Patents

Literature

1144 results about "Electric resistance welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric resistance welding (ERW) refers to a group of welding processes such as spot and seam welding that produce coalescence of faying surfaces where heat to form the weld is generated by the electrical resistance of material combined with the time and the force used to hold the materials together during welding. Some factors influencing heat or welding temperatures are the proportions of the workpieces, the metal coating or the lack of coating, the electrode materials, electrode geometry, electrode pressing force, electrical current and length of welding time. Small pools of molten metal are formed at the point of most electrical resistance (the connecting or "faying" surfaces) as an electrical current (100–100,000 A) is passed through the metal. In general, resistance welding methods are efficient and cause little pollution, but their applications are limited to relatively thin materials and the equipment cost can be high (although in production situations the cost per weld may be low).

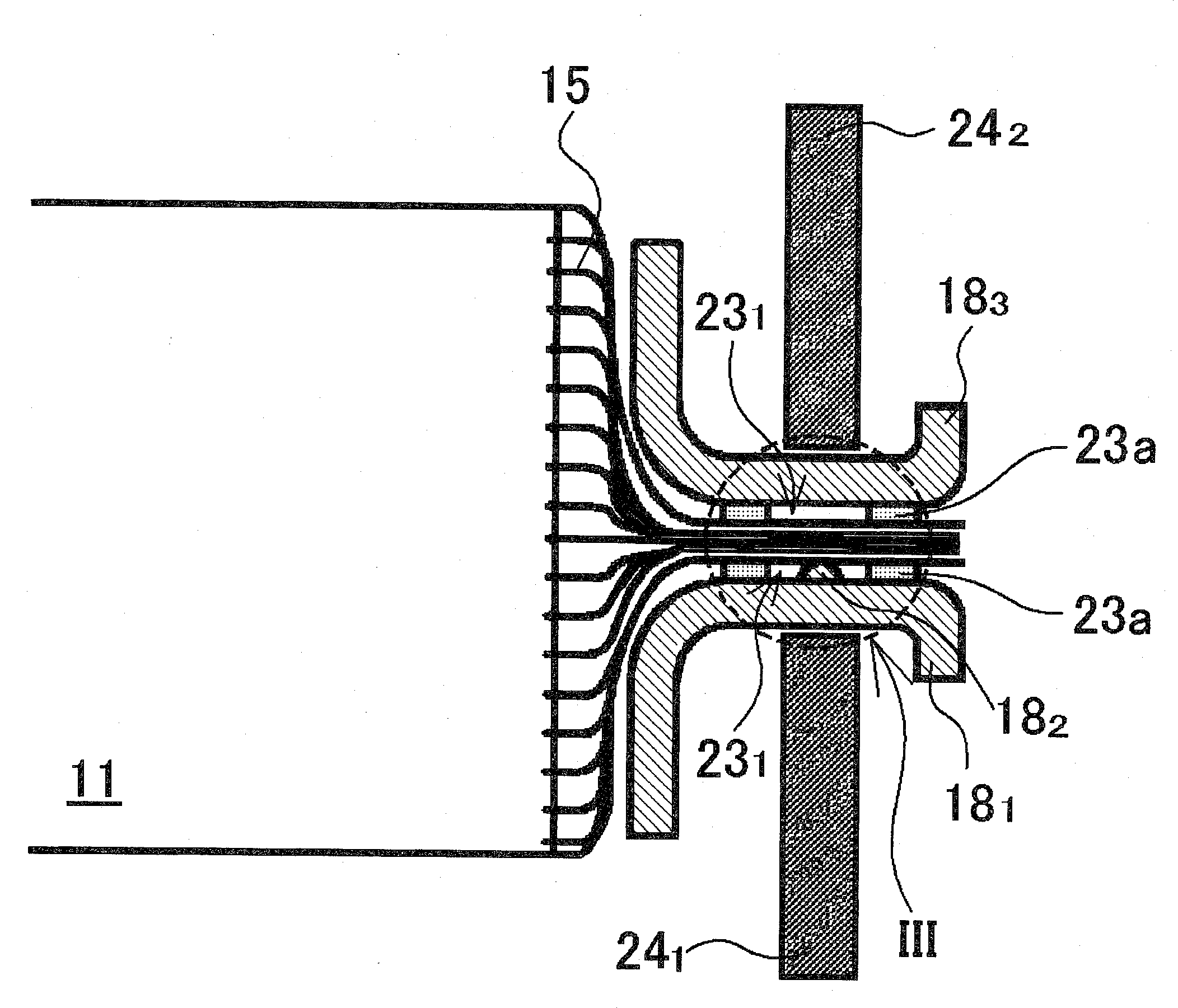

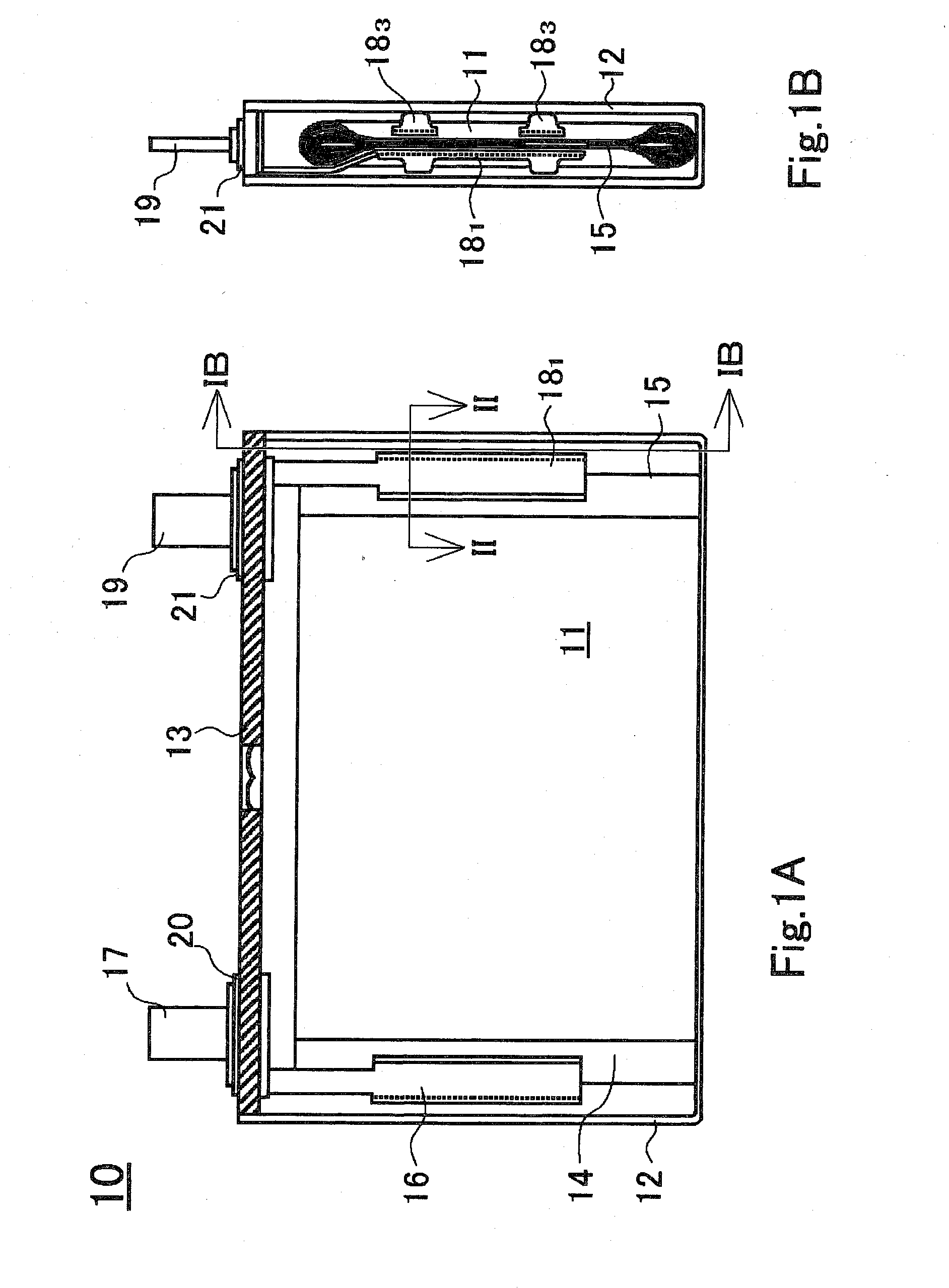

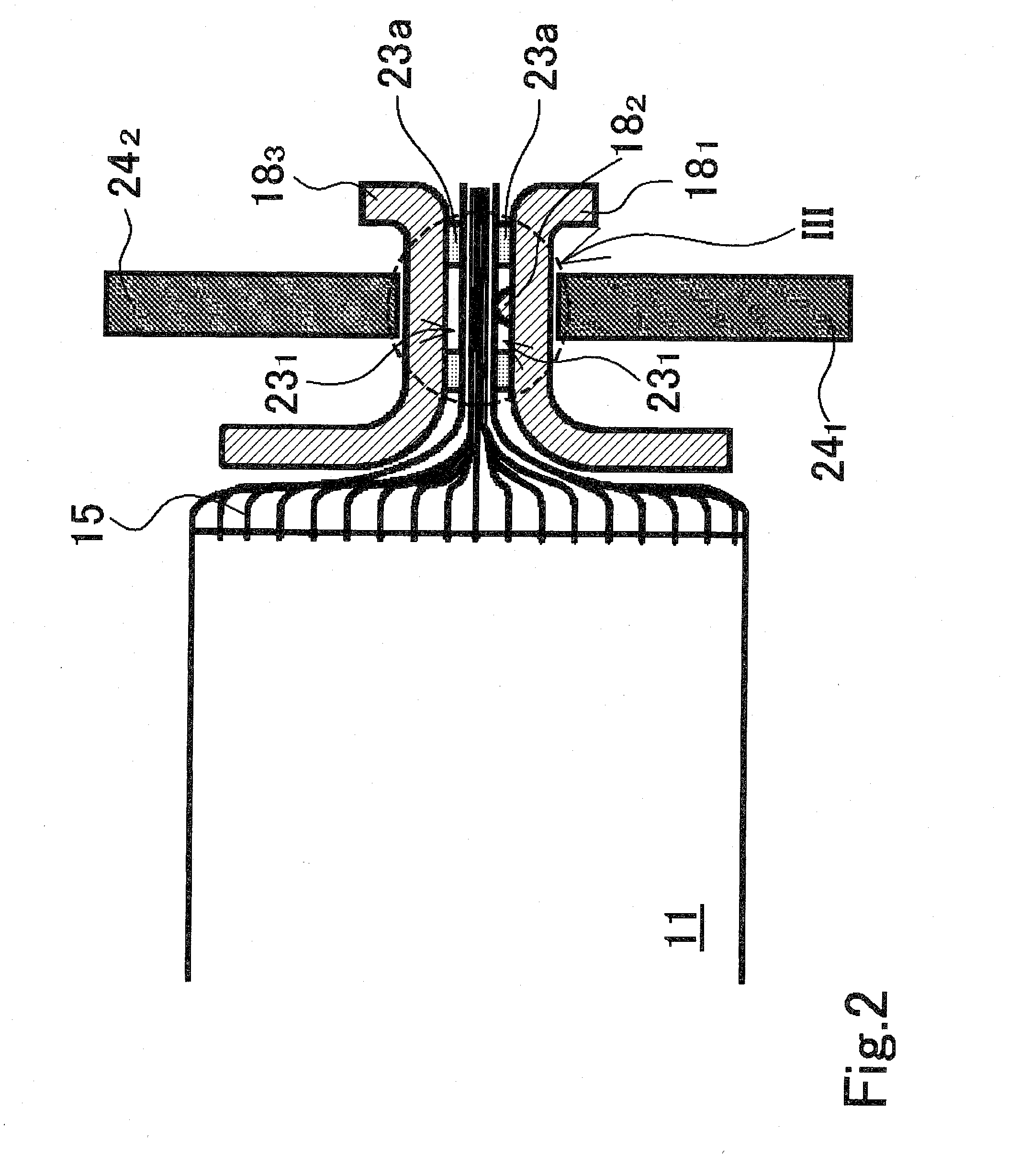

Sealed battery and manufacturing method therefor

ActiveUS20090004561A1High resistance weld reliabilitySatisfy the effectivenessNon-aqueous electrolyte accumulatorsPrimary cellsEngineeringElectrical and Electronics engineering

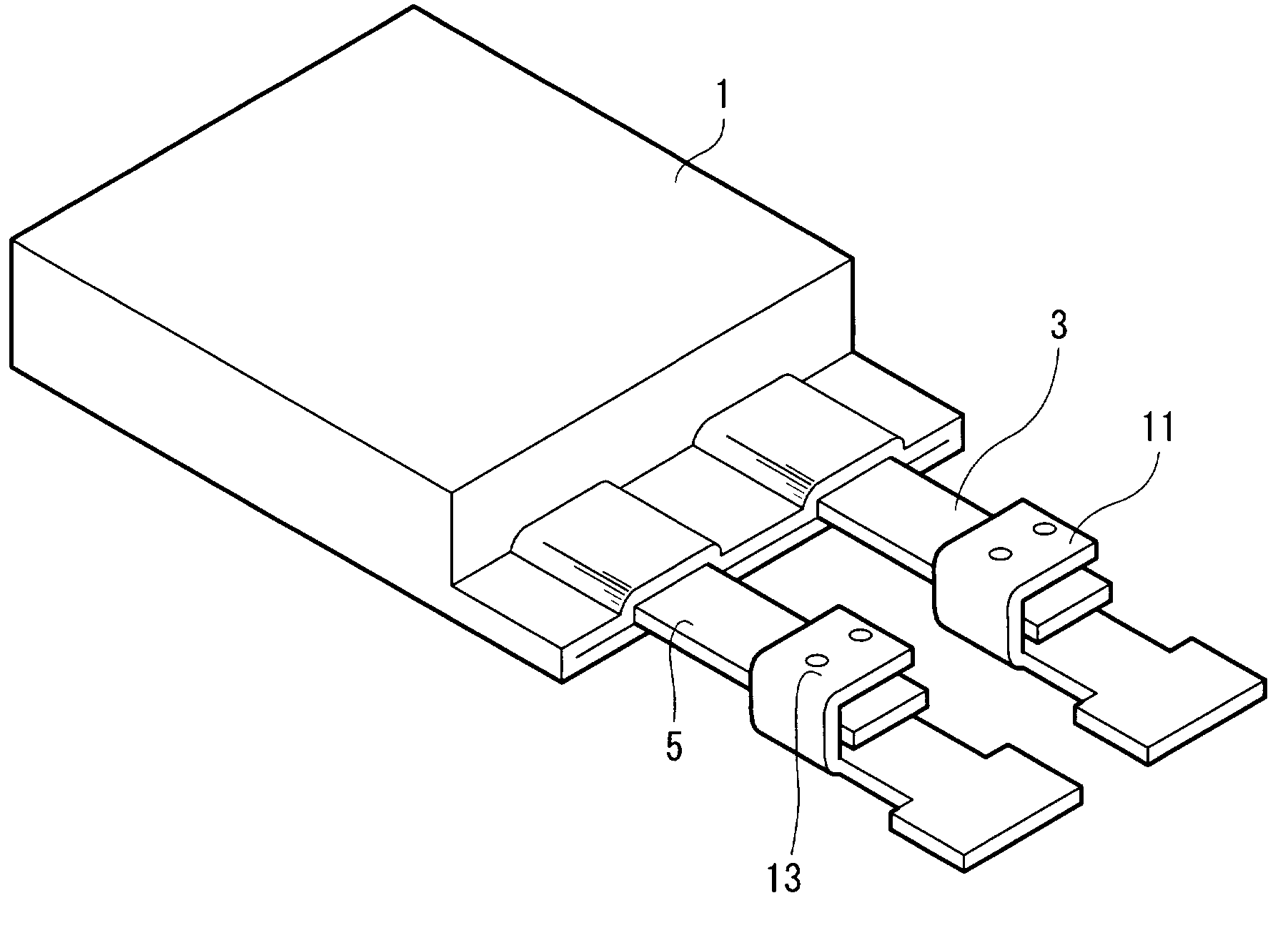

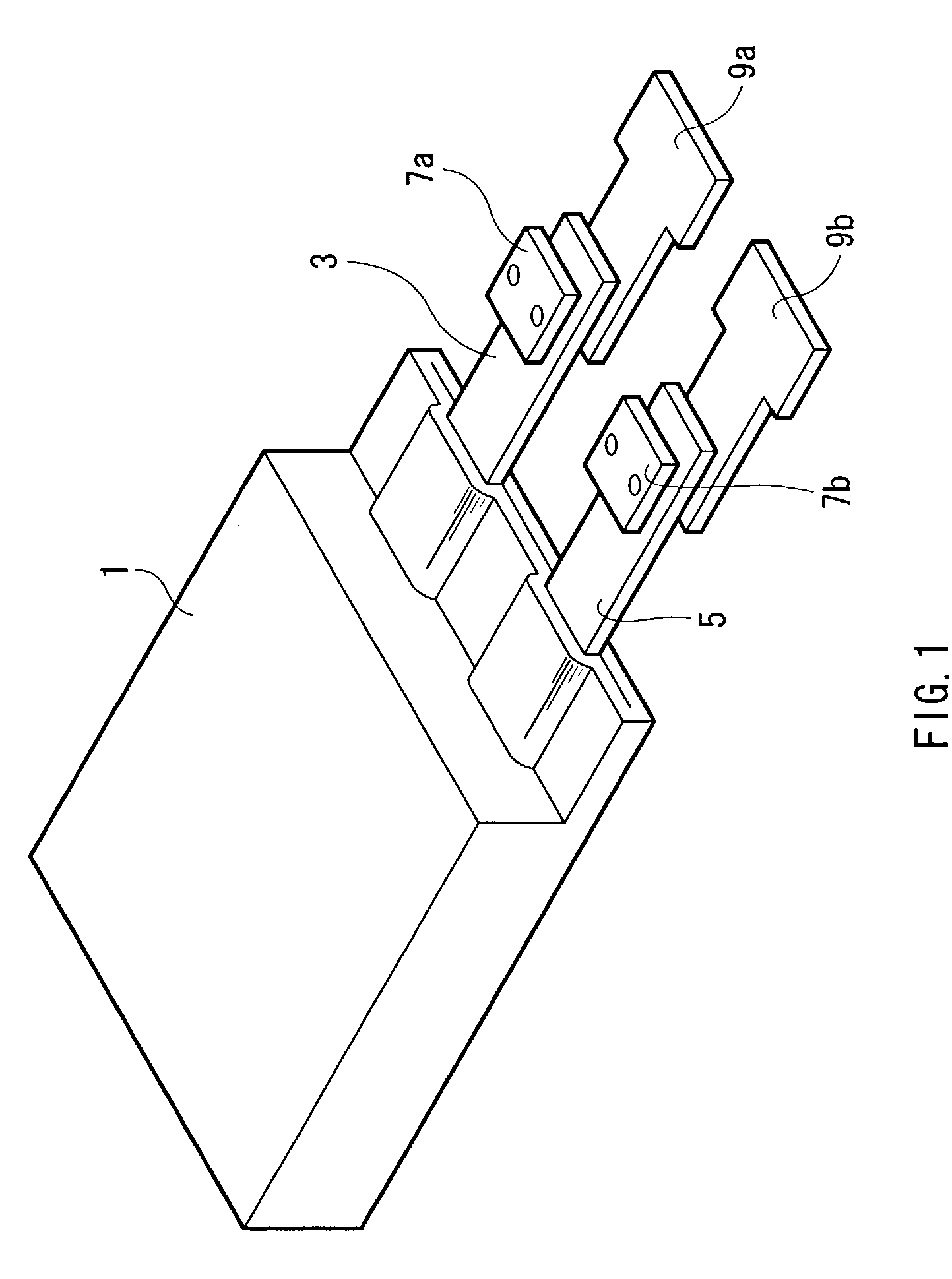

The present invention's manufacturing method for a sealed battery includes: a process whereby a sealed battery application electrode assembly 11 is formed that has multiple positive electrode substrate exposed portions 14 at one end and multiple negative electrode substrate exposed portions 15 at the other end; a process whereby the negative electrode collector 181 and negative electrode collector receiving part 183 are brought against both surfaces of the part to be welded on at least the negative electrode substrate exposed portions 15, with tape 23a constituted of thermodeposited resin and having an opening 231 in the center being interposed; and a process whereby resistance welding is effected by passing current between the negative electrode collector 181 and negative electrode collector receiving part 183 positioned at the two sides.

Owner:SANYO ELECTRIC CO LTD

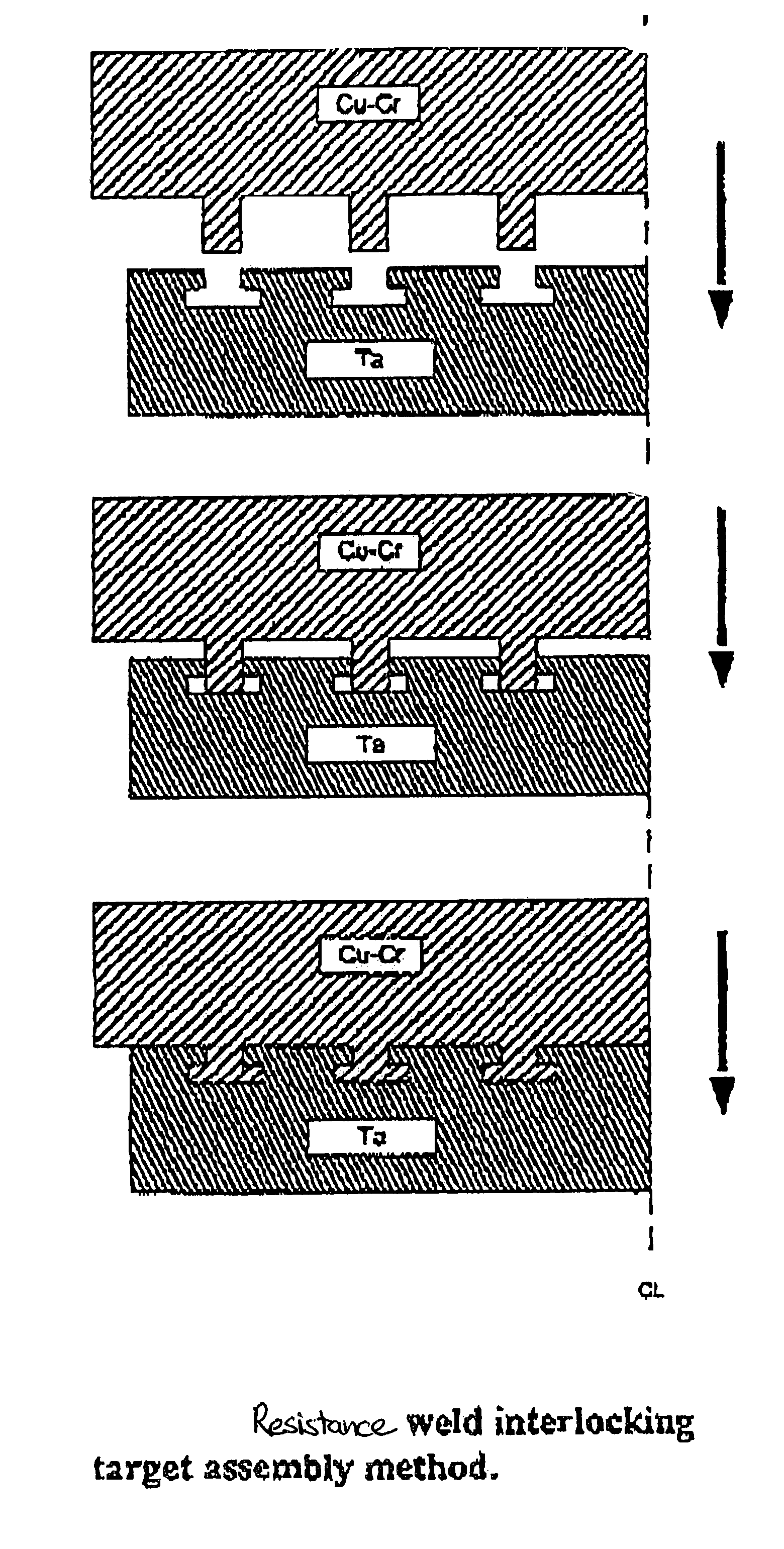

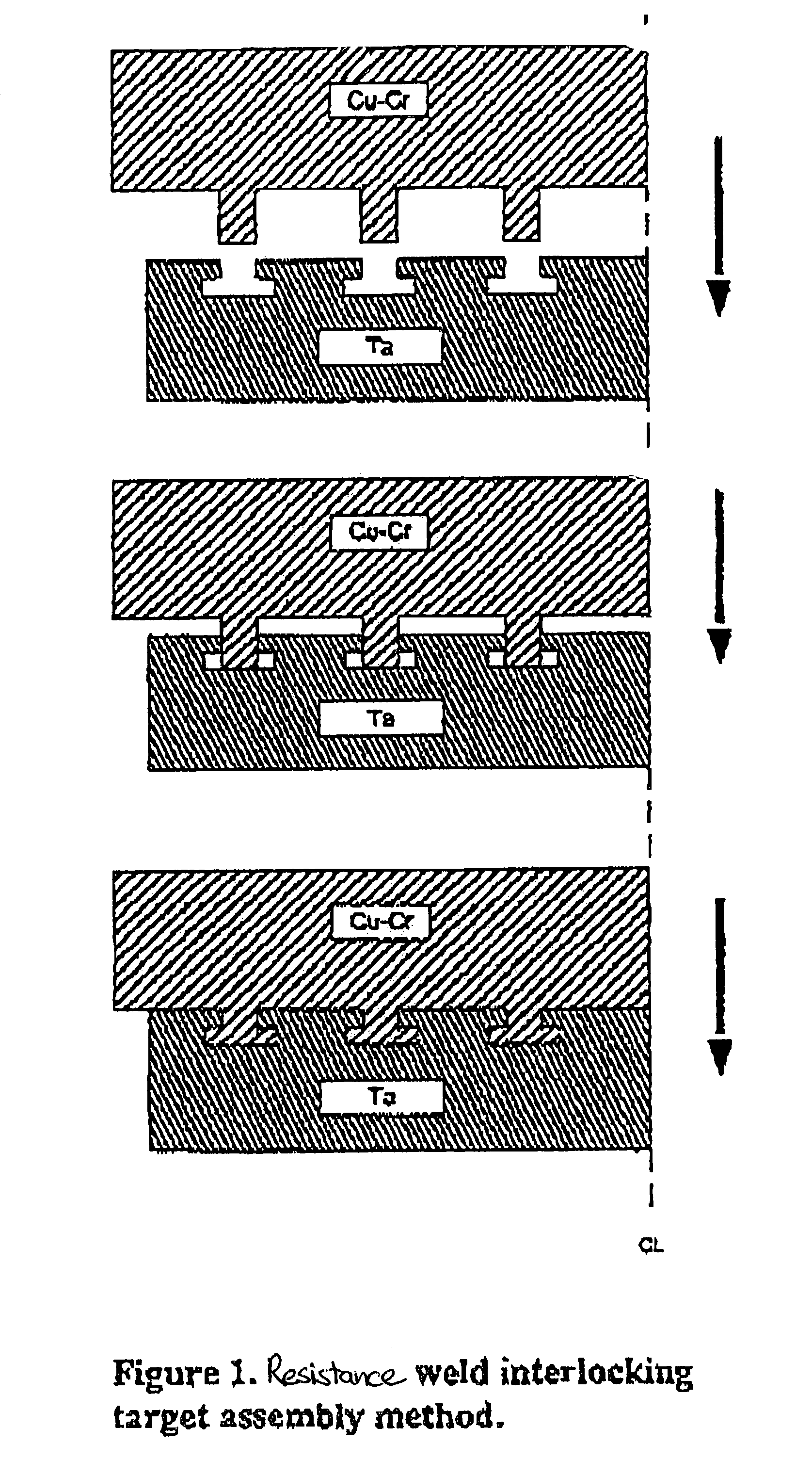

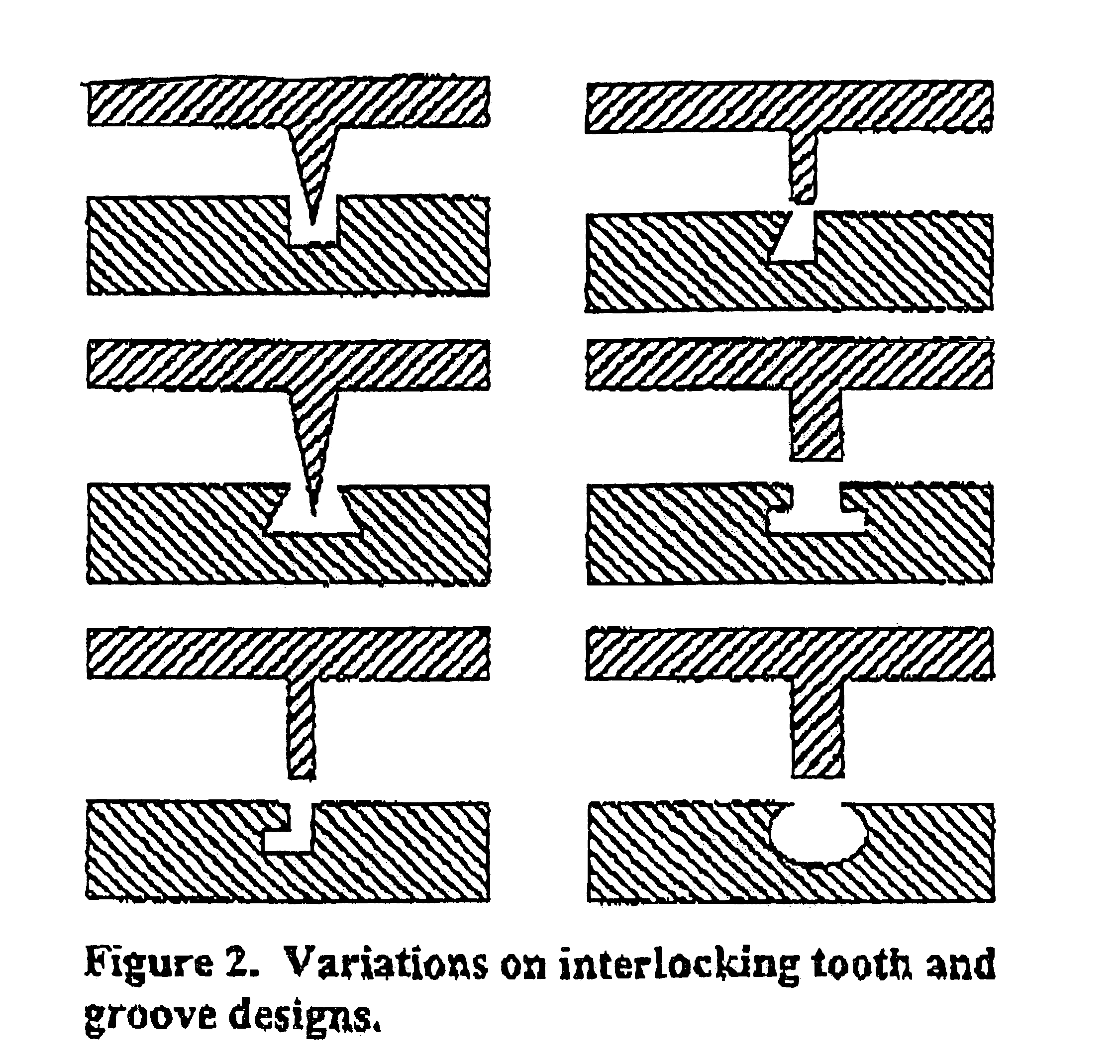

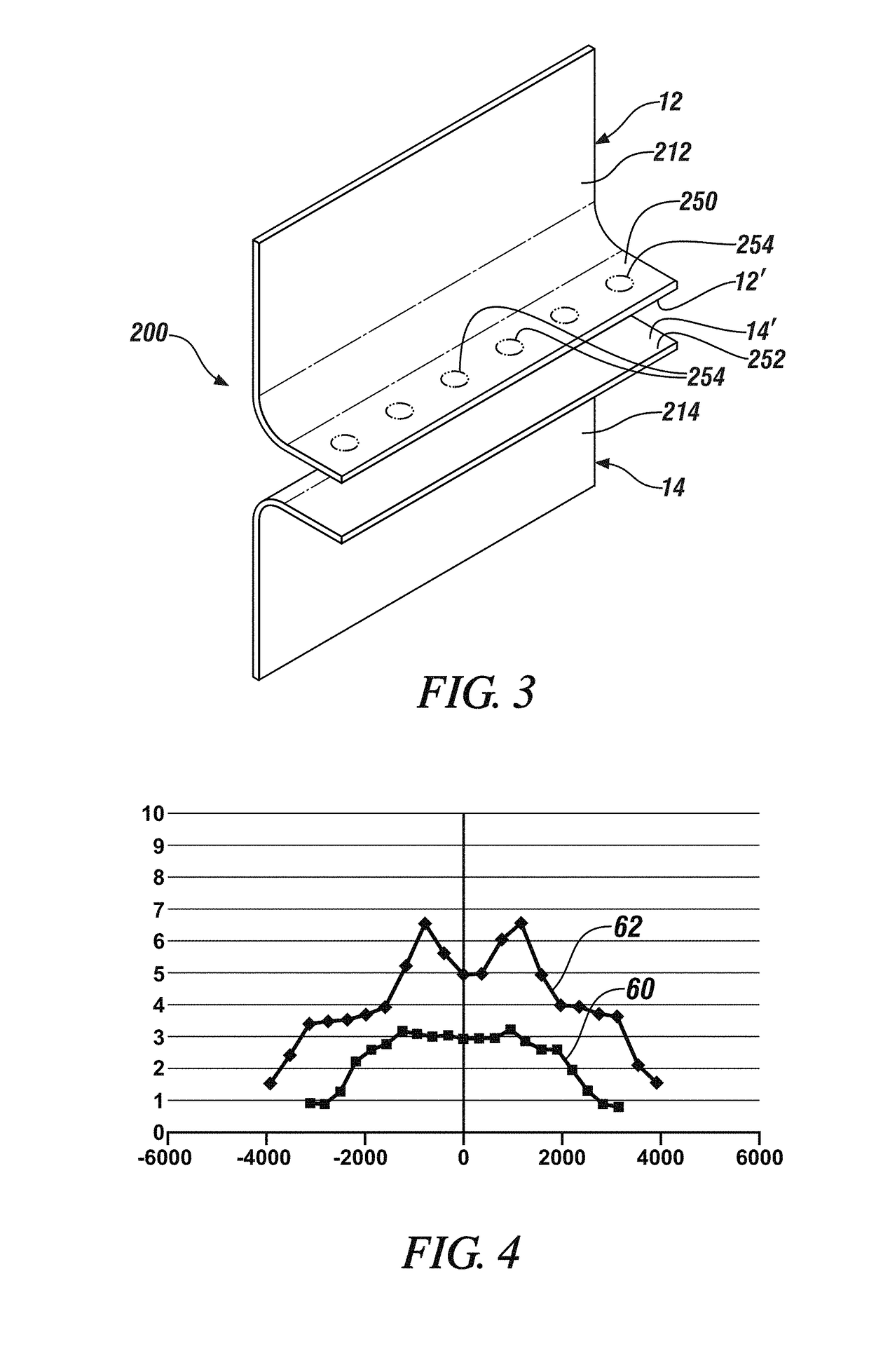

Sputtering target assemblies using resistance welding

ActiveUS6992261B2Reduce heat transferIncrease temperatureCellsElectric discharge tubesElectrical resistance and conductanceEngineering

