Patents

Literature

2514 results about "Notching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Notching is a metal-cutting process used on sheet-metal or thin bar-stock, sometimes on angle sections or tube. A shearing or punching process is used in a press, so as to cut vertically down and perpendicular to the surface, working from the edge of a work-piece. Sometimes the goal is merely the notch itself, but usually this is a precursor to some other process: such as bending a corner in sheet or joining two tubes at a tee joint, notching one to fit closely to the other.

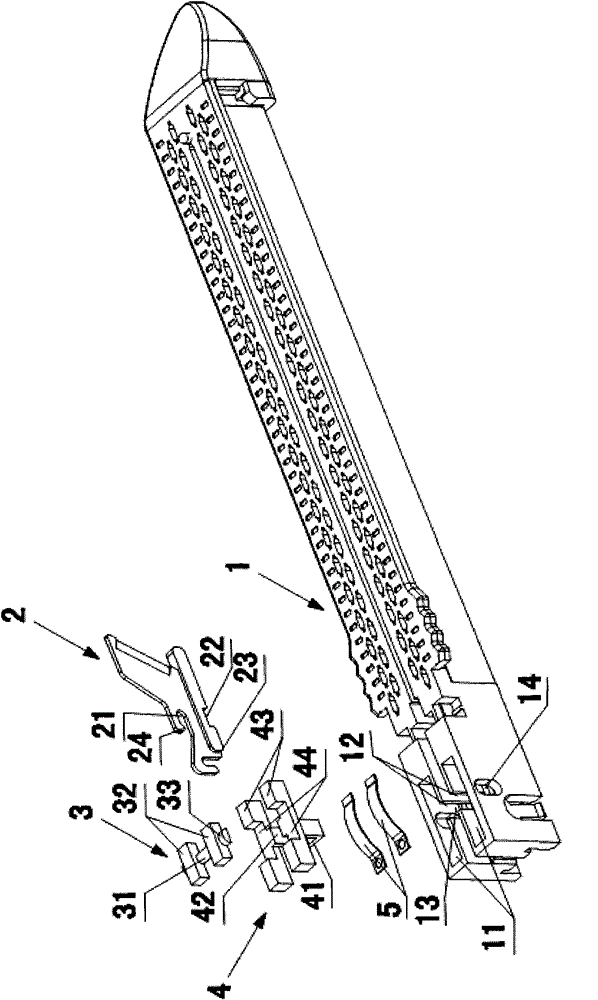

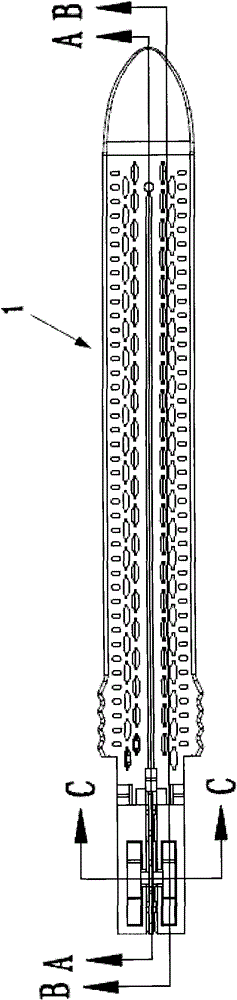

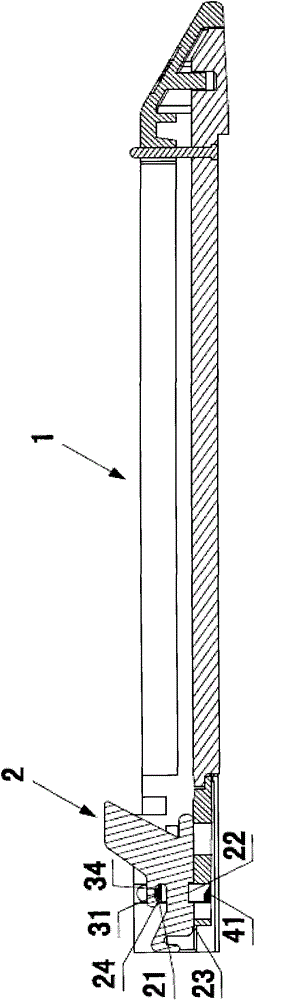

Linear cutting suturing device

The invention discloses a linear cutting suturing device, which comprises an upper tong clamp and a lower tong clamp, wherein the upper tong clamp and the lower tong clamp can realize the mutual closing or opening, the remote end of the lower tong clamp is provided with a nail cabin, a cutter feeding groove is arranged on the nail cabin in the axial direction, the lower tong clamp is in a U shape, a nail pushing rod and a cutter pushing rod are glidingly arranged inside the lower tong clamp, the remote end of the cutter pushing rod is provided with a cutter, the near end of the nail cabin is provided with a safety mechanism, the safety mechanism comprises a first press block, a triggering mechanism and at least one elastic element, the first press block is arranged in the nail cabin, the bottom end of the cutter is provided with a first notch, and the first notch can realize the longitudinal movement in the nail cabin under the effect of the elastic element and the triggering mechanism, so the first press block and the first notch can be selectively clamped and connected or separated. The linear cutting suturing device has the major beneficial effects that the structure is simple, the processing is convenient, safety and reliability are realized, and good popularization values are realized.

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

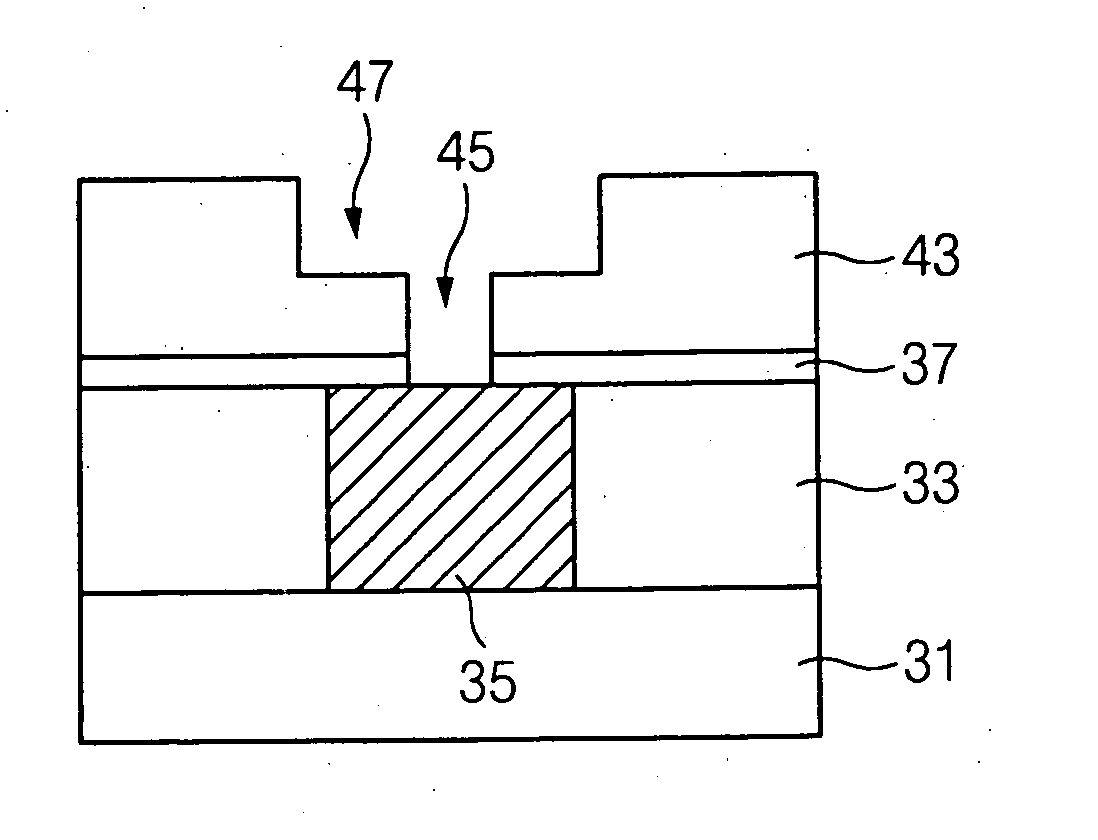

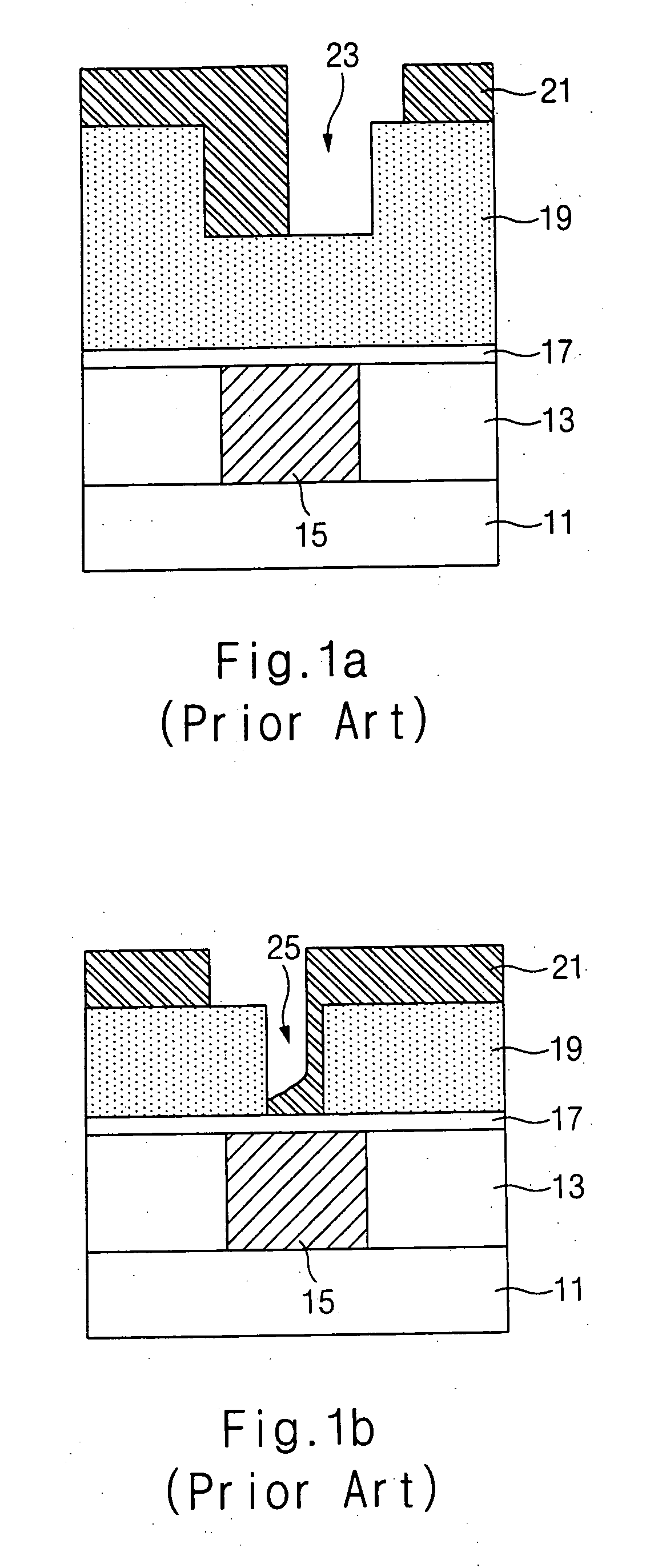

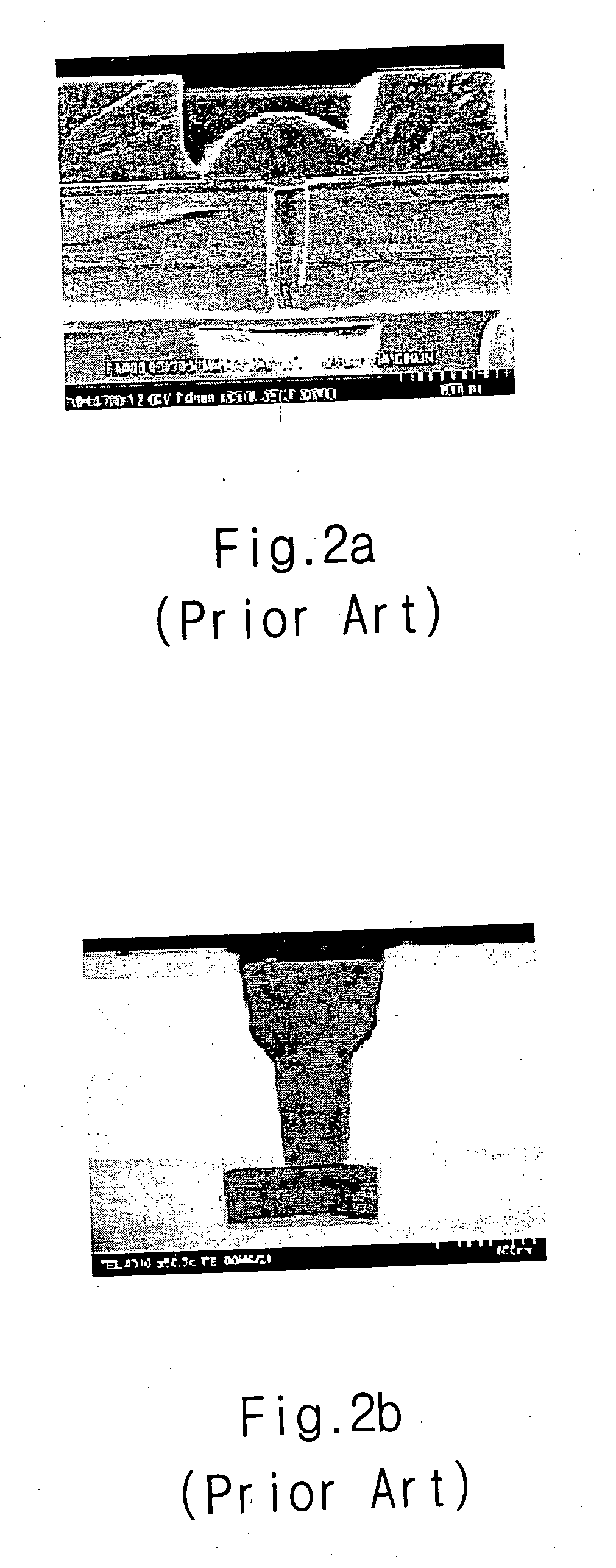

Method for forming conductive wires of semiconductor device

InactiveUS20040161921A1Solid-state devicesSemiconductor/solid-state device manufacturingSemiconductorMetal

A method is provided for forming a conductive wire of a semiconductor device using, for example, a damascene process. A conductive wire, such as a metal wire, is formed, based on a notching phenomenon which occurs when the etching selectivity between a polycrystalline silicon layer and a lower film is approximately 5 to 500:1.

Owner:KEY FOUNDRY CO LTD

Electrochemical Cell and Method of Making an Electrochemical Cell

ActiveUS20050258035A1Increase in manufacturing expenseReduced electrode “ edge ” effectImmobilised enzymesBioreactor/fermenter combinationsEngineeringElectrochemical cell

Electrochemical test cells are made with precision and accuracy by adhering an electrically resistive sheet having a bound opening to a first electrically conductive sheet. A notching opening is then punched through the electrically resistive sheet and the first electrically conductive sheet. The notching opening intersects the first bound opening in the electrically resistive sheet, and transforms the first bound opening into a notch in the electrically resistive sheet. A second electrically conductive sheet is punched to have a notching opening corresponding to that of first electrically conductive sheet, and this is adhered to the other side of the electrically resistive sheet such that the notching openings are aligned. This structure is cleaved from surrounding material to form an electrochemical cell that has a sample space for receiving a sample defined by the first and second conductive sheets and the notch in the electrically resistive sheet.

Owner:AGAMATRIX INC

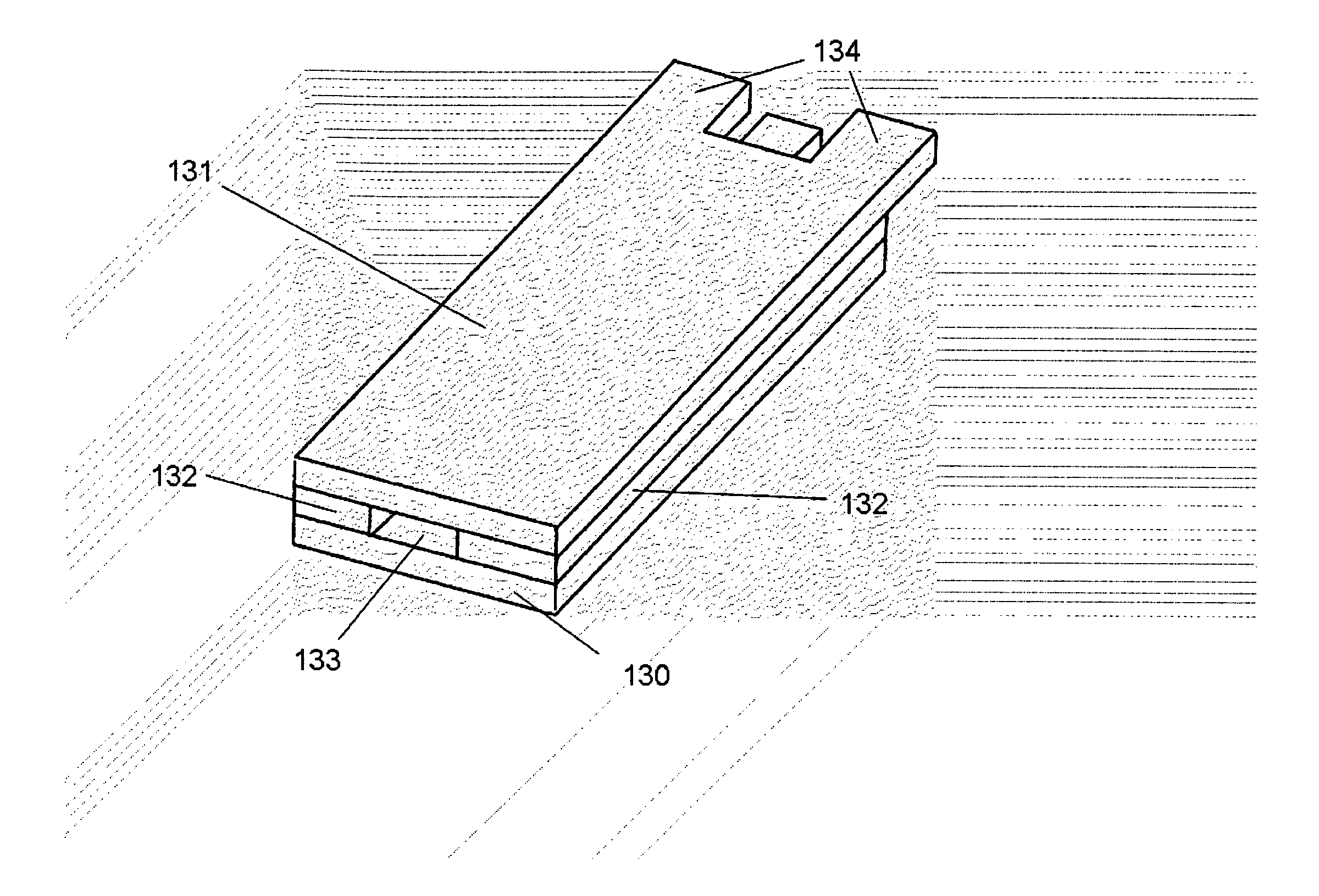

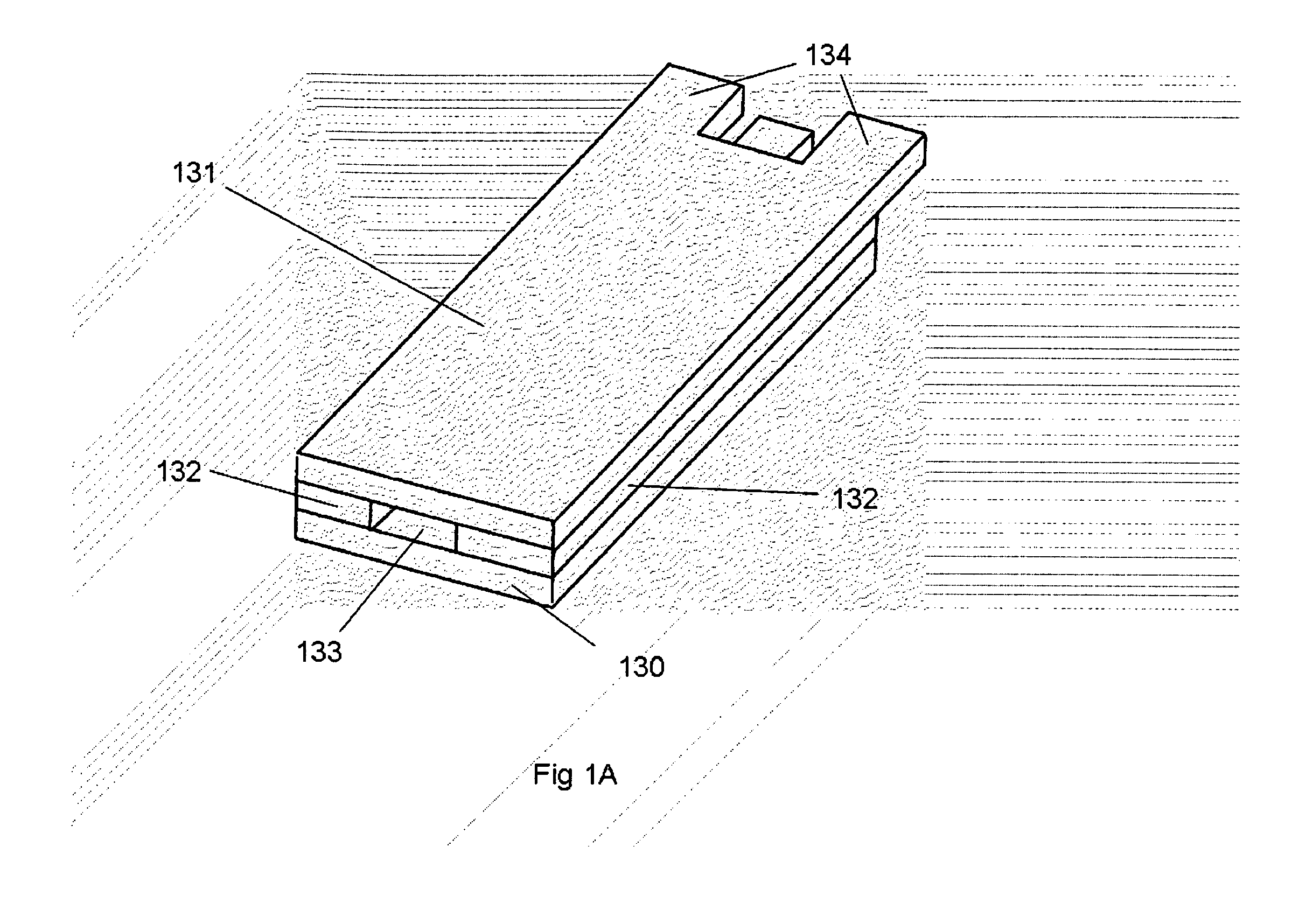

Frequency-notching antenna

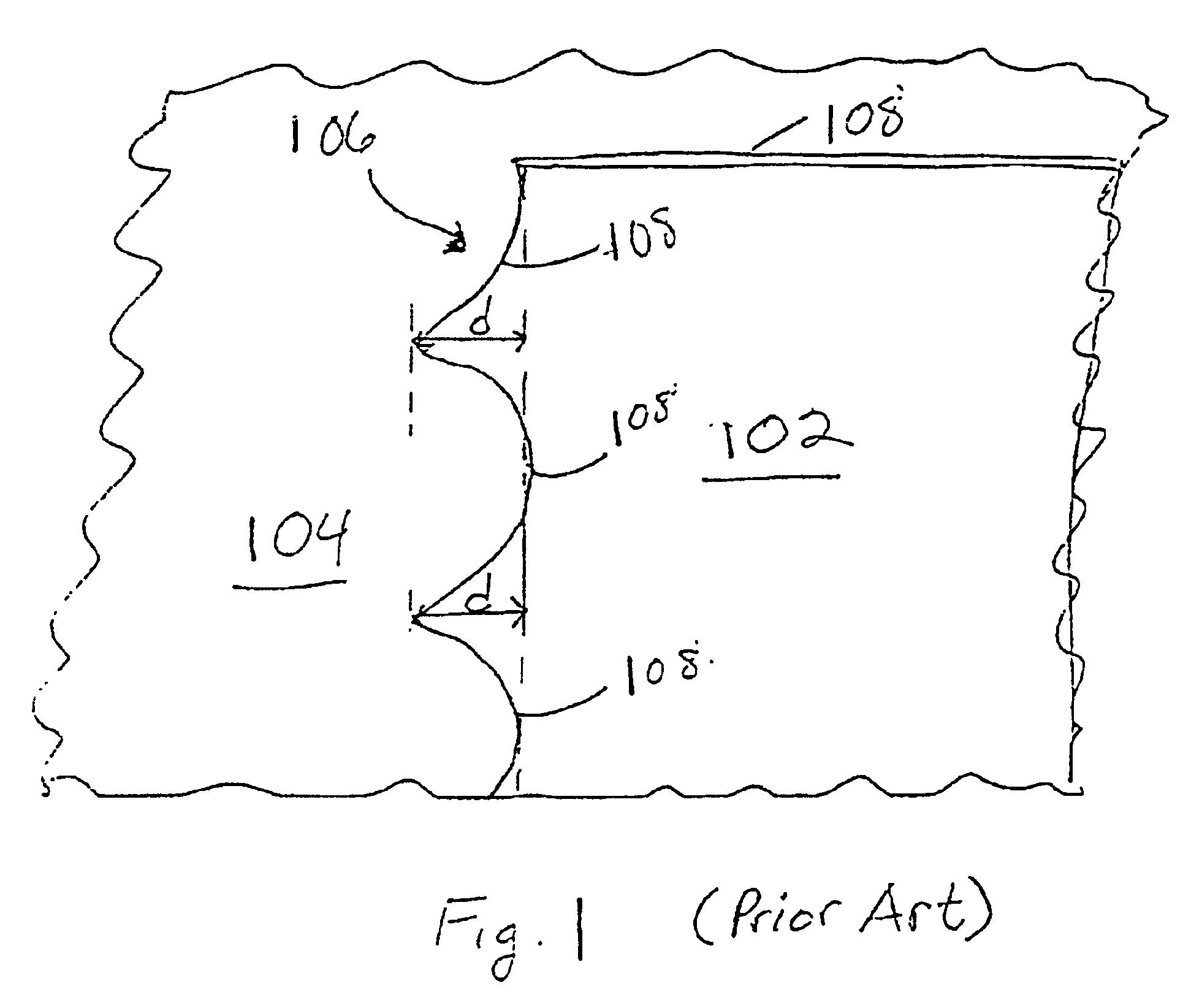

InactiveUS20070069955A1Simultaneous aerial operationsRadiating elements structural formsLine widthConductive materials

