mark shearing function by the aid of compensation for a spindle when detected color marks are normal; setting a compensation value as 0 after loss of a certain color mark is discovered, and switching into a fixed-length shearing working mode; judging the relation between a set judgment distance xi*L and the distance L2 from the position of a new color mark to the position of a last shorn point after a signal of the new color mark is detected, directly using the L2 as a given cut length when the L2 is larger than or equal to the xi*L, using the xi*L as a given cut length when the L2 is smaller than the xi*L, repeating the procedure until the L2 is larger than or equal to the xi*L, and implementing a mark searching function. The color mark shearing method has the advantages that the color mark shearing function and the automatic mark searching function are implemented, the automatic mark searching function is implemented after the certain mark is lost, accordingly, functions of the transverse cutting machine are increased, and the labor cost is reduced during corrugation paper production.

Owner:NANJING UNIV OF TECH +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com