Owner:GLOBAL ADVANCED METALS USA

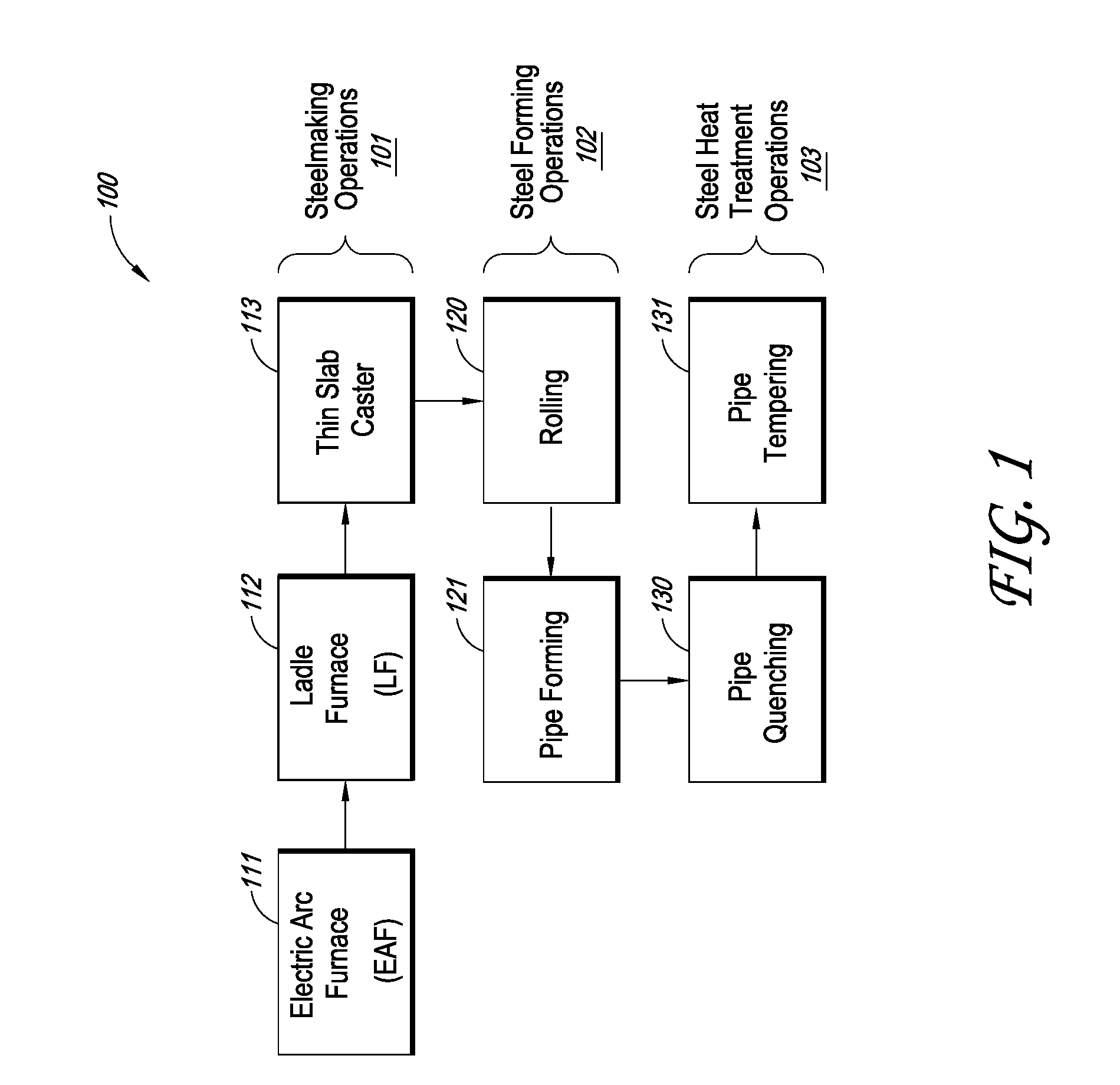

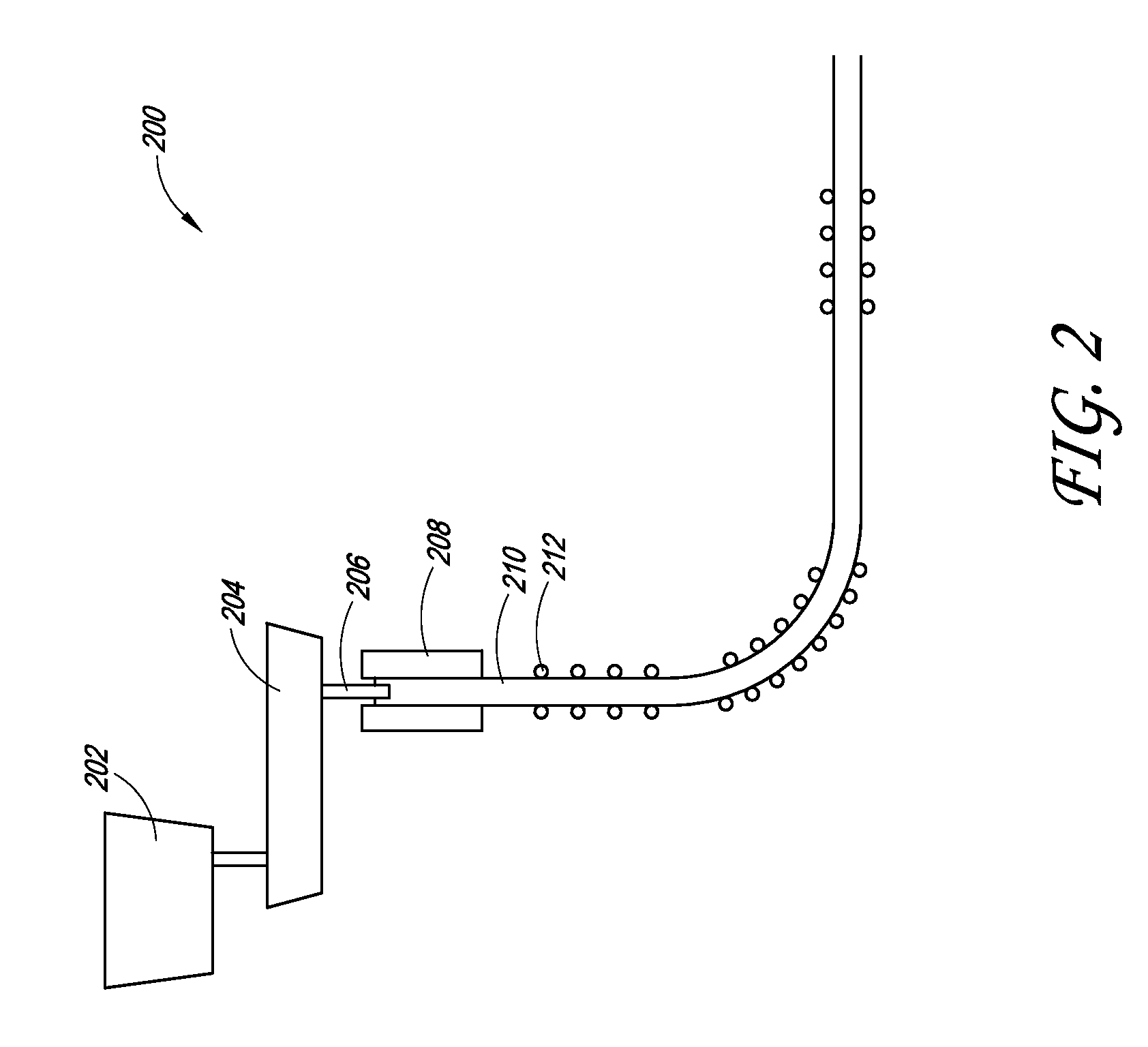

Compact strip or thin slab processing of boron/titanium steels

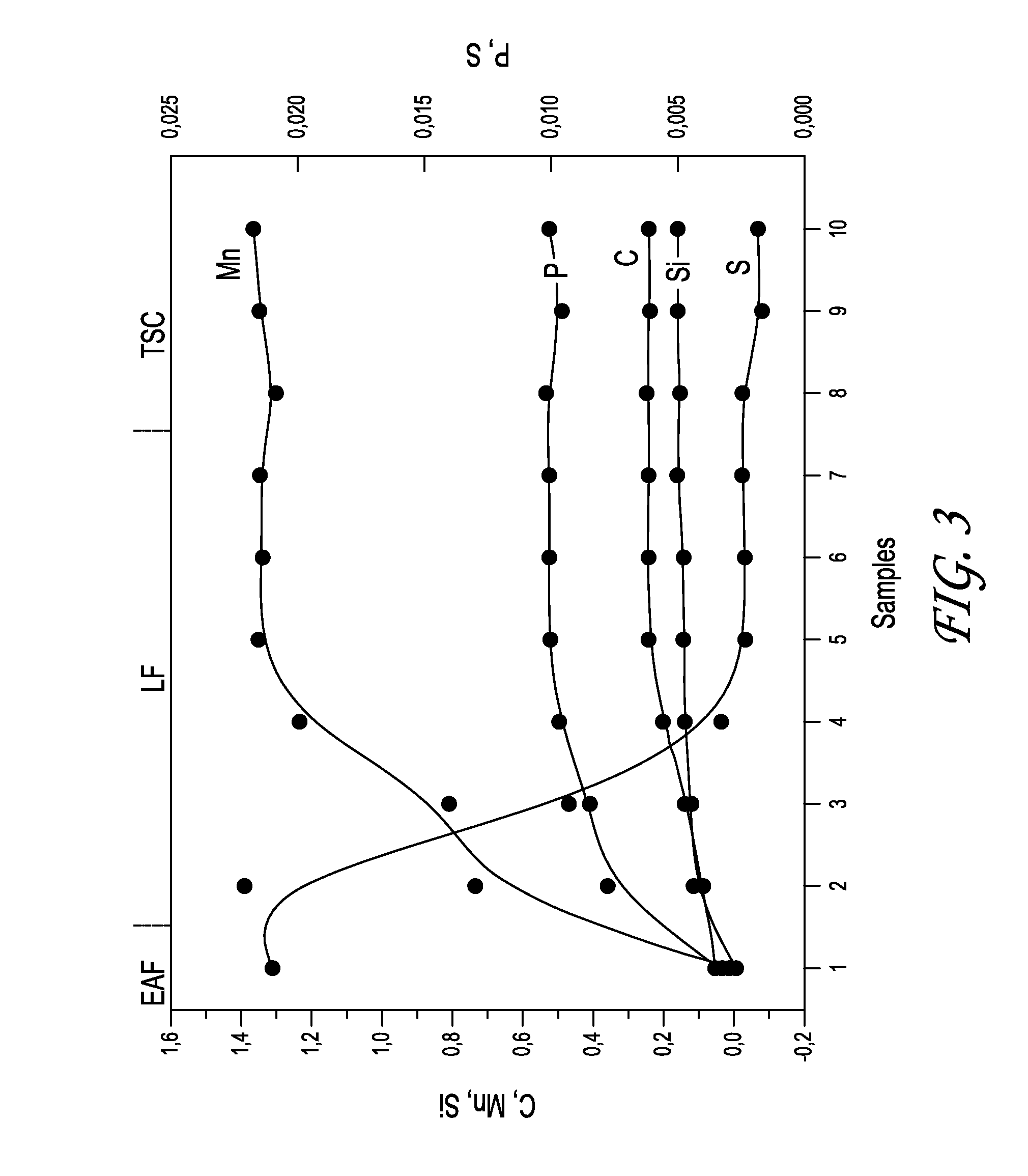

A method for casting medium carbon, B / Ti steel product using compact strip processing or thin slab casting. The method can include providing a steel composition including boron and titanium and casting the steel composition into a slab having a thickness between about 25 and 150 mm. The slab can have a cast composition including about 0.23 to 0.30 wt. % carbon, about 0.0010 to 0.0050 wt. % boron, about 0.010 to 0.050 wt. % titanium, about 1.15 to 1.50 wt. % manganese, less than 0.35 wt. % silicon and a Ti / N ratio greater than 2.9. The amount of each element is provided based upon the total weight of the steel composition. The steel slab can be free from cracks and significant defects. Furthermore, the steel slab can be used for electric resistance welded (ERW) products.

Owner:MAVERICK TUBE +1

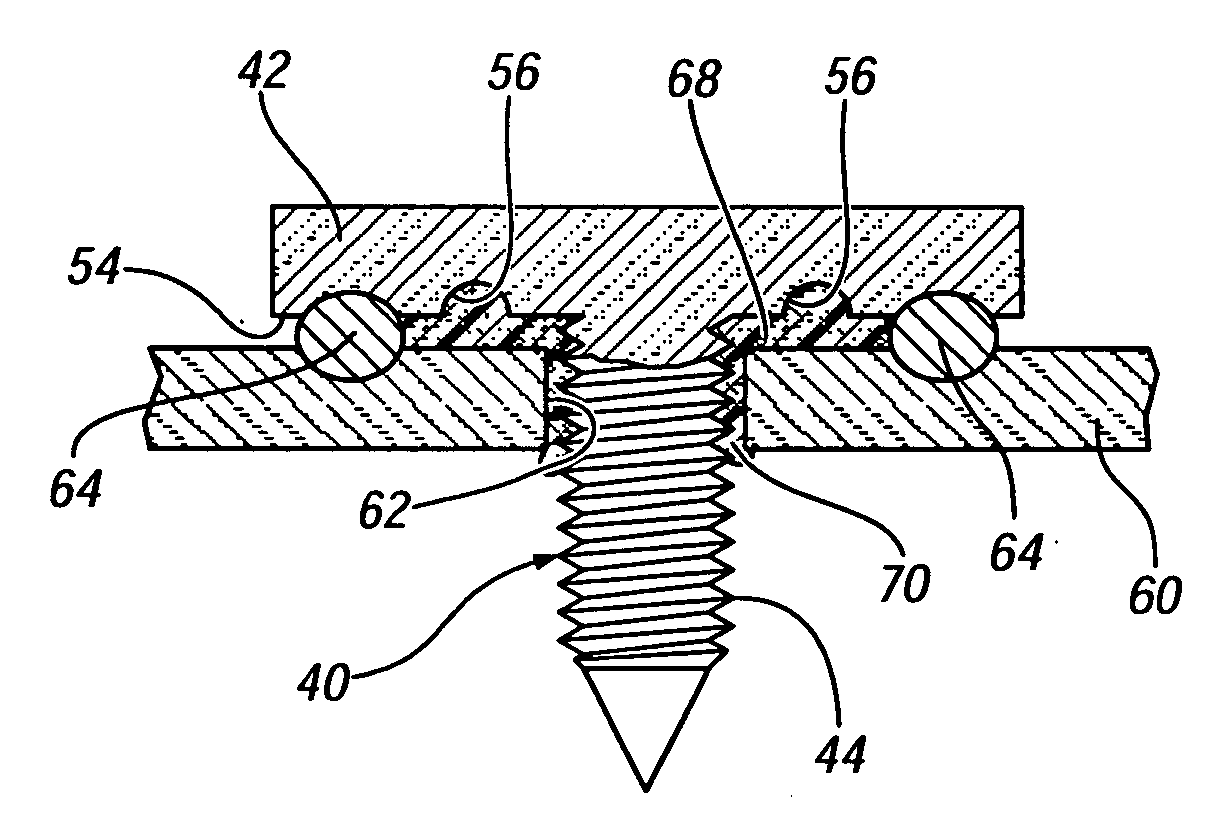

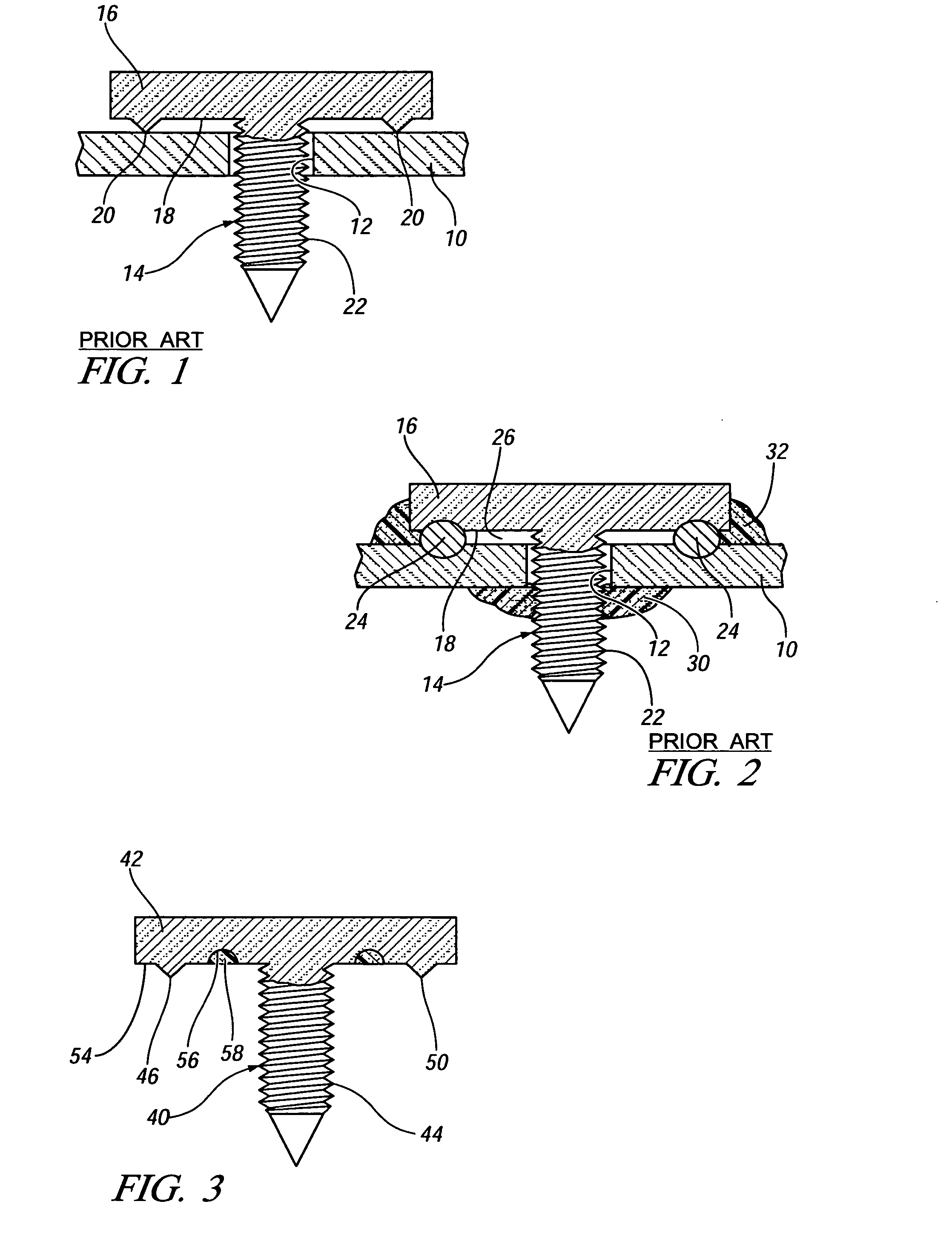

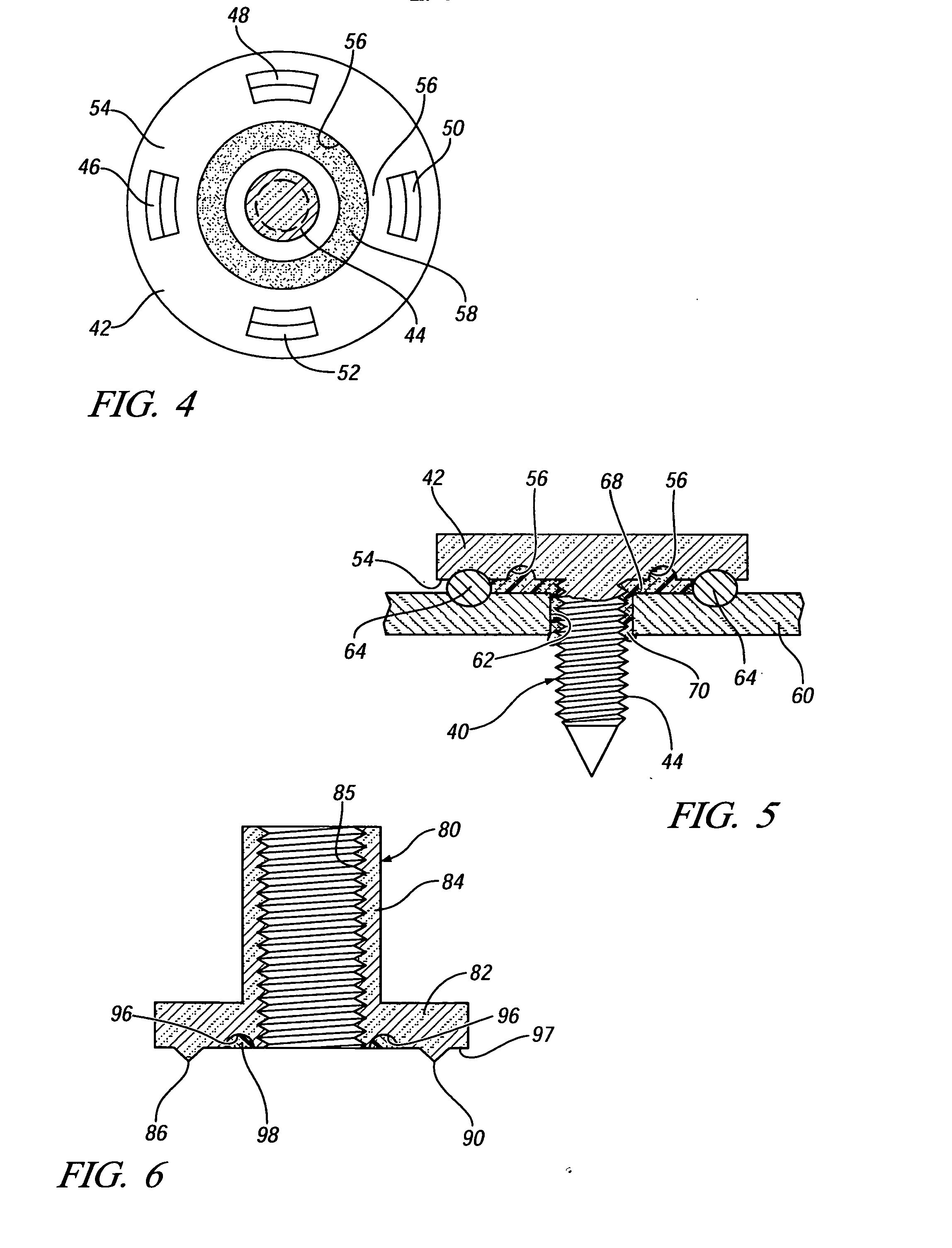

Projection welded fastener with integral sealer

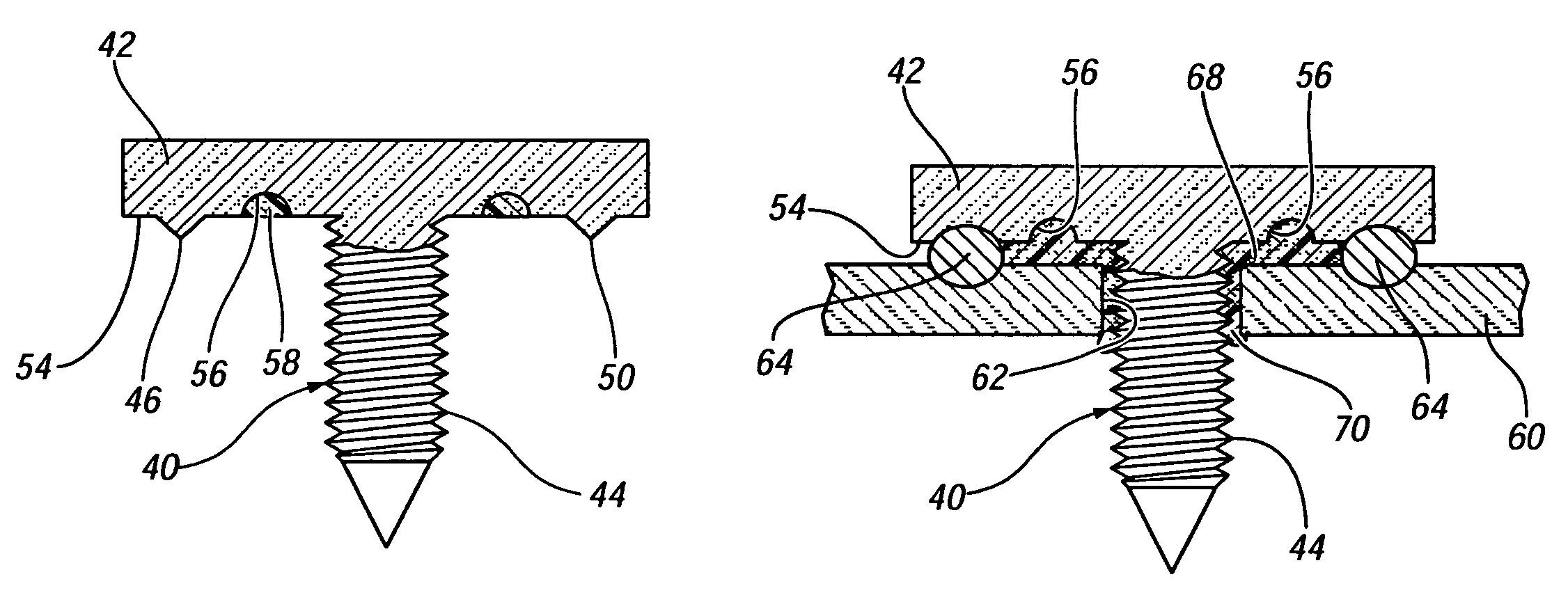

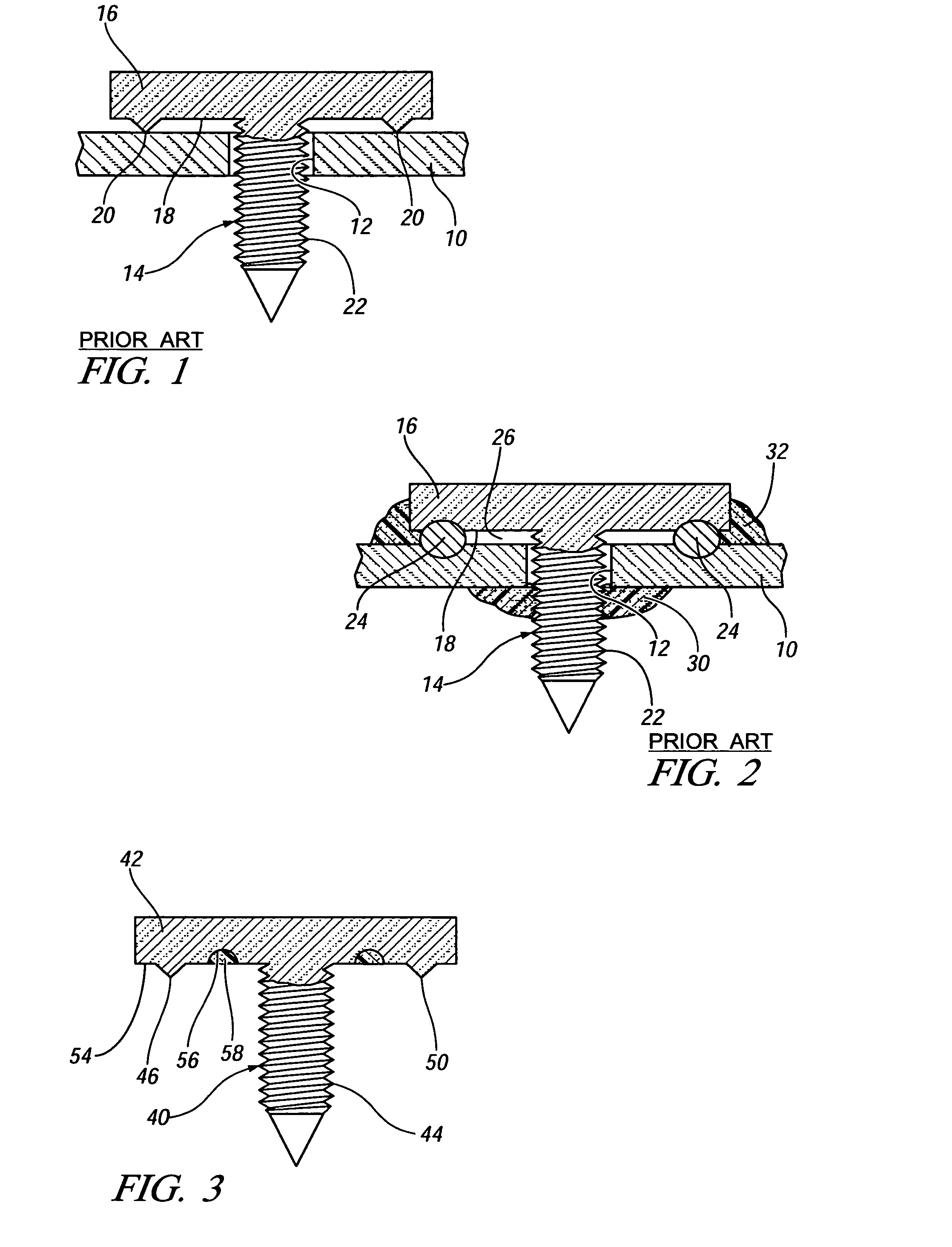

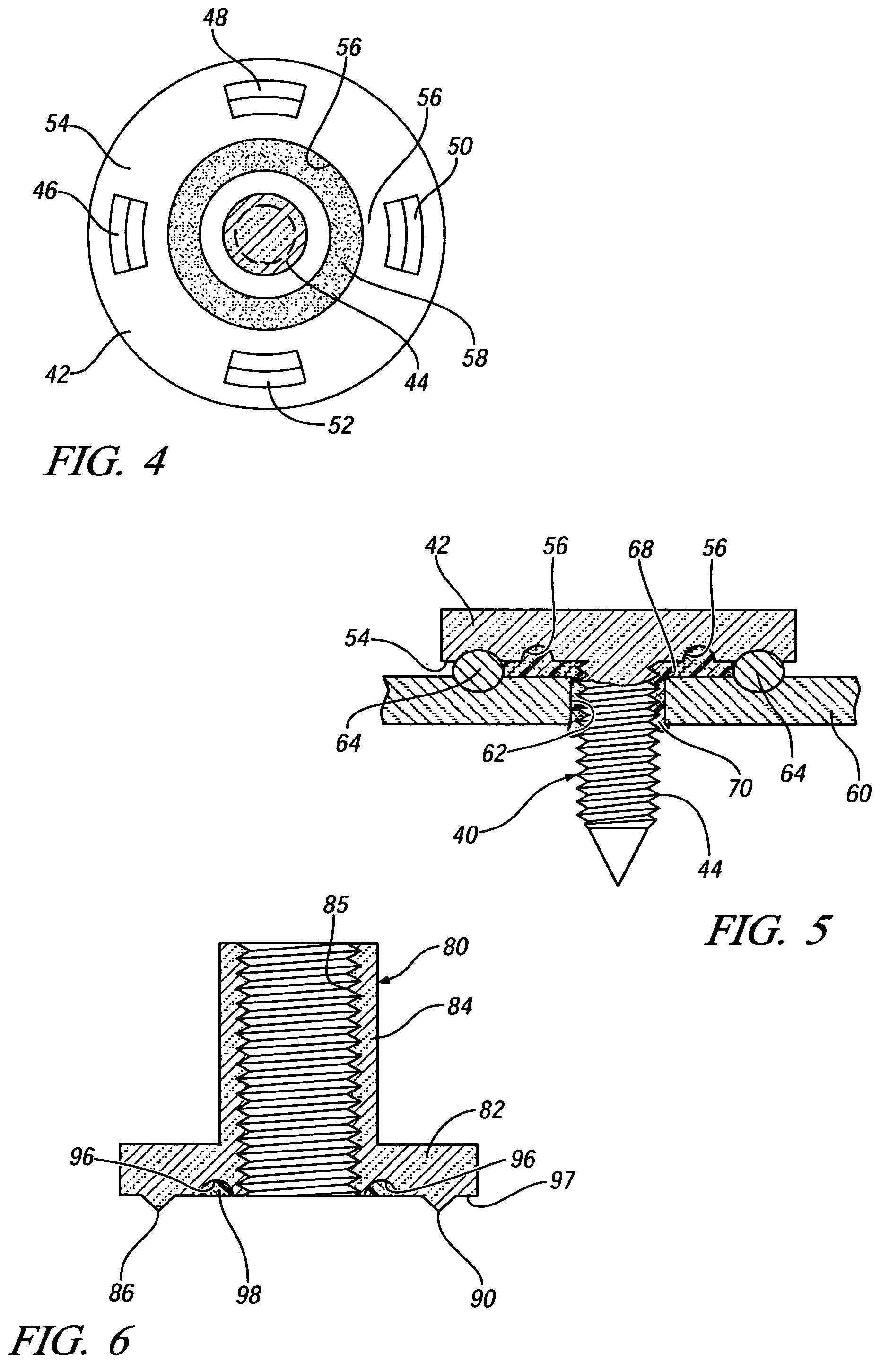

A fastener is provided for projection resistance welding to a panel. The fastener includes a base having a fastening element, such as a threaded stud or a nut integral therewith. Multiple projections formed integral with the base extend therefrom to engage with the panel to be welded to the panel by electric resistance welding. A groove is provided in the base facing the panel and is filled with a heat activated expandable sealer material. Upon heating of the base during the electric resistance welding, or in an oven, the sealer expands to fill and seal any gap between the base and the panel.