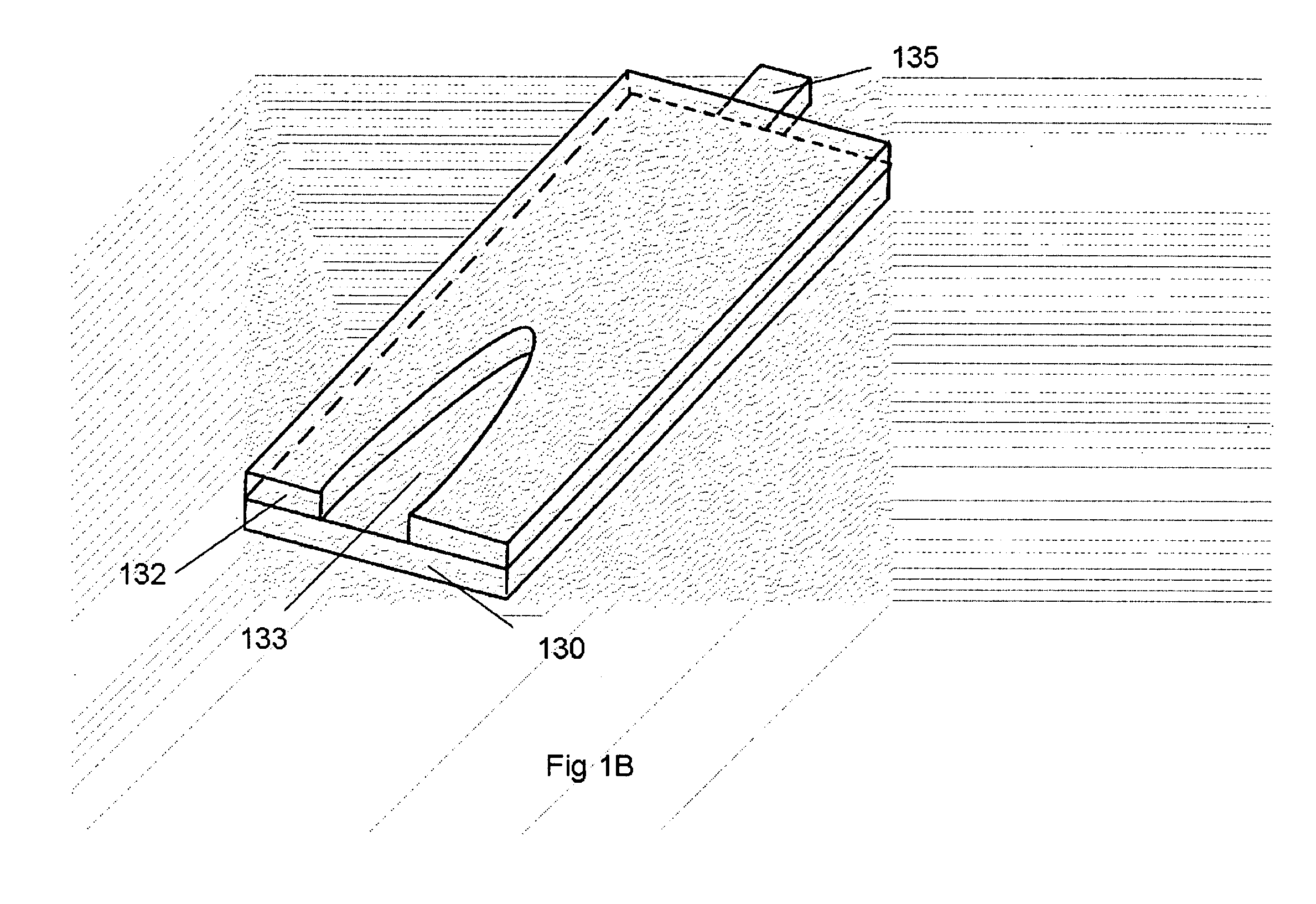

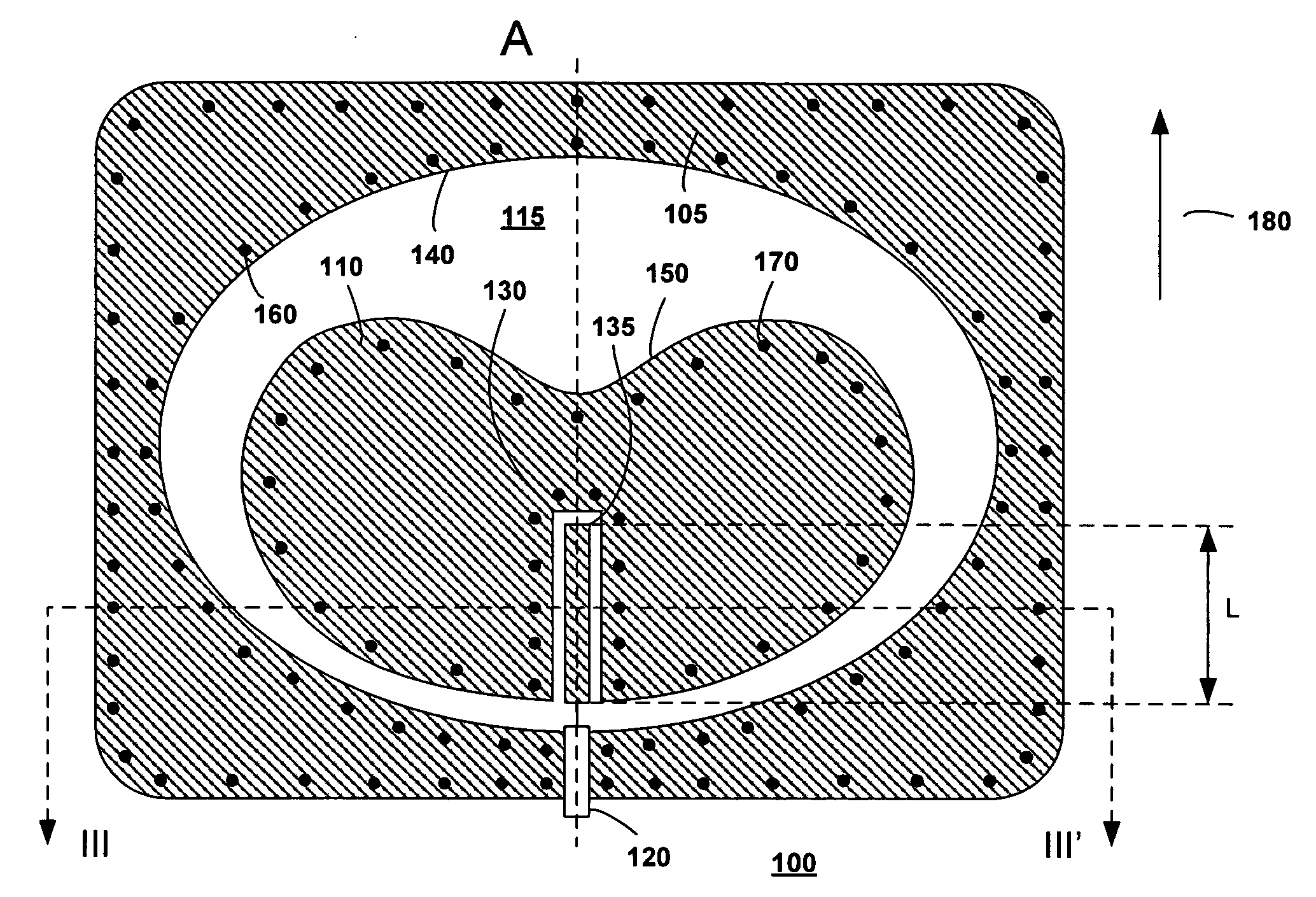

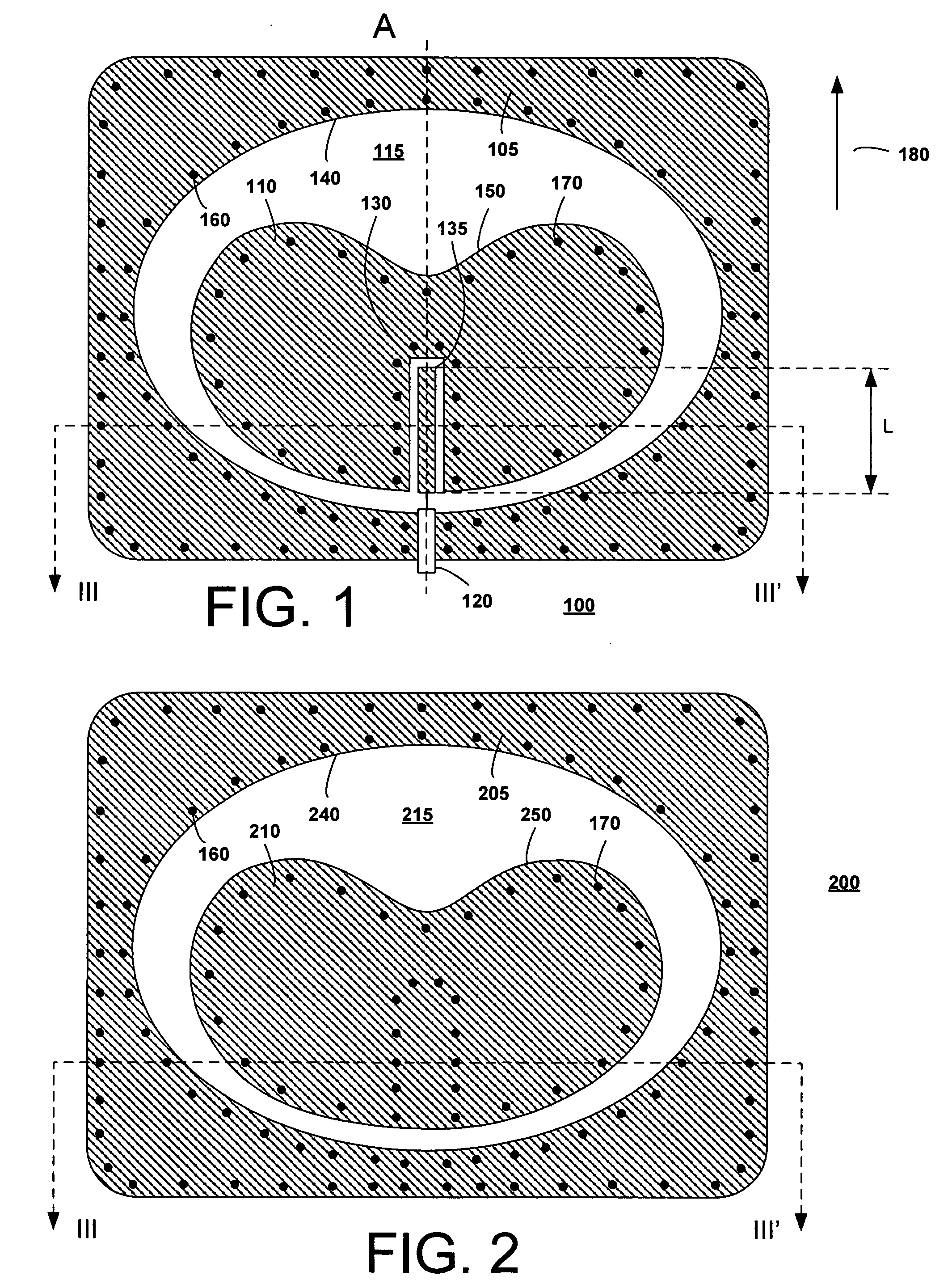

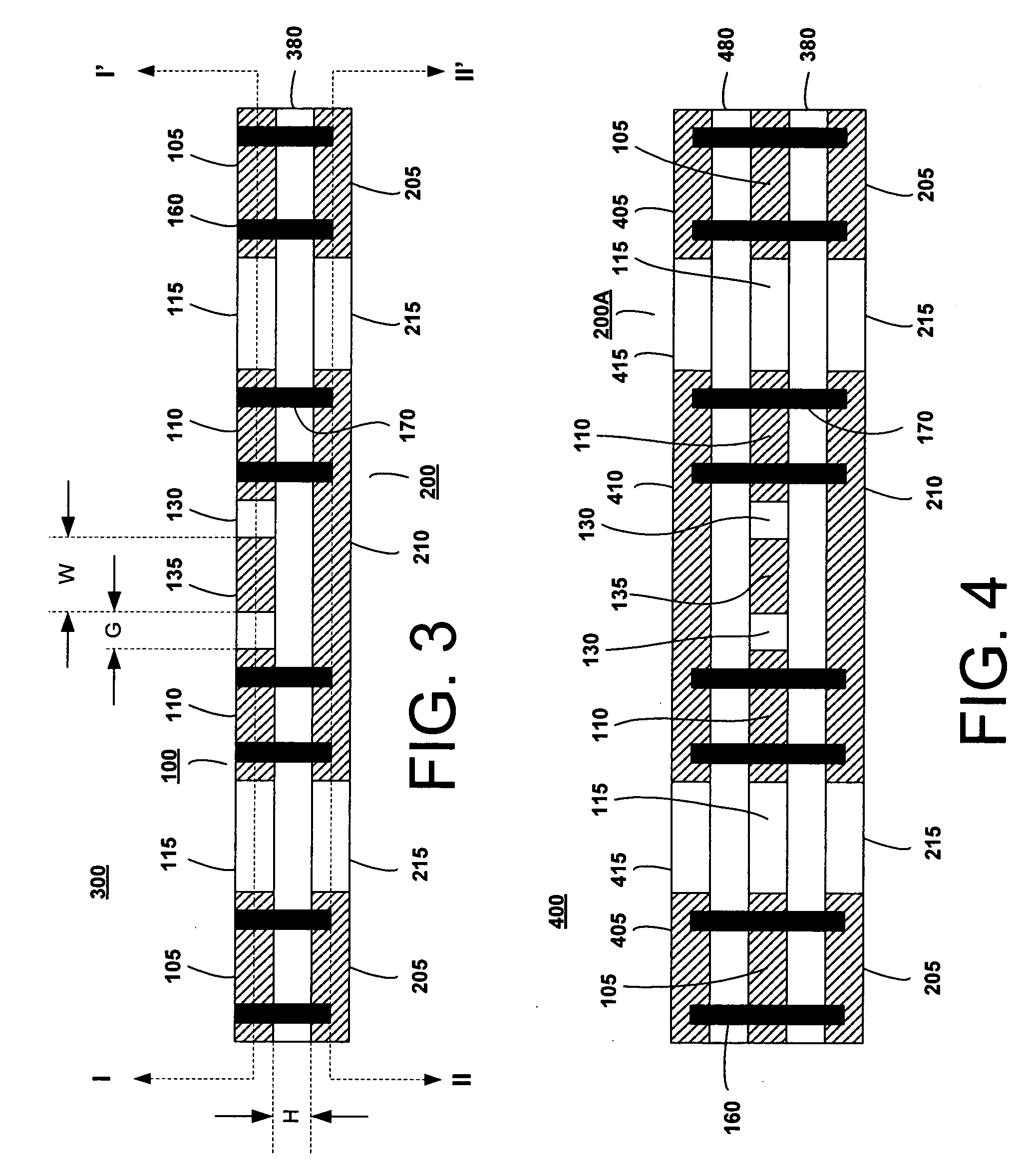

An antenna (100) is provided. The antenna includes: a first ground element (105); a first driven element (110) formed from a planar piece of conductive material, the first driven element being configured to transmit and receive wireless signals, the first driven element including a physical slot (130); a conductive line (135) formed in the physical slot such that the conductive line is separated from the first driven element by a gap (G) filled with non-conductive material, the conductive line having a line impedance that is a function of an effective line width of the conductive line, and an effective gap width of a gap between the conductive line and the first driven element; and a signal line (120) configured to send and receive signals to and from the conductive line.

Owner:NORTH STAR INNOVATIONS

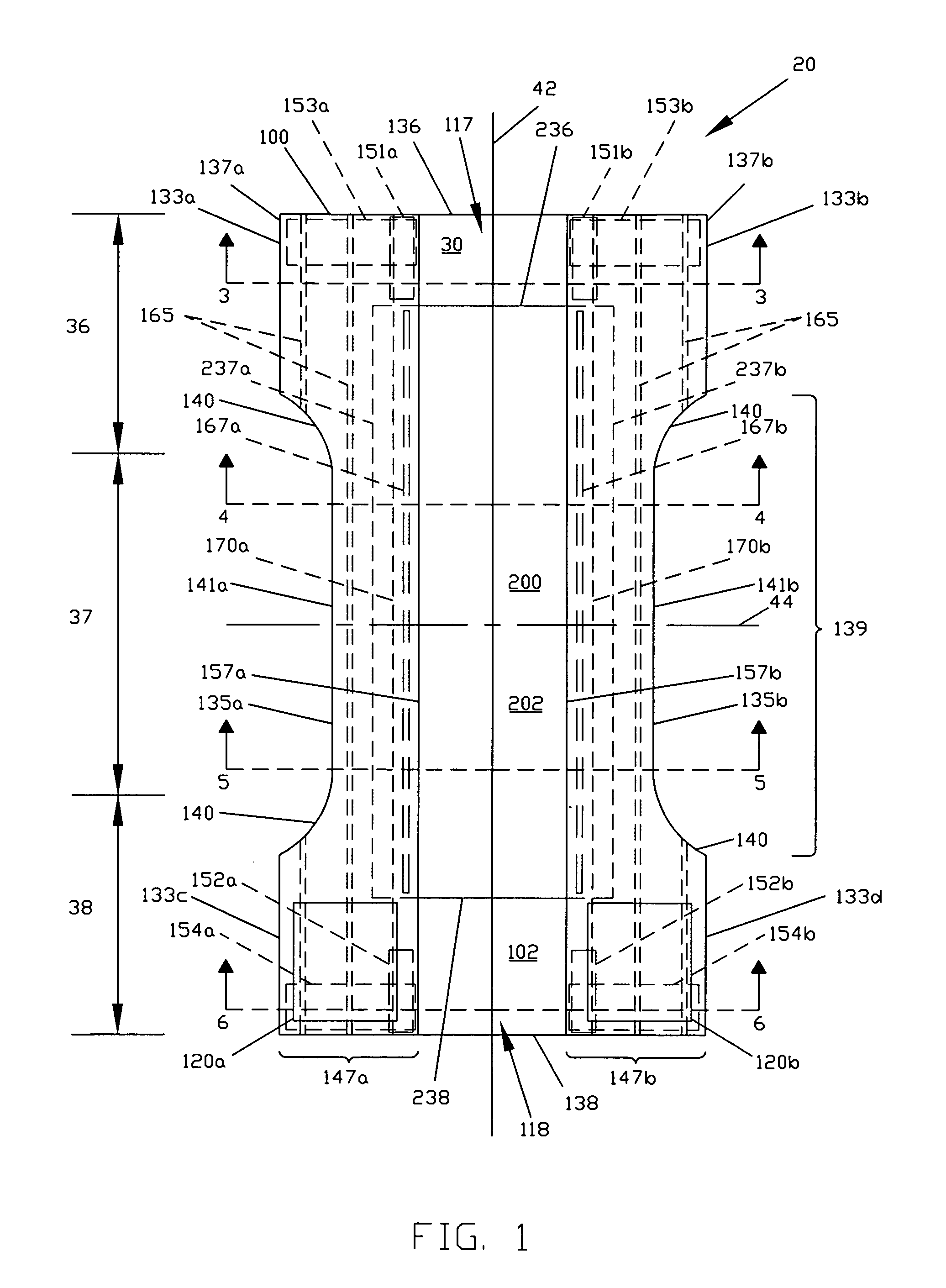

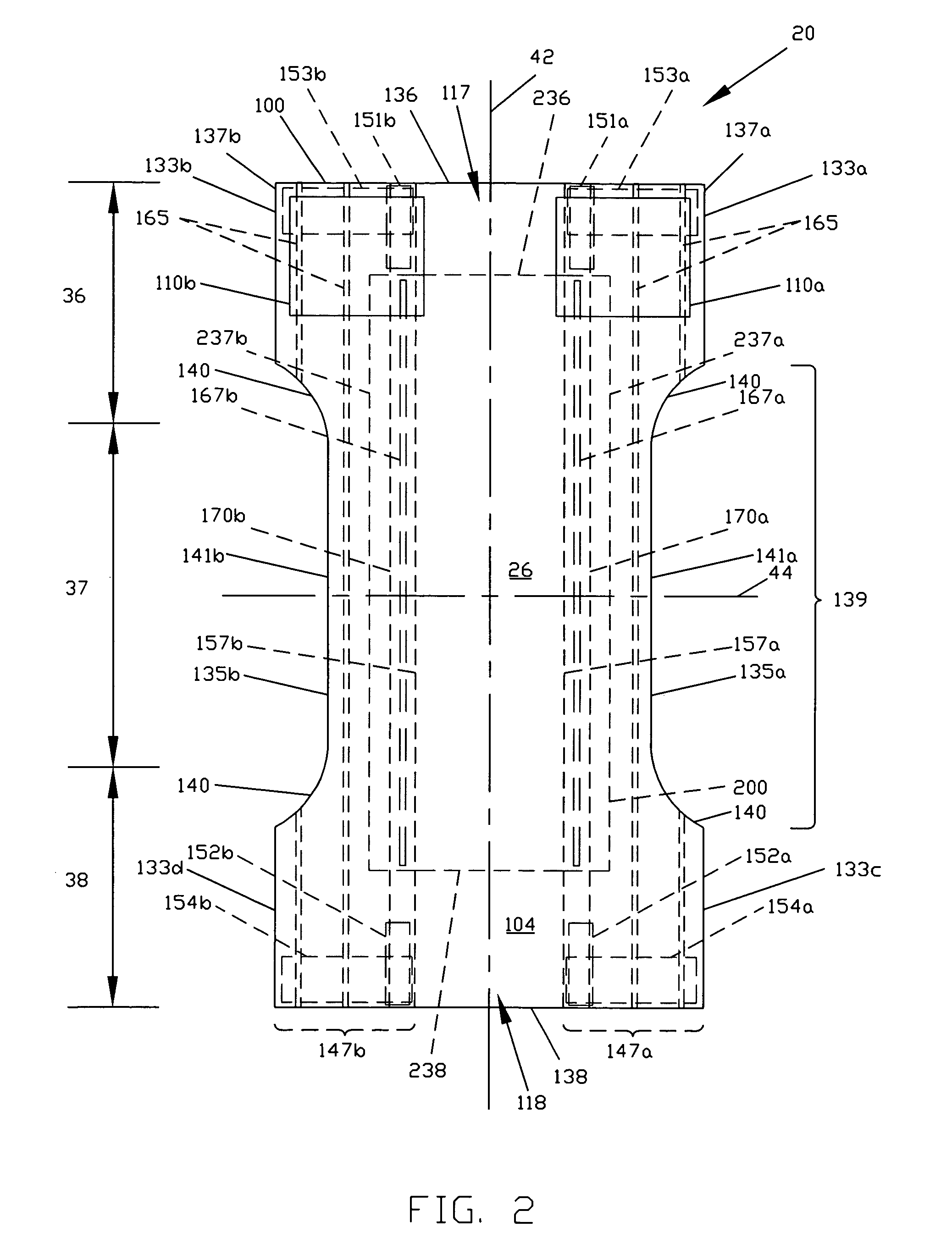

Side notched folded diaper

A disposable absorbent article includes a chassis and an absorbent assembly. The chassis includes a water-impermeable backsheet that is folded laterally inward at both of its side edges to form laterally opposing side flaps. Each side flap is attached to the interior surface of the chassis adjacent to its end edges. Each side flap has a longitudinally extending elastic gathering member attached adjacent to its proximal edge. Each side flap is also attached to the interior surface of the chassis at continuous longitudinally extending laterally opposing water-impermeable side seals. The chassis is side notched to give it an hourglass shape. The chassis may include an extensible formed web material. The absorbent assembly includes an absorbent core that may contain superabsorbent particles, which may be contained inside pockets. The absorbent assembly may be attached in a cruciform pattern to the chassis to allow portions of the chassis to extend laterally.