Owner:GM GLOBAL TECH OPERATIONS LLC

Liquid photo-imaging alkali developable electronic solder-proof ink and its preparing method

InactiveCN1971419AExcellent solder resistanceImprove performancePhotomechanical apparatusInksDiluentFirming agent

The invention discloses liquid photosensitive imaging alkali developing electric resistance welding ink and production method. The ink comprises alkali solulbility photosensitive resin 30-50 %, heat-proof novolac epoxy 5-20 %, firming agent 0.3-1.2 %, firming accelerant 0.1-0.3 %, active diluent 5-15 %, solvent 5-15 %, photo-initiation agent 3-9 %, auxiliary agent 1-3 %, pigment 0.5-0.8 %, brasque 15-30 %; When it is produced, the alkali solulbility photosensitive resin is weighted by mass percent and dispersed evenly by dispersion machine, it is abraded to that fineness is smaller than 15 mum, the viscosity is adjusted by solvent to 50-80ps(25DEG C), the liquid photosensitive imaging alkali developing electric resistance welding ink in the invention is obtained. The operational charactisteric of the invention is simple, development is quick, and the ink also possesses characteristics that heat-proof quality is good; construction is convenient, adhesive force achieves first class; solidness is bigger than 4H.

Owner:SOUTH CHINA UNIV OF TECH

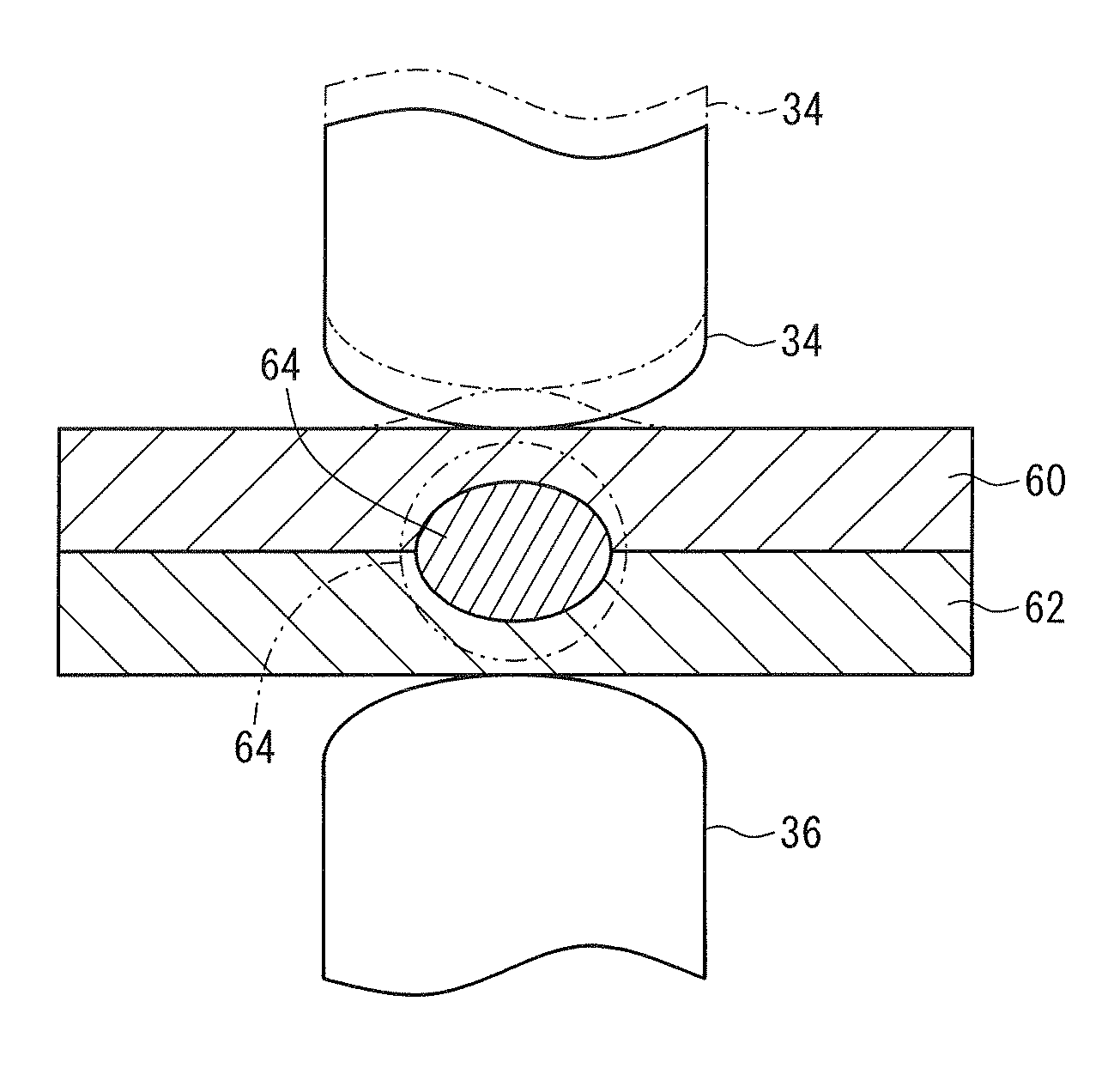

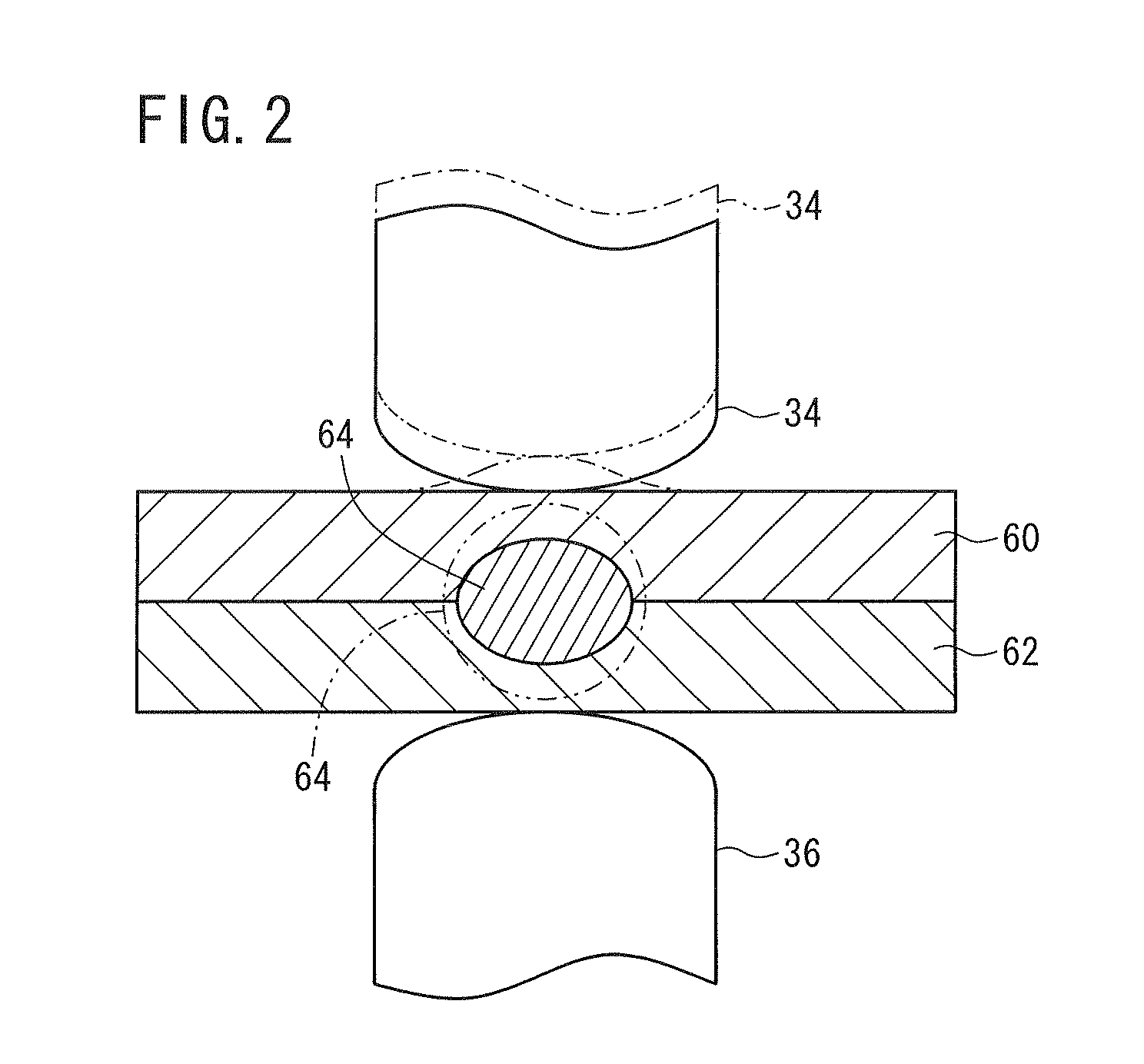

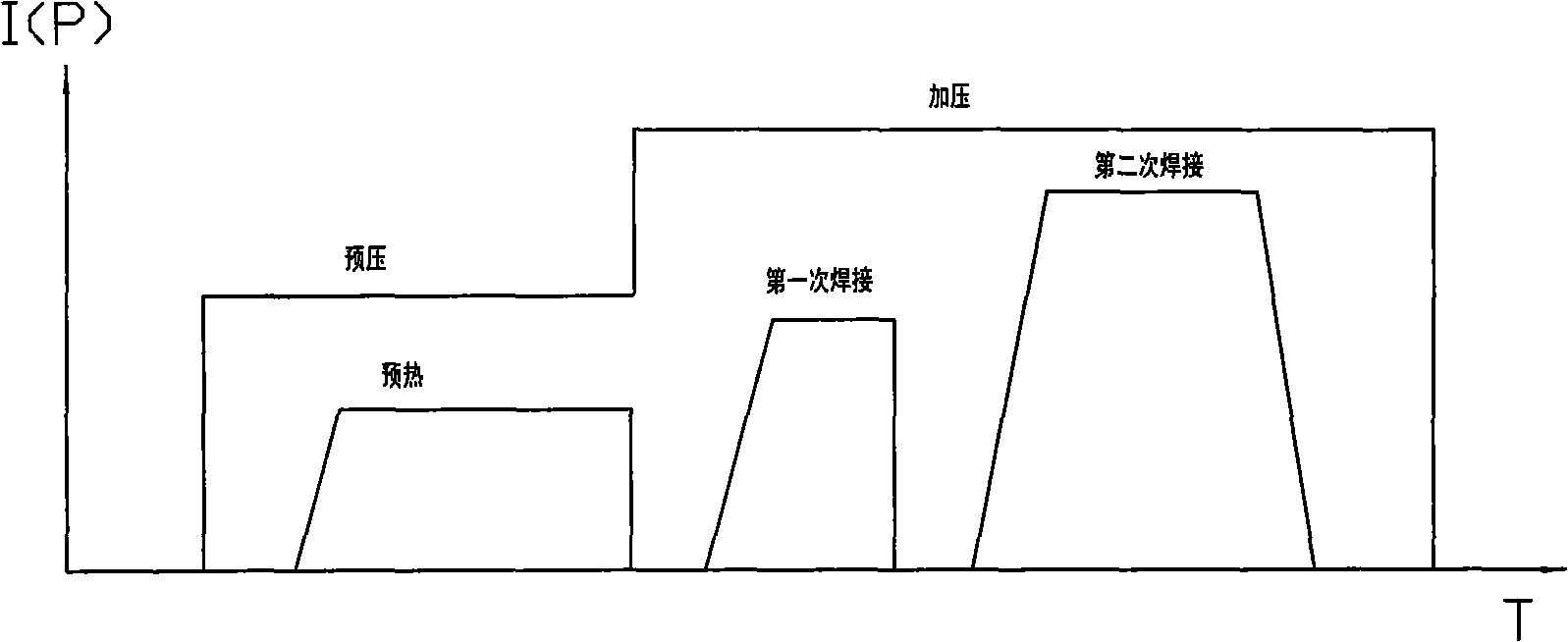

Electric resistance welding method for variable-thickness ultra-high strength hot formed steel plate and low-carbon steel plate

InactiveCN102581459AImprove uniformityImproved cold stiffnessResistance welding apparatusVariable thicknessElectrical resistance and conductance

The invention relates to an electric resistance welding method for a variable-thickness ultra-high strength hot formed steel plate and a low-carbon steel plate. The method is characterized in that the low-carbon steel plate and the ultra-high strength hot formed steel plate are lapped on electric resistance welding machines with different upper and lower electrode end face areas, and are welded by means of preheating and double pulsing. Compared with the prior art, the method has the advantages that the defect of the influence of splash, nugget deviation and the like on welding spot quality in spot welding of variable-thickness dissimilar steel can be avoided, the influence of softening of a heat-affected zone of the ultra-high strength hot formed steel plate on joint quality is decreased, welding quality of electric resistance spot-welded joints of the variable-thickness ultra-high strength hot formed steel plate and the low-carbon steel plate is remarkably improved, and the like.

Owner:SHANGHAI JIAO TONG UNIV +1

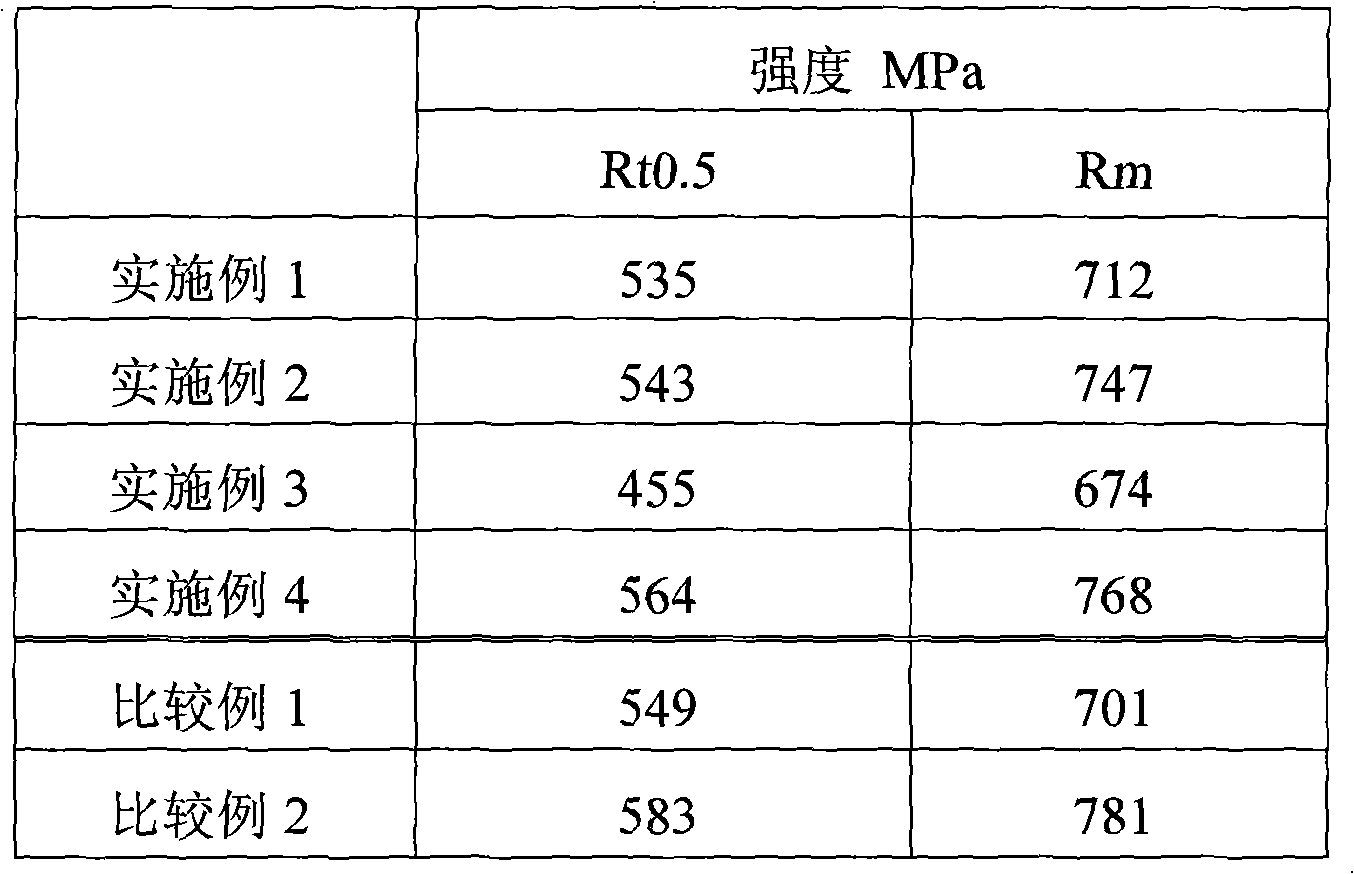

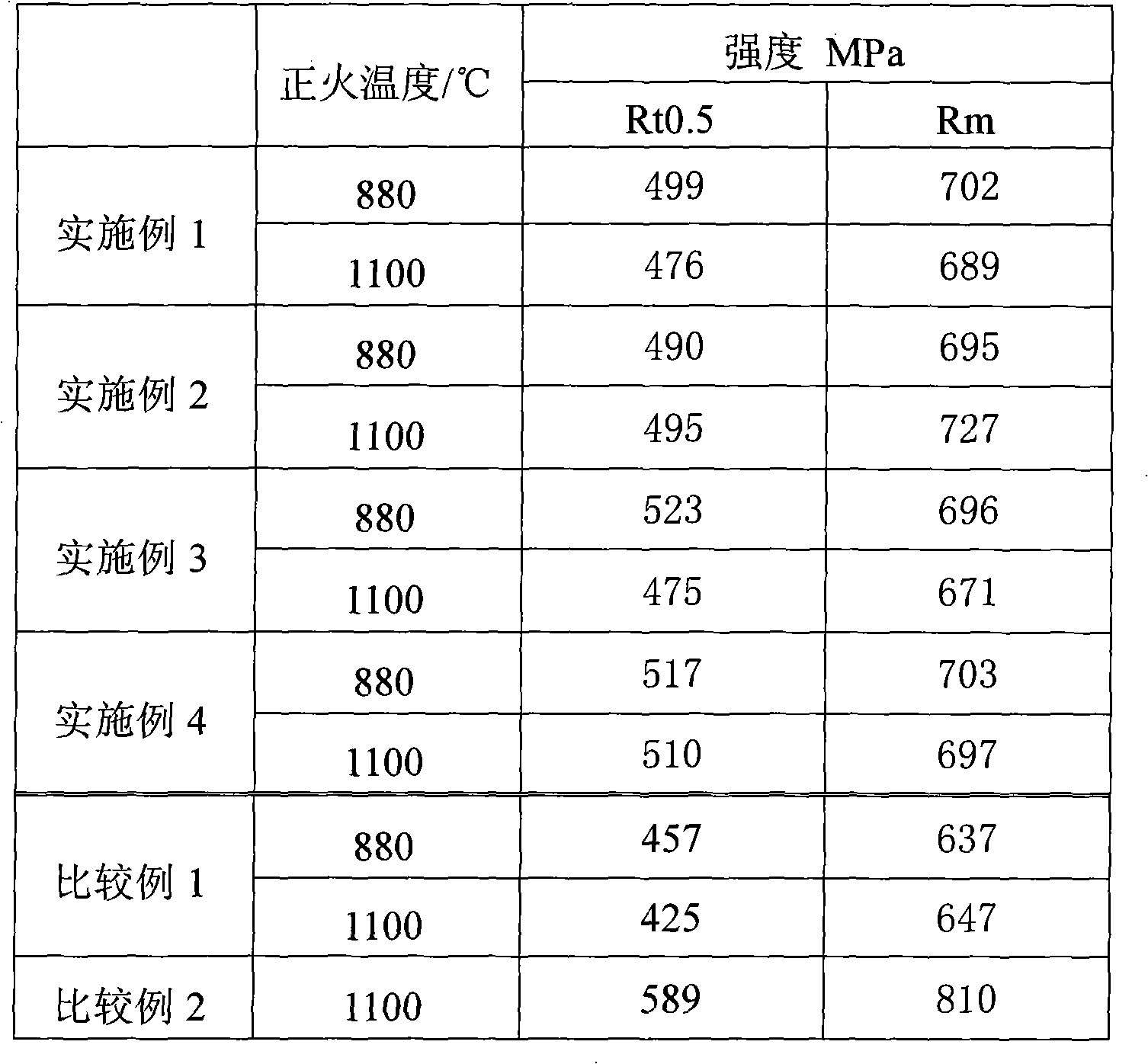

Steel used for straight seam electric resistance welding petroleum casing and casing manufacturing method

ActiveCN101798654AHigh strengthImprove toughnessFurnace typesProcess efficiency improvementWeld seamElectric resistance welding

The invention relates to a steel used for straight seam electric resistance welding petroleum casing and a casing manufacturing method, which is applied to a straight seam electric resistance welding petroleum casing used for an oil and gas well in petroleum and gas industry. The steel used for the straight seam electric resistance welding petroleum casing comprises the following components in percentage by mass: 0.15-0.28% of C, 1.0-1.6% of Mn, 0.2-0.4% of Si, 0. 02-0.06% of Al, less than or equal to 0.01% of P, less than or equal to 0.005% of S, less than or equal to 0.008% of N, 0.001-0.005% of Ca and the balance of Fe. The preparation method comprises the steps of: preparing hot-rolled plate coils, producing straight seam electric resistance welding steel pipes by the hot-rolled plate coils, carrying out welding seam normalization or overall normalization on the welded steel pipes, straightening and cutting the normalized or tempered welded steel pipes into pipe segments with the length of 10-12m, and processing API standard screw threads. The invention has the advantages that the steel has good strength and toughness, the welding seam has no defect, and the properties of the steel are uniform with those of mother material. The yield strength is greater than or equal to 380-760MPa, the tensile strength is greater than or equal to 520-865MPa, the elongation is greater than or equal to 20%, and the impact energy of a room-temperature transverse full-size V-shaped notch is greater than or equal to 40J.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

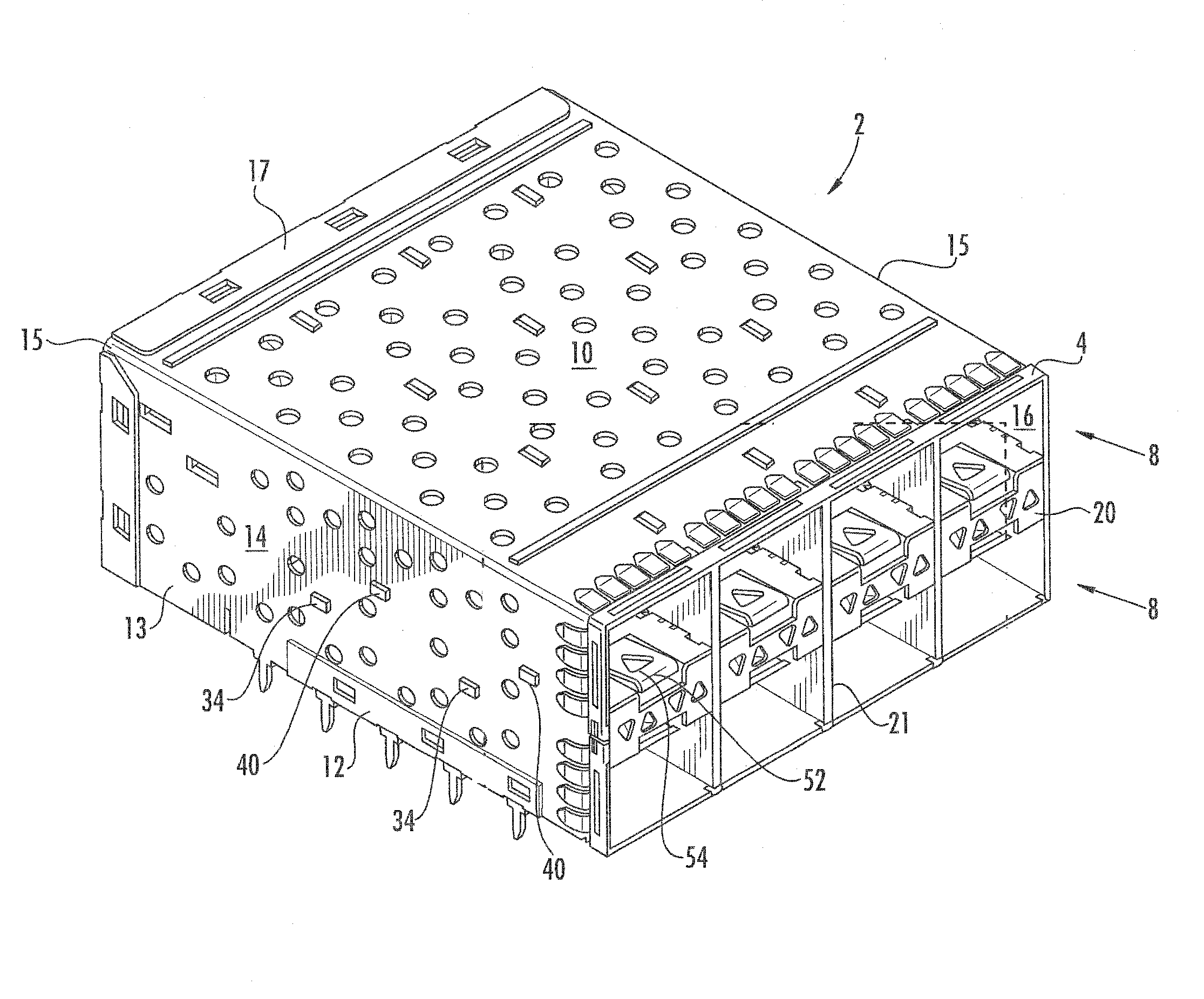

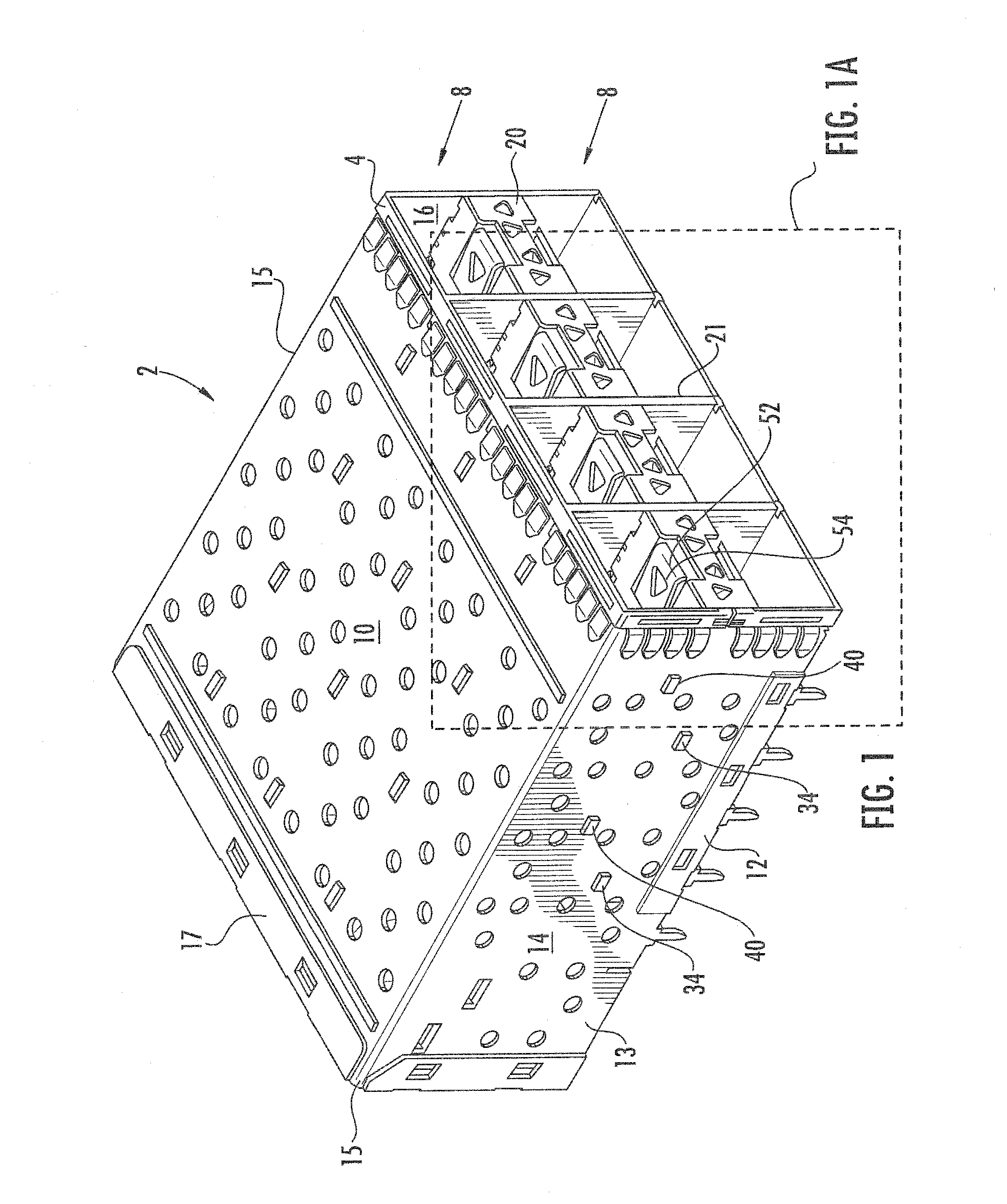

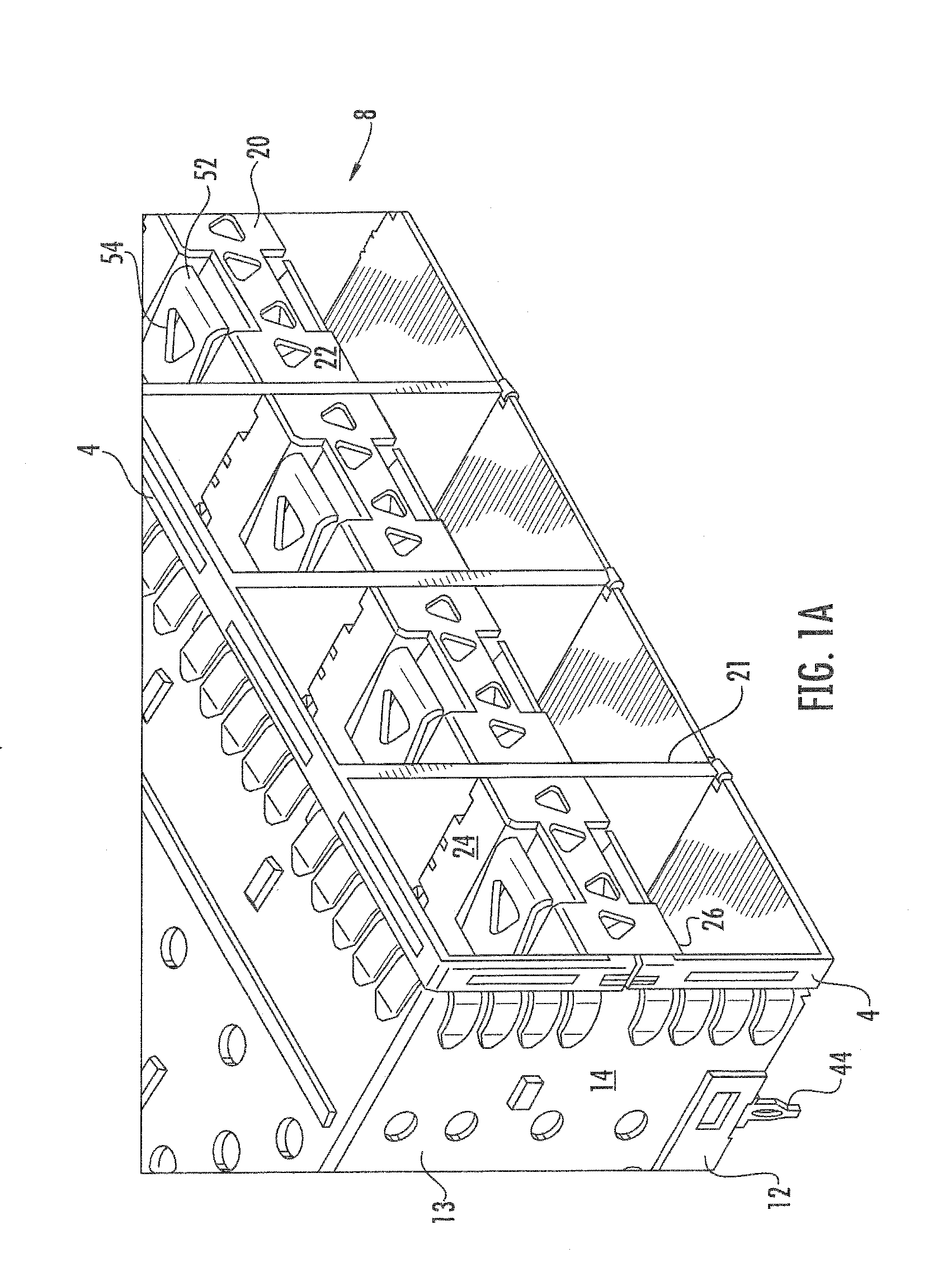

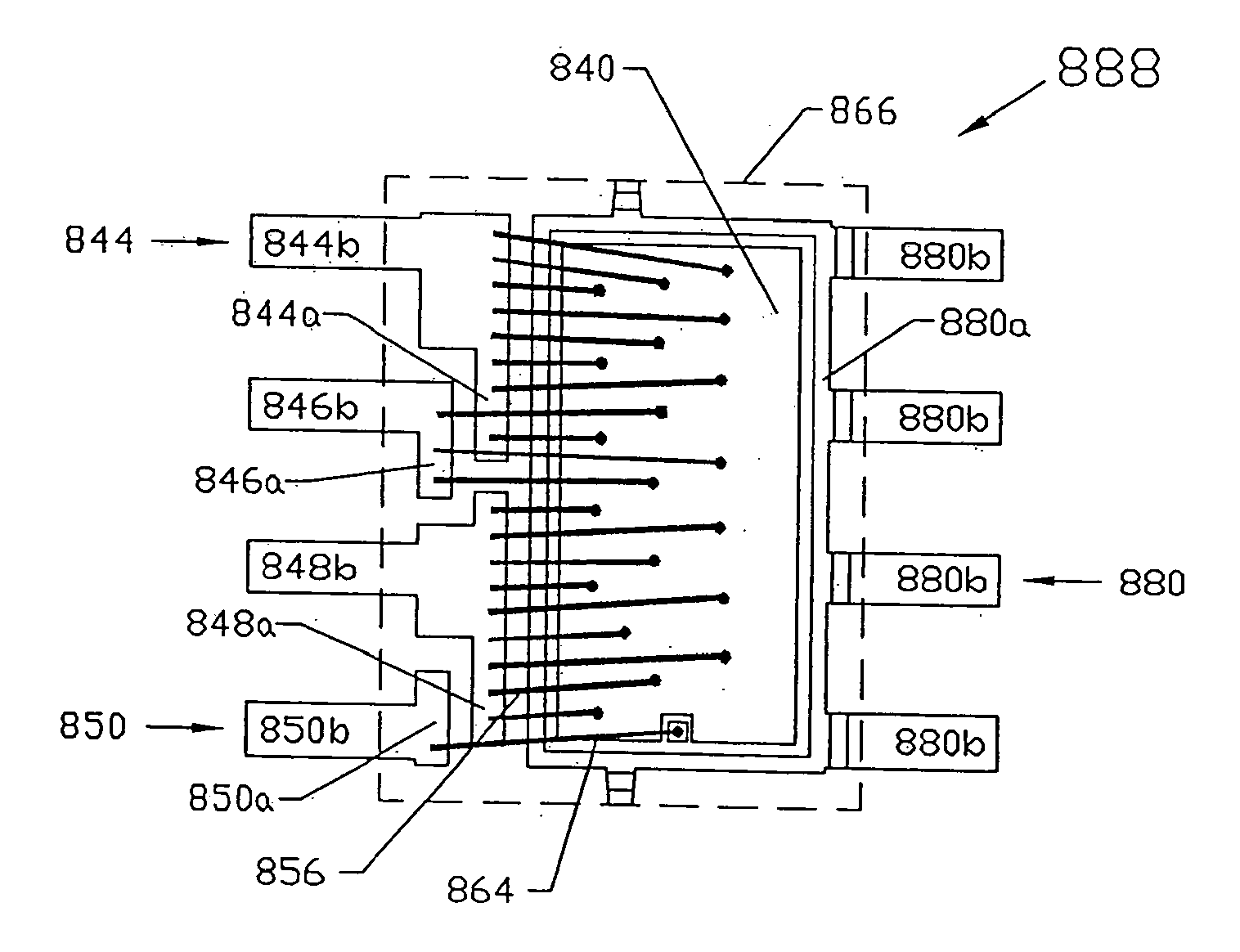

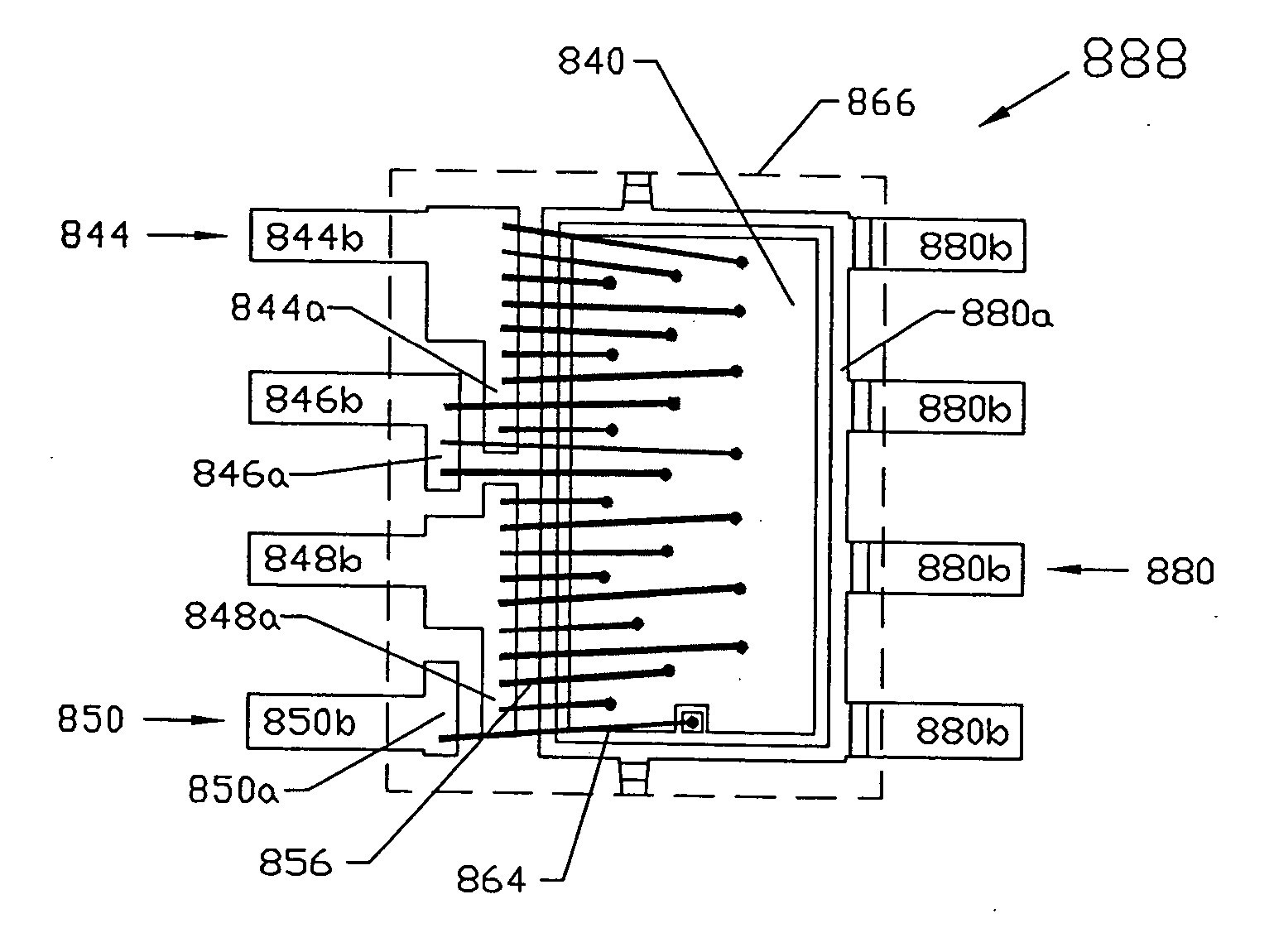

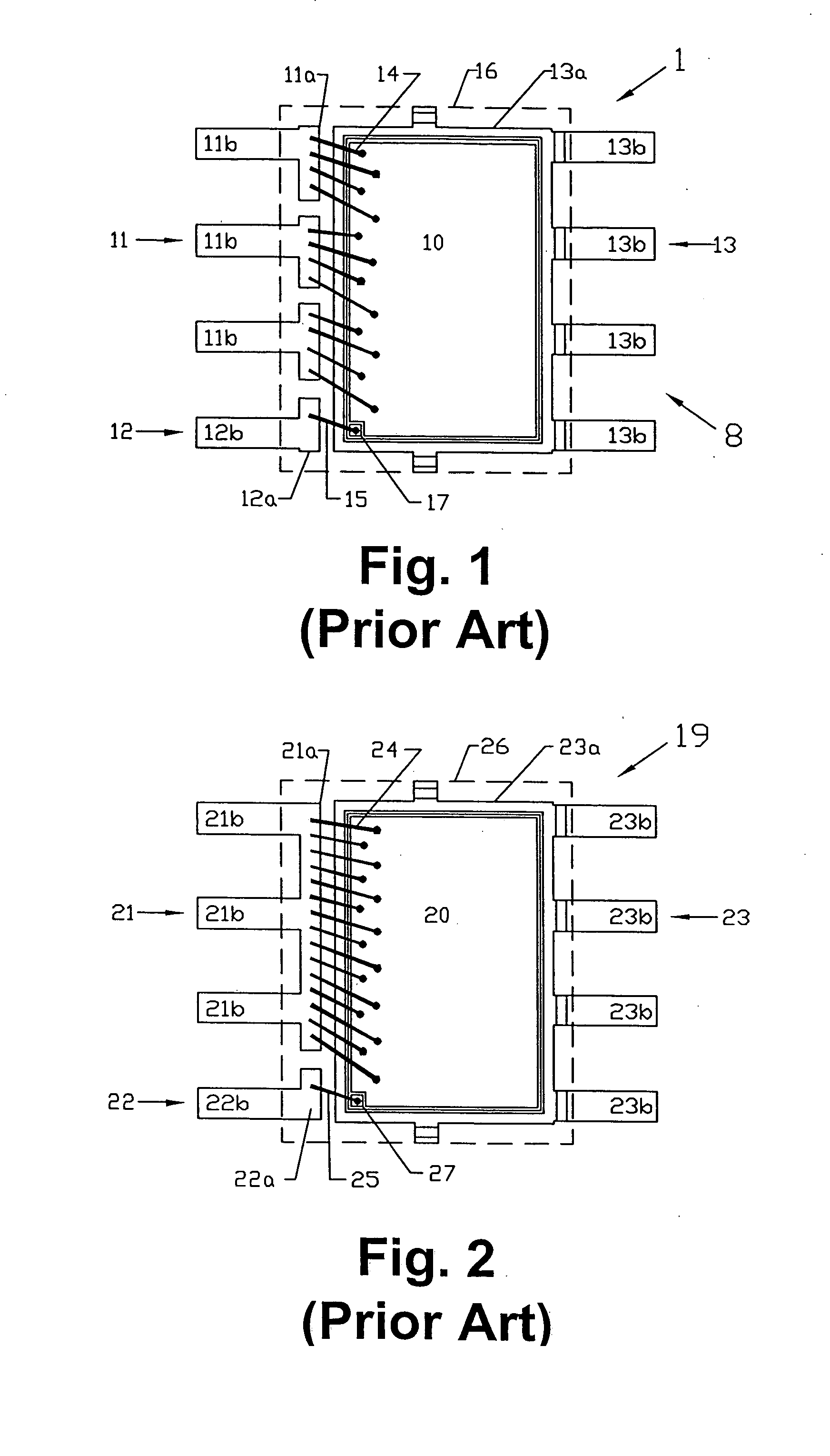

Connector shielding apparatus and methods

ActiveUS20100151733A1Improve EMI performanceLow costElectrically conductive connectionsContact member cases/bases manufactureElectrical resistance and conductanceElectrical connection

An electrical connector assembly having shielded cage assembly with at least one port for receiving modules, and methods of manufacture and use thereof. In one embodiment, the modules comprise SFP-type (small form-factor pluggable) modules, and the shielded cage assembly comprises an EMI shield member that is disposed at a port opening for the electrical connector assembly. In one variant, the EMI shield member can be disposed on the electrical connector cage assembly without the need for secondary processing techniques such as soldering, or resistance welding. This is accomplished via for example the utilization of mechanical snap features.

Owner:CANTOR FITZGERALD SECURITIES

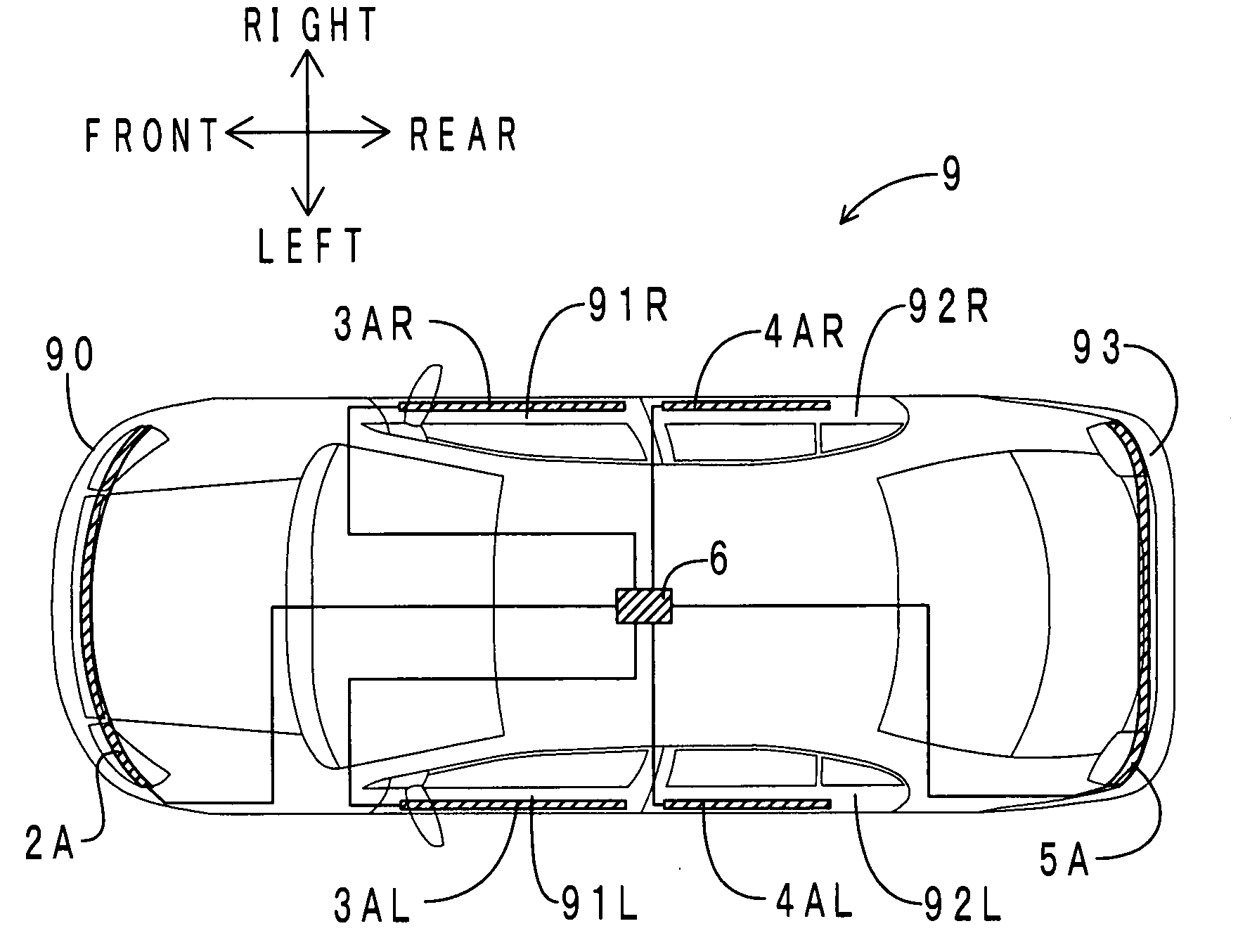

Deformation sensor

InactiveUS20080100046A1CompatibilityImprove compatibilityPedestrian/occupant safety arrangementForce measurementElastomerFilling rate

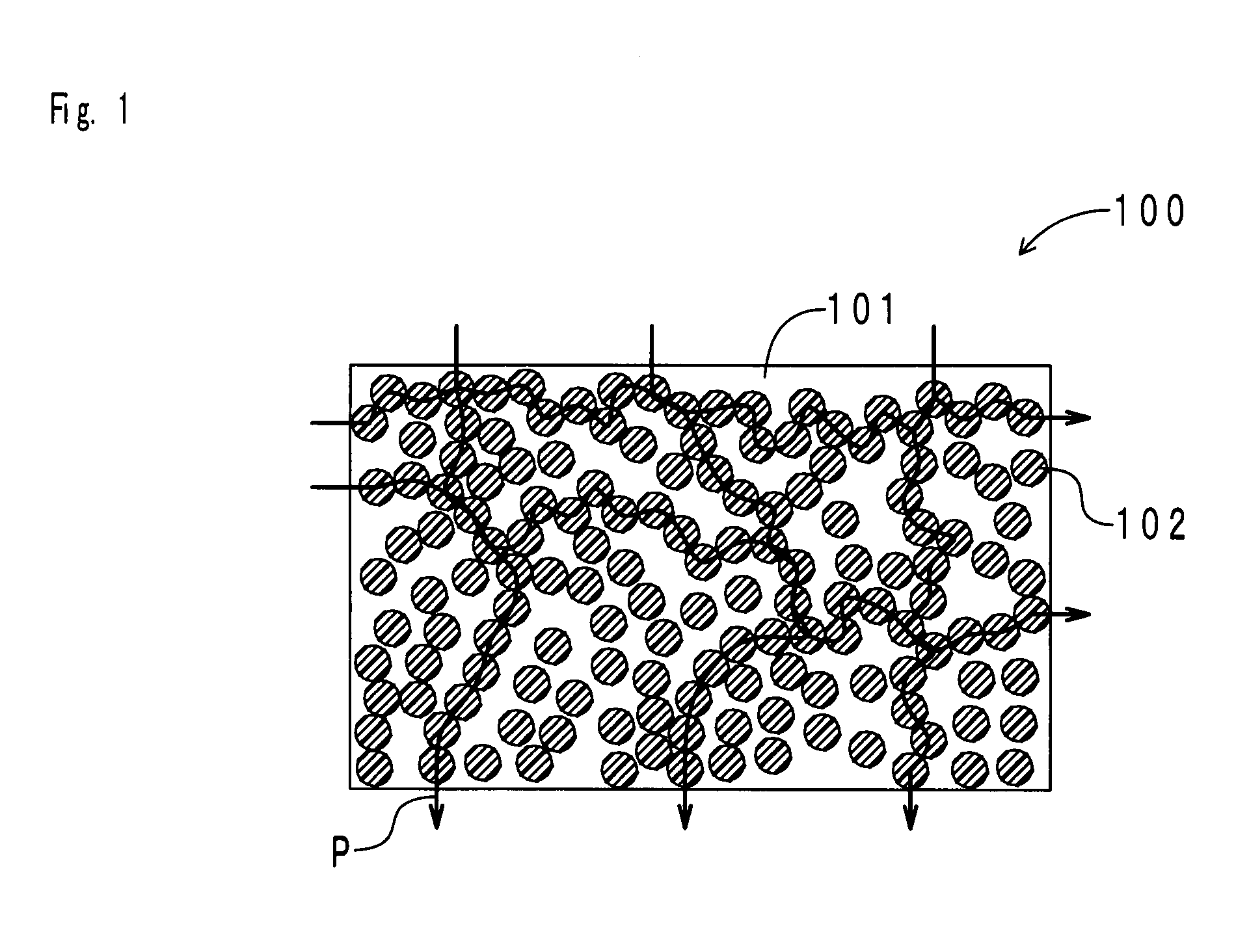

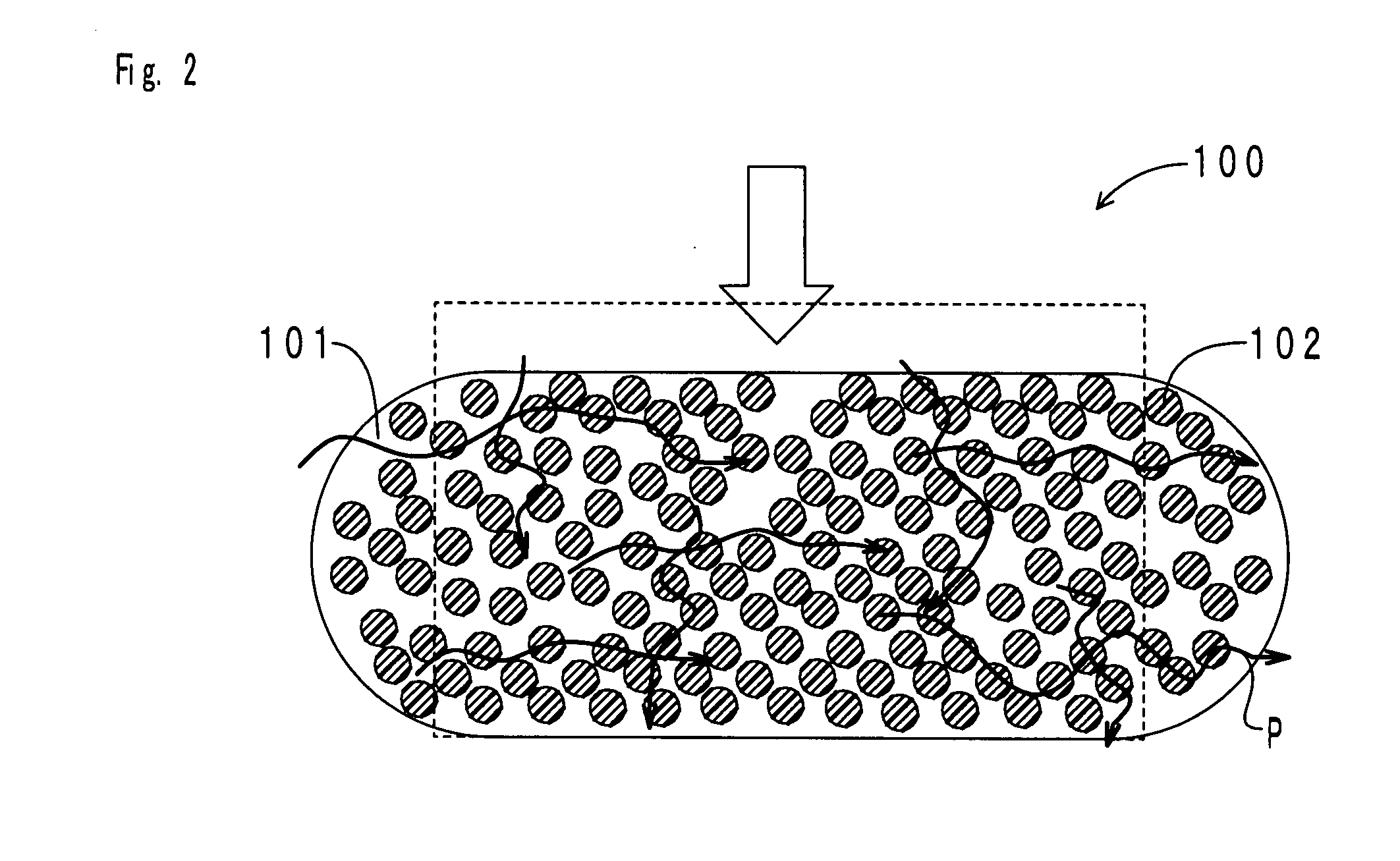

A first deformation sensor is arranged in a shock transmission member which is built in a vehicle and which constitutes a transmission path of a shock applied from the outside. A second deformation sensor is arranged in an exterior member which is exposed to the outside of a vehicle. Each of the first and second deformation sensors comprises a main body of sensor which has an elastomer and spherical conductive fillers blended in the elastomer in an approximately single particle state and with a high filling rate, and in which an electric resistance increases as an elastic deformation increases, and an electrode which is connected with the main body of sensor and is able to output the electric resistance.