Owner:PROCTER & GAMBLE CO

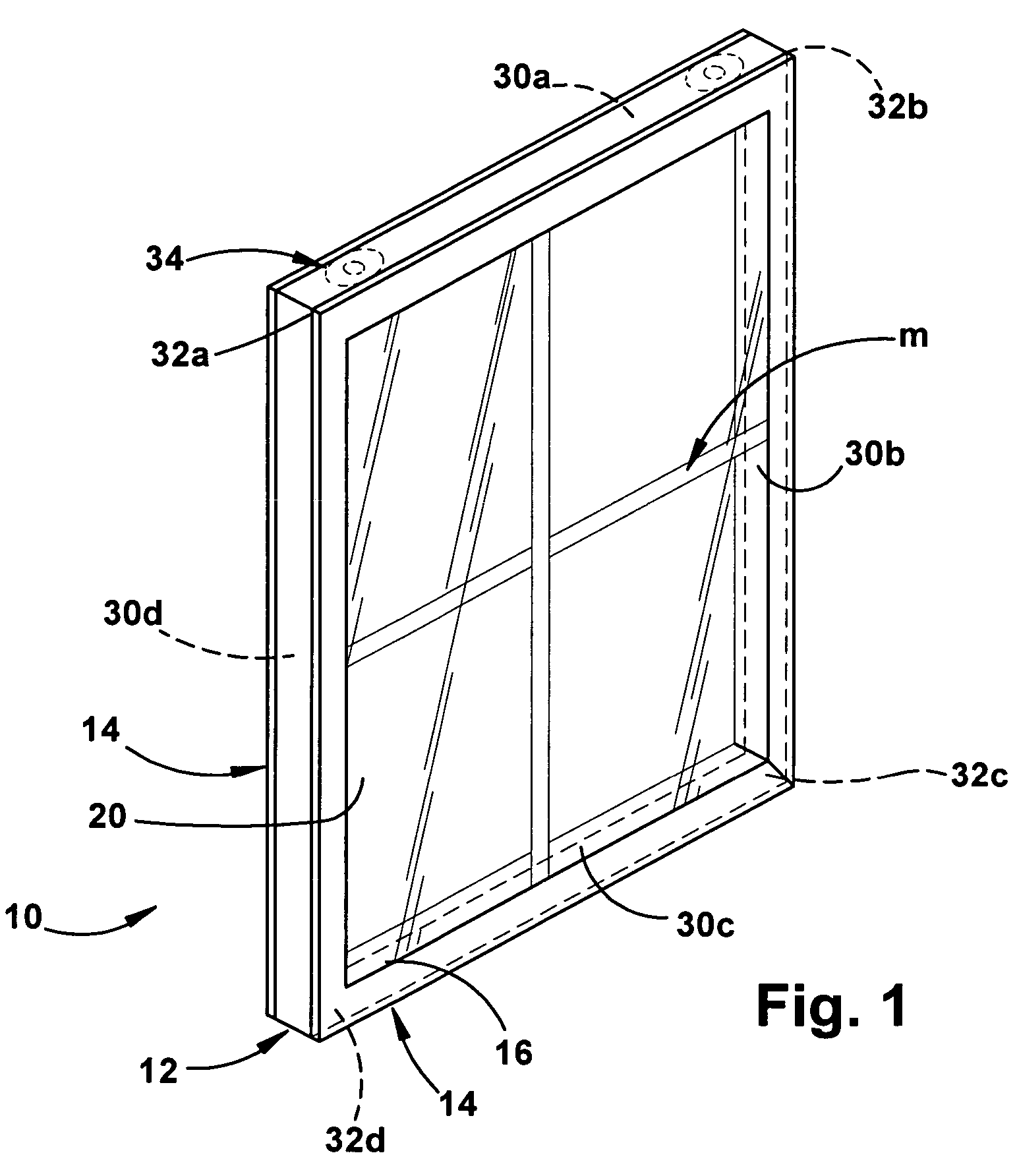

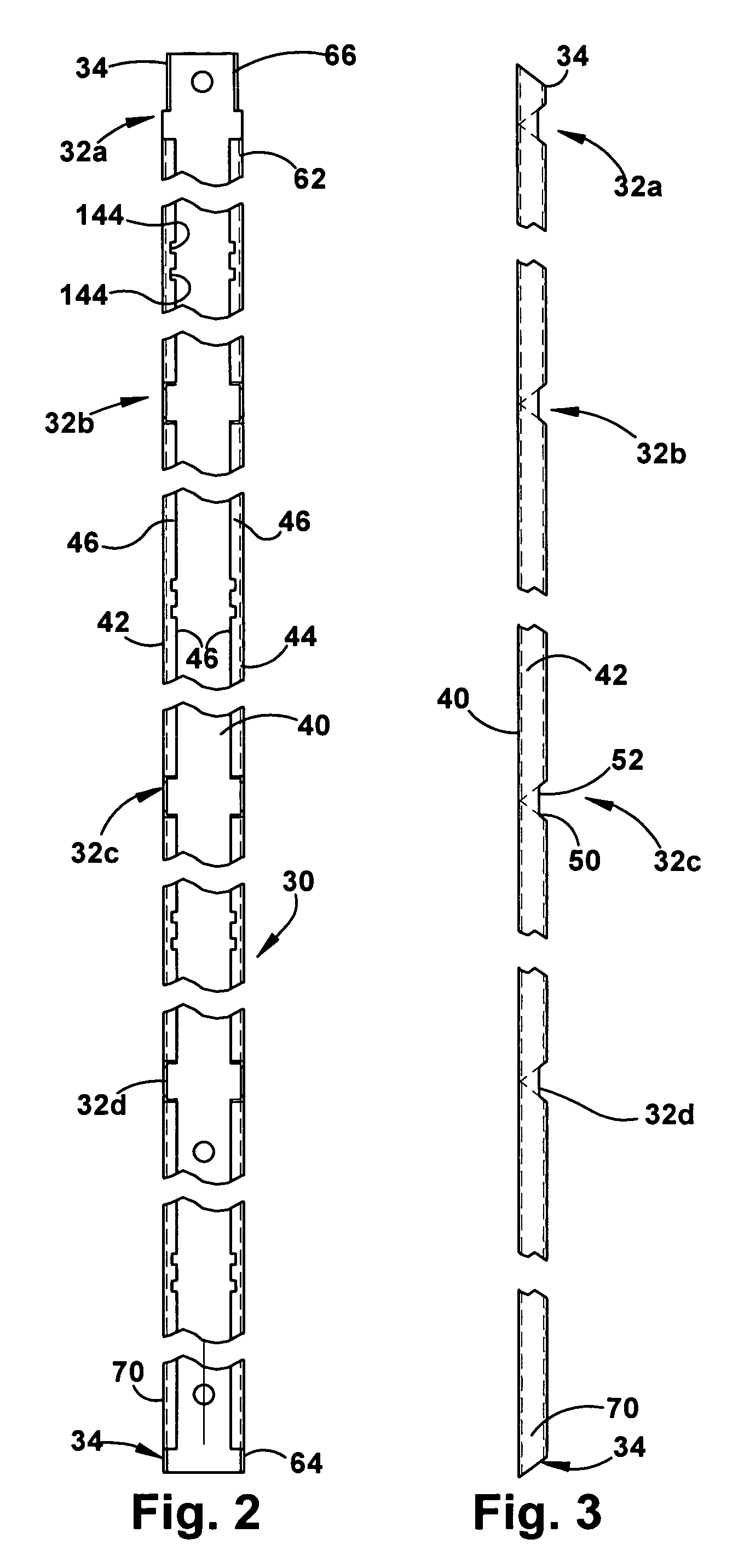

Window frame corner fabrication

Owner:GED INTEGRATED SOLUTIONS

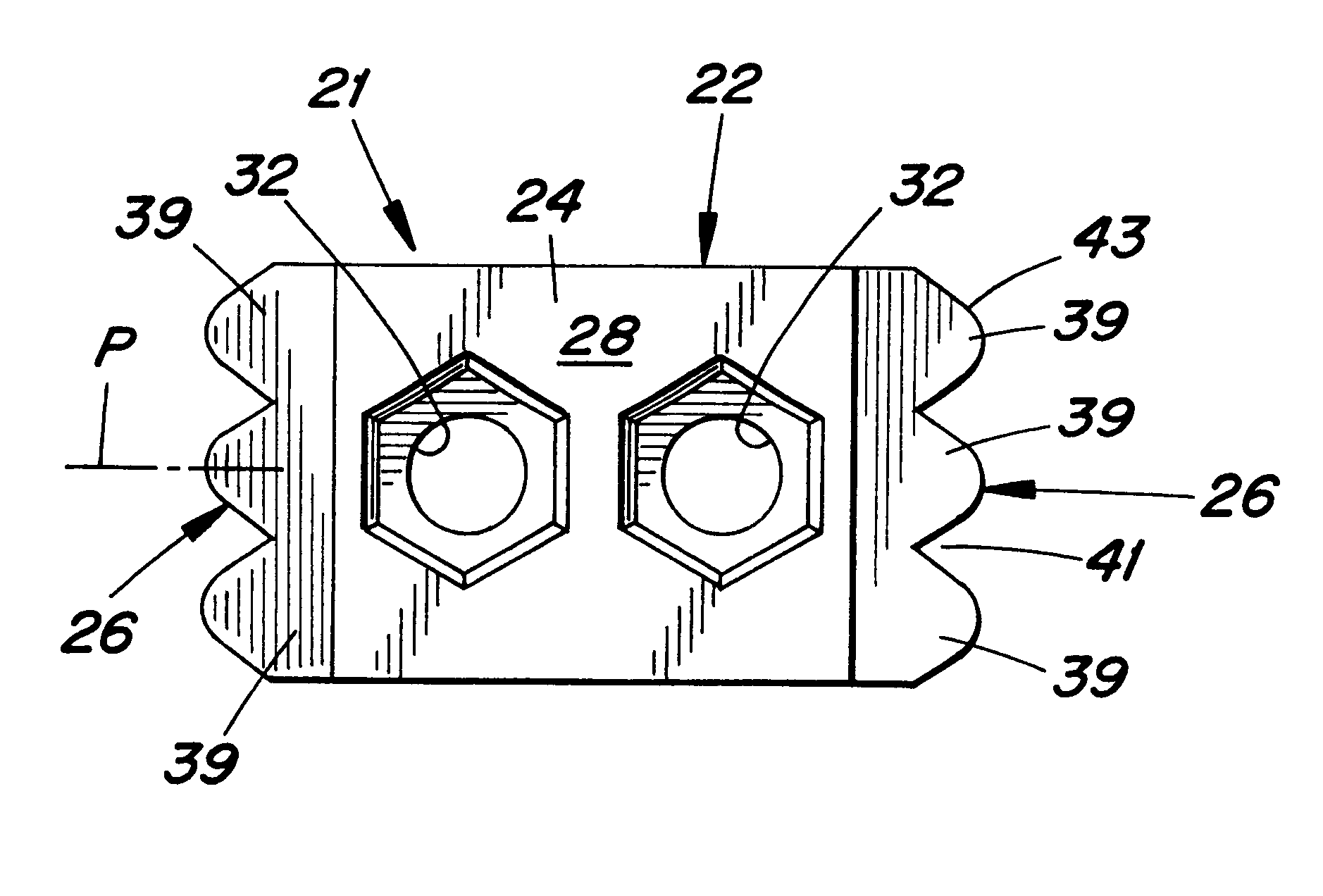

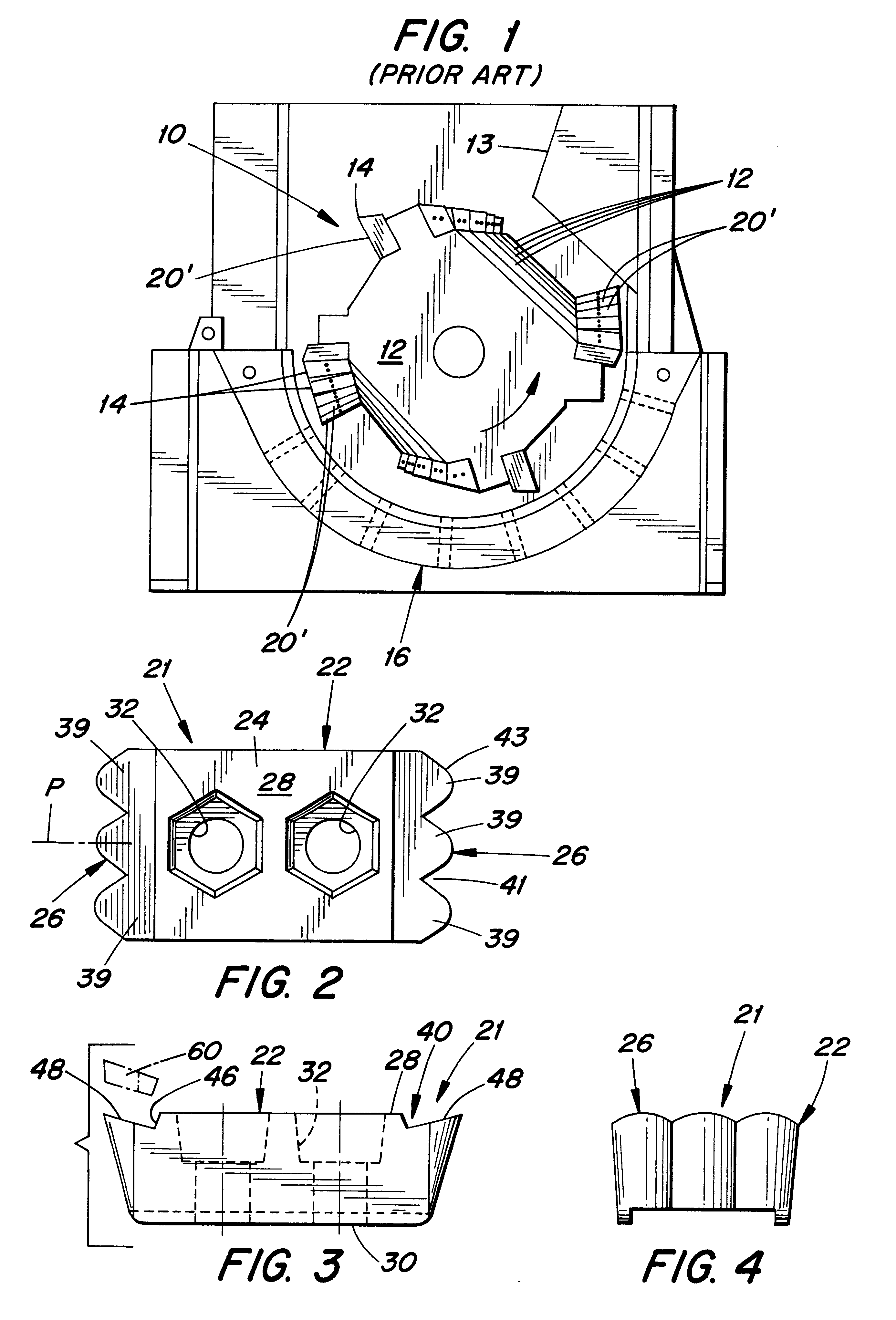

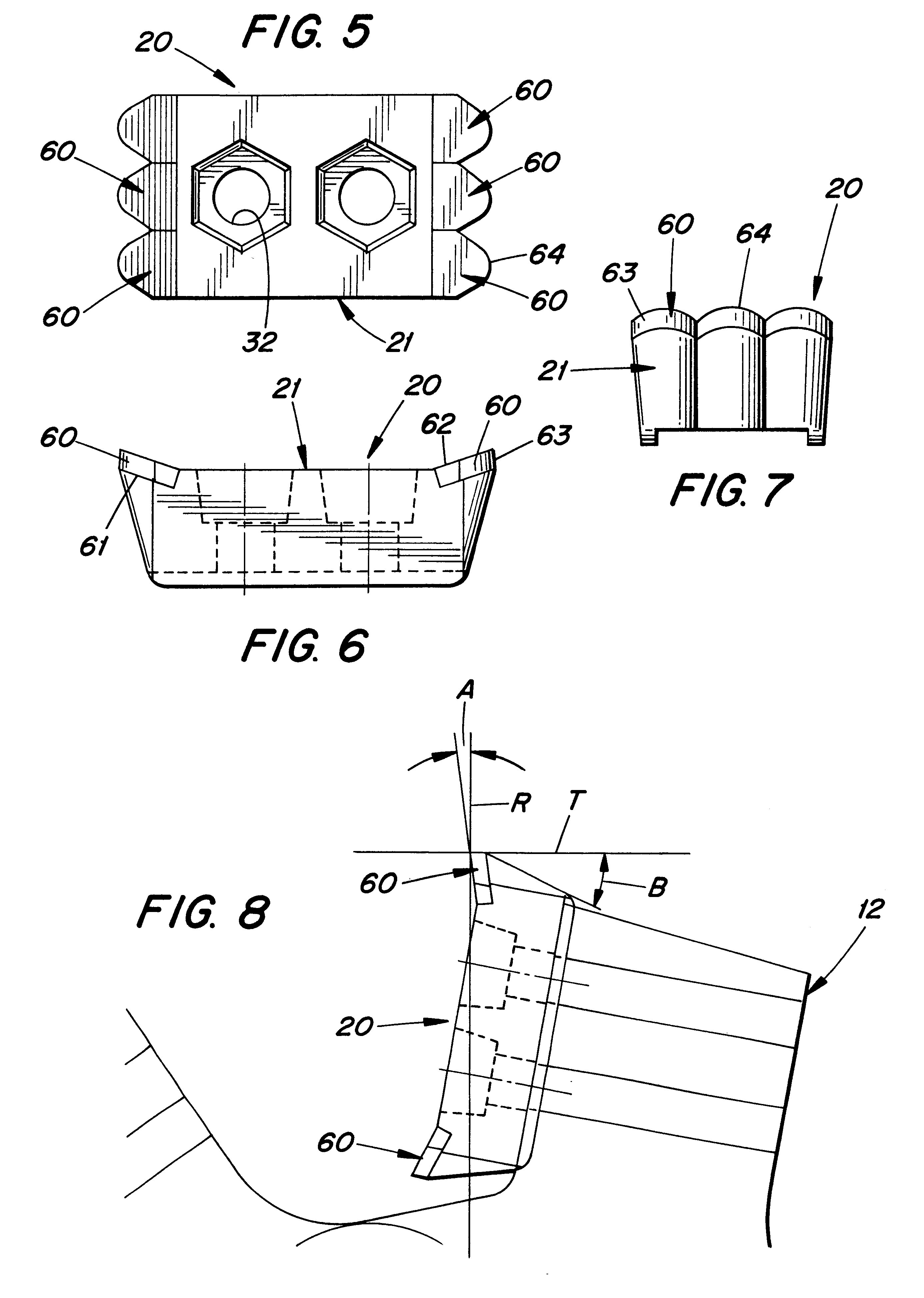

Striker bar for disintegrating breakable materials

A mechanism for disintegrating breakable materials, such as wood, pipes, bricks, etc. includes a rotary drum having striker bars mounted thereon which disintegrate the breakable materials. Each striker bar has a notched cutting edge formed by a row of carbide tips sintered to an edge of a steel body. The cutting edge can be of serrated shape and / or scallop-shape.

Owner:SANDVIK ROCK TOOLS

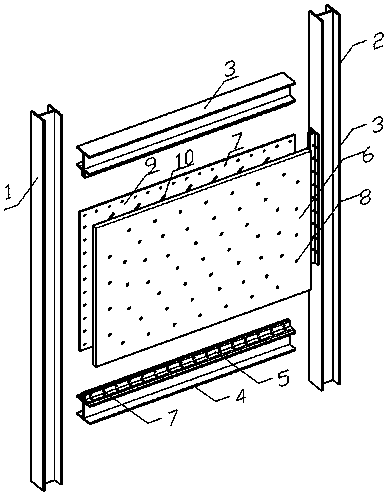

Anti-buckling oblique notching steel plate energy dissipation shear wall

InactiveCN103437456AAdjust the lateral stiffnessIncrease lateral stiffnessWallsShock proofingClassical mechanicsEngineering

The invention relates to an anti-buckling oblique notching steel plate energy dissipation shear wall which belongs to the technical field of structural engineering. The anti-buckling oblique notching steel plate energy dissipation shear wall consists of an oblique notching steel plate, concrete slabs and an edge frame, wherein the concrete slabs are arranged at both sides of the steel plate and are used for restraining out-of-plane deformation of the steel plate; the edge frame is connected with the steel plate; the steel plate is provided with different forms of chutes designed as required; the periphery of the steel plate is connected and embedded into the edge frame by bolts; the bolts passing through the chutes are connected with the concrete slabs at both the sides. By forming the different forms of chutes on the steel plate, a complex stress state of the steel plate is changed, and a stress mode of taking tension and compression deformation of the steel plate among the chutes as the major mode is formed, and thus, not only is the anti-buckling oblique notching steel plate energy dissipation shear wall beneficial for implementing stable tension and compression energy dissipation, but also parameters of inclined plates among the chutes can be regulated by changing the forms and the sizes (length and width) of the formed chutes, and an inefficacy mechanism of the shear wall is effectively controlled, so that resist lateral stiffness, intensity and ductility of the shear wall can be regulated. Used as a novel lateral force resisting and energy dissipation component, the anti-buckling oblique notching steel plate energy dissipation shear wall can be widely applied to multilayer and high-rise structures.

Owner:欧进萍

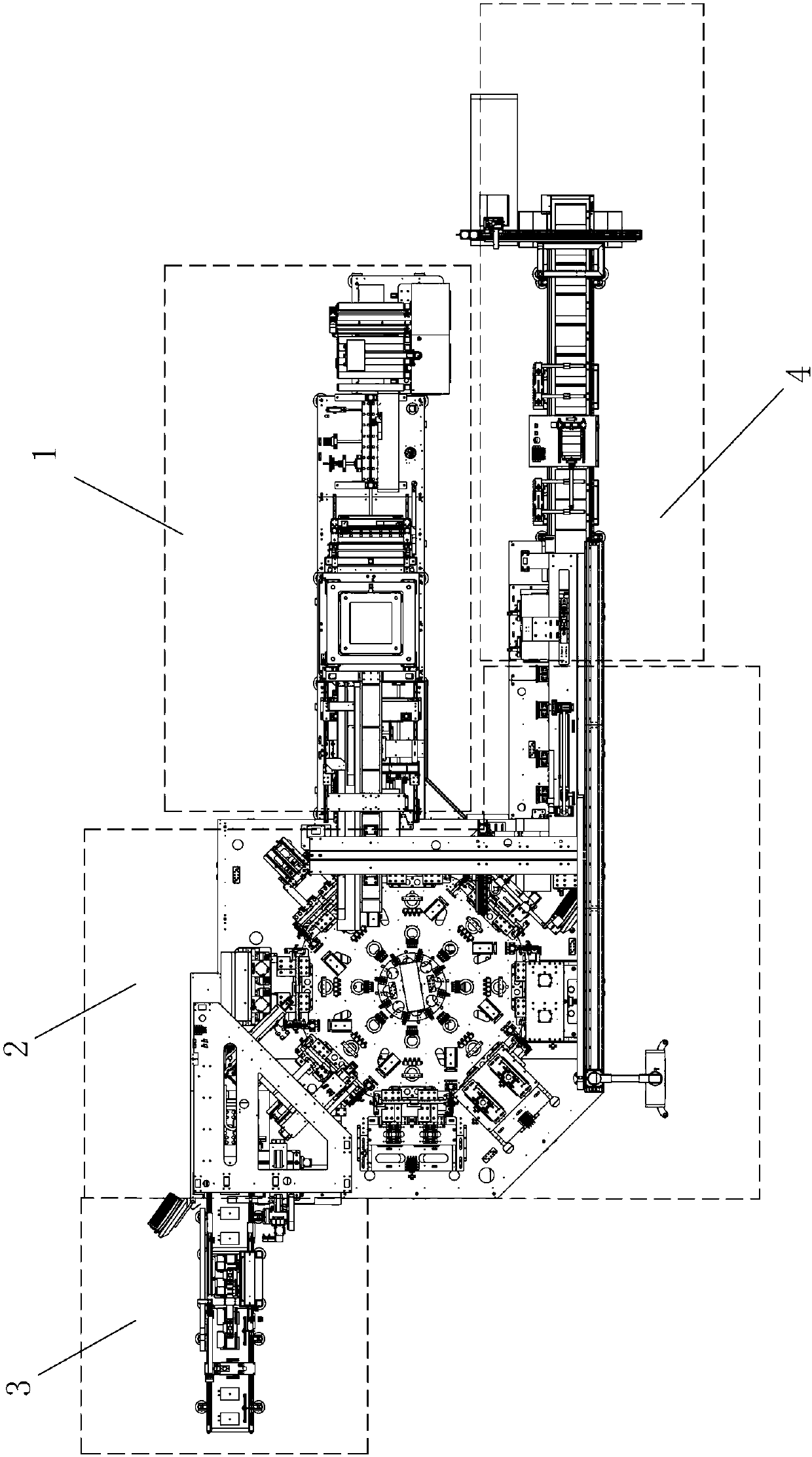

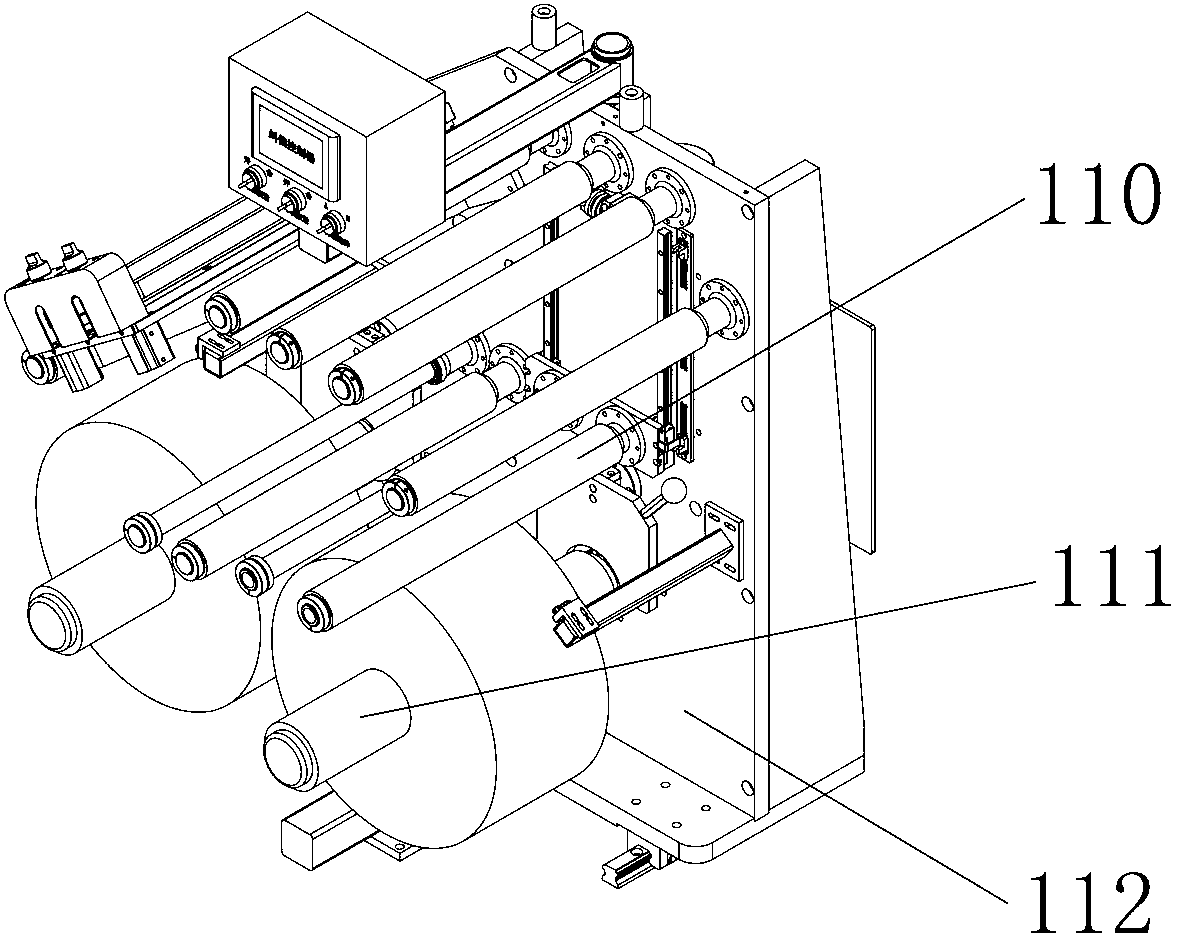

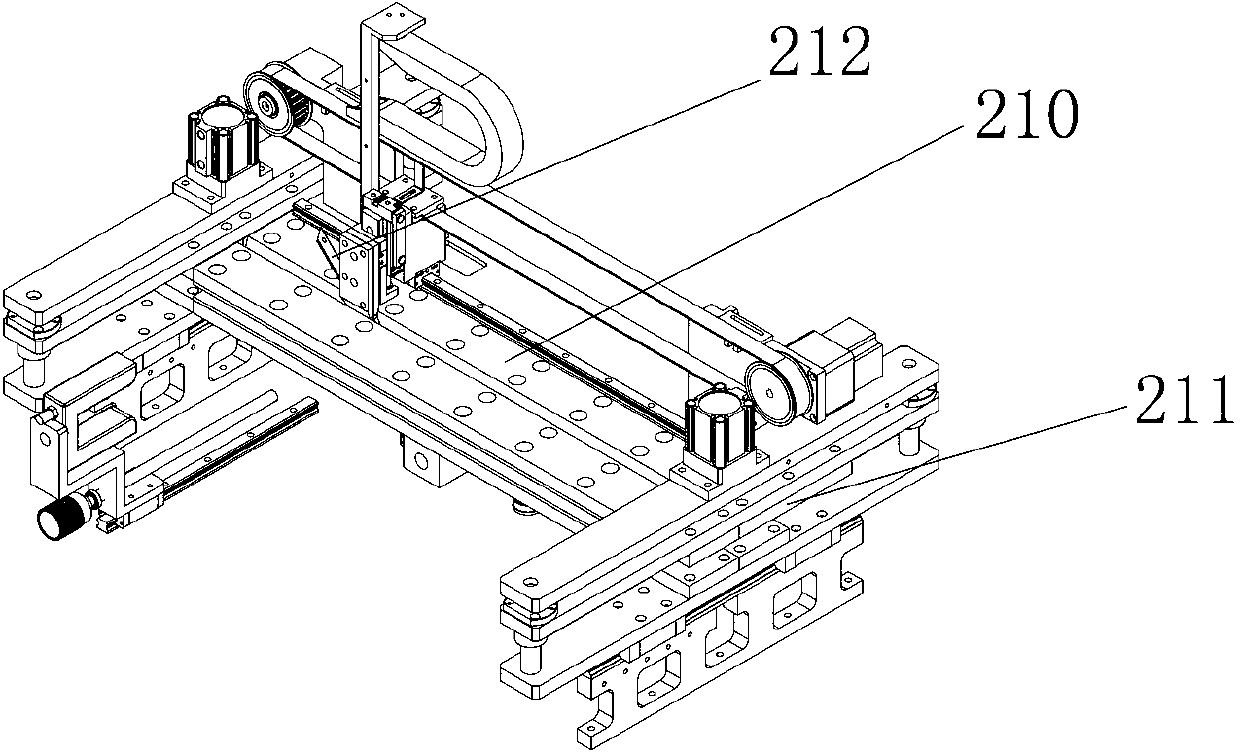

Automatic rotating-disc type packaging and forming apparatus for lithium battery

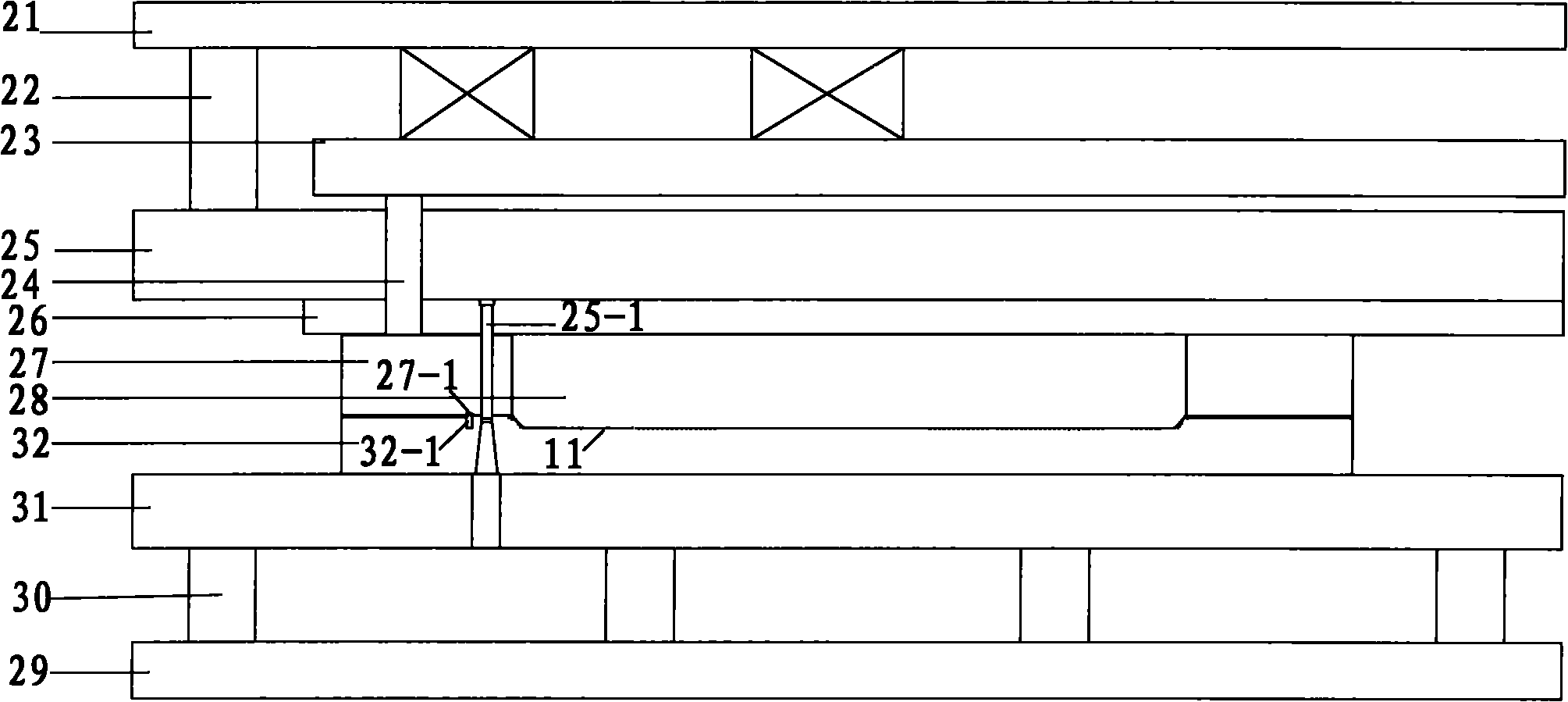

ActiveCN103346352AIncrease productivityReduce demandFinal product manufactureElectrolyte accumulators manufacturePunchingEngineering

The invention discloses an automatic rotating-disc type packaging and forming apparatus for a lithium battery. The apparatus comprises: an aluminum-plastic membrane forming unit, wherein the aluminum-plastic membrane forming unit is used for preparing a shell from the aluminum-plastic membrane through punching and cutting the membrane into slices and comprises an aluminum-plastic membrane unwinding mechanism, a notching mechanism used for slitting the aluminum-plastic membrane, a dedusting mechanism used for dedusting the aluminum-plastic membrane, a shell punching mechanism used for preparing the formed shell through punching and a cutting mechanism used for cutting the aluminum-plastic membrane, and the above-mentioned mechanisms are successively arranged; a feeding unit, wherein the feeding unit is used for delivering an electrical core to the shell and comprises a pulling strip, a CCD scanning and sorting mechanism, a positioning platform, a material feeding manipulator and a shell feeding manipulator, and the feeding unit is used for feeding of the shell and the electrical core; and an electrical core packaging unit (a rotating disc station), wherein the electrical core packaging unit is used for packaging of the electrical core and is connected with the tail of the aluminum-plastic membrane forming unit, the electrical core packaging unit comprises a fixture mechanism used for bearing and doubling the shell, a feeding mechanism used for conveying the fixture mechanism, a shell feeding mechanism, a top sealing mechanism and a side sealing mechanism, and the shell feeding mechanism, the top sealing mechanism and the side sealing mechanism are successively arranged along the feeding mechanism.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