Owner:SUMITOMO RIKO CO LTD

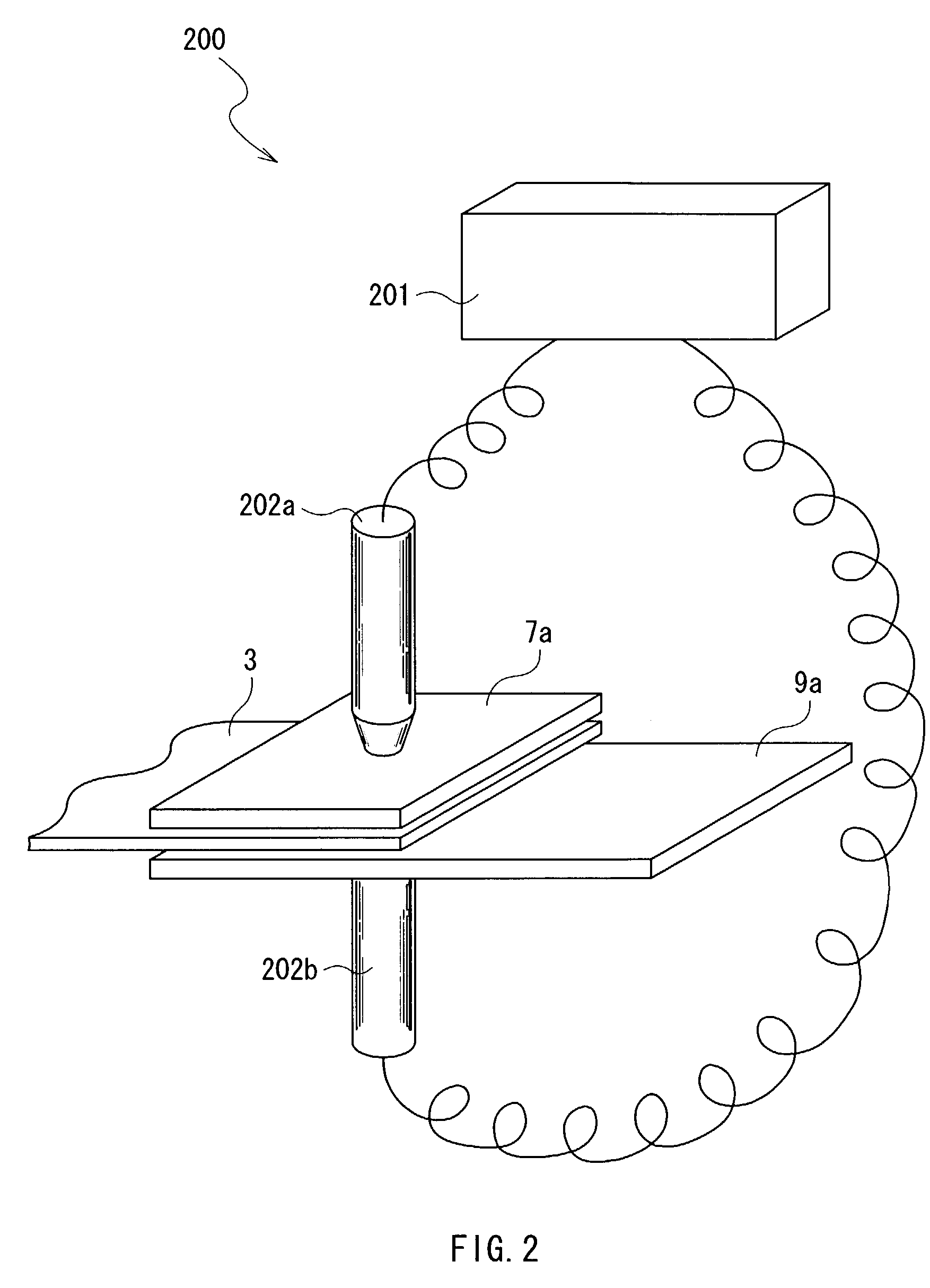

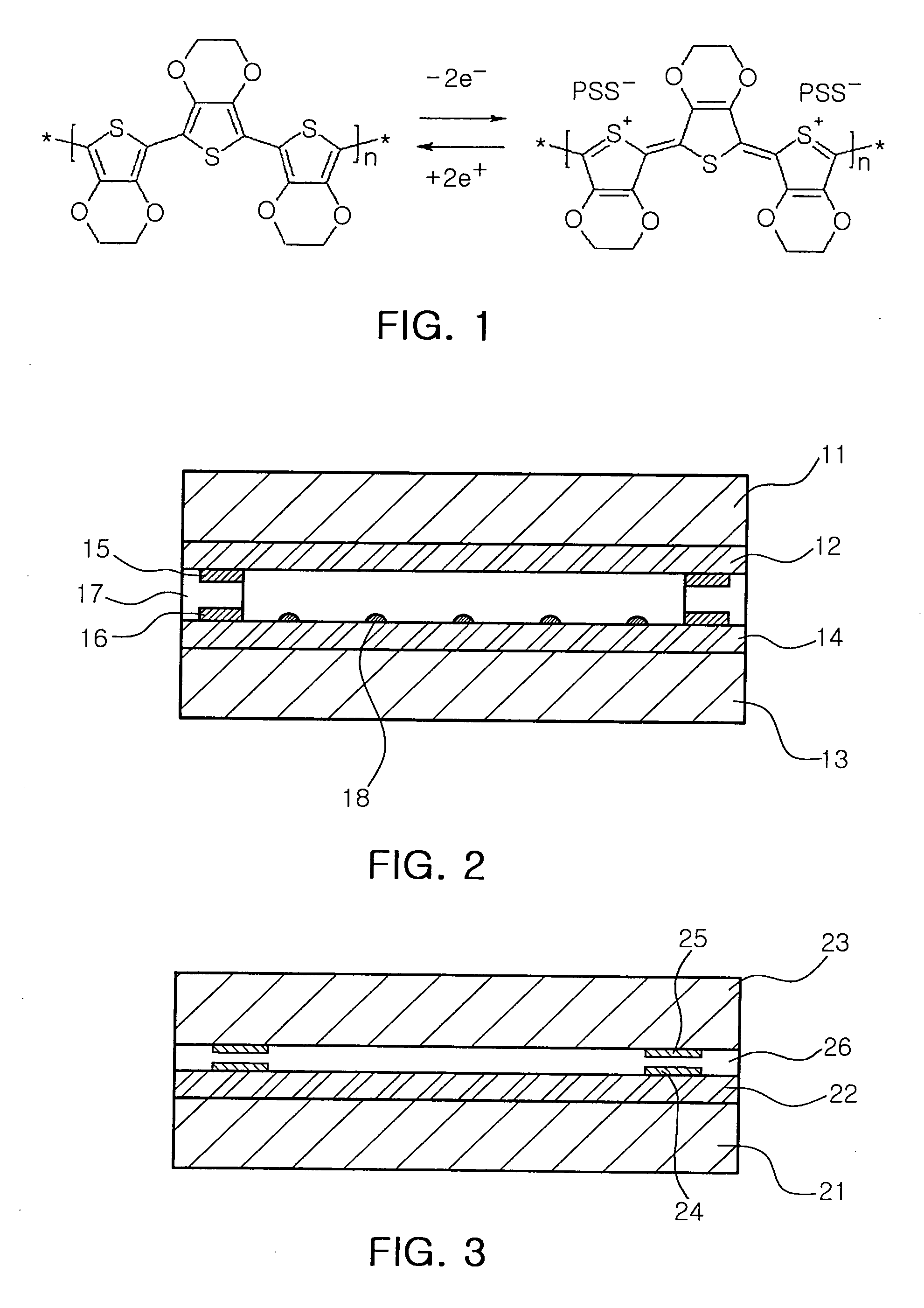

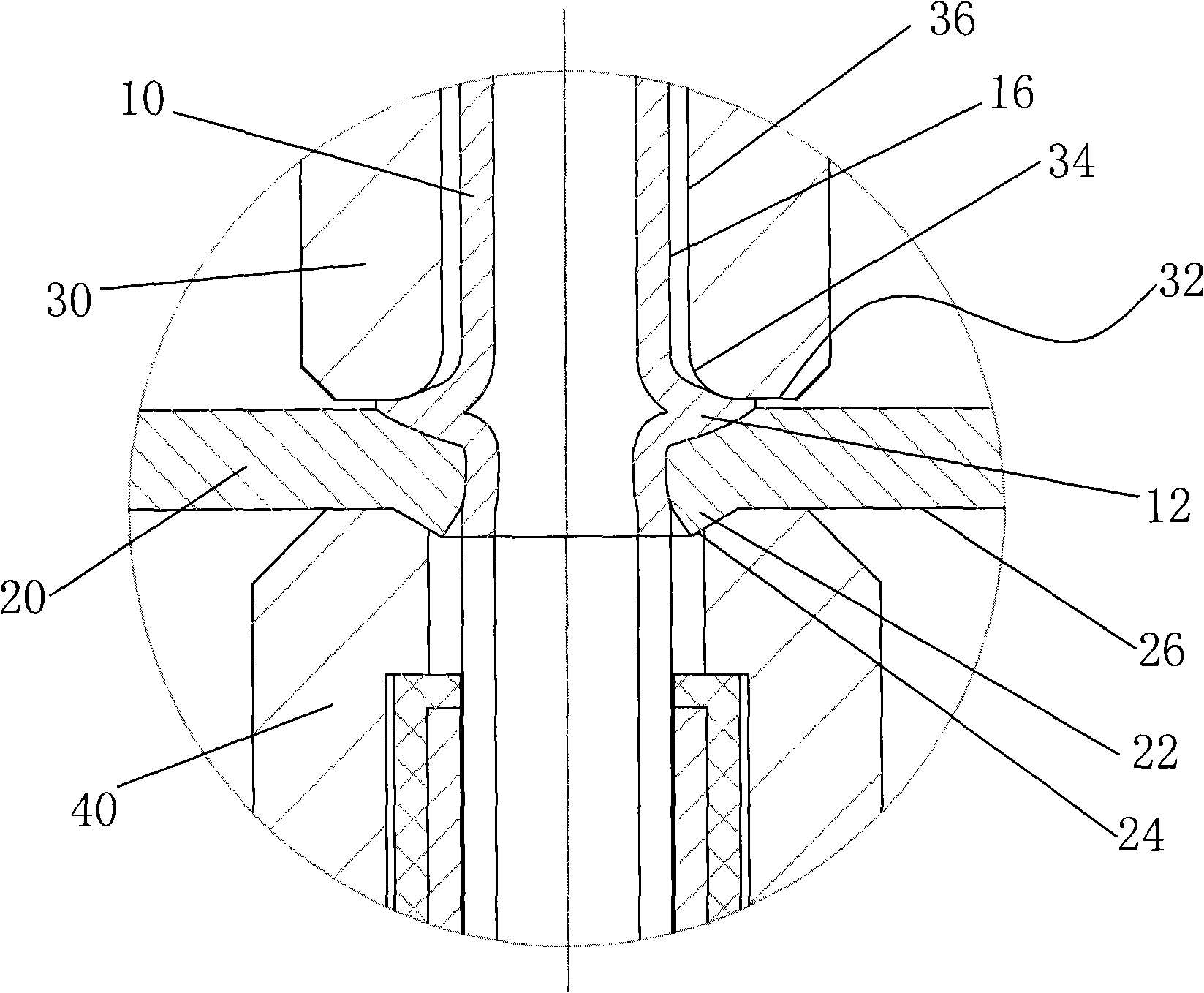

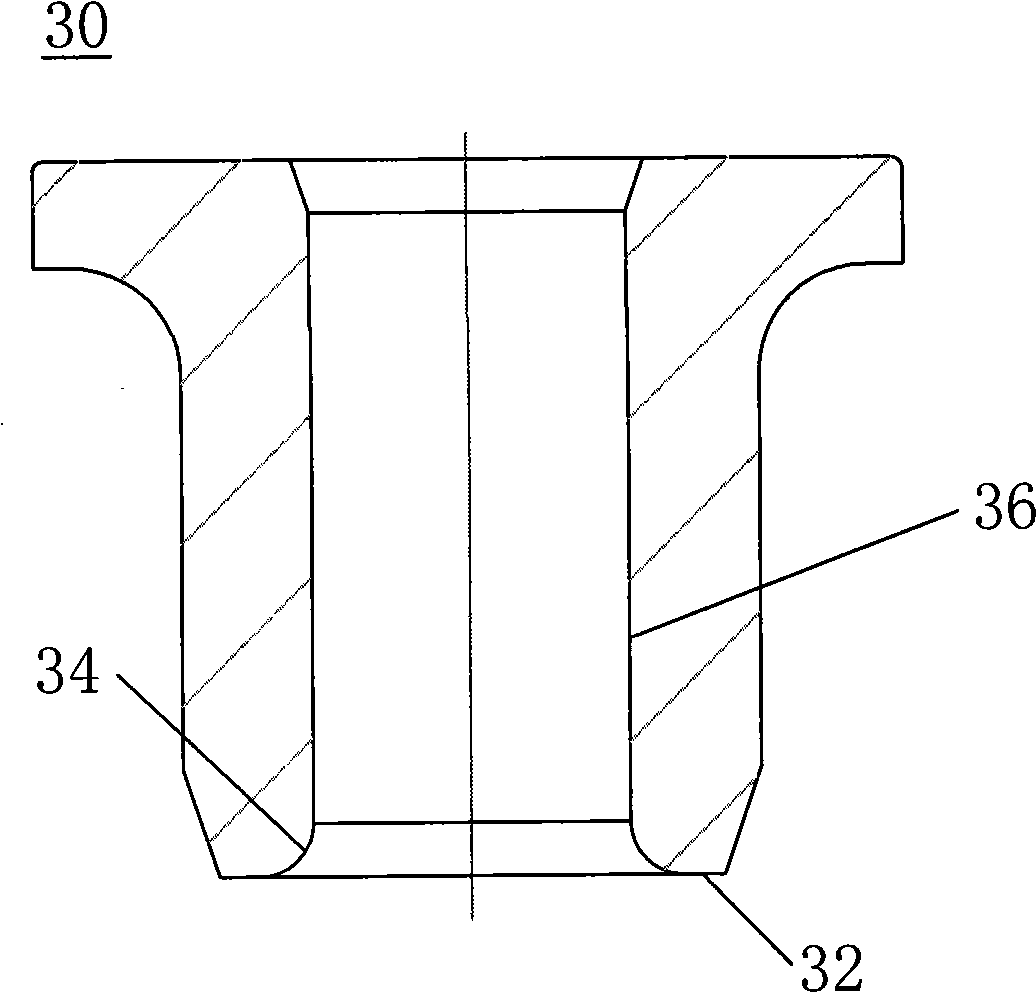

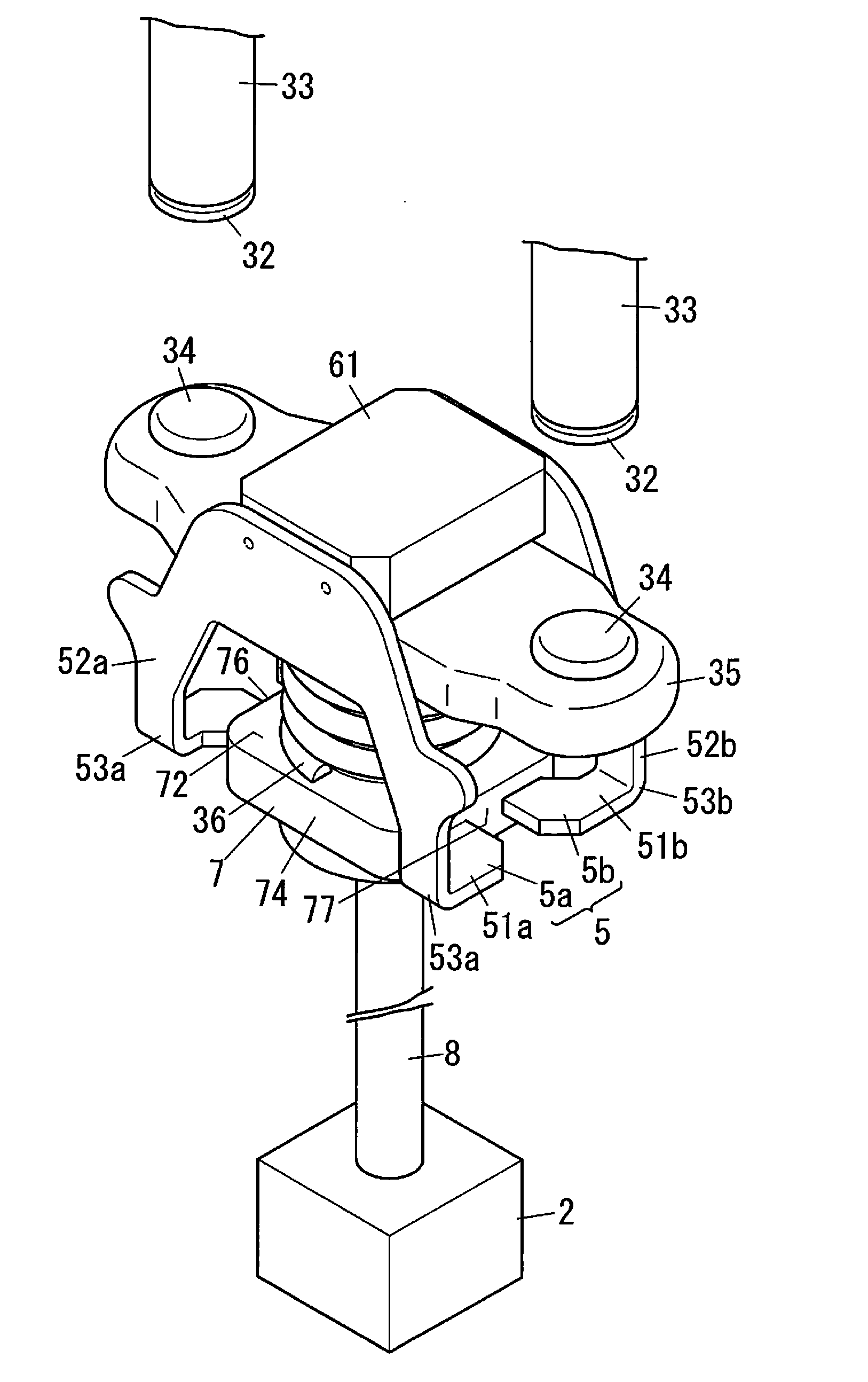

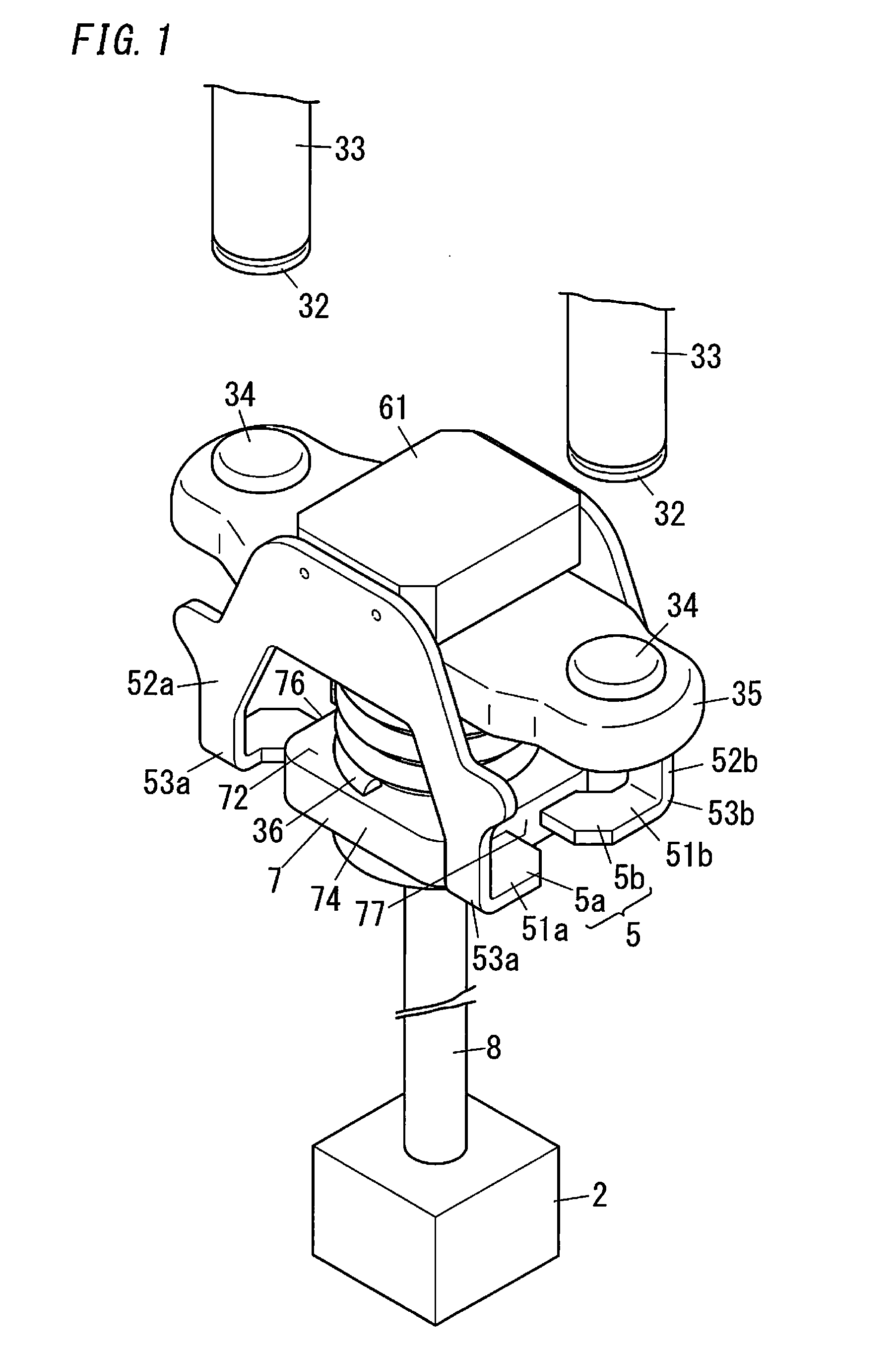

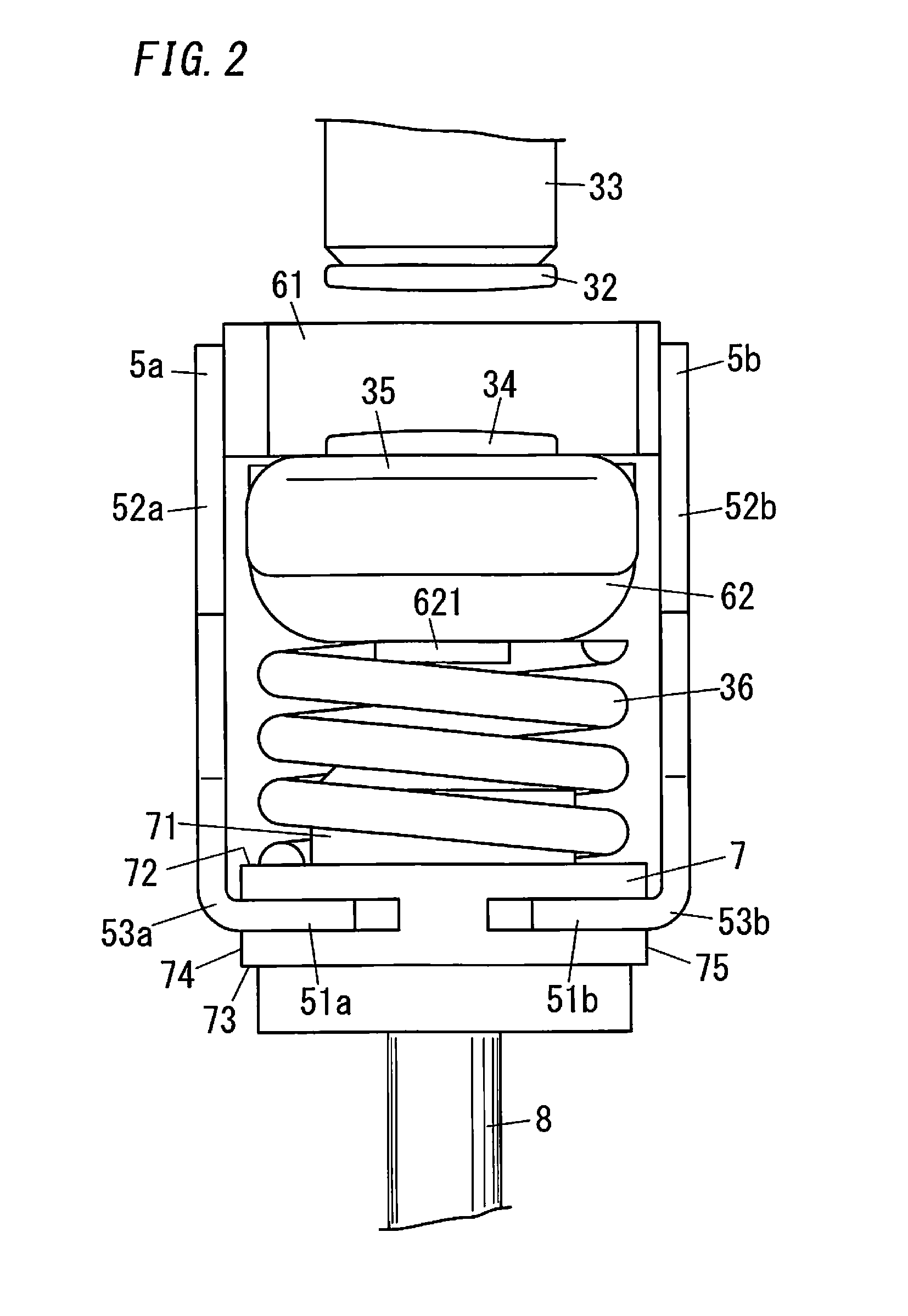

Cell, cell production method, welded article production method and pedestal

InactiveUS7037621B2Easy to weldImprove reliabilityFinal product manufactureActive material electrodesLithiumElectrical resistance and conductance

Owner:MURATA MFG CO LTD

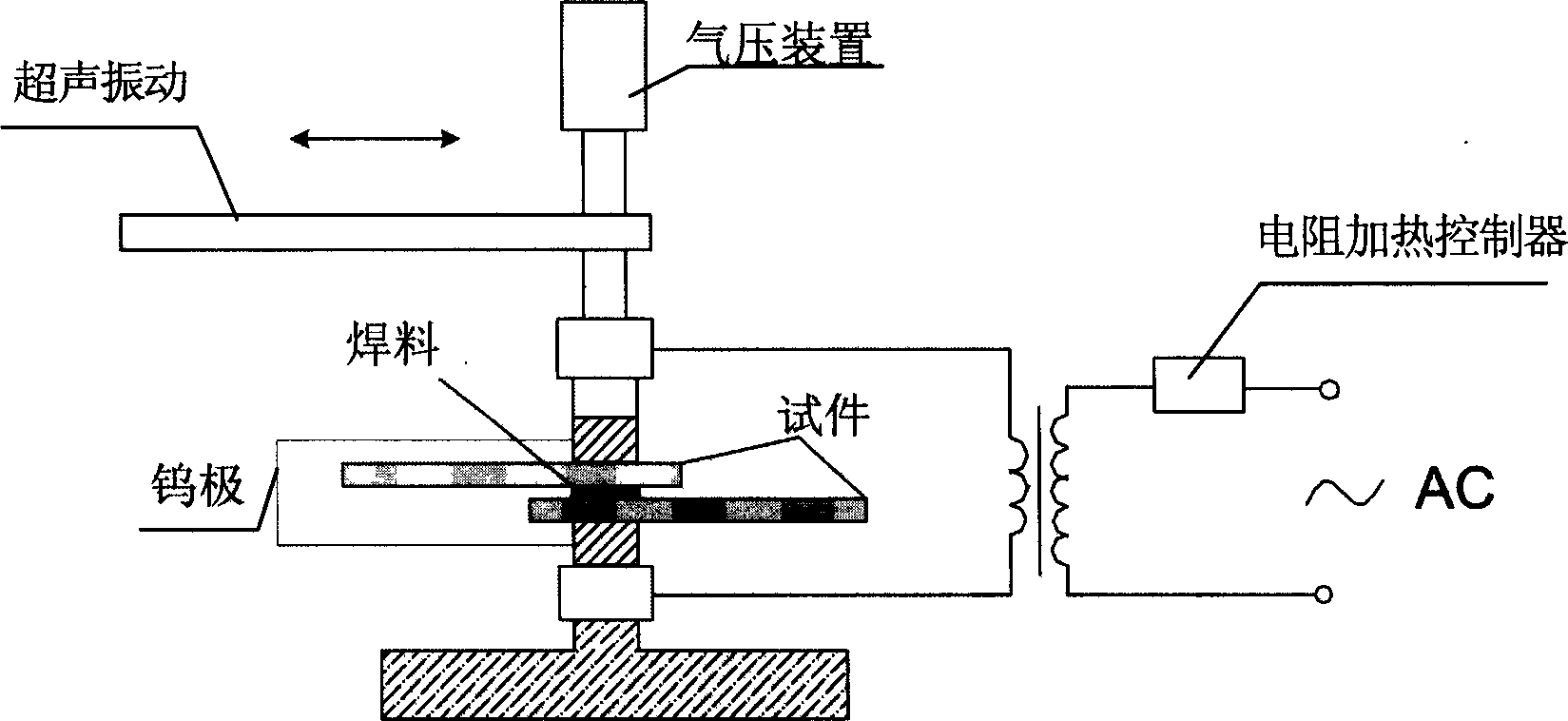

Aluminium base composite material ultra sonic electrical resistance welding method

InactiveCN1686659AEasy to operateStrong designWelding apparatusElectrical resistance and conductanceMegasonic cleaning

An ultrasonic-resistance welding method for the Al-based composition includes grinding the surfaces of Al-based compositions, ultrasonic cleaning, putting the flux between two surfaces to be welded, heating by electric resistance, decreasing the thickness of liquid film between two surfaces, ultrasonic vibrating, pressing and natural cooling.

Owner:HARBIN INST OF TECH

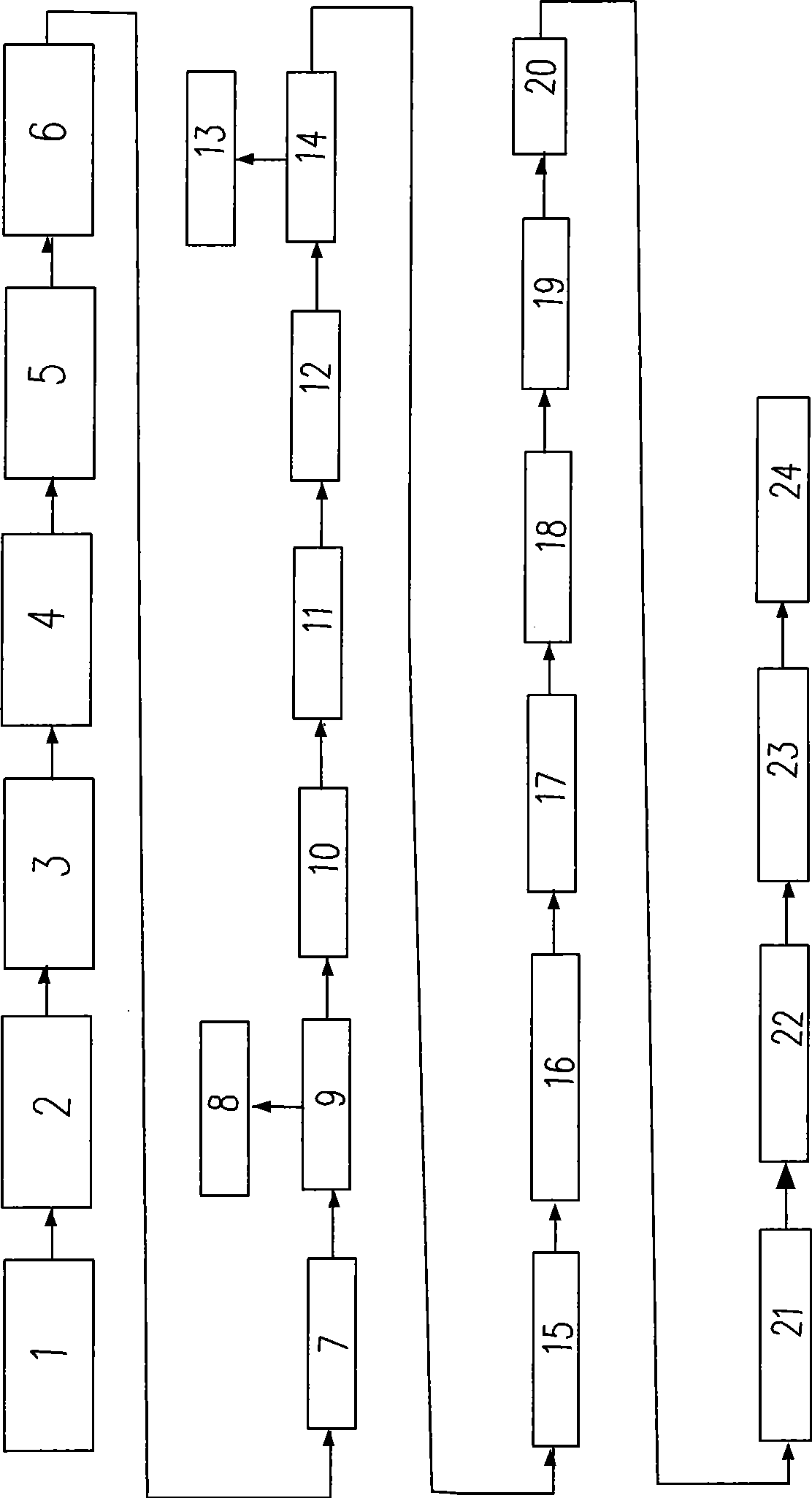

High intensity straight-line joint pipeline steel tube fabrication technique using high-frequency electric resistance welding

InactiveCN101474644AHigh geometric accuracy of appearanceImprove mechanical propertiesHigh frequency current welding apparatusManufacturing technologyPerformance index

The invention relates to the manufacturing technical field of steel pipes for long-distance transport pipes for petroleum, natural gas, mineral powder and the like, in particular to a pipeline steel pipe manufacturing technology employing straight high-frequency resistance welding. Raw materials meeting requirements are purchased, wherein, the requirements comprise physical properties, chemical compositions and mechanical properties of the raw materials. The raw materials are inspected to determine whether the physical properties, the chemical compositions and the mechanical properties meet the requirements. The technology comprises steel pipe manufacturing preparation, determination of production line moulding process parameters, determination of welding process parameters and determination of auxiliary material parameters. The pipeline steel pipe manufacturing technology employing the straight high-frequency resistance welding can help manufacture 632.2X11.1-60 pipeline steel pipes, various performance indexes of the steel pipes meet the requirements of pipeline steel pipes (USA API SPEC 5L PSL2 44 Standard), the heights of an inside seam and an outside seam are identical with the pipe wall of a parent material, and the technology perfectly solves the engineering anti-corrosive difficulties. The straight high-frequency pipeline pipe manufacturing technology has the advantages of high manufacturing efficiency, fast speed and low cost.

Owner:中冶辽宁德龙钢管有限公司

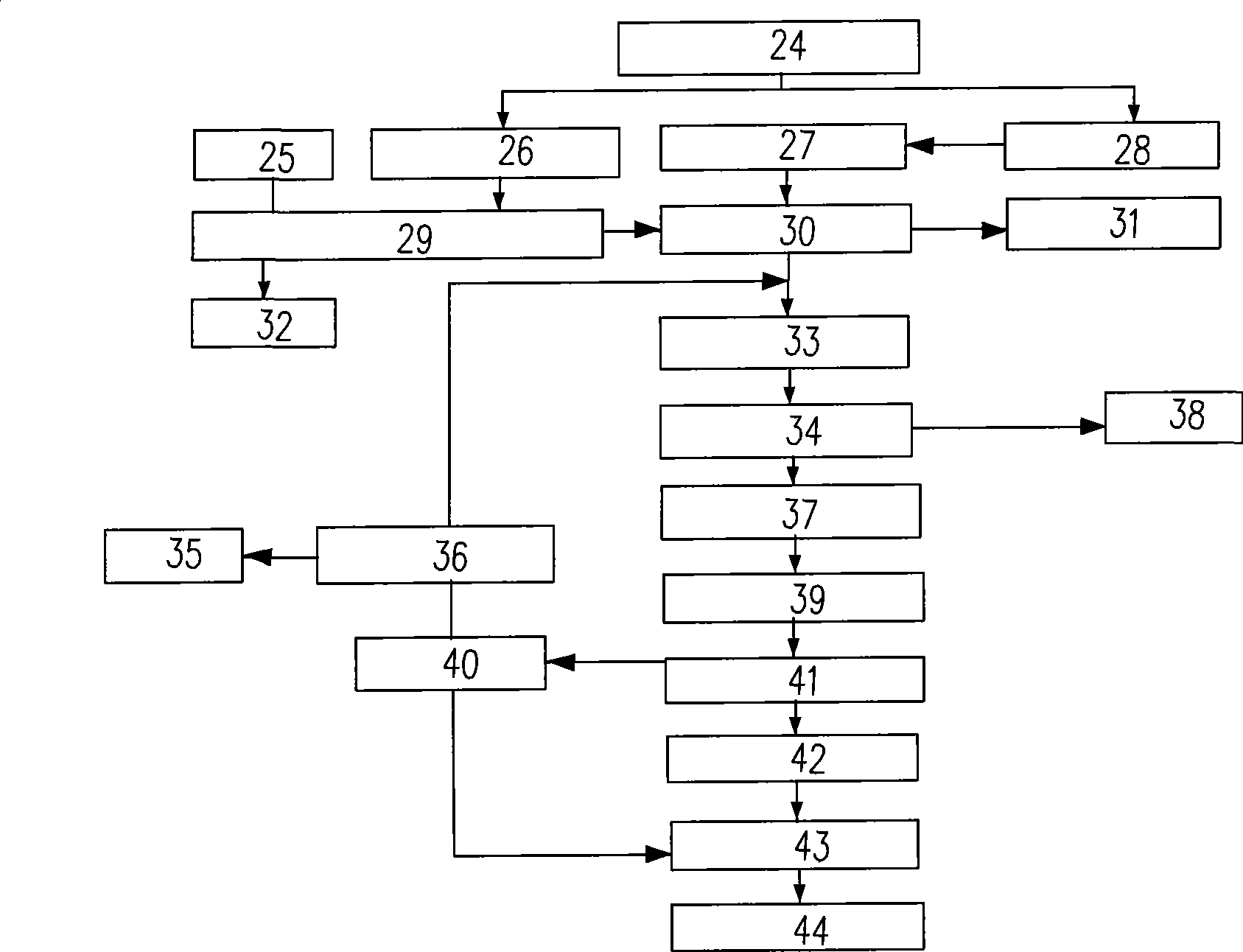

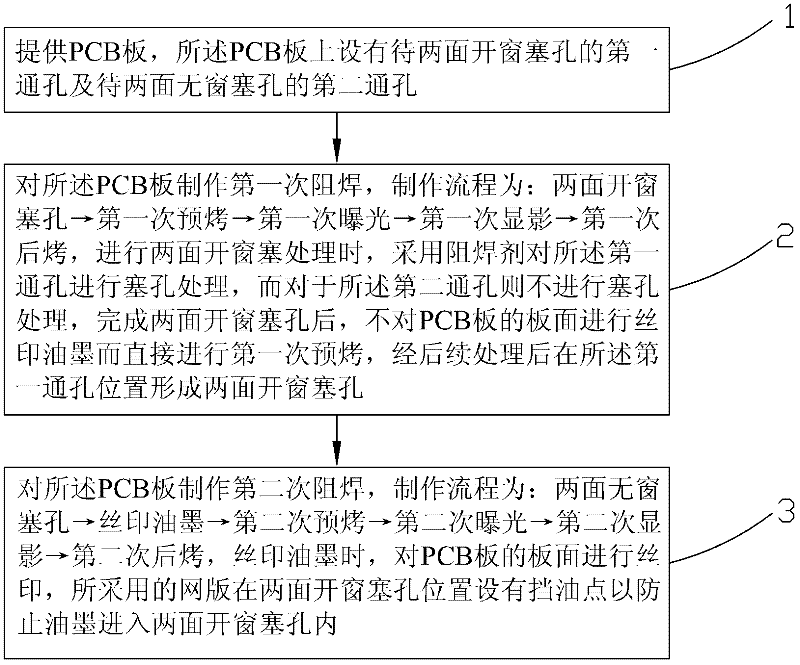

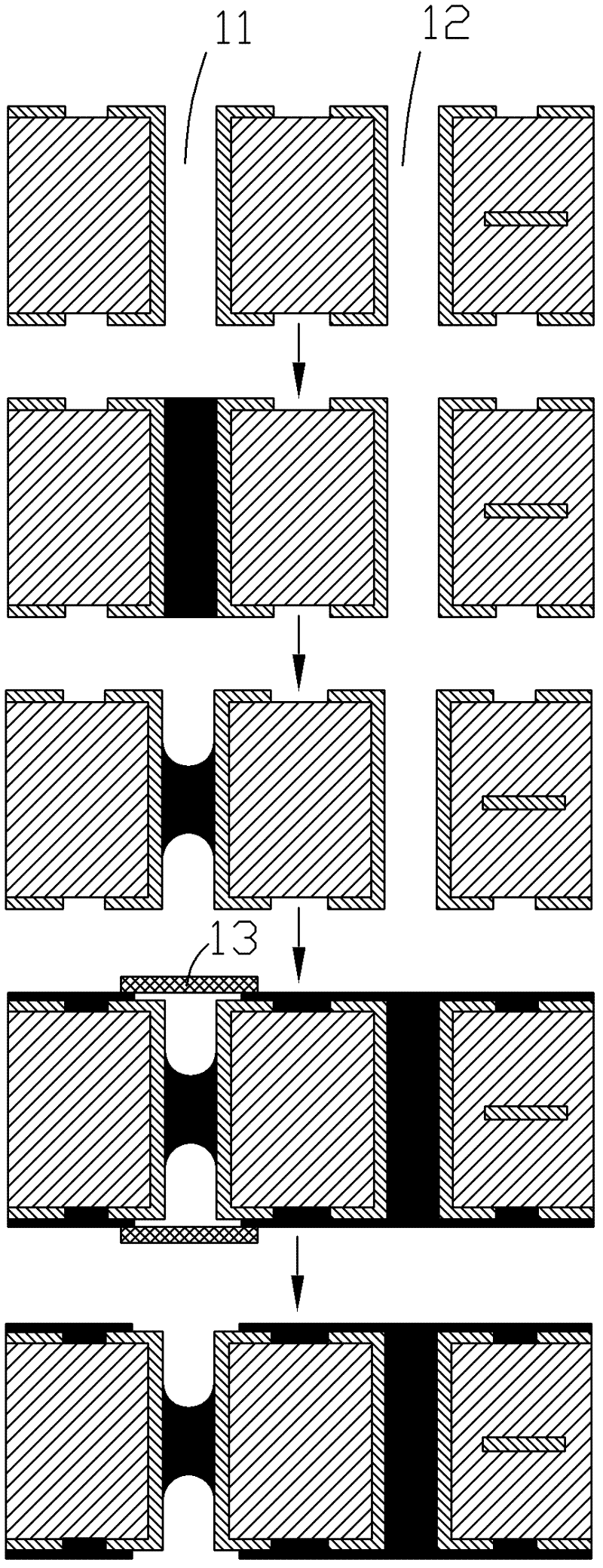

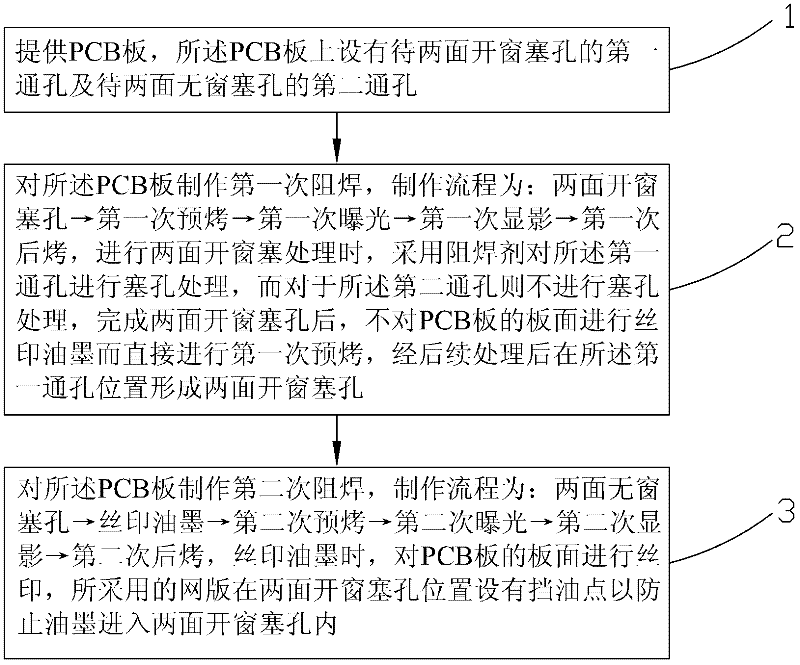

Method for manufacturing window plug holes at two sides during PCB (Printed Circuit Board) resistance welding

The invention relates to a method for manufacturing window plug holes at two sides during PCB (Printed Circuit Board) resistance welding, comprising the following steps of: firstly, providing a PCB board, wherein the PCB board is provided with a first through hole to be provided with the window plug holes at the two sides and a second through hole not to be provided with the window plug holes at the two sides; secondly, carrying out primary resistance welding on the PCB board, wherein a manufacturing process comprises the following steps of: manufacturing the window plug holes at the two sides, carrying out primary prebaking, carrying out primary exposing, carrying out primary developing and carrying out primary after baking, and directly carrying out the primary prebaking without carrying out silk screen printing on the panel of the PCB board after the window plug holes are manufactured at the two sides; and thirdly, carrying out secondary resistance welding on the PCB board, whereinthe manufacturing process comprises the following steps of: manufacturing no window plug hole at the two sides, carrying out the silk screen printing, carrying out secondary prebaking, carrying out secondary exposing, carrying out secondary developing and carrying out secondary after baking. In the method for manufacturing the window plug holes at the two sides during PCB resistance welding, an independent plug hole process is adopted for manufacturing the window plug holes at the two sides, and the defects that the plug hole is punched through and oil is spewed can be effectively overcome.

Owner:DONGGUAN SHENGYI ELECTRONICS

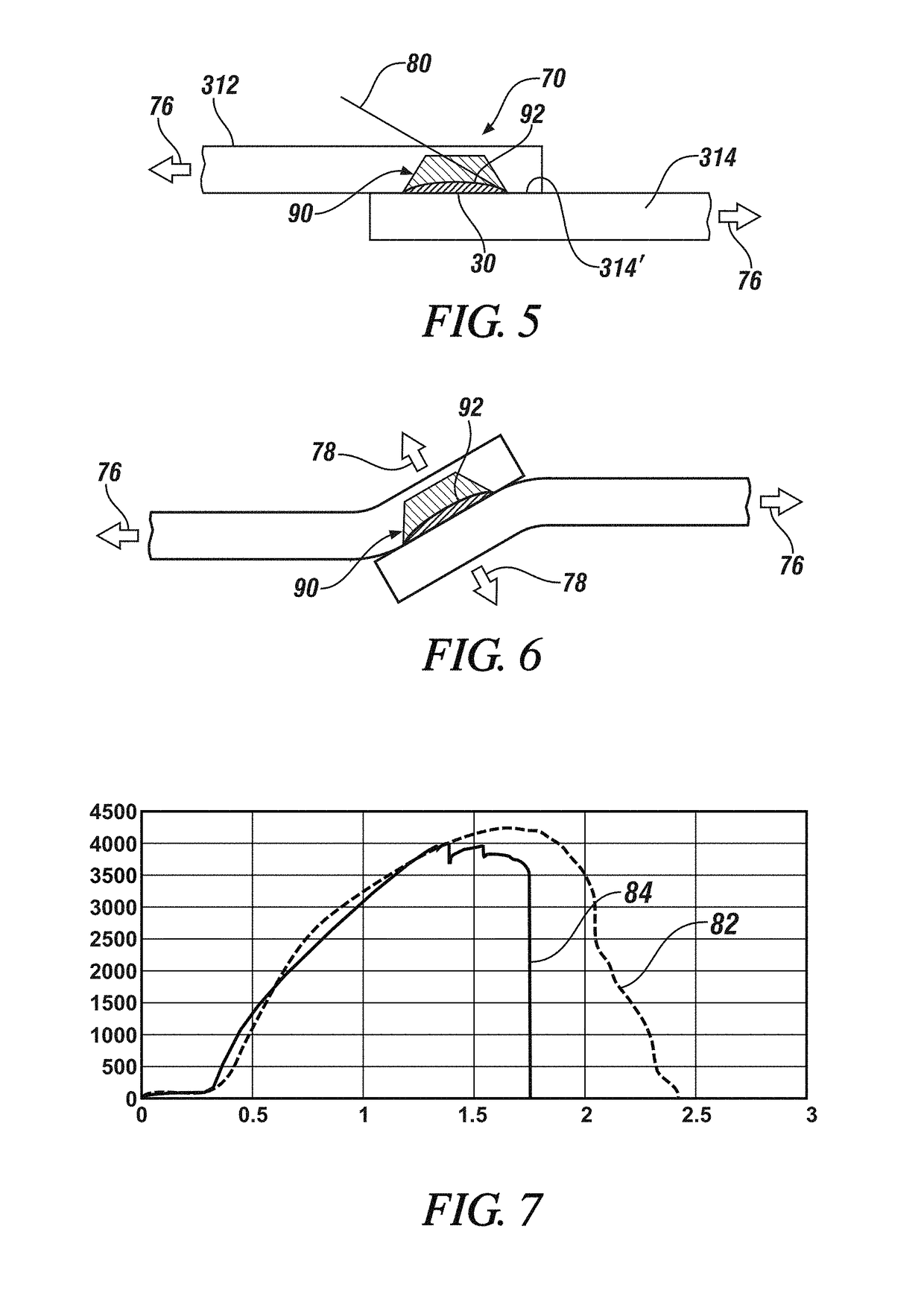

Control of intermetallic compound growth in aluminum to steel resistance welding

ActiveUS20170297136A1Thickness minimizationHigh strengthVehicle componentsWelding/cutting media/materialsManganeseElectric resistance welding

A method of resistance spot welding a workpiece stack-up that includes an aluminum workpiece and an overlapping adjacent steel workpiece so as to minimize the thickness of an intermetallic layer comprising Fe—Al intermetallic compounds involves providing reaction-slowing elements at the faying interface of the aluminum and steel workpieces. The reaction-slowing elements may include at least one of carbon, copper, silicon, nickel, manganese, cobalt, or chromium. Various ways are available for making the one or more reaction-slowing elements available at the faying interface of the aluminum and steel workpieces including being dissolved in a high strength steel or being present in an interlayer that may take on a variety of forms including a rigid shim, a flexible foil, a deposited layer adhered to and metallurgically bonded with a faying surface of the steel workpiece, or an interadjacent organic material layer that includes particles containing the reaction-slowing elements.

Owner:GM GLOBAL TECH OPERATIONS LLC

Projection welded fastener with integral sealer

A fastener is provided for projection resistance welding to a panel. The fastener includes a base having a fastening element, such as a threaded stud or a nut integral therewith. Multiple projections formed integral with the base extend therefrom to engage with the panel to be welded to the panel by electric resistance welding. A groove is provided in the base facing the panel and is filled with a heat activated expandable sealer material. Upon heating of the base during the electric resistance welding, or in an oven, the sealer expands to fill and seal any gap between the base and the panel.

Owner:GM GLOBAL TECH OPERATIONS LLC

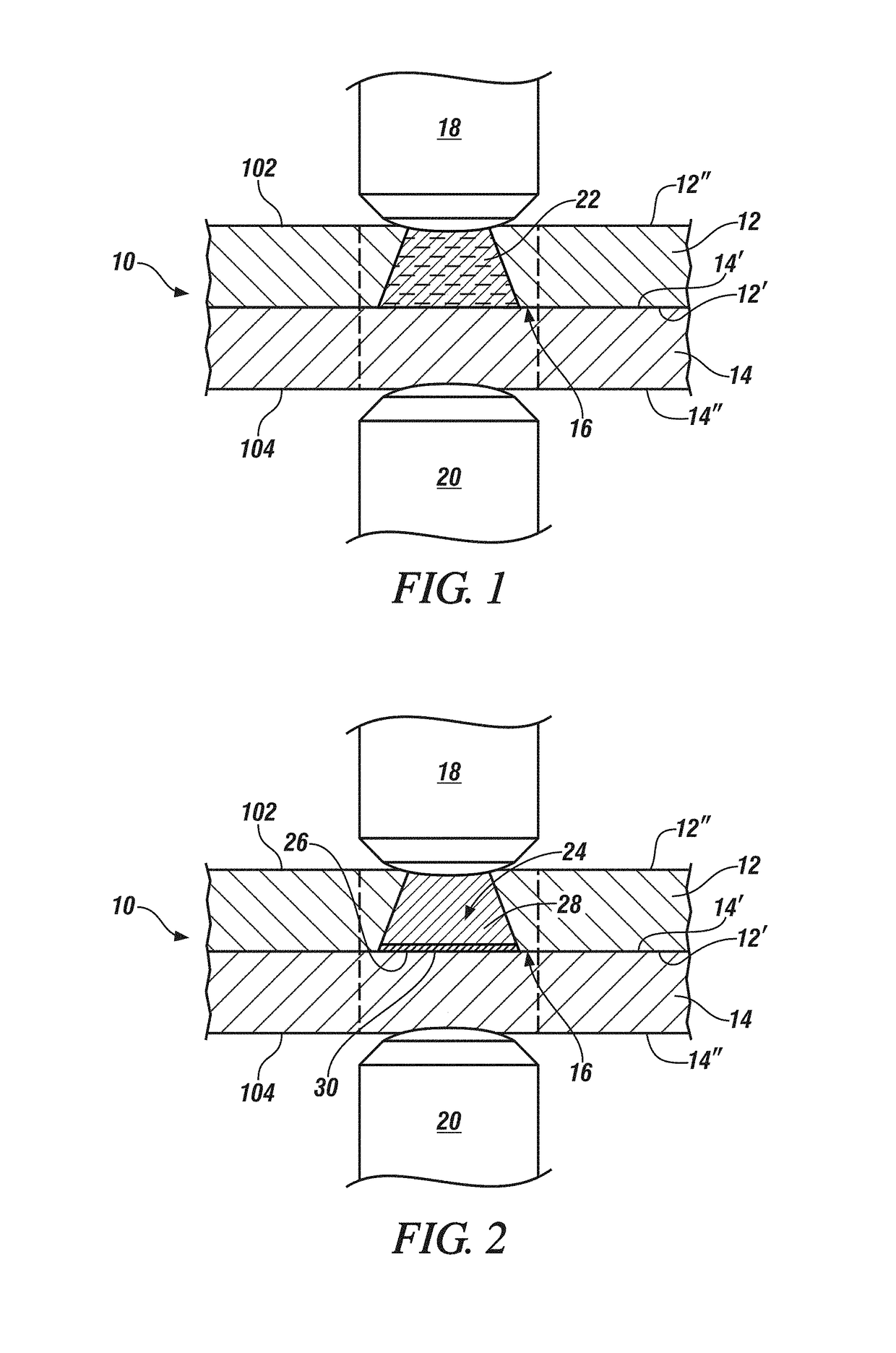

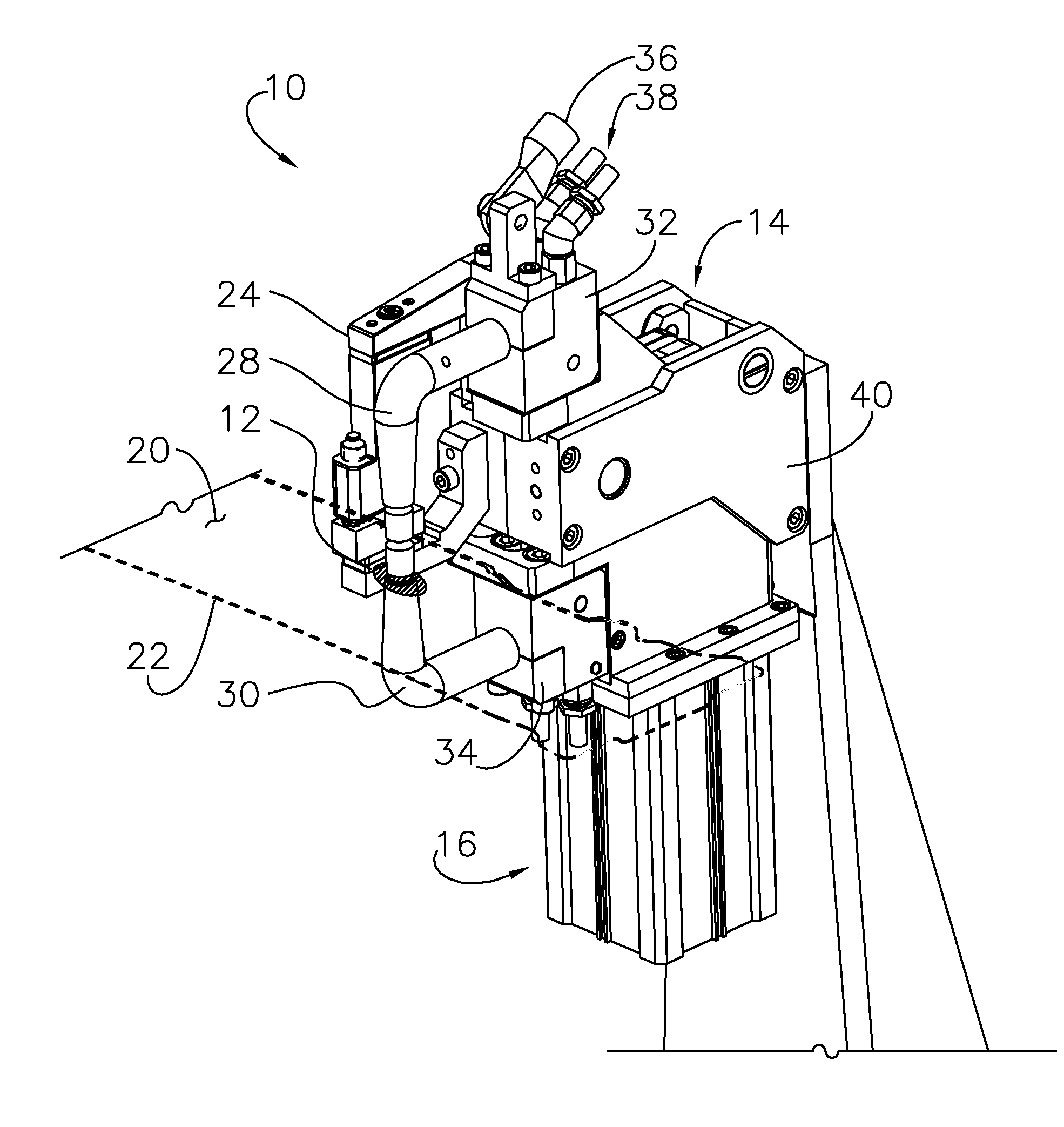

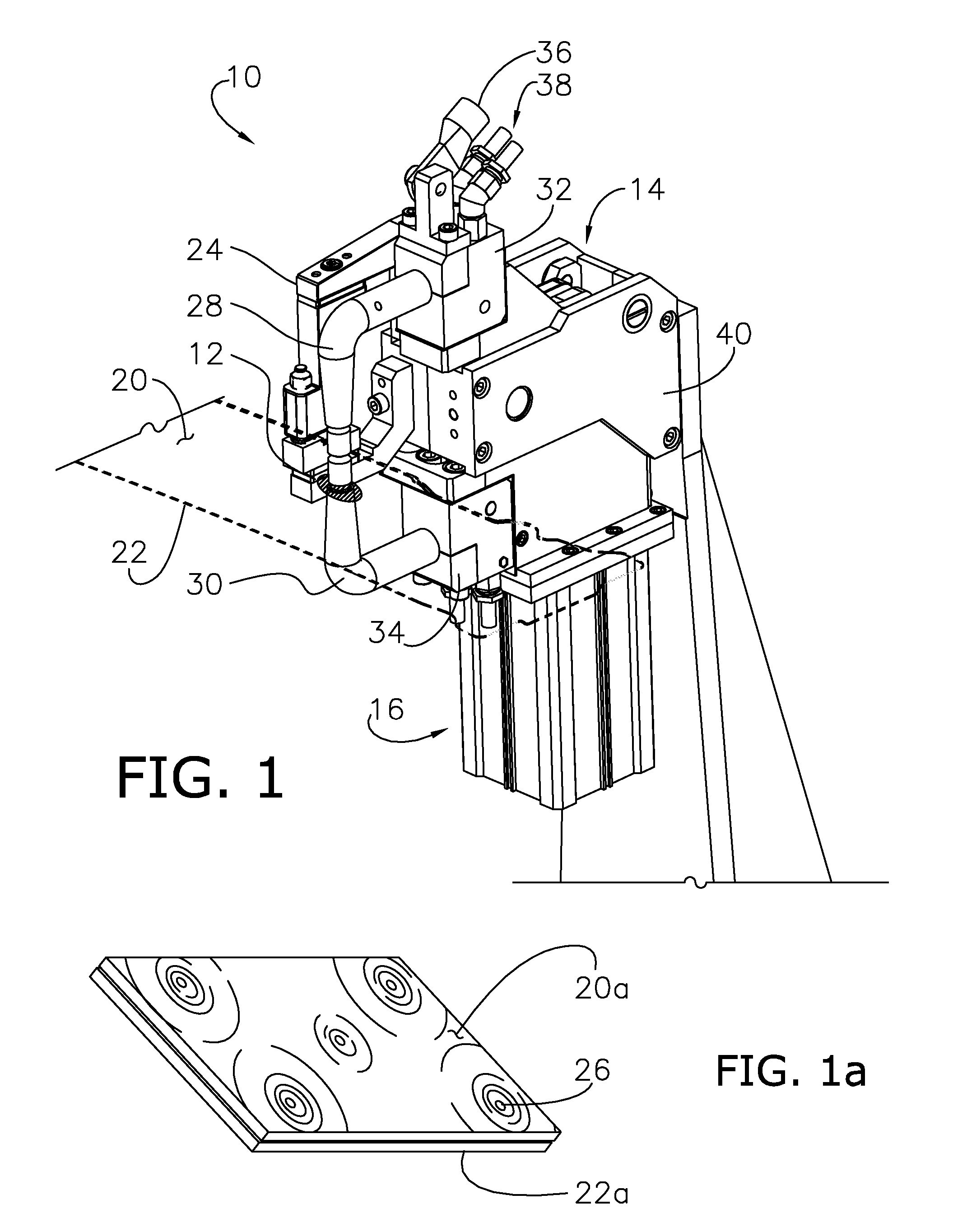

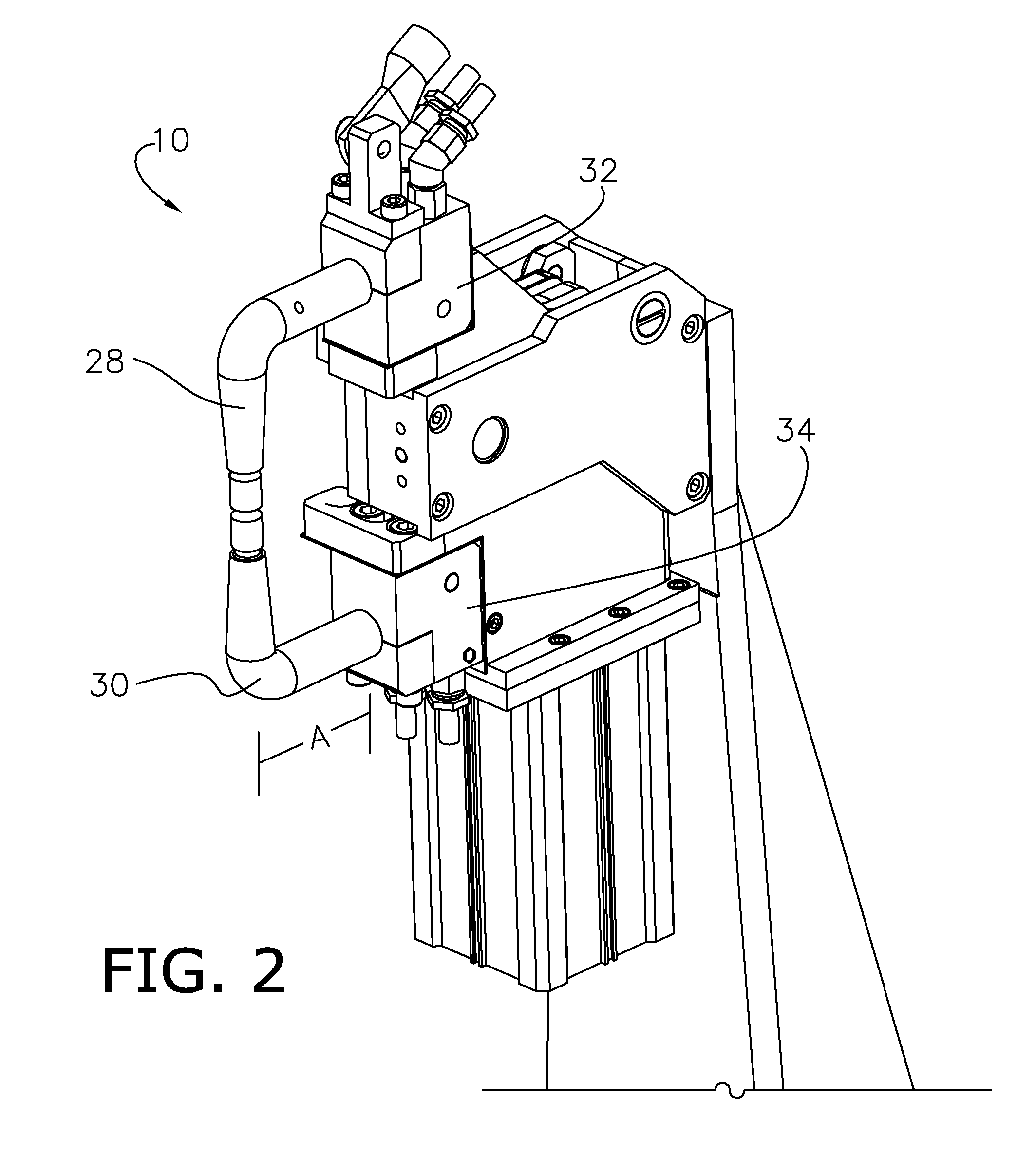

Single drive and source for adjacently clamping and resistance welding

InactiveUS20070175868A1Deformation MinimizationReduce assemblyResistance electrode holdersWelding accessoriesCamEngineering

A resistance spot welding system (10) for sequentially clamping a plurality of workpieces (20,22) at predetermined locations and welding the workpieces (20,22) substantially adjacent the locations, including a clamping element (24) able to be locked in a workpiece engaged position, at least one set of equalizing welding electrodes (28,30) for oppositely engaging the workpieces (20,22) so as to produce the weld (12) without deformation, a singular drive mechanism (14) including a cam coupled to the clamping element (24) and electrodes (28,30), and a singular source (16) for actuating the mechanism (14) and generating the welding and clamping forces.

Owner:GM GLOBAL TECH OPERATIONS LLC

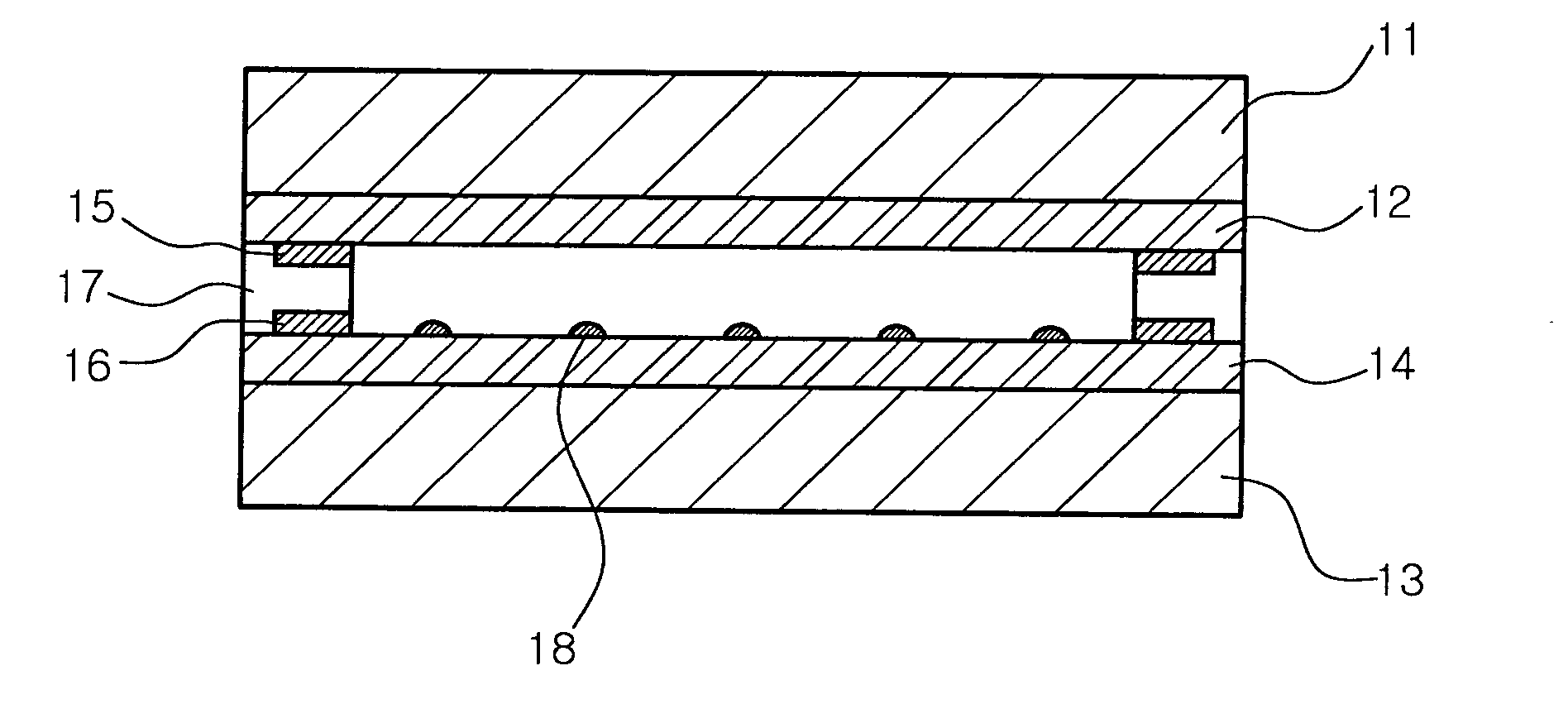

Organic conductive composition and touch panel input device including the same

InactiveUS20110050623A1Increase surface tensionHigh transparencyConductive materialOrganic dyesDopantConductive polymer

An organic conductive composition and a touch panel input device are provided. The organic conductive composition includes a conductive polymer, a dopant lowering electric resistance, an acrylic binder, and a viscosity control agent. The organic conductive composition has excellent transparency, low surface resistance, similar elongation and thermal expansion coefficient to that of a substrate. Accordingly, a conductive film of the touch panel input device including the organic conductive composition is not likely to be peeled off from the substrate, which makes it possible to increase the durability of the input device.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Normalized steel for resistance welding petroleum case pipe with low yield ratio, resistance welding casing tube and its manufacturing method

ActiveCN101270438ASimple processStable mechanical propertiesDrilling rodsTemperature control devicePetroleumCalcium

The invention provides an air hardening steel for oil casing with low yield ratio electrical resistance welding (ERW), an oil casing with low yield ratio electrical resistance welding which is made of the air hardening steel and a preparation method of oil casing. The components of the air hardening steel for oil casing with low yield ratio electrical resistance welding (ERW) in weight percent comprises: 0.19 to 0.29 percent of Carbon, 0.1 to 0.4 percent of Silicon, 1.0 to 1.3 percent of Manganese, less than or equal to 0.015 percent of Phosphorus, smaller than 0.008 percent of Sulfur, 0.002 to 0.04 percent of Aluminum, 0.001 to 0.01 percent of Calcium, 0.08 to 0.14 percent of Vanadium, the remaining part is Ferrum and other inevitable purities. The air hardening steel of the chemical proportion is adopted, continuously casted to form blank, the normalizing heat treatment is carried out for the entire casing after ERW of casing, and then the oil casing with low yield ratio electrical resistance welding of the invention is fabricated out. The yield strength of the oil casing is between 379 to 552 Megapascal, the tensile strength is greater than or equal to 655 Megapascal, and the oil casing has the moderate carbon equivalent and the stable mechanical property of the entire casing.

Owner:BAOSHAN IRON & STEEL CO LTD

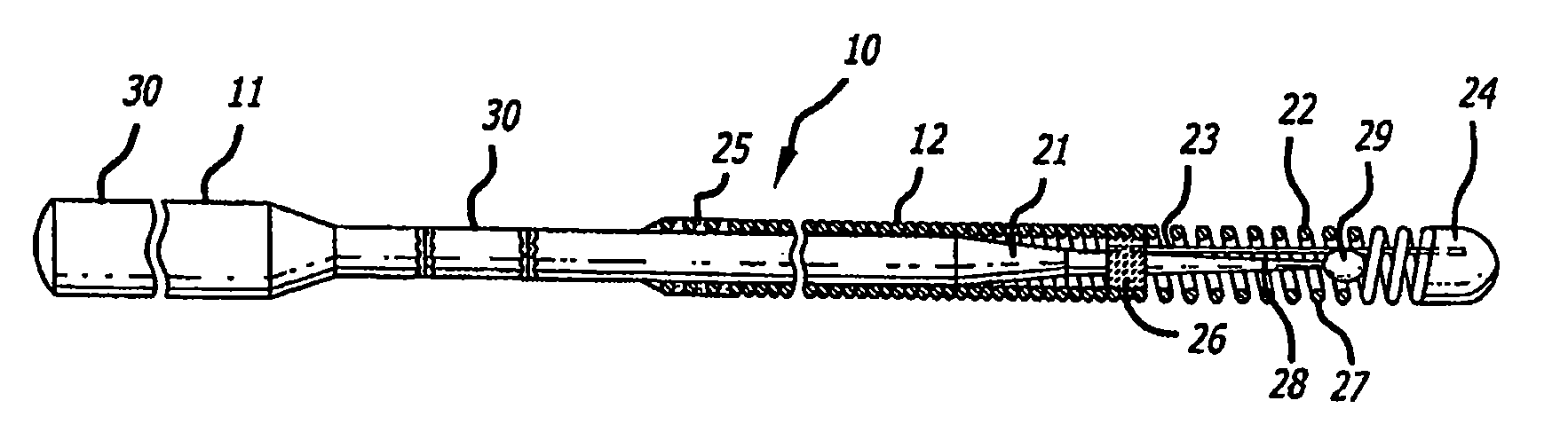

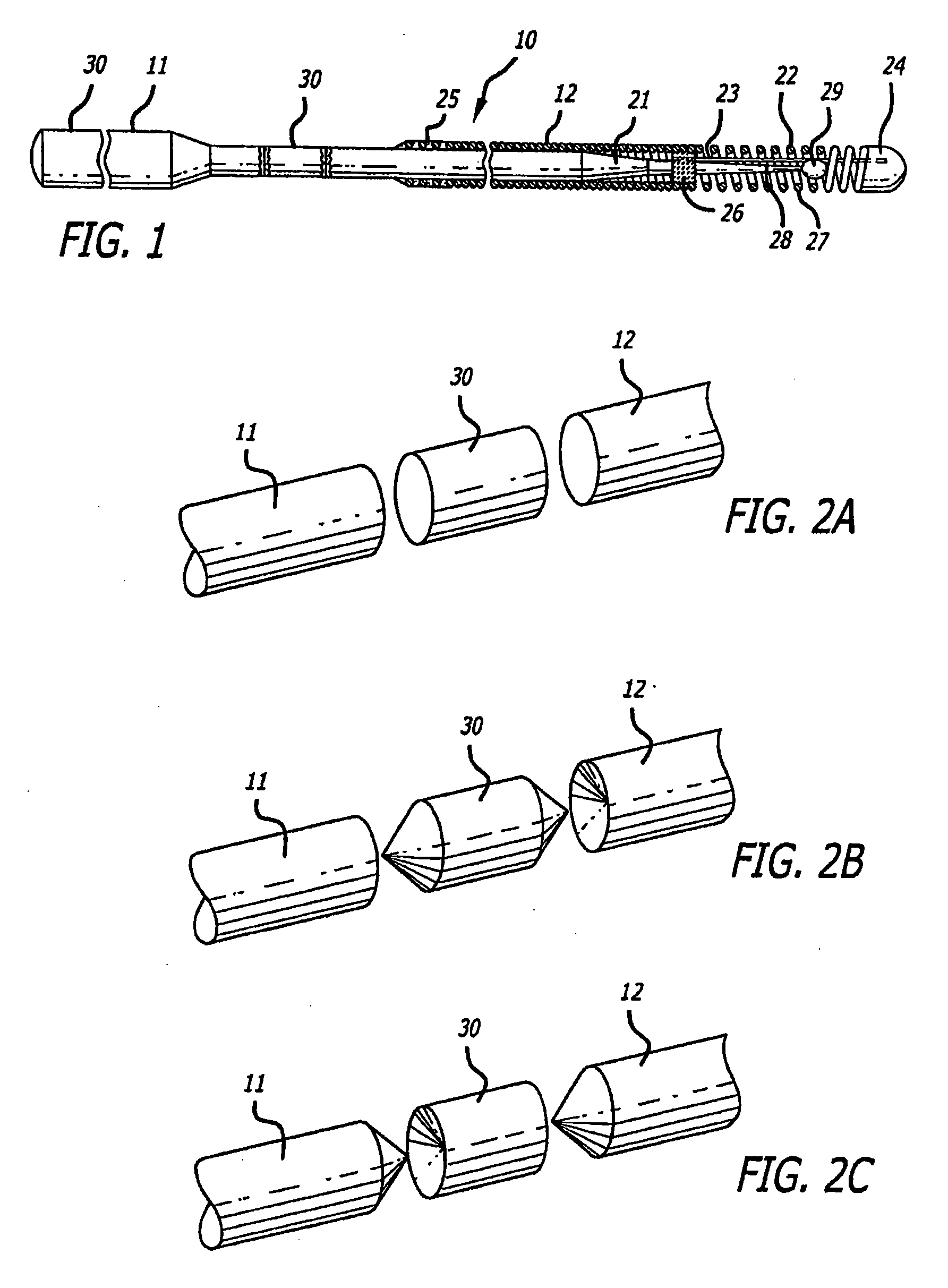

Guide wire with core having welded wire segments

ActiveUS20090227902A1Easy to compressReduce tensionGuide wiresDiagnostic recording/measuringFriction weldingMetal alloy

An intravascular guide wire having two core materials joined together without the use of a connector tube or sleeve, the core materials being stainless steel and psuedoelastic metal alloy, nitinol. The core materials are joined to each other through an intermediate transition piece made essentially of nickel, which is welded on either side to the two core materials. In a multi-segment intravascular guide wire, discrete, high modulus and medium modulus core portions of different materials are welded to a shapeable, low modulus distal core portion made of a third material having a flattened, shapeable section at a most distal end that is not welded to but made from the distal core portion, so the flattened, shapeable section can be deformed to create a steerable tip. Processes such as simultaneous resistance and friction welding can be used to join the core portions.