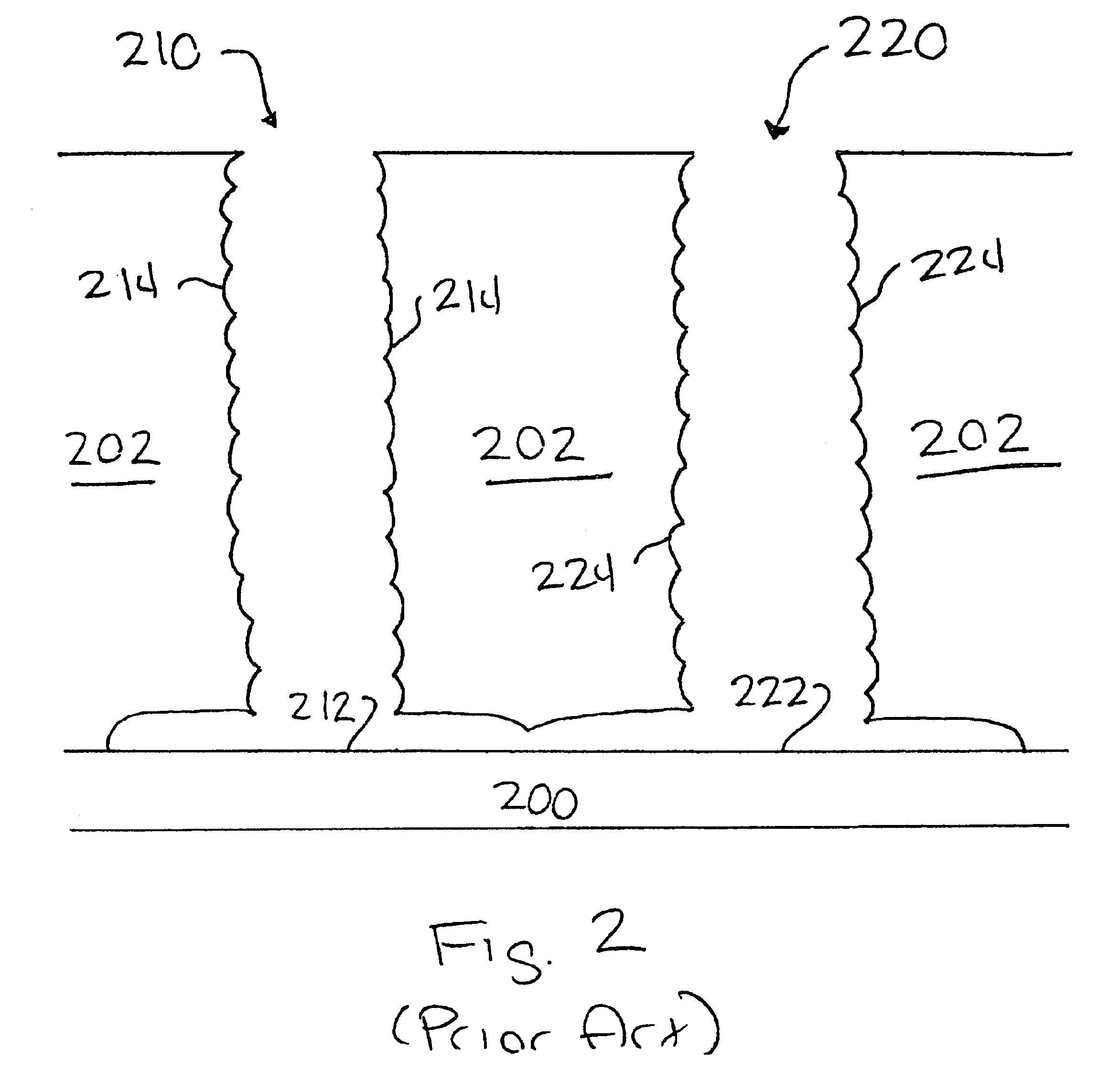

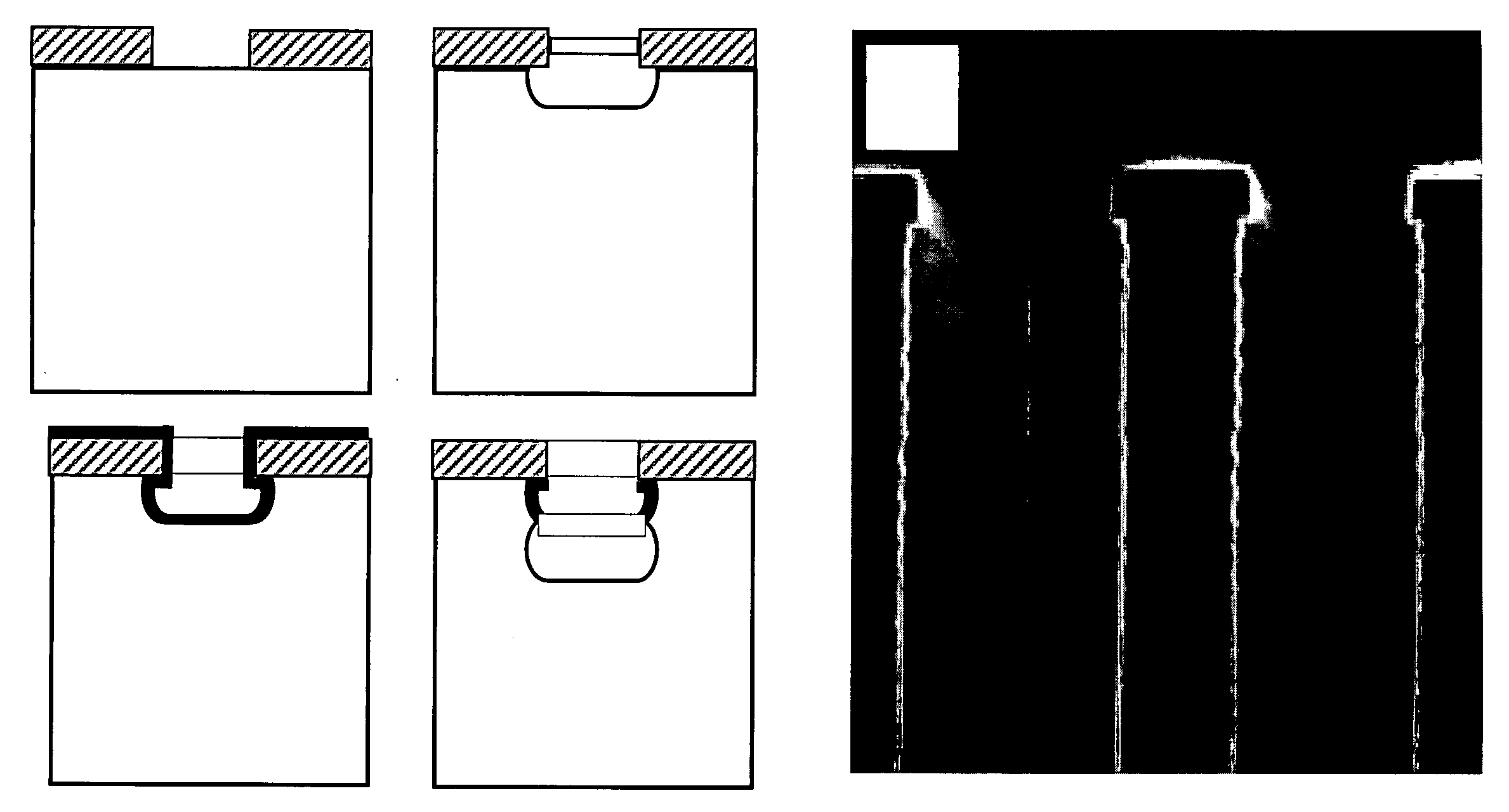

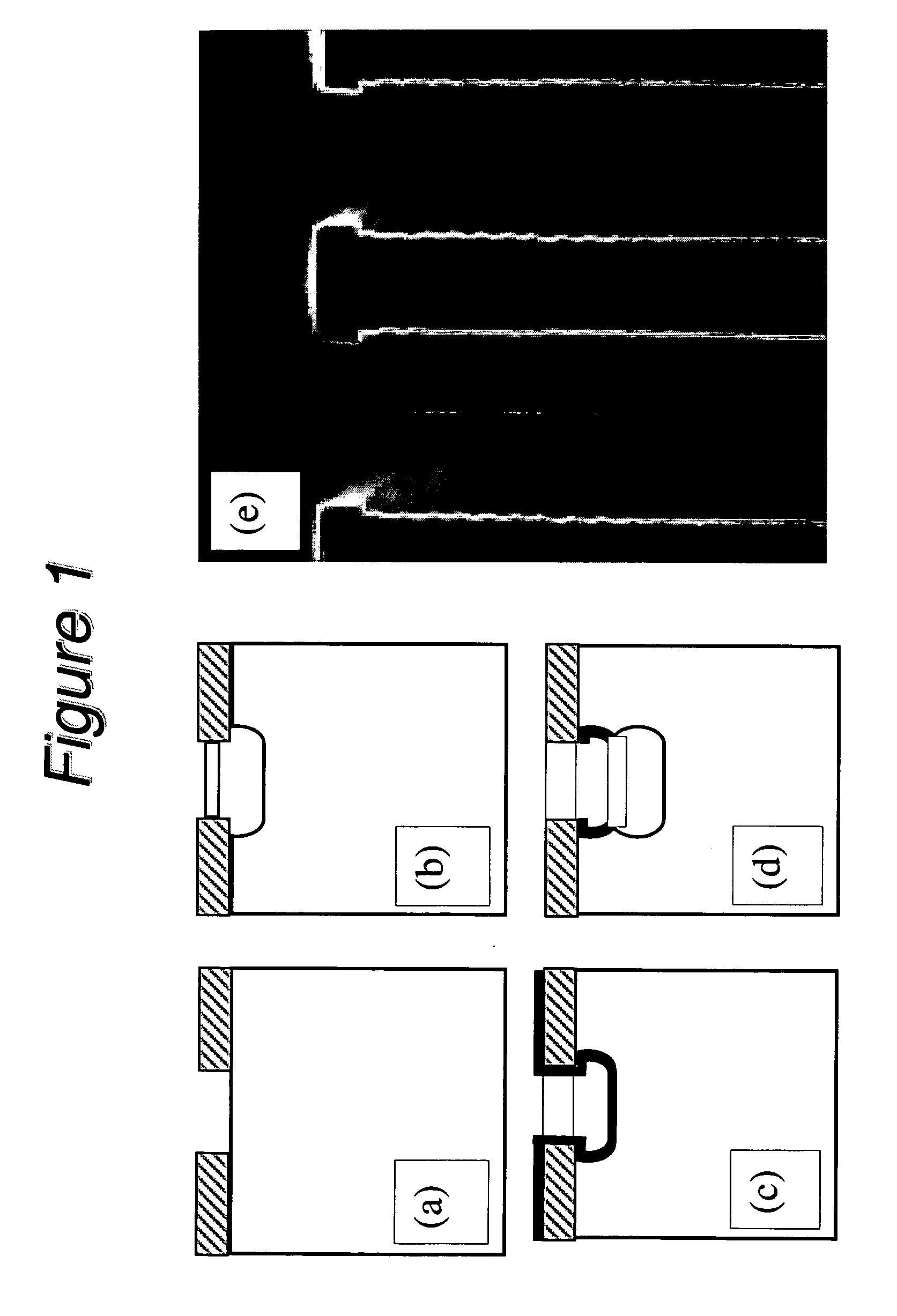

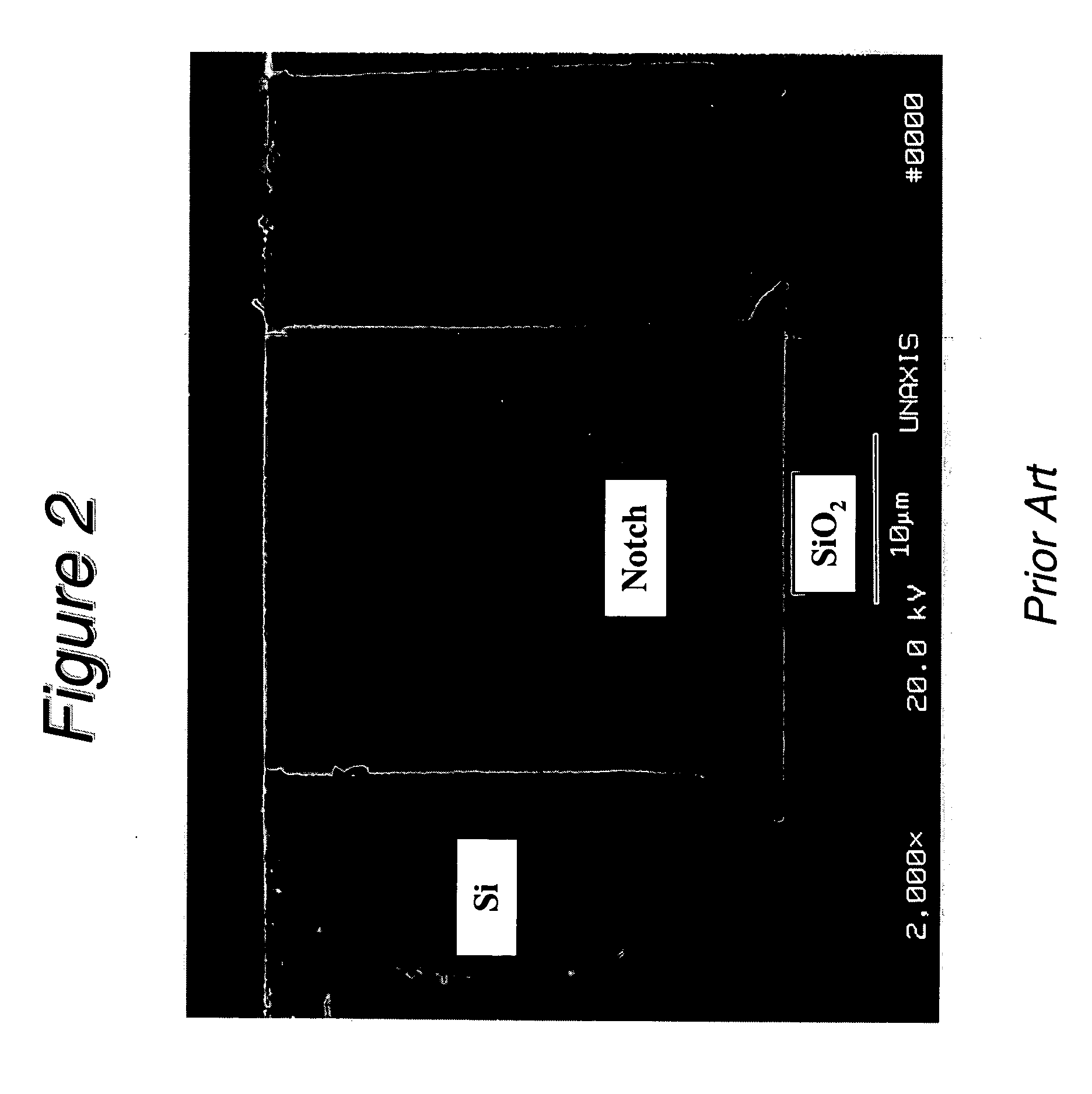

Method of etching a trench in a silicon-on-insulator (SOI) structure

InactiveUS6759340B2Decorative surface effectsSemiconductor/solid-state device manufacturingForming gasFluorine containing

Disclosed herein is a method of etching a trench in silicon overlying a dielectric material which reduces or substantially eliminates notching at the base of the trench, while reducing scalloping on the sidewalls of the trench. The method comprises etching a first portion of a trench by exposing a silicon substrate, through a patterned masking layer, to a plasma generated from a fluorine-containing gas. This etching is followed by a polymer deposition step comprising exposing the substrate to a plasma generated from a gas which is capable of forming a polymer on etched silicon surfaces. The etching and polymer deposition steps are repeated for a number of cycles, depending on the desired depth of the first portion of the trench. The final portion of the trench is etched by exposing the silicon to a plasma generated from a combination of a fluorine-containing gas and a polymer-forming gas.

Owner:APPLIED MATERIALS INC

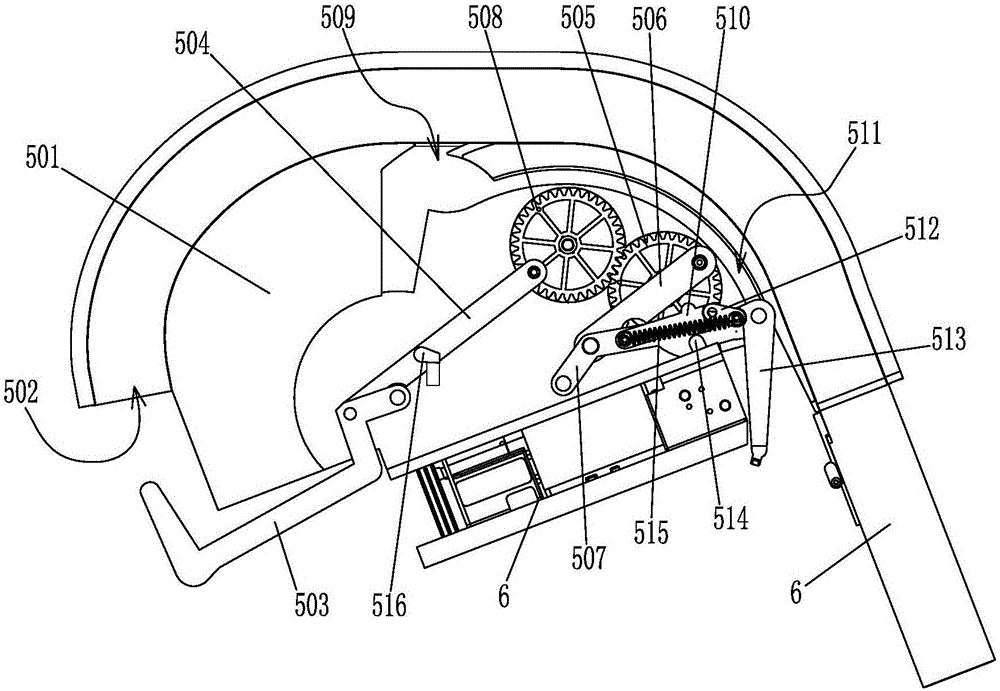

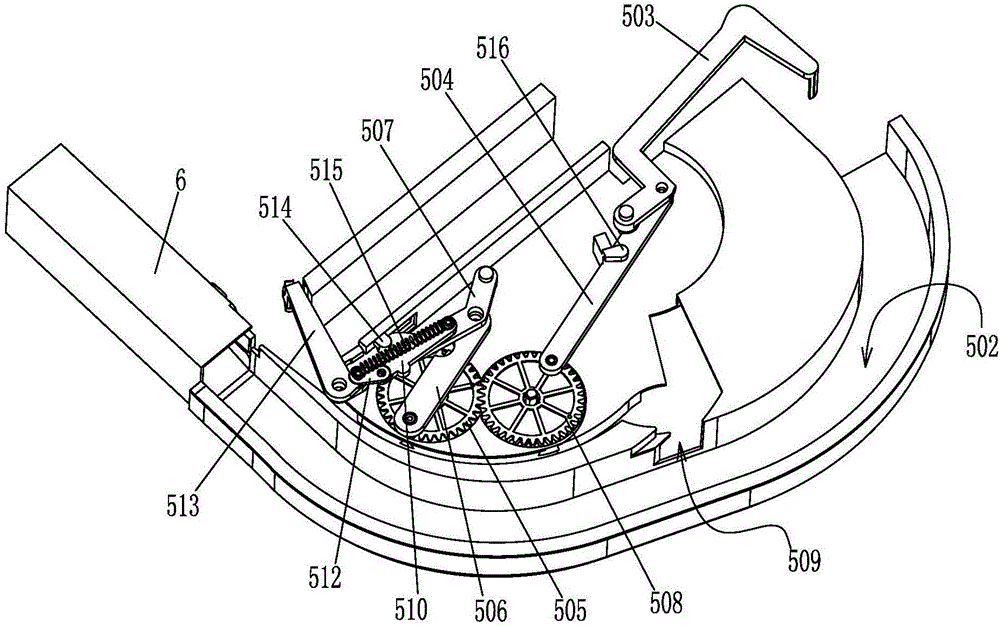

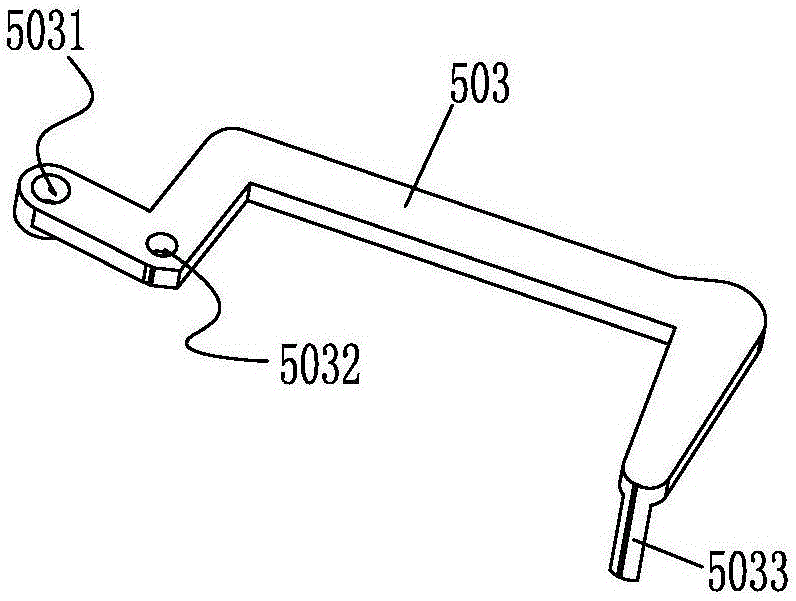

Mahjong machine and slope playing device thereof

The invention discloses a mahjong machine and a slope playing device thereof. The slope playing device comprises a tile feeding assembly and a tile lifting assembly; the tile feeding assembly comprises a tile storage groove, a first tile feeding pushing head and a second tile feeding pushing head; the first tile feeding pushing head is driven by a tile feeding driving mechanism to move to a position near a notch from the outside of a tile inlet of the tile storage groove and then return; the second tile feeding pushing head is driven by the tile feeding driving mechanism to move into a reversing groove from the position of a tile outlet of the tile storage groove and then return; the tile feeding driving mechanism comprises a first tile feeding push rod and a second tile feeding push rod which respectively reciprocate and are matched with each other; the first tile feeding pushing head is arranged on the first tile feeding push rod; the second tile feeding push rod is hinged with a tile feeding swing rod; the second tile feeding pushing head is fixed at the swing end of the tile feeding swing rod; the second tile feeding push rod limits a swinging range of the tile feeding swing rod by a multilink tension spring mechanism. According to the scheme, two tile feeding push rods are adopted to relay to push tiles so as to avoid the defects of high resistance of the tile feeding pushing heads and a guide rail, large working noise of a chain and the like in the prior art.

Owner:ZHEJIANG CHAOSHENG ELECTROMECHANICAL TECH CO LTD

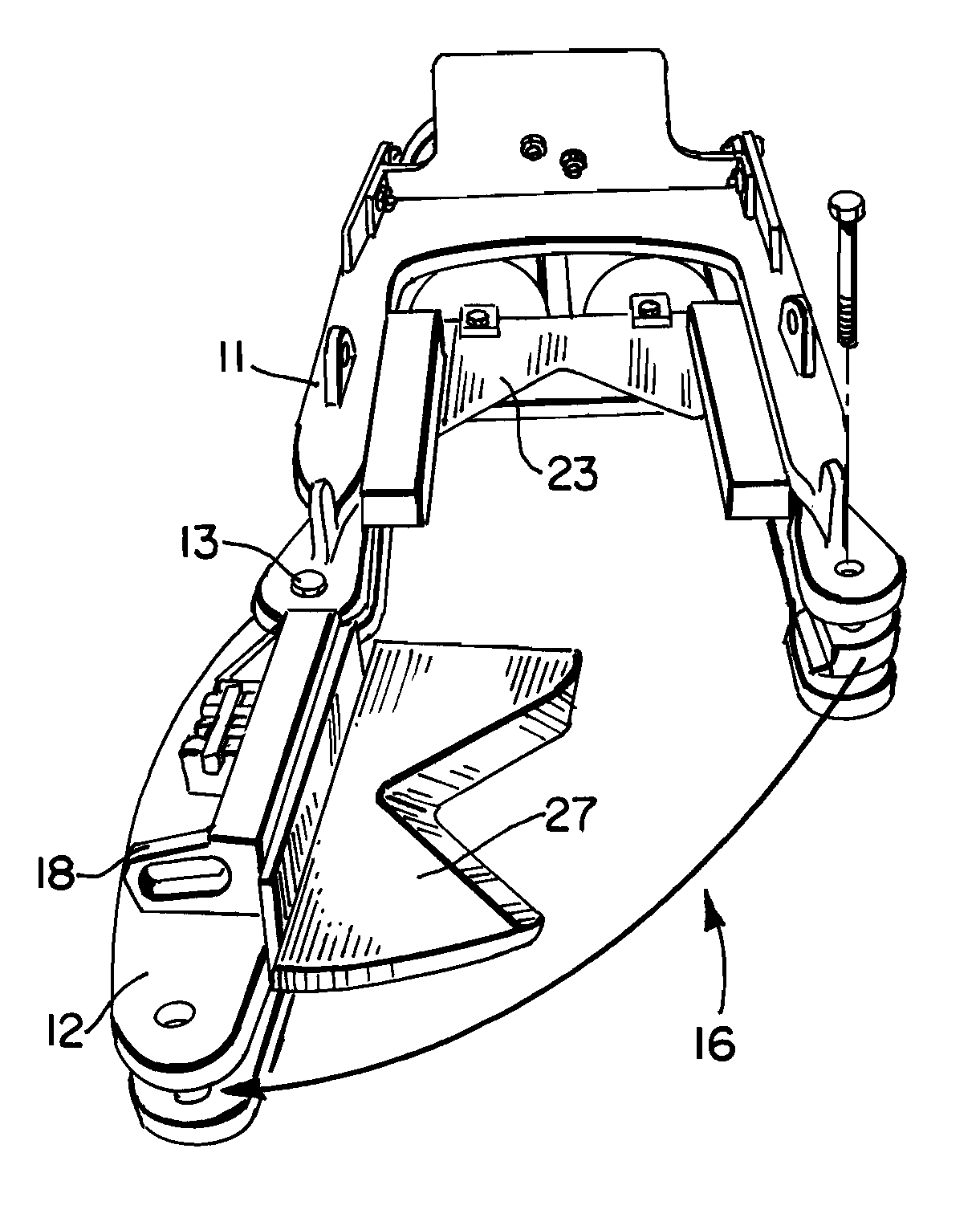

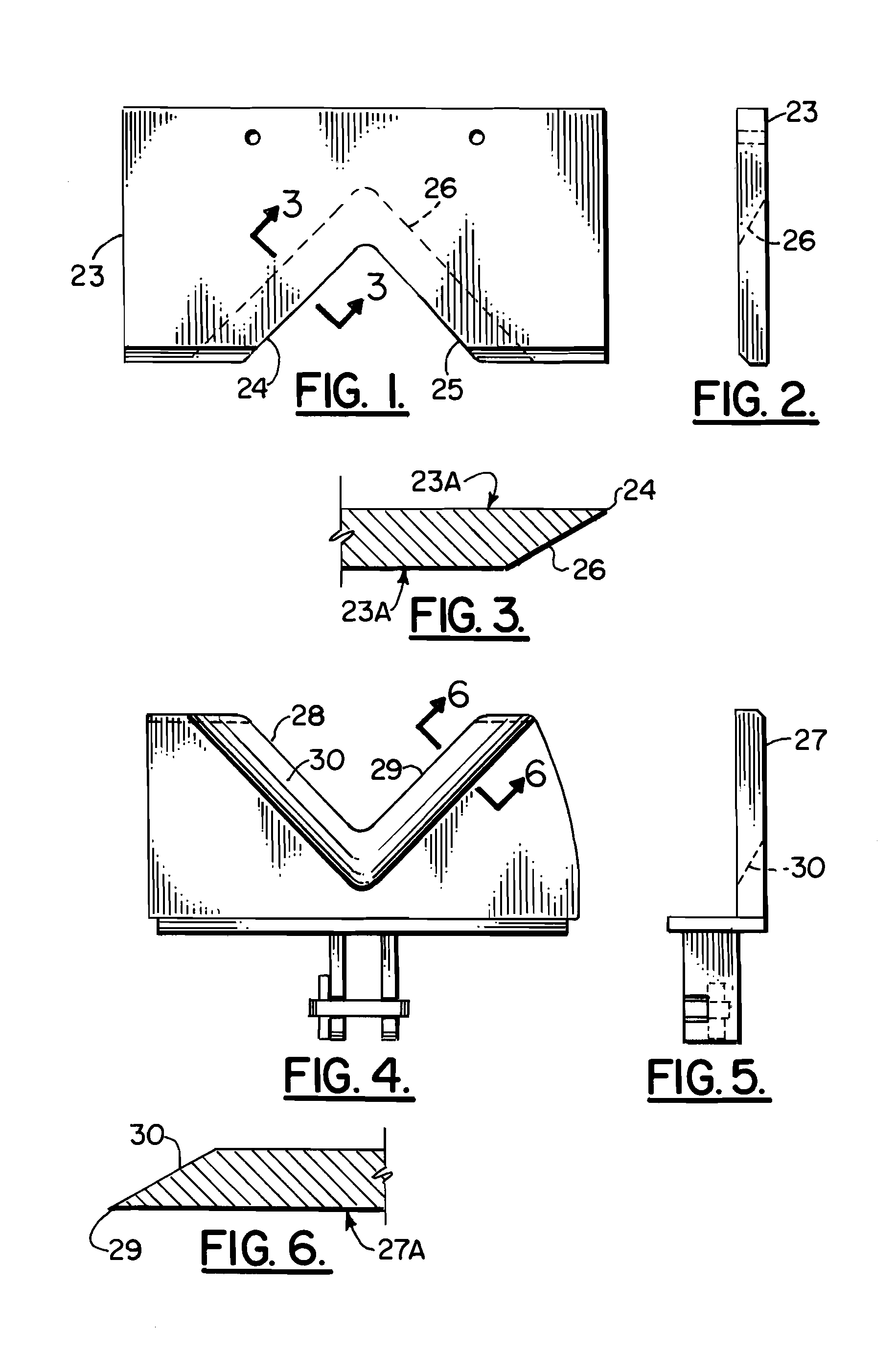

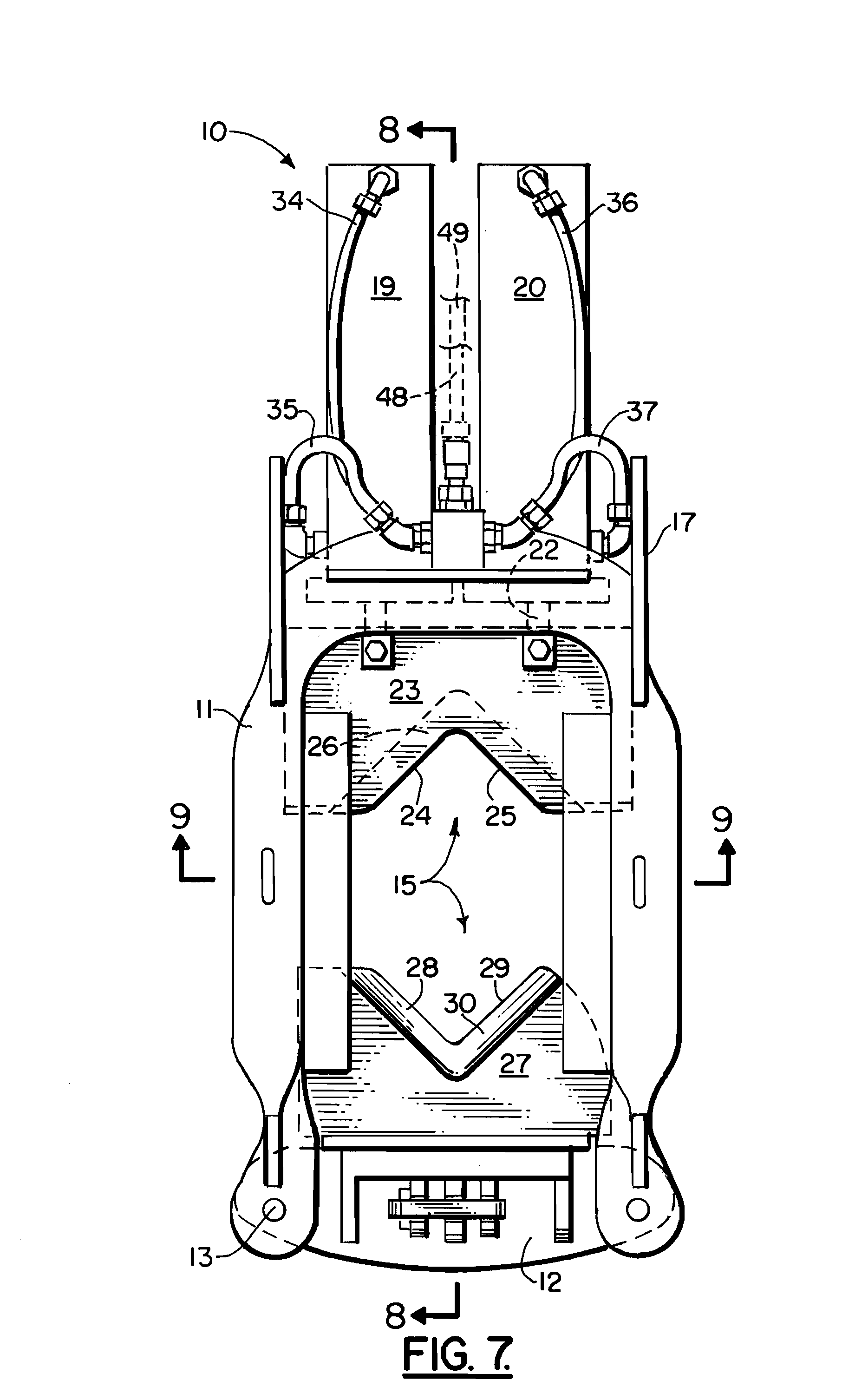

Method and apparatus for salvaging underwater pipelines

A method of salvaging a pipeline in a marine environment is disclosed. The method provides a frame having a perimeter that surrounds a pair of opposed cutting blades, the frame having a gate that enables the frame to be selectively placed around or removed from a section of pipeline to be cut. As part of the method, the frame is placed on a pipeline by first opening the gate and then closing the gate once the pipeline is in an opening that is at the center of the frame. The center opening is generally rectangular in shape once the gate is closed. The cutter blades are moved toward one another, preferably with one blade being the moving blade and the other being a fixed blade. The cutter blades move toward one another until they overlap. At the time that they overlap, the cutter blades are prevented from deflecting in a direction normal to the direction of travel by a pair of guide rails that trap the moving blade in between the fixed blade and the guide rails. The pipeline to be cut is automatically centered within respective v-notched shaped blades prior to being severed as the blades advance relative to one another.

Owner:KELLY JOHN M +1

Notch-free etching of high aspect SOI structures using a time division multiplex process and RF bias modulation

InactiveUS20050112891A1Eliminate gapsSemiconductor/solid-state device manufacturingMultiplexingEngineering

The present invention provides a method and an apparatus for reducing, or eliminating, the notching observed in the creation of SOI structures on a substrate when plasma etching through an alternating deposition / etch process by modulating the RF bias that is applied to the cathode. Modulation of the bias voltage to the cathode is accomplished either discretely, between at least two frequencies, or continuously during the alternating deposition / etch process.

Owner:PLASMA THERM

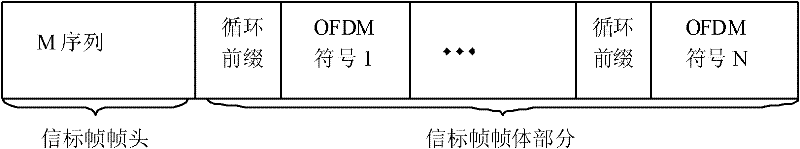

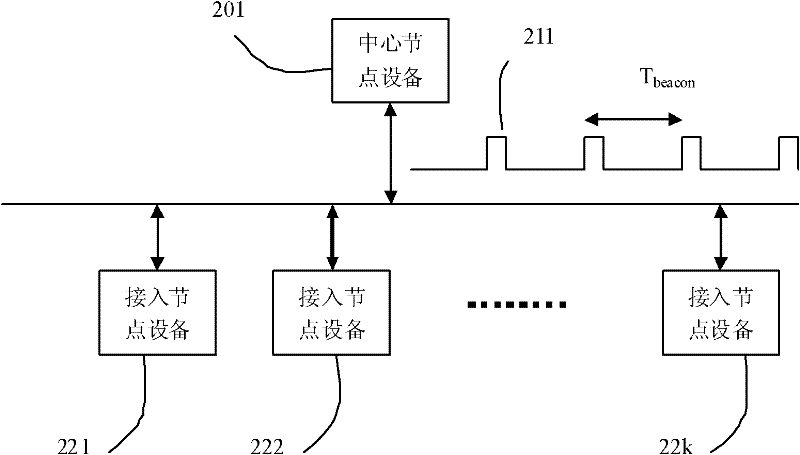

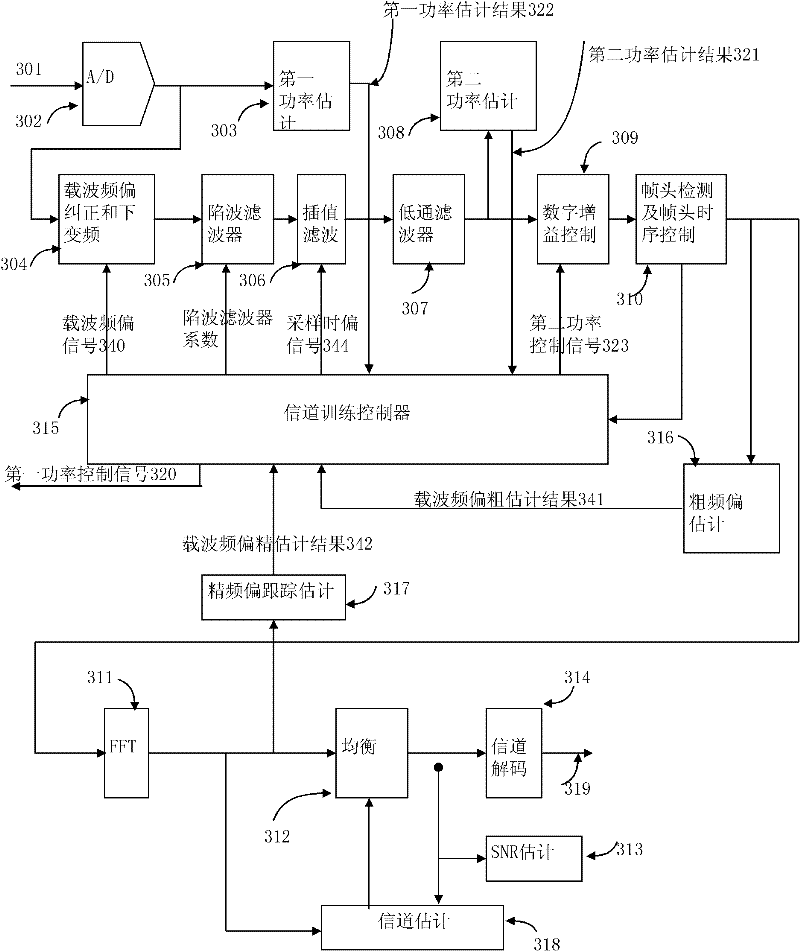

Signal channel training method and signal channel training receiver device based on beacon frame

ActiveCN102546484AImprove reliabilityEstimated accuracy dropsBaseband system detailsMulti-frequency code systemsCarrier frequency offsetBeacon frame

The invention discloses a signal channel training method based on a beacon frame, which includes: performing initial synchronous search for the beacon frame and computing initial estimation of frequency offset of a sampling clock after access terminal equipment is powered on; starting tracking estimation and compensation of frequency offset of the sampling clock based on initial estimation of frequency offset of the sampling clock; estimating in-band narrow-band interference and computing the coefficient of a notching filter according to the frequency point position of the in-band narrow-band interference; performing second power control processing for digital baseband signals processed by means of low-pass filtering and notching filtering; starting coarse carrier frequency offset estimation and compensation; starting fine carrier frequency offset estimation and compensation; starting signal channel frequency response estimation; and leading a receiver to enter a signal channel condition tracking state. The invention further discloses a signal channel training receiver device based on the beacon frame. The success probability of synchronous detection for the beacon frame can be increased, and signal channel estimation precision can also be improved.