Owner:ABBOTT CARDIOVASCULAR

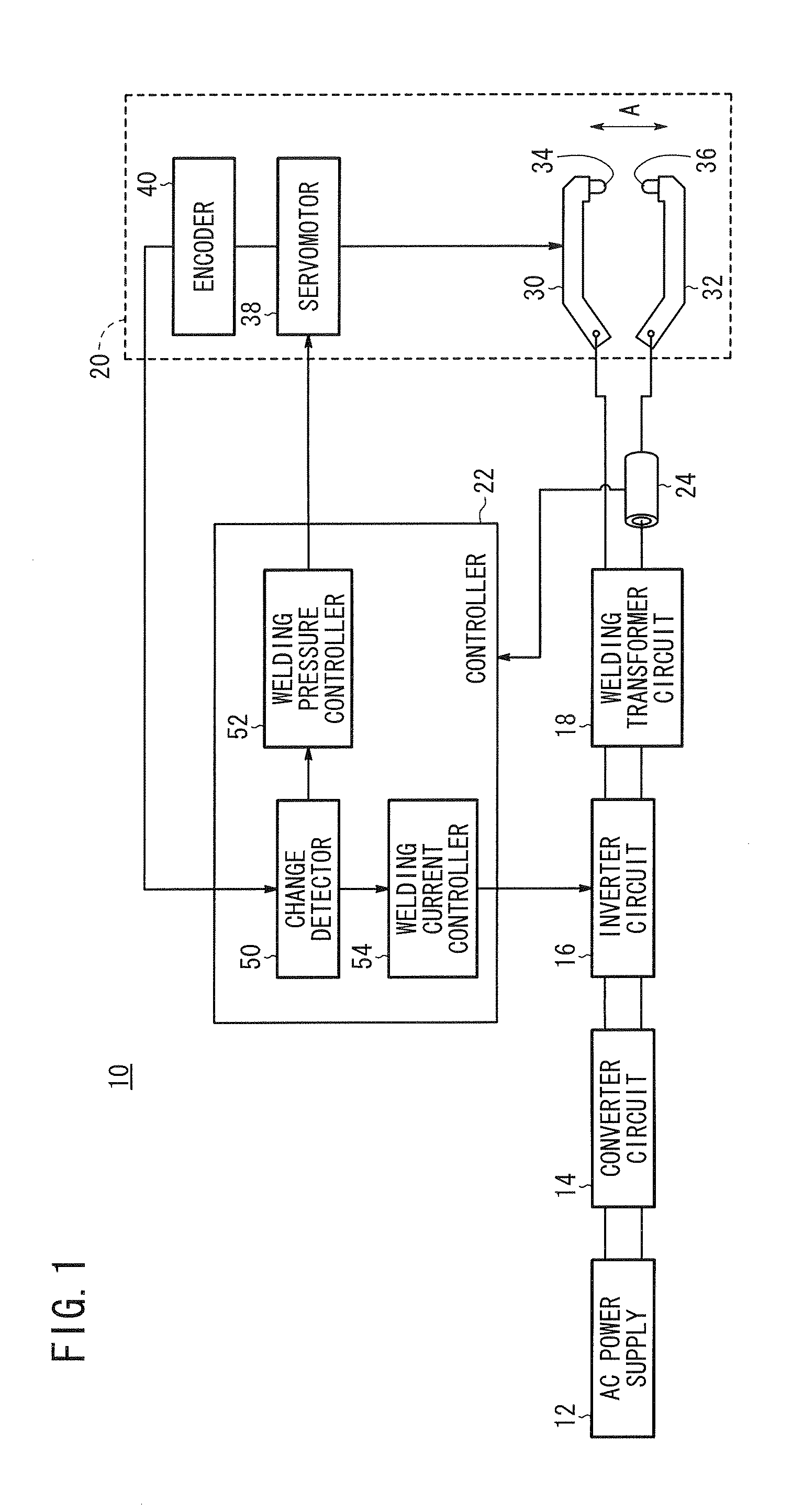

Resistance welding method

InactiveUS20110180518A1Minimize occurrencePromote growthArc welding apparatusWelding monitoring devicesElectrical resistance and conductanceEngineering

A resistance welding method, which resistance-welds a pair of workpieces by gripping the workpieces with a pair of electrode tips under a prescribed welding pressure, and supplies a welding current through the electrode tips to the workpieces, includes the steps of detecting a change in an amount of expansion of a nugget produced in the workpieces, along a direction in which the electrode tips grip the workpieces therebetween, determining whether the detected change is smaller than a threshold value or not, and gradually increasing the welding current flowing through the workpieces after the detected change is judged as being smaller than the threshold value.

Owner:HONDA MOTOR CO LTD

Electric resistance welding method

ActiveCN101318256APromote interpenetrationTightly boundWelding/soldering/cutting articlesResistance welding apparatusElectrical resistance and conductanceWelding power supply

The invention discloses a resistance welding method for welding the copper or copper alloy and the steel or steel alloy, which adopts general principles of the resistance welding to carry out the spot welding or the loop projection welding of the copper or the copper alloy and the steel or the steel alloy to obtain complete liquid phase nuggets by using the technique of applying pulse currents and pressures by sections on special electrode tips of the resistance welding and a special welding power, and the real welding can be realized, wherein, the welding power provides direct current for welding and the discharging time is 110ms to 280ms, the maximum current is 36KA to 280KA, the current frequency before the rectification is 1000Hz, 1200Hz or 1500Hz, the welding current between work pieces and the electrode tips is the direct current, and the pressure is 1 to 5.9Kgf / cm<2>.

Owner:HERON INTELLIGENT EQUIP CO LTD

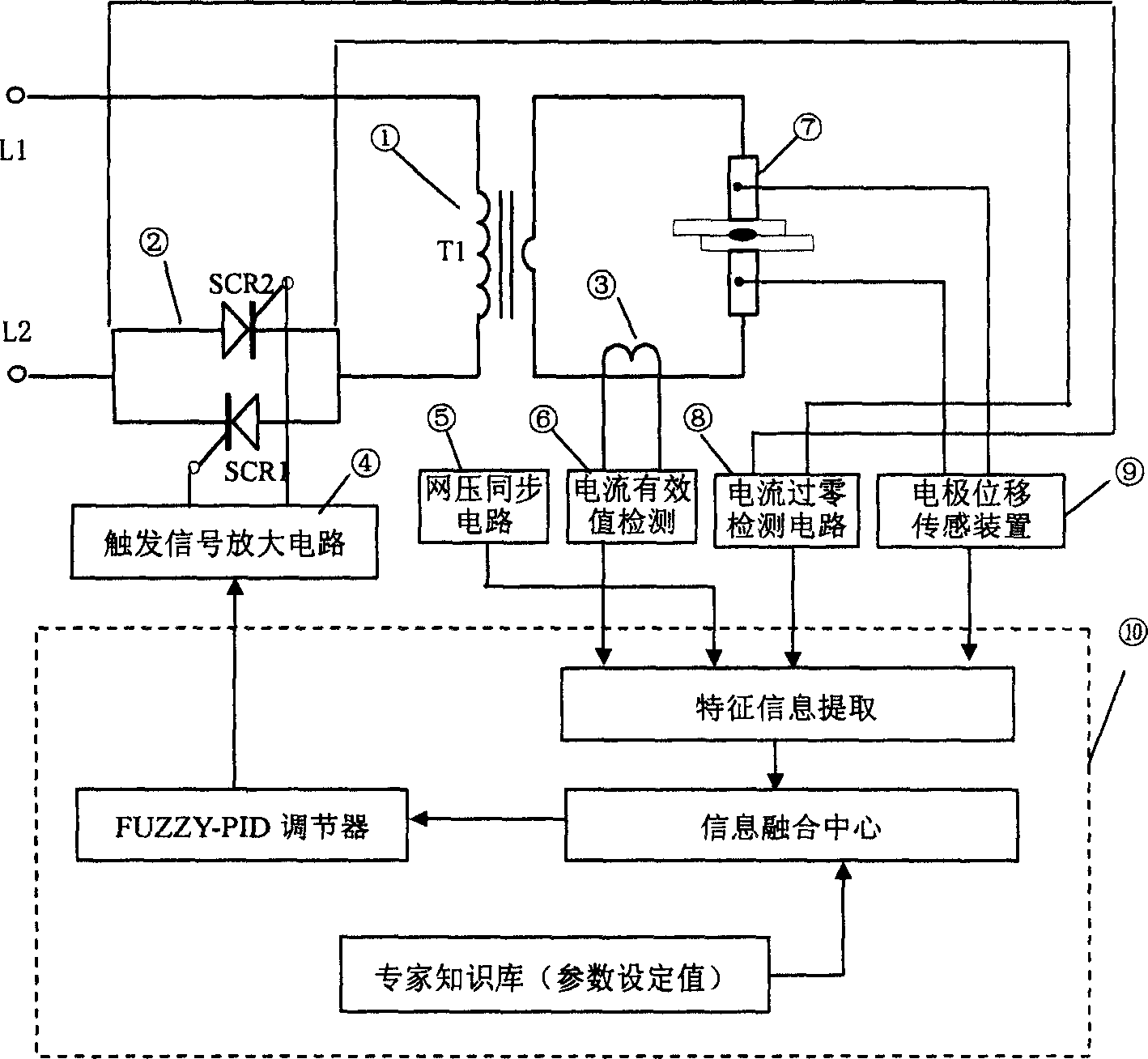

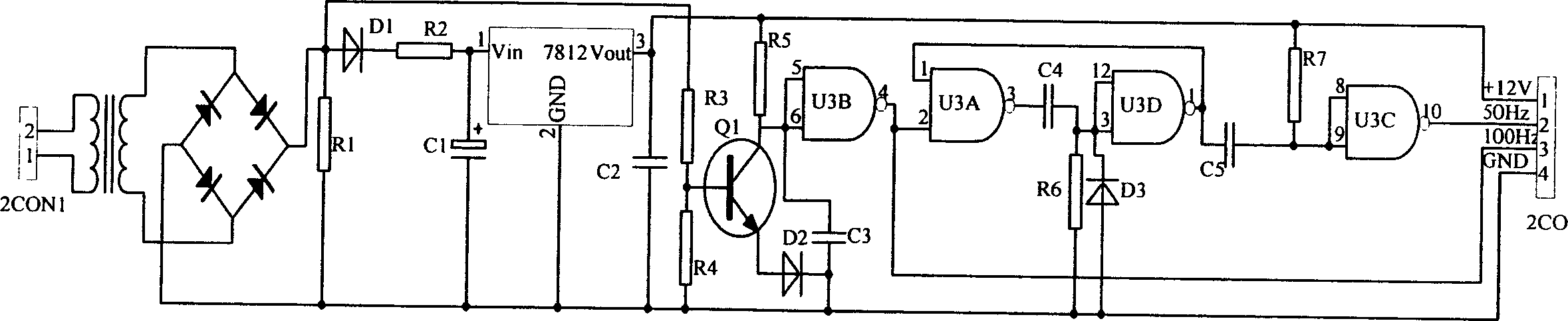

Quality control device and method for resistance spot welding

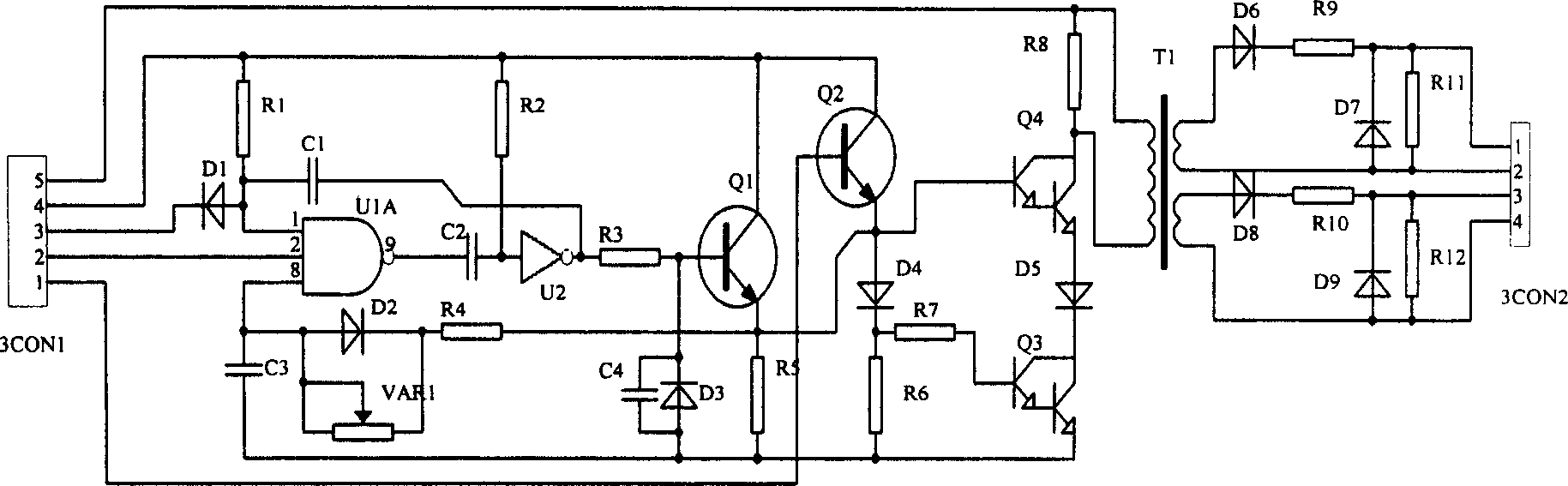

InactiveCN1730220AComprehensive testing informationEasy to controlWelding electric supplyTransformerInformation integration

The invention relates to a resistance spot welding quality control device and method, which pertains to resistance spot welding process information detecting and quality control technology domain. The device comprises potential transformer, inverse paralleling gate circuit transistor, current-sensing device, trigger signal amplifying circuit, synchronous circuit, current effective value detecting circuit, current zero-cross detecting circuit, electrode displacement sensor and SCM control system. The procedure comprises signal pickup, characteristic information abstraction, information anastomosing, control algorithm selection and output power conditioning step. The invention has the advantages of multiple detection information, good control property, high control accuracy and extensive useage.

Owner:SHENYANG POLYTECHNIC UNIV

Electric resistance welding micro-welding spot welding machine

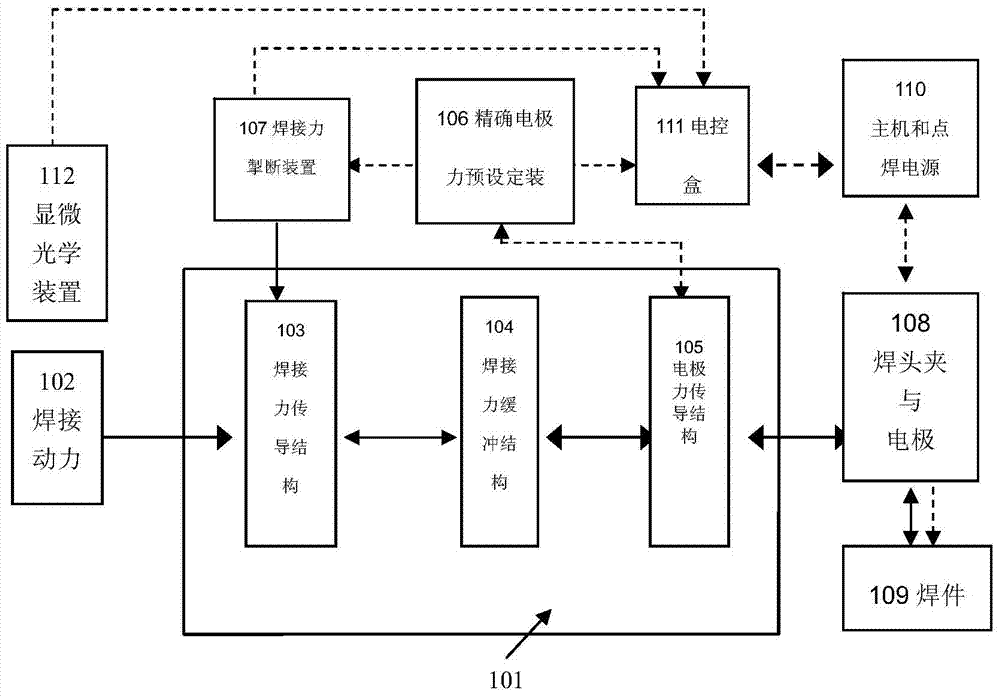

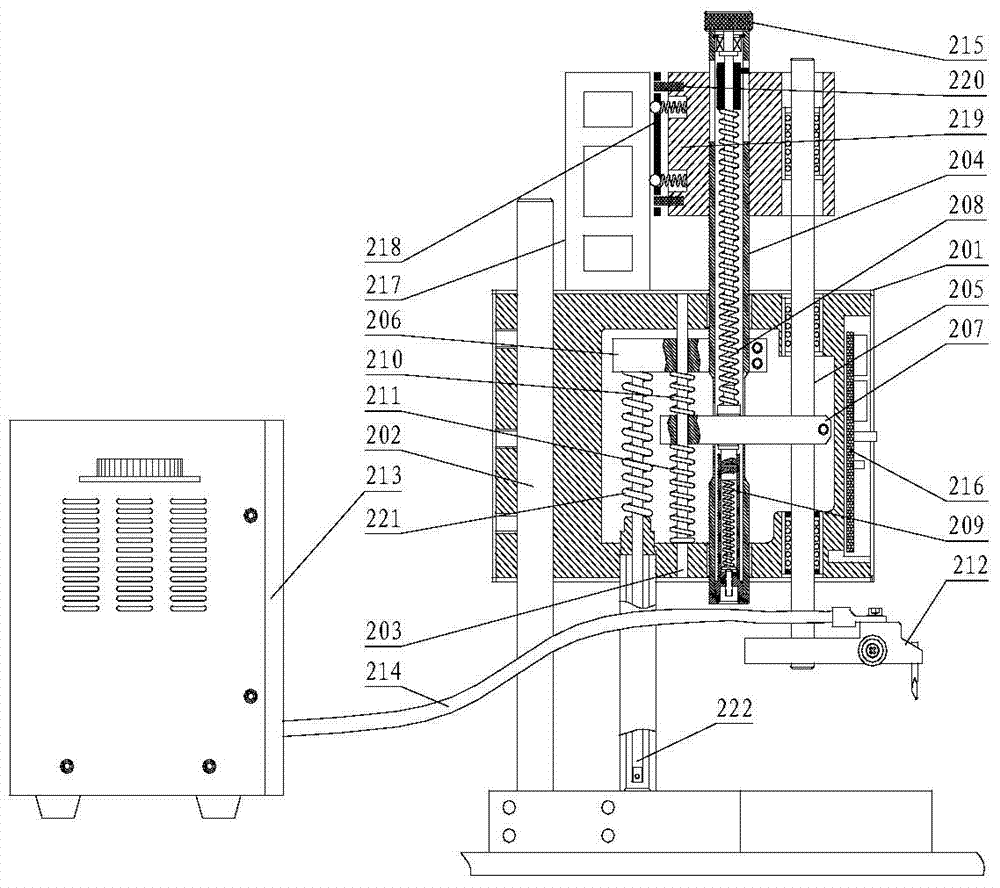

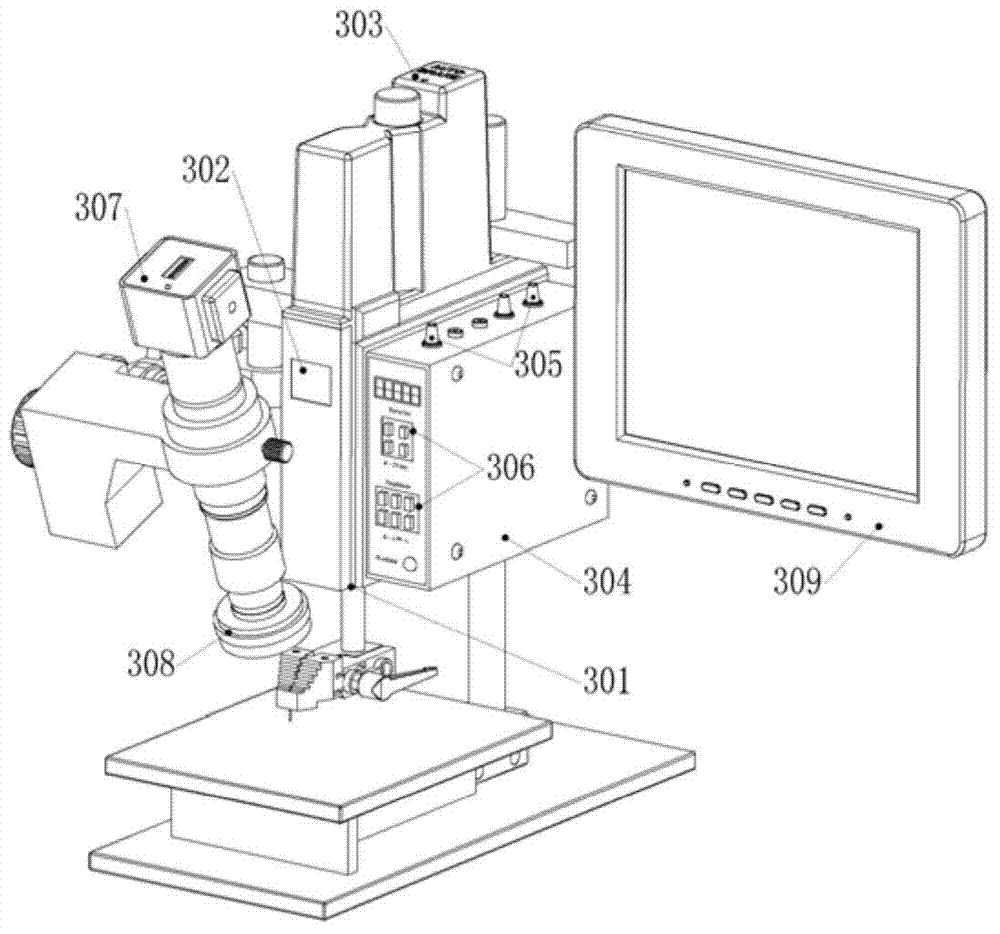

ActiveCN103920981ASimplify and reduce electrical connectionsImprove verticalityResistance electrode holdersWelding monitoring devicesElectricityElectrical resistance and conductance

The invention discloses an electric resistance welding micro-welding spot welding machine and mainly relates to noses. A mechatronics accurate electrode force pressurizing system is mounted on a nose frame, and electrode force is kept in a preset range and relatively constant during whole spot welding by the synergy and interaction of a welding acting force transmission device, an accurate electrode force presetting device and a welding force switching off device. A spot welding machine nose structure with an electric control box is provided, and nose feed and spot welding power supply output presetting are performed through the electric control box. A plastic nose frame and a stepped welding head clamp structure are provided to guarantee accurate torque transmission. A nose and a microscopy optical device are integrated, and the brand new electric resistance welding micro-welding spot welding machine is provided with the unique optical mechatronics spot welding machine nose.

Owner:GUANGZHOU MICRO WELDING EQUIP

Steel for expandable casing for oil well and manufacturing method thereof

ActiveCN101812631APerformanceAvoid easy crackingTemperature control deviceFurnace typesNumerical controlAlloy

The invention discloses steel for an expandable casing for an oil well and a manufacturing method thereof, and the manufacturing method is applied to preparing the expandable casing for the oil well for petroleum and gas industrial oil. The steel alloy material of the expandable casing for the oil well comprises the following components in percentage by weight: 0.08 to 0.2 percent of C, 1 to 2 percent of Mn, 0.15 to 0.35 percent of Si, 0.02 to 0.06 percent of Al, less than or equal to 0.01 percent of P, less than or equal to 0.05 percent of S, less than or equal to 0.08 percent of N, 0.001 to 0.005 percent of Ca, and the balance of Fe. The method for preparing the expandable casing for the oil well comprises the following steps of: preparing hot rolled steel coils; producing straight seam resistance welded steel pipes by using the hot rolled steel coils; normalizing welding lines after welding; and finally, cutting into welded steel pipes, and machining API standard threads or special threads at two ends of each welded steel pipe by using a numerical control machine. The steel for the expandable casing for the oil well has the advantages of excellent comprehensive performance such as expansion deformation capacity, intensity, toughness, and the like, no defect of the welding lines and uniform and consistent performance with base metals.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

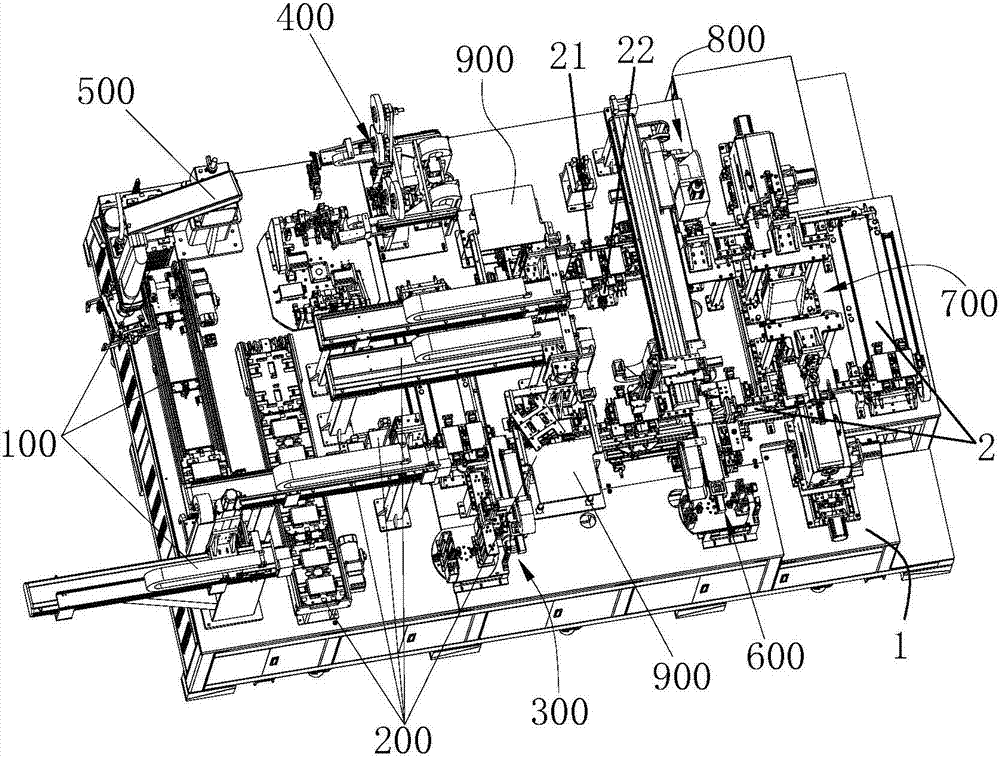

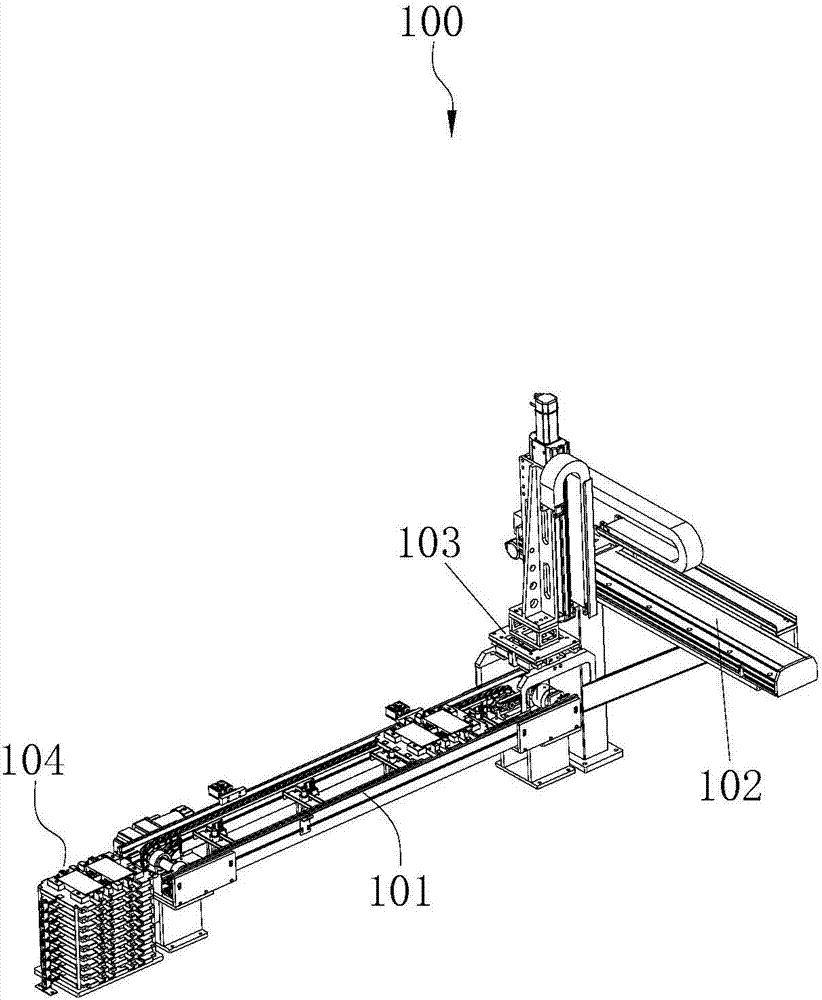

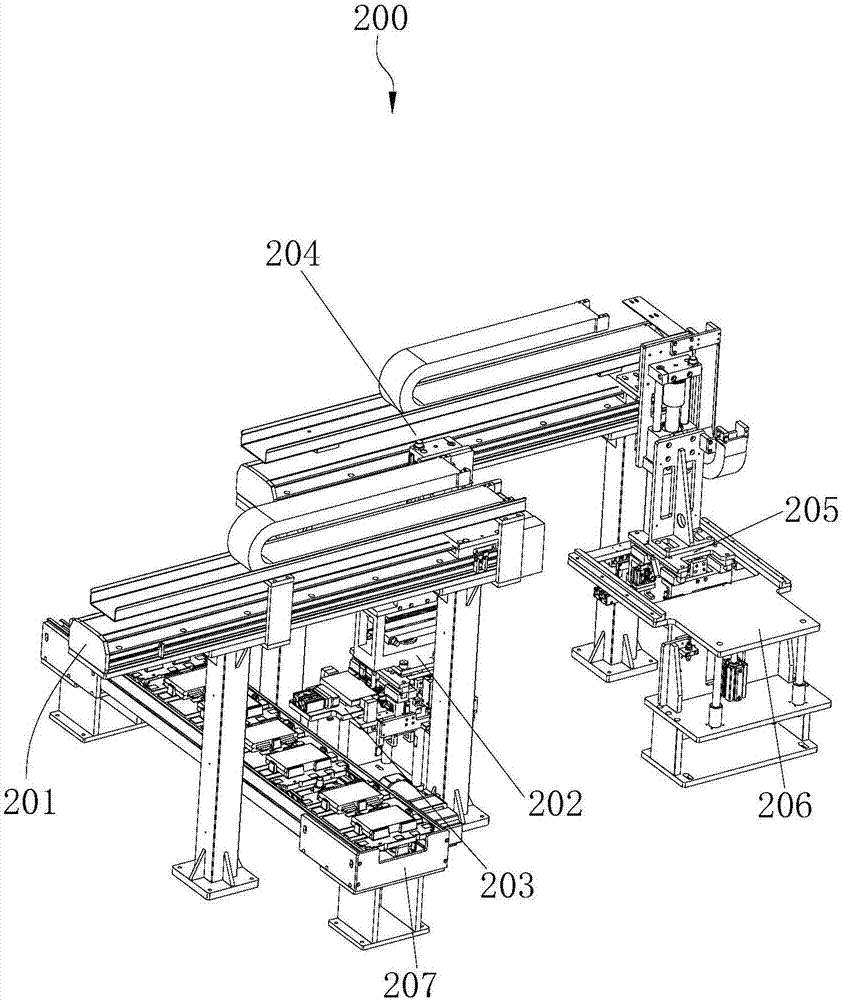

Power battery ultrasonic welding equipment

ActiveCN107096990AHigh degree of automationImprove welding efficiencyNon-electric welding apparatusPower batteryFailure rate

The invention discloses power battery ultrasonic welding equipment. The power battery ultrasonic welding equipment comprises a working table, a tray feeding assembly, a cell feeding assembly, a connecting link feeding assembly, a film-pasting assembly, a cell discharging assembly, a protecting plate feeding assembly, an ultrasonic welding assembly, an electric resistance welding assembly and pressing plate pick-and-place assemblies, wherein the tray feeding assembly, the cell feeding assembly, the connecting link feeding assembly and the film-pasting assembly are arranged on the working table, the tray feeding assembly is used for feeding trays, and the cell feeding assembly is used for positioning cells; the connecting link feeding assembly is used for feeding copper and aluminum connecting links into fixtures, the film-pasting assembly is used for pasting blue glue on the welding area, and the cell discharging assembly is used for outputting the cells pasted with the film; and the protecting plate feeding assembly used for feeding protecting plates, the ultrasonic welding assembly used for compressing and welding positioned lugs, connecting links and protecting plates, the electric resistance welding assembly used for carrying out repair-welding on ultrasonically welded copper poles, and the pressing plate pick-and-place assemblies which are symmetrically arranged on the two sides of a return line body, and are used for transferring pressing plates into the fixtures or disassembling the pressing plates are arranged on the periphery of the return line body. According to the power battery ultrasonic welding equipment, the technical problems that the degree of welding automation of an existing power battery is not high, the manufacturing efficiency, the welding precision and the yield are low, and the manufacturing cost and the failure rate are high are solved; and the power battery ultrasonic welding equipment has the characteristics that the implementation is easy and the stability is high.