Owner:上海明波通信技术股份有限公司

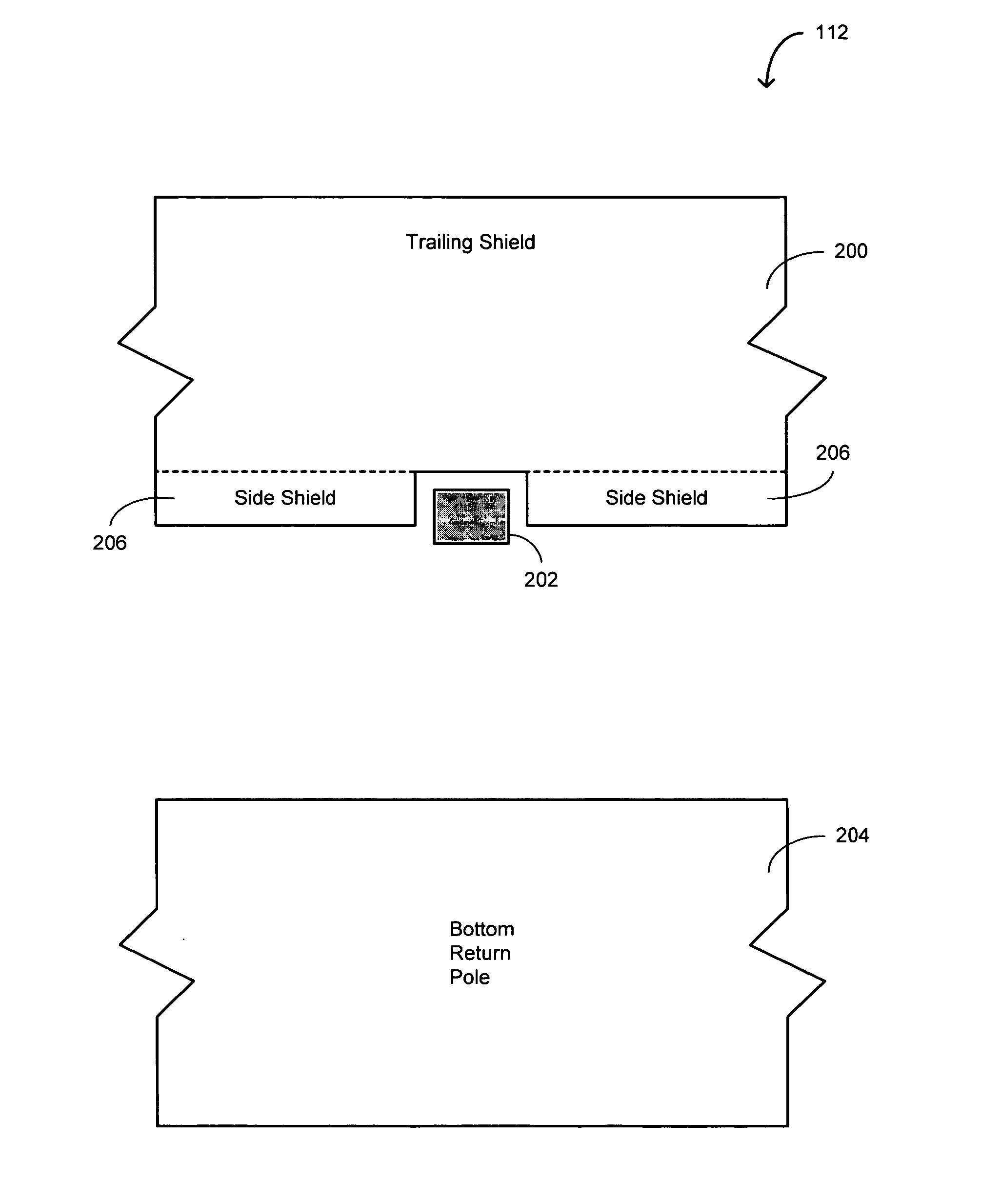

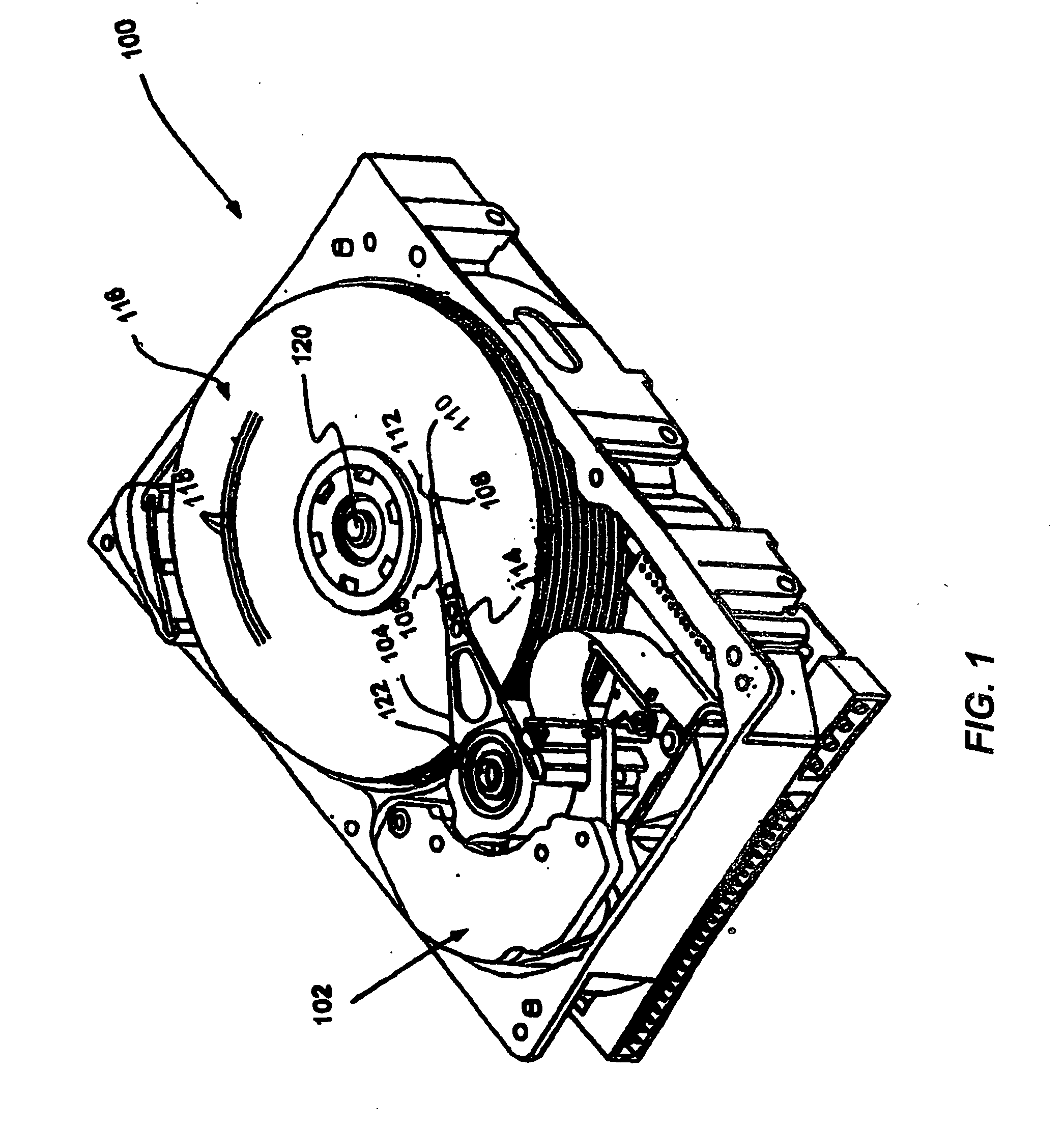

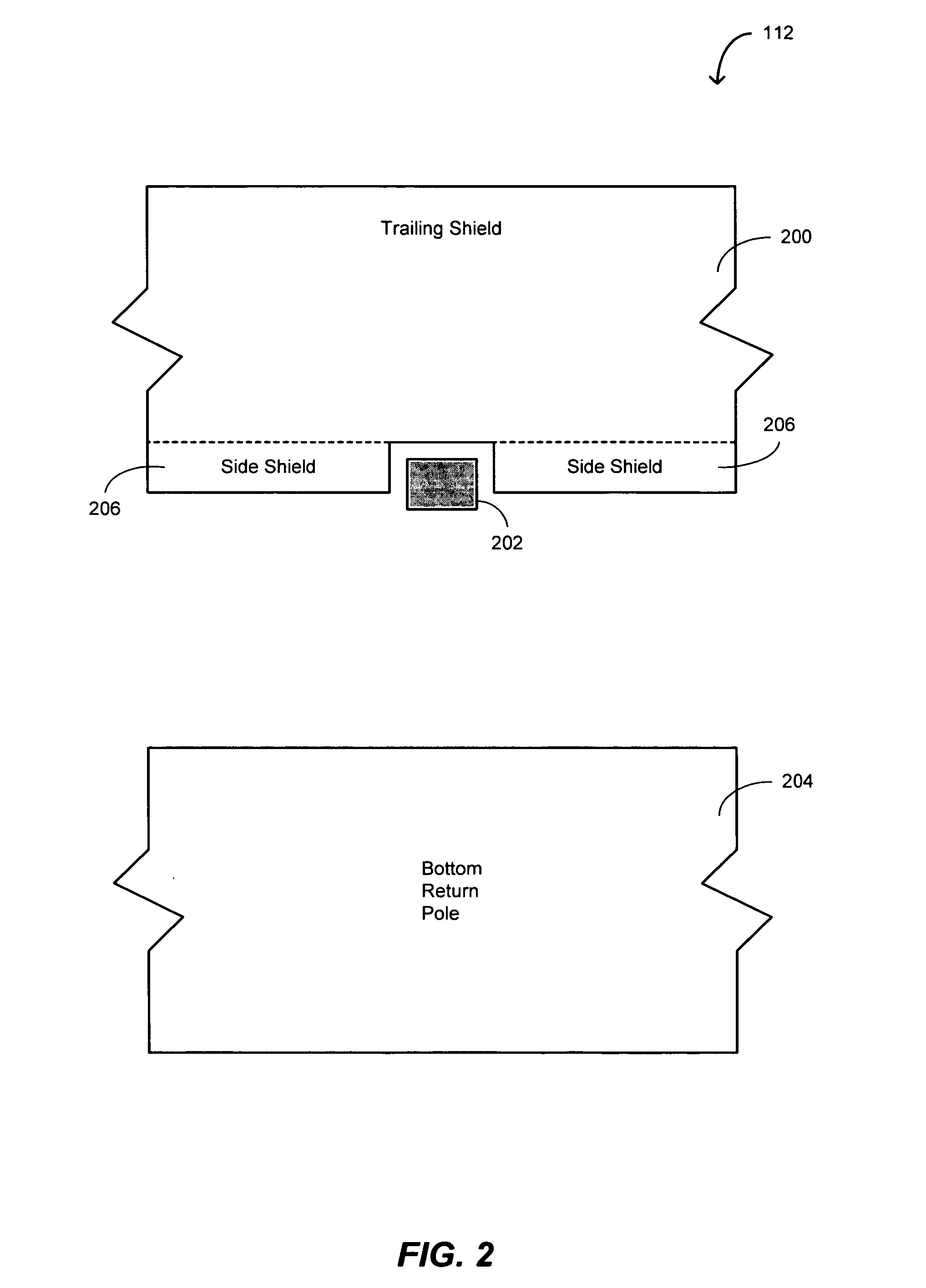

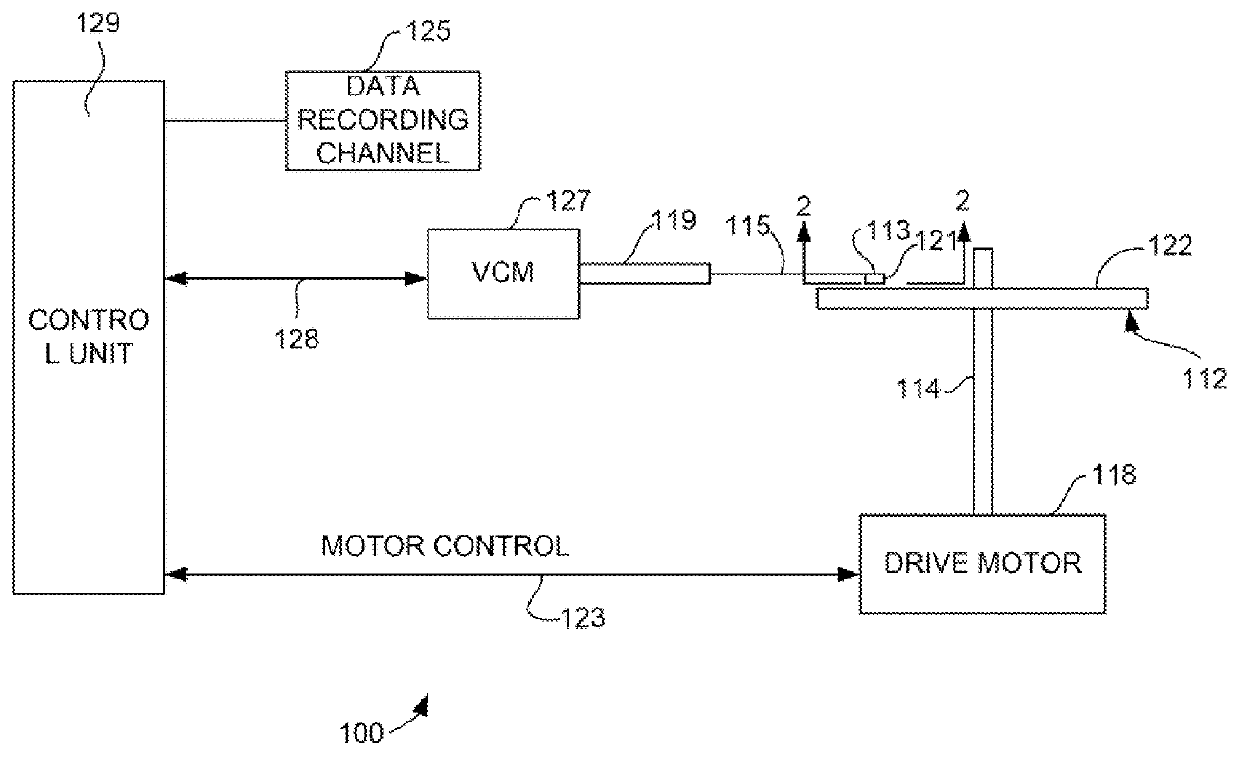

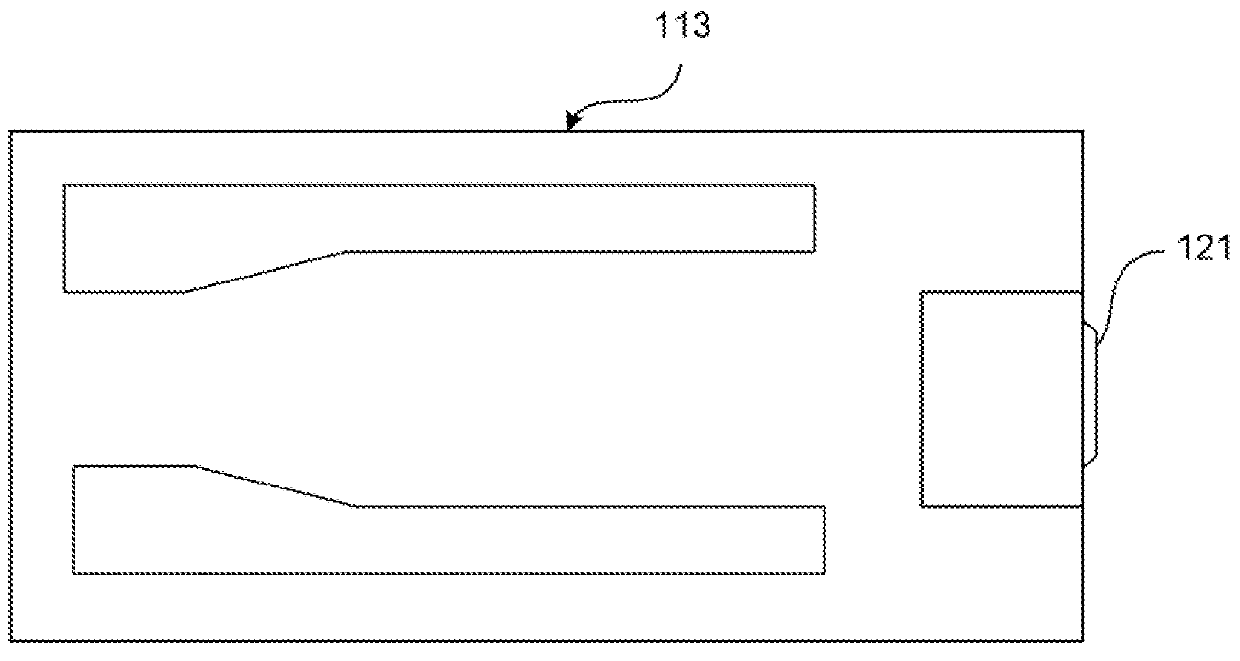

Perpendicular head with self-aligned notching trailing shield process

InactiveUS20070035878A1Improve interferenceRecord information storageHeads for perpendicular magnetisationsNotchingElectrical and Electronics engineering

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

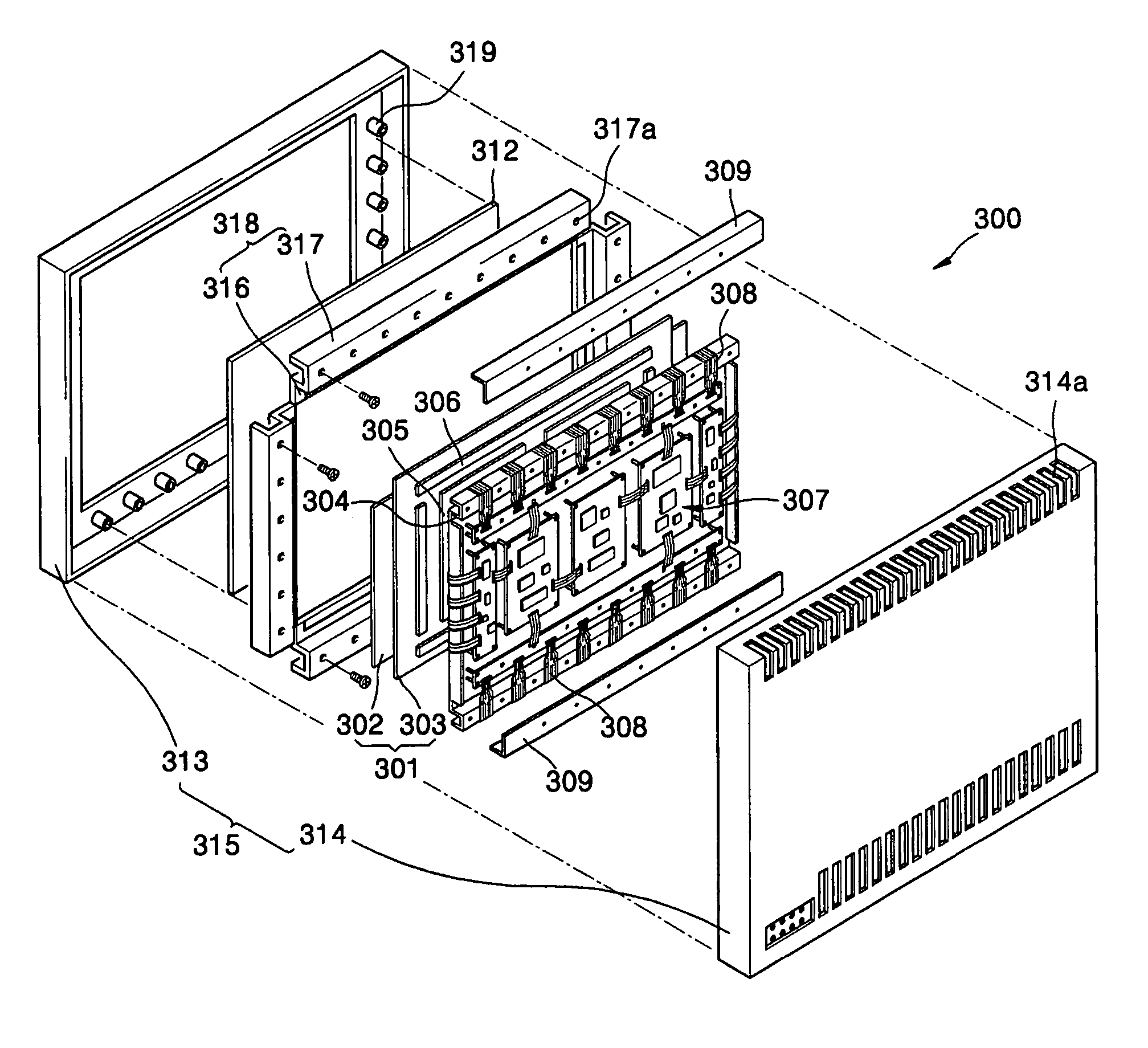

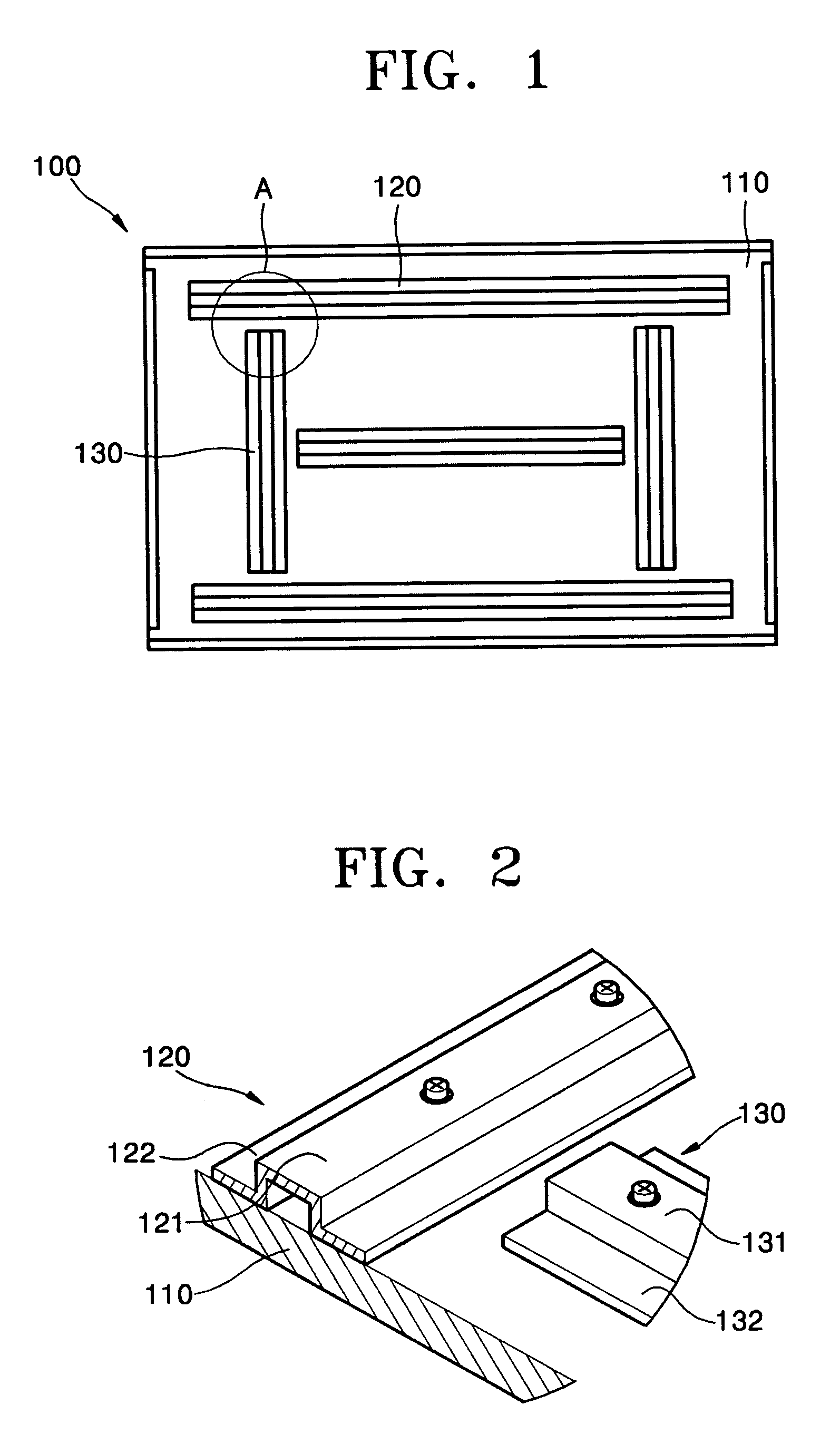

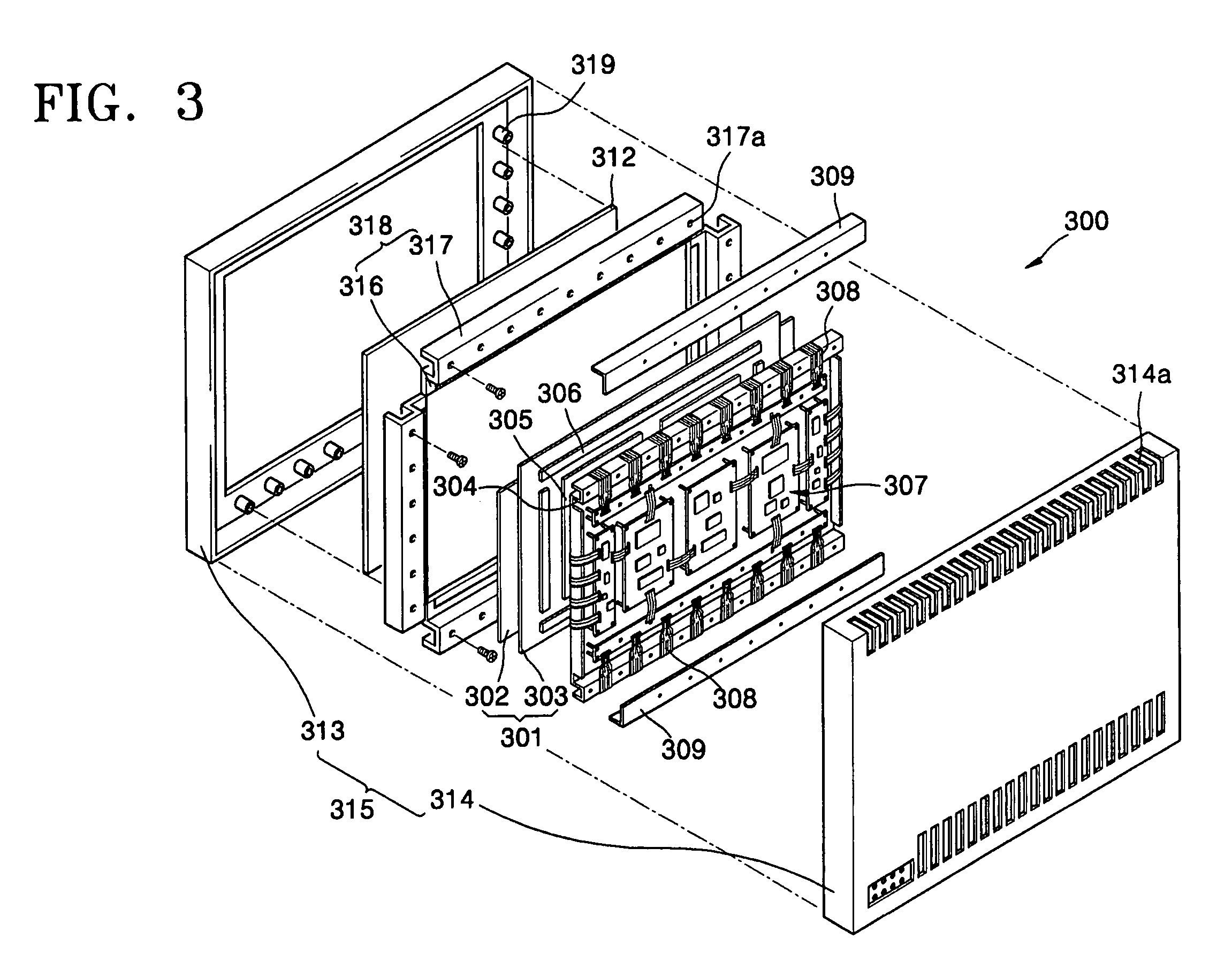

Chassis base assembly, method of manufacturing the chassis base assembly and plasma display panel (PDP) assembly using the chassis base assembly

InactiveUS20060133017A1High strengthAvoid stress concentrationDigital data processing detailsTube contructional detailsStress concentrationEngineering

In a chassis base assembly, a method of manufacturing the chassis base assembly, and a Plasma Display Panel (PDP) assembly, the method includes: preparing a raw flat panel for forming the chassis reinforcing member; forming ribs having a predetermined depth by processing the raw flat panel for forming the chassis reinforcing member using a drawing process; and forming an outer shape of the chassis reinforcing member using a notching process. There are no disconnections at corners where the horizontal and vertical reinforcing members meet to each other since the chassis reinforcing members are formed as a unitary body by a drawing process. Accordingly, stress concentrations at corners of the chassis reinforcing members are prevented, thereby increasing the strength of the chassis base assembly.

Owner:SAMSUNG SDI CO LTD

Steel used for straight seam electric resistance welding petroleum casing and casing manufacturing method

ActiveCN101798654AHigh strengthImprove toughnessFurnace typesProcess efficiency improvementWeld seamElectric resistance welding

The invention relates to a steel used for straight seam electric resistance welding petroleum casing and a casing manufacturing method, which is applied to a straight seam electric resistance welding petroleum casing used for an oil and gas well in petroleum and gas industry. The steel used for the straight seam electric resistance welding petroleum casing comprises the following components in percentage by mass: 0.15-0.28% of C, 1.0-1.6% of Mn, 0.2-0.4% of Si, 0. 02-0.06% of Al, less than or equal to 0.01% of P, less than or equal to 0.005% of S, less than or equal to 0.008% of N, 0.001-0.005% of Ca and the balance of Fe. The preparation method comprises the steps of: preparing hot-rolled plate coils, producing straight seam electric resistance welding steel pipes by the hot-rolled plate coils, carrying out welding seam normalization or overall normalization on the welded steel pipes, straightening and cutting the normalized or tempered welded steel pipes into pipe segments with the length of 10-12m, and processing API standard screw threads. The invention has the advantages that the steel has good strength and toughness, the welding seam has no defect, and the properties of the steel are uniform with those of mother material. The yield strength is greater than or equal to 380-760MPa, the tensile strength is greater than or equal to 520-865MPa, the elongation is greater than or equal to 20%, and the impact energy of a room-temperature transverse full-size V-shaped notch is greater than or equal to 40J.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

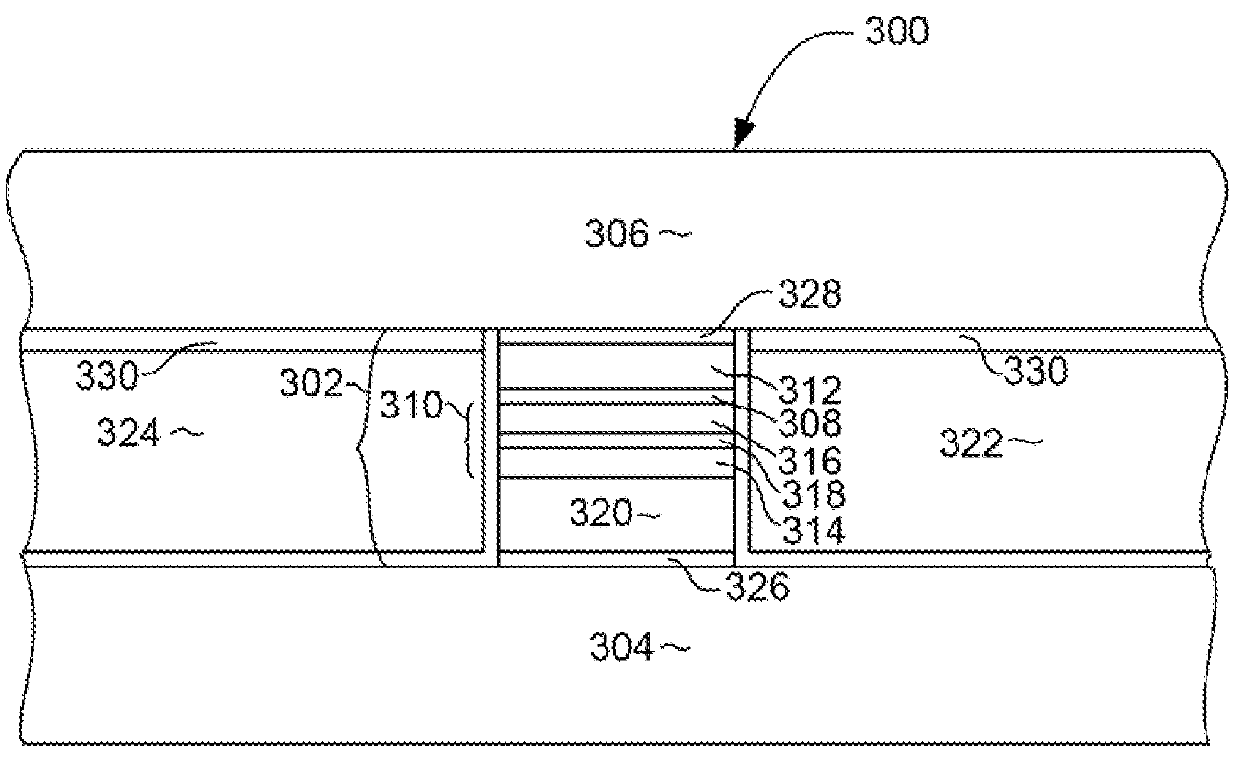

Multi-angle hard bias deposition for optimal hard-bias deposition in a magnetic sensor

InactiveUS20120156390A1Flatter top shield profileIncrease spacingMagnetic measurementsVacuum evaporation coatingBias fieldEngineering

A method for manufacturing a magnetic sensor that result in improved magnetic bias field to the sensor, improved shield to hard bias spacing and a flatter top shield profile. The method includes a multi-angled deposition of the hard bias structure. After forming the sensor stack a first hard bias layer is deposited at an angle of about 70 degrees relative to horizontal. This is a conformal deposition. Then, a second deposition is performed at an angle of about 90 degrees relative to horizontal. This is a notching deposition, that results in notches being formed adjacent to the sensor stack. Then, a hard bias capping layer is deposited at an angle of about 55 degrees relative to horizontal. This is a leveling deposition that further flattens the surface on which the top shield can be electroplated.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

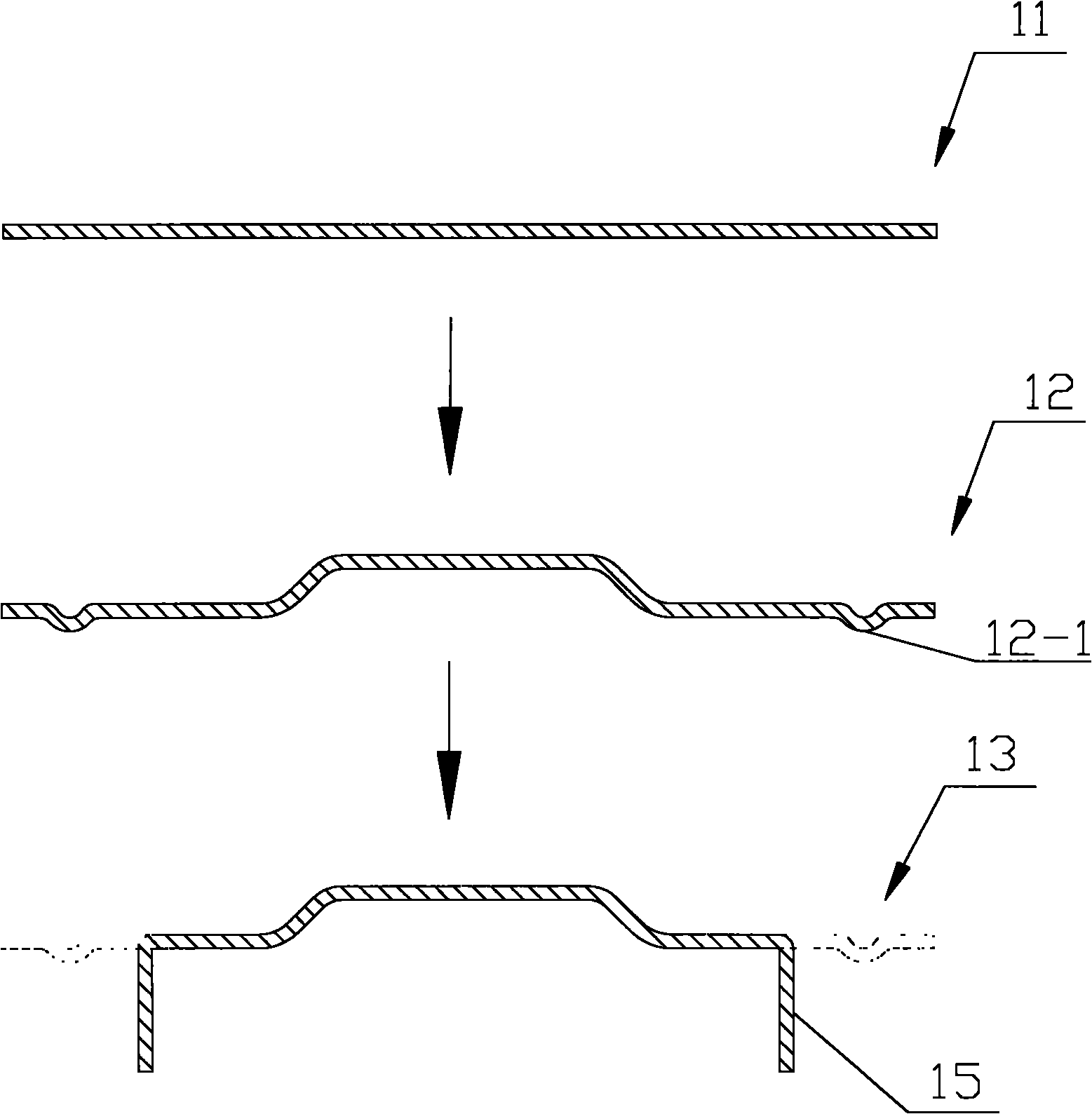

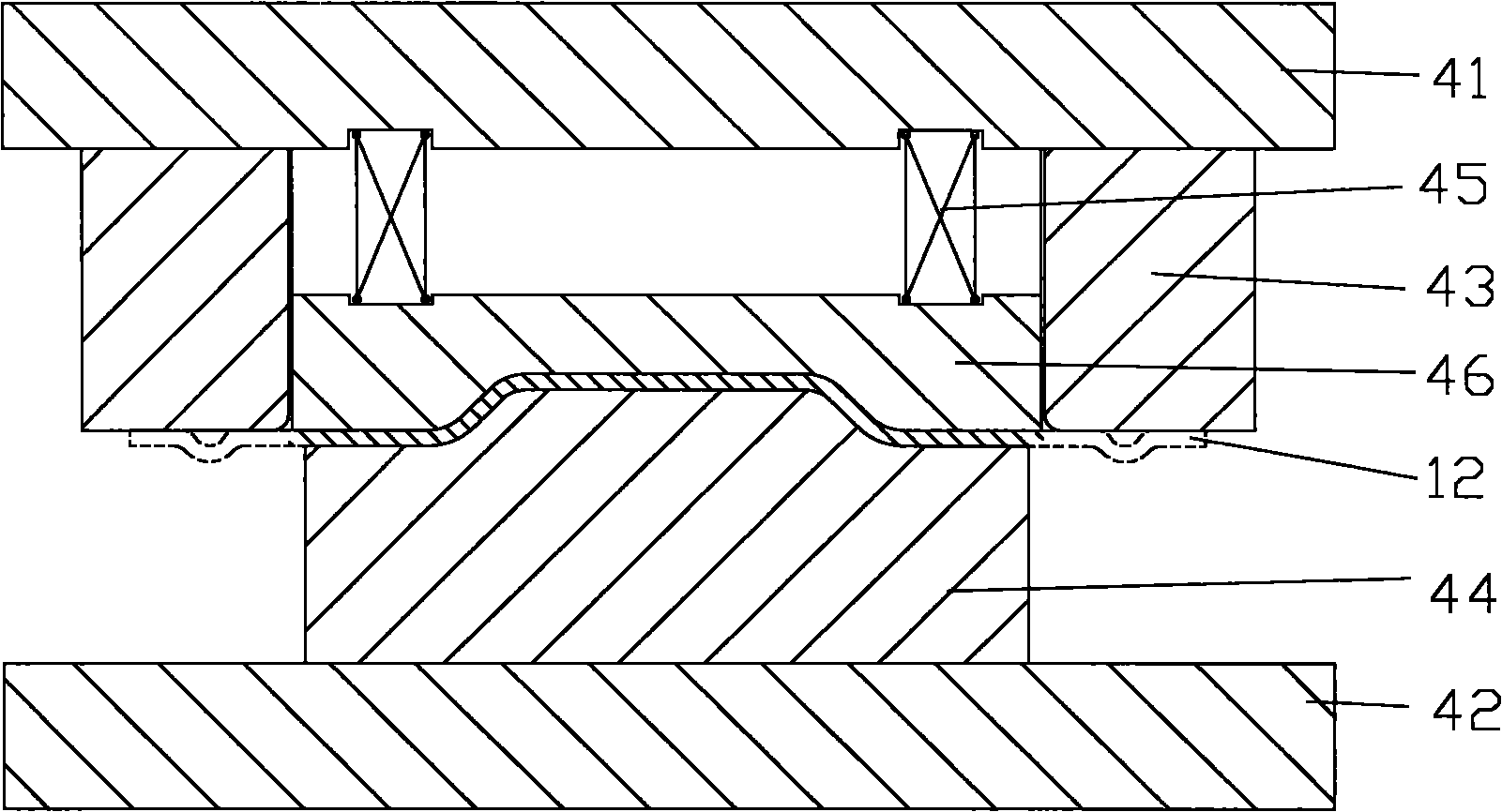

Drawing and bending molding process and die of refrigerator backboard

The invention provides a drawing and bending molding process and die of a refrigerator backboard, which can solve the problems of low product quality and high production cost in the prior art. The technical scheme comprises the following steps: drawing: taking the sheet-metal blanks of the refrigerator backboard, pressing the peripheric edges of the sheet-metal blanks by employing a material-pressing bead and a material-pressing slot on a drawing die to form draw beads, carrying out shallow stretching on the middle parts of the sheet-metal blanks by employing a male die of the drawing die and forming gaps between two adjacent edges of the sheet-metal blanks through cutting; and bending: carrying out bending around the sheet-metal blanks subjected to shallow stretching by employing bending blades on a bending die and simultaneously flattening the draw beads. The invention also provides the molding die special for the refrigerator backboard with the technological draw beads. The invention can get rid of the defect of product distortion, reduce the product molding procedures, save a set of dies and save the cost of raw materials, labor, etc.

Owner:QINGDAO HAIER MOLDS

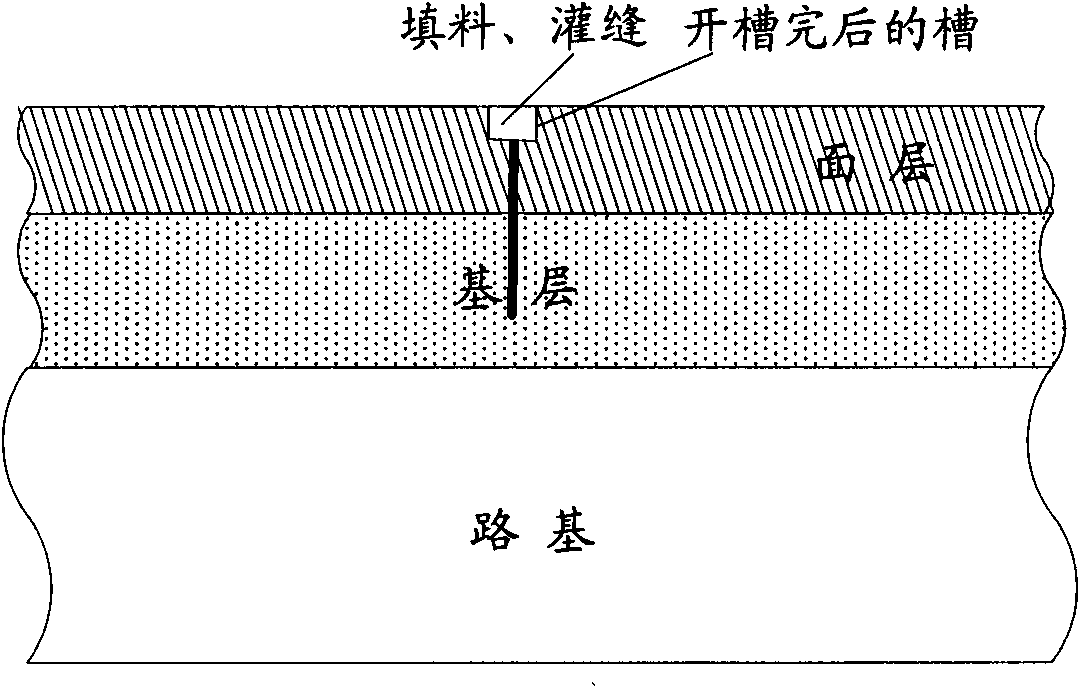

Method for repairing asphalt pavement cracks

The invention discloses a method for repairing asphalt pavement cracks, comprising the following steps: a. opening a trench: setting the trench size according to the crack size and opening the trench;b. cleaning the trench: cleaning disintegrating slags in the trench and dust at the periphery of the trench after finishing opening the trench; c. pouring a crack: pouring cold crack filling materialin the trench, and performing vibration operation on the cold crack filling material after crack pouring; d. filling materials: filling joint stones in the trench and performing vibration compactionoperation on the stones until the stones after vibration and compaction in the trench level with the pavement; and e. curing. By using the method in the invention, asphalt pavement cracks can be effectively repaired by cold-patch notching and vibration, the cracks and gaps at the periphery thereof can be completely closed, the materials in the trench can be integrated with the original asphalt pavement after repairing, thus having high strength, resisting water encroachment thoroughly, improving the service life of the asphalt pavement remarkably and saving investment on whole-life maintenancecosts of the asphalt pavement greatly.

Owner:交通部科学研究院

Cu-Ni-Si-based copper alloy sheet material and method of manufacturing same

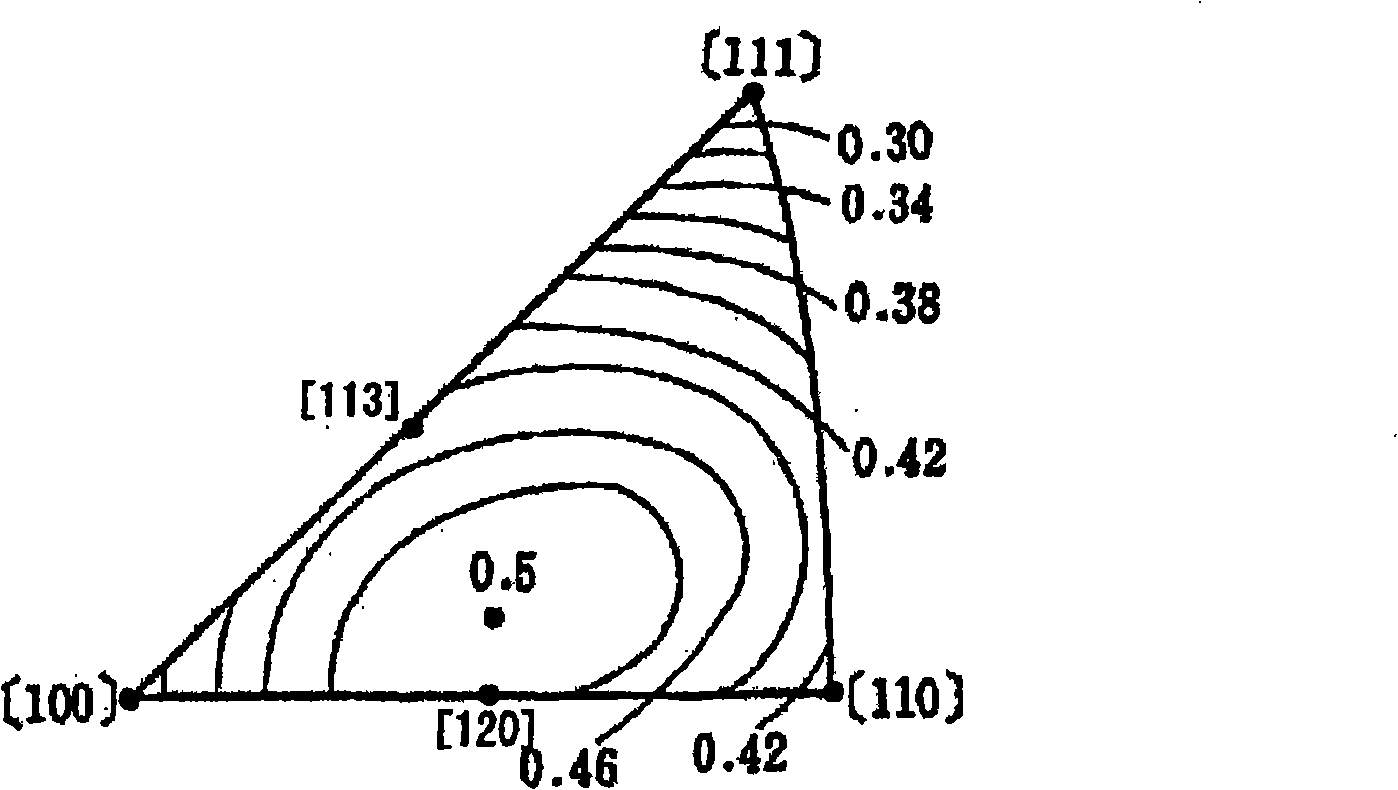

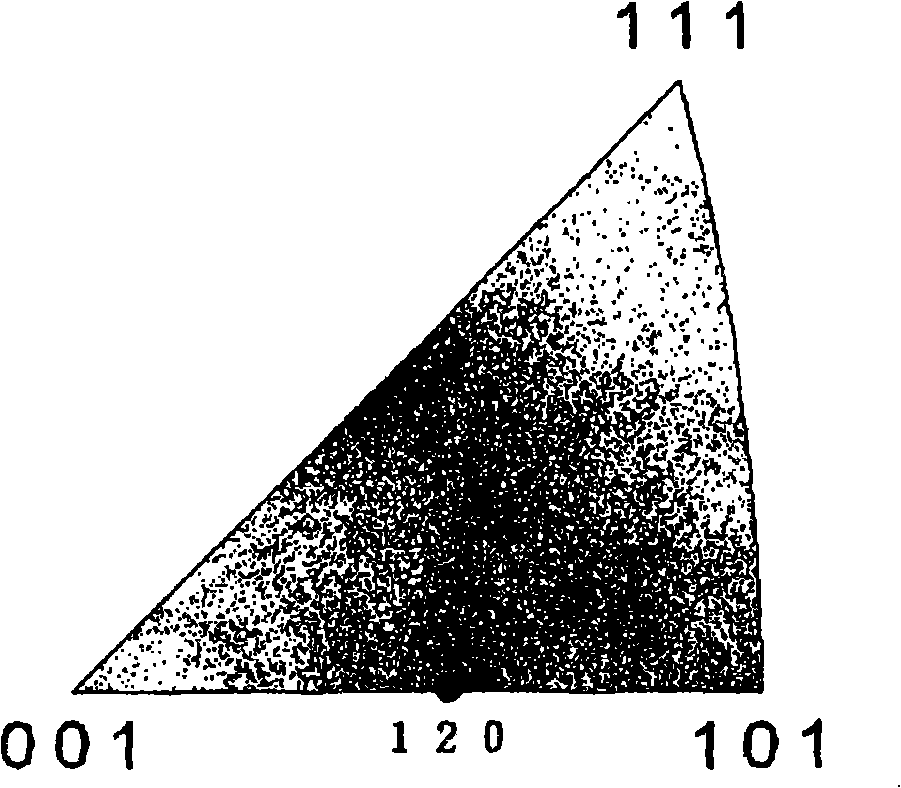

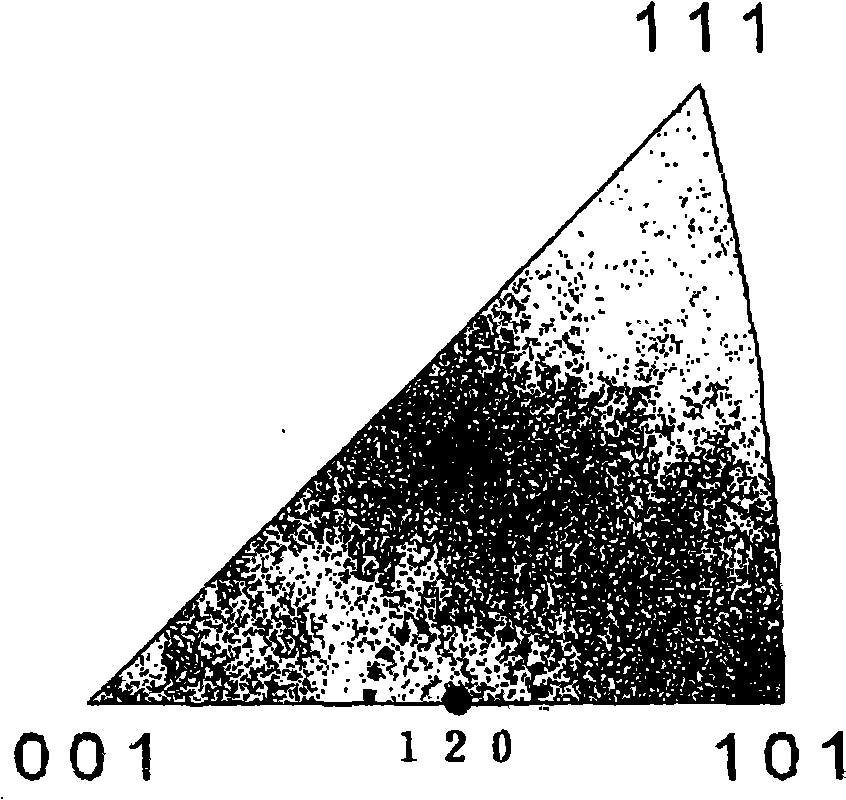

InactiveCN101245422AExcellent stress relaxation resistanceHigh strengthSolid-state devicesSemiconductor devicesX-rayCrystal orientation

Owner:DOWA METALTECH CO LTD

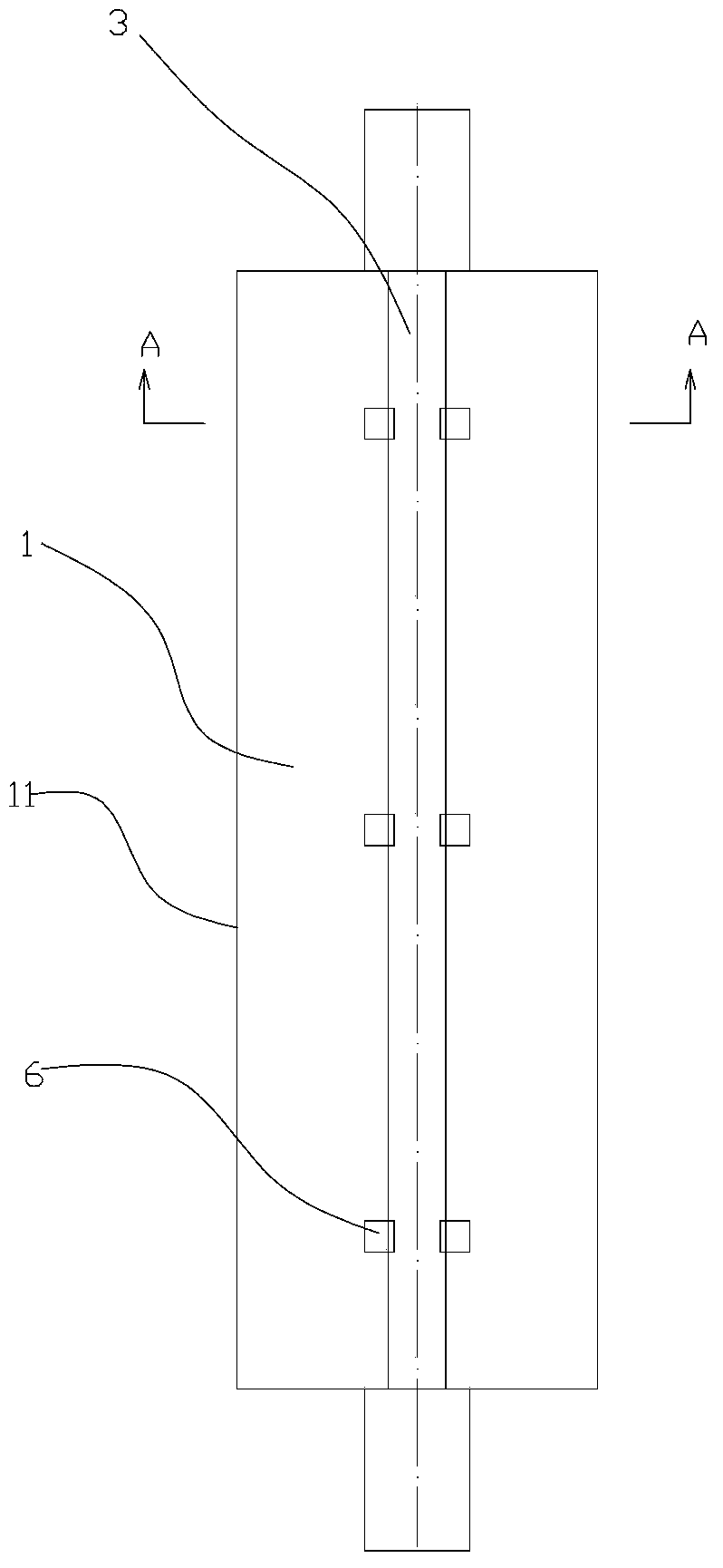

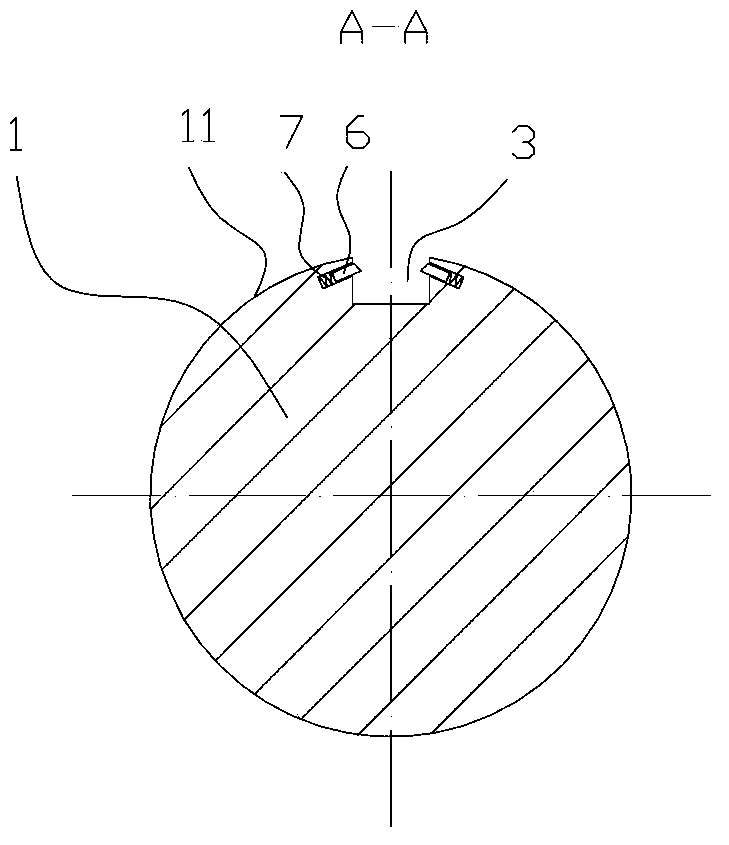

Pipe fittings notching-machine

The invention discloses a notching machine of pipe fitting, comprising frame set on the base, notching wheel with main shaft and radial ring hill set on the frame rotationally. The notching machine of pipe fitting also comprises deceleration driving device, of which the outputting end is connected with one end of main shaft and which drives the main shaft rotate in low speed; pushing device which can push notching wheel move. Support wheel, which can be assembled or disassembled, is fixed at the other end of said main shaft and radial ring concave groove is set on the support wheel. Guiding device, which can control the notching wheel move on the radial direction of support wheel so that the ring hill moves near of far from the ring concave groove on the radial direction is set on the frame. The invention is provided with simple structure. The pipe-diameter range of pipe is big and pipe connecting work is convenient.

Owner:李玉民

Crop straw-polyurethane foam composite material and method for preparing same

InactiveCN101250329AImprove buffering effectIncrease elasticityWood working apparatusDomestic articlesPolymer scienceFoaming agent

Crop straw-polyurethane foam composite material and a preparation process thereof relate to foam composite material and the preparation process. The invention solves the problems existing in the current polyurethane foam of lacking resource and low straw utilization. The invention is mainly prepared by crop straw, polyisocyanate or isocyanate prepolymer, water, foam kicker, foam stabilizer and foaming agent. The preparation process of the invention comprises abutting and sealing mould which is used to place crushed straw aggregates with a foaming box which is added with the mixture which is prepared by agitating polyisocyanate or isocyanate prepolymer, water, foam kicker, foam stabilizer and foaming agent, conducting foaming reaction for 1-30min, filling all gaps in crushed aggregates of crop straw with polyurethane foam by means of foaming expansion force, adhering crushed aggregates together, and placing for 1-24h under constant temperature. The invention makes the crop straw be fully used. The composite material has excellent buffering capacity, strength, heat insulation and sensitivity to notching, and can protect environment.