Owner:CONTEMPORARY AMPEREX TECH CO +1

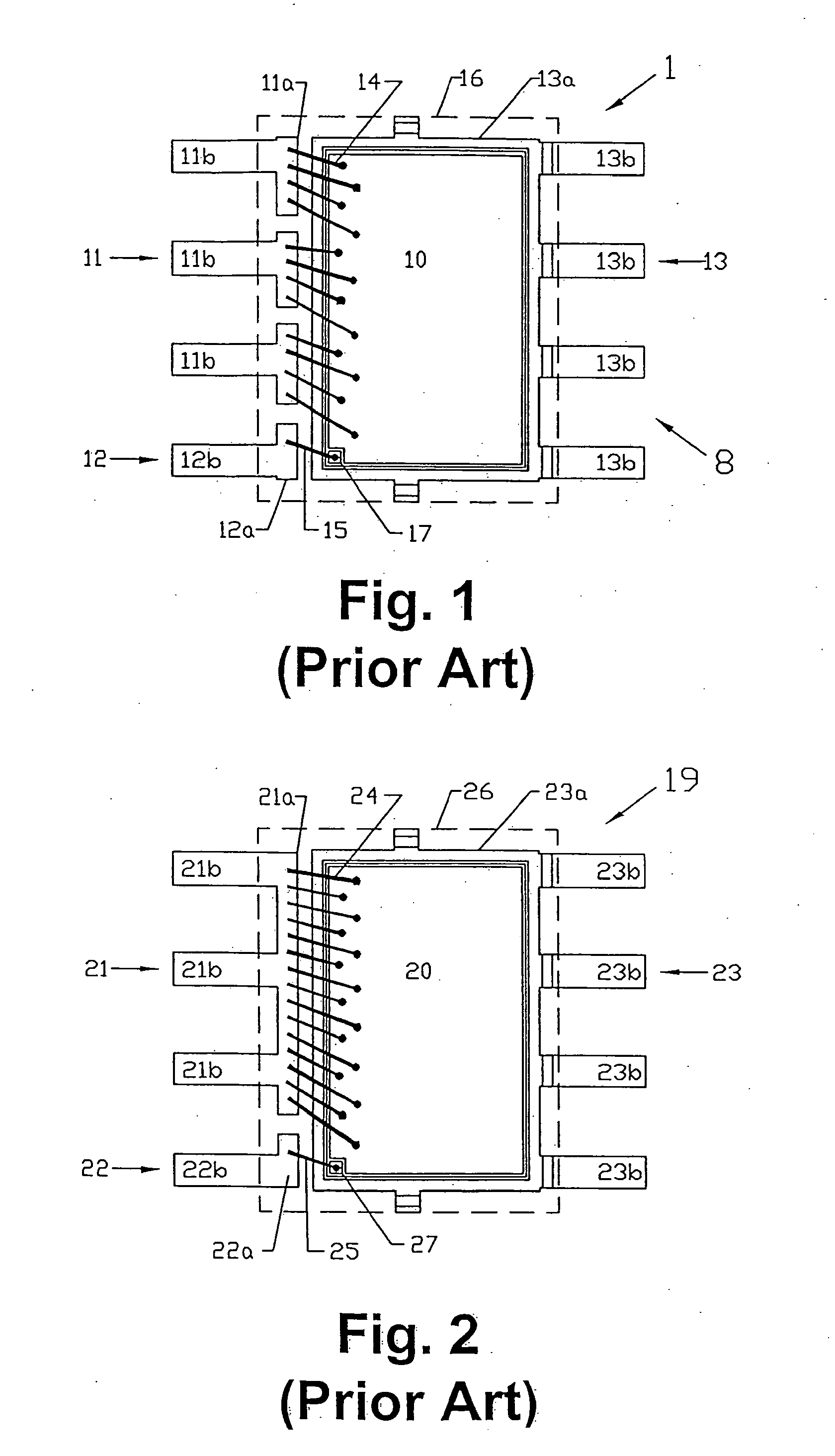

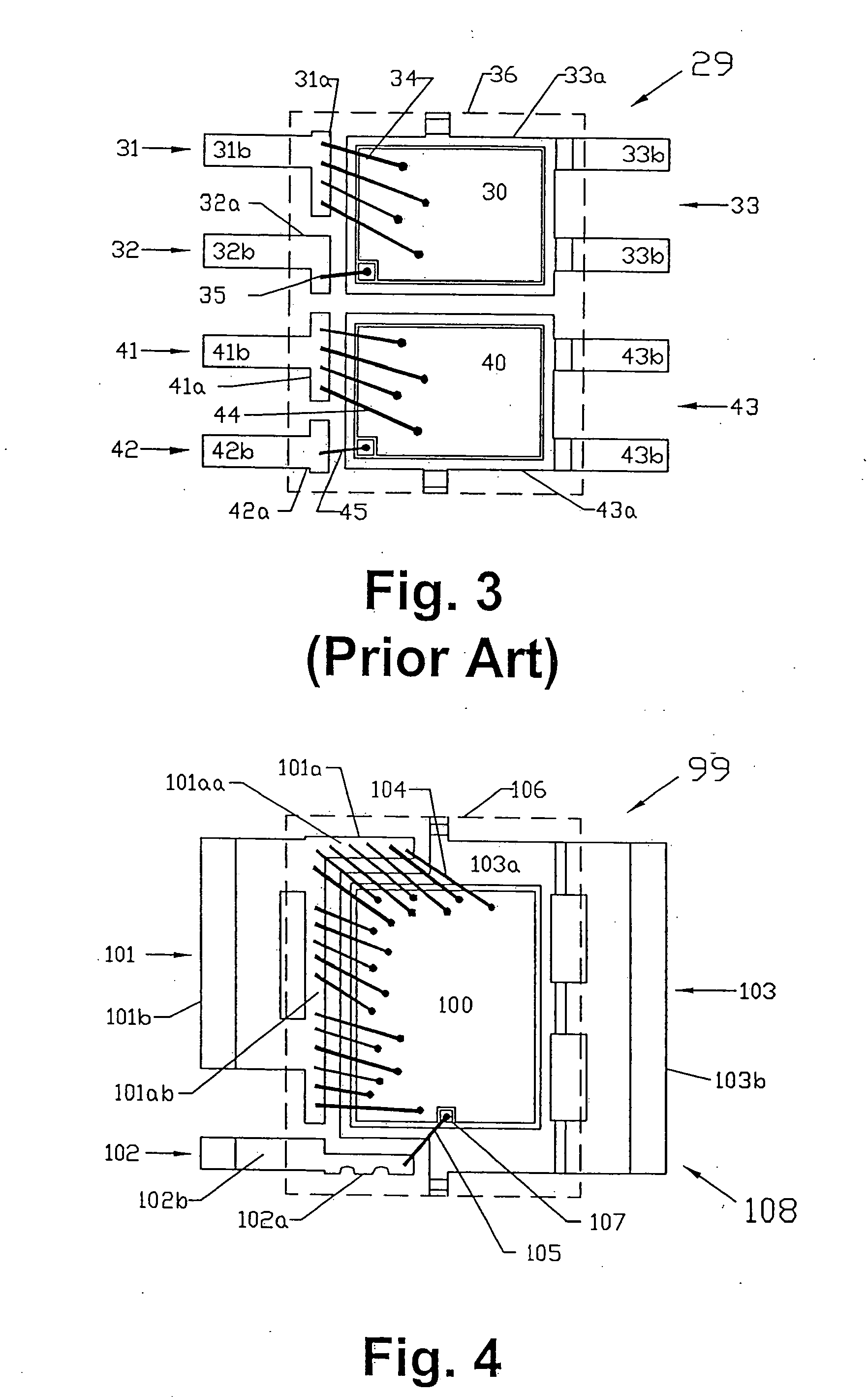

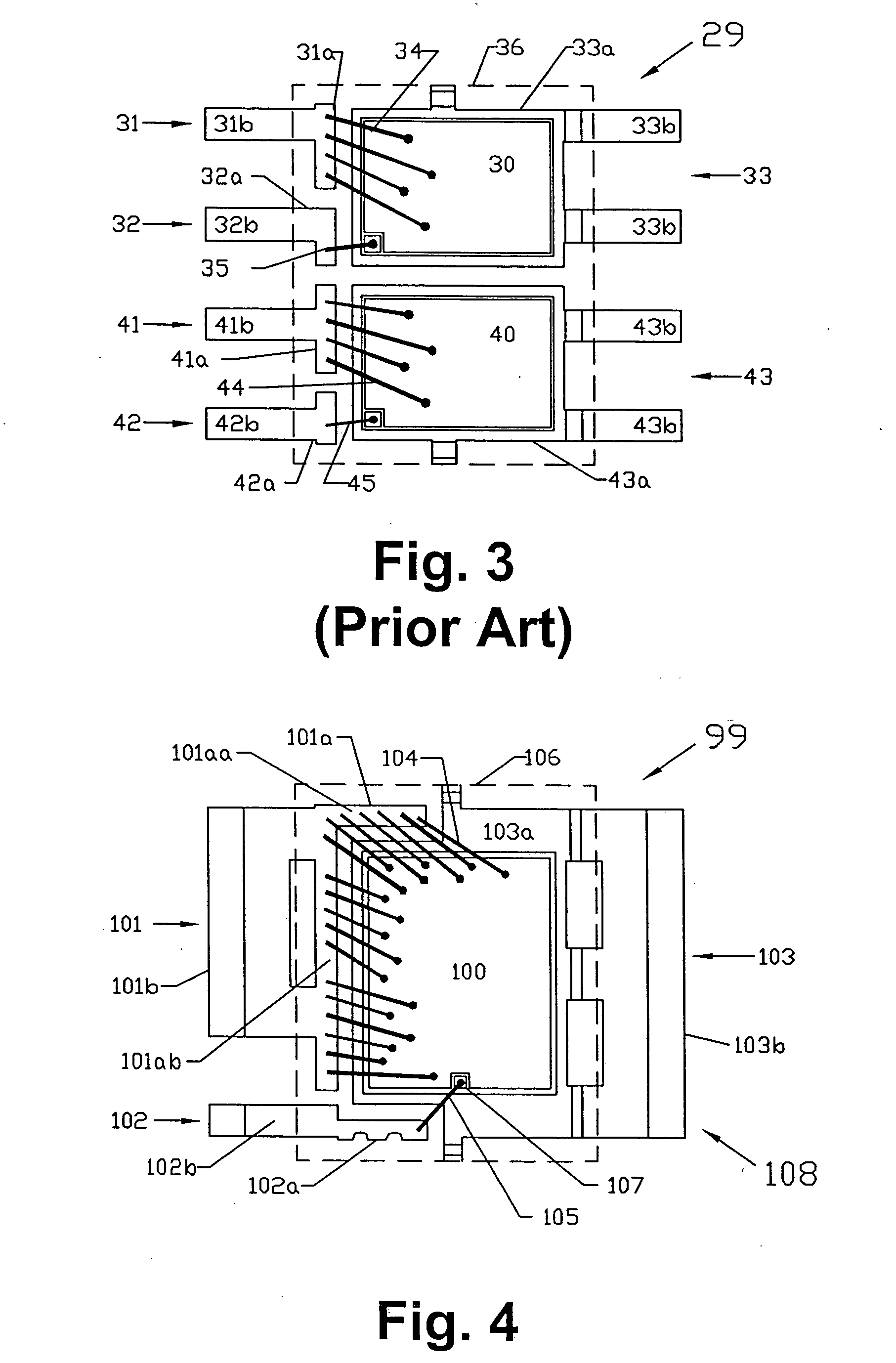

Integrated circuit package for semiconductior devices with improved electric resistance and inductance

ActiveUS20110221005A1Reduce resistanceIncrease surface areaTransistorSemiconductor/solid-state device detailsMOSFETElectrical resistance and conductance

A semiconductor integrated circuit package having a leadframe (108) that includes a leadframe pad (103a) disposed under a die (100) and a bonding metal area (101a) that is disposed over at least two adjacent sides of the die. The increase in the s bonding metal area (101a) increases the number of interconnections between the metal area (101a) and the die (100) to reduce the electric resistance and inductance. Furthermore, the surface area of the external terminals radiating from the package's plastic body (106) is increased if not maximized so that heat can be dissipated quicker and external terminal, resistances reduced. The integrated circuit is applicable for MOSFET devices and the bonding metal area (101a) is used for the source terminal (101). The bonding metal area may have a “L” shape, a “C” shape, a “J” shape, an “I” shape or any combination thereof.

Owner:ALPHA & OMEGA SEMICON INC

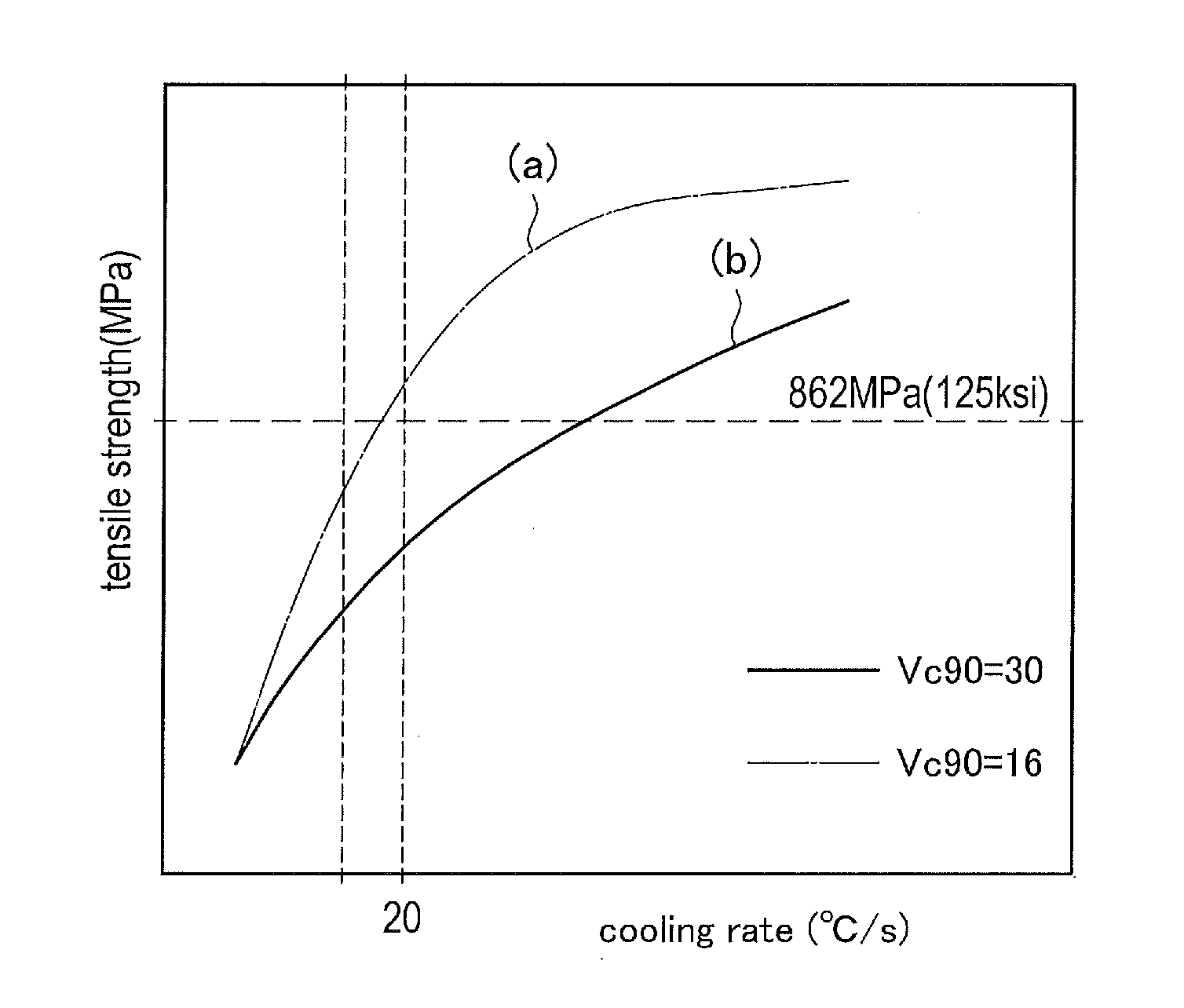

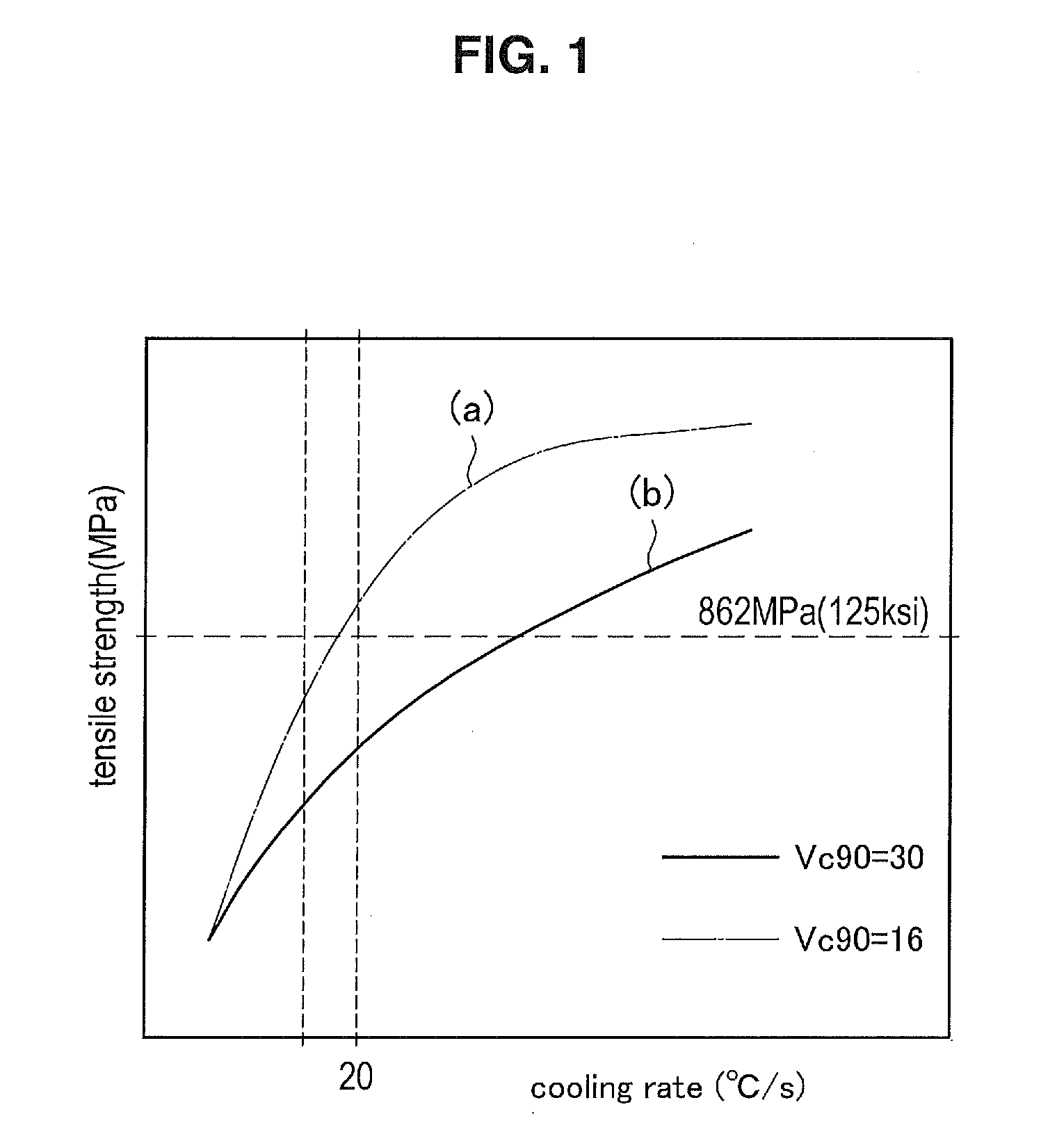

Electric resistance welded oil country tubular goods and manufacturing method of electric resistance welded oil country tubular goods

InactiveUS20130092280A1High strengthFurnace typesPipeline systemsElectrical resistance and conductanceChemical composition

[Summary][Object] There are provided electric resistance welded oil country tubular goods having strength corresponding to API specification 5CT P110 without a heat treatment being performed on the whole steel pipe and further having excellent toughness, and a manufacturing method of an electric resistance welded oil country tubular goods.[Solution] Electric resistance welded oil country tubular goods according to the present invention have a chemical composition that contains, in mass %, C: 0.05 to 0.12%, Si: 0.03 to 0.5%, Mn: 0.80 to 2.2%, P: 0.03% or less, S: 0.003% or less, Al: 0.08% or less, Nb: 0.01% to 0.10%, Ti: 0.005 to 0.03%, B: 0.0005 to 0.0030%, and N: 0.008% or less, and in which Ti>3.4 N is satisfied, its balance is composed of Fe and inevitable impurities, and, VC90 is 15 to 40.

Owner:NIPPON STEEL CORP

Spring load adjustment structure of contact device and spring load adjustment method of contact device

ActiveUS20150077202A1Easy to weldElectromagnetic relay detailsContact engagementsElectrical resistance and conductanceElectrical connection

A contact device includes: fixed terminals; a movable contact maker; a pressing spring; an adjustment plate that comes into contact with an upper face of the movable contact maker; a holding; a movable shaft; and an electromagnet block. The holding portion is divided into first and second holding portions that are separated from each other. The first and second holding portions are electrically connected to each other via only the adjustment plate, due to the adjustment plate being sandwiched by a first side plate of the first holding portion and a second side plate of the second holding portion. The adjustment plate is moved in extending and contracting directions of the pressing spring, and the adjustment plate and each of the first and second side plates are subjected to resistance welding at a position at which pressing force of the pressing spring is a predetermined value.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Integrated circuit package for semiconductor devices with improved electric resistance and inductance

InactiveUS20050145996A1Reduce resistanceStrengthen interconnectionSemiconductor/solid-state device detailsSolid-state devicesMOSFETInterconnection

A semiconductor integrated circuit package having a leadframe (108) that includes a leadframe pad (103a) disposed under a die (100) and a bonding metal area (101a) that is disposed over at least two adjacent sides of the die. The increase in the bonding metal area (101a) increases the number of interconnections between the metal area (101a) and the die (100) to reduce the electric resistance and inductance. Furthermore, the surface area of the external terminals radiating from the package's plastic body (106) is increased if not maximized so that heat can be dissipated quicker and external terminal resistances reduced. The integrated circuit is applicable for MOSFET devices and the bonding metal area (101a) is used for the source terminal (101). The bonding metal area may have a “L” shape, a “C” shape, a “J” shape, an “I” shape or any combination thereof.

Owner:ALPHA & OMEGA SEMICON LTD

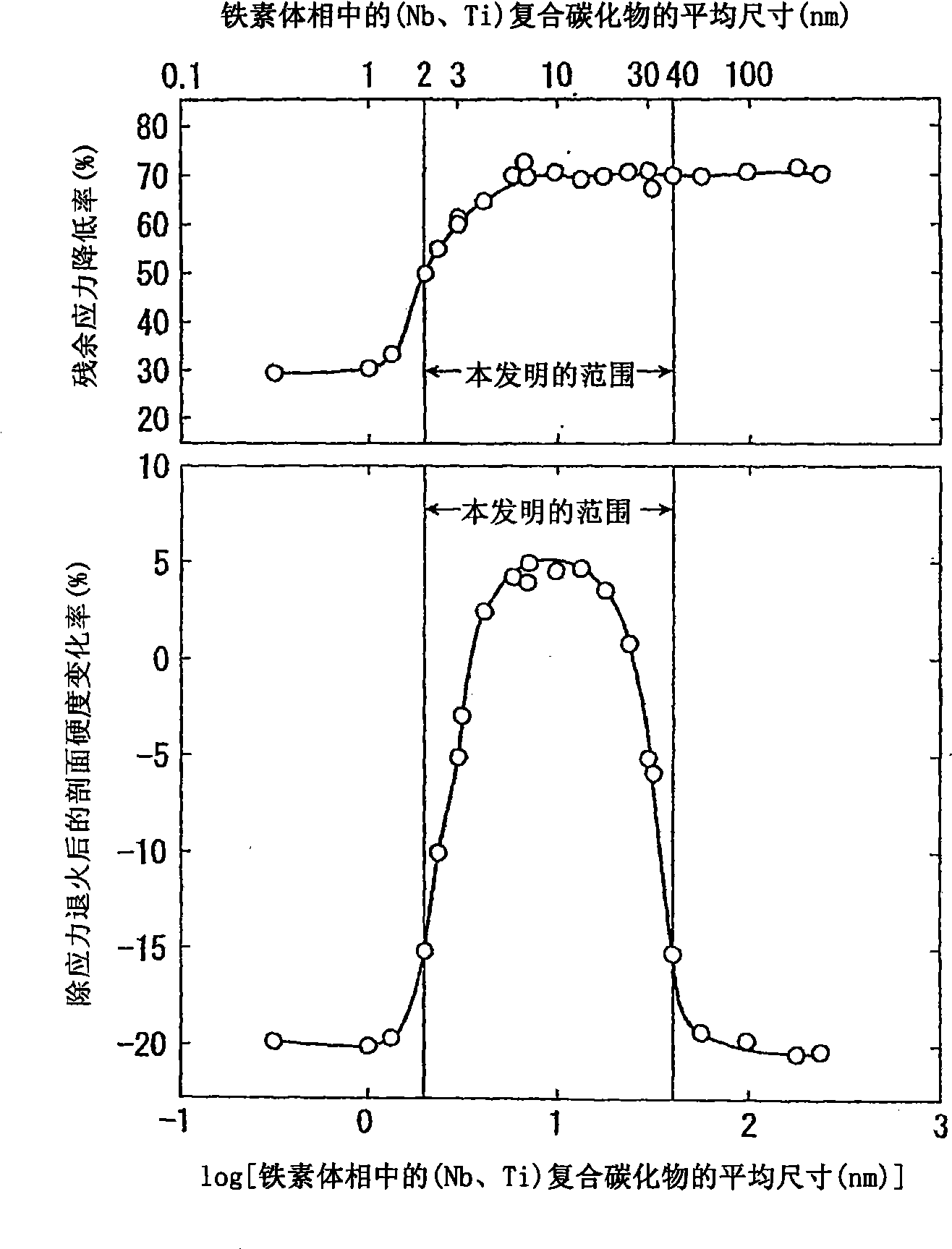

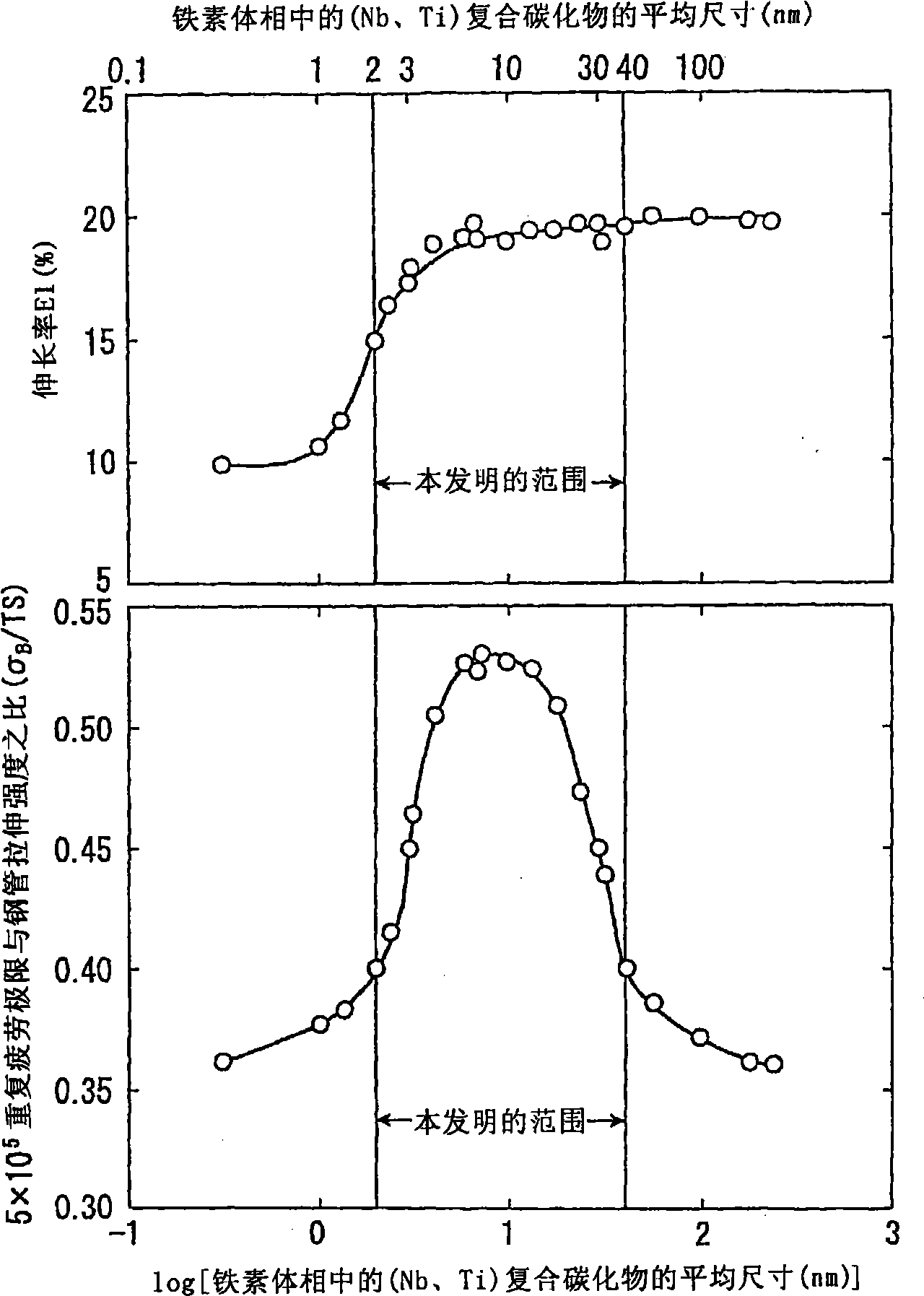

High-tensile strength welded steel tube for structural partsof automobiles and method of producing the same

ActiveCN101484602AExcellent resistance to torsional fatigueGood effectFurnace typesHeat treatment furnacesCarbideHigh intensity

A high-tension welded steel pipe for automotive structural members which has excellent formability and has excellent resistance to torsional fatigue after section forming and subsequent annealing for stress removal; and a process for producing the steel pipe. A raw steel material having a composition which contains C, Si, and Al in amounts in respective proper ranges and further contains 1.01-1.99% Mn, 0.041-0.150% Ti, and 0.017-0.150% Nb, provided that Ti+Nb is 0.08% or more, and in which the amounts of P, S, N, and O have been regulated so as to be not larger than given values is subjected to hot rolling in which the heating temperature and the finish-rolling completion temperature are in proper ranges. After completion of the hot rolling, the steel material is annealed in a temperature range of 750-650 DEG C for 2 seconds or longer. The steel is then wound at a winding temperature of 660-510 DEG C to obtain a hot-rolled steel strip comprising at least 60 vol.% ferrite phase having an average particle diameter of 2-8 [mu]m and a structure comprising an (Nb / Ti) composite carbide having an average particle diameter of 2-40 nm and precipitated in the ferrite phase. This steel strip is subjected to the step of pipe formation by electric-resistance welding at a width reduction of 10% or lower to thereby form a welded steel pipe. Thus, a high-tension welded steel pipe is obtained which has a high yield strength exceeding 660 MPa and is excellent in low-temperature toughness, formability, and resistance to torsional fatigue after annealing for stress removal.

Owner:JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com