Owner:NORTHEAST FORESTRY UNIVERSITY

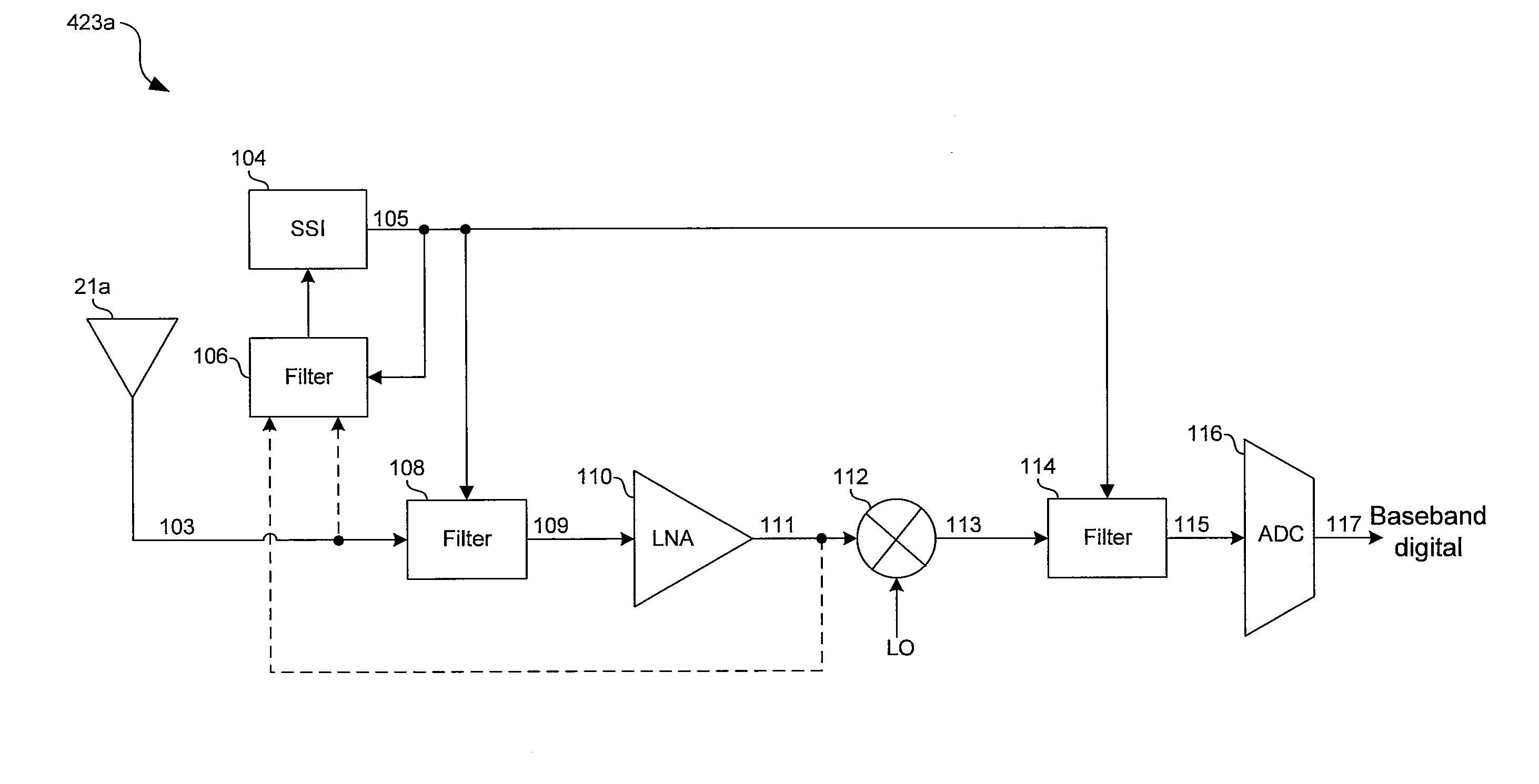

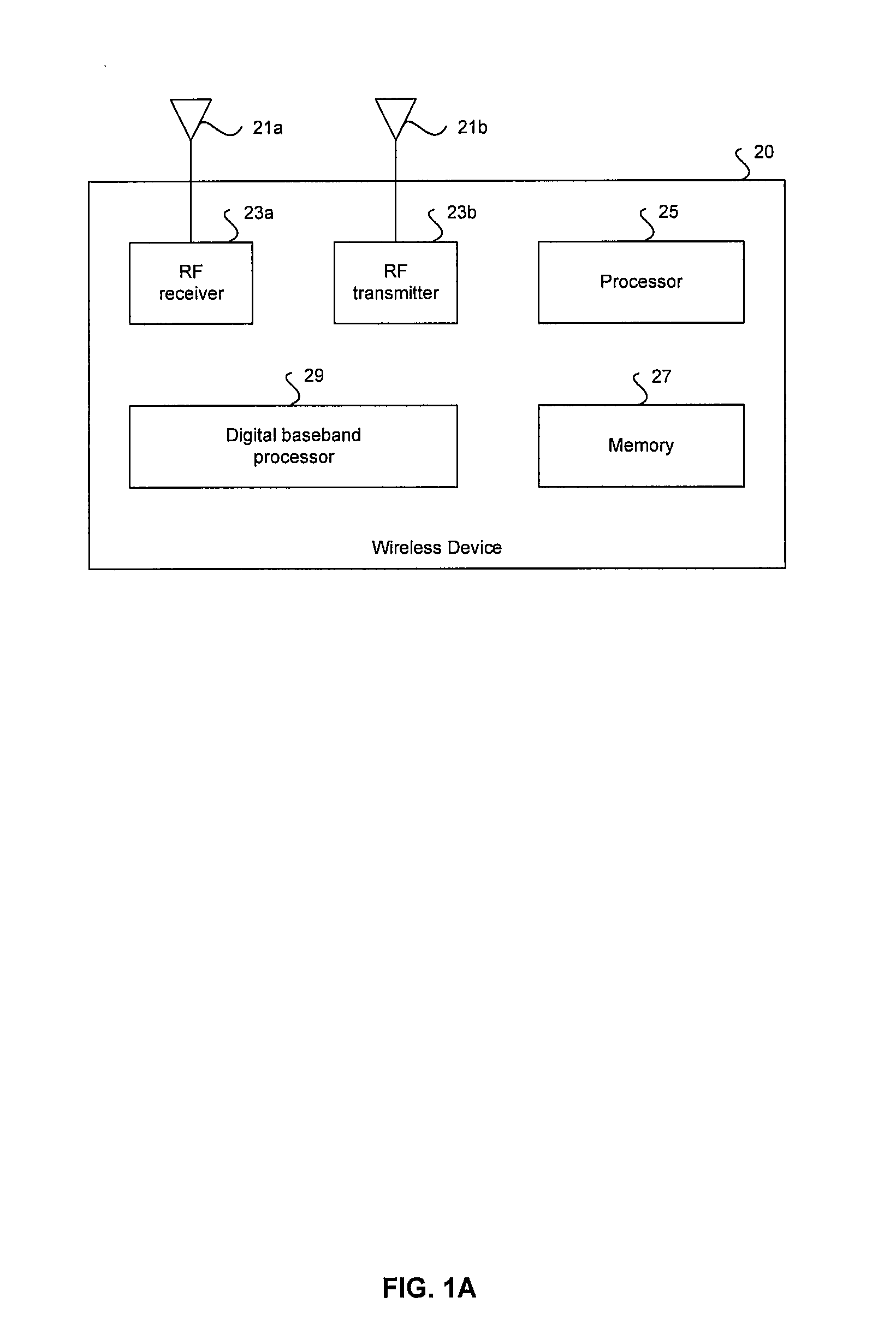

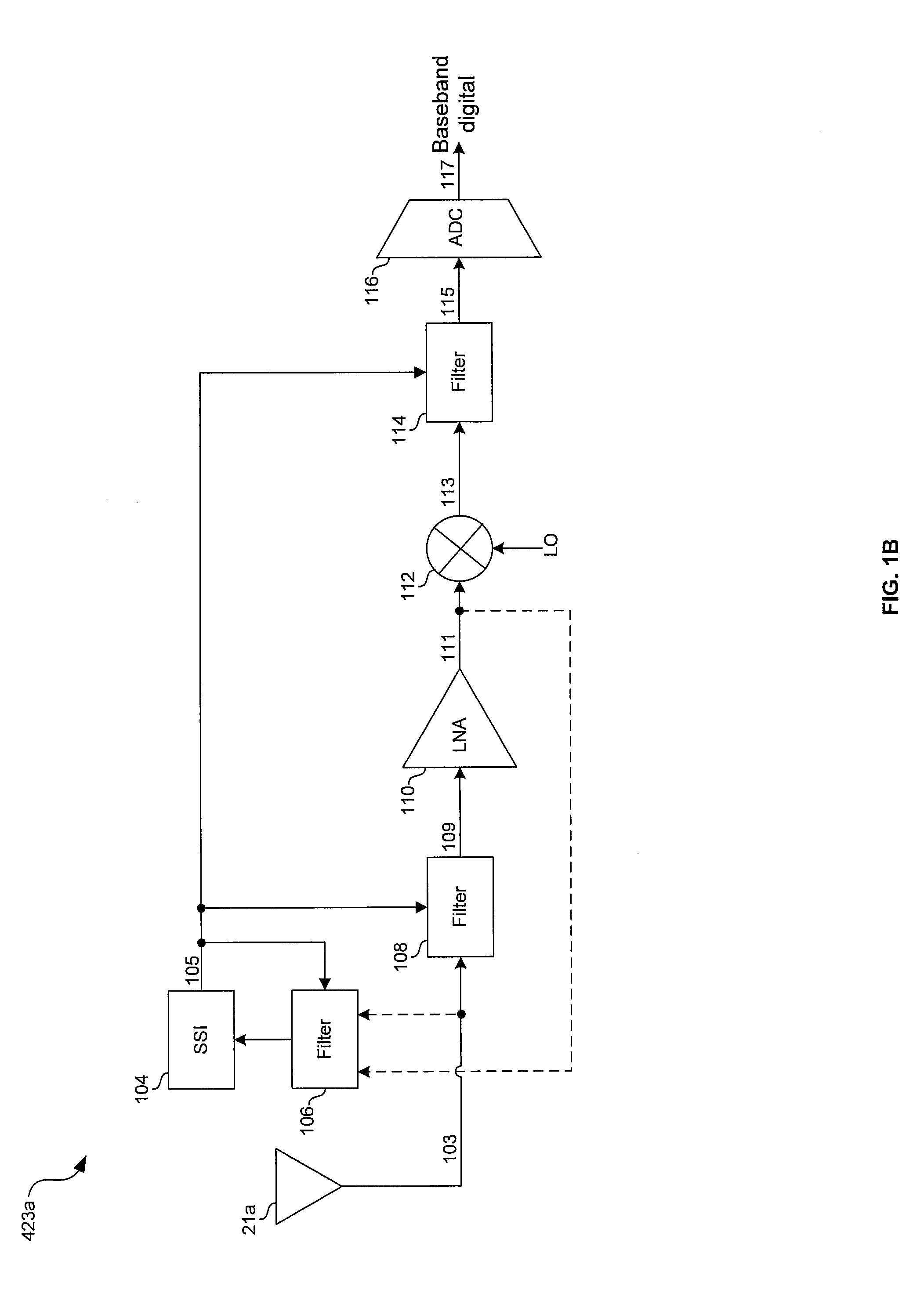

Method And System For On-Demand Signal Notching In A Receiver

Aspects of a method and system for on-demand signal notching in a receiver. In this regard, signal strength measurements of a received signal may enable detection of unwanted signal component(s) and one or more filters in an on-chip receiver may be configured in response to the measurements. The filter(s) may additionally be configured based on power consumption of the filter(s). Signal measurements and / or the corresponding configuration may be performed real-time. The filter(s) may be configured such that a notch in a frequency response of the filter(s) is centered at or near the unwanted component. In this manner, the unwanted component(s) may be filtered out. The filter(s) may be configured, for example, by switching one or more filter stages and / or components into and / or out of a signal path and / or by tuning one or more variable circuit elements within the filter(s).

Owner:AVAGO TECH INT SALES PTE LTD

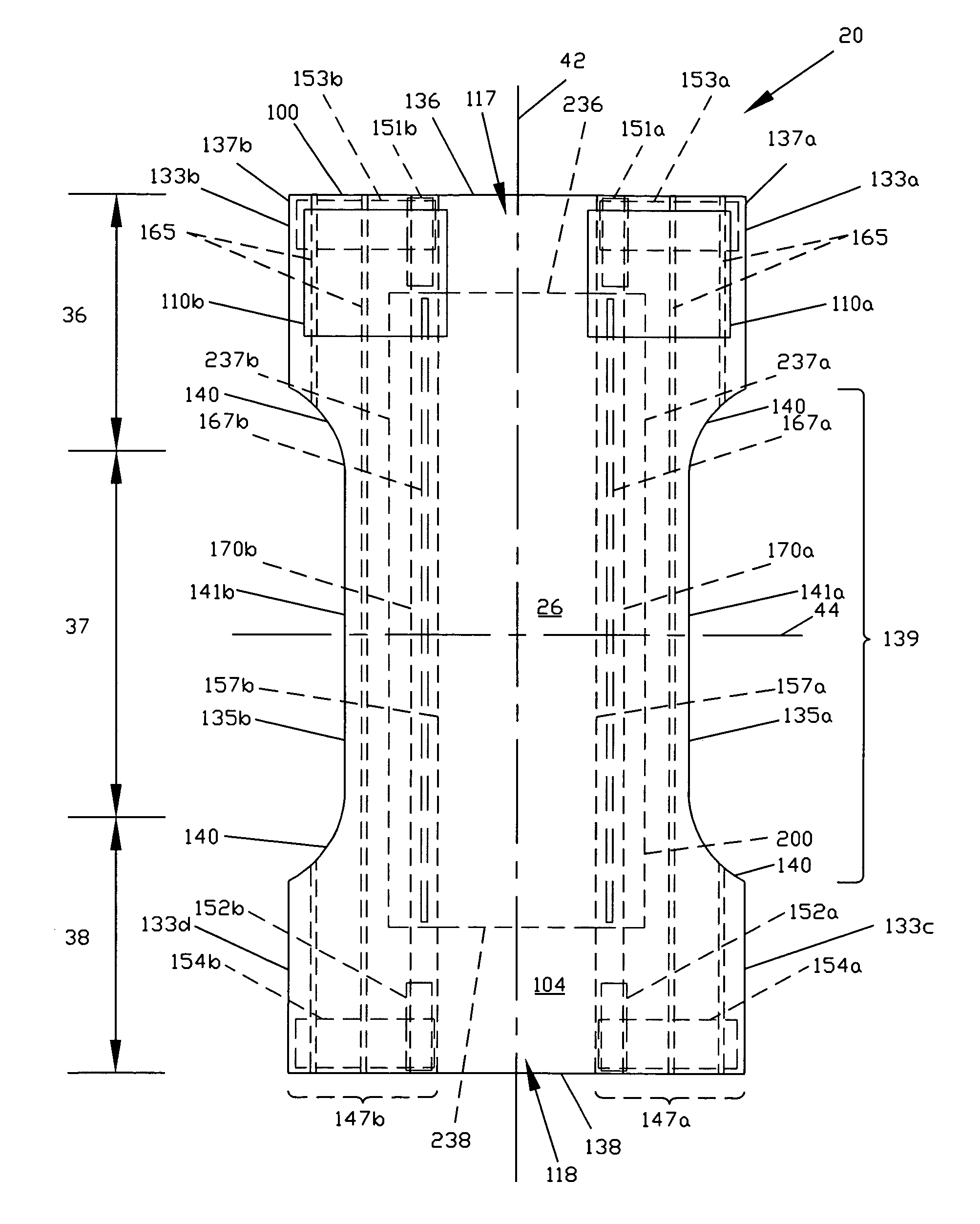

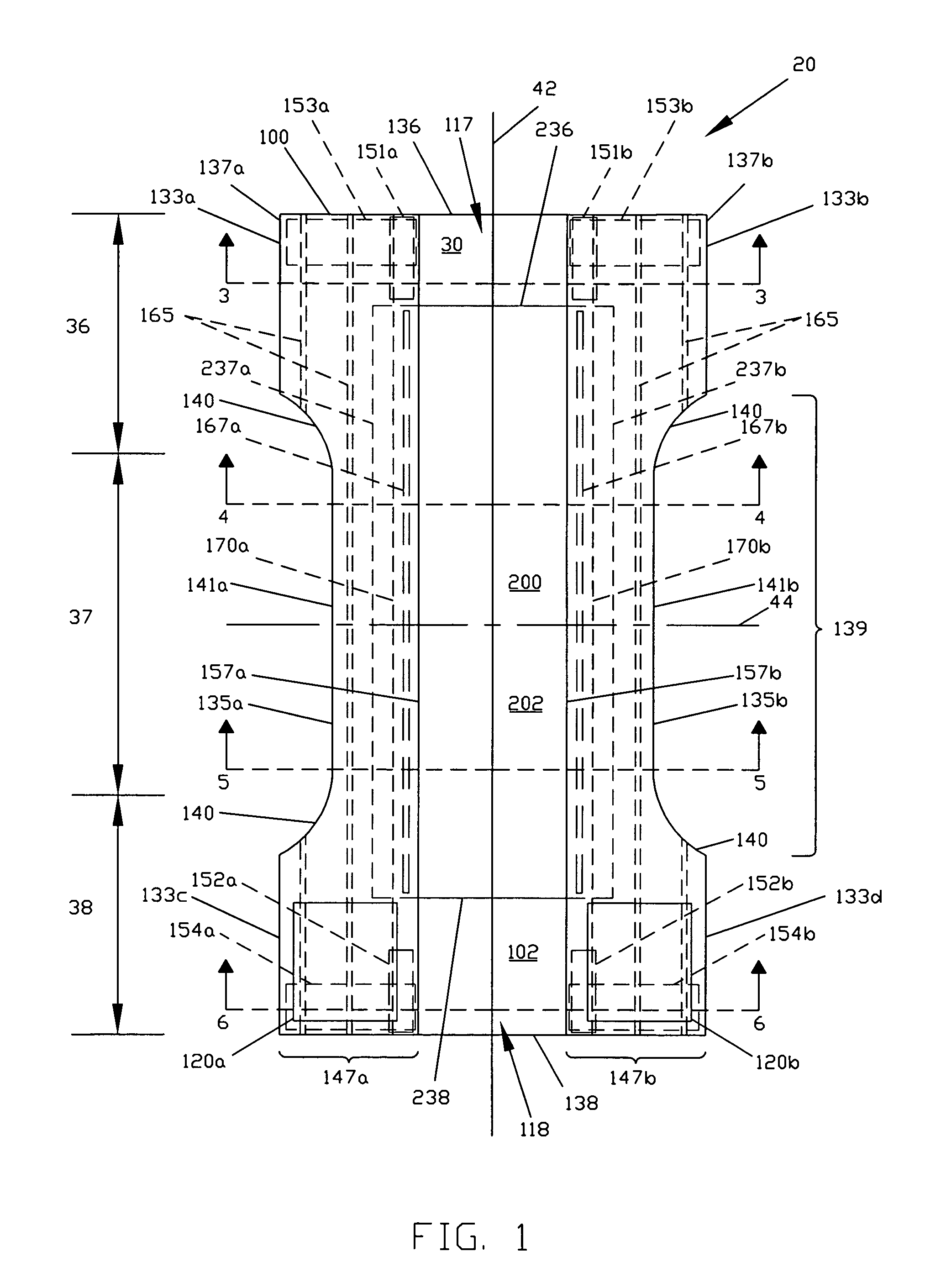

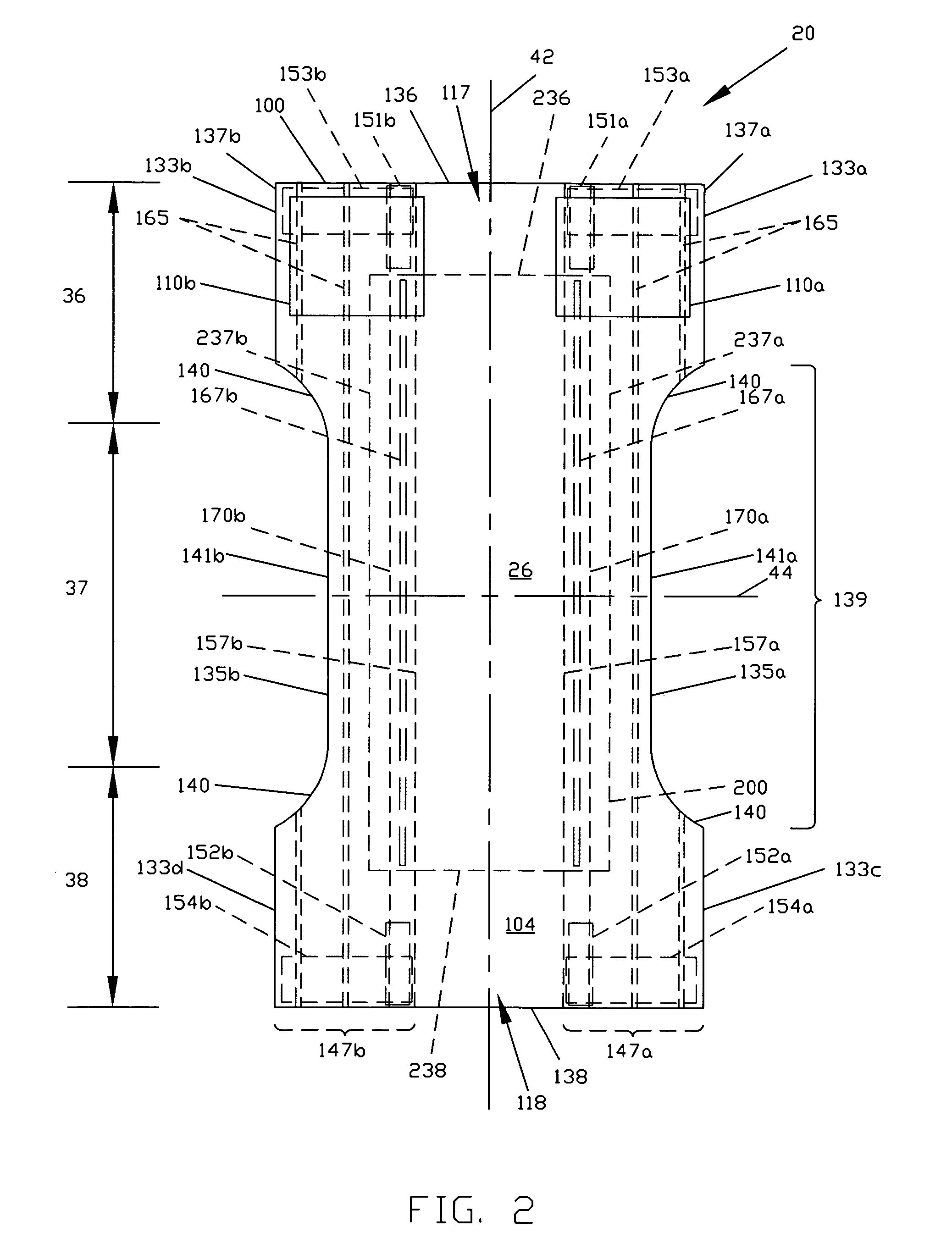

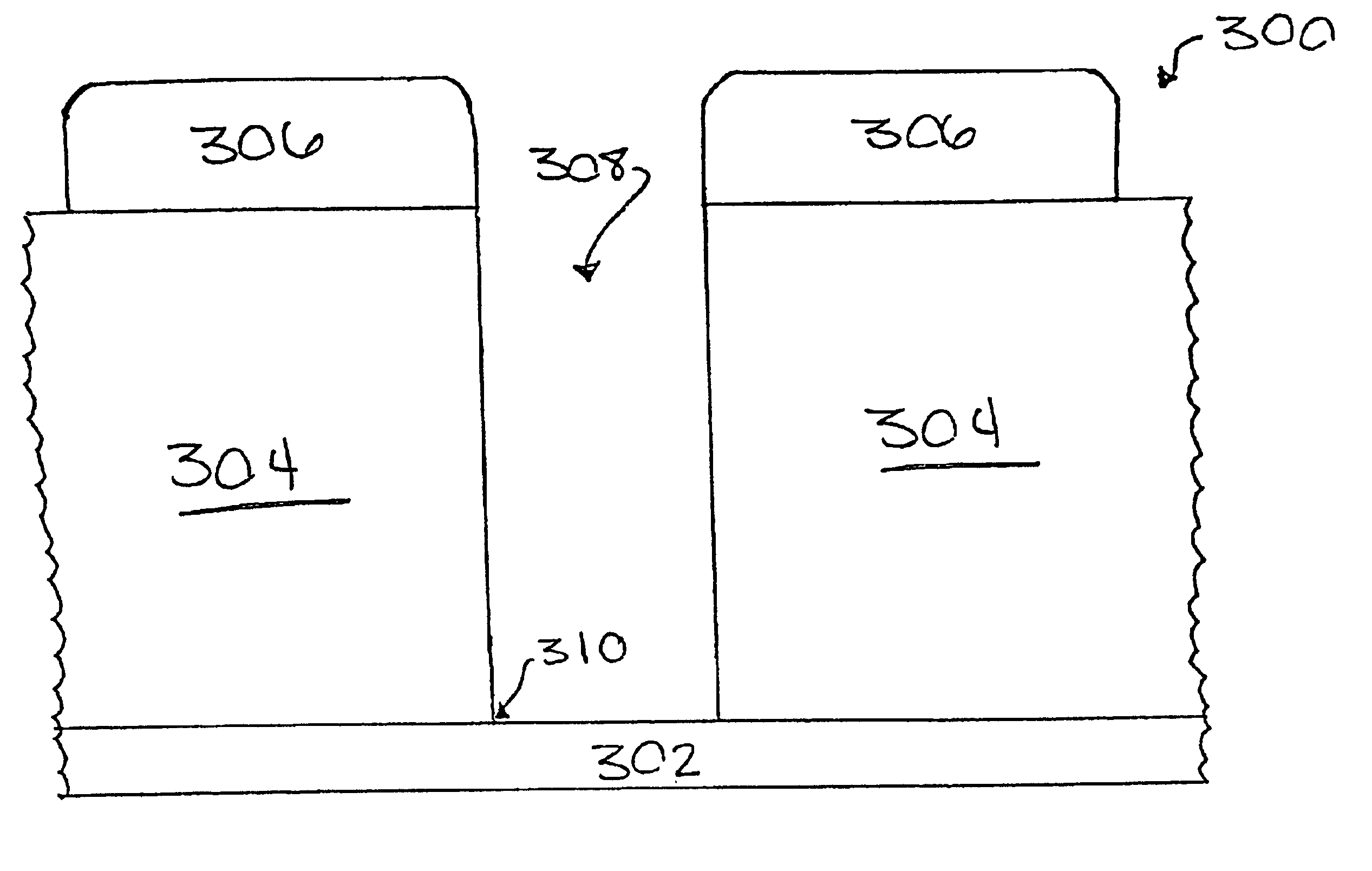

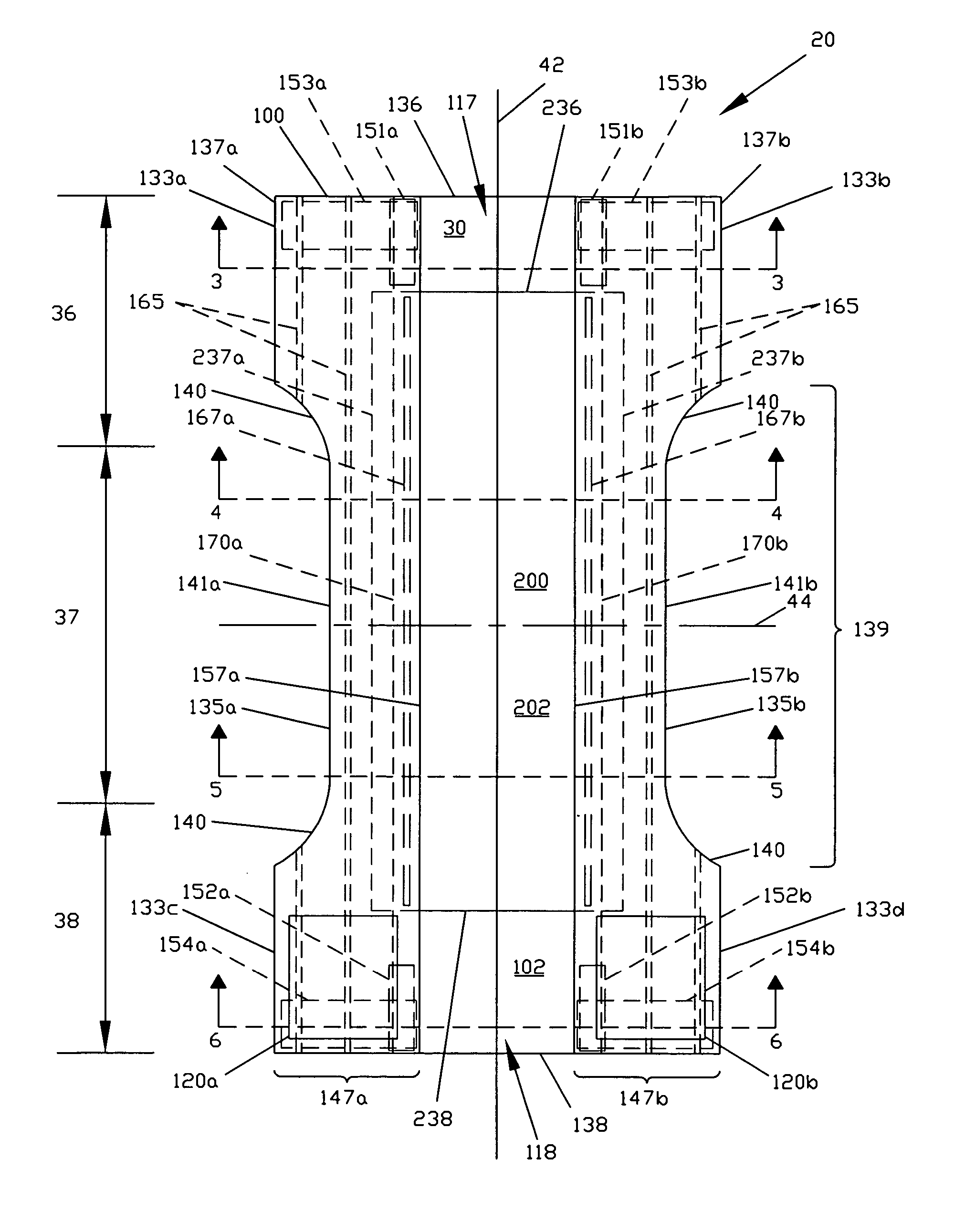

Side notched folded diaper

A disposable absorbent article includes a chassis and an absorbent assembly. The chassis includes a water-impermeable backsheet that is folded laterally inward at both of its side edges to form laterally opposing side flaps. Each side flap is attached to the interior surface of the chassis adjacent to its end edges. Each side flap has a longitudinally extending elastic gathering member attached adjacent to its proximal edge. Each side flap is also attached to the interior surface of the chassis at continuous longitudinally extending laterally opposing water-impermeable side seals. The chassis is side notched to give it an hourglass shape. The chassis may include an extensible formed web material. The absorbent assembly includes an absorbent core that may contain superabsorbent particles, which may be contained inside pockets. The absorbent assembly may be attached in a cruciform pattern to the chassis to allow portions of the chassis to extend laterally.

Owner:THE PROCTER & GAMBLE COMPANY

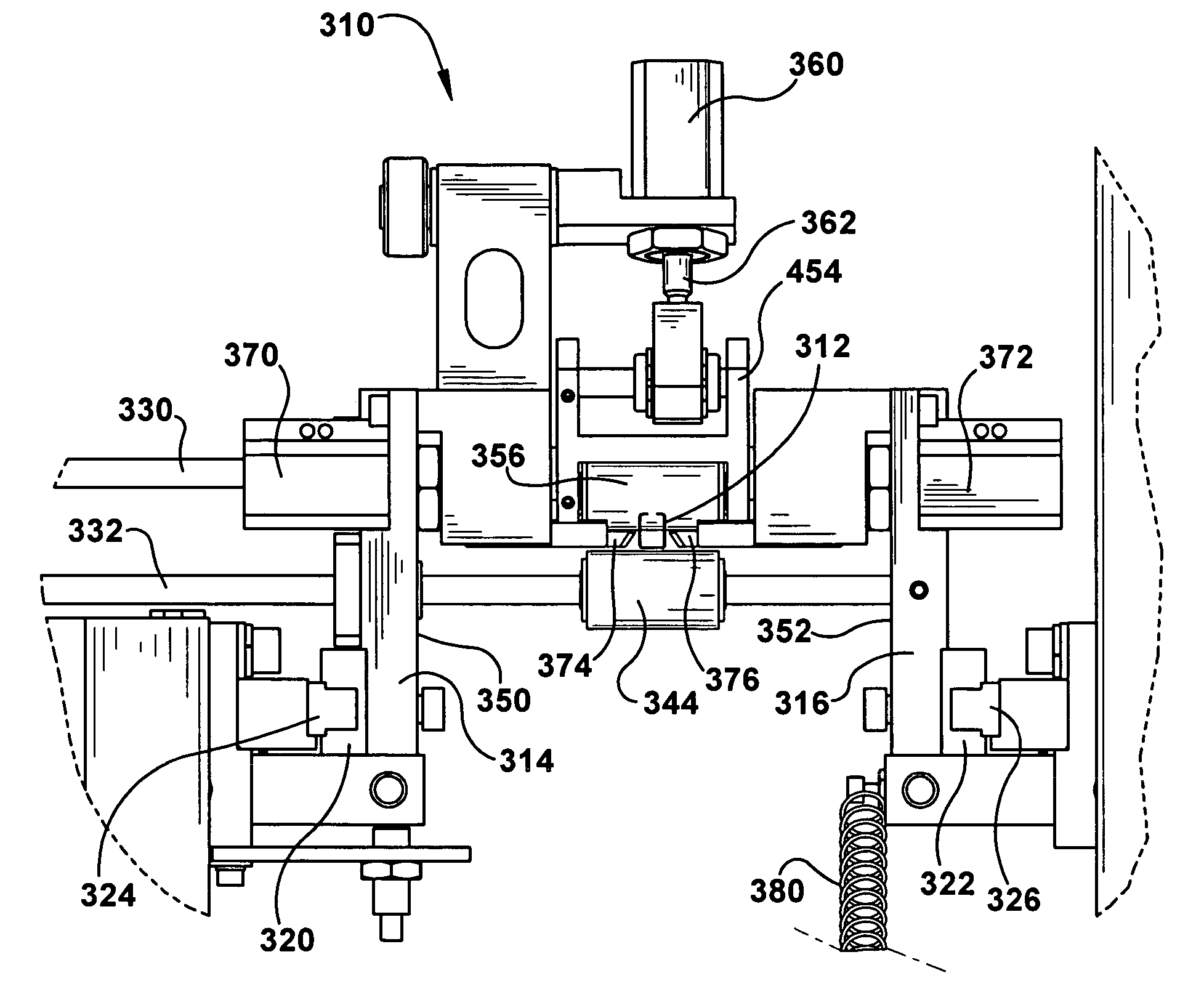

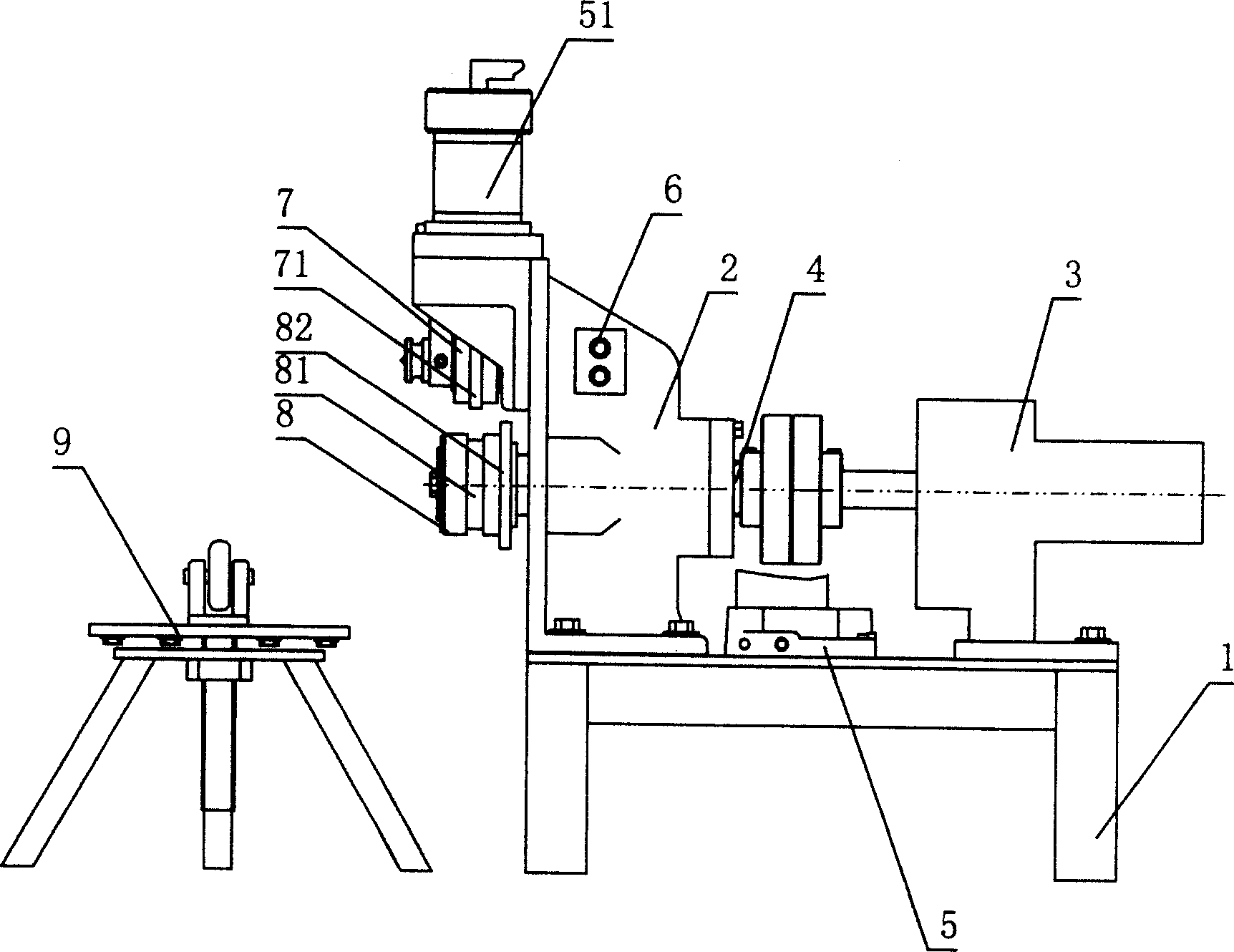

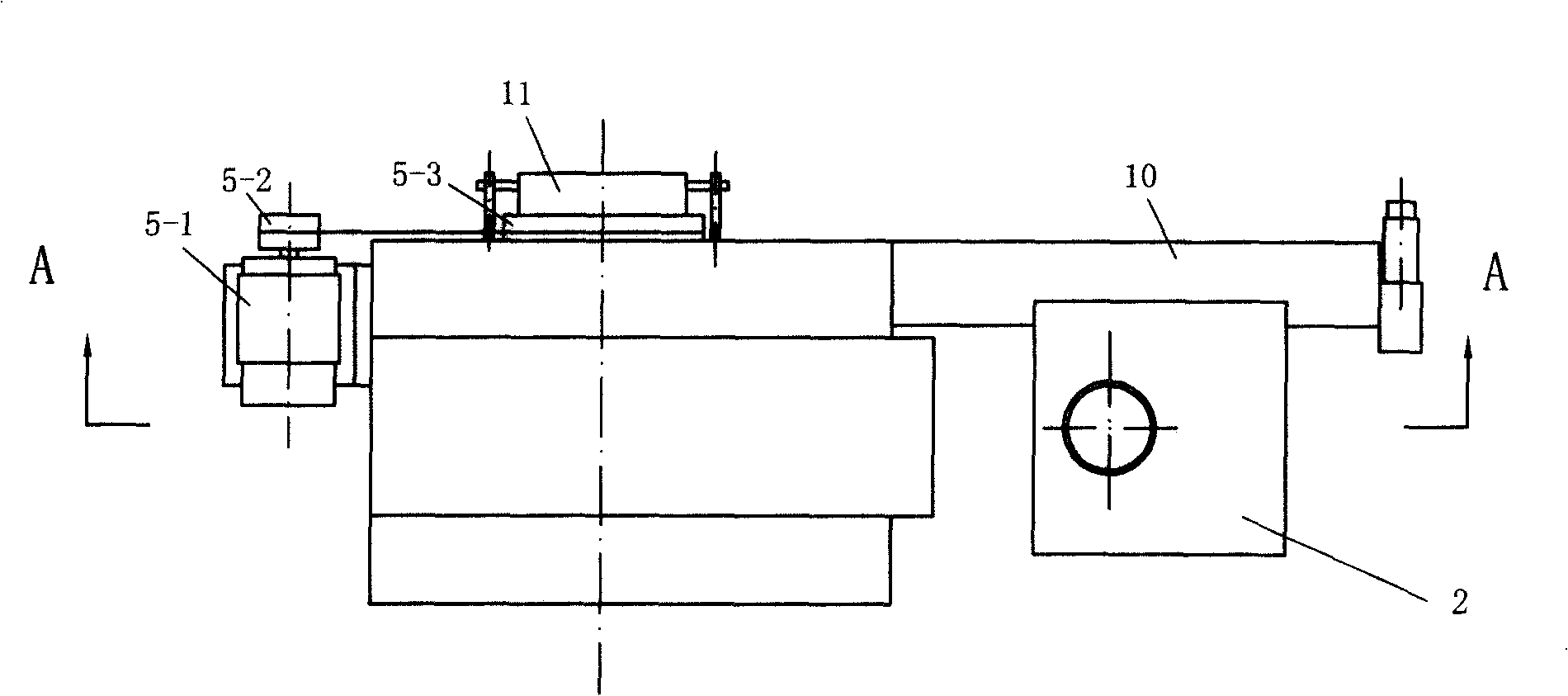

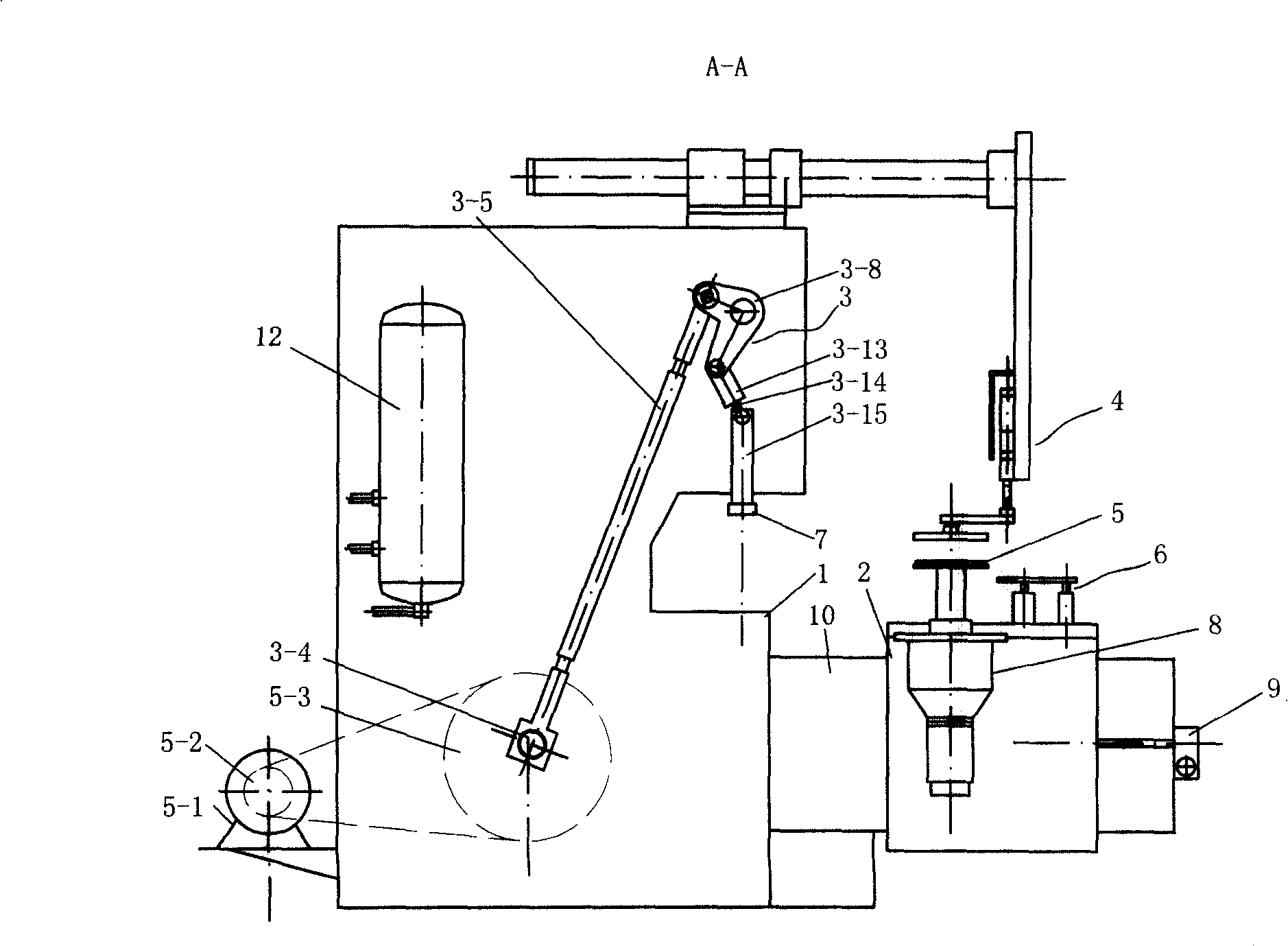

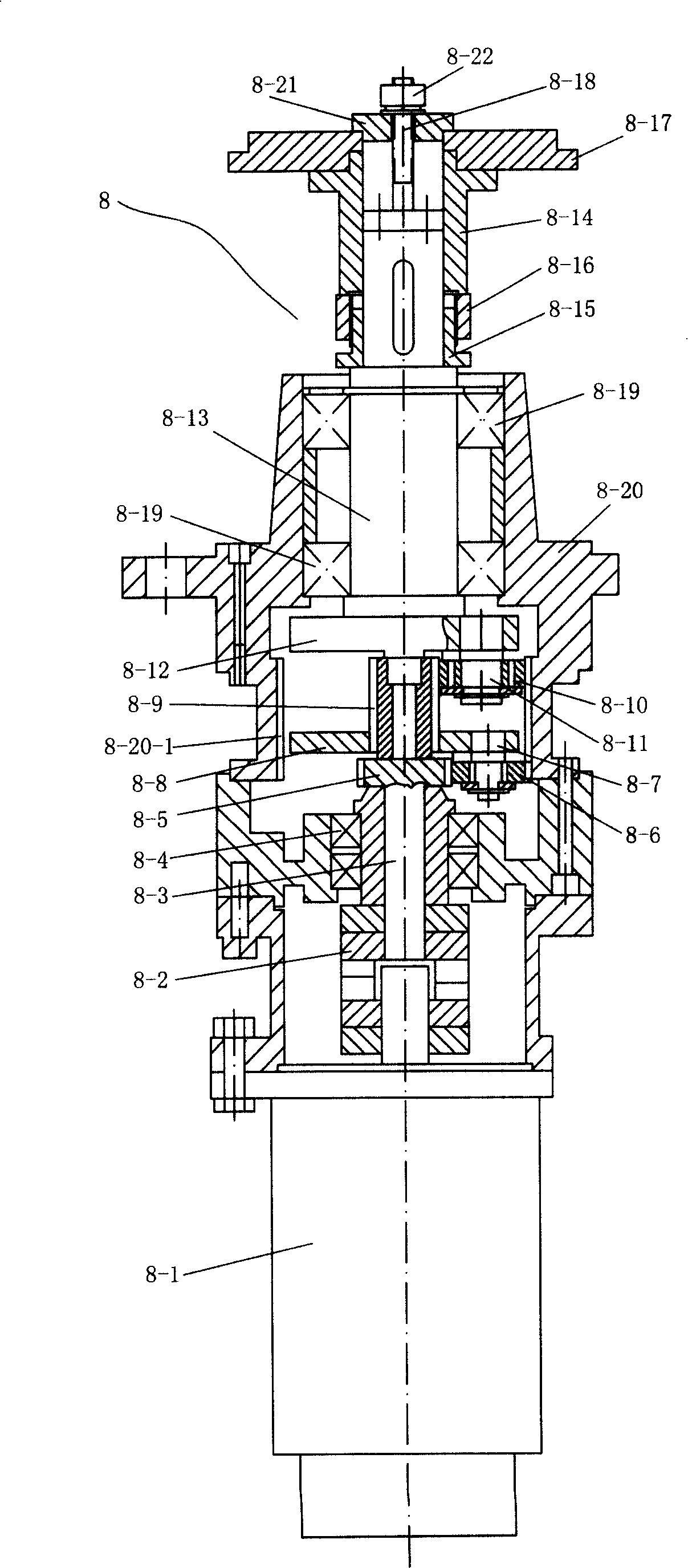

Main unit of numerical control notching press

ActiveCN101244441ASuitable for intelligent controlCompact structureManufacturing dynamo-electric machinesNumerical controlPunching

The invention relates to a mainframe of numerical control notching press, comprising a frame, a worktable, a punching head, a dividing apparatus, a stamping device, a radial feeding device, a pressure system, a tabletting device, and an unloading device. A guide arm is arranged on one side of the frame; the worktable is slide-connected with the guide arm; the dividing apparatus is provided with a casing fixed on the worktable; a planetary reduction mechanism is arranged in the casing; the input shaft of the planetary reduction mechanism is connected with an indexing servomotor, and a height adjust apparatus of pallet is arranged on the output shaft, and is connected with the pallet; the radial feeding device is provided with a speed reducer fixed on the guide arm; the input shaft of the speed reducer is connected with the feeding servomotor, and the output shaft drives the worktable to move through a lead screw transmission pair. The mainframe of numerical control notching press has the advantages of suitability for intellectualized control, high graduation precision of the dividing apparatus, simple and quick adjustment, wide range of indexing groove numbers (both equal indexing and unequal indexing), random stepping size setting of the radial feeding device, high indexing precision and wide application range.

Owner:常州市耀华电机设备有限公司

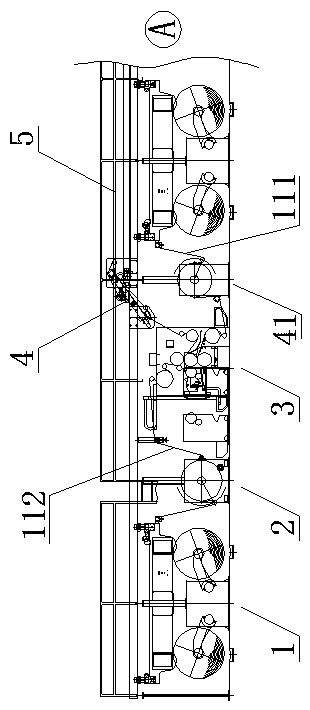

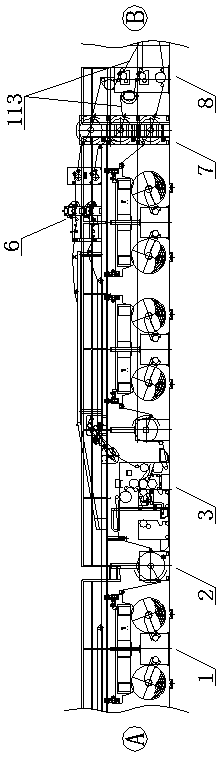

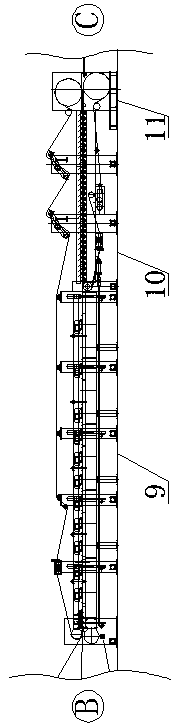

Five-layered corrugated paper production line

ActiveCN109130329AMeet functional needsPrecise position of fixed-point machiningMechanical working/deformationBox making operationsCardboardPaper production

The invention discloses a five-layered corrugated paper production line. The five-layered corrugated paper production line comprises a plurality of body paper racks used for unreeling body paper, facepaper preheating wheels, core paper preheating wheels, a single corrugated paper machine, an upward leading device, a double-layered paper rack, a conveying device, a triple preheating wheel, a pasting machine, a paper board forming machine, a driving device and an N.C. cutting and line pressing edge trimmer, wherein the face paper preheating wheels and the core paper preheating wheels are arranged between every two body paper racks; the single corrugated paper machine is used for roller forming of core paper and further compounding the core paper and face paper into single corrugated paper boards; the upward leading device and the double-layered paper rack are arranged above the single corrugated paper machine; the conveying device is used for conveying the single corrugated paper boards; the triple preheating wheel is used for preheating the single corrugated paper boards and the face paper; the pasting machine is used for pasting the face paper and two layers of the single corrugated paper boards; the paper board forming machine is used for compounding the face paper and the two layers of the single corrugated paper boards into a five-layered corrugated paper board; the drivingdevice is used for conveying the five-layered corrugated paper board; and the N.C. cutting and line pressing edge trimmer is used for shaping the five-layered corrugated paper board. By adoption of the five-layered corrugated paper production line, the corrugated paper board of a five-layered structure can be produced, and fixed-point notching treatment of the five-layered corrugated paper boardcan be conducted; and the automatic detecting and waste discharging functions are further achieved, and the number of discarded products in finished corrugated paper board products is decreased.

Owner:晋江市新达纸箱包装有限公司

Method for producing plastic pipe fitting with insert made from polyphenylene sulfide alloy material

The invention relates to a method for making a plastic pipe with an insert made from a PPS alloy material. Materials such as PPS, nylon, etc. are treated with steps of blending, extrusion, strip stretching, cooling, pelletizing, homogenization, injection molding, etc. so as to obtain the plastic pipe with the insert made from the PPS alloy material. The making method of the invention has simple and easy technique; the alloy material has the advantages of small specific weight, good heat and corrosion resistance as well as good dimensional stability; in addition, the obtained pipe has good sealing, high notched impact strength, etc. The plastic pipe provided by the invention has wide range of application and can be applicable to water supply and drainage systems and drinking water pipe systems, gas transmission systems and industrial pipe systems, heating systems and agricultural pipe systems.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS +1

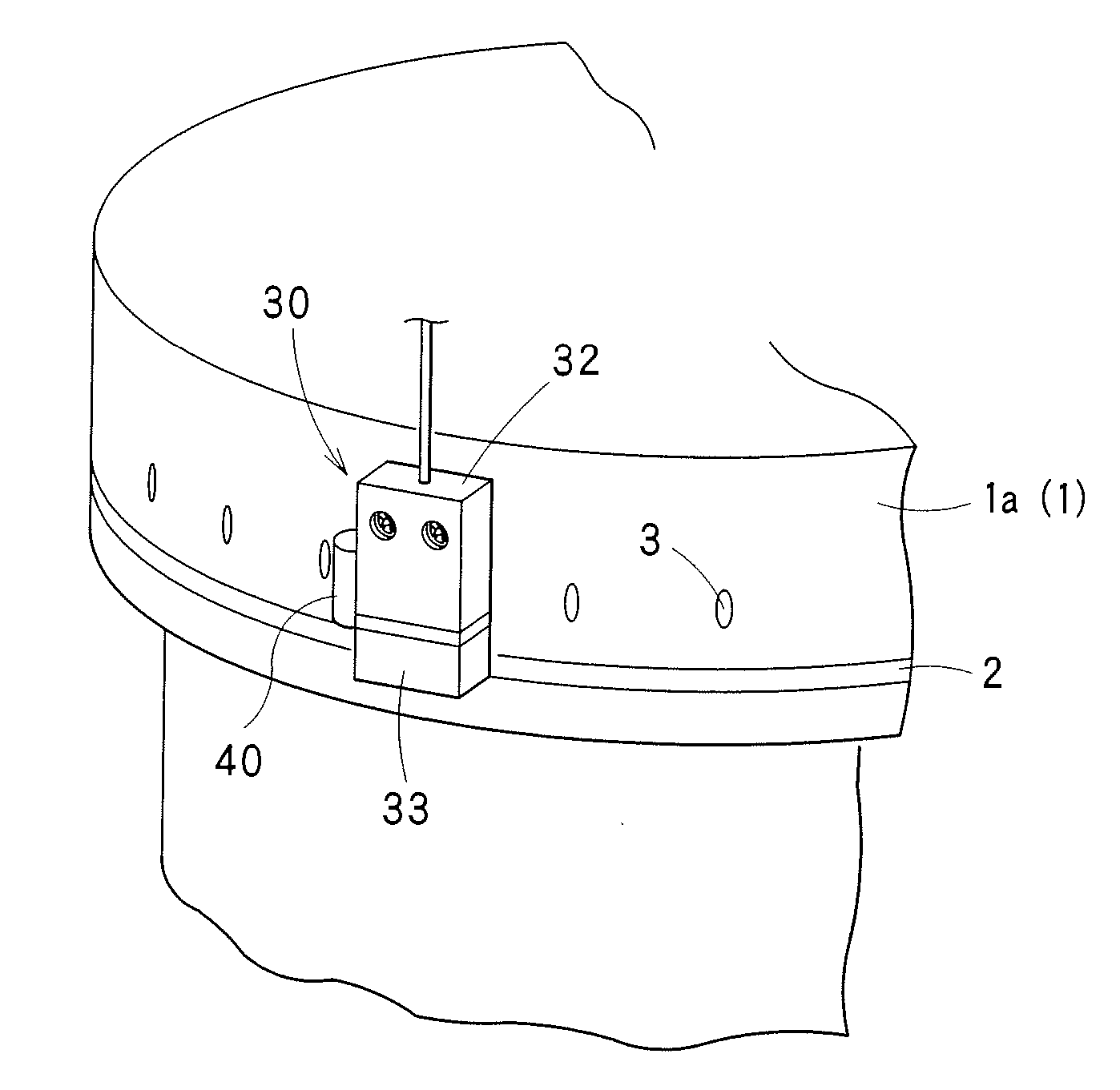

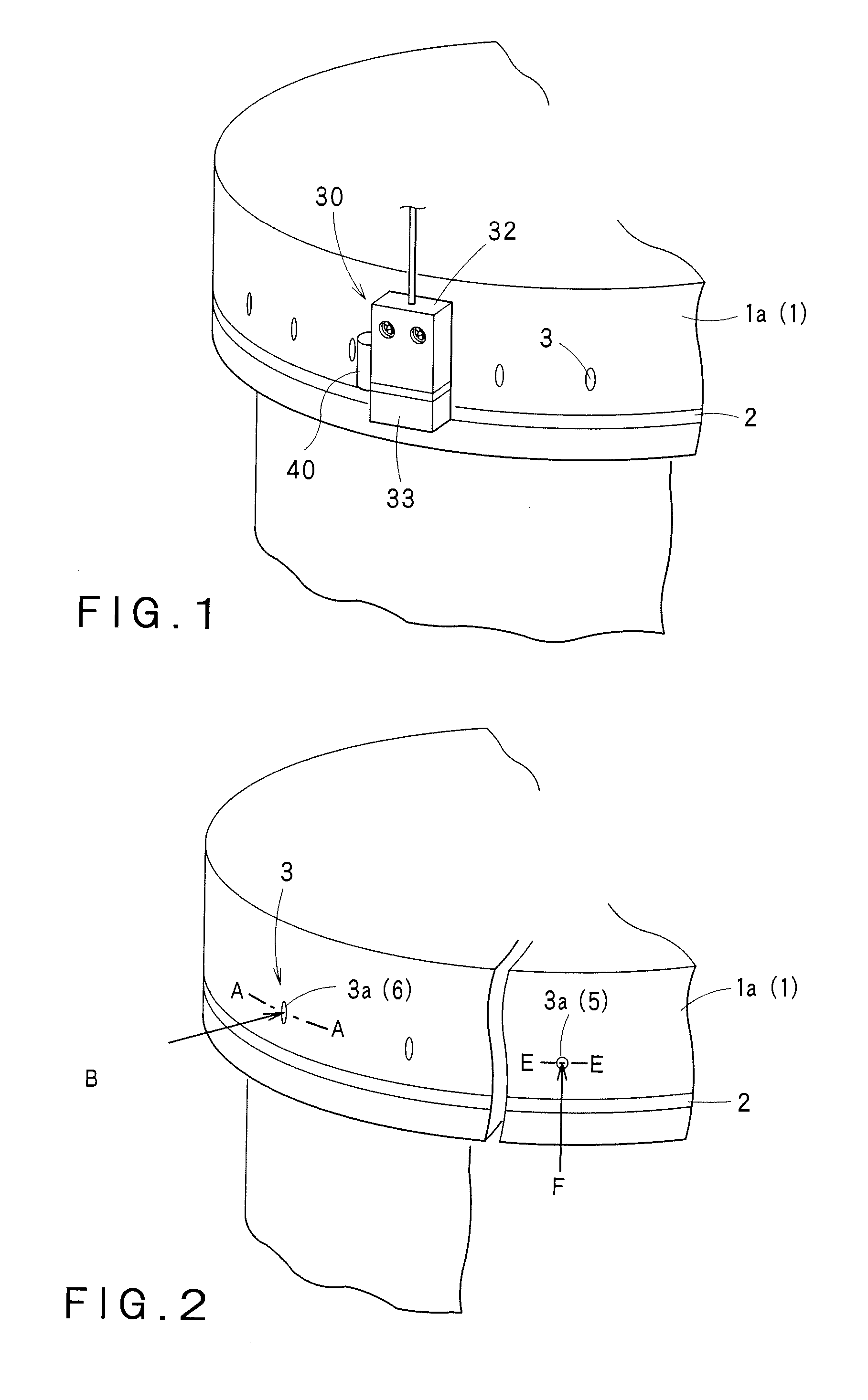

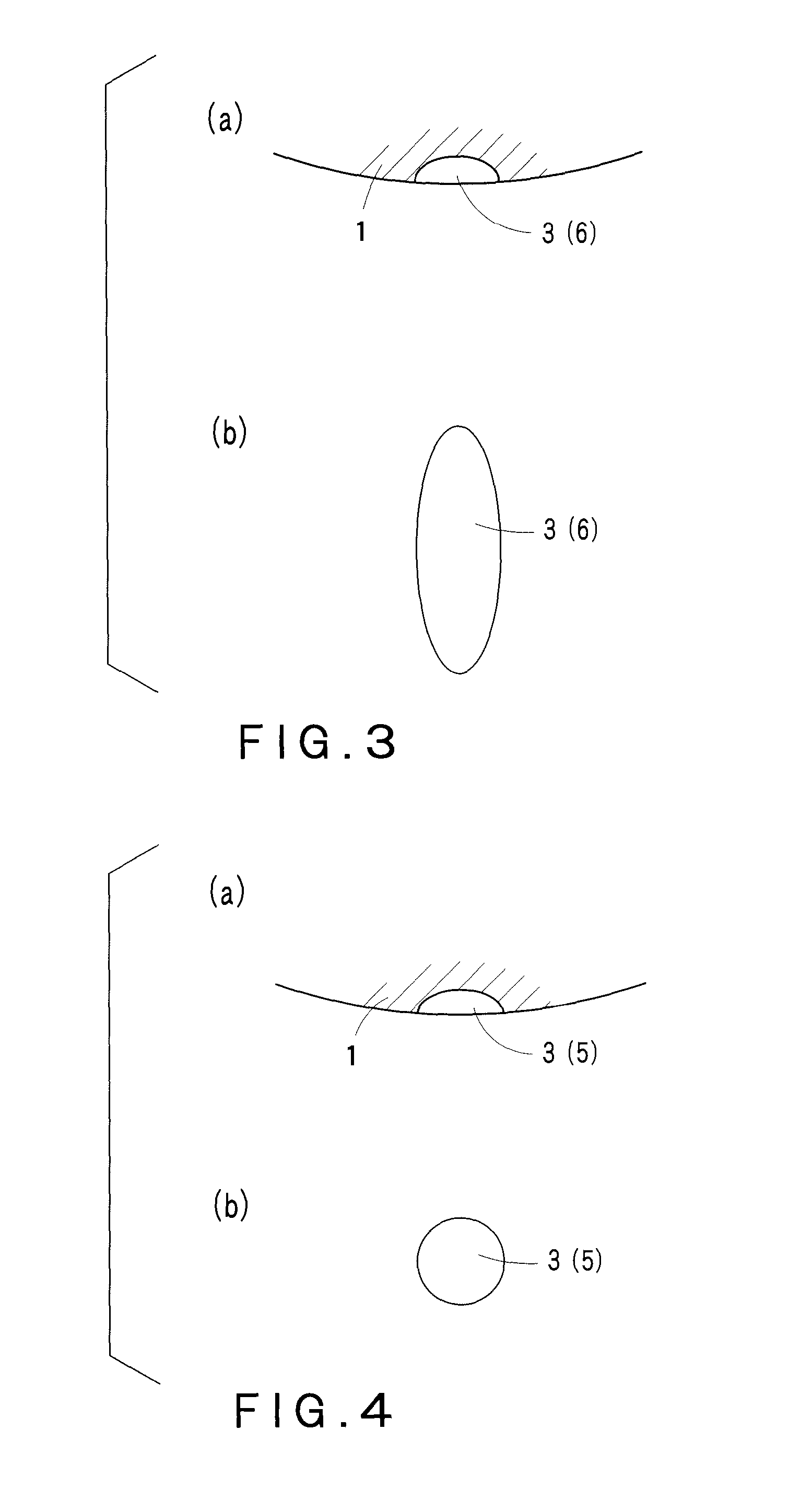

Method for inspection and maintenance of an inside of a nuclear power reactor

InactiveUS20070140403A1Improve accuracyPrecise positioningNuclear energy generationNuclear monitoringTarget surfacePunching

A method for inspection and maintenance of an inside of a nuclear power reactor is provided, which can perform positioning of a remote operated vehicle relative to an inspection target surface in a nuclear power reactor in a short period of time with high accuracy, and enhance the positioning repeatability for the remote operated vehicle, thereby enabling performance of the inspection and maintenance for the inspection target surface securely and satisfactorily. For the inspection or maintenance for the inspection target surface 1a in a nuclear power reactor by using the remote operated vehicle 30, a detection mark 3 is formed in advance by providing a notching, marking, punching or engraving process to the inspection target surface 1a before performing inspection or maintenance of the inside of the nuclear power reactor by using the remote operated vehicle 30. Then, the remote operated vehicle 30 is driven to move in the nuclear power reactor filled with water. During the movement, the detection mark 3 formed in the inspection target surface 1a is detected by using the remote operated vehicle 30 so as to determine the position of the remote operated vehicle 30.

Owner:KK TOSHIBA

Film-rolling-roller film clamping device

The invention discloses a film-rolling-roller film clamping device, relates to an improvement to a film clamping device on a film rolling roller when a film on the film processing tail section of PVC production line equipment is rolled, and provides a film rolling device which can be used for effectively rolling a film at the initial rolling stage of the film. According to the technical scheme, the film-rolling-roller film clamping device is arranged on the surface of a film rolling roller and comprises the film rolling roller and a film rolling cylinder, the film rolling cylinder is connected to the film rolling roller in a sleeved mode and is in close fit with the film rolling roller, the film rolling cylinder is provided with a notch, and the film clamping device further comprises a bar groove, a film clamping bar, a film groove, spring buckles and buckle grooves; the buckle grooves are formed in the walls of the bar groove, at least two buckle grooves are formed in the walls on two sides of the bar groove, and the buckle grooves on the two sides correspond to one another one to one; the spring buckles are arranged inside the buckle grooves and matched with the buckle grooves; the film clamping bar is a strip-shaped bar, the upper portion of the section of the strip-shaped bar is short, the lower portion of the section of the strip-shape bar is long, and the film clamping bar is arranged inside the bar groove; the film groove is formed in the upper surface of the film clamping bar. According to the film-rolling-roller film clamping device, machining processes of the buckle grooves are simplified, and the film clamping bar can be taken out conveniently.

Owner:YANGZHOU HAICHUANG PLASTIC PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com